Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3144 results about "Fracture toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, fracture toughness is a property which describes the ability of a material to resist fracture, and is one of the most important properties of any material for many design applications. The linear-elastic fracture toughness of a material is determined from the stress intensity factor (K) at which a thin crack in the material begins to grow. It is denoted KIc and has the units of Pa√(m) or psi√(in).

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

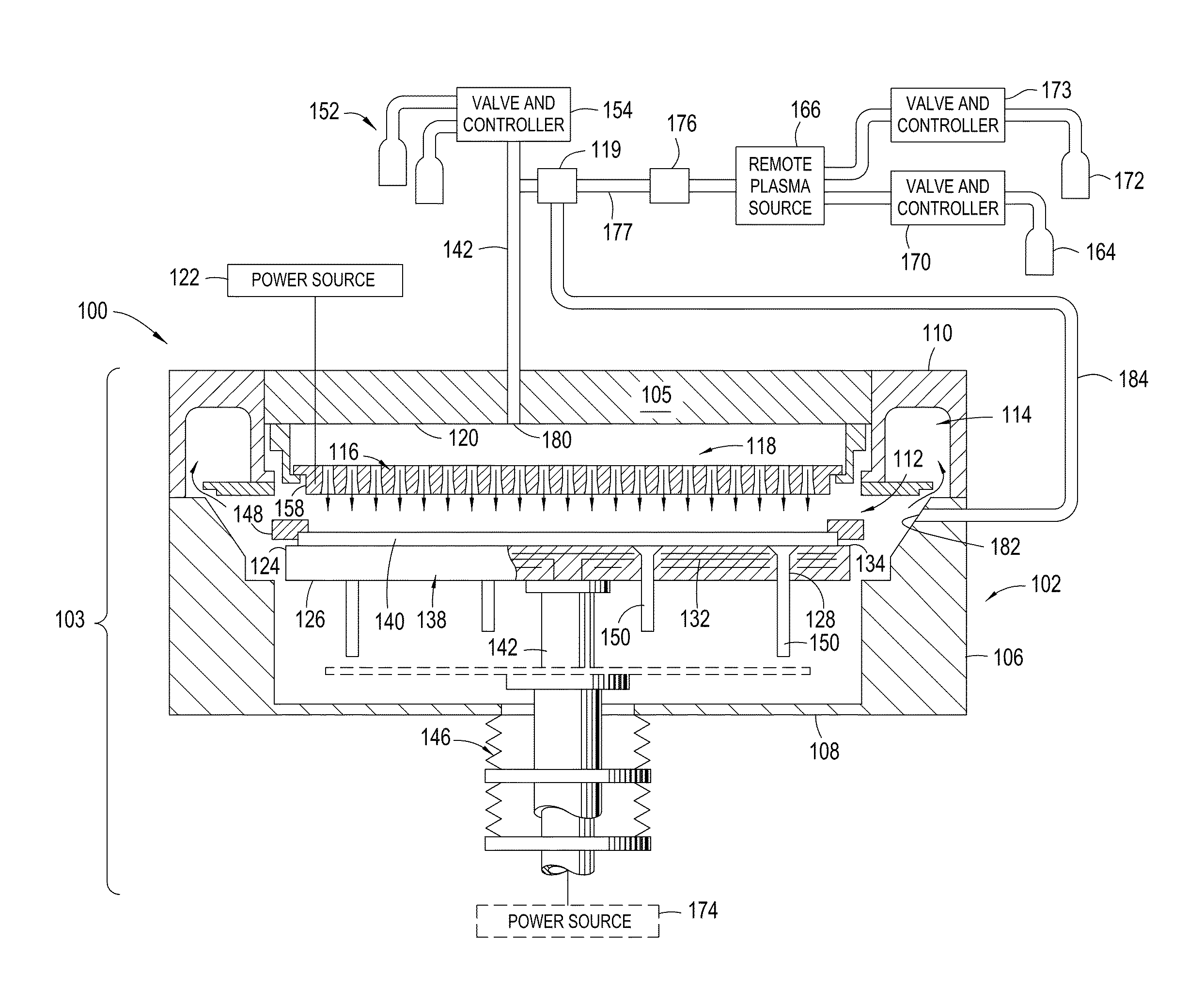

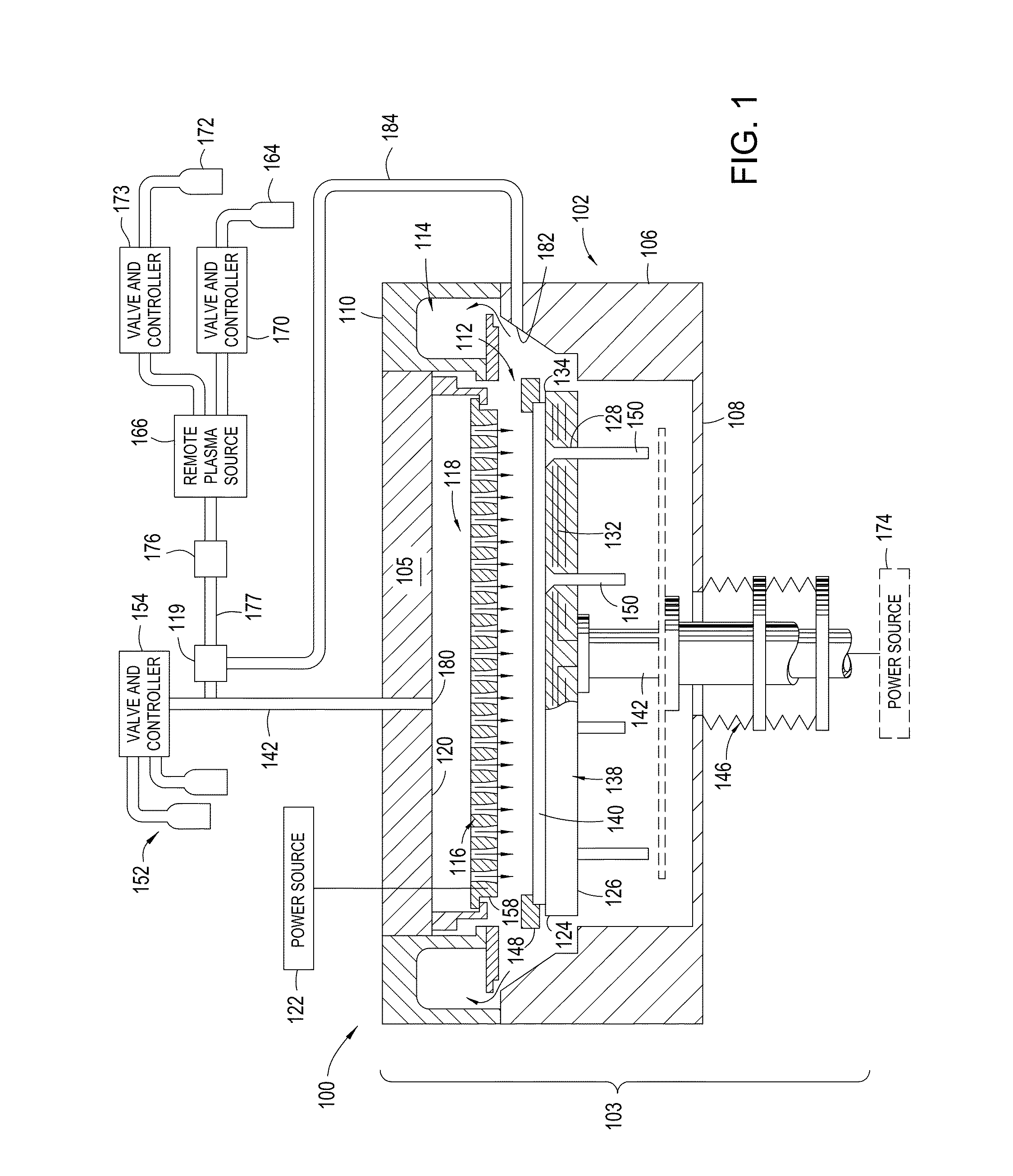

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

SiCOH dielectric

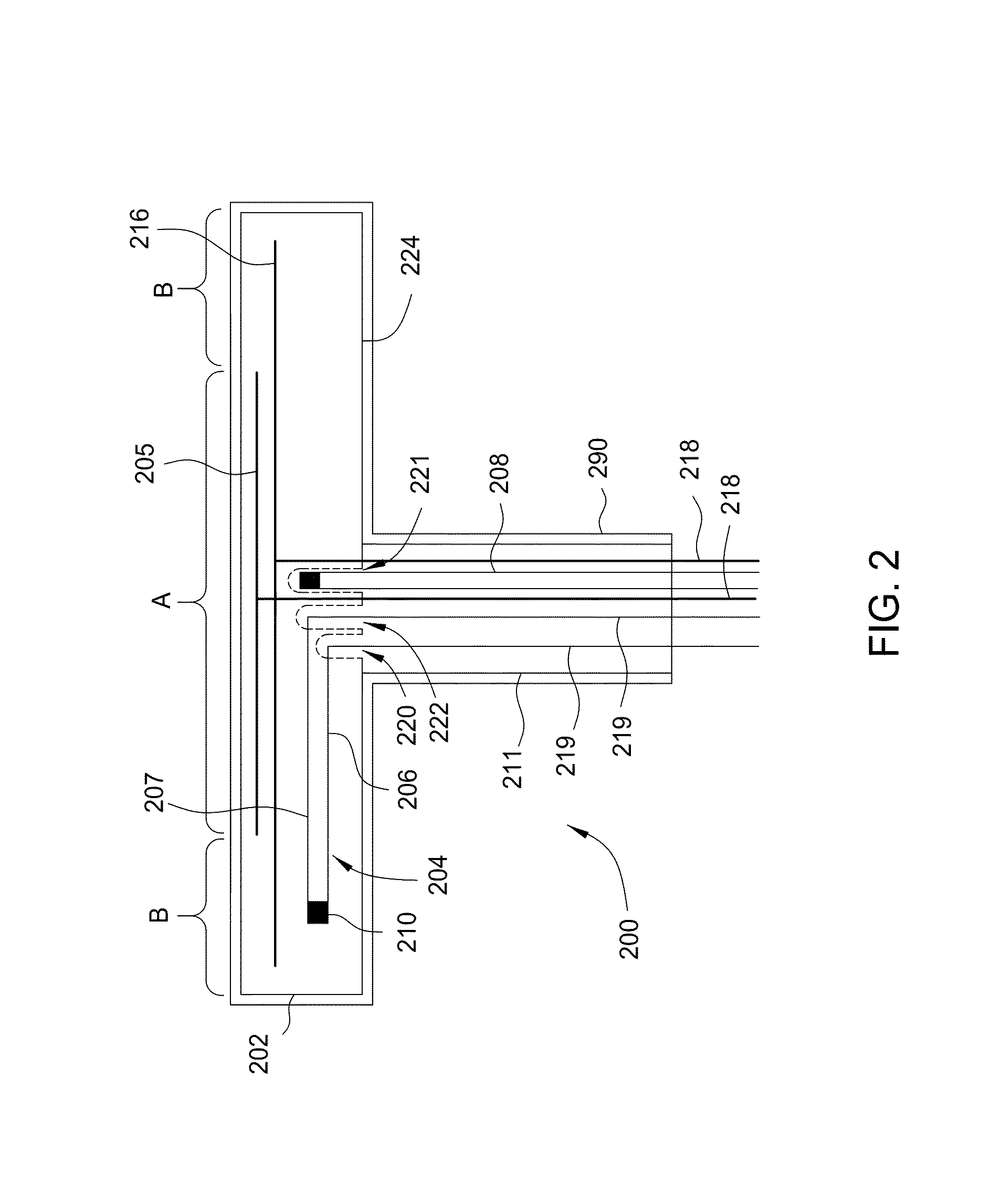

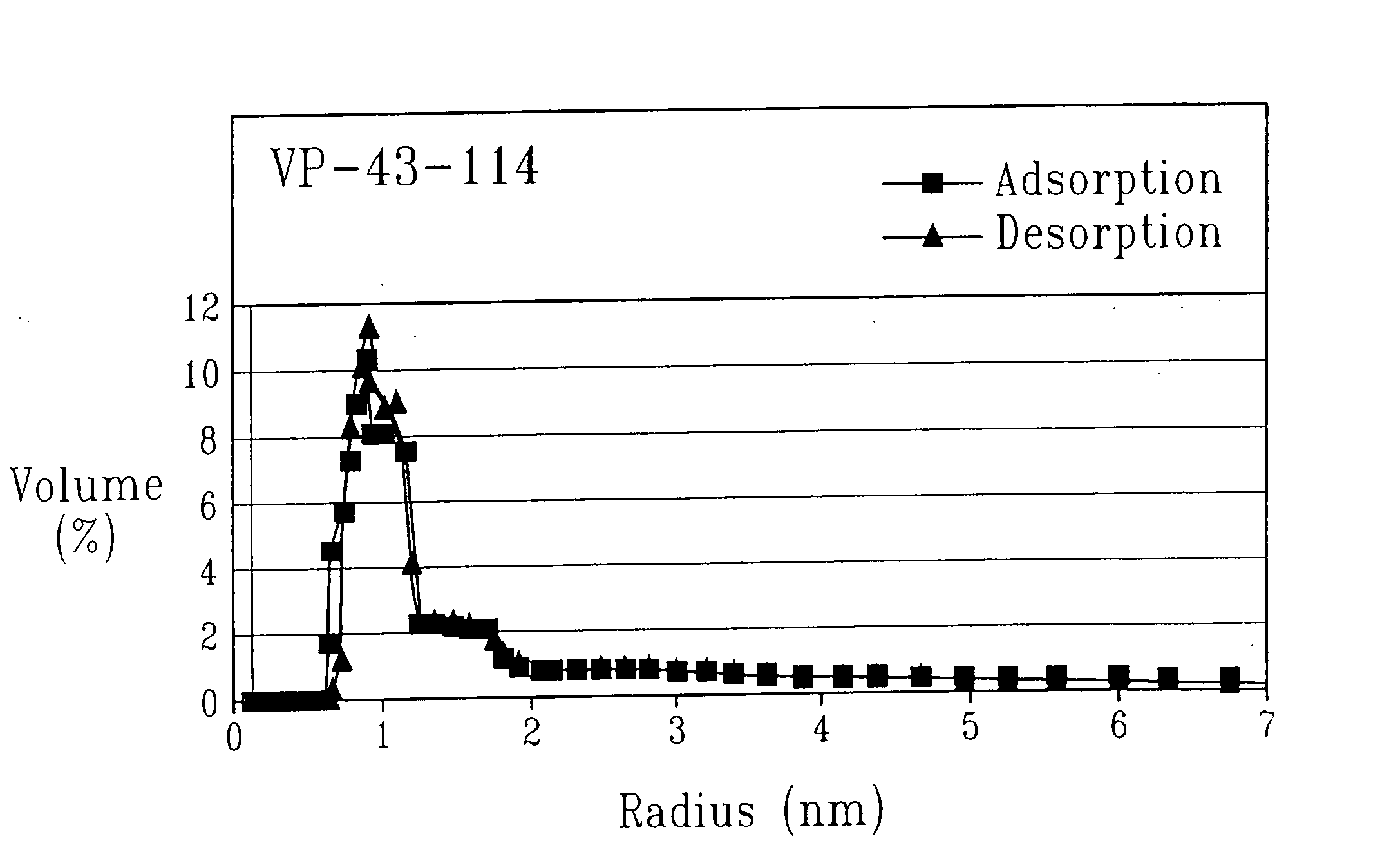

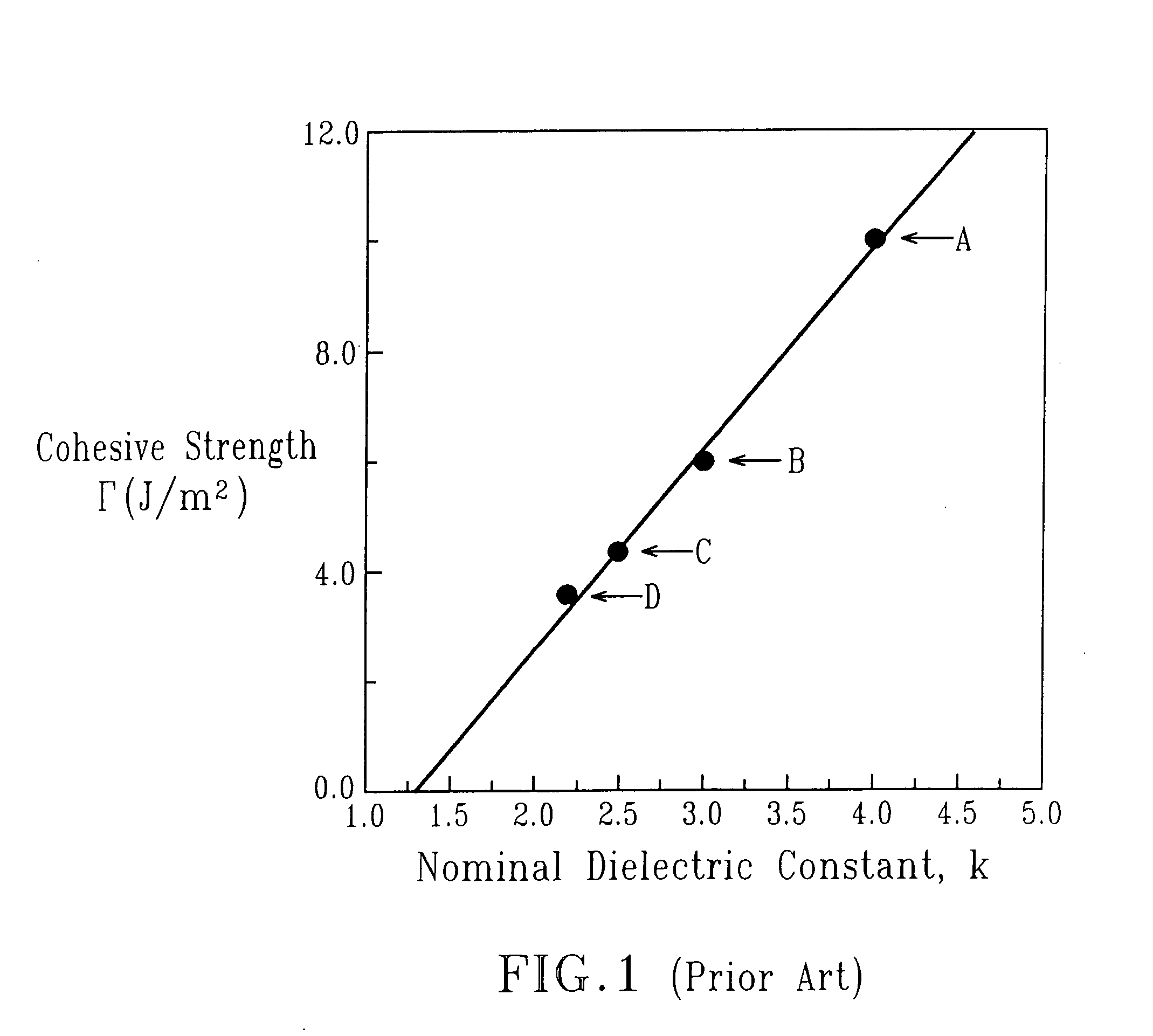

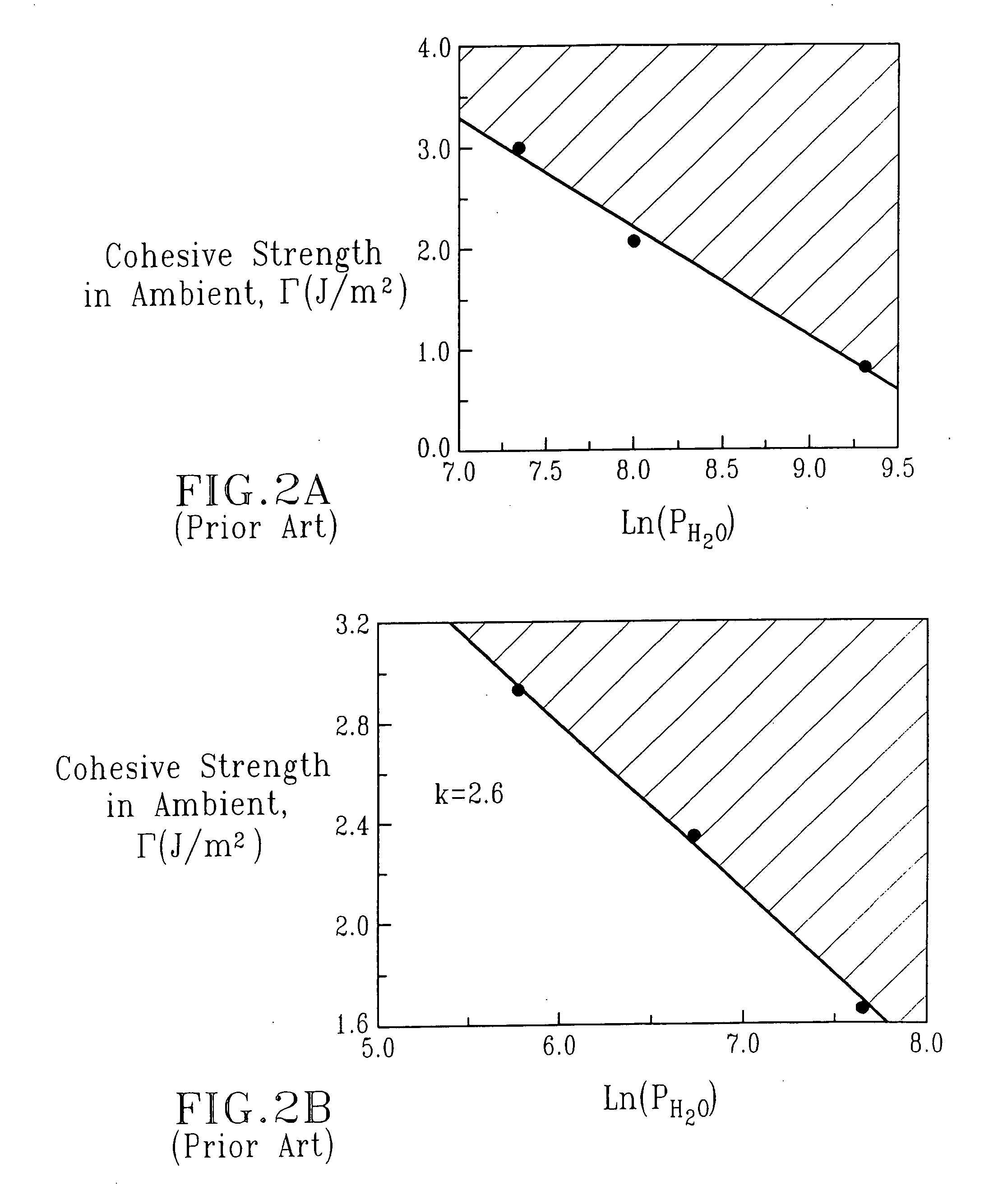

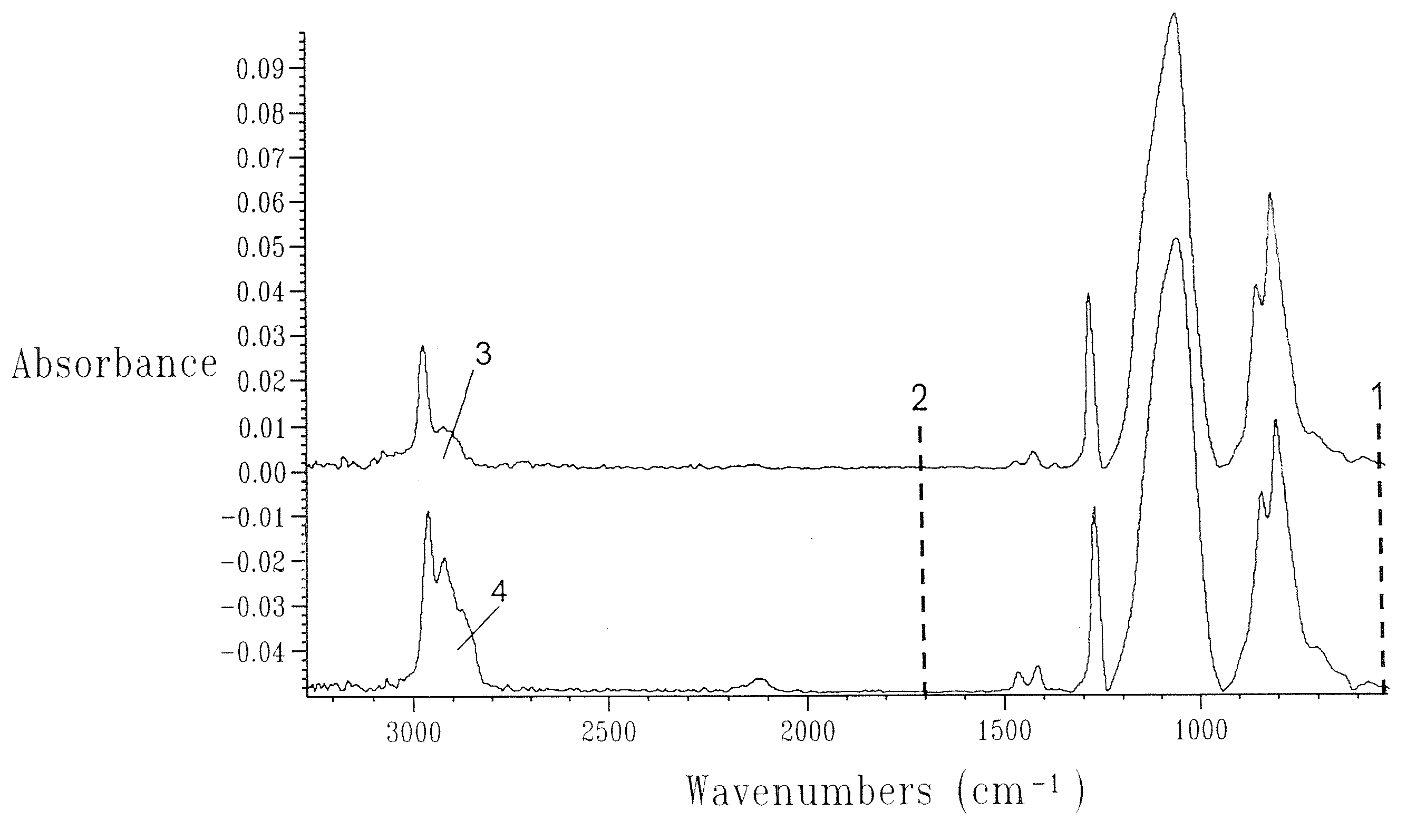

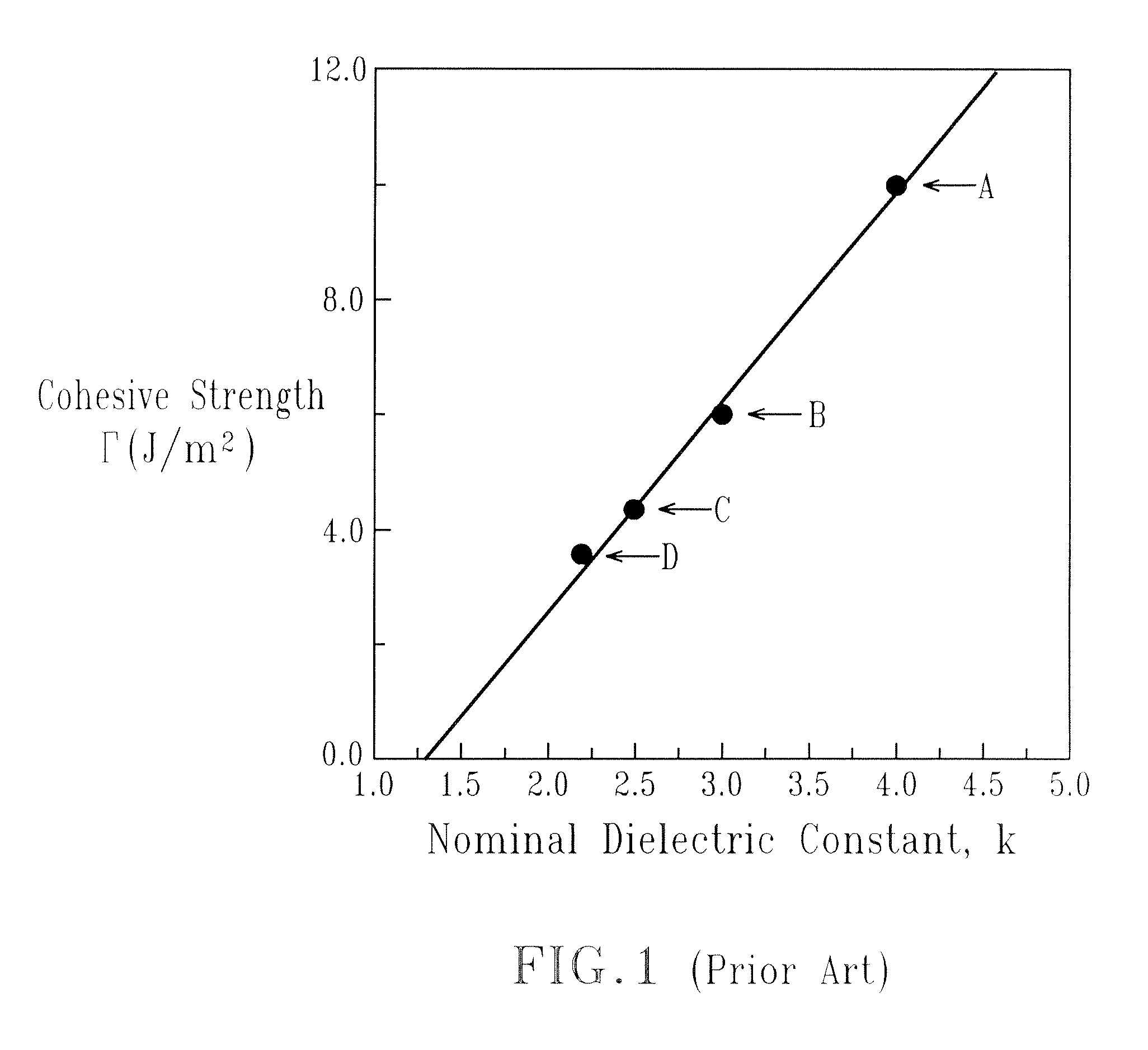

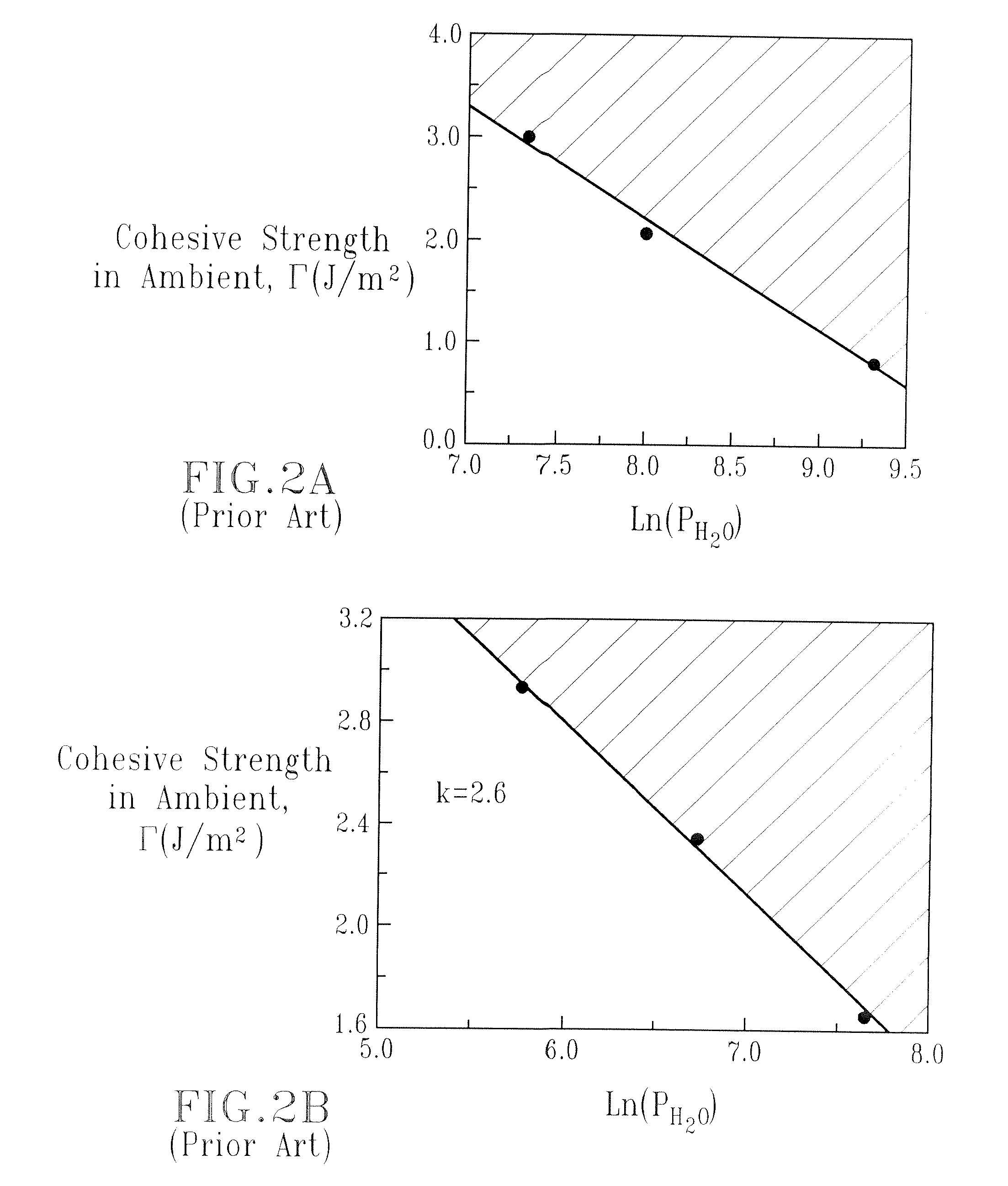

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

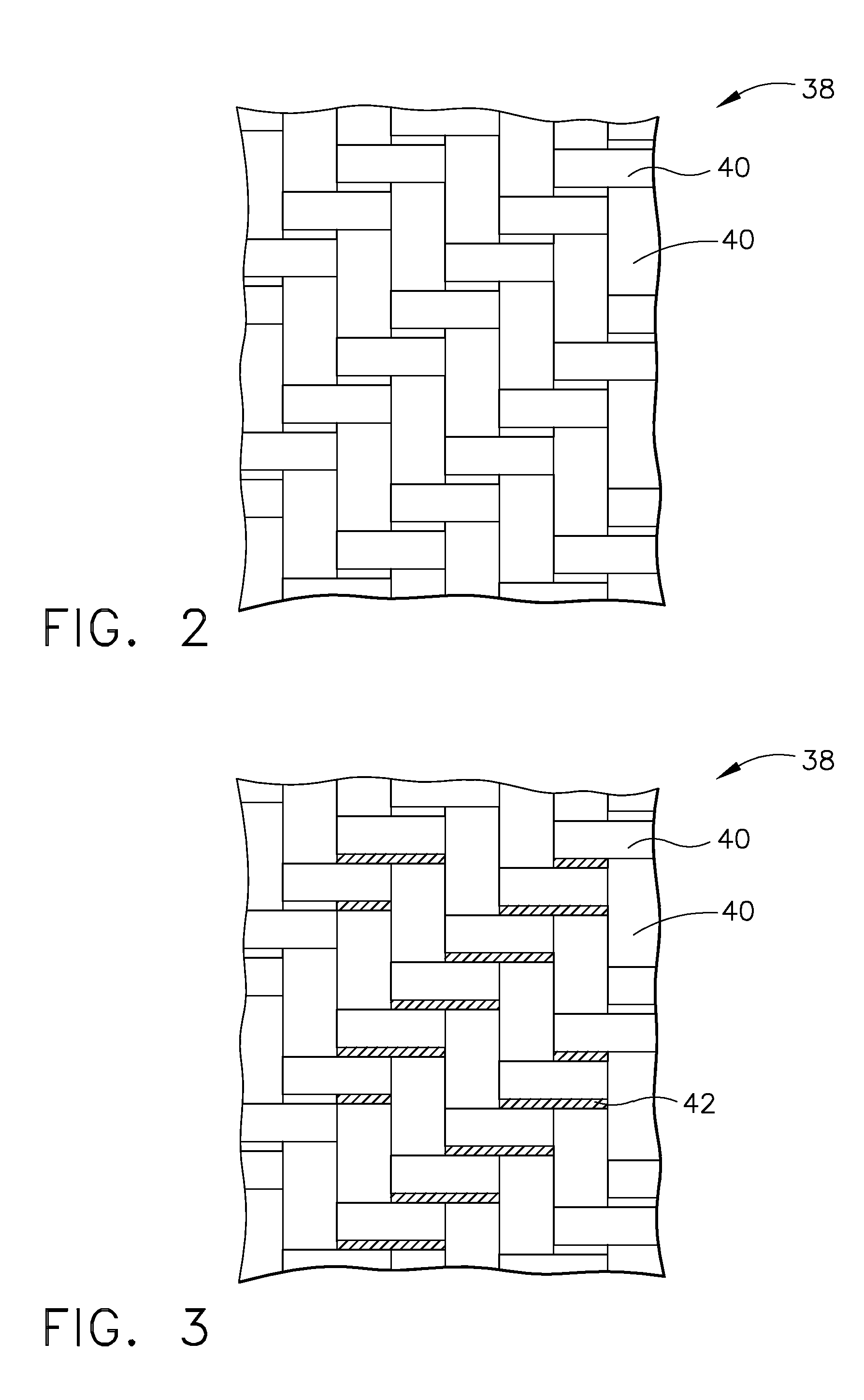

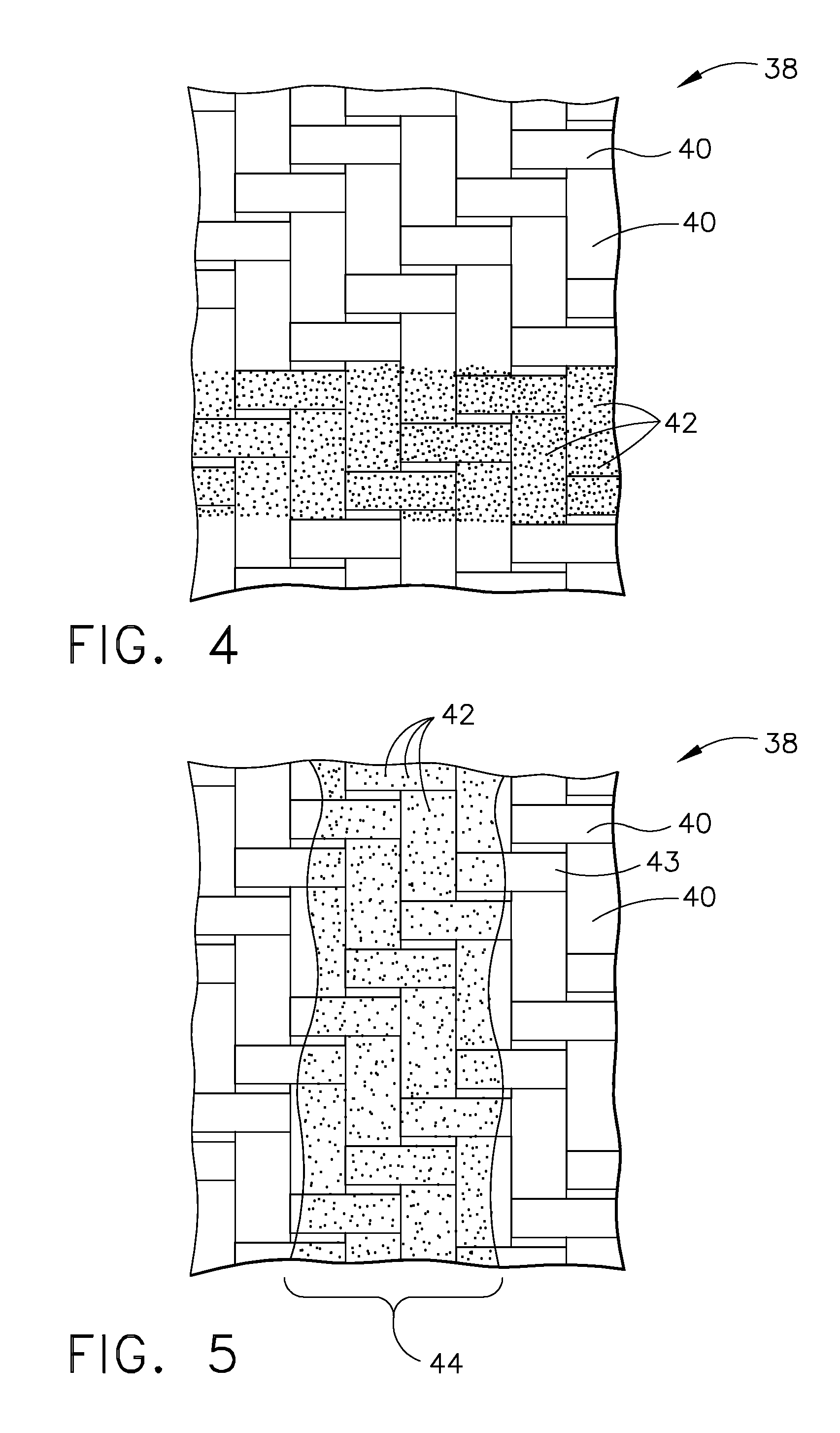

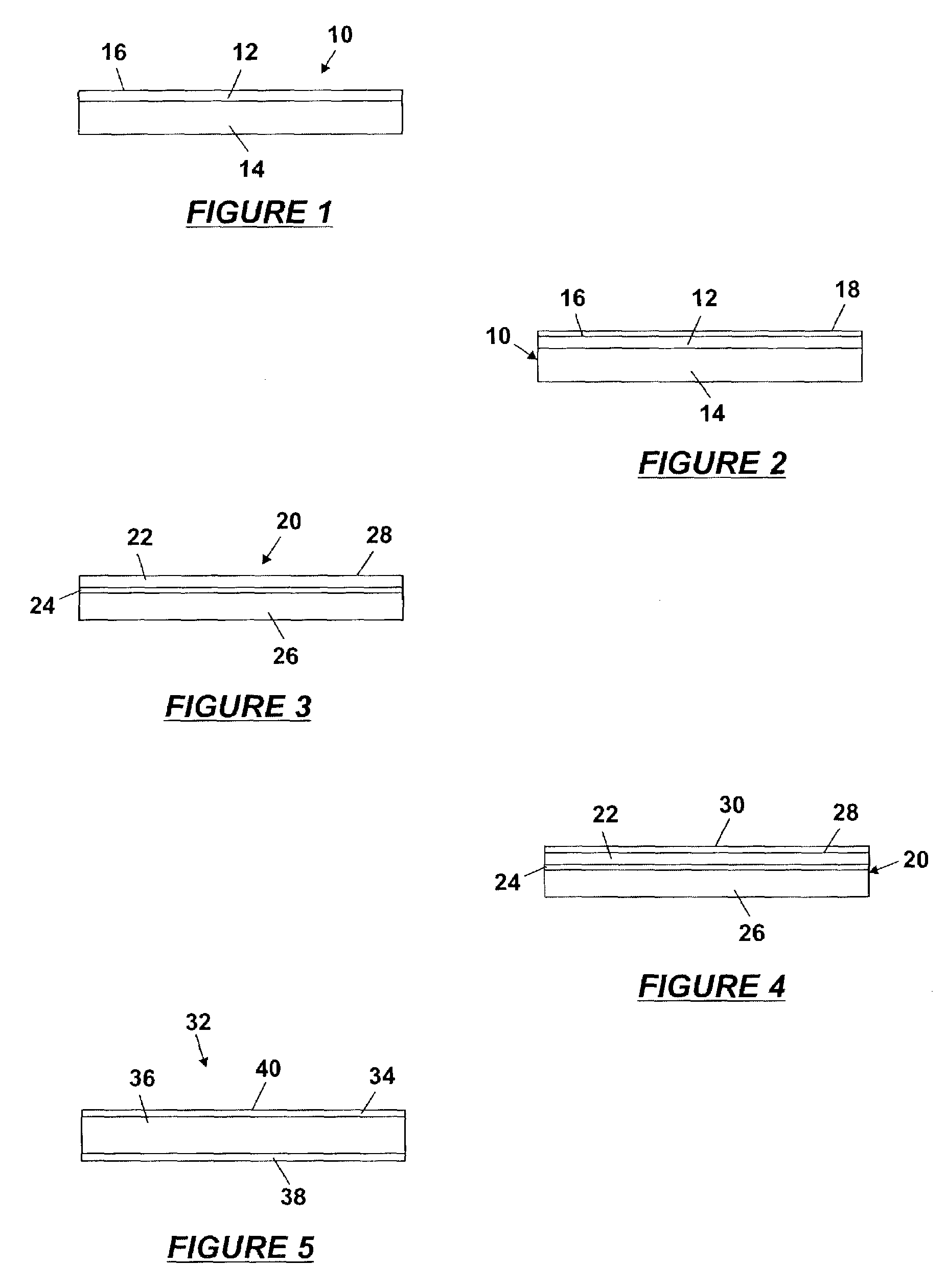

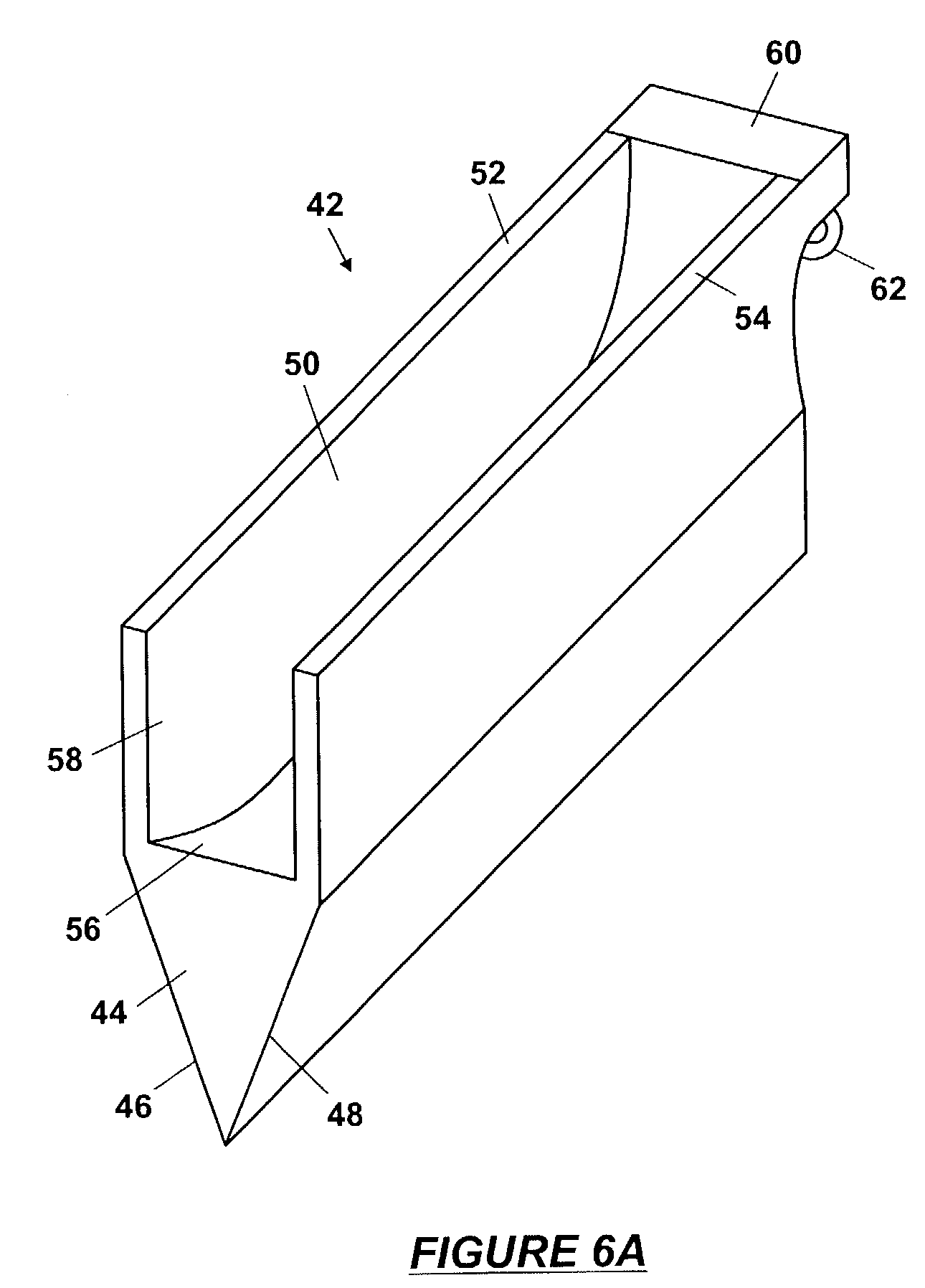

Methods of making articles having toughened and untoughened regions

ActiveUS20100148396A1Weight increaseHigh strengthPretreated surfacesLiquid/solution decomposition chemical coatingProviding materialFracture toughness

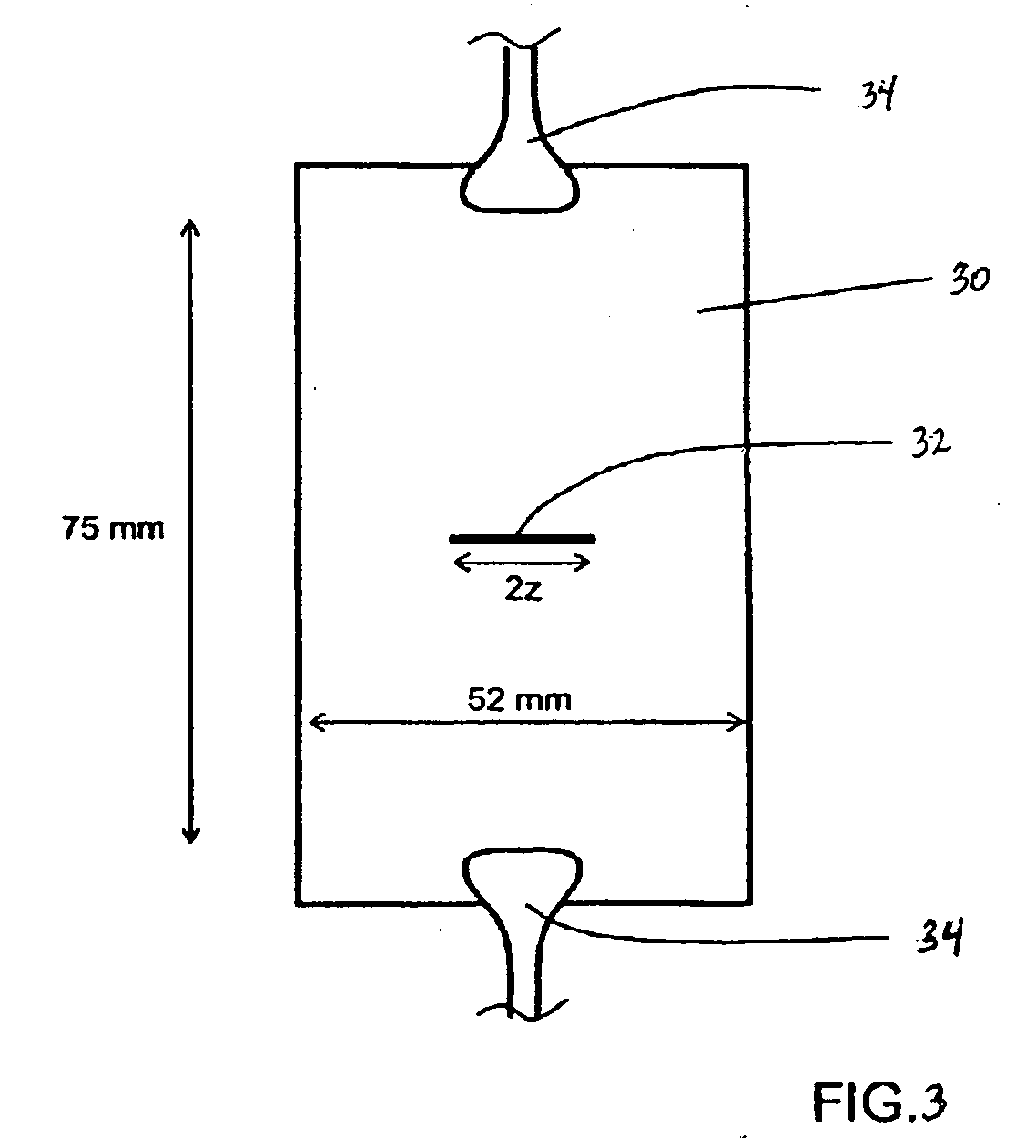

Methods of making an article having at least one toughened region and at least one untoughened region involving providing a material, applying a toughening agent to a portion of the material, shaping the material to produce a preform, applying an untoughened resin to the preform, and curing the preform having the applied untoughened resin to produce the at least one toughened region and the at least one untoughened region wherein the toughened region comprises a toughened resin having a fracture toughness of at least about 1.0 MPa-m1 / 2.

