Cutting knife for fused deposition molding part

A technology of fused accumulation molding and cutting knives, which is applied in the direction of manufacturing auxiliary devices and additive processing, can solve the problems of time-consuming and laborious operation, whitening of the cutting surface, and wire drawing, etc., and achieve safe and convenient operation, high cutting quality, and convenient charging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

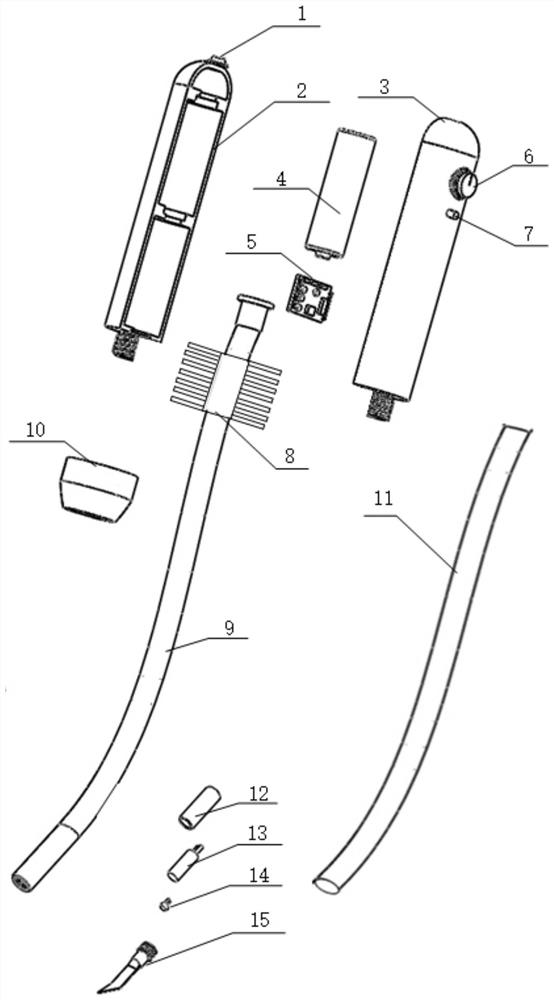

[0023] see figure 1 and figure 2 As shown, a cutting knife for fused deposition moldings, a cutting knife for fused deposition moldings, including a casing, a power supply assembly and a heating assembly.

[0024] The shell includes a left shell, a right shell, an end cover, a heat sink, a universal hose, and a heat-insulating silicone sleeve. The power supply assembly includes a power supply, a push switch, and a charging interface. The heating assembly includes a circuit board, a rotary switch, Insulation cotton, heating tube, temperature sensor and cutter head. The rear end of the left housing is provided with a push switch, which is the main power switch of the cutting knife. The circuit board starts timing after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com