Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1154 results about "Grain growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, grain growth is the increase in size of grains (crystallites) in a material at high temperature. This occurs when recovery and recrystallisation are complete and further reduction in the internal energy can only be achieved by reducing the total area of grain boundary. The term is commonly used in metallurgy but is also used in reference to ceramics and minerals.

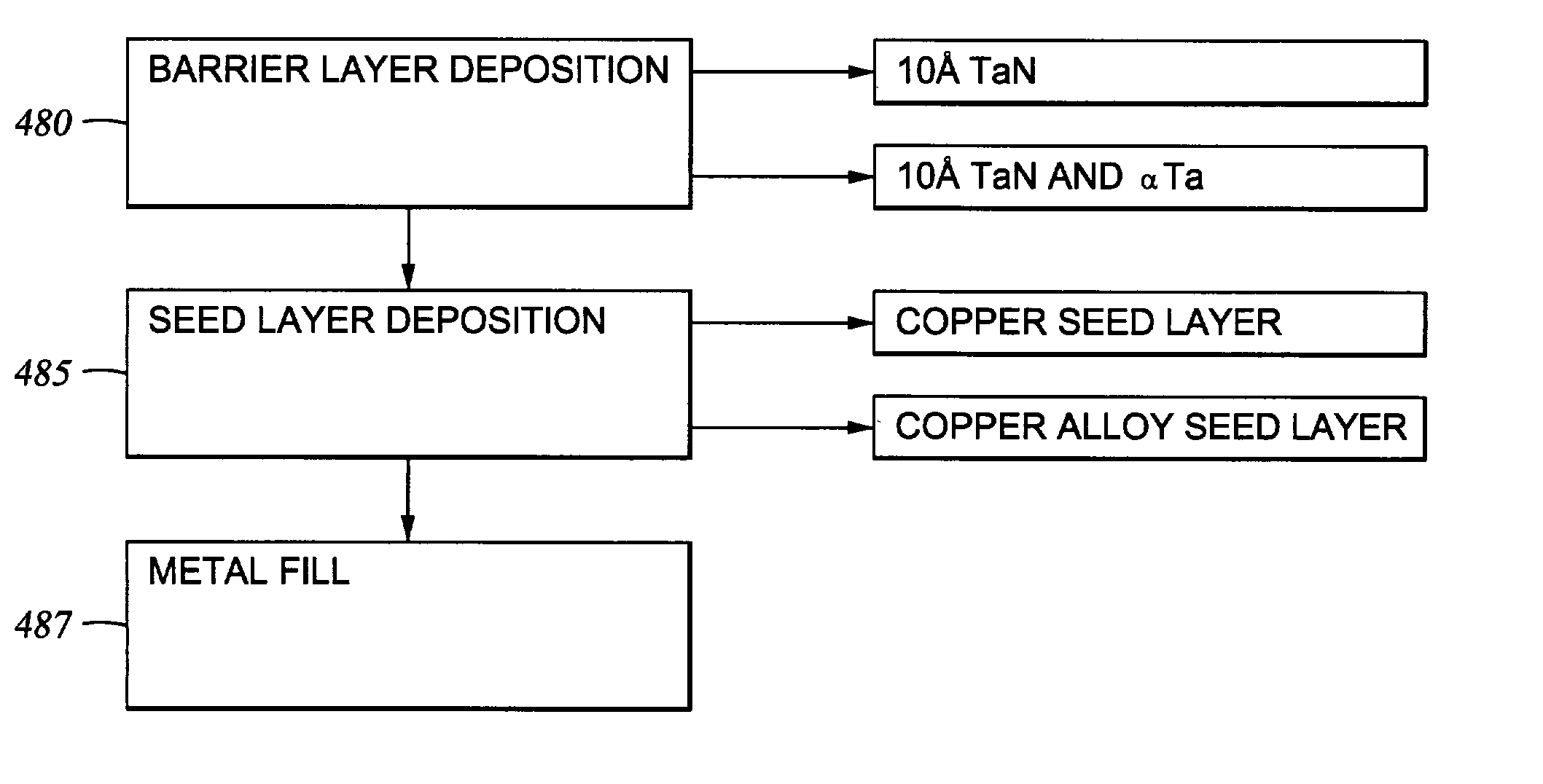

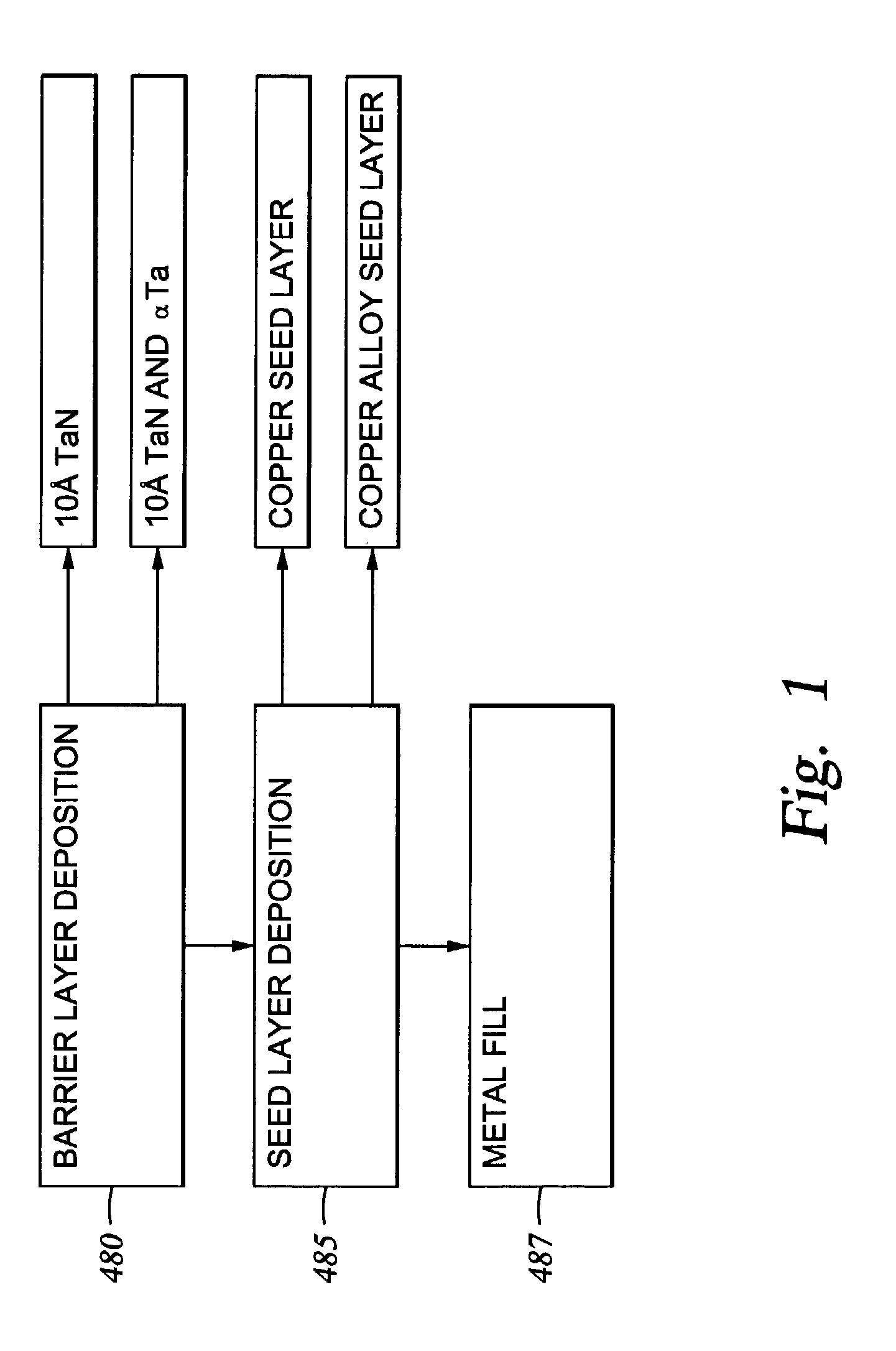

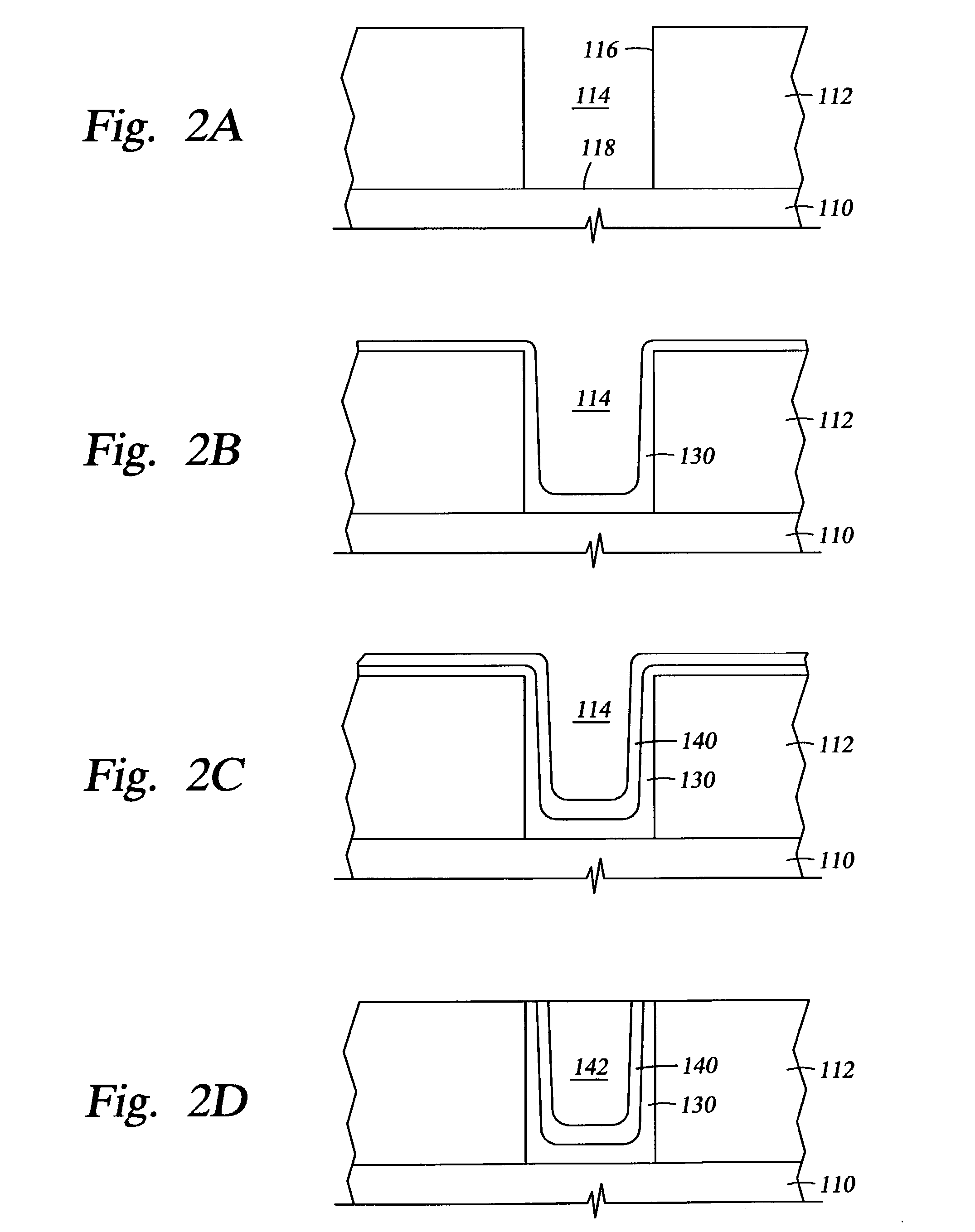

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030082307A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

A method for forming a metal interconnect on a substrate is provided. The method includes depositing a refractory metal-containing barrier layer having a thickness less than about 20 angstroms on at least a portion of a metal layer by alternately introducing one or more pulses of a metal-containing compound and one or more pulses of a nitrogen-containing compound. The method also includes depositing a seed layer on at least a portion of the barrier layer, and depositing a second metal layer on at least a portion of the seed layer. The barrier layer provides adequate barrier properties and allows the grain growth of the metal layer to continue across the barrier layer into the second metal layer thereby enhancing the electrical performance of the interconnect.

