Electric steam boiler

A steam boiler and steam technology, which is applied to steam boilers, steam boiler accessories, and components of steam boilers, etc., can solve the problems of large volume of pressure cookers, and achieve the effects of reduced volume, simple structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

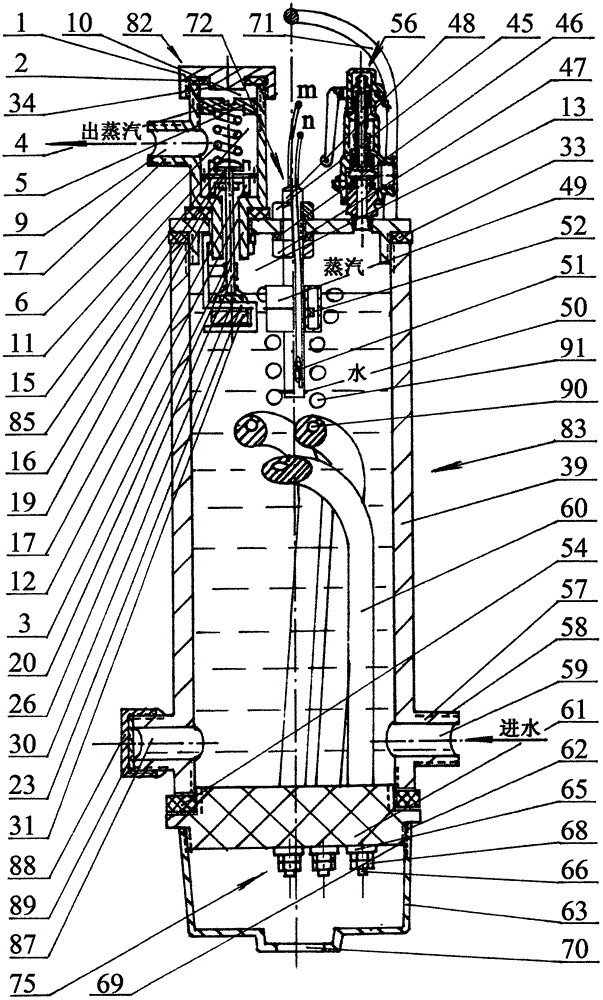

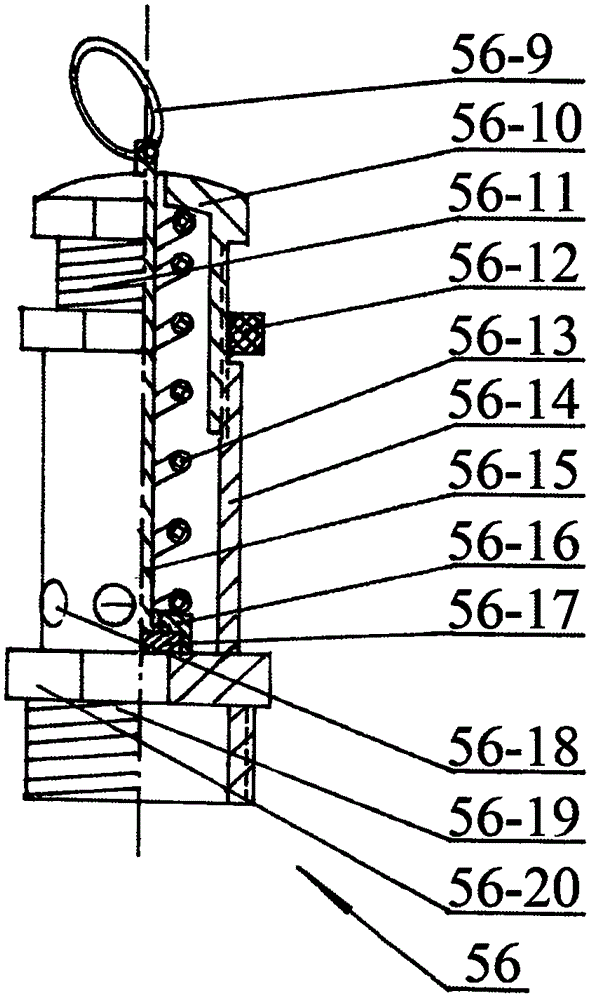

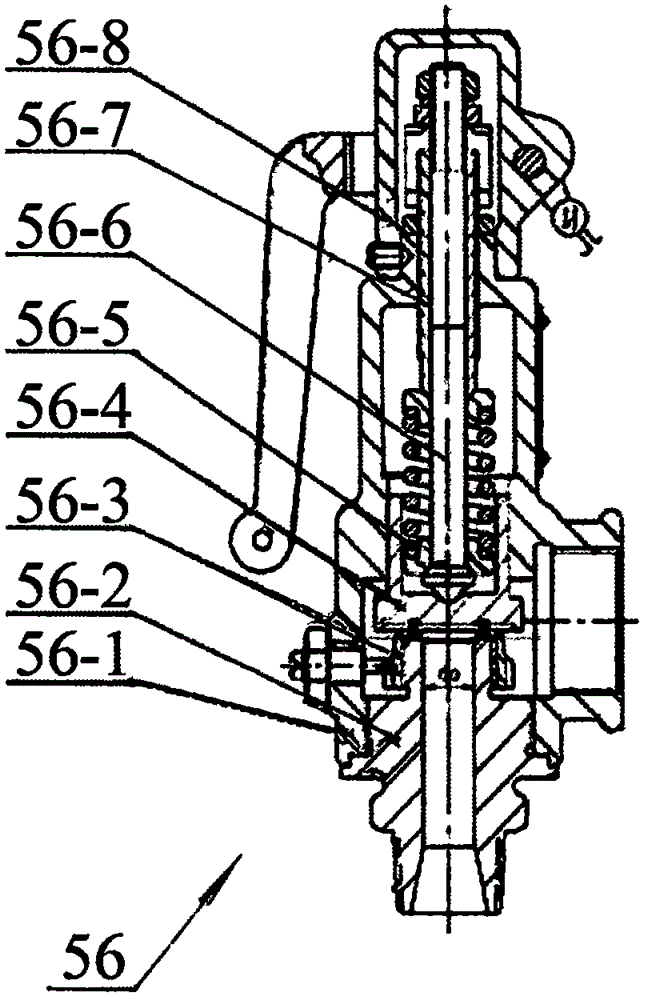

[0032] The electric steam boiler of the invention comprises: a steam and water separator; a pressure vessel; a safety valve; an electric heater; an automatic water supply device;

[0033] figure 1 , Figure 4 , Figure 4-1 to Figure 4-3 The upper cover 1 of the middle valve cylinder can be without the boss 34; On the outer wire 36 of the valve cylinder 3, the No. 3 inner cavity 11 of the valve cylinder 3 and the No. 1 inner cavity 9 of the steam output pipe 7 are connected and welded in a "T" shape, and the outer wire part at the lower end of the valve cylinder 3 extends into the pressure vessel 83. In the hole 76 of the upper head 73, compress the No. 4 sealing ring 21 with the No. 2 compression nut 24 and seal it.

[0034] One of the features is that: the No. 3 sealing ring 17 of the valve core of the steam and water separator 82 is circularly depressed, and the circular depression is in the shape of a dome with a round hole 74 in the middle, or such as Figure 5 With a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com