Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Optimal for incorporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

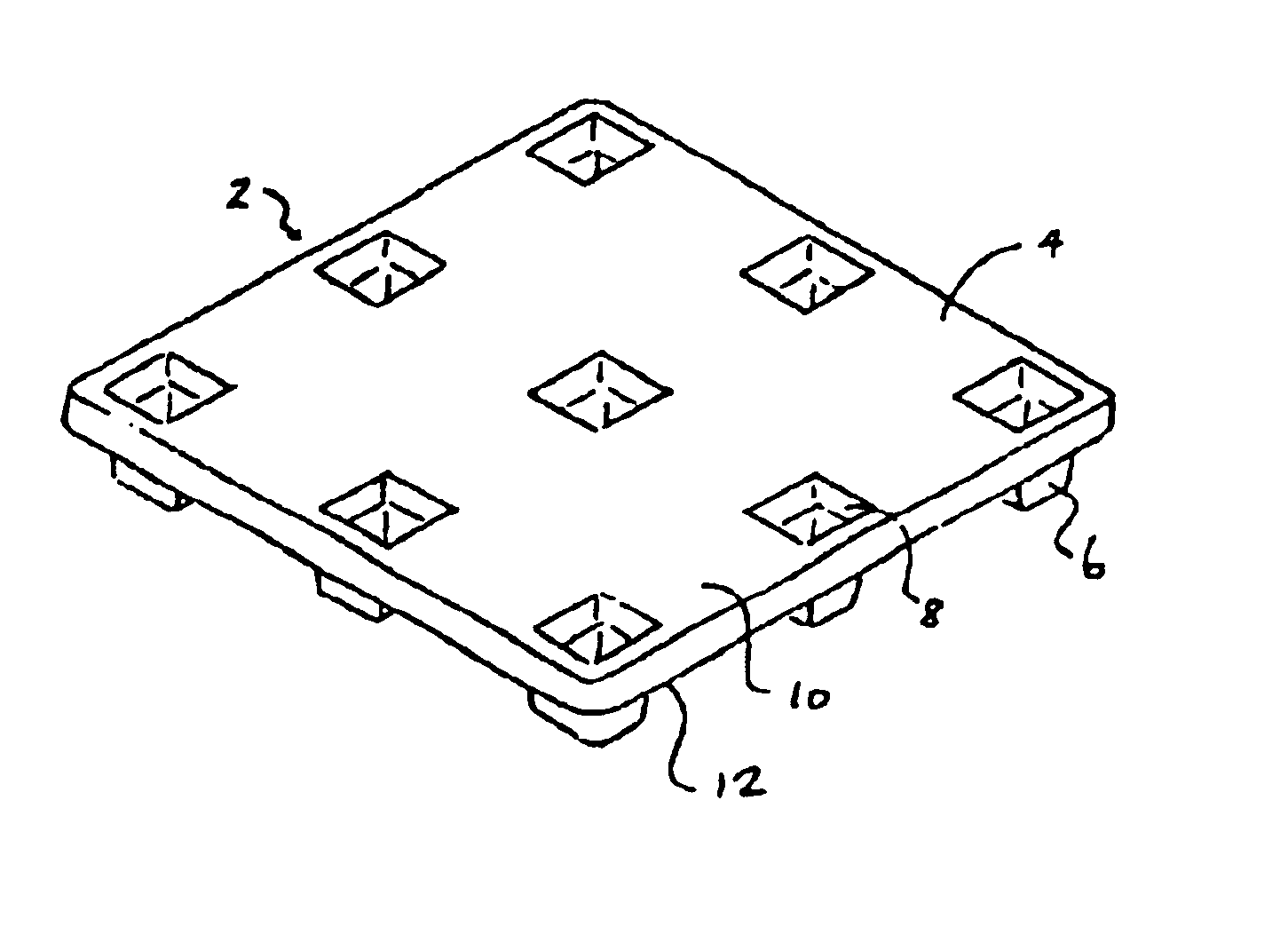

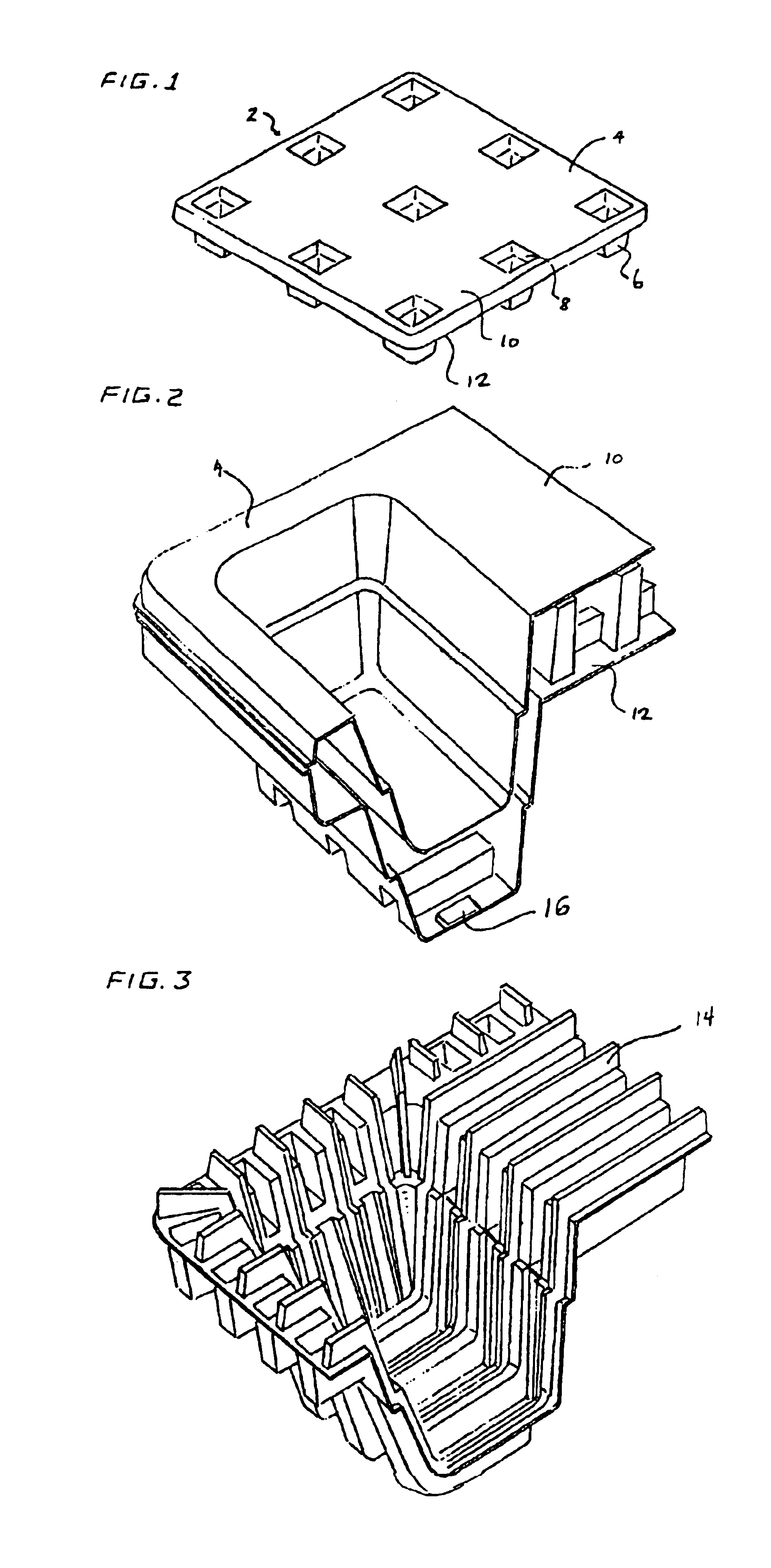