Owner:APPLIED MATERIALS INC

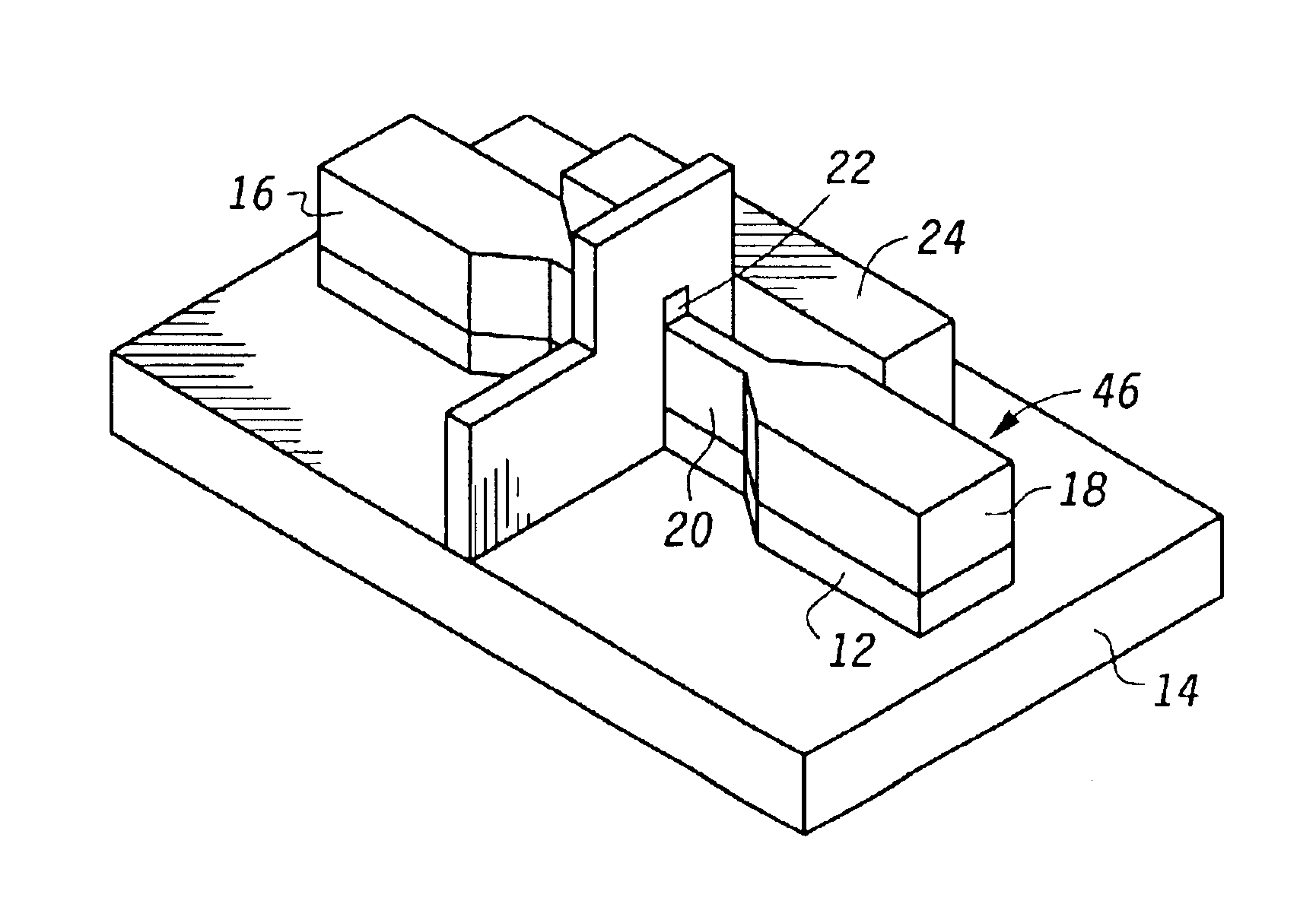

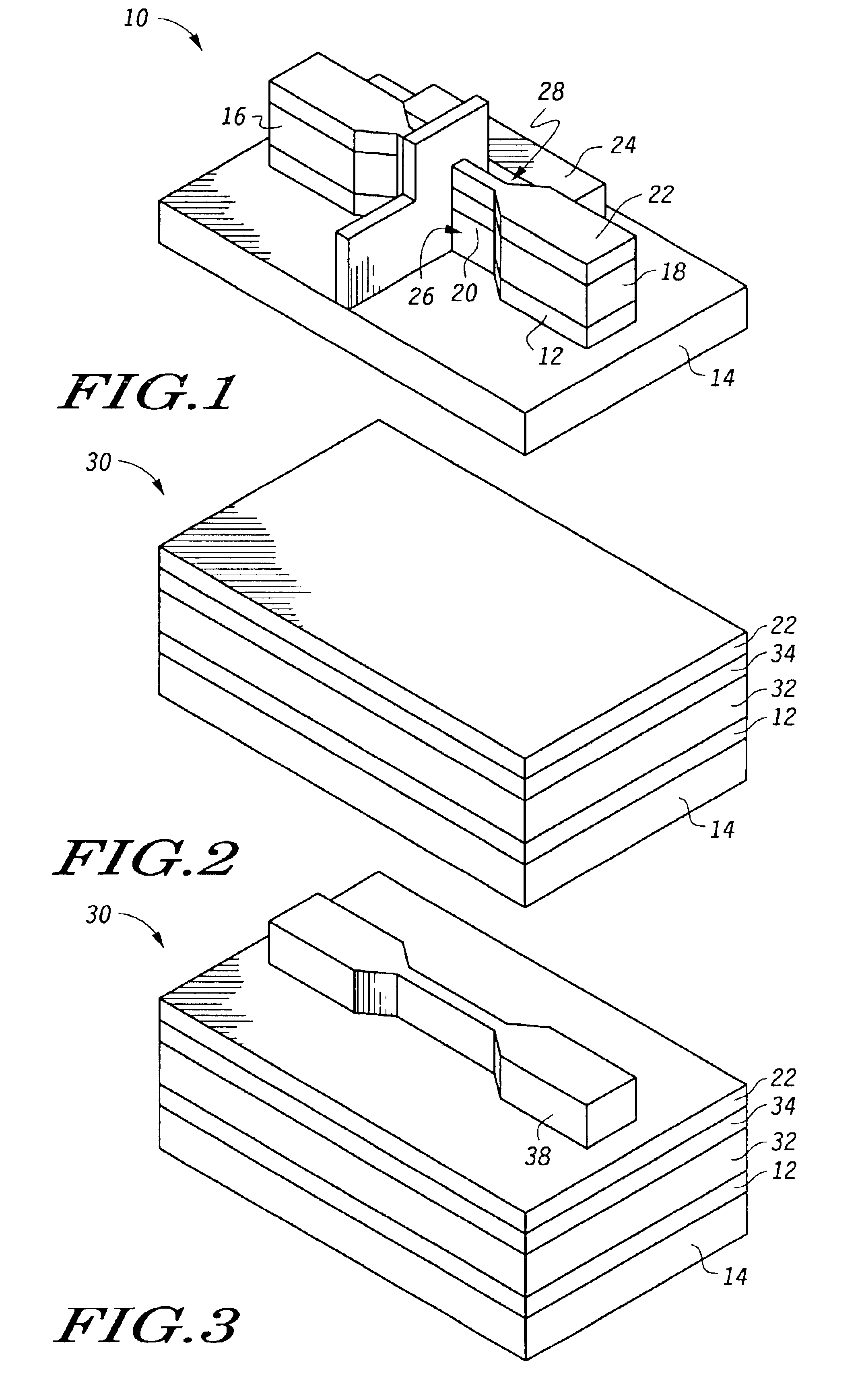

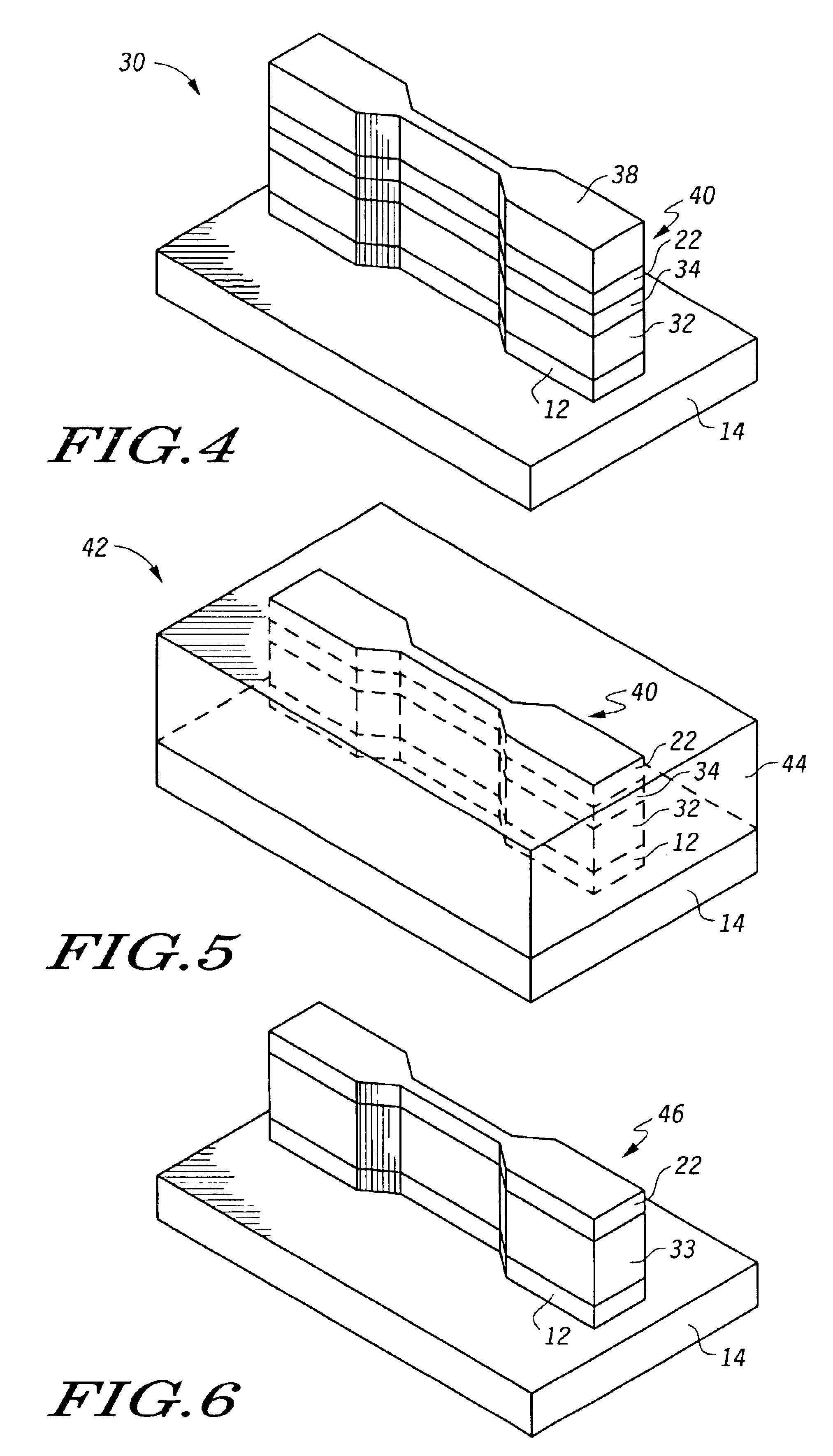

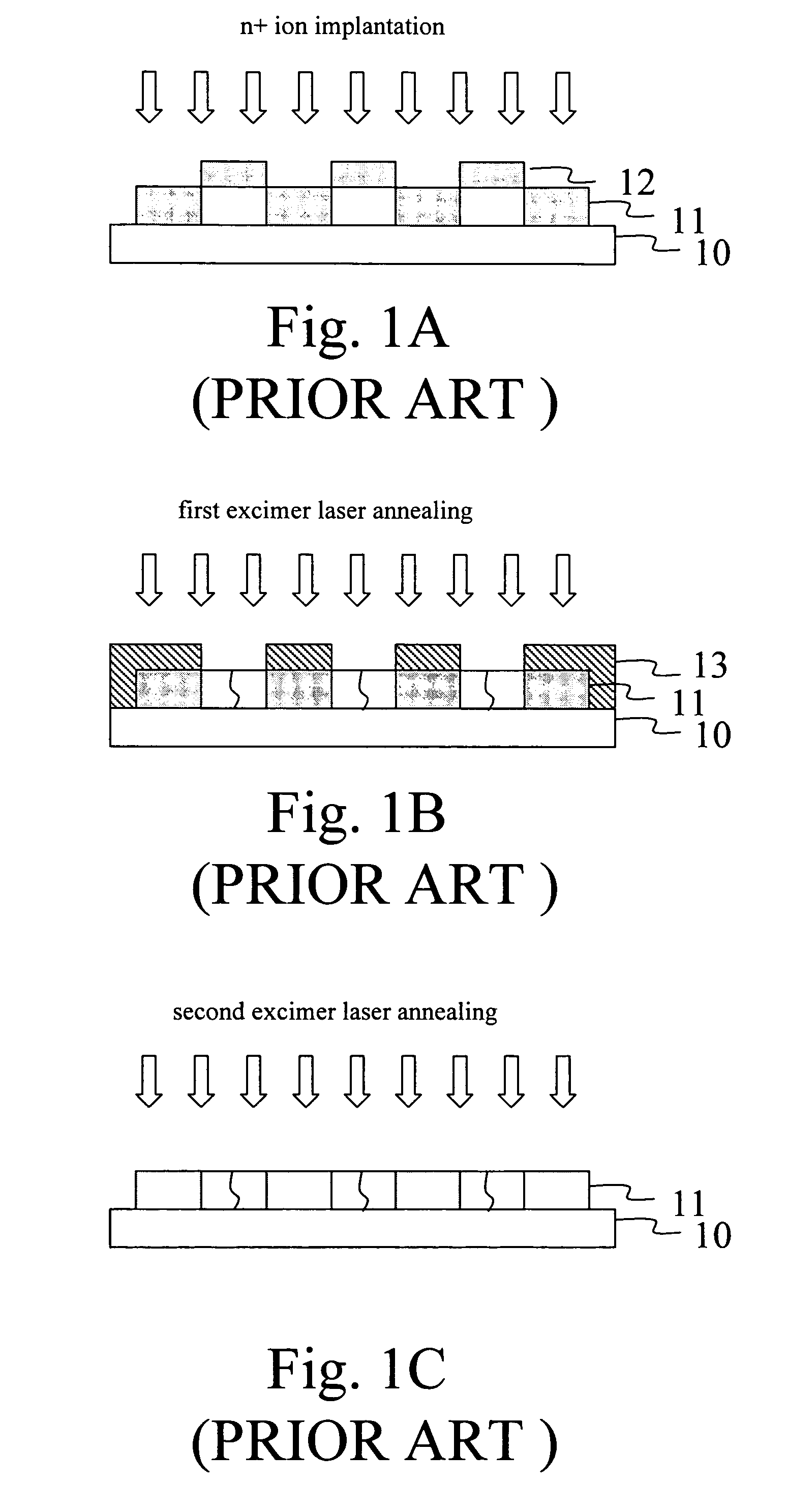

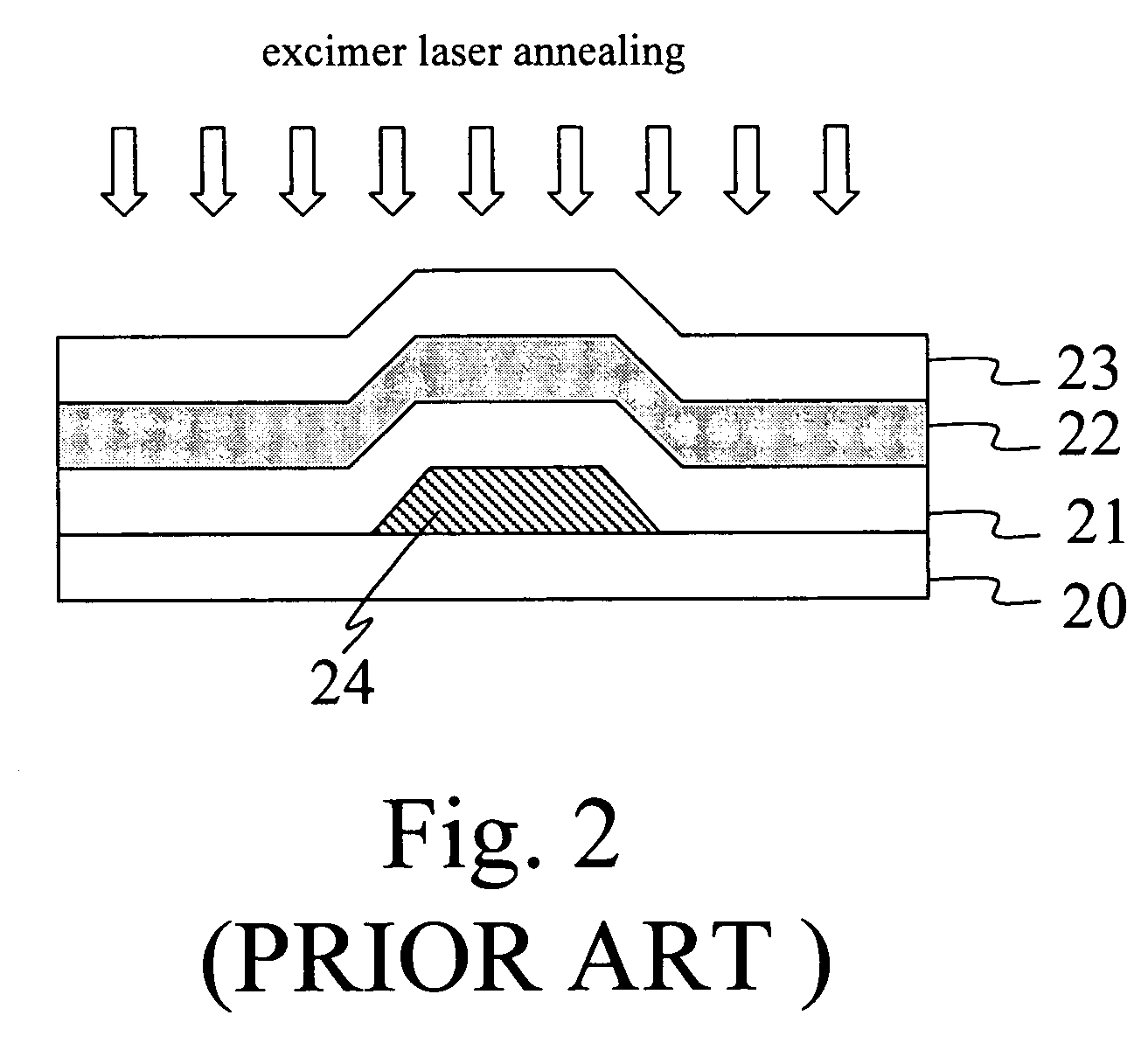

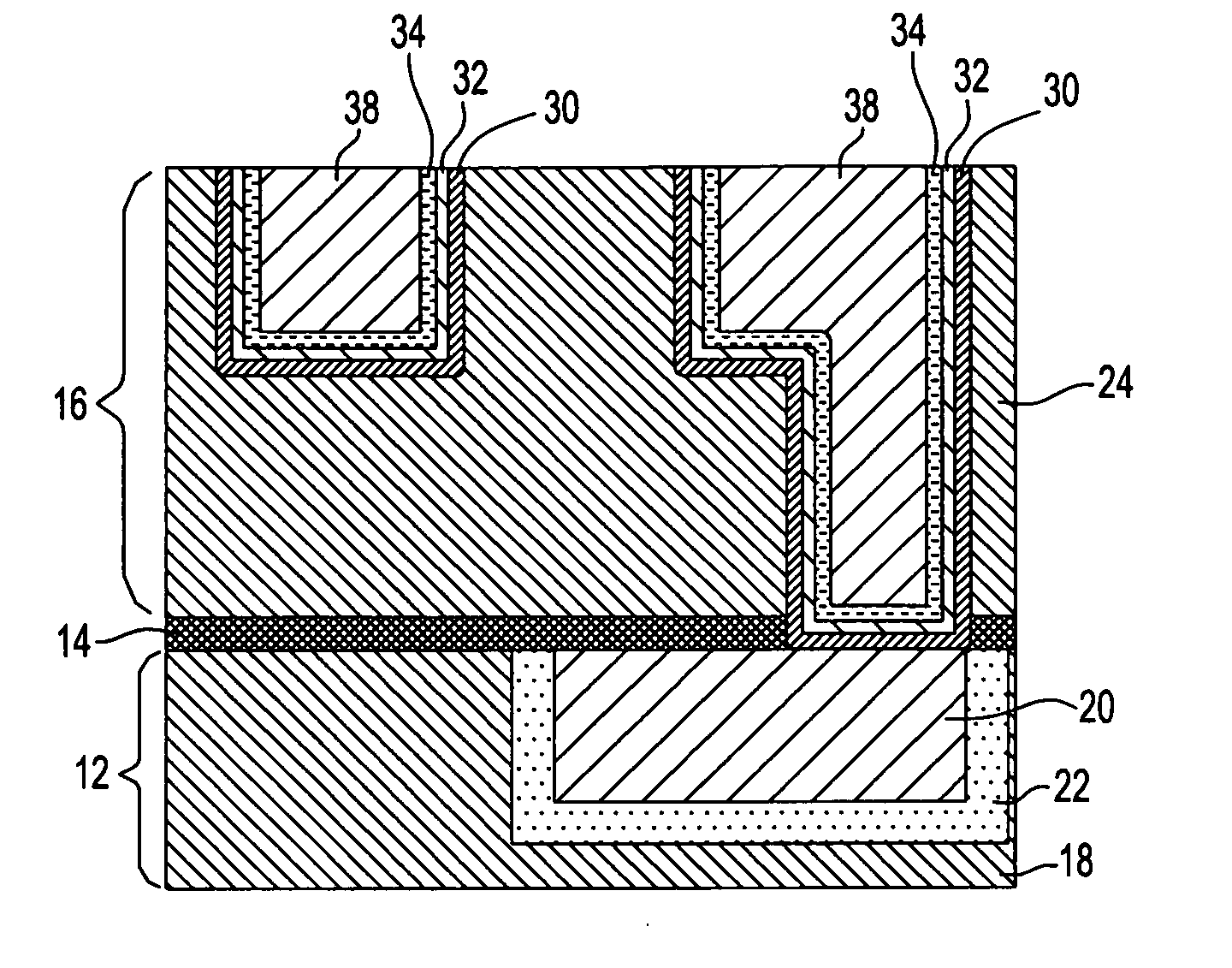

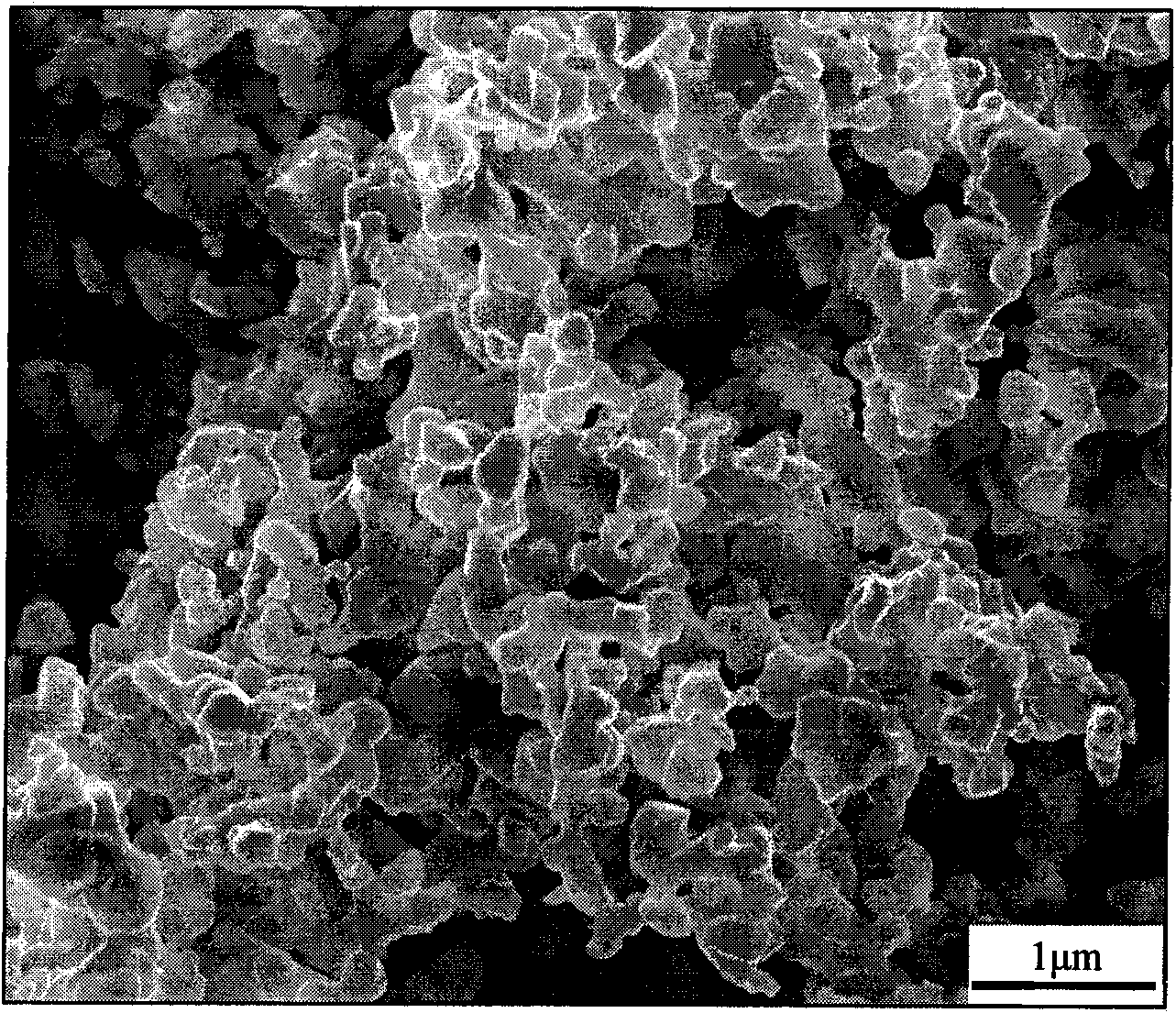

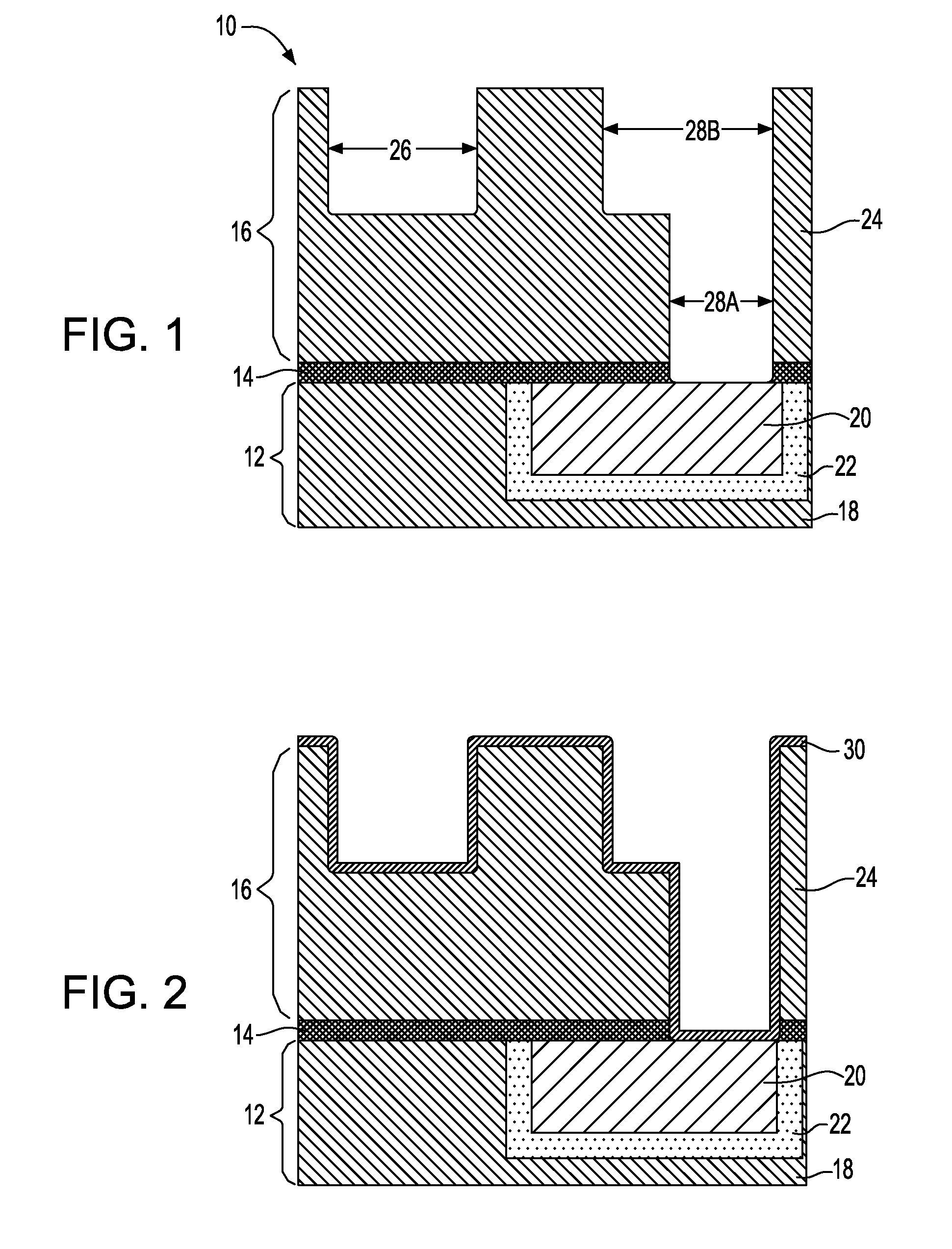

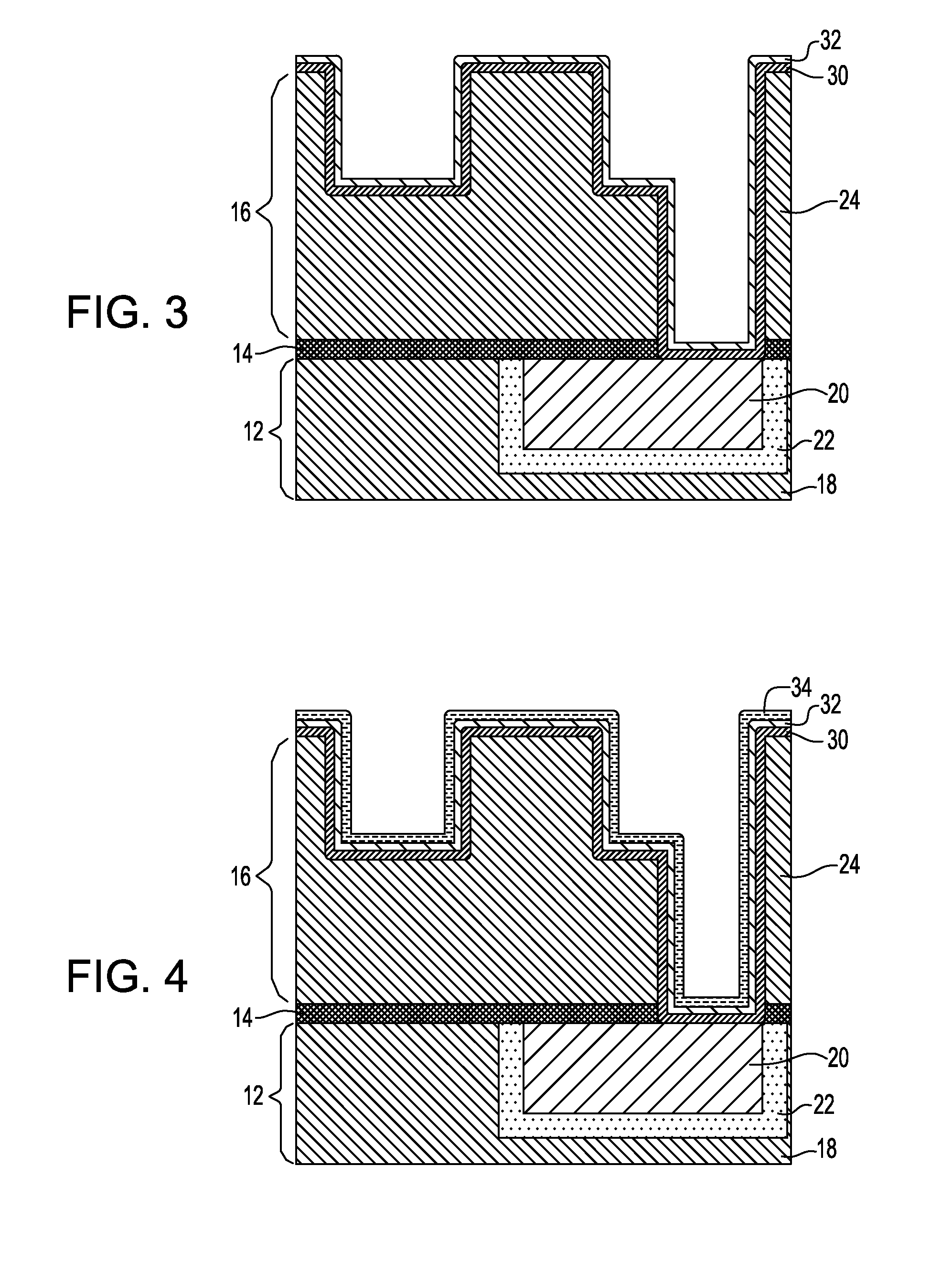

Method for forming a double-gated semiconductor device

A method for forming a polysilicon FinFET (10) or other thin film transistor structure includes forming an insulative layer (12) over a semiconductor substrate (14). An amorphous silicon layer (32) forms over the insulative layer (12). A silicon germanium seed layer (44) forms in association with the amorphous silicon layer (32) for controlling silicon grain growth. The polysilicon layer arises from annealing the amorphous silicon layer (32). During the annealing step, silicon germanium seed layer (44), together with silicon germanium layer (34), catalyzes silicon recrystallization to promote growing larger crystalline grains, as well as fewer grain boundaries within the resulting polysilicon layer. Source (16), drain (18), and channel (20) regions are formed within the polysilicon layer. A double-gated region (24) forms in association with source (16), drain (18), and channel (20) to produce polysilicon FinFET (10).

Owner:NORTH STAR INNOVATIONS

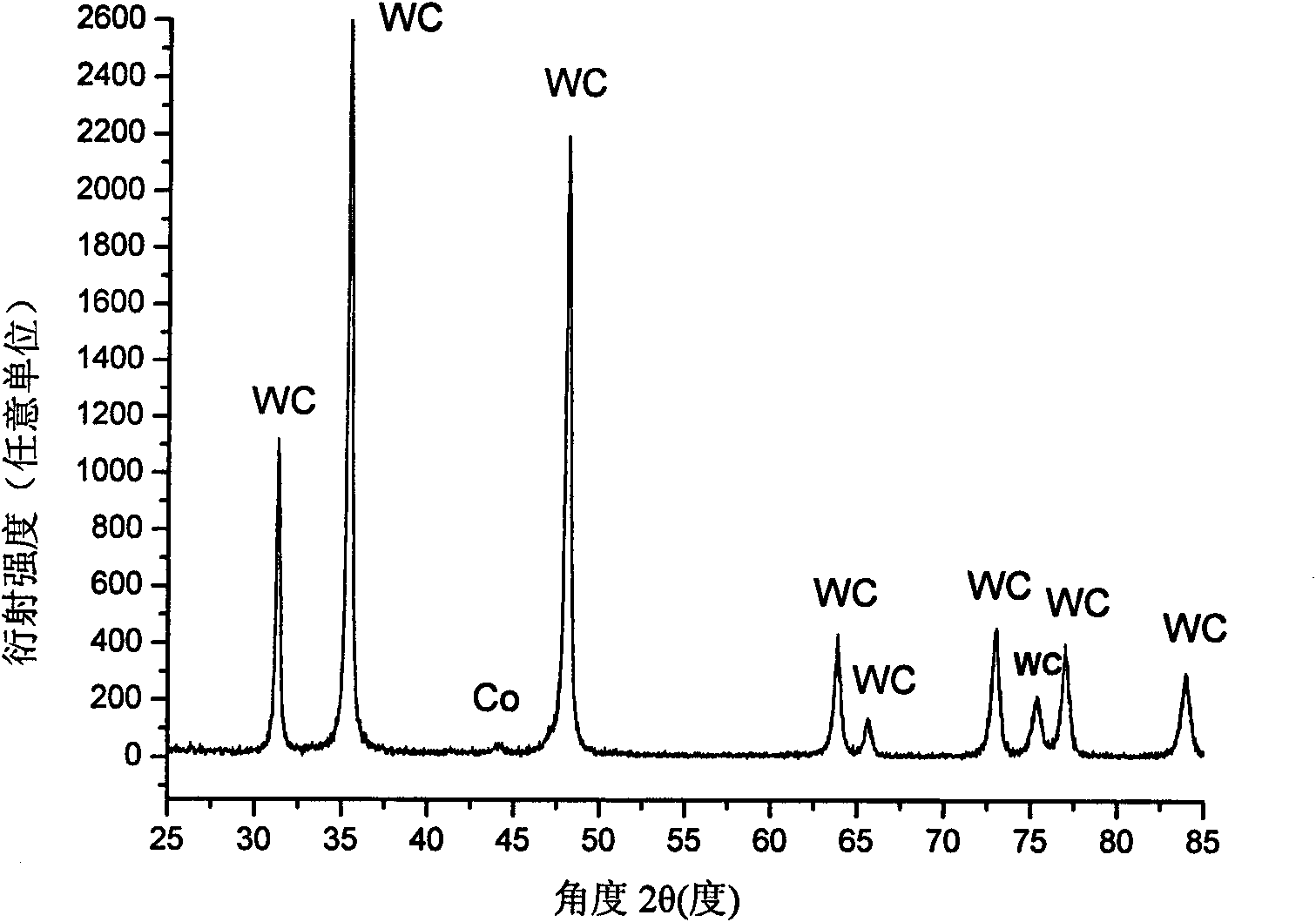

Superfine WC-Co cemented carbide containing rare-earth elements and preparation method thereof

ActiveCN101760685AChange processSteady improvement in overall performanceRare-earth elementChemical reaction

The invention discloses a superfine WC-Co cemented carbide containing rare-earth elements and a preparation method thereof, belonging to the technical field of cemented carbide. In the cemented carbide, the weight of WC rigid phase accounts for 85-94% of that of the cemented carbide, the weight of Co binder phase accounts for 5-14% of that of the cemented carbide, the weight of grain growth inhibitor accounts for 0.3-2.0% of that of the cemented carbide, and the weight of the thulium in the rare earth addition accounts for 0.2-1.2% of that of the Co binder phase. The method comprises the following steps: weighing various powder stocks, ball-milling, drying and pelletizing to form a compound; and suppressing and shaping the compound, sintering and cooling to obtain the cemented carbide. The adding mode of nano rare earth oxide or Co-RE composite powder can be implemented easily and conveniently, and the rare earth is diffusely and evenly distributed, thereby facilitating to perform physo-chemical reactions; and the cemented carbide has the advantages of low production cost, stable and enhanced performance and easy implementation, production and application.

Owner:GRIMAT ENG INST CO LTD

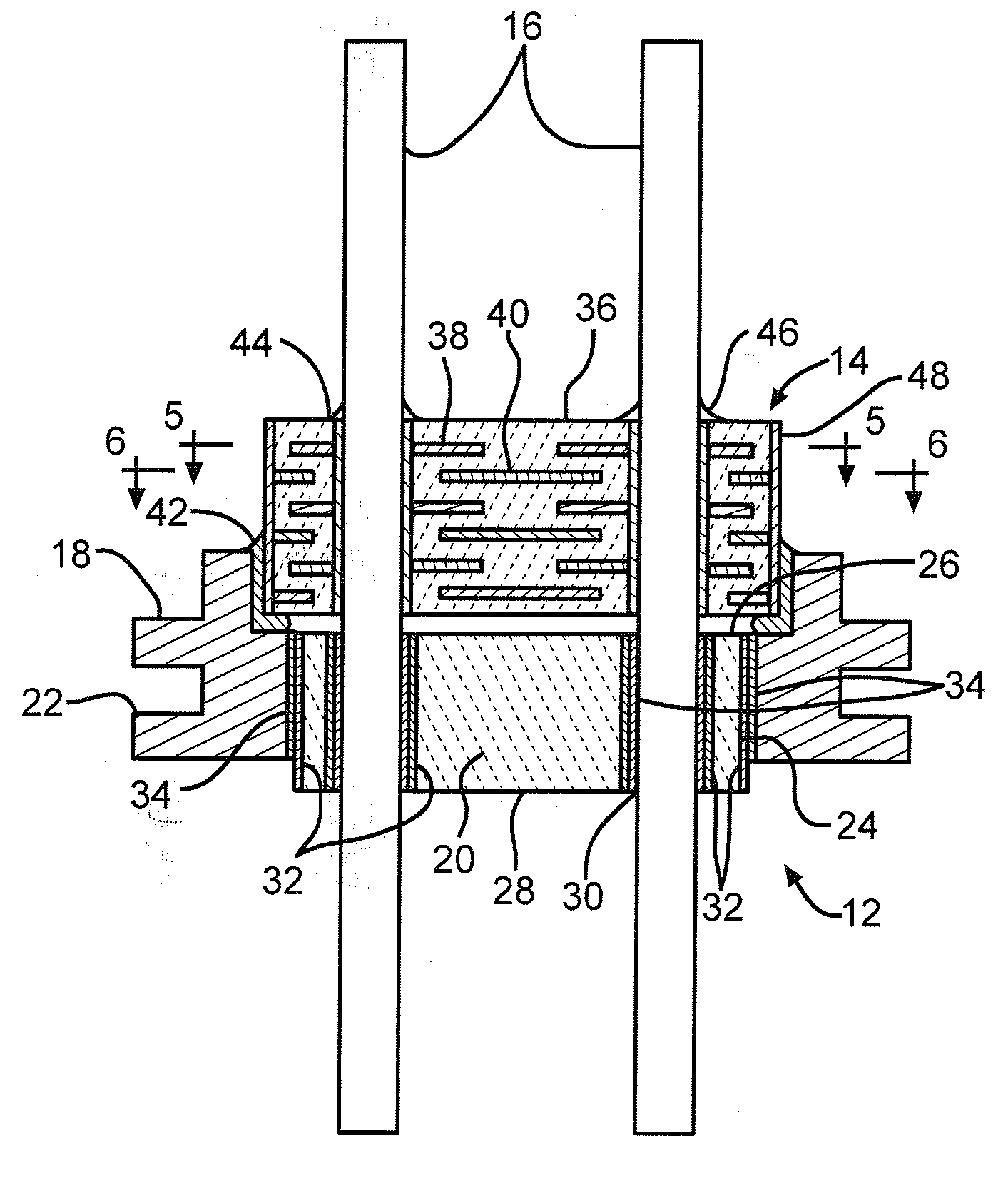

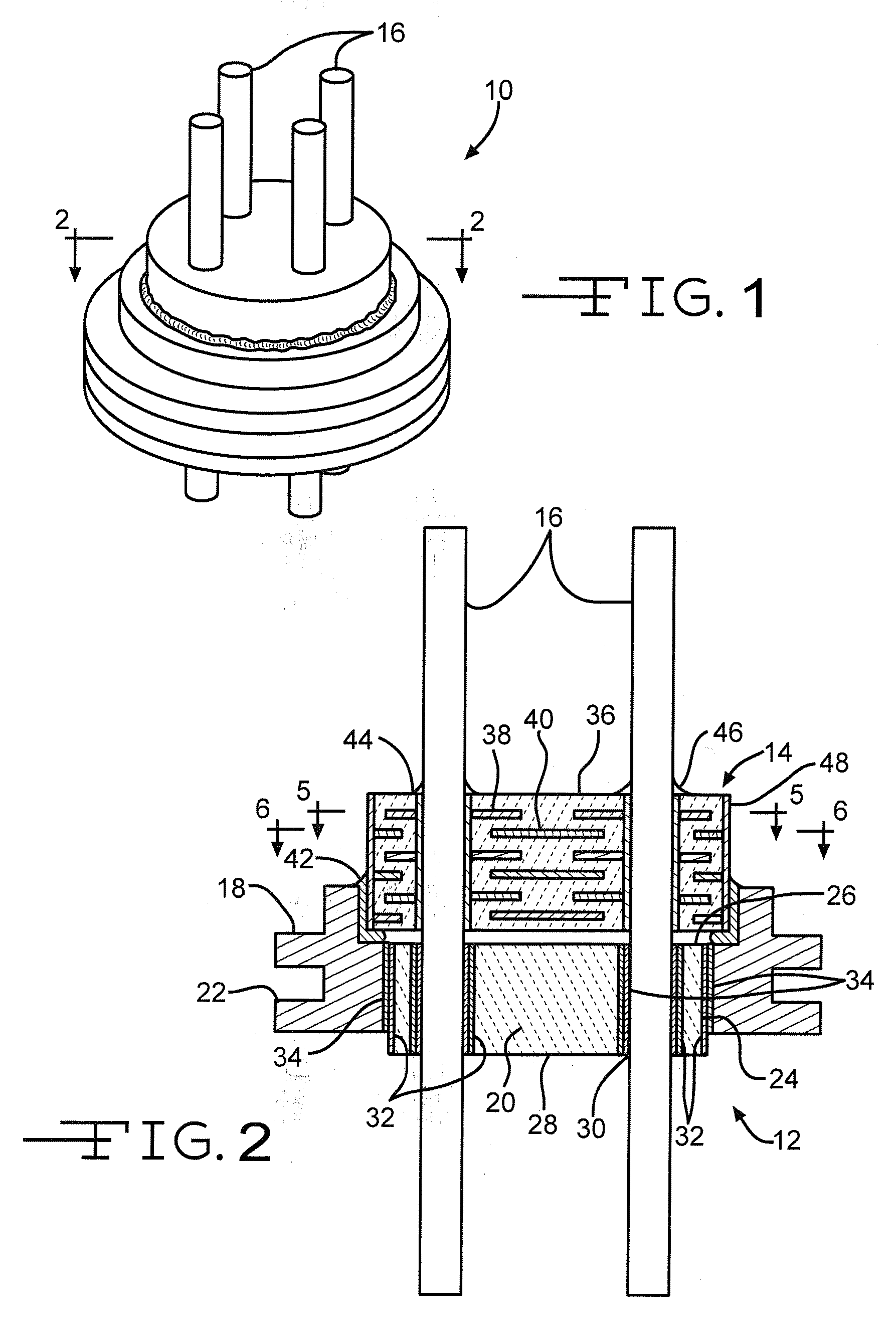

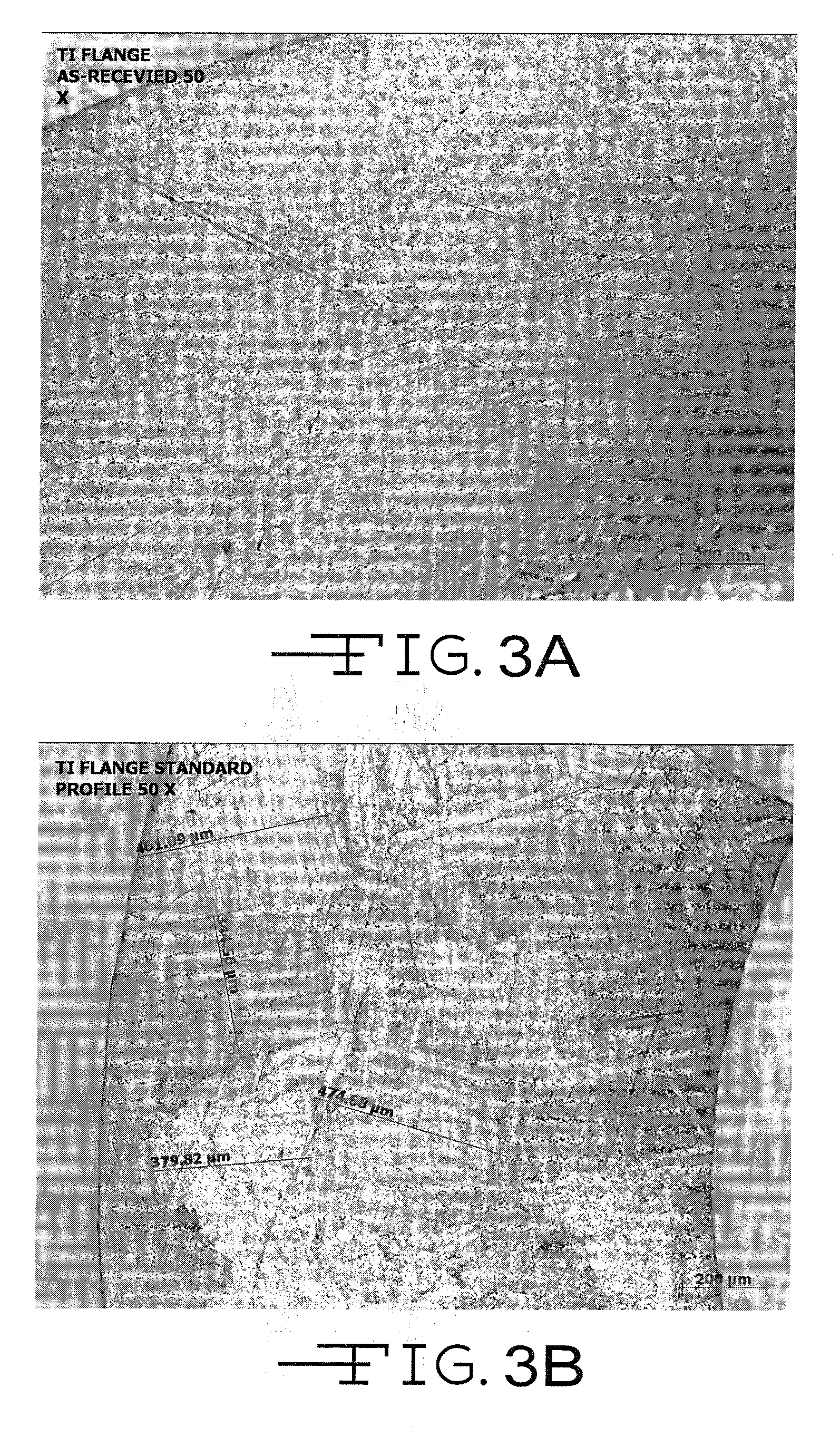

Nano-Titanium For Making Medical Implantable Hermetic Feedthrough Assemblies

InactiveUS20070183118A1Prevent leakagePrevent travelAnti-noise capacitorsFeed-through capacitorsCardiac pacemakerTi 6al 4v

Ferrules made of nano-titanium for incorporation into feedthrough filter capacitor assemblies are described. The feedthrough filter capacitor assemblies are particularly useful for incorporation into implantable medical devices such as cardiac pacemakers, cardioverter defibrillators, and the like, to decouple and shield internal electronic components of the medical device from undesirable electromagnetic interference (EMI) signals. Nano-titanium experiences significantly less grain growth after high temperature brazing in comparison to commercially pure (CP) titanium and the titanium alloy Ti-6Al-4V. For that reason, nano-titanium is an ideal material for use in implantable medical applications where high strength, structural integrity even after heating and corrosion resistance are desired.

