Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1091 results about "Cetane number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cetane number (cetane rating) is an indicator of the combustion speed of diesel fuel and compression needed for ignition. It is an inverse of the similar octane rating for gasoline. The CN is an important factor in determining the quality of diesel fuel, but not the only one; other measurements of diesel fuel's quality include (but are not limited to) energy content, density, lubricity, cold-flow properties and sulphur content.

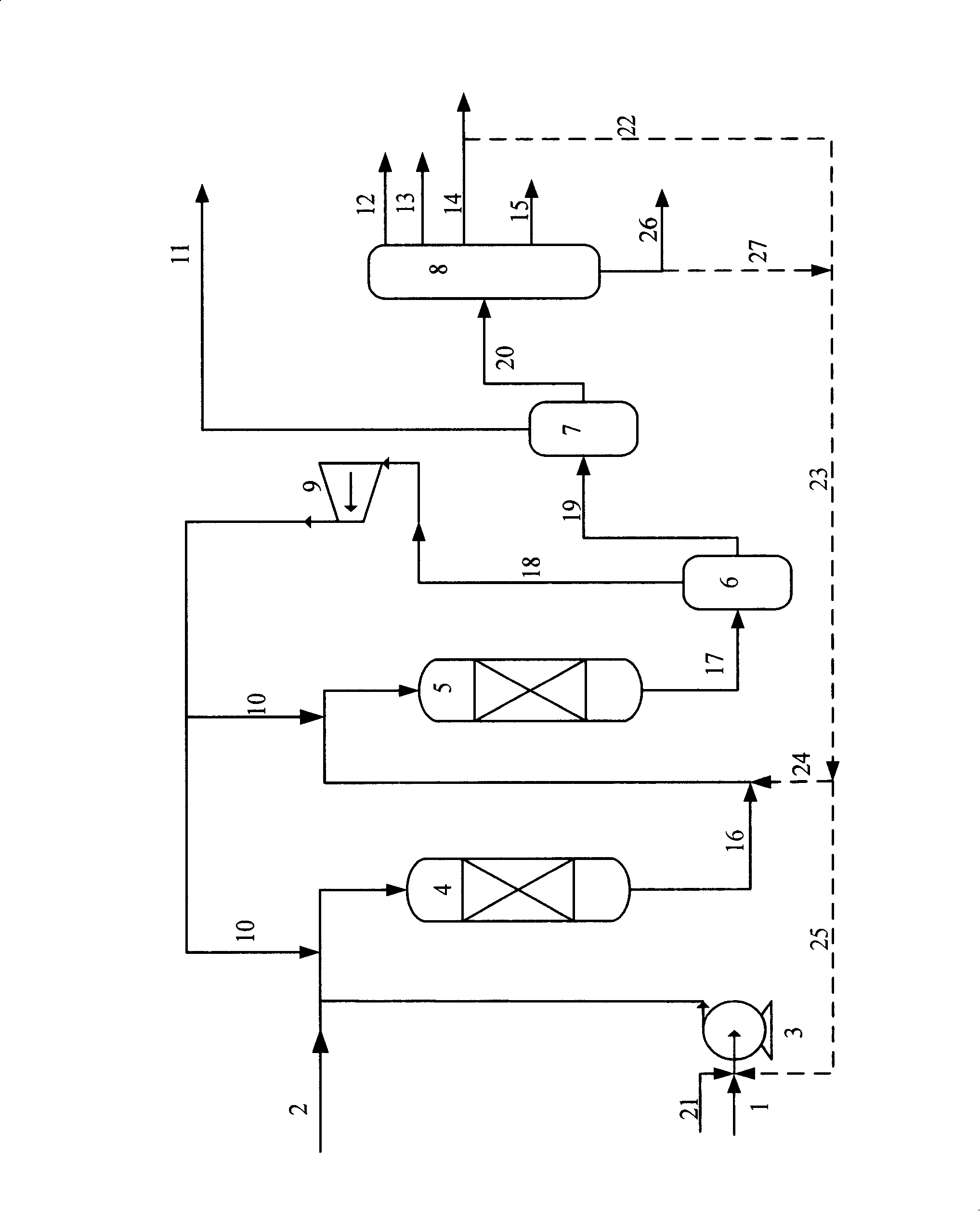

Vegetable oil hydroconversion process

InactiveUS20060186020A1Improved cetane indexAvoid excessive densityMolecular sieve catalystsBiofuelsVegetable oilHydrogen

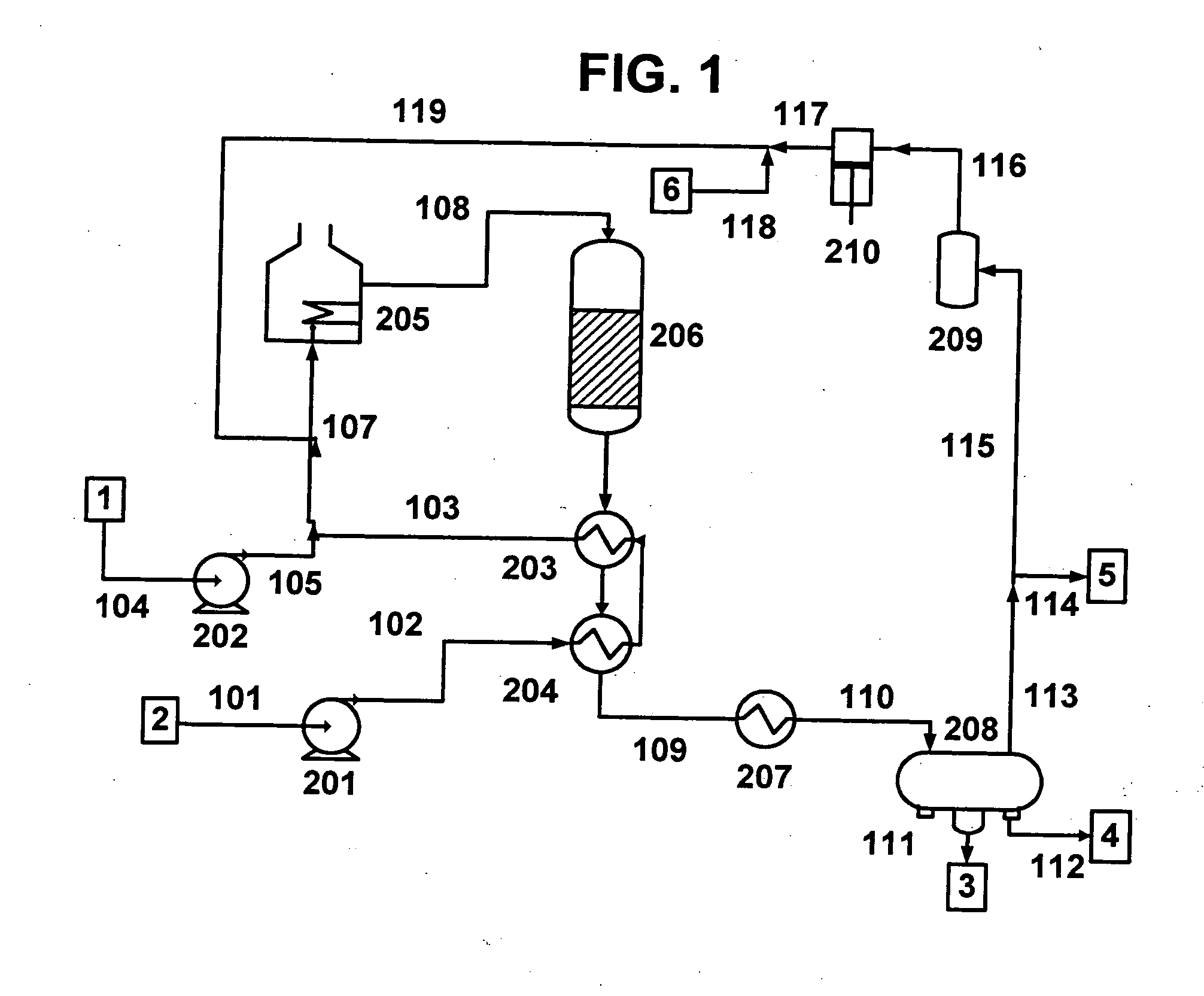

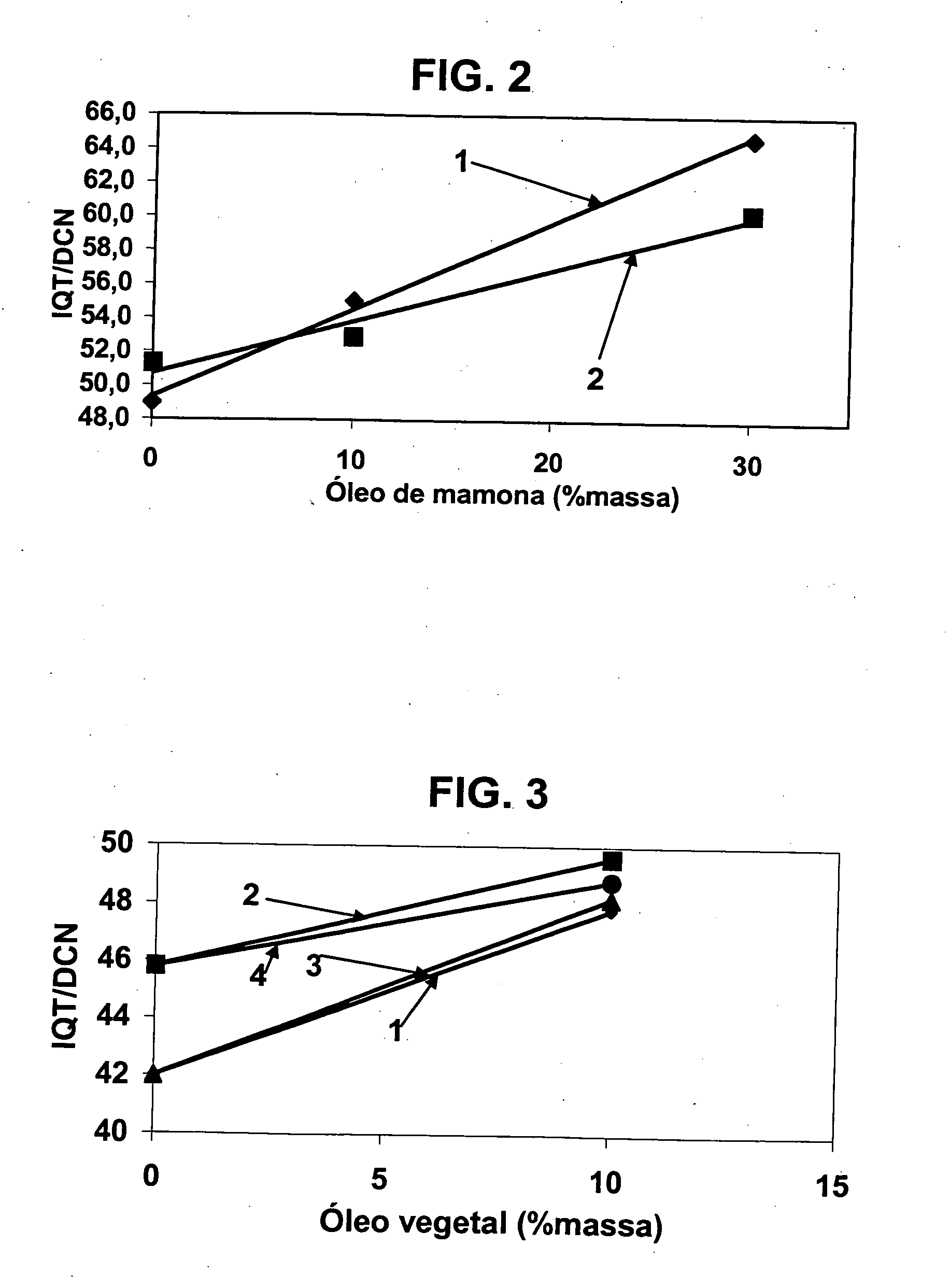

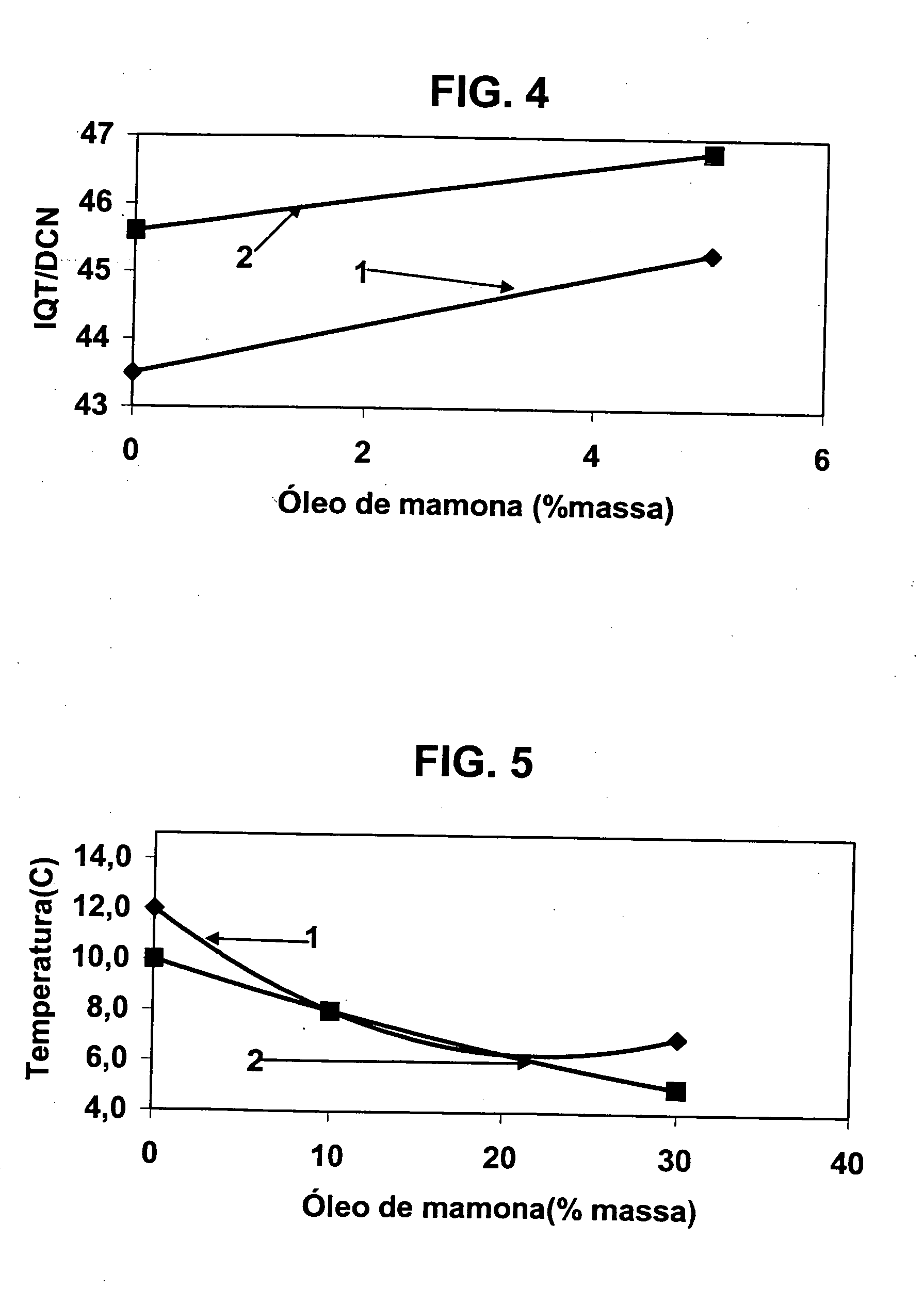

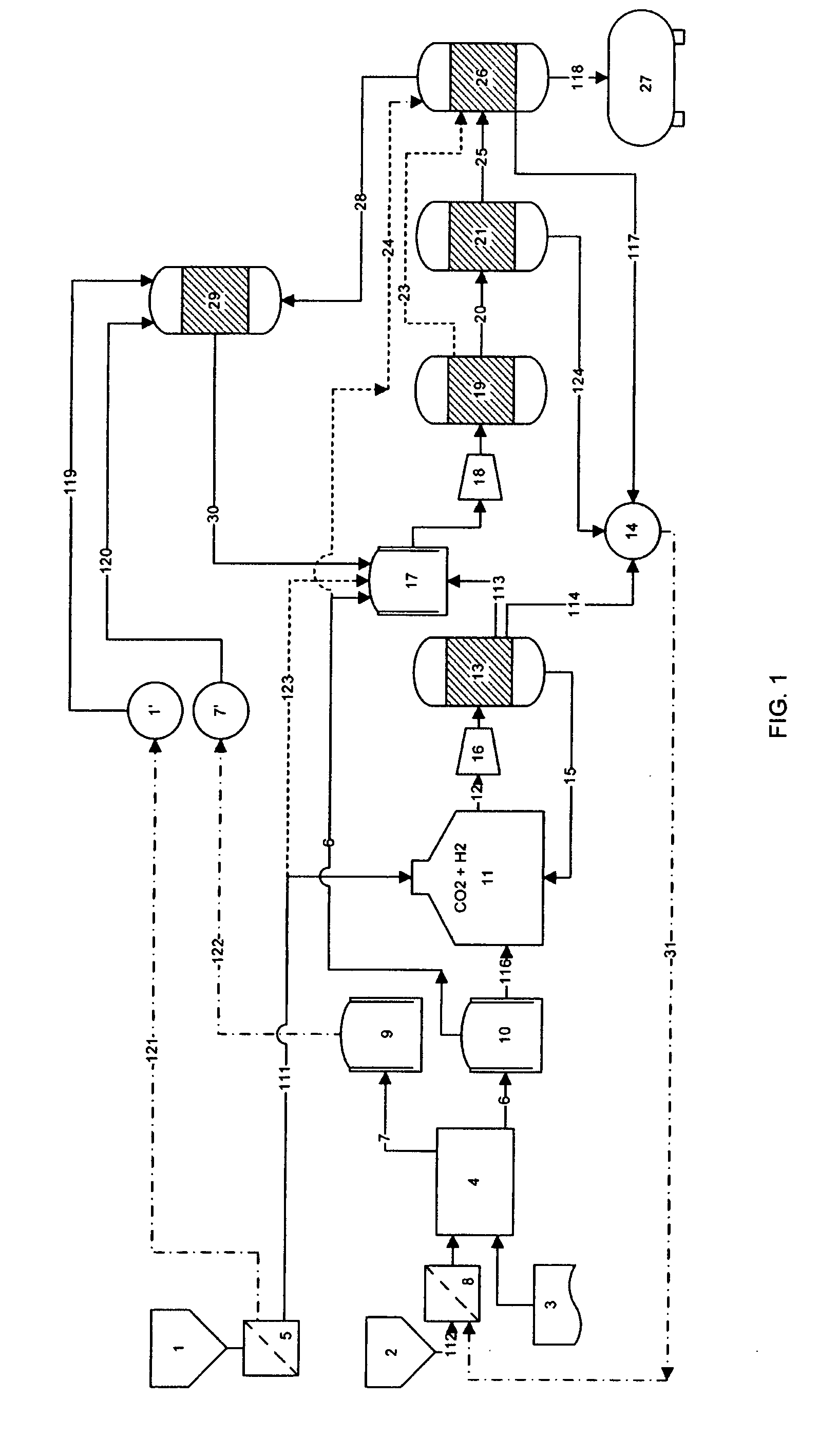

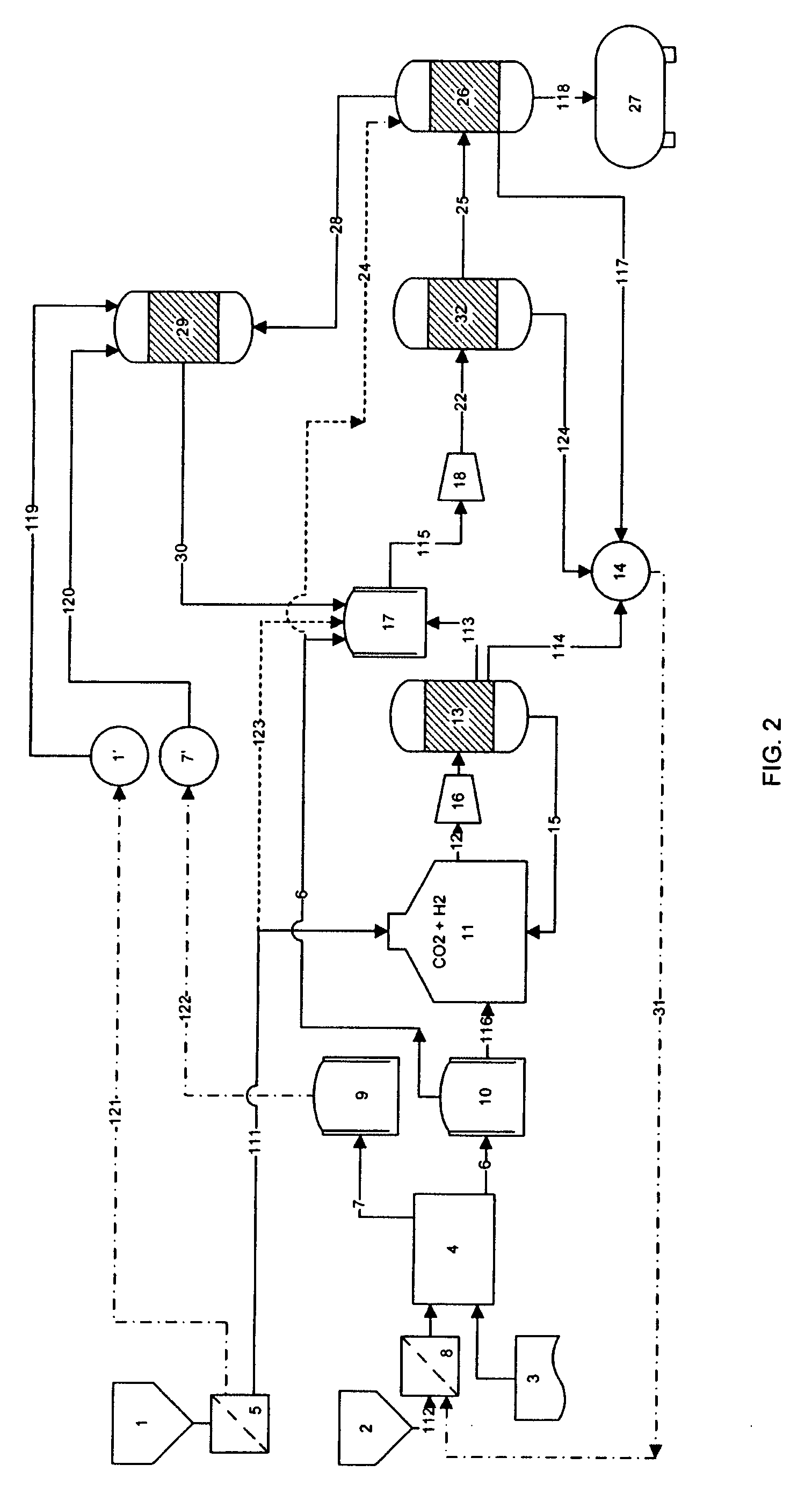

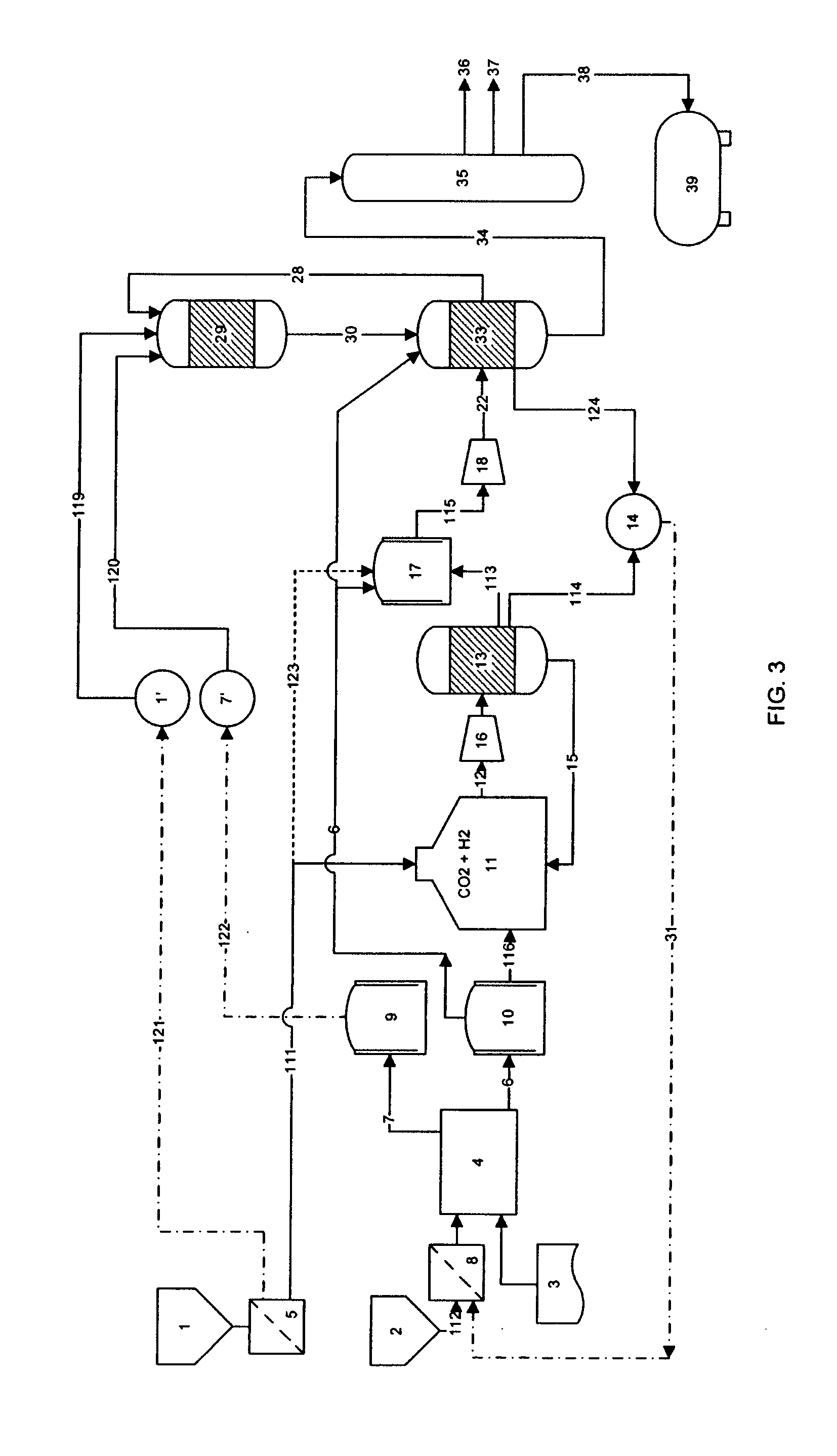

A vegetable oil hydroconversion process is described for hydroconverting a mixture between 1 to 75% in mass of oil or natural fat (1) and the rest mineral oil (2), hydroconverted in a reactor (205) under conditions of pressure, temperature, hydrogen (flow 119) and sulfide catalyst of Groups VIII and VIB, obtaining, after sour water separation (flow 111) and rectification (flow 112), a specified diesel product (4). The product (4) has an ITQ / DCN (cetane number) higher than a product obtained from a pure mineral based oil would have, lower density than from a base oil and a plugging point depending on the mineral oil flow, as well as greater oxidation stability than the base oil.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

