Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491 results about "Fabric softener" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fabric softener (or conditioner) is a conditioner that is typically applied to laundry during the rinse cycle in a washing machine. In contrast to laundry detergents, fabric softeners may be regarded as a kind of after-treatment laundry aid.

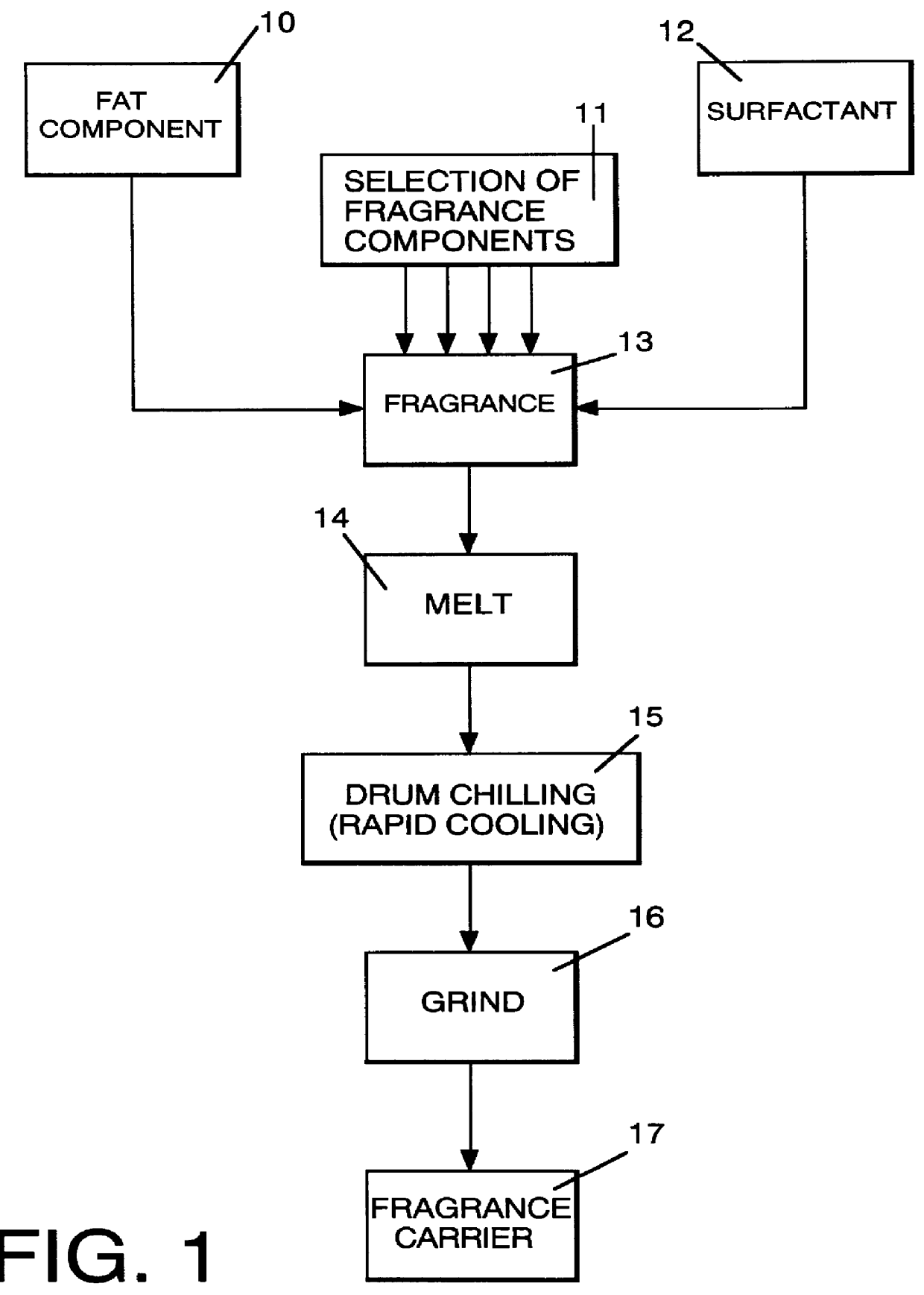

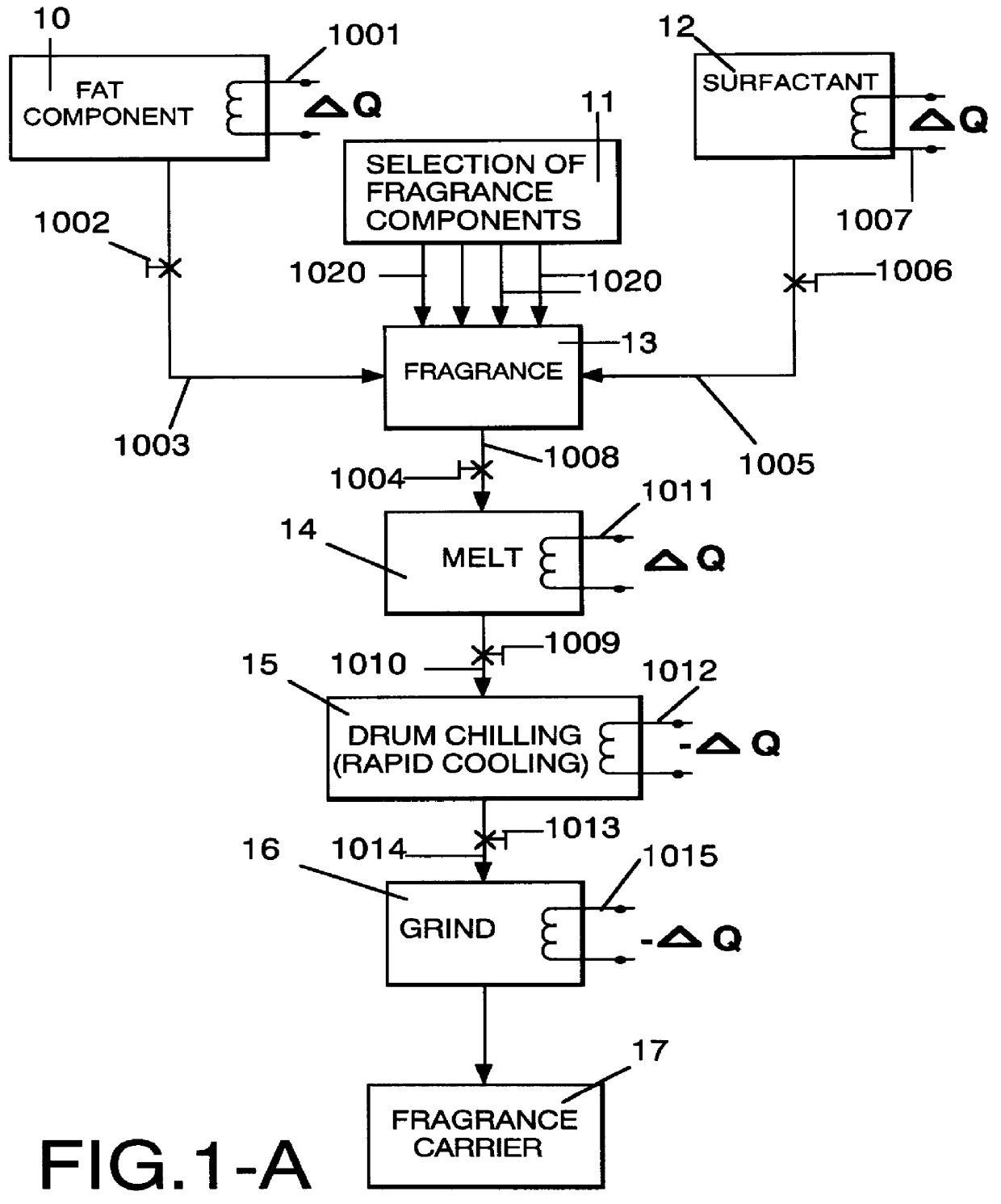

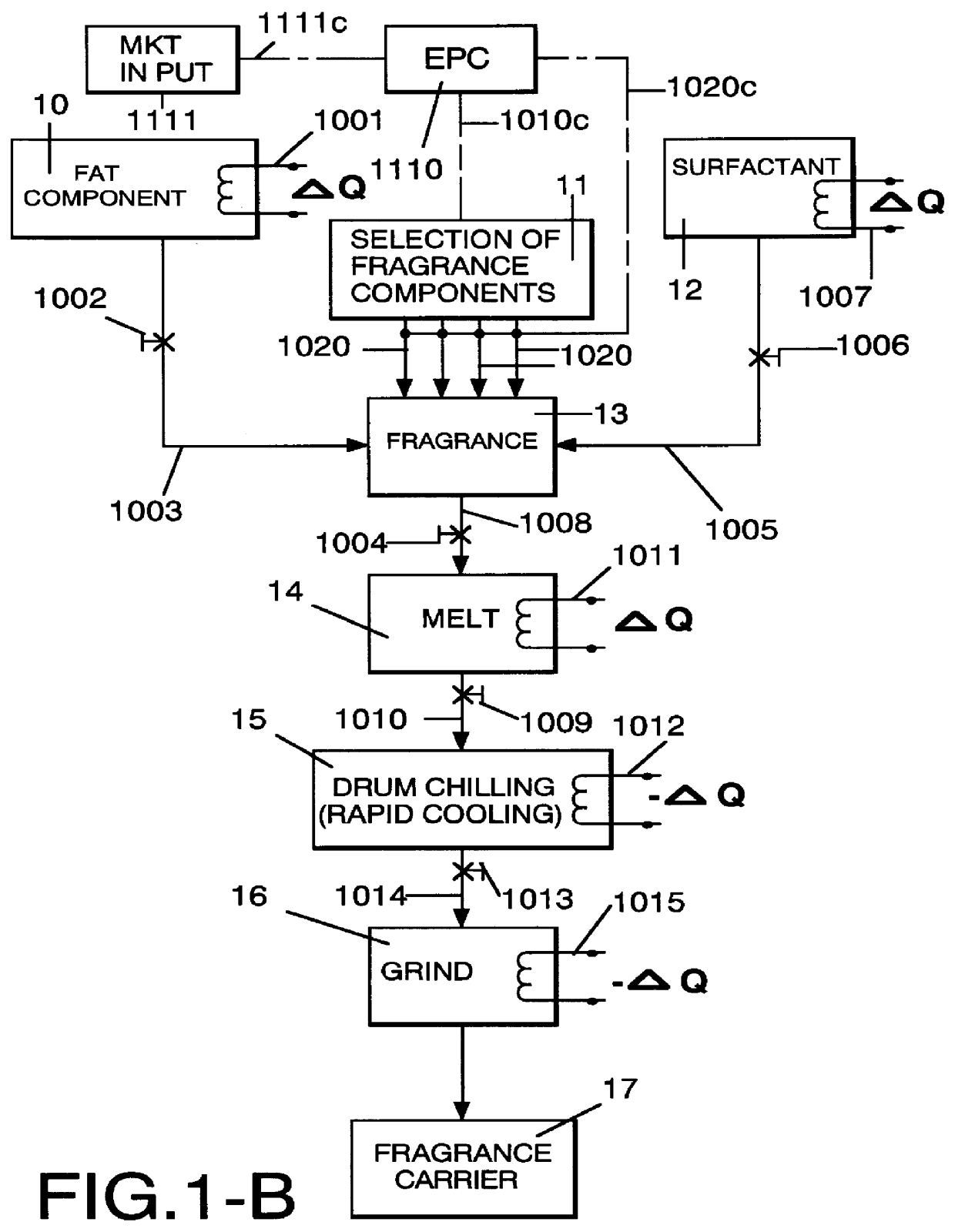

Method employing drum chilling and apparatus therefor for producing fragrance-containing long lasting solid particle

InactiveUS6051540AImproved substantivityMaximum flexibilityNon-ionic surface-active compoundsGaseous substancesDesiccantSolid particle

A method and apparatus is disclosed for producing a fragrance-containing solid particle, capable of controllably releasing the fragrance to the environment in which the particle is contained for incorporation into laundry detergents, fabric softener compositions and drier-added fabric softener articles.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Laundry system having unitized dosing

InactiveUS20030104969A1Facilitated releaseOrganic detergent compounding agentsWrappersPolymer scienceLaundry

Compositions, articles and methods are provided for supplying fabric care benefits to clothing or fabrics in an automated washing machine and by manual washing. The fabric care compositions preferably have less than about 5% detergent surfactants, more preferably less than 3%, even more preferably less than 1% and are most preferably free of detergent surfactants. Similarly, the fabric care compositions preferably have less than about 5% fabric softener actives, more preferably less than 3%, even more preferably less than 1% and are most preferably free of detergent surfactants. The laundry articles can take a variety of forms in a variety of physical states all of which will rapidly dispense a unitized amount of one or more selected fabric care agents to a wash and / or rinse bath solution during the laundering process under a variety of conditions. The invention also pertains to laundry kits that contain a variety of such articles and instructions concerning their use. Likewise, methods for preparing a customized laundry solution to obtain a specific; fabric care benefit selected based on the user's personal preferences and / or the fabric care needs of the fabrics being laundered are also provided. Further, the present invention also concerns methods for assisting a consumer in identifying the unitized articles to be used in preparing a laundry solution that will impart desired fabric care benefits as well as merchandising displays for dispensing the articles, assembling customized laundry kits and instructing the consumer on the selection and use of laundry articles.

