Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1634 results about "Gas engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas engine is an internal combustion engine that runs on a gaseous fuel, such as coal gas, producer gas, biogas, landfill gas or natural gas. In the United Kingdom, the term is unambiguous. In the United States, due to the widespread use of "gas" as an abbreviation for gasoline (petrol), such an engine might also be called a gaseous-fueled engine or natural gas engine or spark ignited.

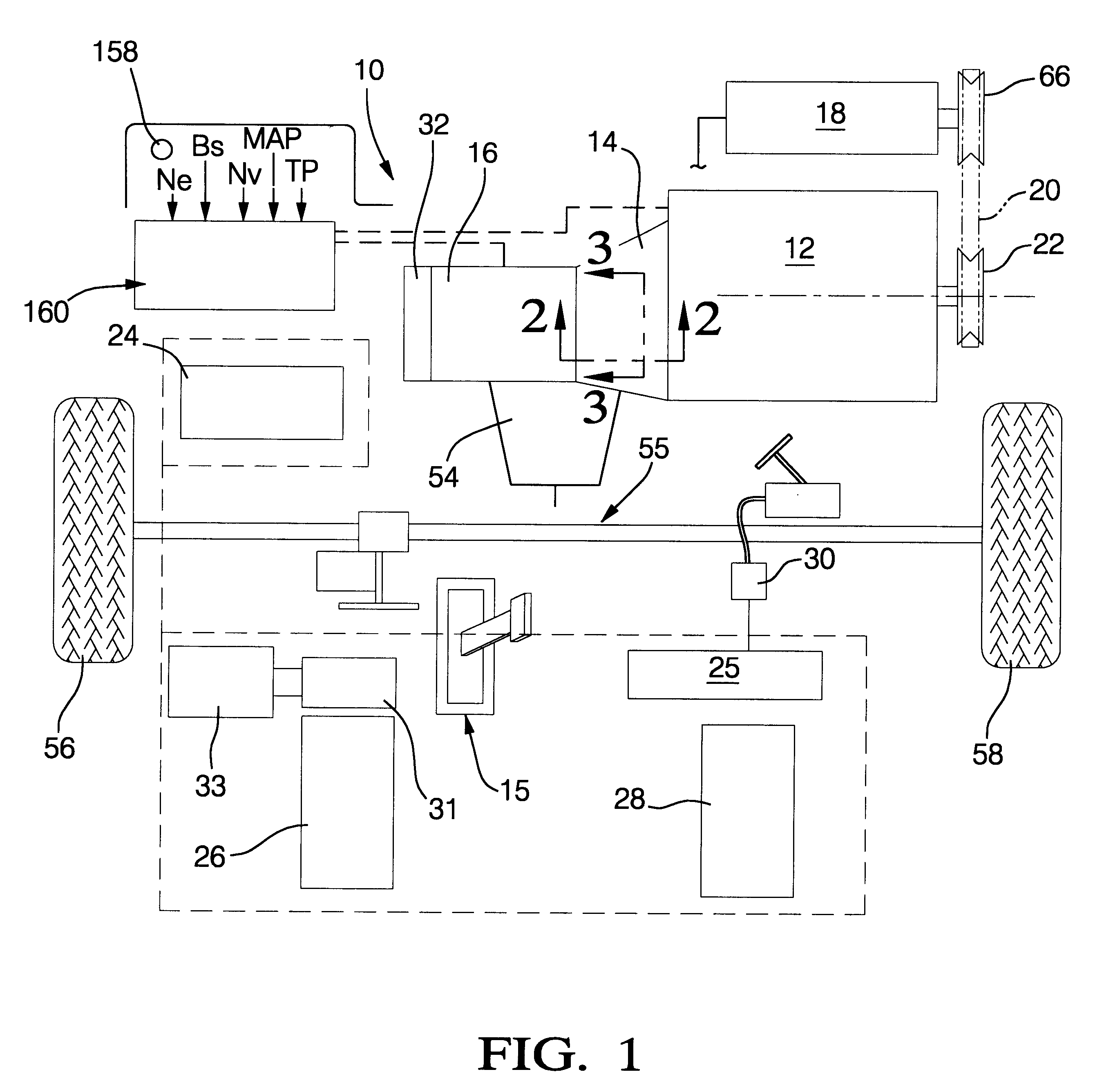

Hybrid electric drive and control method therefor

InactiveUS6376927B1Increase fuel consumptionImprove drivabilityInternal combustion piston enginesGearing controlHysteresisEngineering

A fuel management control method for a hybrid electric vehicle drive having an internal combustion engine and an electric motor arranged in parallel such that both can propel the vehicle; the system including an electric motor driven fuel pump and a programmable microprocessor; and wherein the method further includes monitoring vehicle speed and sensing braking pressure and directing signals of both vehicle speed and braking to the microprocessor and processing such inputs in accordance with an aggressive fuel management program including shut-off of fuel flow to the gas engine in response to vehicle braking at vehicle speeds above a predetermined maximum hysteresis speed and maintaining the fuel shut off during vehicle coasting above a predetermined speed while controlling the electric motor to provide regenerative braking or vehicle start during such fuel shut off modes of operation.

Owner:SATURN CORPORATION

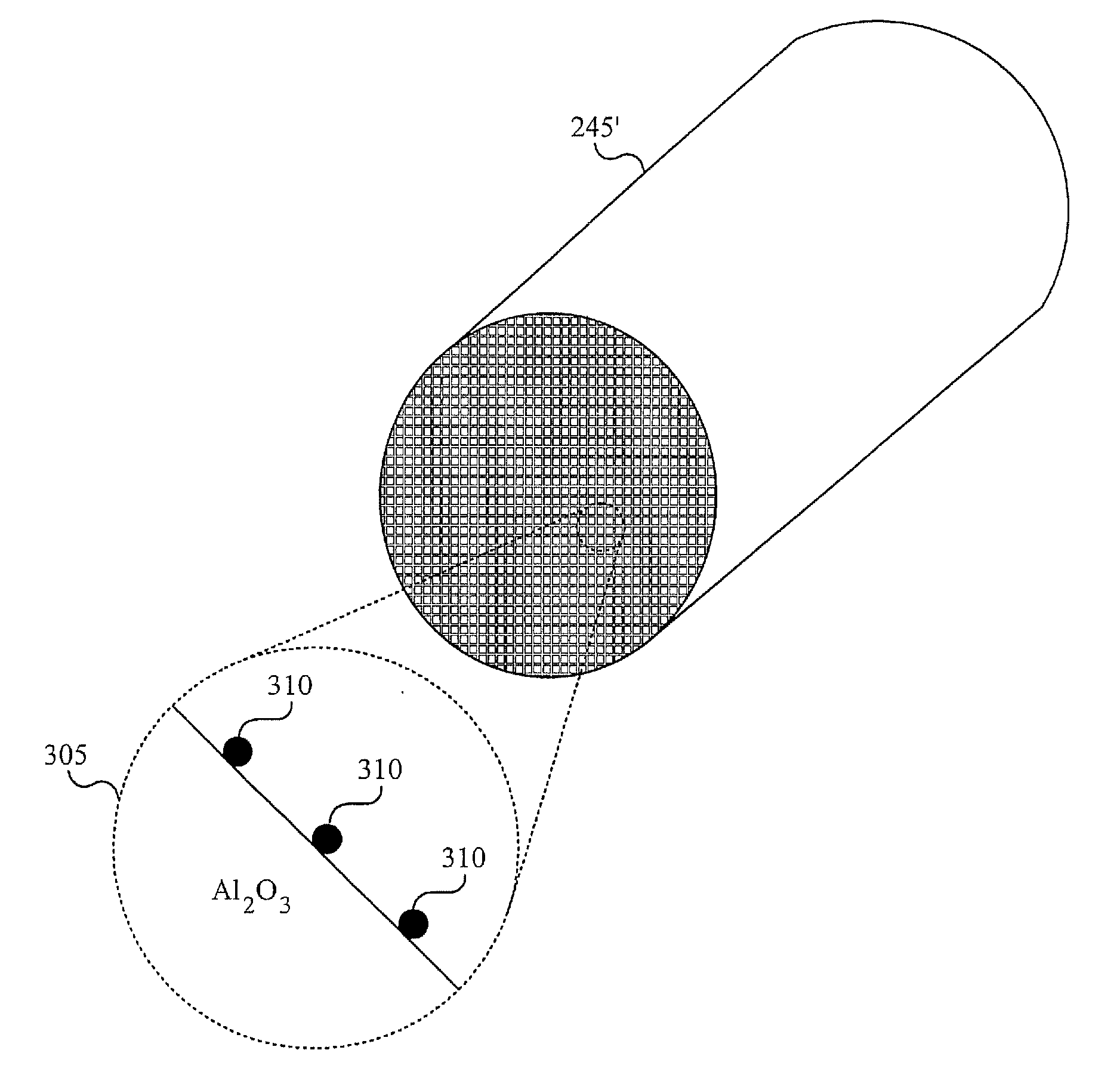

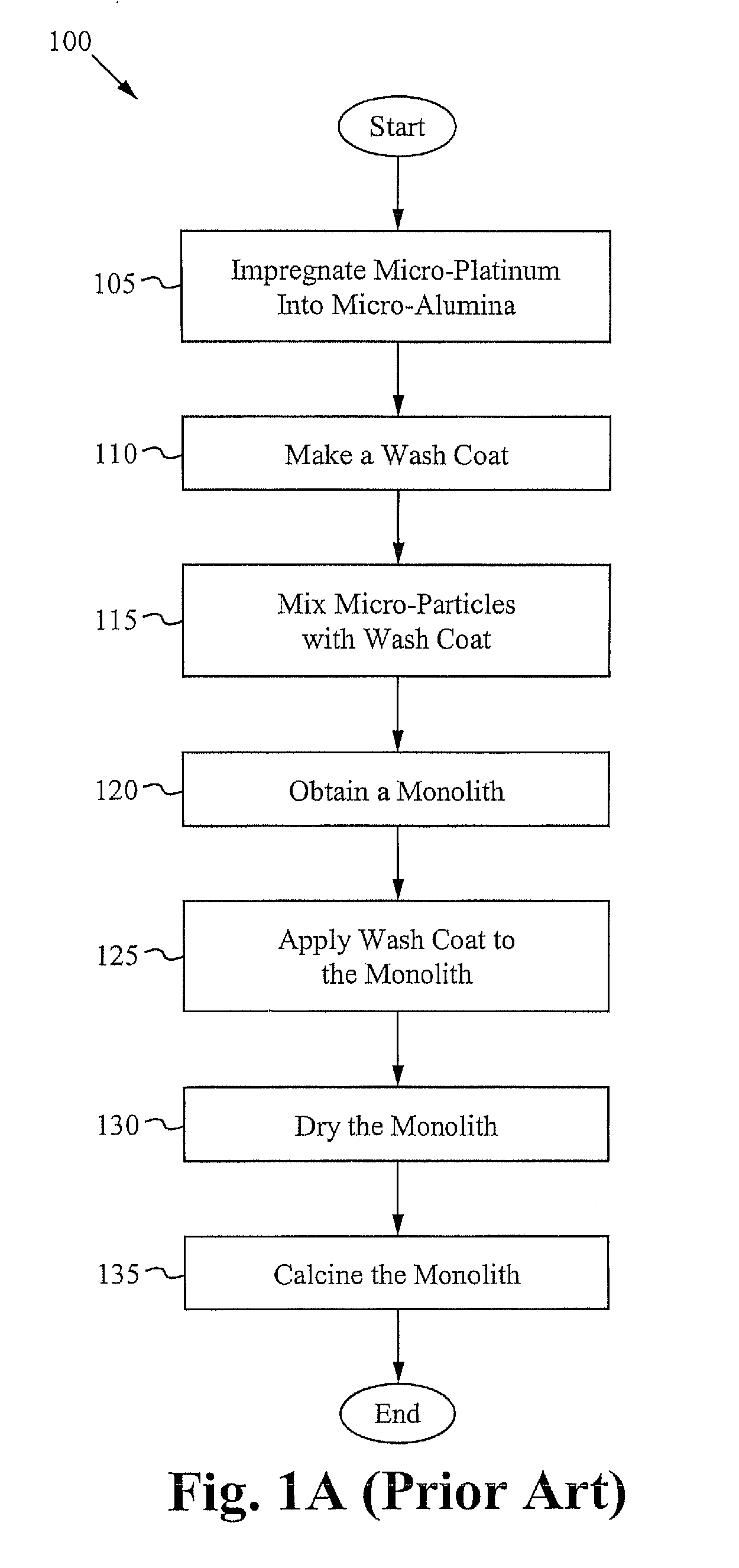

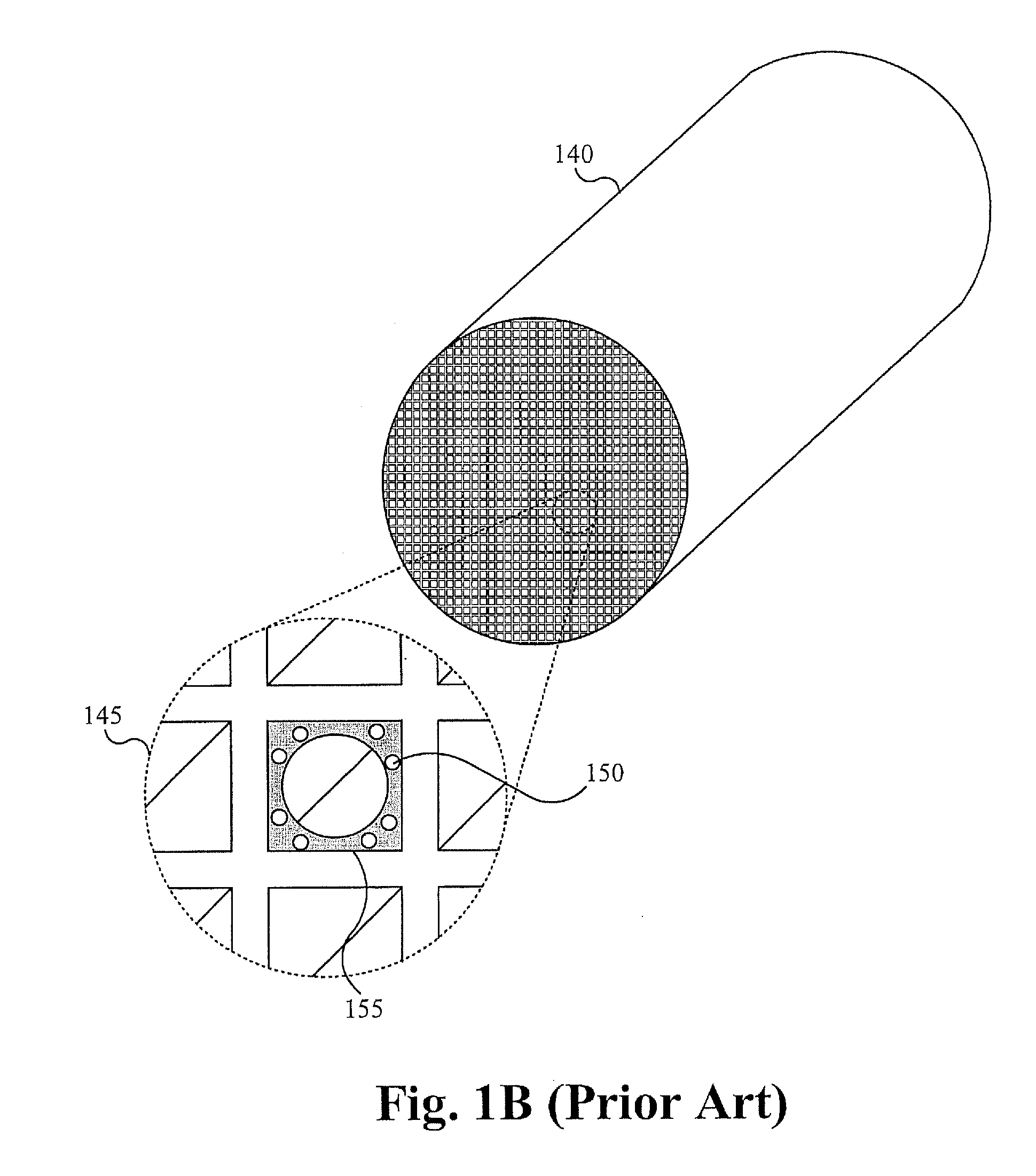

Advanced catalysts for automotive applications

ActiveUS20110143933A1Restrict movementMaterial nanotechnologyMolten spray coatingPlatinumNanoparticle

Embodiments of present inventions are directed to an advanced catalyst. The advanced catalyst includes a honeycomb structure with an at least one nano-particle on the honeycomb structure. The advanced catalyst used in diesel engines is a two-way catalyst. The advanced catalyst used in gas engines is a three-way catalyst. In both the two-way catalyst and the three-way catalyst, the at least one nano-particle includes nano-active material and nano-support. The nano-support is typically alumina. In the two-way catalyst, the nano-active material is platinum. In the three-way catalyst, the nano-active material is platinum, palladium, rhodium, or an alloy. The alloy is of platinum, palladium, and rhodium.

Owner:UMICORE AG & CO KG +1

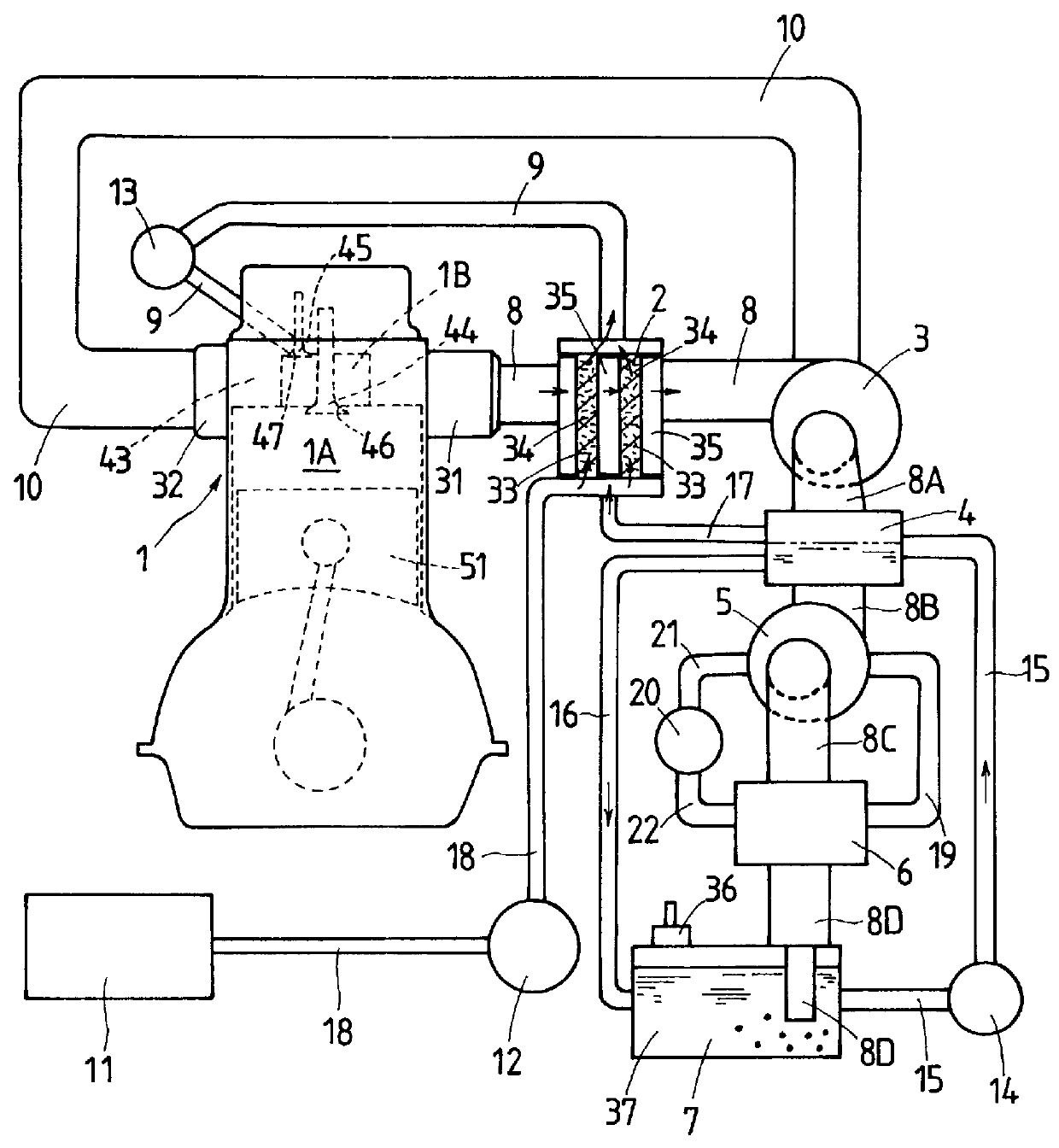

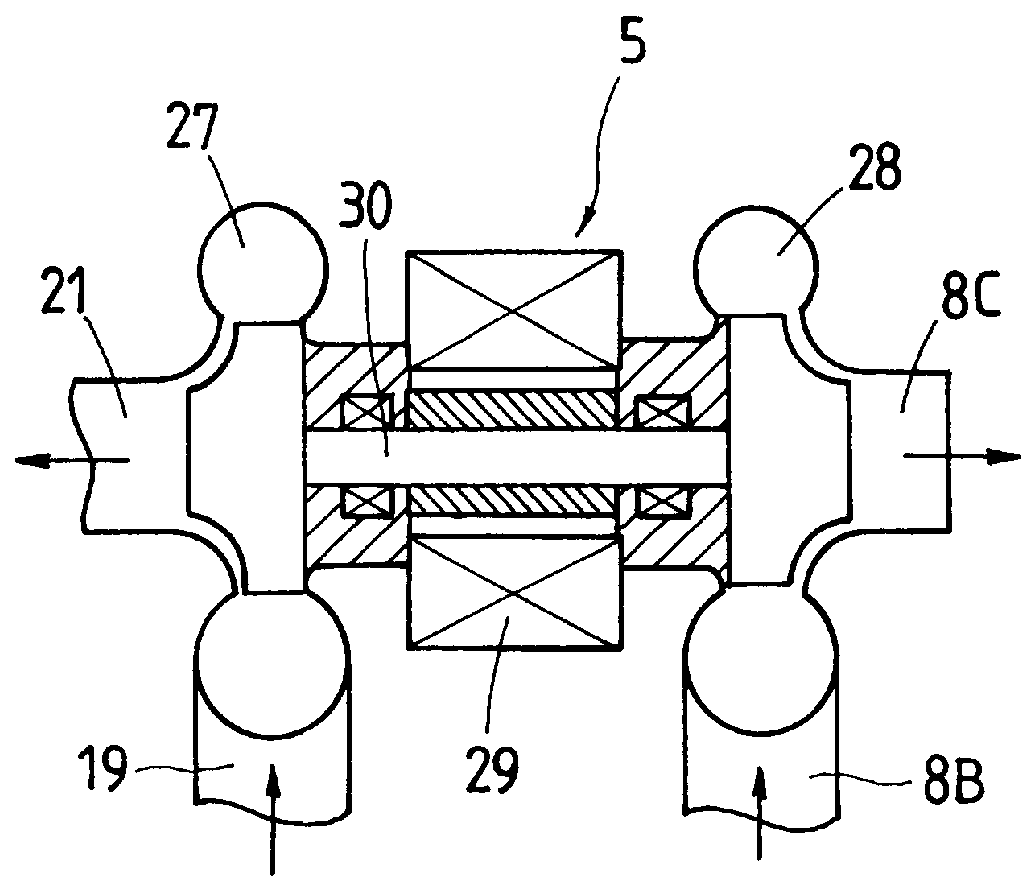

Gas engine with a gas fuel reforming device

InactiveUS6079373AReduce air pollutionMinimize formationInternal combustion piston enginesExhaust apparatusThermal energyCO2 content

The gas engine with a gas fuel reforming device thermally decomposes CH4, a major component of natural gas, into a reformed fuel of CO and H2 to increase the heat produced and thereby reduce the CO2 content in the exhaust gas and prevent the formation of NOx. The gas engine mixes CH4 with CO2 and sends the gas mixture to the catalyst reactor installed in the exhaust passage where the gas mixture is thermally decomposed into a reformed fuel by using the thermal energy of the exhaust gas. CO2 is extracted from the exhaust gas by the CO2 supply device which in turn sends the CO2 to the catalyst reactor. The CO2 supply device comprises a CO2 dissolving device that accommodates a solution to dissolve CO2 of low-temperature exhaust gas and a CO2 delivery device installed in the exhaust passage through which high-temperature exhaust gas flows and adapted to release CO2 from the solution supplied from the CO2 dissolving device. The CO2 supply device can be formed of a CO2 separation membrane that separates CO2 from the exhaust gas.

