Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1910 results about "Glycerol Ethers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

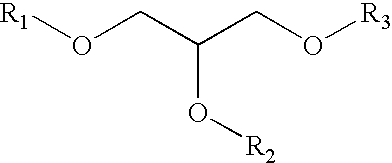

Ethylhexylglycerin is an alkyl glyceryl ether. This means that the ethylhexyl group is bound to glycerin at one end by an ether linkage.

Processes for converting glycerol to glycerol ethers

Processes for converting glycerol to alkyl glycerol ethers that involve providing glycerol, alkyl alcohol and an etherification catalyst, providing an etherification reactor and, adding the glycerol, alkyl alcohol and etherification catalyst to the etherification reactor and reacting the glycerol, alkyl alcohol and etherification catalyst in the etherification reactor to obtain a reaction product comprising alkyl glycerol ethers.

Owner:THE PROCTER & GAMBLE COMPANY

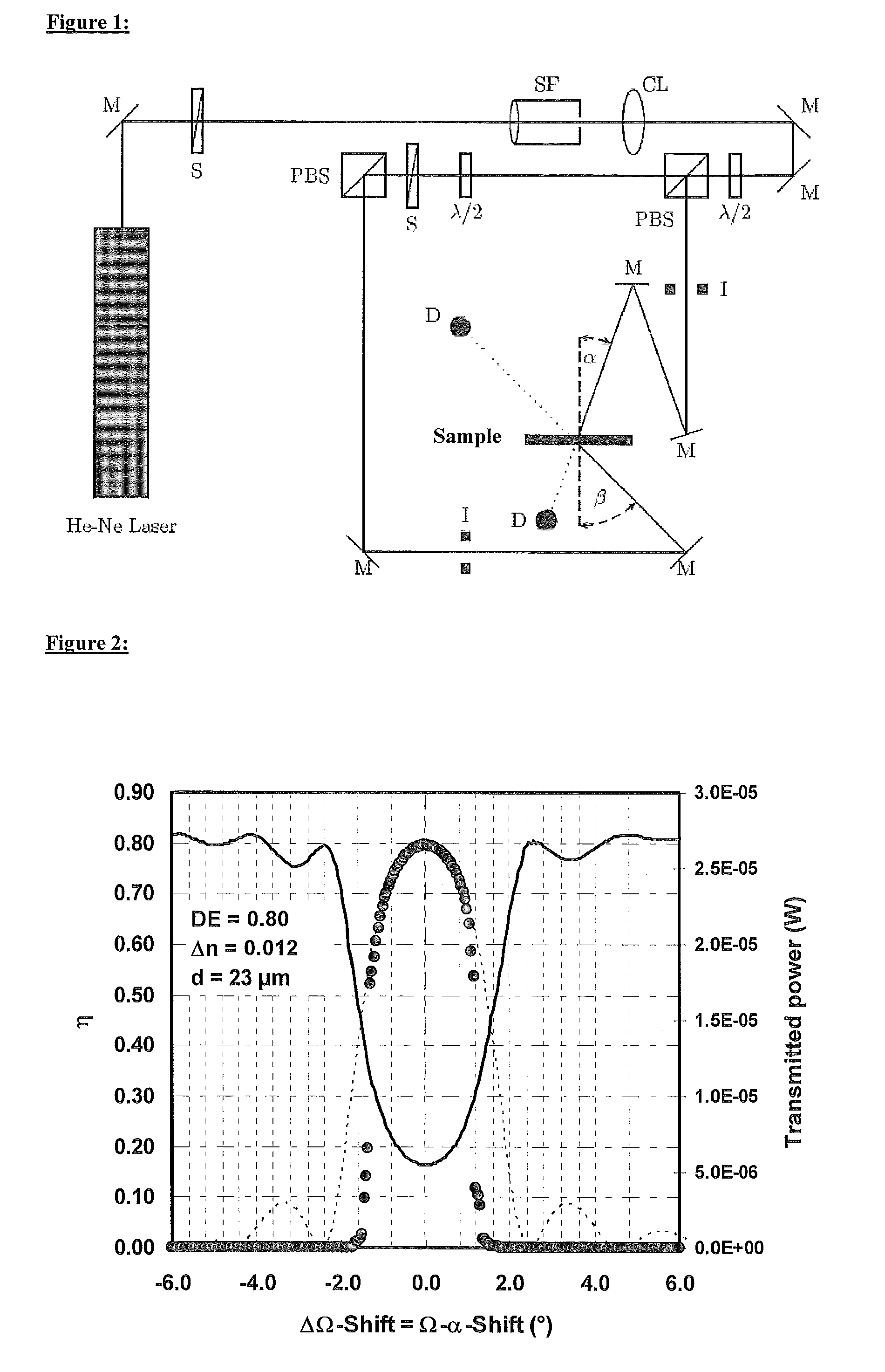

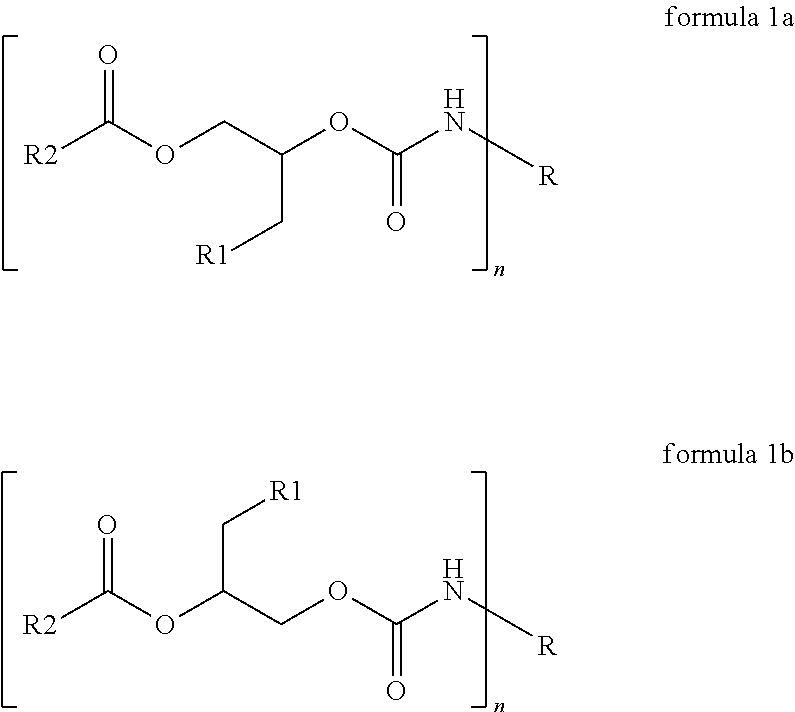

Holographic media and photopolymers

The invention relates to holographic media containing specific photopolymers, a process for the production thereof, and unsaturated glycidyl ether acrylate urethanes as writing monomers which are suitable for the preparation of photopolymers.

Owner:COVESTRO DEUTSCHLAND AG

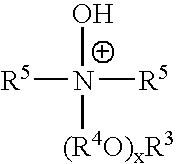

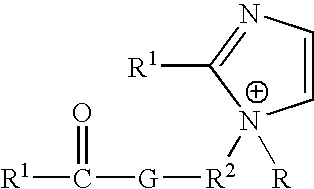

Ionic liquids derived from functionalized anionic surfactants

InactiveUS20060094615A1Inorganic/elemental detergent compounding agentsCationic surface-active compoundsSulfonateAryl

A novel class of ionic liquids and methods for their preparation are disclosed. Specifically, these novel ionic liquids can be derived from anionic surfactants, such as alkyl aryl sulfonates, and mid-chain branched derivatives of alkyl sulfates, alkyl alkoxy sulfates, and alkyl aryl sulfonates. In addition, novel ionic liquids can be derived from other anionic surfactants, such as methyl ester sulfonates (MES), alkyl glycerol ether sulfonates, and alpha olefin sulfonates. Anions may be paired with a variety of cations to achieve various advantageous properties. The present invention also relates to compositions containing these novel ionic liquids and method of using the same.

Owner:THE PROCTER & GAMBLE COMPANY

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

Alternative fuel and fuel additive compositions

InactiveUS20090013591A1Reduce concentrationReduce severityBiofuelsLiquid carbonaceous fuelsParticulatesAlternative fuels

Alternative gasoline, diesel fuel, marine diesel fuel, jet fuel, and flexible fuel compositions are disclosed. The compositions include an alcohol and / or a glycerol ether or mixture of glycerol ethers, which can be derived from renewable resources. When combined with gasoline / ethanol blends, the glycerol ethers can reduce the vapor pressure of the ethanol and increasing the fuel economy. When added to diesel fuel / alcohol blends, glycerol ethers improve the cetane value of the blends. All or part of the diesel fuel in the compositions described herein can be biodiesel fuel and / or synthetic fuel derived from a Fischer-Tropsch synthesis process. Fischer-Tropsch synthesis can also use feedstocks derived from sources other than crude oil, such as methane, methanol, ethanol, lignin and glycerol, which can further reduce reliance on foreign sources of crude oil. When used in jet fuel, glycerol ethers can replace all or part of conventional deicing additives, thus lowering skin toxicity, and glycerol ethers ability to reduce particulate emissions can lower the appearance of contrails. When used in marine diesel, the reduction in particulate emissions can be environmentally significant. In another embodiment, the alternative compositions comprise gasoline, ethanol, and n-butanol, and in one aspect, the ethanol and / or n-butanol can be derived from renewable resources. Fuel additive compositions, including glycerol ethers and hydrocarbons and / or alcohols, are also disclosed.