Owner:THE PROCTER & GAMBLE COMPANY

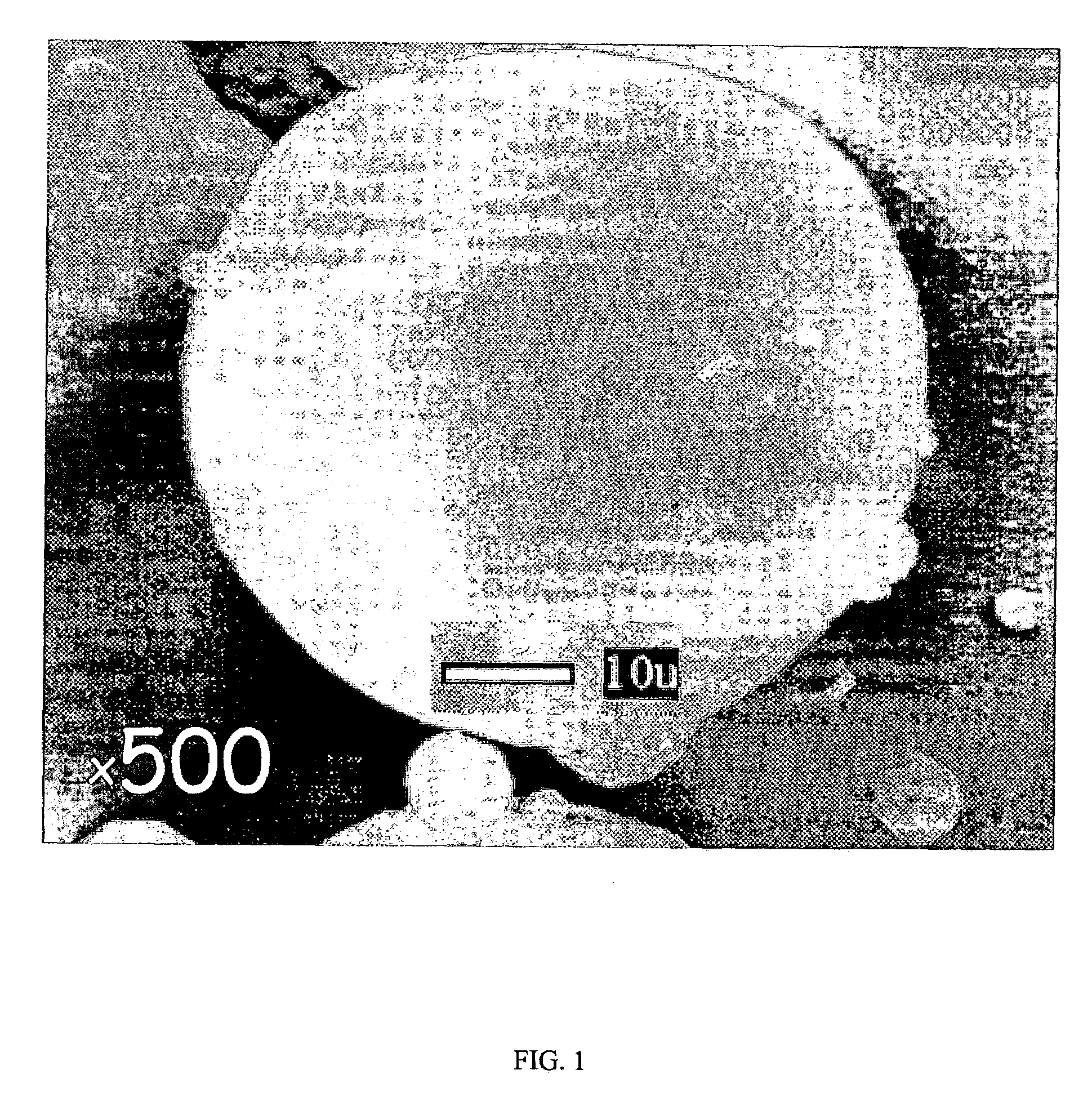

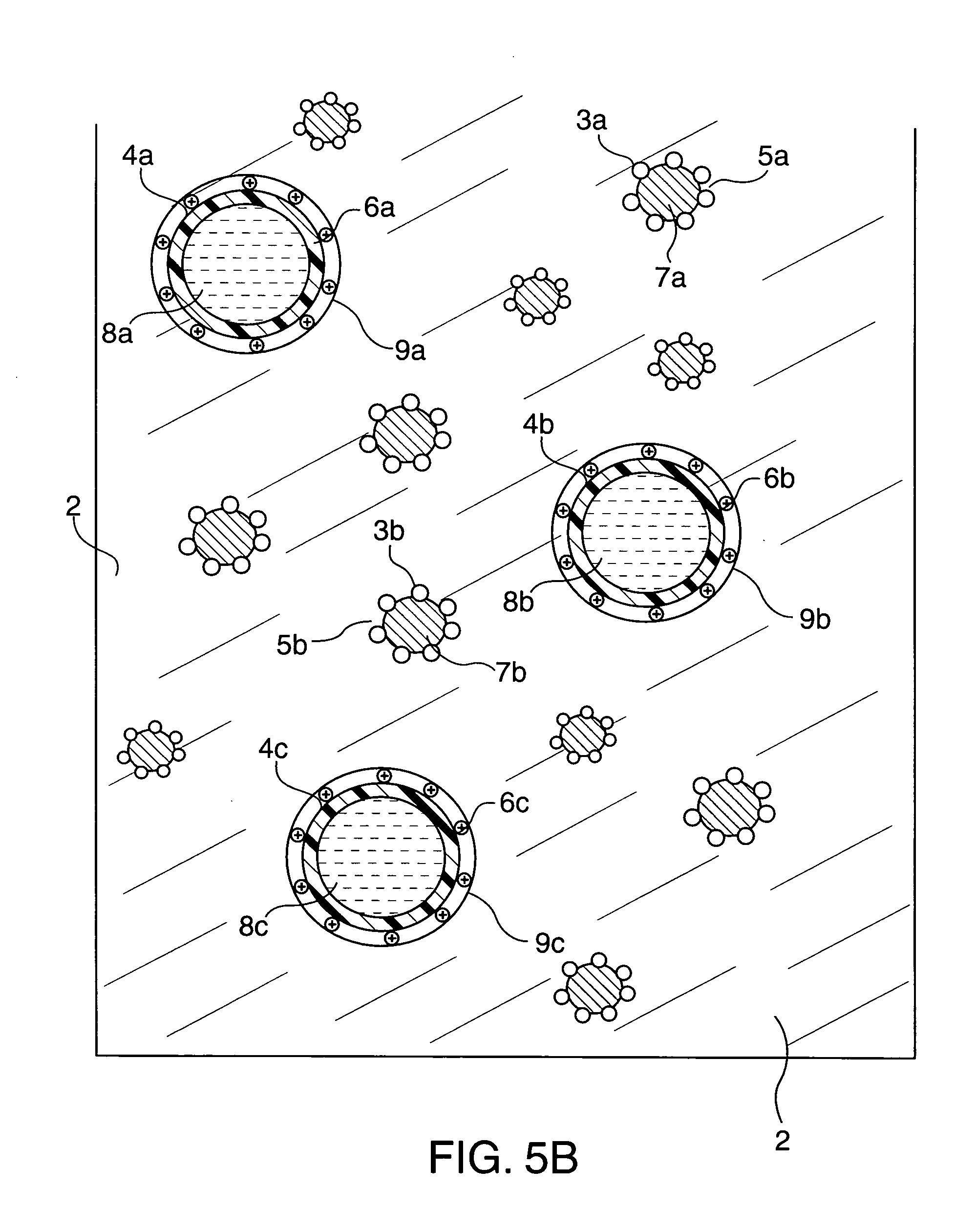

Controlled delivery system for fabric care products

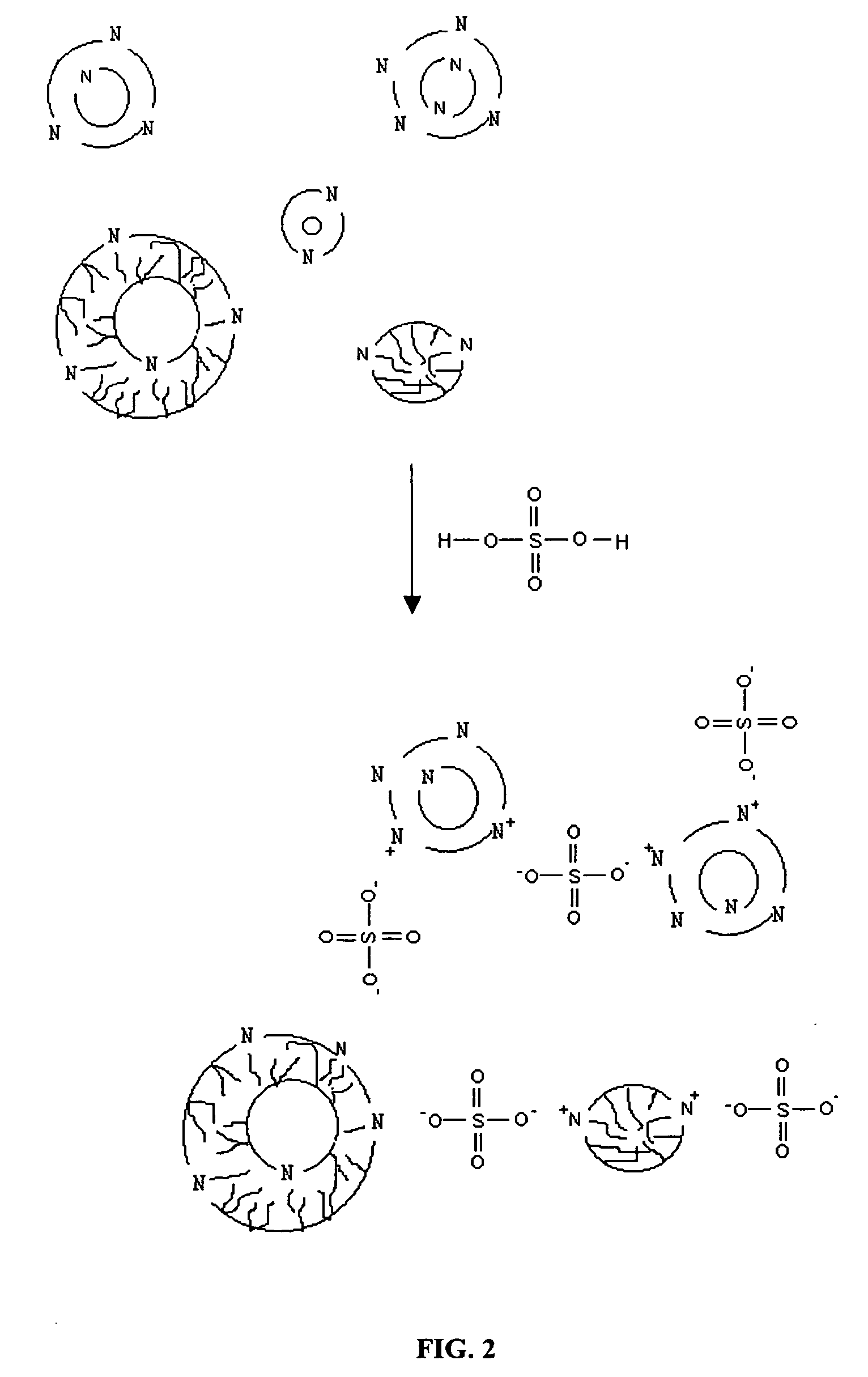

InactiveUS7119060B2Improve impact performanceIncrease depositionCationic surface-active compoundsOrganic detergent compounding agentsControl releaseMedicine

