Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3798results about "Steam boilers components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

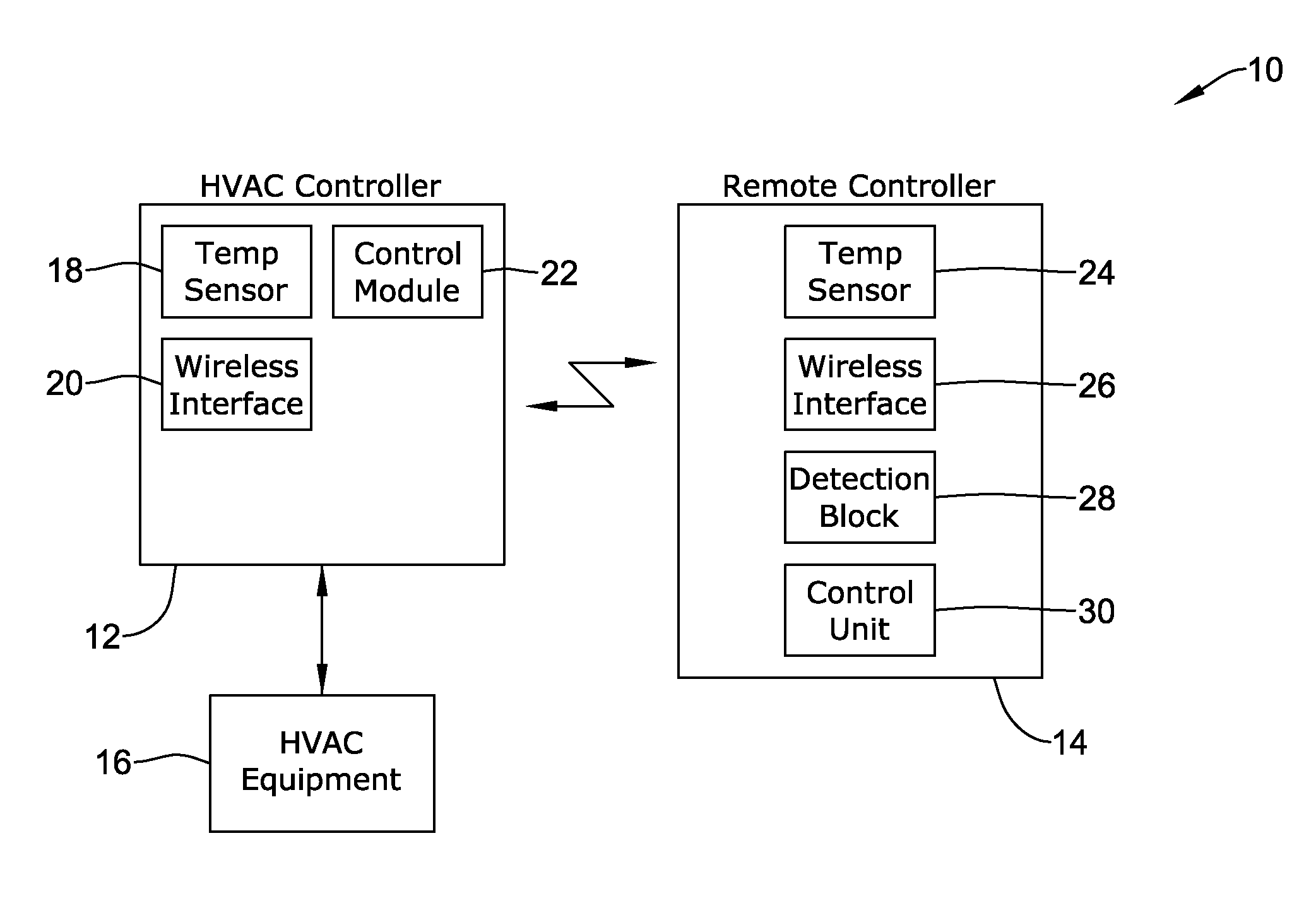

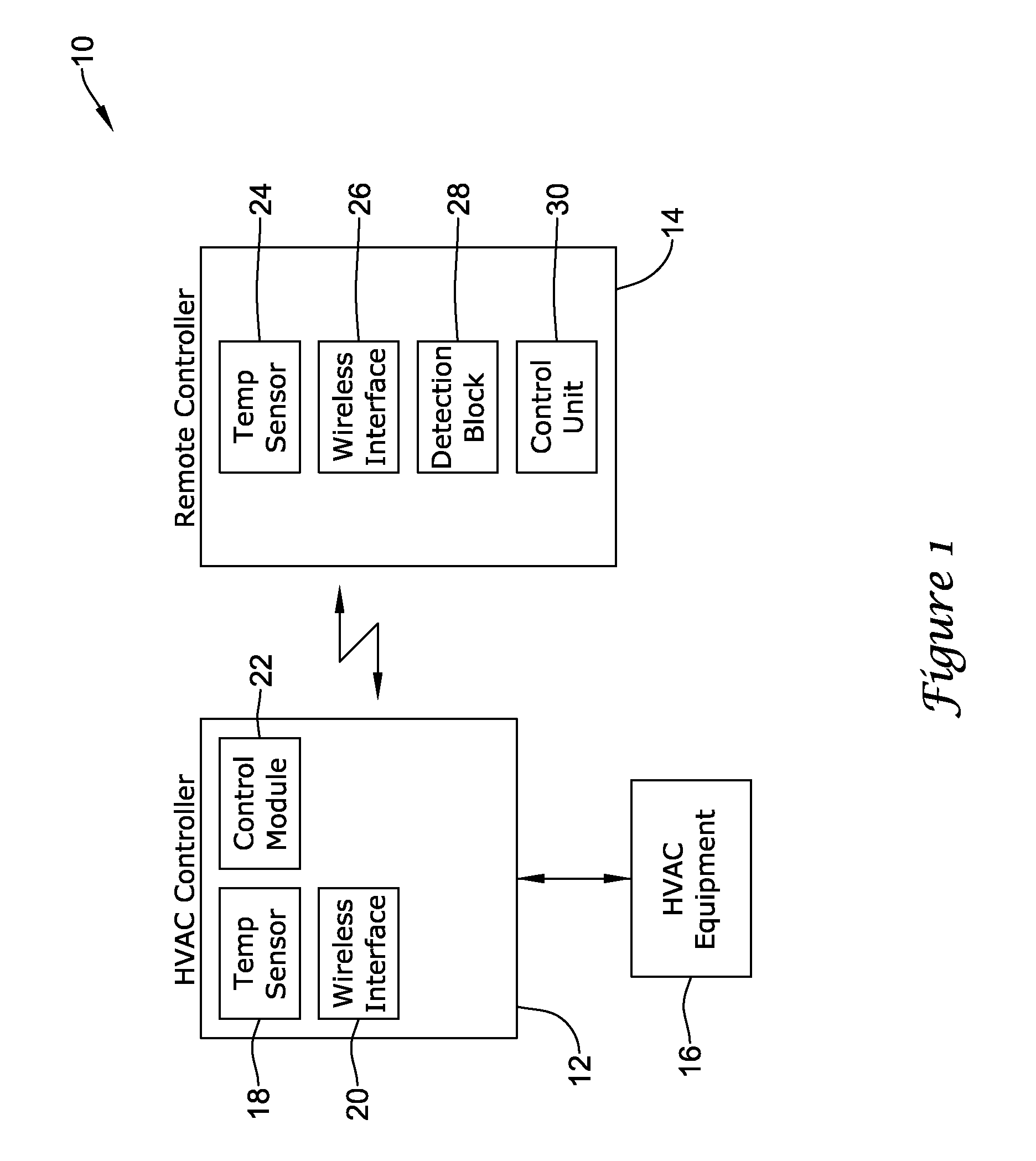

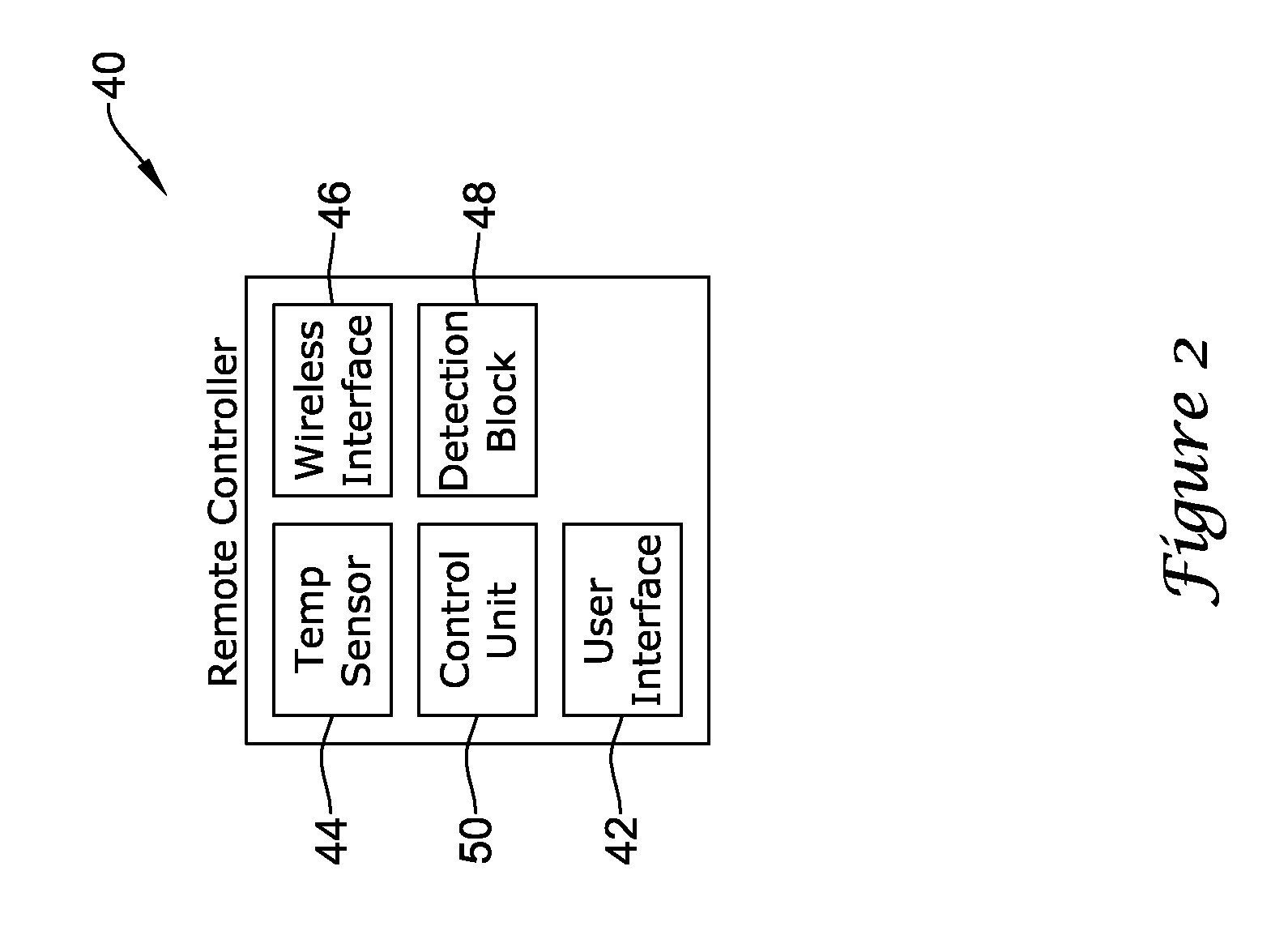

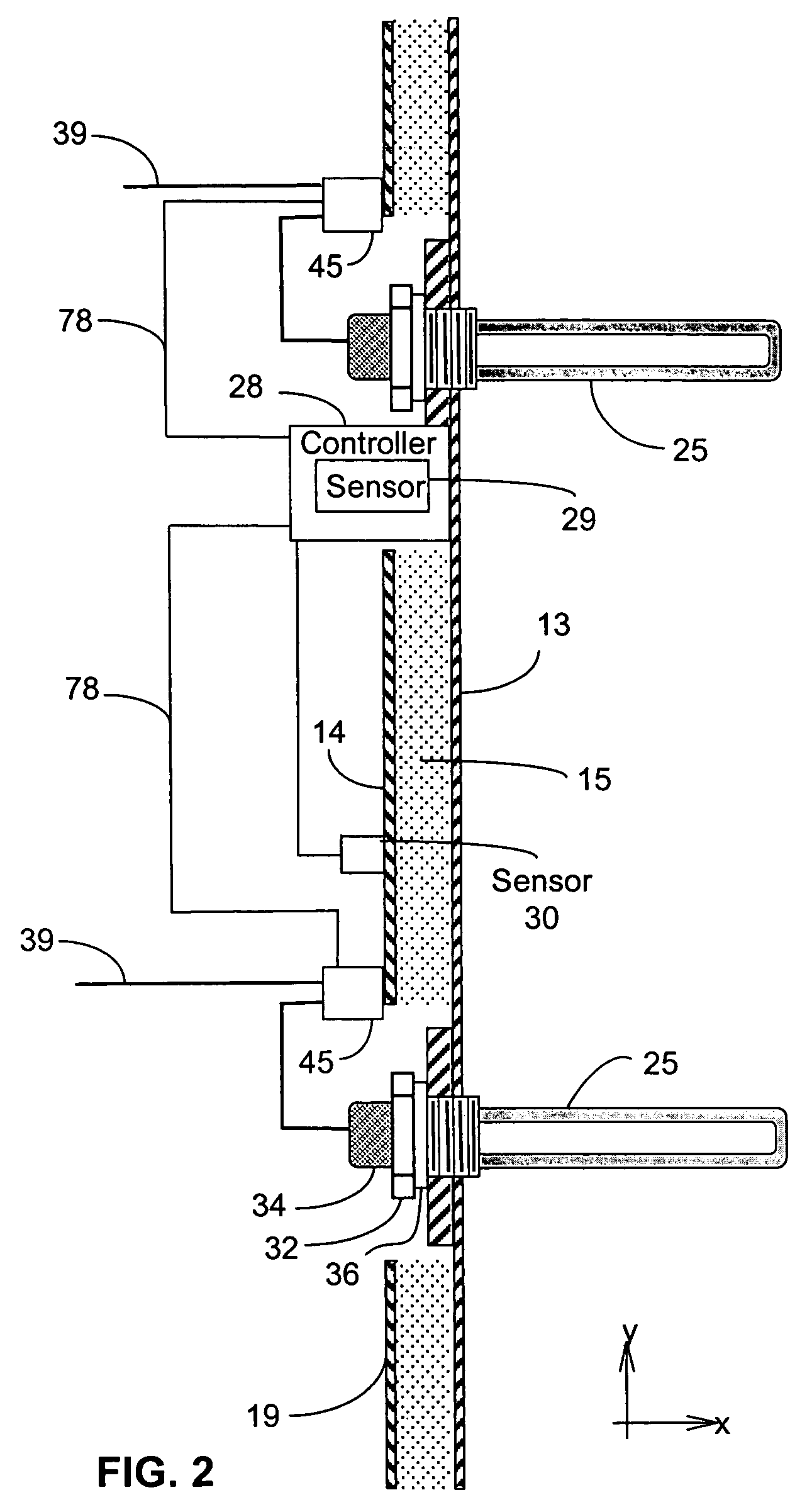

HVAC remote control unit and methods of operation

A comfort control system for controlling the comfort level in a building includes a comfort control unit and a remote control unit. The remote control unit communicates with the comfort control unit from a remote location. In one illustrative embodiment, the remote control unit includes a temperature sensor for sensing an ambient air temperature near the remote control unit, and a measure related to the sensed temperature may be communicated to the comfort control unit. A detection block may be included in the remote control unit for detecting when the ambient air temperature sensed by the temperature sensor in the remote control unit is likely to be influenced by a user or other undesirable condition. The comfort control unit may take this into account when controlling the comfort control system of the building.

Owner:ADEMCO INC

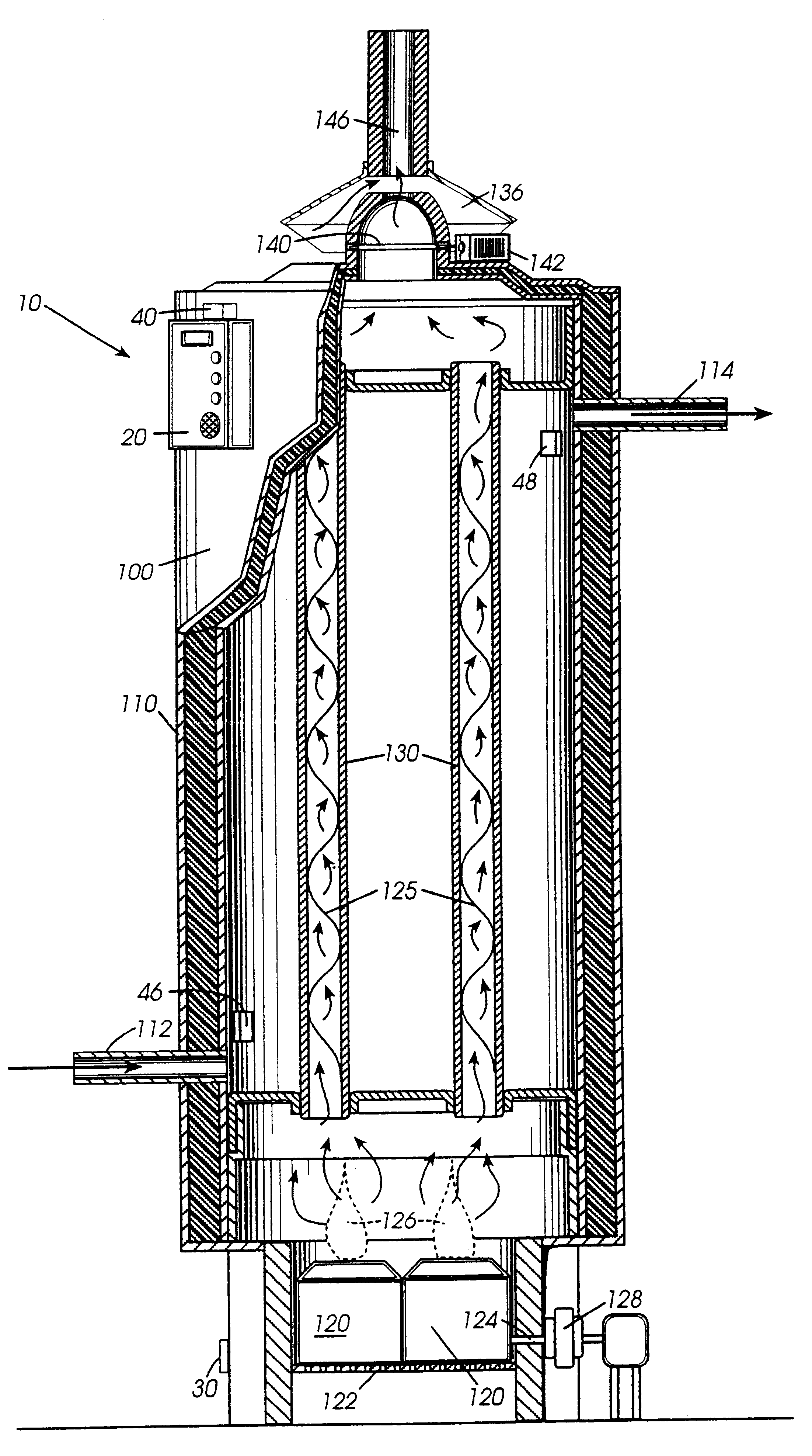

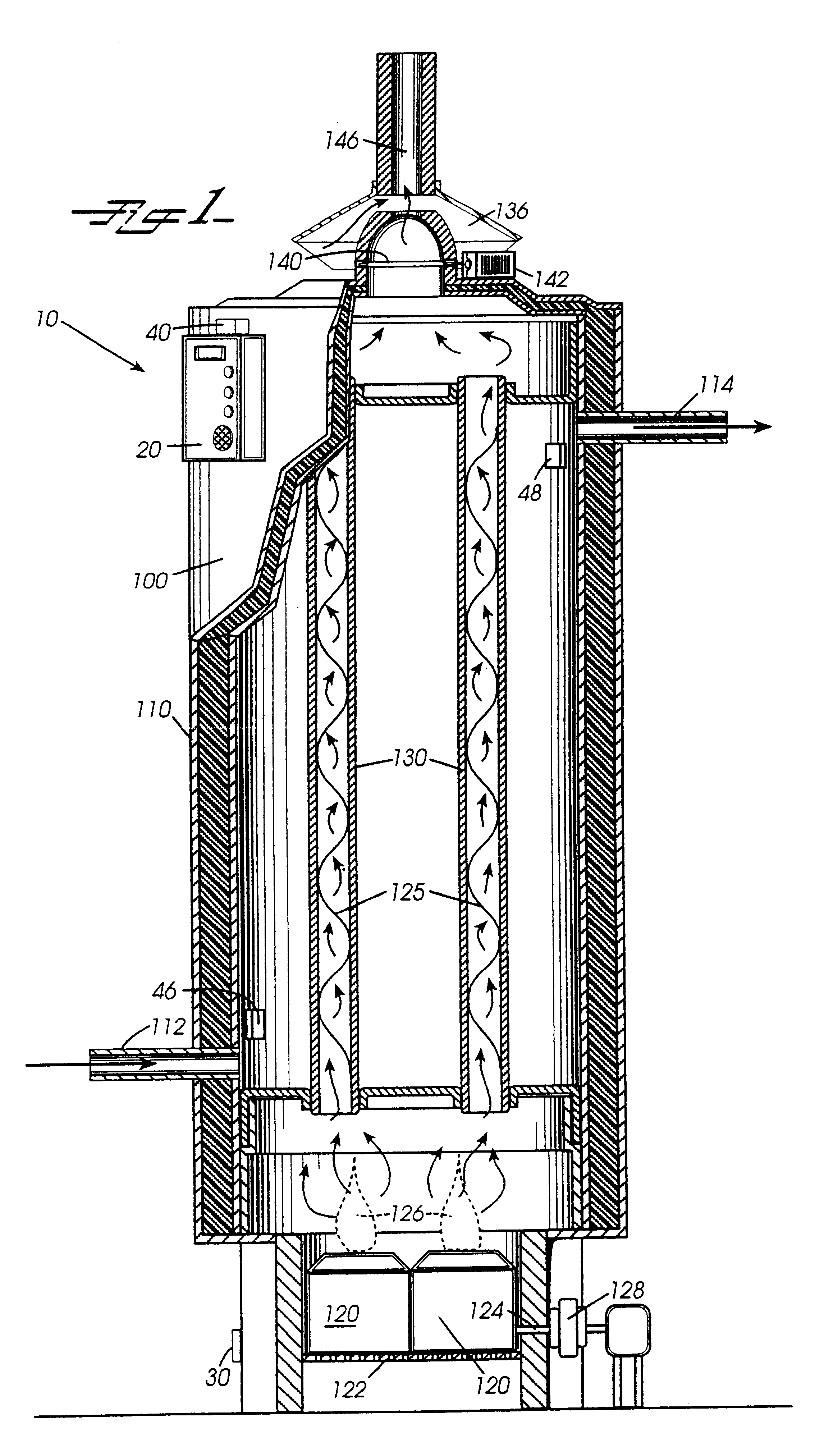

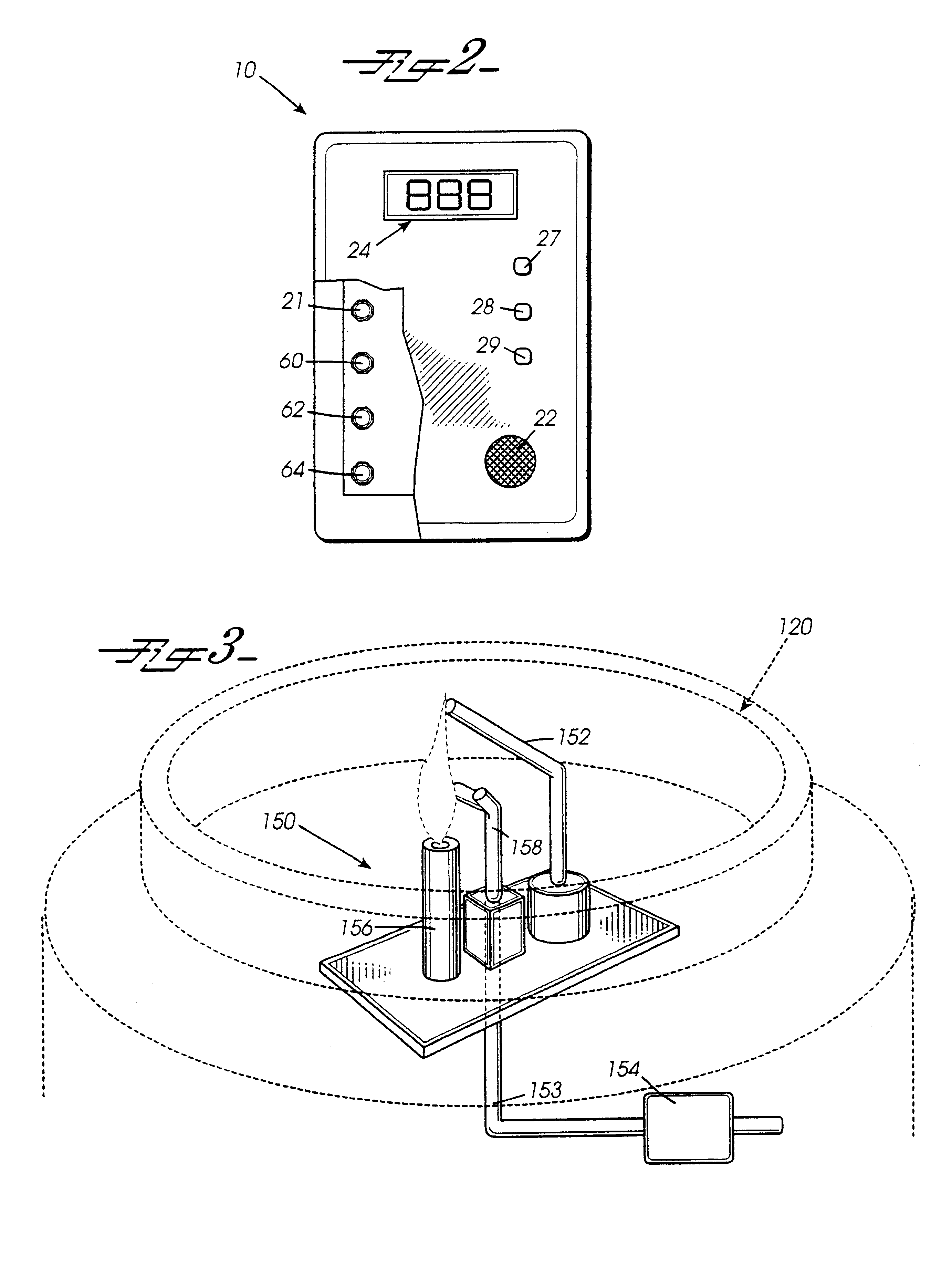

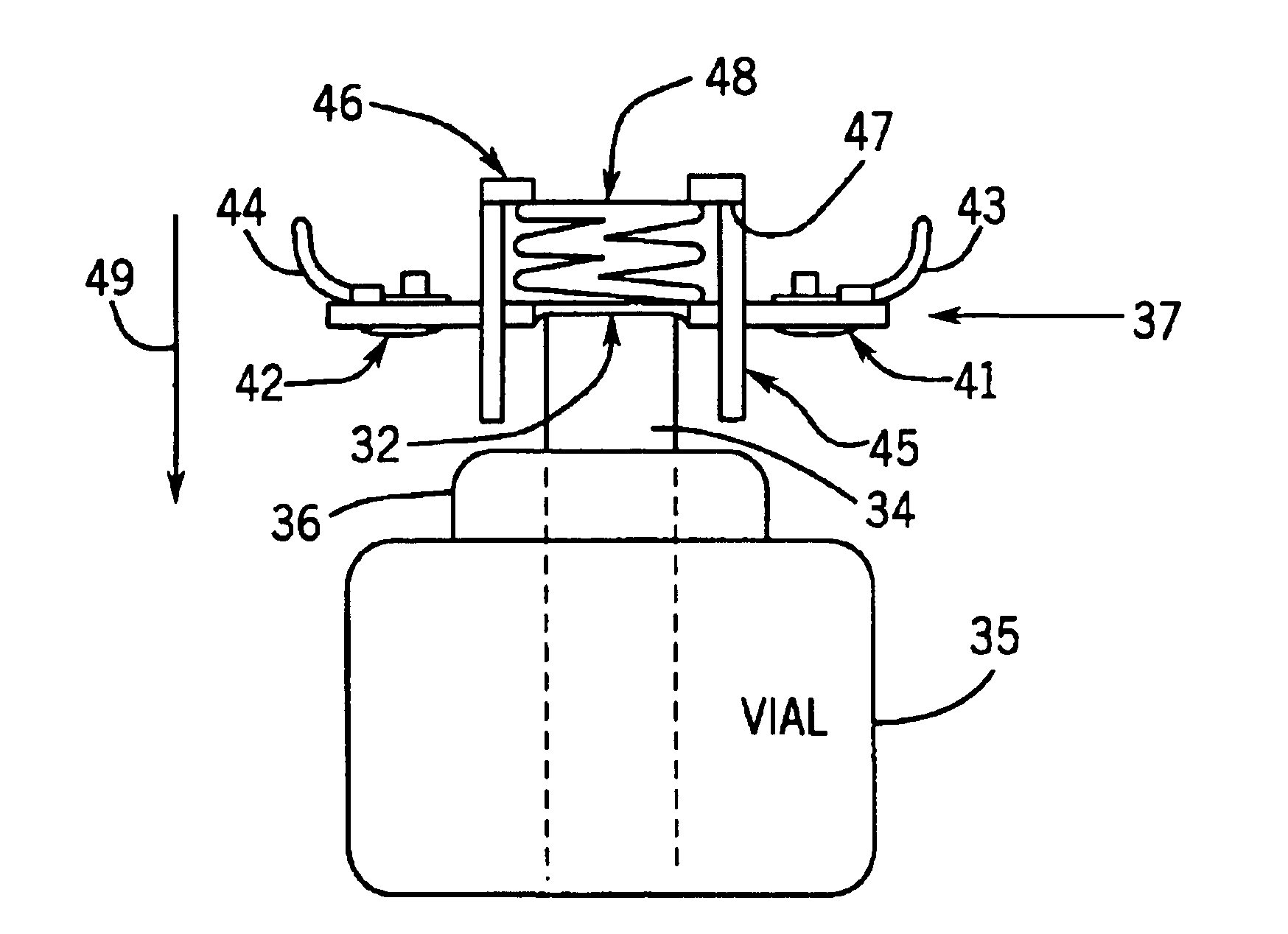

Control system for a water heater

InactiveUSRE37745E1Detect presenceHarmful and dangerousMachines/enginesFuel injecting pumpsCombustorControl system

A multi-function controller for a water heater is advanced comprising a control panel and a plurality of sensors that monitor a variety of functions that impact the operation of a water heater. A flammable gas sensor, placed in proximity to the air intake, detects the presence of an unsafe concentration of gas and issues a signal to the control panel, which subsequently discontinues the operation of the burners. Detection of a blocked vent pipe is achieved by a carbon monoxide sensor placed near the draft hood. The control panel is equipped with circuitry which monitors usage of the heater for a specified time period to develop a pattern of use. Subsequent to the monitoring period, the controller will activate the burners a predetermined time prior to an anticipated period of high use. During periods of low use, the controller will decrease the temperature to which the water is to be heated, thereby resulting in a more efficient heater. Non-volatile memory records data from the sensors so that the operation status of the heater may be ascertained subsequent to a power outage. The control panel contains a plurality of visual alarms, each of which corresponds to a sensor. Consequently, repair and maintenance are simplified because the cause of a malfunction is quickly recognized.

Owner:AOS HLDG CO

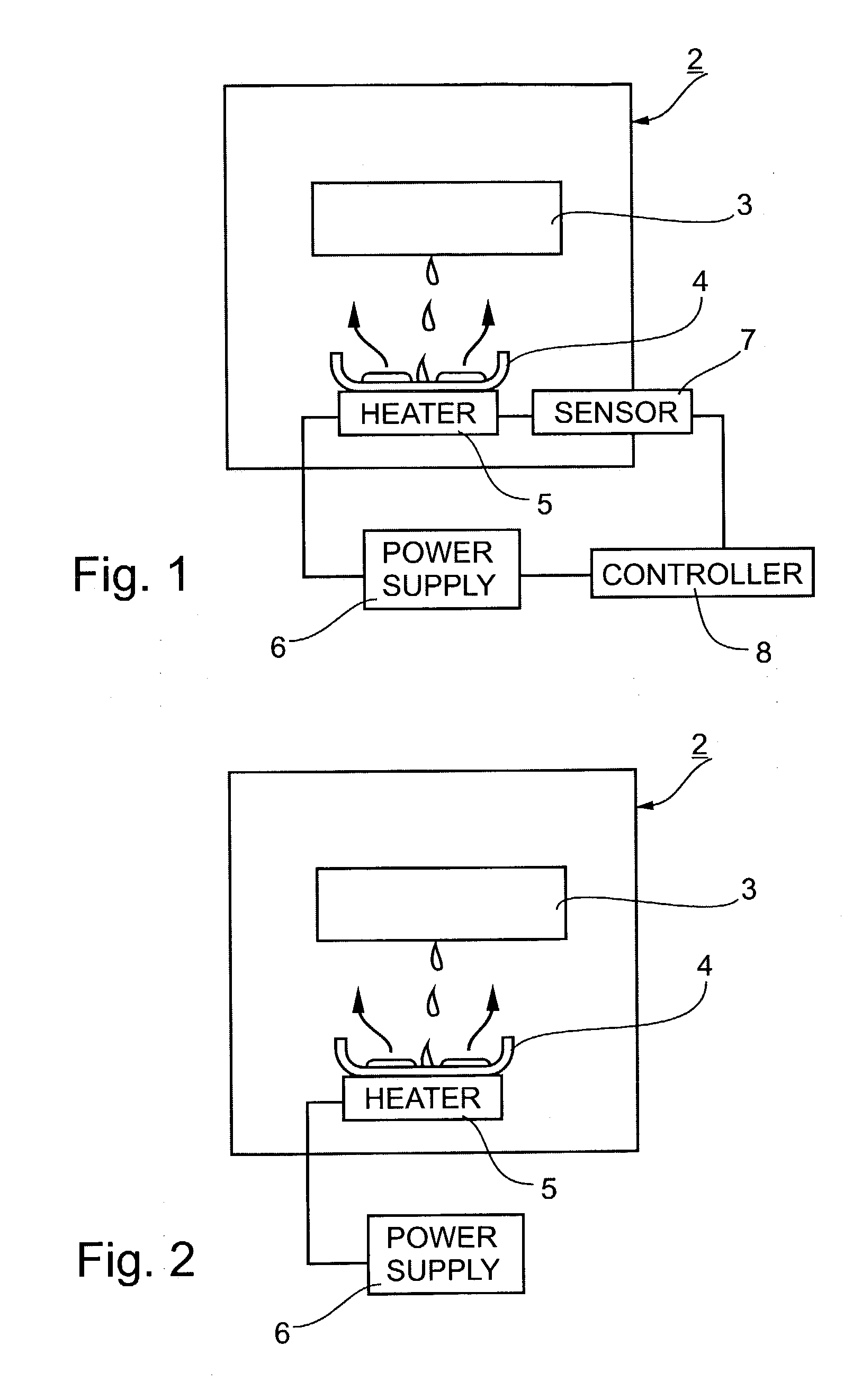

Localized surface volatilization

InactiveUS6909840B2Improved vaporizationIncrease vapor pressureDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceProduct gas

The present invention relates to an apparatus and method for rapid flash-like volatilization of high and low vapor pressure components from liquid or solid emanators which is in contact with a point or localized heat source. Vaporization is promoted by a geometrically small electrically resistive heating element with variable activation for pulsed or cyclic heating of an emanating surface containing the volatile components. The apparatus is primarily directed towards the treatment of residential air for fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, or other ambient air or surface modification by way of gas or vapor distribution.