Owner:BRADIN DAVID +2

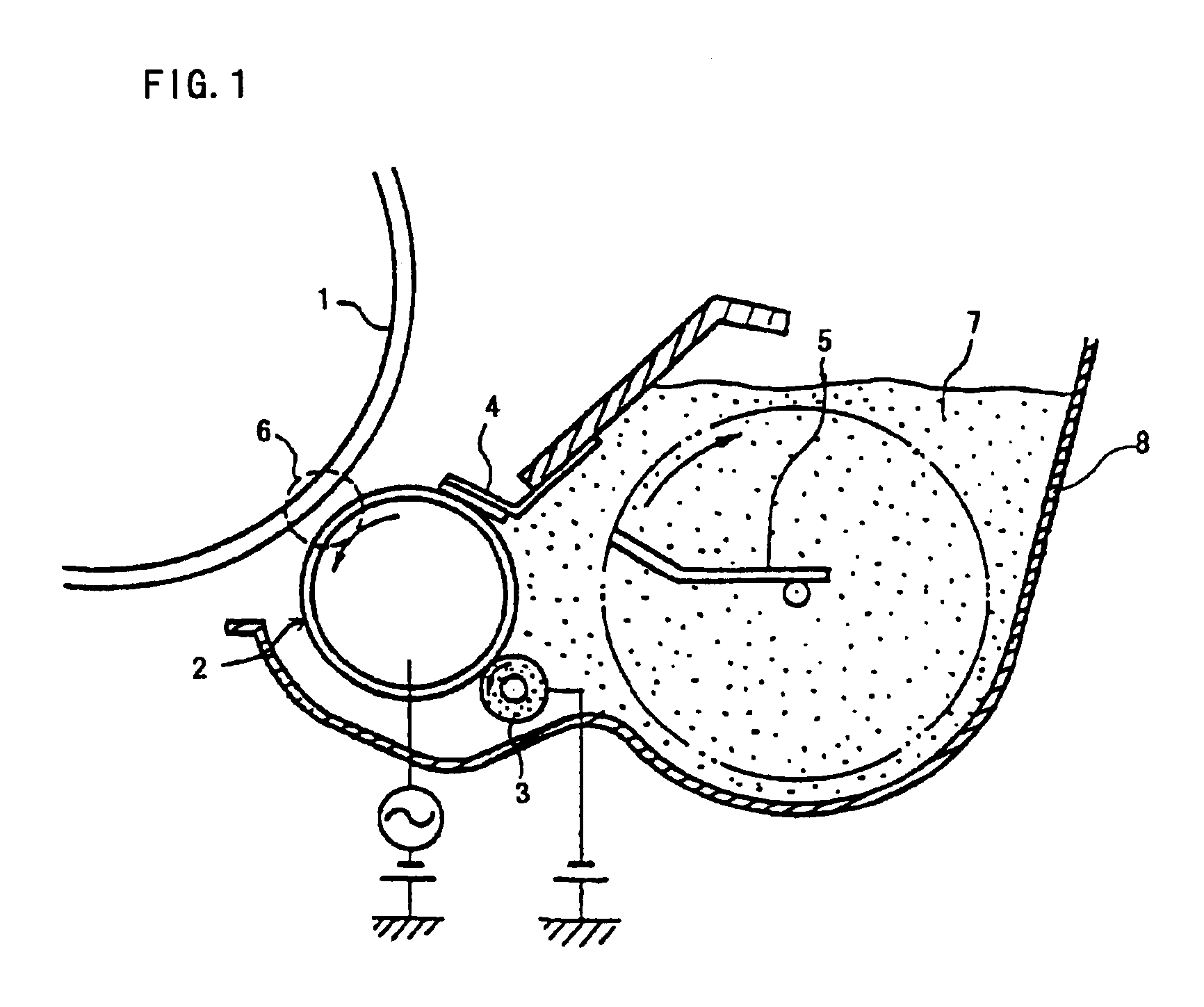

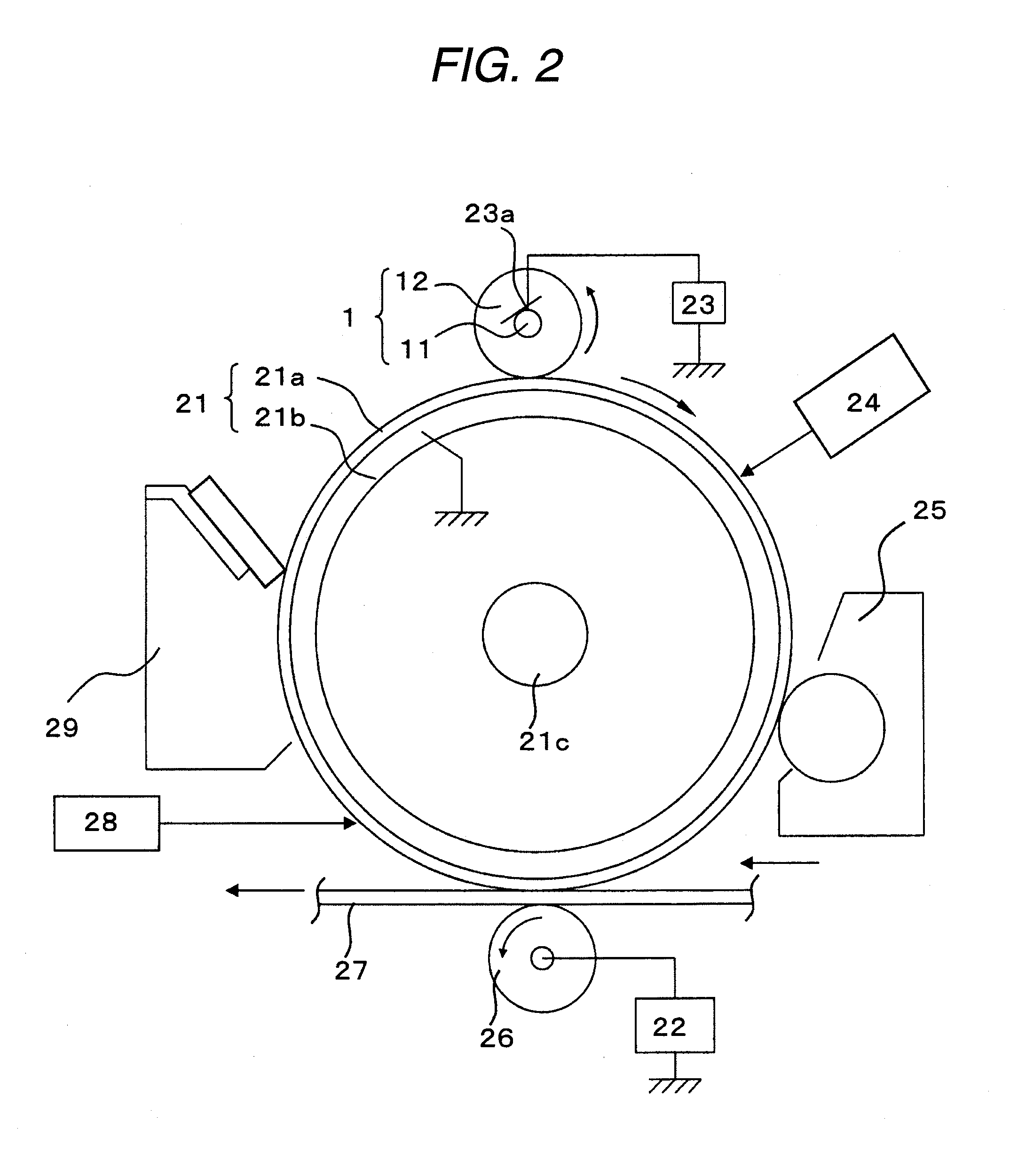

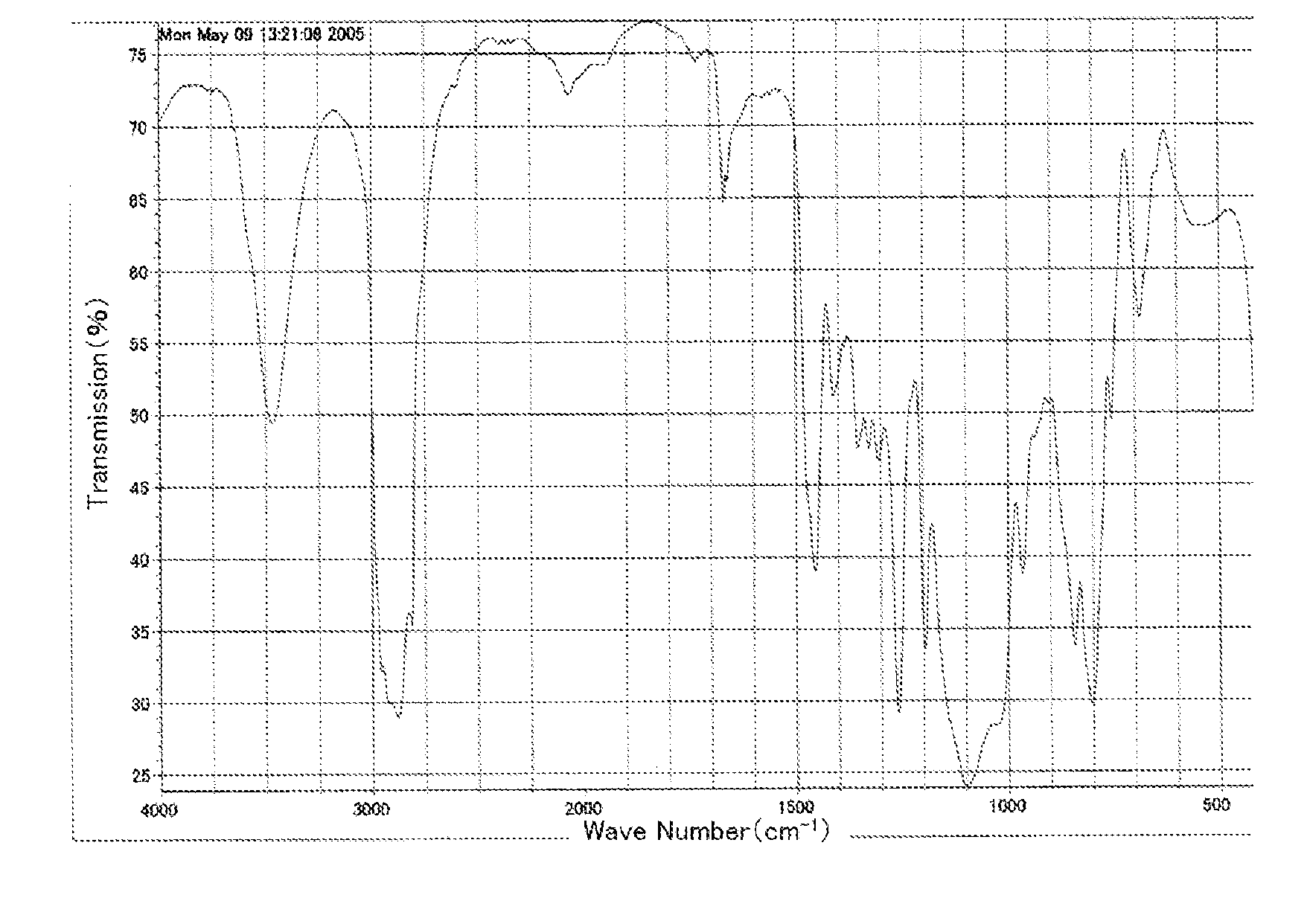

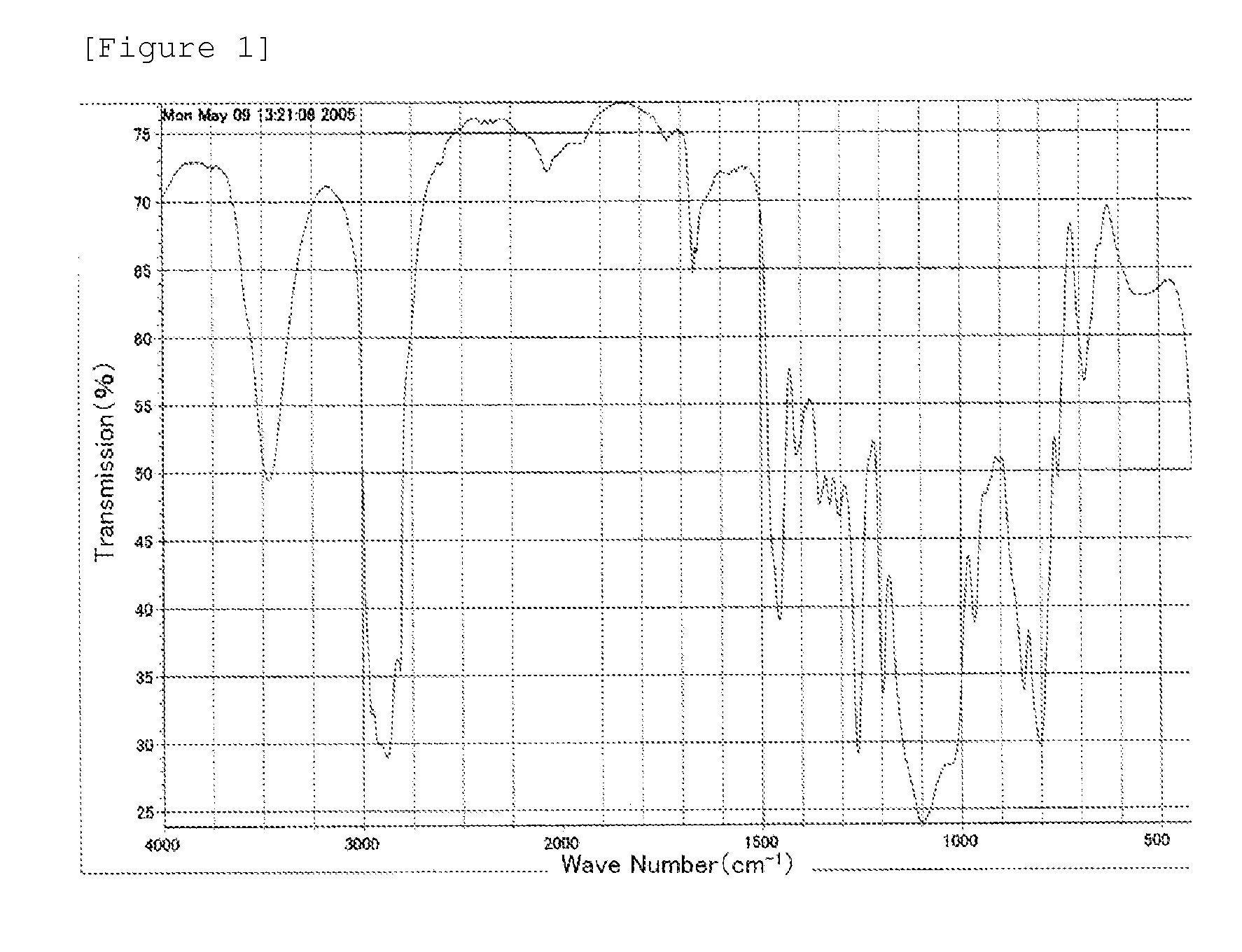

Dry toner for developing electrostatic images

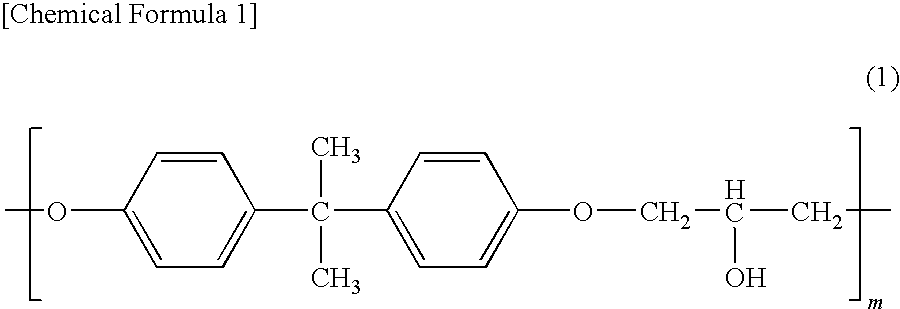

A dry toner for developing electrostatic images, including a colorant and a binder resin which comprises a copolymer resin having (A) a polyol resin moiety having a main chain of polyoxyalkylene and obtained by reaction of (a) an epoxy resin, (b) a dihydric phenol, and (c) an alkylene oxide adduct of a dihydric phenol or a glycidyl ether thereof; and (B) a polyester resin moiety obtained by reacting an alkylene oxide adduct of a dihydric phenol or a glycidyl ether thereof with a polycarboxylic acid, wherein the weight ratio of the epoxy resin of the polyol resin moiety (A) to the polyester resin moiety (B) is 95:5 to 60:40, wherein the epoxy resin includes at least two kinds of bisphenol epoxy resins having different number-average molecular weights, and wherein the binder resin has an acid value of not greater than 5.