Owner:ISUZU MOTORS LTD

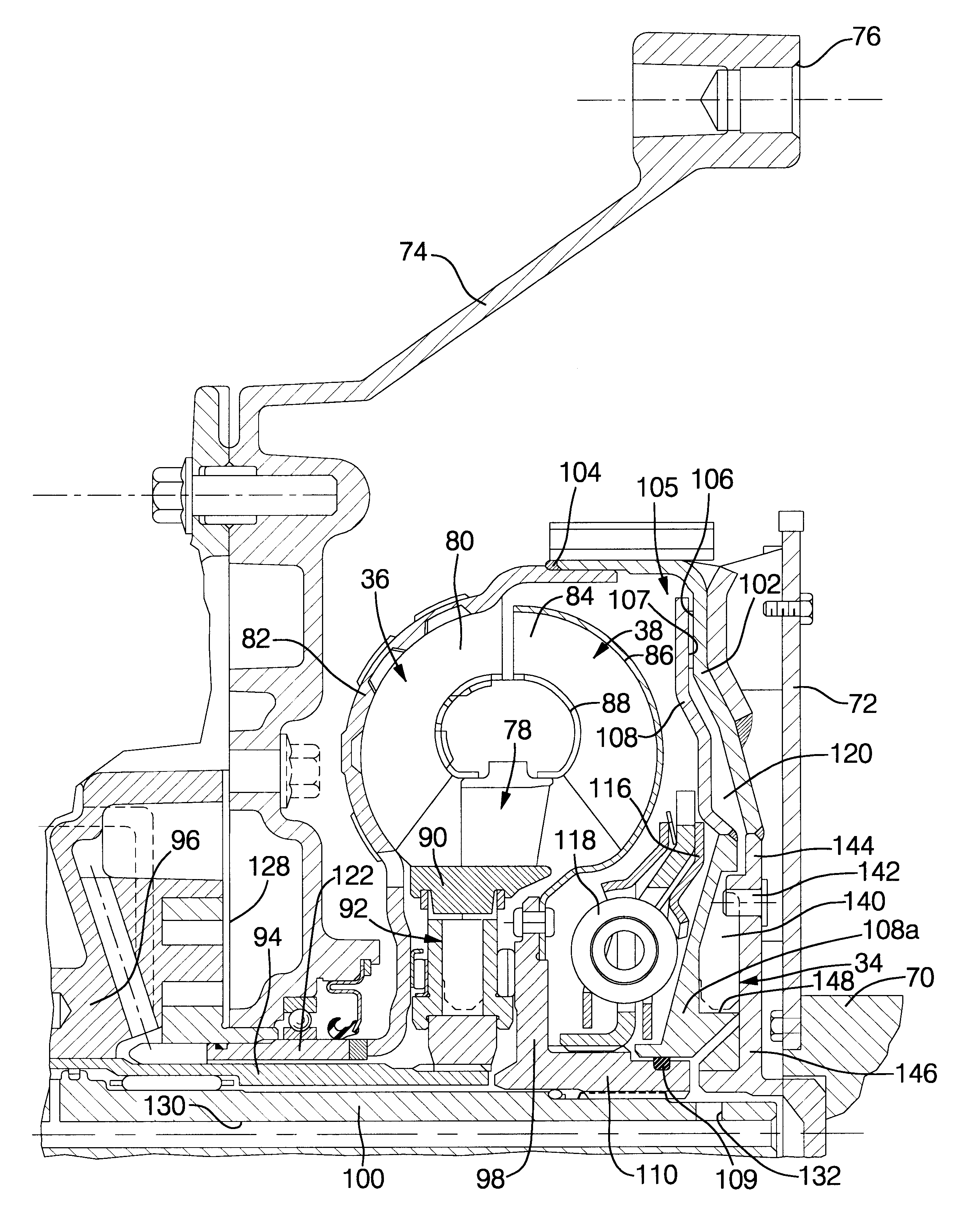

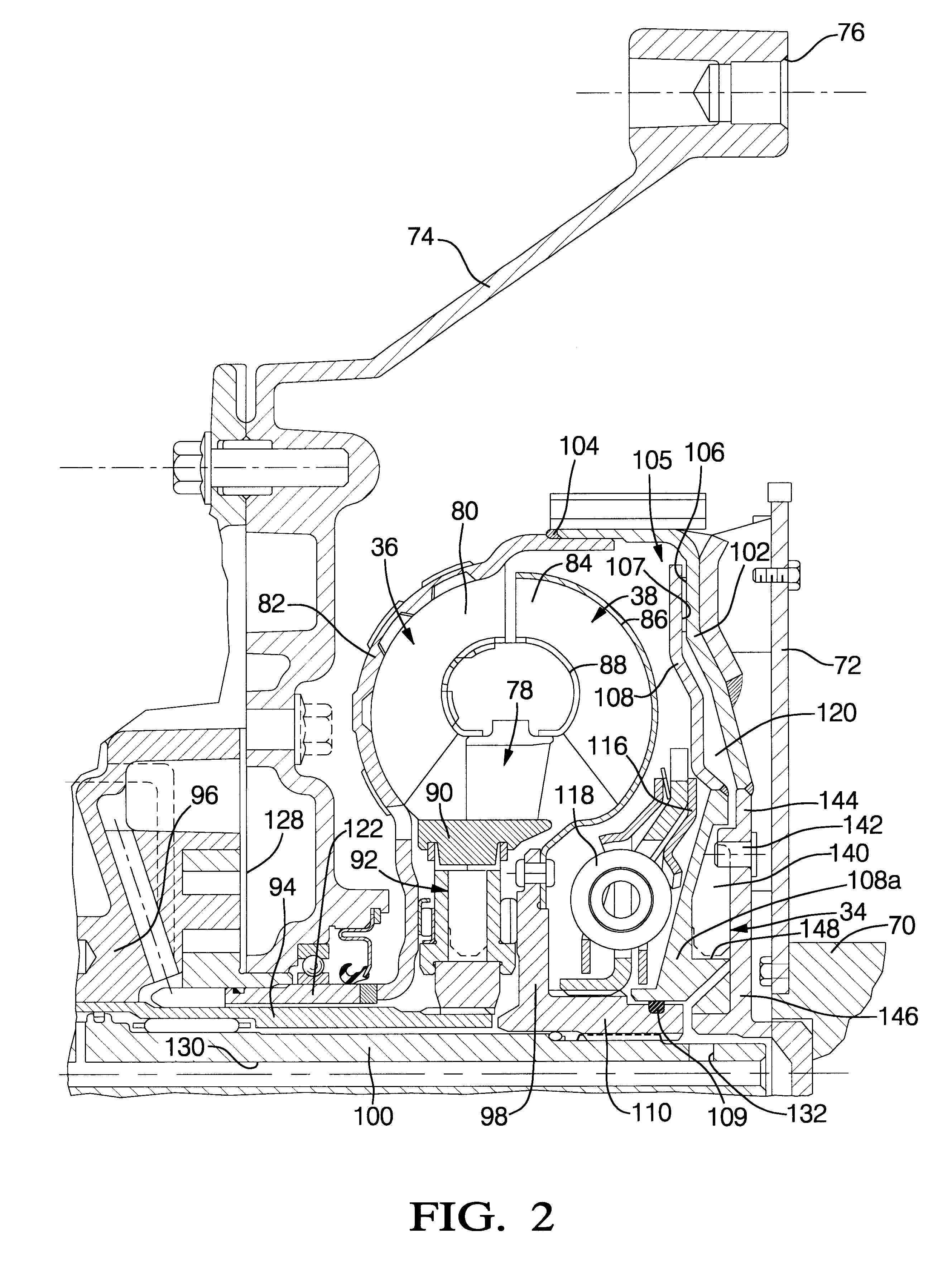

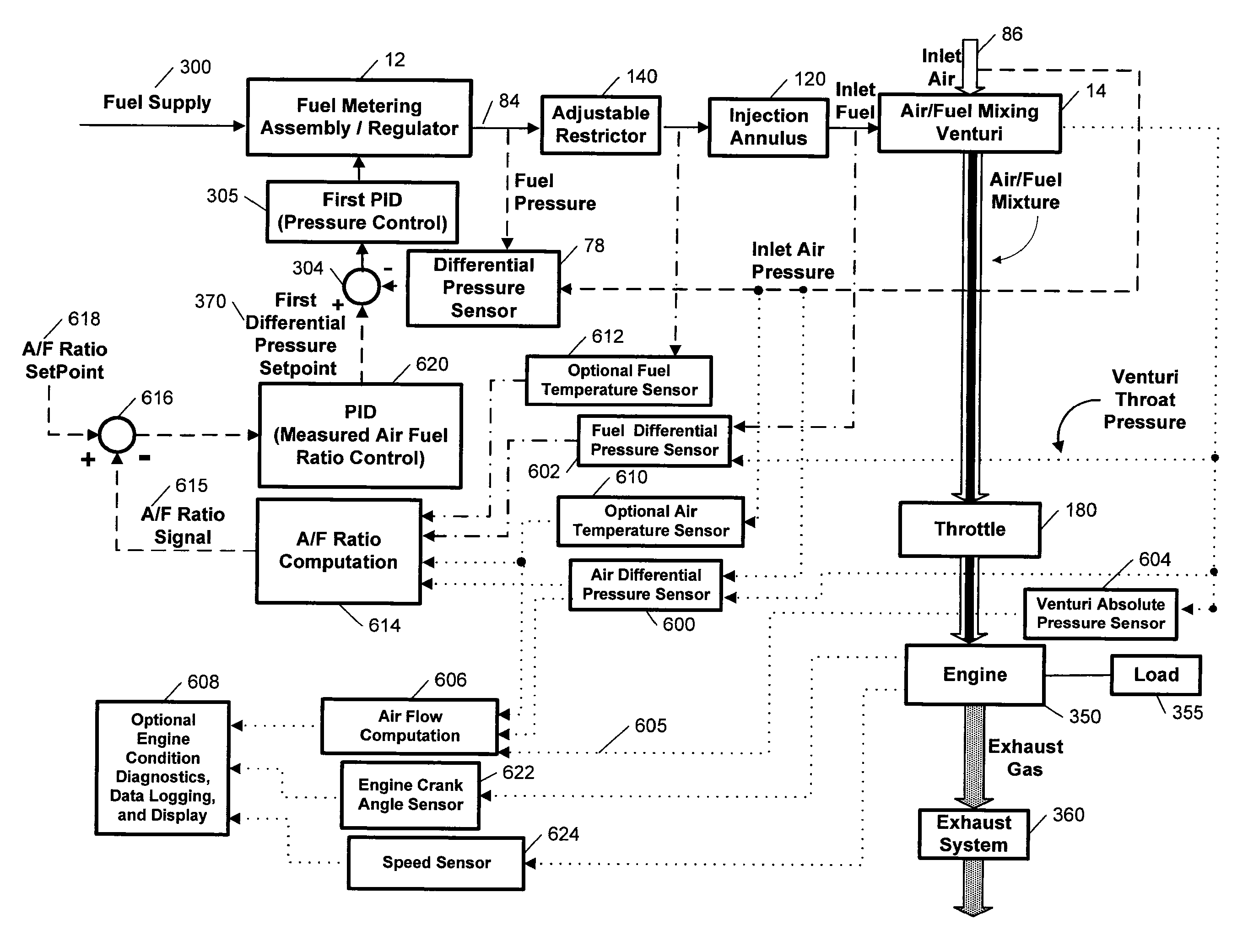

Fuel control system and method for gas engines

InactiveUS8005603B2Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemClosed loop

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

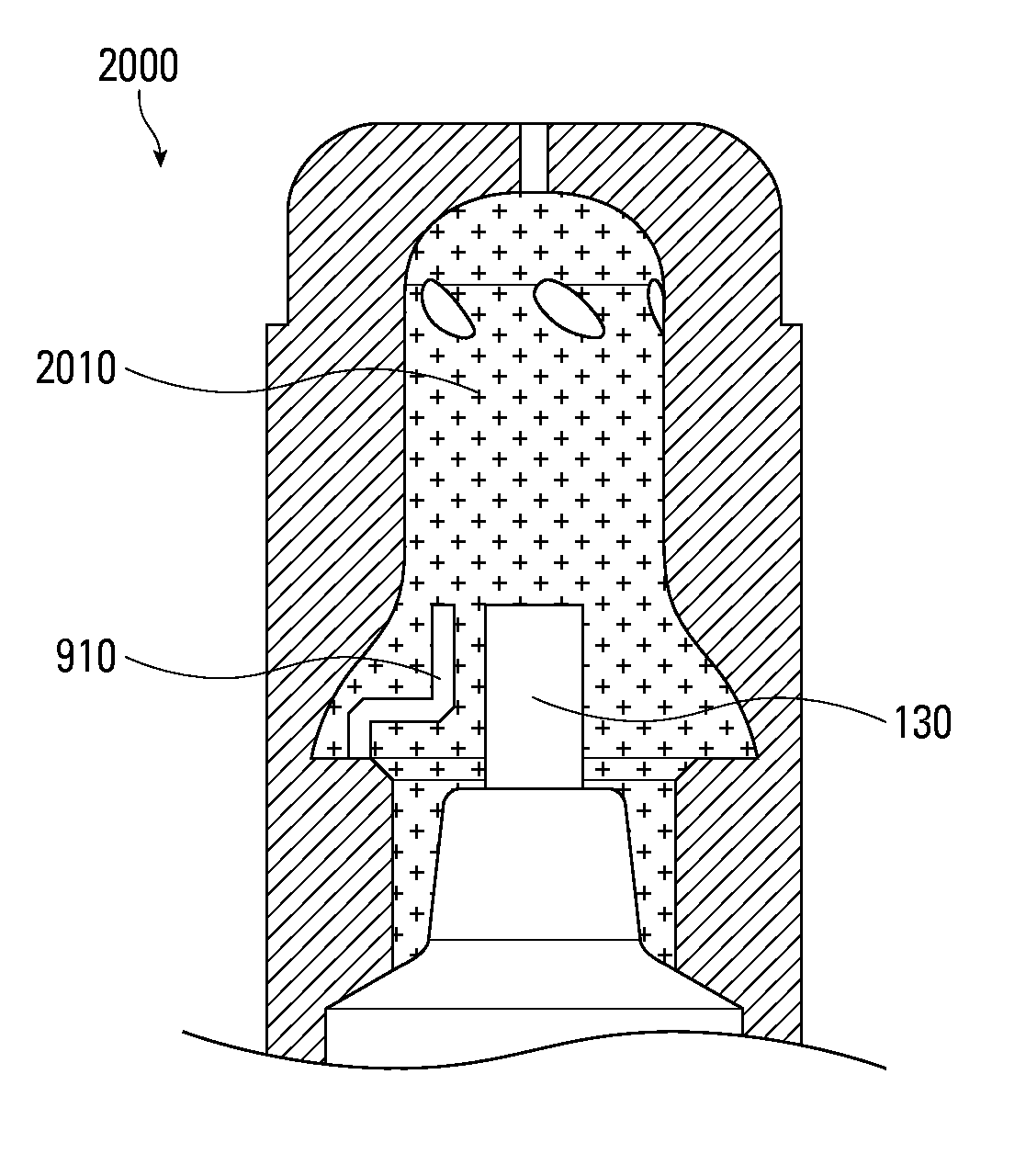

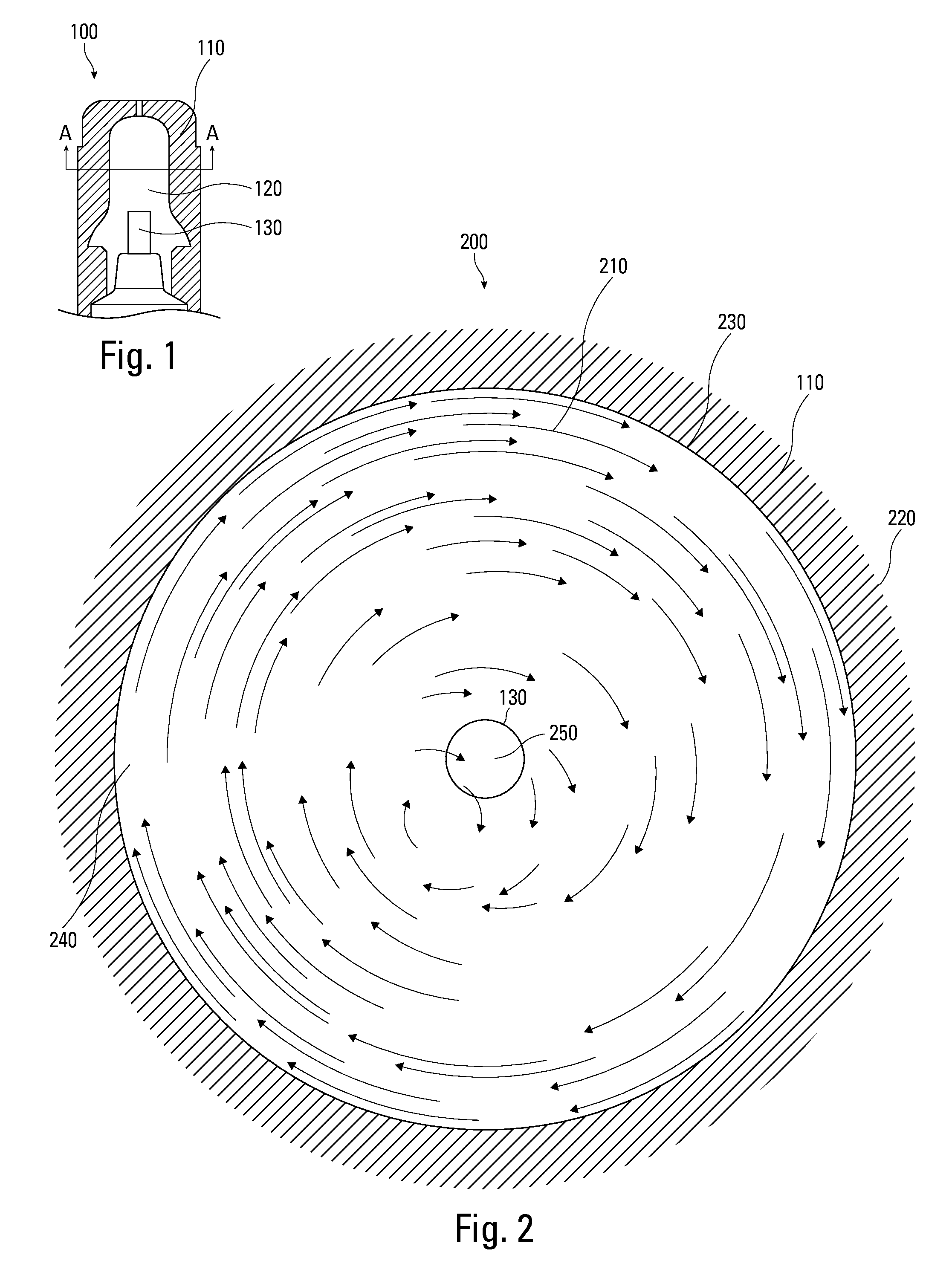

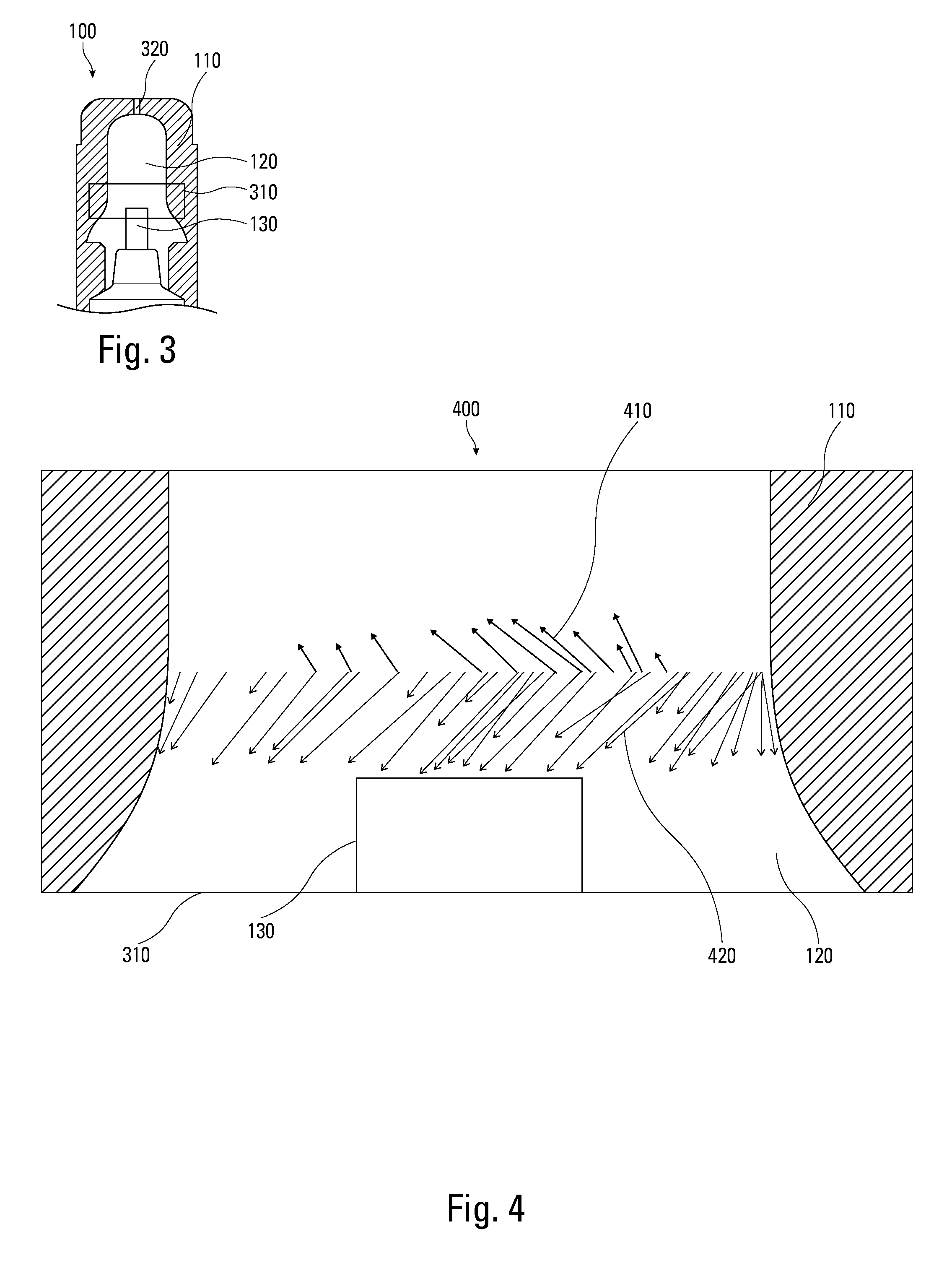

Method and apparatus for achieving high power flame jets while reducing quenching and autoignition in prechamber spark plugs for gas engines

ActiveUS20130055986A1Increase ignition delayPrevent spontaneous combustionSparking plugsInternal combustion piston enginesEngineeringQuenching

A prechamber spark plug may have a prechamber having a pre-determined aspect ratio and hole pattern to achieve particular combustion performance characteristics. The aspect ratio and hole pattern may induce a rotational flow of fuel-air in-filling streams inside the prechamber volume. The rotational flow of the fuel-air mixture may include both radial flow and axial flow characteristics based on the aspect ratio and hole pattern. Axial flow characteristics can include a first axial direction proximate the periphery of the rotational flow and a counter second axial direction approaching the center of the rotational flow. The radial and axial flow characteristics may further include radial air-fuel ratio stratification and / or axial air-fuel ratio stratification. The rotational flow, the radial flow and the axial flow may be adjusted by alteration of the aspect ratio and hole pattern to achieve particular combustion performance characteristics in relation to a wide variety of spark gap geometries.