Owner:SC JOHNSON & SON INC

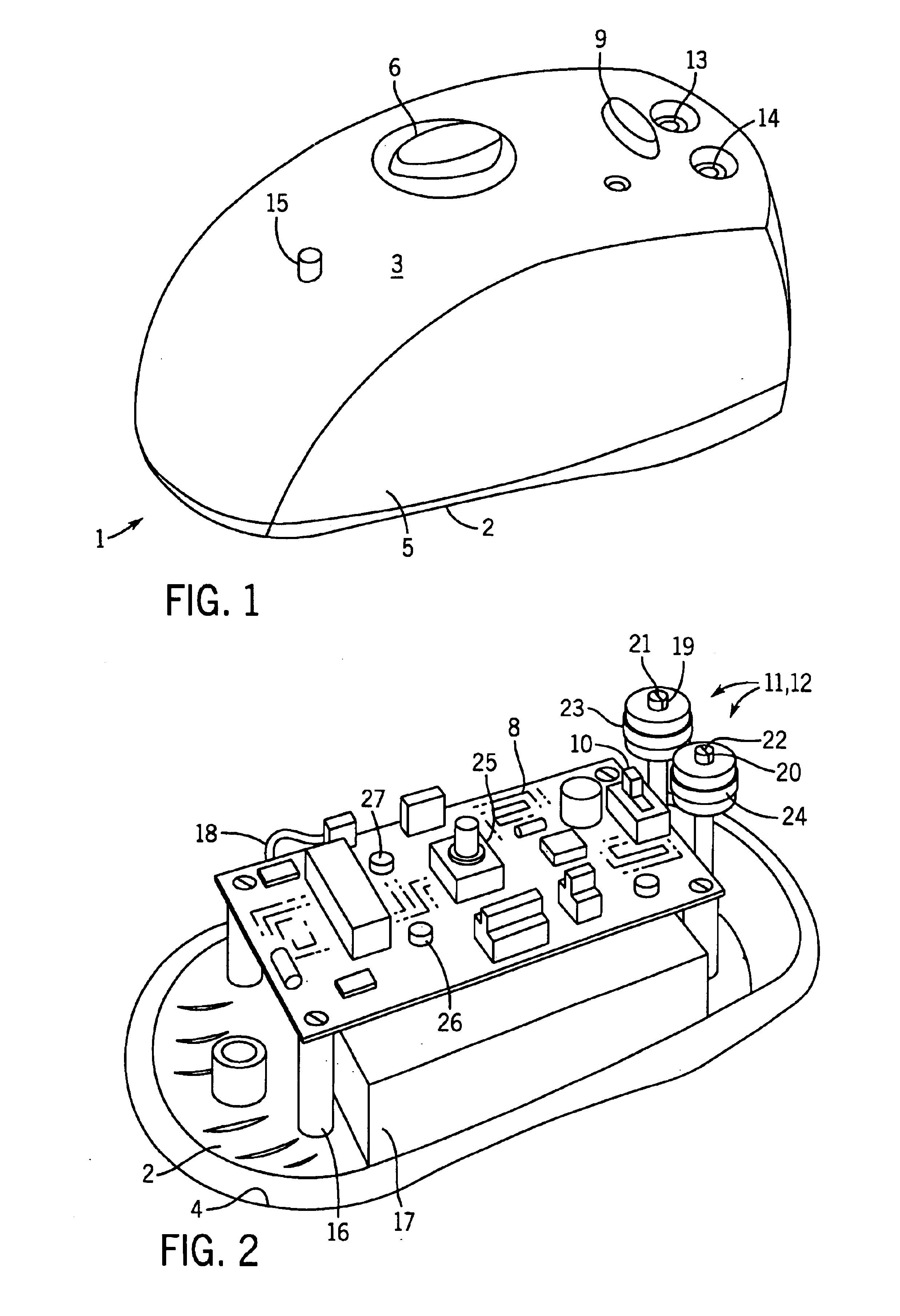

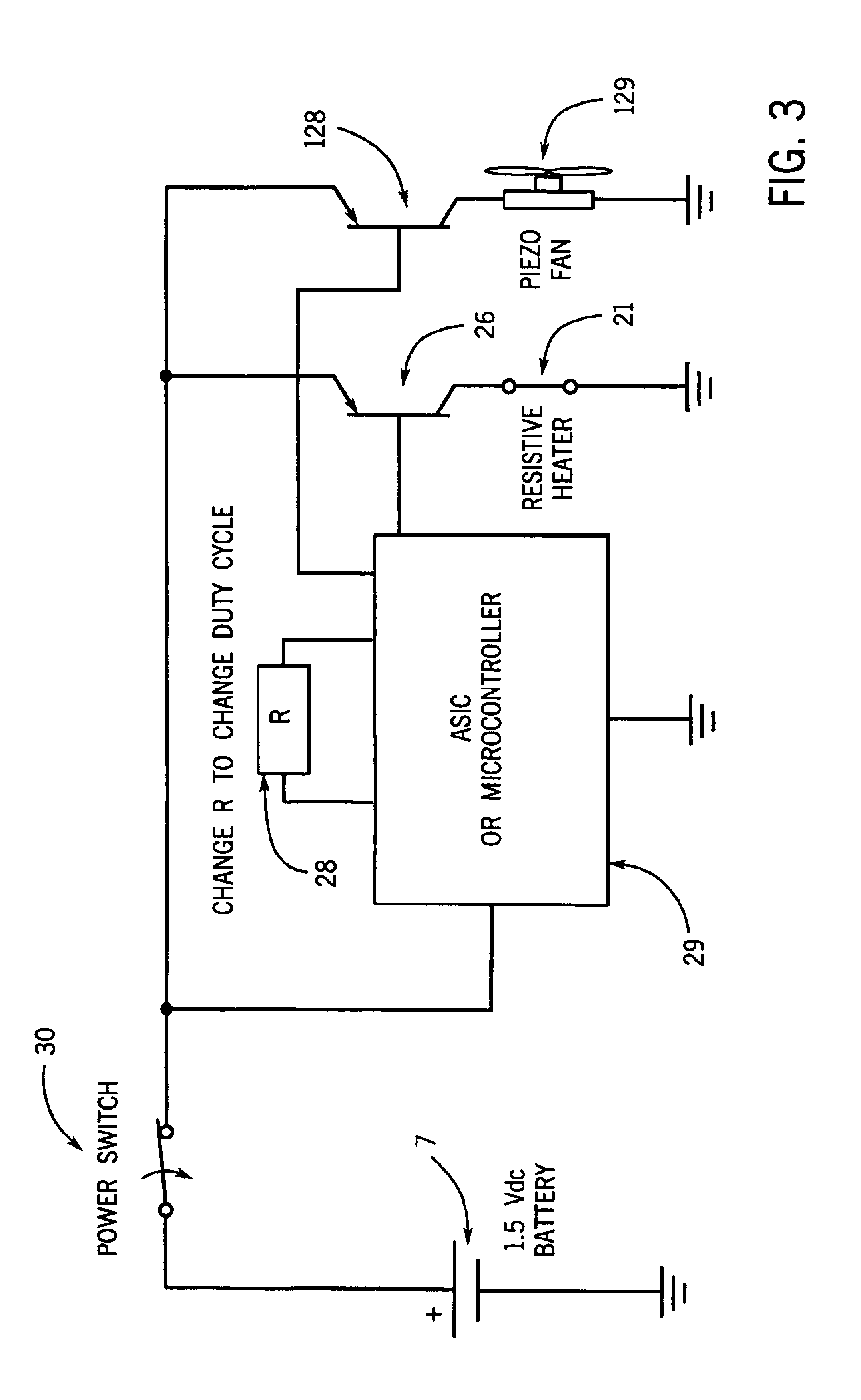

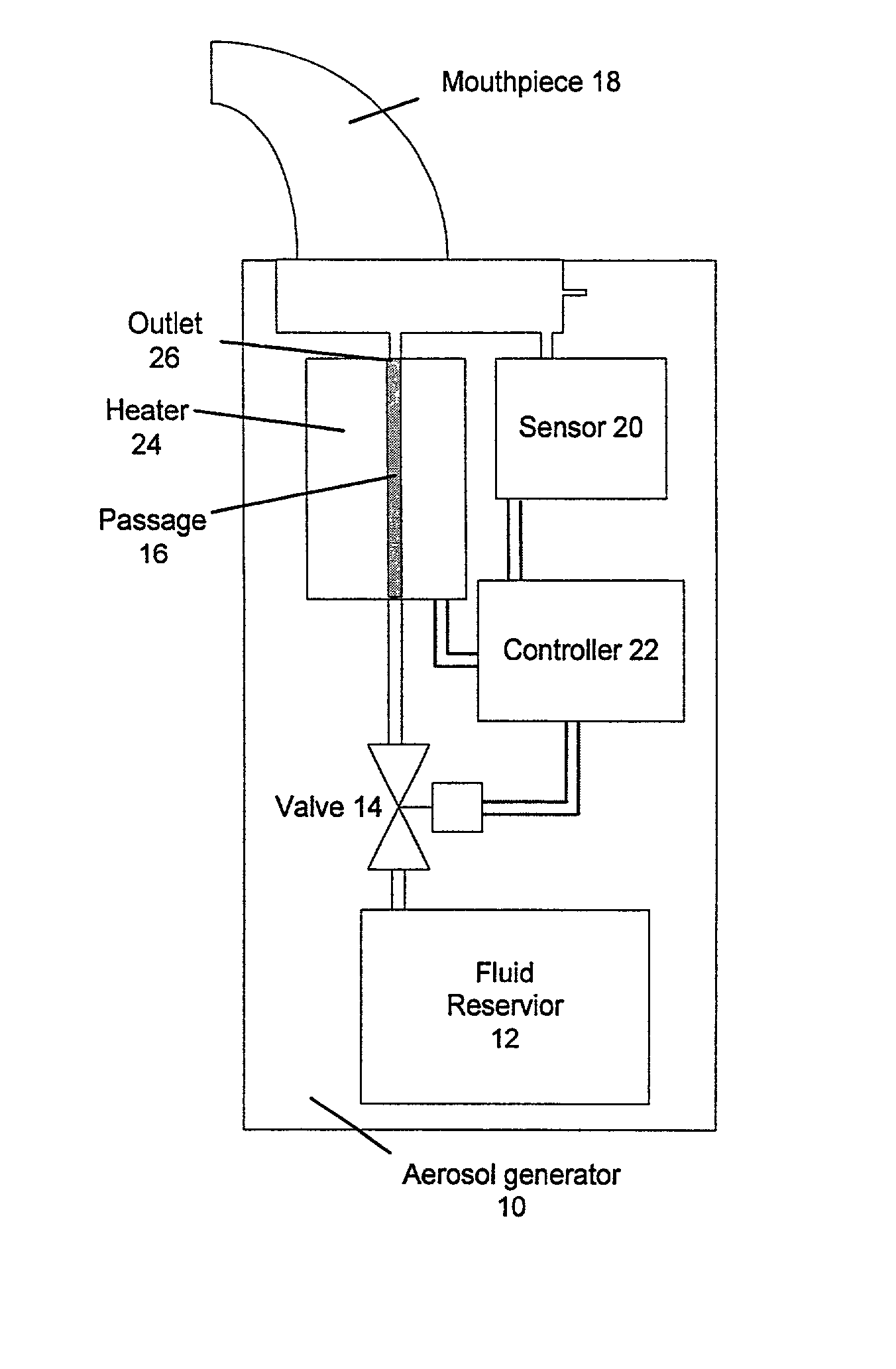

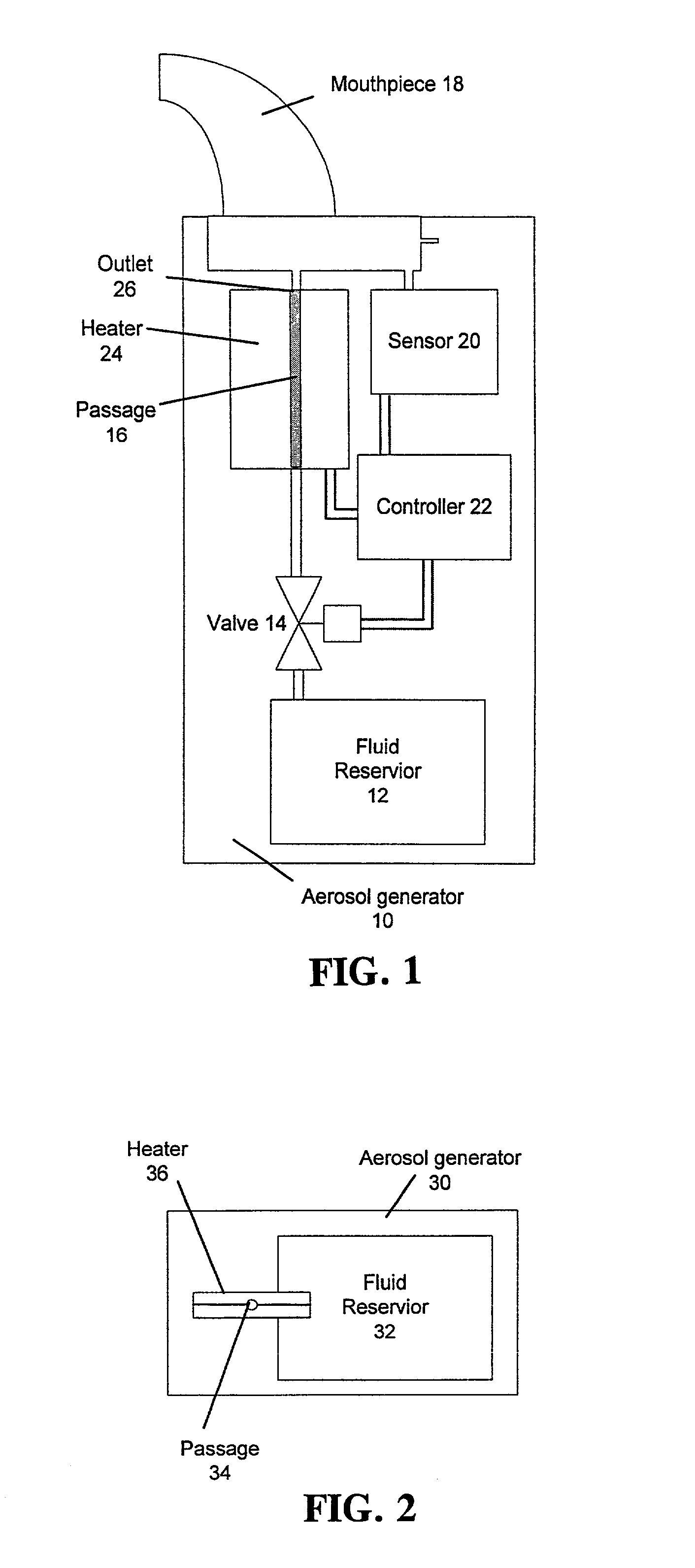

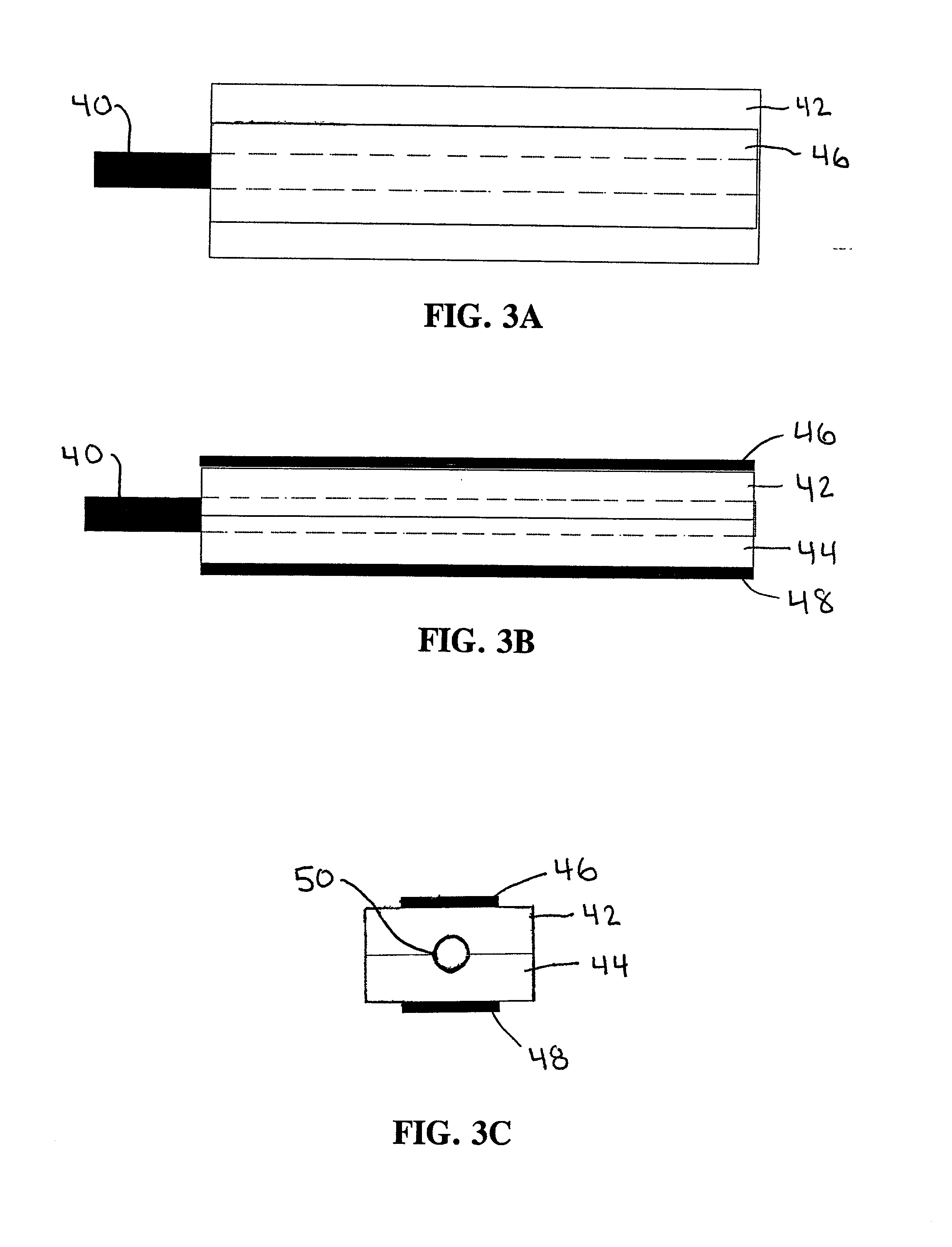

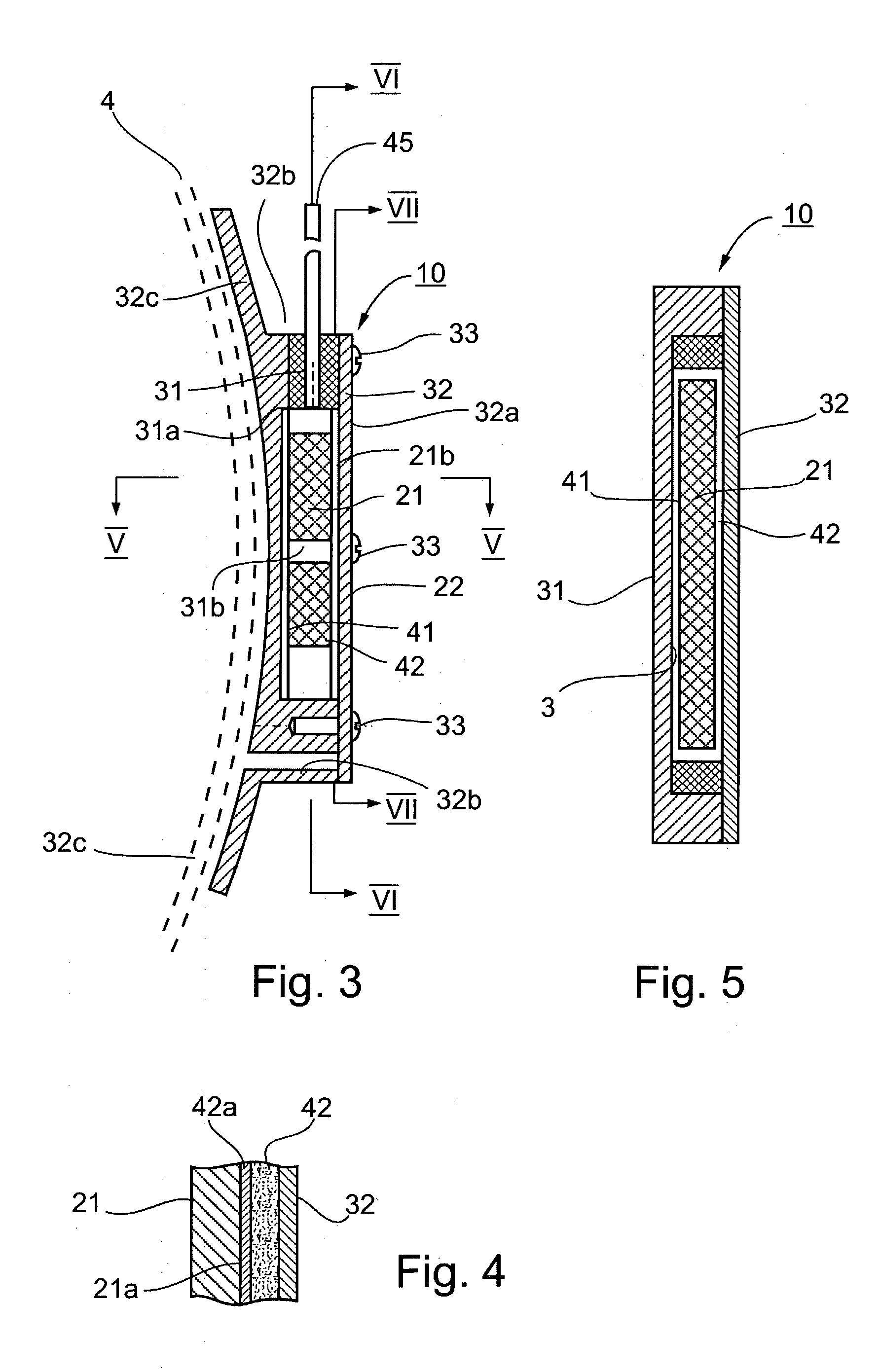

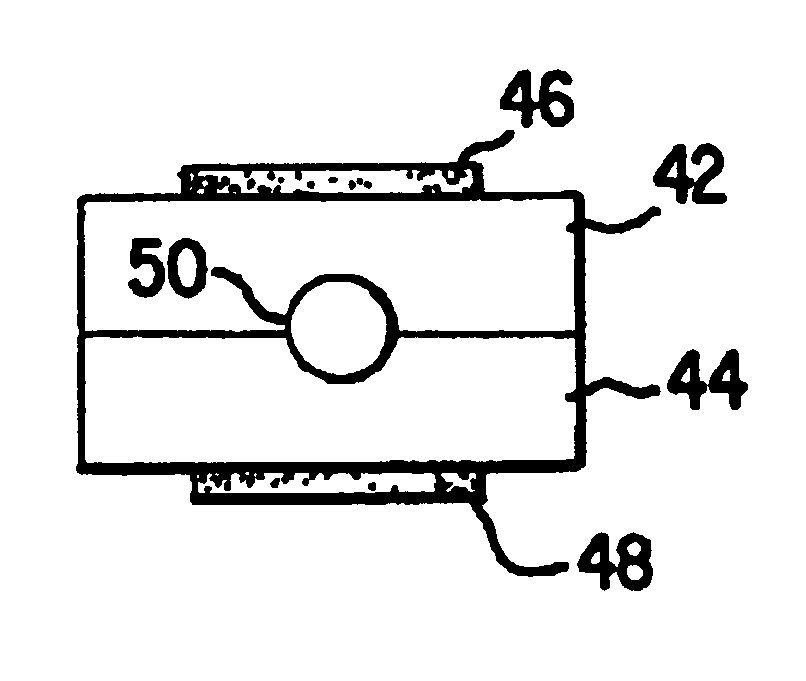

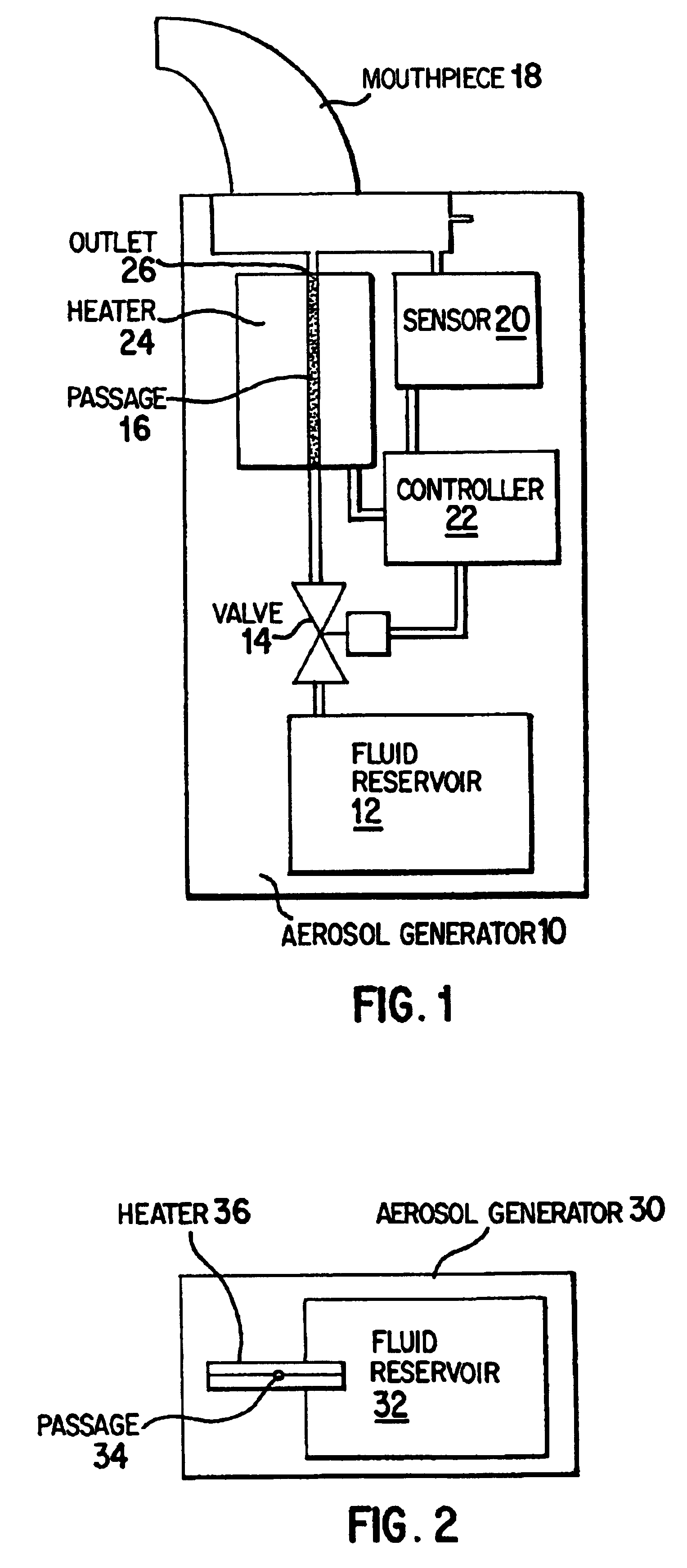

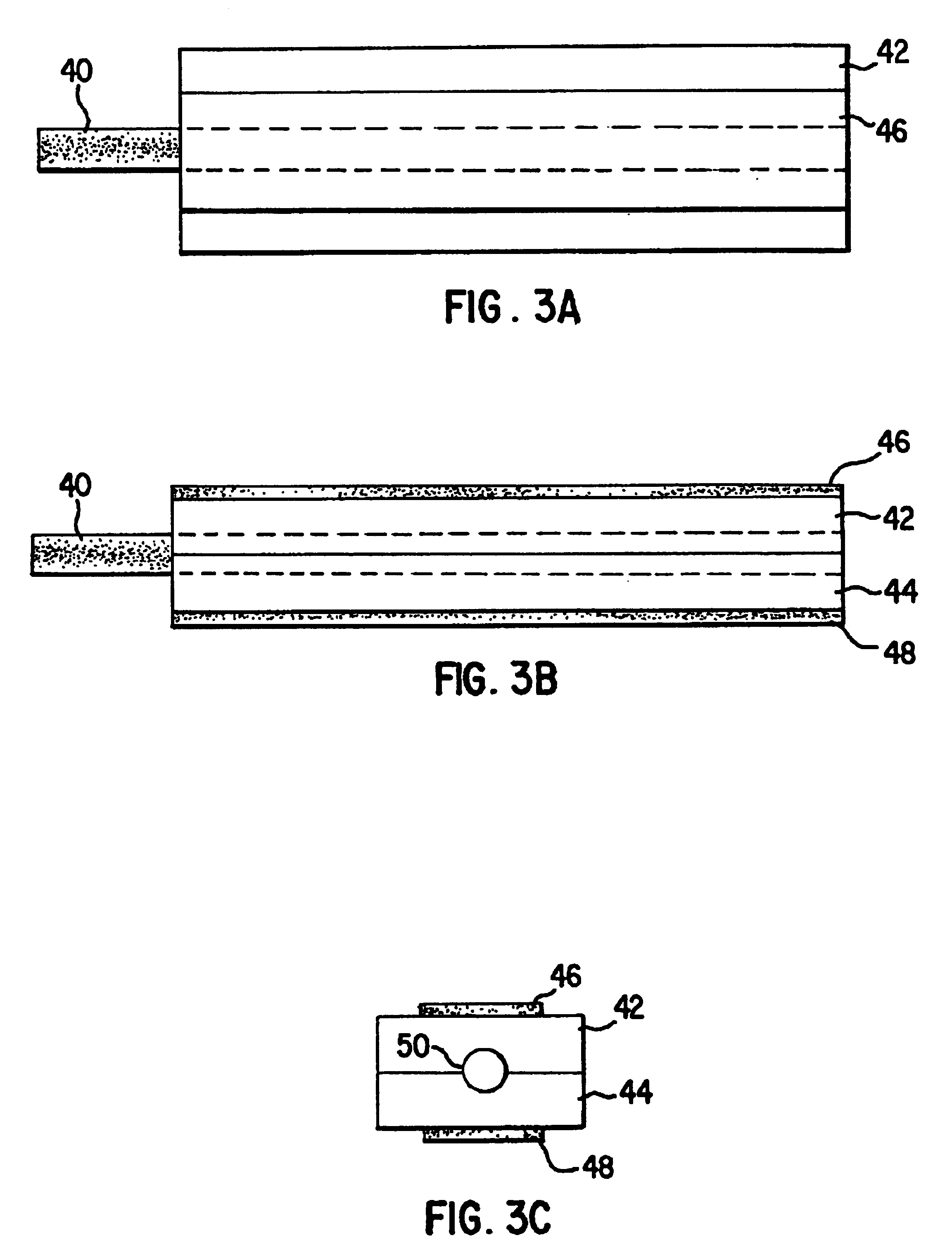

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

InactiveUS20030108342A1Internal combustion piston enginesWater-tube boilersCapillary TubingEngineering