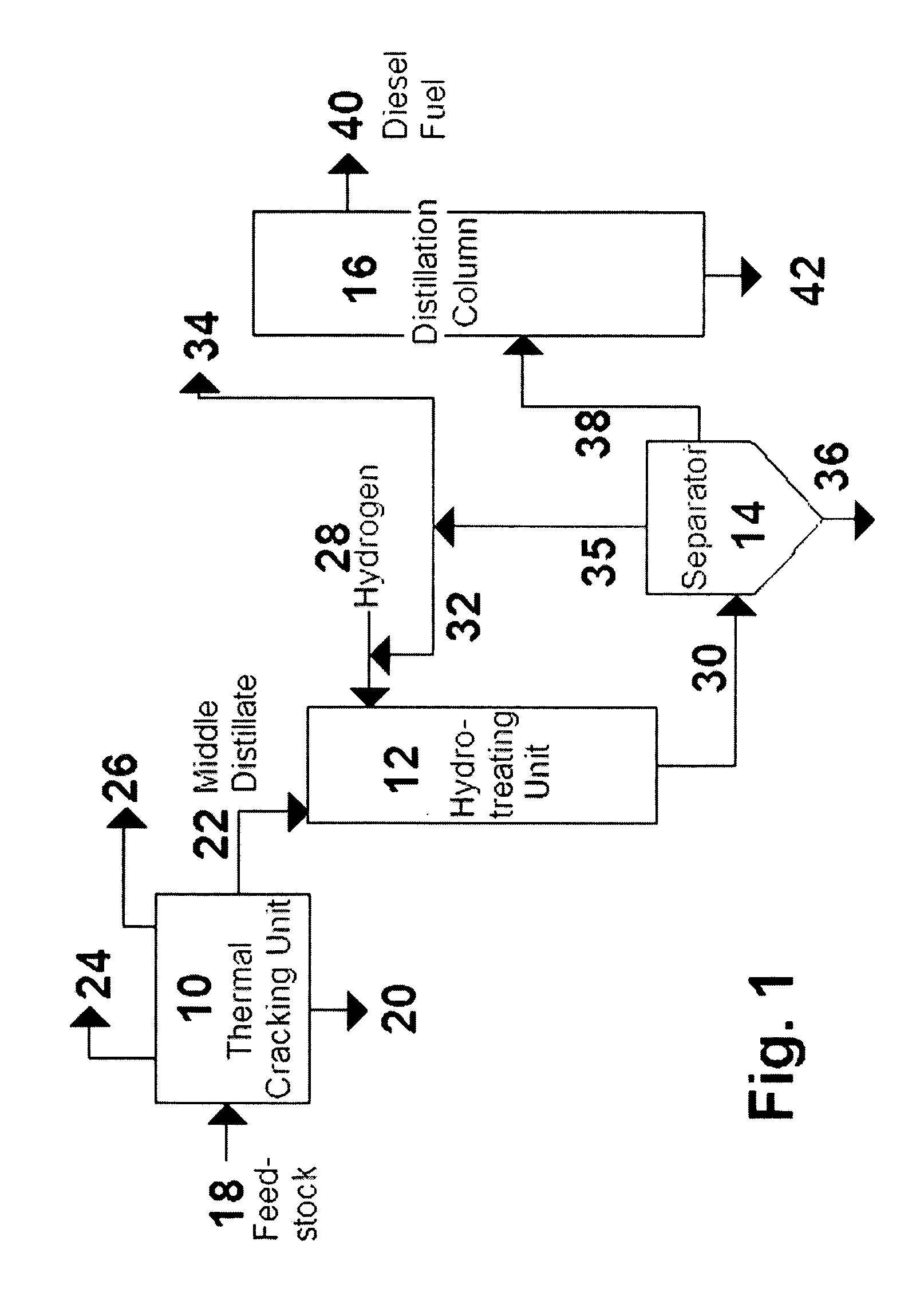

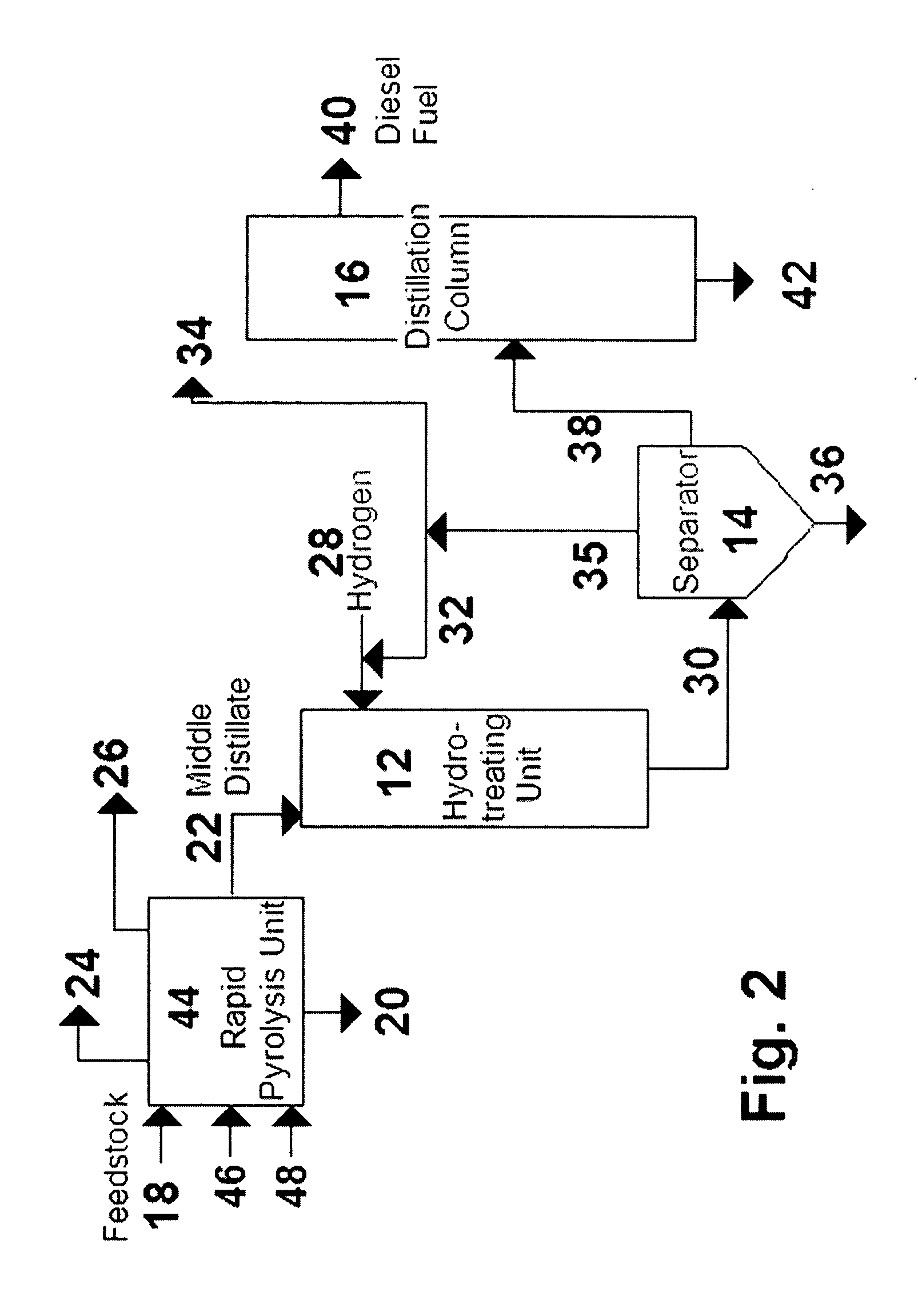

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

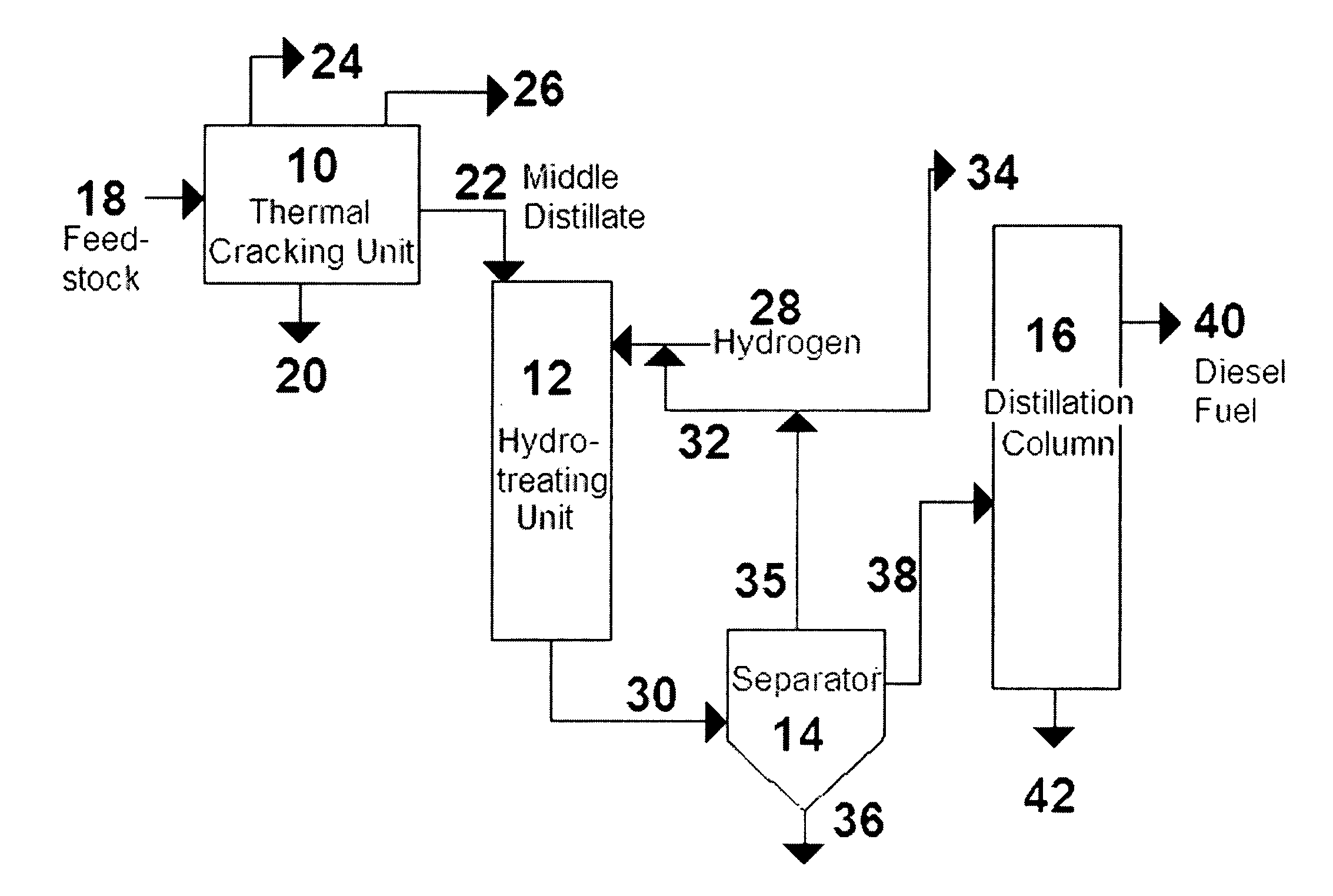

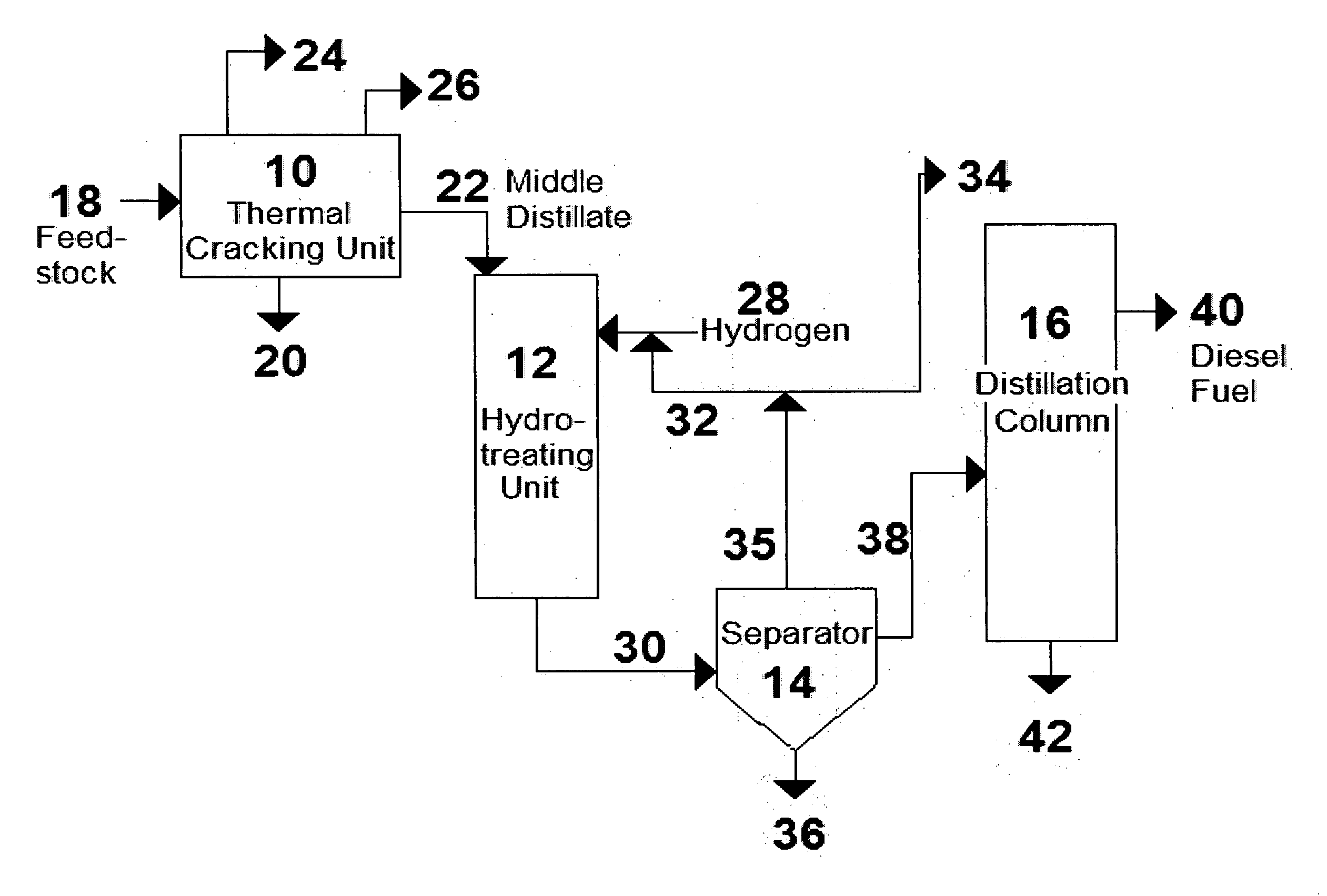

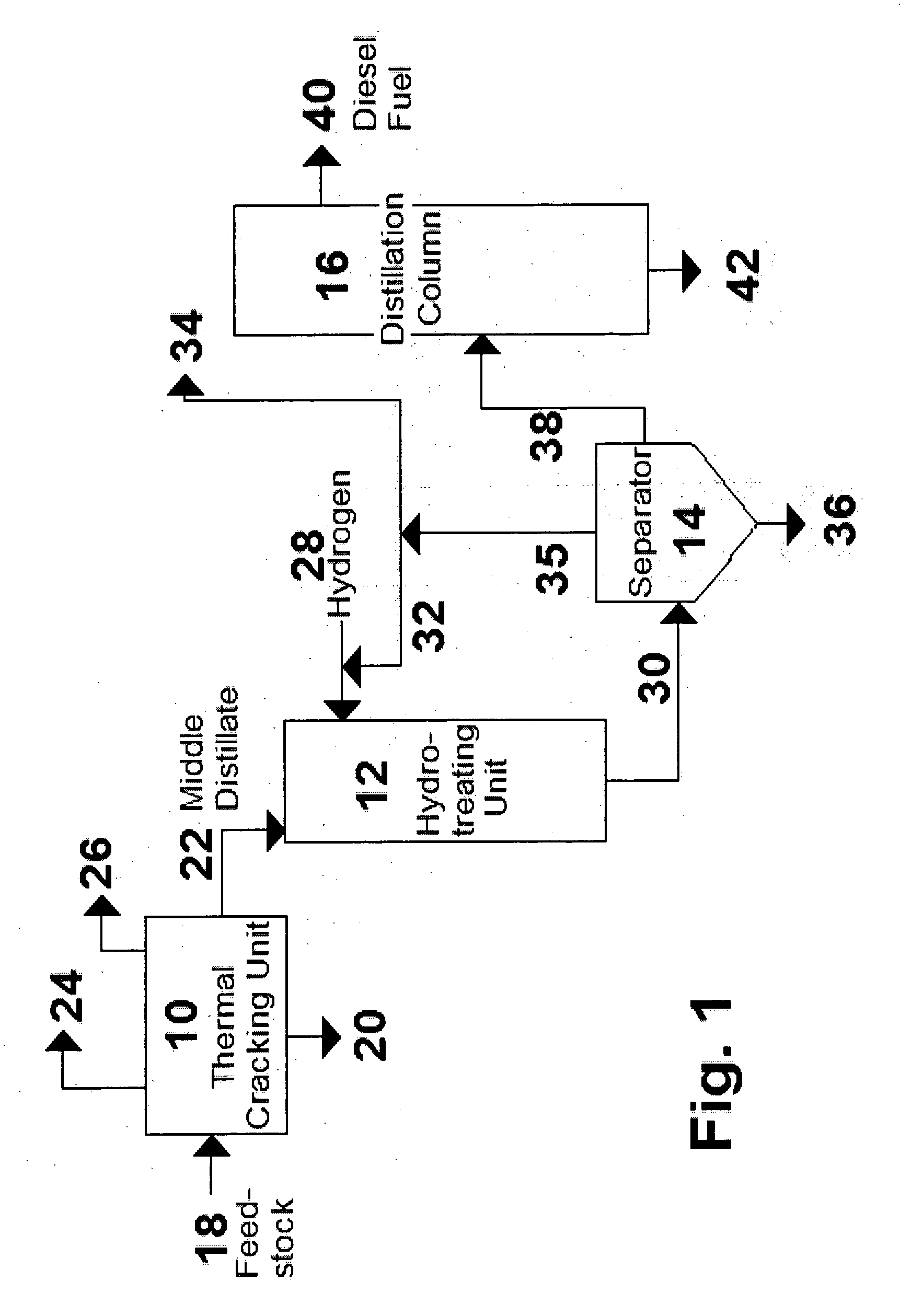

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Process for converting triglycerides to hydrocarbons

ActiveUS20070175795A1High reaction yieldIncrease cetane numberBiofuelsLiquid carbonaceous fuelsBoiling pointHydrocotyle bowlesioides