Owner:PROMETHEUS APPLIED TECH

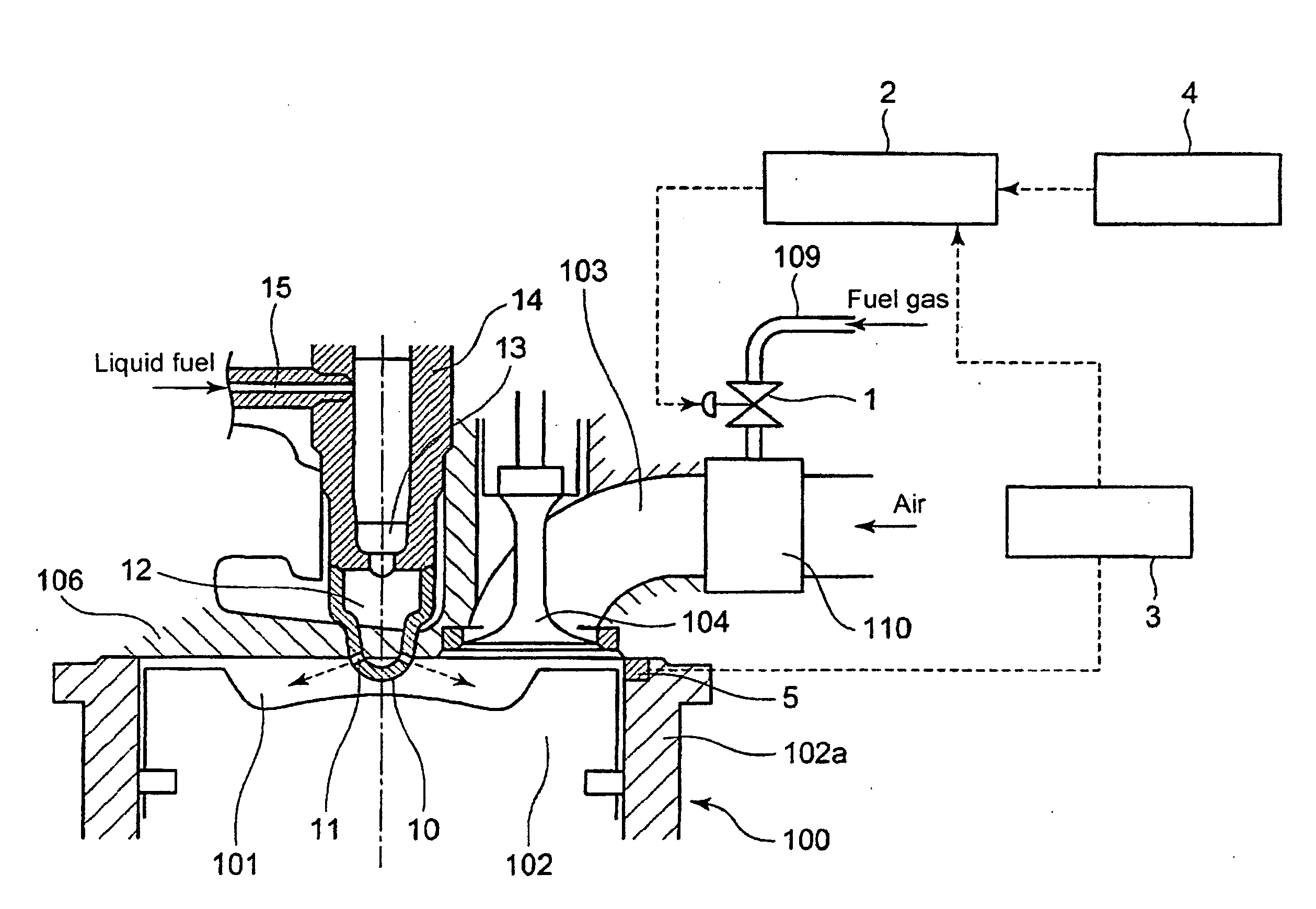

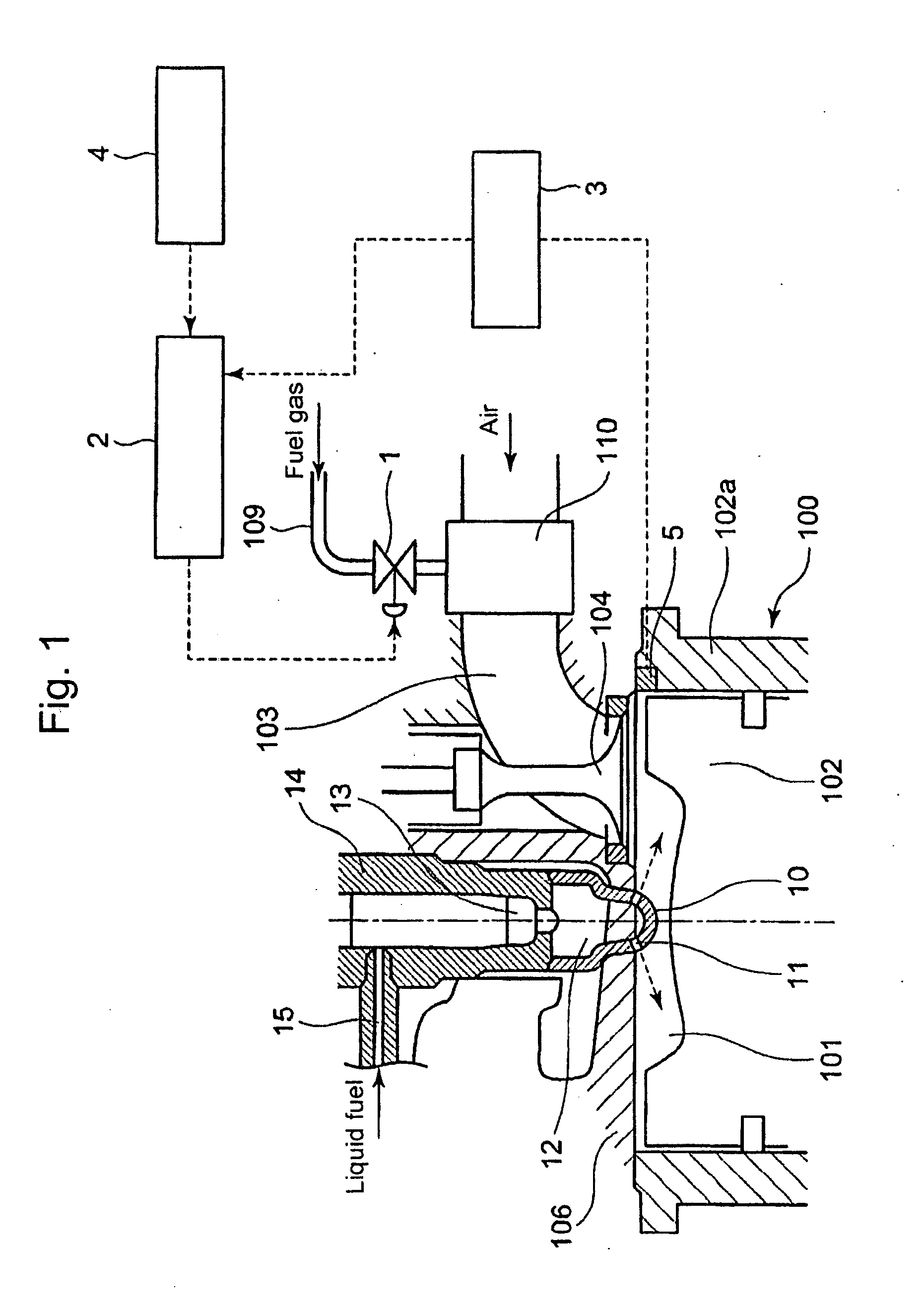

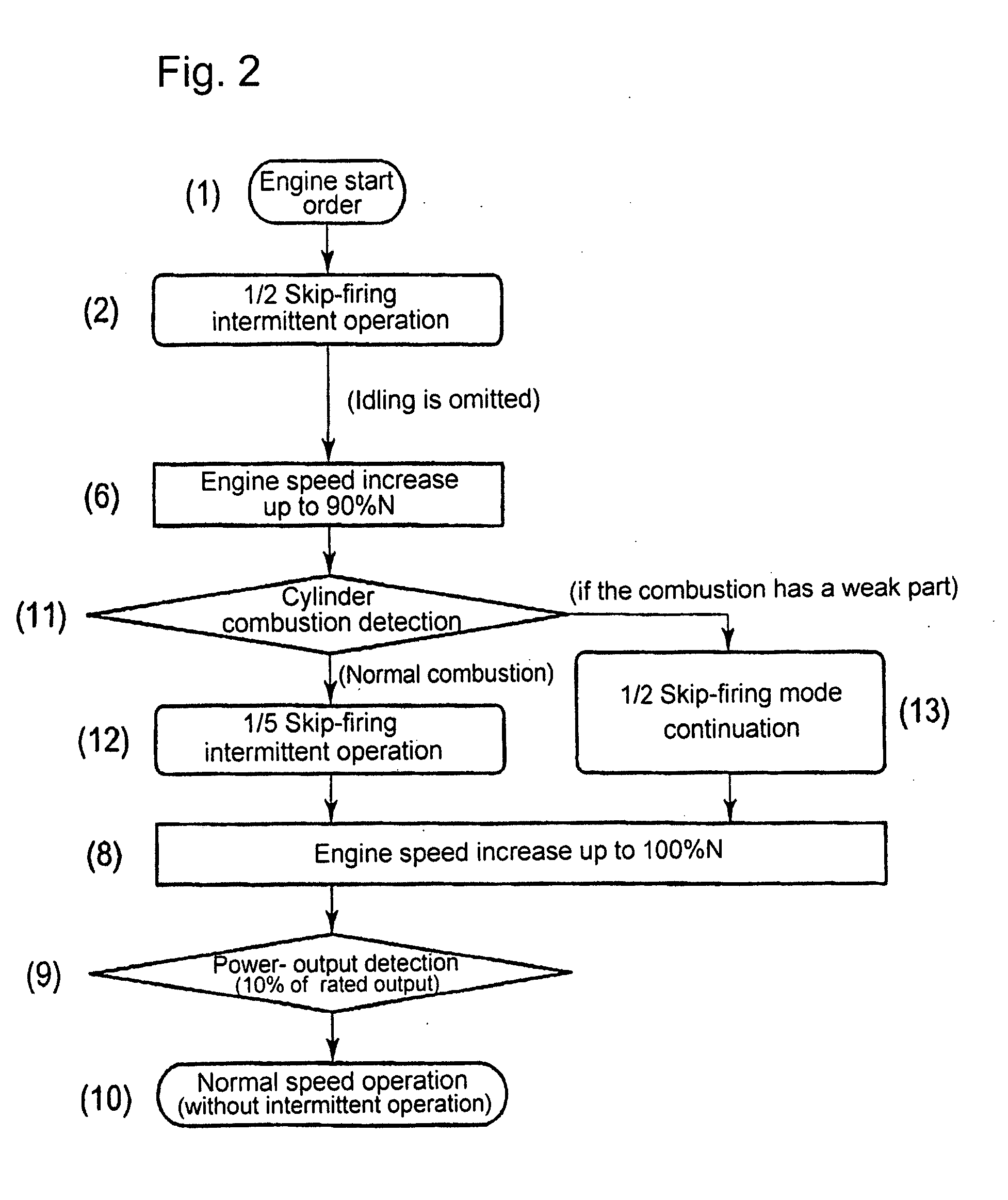

Micro-pilot injection ignition type gas engine

ActiveUS20100043744A1High precisionIdle timeValve arrangementsElectrical controlFuel supplyAir–fuel ratio

What is disclosed is a micro-pilot injection ignition type gas engine, whereby an air fuel ratio control in starting the engine is executed with enhanced precision, by means of introducing skip-firing intermittent operations which reflect the engine operation conditions, while an idling time span can be shortened or omitted.The engine includes: a gas valve that opens and closes a fuel-gas passage in front of each cylinder, so as to arbitrarily control the throat area as well as the opening-closing time span of the gas valve; an engine speed detecting unit to detect the engine speed; a combustion diagnosis unit to detect an engine combustion state through a cylinder pressure distribution along elapsed time, as to each cylinder; an opening-closing control unit as to the gas valve, so as to control the intermittent opening-closing of the gas valve according to the levels of the detected engine speed as well as the cylinder pressure distribution; whereby, in starting the engine, the intermittent opening-closing of the gas-valve enables at least one skip-firing mode that brings an enhanced fuel-supply pressure-pulsation with which a relatively large amount of fuel-gas is supplied per engine cycle with firing so that the air fuel-gas ratio of each cylinder reaches a prescribed target value.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

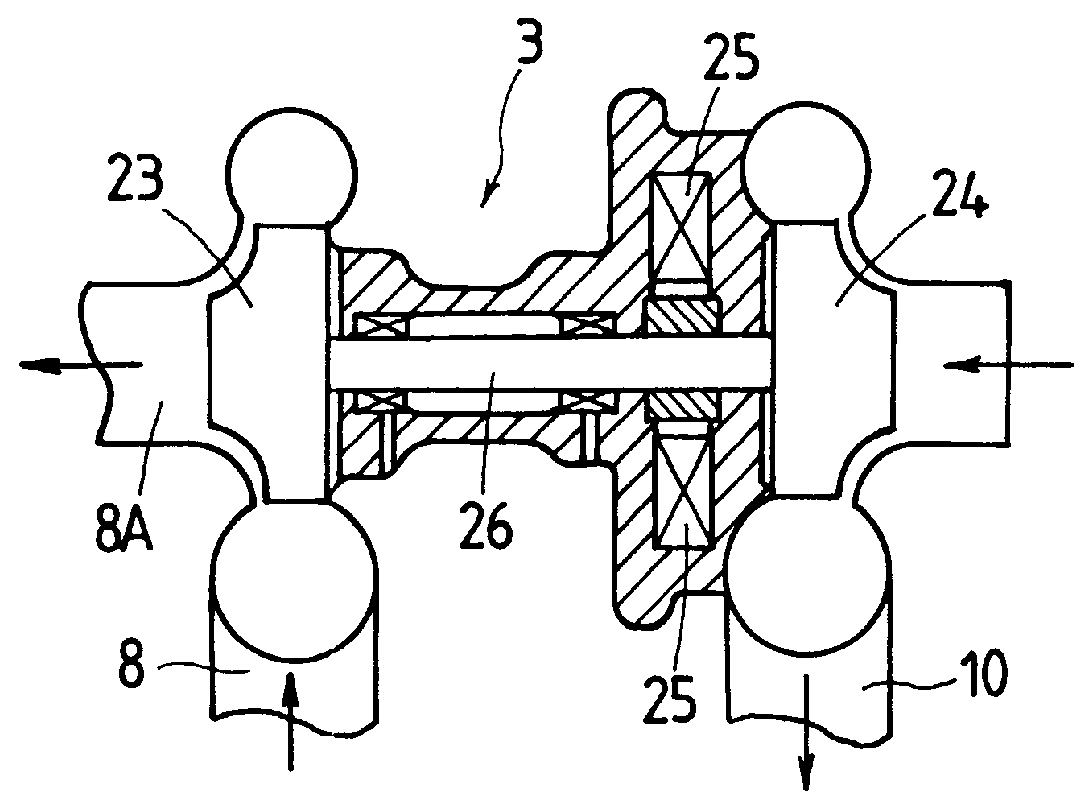

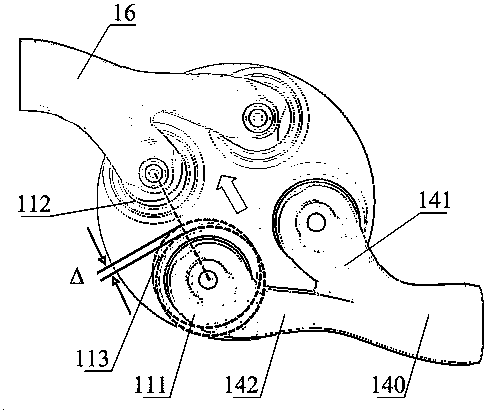

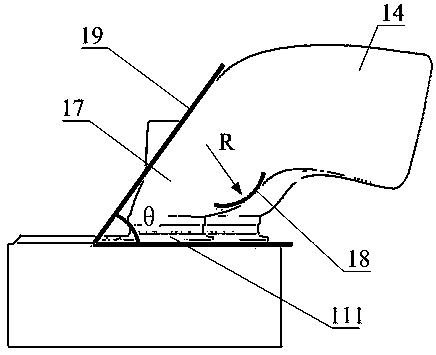

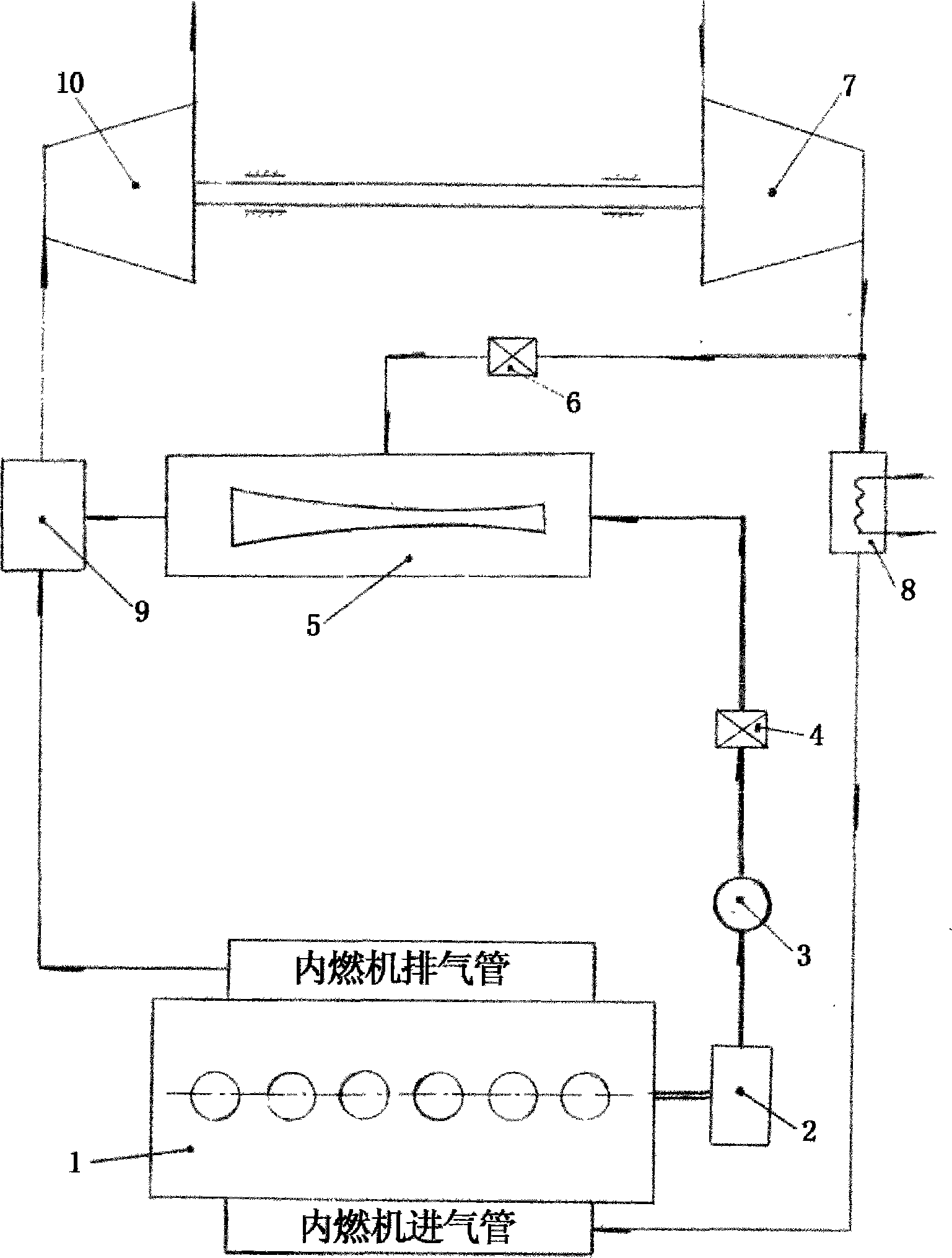

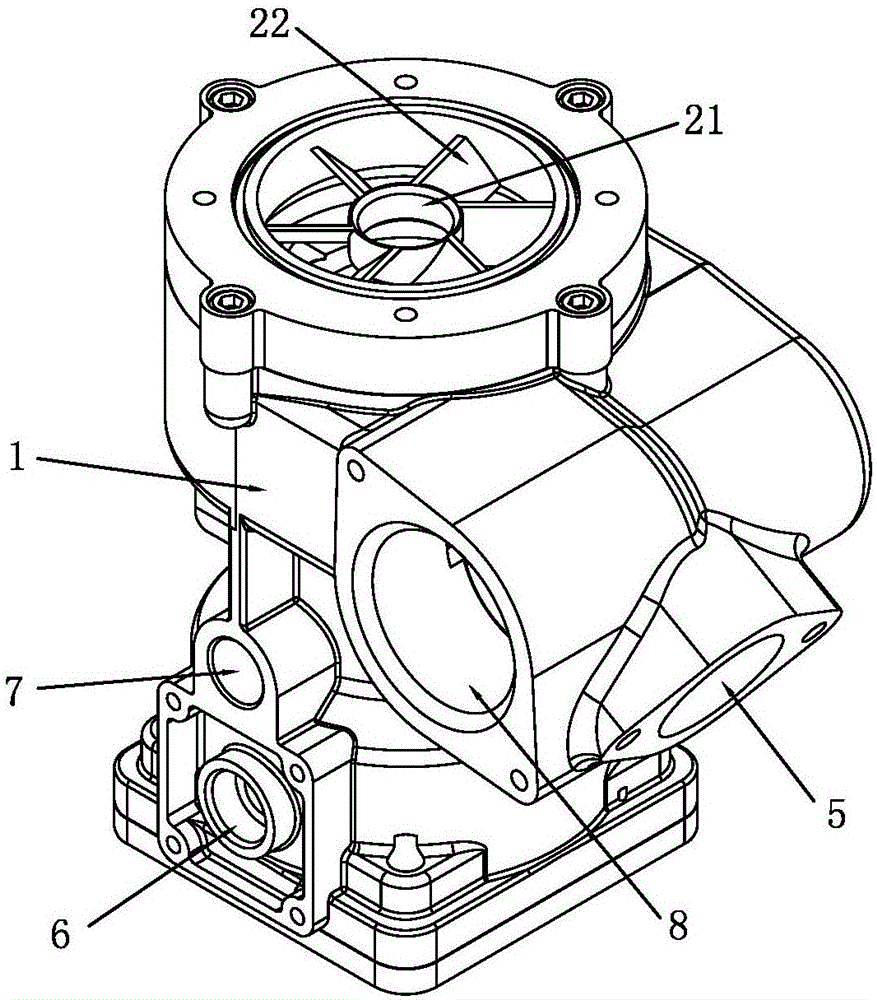

Intake pressure balancing adjuster for supercharged and intercooled gas engine

ActiveCN103603747ASimple structureIncrease the maximum output powerInternal combustion piston enginesFuel supply apparatusIntake pressureStreamflow

Disclosed is an intake control device for a supercharged and intercooled gas engine. By coaxial control bidirectional pressure relief means, the output pressure of two superchargers is simultaneously controlled by the aid of one device, the technical problem of unbalanced output pressure of the two superchargers is solved, a complicated structure respectively controlling the output pressure of the two superchargers is simplified, functional cost is reduced, reliability is improved, the influence of a balancer on maximum intake flow of the engine is thoroughly eliminated, and the maximum output power of the engine is improved. The device is applicable to the gas engine with air and gas respectively supercharged and intercooled.

