Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2970 results about "Steam generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam Generation Steam is generated in main generation plants, and/or at various process units using heat from flue gas or other sources. Heaters (furnaces) include burners and a combustion air system, the boiler enclosure in which heat transfer takes place, a draft or pressure...

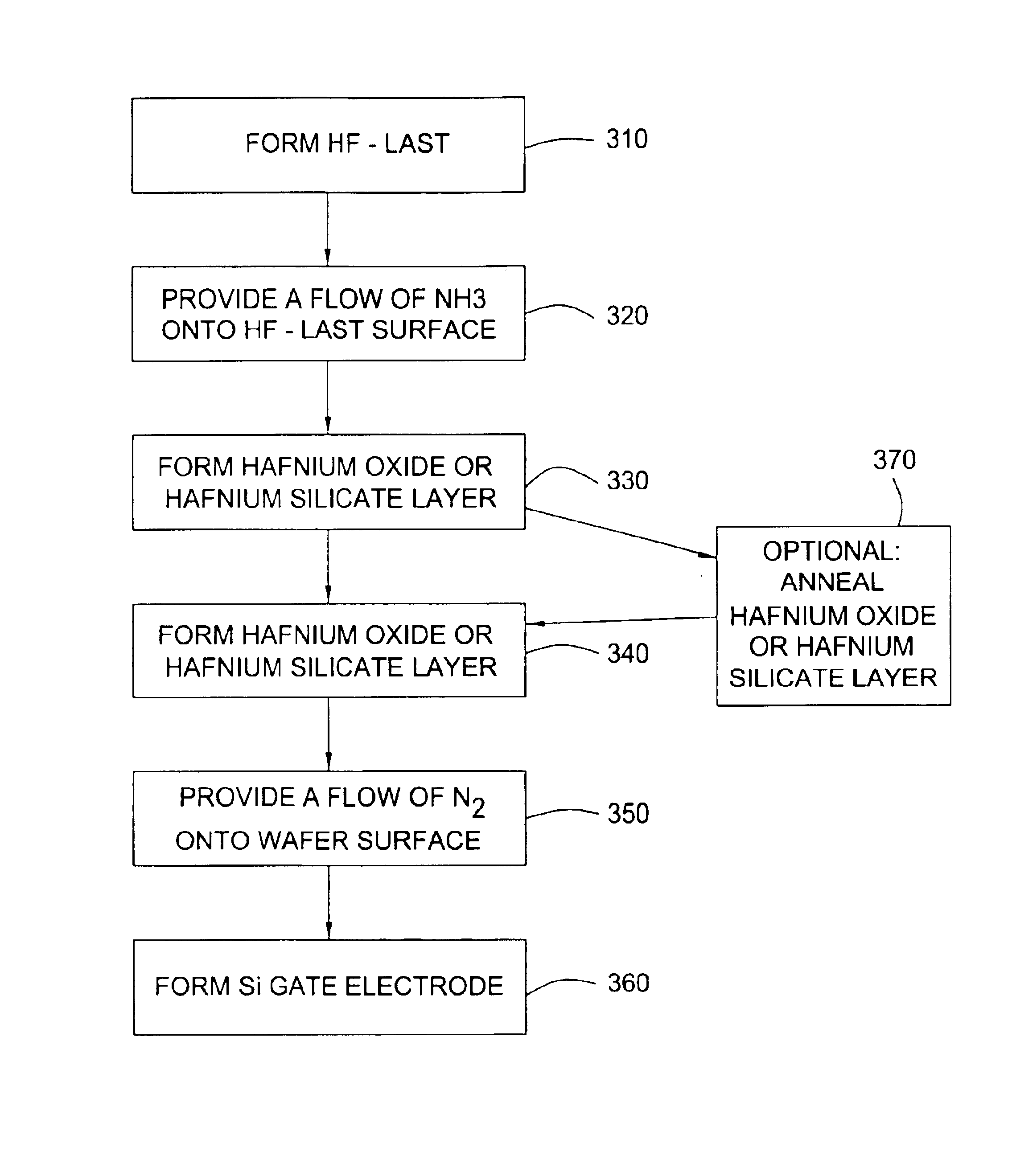

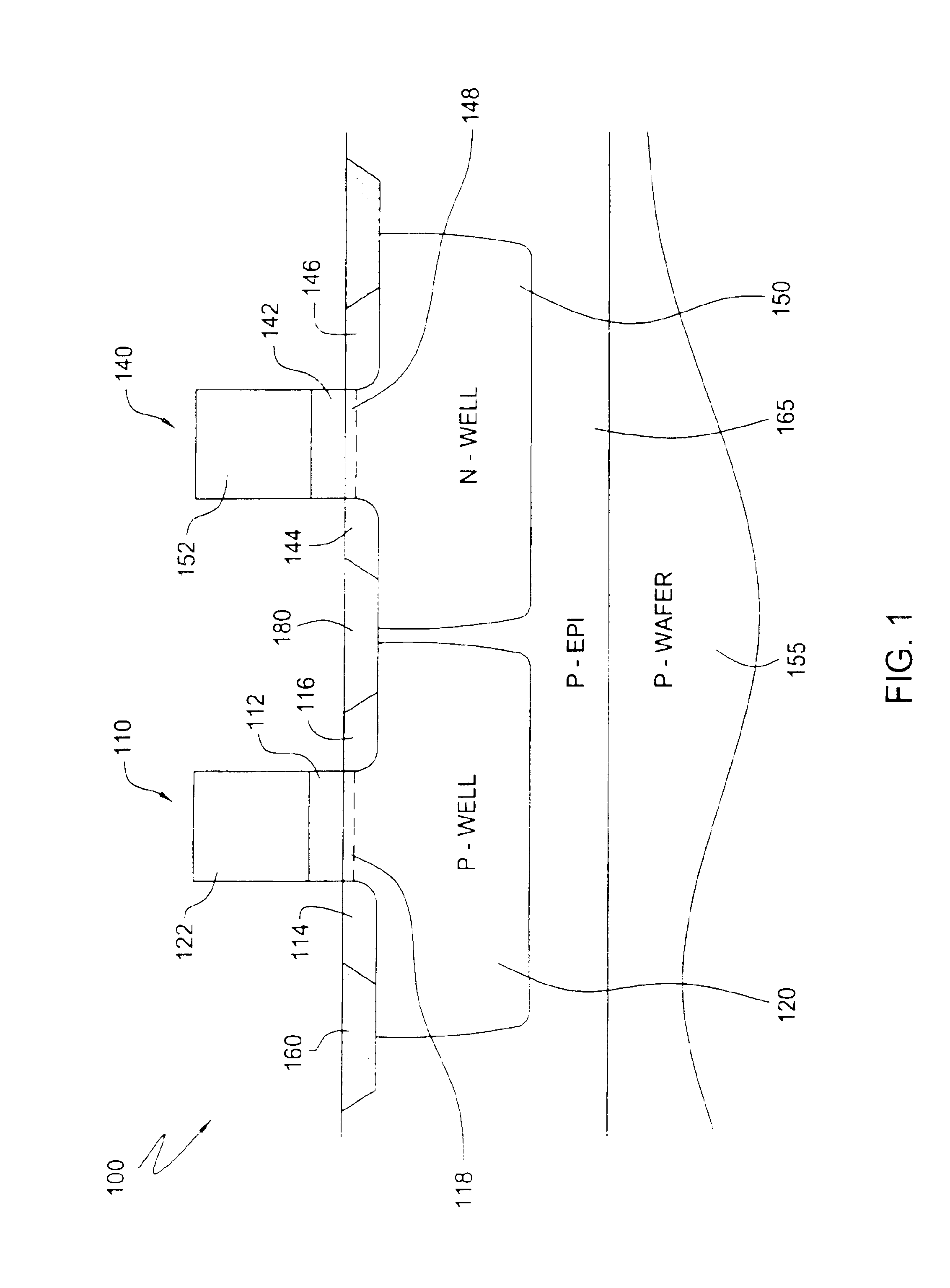

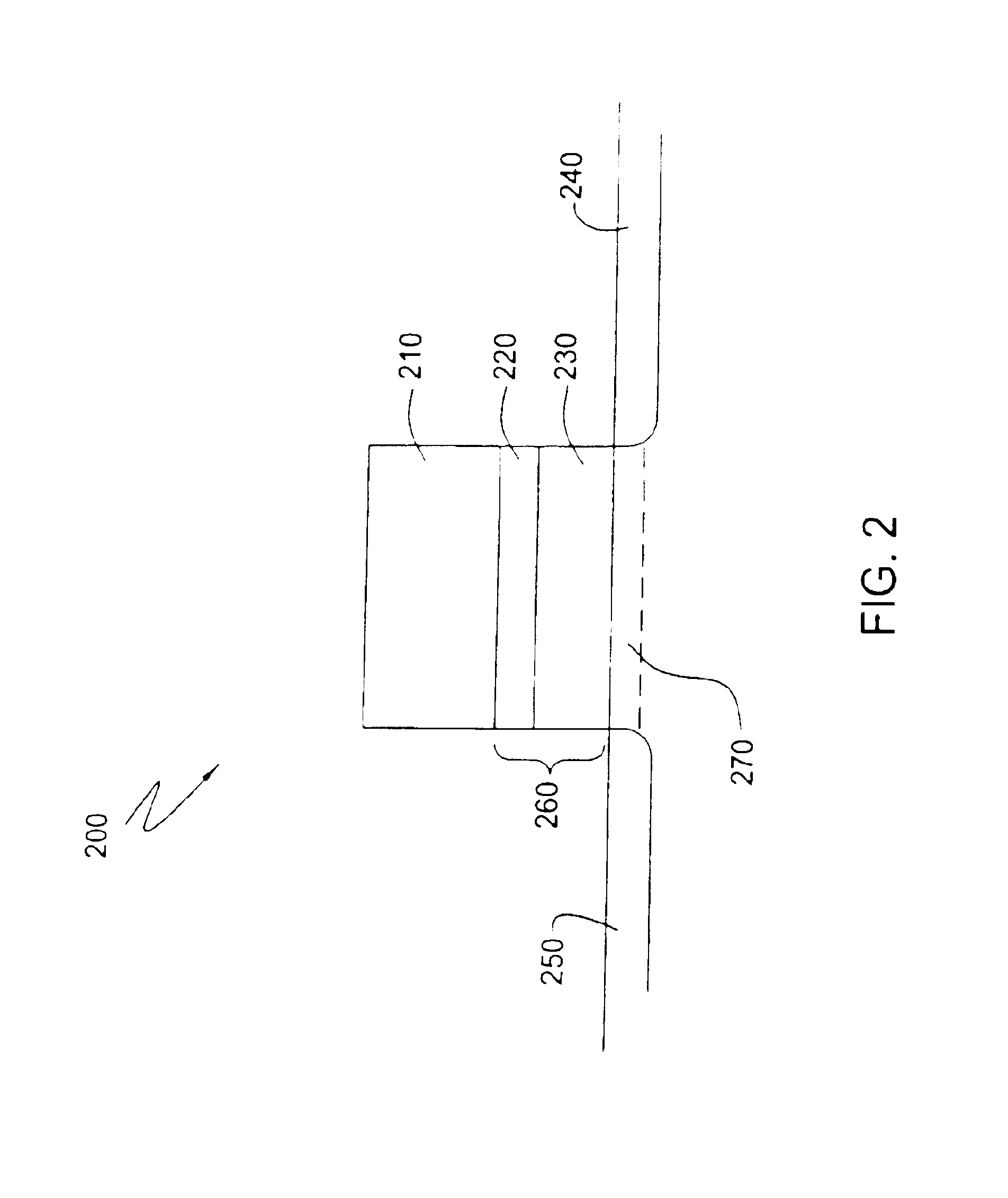

System and method for forming a gate dielectric

InactiveUS6858547B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingHydrofluoric acidGate dielectric

A method of forming a dielectric stack on a pre-treated surface. The method comprises pre-cleaning a semiconductor wafer to remove native oxide, such as by applying hydroflouric acid to form an HF-last surface, pre-treating the HF-last surface with ozonated deionized water, forming a dielectric stack on the pre-treated surface and providing a flow of NH3 in a process zone surrounding the wafer. Alternately, the method includes pre-treating the HF-last surface with NH3, forming the stack after the pre-treating, and providing a flow of N2 in a process zone surrounding the wafer after the forming. The method also includes pre-treating the HF-last surface using an in-situ steam generation process, forming the stack on the pre-treated surface, and annealing the wafer after the forming. The pre-treating includes providing an inert gas flow in a process zone surrounding the HF-last surface, reacting hydrogen with an oxidizer in the process zone for a very short duration, and providing an inert gas flew in the process zone after the reacting.

Owner:APPLIED MATERIALS INC

Steam Generation Processes Utilizing Biomass Feedstocks

Integrated catalytic gasification processes are provided involving generating steam for converting carbonaceous materials to combustible gases, such as methane. Generally, steam generated from the combustion of a biomass is provided to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, a carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide.

Owner:SURE CHAMPION INVESTMENT LTD

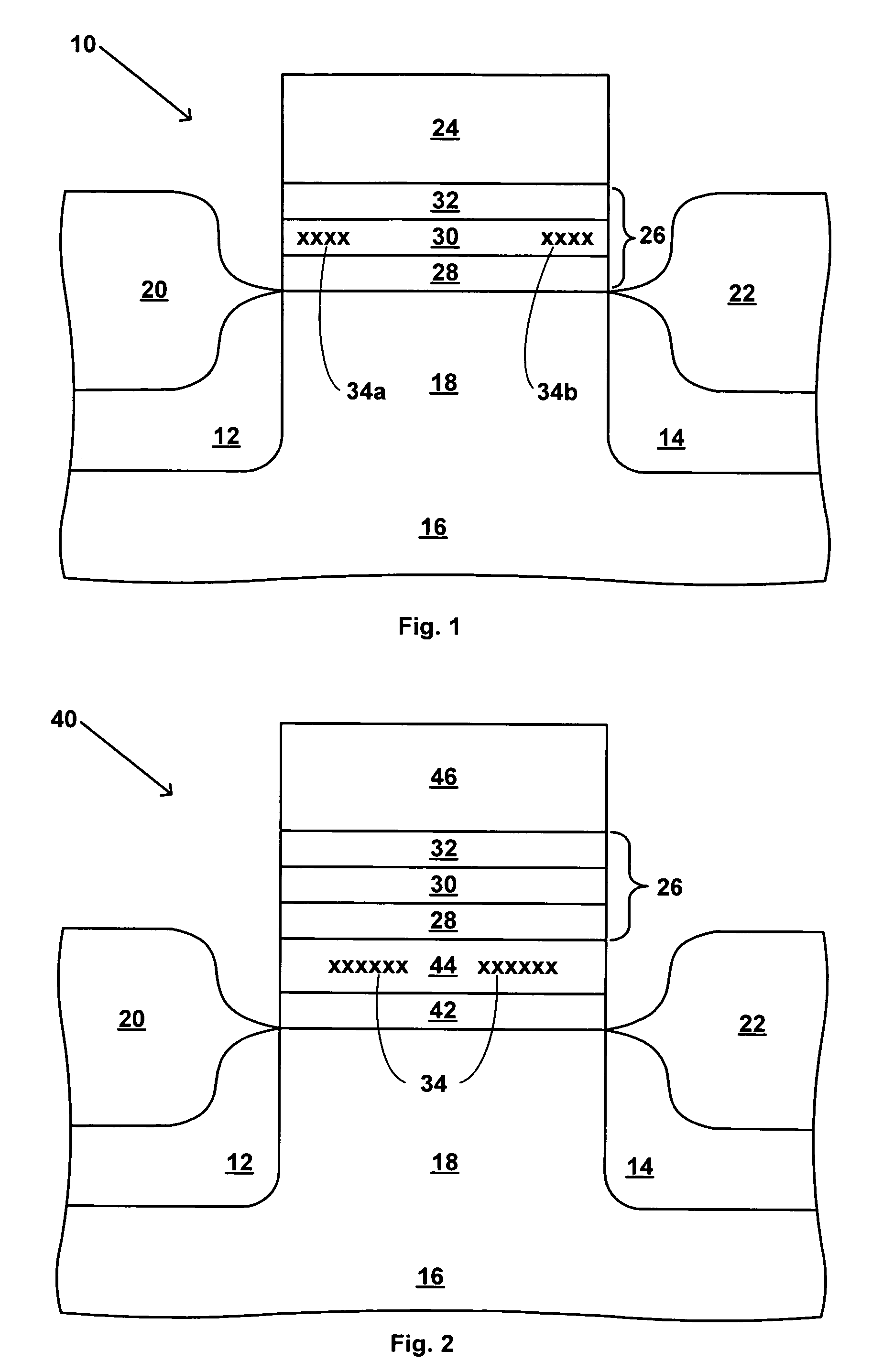

Integrated ONO processing for semiconductor devices using in-situ steam generation (ISSG) process

InactiveUS7115469B1Less carbonThermal budgetSemiconductor/solid-state device manufacturingSemiconductor devicesSteam generationSemiconductor

A process for fabrication of a semiconductor device including an ONO structure as a component of a flash memory device, comprising forming the ONO structure by providing a semiconductor substrate having a silicon surface; forming a first oxide layer on the silicon surface; depositing a silicon nitride layer on the first oxide layer; and forming a top oxide layer on the silicon nitride layer, wherein the top oxide layer is formed by an in-situ steam generation oxidation of a surface of the silicon nitride layer. The semiconductor device may be, e.g., a SONOS two-bit EEPROM device or a floating gate FLASH memory device including an ONO structure.

