Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

210results about "Heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

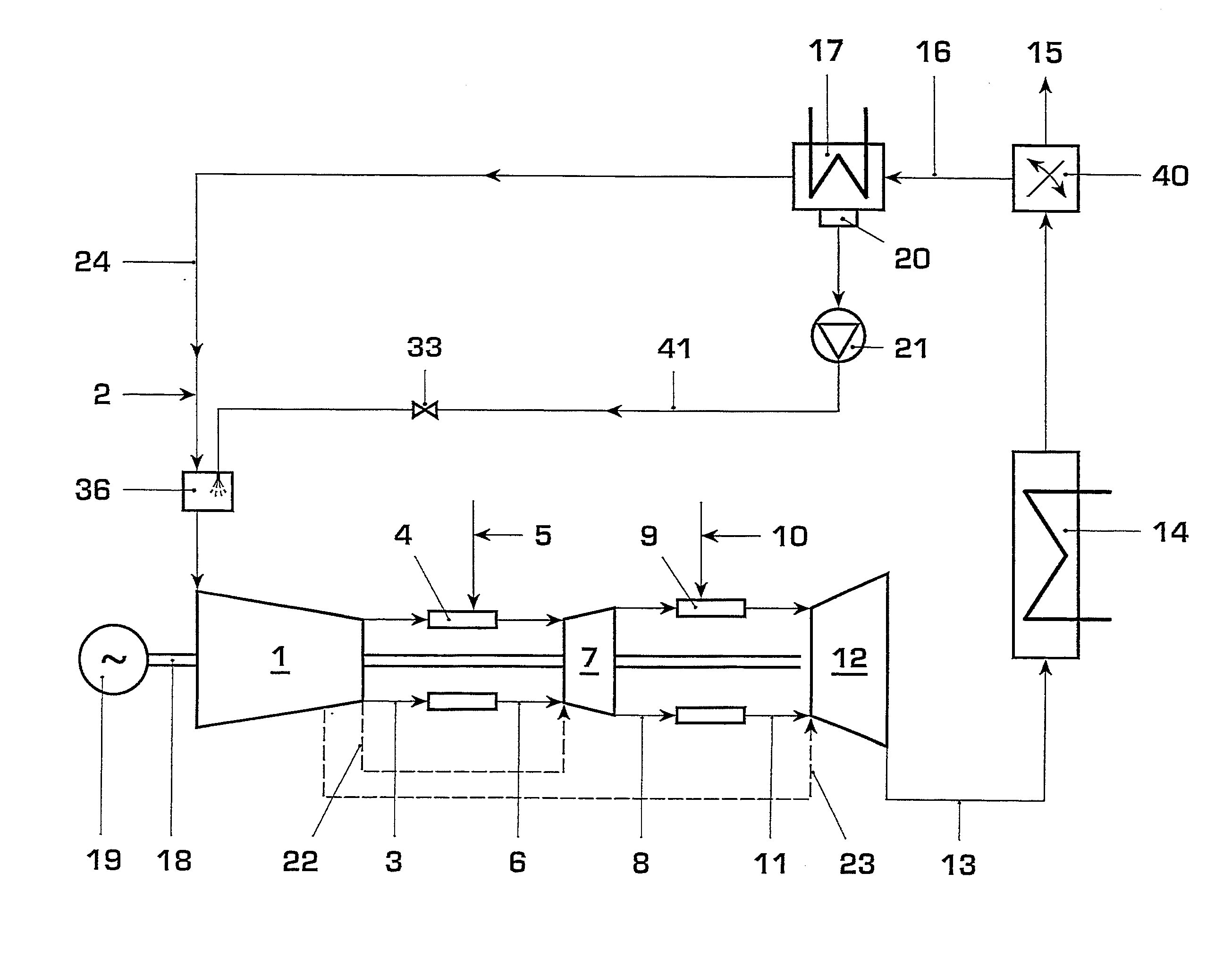

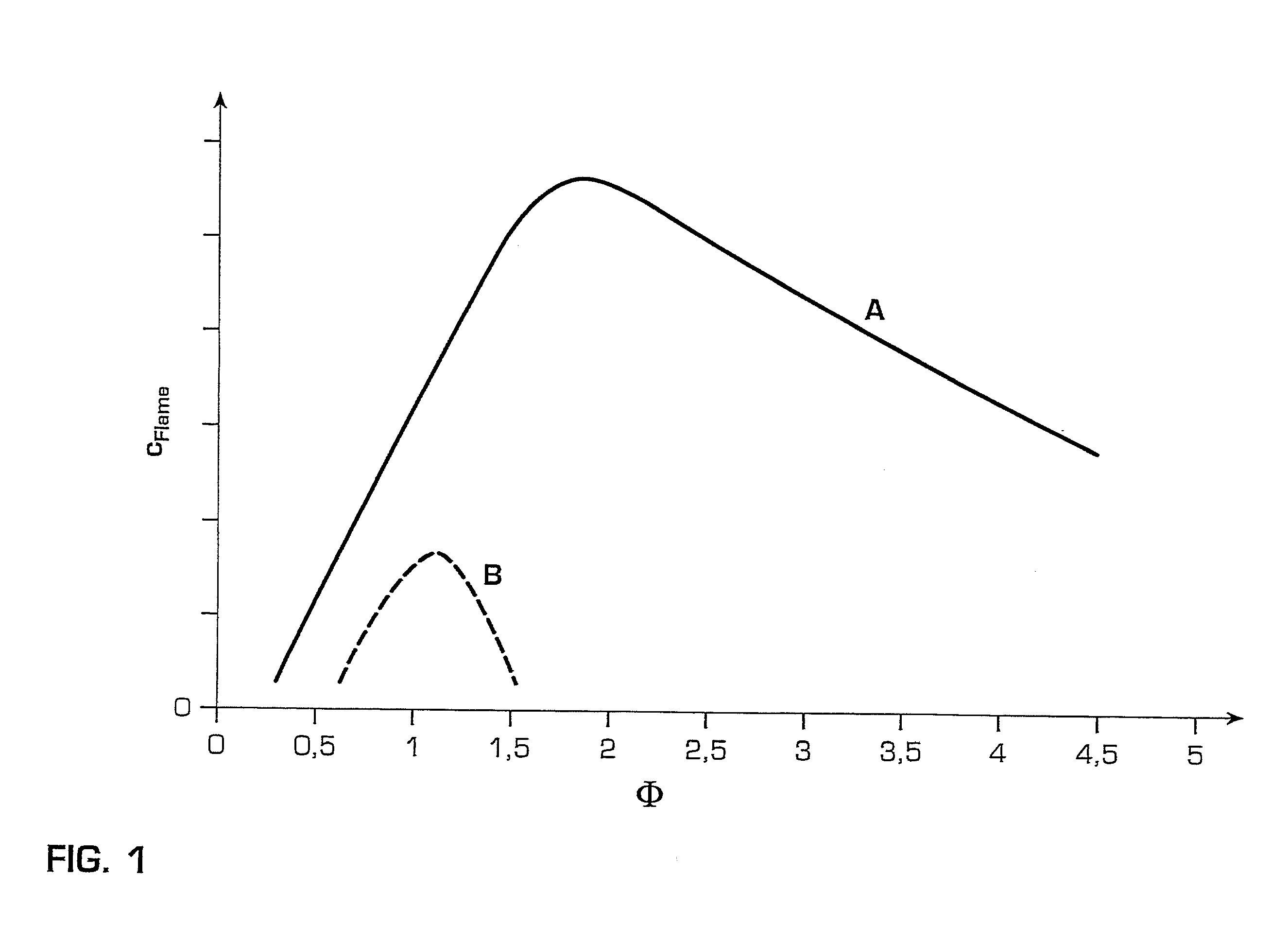

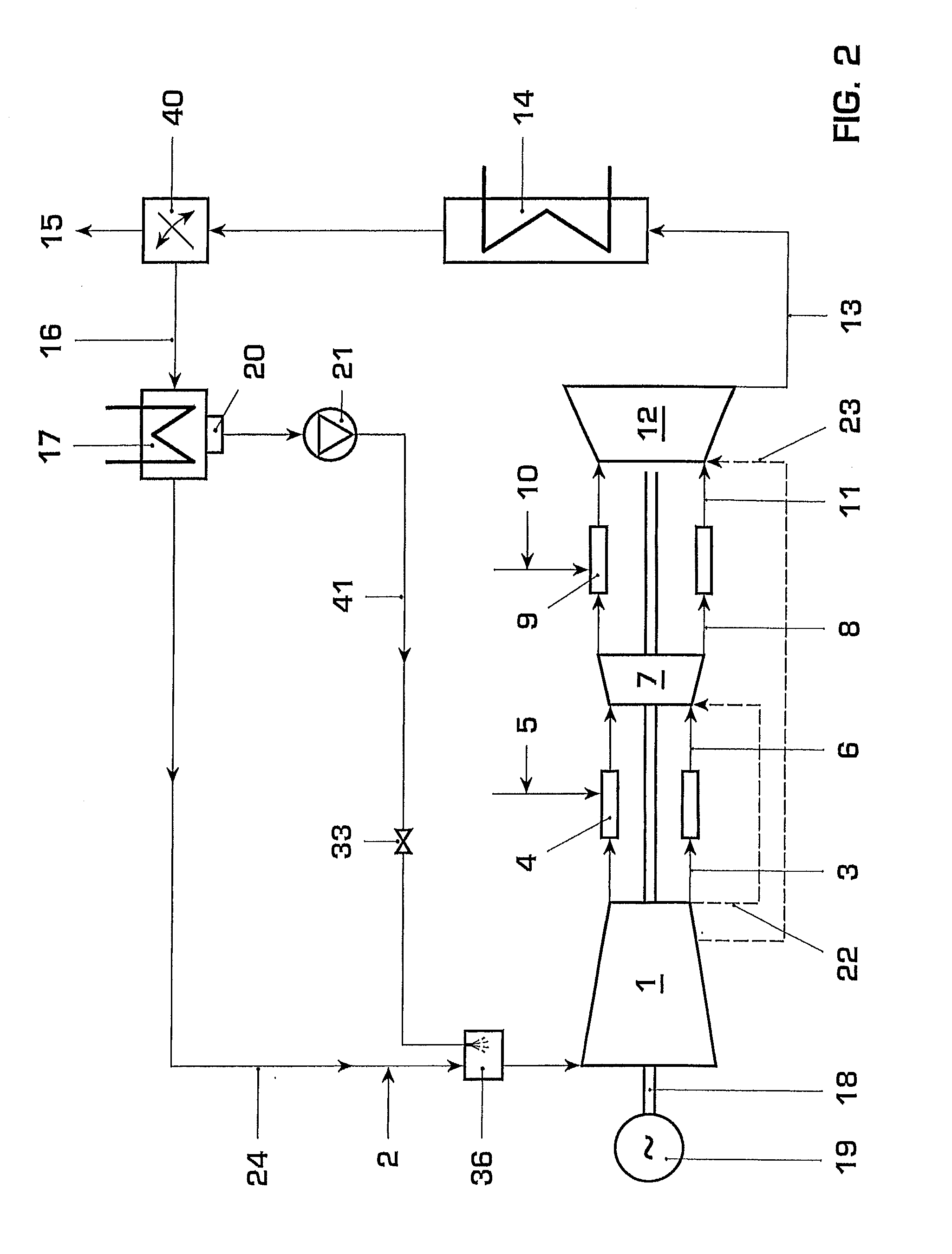

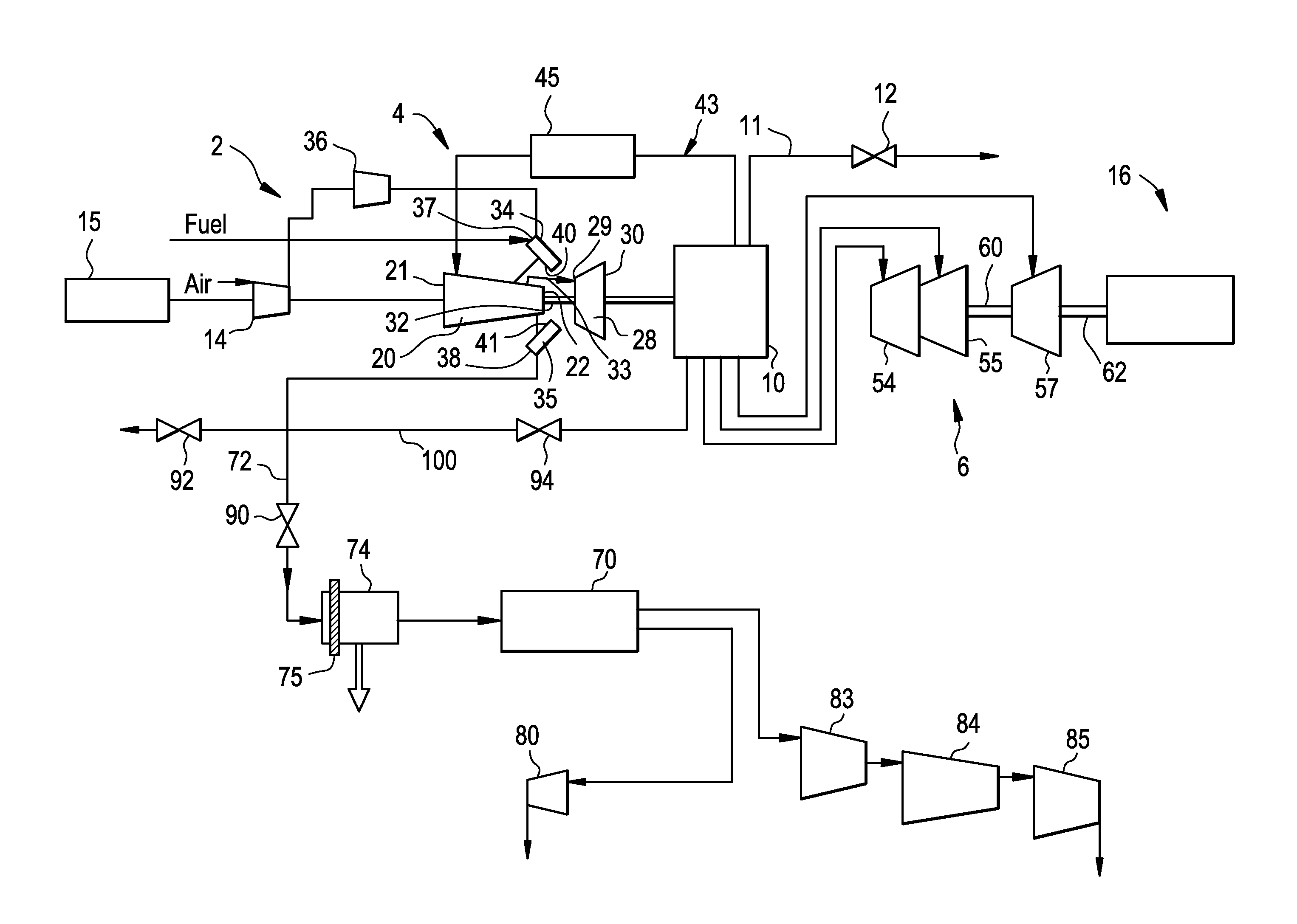

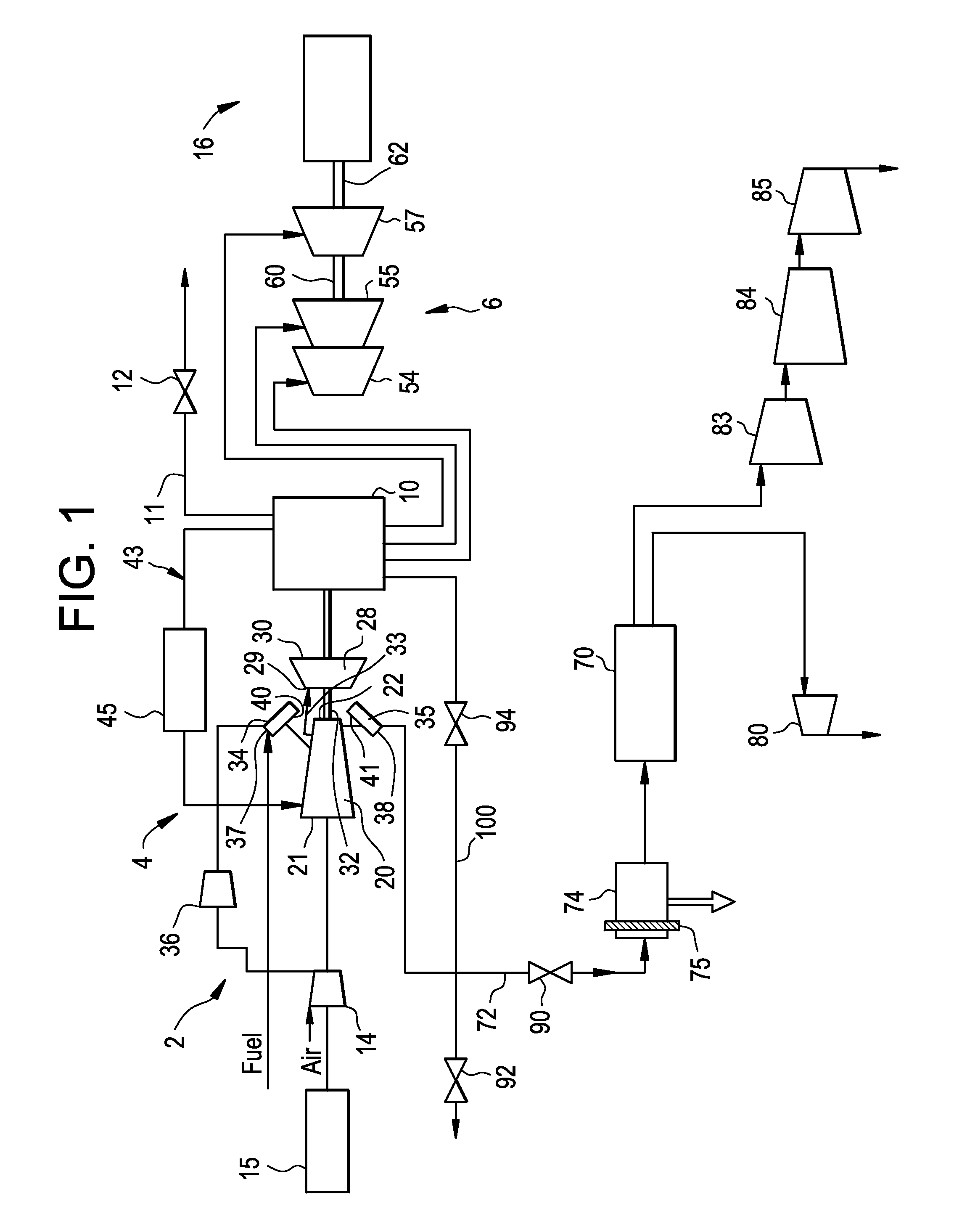

Gas Turbine Installation with Flue Gas Recirculation

A method and installation are disclosed which can, for example, provide for reliable, low-Nox-emission operation of a gas turbine installation with hydrogen-rich fuel gas. An exemplary gas turbine installation includes an arrangement for flue gas recirculation into a compressor inlet and for fuel gas dilution. Oxygen content in combustion air can be reduced by recirculation of recooled flue gas, and the fuel gas can be diluted with compressed flue gas. The oxygen reduction in the combustion air can lead to minimum residual oxygen in the flue gas which can be used for fuel gas dilution. As a result of the flue gas recirculation, water content in the combustion air can be increased by feedback of the water which results as a combustion product. The oxygen reduction, increased water content, and fuel dilution can reduce the flame velocity of hydrogen-rich fuel gases and enable a robust, reliable and low-emission combustion.