Owner:GENERAL ELECTRIC CO

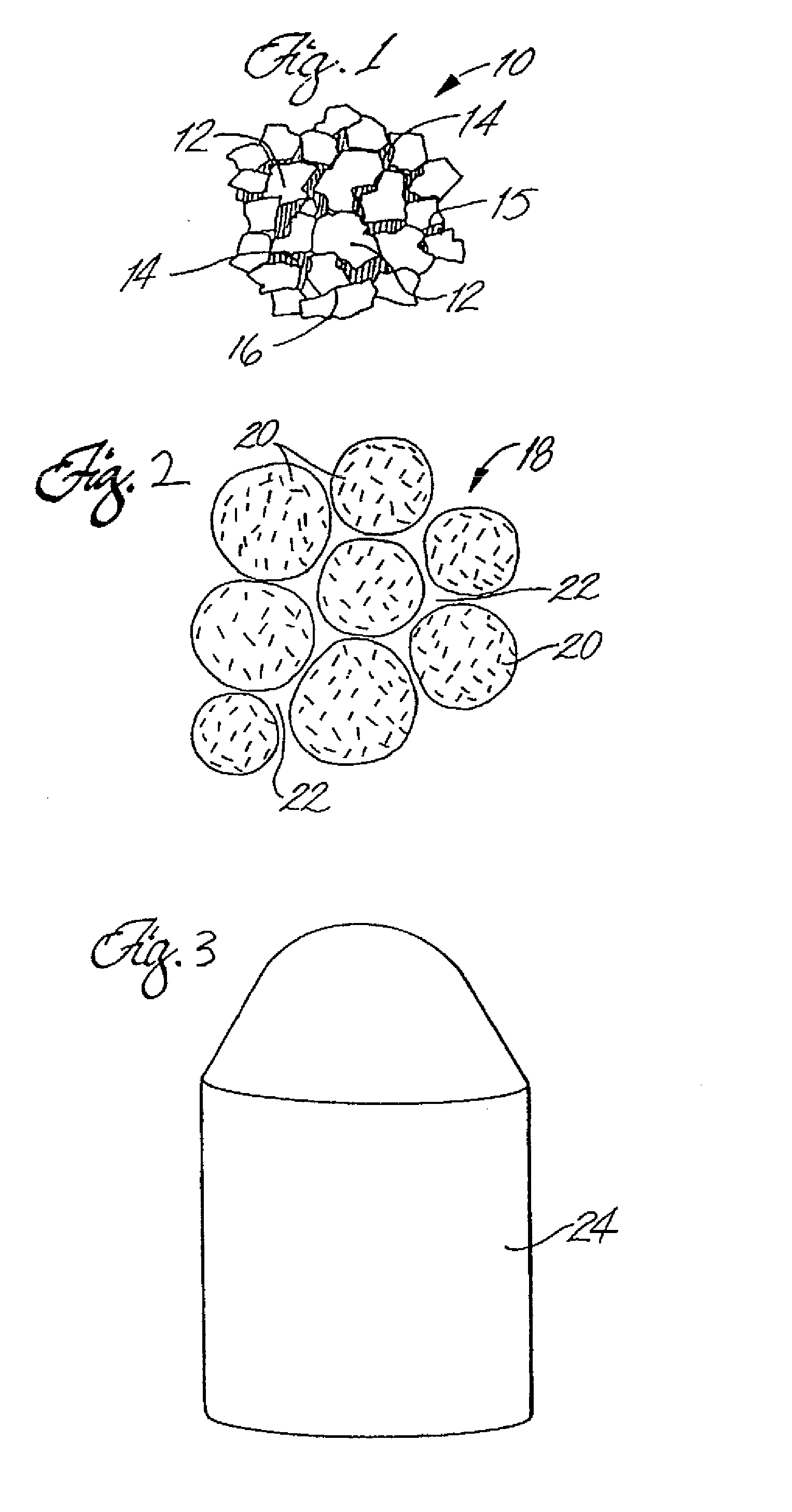

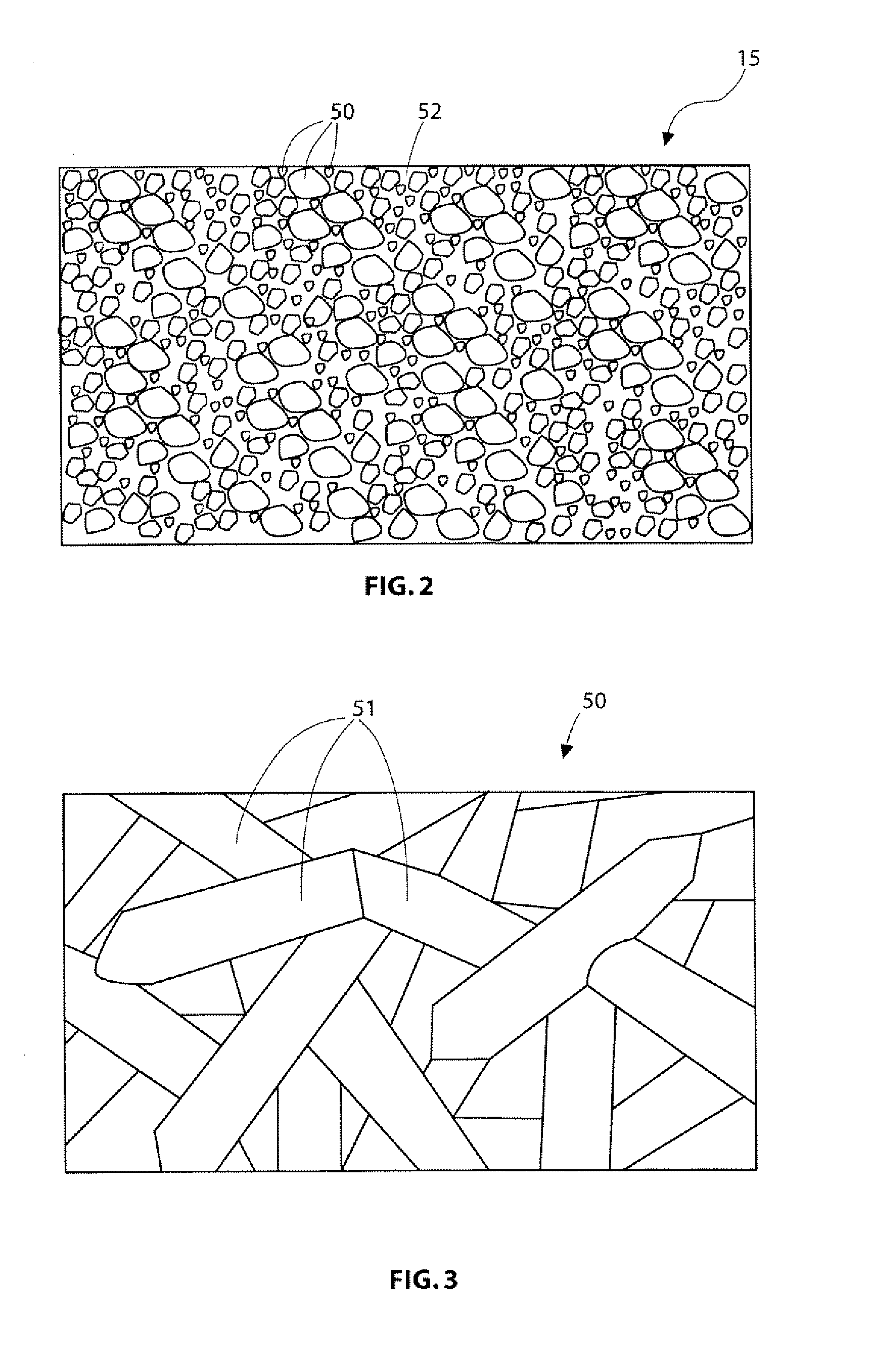

Milled particles

InactiveUS6634576B2Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

A process for milling a solid substrate in the milling chamber of a dispersion or media mill in the presence of a two or more compositions of milling media bodies is disclosed wherein all milling media bodies contribute to the grinding of the solid substrate and wherein at least one composition of media bodies provides fragments of milling media bodies that are retained with the milled solid substrate particles in the form of a synergetic commixture produced in the milling process. More specifically, a process is disclosed for preparing a synergetic commixture comprising small particles of a solid substrate and small particulates of a first material of a desired size comprising the steps of (a) providing to the milling chamber of a media mill a contents comprising a pre-mix of a solid substrate, a fluid carrier, a plurality of milling bodies of a first material having a fracture toughness Kc1, and a plurality of milling bodies of a second material having a fracture toughness Kc2; (b) operating the media mill to grind the solid substrate and degrade at least a portion of the milling bodies of first material to produce a dispersion in the fluid carrier comprising a synergetic commixture of small particulates of the first material and small particles of the solid substrate having a desired size equal to or less than a size Sp; (c) separating the dispersion from any milling bodies and solid substrate particles having a size larger than Sp; and (d) optionally removing the fluid carrier from the dispersion to form a synergetic commixture free of fluid and comprising the particles and the small particulates, wherein KC2 is greater than KC1.

