Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1255results about How to "Improve production stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disintegrant assisted controlled release technology

InactiveUS20060024361A1Controlled release rateEasy to controlOrganic active ingredientsBiocideControlled releaseWater insoluble

A disintegrant assisted controlled release device is disclosed. The device is a combination of a swelling disintegrant or super-disintegrant and water insoluble polymer or water soluble polymer, or both, and one or more water soluble or water insoluble active pharmaceutical ingredient(s). The said device is stabilized by a humectant or trehalose.

Owner:INTELLIPHARMACEUTICS

Localized surface volatilization

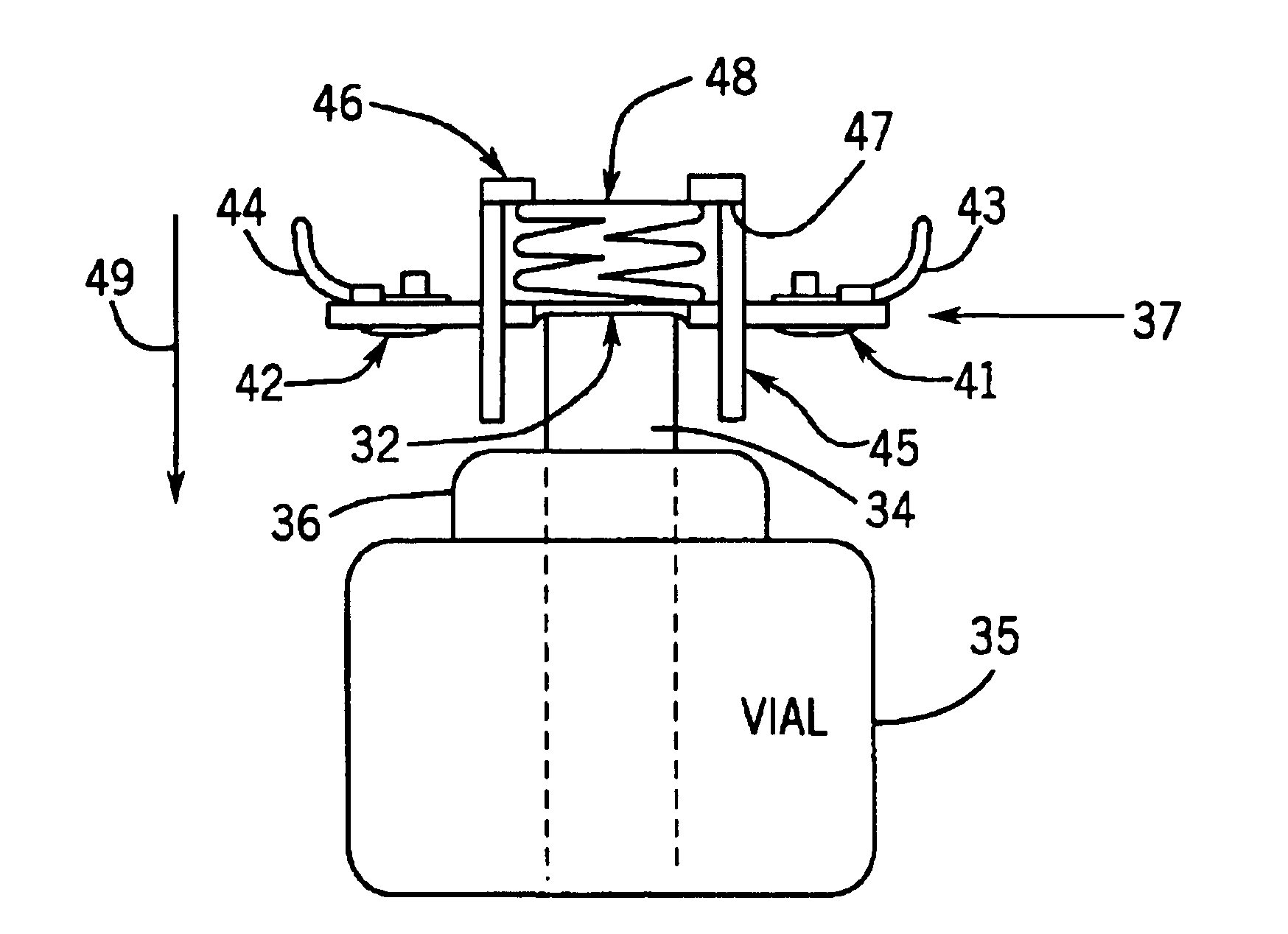

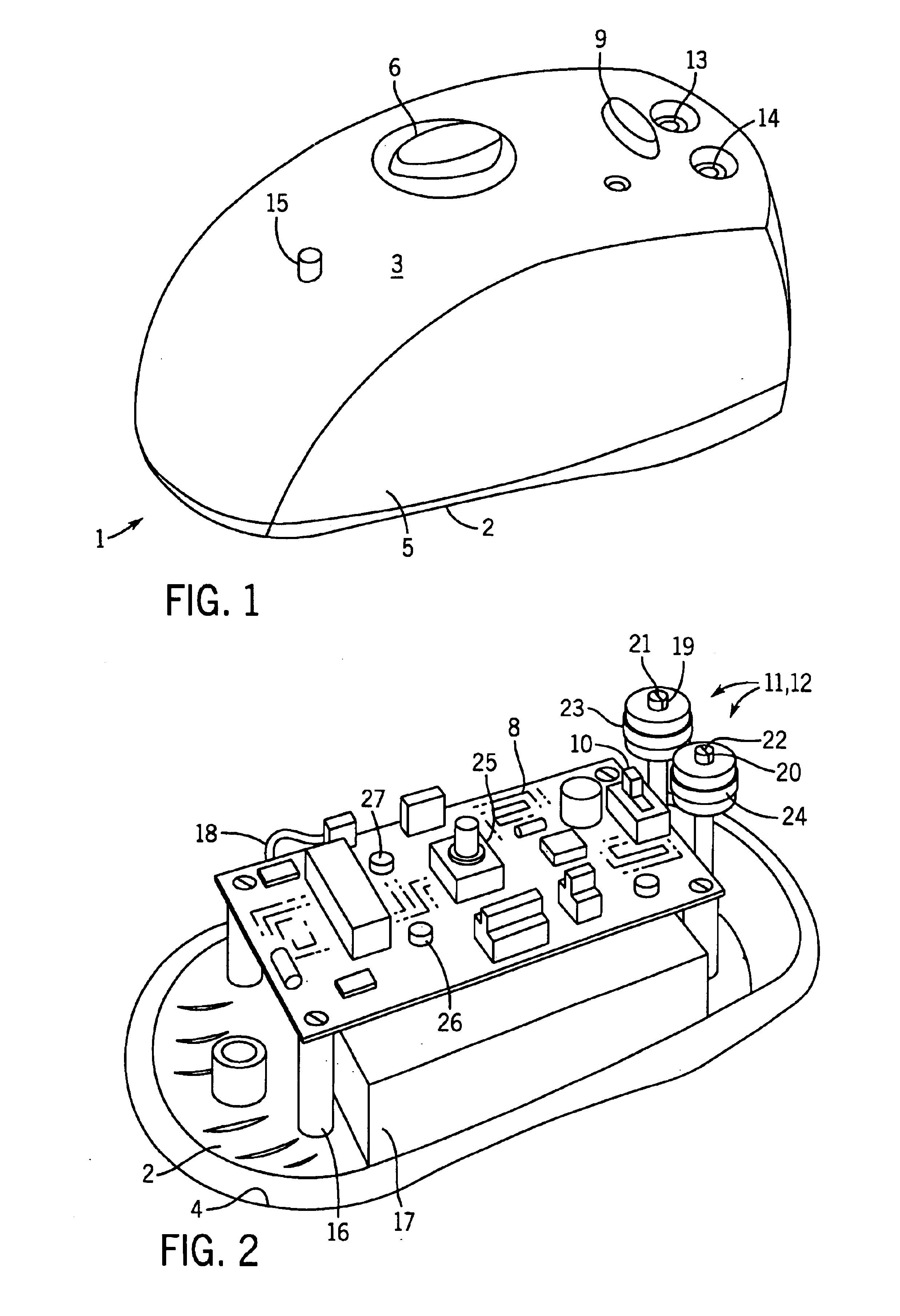

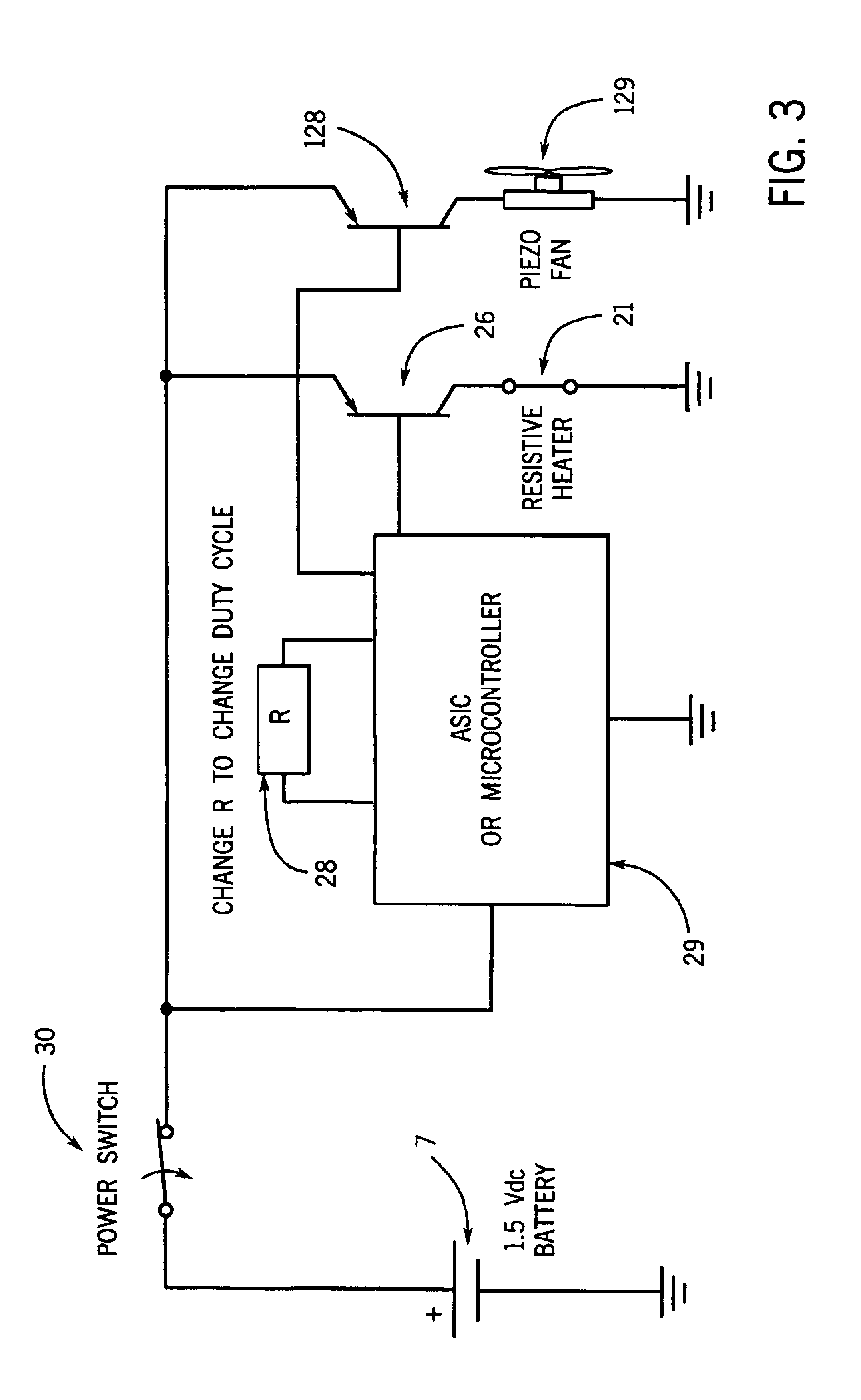

InactiveUS6909840B2Improved vaporizationIncrease vapor pressureDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceProduct gas

The present invention relates to an apparatus and method for rapid flash-like volatilization of high and low vapor pressure components from liquid or solid emanators which is in contact with a point or localized heat source. Vaporization is promoted by a geometrically small electrically resistive heating element with variable activation for pulsed or cyclic heating of an emanating surface containing the volatile components. The apparatus is primarily directed towards the treatment of residential air for fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, or other ambient air or surface modification by way of gas or vapor distribution.