Owner:WILSON GREATBATCH LTD

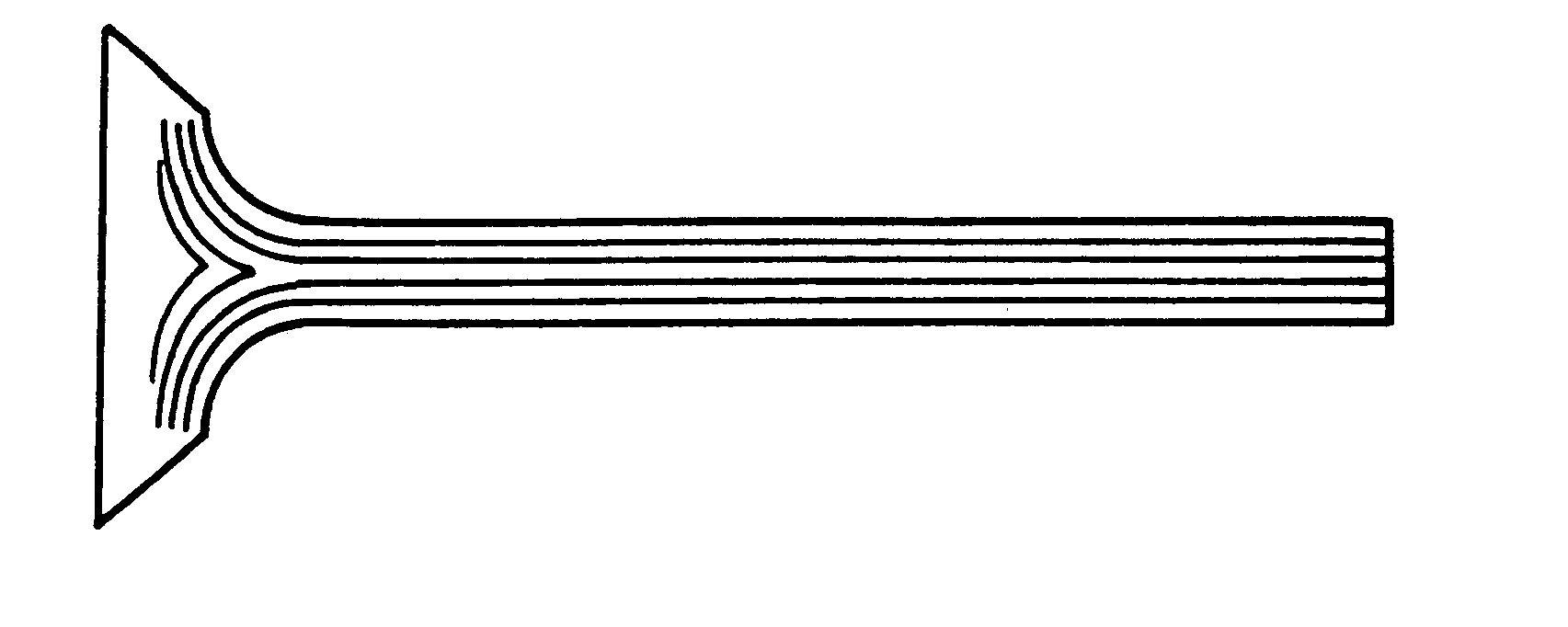

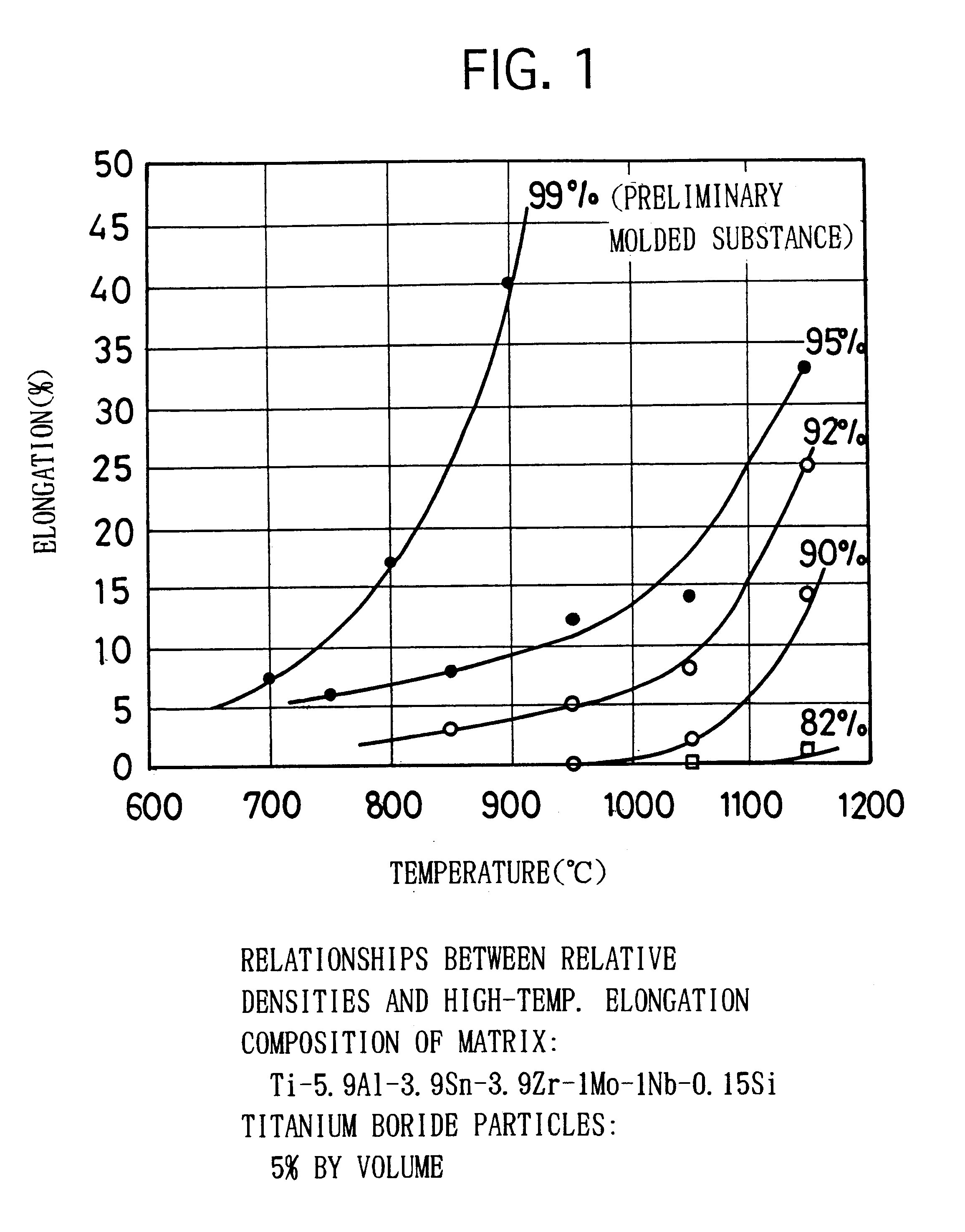

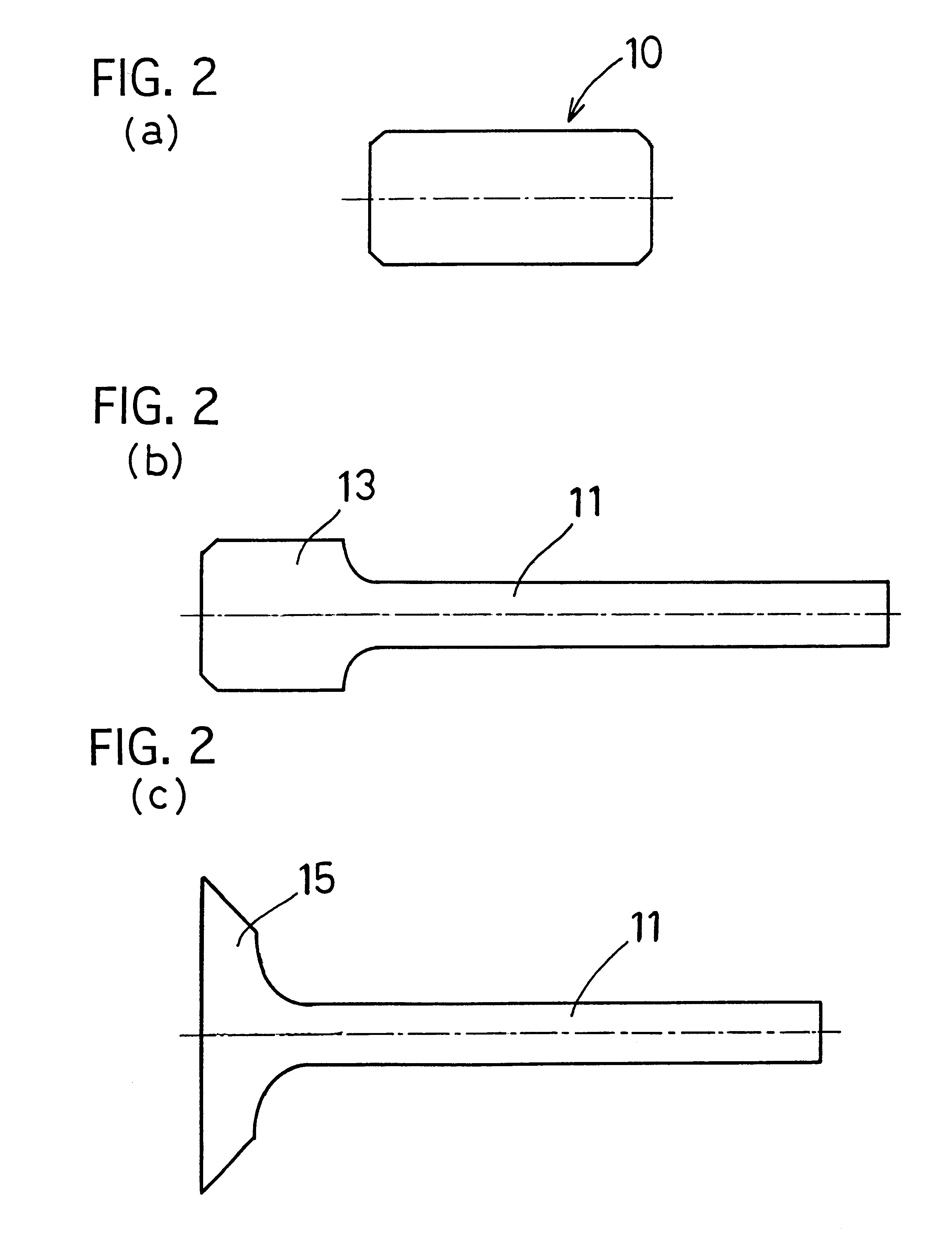

Process for forging titanium-based material, process for producing engine valve, and engine valve

InactiveUS6599467B1Degradation can be suppressedReduced strengthMetal-working apparatusMachines/enginesTitaniumEngine valve

The invention provides a process for forging a titanium-based material comprises the steps of: preparing a titanium-based sintered workpiece including at least one of ceramics particles and pores in a total amount of 1% or more by volume, the ceramics particles being thermodynamically stable in a titanium alloy; and heating the workpiece to a forging temperature and forging the same. In the production process, the pores or the ceramics particles inhibit the grain growth during forging. Accordingly, it is possible to carry out the forging at a relatively high temperature at which the titanium-based material exhibits a small resistance to deformation. Moreover, the titanium-based material can maintain an appropriate microstructure even after the forging. Consequently, the impact value and the fatigue strength are inhibited from decreasing.

Owner:TOYOTA JIDOSHA KK +1

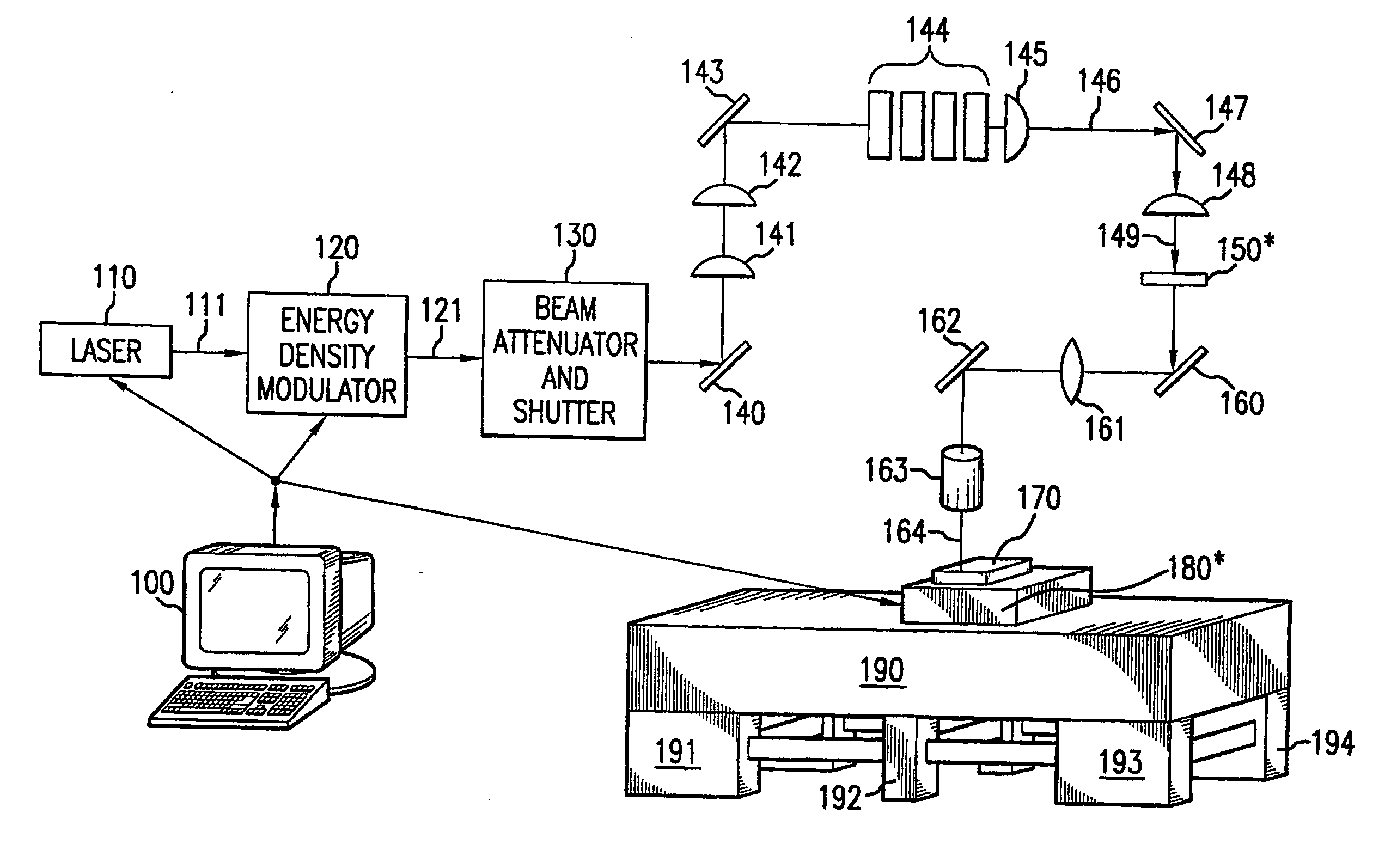

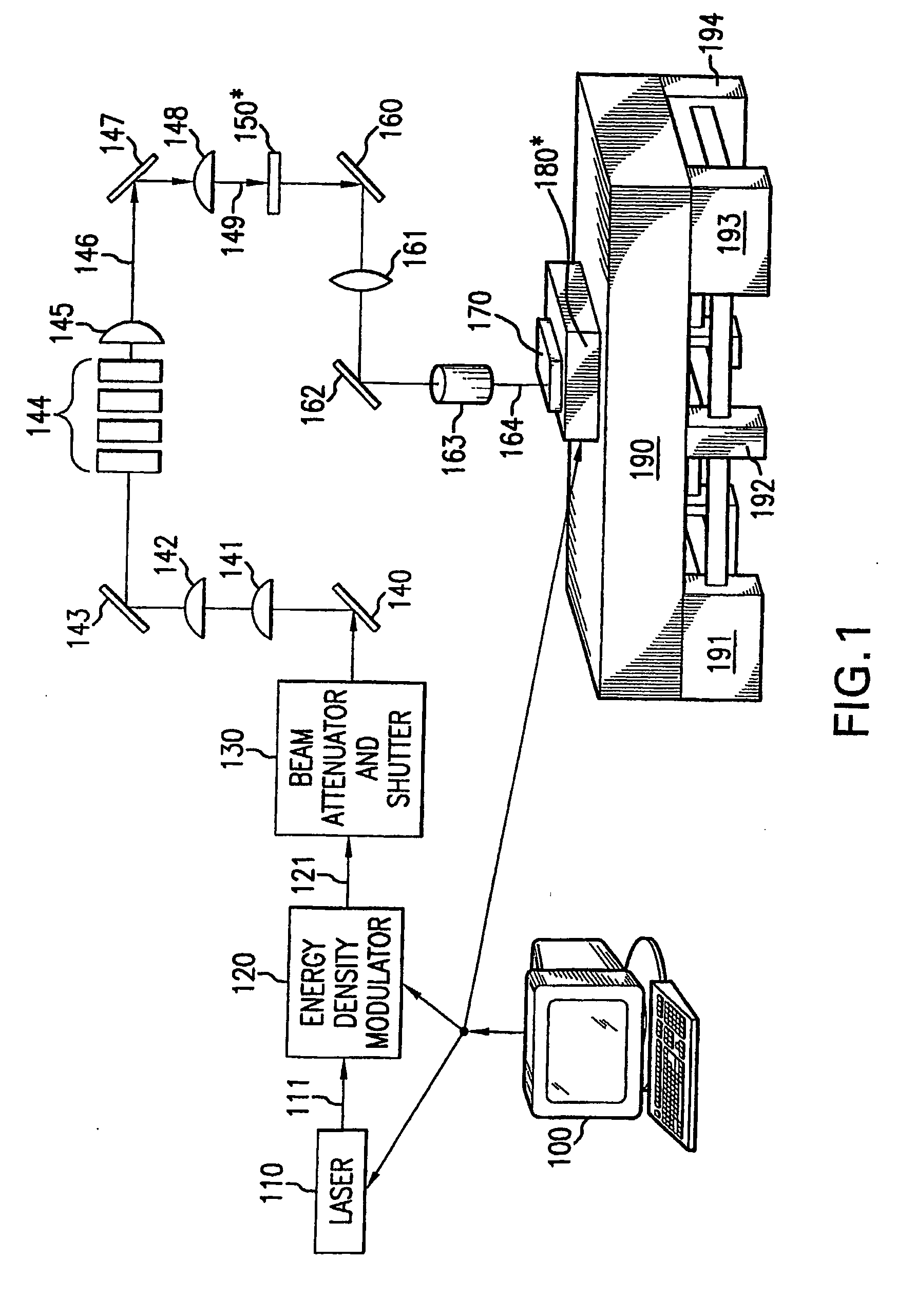

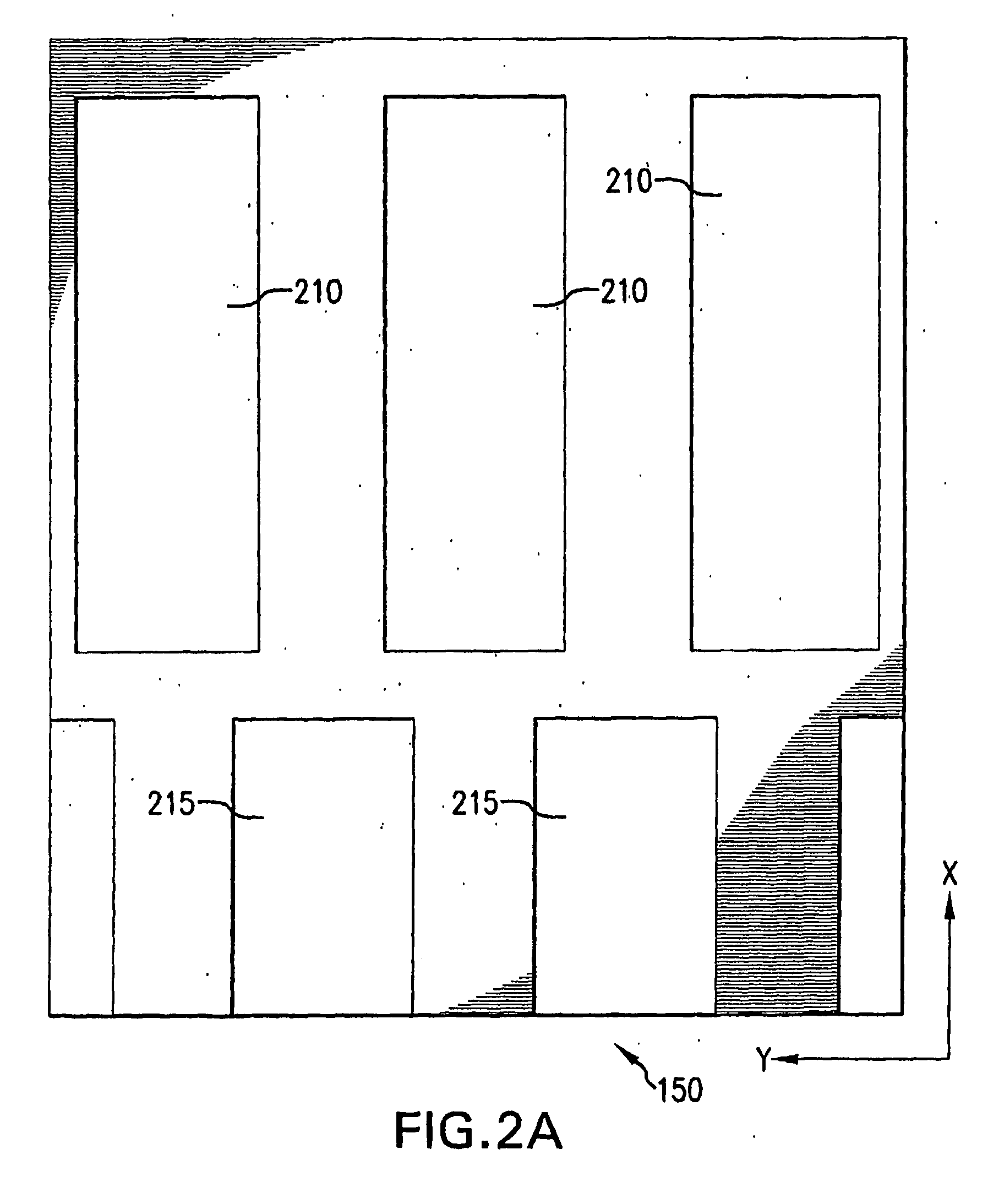

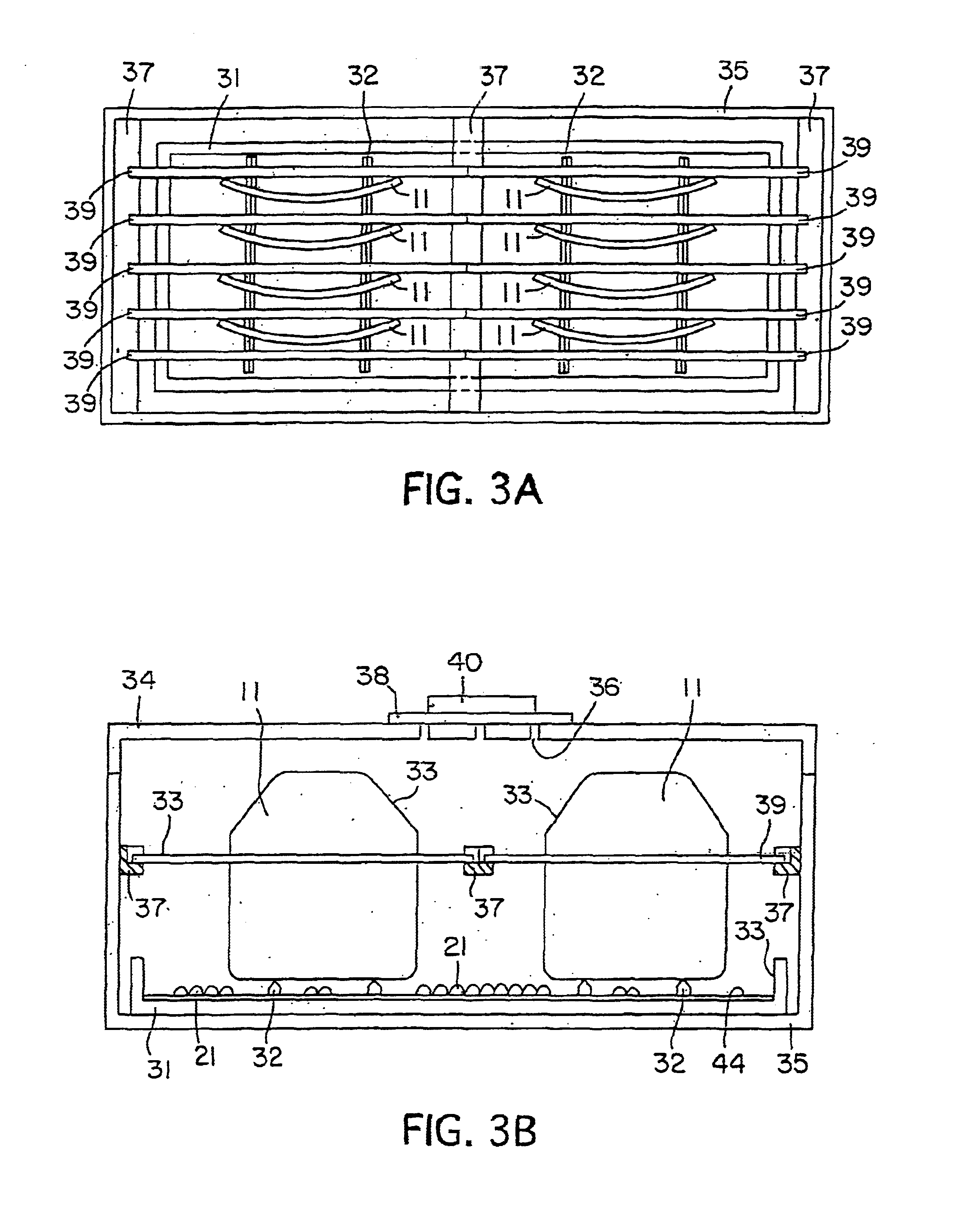

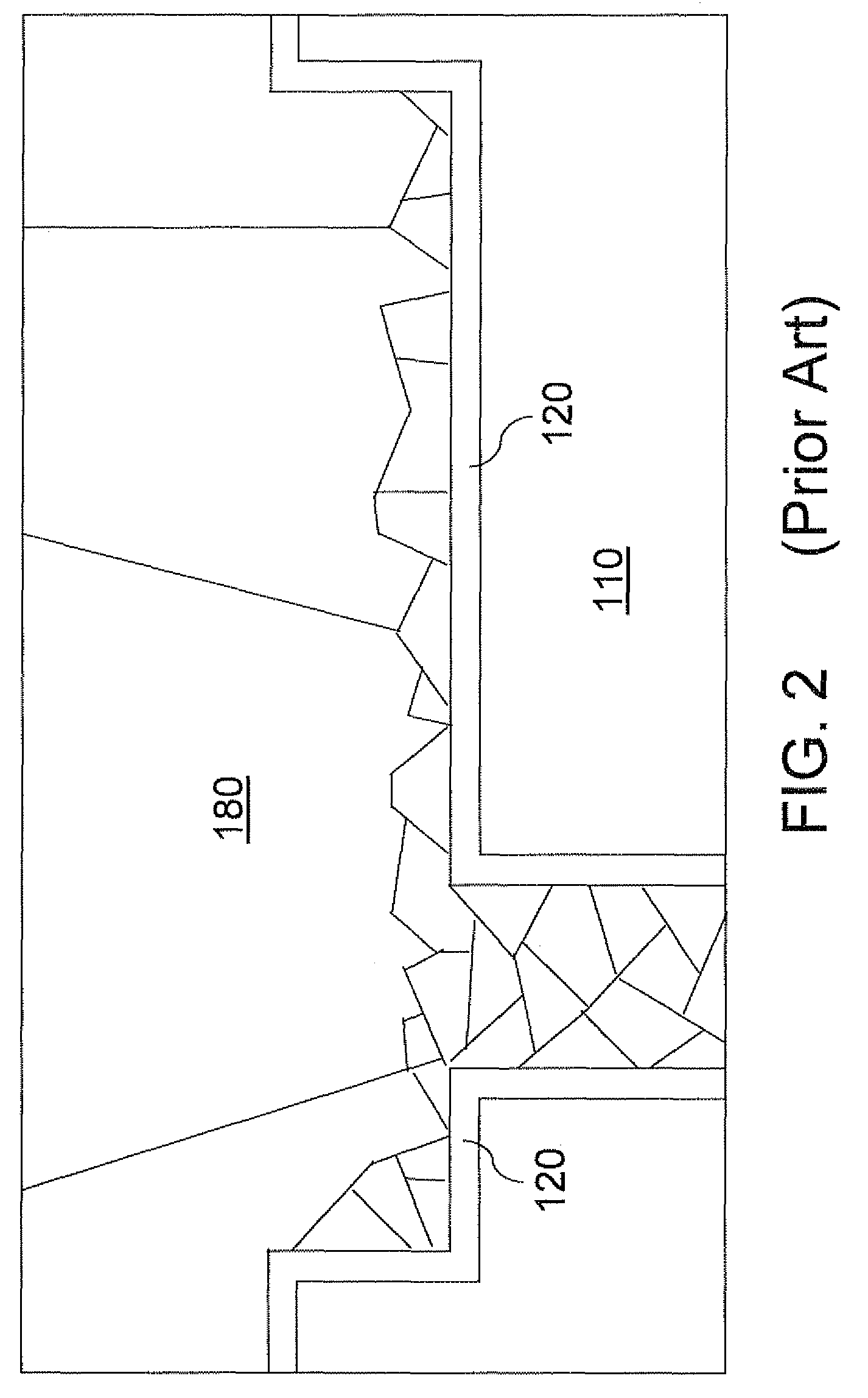

Method and system for providing a continuous motion sequential lateral solidification for reducing or eliminating artifacts, and a mask for facilitating such artifact reduction/elimination

