Fatigue life evaluation method of diesel locomotive

A technology for fatigue life and diesel locomotives, which is applied in the direction of railway vehicle testing, etc., can solve the problem that it is difficult to calculate the damage status of diesel locomotives, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

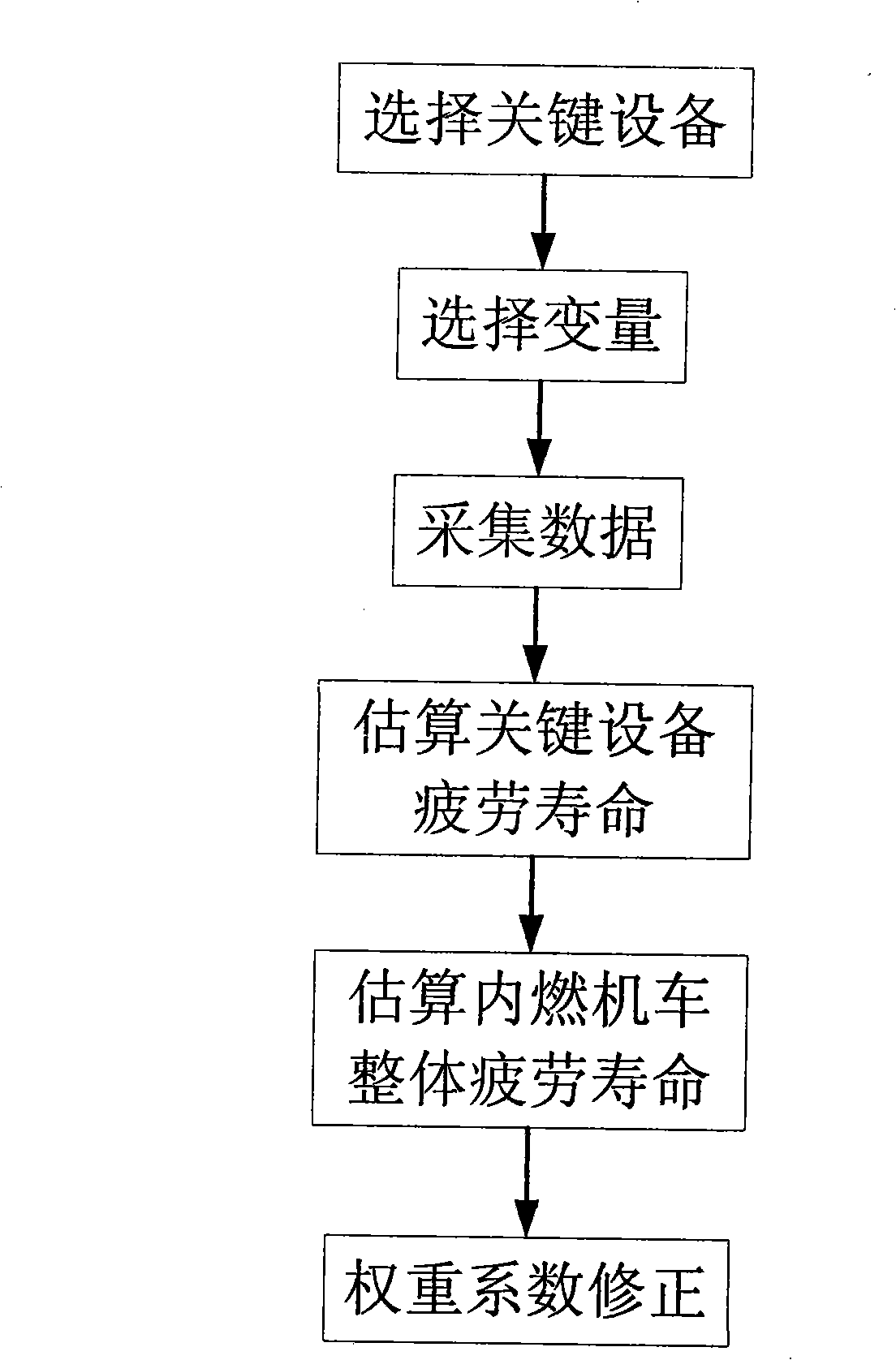

[0029] The specific process of fatigue life estimation of Dongfeng diesel locomotive as an example is given below in conjunction with the accompanying drawings.

[0030] (1) The diesel engine, synchronous main generator, axle and bogie frame are selected as the key equipment for estimating the fatigue life of diesel locomotives.

[0031] (2) Select the variables that affect the fatigue life of key equipment:

[0032] For a diesel engine, the output torque of the crankshaft is selected as a variable to characterize its stress condition;

[0033] Synchronous main generator, select its output current as a variable representing the damage caused by electrical stress;

[0034]For the axle and bogie frame, the output torque of the traction motor is taken as a variable to characterize its stress condition;

[0035] (3) Collect data: collect the output voltage and output current of the synchronous main generator of the locomotive, the speed of the diesel engine, the speed of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com