Owner:SC JOHNSON & SON INC

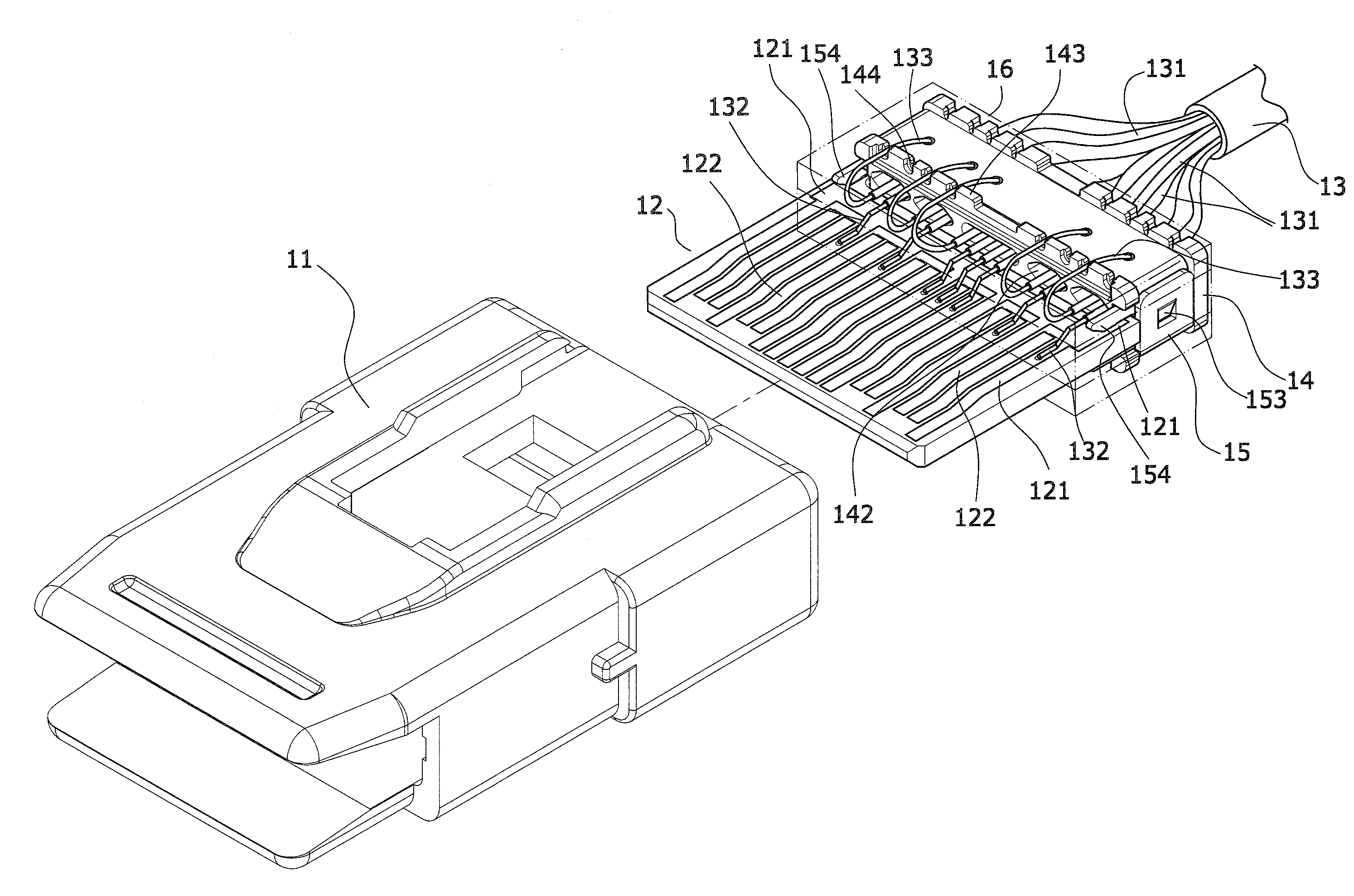

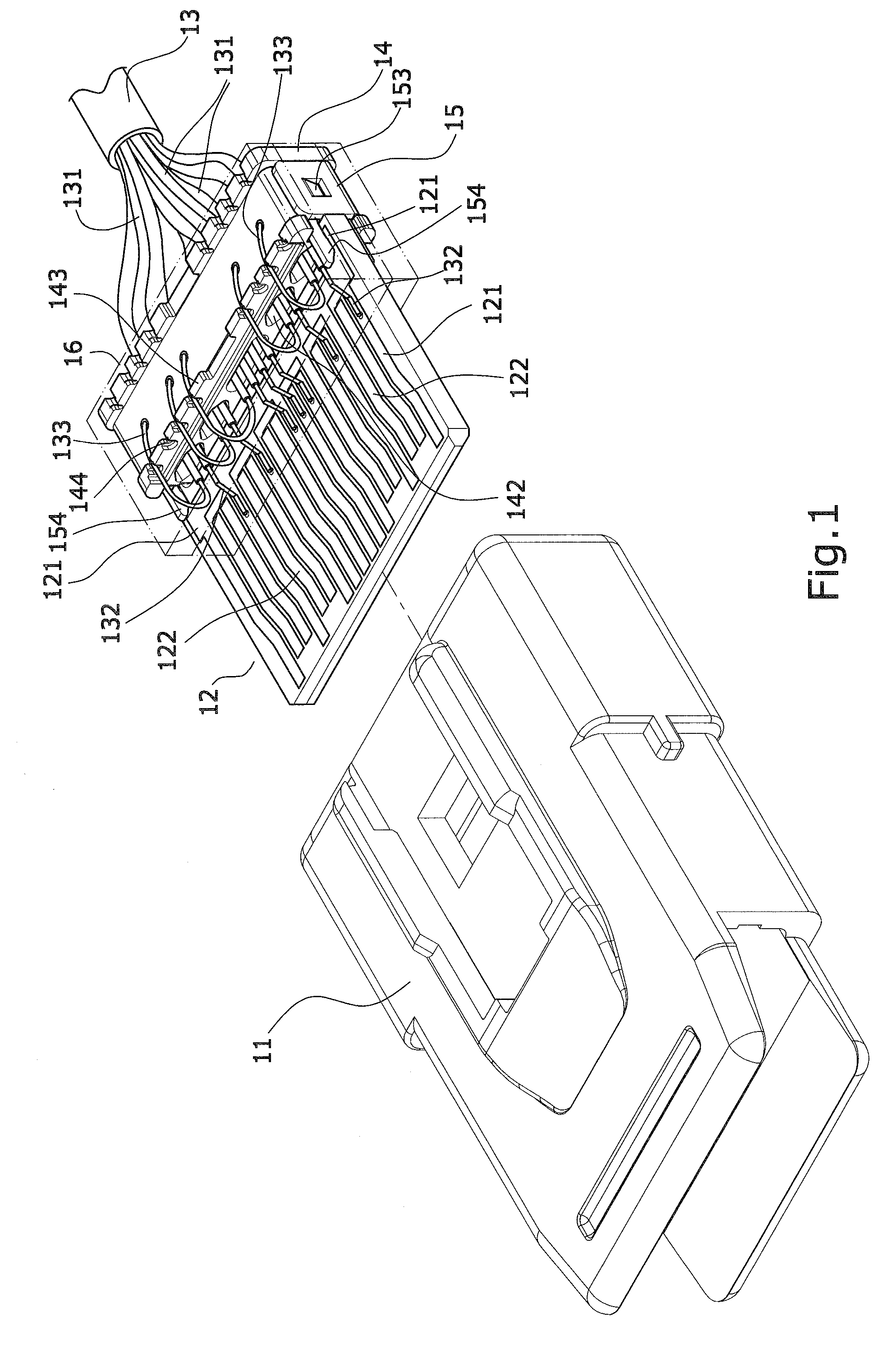

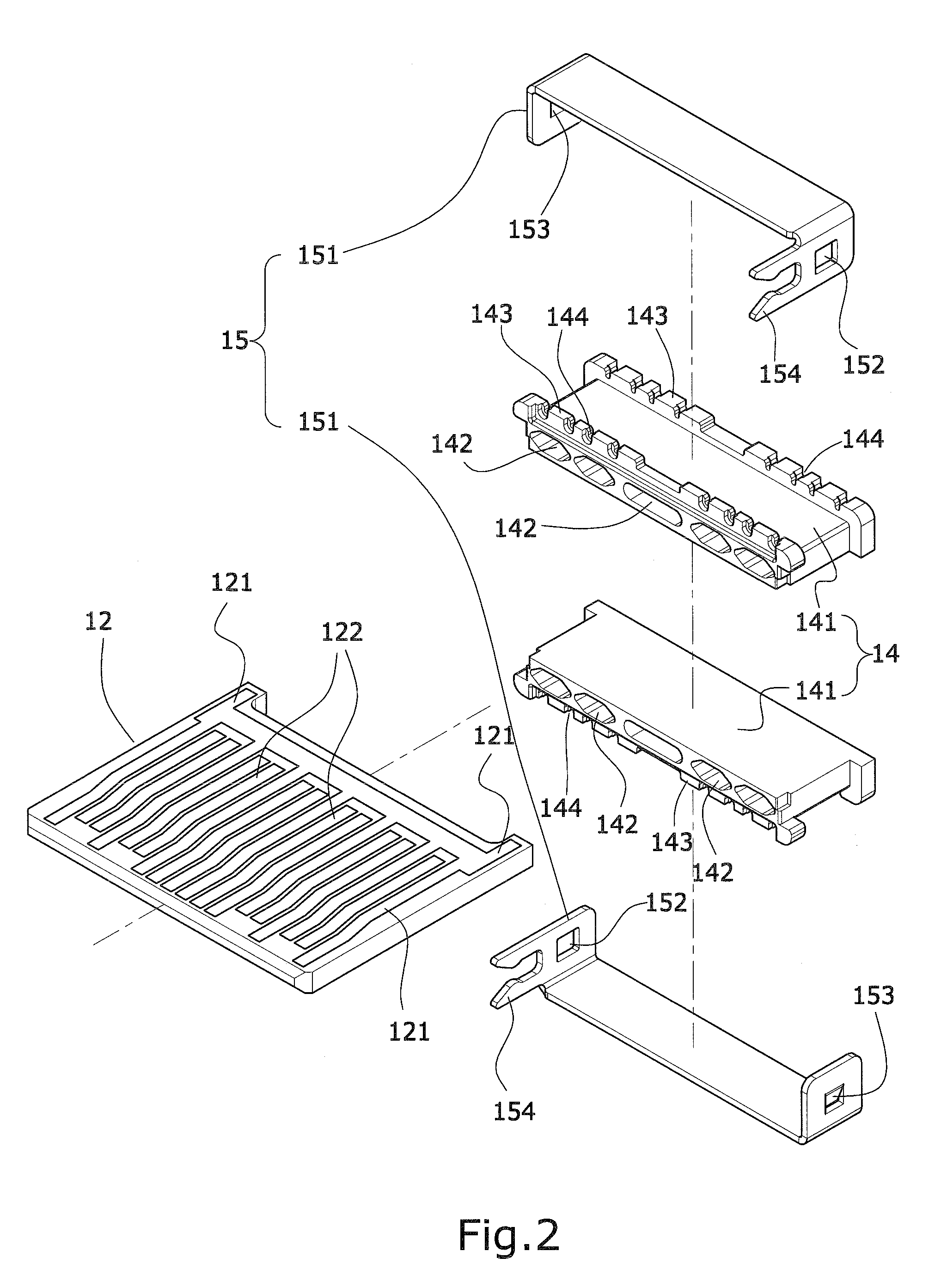

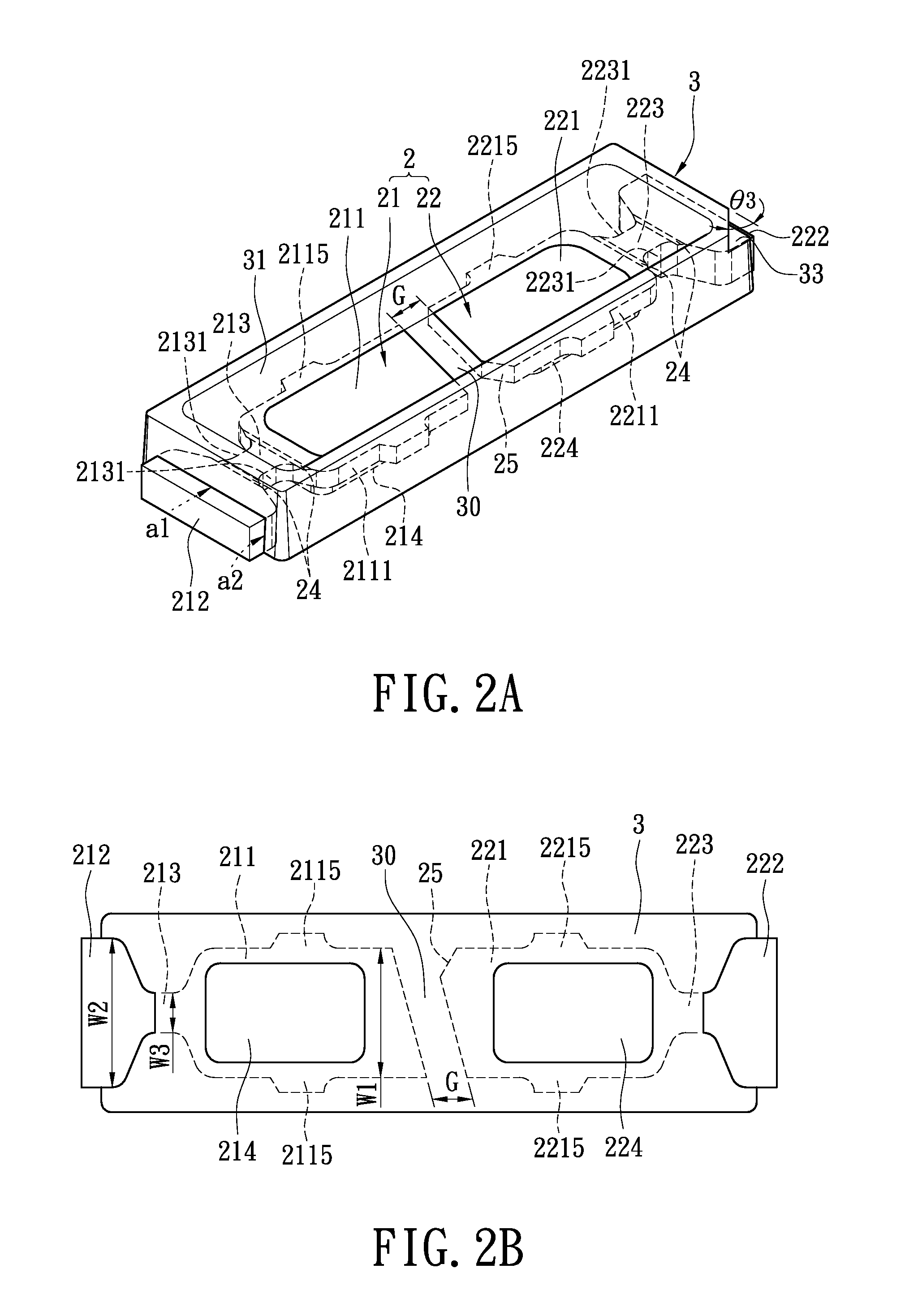

Structure of signal cable connector

InactiveUS7267575B1Good yieldMinimizes operation timeElectrically conductive connectionsCoupling protective earth/shielding arrangementsEngineeringMotherboard

A structure of signal cable connector, which is connected to the signal cable between the hard disk and the computer's main board, comprises at least an enclosure, a circuit board and a wire strand. Wherein a wire block is utilized to affix the signal wires and a ground block to conduct the soldered ground wires so as to minimize the solder points incurred by direct solder of conducting wires on circuit board, resulting in easier assembly and optimized yield.

Owner:UNICONN CORP

Low viscosity polymer polyols

The present invention relates to low viscosity polymer polyols and to a process for the preparation of these low viscosity polymer polyols. These polymer polyols comprise the free-radical polymerization product of (A) a base polyol, (B) a pre-formed stabilizer, and (C) at least one ethylenically unsaturated monomer, in the presence of (D) at least one free-radical polymerization initiator, and (E) at least one polymer control agent. The total amount of polymer control agent present in the polymer polyols of the present invention ranges from greater than about 5.0% up to about 20% by weight, based on 100% by weight of the polymer polyol.

Owner:COVESTRO LLC

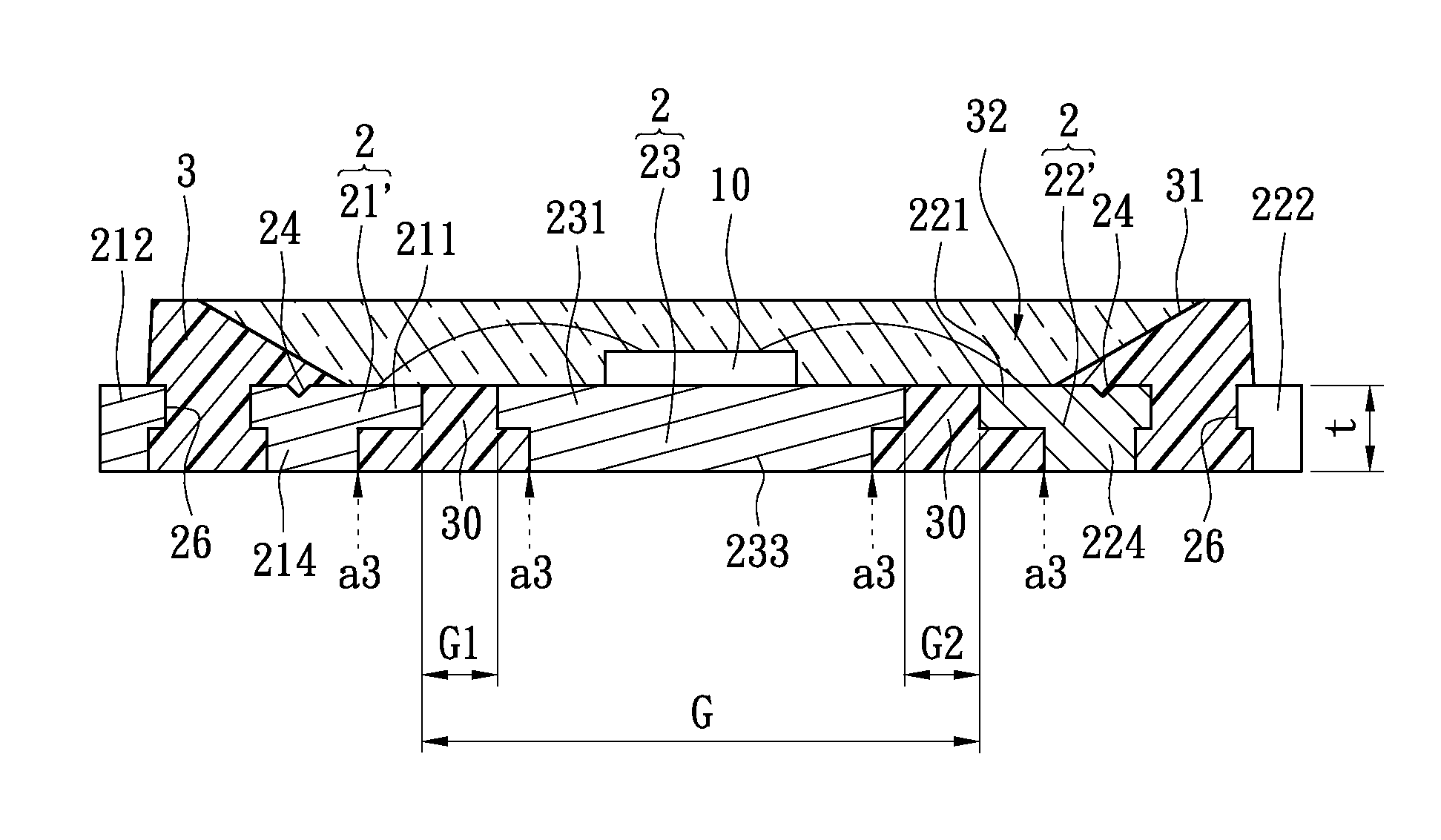

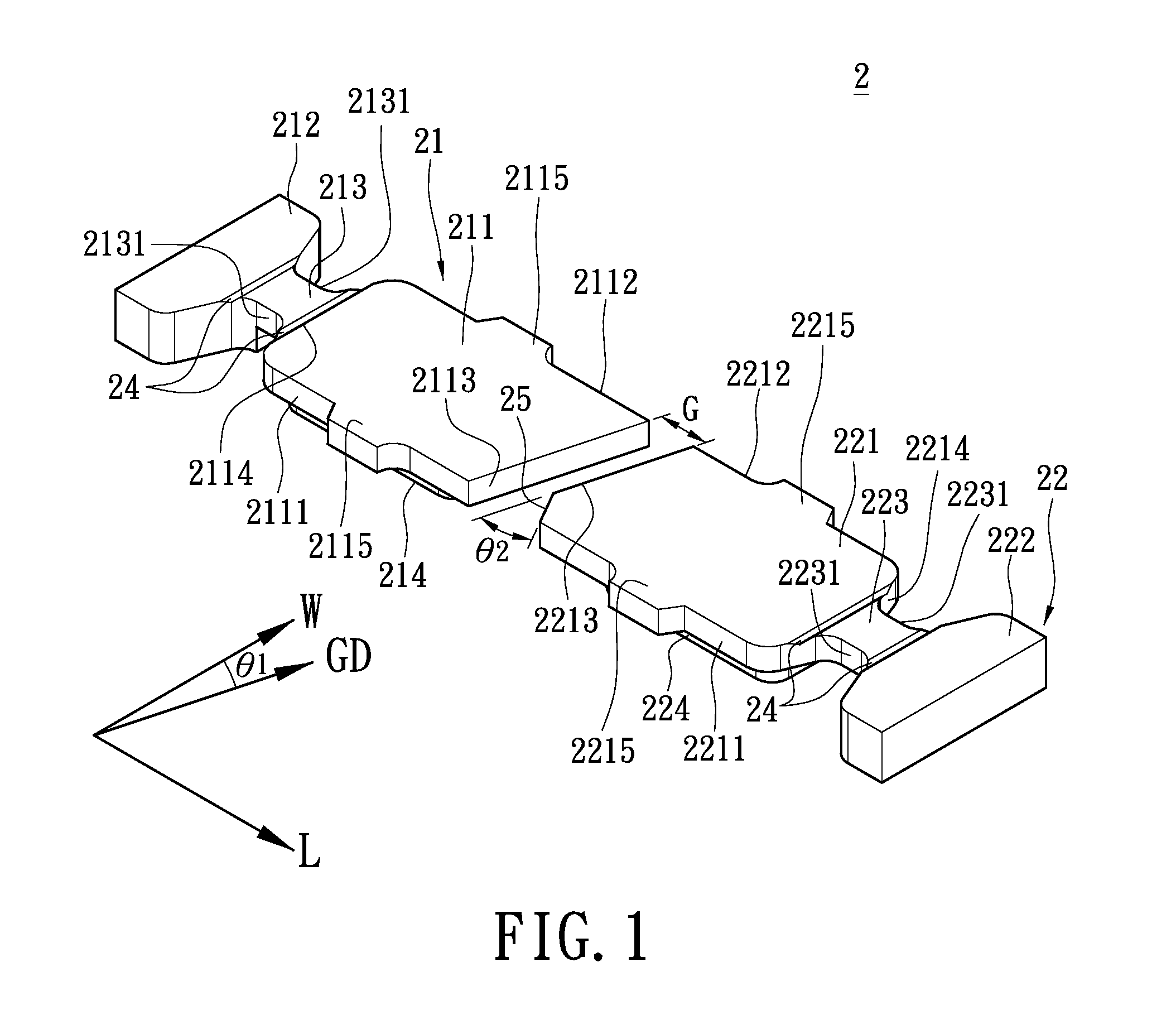

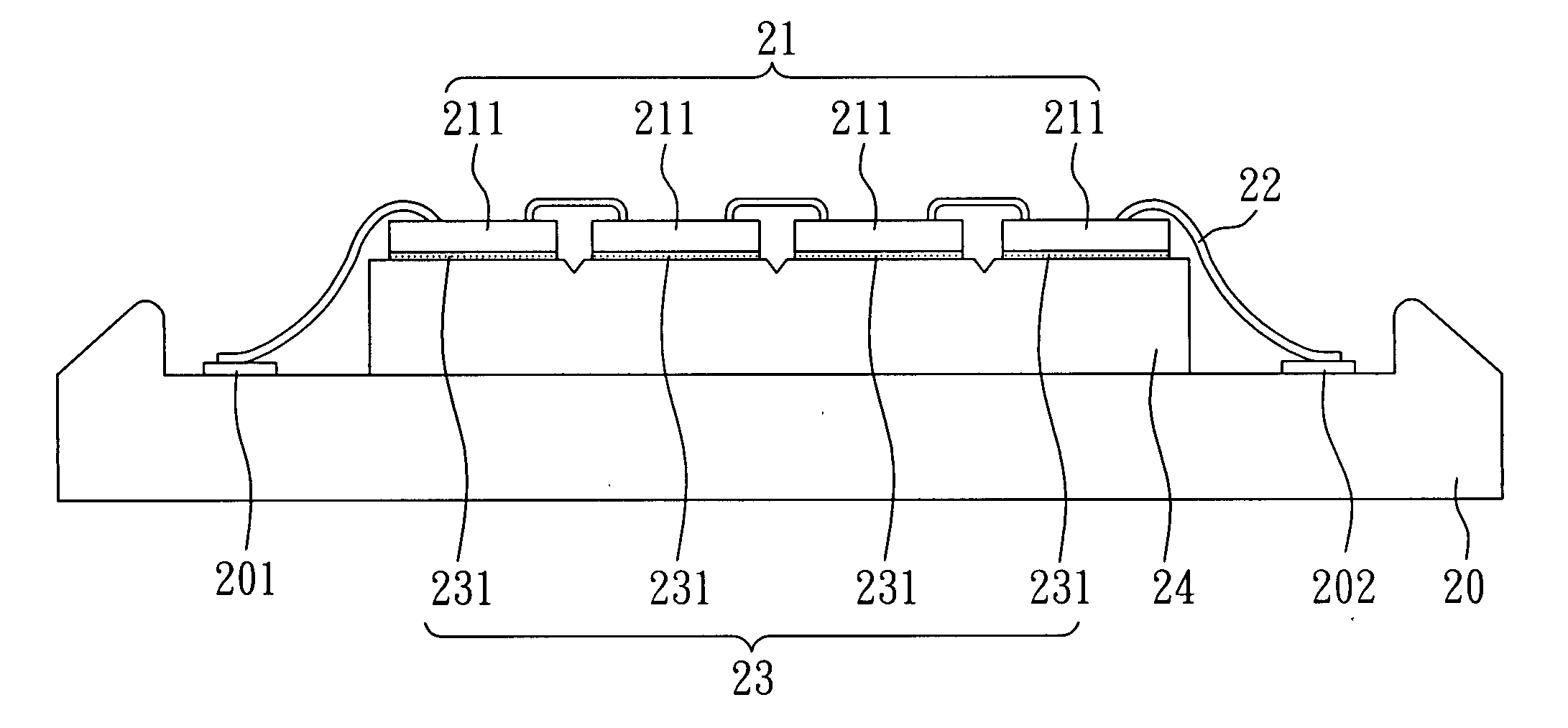

Lead frame structure, a packaging structure and a lighting unit thereof

ActiveUS20120074451A1Reduce moisture attackImprove bindingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A lead frame structure, a packaging structure and a lighting unit are disclosed. The lead frame structure includes at least two first lead frame units having a space therebetween, and the two first lead frame units are arranged in an opposite manner. Each the first lead frame unit has a first conducting portion, a second conducting portion, and a first connection portion between the first and the second conducting portions. Moreover, the first connection portion has at least two grooves on a surface thereof.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Nonionic surfactant foaming agents for foaming cosmetic compositions

InactiveUS6231844B1Stable and clear concentrationImprove production stabilityCosmetic preparationsHair removalFoaming agentEther

Cosmetic foaming compositions and hair mousse compositions employ a foaming agent comprising a mixture of first and second nonionic surfactants and having a total HLB as measured by the Griffin method of at least 12. The first nonionic surfactant is selected from defined polyoxyethylene alkyl ether surfactants, polyoxyethylene alkenyl ether surfactants, polyoxypropylene polyoxyethylene ether surfactants, and mixtures thereof; and the second nonionic surfactant is selected from defined polyoxyethylene long chain alkyl fatty acid or benzene ether surfactants, polyoxyethylene ether surfactants, polyoxypropylene ether surfactants, and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

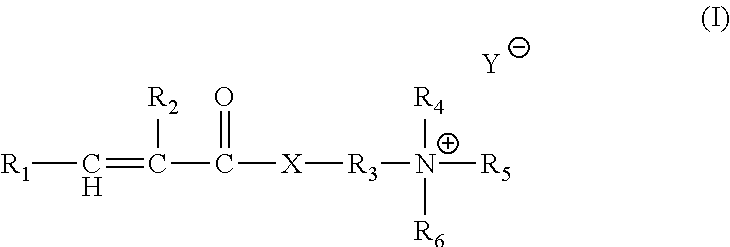

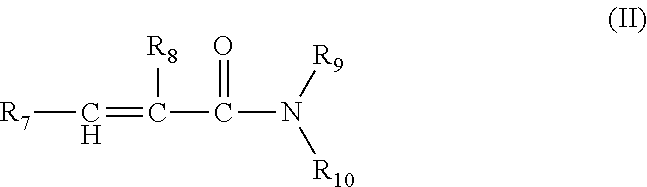

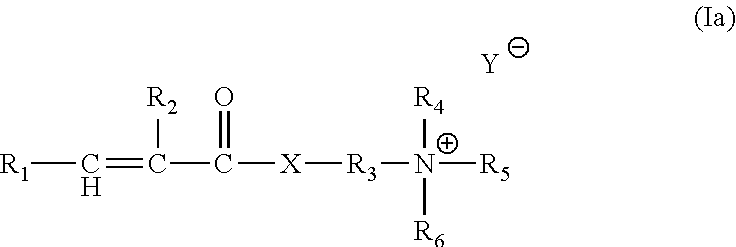

Cationic polymer stabilized microcapsule composition

ActiveUS8765659B2Improve production stabilityOrganic detergent compounding agentsGaseous substancesFabric softenerPolymerization

The present invention relates to the use of a cationic polymer to provide stability to microcapsules in a composition, wherein the microcapsule comprises a shell encapsulating materials having an average C log P of at least 2.5 and more than 60% by weight of the encapsulated materials have a C log P of at least 3.3. The cationic polymer is derived from the polymerization of 5 to 100 mole percent of a cationic vinyl addition monomer, 0 to 95 percent acrylamide, and 5 to 500 ppm of a tetrafunctional vinyl addition monomer cross-linking agent. The cationic polymer and encapsulated material may be used, for example, in a fabric softener composition.