InactiveUS20070020942A1Reduce and eliminate artifactArtifact is reduced and eliminatedSemiconductor/solid-state device manufacturingLaser beam welding apparatusComputer scienceGrain growth

An arrangement, process and mask for implementing single-scan continuous motion sequential lateral solidification of a thin film provided on a sample such that artifacts formed at the edges of the beamlets irradiating the thin film are significantly reduced. According to this invention, the edge areas of the previously irradiated and resolidified areas which likely have artifacts provided therein are overlapped by the subsequent beamlets. In this manner, the edge areas of the previously resolidified irradiated areas and artifacts therein are completely melted throughout their thickness. At least the subsequent beamlets are shaped such that the grains of the previously irradiated and resolidified areas which border the edge areas melted by the subsequent beamlets grow into these resolidifying edges areas so as to substantially reduce or eliminate the artifacts.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

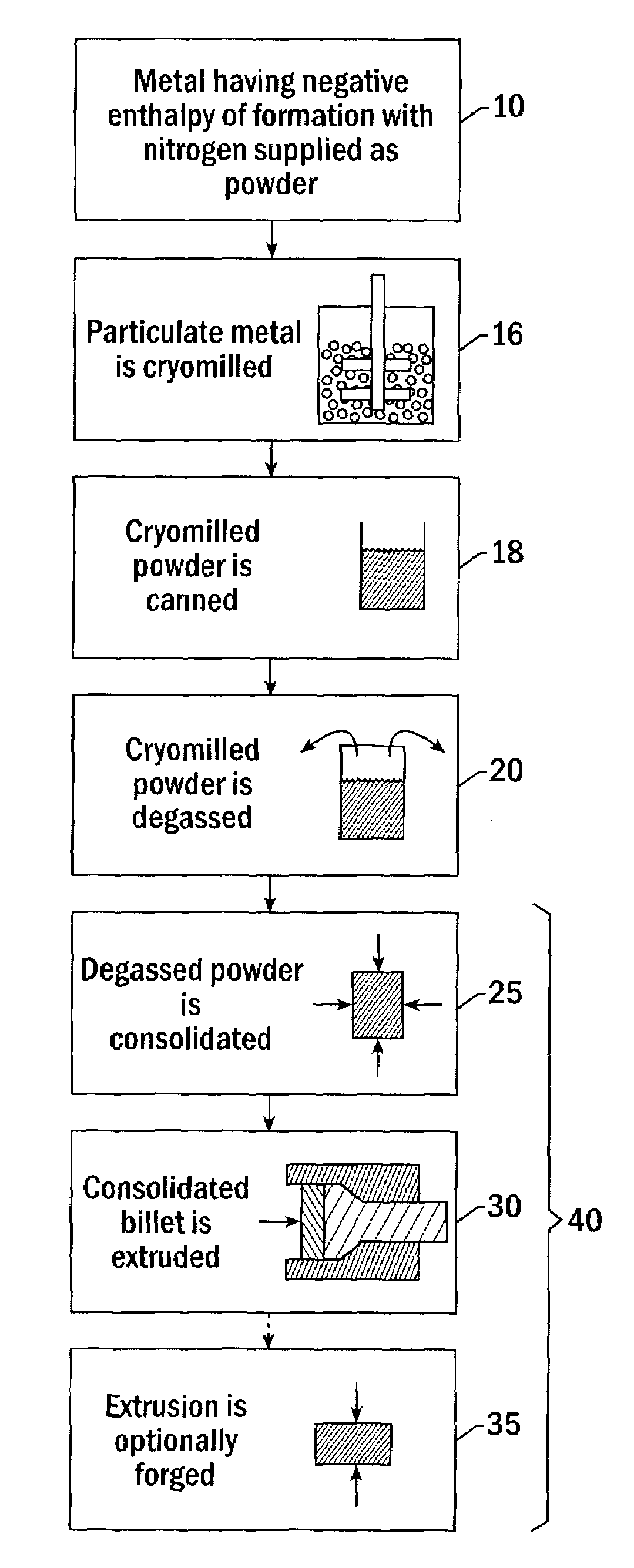

Method for preparing nanostructured metal alloys having increased nitride content

InactiveUS7344675B2Reduce grain growthHigh strengthTransportation and packagingMetal-working apparatusMetal alloyHigh intensity

A method of producing high strength nanophase metal alloy powder by cryomilling metal powder under conditions which cause the formation of intrinsic nitrides, and of producing high strength metal articles by subjecting the nitrided cryomilled powder to thermo-mechanical processing. The intrinsic nitrides present within the alloy significantly reduce grain growth during thermo-mechanical processing, resulting in formed metal products of high strength and improved ductility.

Owner:THE BOEING CO

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

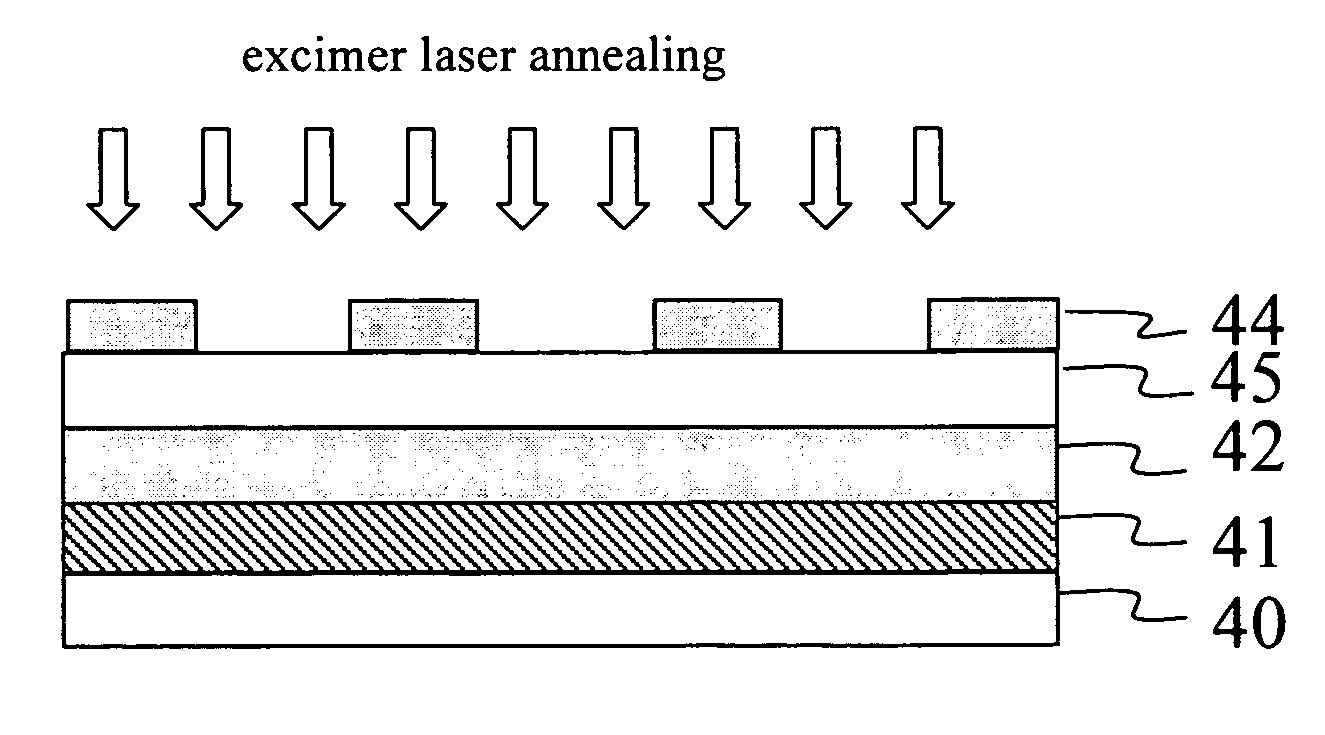

Polysilicon thin film fabrication method

ActiveUS7192818B1Excellent electrical propertiesElectrical uniformitySolid-state devicesSemiconductor/solid-state device manufacturingHeat conductingAmorphous silicon

A polysilicon thin film fabrication method is provided, in which a heat-absorbing layer is used to provide sufficient heat for grain growth of an amorphous silicon thin film, and an insulating layer is used to isolate the heat-absorbing layer and the amorphous silicon thin film. A regular heat-conducting layer is used as a cooling source to control the crystallization position and grain size of the amorphous silicon thin film. Therefore, the amorphous silicon thin film can crystallize into a uniform polysilicon thin film, and the electrical characteristics of the polysilicon thin film can be stably controlled.

Owner:NAT TAIWAN UNIV

High-coercivity and high-stability neodymium iron boron magnet and preparation method based on crystal boundary reconstruction

ActiveCN103106991AImprove organizationImprove distributionPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementAlloy

The invention discloses a high-coercivity and high-stability neodymium iron boron magnet and a preparation method based on crystal boundary reconstruction. The preparation method comprises the steps of separating design and preparation of main alloy and crystal boundary phase alloy powder, nano-modification of crystal boundary phase, powder mixing, magnetic field profiling, isostatic pressing, sintering and thermal treatment. According to the high-coercivity and high-stability neodymium iron boron magnet and the preparation method is based on crystal boundary reconstruction and combines with a rich heavy rear earth novel crystal boundary phase and nano-modification technology, namely the rich heavy rare earth novel crystal boundary phase is redesigned and synthesized, in the process of magnetic sintering and tempering, magnetic hardening is achieved through spread of the heavy rare earth element to the boundary layers of the principle phase crystal grain, and thus a high-coercivity magnetic is prepared under the condition that no or less heavy rear earth is added in the principle phase. Meanwhile the distribution of the crystal boundary and the form of the crystal grain boundary are optimized through a nano-modification method, a pinning domain wall restrains counter magnetic field nucleation and crystal grain growth, and thus high coercivity and high stability of the neodymium iron boron is achieved. The high-coercivity and high-stability neodymium iron boron magnet and preparation method based on crystal boundary reconstruction is simple in process, low in cost and suitable for large-scale volume production.