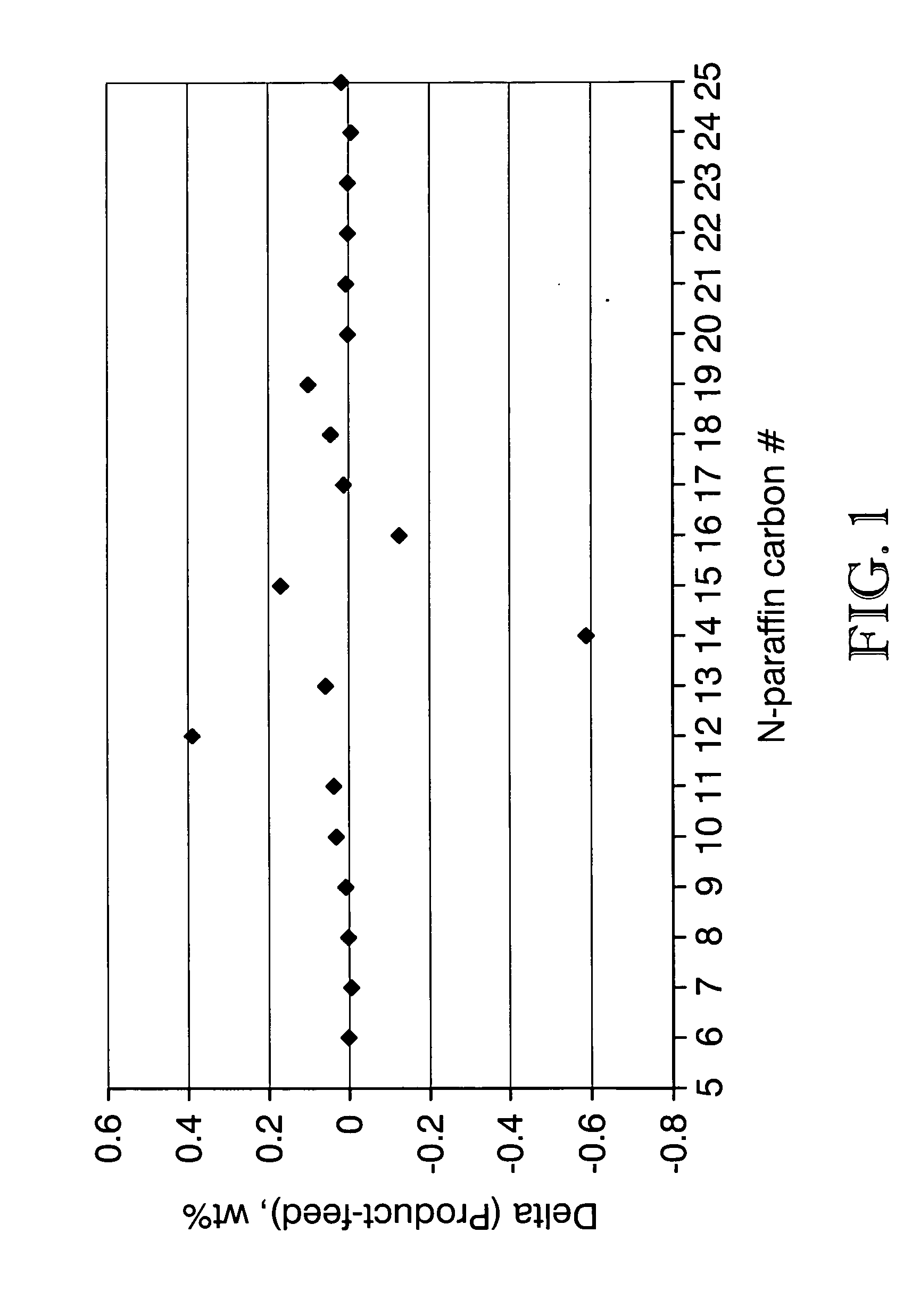

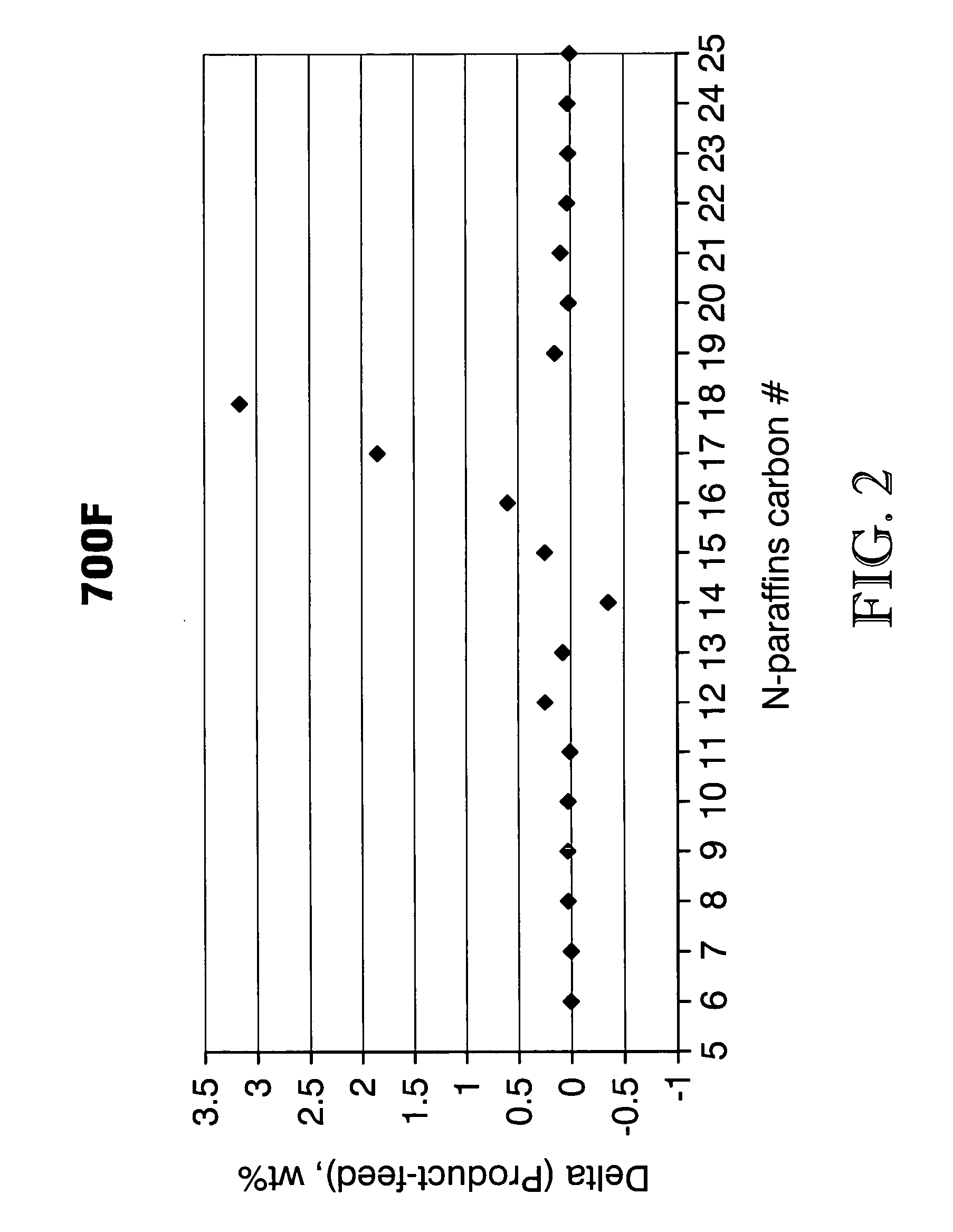

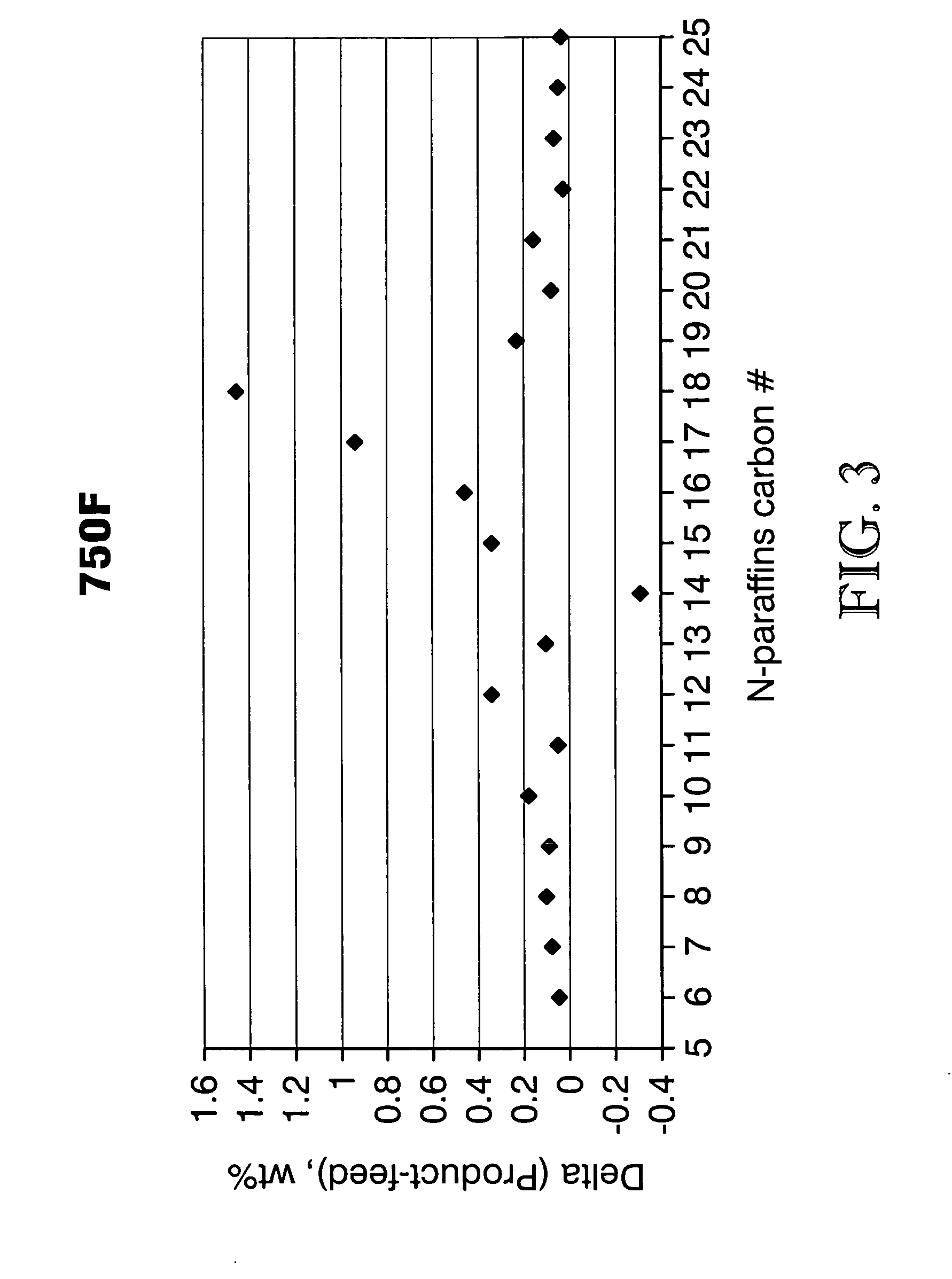

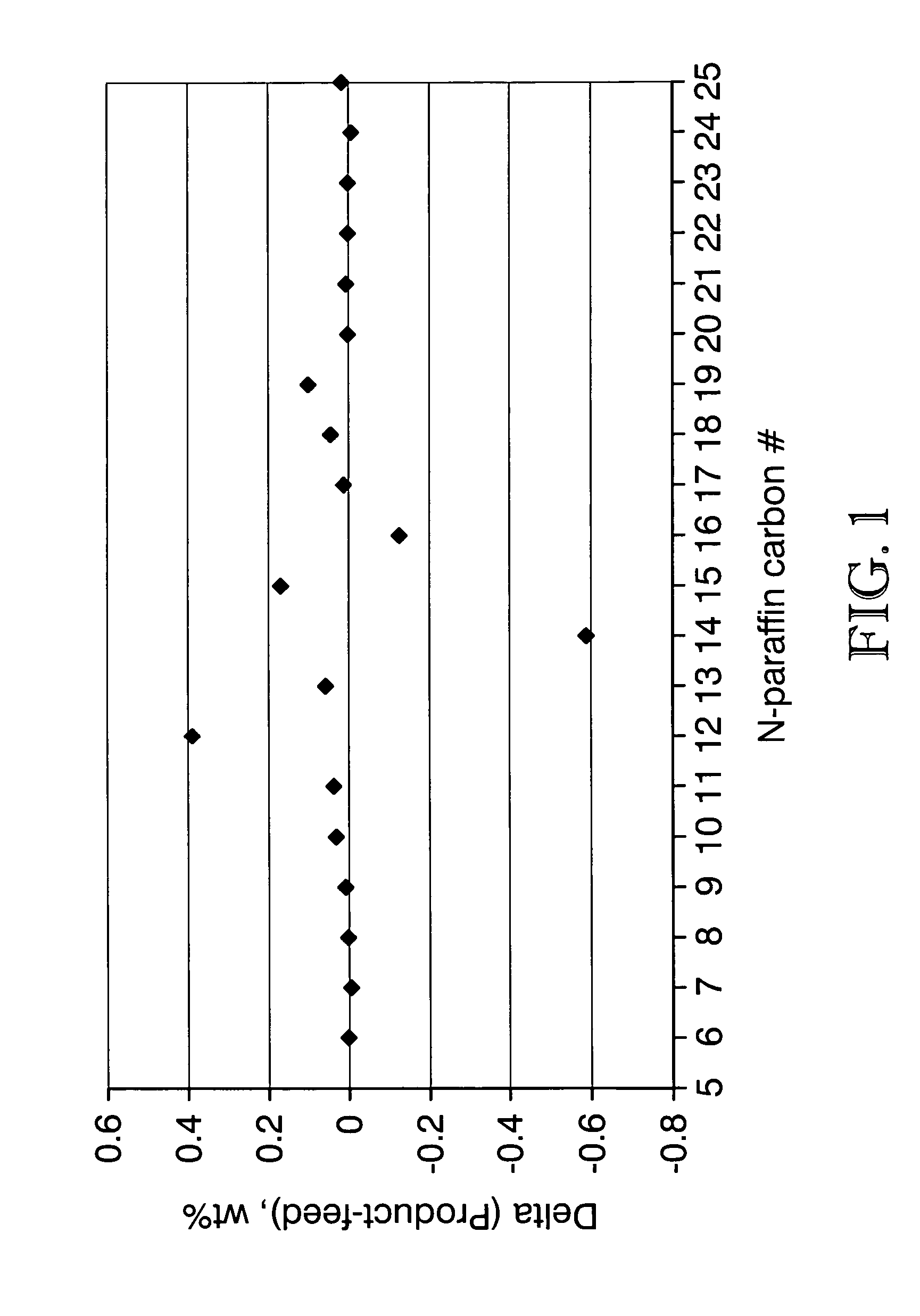

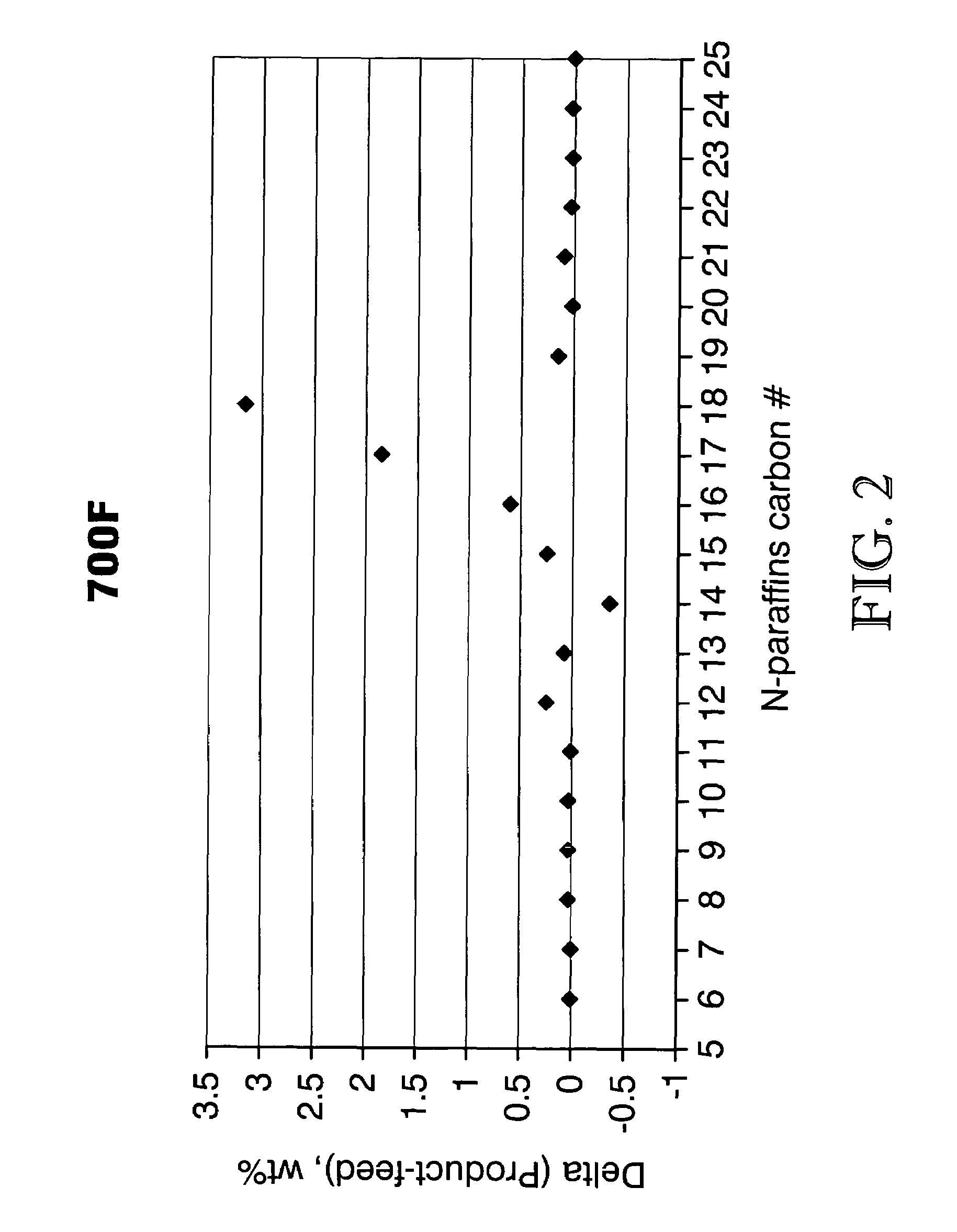

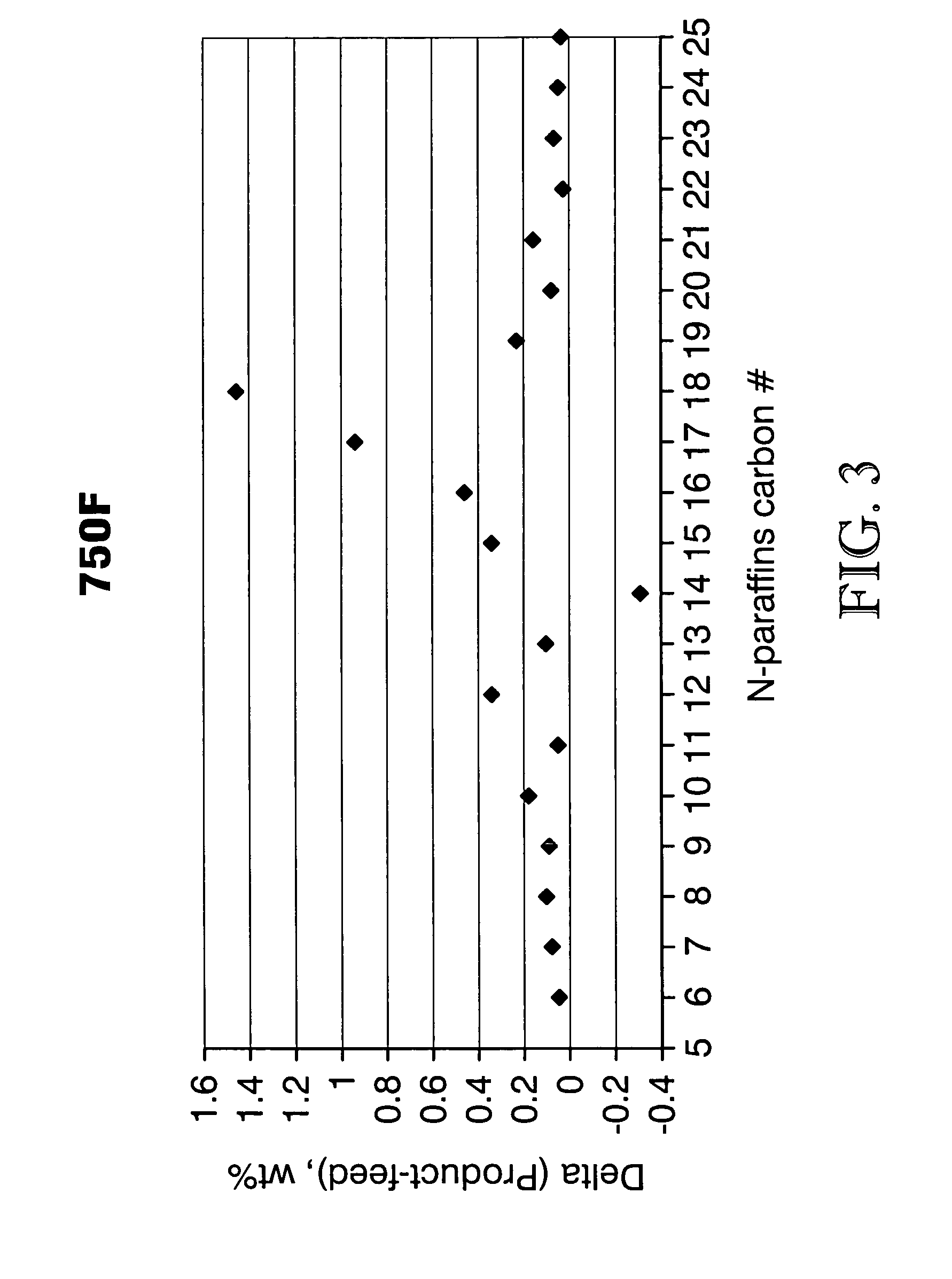

Processes for the conversion of hydrocarbons boiling in the temperature range of from about 80° F. to about 1000° F. to diesel boiling range hydrocarbons, and processes for increasing the cetane number and amount of n-C17 hydrocarbon products in such processes. Diesel boiling range hydrocarbons may be produced by contacting a hydrocarbon boiling in the above-mentioned boiling range with a triglyceride-containing compound to form a mixture, and then contacting the mixture with a hydrotreating catalyst under suitable reaction conditions.

Owner:PHILLIPS 66 CO

Process for converting triglycerides to hydrocarbons

ActiveUS7550634B2High reaction yieldIncrease cetane numberBiofuelsSolid fuelsBoiling pointTG - Triglyceride

Processes for the conversion of hydrocarbons boiling in the temperature range of from about 80° F. to about 1000° F. to diesel boiling range hydrocarbons, and processes for increasing the cetane number and amount of n-C17 hydrocarbon products in such processes. Diesel boiling range hydrocarbons may be produced by contacting a hydrocarbon boiling in the above-mentioned boiling range with a triglyceride-containing compound to form a mixture, and then contacting the mixture with a hydrotreating catalyst under suitable reaction conditions.

Owner:PHILLIPS 66 CO

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with quench injection of the oils on the last catalyst bed

ActiveUS20080173570A1Low costReduce use costCatalytic crackingHydrocarbon oil crackingDistillates petroleumVegetable oil

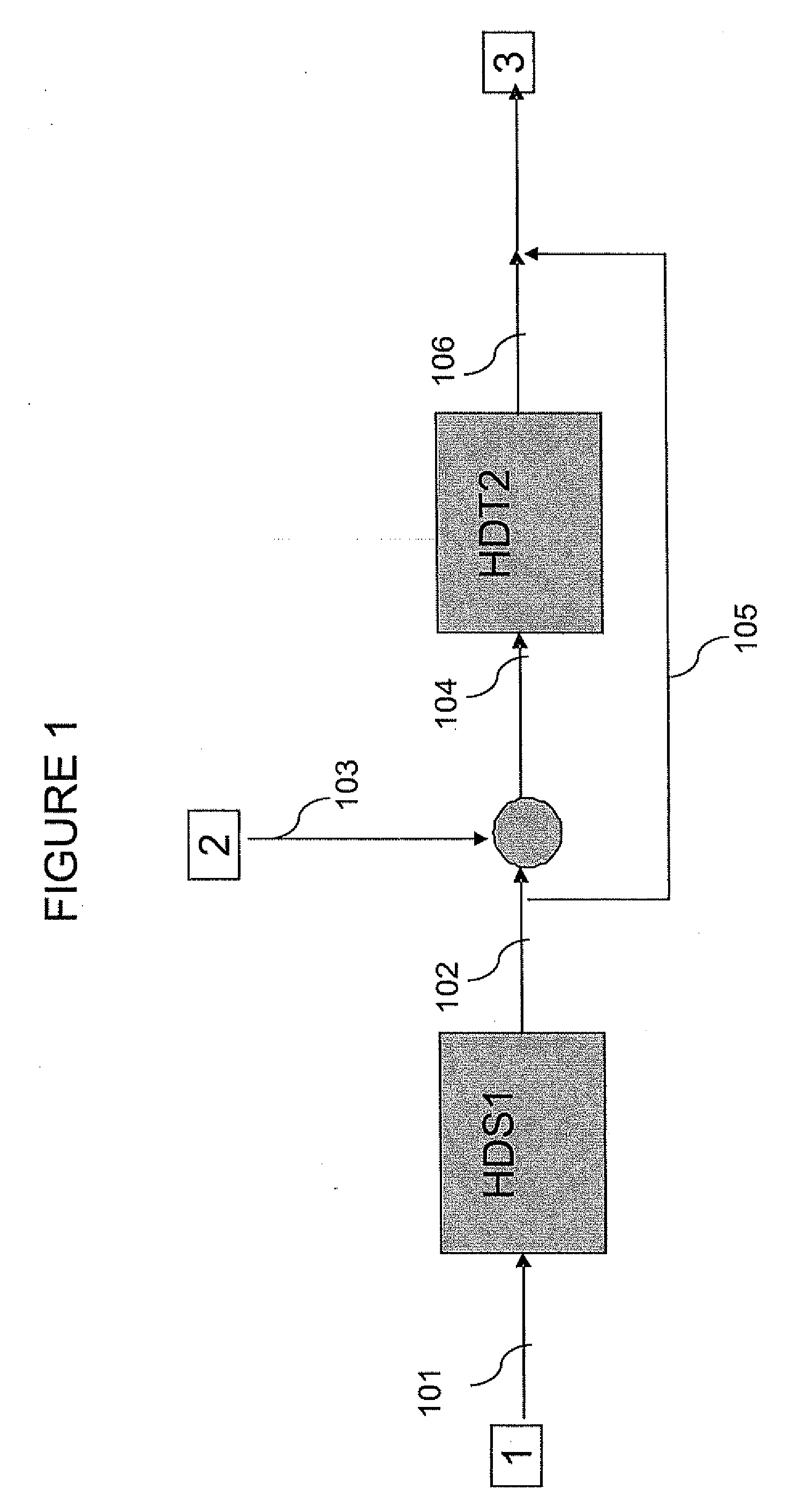

A hydrotreating method uses two catalyst beds with the introduction, on the last catalyst bed, of oils of animal or vegetable origin for co-treating a mixture made up of oils of vegetable or animal origin and of petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil effluents meeting specifications with an improved cetane number. The first catalyst bed is dedicated to only the deep desulfurization reactions (HDS1) of a petroleum type feed. The effluents of the first catalyst bed having an effluent sulfur content below or equal to 50 mg / kg are separated into two streams. The first stream, which is predominant, is sent to the gas oil pool. The second stream is mixed with oils of vegetable or animal origin. The resultant oil-petroleum cut mixture is then subjected to a milder hydrotreatment (HDT2). The effluents obtained at the outlet of the second catalyst bed can optionally be mixed with the predominant stream from the first bed. The process economy, the tolerance to the specifications relative to oils of animal or vegetable origin and the quality of the products obtained are thus greatly improved.