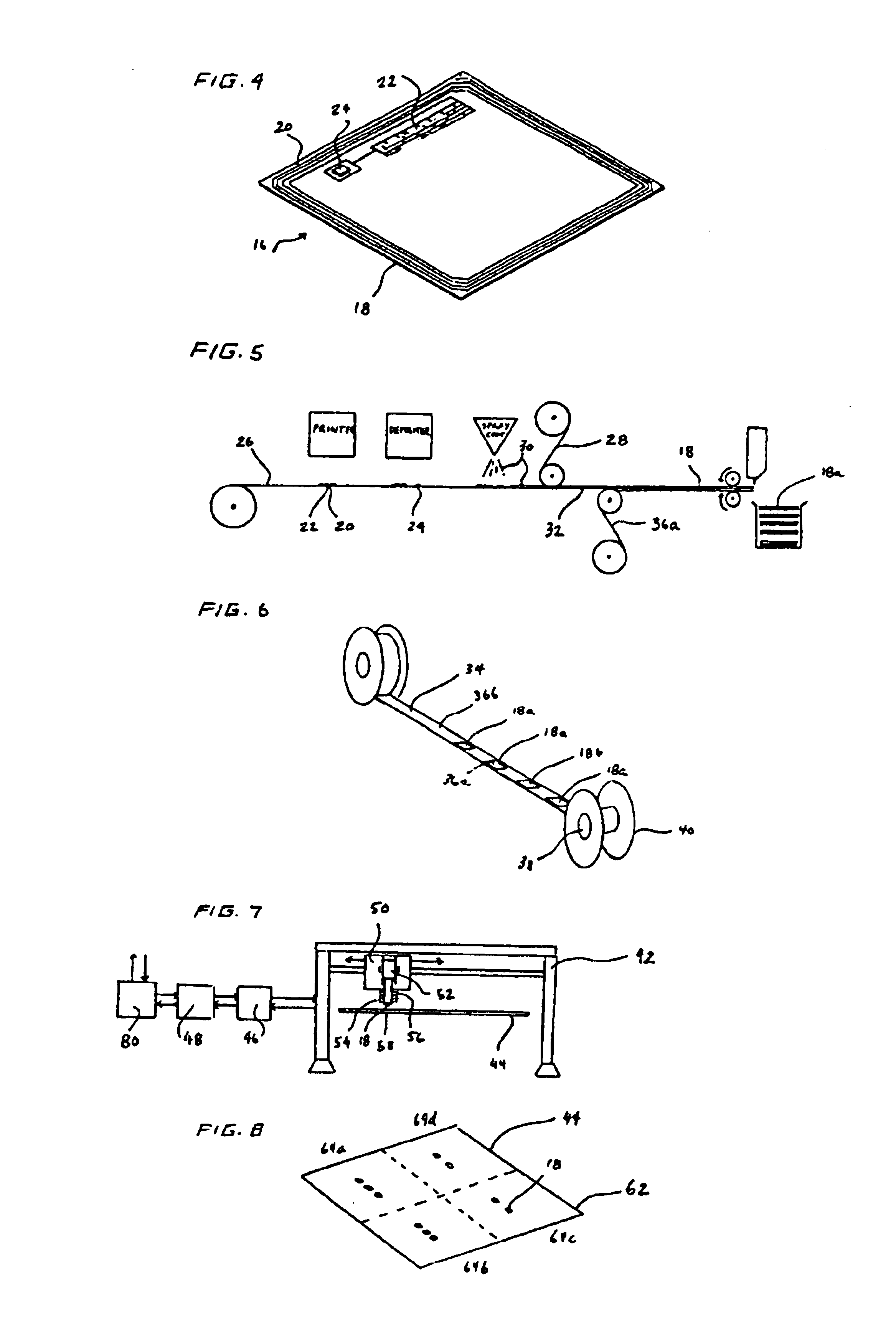

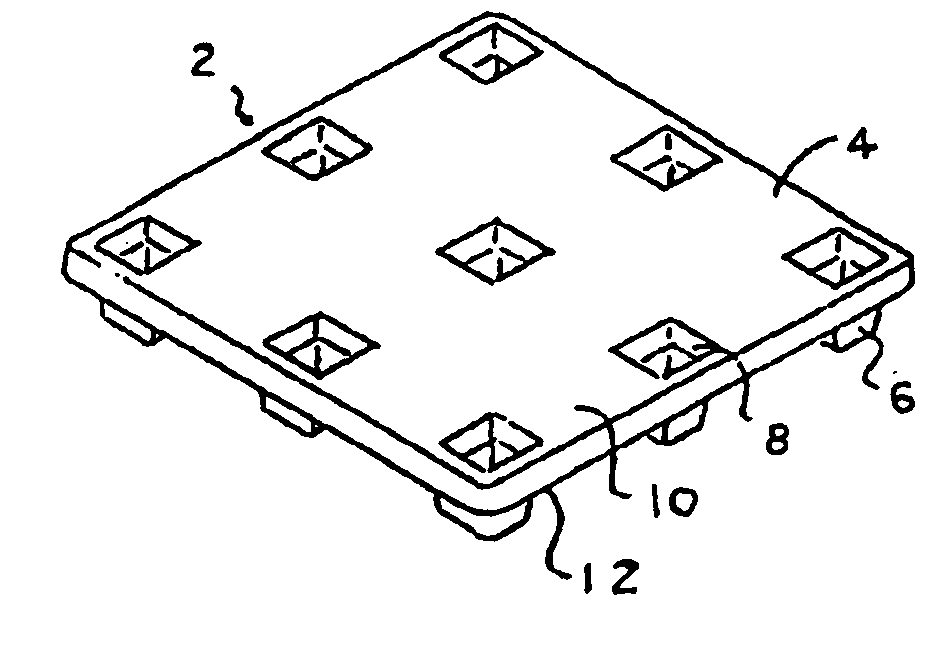

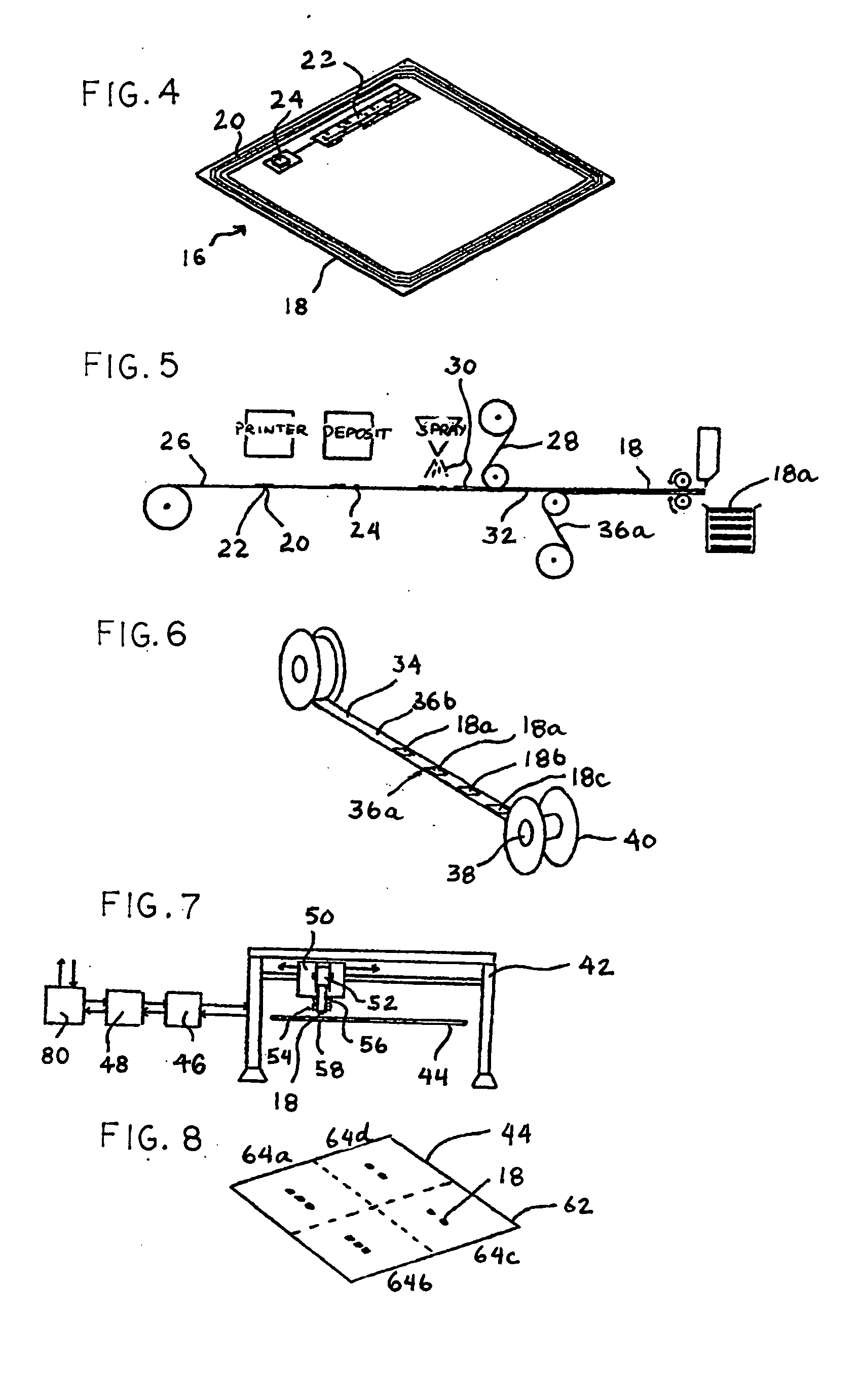

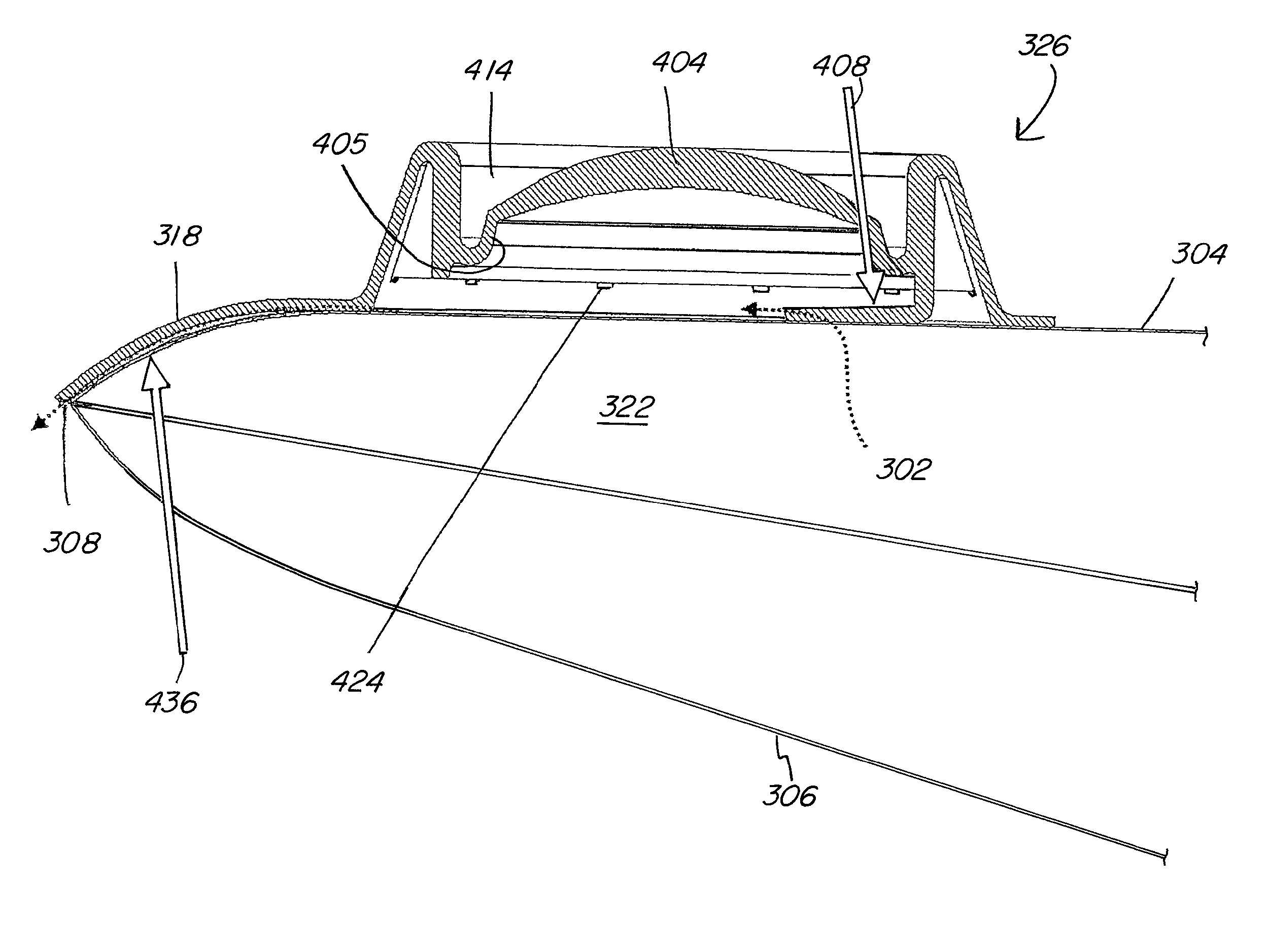

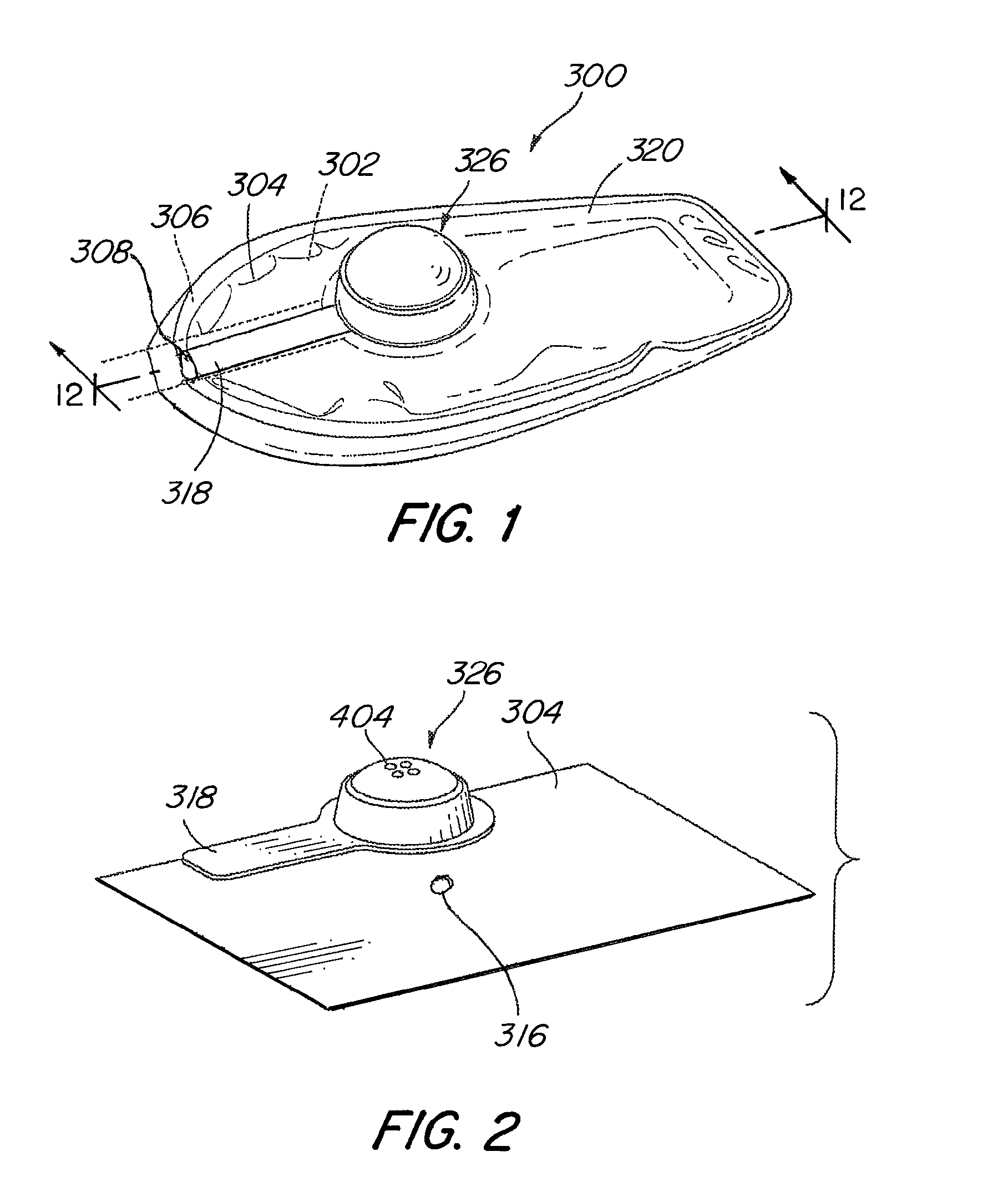

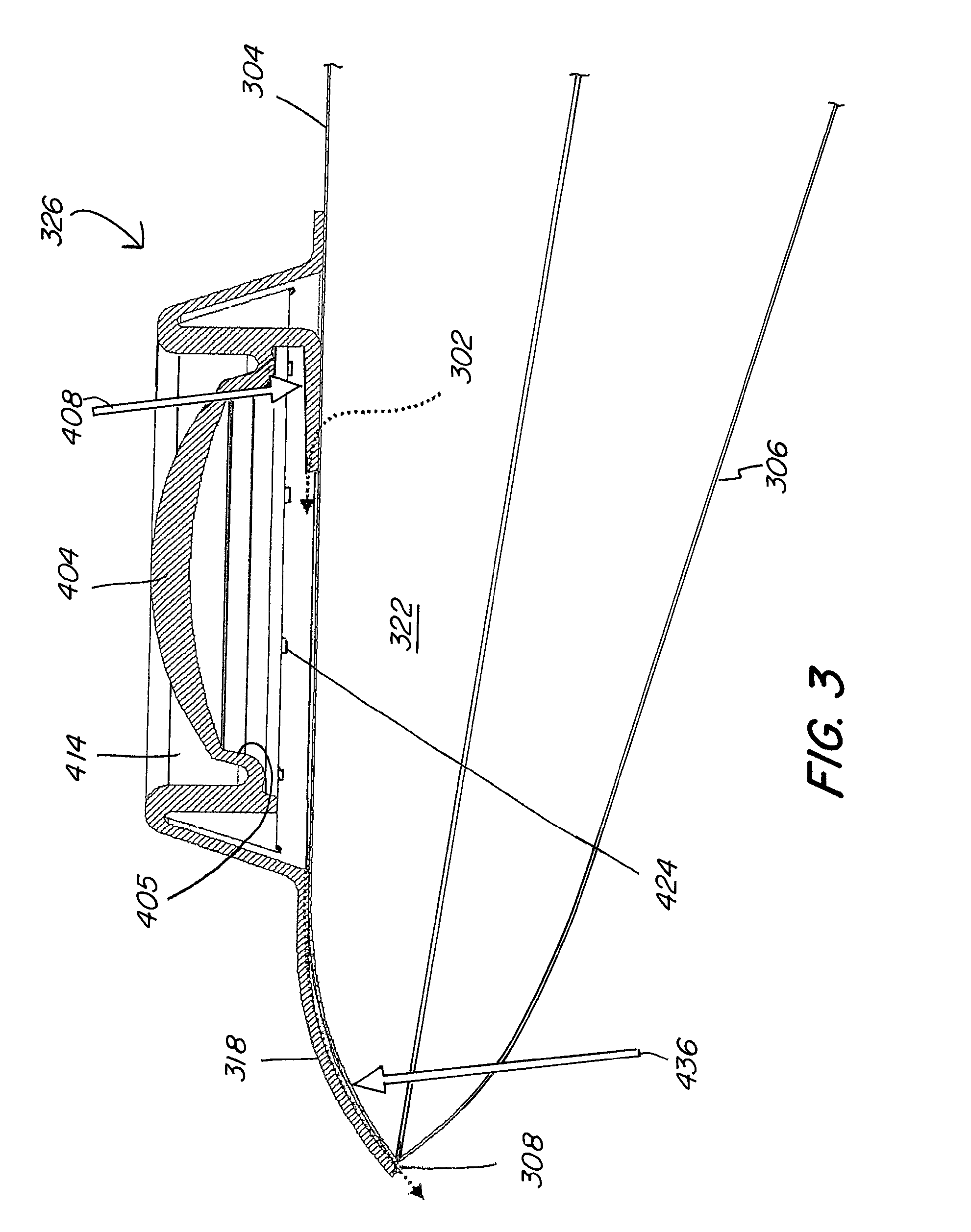

Thermoformed apparatus having a communications device

InactiveUS6943678B2Improve protectionIncreased durabilityRecord carriersDigital data processing detailsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