Owner:ZHEJIANG UNIV

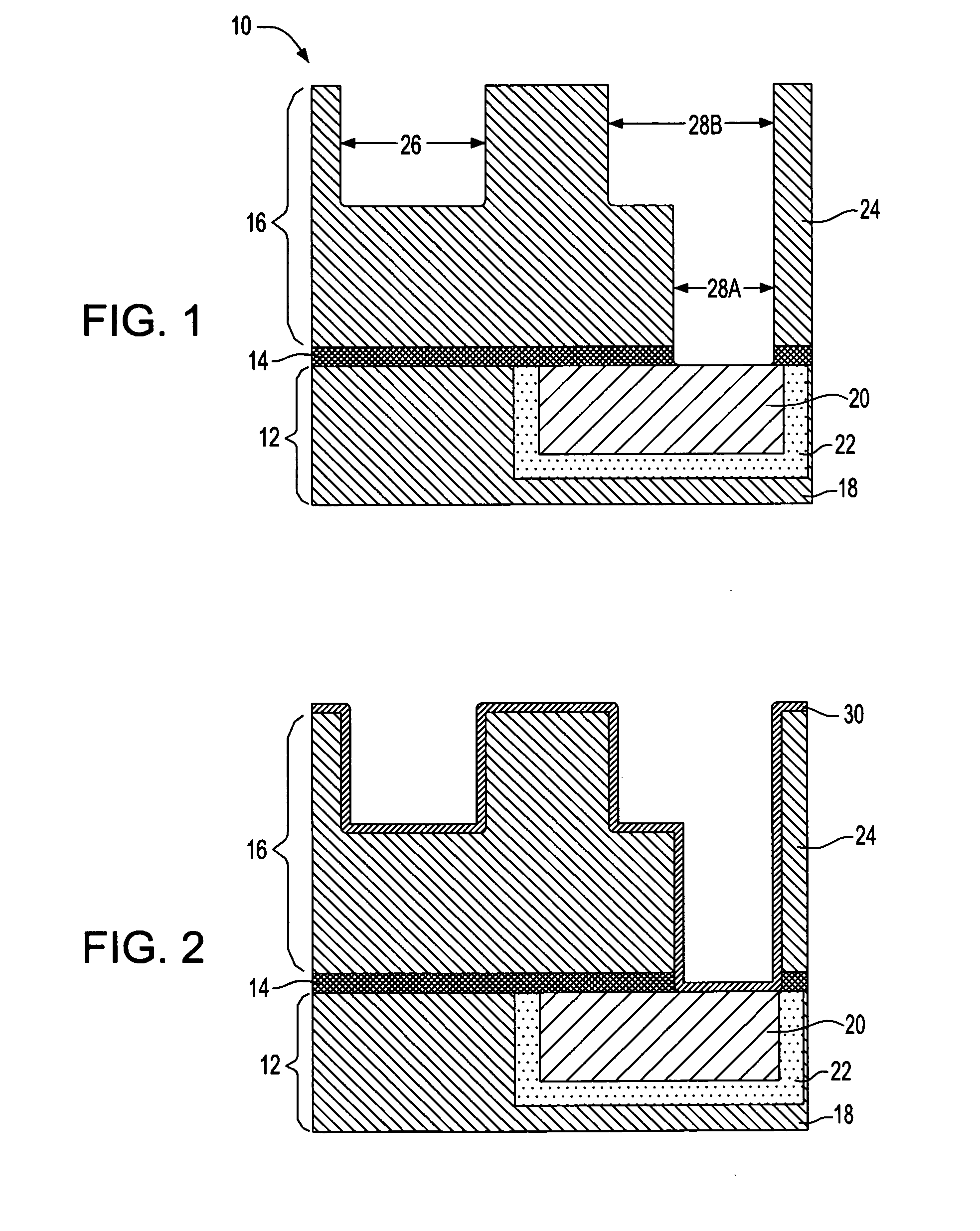

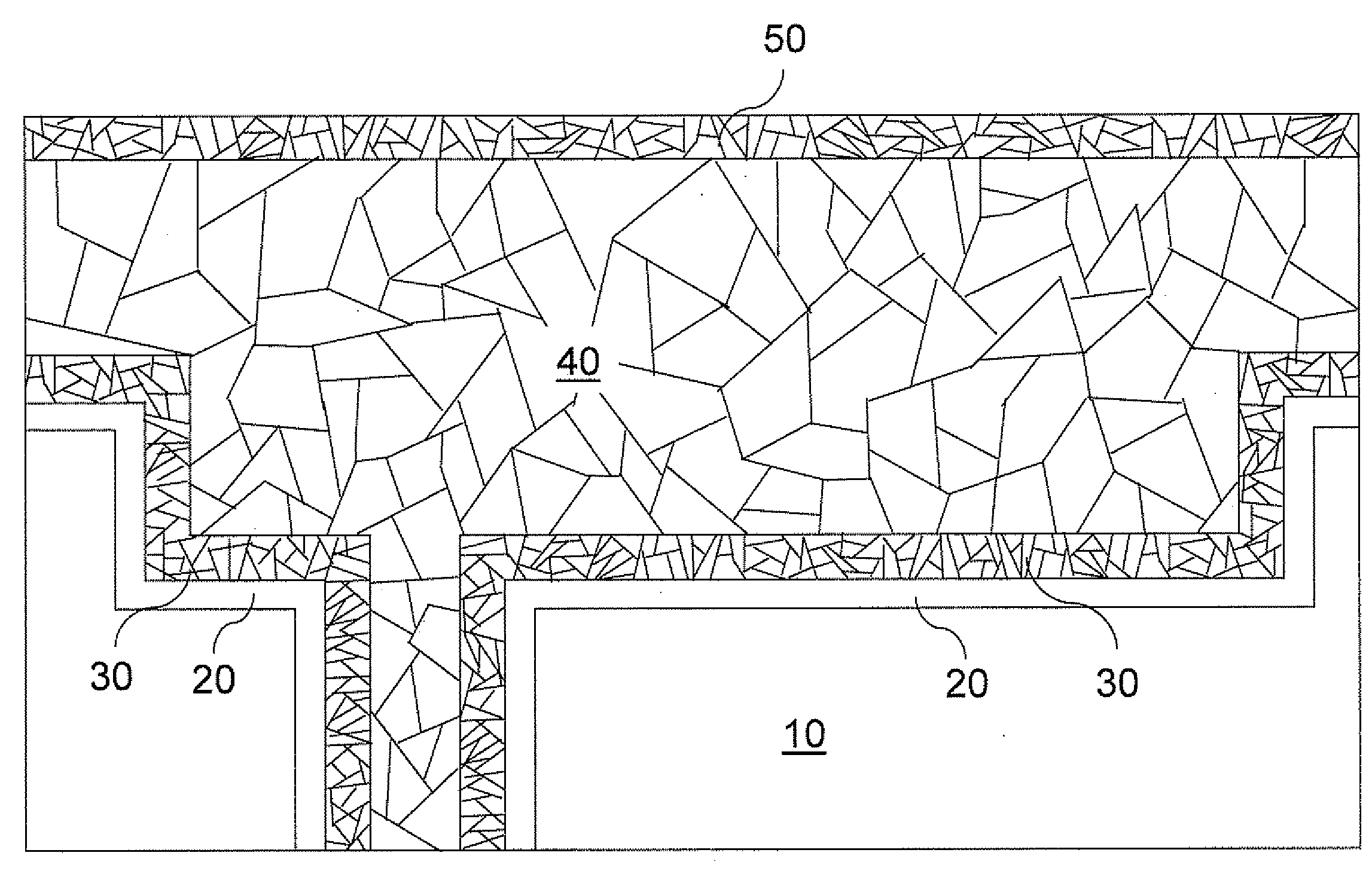

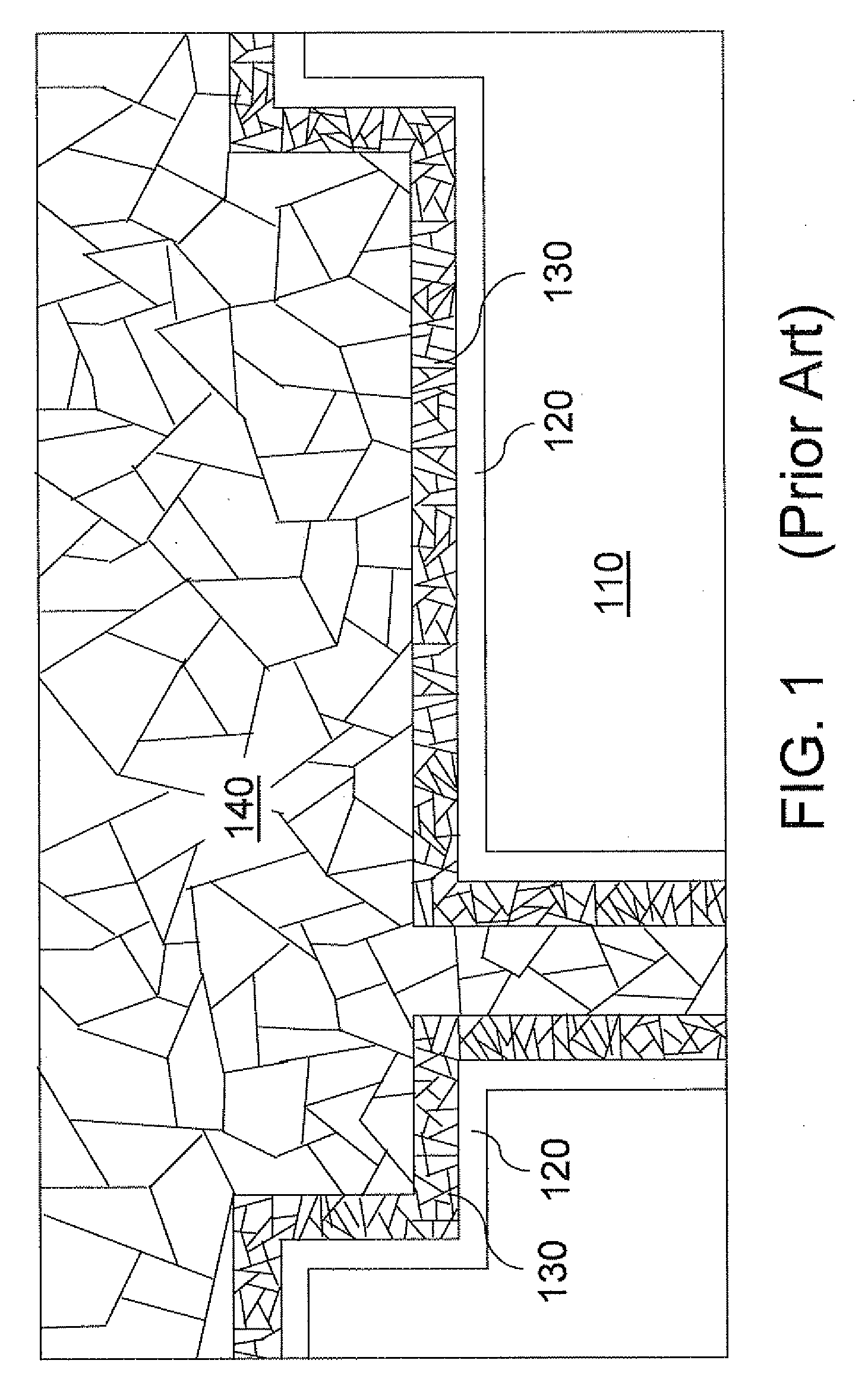

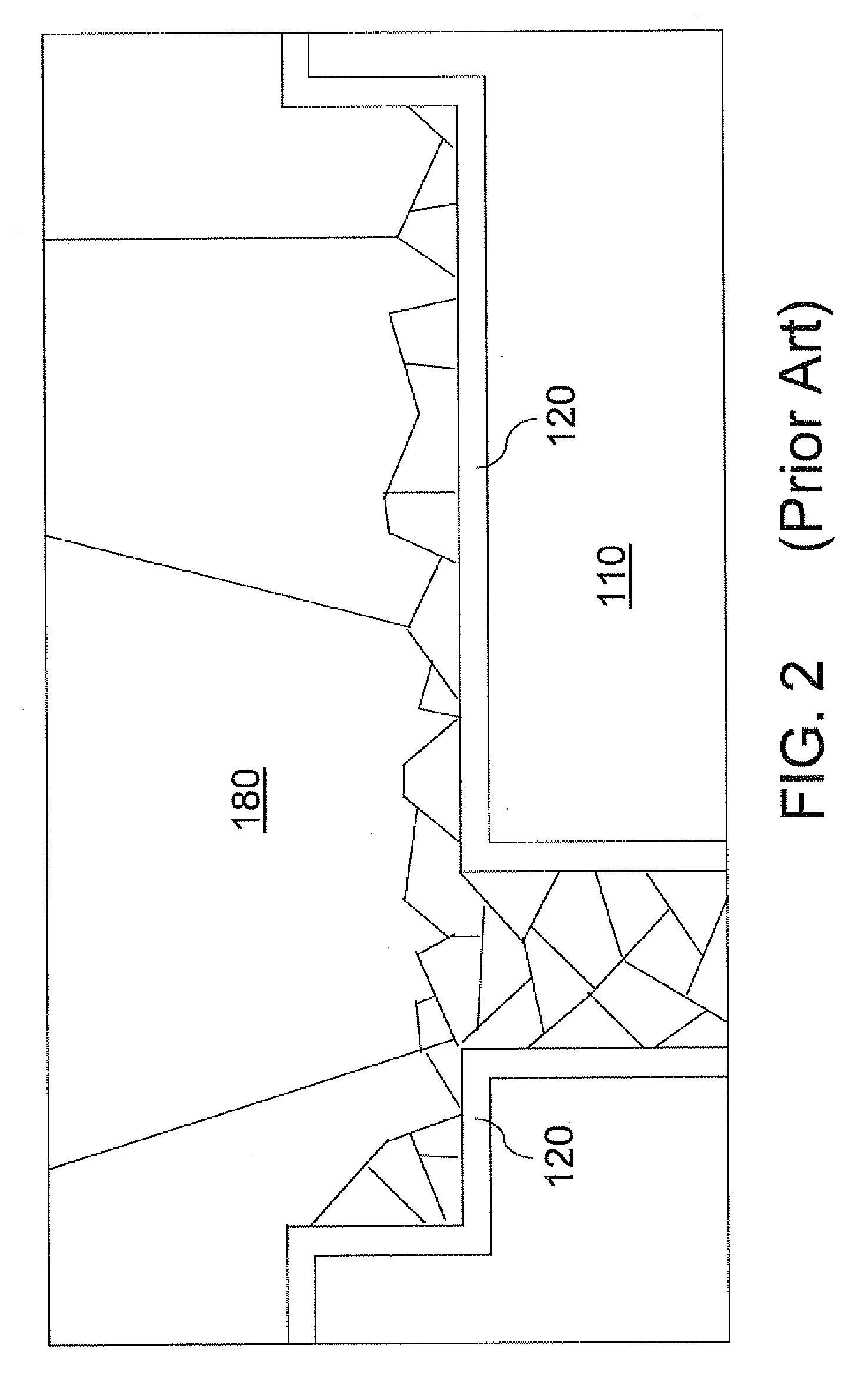

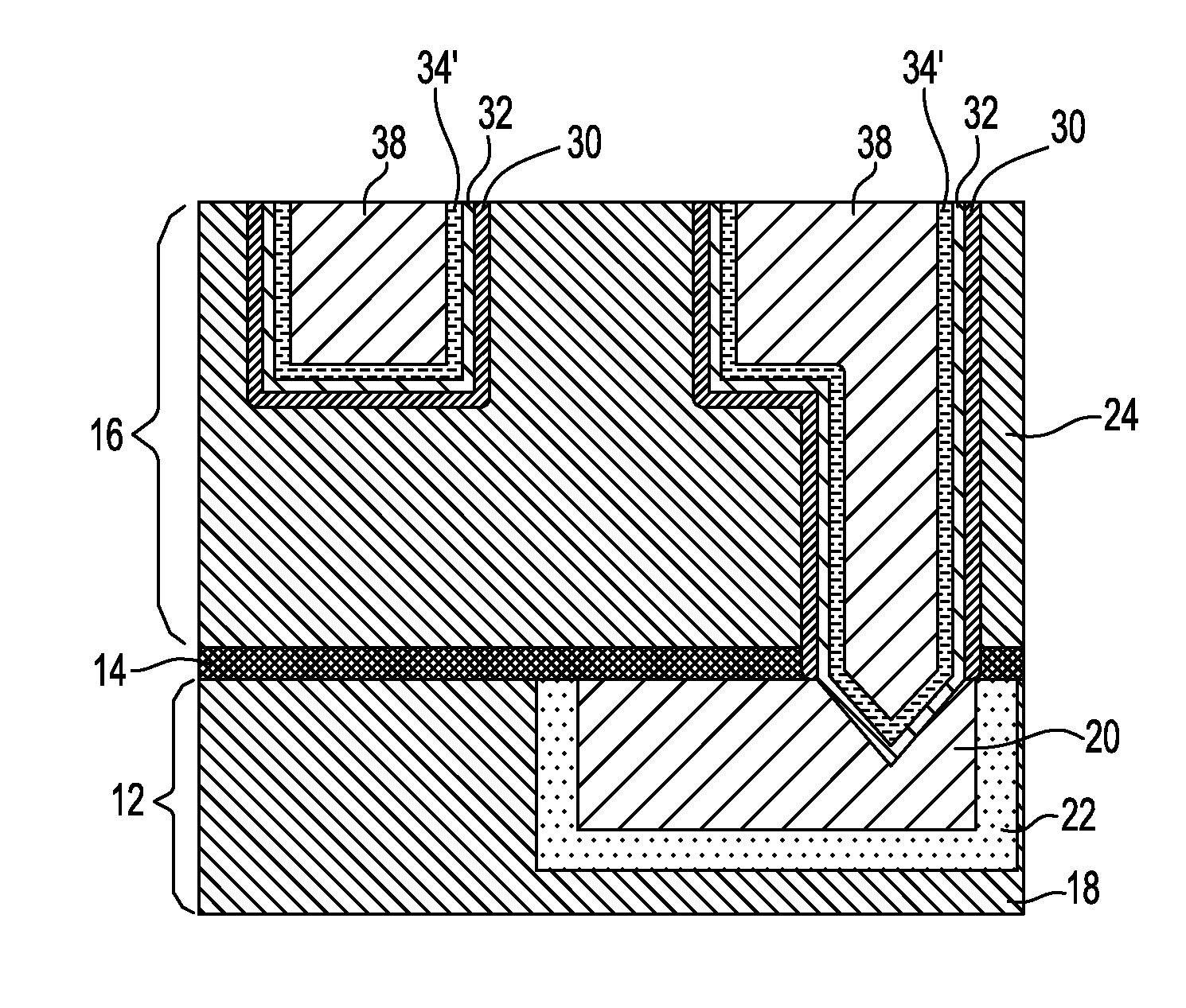

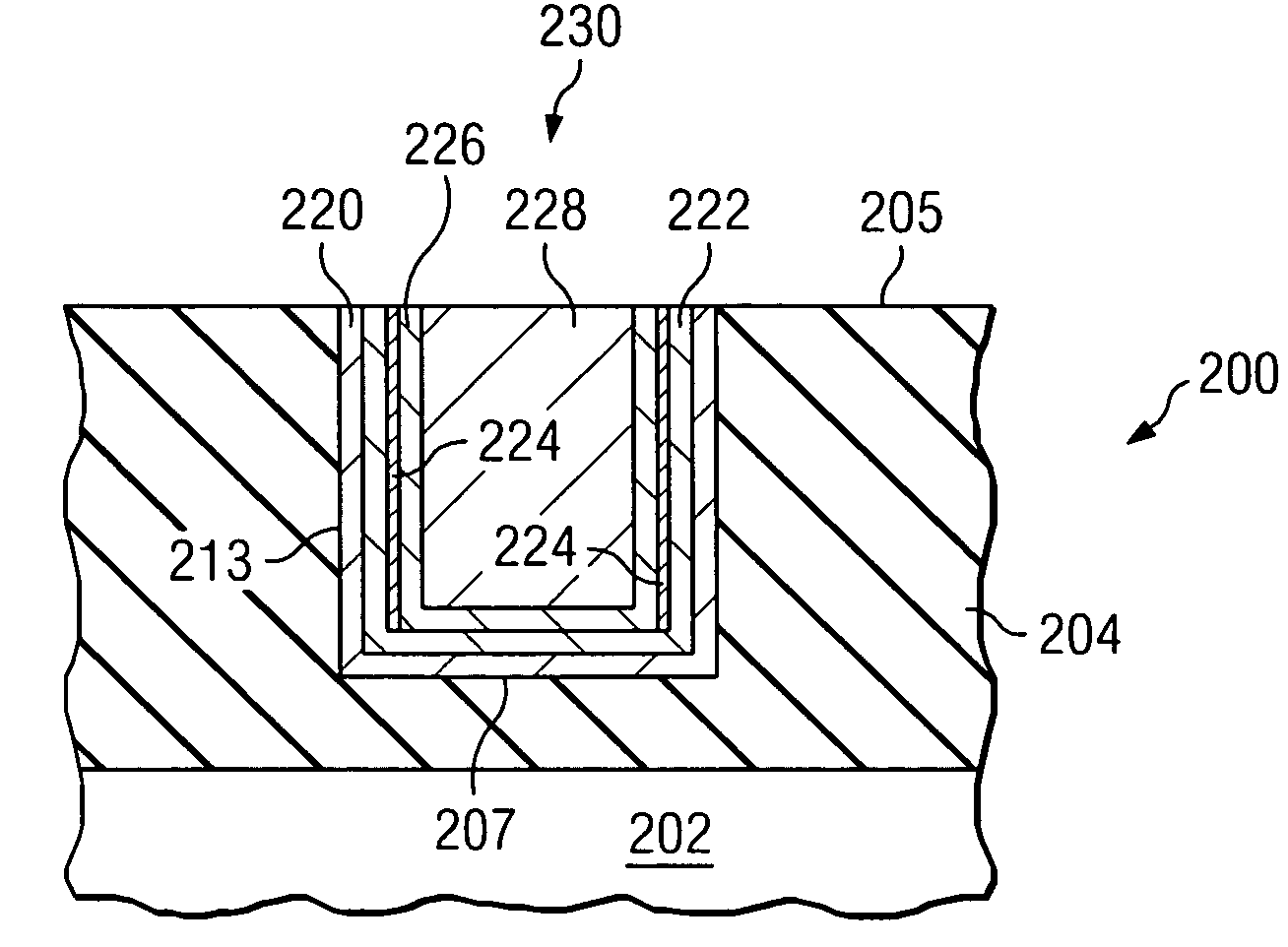

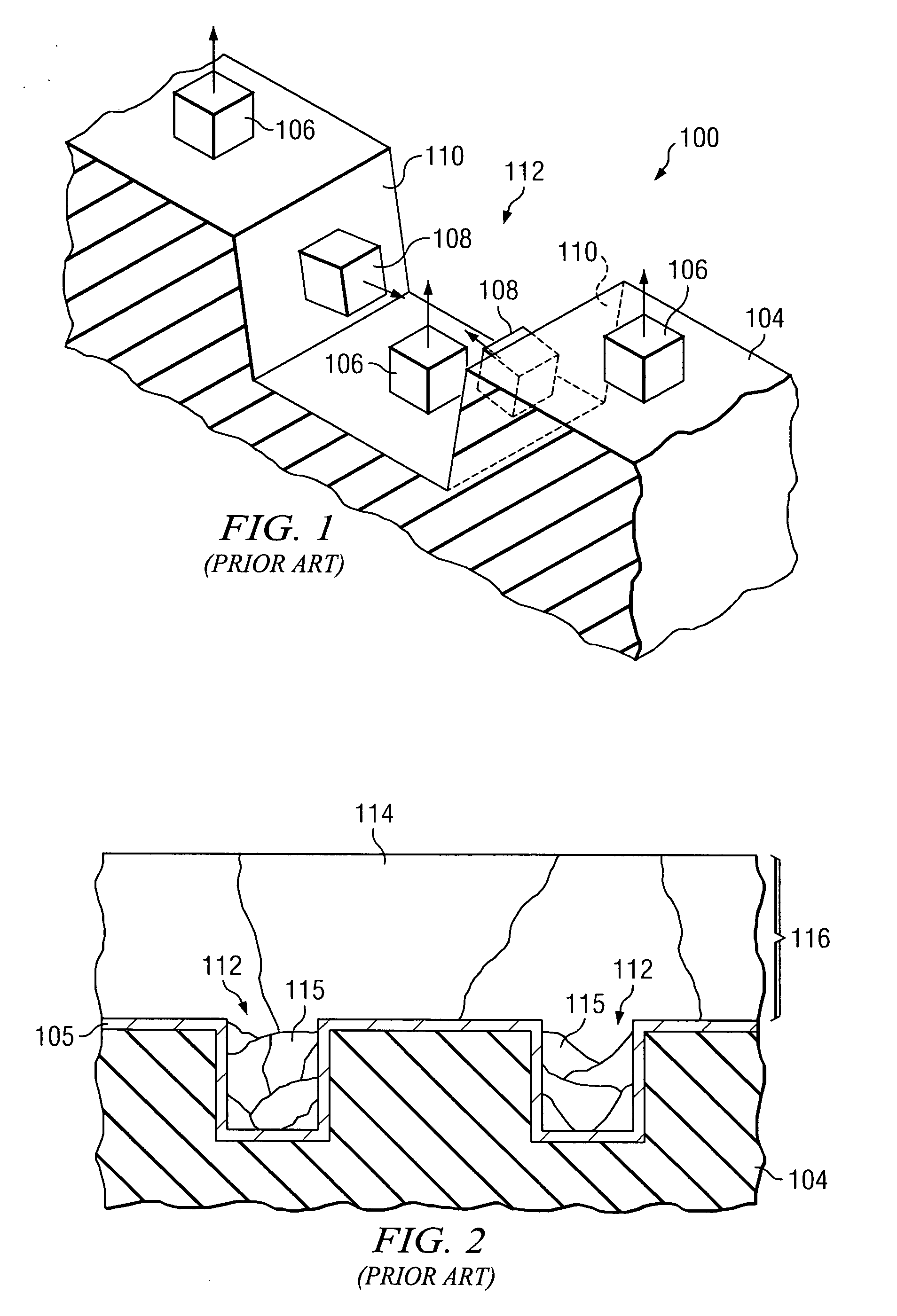

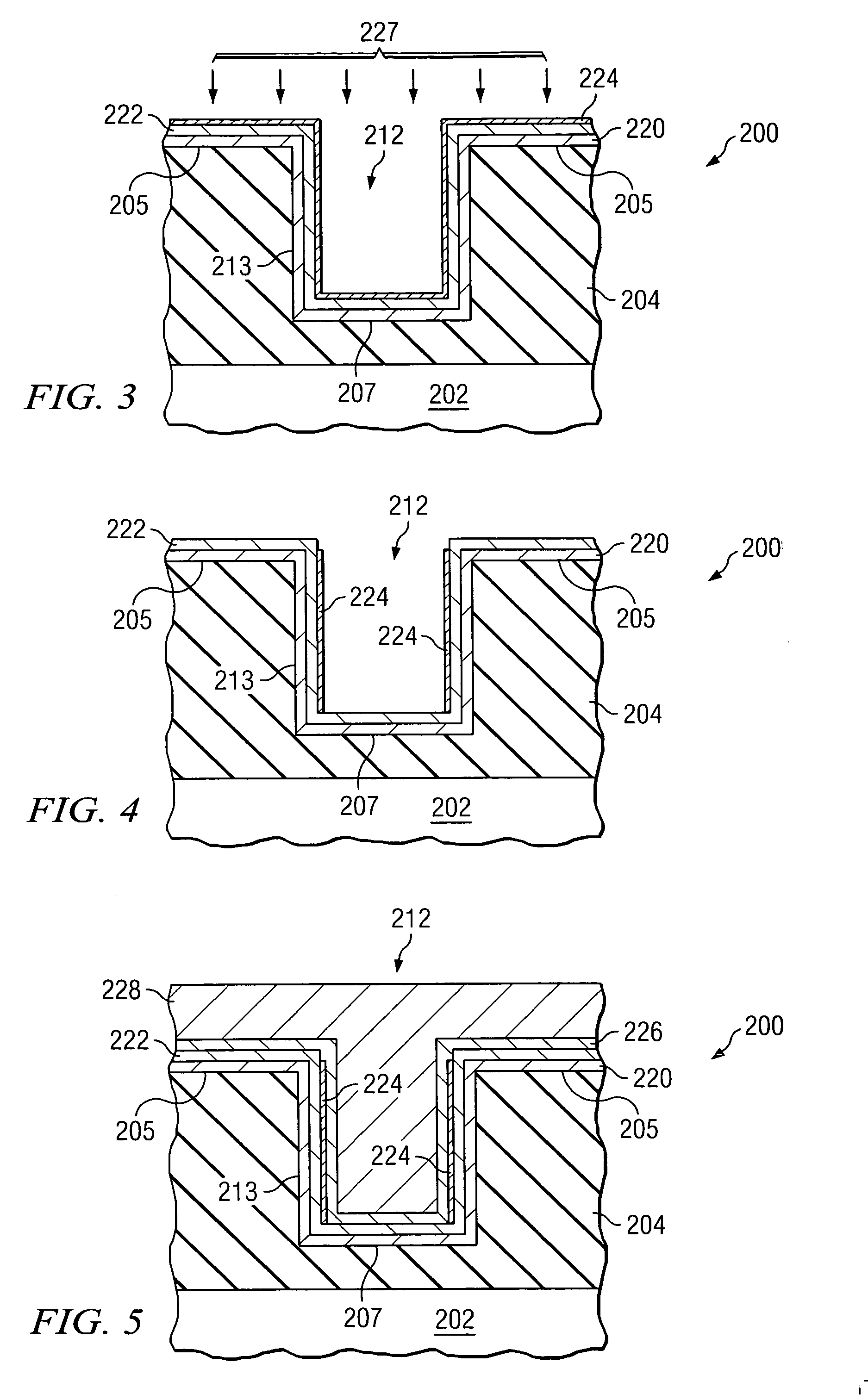

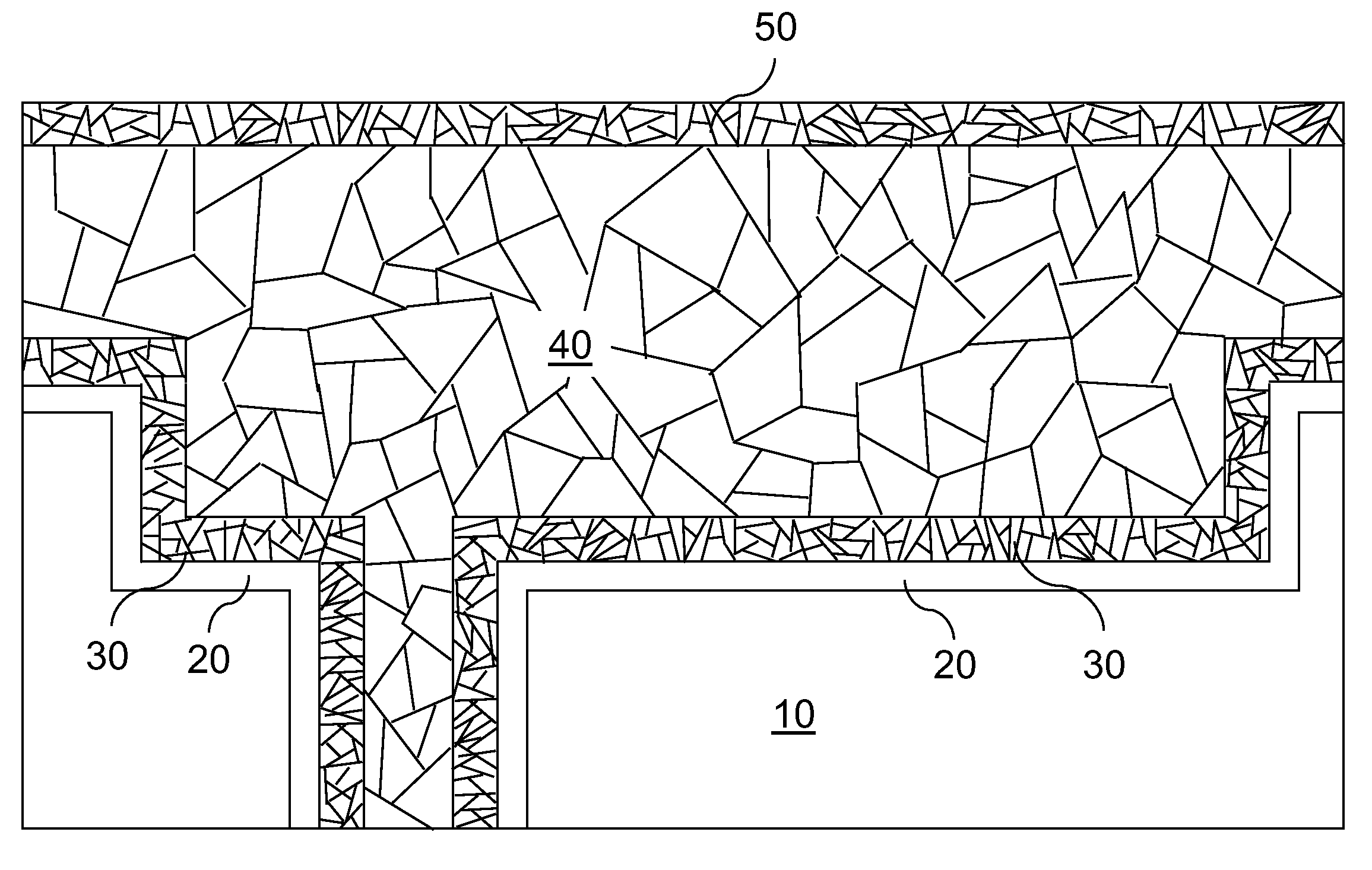

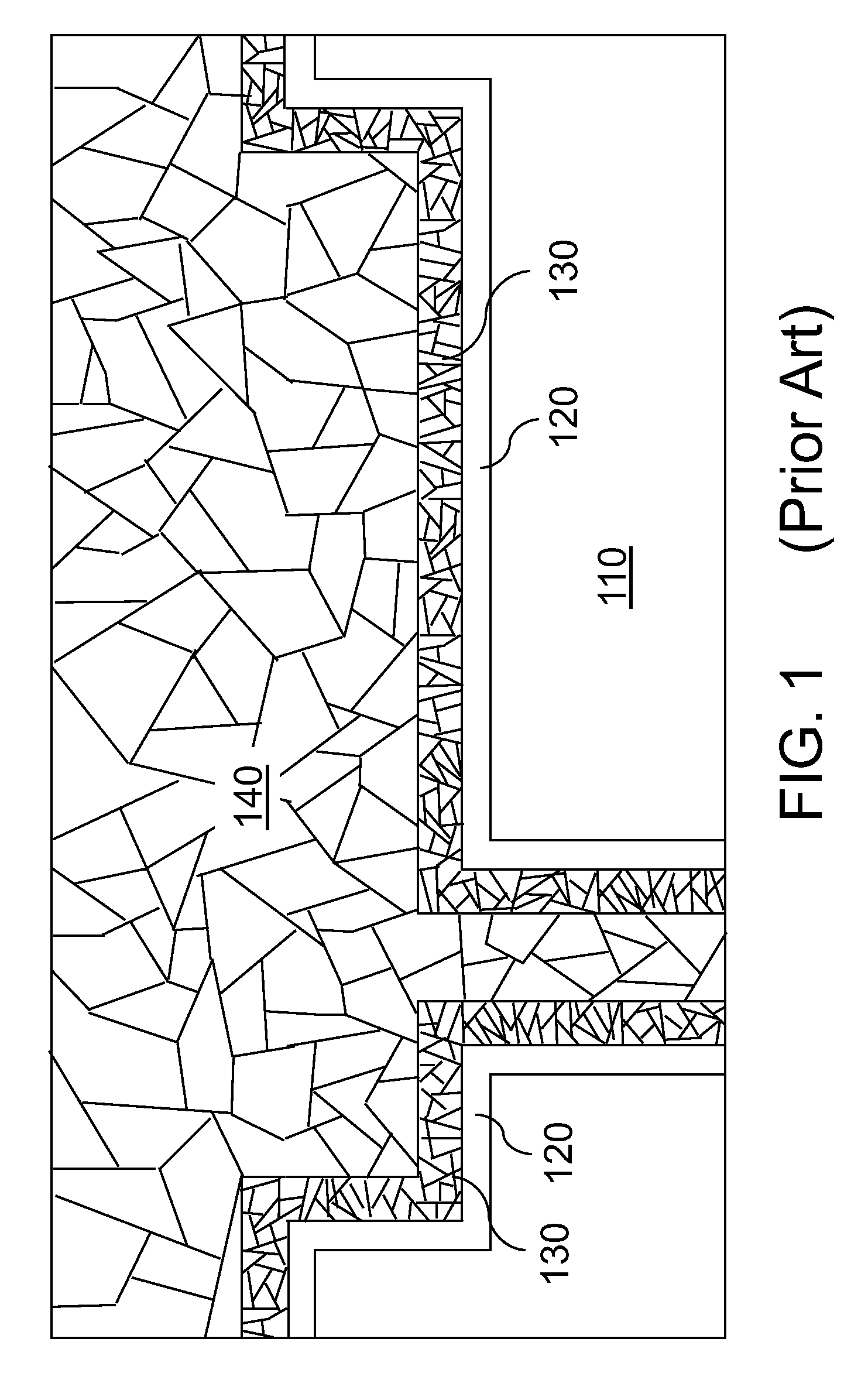

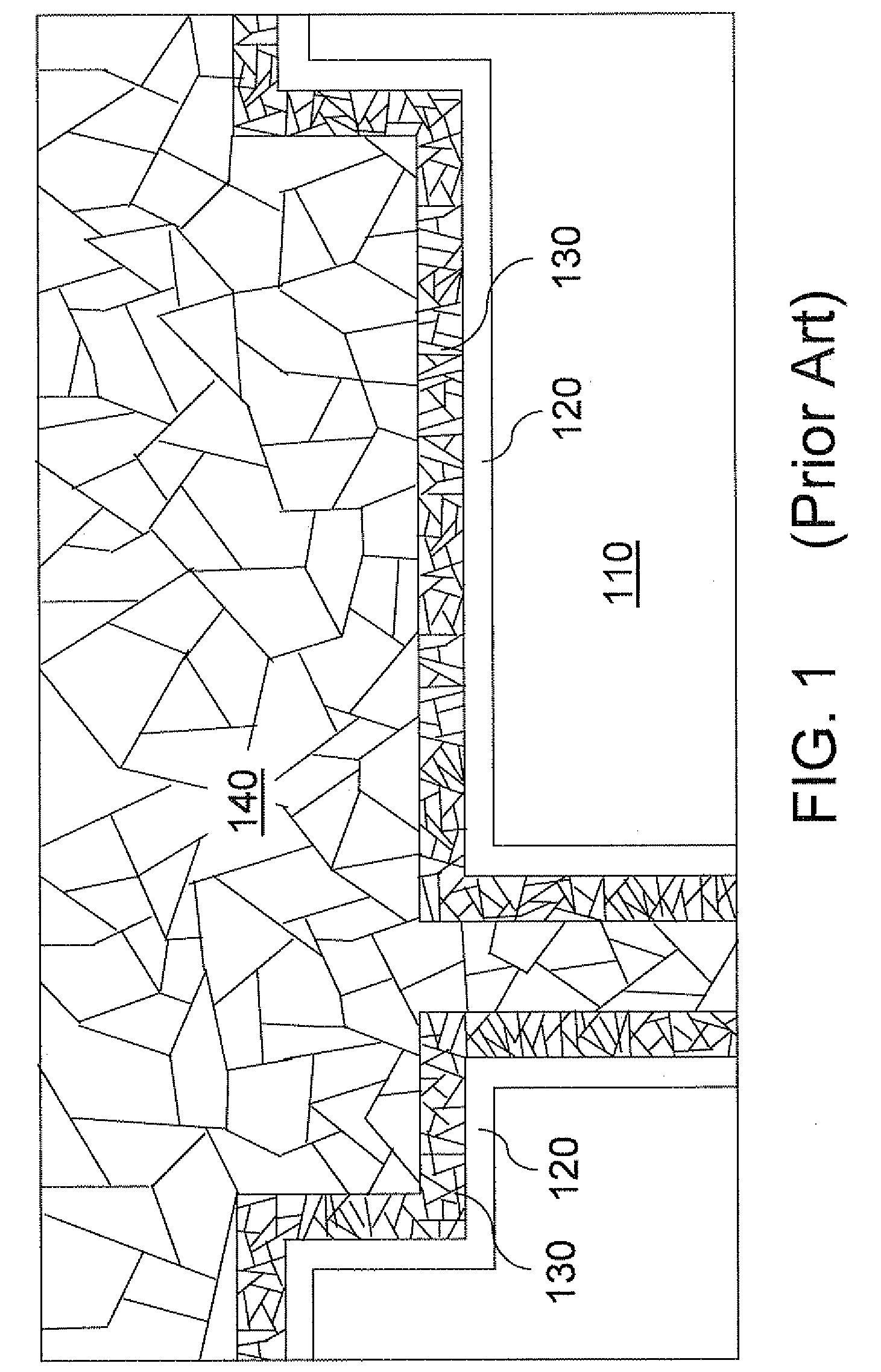

Grain growth promotion layer for semiconductor interconnect structures

ActiveUS20070197012A1Reduce electromigrationPromote formationTransistorSemiconductor/solid-state device detailsGrain growthSemiconductor

An interconnect structure of the single or dual damascene type and a method of forming the same, which substantially reduces the electromigration problem that is exhibited by prior art interconnect structures, are provided. In accordance with the present invention, a grain growth promotion layer, which promotes the formation of a conductive region within the interconnect structure that has a bamboo microstructure and an average grain size of larger than 0.05 microns is utilized. The inventive structure has improved performance and reliability.

Owner:IBM CORP

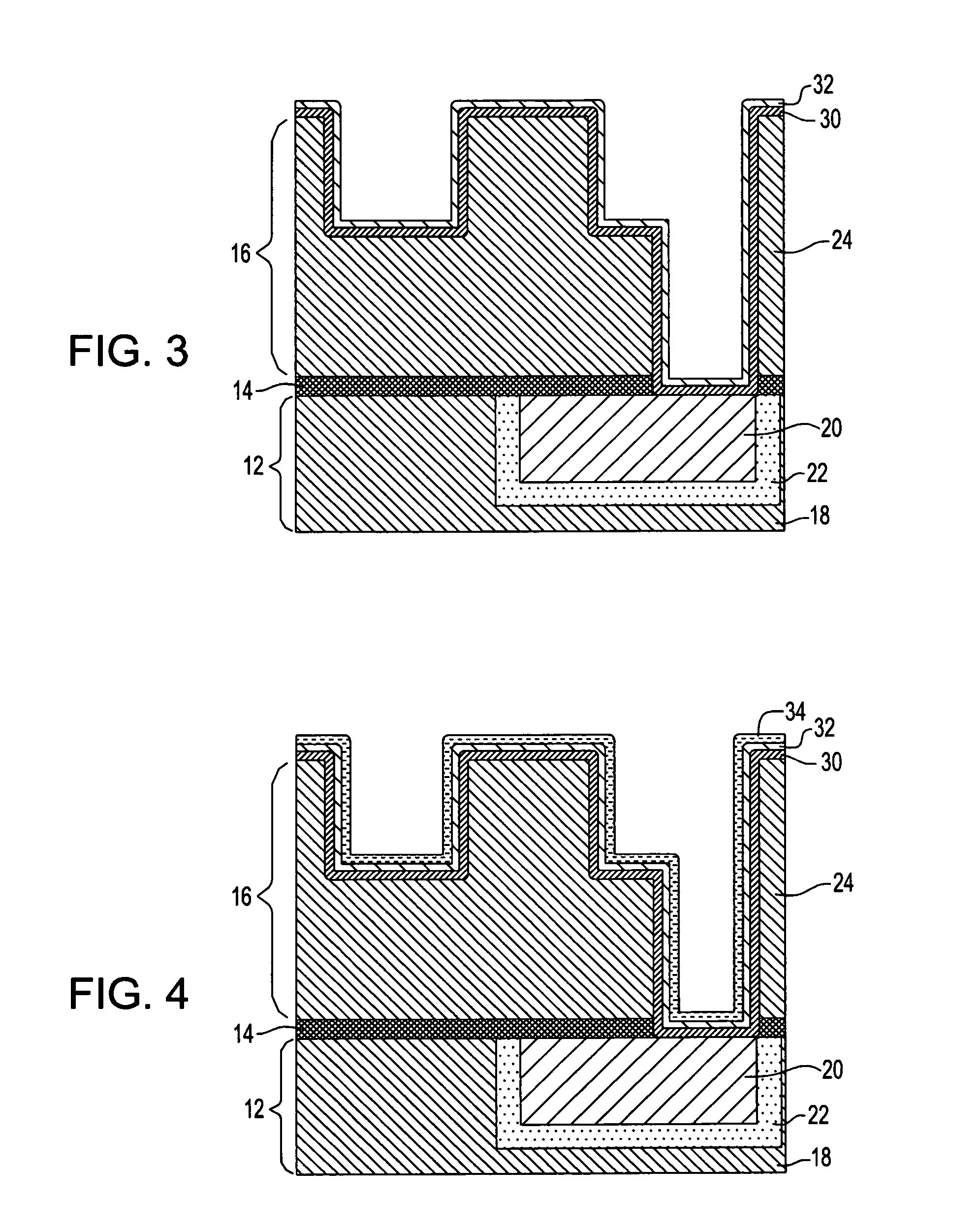

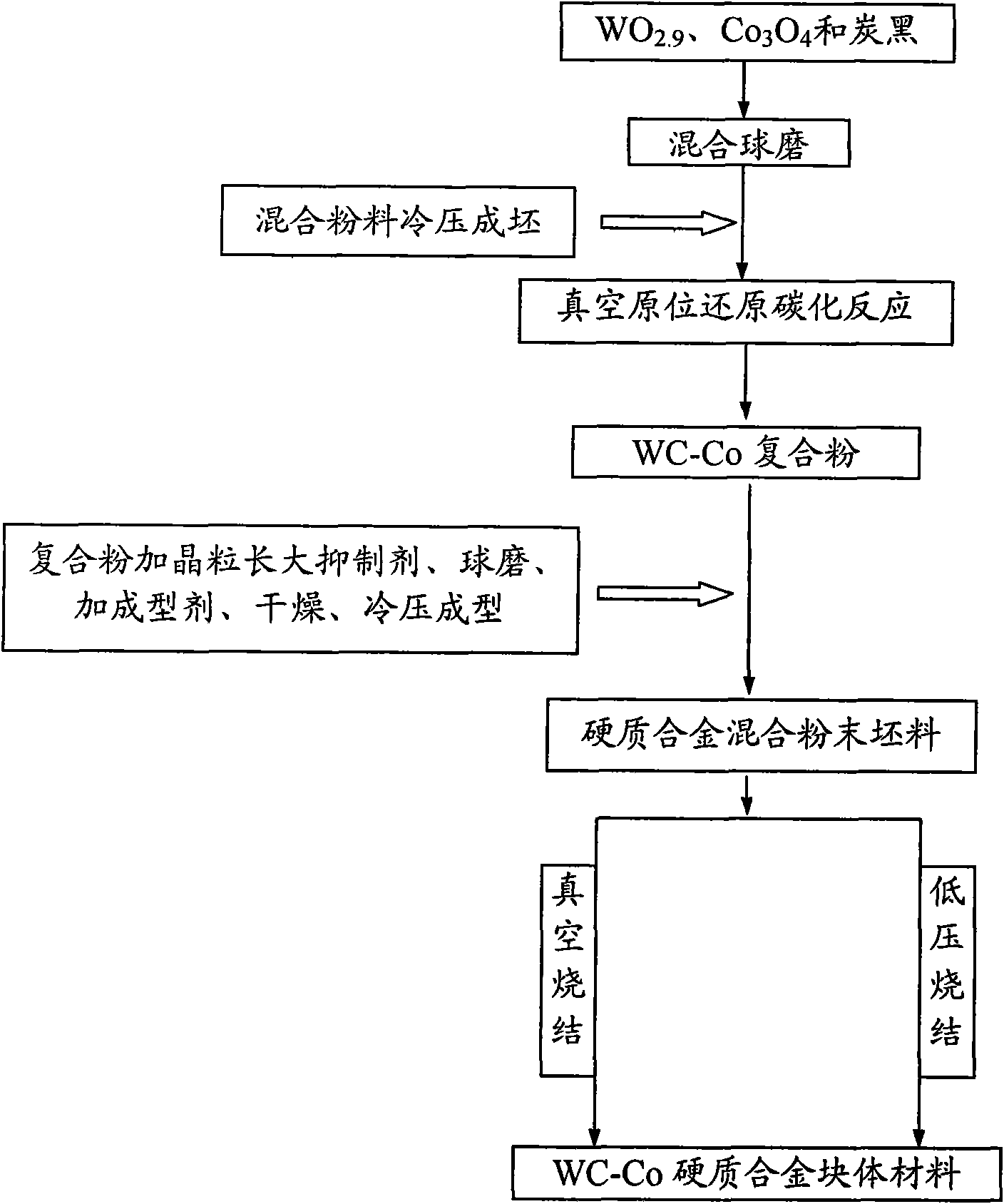

Industrialized preparation method of WC-Co hard alloy with low cost and high performance

ActiveCN101624673ASolve the problem that it is difficult to mix evenlyReduce energy consumptionPolyethylene glycolPrice ratio

The invention relates to an industrialized preparation method of a WC-Co hard alloy with low cost and high performance, which belongs to the technical field of hard alloys and powder metallurgy. The method comprises the following steps: taking WO2.9, Co3O4 and carbon soot as raw materials, and computing the usage ratio of the three materials according to the requirement of the Co content in a final hard alloy block material; adding 0-1.0 percent by weight of grain growth inhibitor into the prepared WC-Co composite powder, and adding polyethylene glycol as a forming agent into a ball milling tank 4-8 hours before ball milling is finished, wherein 30-80ml of polyethylene glycol is added into the powder material per kilogram; acquiring WC-Co mixed powder with a nanocrystal structure after ball milling, and putting the mixed powder into a mould for press forming after vacuum drying; and sintering the mixed powder stock after press forming in a mode of vacuum sintering or low-pressure sintering. The industrialized preparation method markedly shortens a production period, the provided integrated preparation course markedly reduces the production cost while ensuring the high performance of the hard alloy and has a high performance-price ratio, and the preparation method is suitable for industrialized scale production.

