BOG (boil-off gas) treatment process and device under normal operation condition of LNG (liquefied natural gas) receiving station

A technology for normal operation and treatment process, applied in the container discharge method, pipeline system, container filling method, etc., can solve the problems of increased investment in the overall frame structure, complicated control of the recondensation process, unfavorable operation, etc., to reduce the difficulty of construction and construction , the effect of improved safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Treatment unit with a low-pressure BOG compressor;

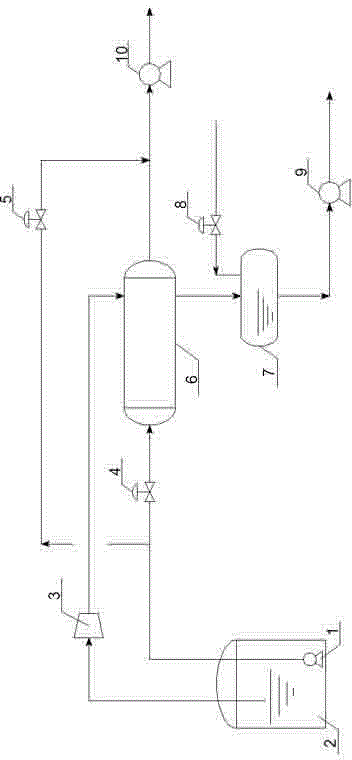

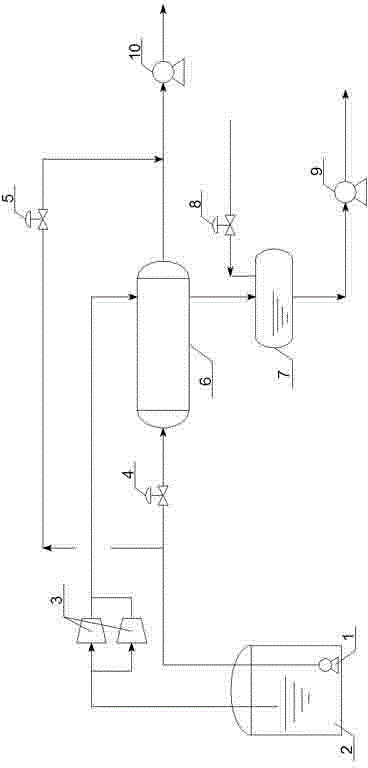

[0021] The BOG processing device used in the normal operating conditions of the LNG receiving station includes an LNG storage tank 2, a low-pressure BOG compressor 3, a plate-shell LNG / BOG heat exchanger 6, and a BOG condensate buffer tank 7, and the LNG storage tank 2 A gas phase outlet pipeline is connected to a low-pressure BOG compressor 3, and the outlet pipeline of the low-pressure BOG compressor 3 is connected to the LNG / BOG heat exchanger 6. There are two outlet pipelines of the LNG / BOG heat exchanger 6, one of which is connected to the LNG high-pressure pump 10 is connected, and the other is connected with the BOG condensate buffer tank 7, and the outlet pipeline of the BOG condensate buffer tank 7 is connected with the booster pump 9; the BOG condensate buffer tank 7 is connected with the nitrogen supply pipeline, and a regulating valve is arranged on the nitrogen supply pipeline Three 8; LNG low-pressure pu...

Embodiment 2

[0028] A treatment unit with two low-pressure BOG compressors arranged in parallel;

[0029] The BOG processing device used in the normal operating conditions of the LNG receiving station includes an LNG storage tank 2, a low-pressure BOG compressor 3, a shell-and-tube LNG / BOG heat exchanger 6 and a BOG condensate buffer tank 7, and the LNG storage tank 2 A gas phase outlet pipeline is connected with two low-pressure BOG compressors 3 arranged in parallel, and the outlet pipeline of the low-pressure BOG compressor 3 is connected with the LNG / BOG heat exchanger 6. There are two outlet pipelines of the LNG / BOG heat exchanger 6, one of which is connected with the The LNG high-pressure pump 10 is connected, the other is connected with the BOG condensate buffer tank 7, and the outlet pipeline of the BOG condensate buffer tank 7 is connected with the booster pump 9; the BOG condensate buffer tank 7 is connected with the nitrogen replenishment pipeline, and the nitrogen replenishment ...

Embodiment 3

[0036] A processing unit with three low-pressure BOG compressors arranged in parallel;

[0037]The BOG processing device used in the normal operating conditions of the LNG receiving station includes an LNG storage tank 2, a low-pressure BOG compressor 3, a plate-fin LNG / BOG heat exchanger 6 and a BOG condensate buffer tank 7, and the LNG storage tank 2 A gas phase outlet pipeline is connected with three low-pressure BOG compressors 3 arranged in parallel, and the outlet pipeline of the low-pressure BOG compressor 3 is connected with the LNG / BOG heat exchanger 6. There are two outlet pipelines of the LNG / BOG heat exchanger 6, one of which is connected with the The LNG high-pressure pump 10 is connected, the other is connected with the BOG condensate buffer tank 7, and the outlet pipeline of the BOG condensate buffer tank 7 is connected with the booster pump 9; the BOG condensate buffer tank 7 is connected with the nitrogen replenishment pipeline, and the nitrogen replenishment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com