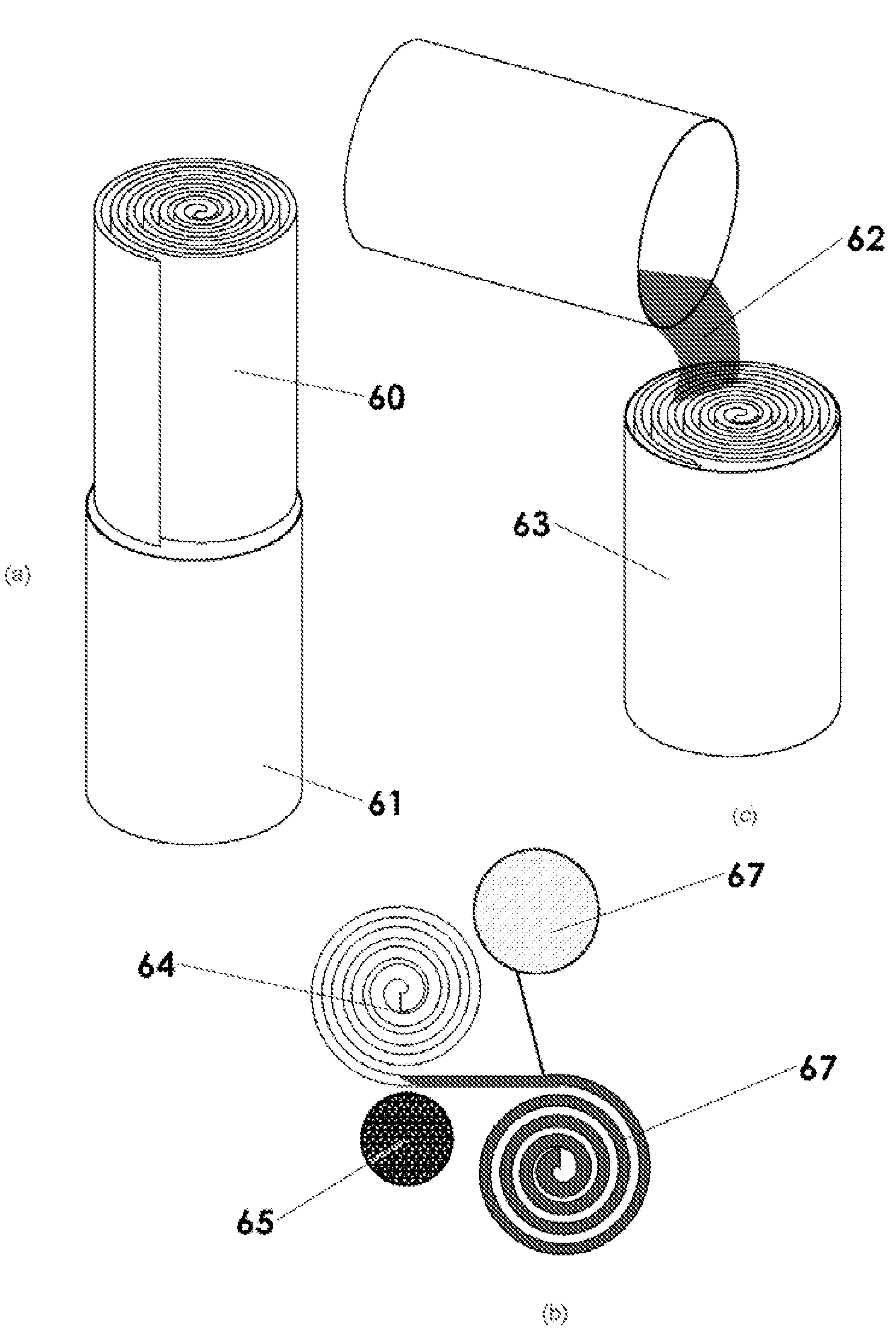

Milled particles

InactiveUS6634576B2Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

A process for milling a solid substrate in the milling chamber of a dispersion or media mill in the presence of a two or more compositions of milling media bodies is disclosed wherein all milling media bodies contribute to the grinding of the solid substrate and wherein at least one composition of media bodies provides fragments of milling media bodies that are retained with the milled solid substrate particles in the form of a synergetic commixture produced in the milling process. More specifically, a process is disclosed for preparing a synergetic commixture comprising small particles of a solid substrate and small particulates of a first material of a desired size comprising the steps of (a) providing to the milling chamber of a media mill a contents comprising a pre-mix of a solid substrate, a fluid carrier, a plurality of milling bodies of a first material having a fracture toughness Kc1, and a plurality of milling bodies of a second material having a fracture toughness Kc2; (b) operating the media mill to grind the solid substrate and degrade at least a portion of the milling bodies of first material to produce a dispersion in the fluid carrier comprising a synergetic commixture of small particulates of the first material and small particles of the solid substrate having a desired size equal to or less than a size Sp; (c) separating the dispersion from any milling bodies and solid substrate particles having a size larger than Sp; and (d) optionally removing the fluid carrier from the dispersion to form a synergetic commixture free of fluid and comprising the particles and the small particulates, wherein KC2 is greater than KC1.

