Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232 results about "Bog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bog or bogland is a wetland that accumulates peat, a deposit of dead plant material—often mosses, and in a majority of cases, sphagnum moss. It is one of the four main types of wetlands. Other names for bogs include mire, quagmire, and muskeg; alkaline mires are called fens. They are frequently covered in ericaceous shrubs rooted in the sphagnum moss and peat. The gradual accumulation of decayed plant material in a bog functions as a carbon sink.

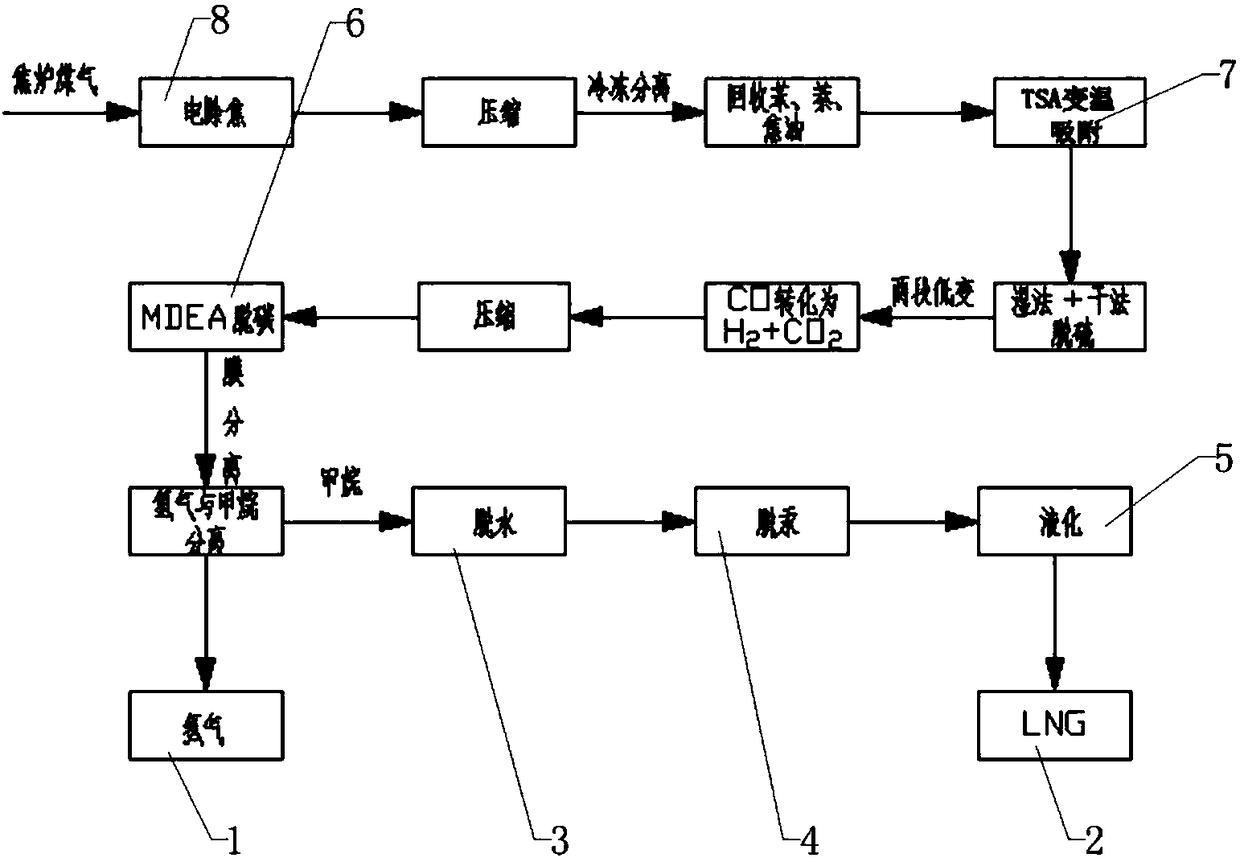

Method for preparing hydrogen and LNG from coke oven gas

InactiveCN108179046ALow investment costLow running costHydrogenGaseous fuelsHigh concentrationSeparation technology

The invention provides a method for preparing hydrogen and LNG from coke oven gas. The method comprises the following steps: electric decoking; boosting of the coke oven gas by a compression system; cooling of the raw gas coke oven gas by using the BOG gas (the BOG gas is a gas formed after the passive heating gasification of LNG) of LNG in order to further remove tar, benzene, naphthalene and like substances in the coke oven gas; and pretreatment using a TSA process to finely remove macromolecular impurities, such as tar, benzene, naphthalene and the like; wet and dry two-stage desulfurization for removing sulfides in the coke oven gas; two-stage low pressure shifting for a reaction of CO and water vapor to form CO2 and hydrogen; and pressurization using a compressor, an MDEA solution process for removing carbon dioxide, a membrane separation technology for separating hydrogen and methane, separation, concentration and purification of the hydrogen and methane, and dehydration, demercuration and liquefaction of the separated high-concentration methane to obtain the LNG. The coke oven gas is finally converted into the hydrogen and the LNG which have high values, so the energy of thecoke oven gas is fully used, and the environment is protected.

Owner:SICHUAN HENGRI GAS ENG CO LTD

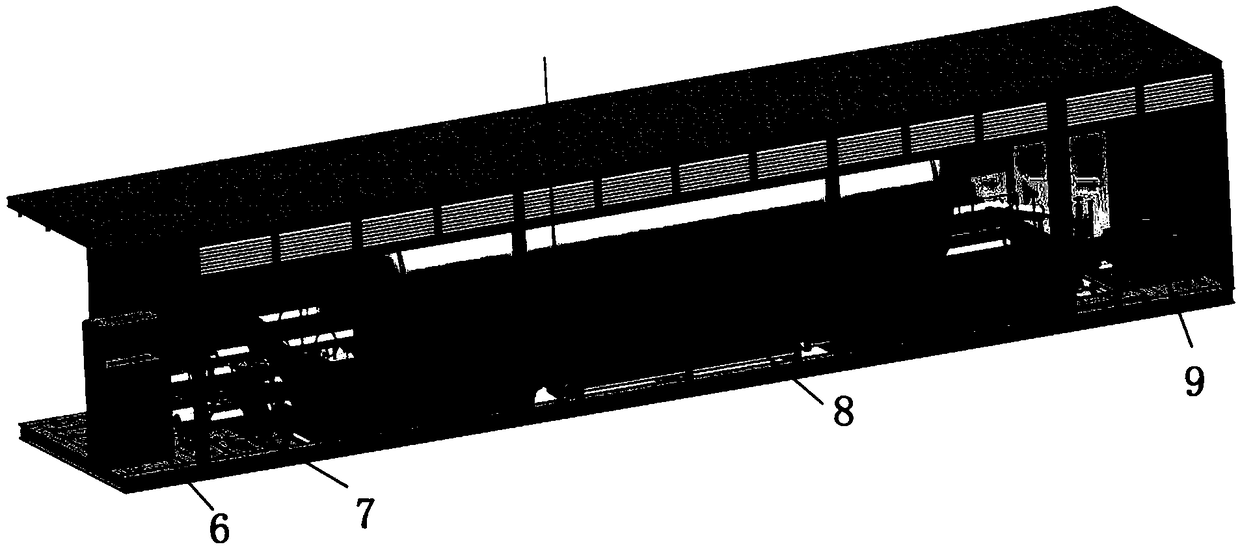

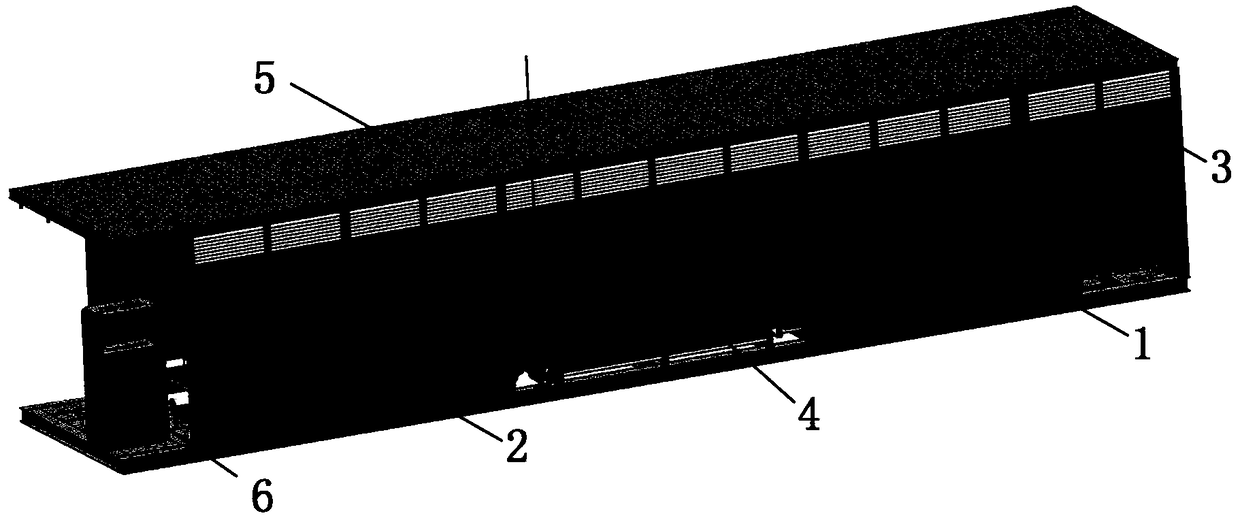

LNG/L-CNG skid-mounted gas station

PendingCN109027662AFunction increaseShort construction periodVessel mounting detailsVessel geometry/arrangement/sizeEngineeringIndustry standard

The invention discloses a LNG / L-CNG skid-mounted gas station. The LNG / L-CNG skid-mounted gas station comprises a first sled base, a second sled base, a LNG pump sled, a low-temperature storage tank, aL-CNG pump sled and a gas filling machine; the L-CNG pump sled is arranged on the first sled base; the low-temperature storage tank, the L-CNG pump sled and the gas filling machine are integrated onthe second sled base in sequence; an unloading table is additionally arranged at the end, near the gas filling machine, of the second sled base; the end, near the low-temperature storage tank, of thesecond sled base is movably connected with the first sled base; the low-temperature storage tank discharges liquid by the head and tail ends; fences are arranged on two sides of the first sled base and the second sled base; the first sled base is connected with the end, near the low-temperature storage tank, of the second sled base; top cover plates are arranged at the tops of the fences; and thehorizontal plane of the top cover plates is higher than the horizontal plane of the top of the low-temperature storage tank. The LNG / L-CNG skid-mounted gas station has the following beneficial effects: through high integration degree, the country and industry standards are met, and the functions of an integrated gas station are expanded; and through the mode of discharging the liquid by the head and tail ends of the low-temperature storage tank, the generation of BOG is greatly reduced, and the liquid outlet speed is accelerated.

Owner:JEREH OIL & GAS ENG

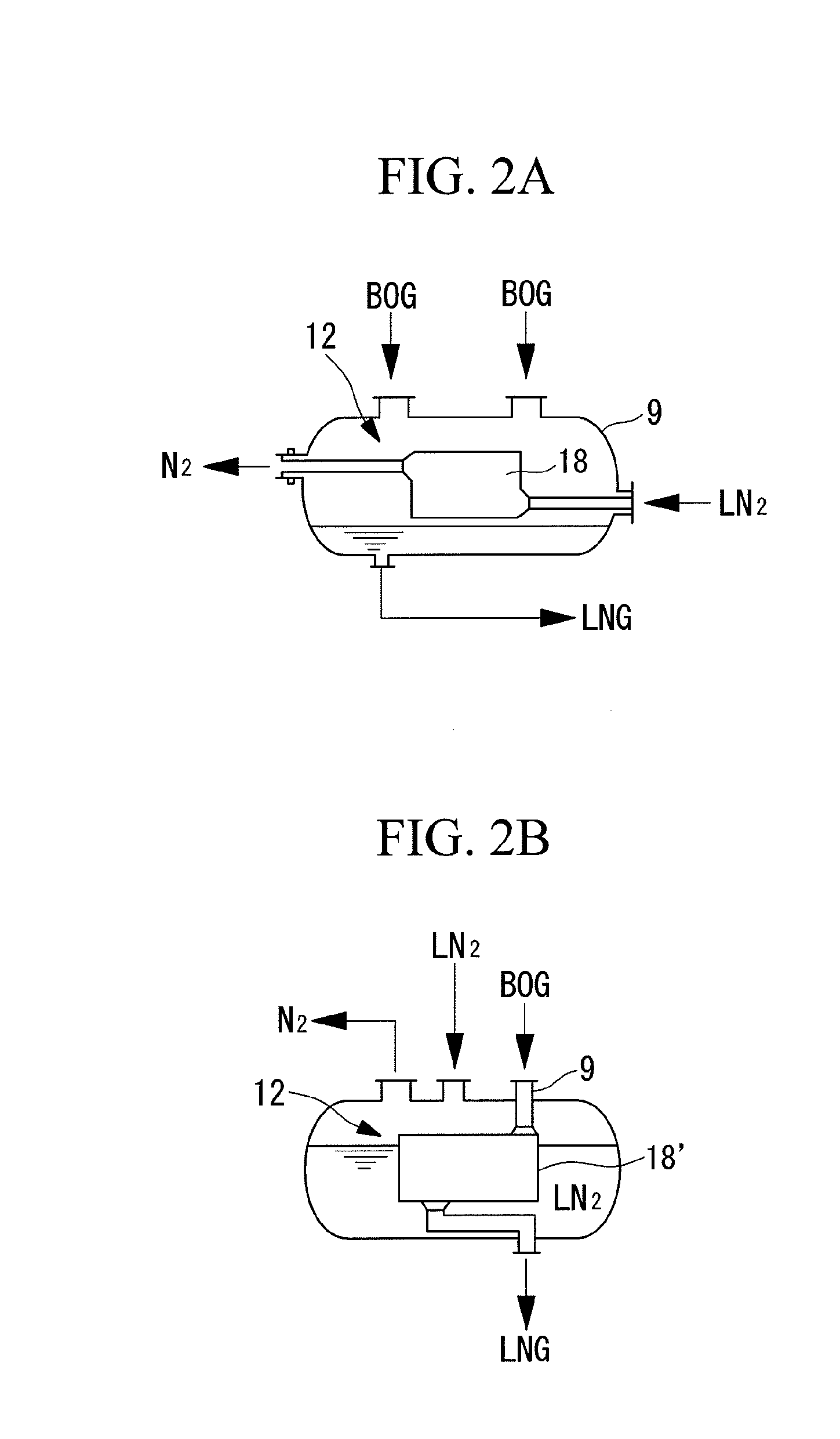

Boil off gas condenser

InactiveUS20070214831A1Avoid pressure fluctuationsAvoid communicationSolidificationLiquefactionStream flowEngineering

