Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

831 results about "Condensation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensation occurs when the water vapours in the air is cooled, the form changing from gas to liquid. This process take place at different temperature, its between 32 and 212 Fahrenheit degrees or 0 and 100 degree celsius.

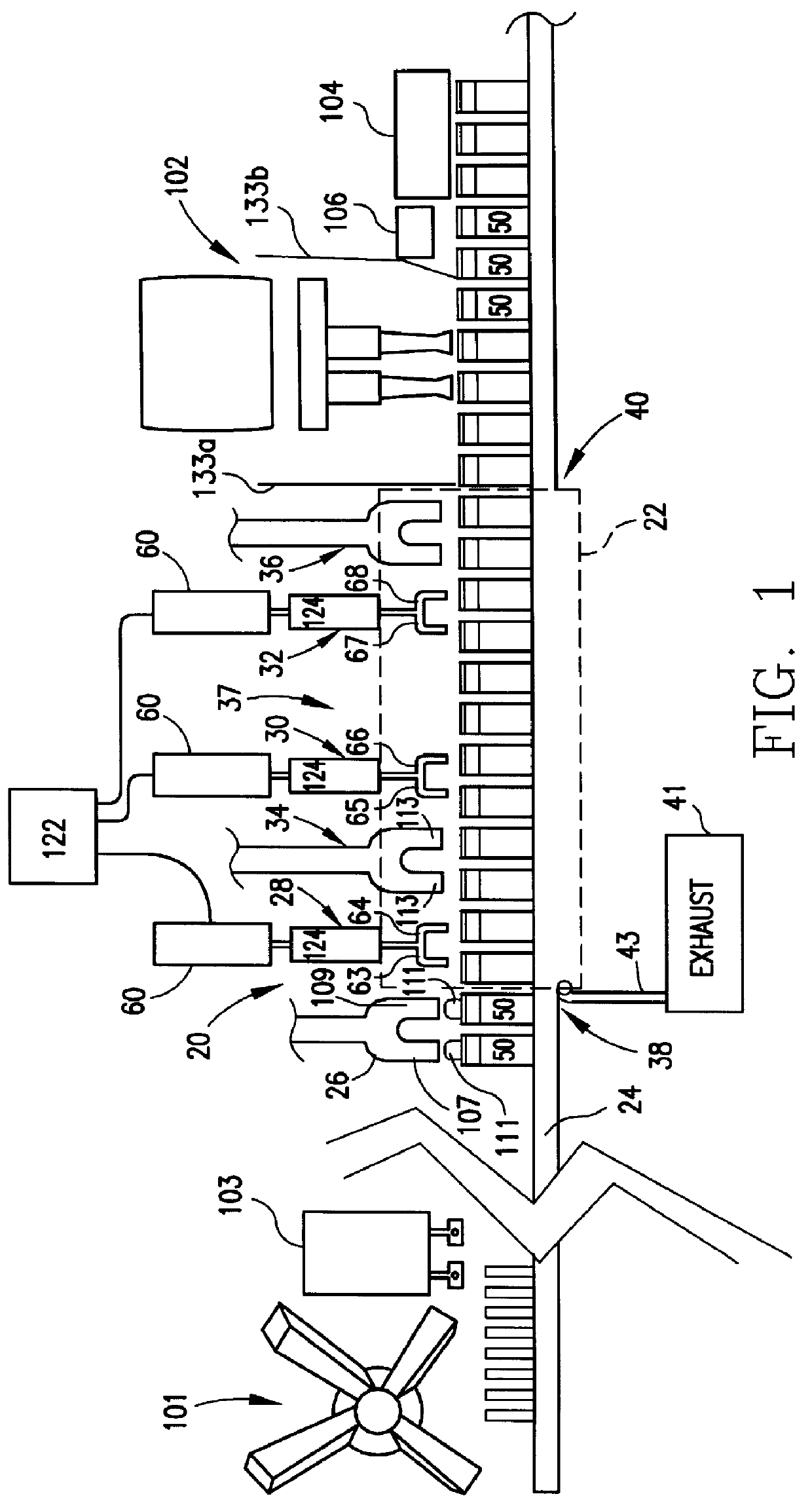

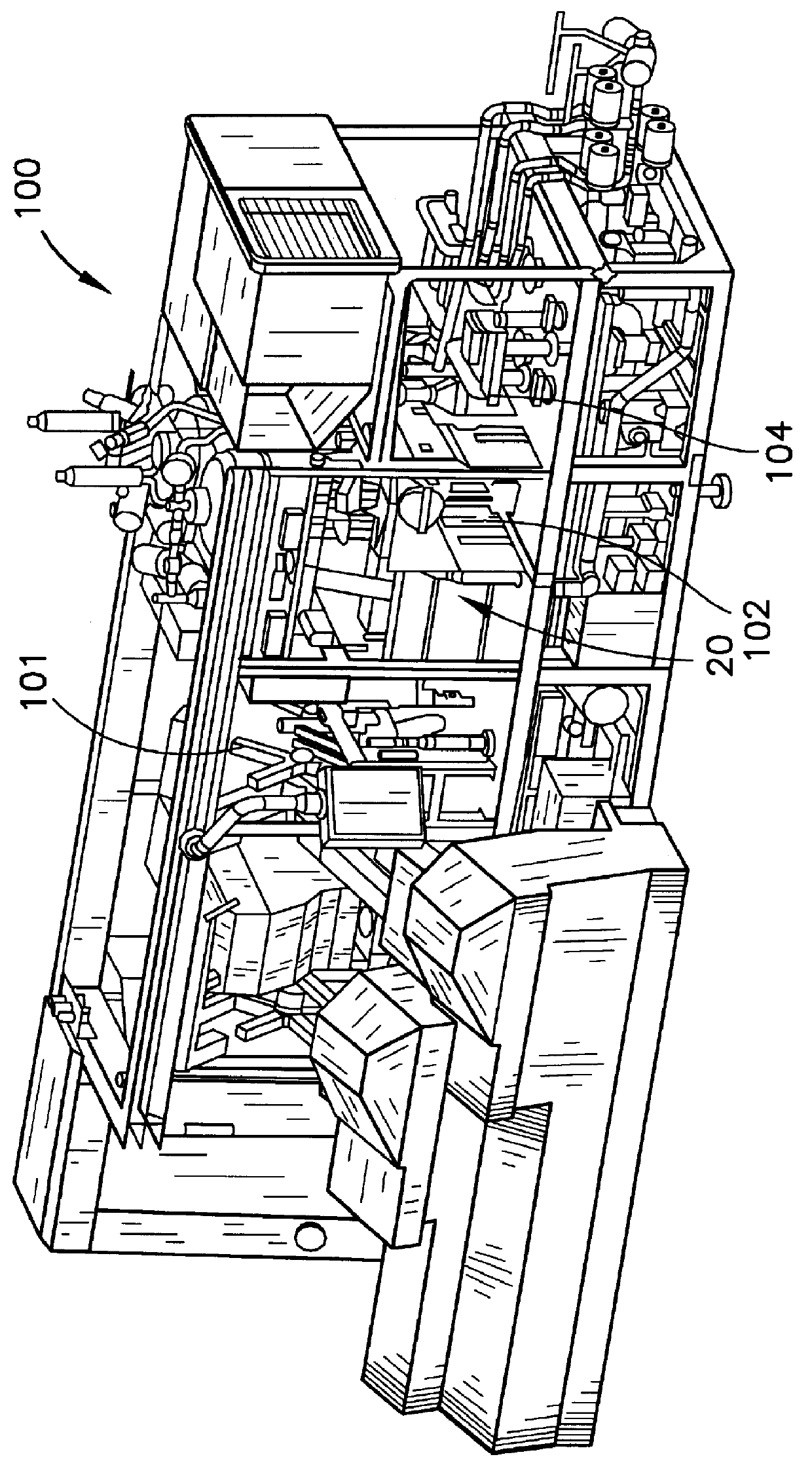

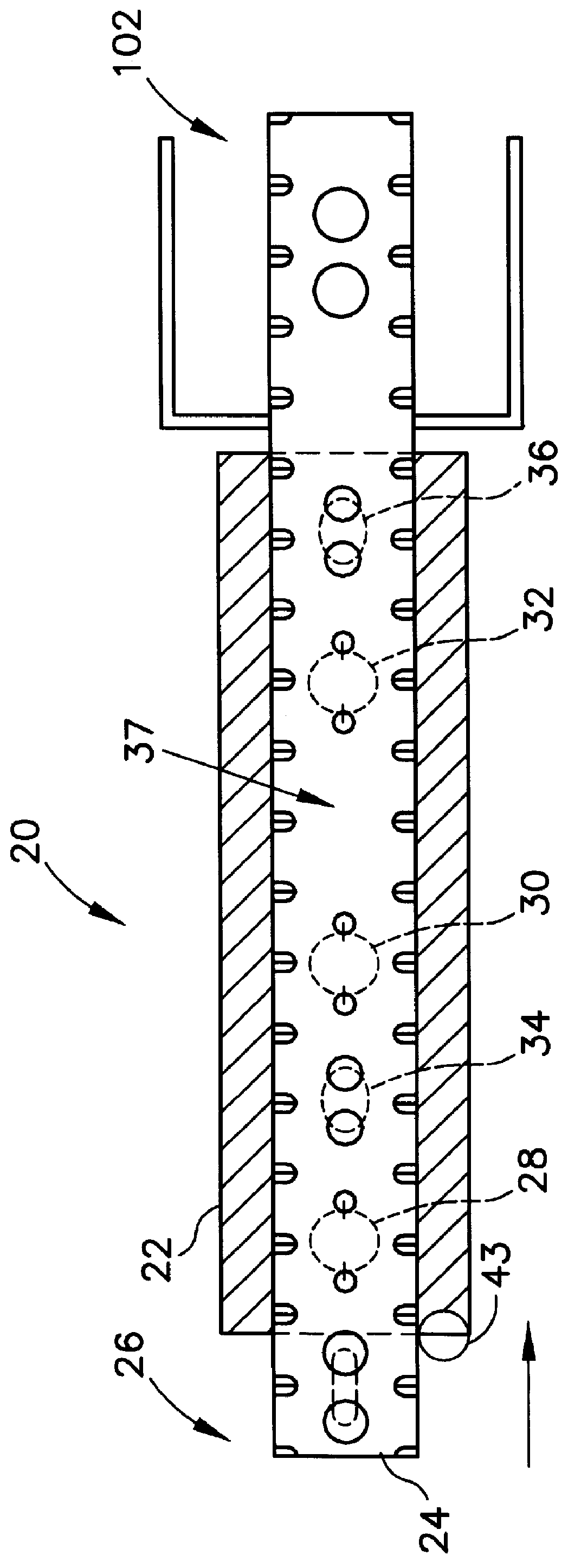

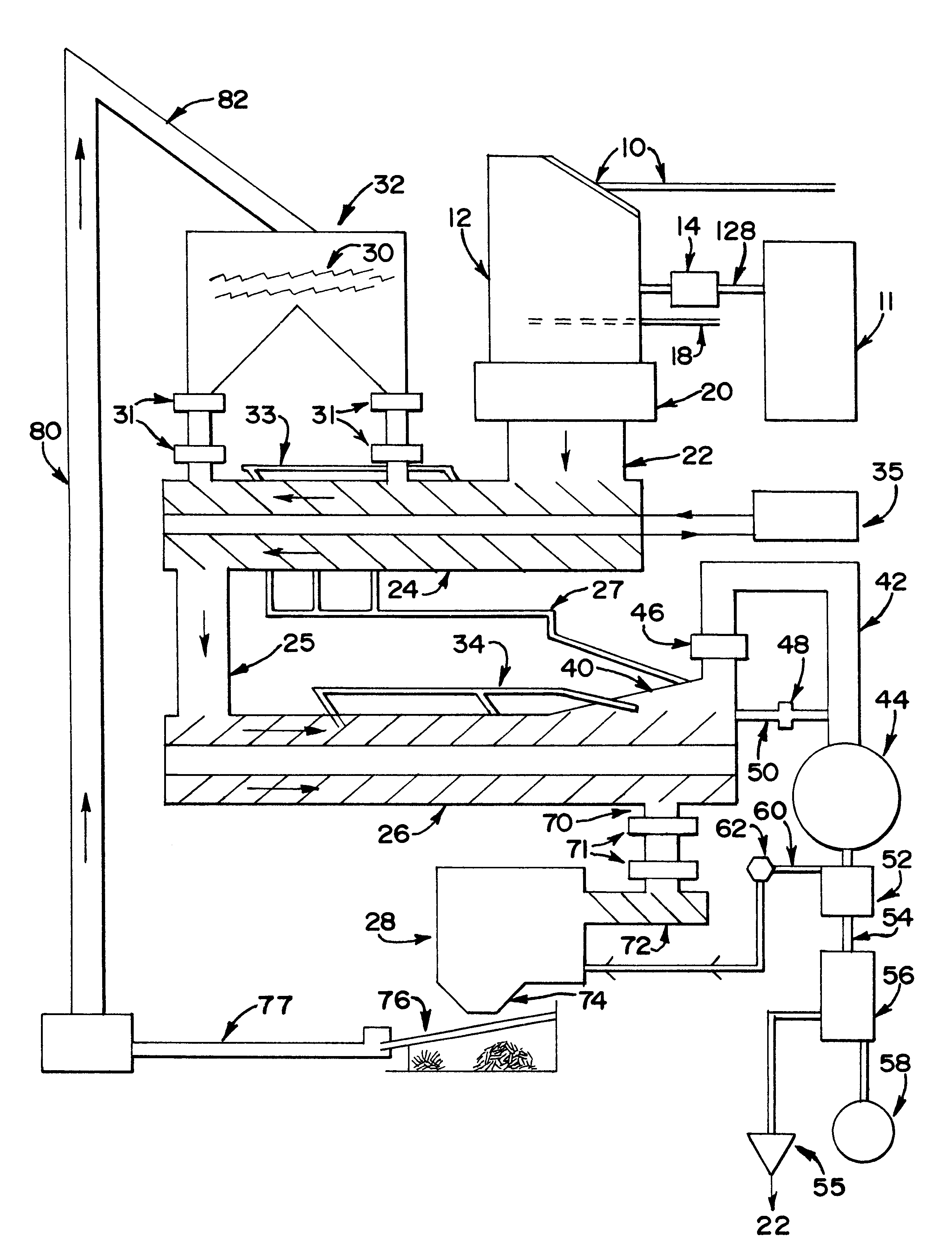

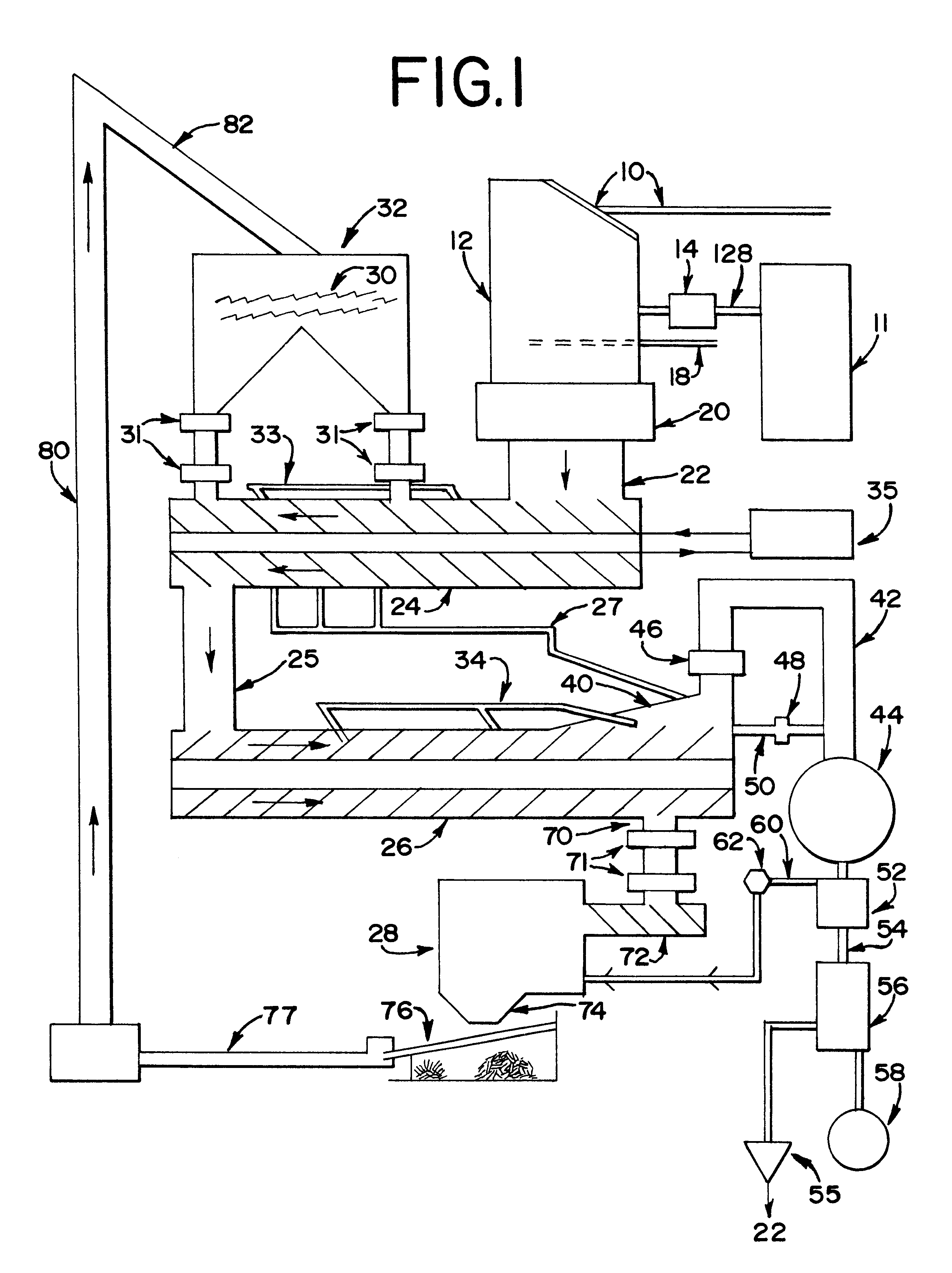

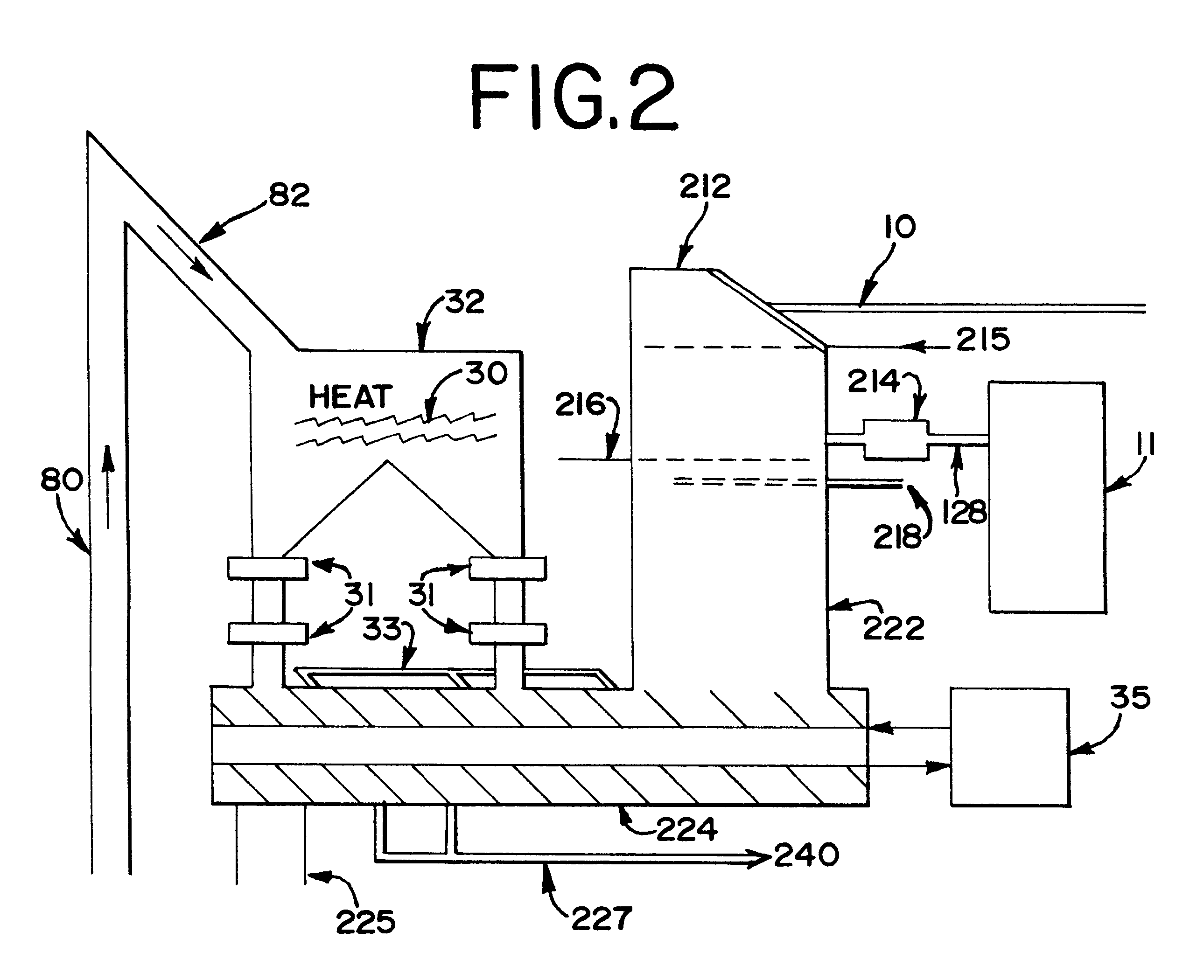

Heat and hydrogen peroxide gas sterilization of container

The present invention discloses a method and apparatus for sterilizing containers with gas-phase hydrogen peroxide and heat on a linear form, fill and seal packaging machine. A partially formed container is subjected to multiple applications of gaseous hydrogen peroxide and hot air within a sterilization tunnel. The sterilization tunnel is maintained at a temperature greater than the condensation temperature of hydrogen peroxide. The present invention sterilizes the container allowing for filling of the container with a high acid product such as orange juice for ambient distribution. The container may be any number of possibilities such as TETRA REX TM gable top cartons, plastic bottles, and the like. The invention allows for the efficacious use of hydrogen peroxide gas having a concentration of up to 53%.