Owner:INST FR DU PETROLE

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

ActiveUS20070068848A1Increase cetane numberBiofuelsLiquid hydrocarbon mixture productionTG - TriglyceridePre treatment

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

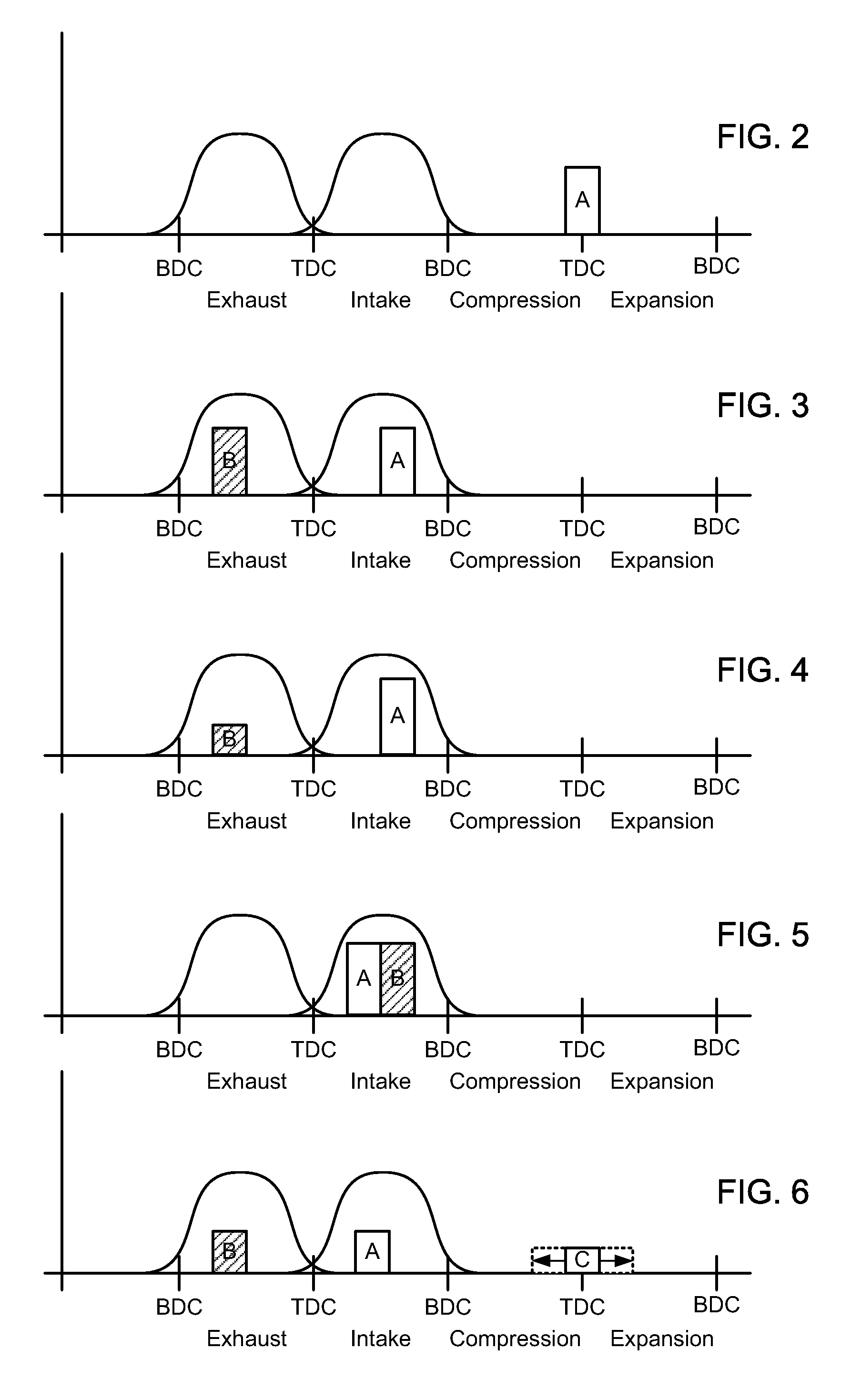

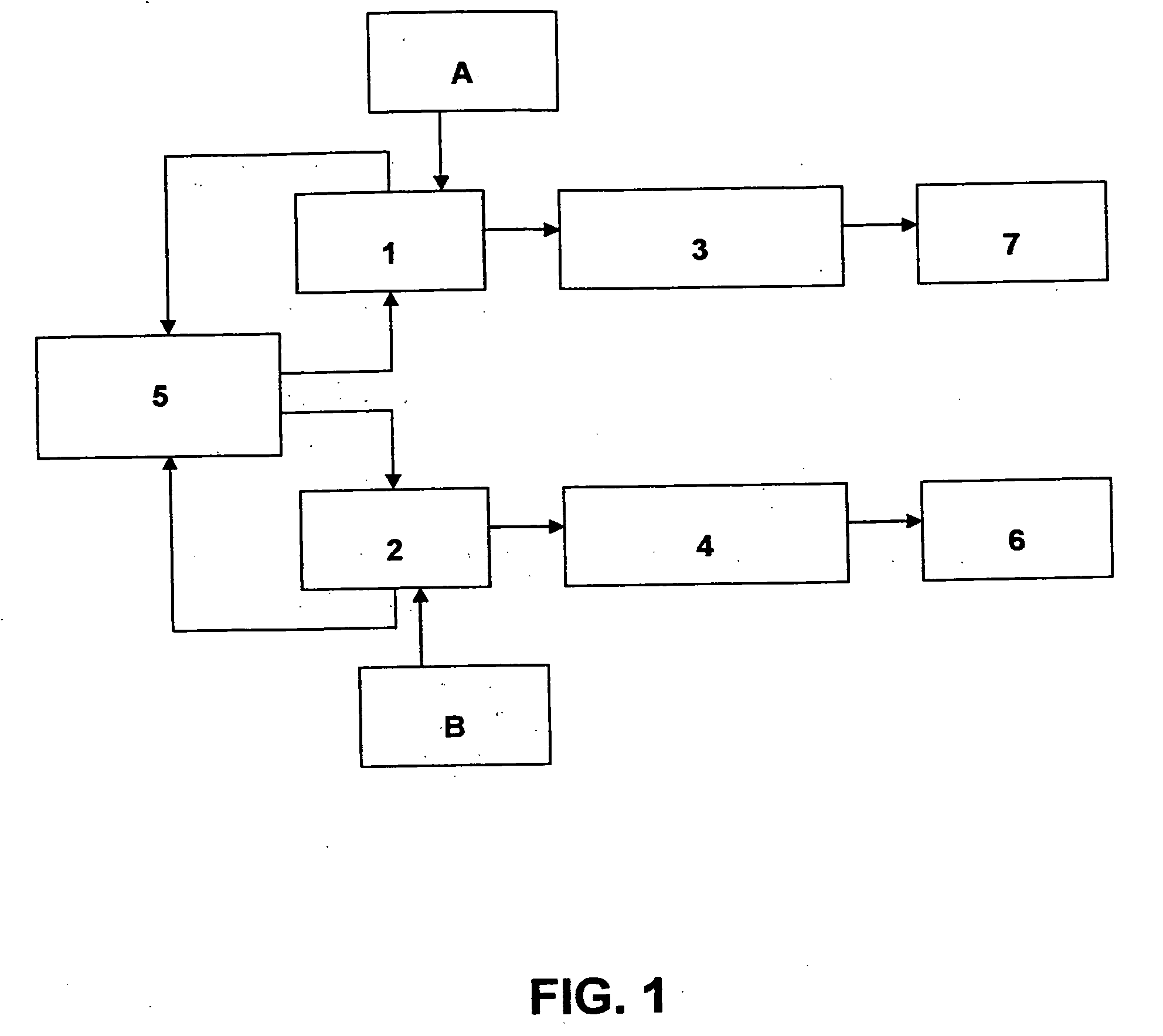

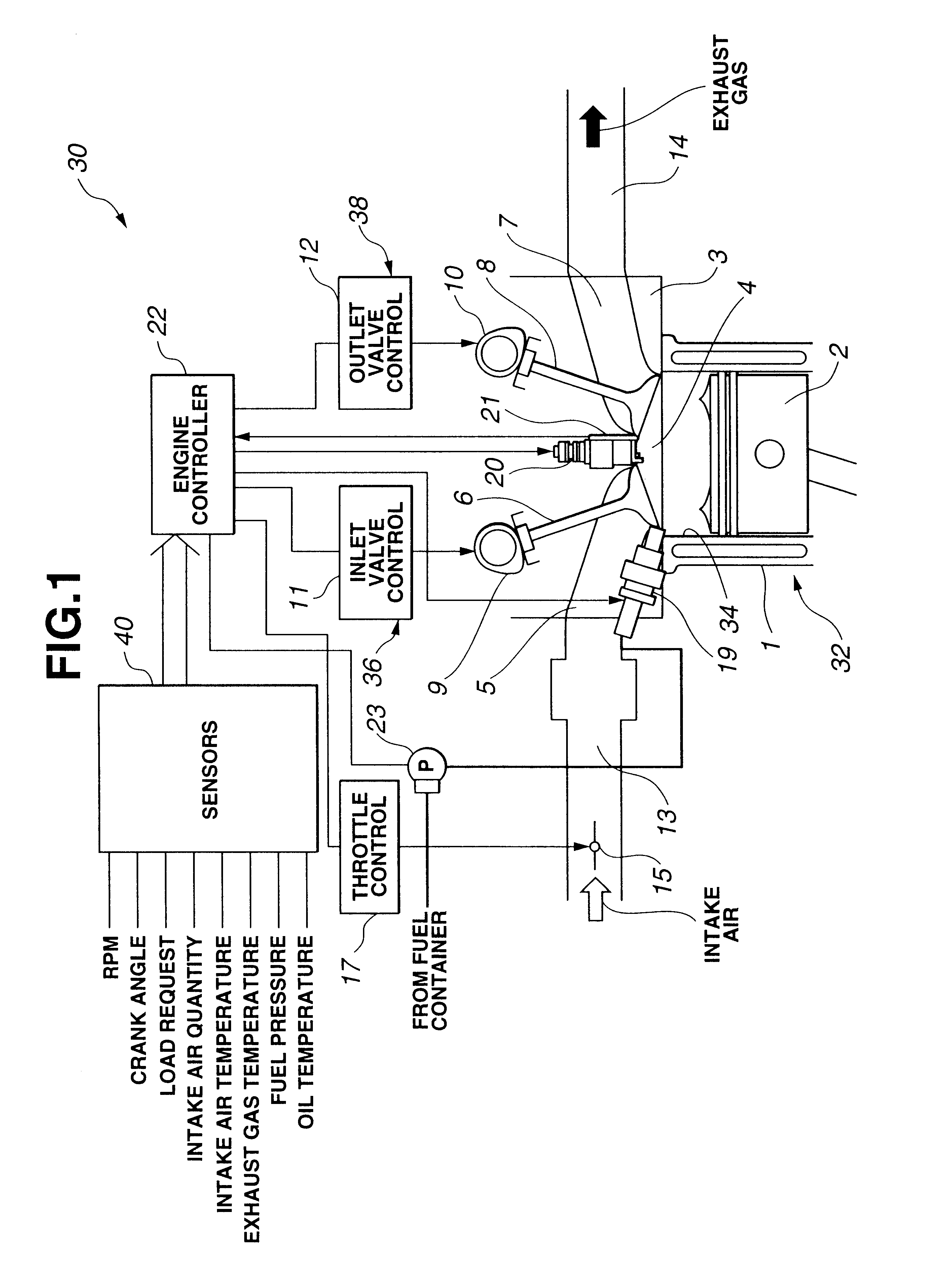

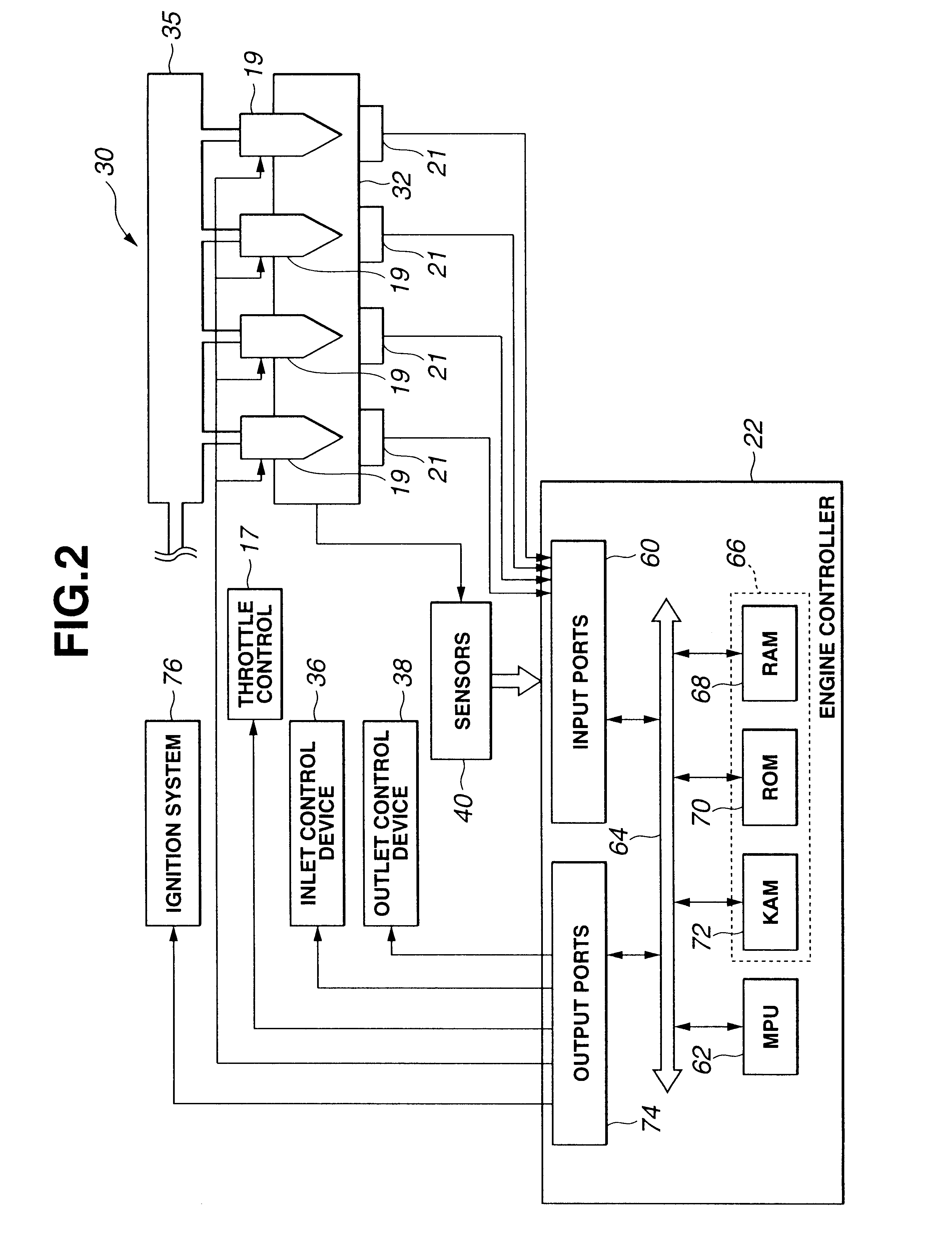

Controlling engine operation with a first and second fuel

InactiveUS7284506B1Less sootHigh production of sootElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

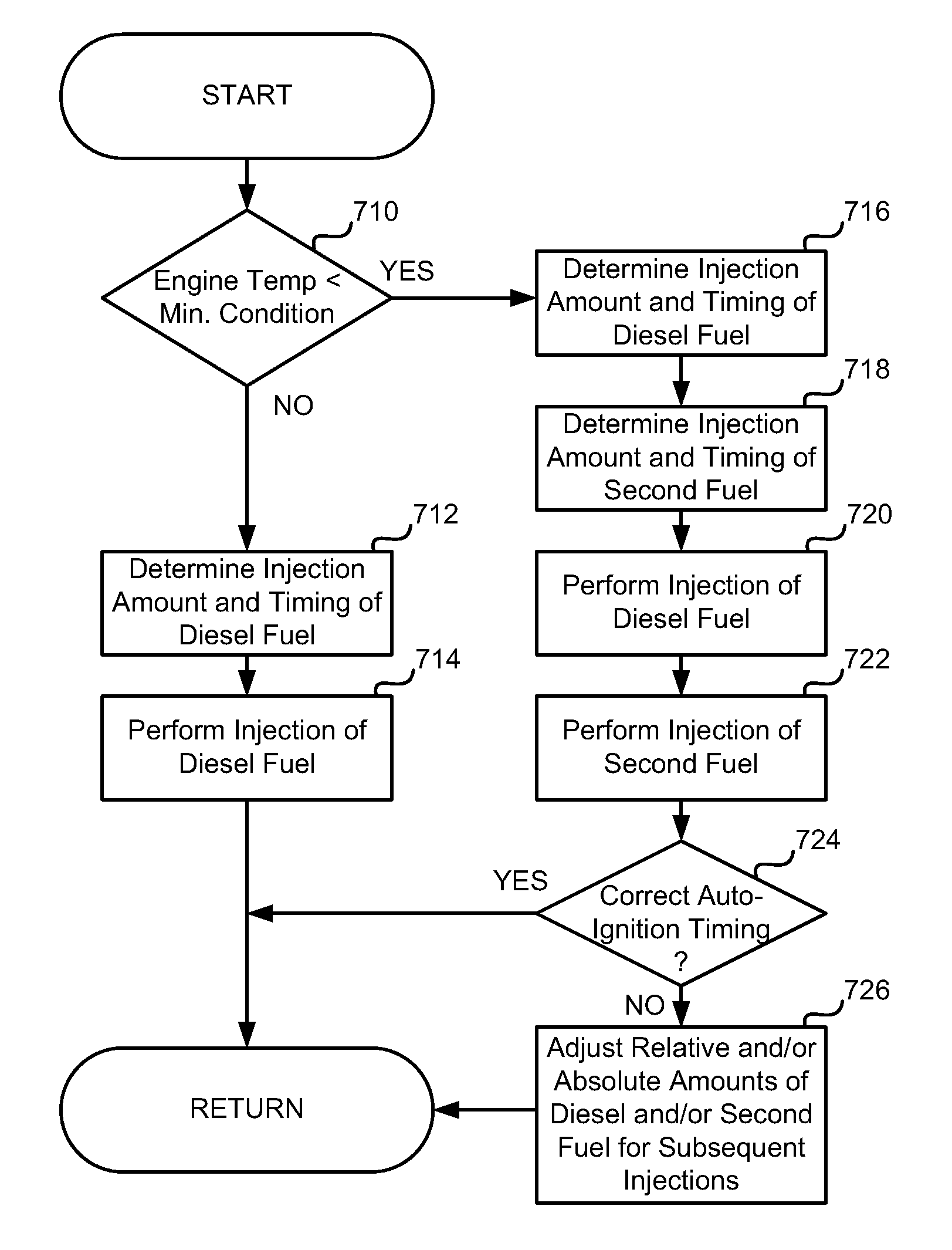

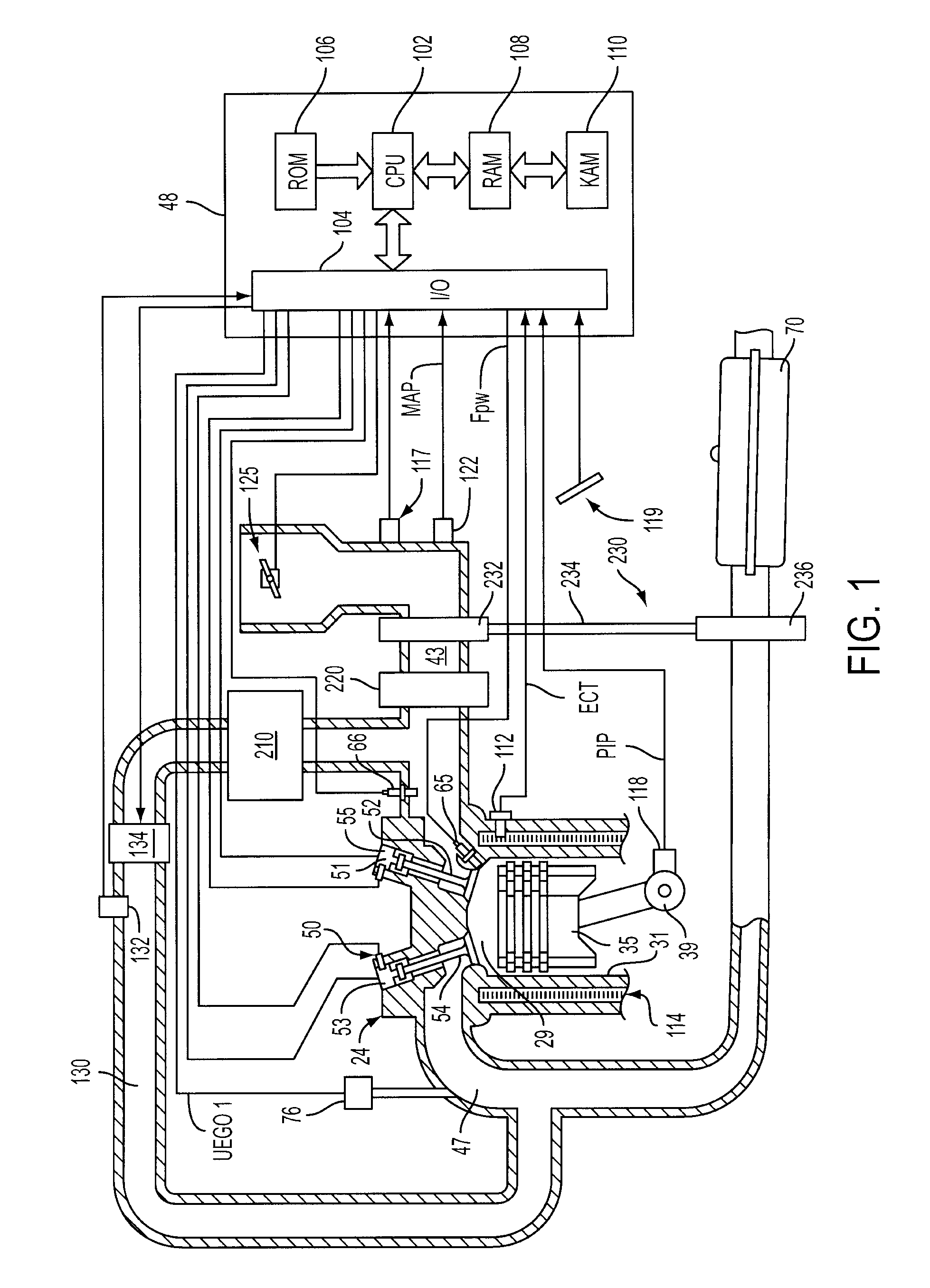

A method of operating an internal combustion engine including at least a combustion chamber having a piston disposed therein, wherein the combustion chamber is configured to receive air, a first fuel and a second fuel to form a substantially homogeneous mixture, and wherein the piston is configured to compress said mixture so that auto-ignition of said mixture is achieved is disclosed. The method comprises varying the amount of at least one of the first fuel and the second fuel that is received by the combustion chamber to adjust the timing of auto-ignition, where the first fuel includes diesel fuel and the second fuel includes such low cetane fuels as: methanol and ethanol.

Owner:FORD GLOBAL TECH LLC

Hydrogenation catalyst of diesel production at most amount and production thereof

A maximum hydrogen catalyst of diesel oil and its production are disclosed. The catalyst consists of amorphous silica aluminum, modified beta molecular sieve, aluminum oxide, VIB family and VIII family metals. Modified beta molecular sieve has high silicon and crystallinity, small crystal grain and acidity. It has good cyclanes selective loop open and alkane isomerization. Its advantages include higher heavy oil hydrogen crack activity and middle oil selectivity, better diesel oil absorption and lower filtering point, and it improves density, colloidal matter, iodine value and color.