Owner:RTP PHARMA +1

Milled particles

InactiveUS20020047058A1Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

Owner:RTP PHARMA +1

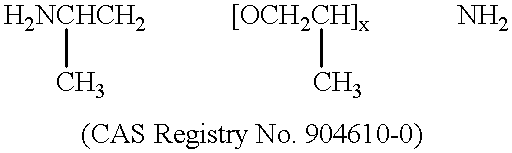

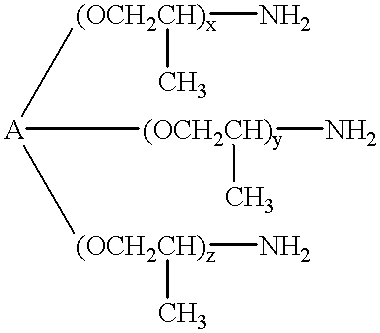

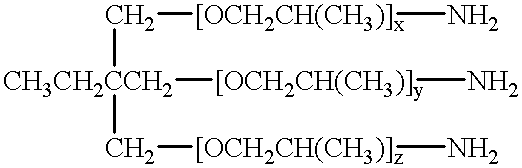

Two part, reinforced, room temperature curable thermosetting epoxy resin compositions with improved adhesive strength and fracture toughness

The present invention provides a room-temperature curable, reinforced thermosetting epoxy resin composition. The composition includes an epoxy resin first component, and an epoxy resin hardener second component. The epoxy resin component includes an epoxy resin, and may further include an inorganic and / or organic filler component, such as a structural reinforcement component. The epoxy resin hardener component includes an amine-based hardener, and may further include an inorganic and / or organic filler component. Cured reaction products of the composition demonstrate at about room temperature an adhesive strength of at least about 6500 psi, such as about 8000 to about 10000, and a fracture toughness of at least about 10 in-lbs / in.sup.2, such as about 20 to about 35 in-lbs / in.sup.2. In addition, the cured reaction products of the composition demonstrate a creep resistance at about room temperature at least about 6000 psi of at least about 1 hour. After mixing together the first and second components and at about room temperature, the composition has a pot life of at least about 3 hours at about room temperature, and after application onto a surface of a substrate has a slump resistance at about 30 minutes of less than about 0.5 inches.

Owner:LOCTITE

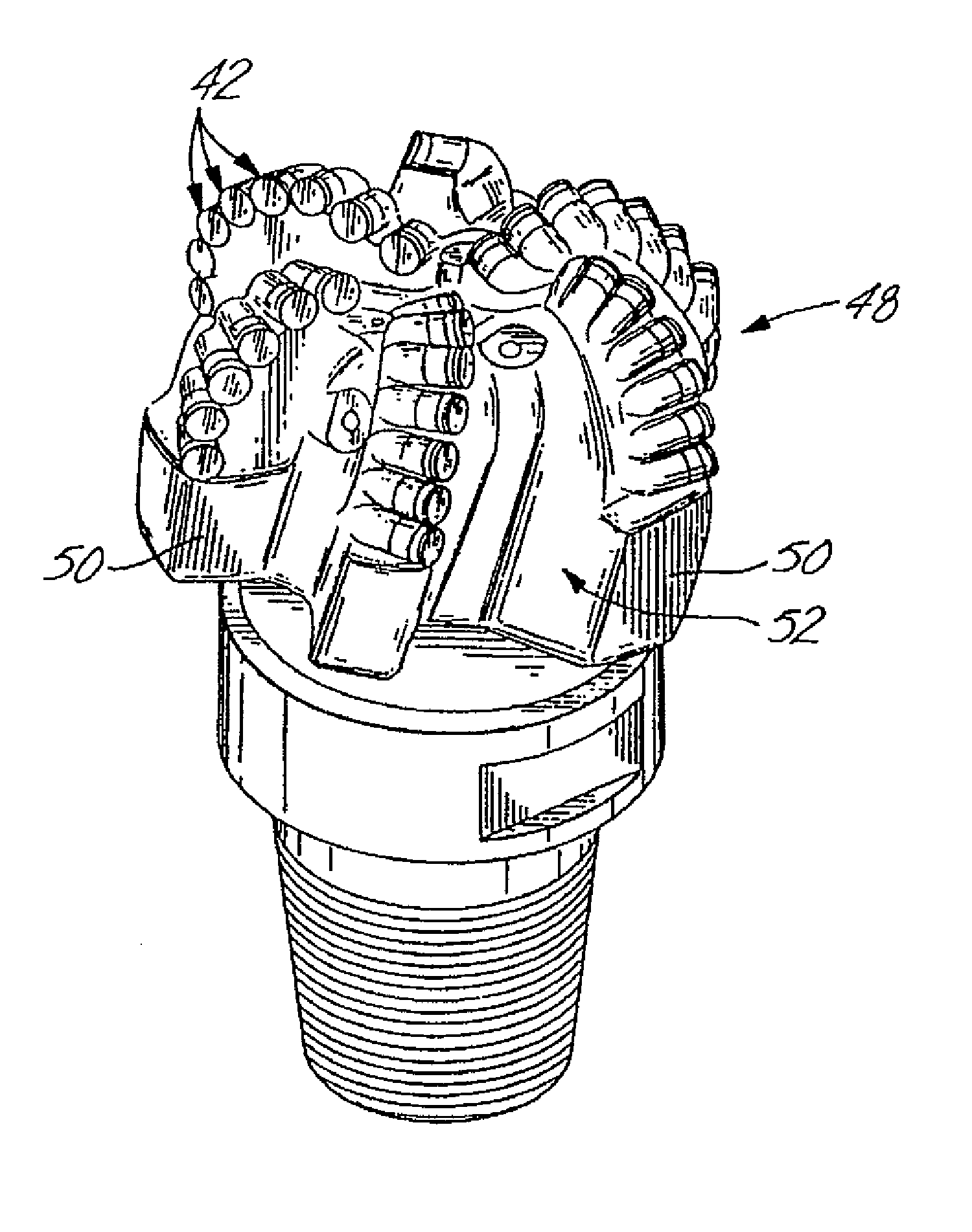

Polycrystalline diamond carbide composites

InactiveUS20070193782A1Improve fracture toughnessEasy to useDrill bitsOther chemical processesPolycrystalline diamondCarbide

Owner:SMITH INT INC

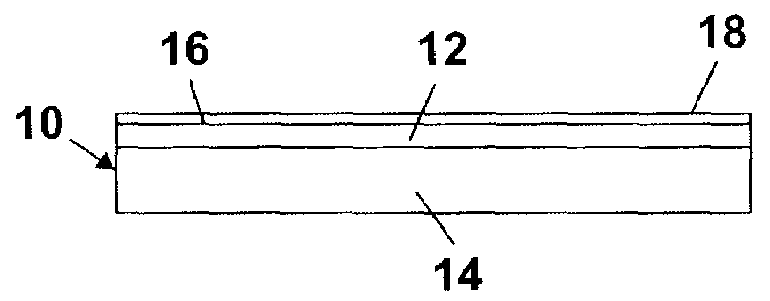

High-strength laminated sheet for optical applications

InactiveUS7514149B2Increase stiffnessHigh modulusGlass forming apparatusRecord information storageSurface layerHigh intensity

A laminated sheet includes a surface layer having an optical surface that is of fire-polished quality and a core layer having a higher modulus than the surface layer to increase an overall stiffness or fracture toughness of the laminated sheet.

Owner:CORNING INC

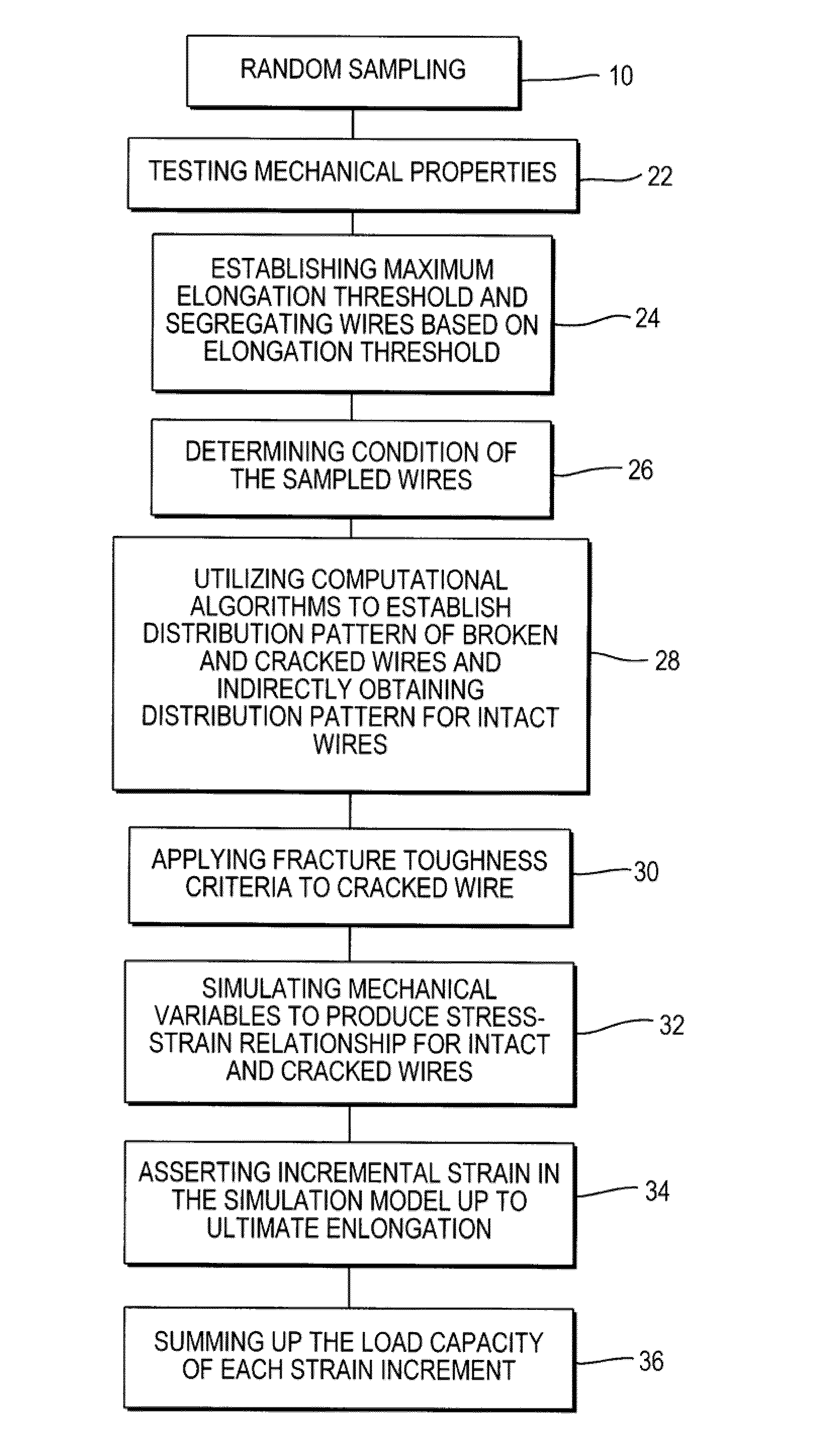

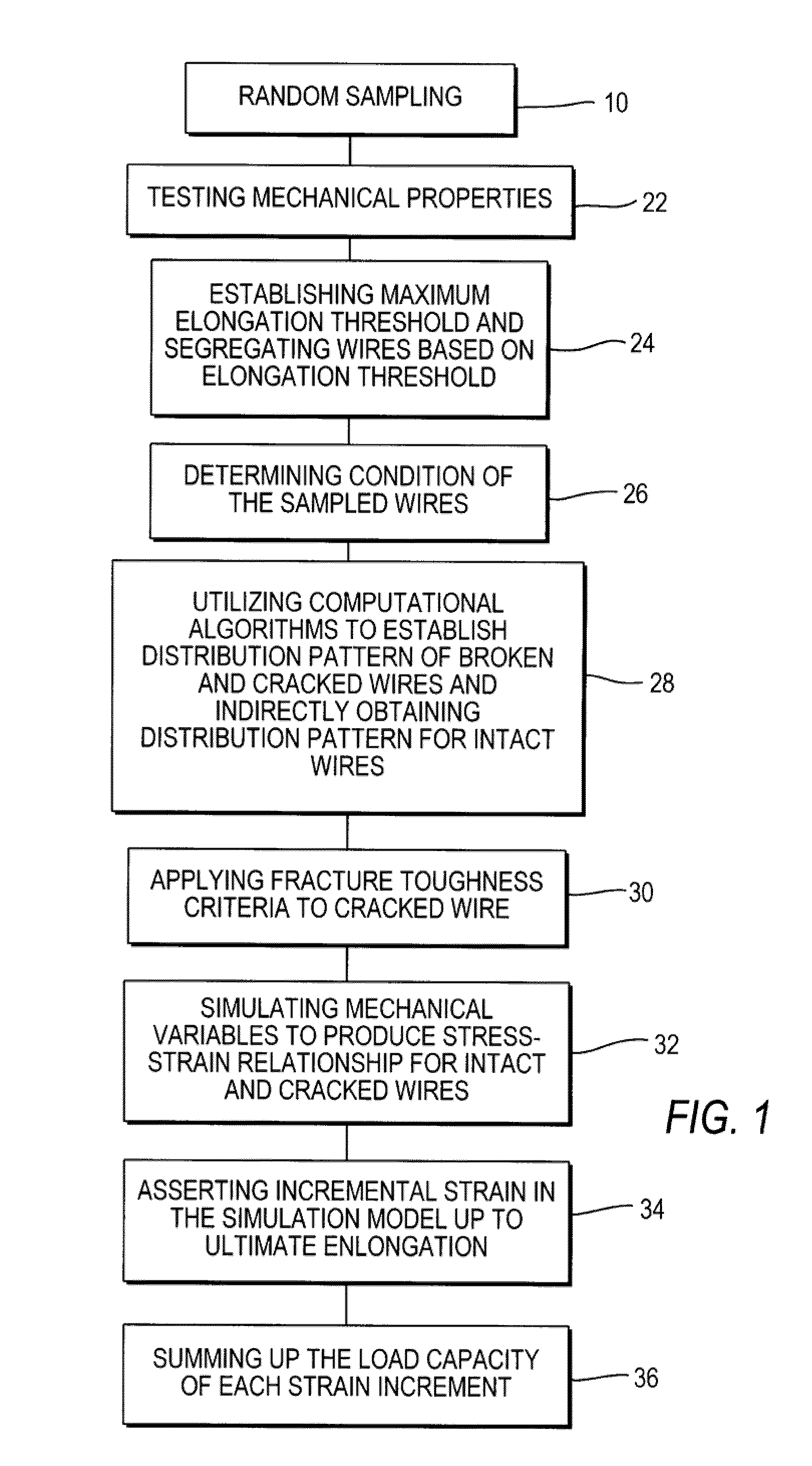

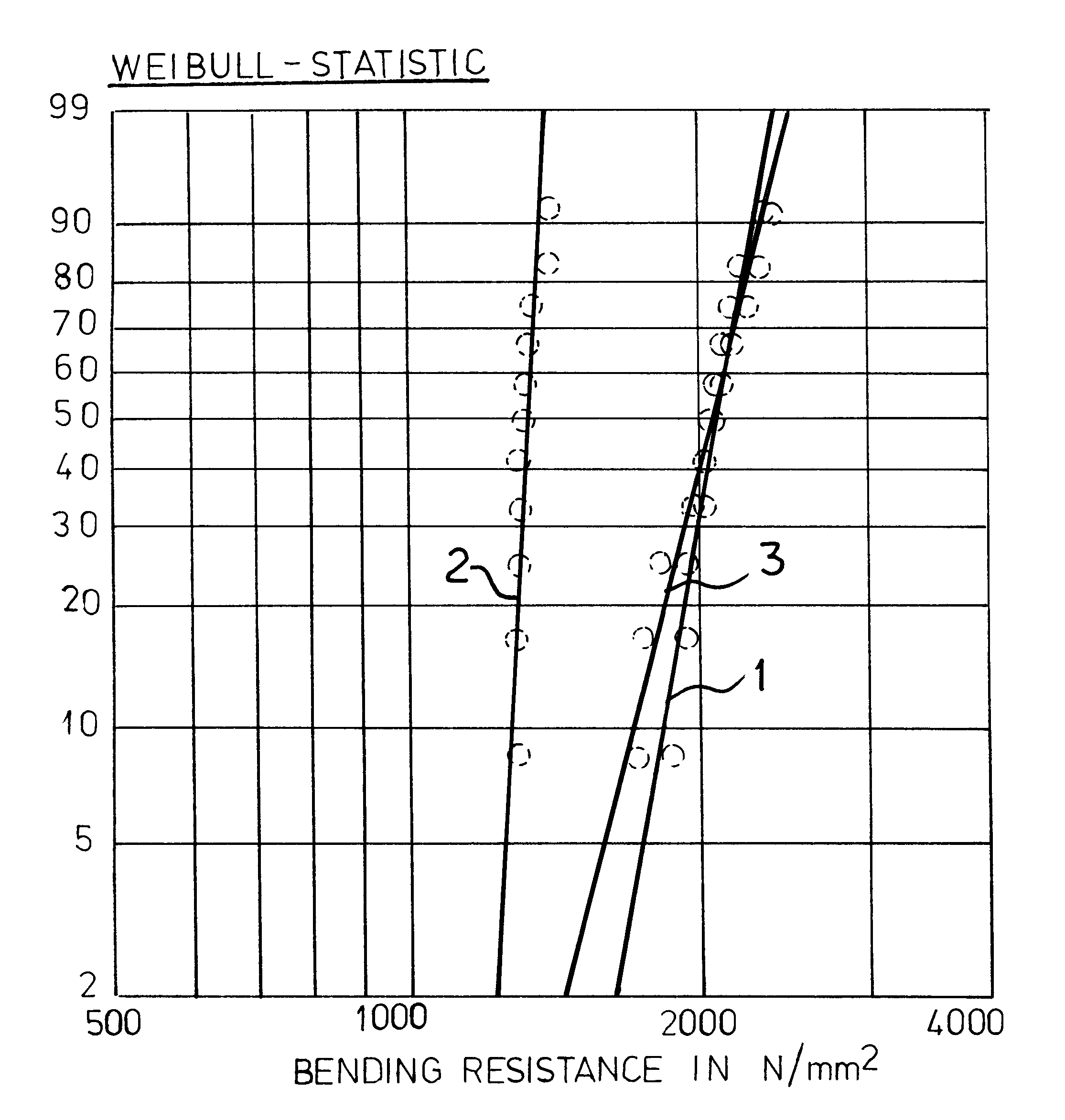

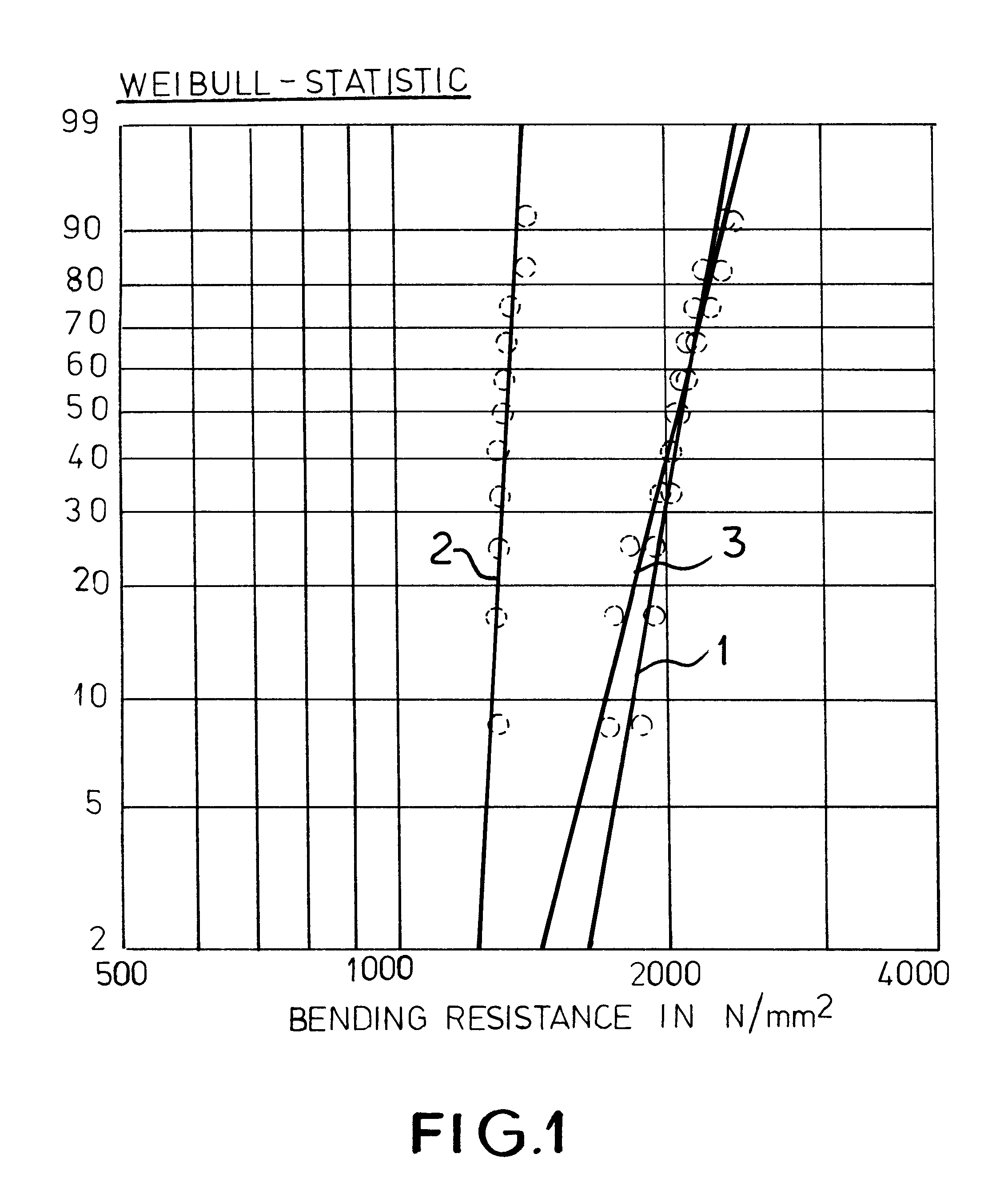

Method for assessment of cable strength and residual life

ActiveUS7992449B1Minimizes vulnerabilityMaterial strength using tensile/compressive forcesStress–strain curveEngineering

A method for determining the condition assessment and residual life span of bridge cables based on a parametric statistical model. The method includes random sampling of individual cable wires, mechanically testing the sampled wires, determining the probability of broken and cracked wires and the ultimate strength of cracked wires using fracture toughness and imputing the above data to simulate stress-strain curves for each wire in the cable, applying strain increments until reaching ultimate elongation. Assessing remaining service life of the cable by determining the rate of change of broken wires detected over a time frame, measuring the rate of change of fracture toughness over said time frame, and applying the rates of change to a time-dependent degradation prediction model.

Owner:MAHMOUD KHALED M

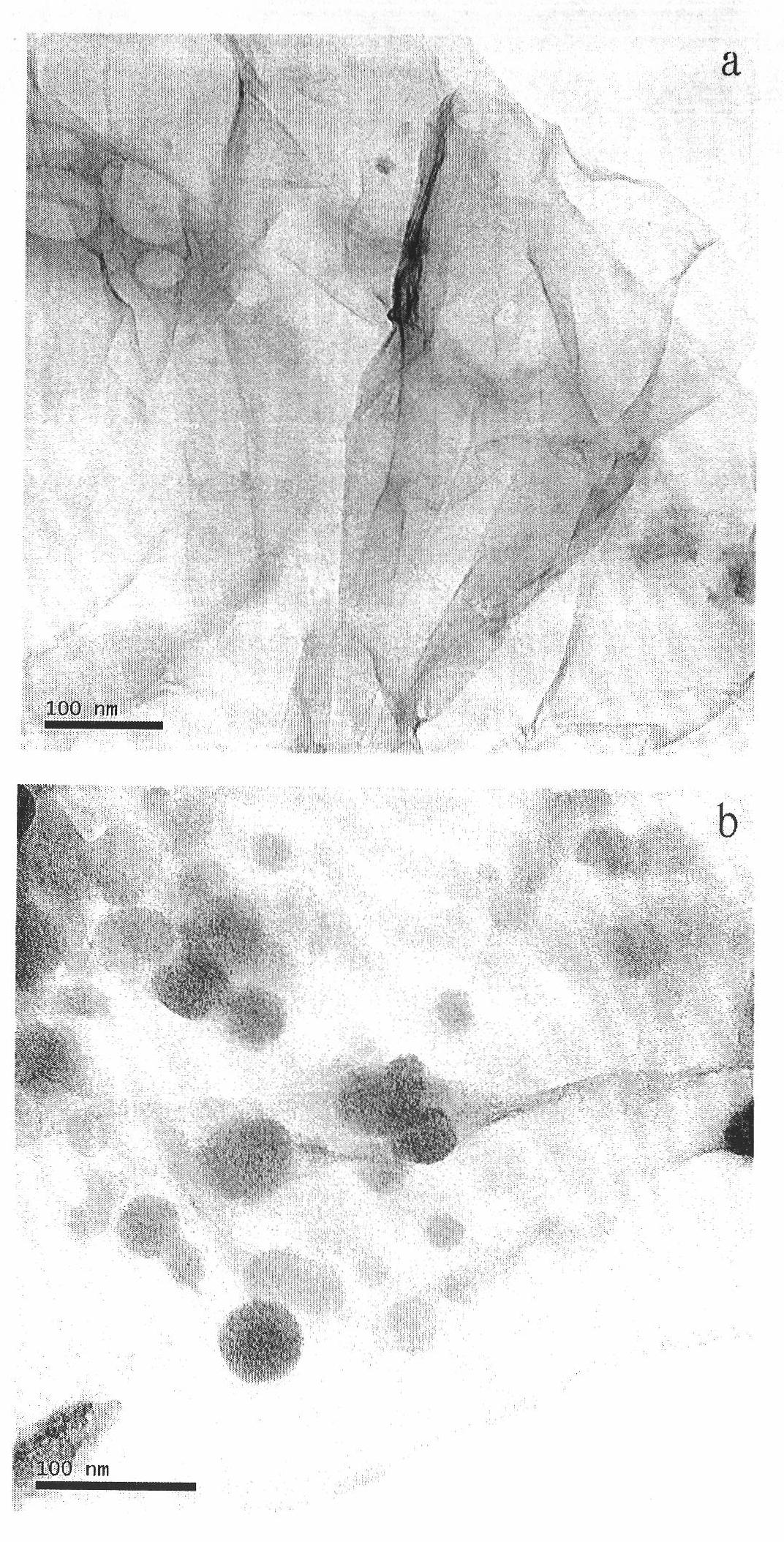

Graphene-based barrier composite material and preparation method thereof

The invention discloses a graphene-based barrier composite material, which has high barrier and mechanical performance and is prepared by using grapheme sheets which are two-dimension nano materials as an intensifier and uniformly dispersing the grapheme sheets in a polyolefin polymer by chemical crosslinking. The preparation method of the barrier composite material comprises: 1, functionally modifying the surface of the graphene oxide by using coupling agent to graft active functional groups on the surface of the graphene oxide, and reducing the modified graphene oxide into grapheme; and 2, uniformly dispersing the modified graphene into solution of the polyolefin to perform crosslinking under the action of an initiator to obtain the nano composite material. In the invention, the raw material is low in cost and readily available; the operation is easy, the process is simple, the repeatability is high, the graphene can well disperse in the polyolefin, and the prepared graphene-based barrier composite material has high polar and nonpolar solvent barrier performance and is obviously improved in tensile strength and fracture toughness.