Owner:TECHNIP US

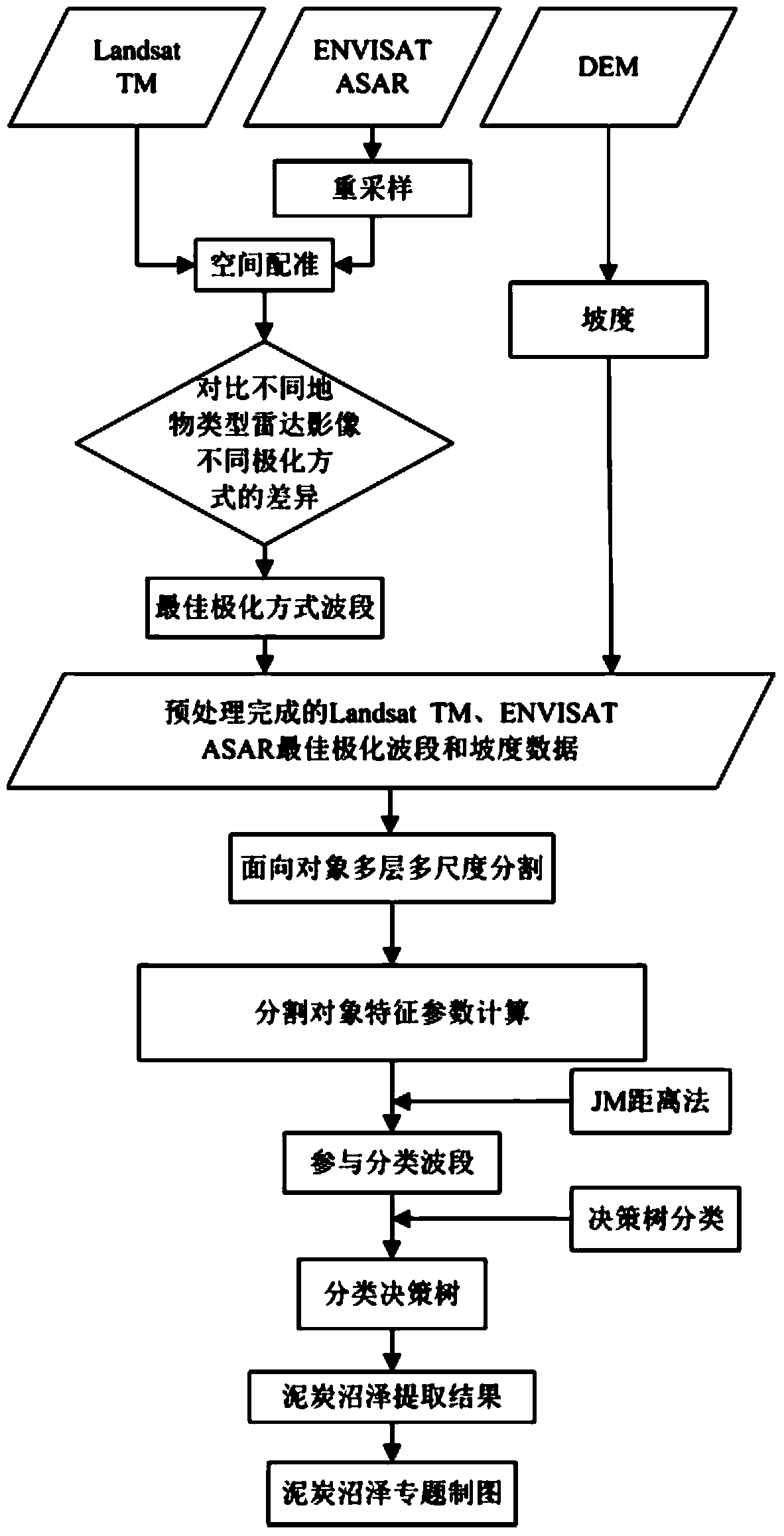

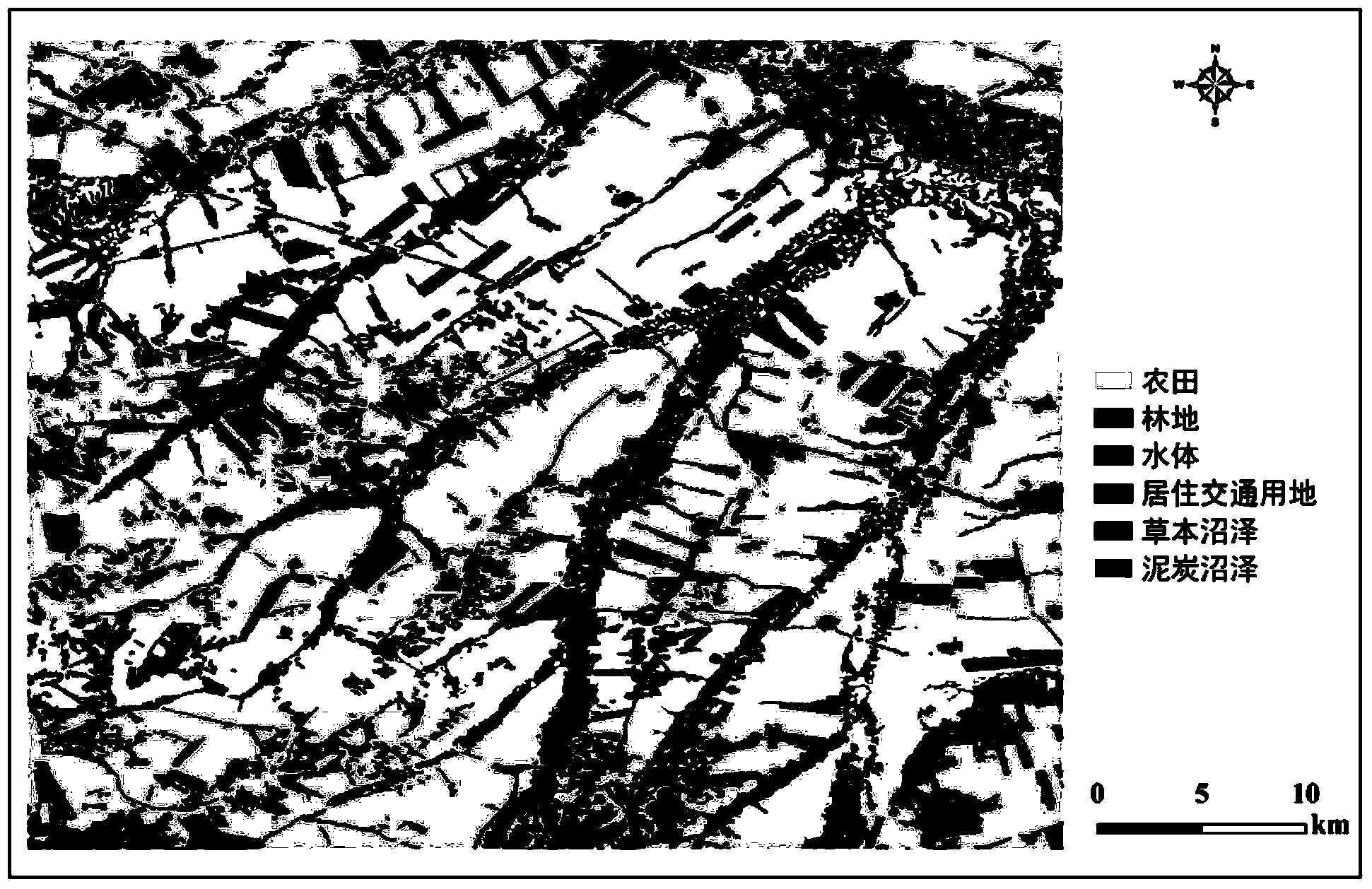

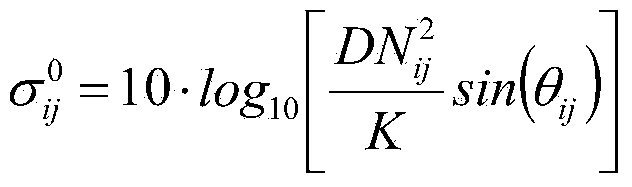

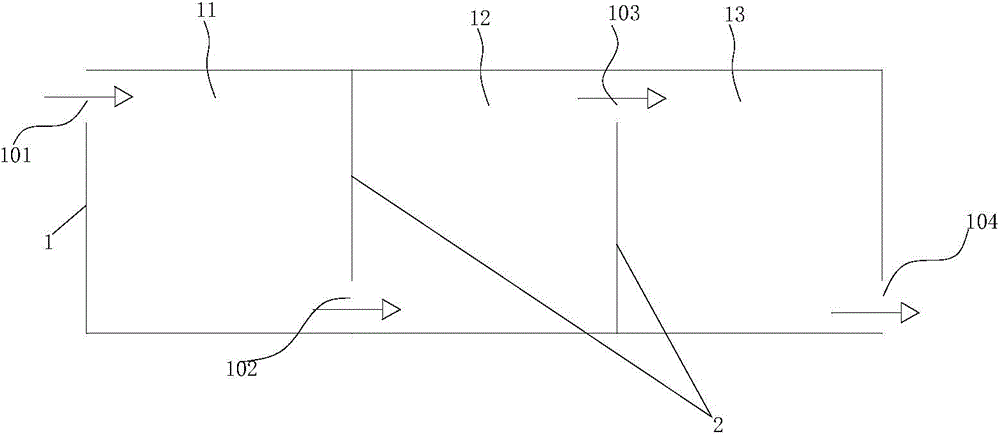

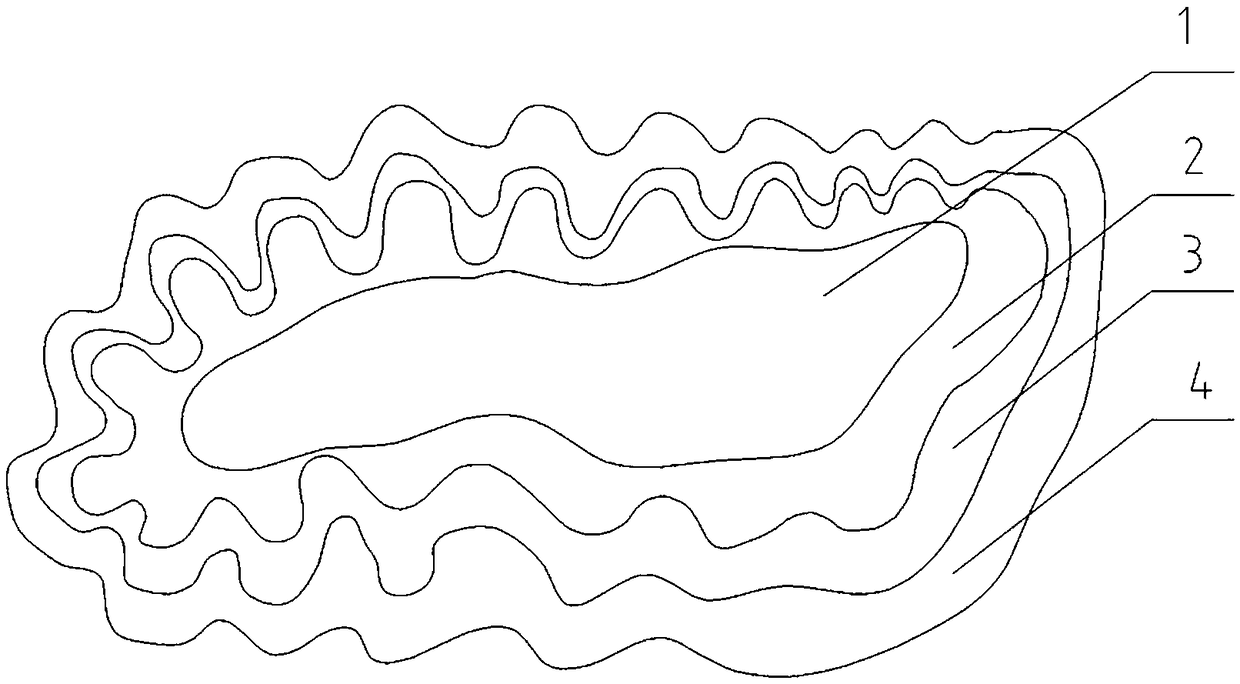

Peat bog information extracting method based on ENVISAT ASAR, Landsat TM and DEM data

ActiveCN104361338AAutomatic fast and accurate extractionAutomatic Extraction FastScene recognitionLand coverPeat

The invention relates to peat bog information extracting methods, in particular to a peat bog information extracting method based on ENVISAT ASAR, Landsat TM and DEM data, and solves the problem that peat bog and other bog types cannot be distinguished by a conventional method. The peat bog information extracting method includes step 1, preprocessing Landsat TM data; step 2, preprocessing ENVISAT ASAR data; step 3, re-sampling the ENVISAT ASAR data; step 4, acquiring an ENVISAT ASAR image; step 5, acquiring gradient data; step 6, extracting back scattering coefficient; step 7, determining optimal polarization mode waveband of the ENVISAT ASAR image; step 8, acquiring a division unit; step 9, extracting feature parameters; step 10, determining optimal classification waveband; step 11, establishing a classification decision-making tree; step 12, generating a soil covering type vector file; step 13, making a peat bog map. The peat bog information extracting method is applied to the field of peat bog information extracting.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