Owner:CHINA PETROLEUM & CHEM CORP +1

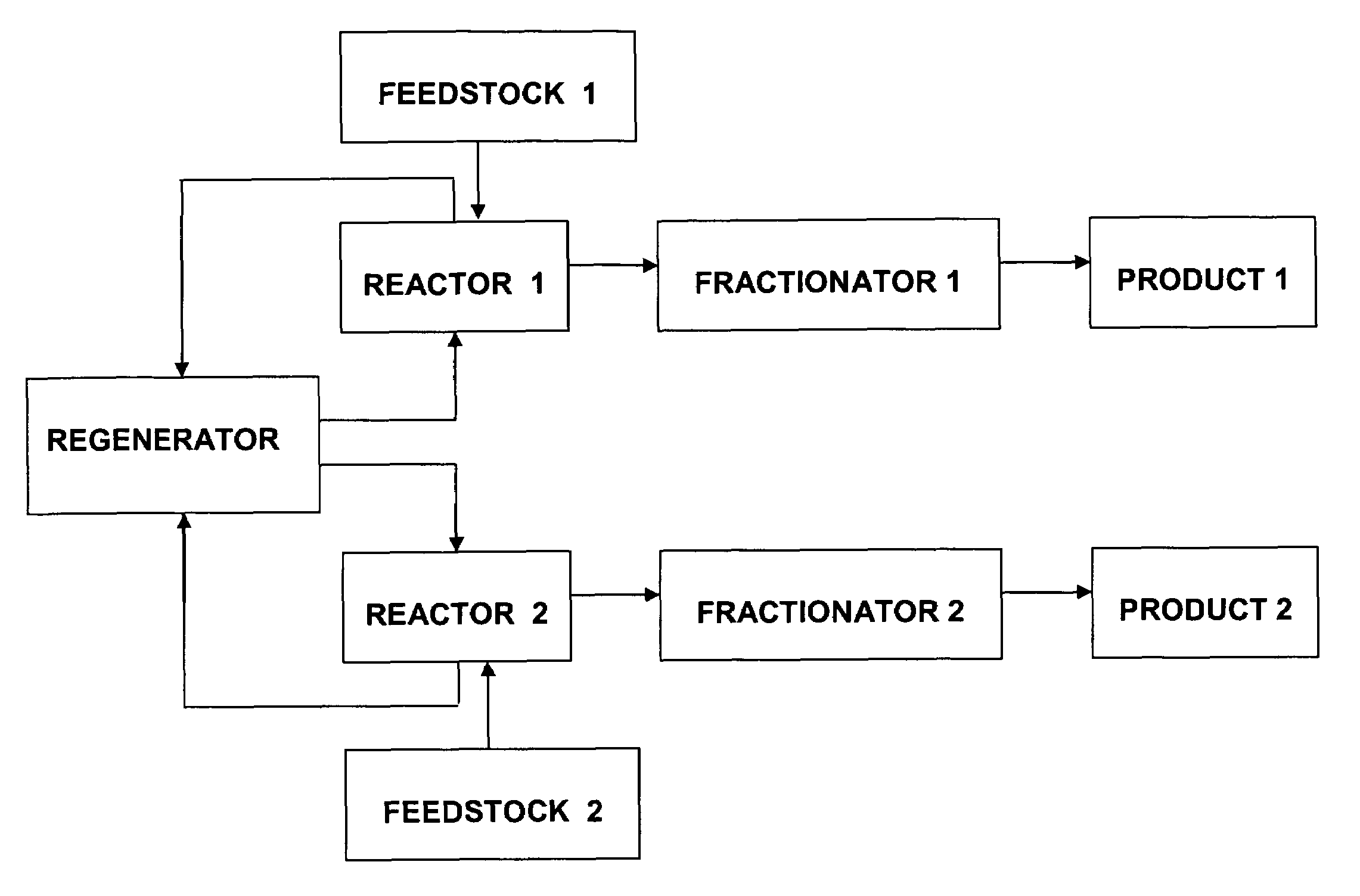

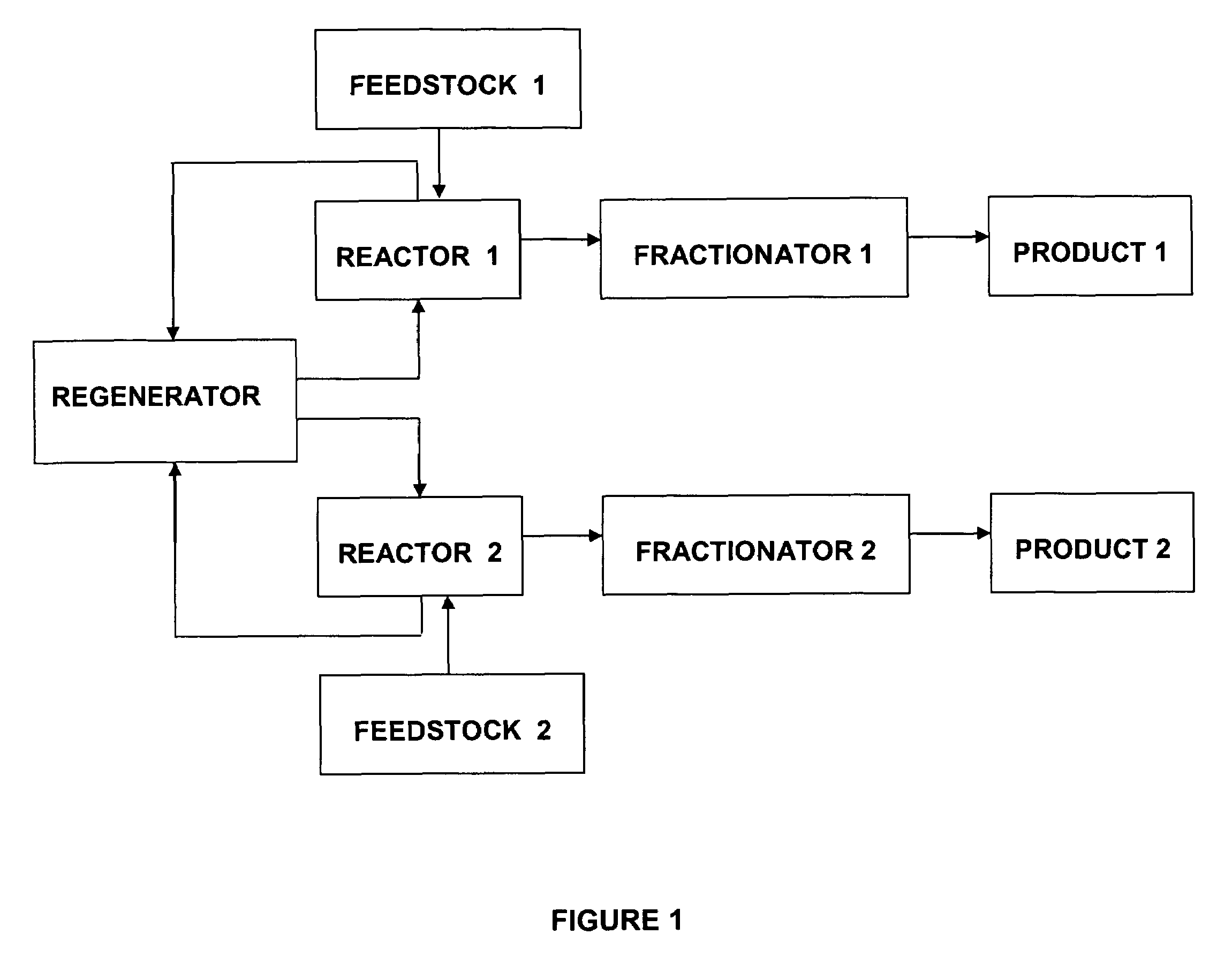

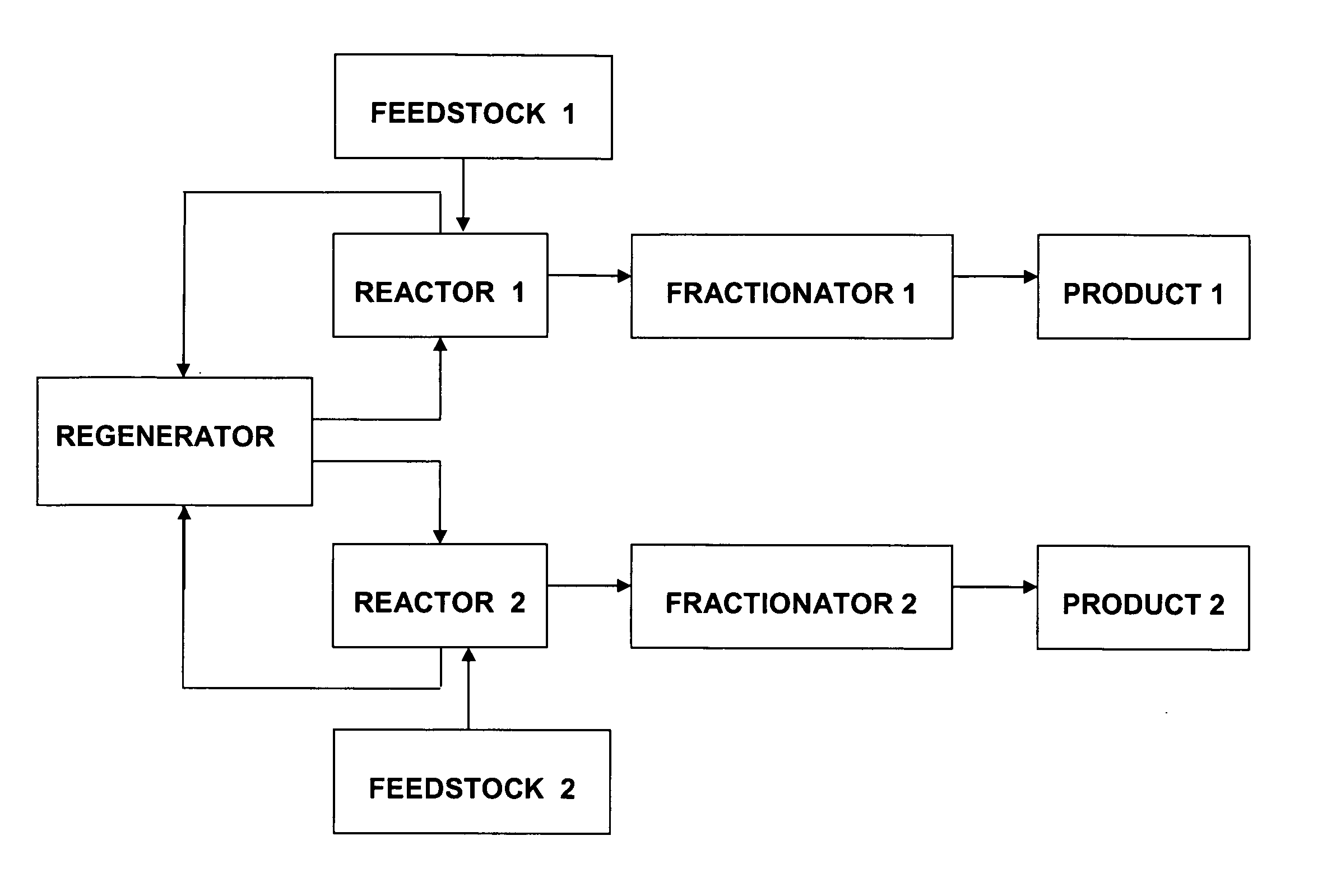

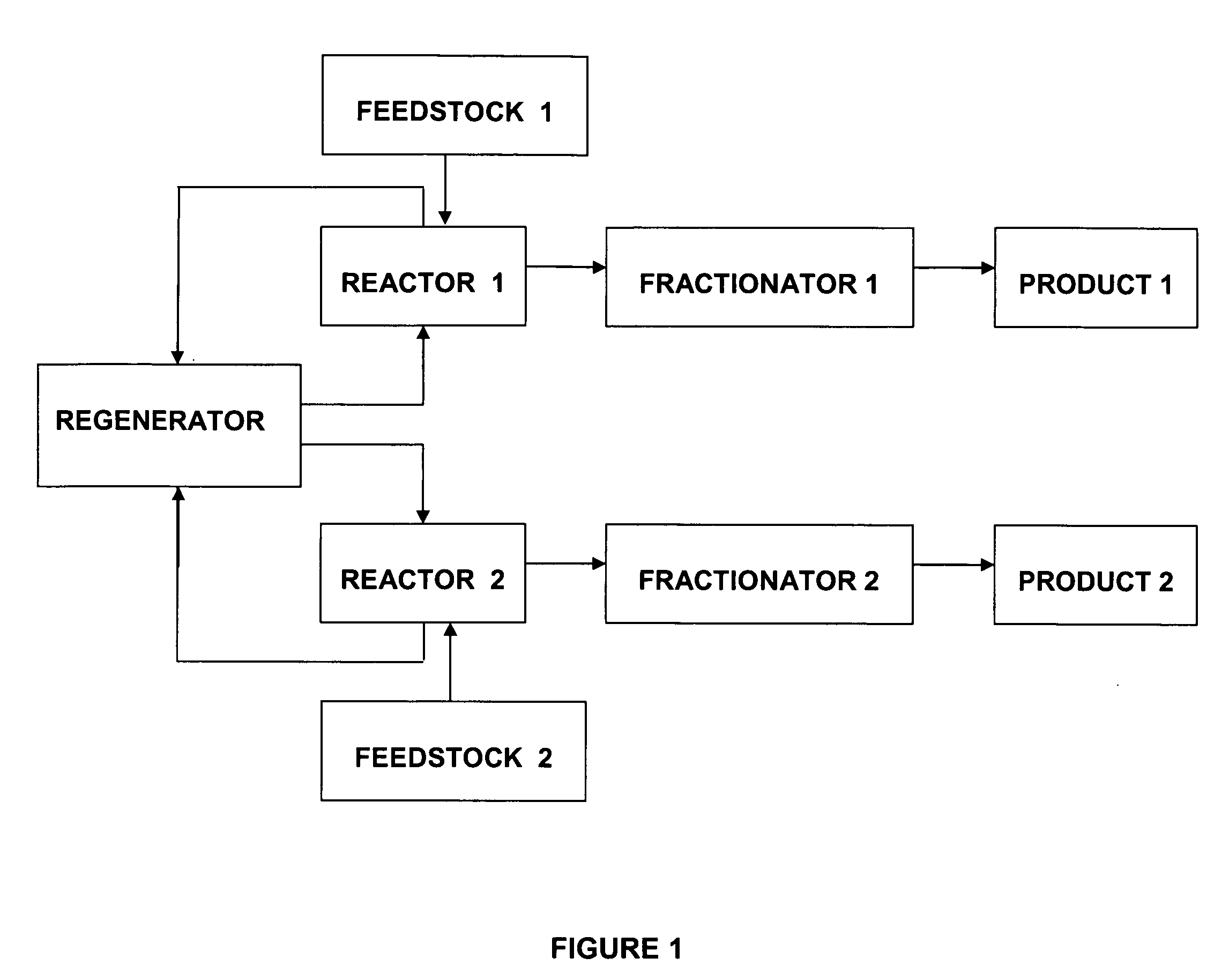

Catalytic cracking process for production of diesel from seeds of oleaginous plants

ActiveUS20080313955A1Production is possibleCatalytic crackingFatty acid chemical modificationEngineeringCracking reaction

The present invention comprises a thermocatalytic cracking process for the production of diesel oil from a charge of vegetable origin made from seeds of oleaginous plants in refineries possessing at least two FCC reactors. At least -one of such reactors processes heavy gas oil or residue under conventional conditions whilst at least one of such reactors processes the charge of vegetable origin made from seeds of oleaginous plants under conditions suitable, for production of diesel oil. Said process employs the same catalyst utilised in the fluid catalytic cracking process which, simultaneously, processes a conventional charge.The diesel, or biodiesel, oil produced by means of said process is of superior quality having a cetane number exceeding 40 given that the cracking reactions occur at low temperatures and the products obtained are less oxidised and consequently purer than products obtained by means of existing technology.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

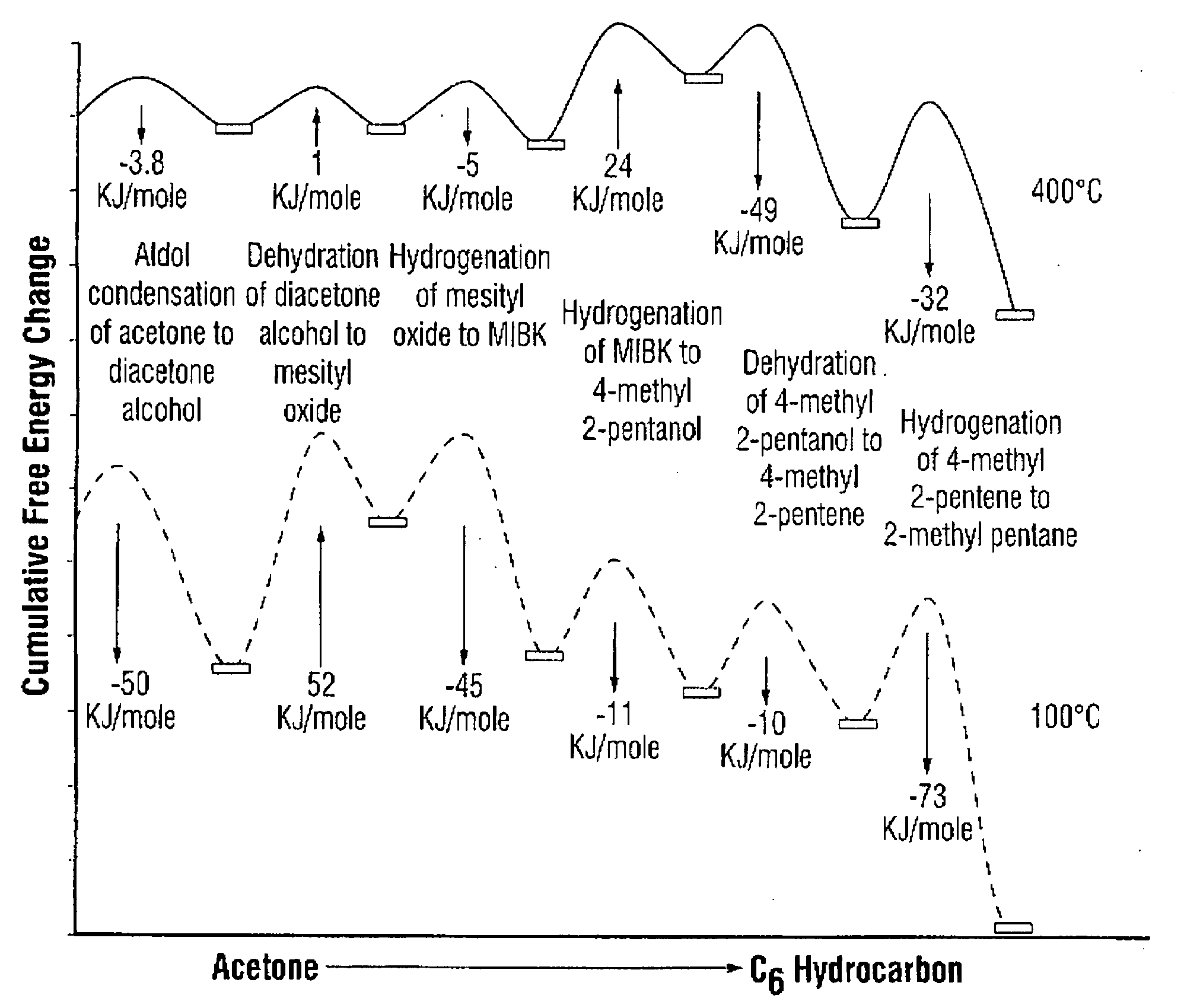

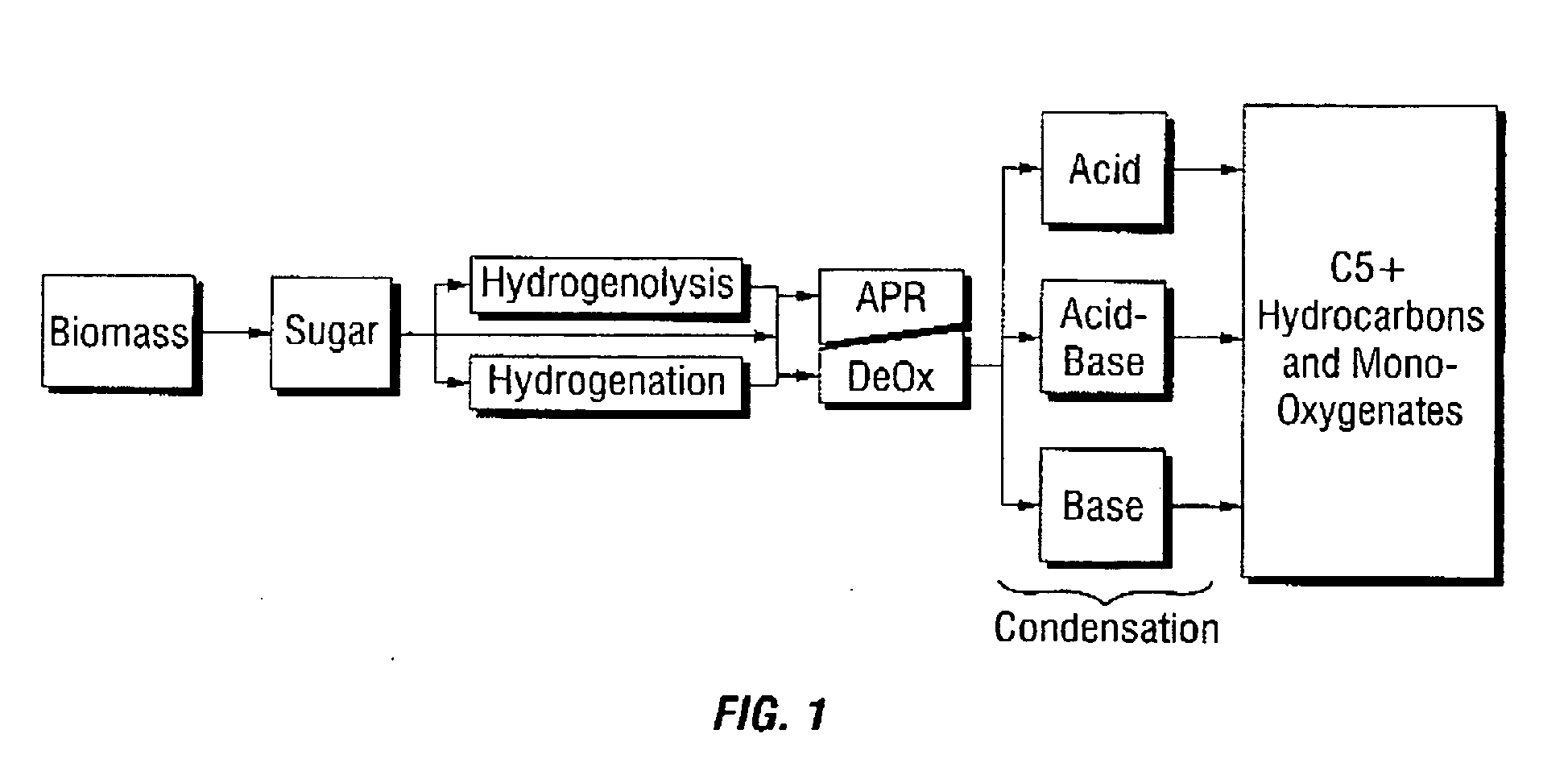

Liquid fuel compositions

The present invention provides a liquid fuel composition comprising a distillation fraction of a component having at least one C4+ compound derived from a water-soluble oxygenated hydrocarbon prepared by a method comprising:providing water and a water-soluble oxygenated hydrocarbon comprising a C1+O1+ hydrocarbon in an aqueous liquid phase and / or a vapor phase;providing H2;catalytically reacting in the liquid and / or vapor phase the oxygenated hydrocarbon with the H2 in the presence of a deoxygenation catalyst at a deoxygenation temperature and deoxygenation pressure to produce an oxygenate comprising a C1+O1-3 hydrocarbon in a reaction stream; andcatalytically reacting in the liquid and / or vapor phase the oxygenate in the presence of a condensation catalyst at a condensation temperature and condensation pressure to produce the C4+ compound,wherein the C4+ compound comprises a member selected from the group consisting of C4+ alcohol, C4+ ketone, C4+ alkane, C4+ alkene, C5+ cycloalkane, C5+ cycloalkene, aryl, fused aryl, and a mixture thereof;wherein the liquid fuel composition is selected from:a gasoline composition having an initial boiling point in the range of from 15° C. to 70° C. (IP123), a final boiling point of at most 230° C. (IP123), a RON in the range of from 85 to 110 (ASTM D2699) and a MON in the range of from 75 to 100 (ASTM D2700);a diesel fuel composition having an initial boiling point in the range of from 130° C. to 230° C. (IP123), a final boiling point of at most 410° C. (IP123) and a cetane number in the range of from 35 to 120 (ASTM D613); anda kerosene composition having an initial boiling point in the range of from 80 to 150° C., a final boiling point in the range of from 200 to 320° C. and a viscosity at −20° C. in the range of from 0.8 to 10 mm2 / s (ASTM D445).