Owner:GENERAL ELECTRIC TECH GMBH

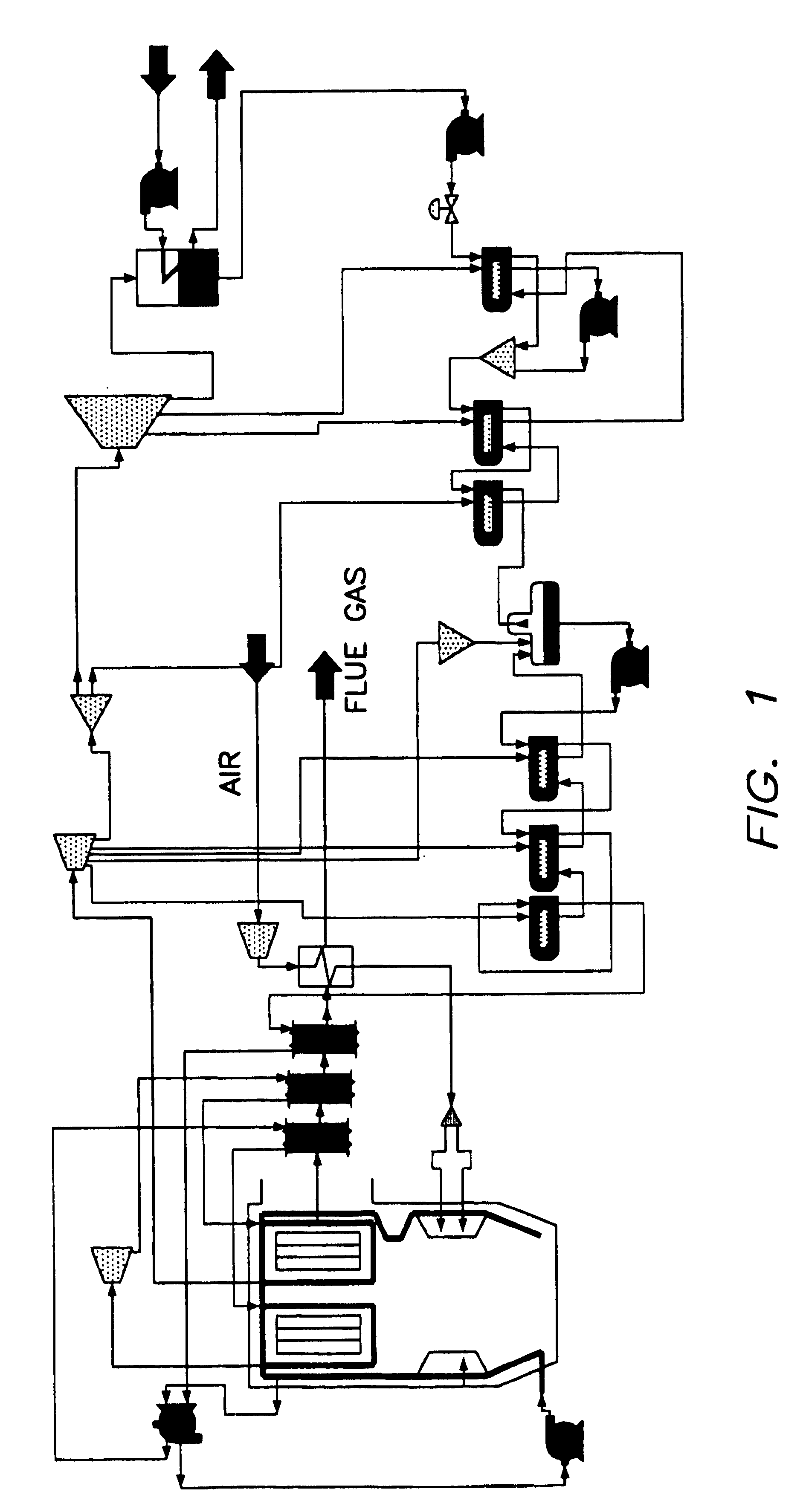

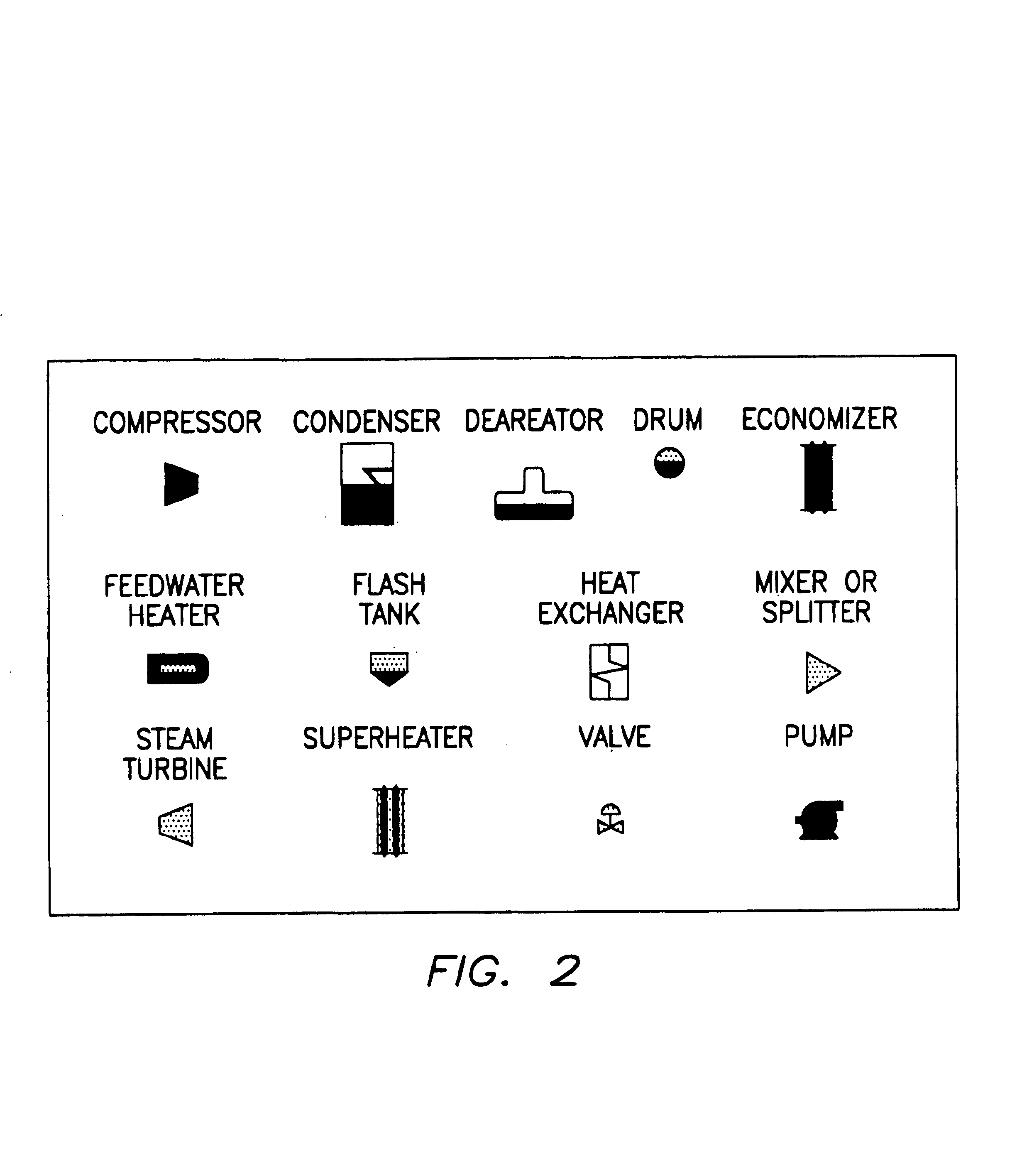

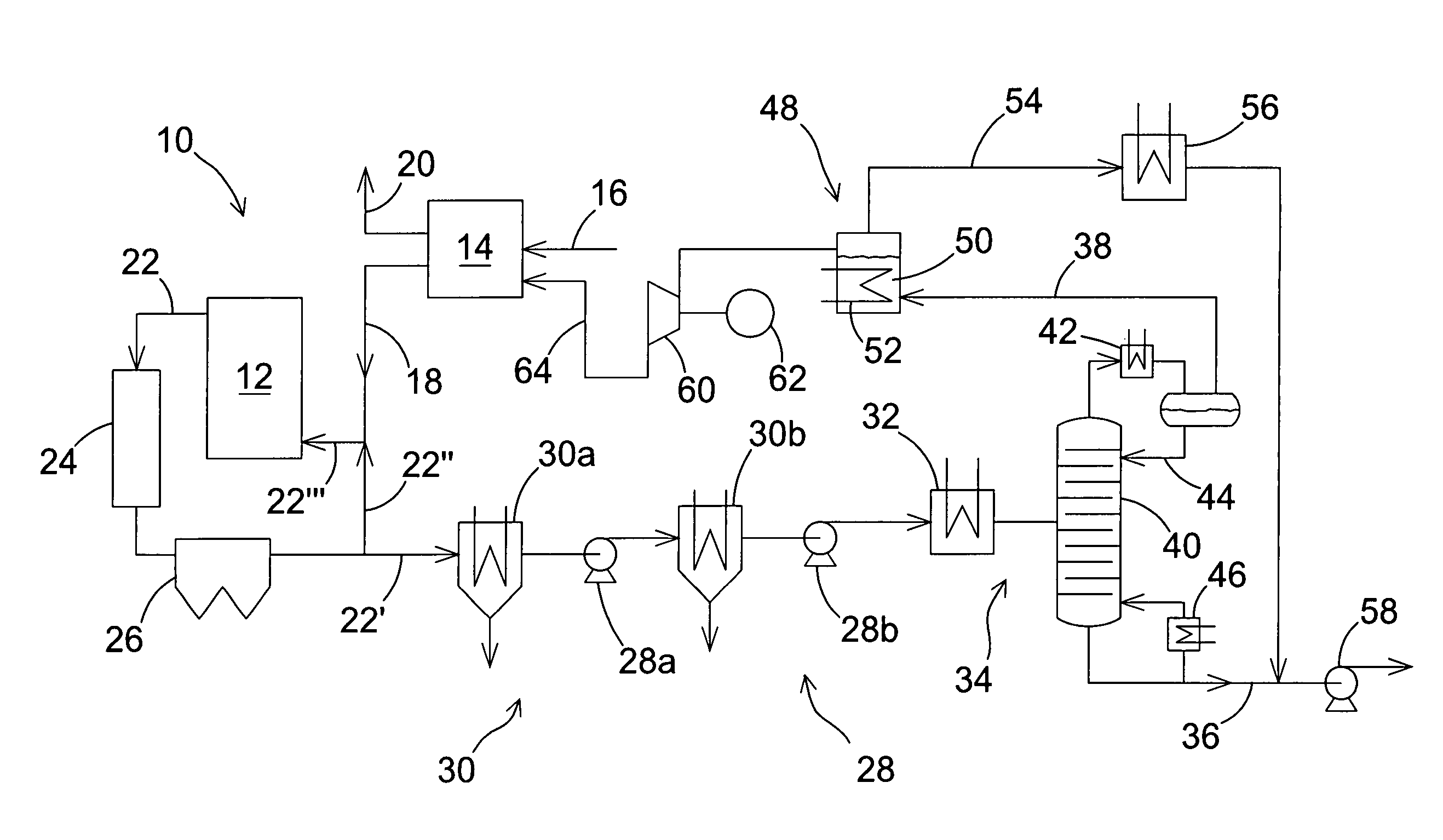

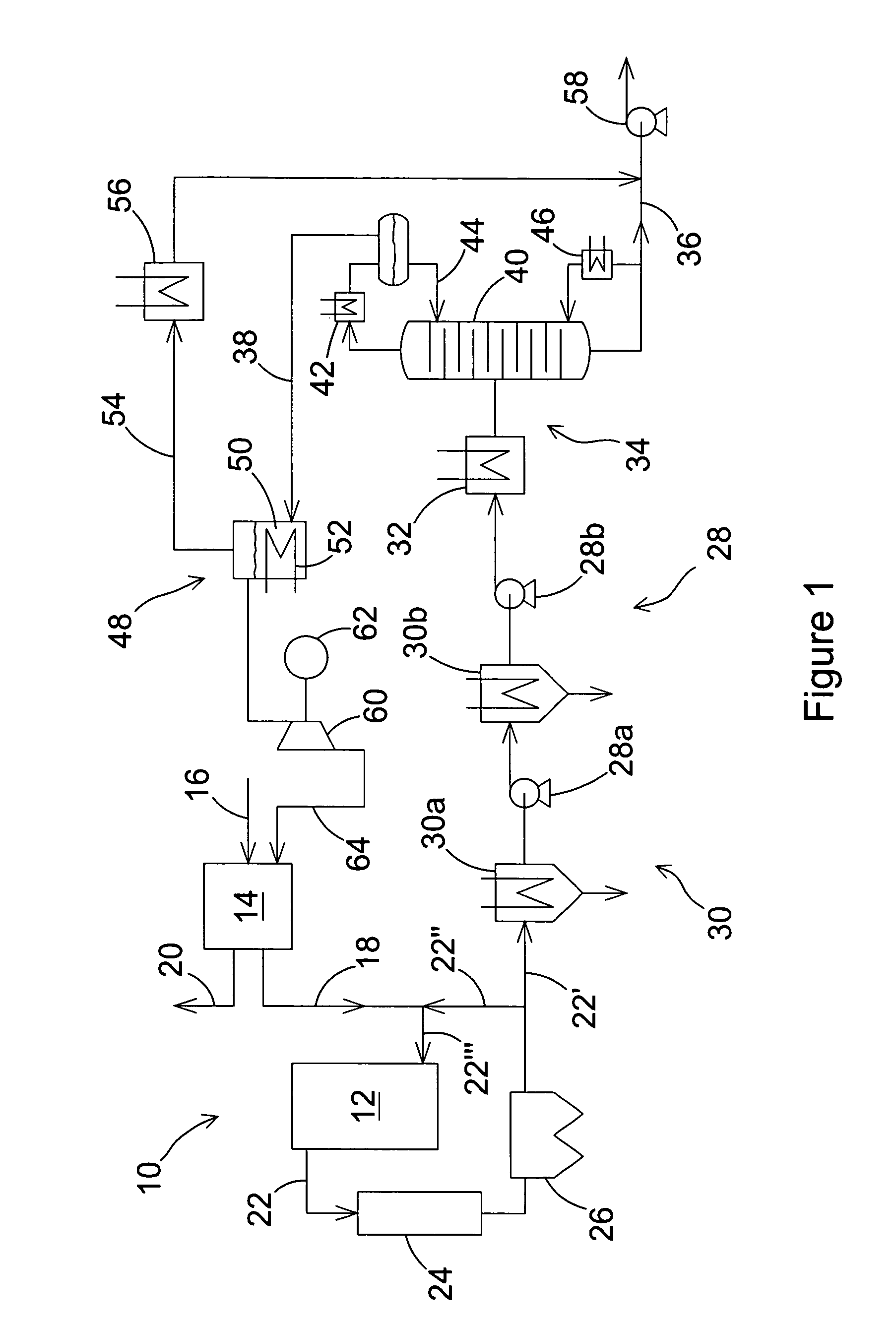

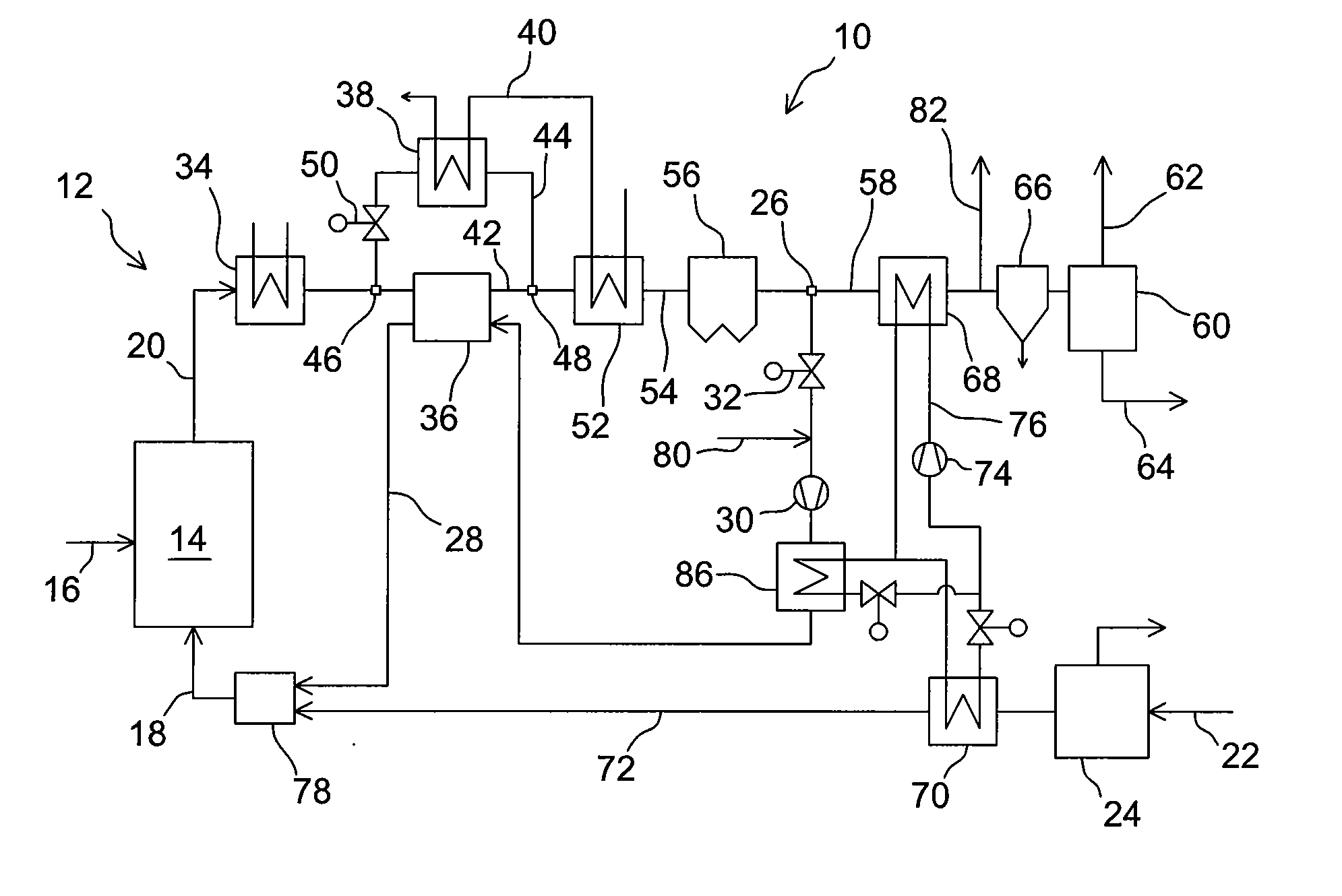

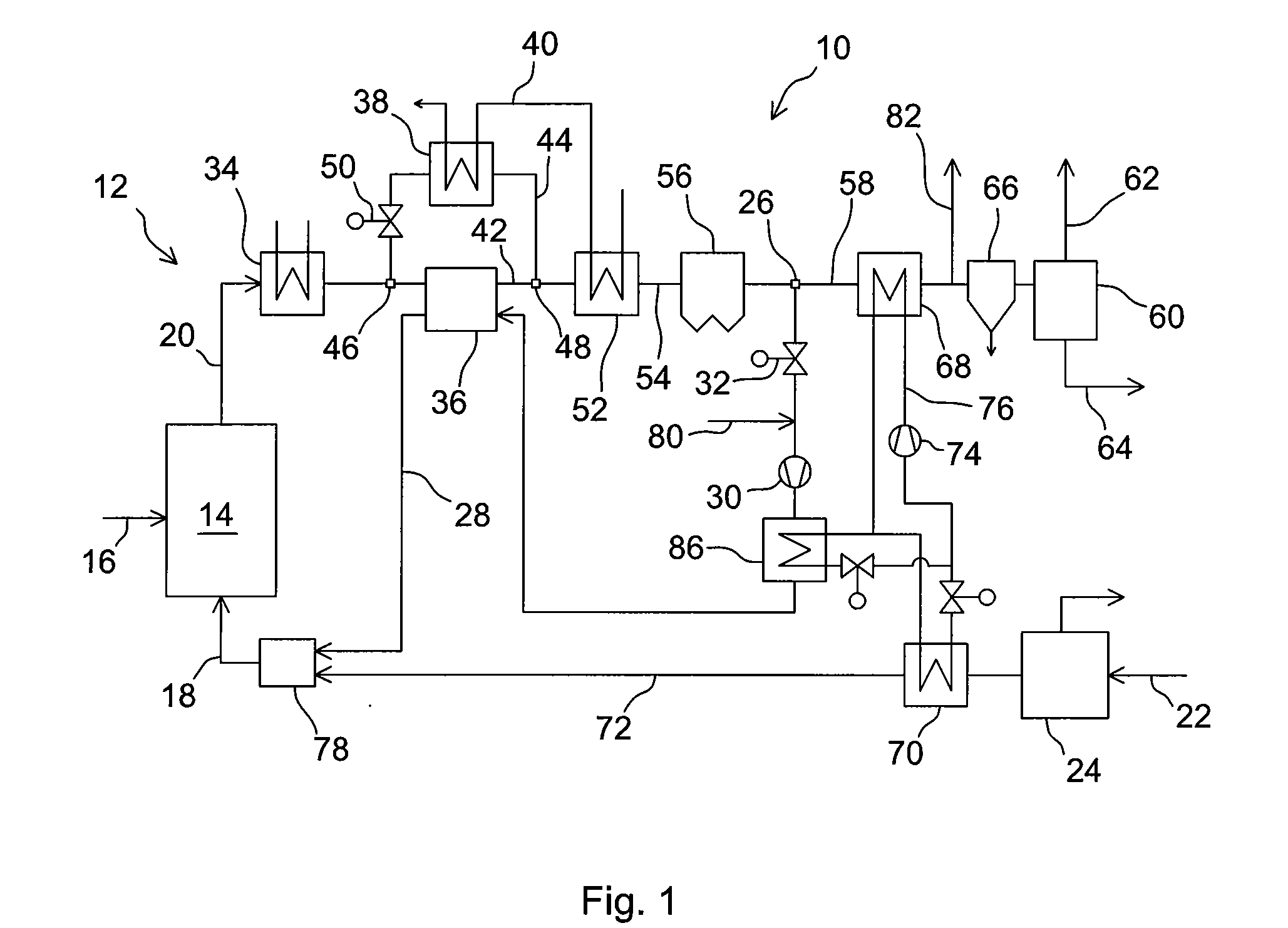

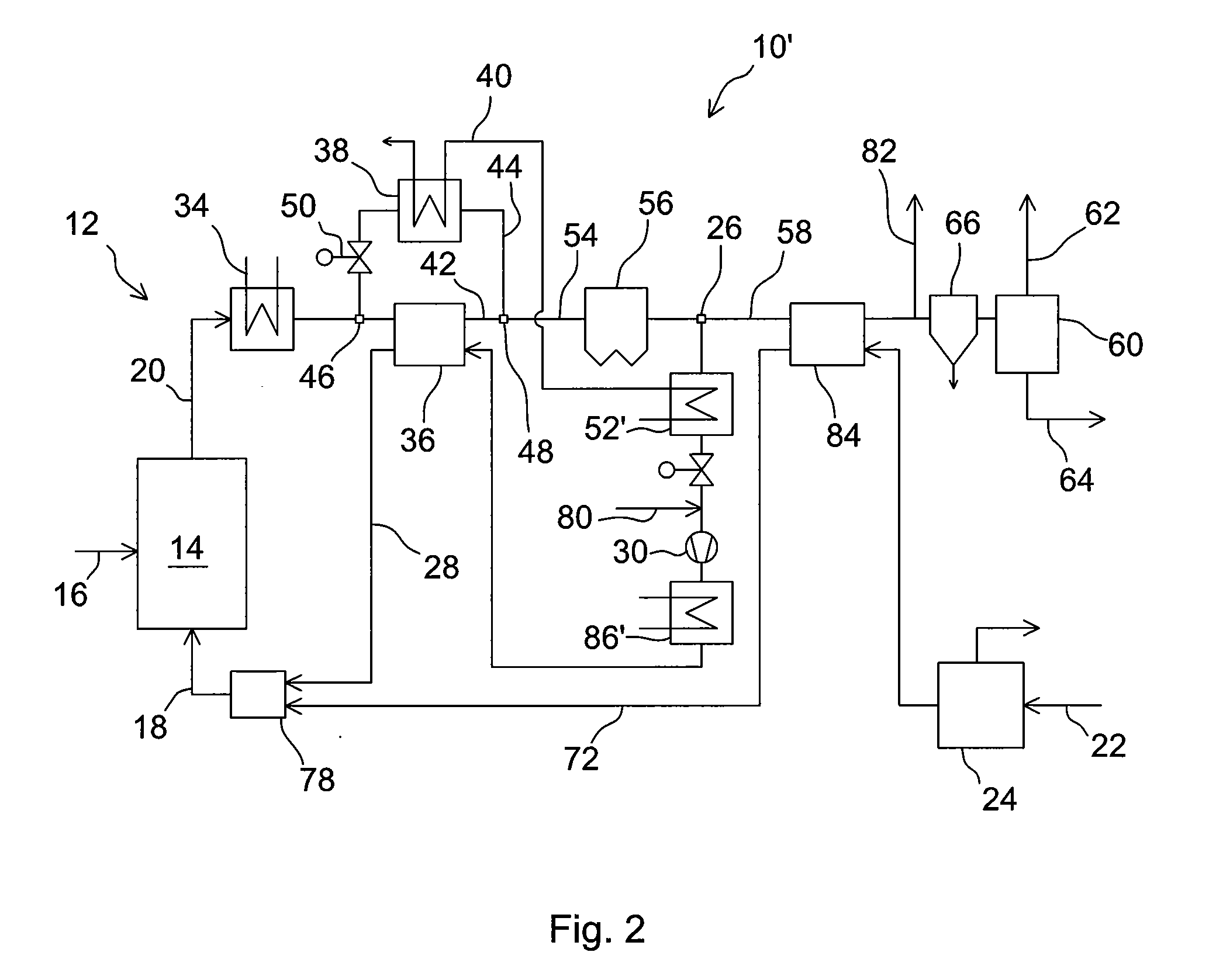

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

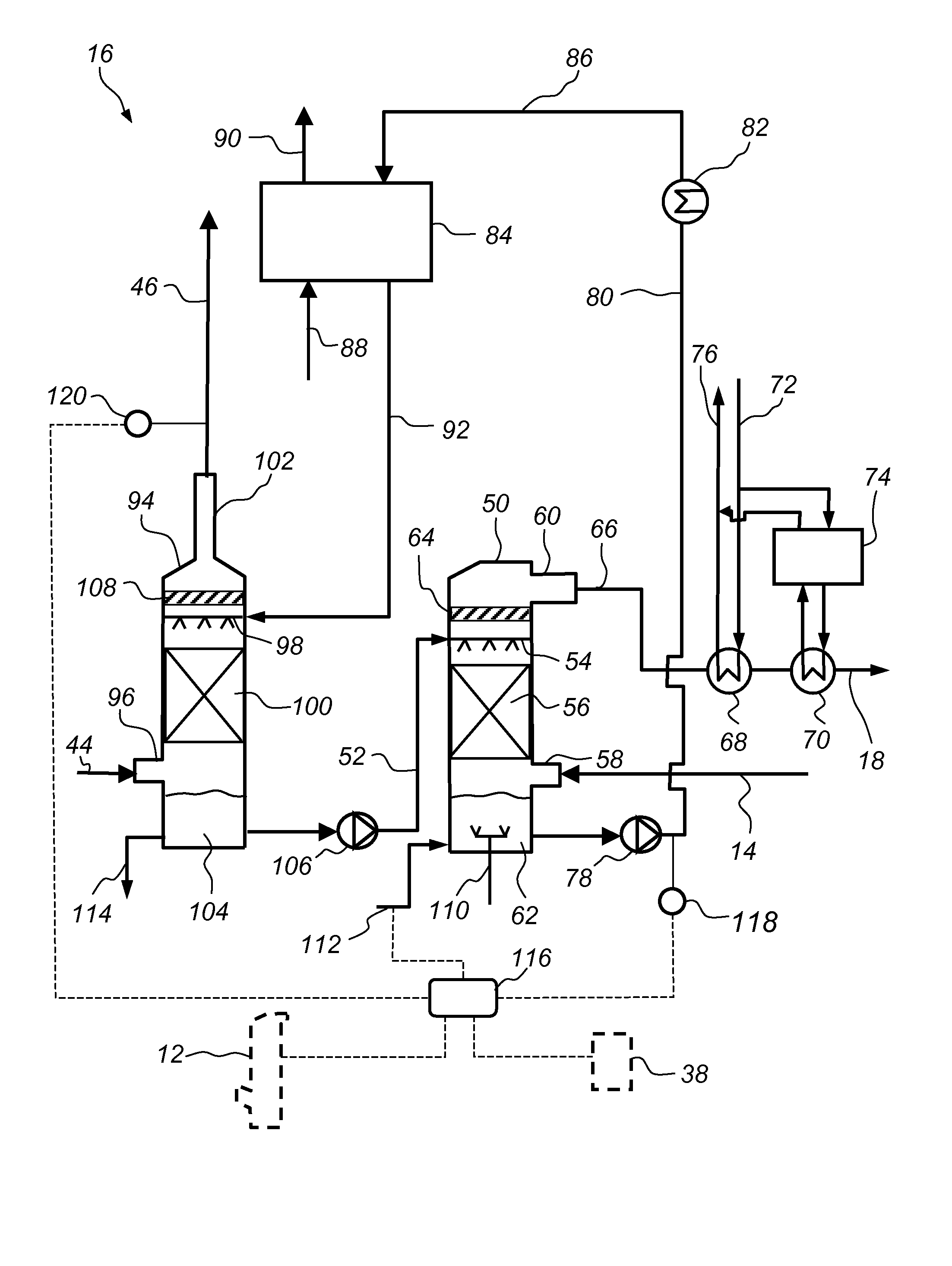

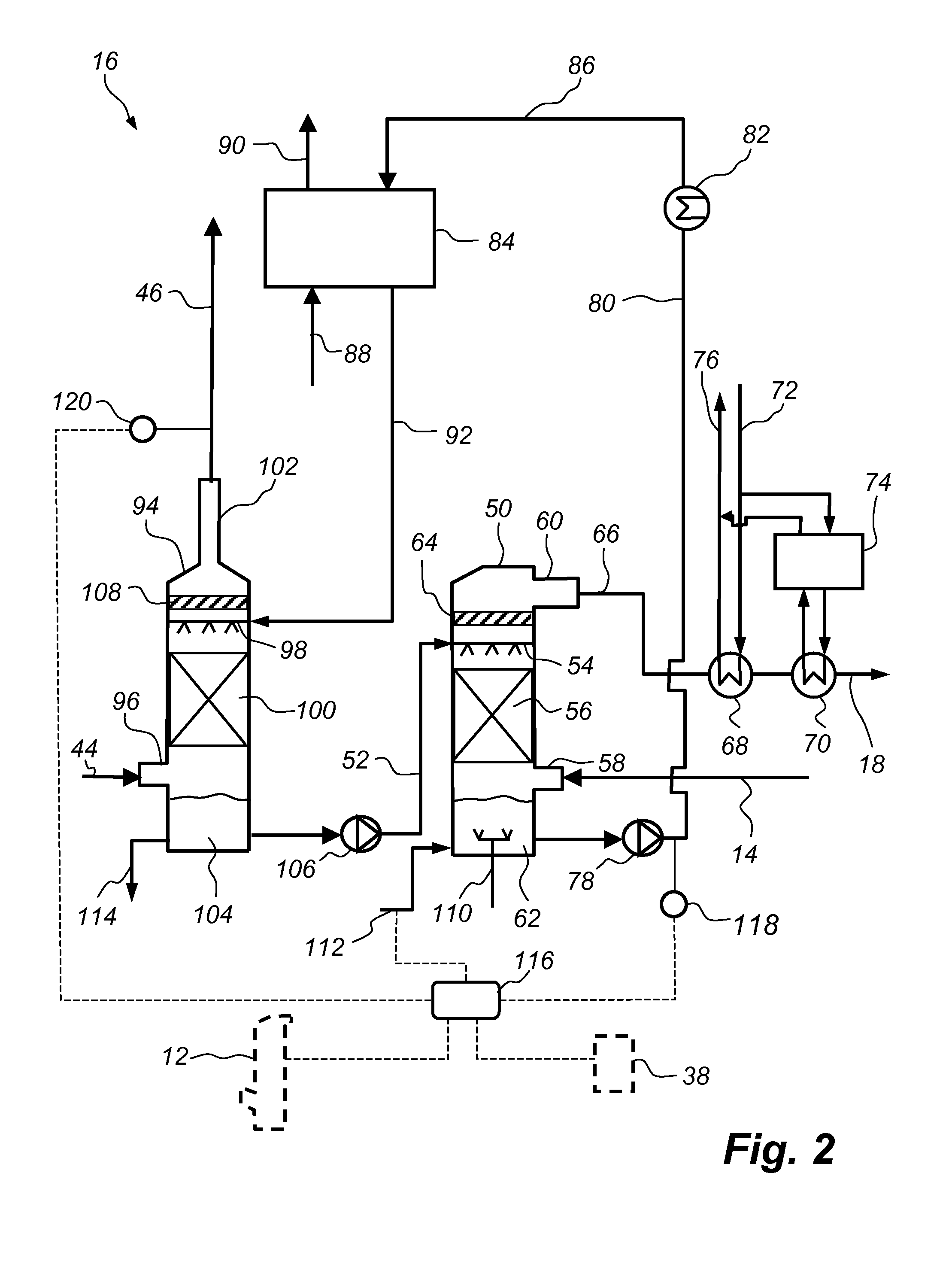

Use of so2 from flue gas for acid wash of ammonia

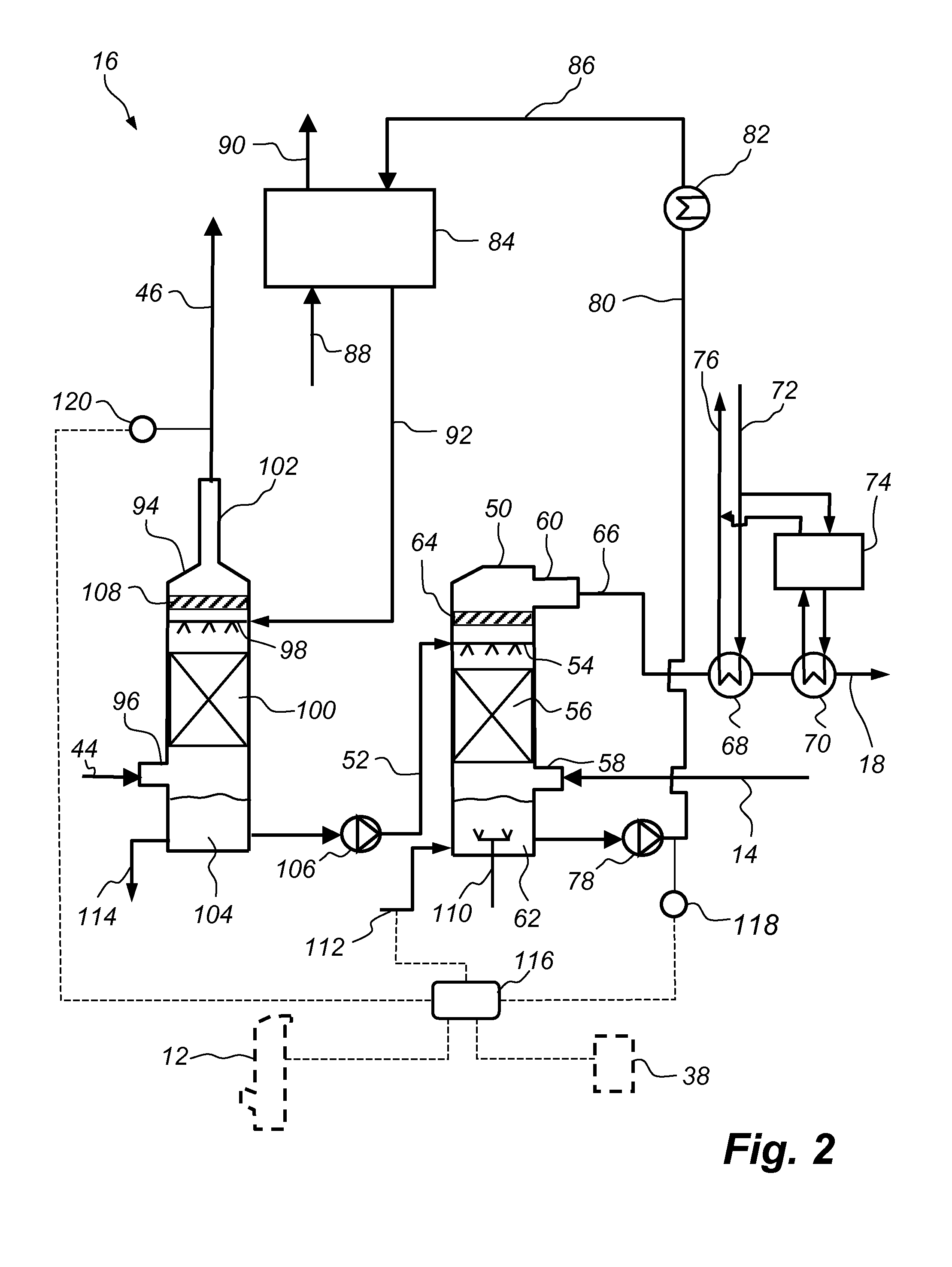

ActiveUS20080178733A1Efficient and environmentally acceptableGas treatmentDispersed particle filtrationSulfateFlue gas

A gas cleaning system, which is operative for cleaning a process gas containing carbon dioxide and sulphur dioxide, comprises a combined cooling and cleaning system (16), and a CO2-absorber. The combined cooling and cleaning system (16) comprises a first gas-liquid contacting device (50) located upstream of the CO2-absorber and operative for cooling the process gas by means of a cooling liquid, and for absorbing into the cooling liquid sulphur dioxide of the process gas, such that a cooling liquid containing sulphate is obtained. The combined cooling and cleaning system (16) further comprises a second gas-liquid contacting device (94) located downstream of the CO2-absorber and operative for removing ammonia from the process gas, which has been treated in the CO2-absorber, by means of bringing the process gas containing ammonia into contact with the cooling liquid containing sulphate.

Owner:GENERAL ELECTRIC TECH GMBH

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

Combined cycle power plant including a carbon dioxide collection system

A combined cycle power plant includes a compressor section including a compressor inlet and a compressor outlet, and a turbine section operatively connected to the compressor section. The turbine section includes a turbine inlet and a turbine outlet. A heat recovery steam generator (HRSG) is fluidly connected to the turbine outlet. A combustor includes a head end and a combustor discharge. The head end is fluidly connected to the compressor outlet and the combustor discharge is fluidly connected to the turbine inlet. A carbon dioxide collection system is fluidly connected to one of the compressor outlet and the head end of the combustor. The carbon dioxide collection system is configured and disposed to extract a first fluid comprising carbon dioxide and a second fluid from a substantially oxygen free fluid flow passed from the one of the compressor outlet and the head end of the combustor.

Owner:GENERAL ELECTRIC CO

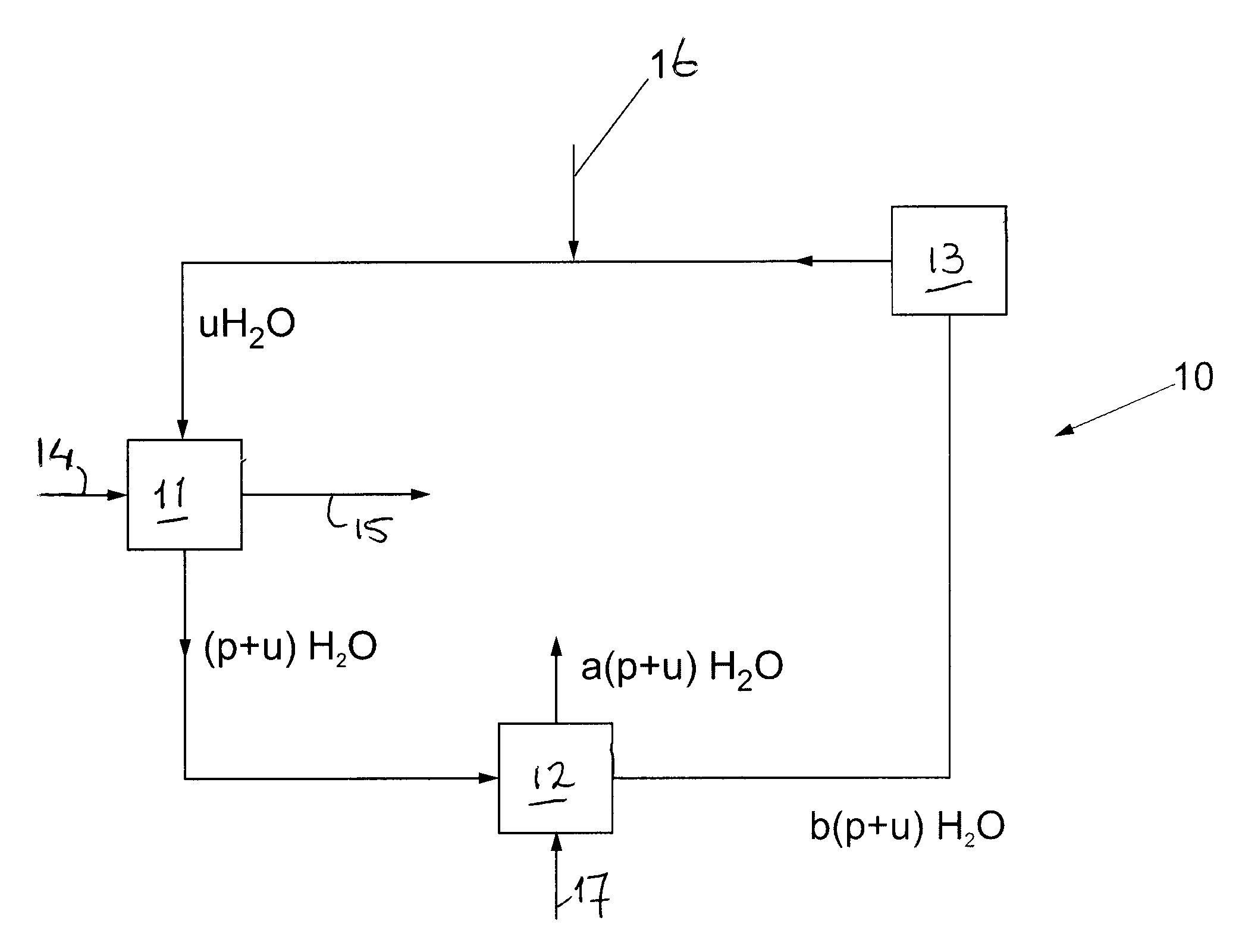

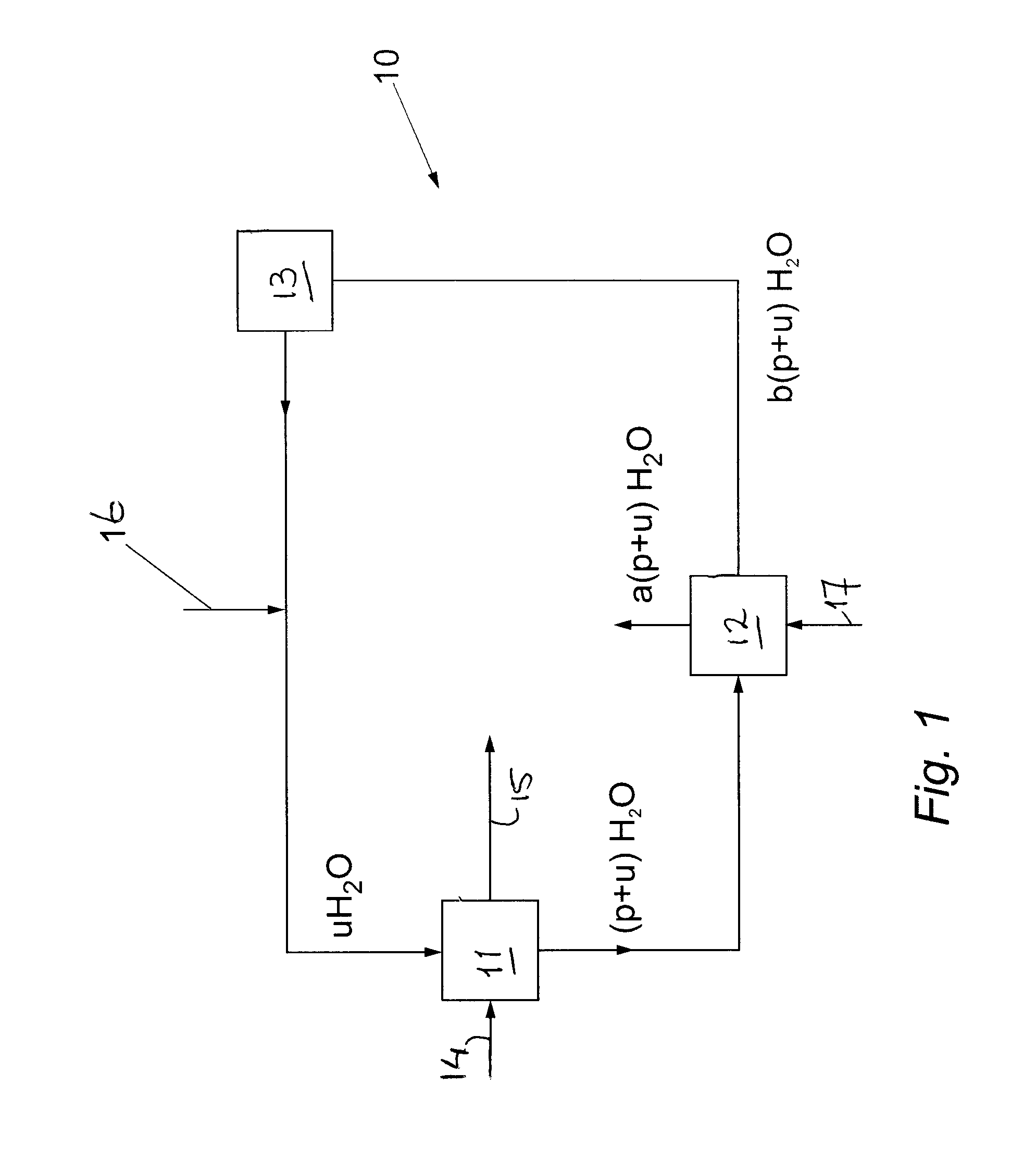

Process for cooling down a hot flue gas stream

InactiveUS7655071B2Reduce water consumptionConserve waterMethane captureCarbon compoundsFlue gasEvaporation

A process for cooling down a hot flue gas stream comprising water vapour and carbon dioxide, the process including: (a) heat exchange between the hot flue gas stream and a cooling water stream so that the hot flue gas stream is cooled to a cooled down gas stream at a temperature at which at least part of the water vapour therein has condensed and the cooling water stream increases in temperature; (b) combining the condensed water vapour and the cooling water stream to produce a combined water stream; (c) separation of the cooled down gas stream from the combined water stream; (d) cooling the combined water stream by contact with air from the atmosphere and by evaporation of a portion of the combined water stream; (e) using at least part of any non-evaporated and cooled water of the combined water stream as at least part of the cooling water stream for cooling the hot flue gas stream in step (a); and (f) storing any non-evaporated and cooled water of the combined water stream that is not used in step (e) and using the stored water later as at least part of the cooling water stream in step (a).