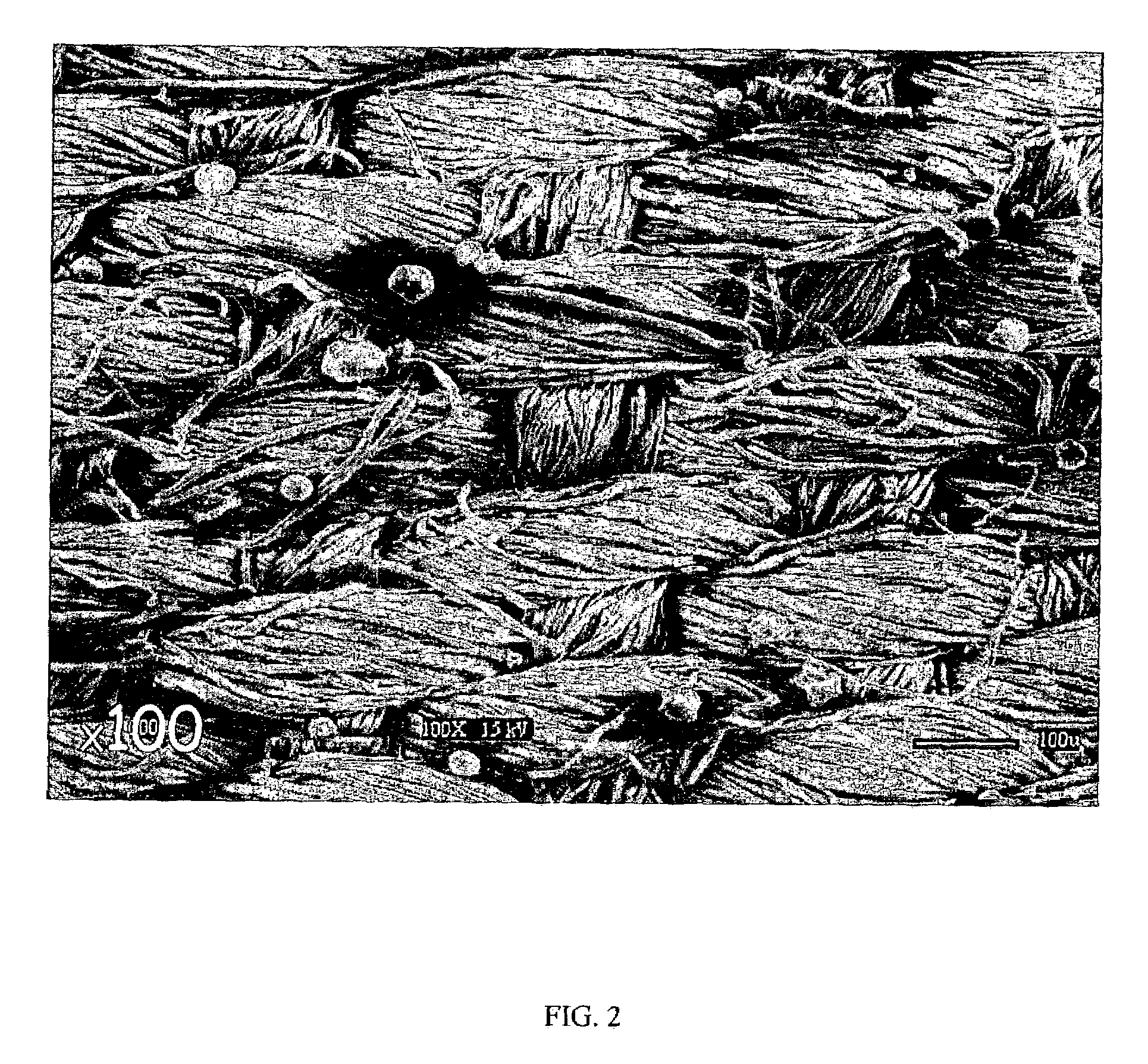

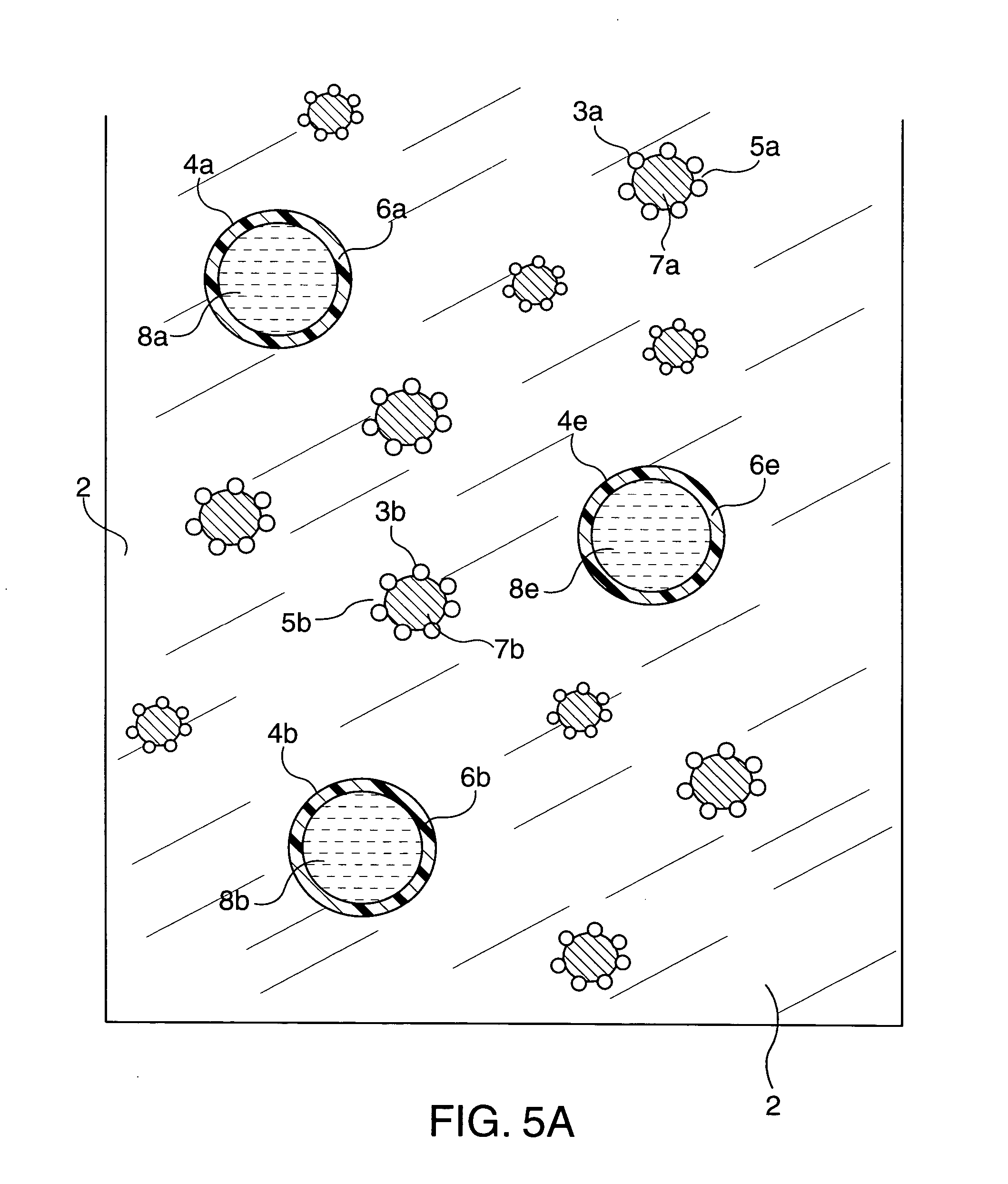

The present invention relates to a controlled delivery system that can be incorporated in liquid, as well as, dry granular, or powder, fabric care products, such as fabric softeners, laundry detergents, rinse added products, and other fabric care products, to enhance fragrance performance. The controlled delivery system of the present invention is a solid, substantially spherical particle comprising hydrophobic cationic charge enhancing agents in conjunction with cationic fabric softening agents that assist in adhering the particles onto fabric. The particles can also include a fragrance. The particle can have an average particle diameter of from about 1 micron to about 500 microns. The controlled delivery system of the present invention can be utilized to deliver a broad range of fragrance ingredients onto fabric and prolong fragrance release from the dry laundered fabric over an extended period of time, or yield a high impact fragrance “burst” upon ironing the fabric. The invention also pertains to fabric care products comprising the controlled release system of the present invention.

Owner:SALVONA

Compositions and method for targeted controlled delivery of active ingredients and sensory markers onto hair, skin, and fabric

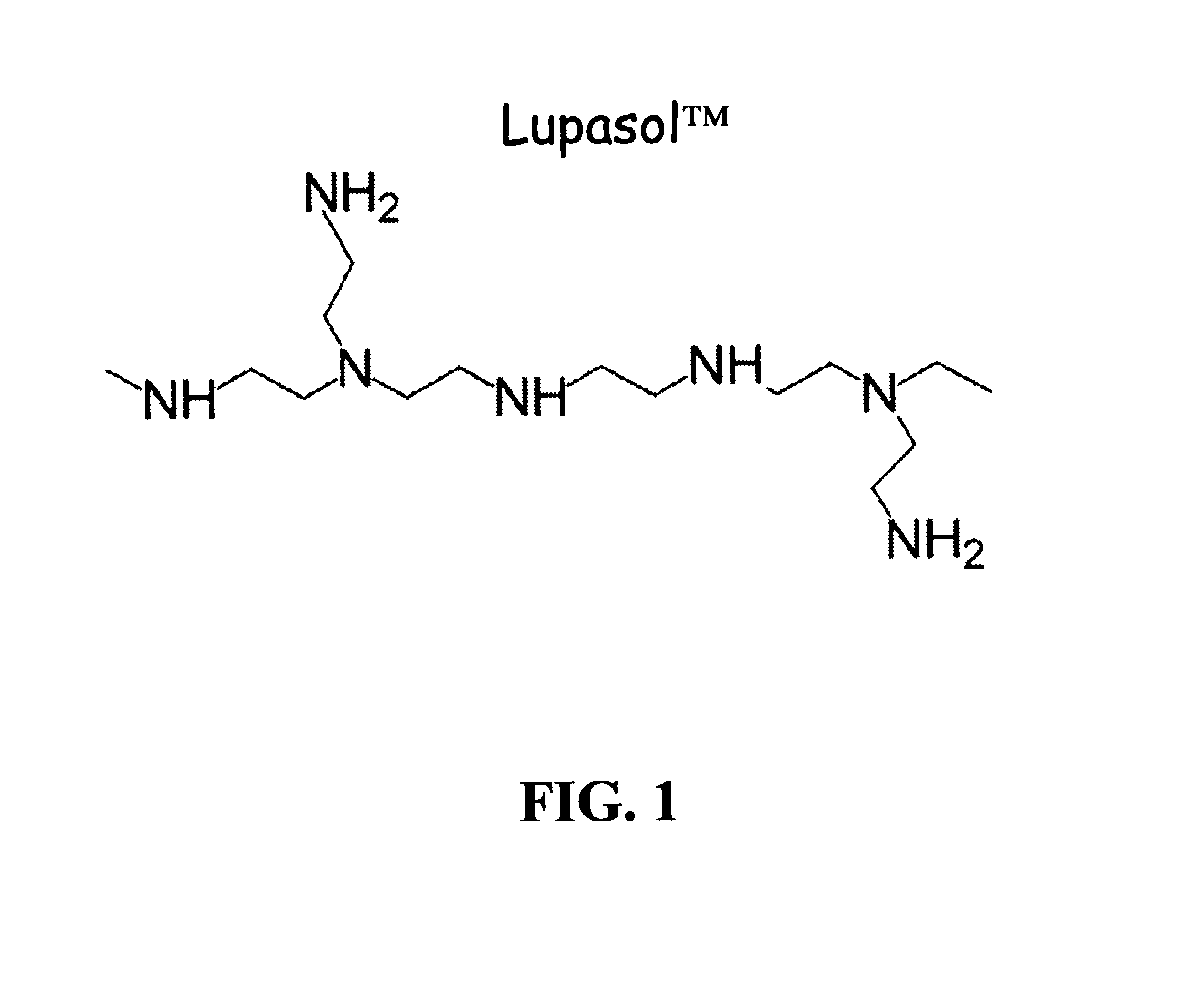

InactiveUS6979440B2Increase depositionHigh cationic charge densityCosmetic preparationsCationic surface-active compoundsActive agentBULK ACTIVE INGREDIENT

The present invention is a controlled delivery system that can be incorporated in hair, skin, and fabric care products such as shampoos, conditioners, hair styling products, lotions, creams, liquid laundry detergents, fabric softener, and other hair, skin, and fabric care products to effectively deliver a broad range of active agents and sensory markers onto the hair, skin, and fabric. The system also prolongs the release rate of the active agents or sensory markers over an extended period of time, or provides heat triggered release of the active agents and yields a high impact fragrance “burst” upon blow drying the hair, ironing the fabric, or other types of heat treatment. The controlled delivery system of the present invention is a nano-sphere, having an average sphere diameter of from about 0.01 microns to about 10 microns. The nano-sphere comprises hydrophobic materials, cationic conditioning agent or, cationic conditioning agent in conjunction with a cationic charge booster to assist in adhering the spheres onto hair, skin, and fabric. The invention further relates to a controlled delivery system where the release rate of the active ingredients is synchronized with that of a sensory marker to convey to the consumer the product performance.