Owner:RICOH KK

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

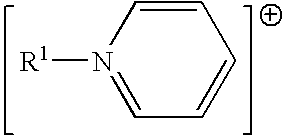

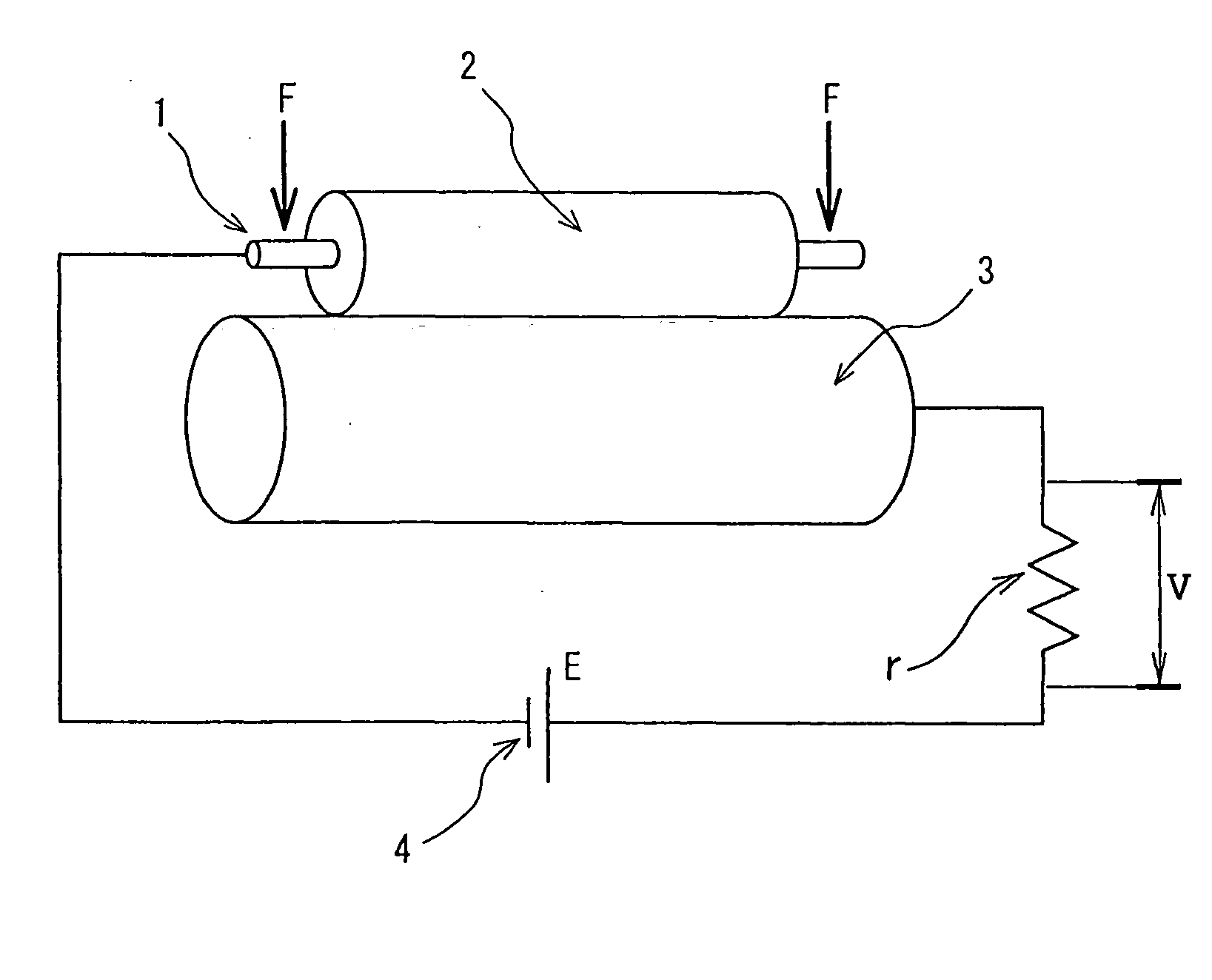

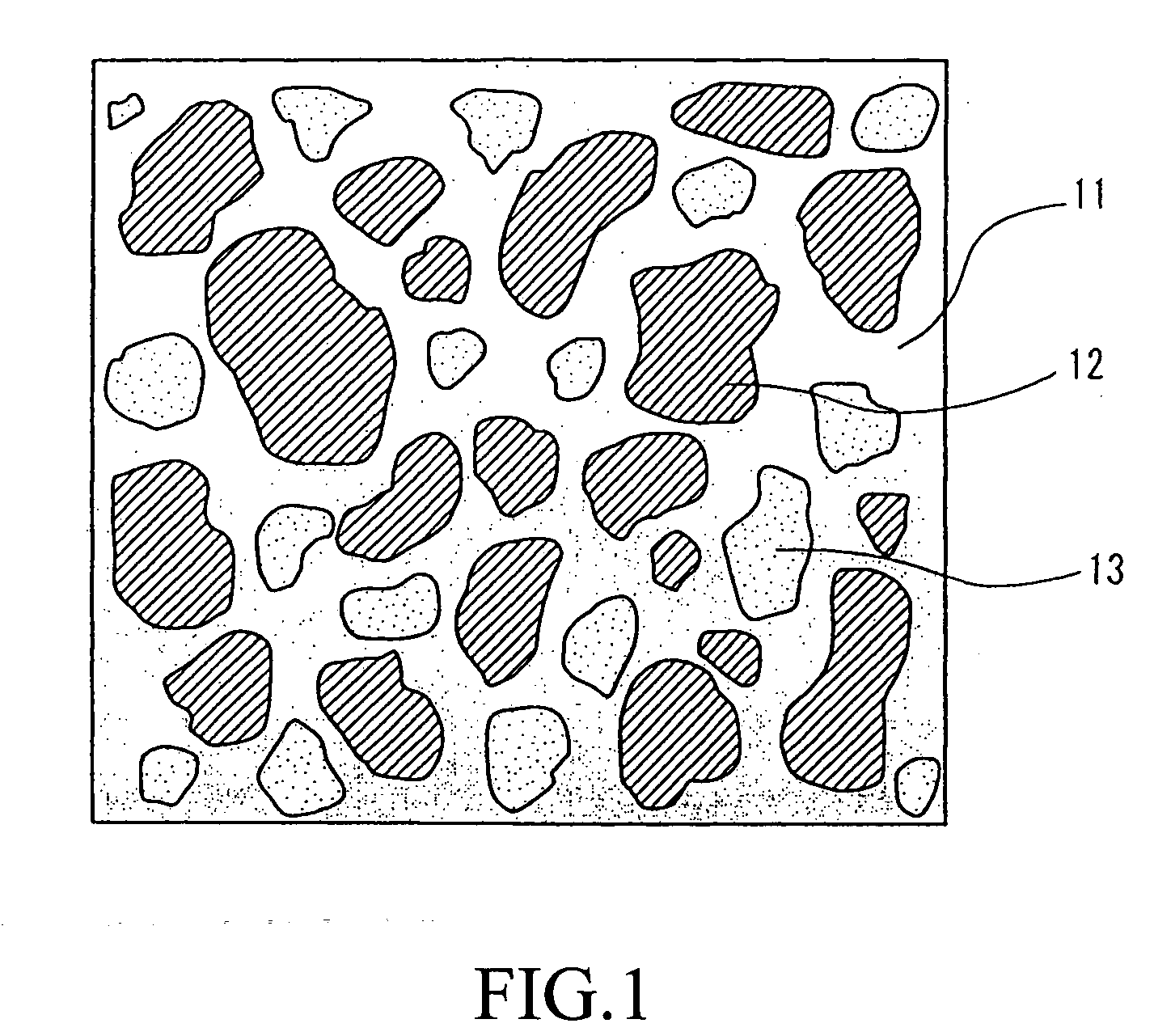

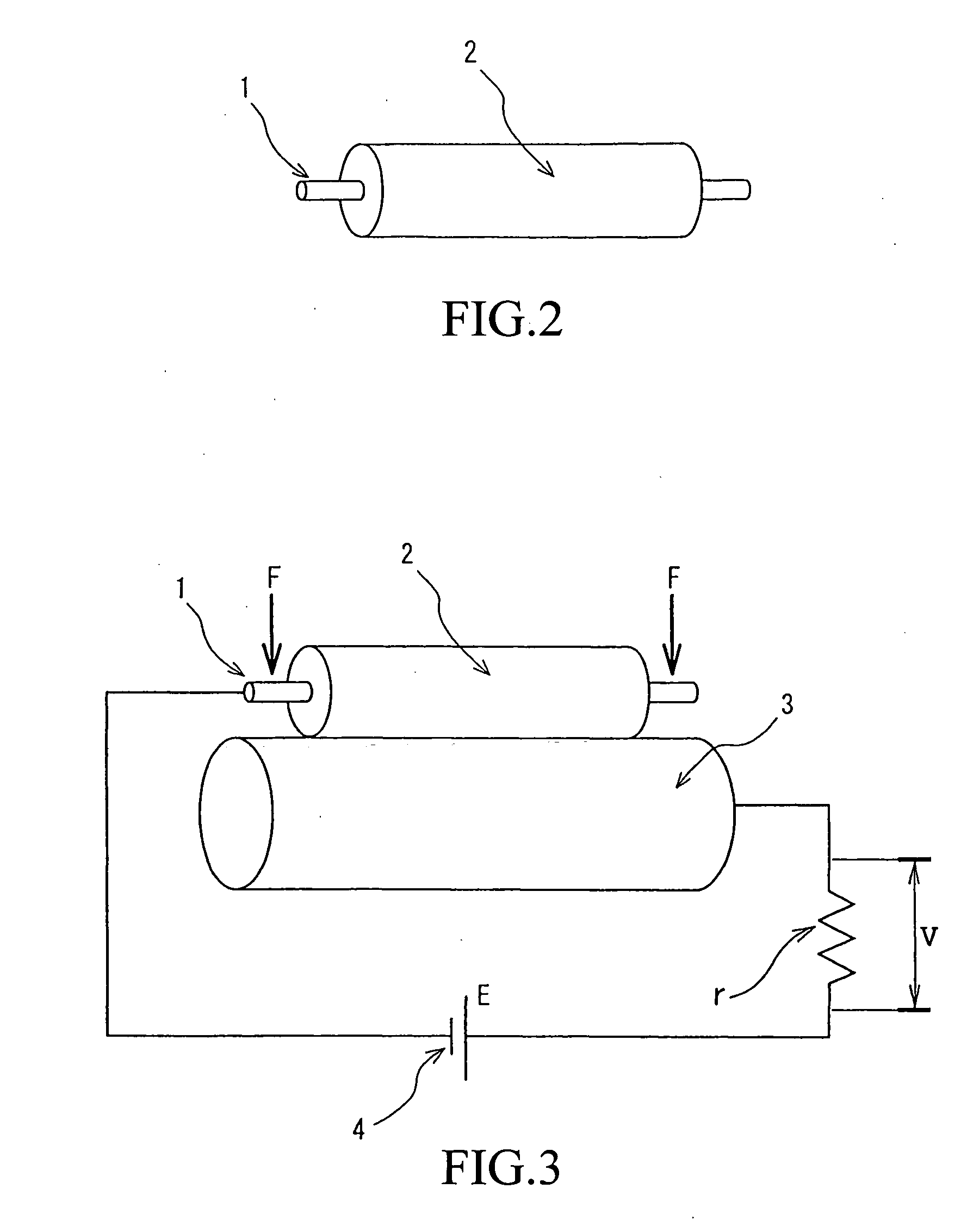

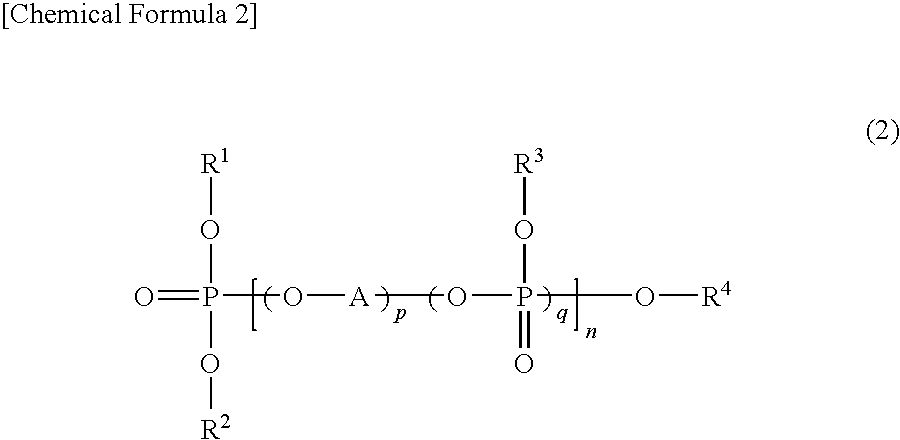

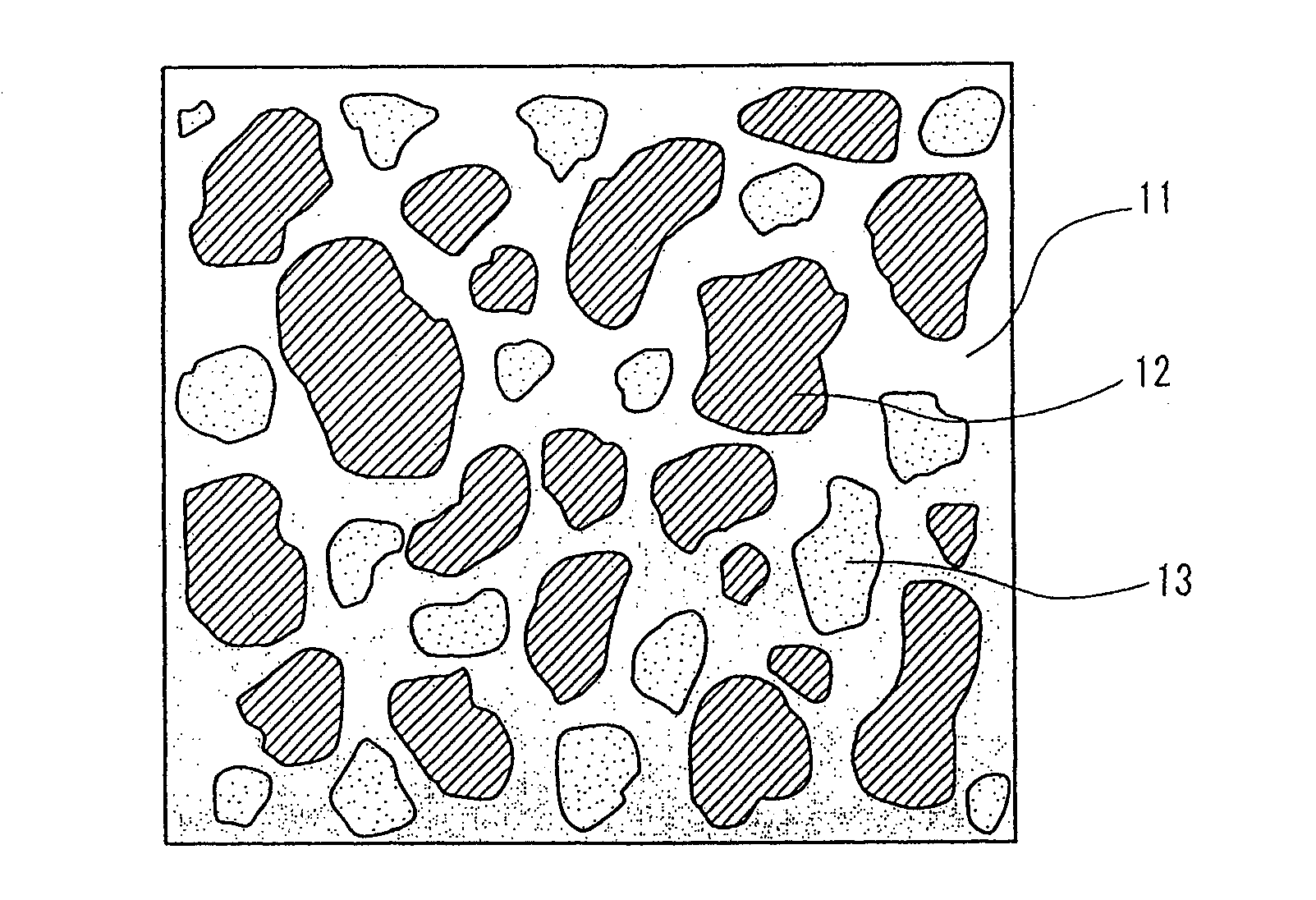

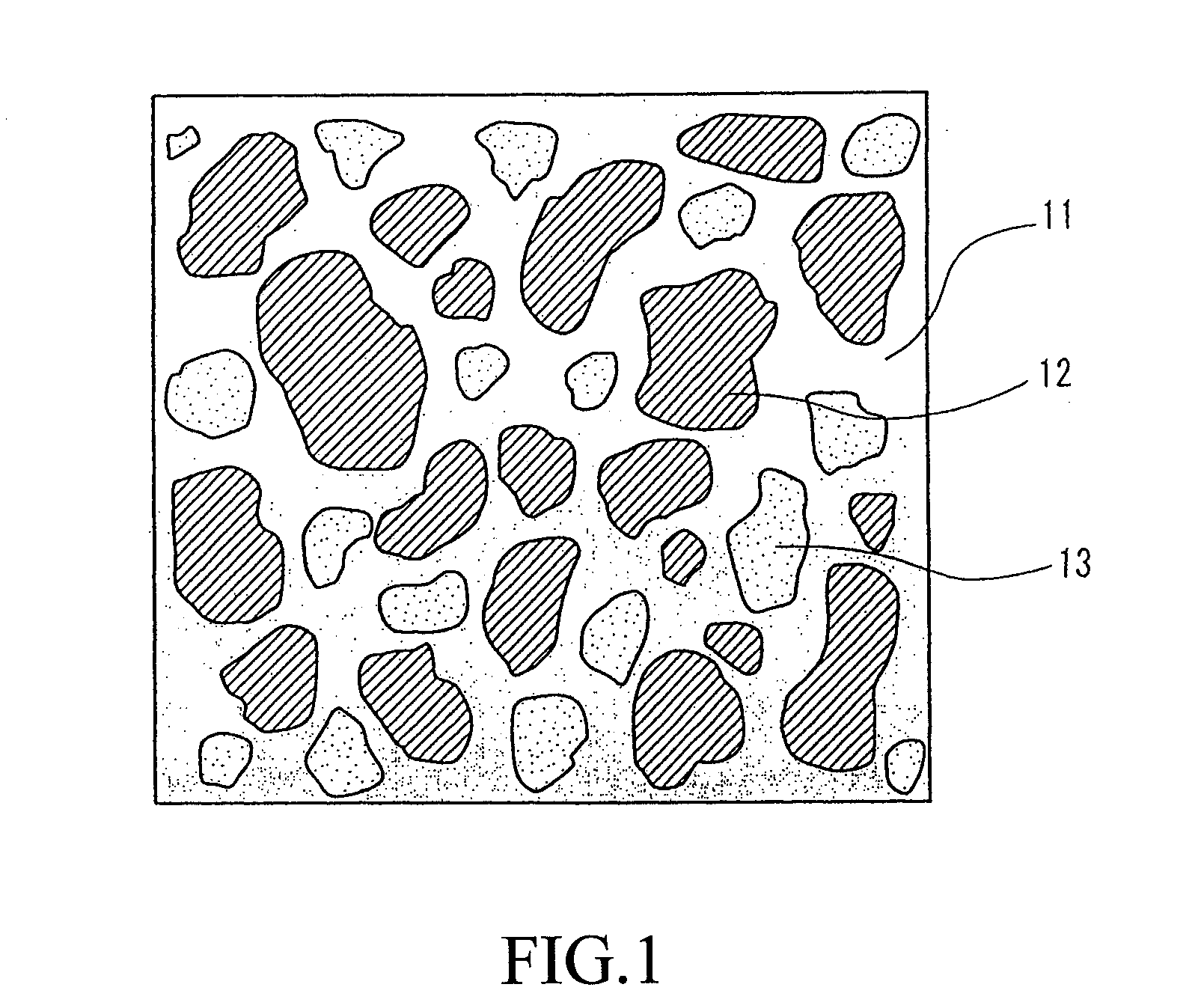

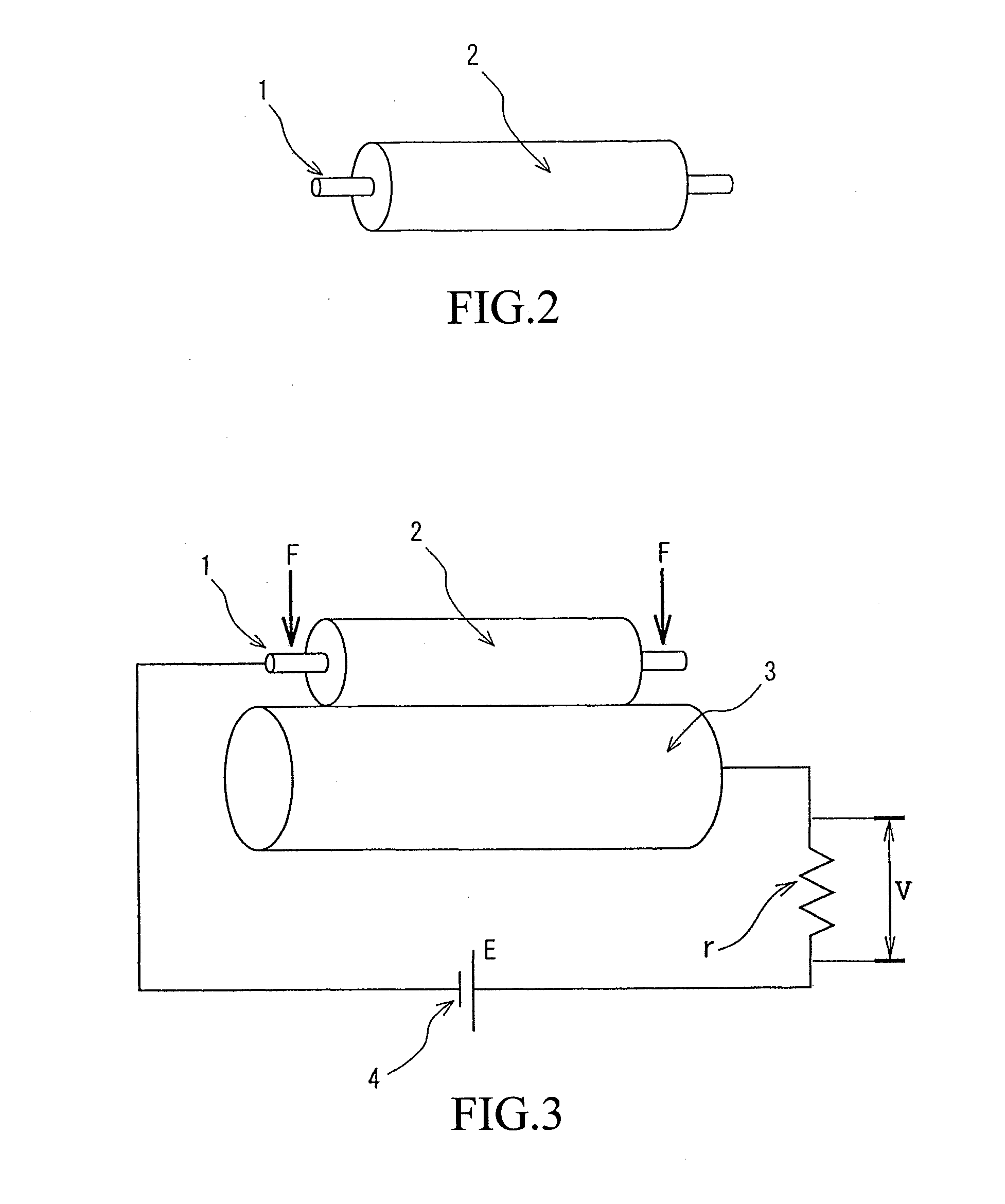

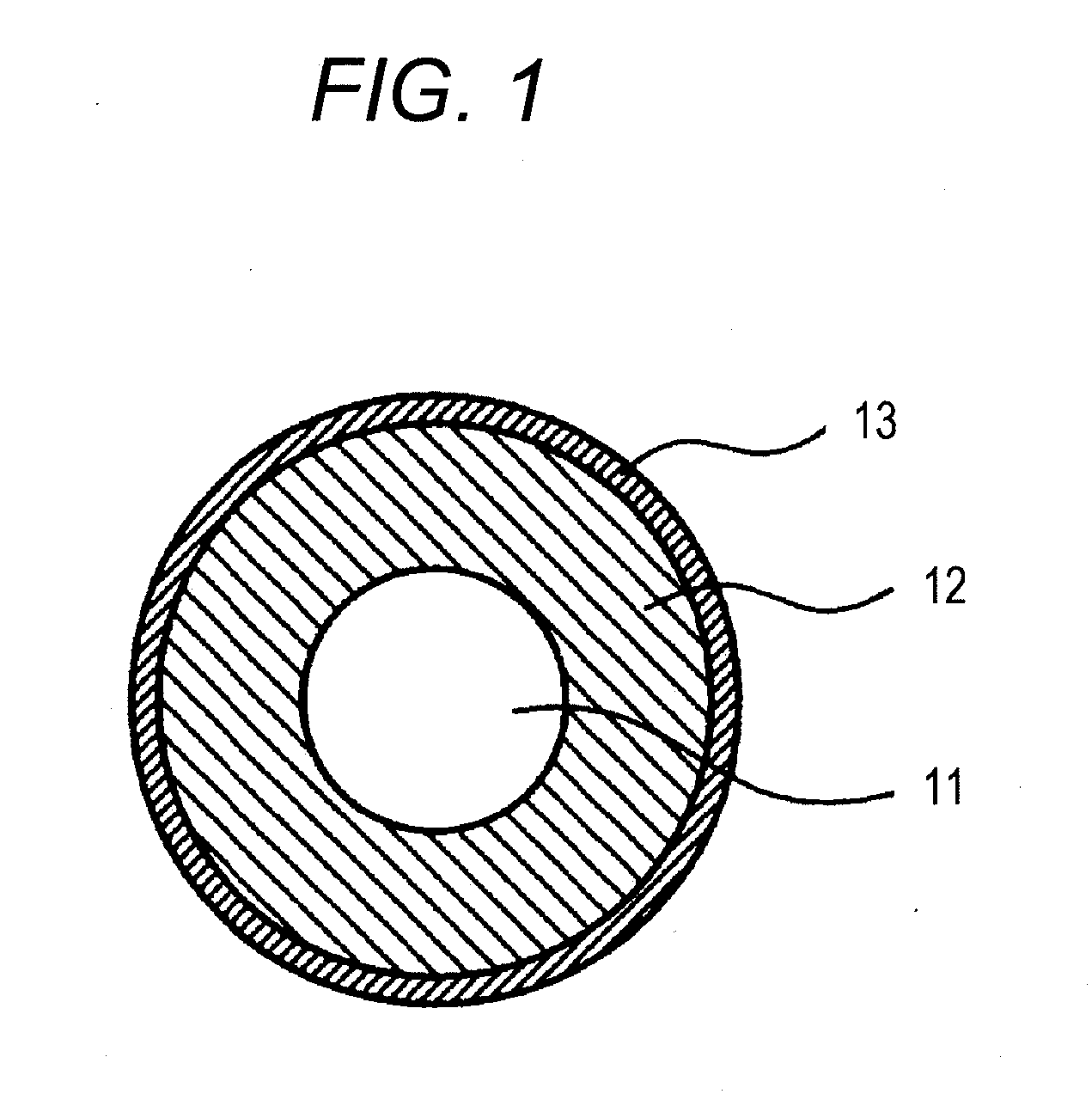

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20080315159A1Low compression setDecreasing variation of electric resistanceShaft and bearingsConductive materialElastomerPolymer science

A conductive thermoplastic elastomer composition including a continuous phase and first and second uncontinuous phases. The continuous phase and the first and second uncontinuous phases form a sea-island structure; and the first and second uncontinuous phases independently forming island structures. In this structure, the continuous phase contains a composition (A) which is a mixture of a thermoplastic elastomer and a thermoplastic resin; the first continuous phase contains a rubber component (B) containing at least one of diene rubber and ethylene-propylene-diene rubber; and the second continuous phase contains an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer containing an anion-containing salt having a fluoro group and a sulfonyl group (component (C)).

Owner:SUMITOMO RUBBER IND LTD

Epoxy resin compositions for fiber-reinforced composite materials, process for production of the materials and fiber-reinforced composite materials

InactiveUS20040247882A1Low costLow viscositySynthetic resin layered productsEpoxy resin adhesivesSatelliteEther

The present invention relates to an epoxy resin composition for fiber reinforced composite material comprising the following components (1)-(3) as essential components, their mixing ratios meeting the following conditions (I)-(IV), and component (3) being dissolved homogeneously: component (1): epoxy resin that is liquid at room temperature, component (2): aromatic polyamine that is liquid at room temperature, component (3): diaminodiphenylsulfone, condition (I): The proportion of component (1) relative to the entire epoxy resin in the composition is 60-100 wt %, condition (II): The sum of the proportions of components (2) and (3) relative to the entire polyamine in the composition is 70-100 