Owner:陕西中唐电力能源科技有限公司

Fuel control system and method for gas engines

InactiveUS20090088950A1Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemEngineering

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

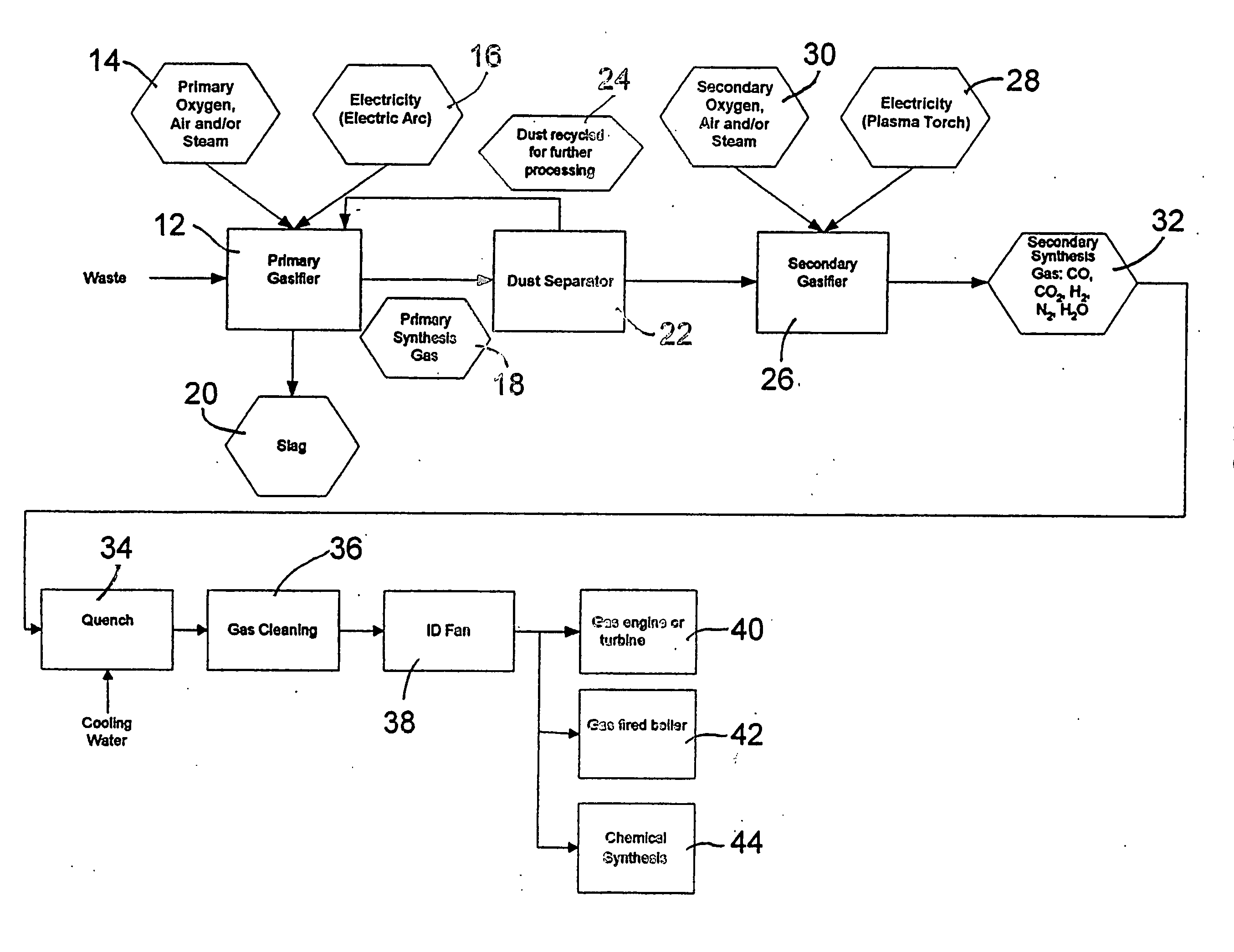

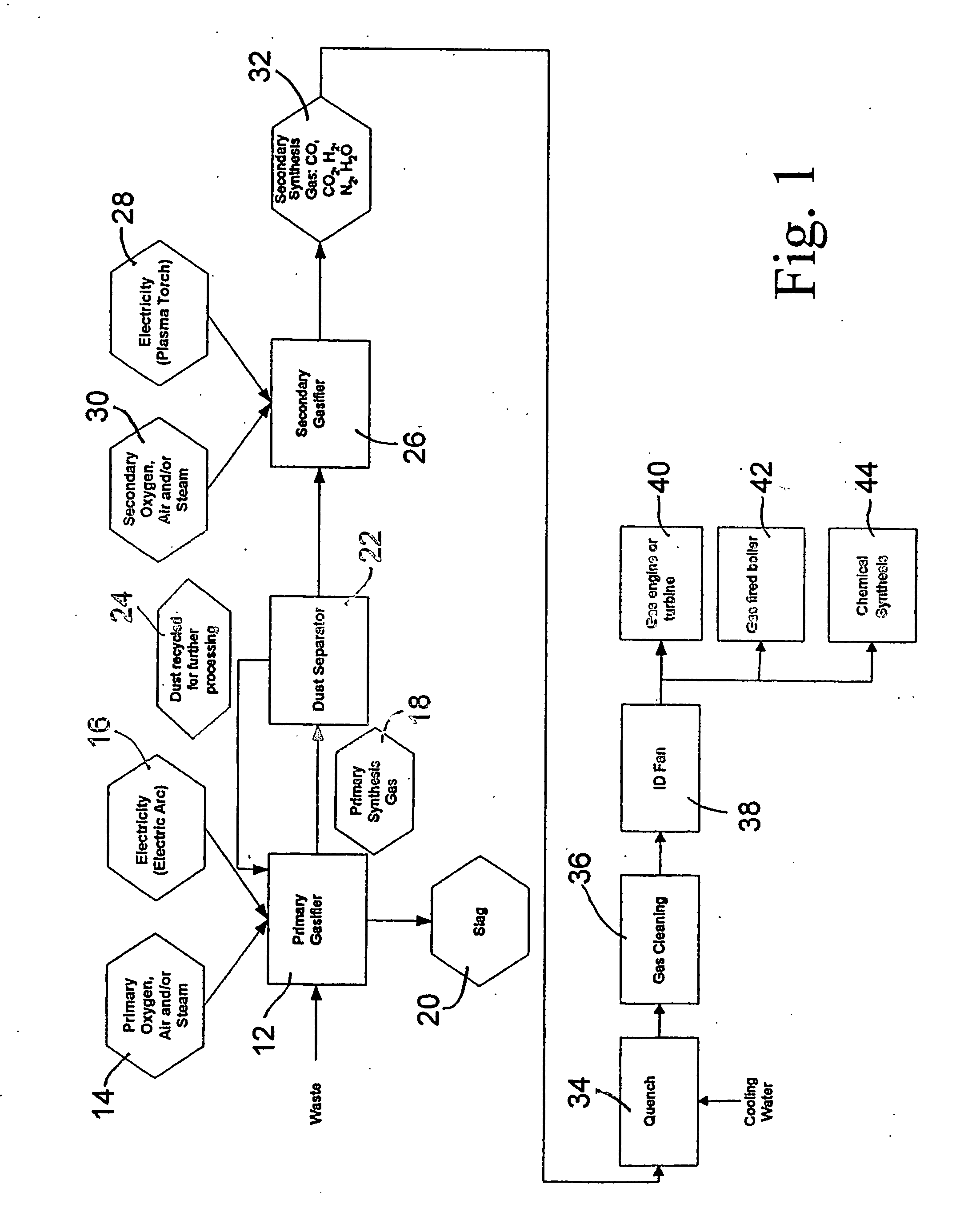

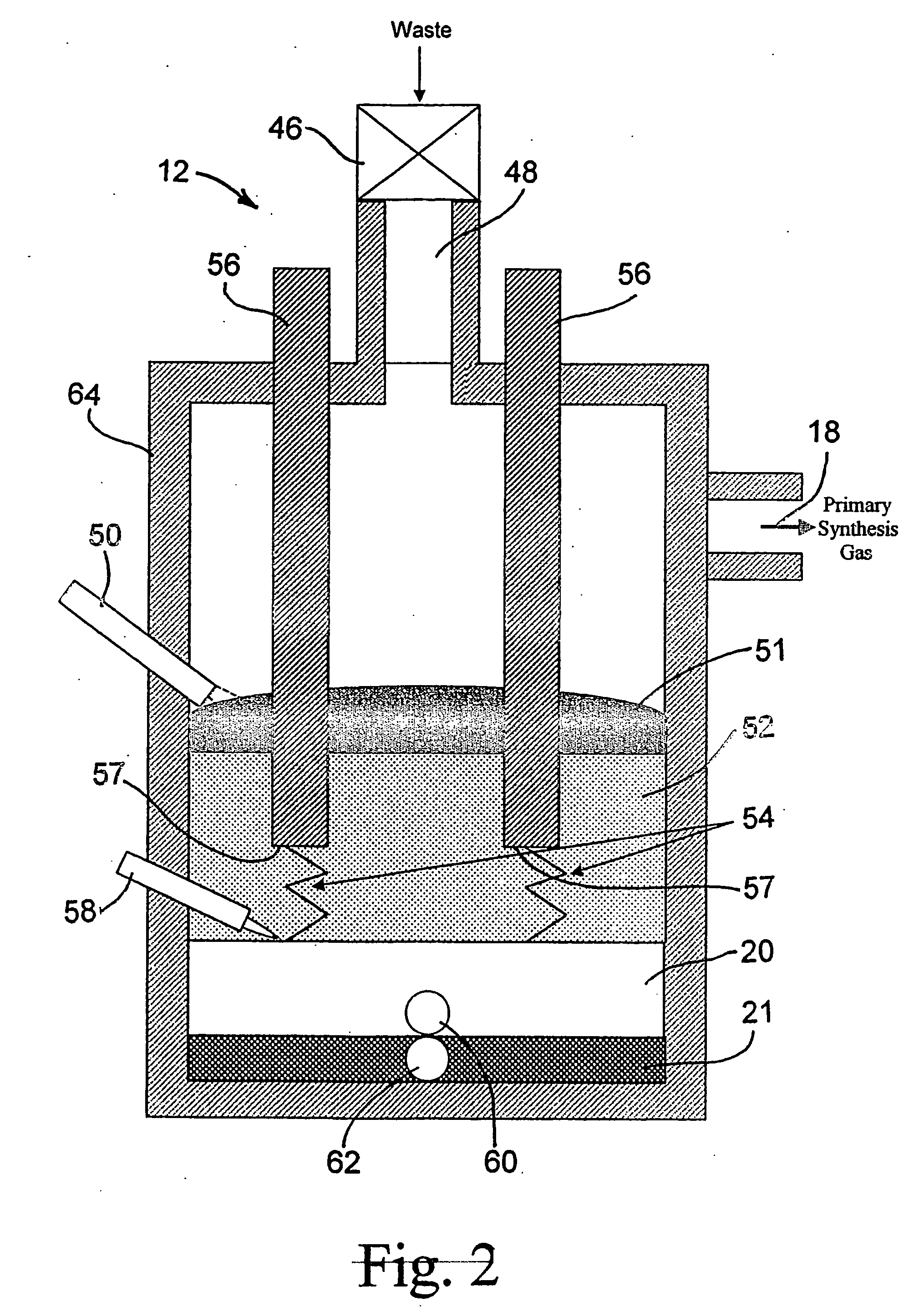

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

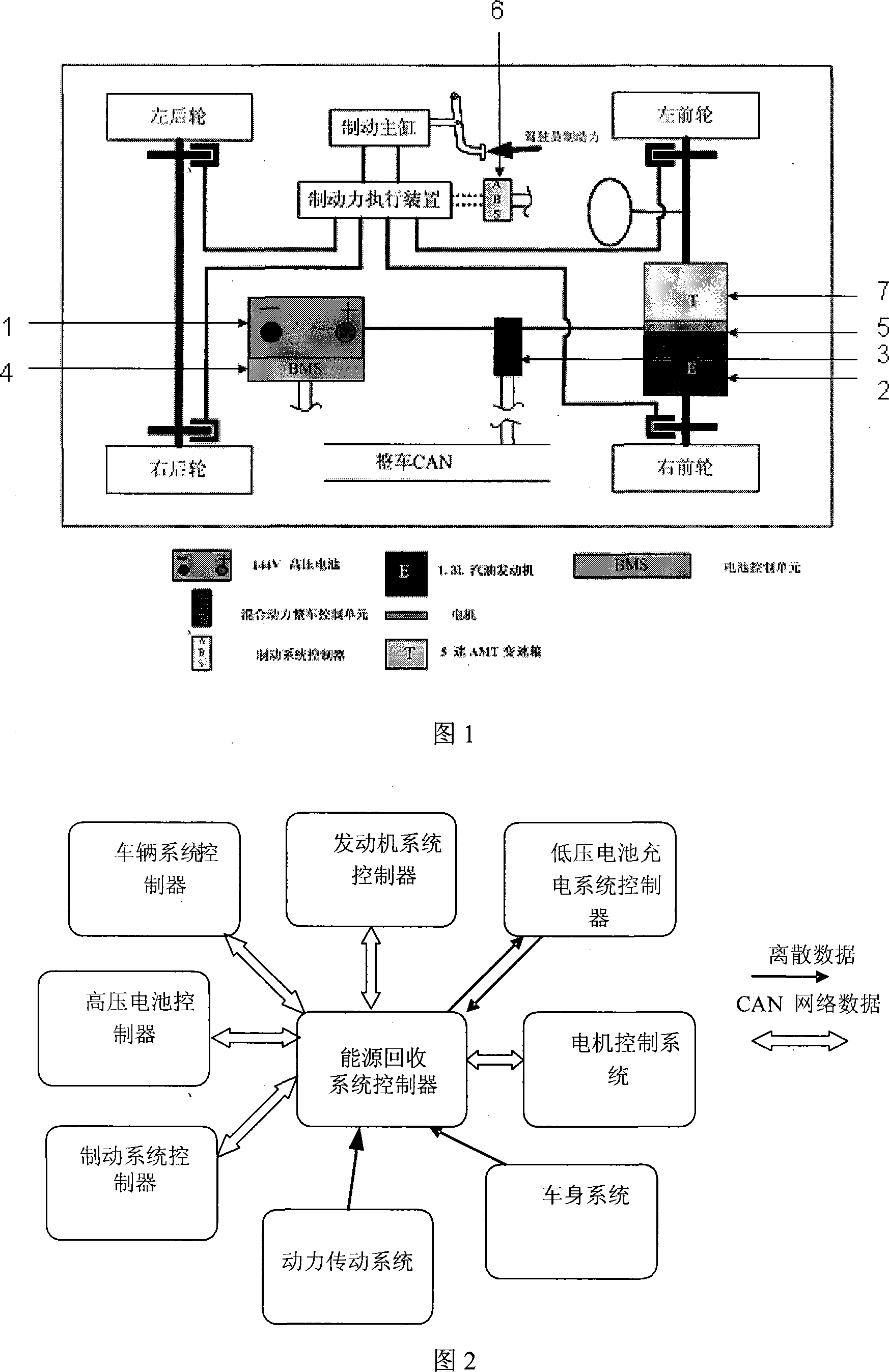

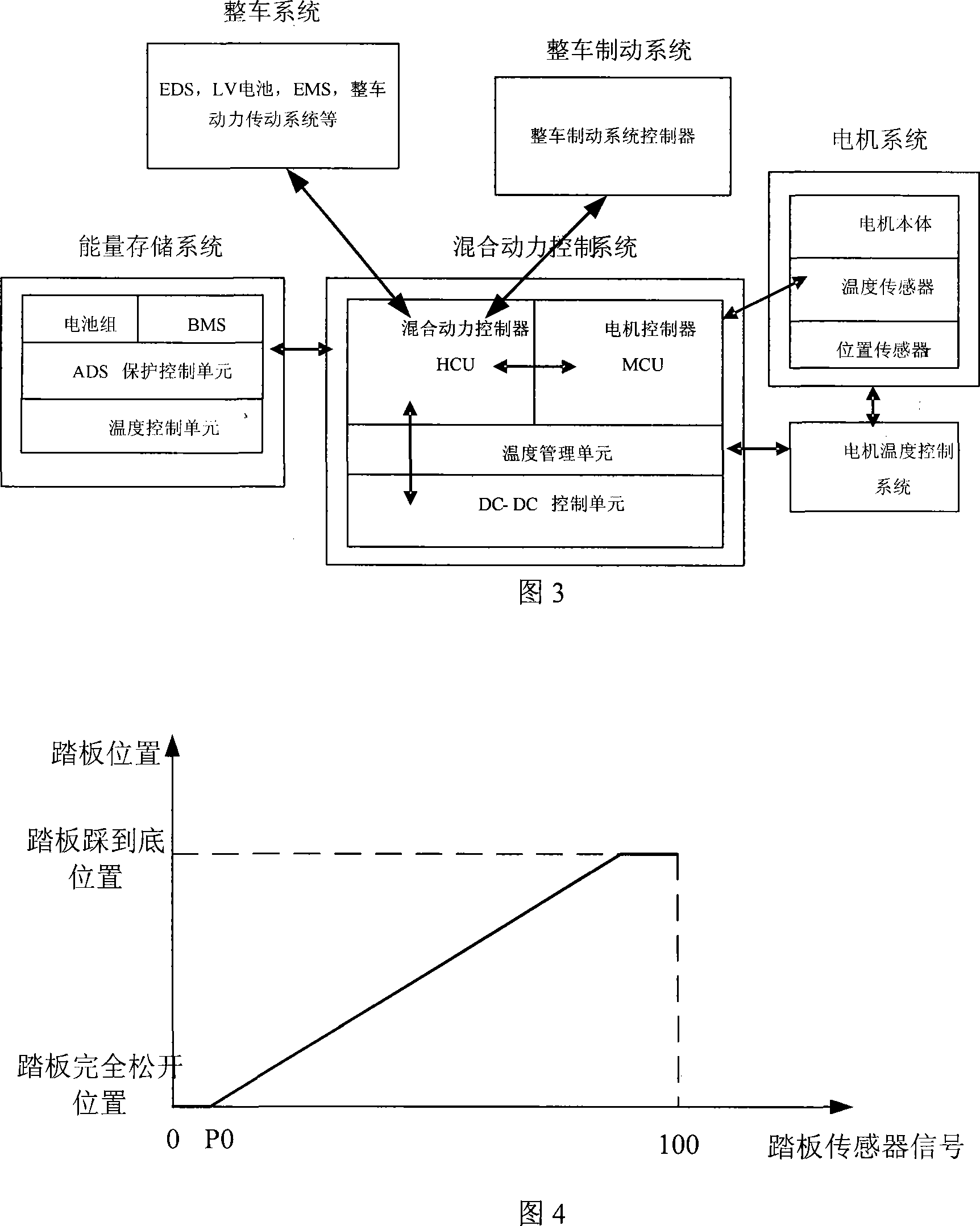

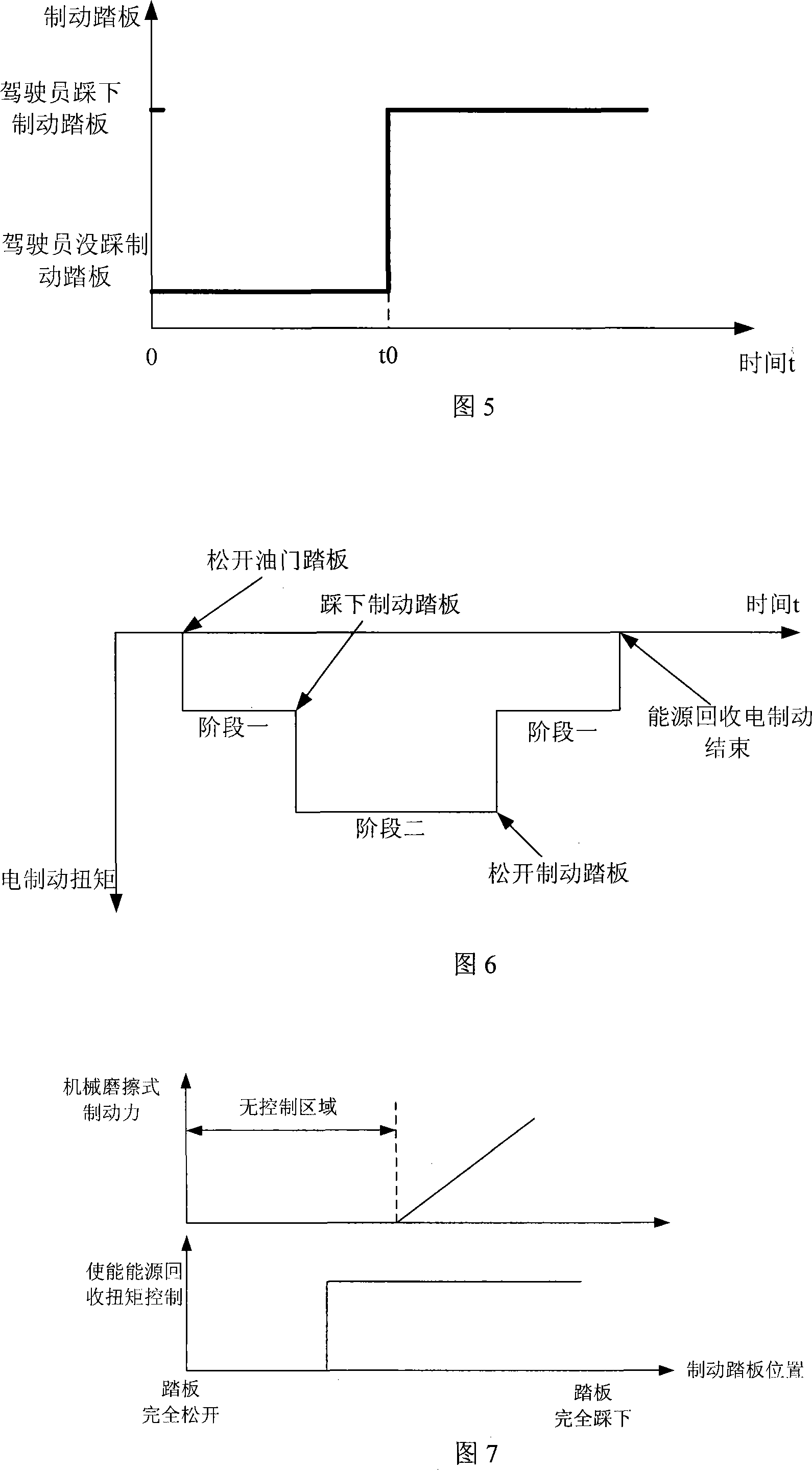

Automobile energy source regenerative braking system and the control method thereof

The invention discloses a mixing power energy regeneration brake and control method, which includes the determination of feasible conditions of the whole vehicle energy source recovery, determination of the energy source recovery stage, the calculation of the electric brake force when the energy source is recovered, the distribution of the brake force between the mechanical brake and the electric brake, and the system safety protection control of the energy source recovery of the mixing power vehicle. The invention also discloses an energy source regeneration brake system implementing the mixing power energy source regeneration brake control method; the system includes a 144V high-voltage nickel-hydrogen power battery, a 1.3-litre gas engine, a mixing power whole vehicle control unit, a battery control unit, a motor, a brake system controller and a 5-speed AMT gearbox. The secondary control optimization of the energy source recovery for the whole vehicle system with the energy source recovery control scheme ensures the recovery of the whole vehicle energy source to be more reasonable and efficient.