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

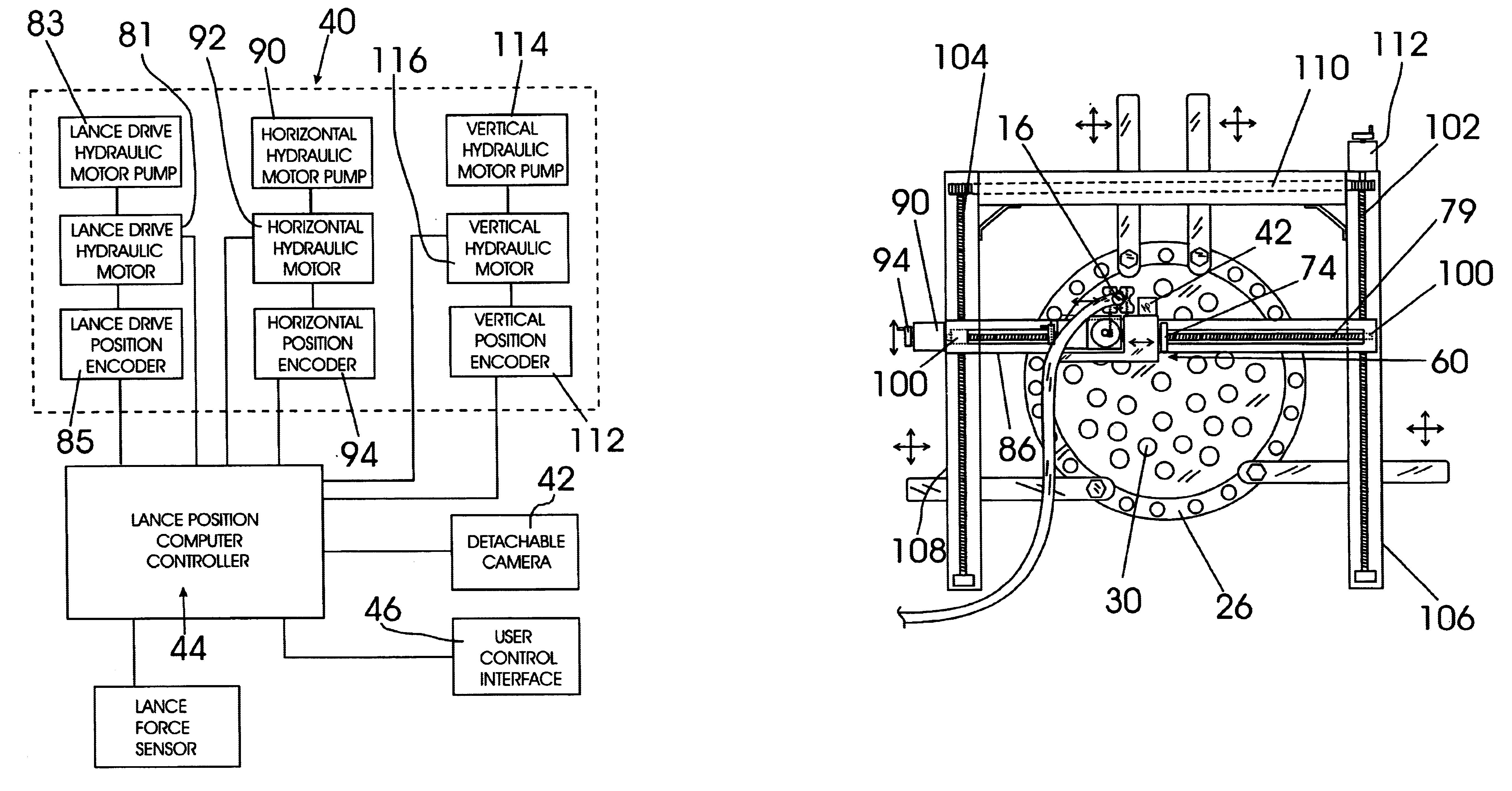

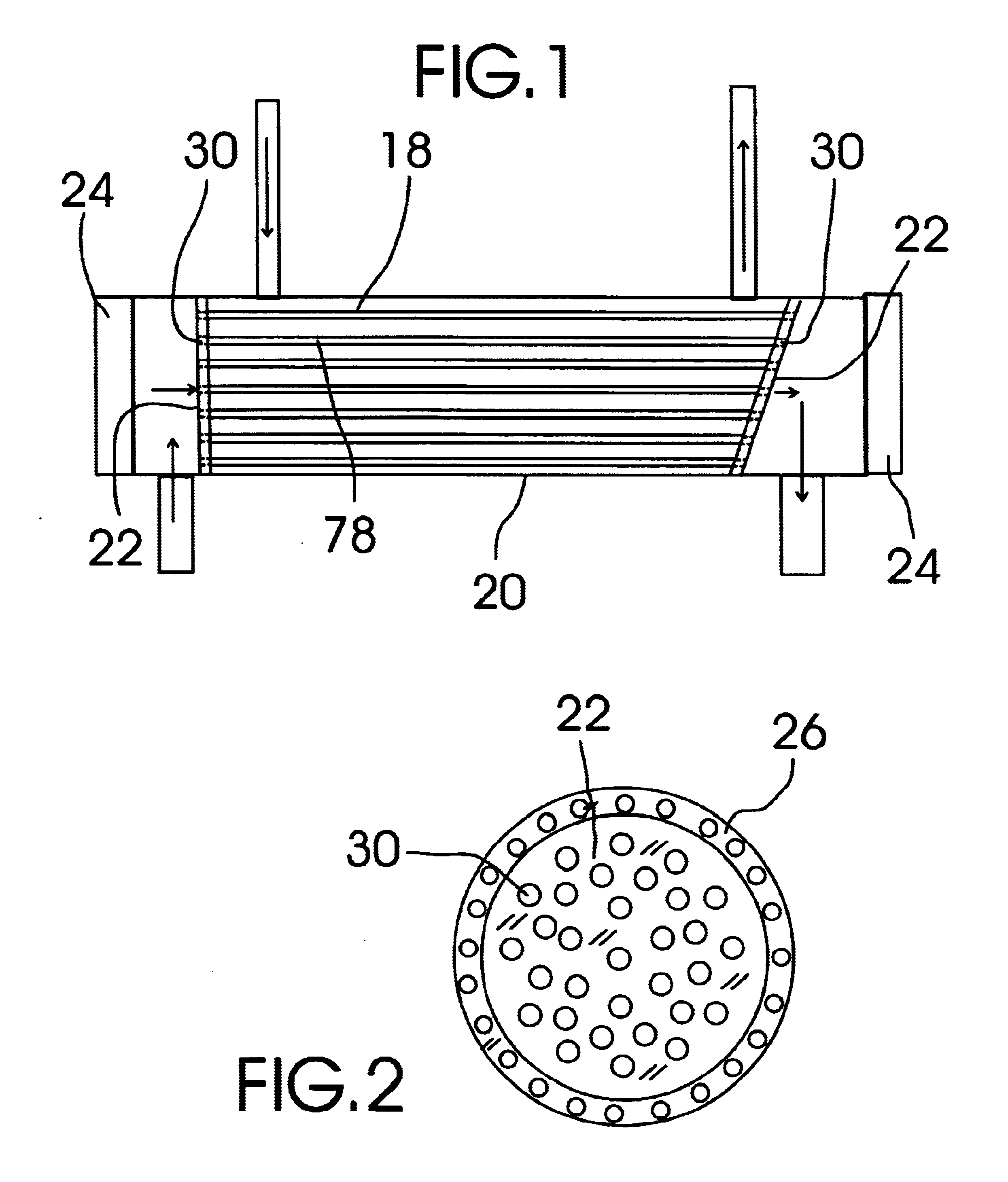

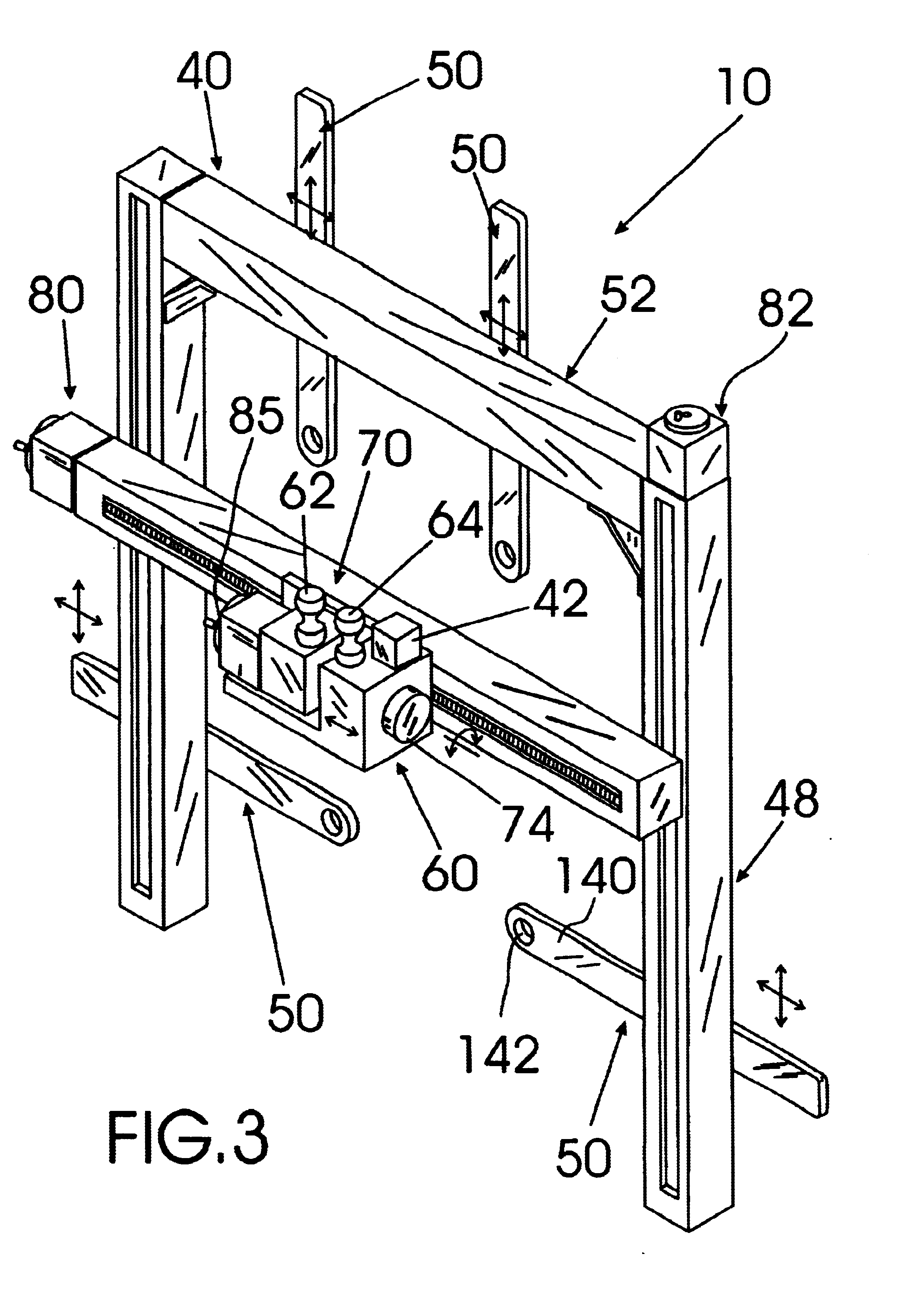

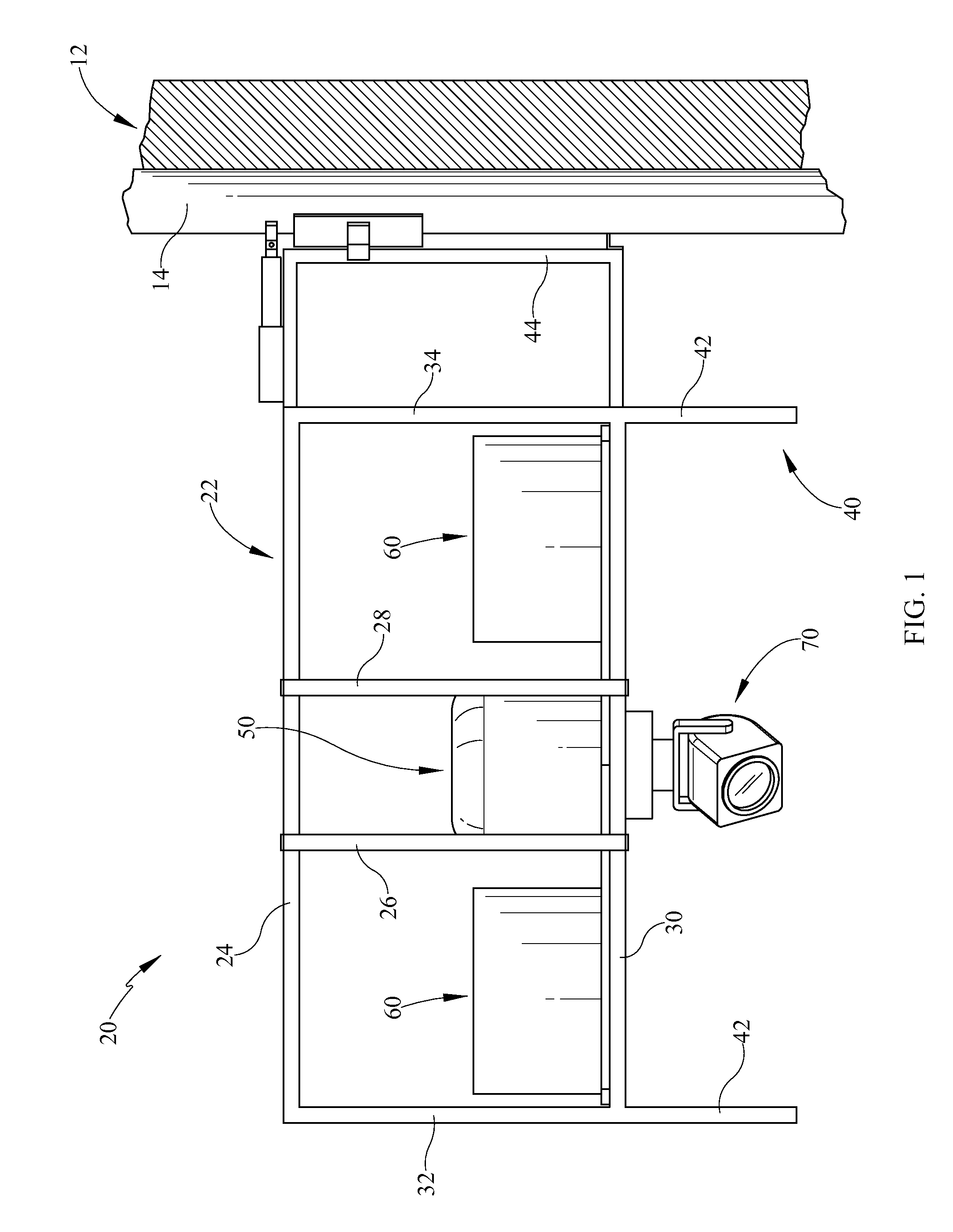

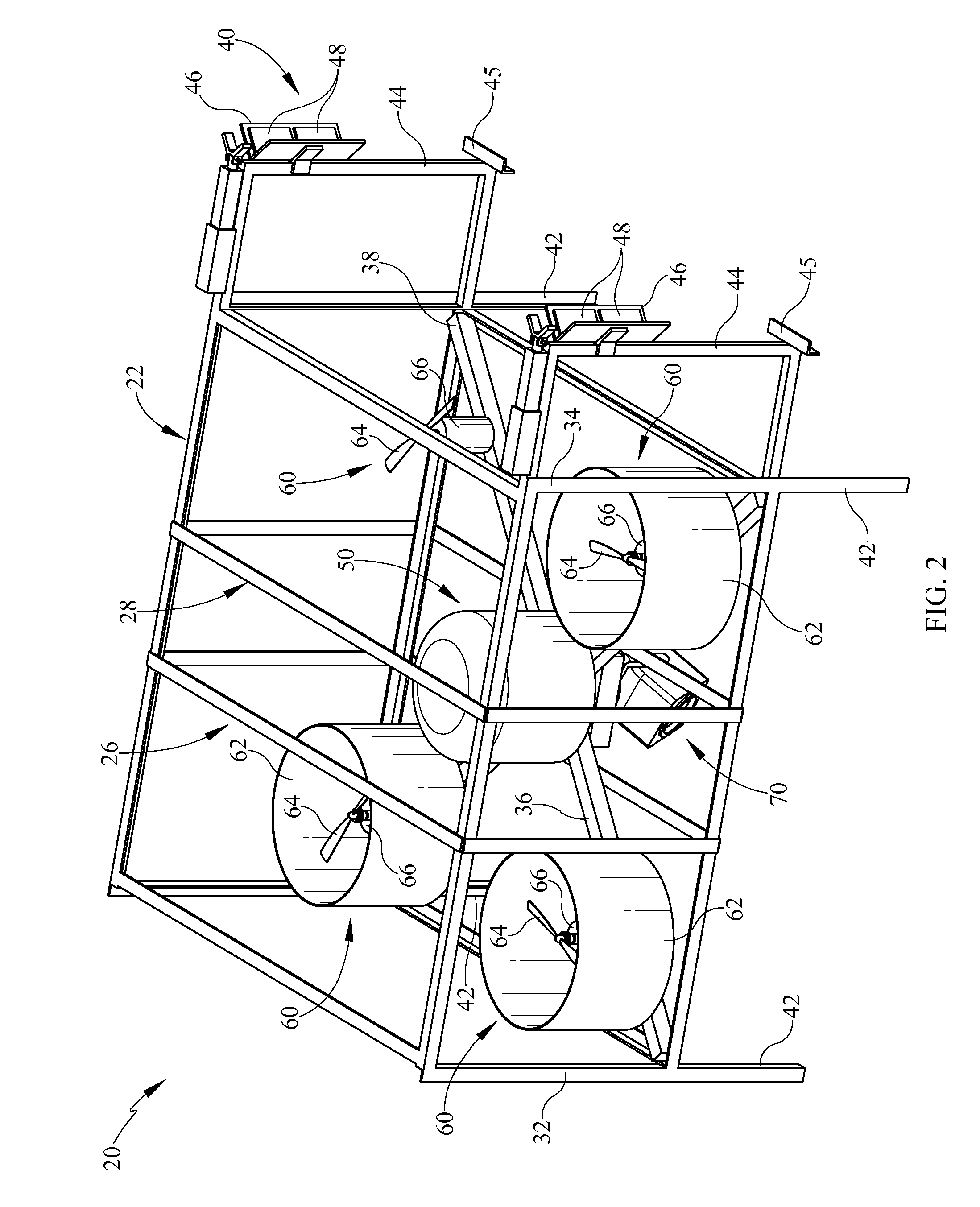

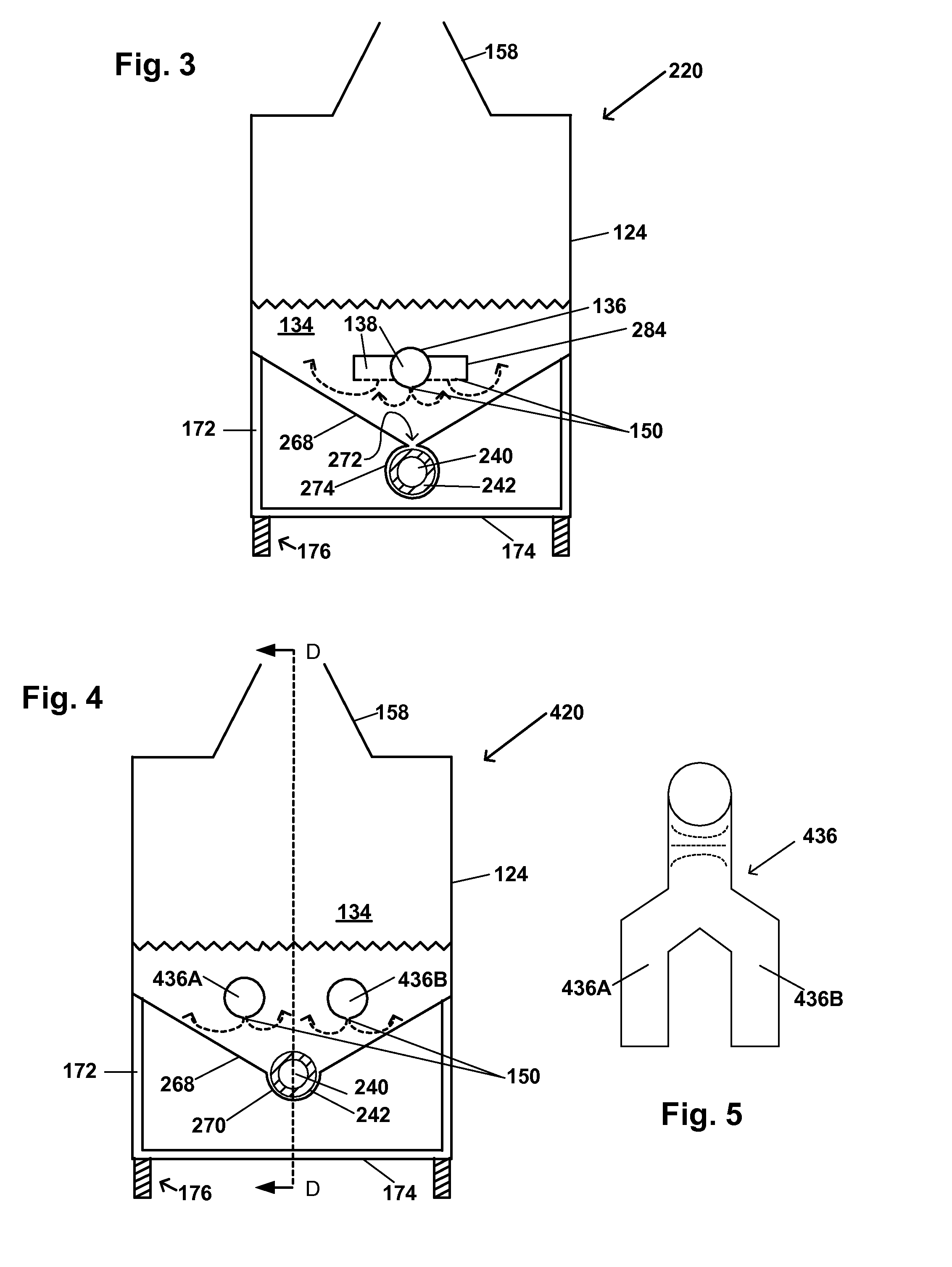

Heat exchanger exchange-tube cleaning lance positioning system

A heat exchanger exchange-tube cleaning lance positioning system that includes a three axis cleaning lance positioning mechanism that is attachable to the end of a heat exchanger and that is controlled by a lance position computer controller that determines the locations of each of the openings of the exchange-tubes of the heat exchanger by analyzing an image signal generated by a camera mounted to the three axis cleaning lance positioning mechanism and then positions a connected exchange tube cleaning lance into and through each of the exchange-tube passageways to clean the exchange-tube passageways automatically.

Owner:BALZER BRENT A

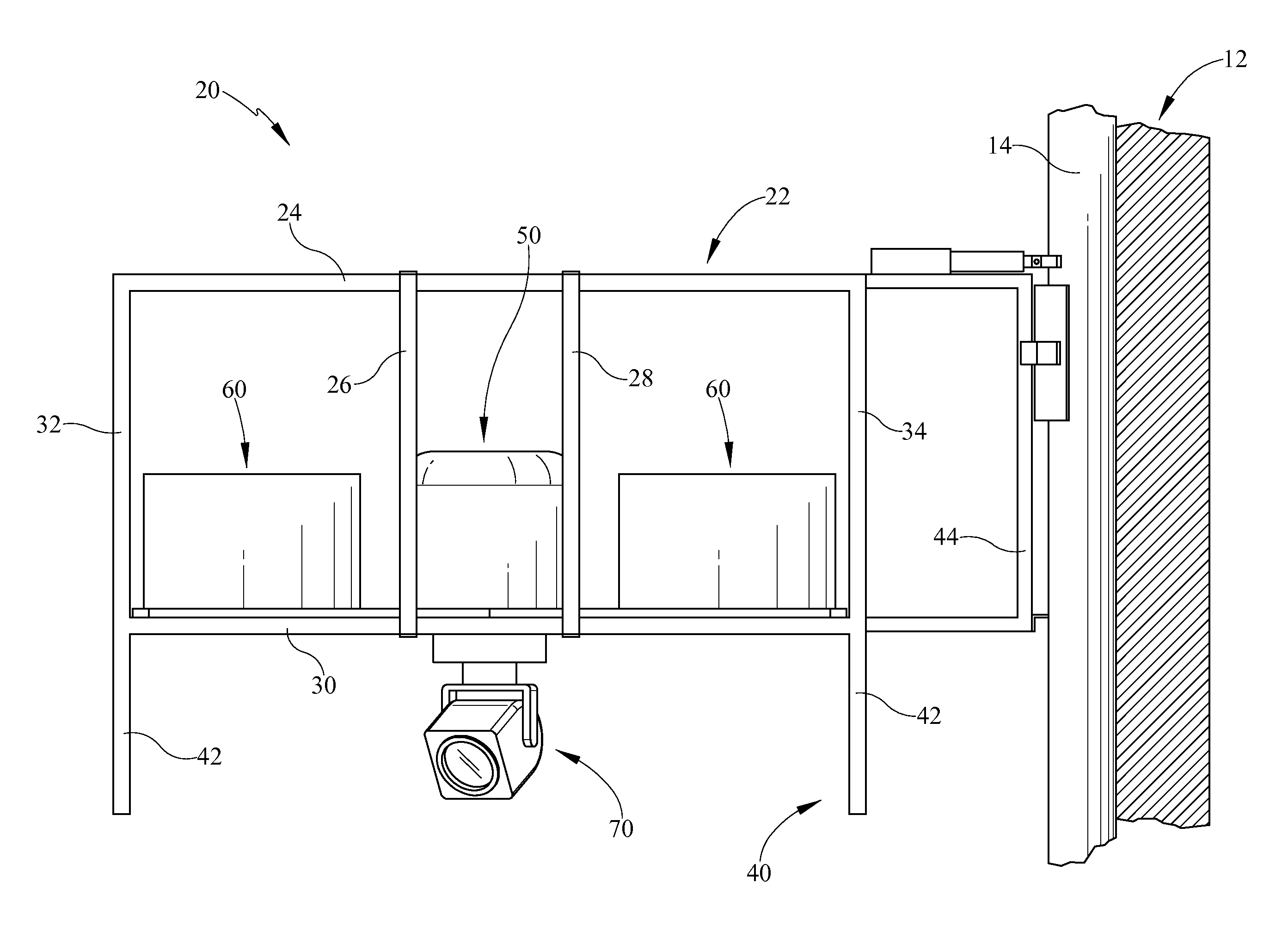

Drone for inspection of enclosed space and method thereof

Embodiments of a drone for inspection and a method of use are depicted wherein the drone is utilized in an enclosed space and is capable of being controlled with or without line of sight to the aircraft. The drone may land on generally horizontal or vertical surfaces. A method of use is taught as well.

Owner:UNITED DYNAMICS ADVANCED TECH

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

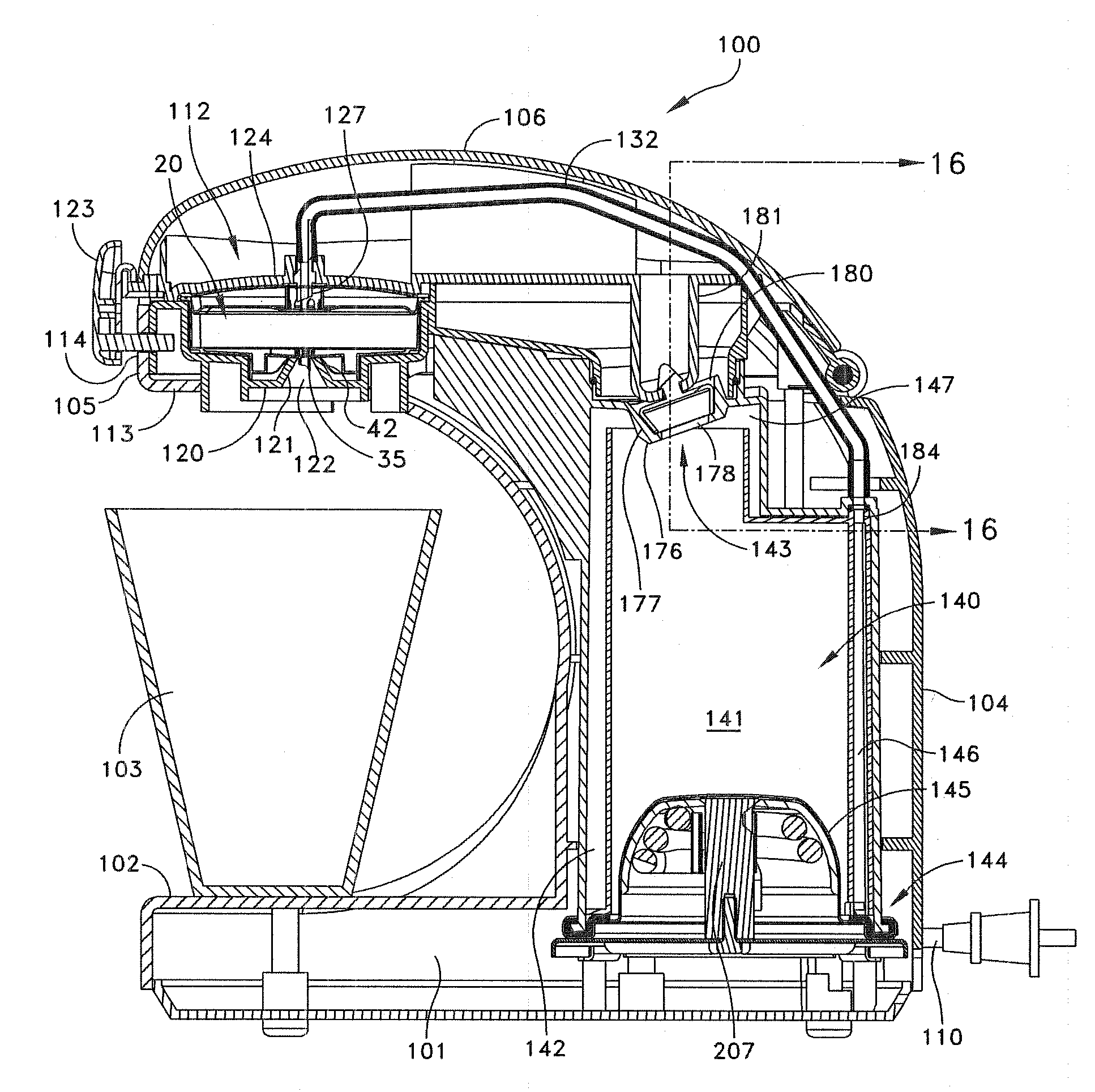

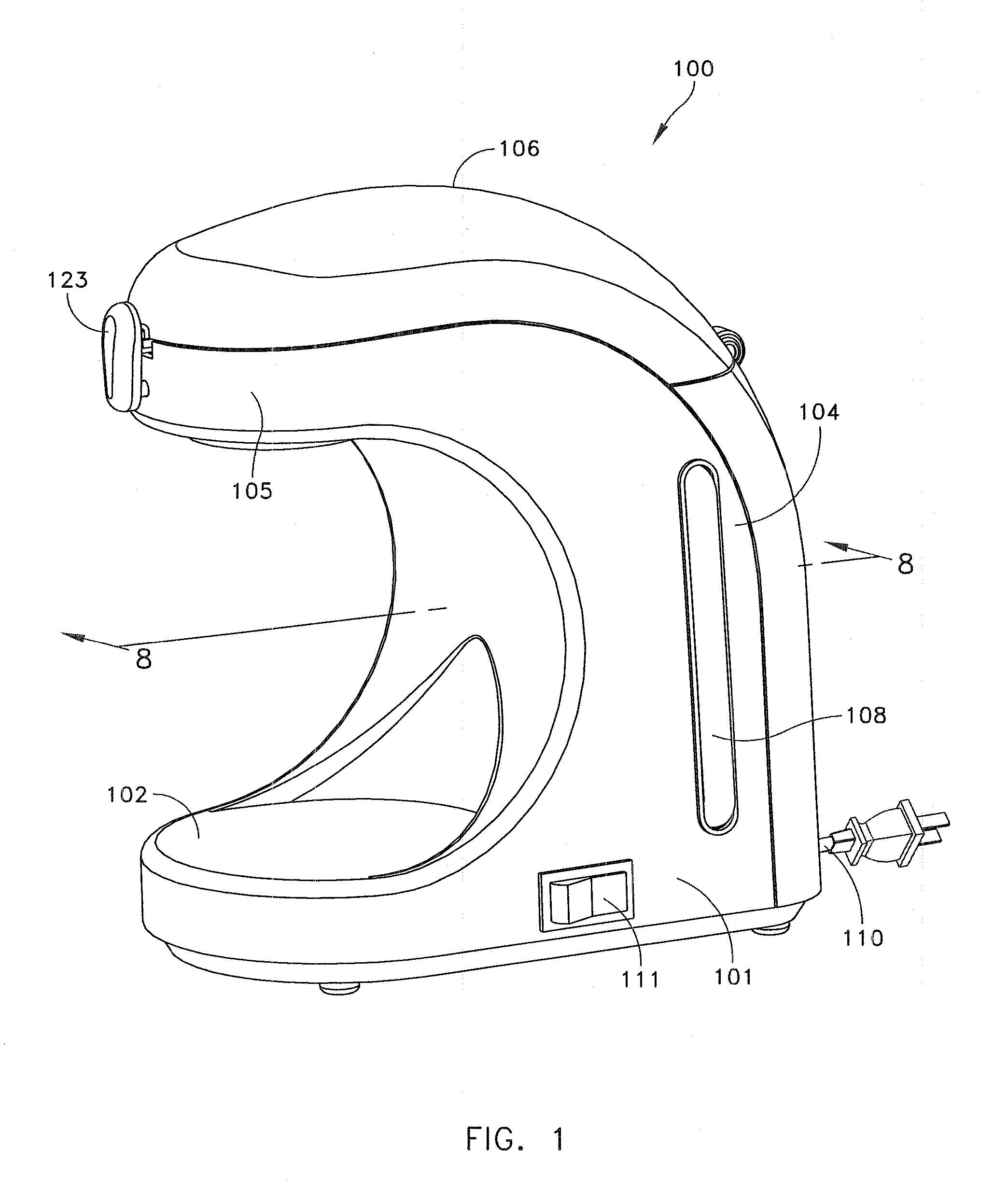

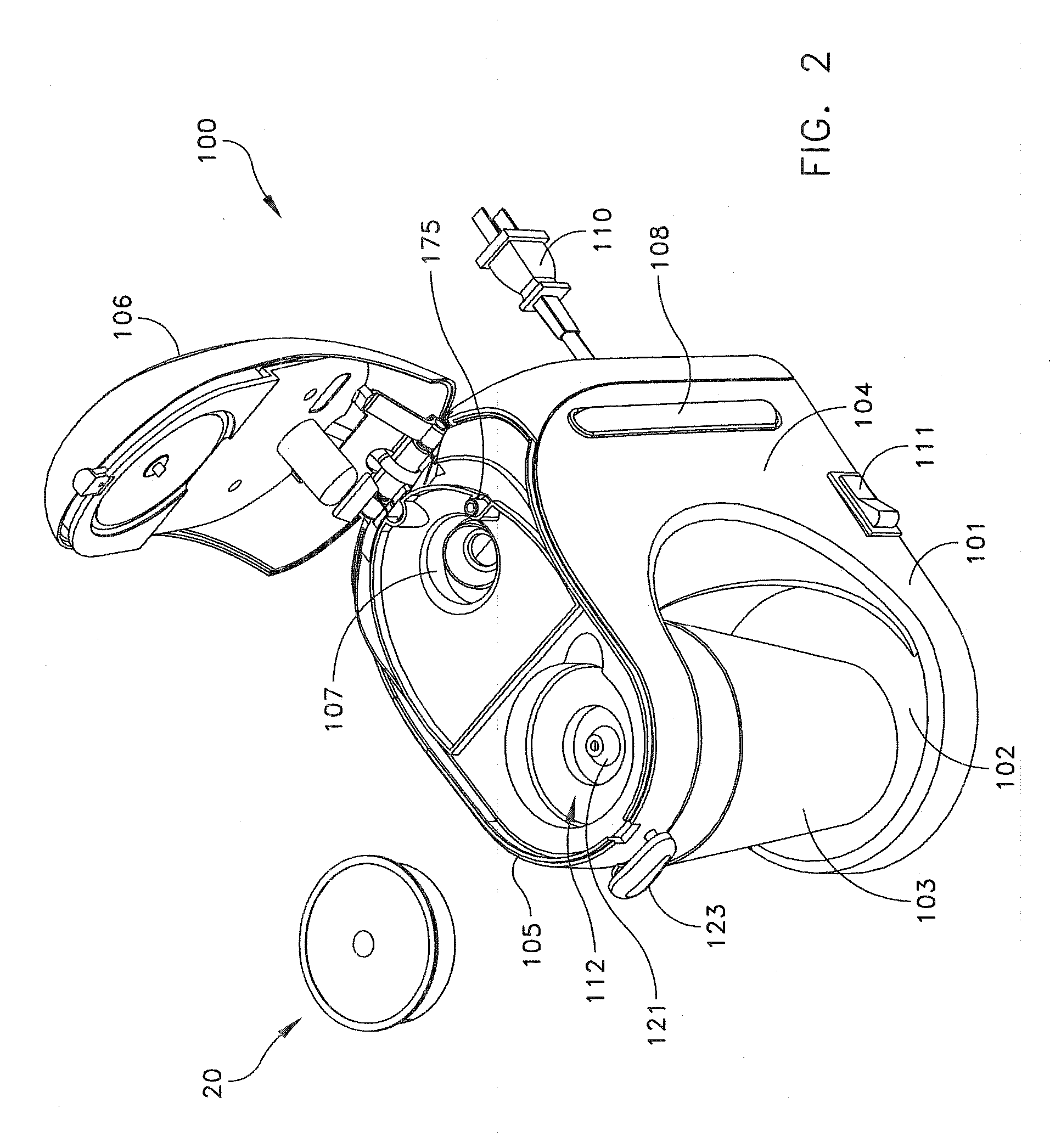

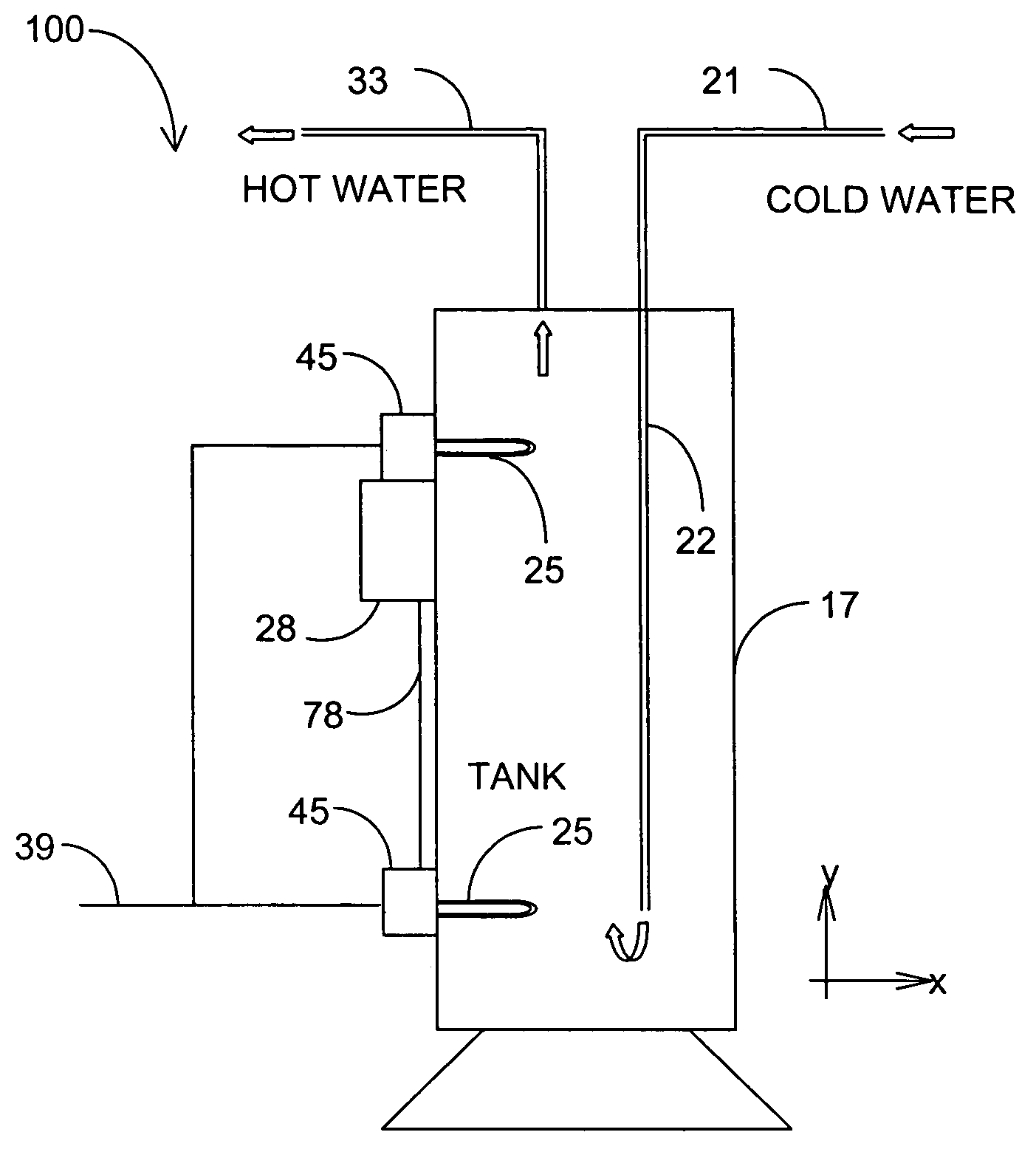

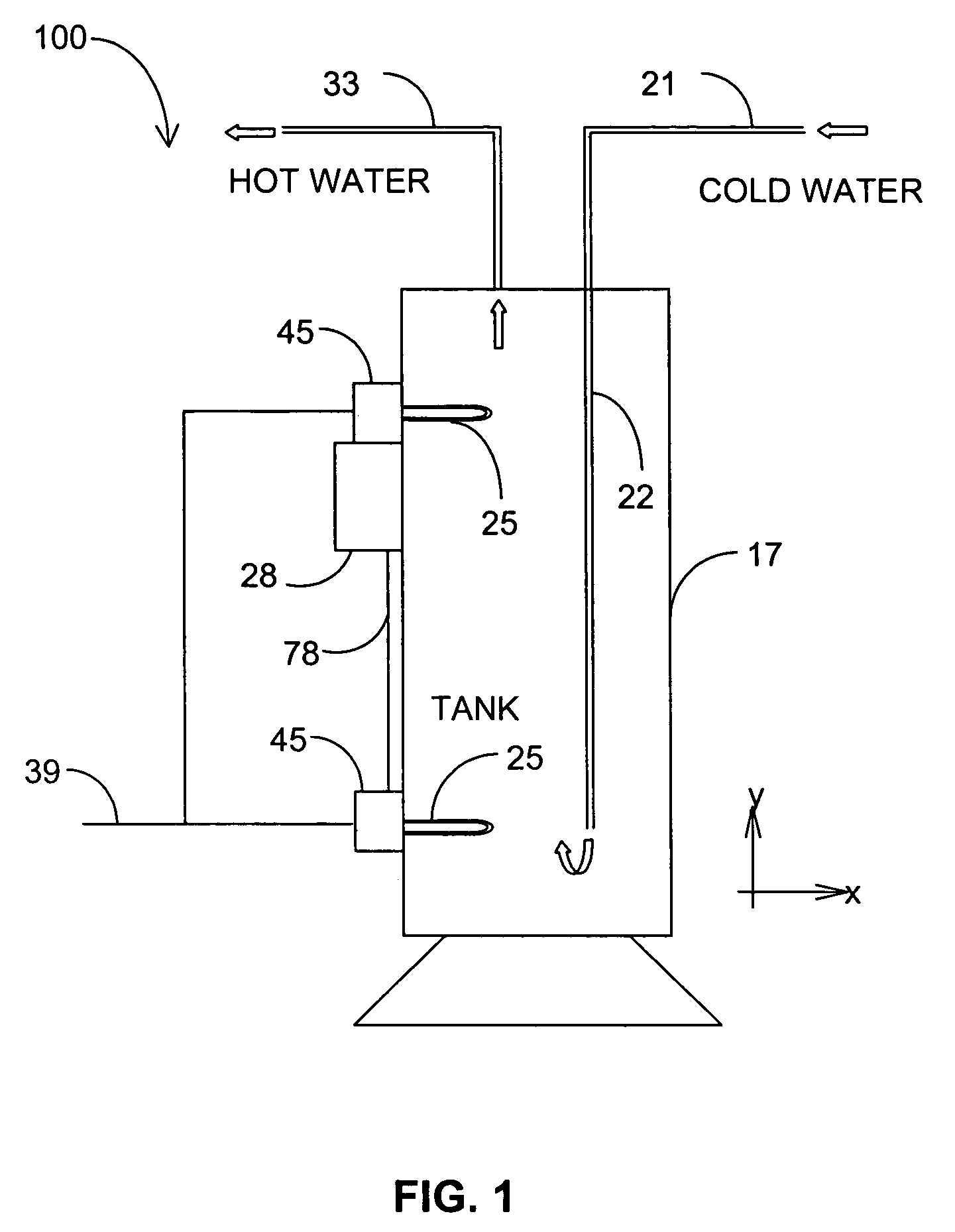

Hot beverage brewing apparatus

ActiveUS20090007792A1Easy to controlCompact and reliable and inexpensive to manufactureSteam generation heating methodsBoiler flue tubes/fire tubesProcess engineeringHot liquids

A hot beverage brewing apparatus. A pressurized hot liquid delivery system provides liquid under pressure within a range of acceptable brewing temperatures without any mechanical pump. Water is apportioned into sealable tank volumes, one of which is heated to boil the liquid and produce steam under pressure. The pressurized steam displaces the liquid from the tank volumes in proportion and at a temperature that is within the acceptable brewing range. The hot liquid under pressure is directed to a capsule receiving station to infuse a material in a capsule. The capsule dispenses the brewed beverage without contacting the brewing apparatus.