Owner:SHELL OIL CO

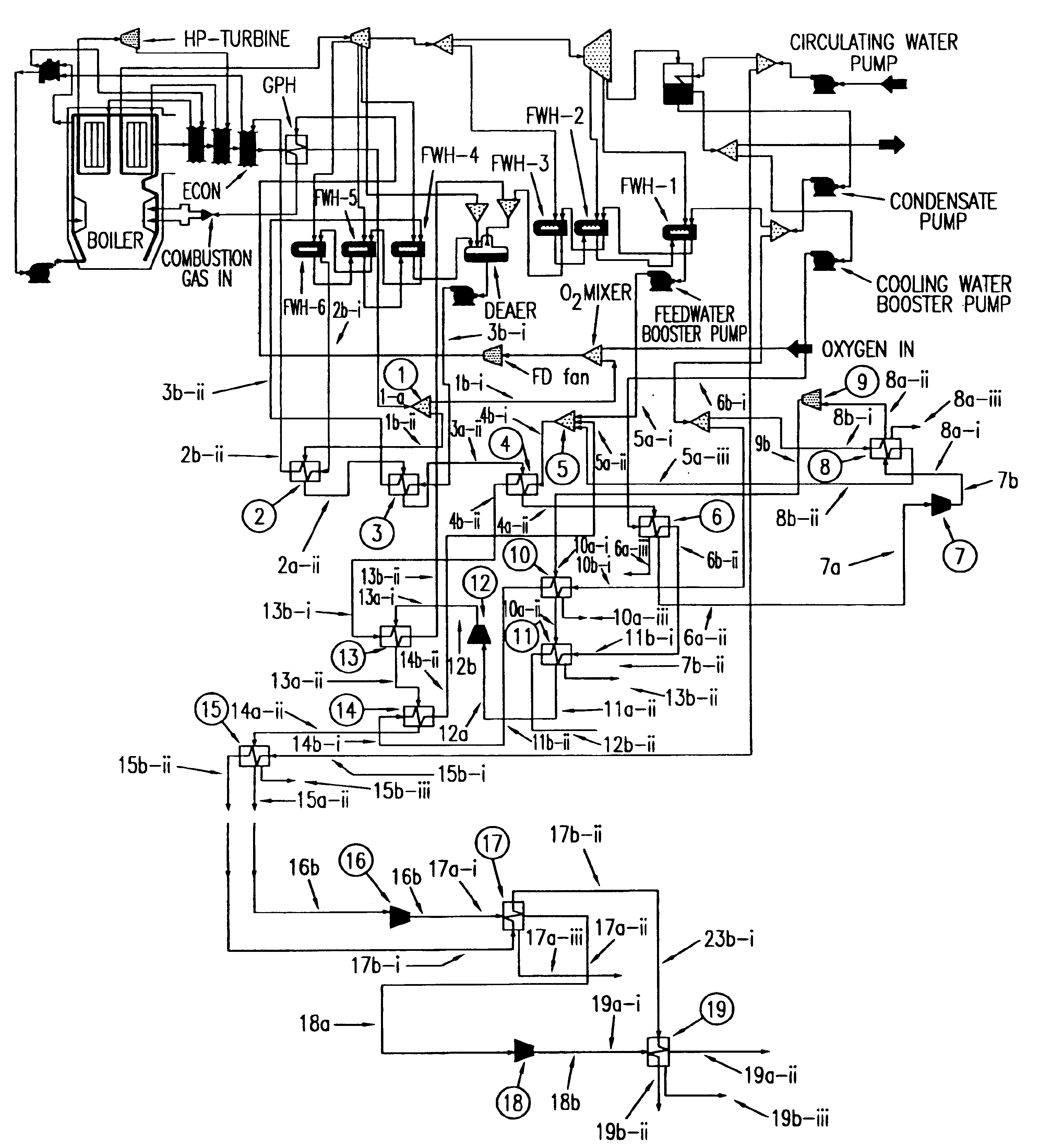

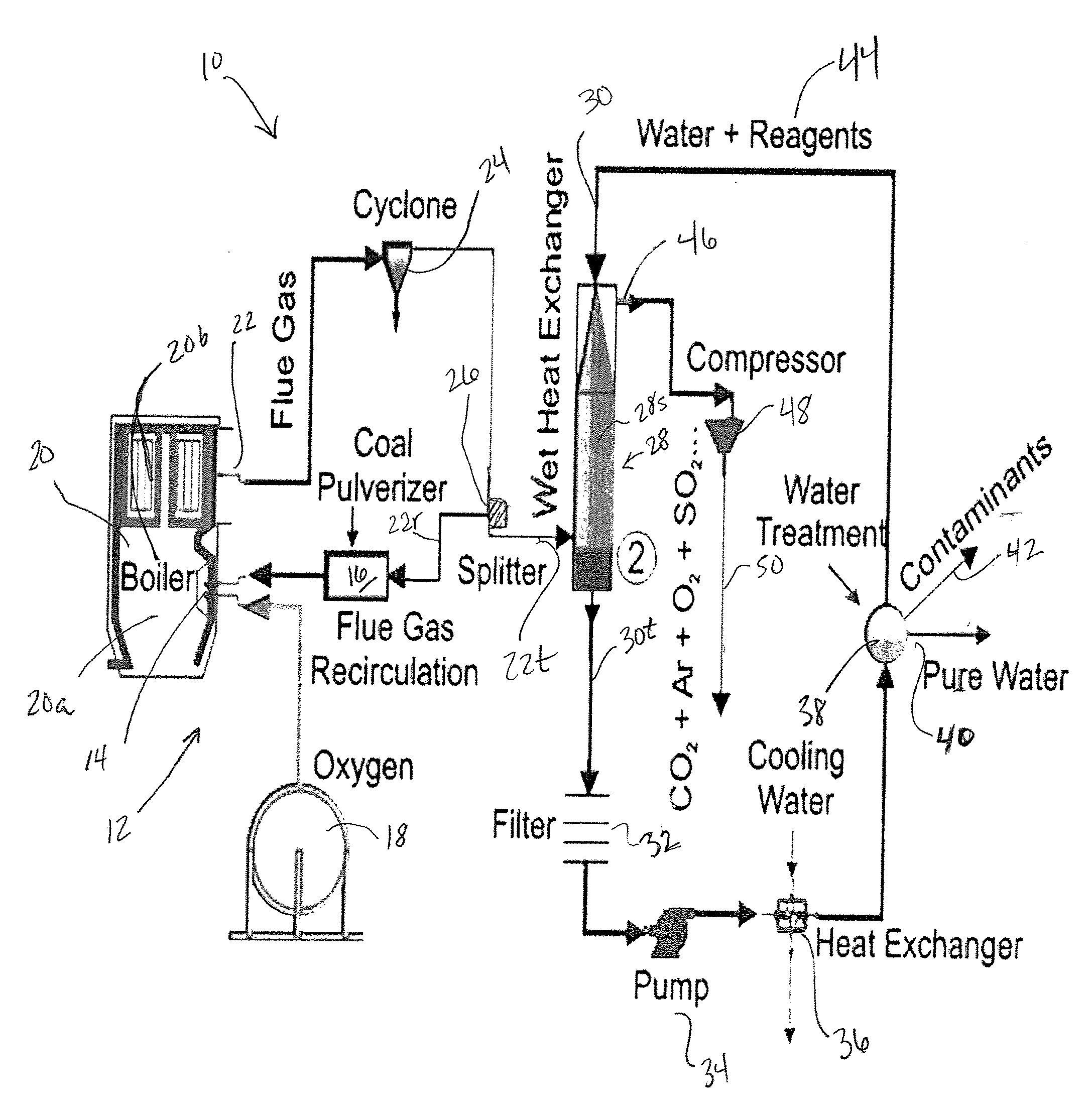

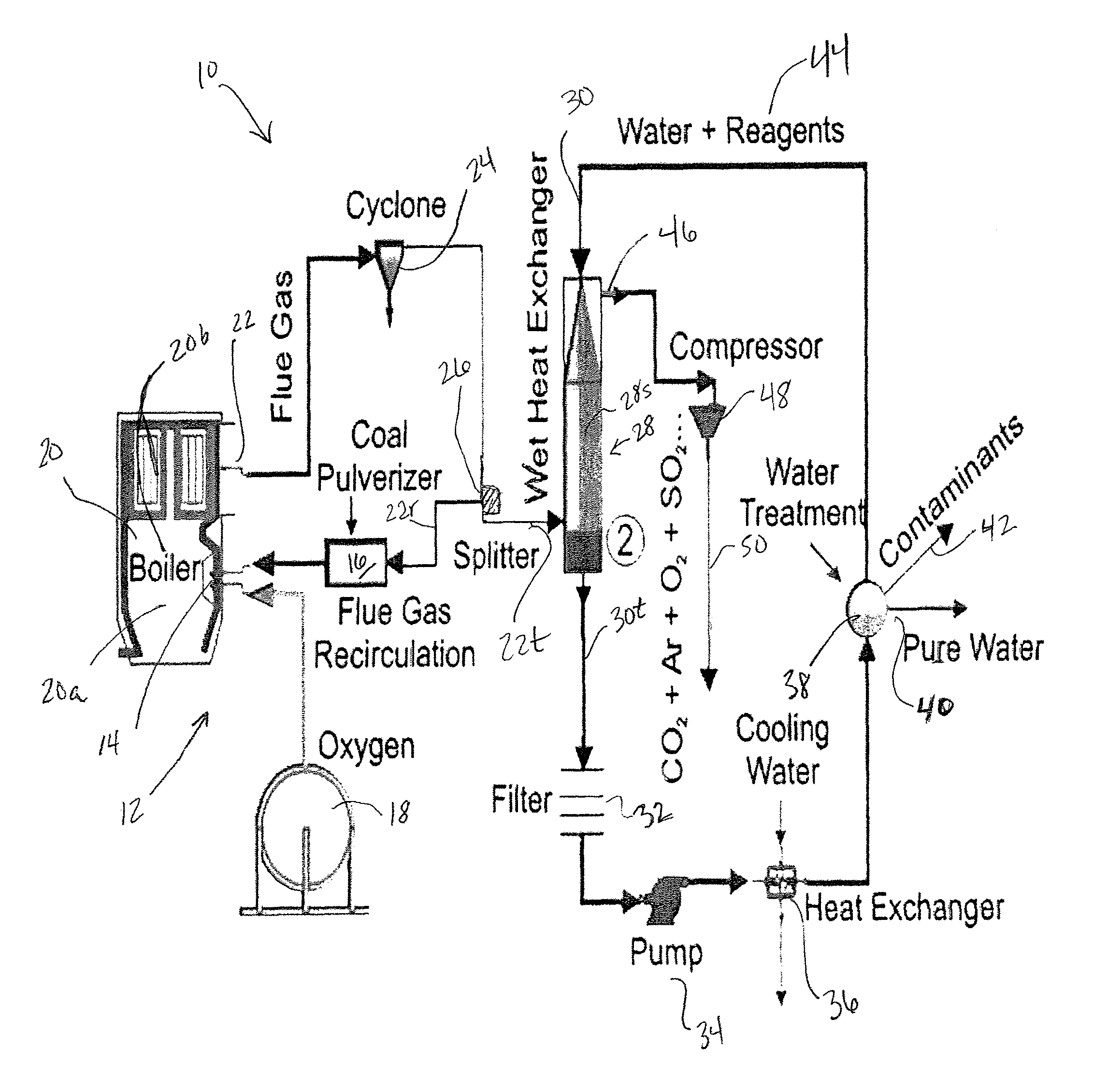

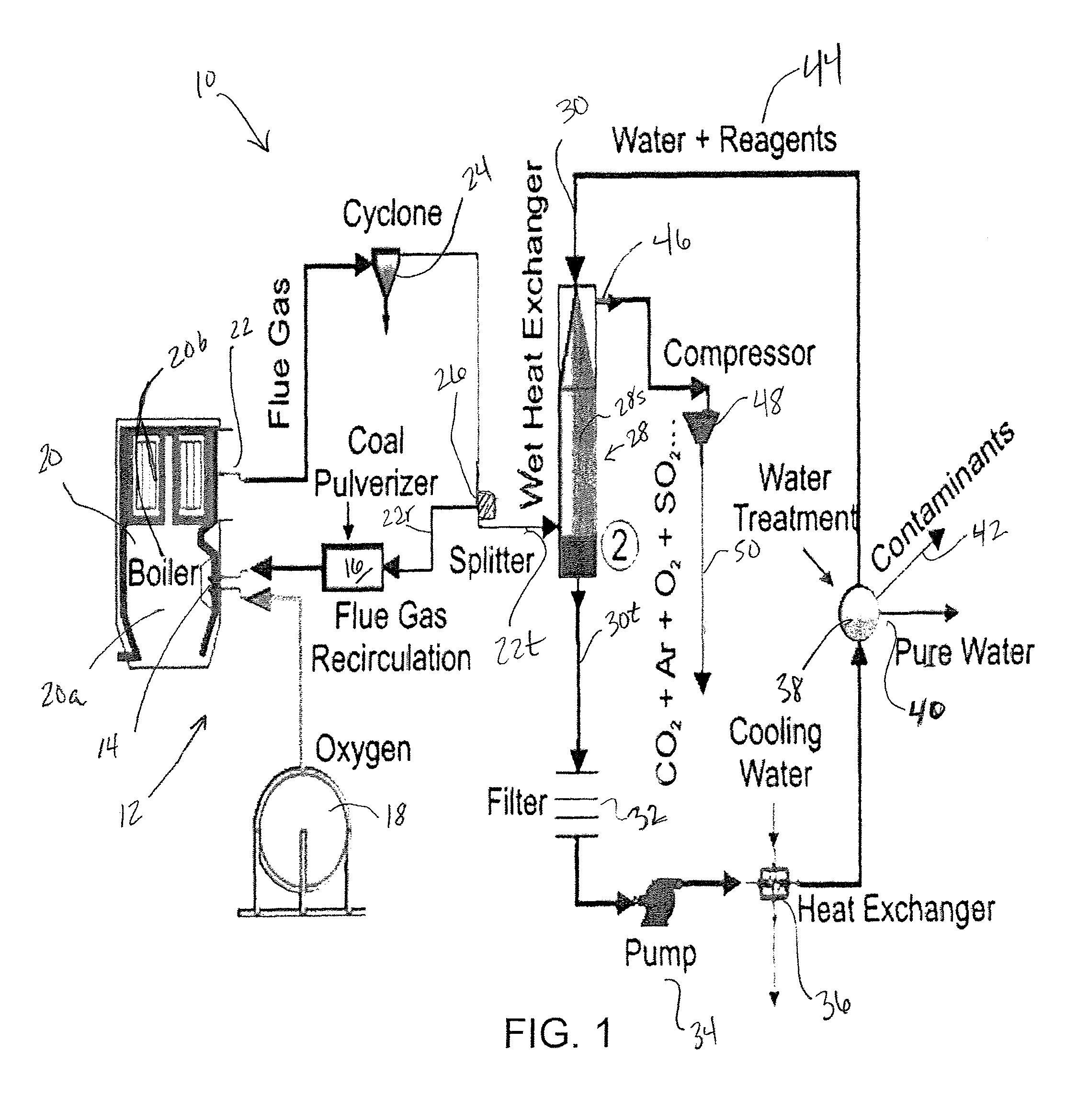

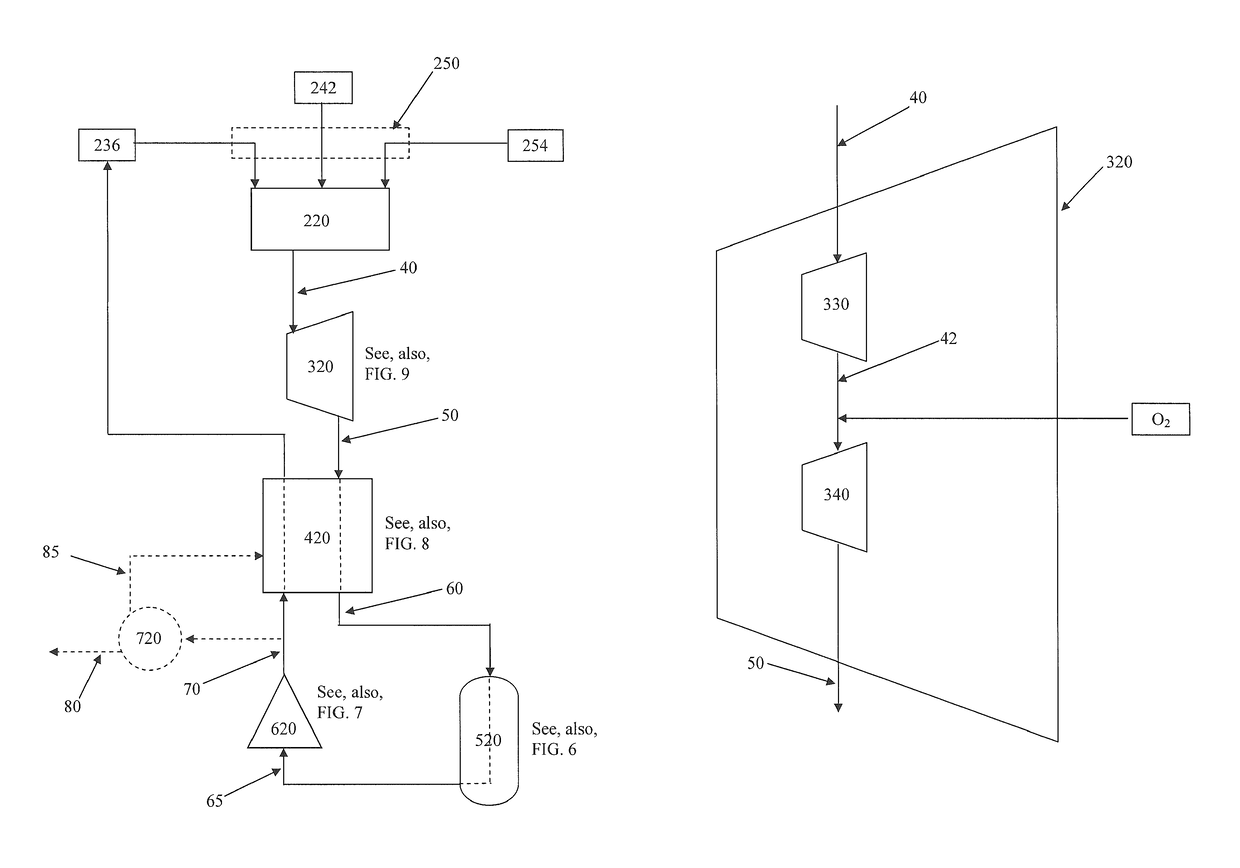

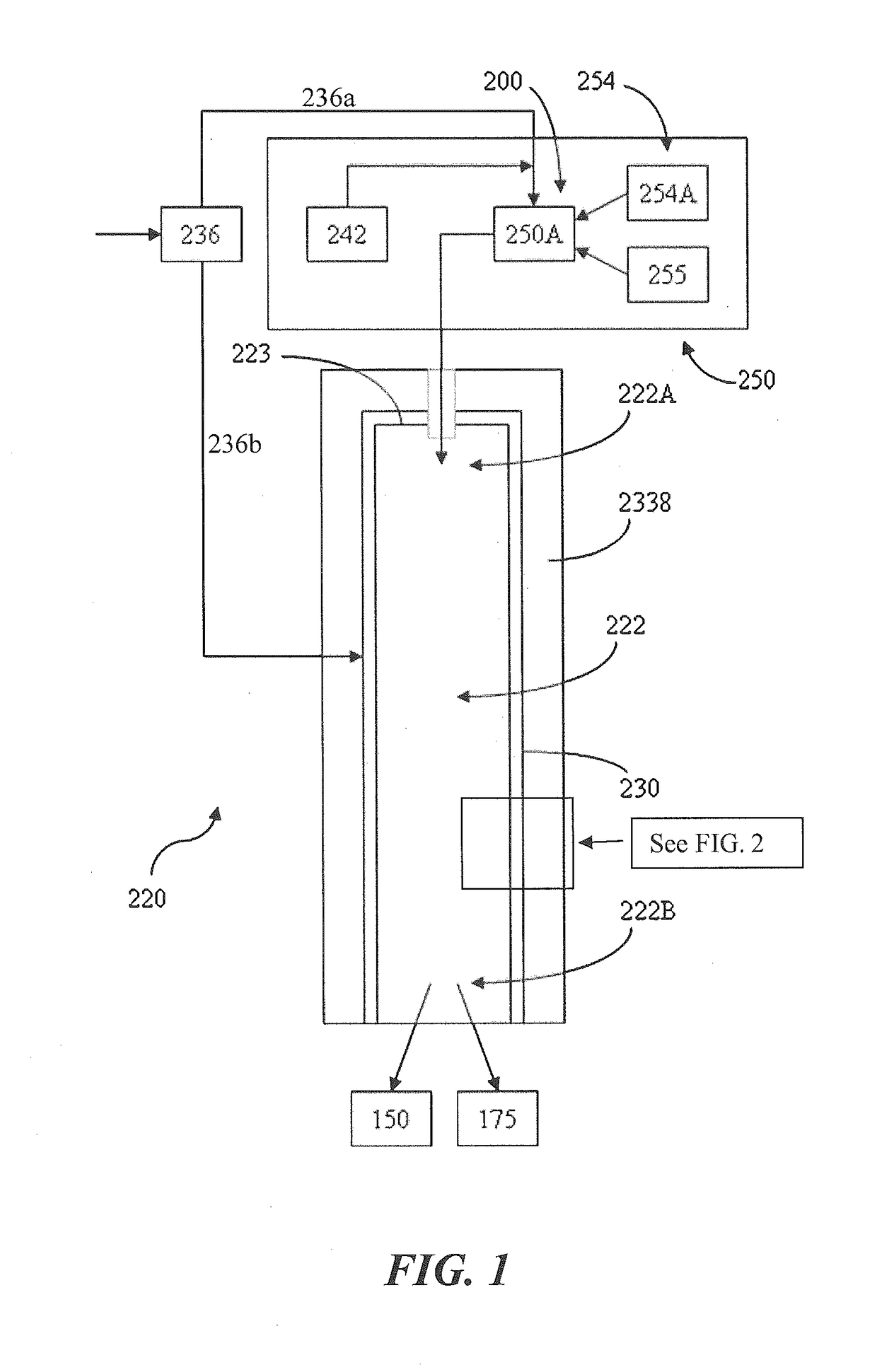

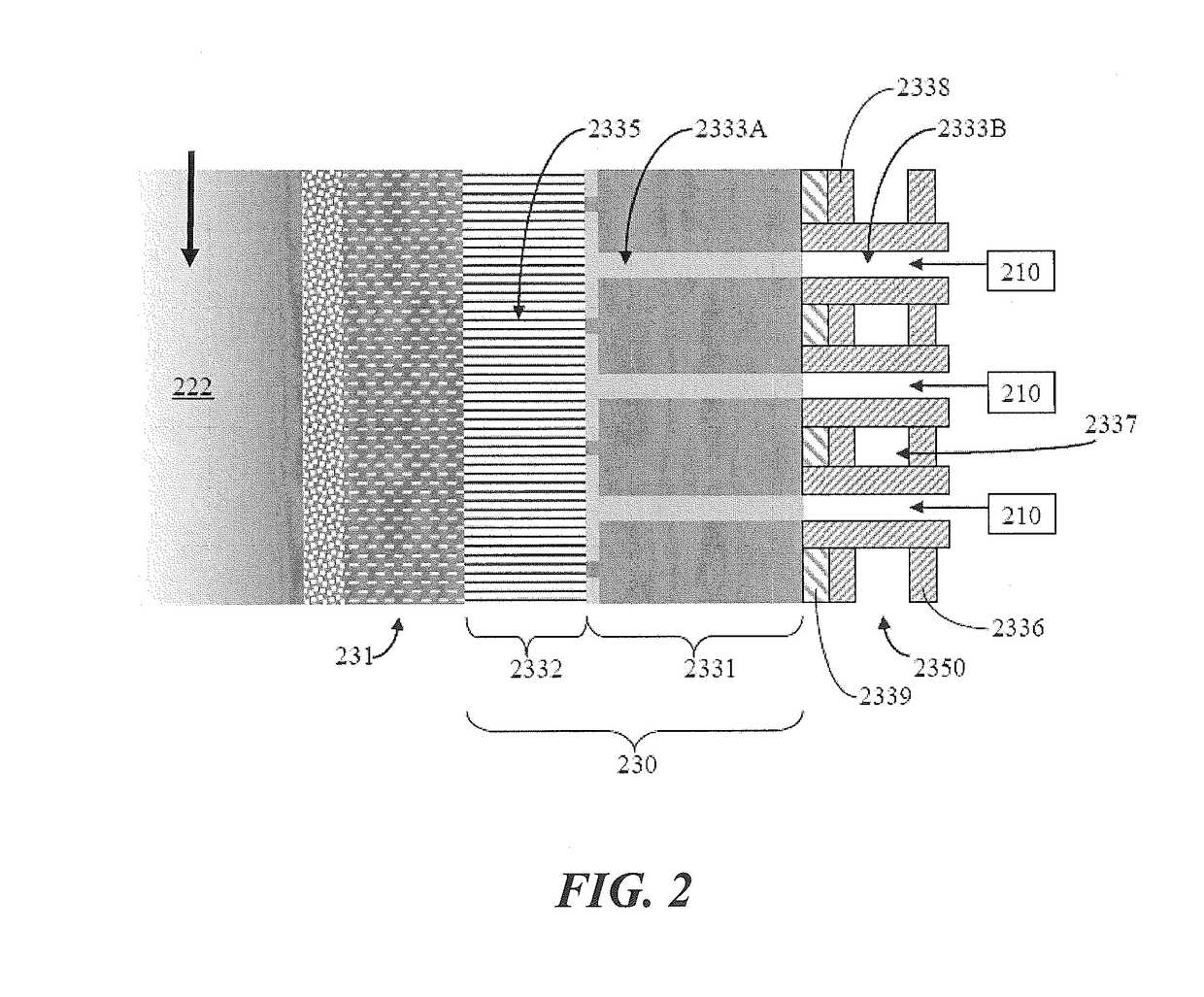

Integrated capture of fossil fuel gas pollutants including co2 with energy recovery

ActiveUS20080016868A1Increase costMaximum recoveryUsing liquid separation agentEmission preventionParticulatesEnergy recovery

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

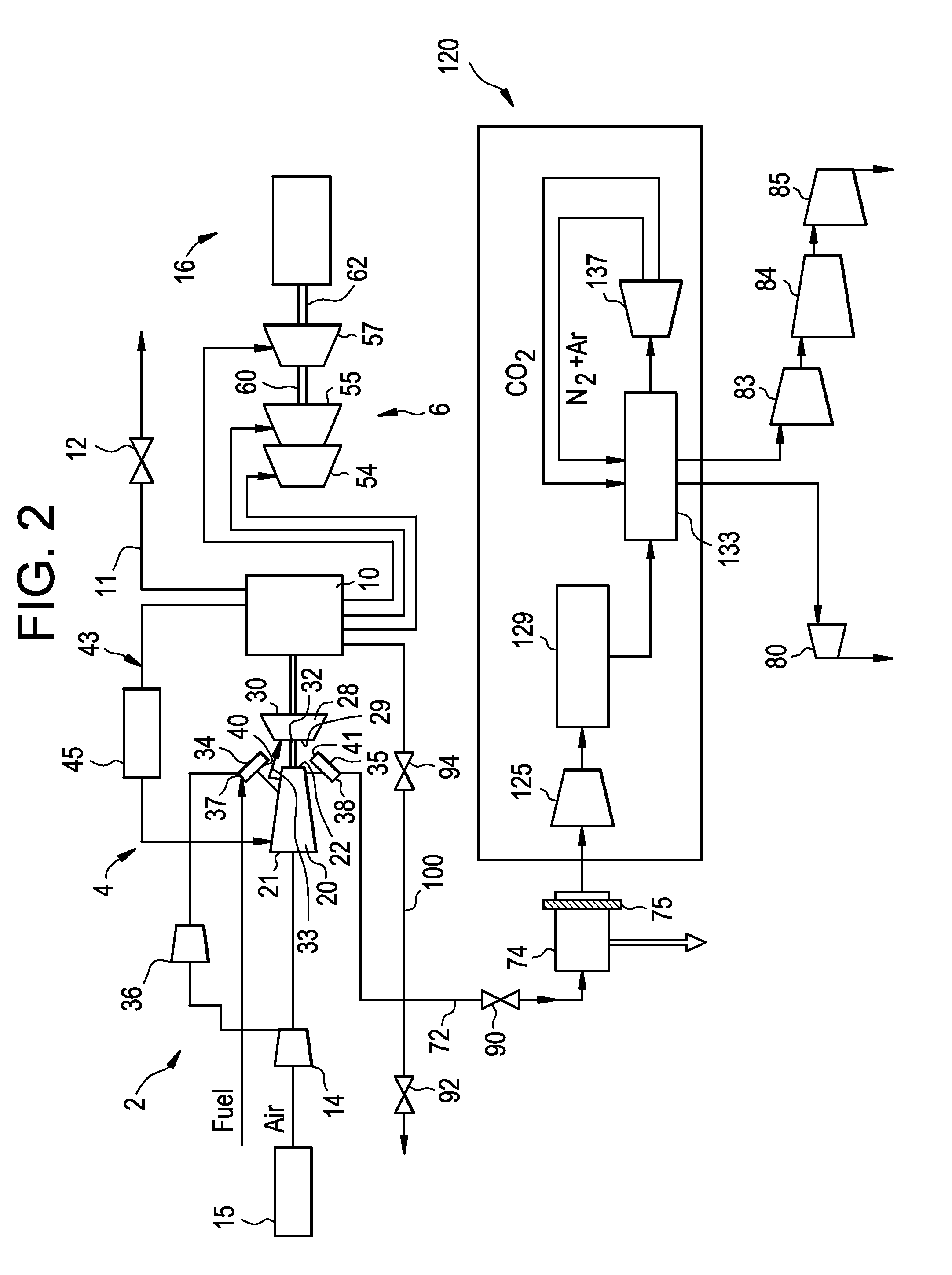

Integrated capture of fossil fuel gas pollutants including CO2 with energy recovery

ActiveUS8038773B2Maximum recoveryUsing liquid separation agentEmission preventionParticulatesAtmospheric air

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

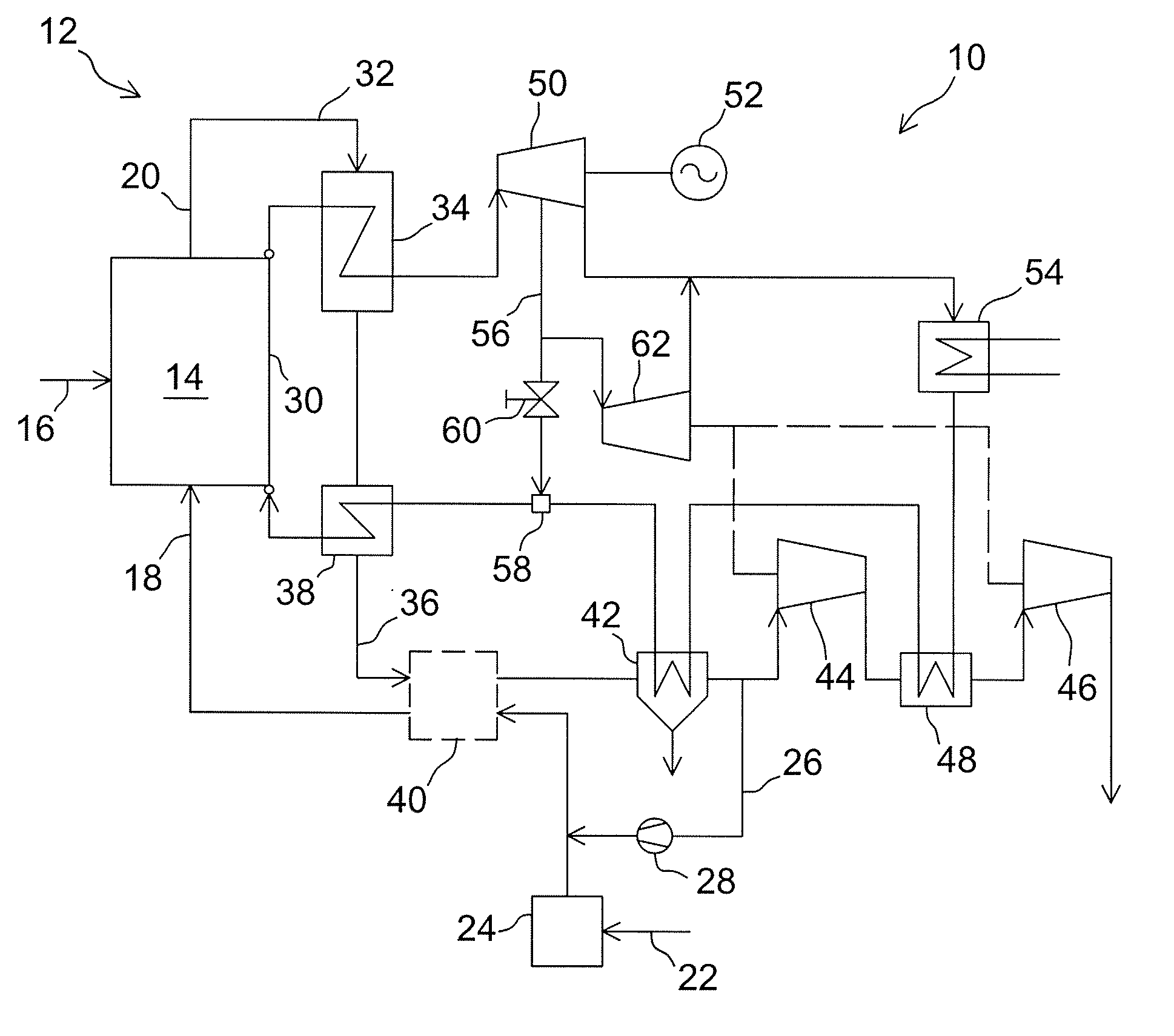

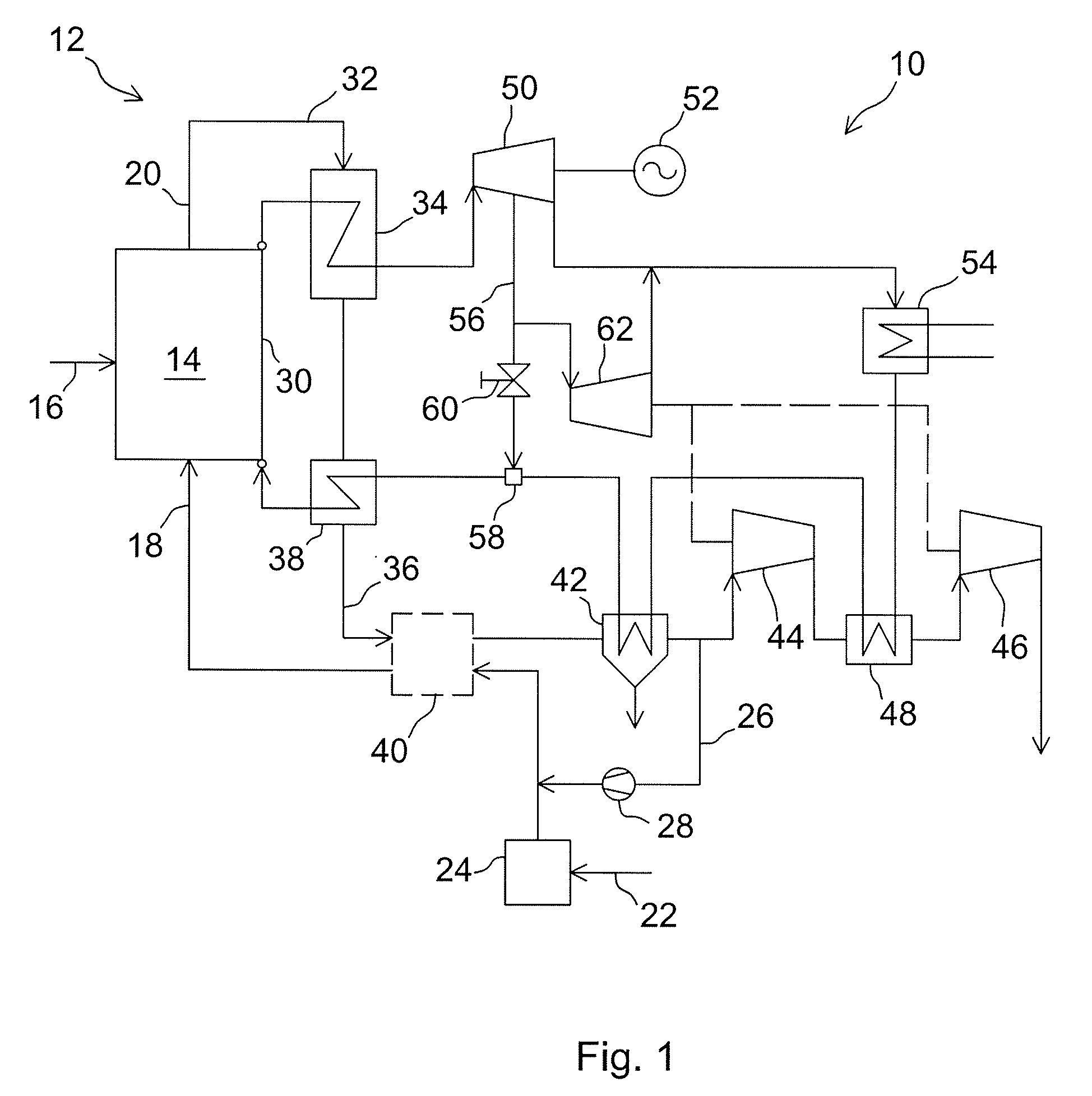

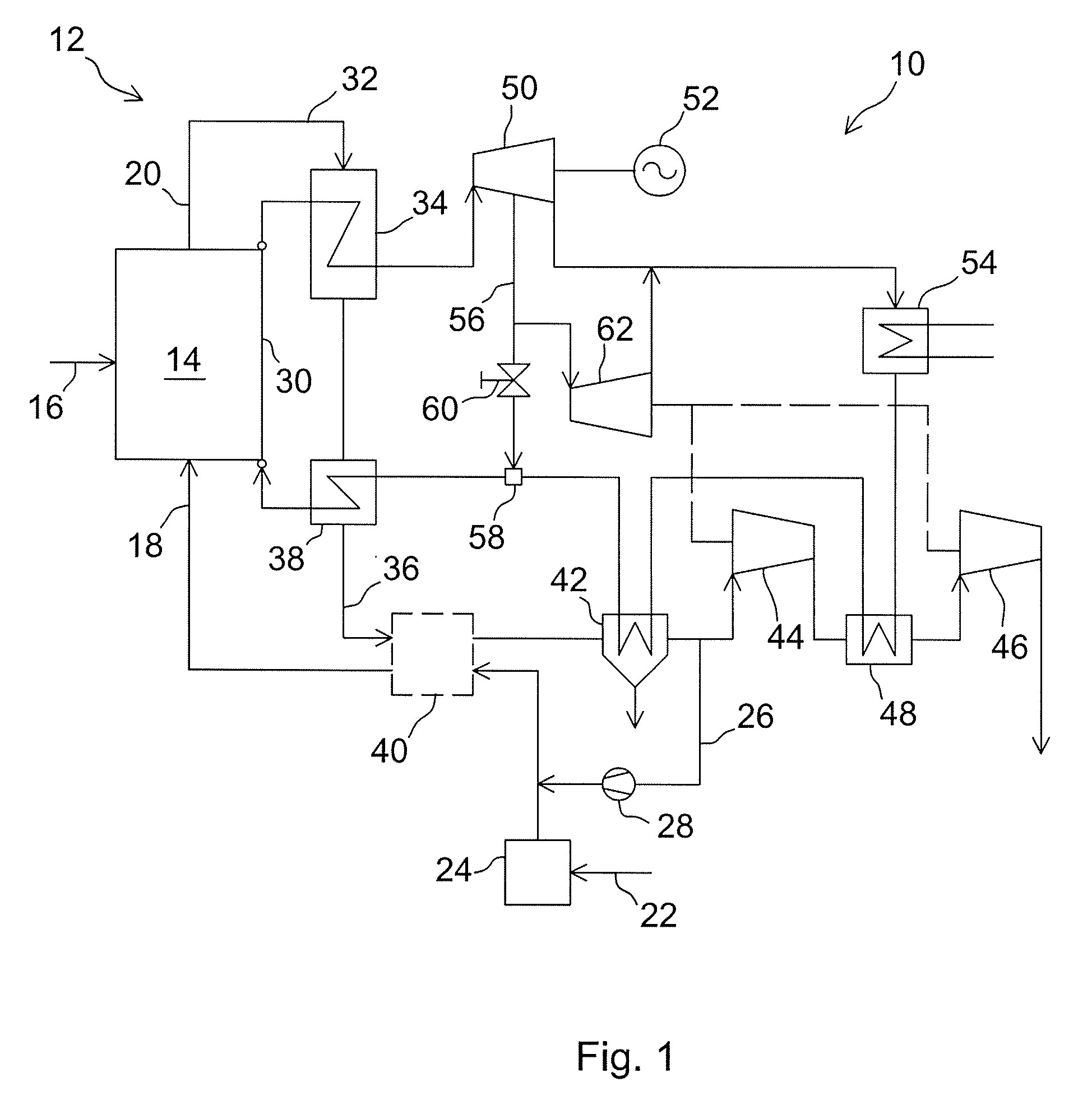

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20130213049A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