Owner:THE PROCTER & GAMBLE COMPANY

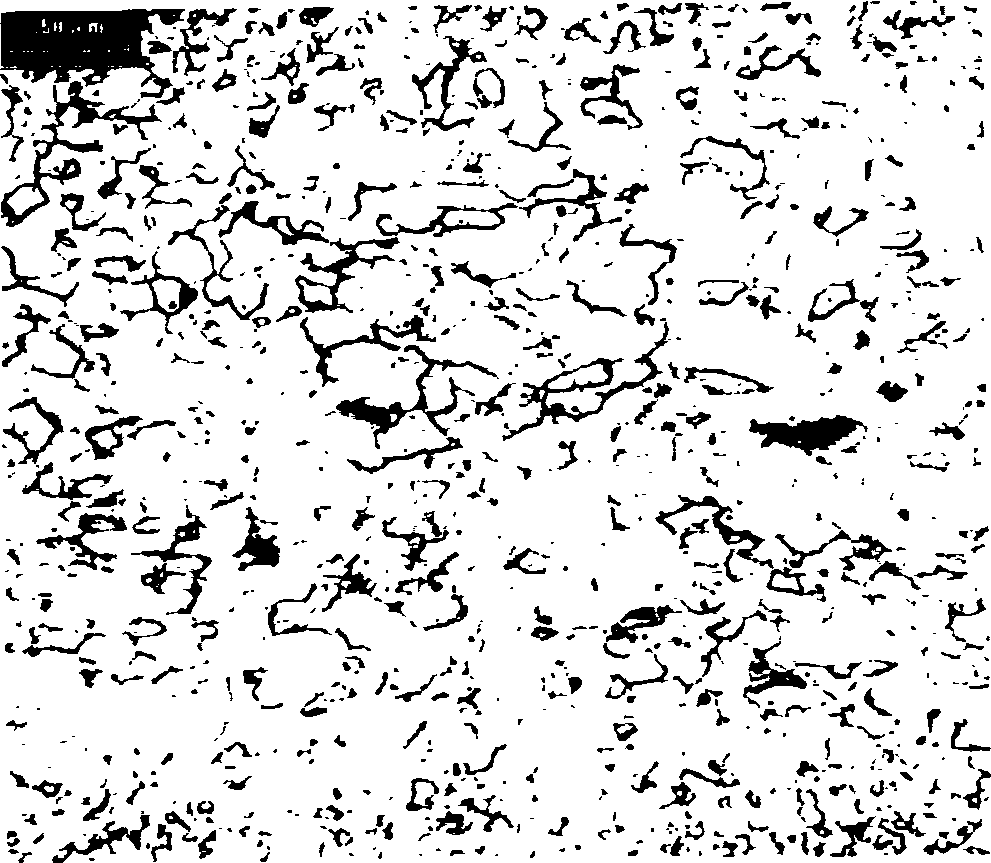

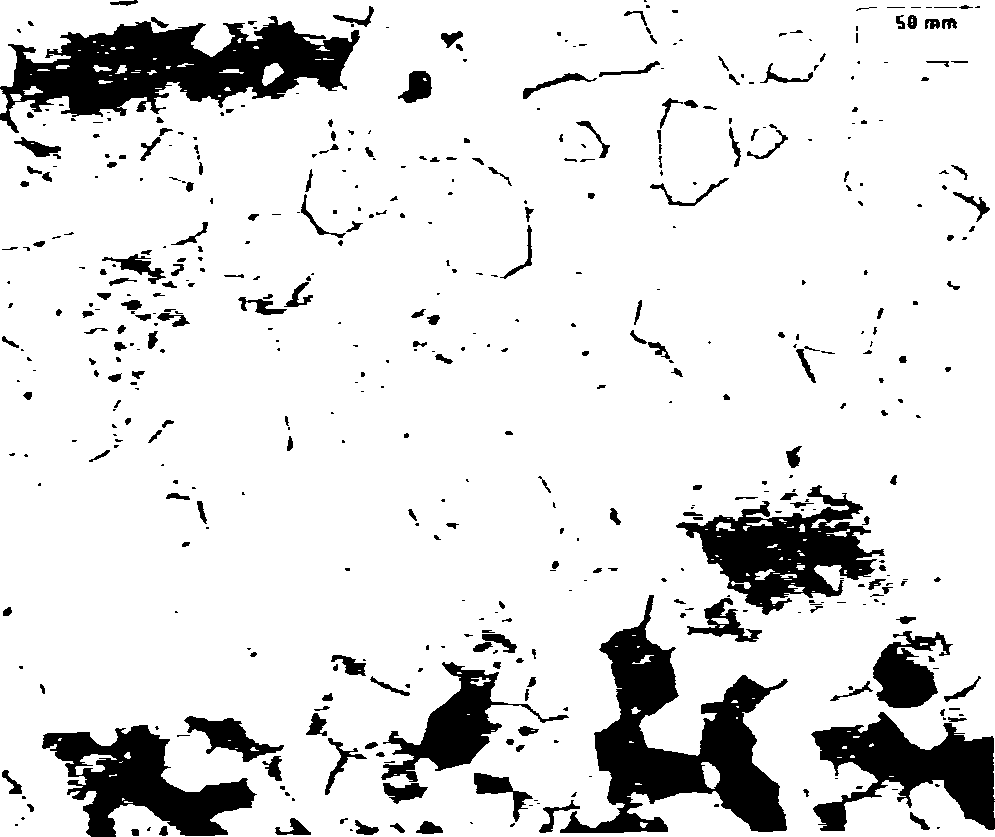

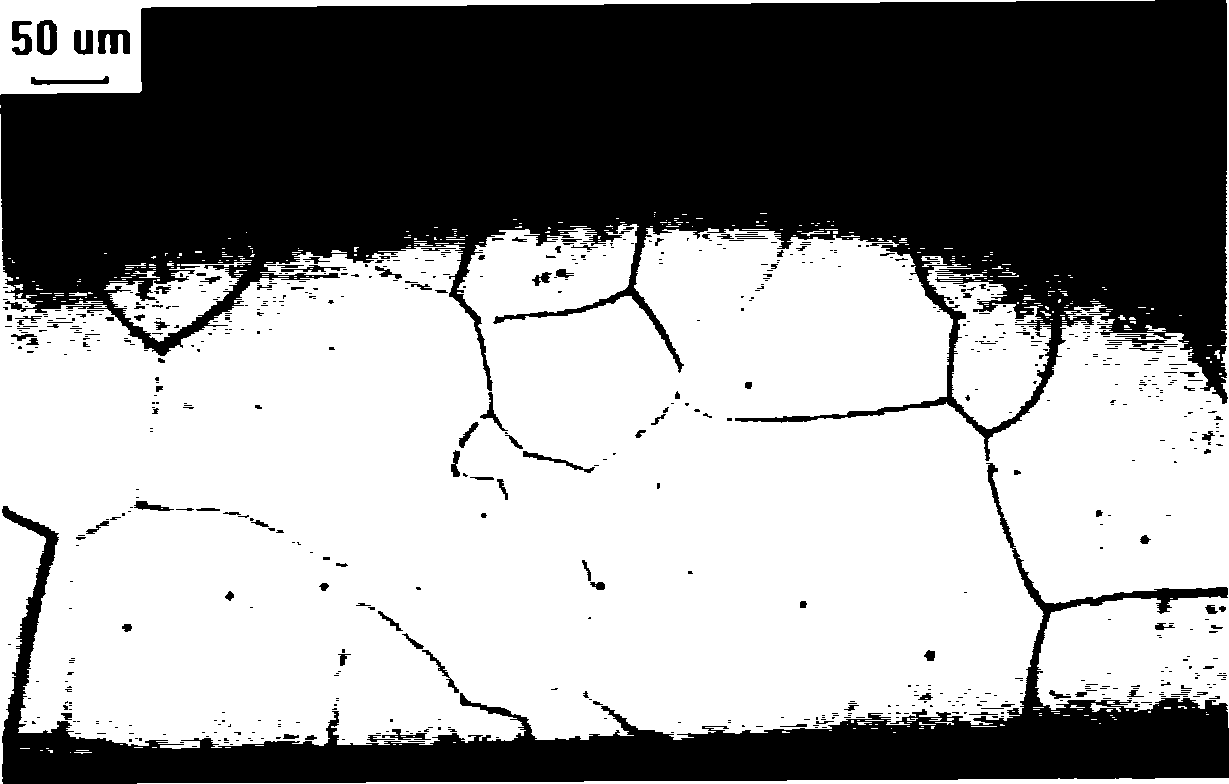

High magnetic induction and high grad non-orientation electrical steel and its making process

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

Low viscosity polymer polyols

The present invention relates to low viscosity polymer polyols and to a process for the preparation of these low viscosity polymer polyols. These polymer polyols comprise the free-radical polymerization product of (A) a base polyol, (B) a pre-formed stabilizer, and (C) at least one ethylenically unsaturated monomer, in the presence of (D) at least one free-radical polymerization initiator, and (E) at least one polymer control agent. The total amount of polymer control agent present in the polymer polyols of the present invention ranges from greater than about 5.0% up to about 20% by weight, based on 100% by weight of the polymer polyol.

Owner:COVESTRO LLC

Polyurethane foam compositions

A polyurethane foam assemblage contains an A component and a B component and the A component contains the polyether polyol, the polymer polyol, the crosslinking agent, the catalyst, the stabilizer and the foaming agent; the B component contains the isocyanate; wherein, the catalyst is the mixed catalyst containing the 2-dimethylamine ethanol, the triethylenediamine, the Bis(2-dimethylaminoethyl) ether and the organotin. Compared with the existing high elastic foam, the polyurethane foam assemblage of the invention has lower density, and thus has lower cost and stable formula and simple process on the premise of the same tensile and tear strength. The polyurethane foam assemblage provided by the invention has the advantages of low density, high resilence, cold curing, etc., is in particular suitable for automobile cushion, sofa, mattress, etc.

Owner:BYD CO LTD

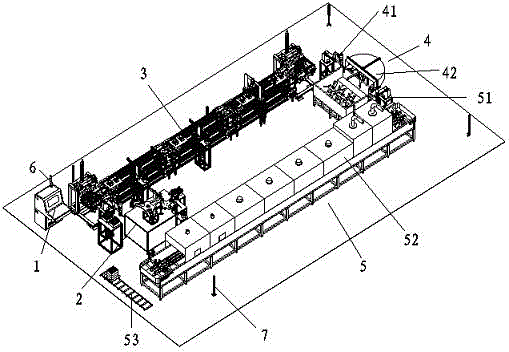

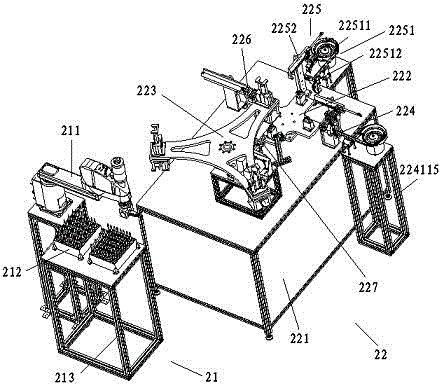

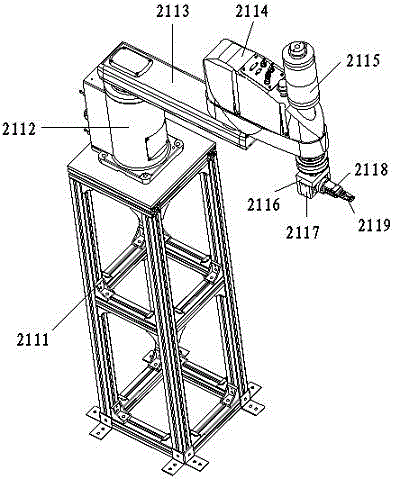

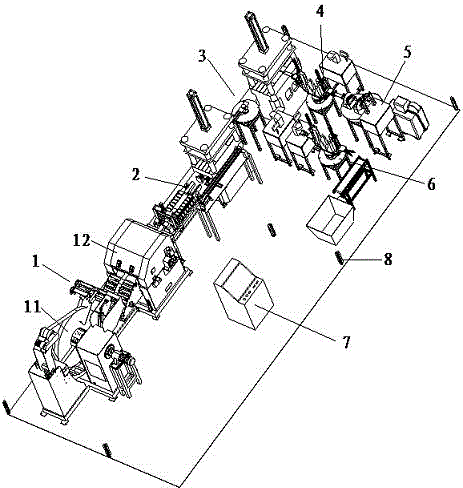

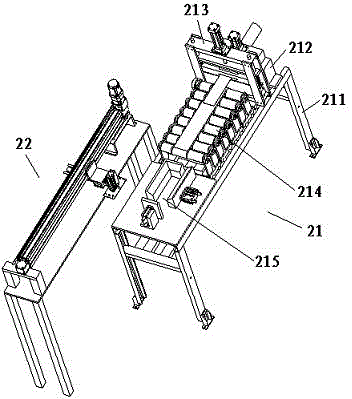

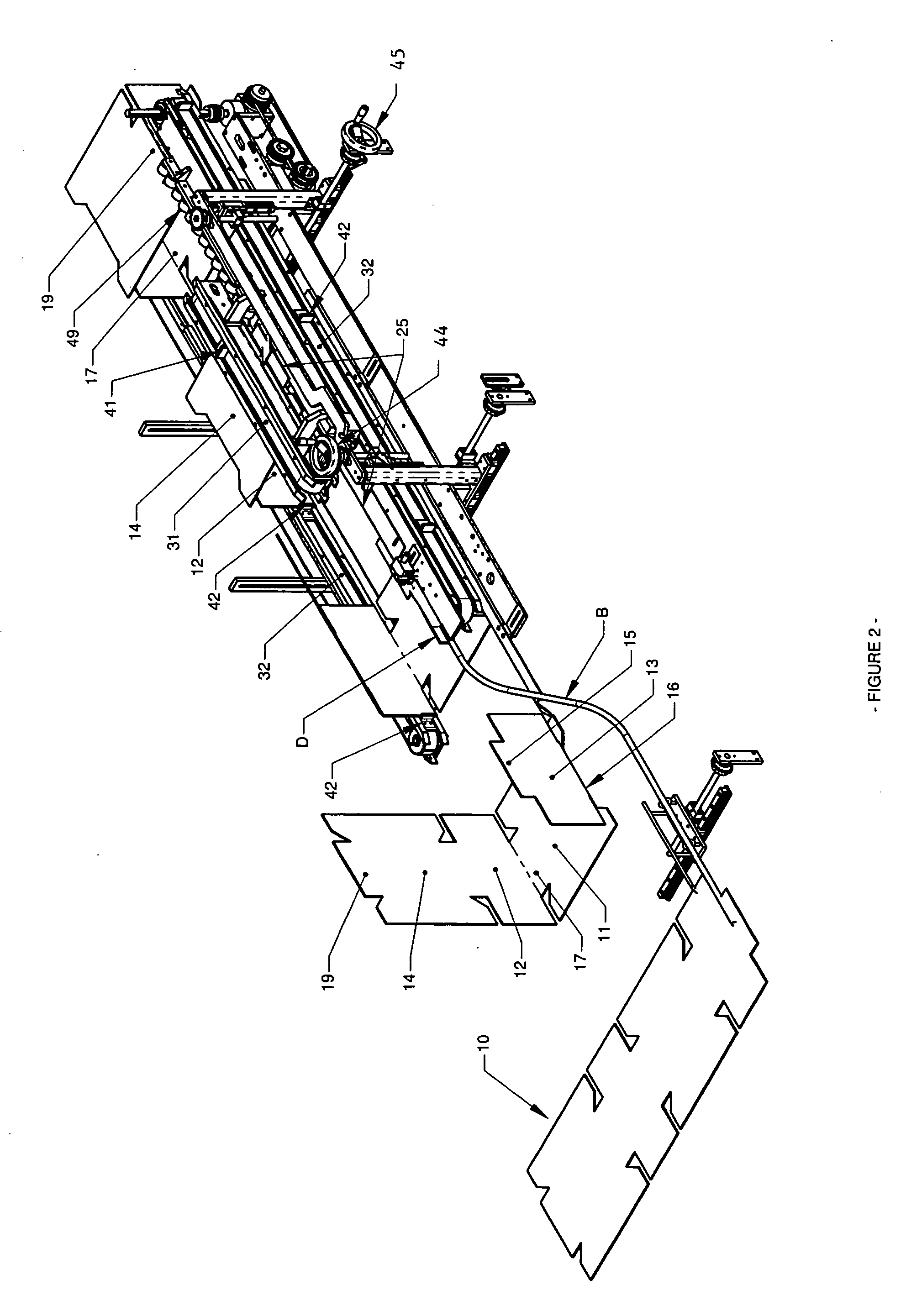

Electric heating rod assembly machine

ActiveCN105855897AImprove assembly and welding efficiencyImprove production stabilityAssembly machinesOther manufacturing equipments/toolsElectricityGrating

The invention discloses an electric heating rod assembly machine. The electric heating rod assembly machine comprises an electric control box, a rotary assembly mechanism, a chain assembly line, a coating mechanism, a drying mechanism, an indicator lamp tower and area safety gratings, wherein the indicator lamp tower is mounted on the top plate of the electric control box; the front side of the electric control box is provided with the rotary assembly mechanism; the rotary assembly mechanism is used for conveying a workpiece assembled for a first time to the chain assembly line at the rear side of the rotary assembly mechanism; the chain assembly line is used for conveying a wokpiece assembled for a second time to the coating mechanism at the front right side of the chain assembly line; the coating mechanism is used for conveying an assembled electric heating rod to the drying mechanism at the front side of the coating mechanism; and the area safety gratings are arranged around in a rectangular manner. In this way, the assembly welding efficiency is high, the production stability is good, the product scrap rate is low, and the overall production efficiency is high.

Owner:南通江海港建设工程有限公司

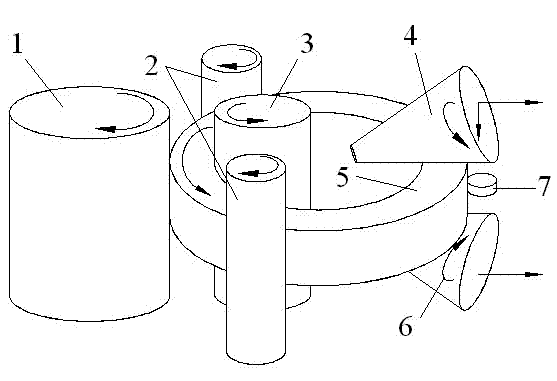

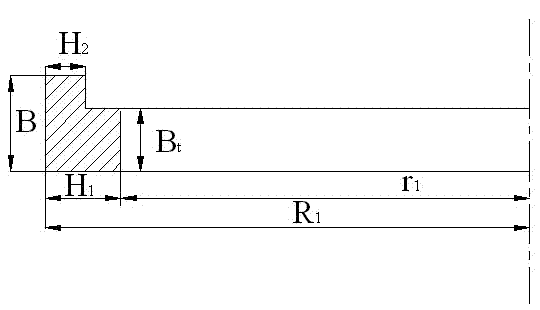

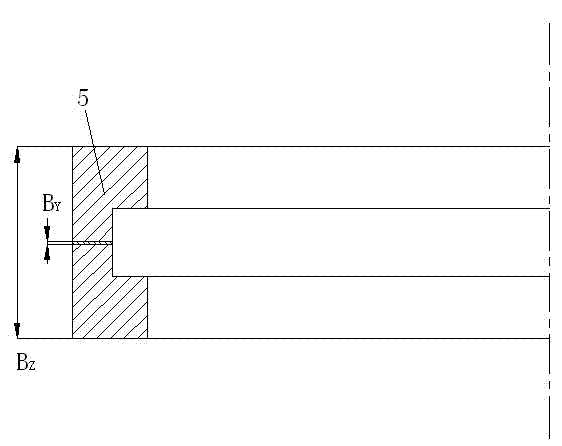

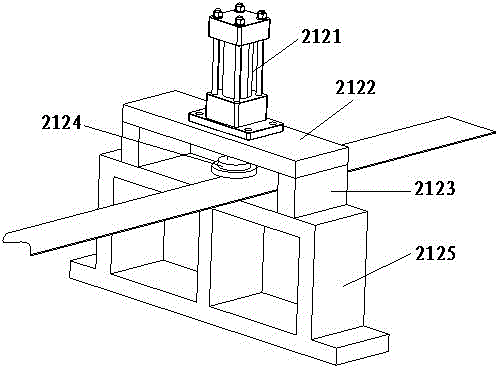

Symmetric rolling forming method of large inner-step ring parts

The invention relates to a symmetric rolling forming method of large inner-step ring parts, mainly comprising the following steps of: (1) blanking, upsetting, punching, punching the wad, and preparing a ring part blank used for rolling, wherein the size of the ring part blank is determined by the size of the ring part, a rolling ratio, and a radial feed / axial feed ratio; (2) designing a rolling groove, wherein the rolling groove is composed of a driven roller working surface and a core roller working surface and sizes of the driven roller working surface and the core roller working surface are determined by a rolling linear speed, equipment parameters, rolling deformation conditions, the ring part blank size, and the ring part size; (3) rolling forming which comprises placing the well-prepared ring part blank on a ring rolling machine and controlling the rolling process in a way that the feed speed and the feed amount are reasonably distributed according to three stages of pre-rolling, main rolling, and shaping rolling, and ending the rolling process when an outer diameter of the tested ring part achieves a predetermined value; and (4) machining cutting which comprises placing the well-rolled ring part on a sawing machine and cutting the ring part into two required inner-step ring parts from a high portion in the middle. The symmetric rolling forming method provided by the invention has the characteristics of good production stability, high efficiency, and high product performance.