Owner:TETRA LAVAL HLDG & FINANCE SA

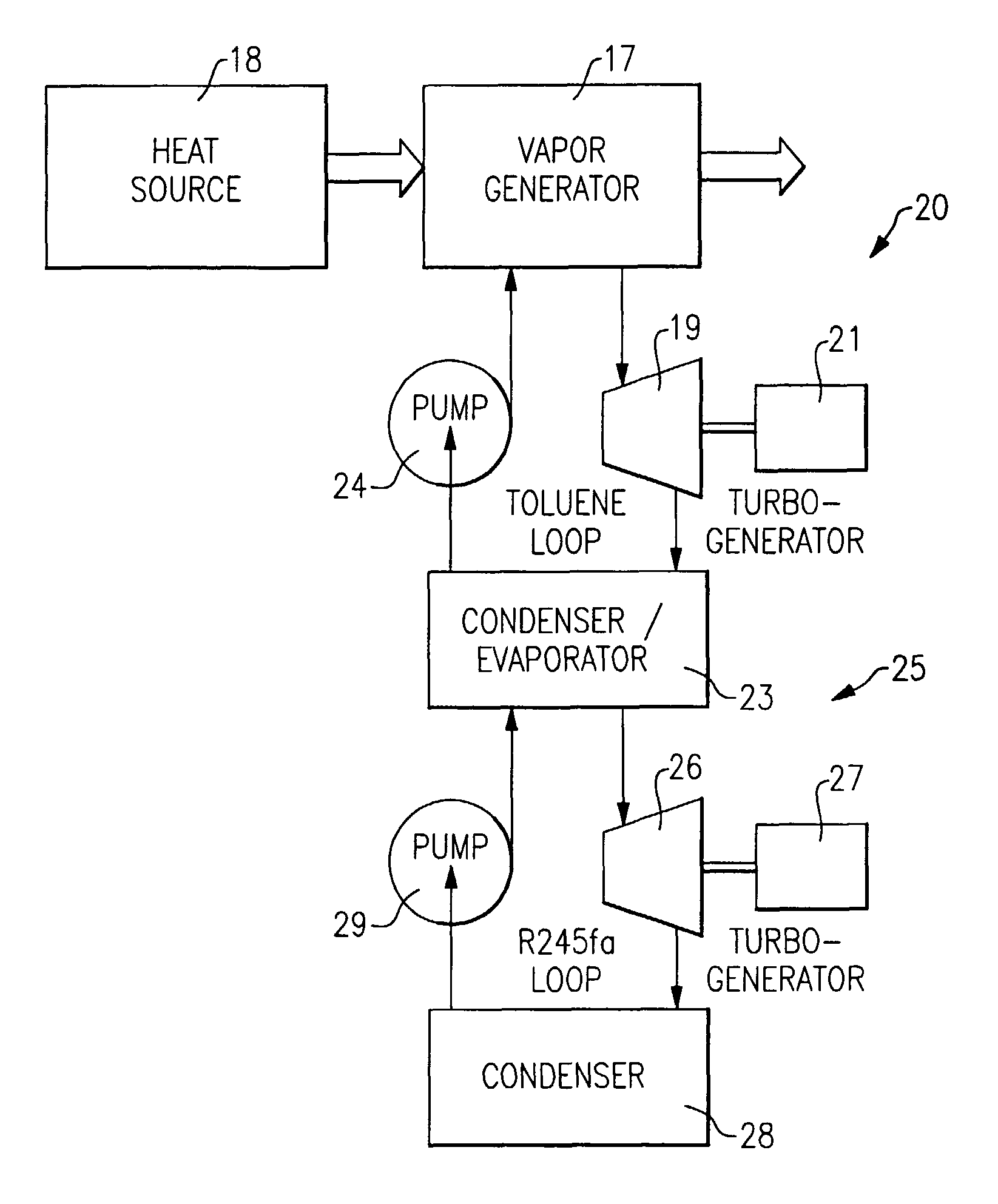

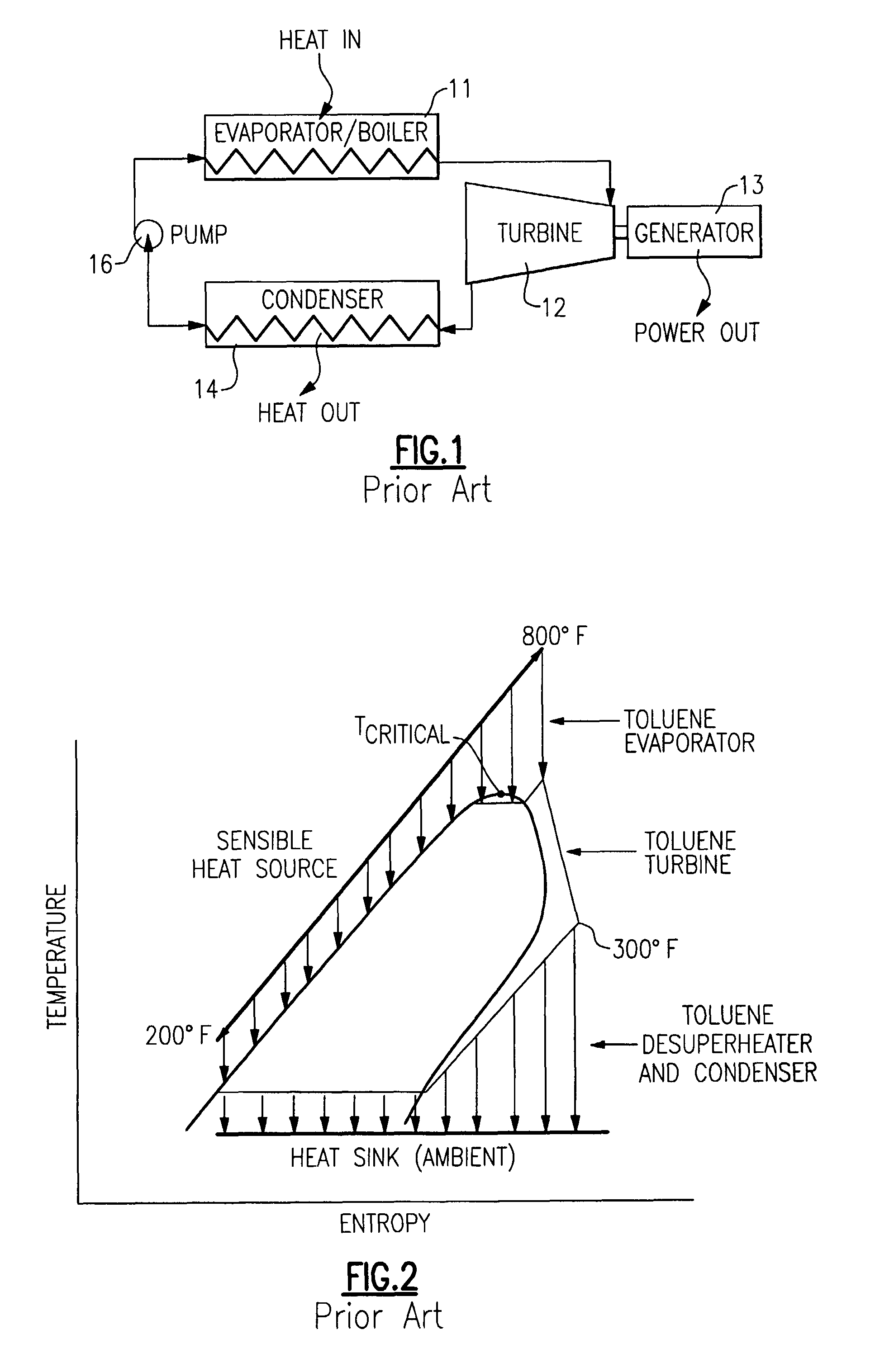

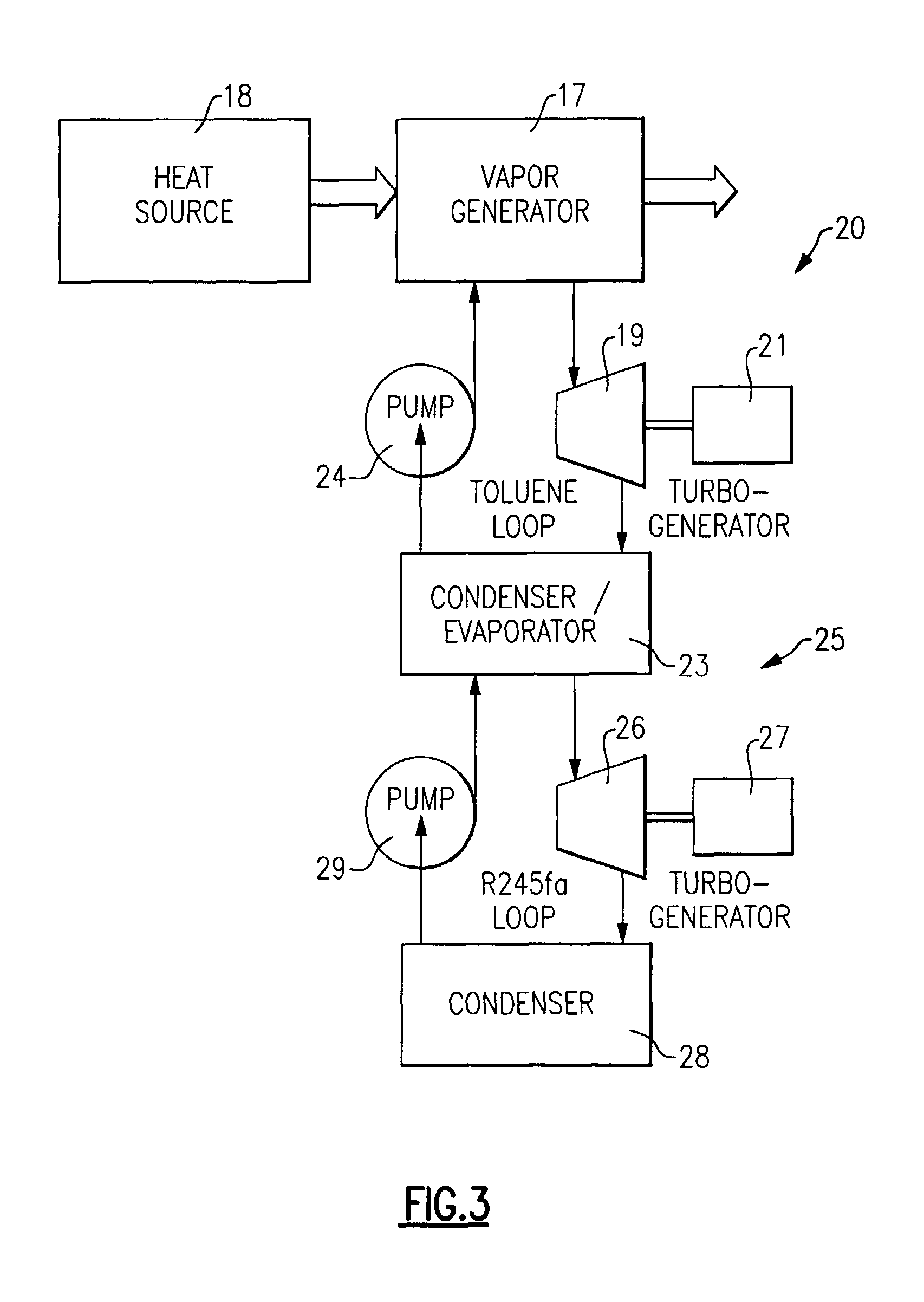

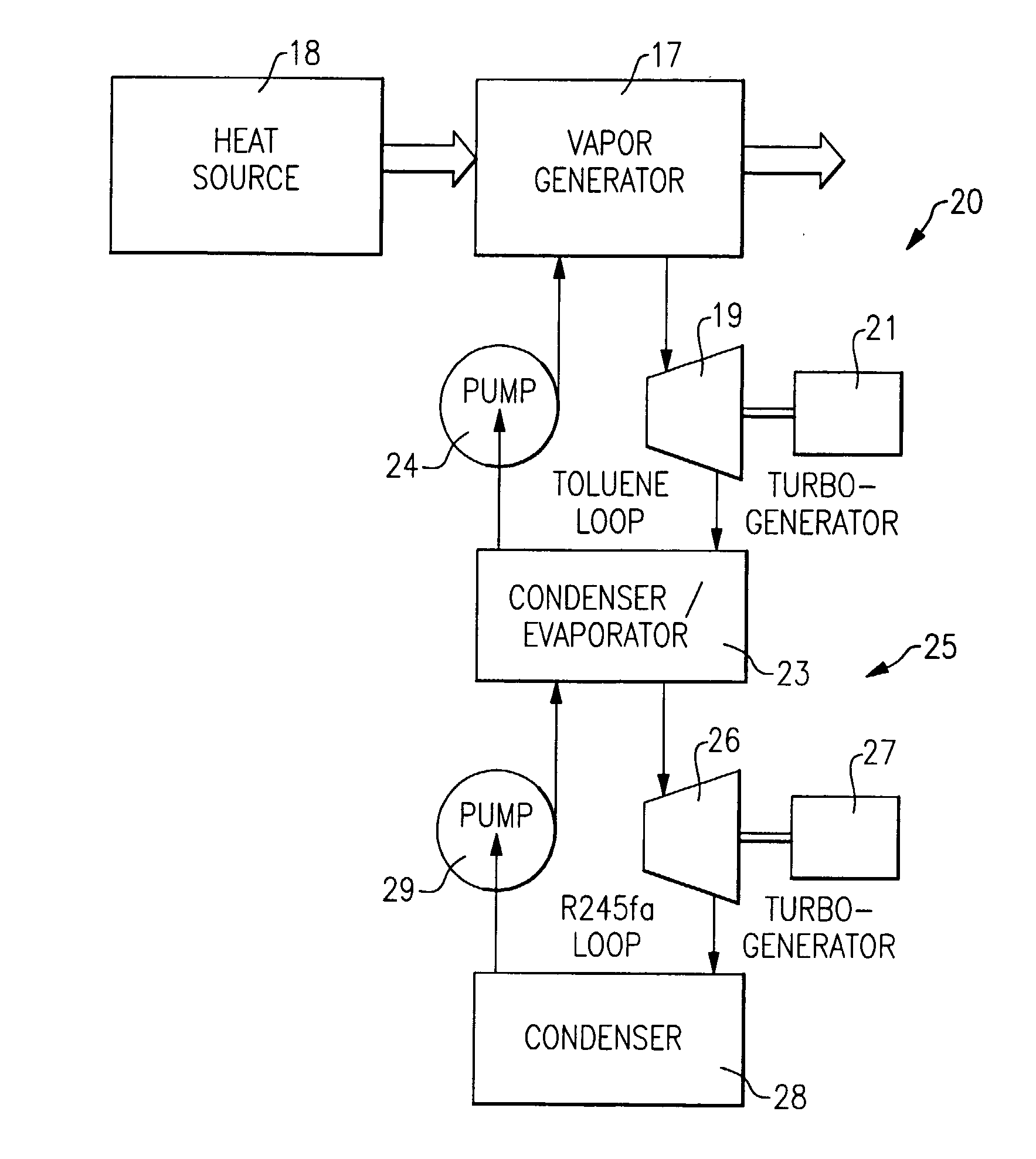

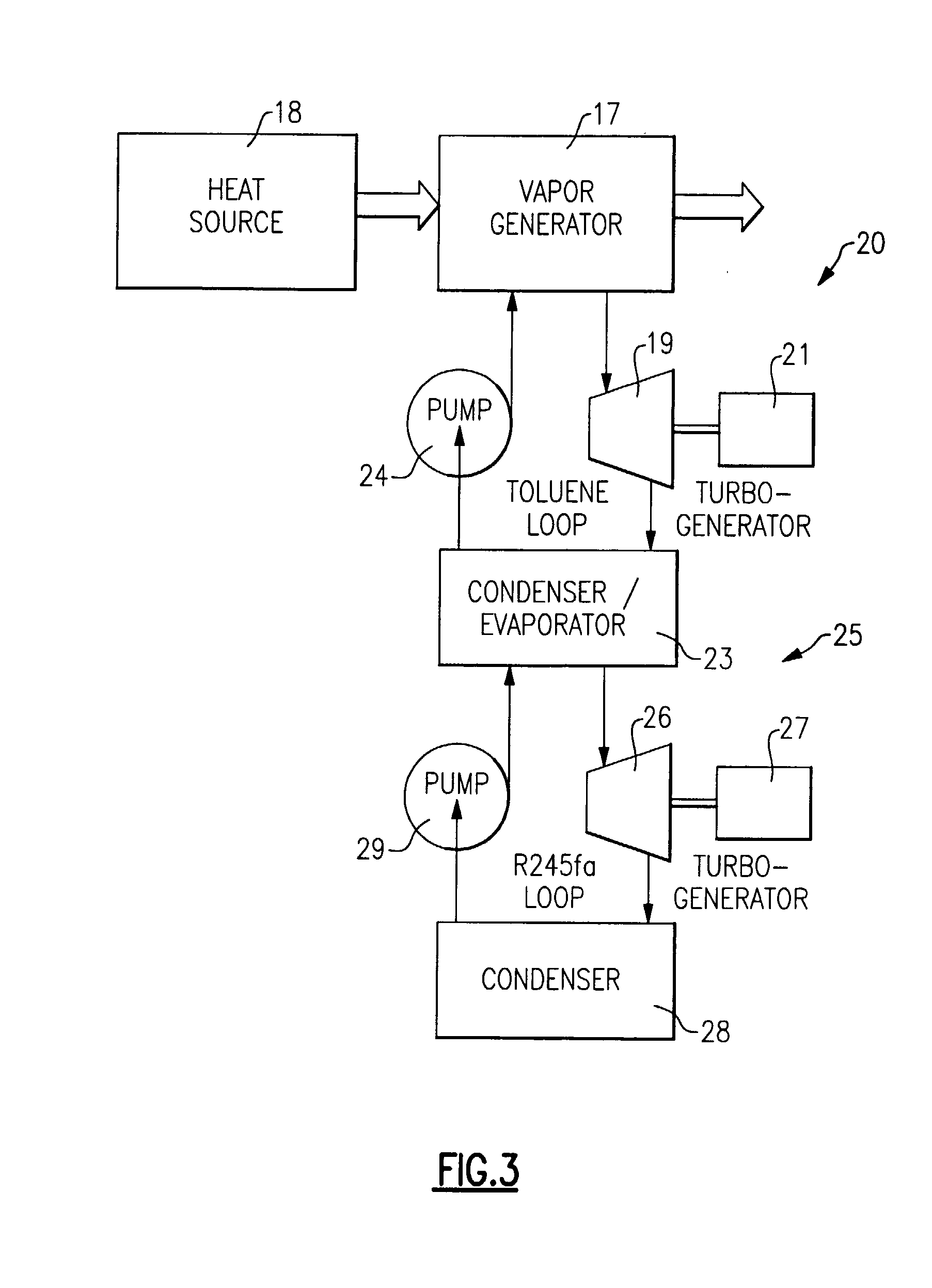

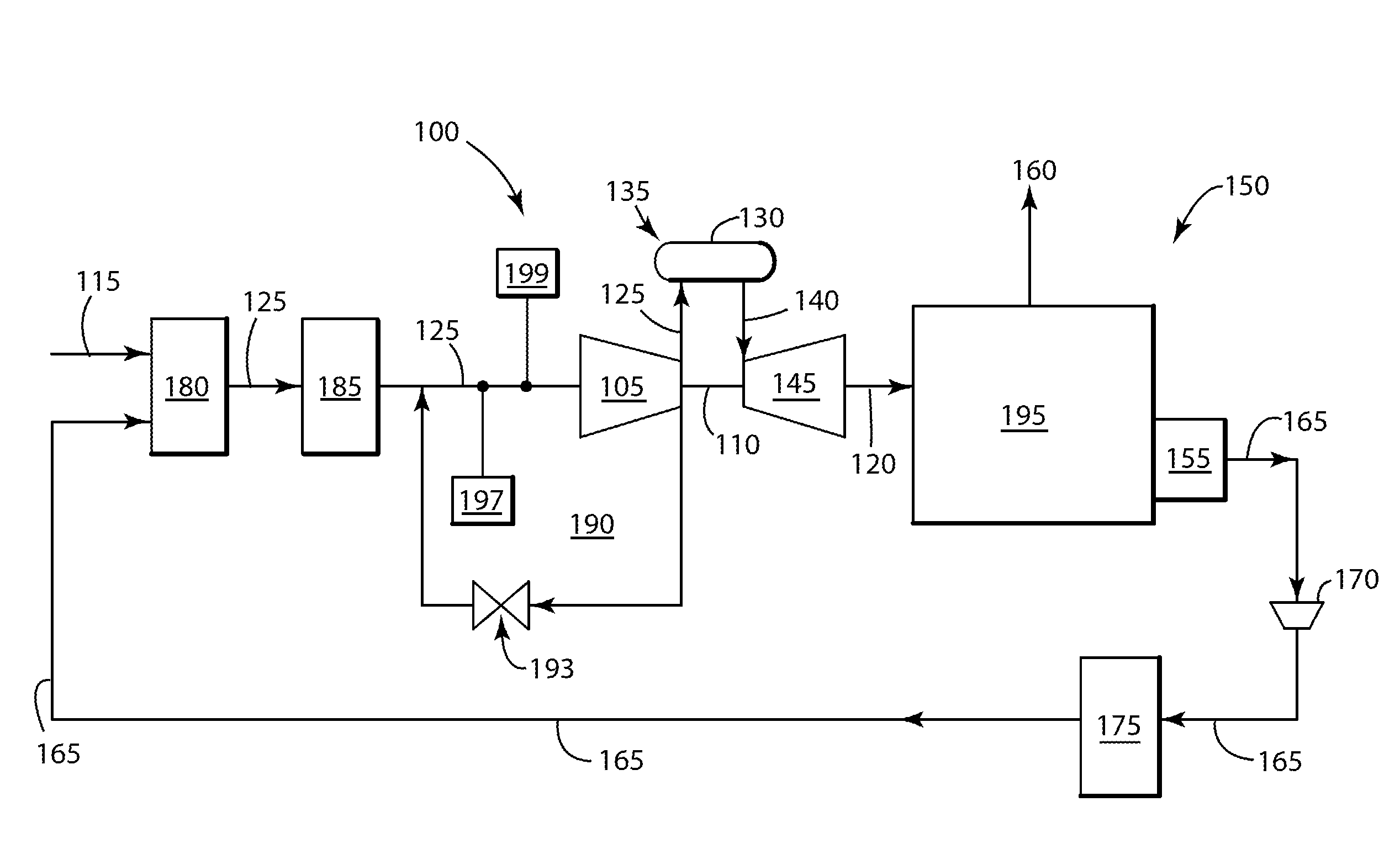

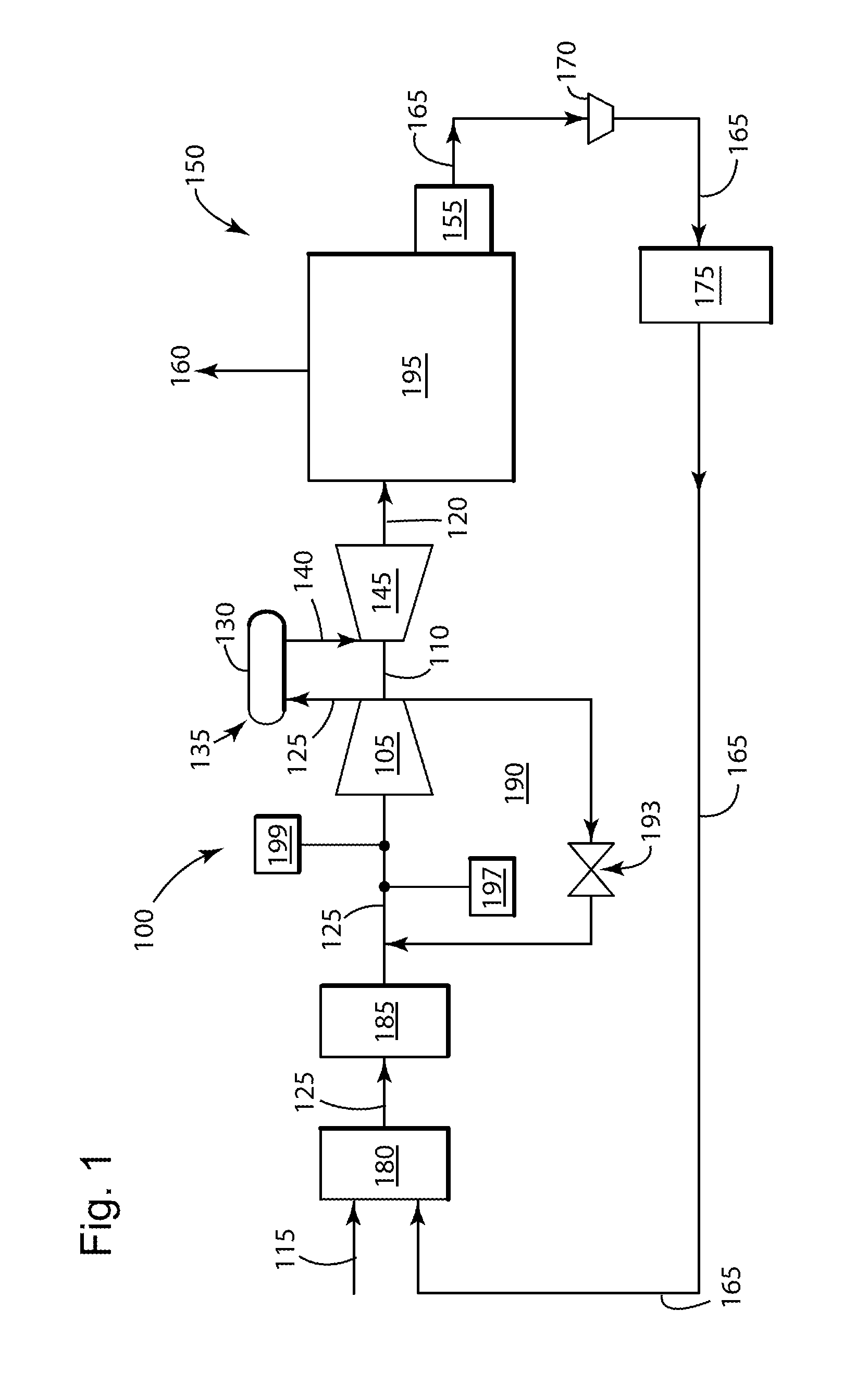

Cascaded organic rankine cycles for waste heat utilization

InactiveUS7942001B2Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

Cascaded Organic Rankine Cycles for Waste Heat Utilization

InactiveUS20080168772A1Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

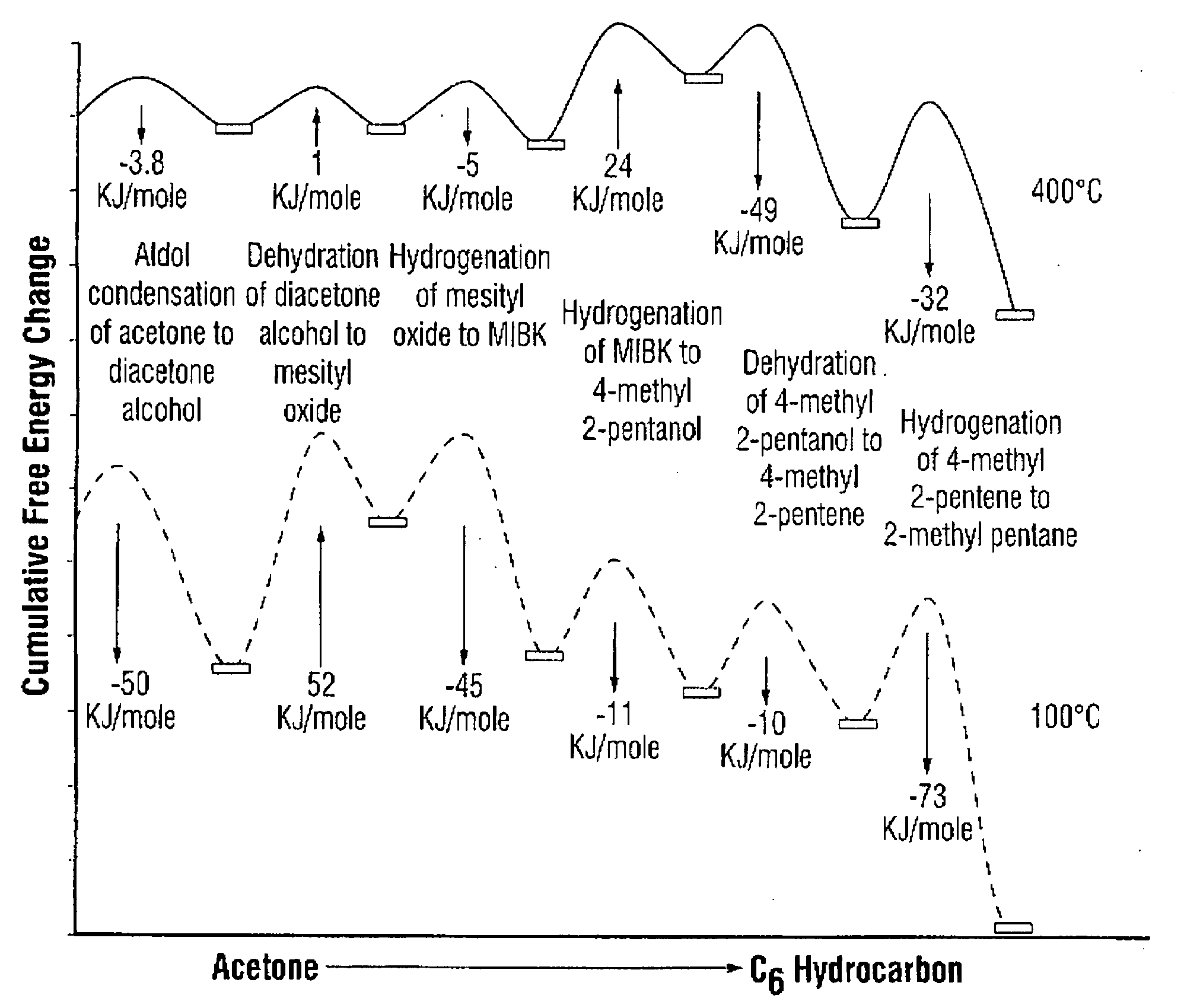

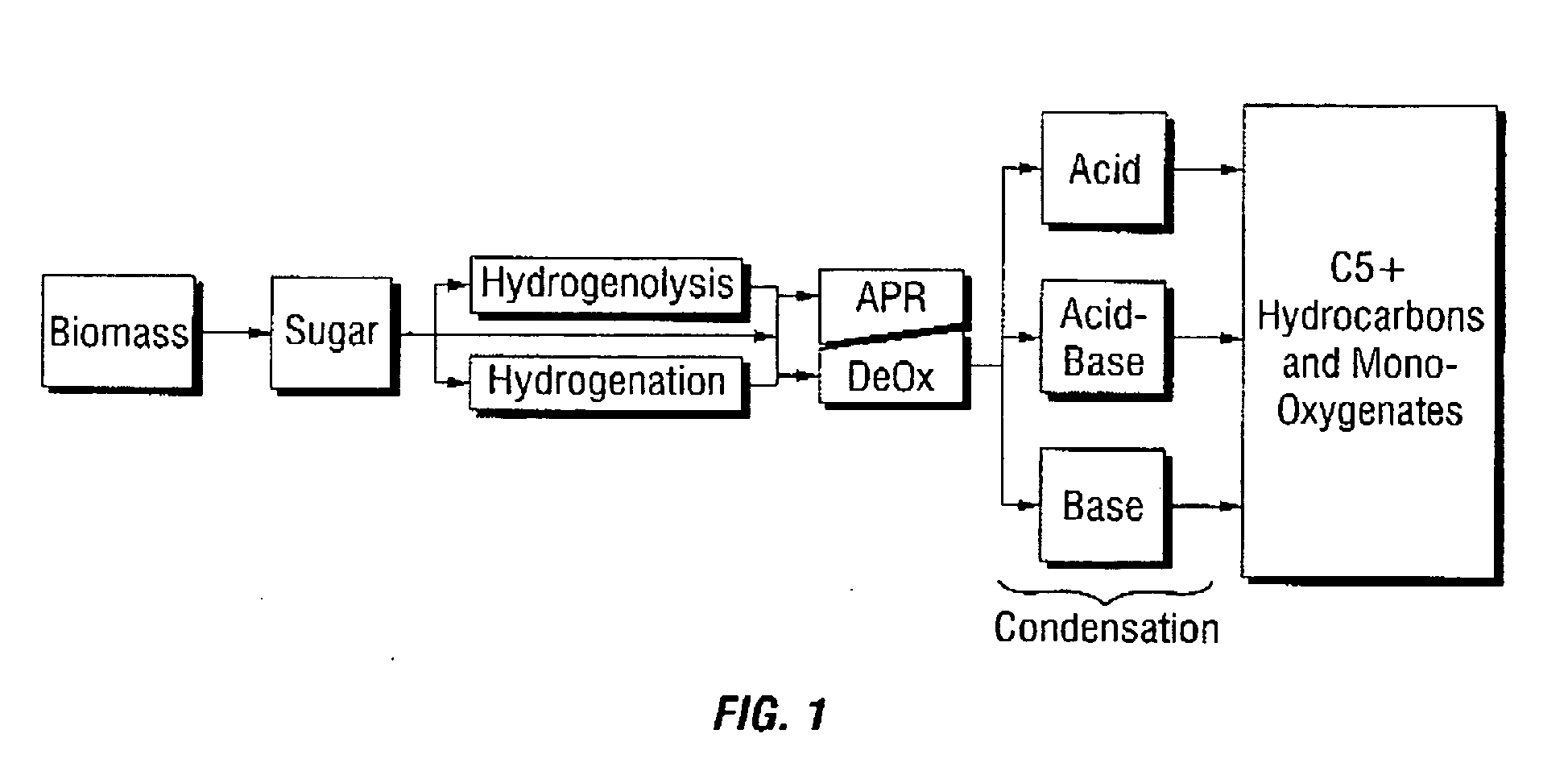

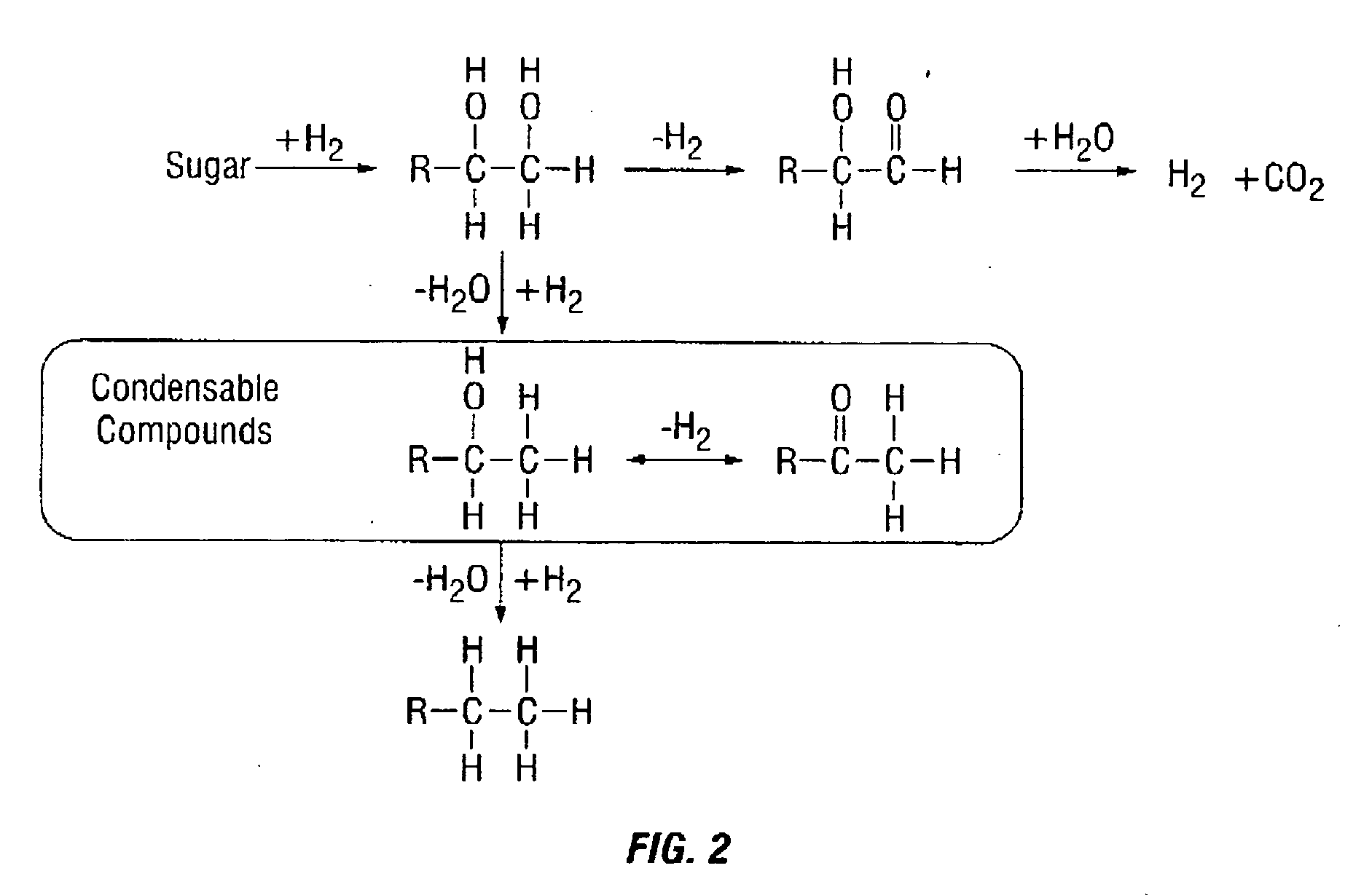

Liquid fuel compositions

The present invention provides a liquid fuel composition comprising a distillation fraction of a component having at least one C4+ compound derived from a water-soluble oxygenated hydrocarbon prepared by a method comprising:providing water and a water-soluble oxygenated hydrocarbon comprising a C1+O1+ hydrocarbon in an aqueous liquid phase and / or a vapor phase;providing H2;catalytically reacting in the liquid and / or vapor phase the oxygenated hydrocarbon with the H2 in the presence of a deoxygenation catalyst at a deoxygenation temperature and deoxygenation pressure to produce an oxygenate comprising a C1+O1-3 hydrocarbon in a reaction stream; andcatalytically reacting in the liquid and / or vapor phase the oxygenate in the presence of a condensation catalyst at a condensation temperature and condensation pressure to produce the C4+ compound,wherein the C4+ compound comprises a member selected from the group consisting of C4+ alcohol, C4+ ketone, C4+ alkane, C4+ alkene, C5+ cycloalkane, C5+ cycloalkene, aryl, fused aryl, and a mixture thereof;wherein the liquid fuel composition is selected from:a gasoline composition having an initial boiling point in the range of from 15° C. to 70° C. (IP123), a final boiling point of at most 230° C. (IP123), a RON in the range of from 85 to 110 (ASTM D2699) and a MON in the range of from 75 to 100 (ASTM D2700);a diesel fuel composition having an initial boiling point in the range of from 130° C. to 230° C. (IP123), a final boiling point of at most 410° C. (IP123) and a cetane number in the range of from 35 to 120 (ASTM D613); anda kerosene composition having an initial boiling point in the range of from 80 to 150° C., a final boiling point in the range of from 200 to 320° C. and a viscosity at −20° C. in the range of from 0.8 to 10 mm2 / s (ASTM D445).

Owner:SHELL USA INC

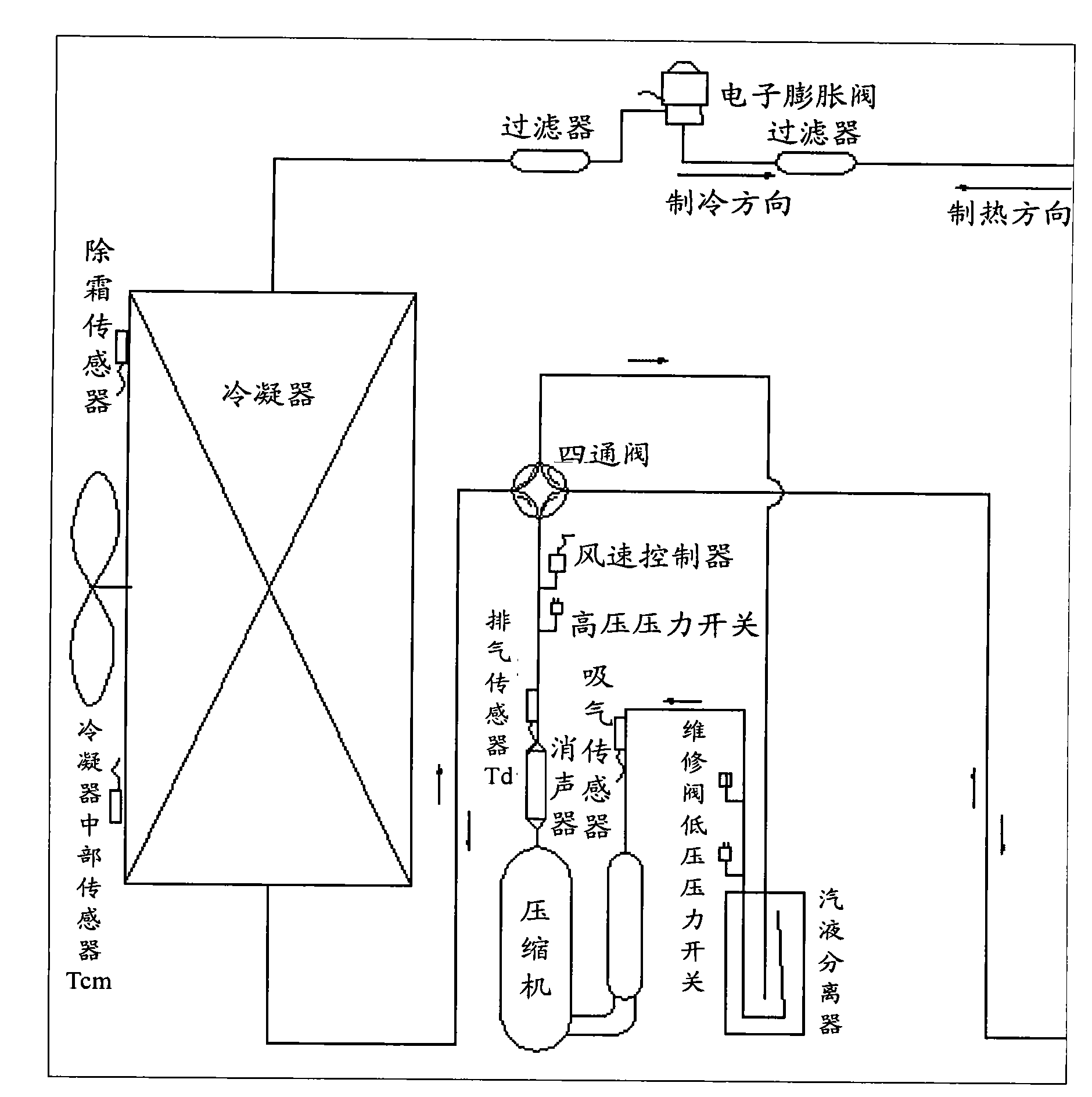

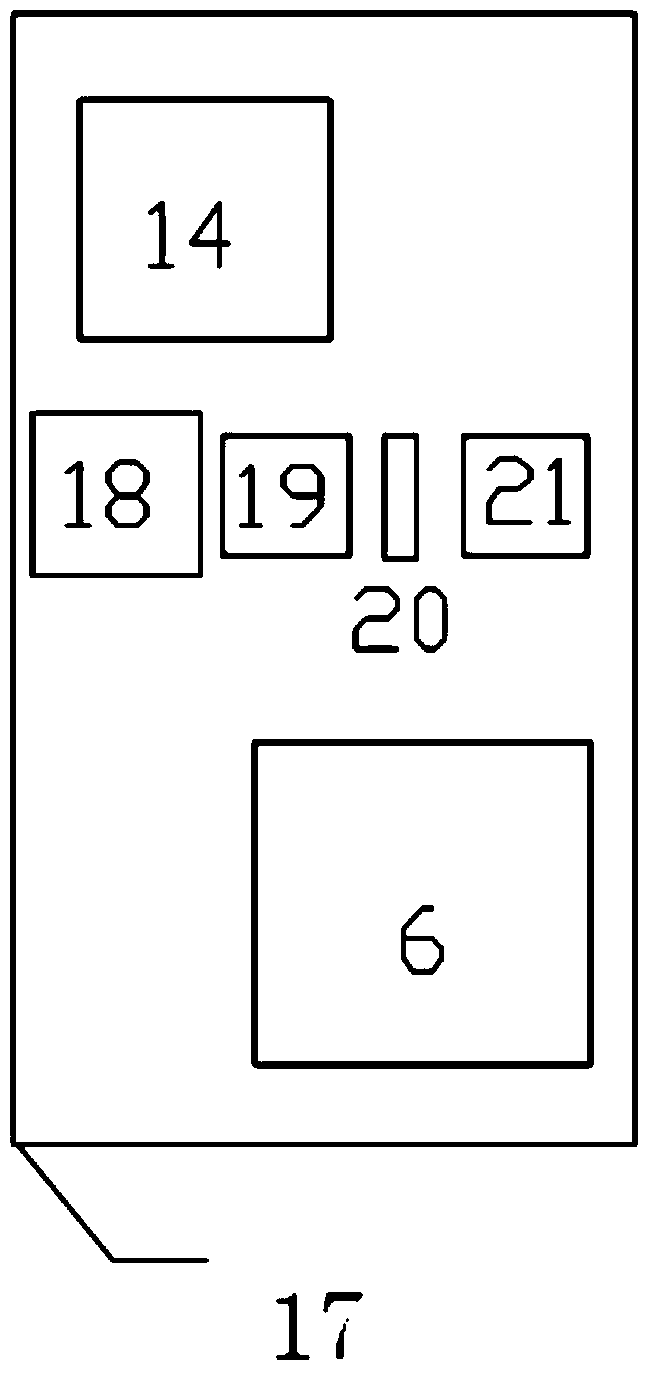

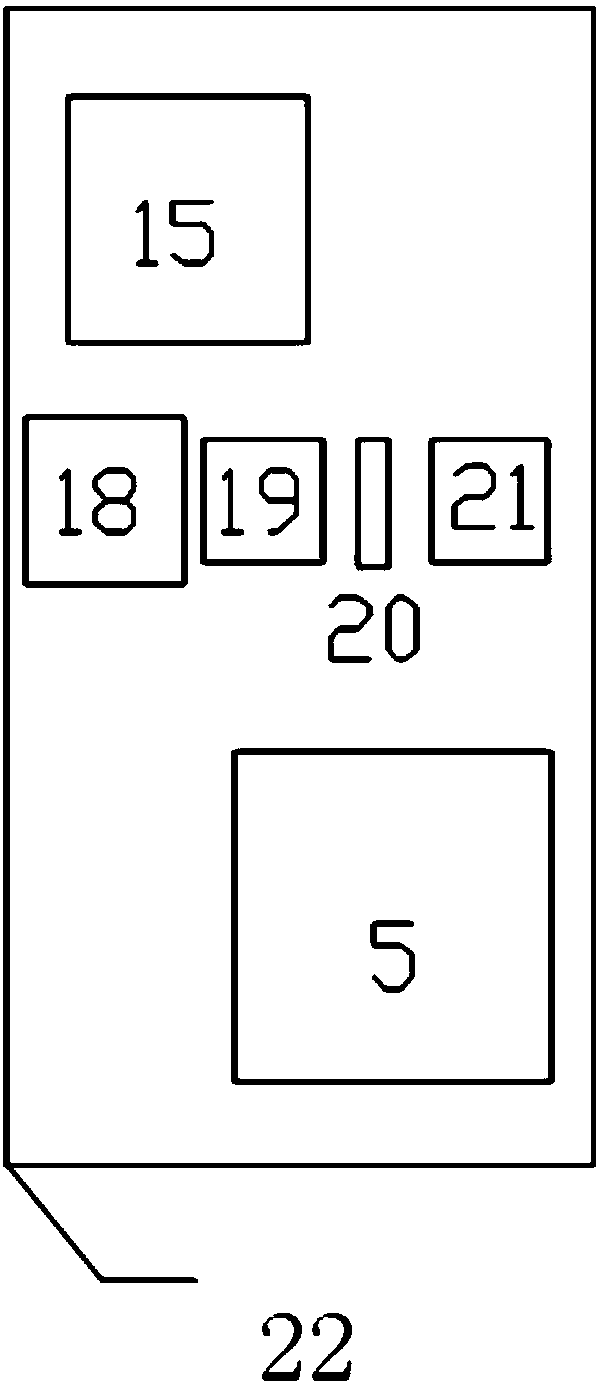

Low-temperature refrigeration air conditioner and wind speed control method thereof

InactiveCN101650064AImprove low temperature heating performanceHigh degree of standardizationSpace heating and ventilation safety systemsLighting and heating apparatusControl systemControl signal

