Industrialized preparation method of WC-Co hard alloy with low cost and high performance

A cemented carbide, high-performance technology, applied in the field of cemented carbide and powder metallurgy, can solve the problems of limited material quantity, high price, and inability to promote, and achieve the effects of saving resources, shortening the cycle, and simplifying production equipment and process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

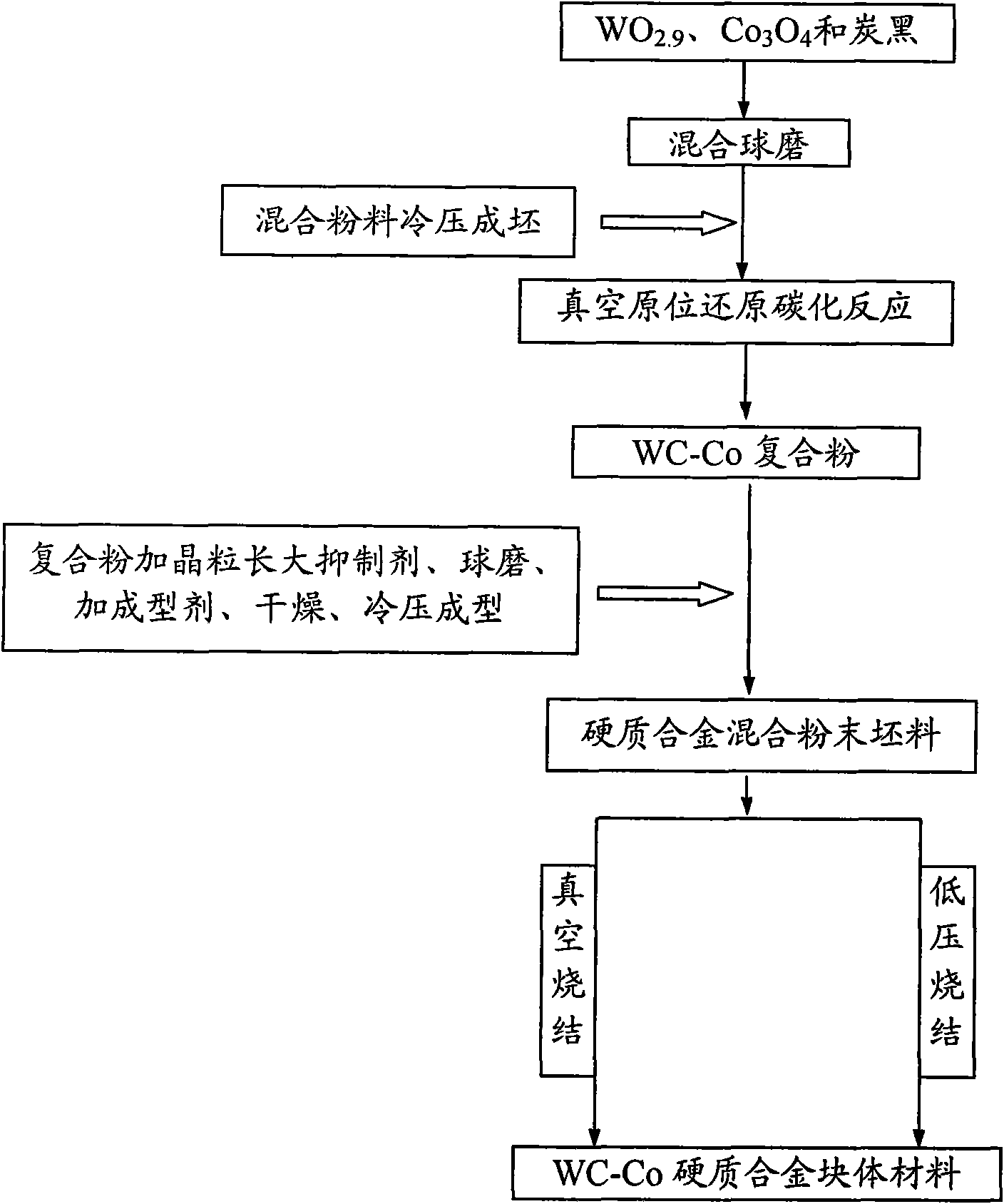

Method used

Image

Examples

example 1

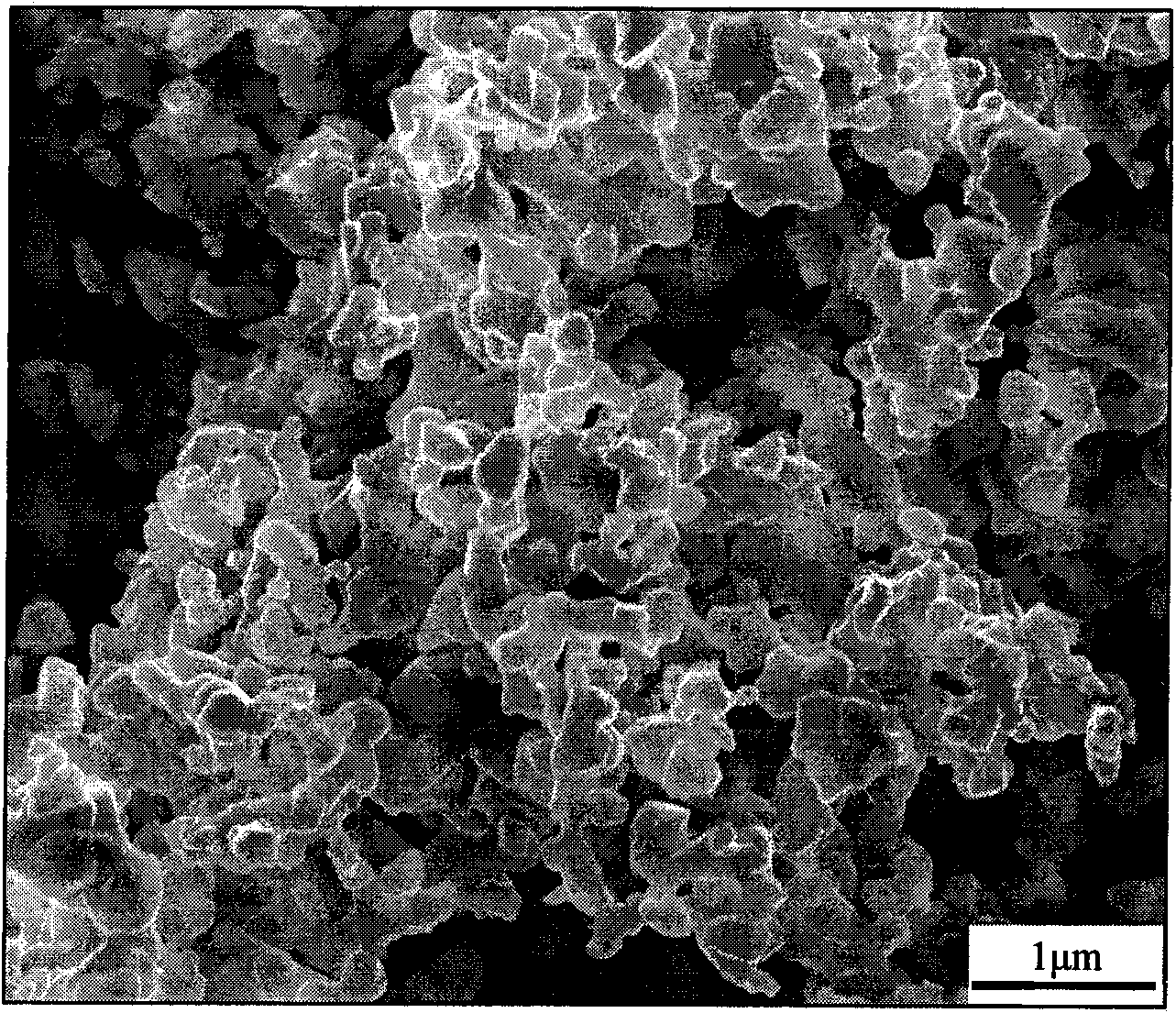

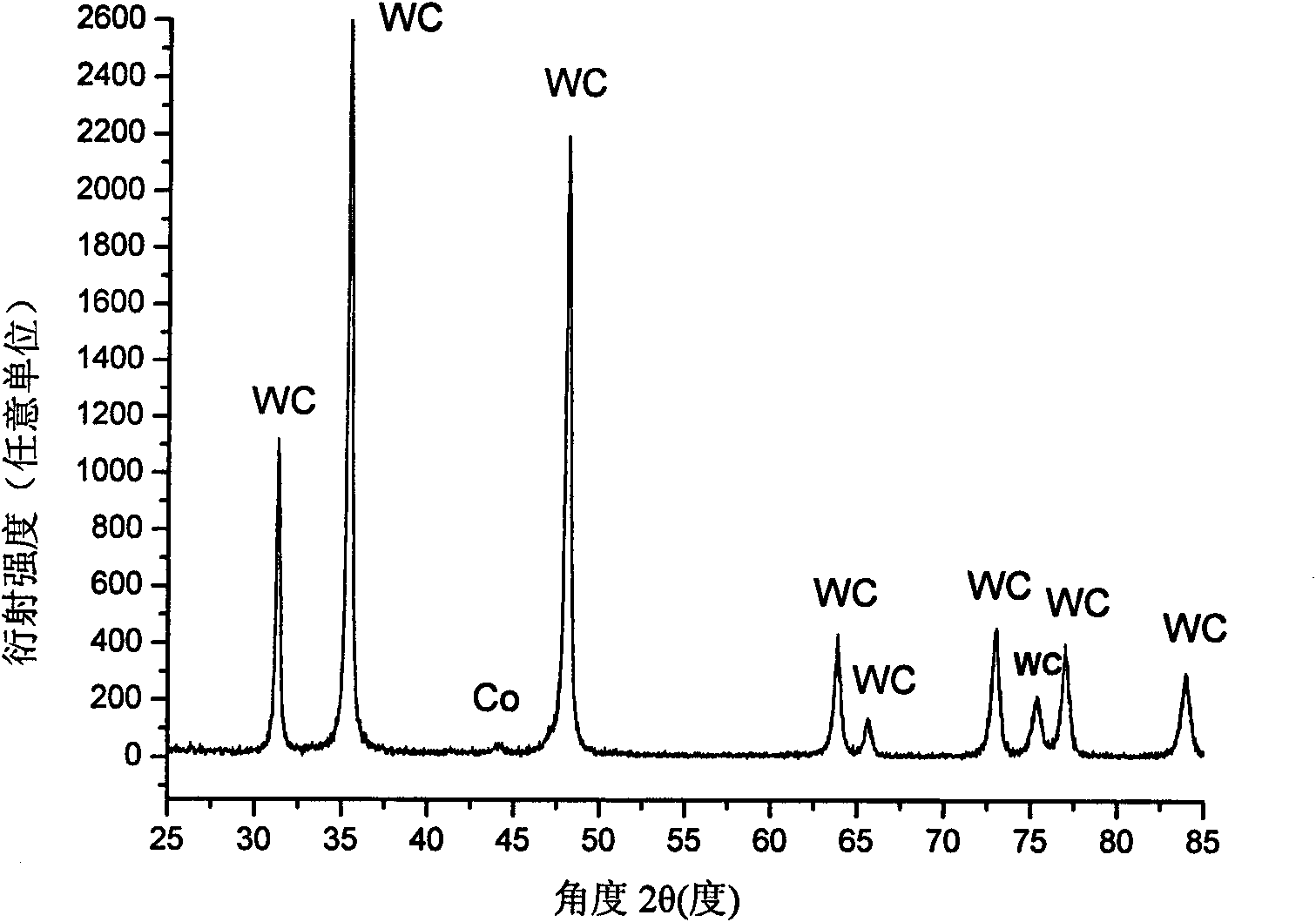

[0022] The final product is WC-6wt.%Co(YG6) cemented carbide bulk material. Take WO 2.9 , Co 3 O 4 And carbon black powder as raw materials, according to the requirements of the Co content in YG6 cemented carbide, the weight ratio of WO is 110.9:8.2:24.2 2.9 , Co 3 O 4 It is mixed with carbon black and ball milled, and the powder after ball milling is cold pressed and sent to a vacuum furnace with a vacuum gas pressure less than 0.004Pa. The WC-Co composite powder was prepared in a vacuum furnace with the following process parameters: the heating rate was 30 / ℃ min, the holding temperature was 