Owner:RTP PHARMA +1

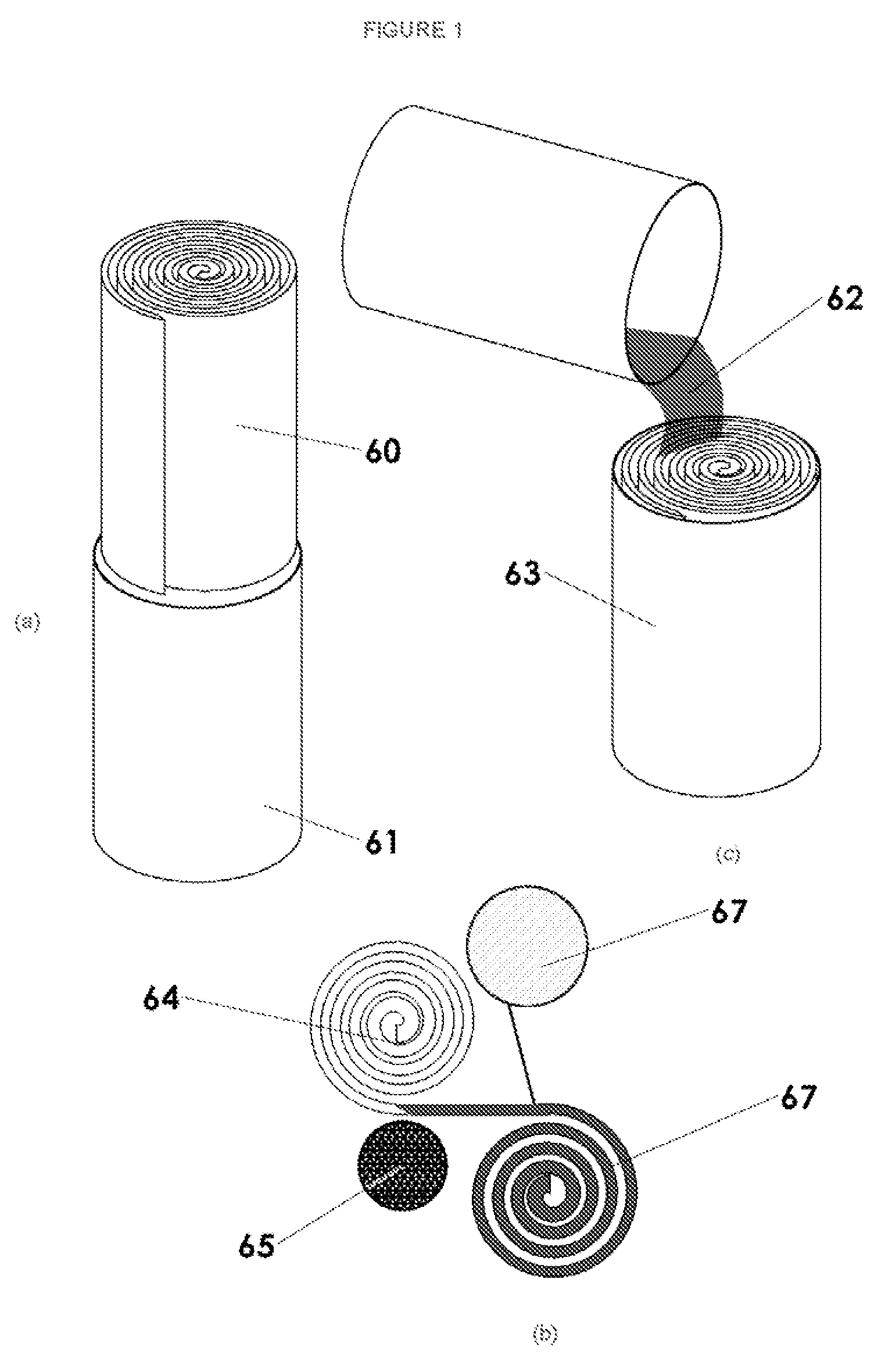

Aerogel-foam composites

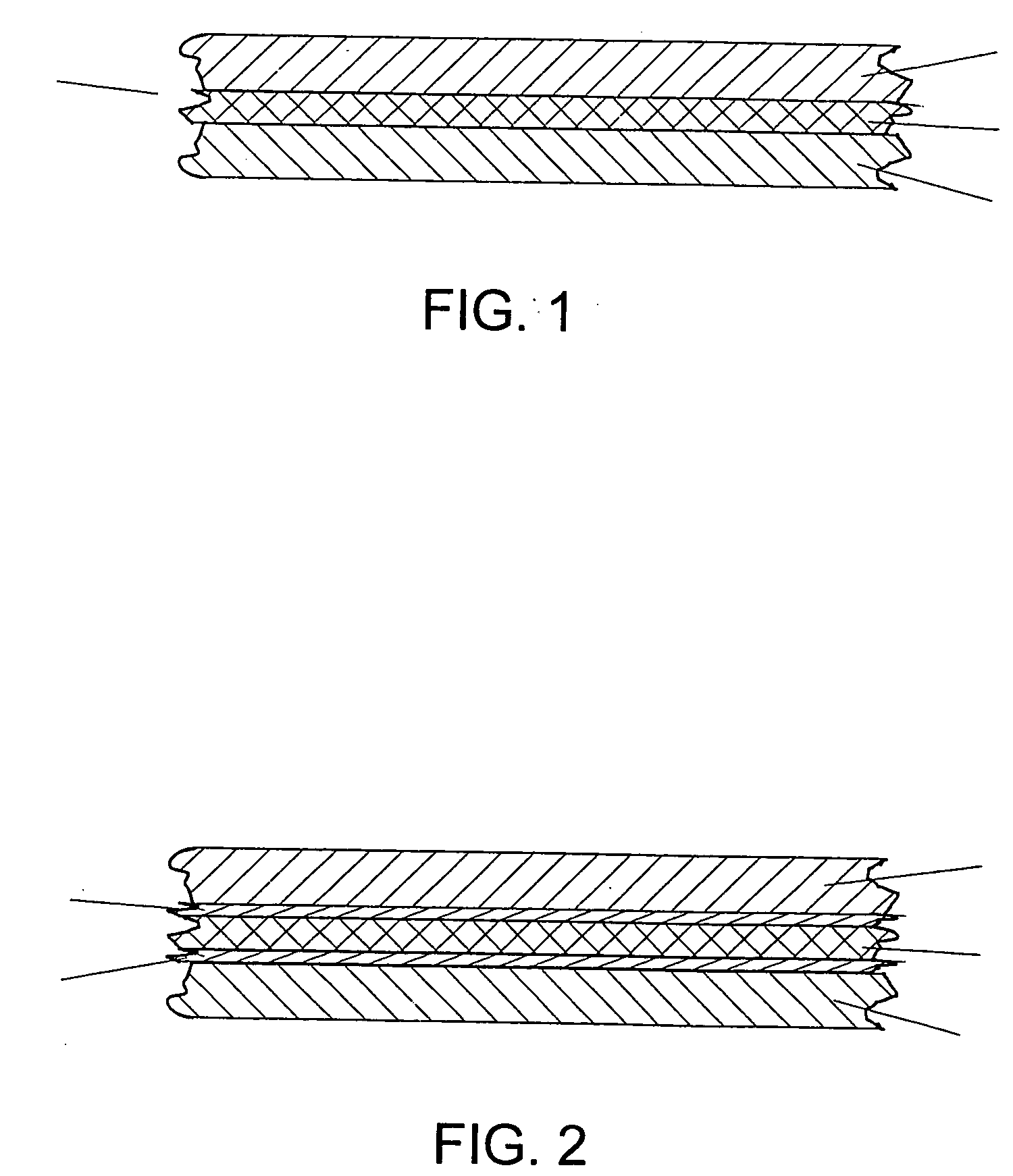

InactiveUS20090029147A1Increase flexibilityMaintain good propertiesSolar heat devicesSynthetic resin layered productsPolymer scienceMonolith

The invention provides reinforced aerogel monoliths as well as reinforced composites thereof for a variety of uses. Compositions and methods of preparing the monoliths and composites are also provided. Application of these materials in transparent assemblies is also discuss.

Owner:ASPEN AEROGELS

Thermoformed platform having a communications device

InactiveUS20050241548A1Improve protectionImprove reliability and durabilityContainer decorationsLevel indicationsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

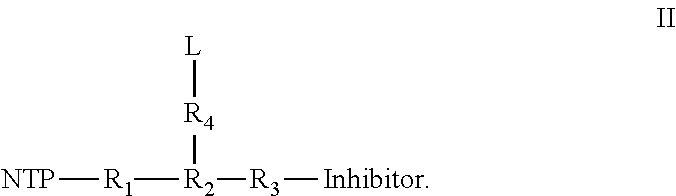

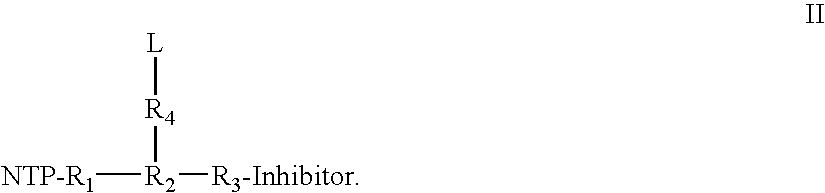

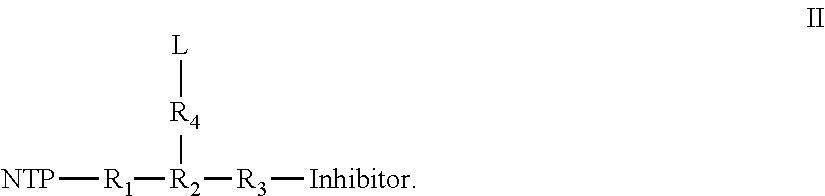

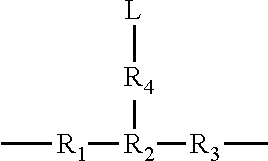

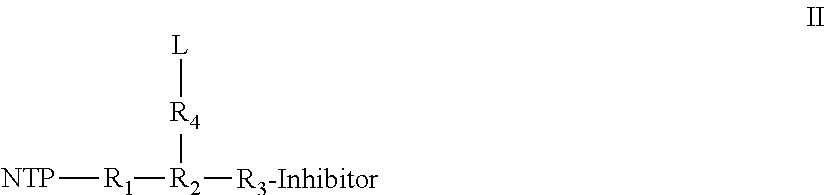

Nucleotide analogs

ActiveUS8071755B2Optimal for incorporationDetectable labelSugar derivativesMicrobiological testing/measurementNucleotideComputational biology

The invention provides for nucleotide analogs and methods of using the same, e.g., for sequencing nucleic acids.

Owner:FLUIDIGM CORP

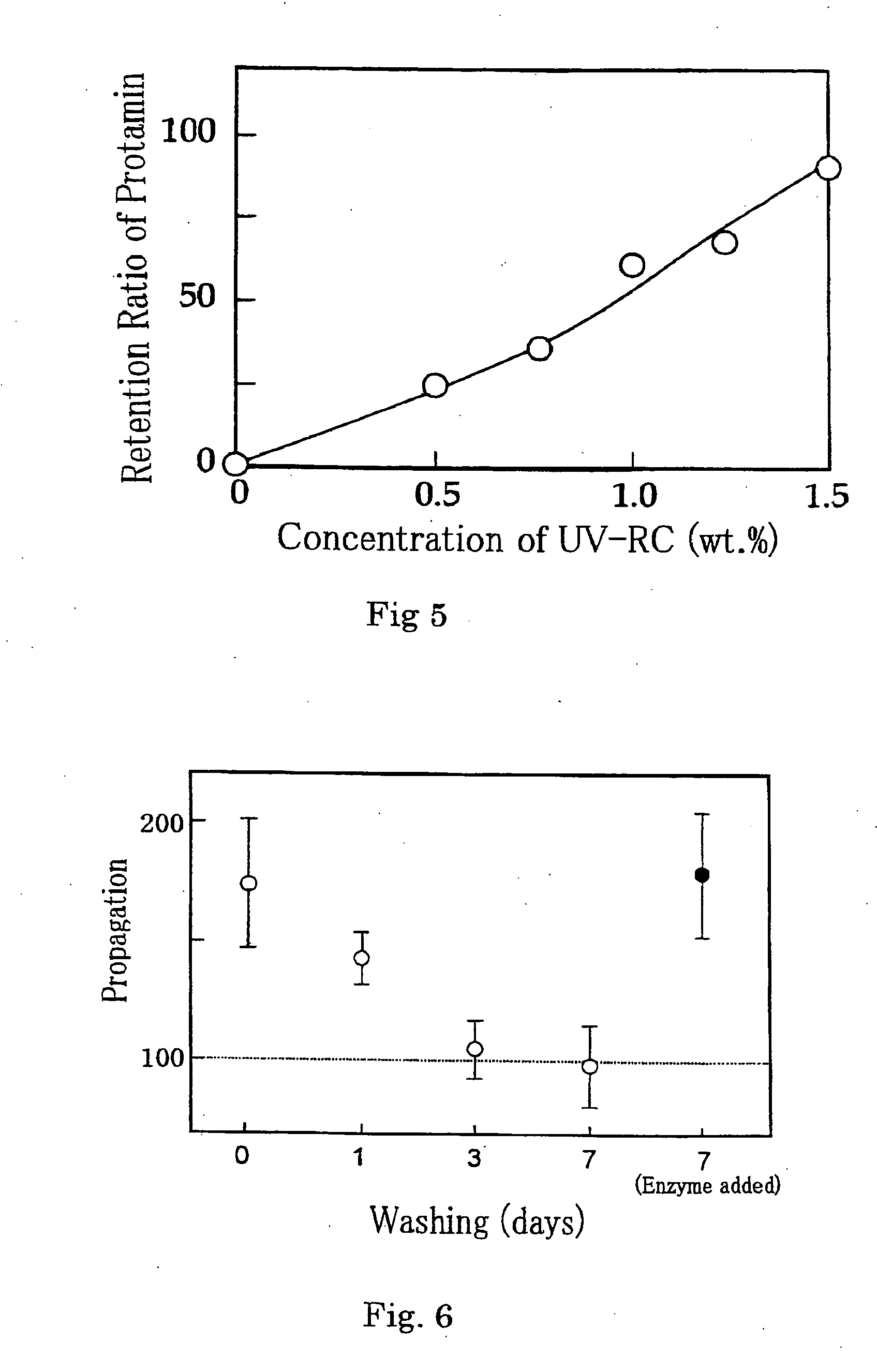

Antimicrobial radiation curable coating

InactiveUS7098256B2The environment is moreOptimal for incorporationBiocideAntifouling/underwater paintsCross-linkCarbamate

Owner:MICROBAN PROD CO INC

Antimicrobial radiation curable coating

InactiveUS20050080158A1Activity depletedInferior antimicrobial efficacyBiocideAntifouling/underwater paintsCross-linkOligomer

The invention is a radiation curable coating containing an antimicrobial agent, where upon irradiation with UV light, the radiation curable coating rapidly cures to a polymeric coating. The polymeric coating has durable antimicrobial properties, being especially effective at preventing the growth of Staphylococcus aureaus and Kleibsella pneunoniae on wood flooring and furniture. The major components in the radiation curable coating are a urethane acrylic oligomer, a radiation cure package, an antimicrobial agent, a cross-linking agent, and optionally, an additive package. The radiation curable urethane oligomer is a relatively short chain backbone urethane polymer that is end capped with a radiation curable moiety, where the moiety is an acrylic. The cross-linking agent is one or more monomers used to lower the viscosity and promote cross-linking, and include acrylate esters of mono-, di-, tri-, or tetrafunctional alcohols. The radiation cure package contains at least one photoinitiator.