The invention discloses a low-temperature refrigeration air conditioner and a wind speed control method thereof. The low-temperature refrigeration air conditioner comprises a wind speed control deviceof an outdoor unit fan. The wind speed fan control device comprises a temperature detection unit, a fan control unit and the outdoor unit fan, wherein the temperature detection unit detects the temperature of a condenser of the air conditioner so as to obtain a simulated condensation temperature; the fan control unit generates control signals of the rotation speed change and on-off of the fan according to the simulated condensation temperature; and the outdoor unit fan responds to the control signals of the fan control unit and generates corresponding outdoor unit wind speed. The method for controlling the wind speed of the low-temperature refrigeration air conditioner controls the rotation speed change and on-off of the fan by simulating the condensation temperature of the condenser so as to provide different wind speeds for an outdoor unit. Because of simulating a pressure signal by detecting a temperature signal, the air conditioner and the method avoid direct contact between a wind speed control system and a refrigerant system so as to avoid leakage.

Owner:HAIER GRP CORP +1

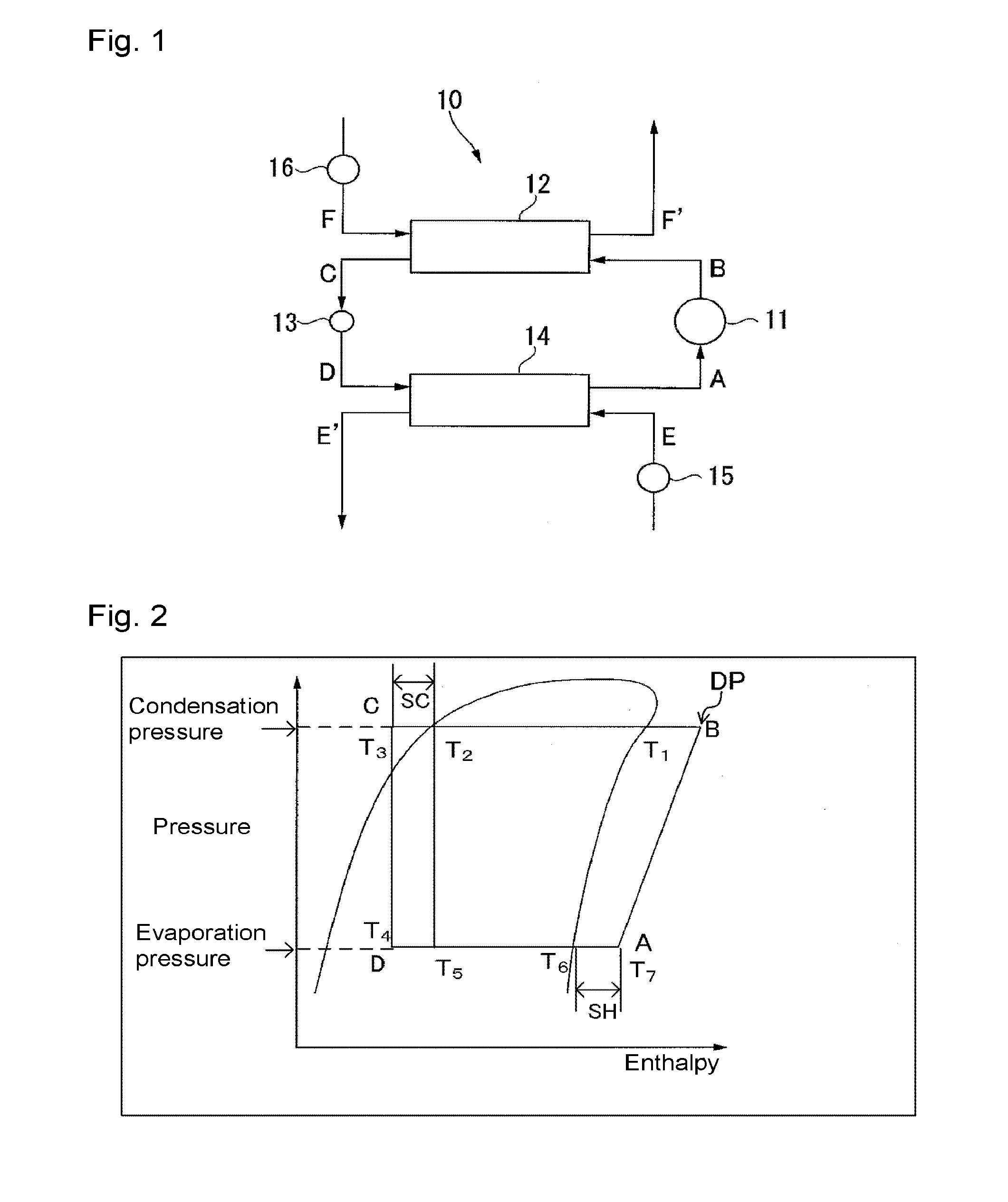

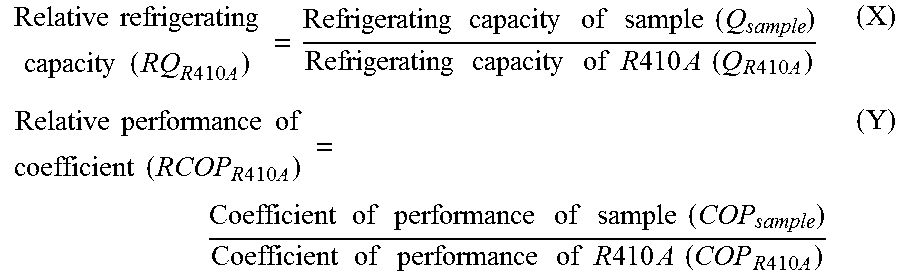

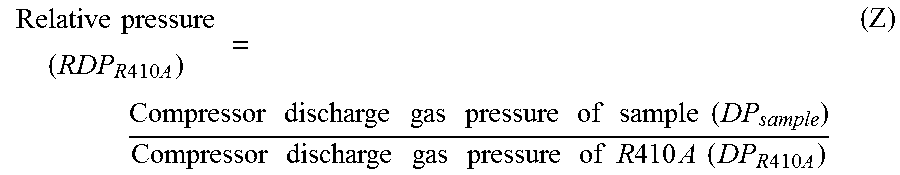

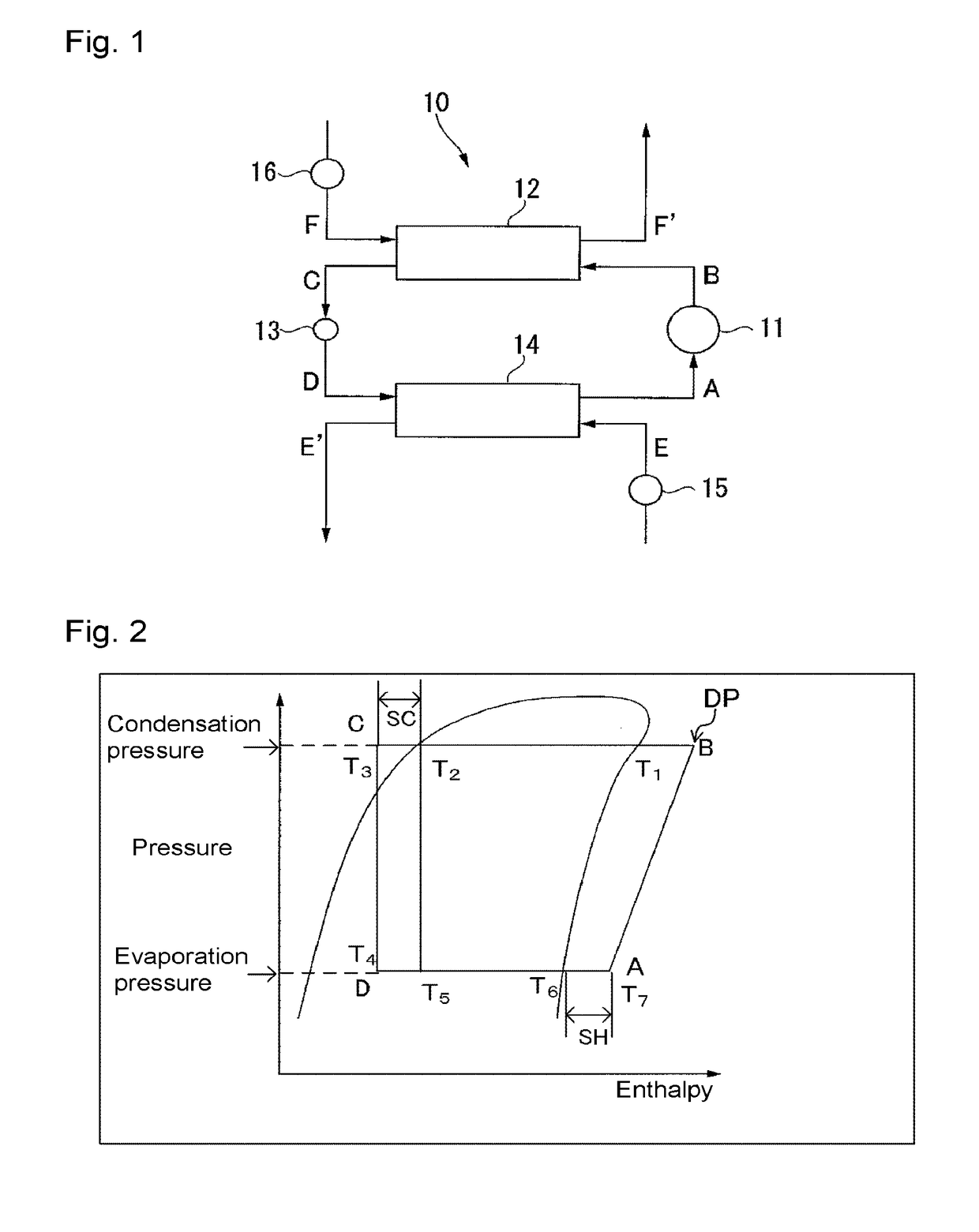

Working fluid for heat cycle, composition for heat cycle system, and heat cycle system

ActiveUS20160333243A1Stably used continuouslyCycle performance sufficientHeat-exchange elementsWorking fluidMetal working fluid

To provide a working fluid which has cycle performance sufficient as an alternative to R410A while the influence over global warming is sufficiently suppressed, which does not significantly increase the load to an apparatus as compared with a case where R410A is used, and which can be stably used continuously without any special measures, a composition for a heat cycle system comprising the working fluid, and a heat cycle system employing the composition.A working fluid for heat cycle, wherein the global warming potential is less than 300; the product of the relative coefficient of performance and the relative refrigerating capacity is at least 0.820 relative to R410A in a standard refrigerating cycle under conditions of an evaporation temperature of 0° C., a condensing temperature of 40° C., a supercoiling degree of 5° C. and a degree of superheat of 5° C.; the relative compressor discharge gas pressure is at most 1.100; the lower limit of the combustion range by method A in High Pressure Gas Safety Act is at least 5 vol %; and the pressure will not exceed 2.00 MPaG in a combustion test by method A in High Pressure Gas Safety act under 0.98 MPaG at 250° C.

