An image sensor chip testing and sorting all-in-one machine

An image sensor and chip testing technology, which is applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, radiation control devices, etc., can solve problems such as not being integrated in one machine, increasing the risk of chip damage or contamination, etc. , to reduce the risk of pollution, avoid elongation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

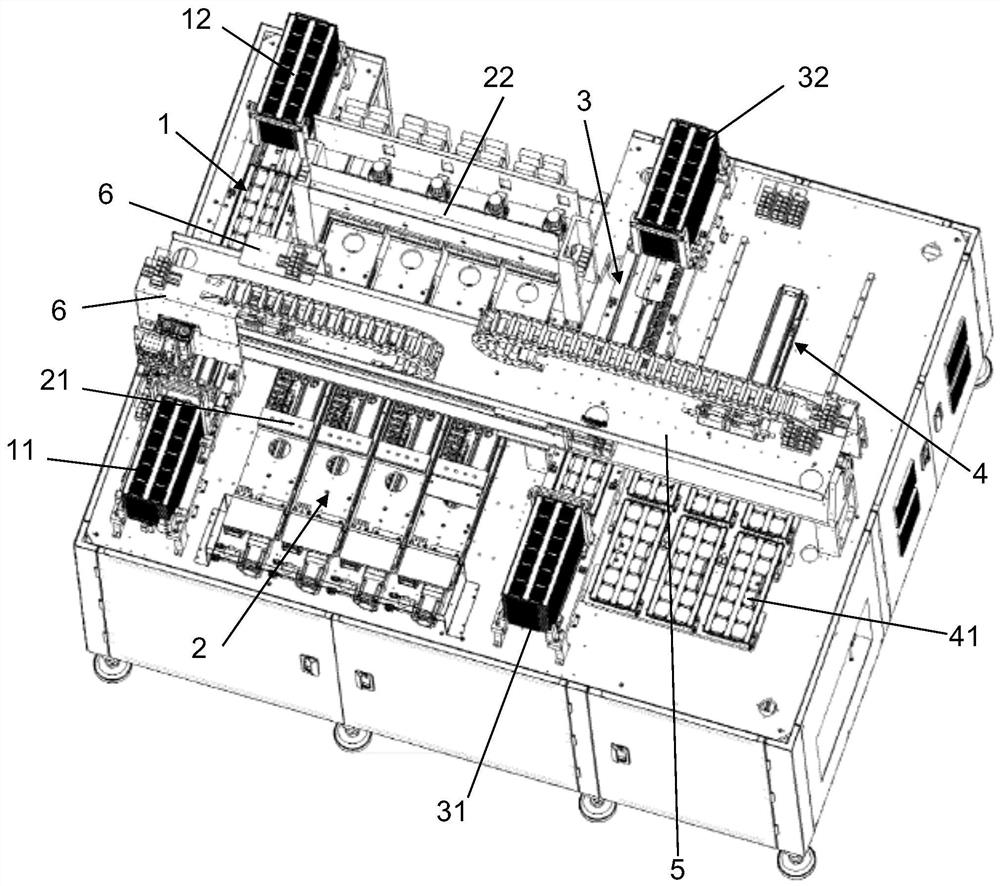

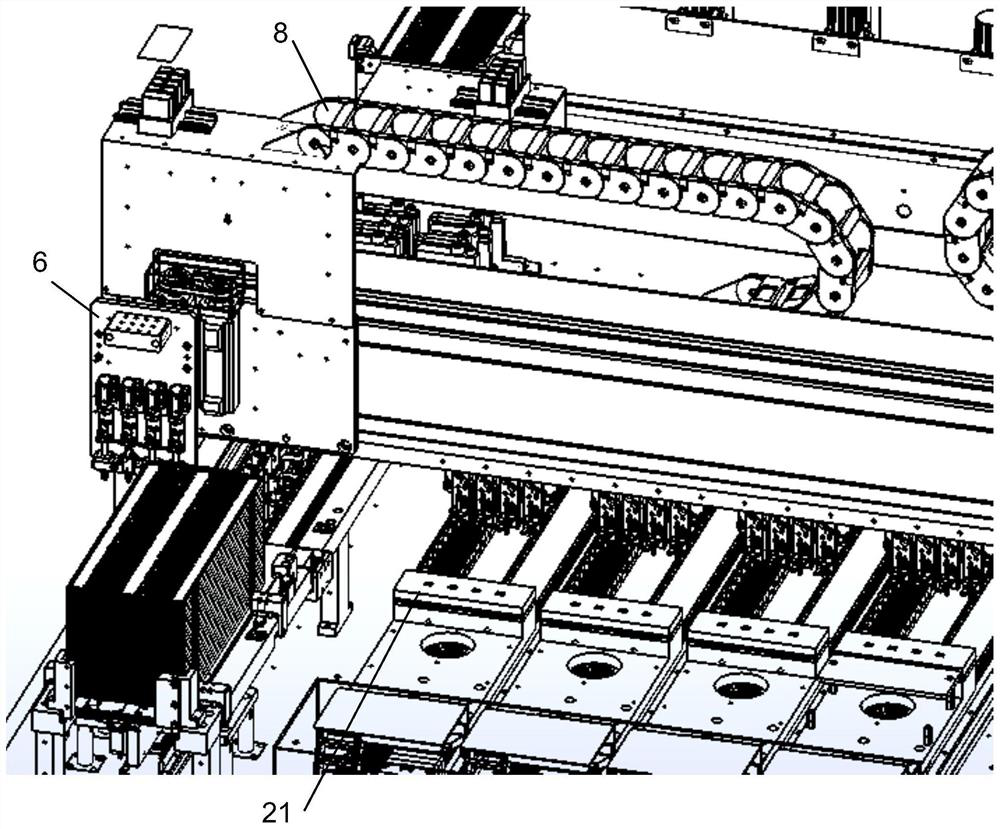

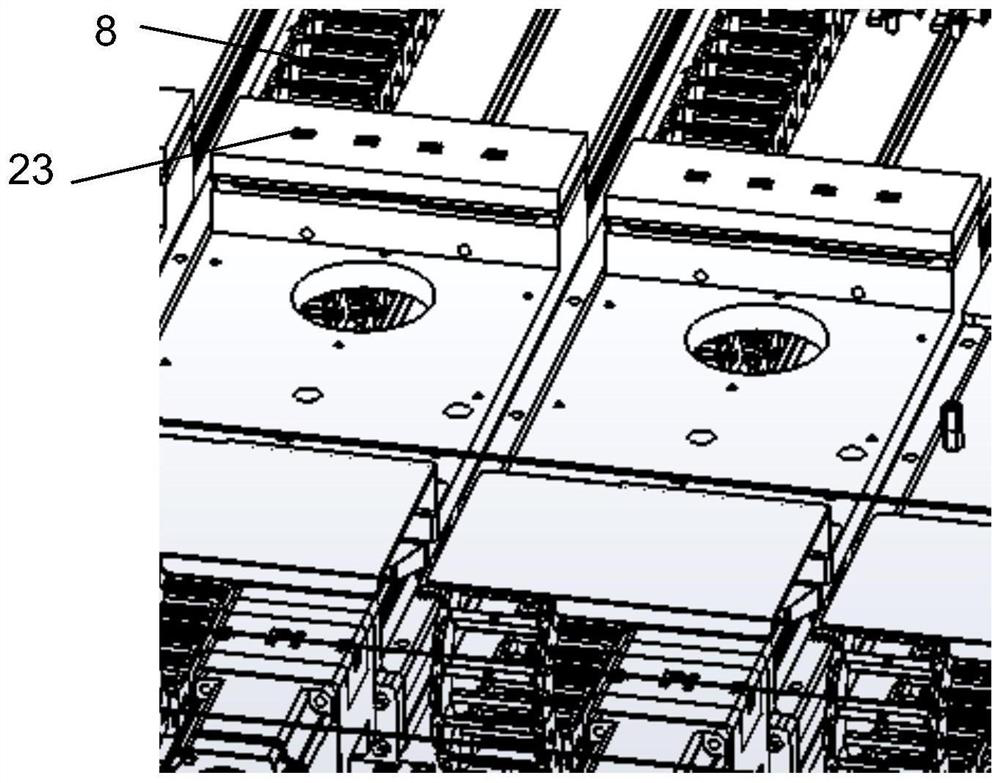

[0032] The image sensor chip testing and sorting all-in-one machine of the present invention is as follows: Figure 1-Figure 4 As shown, it mainly includes a test flow channel 1, a test flow channel 2, a good product flow channel 3, and a defective product flow channel 4, which are arranged horizontally in sequence and each has a conveying mechanism. Among them, please combine Figure 8 As shown, the conveying mechanisms in the flow channel 1 to be tested and the good product flow channel 3 all include a track 13 and a shuttle mechanism 9 arranged in the track 13, and the shuttle mechanism 9 includes a shuttle car 91 and a mechanism for driving the shuttle car 91 back and forth. The linear module 8 clamps the carrier pallet 10 through the shuttle car 91, drives the shuttle car 91 through the linear module 8 and drags the pallet 10 for backward transport, and returns empty-loaded. The front end of the flow channel 1 to be tested is provided with a tray loading bin 11 full of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com