Owner:MICROBAN PROD CO INC

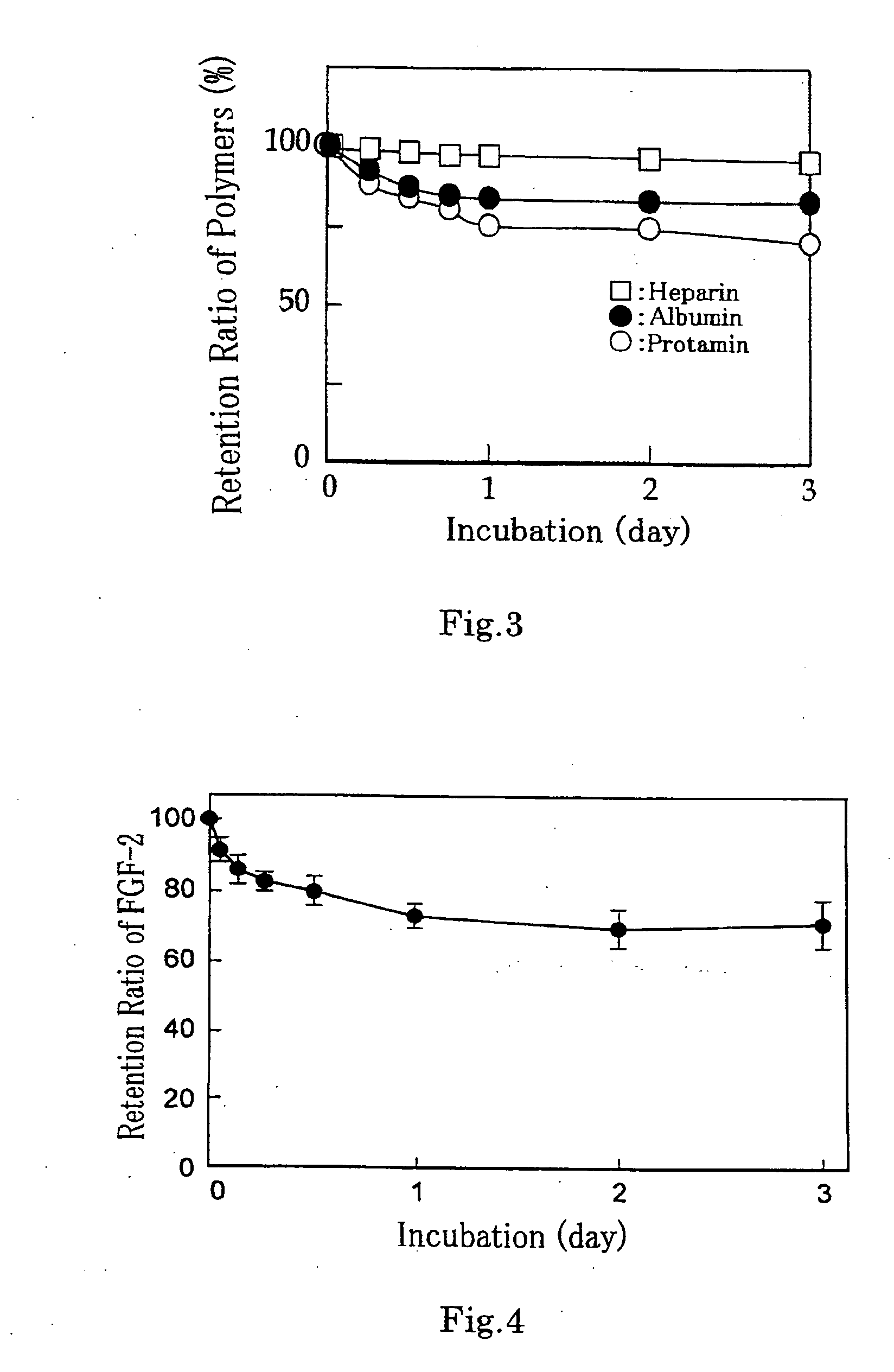

Medical composition containing photocrosslinkable chitosan derivative

InactiveUS20050238702A1Promote tissue regenerationFree from riskPowder deliveryOrganic active ingredientsSide effectMedicine

A medical composition is provided which is advantageous as a sealant for wound openings as well as have a function promoting healing of intractable wound or incision wound, and which accelerate tissue regeneration but does not cause any side effect such as canceration. The present invention relates to a medical composition comprising a photo-crosslinkable chitosan derivative and a wound healing promoter. The photo-crosslinkable chitosan derivative is preferably a polymer obtainable by incorporating a carbohydrate chain containing a reducing terminal to at least one portion of amino groups of chitosan back bone and incorporating a photoreactive group to at least another part of the amino groups. The wound healing promoter is preferably a growth factor.

Owner:NETECH

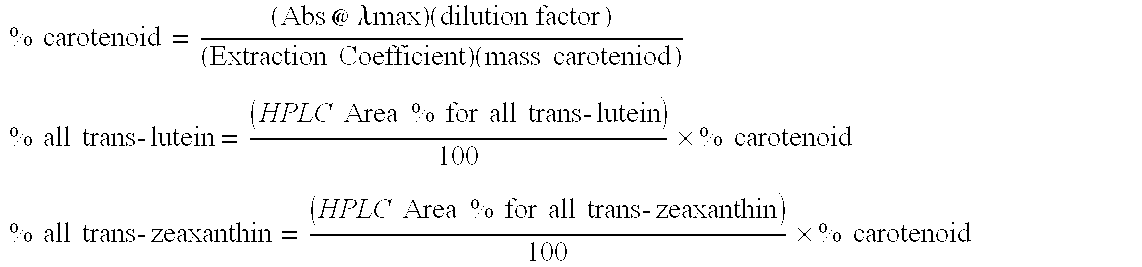

Carotenoid nanodispersions for use in water-based systems and a process for their preparation

InactiveUS20050037115A1Effective absorptionGuaranteed normal transmissionCosmetic preparationsToilet preparationsWater basedSucrose

A stable product containing an aqueous solution of one or more carotenoids for use in supplementing aqueous systems, such as foods, beverages, dietary supplements, and personal care products, with the carotenoid. An ester is dissolved in water and a source of the carotenoid is added to the solution. The concentrated product may be added to the aqueous systems or dried to form a powder that is readily dispersible in aqueous systems. The product may also include an antioxidant to preserve the activity of the carotenoid. Esters particularly suited for use include sucrose fatty acid esters. The product is produced without the use of organic solvents or elevated temperatures. The particles of carotenoids dispersed in the liquid form of the product will pass through a 0.2 micron (μm) sterile filter.

Owner:KEMIN FOODS L C

Shampoo compositions

InactiveUS20020119113A1Easily visualisedEnhancing performance and deliveryCosmetic preparationsHair removalSterolBULK ACTIVE INGREDIENT

A shampoo composition comprising an active ingredient and multilamellar vesicles, characterised in that the multilamellar vesicles consist essentially of anionic surfactant and a sterol.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