Owner:ASAHI GLASS CO LTD

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

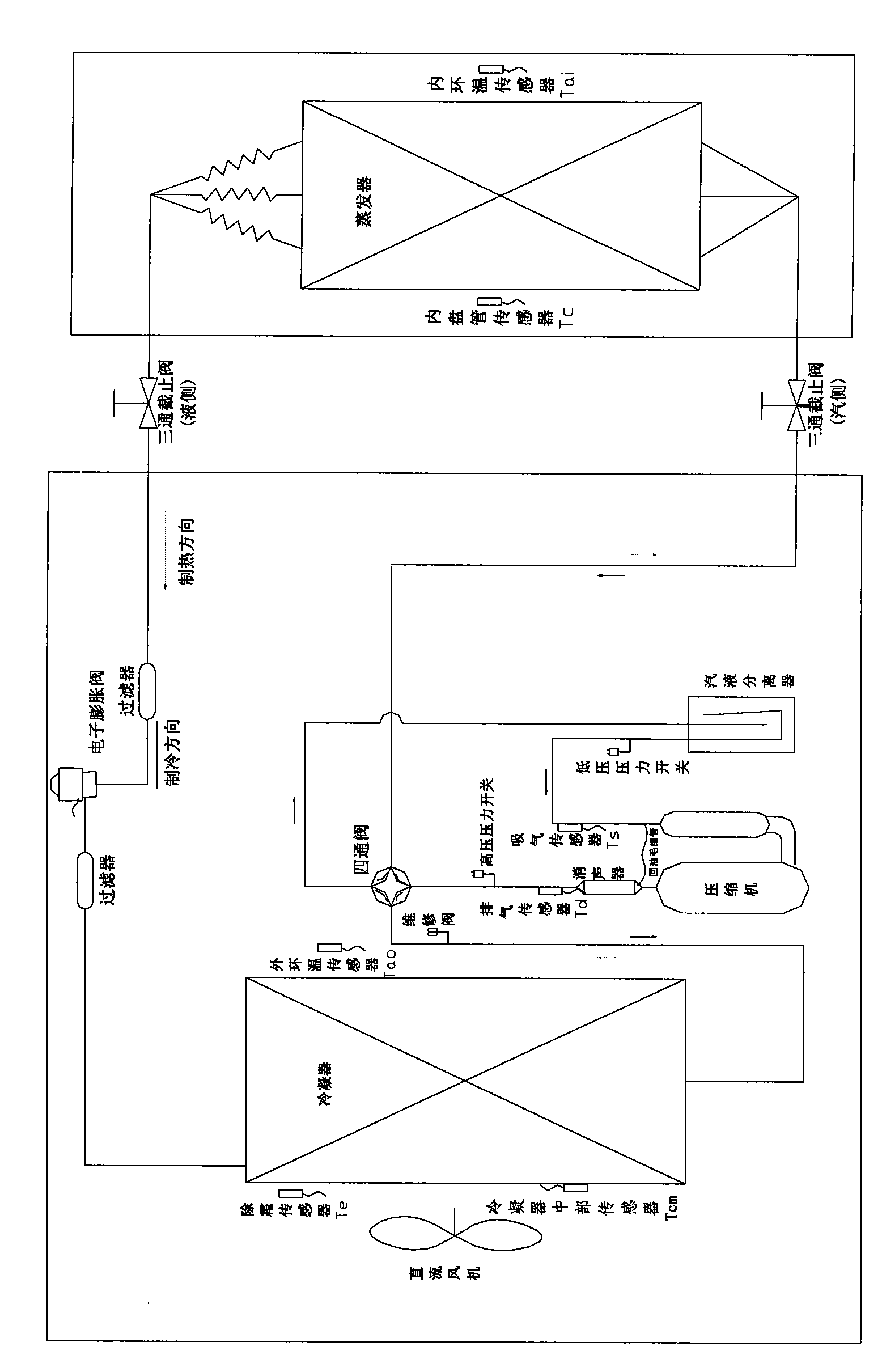

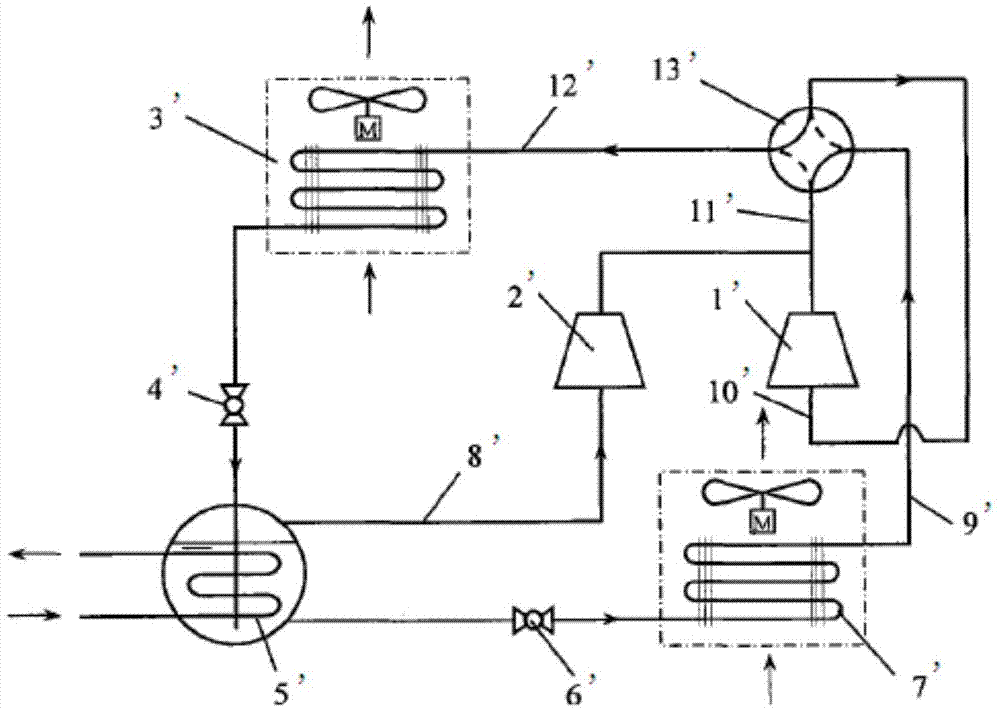

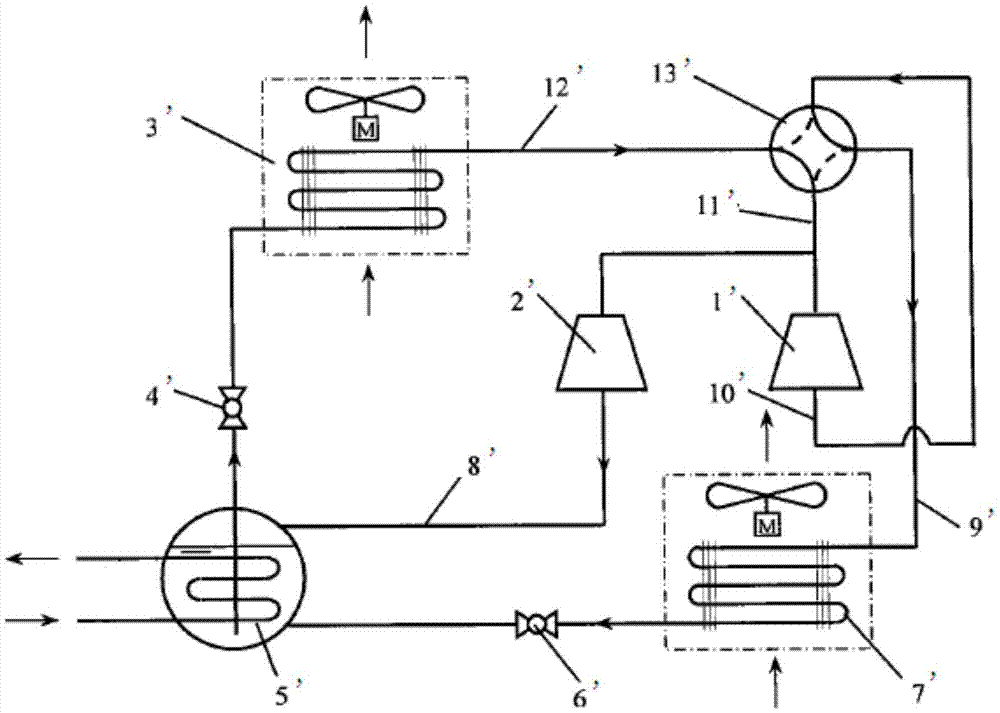

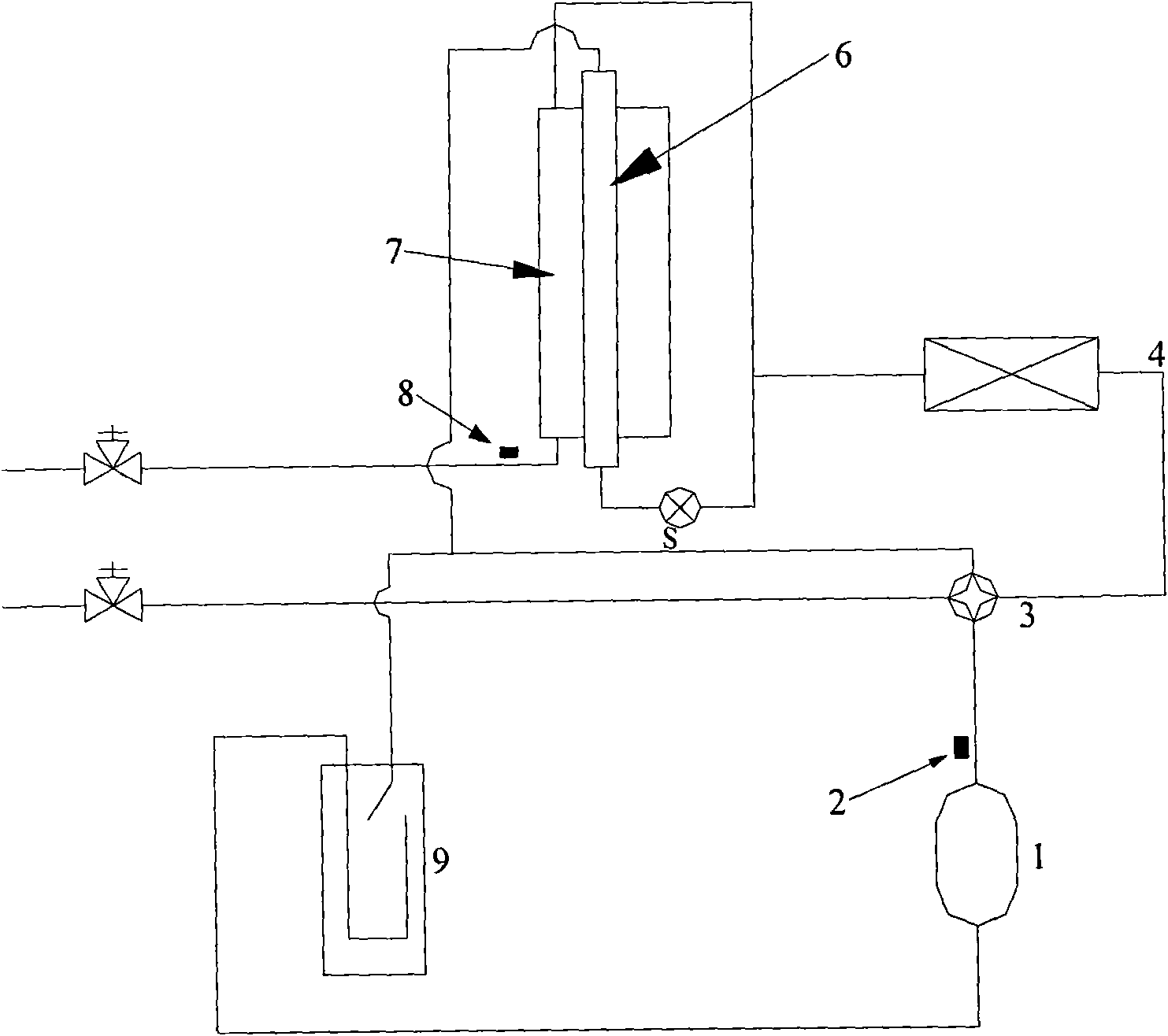

Double-temperature refrigerating and heating system

ActiveCN105444453AImprove energy efficiencyCompression machines with reversible cycleHeating and refrigeration combinationsFour-way valveEngineering

The invention relates to the technical field of air conditioning equipment, and in particular, discloses a double-temperature refrigerating and heating system, wherein a first cylinder, a first four-way valve, a first-grade throttle valve, an outdoor heat exchanger, a first-grade indoor heat exchanger, a gas-liquid separator, a second-grade throttle valve and a second-grade indoor heat exchanger of a compressor are connected through a pipeline to form a low-temperature evaporation loop; and a second cylinder, a second four-way valve, a first-grade throttle valve, an outdoor heat exchanger, a first-grade indoor heat exchanger and a gas-liquid separator of the compressor are connected through a pipeline to form a middle-temperature evaporation loop. The double-temperature refrigerating and heating system realizes switchover of refrigerating / heating modes through reversing of two four-way valves, realizes double-evaporation temperature refrigeration or double-condensation temperature heating, and effectively improves whole system energy efficiency; and obtained double-evaporation or double-condensation temperature can be widely applied to such places as freezing and refrigeration, air conditioner cold radiation and dehumidification, double-temperature heat source heat pump, air conditioner heat radiation and hot air or air conditioner heat radiation and living hot water.

Owner:GREE ELECTRIC APPLIANCES INC

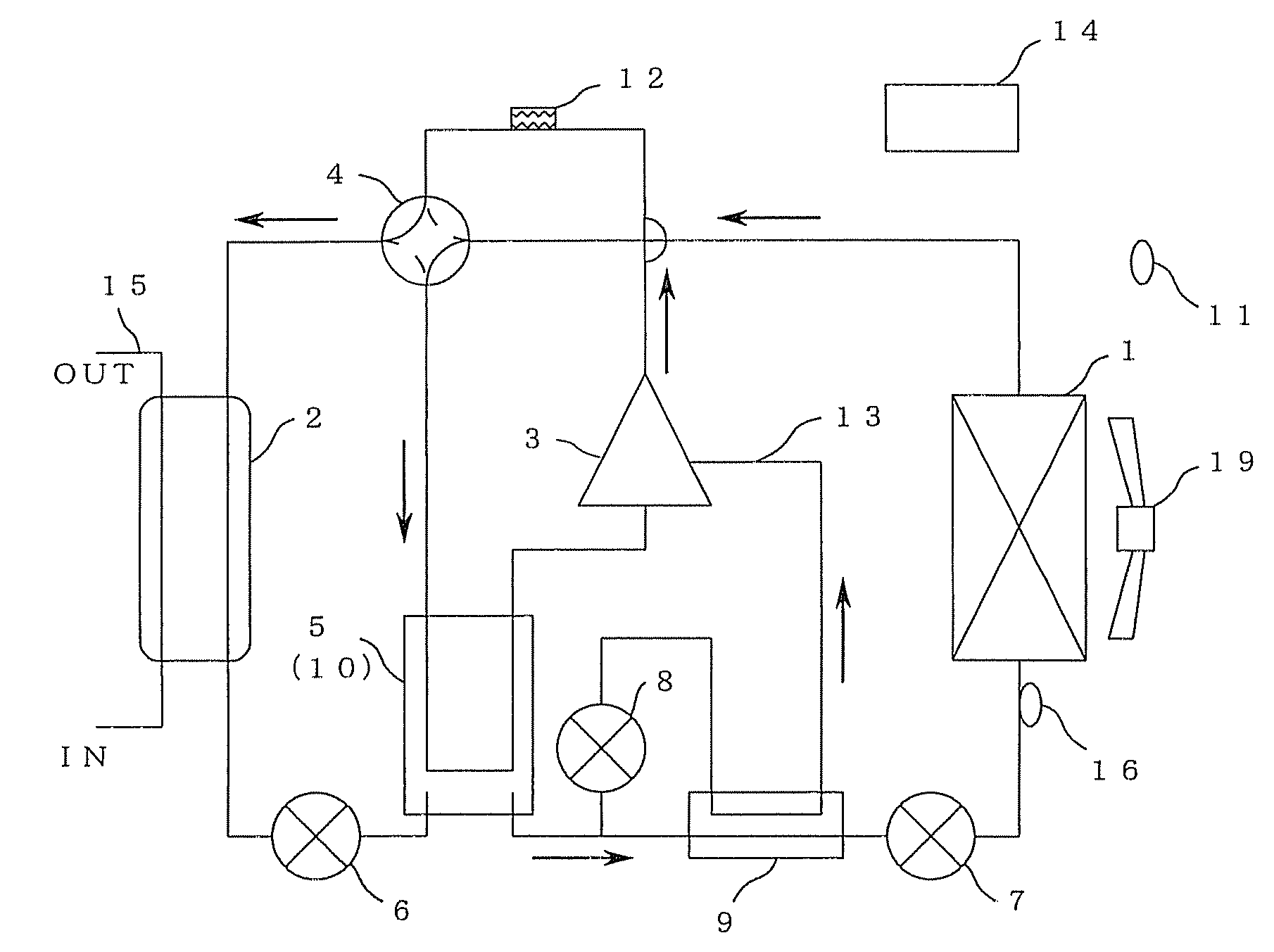

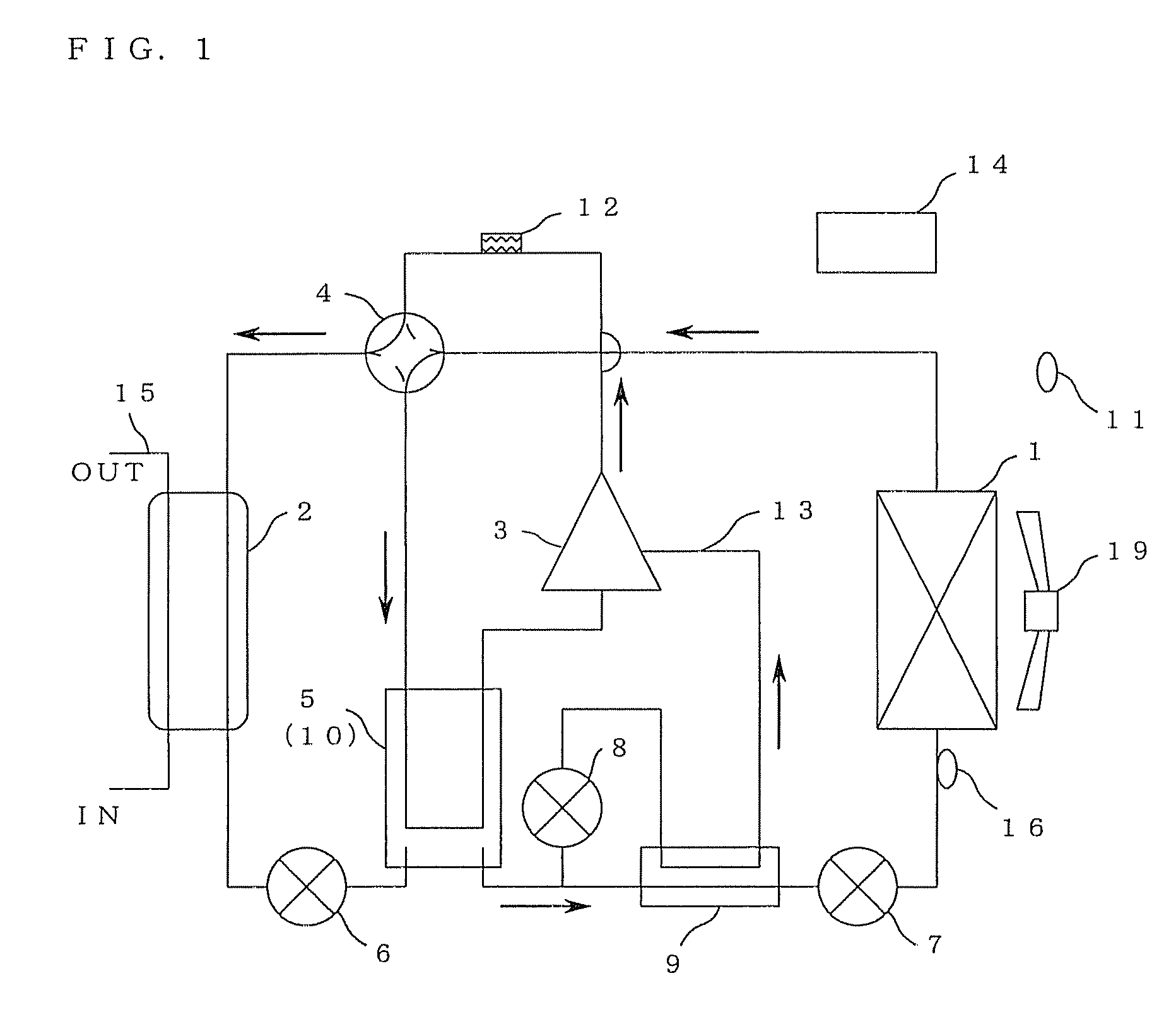

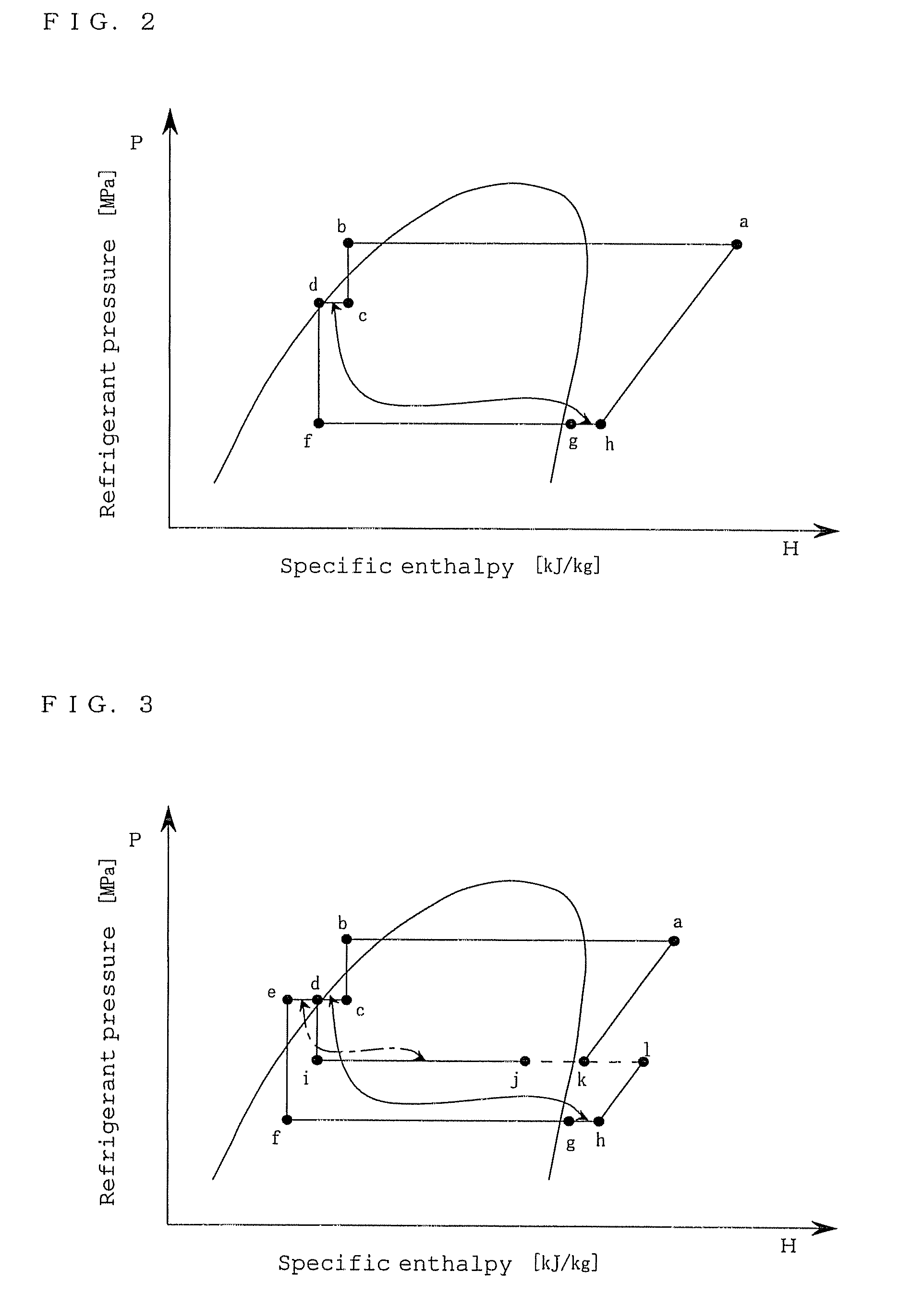

Heat pump type hot water supply outdoor apparatus

ActiveUS20090241569A1High hot water supply/heating capabilityHighly effective hot water supply/heating operationMechanical apparatusCompression machines with non-reversible cyclePlate heat exchangerCondensation temperature

A heat pump type hot water supply outdoor apparatus, in a compressor, a water heat exchanger, a first expansion valve, a medium pressure receiver, a second expansion valve, and an air heat exchanger are connected circularly, has an injection circuit, which is a bypass for a part of the refrigerant between the medium pressure receiver and the second pressure reduction unit, to inject the part of refrigerant into a compression chamber of the compressor, and has a third expansion valve and an internal heat exchanger for carrying out heat exchange between the refrigerant whose pressure is reduced by the third expansion valve and the refrigerant between the medium pressure receiver and the second expansion valve, a pressure detection sensor for detecting a condensing pressure, and a controller for starting an injection control by the third expansion valve at the time when the condensing pressure detected by the pressure sensor or the condensing temperature calculated from the condensing pressure becomes a first predetermined value or more and stopping the injection control at the time when the condensing pressure or the condensing temperature becomes a second predetermined value which is smaller than the first predetermined value, or less. With this arrangement, an appropriate injection control can be realized and a high hot water supply / heating capability operation can be carried out.