Owner:北硬科技香河有限公司

Nano-crystal austenitic steel bulk material having ultra-hardness and toughness and excellent corrosion resistance, and method for production thereof

InactiveUS20060193742A1Easy to prepareImprove corrosion resistanceTransportation and packagingMetal-working apparatusGrowth retardantManganese

The invention provides a super hard and tough, nano-crystal austenite steel bulk material having an improved corrosion resistance, and its preparation process. The austenite steel bulk material comprises an aggregate of austenite nano-crystal grains containing 0.1 to 2.0% (by mass) of a solid solution type nitrogen, wherein an oxide, nitride, carbide or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in said nano-crystal grains. For preparation, fine powders of austenite steel-forming components, i.e., iron and chromium, nickel, manganese, carbon or the like are mixed with a substance that becomes a nitrogen source. Mechanical alloying (MA) is applied to the mixture, thereby preparing nano-crystal austenite steel powders having a high nitrogen concentration. Finally, the austenite steel powders are consolidated by sintering by means of spark plasma sintering, rolling or the like.

Owner:MIZUTANI MASARU

High magnetic induction and high grad non-orientation electrical steel and its making process

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

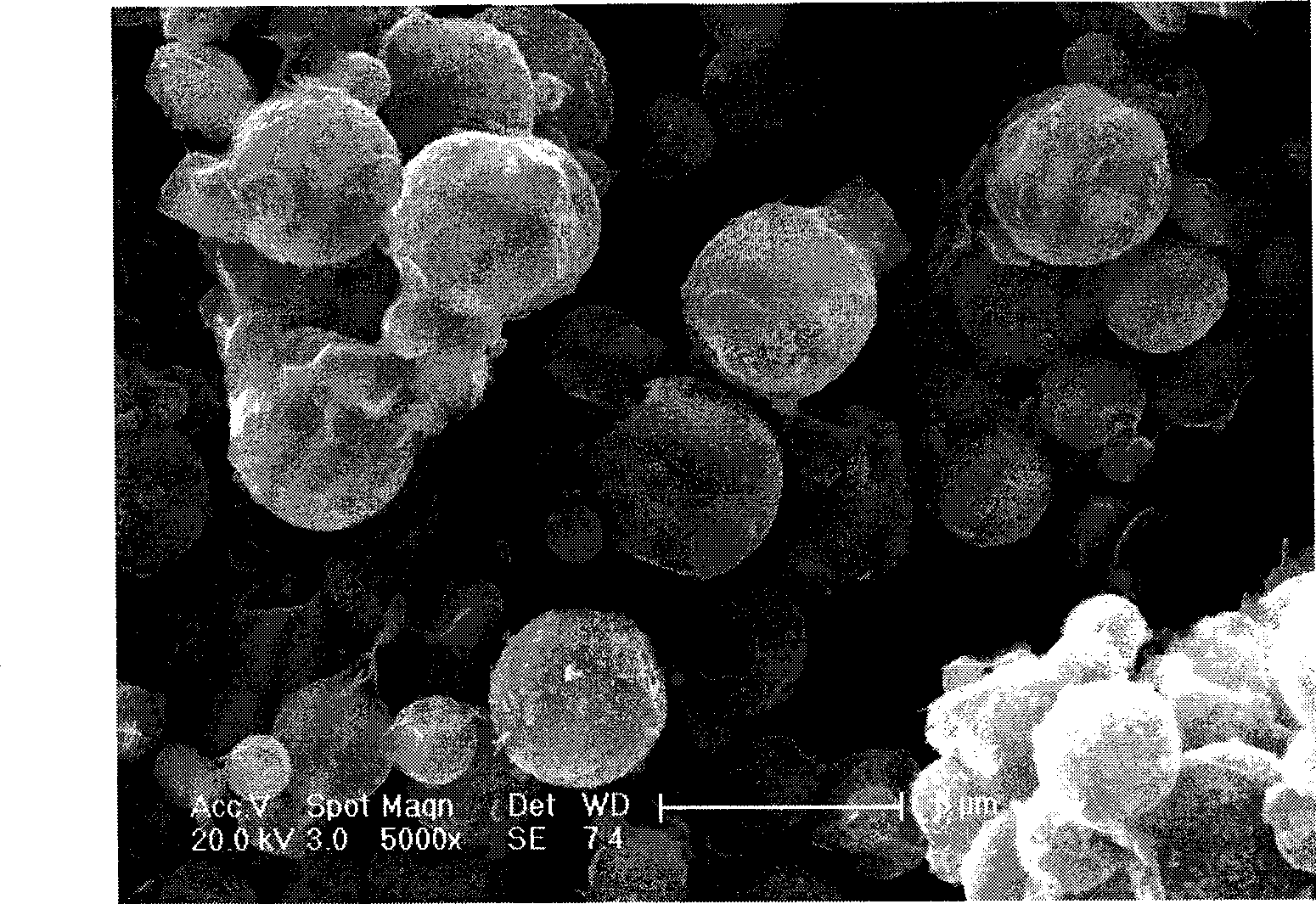

Preparation of lithium iron phosphate nano composite microsphere

ActiveCN101475157AImprove conductivityHigh tap densityElectrode manufacturing processesPhosphorus compoundsMicrospherePhosphoric acid

The invention discloses a method for preparing a lithium iron phosphate nano composite microsphere for a lithium-ion secondary battery anode material by a hydrothermal method, which comprises the following steps: evenly mixing a lithium source, an iron source and a phosphoric acid source according to the stoichiometric ratio of 1-1.05:1:1 to prepare an aqueous solution with certain concentration, adding proper amount of reducing agent, carbonizing agent, ion dopant and the like into the aqueous solution, growing and curing crystals under high-temperature hydrothermal condition, removing a solvent from a hydrothermal product, and burning the hydrothermal product in inert or reducing atmosphere to obtain a final product. The lithium iron phosphate anode material prepared by the method has a regular nano composite microsphere structure, has a particle diameter of between 2 and 4 mu m, even distribution, tap density up to 1.3 to 1.6 g / cm, and has excellent cycle performance and multiplying power performance. The method has simple and easily-controlled process, can use cheap trivalent iron as the iron source, can obtain rich raw materials, and is a practical technique for preparing lithium iron phosphate.

Owner:湖北金泉新材料有限公司

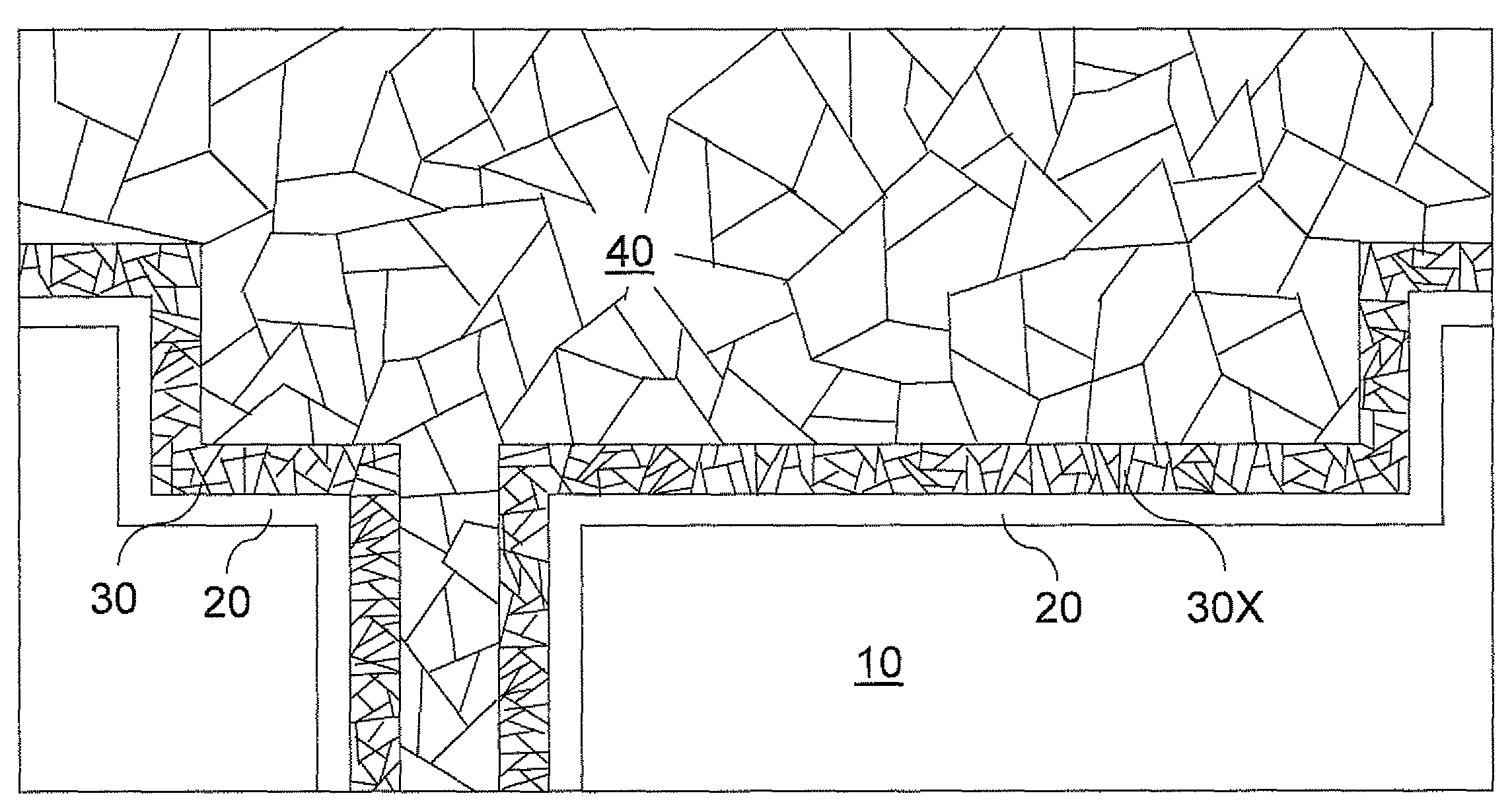

Ceramic-rich composite armor, and methods for making same

InactiveUS7104177B1Reduce manufacturing costHighly dimensionally accurate shaped articleCeramic layered productsArmour platesReaction bonded silicon carbideGrain growth

Silicon infiltration technology, e.g., siliconizing or reaction-bonding, is used to produce ceramic-rich composite bodies having utility as ballistic armor. In the main embodiment of the invention, the ballistic armor includes a reaction-bonded silicon carbide body (RBSC). Good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers, and by limiting the size of the morphological features making up the composite body. This control of “grain size” can be accomplished by controlling the size of the largest particles making up the porous mass to be infiltrated, but also of importance is controlling the processing conditions, particularly by controlling the factors that cause grain growth, coarsening of microstructure, and / or grain coalescence.

Owner:II VI DELAWARE INC

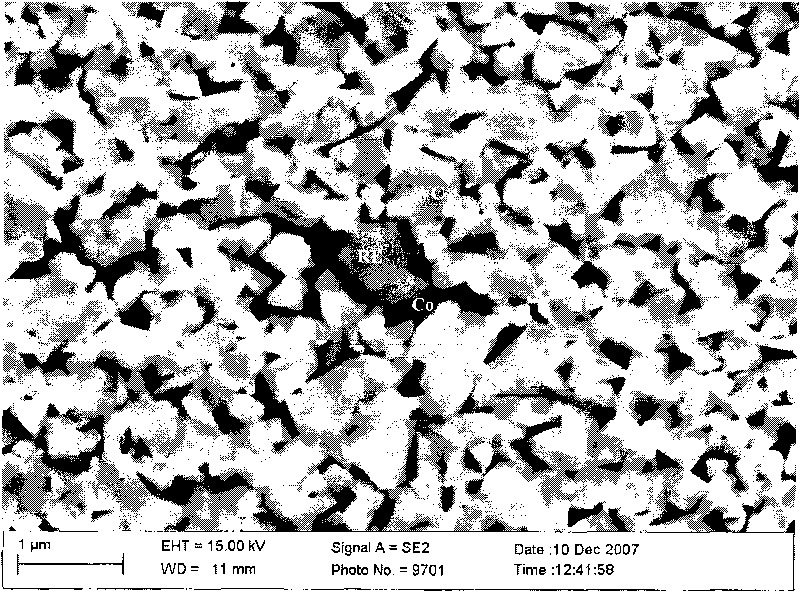

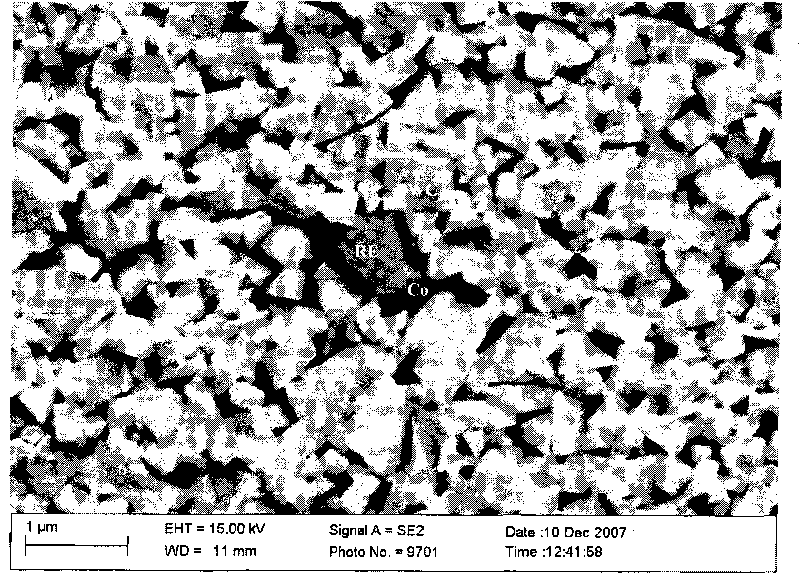

Microstructure modification in copper interconnect structure

ActiveUS20090206484A1Preventing diffusion of copperFaster rateSemiconductor/solid-state device detailsSolid-state devicesCopper platingMetal interconnect

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

Large grain size conductive structure for narrow interconnect openings

ActiveUS20110062587A1Eliminates and high resistanceIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesCrystal orientationOptoelectronics

An interconnect structure having reduced electrical resistance and a method of forming such an interconnect structure are provided. The interconnect structure includes a dielectric material including at least one opening therein. The at least one opening is filled with an optional barrier diffusion layer, a grain growth promotion layer, an agglomerated plating seed layer, an optional second plating seed layer a conductive structure. The conductive structure which includes a metal-containing conductive material, typically Cu, has a bamboo microstructure and an average grain size of larger than 0.05 microns. In some embodiments, the conductive structure includes conductive grains that have a (111) crystal orientation.

Owner:GLOBALFOUNDRIES US INC

Barrier layers for conductive features

InactiveUS20060202345A1Lower resistanceImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsGrain growth

Barrier layers for conductive features and methods of formation thereof are disclosed. A first barrier material is deposited on top surfaces of an insulating material, and a second barrier material is deposited on sidewalls of the insulating material, wherein the second barrier material is different than the first barrier material. The first barrier material induces grain growth of a subsequently deposited conductive material at a first rate, and the second barrier material induces grain growth of the conductive material at a second rate, wherein the second rate is slower than the first rate.

Owner:INFINEON TECH AG

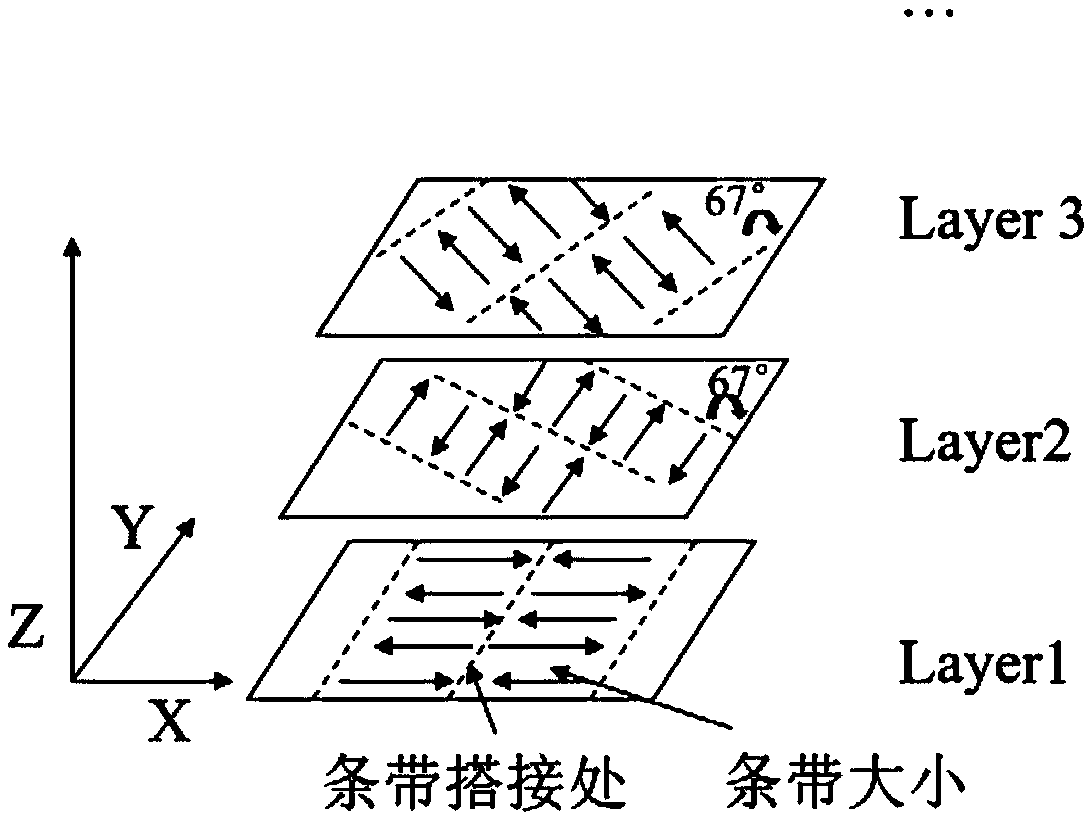

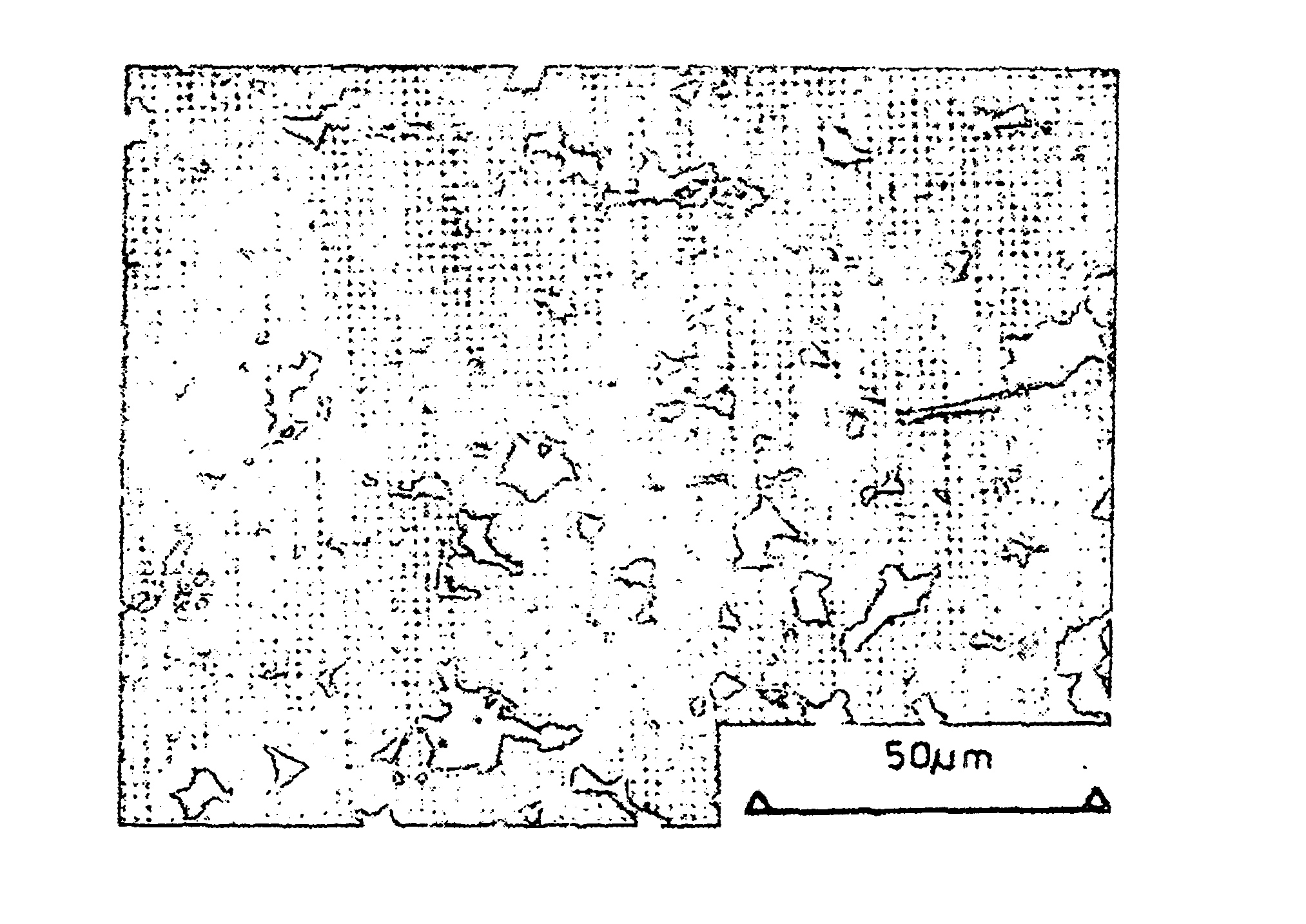

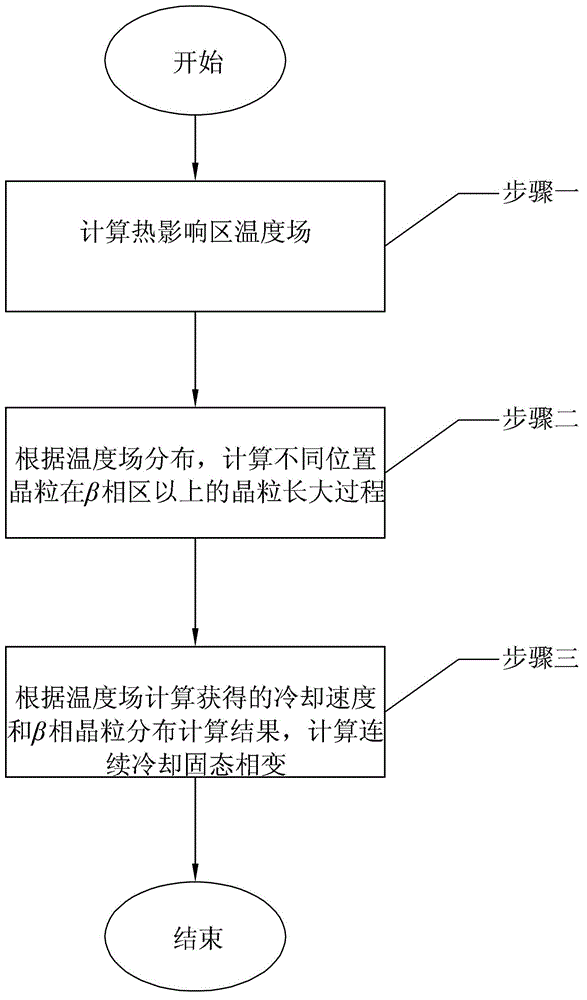

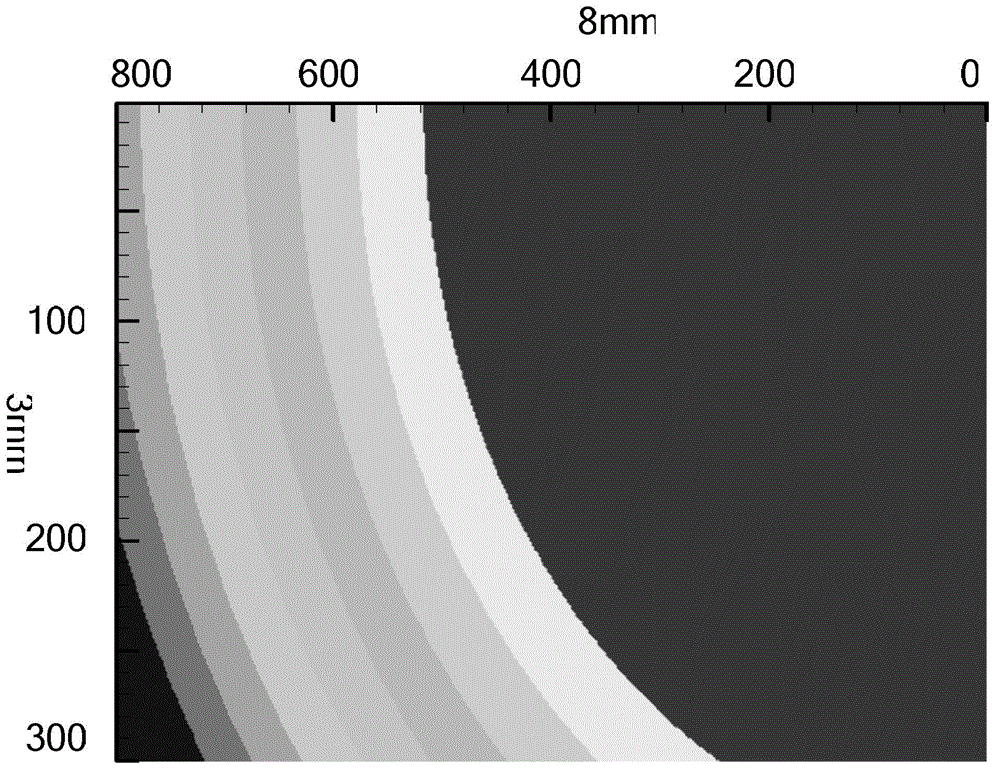

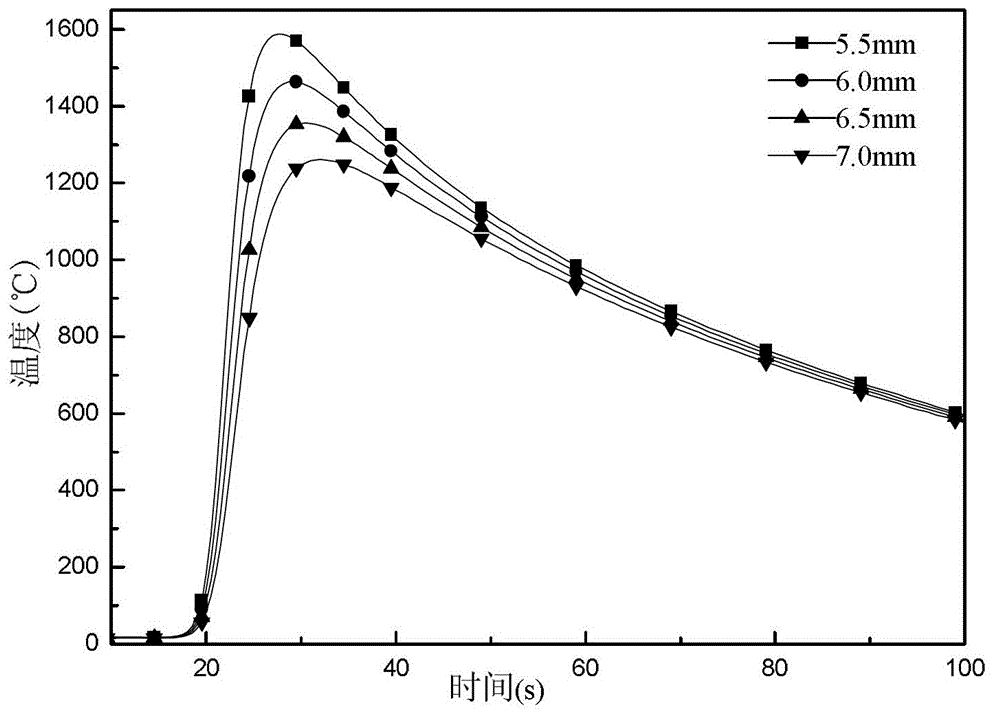

Simulation method of texture evolvement of heat affected zone in welding process

ActiveCN102750425AImprove microstructureImprove mechanical propertiesFurnace typesHeat treatment process controlHeat-affected zoneMaterials science

The invention discloses a simulation method of texture evolvement of a heat affected zone in a welding process, relating to a fine texture simulation method of a welding connector and aiming at solving the problems that the quantification of the present fine texture evolvement of a weld joint is mainly based on an experiential or half experiential deterministic model or analysis calculation, and only the texture content is calculated but the state, the size and the distribution of the texture cannot be reflected dynamically. The method comprises the following steps: step 1, calculating the temperature fields of the heat affected zone; step 2, calculating the crystalline grain growth process of crystalline grains at different positions above a beta phase zone according to the distribution of the temperature fields; and step 3, calculating continuous cooling solid state phase change according to the cooling velocity and the beta phase crystalline grain distribution calculation result obtained through the temperature field calculation. The simulation method is used for the fine texture simulation of the welding connector.