Owner:HUBEI UNIV

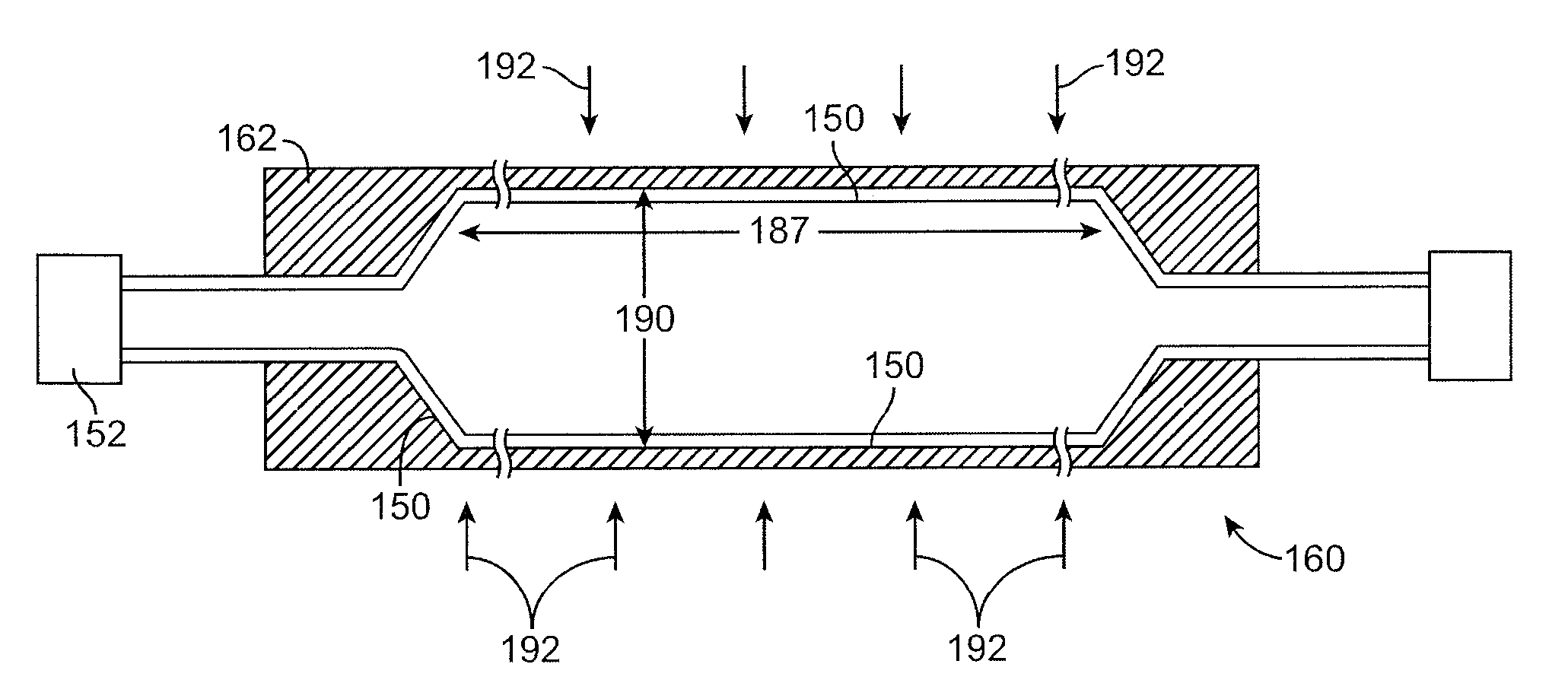

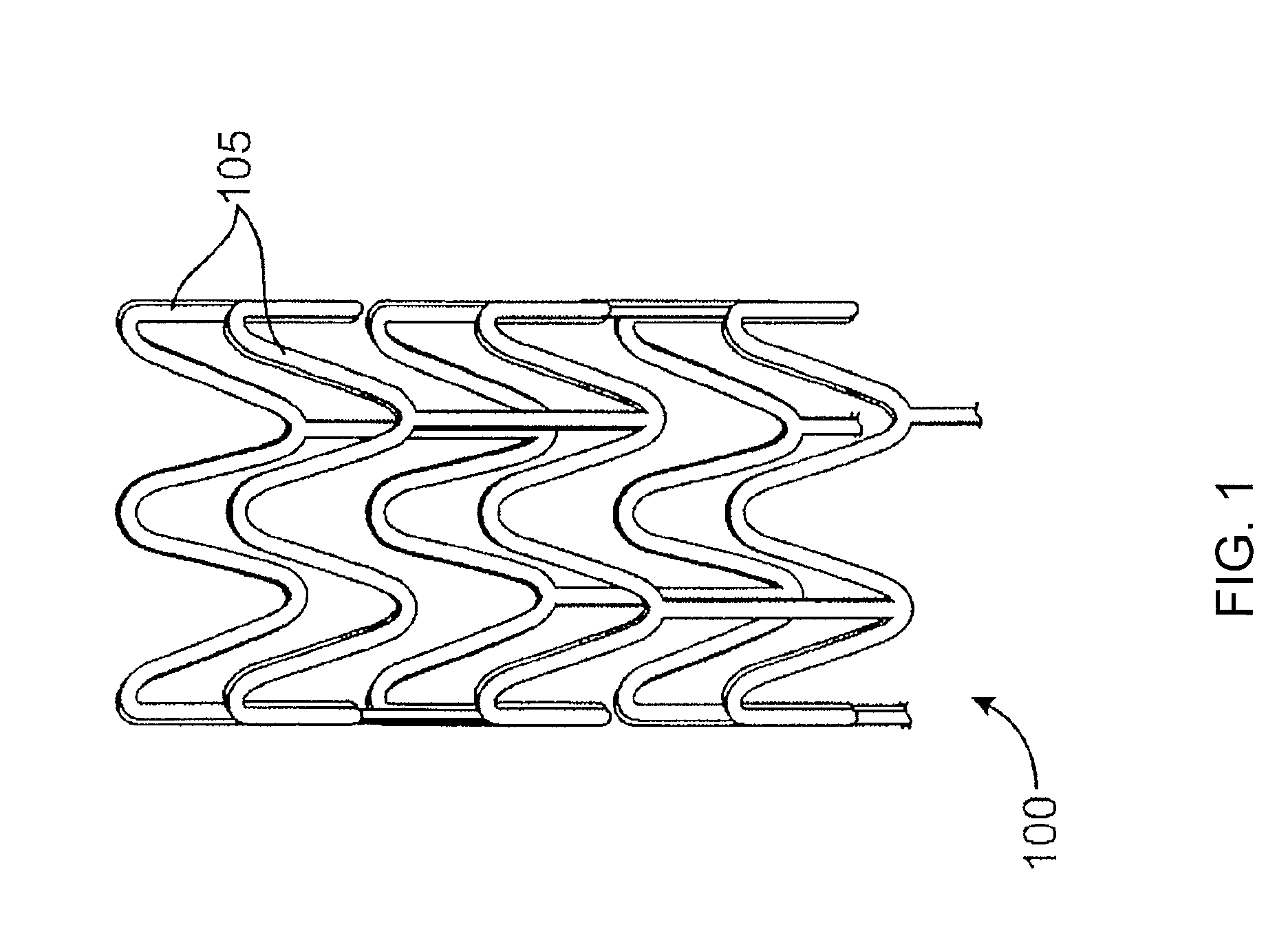

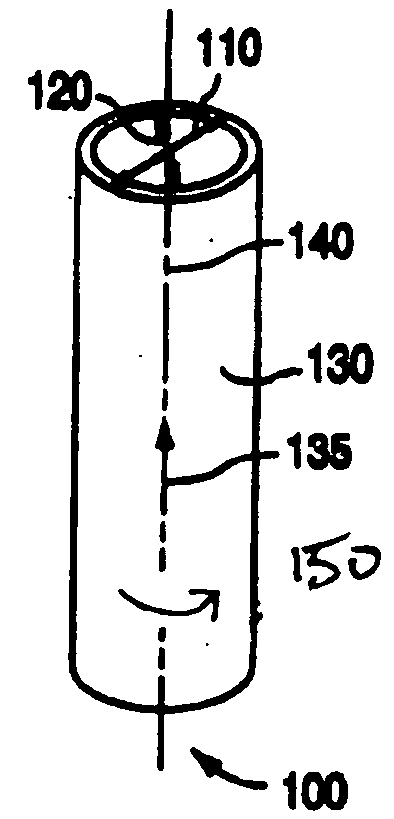

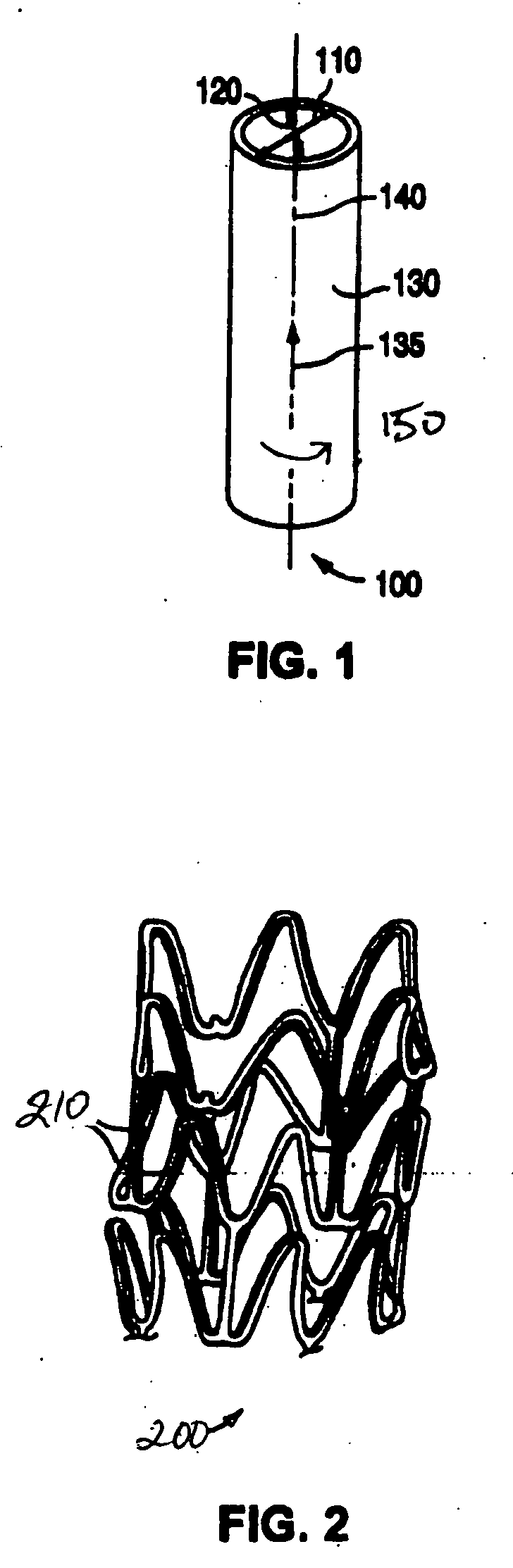

Tube expansion process for semicrystalline polymers to maximize fracture toughness

Methods of fabricating a polymeric stent with improved fracture toughness including radial expansion of a polymer tube along its entire length at the same time and fabricating a stent from the expanded tube are disclosed herein.

Owner:ABBOTT CARDIOVASCULAR

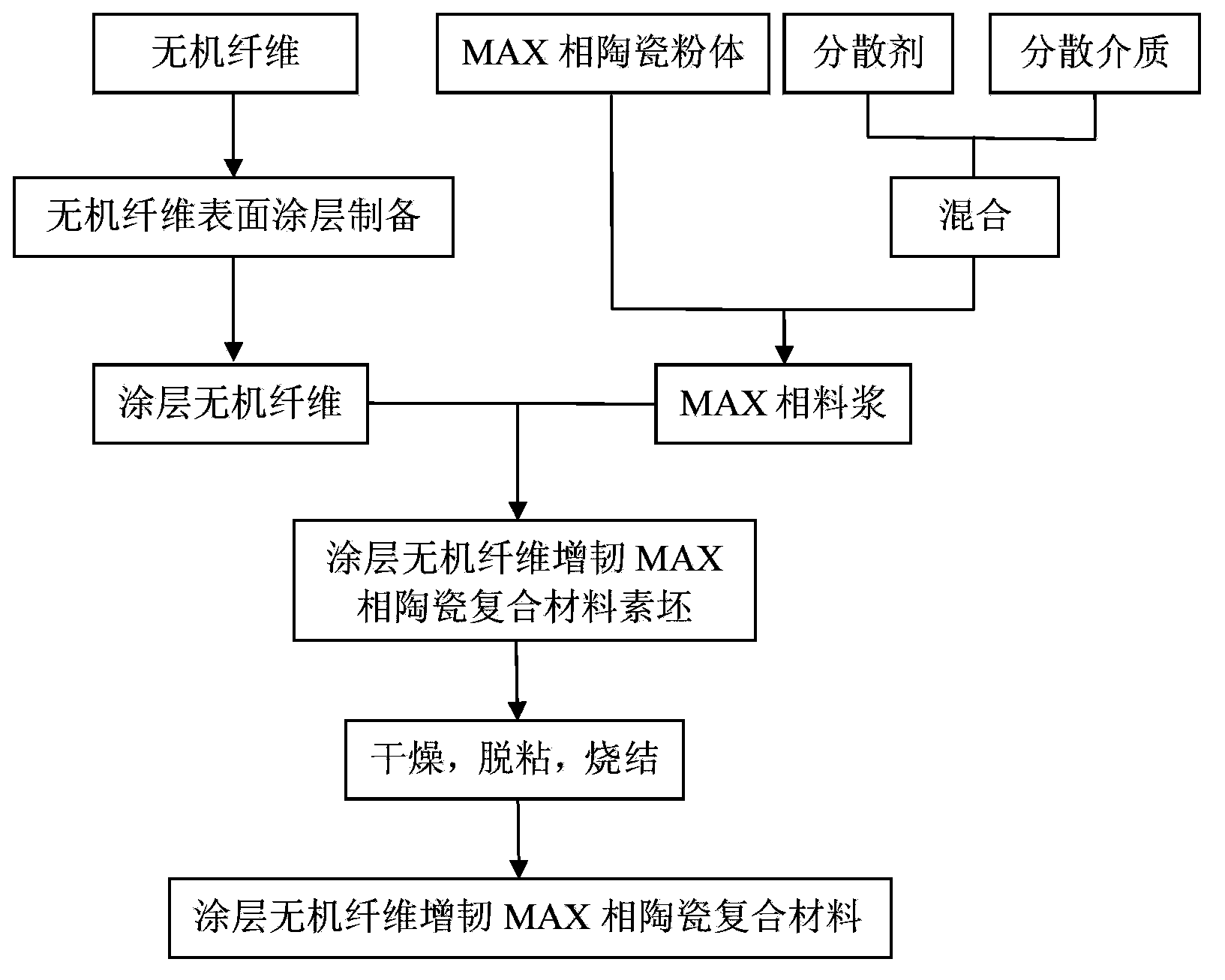

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Methods to form SiCOH or SiCNH dielectrics and structures including the same

InactiveUS20080009141A1Low costSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricElectronic structure

Methods of forming dielectric films comprising Si, C, O and H atoms (SiCOH) or Si, C, N and H atoms (SiCHN) that have improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties are provided. Electronic structures including the above materials are also included herein.

Owner:GLOBALFOUNDRIES INC

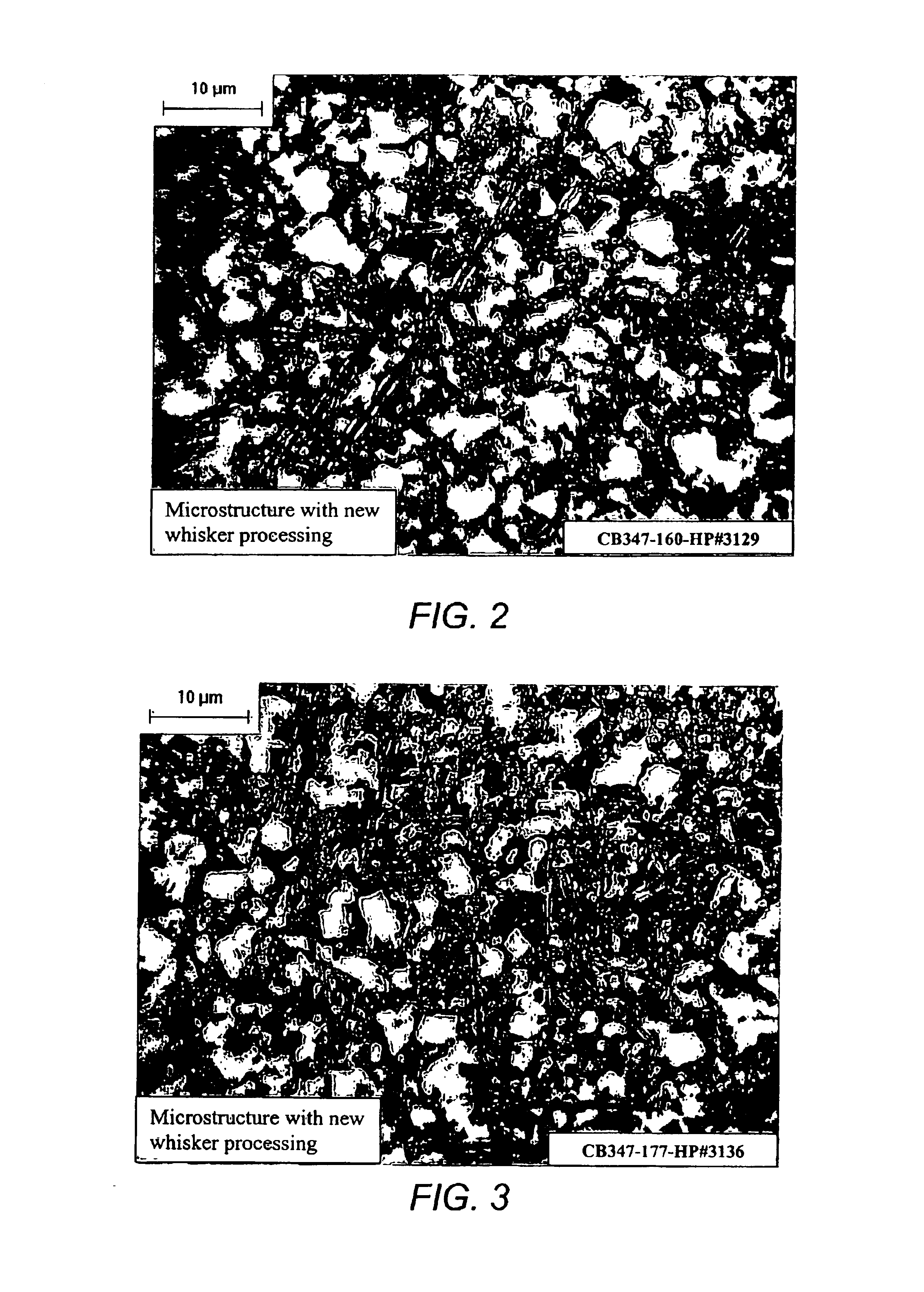

Ceramic body reinforced with coarse silicon carbide whiskers and method for making the same

InactiveUS6905992B2Solve the lack of densityThin material handlingMetal layered productsPowder mixtureSquare Millimeter

A ceramic composite made by compacting a starting powder blend. The composite includes between about 50 volume percent and about 99 volume percent of a ceramic matrix; and between about 1 volume percent and about 50 volume percent as-processed silicon carbide whiskers. The ceramic composite having a fracture toughness (KIC) of greater than about 4.0 MPam1 / 2. The ceramic has a silicon carbide whisker density as measured in whiskers per square millimeter equal to or less than about 1500 times the volume percent of silicon carbide whiskers, but in a density sufficient for the ceramic composite to have the fracture toughness.

Owner:KENNAMETAL INC

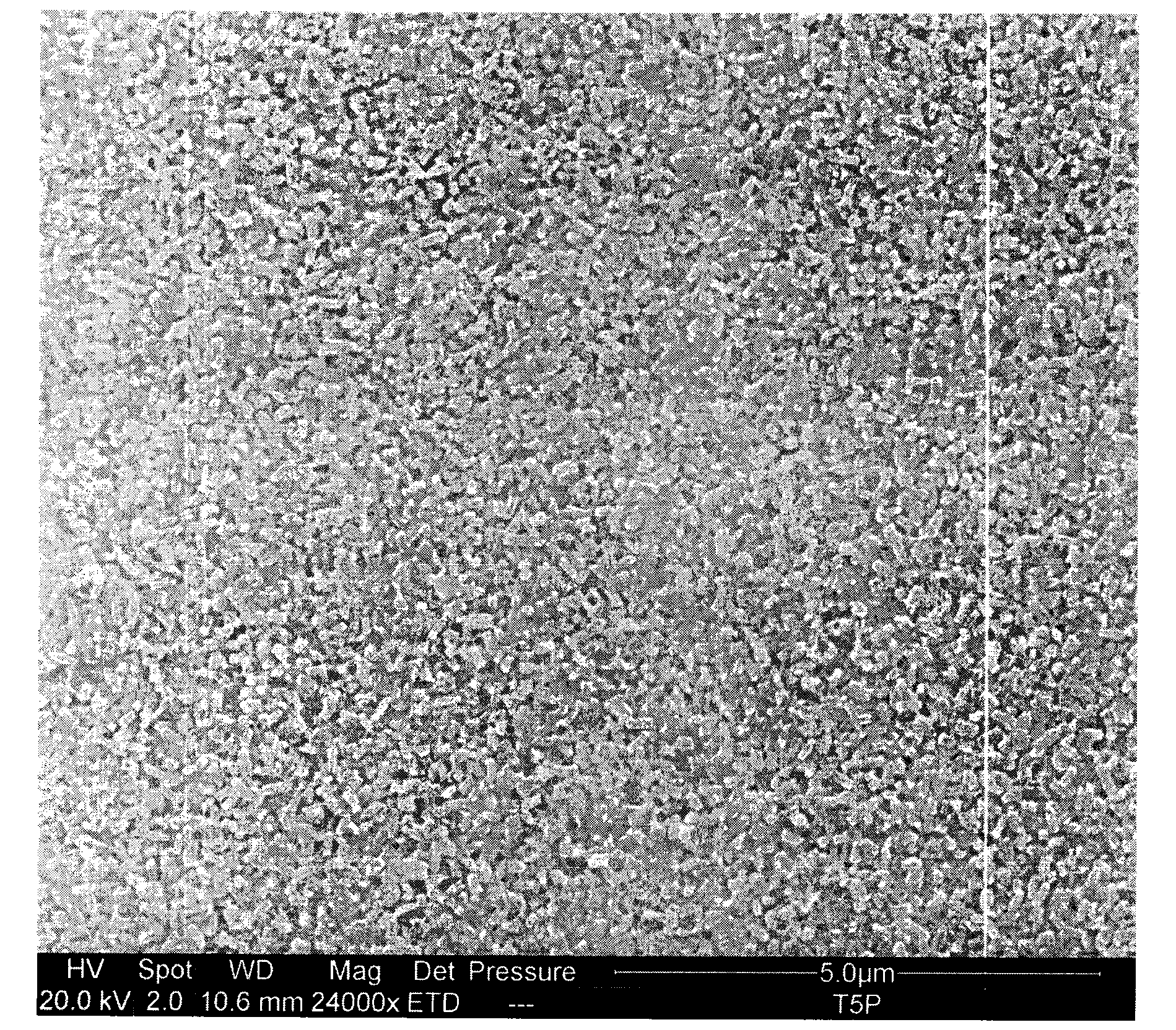

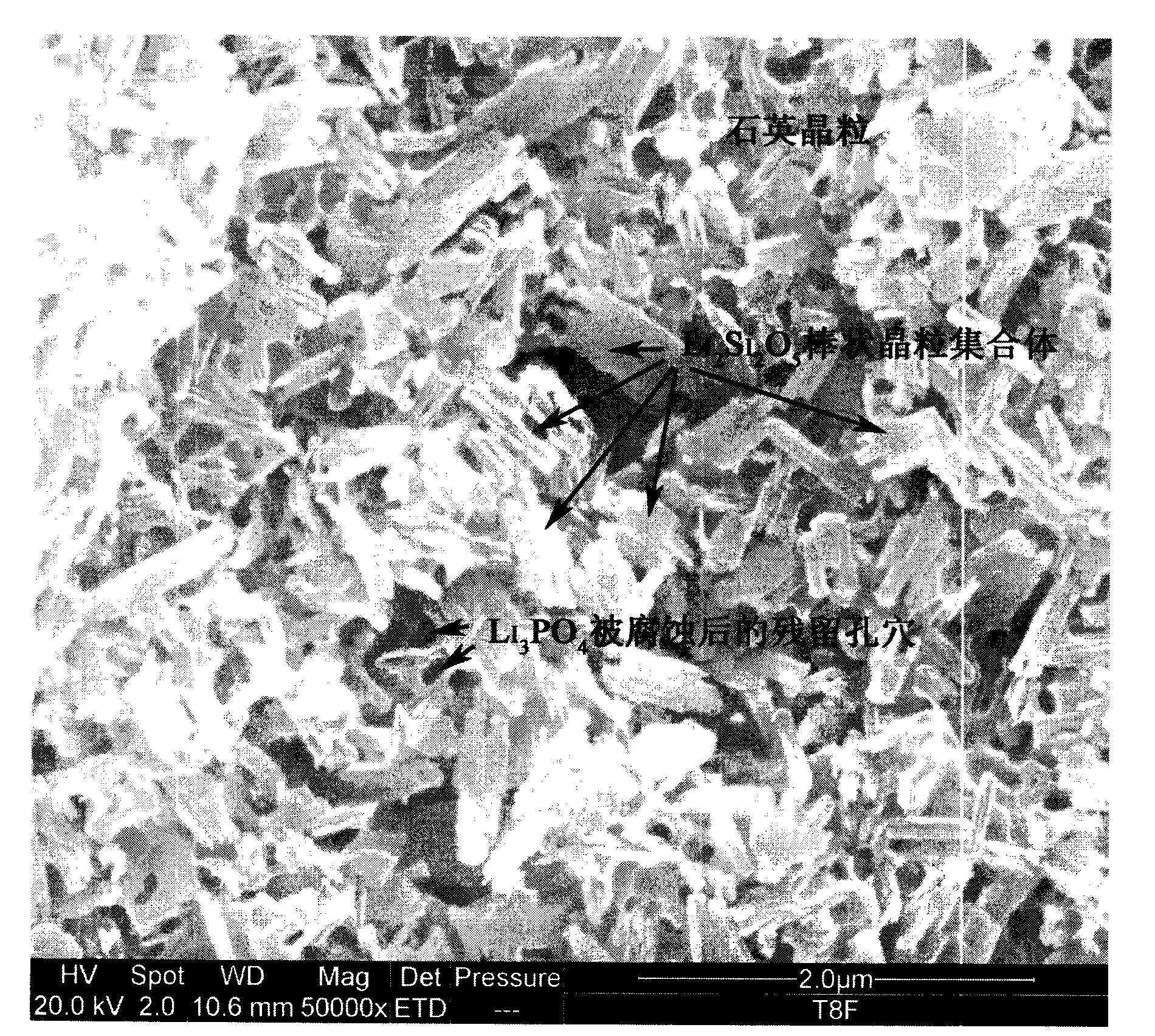

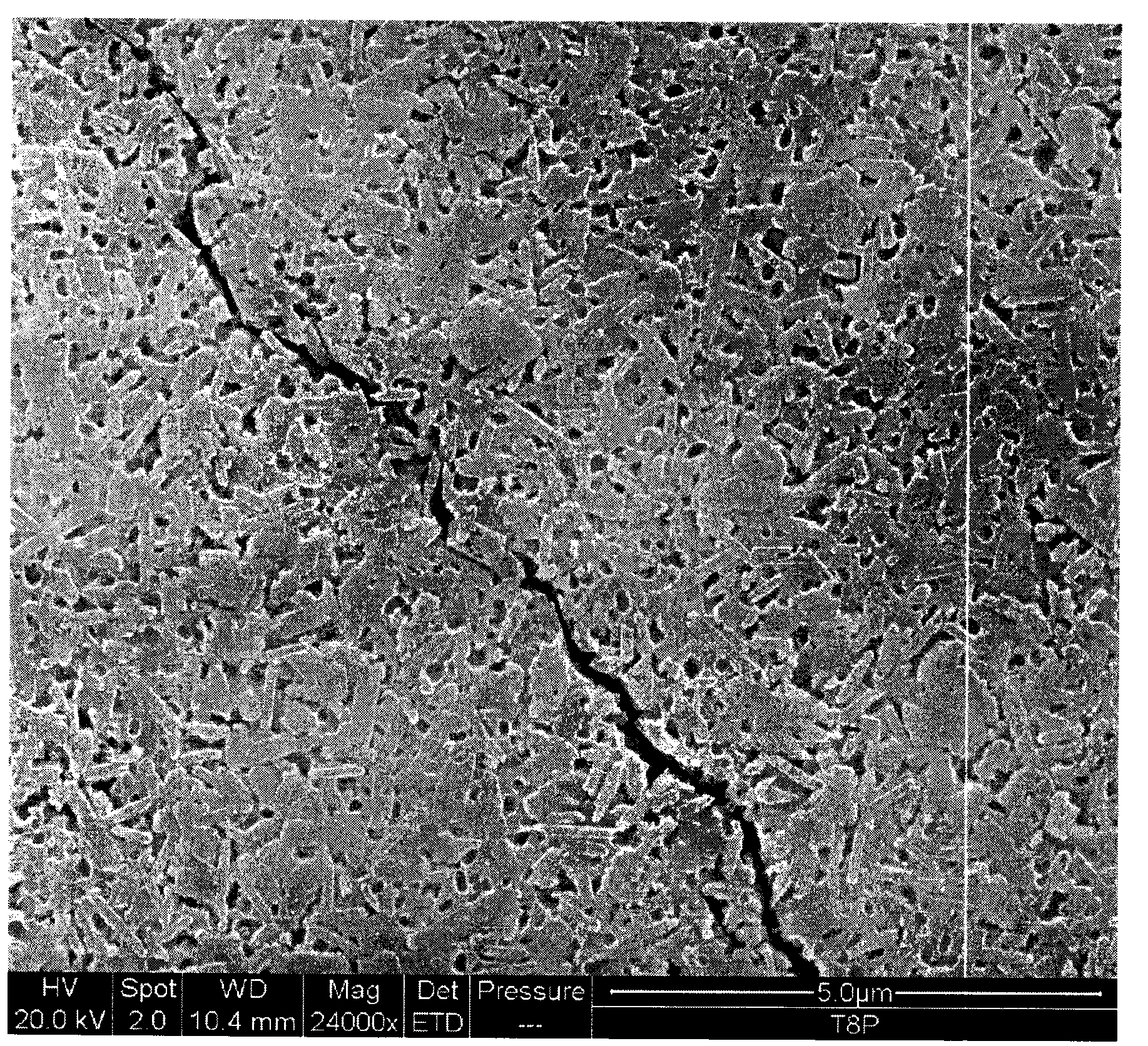

High-strength lithium disilicate glass ceramic and preparation method thereof

The invention discloses high-strength lithium disilicate glass ceramic and a preparation method thereof. The glass ceramic comprises the following chemical components in percentage by weight: 59-80% of SiO2, 10-18% of Li2O, 0.1-14% of MgO, 0-15% of Al2O3, 1-8% of P2O5, 0-5% of Na2O, 0-7% of CaO, 0-9% of K2O, 0.5-8% of stabilizer and 0-10% of colorant, wherein the stabilizer is selected from one or more of ZrO2, SrO, BaO and Y2O3, and the colorant is selected from one or more of Eu2O3, CeO<+>, Tb4O7, La2O3, Ta2O5, MnO2 and Fe2O3. The lithium disilicate glass ceramic is a material which contains a residual glass phase, a Li2Si2O5 principal crystalline phase and a small quantity of Li3PO1, quartz, cristobalite, zirconium oxide or magnesium-aluminum silicate phase and is prepared by controlling nucleation and crystallization processes after carrying out heat treatment on lithium disilicate matrix glass. The lithium disilicate glass ceramic is very high in bending strength and fracture toughness and favorable in translucence and chemical stability and can serve as a full-ceramic dental material applied to the field of dental restoration.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