wt %, condition (III): The proportion of component (3) relative to the entire polyamine in the composition is 25-60 wt %, and condition (IV): The stoichiometric ratio of the entire polyamine to the entire epoxy resin in the composition is 0.7-1.3. Another embodiment of the invention relates to an epoxy resin composition for fiber reinforced composite material that contains at least the following components (4)-(6), forms a cured product with a theoretical molecular weight between crosslinking points in the range of 250-350 g / mol, and has an initial viscosity at 80° C. of 1-500 MPa.s: (4): aromatic epoxy resin with tri- or higher functionality, (5): aromatic epoxy resin with di- or higher and lower than tri-functionality, and (6): aromatic polyamine, the molecular weight between crosslinking points being defined as the weight of the entire cured epoxy resin divided by the number of crosslinking points contained in the entire cured epoxy resin. The invention also relates to an epoxy resin composition for fiber reinforced composite material that consists of the following components (7) and (8): (7) a polyglycidyl ether of phenol aralkyl resin as represented by the following formula: where R<1>, R<2>, R<3 >and R<4>denote a hydrogen atom, an alkyl group having 1-8 carbon atoms, or a halogen atom, and m and n denote an integer of 1-4 and a real number of 0 or more and less than 1, respectively, and (8) polyamine. With the constitution described above, the present invention can provide a liquid epoxy resin composition for low cost production of high performance fiber reinforced composite material, that has a low viscosity at relatively low temperatures, and that after being cured, the cured product is high in glass transition temperature, elastic modulus and toughness while being small in the glass temperature decrease caused by water absorption and also small in the coefficient of linear expansion; and can provide a method to produce fiber reinforced composite material therefrom. Fiber reinforced composite material produced according to the present invention can serve as material for parts of aircraft, including main wing, tail, rotor blade, fairing, cowl, and door; parts of spacecraft, including motor case and main wing; and parts of space satellite body structure. They can also be used preferably as material for automobile chassis and railroad vehicle body structure.