Owner:SOLABEV

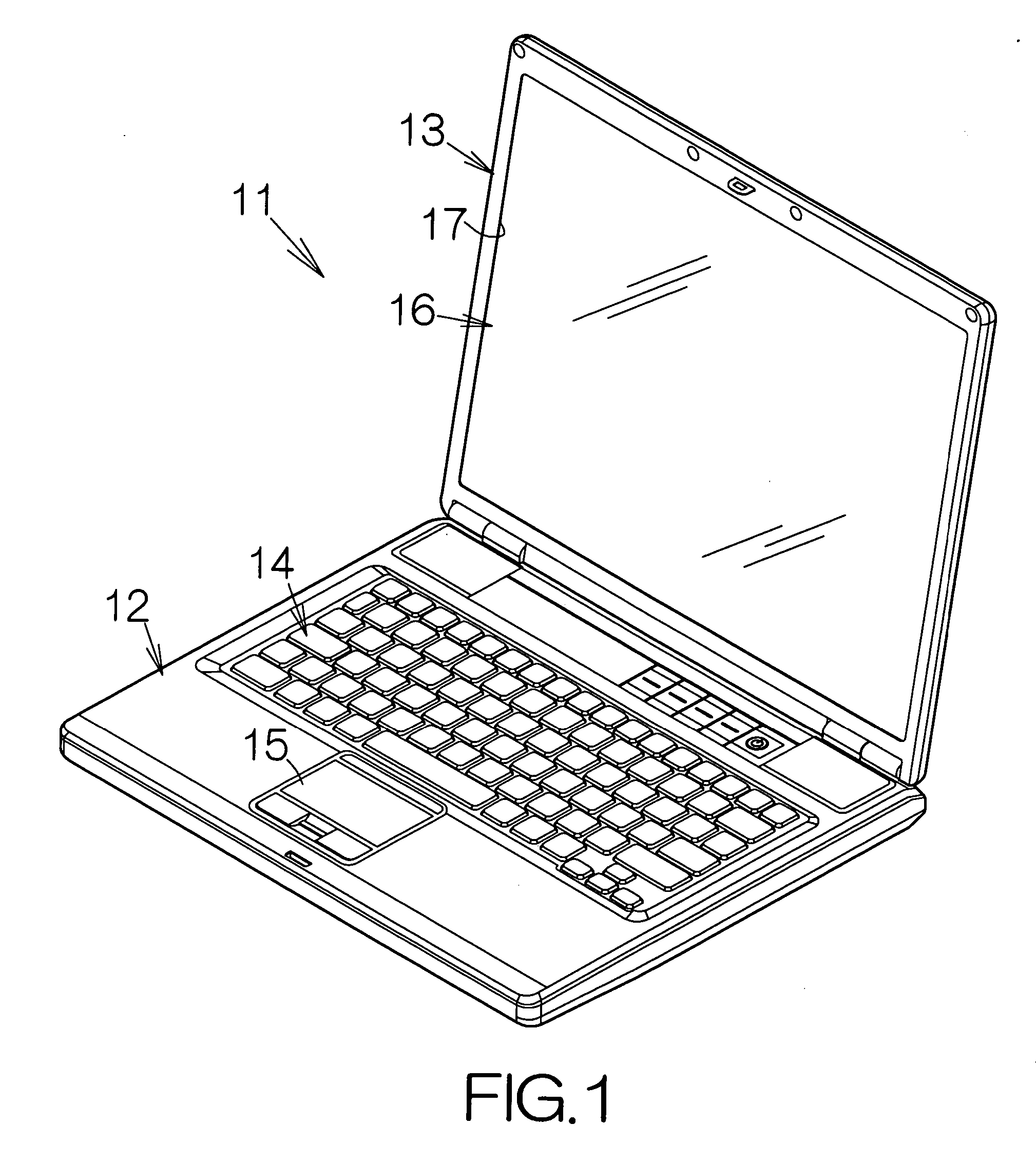

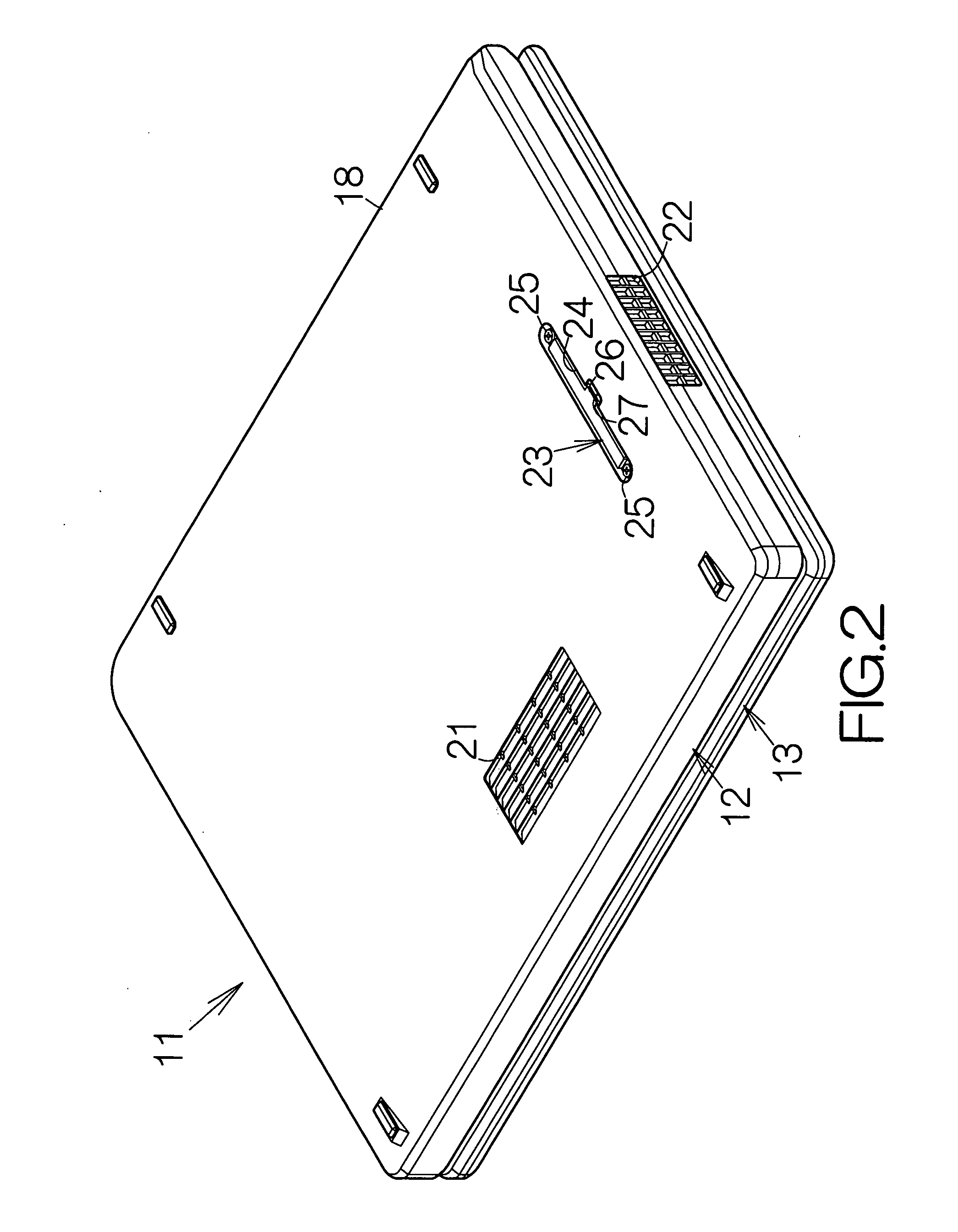

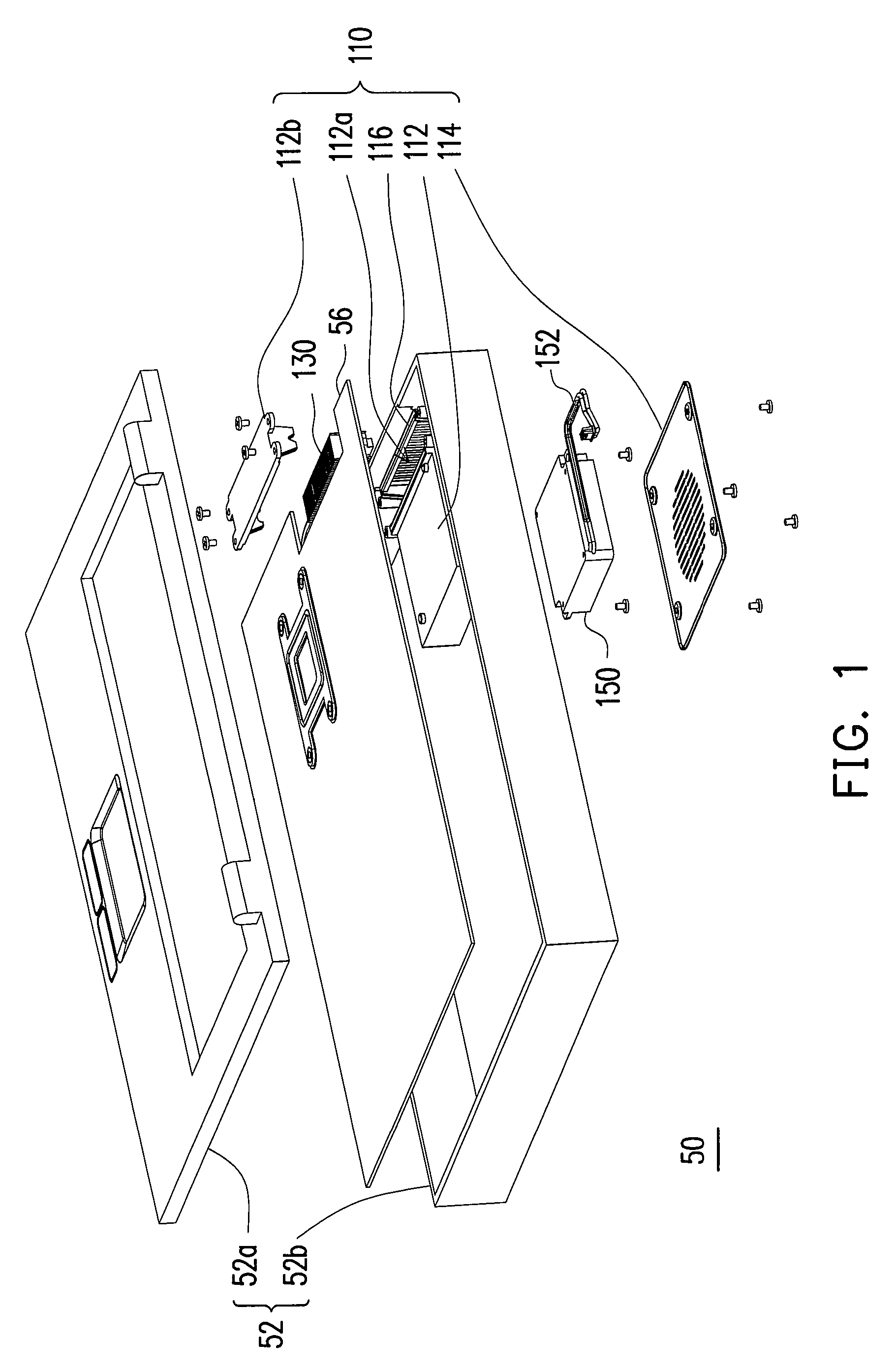

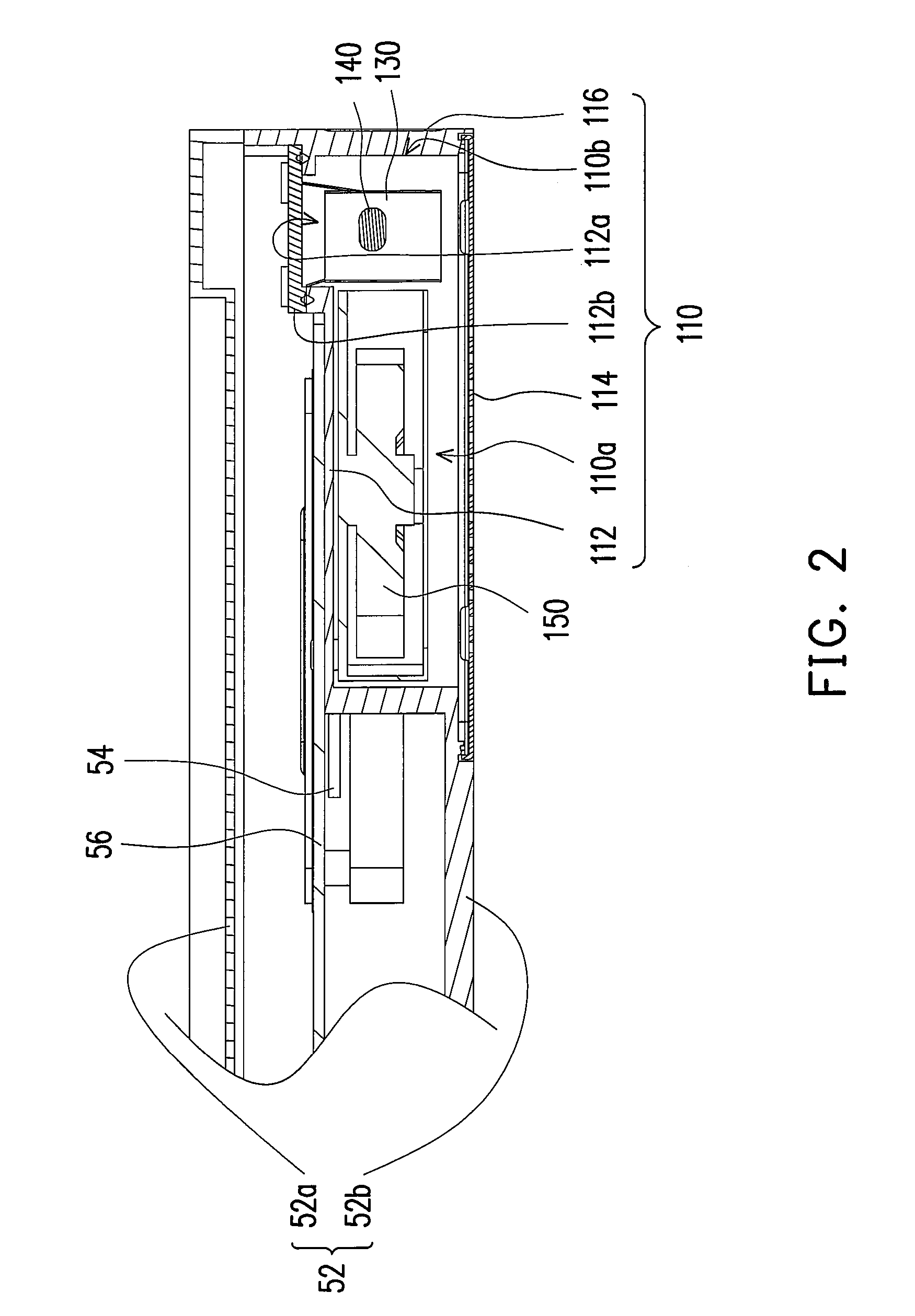

Electronic apparatus including removable dust catcher

InactiveUS20070131383A1Effective radiationAvoid painCombination devicesDispersed particle filtrationEngineeringHeat sink

A fan is enclosed in the enclosure of an electronic apparatus. The fan discharges air out of a ventilation opening of the fan itself. Heat radiating fins are located in an air passage extending from the ventilation opening. A dust catcher is removably mounted in an opening of the enclosure from the outside of the enclosure. The dust catcher is located in the air passage between the heat radiating fins and the ventilation opening. The dust catcher serves to catch the dust in the air passage. The dust catcher is removed from the enclosure along with the dust. The dust is thus reliably cleared from the air passage. The dust catcher can then be cleaned. The cleaned dust catcher can again be set in the opening of the enclosure. Airflow of a sufficient amount is in this manner always kept in the air passage.

Owner:FUJITSU CLIENT COMPUTING LTD

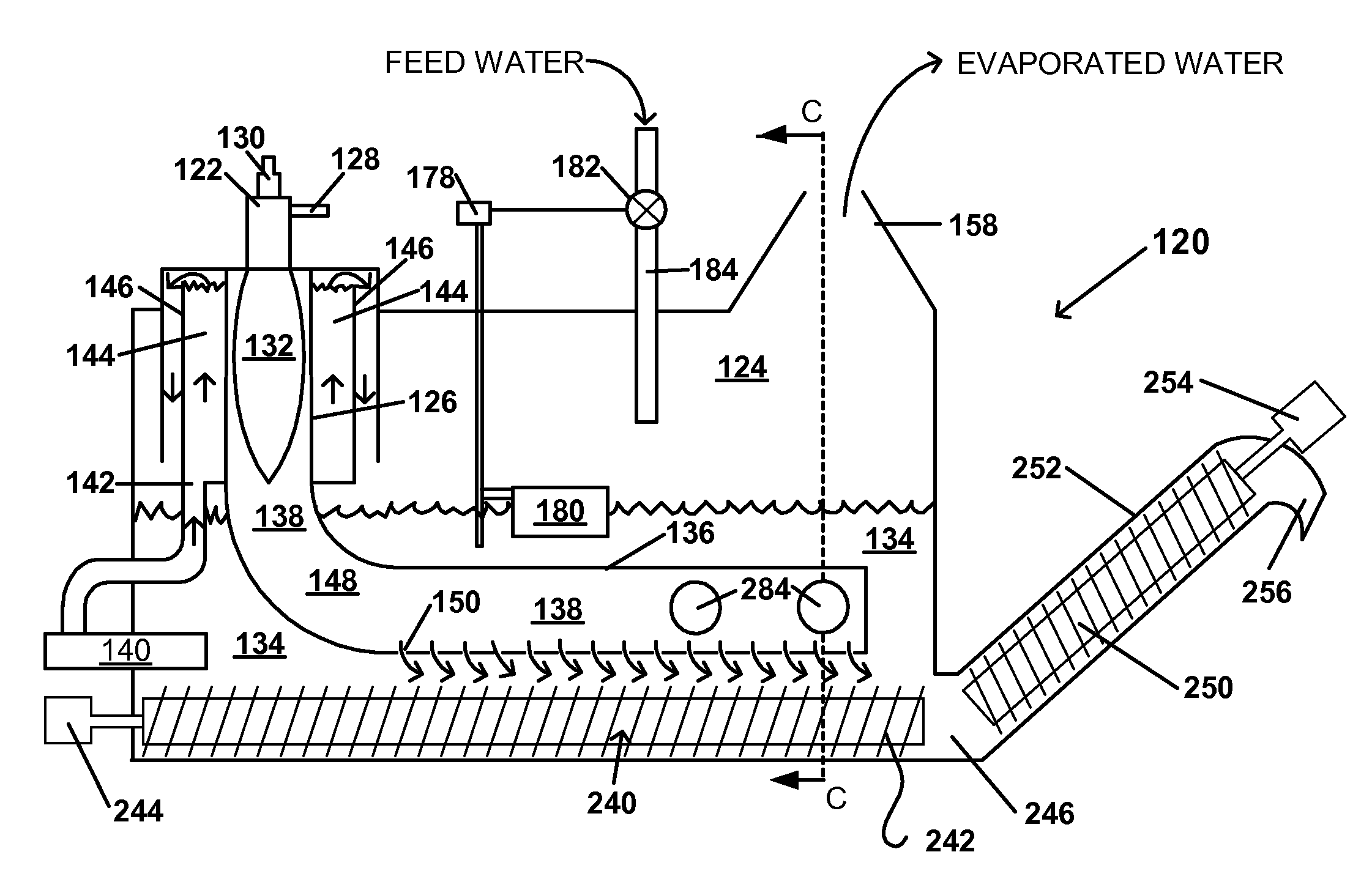

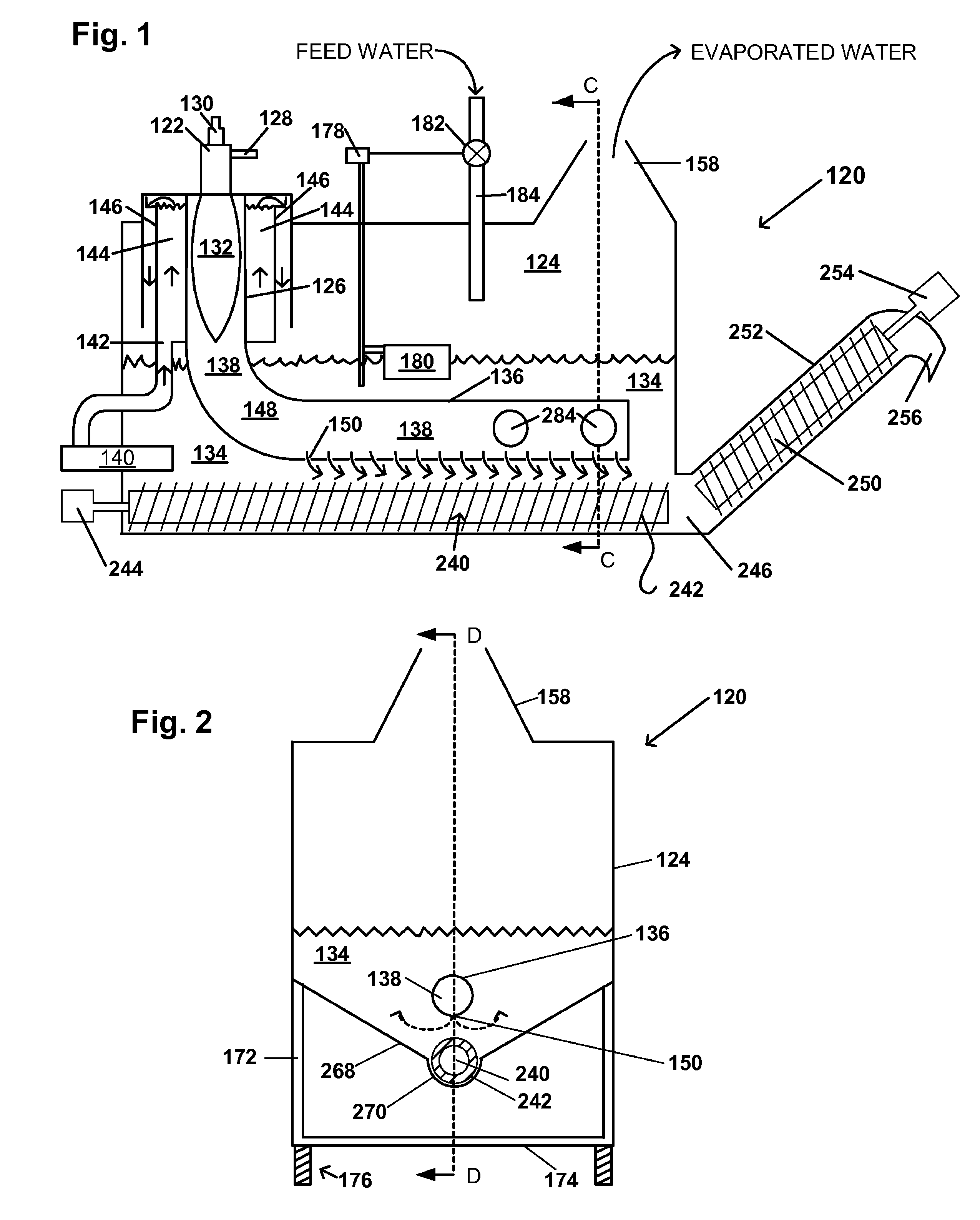

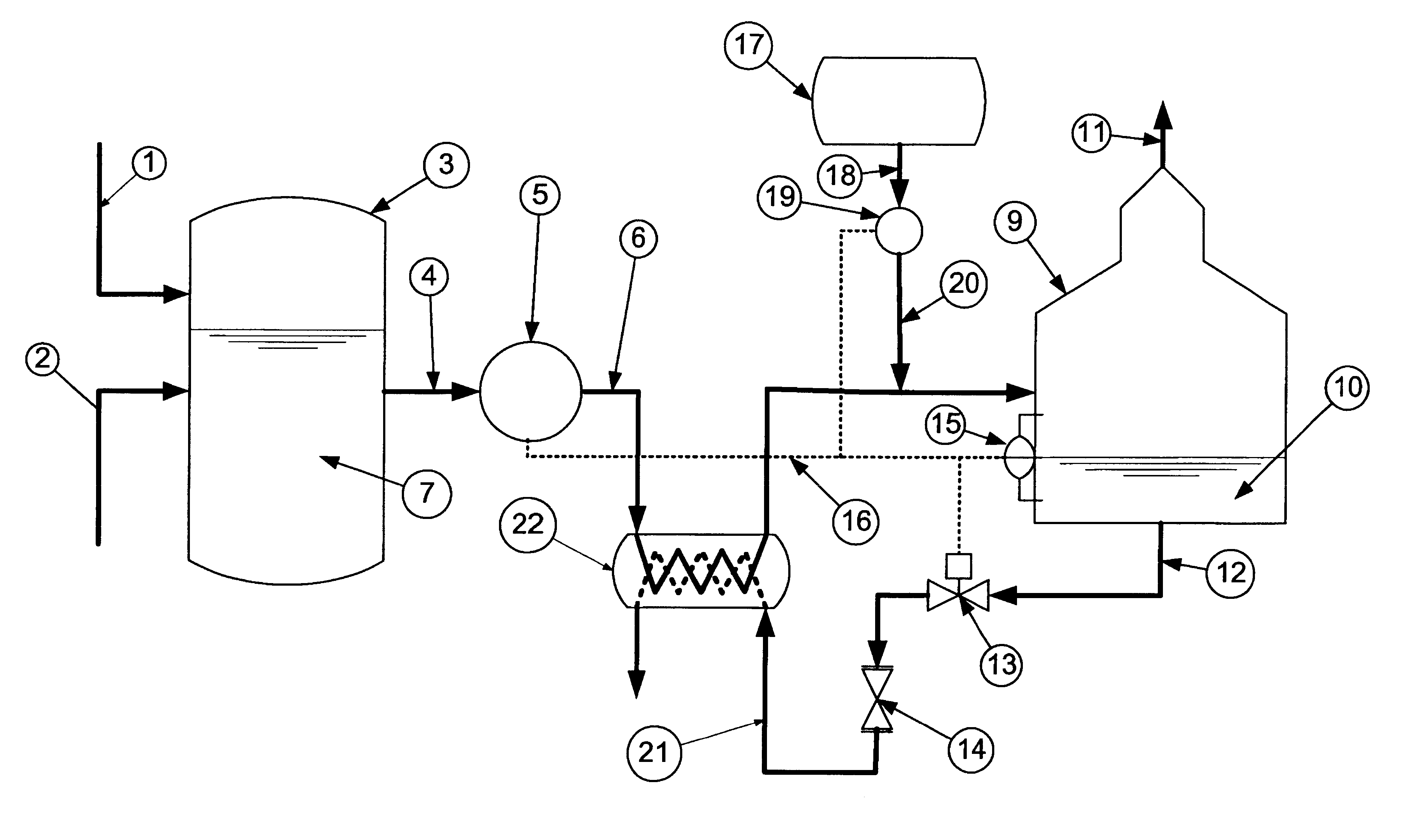

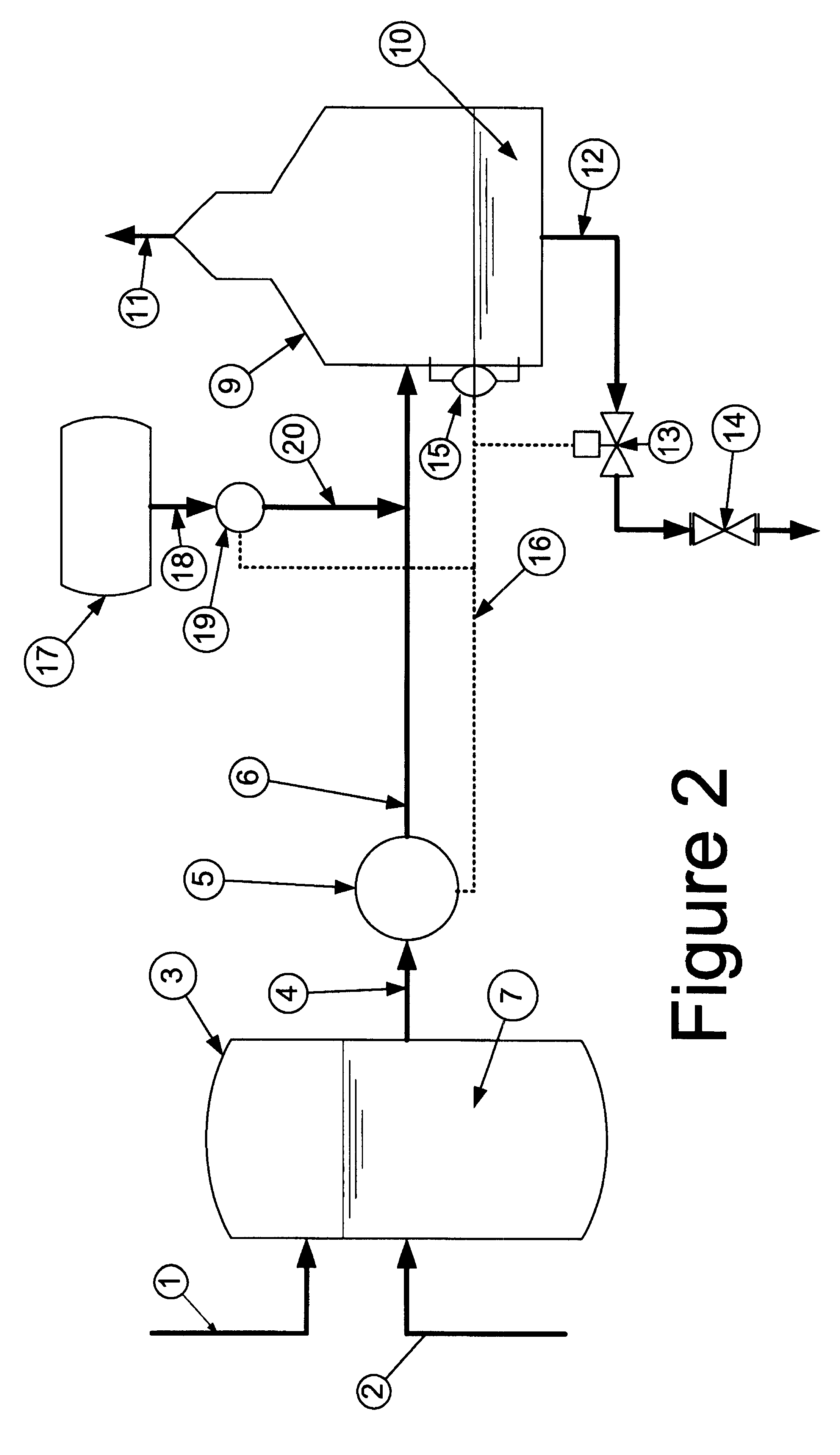

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

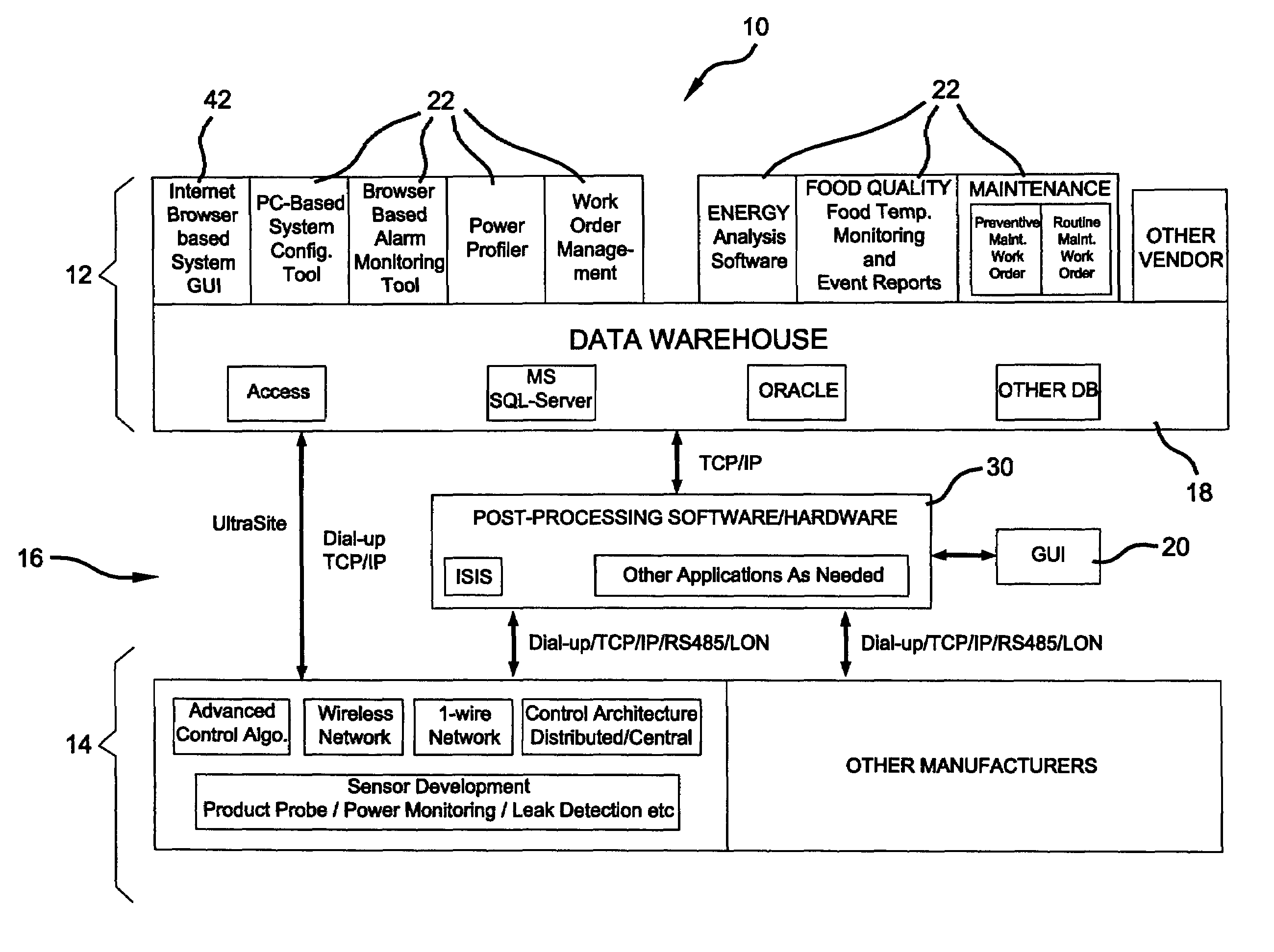

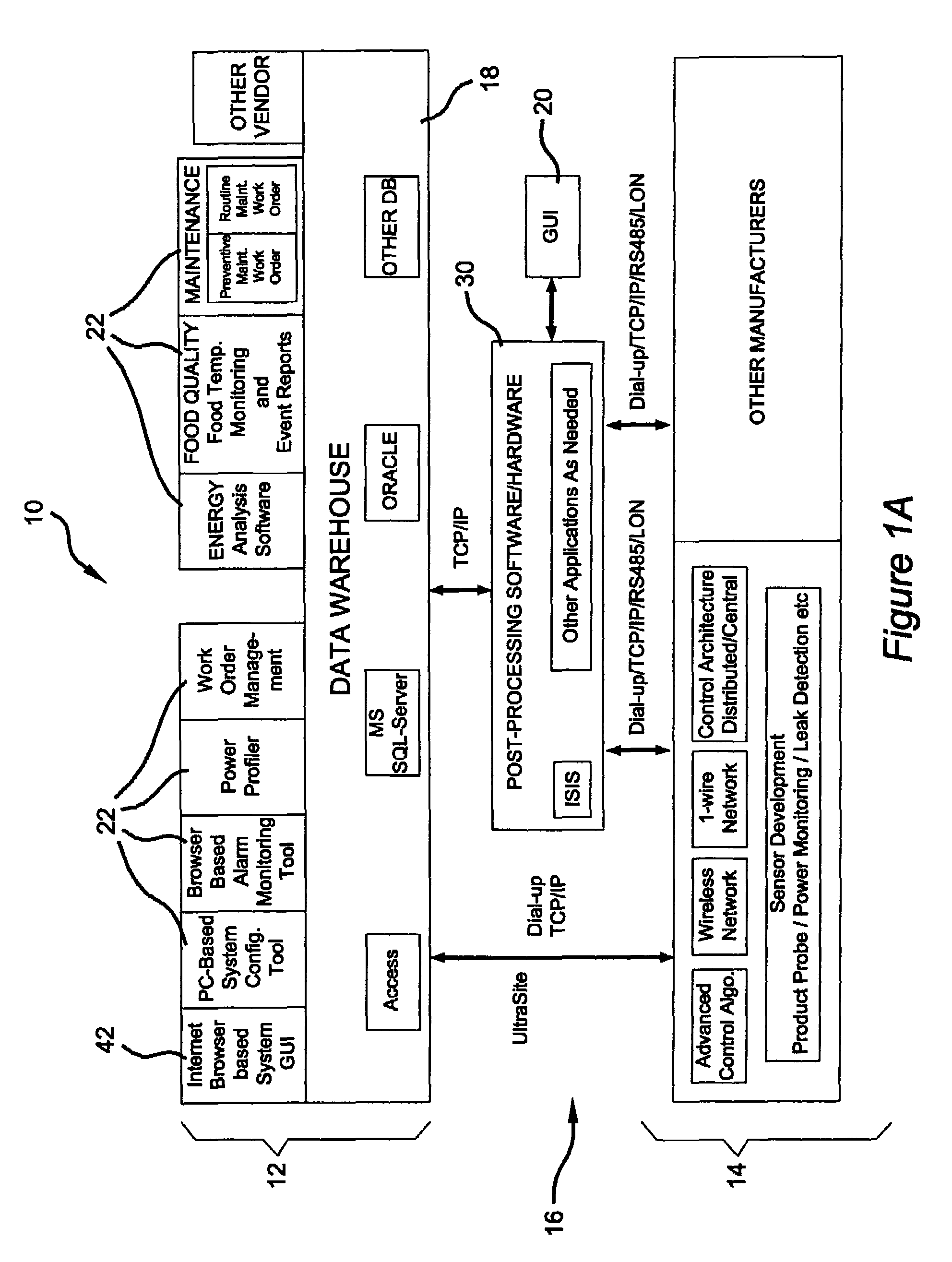

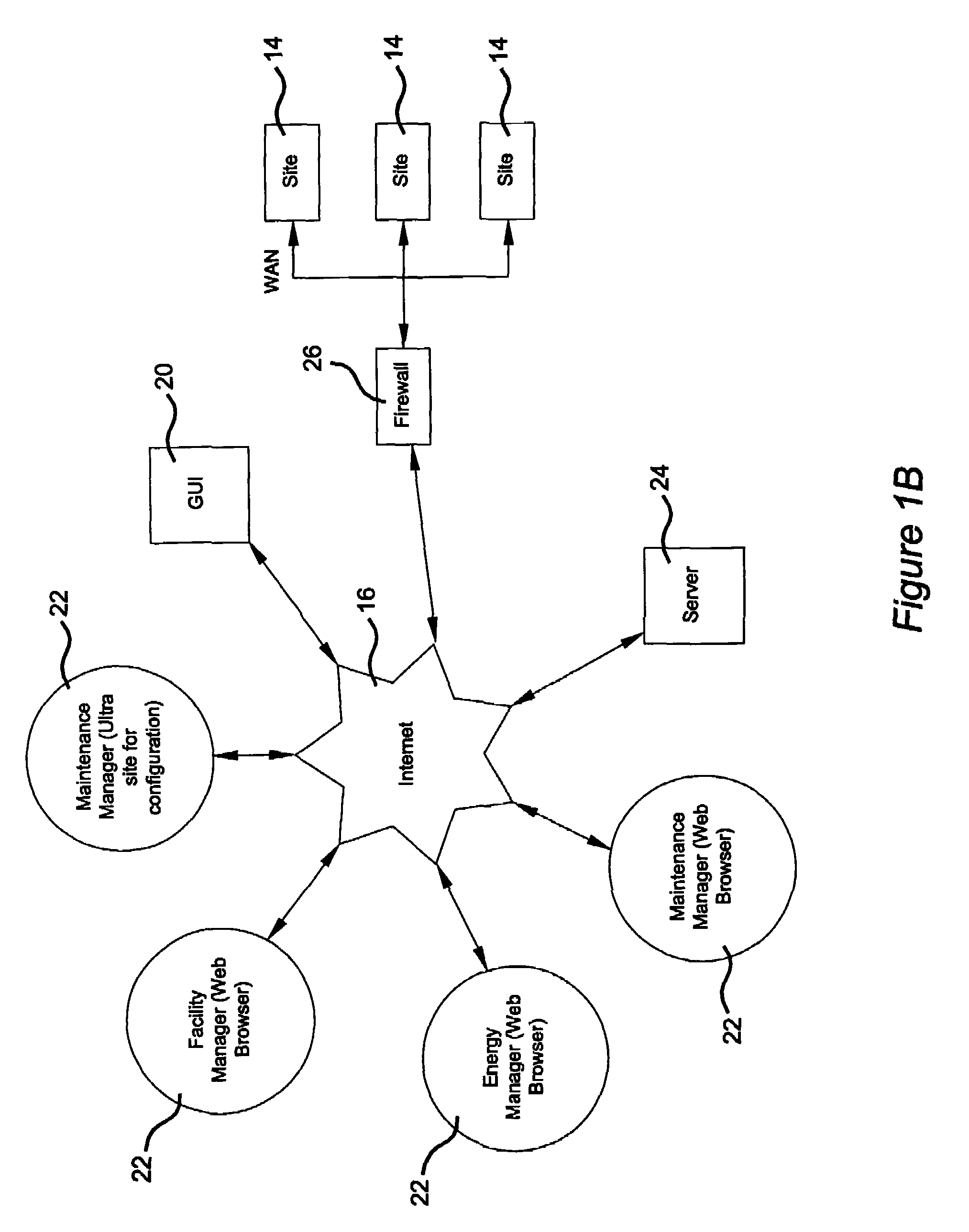

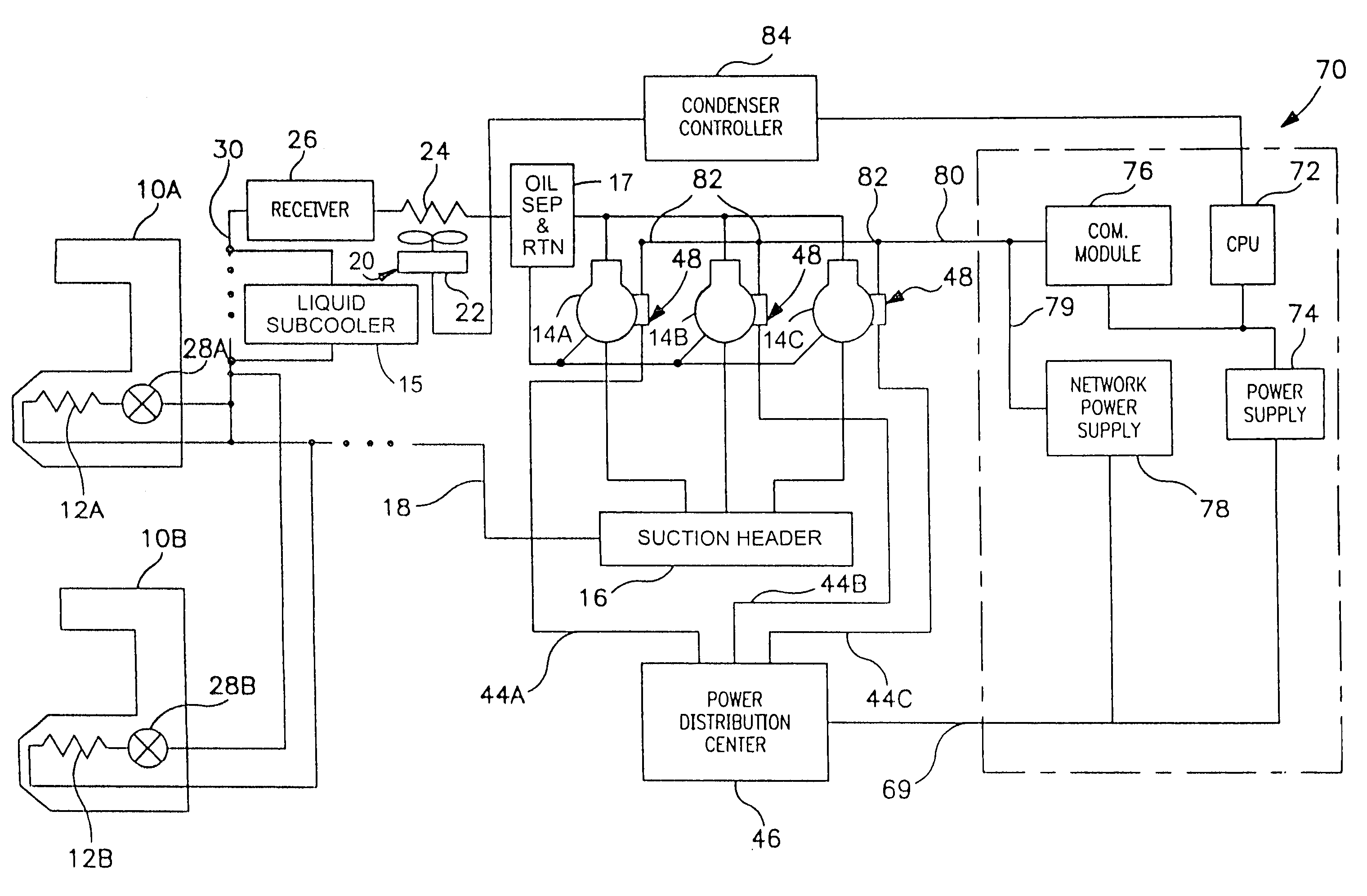

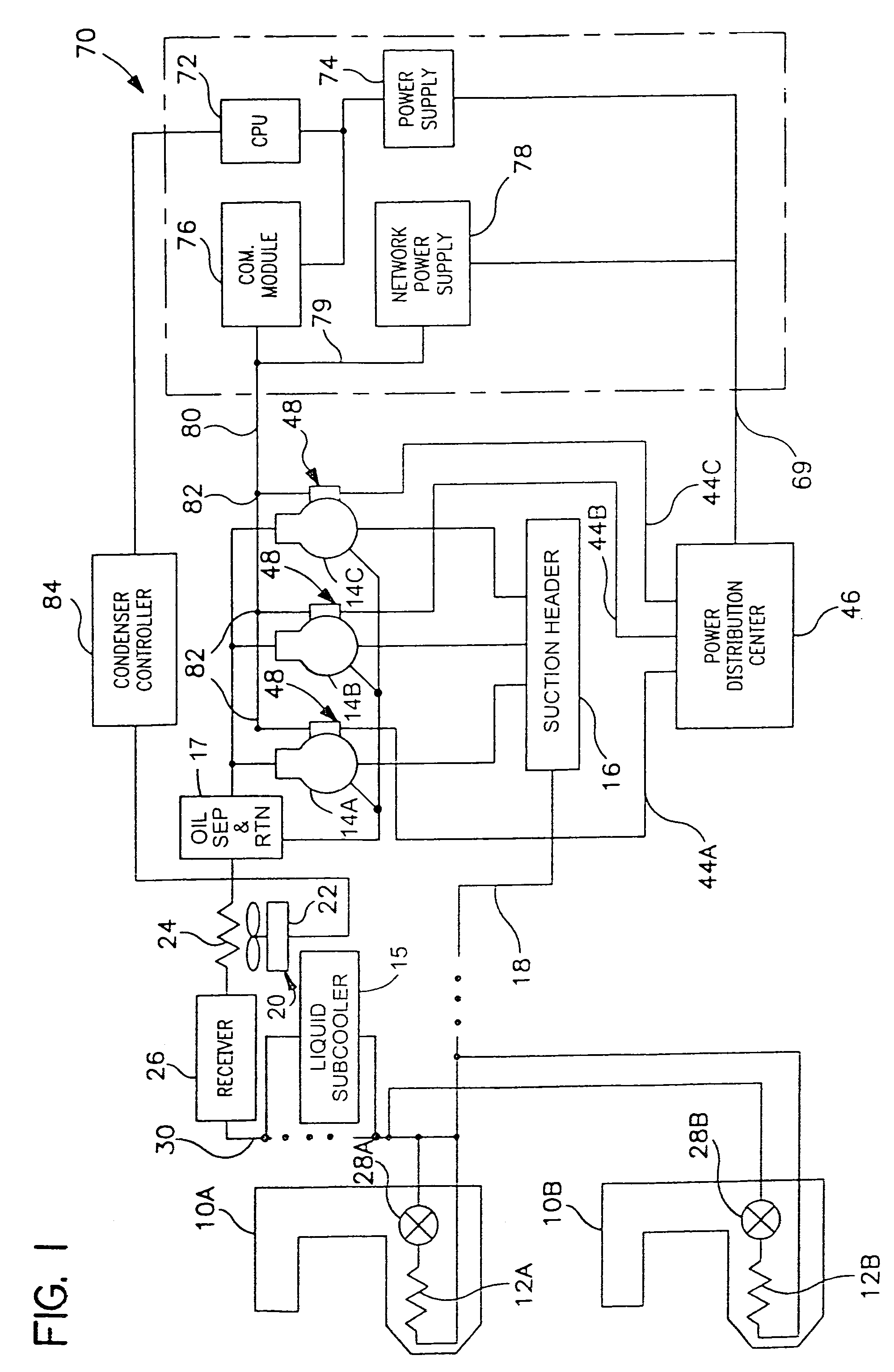

Method of managing a refrigeration system

A method of managing a refrigeration system includes transmitting energy consumption, maintenance indicator, and food condition data from the refrigeration system to a management center; analyzing the energy consumption, maintenance indicator, and food condition data at the management center; and monitoring, diagnosing and prognosing the performance of the refrigeration system in response to the analysis. The method may also include altering a configuration of the refrigeration system in response to the analysis. The refrigeration system may be located at a retail location and the management center may be located remotely to the retail location.