Owner:LONGITUDE FLASH MEMORY SOLUTIONS LTD

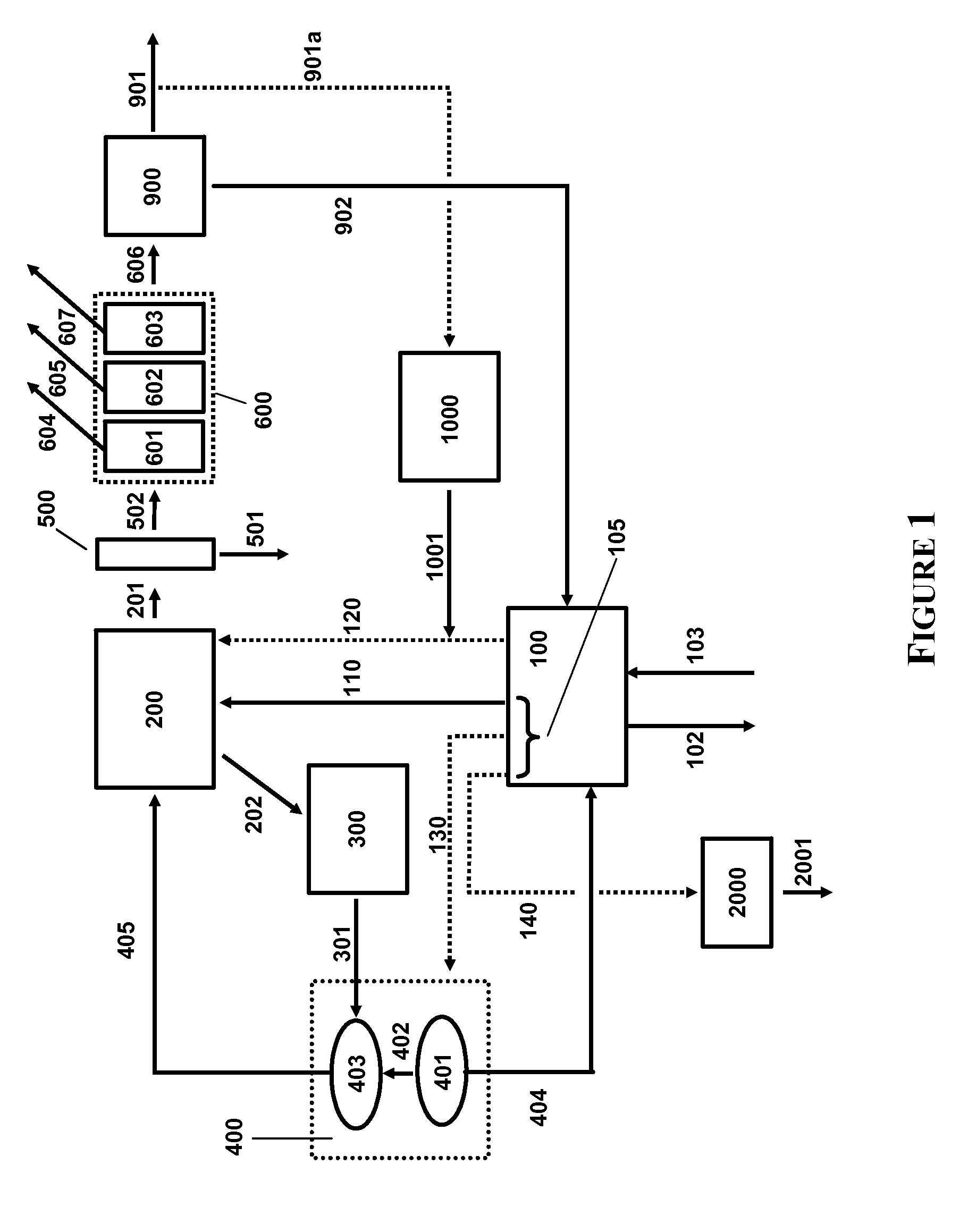

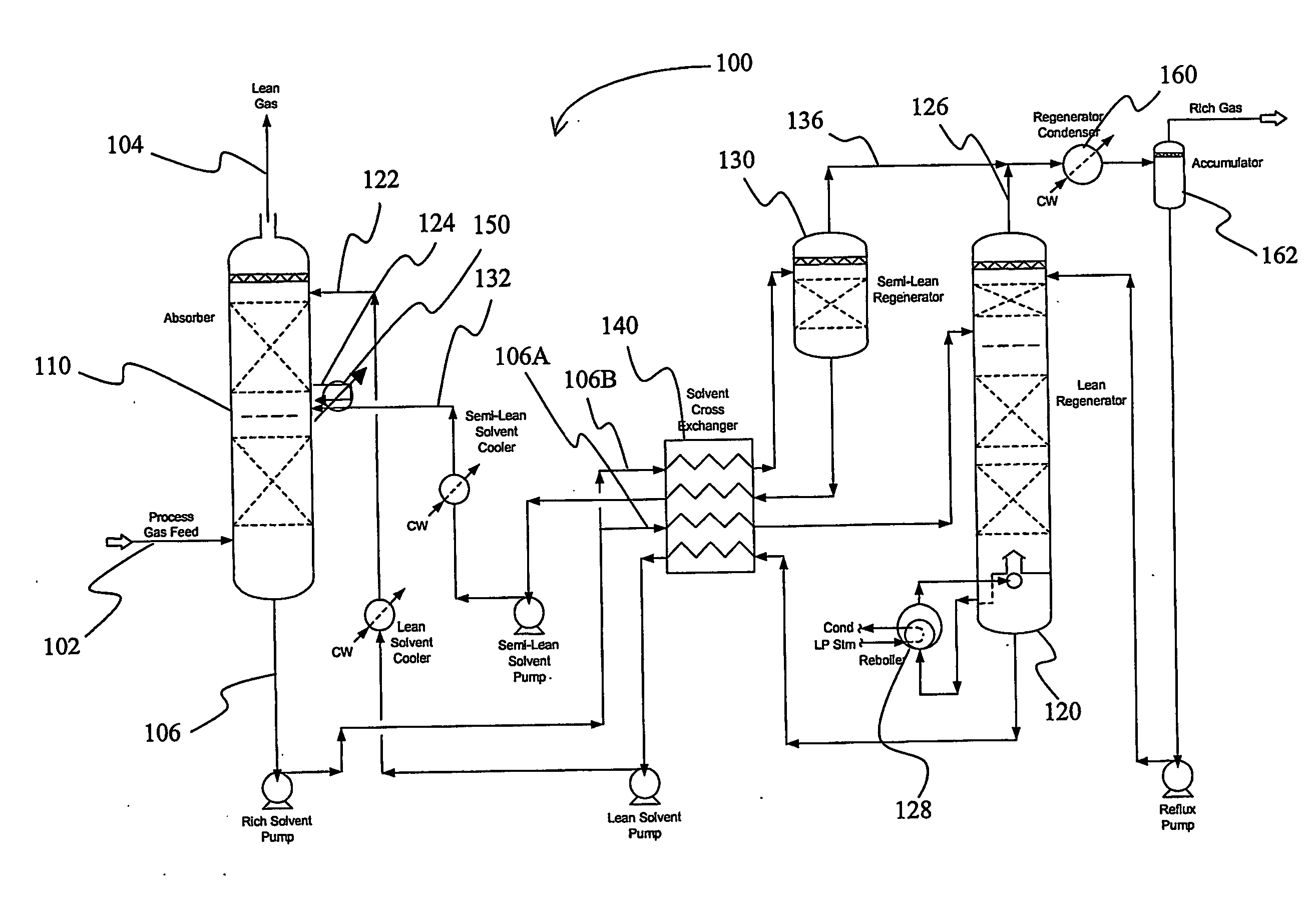

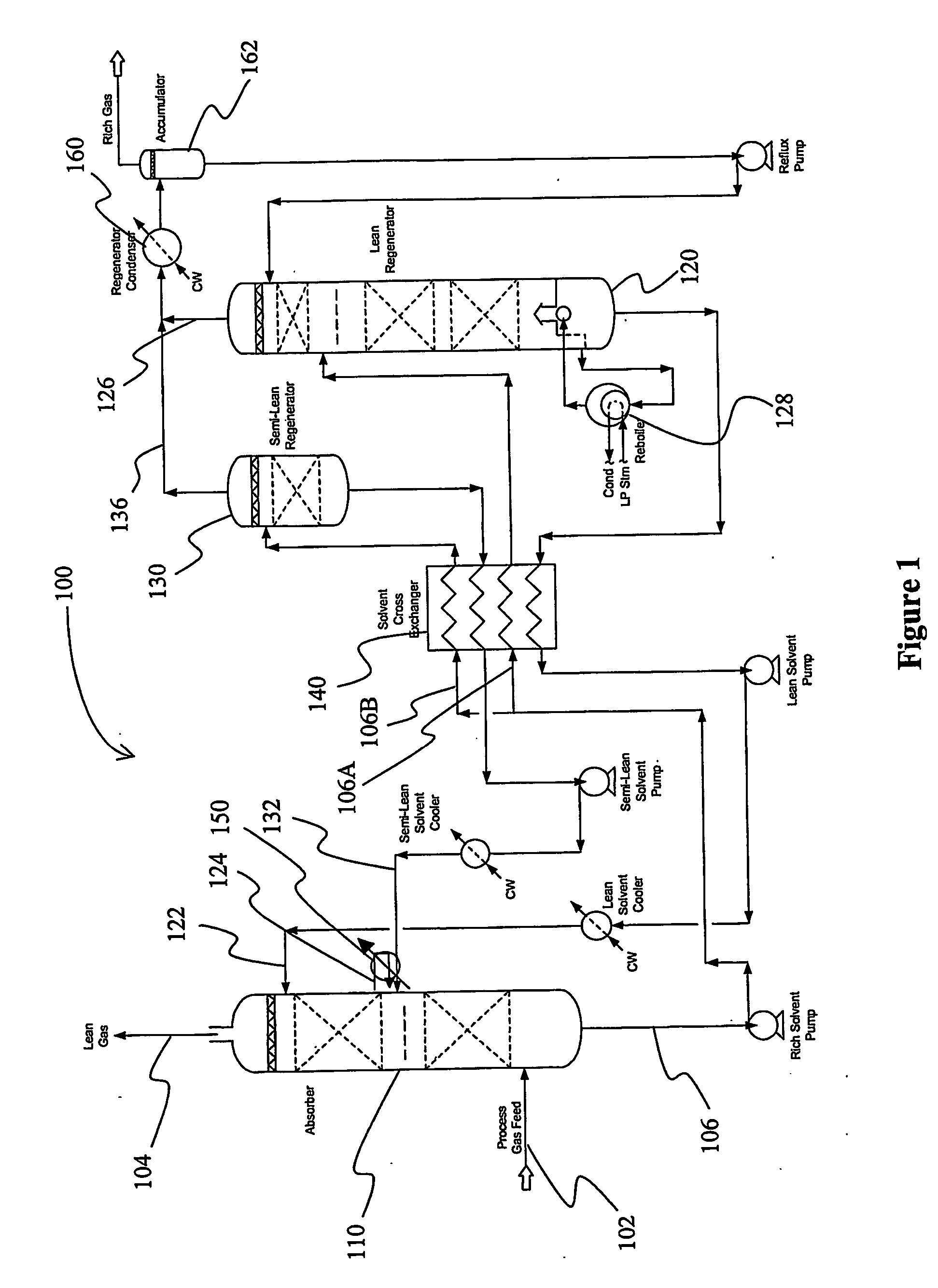

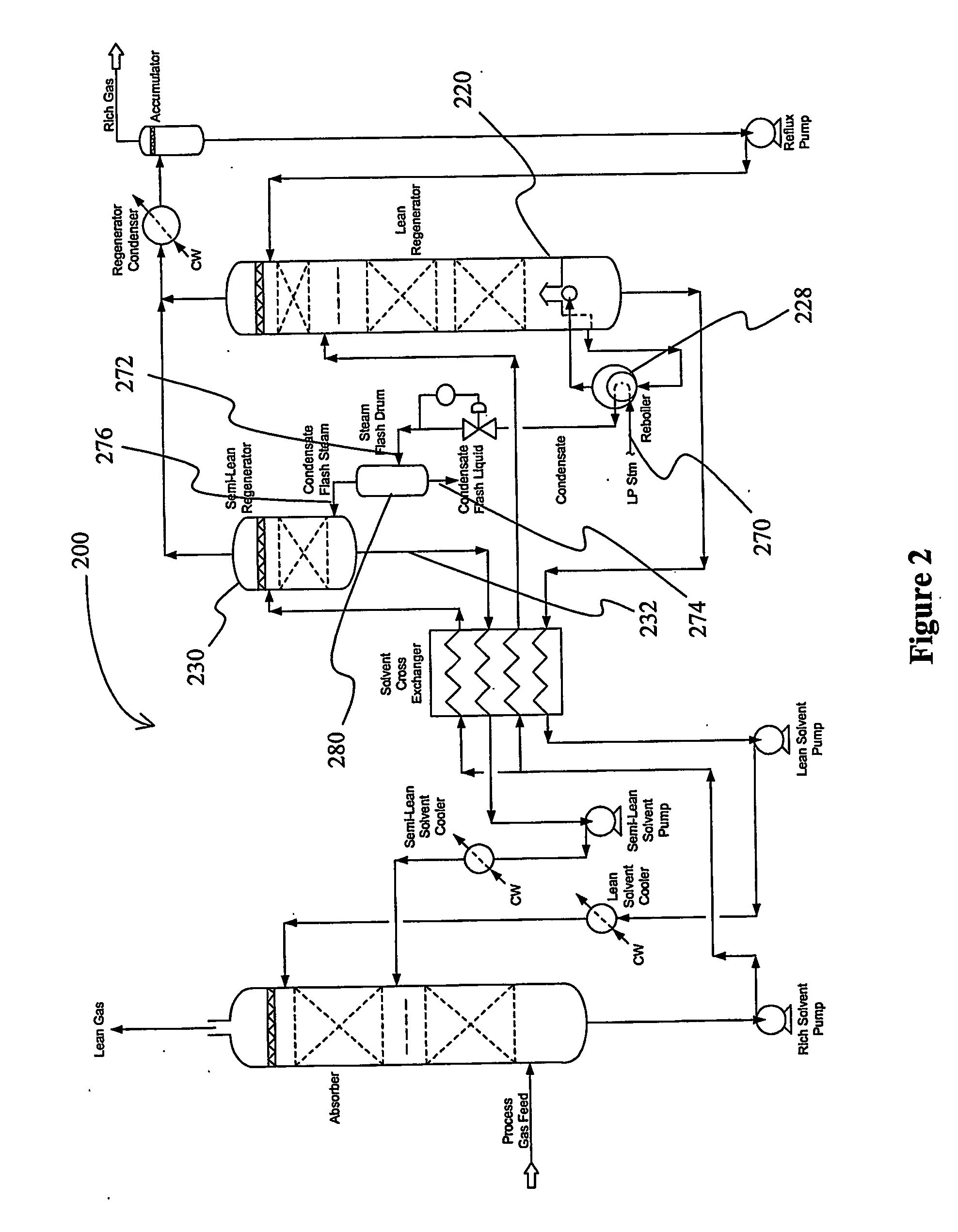

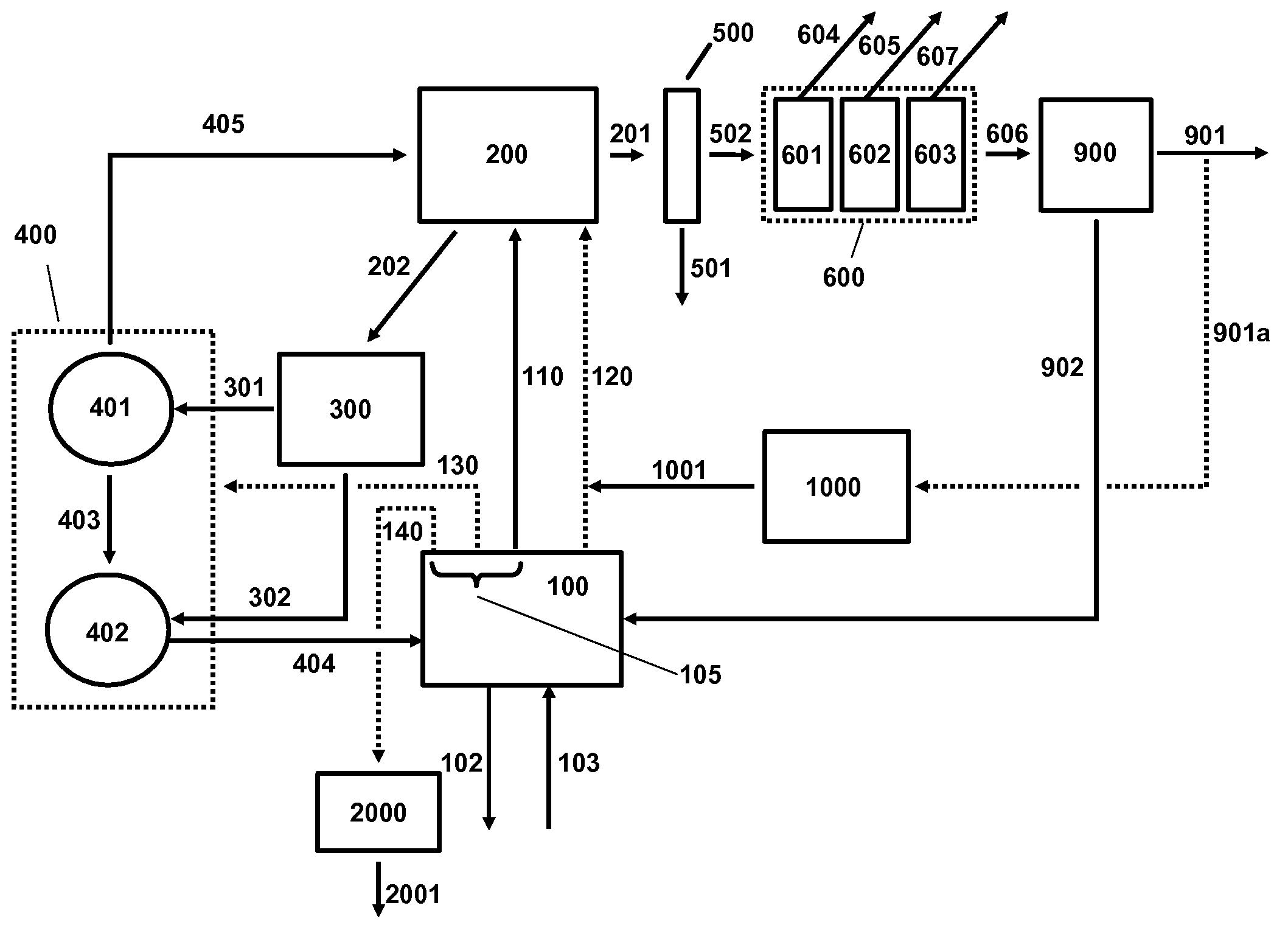

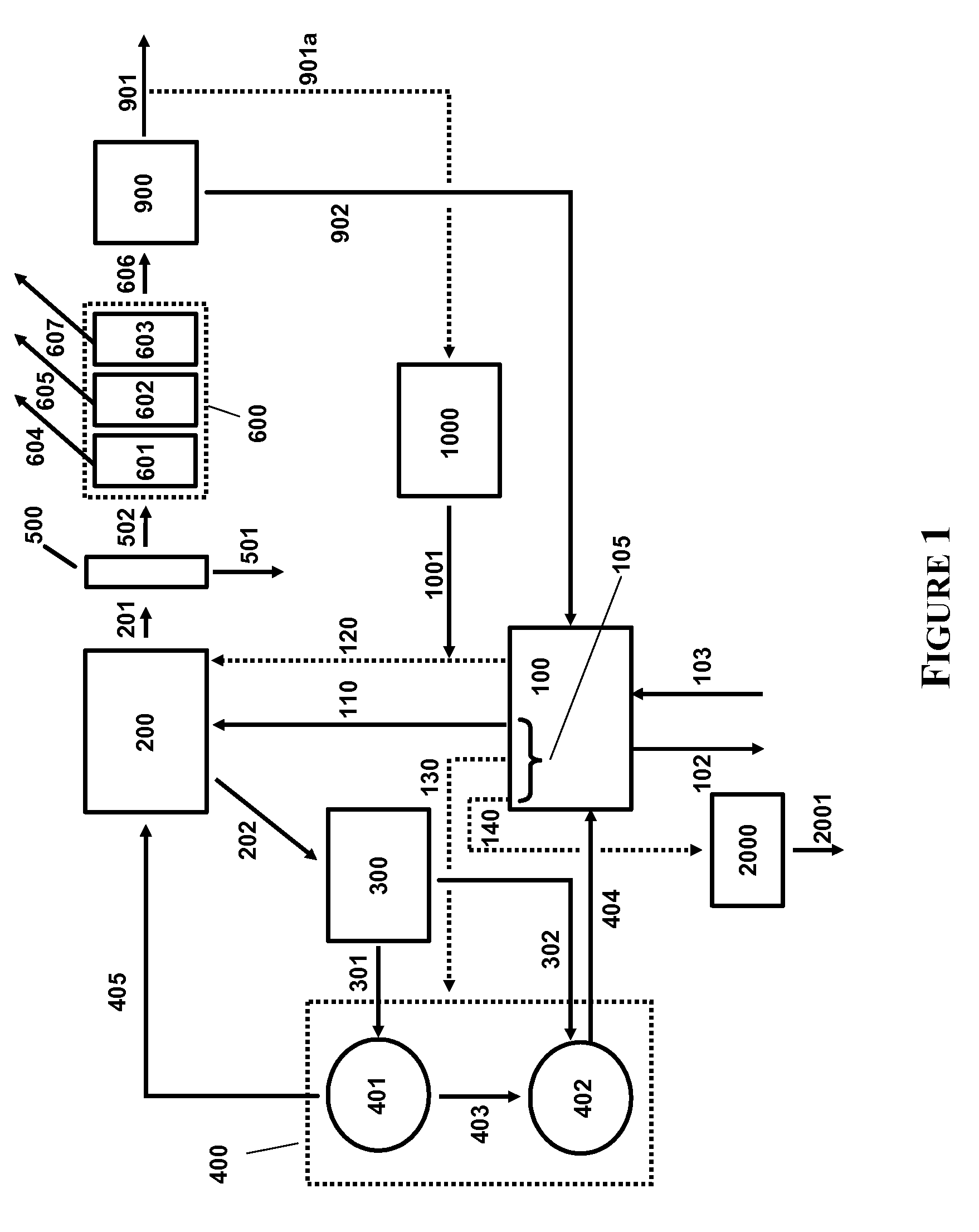

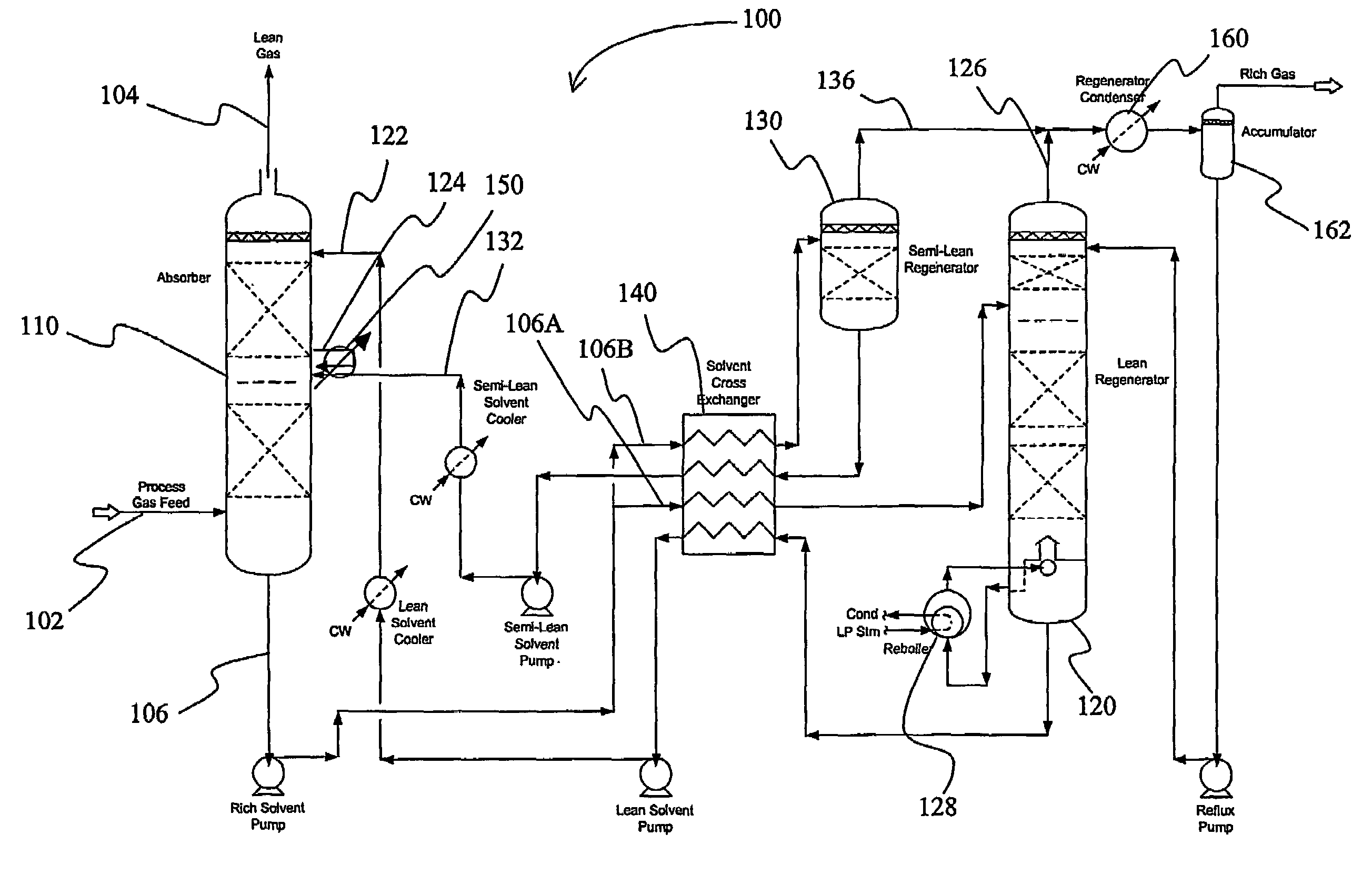

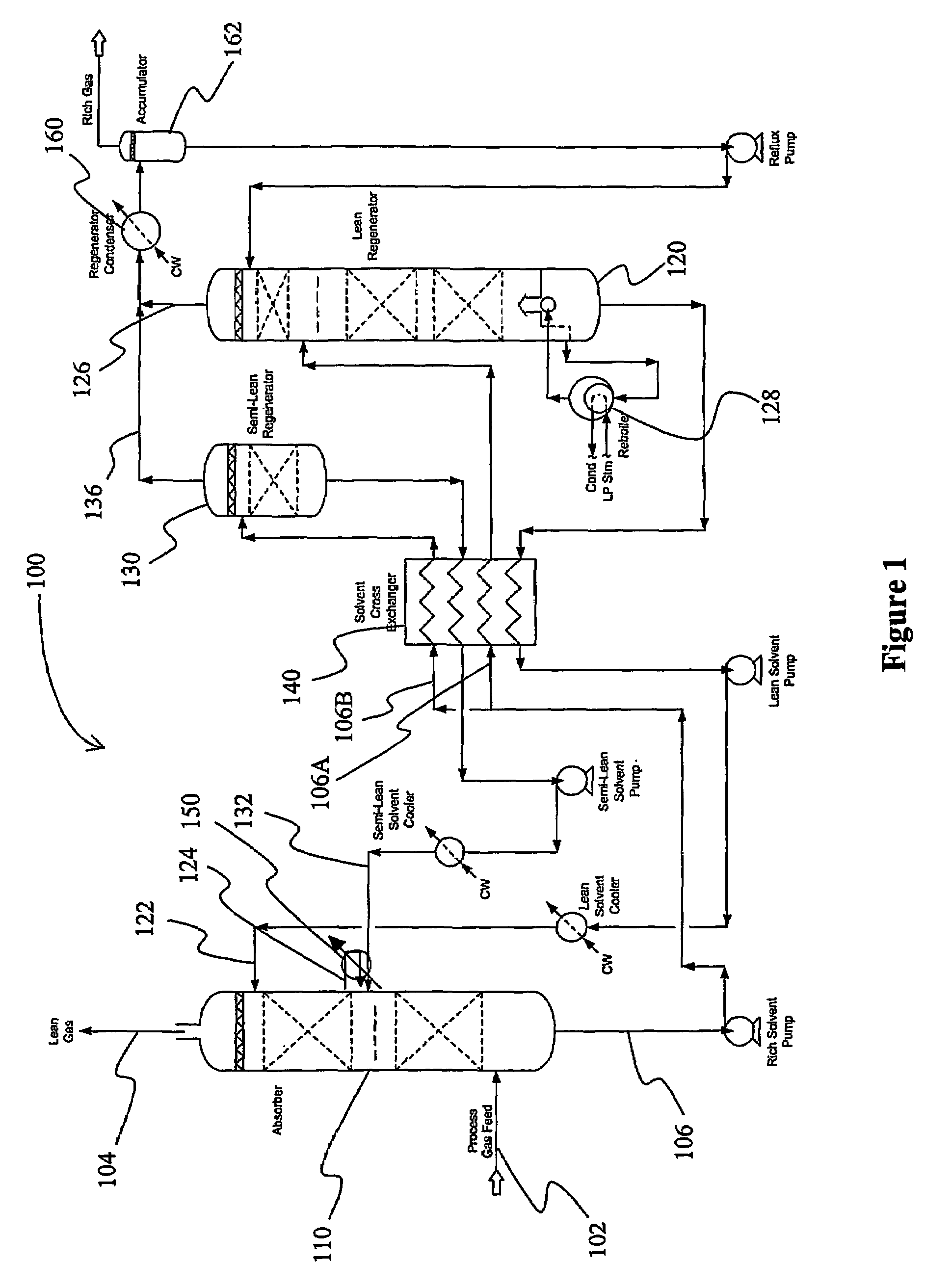

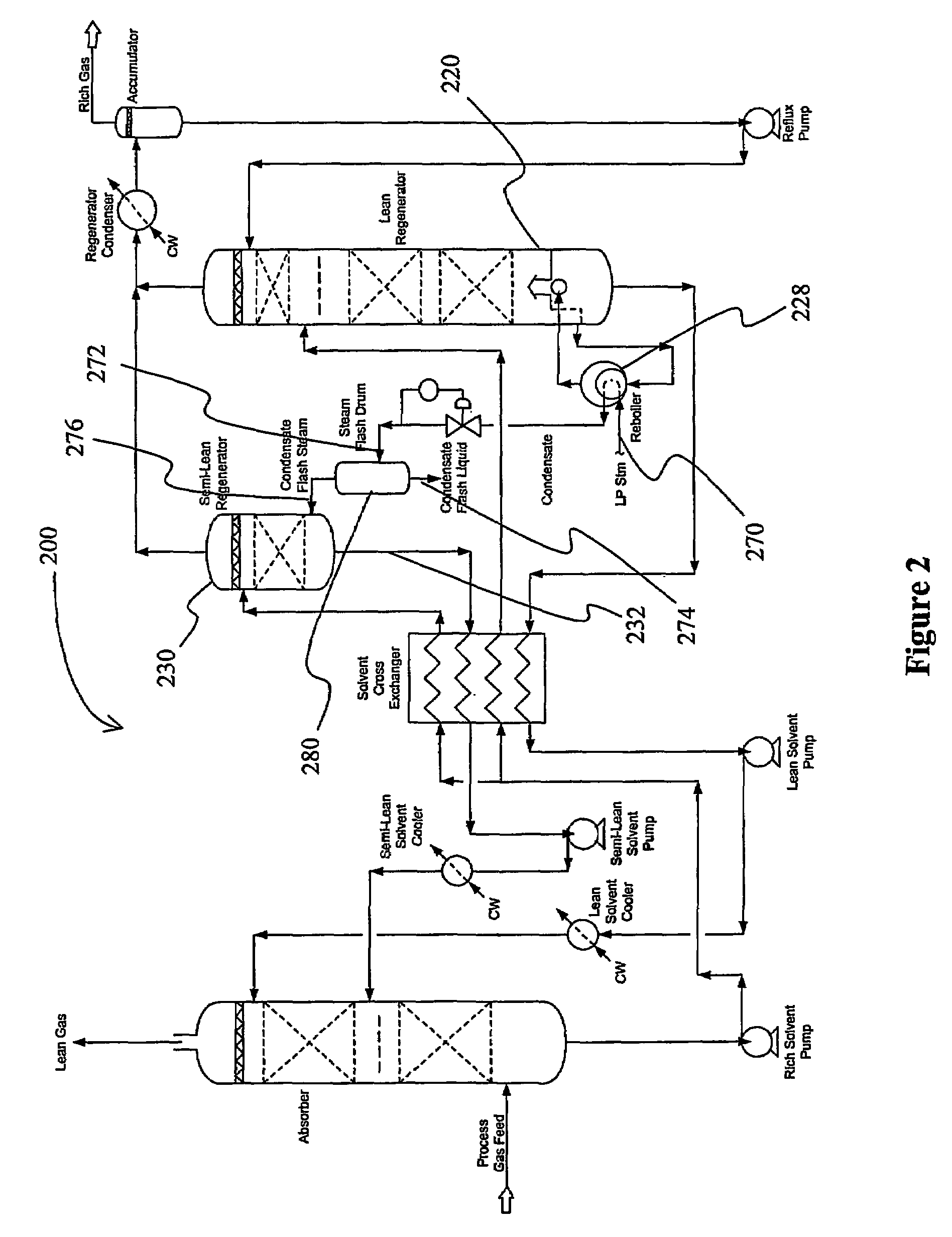

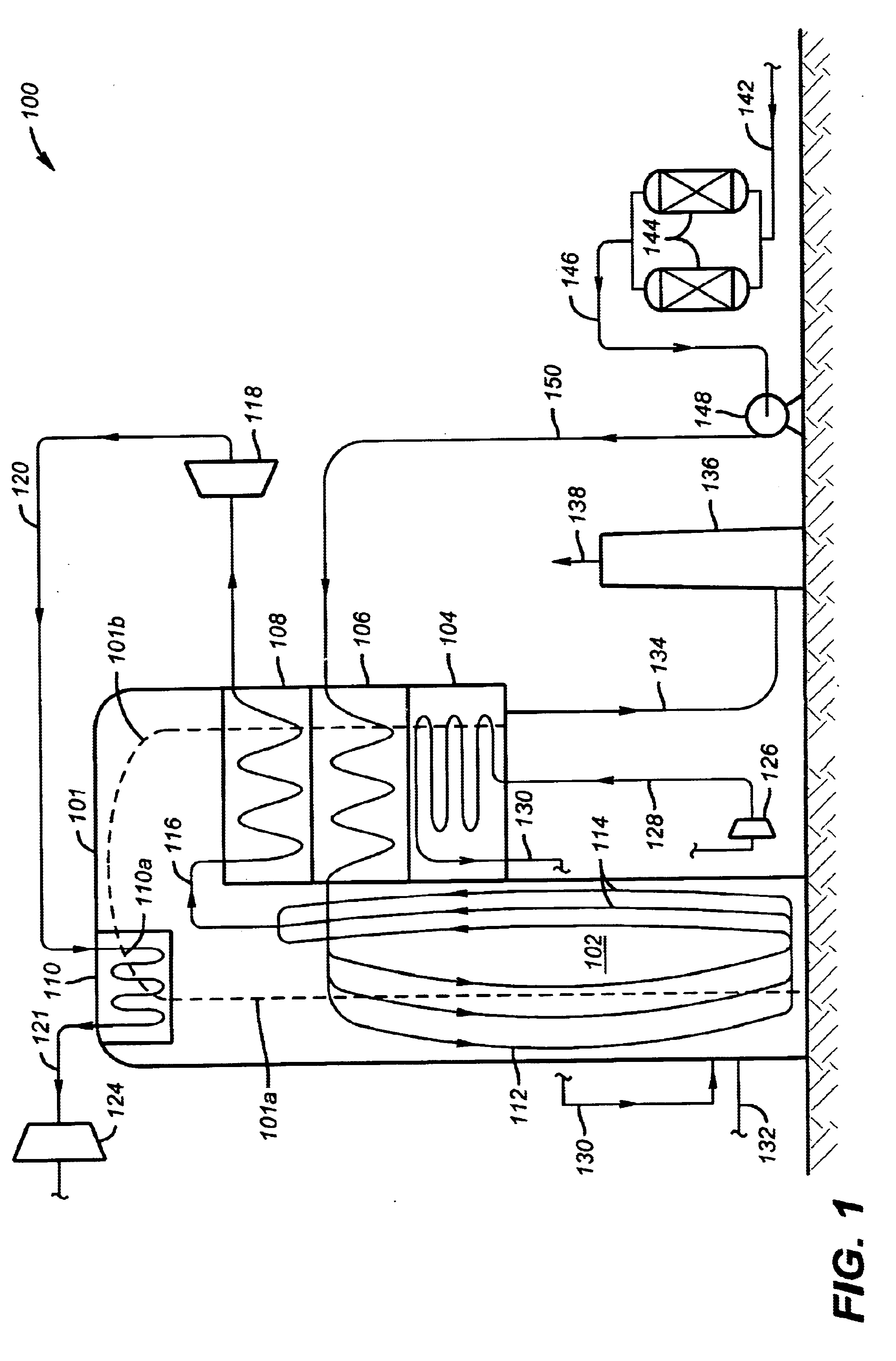

Split flow process and apparatus

An acid gas removal plant includes an absorber that provides a rich solvent to two regenerators that independently generate a lean and a semi-lean solvent, wherein the semi-lean solvent is produced in one of the regenerators using heat and / or steam derived from the other regenerator. Further heat integration is particularly contemplated with power plants in which the power plant provides high-level heat to the acid gas removal plant and wherein the power plant receives low-level heat from the acid gas removal plant.

Owner:FLUOR TECH CORP

Reduced Carbon Footprint Steam Generation Processes

Processes for the generation of steam are provided for use in an integrated catalytic gasification process for converting carbonaceous materials to combustible gases, such as methane. Generally, the exhaust gas from a steam generating reactor is provided along with steam, a carbonaceous feedstock, and a gasification catalyst, to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, the carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide. As substantially all the carbon dioxide produced from the steam generation process and the gasification process are subsequently directed though gas purification and separation processes, substantially all the carbon dioxide may be recovered, yielding a process having a near zero carbon footprint.

Owner:SURE CHAMPION INVESTMENT LTD

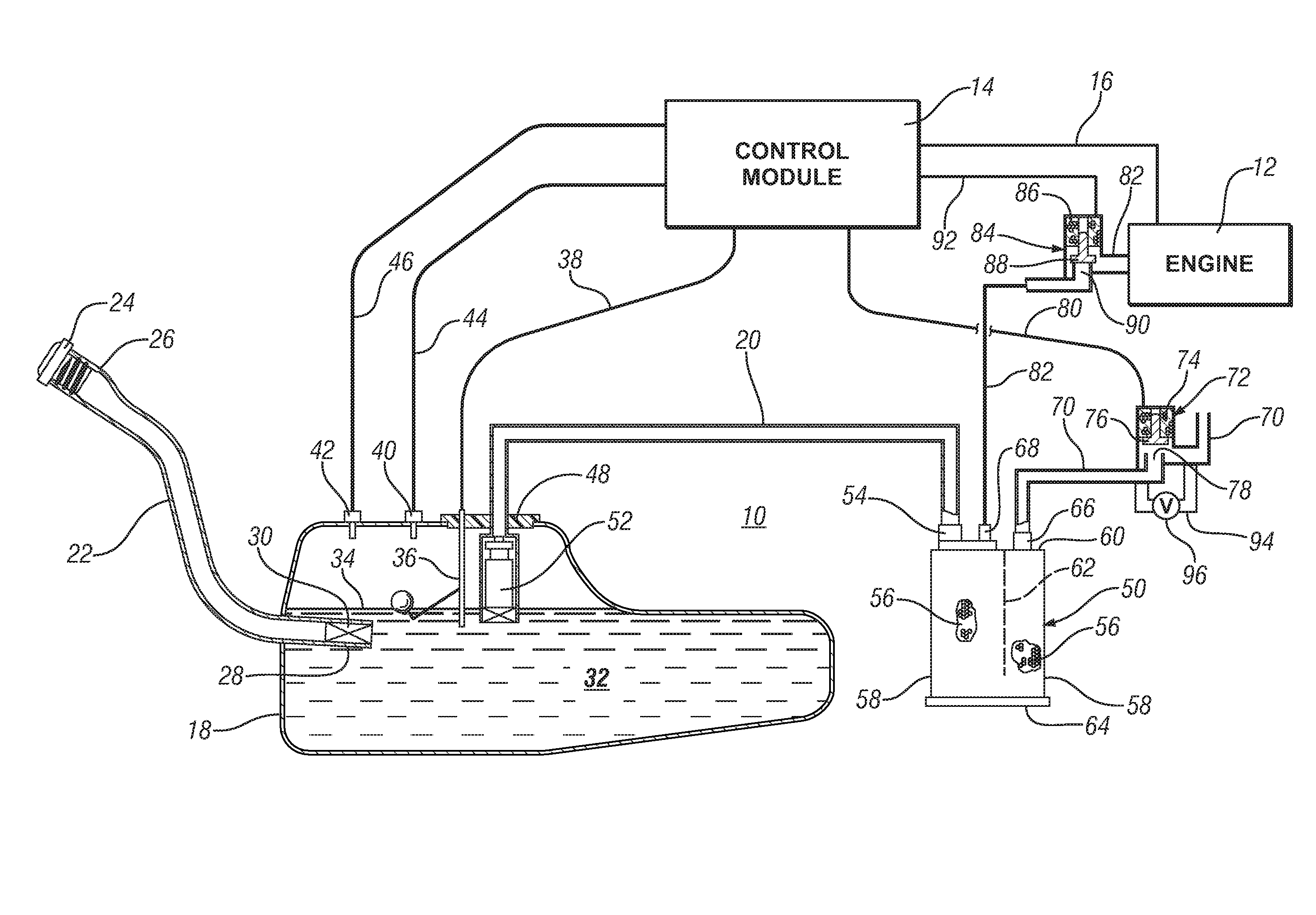

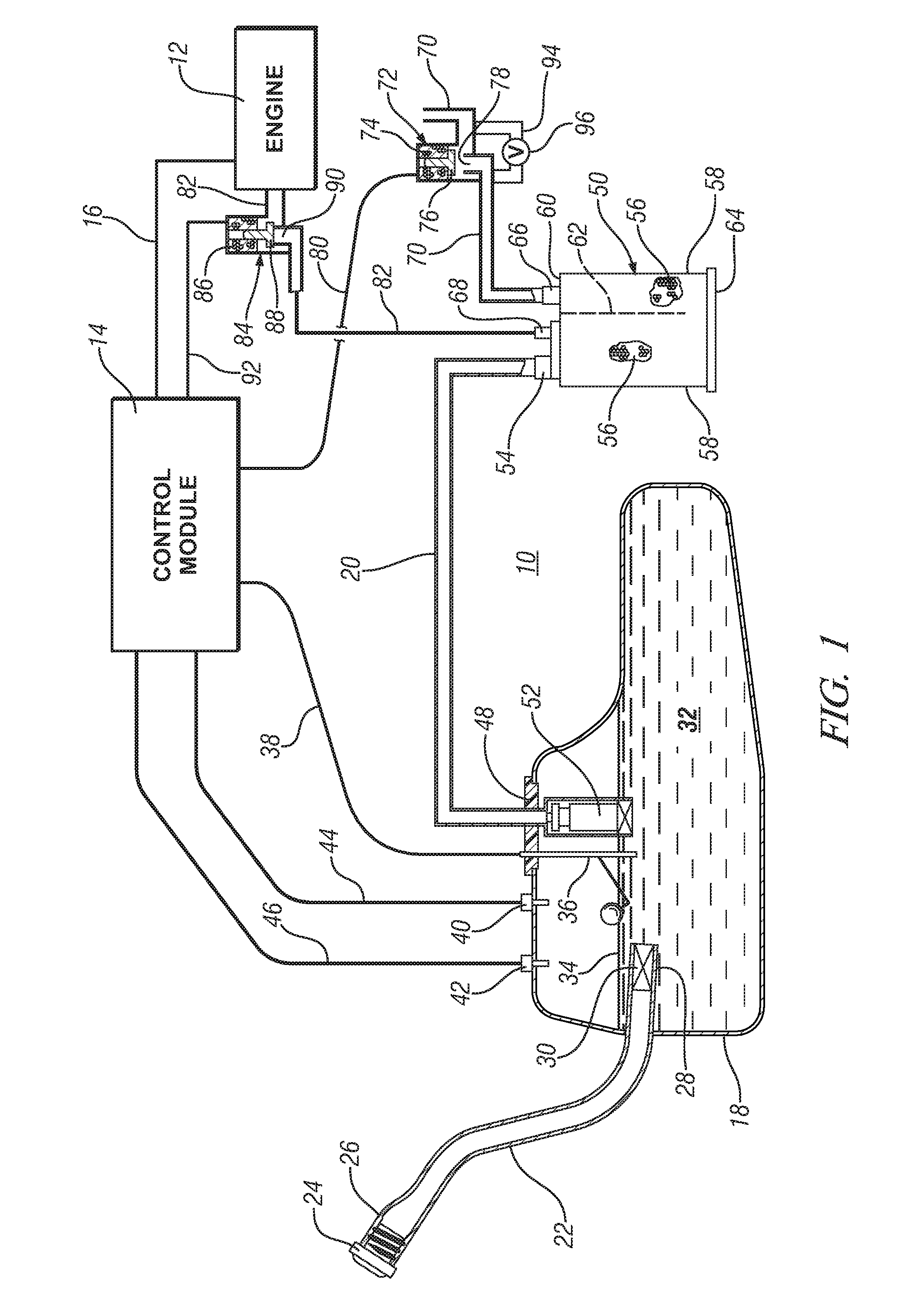

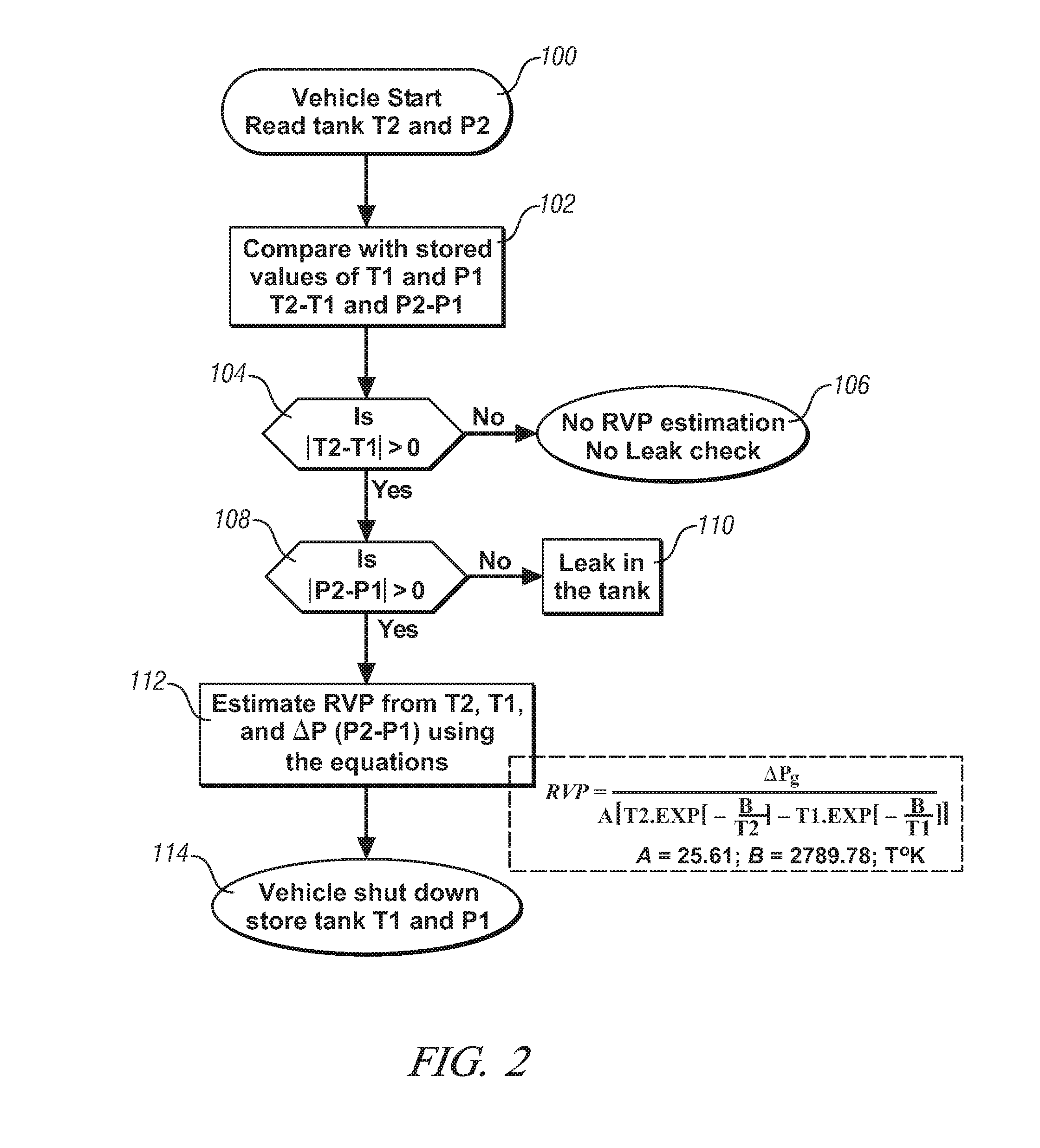

Evaporative emission control in battery powered vehicle with gasoline engine powered generator

InactiveUS7448367B1Preventing bleed emissionElectrical controlNon-fuel substance addition to fuelGasolineEngine power

A plug-in hybrid vehicle is driven by one or more electric motors powered by a battery system with supplemental electric power provided by a gasoline engine powered generator. A canister, connected by a fuel vapor vent passage, is used to admit and temporarily adsorb fuel vapor from a vehicle fuel tank during refueling. The canister also has a first fuel vapor and air flow passage for venting the canister and introducing ambient air (in the reverse flow direction) for removing vapor stored in the canister during tank refueling. The canister has a second passage for conducting air and purged vapor from the canister to the operating engine. The first and second passages are opened only during engine operation for purging of stored fuel vapor. The first flow passage is selectively opened when the tank is being refueled. The sealed fuel system eliminates diurnal fuel tank vapor generation and canister bleed emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

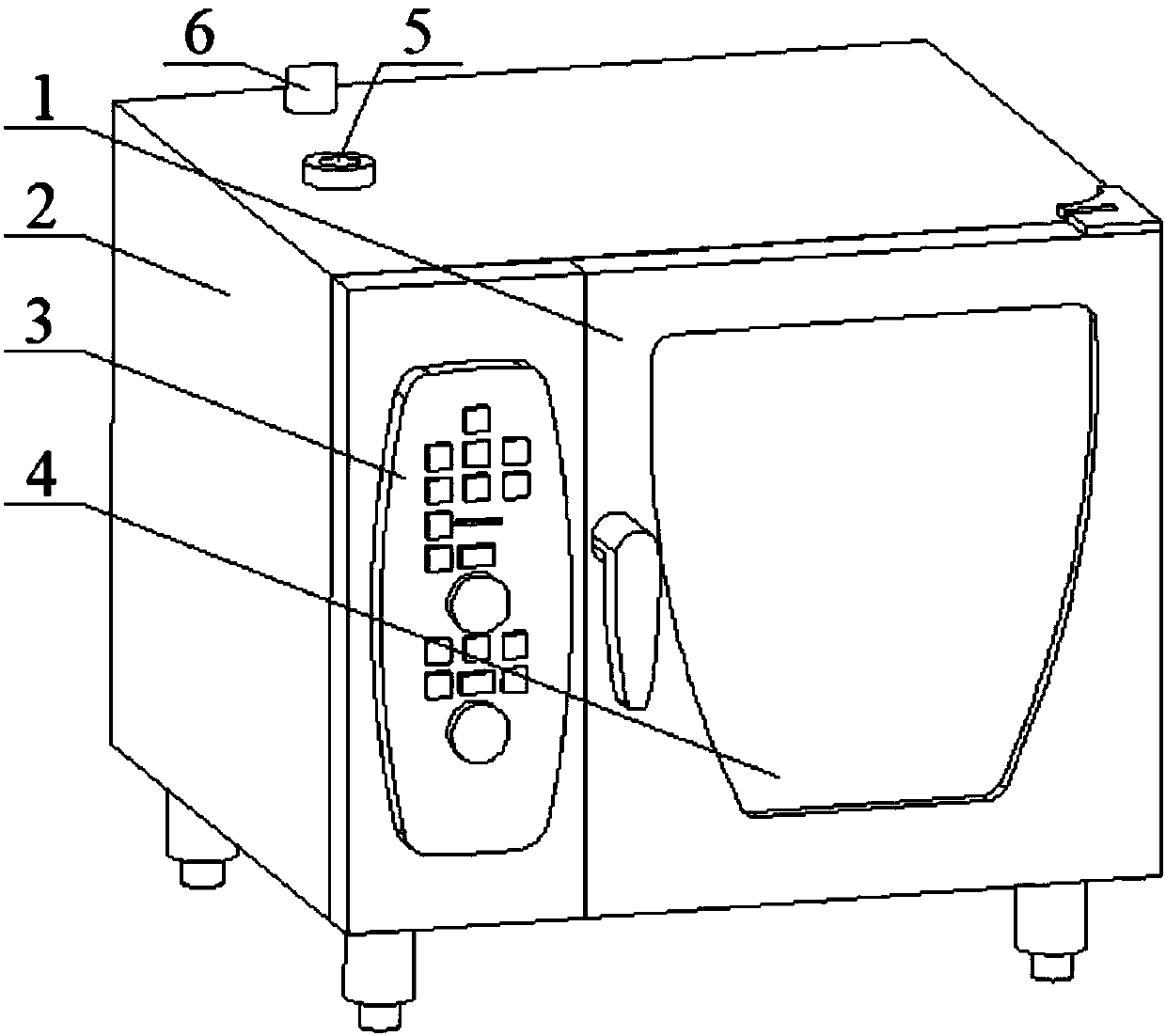

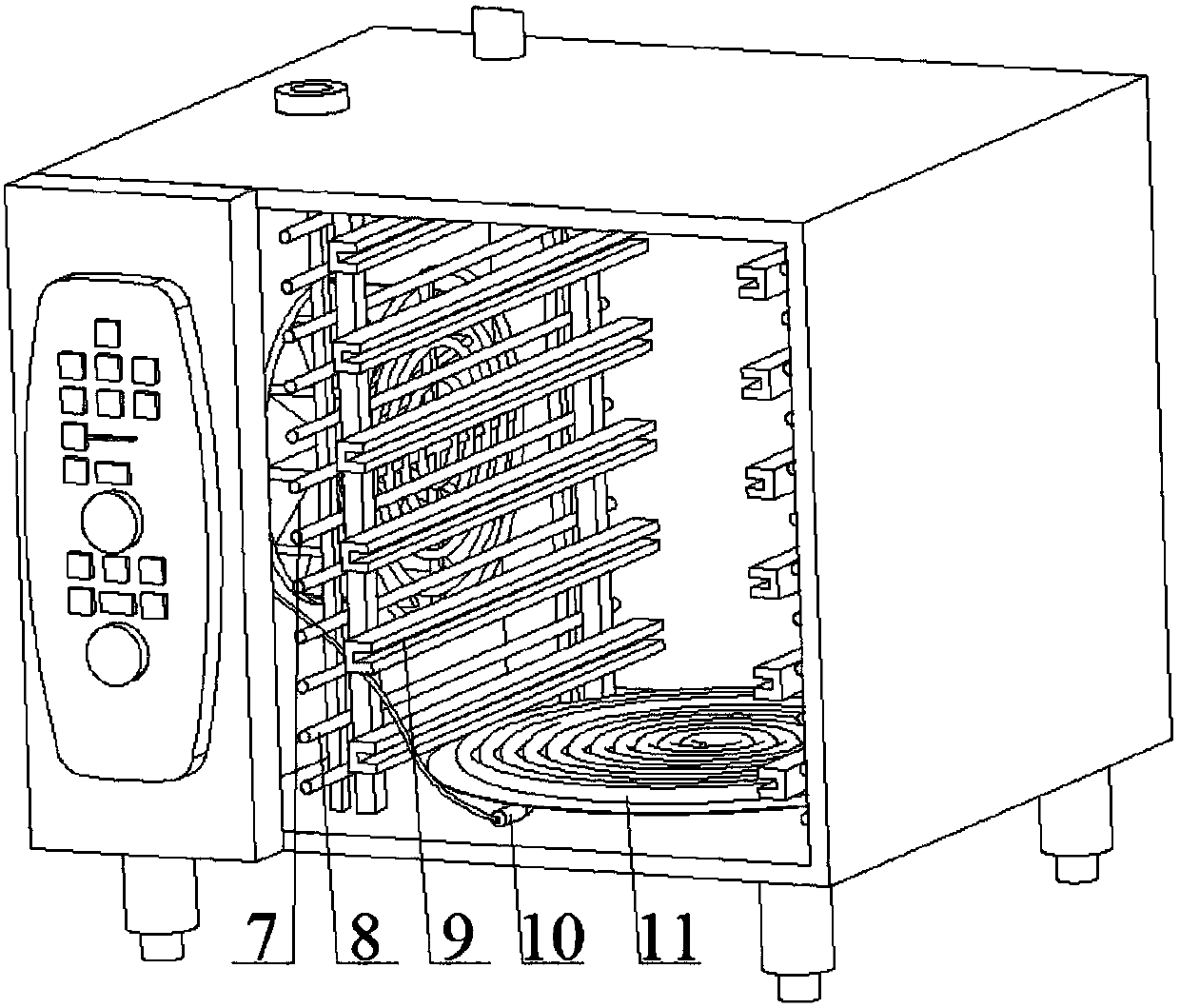

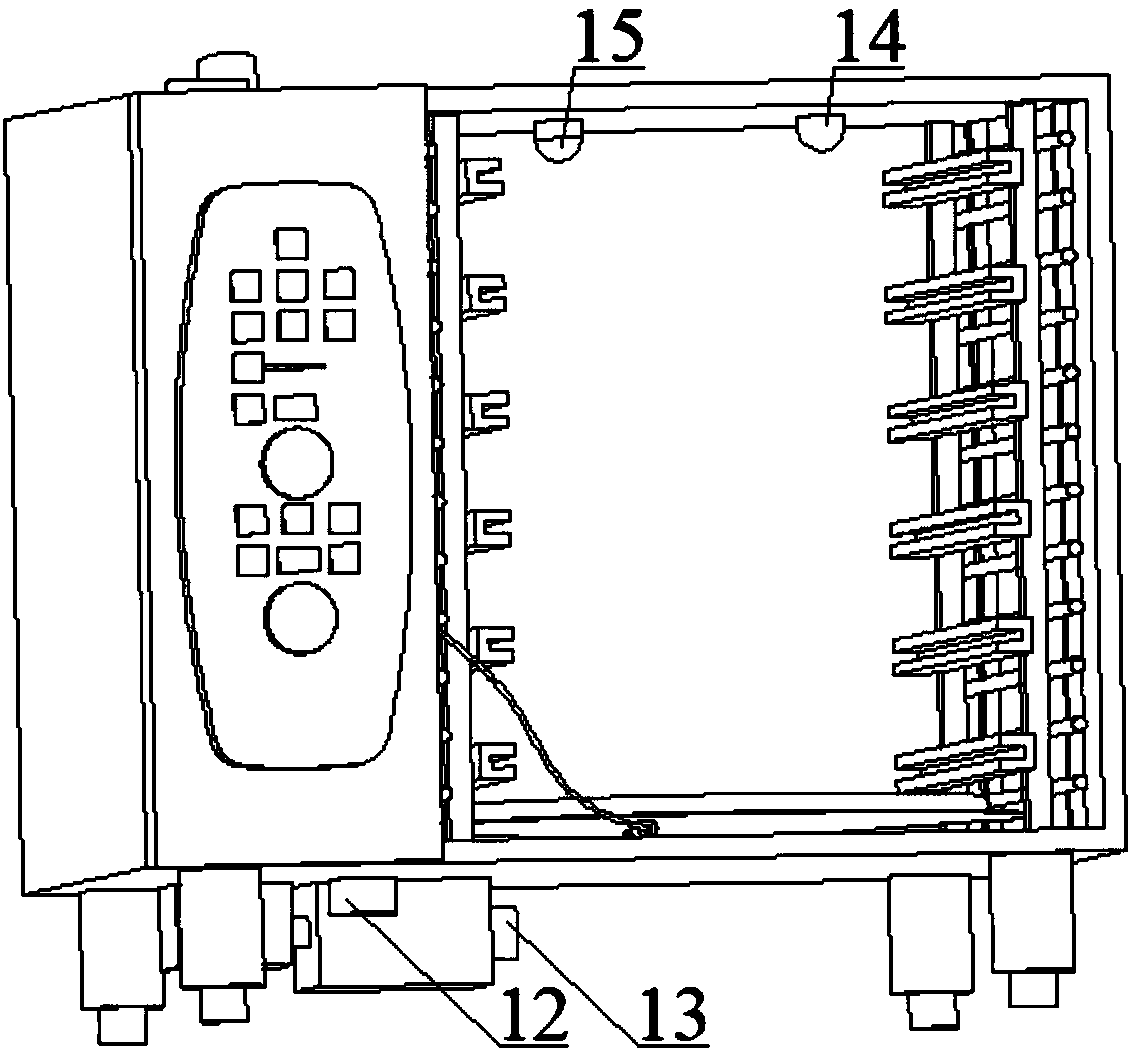

Steaming oven having multiple operating modes

PendingCN107898351AMeet the diverse needs of processingRapid coolingRoasters/grillsWarming devicesComputer moduleEngineering

The invention provides a steaming oven having multiple operating modes. The steaming oven is characterized by comprising an oven body, a steaming-baking module, a humidity regulating and detecting module, a menu editing and storing module, a central temperature detecting module and a control module, wherein the oven body comprises a steaming-baking chamber and a control chamber, the steaming-baking module comprises heating tubes, a steam generator, a turbo fan and an infrared thermodetector, the humidity regulating and detecting module comprises a dryer, a humidifier and a humidity detecting gauge, the menu editing and storing module comprises a menu memorizer and a USB flash disk reading port, the central temperature detecting module is used for food internal-temperature detection, and the control module comprises a photographing camera, a timer, an alarm apparatus, a controller and a central processing unit and is used for providing operation control. The steaming oven has multiple operation modes by arranging the modules, can meet the diversified food processing demands and is high in processing efficiency.