Owner:CHERY AUTOMOBILE CO LTD

Method and device for integrative control of gas engine

ActiveUS20090076709A1Accurate air-fuel ratio controlLoad responsivity is improvedAnalogue computers for vehiclesElectrical controlResponsivityControl valves

An integrative control method and device for controlling gas engines is proposed which load responsivity of the engine is improved while maintaining air fuel ratio control and stable control is performed when fuel gas of different calorific value is used. The control method comprises a speed control process for controlling engine rotation speed by controlling the fuel gas flow control valve based on deviation of actual engine rotation speed from a target command value of rotation speed, and an air fuel ratio control process for controlling air fuel ratio of fuel-air mixture by controlling throttle valve opening based on deviation of the actual mixture flow rate from the command value of mixture flow rate, whereby correction of theoretical air fuel ratio in accordance with exhaust temperature is performed in the air fuel ratio control process, the correction being done to correct the theoretical air fuel ratio used to calculate the command value of fuel-air mixture flow rate in accordance with exhaust temperature based on deviation of actual exhaust temperature from target exhaust temperature prescribed for various engine rotation speeds and load factors.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

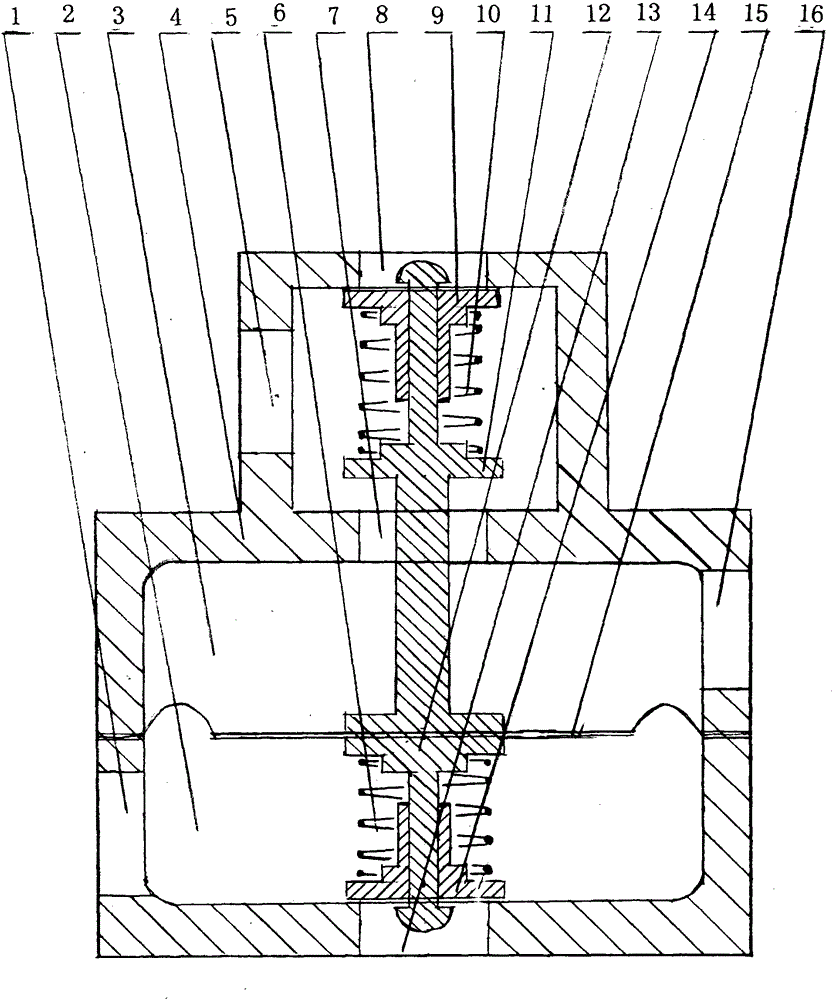

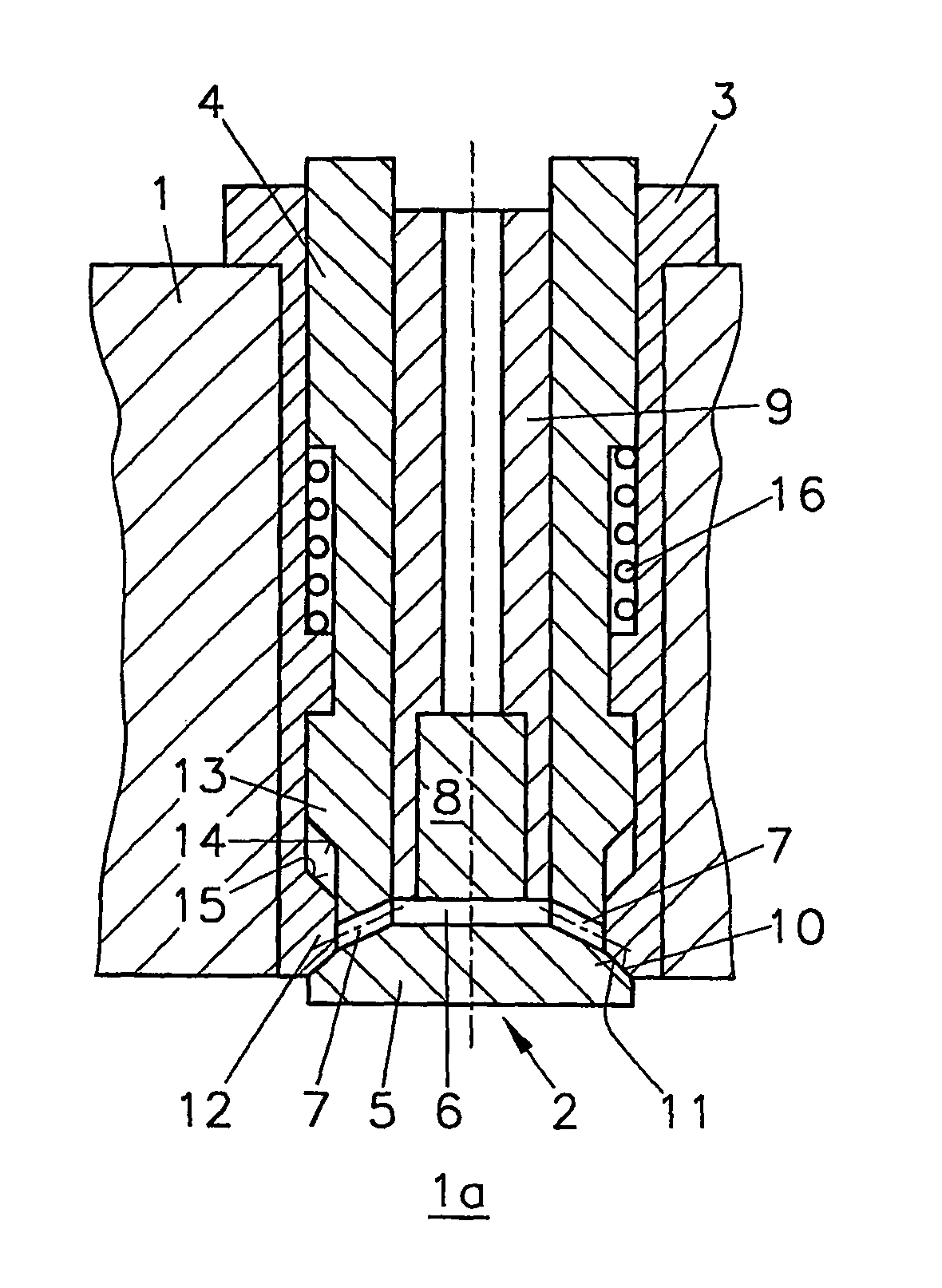

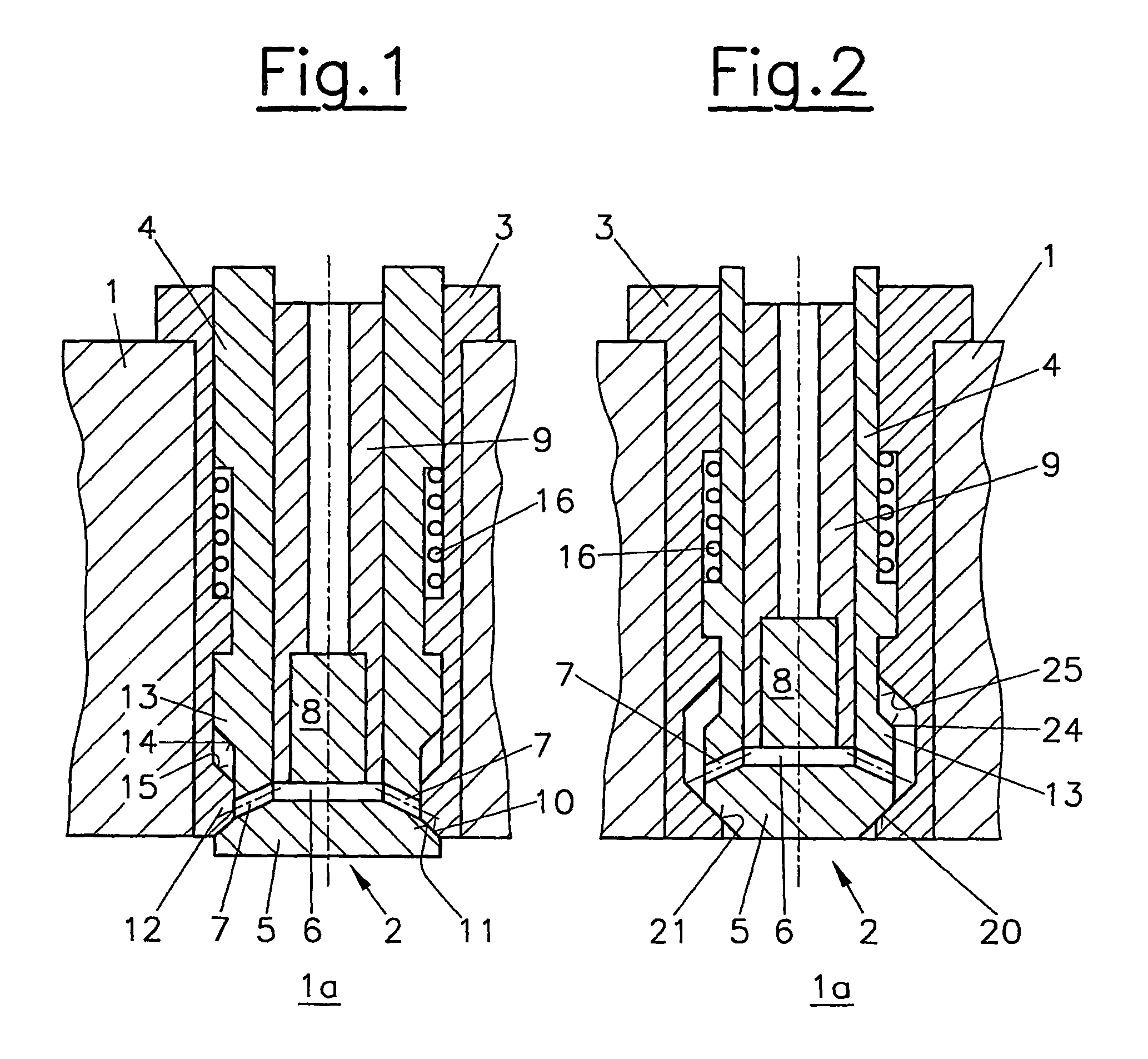

Apparatus for measuring the cylinder internal pressure of internal combustion engines

InactiveUS8096170B2Solve bulkyCompact designInternal-combustion engine testingRapid change measurementInternal pressureInterior space

The invention relates to an apparatus for measuring the cylinder internal pressure of internal combustion engines and, in particular, of gas engines, said apparatus having a first valve (5) which opens into the cylinder interior space, a measurement chamber (6) which can be connected to the cylinder interior space (1a) and can be disconnected from the latter by means of the first valve (5), and a pressure sensor (8) which is arranged in the region of the measurement chamber (6) in order to measure the pressure in the cylinder interior space when the first valve (5) is open. Permanent operation without thermal overload is enabled in such a way that at least one second valve (13) is provided in the region of the measurement chamber (6), said second valve being able to be changed to a closed position at least when the first valve (5) is open in order to seal off the measurement chamber (6) towards the outside.