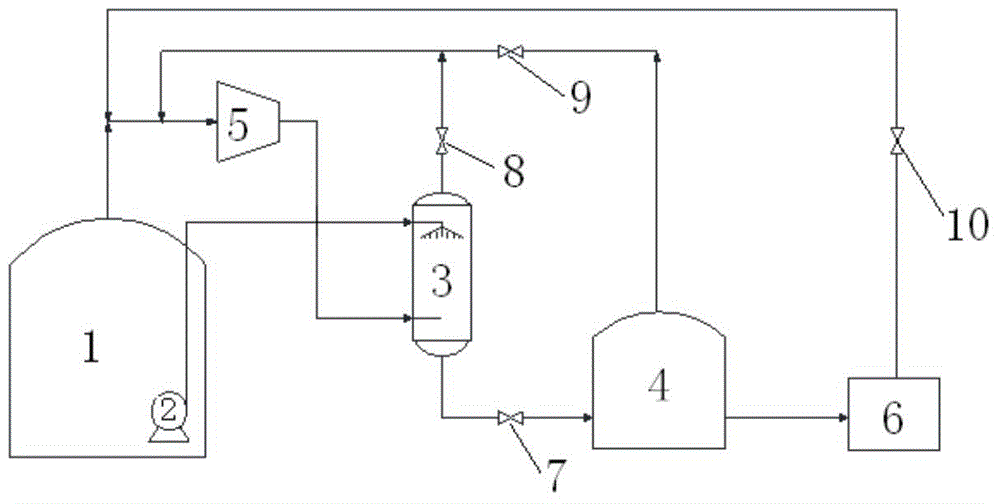

Liquefied gas reliquefier, liquefied-gas storage facility and liquefied-gas transport ship including the same, and liquefied-gas reliquefaction method

ActiveUS20100170297A1Simple configurationIncrease redundancySolidificationVessel mounting detailsRefrigerator carEvaporation

A liquefied gas reliquefier that can be configured compactly and that is easy to handle is provided. A liquefied gas reliquefier (1) reliquefies BOG resulting from evaporation of LNG in a cargo tank (3). The liquefied gas reliquefier (1) includes a refrigerator group (20) disposed in a secondary-refrigerant circulating channel (24) through which nitrogen, which has a lower condensation temperature than the BOG, circulates to liquefy the nitrogen; a feed pump (22) for feeding the liquid nitrogen cooled by the refrigerator group (20) through the secondary-refrigerant circulating channel (24); and a heat exchanger (12) disposed in the secondary-refrigerant circulating channel (24) to condense the BOG by heat exchange between the BOG and the liquid nitrogen fed by the feed pump (22). The heat exchanger (12) is disposed near the cargo tank (3).

Owner:MITSUBISHI SHIPBUILDING CO LTD

System and method for treating rural sewage by using ecological system based on multi-submerged plant combinations

ActiveCN103951067ACompensate for lack of processing powerEasy to handleSustainable biological treatmentBiological water/sewage treatmentVallisneria spinulosaVallisneria spiralis

The invention discloses a system and method for treating rural sewage by using an ecological system based on multi-submerged plant combinations. From the water inlet to the water outlet, the system sequentially comprises three regions in a pond, wherein a submerged plant combination A, which comprises more than any two of hydrilla, waterweed, Najas minor, curly pondweed and bog pondweed, is planted in the first treatment region; a submerged plant combination B, which at least comprises Vallisneria spiralis and vallisneria spinulosa, is planted in the second treatment region; and a submerged plant combination C, which comprises more than any two of hydrilla, waterweed, Najas minor, Vallisneria spiralis, vallisneria spinulosa, curly pondweed, bog pondweed, watermilfoil and hornwort, is planted in the third treatment region. The system and method are simple to implement, have the advantages of low cost and favorable effect, and do not need additional pipe network engineering and land; and the effluent water can achieve Grade 1 A above in Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant. The system can be used as a natural landscape, and has the advantages of high transparency of the water body, high biodiversity and high ecological landscape value.

Owner:GUANGZHOU RESOURCE ENVIRONMENTAL PROTECTION TECH CO LTD

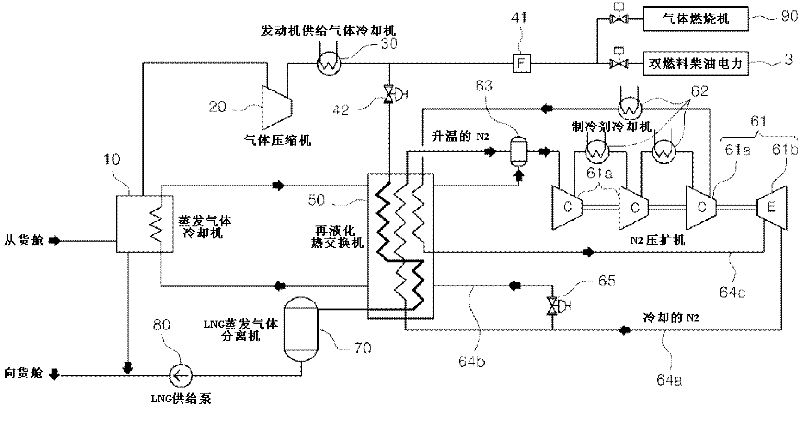

Boil-off gas treatment apparatus for electric-propelled LNG carrier having re-liquefaction function and method thereof

InactiveCN102341303AReduce wasteAchieve economySolidificationLiquefactionProcess engineeringGas cooler

The present invention relates to a boil-off gas treatment apparatus for an electric-propelled LNG carrier having a re-liquefaction function and a method thereof comprising: a boil-off gas cooler (10) which receives natural boil-off gas (N-BOG) produced in an LNG cargo tank and cools the gas through heat exchange with a coolant, a gas compressor (20) which receives the cooled N-BOG from the boil-off gas cooler (10) and compresses the gas to a pressure suitable for use in a DFDE (Duel Fuel Diesel Electric) propelled engine (3), an engine feed gas cooler (30) which cools the N-BOG, whose temperature has risen passing through the gas compressor (20), to a temperature suitable for use in the DFDE propelled engine (3) and supplies the cooled gas to the DFDE propelled engine (3), and a re-liquefaction heat exchanger (50) which receives the extra N-BOG unused in the DFDE propelled engine (3); from the downstream of the engine feed gas cooler (30) and supplies the gas to the LNG cargo tank after cooling and re-liquefying through heat exchange with a coolant. The present invention re-liquefies the extra gas unused for propulsion as well as using the natural boil-off gas produced in the LNG cargo tank as a drive source for propelling a vessel, thereby minimizing the waste of N-BOG.

Owner:STX OFFSHORE & SHIPBUILDING CO LTD

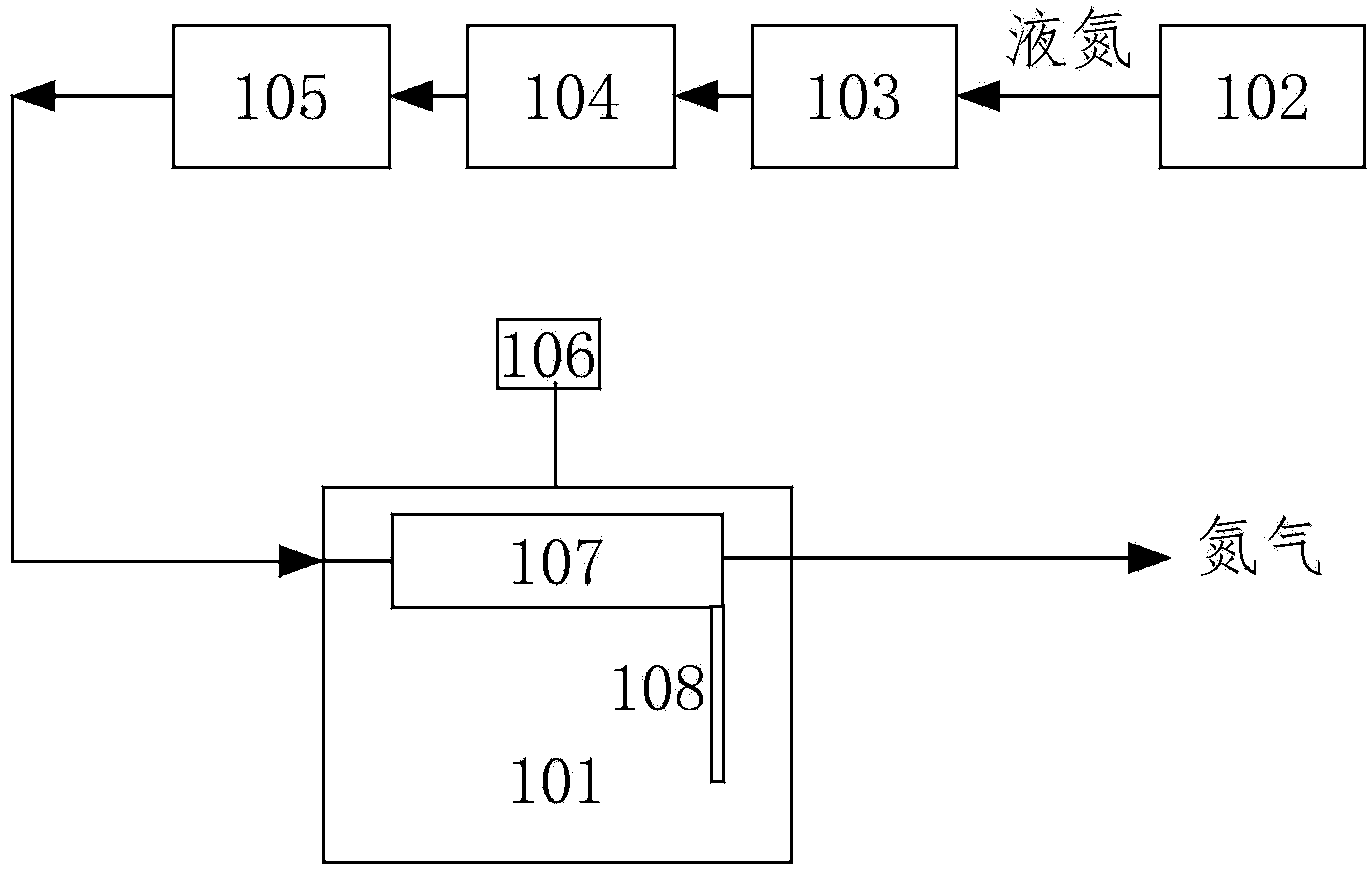

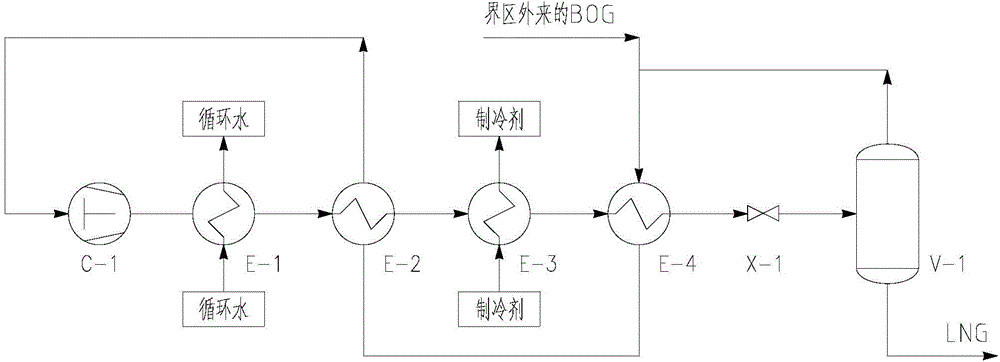

Technology of BOG recovery and device thereof

InactiveCN103343881AEasy to operateReduce equipment costsSolidificationLiquefactionProduct gasEngineering

The invention discloses a technology of BOG recovery and a device of the technology of the BOG recovery. According to the technology of the BOG recovery, nitrogen from a nitrogen storage tank is compressed, and high-pressure nitrogen is obtained and enters a BOG recovery system; in the BOG recovery system, water cooling is performed on the nitrogen, then heat exchanging is performed on the nitrogen, low-temperature and high-pressure nitrogen is obtained and expanded to be in a normal-pressure state, temperature is further decreased, cooling capacity contained in the nitrogen is supplied to BOG from an LNG storage tank so that the BOG can be liquefied, and after the temperature of the nitrogen in the BOG recovery system goes up again to the temperature of the nitrogen storage tank, the nitrogen returns to the nitrogen storage tank. Through the method, using of an imported BOG compressor and compression of flammable and combustible hydrocarbon gas are omitted, the stable nitrogen serves as a cold carrier medium, and the BOG recovery is achieved through a common compressor and a common expanded machine in the market. The technology of the BOG recovery and the device are convenient to control, safe, simple in technological process and small in equipment investment, and have good industrialized popularization and application prospects.