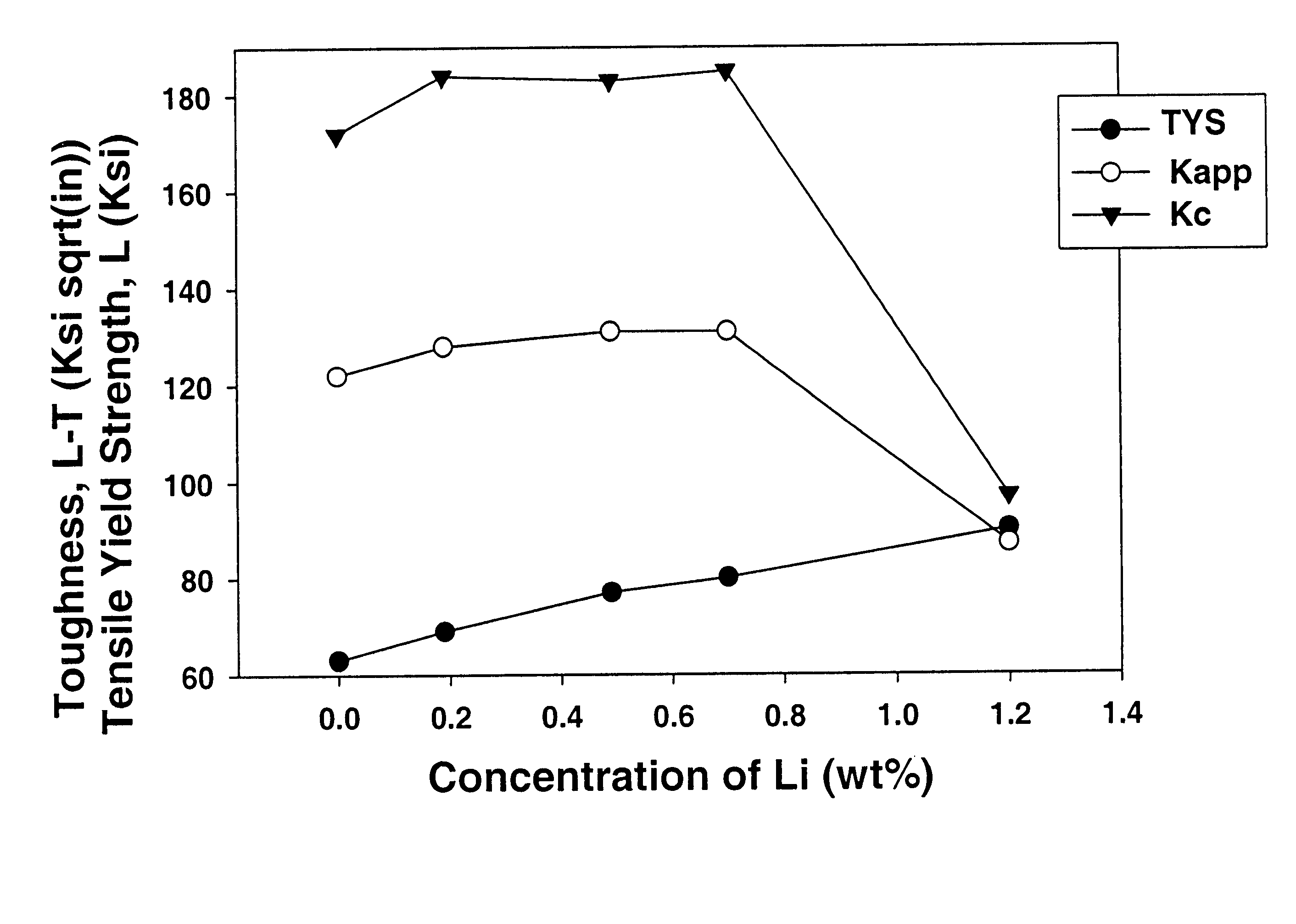

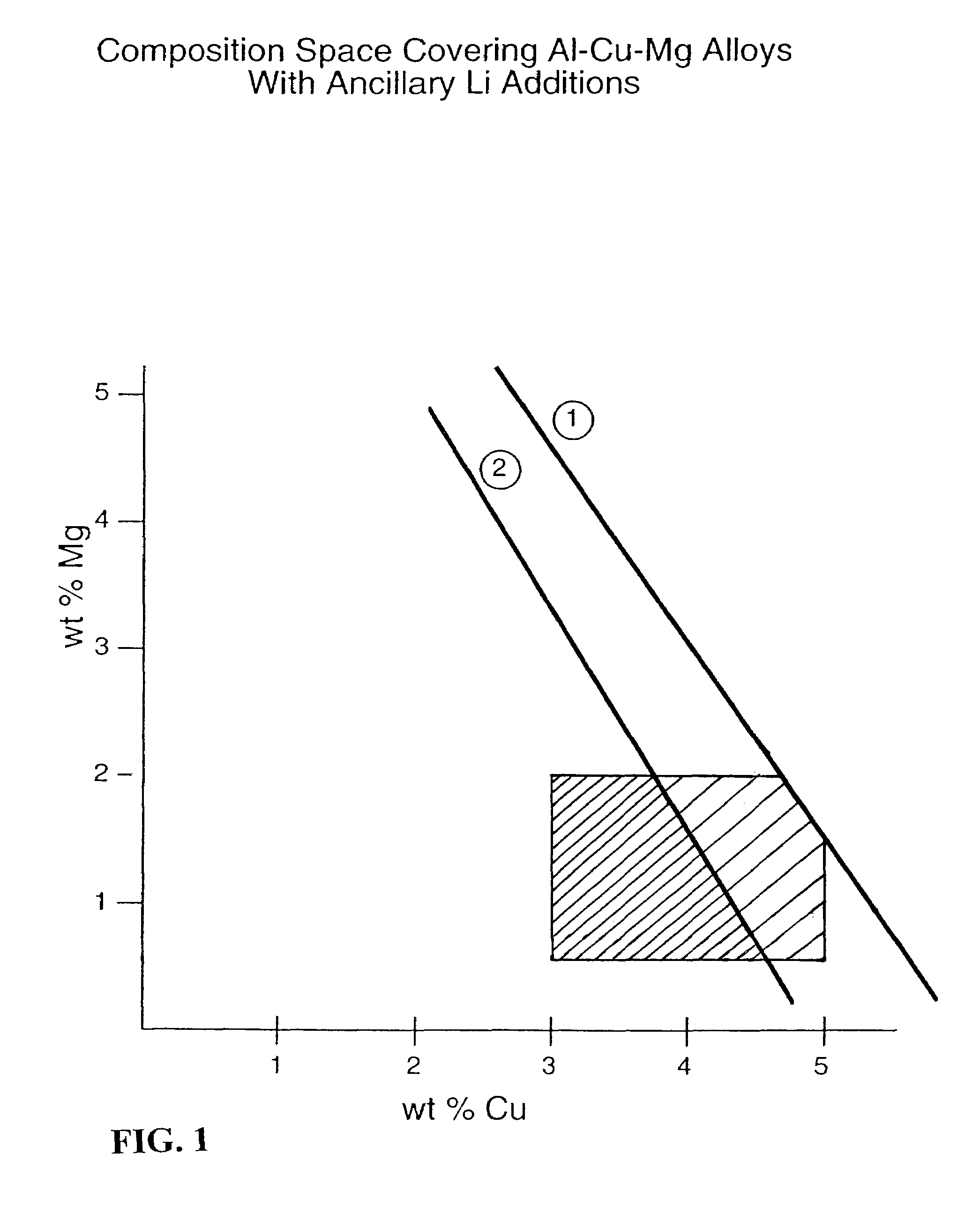

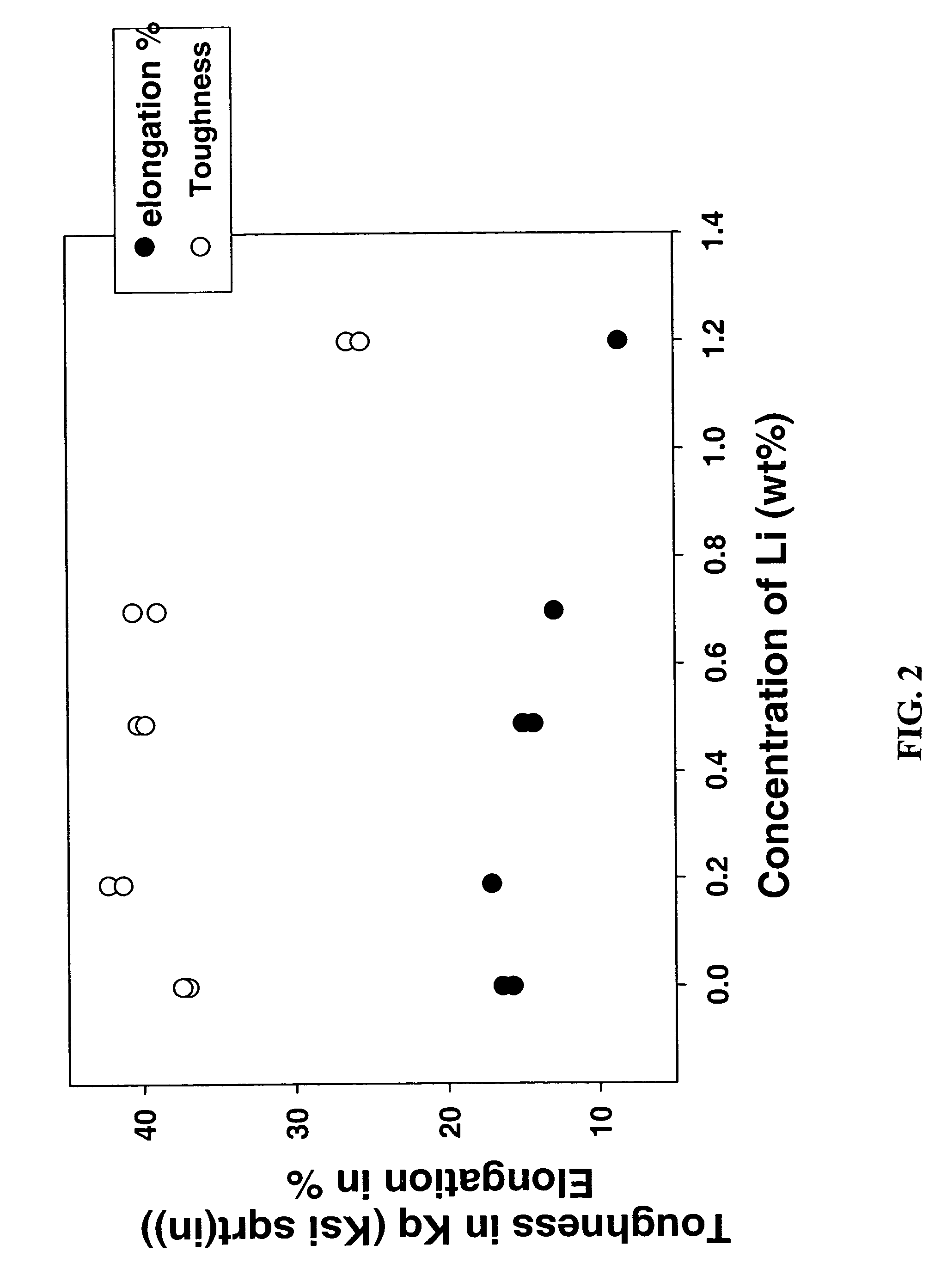

Aluminum-copper-magnesium alloys having ancillary additions of lithium

InactiveUS7438772B2Improve fracture toughnessEquivalent and improved fatigue crack growth resistanceSolubilityLithium

An aluminum-copper-magnesium alloy having ancillary additions of lithium. The alloy composition includes from about 3 to about 5 weight percent Cu, from about 0.5 to about 2 weight percent Mg, and from about 0.01 to about 0.9 weight percent Li. The combined amount of Cu and Mg is maintained below a solubility limit of the aluminum alloy. The alloys possess improved combinations of fracture toughness and strength, and also exhibit good fatigue crack growth resistance.

Owner:ARCONIC INC

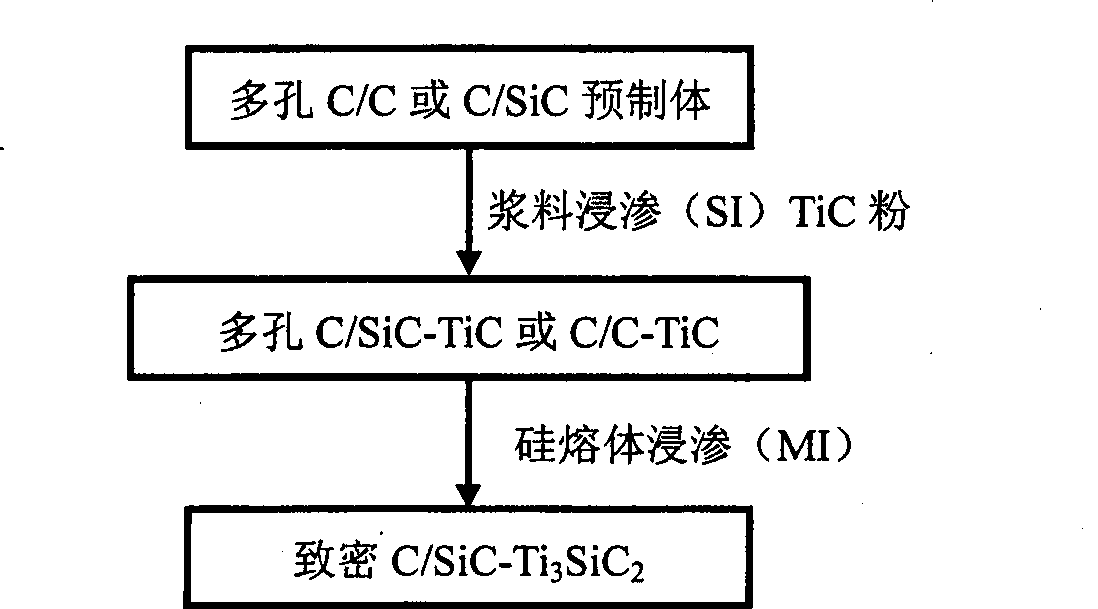

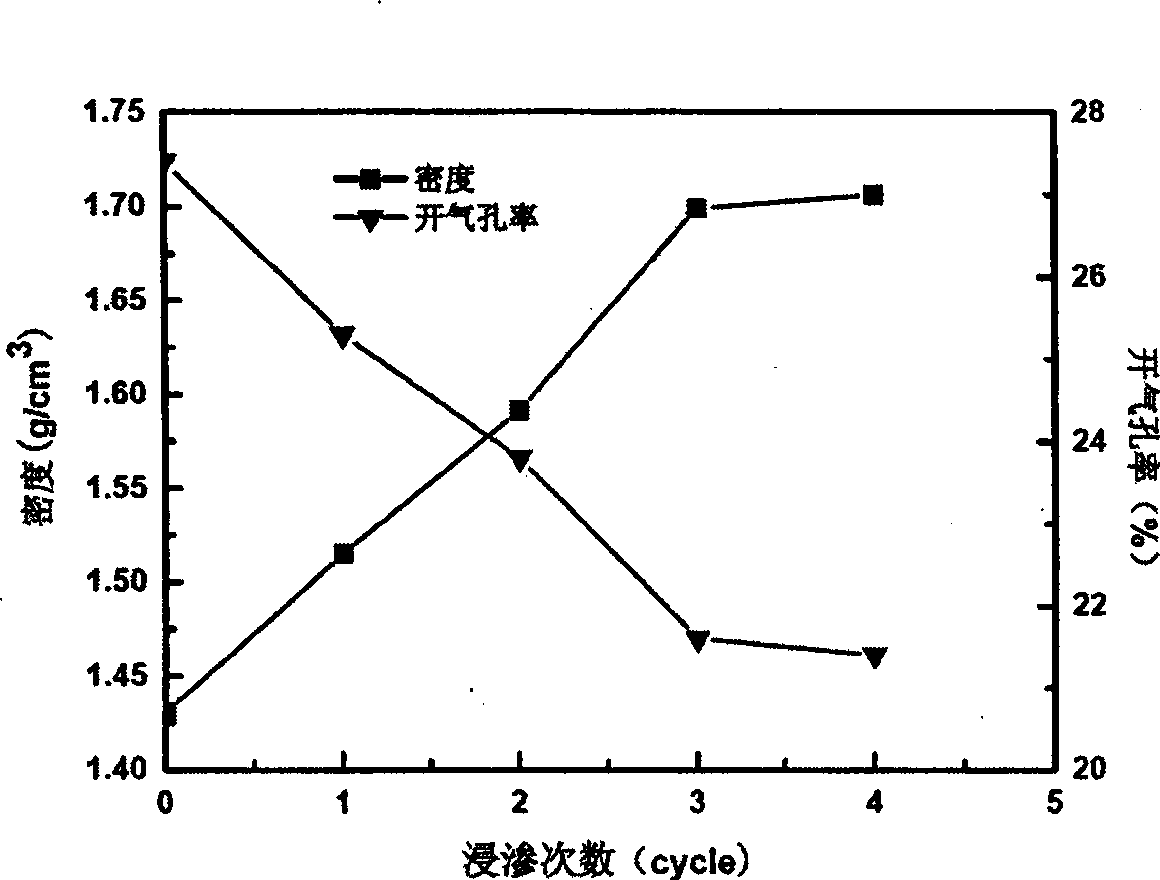

Process for producing composite material of Ti3SiC2 modified C/SiC

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

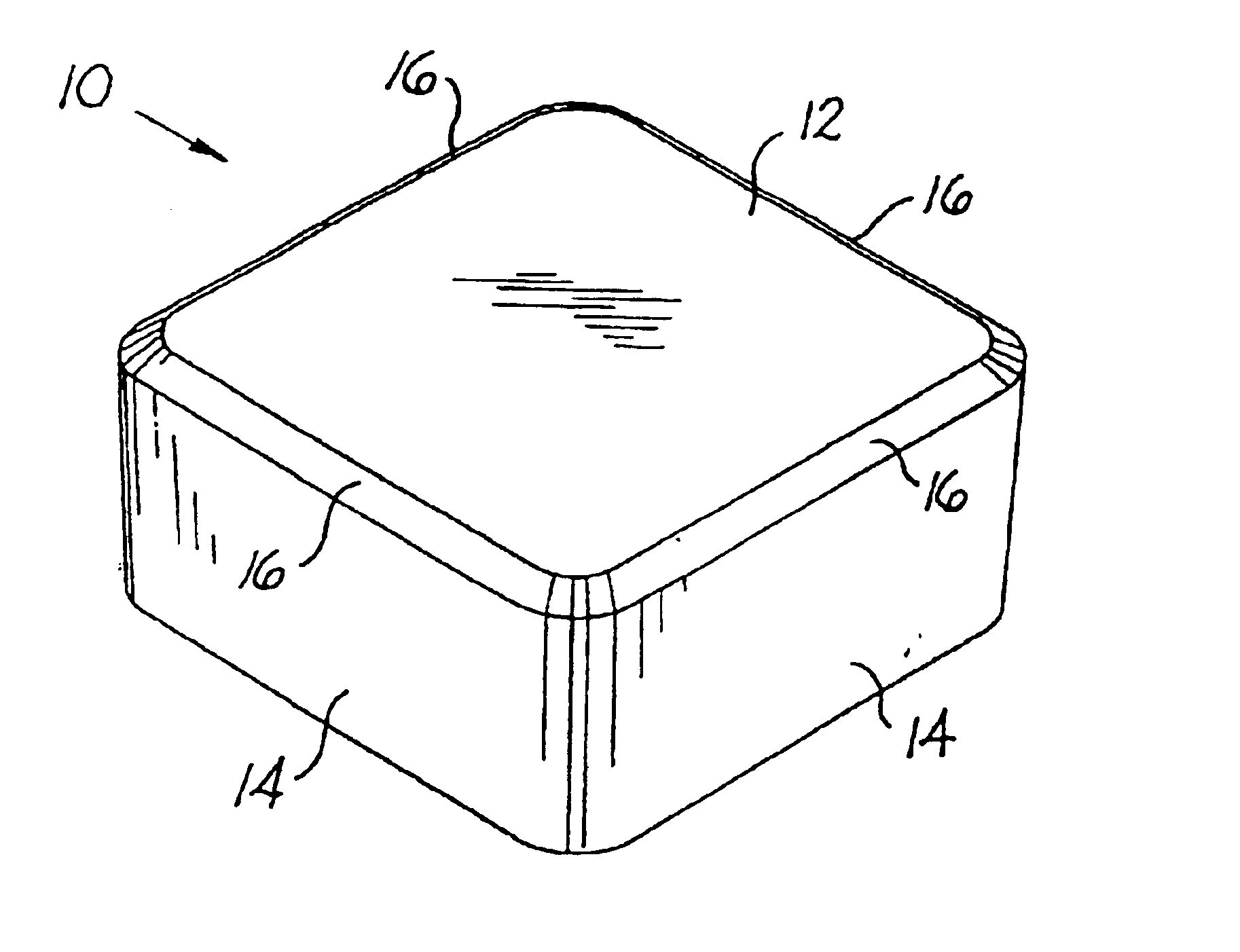

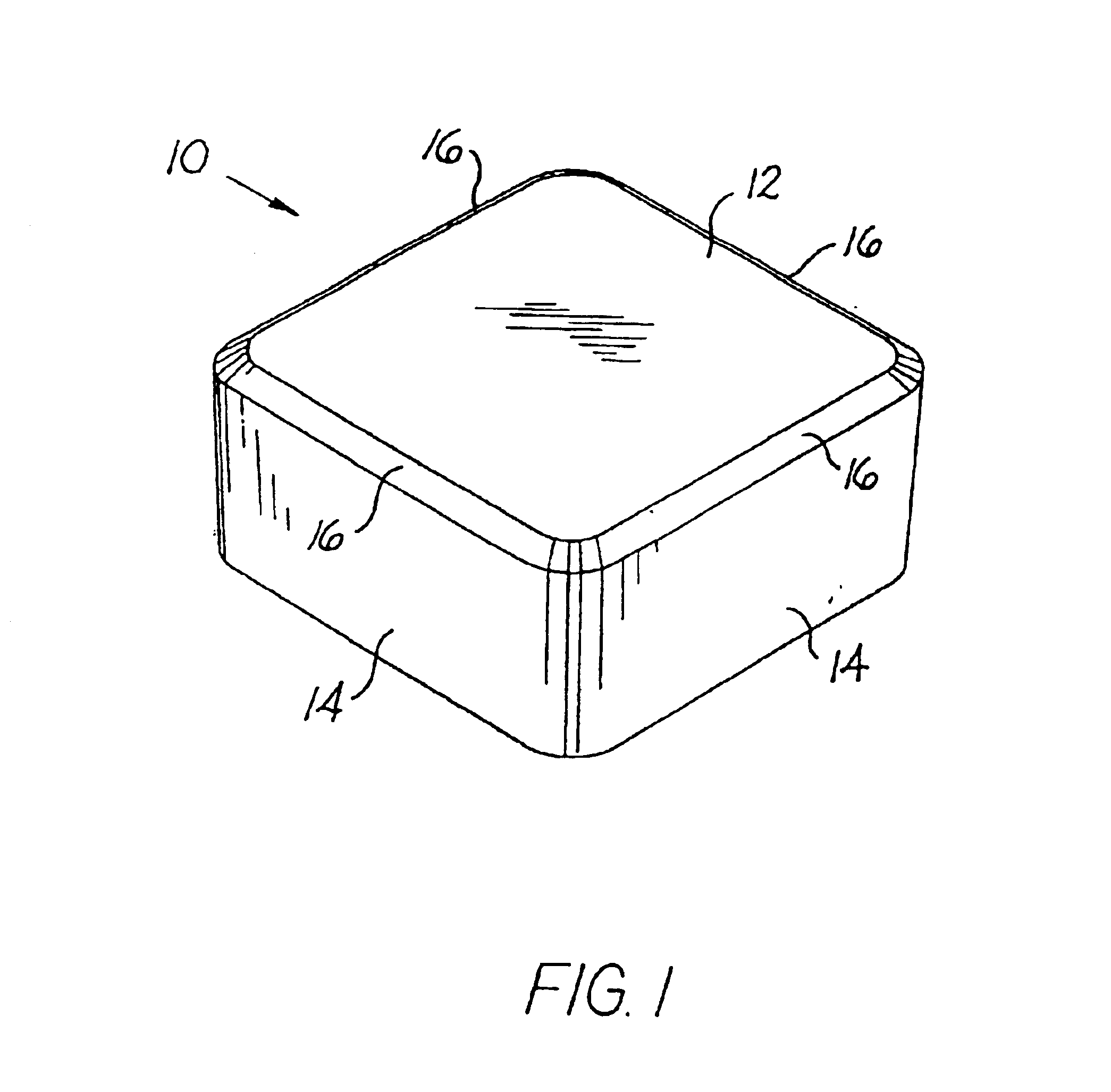

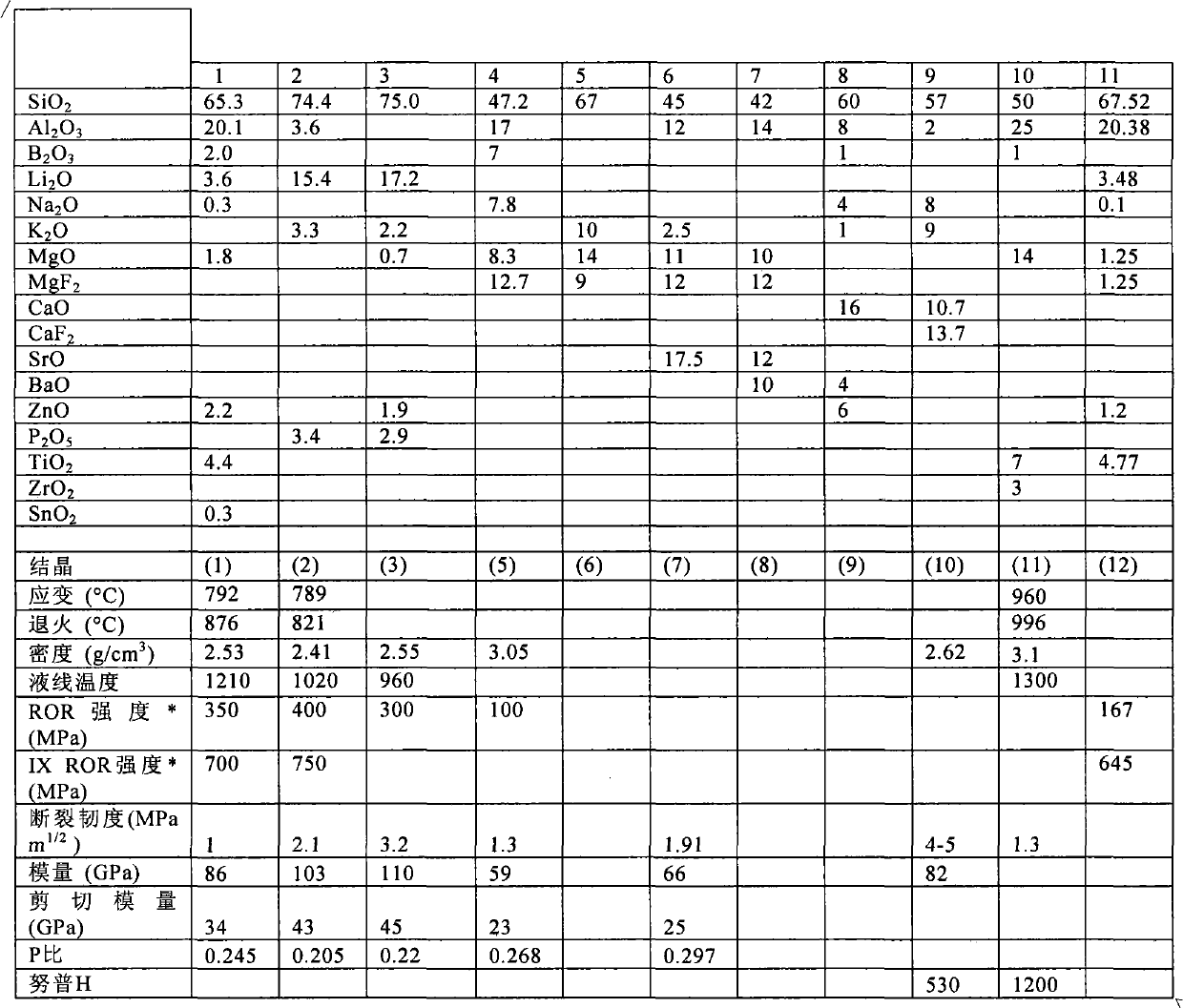

Durable glass-ceramic housings/enclosures for electronic devices

The invention relates glass ceramic articles suitable for use as electronic device housing or enclosures which comprise a glass-ceramic material. Particularly, a glass-ceramic article housing / enclosure comprising a glass-ceramic material exhibiting both radio and microwave frequency transparency, as defined by a loss tangent of less than 0.5 and at a frequency range of between 15 MHz to 3.0 GHz, a fracture toughness of greater than 1.5 MPam 1 / 2 , an equibiaxial flexural strength (ROR strength) of greater than 100 MPa, a Knoop hardness of at least 400 kg / mm2, a thermal conductivity of less than 4 W / m DEG C and a porosity of less than 0.1 %.