Owner:AVL LIST GMBH

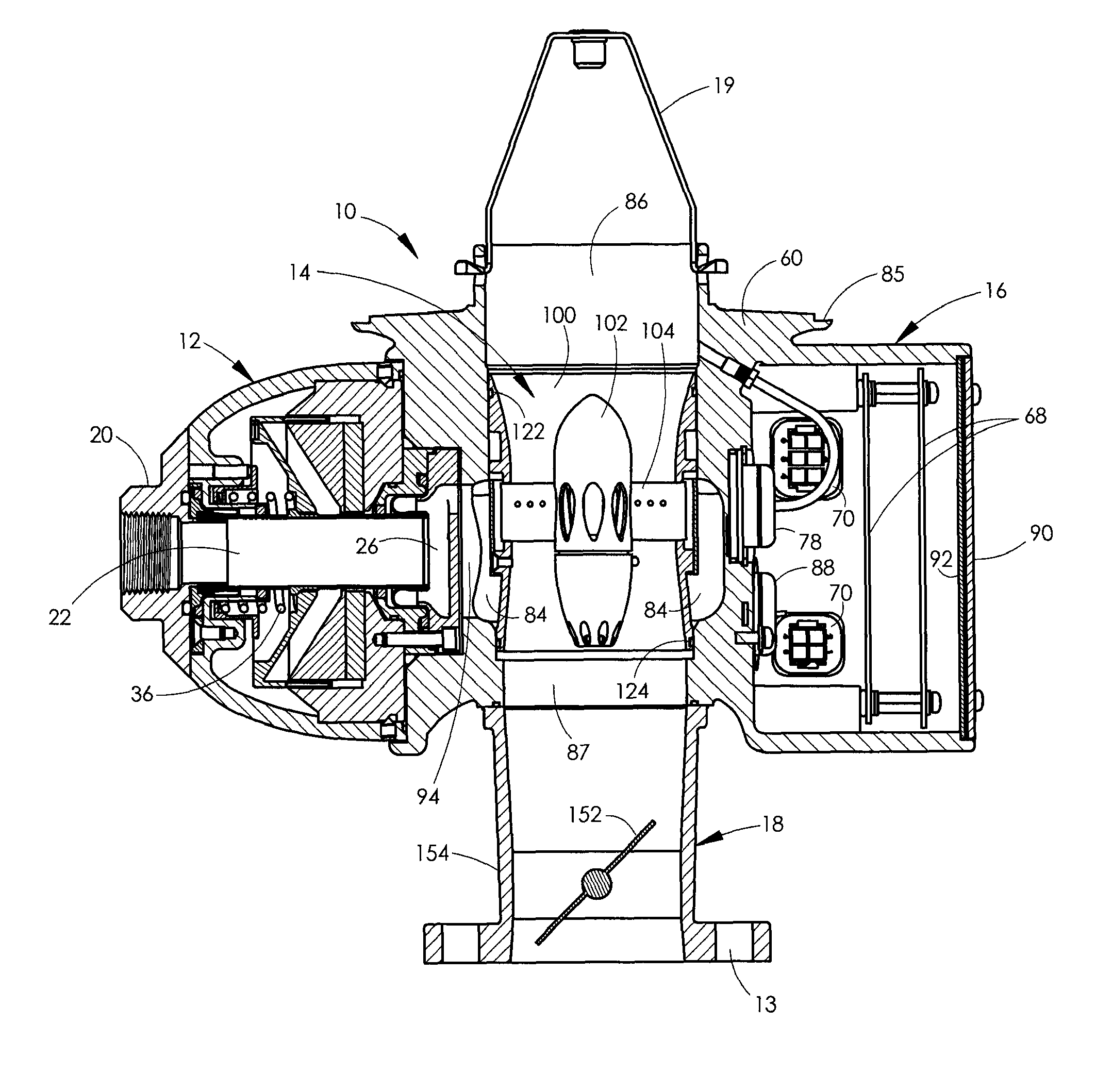

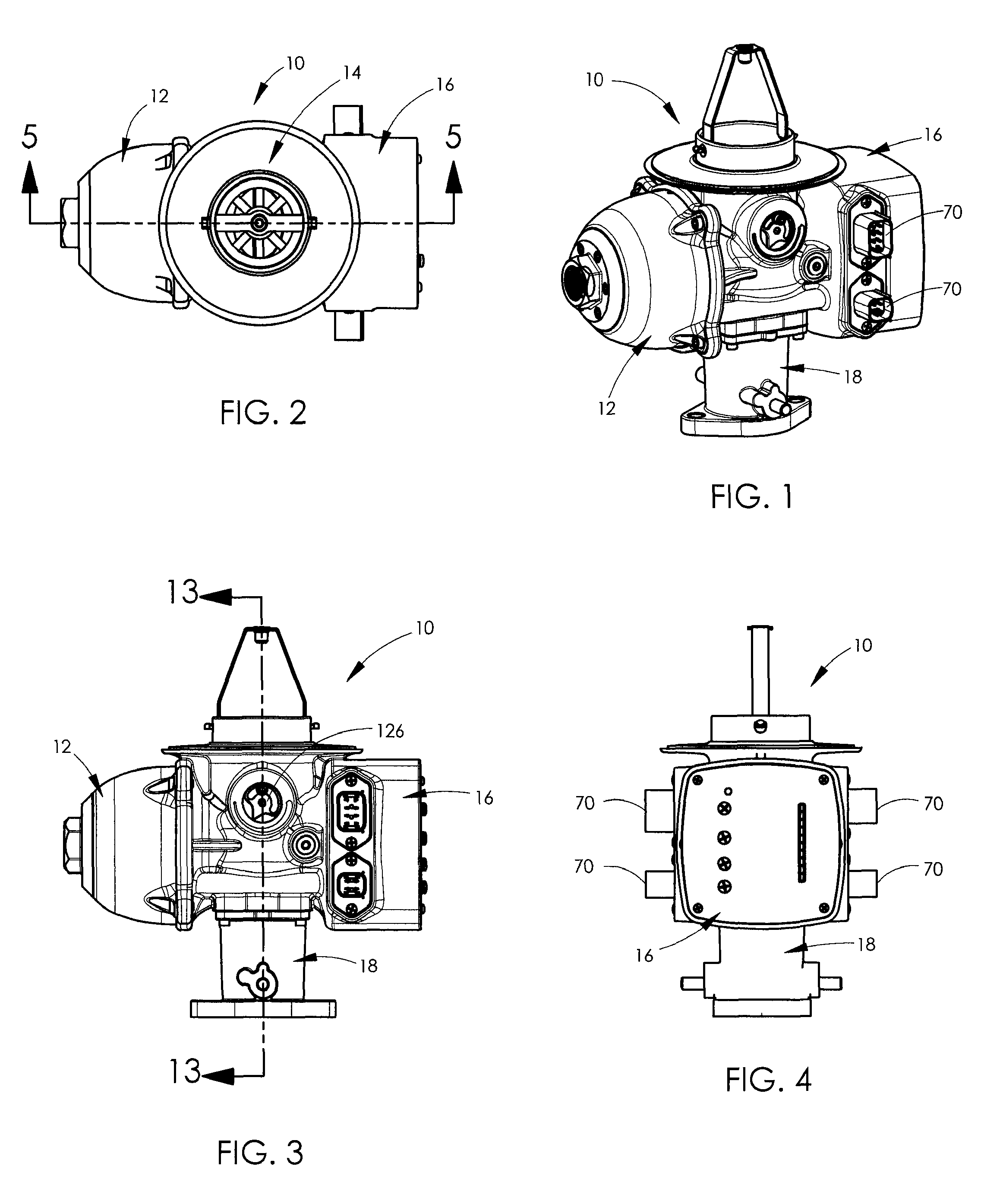

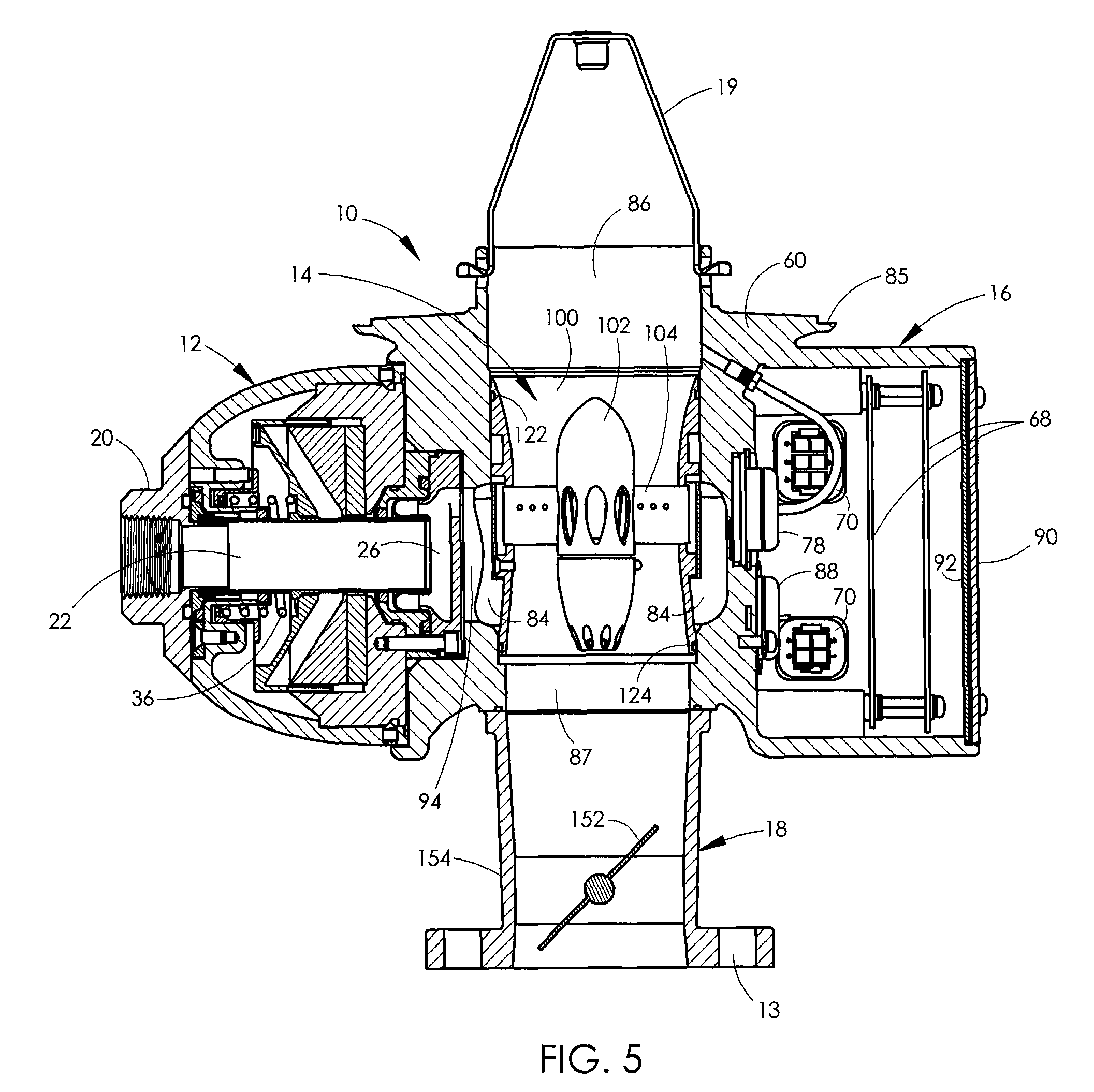

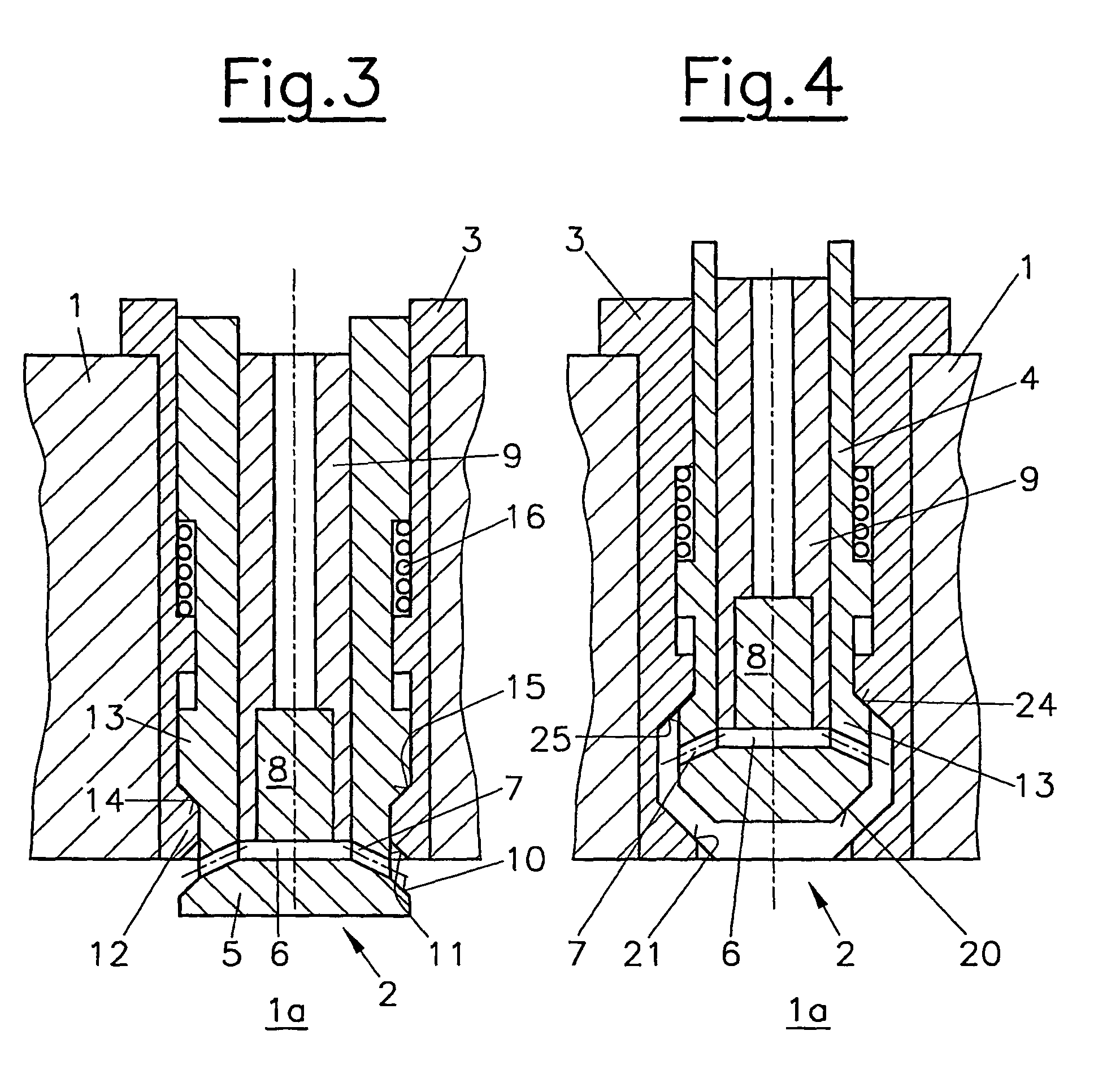

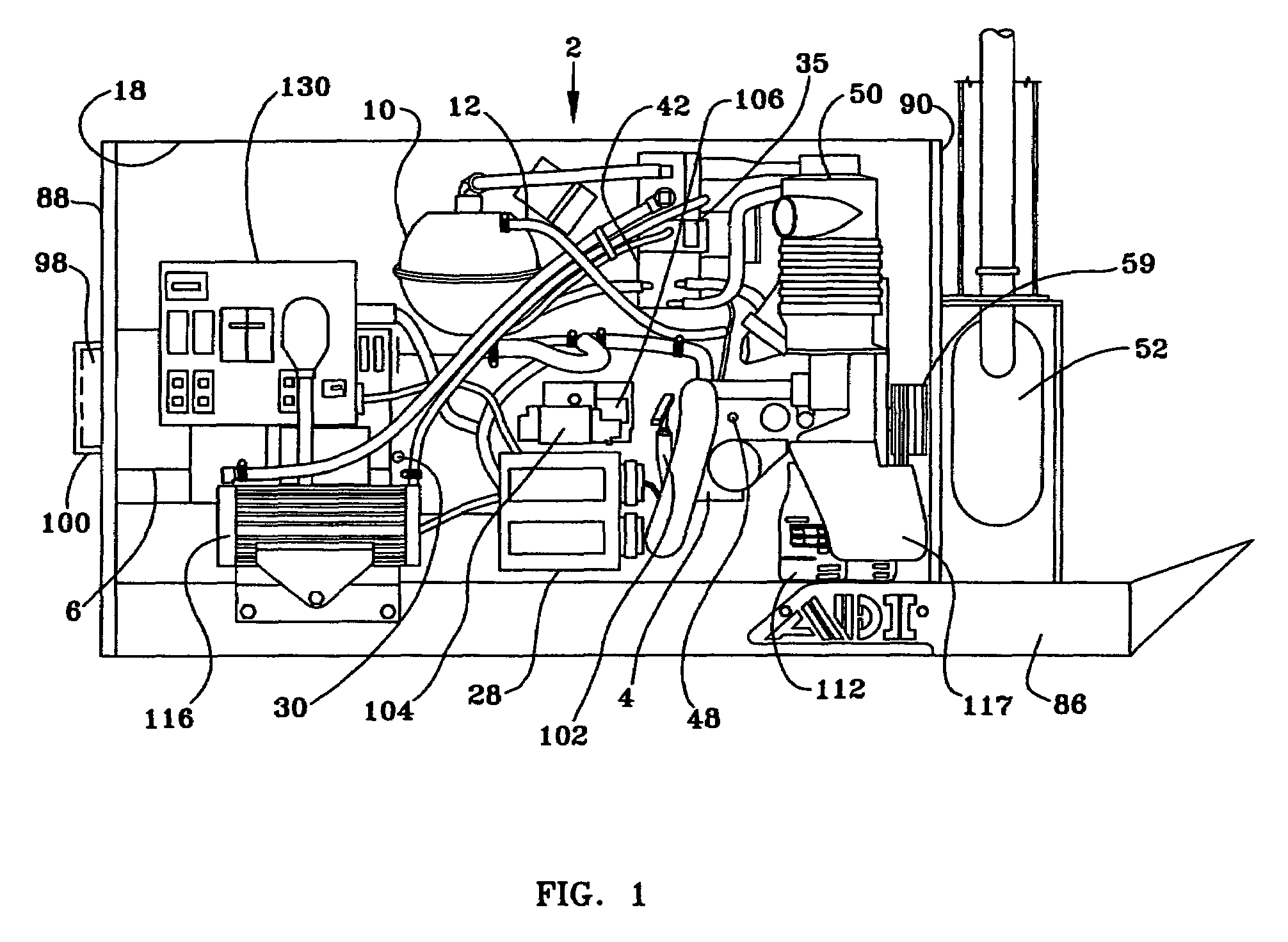

Low NOX emission single side access gas engine driven electrical generating system

ActiveUS7193333B1Enhanced radiative exhaust heat removal capabilityGenset compartment operating temperatureMachines/enginesMechanical energy handlingEmission standardConfined space

The present invention is a gasoline engine driven electrical generating system for use in confined space enclosures wherein all routine servicing can be accomplished from the single exposed side. The ambient operating temperature of the confined enclosure is minimized by a combination of component locations, sizing and a thermal siphoning exhaust enclosure. Through the use of an electronic fuel management system, throttle body furl injection and a catalytic converter all current EPA NOX emission standards can be met.

Owner:ADVANCED DYNAMO INDS

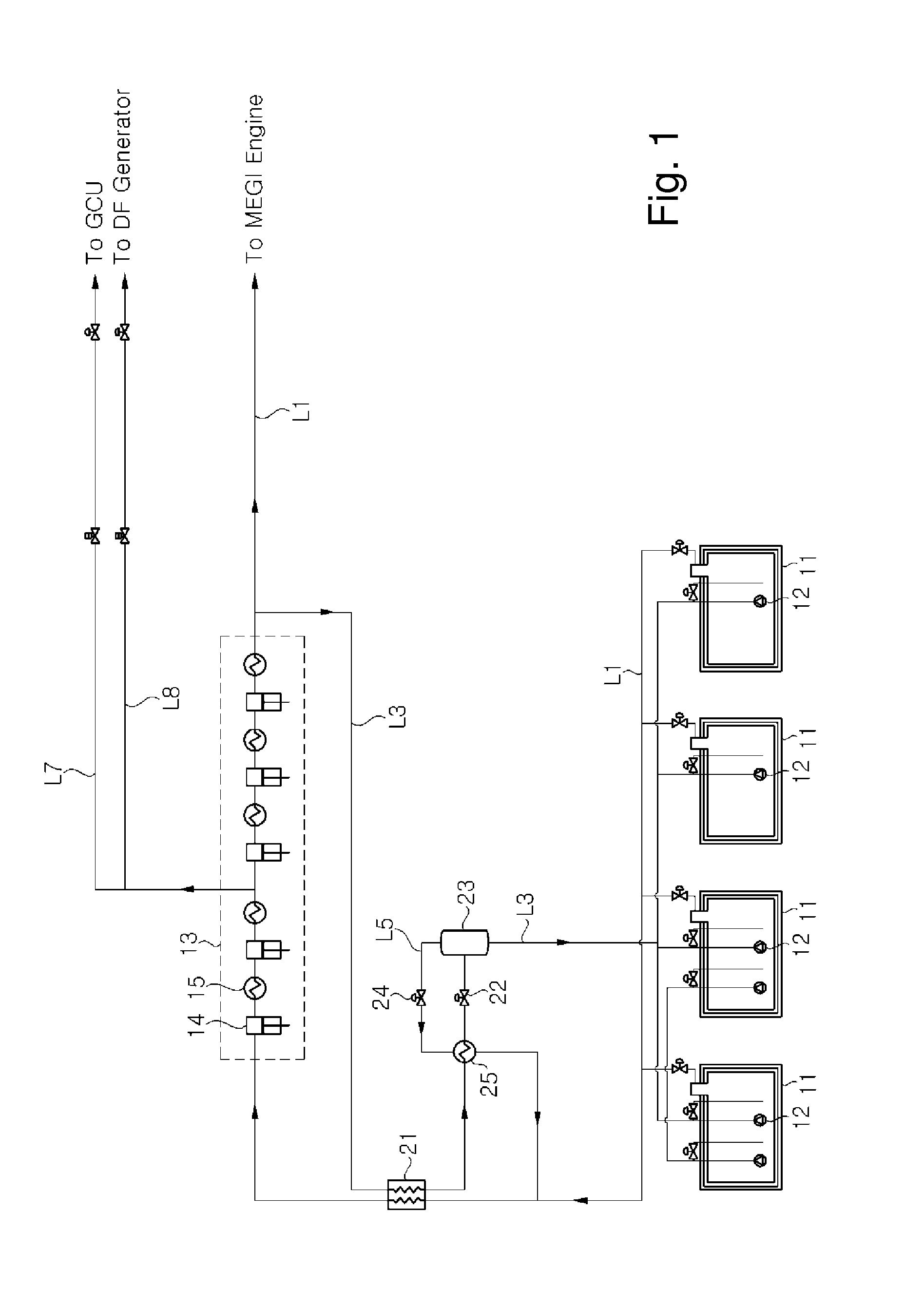

System and method for treating boil-off gas in ship

ActiveUS20160114876A1Save energy consumptionReduce the amount requiredSolidificationLiquefactionEngineeringGas engine

In a BOG treatment system, boil-off gas (BOG) discharged from a storage tank is compressed, most of the BOG is used as the fuel of vessel engines, and a remaining part of the BOG is liquefied by cold energy of BOG newly discharged from the storage tank and is returned to the storage tank, thereby efficiently utilizing the BOG. The BOG treatment system for a vessel includes a compressor compressing the BOG discharged from the storage tank; a medium pressure gas engine receiving at least a part of the BOG compressed by the compressor, as fuel; a heat exchanger exchanging heat between the remaining part of the BOG, which is not supplied to the medium pressure gas engine as fuel, and the BOG, which is discharged from the storage tank and is not compressed; and an expander decompressing the remaining part of the BOG cooled by the heat exchanger.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

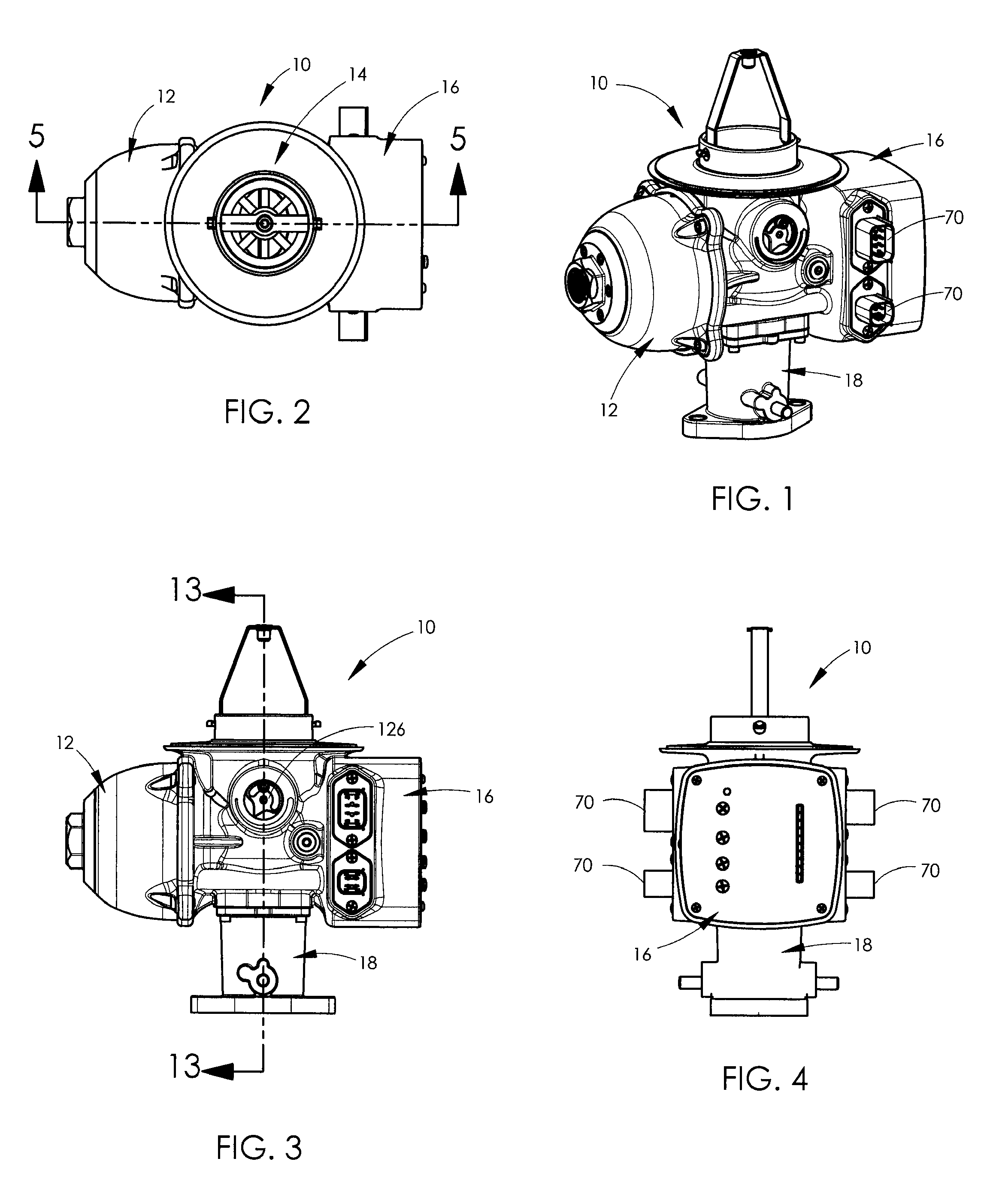

Emission control valve for gas-fueled engines

InactiveUS20040139951A1Electrical controlOperating means/releasing devices for valvesActuatorInternal combustion engine

An emission control device for use with stationary or mobile gas-fueled internal combustion engines is described, which is placed in the fuel supply line and operates with full fuel authority. An oxygen sensor measures exhaust oxygen content. The valve internally houses a programmable microprocessor, a pressure transducer and a fuel flow conduit throttled by a balanced poppet valve. Signals to the microprocessor from the oxygen sensor, the pressure transducer indicating outflow gas pressure cause the microprocessor to motivate an actuator to move the valve within the gas stream and thus regulate the outlet pressure and also the gas flow rate to maintain a desired air / fuel ratio to the engine and keep exhaust emissions at an optimum level consistent with the engine operating load requirements and characteristics. Finite incremental control of valve position, preferably assisted by an internal position transducer, permits close control of the exhaust emissions.