Owner:SHELL USA INC

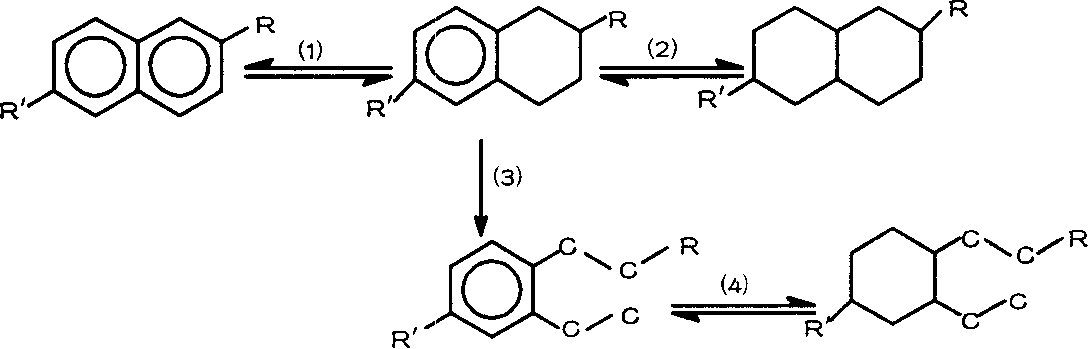

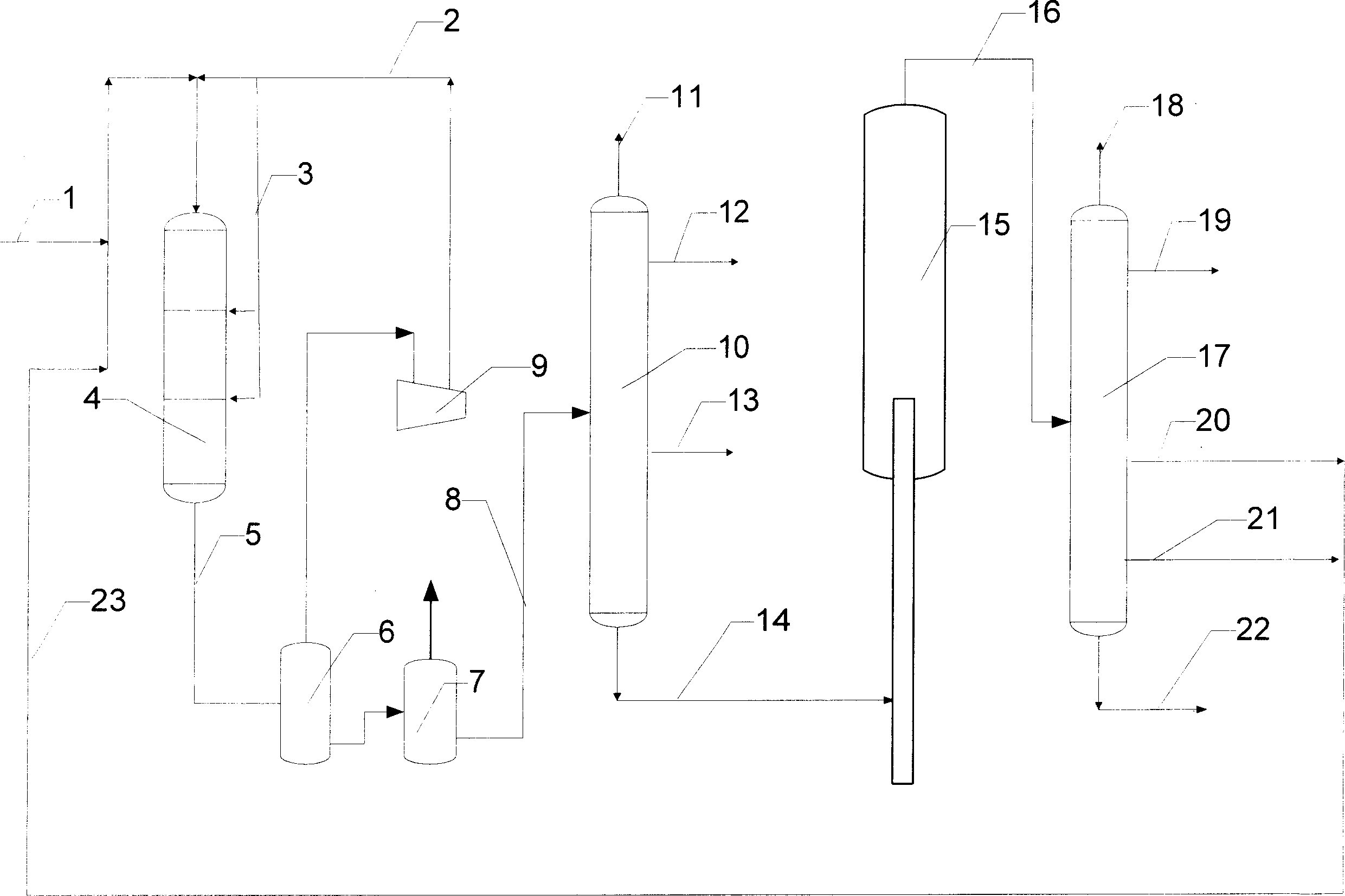

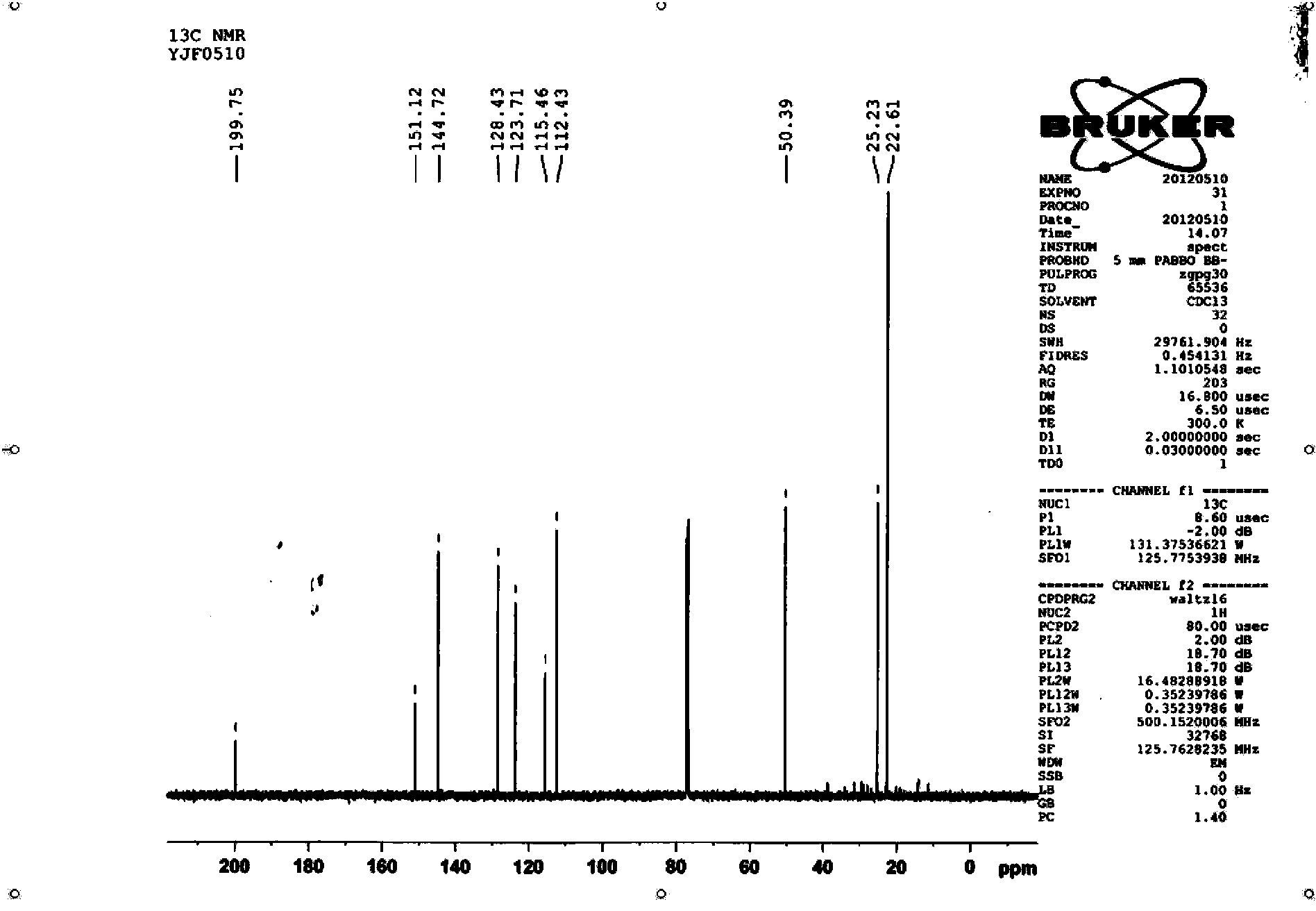

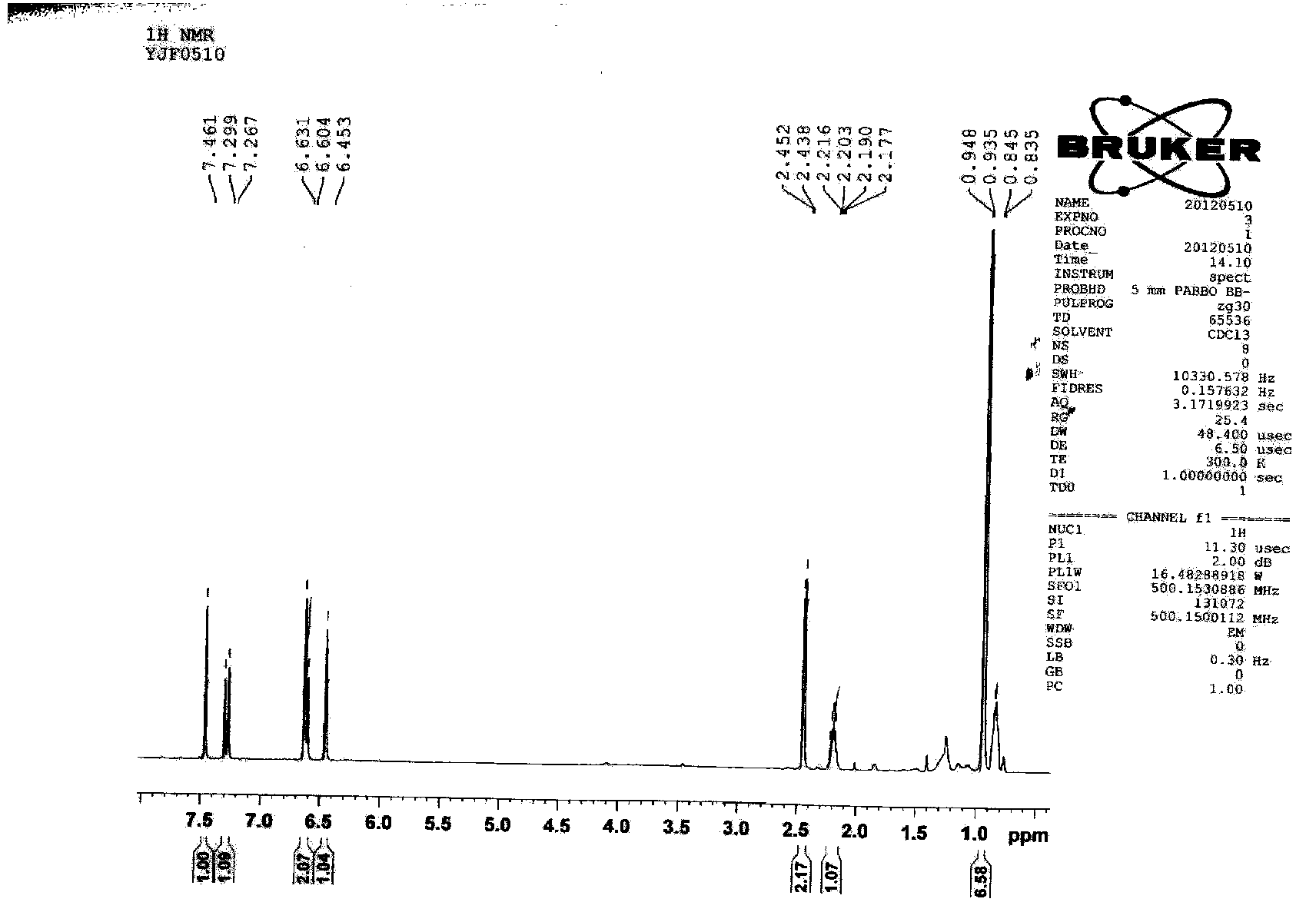

Method for preparation of aviation kerosene and diesel oil from biomass derivative

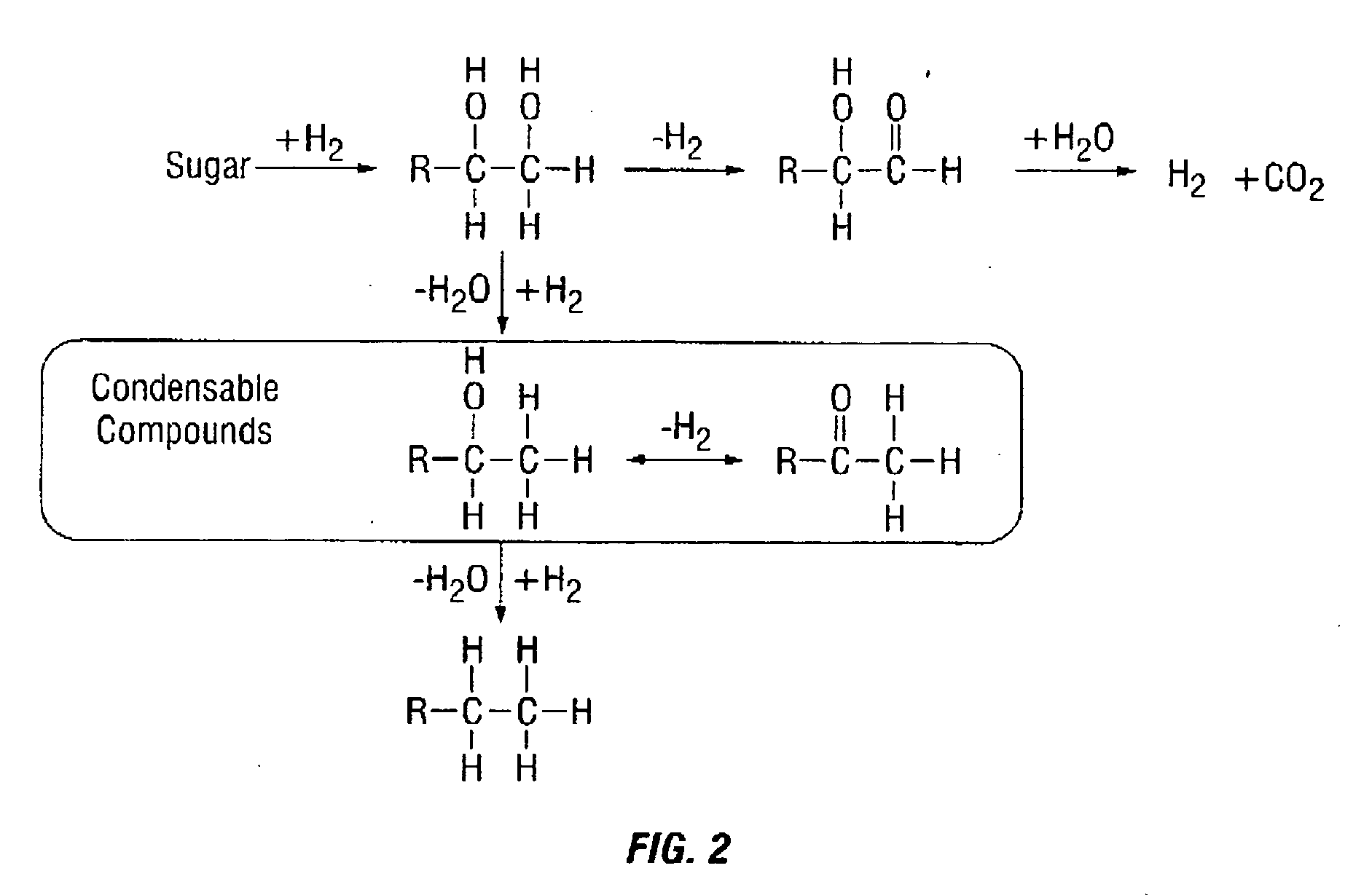

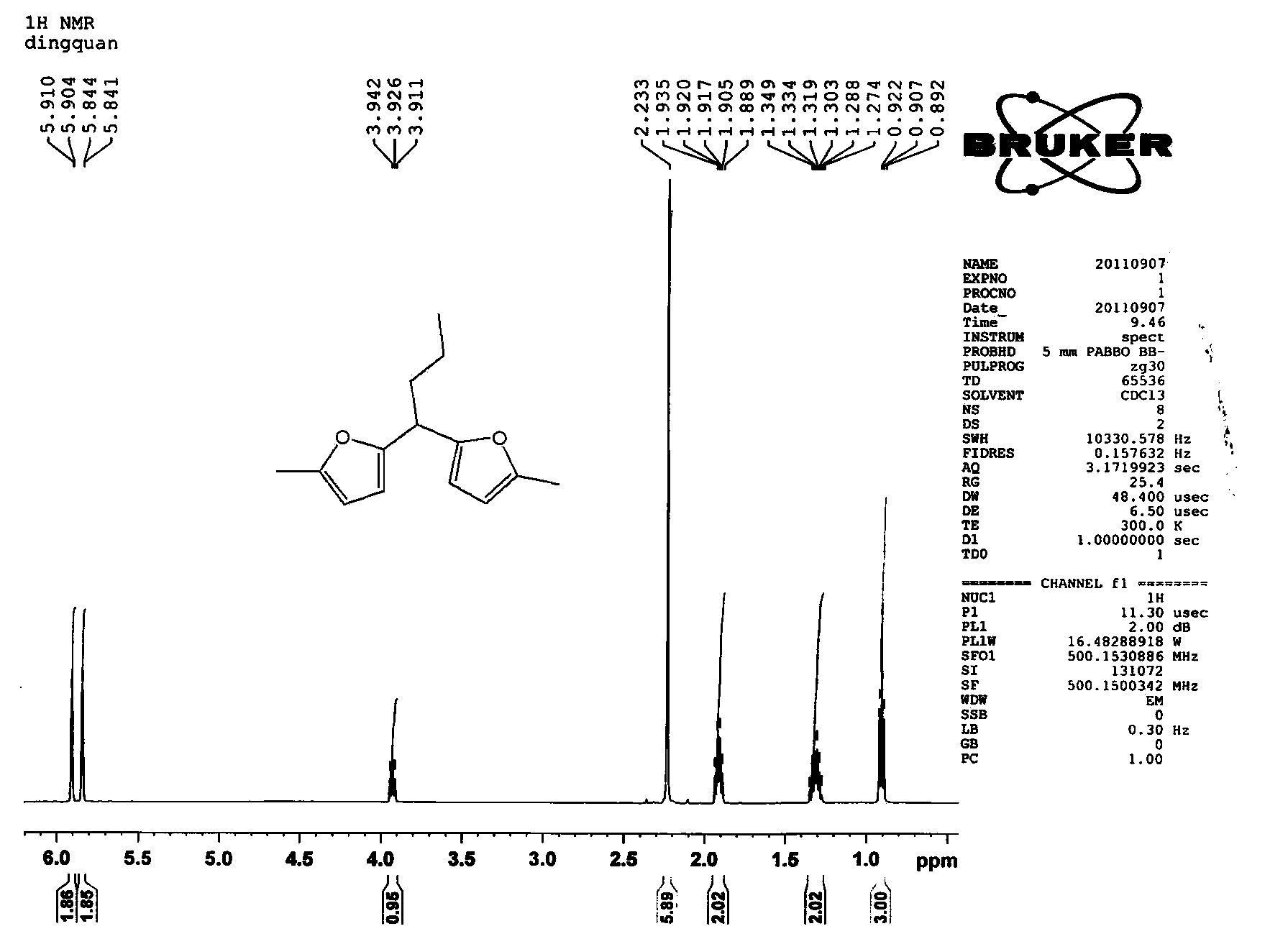

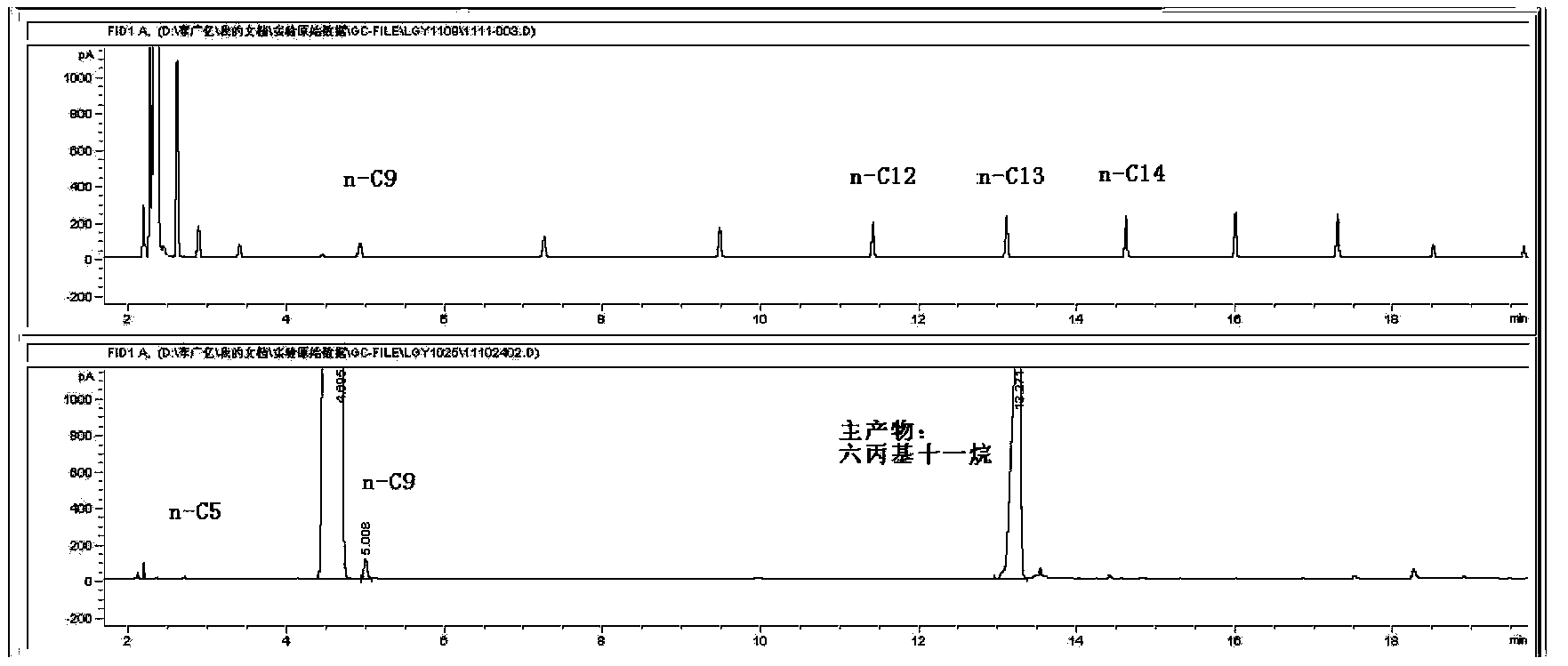

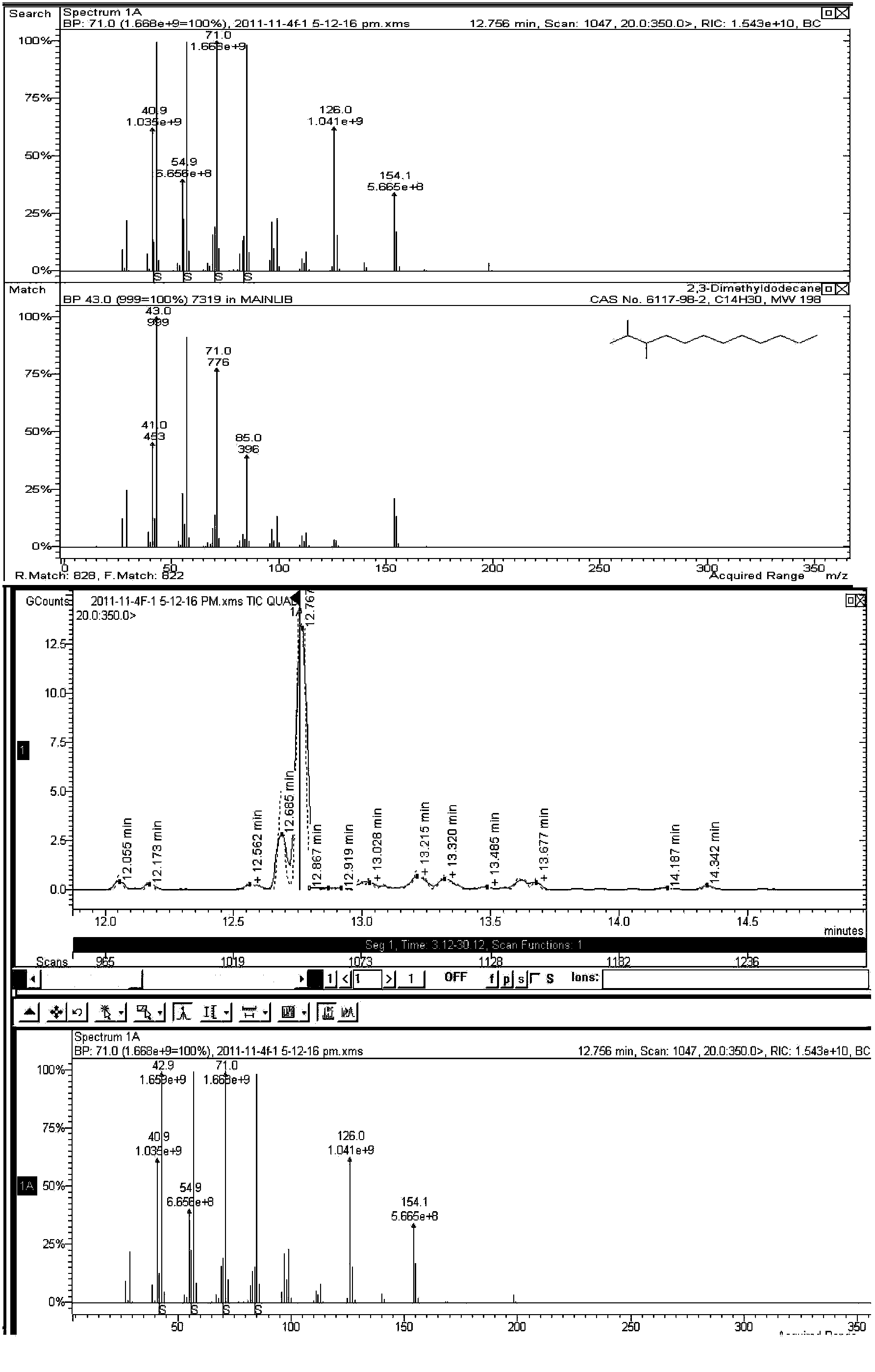

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalytic cracking process for the production of diesel from vegetable oils

The present invention relates to a thermo catalytic process to produce diesel oil from vegetable oils, in refineries which have two or more Catalytic Cracking (FCC) reactors. At least one reactor processes heavy petroleum or residue in conventional operation conditions while at least one reactor processes vegetable oils in proper operation conditions to produce diesel oil. This process employs the same catalyst employed in the FCC process, which processes conventional feedstocks simultaneously. This process transforms high heat content raw materials into fuel hydrocarbons. It may improve efficiency for the obtainment of highly pure products and may not yield glycerin, one by-product of the transesterification process. The diesel oil produced by said process may have superior qualities and / or a cetane number higher than 40. Once cracking conditions occur at lower temperatures, it may form a less oxidized product, which is consequently purer than those obtained by existent technology.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

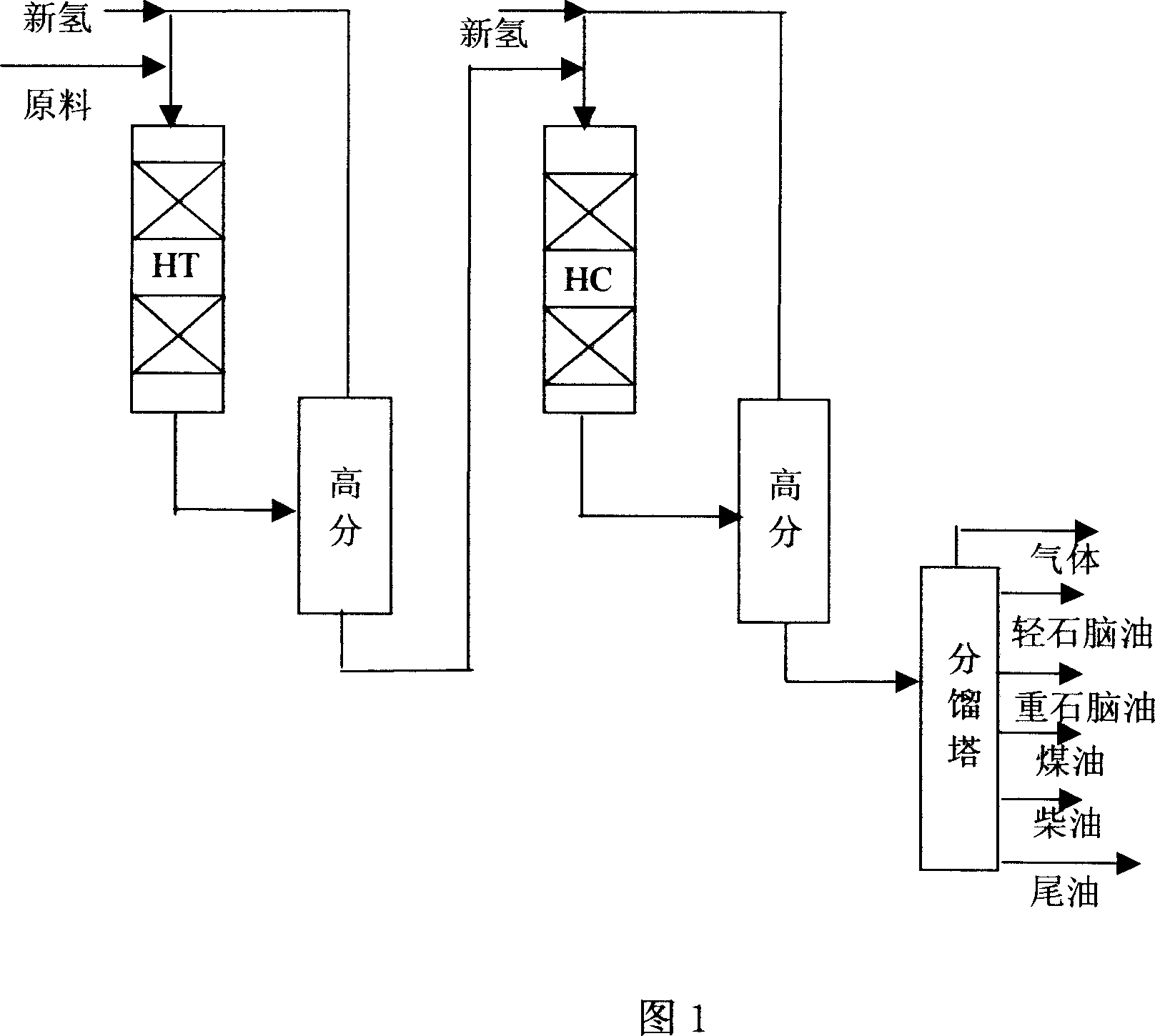

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

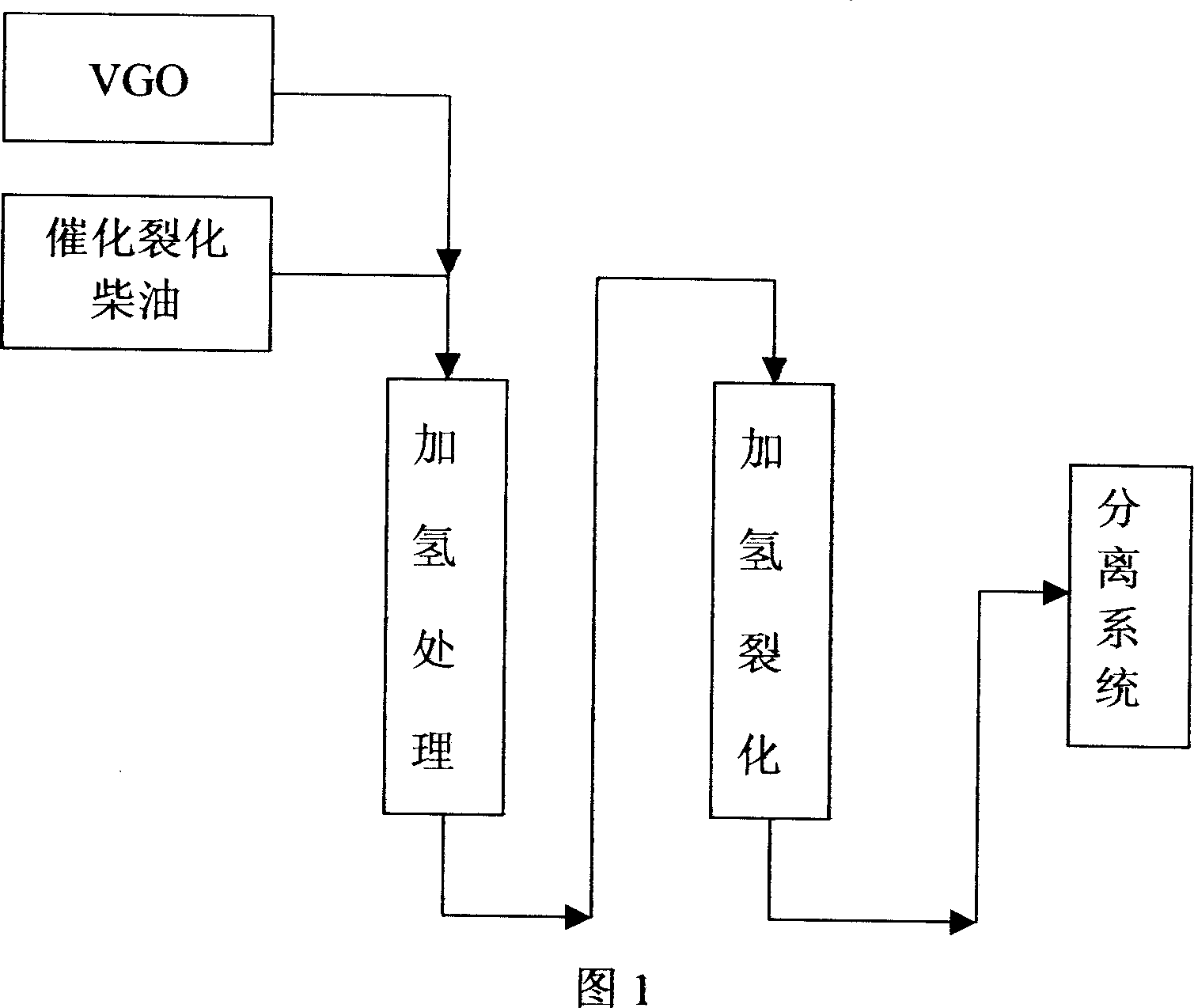

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

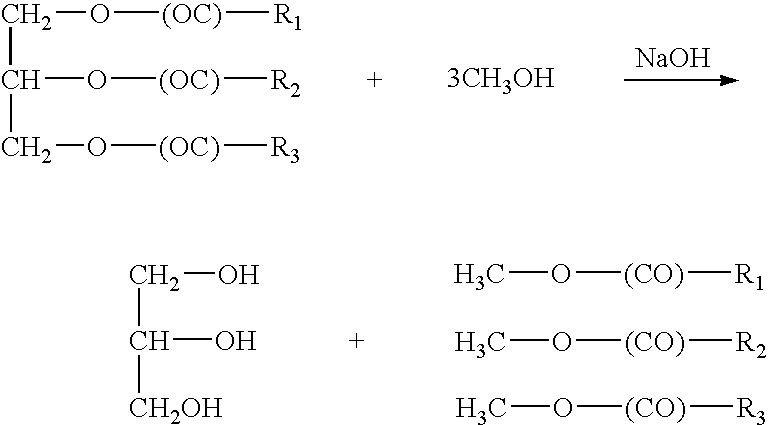

Alternative fuel and fuel additive compositions

InactiveUS20090013591A1Reduce concentrationReduce severityBiofuelsLiquid carbonaceous fuelsParticulatesAlternative fuels