Owner:EMERSON DIGITAL COLD CHAIN INC

Low Energy Vaporization of Liquids: Apparatus and Methods

ActiveUS20090224064A1Optimize quantityReduced Power RequirementsSpray nozzlesTobacco devicesAtmospheric airProduct gas

The present invention relates to an apparatus and method for the low energy flash-like vaporization of liquids and the release of the resulting vaporized liquid into the atmosphere in the form of a visible plume, mist or cloud. Vaporization is occasioned in a geometrically small device capable of producing vaporized liquid that varies little in composition in comparison to the starting liquid feed to the device. The apparatus and method are primarily directed towards the treatment of small areas for residential air fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, administration of personal pharmaceuticals or medicaments, as well as other ambient air or surface modification by way of gas, vapor or droplet distribution.

Owner:VAPORE

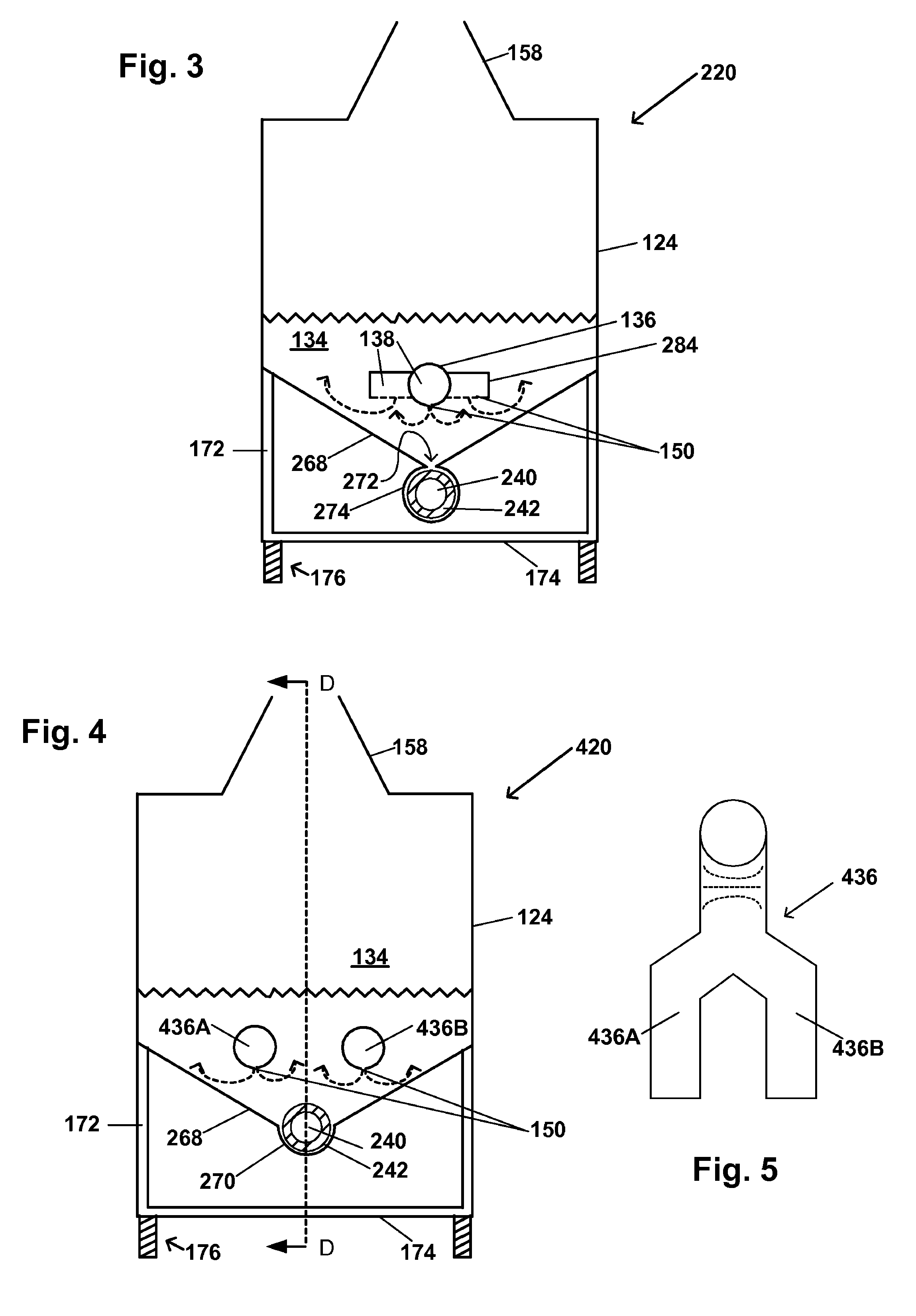

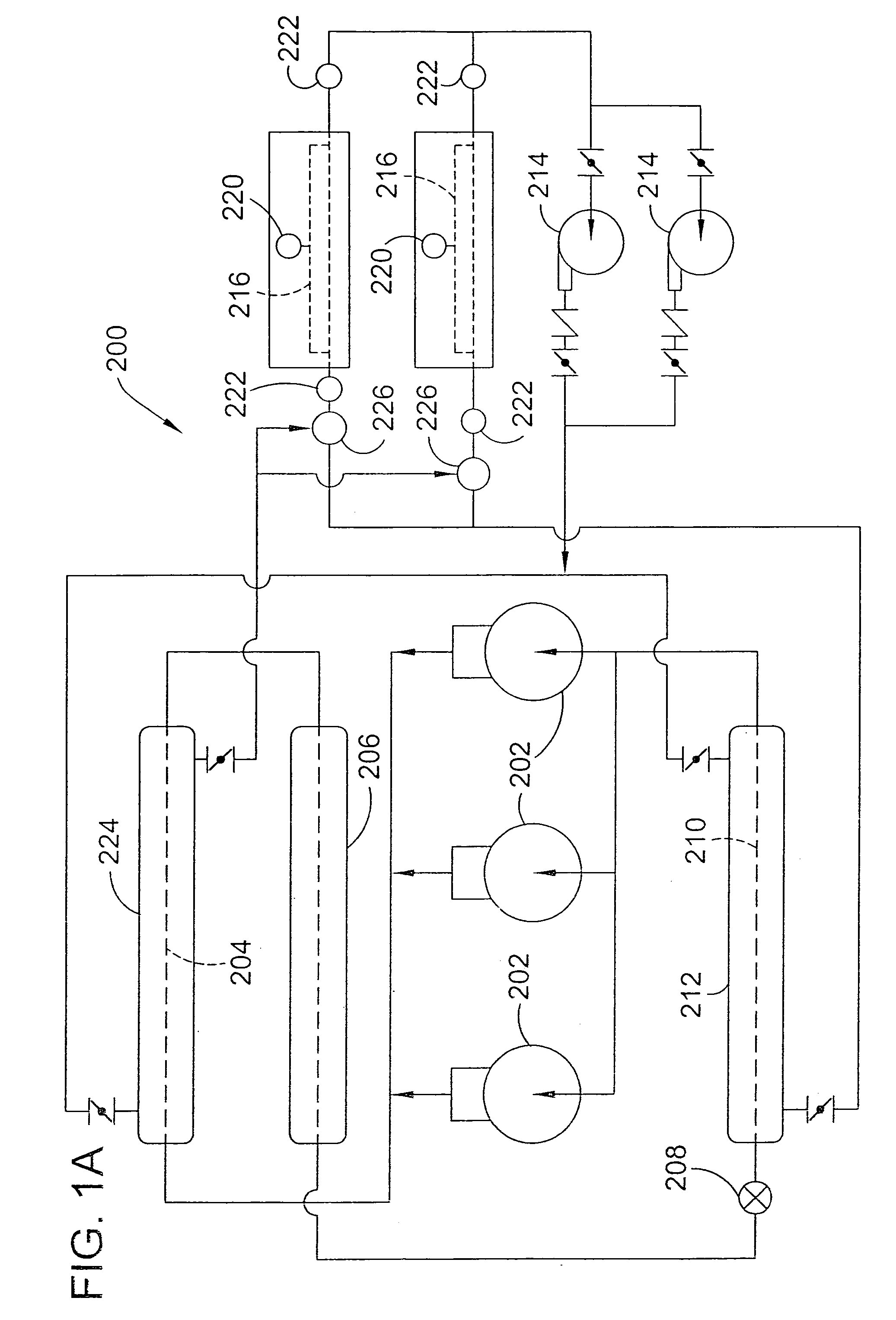

Distributed intelligence control for commercial refrigeration

InactiveUS7270278B2Easy to assembleEasy to installMechanical apparatusEfficient regulation technologiesDistributed intelligenceControl theory

A commercial refrigeration system including a compressor, a condenser, a valve, and an evaporator coil, all of which are in fluid communication. The refrigeration system further including a fixture adapted to be cooled by the evaporator coil, a system controller operable to control operation of the refrigeration system, and a subsystem controller in communication with the system controller. The subsystem controller being operable to monitor at least one parameter of a subsystem having at least one of the compressor, condenser, valve, and fixture, and being further operable to execute a command from the system controller to affect the operation of the subsystem.

Owner:HUSNN

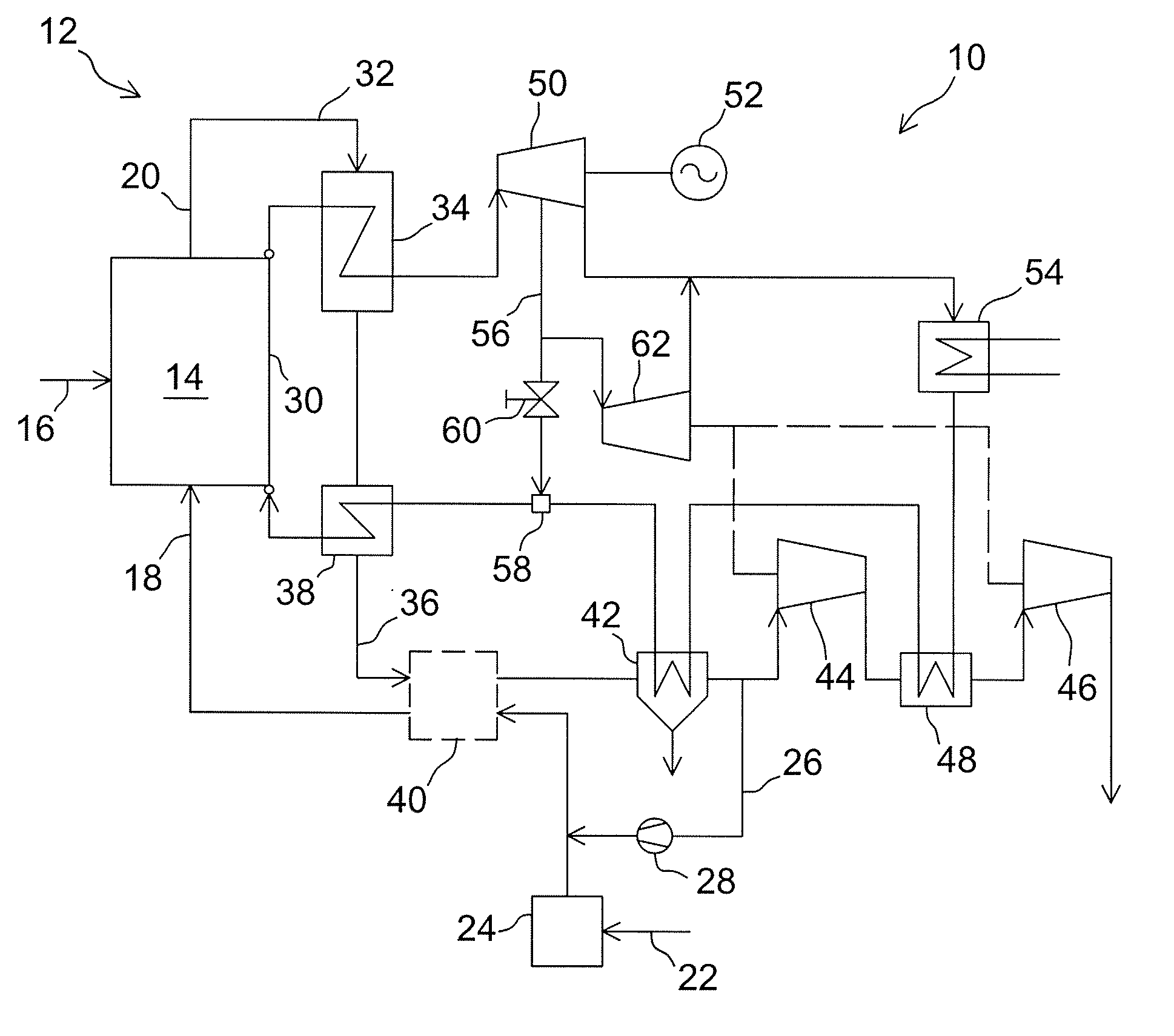

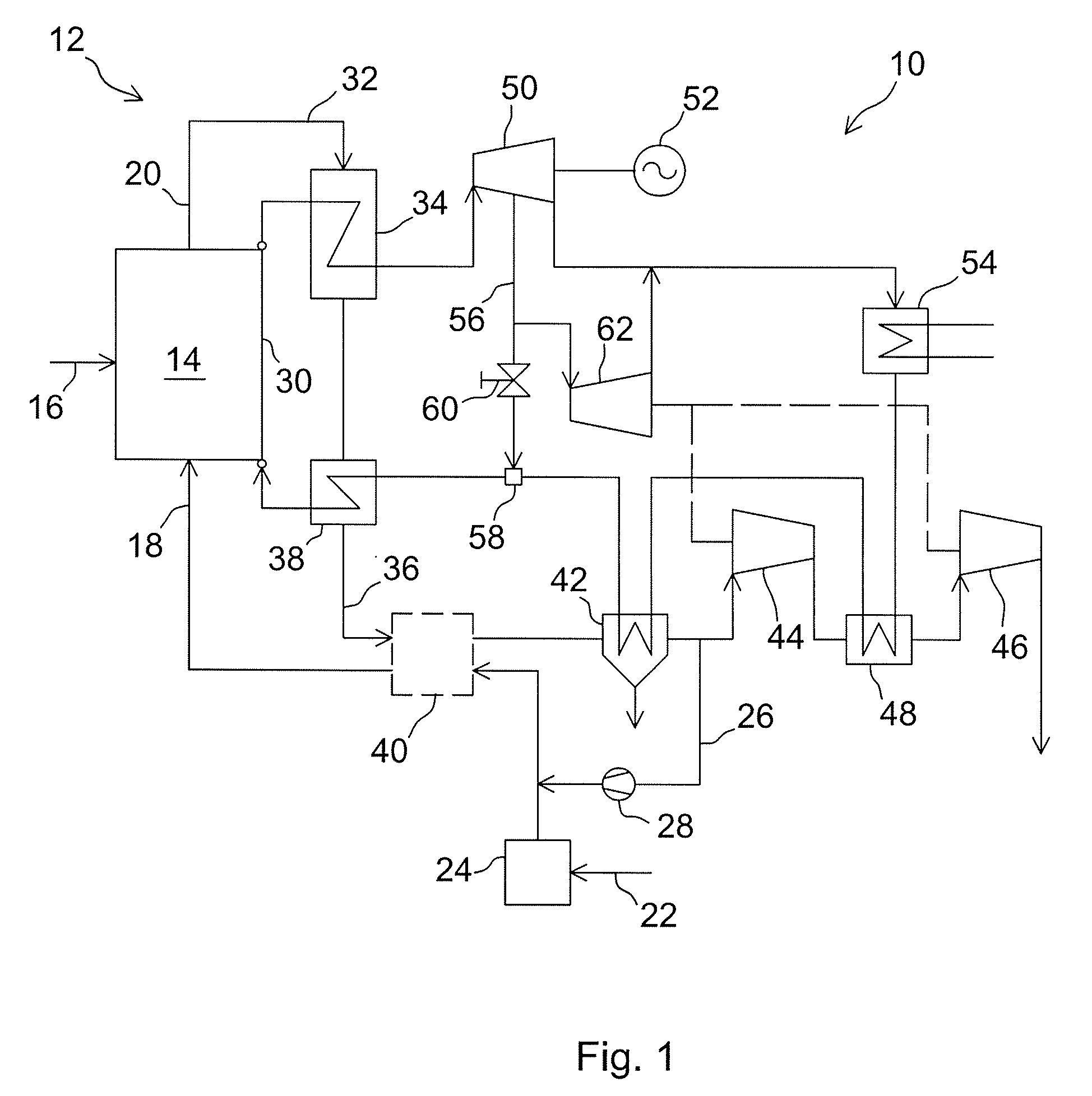

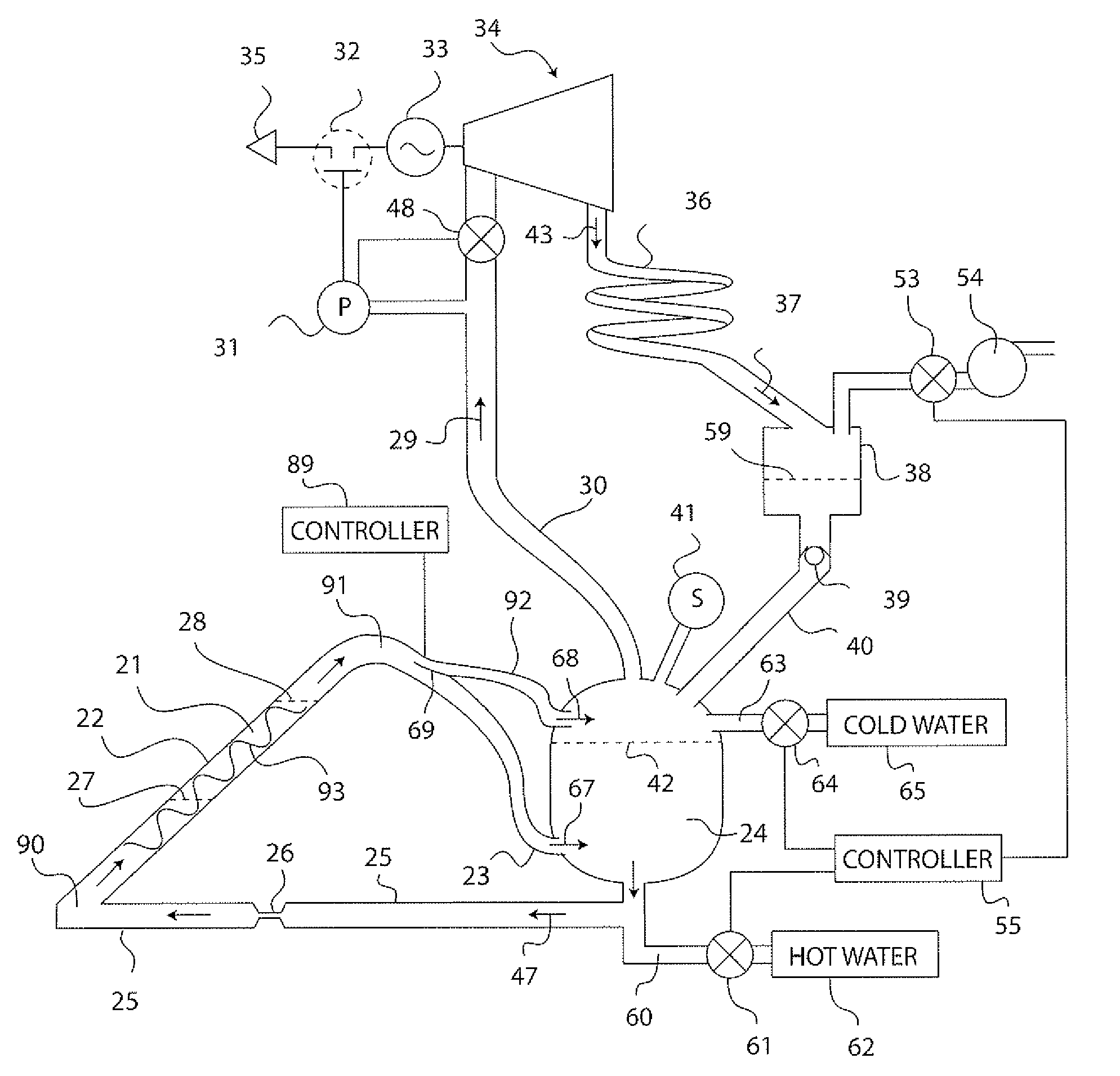

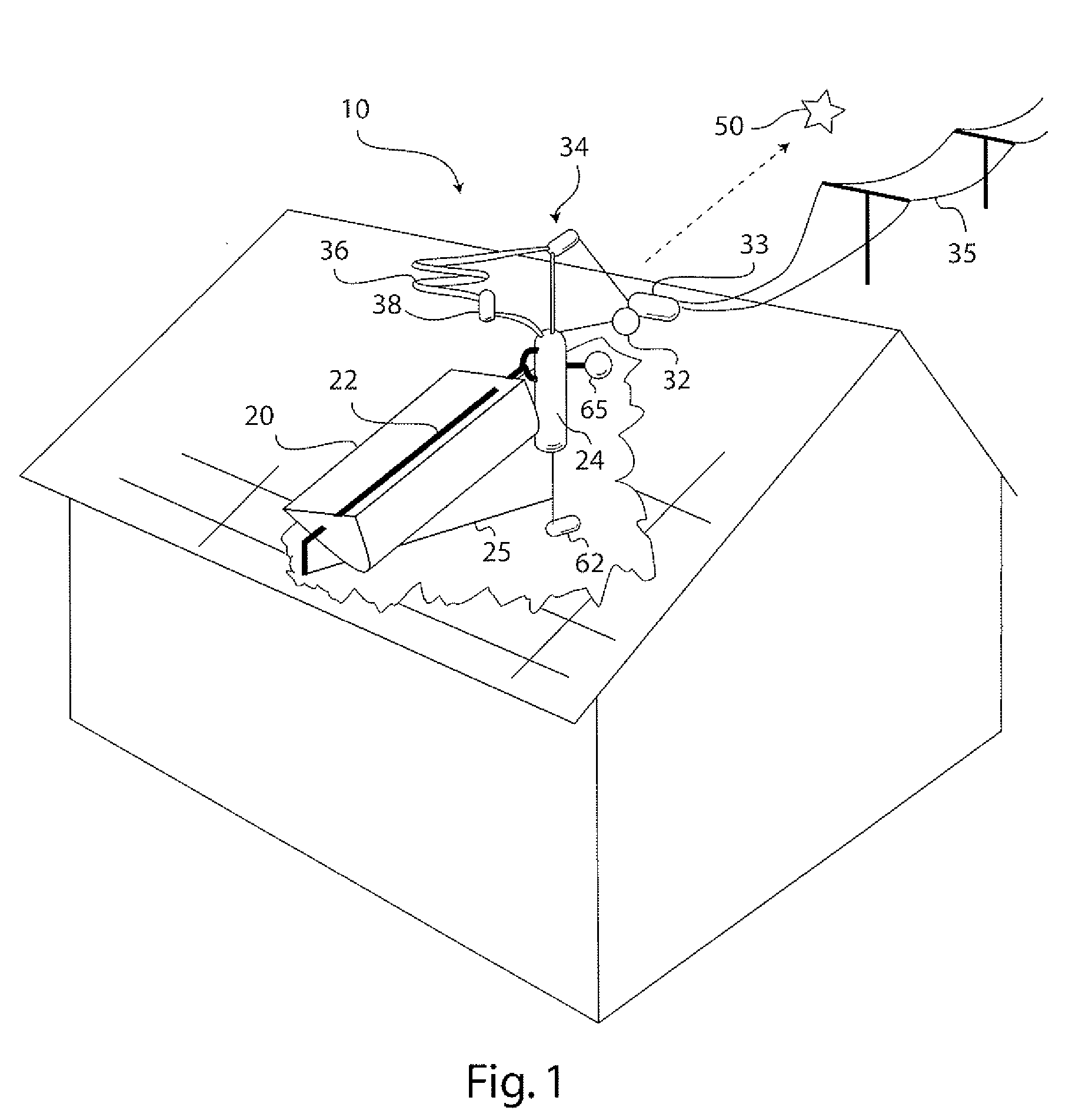

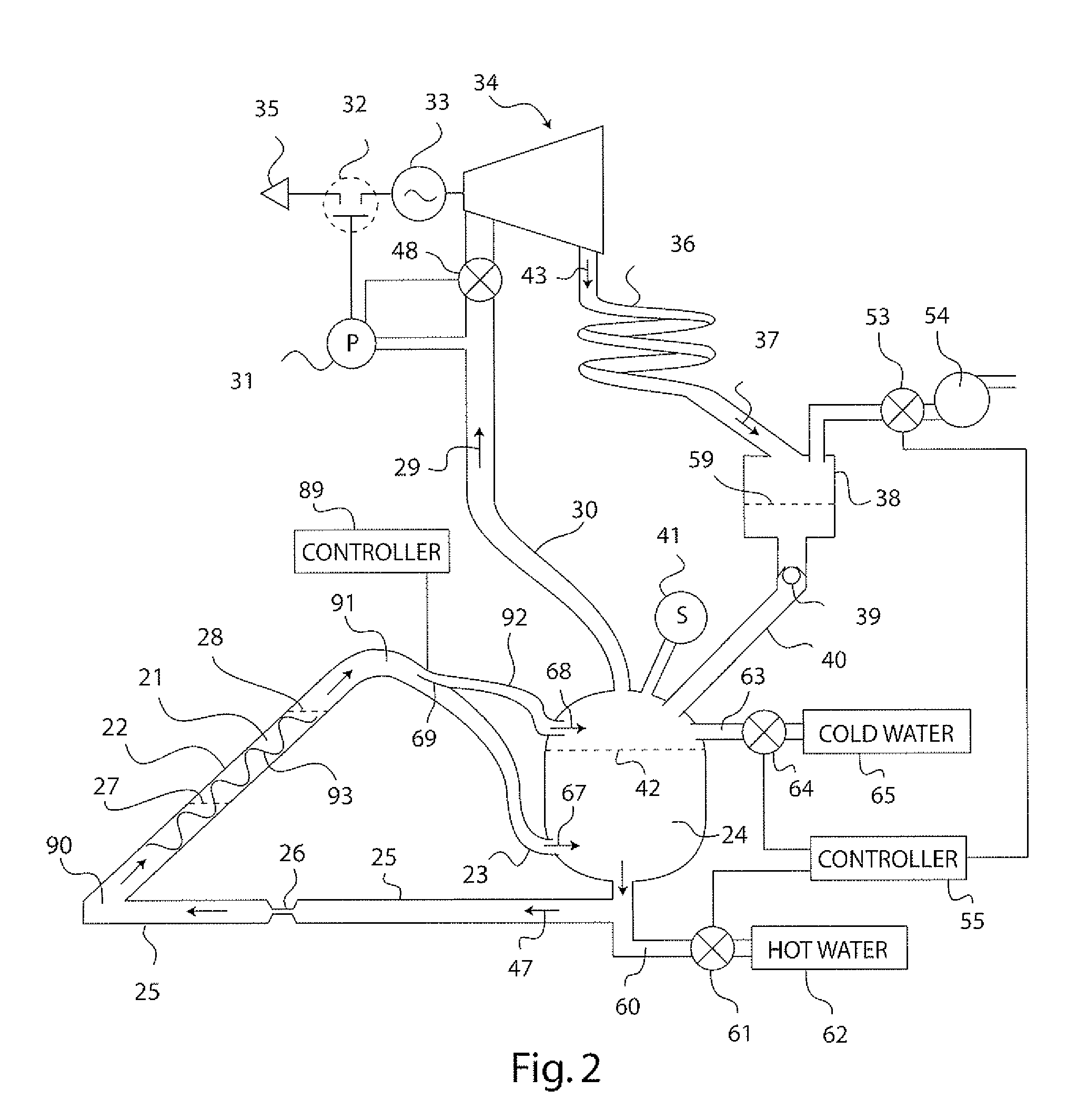

Solar Thermal Power System

InactiveUS20090199557A1Simple efficiencyTechnology being suitableAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