Owner:TORAY IND INC

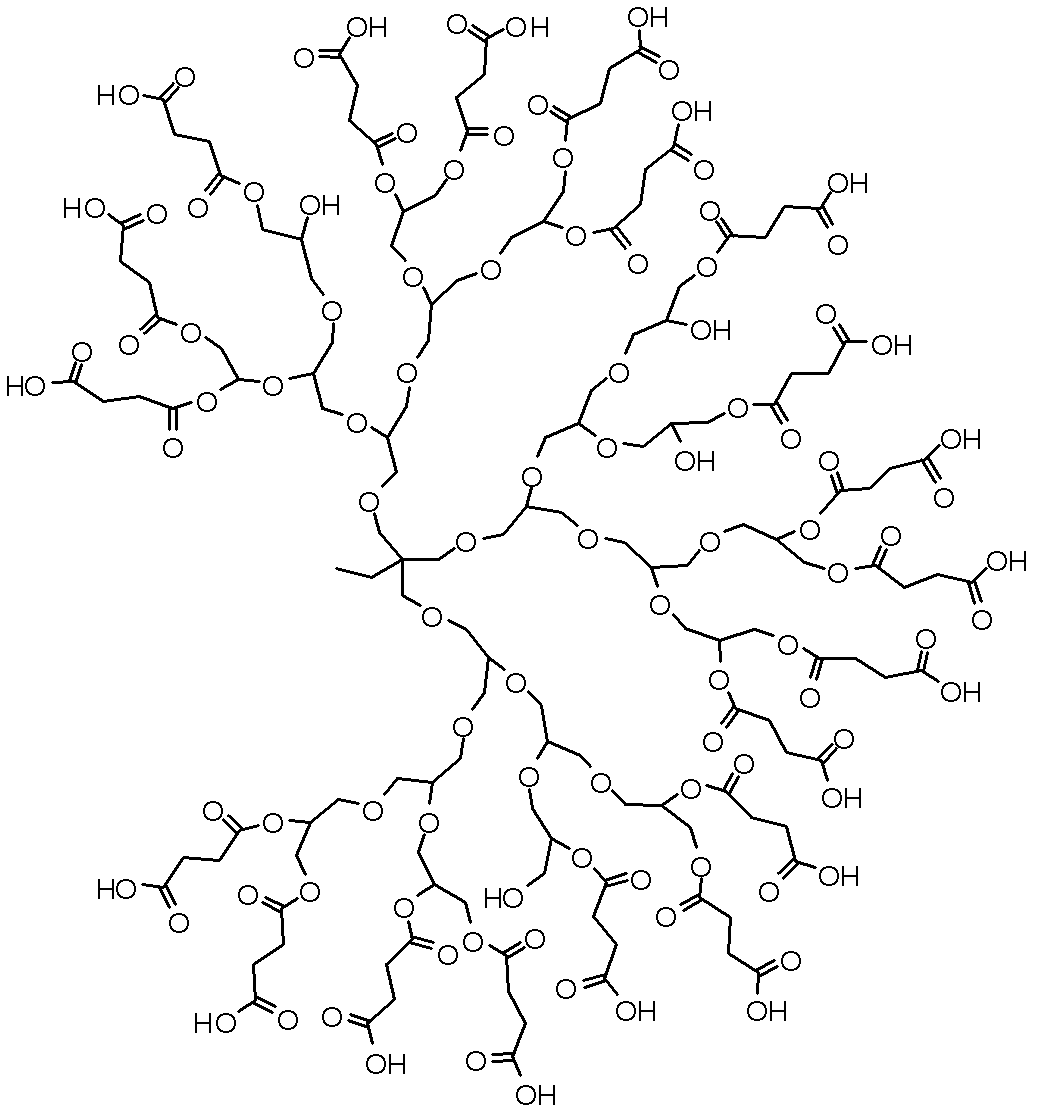

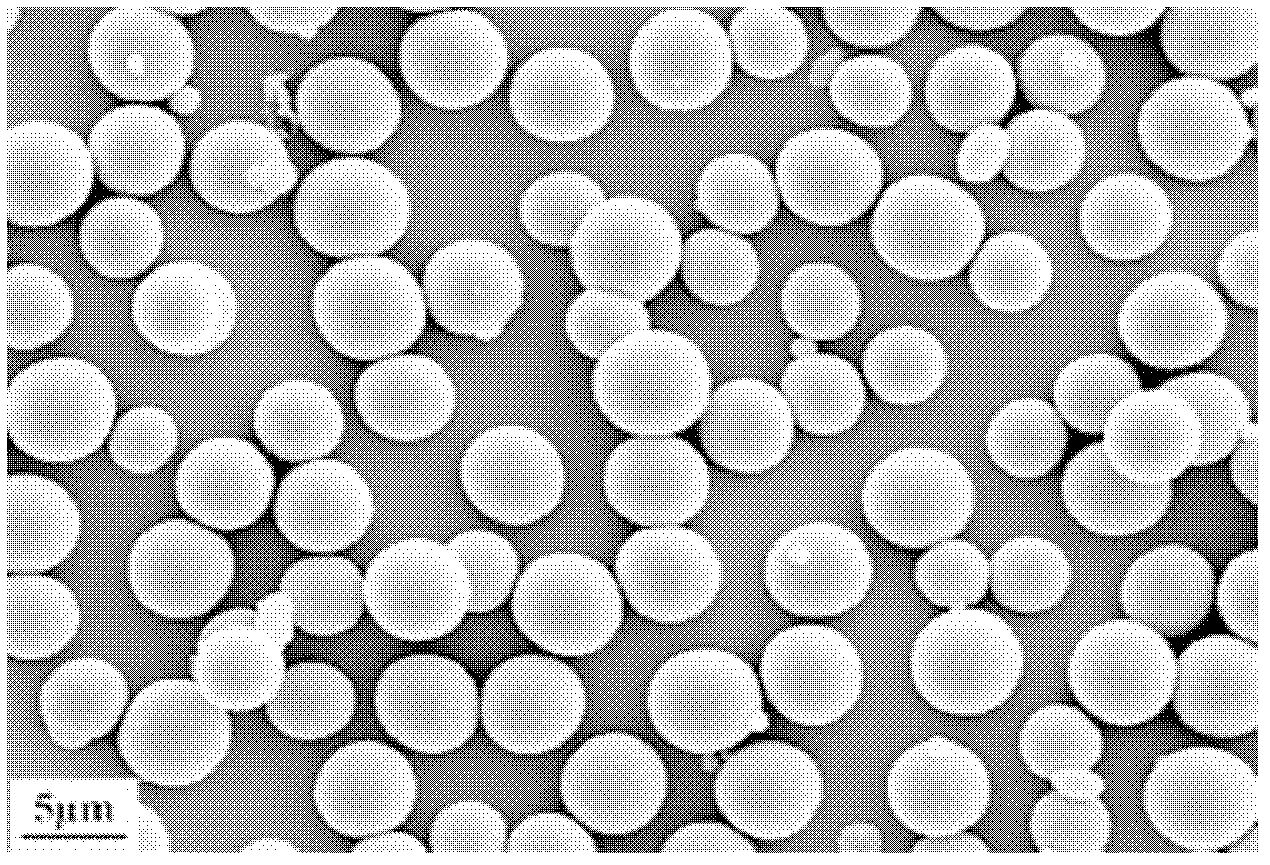

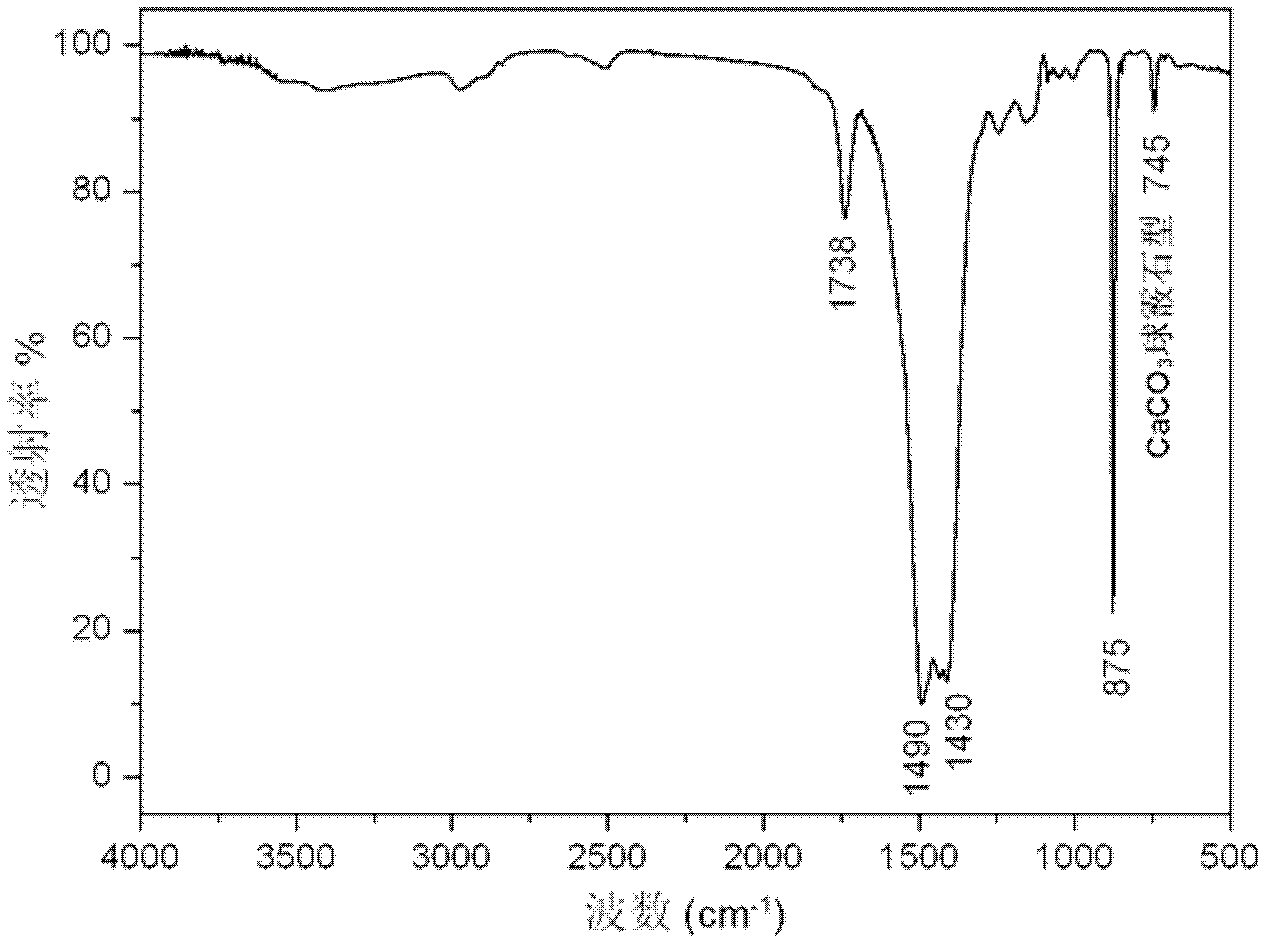

Monodispersed vaterite type calcium carbonate microsphere and preparation method thereof

InactiveCN102583485AIncrease the degree of branchingHigh density of surface functional groupsCalcium/strontium/barium carbonatesBicarbonateCalcium carbonate

The invention relates to a preparation method of a monodispersed vaterite type calcium carbonate microsphere, which comprises the following steps of: (1) preparing a calcium salt aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the calcium salt aqueous solution to 8.5-10; (2) preparing a carbonate or hydrocarbonate aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the carbonate or hydrocarbonate aqueous solution to 8.5-10; (3) preparing a functional hyperbranched polyglycerol aqueous solution with the concentration of 20-400mg / L, and then, adjusting the pH value of the functional hyperbranched polyglycerol aqueous solution to 8.5-10; (4) mixing and uniformly stirring the carbonate or hydrocarbonate aqueous solution, the calcium salt aqueous solution and the functional hyperbranched polyglycerol aqueous solution at the temperature of 10-35 DEG C, and aging for 1-12h; and (5) centrifuging or filtering the mixed solution, cleaning a sediment, and drying to obtain the monodispersed vaterite type calcium carbonate microsphere. The monodispersed vaterite type calcium carbonate microsphere prepared by using the preparation method provided by the invention has the advantages of uniform particle size, stable crystal form and industrial application value.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST +1