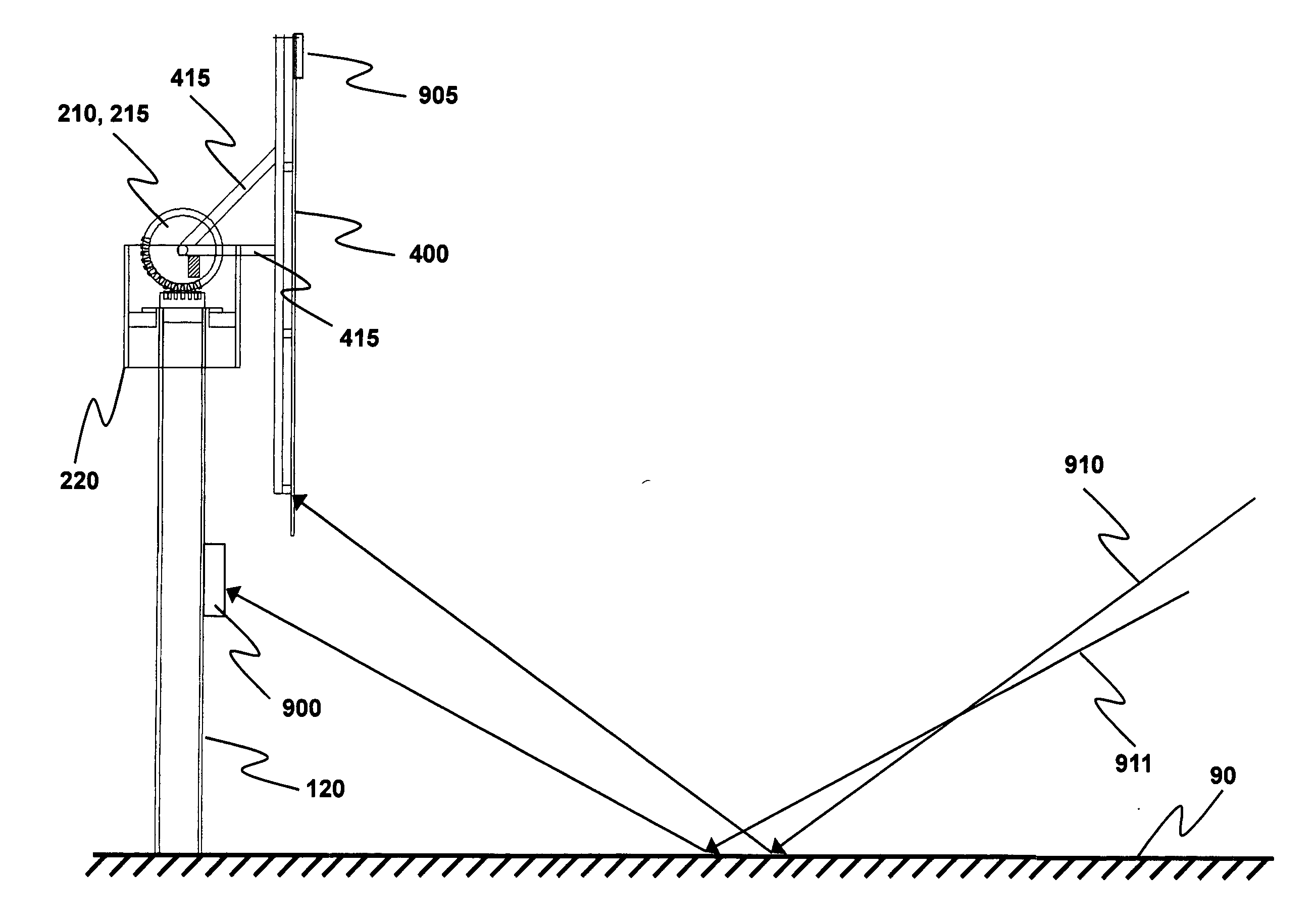

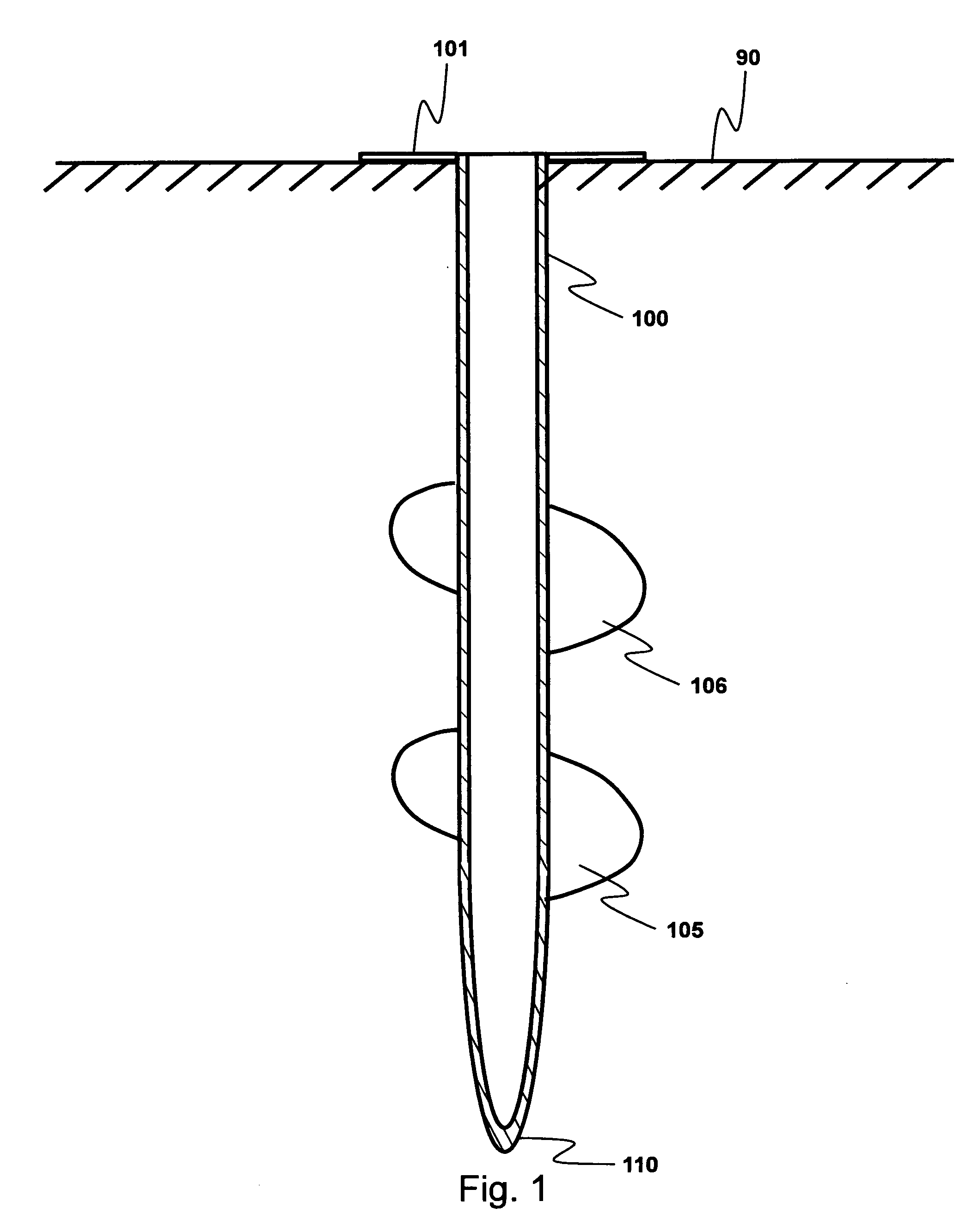

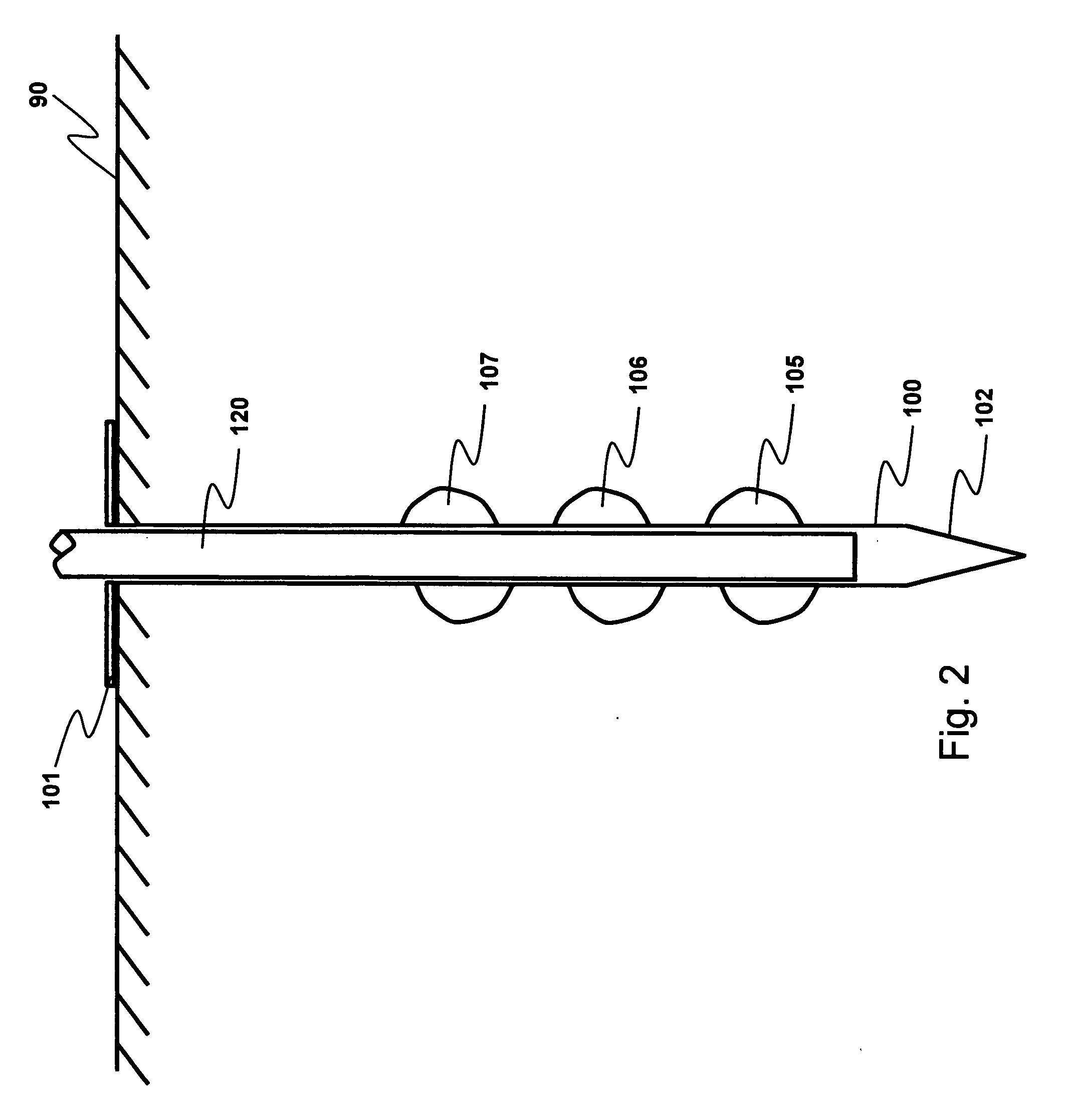

Solar photovoltaic support and tracking system with vertical adjustment capability

InactiveUS20110120523A1Reduces and prevents shadingReduce maintenancePhotovoltaic supportsSolar heating energySmall footprintEngineering

Installation of solar energy systems is made easier through the use of augur tubes. The base augur tube accommodates telescoping sections which enable these systems to exhibit a smaller footprint with enhanced power ratings. A tracking head is provided in which dual axis tracking is provided using a single drive mechanism. These features are employed either together or independently.