Owner:GUANGZHOU HUAFENG ENERGY TECH

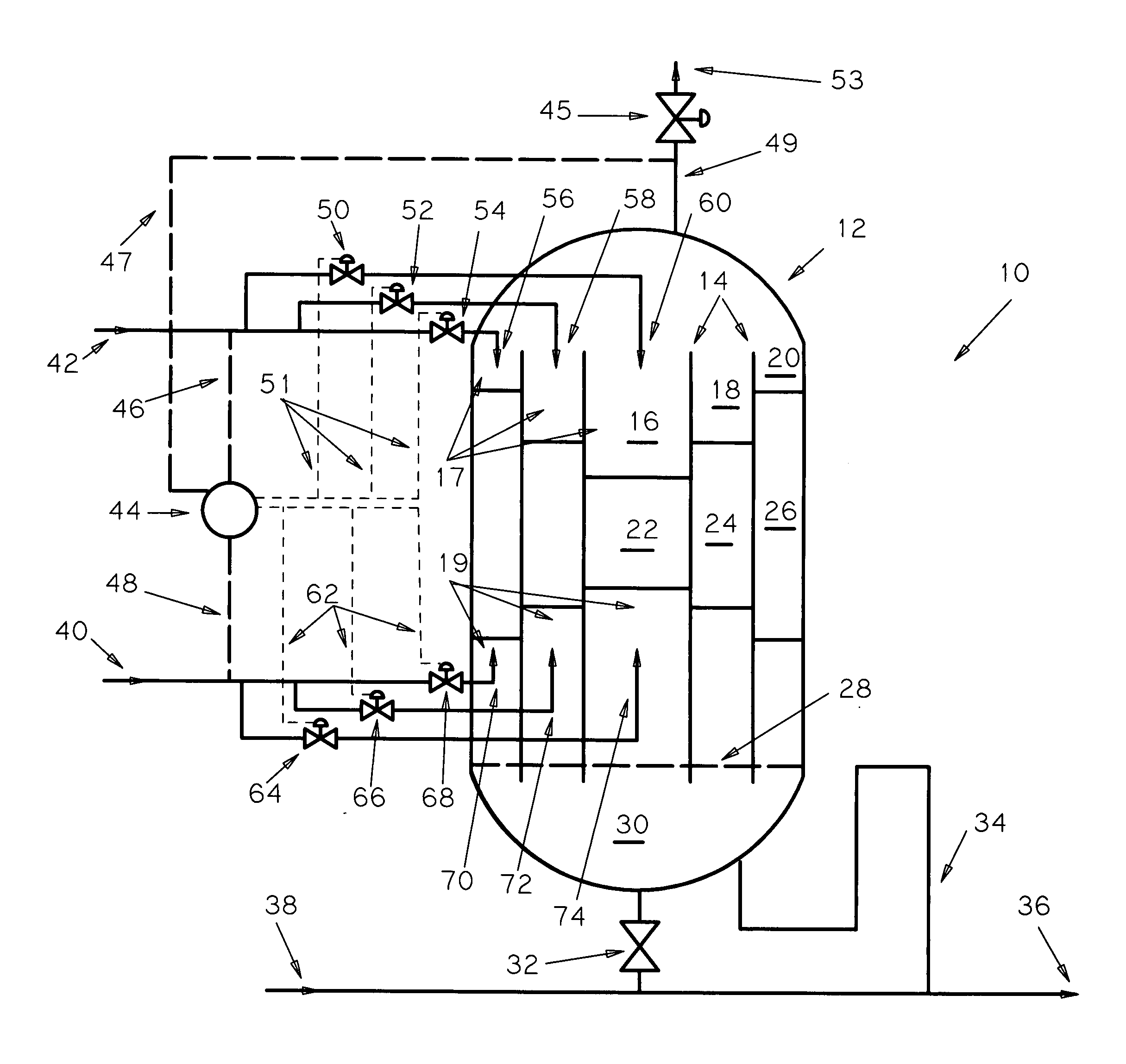

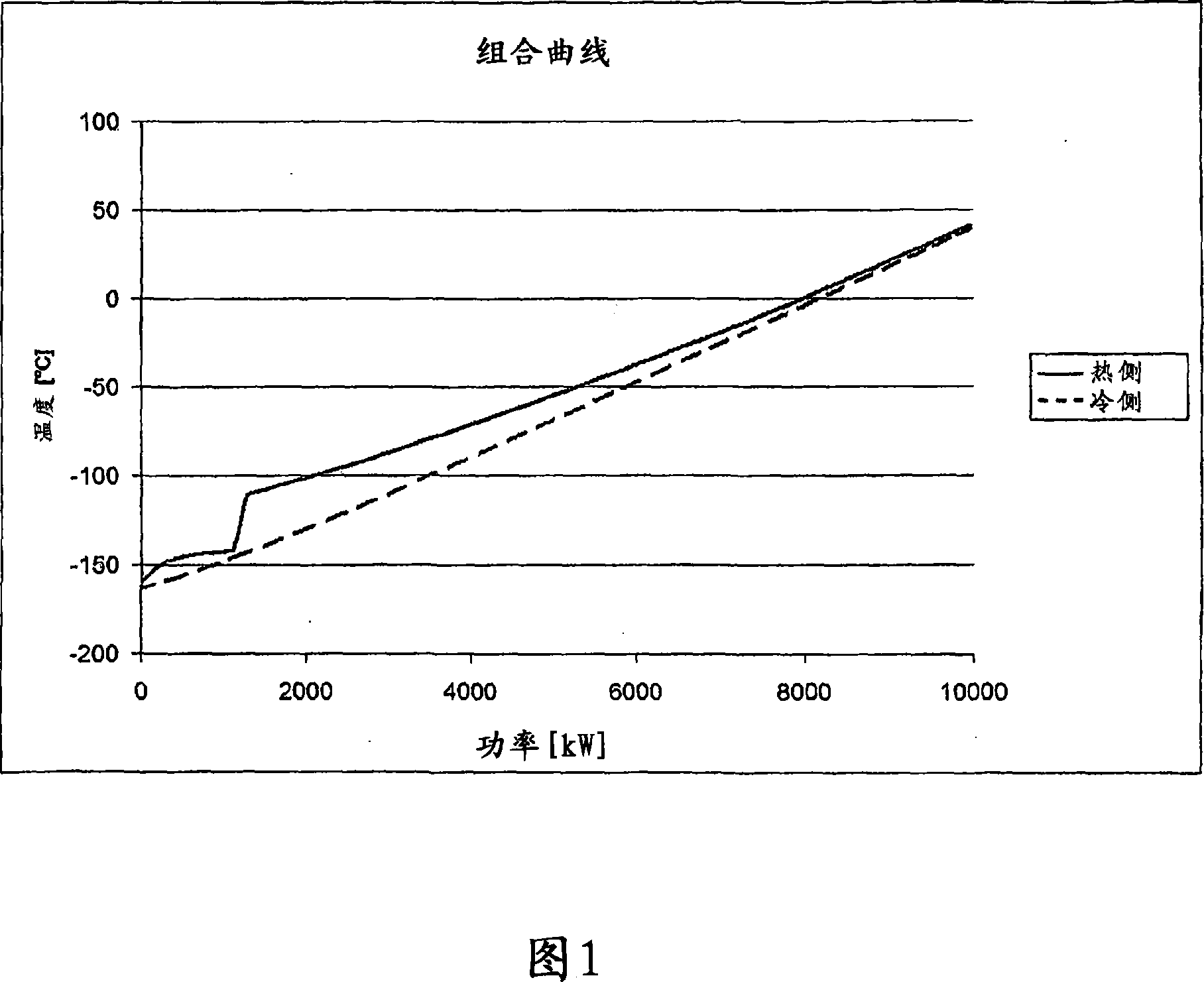

Method and apparatus for pre-heating LNG boil-off gas to ambient temperature prior to compression in a reliquefaction system

The present invention provides a method and an apparatus of pre-heating LNG boil-off gas (BOG) stream (1) flowing from a reservoir (74) in a reliquefaction system, prior to compression (C11, C12, C13). The method comprises heat exchanging the BOG stream in a first heat exchanger (H10), against a second coolant stream (59) having a higher temperature than the BOG stream (1), where the second coolant stream (59) is obtained by selectively splitting a first coolant stream (56) into said second coolant stream (59) and a third coolant stream (57), said third coolant stream being flowed into a first coolant passage in a reliquefaction system cold box (H20), whereby the BOG has reached near-ambient temperatures prior to compression and the low temperature duty from the BOG is substantially preserved within the reliquefaction system, and thermal stresses in the cold box (H20) are reduced. Prior to the compression step, the BOG is pre-heated to substantially ambient temperatures, by heat exchanging (H10) the BOG with said coolant, said coolant prior to the heat exchange having a higher temperature than the BOG.

Owner:WARTSILA OIL & GAS SYST

Anti-disease broccoli cultivation method

InactiveCN104956862AMeet the nutritional needs of the growth periodIncrease water permeability and breathabilityVegetative propogationDiseaseBlack spot

The invention discloses an anti-disease broccoli cultivation method using urea, Chinese photinia leaf, dried orange peel, perlite, deer bog soil, biology sludge ceramsite, sawdusts, and borax to serve as basic raw materials, boron element is rich, thus improving broccoli output; after broccoli seeds are sowed and before broccoli seedling emergence, Chinese cassia tree water boiling liquid is sprayed on the cultivation basic material in every 3 days, thus preventing the broccoli seedling from being affected by black spot disease with prevention rate above 99%; in a growth period between the broccoli seedling and broccoli ball-flower, an anti-pest sprinkling liquid is sprayed on the top surface and bottom surface of the broccoli true leaves and on the broccoli ball-flower, thus fertilizing the leaves, and preventing and killing diamondback moth, vegetable webworms and aphids with prevention rate between 95-98%; the anti-pest liquid is sprayed on the broccoli ball-flower so as to prevent broccoli aphid invasion with prevention rate between 92-93%. The method can prevent pests in advance in different plantation periods, thus obviously reducing a broccoli pest generation scope and kinds, and the cultivated broccoli is green and organic.

Owner:蚌埠市乔峰农业蔬菜专业合作社

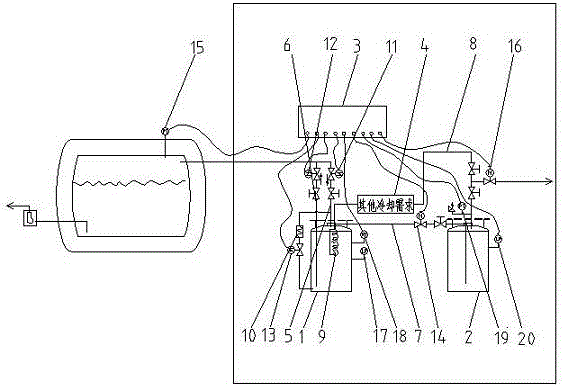

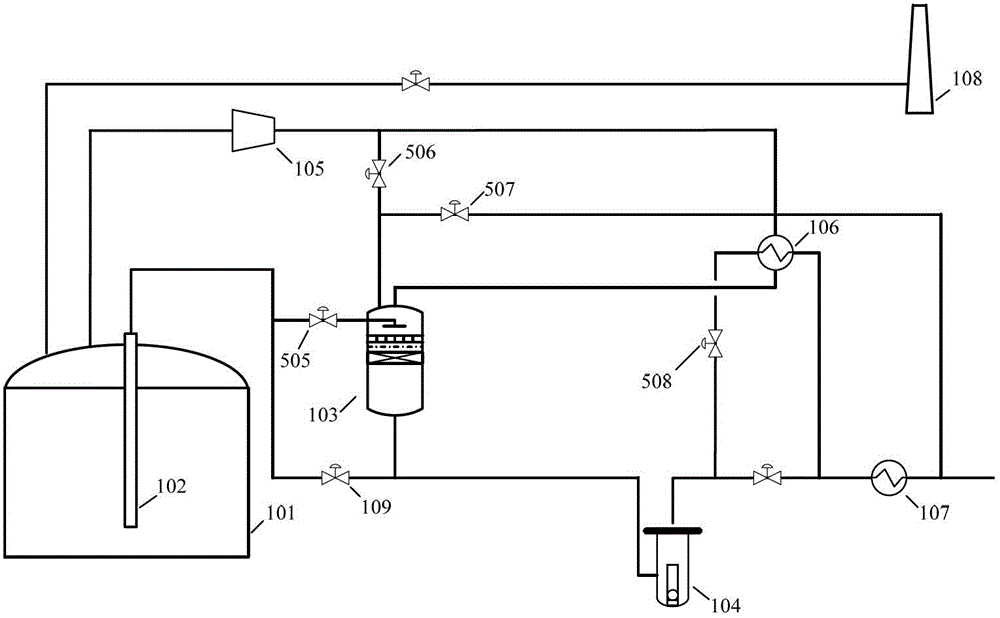

Modularized BOG (Boil Off Gas) re-liquefaction system of low-temperature liquid storage tank

The invention discloses a modularized BOG (Boil Off Gas) re-liquefaction system of a low-temperature liquid storage tank. The re-liquefaction system comprises a control system, a condensing tank and a cooling medium storage tank, wherein a medium conveying pipeline and a medium reflux pipeline are connected on the condensing tank; the condensing tank and the cooling medium storage tank are communicated through a cooling medium conveying pipeline and a cooling medium reflux pipeline; a condenser is arranged in the condensing tank and is communicated with the cooling medium conveying pipeline; a pressurizer is connected on the condensing tank and is communicated with the medium reflux pipeline. Through the manner, the BOG re-liquefaction system of the low-temperature liquid storage tank can be modularized and is suitable for all low-temperature liquid storage systems facing the BOG treatment problem in the market; the system is simple in structure and flexible in application, and has modularized design.