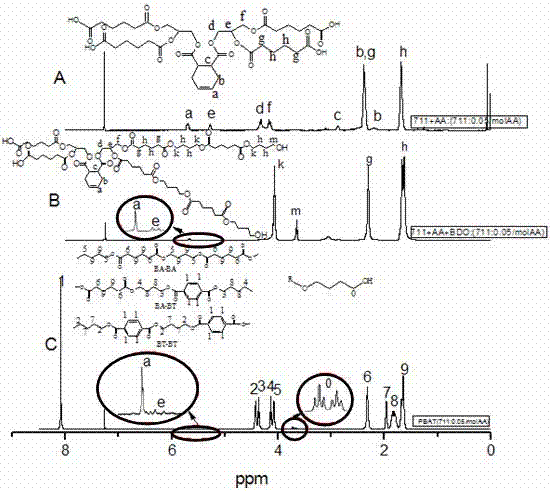

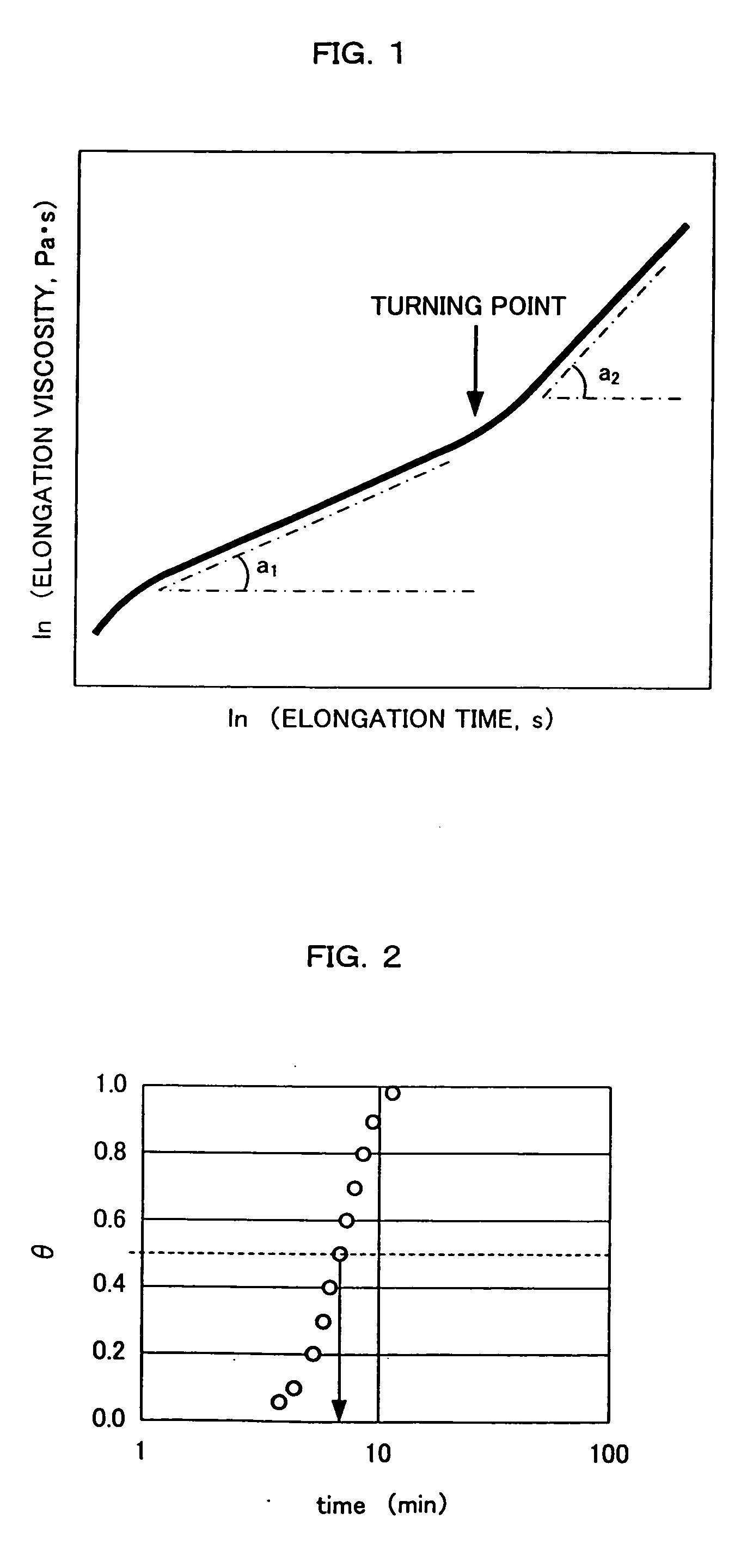

Long chain branched polyester and preparation method thereof

The invention discloses long-chain branched polyester and a preparation method thereof. The long-chain branched polyester is obtained by carrying out esterification and polycondensation on a diacid component A, a diacid component B and a bifunctional branching agent component C such as biglycidyl ester, diglycidyl ether or glycidol and the like. According to the invention, a non-toxic bifunctional branching agent is directly adopted to in situ generate branching points; the preparation method is unique, preparation process is simple and environmentally-friendly, branching reaction is uniform,branching degree is easy to regulate and control, and the high molecular weight long-chain branched polyester can be prepared; and the preparation method can be used for preparation of non-degradablepolyester and preparation of biodegradable polyester, thereby being beneficial to the realization of commercialization. The long-chain branched polyester has the characteristics of long-chain branching and large molecular weight in structure and is beneficial to increase of melt strength and improvements of blow molding and foaming processing performance.

Owner:ZHEJIANG UNIV

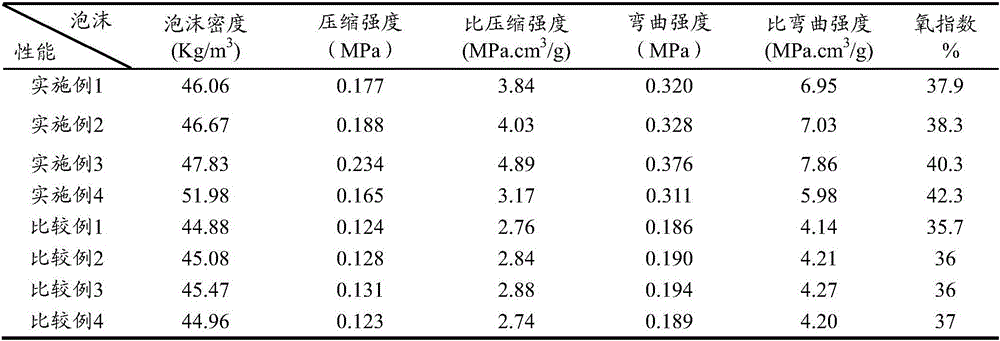

Phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and preparation method thereof

The invention relates to a phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and a preparation method thereof. The preparation method comprises the following steps: synthesizing cardanol glycidol ether from cardanol and epoxy chloropropane under alkaline conditions, and hydrolyzing under acidic conditions to generate cardanol-base dibasic alcohol; by using the cardanol-base dibasic alcohol as the raw material, dropwisely adding oxydol to react under acidic conditions to obtain the epoxy cardanol-base dibasic alcohol, carrying out reaction on the epoxy cardanol-base dibasic alcohol and a phosphorus-containing flame retardant to obtain phosphorus-containing cardanol-base polylol; carrying out reaction on the phosphorus-containing cardanol-base polylol and isocyanate to obtain a phosphorus-containing cardanol-base polyurethane prepolymer; and mixing the phosphorus-containing cardanol-base polyurethane prepolymer with a phenolic resin, and sequentially adding a surfactant, a foaming agent and a curing agent, thereby obtaining the phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam thermal-insulation material. The mechanical properties of the phenolic foam thermal-insulation material are obviously enhanced. The flame-retardant element phosphorus is introduced into the polyurethane prepolymer, thereby solving the problem of degradation of foam flame retardancy due to the carbamate introduced into the phenolic foam.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Partial condensate of glycidyl ether group-containing alkoxysilane, silane-modified resin, compositions thereof and preparation methods thereof

The present invention provides a partial condensate of glycidyl ether group-containing alkoxysilane which is obtainable by dealcoholization reaction between glycidol and a partial condensate of alkoxysilane, compositions comprising the same and preparation methods thereof. Further, the present invention provides an alkoxy-containing silane-modified polyimide resin, alkoxy-containing silane-modified polyamide-imide resin and alkoxy-containing silane-modified phenol resin which are modified with the partial condensate of glycidyl ether group-containing alkoxysilane, and preparation methods thereof.

Owner:ARAKAWA CHEM IND LTD

Biodegradable polyester resin composition, preparation method therefor, and foamed article and molded article produced therefrom

InactiveUS20070179253A1Low gel contentImprove heat resistanceSynthetic resin layered productsMeth-Polyester resin

A biodegradable polyester resin composition which comprises a thermoplastic polymer comprising 100 parts by mass of an aliphatic polyester (A) and 0.01 to 5 parts by mass of a (meth)acrylic ester (B1) and / or a glycidyl ether (B2), and has a gelation index (1) of not lower than 0.1% and a gelation index (2) of not higher than 0.5%.

Owner:UNITIKA LTD

Preparation method of low-temperature secondary cross-linked sodium hyaluronate gel

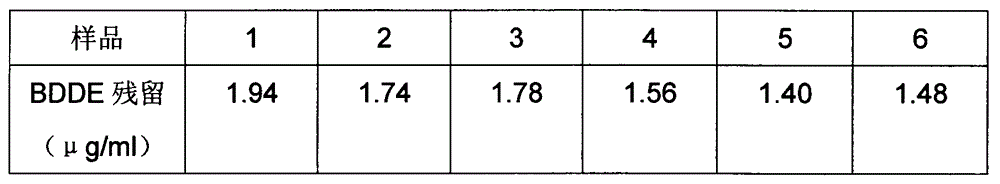

InactiveCN103146003AImprove cross-linking efficiencyAvoid the disadvantages of yellowingProsthesisHigh concentrationCross linker

The invention relates to a preparation method of 1,4-butanediol diglycidyl ether cross-linked sodium hyaluronate gel. The method comprises the steps of: by taking high-concentration sodium hyaluronate solution as reaction matrix, performing first cross-linking for a longer time under the low-temperature condition by adding less cross-linking agent, then performing secondary deep cross-linking under high-temperature condition, and finally processing and pelleting through short-time dialysis technique, thereby obtaining the sodium hyaluronate gel product. With the method, the cross-linking condition of the high-concentration cross-linking agent under the traditional high-temperature condition can be eliminated, milder secondary depth cross-linking condition is adopted, the reaction efficiency of the less cross-linking agent can be greatly improved, the residual cross-linking agent is more easily removed, and the excellent biocompatibility of the cross-linked sodium hyaluronate gel can be ensured. The method is simple in preparation technique, excellent in controllability and easier to practically produce on large scale.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