Owner:CONTINENTAL CONTROLS CORP

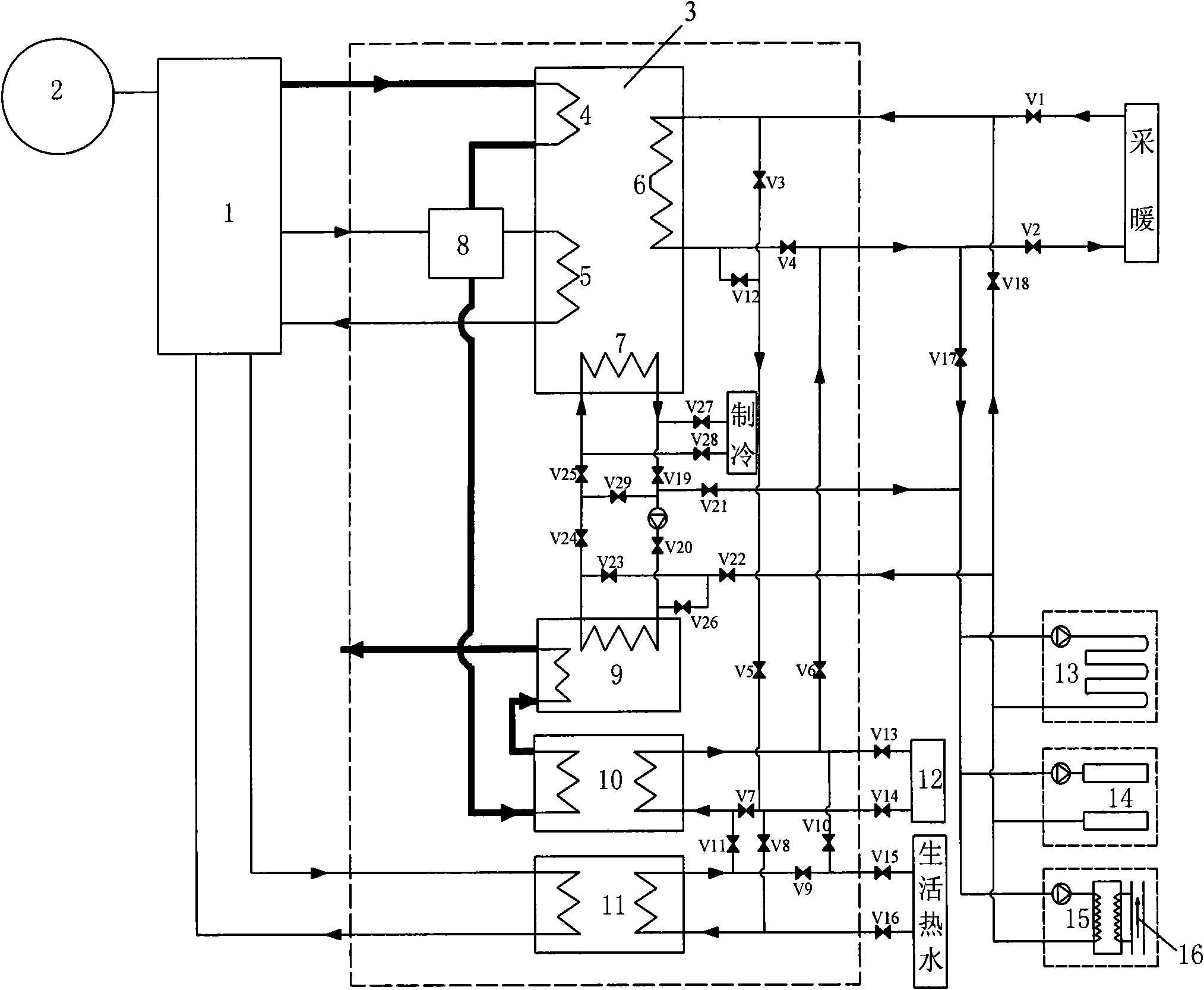

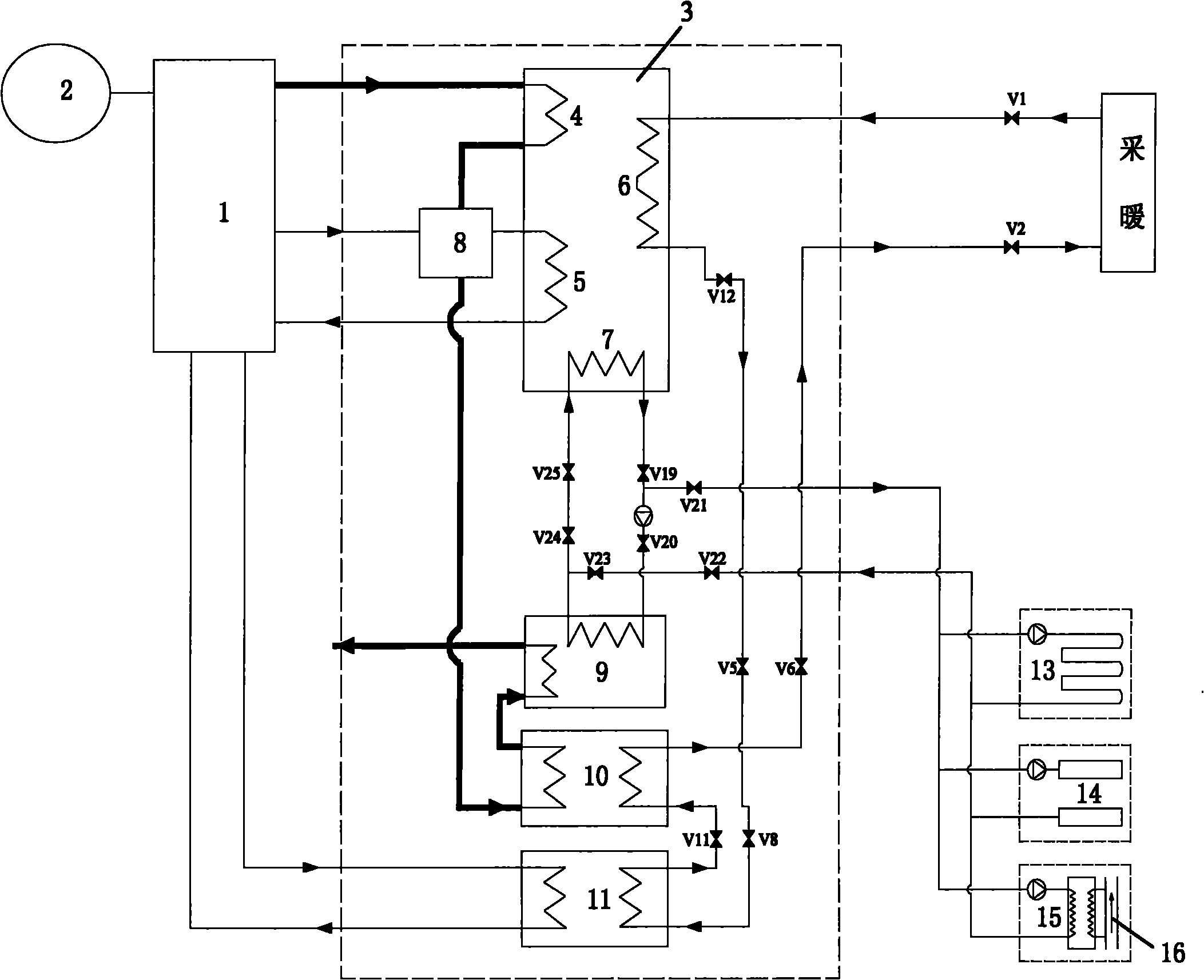

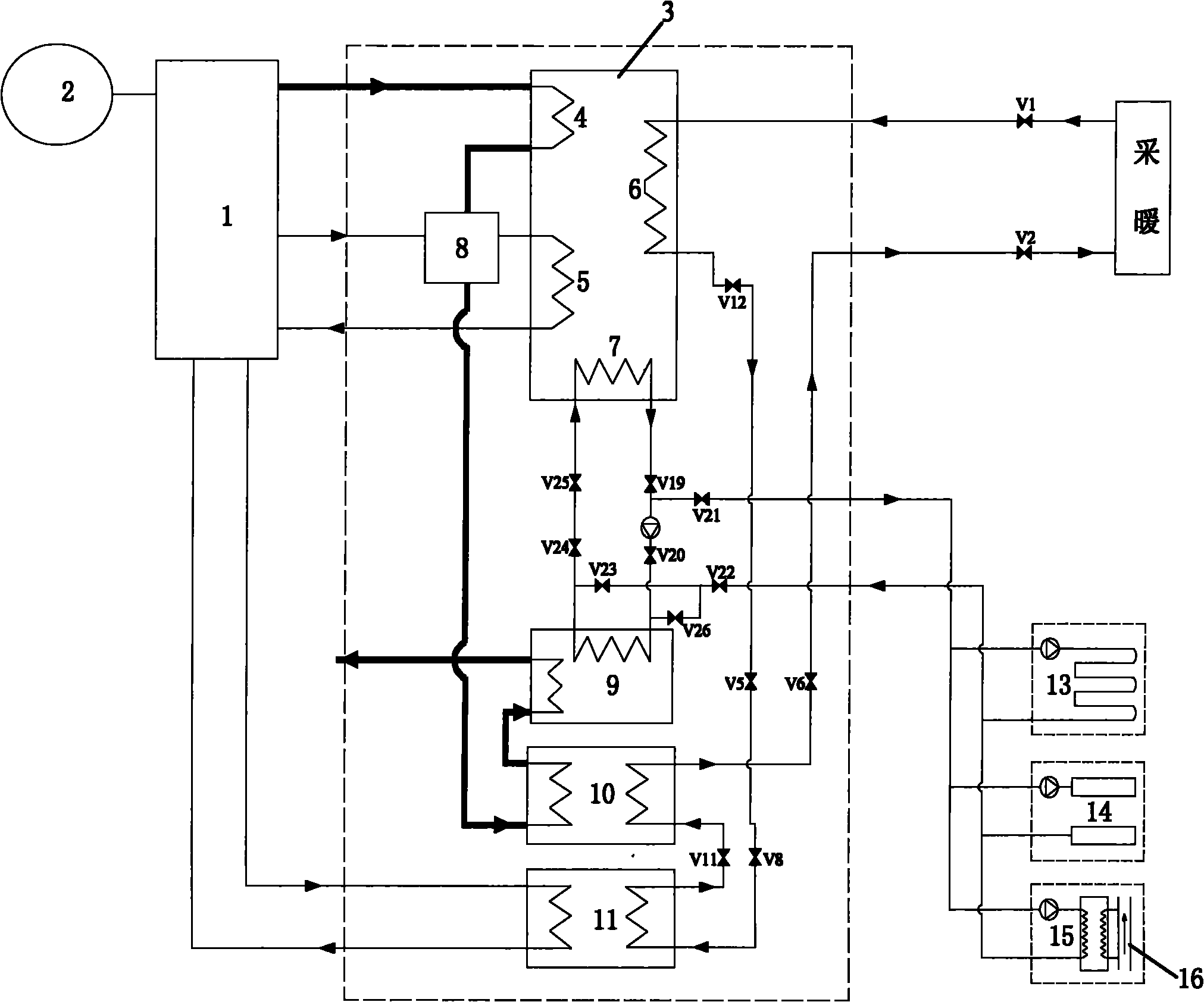

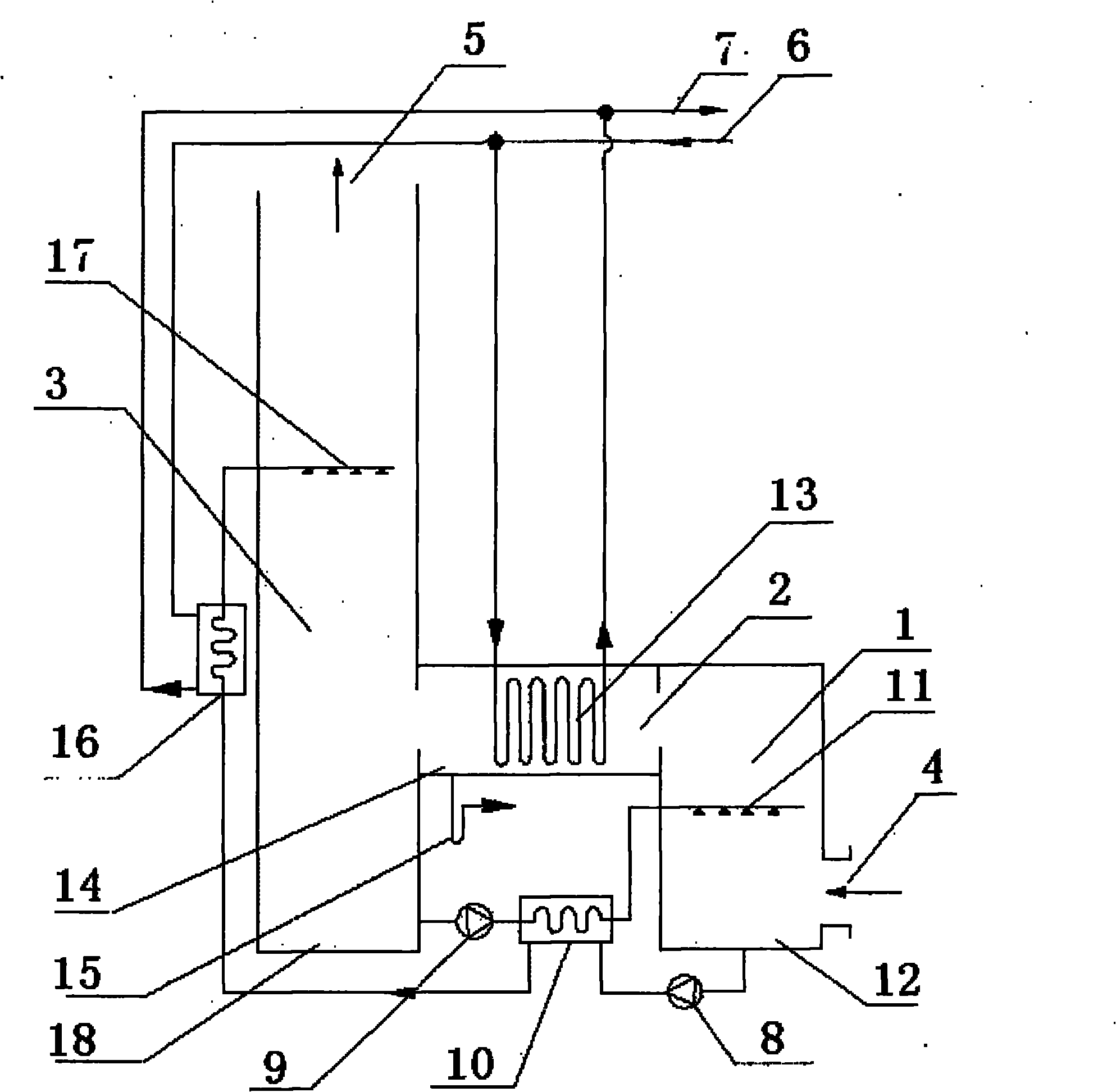

Heat-gaining combined heat and power system

ActiveCN101799226ARealize cascade utilizationEmission reductionClimate change adaptationHeating and refrigeration combinationsEnergy technologyAbsorption heat pump

The invention relates to a heat-gaining combined heat and power system, which belongs to the application field of the energy technology, and consists of a gas engine, a power generator, an absorption-type heat pump, a high-temperature smoke-water heat exchanger, a middle-temperature smoke-water heat exchanger, a low-temperature smoke-water heat exchanger, a water-water heat exchanger, a solution dehumidifying system, a ground heat exchanger, a superficial-layer underground water well or a sewage heat exchanger and accessories such as connection pipes and valves. The system can realize two work conditions of heat supply and coldness supply, and is provided with multiple pipeline switching forms under the work conditions of the heat supply and the coldness supply so as to adapt to the requirements of different situations; the system can ensure the adequate utilization of the heat of the gas engine, can adequately recycle the surplus heat of the exhausted smoke of the gas engine in winter, and can realize the extraction of the heat of the low-temperature heat source so as to improve the comprehensive efficiency of the system and to reduce the environmental pollution; and the system can discharge the heat of the low-temperate smoke and the heat of the cooling water into the low-temperature heat source to be stored in summer; and moreover combined with the solution dehumidification and the living hot water, the energy utilization efficiency of the system can be improved.

Owner:TSINGHUA UNIV +1

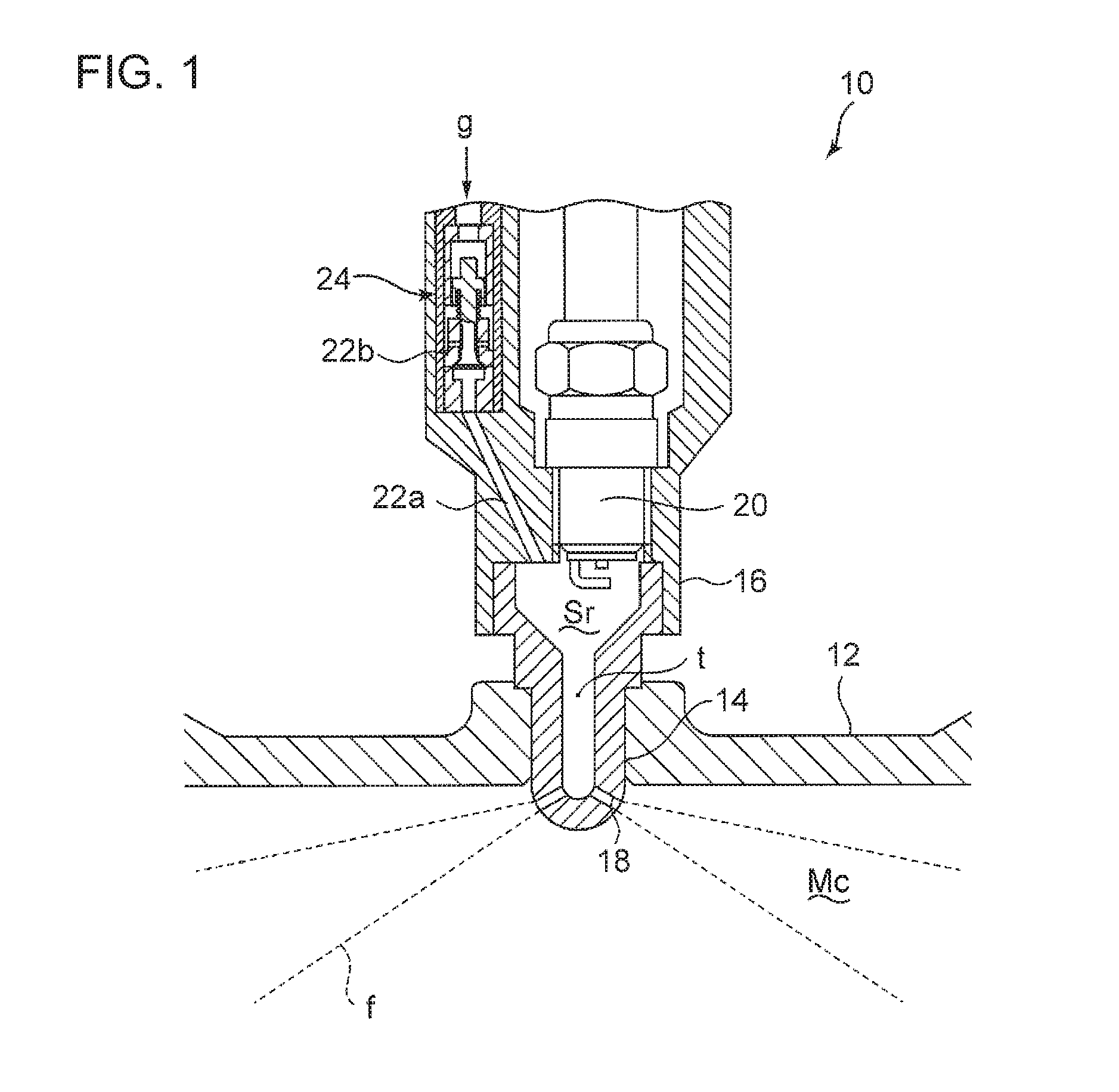

Pre-combustion-chamber type gas engine

ActiveUS20160245151A1Extension of timeImprove combustion efficiencyInternal combustion piston enginesFuel supply apparatusCombustion chamberCylinder head

An object is to improve a trap effect to trap ignition fuel gas supplied to a pre-combustion chamber and reduce an amount of non-combusted ignition fuel gas flowing out of the pre-combustion chamber to suppress a decrease in combustion efficiency. A pre-combustion-chamber type gas engine includes: a pre-combustion chamber Sr disposed on a cylinder head portion 10; a spark plug 20 disposed on an upper part of the pre-combustion chamber Sr; a pre-combustion-chamber gas supply mechanism configured to supply ignition fuel gas “g” to the pre-combustion chamber Sr via gas supply channels for the pre-combustion chamber 22a and 22b with an opening on an upper part of the pre-combustion chamber Sr; and a check valve 24 disposed in the gas supply channel 22b for the pre-combustion chamber. The opening of the gas supply channel 22a for the pre-combustion chamber is disposed on a lower surface of a cover member 16 forming the pre-combustion chamber Sr or on an upper section of a side wall of a pre-combustion-chamber member 14, the opening facing in a tangent direction of a side-wall inner peripheral surface 14a of the pre-combustion-chamber member 14. The ignition fuel gas “g” supplied to the pre-combustion chamber Sr forms a swirl flow s1 which swirls about a longitudinal axis x of the pre-combustion chamber Sr inside the pre-combustion chamber Sr.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Gas injection device of gas engine

InactiveUS20020148451A1Smooth supplyWell mixedInternal combustion piston enginesFuel supply apparatusInterior spaceCylinder head

A gas injection device in which an tunnel-like inner room is formed by surrounding with an inner wall, the inner room is communicated to the intake air flow passage of the intake pipe to allow the intake air to flow through the inner room, the inner wall is surrounded with an outer wall to form between the inner wall and outer wall an outer gas chamber into which fuel gas is introduced, and gas injection holes are provided in the inner wall to permit the gas in the outer gas chamber to sprout out from the injection holes into the air stream flowing through the inner room. The inner room may be partitioned into a plurality of tunnel-like rooms to correspond to the number of the intake air passages in the cylinder head.

Owner:MITSUBISHI HEAVY IND LTD

Mixed power gas heat pump air conditioner and its operating method

InactiveCN1776328AImprove running stabilityExtended service lifeHeating and refrigeration combinationsEngineeringAir compressor

With more than two power sources being installed, the disclosed new type system includes unit of combining dynamic forces, heat recovery device, fuel gas allocation unit, refrigerating unit and auxiliary device etc. The unit of combining dynamic forces is composed of gas engine, electric motor, generator and accumulation device etc. The refrigerating unit includes compressor, restricting elements, vaporizer and condenser etc. Main features of the system are that gas engine and accumulation device are combined to drive compressor; when load of the compressor is larger than drive provided by the gas engine, then both the gas engine and accumulation device provides power for the compressor; when load of the compressor is smaller than drive provided by the gas engine, then the gas engine stops operation if the accumulation device provides enough power; otherwise, the gas engine provides part of power to drive the compressor, and surplus power in use for charging the accumulation device.

Owner:SOUTHEAST UNIV

Divided-chamber gas engine

InactiveUS20130000598A1Avoid deformationAvoid performance degradationInternal combustion piston enginesCylinder headsCombustion chamberStaged combustion

A gas engine is configured to inject a combustion gas from an auxiliary combustion chamber through a plurality of nozzles, through which the auxiliary combustion chamber and a main combustion chamber are in communication with each other, so as to ignite a fuel in the main combustion chamber. An opening edge, at the auxiliary combustion chamber side, of each of the plurality of nozzles is formed to have a curved surface. This structure makes it possible to maintain stable combustion in the main combustion chamber while preventing degradation in combustion performance.

Owner:KAWASAKI HEAVY IND LTD

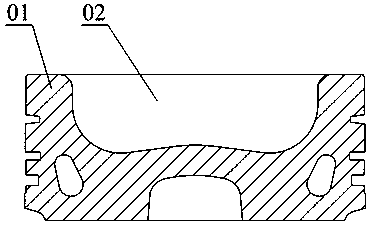

Weak tumble rapid combustion system and gas engine

ActiveCN111287860AImprove gas utilizationHigh feasibilityInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses a weak tumble rapid combustion system and a gas engine. The weak tumble rapid combustion system comprises a piston, a cylinder cover, an air intake channel and an exhaust channel, a combustion chamber is formed between the top of the piston and the cylinder cover, the cylinder cover is provided with an air intake throat and an exhaust throat, the section, close to the air intake throat, of the air intake channel is a tumble guide air channel, the axis of the tumble guide air channel is obliquely arranged relative to the bottom face of the cylinder cover, the upper sideface of the tumble guide air channel is an undershoot guide face obliquely arranged relative to the bottom face of the cylinder cover, the lower side face of the tumble guide air channel is an arc-shaped guide face sunken towards the bottom face of the cylinder cover, an eccentric chamfer is arranged at the lower end of the air intake throat, and the eccentric direction of the eccentric chamfer deviates along the direction of a central connecting line from the air intake throat to the air outlet throat. According to the weak tumble rapid combustion system, during air suction, fuel gas forms large-scale weak tumble motion in the air cylinder and is broken into small-scale turbulent flow in the last stage of compression, so that the flame propagation speed is increased, and the fuel gas utilization rate and the engine heat efficiency are improved.

Owner:WEICHAI POWER CO LTD

Flue gas waste heat recovery system based on solution absorption cycle

ActiveCN101922799ALower dew point temperatureDiffusion of influenceClimate change adaptationEnergy efficient heating/coolingWater vaporMoisture

The invention belongs to the technical field of energy resources, in particular to a flue gas waste heat recovery system based on solution absorption cycle, which is used for recovering flue gas waste heat and moisture in natural gas. The system consists of a generator, a condenser and an absorber, and the absorber is a one-level absorber or multiple-level serial absorber. High temperature flue gas from a boiler or a gas engine is used for heating a dilute solution in the generator, moisture in the solution is absorbed, the high temperature flue gas becomes high humidity fuel gas, and the dilute solution becomes a concentrated solution. The high humidity fuel gas and cooling water exchange heat in the condenser, the high humidity fuel gas is cooled to below dew point temperature, condensate water is separated out, after being cooled through a solution / solution heat exchanger and a solution / water heat exchanger, the concentrated solution sprays in the absorber and flows downwards, the flue gas flows from bottom to top in the direction opposite to that of the solution, water vapor in the flue gas is absorbed by the solution, and simultaneously, latent heat is discharged and the flue gas is discharged from a chimney. Heating backwater absorbs heat from the condenser, the absorber and the solution / water heat exchanger, and after being heated, the heating backwater can supply heat to a city heating net directly or after being heated by the boiler.

Owner:TSINGHUA UNIV +1

Air-conditioning and electric power generating system and control method for the same

InactiveCN101135512AInternal combustion piston enginesClimate change adaptationElectromagnetic clutchOperation mode

The present invention relates to an air conditioner-power generation system and a control method thereof, which are controlled so as to achieve a required NOx emission concentration or NOx emission amount in each operation mode. It comprises: a gas engine (10); an air conditioner having an outdoor heat exchanger, a decompression device, an indoor heat exchanger and a compressor (12) connected to the gas engine (10) through an electromagnetic clutch (14); a generator (11), which is driven by a gas engine (10), and has a power generation capability corresponding to the driving capability of the gas engine (10) when the compressor is separated from the gas engine (10) by an electromagnetic clutch (14); system link Converter (33), it is connected with generator (11) and carries out electric output to commercial system; Exhaust heat exchanger (29), it utilizes the waste heat of gas engine; Outdoor controller (39), as the gas engine (10) The driving mode of driving control, which has: the first control mode as a gas engine control for driving the compressor (12) and the generator (11) and the gas engine control mode as a gas engine for driving the generator (11) The second control mode of the control.

Owner:SANYO ELECTRIC CO LTD

Method and device for integrative control of gas engine

ActiveUS20090071439A1Easy to controlElectrical controlInternal combustion piston enginesCombustion chamberResponsivity

An integrative control method and device for controlling gas engines is proposed which is improved load responsivity of the engine while maintaining air fuel ratio control. The control method comprises a speed control process for controlling engine rotation speed by calculating a command value of fuel gas flow rate based on deviation of a detected engine rotation speed from a target command value of engine rotation speed and controlling fuel gas flow rate flowing through the fuel gas flow control valve to coincide with the calculated command value of fuel gas flow rate, and an air fuel ratio control process for controlling air fuel ratio of fuel-air mixture supplied to the combustion chamber of the engine through performing feedback control in which such a command value of fuel-air mixture flow rate is calculated that air fuel ratio of the mixture is appropriate with the fuel gas flow flowing at the commanded fuel gas flow rate and a target opening of the throttle valve is determined based on deviation of the actual mixture flow rate calculated based on detected values of operating conditions of the gas engine from the calculated command value of fuel-air mixture flow rate.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Method and apparatus for achieving high power flame jets while reducing quenching and autoignition in prechamber spark plugs for gas engines

A prechamber spark plug may have a prechamber having a pre-determined aspect ratio and hole pattern to achieve particular combustion performance characteristics. The aspect ratio and hole pattern may induce a rotational flow of fuel-air in-filling streams inside the prechamber volume. The rotational flow of the fuel-air mixture may include both radial flow and axial flow characteristics based on the aspect ratio and hole pattern. Axial flow characteristics can include a first axial direction proximate the periphery of the rotational flow and a counter second axial direction approaching the center of the rotational flow. The radial and axial flow characteristics may further include radial air-fuel ratio stratification and / or axial air-fuel ratio stratification. The rotational flow, the radial flow and the axial flow may be adjusted by alteration of the aspect ratio and hole pattern to achieve particular combustion performance characteristics in relation to a wide variety of spark gap geometries.