Owner:SALVONA

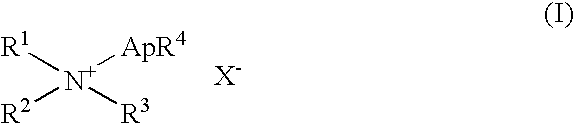

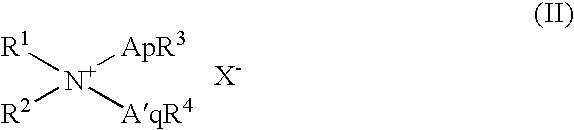

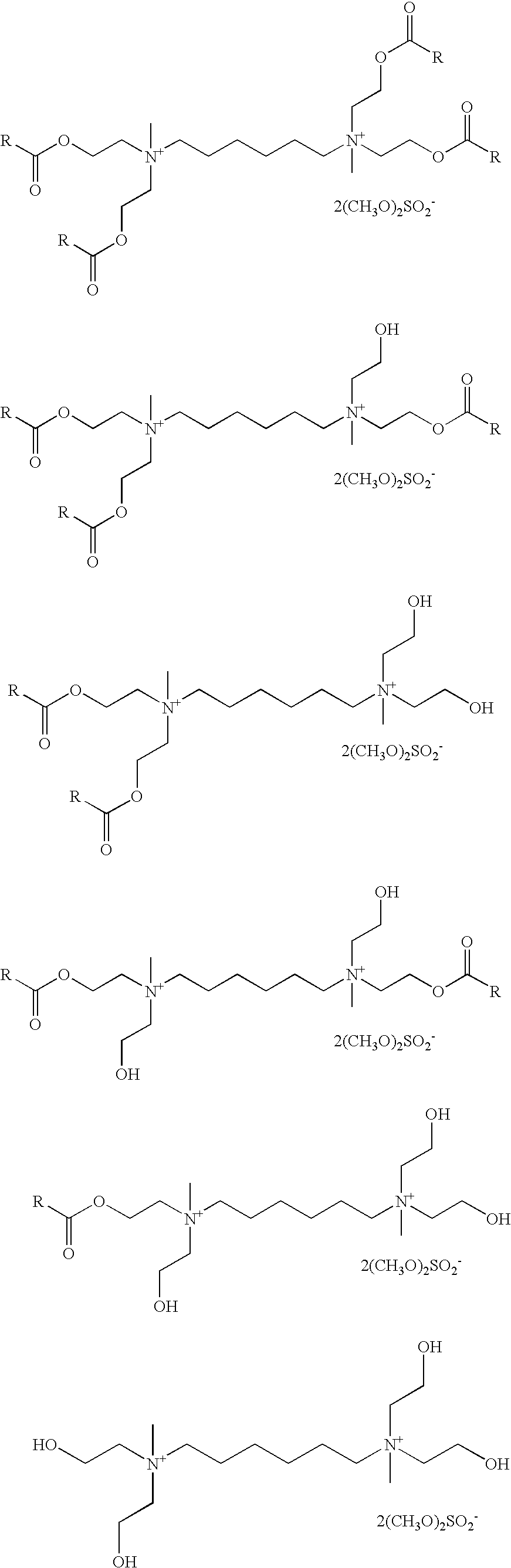

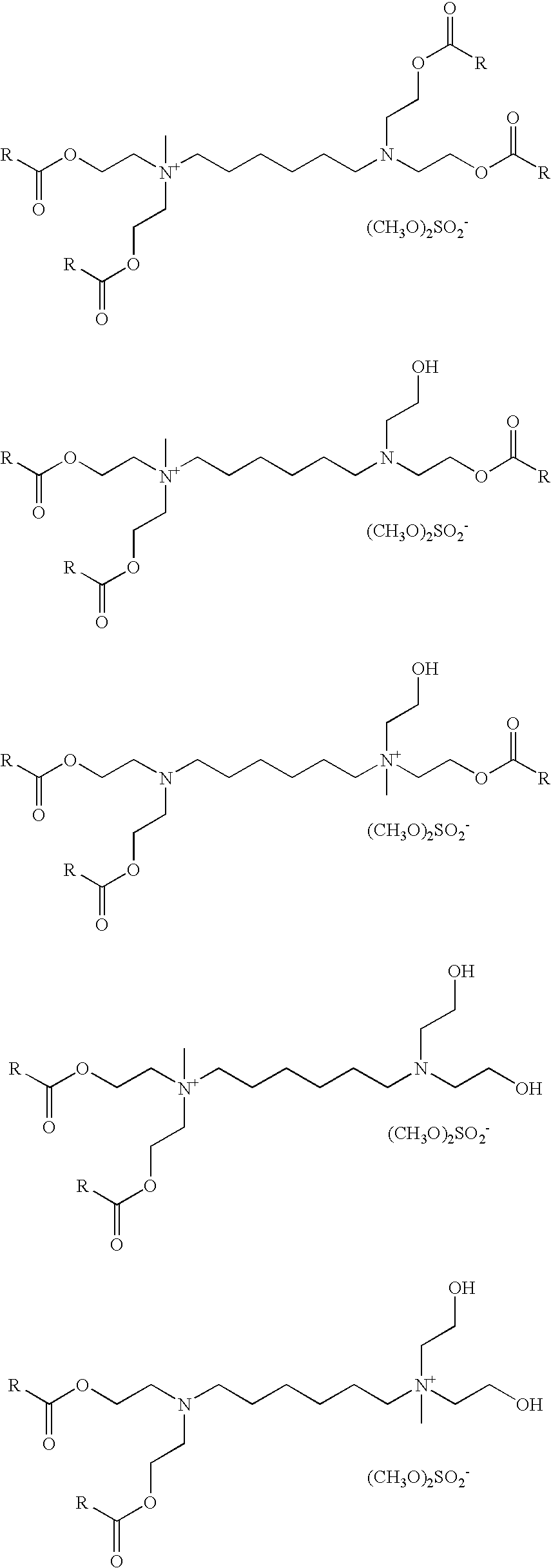

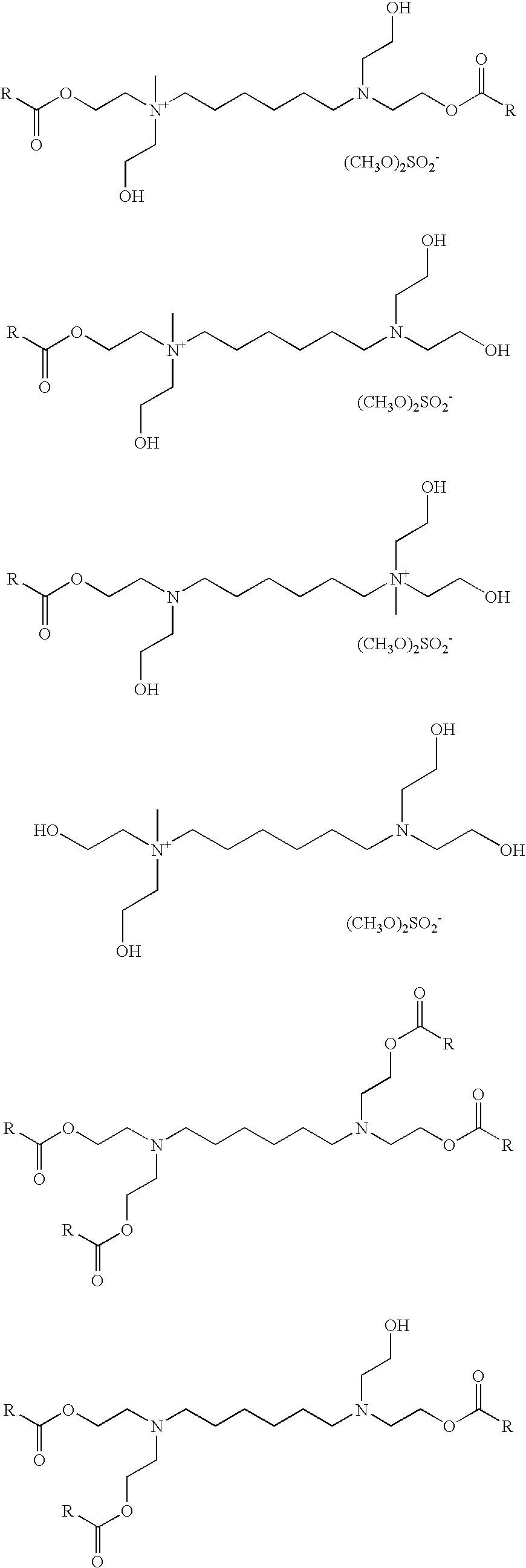

Surfactant compositions with enhanced soil release properties containing a cationic gemini surfactant

InactiveUS6358914B1Improve decontamination abilityImproves suspending/stabilizing propertyCationic surface-active compoundsOrganic detergent compounding agentsSURFACTANT BLENDCopolymer

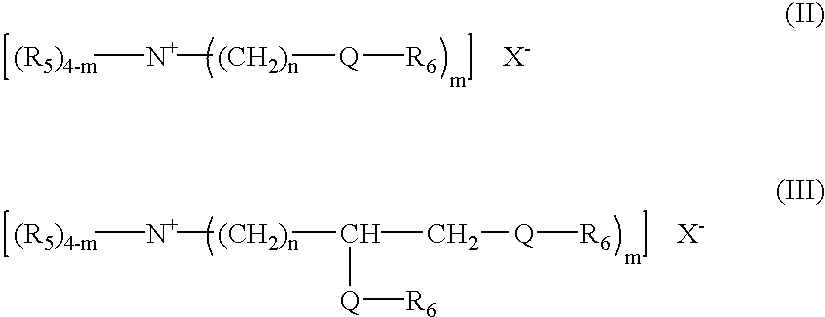

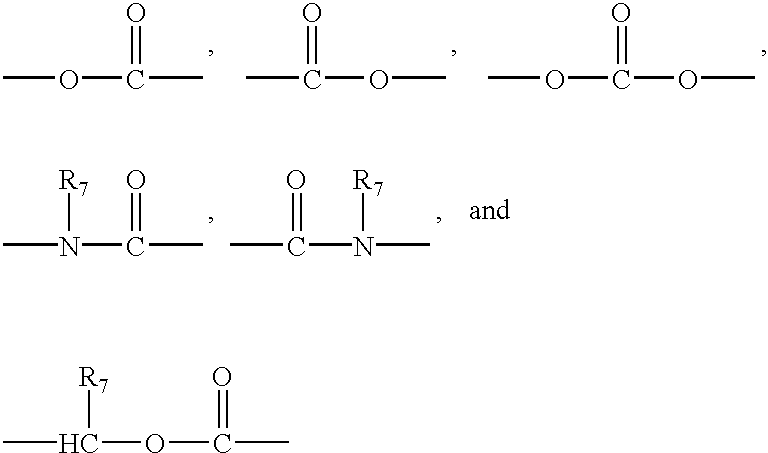

Compositions are disclosed comprising a conventional surfactant, a cationic or amphoteric gemini surfactant and a polymeric soil release agent. The conventional surfactant comprises a hydrophilic group and a hydrophobic group. The gemini surfactant comprises two surfactant moieties attached to each other by a spacer moiety. Each surfactant moiety having at least one hydrophilic group and at least one hydrophobic group. Novel trimeric and tetrameric cationic gemini surfactants are also disclosed along with their use in combination with soil release polymer compositions that exhibit superior cleaning efficacies when incorporated in laundry and other cleaning detergent systems. Novel surfactant / soil release polymer compositions are also disclosed employing known cationic gemini surfactants. The polymeric soil release agent can be any conventional polymeric soil release agent, but preferably comprising PET-POET copolymer. The compositions are useful as surfactant additive packages, detergents and fabric softeners.

Owner:RHODIA OPERATIONS SAS

Stable fragrance microcapsule suspension and process for using same

InactiveUS20050227907A1Improve performanceReduce diffuseCosmetic preparationsToilet preparationsDeodorantNon ionic

Described is a stable initial impact and continuous impact fragrance and / or benefit agent-imparting aqueous suspension of microencapsulated fragrance and / or benefit agent, e.g., malodour counteractant suspended in a non-confined fragrance-containing and / or benefit agent-containing liquid phase oil-in-water emulsion. On storage, the viscosity of the suspension undergoes a minimal increase over an extended period of time thereby avoiding undesirable agitation resistance during the blending of the suspension with other materials. The suspension is thus useful for imparting a benefit or an aroma to a consumable material such as a liquid anionic, cationic, non-ionic or zwitterionic detergent, a shampoo, a bodywash, liquid soaps, hair conditioners, skin lotions, anti-perspirants, deodorants or liquid fabric softener and / or conditioner compositions. Also described is a process for preparing such stable suspensions and apparatus for carrying out such process.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

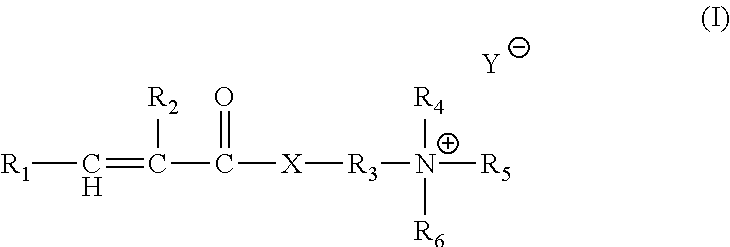

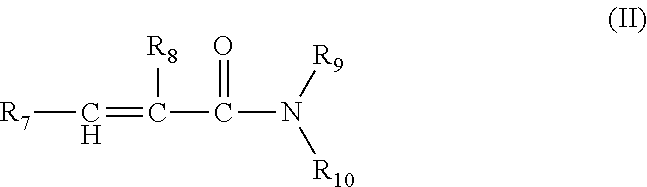

Aqueous laundry detergent compositions having improved softening properties and improved aesthetics

InactiveUS20050164905A1Cationic surface-active compoundsDetergent compounding agentsLiquid laundry detergentSurface-active agents

