Preparation method and application of low-voltage efficient nano carbon material electrothermal film

A nano-carbon material, electrothermal film technology, applied in electrothermal devices, ohmic resistance heating, heating element materials, etc., to achieve the effects of low energy consumption, easy film formation, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

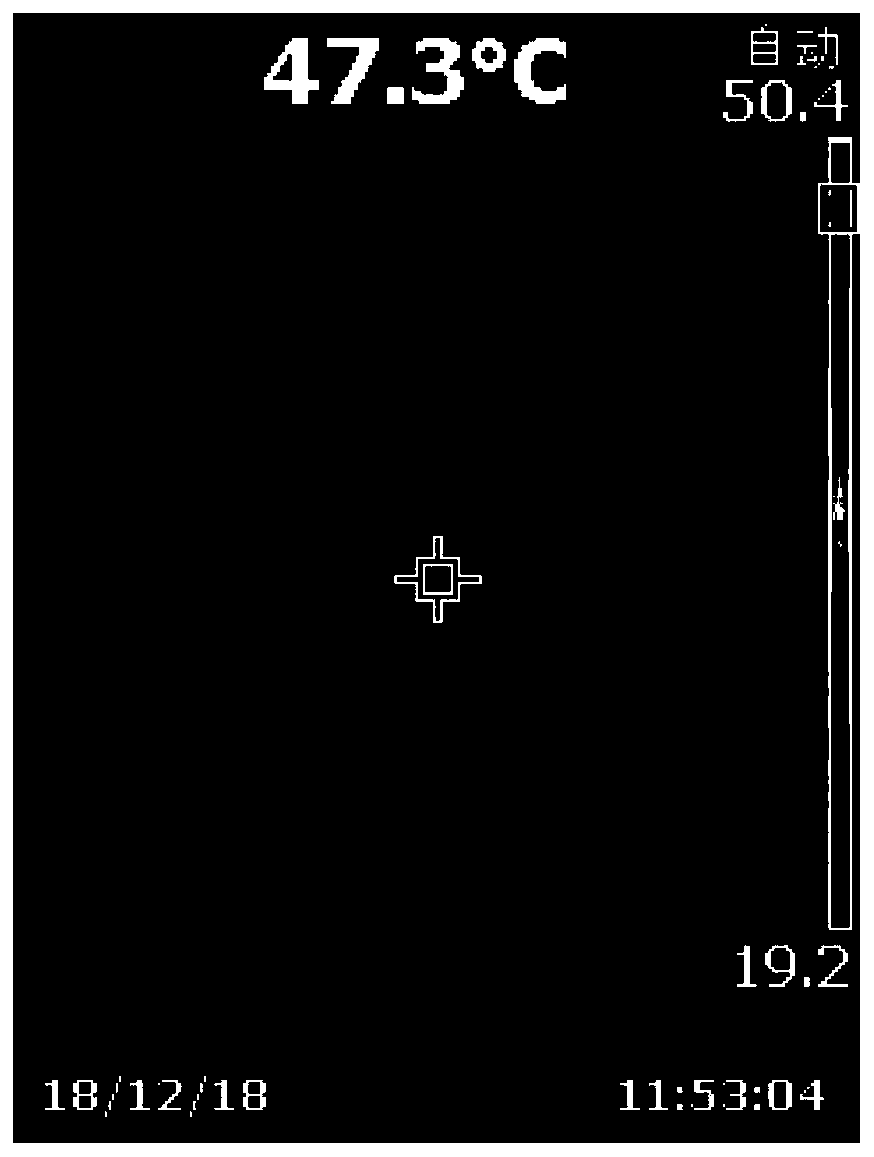

Embodiment 1

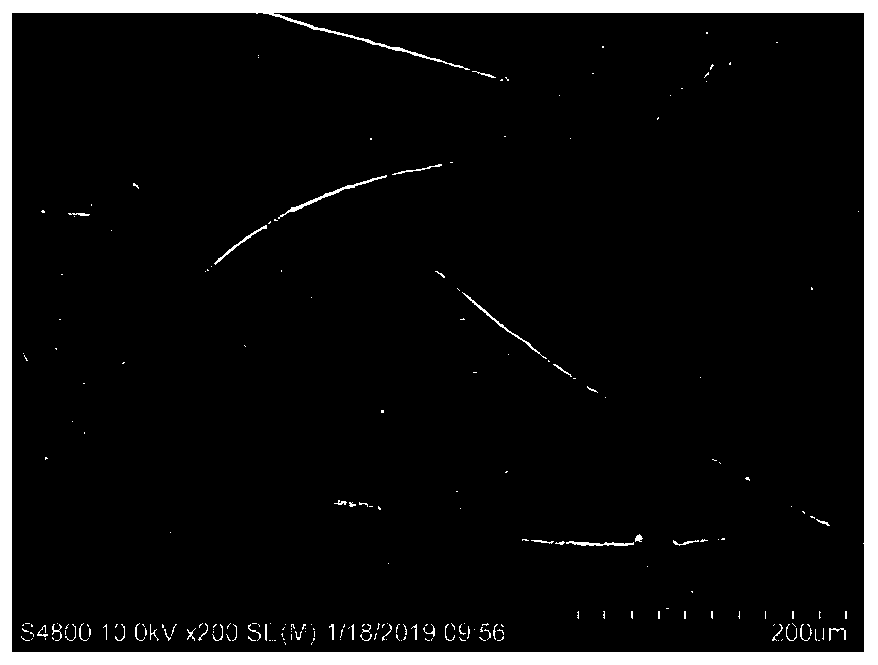

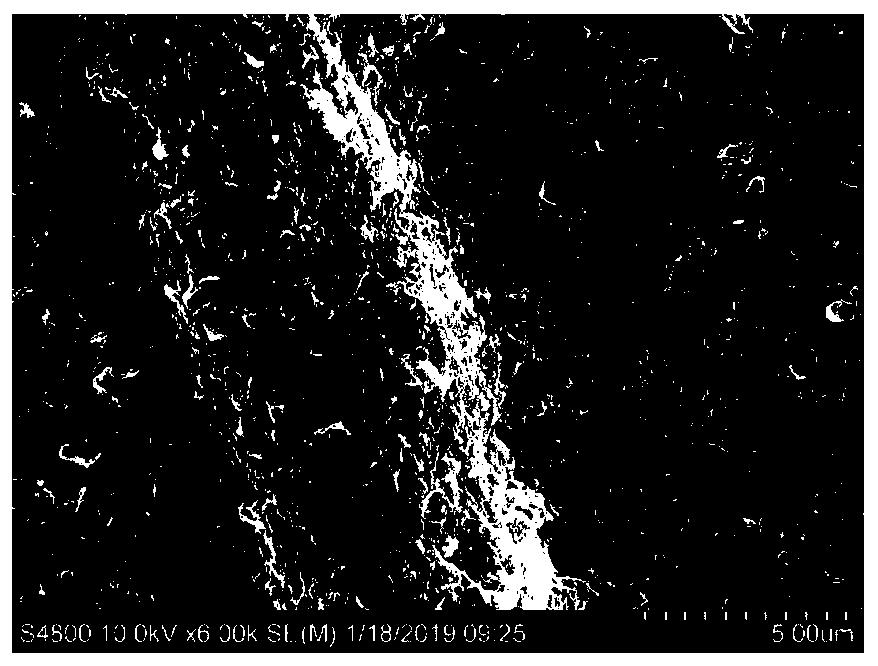

[0072] (1) 0.203g multi-walled carbon nanotubes, 0.029g graphene and 0.348g cationic nanocellulose fibrils (that is, the mass ratio of each component is 35:5:60) are placed in a beaker, and then 0.05g Nano carbon material dispersant, and add 50g of distilled water, then ultrasonic treatment under 600W ultrasonic power for 5min and then magnetic stirring treatment at 1000r / min for 30min to prepare an aqueous solution containing carbon nanotubes, graphene and nanocellulose.

[0073] (2) The aqueous solution containing carbon nanotubes, graphene and nanocellulose prepared in step (1) is poured into the Buchner funnel of the vacuum suction filter device that has been assembled and is in operation (the funnel diameter is 110mm, The PTFE filter membrane has been placed in the funnel), and treated for 4 hours under a vacuum filtration pressure of 0.1 MPa to prepare a carbon nanotube-graphene-nanocellulose nanocarbon material electrothermal membrane positioned on the PTFE filter membra...

Embodiment 2