Owner:汇洲智能技术集团股份有限公司 +1

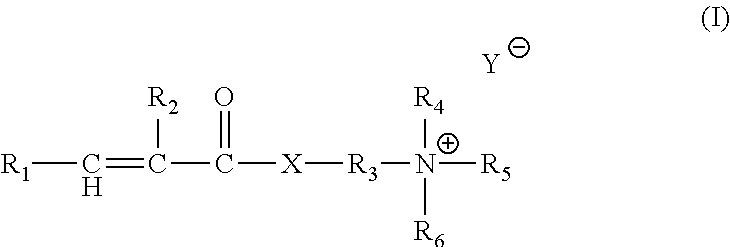

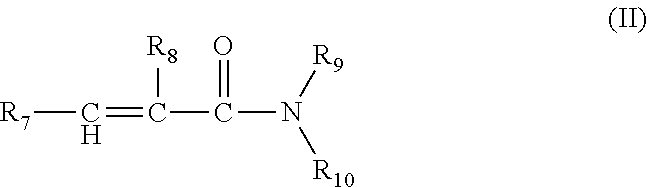

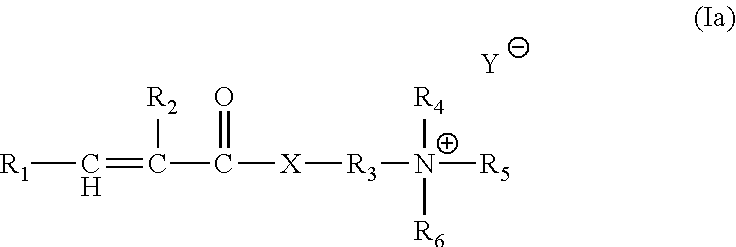

Cationic polymer stabilized microcapsule composition

ActiveUS20110245141A1Improve production stabilityGaseous substancesDeodrantsPolymer scienceIonic polymerization

The present invention relates to the use of a cationic polymer to provide stability to microcapsules in a composition, wherein the microcapsule comprises a shell encapsulating materials having an average C log P of at least 2.5 and more than 60% by weight of the encapsulated materials have a C log P of at least 3.3. The cationic polymer is derived from the polymerization of 5 to 100 mole percent of a cationic vinyl addition monomer, 0 to 95 percent acrylamide, and 5 to 500 ppm of a tetrafunctional vinyl addition monomer cross-linking agent. The cationic polymer and encapsulated material may be used, for example, in a fabric softener composition.

Owner:THE PROCTER & GAMBLE COMPANY

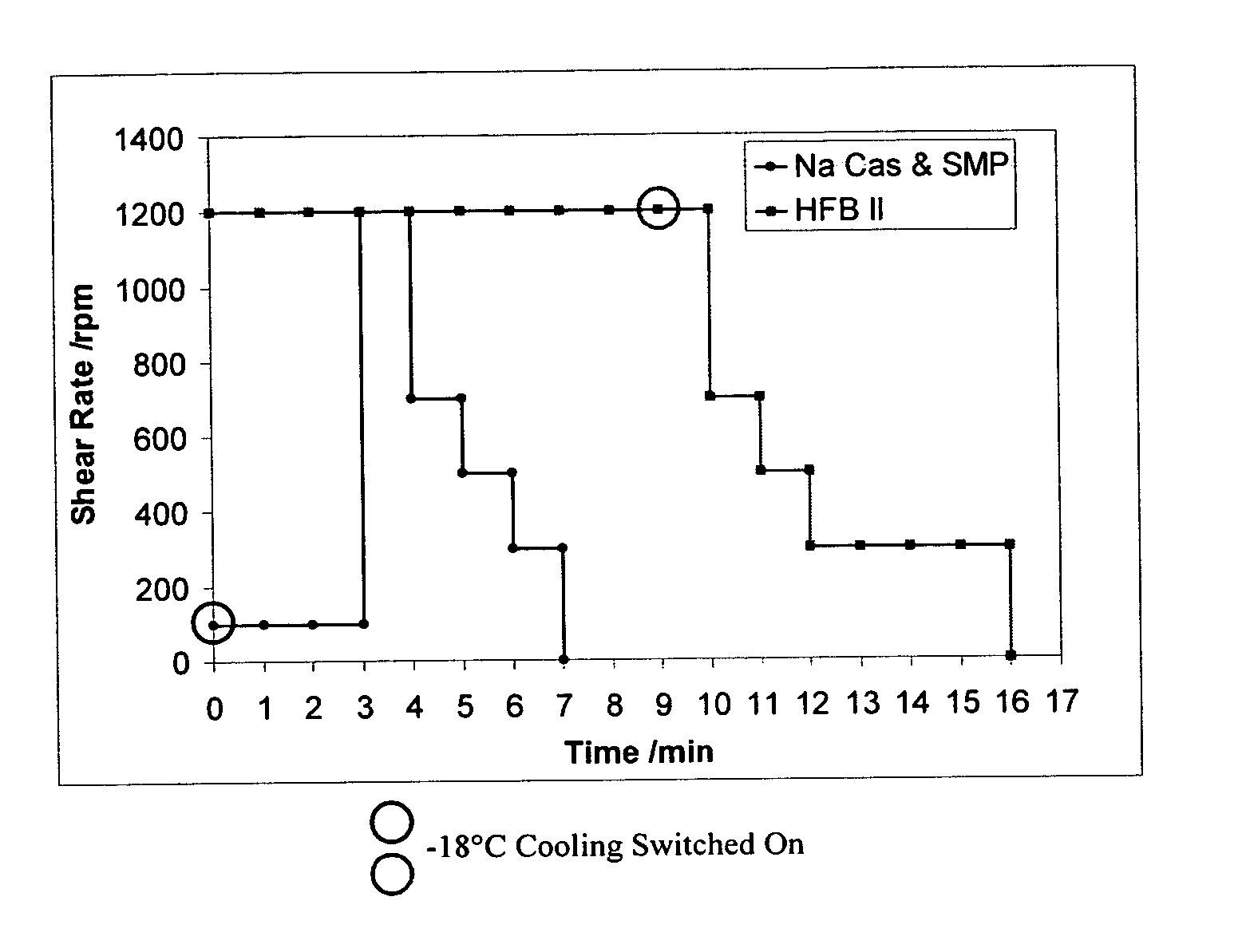

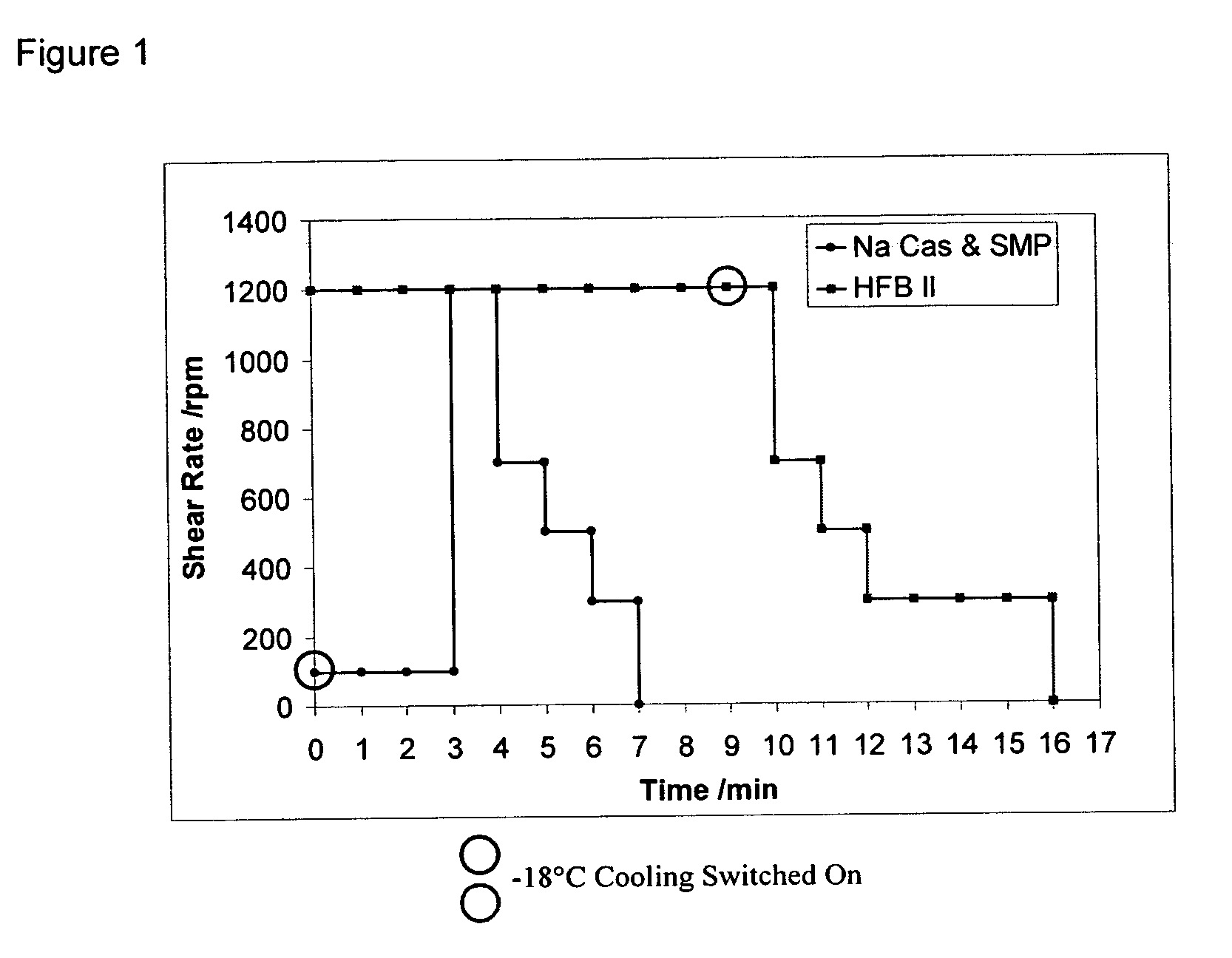

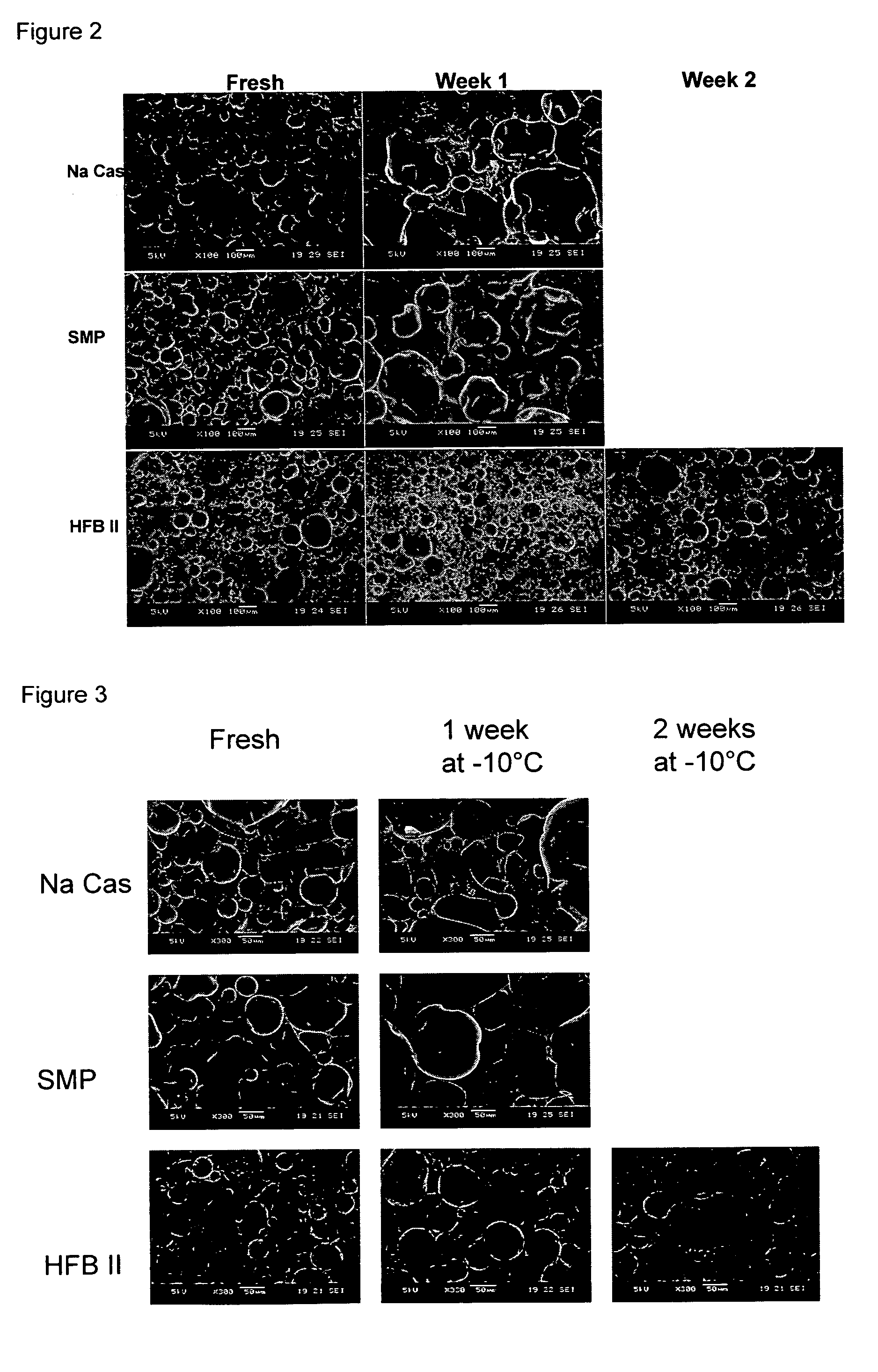

Frozen products

InactiveUS20060024419A1Reduce volumeExtended shelf lifeMilk preparationFrozen sweetsHydrophobinIce crystals

A frozen composition is provided which includes hydrophobin. Also provided is the use of hydrophobin in inhibiting ice crystal growth and / or modifying ice crystal habit in frozen food products.

Owner:CONOPCO INC D B A UNILEVER

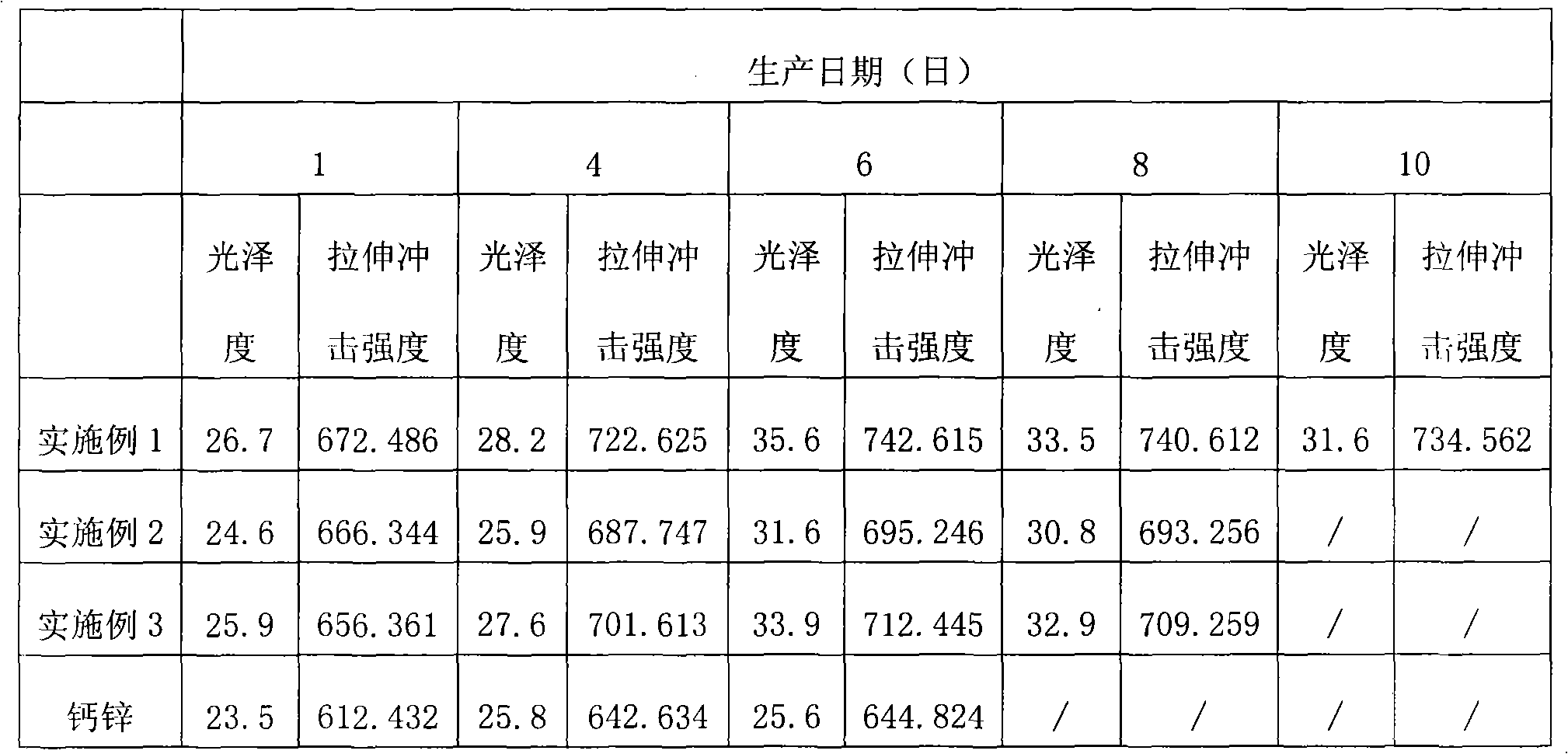

Zn-Ca compound stabilizer

The invention discloses a Zn-Ca compound stabilizer, comprising the following components in parts by weight: 28-35 parts of zinc stearate, 8-11 parts of calcium stearate, 18-32 parts of hydrotalcite, 14-22 parts of polyalcohol, 4.5-10.5 parts of Stearoylbenzoylmethane, 3.6-12 parts of external lubricant, 3.8-9.8 parts of internal lubricant and 1.0-5 parts of antioxidant. Compared with the prior art, the invention has the following characteristics of long continuous production period and good production stability; realization of toxicity and environmental protection without containing heavy metals, such as Ba, Cd, Pb and the like in the components; and avoidance of discoloration at the time of switching mercaptan organic tin without containing heavy metals, such as Ba, Cd, Pb and the like.