Owner:HARBIN INST OF TECH

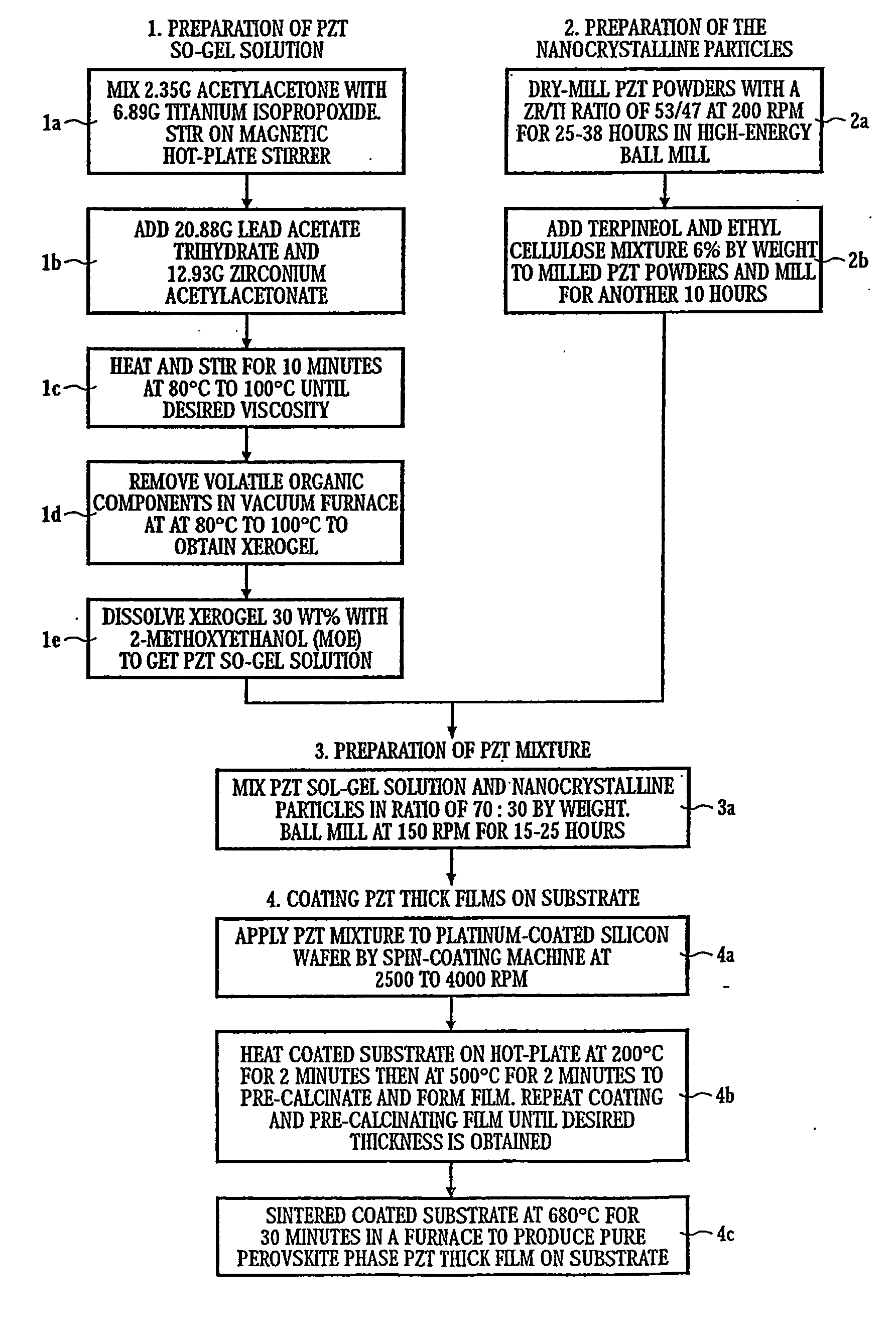

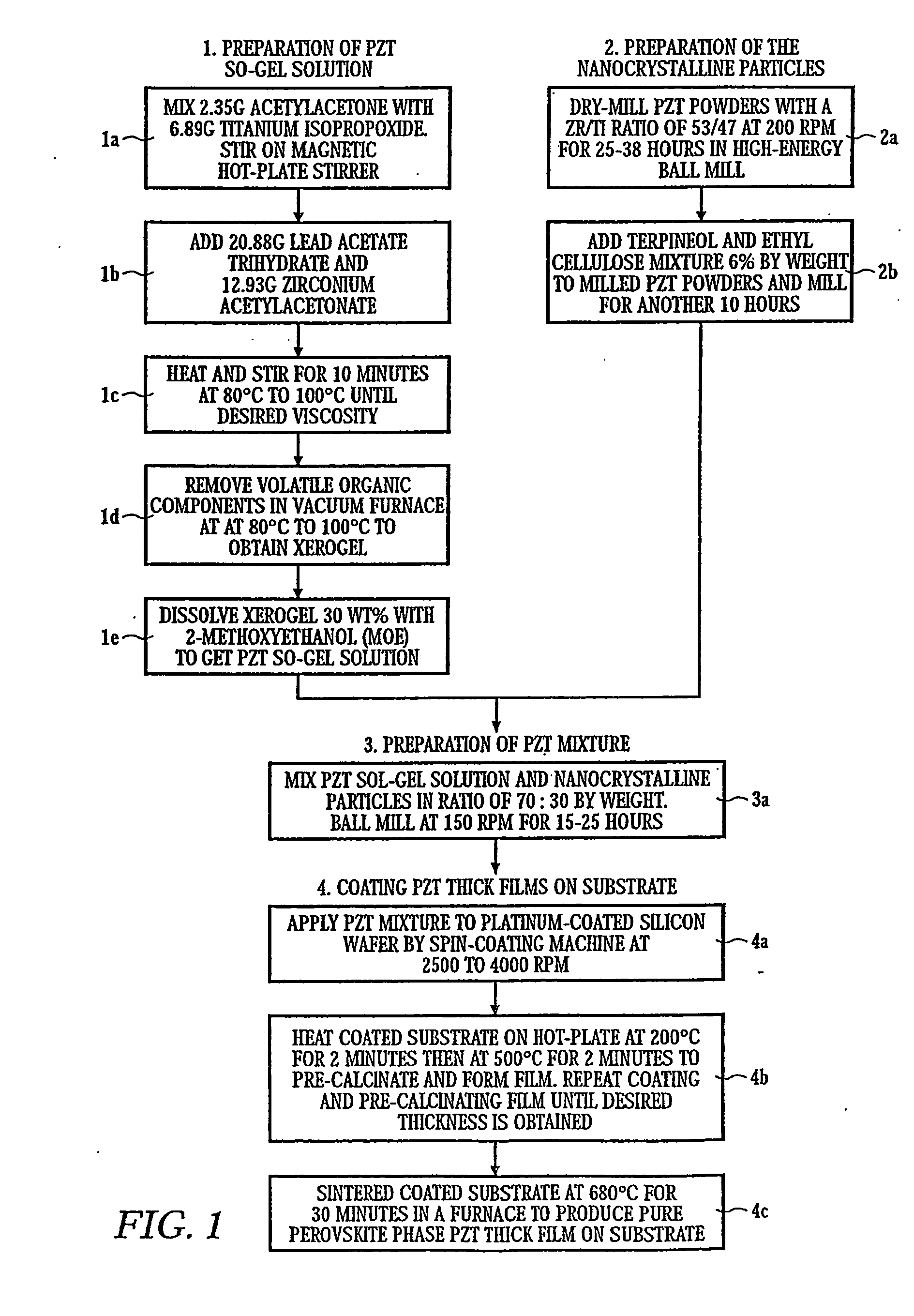

Process for producing nanorcrystalline composites

InactiveUS20050255239A1Reduce reunionHigh densityMaterial nanotechnologyLayered productsPorosityVolumetric Mass Density

A process to produce dense nanocrystalline composites such as ceramic bodies, coatings and multi-layered devices with uniform microstructure is disclosed. The invention utilizes sol-gel solutions to reduce agglomeration of nanocrystalline powders in the production of “green bodies” or intermediate products. This novel use of sol-gel solutions also reduces grain growth and porosity in products during sintering. In finished products, final grain sizes are typically less than 100 nm with densities of the final products approaching 99.5% of theoretical densities. In addition, sintering temperatures required are lower than those in conventional methods, typically less than 1,100° C. While FIG. 1 shows one application of this novel process, this invention has wide application in the manufacture of many other products, particularly for composite coatings and in the production of nanodevices.

Owner:NANYANG TECH UNIV

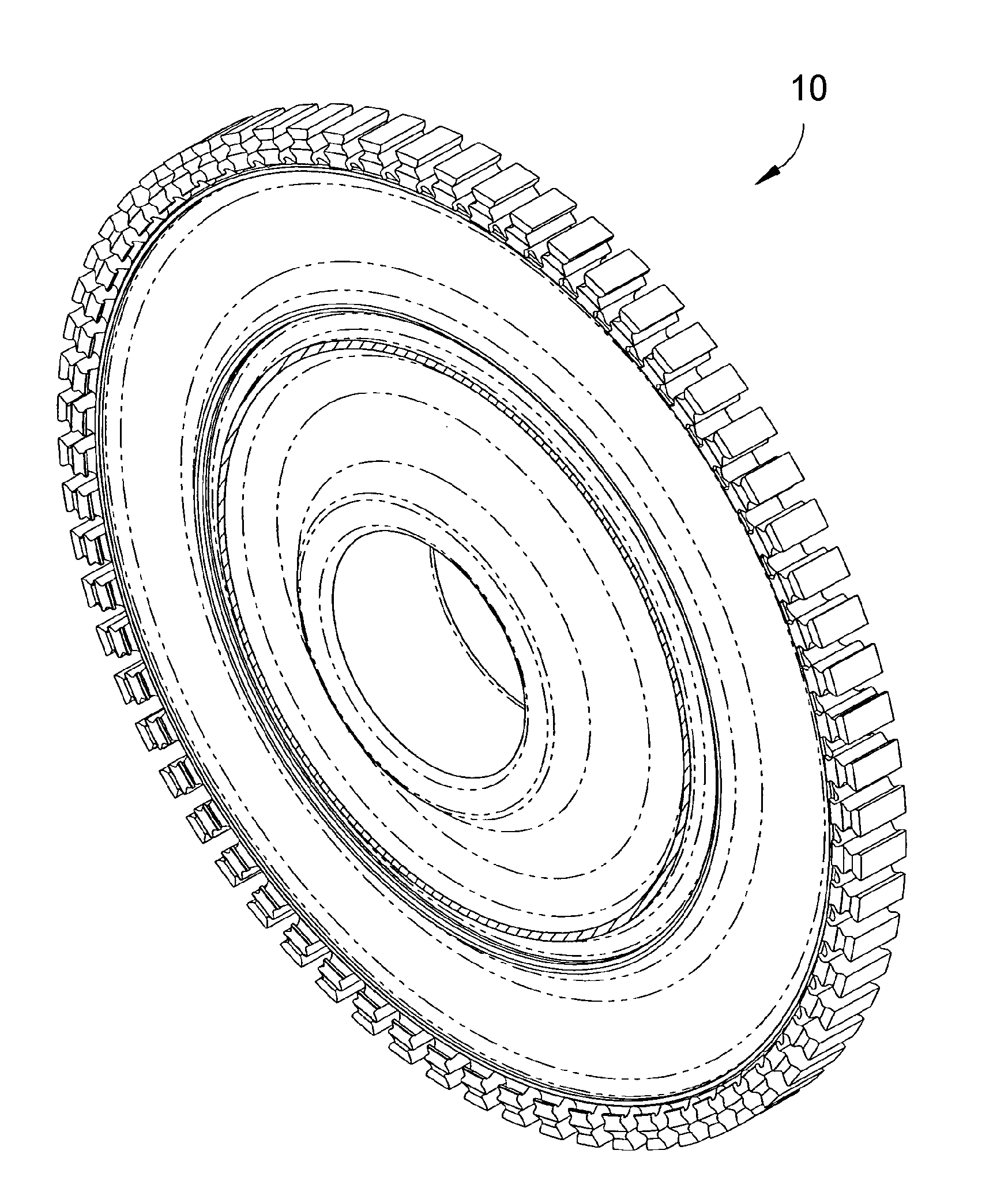

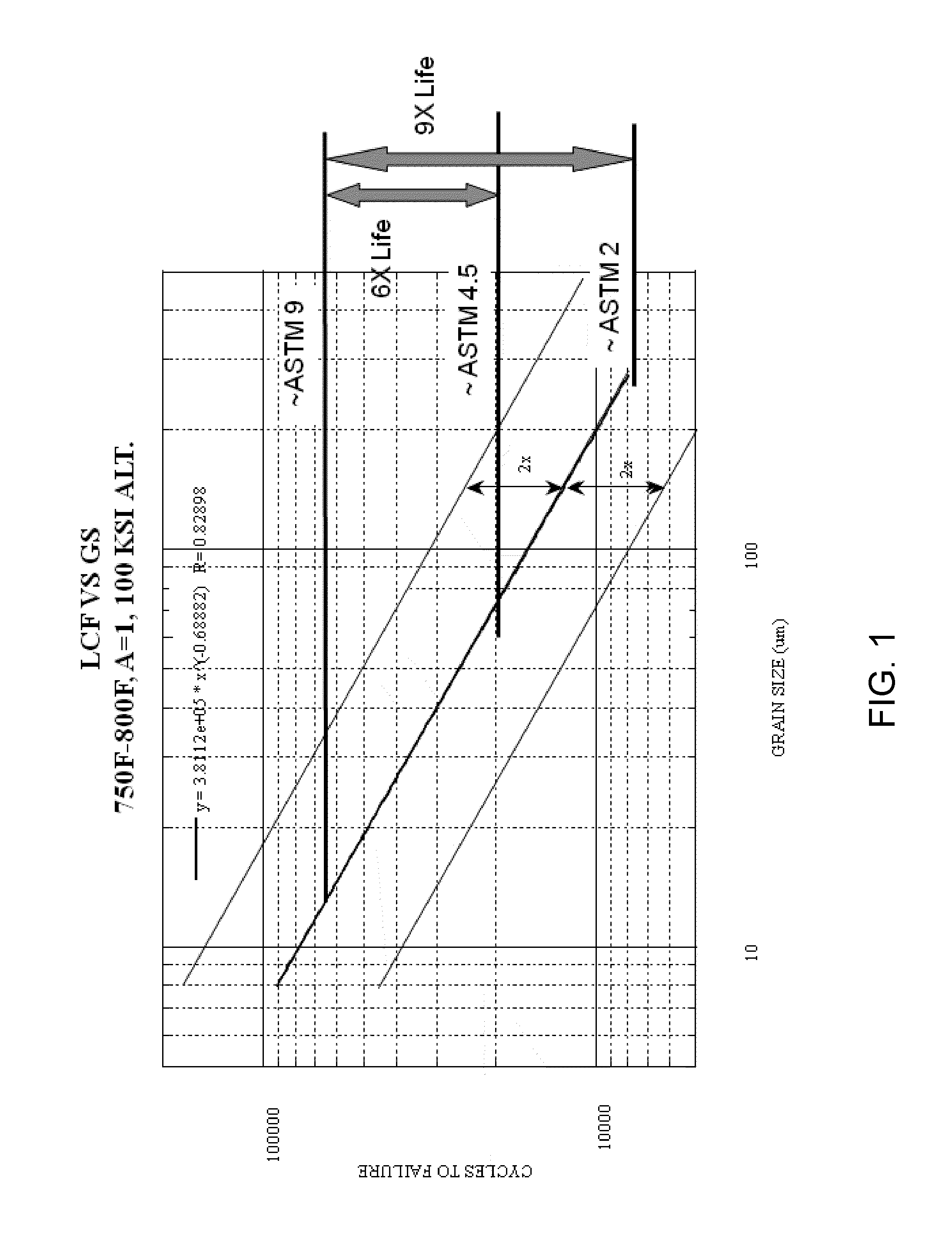

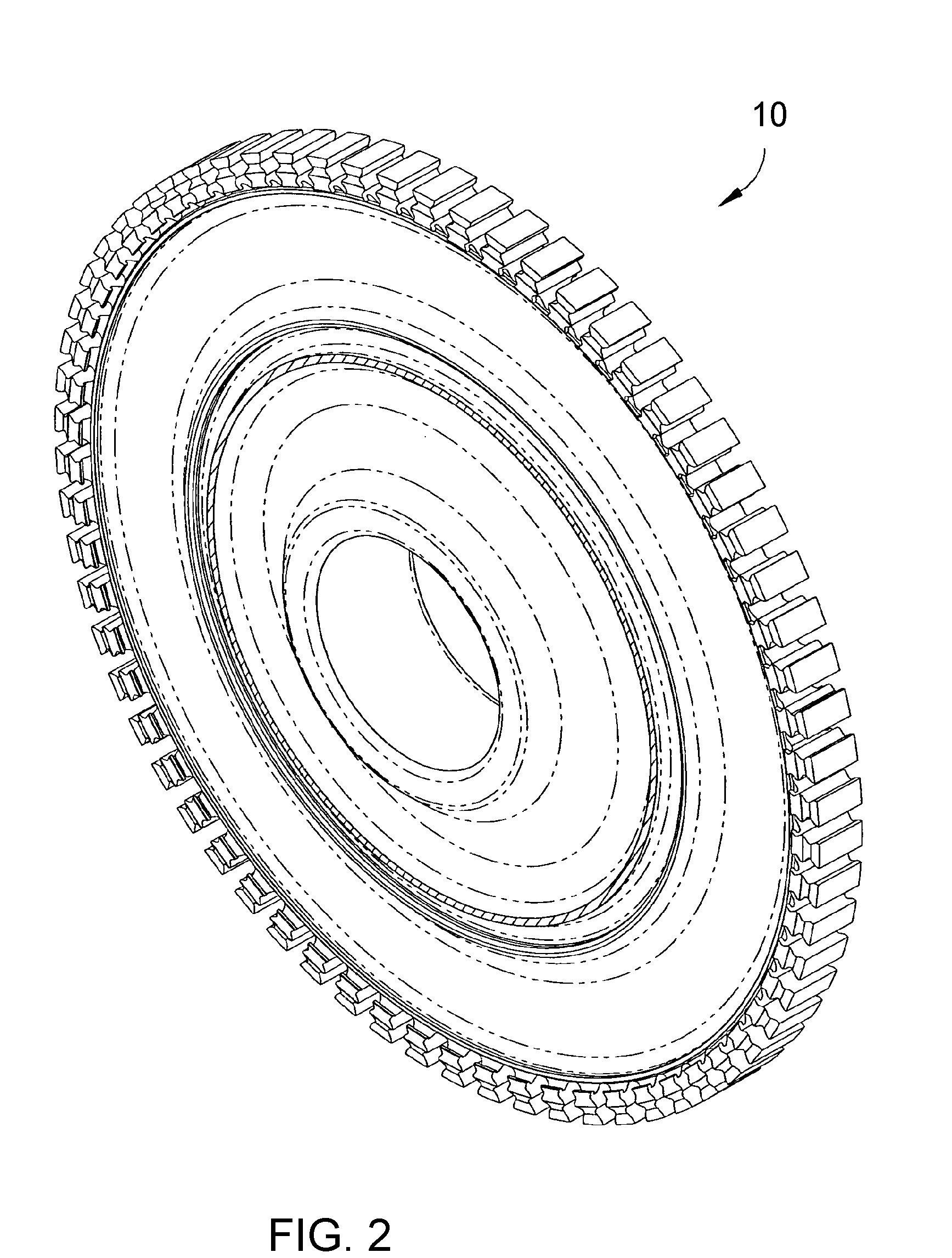

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20100329883A1Finer uniform grain sizeImproved low cycle fatigue behaviorPropellersEngine manufactureRheniumNiobium

A gamma prime precipitation-strengthened nickel-base superalloy and method of forging an article from the superalloy to promote a low cycle fatigue resistance and high temperature dwell behavior of the article. The superalloy has a composition of, by weight, 16.0-22.4% cobalt, 6.6-14.3% chromium, 2.6-4.8% aluminum, 2.4-4.6% titanium, 1.4-3.5% tantalum, 0.9-3.0% niobium, 1.9-4.0% tungsten, 1.9-3.9% molybdenum, 0.0-2.5% rhenium, greater than 0.05% carbon, at least 0.1% hafnium, 0.02-0.10% boron, 0.03-0.10% zirconium, the balance nickel and incidental impurities. A billet is formed of the superalloy and worked at a temperature below the gamma prime solvus temperature of the superalloy so as to form a worked article, which is then heat treated above the gamma prime solvus temperature of the superalloy to uniformly coarsen the grains of the article, after which the article is cooled to reprecipitate gamma prime. The article has an average grain size of not coarser than ASTM 7 and is substantially free of critical grain growth.

Owner:GENERAL ELECTRIC CO

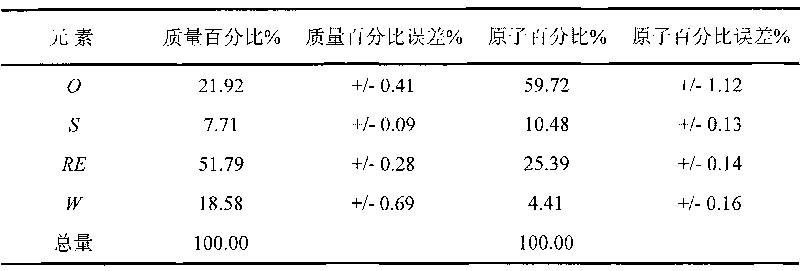

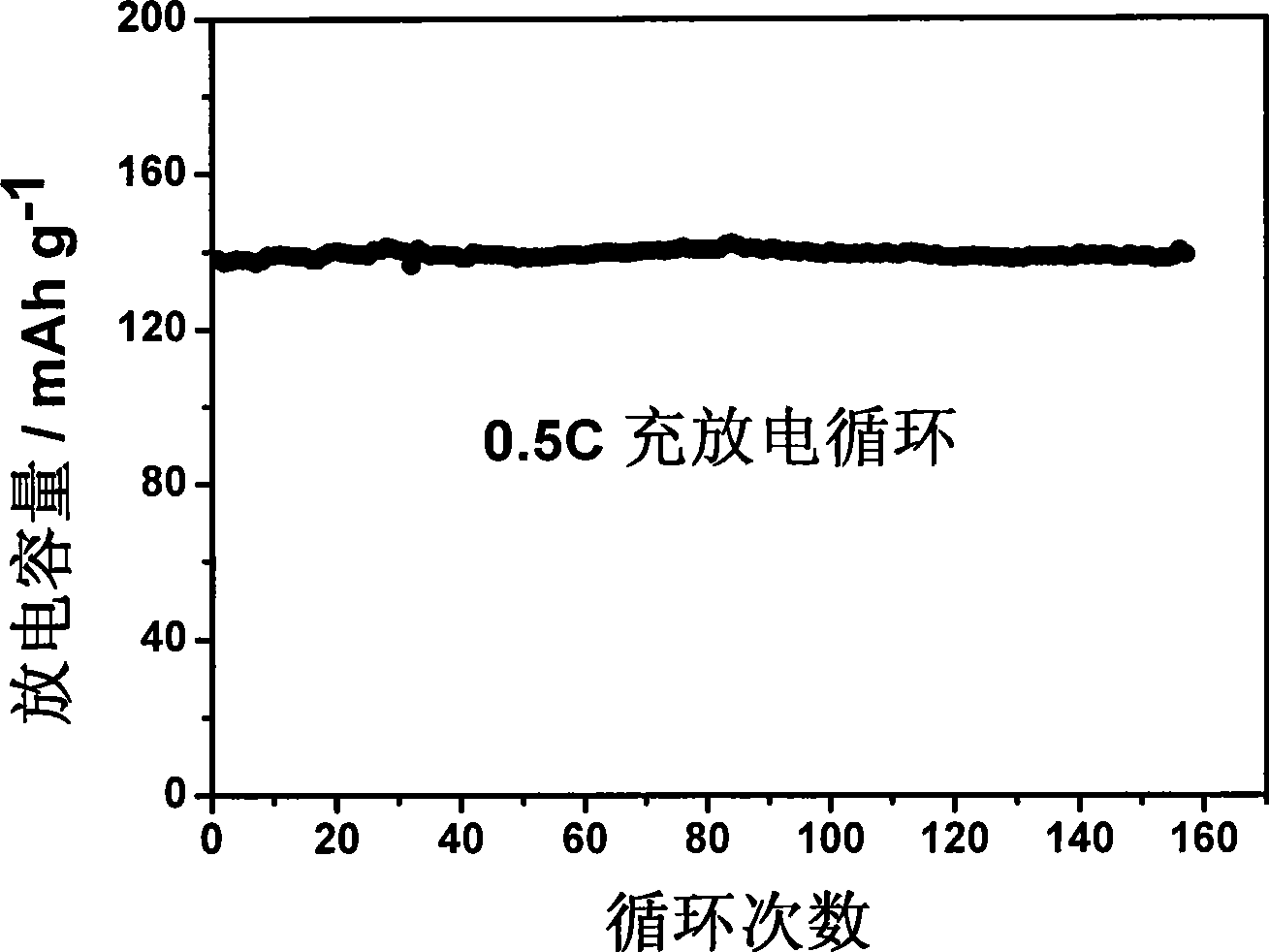

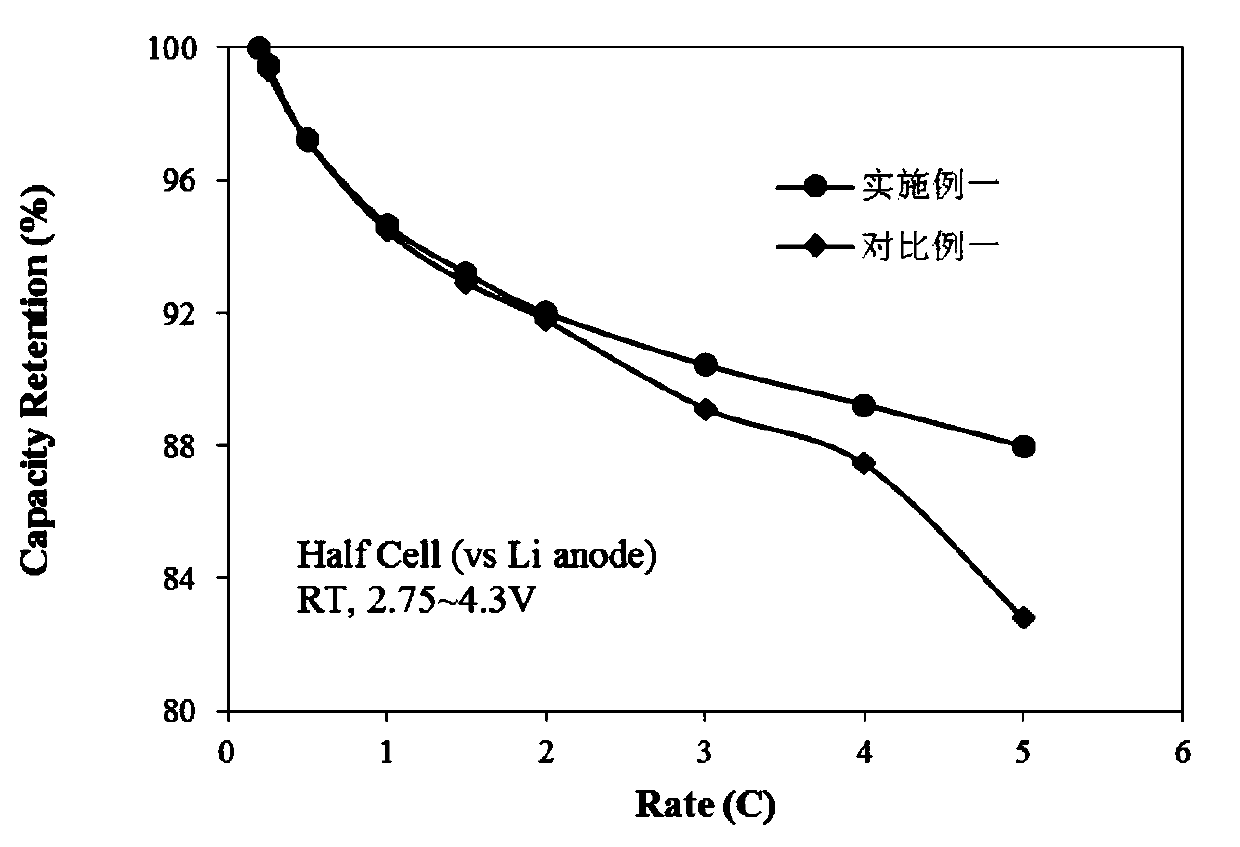

Tungsten-doped boride-coated lithium battery anode material and preparation method thereof

ActiveCN107895793AImproved magnification performanceImprove rate capacity retentionCell electrodesMixed materialsGrain growth

The invention is applicable to the technical field of lithium batteries and provides a tungsten-doped boride-coated lithium battery anode material and a preparation method thereof. Firstly, tungsten source is dissolved in water, sprayed onto a mixed material of a ternary precursor and lithium source and then stirred to obtain a dried material; the dried material is placed and baked in a saggar toobtain a tungsten-doped ternary anode material; finally, metal boride is added to the tungsten-doped ternary anode material, stirred uniformly and sintered at a certain temperature to obtain the tungsten-doped boride-coated lithium battery anode material. According to the tungsten-doped boride-coated lithium battery anode material, the synergistic effect between tungsten doping and the metal boride takes full advantage of the tungsten doping and the metal boride, the tungsten doping can significantly inhibit grain growth and shorten the transmission distance of Li+, MgB2 as a superconductor has fast ion transmission properties, and the tungsten doping and the metal boride improve rate capability of the tungsten-doped boride-coated lithium battery anode material. Meanwhile, the boride coating can inhibit the reaction between the surface of an electrode material and electrolyte, thereby improving the safety performance and cycle stability of the tungsten-doped boride-coated lithium battery anode material.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Microstructure modification in copper interconnect structure

InactiveUS20100323517A1Inhibited DiffusionFaster rateSemiconductor/solid-state device detailsSolid-state devicesCopper platingMetal interconnect