Owner:CHART CRYOGENIC ENG SYST CHANGZHOU

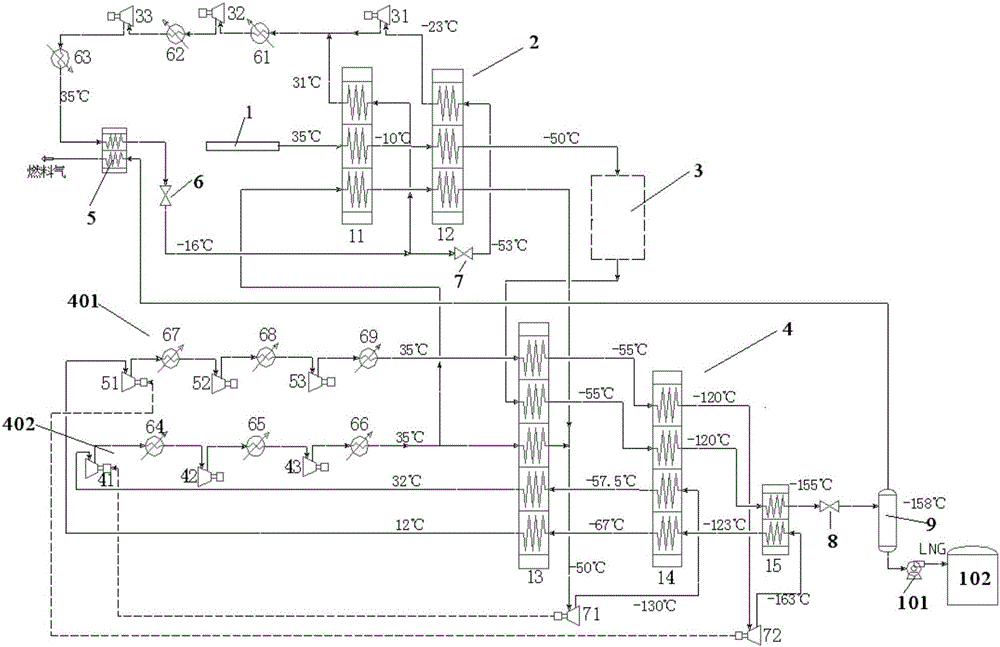

Natural gas liquefying system for carbon dioxide precooling double-stage nitrogen expansion

ActiveCN106440656AOptimize process flowIncreased processing flexibilitySolidificationLiquefactionNitrogenEnergy expenditure

The invention discloses a natural gas liquefying system for carbon dioxide precooling double-stage nitrogen expansion. The natural gas liquefying system comprises a natural gas conveying pipe, a carbon dioxide precooling circulating device, a heavy hydrocarbon removing device, a double-stage nitrogen cooling circulating device, a BOG heat exchanger, a first throttling valve, a second throttling valve, a LNG throttling valve, a gas-liquid separation device, a LNG pump and a LNG tank. The natural gas liquefying system realizes precooling through carbon dioxide and deep cooling through nitrogen, optimally designs the technological process of a carbon dioxide precooling double-stage nitrogen expansion liquefying system, improves the process flexibility, reduces the energy consumption of the liquefying system, improves the safety, and can realize stable, efficient and continuous production demands of offshore liquefied natural gas under the conditions of different sea areas and different gas properties.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

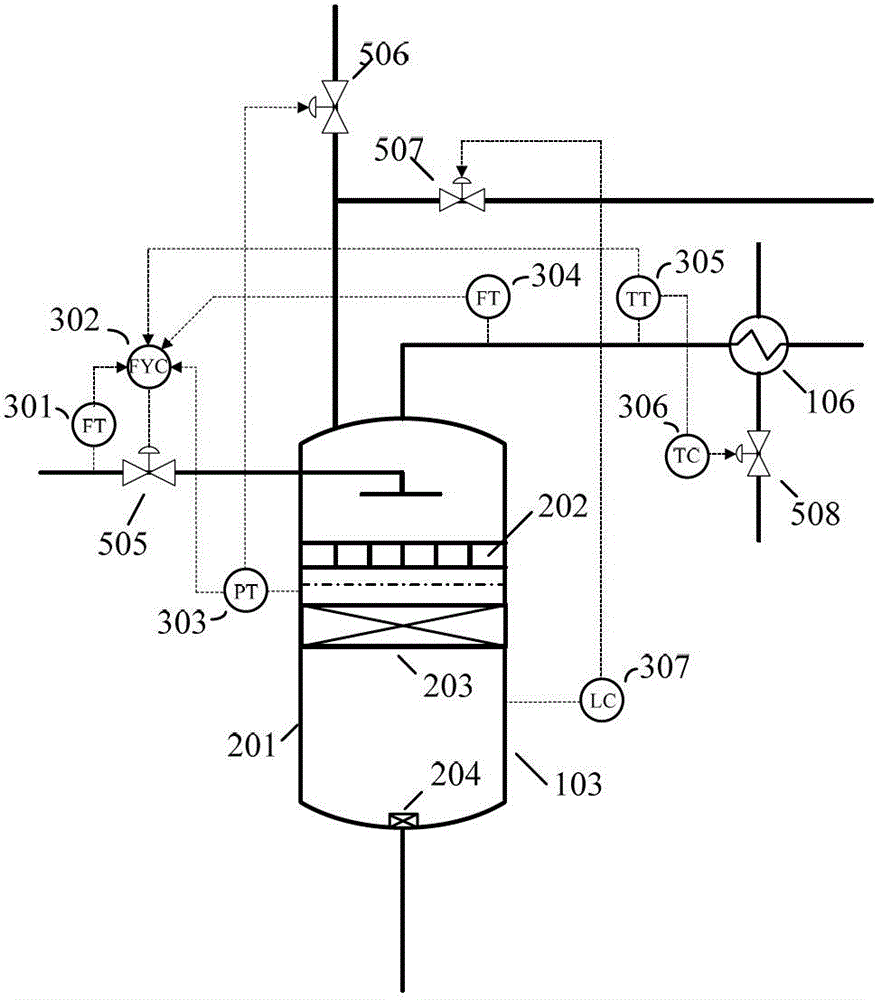

BOG (boil off gas) recovery processing method and system for LNG (liquid natural gas) receiving terminal

ActiveCN104964161AEnable effective recyclingReasonable designContainer filling methodsContainer discharging methodsThrottle controlEngineering

The invention relates to a BOG (boil off gas) recovery processing method and system for an LNG (liquid natural gas) receiving terminal, and the BOG recovery processing method comprises the following steps: 1) setting a BOG recovery processing system under the working condition of no output operation of the LNG receiving terminal; 2) feeding BOG produced in an LNG full containment storage tank to the lower end of a BOG re-condenser after BOG is pressurized by a BOG compressor; 3) conveying overcooled LNG from the LNG full containment storage tank to the upper end of the BOG re-condenser by virtue of a pump in the LNG tank, and coming into contact with the BOG at the lower end of the BOG re-condenser to perform heat transfer so as to condense the BOG into LNG; 4) feeding LNG from the BOG re-condenser into an LNG main-sub tank, and then feeding the LNG from the LNG main-sub tank into an output loading system; and 5) feeding the BOG produced in the BOG re-condenser, the LNG main-sub tank and the output loading system into the BOG compressor for pressurizing together with the BOG in the LNG full containment storage tank through throttle control, feeding the pressurized BOG to the lower end of the BOG re-condenser, and going back to the step 3). The invention provides a BOG recovery processing method and system, which are capable of ensuring effective recovery utilization of BOG and can be widely applied to recovery utilization of BOG in the LNG receiving terminal.

Owner:CNOOC GAS & POWER GRP

BOG and oil gas combined recycling system of LNG oil gas cooperative station

ActiveCN106402644AReduce investmentReduce energy consumptionGas handling applicationsGas handling/storage effectsSuper coolingProcess engineering

The invention discloses a BOG and oil gas combined recycling system of an LNG oil gas cooperative station. According to the BOG and oil gas combined recycling system, BOG and oil gas are synchronously recycled, in the oil gas recycling process, mixed gas is compressed and subjected to water cooling and is pre-cooled through a refrigerating medium, and then, the mixed gas is sequentially subjected to the common condensation link in which the cooling capacity is provided by the low-temperature BOG and the copious cooling link for oil gas recycling; and the obtained low-temperature oil gas exhausted gas is conveyed into a pre-cooling heat exchanger, and the amount of the refrigerating medium for pre-cooling and the refrigerating energy consumption are reduced. In the BOG recycling process, the low-temperature BOG is heated to the normal temperature after being subjected to heat exchange in the copious cooling link and the common condensation link, the BOG is compressed through an ordinary compressor and then is subjected to water cooling, combined cooling of the low-temperature oil gas exhausted gas and the refrigerating medium, low-temperature BOG cooling, one-time throttling expansion cooling and the super-cooling LNG cooling to be cooled step by step, and finally the LNG is formed through secondary throttling expansion condensation. According to the BOG and oil gas combined recycling system, the BOG cooling capacity is sufficiently utilized for oil gas and BOG recycling, the exhausted gas adsorption link is not needed, a BOG compressor is not needed, the cooling capacity is exchanged step by step, operation is convenient, energy saving and consumption reduction are achieved, safety is high, and equipment investment is small.