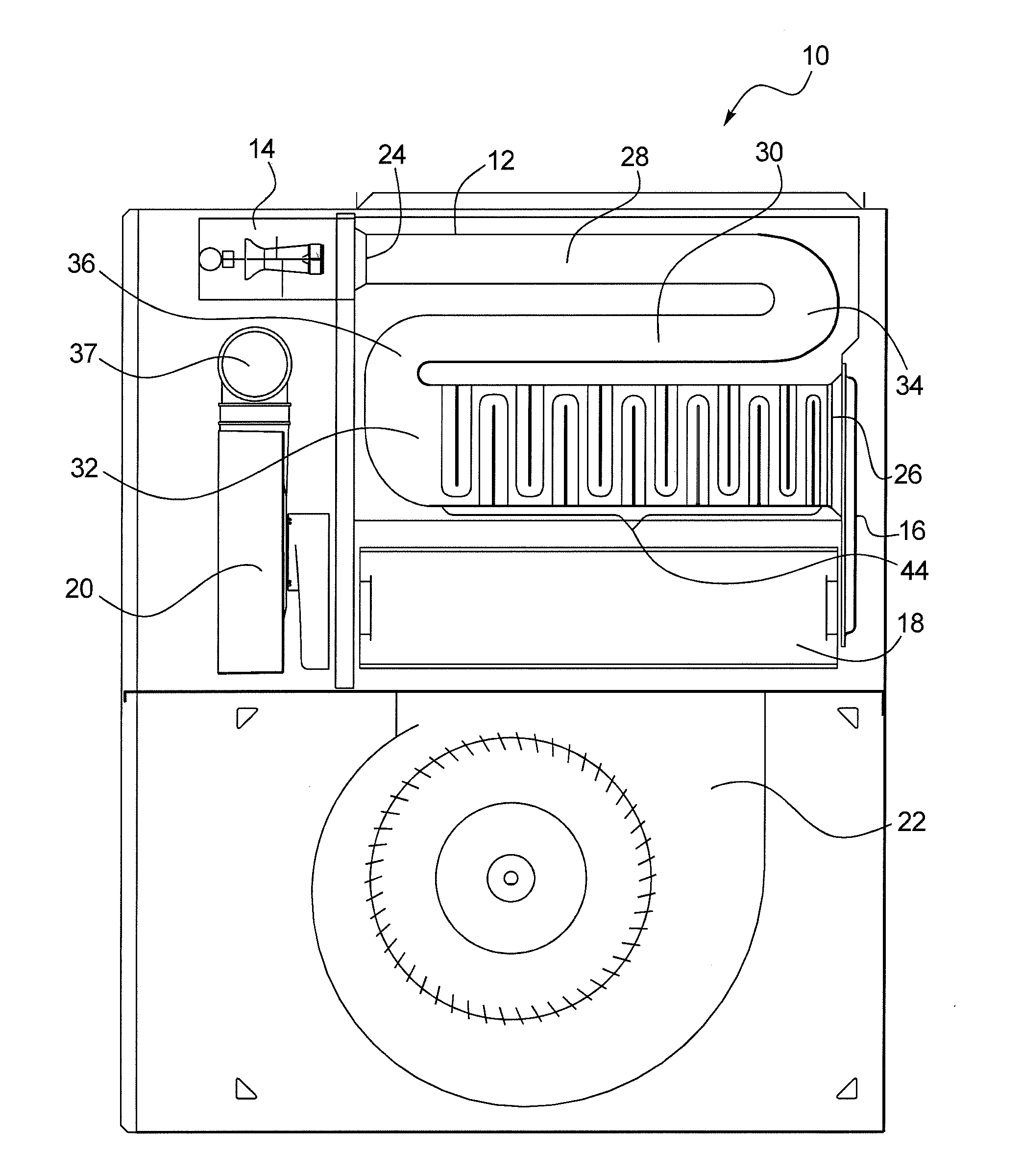

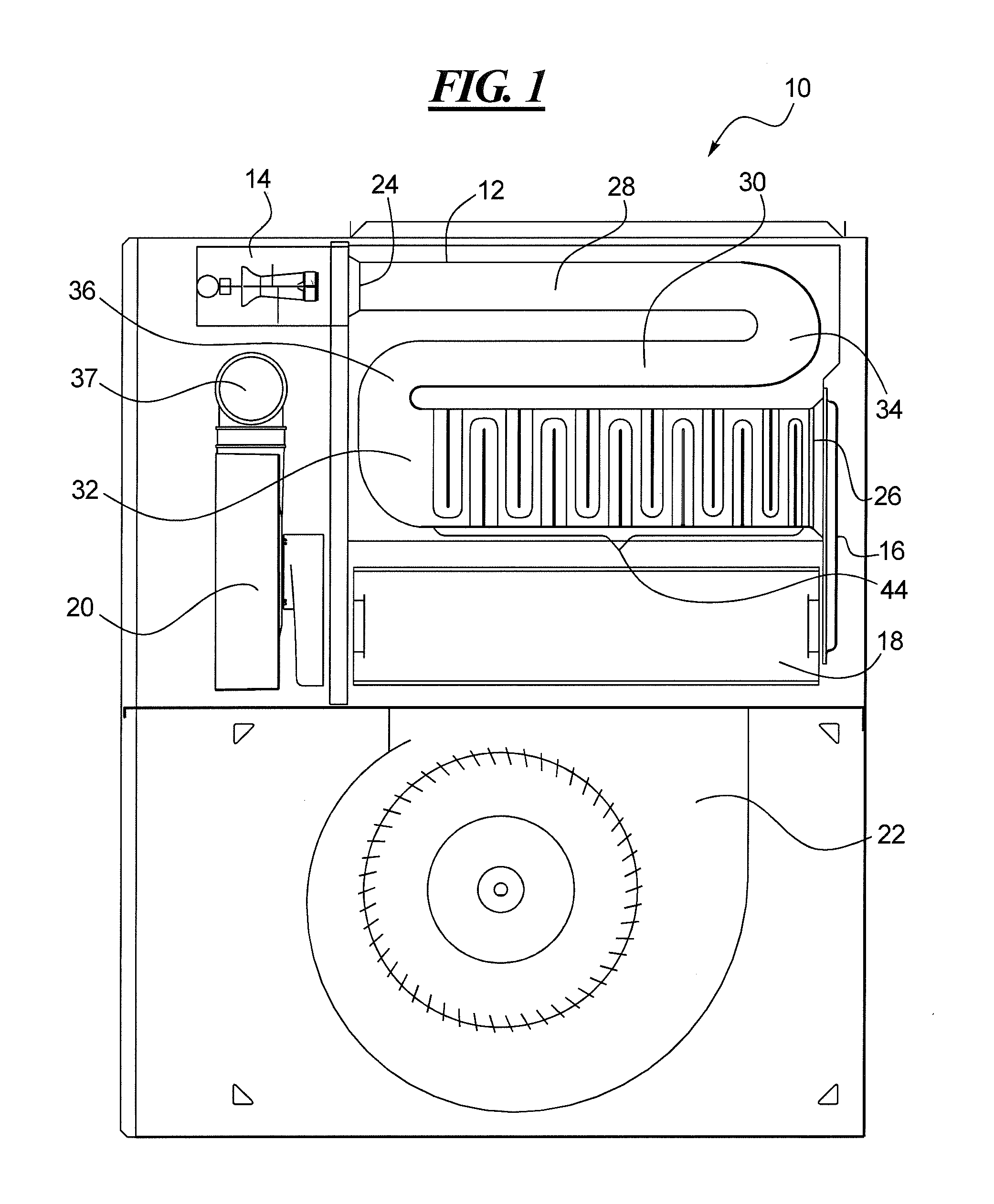

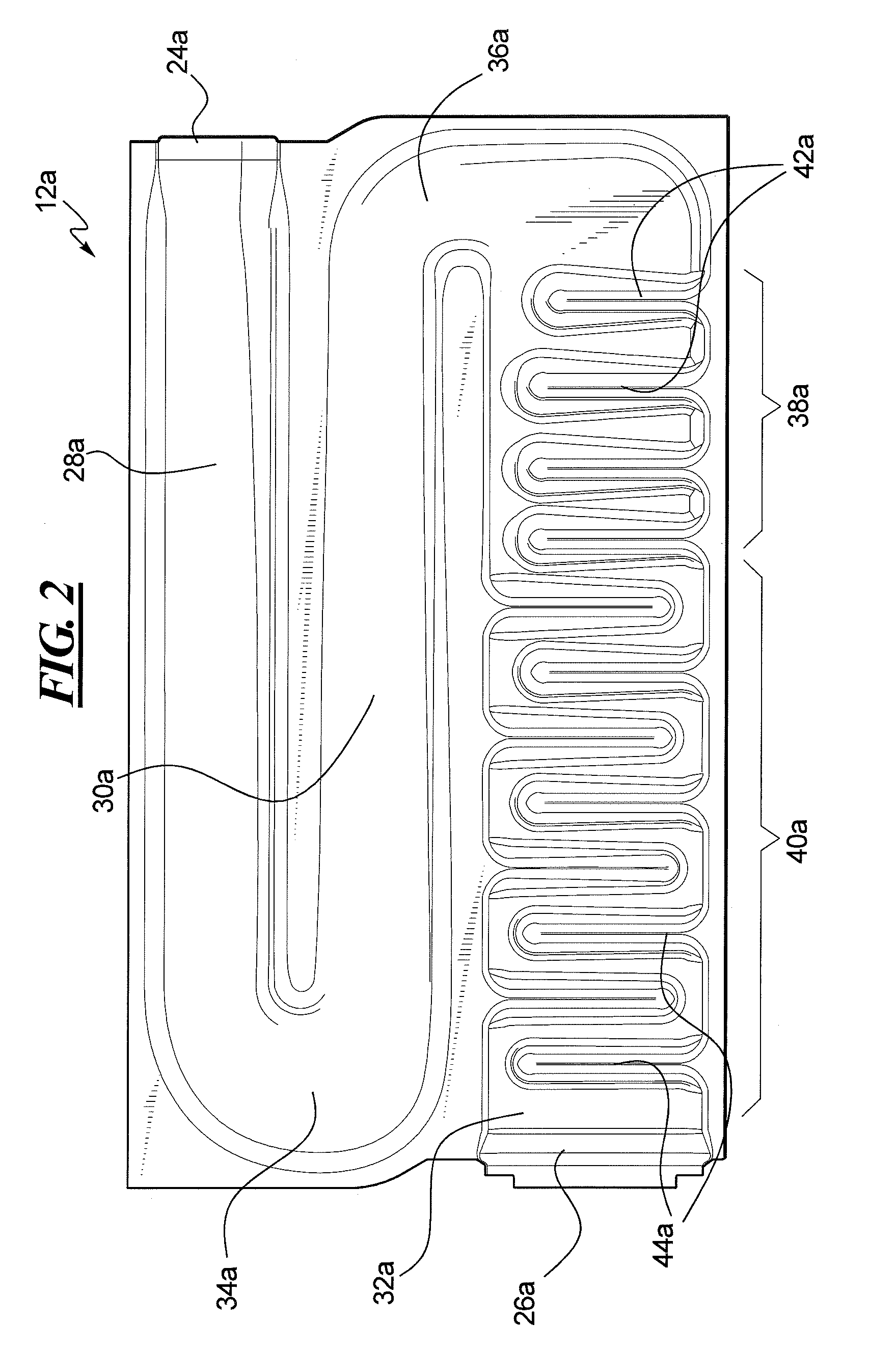

Primary Heat Exchanger Design for Condensing Gas Furnace

ActiveUS20110174301A1Domestic stoves or rangesEnergy efficient heating/coolingProcess engineeringHeat exchanger

A compact furnace heat exchanger for a gas furnace is disclosed. The compact furnace heat exchanger may include a first pass having an inlet end, a second pass in fluid communication with the first pass through a first return bend, and a third pass having an outlet end and in fluid communication with the second pass through a second return bend. The third pass may further include a plurality of irregularities for optimizing performance of the compact furnace heat exchanger and the associated gas furnace.

Owner:CARRIER CORP

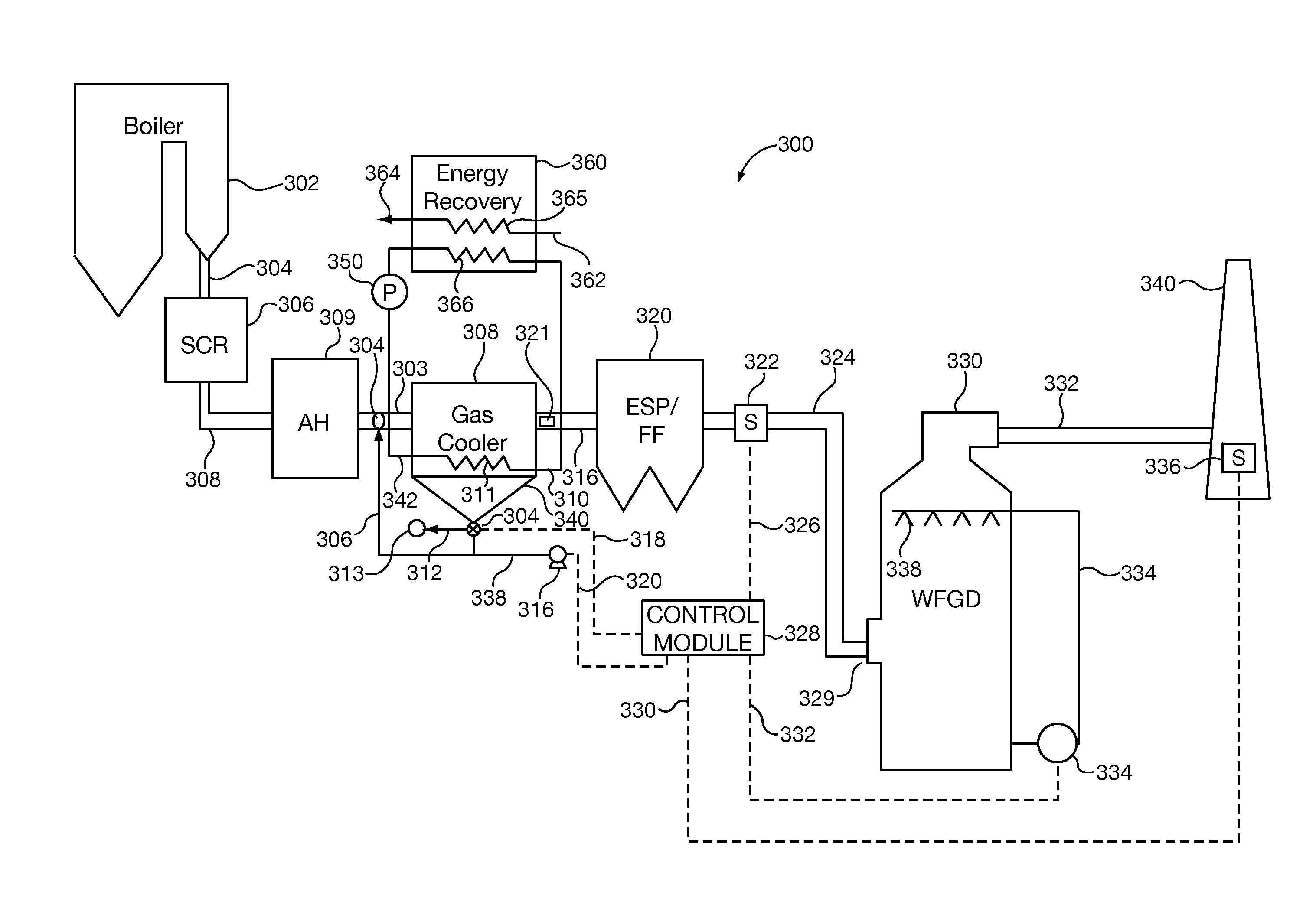

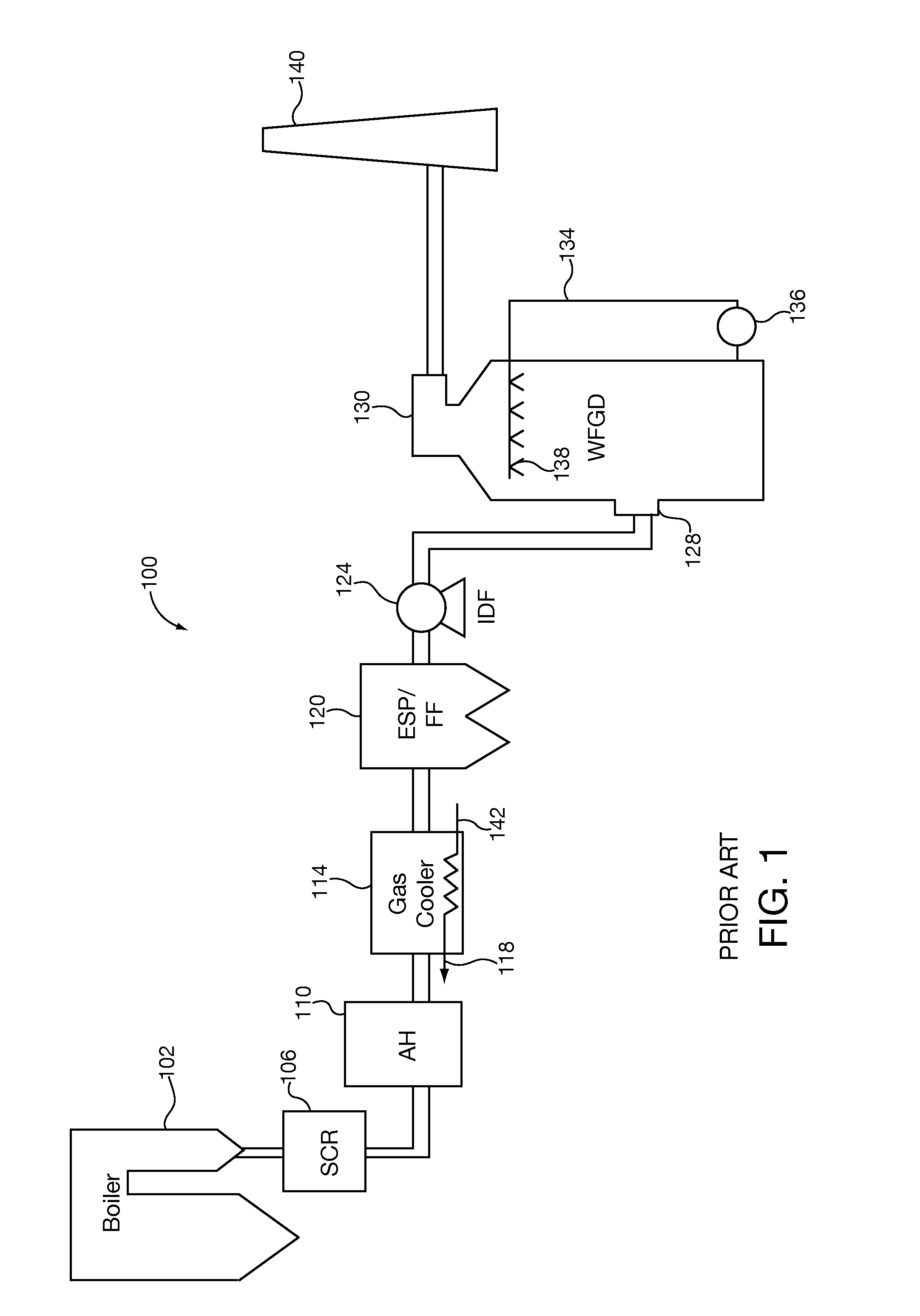

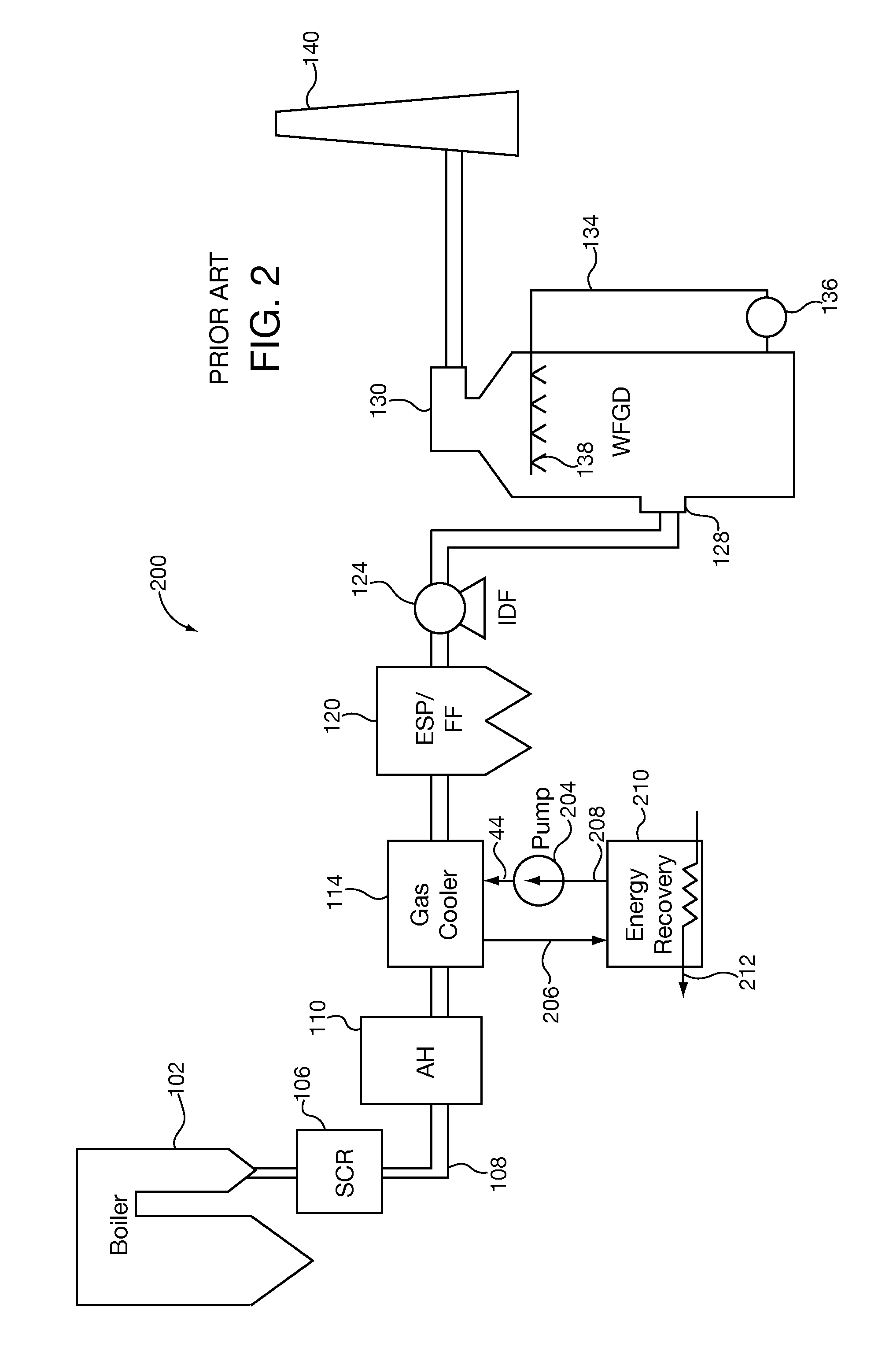

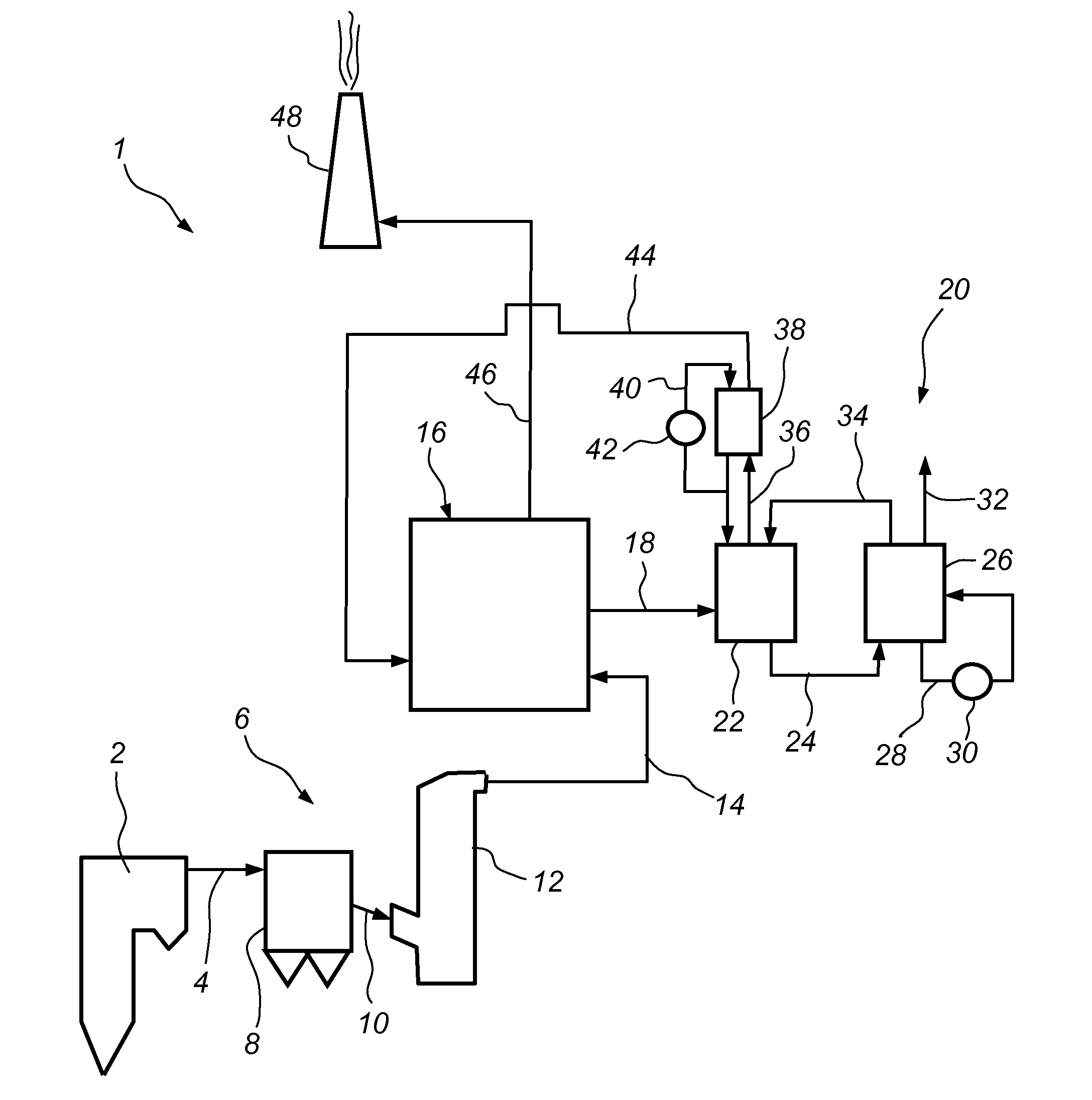

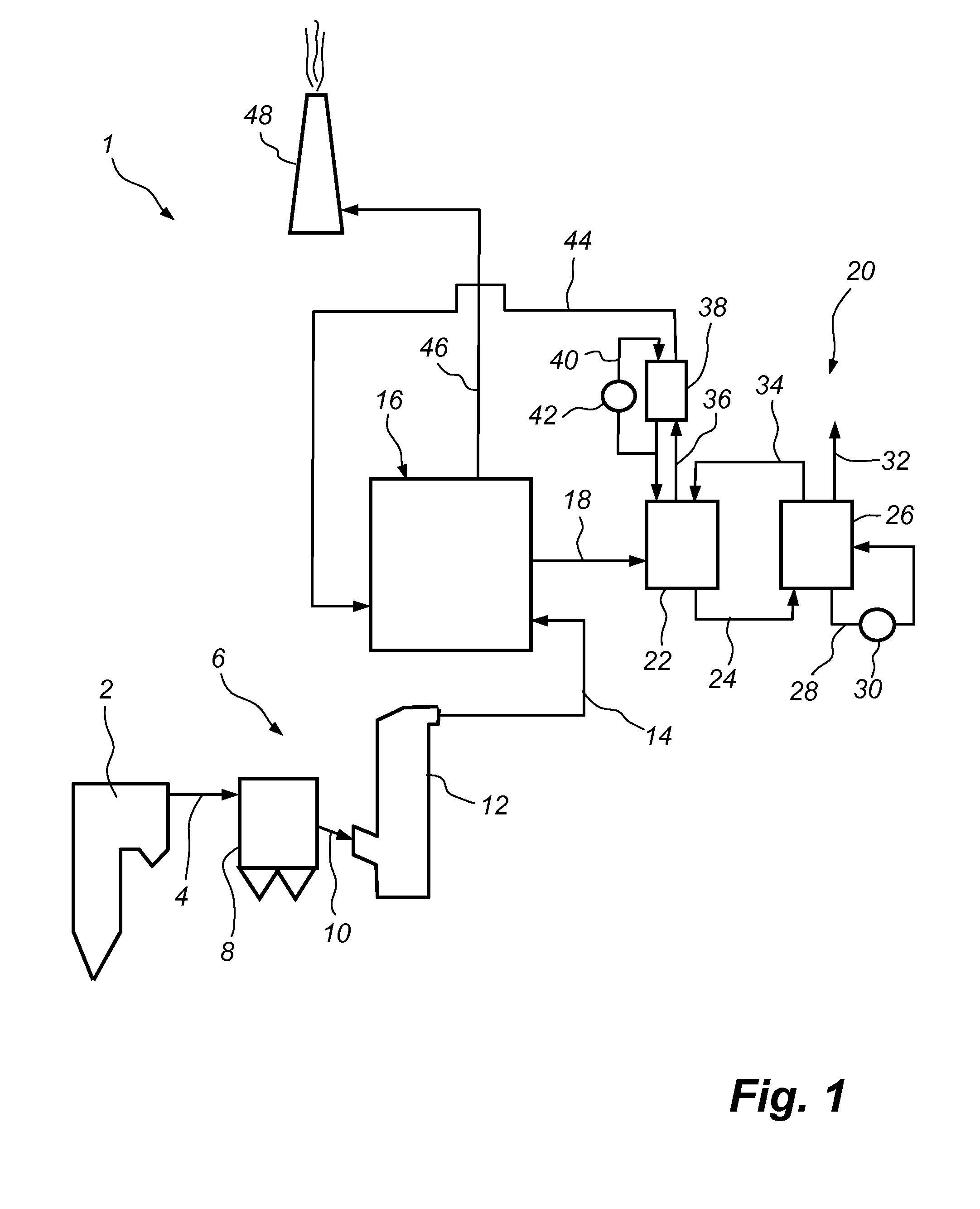

Methods and apparatus for performing flue gas pollution control and/or energy recovery

ActiveUS20090078177A1Improve system efficiencyAvoid and eliminate and reduce any needCombustion using gaseous and pulverulent fuelGas treatmentParticulatesRe introduction

Methods and apparatus for pollution control which are well suited for use in a coal power plant are described. Ash is collected and injected into the flue gas stream at a location upstream of a cooling module. The ash acts as an absorbent and / or reactant material onto which condensate may condense. By re-introducing ash to keep the condensation forming wet areas within the system, lower cost materials which are less corrosion resistant than needed for wet operating conditions can be used. Mercury recovery and SO3 removal is facilitated by the cooling process and re-introduction of collected ash. Activated carbon and / or an alkali absorbent material may be added. Use of a dry ESP and / or fabric filter as opposed to a wet ESP for particulate collection leads to cost benefits. Energy recovered by the cooling of the flue gas may be re-used to heat turbine condensate leading to improved energy efficiency.

Owner:MITSUBISHI POWER AMERICAS INC

Method of and apparatus for CO2 capture in oxy-combustion

InactiveUS20080184880A1Efficient methodLow costCombination devicesSolidificationPower stationCombustion chamber

A method of and an apparatus for capturing CO2 from flue gas emanating from a carbonaceous fuel combusting power plant, which includes a source of oxygen and a combustion chamber for combusting the fuel with oxygen and thereby producing flue gas that includes CO2, water and excess oxygen as its main components. At least a portion of the flue gas is compressed to a pressure higher than about sixty bar, the compressed flue gas is cooled in a primary CO2 separating unit for capturing a first portion of the CO2 by condensing it to produce a liquid CO2 stream and a high pressure vent gas stream that includes oxygen and excess CO2, the liquid CO2 stream is discharged from the power plant, and the high pressure vent gas stream is conducted to a secondary CO2 separating unit for capturing a second portion of the CO2 by adsorbing it to an adsorbing material.

Owner:FOSTER WHEELER ENERGY CORP

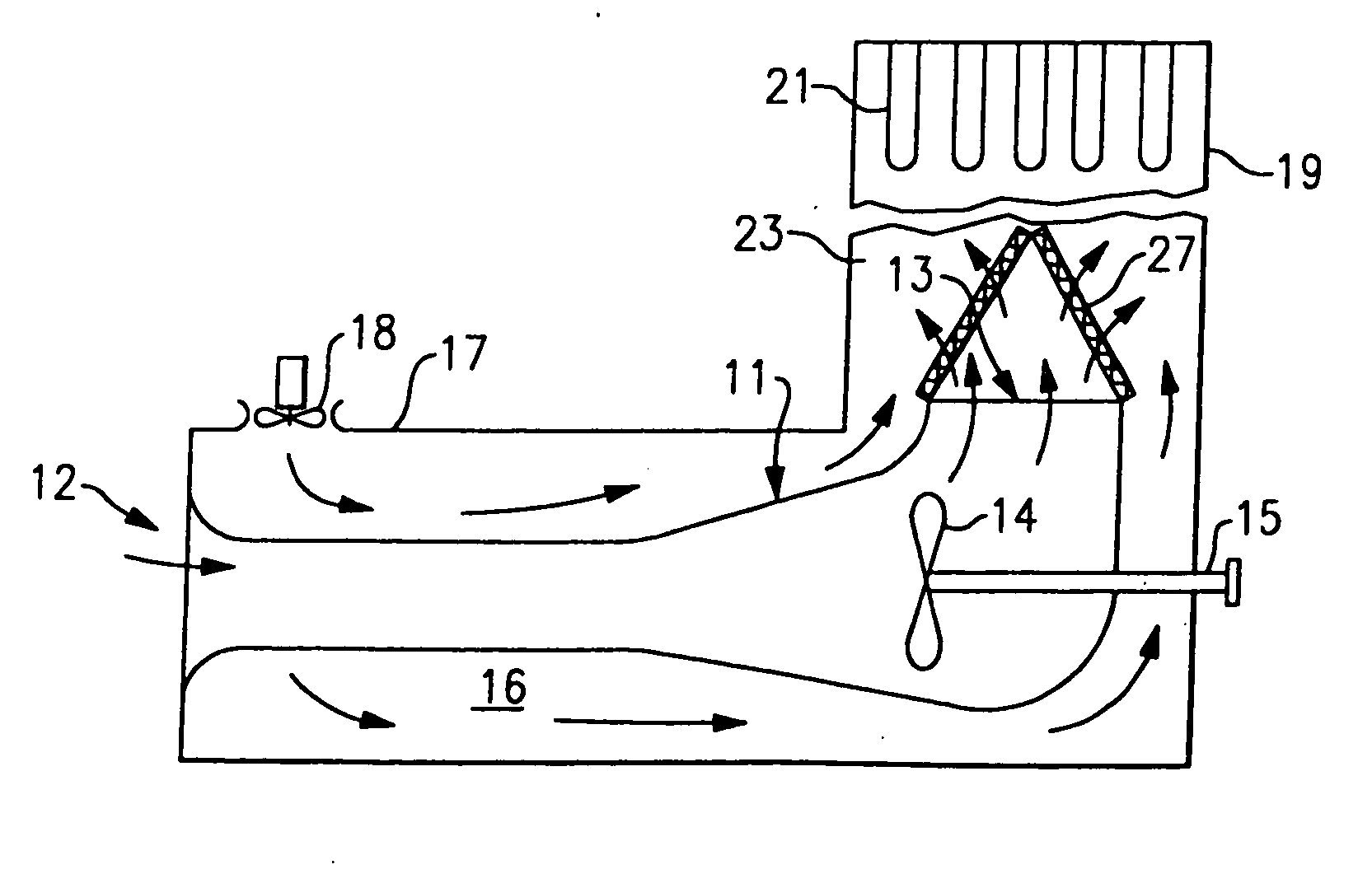

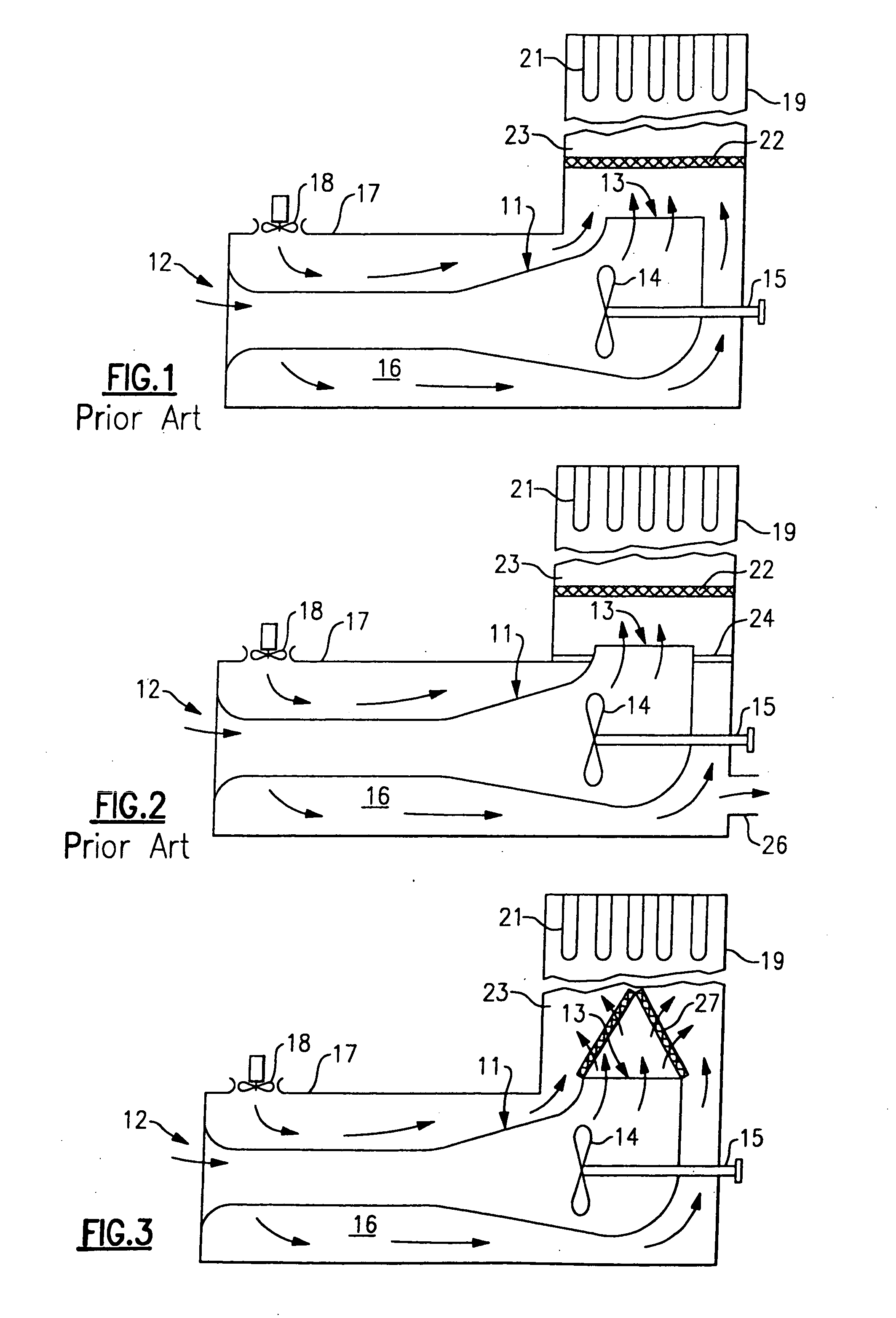

Turbine exhaust catalyst

ActiveUS20070068167A1Reduce stressCatalyst effectiveness is optimizedTurbine/propulsion fuel supply systemsContinuous combustion chamberTurbineGas turbines

In a gas turbine installation having an enclosure for passing cooling air therethrough and around the gas turbine, provision is made for a mixing of the cooling air with the exhaust gases being emitted from the gas turbine to thereby reduce the temperature thereof prior to its passing into the exhaust stack, but only after the primary air has passed through a catalyst bed which is disposed in a position over the gas turbine exhaust opening. The shape of the catalyst bed is preferably A-shaped in cross-section to thereby increase the surface area thereof. In this way, the temperature at the catalyst bed is maintained at an elevated level to obtain superior performance while a subsequent mixing of the primary air with the cooling air results in lower temperatures of the gases passing through the exhaust stack.