Owner:珠海家宝德科技有限公司

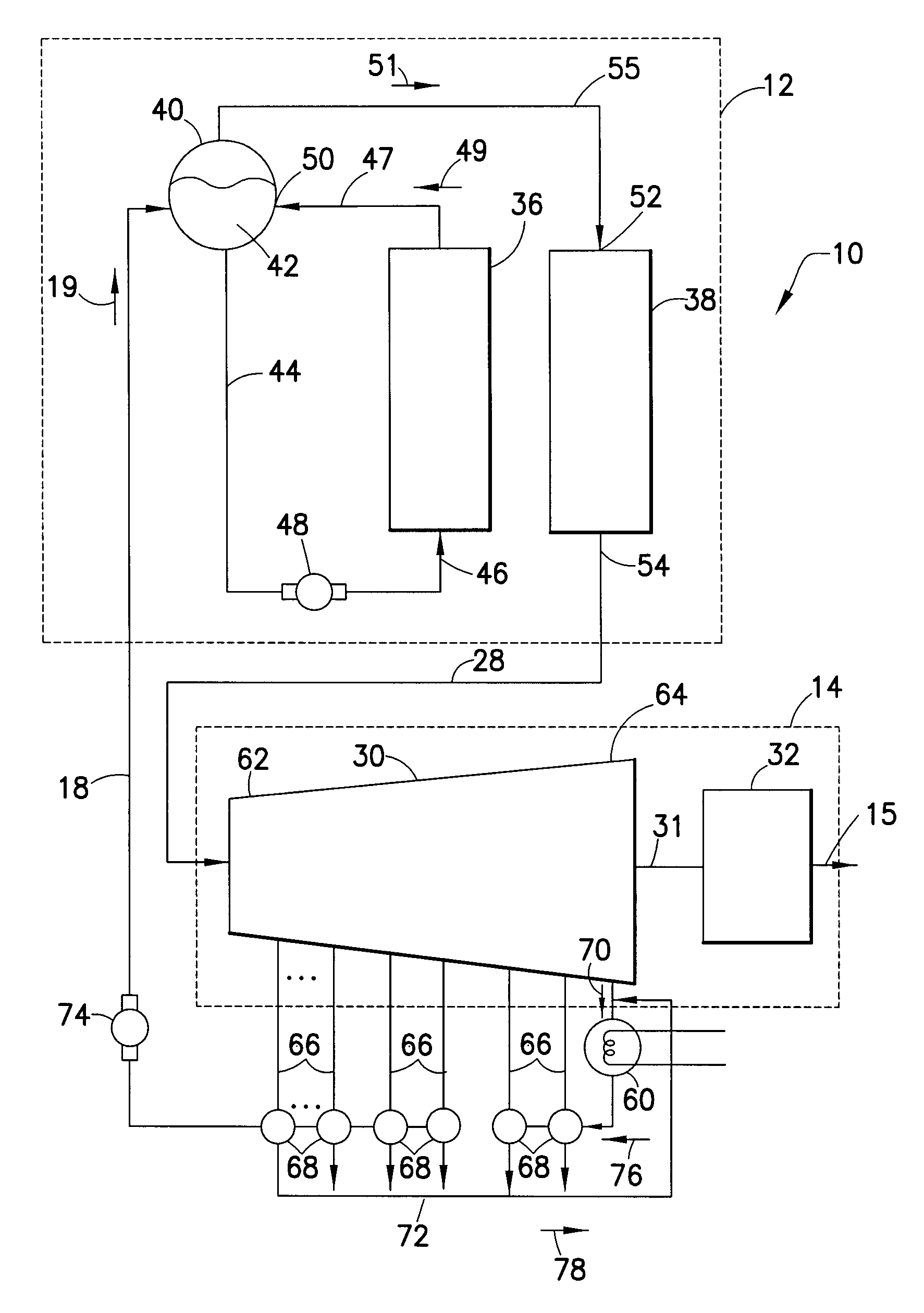

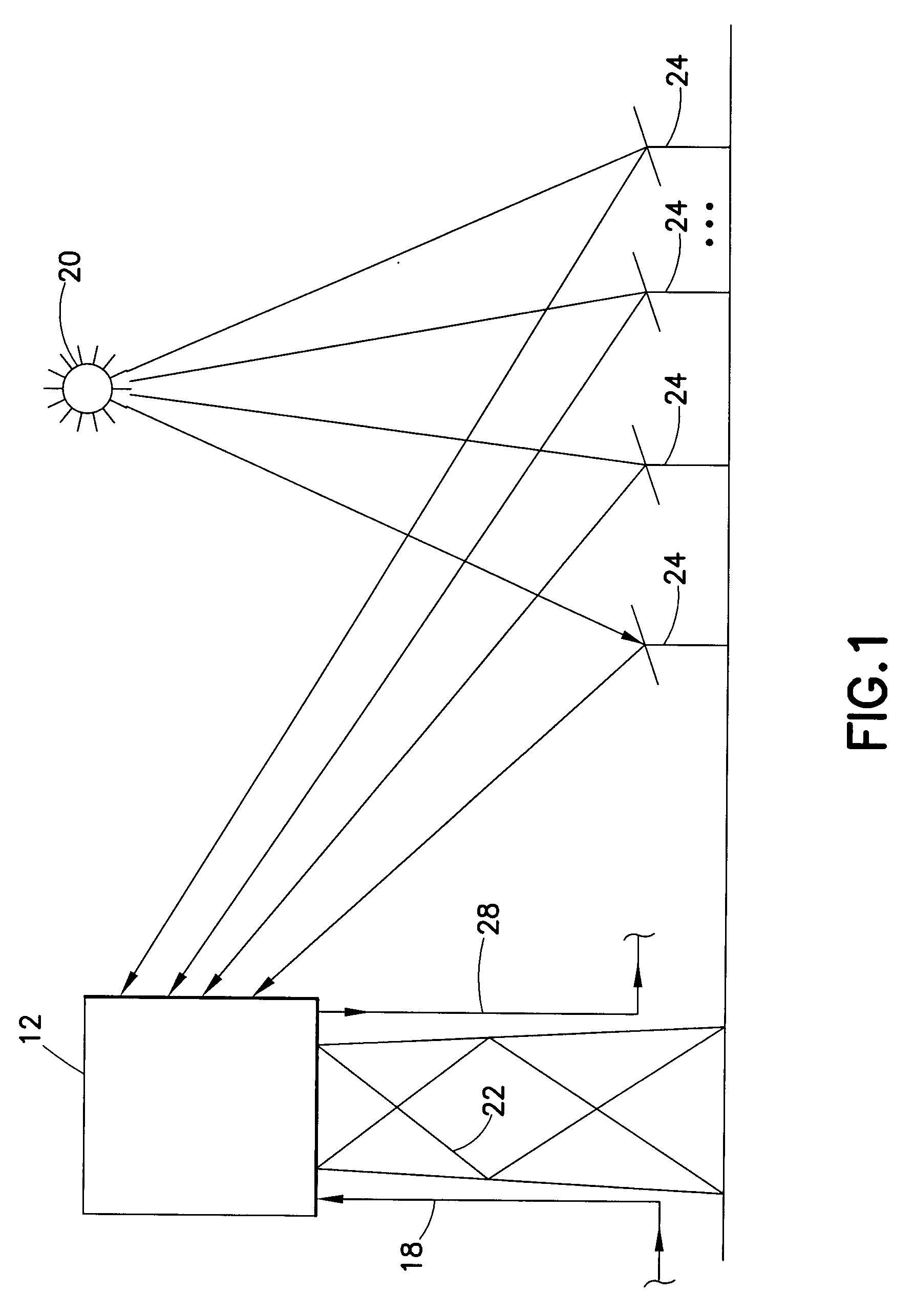

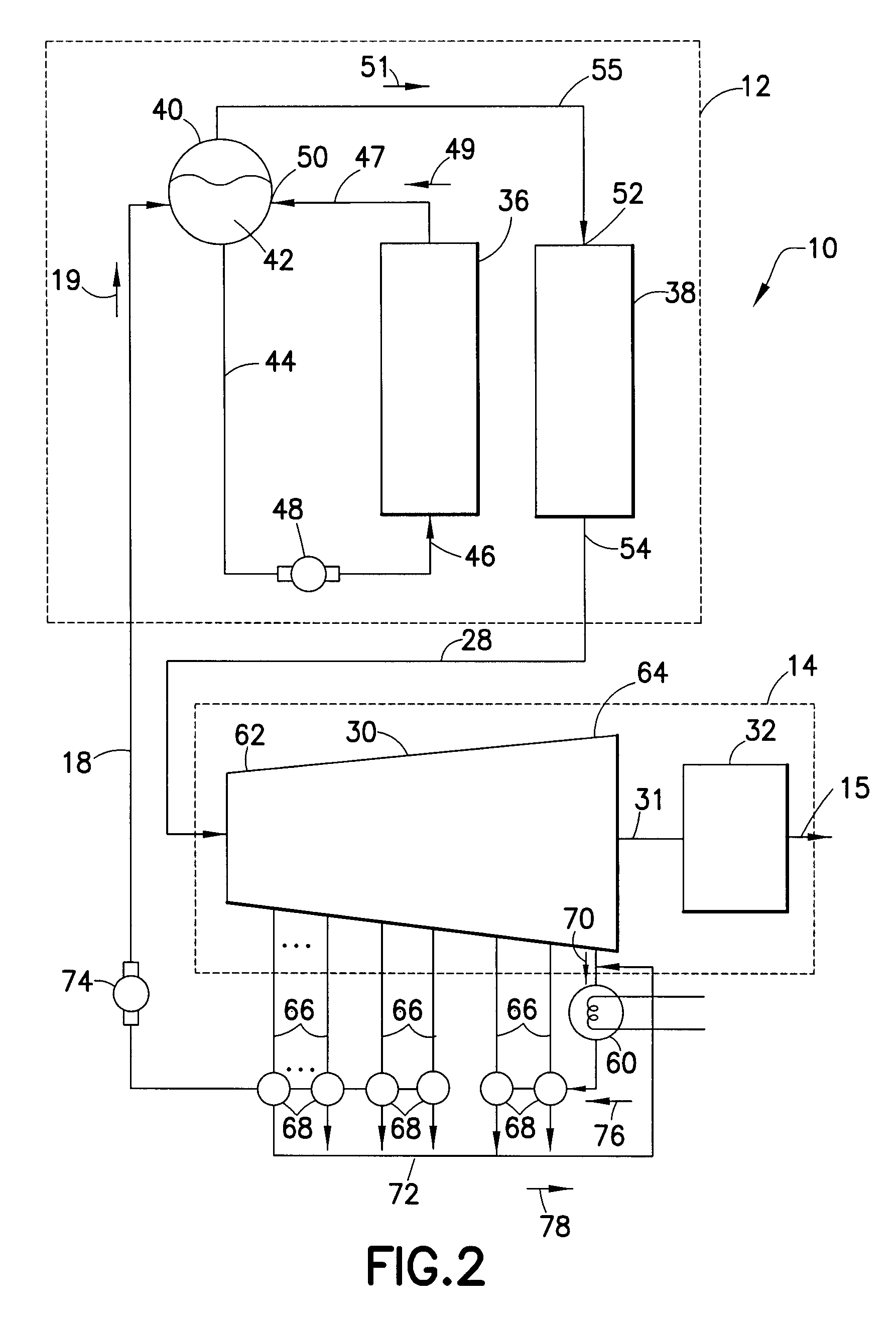

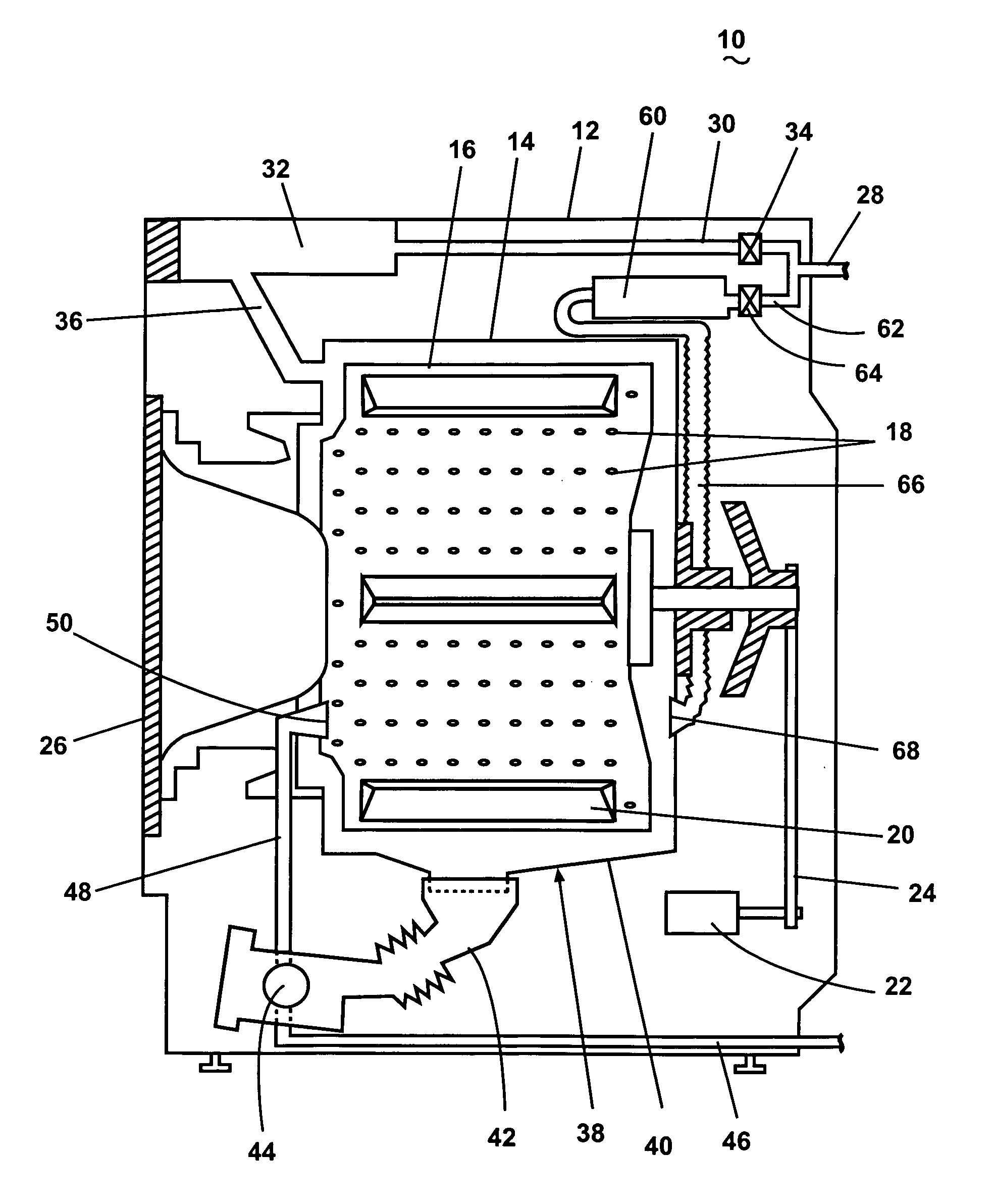

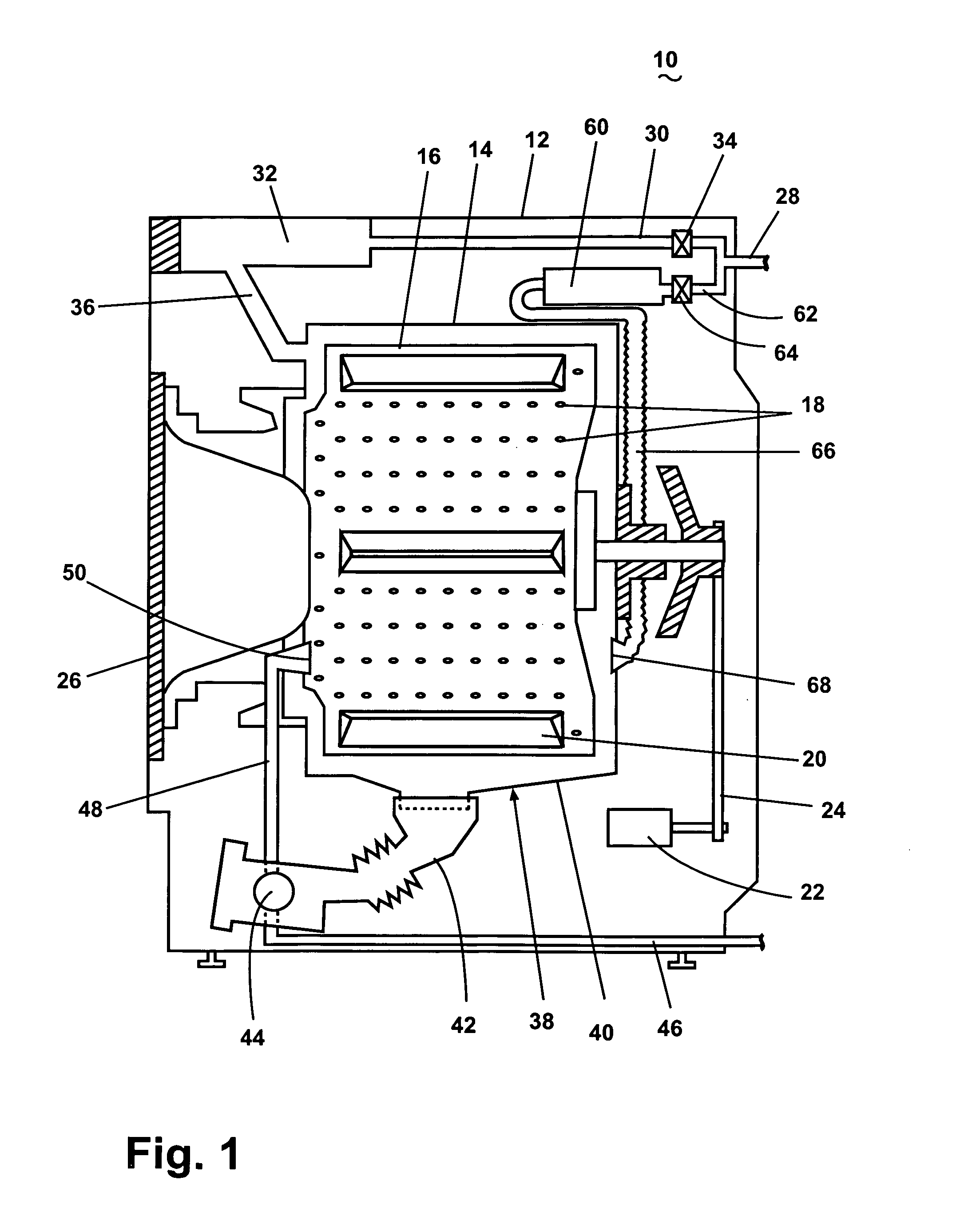

Solar thermal power plant

A solar thermal power plant 10 includes a steam generation portion 12 and a turbine 30. The steam generation portion 12 includes a steam drum 50 that separates water and steam, and an evaporator 36 and super heater 38 in fluid communication with the steam drum. The evaporator 36 receives and heats a portion of a flow of water from the steam drum 50 to provide the steam using solar energy provided thereto. The super heater 38 heats the steam from the evaporator 36 to provide super heated steam. A turbine 30 receives the super heated steam from the steam generation portion 12 to rotate the turbine. A plurality of extraction stages 66 extracts steam from the turbine 30 and provides the steam to a plurality of feedwater heaters 68. The feedwater heaters 68 heat the feedwater provided by the turbine 30, wherein the heated feedwater is provided to the steam generation portion 12.

Owner:ALSTOM TECH LTD

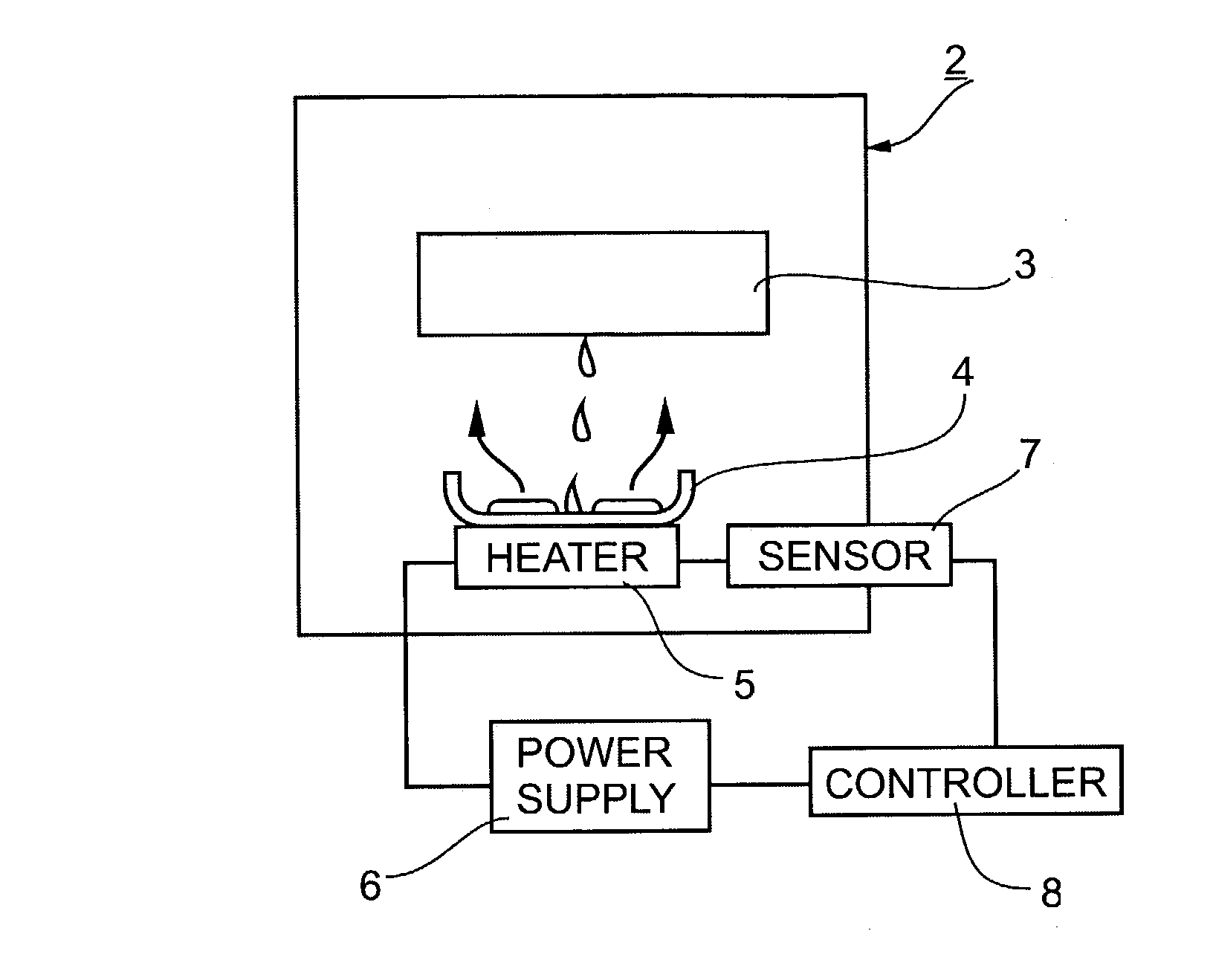

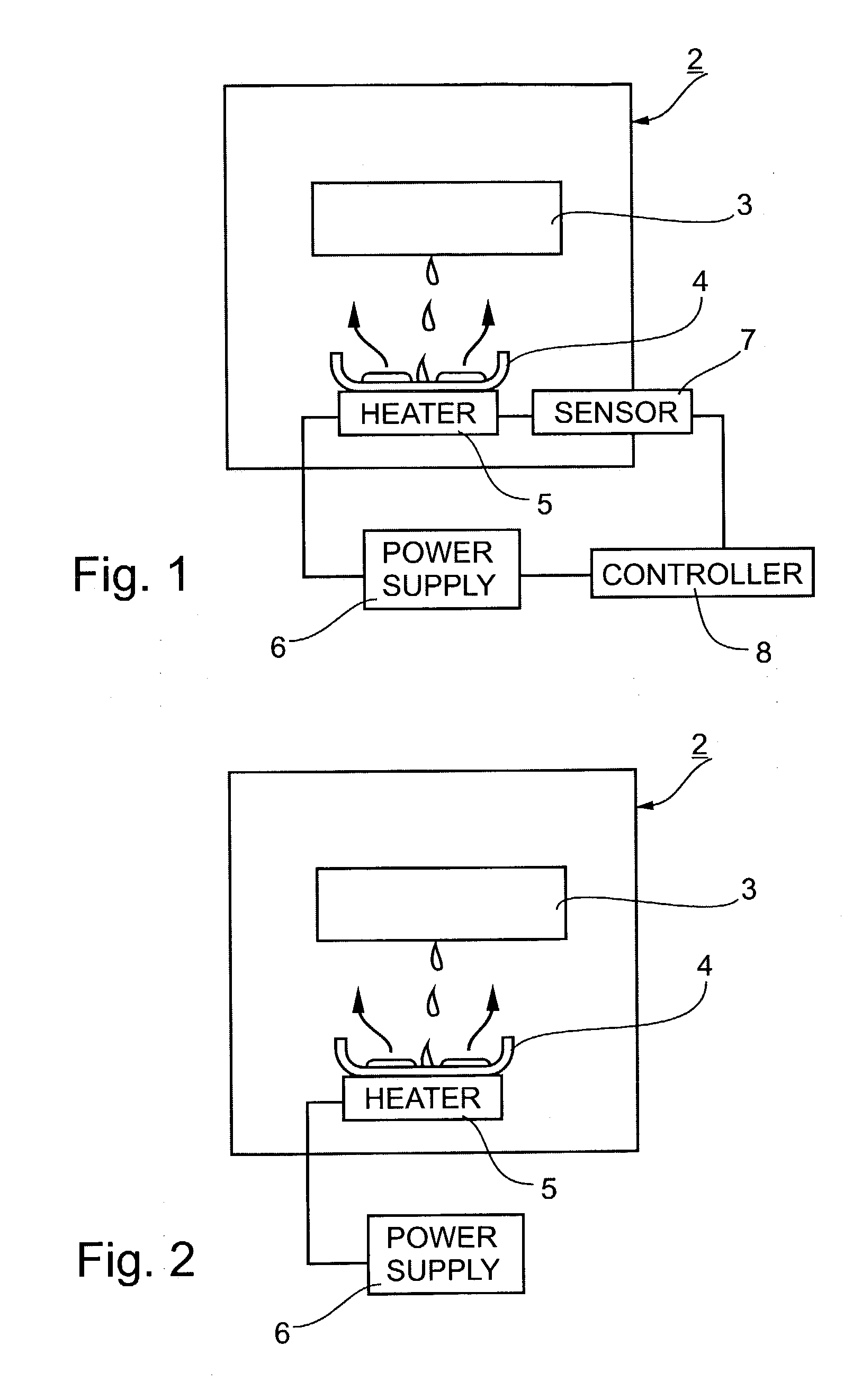

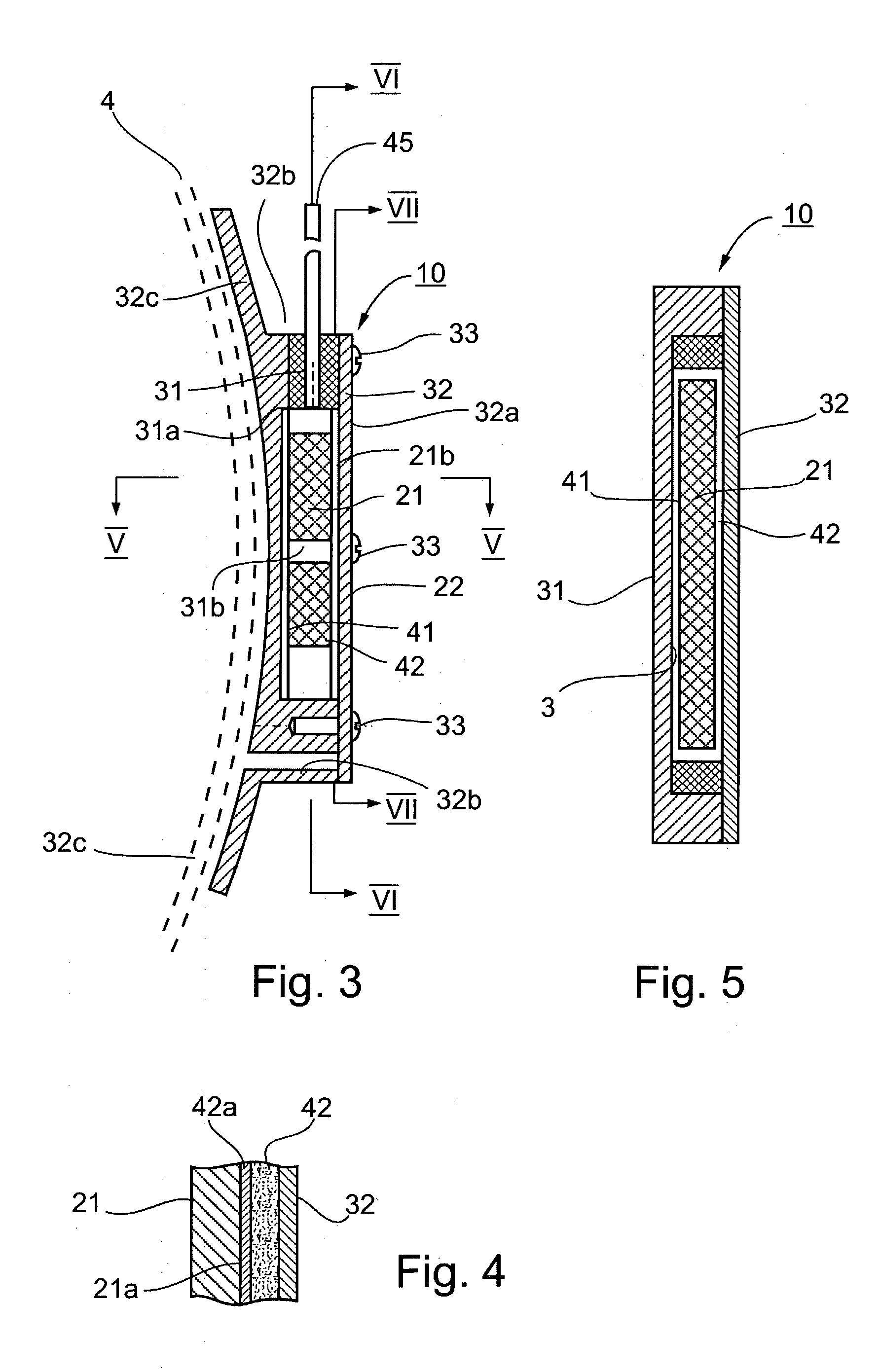

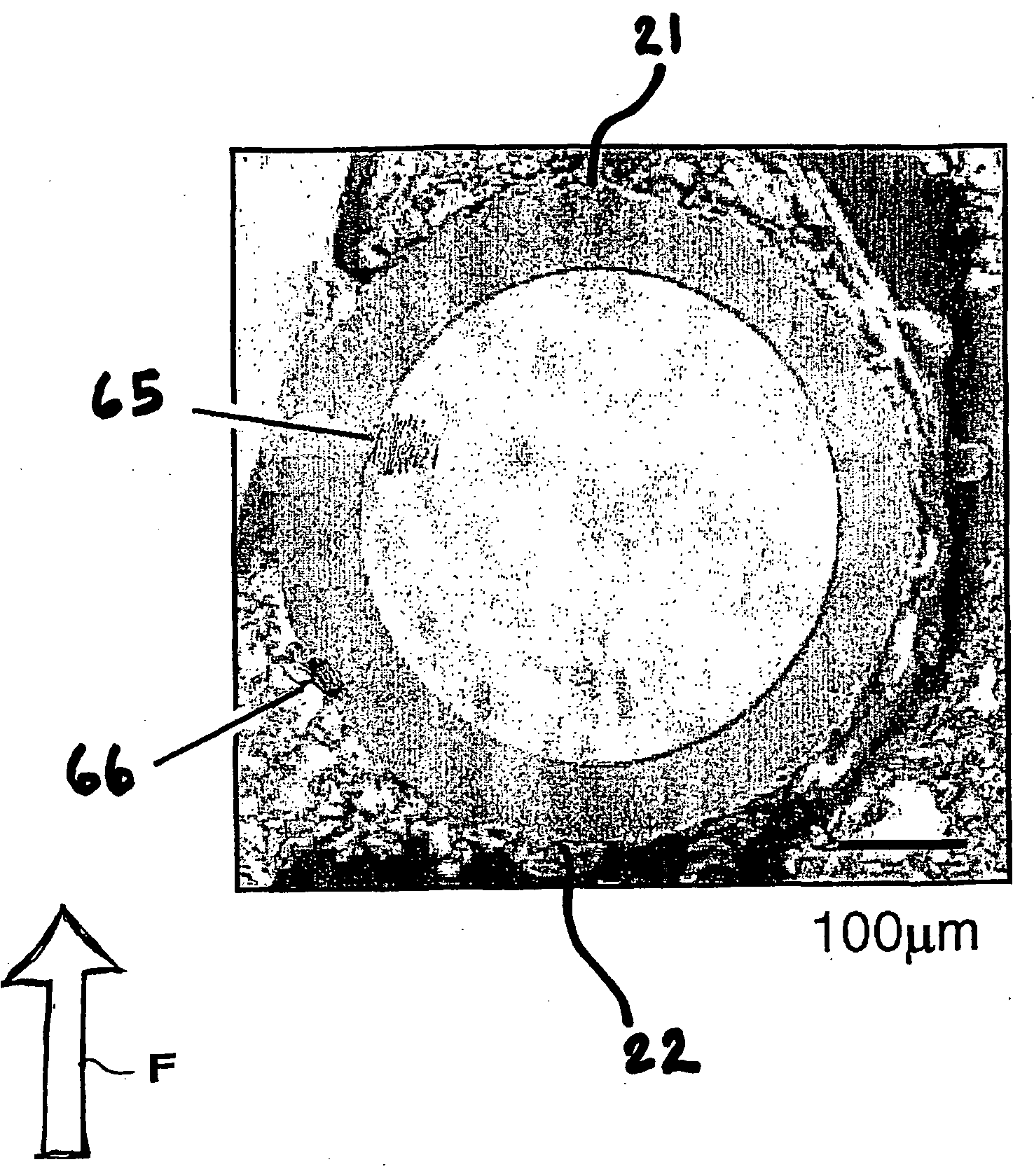

Liquid heating method and apparatus particularly useful for vaporizing a liquid condensate from cooling devices

InactiveUS20030206730A1Minimize power consumptionRule out the possibilitySpace heating and ventilationSteam cooking vesselsElectrical resistance and conductanceBoiling point

A method and heating device for heating a liquid, particularly useful for removing liquid condensate from cooling devices, by wetting a heating plate with the liquid and controlling the electrical power supply to maintain the heating plate at a the predetermined temperature above the boiling point of the liquid, such that when the heating plate is not wetted by the liquid, the electrical power supply to the heating plate is automatically maintained at a relatively low value, but as soon as the heating plate is wetted by the liquid, the electrical power supplied to the heating plate is automatically increased until the liquid is completely evaporated. The heating plate is heated by one or more PTC thermistors in which the electrical resistance increases with temperature to automatically maintain the predetermined temperature. Besides evaporating liquid condensate, the heating device is described for use in many other applications including steam generation, space heating and plastic molding.