Owner:CHANGZHOU UNIV

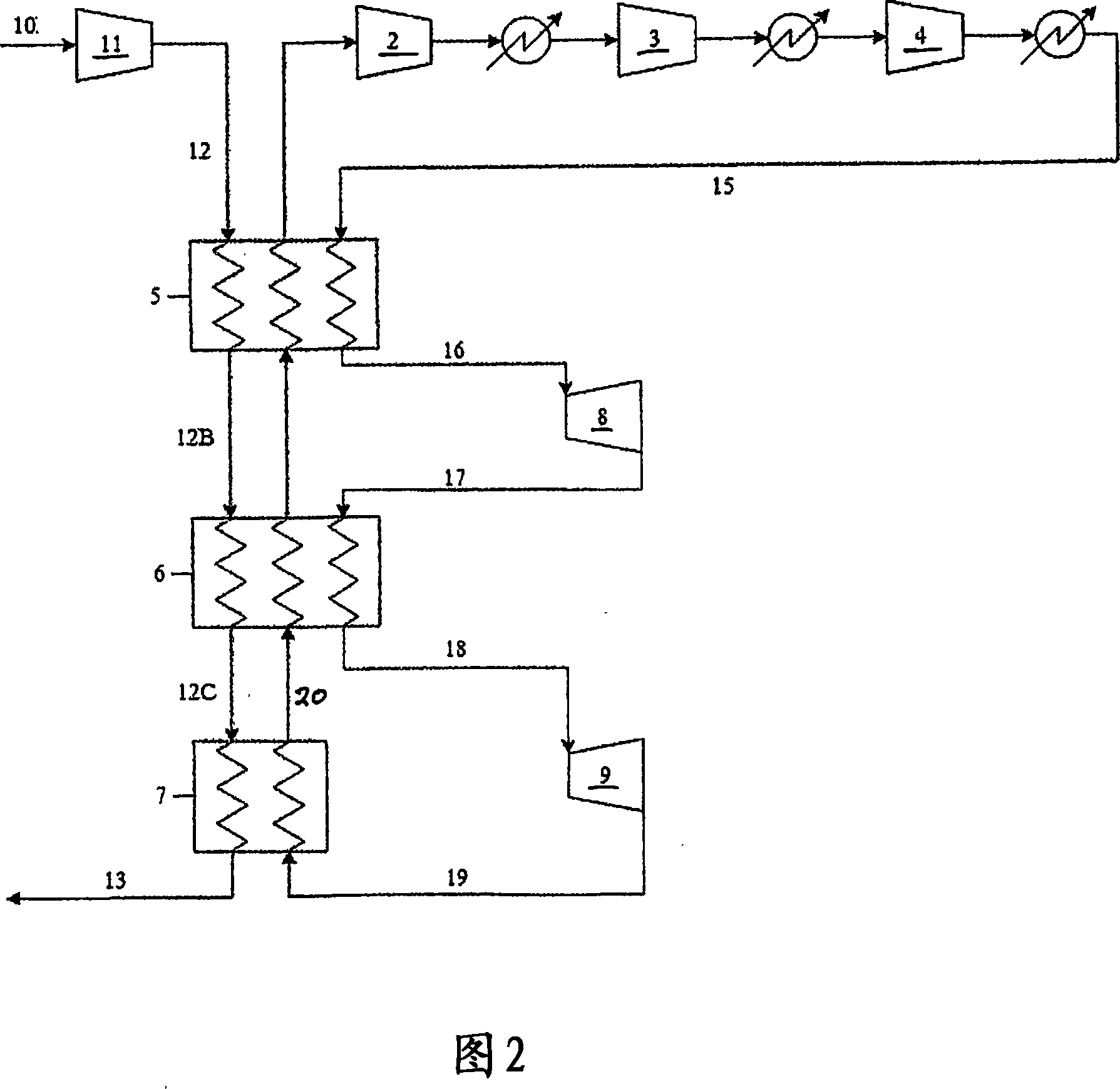

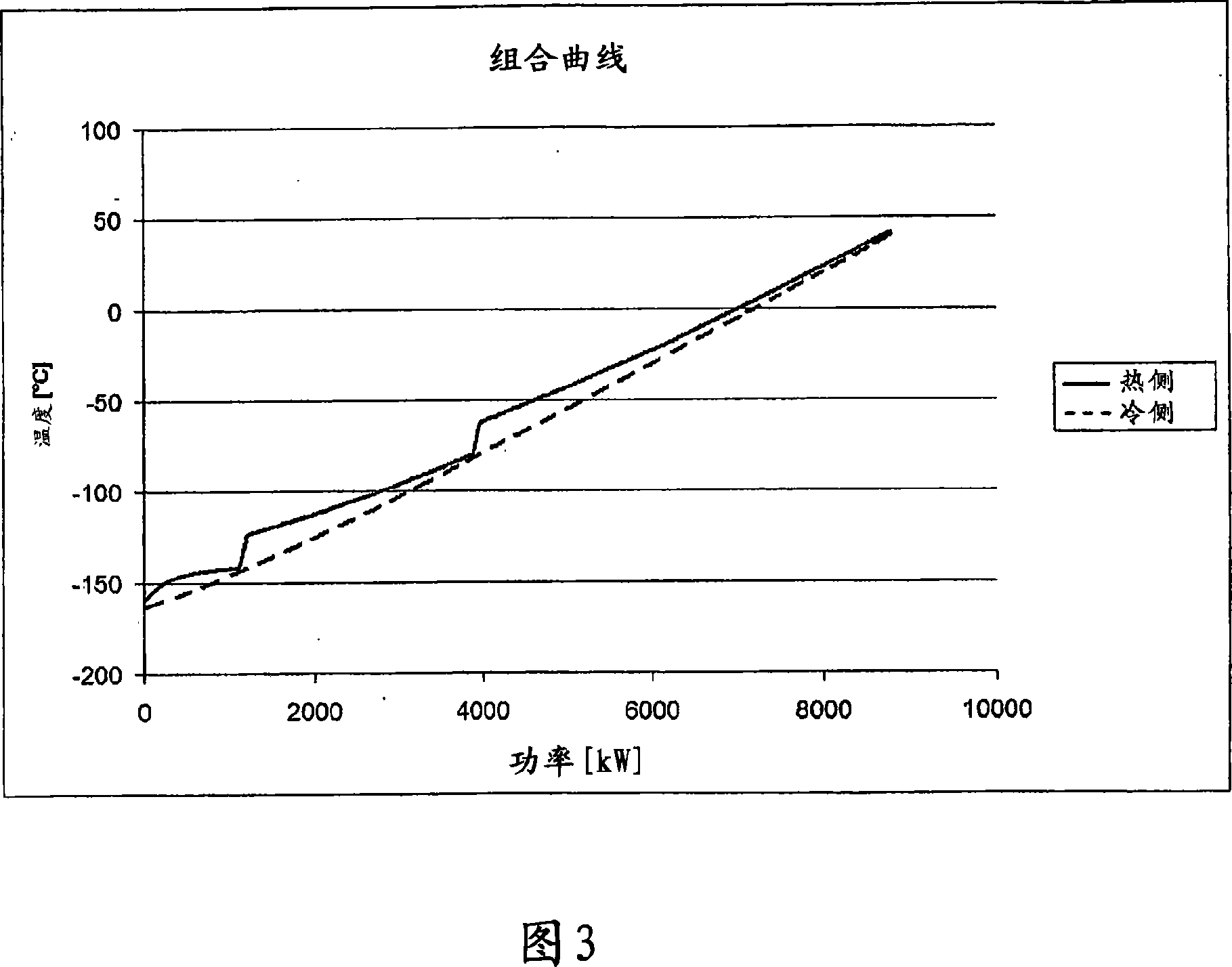

System and method for cooling a bog stream

A system for cooling a boil-off gas (BOG) stream prior to compression in a boil-off reliquefaction plant, comprising a line ( 10 ) for feeding BOG into a compressor ( 11; 11 '') prior to heat exchange with a closed-loop refrigeration system. The refrigeration system comprising compressors ( 2, 3, 4 ) and expanders( 8, 9 ) and a number of heat ex-changers for heat exchange with the BOG stream. The expanders ( 8, 9 ) are arranged in series. A precooler in the feed line ( 10 ) is fluidly connected ( 32, 33 ) to the closed-loop refrigeration system, whereby said BOG is pre-cooled in heat exchange with a portion of the coolant in the closed-loop refrigeration system prior to said compression.

Owner:海威KSE气体系统公司

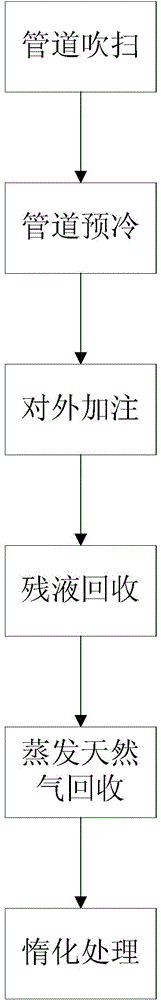

LNG (Liquefied Natural Gas) filling method for small ships

ActiveCN104565806AUnique efficient recycling functionSimple processContainer discharging methodsContainer filling under pressureGas phaseInlet valve

The invention discloses an LNG (Liquefied Natural Gas) filling method for ships. The LNG filling method comprises the following steps: I. pipeline precooling: detecting the dew point, enabling BOG (boil off gas) to enter a BOG storage tank or emptying a vent pipe of a stand column; II. filling outwards: opening an LNG liquid inlet valve, a second liquid phase filling arm ball valve, a filled ship liquid inlet valve, a filled ship gas return valve, a second gas phase filling arm ball valve and a BOG storage tank gas return valve for LNG filling; III. residual liquid recovery: opening a BOG blow-down valve and a third liquid phase filling arm ball valve, pressing residual LNG in a first conveying branched pipe of the pipeline at the top part of a conveying filling arm and in a three-dimensional joint into a filled ship tank, pressing residual LNG in the stand column and a second conveying branched pipe of the pipeline at the top part of the conveying filling arm into an LNG storage tank, thereby finishing residual liquid recovery. The method can realize recovery of BOG and residual LNG, is energy-saving and emission-reduction, can meet the national low-carbon and environment-friendly requirements and can be widely applied to the field of ship energy resource transportation.

Owner:WUHAN YUANFANG SCI & TECH CO LTD OF CHINA SANJIANG SPACE GRP

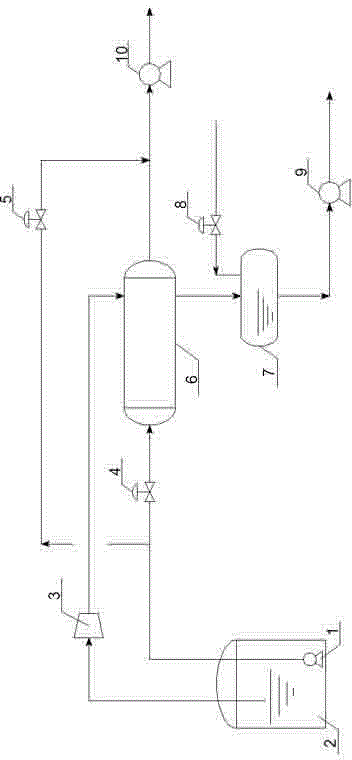

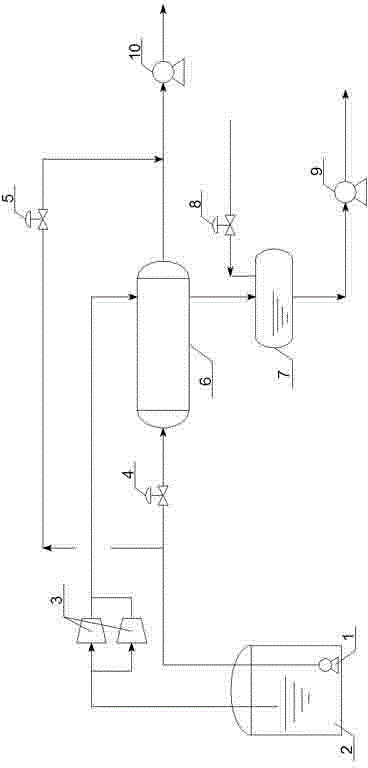

System and method for re-condensing boil off gas (BOG) of liquefied natural gas

ActiveCN104034122AImprove condensation efficiencyIncrease the areaSolidificationLiquefactionVapor–liquid separatorProduct gas

The invention discloses a system and a method for re-condensing a boil off gas (BOG) of a liquefied natural gas. The system comprises a liquefied natural gas storage device, a BOG re-condensing device and a liquefied natural gas conveying device, wherein the BOG re-condensing device comprises a static mixer and a gas-liquid separator, an outlet in the top of the gas-liquid separator is connected with a BOG main pipe of a liquefied natural gas storage tank, an outlet in the bottom of the gas-liquid separator is connected with a liquefied natural gas low-pressure outward conveying main pipe, one end of the static mixer is connected with the gas-liquid separator, the other end of the static mixer is connected with the liquefied natural gas low-pressure outward conveying main pipe, and the BOG main pipe is sequentially connected with a compressor and a heat exchanger to be connected with the static mixer. The method includes mixing the liquefied natural gas and the BOG in the static mixer, then feeding the liquefied natural gas and the BOG into the gas-liquid separator, returning a separated gas to the BOG main pipe, and feeding a separated liquid phase into a booster pump outside the tank. According to the system and the method for re-condensing the BOG of the liquefied natural gas, by means of a static mixing and condensation manner, condensation efficiency of the BOG is increased, energy consumption is reduced, and purposes of saving equipment investment and facilitating system operation and maintenance are achieved.

Owner:SINOPEC ENG +1

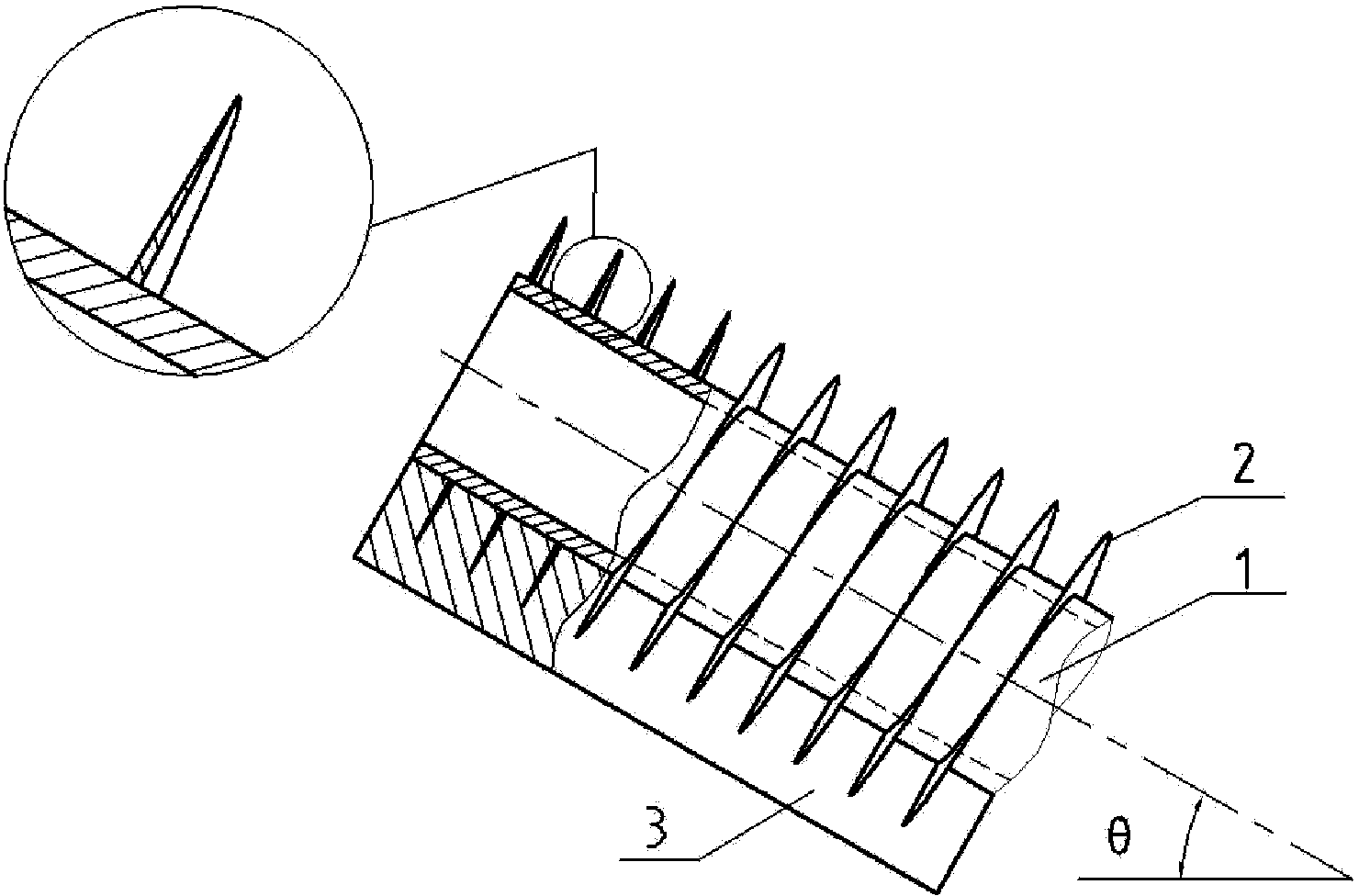

BOG (Boil Off Gas)-zero emission LNG (Liquefied Natural Gas) storage method and device

ActiveCN103759135AAchieving zero emissionsImprove securityContainer filling methodsPressure vesselsSlant angleGas phase

The invention discloses BOG (Boil Off Gas)-zero emission LNG (Liquefied Natural Gas) storage method and device. The BOG-zero emission LNG storage device is characterized in that one end of a flow guide pipe is connected to a BOG condenser, and the other end of the flow guide pipe is immersed in liquid phase of an LNG storage tank; the BOG condenser is arranged in a gas phase space of the upper part of the LNG storage tank; an LNG storage tank pressure detector is arranged in the gas phase space of the upper part of the LNG storage tank; a condenser pipe comprises a hollow pipe, a helical fin and an axial flow guide plate, liquid nitrogen is in pipe pass, and the outer part of the pipe is filled with BOG; the helical fin is arranged on the periphery of the hollow pipe, and the axial guide plate is arranged at the right lower end of the hollow pipe; the hollow pipe is slantwise arranged from an inlet end to an outlet end, and the slant angle theta between the hollow pipe and the horizontal plane is 10 degrees to 30 degrees. The BOG (Boil Off Gas)-zero emission LNG (Liquefied Natural Gas) storage method and device realize the effective integration of LNG storage and BOG recovery and the zero emission of BOG while realizing the effective storage of LNG, has strong applicability and is easy to control.

