LNG/L-CNG skid-mounted gas station

An L-CNG and gas filling station technology, applied in the field of liquefied natural gas filling, can solve problems such as difficulty in approving large-scale land use, difficult procedures, etc., and achieves less civil work and equipment installation workload, and simplified installation. Convenient and reduce the effect of BOG

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

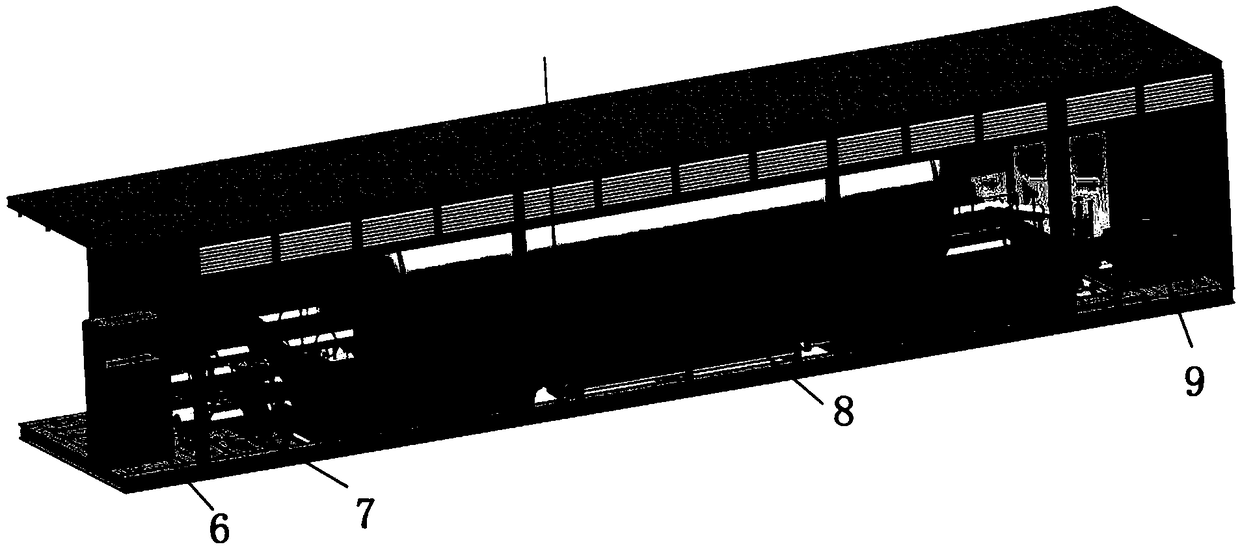

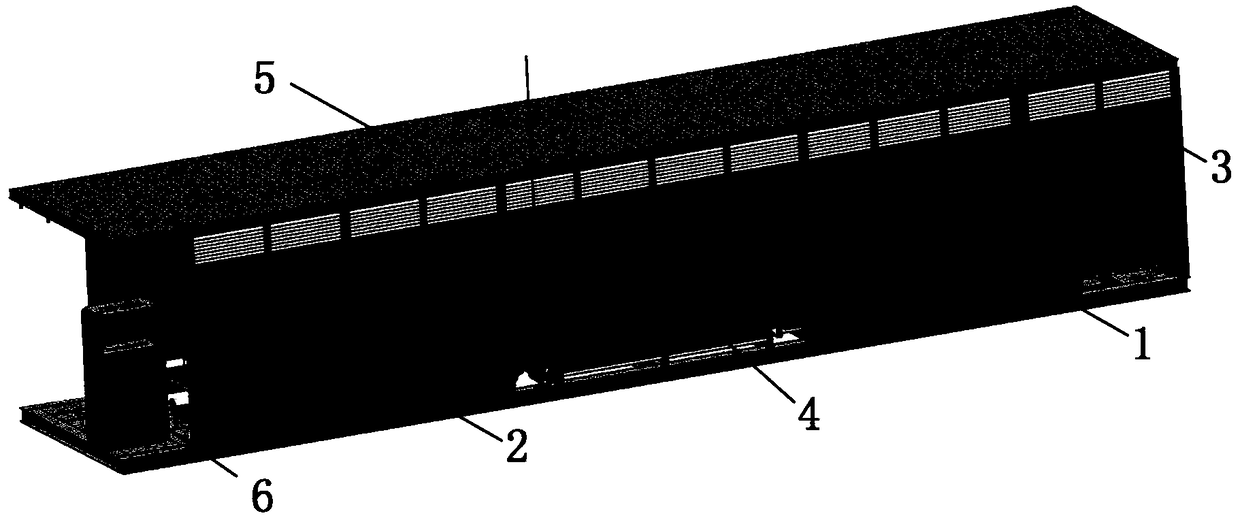

[0020] Examples such as Figures 1 to 2 As shown, an LNG / L-CNG skid-mounted gas filling station includes a first skid base 1, a second skid base 2, a gas dispenser 6, an LNG pump skid 7, a cryogenic storage tank 8 and an L-CNG pump skid 9 , the L-CNG pump skid 9 is set on the first skid base 1, the cryogenic storage tank 8, the LNG pump skid 7, and the gas dispenser 6 are sequentially integrated on the second skid base 2, and the second skid base 2 is close to the fuel tank One end of the gas machine 6 is provided with an unloading platform, and the end of the second skid base 2 close to the low-temperature storage tank 8 is flexibly connected with the first skid base 1. The low-temperature storage tank 8 is a horizontal low-temperature storage tank, and the low-temperature storage tank 8 is sealed from both ends. The head of the cryogenic storage tank 8 is connected with the submersible pump on the LNG pump sled 7 at the liquid outlet near the end of the LNG pump sled 7. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com