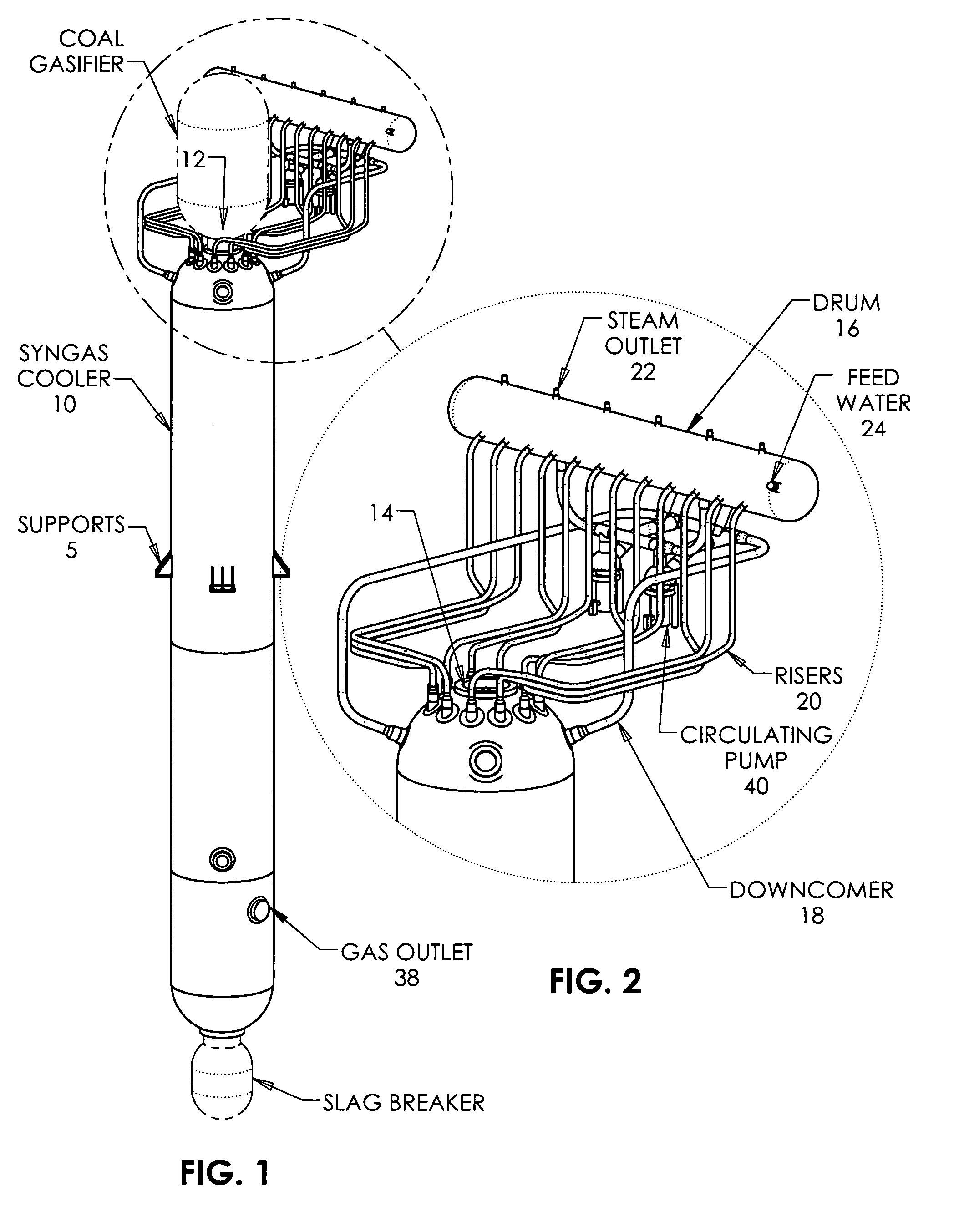

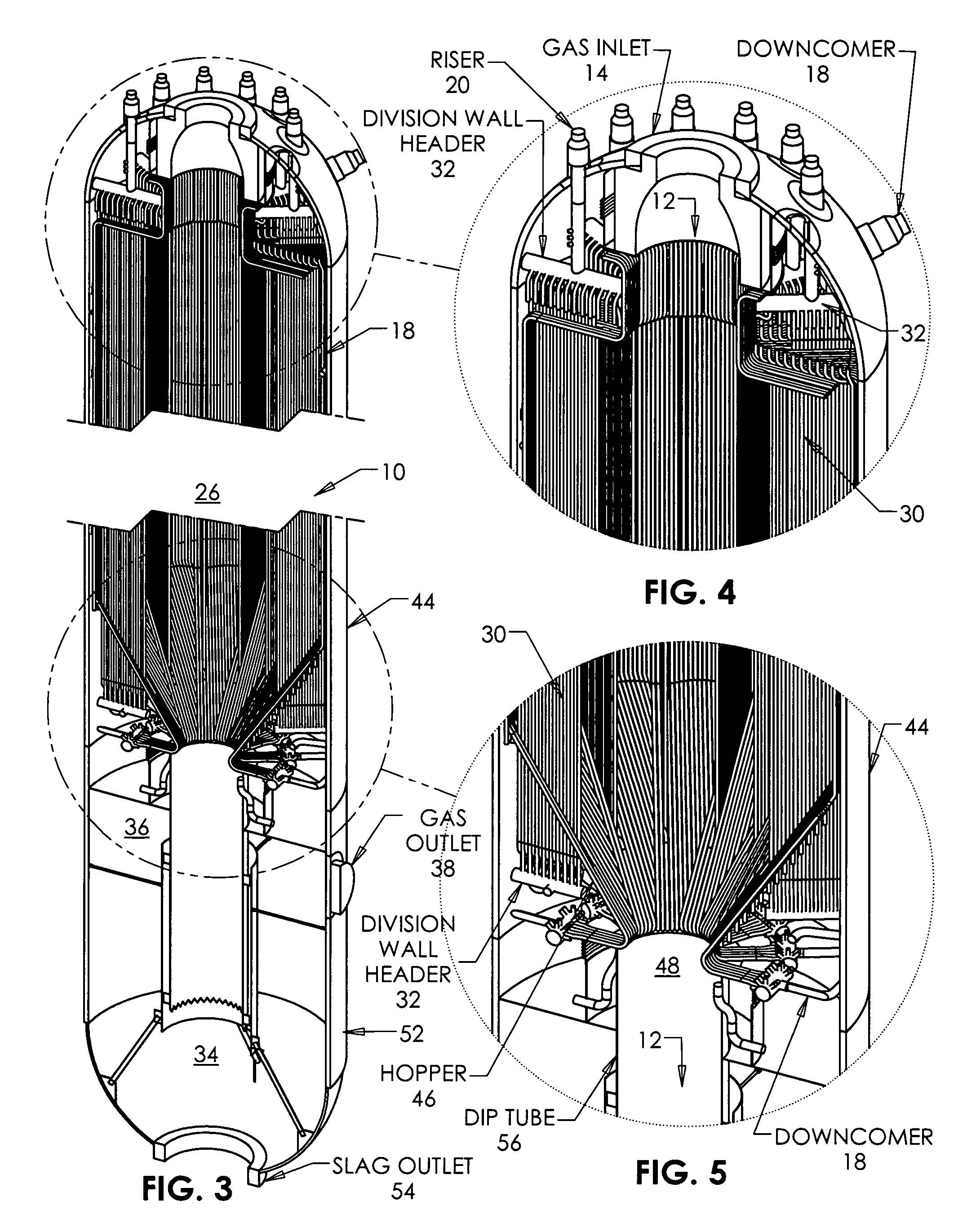

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

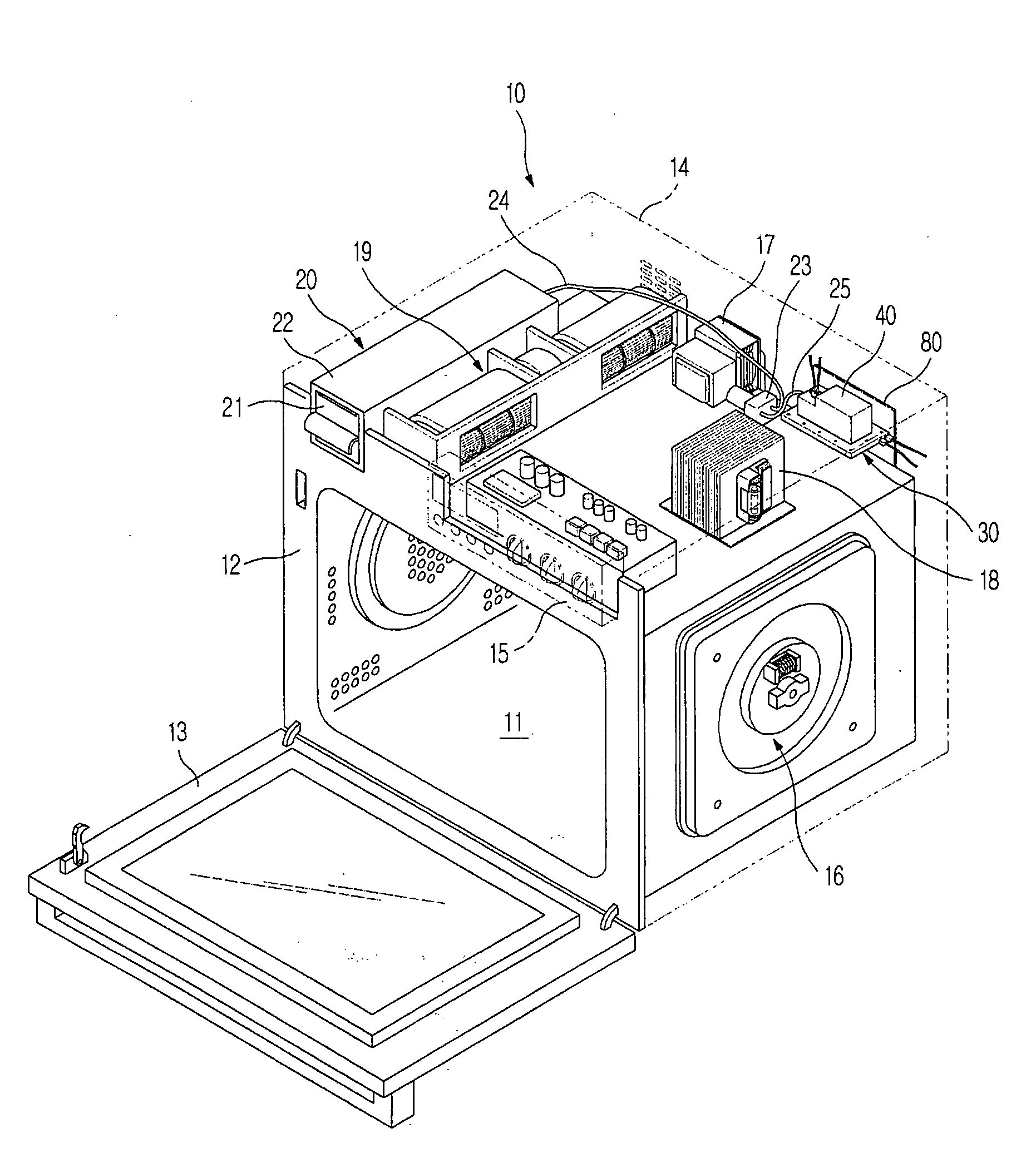

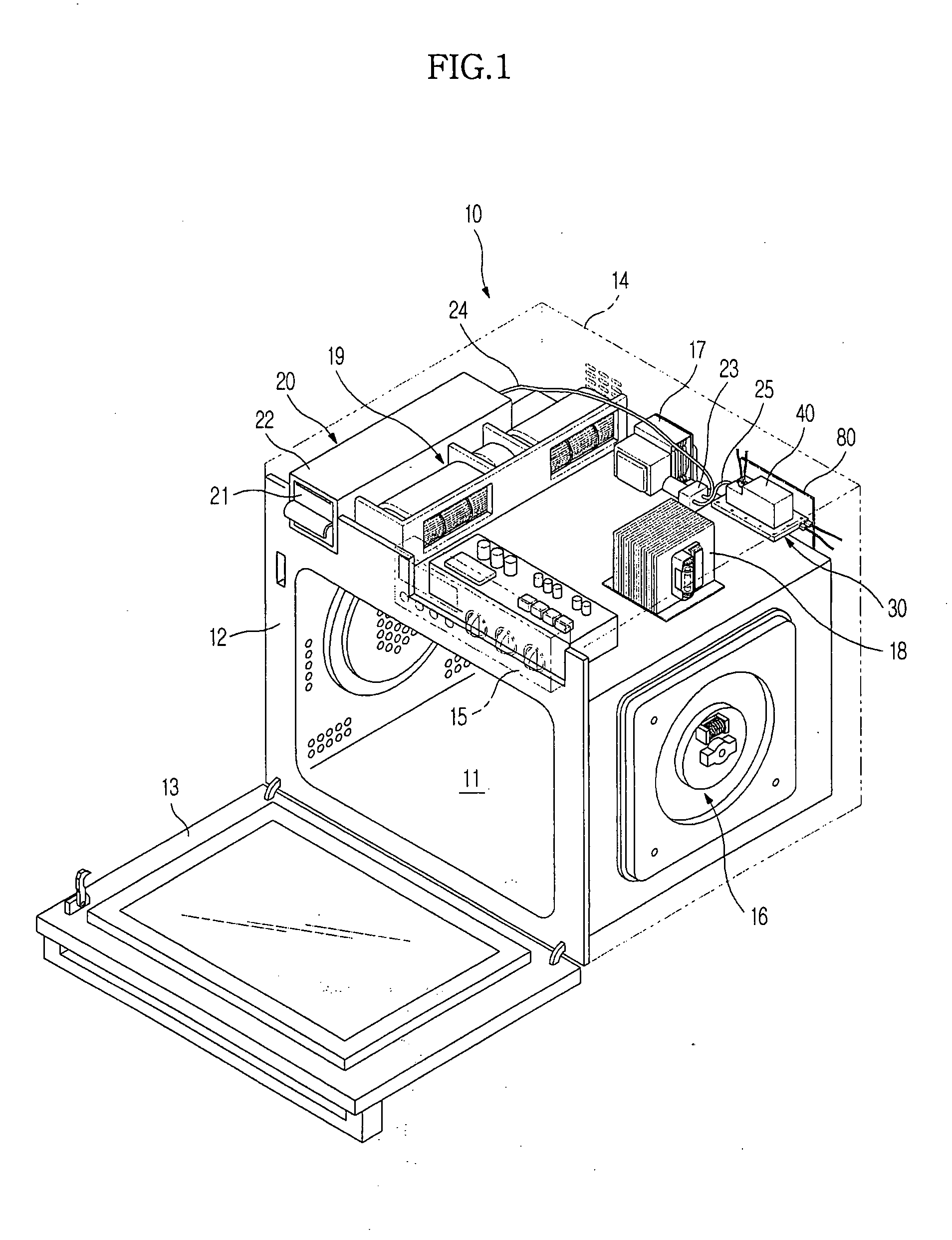

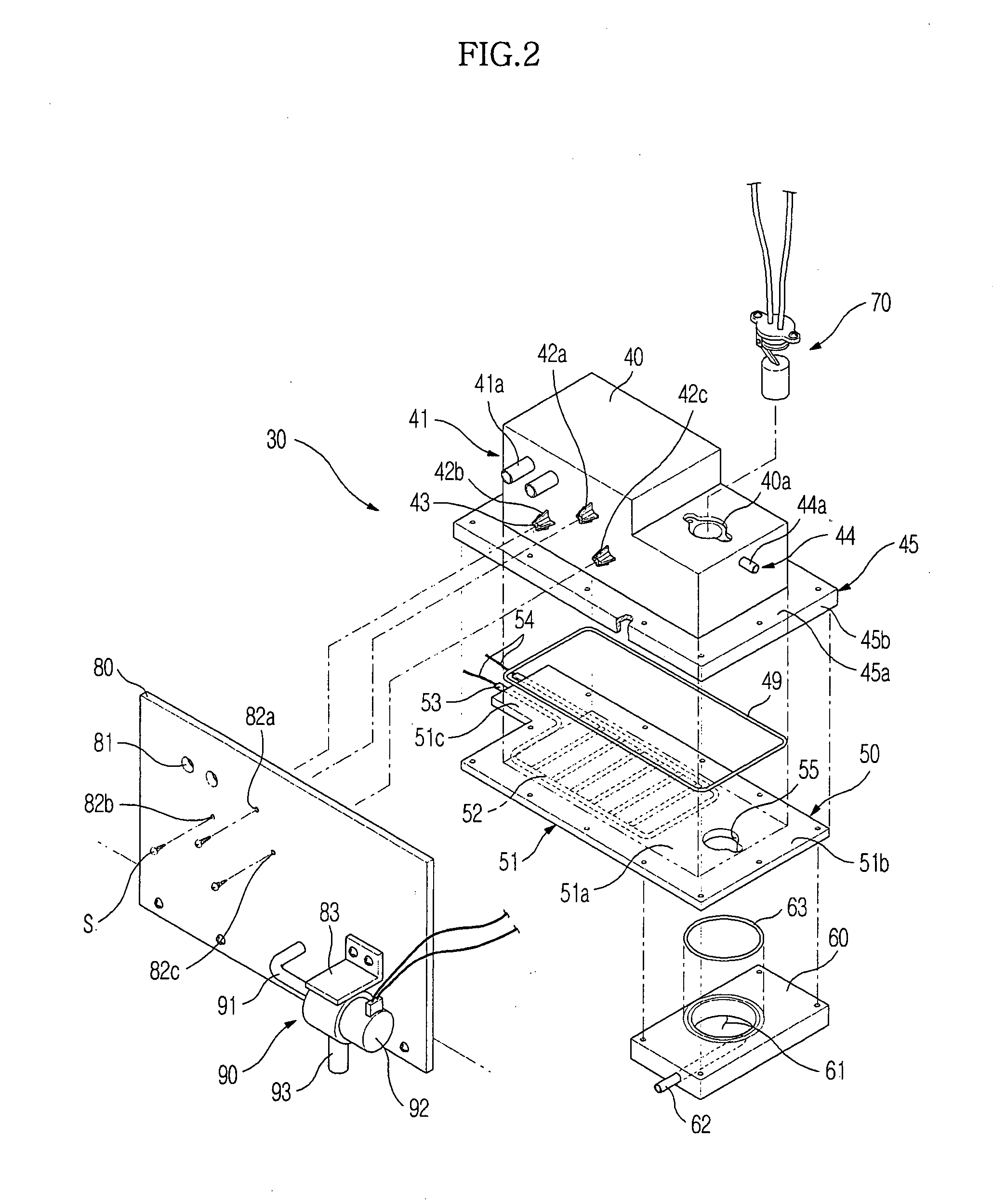

Steam generator and heating cooking apparatus having the same

A heating cooking apparatus including a body, a steam container, a steam heater, and a heater covering portion. The body has a cooking compartment in which food is disposed. The steam container includes a chamber, a water supply portion to supply water into the chamber, and a steam discharge portion to discharge steam generated in the chamber into the cooking compartment. The steam heater has a chamber bottom forming portion that is coupled to a lower end of the steam container so as to cover a bottom of the chamber and adapted to heat water supplied into the chamber. The heater covering portion is configured to cover a rim of the steam heater. Covering the rim of the steam heater using the heater covering portion alleviates the risk of power leakage accidents caused when water at the outside of a steam generator comes into contact with the steam heater.

Owner:SAMSUNG ELECTRONICS CO LTD

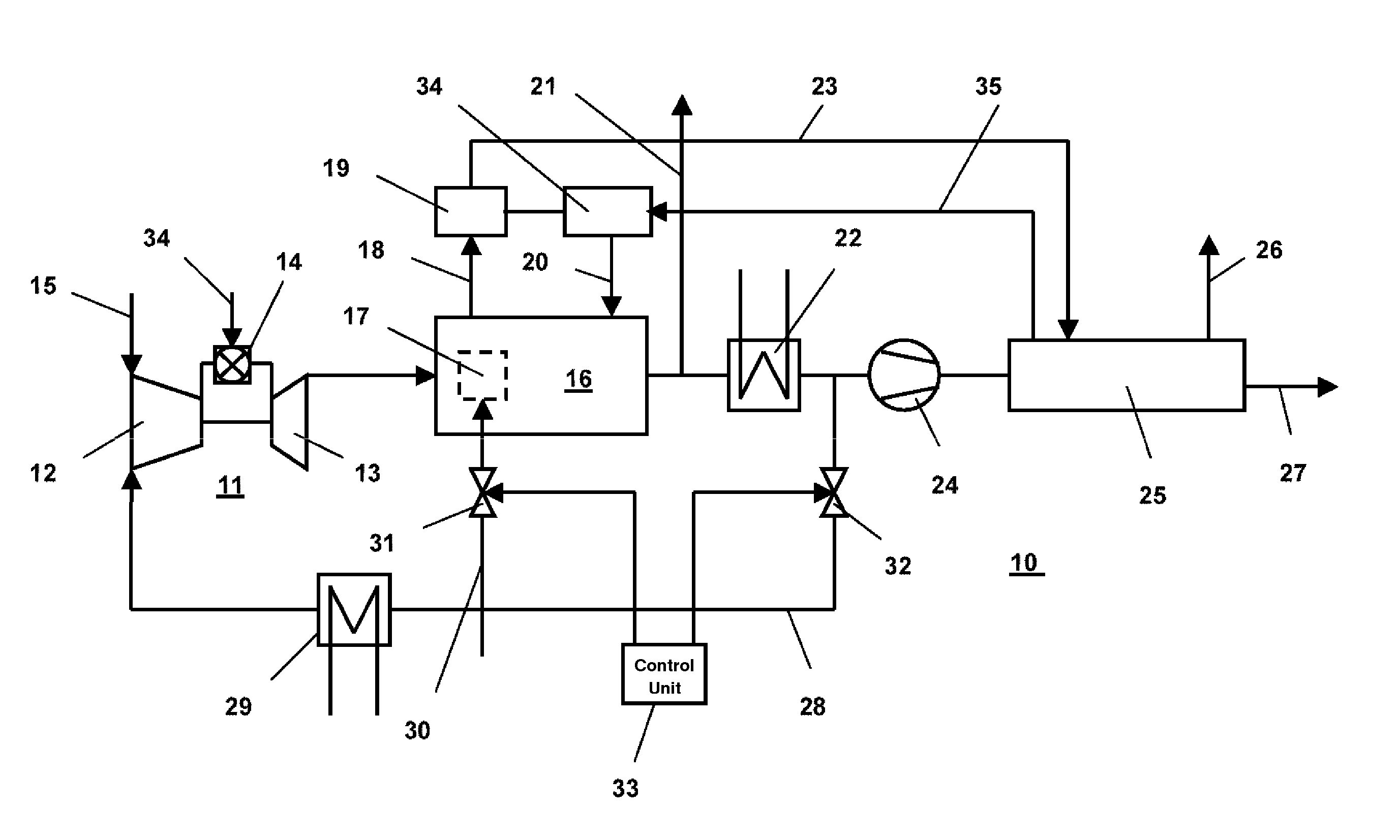

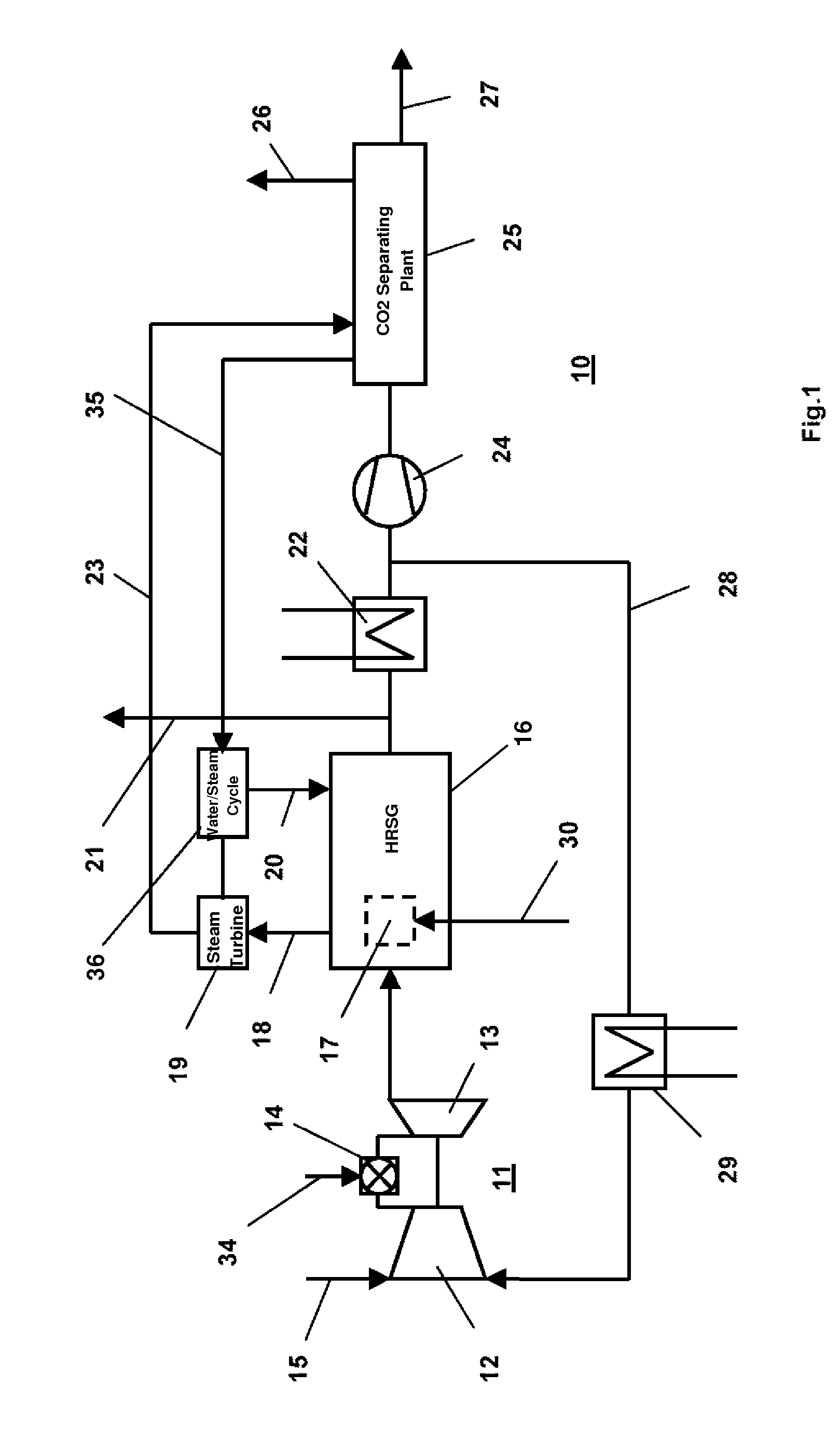

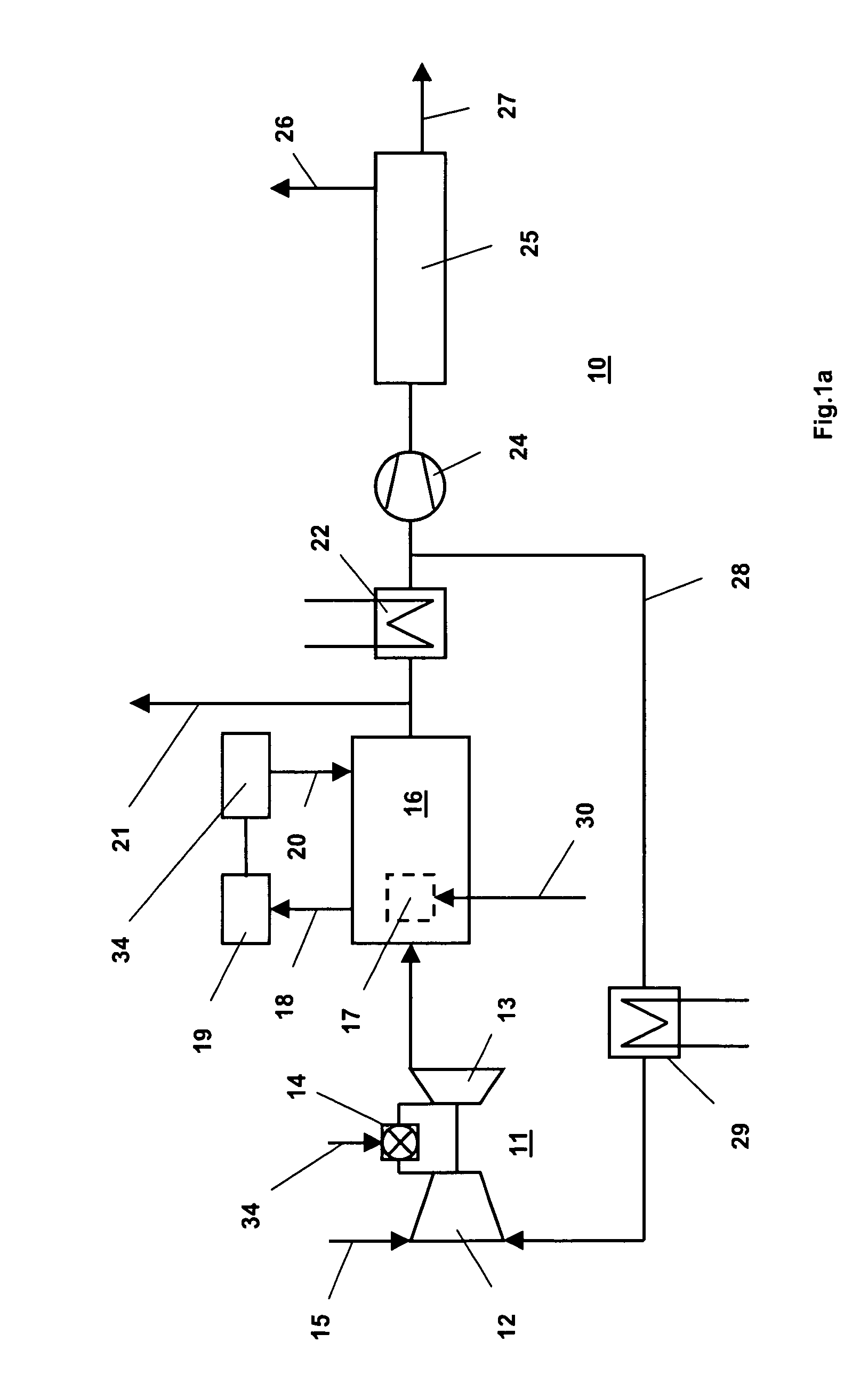

Combined-cycle power plant with exhaust gas recycling and CO2 separation, and method for operating a combined cycle power plant

InactiveUS8424282B2High outputReduce probabilityGas turbine plantsDirect carbon-dioxide mitigationPower stationExhaust fumes

Owner:GENERAL ELECTRIC TECH GMBH

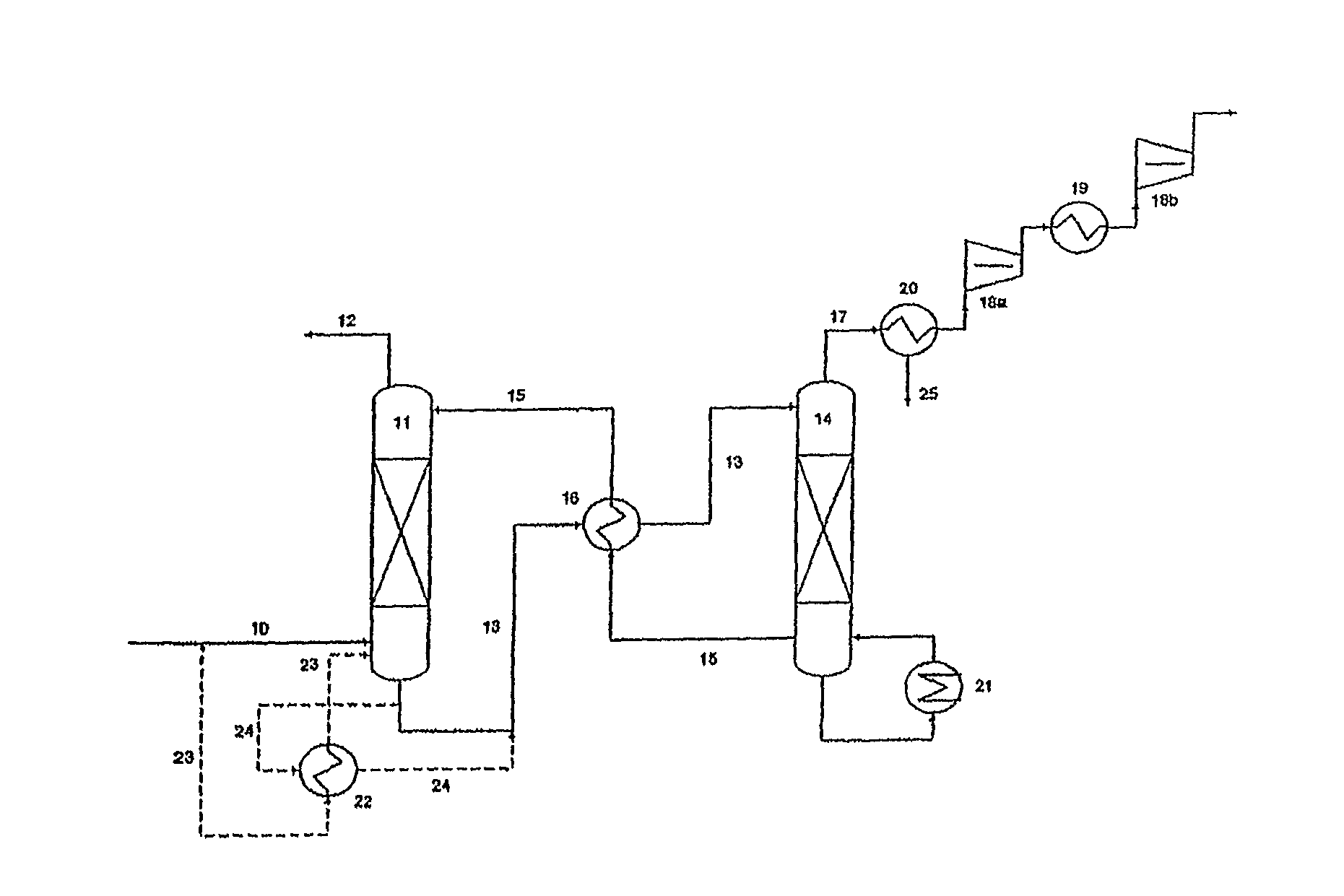

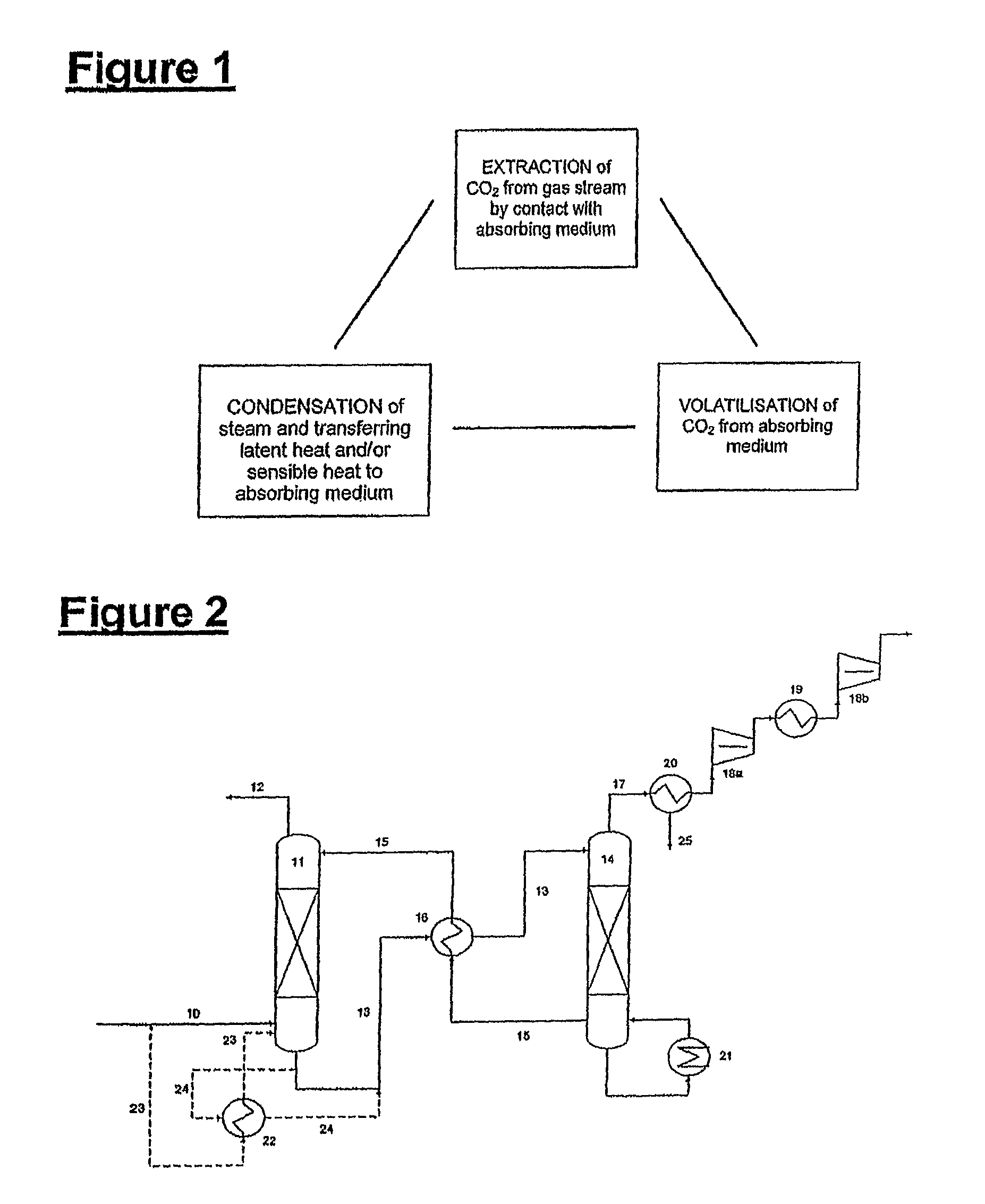

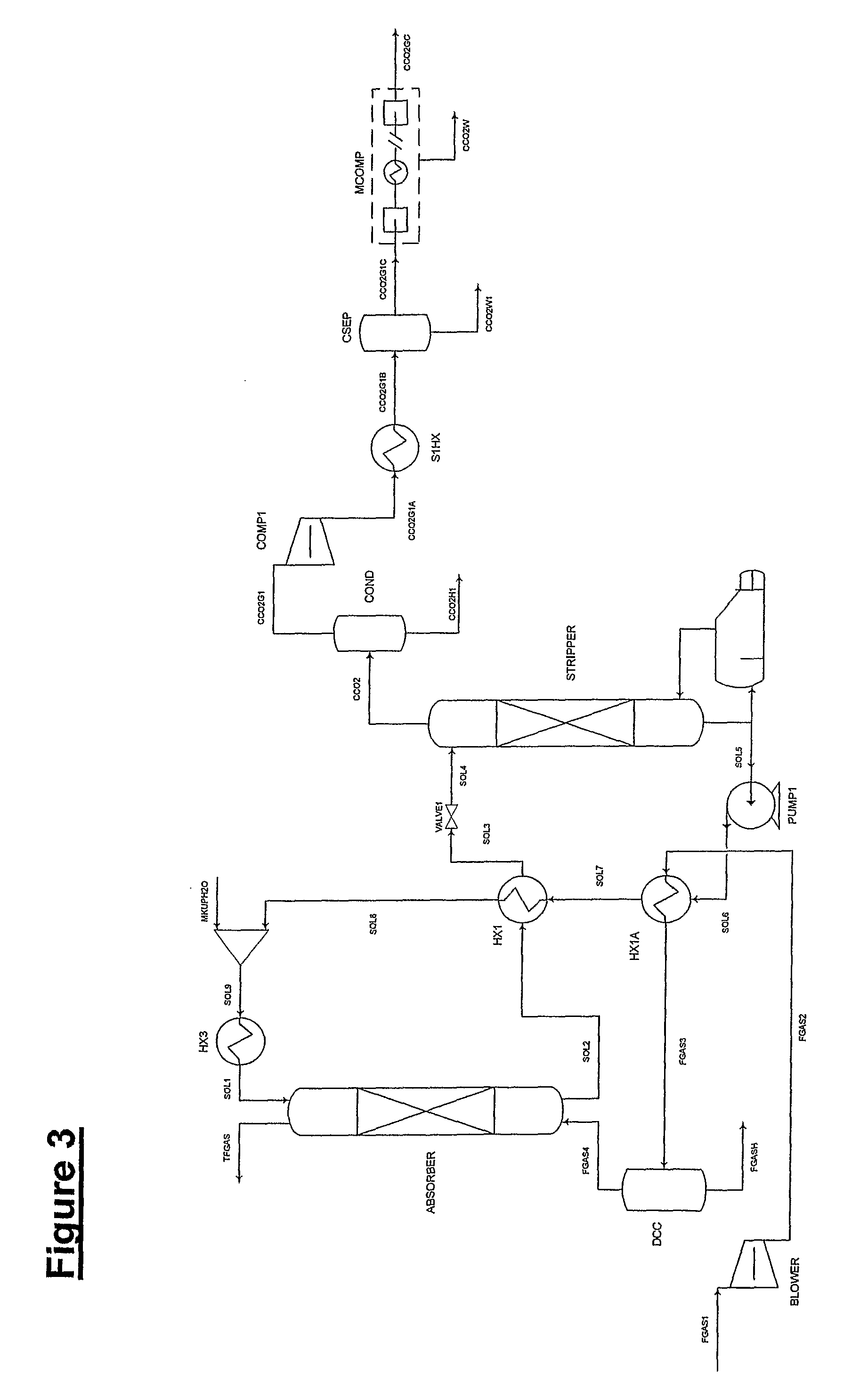

Plant and process for removing carbon dioxide from gas streams

ActiveUS7976803B2Minimizing overall energy requiredAssist in volatilizationFluidized bed combustionIndirect heat exchangersComponents of crude oilCoal

Owner:KC8 CAPTURE TECH LTD

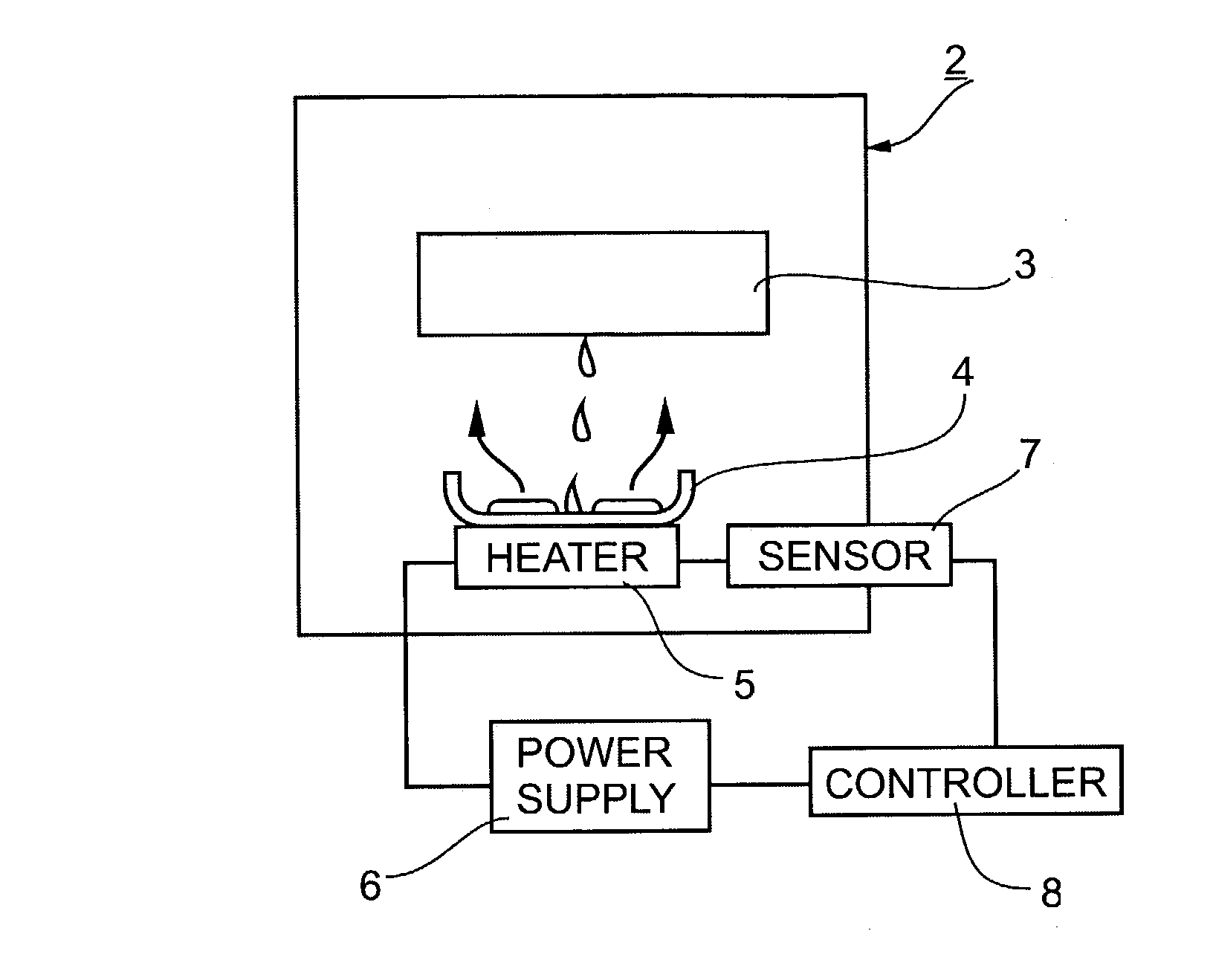

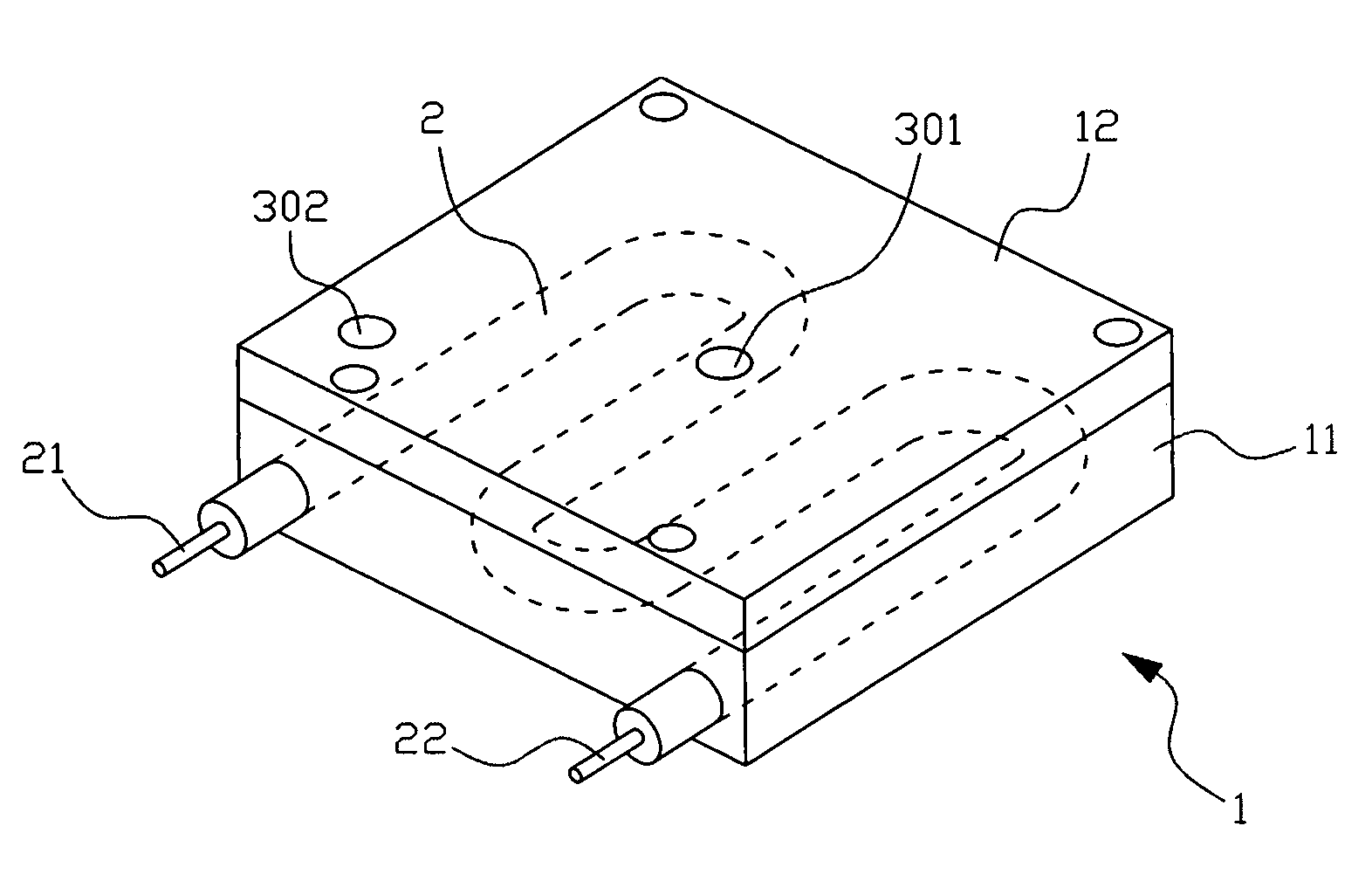

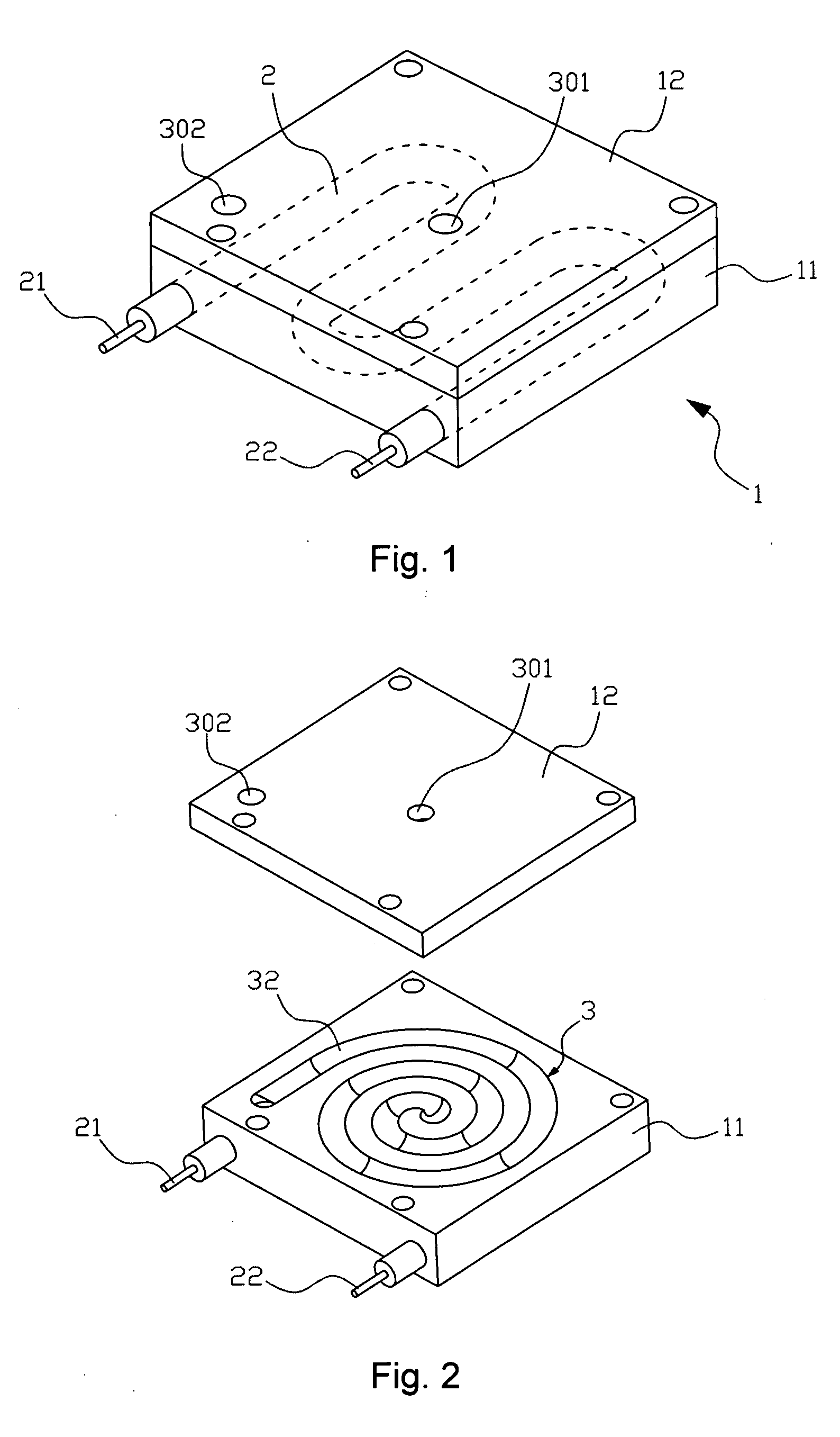

Liquid heating method and apparatus particularly useful for vaporizing a liquid condensate from cooling devices

InactiveUS20030206730A1Minimize power consumptionRule out the possibilitySpace heating and ventilationSteam cooking vesselsElectrical resistance and conductanceBoiling point

A method and heating device for heating a liquid, particularly useful for removing liquid condensate from cooling devices, by wetting a heating plate with the liquid and controlling the electrical power supply to maintain the heating plate at a the predetermined temperature above the boiling point of the liquid, such that when the heating plate is not wetted by the liquid, the electrical power supply to the heating plate is automatically maintained at a relatively low value, but as soon as the heating plate is wetted by the liquid, the electrical power supplied to the heating plate is automatically increased until the liquid is completely evaporated. The heating plate is heated by one or more PTC thermistors in which the electrical resistance increases with temperature to automatically maintain the predetermined temperature. Besides evaporating liquid condensate, the heating device is described for use in many other applications including steam generation, space heating and plastic molding.