Owner:广东广大新能源科技有限公司

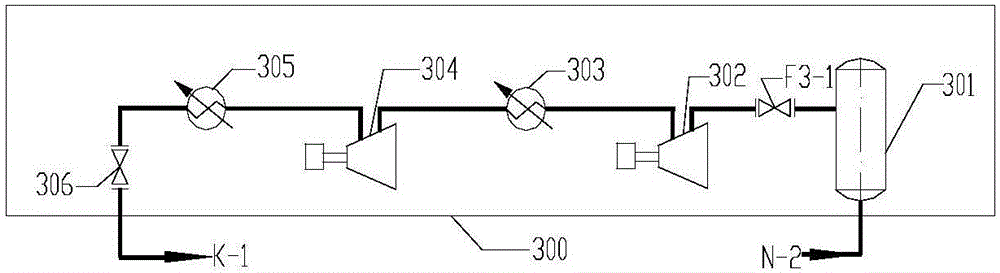

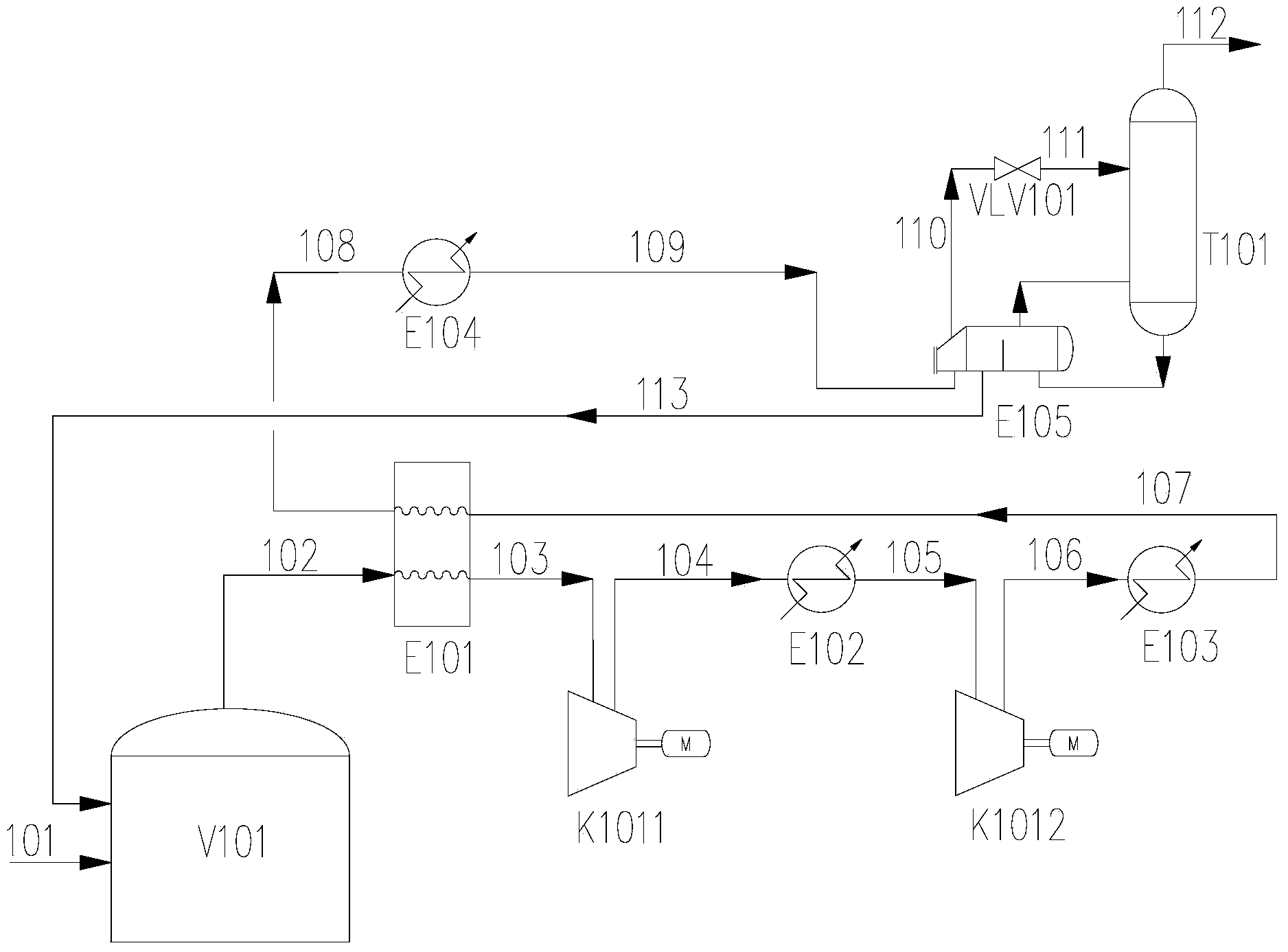

Denitrification device and denitrification process for natural gas

ActiveCN104061755AReduce nitrogen contentReduce wasteSolidificationLiquefactionNitrogen removalProduct gas

The invention discloses a process for removing nitrogen in natural gas. The process comprises the following steps: reheating BOG (boil off gas) in an LNG (liquefied natural gas) storage tank through a BOG cold box, feeding the BOG into a BOG supercharging system, supercharging the BOG to 0.6Mpa to 1.5Mpa; cooling the BOG to liquid at the temperature of minus 154 DEG C to minus 165DEG C after sequentially passing through the BOG cold box and a liquefying cold box, further cooling the BOG to minus 168DEG C to minus 176DEG C in a denitrification heat exchanger, cooling the BOG to the minus 178DEG C to minus 185DEG C after being throttled and expanded, discharging the nitrogen gas separated from the nitrogen removal device, and recycling the purified natural gas by utilizing the LNG storage tank. The nitrogen is removed after the BOG in the LNG storage tank is further cooled, the process is mature, the applicability is strong, the denitrification device and the denitrification process are particularly applicable to the working condition with high nitrogen content and large fluctuation range of the raw gas, the exhausted natural gas of the LNG storage tank can be partially recycled, and the storage safety of the storage tank can be improved.

Owner:天津市振津石油天然气工程有限公司

Nano bog muck series compositions, and their produsts and uses

InactiveCN1470600AChange physical propertiesChange chemical propertiesOrganic fertilisersSoil conditioning compositionsPeatMaterial physics

The present ivnention provides a method for combining nano material technology with peat and adopts different formulae and additives to form natural environment-protecting series products with several functions, several varieties and several purposes. Said nano material comprises compounds and oxides of nano metal and nonmetal, and the peat is the screened impurities (including sand and stone)-removed low-grade or high-grade peat whose organic substance content is above 50%, fibre content is above 35% and water content is 15-35%. Its concrete application includes (1). nano peat plant culture nutrient mechanism; (2) nano peat high-effective water and soil improvement environment-protecting nutrients mechanism; (3) nano peat pollution prevention and control mechanism; and (4) nano peat refuse degradation natural activity mechanism.

Owner:吴笑天

City emergency peak-shaving LNG (liquefied natural gas) gas store

InactiveCN104728605ASave construction investmentShort processContainer filling methodsPipeline systemsGas phaseEngineering

The invention discloses a city emergency peak-shaving LNG (Liquefied Natural Gas) gas store. The city emergency peak-shaving LNG gas store comprises an LNG storage tank which is provided with a liquid phase inlet and a gaseous phase outlet, wherein the liquid phase inlet is connected with an LNG liquid phase arm through an LNG unloading flow adjustment valve. The city emergency peak-shaving LNG gas store further comprises an NG (natural gas) gaseous phase arm and a pressurized interface hose, wherein the pressurized interface hose is connected with the NG gaseous phase arm through a self-pressurization control valve and an air-heated type self-pressurization vaporizer. The city emergency peak-shaving LNG gas store is characterized in that the gaseous phase outlet is connected with a BOG (boil off gas) treatment system, the BOG treatment system comprises tube sides or shell sides of BOG heat exchangers sequentially connected with the gaseous phase outlet, BOG air-heated reheating devices, a BOG cushion tank, a BOG normal temperature compressor group and a natural gas store tank, and is connected with a natural gas master tube, and the outlet of the natural gas store tank is further connected with the shell sides or tube sides of the BOG exchangers, a BOG pressure reducing valve, a BOG storage tank, a BOG pressure stabilizing valve and the NG gaseous phase arm. The city emergency peak-shaving LNG gas store is simple in system, short in process flow, low in equipment investment and operation cost, simple in operation maintenance and high in reliability.

Owner:WUHUAN ENG

Boil-off gas (BOG) liquefying process and device

ActiveCN104913593AWill not affect normal operationReasonable heat transferSolidificationLiquefactionEngineeringHigh pressure

The invention relates to a boil-off gas (BOG) liquefying process and device. The BOG liquefying process comprises reheated low-temperature BOG is compressed to high pressure through a compressor, precooled and throttled, and most of the BOG is liquefied according to the high-pressure throttling and refrigerating principle. The BOG liquefying process is simple, single refrigerating fluid is adopted, no influence is imposed on an original system, a unified skid-mounting device can be manufactured easily, and the BOG liquefying process and device are particularly suitable for LNG storage and distribution stations and LNG charging stations.

Owner:SHANXI QINSHUI XINAO GAS

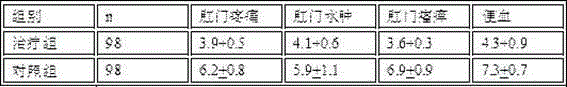

Traditional Chinese medicine composition for preventing haemorrhoid attack and treating haemorrhoids

InactiveCN104547672AEasy to acceptImprove securityAnthropod material medical ingredientsOintment deliveryPostoperative complicationMYRRH TINCTURE

The invention provides a traditional Chinese medicine composition for preventing haemorrhoid attack and treating haemorrhoids. The traditional Chinese medicine composition comprises the following raw materials: coptis chinensis, myrrh, Indian buead, immature bitter orange, pricklyash peel, Chinese nut-gall, belvedere fruit, leaf and fruit of Chinese helwingia, dendrobenthamia capitata, herb of bog starwort, all-grass of bluecalyx Japanese rabdosia, Chinese ephedra, manyprickle acanthopanax root, threevein aster, garden burnet root, natural indigo, goosegrass herb and leaf of caudate sweetleaf. The traditional Chinese medicine composition provided by the invention is high in safety, little in pain and fast in recovery time, ensures that postoperative complications can be greatly reduced, is convenient to operate, can be easily accepted by patients, is easy to popularize clinically, and is worthy of learning.

Owner:杜柏荣

BOG (boil-off gas) treatment process and device under normal operation condition of LNG (liquefied natural gas) receiving station

ActiveCN104913196AReasonable designEasy to controlContainer filling methodsPipeline systemsPlate heat exchangerBuffer tank

The invention discloses a BOG (boil-off gas) treatment process and device under normal operation condition of an LNG (liquefied natural gas) receiving station. The treatment process includes the steps: conveying BOG from an LNG storage tank into a low-pressure BOG compressor, pressurizing the BOG to reach 0.5-0.8MPaG, reaching the outlet temperature of 0-5 DEG C and then enabling the BOG to enter an LNG / BOG heat exchanger; conveying LNG into the LNG / BOG heat exchanger by a low-pressure LNG pipeline from an LNG low-pressure pump, exchanging heat with the BOG at an outlet of the low-pressure BOG compressor and finally condensing the BOG into liquid; enabling condensed BOG condensate to a BOG condensate buffer tank; arranging a nitrogen pipeline on the BOG condensate buffer tank and maintaining the pressure of the buffer tank at 0.6MPaG; enabling the condensate from the BOG condensate buffer tank to enter a pressurizing pump, pressurizing the condensate to reach 1.0MPaG, conveying the condensate to an LNG tank car for loading, and treating the BOG. The treatment process has the advantages of reasonable design, simplicity in control, easiness in operation, convenience in mounting and the like, a horizontal LNG / BOG shell-and-tube or shell-and-plate heat exchanger replaces a previous overhead re-condenser, construction difficulty is greatly reduced, and safety can be improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

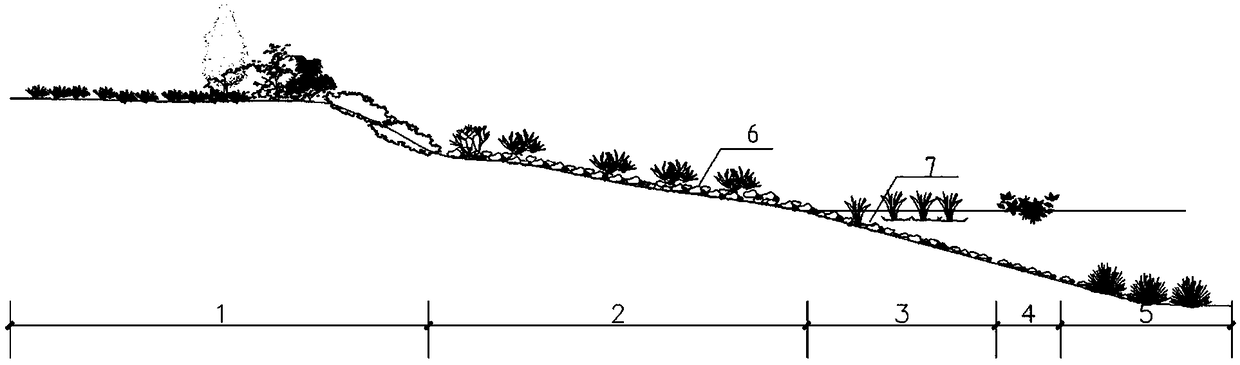

Method for constructing artificial bird island structure in wetland park

ActiveCN109399802ARich habitat typesIncrease biodiversityFlowers cultivationArtificial islandsWater qualityEngineering

The invention relates to a method for constructing an artificial bird island structure in a wetland park. The method includes transforming an outer contour of an artificial bird island into a zigzag shape to meet the condition that the circumference area ratio PAR index of the artificial bird island is greater than or equal to 5%; constructing a main island area, a meadow area, a shallow water area, a medium and deep water area and a deep water area from the inside to the outside of the artificial bird island and adopting an ecological revetment below the flood level; planting arbor plants, shrub plants, herbaceous plants, bog plants and aquatic plants in the main island area, the meadow area, the shallow water area, the medium and deep water area and the deep water area to form an arbor-shrub-herbaceous-bog-aquatic horizontal plant transition zone; conducting routine maintenance on the plants in the main island area, the meadow area, the shallow water area, the medium and deep water area and the deep water area. The method achieves transformation of the existing island, the overall engineering quantity is small, and the method has the advantages of wide island coastline, multiplehabitat types, good water purification effect, good ecological landscape and low transformation cost.