Owner:WUHU CONCH NEW MATERIAL

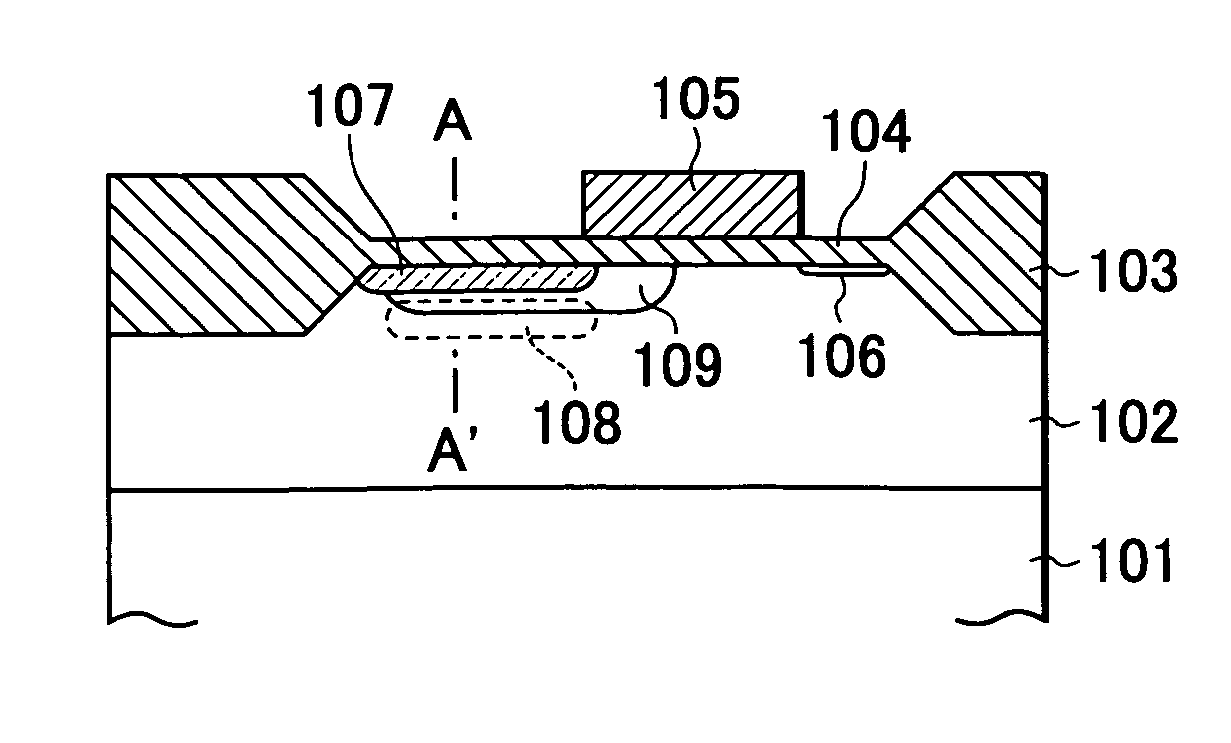

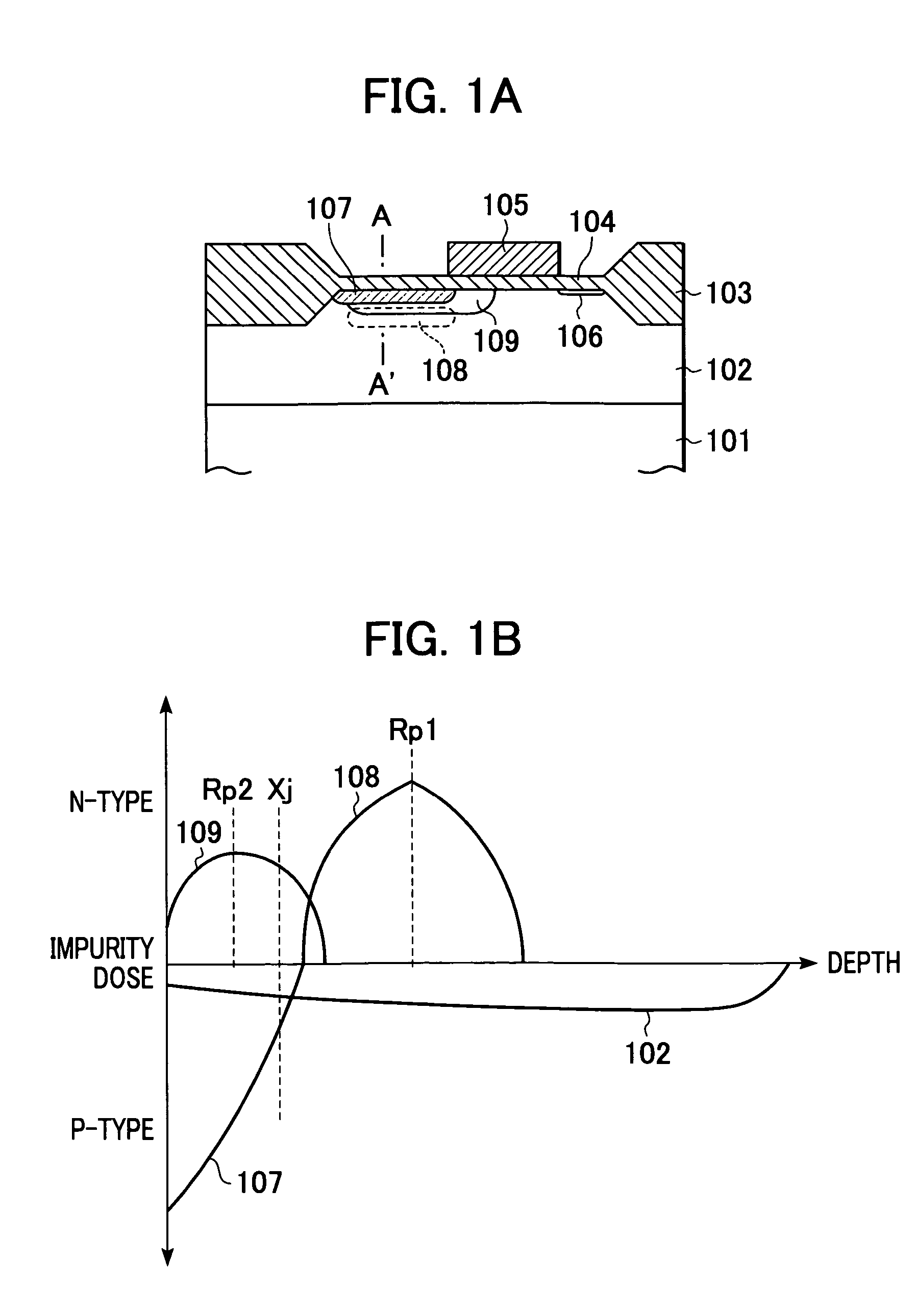

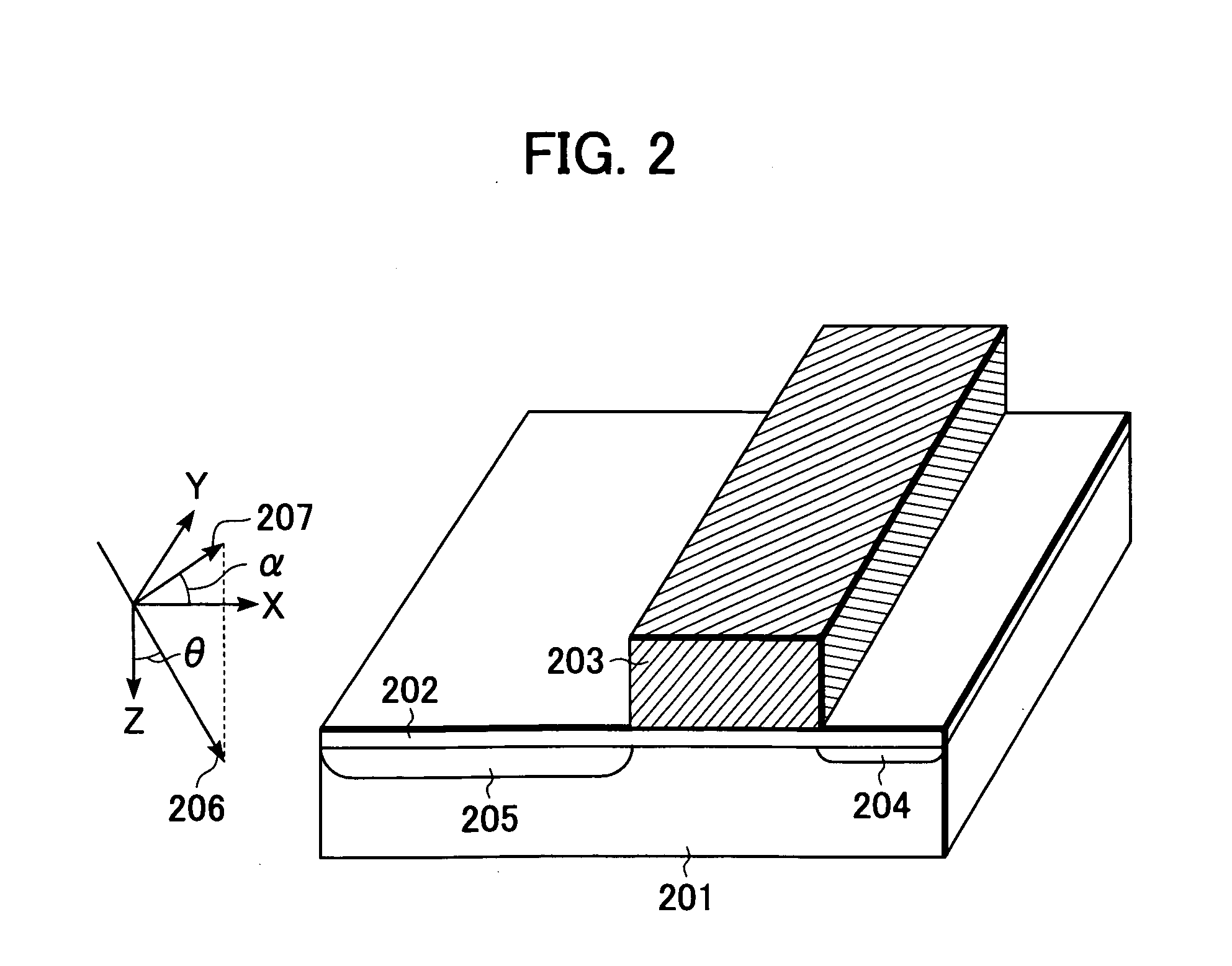

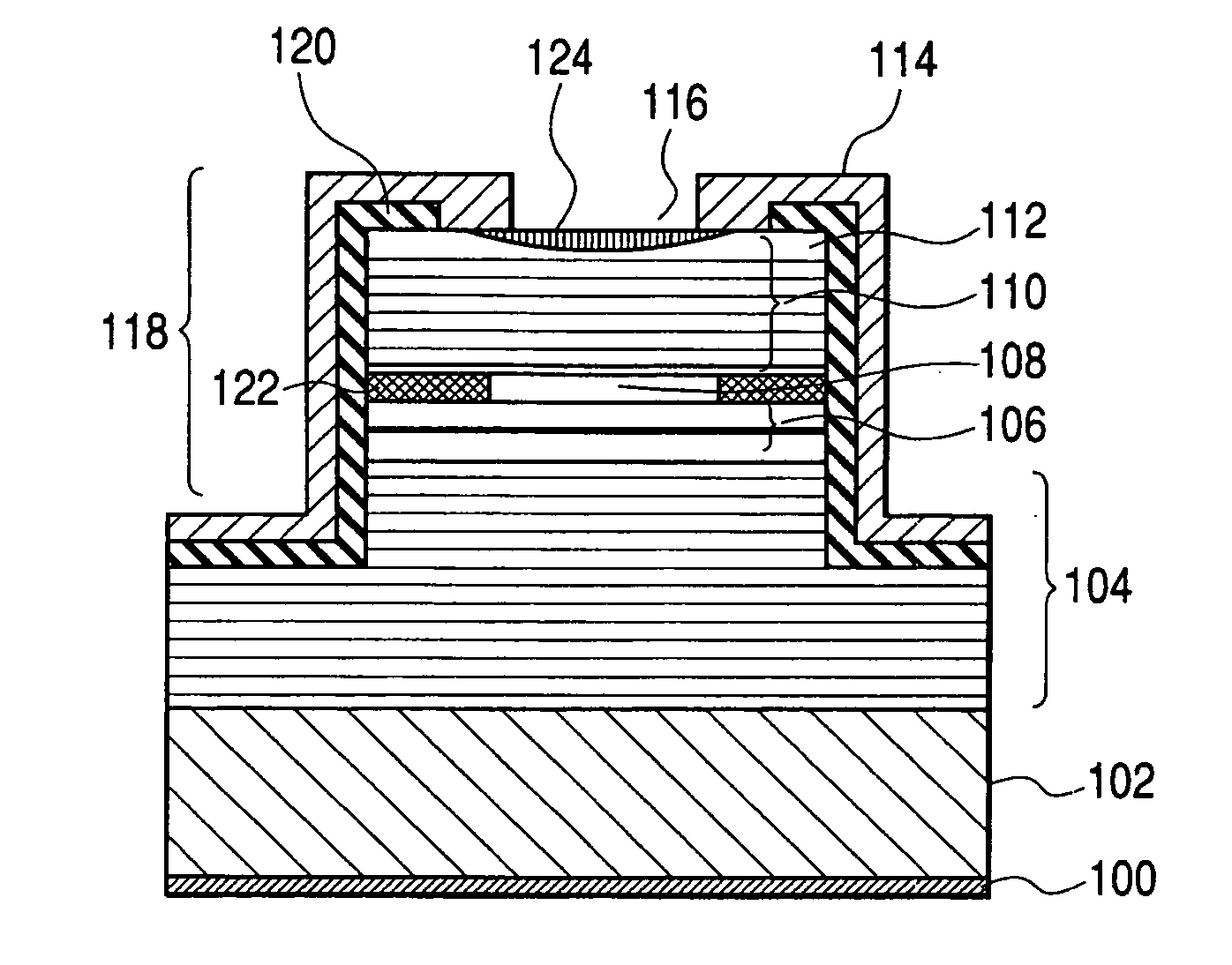

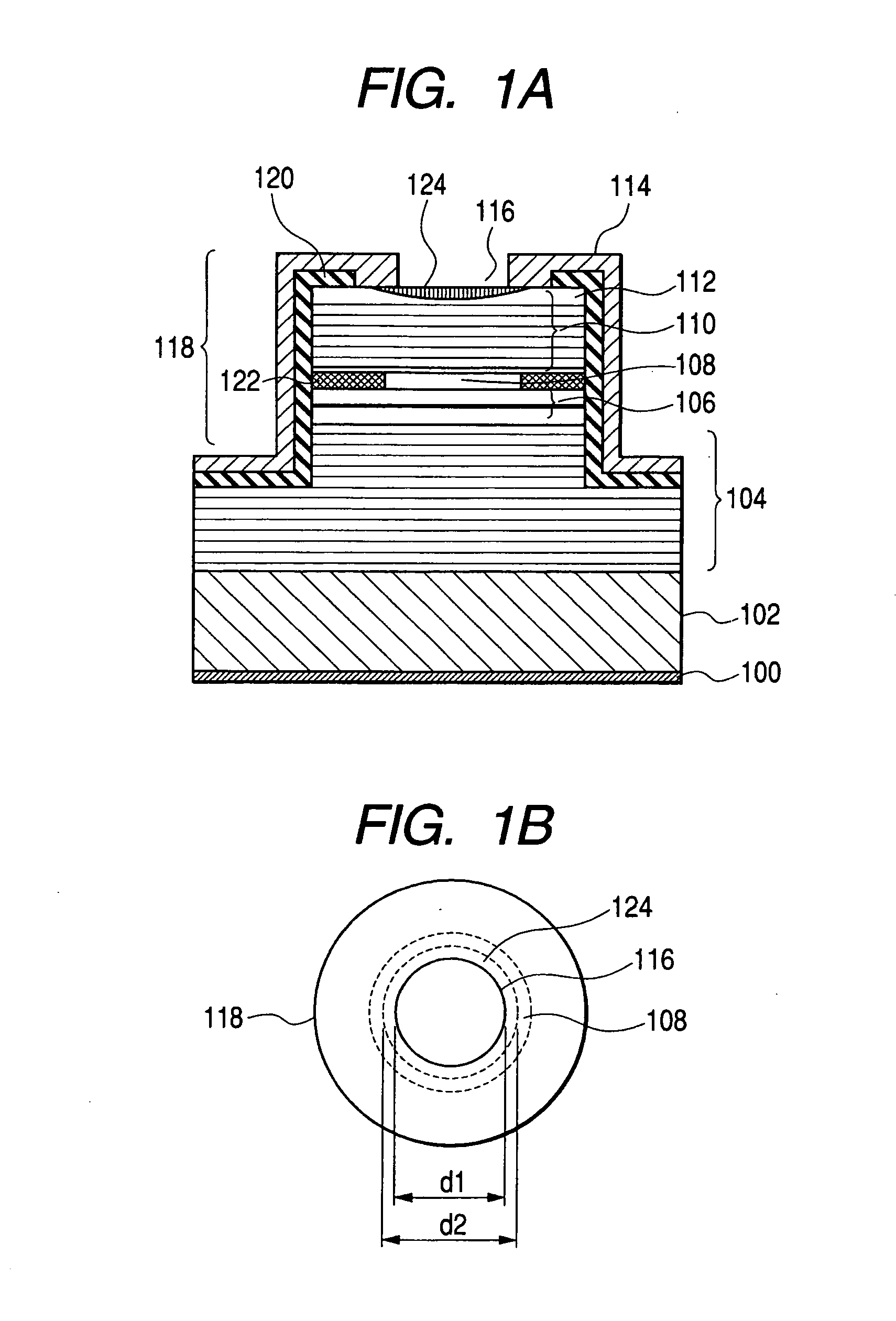

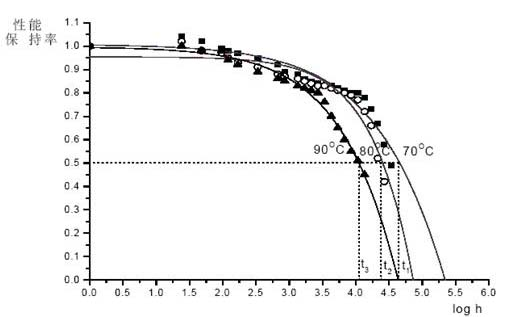

Solid-state image sensor, production method for solid-state image sensor, and camera using solid-state image sensor

InactiveUS20050006676A1Reduces power voltage and power consumptionHigh SIN ratioTelevision system detailsSolid-state devicesSolid-stateImage sensor

A solid-state image sensor includes, in each pixel, a p-type well provided on a semiconductor substrate, a photodiode provided in the p-type well, a transfer gate for transferring photocharges accumulated in the photodiode, and an n-type diffusion region for receiving the transferred photocharges. The photodiode includes a first n-type accumulation region, and a second n-type accumulation region having a concentration higher than that of the first accumulation region and provided at a position deeper than the first accumulation region. The first accumulation region extends toward an end of the transfer gate, and the second accumulation region is separate from the transfer gate.

Owner:CANON KK

Stamping-welding line

ActiveCN104889691AHigh stamping welding efficiencyImprove production stabilityShaping toolsWelding/cutting auxillary devicesEngineeringManufacturing line

The invention discloses a stamping-welding line comprising a feeding mechanism, a cutting switching mechanism, a stamping detection mechanism, a clamping detection mechanism, a welding mechanism, a welding detection mechanism, a main electrical cabinet and area sensors, all mounted on the ground in a factory. The feeding mechanism, the cutting switching mechanism and the stamping detection mechanism are transversely arranged side by side on the ground in the factory; the clamping detection mechanism and the welding mechanism are disposed in order in the front of the stamping detection mechanism; the welding detection mechanism and the main electrical cabinet are disposed in order on the left of the welding mechanism; the area sensors are arranged in a rectangular form around; the feeding mechanism comprises a winding feeder and a straightener; the winding feeder is provided with a roll of material; the roll of material is connected to the cutting switching mechanism through the straightener. The stamping-welding line has the advantages that the stamping-welding efficiency is high, production stability is good, product scrap rate is low, and total production efficiency is high.

Owner:河南九天封头制造有限公司

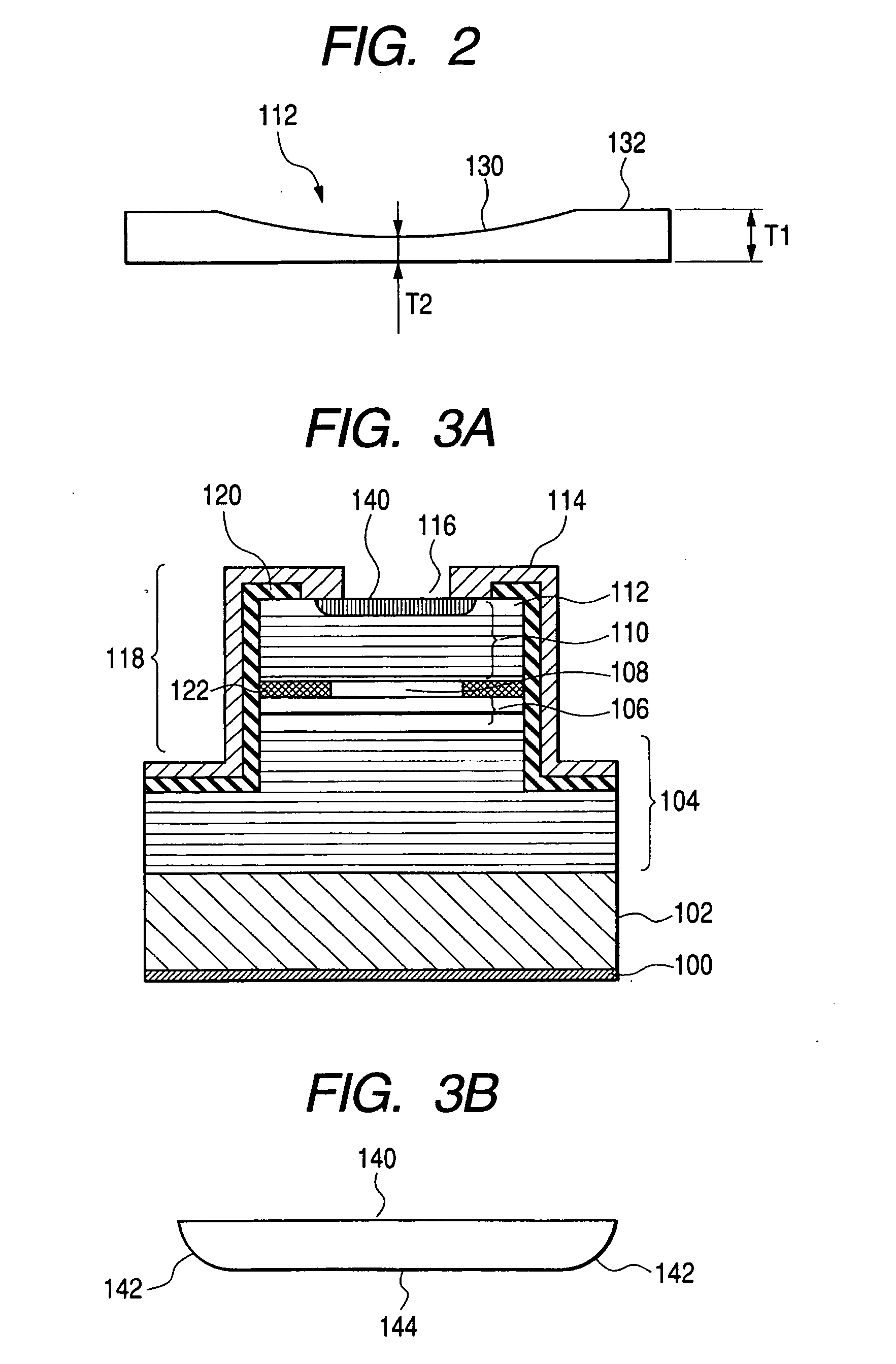

Vertical cavity surface emitting laser diode and process for producing the same

ActiveUS20050286597A1Small divergence angleSmall signal characteristicLaser detailsSemiconductor laser optical deviceVertical-cavity surface-emitting laserLaser light

A vertical cavity surface emitting laser diode includes a lower semiconductor reflector, an active region, an upper semiconductor reflector constituting a resonator with the lower semiconductor reflector, a metallic part being formed on the upper semiconductor reflector, which has a first aperture defining an output region of laser light generated in the active region, and a light confining region being provided between the metallic part and the lower semiconductor reflector, and having a second aperture defining an emission region of the laser light. The upper semiconductor reflector includes a lenticular medium having a convex surface toward the lower semiconductor reflector.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Beta-carotene microcapsule production method

ActiveCN103976353AIncrease productivityFacilitate large-scale industrial productionFood shapingFood ingredient functionsBeta-CaroteneOil phase

Owner:武汉星辰现代生物工程有限公司

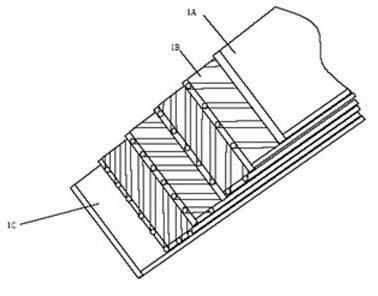

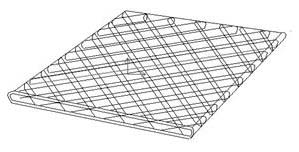

Large high-pressure seamless rubber airbag and production process thereof

ActiveCN102086637AHigh compressive strengthEasy to operateBarrages/weirsLifting devicesFiberPolymer science

The invention discloses a large high-pressure seamless rubber airbag and a production process thereof, relating to a rubber product and a production process thereof. The large high-pressure seamless rubber airbag comprises the following compositions: EPDM (ethylene-propylene-diene monomer) externally-covered rubbers with excellent weather resistance, at least four (even number) skeleton layers, a middle adhesive layer and an inner adhesive layer, wherein each skeleton layer is composed of continuous high-strength tyre cords which are mutually crossed with an angle of 90 degrees and formed into an angle of 46-56 degrees, the middle adhesive layer is composed of chloroprene rubbers and natural synthetic rubbers, and the inner adhesive layer is made of butyl rubbers with excellent air tightness. The production process of the large high-pressure seamless rubber airbag comprises the following steps: (1) sequentially carrying out plastication, coordination, mixing and batching on raw rubbers; (2) carrying out impregnation and rubberizing on the high-strength tyre cords; (3) carrying out rotating preforming on the obtained object by using a roller; weaving open-end fibers, so that the joints of the fibers are arranged in a continuous shape, and sticking films on the fibers; (4) carrying out integral molding on the obtained object once; (5) carrying out integral vulcanization on the obtained object; and (6) carrying out reinforced heat vulcanization on edges and corners of the obtained product. The production process disclosed by the invention is simple and convenient in operation; the service time of the rubber airbag is more than 50 years, and the environmental sanitation index of the rubber airbag exceeds four orders of magnitude of the international standard requirement. The large high-pressure seamless rubber airbag and production process disclosed by the invention are used for the hoisting of pneumatic-shield gate dams and heavy objects.