Owner:A T C T ADVANCED THERMAL CHIP TECH

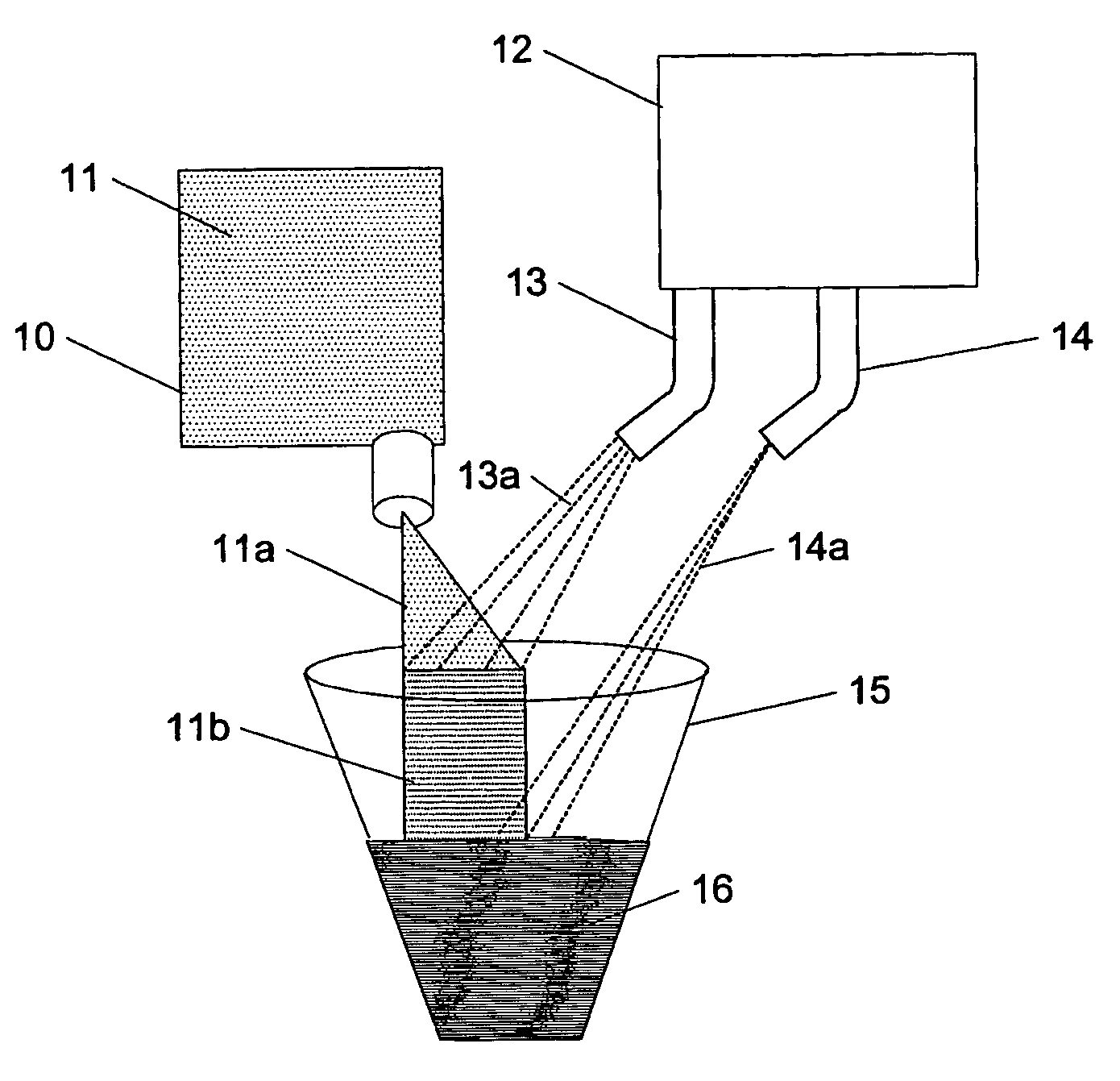

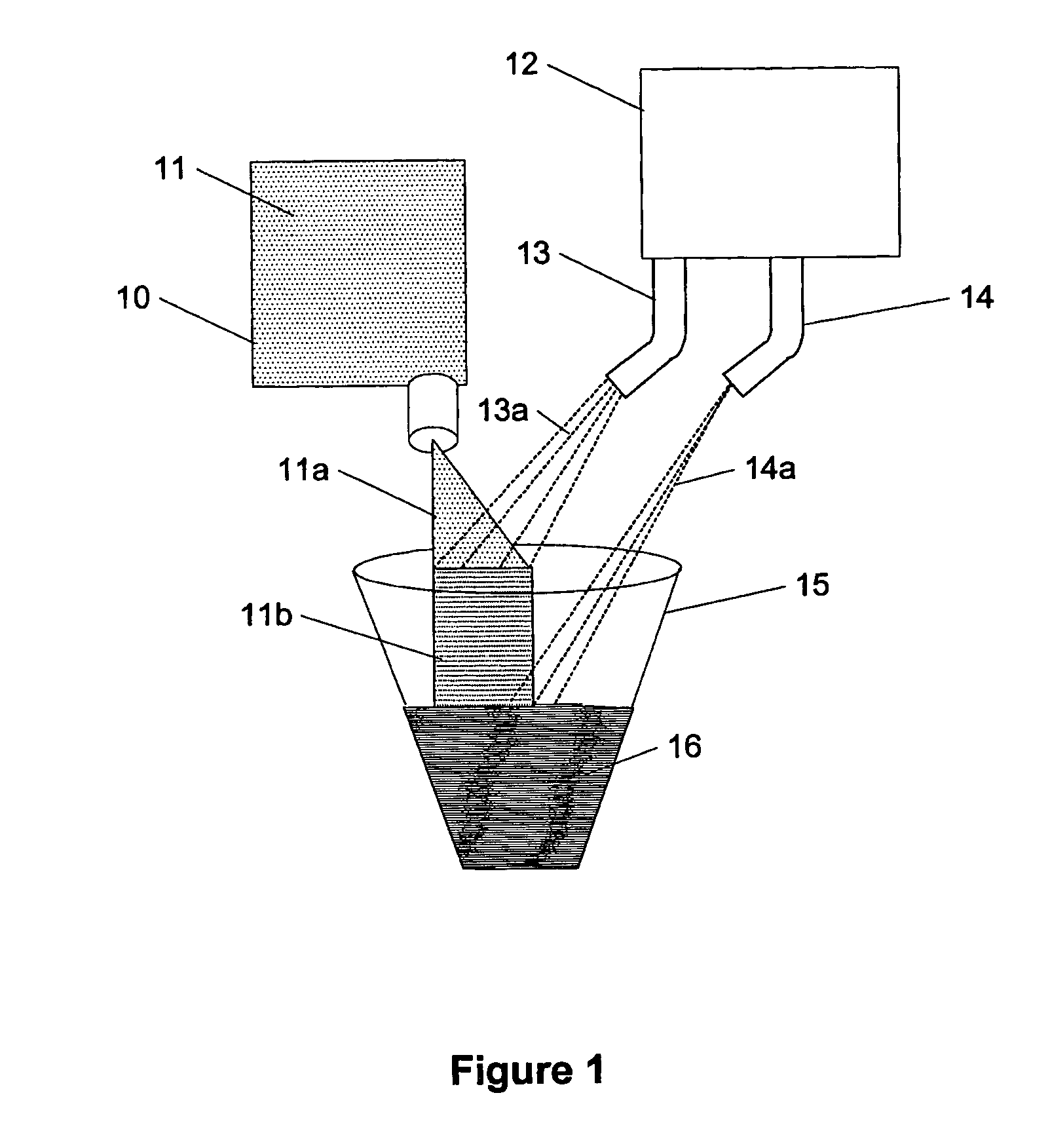

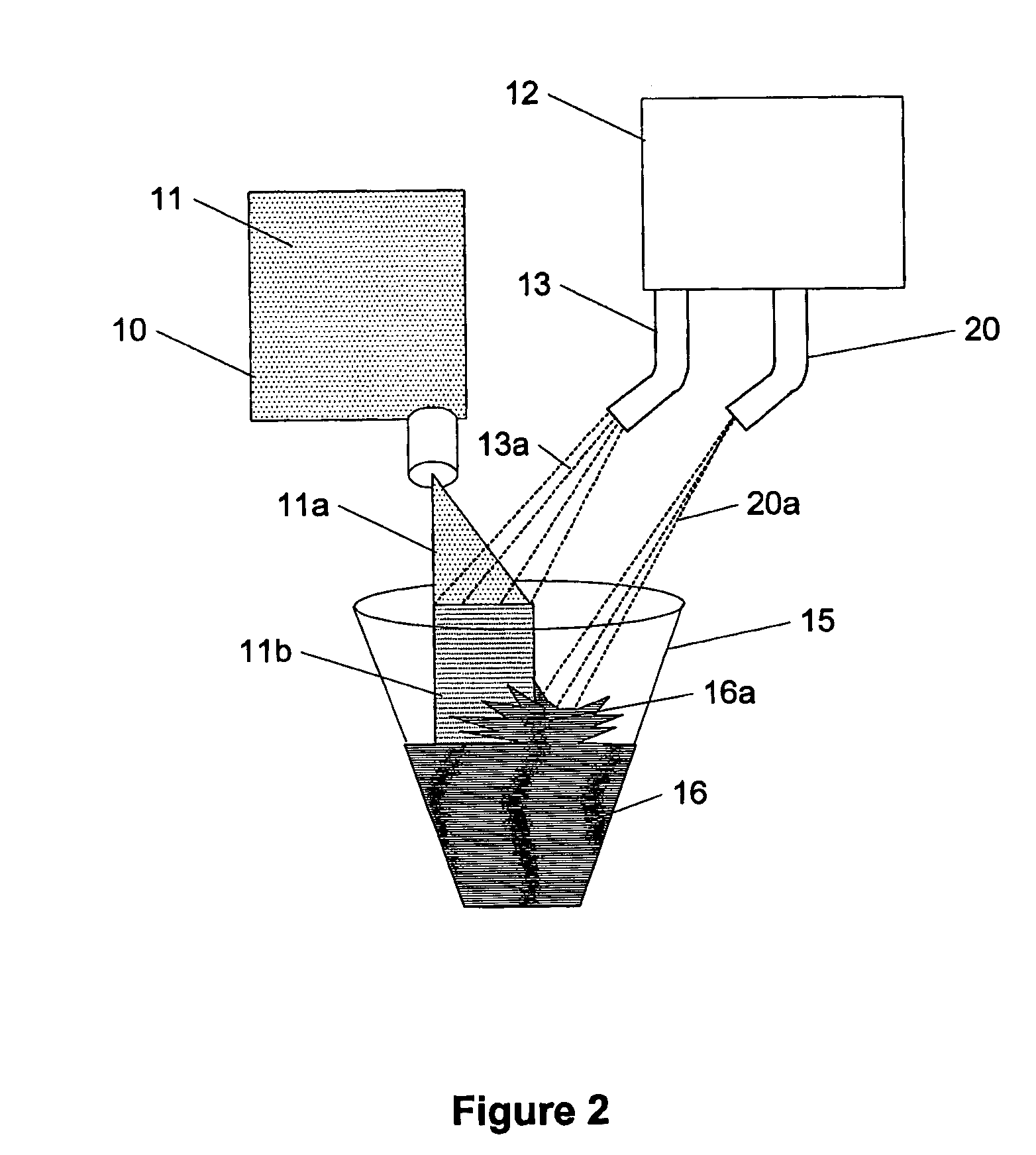

Apparatus and method for applying coatings onto the interior surfaces of components and related structures produced therefrom

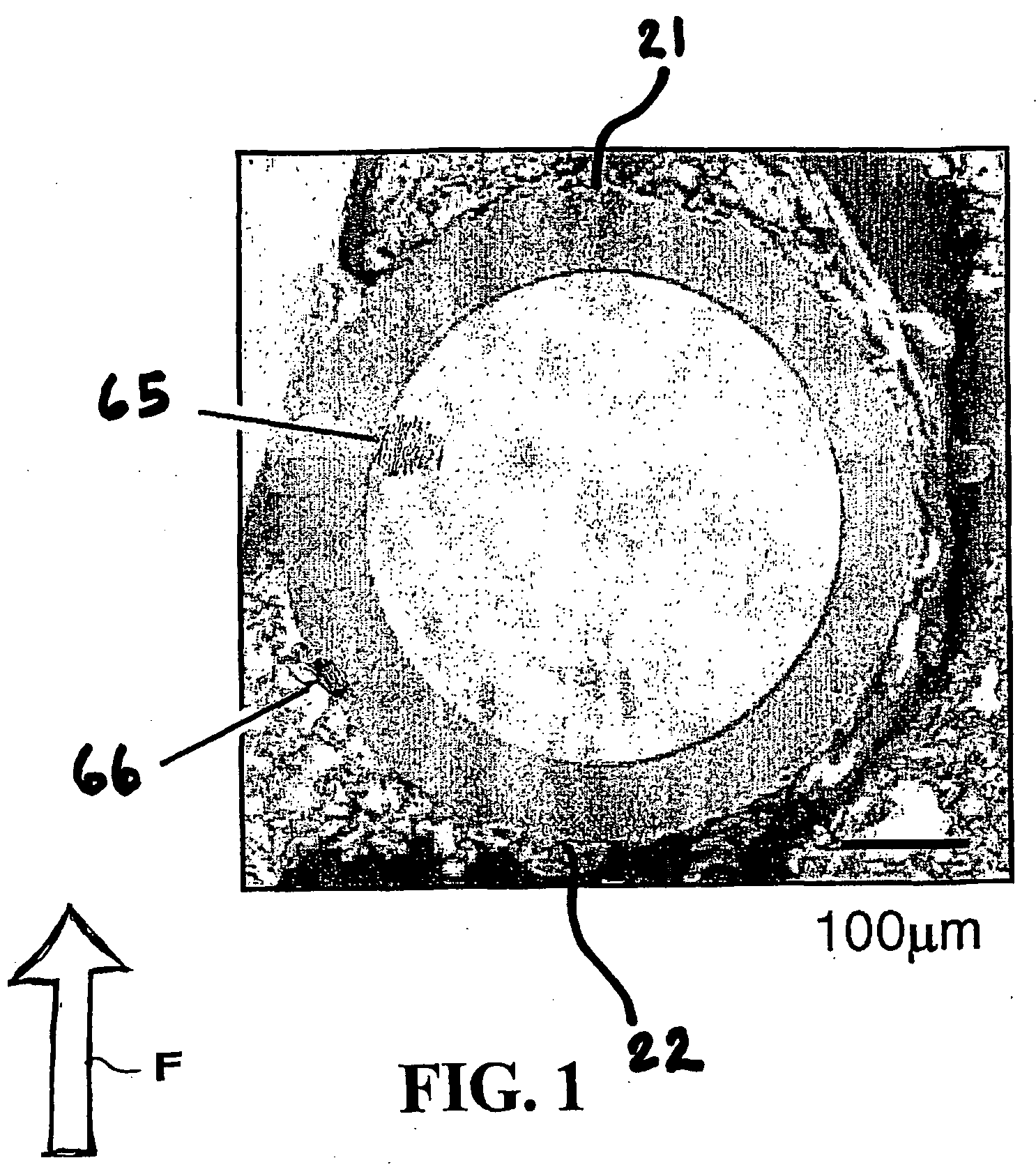

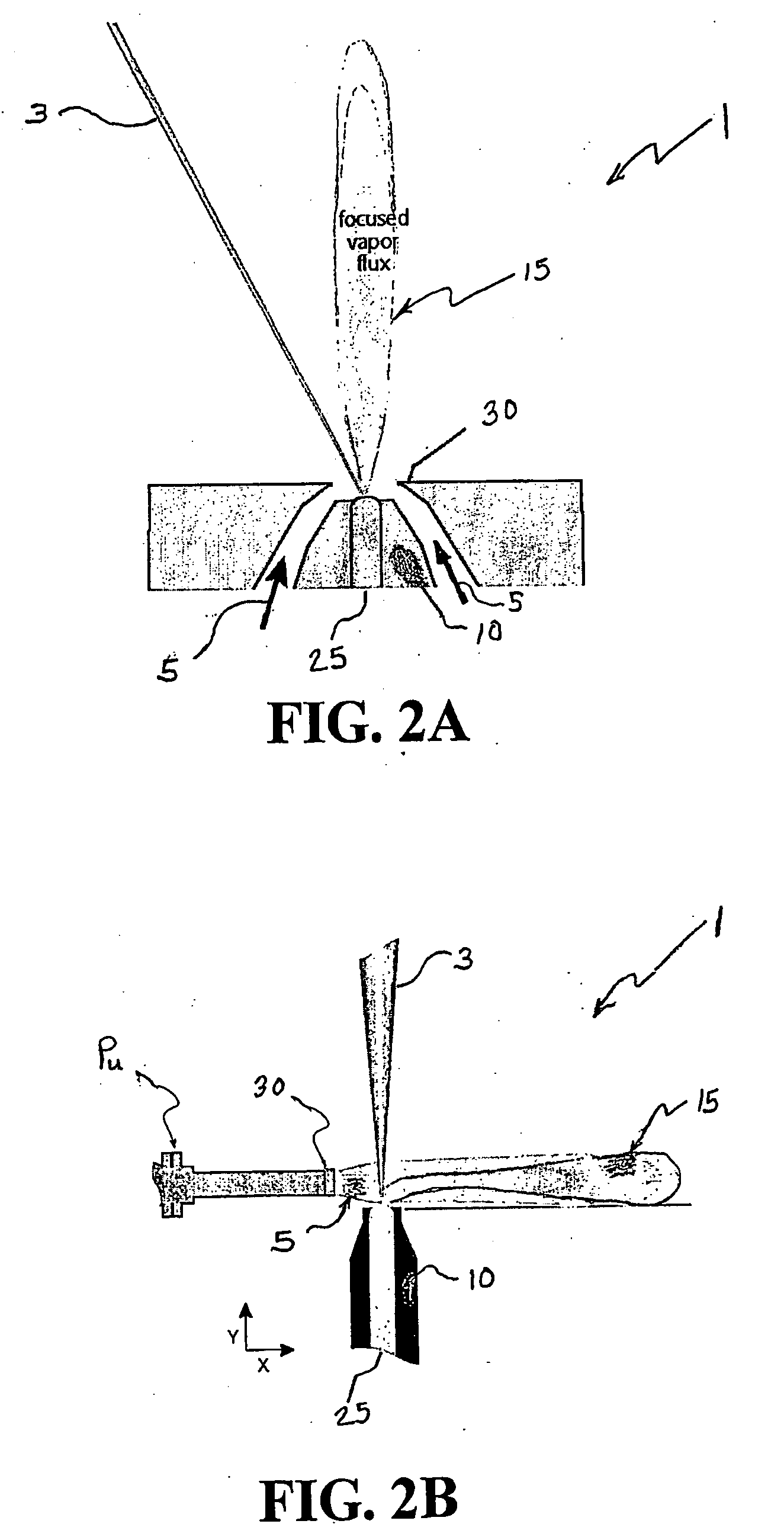

ActiveUS20090017217A1Limited effectivenessWide rangeMolten spray coatingElectric discharge heatingEngineeringVacuum chamber

Provided is a methodology and system for applying coatings onto the interior surfaces of components. The approach comprises a vapor creation device (for example an electron beam or laser that evaporates a single or multiplicity of solid or liquid sources), a vacuum chamber having a moderate gas pressure (between about 10−4 to about 103 Torr) and a inert gas jet having controlled velocity and flow fields of gas jet. The gas jet is created by a rarefied, inert gas supersonic expansion through a nozzle. By controlling the carrier gas flow into a region upstream of the nozzle an upstream pressure is achieved (i.e. the gas pressure prior to its entrance into the processing chamber through the nozzle). The carrier gas flow and chamber pumping rate control the downstream (or chamber) pressure (i.e., downstream of the nozzle). The ratio of the upstream to downstream pressure along with the size and shape of the nozzle opening controls the speed of the gas entering the chamber. The carrier gas molecular weight (compared to that of the vapor) and the carrier gas speed controls its effectiveness in redirecting the vapor atoms via binary collisions towards the substrate. The speed and flux of the atoms entering the chamber, the nozzle parameters, and the operating chamber pressure can all vary leading to a wide range of accessible processing conditions. Vapor created from a source is transported into the interior regions of a component using binary collisions between the vapor and gas jet atoms. Under certain process conditions these collisions enable the vapor atoms to scatter onto the interior surfaces of the component and deposit.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Solar selective coating having higher thermal stability useful for harnessing solar energy and a process for the preparation thereof

InactiveUS20070196670A1Easy to optimizeImprove thermal stabilitySolar heat devicesVacuum evaporation coatingAbsorptanceEngineering

The present invention provides an improved solar selective multilayer coating having higher thermal stability and a process for the preparation thereof. Solar selective coatings having higher thermal stability are useful in solar steam generation, solar steam turbines to produce electricity and also on automobile engine components. In the present invention, a tandem stack of three layers of TiAlN, TiAlON and Si3N4 is deposited on metal and non-metal substrates at room temperature using a planar reactive direct current magnetron sputtering process. The first two layers function as the absorber and the third antireflection layer further enhances the coating's absorptance. The solar selective coatings were annealed in air and vacuum to test the thermal stability at different temperatures and durations. The coatings of the present invention deposited on copper substrates are stable in air up to a temperature of 625° C. for a duration of 2 hours and exhibit higher solar selectivity in the order of 9-10 and these coating also show no change in the absorptance and the emittance values even after vacuum annealing at 600° C. for 3 hours. Coatings deposited on copper substrates showed no significant degradation in the optical properties even after continuous heating in air at 525° C. for 50 hours. The solar selective coatings of the present invention exhibit high hardness, high oxidation resistance, chemical inertness and stable microstructure.

Owner:COUNCIL OF SCI & IND RES

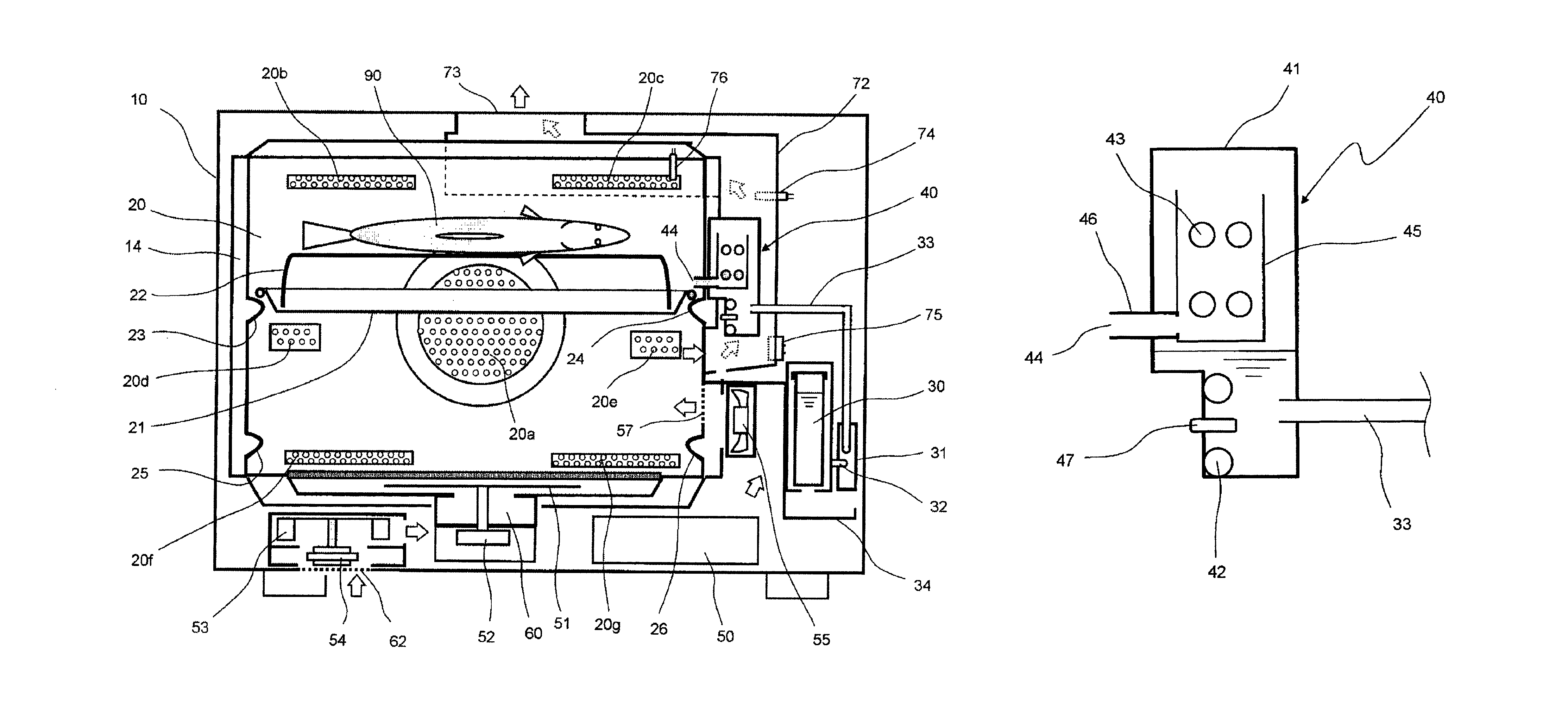

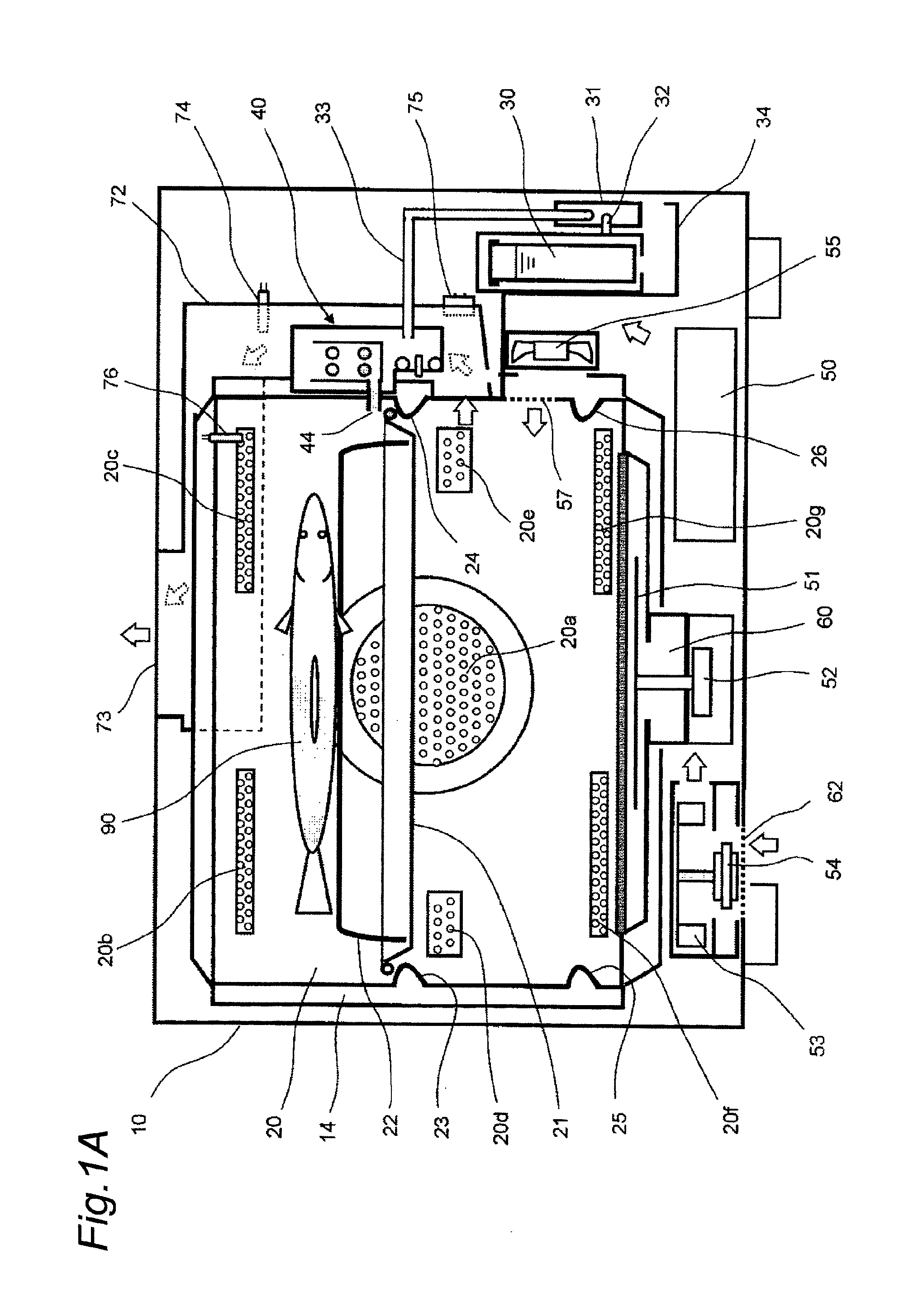

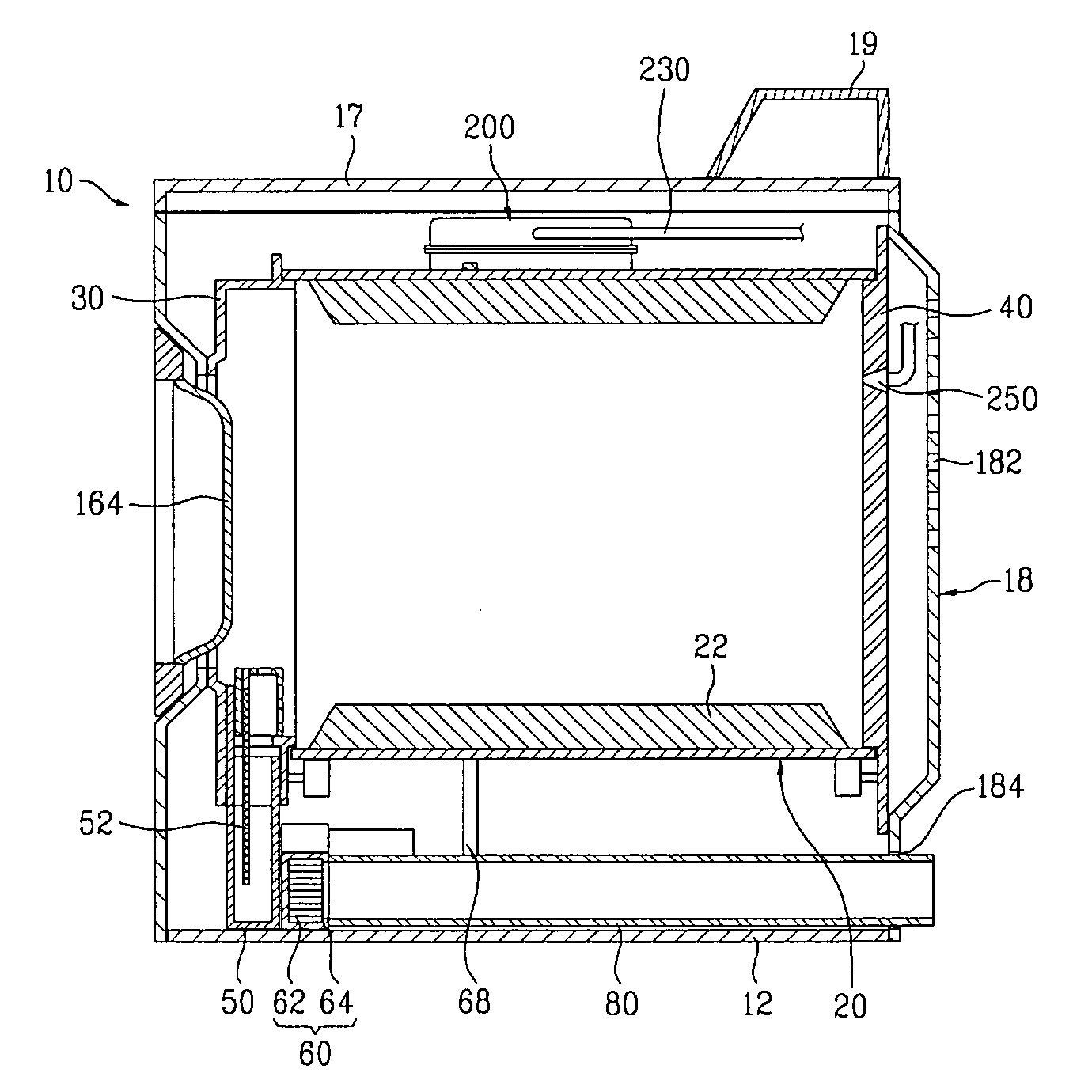

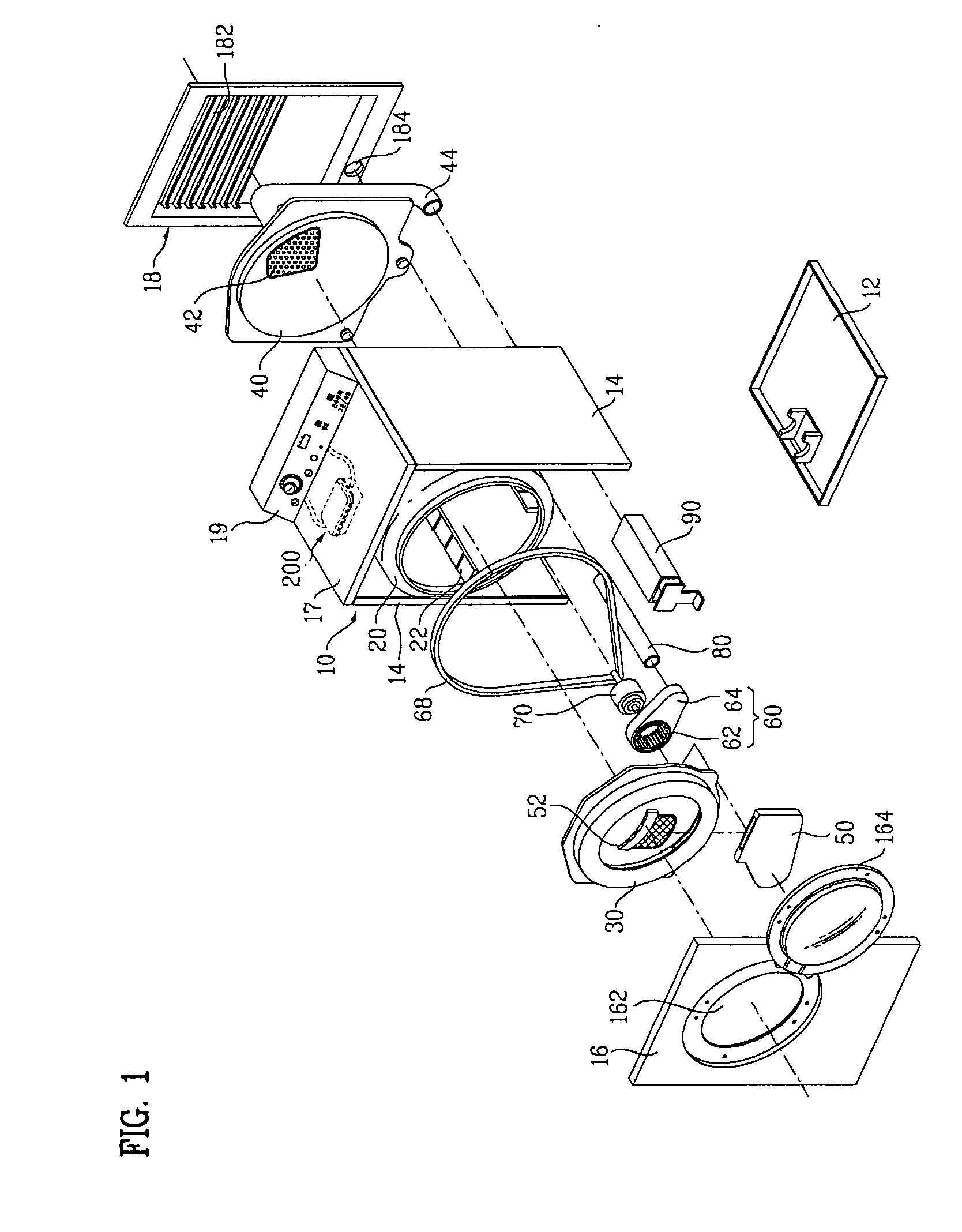

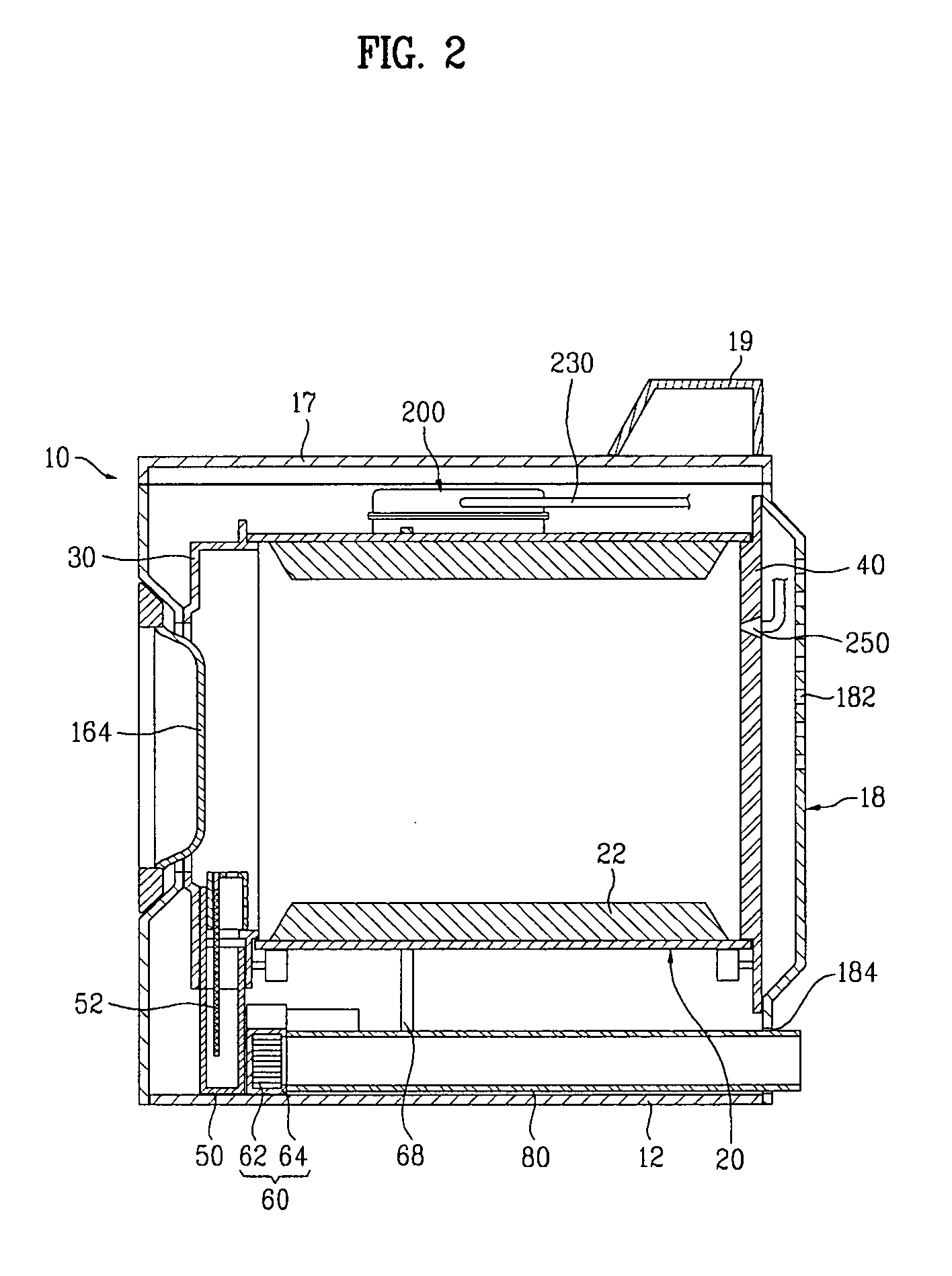

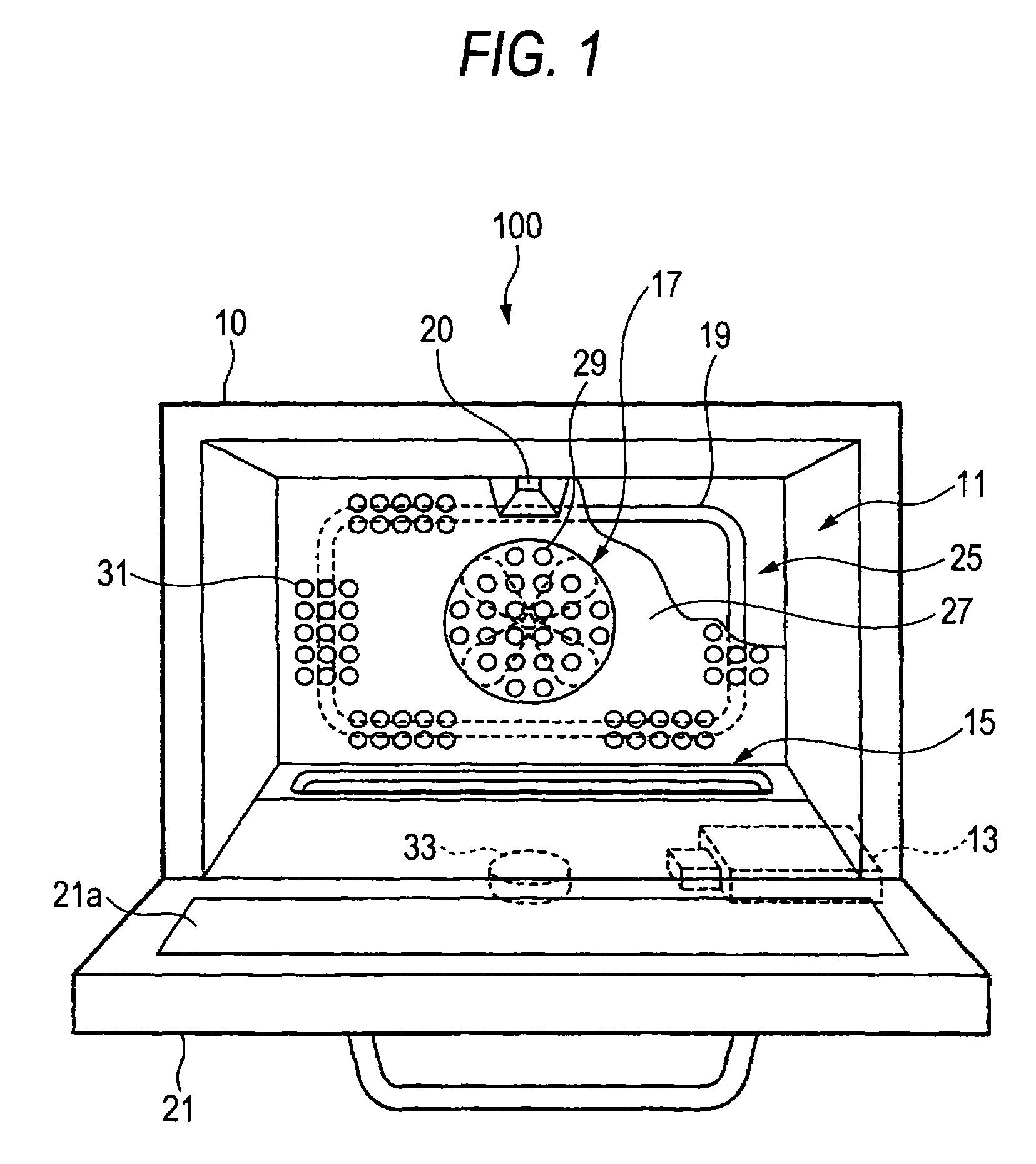

Cooking appliance

ActiveUS8695487B2Simple structureLow costDomestic stoves or rangesBaking ovenEngineeringSteam generation

Disclosed is a cooking appliance provided with: a water tank (30) disposed inside a main case (10); a steam-generation device (40) that generates steam by heating water supplied from the water tank (30); a heating chamber (20) to which steam from the steam-generation device (40) is supplied; an exhaust duct (72), provided inside the main case (10), for expelling exhaust from inside the heating chamber (20) to outside the main case (10); an exhaust temperature sensor (74) that measures the temperature of the exhaust air inside the exhaust duct (72); and a steam-generation decision unit that, upon cooking in which steam is supplied from the steam-generation unit (40) into the heating chamber (20), uses information on a physical quantity (the exhaust temperature measured by the exhaust temperature sensor (74)), which indirectly indicates whether there is water in the steam-generation device (40), to decide whether or not to halt steam generation, including the case in which the water tank (30) is out of water.