Owner:MITSUBISHI ELECTRIC CORP

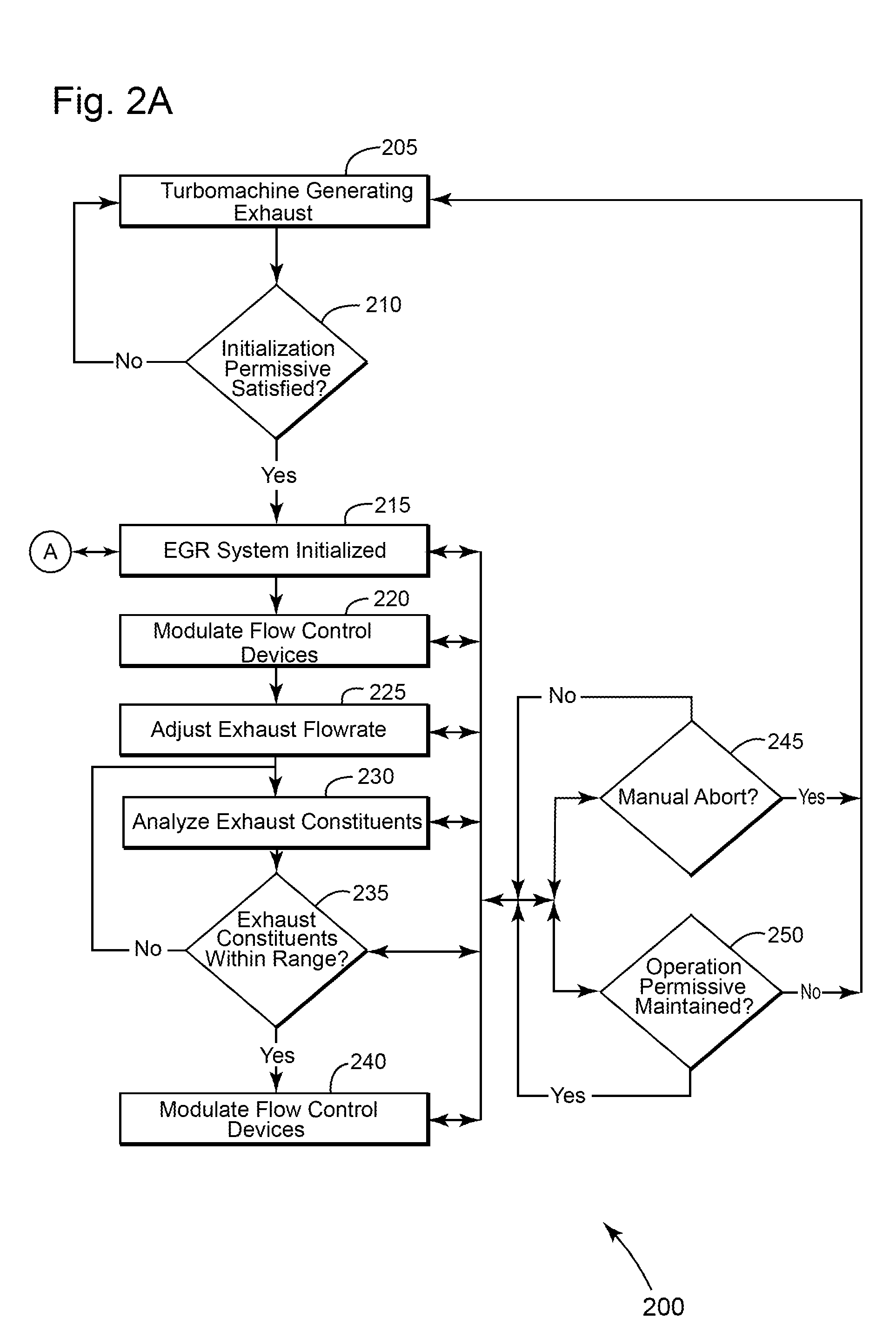

Method for controlling an exhaust gas recirculation system

InactiveUS20100126181A1Lower the liquid levelReduce the possibilityNon-fuel substance addition to fuelInternal combustion piston enginesLiquid productCondensation temperature

An embodiment of the present invention takes the form of a method and system that may reduce the level of SOx emissions by recirculating a portion of the exhaust of at least one turbomachine; the portion of exhaust may be mixed with the inlet air prior to re-entering the turbomachine. An embodiment of the present invention may incorporate an inlet bleed heat system to reduce the likelihood of the liquid products forming from SOx emissions. Here, a method may maintain a temperature of the inlet fluid above a condensation temperature.

Owner:GENERAL ELECTRIC CO

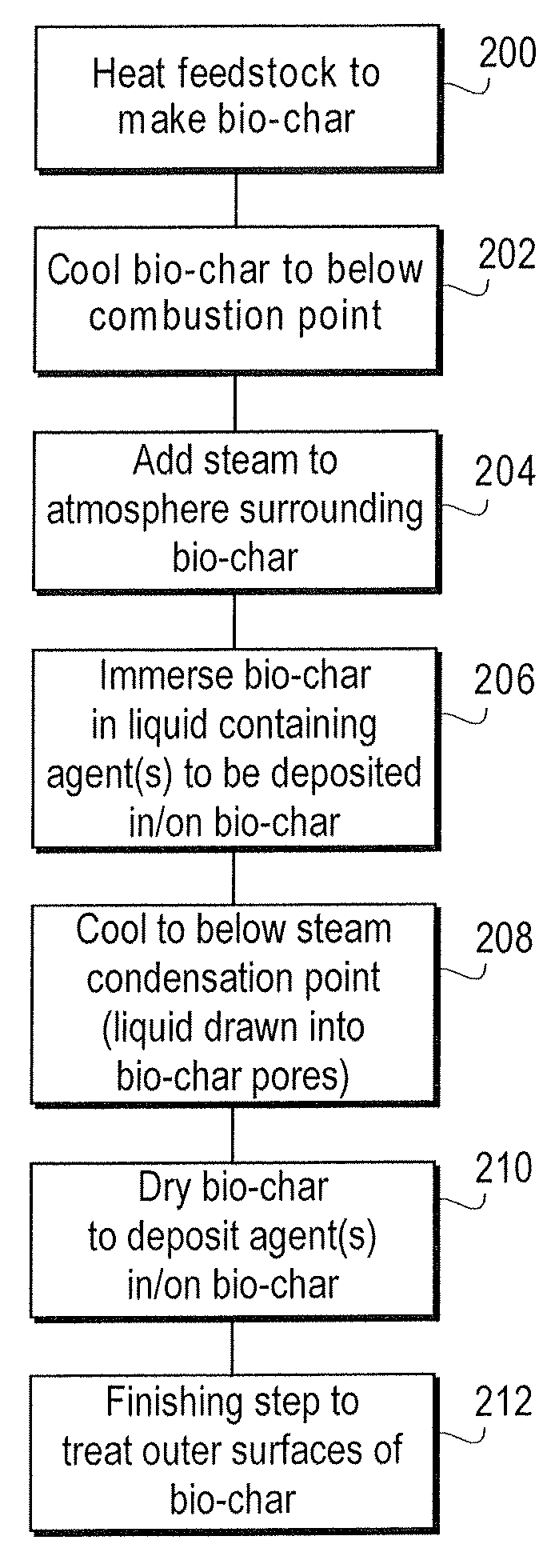

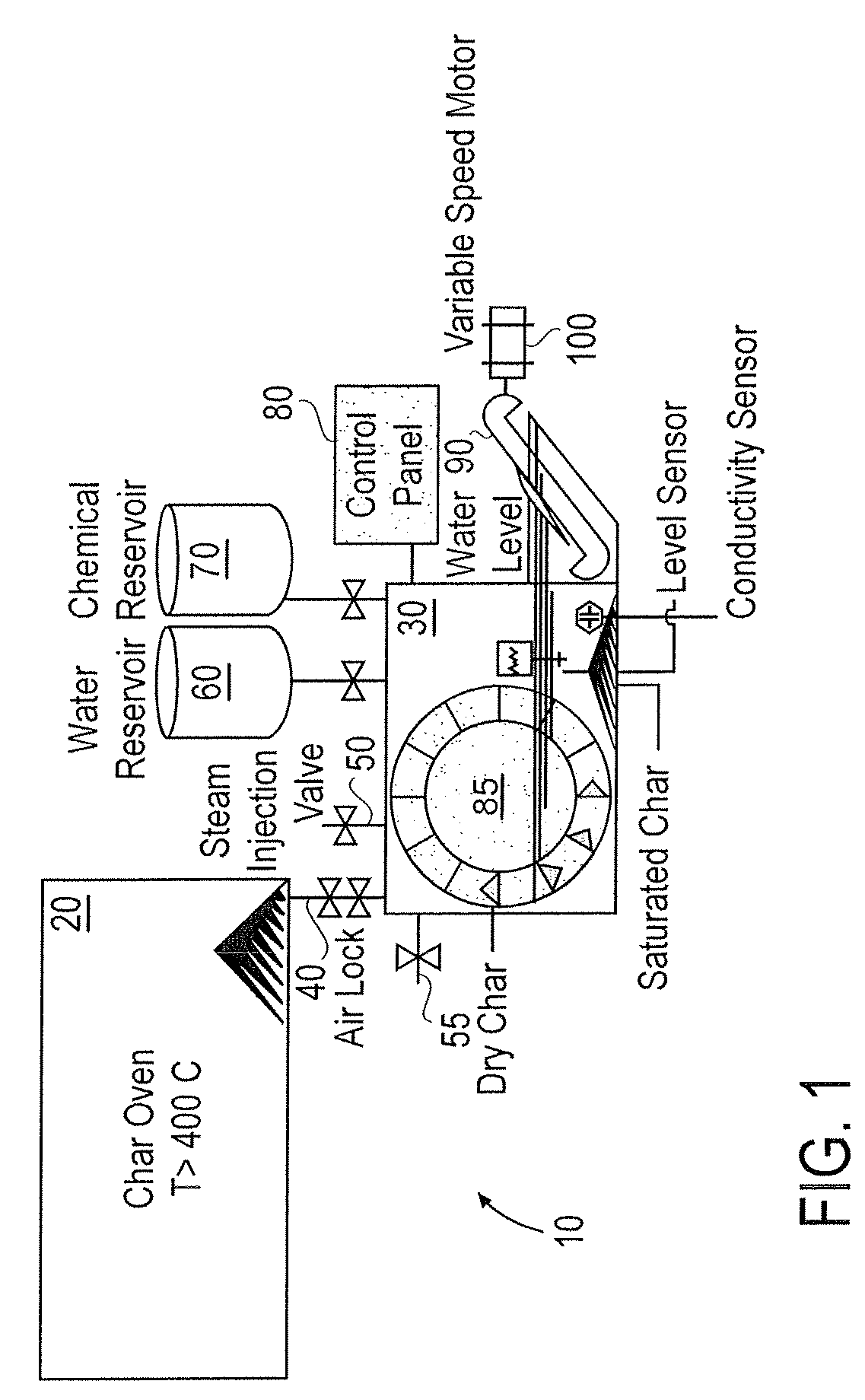

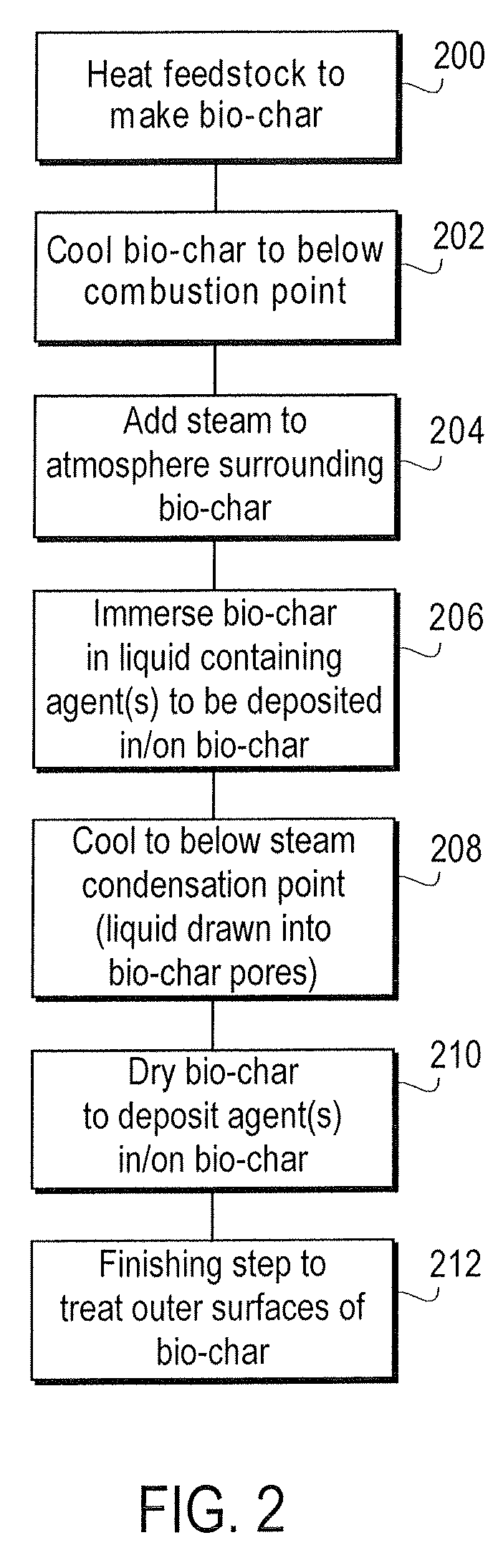

Method and apparatus for depositing agents upon and within bio-char

Methods and apparatuses for depositing agents relatively deep within pores of bio-char. Bio-char is first produced in an airtight oven by heating biomass feedstock. The bio-char is then cooled and steam is diffused into the pores of the bio-char. The steam-laden bio-char is immersed in a liquid bath containing soluble agents that are to be deposited in the pores of the bio-char. The liquid bath cools the char to below the condensation temperature of the steam, whereupon the condensing steam generates a partial vacuum within the pores, drawing the liquid into the pores. The bio-char is then removed from the liquid bath and dried so that the liquid within the pores evaporates, leaving behind the soluble agent. Accordingly, the invention yields bio-char that has soluble agent embedded relatively deep within its pores.

Owner:CARBON TECH HLDG LLC

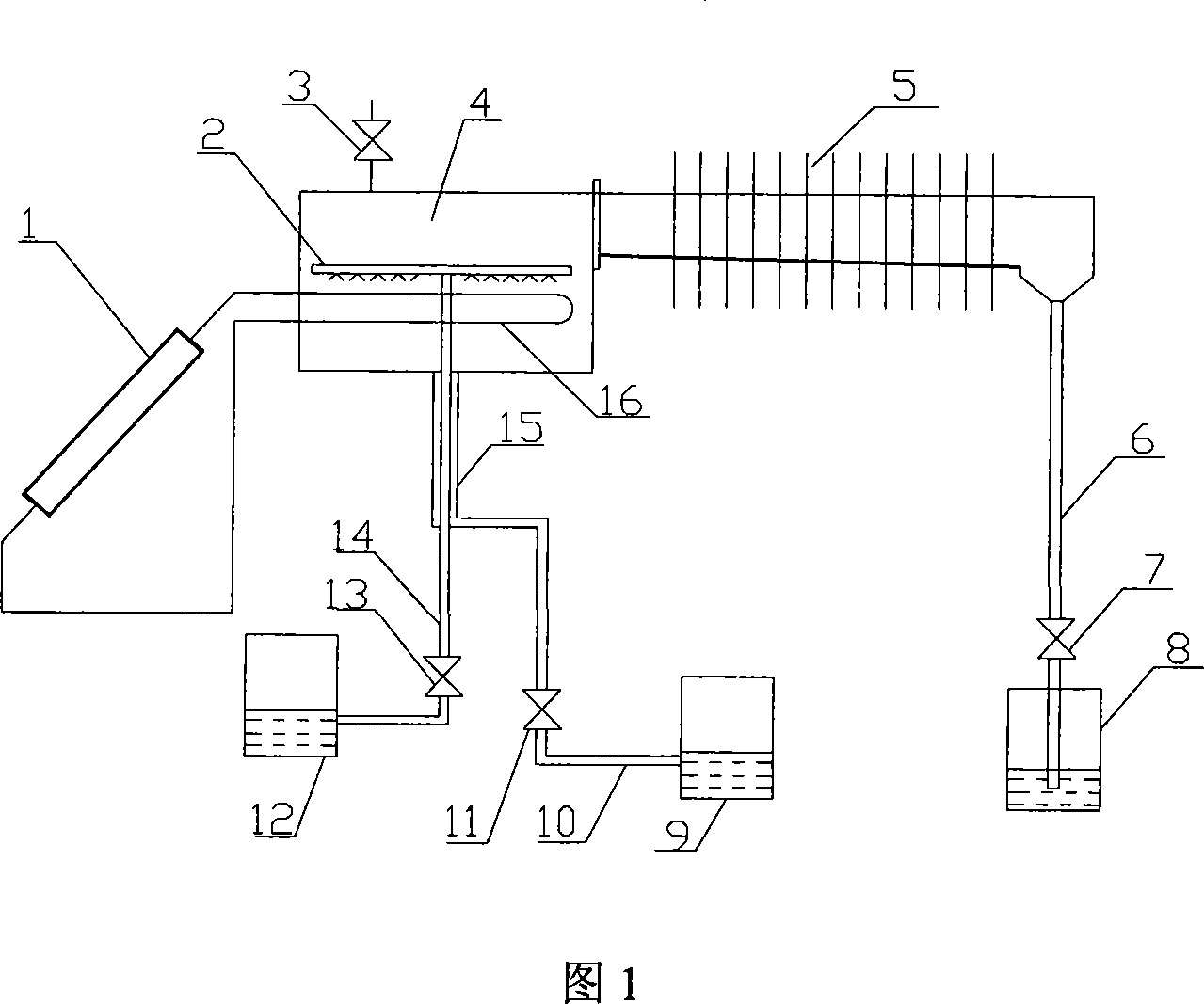

Natural vacuum low temperature distillation sea water desalination method and device

InactiveCN101177308ALower desalination costsEnergy saving effect is obviousGeneral water supply conservationSeawater treatmentWater desalinationWater vapor

The invention relates to a seawater desalination method and device of natural vacuum and low temperature distillation, which is characterized in that the system must be airtight before operation, the water injection valve on the system top is switched on to fill up the system with seawater; the drain valves of all drainage pipes connected with the evaporation chamber are switched on, then the seawater is flowed out under the influence of the gravity; the air in the system is discharged to make the system vacuum; the heat source can be conveyed to the evaporation chamber now; when the temperature of heat source is higher than the condensation temperature, the evaporation pressure of the heated seawater is higher than the condensation temperature of fresh water, the evaporated vapor is condensed by the condenser under the action of pressure difference between the evaporation pressure and the condensing pressure and finally the desalinated water can be obtained. The invention has the advantages that a sleeve regenerator is arranged on the connection section of the water supply pipe of seawater and the evaporation chamber, the heat of the strong brine discharged by the evaporator is partially adopted to preheat the seawater in the evaporator, the liquid in the system can flow freely due to the pressure difference, thus the method can economize energy source and the device can be used to desalinate the seawater on any sea island, water-deficient area or brackish water area.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

High efficiency aliphatic sulfonate water reducing agent and method for preparing same

InactiveCN1634794AExcellent water reducing rateImprove performanceHigh strength concreteSuperplasticizer

The present invention relates to a high efficiency water reducing agent for manufacturing high performance cement based material such as high-strength concrete, fluid state and / or pumping concrete, etc. and method for preparing same. The invention takes ketones compound and aldehydes as condensation monomer, and sulphite as sulphonating agent, and take condensation reaction in alkaline aqueous solution. Then a water-soluble high-polymer condensate containing hydrophilic group such as sulfonic group, carboxy, hydroxyl, etc. in molecule with molecular weight ranging from 3000 to 10000 is obtained. By changing the matching, charging sequence of raw material, the technological process is simplified, the reaction time is shortened, and burst boiling and geling phenomena are also avoided at the same time. By controlling charging rate and condensation temperature, the condensation product is made with required molecular weight and can meet application performance. The fatty group sulphonate condensation compound made by the invention can be served as high efficiency water reducing agent of cement concrete, the water reducing, dispersion and reinforcing effects are better than the traditional albocarbon group high efficiency water reducing agent. The water reducing agent provided by the invention has the advantages of wide raw material source, simple synthesizing process, clean and suitable for industrial production.

Owner:吴霖秀 +2

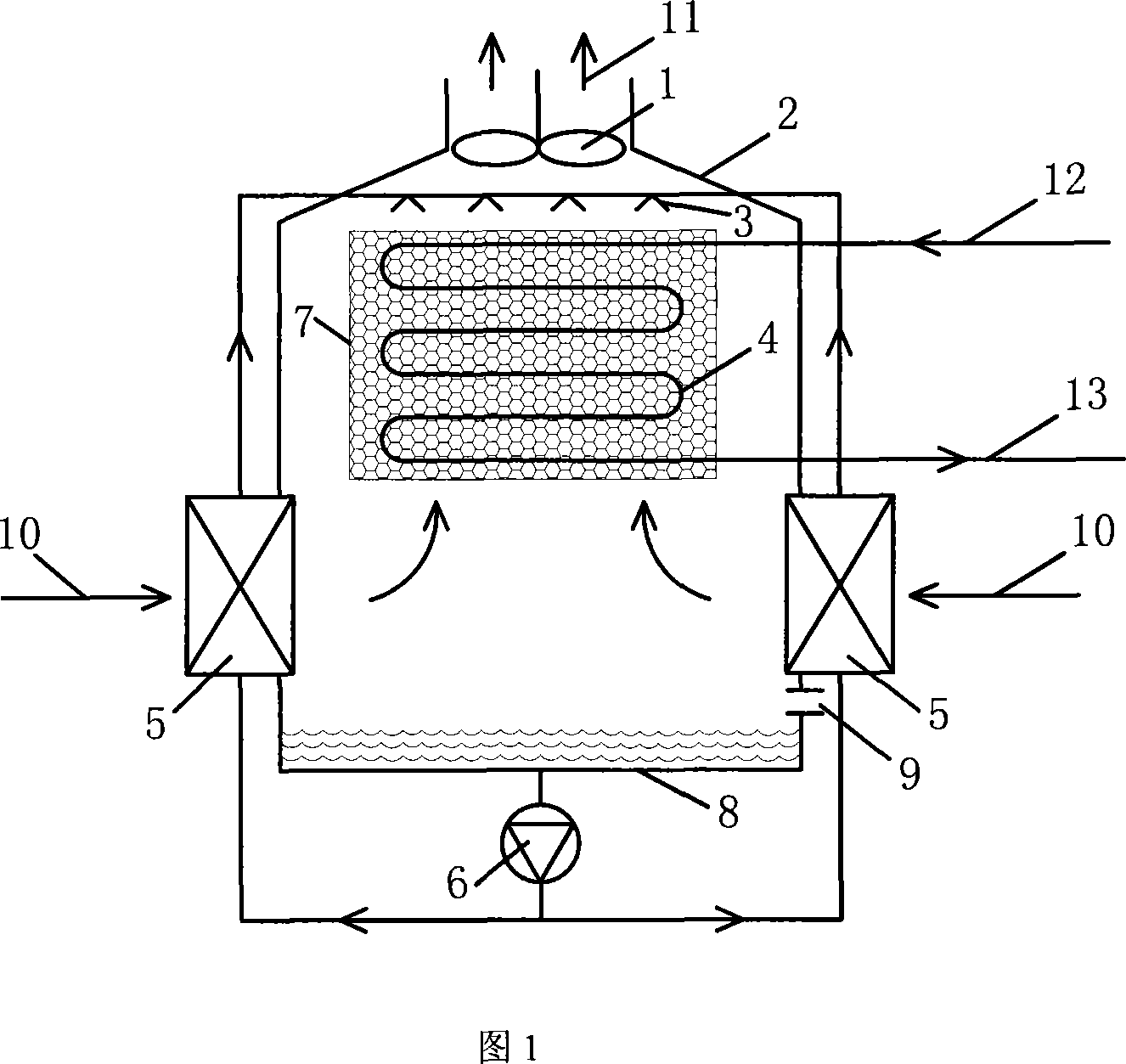

Indirect evaporation type cooling/condensing device

InactiveCN101169299AOutlet temperature dropsRealize energy-saving operationEvaporators/condensersTrickle coolersCooling towerEvaporation

An indirect evaporating cooling / condensing device comprises a blower, a shell body, a spraying machine, a dividing wall type heat exchanger, a wind inlet, a water pump and a water collecting plate, and an air-water heat exchanger which is arranged on the wind inlet. The water pump pumps water from the water collecting plate and sends to the water channel of the air-water heart exchanger, cools the environmental air inducted from the wind inlet enters the spraying machine after being cooled; the water which flows out from the spraying machine is sprayed on the outer surface of the dividing wall type heat exchanger, the water flows back to the water collecting plate depending on the gravity; and the cooled medium which enters into the dividing wall type heat exchanger from the entrance is cooled by the water sprayed from the spraying machine and then flow out from the cooled medium exit. The invention not only can be used as the enclosed type cooling tower, but also can be used as the evaporating type condenser; and compared with the prior art, the utility model can make the temperature of the out flowing liquid of the liquid with single-phase much lower in winter, and also can reduce the condensing temperature of the refrigerating and the chemical liquid system; the utility model has cooling / condensing function for the whole year and is useful for the energy saving running of air-conditions, refrigerating and chemical systems.

Owner:TSINGHUA UNIV

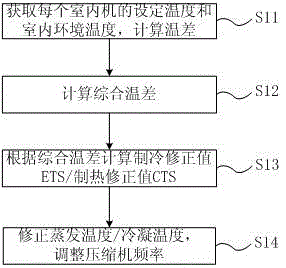

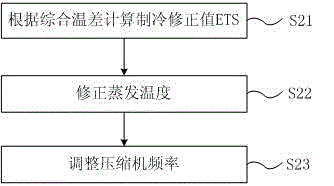

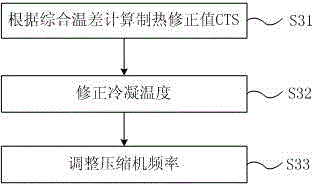

Multiple online control method and system

ActiveCN105571067AGuaranteed cooling and heating effectGood cooling and heating effectSpace heating and ventilation safety systemsLighting and heating apparatusStart stopRefrigeration temperature

The invention discloses a multiple online control method and system. The method comprises the steps that the set temperature and the indoor environment temperature of each indoor unit are obtained, and the temperature difference is calculated; the comprehensive temperature difference is calculated; a refrigeration modification value ETS / a heating modification value CTS is calculated according to the comprehensive temperature difference; and the evaporation temperature / condensation temperature is modified, and the frequency of each compressor is adjusted. According to the multiple online control method, the frequency of each compressor is adjusted according to the modified evaporation temperature / refrigeration temperature, energy is saved, and meanwhile the refrigerating / heating effect of each indoor unit can be guaranteed. When the requirement for each indoor unit is low, the frequency of the corresponding compressor is reduced, the corresponding compressor runs at the low frequency and is kept running with the low output in a low energy consumption manner, the corresponding compressor is protected against start stop, and accordingly power rise caused by start stop of the corresponding compressor is avoided. Meanwhile, the indoor units continuously run, so that the indoor temperature is maintained near the set temperature, the constant indoor temperature is achieved, a good refrigerating / heating effect is guaranteed, and the comfort degree is improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD

Cooling method and cooling system for electronic device

InactiveUS20110271695A1Cost electrical powerReduce electricity costsMechanical apparatusDigital data processing detailsCooling towerCondensation temperature

A cooling method for an electronic device, comprising:naturally circulating a refrigerant between: an evaporator which vaporizes the refrigerant by heat exchange with exhaust hot air from the electronic device, and cools the exhaust hot air; and one of a cooling tower and a condenser which is placed at a position higher than the evaporator, and liquefies the vaporized refrigerant; andvalve-controlling a flow rate of a refrigerant liquid to be supplied to the evaporator so that an air temperature after heat has been exchanged for cooling by the evaporator becomes a temperature suited to an operating environment of the electronic device, whereinone of a condensation temperature and a condensation pressure of a refrigerant gas in one of the cooling tower and the condenser do not fluctuate even when the flow rate of the refrigerant liquid to be supplied to the evaporator is valve-controlled.