Owner:BEIJING ORIENT LANDSCAPE +1

Cultivation of selenium enriched edible fungus and method of producing natural selenium enriched milk using its tailing

InactiveCN100358411CSimple processEasy to operateFood processingAnimal feeding stuffBiotechnologyBran

A method for culturing the Se-enriched edible fungus includes such steps as preparing culture medium from corn cob, straw powder, rice (or wheat) bran, gypsum, magnesium sulfate, zinc sulfate, Se salt and water, loading it in bogs, sealing, sterilizing, inoculating edible fungus spawn, fermenting, culturing mycelia, and spraying Se-enriched nutritive liquid. A method for producing Se-enriched milk by use of the leftover generated by culturing Se-enriched edible fungus features that the leftover is used as the additive of feed for quantitatively feeding the milk cow.

Owner:辽宁东方生物技术研究所

Method for culturing chrysanthemum morifolium by using reproducible substrates

ActiveCN103999752ASave storage spaceAchieve protectionCultivating equipmentsSoilless cultivationBiotechnologyAnthesis

The invention relates to a method for culturing chrysanthemum morifolium by using reproducible substrates, and belongs to the technical field of plant culture substrates. The method comprises the following steps that: the following ingredients including 3 to 5 parts of coco coir, 1 to 3 parts of cornstalk ferments, 1 to 3 parts of humus, 0.1 to 0.5 part of boggy soil, 0.5 to 1 part of kieselguhr, 0.05 to 0.2 part of sphagna and 0.1 to 0.2 part of eastern bracken fern rhizome are adopted according to volume parts; and the cornstalk ferments are obtained through cutting cornstalks into small sections with the length of 5 to 7cm, covering thin films onto the surfaces of the cornstalks for piling fermentation and turning and stirring the cornstalks once every 4 to 5 days, and the cornstalk ferments can be obtained after all of the cornstalks become rotten and black brown but without objectionable odor during the piling fermentation. The method has the advantages that the culture substrates are mixed according to different proportions, and relevant conditions required by the growth of the chrysanthemum morifolium are met to a great degree. The chrysanthemum morifolium plants cultured by adopting the substrates are strong, and the stalks are thick; and the flowering period of the chrysanthemum morifolium is prolonged to a certain degree, and the ornamental value of the chrysanthemum morifolium is improved.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI +1

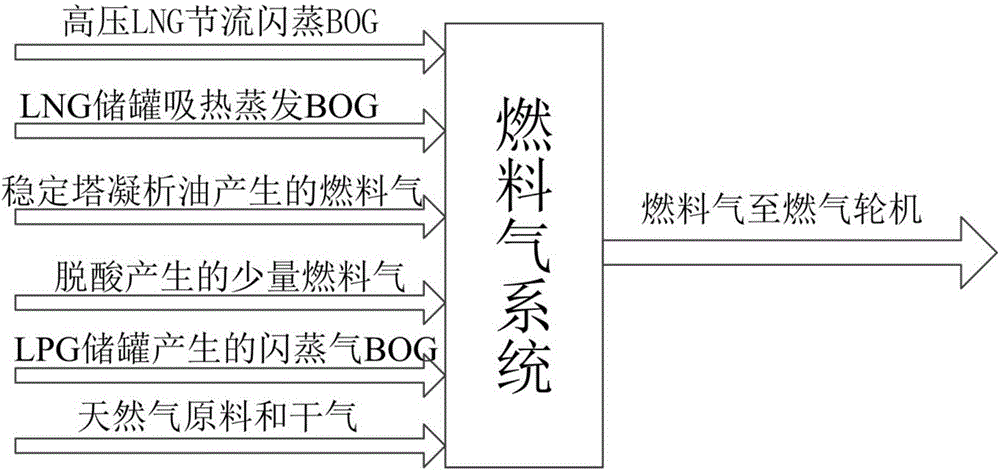

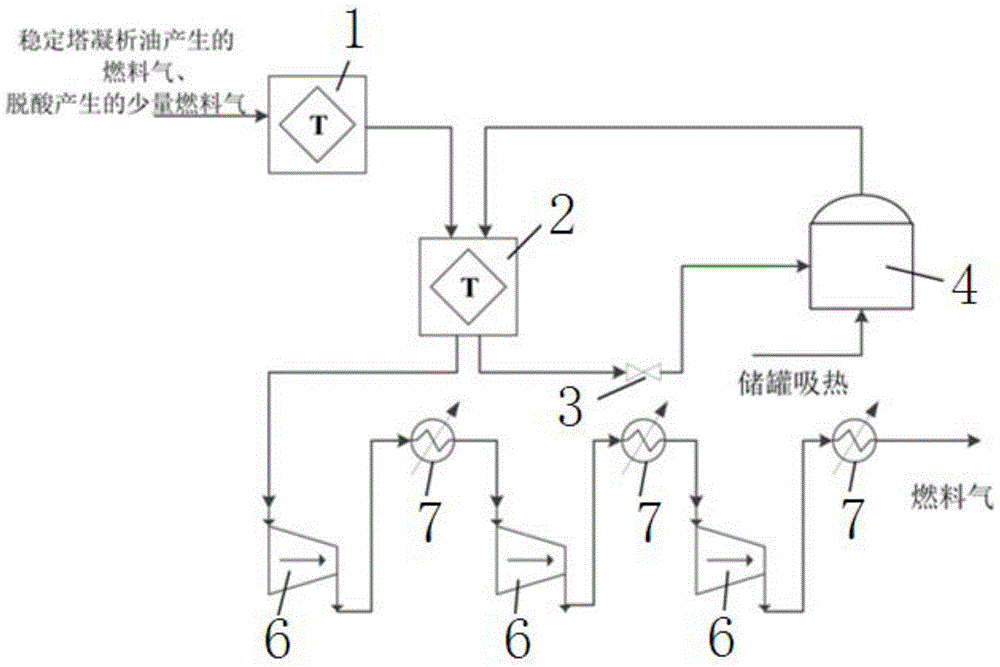

Fuel gas processing method for FLNG (floating liquefied natural gas) oil-gas storage and offloading device

ActiveCN104862025ATake advantage ofLiquefaction rate decreasedGaseous fuelsFor bulk goodsEvaporationHigh pressure

The invention relates to a fuel gas processing method for an FLNG (floating liquefied natural gas) oil-gas storage and offloading device. The method comprises the following steps: 1), multiple fuel gas sources are prepared; 2), a low-temperature compression system and a normal-temperature compression system are arranged, wherein the low-temperature compression system comprises a precooling device, a liquefying device, a throttle valve, an LNG storage tank and a low-temperature BOG (boil off gas) compressor, and the normal-temperature compression system comprises a precooling device, a liquefying device, a throttle valve, an LNG storage tank, three normal-temperature BOG compressors and three coolers; 3), the BOG obtained through high-pressure LNG throttling and flash evaporation, the BOG obtained through heat absorption and evaporation of the LNG storage tank and the BOG obtained through heat absorption and evaporation of an LPG (liquefied petroleum gas) storage tank are controlled to enter the low-temperature compression system, the fuel gas produced by condensate oil of a stabilizer and a small amount of fuel gas produced through deacidification are controlled to enter the normal-temperature compression system, a fuel gas low-temperature compression process and a fuel gas normal-temperature compression process are finished respectively; 4), technological process simulation software is adopted to calculate power consumption of each processing device and the total power consumption; 5), the processing process of the fuel gas sources is further optimized and analyzed. The fuel gas processing method can meet the operation requirement of the LFNG in a special maritime environment, and the operation safety and economy are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Voltage transformer handcart

InactiveCN104426088AImprove insulation performanceMeet the cabinet requirementsSwitchgear with withdrawable carriageFailure rateAviation

The invention discloses a voltage transformer handcart. The voltage transformer handcart comprises a vehicle frame, a rocker-in mechanism, a voltage transformer, a spring, a high-pressure fuse, a plum blossom-shaped contact, a contact arm, a connected insulator, an aviation plug and a bog panel, wherein an observing window is formed in the big panel; the spring and the high-pressure fuse are arranged in the contact arm; the plum blossom-shaped contact is arranged on the end part of the contact arm; the contact arm is connected with the connected insulator. The voltage transformer handcart has the excellent effects that the voltage transformer handcart is suitable for a PT cabinet and a metering cabinet; as an independent drawing unit, the voltage transformer can flexibly go into / out of a power distributing system, and the normal operation of other equipment is not affected; the voltage transformer handcart is very convenient in repairing and low in failure rate and has good interchangeability.

Owner:XINJIANG TBEA AUTOMATIC EQUIP

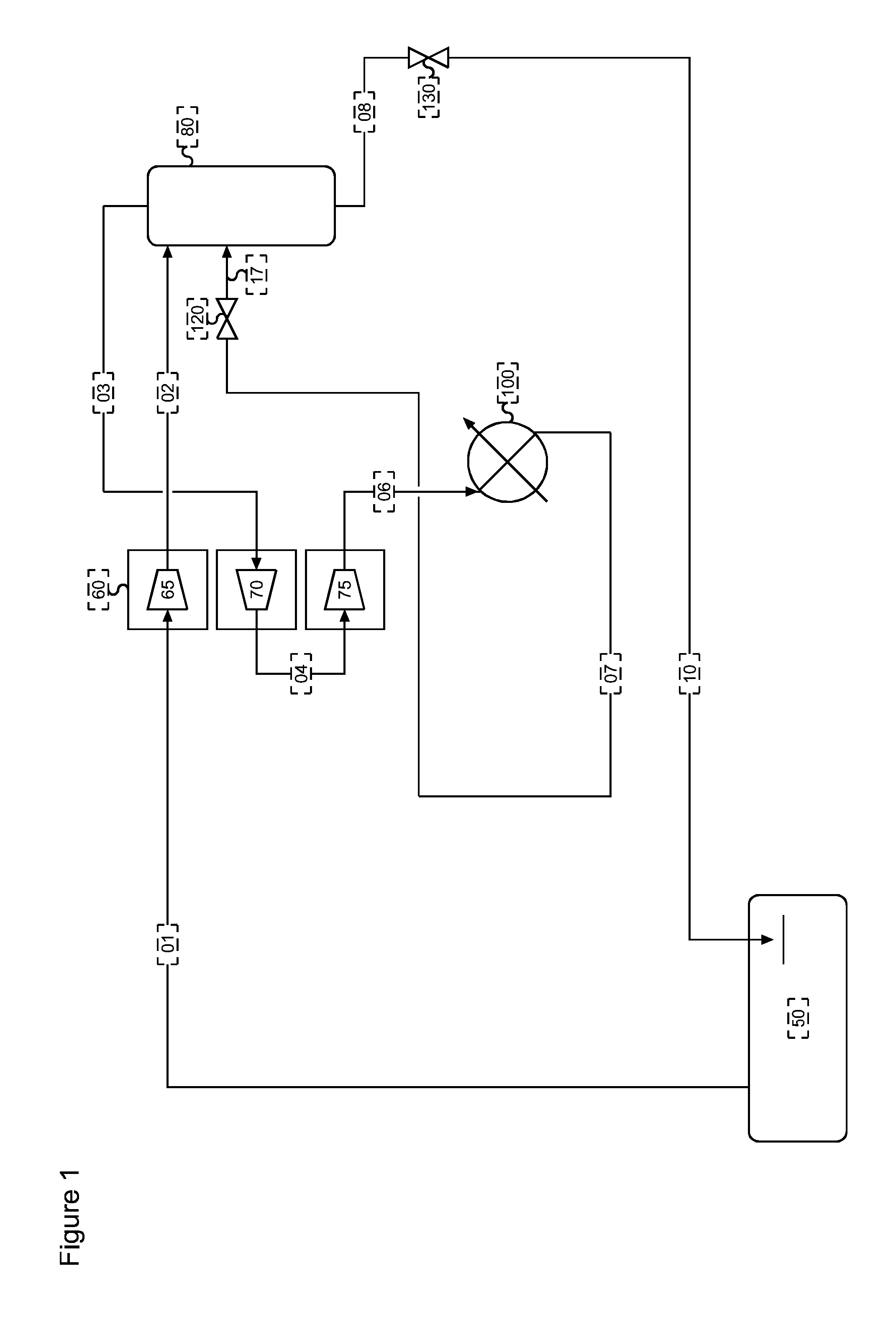

Method of cooling boil off gas and an apparatus therefor

InactiveUS20140123699A1Improve the overall coefficientIncrease pressureSolidificationLiquefactionBoiling pointEngineering

The disclosure relates to a method and apparatus for cooling, preferably liquefying a boil off gas (BOG) stream from a liquefied cargo in a floating transportation vessel, said liquefied cargo having a boiling point of greater than −110° C. at 1 atmosphere, said method comprising at least the steps of: -compressing a boil off gas stream (01) from said liquefied cargo in three or more stages of compression comprising at least a first stage (65), a second stage (70) and final stage (75) to provide a compressed discharge stream (06), wherein intermediate compressed BOG streams (02, 04) are provided between consecutive stages of compression; -cooling the compressed discharge stream (06) to provide a cooled compressed discharge stream (07); -heat exchanging an expanded, optionally further cooled, portion of the cooled compressed discharge stream (07), with (i) one or more intermediate compressed BOG streams (04) from consecutive stages selected from between the second and final stages (75) of compression to provide one or more cooled intermediate compressed BOG streams (05) and optionally (ii) one or more portions (07a, 108a), optionally after further cooling, of the cooled compressed discharge stream (07); and -passing the one or more cooled intermediate compressed BOG streams (05) to the next stage of compression (75).

Owner:BABCOCK IP MANAGEMENT NUMBER ONE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com