Owner:SHARP KK

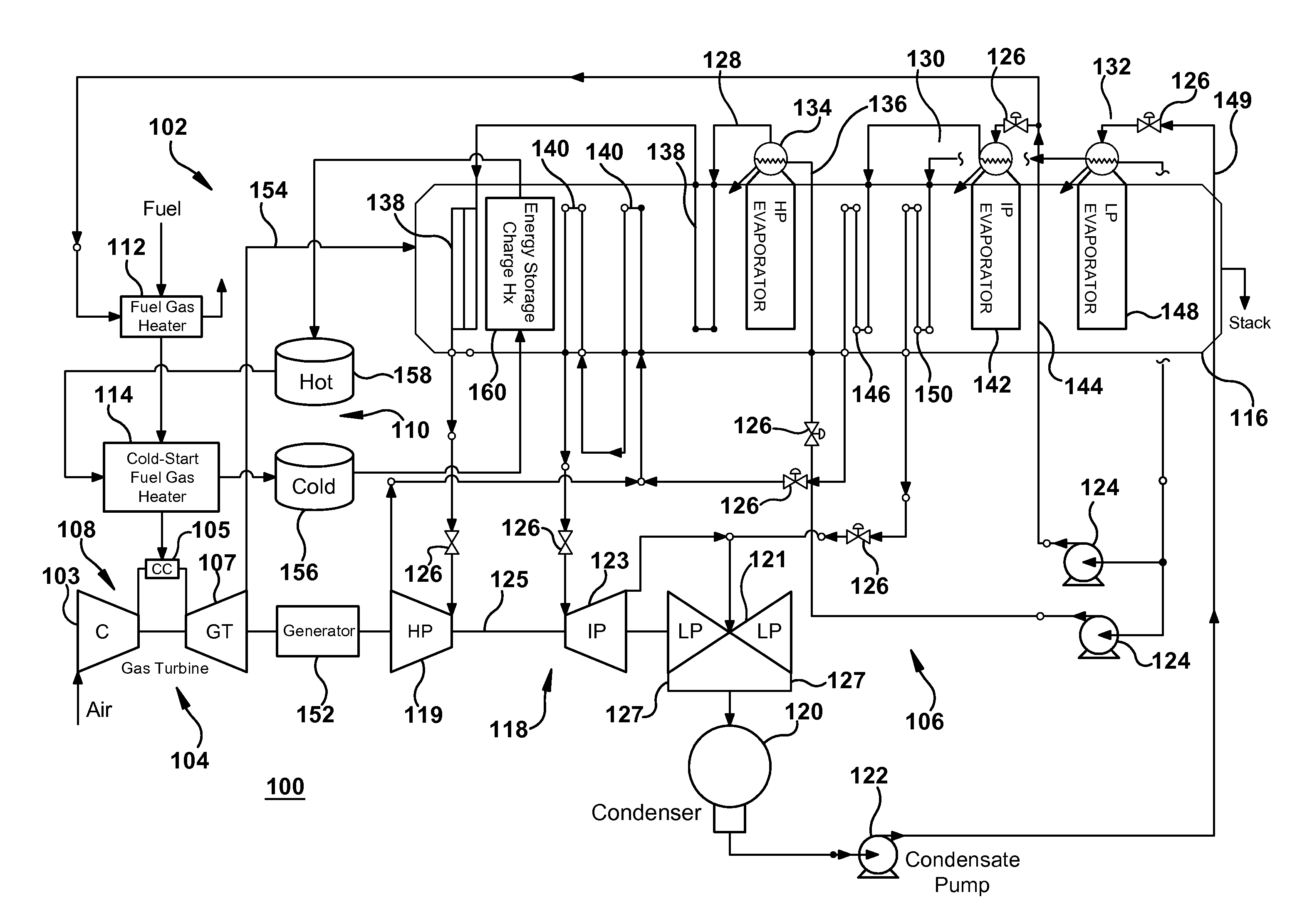

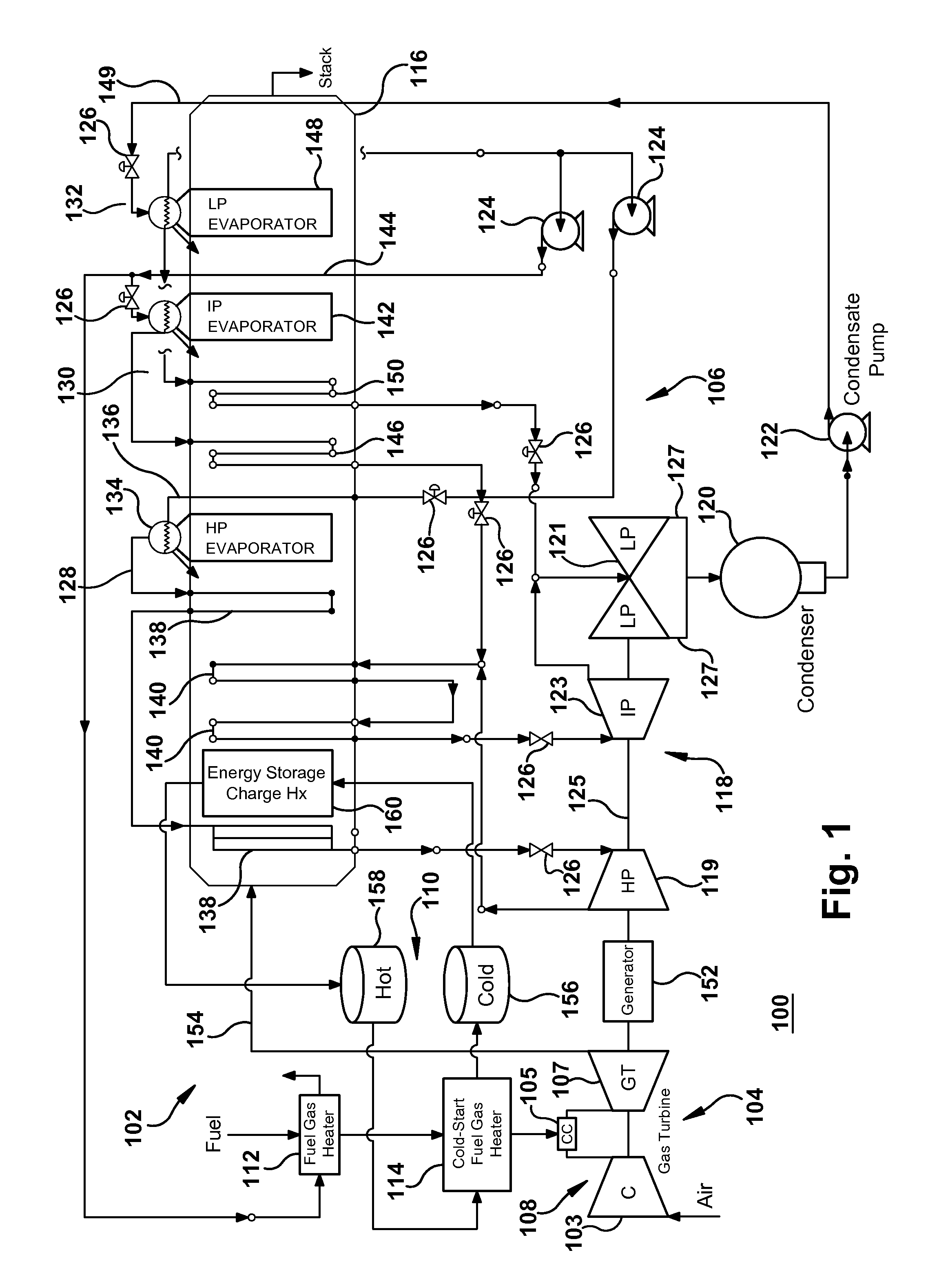

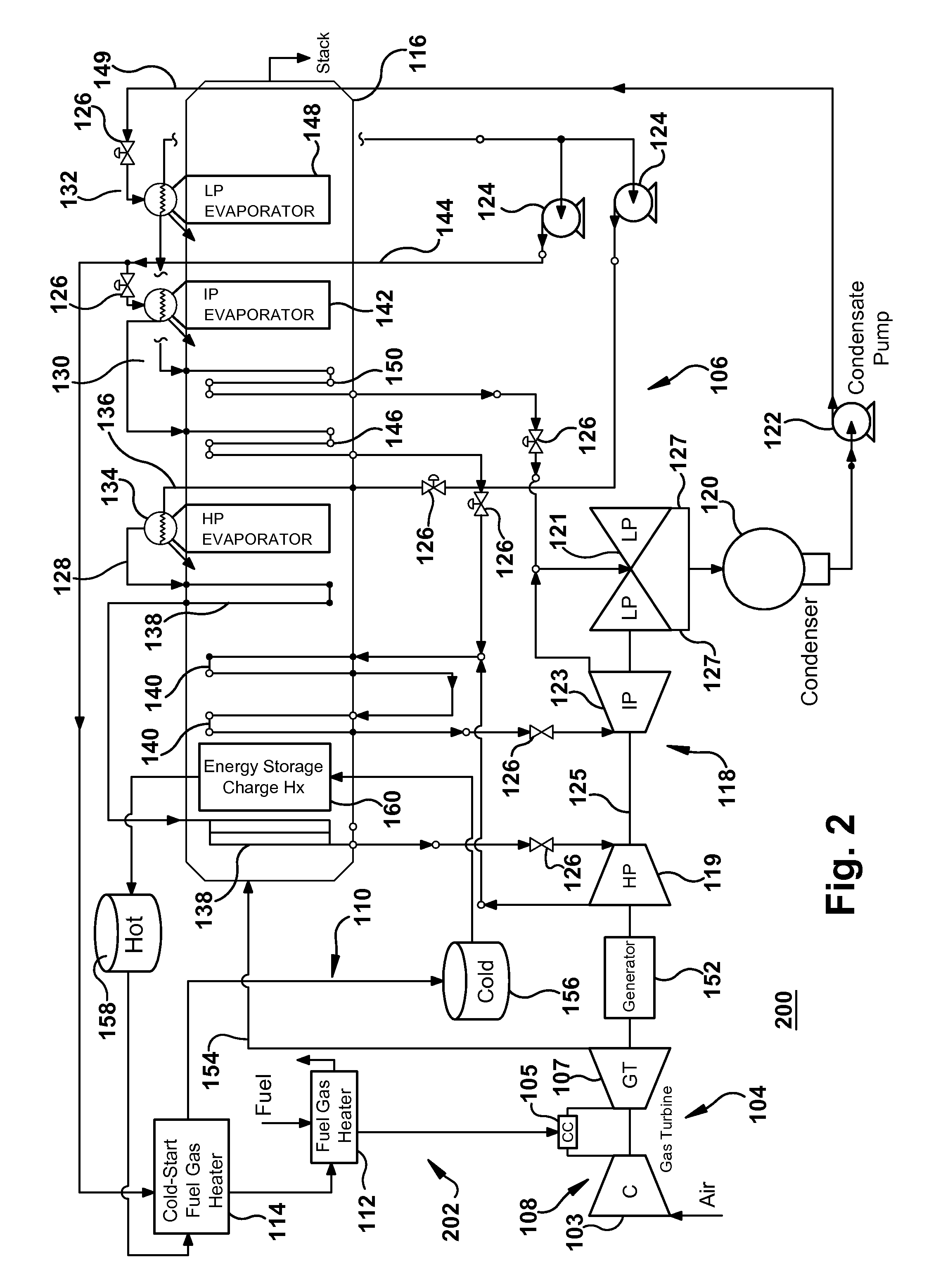

Fuel gas heating with thermal energy storage

Thermal energy storage containing thermal energy extracted from a bottom cycle heat engine is leveraged to heat fuel gas supplied to a gas turbine engine operating in a top cycle heat engine. Further, an extracted portion of a working fluid generated in a steam generation source of the bottom cycle heat engine can be used along with the thermal energy storage to heat fuel gas.

Owner:GENERAL ELECTRIC CO

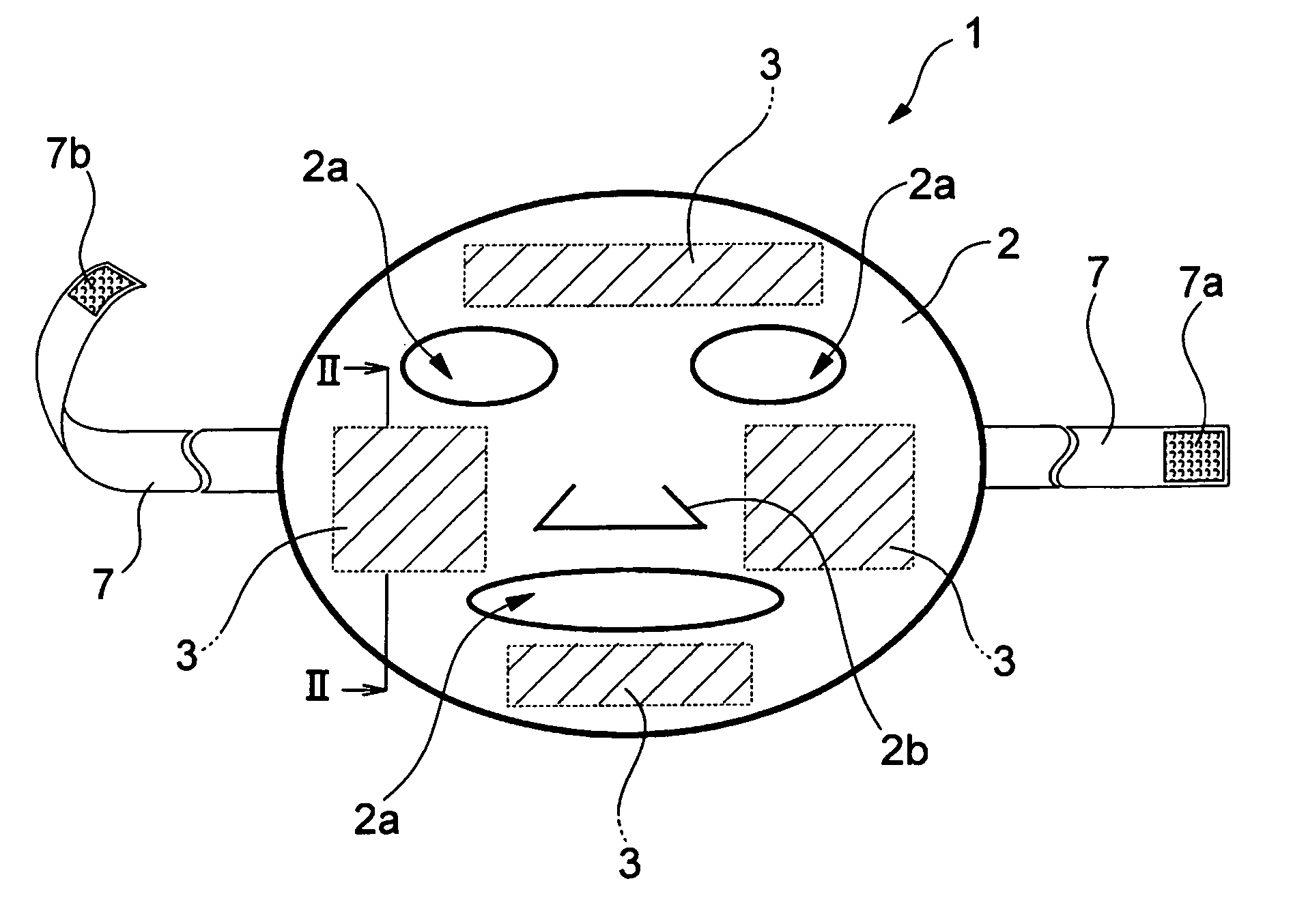

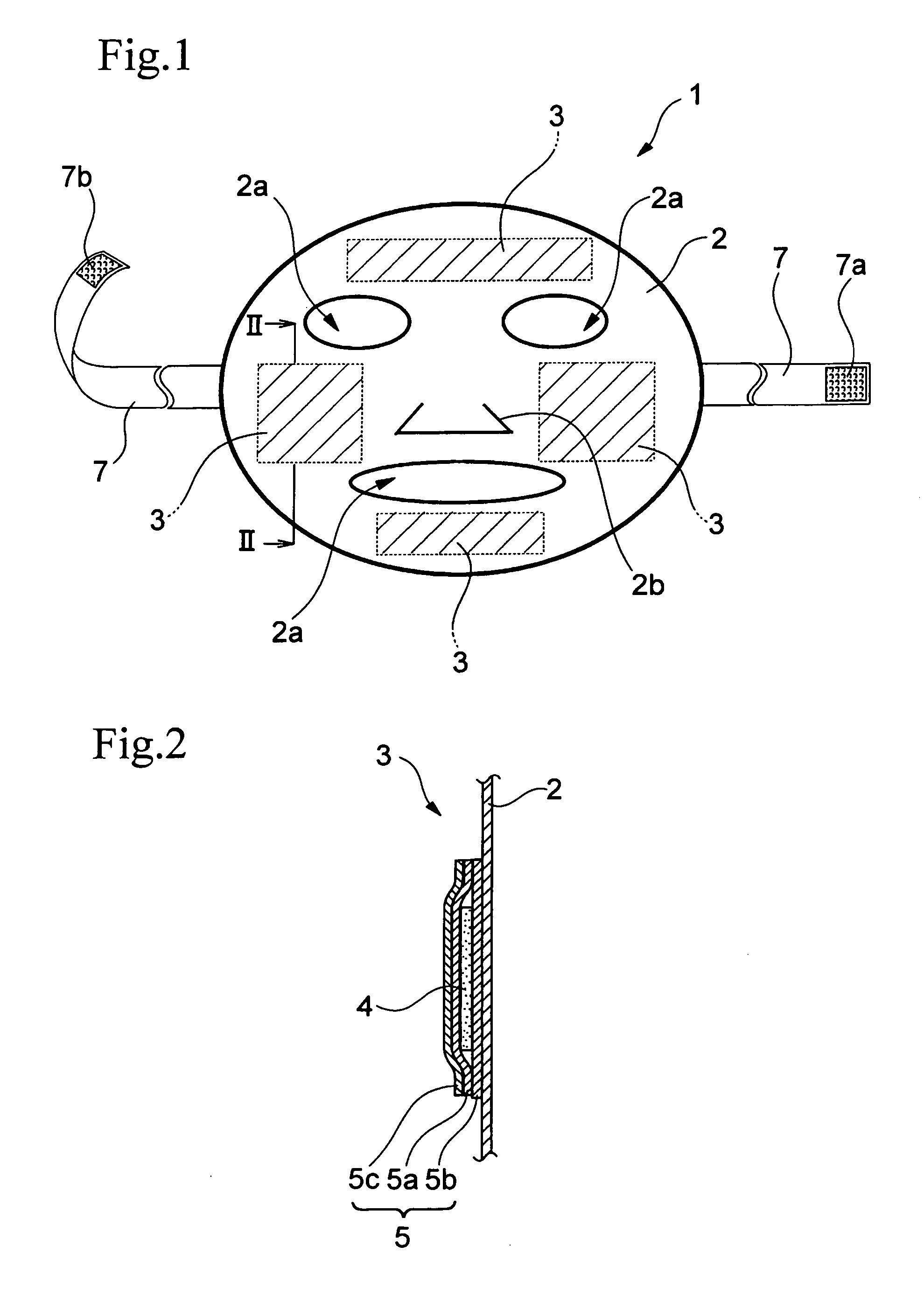

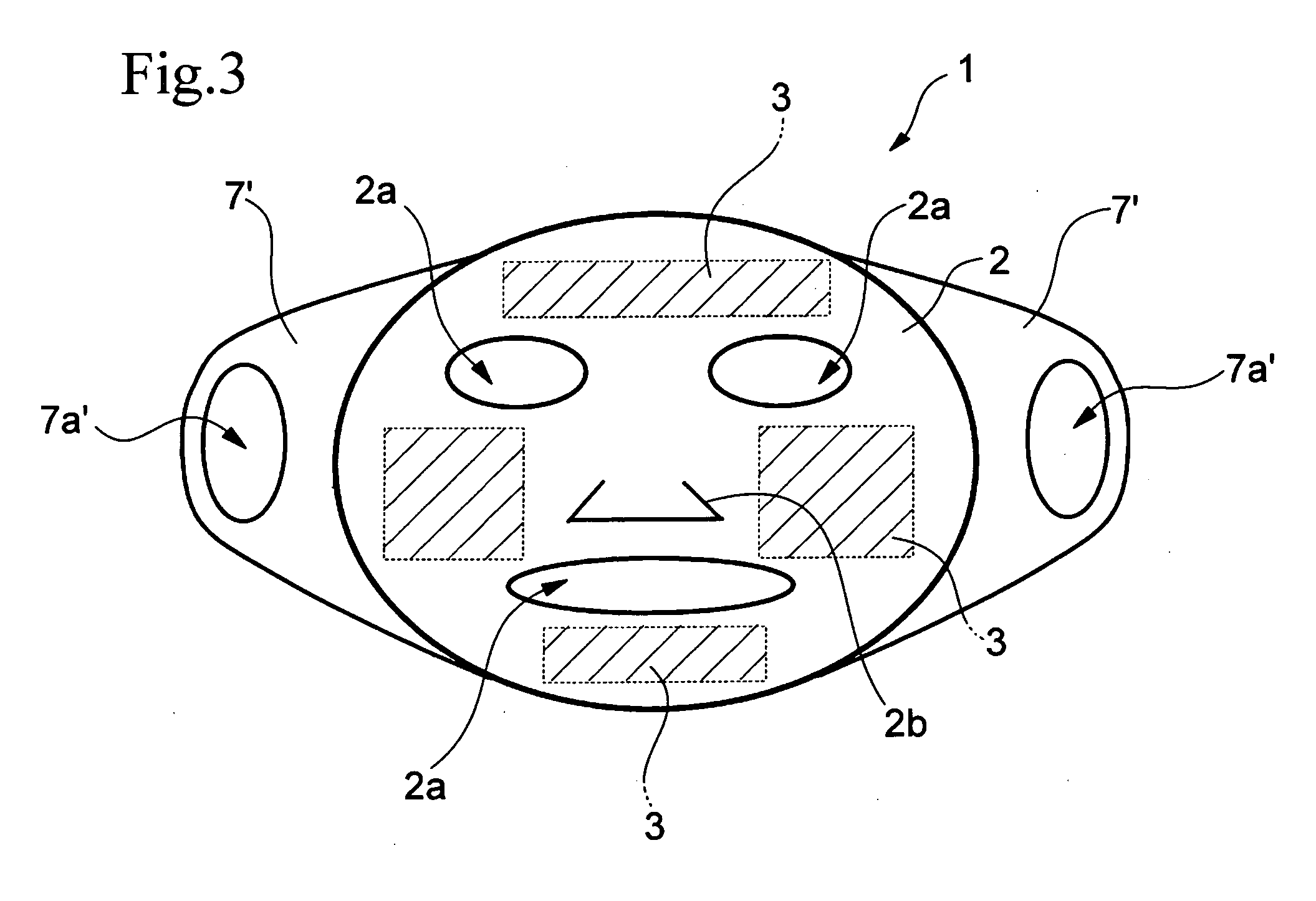

Heat-generative, steam generation sheet for face

A heat-generative, steam generation facial sheet that is planar and is adapted to cover a part or the whole of a wearer's face in intimate contact. It has a planar heat generator capable of generating steam upon contact with oxygen in such a manner that the skin surface temperature reaches 34° C. or higher within 120 seconds from the contact with air and the skin surface temperature is maintained at 34° C. or higher for at least 5 minutes.

Owner:KAO CORP

Split flow process and apparatus

An acid gas removal plant includes an absorber that provides a rich solvent to two regenerators that independently generate a lean and a semi-lean solvent, wherein the semi-lean solvent is produced in one of the regenerators using heat and / or steam derived from the other regenerator. Further heat integration is particularly contemplated with power plants in which the power plant provides high-level heat to the acid gas removal plant and wherein the power plant receives low-level heat from the acid gas removal plant.

Owner:FLUOR TECH CORP

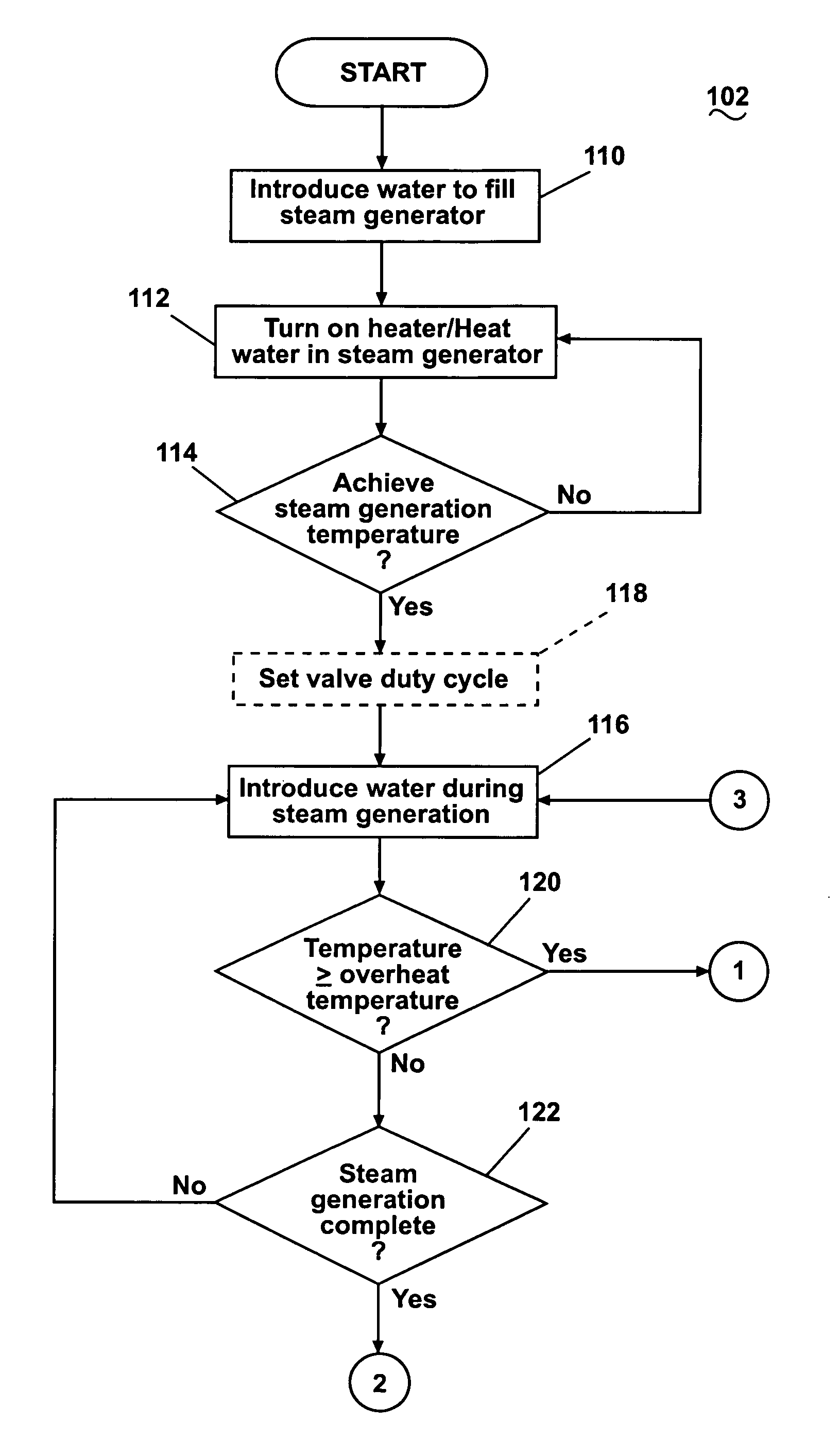

Draining liquid from a steam generator of a fabric treatment appliance

InactiveUS20070283509A1Other washing machinesCleaning using liquidsNuclear engineeringSteam generation

A method of operating a fabric treatment appliance comprises a steam generation step and, after the completion of the steam generation step, a draining step comprising draining liquid remaining in a chamber of the steam generator to a tub of the fabric treatment appliance. The steam generator in one embodiment can comprise the chamber, an inlet configured to introduce liquid into the chamber, an outlet configured to exhaust steam from the chamber, and a drain coupling the chamber to the tub and configured to drain liquid from the chamber to the tub.

Owner:WHIRLPOOL CORP

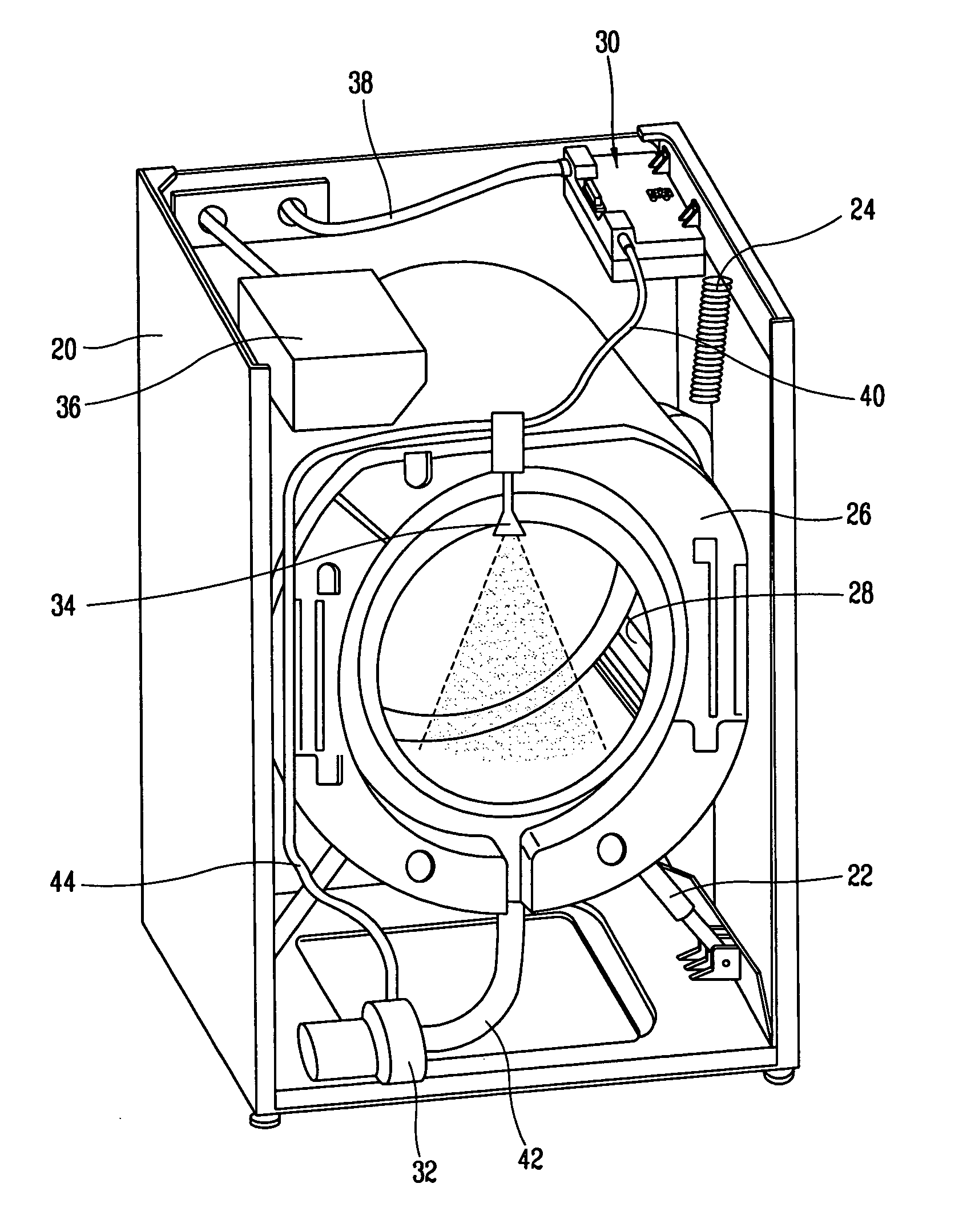

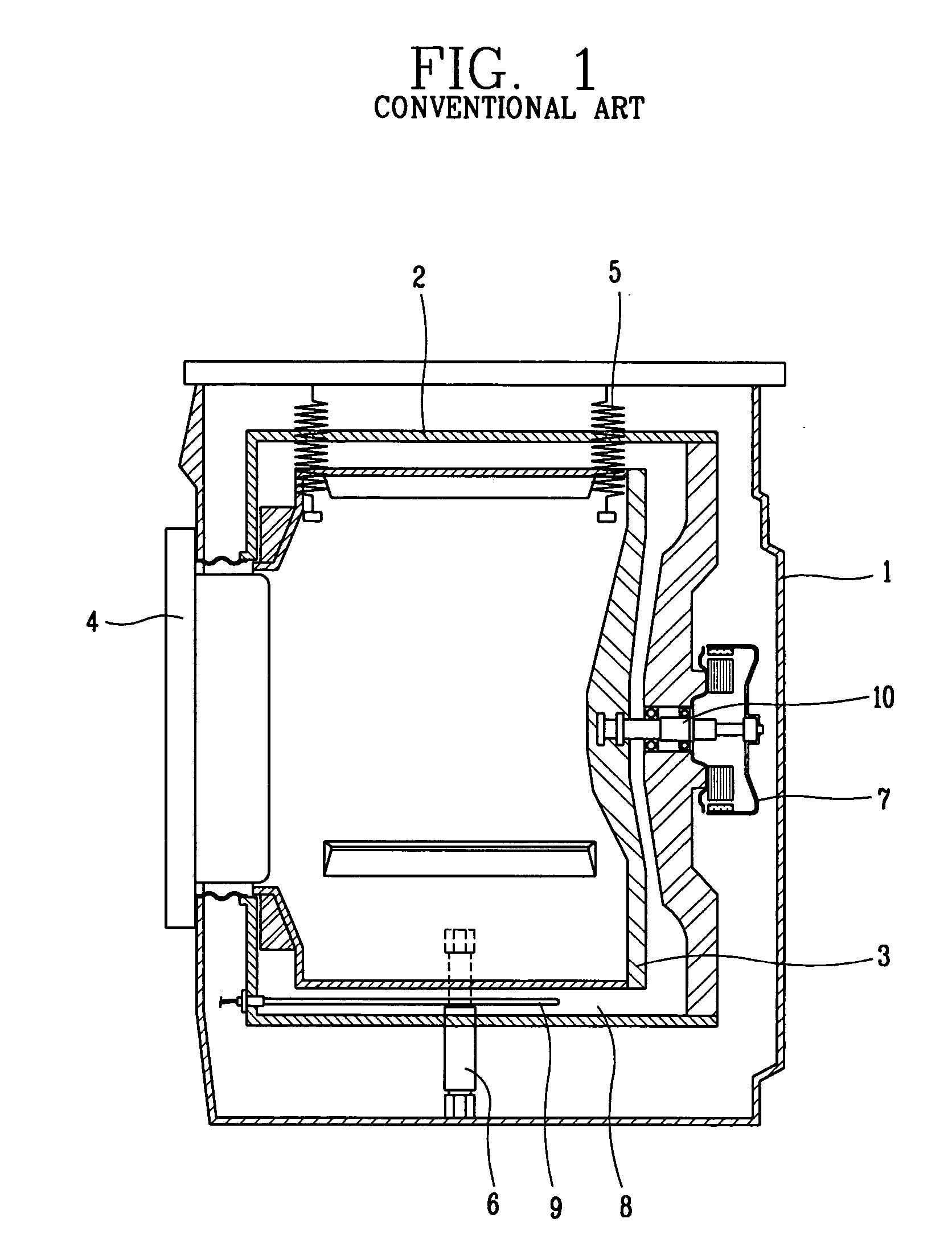

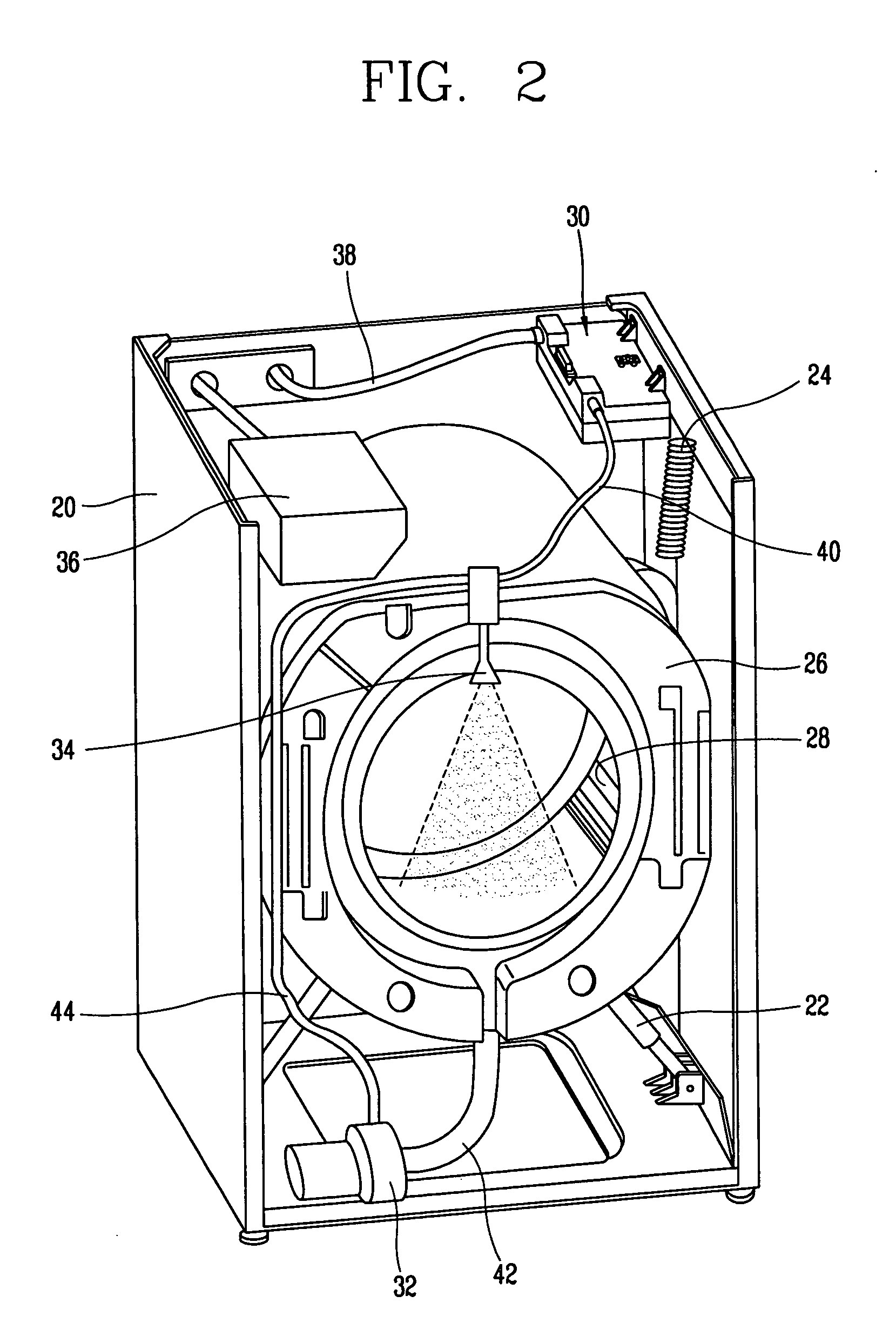

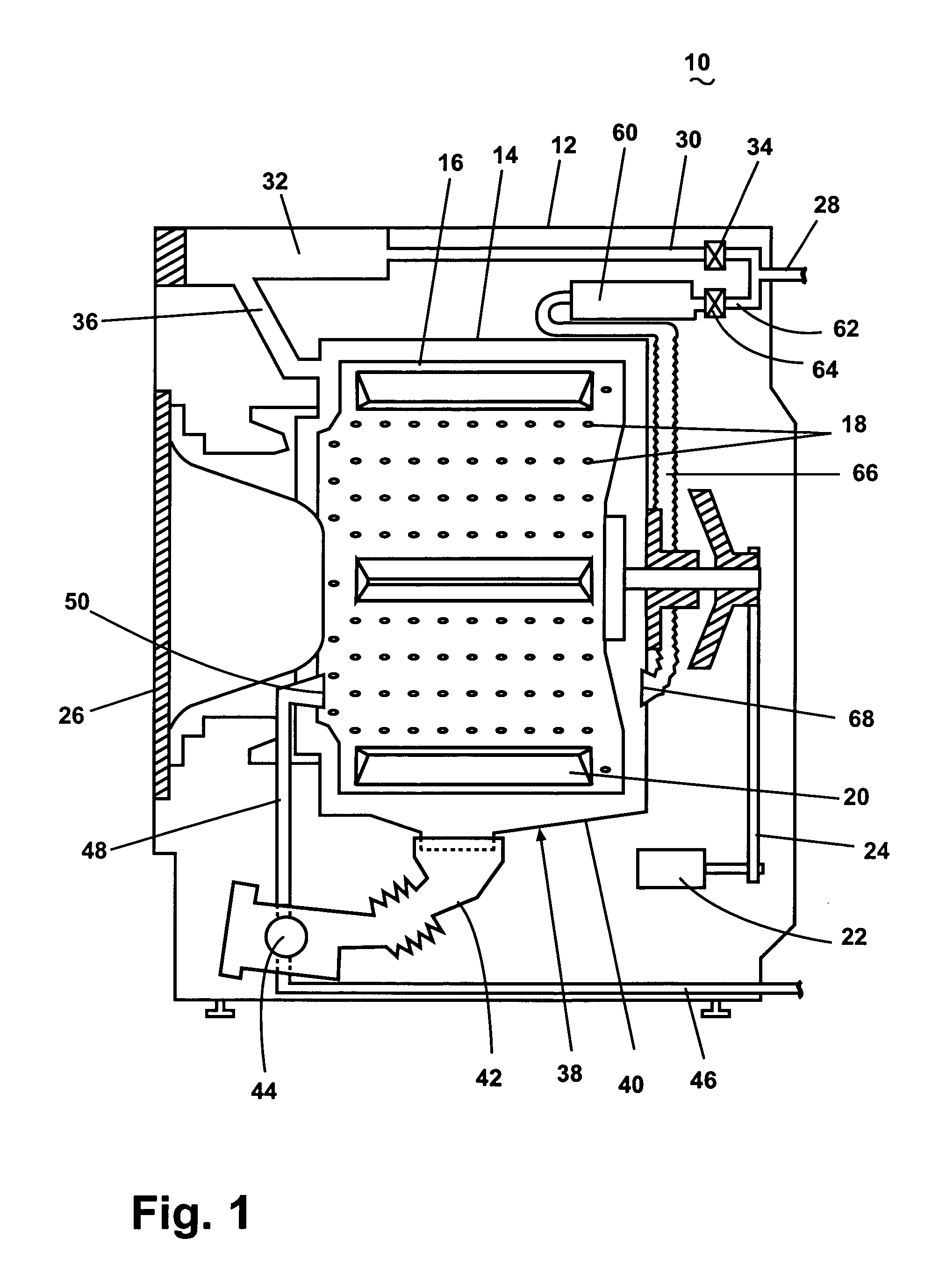

Steam generation apparatus for washing machine

ActiveUS20060010937A1Reduce the amount requiredSmall sizeOther washing machinesControl devices for washing apparatusEngineeringWater level

A steam generation apparatus for a washing machine includes: a case having an accommodating space for storing water; a heater disposed inside the case to heat the water stored in the case; and a heater overheating prevention unit for cutting off power of the heater when the heater is overheated above the set temperature, so that a fire and deflection of a case can be prevented by preventing overheating of the heater by cutting off power being supplied to the heater when the heater is overheated due to malfunctions of a water level sensor or a clogged spray nozzle or a clogged flow passage.