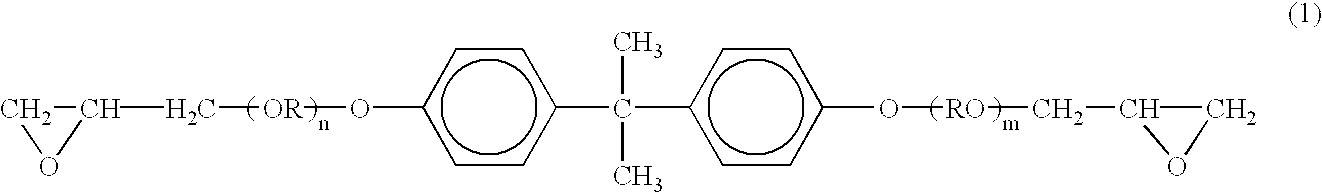

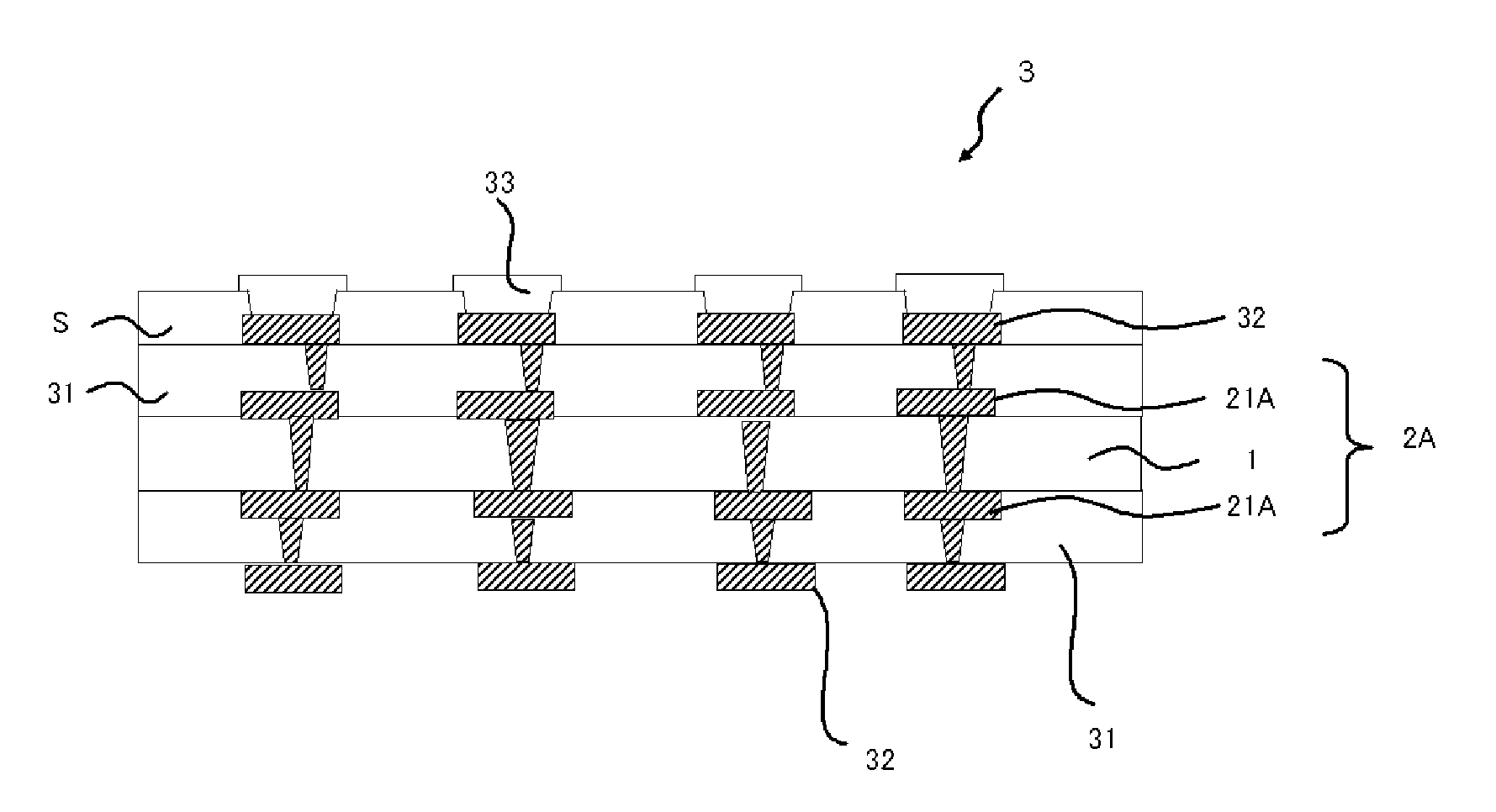

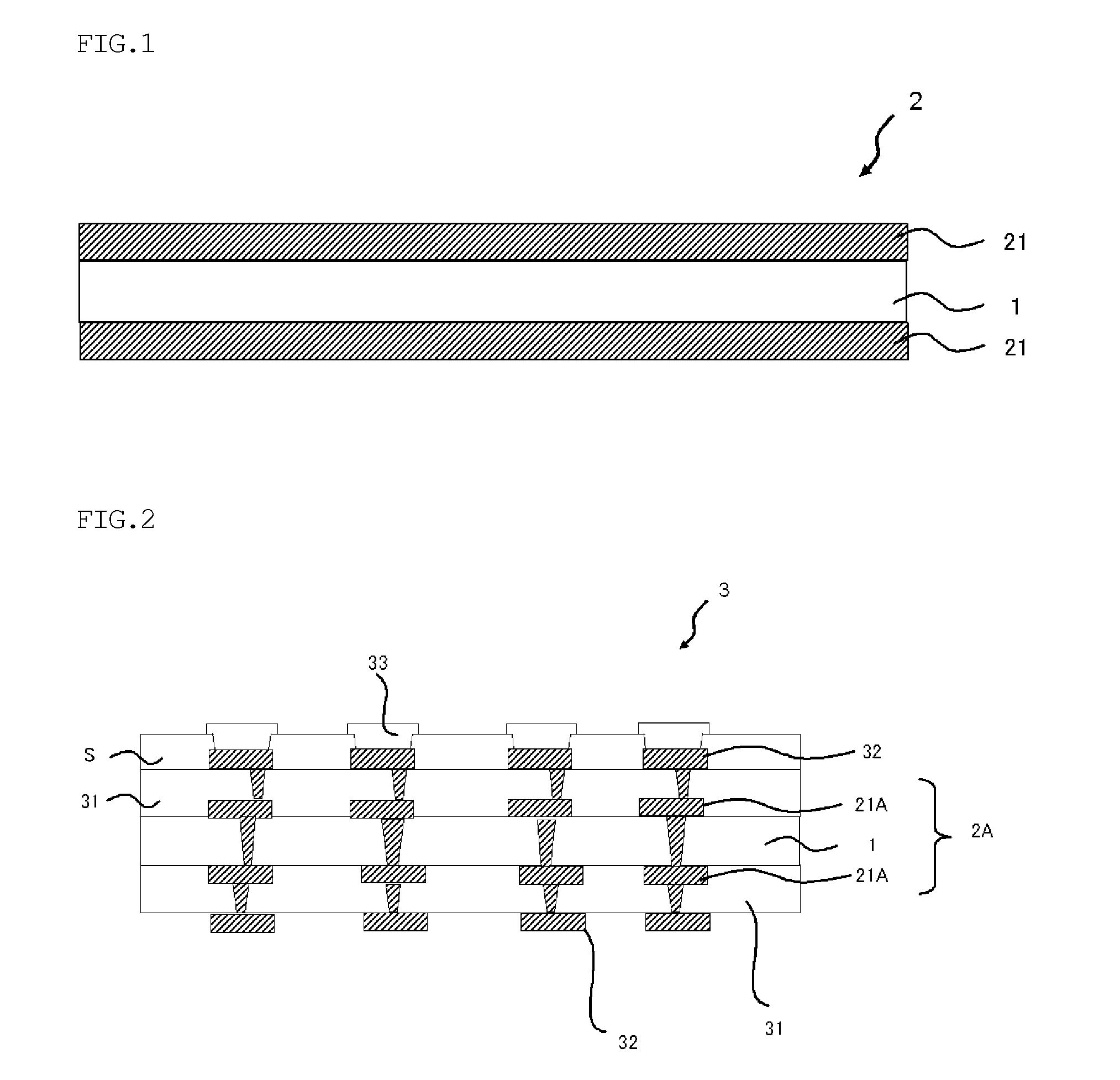

Epoxy resin composition, prepreg, laminate board, multilayer printed wiring board, semiconductor device, insulating resin sheet, and process for manufacturing multilayer printed wiring board

InactiveUS20100227170A1Reduction factorPreventing defect in appearanceSynthetic resin layered productsPrinted circuit aspectsHydrogenEthyl group

Disclosed is an epoxy resin composition essentially containing (A) an epoxy resin having a structure represented by the general formula (1), (B) a curing agent, (C) an inorganic filler and (D) a cyanate resin and / or a prepolymer thereof, wherein Ar represents a fused aromatic hydrocarbon group; r is an integer of 1 or more; X is a hydrogen or an epoxy group (glycidyl ether group); R1 represents one selected from the group consisting of a hydrogen, a methyl group, an ethyl group, a propyl group, a butyl group, a phenyl group and a benzyl group; n is an integer of 1 or more; p and q are an integer of 1 or more; and p's and q's in respective repeating units may be the same as or different from one another.

Owner:SUMITOMO BAKELITE CO LTD

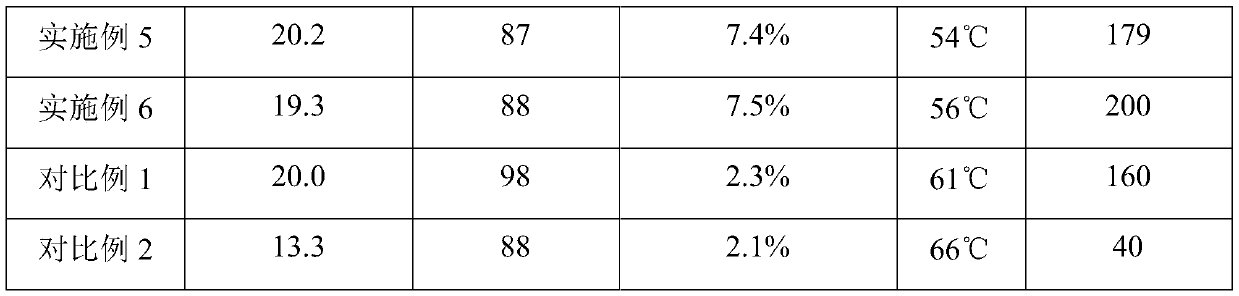

Sticking glue for diamond wire silicon slice and preparation method

InactiveCN109880567ALower Tg valueImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersWater circulation

The invention discloses a sticking glue for a diamond wire silicon slice and a preparation method. The sticking glue comprises a component A and a component B; the component A includes glycidyl estertype epoxy resin, general bisphenol A epoxy resin, glycidyl ether, filler, defoaming agent, anti-settling agent and coupling reagent; the component B includes modified polythiol, self-prepared m-xylylenediamine prepolymer, accelerant, filler, defoaming agent and anti-settling agent. On the basis of the prior art, the invention modifies the last generation sticking glue and provides the sticking glue for the diamond wire silicon slice and the preparation method thereof. Boiling degumming without acid can be completed without adding degumming factors; the boiling degumming temperature is 10 DEGC lower than the present one; electrical conductivity of solution in cooling water or degumming water is reduced; normal working of cooling water circulation system is guaranteed; the service life ofmachine is prolonged; production efficiency of factory is guaranteed and potential safety hazard of easiness in causing machine failure is solved.

Owner:广西珀源新材料有限公司

Environment-friendly permeable high-strength waterborne epoxy slurry and preparation method and application thereof

ActiveCN105885755APromote environmental protectionImprove permeabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesMass ratioPolyamide

The invention discloses environment-friendly permeable high-strength waterborne epoxy slurry and a preparation method and an application thereof. The method comprises the following steps: mixing 40-70wt% of liquid epoxy resin and 60-30wt% of glycidyl ether to obtain a 100wt% of a component A; mixing 10-50wt% of water-swellable self-emulsified polyamide-amine, 85-30wt% of hydrophobic modified aliphatic amine and 5-20wt% of aliphatic amine polyoxyethylene-polyoxypropylene to obtain a 100wt% of a component B; premixing the component A and the component B at the mass ratio of 100 to (60-90) to obtain environment-friendly permeable epoxy net slurry with low initial viscosity; and mixing the epoxy net slurry and a component C (including 50-100wt% of an inorganic filler, 0-50wt% of water and 0-1wt% of an assistant) at the mass ratio of 100 to (60-300), and curing to obtain a high-strength non-shrinkage epoxy-based composite material. The high-strength non-shrinkage epoxy-based composite material can be used for preparing a high-strength open-cell or closed-cell material, and has a wide application prospect in the field of grouting, a mold and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Reinforced Thermoplastic Resin Composition And Molded Article

The present invention relates to a reinforced thermoplastic resin composition having excellent moldability, processability, and mechanical strengths, as well as being capable of improving the drop impact resistance (surface impact strength determined by a falling ball test). The reinforced thermoplastic resin composition of the present invention includes 10 to 60% by mass of a graft copolymer (A) having a graft chain (A2) grafted to a rubber polymer (A1); 40 to 90% by mass of a matrix polymer (B) which includes one or more types of polymers selected from the group consisting of a vinyl-based copolymer (B-1), a polycarbonate resin (B-2), and a polyester resin (B-3); 0.1 to 50 parts by mass of an inorganic filler (D) and 0.5 to 20 parts by mass of a glycidyl ether unit-containing polymer (E) having a mass average molecular weight of 3,000 to 200,000.

Owner:TECHNO UMG CO LTD

Graphene oxide-based curing agent as well as preparation and use thereof

InactiveCN104262588AImprove thermal stabilityLow resistivityNon-macromolecular adhesive additivesEpoxy resin adhesivesArray data structureGlycidyl ethers

The invention discloses a preparation method of a graphene oxide-based curing agent and application of the graphene oxide-based curing agent in epoxy resin conductive glue. The conductive glue consists of the following components in parts by weight: 1-2 parts of a graphene oxide-based curing agent, 3-10 parts of a conventional curing agent, 10-20 parts of E-51 epoxy resin, 10-20 parts of AG-80 epoxy resin, 15-25 parts of carbon black, 15-25 parts of silver precipitate powder, 1-8 parts of amine accelerants, 1-5 parts of a liquid imidazole defoaming agent and 1-20 parts of glycidyl ether diluents. The preparation method of the graphene oxide-based curing agent comprises the following steps: firstly, preparing graphene oxide and then modifying the graphene oxide to obtain a graphene oxide-based curing agent capable of conducting and toughening; and then, blending according to a formula of the conductive glue and curing to obtain a graphene oxide-based epoxy resin composite material. The graphene oxide-based curing agent with capacity of conducting and toughening is obtained by the preparation method; and an epoxy-based composite adhesive material prepared by taking the graphene oxide as the curing agent has good conducting capacity, acid and alkaline resistance, thermal stability and mechanical performance; and the adhesive is suitable for adhering electronic elements.

Owner:HUNAN UNIV

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20110042624A1Good molding effectEasy to recycleConductive materialNon-conductive material with dispersed conductive materialElastomerPolymer science

Owner:MINAGOSHI AKIRA

Conductive rubber elastic material, charging member and electrophotographic apparatus

ActiveUS20120224887A1Improve charging effectEasy to changeNon-metal conductorsConductive materialRubber materialPolymer science

A conductive rubber elastic material is stably provided which can produce a charging member that may less vary in electrical resistance even with changes in applied voltage, promises uniform electrical properties, has charge characteristics not affected by changes in environments such as temperature and humidity, and enables a charging object member such as a photosensitive member to be kept from being contaminated. It is a conductive rubber elastic material which contains a matrix containing at least one ionically conductive rubber selected from the group consisting of epichlorohydrin rubber, epichlorohydrin-ethylene oxide rubber, epichlorohydrin-ethylene oxide-allyl glycidyl ether rubber, acrylonitrile-butadiene rubber and a hydrogenated product of acrylonitrile-butadiene rubber and domains composed of an electronically conductive rubber material containing i) a rubber having a butadiene skeleton and ii) carbon black, and the rubber having a butadiene skeleton is modified at a molecular terminal thereof with a specific atomic group.

Owner:CANON KK

Propellant with high energy and low temperature sensitive coefficient of burning

ActiveCN105130720ABoost energy levelsLow burning rate temperature sensitivity coefficientExplosivesAl powderExplosive Agents

A propellant with high energy and low temperature sensitive coefficient of burning comprises 12-15% of an adhesive, 10-13% of a plasticizer, 15-18% of an oxidant, 38-50% of an energetic explosive, 10-18% of a metal fuel and 1.5-2.0% of a small group, wherein the adhesive is glycidyl azide polymer; the plasticizer is triethylene glycol dinitrate or 2,4-dinitro-2,4-diazaalkane; the oxidant is ammonium perchlorate; the energetic explosive is octogen; and the metal fuel is aluminum powder. The propellant has the characteristics of high energy (standard measured specific impulse is greater than 2450N.s / kg) and low temperature sensitive coefficient of burning (not greater than 0.15%K<-1>), and is suitable for tactical missile engines with far required range, strong penetration ability, high reliability and accurate guidance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

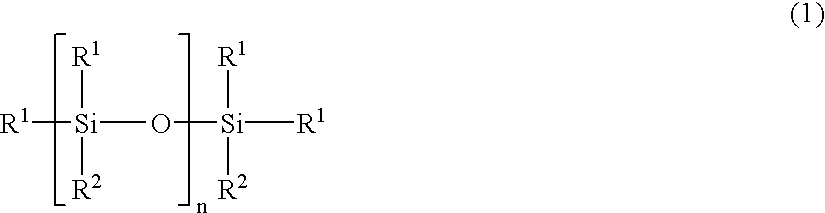

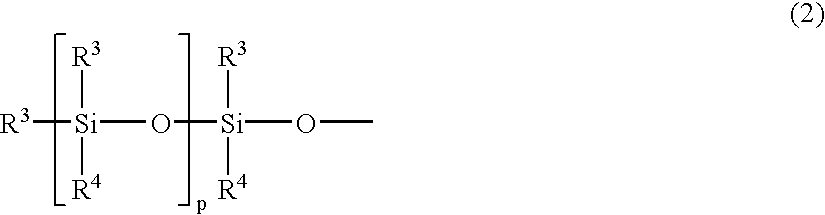

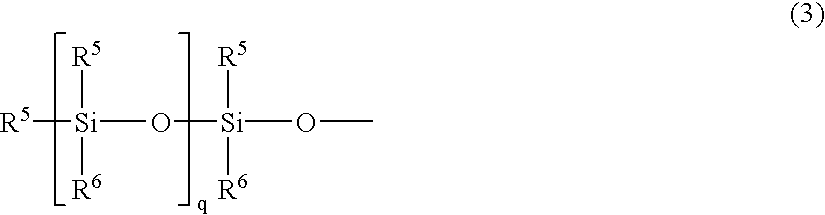

Polyether-Modified Organopolysiloxane, Diorganopolysiloxane-Polyether Block Copolymer, Their Production Methods, and Cosmetic Preparation

ActiveUS20100036062A1Good environmental compatibilityImprove production stabilityCosmetic preparationsHair cosmeticsPolymer scienceHydrosilylation

(Problem) To provide a novel polyether-modified organopolysiloxane and a novel diorganopolysiloxane-polyether block copolymer that are more resistant to oxidation than the heretofore existing polyoxyalkylene-modified organopolysiloxanes and that are thus more resistant to producing allergenically antigenic oxidation products during elapsed time in storage. Also, to provide methods of producing this novel polyether-modified organopolysiloxane and novel diorganopolysiloxane-polyether block copolymer.(Solution) Organopolysiloxane that is modified by silicon-bonded polyglycidyl ether or glycidyl ether / alkylene oxide copolymer; diorganopolysiloxane-polyglycidyl ether block copolymer; a method of producing the preceding by a hydrosilylation reaction between organohydrogenpolysiloxane and polyglycidyl ether having a terminal double bond or a glycidyl ether / alkylene oxide copolymer having a terminal double bond; and a cosmetic that contains this modified organopolysiloxane or diorganopolysiloxane-polyglycidyl ether block copolymer.