Owner:TIELIN ERFAN RUBBER R & D CO LTD +1

Low Fat Frozen Confectionery Product

InactiveUS20070286936A1Improve production stabilityMasks/reduces deleterious effectMilk preparationFrozen sweetsChemistry

A low fat dairy frozen confectionery product is provided having 3% or less fat which product comprises an ice structuring protein (ISP).

Owner:CONOPCO INC D B A UNILEVER

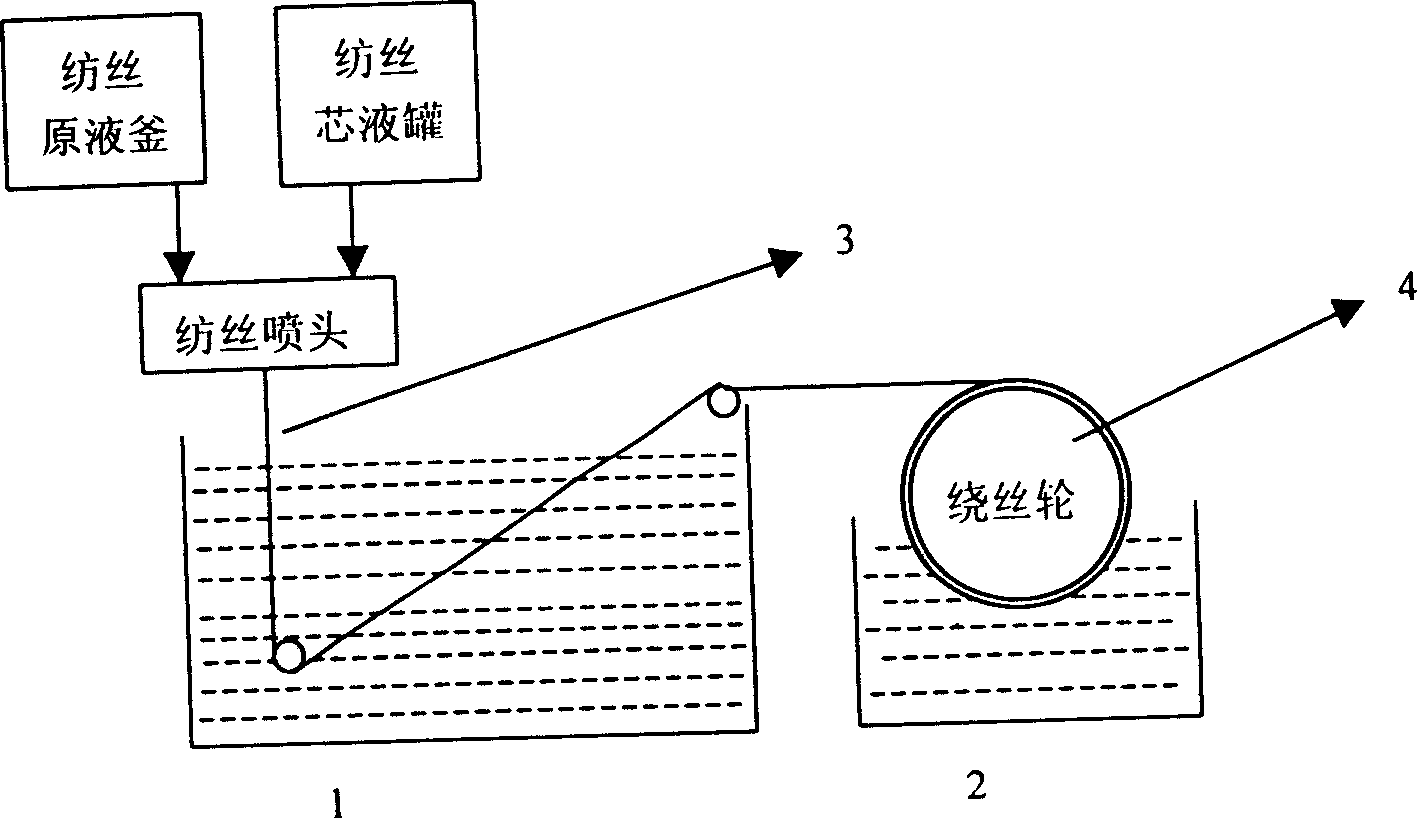

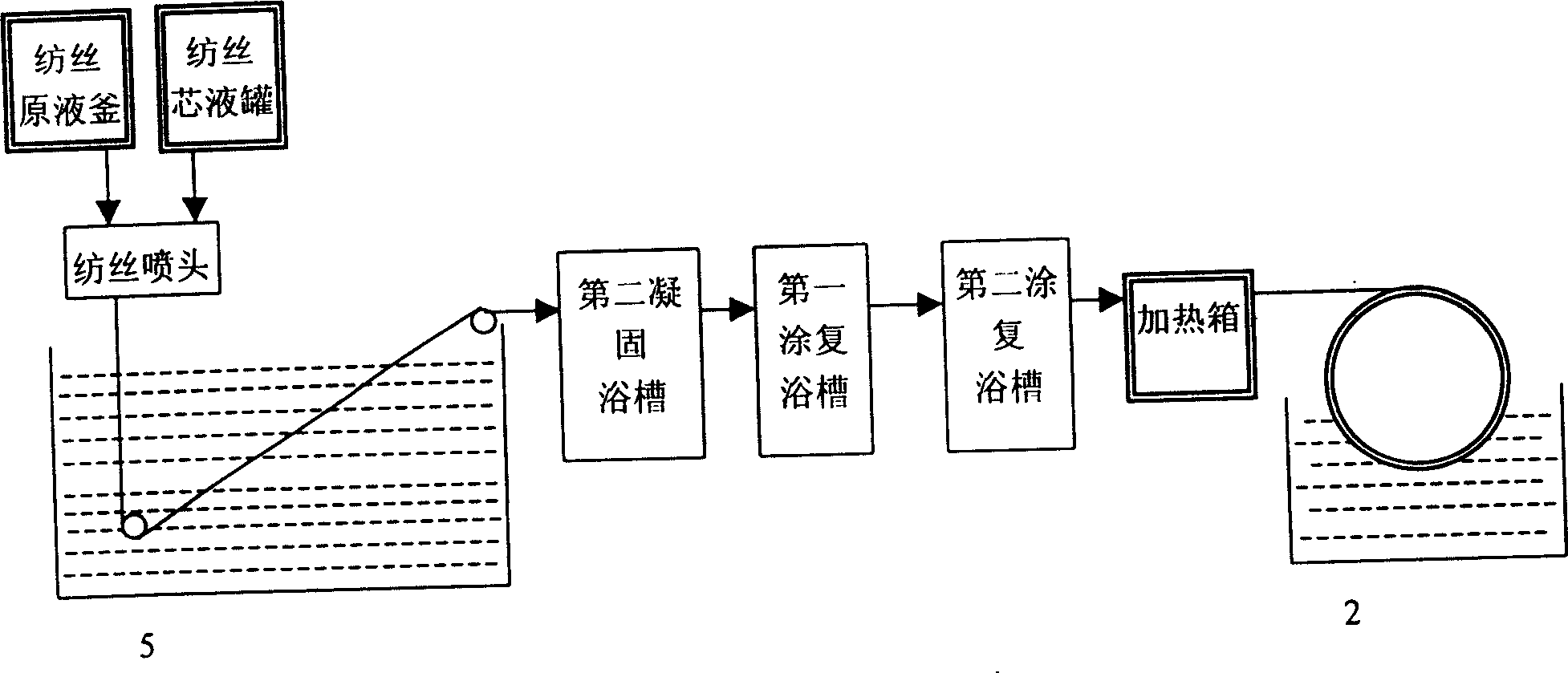

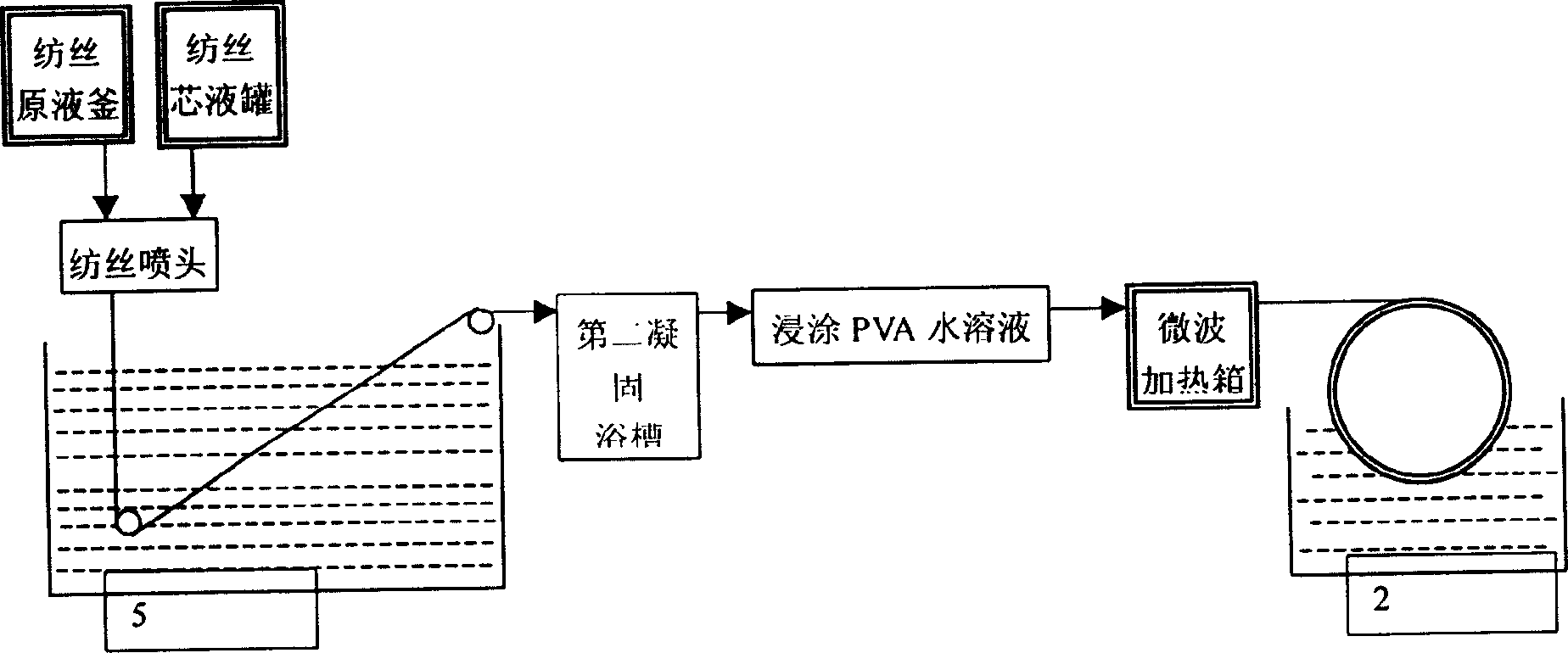

Method and apparatus for primary shaping composite or modified hollow fibre membrane

InactiveCN1552507AContinuous productionIncrease productivitySemi-permeable membranesFilament/thread formingPolymer scienceHollow fiber membrane

A process for preparing the composite or modifier hollow fibre membrane includes such steps as spinning, preparing membrane, solidifying, coating compound or modifying substance, and heating for further reaction. Its apparatus is composed of solidifying bathtub, the bathtub containing compound or modifying solution, and heating box.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

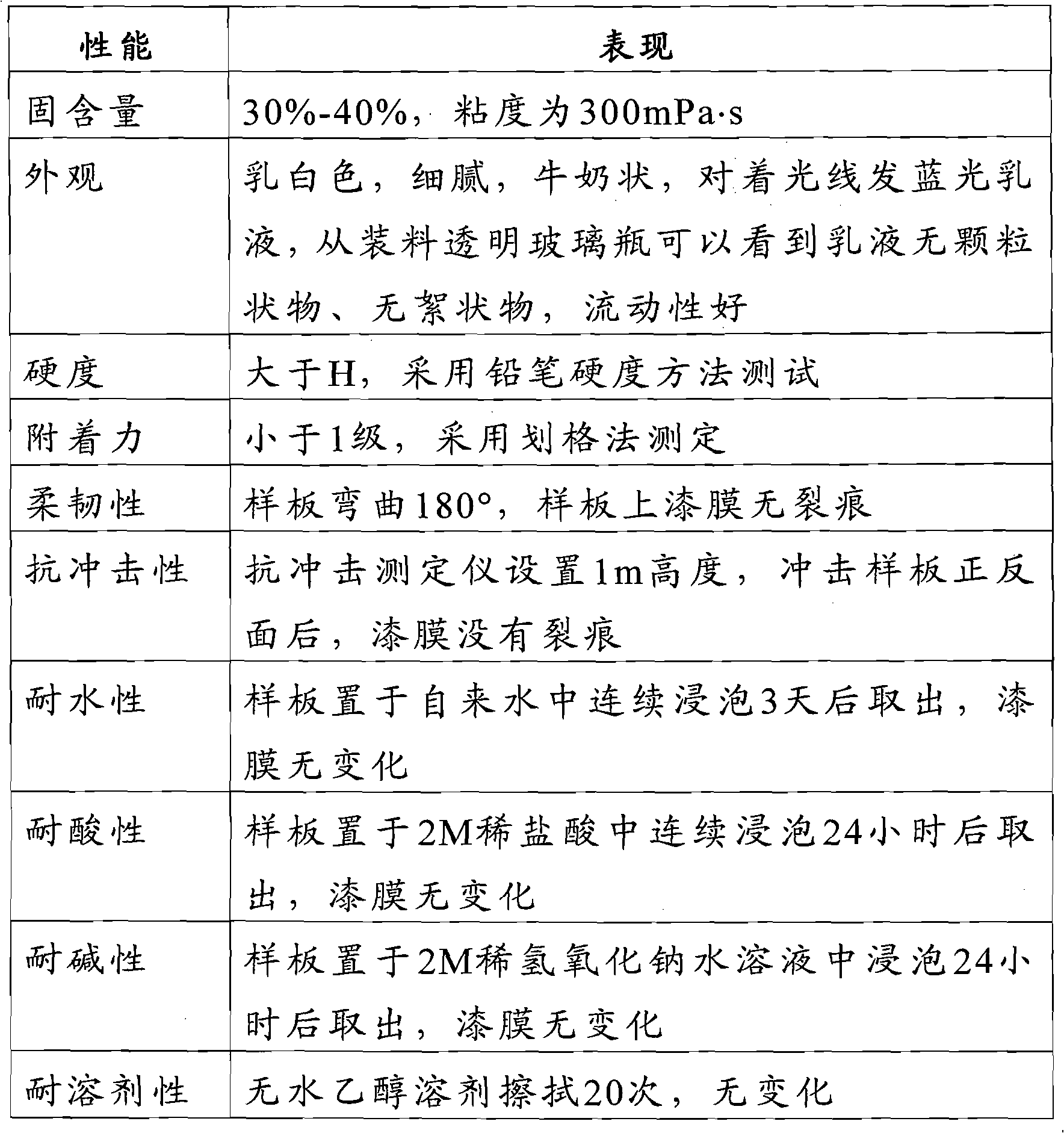

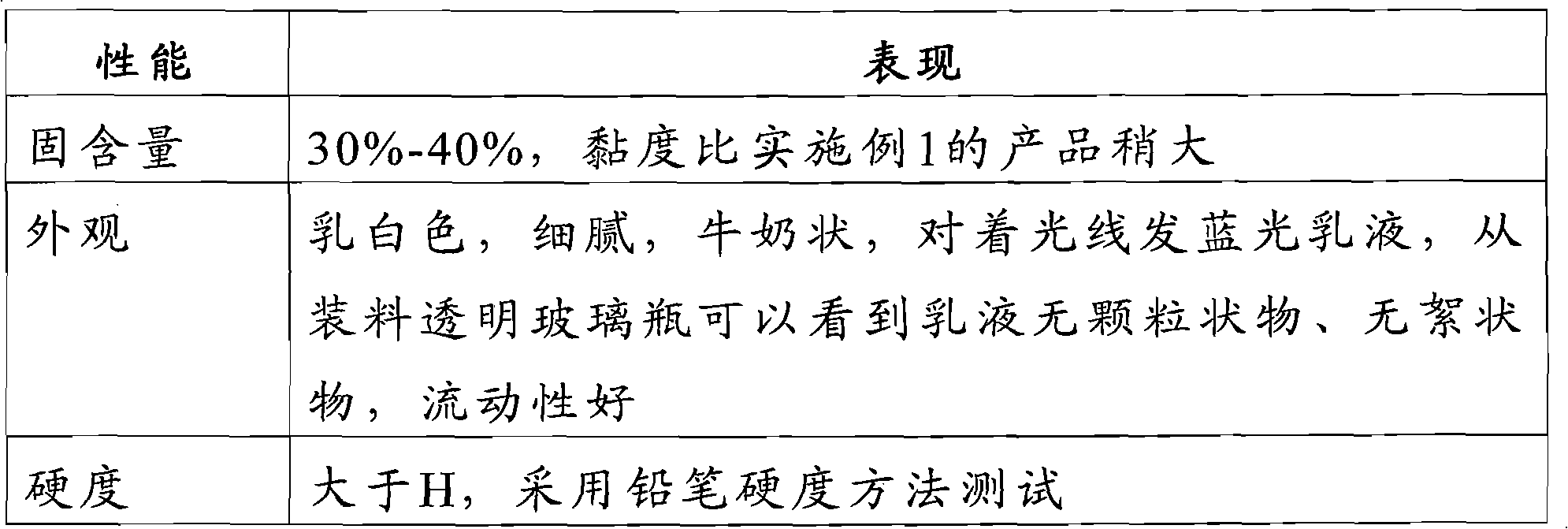

Method for preparing acrylate water-based dispersion by continuously dripping under low temperature condition

The invention relates to a method for preparing acrylate water-based dispersion, in particular to a method for preparing acrylate water-based dispersion by adopting a continuous dripping manner under low temperature condition. The method provided by the invention has good production stability, the obtained acrylate water-based dispersion product has good storage stability and is green, solid content can reach 30-40%, appearance is oyster white and is fine and smooth, no particle or floccule is contained, and liquidity is good. Hardness is more than H (adopting a pencil hardness method); adhesion is lower than one grade (determined by adopting a griding method), and flexibility and shock resistance are high; besides, water resistance, acid resistance, alkali resistance and solvent resistance are high.