Owner:LG ELECTRONICS INC

Dryer

ActiveUS20090113745A1Improve user convenienceEliminate wrinklesTextile treatment machine partsDrying gas arrangementsProcess engineeringSteam generation

A laundry machine, more particularly, a dryer is disclosed. A dryer includes a cabinet, a drum in which a drying object is held, a steam generation device to supply steam to the drum, a water supply device to supply water to the steam generation device in order to generate steam, an additive holding part in which an additive is held, and an additive supply device to supply the additive held in the additive holding part to the drum.

Owner:LG ELECTRONICS INC

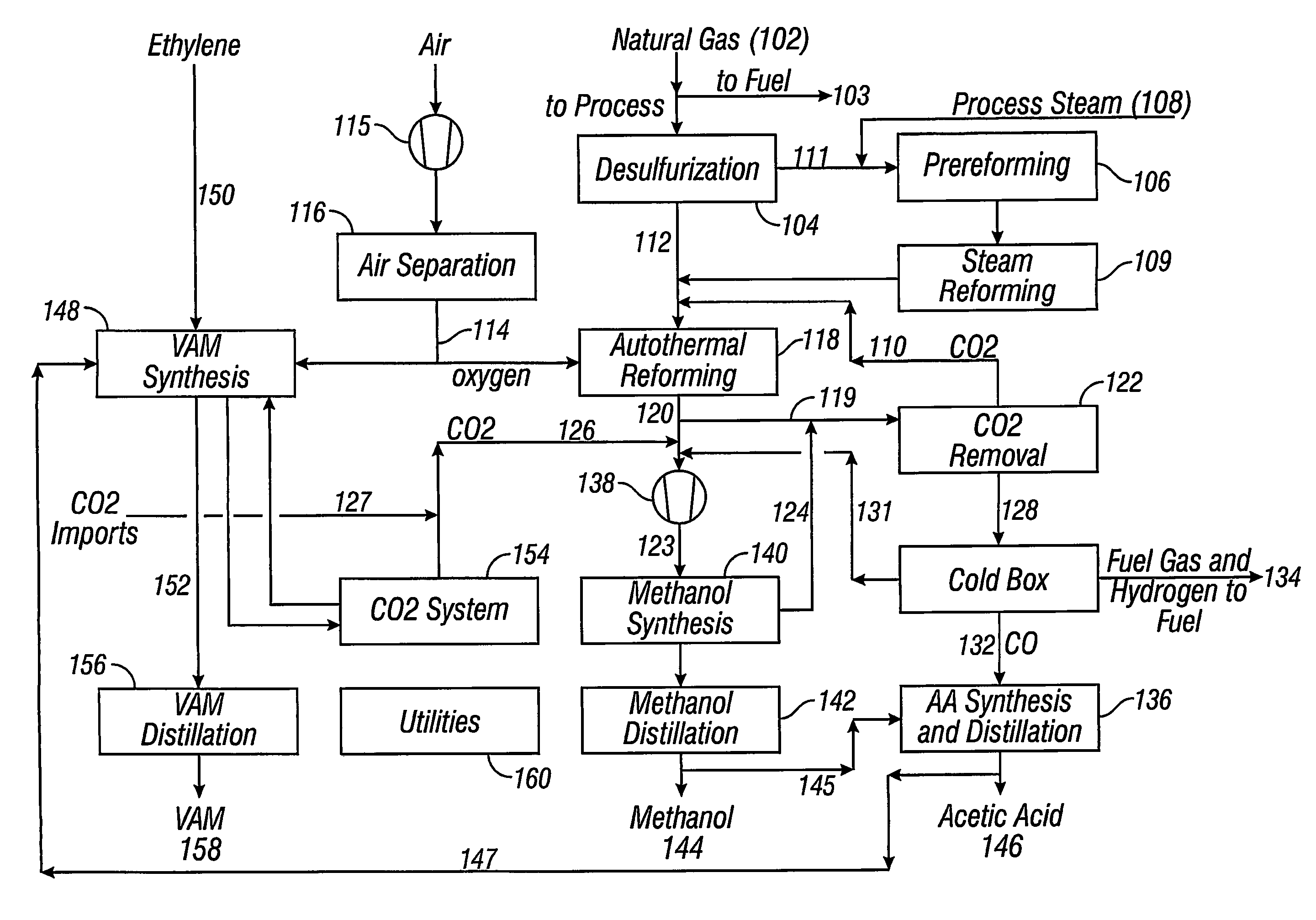

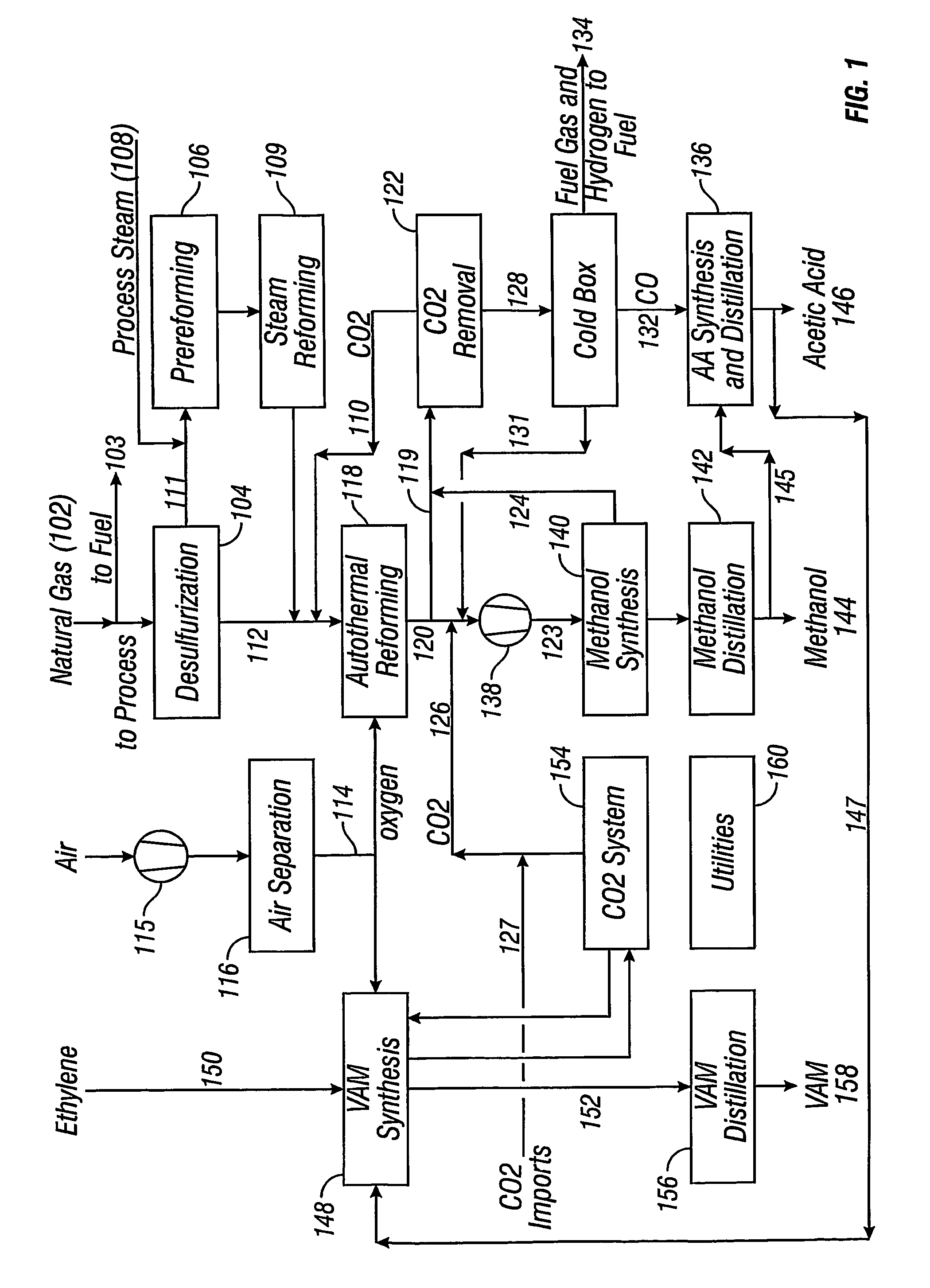

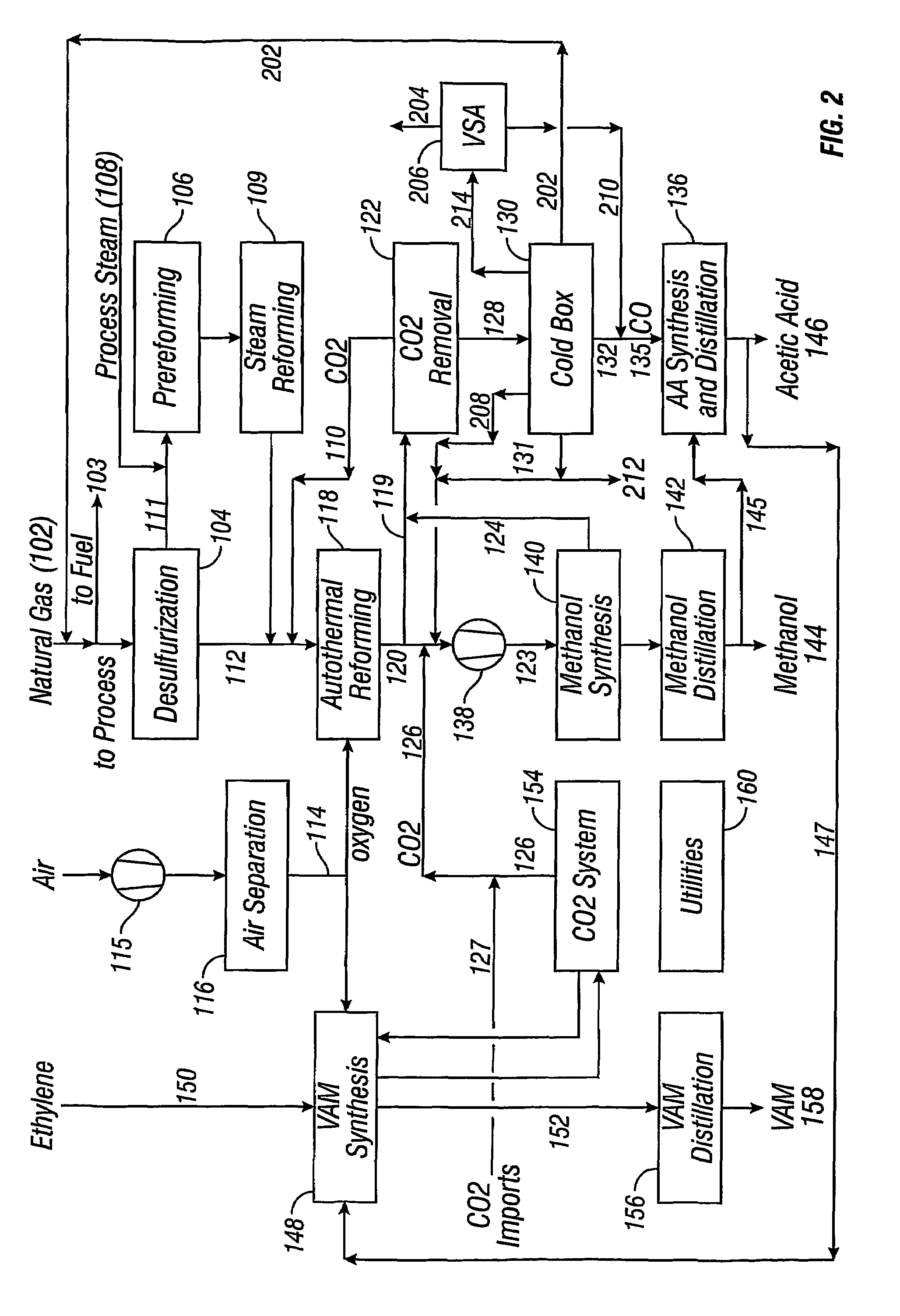

Integrated process for acetic acid and methanol

InactiveUS7470811B2Improve matchIncrease productionOrganic compound preparationCarboxylic acid esters preparationSteam reformingCo2 removal

Owner:ACETEX

Removal of scale and sludge in a steam generator of a fabric treatment appliance

ActiveUS20070283505A1Other washing machinesLiquid/gas/vapor textile treatmentNuclear engineeringSludge

A method of operating a fabric treatment appliance comprises a steam generation step and a steam generator cleaning step. In the steam generator cleaning step, a chamber of the steam generator can be flushed by introducing a volume of liquid into the chamber greater than the internal volume. The steam generator cleaning step can also involve thermally shocking scale formed within the chamber.

Owner:WHIRLPOOL CORP

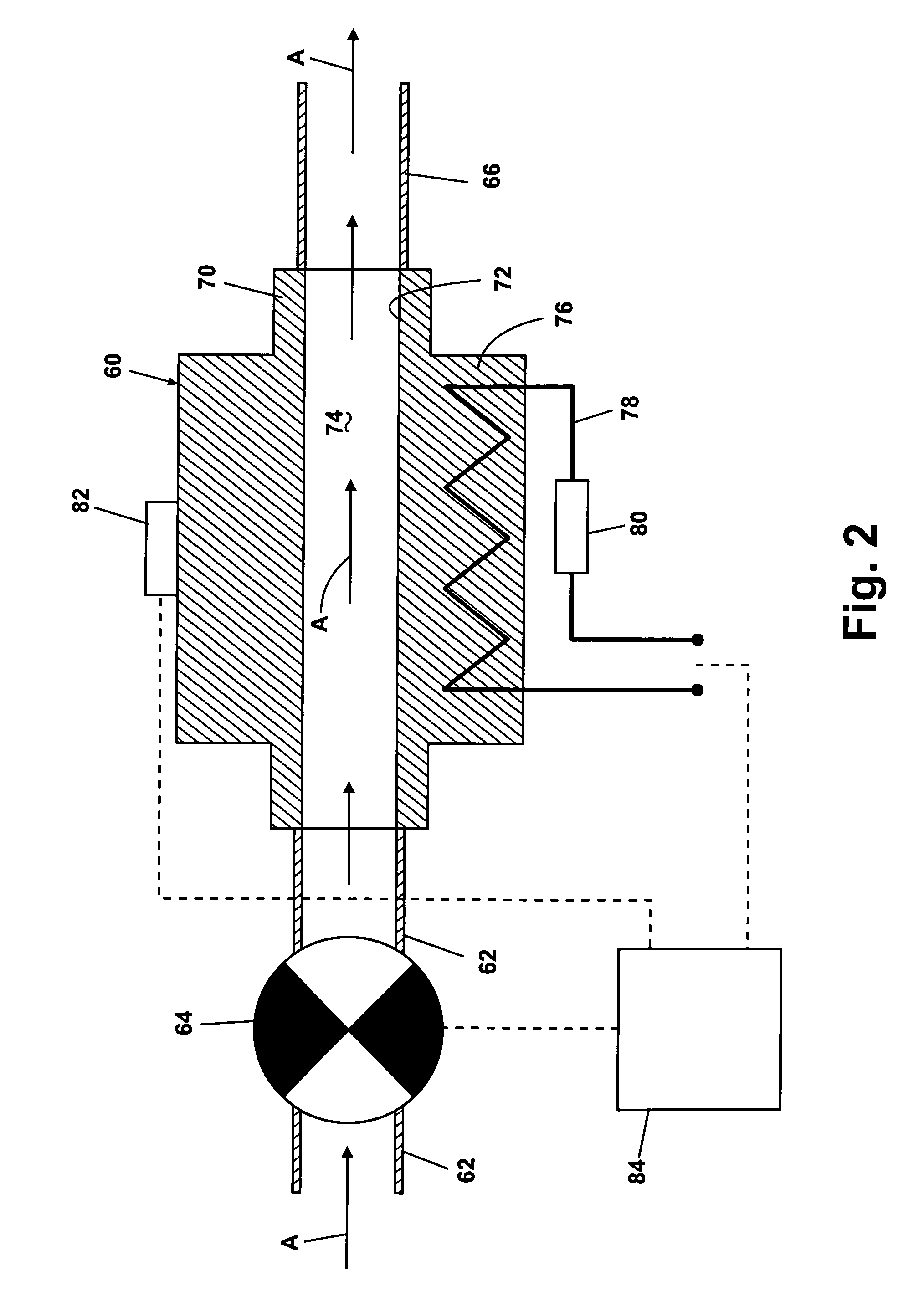

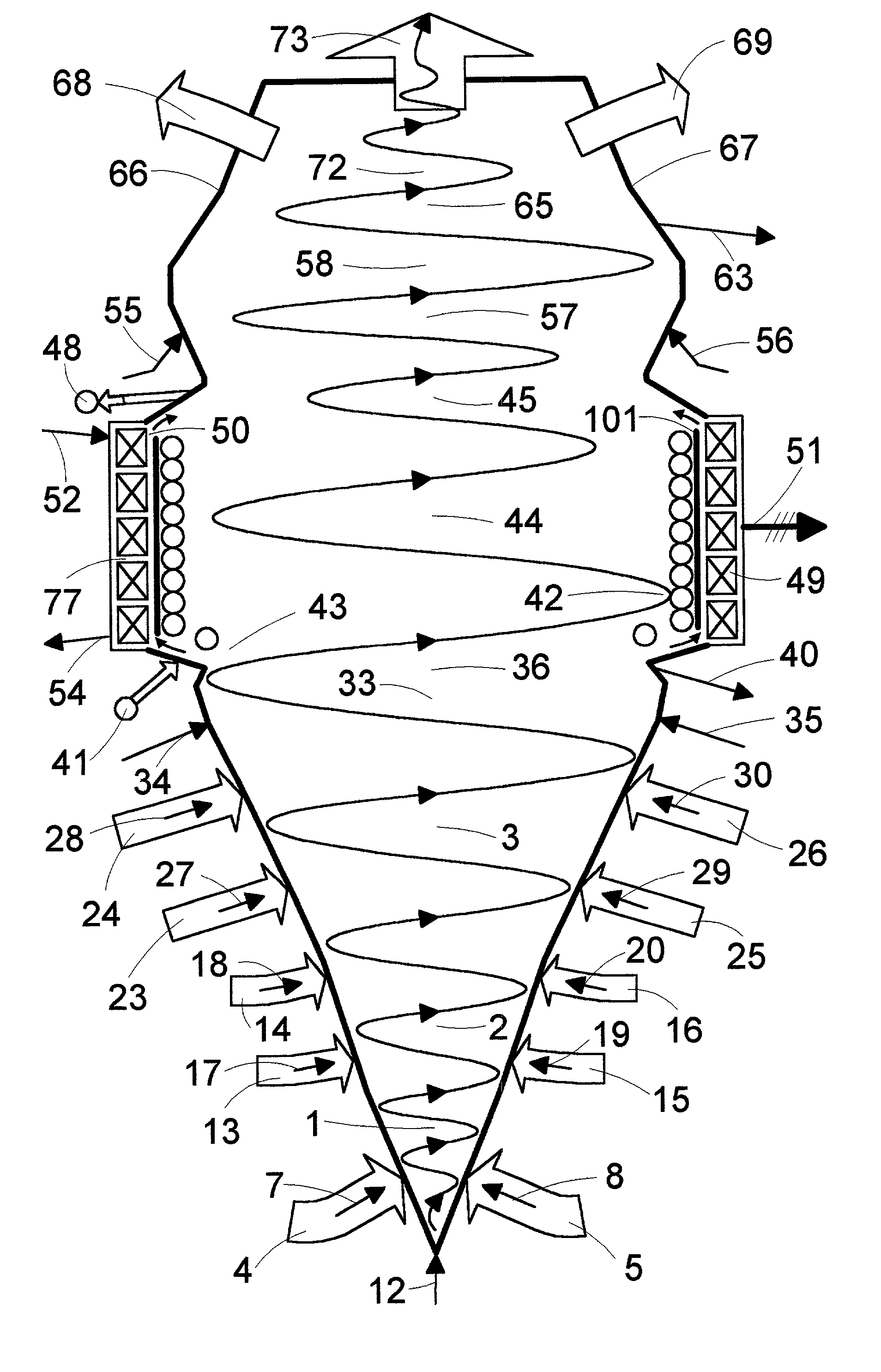

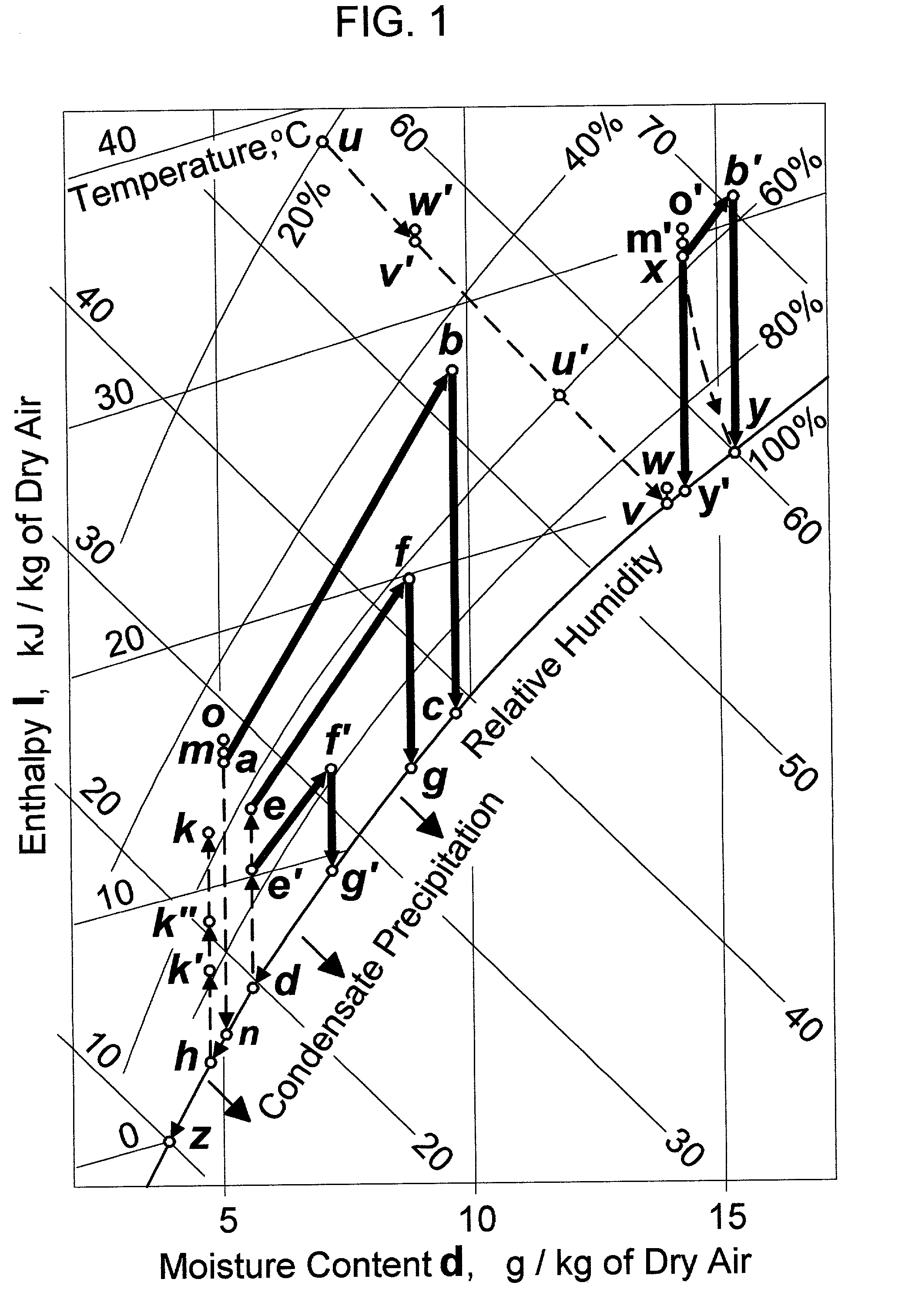

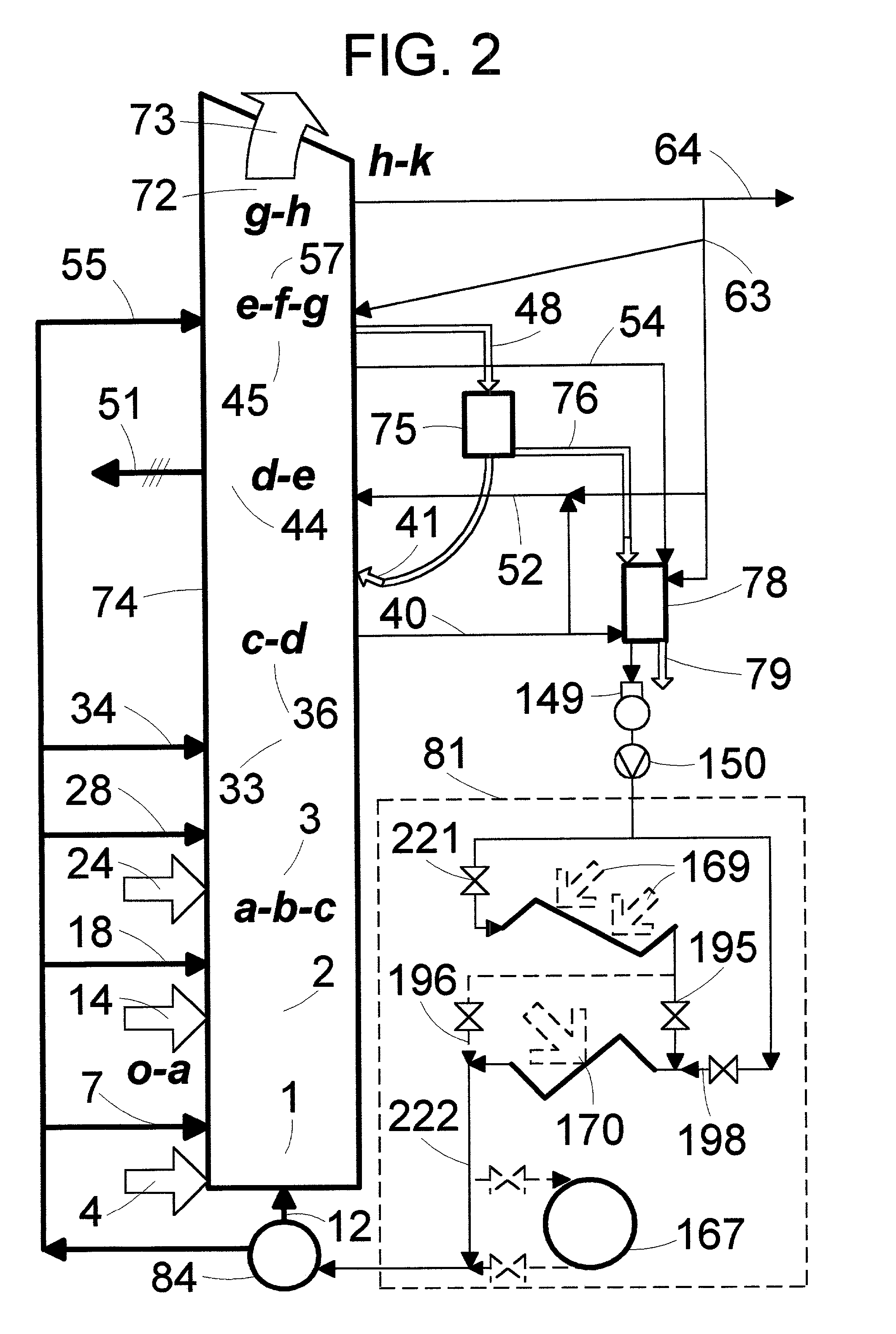

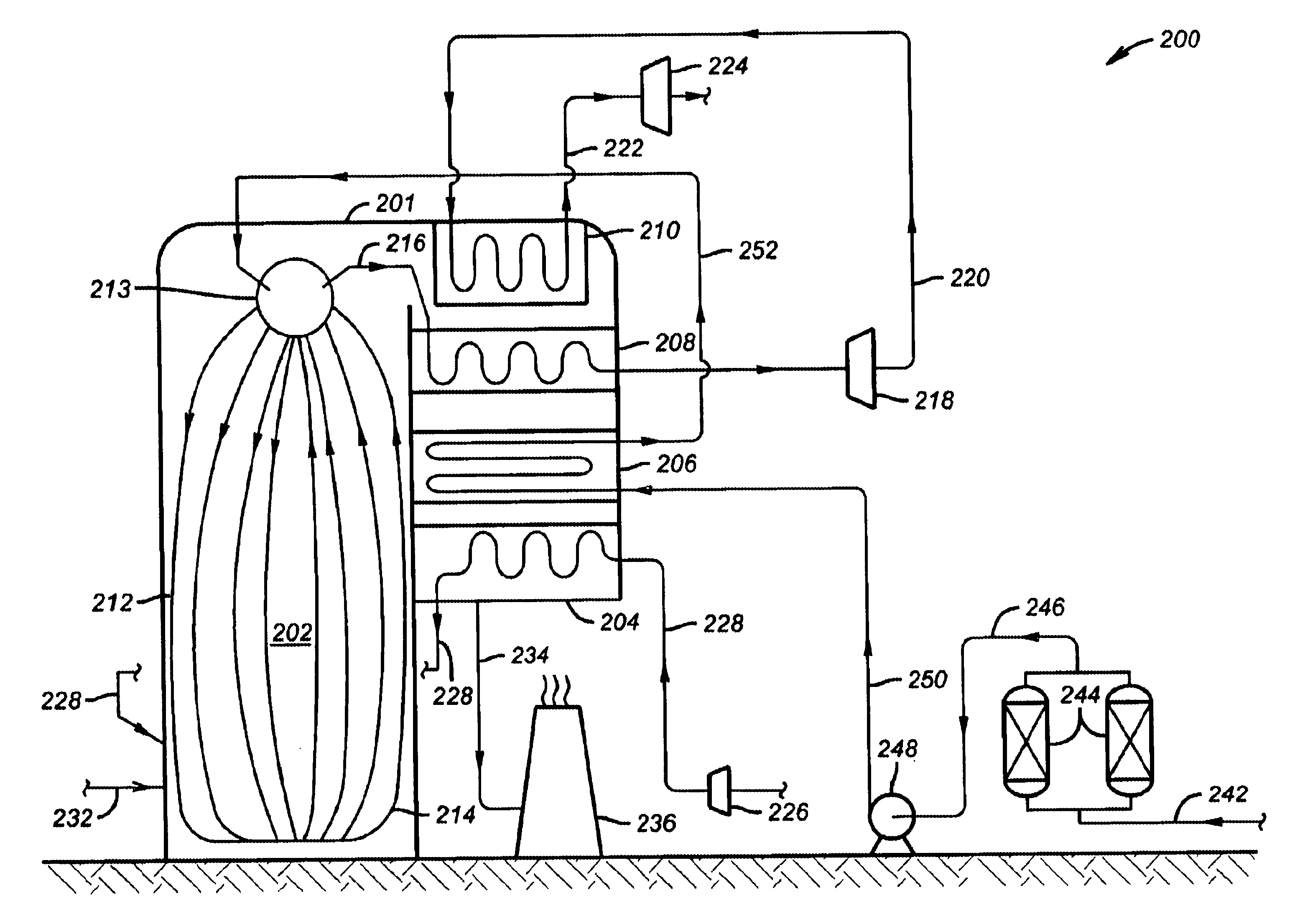

All-weather energy and water production via steam-enhanced vortex tower

InactiveUS20030201646A1Wind motor with solar radiationEngine fuctionsAtmospheric airWater production

The large-scale green power, pure chilled, heated water and / or conditioned directed air are produced using wind, heat and vapor of the free humid air in the structured multi-unit space-saving vortex tower providing direct three-phase voltage induction with alternating magnetic whirl formed by pole radial self-orienting magnetic concentrators swirled via all-weather multi-step tornado-like flow supplementary energized, enhanced and controlled by a spatial system of fast directing and accelerating low-temperature steam jets injected through fleshing of recycled, separated and stored condensate slightly heated with any renewable, waste, secondary, or prime source of low-temperature heat, partly via combining with solar pond and heaters or / and geothermal media, or / and waste, secondary or initial heat of large thermal, atomic power plant or intensively energy consuming industry, reducing specific investment, energy and pure water costs, quality requirements, specific pollution and waste heat atmospheric injection, with possibilities of partial local weather corrections through conditioned directed waste tower air; a new sector with various directions can be widened, based on applying of the same principles of energizing, enhancement, control and usage of any kind of fast gaseous confined vortex flow via any kind of supplementary low-temperature steam