Owner:CORNING INC

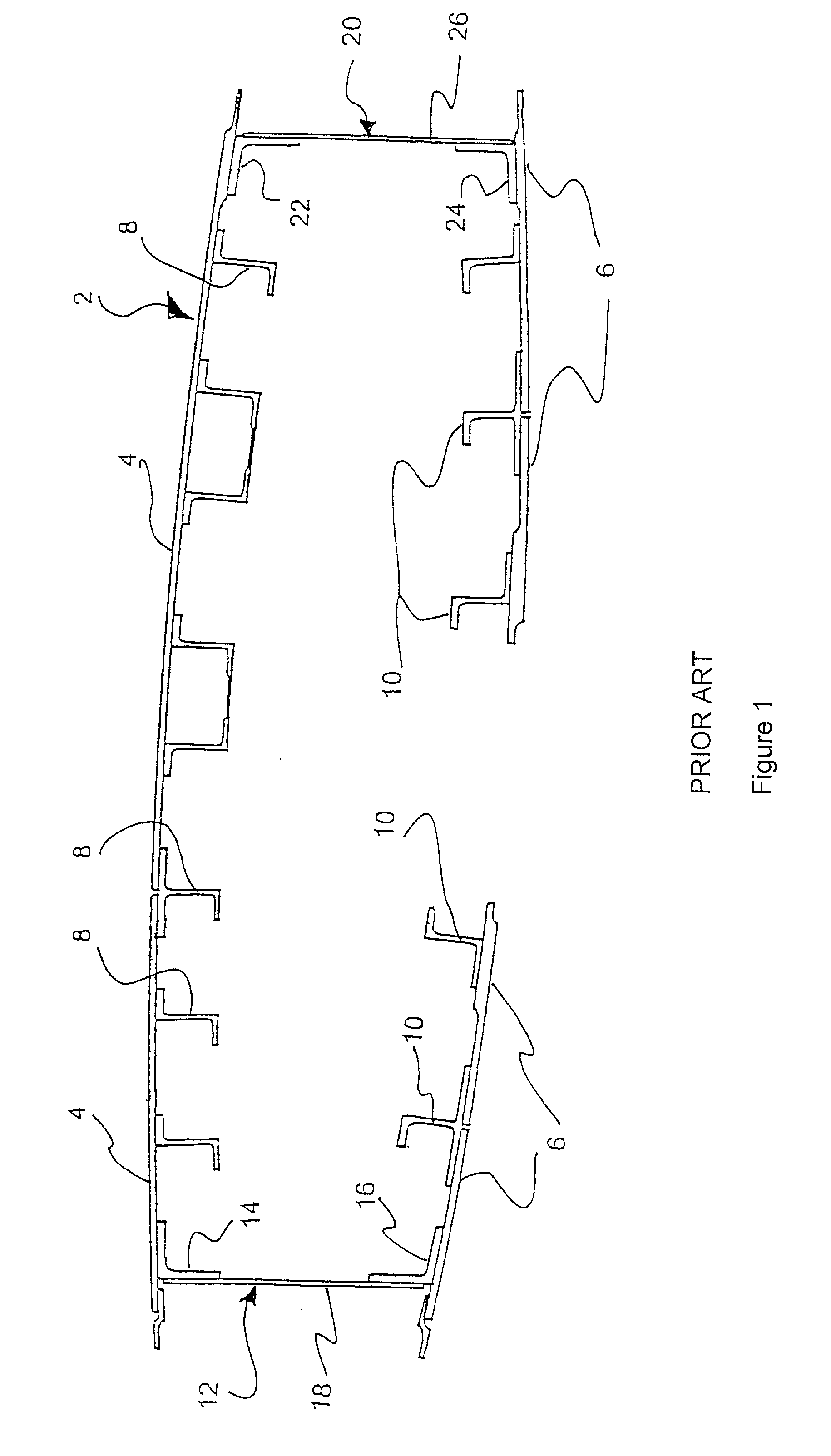

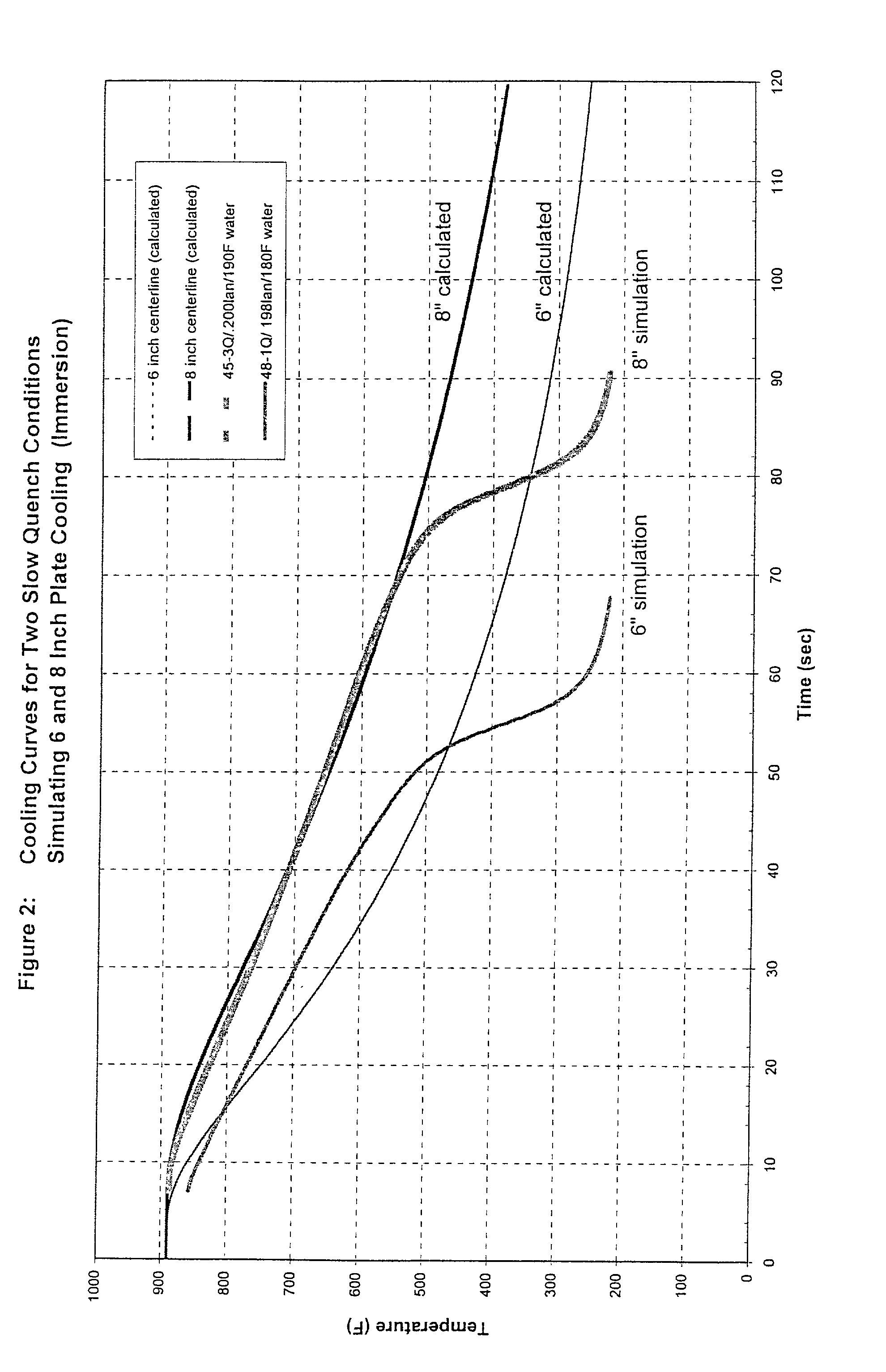

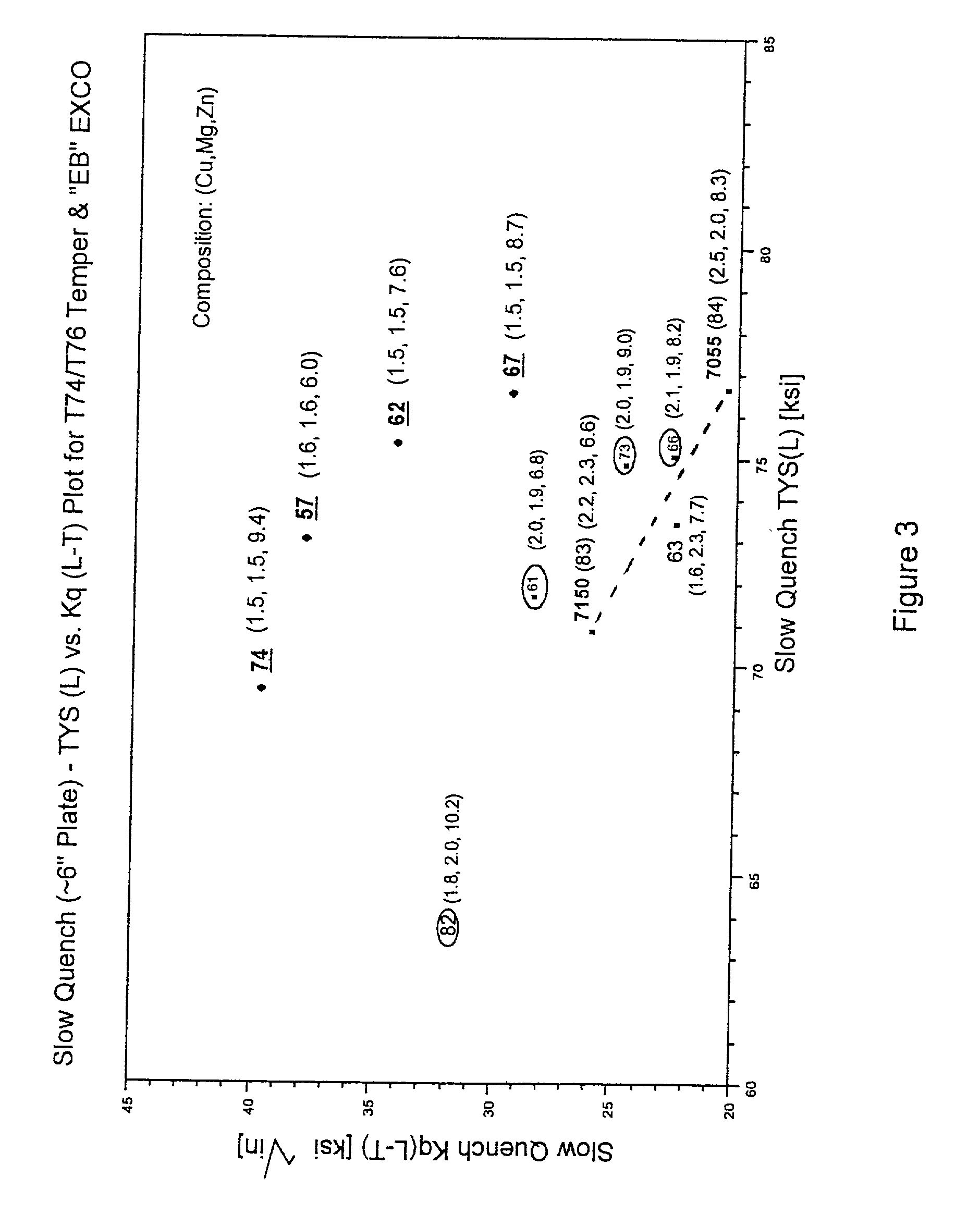

Aluminum alloy having superior strength-toughness combinations in thick gauges

A 7XXX series aluminum alloy having reduced quench sensitivity suitable for use in aerospace structural components, such as integral wing spars, ribs, extrusions and forgings comprises, in weight %: 6 to 10 Zn, 1.3 to 1.9 Mg, 1.4 to 2.2 Cu, wherein Mg<=Cu+0.3, one or more of 0 to 0.4 Zr, up to 0.4 Sc, up to 0.2 Hf, up to 0.4 Cr, up to 1.0 Mn and the balance Al plus incidental additions including Si, Fe, Ti and the like plus impurities. By controlling the Mg content to 1.3 to 1.7 wt. %, limiting Mg<=Cu+0.3 and 6.5<=Zn<=8.5, the alloy provides significantly improved combined strength and fracture toughness in heavy gauges. For example, in a six-inch thick plate there is provided a combination of about 75 ksi quarter-plane tensile yield strength (L) with a fracture toughness (L-T) of about 33 ksi{square root}in which progresses by artificial aging / tempering to a combined strength and fracture toughness of about 67 ksi tensile yield strength (L) and a fracture toughness (L-T) of about 40 ksi{square root}in. The alloy product possesses equally attractive combinations of strength and fracture toughness when intentionally quenched slowly following solution heat treatment so as to lessen dimensional distortion, particularly in shapes of varying cross section.

Owner:ARCONIC INC

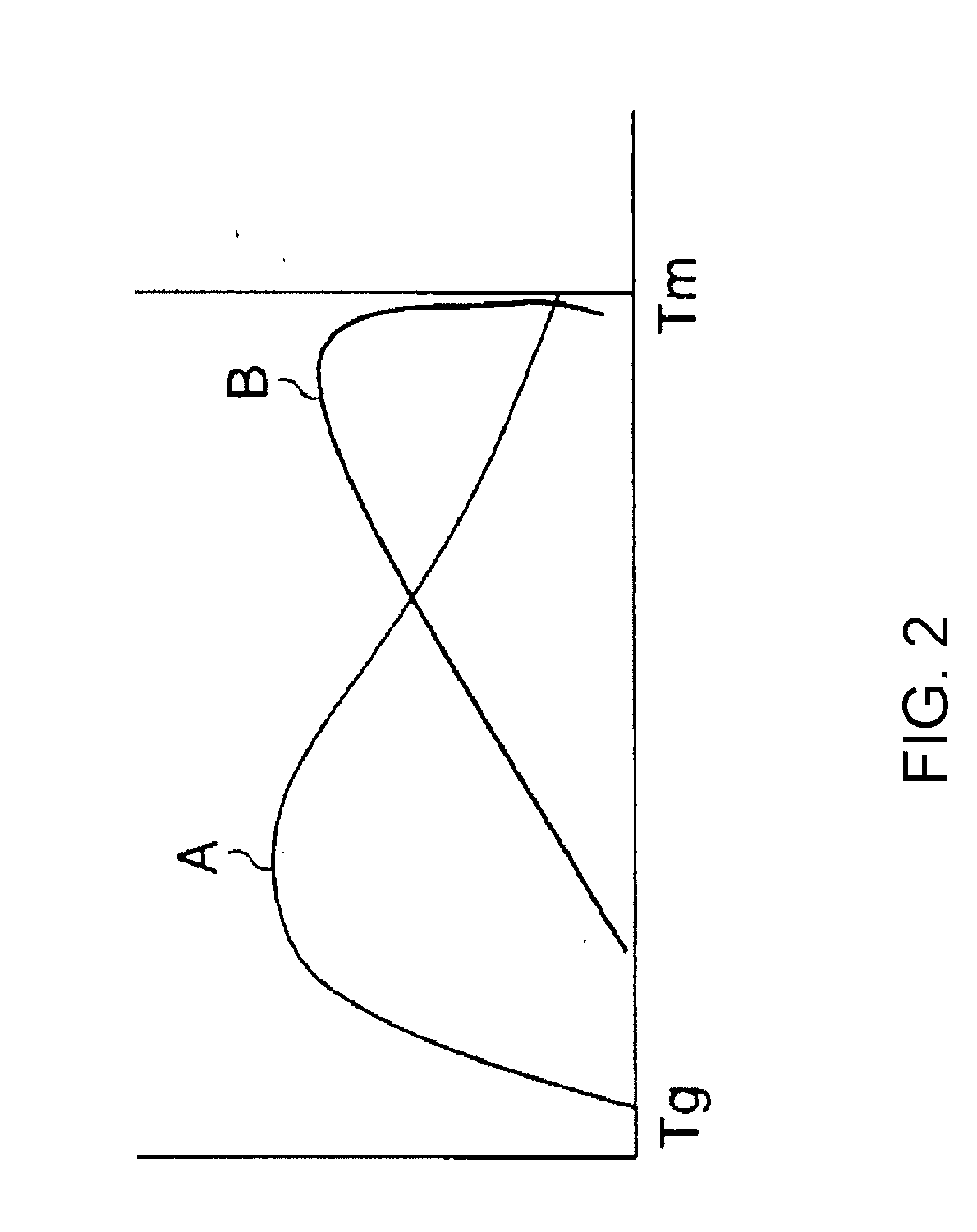

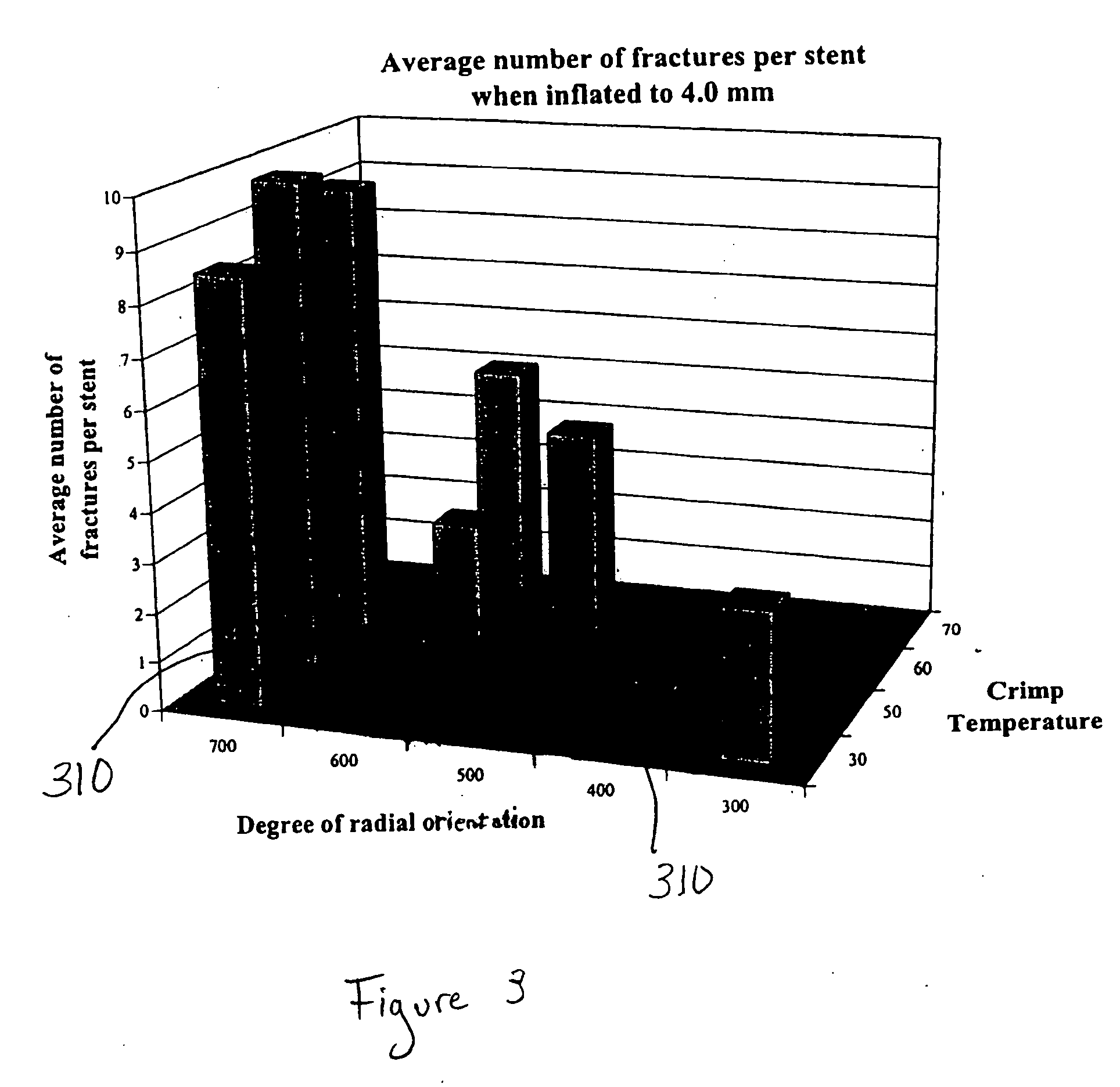

Optimizing fracture toughness of polymeric stent

Disclosed herein is a method of fabricating a stent assembly comprising radially expanding a polymeric tube to an optimal degree of radial expansion; fabricating a stent from the expanded polymeric tube; and crimping the stent onto a catheter assembly, wherein the temperature of the stent during crimping is an optimal crimping temperature, wherein the optimal degree of radial expansion and the optimal crimping temperature correspond to an optimal fracture toughness exhibited by the crimped stent upon its deployment as a function of degree of radial expansion and crimping temperature.