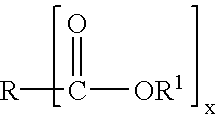

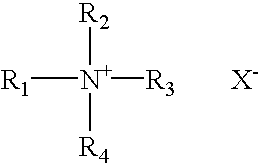

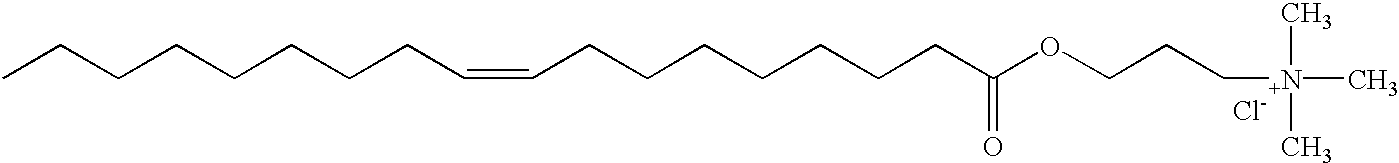

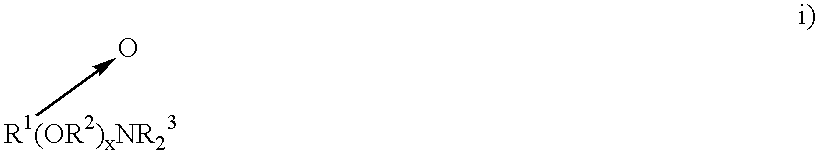

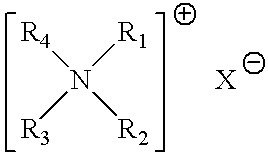

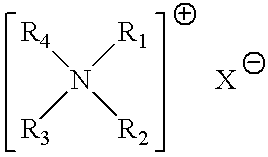

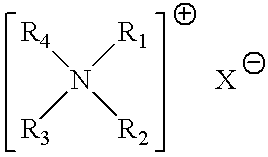

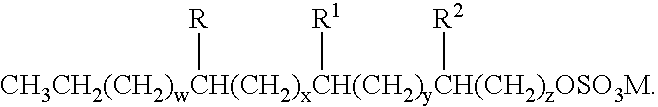

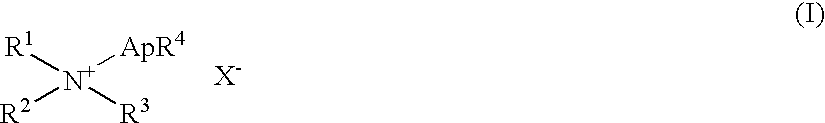

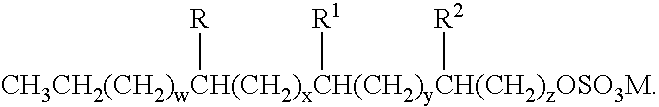

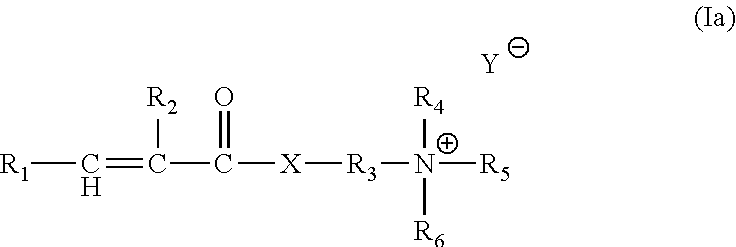

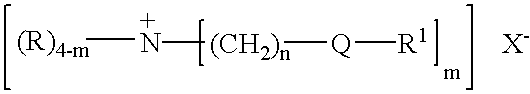

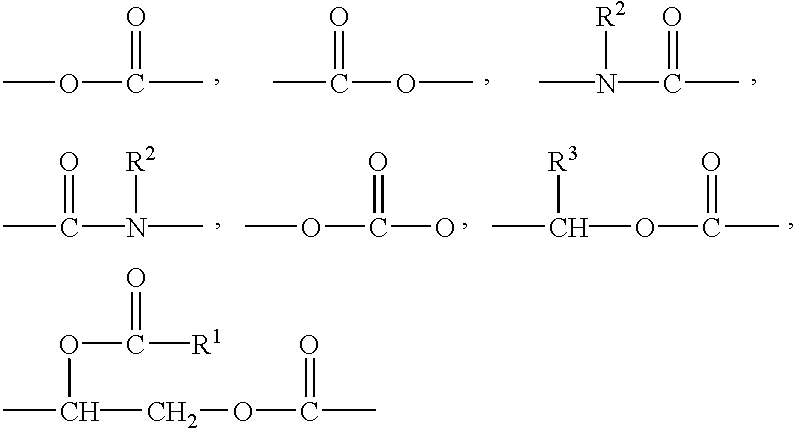

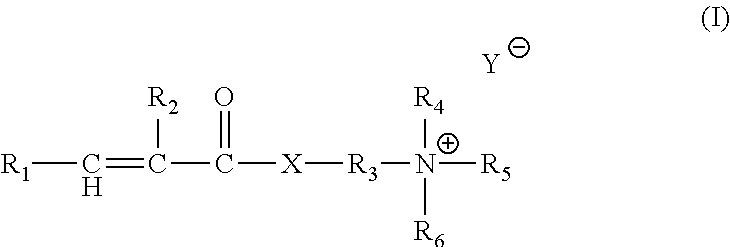

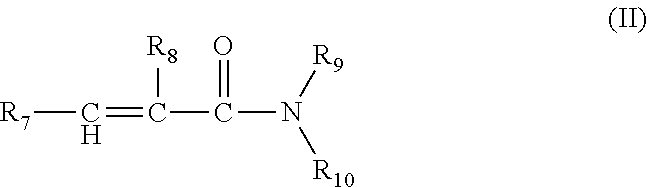

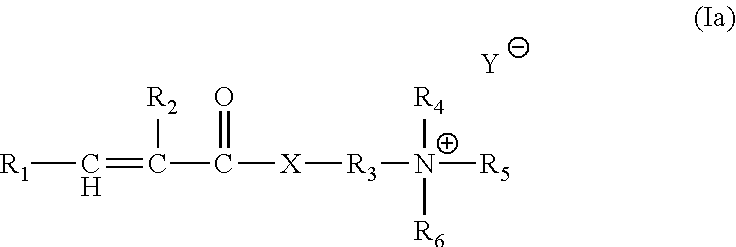

Aqueous heavy duty liquid laundry detergent compositions useful for laundering fabrics and providing cleaning and softening benefits. Such detergent compositions contain at least 5%, by weight of the composition, of a surfactant component; from about 0.1% to about 10% of a quaternary ammonium fabric-softening agent having the formula wherein R1 and R2 are individually selected from the group consisting of C1-C4 alkyl, C1-C4 hydroxy alkyl, benzyl, and —(C2H4O)xH where x has a value from about 2 to about 5; X is an anion; and (1) R3 and R4 are each a C8-C14 alkyl or (2) R3 is a C8-C22 alkyl and R4 is selected from the group consisting of C1-C10 alkyl, C1-C10 hydroxy alkyl, benzyl, and —(C2H4O)xH where x has a value from about 2 to about 5; and such compositions contain less than 10 ppm of trimethylamine and dimethylamine impurities.

Owner:THE PROCTER & GAMBLE COMPANY

Single compartment unit dose fabric treatment product comprising pouched compositions with cationic fabric softener actives

InactiveUS20040142840A1Good flexibilityCationic surface-active compoundsDetergent materialsWater solubleGuar gum

Owner:THE PROCTER & GAMBLE COMPANY

Concentrated fabric softener active compositions

InactiveUS20070054835A1Cationic surface-active compoundsOrganic detergent compounding agentsOrganic chemistryFabric softener

Owner:THE PROCTER & GAMBLE COMPANY

Single compartment unit dose fabric treatment product comprising pouched compositions with non-cationic fabric softener actives

InactiveUS20040142841A1Disintegrate quickly and completelyEasy to cleanOrganic detergent compounding agentsLiquid soapsMedicineWater soluble

The present invention relates a unit dose fabric treatment product comprising a non-aqueous liquid fabric treatment composition contained in a single compartment water-soluble pouch. The inner space of said pouch comprises (A) a cleaning system comprising more than 5% by weight of the fabric treatment composition of at least one anionic surfactant; and (B) a fabric softening system comprising at least one non-cationic fabric softening active selected from the group consisting of fabric softening clays, fabric softening silicones, and mixtures thereof, wherein the fabric softening clay is added as a premix comprising the clay and a solvent; wherein the fabric softening silicone is added as a premix comprising the silicone and a solvent or wherein the fabric softening silicone is added as pure compound without any solvent. The invention further relates to a method of producing such compositions and to the use of such compositions to impart fabric-cleaning and fabric-softening benefits via single compartment water-soluble pouches to fabrics treated therewith.

Owner:THE PROCTER & GAMBLE COMPANY

Cationic polymer stabilized microcapsule composition

ActiveUS8765659B2Improve production stabilityOrganic detergent compounding agentsGaseous substancesFabric softenerPolymerization

The present invention relates to the use of a cationic polymer to provide stability to microcapsules in a composition, wherein the microcapsule comprises a shell encapsulating materials having an average C log P of at least 2.5 and more than 60% by weight of the encapsulated materials have a C log P of at least 3.3. The cationic polymer is derived from the polymerization of 5 to 100 mole percent of a cationic vinyl addition monomer, 0 to 95 percent acrylamide, and 5 to 500 ppm of a tetrafunctional vinyl addition monomer cross-linking agent. The cationic polymer and encapsulated material may be used, for example, in a fabric softener composition.

Owner:THE PROCTER & GAMBLE COMPANY

Fabric maintenance softener

ActiveCN101736580AReduce wearImprove the lubrication effectOrganic detergent compounding agentsVegetal fibresWrinkleFabric softener

The invention provides a fabric maintenance softener, which consists of active ingredients and auxiliary material. The fabric maintenance softener is characterized in that the active ingredients comprise a cationic polymer and a quaternary ammonium salt fabric softener. The fabric maintenance softener not only can provide more effective functions of softening, removing static electricity and deodorizing, but also can play a role in maintaining, fixing color, keeping new and removing wrinkles for the fabrics.