Owner:KAPLOUN SOLOMON

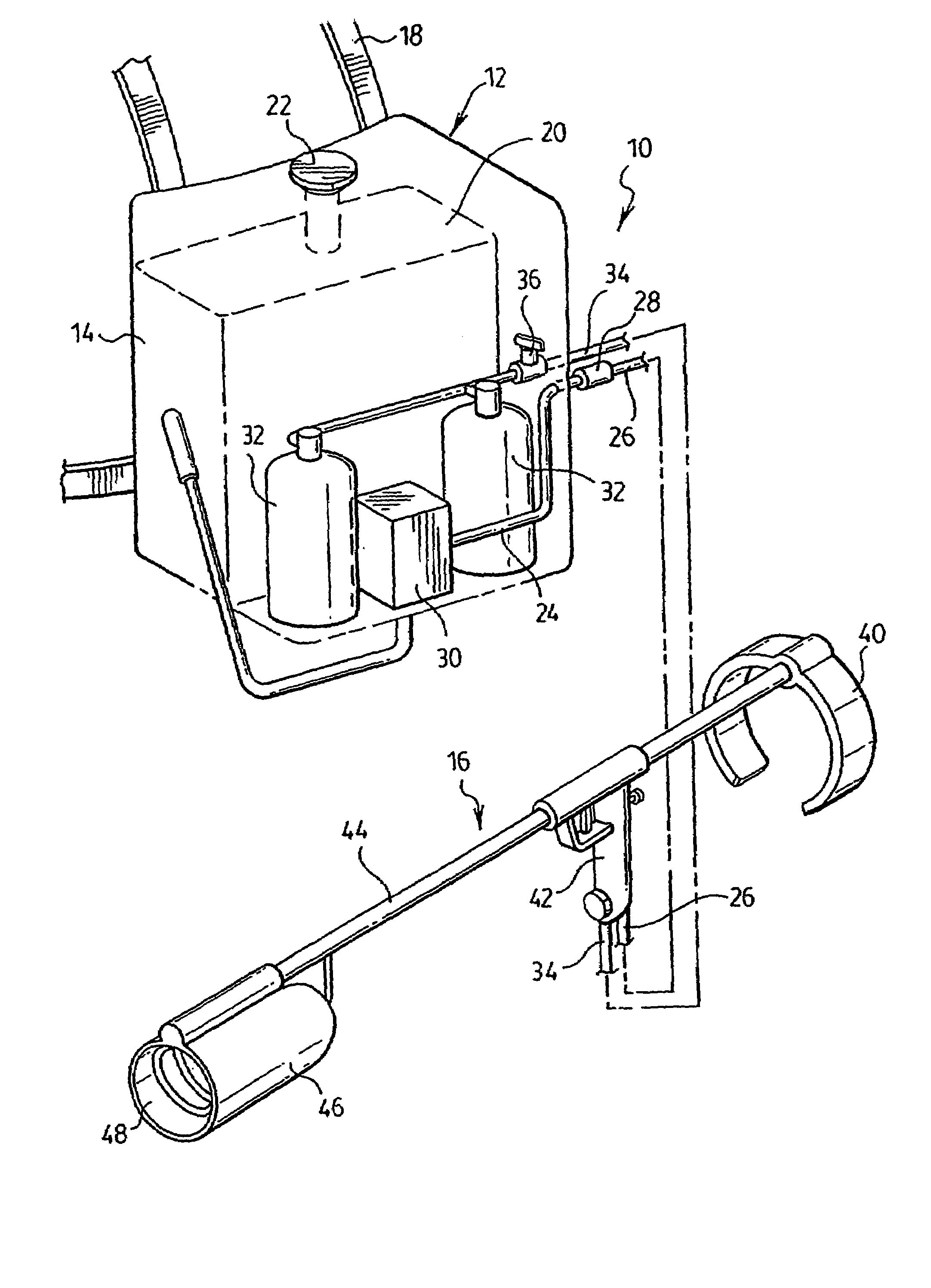

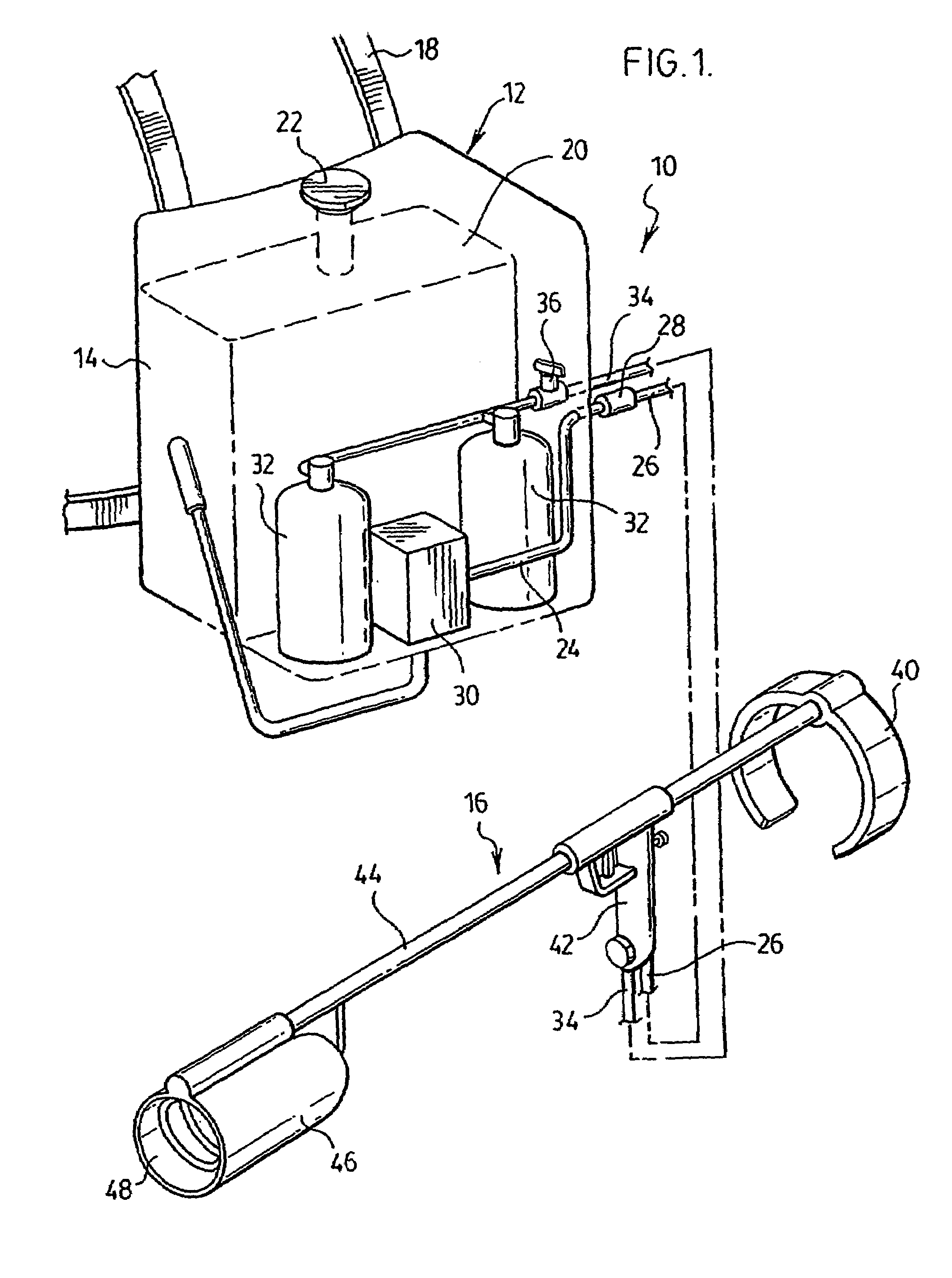

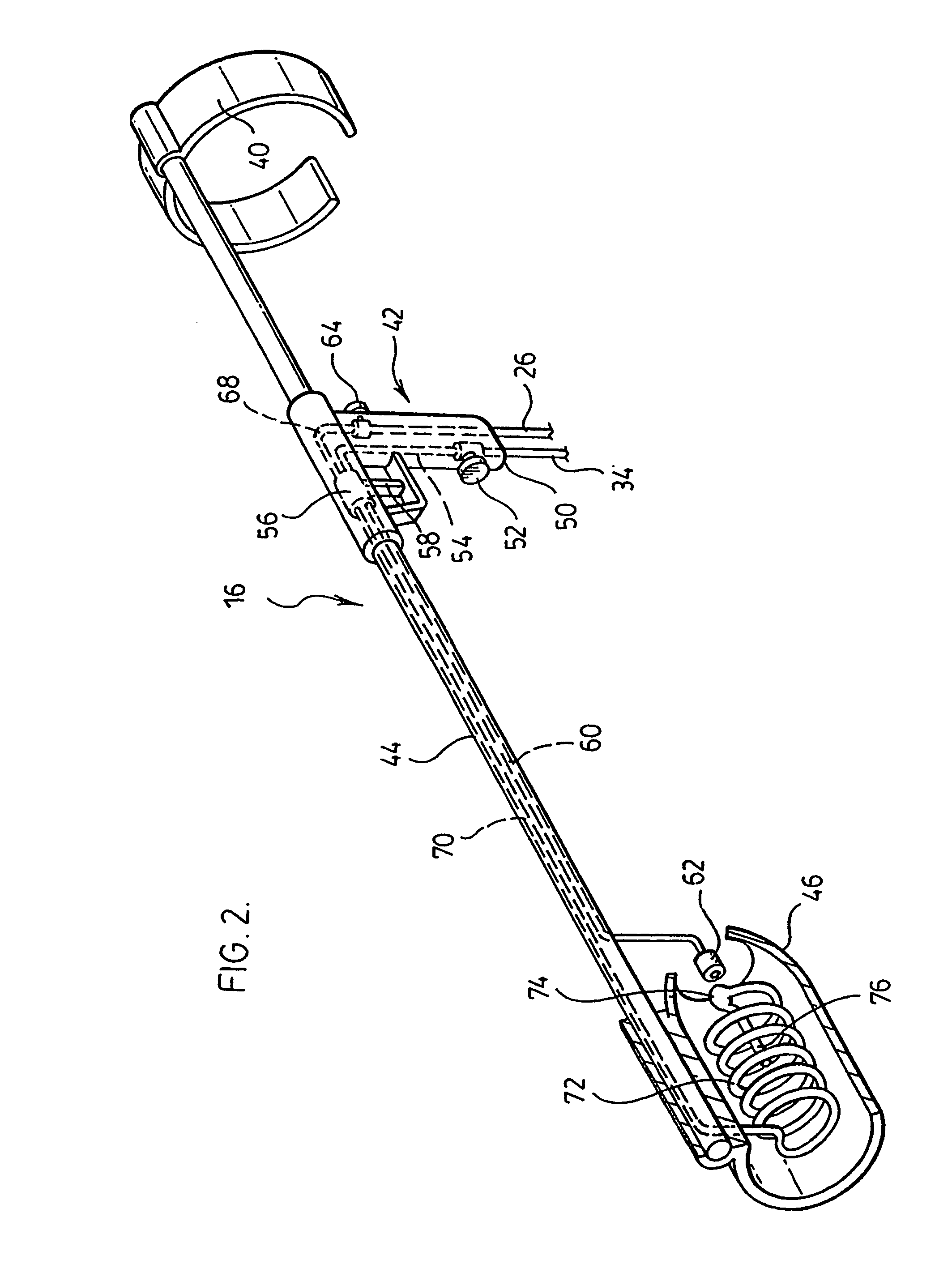

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

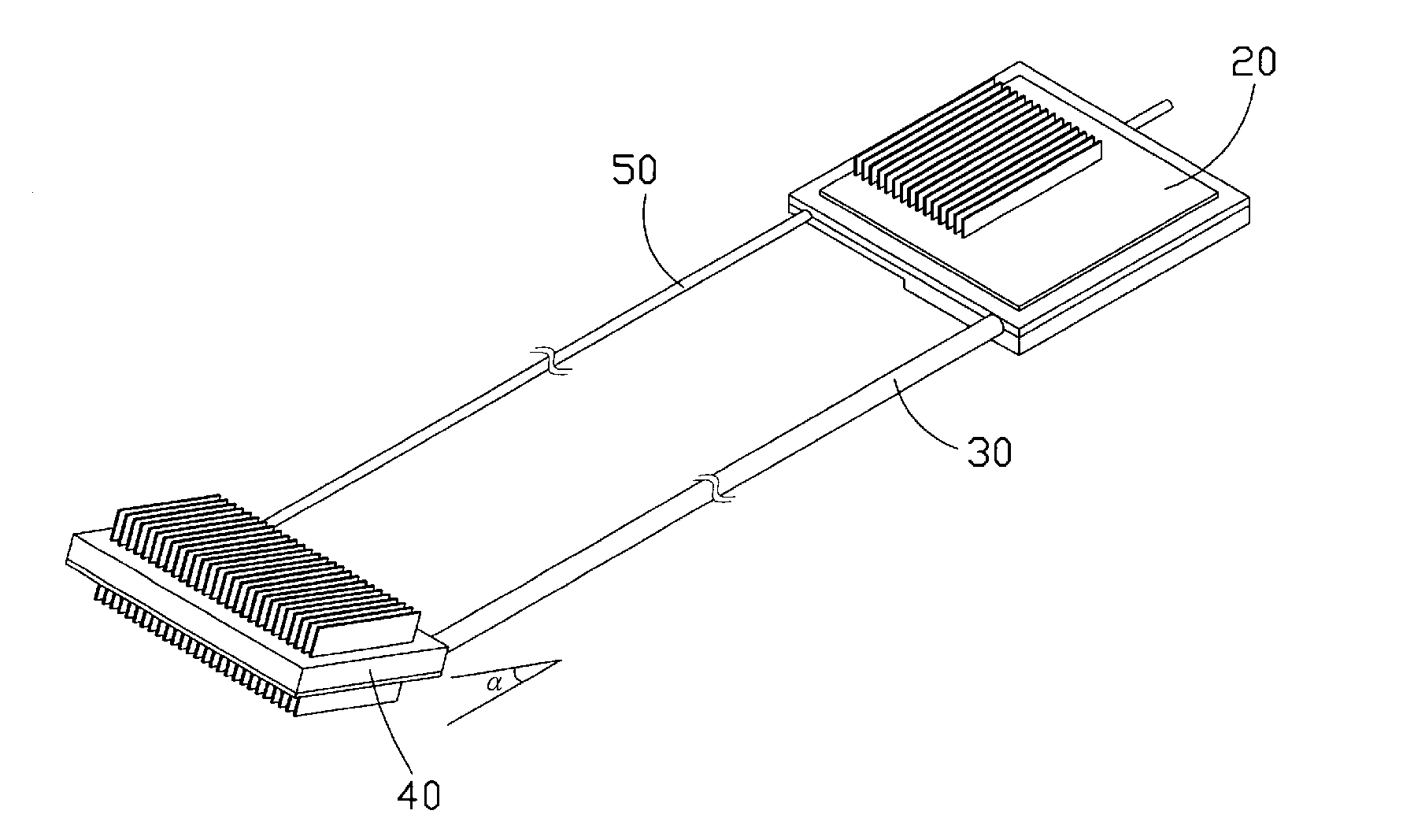

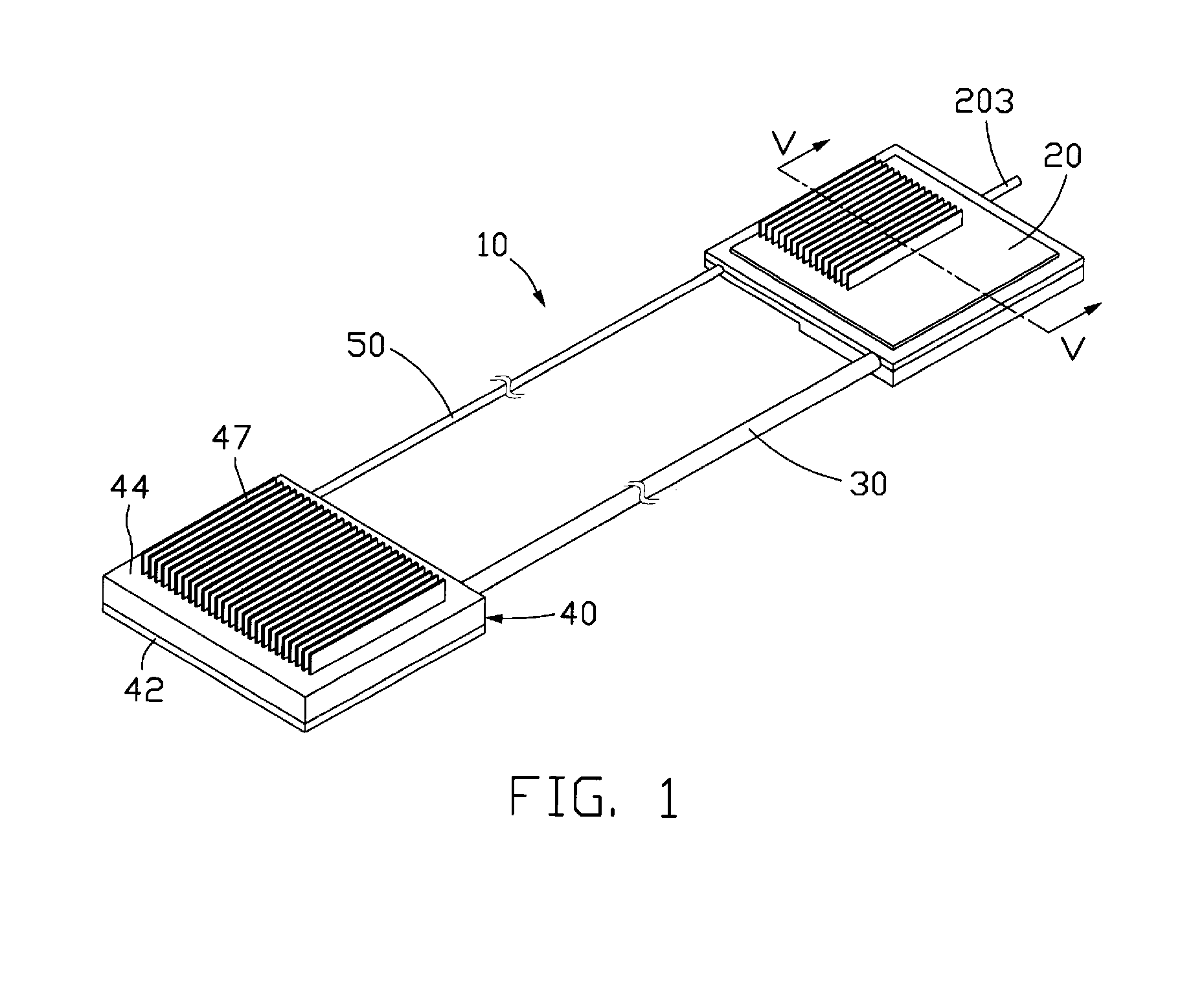

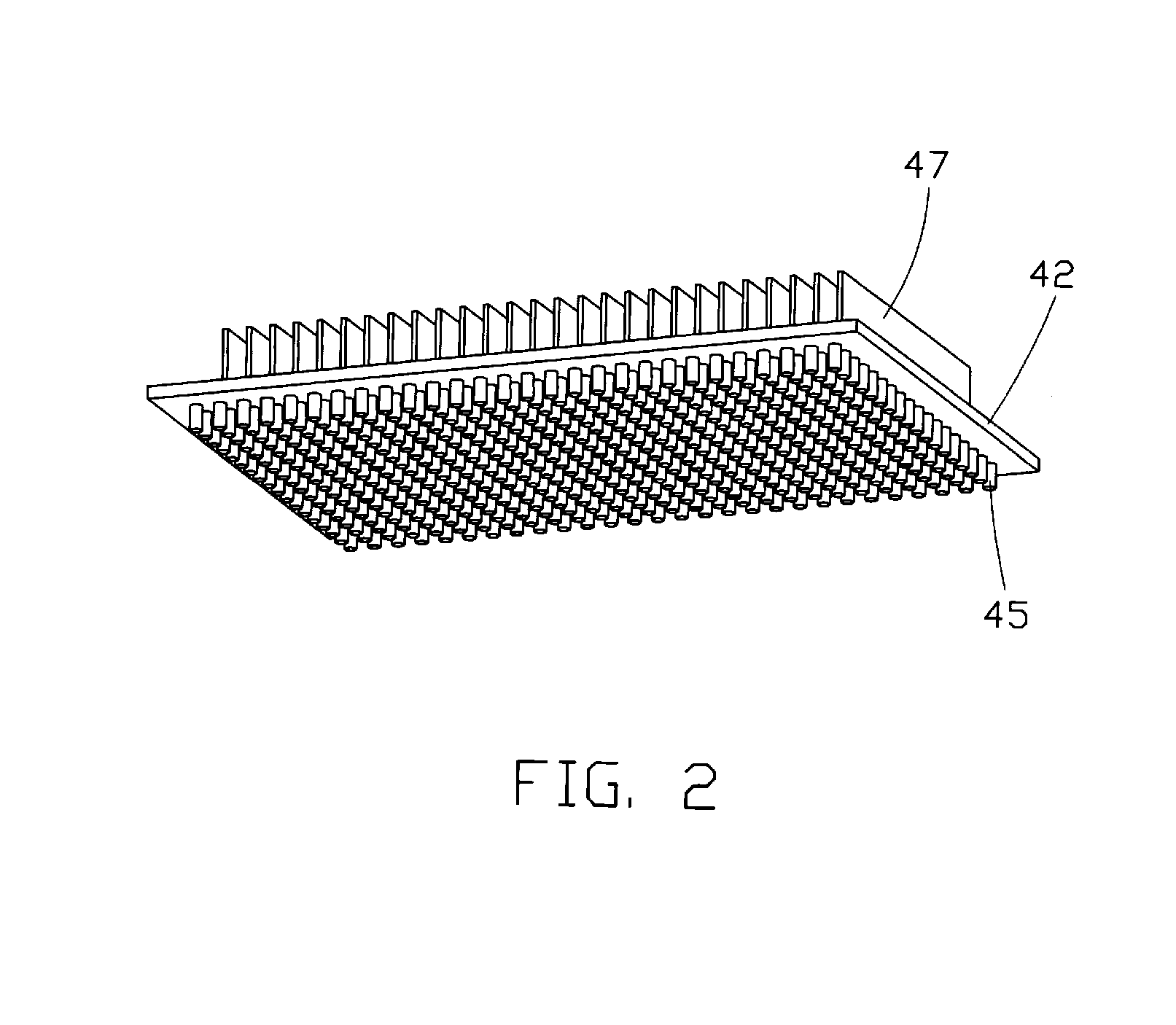

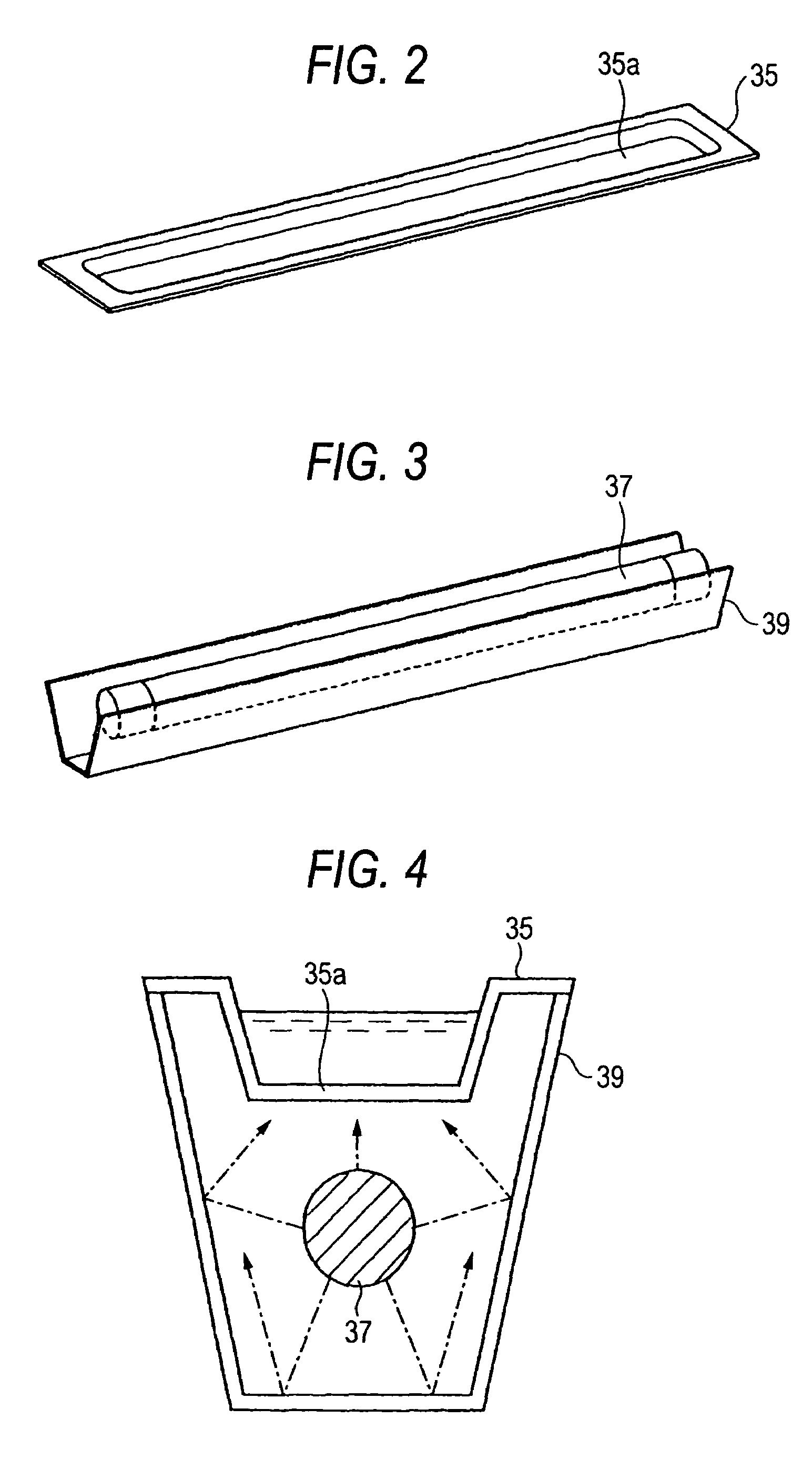

Loop-type heat exchange device

InactiveUS20060283577A1Improve heat exchange capacityHigh heat-absorbing surface areaSolar heat devicesHeat exhanger conduitsWorking fluidEvaporation

A loop-type heat exchange device (10) is disclosed, which includes an evaporator (20), a condenser (40), a vapor conduit (30) and a liquid conduit (50). The evaporator contains therein a working fluid. The working fluid in the evaporator evaporates into vapor after absorbing heat, and the generated vapor flows, via the vapor conduit, to the condenser where the vapor releases its latent heat of evaporation and is condensed into condensate. The condensate then returns back, via the liquid conduit, to the evaporator to thereby form a heat transfer loop. The condenser defines therein a chamber, and a plurality of heat-exchange pins is provided inside the chamber for effectively exchanging heat with the vapor entering into the condenser.

Owner:HON HAI PRECISION IND CO LTD

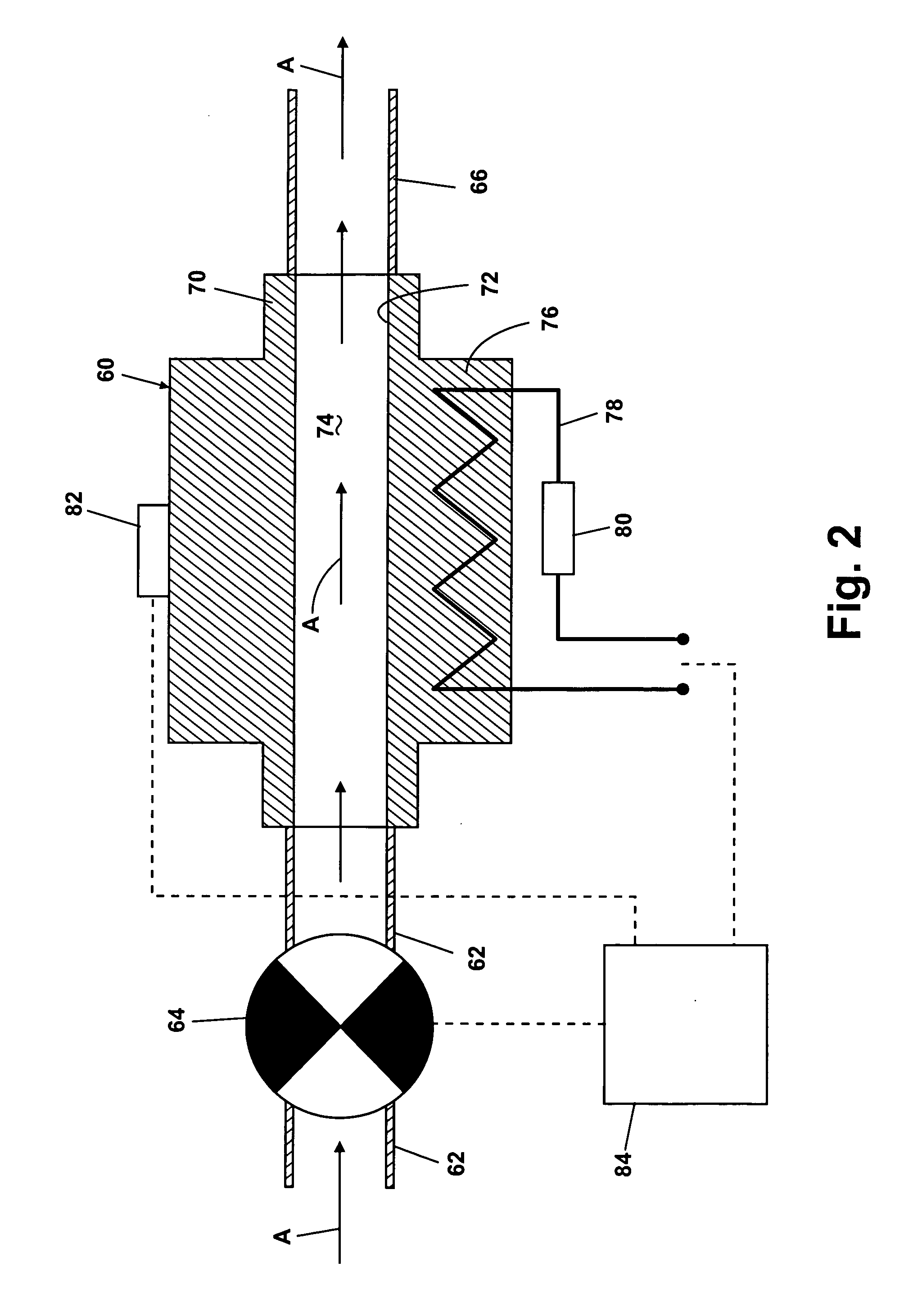

Steam generation apparatus and methods

Steam generation apparatus and methods are presented that are dedicated to oxygen-enriched air combustion of a fuel, wherein the oxygen concentration of the oxygen-enriched air may range from just above 21 percent to 100 percent. One apparatus comprises an oxygen-enriched air preheater through which oxygen-enriched air flows and exchanges heat indirectly with flue gas, creating a preheated oxygen-enriched air stream. The apparatus further comprises a boiler having a radiant section and a convection section, and other heat transfer units adapted to handle reduced flue gas flow rate and higher temperature flue gases than comparable air / fuel combustion boilers, thus allowing a smaller heat transfer surface area, a more compact design and a higher efficiency.

Owner:AIR LIQUIDE AMERICA INC +1

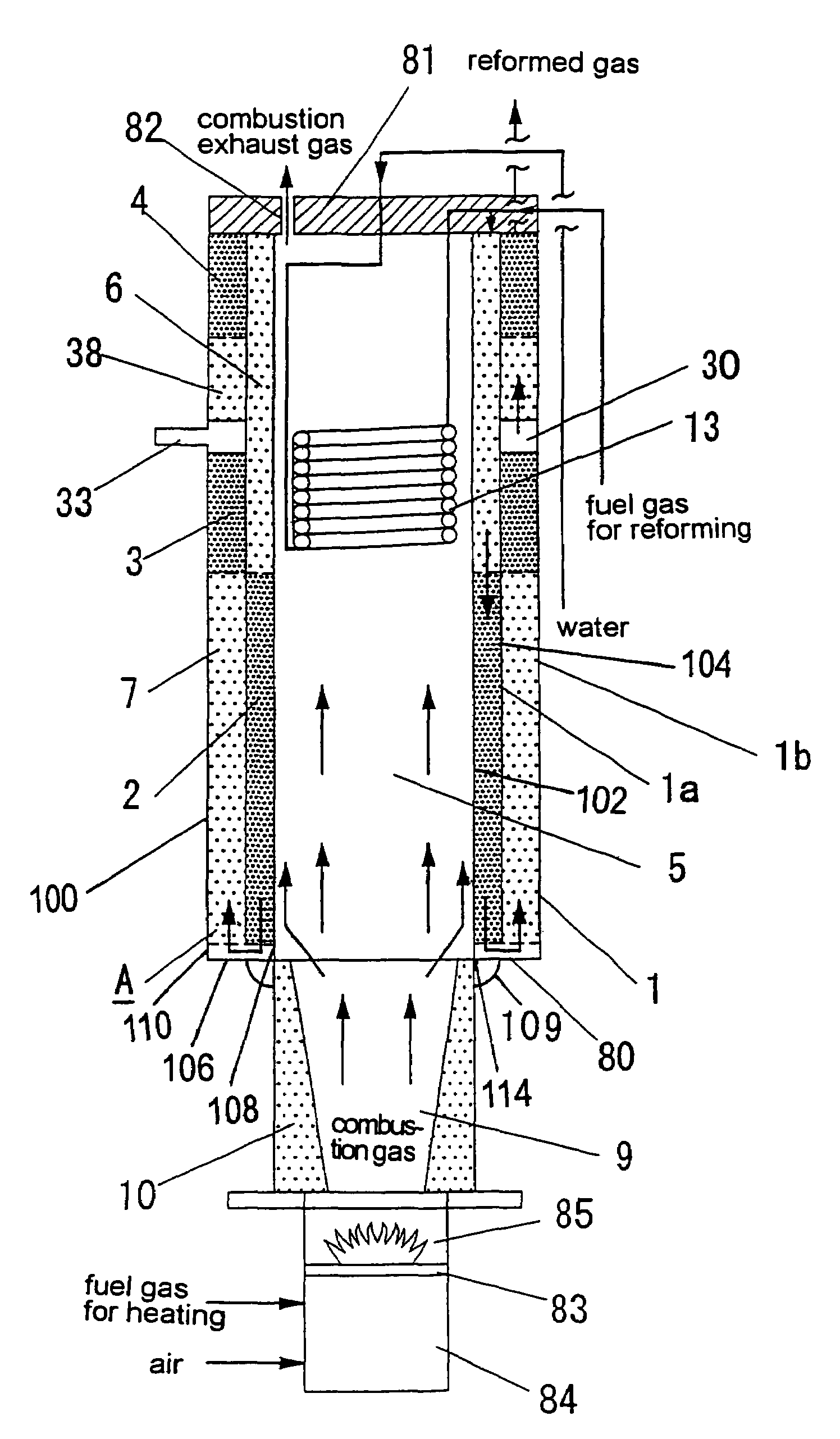

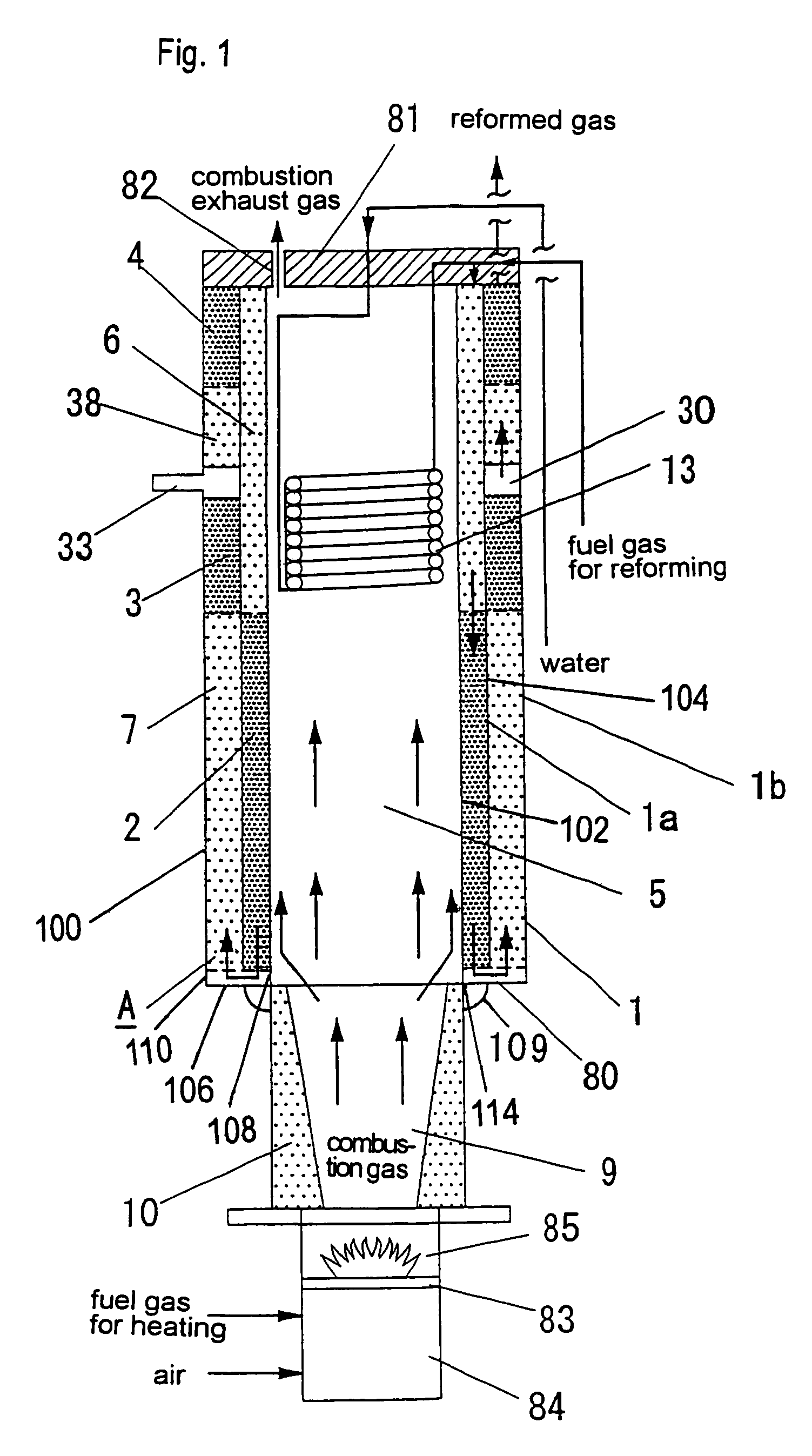

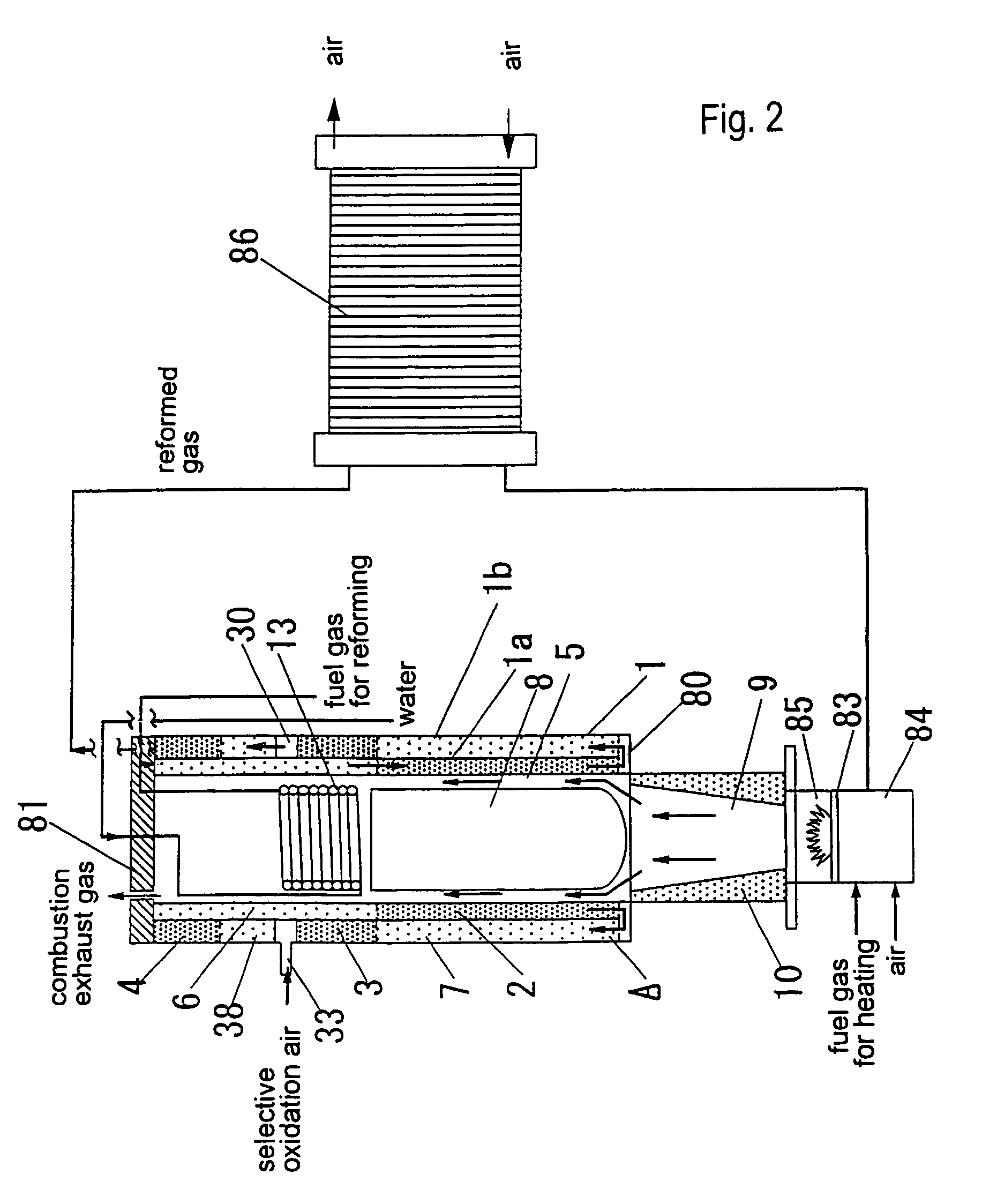

Reforming apparatus

ActiveUS7156886B2Improve efficiencyExcellent operation-starting performanceHydrogenPhysical/chemical process catalystsEngineeringMechanical engineering

A reforming apparatus for producing a reformed gas from a fuel gas and steam, including a reformed gas-producing passage and a combustion gas passage, the reformed gas-producing passage having reforming catalyst, shift catalyst, and CO-selective oxidizing catalyst sections along a flowing direction of the reformed gas, the reformed gas-producing passage having a first passage adjacent to the combustion gas passage and including the reforming catalyst section and a second passage adjacent to the first passage, the second passage including a first heat-recovering section adjacent to the reforming catalyst section, and the first passage having a second heat-recovering section adjacent to one of the shift catalyst and CO-selective oxidizing catalyst sections, the first heat-recovering section located on an upstream side along the flow direction of the reformed gas relative to the reforming catalyst section.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