Owner:ABBOTT CARDIOVASCULAR

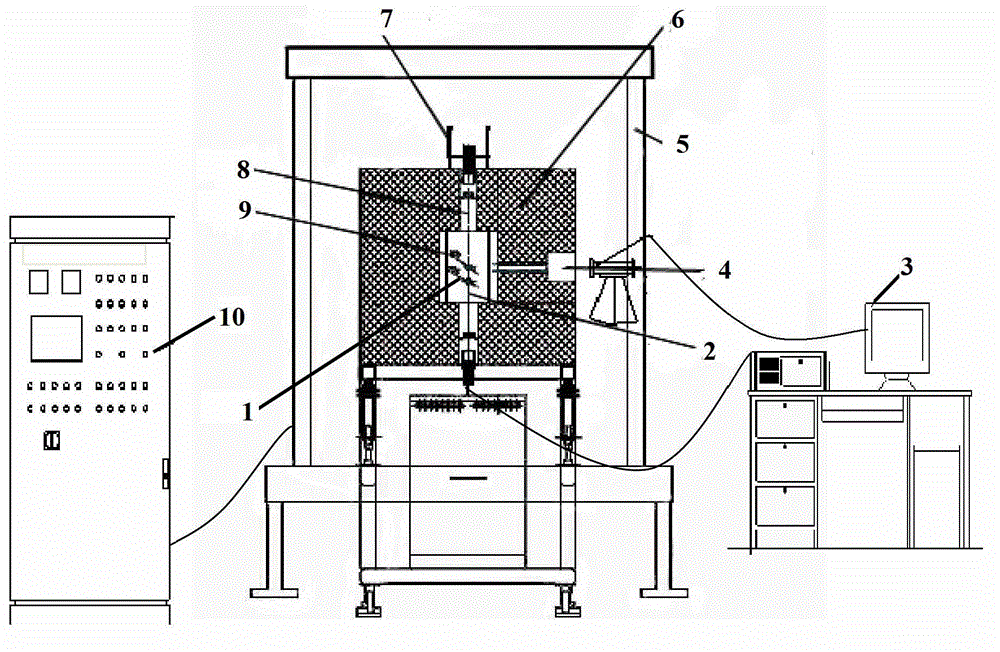

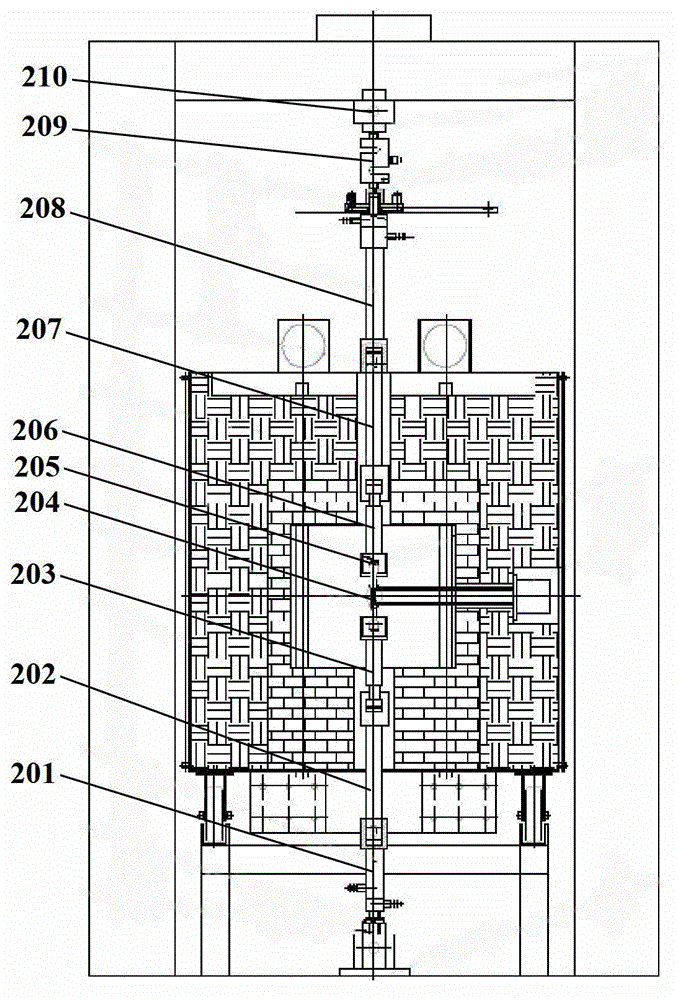

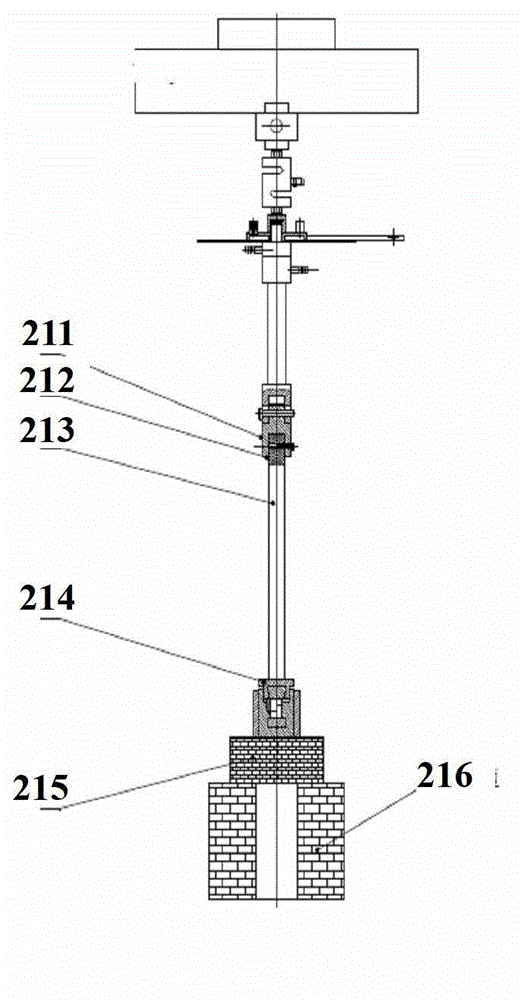

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

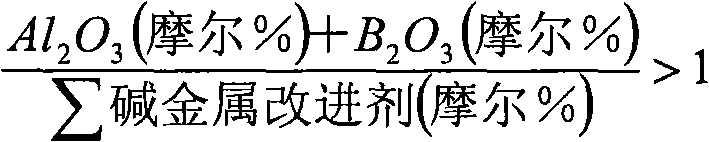

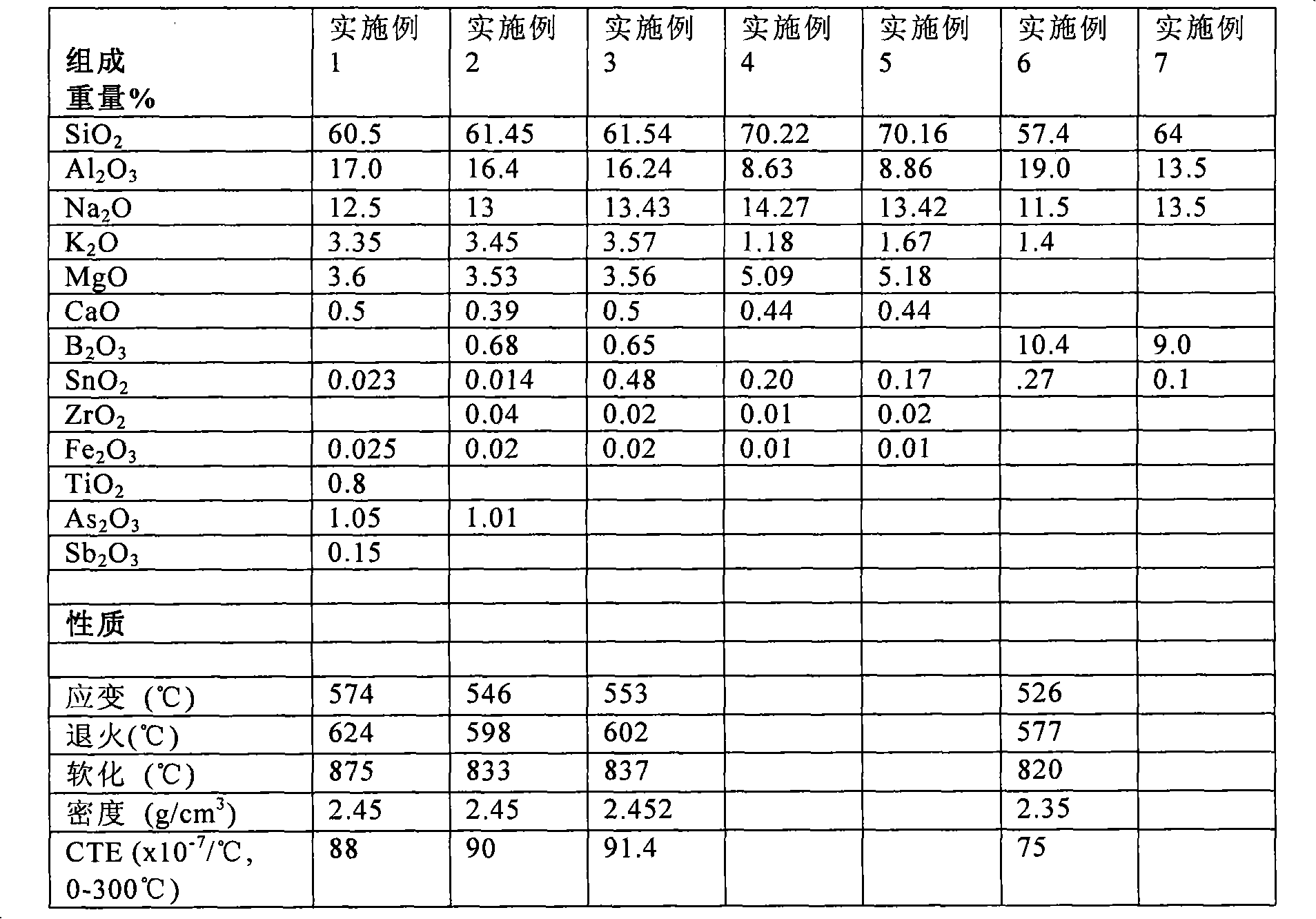

Durable glass housings/enclosures for electronic devices

The invention relates to glass articles suitable for use as electronic device housing / enclosure or protective cover which comprise a glass material. Particularly, a housing / enclosure / cover comprising an ion-exchanged glass exhibits the following attributes: (1) radio, and microwave frequency transparency, as defined by a loss tangent of less than 0.03 and at a frequency range of between 15 MHz to 3.0 GHz; (2) infrared transparency; (3) a fracture toughness of greater than 0.6 MPa*m<1 / 2>; (4) a 4-point bend strength of greater than 350 MPa; (5) a Vickers hardness of at least 450 kgf / mm<2> and a Vickers median / radial crack initiation threshold of at least 5 kgf; (6) a Young's Modulus ranging between about 50 to 100 GPa; (7) a thermal conductivity of less than 2.0 W / m DEG C; and (9) at least one of the following attributes: (i) a compressive surface layer having a depth of layer (DOL) greater and a compressive stress greater than 400 MPa, or, (ii) a central tension of more than 20 MPa.

Owner:CORNING INC

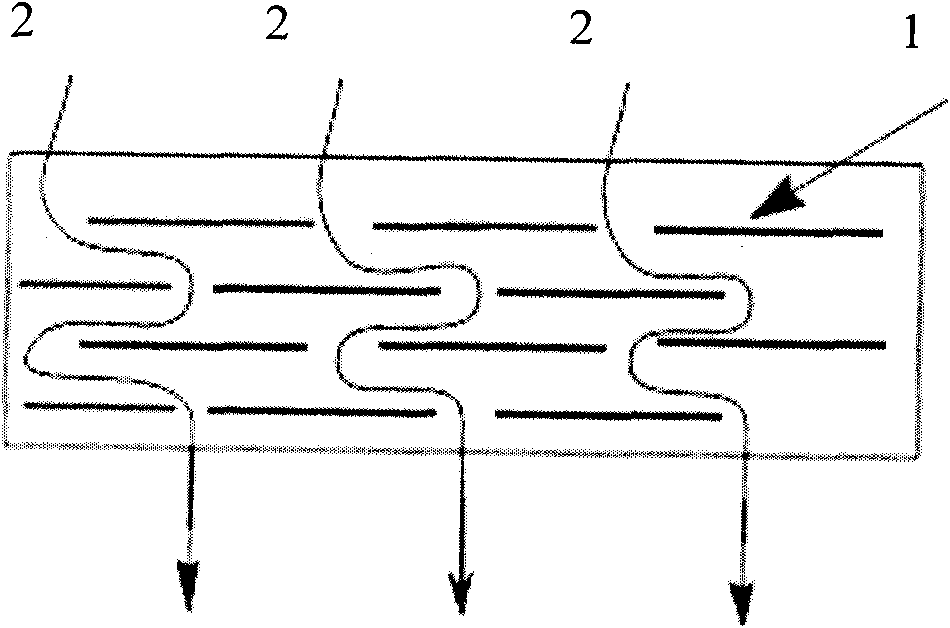

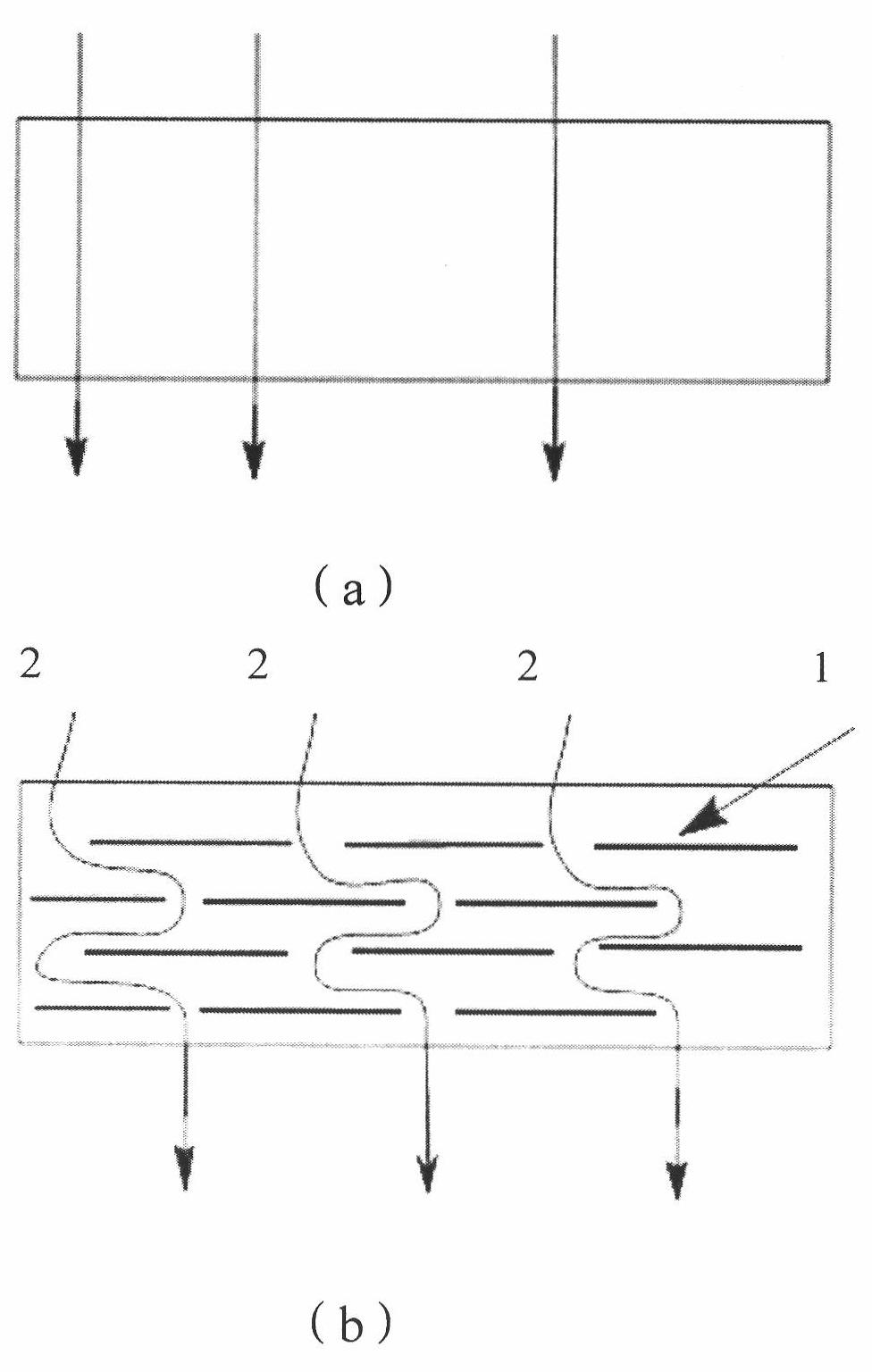

Fiber-reinforced ceramic composite material comprising a matrix with a nanolayered microstructure

InactiveUS20050181192A1Improve the immunityHigh strengthSynthetic resin layered productsCeramic layered productsCeramic compositeToughening

A fiber-reinforced ceramic matrix composite material exhibiting increased matrix cracking strength and fracture toughness is produced by sequentially depositing a plurality of 5-500 nanometer-thick layers of a primary ceramic matrix material phase periodically separated by 1-100 nanometer-thick intermediate layers of a secondary matrix material phase onto the reinforcing fibers upon their consolidation. The resultant nanolayered matrix enhances the resistance to the onset of matrix cracking, thus increasing the useful design strength of the ceramic matrix composite material. The nanolayered microstructure of the matrix constituent also provides a unique resistance to matrix crack propagation. Through extensive inter-layer matrix fracture, debonding and slip, internal matrix microcracks are effectively diverted and / or blunted prior to their approach towards the reinforcing fiber, thus increasing the apparent toughness of the matrix constituent. This unique toughening mechanism serves to dampen energetic co-planar macrocrack propagation typically observed in conventionally manufactured ceramic matrix composites wherein matrix cracks are usually deflected at the fiber / matrix interphase region.

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

Processing insert, and production of same

InactiveUS6350510B1Improve fracture resistanceAvoid disadvantagesVacuum evaporation coatingSputtering coatingHard metalCarbide

The invention pertains to a processing insert comprised of a body with a hard metal or ceramic substrate and with a multilayer coating and the manufacture of same. In order to have a highly fracture-tough insert with a relatively thick coating, it is suggested that an external layer (protective layer) be applied according to the CVD process, said layer being either a monophase or multiphase layer of Zr-based or Hf-based carbide nitride or carbonitride, and presenting internal compressive stresses. The layer(s) underlying the external layer, also applied according to the CVD process, also present(s), without any exception, internal compressive stresses, while at least one of them, maybe the only one laying under the protective layer is made of TiN, TiC and / or TiCN. The coating is applied according to a continuous CVD process at temperatures of 900° C. to 1100° C. and involves a specific modification of the gas compounds.

Owner:WIDIA

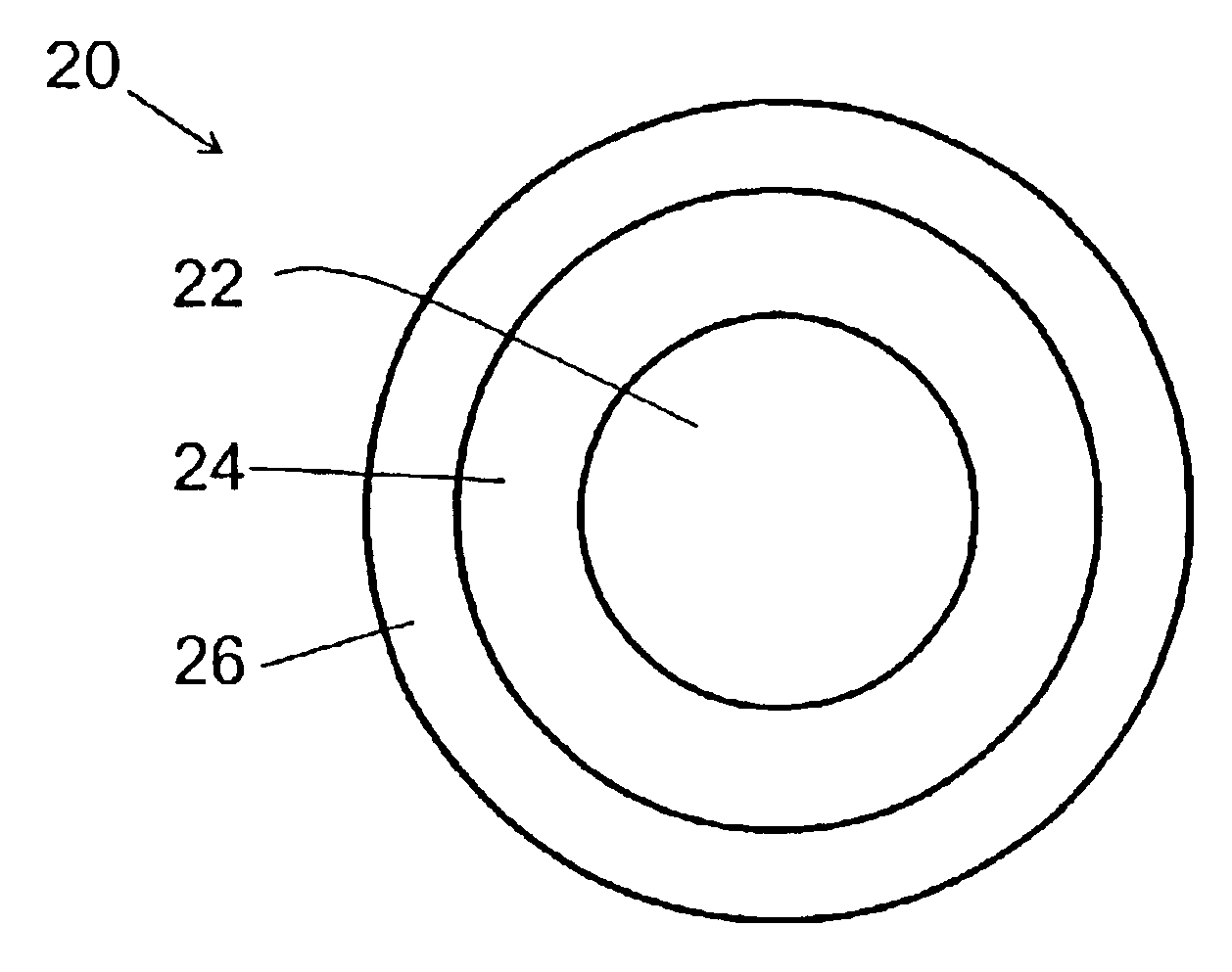

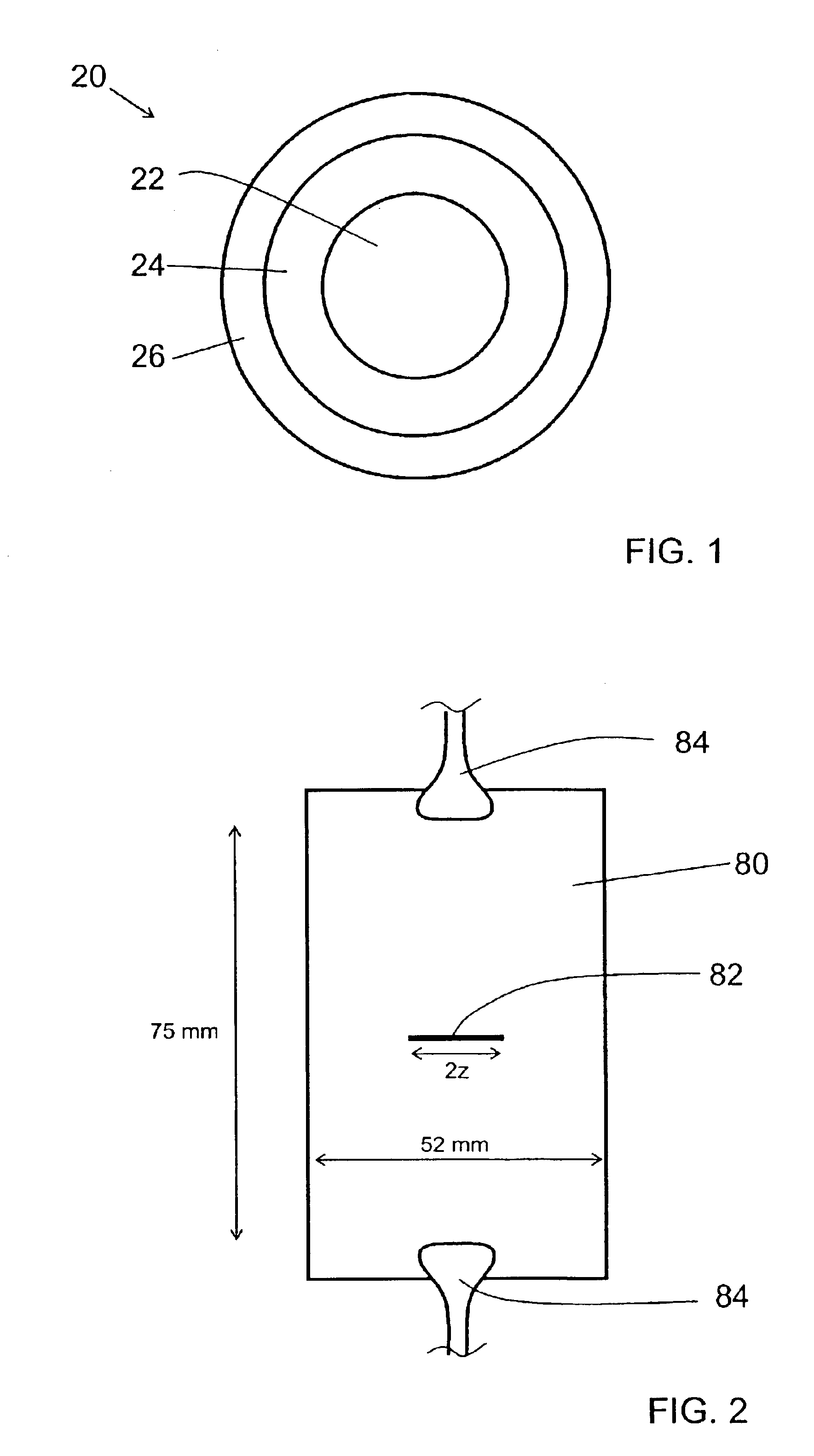

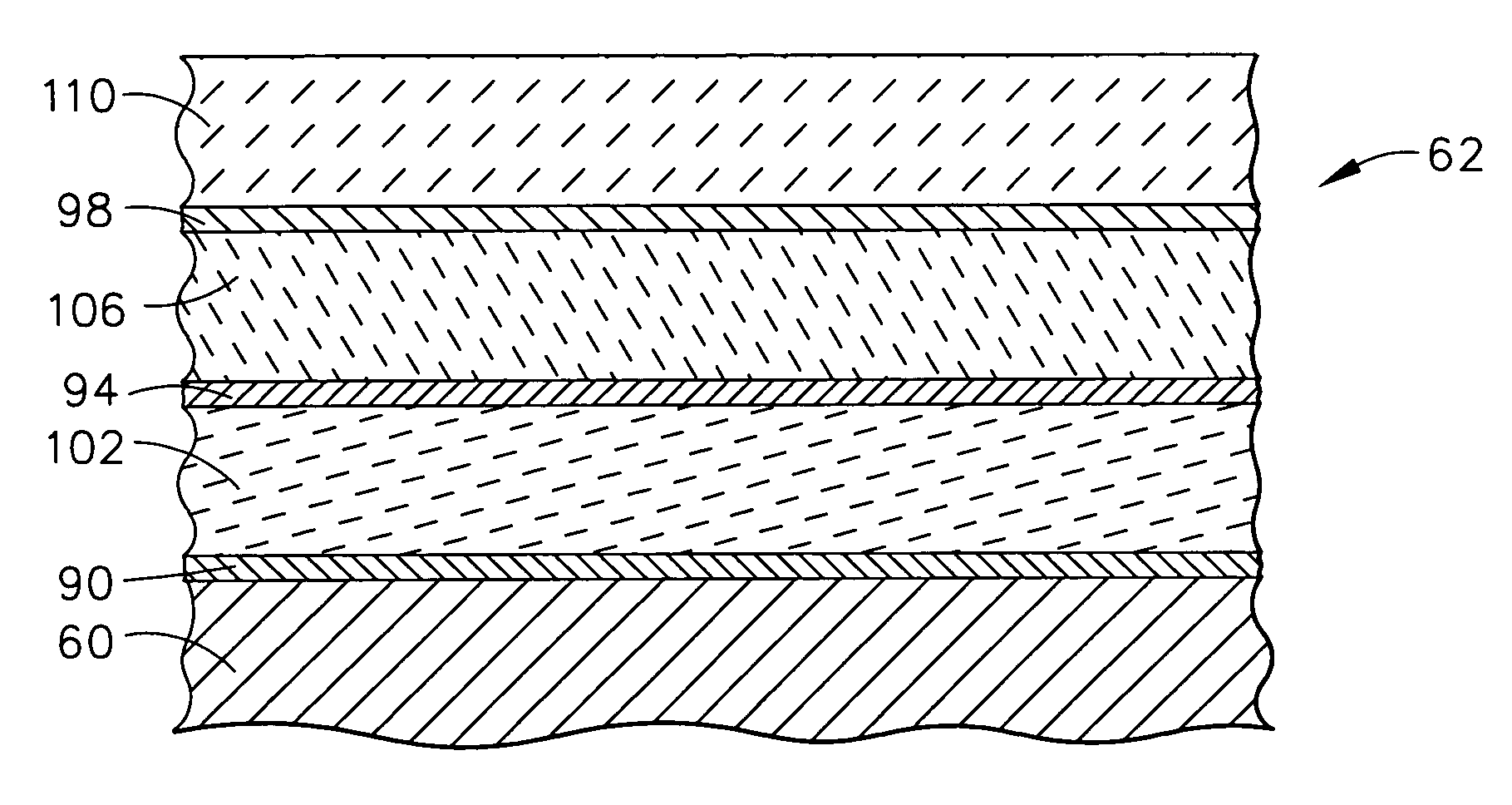

Coated optical fiber and curable compositions suitable for coating optical fiber

InactiveUS6862392B2EnvironmentalReduce sensitivityOptical fibre with multilayer core/claddingCoatingsOligomerYoung's modulus

The present invention provides materials suitable for use as secondary coatings of optical fibers. According to one embodiment of the invention, a curable composition includes an oligomer and at least one monomer, which when cured forms a cured polymeric material having a Young's modulus of at least about 1200 MPa, and a fracture toughness of at least about 0.7 MPa·m1 / 2. According to another embodiment of the invention, a coated optical fiber includes an optical fiber; a primary coating encapsulating the optical fiber; and a secondary coating encapsulating the primary coating, the secondary coating having a Young's modulus of at least about 1200 MPa, and a fracture toughness of at least about 0.7 MPa·m1 / 2.

Owner:CORNING INC

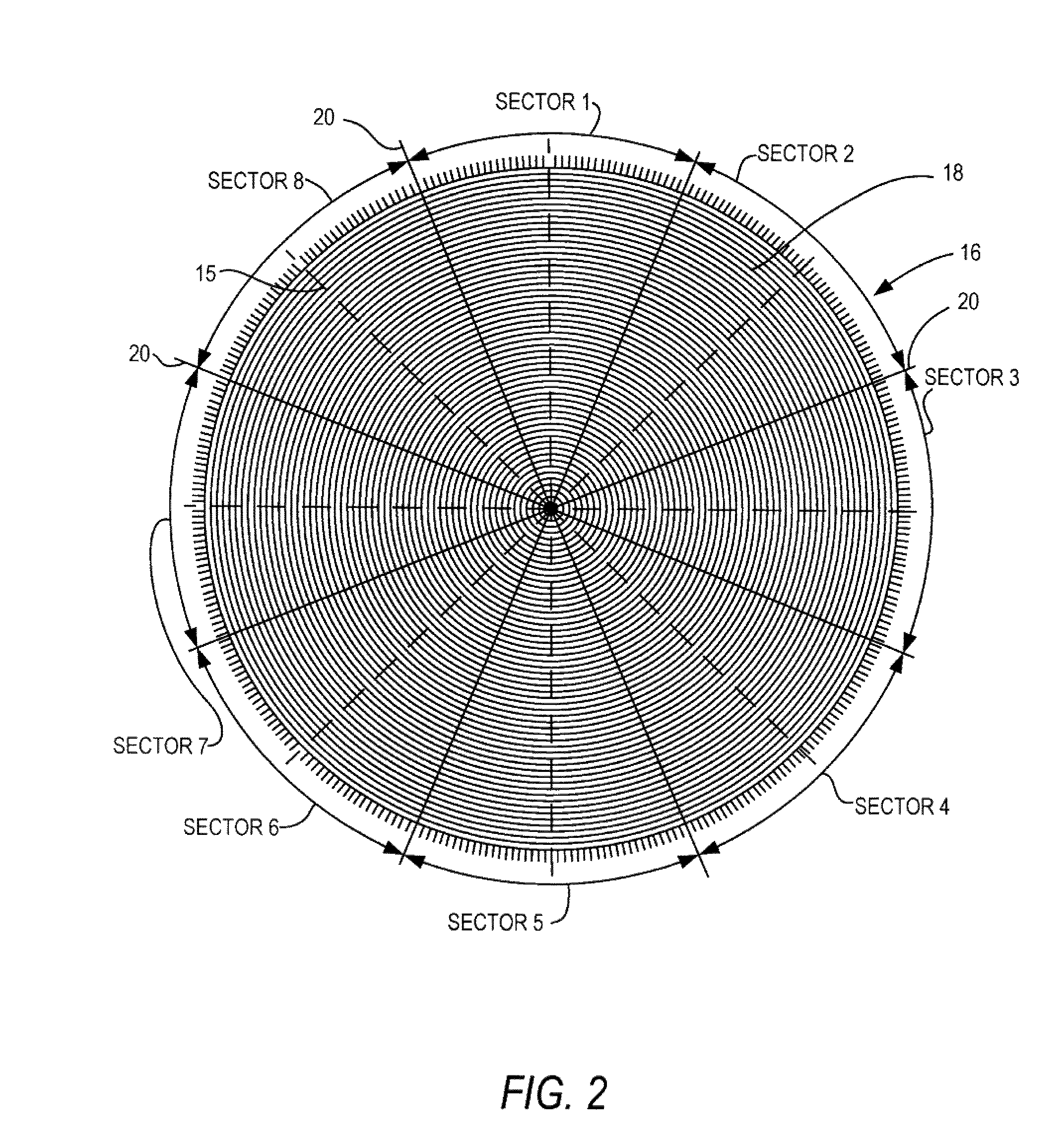

Ceramic substrate for a semiconductor production/inspection device

InactiveUS6891263B2Increase the number ofLower volume resistivitySemiconductor/solid-state device detailsSolid-state devicesNon oxide ceramicsElectrical conductor

The present invention provides a ceramic substrate which can keep a sufficiently large breakdown voltage even if the pore diameter of its maximum pore is 50 μm or less to be larger than that of conventional ceramic substrates, can give a large fracture toughness value because of the presence of pores, can resist thermal impact, and can give a small warp amount at high temperature. The ceramic substrate of the present invention is a ceramic substrate for a semiconductor-producing / examining device having a conductor formed on a surface of the ceramic substrate or inside the ceramic substrate, wherein: the substrate is made of a non-oxide ceramic containing oxygen; and the pore diameter of the maximum pore thereof is 50 μm or less.