Owner:M ITSUBISHI POWER AERO LLC

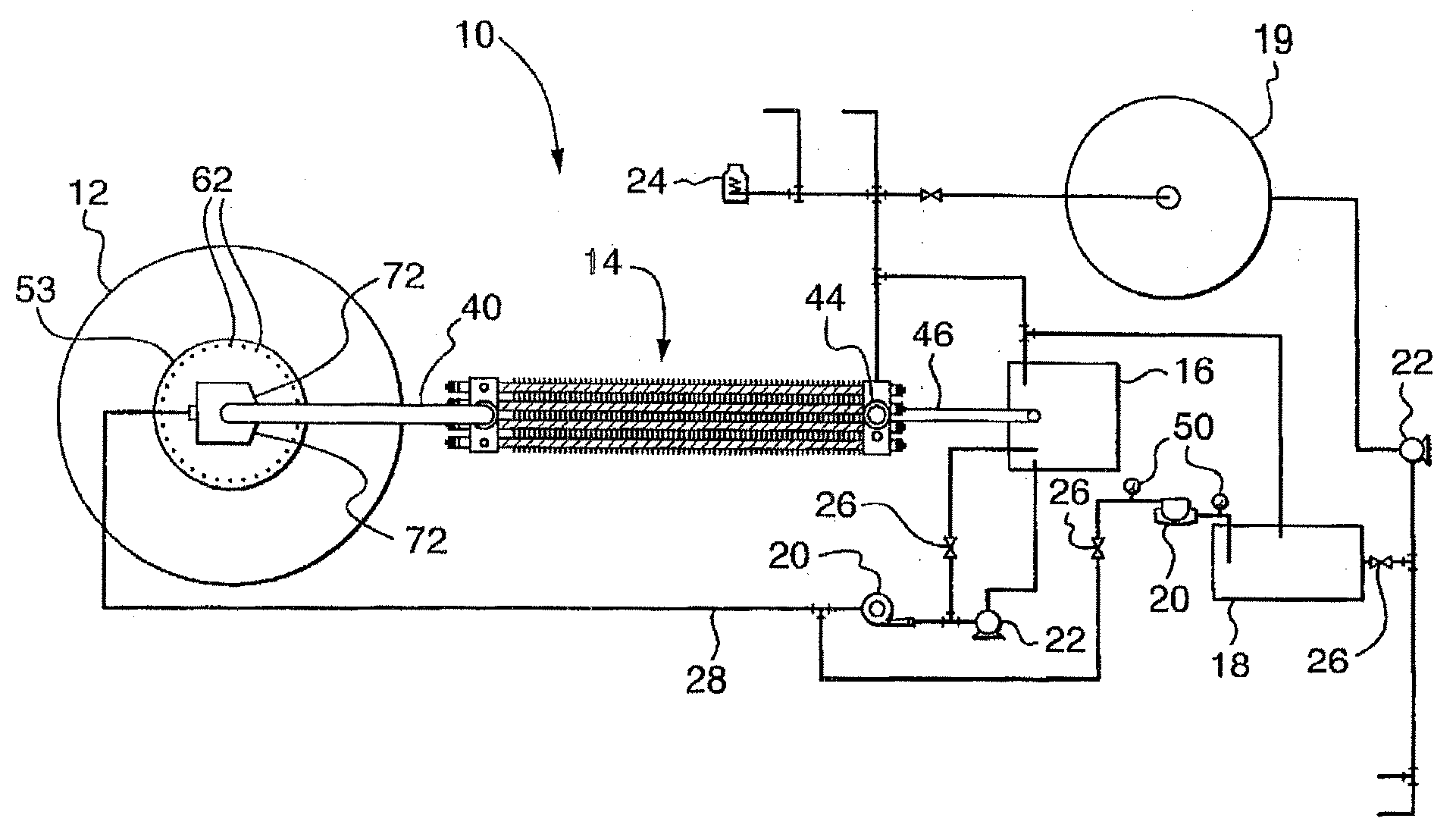

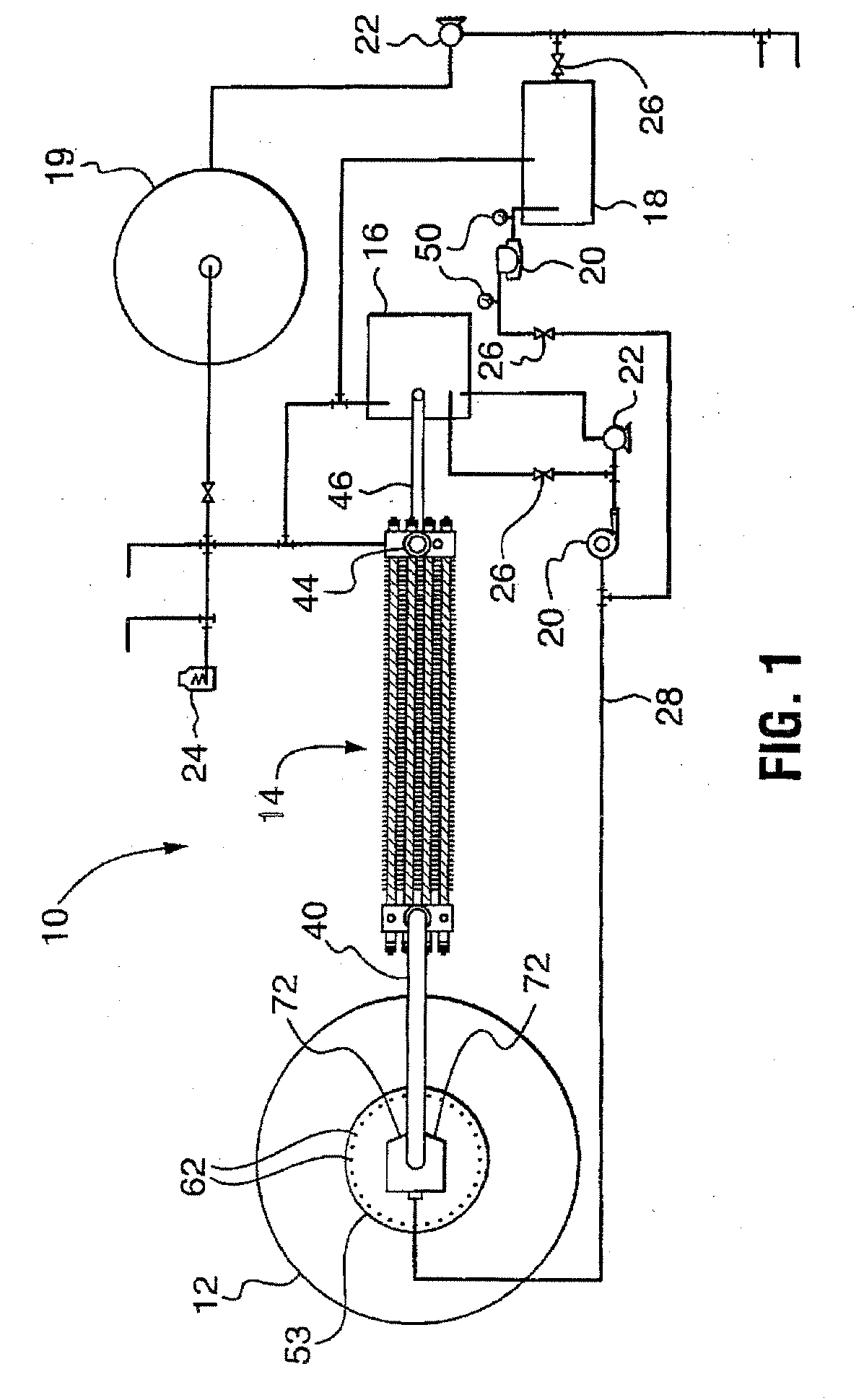

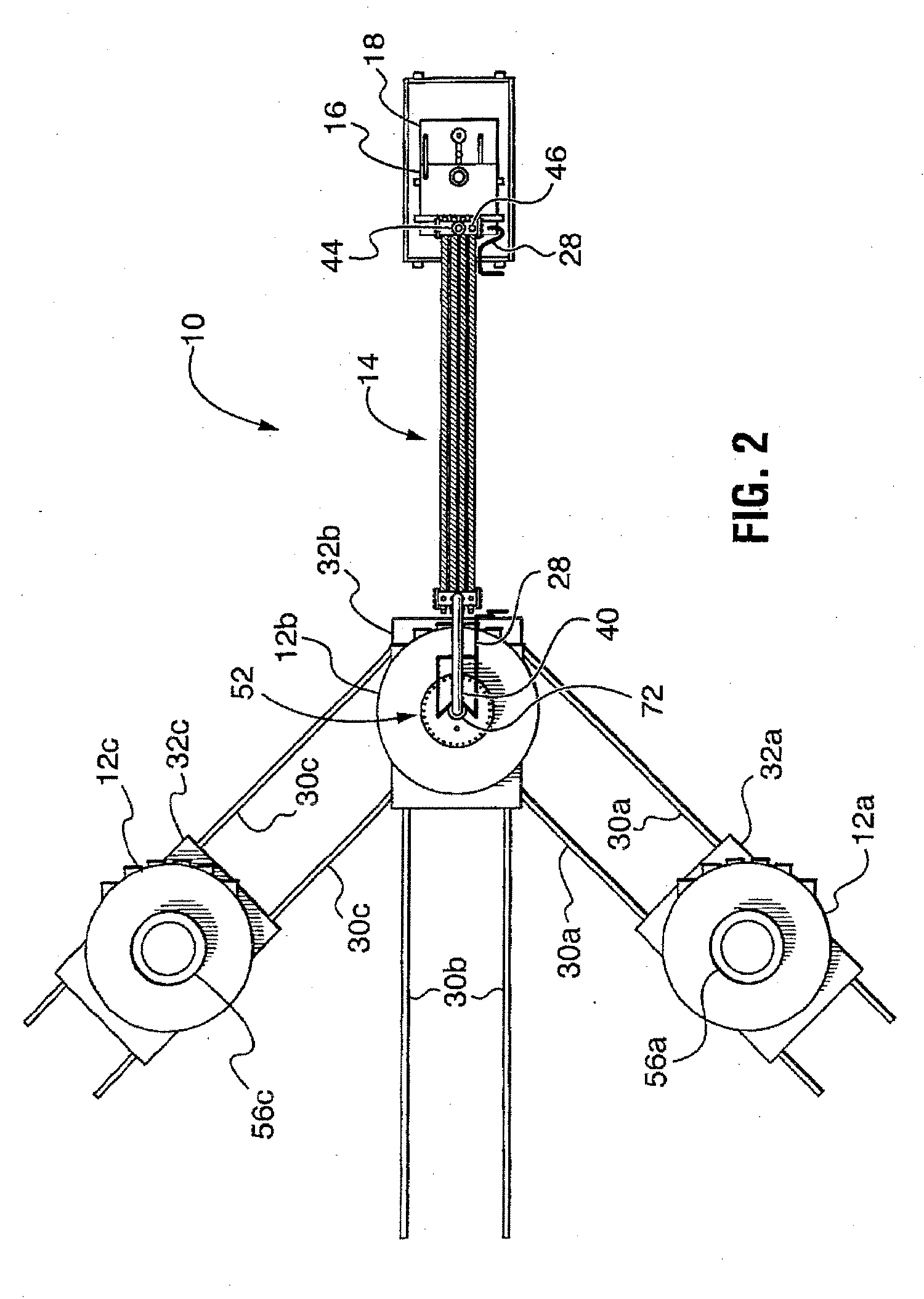

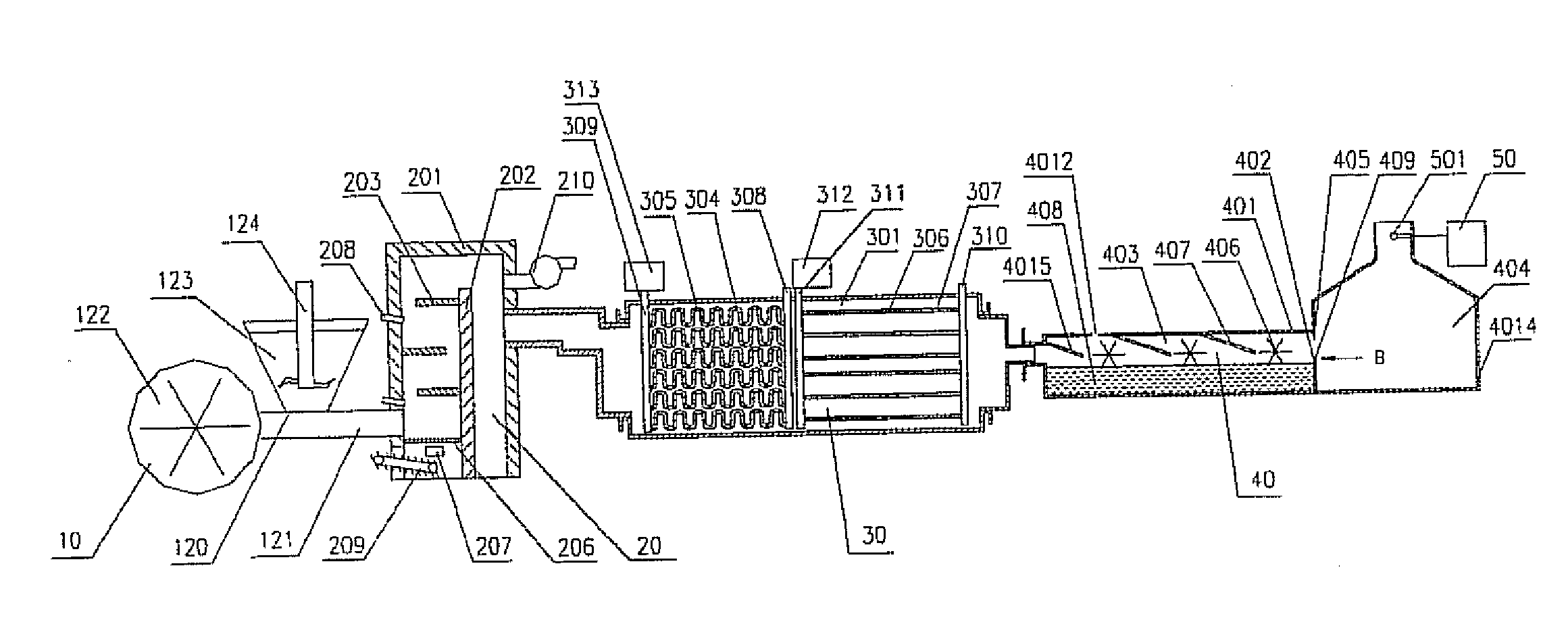

Pyrolysis system for waste rubber

InactiveUS20090211892A1Indirect and direct heating destructive distillationHeat recoveryWaste rubberProduct gas

An apparatus for separating components of batches of waste rubber by pyrolysis comprises at least one heating chamber interconnected with a condenser by a conduit. The heating oven is provided with a plurality of cooperating heating elements, an inlet for receiving waster rubber, and an outlet for egress of pyrolyzed gaseous components. The condenser condenses and separates cooled liquid components from the gaseous components. Separated gaseous components are exhausted from the condenser. Cooled liquid components are conveyed from the condenser to a re-circulation tank. The conduit is provided with a pair of opposed injectors adjacent the outlet of the heating oven. A re-circulation line interconnects the re-circulation tank with the injectors and is provided with a pressurizing device for injecting cooled liquid components through the injectors into the conduit in the form of intersecting liquid laminar sheets thereby applying a vacuum draw on the egressing pyrolyzed gaseous components.

Owner:ANDERSEN DAN

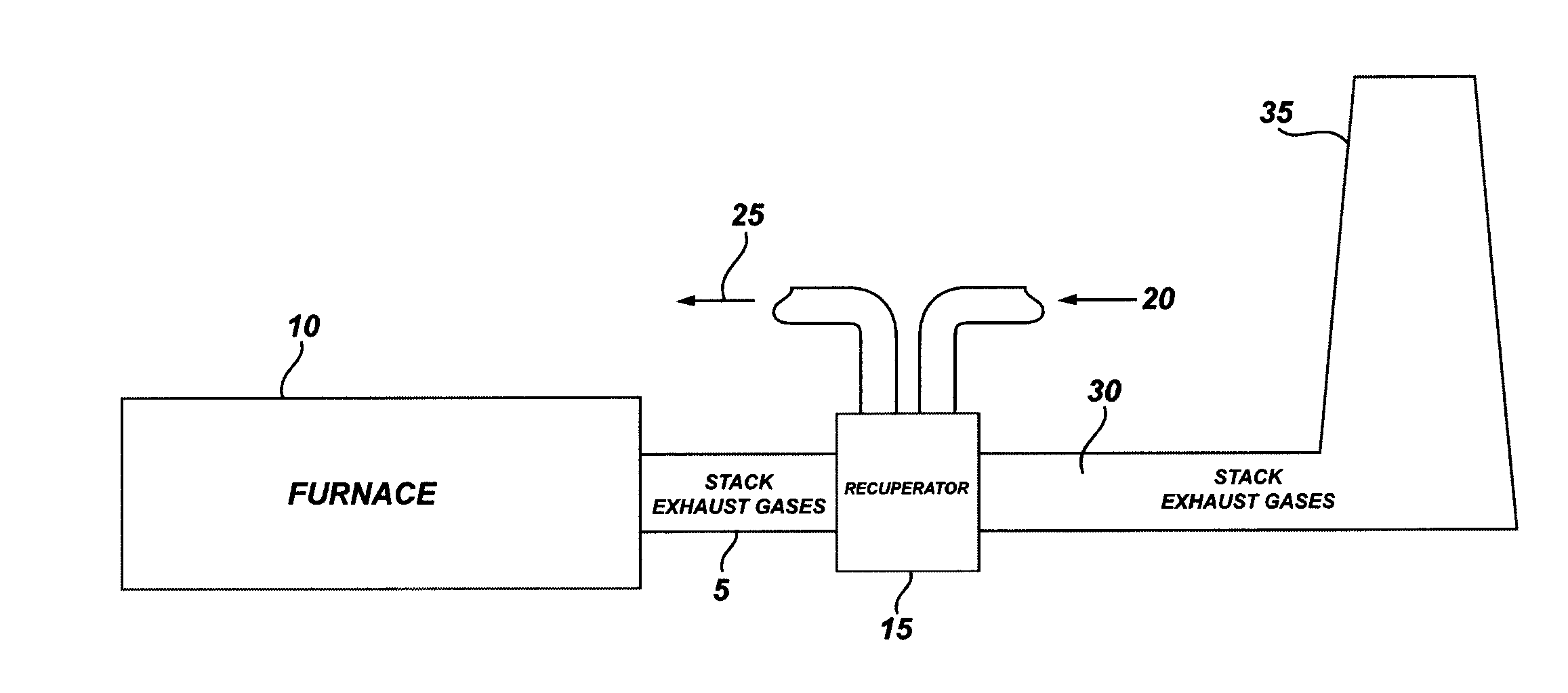

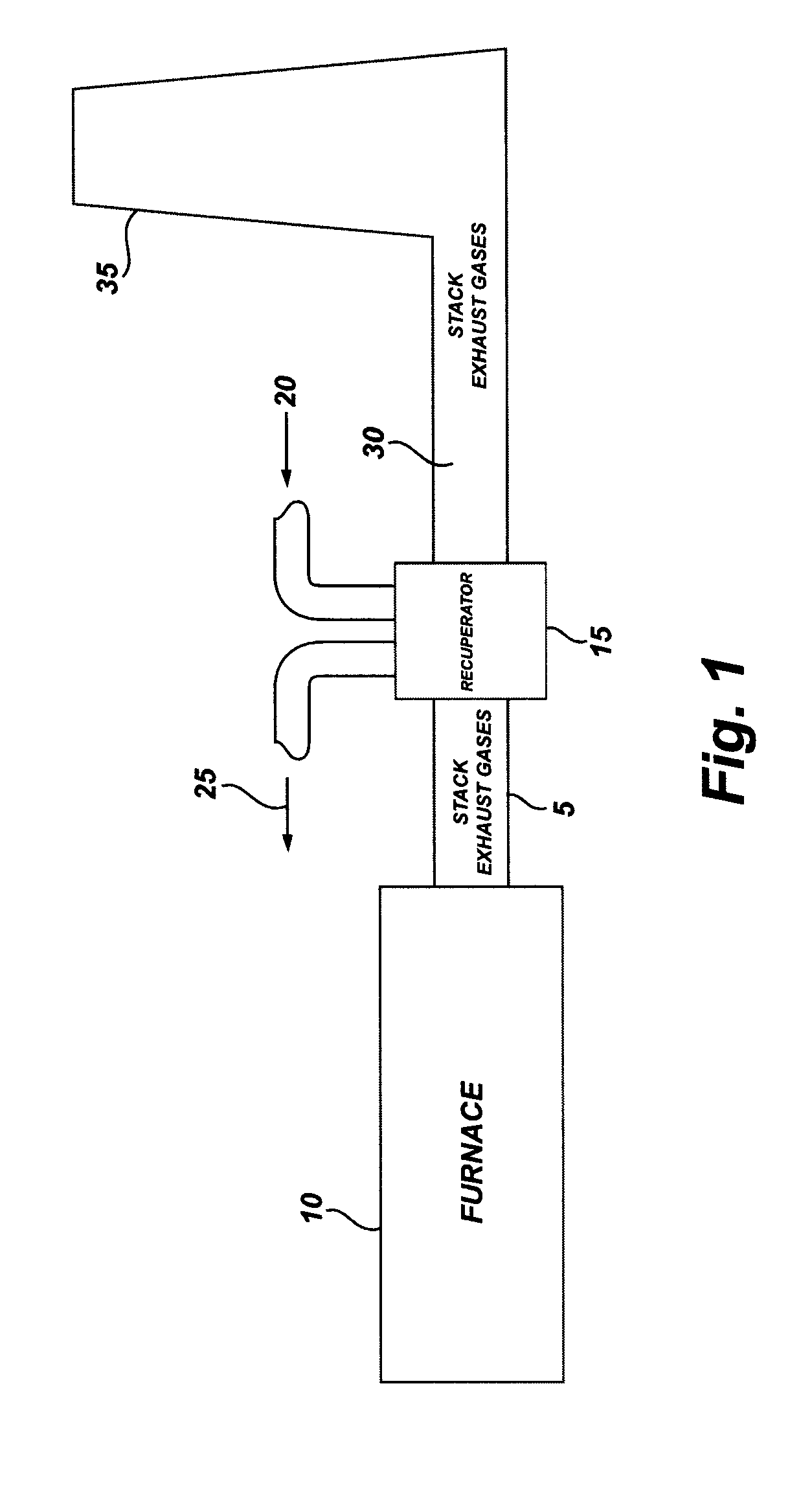

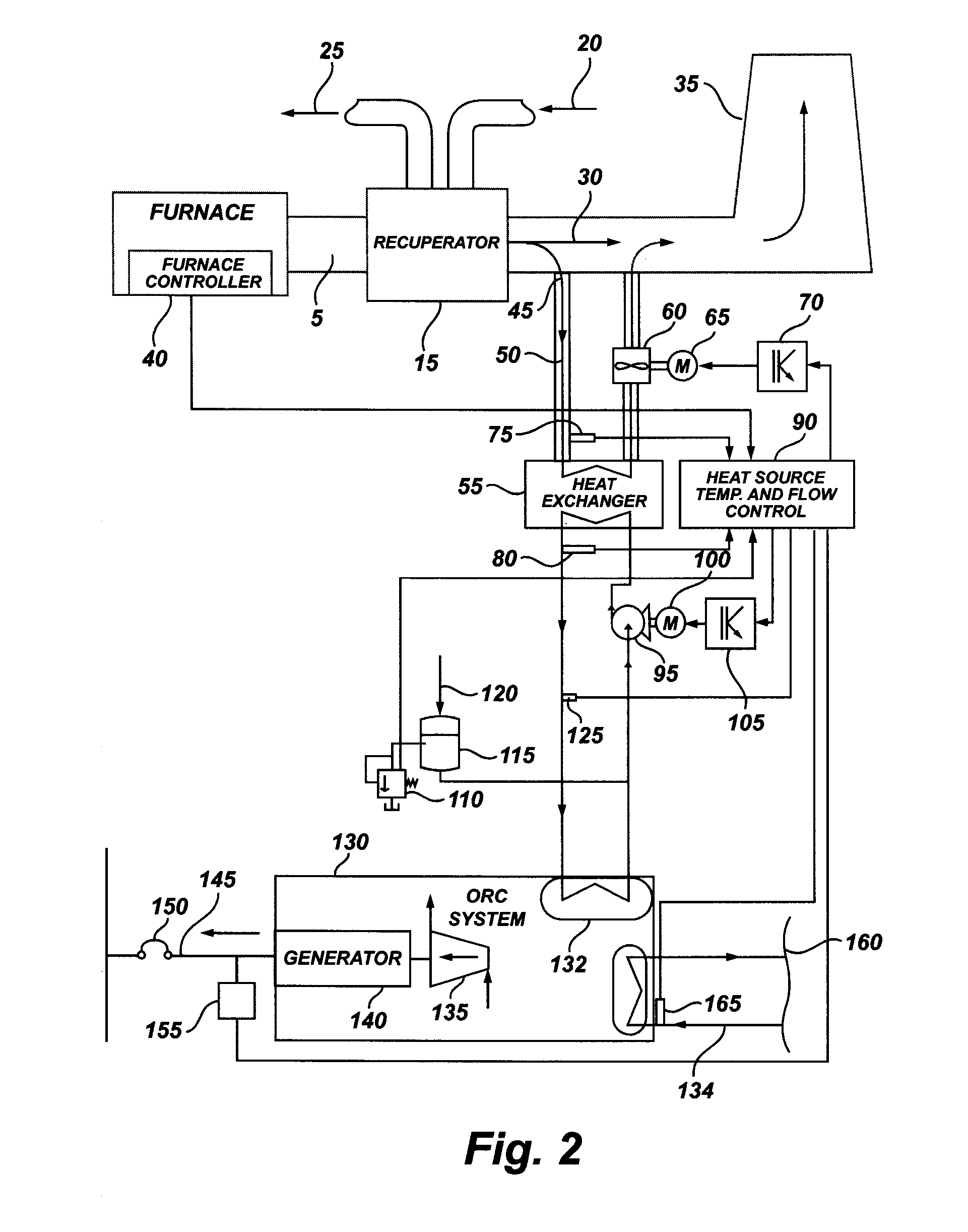

Energy Recovery System and Method

A system and method for converting otherwise wasted energy produced in the form of heated gases as a byproduct of an industrial process into electrical energy. At least some waste gases are diverted from a typical exhaust structure through a heat exchanger and back into the exhaust structure. The amount of gases flowing through the heat exchanger is monitored and regulated by a controller. A heat source liquid is simultaneously circulated under pressure through the heat exchanger and through an organic Rankine cycle system. The amount of heat source liquid being circulated is also monitored and regulated by the controller. The ORC system converts the heat from the heat source liquid into electricity.

Owner:TMEIC

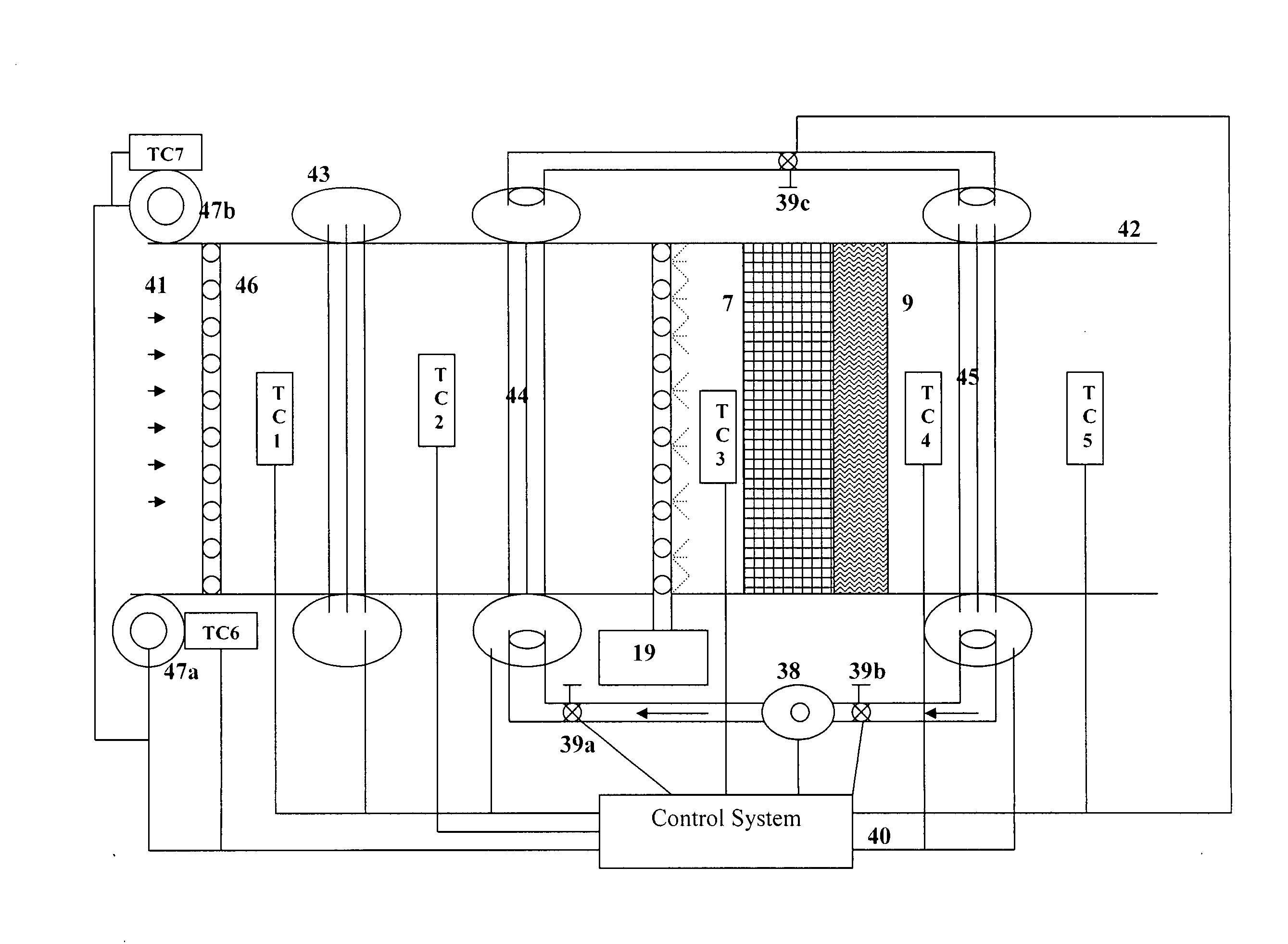

Emission reduction system for use with a heat recovery steam generation system

InactiveUS20090282803A1Quantity minimizationSmall sizeSteam generation heating methodsExhaust apparatusCombustorExhaust fumes

A system and method of maintaining an optimal temperature range for a catalyst section in a HRSG comprising placing a portion of the exhaust stream in a heat exchanger and superheater, diverting a second portion around the heat exchanger and superheater, combining the two portions and contacting the two portions with a catalyst section. Alternatively, a system of heat exchangers are employed to address the fluctuating exhaust temperature caused by the intermittent use of the duct burners.