Owner:HITACHI PLANT TECH LTD

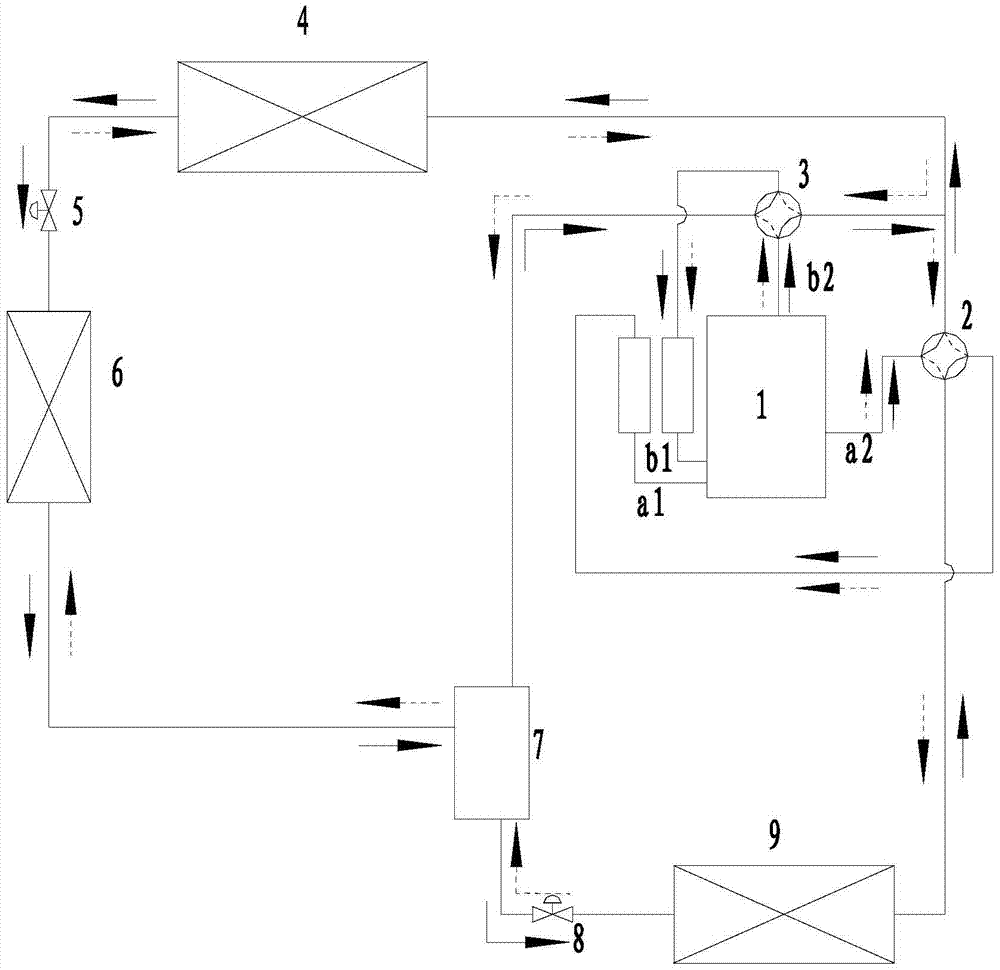

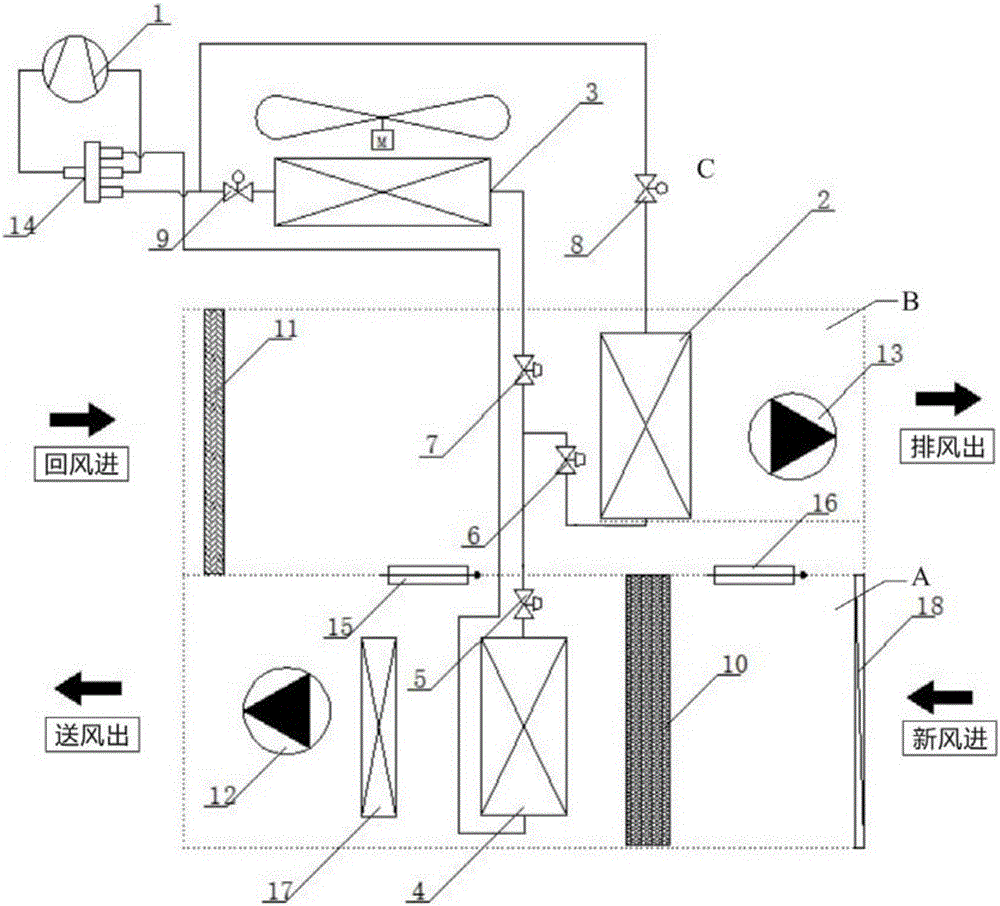

Multi-condenser and double-return-air bypass dehumidification fresh air unit and air conditioning method

ActiveCN105890070ALower condensation temperatureAvoid lossMechanical apparatusSpace heating and ventilation safety systemsEvaporationCondensation temperature

The invention relates to a multi-condenser and double-return-air bypass dehumidification fresh air unit and an air conditioning method. The multi-condenser and double-return-air bypass dehumidification fresh air unit comprises an air feed channel and an exhaust channel. A first heat exchanger and an air feeder are sequentially arranged at the position of the air feed channel. A second heat exchanger and an exhaust fan are sequentially arranged at the position of the exhaust channel. The second heat exchanger is connected with an auxiliary heat exchanger. A first return air bypass valve and a second return air bypass valve are arranged between the air feed channel and the exhaust channel. According to the multi-condenser and double-return-air bypass dehumidification fresh air unit, during refrigerating, the second heat exchanger serves as a condenser, a refrigerant is condensed through the indoor low-temperature exhaust air, the condensation temperature of the unit is reduced, and reheating is conducted through mixing of bypass return air and low-temperature fed air on the air feed side so that cooling capacity losses caused by cold and heat offset can be avoided; in a heating inner circulation mode, an outdoor unit can be started to rapidly increase the indoor environment temperature; and in an outer circulation mode, the second heat exchanger serves as an evaporator, the refrigerant is made to be evaporated through the heat of indoor exhaust air, the evaporation pressure and the heating capacity of the unit are increased, the power consumption of the unit is reduced, and the frosting risk of the unit is avoided.

Owner:JIANGSU HUIJU ARCHITECTURE TECH CO LTD

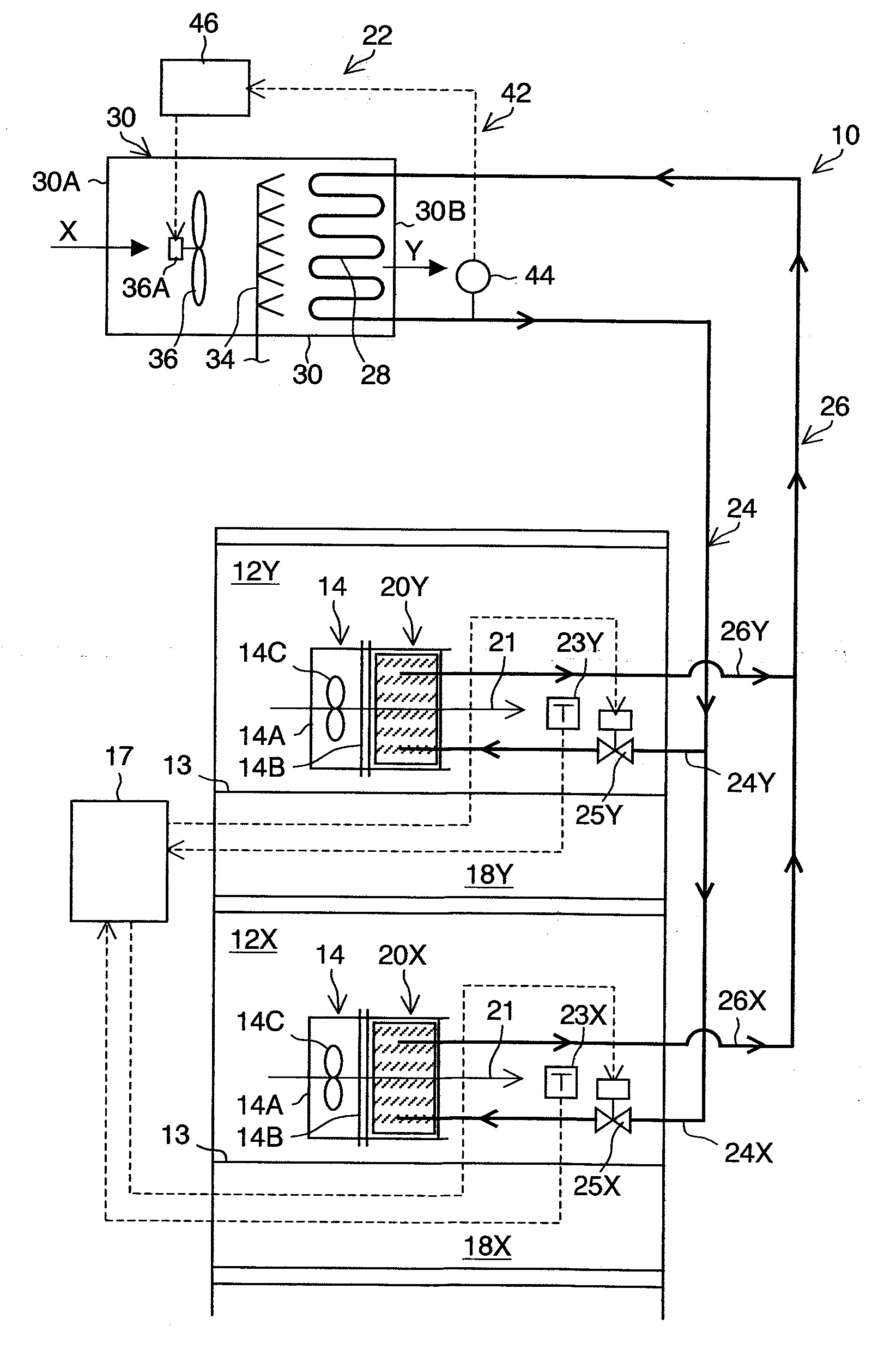

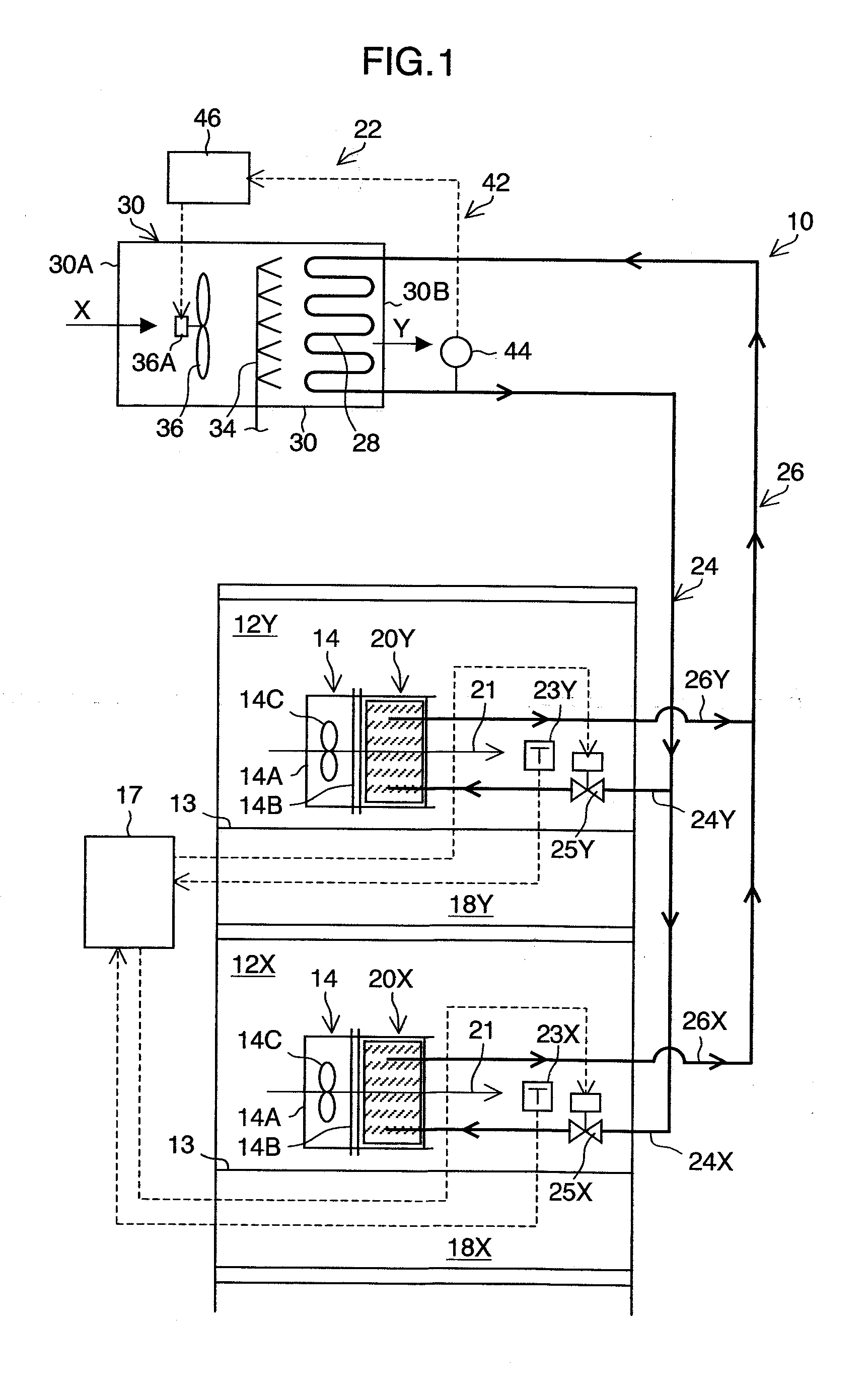

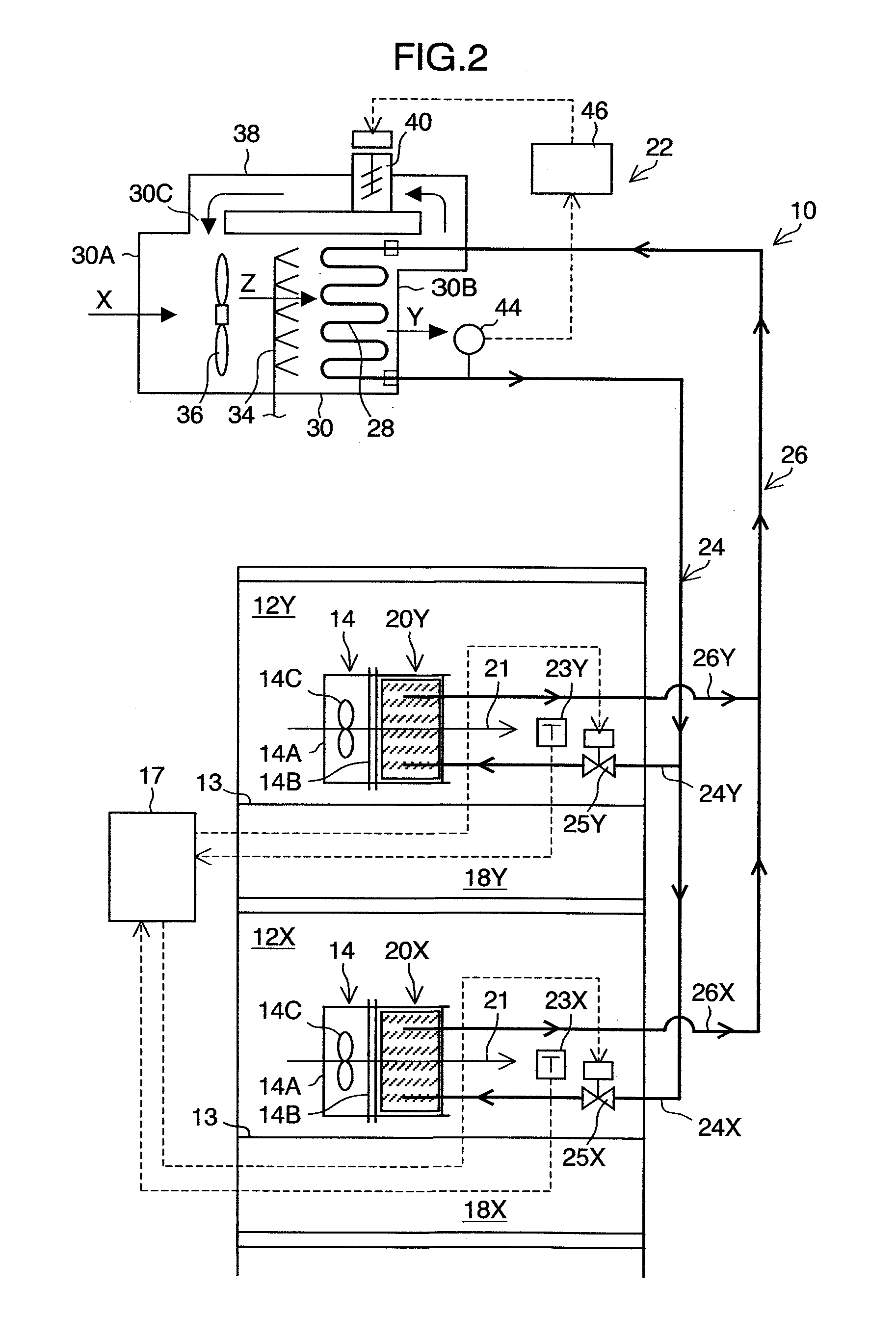

Compressor operation control device and air conditioner using the same

InactiveCN101809372AImprove comfortImprove energy savingMechanical apparatusSpace heating and ventilation safety systemsCondensation temperatureDischarge pressure

An air conditioner is so configured that only a signal associated with the ON / OFF state of a compressor is outputted from a control terminal. It is possible to perform inverter control of the compressor. An operation control device (3) of the compressor (11) is configured so as to inverter-control the compressor according to the ON signal outputted from a control interface (50) of the air conditioner (1). More specifically, the compressor (11) has a frequency controlled by correcting a target value of at least of one of the following: the blow-out temperature, the evaporation temperature, the condensation temperature, the intake pressure, and the discharge pressure of the compressor (11) according to the continuation time of the ON signal or the continuation time of the OFF state.

Owner:DAIKIN IND LTD

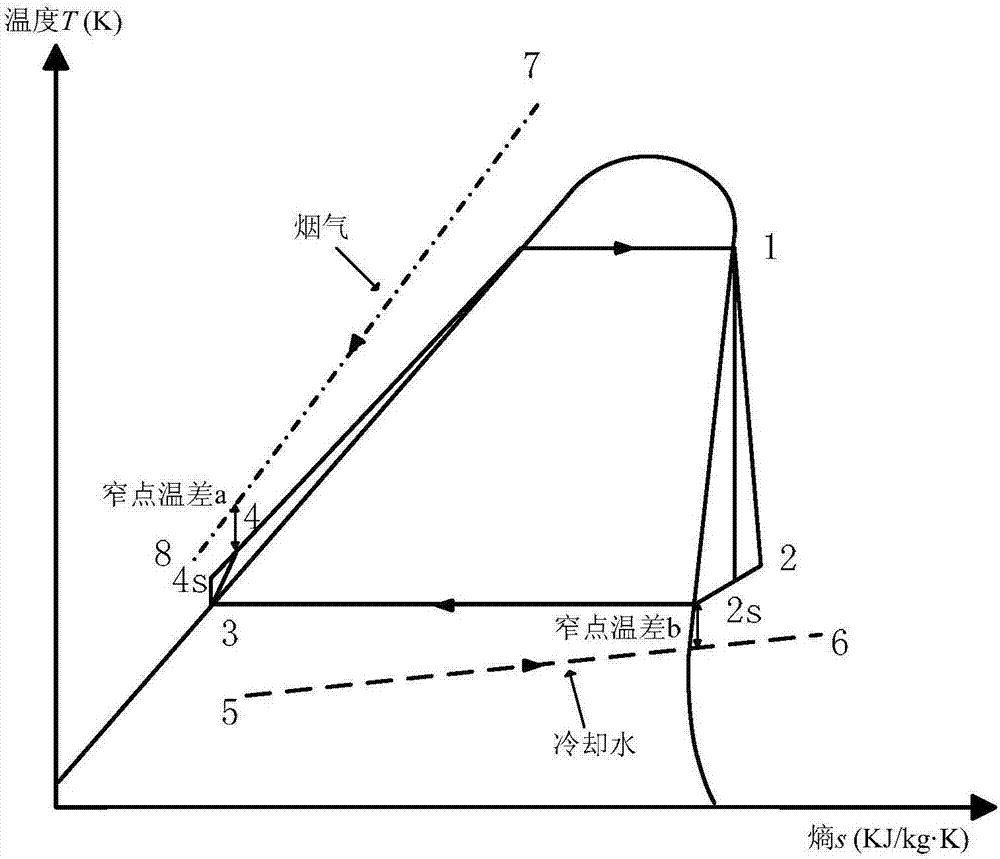

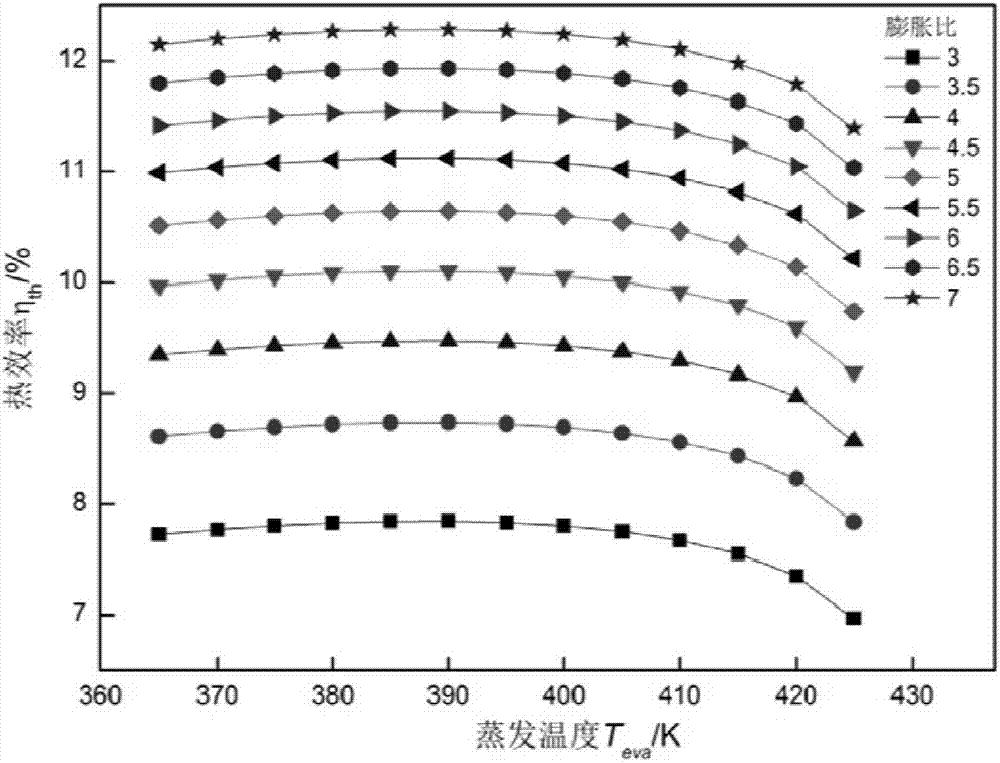

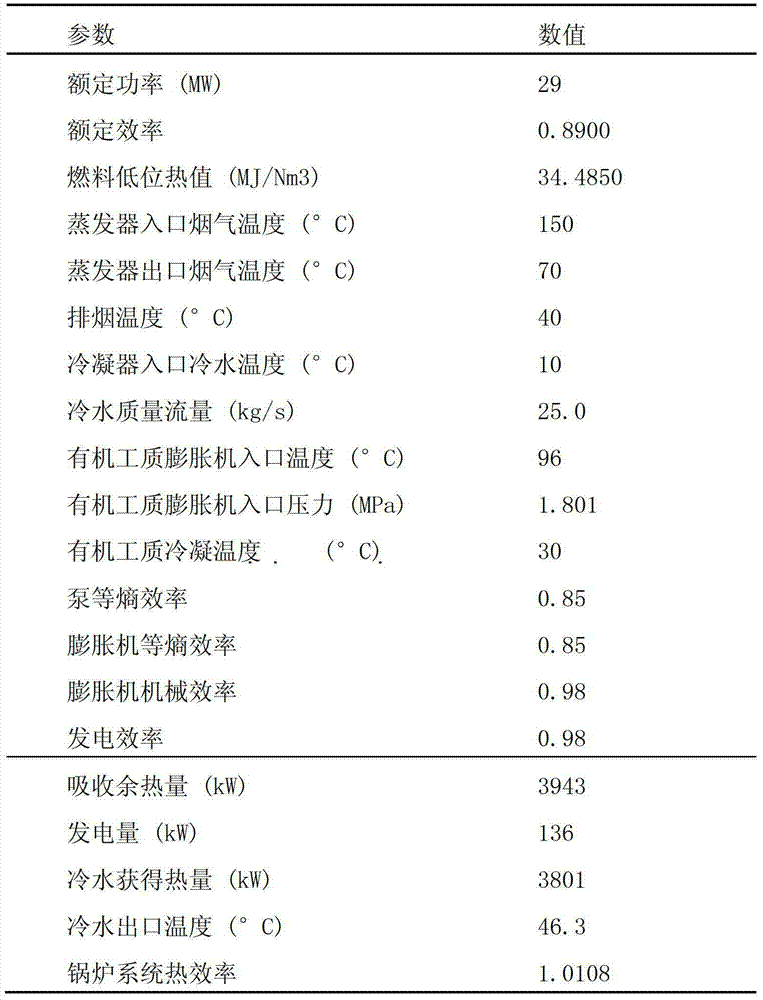

Optimization method for determining flue gas excess heat organic Rankine cycle system parameter

InactiveCN107016187AIncrease profitEmission reductionGeneral water supply conservationForecastingOrganic Rankine cycleSecond law of thermodynamics

The invention provides an optimization method for determining a flue gas excess heat organic Rankine cycle system parameter. The optimization method comprises the steps of taking into account of a cooling water cycle to establish a thermodynamic model; through a first law of thermodynamics and a second law of thermodynamics, obtaining system net output power, water pump waste power, heat efficiency, (the formula is shown in the description) efficiency and irreversible loss, and according to the influence of an evaporation temperature and an expansion ratio on system thermodynamic performance, determining an optimal evaporation temperature; under the optimal evaporation temperature, calculating heat exchange areas of an evaporator and a condenser, wherein it is defined that an economical objective function is the ratio of the system net output power to the area of the evaporator to the area of the condenser, and the comprehensively evaluation function is the weighted sum the economical objective function (the formula is shown in the description) and the efficiency; with the comprehensive evaluation function being an optimization target, determining an optimal condensation temperature; according to the optimal evaporation temperature and the optimal condensation temperature, determining system parameters of work medium mass, cooling water mass, evaporation pressure, condensation pressure, an expansion ratio, the net output power, the heat efficiency and the irreversible loss. According to the optimization method for determining the flue gas excess heat organic Rankine cycle system parameter, the optimal evaporation temperature and the condensation temperature can be determined, and thus the optimal system parameter is determined.