Owner:IBIDEN CO LTD

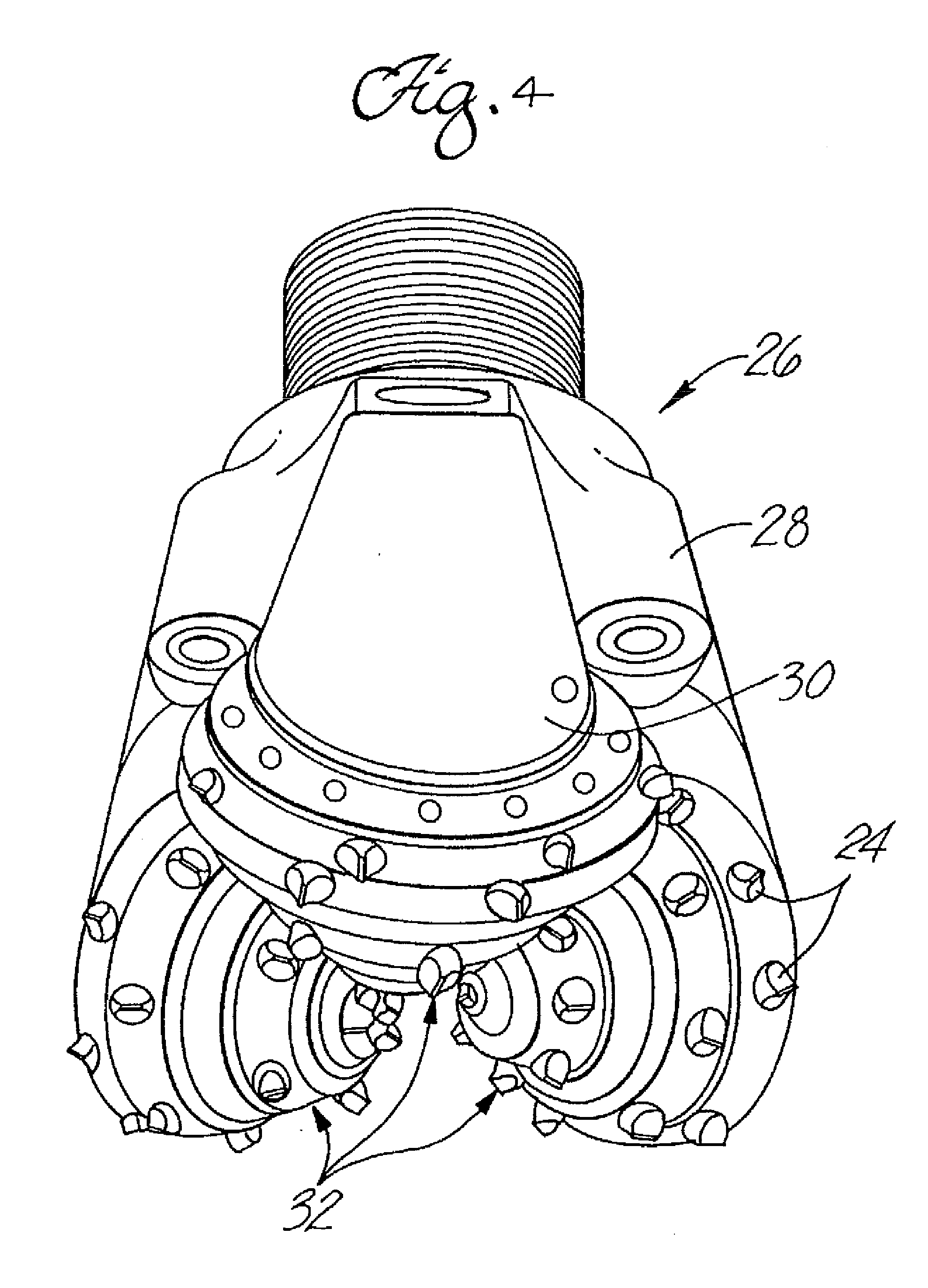

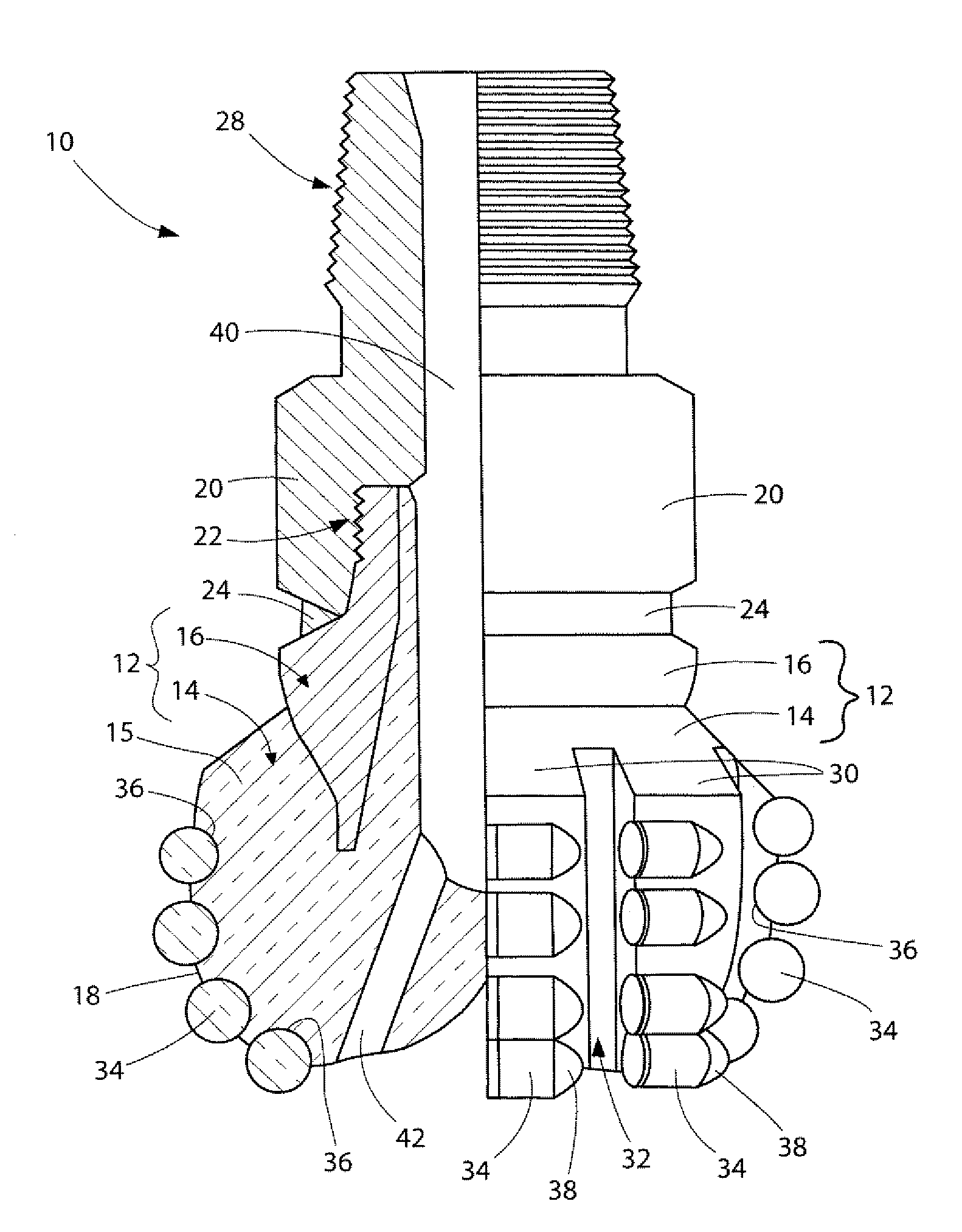

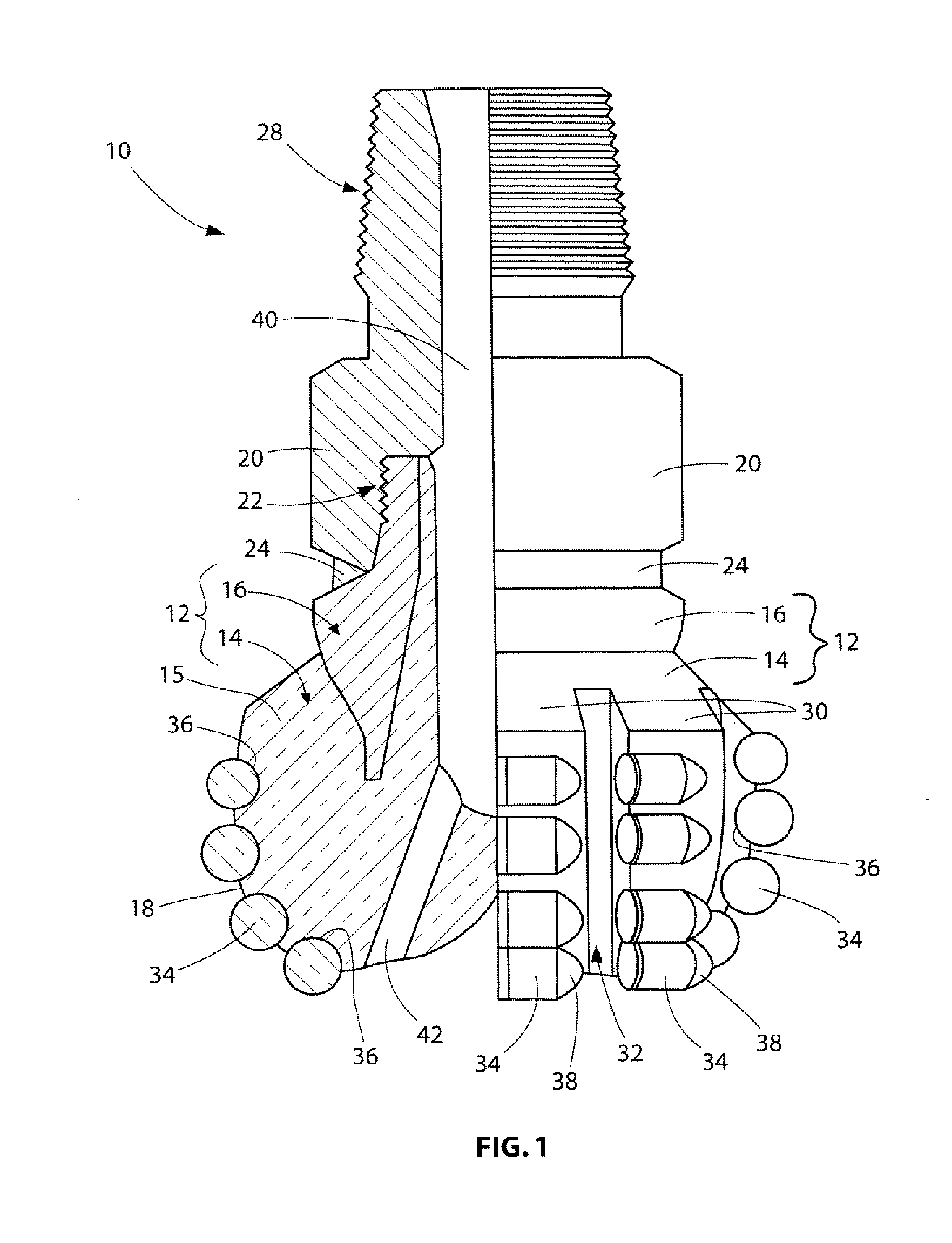

Silicon carbide composite materials, earth-boring tools comprising such materials, and methods for forming the same

Earth-boring tools for drilling subterranean formations include a particle-matrix composite material comprising a plurality of silicon carbide particles dispersed throughout a matrix material, such as, for example, an aluminum or aluminum-based alloy. In some embodiments, the silicon carbide particles comprise an ABC—SiC material. Methods of manufacturing such tools include providing a plurality of silicon carbide particles within a matrix material. Optionally, the silicon carbide particles may comprise ABC—SiC material, and the ABC—SiC material may be toughened to increase a fracture toughness exhibited by the ABC—SiC material. In some methods, at least one of an infiltration process and a powder compaction and consolidation process may be employed.

Owner:BAKER HUGHES INC

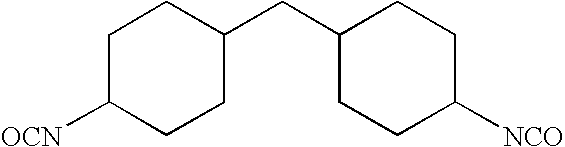

Non-reactive additives for fiber coatings

InactiveUS20070100039A1Easy to operateImprove performanceLayered productsPolyurea/polyurethane coatingsOligomerMonomer

The present invention relates to a curable composition having an oligomer, at least one monomer, and an amount of a substantially non-reactive oligomeric additive. The substantially non-reactive oligomeric additive is present in an amount effective to yield a cured product having a fracture toughness value that is higher than the fracture toughness value of a cured product of an otherwise identical composition lacking the non-reactive oligomeric additive. The present invention also relates to coated optical fibers, optical ribbons or bundles, and telecommunication systems having the curable composition.

Owner:CORNING INC

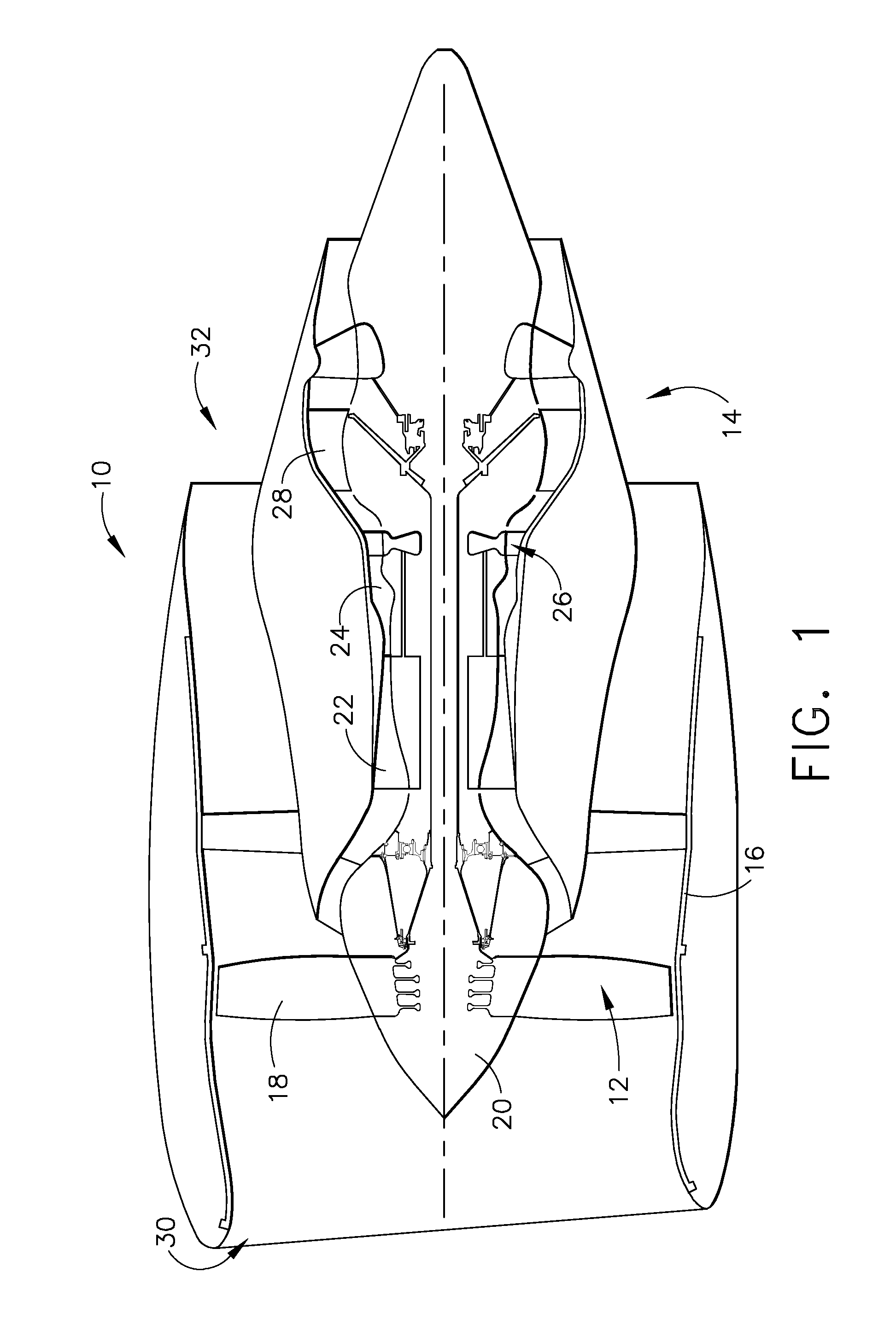

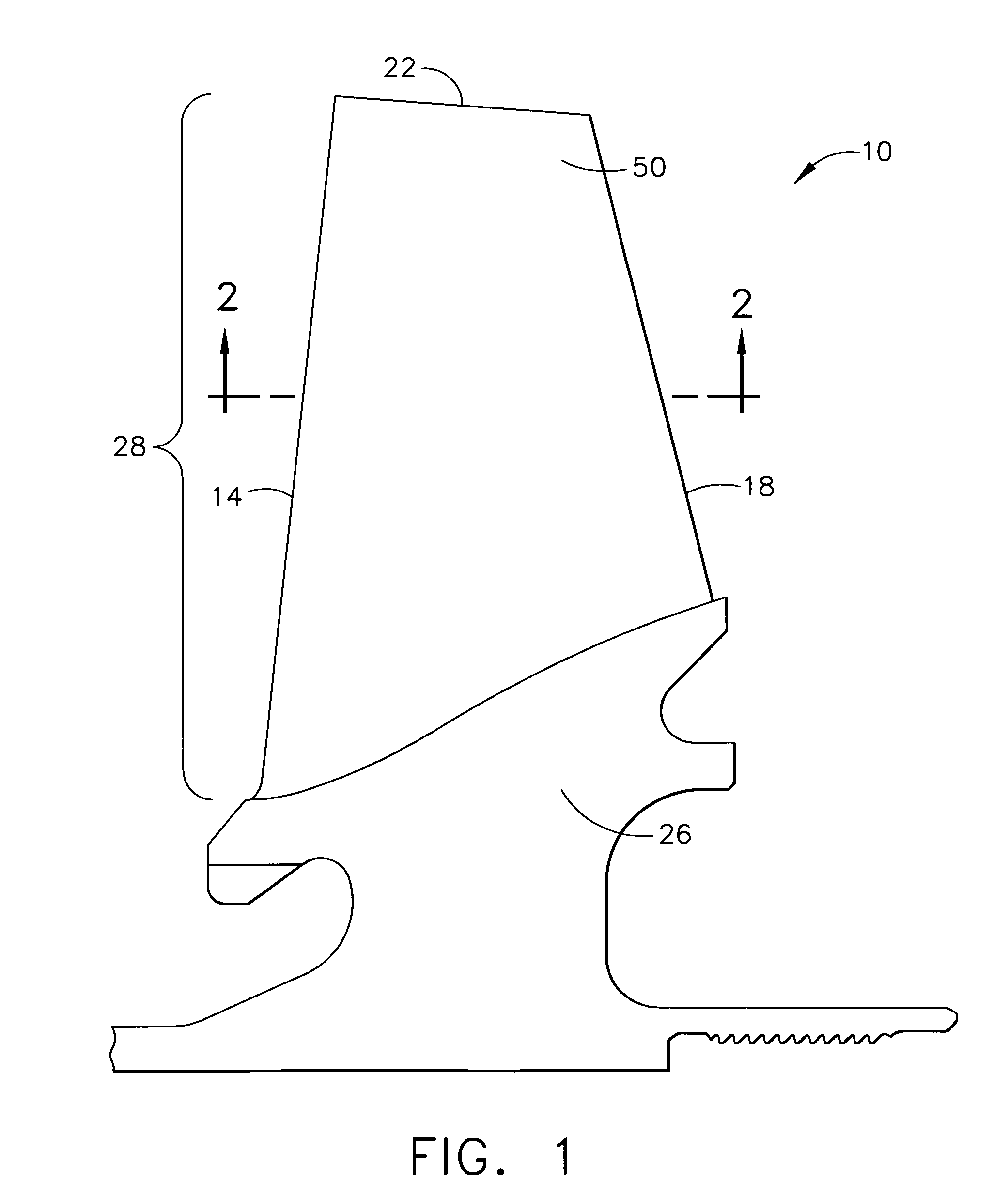

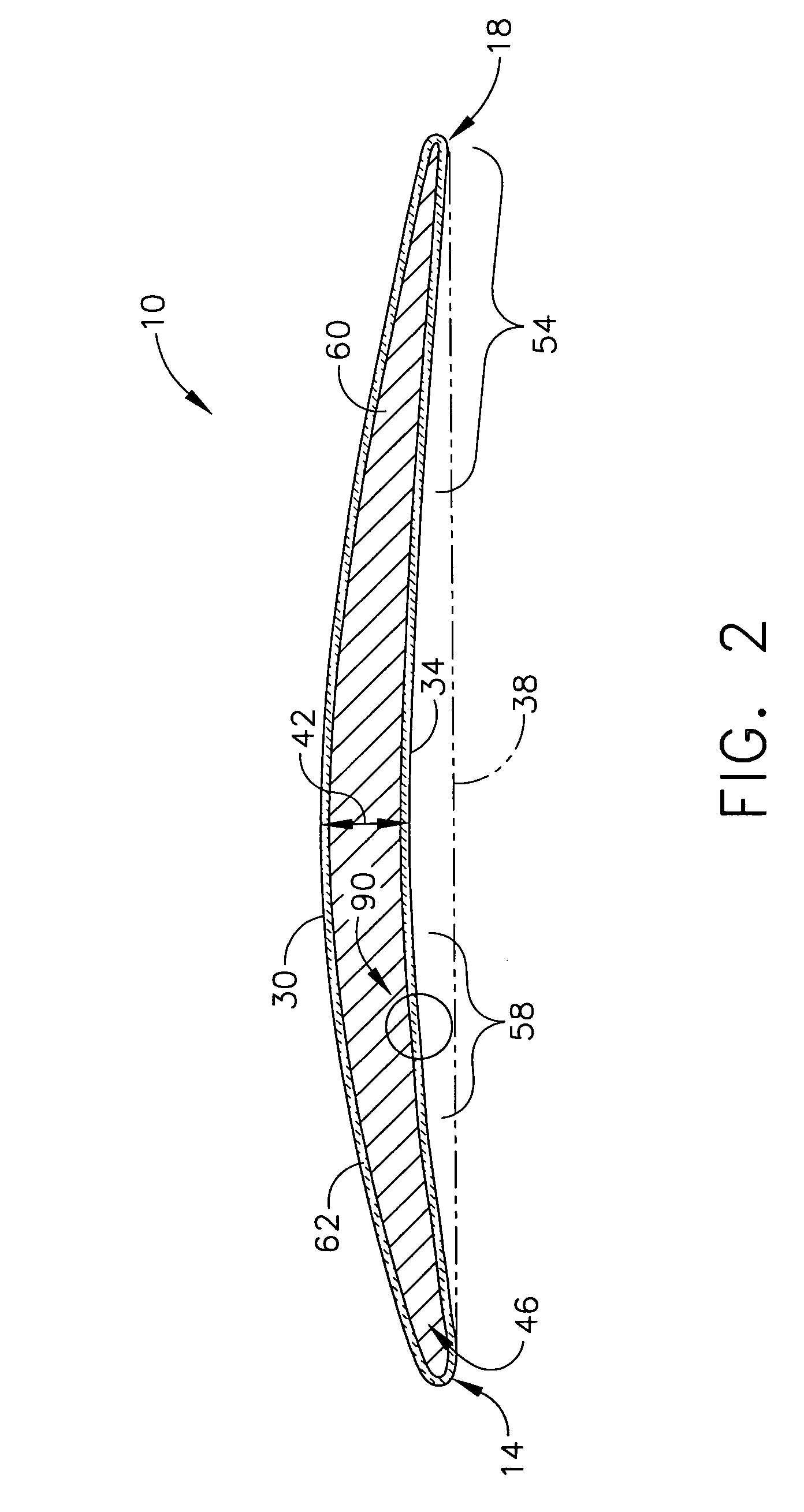

Airfoil having improved impact and erosion resistance and method for preparing same

InactiveUS7186092B2Improve impact resistanceImprove corrosion resistanceSpecific fluid pumpsPropellersLeading edgeStructural engineering

Owner:GENERAL ELECTRIC CO

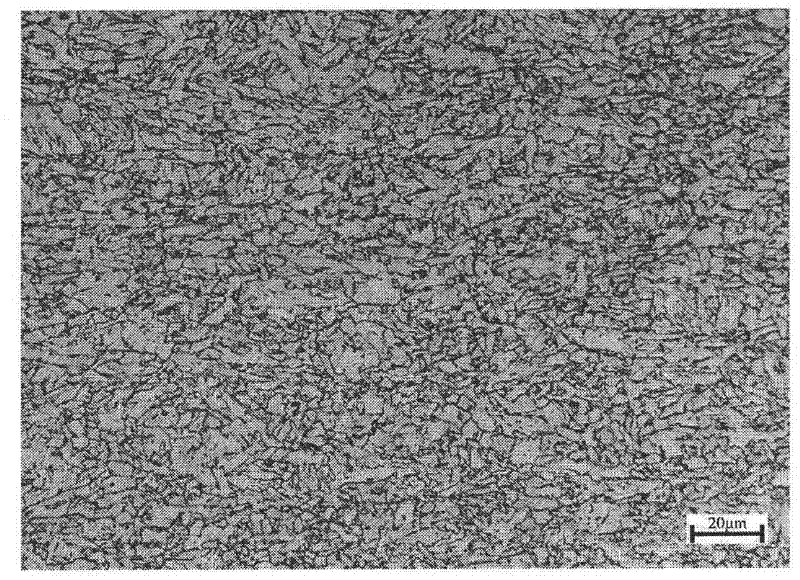

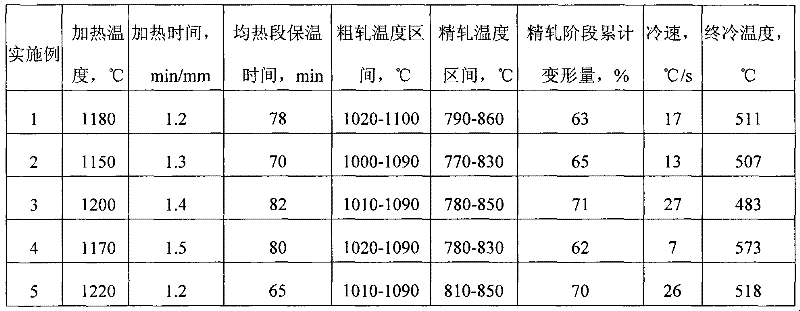

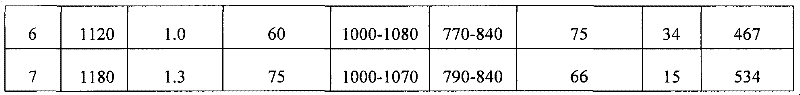

Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

ActiveCN102409224AGuaranteed toughnessSuitable for solderabilityRoll mill control devicesMetal rolling arrangementsHydrogenChemical composition

The invention provides a hot rolled steel plate with excellent low-temperature toughness for a thick submerged pipeline and a production method of the hot rolled steel plate. The hot rolled steel plate comprises the following chemical components by weight percentage: 0.02%-0.07% of C, 0.15%-0.40% of Si, 1.0%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.003% of S, less than or equal to 0.06% of Nb, less than or equal to 0.025% of Ti, less than or equal to 0.06% of V, less than or equal to 0.20% of Mo, less than or equal to 0.25% of Cu, 0.10%-0.30% of Ni, less than orequal to 0.25% of Cr, less than or equal to 0.008% of N, 0.010%-0.040% of Al, more than or equal to 2 of Al / N and the rest Fe and inevitable impurities. According to the steel for the submerged pipeline with the thickness being over 28mm, disclosed by the invention, the transversal and longitudinal bending strength can reach over 480MPa or 510MPa, the transversal and longitudinal tensile strengthcan reach over 560MPa or 600 MPa, the transversal impact toughness at the temperature of 60 DEG below zero is larger than or equal to 400 J, the transversal DWTT (Drop-Weight Tear Test) shearing areaat the temperature of 25 DEG C below zero is larger than or equal to 85%, simultaneously, the corrosion resistant of the steel plate is excellent, and the result of a 96-hour HIC (Hydrogen Induced Cracking) test conforms to the requirements of the standard 0284 of the NACE (National Association of Corrosion Engineers). The hot rolled steel plate is suitable to be as a raw material for manufacturing a pipeline for submerged oil and gas transmission.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com