Owner:JOHNSON MATTHEY INC

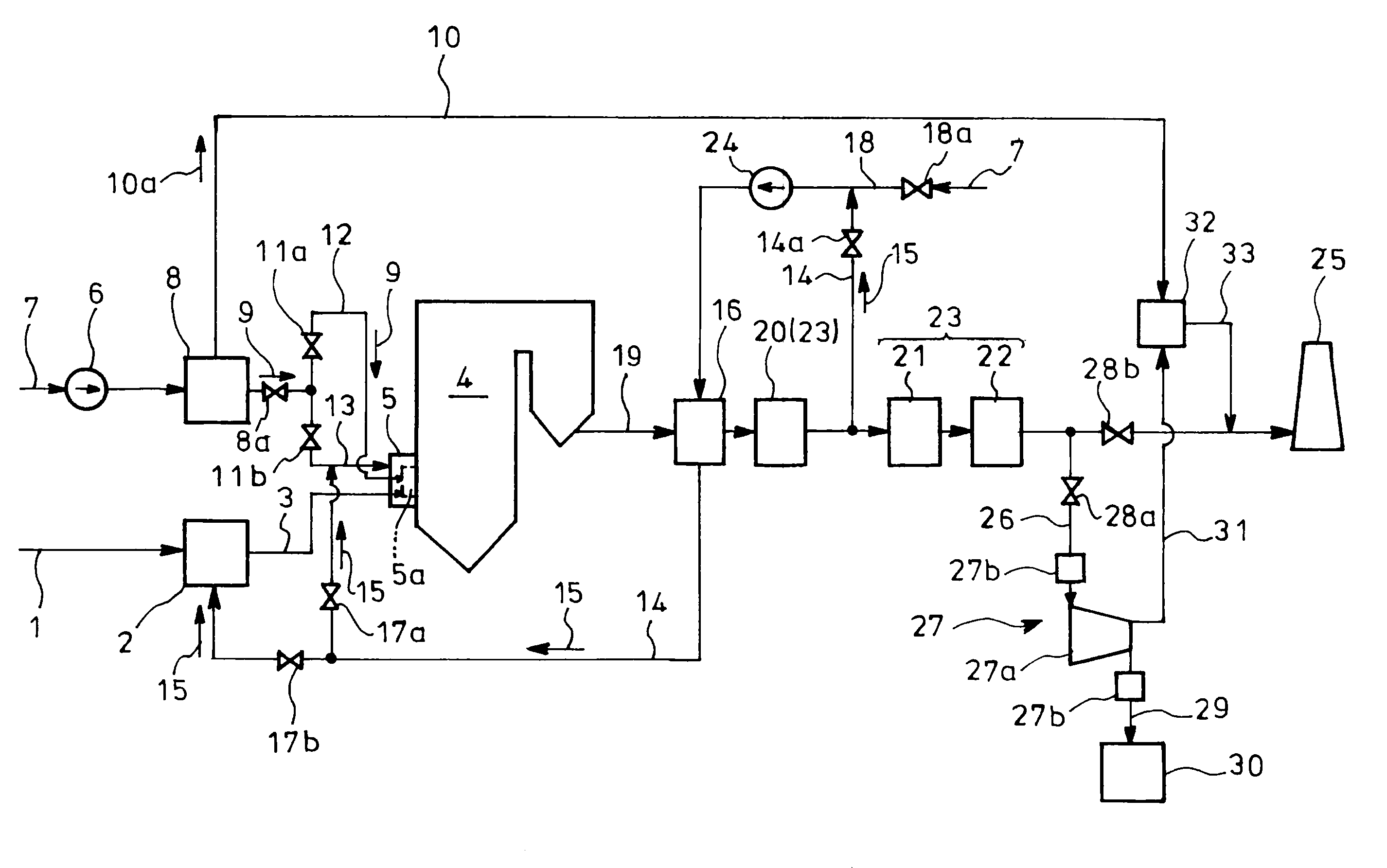

Disposal method and equipment for exhaust gas from combustion system

InactiveUS20090031933A1Great advantageGood effectBurnersLiquefactionCombustion systemAtmospheric air

Carbon dioxide in combustion exhaust gas can be effectively separated and the combustion exhaust gas including the other exhaust gas components condensed through the separation of carbon dioxide can be discharged to the atmosphere.Air 7 is separated by an air separation unit 8 into oxygen 9 and other nitrogen-prevailing gas 10a. The obtained oxygen 9 and coal 1 are burned by a burner 5a of a combustion furnace 4. Exhaust gas treatment is conducted for the resultant combustion exhaust gas from the furnace 4. Then, part of the combustion exhaust gas is recirculated to the burner 5a and the remaining unrecirculated combustion exhaust gas is compressed to take out liquefied carbon dioxide 29. The other exhaust gas components 31 unliquefied through the compression is mixed and diluted with the other nitrogen-prevailing gas 10a in the separation of the oxygen 9 from the air 7 in the air separation unit 8 and is discharged to the atmosphere.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY +1

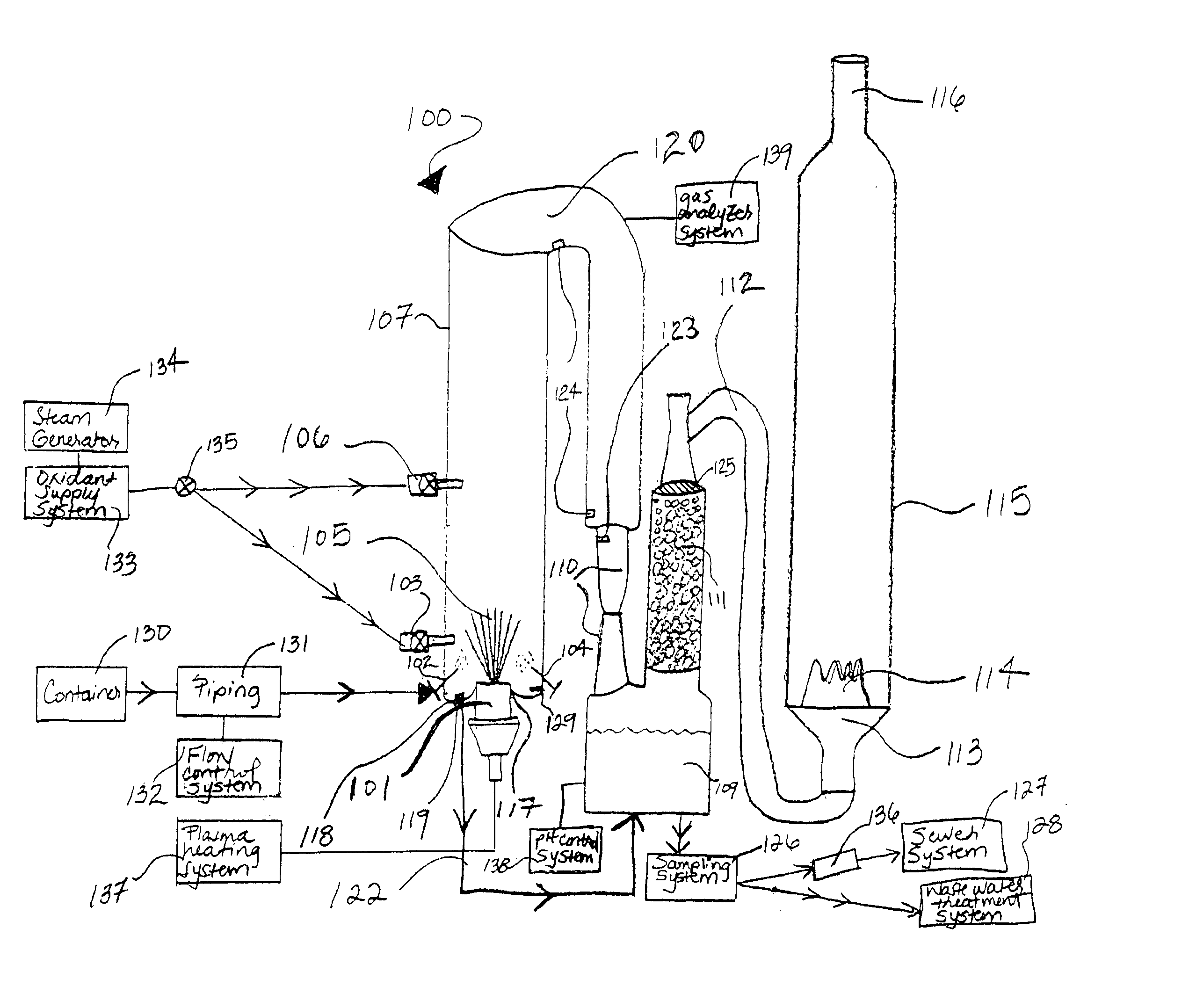

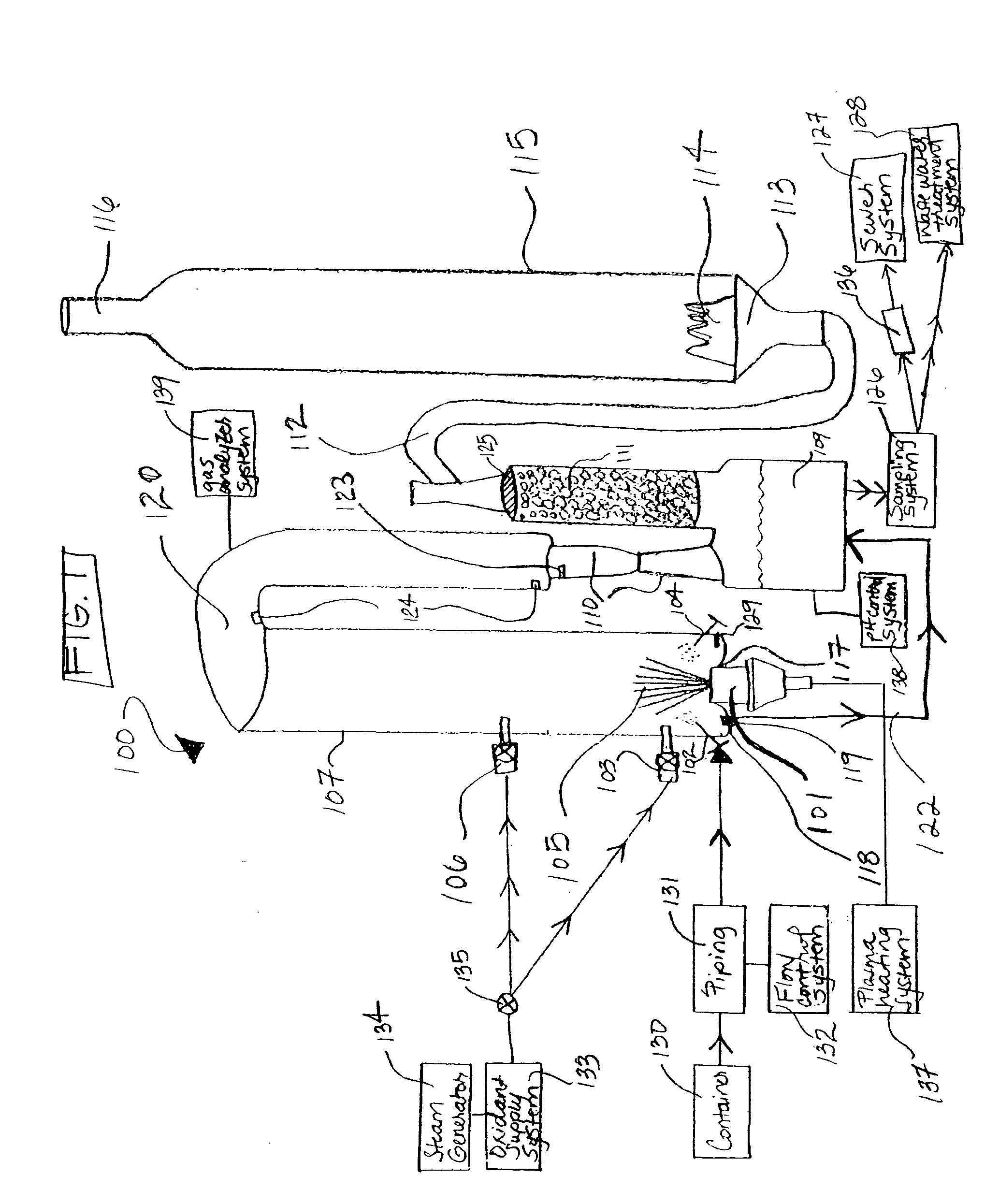

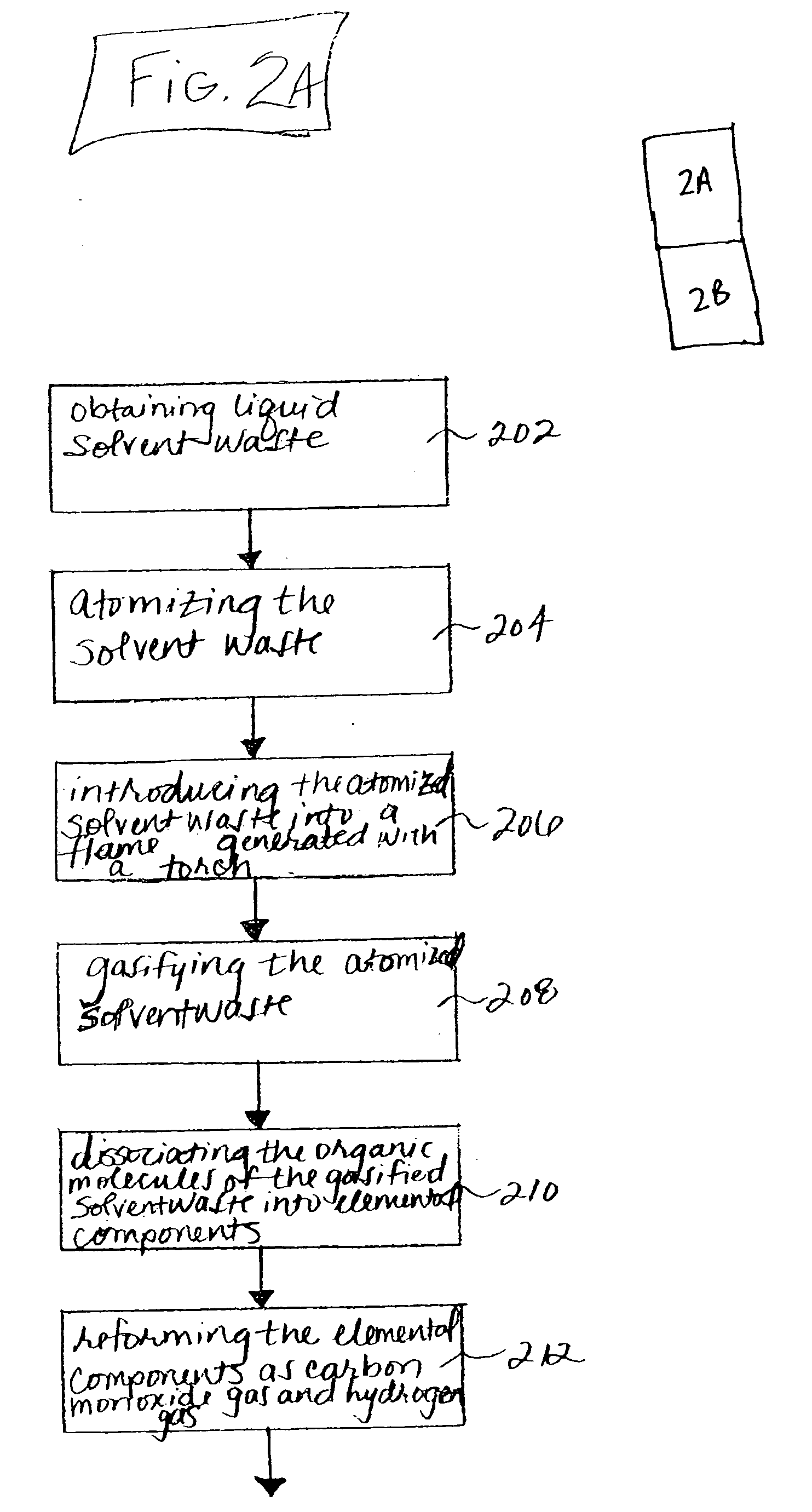

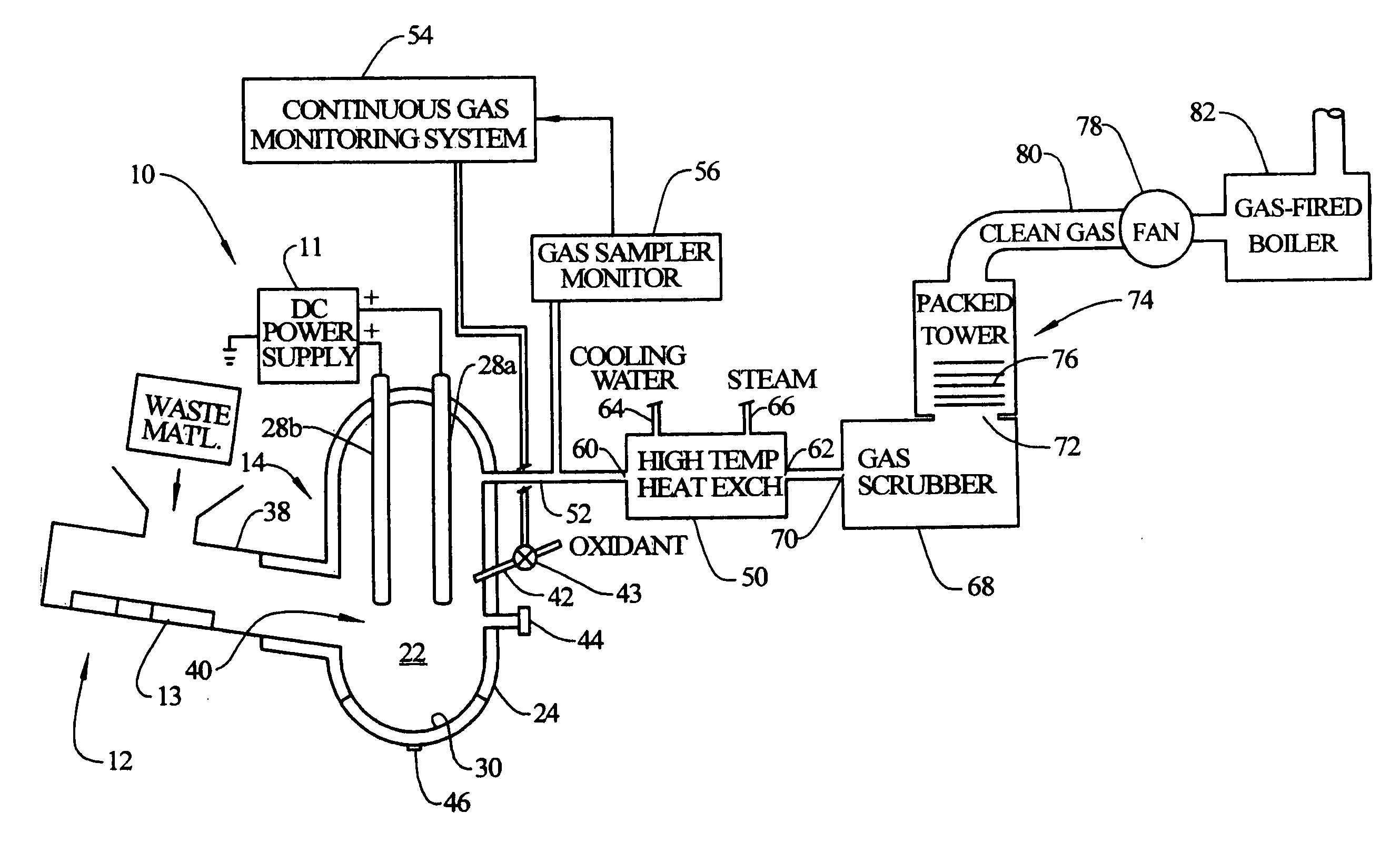

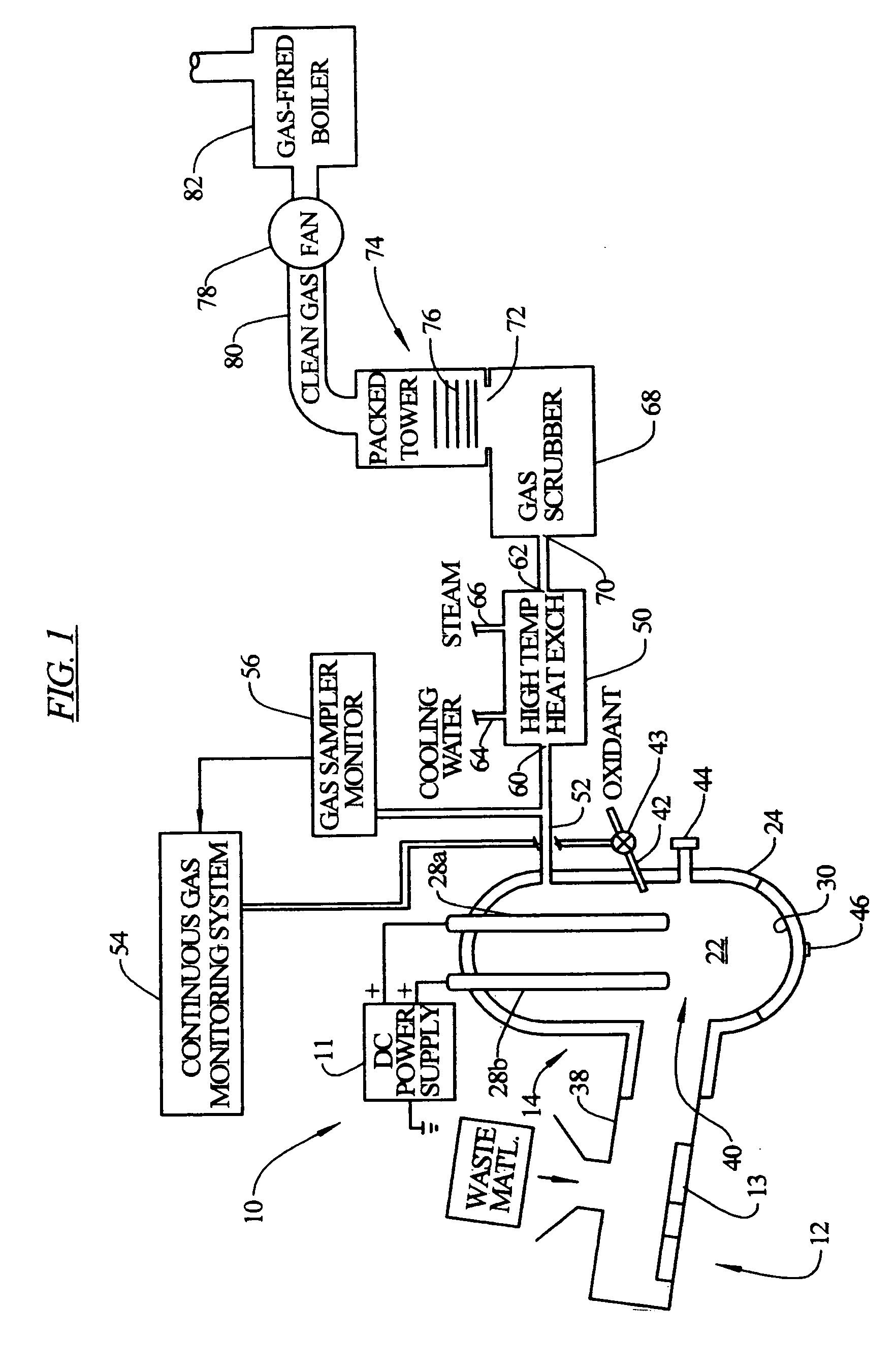

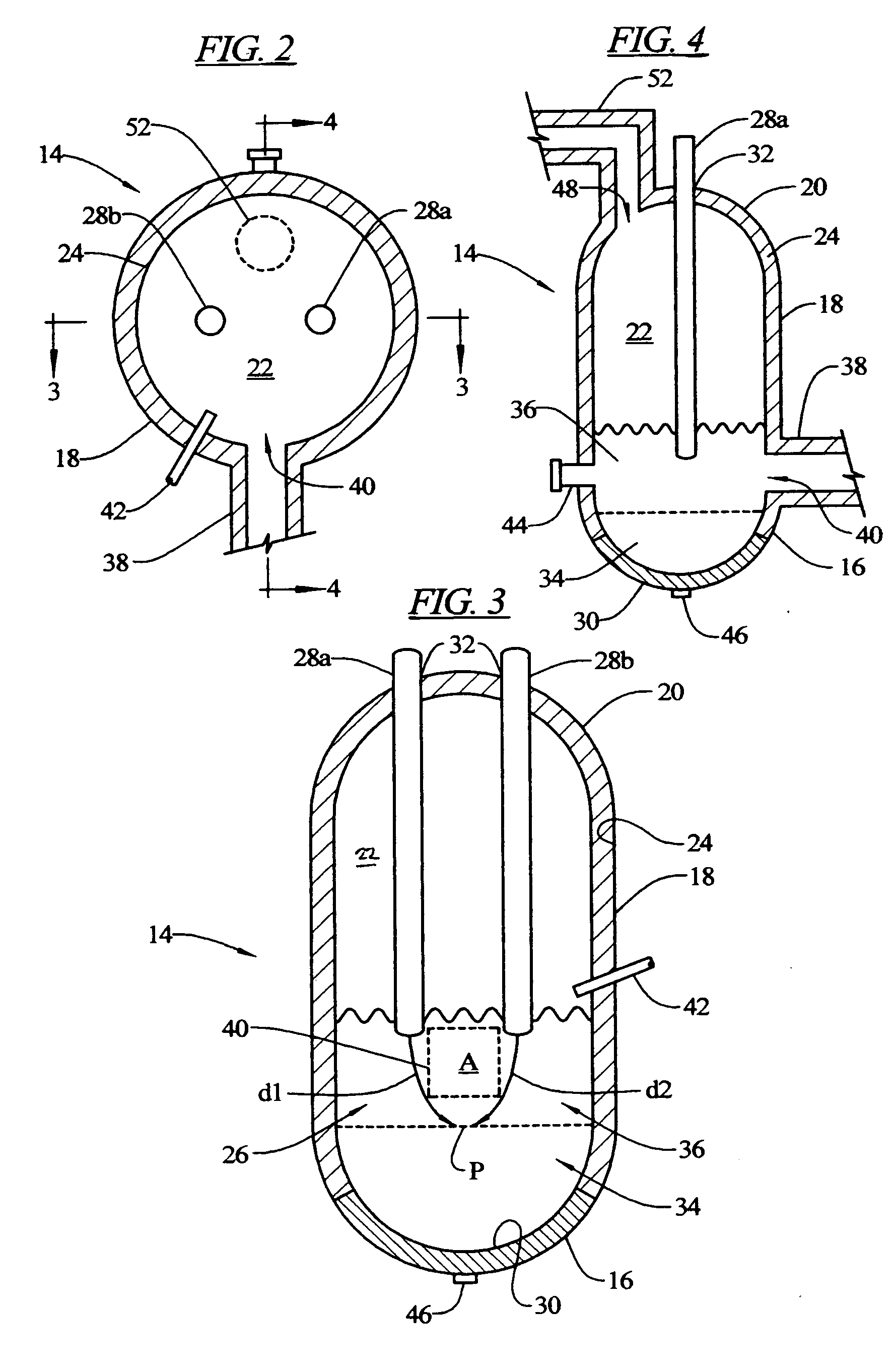

Method and apparatus for treating liquid waste

An apparatus for treating liquid waste includes a vessel, an AC plasma torch mounted with the vessel, and at least one nozzle mounted in the vessel. The nozzle is positioned so that liquid waste introduced through the nozzle into the vessel will be sprayed into or above a flame emitted by the AC plasma torch. Liquid waste is atomized by the nozzle and sprayed into the flame. The energy from the flame causes the organic portion of the atomized liquid waste to gasify and dissociate into elemental components. This dissociation destroys any hazardous or toxic constituency of the waste material.

Owner:PEAT INT INC

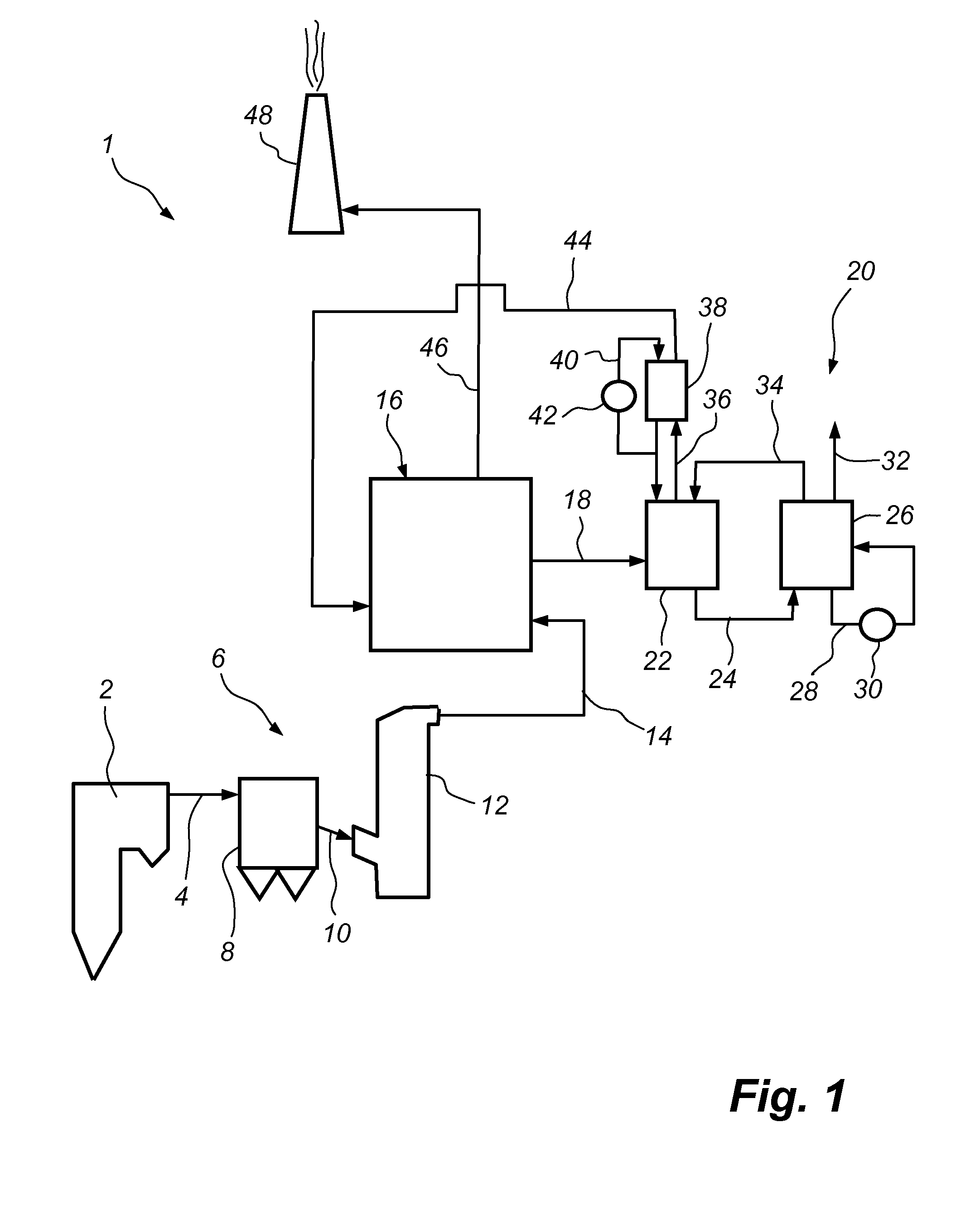

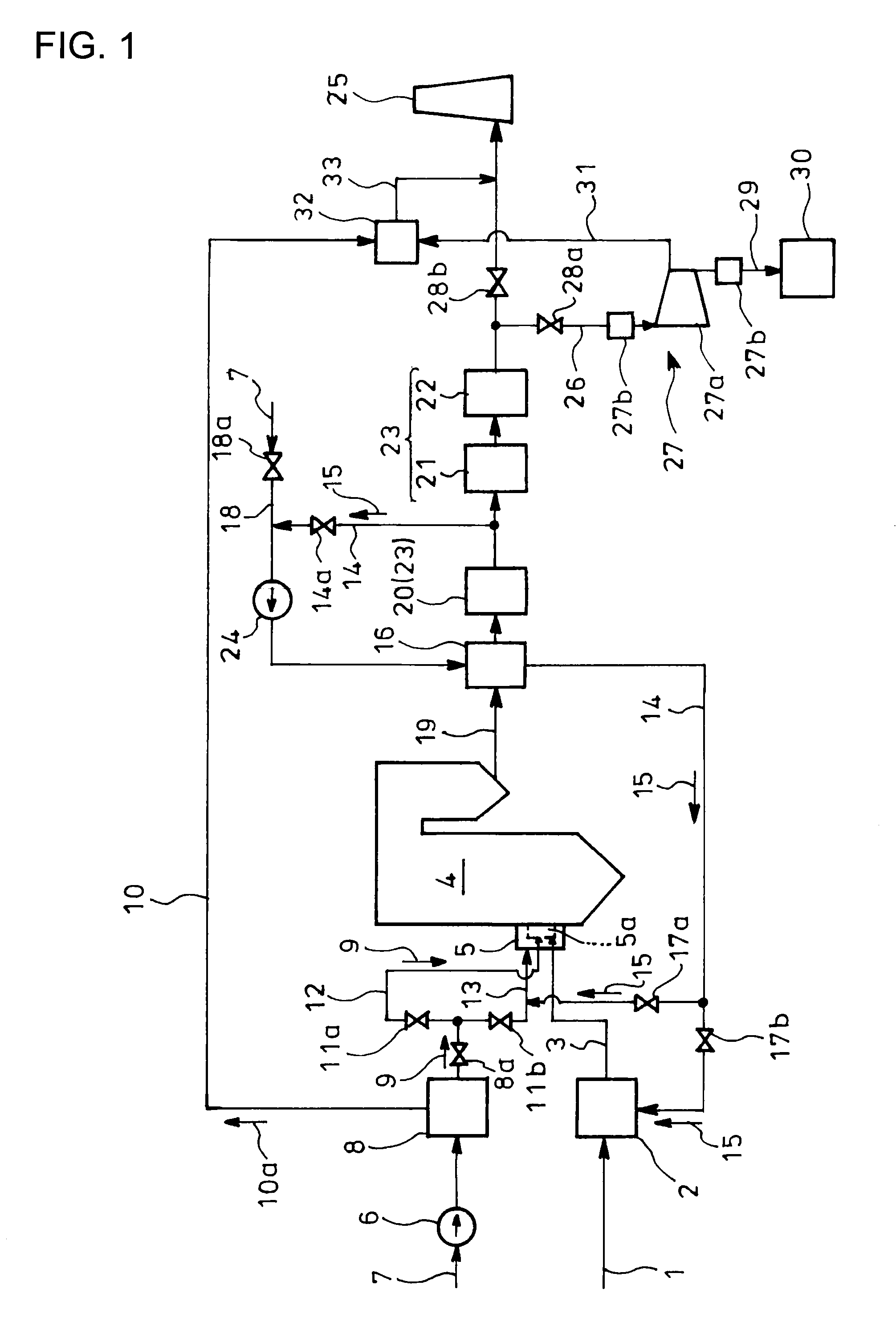

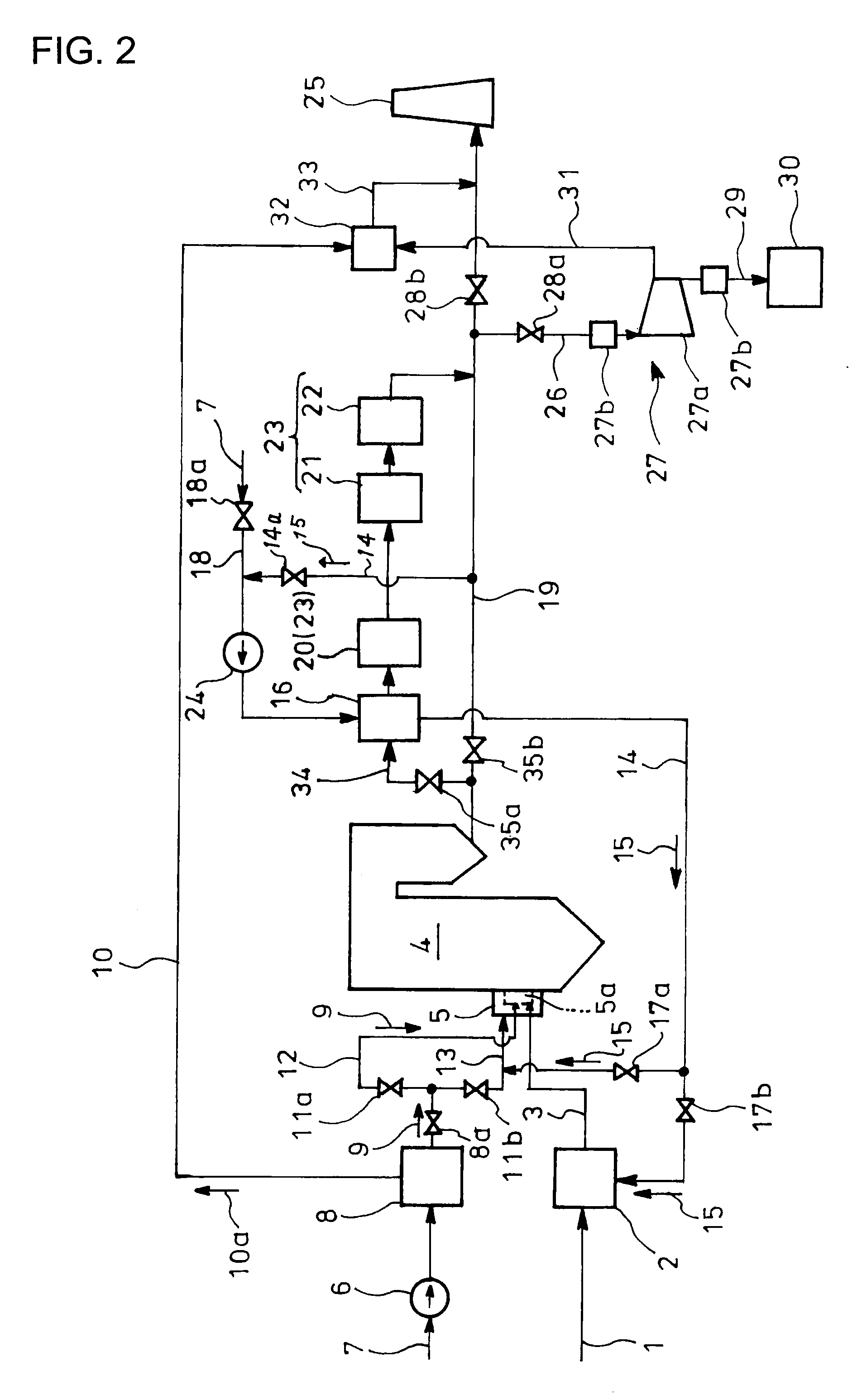

Method of and power plant for generating power by oxyfuel combustion

InactiveUS20080302107A1Costs lossesLosses of powerGas turbine plantsHeat recoveryCombustionPower station

A method of and a power plant for generating power by combusting carbonaceous fuel with substantially pure oxygen, and a method of modifying a process of generating power by combusting carbonaceous fuel from combusting the fuel with air to combusting the fuel with substantially pure oxygen. The methods include feeding substantially pure oxygen into a furnace for combusting fuel with the oxygen to produce exhaust gas including mainly carbon dioxide and water, recovering low-grade heat from the exhaust gas by using multiple exhaust gas coolers arranged in a downstream portion of the exhaust gas channel, wherein a first portion of the recovered low-grade heat is used for preheating feedwater; pressurizing a first portion of the exhaust gas in multiple exhaust gas compressors so as to produce liquid carbon dioxide, recycling a second portion of the exhaust gas to the furnace via an exhaust gas recycling channel, using a first portion of steam extracted from a steam turbine system to preheat feedwater, wherein the first portion of the recovered low-grade heat is more than 50% of the total amount of recovered low-grade heat, or larger than the first portion of the recovered low-grade heat in the air-fired process, allowing minimizing of the first portion of the extracted steam, and the expanding of a second portion of the extracted steam in at least one auxiliary steam turbine for driving at least one compressor or at least one pump of the power plant.