Owner:杭州千岛湖佳蔚日用品有限公司

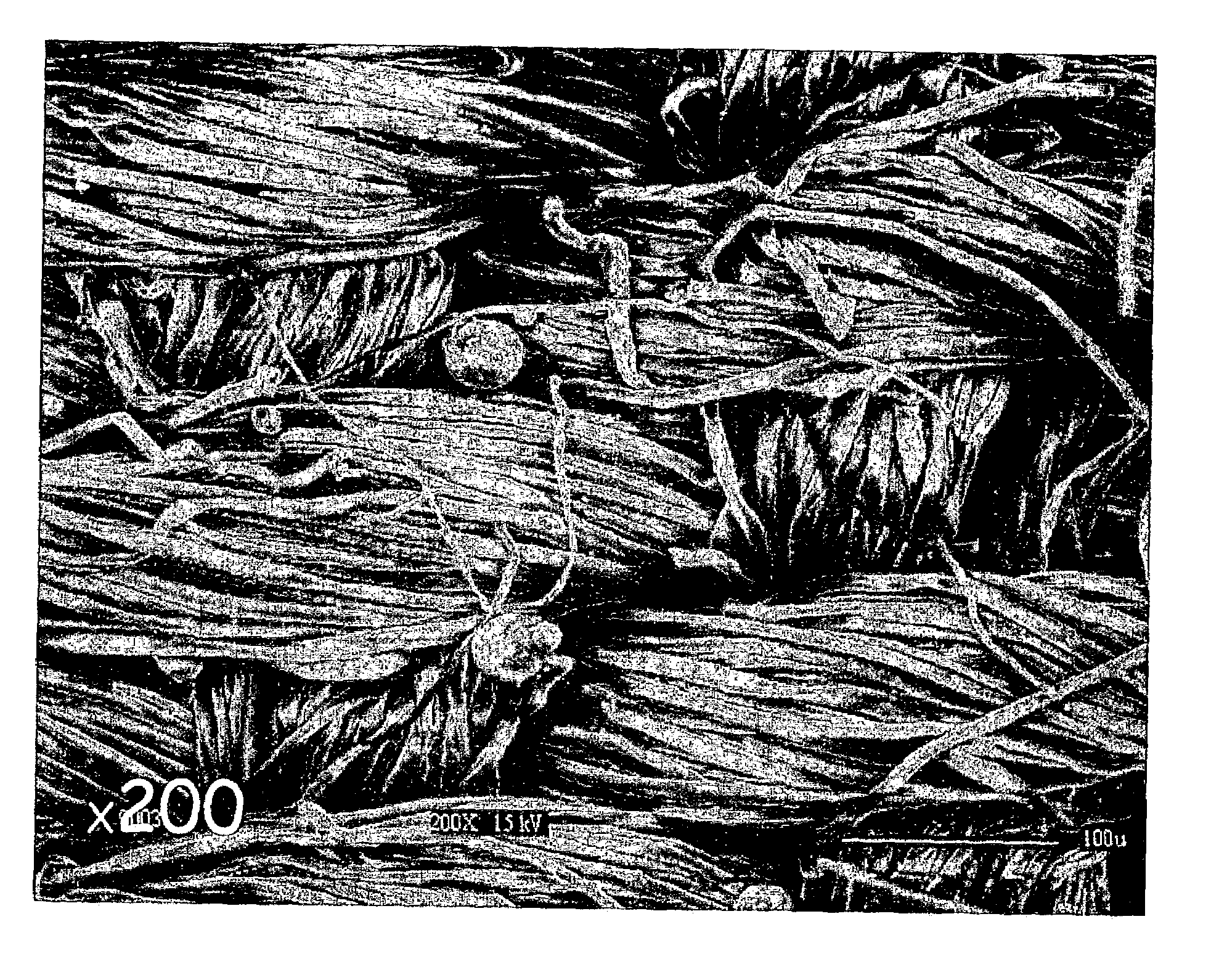

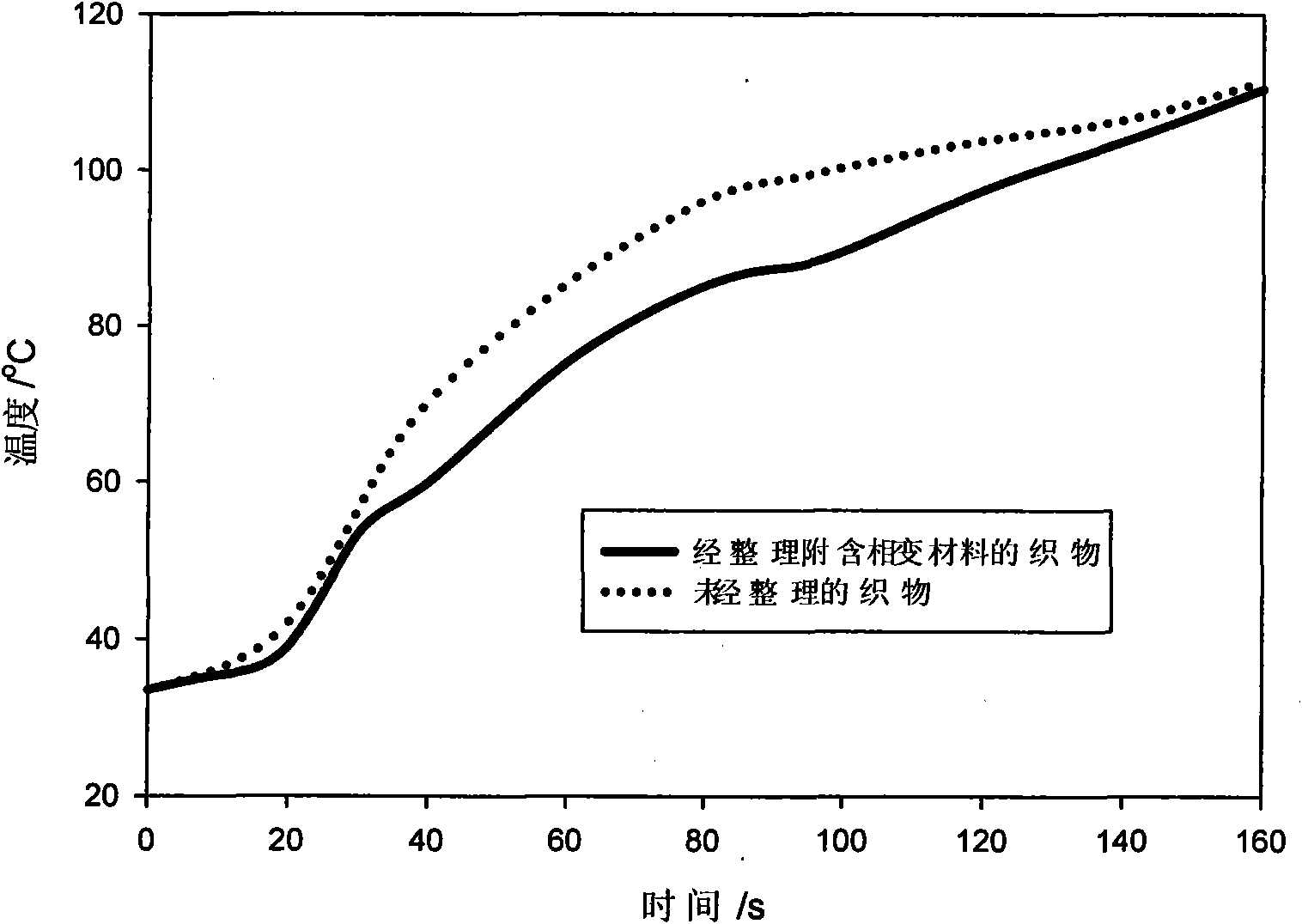

Preparation method of fire resistant phase transition thermal insulation layered fabric for firefighter clothing

InactiveCN102337673ANot burnImprove wearing comfortChemical protectionHeat protectionChemical industryCross-link

A preparation method of fire resistant phase transition thermal insulation layered fabric for firefighter clothing comprises the following steps of: immersing nonwoven felt prepared by combining 50-90% of aramid fiber 1313 fiber, 5-20% of carbon fiber and 0-30% of fire resistant viscose fiber into a prepared fire resistant phase transition microcapsule operating fluid, and carrying out two dipping and padding technology to obtain the fire resistant and temperature regulated phase transition thermal insulation layered fabric for firefighter clothing. A prepared phase transition finishing liquid contains 5-10% of an adhesive, 5-10% of a cross-linking fire retardant, 1-5% of a thickening agent and 1-5% of a fabric softener. The thermal insulation layered fabric which has undergone phase transition finishing is used to obviously raise thermal protective performance of firefighter clothing. The prepared fibrofelt fabric is applied in fire extinguishment and is also widely applied for individual protection equipment in different industries and fields such as metallurgy, petroleum, steel chemical industry, army war clothing and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Concentrated fabric softener active compositions

InactiveUS20060089293A1Cationic surface-active compoundsSoftening compositionsSolventFabric softener

Fabric softening active composition comprising (a) at least about 20% to less than 100% fabric softener active and (b) solvent or combination of solvents wherein at least one of the solvents has a Clog P of from about −2 to about 2, are cost-effective for transporting to developing markets.

Owner:THE PROCTER & GAMBLE COMPANY

Low solids, high viscosity fabric softener compositions and process for making the same

InactiveUS20060264352A1Improve propertiesImprove stabilityCationic surface-active compoundsDetergent mixture composition preparationViscosityOrganic chemistry

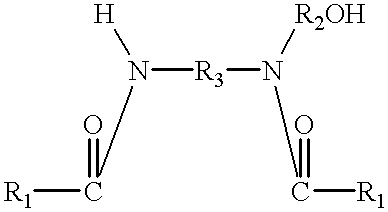

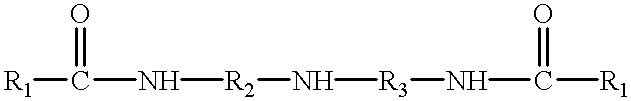

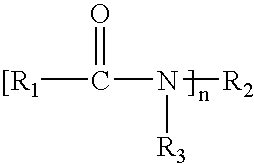

Disclosed are low solids and high viscosity fabric softener compositions and processes for preparing them. The composition contains from about 0.05% to about 10% by weight of a rheology modifying fabric softening active comprising at least one long chain amine of the present technology, a derivative thereof, or a mixture thereof, and from about 0% to 10% by weight of an additional fabric softening active dispersed in water.

Owner:STEPAN COMPANY

Multi-phase fabric care composition for delivering multiple fabric care benefits

A liquid rinse-added fabric care composition that is characterized by at least two visually distinct phases when the composition is at rest and wherein at least one of the phases contains a fabric care agent is provided. The composition forms a temporary mixture when shaken that allows a consumer to dose a representative sample of the composition and spontaneously re-forms at least two visually distinct phases when allowed to remain at rest. The fabric care agents present in one or more phases of the composition may include fabric softener actives, color care agents, perfumes, antibacterial agents, malodor control agents, ultraviolet protection agents, anti-abrasion, anti-wear & fabric integrity agents, wrinkle control agents, and mixtures thereof. The composition should also contain less than about 5%, preferably less than about 3%, and even more preferably less than about 1% by weight of detergent actives. The composition optionally may contain an electrolyte, phase stabilizer, a phase separation inducing polymer and / or a solvent. Methods for delivering one or more fabric care benefits to a fabric during a laundering operation using the compositions are also disclosed. Methods for conveying information to a consumer concerning a multi-phase liquid rinse-added fabric care composition are also provided. An article of manufacture comprising a liquid rinse-added fabric care composition that has at least two visually distinct phases and a container that enables a consumer to view the visually distinct phases that are present in the composition is also described. Alternatively, the container may comprise a double walled cap and an insert for removing excess composition that may adhere to the cap.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent compositions

InactiveUS20020115583A1Efficient dosingCationic surface-active compoundsAnionic-cationic-non-ionic surface-active compoundsLaundry washing machineActive agent

The present invention relates to a shaped detergent composition comprising surfactant and cationic fabric softener, characterized in that the composition disintegrates within 5 minutes of been placed in deionised water at 20° C. and that after disintegration, the average particle size of the composition is less than 5 mm, preferably less than 3 mm. The compositions of the present invention can be effectively dosed via the dispensing drawer of standard washing machines and can deliver two or more actives to the wash liquor, even if such actives are incompatible with each other.

Owner:THE PROCTER & GAMBLE COMPANY

Cationic polymer stabilized microcapsule composition

ActiveUS20110245141A1Improve production stabilityGaseous substancesDeodrantsPolymer scienceIonic polymerization

The present invention relates to the use of a cationic polymer to provide stability to microcapsules in a composition, wherein the microcapsule comprises a shell encapsulating materials having an average C log P of at least 2.5 and more than 60% by weight of the encapsulated materials have a C log P of at least 3.3. The cationic polymer is derived from the polymerization of 5 to 100 mole percent of a cationic vinyl addition monomer, 0 to 95 percent acrylamide, and 5 to 500 ppm of a tetrafunctional vinyl addition monomer cross-linking agent. The cationic polymer and encapsulated material may be used, for example, in a fabric softener composition.

Owner:THE PROCTER & GAMBLE COMPANY

Heat Stable Fabric Softener

InactiveUS20110239377A1Cationic surface-active compoundsOrganic detergent compounding agentsEngineeringFabric softener