Owner:TIANJIN UNIV

Working fluid for heat cycle, composition for heat cycle system, and heat cycle system

ActiveUS10131827B2Stably used continuouslyCycle performance sufficientHeat-exchange elementsWorking fluidEngineering

To provide a working fluid which has cycle performance sufficient as an alternative to R410A while the influence over global warming is sufficiently suppressed, which does not significantly increase the load to an apparatus as compared with a case where R410A is used, and which can be stably used continuously without any special measures, a composition for a heat cycle system contains the working fluid, and a heat cycle system employs the composition. A working fluid for heat cycle, wherein the global warming potential is less than 300; the product of the relative coefficient of performance and the relative refrigerating capacity is at least 0.820 relative to R410A in a standard refrigerating cycle under conditions of an evaporation temperature of 0° C., a condensing temperature of 40° C., a supercoiling degree of 5° C. and a degree of superheat of 5° C.; the relative compressor discharge gas pressure is at most 1.100; the lower limit of the combustion range by method A in High Pressure Gas Safety Act is at least 5 vol %; and the pressure will not exceed 2.00 MPaG in a combustion test by method A in High Pressure Gas Safety act under 0.98 MPaG at 250° C.

Owner:ASAHI GLASS CO LTD

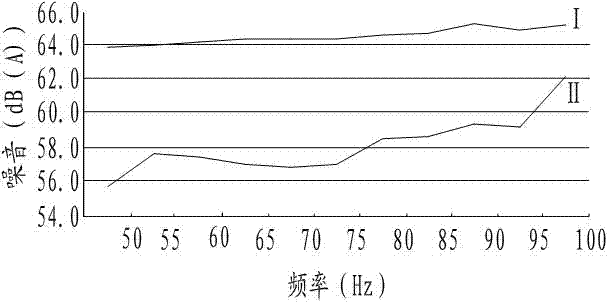

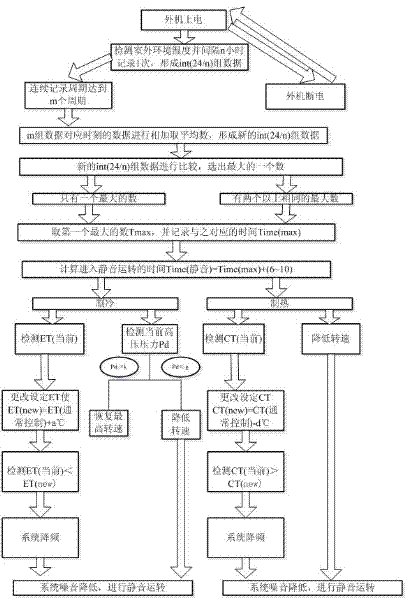

Method for controlling operation of air conditioner in mute mode

ActiveCN102418981ALow RPMReduce outputSpace heating and ventilation safety systemsLighting and heating apparatusLow noisePower conditioner

The invention provides a method for controlling operation of an air conditioner in a mute mode. In the method, the air conditioner can automatically enter a mute control mode according to the change of outdoor environment temperatures, so that automatic control is realized. The method comprises the following steps of: calculating the time when the air conditioner starts to operate in the mute mode; during refrigeration, controlling the relation of the common target evaporation temperature during operation of an air conditioning system in an unmute mode and a new target evaporation temperature; and during heating, controlling the relation of the common target condensation temperature during operation of the air conditioning system in the unmute mode and a new target condensation temperature. By the method, the frequency and the noise of the air conditioning system are reduced, and the air conditioning system operates in the mute mode; and the change of the environment temperature is scientifically calculated, the air conditioning system is intelligently controlled, an outdoor unit is automatically controlled, and operation such as dial-up setting and the like is not required, so requirements of customers on the effect of the air conditioner can be met, requirements of the customers on low noise can also met, and system failures can be avoided.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Efficient and energy-saving control algorithm for variable frequency air conditioner

ActiveCN104019528AImprove energy efficiency ratioWeakened comfortSpace heating and ventilation safety systemsLighting and heating apparatusBusiness efficiencyHigh energy

The invention discloses an efficient and energy-saving control algorithm for a variable frequency air conditioner. The efficient and energy-saving control algorithm comprises the following steps: detecting a difference value between a target condensation temperature and a current condensation temperature and a difference value between a target evaporation temperature and a current evaporation temperature; determining control logics of an electronic expansion valve and a compressor, an indoor draught fan and a draught fan of an outdoor unit; and controlling the operation of the air conditioner by taking the highest energy efficiency ratio as a target and taking the maximum energy efficiency ratio in unit time as a control target so as to realize the energy-saving aim, weaken the comfort level of a user and increase the energy efficiency ratio of the air conditioner.

Owner:东元总合科技(杭州)有限公司

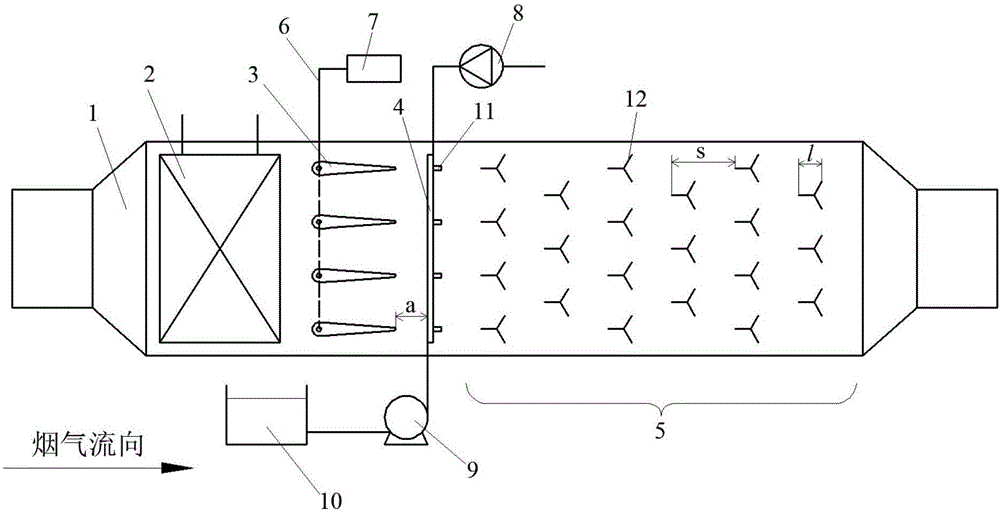

Device and method for atomizing turbulent agglomerated granules

InactiveCN106492581AEfficient collisionImprove controllabilityGas treatmentAuxillary pretreatmentParticulatesAxis of symmetry

The invention discloses a device and method for atomizing turbulent agglomerated granules. The device is simple in structure, good in agglomeration effect and good in universality. The device comprises a shell, wherein a fume channel is formed inside the shell; a fume heat exchanger, guide blades, a double-fluid ejection atomization section and a turbulent agglomeration section are sequentially arranged inside the shell in a fume flowing direction; the fume heat exchanger is used for reducing the temperature of dust-containing fume to T, wherein T is not higher than condensation temperature of steam in the dust-containing fume; the guide blades are used for adjusting the flowing direction so that the flowing direction of granules in the dust-containing fume trends to be accordant with that of the fume; the double-fluid ejection atomization section comprises a gas supply pipeline, a water supply pipeline and double-fluid nozzles; the ejection directions of the double-fluid nozzles for connecting the gas supply pipeline and the water supply pipeline are parallel to the flowing direction of the fume; the turbulent agglomeration section comprises a plurality of turbulent elements which are arranged in sequence or in a staggered manner, and two ends of each turbulent element are fixed on the inner wall of the shell; and the turbulent elements comprise boundary plates which are symmetrically arranged by taking the fume direction as an axis of symmetry, and the front ends of the boundary plates are fixedly connected.

Owner:XI AN JIAOTONG UNIV

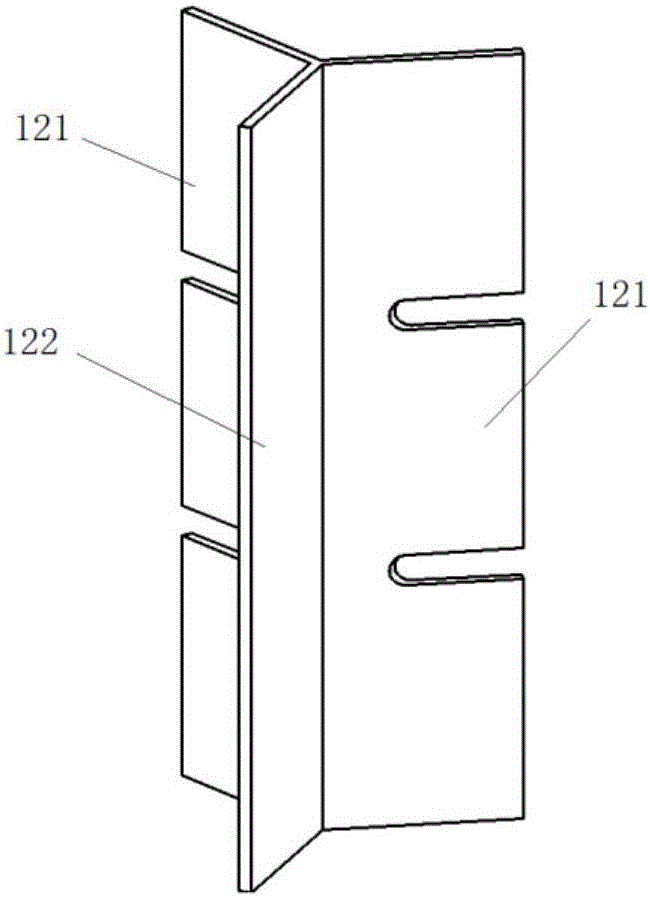

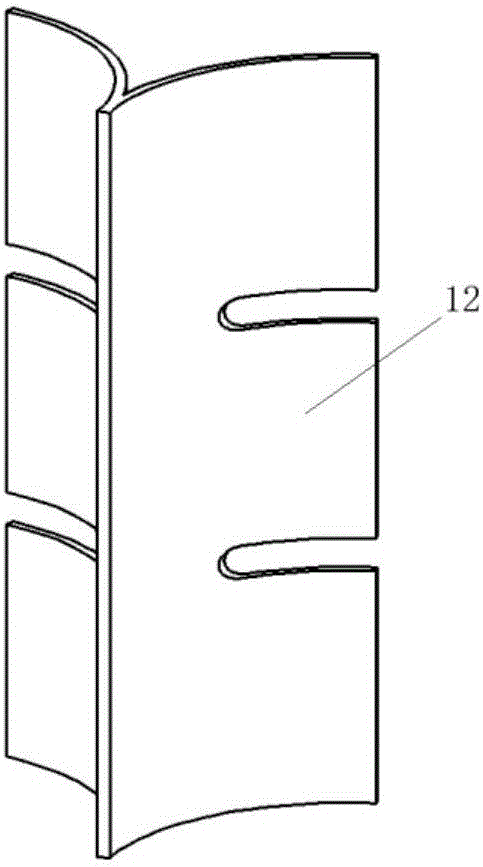

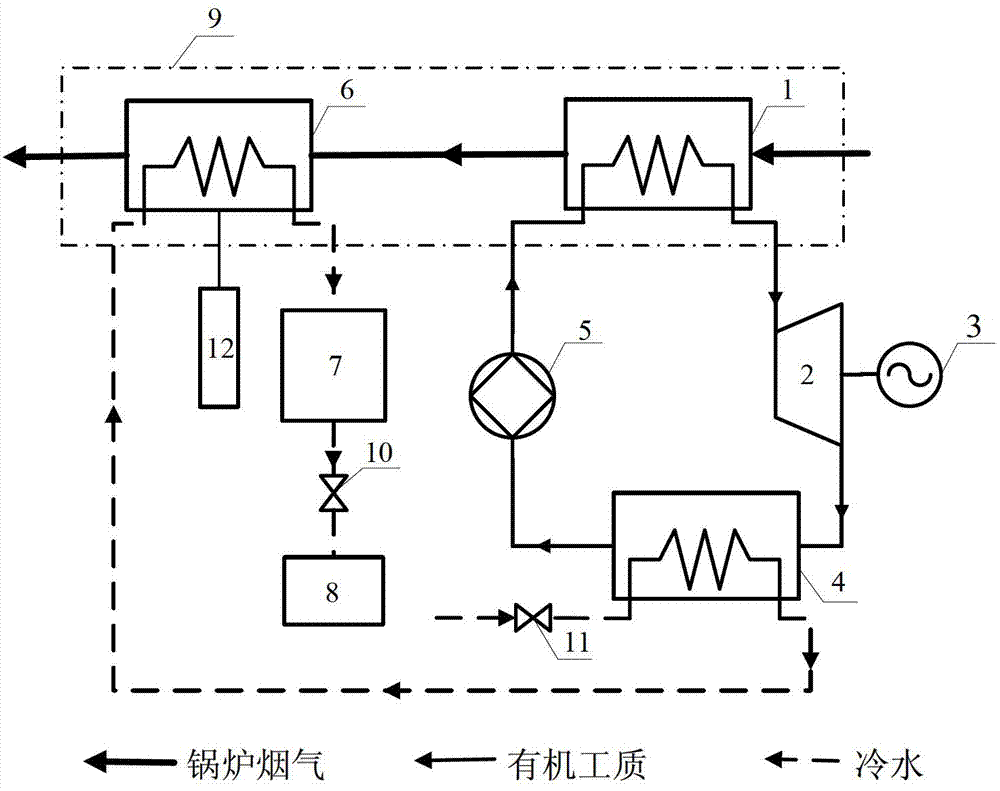

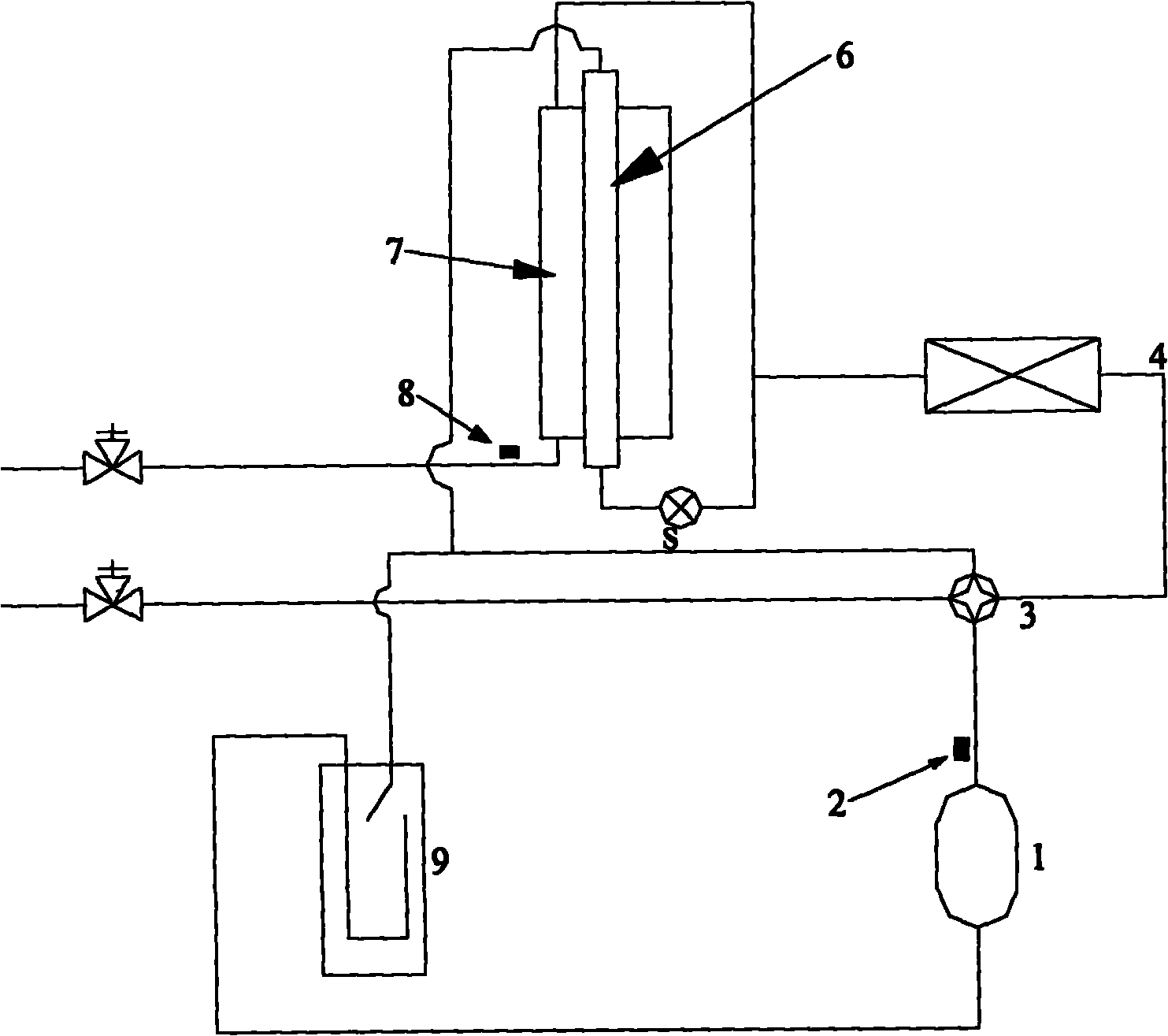

Smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle

ActiveCN103244214AHigh thermal efficiencyImprove utilization efficiencyEnergy efficient heating/coolingSteam useThermal energyOrganic Rankine cycle

The invention relates to a smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle and belongs to the technical field of energy utilization. The system comprises an evaporator (1), a condenser (4) and the like. The evaporator (1) and a smoke condensation heat exchanger (6) are disposed in a boiler tail flue. The system is used for step recovery of boiler smoke sensible heat and latent heat to allow for gradient deep utilization of smoke waste heat; high-quality sensible heat in the smoke is absorbed and utilized to output electric energy by organic Rankine cycle; and low-quality sensible heat and vapor latent heat in the smoke are absorbed by cold water, and the smoke is cooled to the temperature below dew point. In addition, organic Rankine cycle condensation temperature is lower than smoke temperature, so that the cold water sequentially passes the condenser and the smoke condensation heat exchanger to be heated and smoke waste heat is utilized deeply. The smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle allows for combined heat and power supply by organic Rankine cycle and gradient deep utilization of natural gas boiler smoke and fully recovers the heat; is environment-friendly; and is important to improving comprehensive utilization rate of fossil energy in China and promoting industrial energy conservation.

Owner:淳能热电科技股份有限公司

Air-conditioning system and method for judging whether refrigerant perfused amount is proper

InactiveCN101839580AOvercoming indeterminationGuaranteed circulationCompression machines with several evaporatorsSubcoolersCondensation temperatureMaster controller

The invention provides an air-conditioning system with a subcooler, a temperature sensor is arranged on a pipeline between a subcooler liquid pipe and an indoor unit, a pressure sensor is arranged at the exhaust port of a compressor, and the temperature sensor and the pressure sensor are connected on a master controller. The invention also provides a method for judging whether the refrigerant perfused amount in the air-conditioning system with the subcooler is proper, comprising the following steps: calculating the difference between the high voltage condensation temperature of refrigerant at the exhaust port of the compressor and the temperature of the refrigerant at the liquid outlet of a high voltage side of the subcooler, namely obtaining an actual subcooling degree; and comparing the difference of the actual subcooling degree and a target subcooling degree with a judgment value, and judging whether the refrigerant perfused amount is proper according to the comparing result. The invention overcomes the problem that the refrigerant perfused amount can not be judged in the existing air-conditioning system with a subcooler, can ensure circulated operation of the air conditioning system with a proper refrigerant, improves the operation efficiency and service life of a unit and ensures the use effect for users.

Owner:GREE ELECTRIC APPLIANCES INC

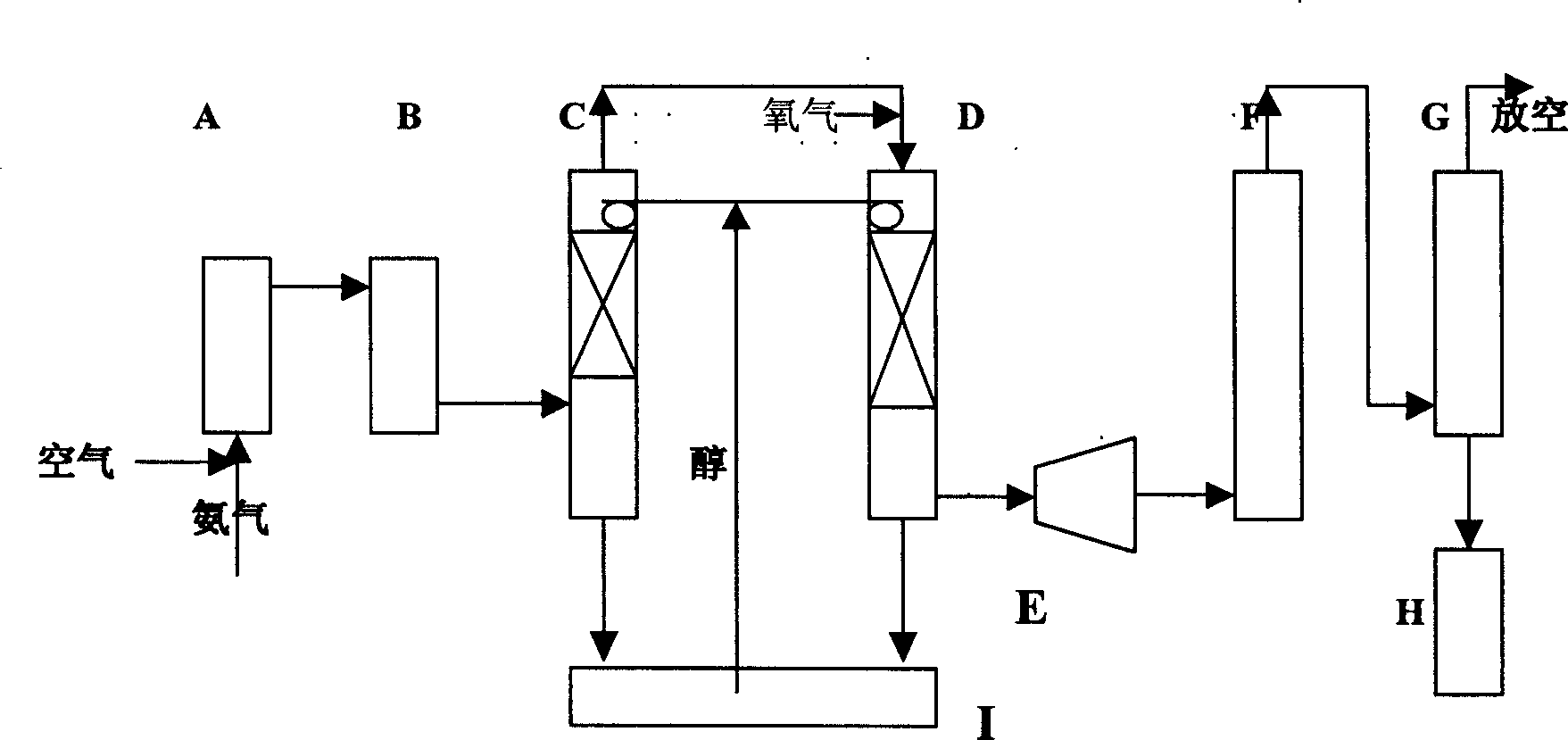

Production process of No gas for synthesizing oxalate

The production process of NO gas for synthesizing oxalate belongs to the field of chemical and environment protection technology. The production process includes ammoxidation of air to produce NOx as the NO gas for synthesizing oxalate, or utilizing the NOx in nitric acid producing tail gas as the NO gas for synthesizing oxalate, absorbing nitrite with alcohols and compression and condensation to recover alcohols and nitrite from the tail gas. The production process has liquid ammonia or gaseous ammonia of concentration 1-30 vol%, oxygen of concentration 1-30 vol%, alcohol concentration of 50-100 wt%, pressure of 0.1-10 MPa, and condensation temperature of ¿C20 to 100 deg.c. The present invention has high economic utility and social utility.