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

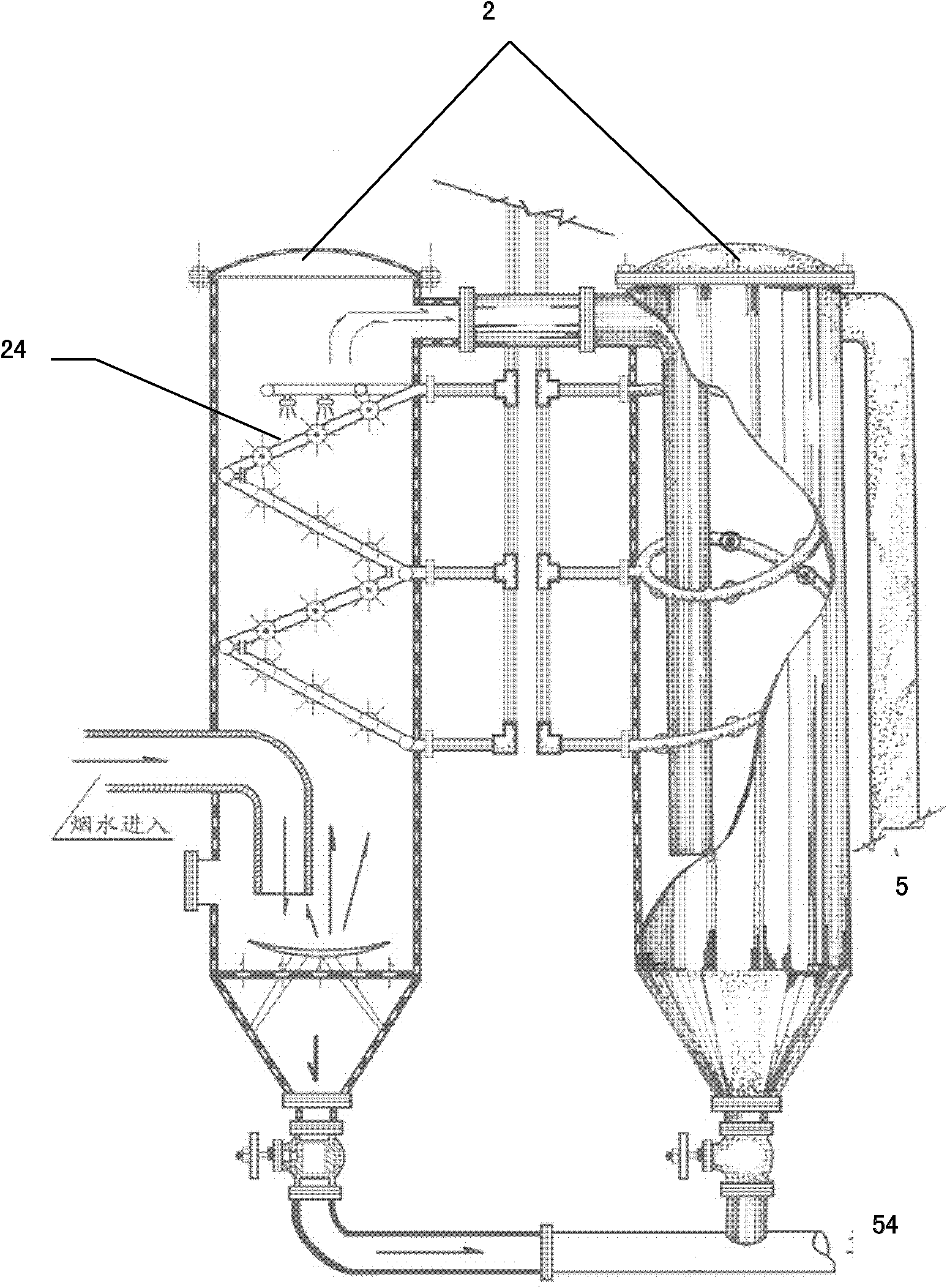

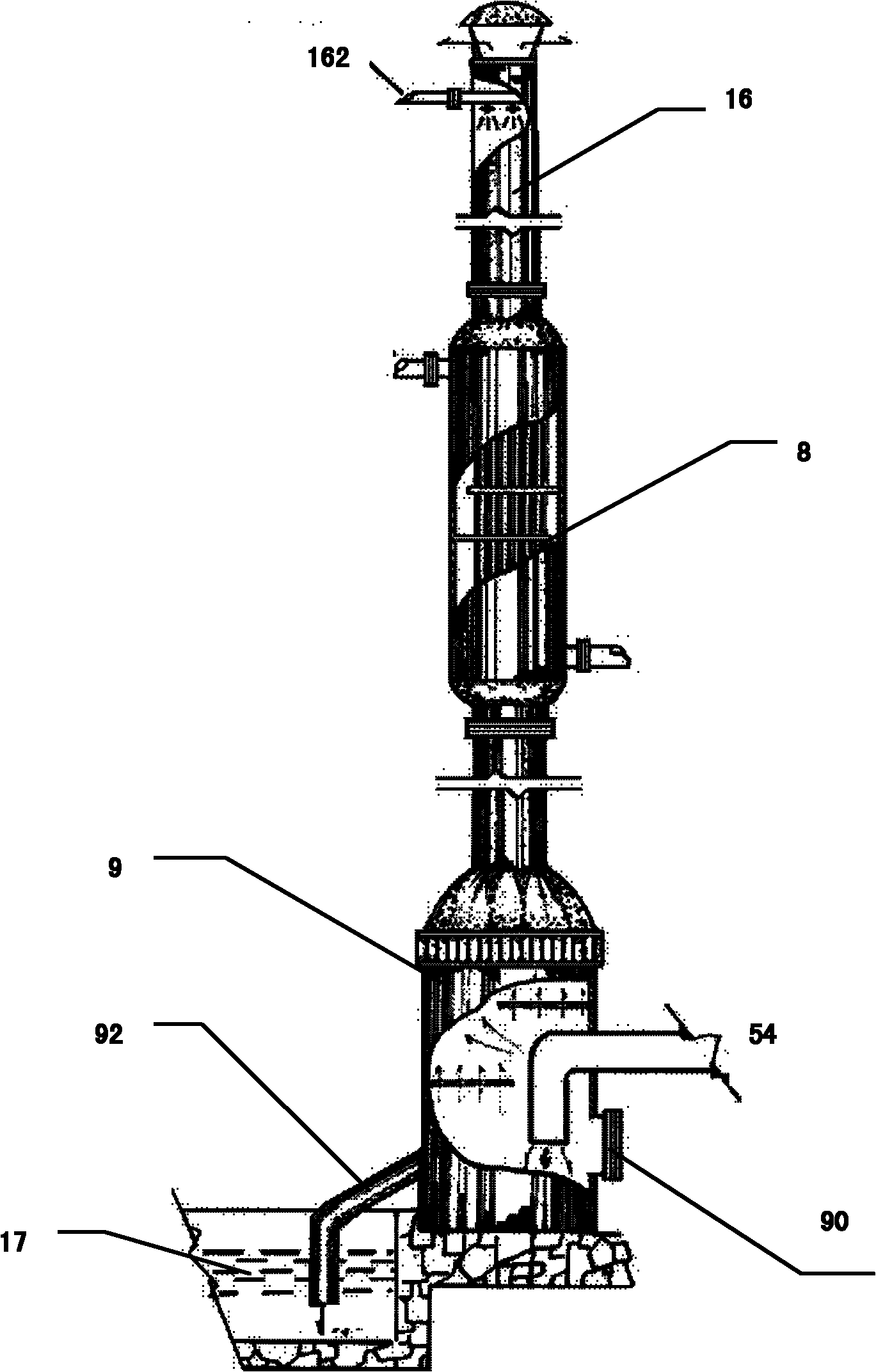

Tail gas treatment system for through which

InactiveCN101816874AEmission reductionChange fragile defectsCombination devicesLighting and heating apparatusAtmospheric airFiltration

The invention discloses a fuel cracking furnace containing a boiler, horizontal waste plastics and a waste tyre cracking furnace tail gas treatment system, wherein, fuel comprises solid fuel and gas fuel or liquid fuel. The tail gas treatment system comprises a carbon dust particle filtration system connected with the fuel cracking furnace, a gas-solid separation system connected with the carbon dust particle filtration system, a flue gas emission system connected with the gas-solid separation system, and a circulating water cooling system. Compared with the prior art, the tail gas treatment system is environmental-friendly and economical; the system has long service life and convenient and fast assembly and disassembly; and the system can reduce or eliminate carbon dust particles in tail gas, and the emission temperature is approximately identical with the atmospheric temperature.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

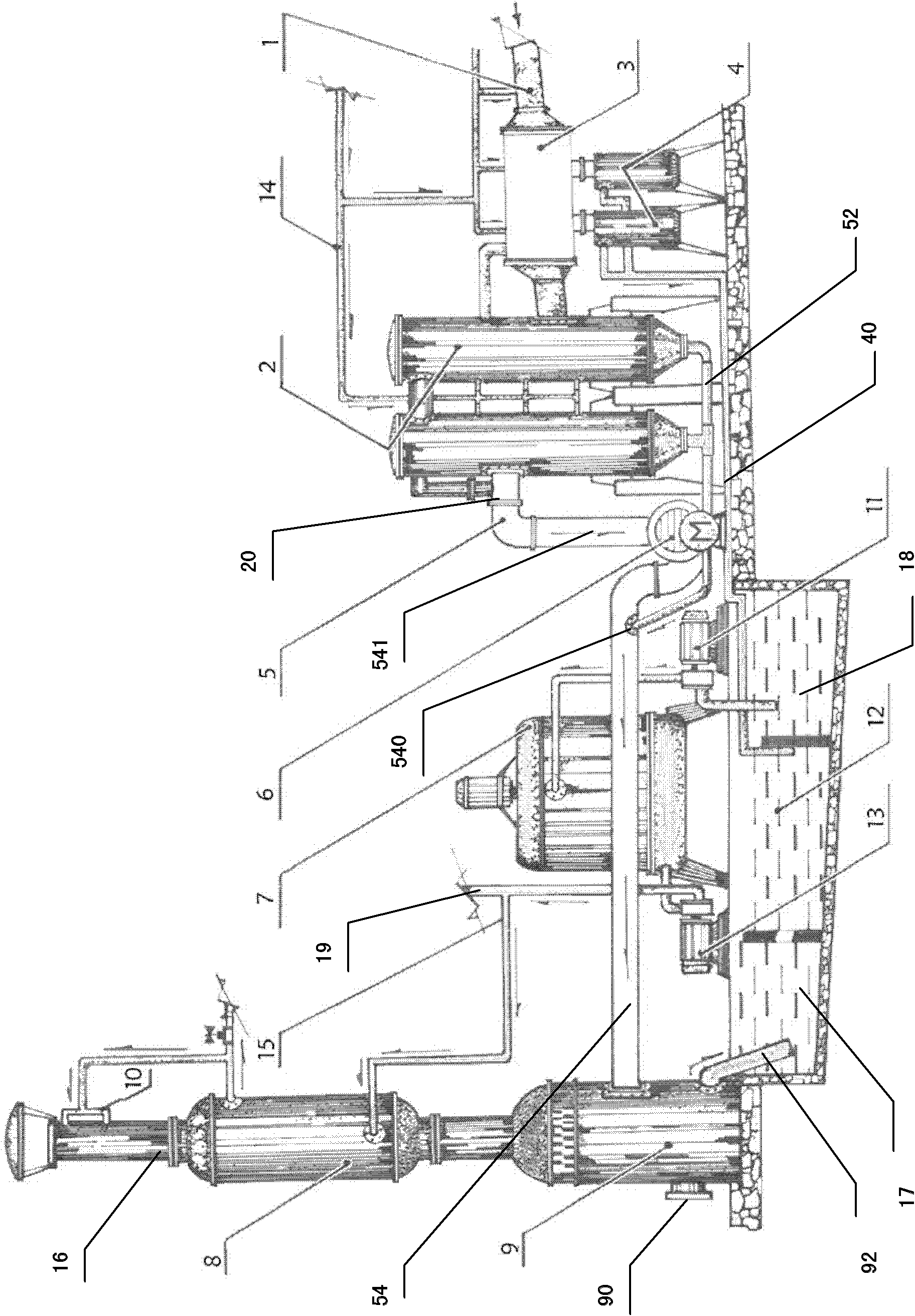

Method and apparatus for plasma gasification of waste materials

InactiveUS20060144305A1Simple and inexpensive in designSimple and inexpensive in and constructionEmission preventionHeat recoveryParticulatesHydrogen

A method and apparatus for plasma gasification of waste materials consisting of organic and inorganic portions is provided which includes a refractory-lined reactor vessel, a feeder mechanism, and a DC electrode device. The refractory-lined reactor vessel has a processing chamber formed therein. The feeder mechanism feeds continuously waste materials into the processing chamber at a controlled feed rate. The DC electrode device is used for heating the processing chamber to a sufficient temperature so as to convert the organic portions of the waste materials to a synthetic gas consisting of hydrogen and carbon monoxide and to a carbon particulate, and to convert the inorganic portions of the waste materials to a molten material consisting of a lower metallic layer and a slag layer formed on top of the metallic layer.

Owner:PLASMA WASTE RECYCLING

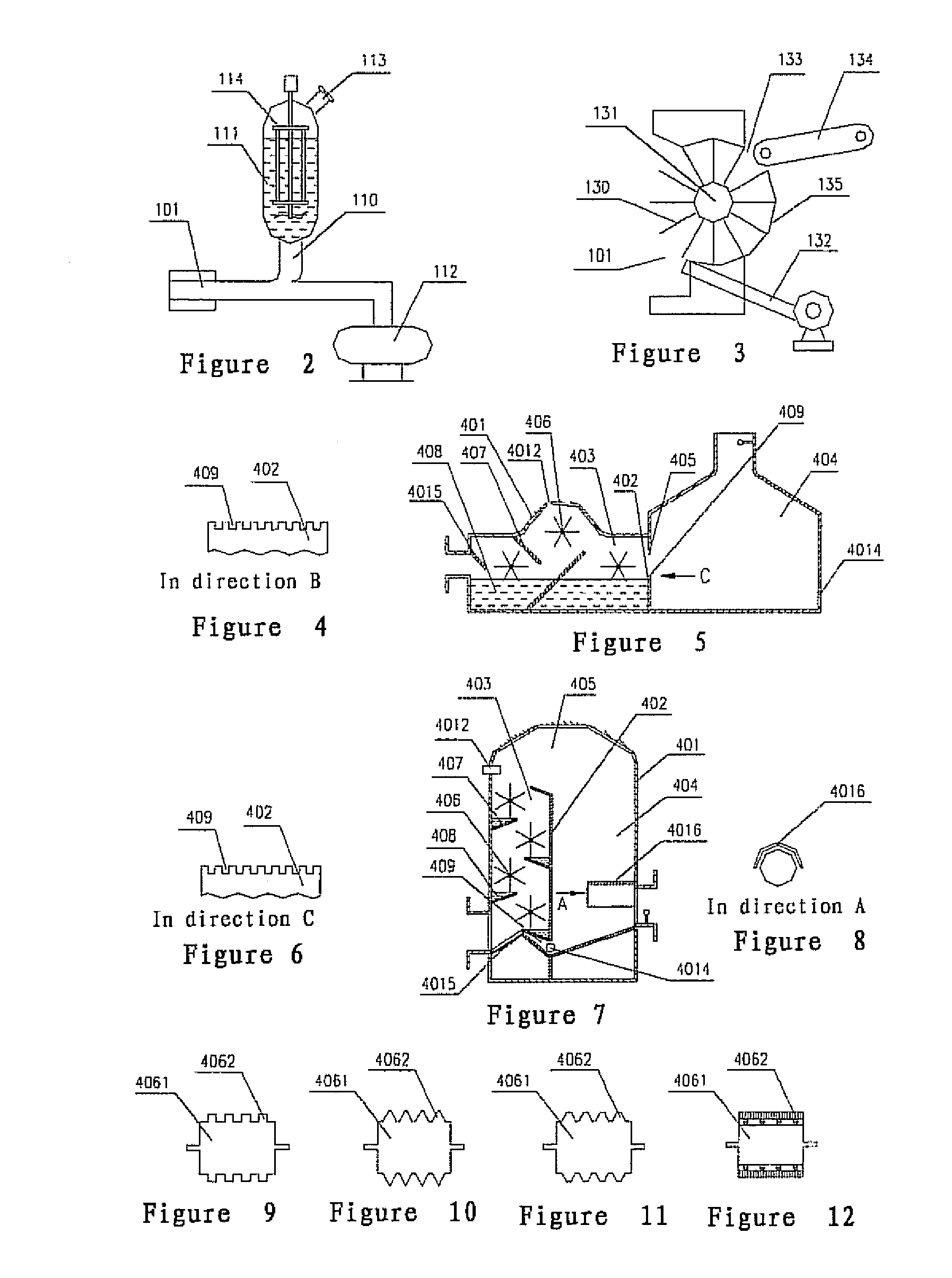

Apparatus for incinerating waste and process for comprehensive utilization of waste

ActiveUS20090031930A1Full heat exchangeEasy dischargeOxide/hydroxide preparationEmission preventionThermal energyFuel tank

The present invention relates to apparatus for incinerating dangerous waste, and in particular, apparatus for incinerating dangerous waste in various forms. It comprises a continuous feeding device, an incineration furnace, a flue gas quenching device, a flue gas treating device, and an online monitoring system. The continuous feeding device includes device for feeding paste, powder, and solid device. The quenching device is connected to a steam boiler and a thermal oil tank, thus achieving comprehensive utilization of the thermal energy generated during incineration of the waste. Apparatus for incinerating dangerous waste according to the present invention enables sufficient combustion of the waste, recycling of the metal oxides or noble metals from the combustion flue gas and / or sinters and / or furnace ashes, effective elimination of the concurrent degradation and re-forming of dioxins. In addition, users can purchase one set of the apparatus for incinerating dangerous waste of the present invention for treating various forms of waste, thus substantially reducing the related capital cost.

Owner:SHEN FUCHANG

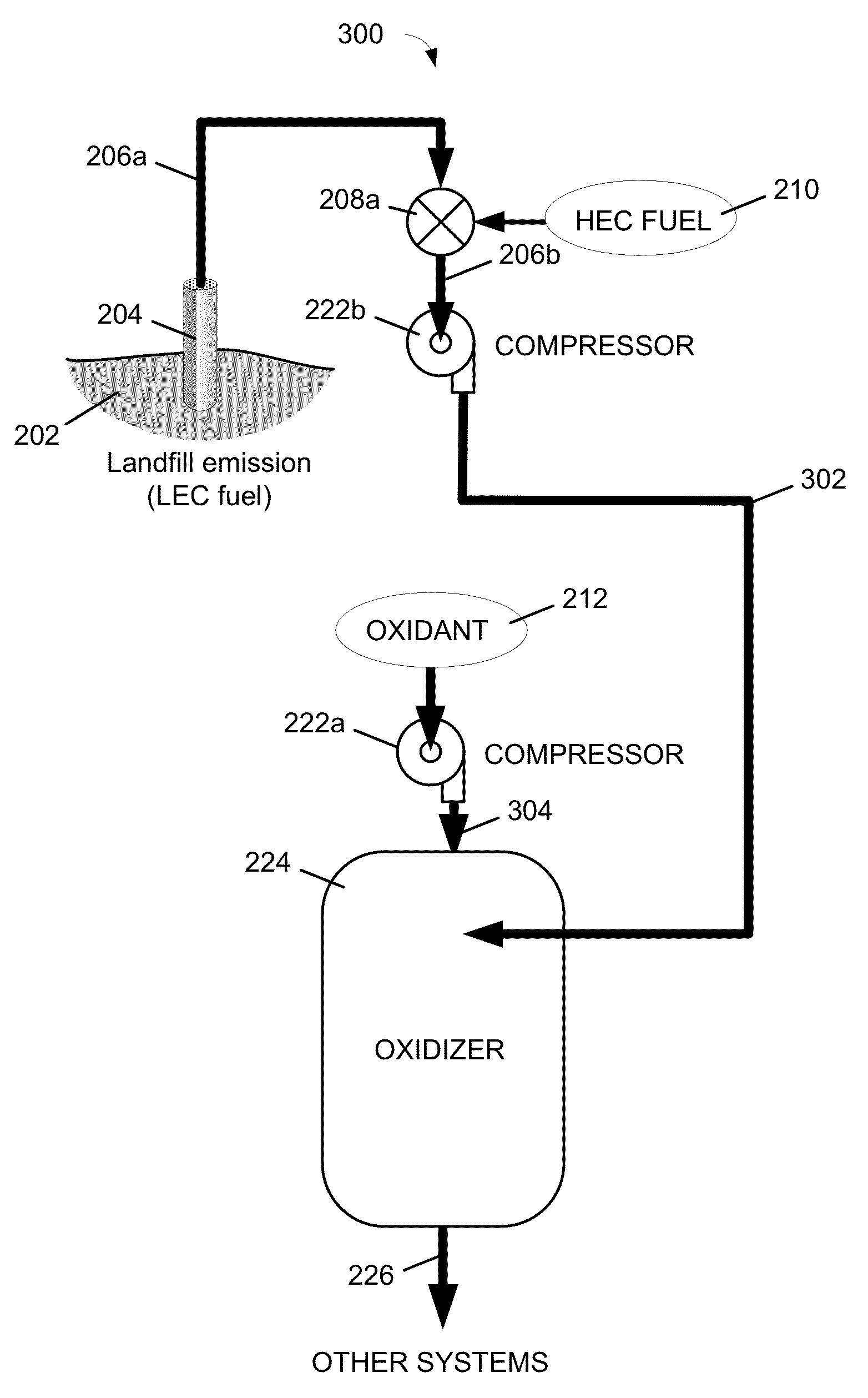

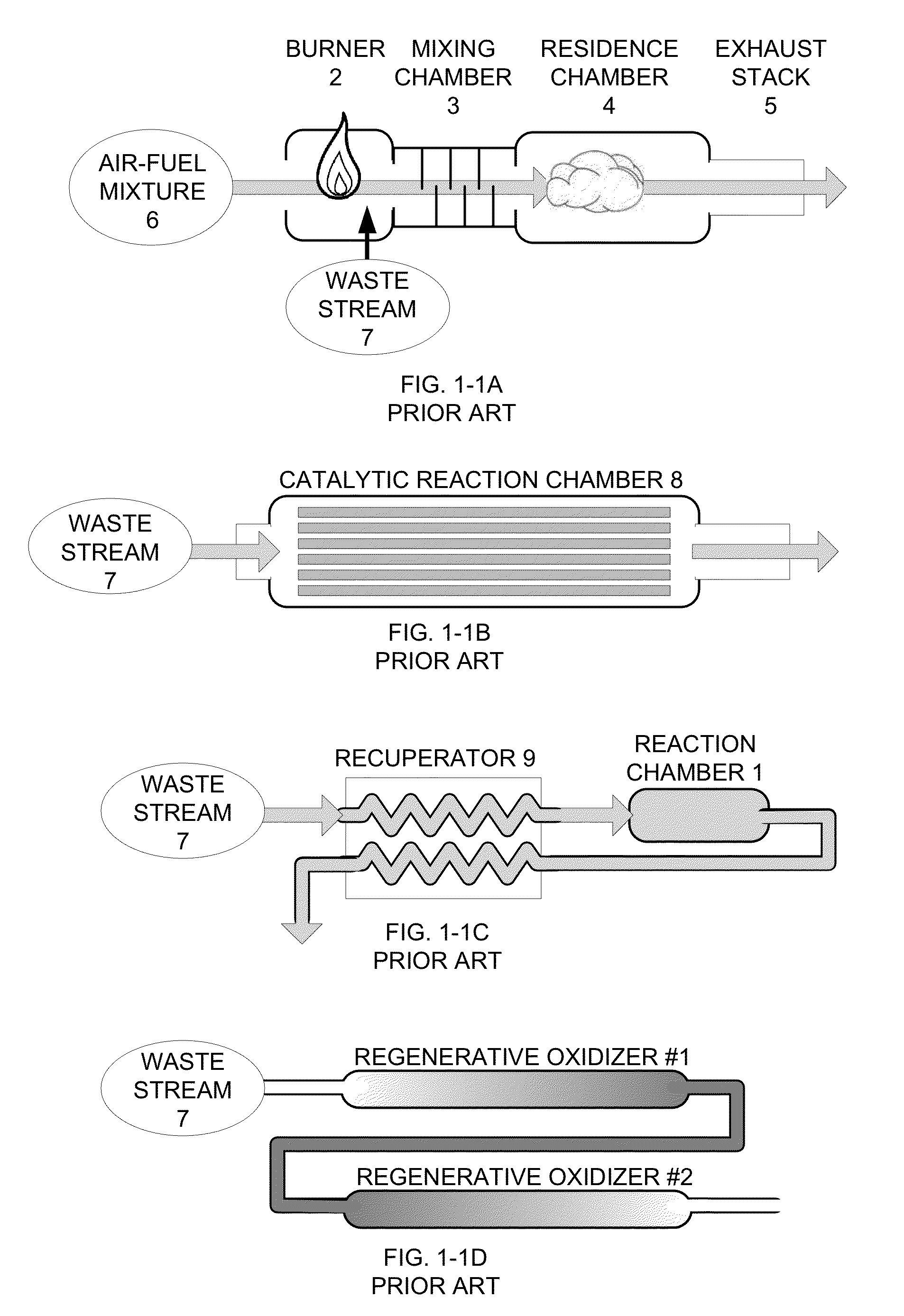

Gradual oxidation with heat transfer

ActiveUS20130232985A1Reduce formationAvoid and decrease expenseFuel supply regulationContinuous combustion chamberFlameoutReaction temperature

Described herein are embodiments of systems and methods for oxidizing gases. In some embodiments, a reaction chamber is configured to receive a fuel gas and maintain the gas at a temperature within the reaction chamber that is above an autoignition temperature of the gas. The reaction chamber may also be configured to maintain a reaction temperature within the reaction chamber below a flameout temperature. In some embodiments, heat and product gases from the oxidation process can be used, for example, to drive a turbine, reciprocating engine, and injected back into the reaction chamber.

Owner:REDUCTONOX CORP

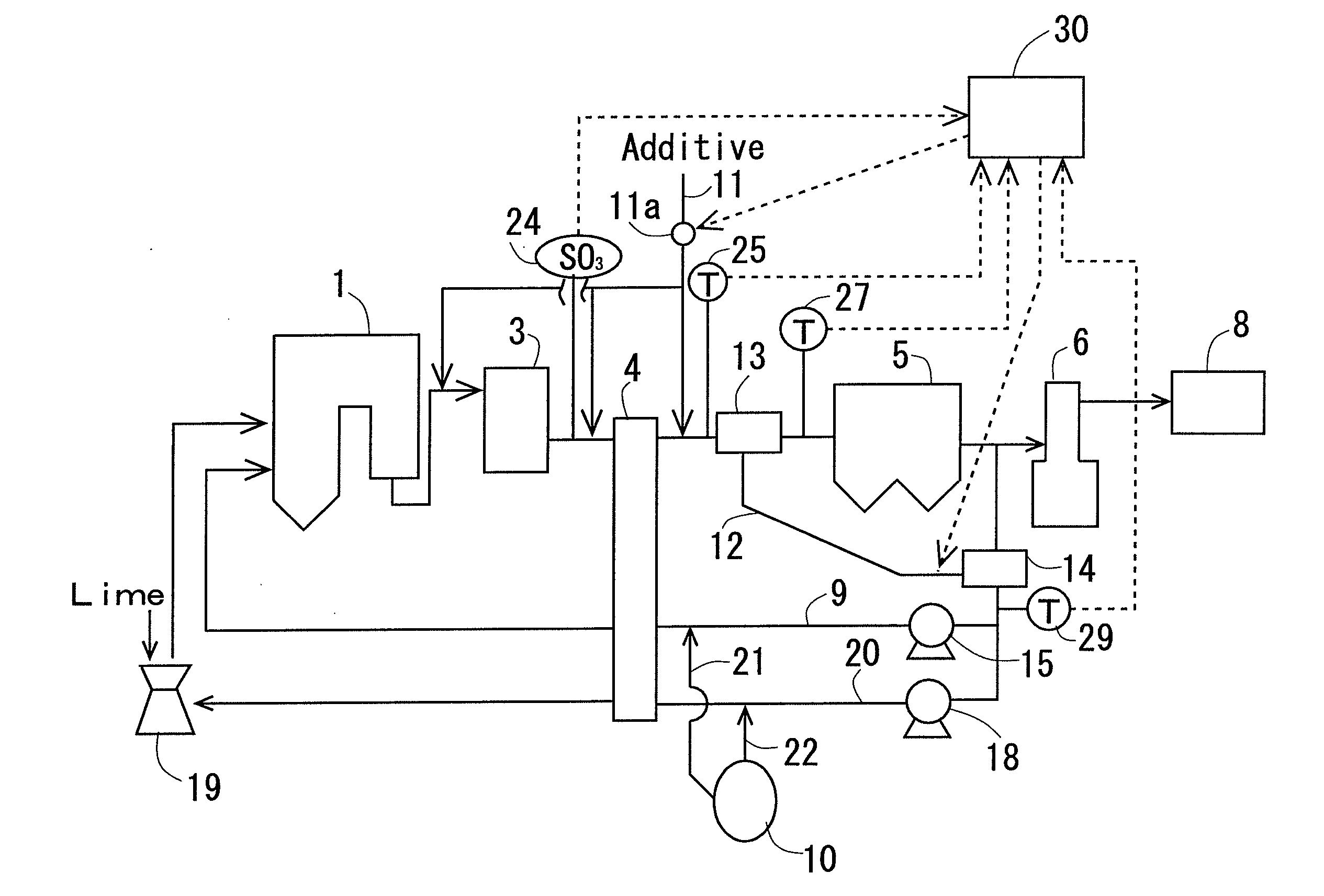

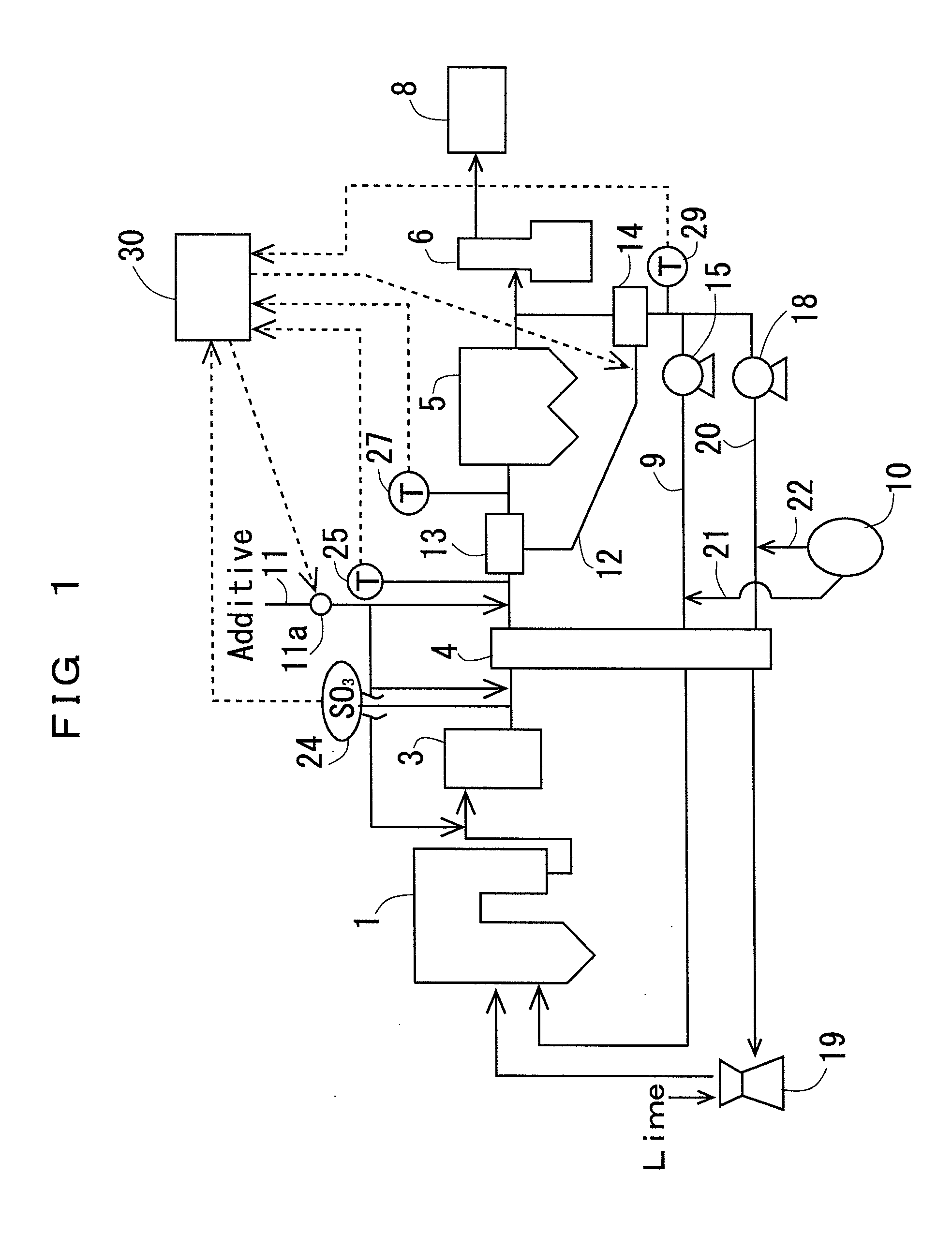

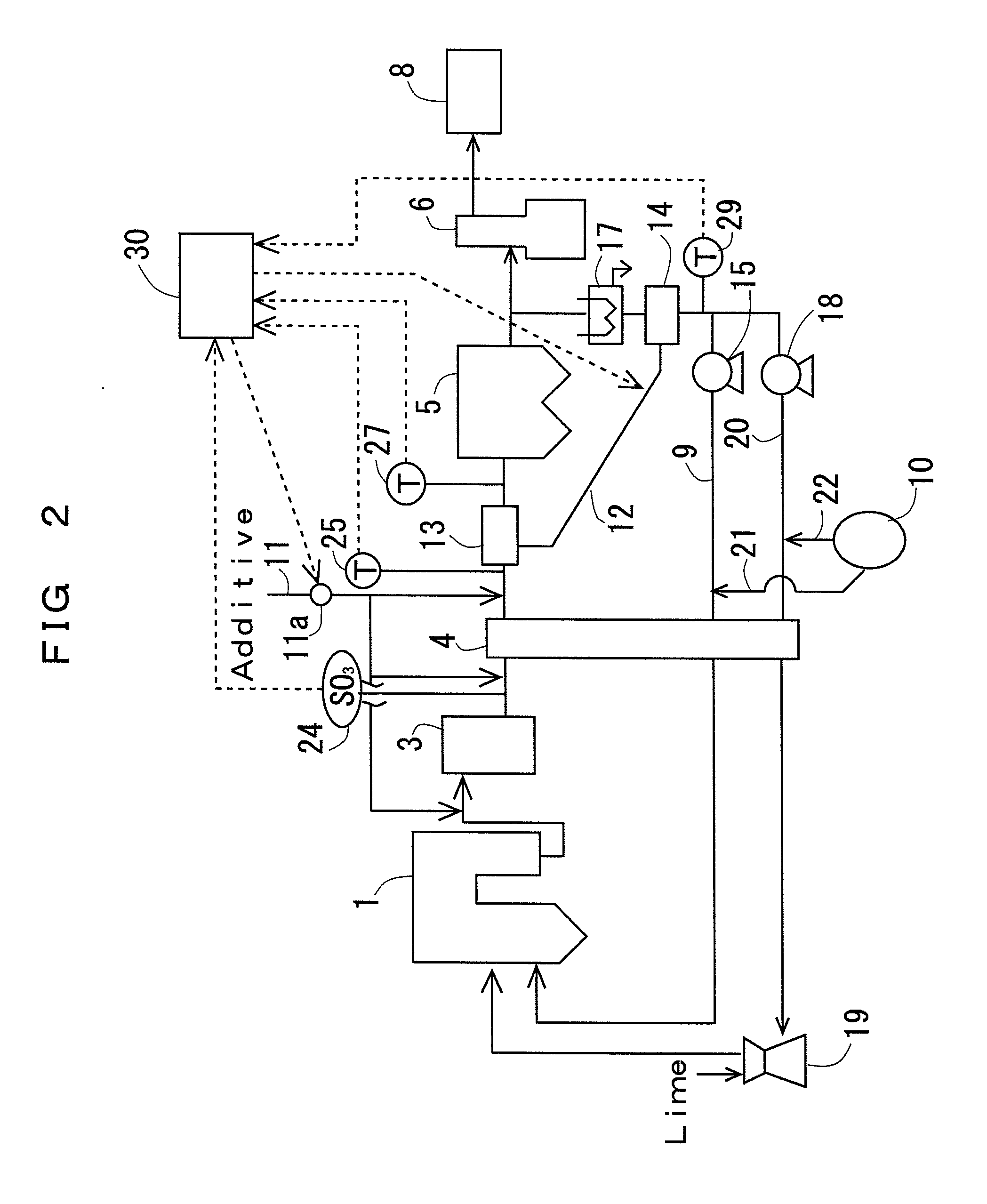

Exhaust gas treatment device for an oxygen combustion system

InactiveUS20120272626A1Efficient removalAvoid corrosionCombination devicesGas treatmentAir preheaterCombustion chamber

In an exhaust gas treatment device provided with: an exhaust gas treatment unit in which an oxygen combustion boiler 1 using coal as fuel, a denitration device 3, an air preheater 4, a dust-collection device 5, a desulfurization device 6, and a carbon dioxide recovery device 8 are sequentially arranged from the upstream side to the downstream side of an exhaust gas duct; and an exhaust gas circulation unit which branches off from the exhaust gas duct at an outlet of the dust-collection device 5 or an outlet of the desulfurization device 6 and through which the exhaust gas is preheated by the air preheater 4 and returned to the oxygen combustion boiler 1, a heat-recovery heat exchanger 13 that adjusts a gas temperature at an inlet of the dust-collection device 5 to be not greater than an acid dew point of SO3 and not lower than a water dew point is provided between the air preheater 4 and the dust-collection device 5, a reheating heat exchanger 13 that adjusts a gas temperature to be not lower than the acid dew point of SO3 is provided in the vicinity of a branch of the exhaust gas circulation unit, adjusting the gas temperature at the inlet of the dust-collection device 4 to be not greater than the acid dew point of SO3 makes it possible to prevent corrosion of pipes in the exhaust gas circulation unit and to avoid a decrease in fluidity or combustibility of the pulverized coal in the pipes in the mill.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS10018115B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

Method of and System For Generating Power By Oxyfuel Combustion

InactiveUS20090297993A1Increase temperatureEasy to switchExhaust apparatusGas turbine plantsCombustion systemExhaust fumes

An oxyfuel combustion system for generating power that includes a furnace for combusting carbonaceous fuel and substantially pure oxygen to produce exhaust gas including mainly carbon dioxide and water. An exhaust gas channel system discharges the exhaust gas from the furnace. The exhaust gas channel system has an upstream channel, an outlet channel and a gas recycling channel. The upstream channel recycles a recycling portion of the exhaust gas through the recycling channel to the furnace, and conveys an end portion of the exhaust gas through the outlet channel for final processing. The upstream channel is divided between a first divider piece and a connecting piece into a first exhaust gas channel portion and a second exhaust gas channel portion. A gas-gas heat exchanger arranged in the first exhaust gas channel portion transfers heat from exhaust gas in the first exhaust gas channel portion to gas in the gas recycling channel. A first economizer arranged in the second exhaust gas channel portion transfers heat from exhaust gas in the second exhaust gas channel portion to a flow of feedwater in a feedwater line, and a second economizer arranged in the exhaust gas channel system downstream of the connecting piece transfers heat from gas in the exhaust gas channel system to the flow of feedwater in the feedwater line.