[0078] Carbon nanotube-graphene-nanocellulose nano-carbon material electrothermal film is prepared according to the method in Example 1, the difference is only that the consumption of multi-walled carbon nanotubes, graphene and cationic nanocellulose fibrils is respectively 0.116 g, 0.116g and 0.348g (that is, the mass ratio of each component is 20:20:60).

[0079] The performance test of the prepared carbon nanotube-graphene-nanocellulose nano-carbon material electric heating film shows that its breaking strength is 40.5MPa, and the maximum strain is 0.52%. The heating temperature reached 53.9°C in 3 minutes, and the electric-thermal radiation conversion efficiency was 37.4mW / °C when the voltage range was 4-20V.

Embodiment 3

[0081] Carbon nanotube-graphene-nanocellulose nano-carbon material electrothermal film is prepared according to the method in Example 1, the difference is only that the consumption of multi-walled carbon nanotubes, graphene and cationic nanocellulose fibrils is respectively 0.029 g, 0.203g and 0.348g (that is, the mass ratio of each component is 5:35:60).

[0082] The performance test of the prepared carbon nanotube-graphene-nanocellulose nanocarbon material electrothermal film shows that its breaking strength is 48.5MPa, the maximum strain is 0.9%; the conductivity is 1.17S / cm; when energized at 20V, The heating temperature reaches 39.7°C in 3 minutes, and the electric-thermal radiation conversion efficiency is 40.1mW / °C when the voltage range is 8-28V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com