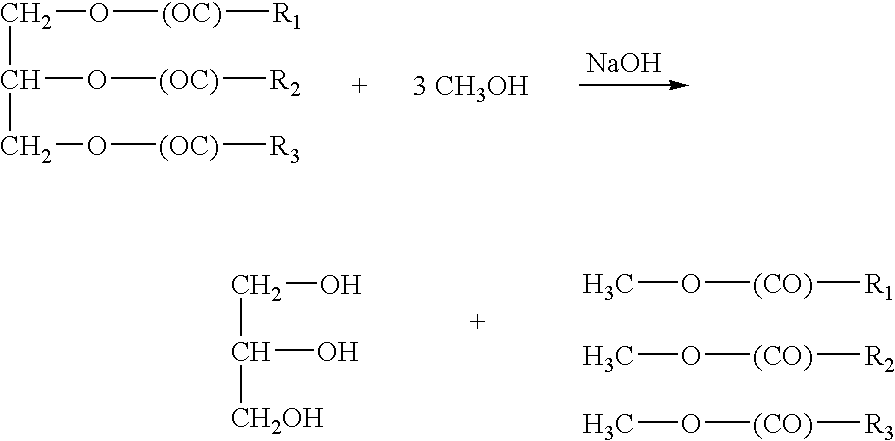

Alternative gasoline, diesel fuel, marine diesel fuel, jet fuel, and flexible fuel compositions are disclosed. The compositions include an alcohol and / or a glycerol ether or mixture of glycerol ethers, which can be derived from renewable resources. When combined with gasoline / ethanol blends, the glycerol ethers can reduce the vapor pressure of the ethanol and increasing the fuel economy. When added to diesel fuel / alcohol blends, glycerol ethers improve the cetane value of the blends. All or part of the diesel fuel in the compositions described herein can be biodiesel fuel and / or synthetic fuel derived from a Fischer-Tropsch synthesis process. Fischer-Tropsch synthesis can also use feedstocks derived from sources other than crude oil, such as methane, methanol, ethanol, lignin and glycerol, which can further reduce reliance on foreign sources of crude oil. When used in jet fuel, glycerol ethers can replace all or part of conventional deicing additives, thus lowering skin toxicity, and glycerol ethers ability to reduce particulate emissions can lower the appearance of contrails. When used in marine diesel, the reduction in particulate emissions can be environmentally significant. In another embodiment, the alternative compositions comprise gasoline, ethanol, and n-butanol, and in one aspect, the ethanol and / or n-butanol can be derived from renewable resources. Fuel additive compositions, including glycerol ethers and hydrocarbons and / or alcohols, are also disclosed.

Owner:BRADIN DAVID +2

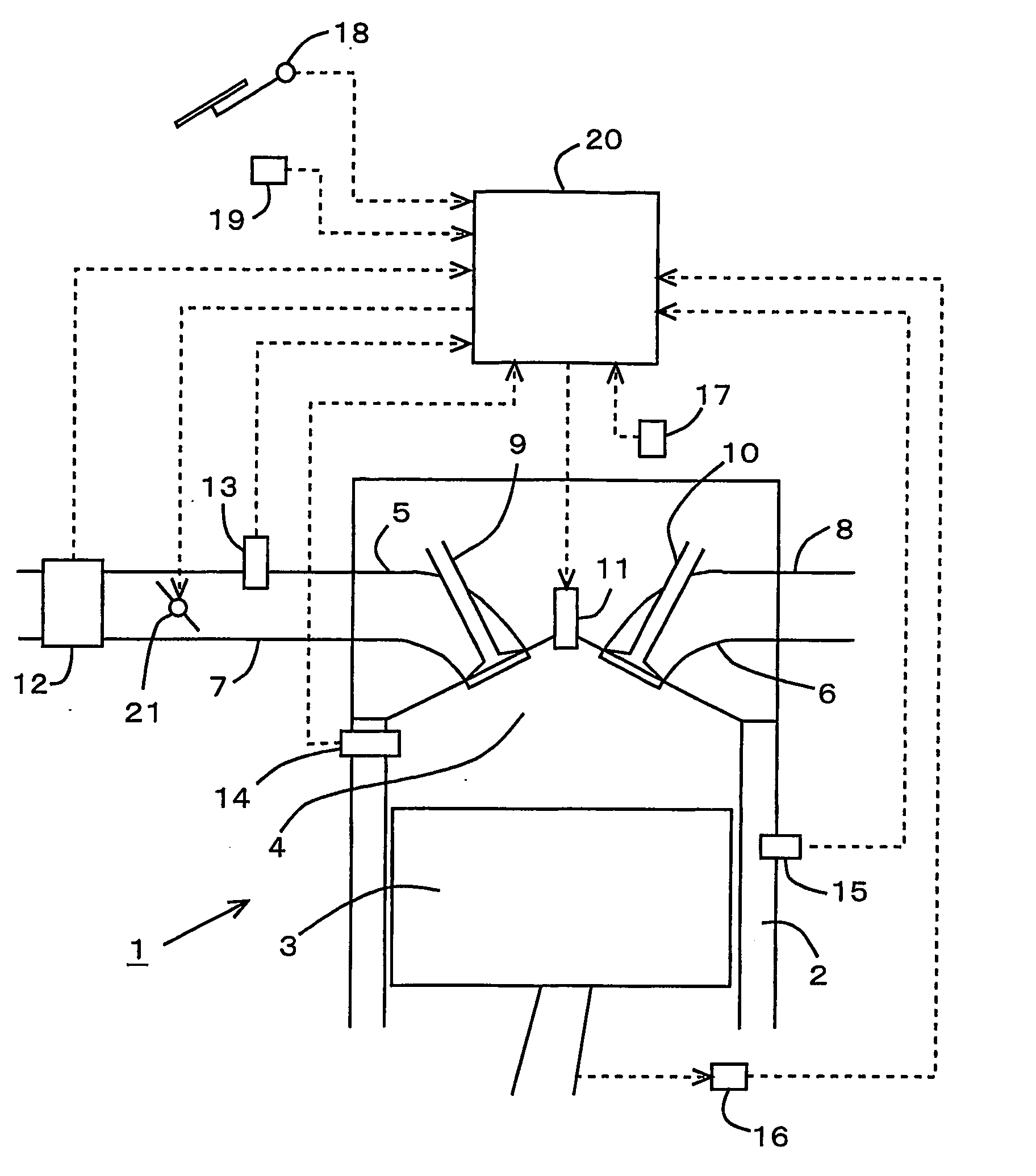

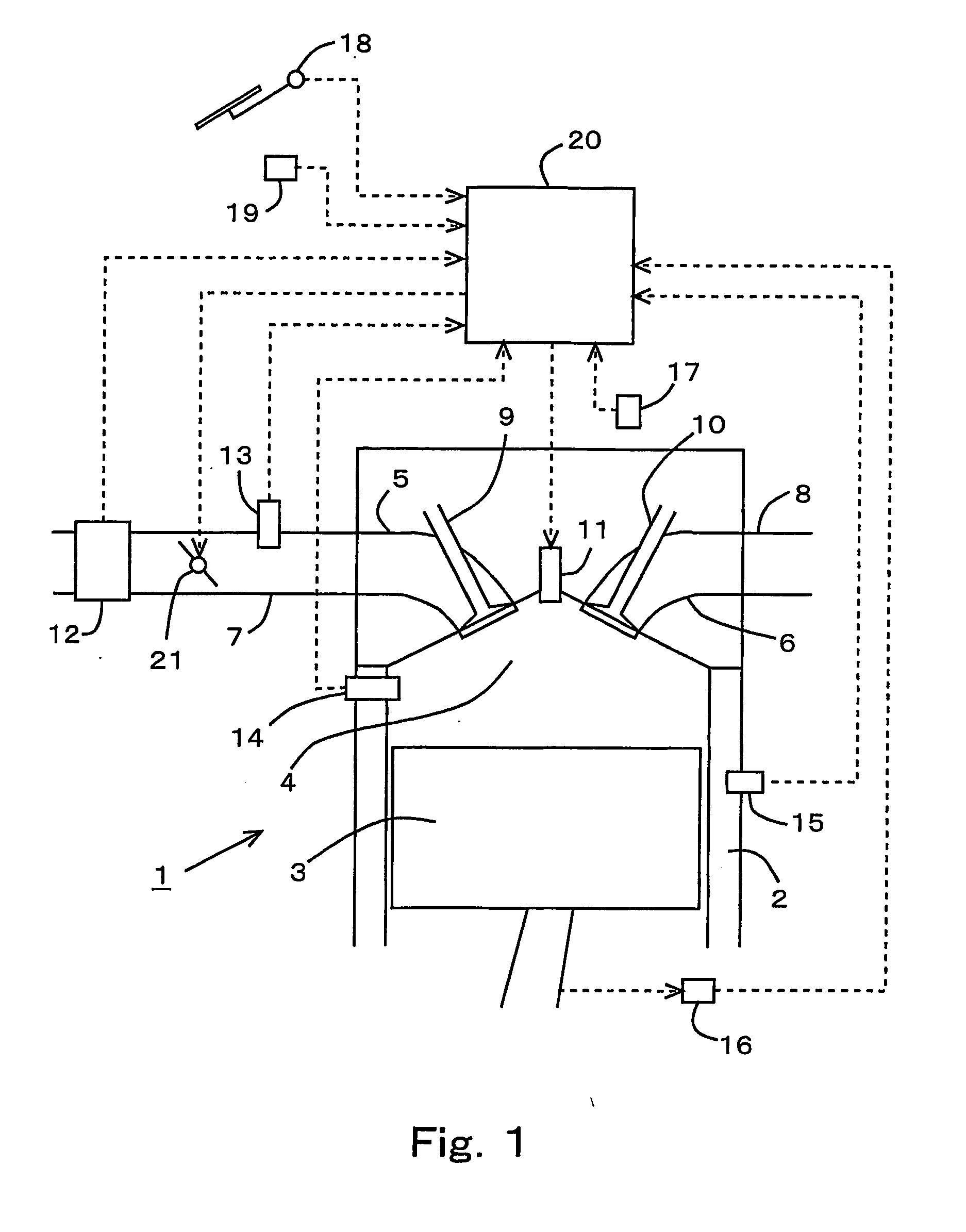

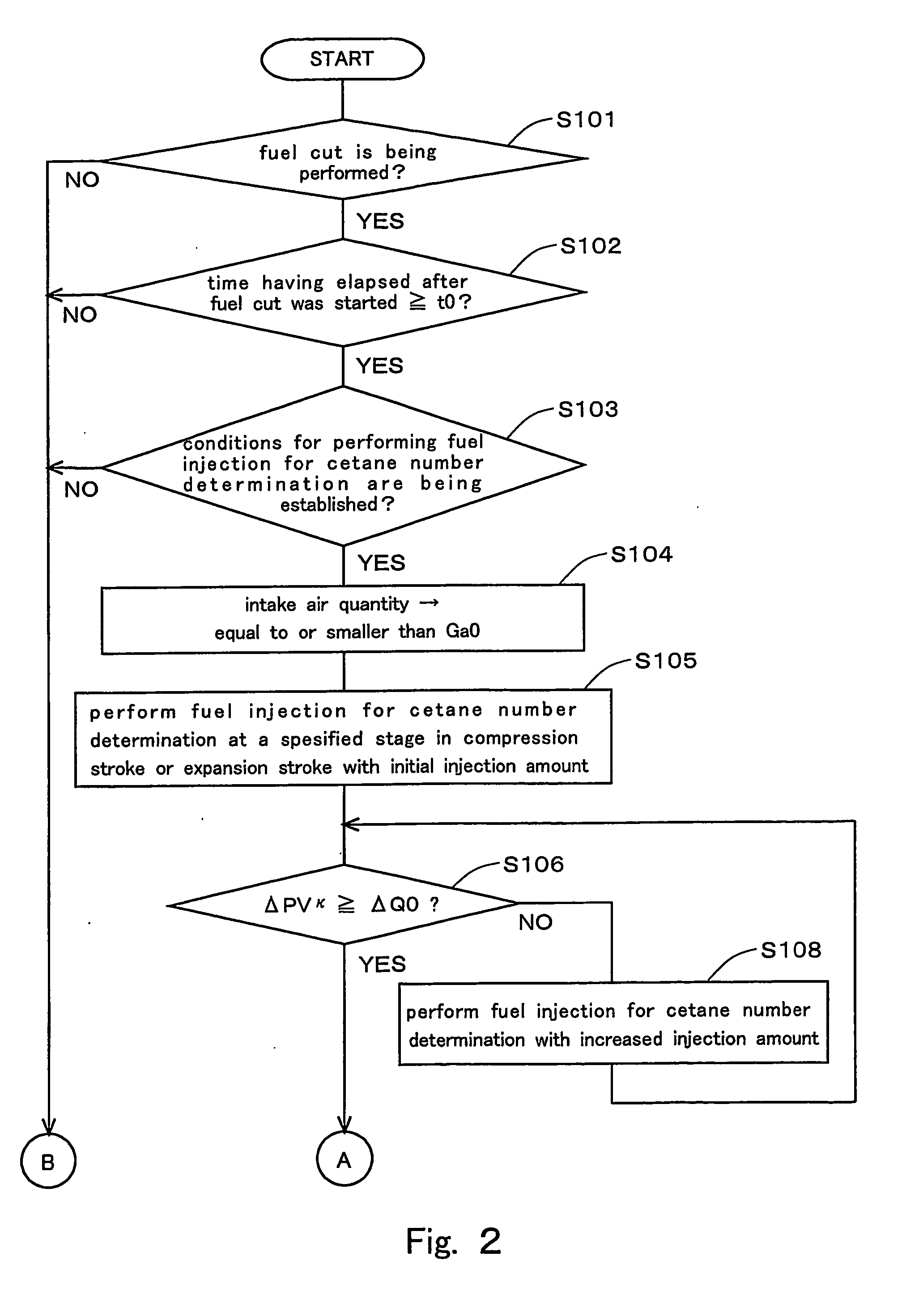

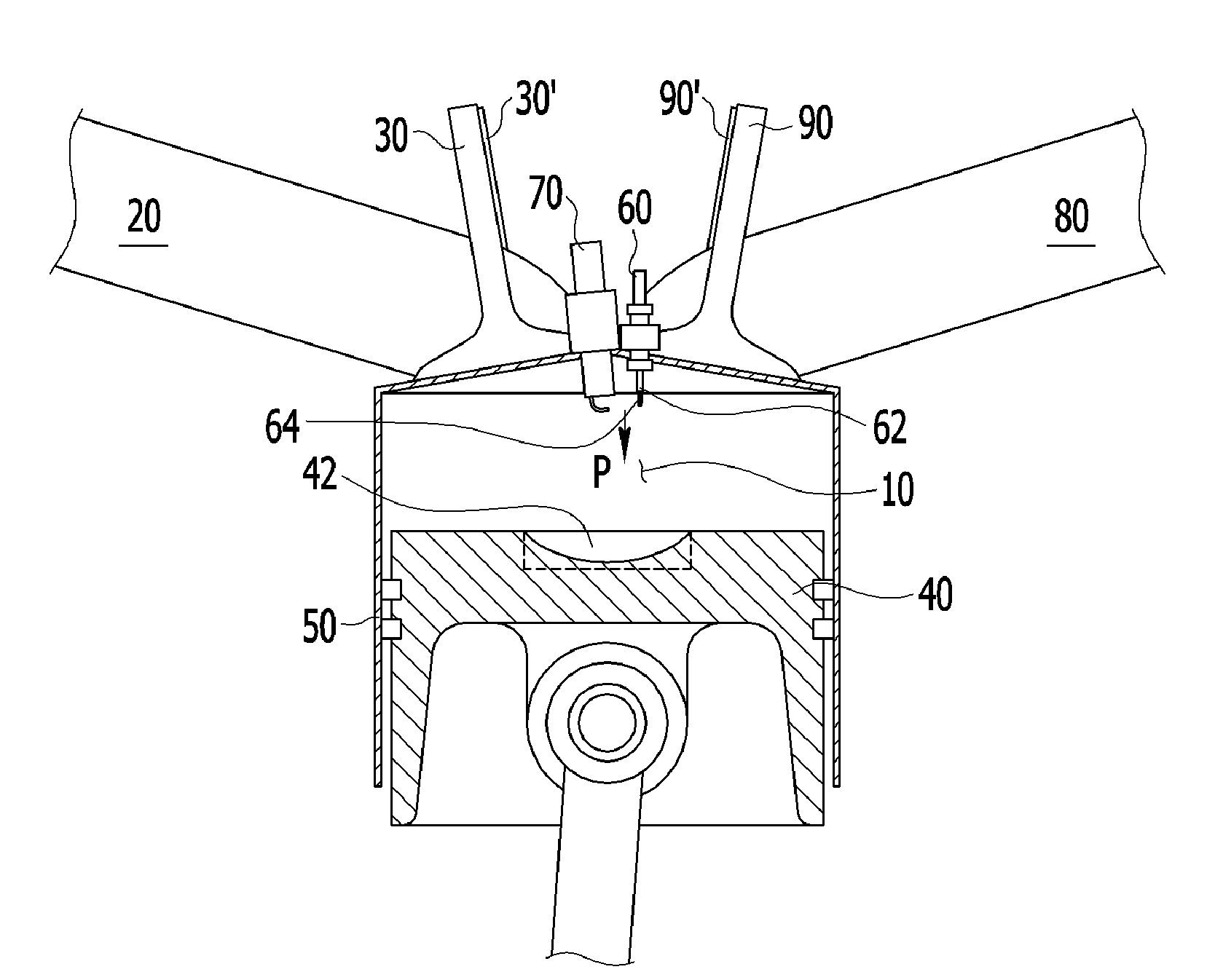

Method of determining cetane number of fuel in internal combustion engine

InactiveUS20070079647A1Easy to igniteShorter ignition delay timeElectrical controlInternal combustion piston enginesCombustion chamberEngineering

An object of the present invention is to provide a technology that enables to determine the cetane number of fuel in a state in which it is actually used for running an internal combustion engine with an improved degree of accuracy. A fuel injection for cetane number determination in which a specified quantity of fuel is injected into a combustion chamber during a compression stroke or expansion stroke, is performed while the internal combustion engine is in a fuel cut state. The cetane number of the fuel is determined based on the time period from a specified time to a time of ignition at which the fuel injected by the fuel injection for cetane number determination is ignited.

Owner:TOYOTA JIDOSHA KK

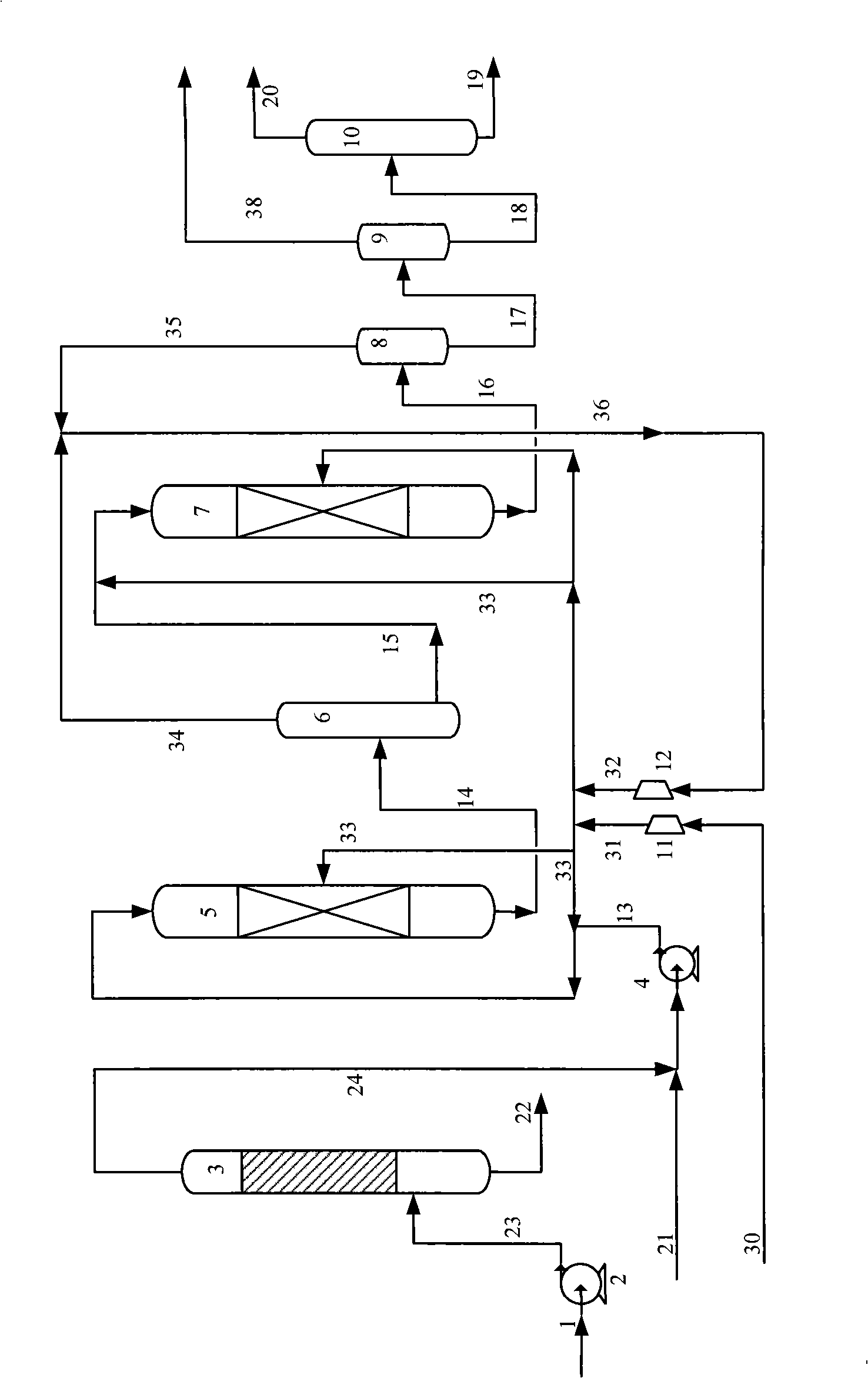

Two-stage hydrocracking method

ActiveCN1955262AEfficient processingLow BMCITreatment with hydrotreatment processesHexadecaneNaphtha

This invention discloses a poor quality catalytic cracking diesel hydrogenation method. This invention includes two stages hydrocracking dealing with catalytic cracking diesel, especially the poor quality catalytic cracking diesel from catalytic hydrogen transfer process. The density of the related poor quality catalytic cracking diesel is 0.90g / ml at 20deg.C, and its aromatic hydrocarbon is over 60wt%, and the value of hexadecane is less than 30. Mixing poor quality catalytic cracking diesel and heavy cracking material and conducting hydrogenation, hydrocracking is conducted after removal of sulphur, nitrogen and other impurities from reaction oil. It is a sufficient utilization of the feature that low hydrogen and high aromatic hydrocarbon content of catalytic cracking diesel to produce Gaofangqian heavy naphtha in order to realize the effective utilization of the poor quality catalytic cracking diesel.