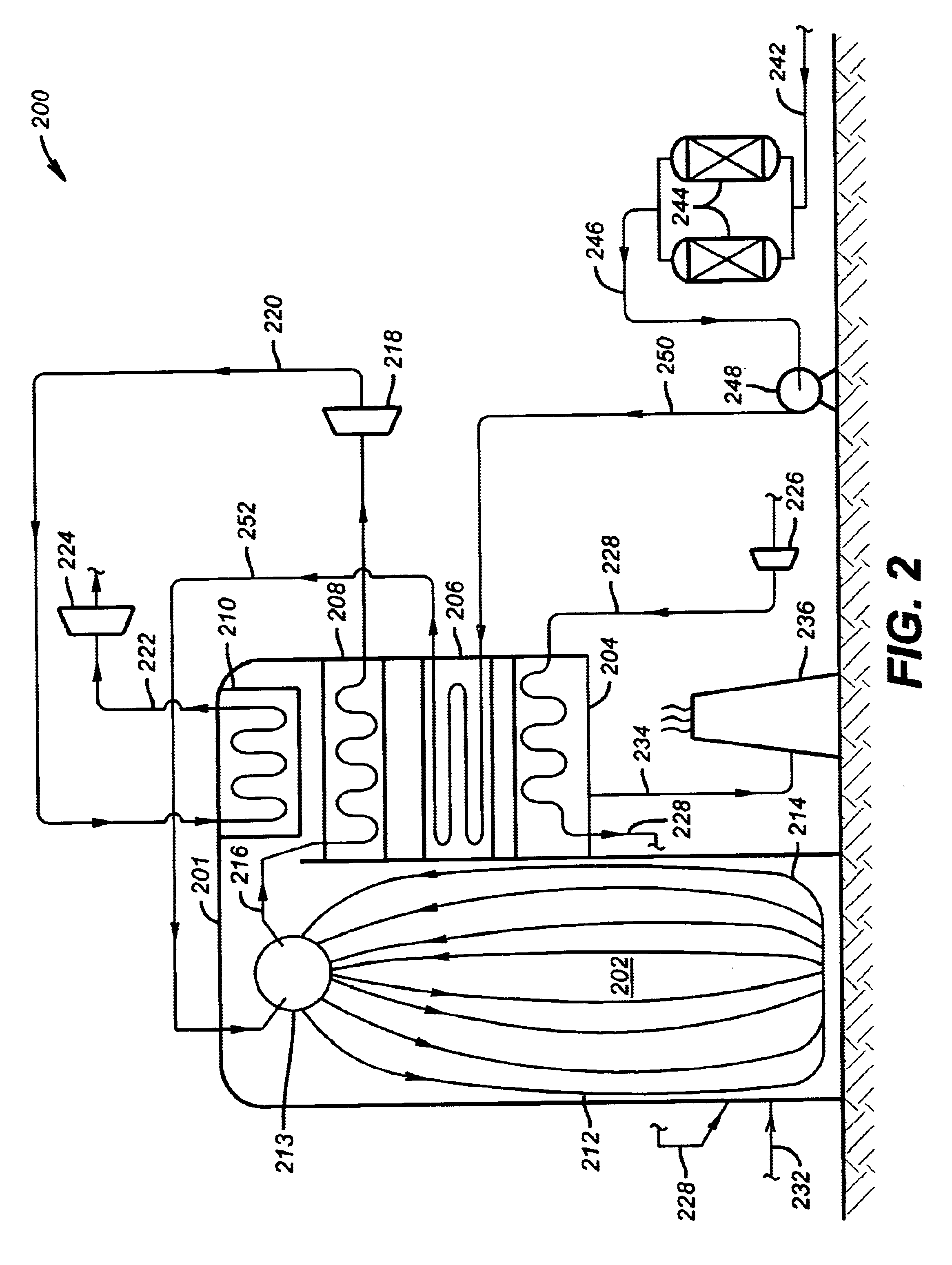

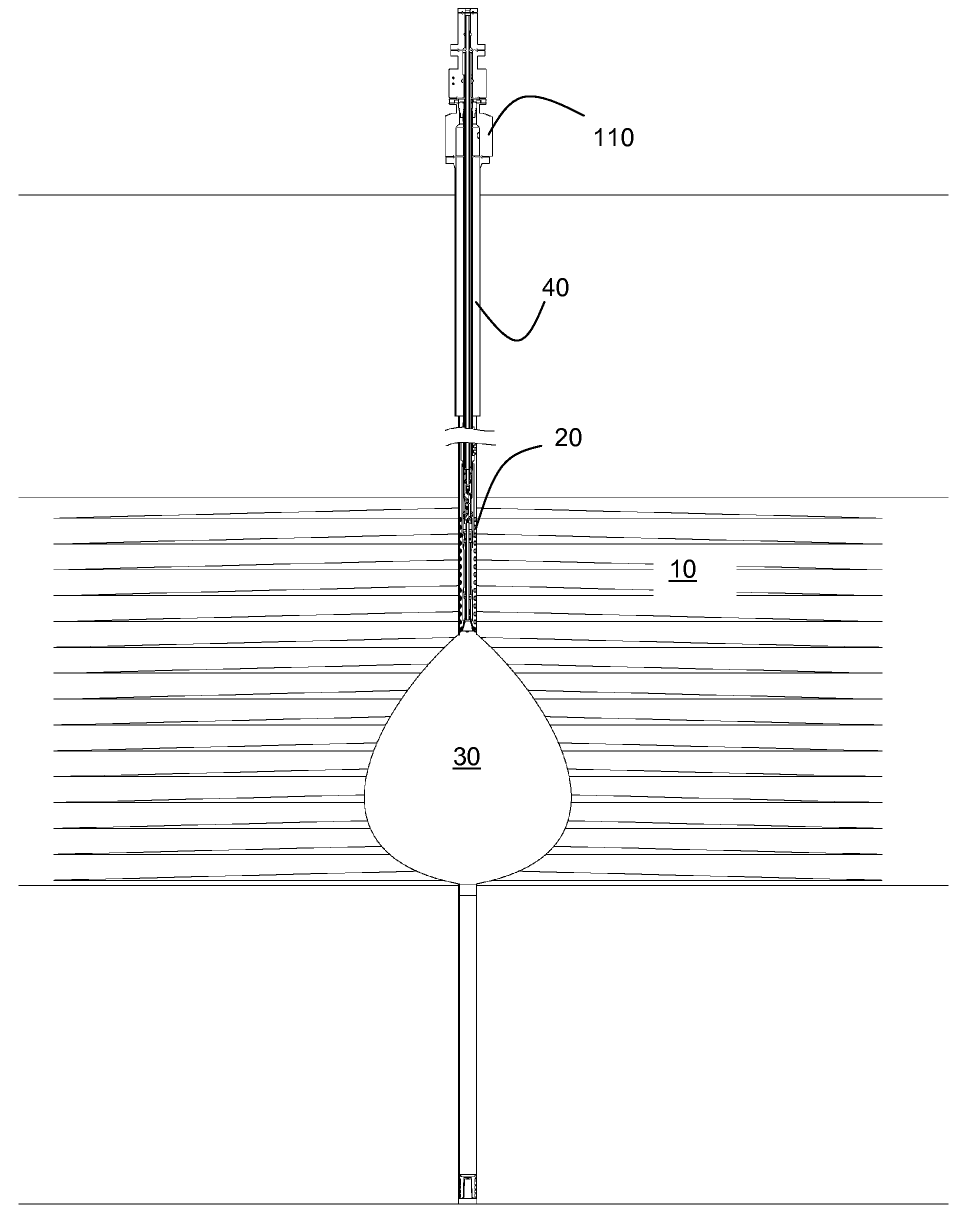

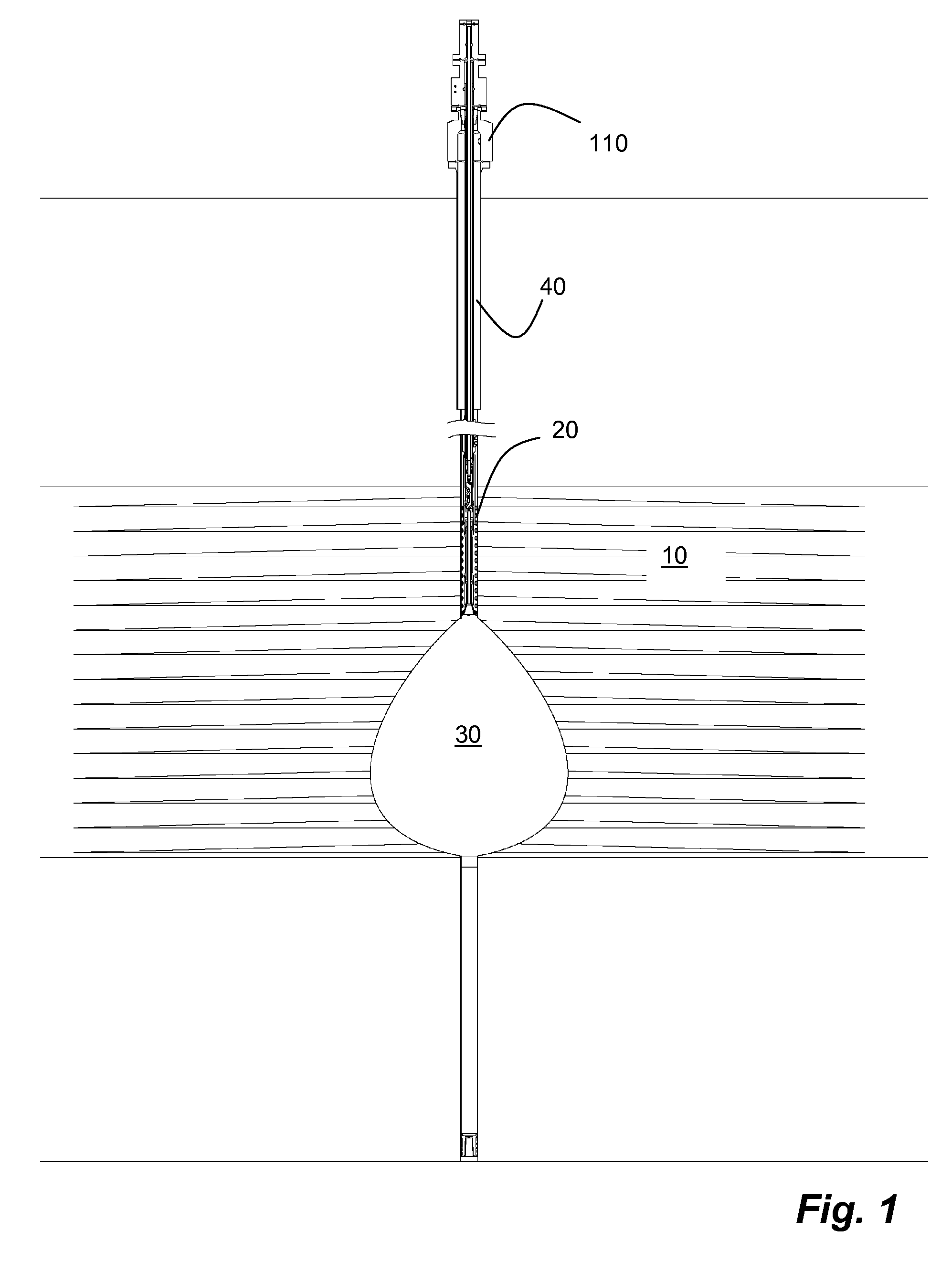

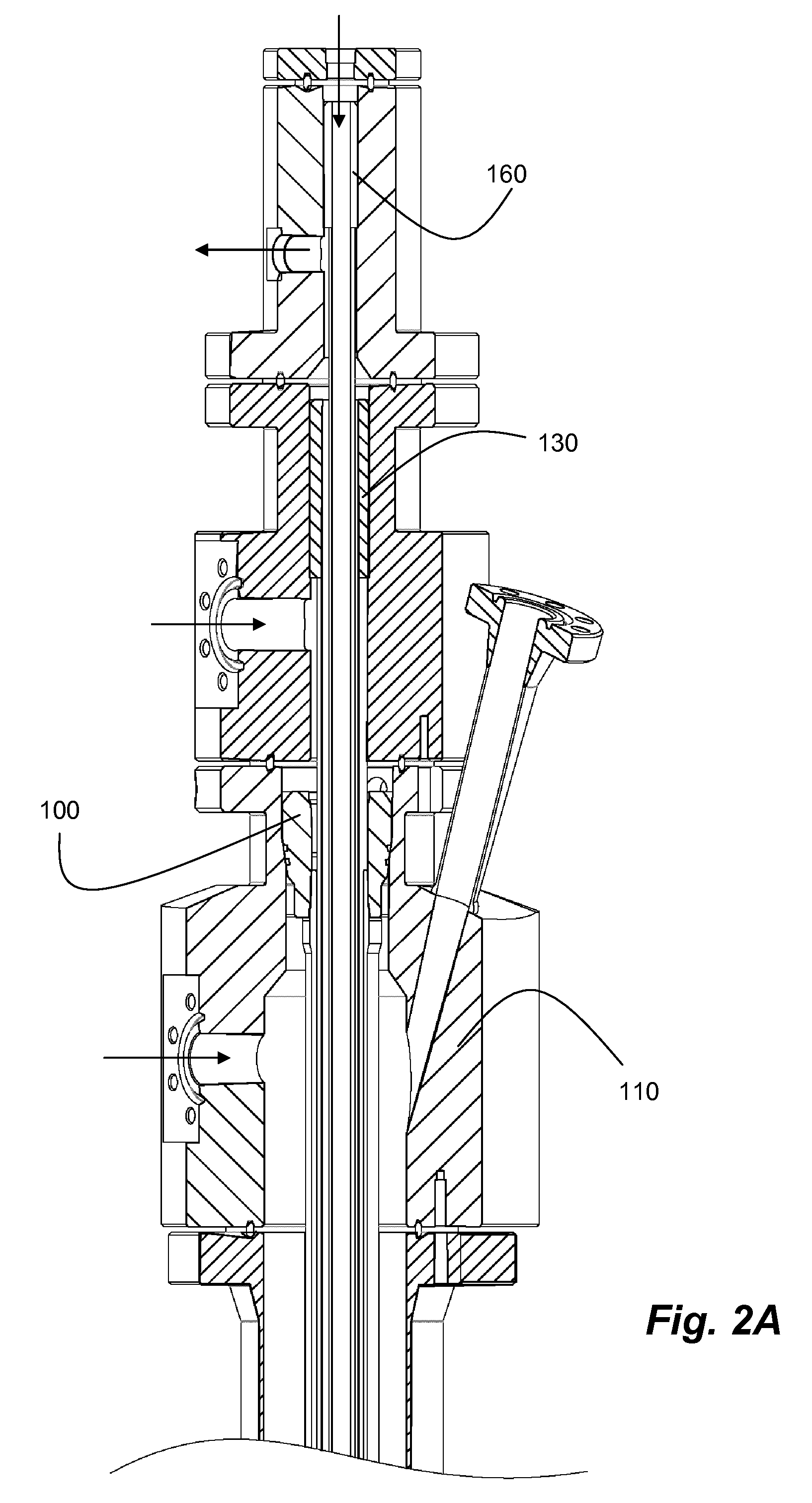

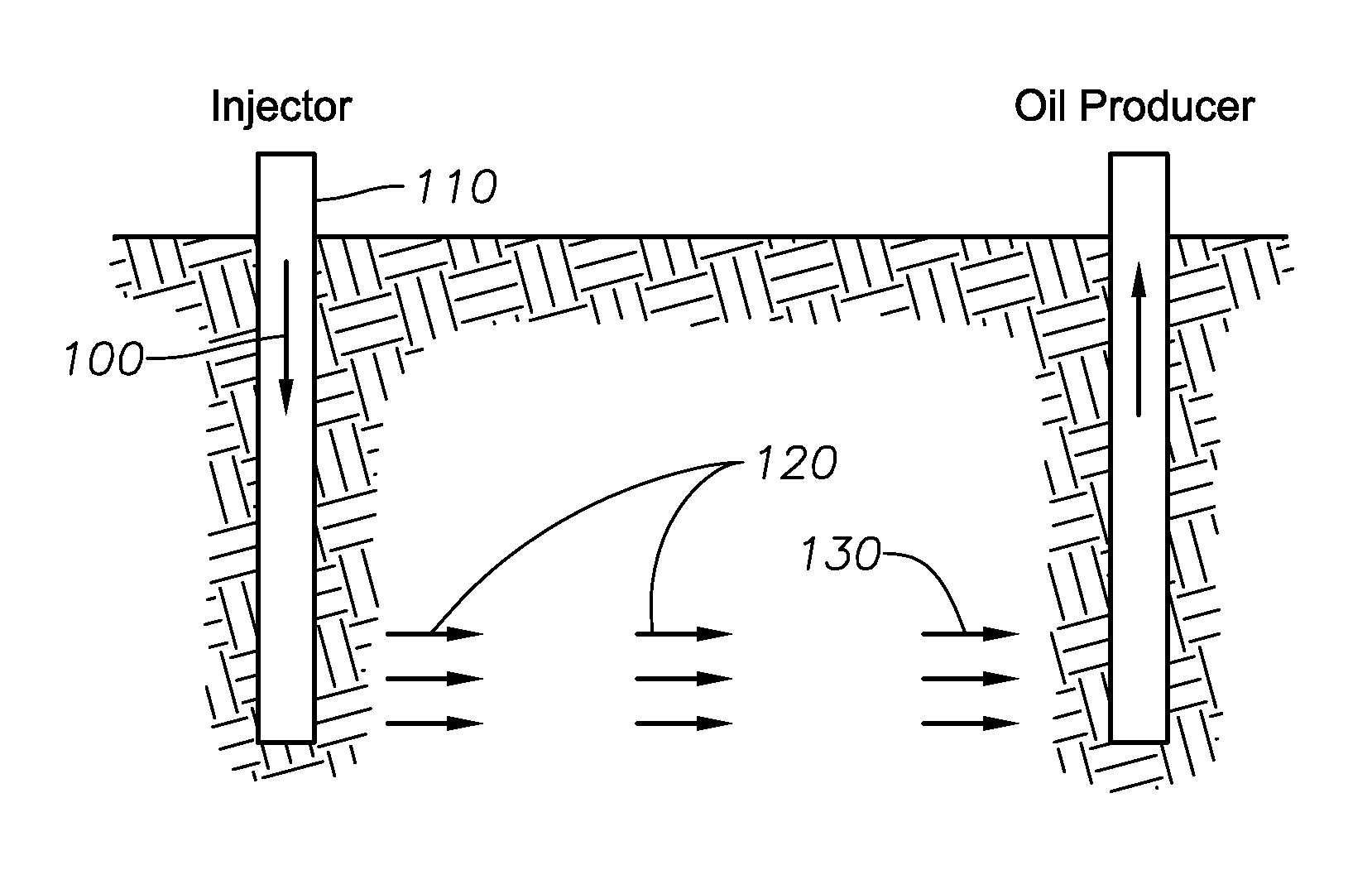

Apparatus and method for downhole steam generation and enhanced oil recovery

A burner with a casing seal is used to create a combustion cavity at a temperature sufficient to reservoir sand. The burner creates and sustains hot combustion gases at a steady state for flowing into and permeating through a target zone. The casing seal isolates the combustion cavity from the cased wellbore and forms a sealed casing annulus between the cased wellbore and the burner. Water is injected into the target zone, above the combustion cavity, through the sealed casing annulus. The injected water permeates laterally and cools the reservoir adjacent the wellbore, and the wellbore from the heat of the hot combustion gases. The hot combustion gases and the water in the reservoir interact to form a drive front in a hydrocarbon reservoir.

Owner:ESPRESSO CAPITAL LTD

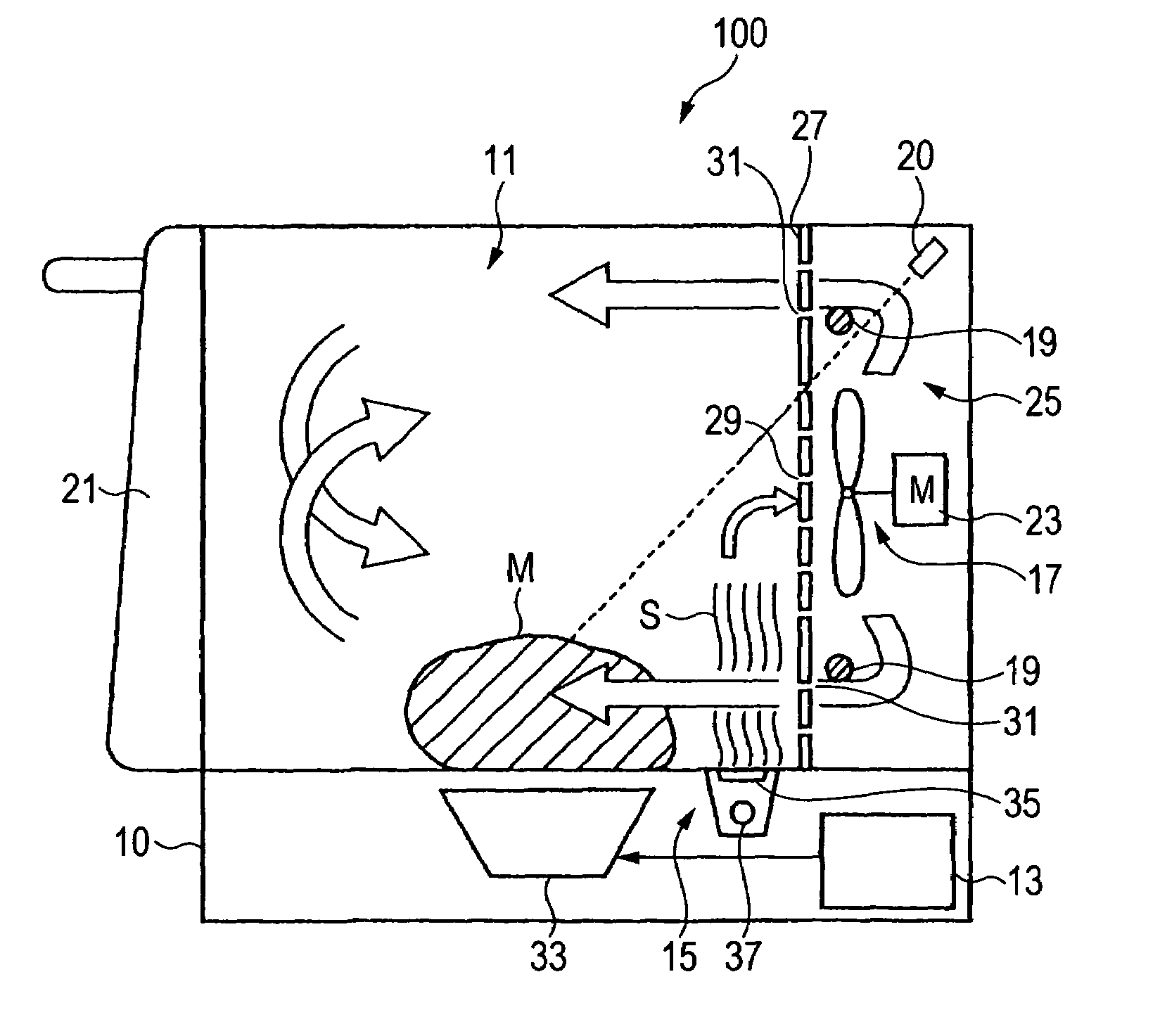

High frequency heating apparatus with steam generating function

InactiveUS7087873B2Easy to cleanAccurate measurementMilk preservationDomestic stoves or rangesEvaporating dishEngineering

Owner:PANASONIC CORP

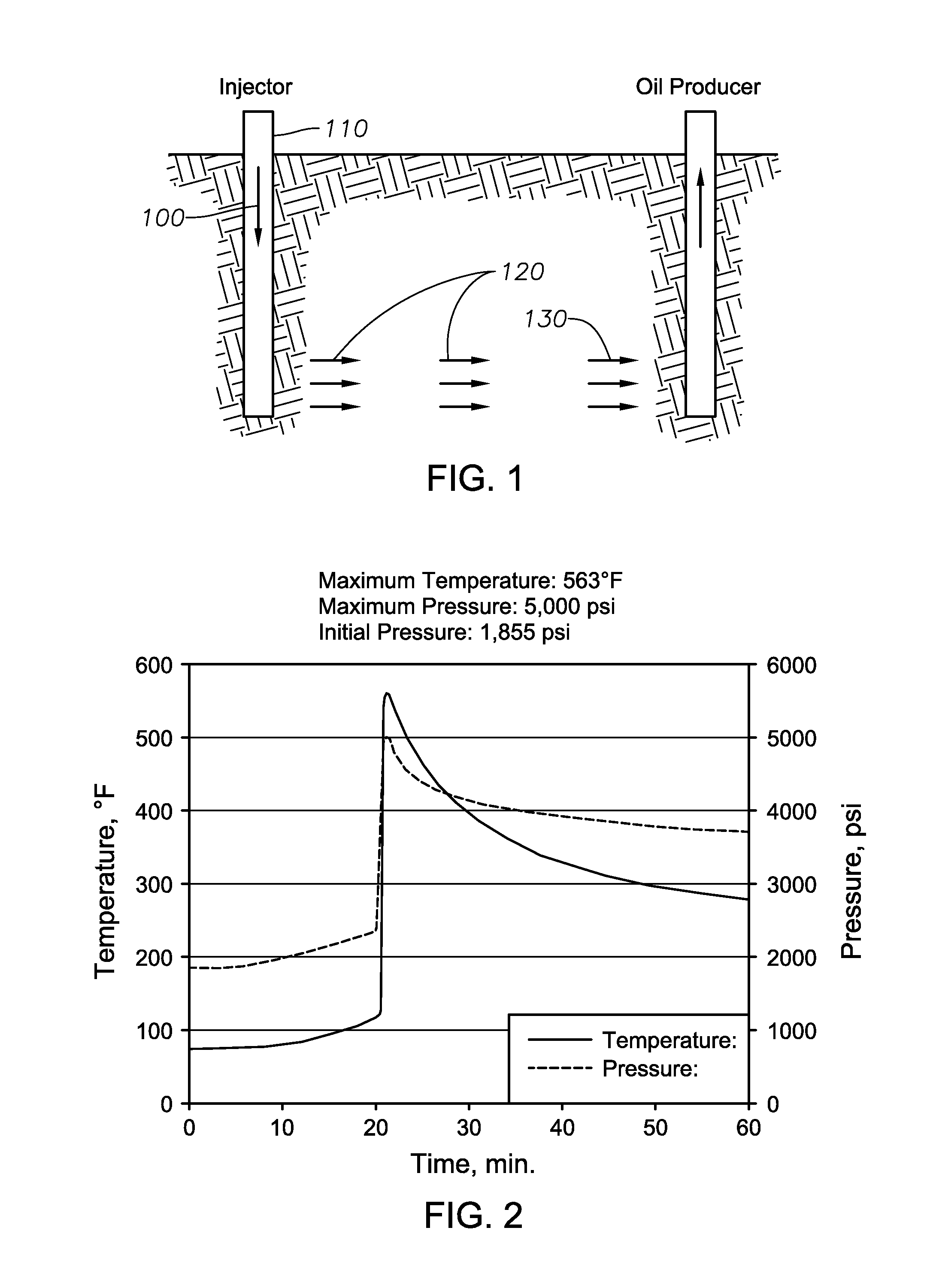

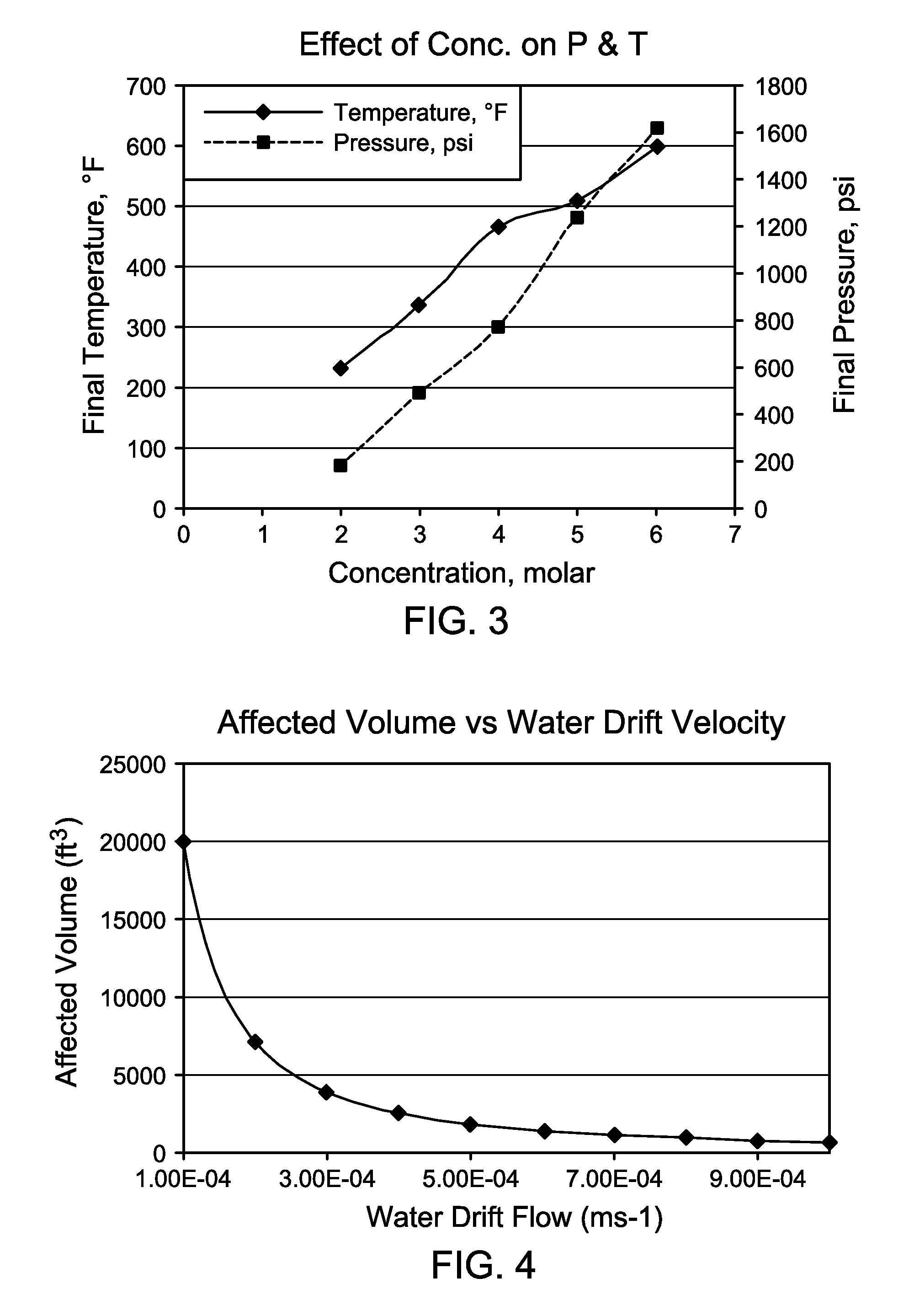

Enhanced oil recovery by in-situ steam generation

ActiveUS20140090839A1Improve oil mobilityIncrease oil productionInsulationFluid removalTight oilFuel oil

Embodiments of the invention provide methods and composition for stimulating a hydrocarbon-bearing, heavy oil containing formation, a deep oil reservoir, or a tight oil reservoir, whereby exothermic reactants are utilized to generate in-situ steam and nitrogen gas downhole in the formation or the reservoir as an enhanced oil recovery process. An oil well stimulation method is provided, which includes injecting, into the one of the formation and the reservoir, an aqueous composition including an ammonium containing compound and a nitrite containing compound. The method further includes injecting, into the one of the formation and the reservoir, an activator. The activator initiates a reaction between the ammonium containing compound and the nitrite containing compound, such that the reaction generates steam and nitrogen gas, increasing localized pressure and improving oil mobility, in the one of the formation and the reservoir, thereby enhancing oil recovery from the one of the formation and the reservoir.

Owner:SAUDI ARABIAN OIL CO

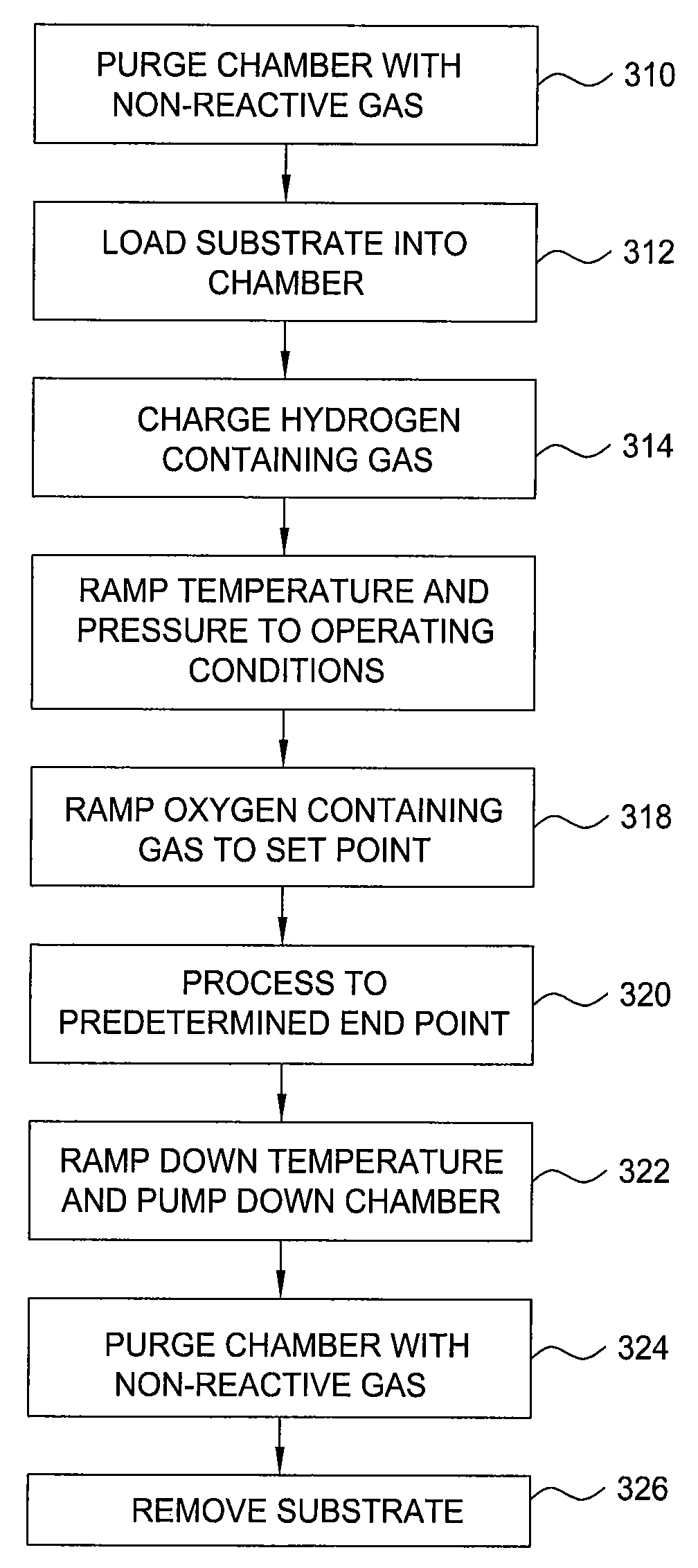

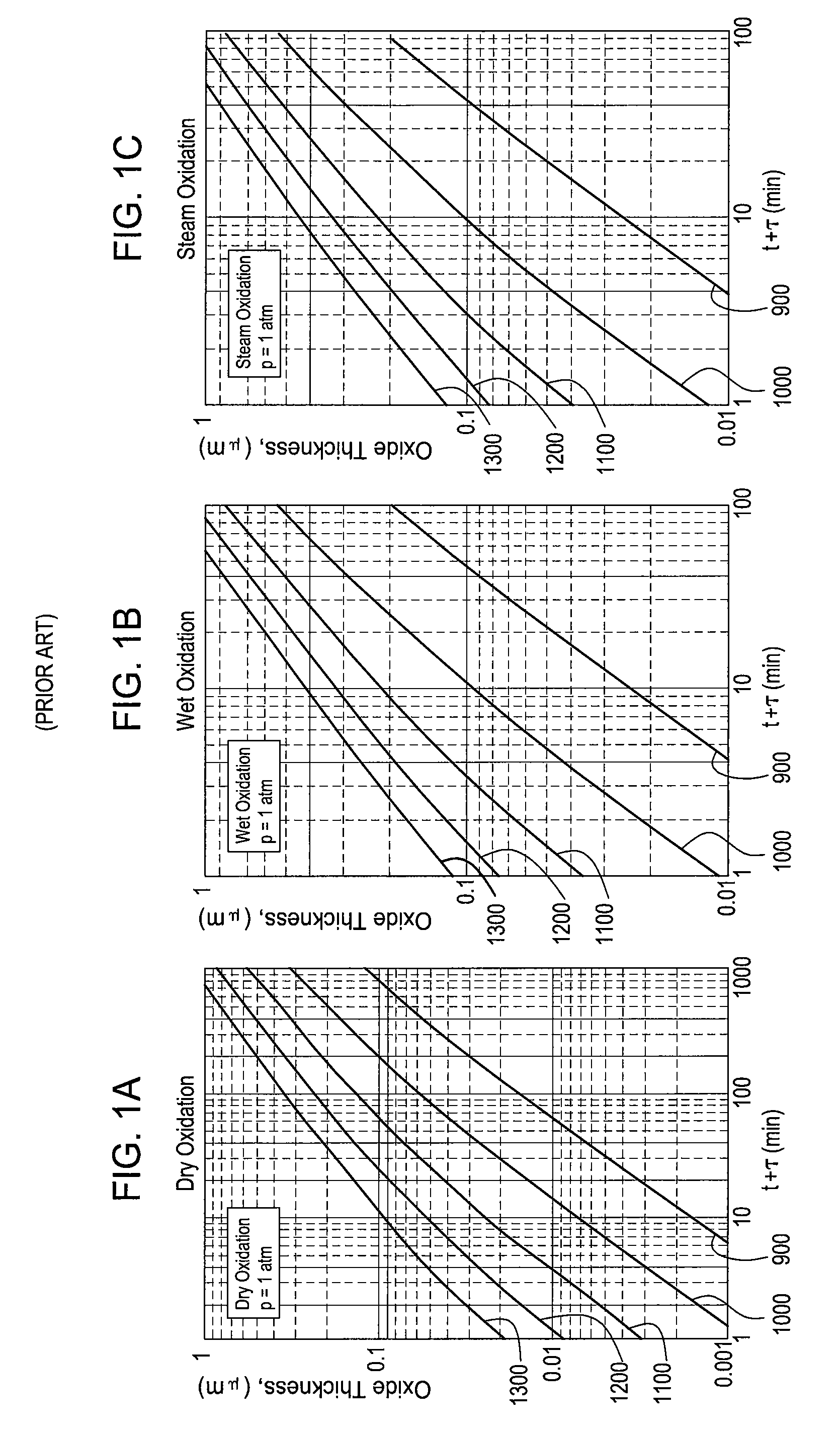

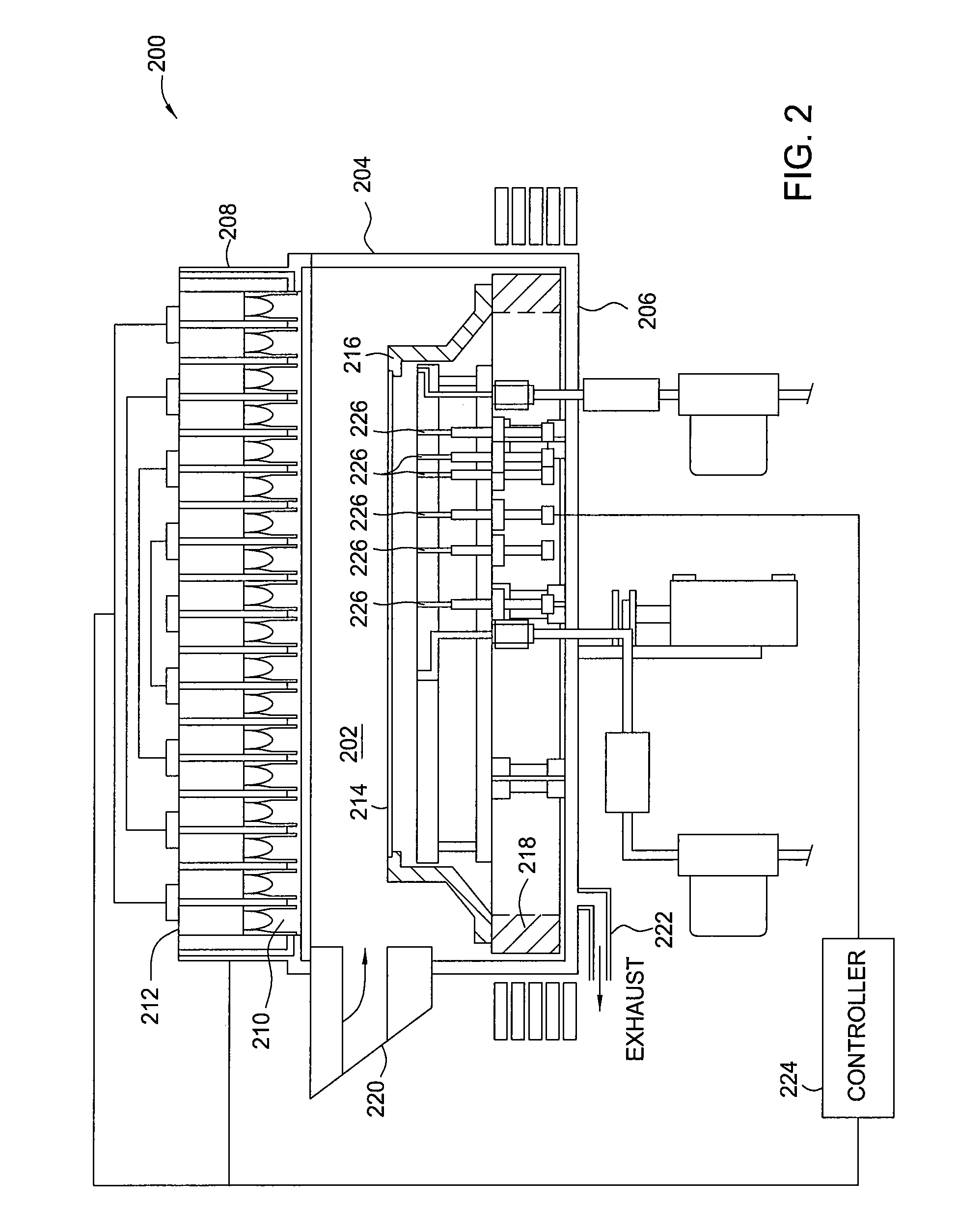

Method of improving oxide growth rate of selective oxidation processes

A method for selective oxidation of silicon containing materials in a semiconductor device is disclosed and claimed. In one aspect, a rapid thermal processing apparatus is used to selectively oxidize a substrate by in-situ steam generation at high pressure in a hydrogen rich atmosphere. Other materials, such as metals and barrier layers, in the substrate are not oxidized.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com