Owner:DOW TORAY CO LTD

Silane coupling agent and preparation method thereof

InactiveCN102584886AHas anti-aging functionSimple manufacturing methodGroup 4/14 element organic compoundsSilanesNitrogen

The invention discloses a silane coupling agent and a preparation method thereof. The method comprises the steps of: mixing a coupling agent (gamma-glycidyl ether oxopropyl trimethoxy-silane) and aminophenol p-diphenylamine (PPDA) according to a certain molar ratio; before temperature raising and heating, introducing nitrogen till the end of reaction, and continuously reacting for a period of time under the condition of magnetic force stirring, thus obtaining the silane coupling agent. The prepared silane coupling agent can be used for inorganic filler such as white carbon black and argil; compared with white carbon black modified with the common silane coupling agent, white carbon black modified with the silane coupling agent disclosed by the invention has an excellent aging-preventing function besides the enhancement of the compatibility between the filler and plastic matrixes, and thus the service life of mad products can be prolonged; and when applied to butylbenzene and hevea rubber, the silane coupling agent has excellent performance superior to 2-(gamma-( triethoxy) propyl group) tetrasulfide, so the silane coupling agent can completely replace the 2-(gamma-( triethoxy) propyl group) tetrasulfide to be applied to some rubber.

Owner:SOUTH CHINA UNIV OF TECH

Polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and preparation method thereof

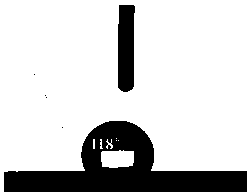

The invention discloses a polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and a preparation method thereof. The polysiloxane fire retardant is prepared through utilizing mutual reaction of hydrogen-containing silicone oil, allyl glycidyl ether, isocyanate silane and a phosphorus-containing active matter in a solvent. The fire retardant has a certain degree of polymerization, organic groups such as a benzene ring and longer -Si-O-Si- main chain are contained in a molecule, the fire retardant has favorable hydrophobicity, a contact angle reaches 118 degrees, and the compatibility of the fire retardant and a high polymer can be remarkably improved; the fire retardant is rich in carbon, nitrogen, phosphorus and silicon elements so as to have a synergistic flame retardant effect of various flame retardant elements, a high carbonization ability, and high flame retardant efficiency; the fire retardant has higher heat stability, and can meet the processing requirement of the high polymer; the polysiloxane fire retardant is rich in -Si-O-CH2CH3 group, and can be used as a modifying agent to modify other substances so as to obtain a functional fire retardant.

Owner:TAIYUAN UNIV OF TECH

Thermosetting resin composition, and prepreg and laminated board made from thermosetting resin composition

ActiveCN104861652AImprove toughnessHigh peel strengthSynthetic resin layered productsLaminationBottleFire retardant

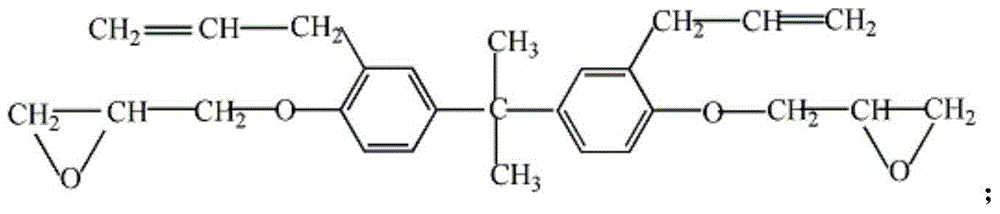

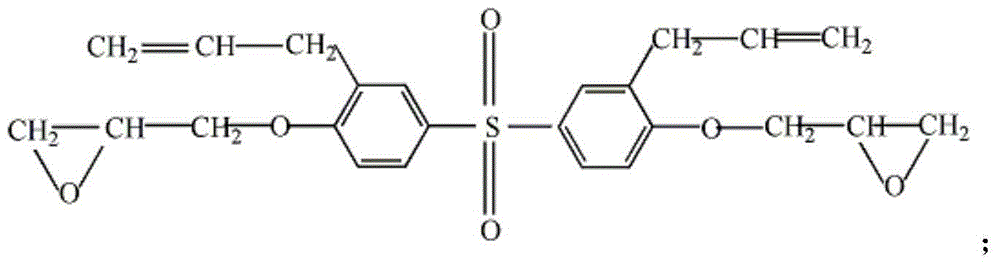

The invention discloses a thermosetting resin composition. The thermosetting resin composition comprises the following solids by weight: (a) a modified bismaleimide prepolymer, (b) a curing accelerator, (c) a fire retardant, and (d) inorganic fillers. A preparation method of the modified bismaleimide prepolymer comprises the following step: heating bismaleimide and a composite allyl compound in a reaction bottle, wherein the composite allyl compound is composed of a first-class allyl compound and a second-class allyl compound, the first-class allyl compound is selected from one or more of diallyl bisphenol A, diallyl bisphenol S, allyl phenoxy resin and diallyl diphenyl ether, and the second-class allyl compound is selected from one or more of diallyl bisphenol A diglycidyl ether, diallyl bisphenol S diglycidyl ether and diallyl diphenyl ether diglycidyl ether. A laminated board integrates high heat resistance, high toughness, low water absorption, excellent dielectric property and good fire resistance.

Owner:SHENGYI TECH SUZHOU

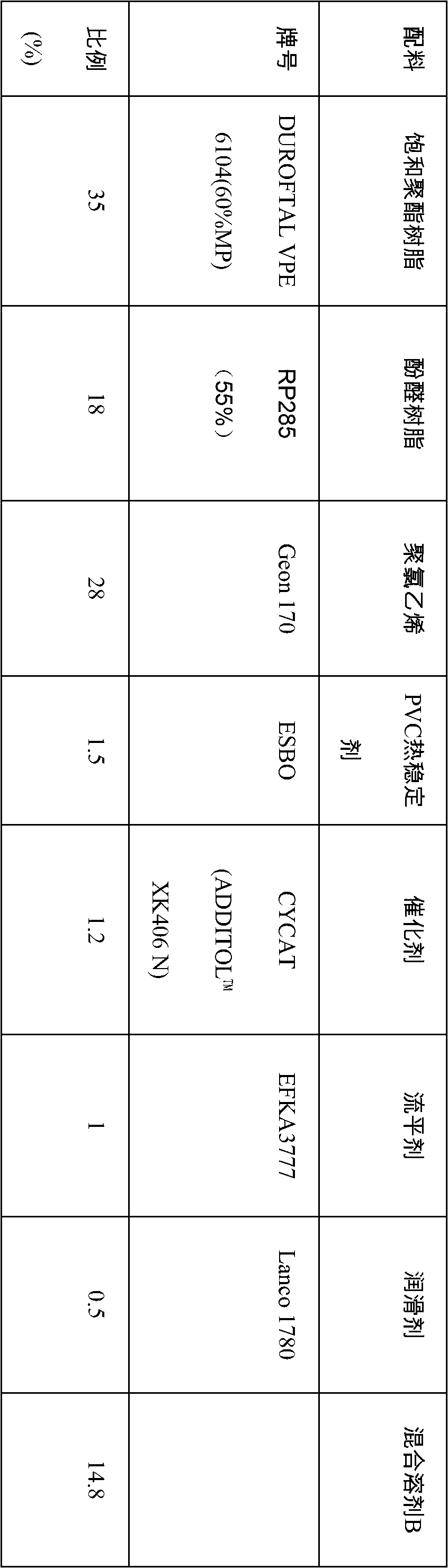

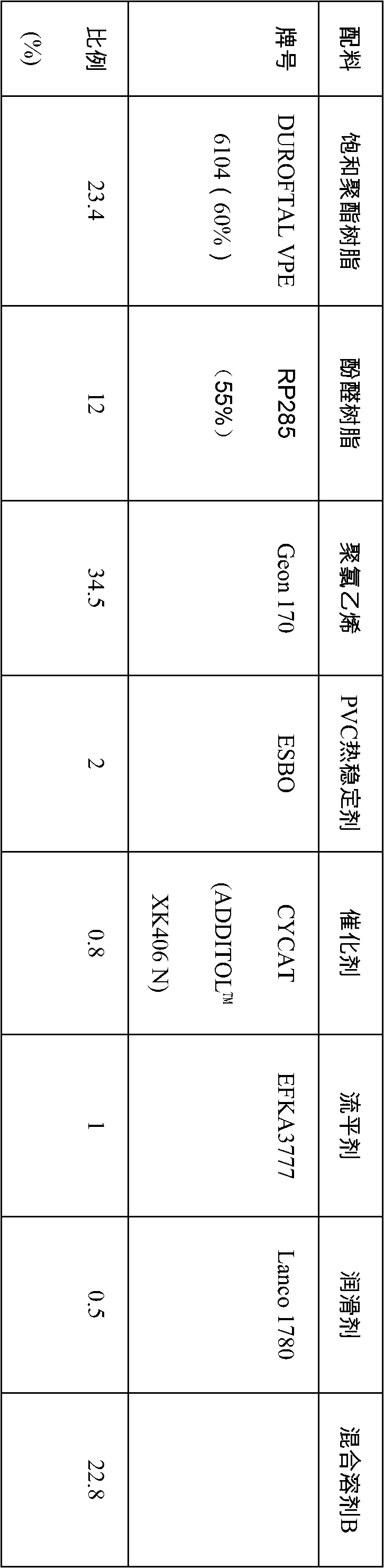

Coating composition and application of coating composition to metal base material

The invention discloses a coating composition and an application of the coating composition to a metal base material. The solid content of the coating composition is 40-70%. The coating composition comprises the following components of, by weight, 5-60% of saturation polyester resins, 0-25% of crylic acid resins, 2-30% of crossing-link agents, 20-80% of polyvinyl chloride homopolymer, 0-15% of additives, 0-40% of pigments and the balance dilution solvents, wherein average molecular weight Mn of the saturation polyester resins is 3000-8000, the vitrification temperature of the saturation polyester resins is 10-20 DEG C, the acid value of the saturation polyester resins is 0-5, the hydroxyl value of the saturation polyester resins is 30-90, and the saturation polyester resins are free of neopentyl glycol. The coating composition is free of bisphenol-A diglycidyl glycerol ether (BADGE) and bisphenol A (BPA). According to the coating composition, the polyester resins which meet requirements can be easily obtained, improved space of resin performances is large, 40%-70% of the solid content of final products can be achieved, and a large quantity of organic solvents are saved.

Owner:HANGZHOU CPMC +1

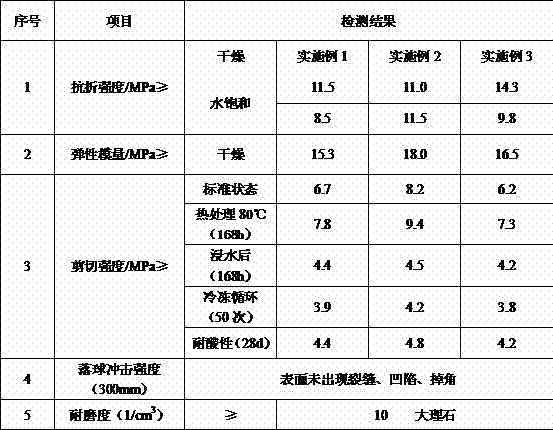

Modified epoxy adhesive for stone combination and preparation method thereof

ActiveCN102786903AHigh hardnessLow shrinkageNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFatty amine

The invention relates to a two-component modified epoxy adhesive for stone combination and a preparation method thereof, which is characterized in that an A component is prepared by bisphenol A epoxy resin, bisphenol F epoxy resin, an active diluent, a bisphenol A, an anti-yellowing additive, a wetting agent, and inorganic powder, and a B component is prepared by self-made ketoimine, nonyl phenolglycidyl ether modified aliphatic amine, alicyclic amine, a coupling agent, a wetting agent, and a curing accelerator; the A and B components are mixed and used according to a mass ratio of 10:2.5-5.In the ketoimine preparation, the mass ratio of butanone to diethylenetriamine is 70-90:100; in the modified aliphatic amine preparation, the mass ratio of nonyl phenol glycidyl ether to diethylenetriamine is 100:21-32; the two-component modified epoxy adhesive for stone combination has the characteristics of good curing performance, and low cost.

Owner:HUNAN KOSEN NEW MATERIAL

Long-chain polyether type silane coupler of glycidol-ether-radical end-capping

InactiveCN101070380APromote decentralizationGood dispersionSilicon organic compoundsNano sio2Silane coupling

The present invention discloses a glycidyl ether blocking long-chain polyether silane coupling agent, with the following general formula: (CH3)aSiX3-aCH2CH2CH2O(CH2CH2O)n(CH2CH(CH3)O)mCH2CH(O)CH2, in which n, m is 1-50 integer, X is Cl, -OCH3 or -OCH2CH3, and a is 0, 1, 2 or 3. The present invention provides the long-chain polyether silane coupling agent with glycidyl ether blocking. The glycidyl ether on its terminal which can react with the matrixes such as epoxy resin, polyurethane, etc., promotes the compatibility of nano-SiO2 with organic matrixes, and its polyether chain which can activate the encapsulation and surface of nano-SiO2, promotes the dispersion of nano-SiO2 in organic matrixes. Therefore, it largely increases the dispersion and stability of the nano-SiO2 in organic solvent, especially in organic polymer matrixes, such as epoxy resin and polyurethane.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com