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for direct synthesis of diesel distillates with high quality from synthesis gas through Fischer-Tropsch synthesis

InactiveUS6765025B2Organic compound preparationOxygen compounds preparation by reductionActivated carbonSyngas

Diesel fuels or blending stocks having excellent lubricity, oxidative stability and high cetane number are directly produced from synthesis gas over activated carbon supported cobalt based Fischer-Tropsch catalyst under the condition of temperature within the range of 120 to 400° C., reaction pressure within the range of 0.5 to 10.0 MPa, volume hourly space velocity of a mixture of hydrogen and carbon monoxide within the range of 100 to 5000, the mole ratio of hydrogen to carbon monoxide within the range of 1 to 4. Diesel fuels containing at least 95 wt % paraffins with an iso to normal ratio of about 0.03 to 0.3, <50 ppm (wt) of sulfur and nitrogen, less than about 2 wt % unsaturates, and about 0.001 to less than 0.3 wt % oxygen were obtained by separating the Fischer-Tropsch product into a lighter (180 to 245 ° C. fraction) and heavier fractions (245 to 380° C. fraction) utilizing a rough flash, and combining the 180 to 245° C. portion of the lighter product with the 245 to 380° C. fraction in desired ratios.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

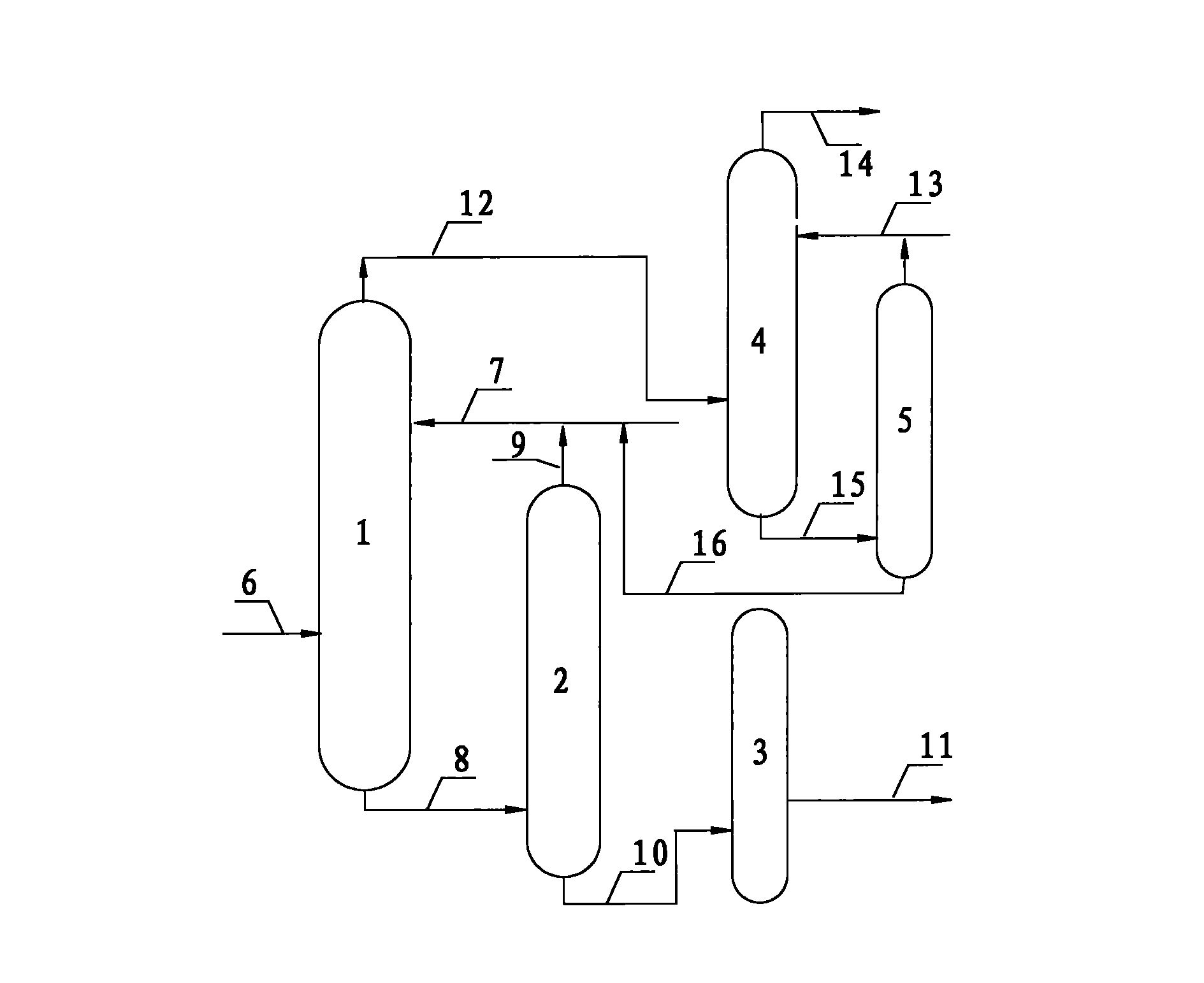

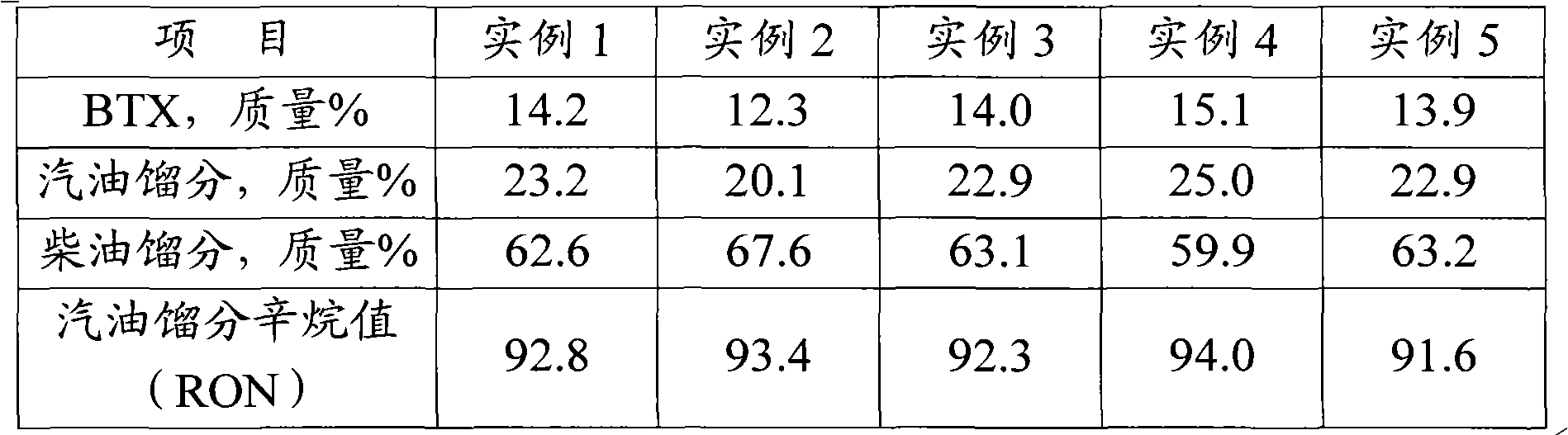

Method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel

ActiveCN103214332AEasy to handleReduce the difficulty of operationHydrocarbon purification/separationHydrocarbonsAlkanePolycyclic aromatic hydrocarbon

The invention discloses a method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel. The method comprises the following steps of 1, carrying out extraction of catalytically cracked diesel by an extraction solvent to obtain polycyclic aromatic hydrocarbon-rich extract oil and alkane-rich raffinate oil, 2, carrying out hydrofining and hydrocracking of the polycyclic aromatic hydrocarbon-rich extract oil under the hydrogenation reaction conditions to obtain light aromatic hydrocarbons and a high-octane number gasoline fraction. The method can realize production of light aromatic hydrocarbons, high-cetane number diesel and high-octane number gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diesel production from hydrogenation upgrading isomerizing pour-point reduction

ActiveCN1712499ALittle impact on yieldLowering the freezing pointRefining to change hydrocarbon structural skeletonIsomerizationCrystallinity

Production of hydrogenated and pour-point reducing modified isomerization diesel oil is carried out by using fraction oil as raw material from one-stage or series process flow, passing fraction oil raw material and hydrogen gas into catalyst bed which consists of beta molecular sieve 1í½9wt%, and obtaining clean high-quality diesel product and naphtha product with low sulfur nitrogen and high arene content. The beta molecular sieve has small crystal grain, low acidity, high silica-alumina ratio and crystallinity. It achieves simple process, higher productivity and less impurities, and improves density and freezing point.

Owner:CHINA PETROLEUM & CHEM CORP +1

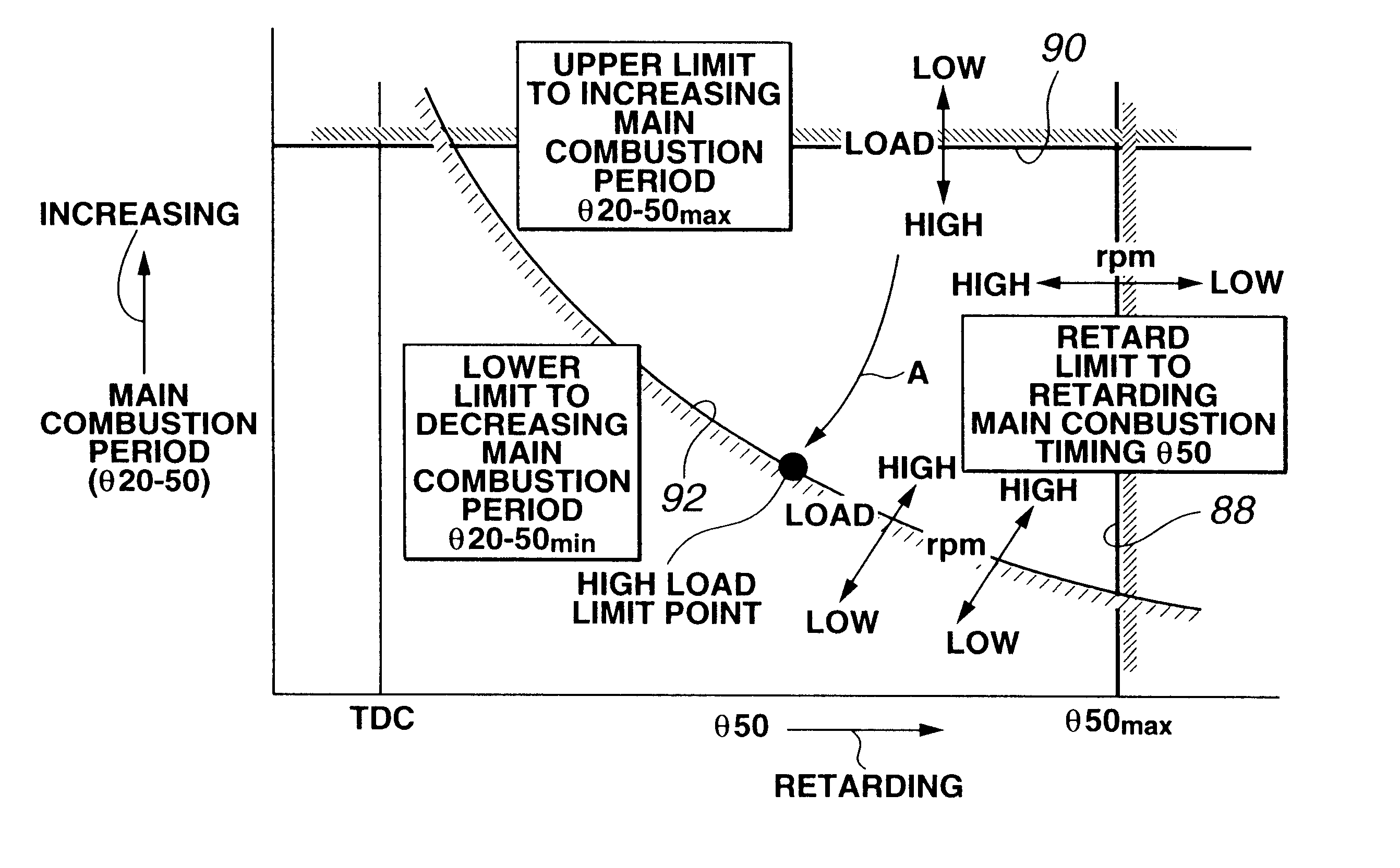

Auto-ignition combustion management in internal combustion engine

An internal combustion engine is operated on auto-ignition combustion of fuel with low cetane number like gasoline. The engine has at least one cylinder and a reciprocating piston in the cylinder to define a combustion chamber. Combustion event in the cylinder is expressed in terms of two variables. They are main combustion timing (theta50) and a main combustion period (theta20-50). The main combustion timing (theta50) represents a crank position when mass burnt rate is 50 percent. The main combustion period (theta20-50) represents a period from a crank position when mass burnt is 20 percent to a crank position when mass burnt is 50 percent. Controlled parameters governing main combustion are varied to adjust the main combustion timing on an advance side of a retard limit (theta50 max) and to adjust the main combustion period within a range between an upper limit (theta20-50 max) and a lower limit (theta20-50 min).

Owner:NISSAN MOTOR CO LTD

Inferior diesel hydrogenation catalyst

InactiveCN1778873AHigh yieldWeak ring opening cracking performanceRefining to eliminate hetero atomsLanthanumChemistry

A hydrotreating catalyst of inferior diesel consists of alumina 20.0í½80.0wt% and molecular sieve 3.0í½60.0w%. The catalyst is prepared by loading at least one Fe, Co and Ni metal of ó° family and MO and W metal of ó÷B family as metal active component and adding one or above oxide or fluorinated compound of titanium, magnesium, zirconium, lanthanum, iron, phosphorus, silicon and boron as active auxiliaries. It can decrease content of sulfur and arenes and increase cetyl value in products. It can be used for cryogenic hydrogenation desulfurization, denitridation and hydrogenation dearomatization.

Owner:PETROCHINA CO LTD +1

Method of hydro up grading isomerizing pour point depression to produce diesel oil

ActiveCN1718683ALittle impact on yieldExtended operating cycleHydrocarbon oils refiningNaphthaSulfur

A process for preparing the clean diesel oil by hydromodifying, isomerizing and lowering pour point features that the fractional oil raw material and H2 pass through a catalyst bed to obtain clean high-quality diesel and the naphtha product with low contents of sulfur and nitrogen and high content of arylhydrocarbon. Said catalyst bed contains hydrocatalyst bed containing beta zeolite (0.5-20 wt.%).

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for producing chemical raw material

ActiveCN1955257AHigh yieldIncrease the potential content of aromaticsHydrocarbon oil crackingHexadecaneCatalytic reforming

This invention relates to a hydrocracking preparation of chemical materials production. Poor quality catalytic cracking Diesel and heavy hydrocracking material is mixed according to a proportion, and then hydrogenation and hydrocracking are conducted. The yield of heavy naphtha reaches 40wt% by controlling operating conditions, making sure the yield of tail oil 20wt%. The quality features of this poor quality catalytic cracking Diesel are high density, high content of aromatic hydrocarbon and low value of hexadecane. The density of the poor quality catalytic cracking diesel oil is above 0.95g / ml, and the aromatic hydrocarbon is over 90wt% and the value of hexadecane is under 20. Comparing with present technology, this invention combines poor quality catalytic cracking diesel and VGO organicly. High quality chemical material is effectively transformed with obtaining low BMCI value of tail oil, which is high quality material for ethylene preparation by steam cracking.

Owner:CHINA PETROLEUM & CHEM CORP +2

Coal tar hydrogenating modified method by two-stage method

ActiveCN101307257AGood Ring Opening Cracking PerformanceGood nitrogen resistanceTreatment with hydrotreatment processesGas phaseDistillation

The invention discloses a two-stage method coal tar hydro-upgrading method. Coal tar is subject to the atmospheric distillation and / or the reduced pressure distillation and is cut into coal tar light cut and coal tar heavy cut; after the coal tar light cut and optional distillate oil are mixed with hydrogen, the mixture enters a first hydrogeneration reaction zone and performs the contact reaction with hydrorefining catalyst; gas phase impurities of a reaction effluent is removed through an intermediate flash distillation column or a high-pressure stripping tower, and then the reaction effluent enters a second hydrogeneration reaction zone to perform the contact reaction with the hydro-upgrading catalyst or the hydrocracking catalyst; and the obtained reaction effluent is cooled, separated and fractionated to produce diesel fraction and naphtha cut. The invention provides a clean and effective coal tar processing and utilizing method, the coal tar light cut is hydro-upgraded to produce diesel oil for vehicles, the sulfur content of the obtained diesel product is less than 50 mu g / g, the content of polycyclic aromatic hydrocarbon is less than 11 weight percent, and the diesel oil cetane number of the product is improved by not less than 20.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking process for the production of diesel from vegetal oils

ActiveUS20070007176A1Increase cetane numberCatalytic crackingCatalytic naphtha reformingHydrocotyle bowlesioidesTransesterification

The present invention comprises a thermo catalytic process to produce diesel oil from vegetal oils, in refineries which have two or more Catalytic Cracking (FCC) reactors. At least one reactor processes heavy gasoleum or residue in conventional operation conditions while at least one reactor processes vegetal oils in proper operation conditions to produce diesel oil. This process employs the same catalyst employed in the FCC process, which processes conventional feedstocks simultaneously. This process transforms high heat content raw materials into fuel hydrocarbons. It shows excellent efficiency for the obtention of highly pure products and do not yield glycerin, one by-product of the transesterification process. The diesel oil produced by said process presents quality superior and cetane number higher than 40. Once cracking reactions occur at lower temperatures, it forms less oxidized product, which is consequently purer than those obtained by existent technology are.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

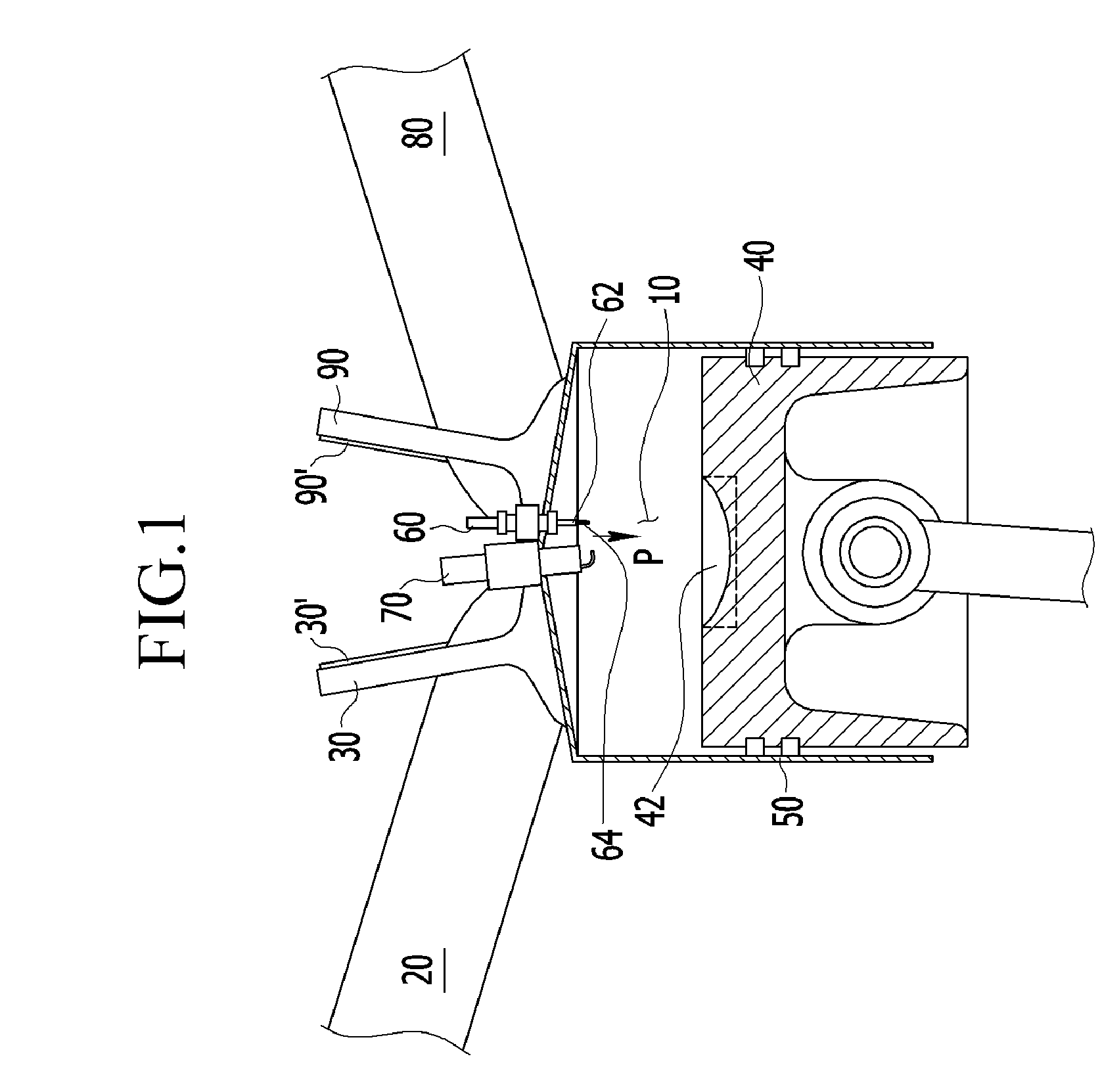

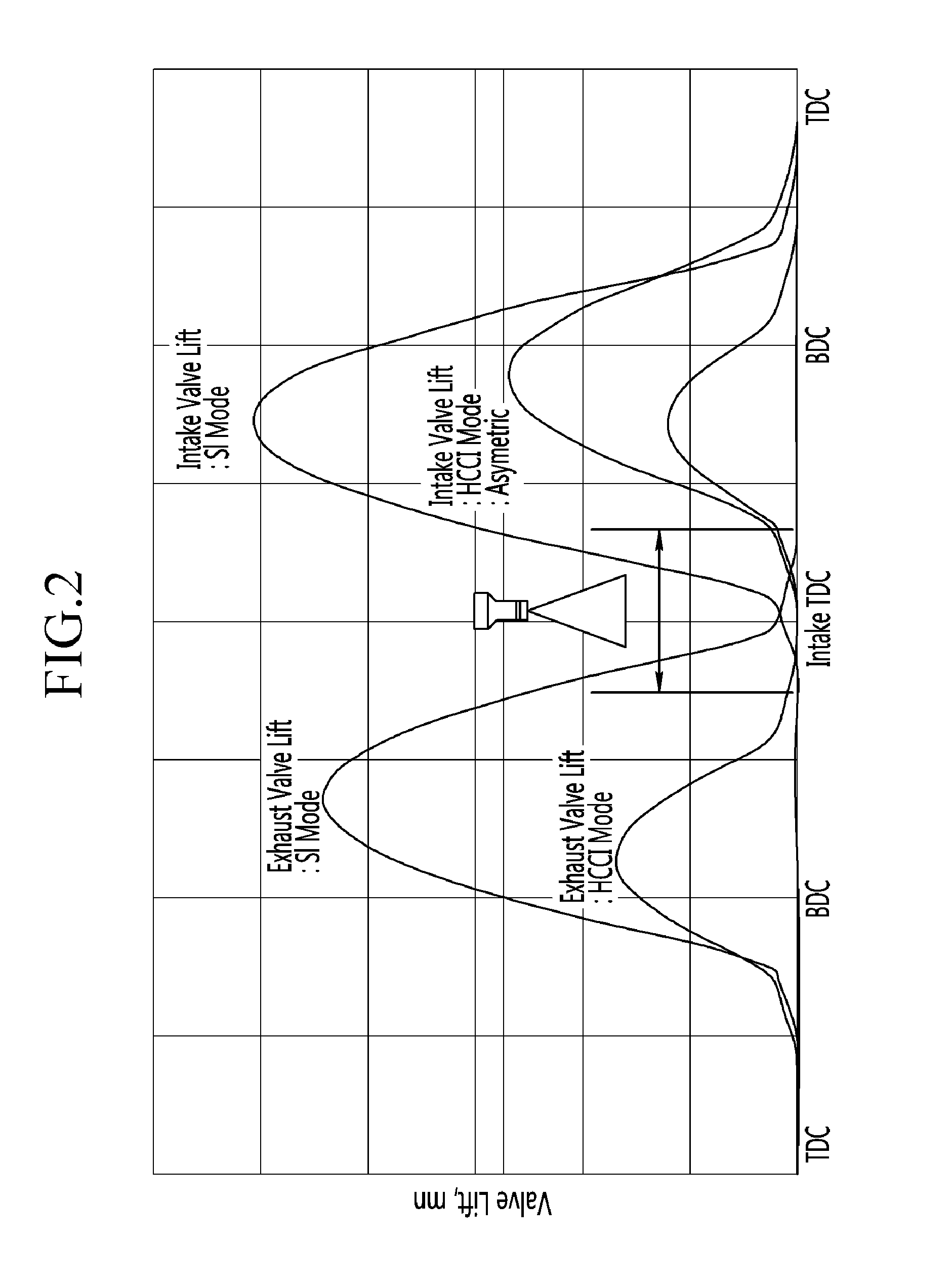

Compression ignition gasoline engine

ActiveUS20110108001A1Suppress excessive self-ignitionRapid increase of combustion noiseValve arrangementsElectrical controlCombustion chamberExhaust valve

A compression ignition gasoline engine uses low-cetane number fuel, such as gasoline. The engine includes a combustion control device having an injector directly injecting fuel into a combustion chamber, intake and exhaust valves, and a variable valve device changing a valve timing, in which the compression ignition gasoline engine includes: at least two intake valves and two exhaust valves; a spark plug positioned at the center portion of the combustion chamber; and an injector positioned adjacent to the spark plug toward the center portion of the combustion chamber, in which the exhaust valve is a symmetric valve lift in which the lift and the opening section of the tow exhaust valves are the same in low lift, and the intake valve is an asymmetric valve lift in which the lift and the opening of the two intake valves are different in the low lift.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com