Owner:A T C T ADVANCED THERMAL CHIP TECH

System and method for preventing overheating of water within a water heater tank

A water heating system has a tank, a first heating element, a first temperature sensor, and a controller. The first heating element is mounted on the tank, and the controller is electrically coupled to the first temperature sensor. The controller is configured to detect a stacking condition based on the first temperature sensor and to disable the first heating element in response to detection of the stacking condition.

Owner:A O SMITH

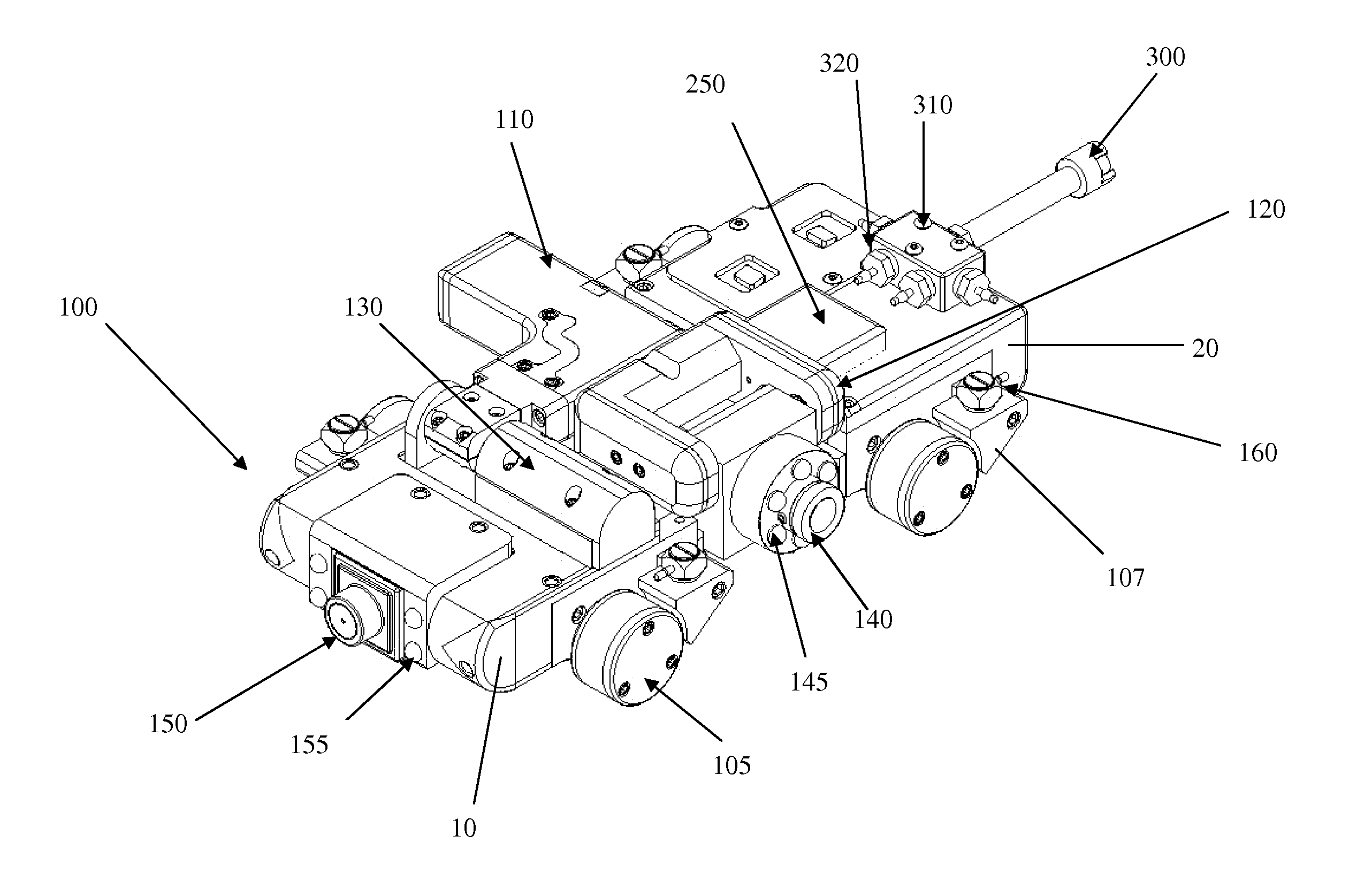

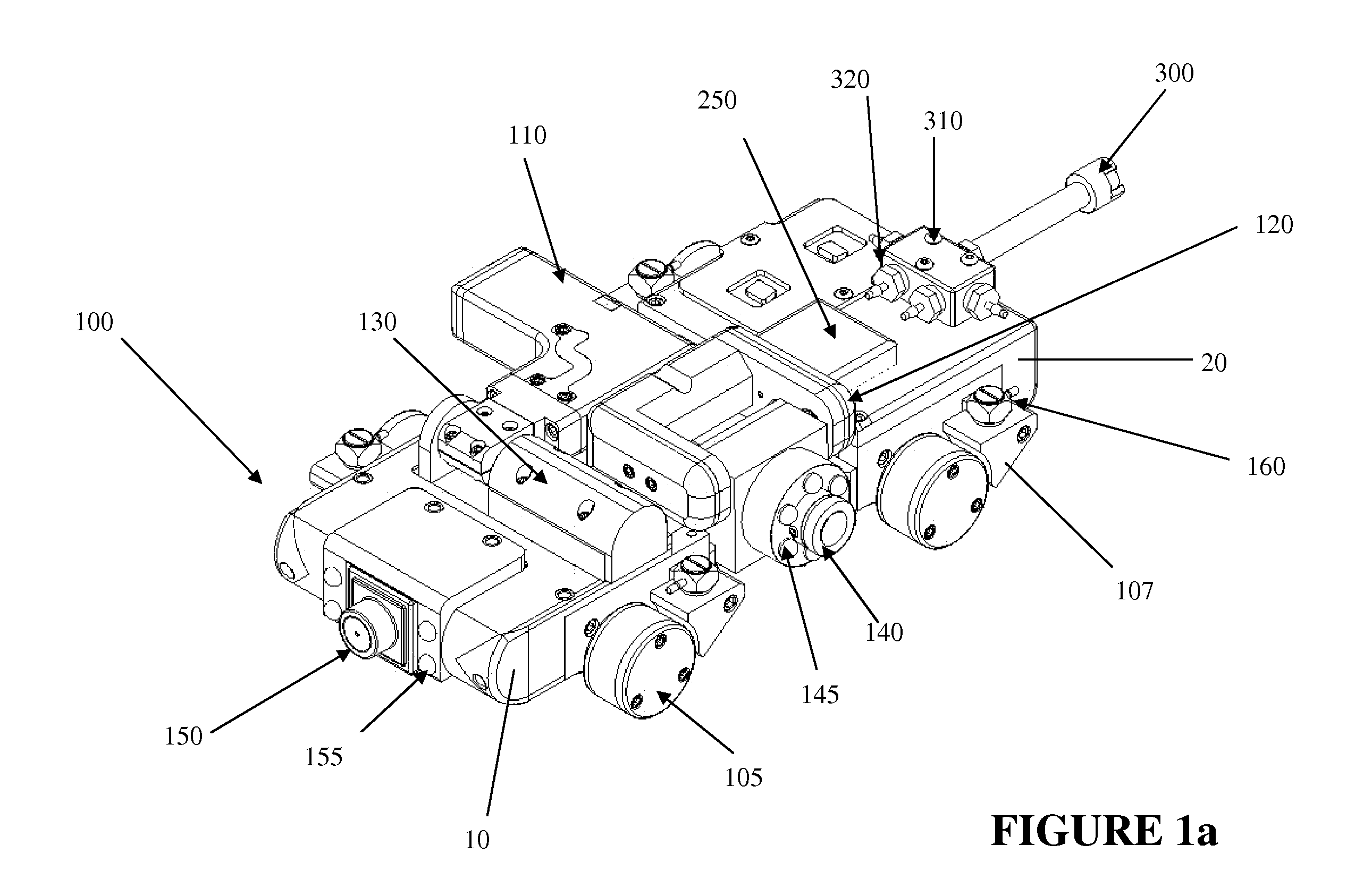

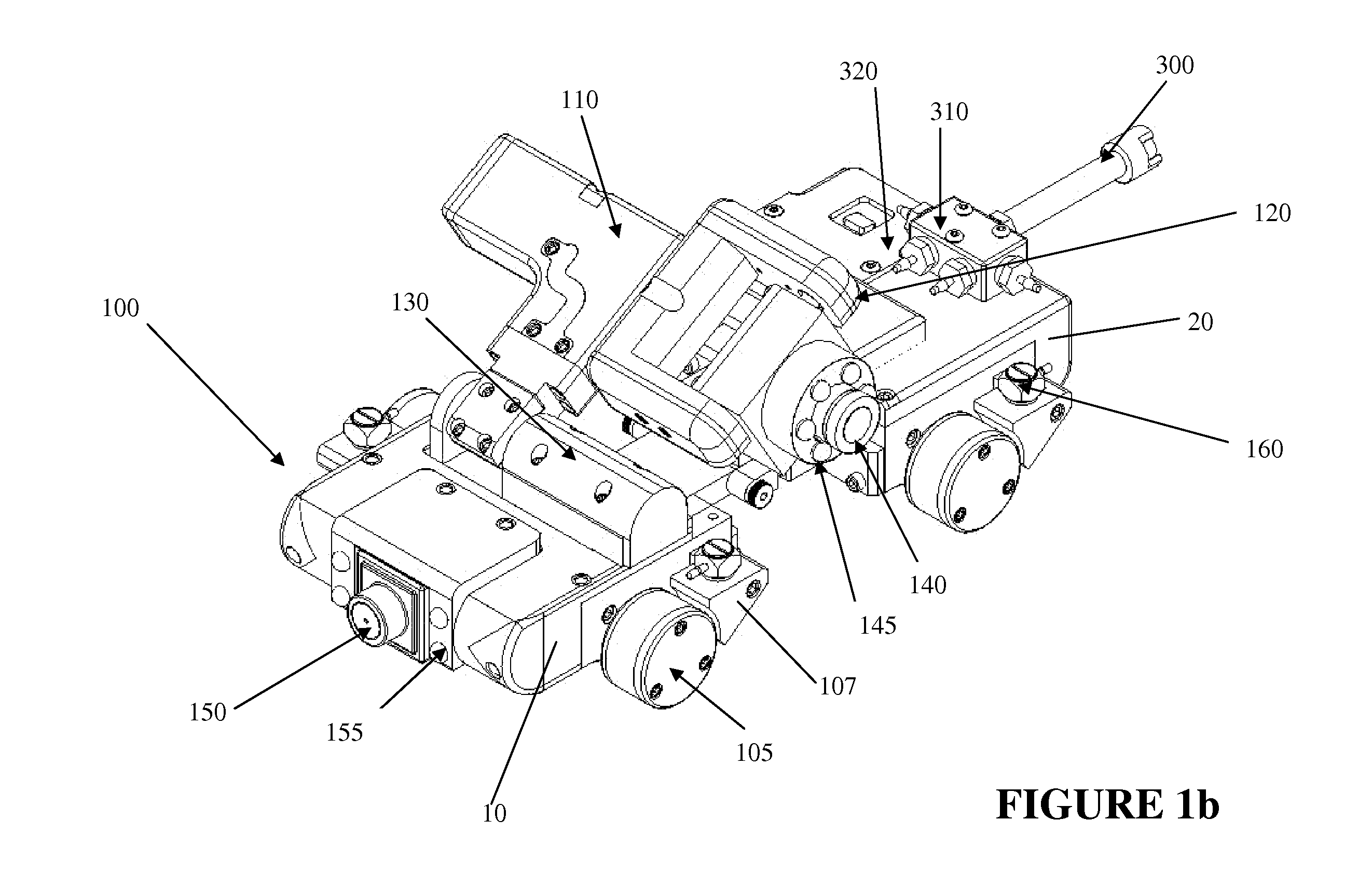

Inspection system and inspection process utilizing magnetic inspection vehicle

An inspection vehicle configured to inspect steam generators includes a front chassis having two independently driven magnetic wheels, a rear chassis having two independently driven magnetic wheels, and a connecting member flexibly connecting the front chassis to the rear chassis to permit relative motion between the front chassis and the rear chassis along at least one axis. The connecting member, front chassis, and rear chassis collectively define a receiving area. The inspection vehicle also includes a navigation camera disposed on the front chassis and a pan and tilt inspection camera assembly including a first rotatable arm driven by a first motor, a second rotatable arm disposed on a distal portion of the first rotatable arm, the second rotatable arm being driven by a second motor, and an inspection camera rotatably disposed on a distal portion of the second arm, the inspection camera being driven by a third motor, the camera assembly being dimensioned to be received within the receiving area in a stowed position.

Owner:ROLLS ROYCE CONTROL SYST HLDG CO

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

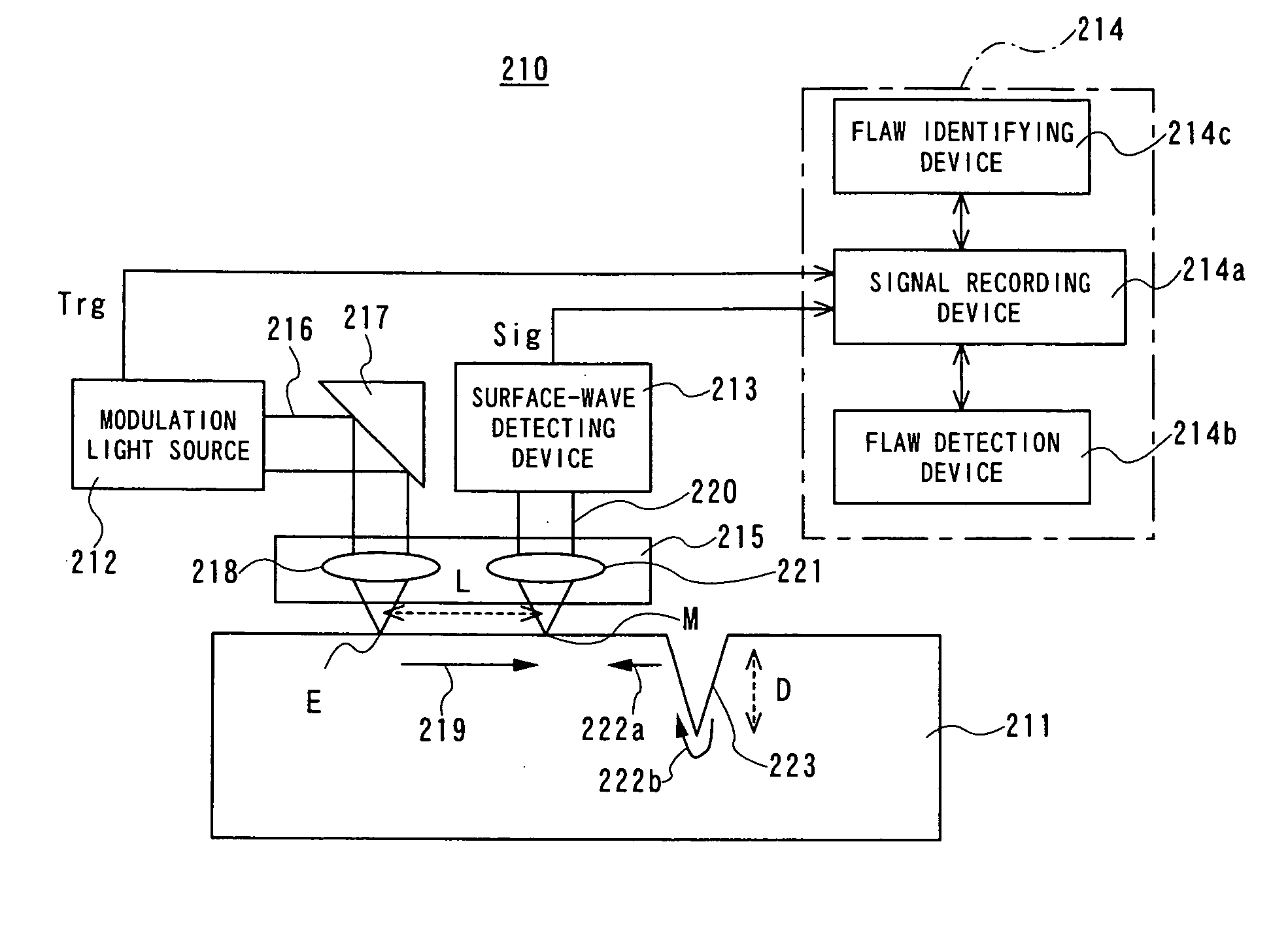

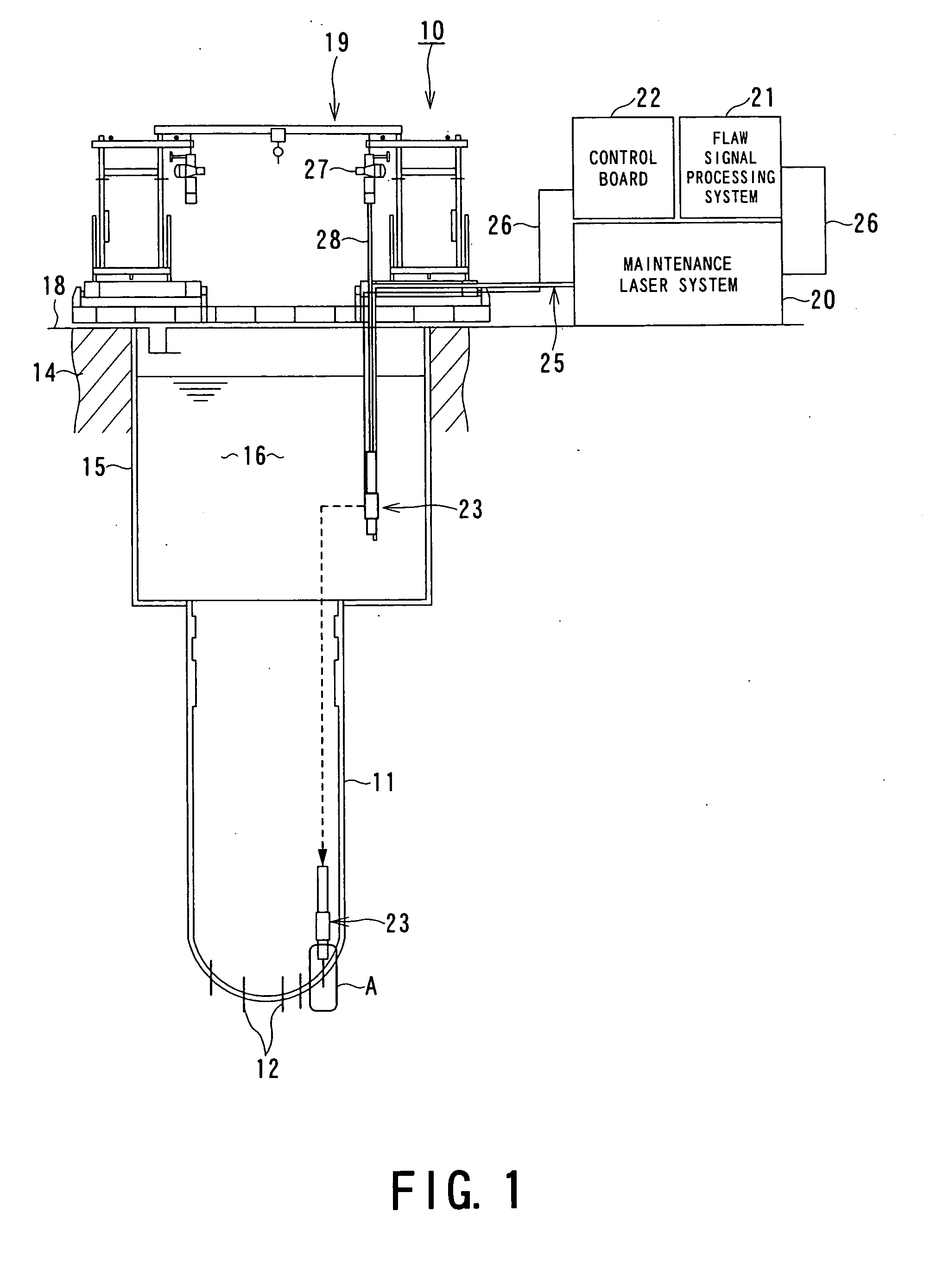

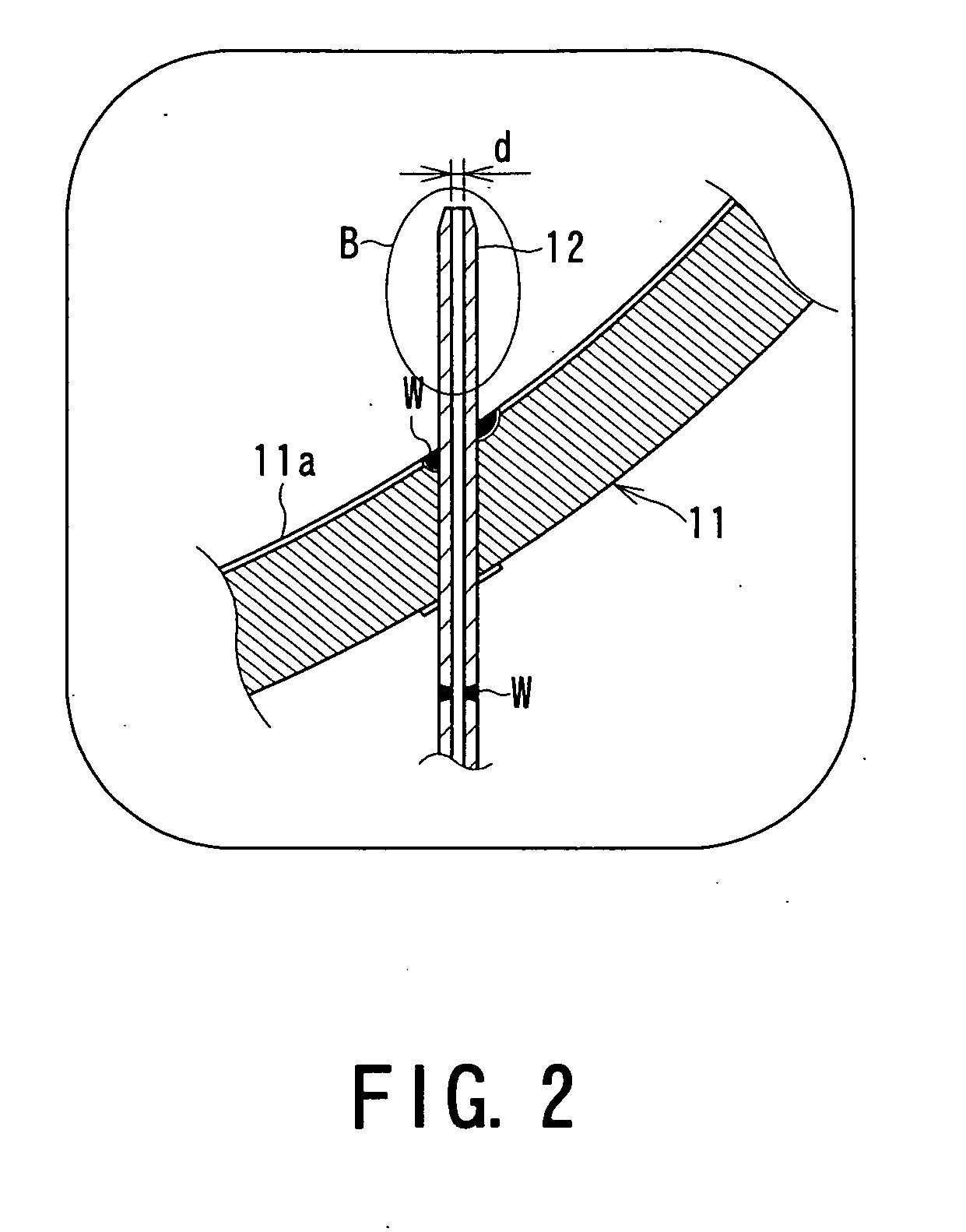

Laser-based maintenance apparatus

ActiveUS20070157730A1Shorten the timeEfficient and effectiveAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationOptoelectronicsLaser light

A laser maintenance apparatus is provided with a laser system including a laser light source and an optical system and emitting a laser light, a light transmitting device for generating the laser light emitted from the laser system, and a laser irradiation device for irradiating the laser light generated by the light transmitting device to an object portion. The laser system includes an element for changing an irradiation condition of the laser light.

Owner:KK TOSHIBA

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

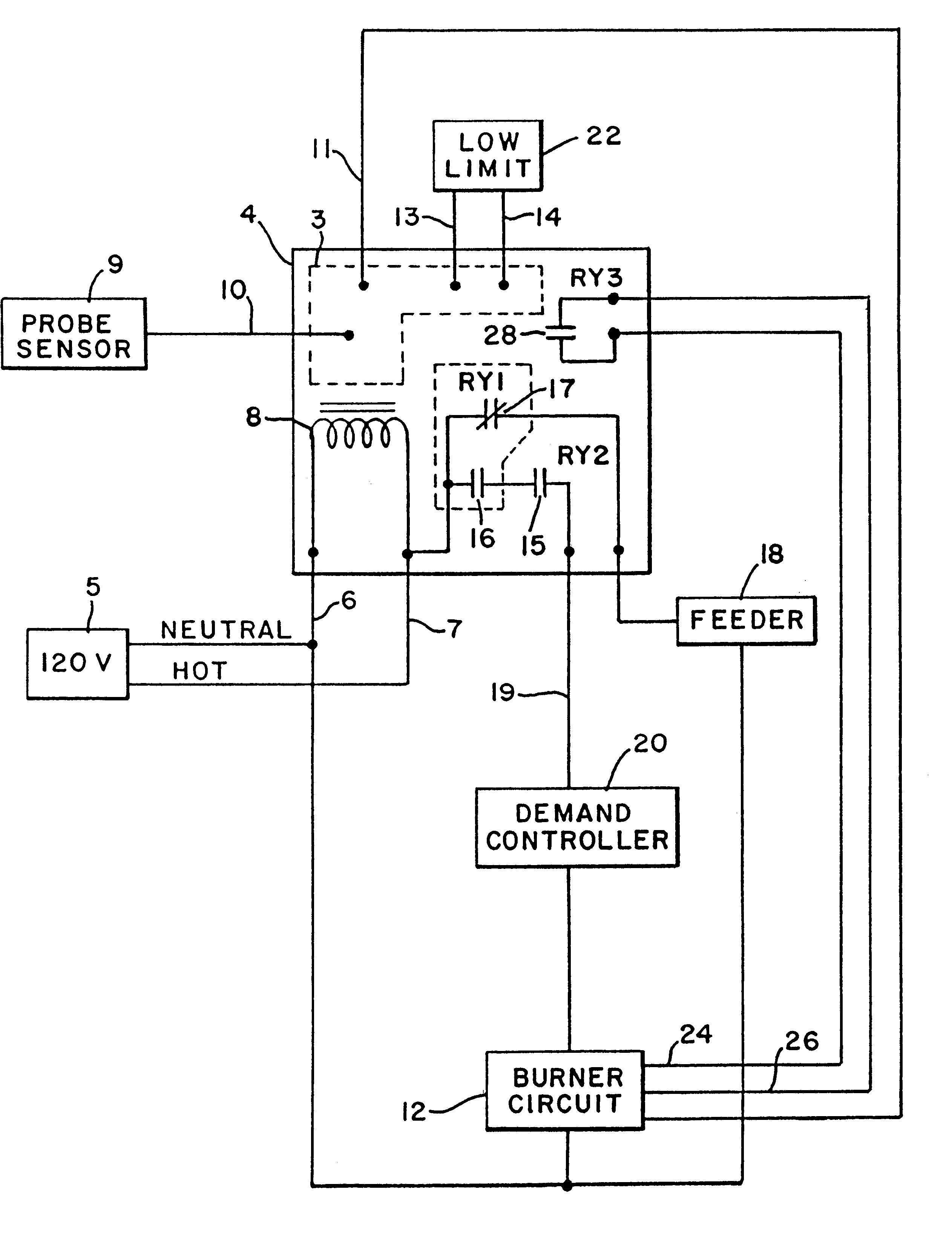

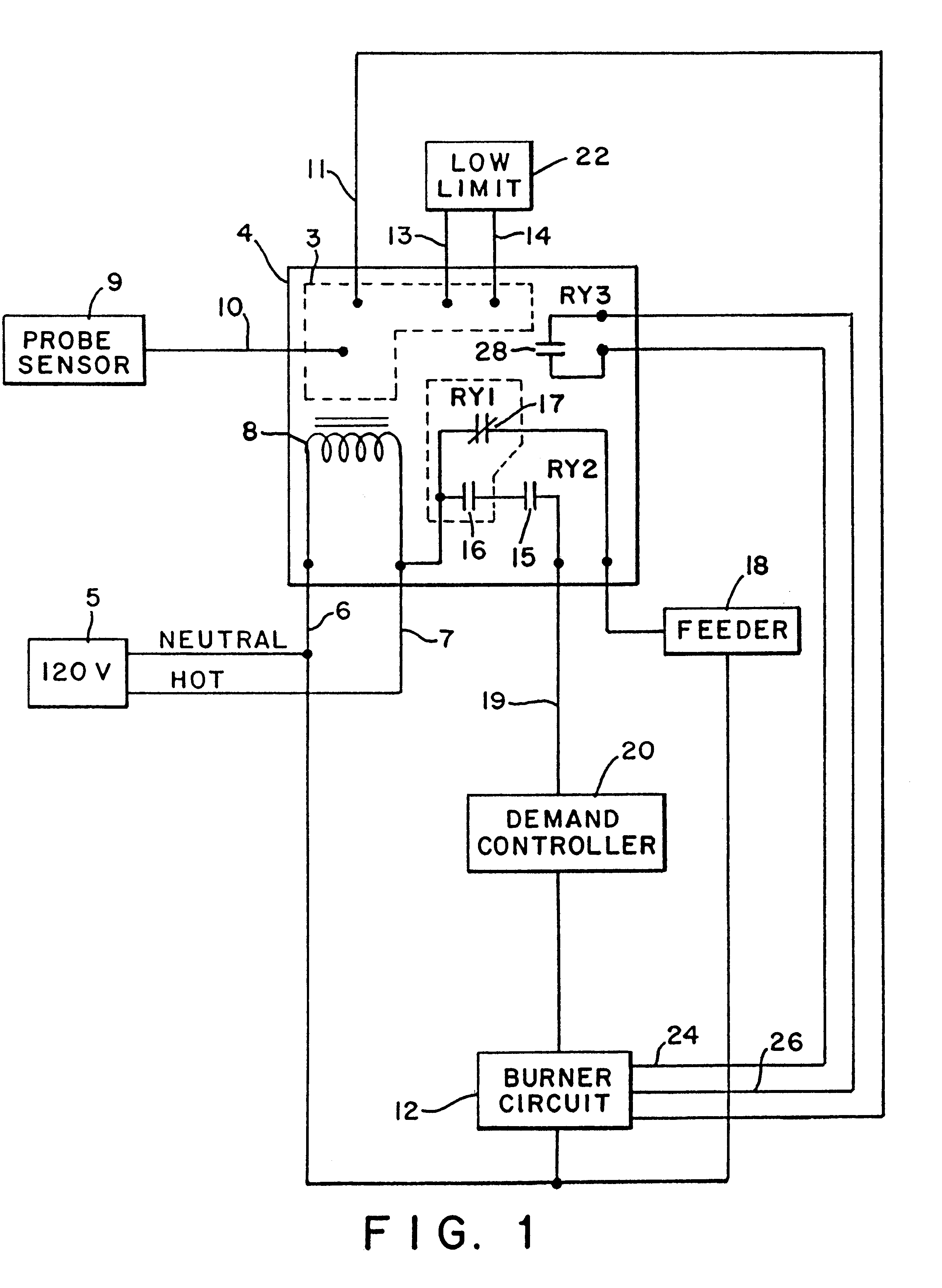

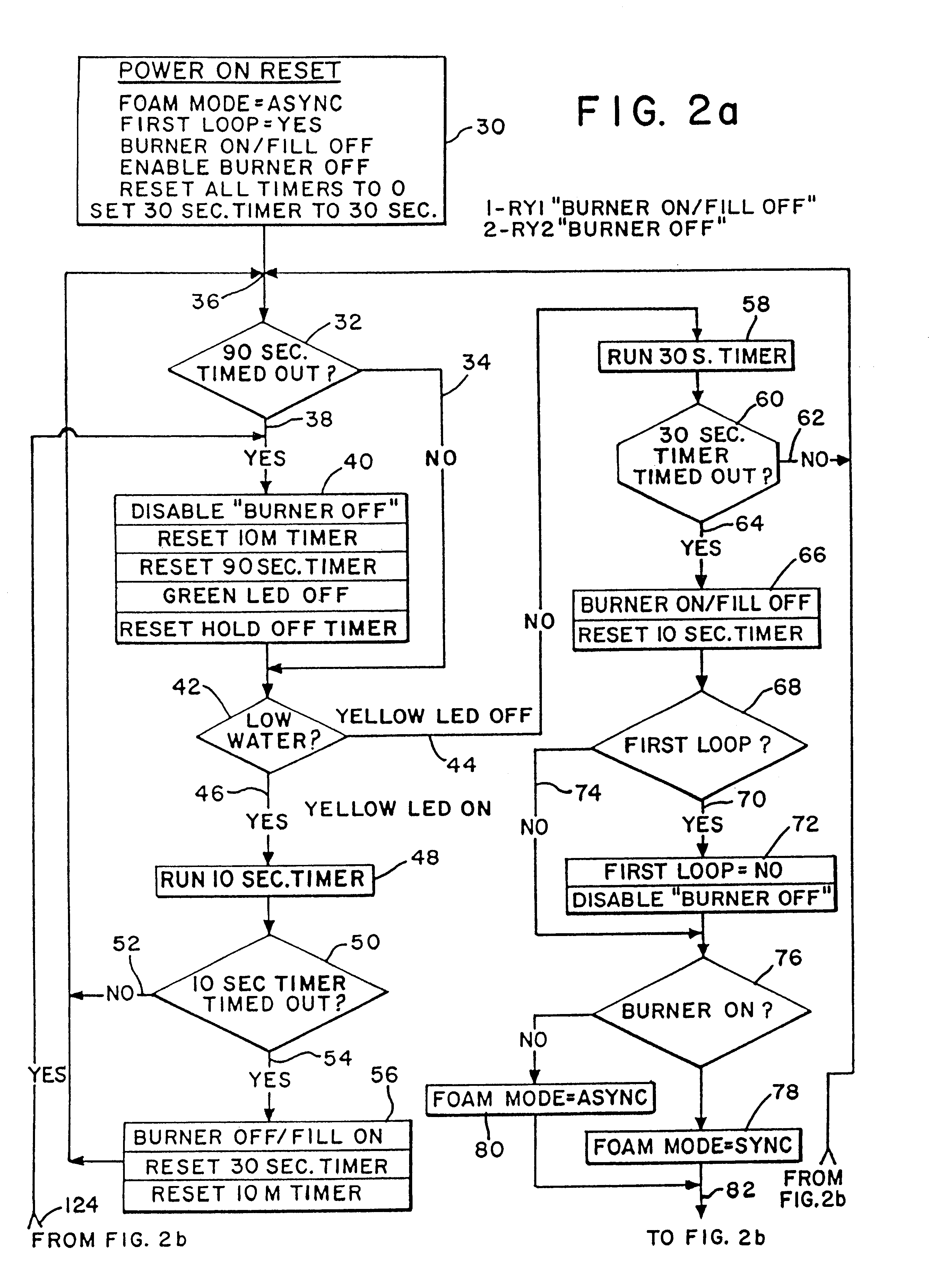

Cycle control system for boiler and associated burner

A cycle control system for use with a boiler having a fluid therein and a method of monitoring a boiler to determine the presence of an adequate level of fluid therein. The cycle control system includes a timing circuit producing a burner control signal having alternating on and off states corresponding to on and off period timers to allow foam to settle so that a probe can accurately check the fluid level in the boiler. A burner monitor circuit monitors when a demand controller turns the burner on and off responsive to demand. The on-period timer is reset whenever the burner monitor circuit indicates the demand control circuit has turned off the burner for a length of time sufficient for the probe to accurately check the fluid level.