Owner:THE PROCTER & GAMBLE COMPANY

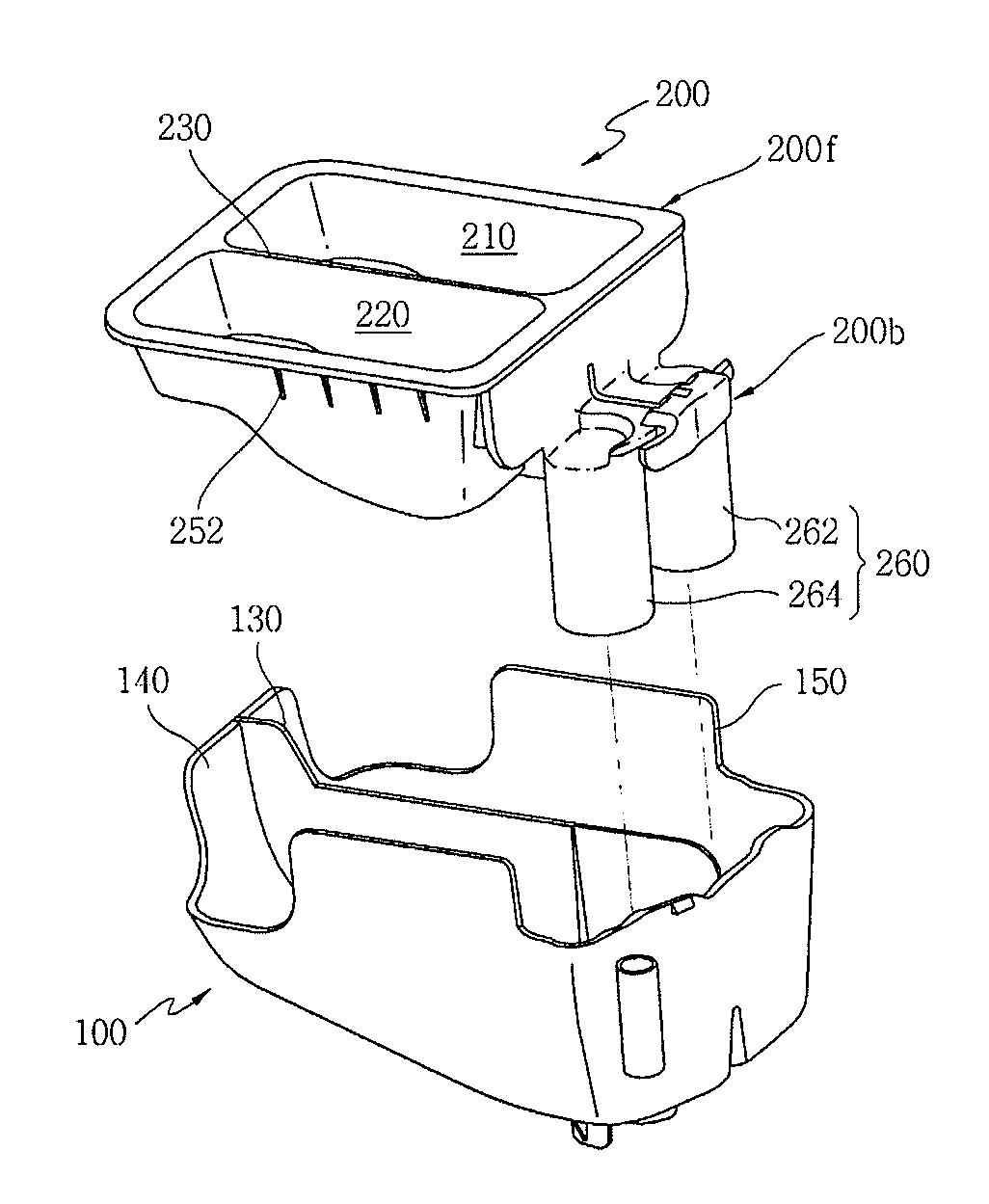

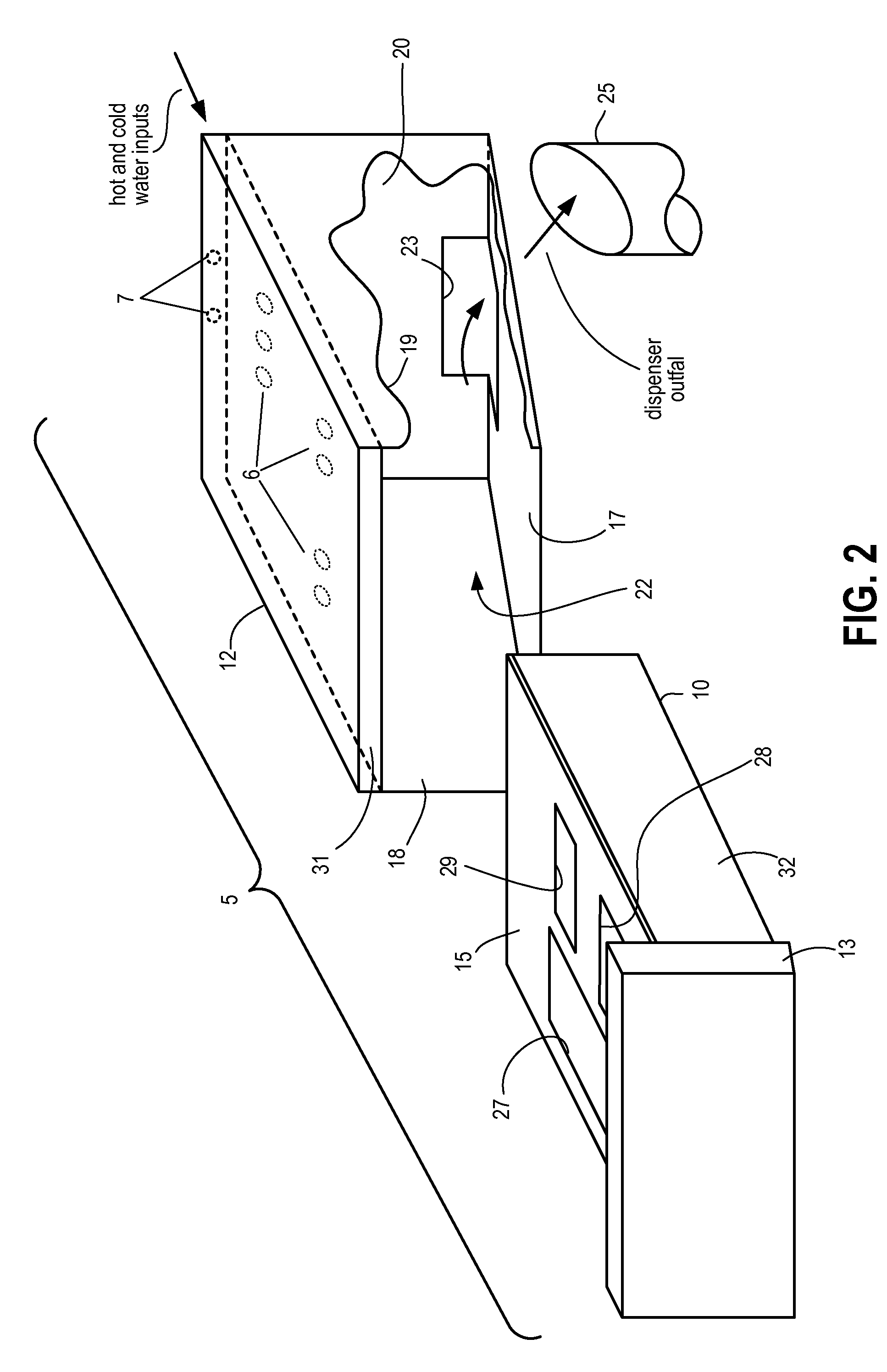

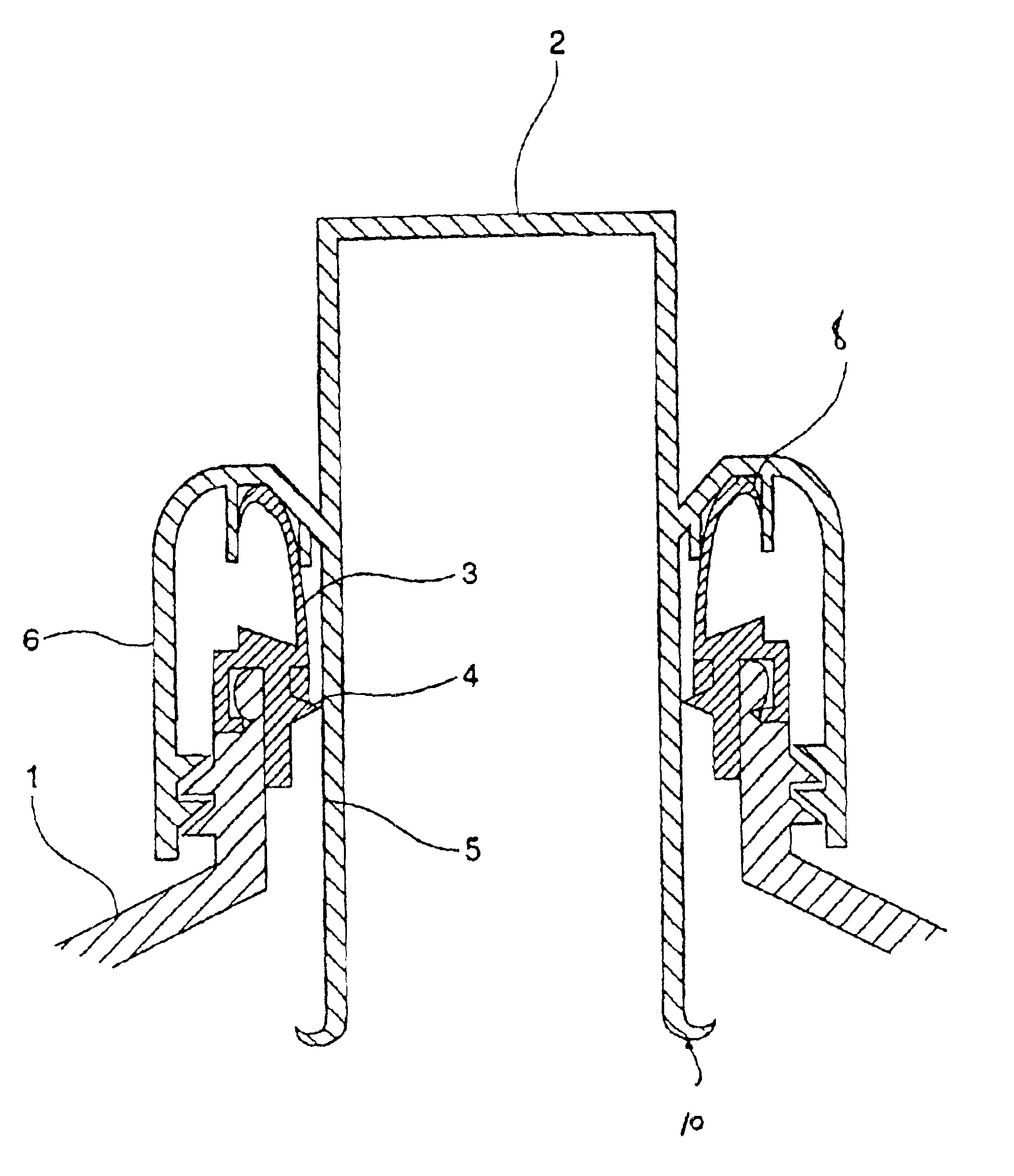

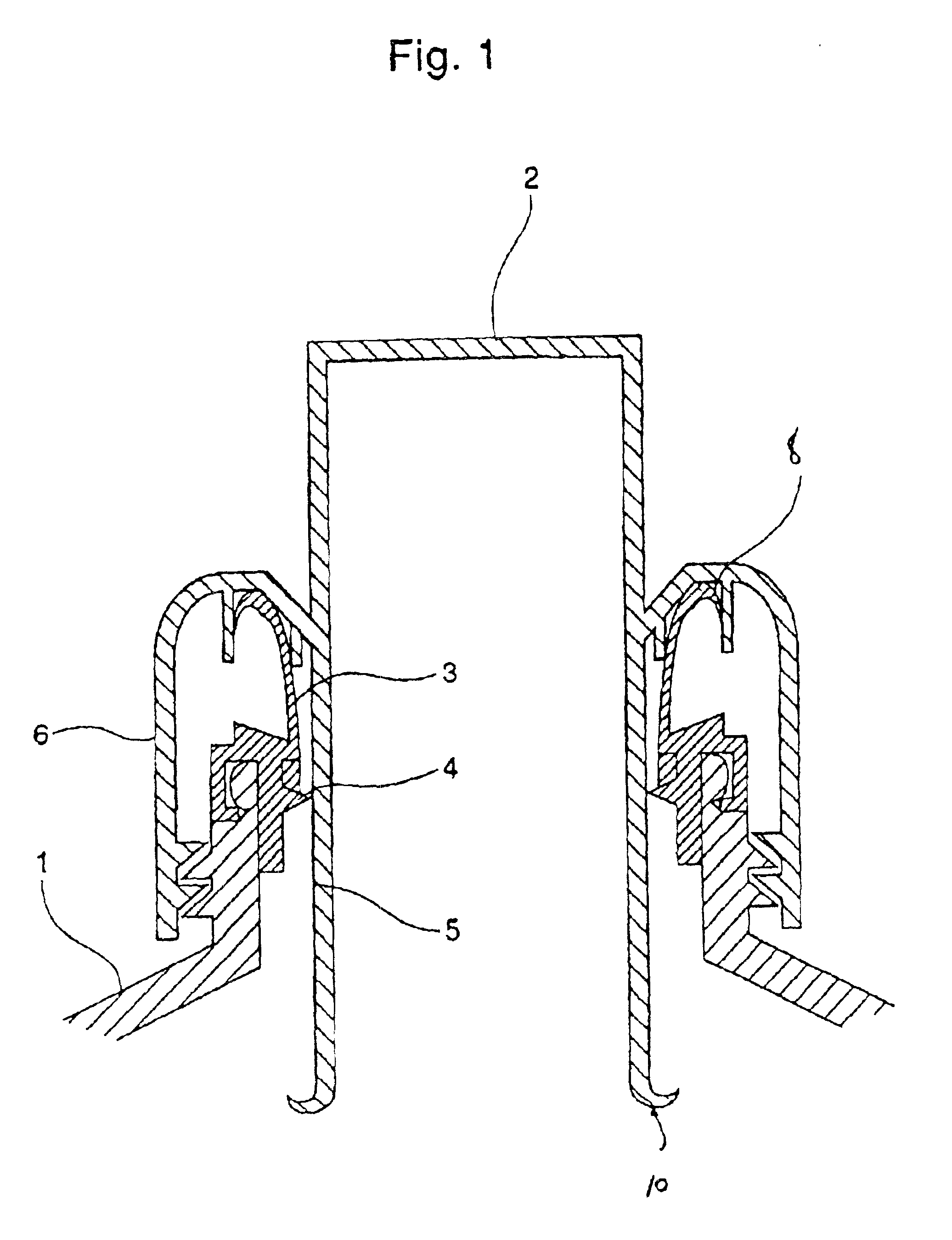

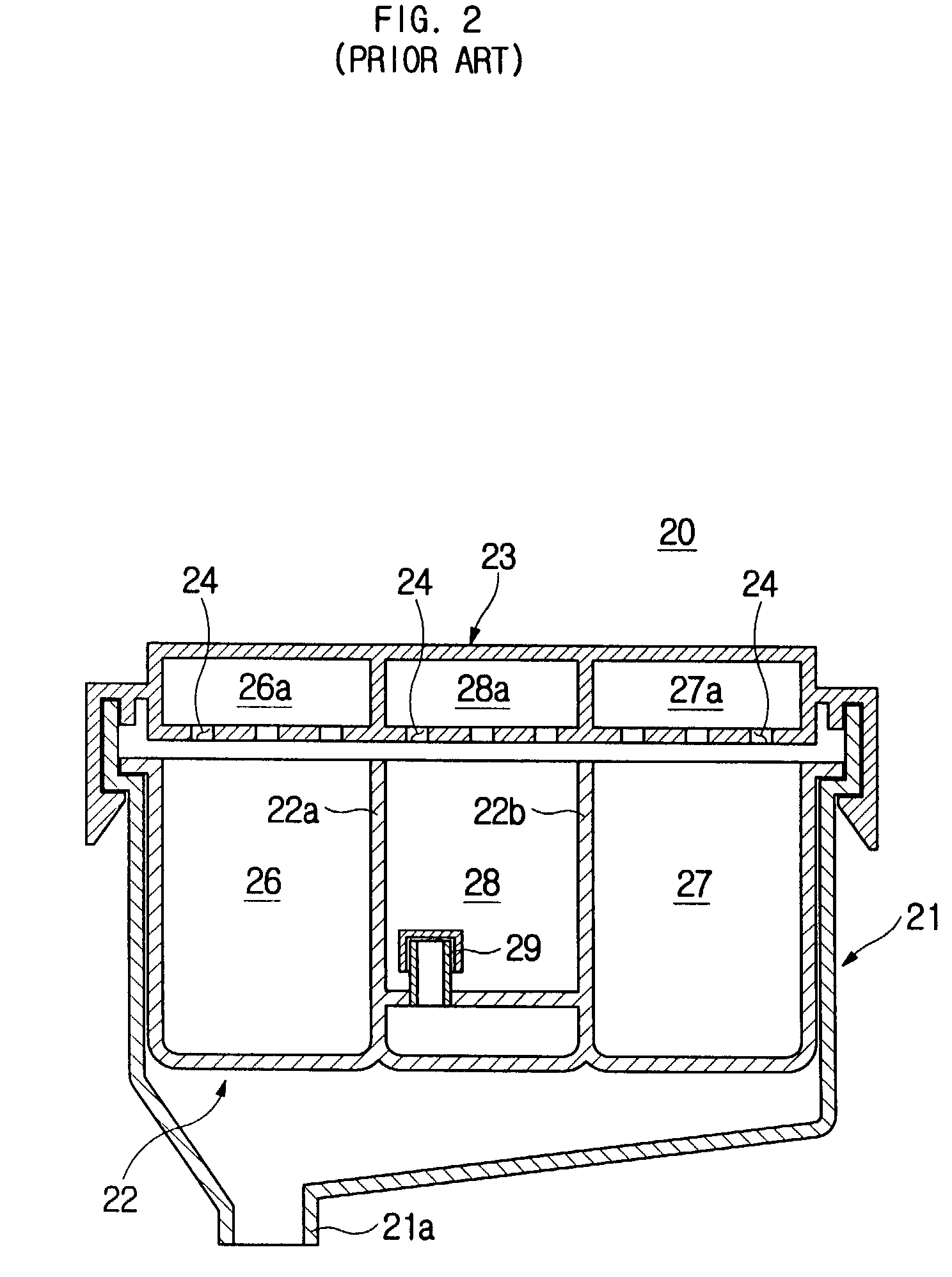

Fluid detergent and fabric softner box assembly for laundry machine and detergent dispenser having the same

ActiveUS20100095712A1Avoid bubblingMaximize the effectOther washing machinesControl devices for washing apparatusEngineeringLaundry

The present invention relates to a detergent supply apparatus for a drum laundry machine, and more particularly to, a fluid detergent and fabric softener box assembly which can be attached and detached to / from a detergent supply apparatus, and temporarily stores a fluid detergent and a fabric softener until they are selectively introduced into a washing room in water supply. A fluid detergent and fabric softener box assembly includes a cap which can prevent a fabric softener and a fluid detergent from being splashed into another section in a barrier portion between the fluid detergent and the fabric softener due to a fall head of water supplied from a water supply inlet of a dispenser.