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

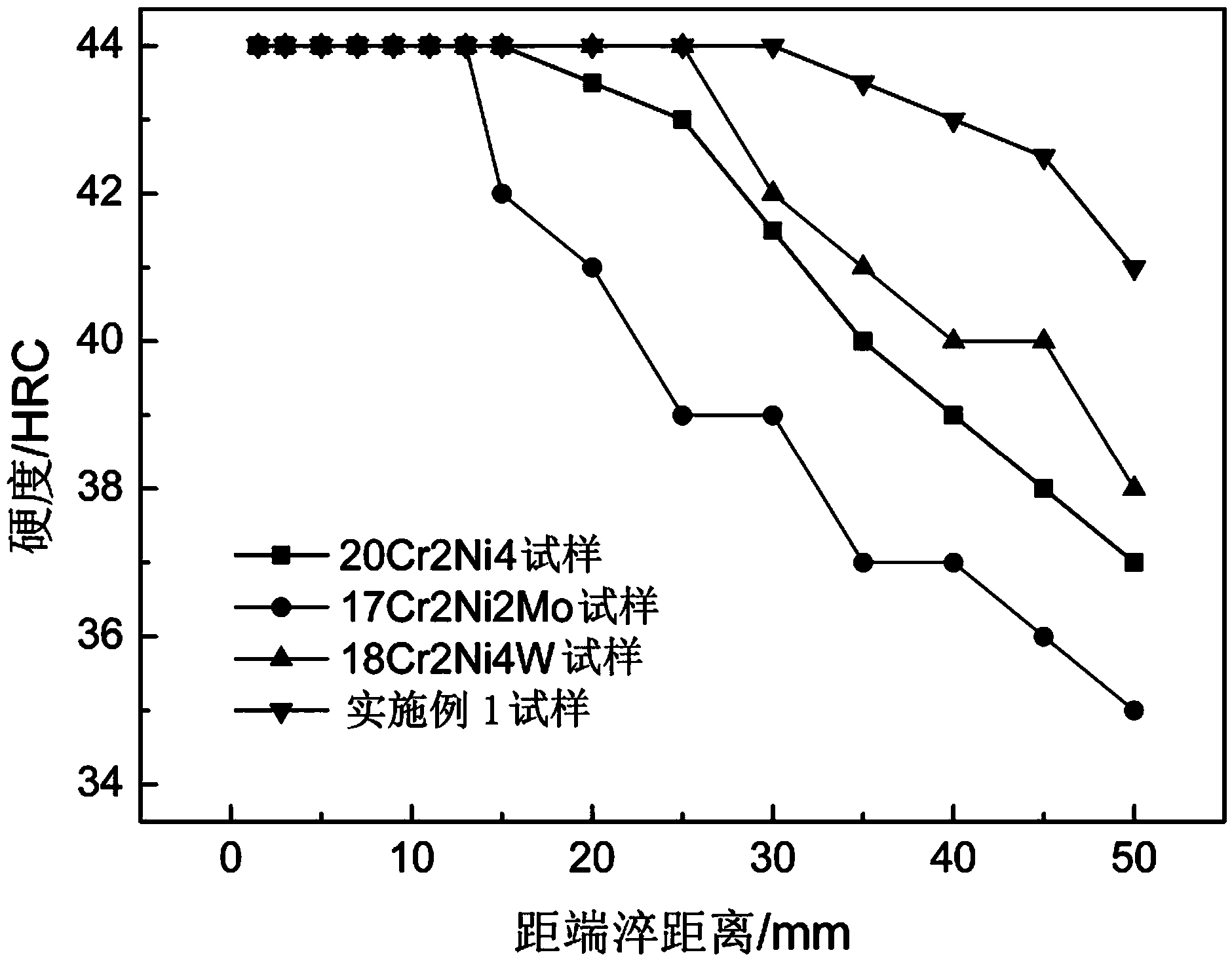

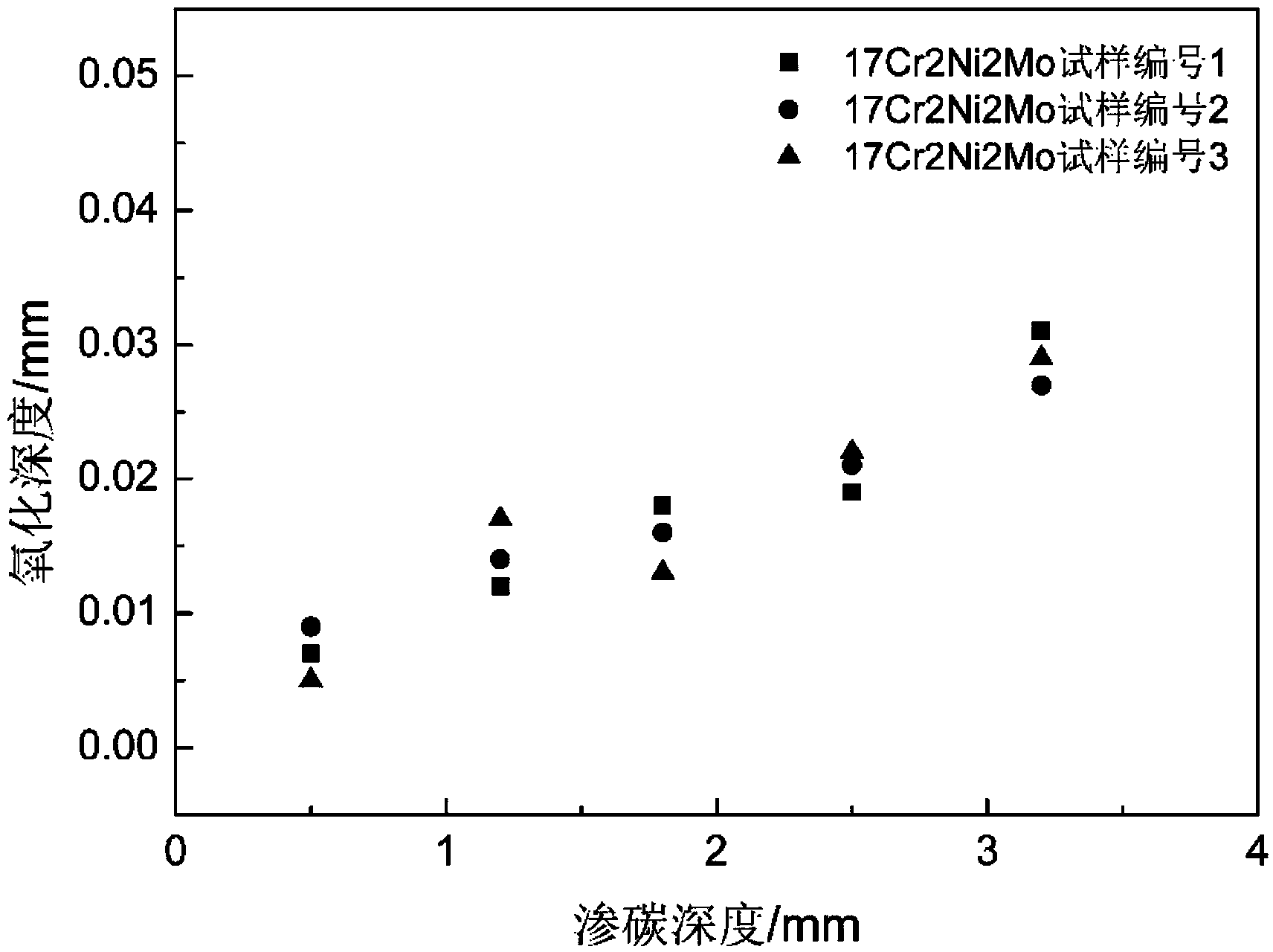

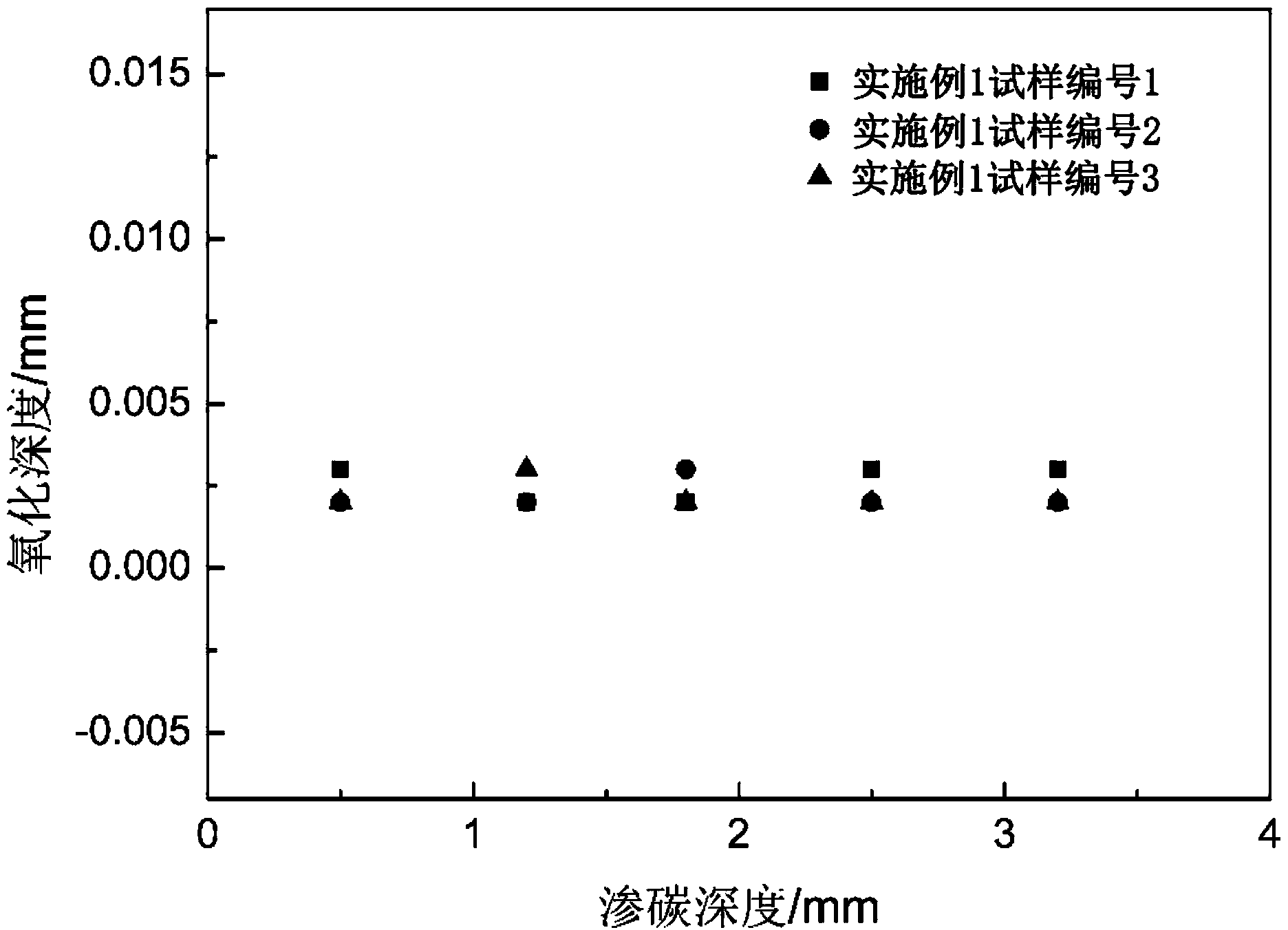

Carburizing alloy steel, and preparation method and application thereof

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

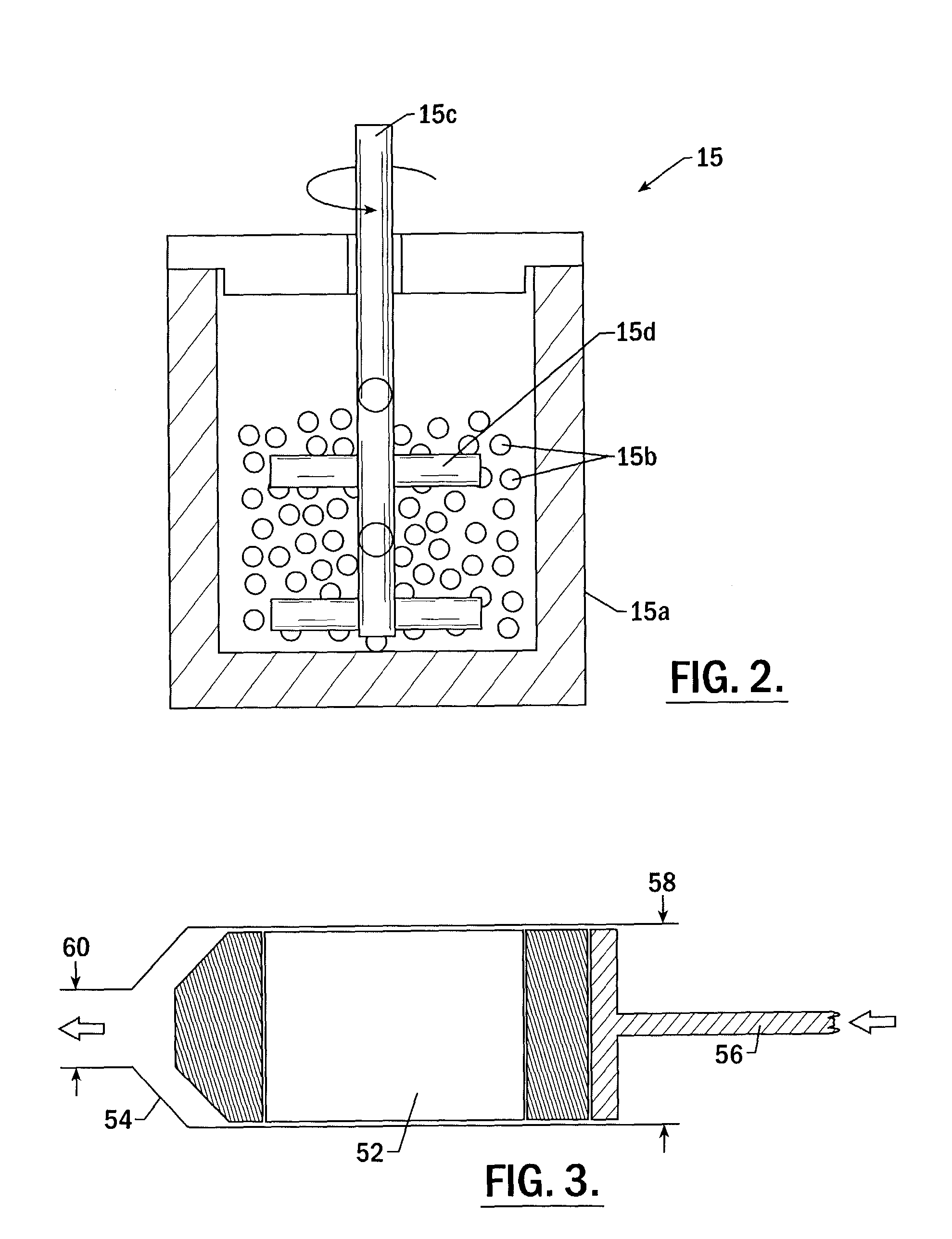

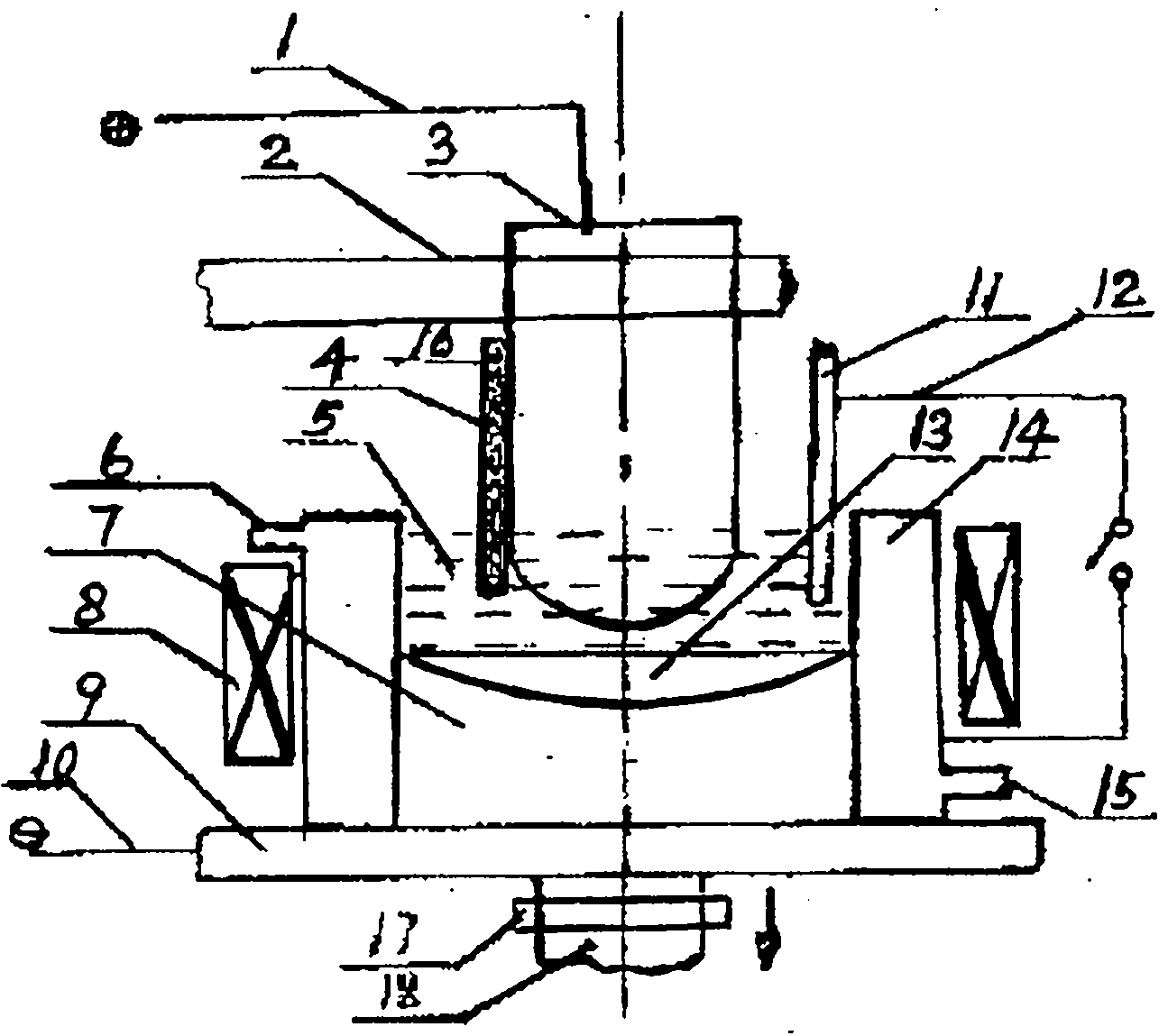

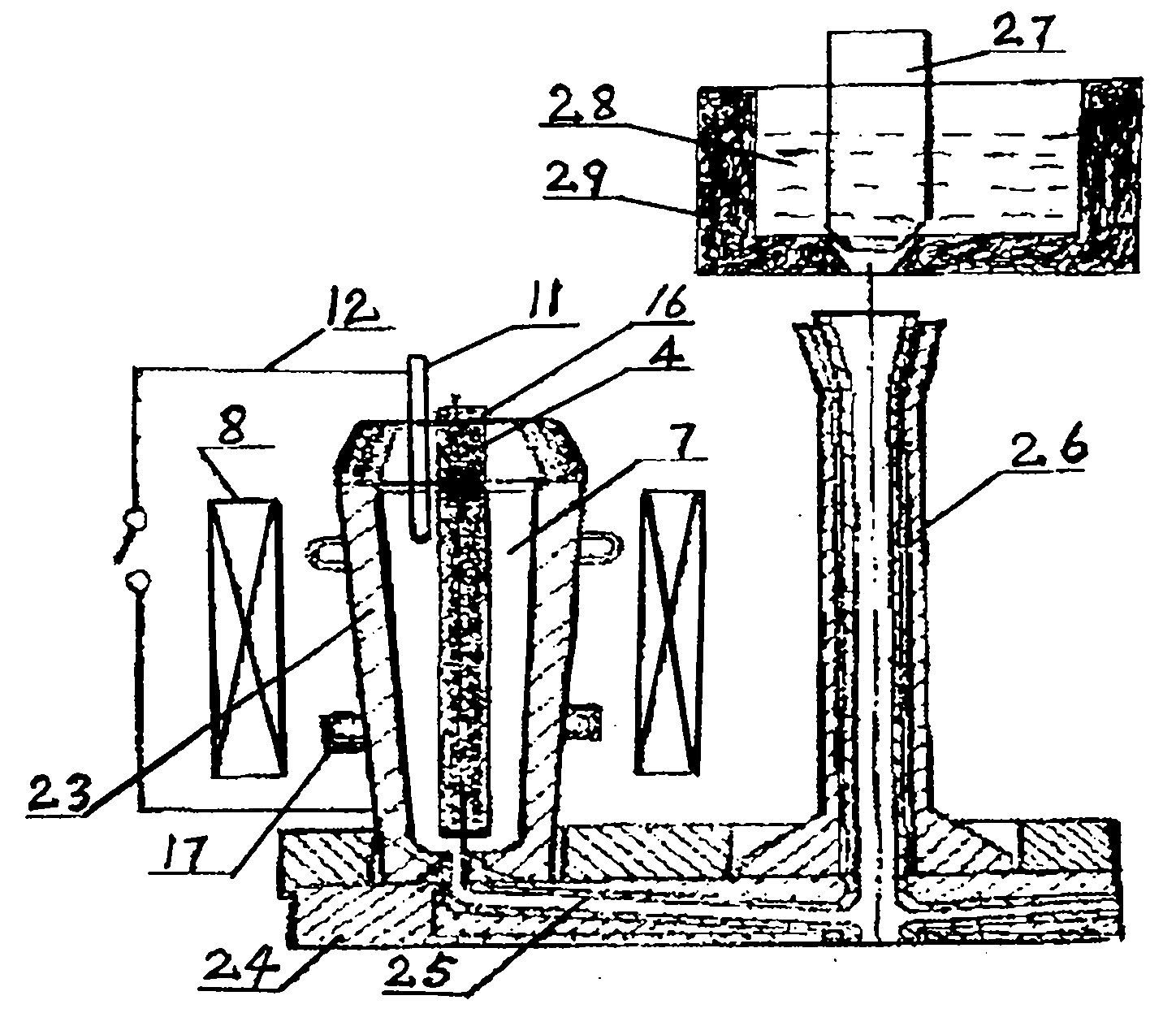

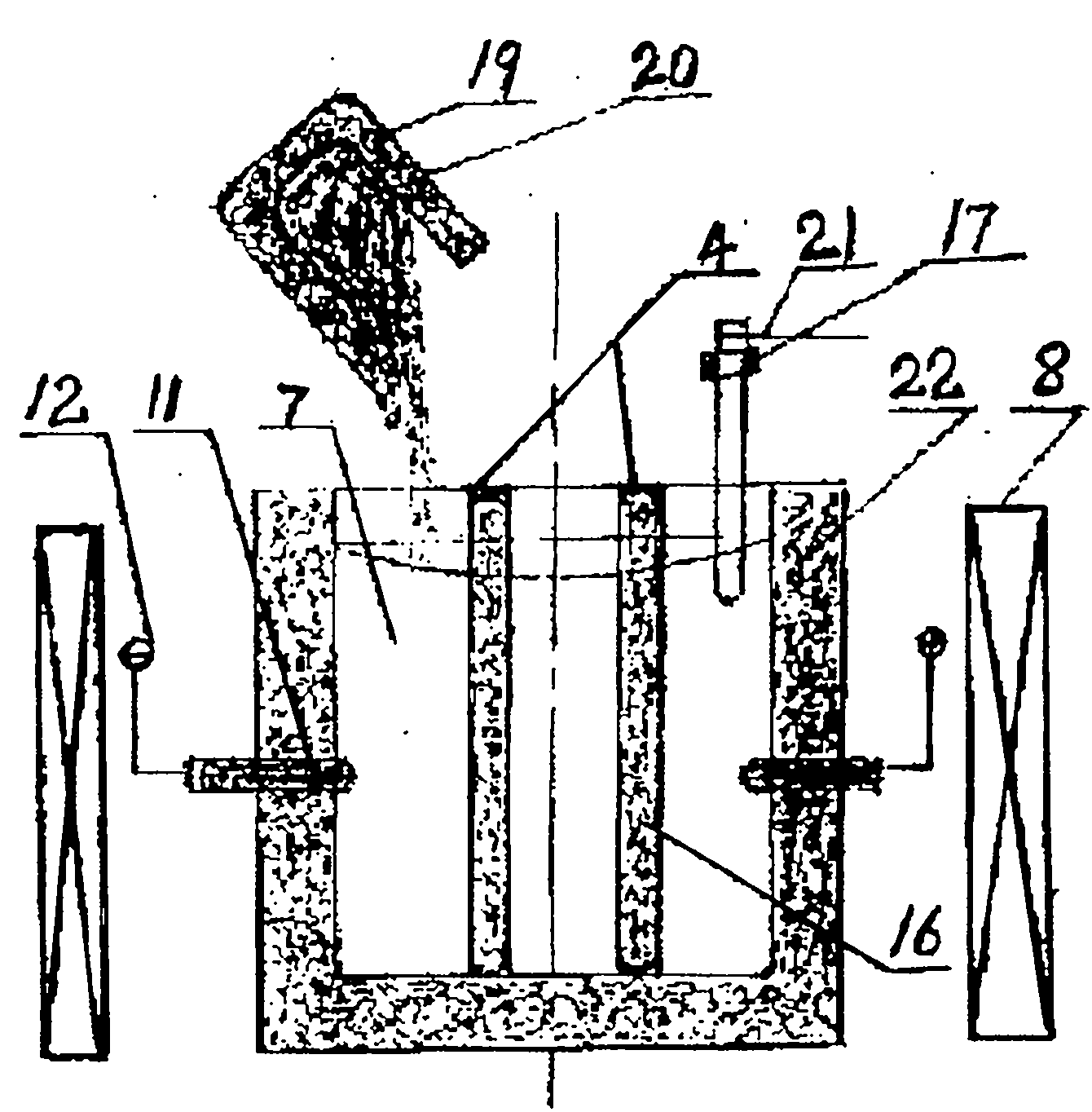

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

Method for preparing nano oxide dispersion reinforced superfine crystal tungsten-based composite material

The invention provides a method for preparing a nano oxide dispersion reinforced superfine crystal tungsten-based composite material. The method comprises the following steps of: taking 0.1 to 1 weight percent of micro tungsten powder, nano yttrium oxide powder or yttrium metal powder and 0 to 2 weight percent of titanium metal powder or molybdenum powder or tantalum powder, blending the materials, mechanically alloying the materials, sintering discharge plasma and the like to prepare the superfine crystal tungsten composite material. The method has the following advantage that: the nearly full-densification superfine crystal tungsten-based composite material can be obtained by the method for preparing the nano oxide dispersion reinforced superfine crystal tungsten-based composite material. Complex phase doping of yttrium oxide or yttrium metal and titanium metal, molybdenum or tantalum powder not only realizes sintering densification of tungsten at a lower temperature, but also inhibits grain growth of tungsten crystals during sintering. The tungsten crystal grain size of the yttrium oxide reinforced superfine crystal tungsten-based composite material prepared by adopting the method is less than or equal to 3 microns, and the composite material has good mechanical property and thermal shock resistance.

Owner:UNIV OF SCI & TECH BEIJING

Microstructure modification in copper interconnect structure

ActiveUS7843063B2Inhibited DiffusionFaster rateSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectCopper plating

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

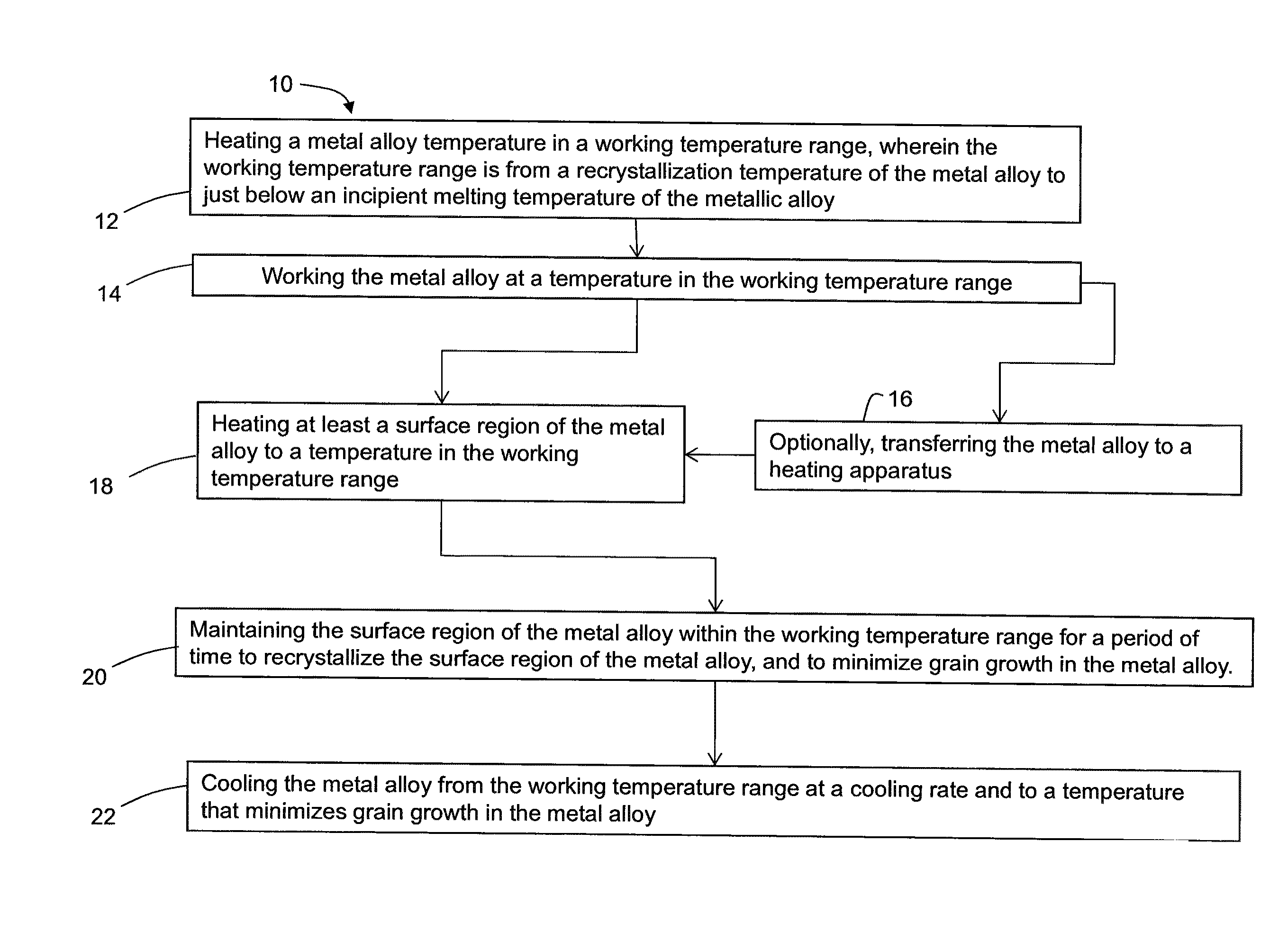

Methods for processing metal alloys

ActiveUS20150129093A1Minimize grain growthInhibition formationMetal-working apparatusMetal alloyWorking temperature

A method of processing a metal alloy includes heating to a temperature in a working temperature range from a recrystallization temperature of the metal alloy to a temperature less than an incipient melting temperature of the metal alloy, and working the alloy. At least a surface region is heated to a temperature in the working temperature range. The surface region is maintained within the working temperature range for a period of time to recrystallize the surface region of the metal alloy, and the alloy is cooled so as to minimize grain growth. In embodiments including superaustenitic and austenitic stainless steel alloys, process temperatures and times are selected to avoid precipitation of deleterious intermetallic sigma-phase. A hot worked superaustenitic stainless steel alloy having equiaxed grains throughout the alloy is also disclosed.

Owner:ATI PROPERTIES LLC

Preparation method of complex phase ceramic material containing zirconium boride

InactiveCN102173813AControlling chemical reaction driving forcesControl the severity of the reactionBorideMaterial defect

The invention relates to a preparation method of a complex phase ceramic material containing zirconium boride, relating to a preparation method of ceramic materials and aiming to overcome the material defects of abnormal crystal grain growth, phase clustering, and the like which are caused by difficult control and overhigh partial temperature in the traditional reaction sintering preparation method and solve the problems of tissue uniformity and comprehensive mechanical property of the complex phase ceramic material. The preparation method comprises the following steps of: 1, placing zirconium oxide and a boron-containing compound or a boron-containing composite into a ball mill to form composite powder; 2, drying the composite powder, then crushing, and screening through a sieve of 200 meshes to obtain uniform mixed powder; 3, carrying out mould pressing or cold isostatic pressing on the mixed powder, and then carrying out pressureless sintering, hot pressing sintering or hot isostatic pressing sintering to obtain the complex phase ceramic material containing the zirconium boride. The complex phase ceramic material containing the zirconium boride has uniform crystal grain size and distribution, the fracture toughness of 3.5-7.5 MPa.m<-1 / 2> and the bending strength of 250-700 MPa and can be used in the field of high-temperature resistant structural members and the like.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com