Owner:TONGLIAO GOLD COAL CHEM

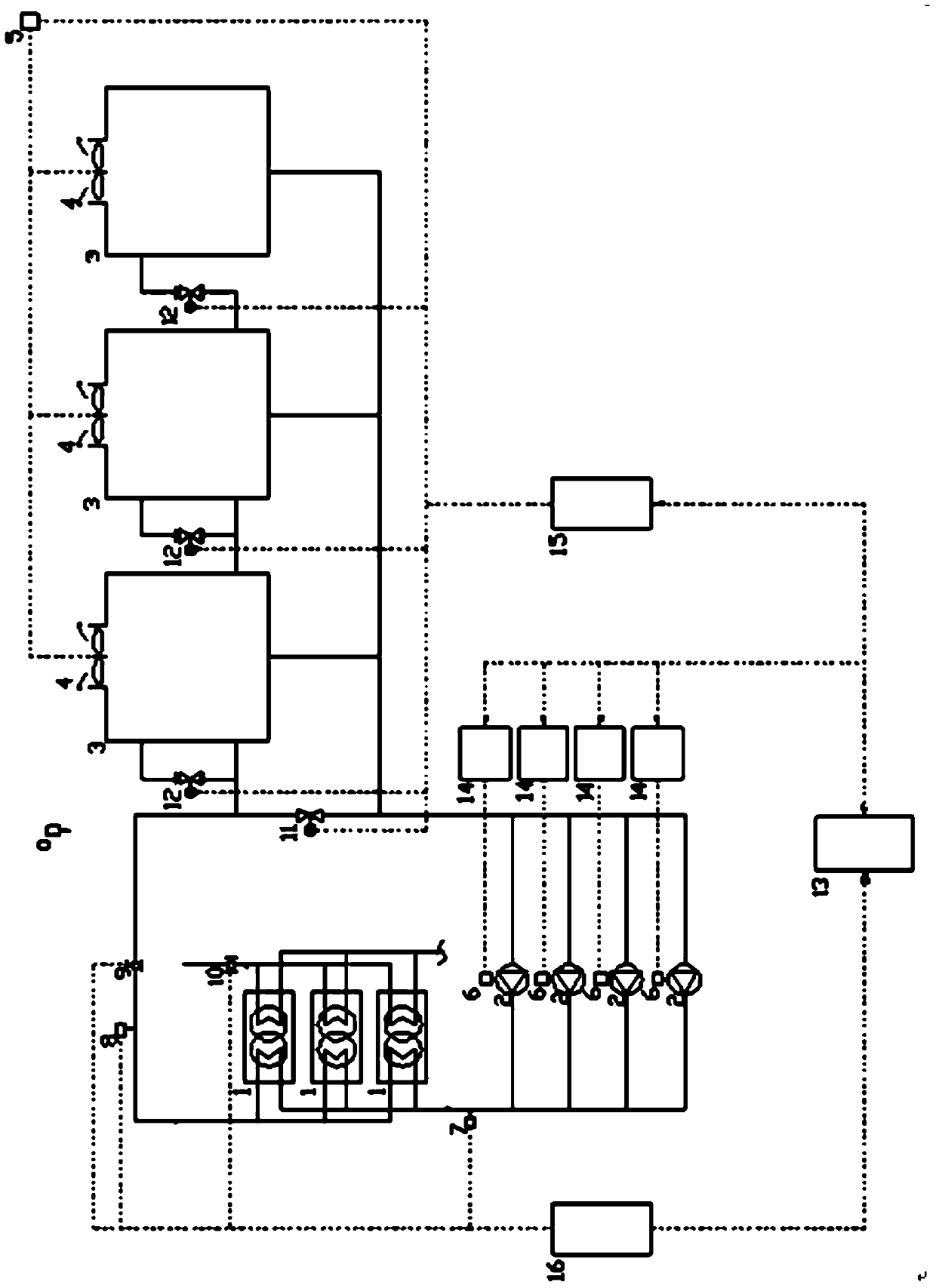

Cooling efficiency maximization method for cooling water system in central air-conditioner and control device

ActiveCN104089362ALow powerImprove dynamic performanceSpace heating and ventilation safety systemsLighting and heating apparatusNerve networkCooling tower

The invention relates to the field of energy conservation of central air-conditioner systems and aims at providing a cooling efficiency maximization method for a cooling water system in a central air-conditioner and a control device. The control device comprises a cooling water pump control cabinet, a cooling tower control cabinet, a main controller and an information acquisition module, wherein the information acquisition module, the cooling water pump control cabinet and the cooling tower control cabinet are bidirectionally connected with the main controller through signal wires respectively to achieve data transmission and signal control; the cooling water pump control cabinet comprises an intelligent cooling water pump controller with a communication port; the cooling tower control cabinet comprises an intelligent cooling tower controller with a communication port. The control device has the benefits that the cooling water system is dynamically adjusted according to the best condensation temperature under different loads and different outdoor wet-bulb temperatures; compared with fuzzy control, a self-organized fuzzy control mode based on a nerve network has the characteristics that the dynamic performance is improved and the target value can be closely followed.

Owner:HANGZHOU ZETA TECH

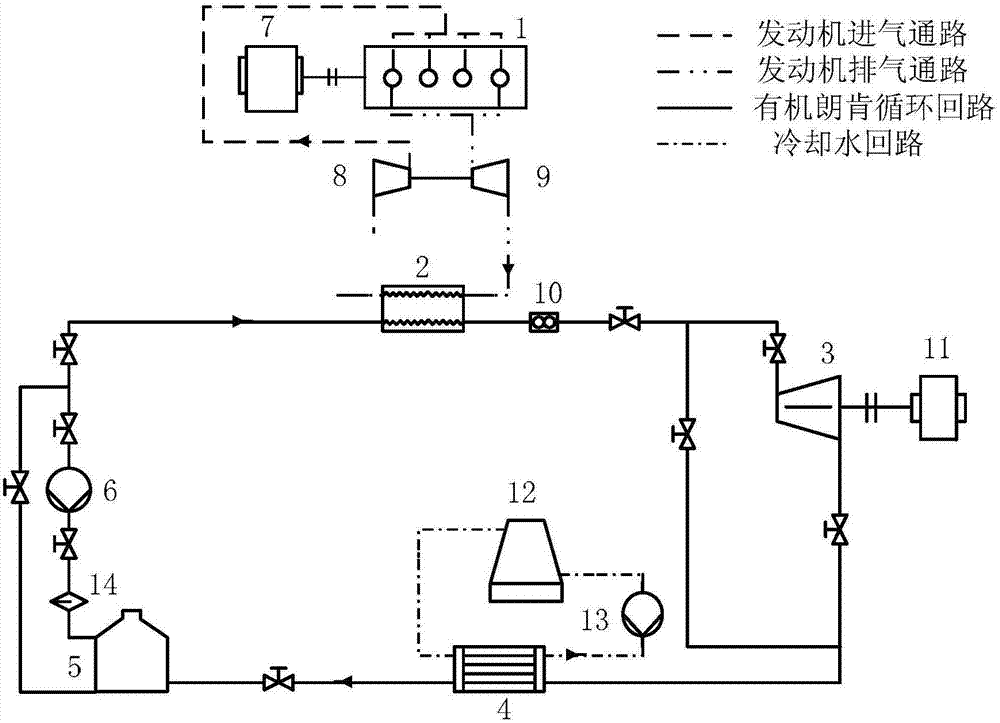

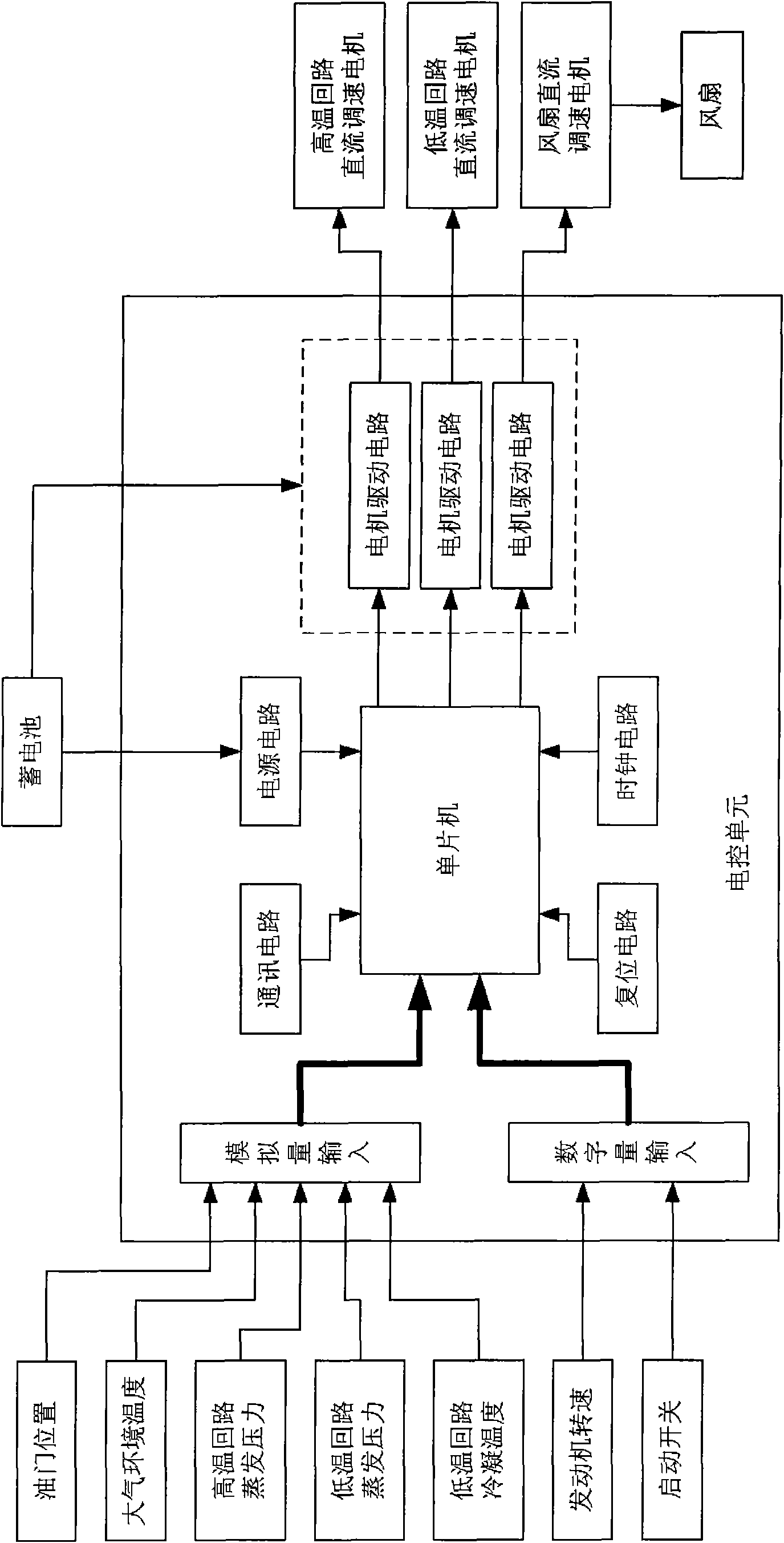

Control system and method for generating power by waste heat of diesel engine

InactiveCN102003229AHigh output useful workImprove useful workInternal combustion piston enginesEngine componentsClosed loop feedbackOrganic Rankine cycle

The invention provides a control system and method for generating power by waste heat of vehicle diesel engine, wherein the control method comprises the following steps: converting the waste heat which is taken away by the exhaust of a diesel engine to an available power by using an organic rankine cycle with a high-temperature circuit of close-loop feedback control, outputting the available power, converting the waste heat which is taken away by the cold solution of the diesel engine to an available power by using an organic rankine cycle with a low-temperature circuit of close-loop feedback control, outputting the available power and driving the electric generator generate electricity; the flow rate of working medium is controlled by regulating the revolution speed of a motor, and a pressure regulation valve of high-temperature circuit is connected to the working medium of the high-temperature circuit in parallel so as to limit the supreme evaporating pressure and control the flow rate of the cold air which is flown through a condenser and to regulate condensation temperature of the low-temperature circuit. The control system for generating power by waste heat is used for judging the working condition of the engine by collecting the revolution speed of the engine and the position signal of the accelerator pedal, accurately regulating flow rates of the working mediums of high-temperature circuit and low-temperature circuit, fully utilizing the waste heat of diesel engine, improving the thermal efficiency of the diesel engine and simultaneously reducing the harm of exhaust of the diesel engine to the environment.

Owner:BEIJING UNIV OF TECH

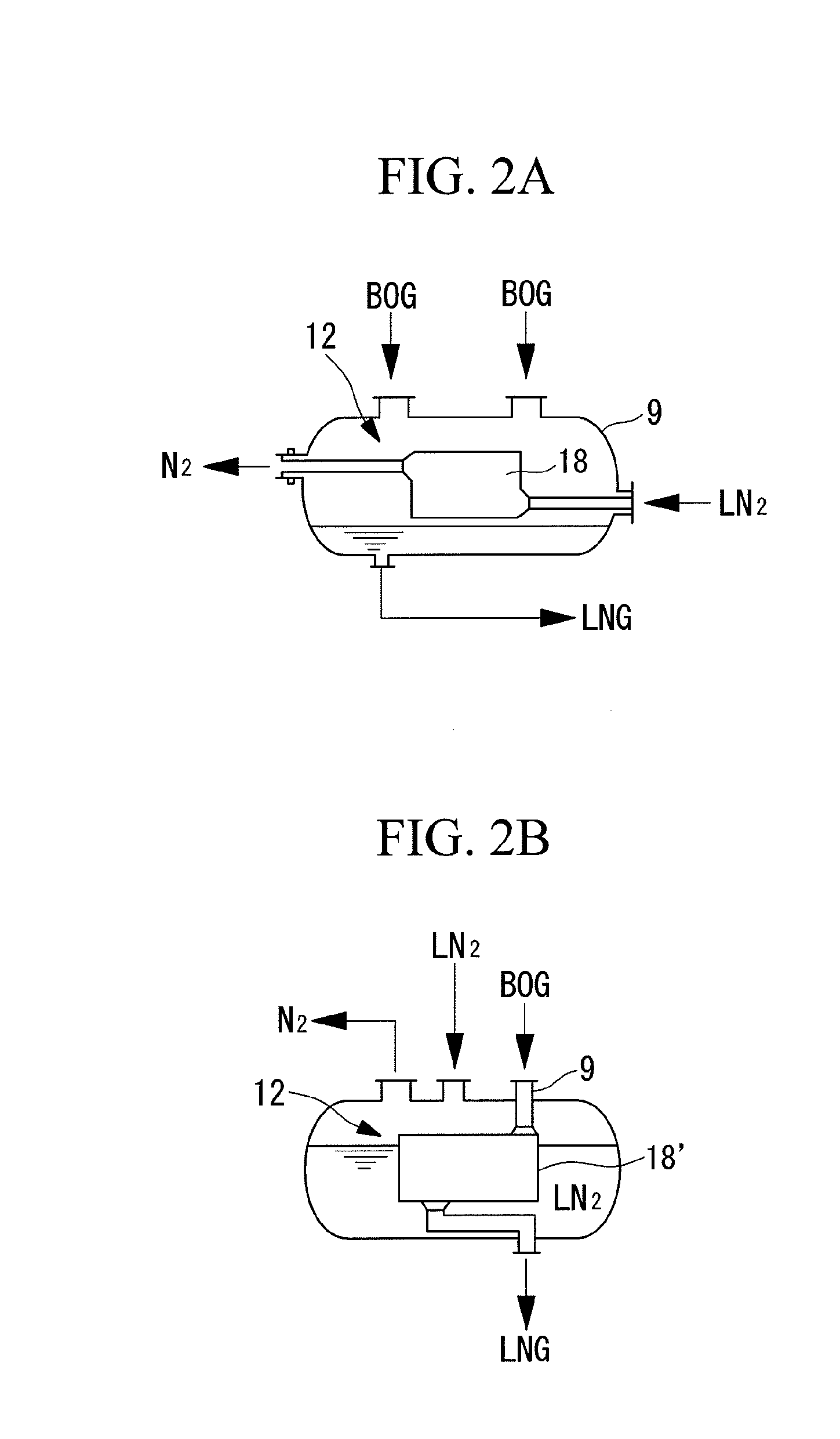

Liquefied gas reliquefier, liquefied-gas storage facility and liquefied-gas transport ship including the same, and liquefied-gas reliquefaction method

ActiveUS20100170297A1Simple configurationIncrease redundancySolidificationVessel mounting detailsRefrigerator carEvaporation

A liquefied gas reliquefier that can be configured compactly and that is easy to handle is provided. A liquefied gas reliquefier (1) reliquefies BOG resulting from evaporation of LNG in a cargo tank (3). The liquefied gas reliquefier (1) includes a refrigerator group (20) disposed in a secondary-refrigerant circulating channel (24) through which nitrogen, which has a lower condensation temperature than the BOG, circulates to liquefy the nitrogen; a feed pump (22) for feeding the liquid nitrogen cooled by the refrigerator group (20) through the secondary-refrigerant circulating channel (24); and a heat exchanger (12) disposed in the secondary-refrigerant circulating channel (24) to condense the BOG by heat exchange between the BOG and the liquid nitrogen fed by the feed pump (22). The heat exchanger (12) is disposed near the cargo tank (3).

Owner:MITSUBISHI SHIPBUILDING CO LTD

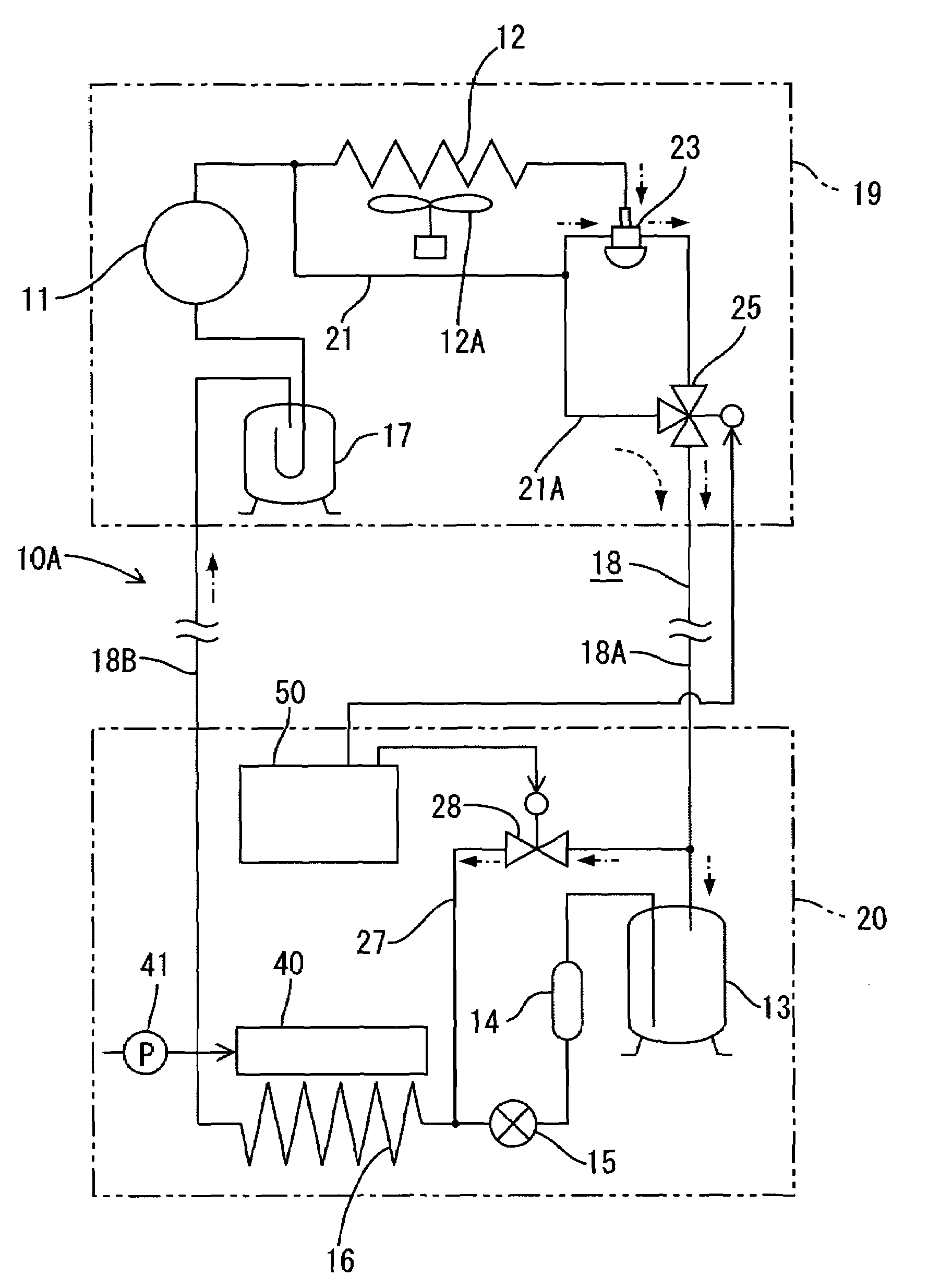

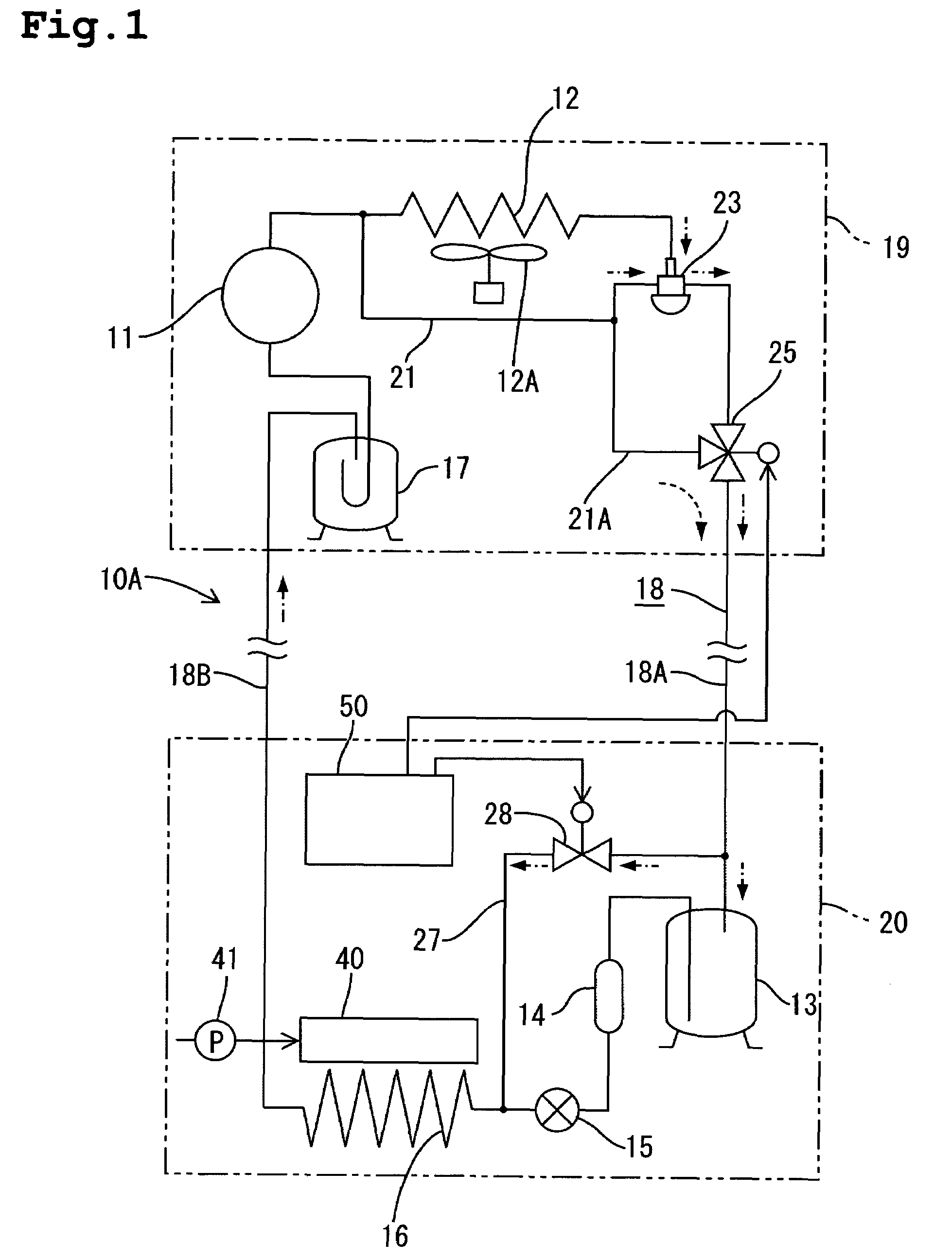

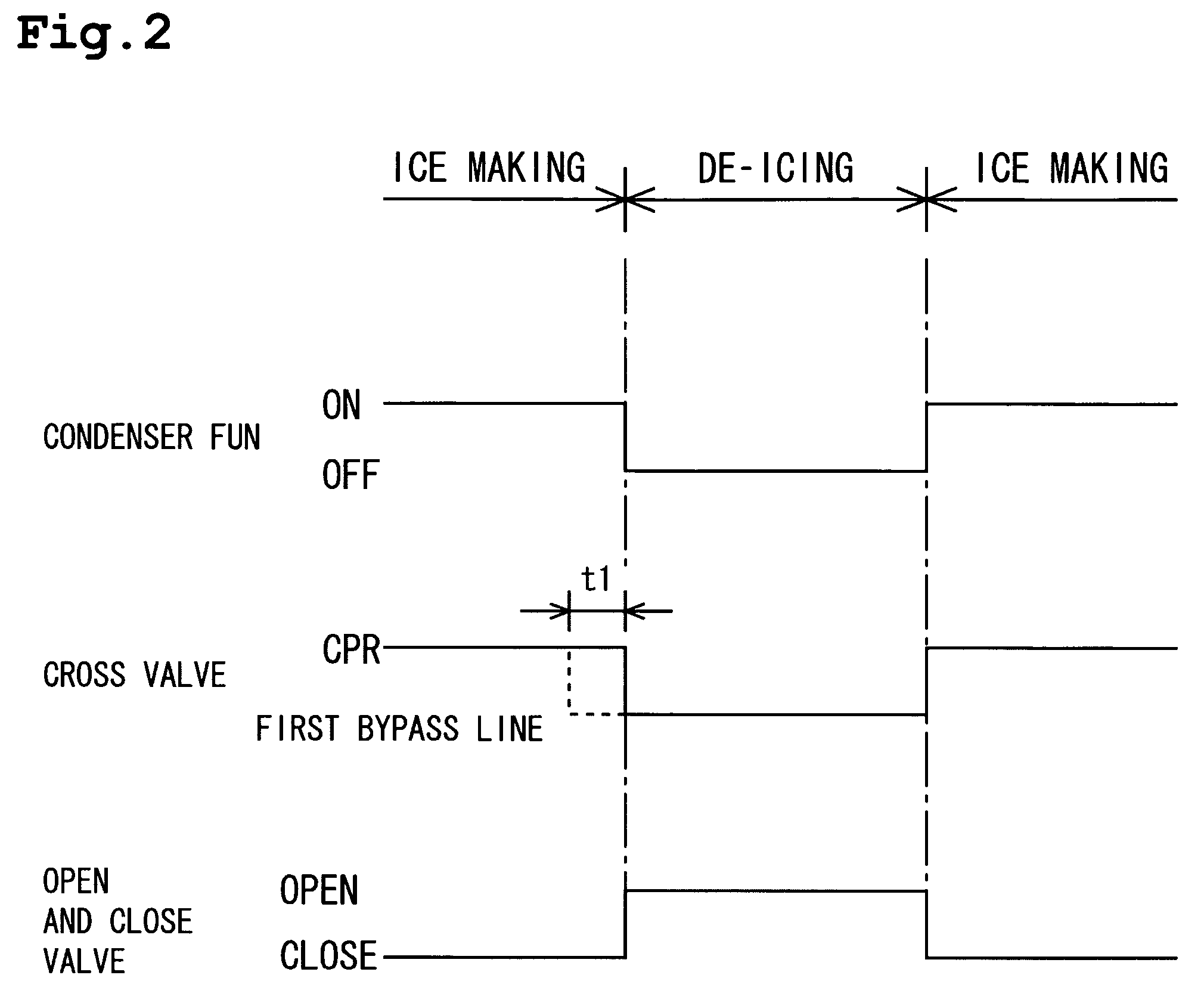

Ice making machine

In external unit 19, three-way valve 25 provided downstream of CPR 23 enables a switching connection between CPR 23 and branch line 21A of first bypass line 21 with respect to liquid line 18 A. In internal unit 20, second bypass line 27 connects inlet side of receiver 13 and inlet side of evaporator 16, and open / close valve 28 is provided along second bypass line 27. At de-icing, three-way valve 25 switches to first bypass line 21 side and open / close valve 28 opens. There upon, hot gas from compressor 11 circulates from first bypass line 21 to liquid line 18A to enter evaporator 16 through second bypass line 27 while squeezing out liquid refrigerant. Evaporator 16 is heated by manifest heat of introduced hot gas, and when the internal pressure of vaporator 16 rises to a condensation temperature over 0° C., de-icing is performed efficiently by manifest heat plus latent heat.

Owner:HOSHIZAKI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com