Owner:LG ELECTRONICS INC

Laundry Composition with Encapsulated Liquid Benefit Agent

InactiveUS20110190191A1Good storage stabilityLiquid surface applicatorsDetergent compounding agentsSlurryLotion

A process for making aggregate granules comprising encapsulates or microcapsules of liquid benefit agent, preferably perfume, the process comprising the steps of: a) providing a powdered and / or granulated laundry composition comprising detergent particles selected from surfactants, fabric softeners and / or detergency builders; b) preparing a slurry comprising water, optional soluble materials, and encapsulates of liquid benefit agent; c) spraying the slurry prepared in step b) onto the laundry composition provided in step a) using a high rate of spray to create droplets larger than 70 micron in order to form aggregate granules of liquid benefit agent encapsulates anchored to detergent particles. Also, to particulate detergent compositions including the aggregate granules obtainable by the process and use of the compositions in laundry processes.

Owner:HENKEL IP & HOLDING GMBH

Fabric softener composition and methods for manufacturing and using

ActiveUS7381697B2Cationic surface-active compoundsOrganic detergent compounding agentsEngineeringLaundry

A fabric softener composition is provided by melt mixing a fabric softener component and a carrier component to provide a fabric softener composition exhibiting a melting point greater than 90° C. The weight ratio of the fabric softener component to the carrier component can be between about 1:19 and about 19:1. Methods for manufacturing the fabric softener composition and using the fabric softener composition to soften fabric while drying laundry in a dryer are provided.

Owner:ECOLAB USA INC

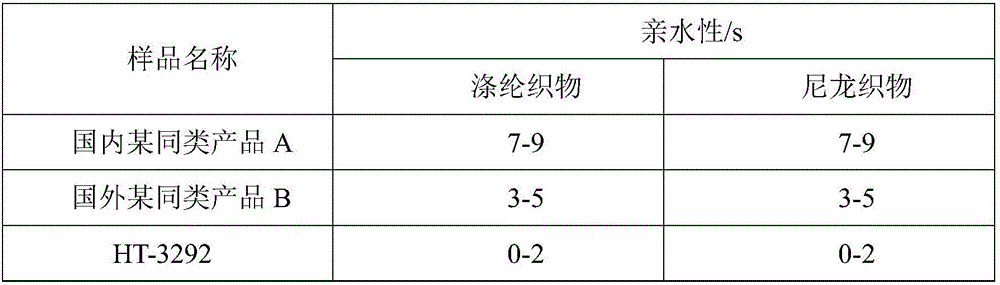

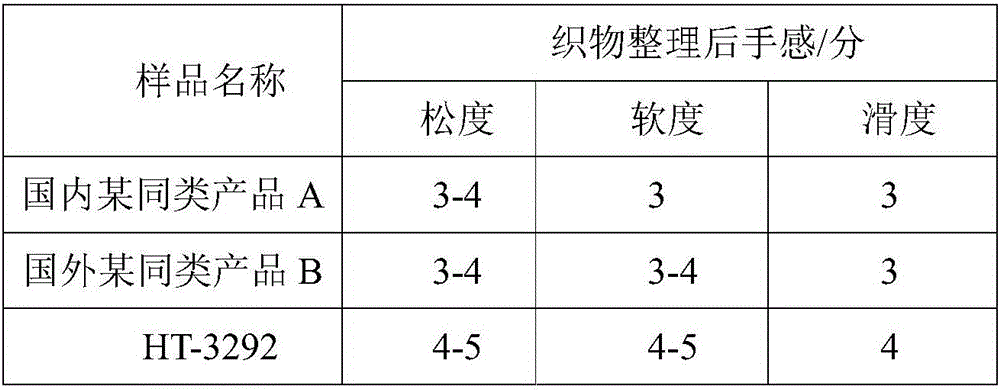

Terpolymer block hydrophilic amino silicone oil and preparation method and application thereof

The invention provides terpolymer block hydrophilic amino silicone oil and a preparation method and application thereof. The terpolymer block hydrophilic amino silicone oil is prepared by: reflux-reacting epoxy-terminated polyether silicone oil, amino-terminated polyether and isopropanol at 80-83 DEG C for 8-10 hours, adding a quaternization reagent for modifying, and distilling a modified product under reduced pressure. The terpolymer block hydrophilic amino silicone oil, as a chemical fiber fabric softener, can improve handle characteristics of bulkiness, softness and smoothness to chemical fiber fabric, is good in permeability and can go hydrophilic instantly on nylon fabric; the terpolymer block hydrophilic amino silicone oil has low influence on fabric yellowing and discoloration; the terpolymer block hydrophilic amino silicone oil has excellent chemical stability in resistance to acids, alkalis and salts, has good compounding stability with the aids such as a brightener, saves cost for customers in terms of energy conservation and emission reduction, and provides conveniences.

Owner:HT FINE CHEM CO LTD +1

Methods and Systems for Water Delivery in an Additive Dispenser

ActiveUS20090158782A1Avoid residueSpeed up siphoningControl devices for washing apparatusMachines/enginesSiphonLaundry washing machine

A washing apparatus such as an automatic laundry washing machine includes a wash agent dispenser drawer including an additive compartment for storing various additives such as detergent, bleach and fabric softener. One or more water inflow tubes may extend downwardly into the additive compartment and may be configured to deliver water for diluting the additives contained in the compartment. The inflow tubes are of sufficient length to reach a sub-surface portion of additive held in the compartment. Water may simultaneously be delivered to the surface of the additive. Furthermore, inflow tubes have their outlets positioned adjacent to the base(s) of one or more siphon post / cap assemblies located in the additive compartments, such that a churning effect is produced from the injection of water through the tubes and the siphoning action of the siphon post, whereby mixing is enhanced and additive buildup may be avoided and / or removed.

Owner:ELECTROLUX HOME PROD CORP NV

Highly concentrated fabric softener compositions and articles containing such compositions

InactiveUS6958313B2Cationic surface-active compoundsNon-ionic surface-active compoundsPolyvinyl alcoholPolymer chemistry

An article comprising a polyvinyl alcohol film encapsulating a fabric care composition is useful for conditioning laundry.

Owner:PROCTER & GAMBLE CO

Multi-phase fabric care composition for delivering multiple fabric care benefits

InactiveUS6884766B2Multiple benefitsCapsCationic surface-active compoundsMedicineUltraviolet protection

A liquid rinse-added fabric care composition that is characterized by at least two visually distinct phases when the composition is at rest and wherein at least one of the phases contains a fabric care agent is provided. The composition forms a temporary mixture when shaken that allows a consumer to dose a representative sample of the composition and spontaneously re-forms at least two visually distinct phases when allowed to remain at rest. The fabric care agents present in one or more phases of the composition may include fabric softener actives, color care agents, perfumes, antibacterial agents, malodor control agents, ultraviolet protection agents, anti-abrasion, anti-wear & fabric integrity agents, wrinkle control agents, and mixtures thereof. The composition should also contain less than about 5%, preferably less than about 3%, and even more preferably less than about 1% by weight of detergent actives. The composition optionally may contain an electrolyte, phase stabilizer, a phase separation inducing polymer and / or a solvent. Methods for delivering one or more fabric care benefits to a fabric during a laundering operation using the compositions are also disclosed. Methods for conveying information to a consumer concerning a multi-phase liquid rinse-added fabric care composition are also provided. An article of manufacture comprising a liquid rinse-added fabric care composition that has at least two visually distinct phases and a container that enables a consumer to view the visually distinct phases that are present in the composition is also described. Alternatively, the container may comprise a double walled cap and an insert for removing excess composition that may adhere to the cap.

Owner:PROCTER & GAMBLE CO

Laundry system having unitized dosing

InactiveUS7166565B2Improve convenienceIncrease flexibilityOrganic detergent compounding agentsWrappersMedicineLaundry

Compositions, articles and methods are provided for supplying fabric care benefits to clothing or fabrics in an automated washing machine and by manual washing. The fabric care compositions preferably have less than about 5% detergent surfactants, more preferably less than 3%, even more preferably less than 1% and are most preferably free of detergent surfactants. Similarly, the fabric care compositions preferably have less than about 5% fabric softener actives, more preferably less than 3%, even more preferably less than 1% and are most preferably free of detergent surfactants. The laundry articles can take a variety of forms in a variety of physical states all of which will rapidly dispense a unitized amount of one or more selected fabric care agents to a wash and / or rinse bath solution during the laundering process under a variety of conditions. The invention also pertains to laundry kits that contain a variety of such articles and instructions concerning their use. Likewise, methods for preparing a customized laundry solution to obtain a specific fabric care benefit selected based on the user's personal preferences and / or the fabric care needs of the fabrics being laundered are also provided. Further, the present invention also concerns methods for assisting a consumer in identifying the unitized articles to be used in preparing a laundry solution that will impart desired fabric care benefits as well as merchandising displays for dispensing the articles, assembling customized laundry kits and instructing the consumer on the selection and use of laundry articles.

Owner:THE PROCTER & GAMBLE COMPANY

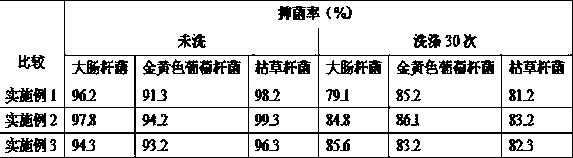

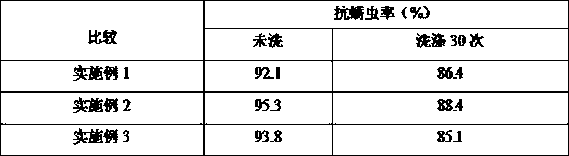

Antibacterial fabric, preparation technology thereof and textile thereof

InactiveCN103255522ANon-irritatingImprove thermal stabilityWeft knittingCarbon fibresBiotechnologyPolyester

The invention relates to the field of functional fabrics, in particular to an antibacterial fabric, a preparation technology of the antibacterial fabric and textile of the antibacterial fabric. The antibacterial fabric comprises, by weight, 10-20 parts of short fiber silk, 20-25 parts of anion polypropylene staple fibers, 15-25 parts of nano bamboo carbon fiber, 2-5 parts of nano-titanium dioxide, 5-10 parts of nano-silver fiber, 2-4 parts of anti-mite finishing agent, 3-8 parts of sweat-absorbent quick-drying processing agent, 12-18 parts of binder, 2-4 parts of dispersing agent, 3-5 parts of fabric softener and 80-85 parts of polyester cotton fiber. Due to the fact that the anion polypropylene staple fibers are added, effects of nerve stability, sleep improvement, inflammation diminishing and pain relief are provided. Due to the fact that the anti-mite finishing agent is added, trouble caused by mites to a human body can be effectively prevented. Due to the fact that the sweat-absorbent quick-drying processing agent is added, sweat generated by the body can be rapidly absorbed, discomfort can be reduced, and breeding of germs under a humid environment can be prevented. The antibacterial fabric can be applied to clothing, home textiles, sports goods, medical care, bacteria resistance and insect prevention textiles.

Owner:广东雄兴内衣实业有限公司

Washing machine having detergent supply apparatus

ActiveUS7093467B2Other washing machinesLiquid transferring devicesMechanical engineeringFabric softener

A washing machine includes a detergent supply apparatus having a detachable partition member. The detergent supply apparatus includes a casing which defines an outer appearance of the detergent supply apparatus, and a detergent / fabric softener container slidably set in the casing. The detergent / fabric softener container includes a fixed partition member which partitions the detergent / fabric softener container into a detergent chamber and a fabric softener chamber, and the detachable partition member is removably mounted in the detergent chamber, so as to partition the detergent chamber into a secondary detergent storing section and a main detergent storing section. The detergent chamber is entirely used as the main detergent storing section in response to removal of the detachable partition member from the detergent chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Antimicrobial transfer substrates and methods of use therewith

InactiveUS6454813B1Highly effective transfer mechanismEfficient transferInorganic/elemental detergent compounding agentsBiocideFiberAntimicrobial compound

Specific transfer methods and articles to impart a metal-ion based antimicrobial finish to recipient textile surfaces. Such treatments preferably comprise silver ions, particularly as constituents of inorganic metal salts or zeolites. In particular, the inventive method involves the application of a solid, inorganic antimicrobial material to a donor substrate (such as a dryer sheet), and the subsequent placement of such a substrate within a tumble drying machine containing textile fabrics and operating the machine. The donor substrate, upon contact with the recipient textile fabrics, transfers antimicrobially effective amounts of the metal-ion based compounds to such recipient fabrics thereby imparting at least a temporary antimicrobial finish over at least a portion of such fabrics. The donor substrates, with either the antimicrobial compound alone or mixed with standard tumble dryer additives (such as perfumes, fabric softeners, fiber lubricants, and the like) are also contemplated within this invention.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com