Owner:河南索顿新材料有限公司

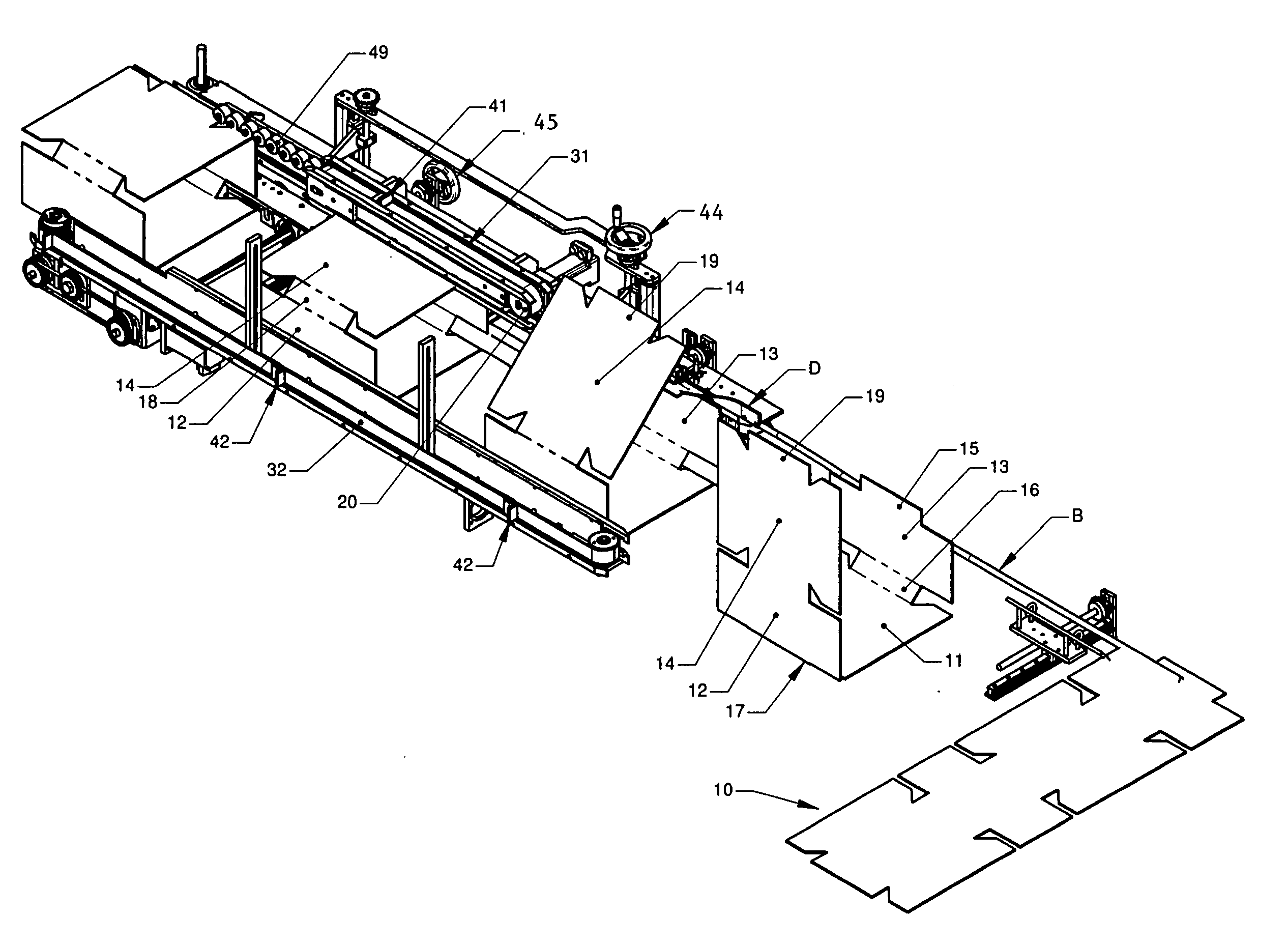

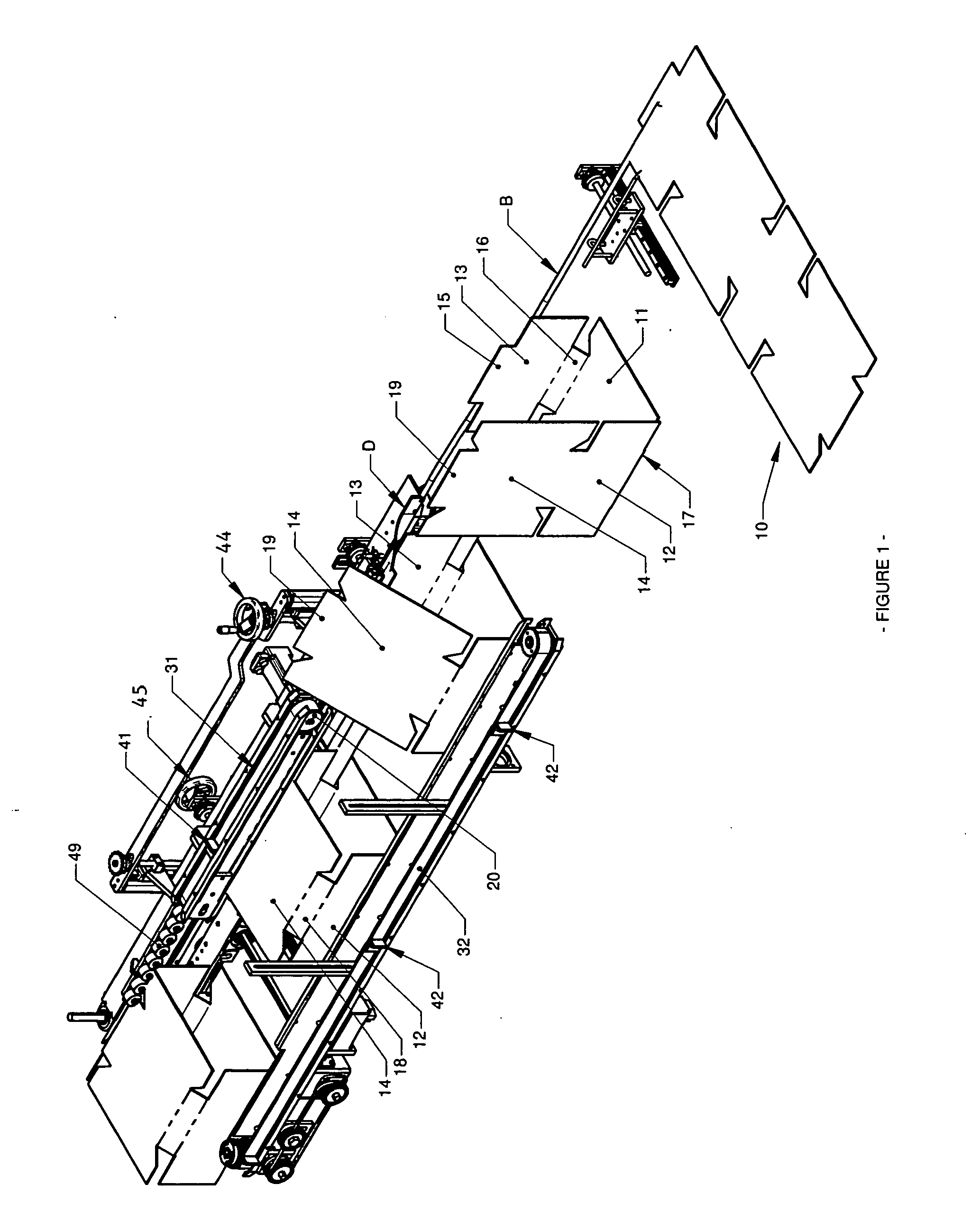

Method and apparatus for forming multi-sided containers

InactiveUS20050075230A1Reduce in quantityFast formingBoxes/cartons making machineryPaper-makingLeading edgePaperboard

The present invention is an apparatus for forming multi-sided containers from flat paperboard blanks without the use of a mandrel or inserted products, and which assures proper alignment of the leading and trailing edges of the container blank before adhering the first and last body panels of the blank together. The apparatus may be incorporated into any container assembly device as an alternative to a mandrel or analogous component. The interaction of numerous plows and guides eventually causes a wrapping action to occur bringing the last panel of the blank into the proximity of the first panel, but friction may cause the last panel to lag behind the first panel. A unique apparatus is provided which maintains separation between the first and last panels upon which adhesive has been applied that includes a mechanism to “catch up” any straggling panels to bring them into proper alignment. Once alignment is accomplished, the panels are pressed together and bonded by the adhesive.

Owner:MOSHIER JAMES +2

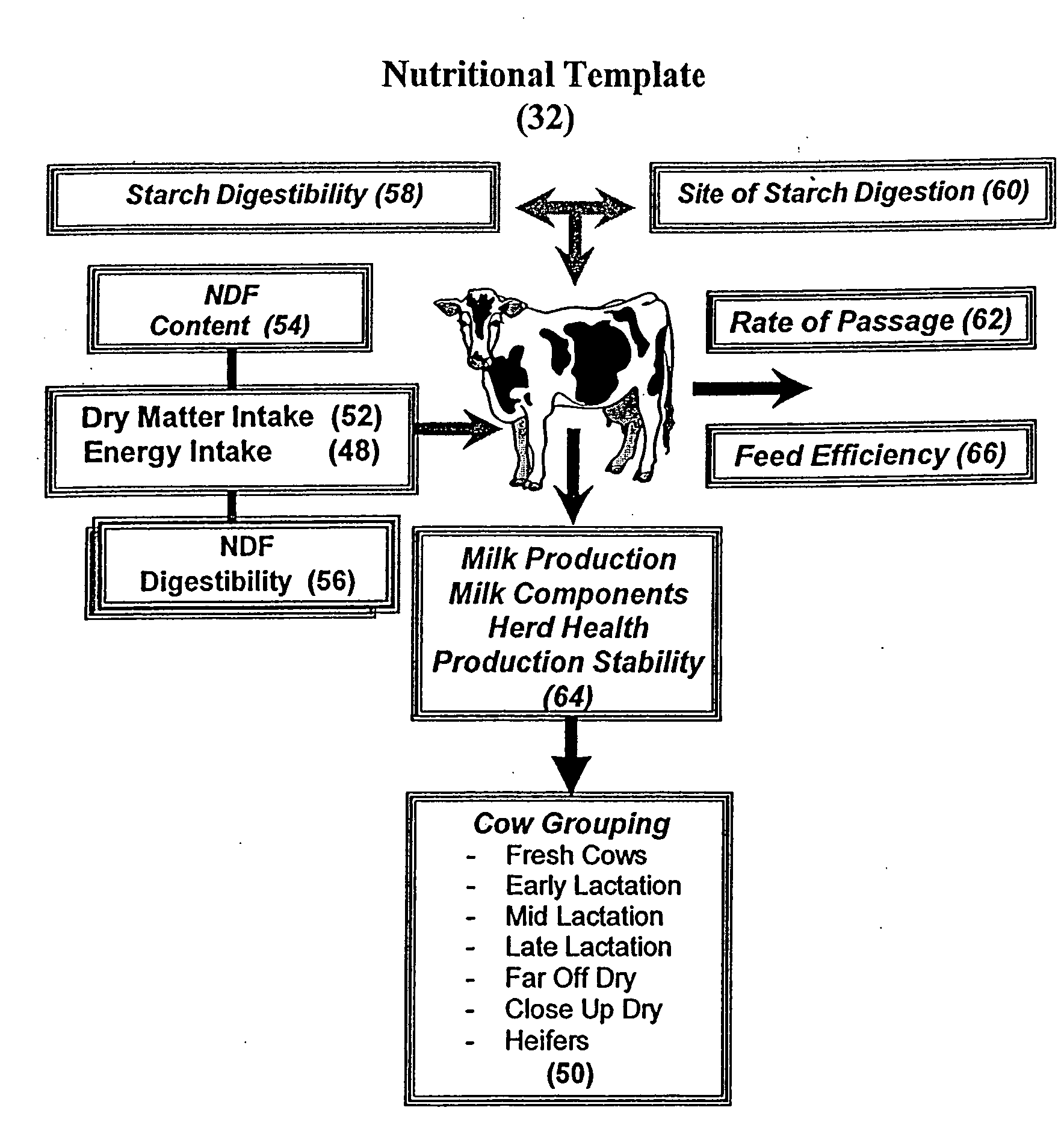

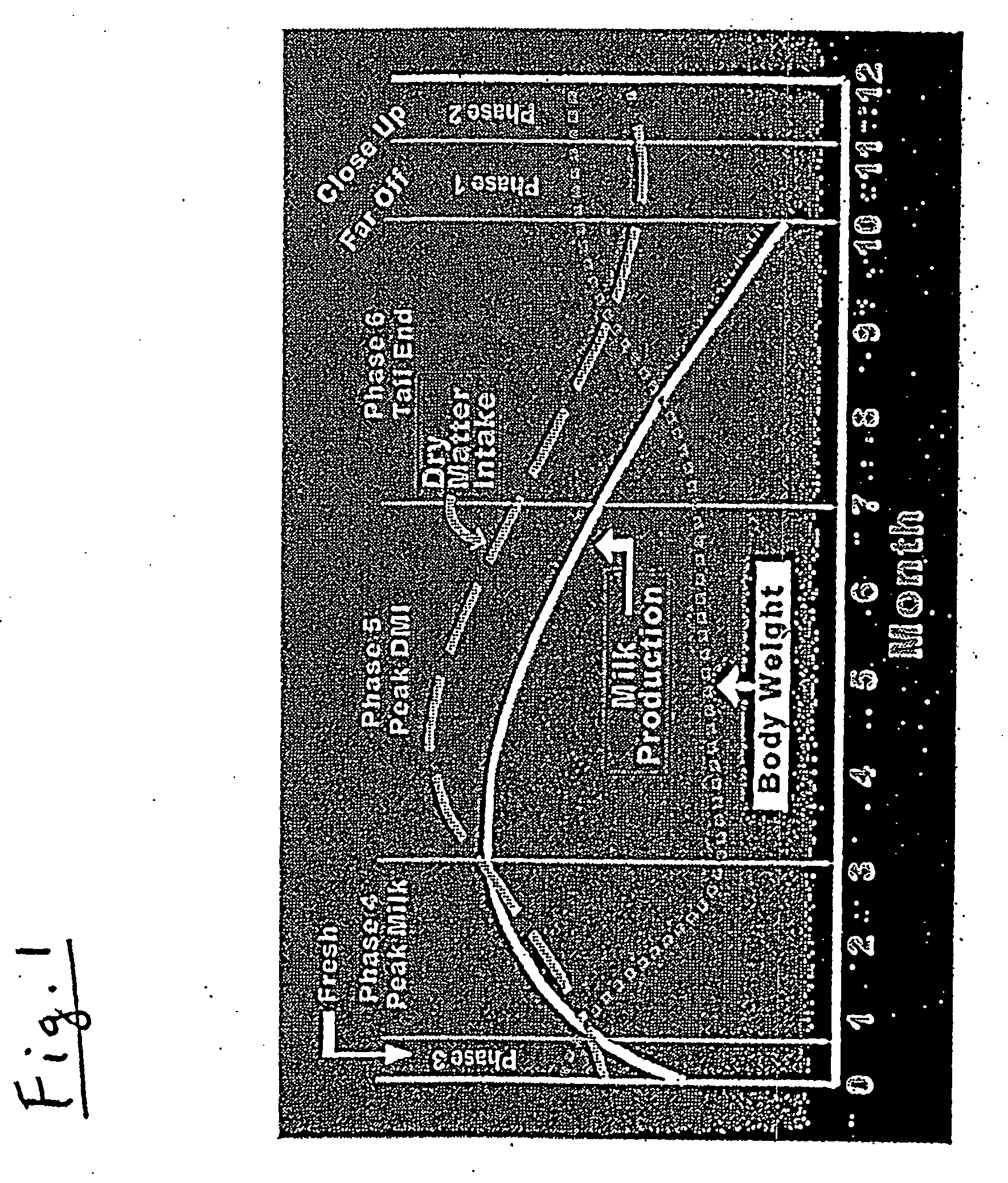

Feed delivery system for enhancing ruminant animal nutrition

InactiveUS20080215167A1Precisely formulatedImprove production stabilityAnimal feeding stuffSpecial data processing applicationsAgricultural scienceAnimal Foraging

A feed delivery system for a dairy farm wherein a third-party supplier of the system can provide the dairy farm with lists of approved hybrids for the feed components, necessary information inputs for practicing the feed method, and all or a portion of its component needs for the feed ration corresponding to a feed ration that contains: at least one primary forge source selected from the group consisting of brown midrib corn silage, dual-purpose corn silage, leafy corn silage, and grass silage; a secondary forage source selected from the group consisting of dual-purpose corn silage, alfalfa haylage, alfalfa dry hay, grass silage, and alfalfa / grass mix; a corn grain of floury and / or vitreous endosperm starch grain into which normal dent corn or mutt corn may be blended in order to achieve a predetermined level of in vitro starch digestibility; such grain component being further processed to produce a specific particle size of the blended starch. The feed delivery system can also provide the dairy farm with real-time characterizations of at least some of its feed ingredients, and re-penning strategies for maximizing the milk productivity of the cows.

Owner:NUTRI INNOVATIONS LLC

Low fat frozen confectionery product

A low fat frozen confectionery product is provided having 5 wt % or less fat which product comprises a combination of an ice structuring protein (ISP) and a polyol ester of a fatty acid.

Owner:CONOPCO INC D B A UNILEVER

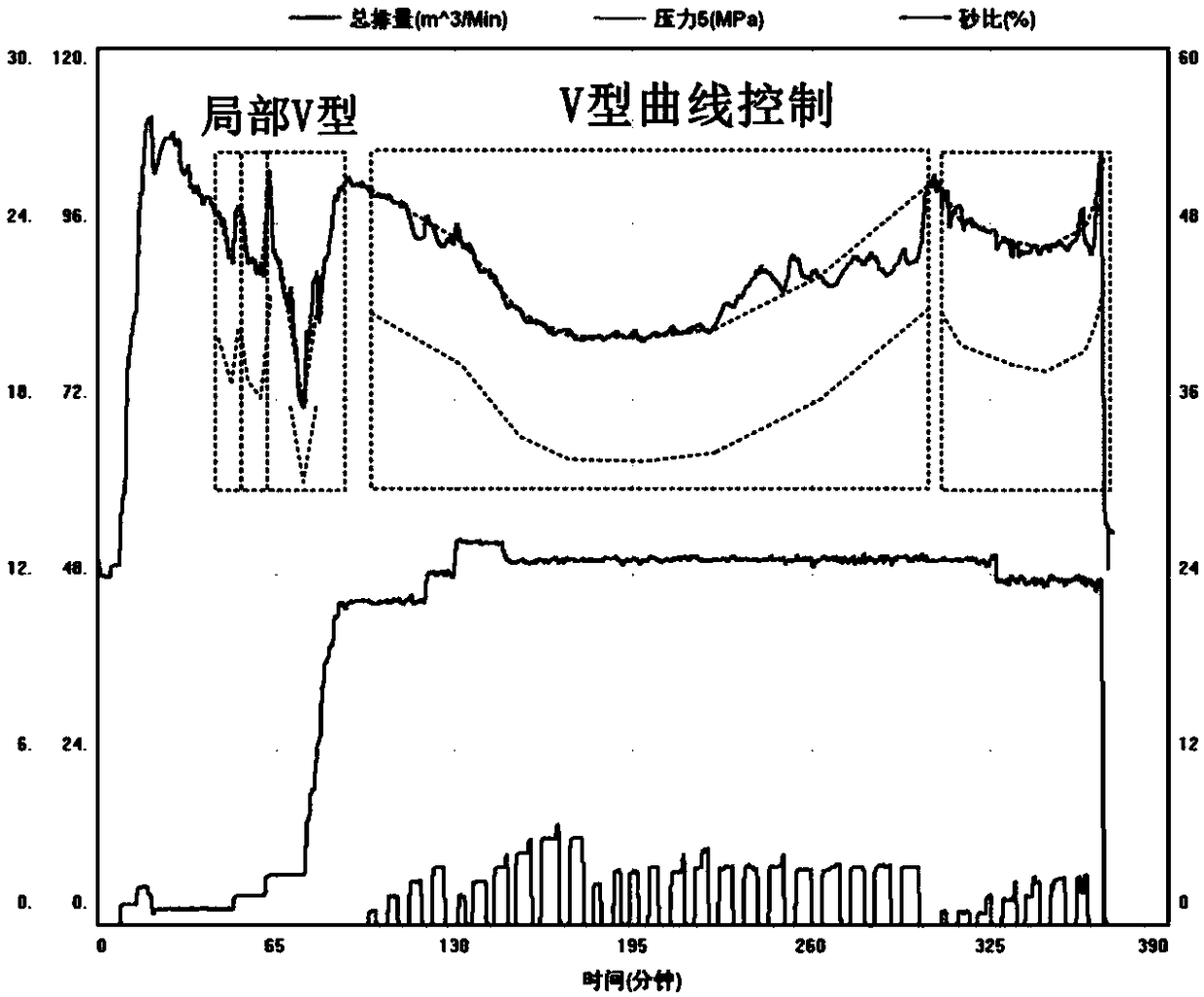

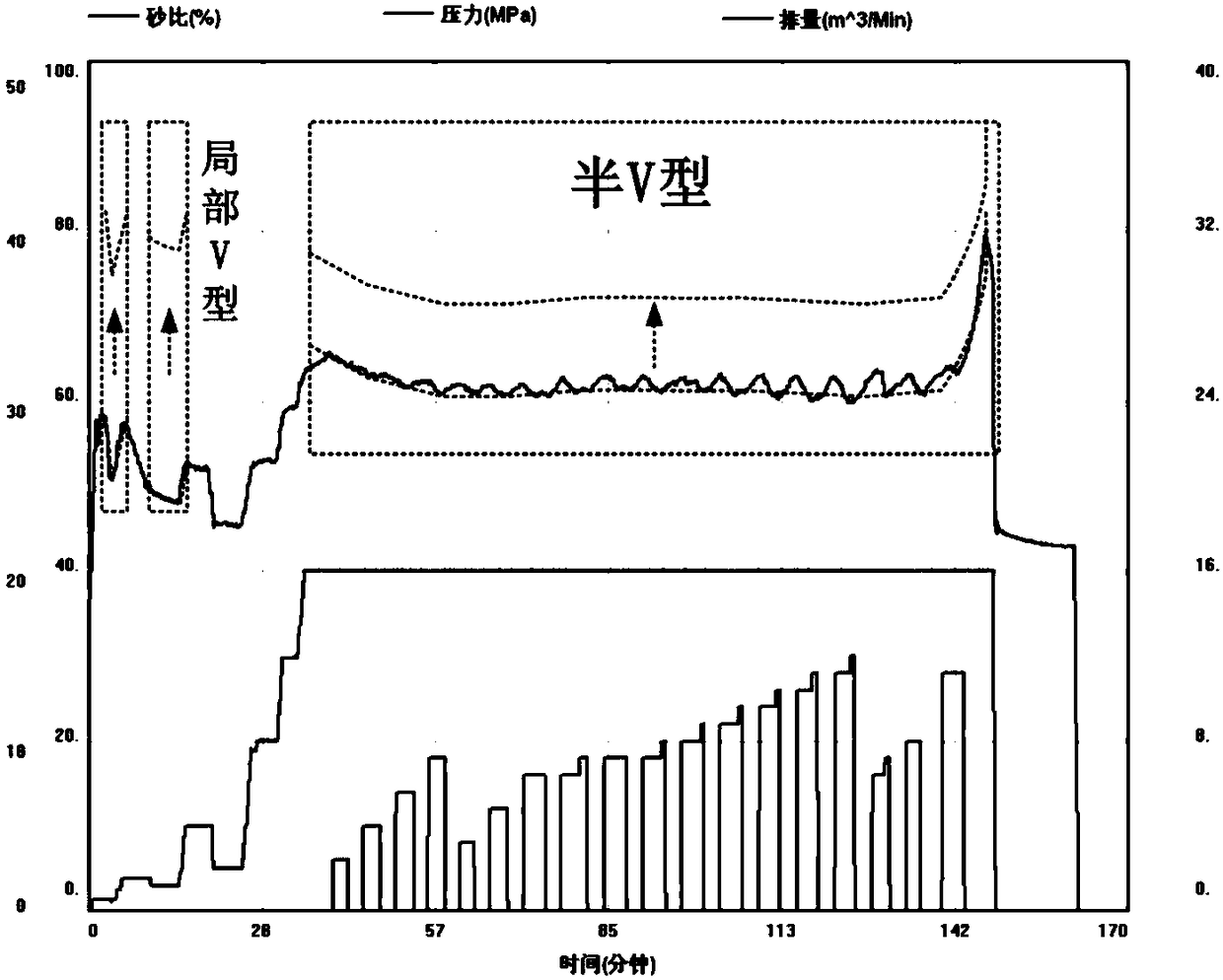

Fracturing method for deep shale gas through V-shaped pressure curve

ActiveCN109113703AIncrease the effective transformation volumeImprove fill rateFluid removalLiquid ratioPressure curve

