Biomass fuel blast heater with cooling function

A biomass fuel, hot air technology, applied in lighting and heating equipment, air heaters, fluid heaters, etc., can solve problems such as thermal energy loss, overheating of outlet air temperature, and fuel waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be understood that in the description of the present invention, unless otherwise specified, "plurality" means two or more.

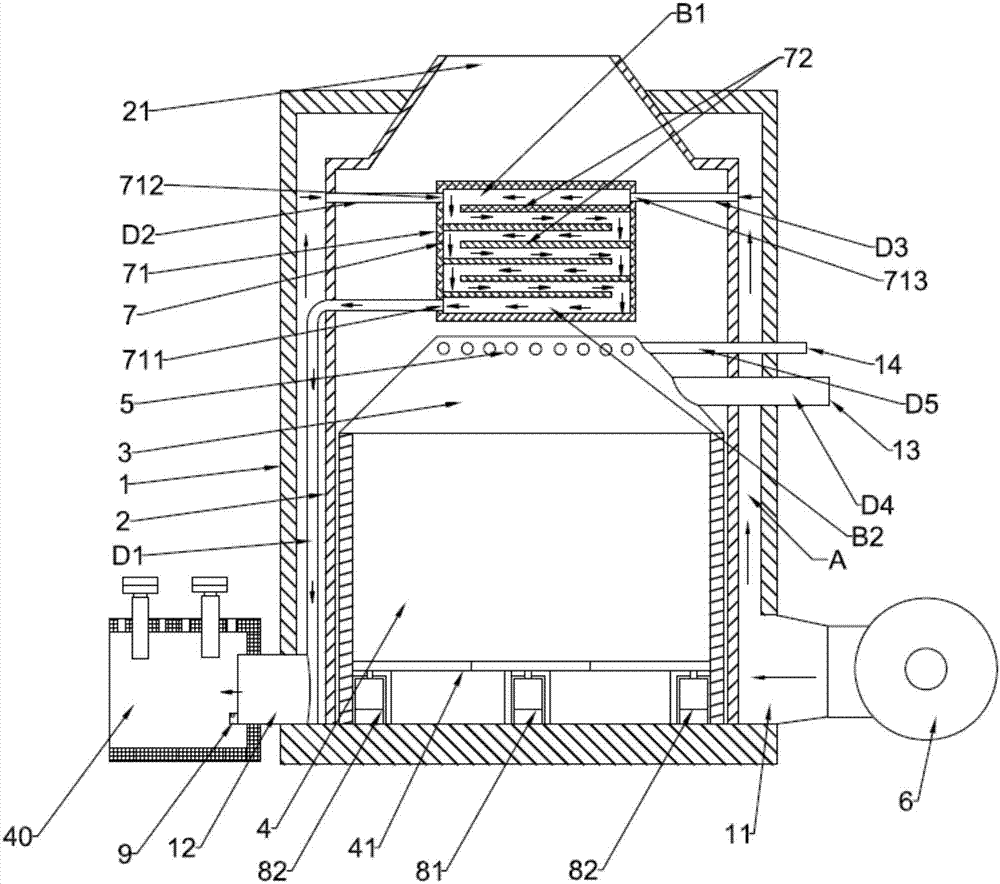

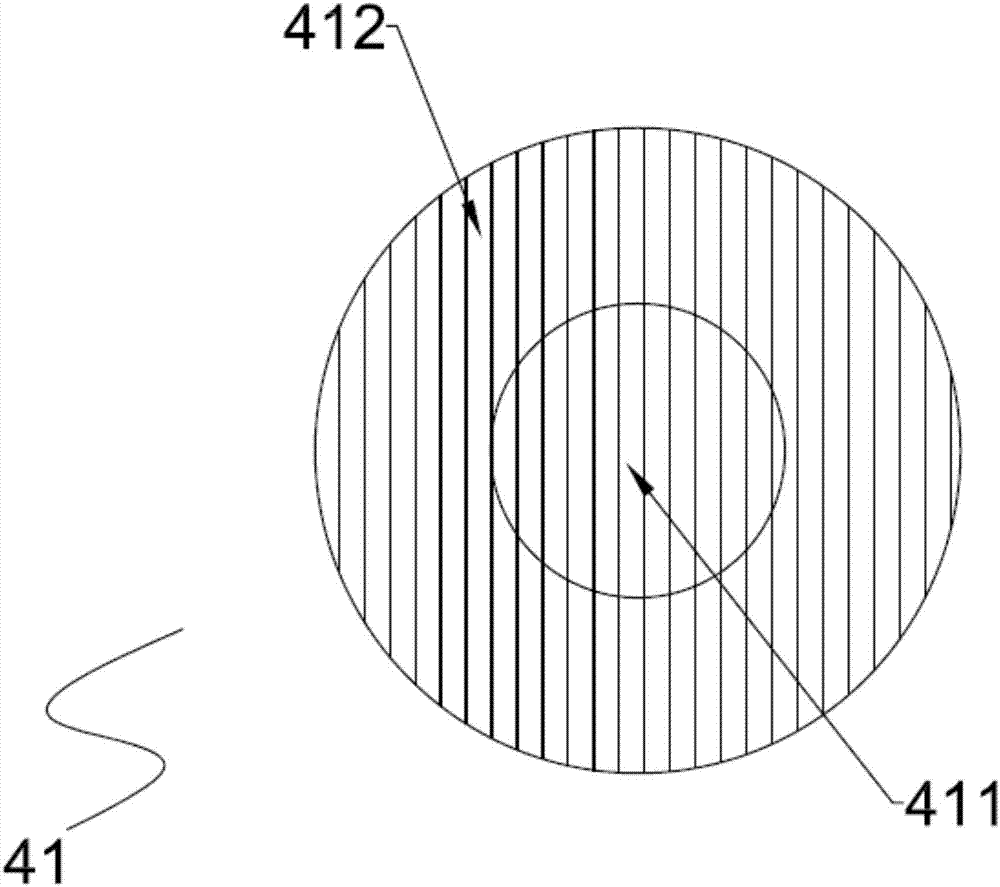

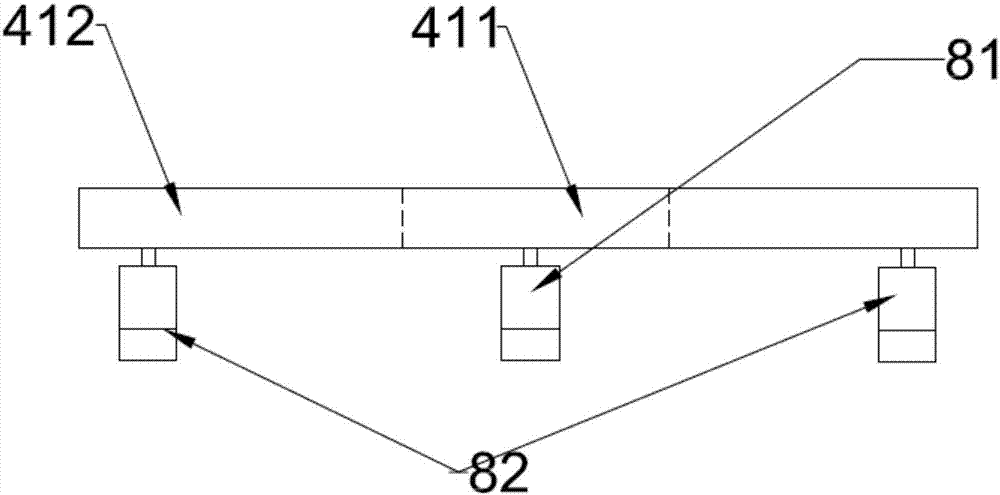

[0045] see figure 1 , the present invention provides a biomass fuel hot air equipment that can cool down, which includes a furnace body 1, an inner tank 2, a combustion bin 3, a fuel bin 4, an oxygen supply 5, a blower 6, an air heating unit 7, and at least two groups Lifting mechanism and heating control unit. In this embodiment, there are two sets of lifting mechanisms (81 and 82), and each set of lifting mechanisms may include one or more lifting mechanisms.

[0046] The furnace body 1 is provided with a cold air inlet 11 , a hot air outlet 12 , a material inlet 13 and an oxygen inlet 14 ; the hot air outlet 12 is provided with a temperature sensor 9 .

[0047] The inner tank 2 is arranged in the furnace body 1, and the space between its outer wall and the inner wall of the furnace body 1 forms a heating chamber A; the top of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com