Owner:COWLES OPERATING CO

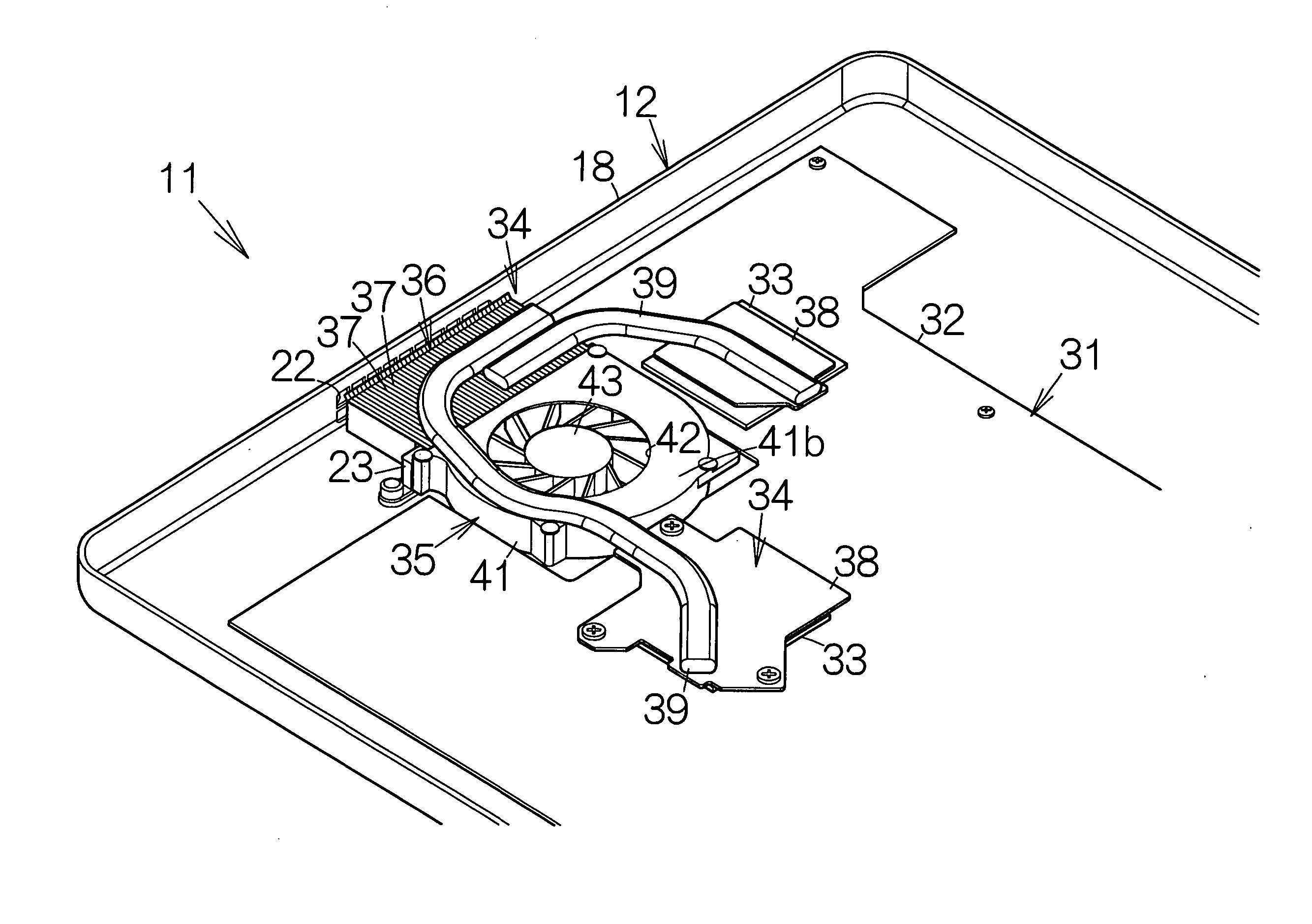

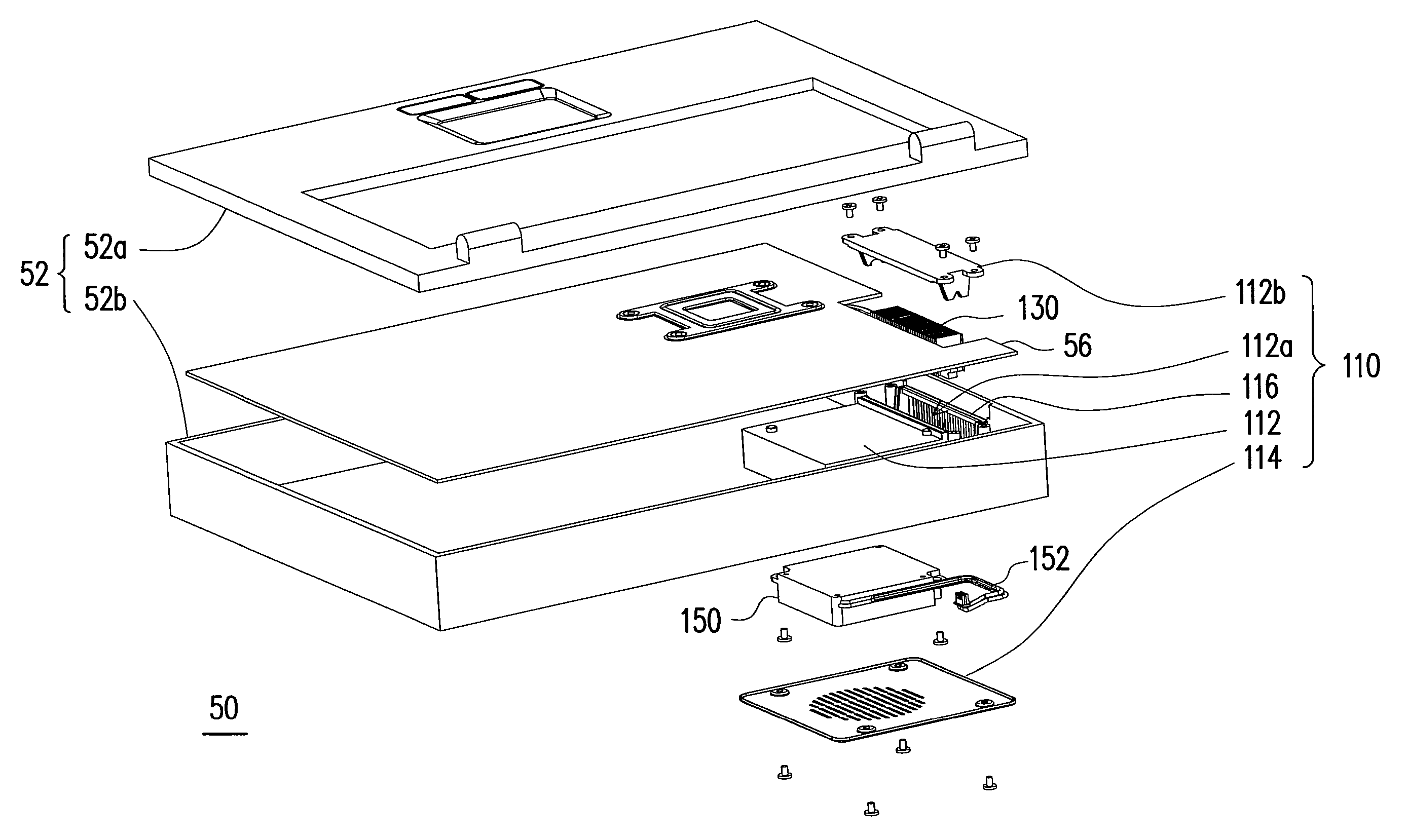

Waterproof thermal management module and portable

InactiveUS7336489B1Reduce thicknessSimplify the assembly processDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat pipe

Owner:COMPAL ELECTRONICS INC

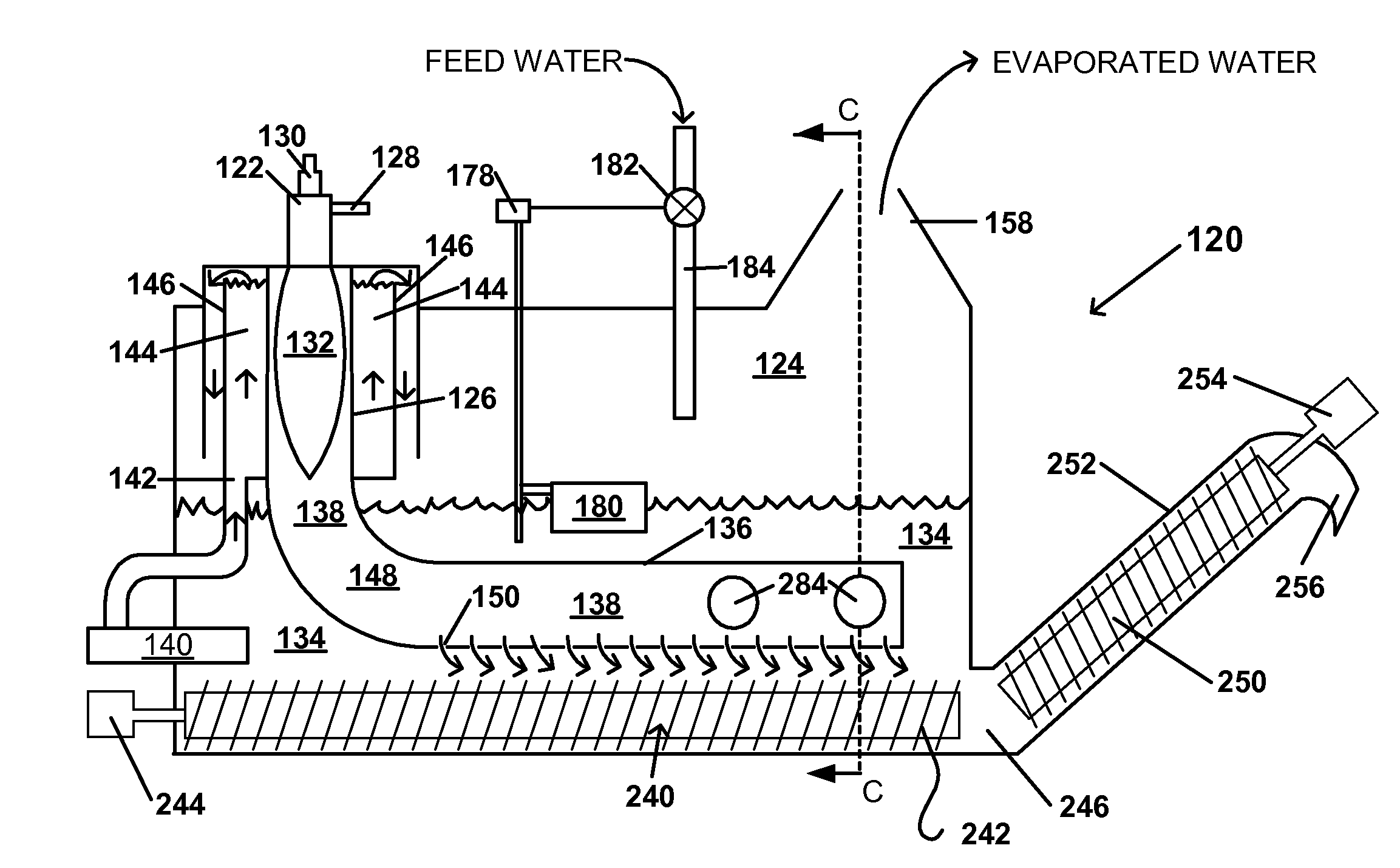

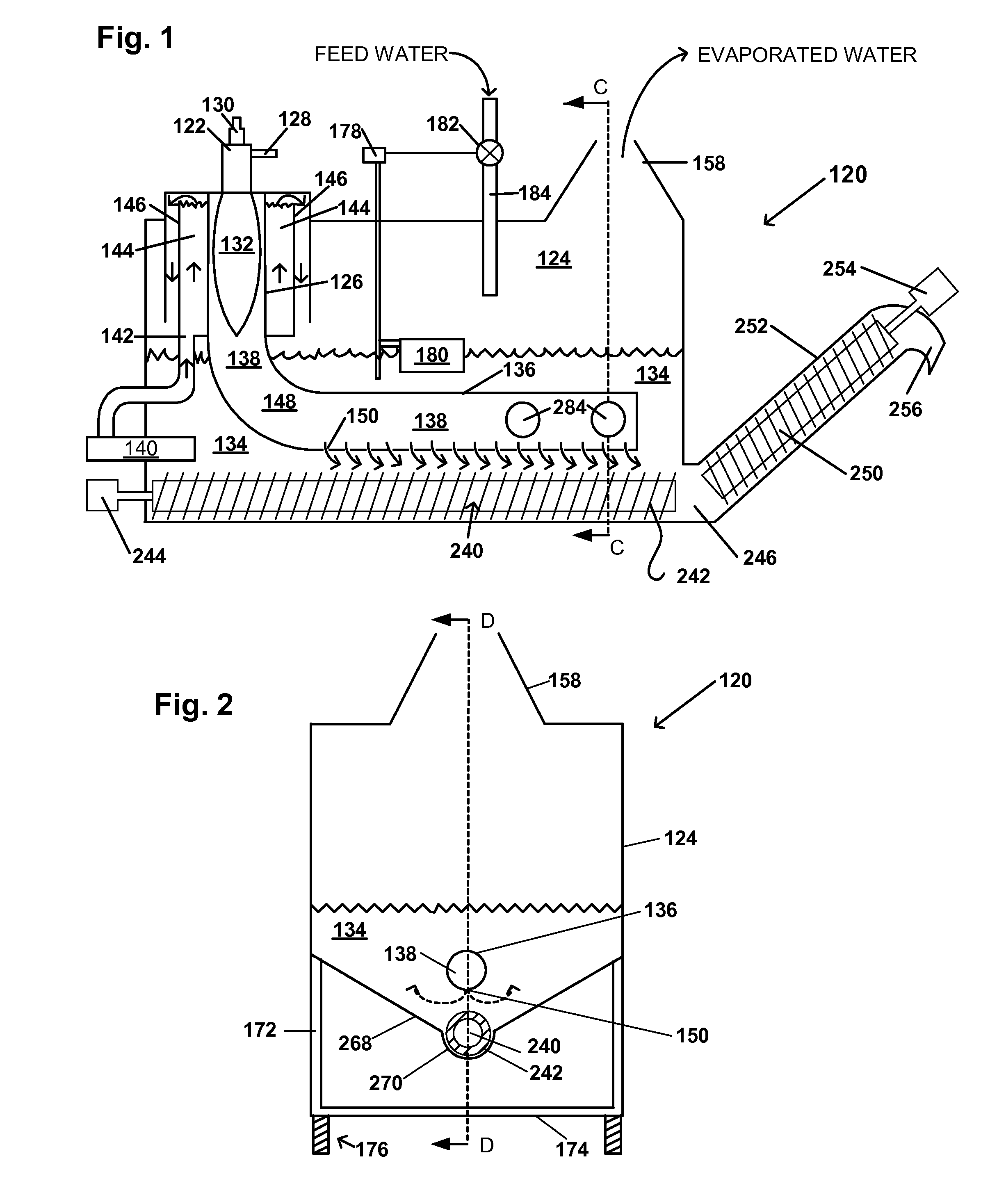

Submerged combustion disposal of produced water

InactiveUS20080110417A1Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

Method and device for forming steam for household appliance

InactiveUS20080115740A1Overcomes drawbackBoiler water tubesWater-tube boilersWater contactEngineering

Owner:YOU TUMING

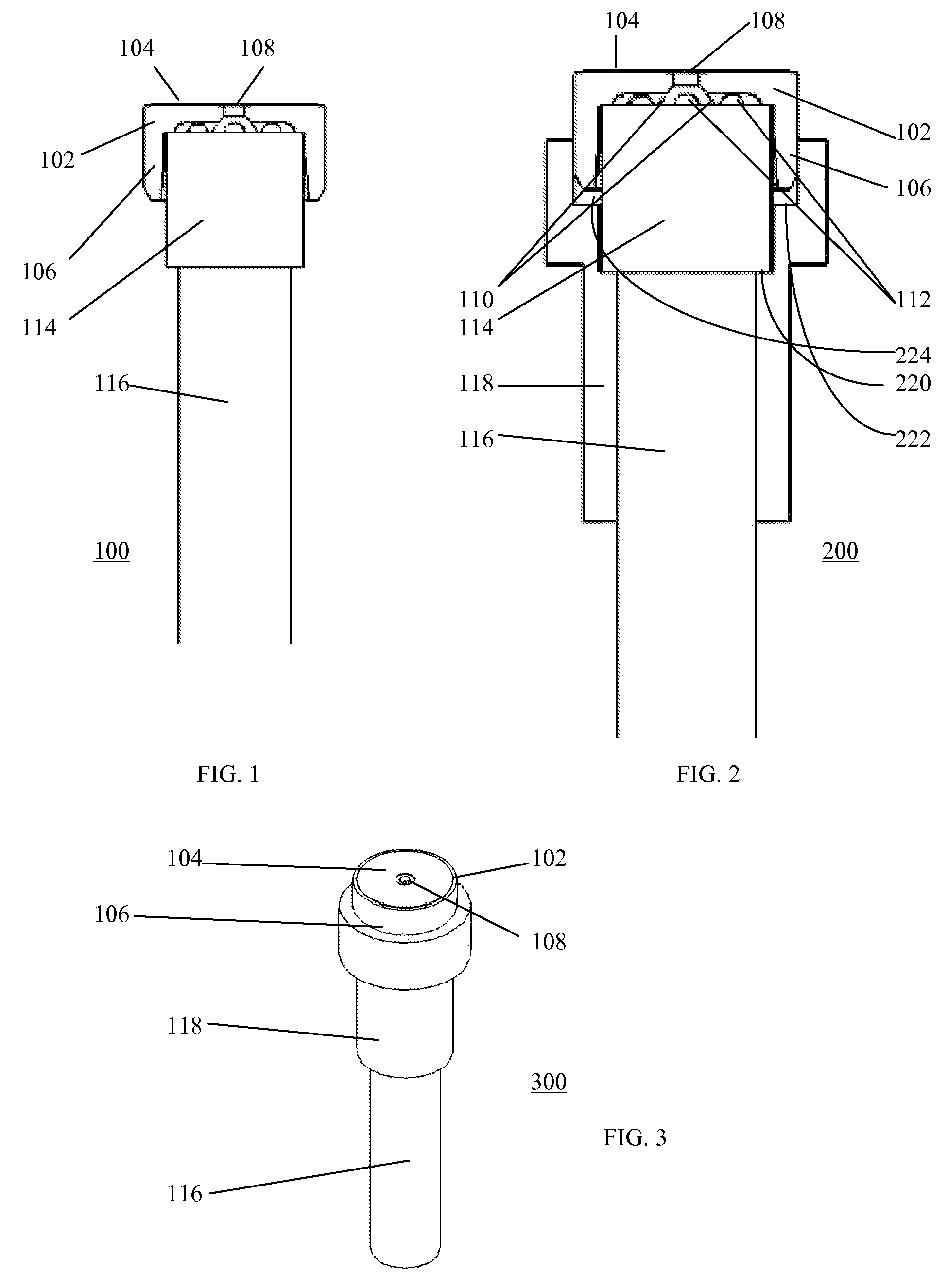

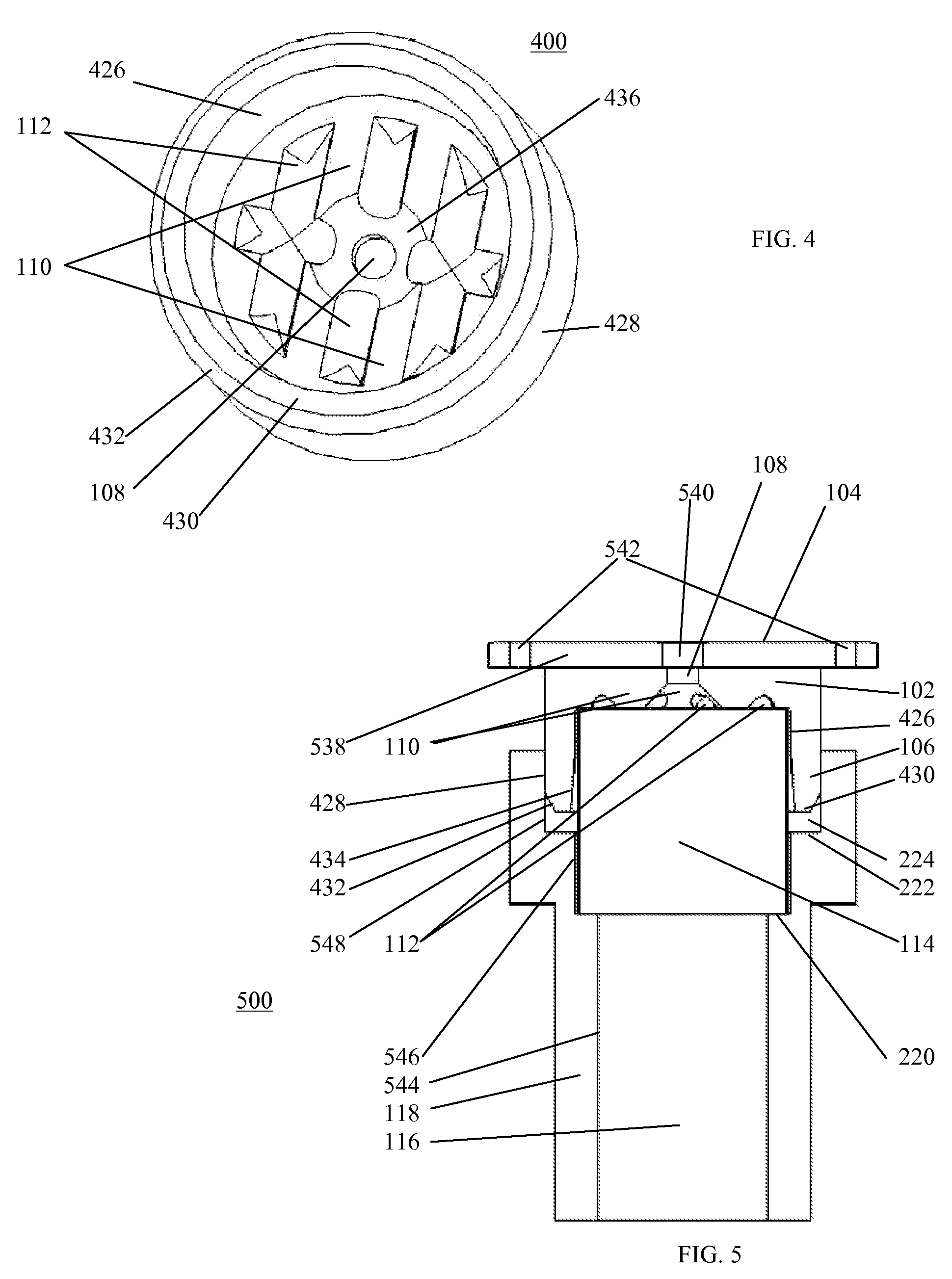

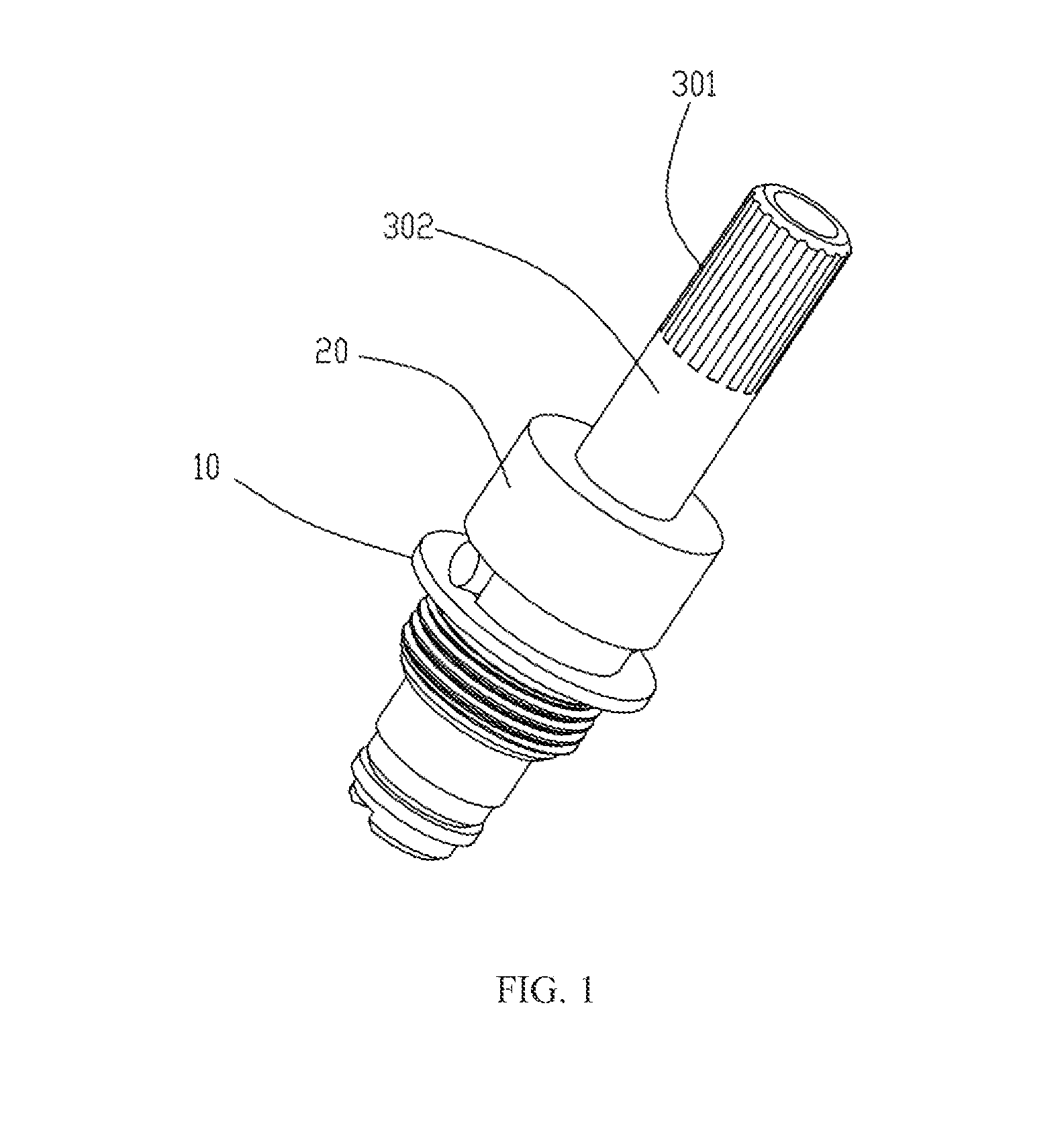

Atomizing assembly, atomizer and electronic cigarette having same

ActiveUS20150128977A1Performance of electronic is unsatisfactoryLow costSteam generation heating methodsHeater elementsElectronic cigaretteHeating element

An exemplary atomizing assembly includes a heating component, a holder, an electrode, and a cover. The heating component includes a liquid conducting element and a heating element in contact with the liquid conducting element. The holder includes two arms extending from a first end thereof The two arms and the cover cooperatively define a receiving space. The heating component is received in the receiving space. The electrode is arranged in the holder and is insulated from the holder. Two ends of the heating element are connected with the holder and the electrode respectively. The holder further includes a connection part arranged at an opposite second end, and the connection part is configured for detachably engaging with an external component.

Owner:SHENZHEN FIRST UNION TECH CO LTD

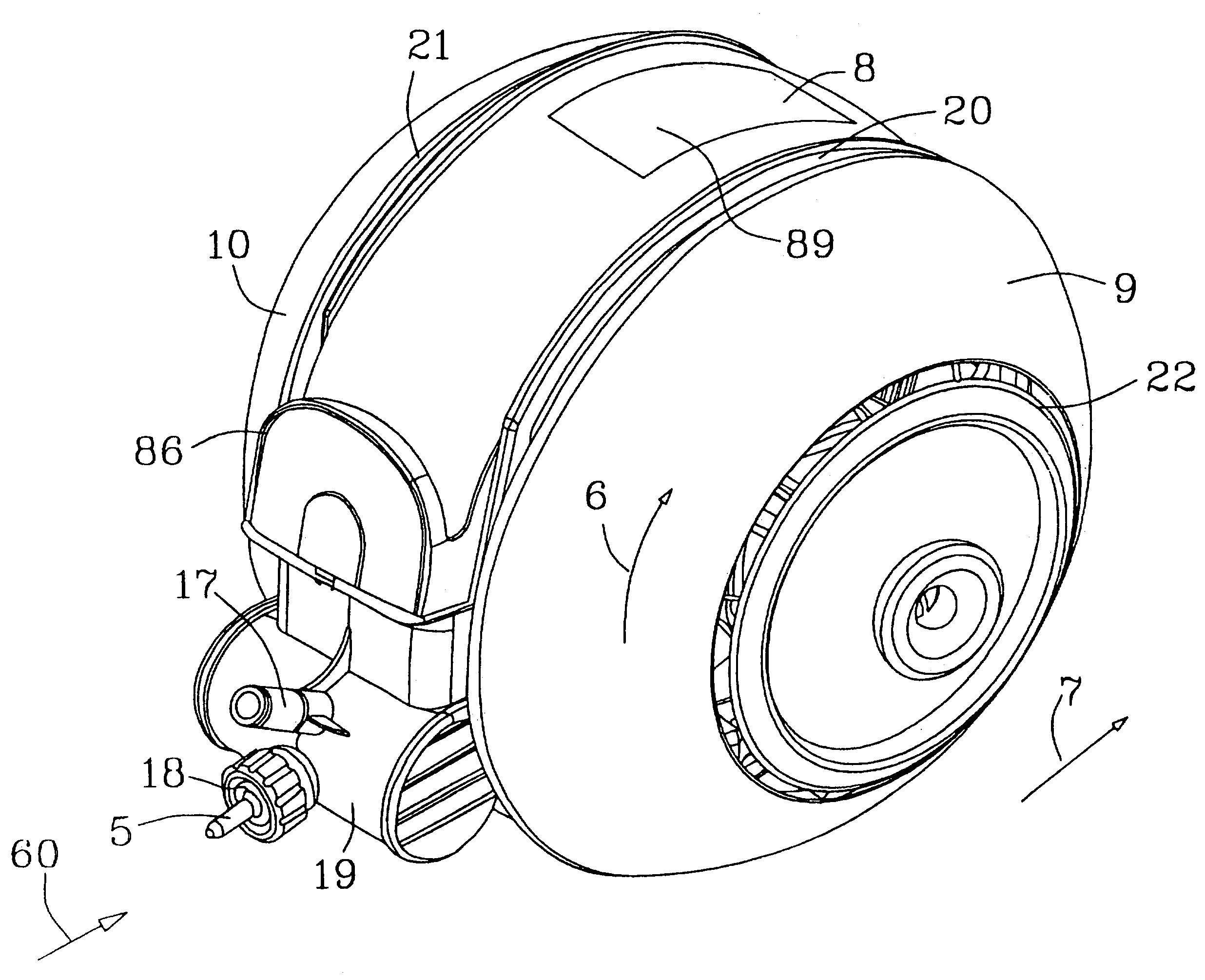

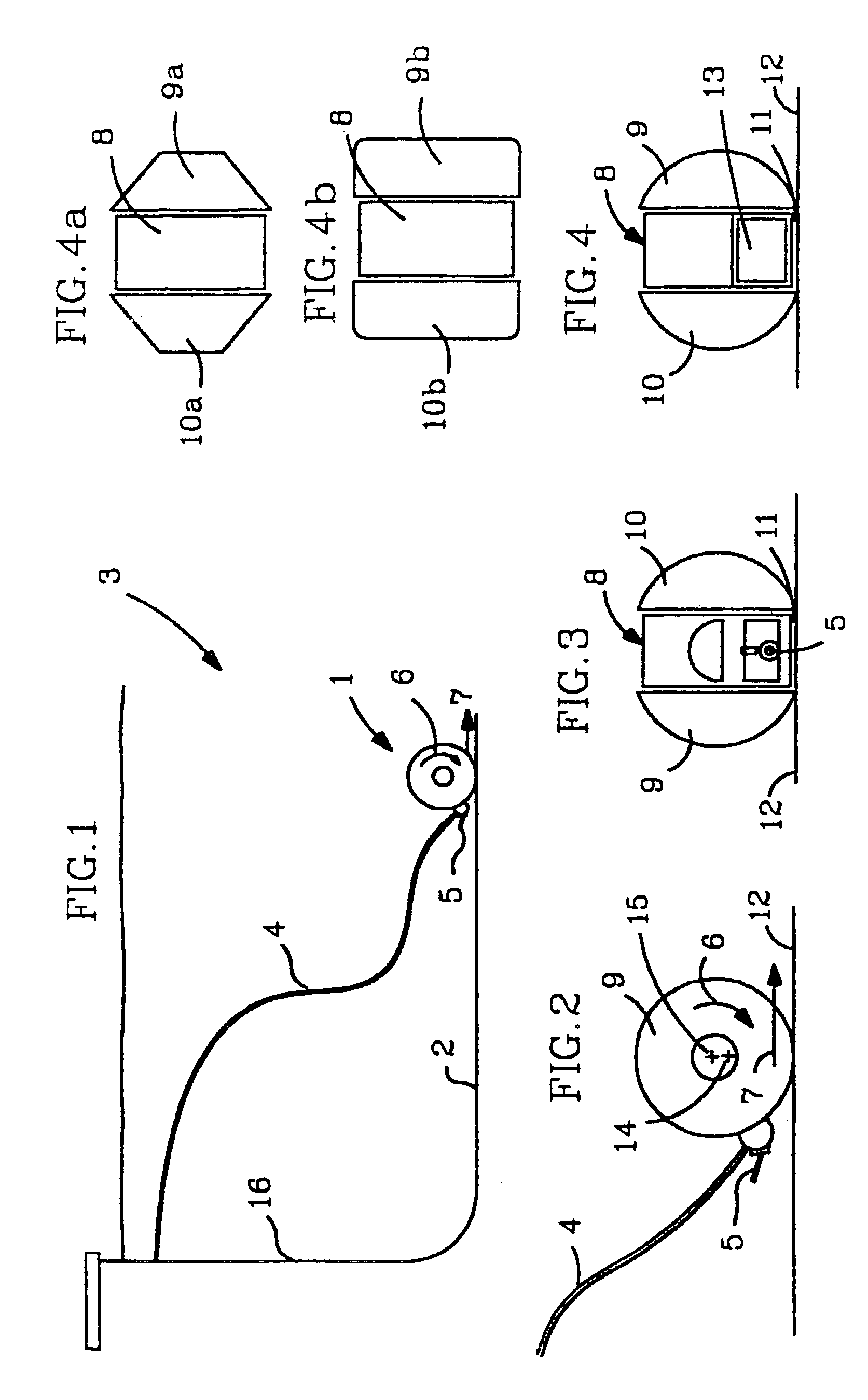

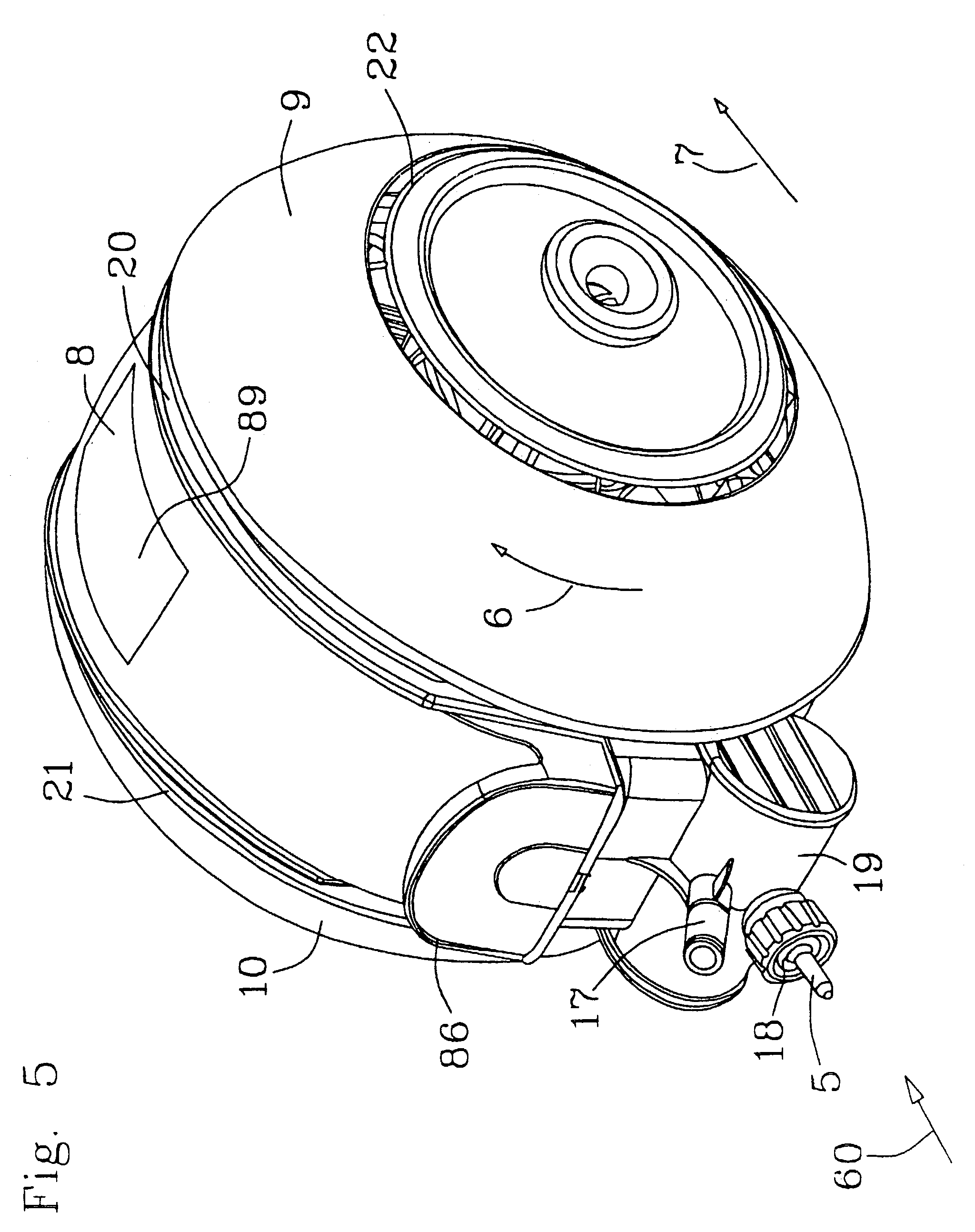

Pool cleaner

InactiveUS7039980B2Less stable device under waterTolerableBoiler cleaning apparatusWater/sewage treatmentWater flowMechanical engineering

A push side pool cleaner (1) has a spheroidal overall shape, within this shape two outer segments (9, 10) serve as wheels and a central zone (8) carries a suction passage (33) and a debris collector (32) also located entirely within the overall shape. The wheels are driven directly by water jets (44, 45) without any gears or other transmission. A flow splitter is provided in the cleaner (1) to divide push side water flow between the jets (44, 45) which drive the wheels and jets (43) which provide impulsion to the suction passage (33).

Owner:ZODIAC POOL SYST LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com