1050℃, and the holding time was 3 hours. The microstructure of the WC-Co composite powder prepared by the above process is shown in figure 1 , The average particle size is about 210 nanometers. The WC-Co composite powder prepared above is directly ball milled without adding a grain growth inhibitor, using anhydrous ethanol as the grinding medium, the volume ratio of material to liquid is 1...

example 2

[0024] The final product is WC-10wt.%Co(YG10) cemented carbide bulk material. Take WO 2.9 , Co 3 O 4 And carbon black powder as raw materials, according to the requirement of Co content in YG10 cemented carbide, according to the mass ratio of 106.2:13.6:23.3 WO 2.9 , Co 3 O 4 It is mixed with carbon black and ball milled, and the powder after ball milling is cold pressed and sent into a vacuum furnace with a vacuum gas pressure of less than 0.001 Pa. The WC-Co composite powder was prepared in a vacuum furnace using the following process parameters: the heating rate was 20°C / min, the holding temperature was 1100°C, and the holding time was 3.5 hours. Add 0.4wt.%VC+0.4wt.%Cr to the WC-Co composite powder prepared above 3 C 2 The mixed powder is then ball milled with absolute ethanol as the grinding medium, the volume ratio of material to liquid is 1:2, the mass ratio of ball to material is 3:1, the speed of the ball mill is 200r / min, and the ball mill The time is 30 hours, 6 hour...

example 3

[0026] The final product is WC-12wt.%Co(YG12) cemented carbide bulk material. Take WO 2.9 , Co 3 O 4 And carbon black powder as raw materials, according to the requirements of the Co content in YG12 cemented carbide, the WO will be combined with a mass ratio of 103.8:16.3:22.8 2.9 , Co 3 O 4 It is mixed with carbon black and ball milled, and the powder after ball milling is cold pressed and sent to a vacuum furnace with a vacuum gas pressure less than 0.0004Pa. The WC-Co composite powder was prepared in a vacuum furnace with the following process parameters: the heating rate was 15 / ℃ min, the holding temperature was 1150℃, and the holding time was 3 hours. Add 1.0wt.% VC crystal growth inhibitor to the WC-Co composite powder prepared above, and then ball mill the mixed powder with absolute ethanol as the grinding medium. The volume ratio of material to liquid is 1:3. The material mass ratio is 1:1, the ball mill speed is 100r / min, the ball milling time is 50 hours, and the form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com