Owner:FOSTER WHEELER ENERGIA OY

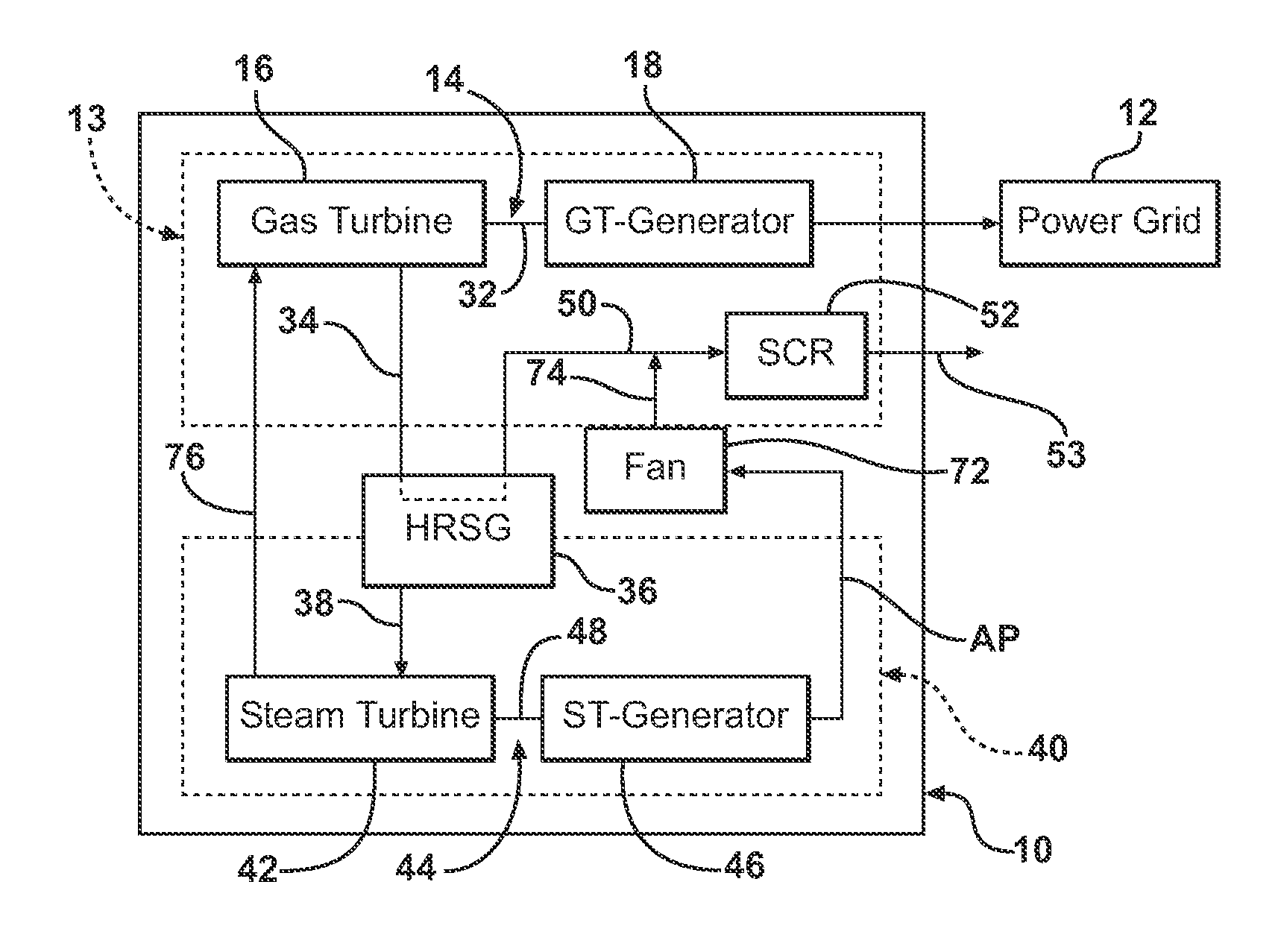

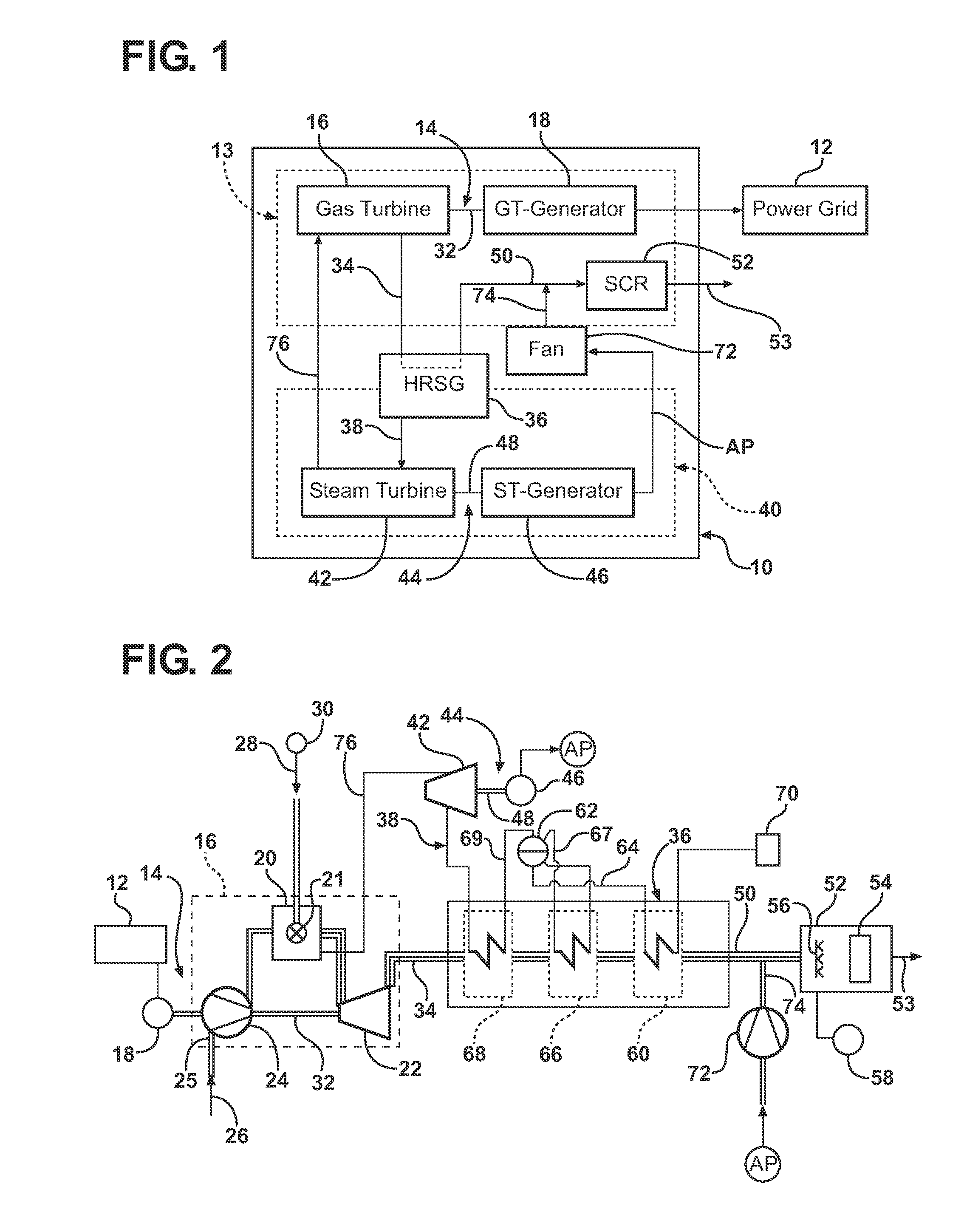

Method of Operating a Gas Turbine Power Plant with Auxiliary Power to Reduce Emissions

InactiveUS20110138771A1Emission reductionReduce the temperatureTurbine/propulsion fuel supply systemsExhaust apparatusPower stationEngineering

A method of operating a gas turbine power plant including an auxiliary power output for reducing power plant emissions. A heat recovery steam generator receives an expanded working medium from a gas turbine and removes heat from the expanded working medium to form a reduced temperature exhaust gas and to generate steam from the heat removed from the expanded working medium. A steam turbine and generator assembly operates on the steam to produce an auxiliary plant output. A selective catalytic reduction (SCR) system is provided for receiving the reduced temperature exhaust gas; and an auxiliary fan is powered by the auxiliary plant output to supply dilution air for further reducing the temperature of the exhaust gas to prior to passing the exhaust gas through the SCR system.

Owner:SIEMENS ENERGY INC

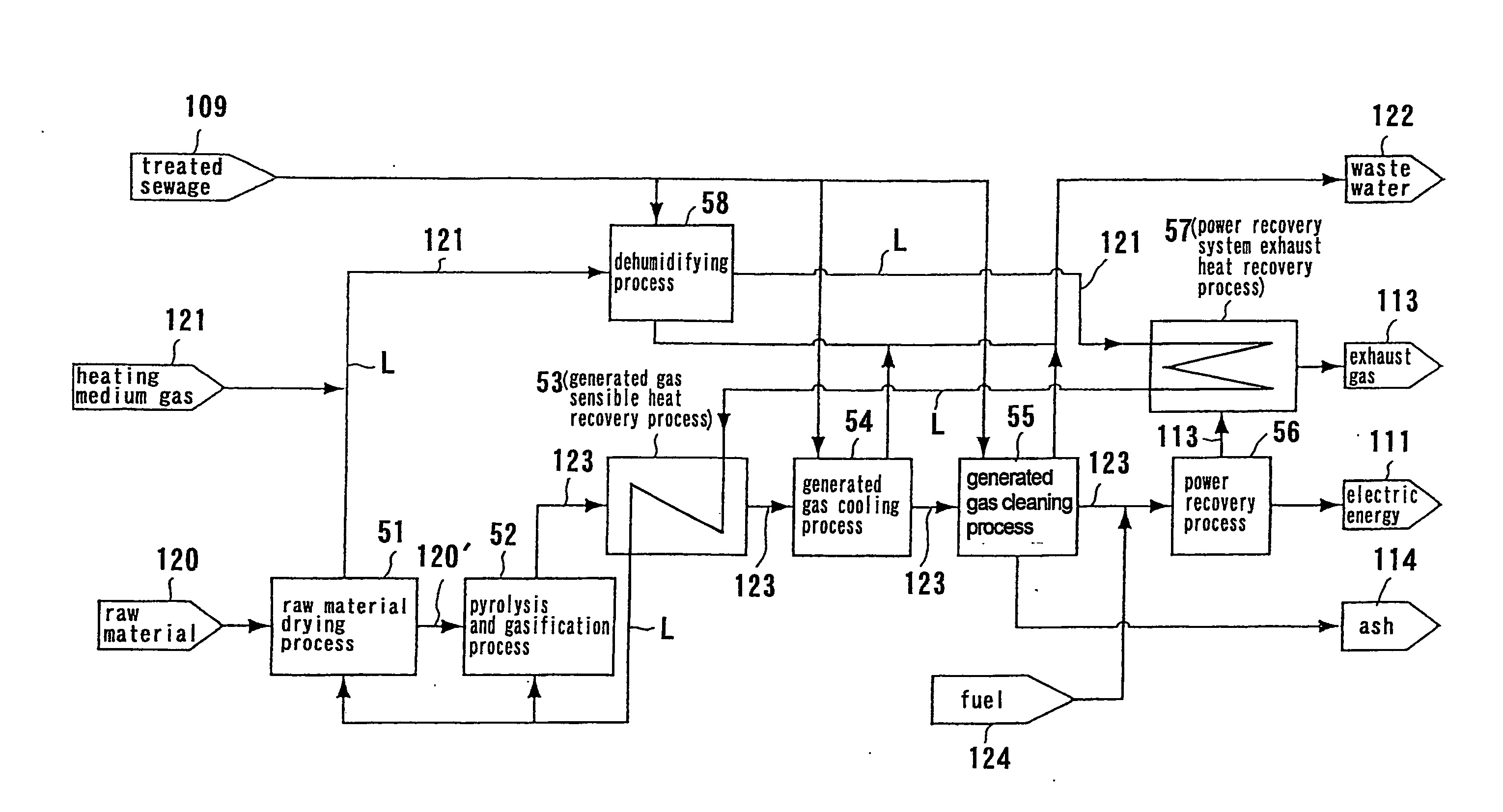

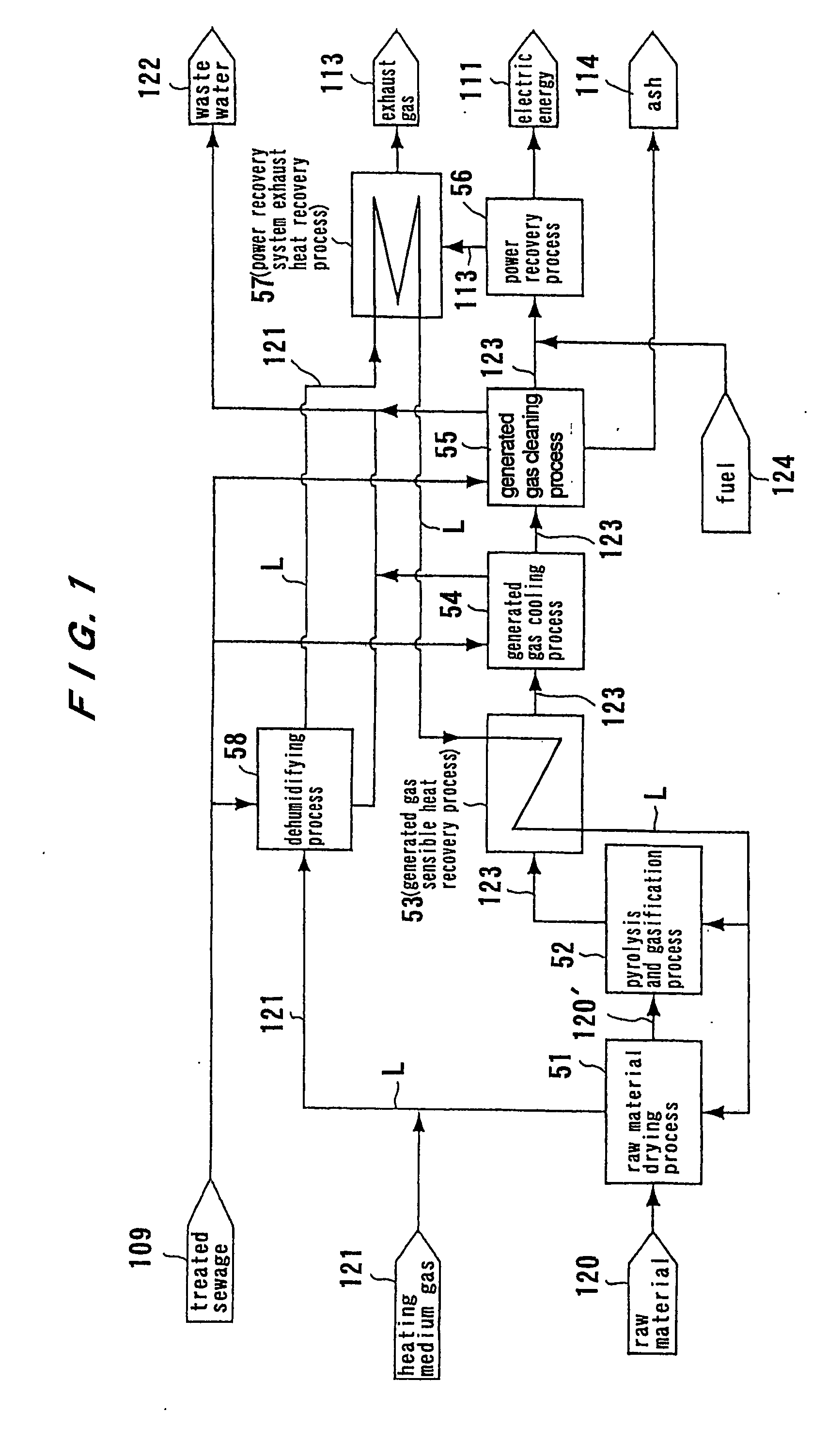

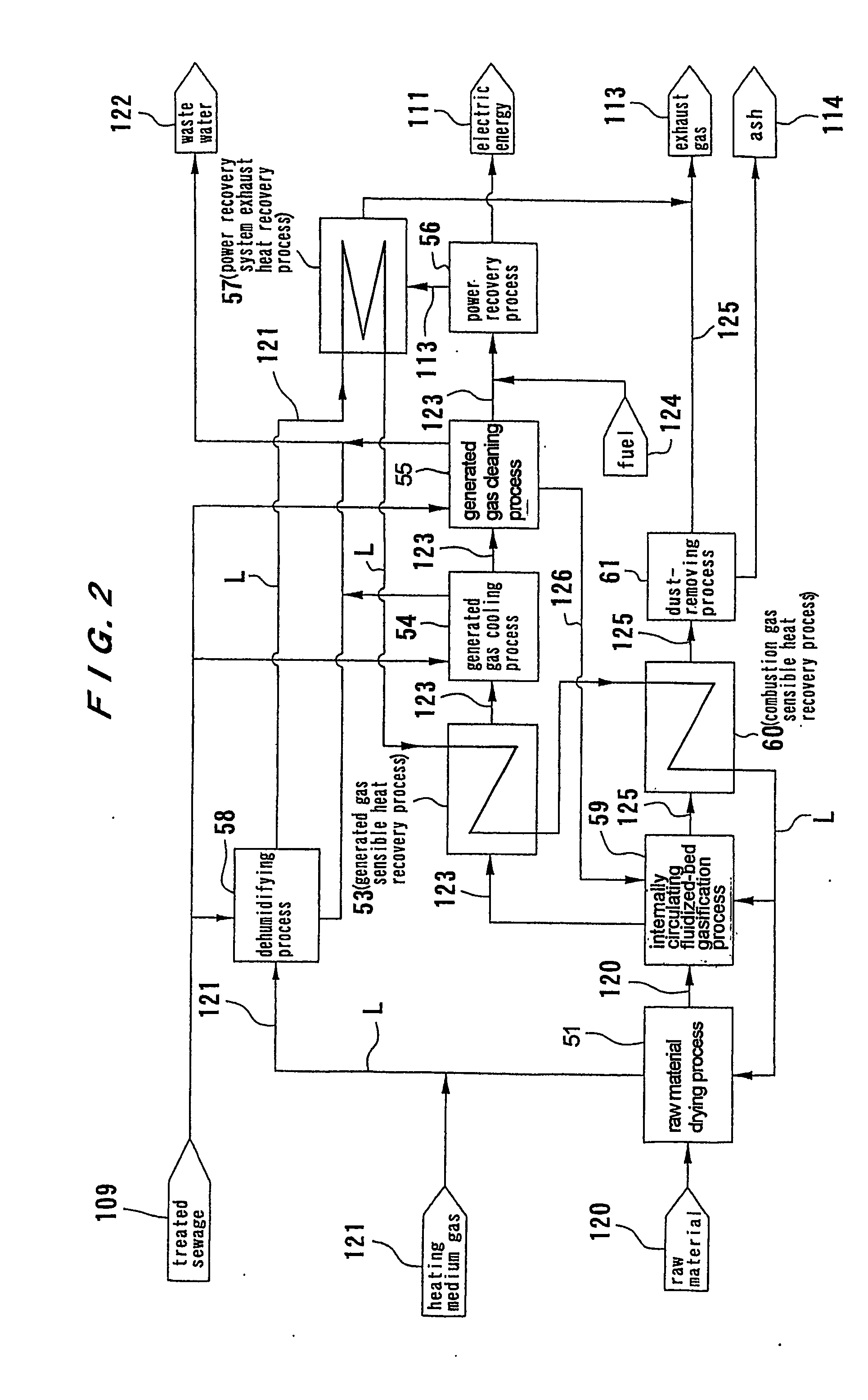

Method and apparatus for treating organic matter

InactiveUS20060260190A1Lower initial costLow running costBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeCombustible gas

An organic matter such as sewage sludge (101) is treated by gasifying the organic matter into a combustible gas and using the combustible gas as a fuel for a gas engine or a gas turbine to recover power (energy). In a method of treating the organic matter, an organic matter as a raw material is dried in a drying process (51), the dried raw material is gasified to produce a generated gas (123), and the sensible heat from the generated gas and / or a combustion gas produced by gasification is recovered by using a heating medium in a recovery process. Then, the heating medium heated in the recovery process is introduced into the drying process as a heating medium gas for drying.

Owner:EBARA CORP

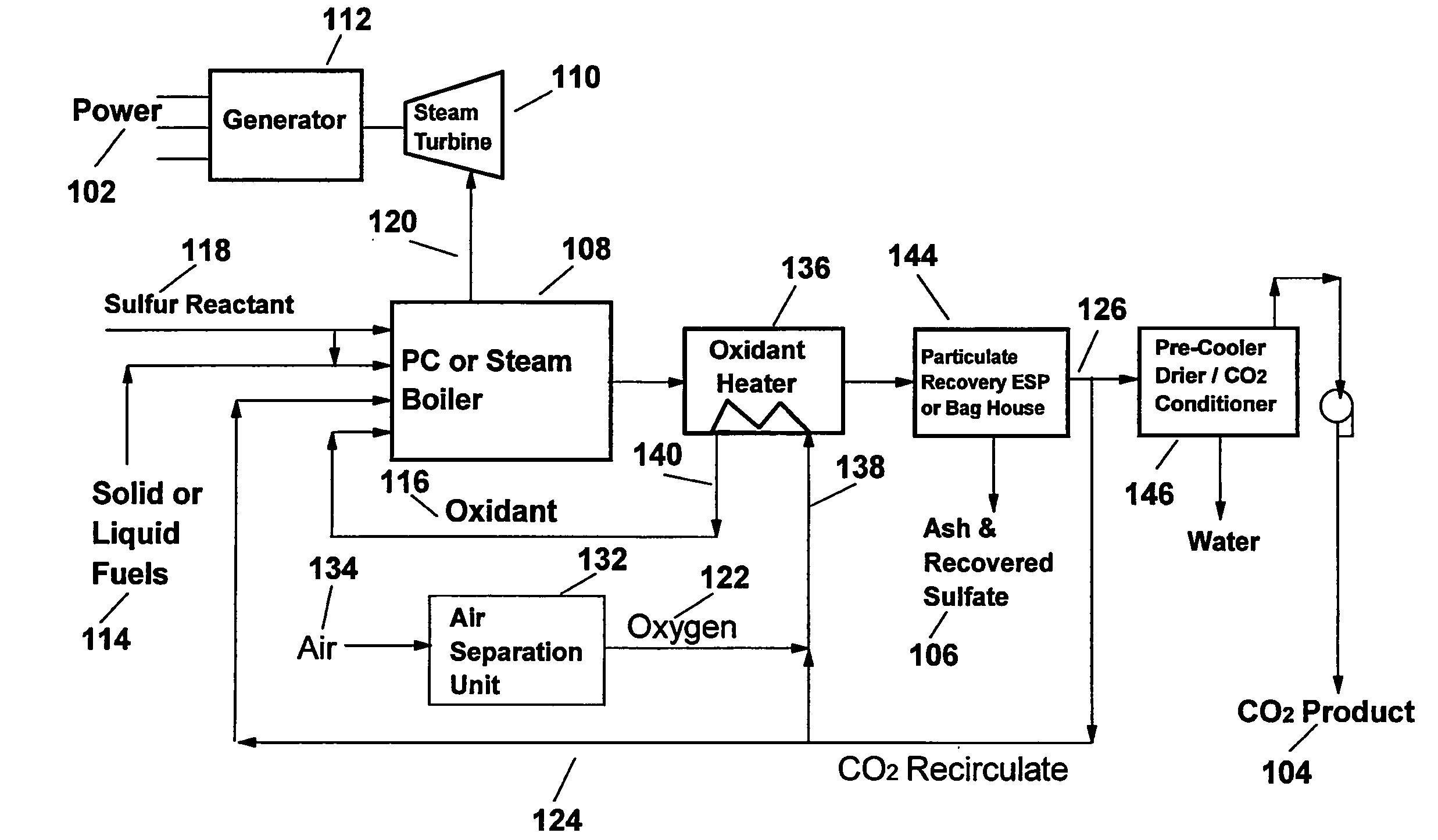

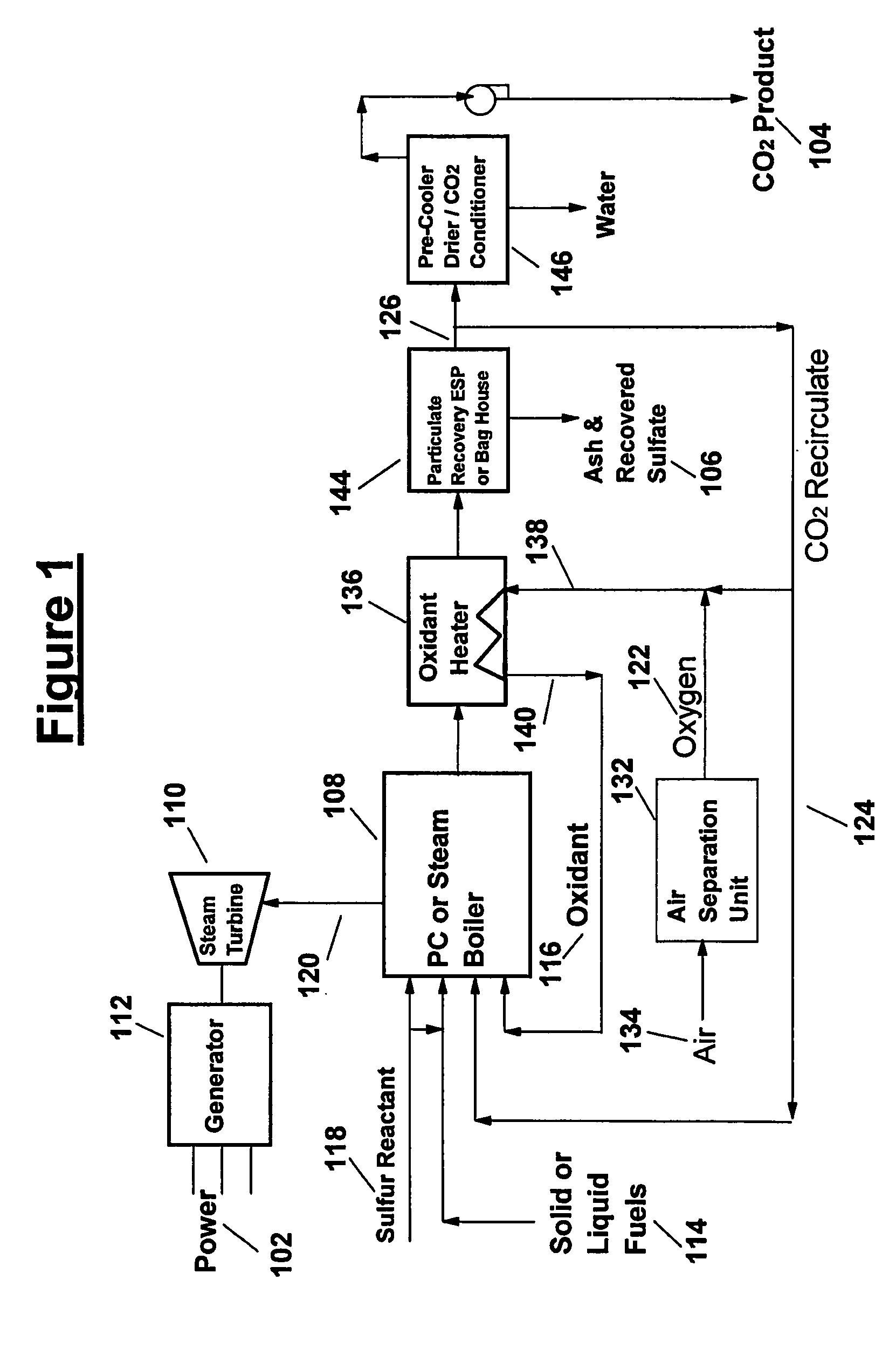

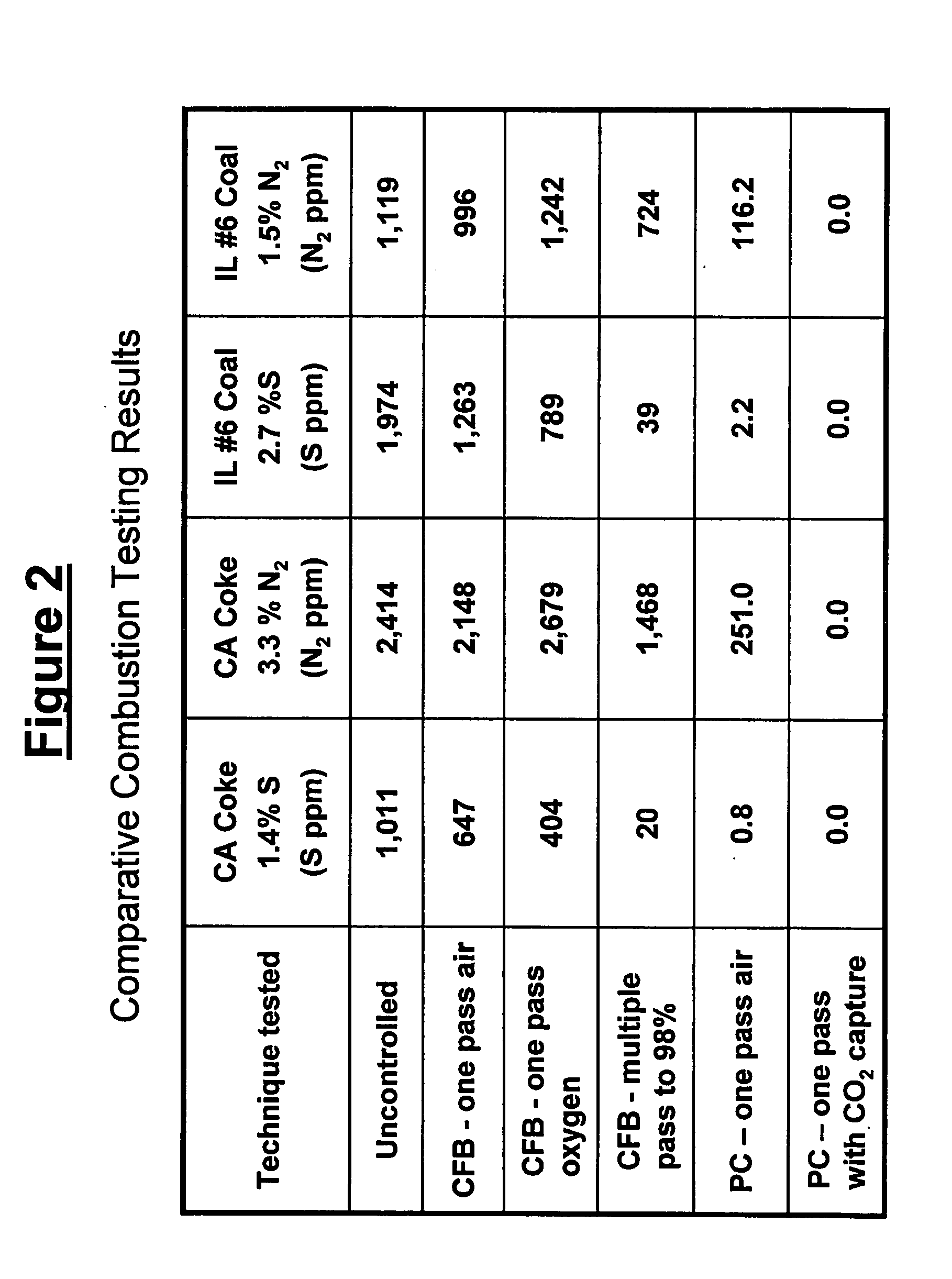

Coal/Coke/Heavy Residual Oil Boiler With Sulfur And Carbon Dioxide Capture And Recovery

A pulverized coal / coke (PC) boiler combusts carbon-based fuel with substantially pure oxygen and a flue gas recirculation stream (containing predominately carbon dioxide) at varied ratios to achieve a desired boiler temperature profile while producing captured sulfur, a high purity captured CO2 and electric power. The boiler includes at least one of (a) a mechanism for admixing a pulverized solid carbon-based fuel with an alkali metal salt and (b) injecting alkali metal salt into the boiler combustion zone containing a pulverized solid carbon-based fuel.

Owner:PLASMA POWER PROD

Use of SO2 from flue gas for acid wash of ammonia

ActiveUS7867322B2Efficient and environmentally acceptableGas treatmentDispersed particle filtrationFlue gasSulfate

A gas cleaning system, which is operative for cleaning a process gas containing carbon dioxide and sulphur dioxide, comprises a combined cooling and cleaning system (16), and a CO2-absorber. The combined cooling and cleaning system (16) comprises a first gas-liquid contacting device (50) located upstream of the CO2-absorber and operative for cooling the process gas by means of a cooling liquid, and for absorbing into the cooling liquid sulphur dioxide of the process gas, such that a cooling liquid containing sulphate is obtained. The combined cooling and cleaning system (16) further comprises a second gas-liquid contacting device (94) located downstream of the CO2-absorber and operative for removing ammonia from the process gas, which has been treated in the CO2-absorber, by means of bringing the process gas containing ammonia into contact with the cooling liquid containing sulphate.

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com