Owner:PROMETHEUS APPLIED TECH

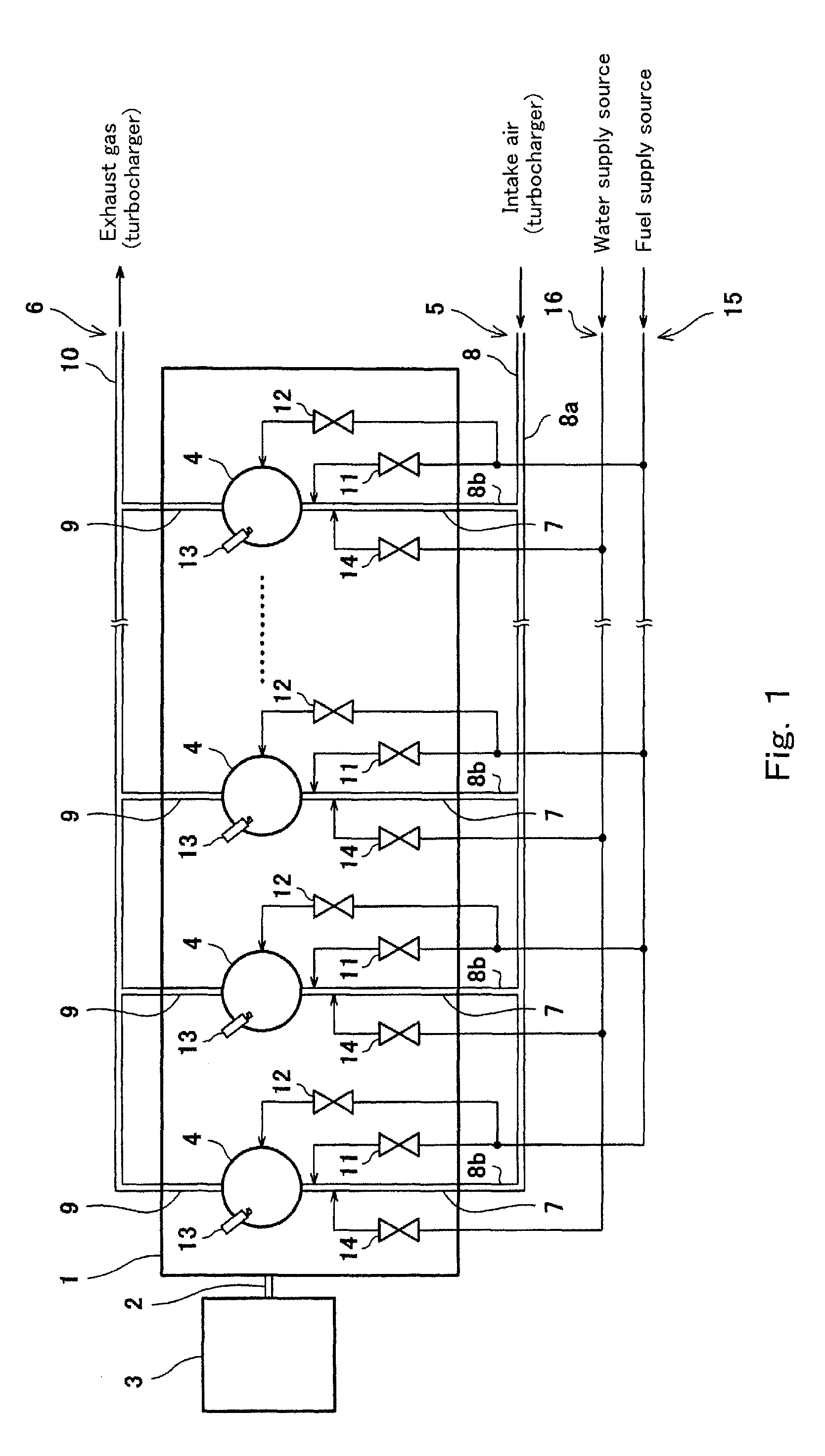

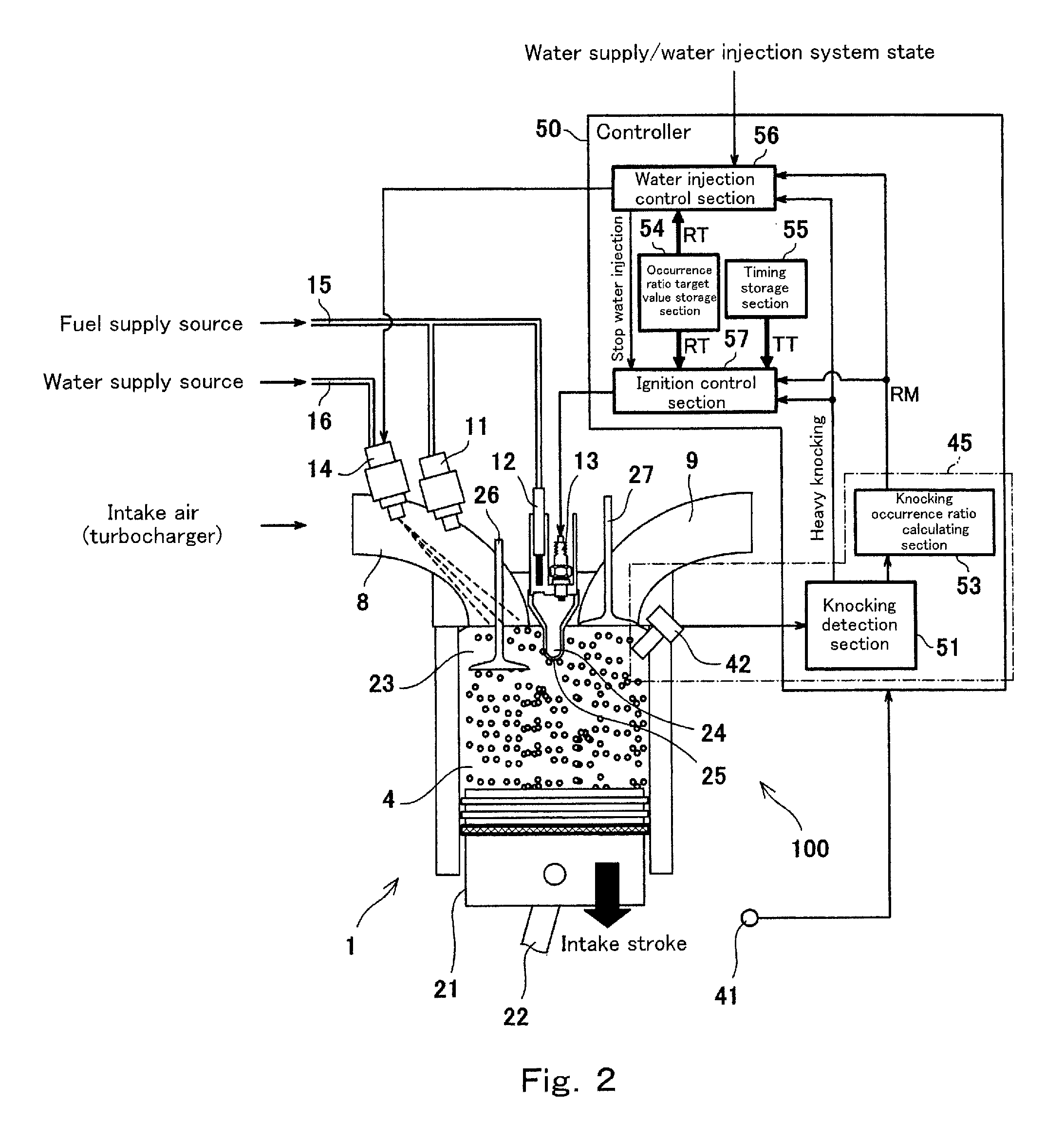

Gas engine, control system and control method for gas engine

ActiveUS9291125B2Improve gas efficiencyImprove efficiencyElectrical controlNon-fuel substance addition to fuelControl systemEnvironmental engineering

Owner:KAWASAKI HEAVY IND LTD

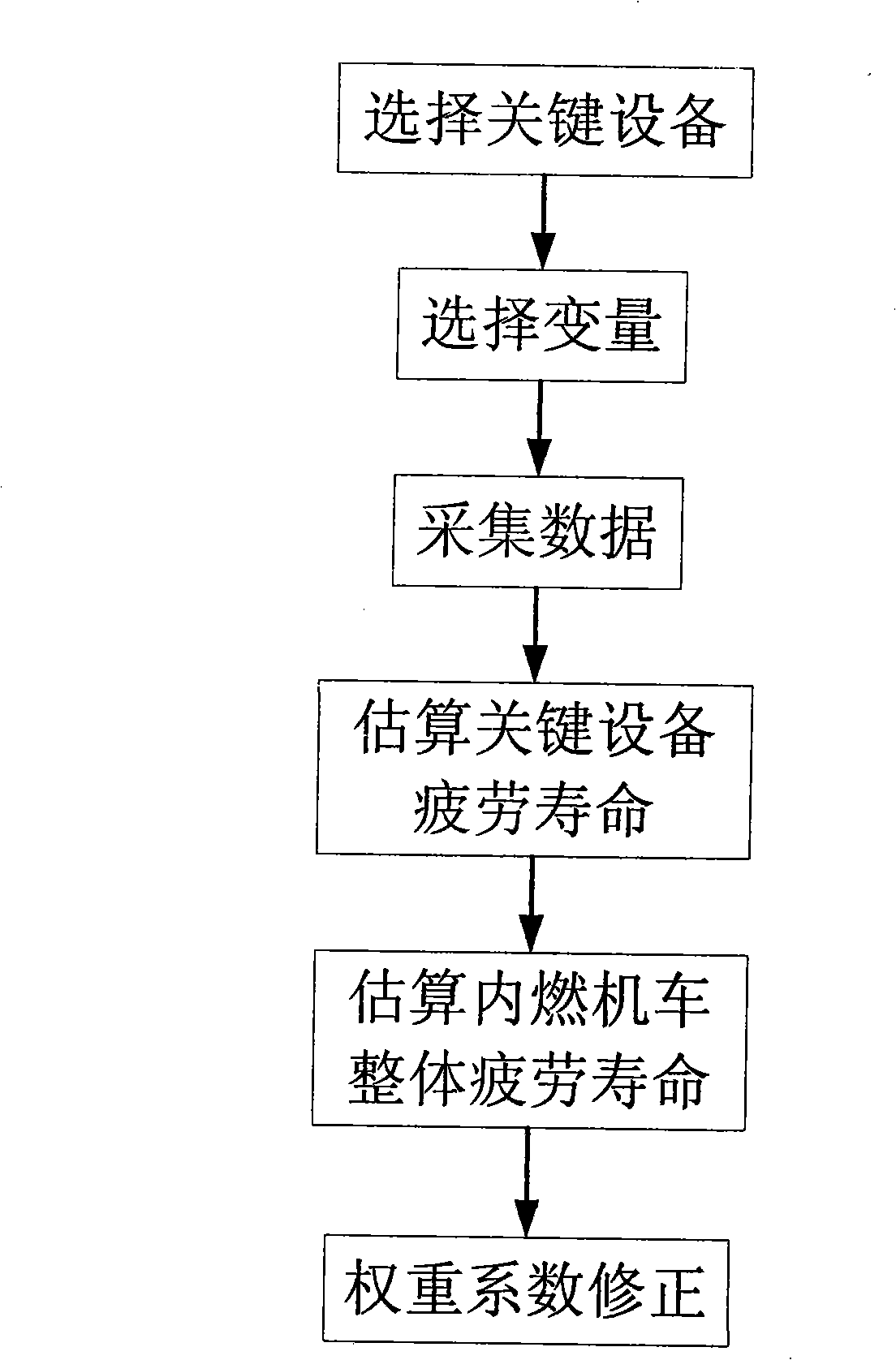

Fatigue life evaluation method of diesel locomotive

InactiveCN101319966AReflect damageIncrease credibilityRailway vehicle testingFatigue damageWeight coefficient

The invention relates to a fatigue service life estimation method for a gas engine which includes the follows: firstly selecting the key devices for estimating the fatigue service life of the gas engine; then selecting a variable which affects the fatigue service life of each key device; obtaining the needed variable value by collecting relevant data; working out the injury tolerance of each key device by utilizing a Miner rule in a fatigue accumulation injury theory; when the value is equal to 1, considering the devices to reach the fatigue service life and need to be overhauled. The integral fatigue injury tolerance for the gas engine is equal to the fatigue injury tolerance of each key device multiplied by the sum of the corresponding weight coefficients; when the value is larger than 1, then the engine is considered to reach the fatigue service life and need to be heavily repaired. Finally an estimation result is led to approach the actual injury situation of the engine by correcting the weight coefficients, thus being used as a basic for confirming the heavy repair period of the engine. The invention is different from the traditional method which uses the running kilometrages and the equivalent kilometrages to confirm the period for the heavy repair of the engine and essentially reflects the injury situation of the gas engine; so the reliability of the estimation result is higher.

Owner:BEIJING JIAOTONG UNIV +1

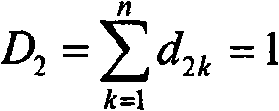

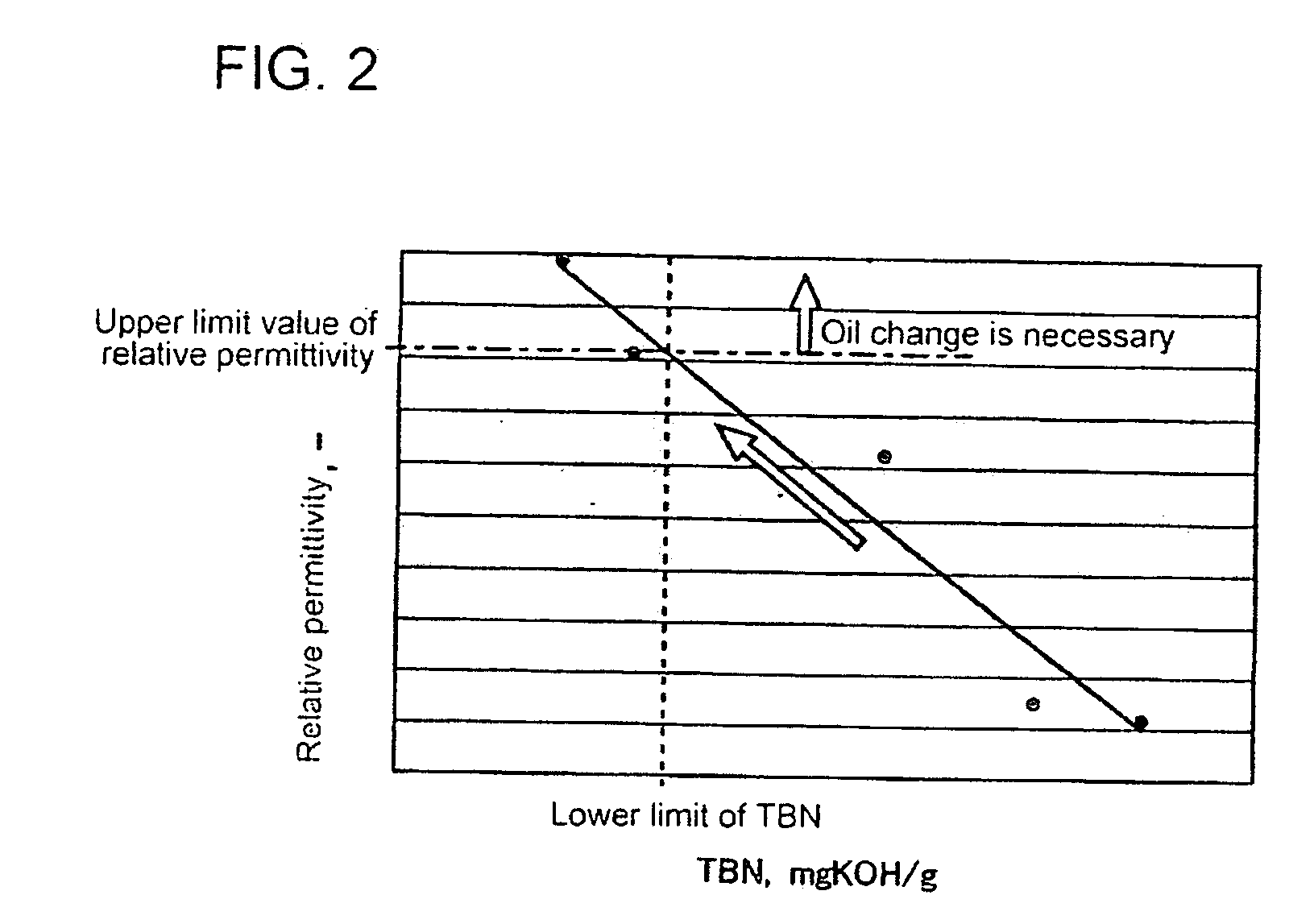

Method of monitoring deterioration of lubricating oil and device therefore

InactiveUS20090216471A1Stable measurement of permittivityUnnecessary changing of oil can be evadedResistance/reactance/impedenceVoltage-current phase angleTotal Base NumberForeign matter

A method of monitoring deterioration of lubricating oil and a device therefore capable of judging deterioration of the oil with high accuracy suppressing measurement error due to mixing of foreign matter in the oil. Correlation between relative permittivity and TBN (total base number) of the lubricating oil is obtained beforehand (step S1), electric current and voltage are measured (step S2) when high-frequency voltage is applied between a pair of electrodes located in an oil path in a gas engine, permittivity of the oil is detected (step S3) based on the measurement of current and voltage, TBN of the oil is obtained (step S4) from the correlation between relative permittivity and TBN, and deterioration of the oil is judged by the obtained value of TBN.

Owner:MITSUBISHI HEAVY IND LTD

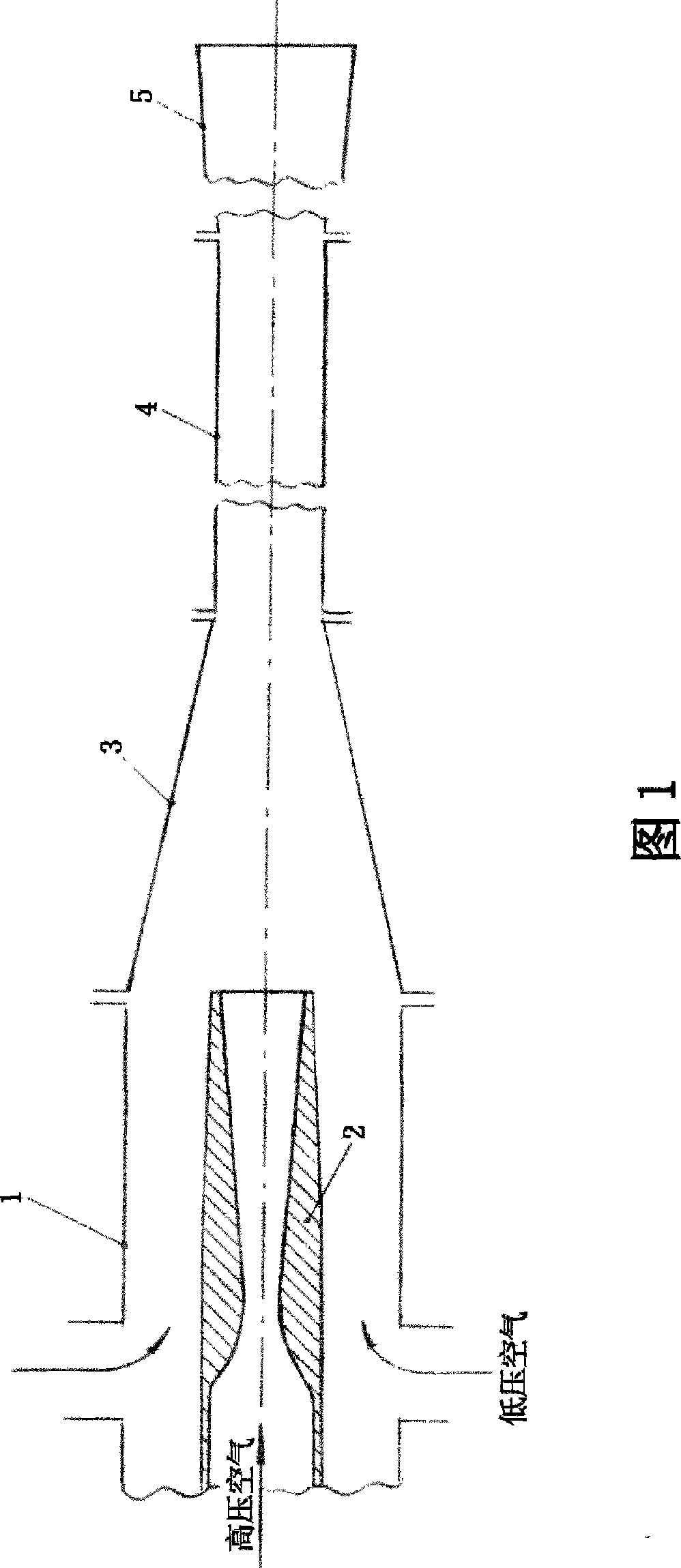

Ejection air-supplying turbosupercharger

InactiveCN101245714AOperating condition maintenance and continuityGood effectInternal combustion piston enginesEngine componentsForming gasTurbocharger

The invention discloses a turbocharger which utilizes the outer source compressed air to apply complementary energies on a rotor of the turbocharger, so as to improve the pressurizing pressure and improve the lower working situation property and instant characteristics of a gas engine. The turbocharger is formed by combining three parts of a turbocharger with ordinary structure and two accessories - a gas ejector and a gas complementing chamber. The outer source high-pressure compressed air ejects partial low-pressure pressurizing air through the gas ejector to form gas complementing air to flow in the gas complementing chamber to be mixed with the exhaust gas of the gas engine, thus increasing the fuel gas flow flowing into a turbine and improving the power and pressurizing pressure of the turbine. Compared with the prior art, the turbocharger has the advantages of mature technology, simple structure, reliable and safe use, low cost, direction pressure control, large adjusting and controlling degree, fast response and good effect; besides, the turbocharger can ensure the working situation to operate continuously after being adjusted and controlled and can be used on the gas engines of vehicles, ships and engineering plants.

Owner:孙敏超 +1

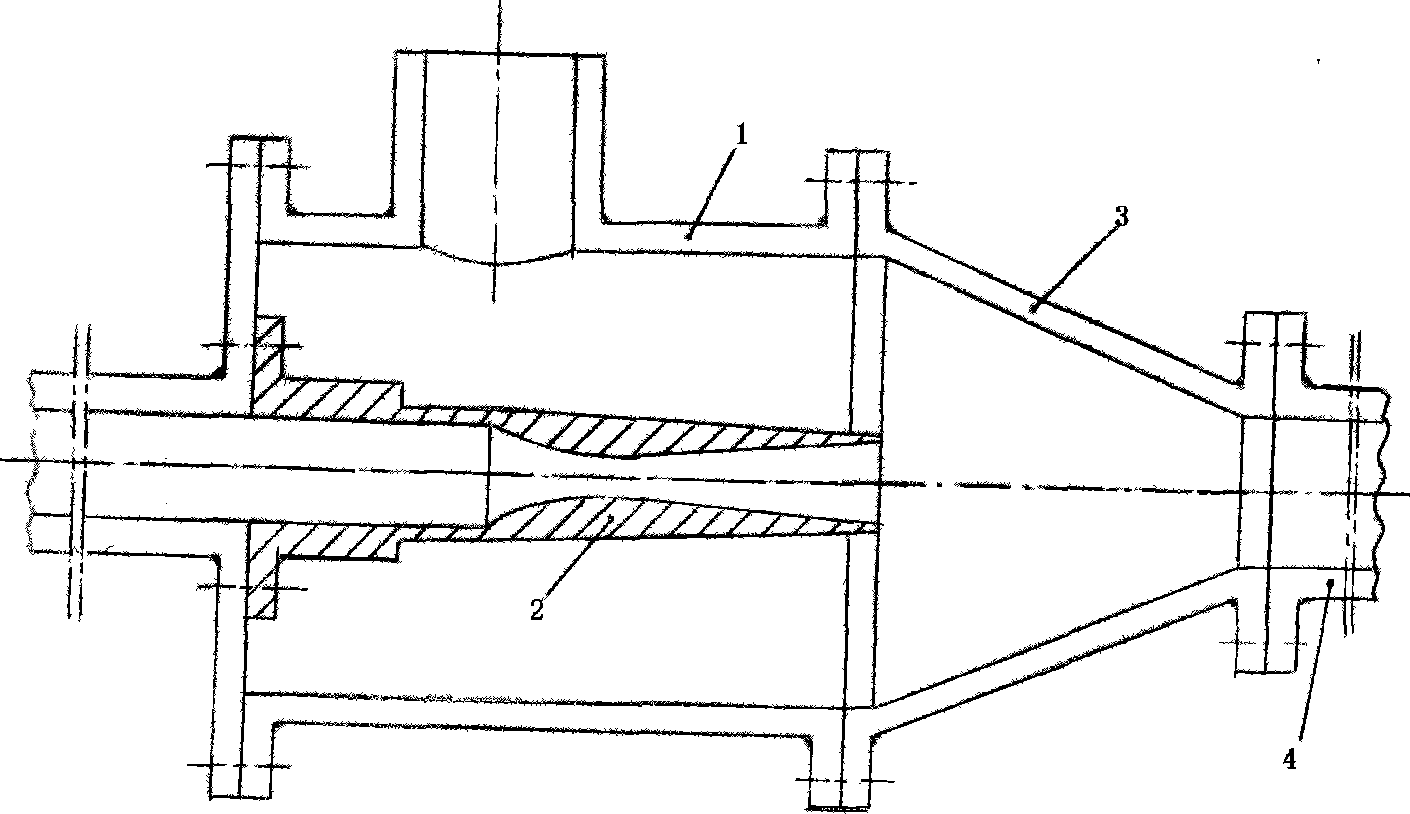

Mixer for gas engine and exhaust gas recirculation (EGR) mixer

ActiveCN106762245AGuaranteed uptimeImprove gas utilization efficiencyInternal combustion piston enginesExhaust gas recirculationProcess engineeringExhaust gas recirculation

The invention discloses a mixer for a gas engine and an exhaust gas recirculation (EGR) mixer. The mixer for the gas engine comprises a through mixer body. A turbulent flow body is arranged at an air inlet of the mixer body. A gas core is arranged at an air outlet of the mixer body. An EGR core is arranged between the turbulent flow body and the gas core. An exhaust gas inlet and a gas inlet are formed in the mixer body. The EGR core communicates with the exhaust gas inlet. The gas core communicates with the gas inlet. The mixer for the gas engine is suitable for various kinds of gas engines, the mixing efficiency is high, operation of the engine is more stable, and the utilization efficiency of gas is higher. Requirements for periphery conditions are lower than those of independent gas mixers and EGR mixers, the total cost is lower, safety and reliability are achieved, the sealing performance is good, and the mixer for the gas engine and the EGR mixer have great market application value.

Owner:成都耐尔特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com