The invention discloses a fracturing method for deep shale gas through a V-shaped pressure curve. The fracturing method comprises the steps of (1) key reservoir parameter evaluation, (2) optimizationof fracture parameters and fracturing construction parameters, (3) perforation position determination and perforation operation, (4) acid pretreatment, (5) variable-displacement and low-viscosity slick water joint forming construction, (6) powder pottery construction for adding different sand liquid ratios into low-viscosity slick water, (7) medium-particle-size proppant construction for adding different sand liquid ratios into medium-viscosity slick water, (8) high-viscosity gel and large-particle-size carrying proppant construction, and (9) displacing operation. According to the fracturing method, complexity of fracturing fractures of the deep shale gas is improved, the filling ratios of systems with different scales of fractures such as near wells, far wells, main fractures and micro-fractures are increased, the effective stimulation volume of the deep shale gas is increased, and the yield increasing and stabilizing effects after pressure are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

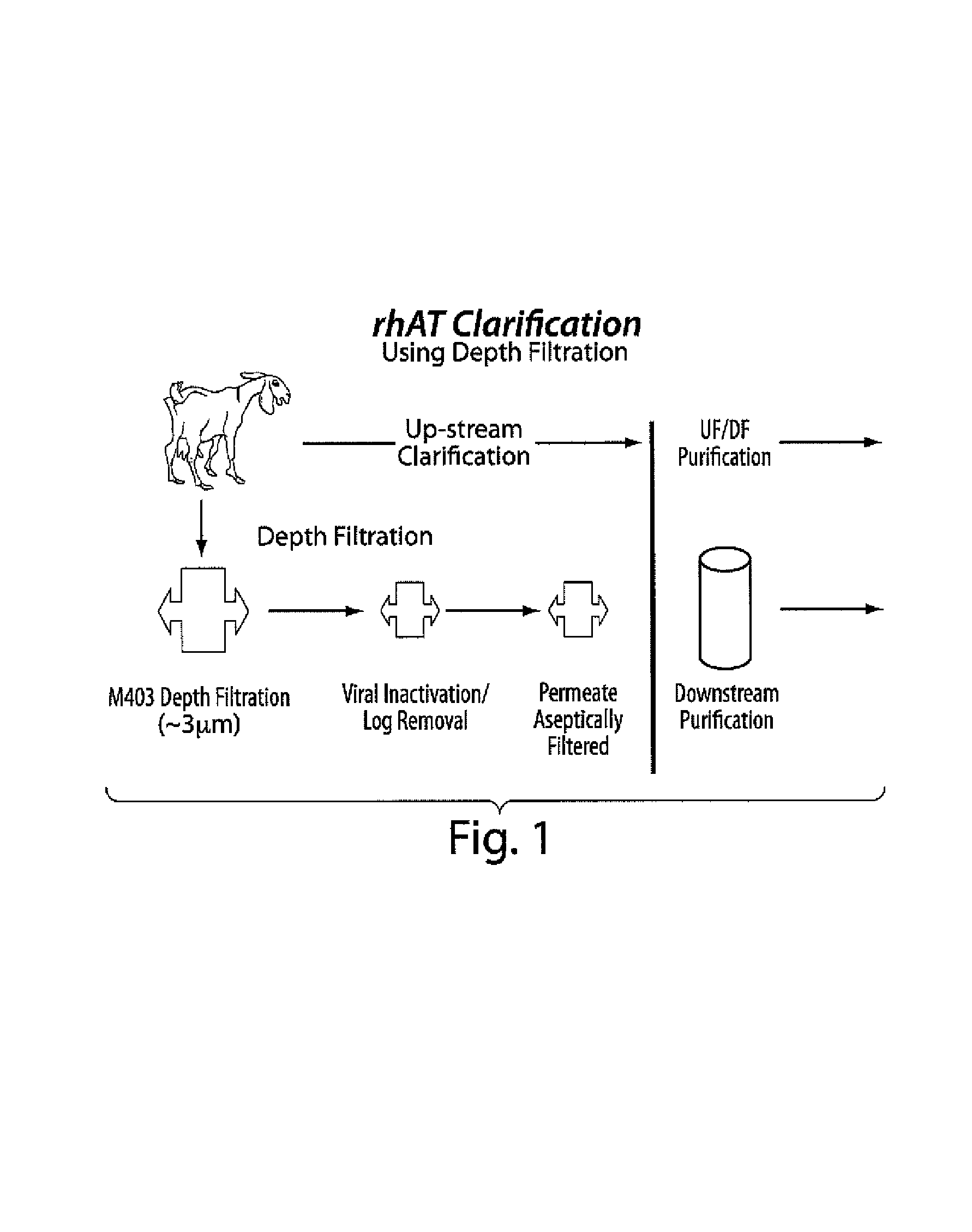

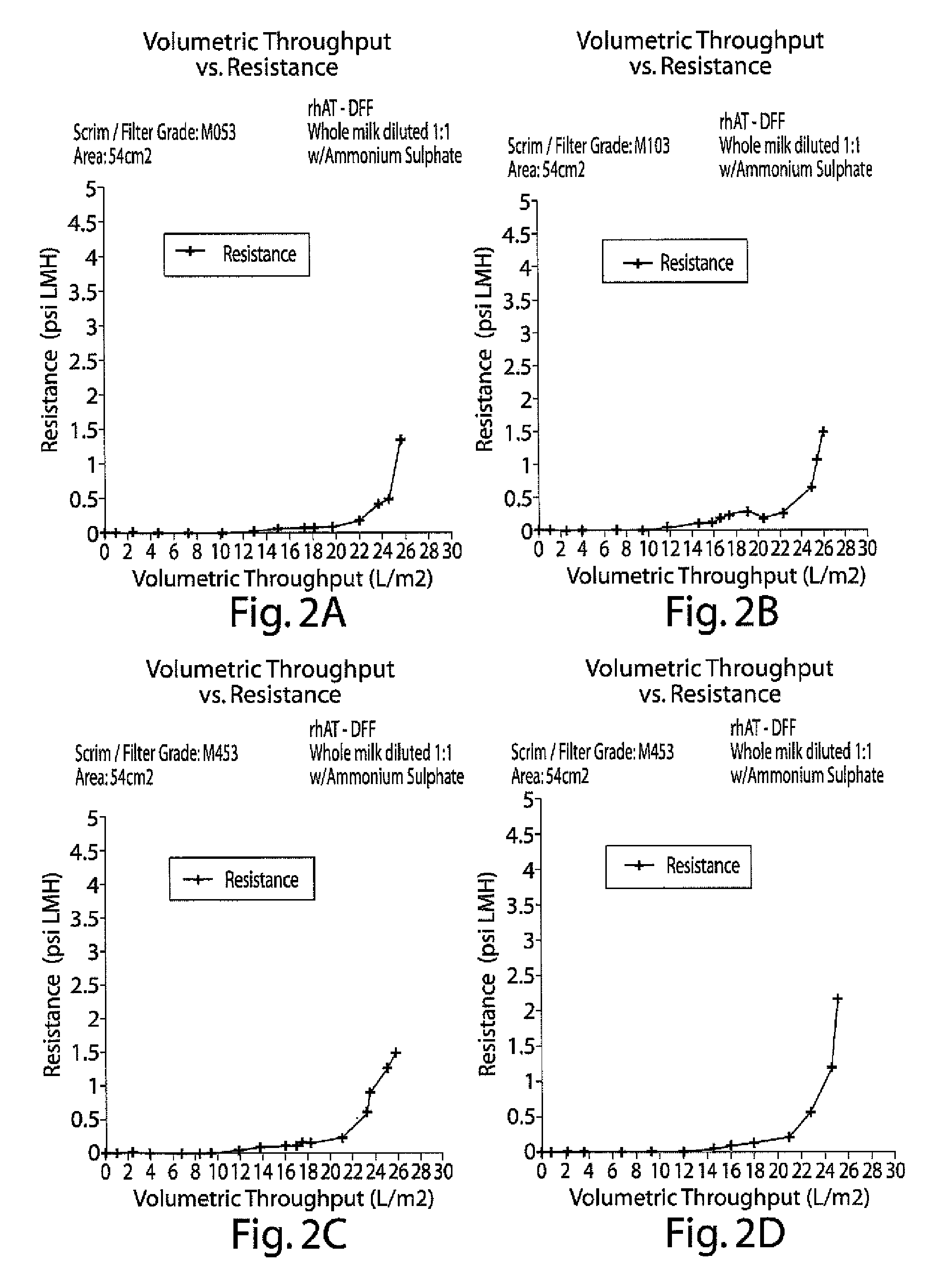

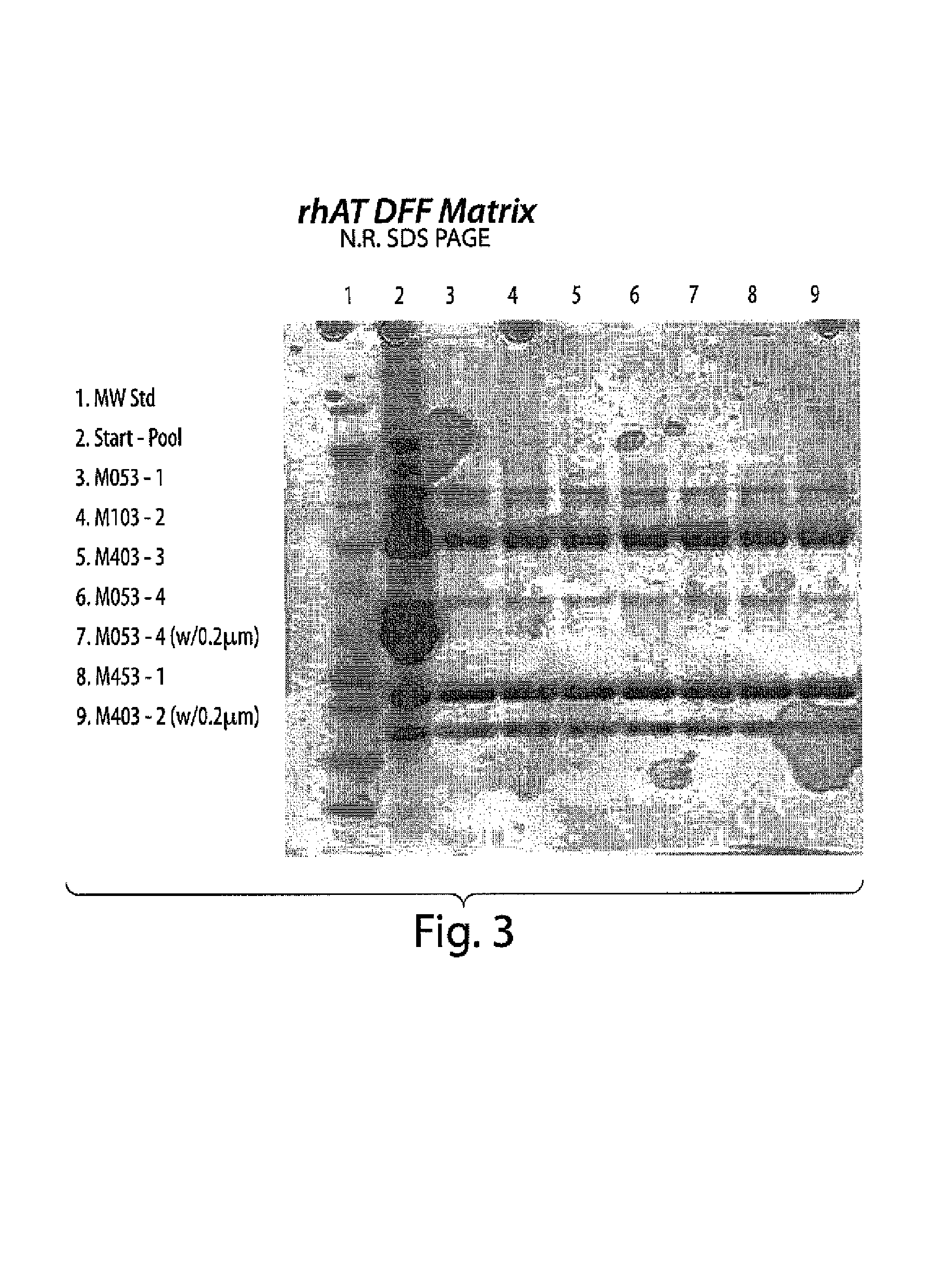

Clarification of transgenic milk using depth filtration

ActiveUS7531632B2Good clarificationImprove fractionationPeptide/protein ingredientsHydrolasesFiltrationBacilli

Processes and apparati are provided for separating molecules of interest from a mixture by depth filtration (DF). The DF of the invention is useful in the clarification and processing of various feedstreams for the removal of a molecule of interest. According to a preferred embodiment, a transgenic milk feedstream is stabilized and particulate matter such as fat, casein miscelles and bacteria are removed. An aseptic filtration step was also developed to remove any bacteria remaining in a clarified transgenic milk feedstream.

Owner:LFB USA

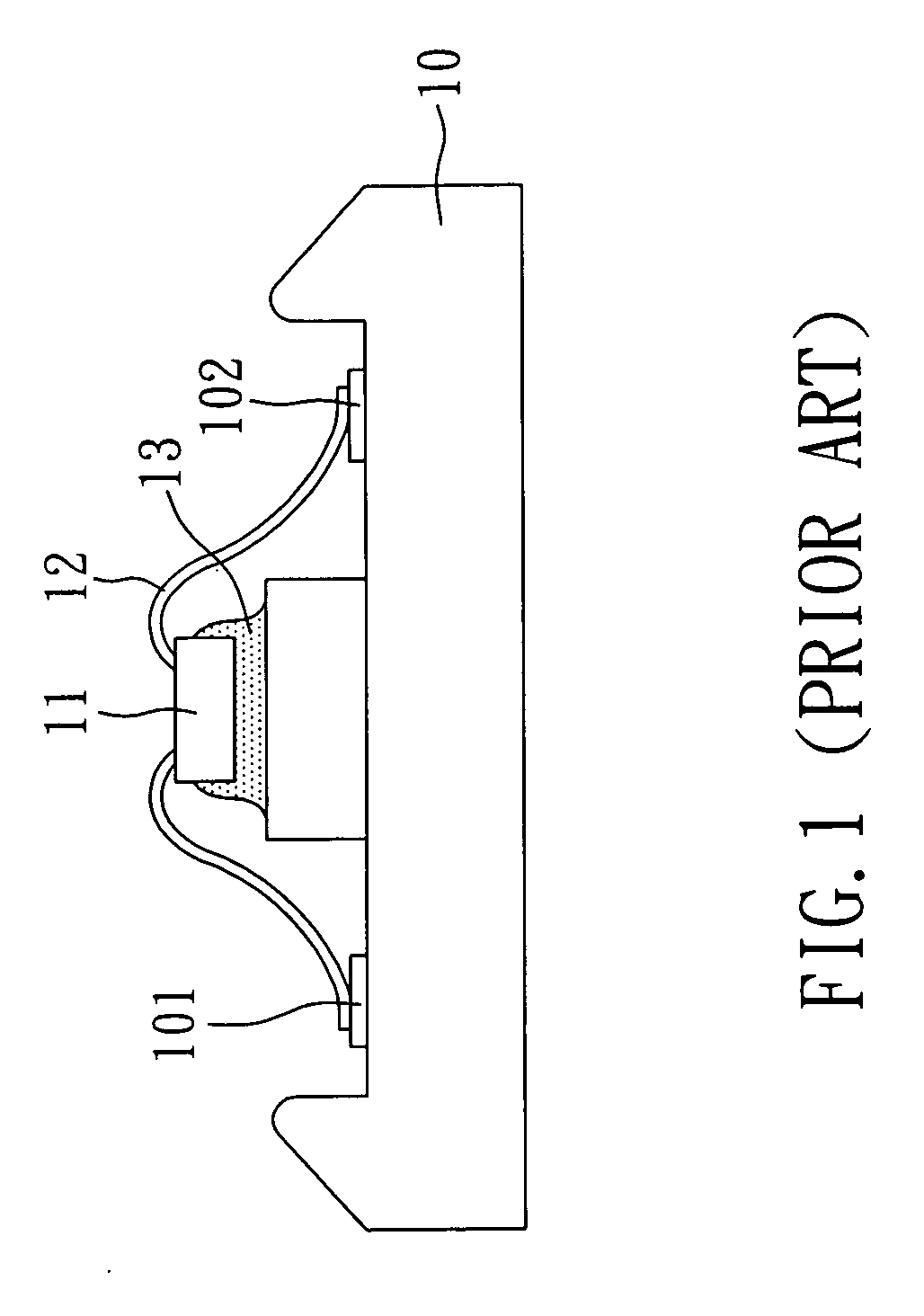

Packaging Structure of AC light-emitting diodes

InactiveUS20110089443A1Increased power consumptionImprove insulation performanceSolid-state devicesSemiconductor devicesEngineeringDie bonding

A packaging structure of AC LEDs is provided, which comprises: a carrier containing a positive electrode connecting end, and a negative electrode connecting end; an AC LED module disposed on the carrier, wherein the AC LED module electrically connects to the positive electrode connecting end and the negative electrode connecting end of the carrier; and a die-bonding insulating layer disposed between the AC LED module and the carrier.

Owner:FORWARD ELECTRONICS CO LTD

Parameter setting and reeling method of thermal tandem rolling stainless steel band reeling equipment

ActiveCN101716617AReduce the number of scrap coilsImprove production stabilityComputer controlMaterials science

The invention relates to a parameter setting and reeling method of thermal tandem rolling stainless steel band reeling equipment. The method sets the following parameters: an advance speed set value of each sets of roller ways=a final finish rolling frame speed set value*(a total roller way advance rate+a corresponding grouped advance rate); a lagged set speed value of each sets of roller ways=a final finish rolling frame speed set value*a roller way lagged rate; the setting of the openness of a side guide plate; the pressure coefficient of the side guide plate of 0.5-0.8; the added value of the side guide plate of 0 to +15mm; and the settings of a pinch roll: calibration of the pinch roll of the reeling machine by guaranteeing normal calibration, the advance rate and the lagged rate of the pinch roll, the pressure coefficient of the pinch roll, the diameter of an upper roll of the pinch roll of the reeling machine, and the diameter of a lower roll of the pinch roll of the reeling machine. In the reeling method, a computer controls reeling equipment to reel according to the set parameters. The parameter setting and reeling method of thermal tandem rolling stainless steel band reeling equipment improves the appearance and surface quality of steel rolls.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com