Owner:SILVER CHARLES

Two-component polyurethane composition

InactiveUS20150259465A1Easy to adjustKeep for a long timeAdhesive processesPolyureas/polyurethane adhesivesPolyolAdhesive

The invention relates to a two-component polyurethane composition containing a polyol, a polyisocyanate, a blocked amine and a bismuth(III)- or zirconium(IV)-catalyst. The composition is easy to process, cures quickly and without bubbles, and has unexpectedly high strengths when in its cured state. It is particularly suitable as an adhesive, sealant, coating or potting compound.

Owner:SIKA TECH AG

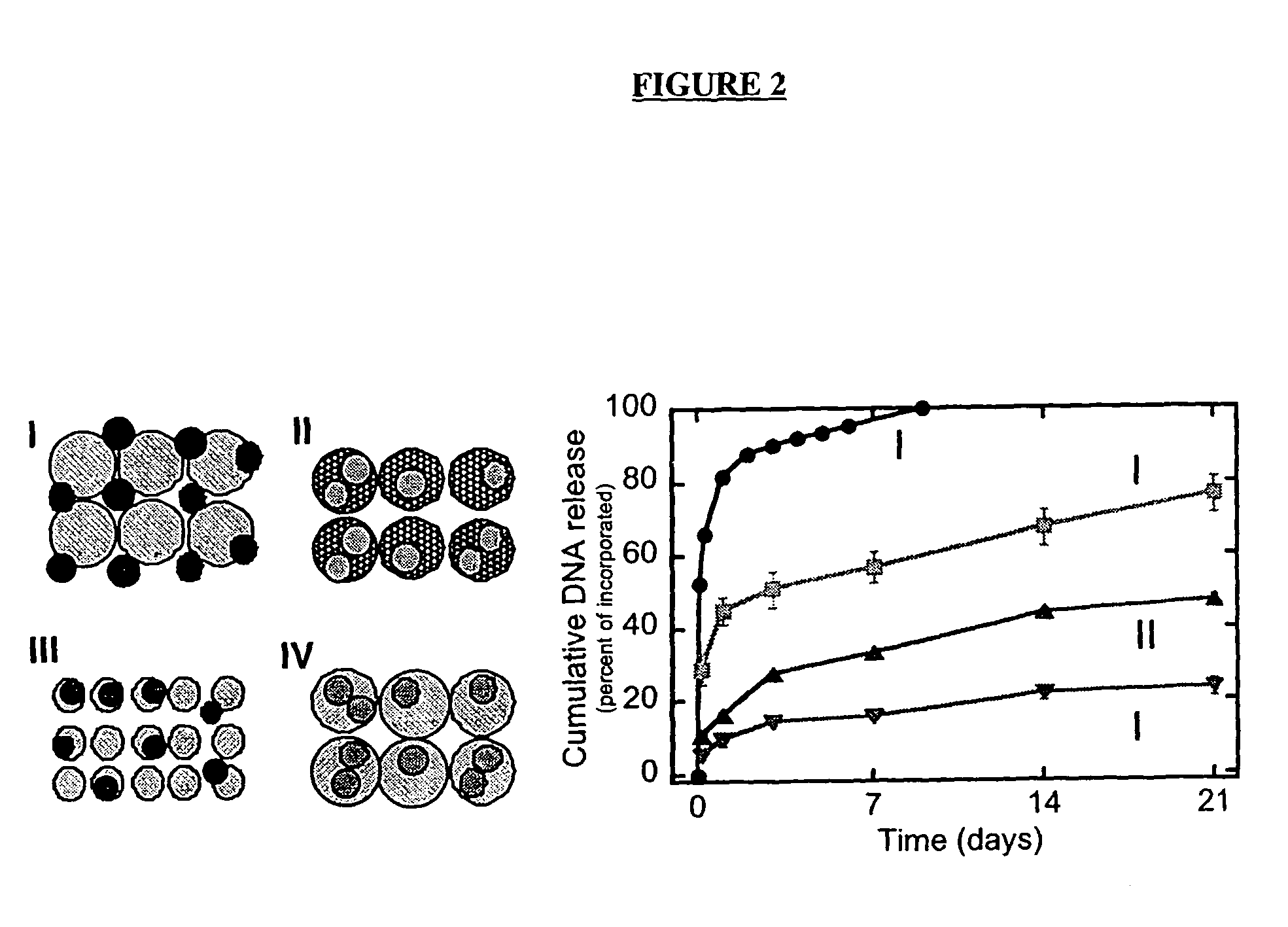

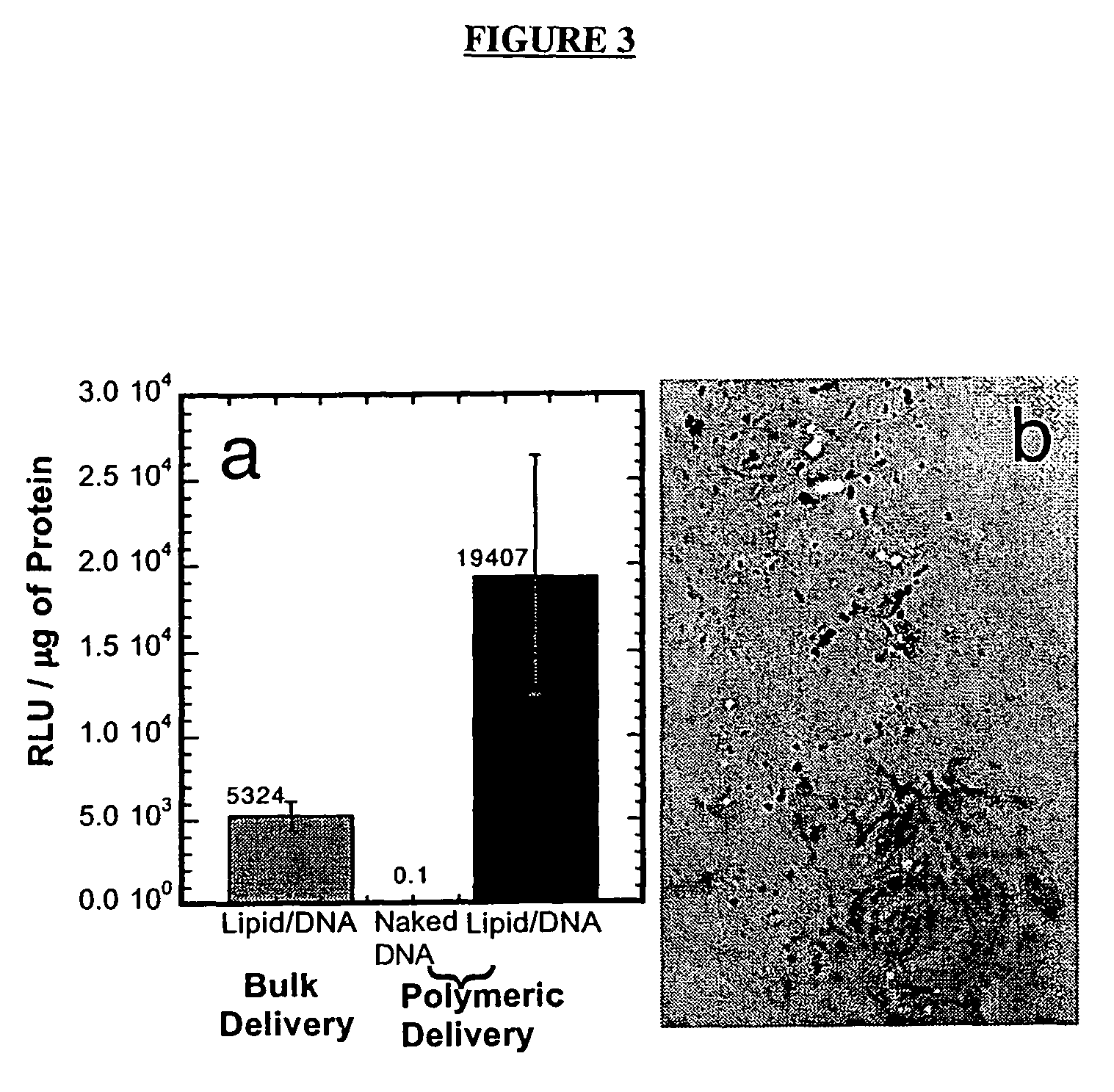

Biodegradable scaffolds and uses thereof

InactiveUS7846466B2Optimal for incorporationPromote tissue growthPowder deliveryPeptide/protein ingredientsBiodegradable scaffoldDNA

The invention is directed to scaffolds containing porous polymer material prepared by a process of gas foaming / particulate leaching and a wet granulation step prior to gas foaming and particulate leaching, particularly having a characteristic interconnected pore structure, as well as sustained release of protein, DNA or cells, and to methods for using such porous polymer material for preparation of scaffolds, particularly for tissue engineering.

Owner:NORTHWESTERN UNIV

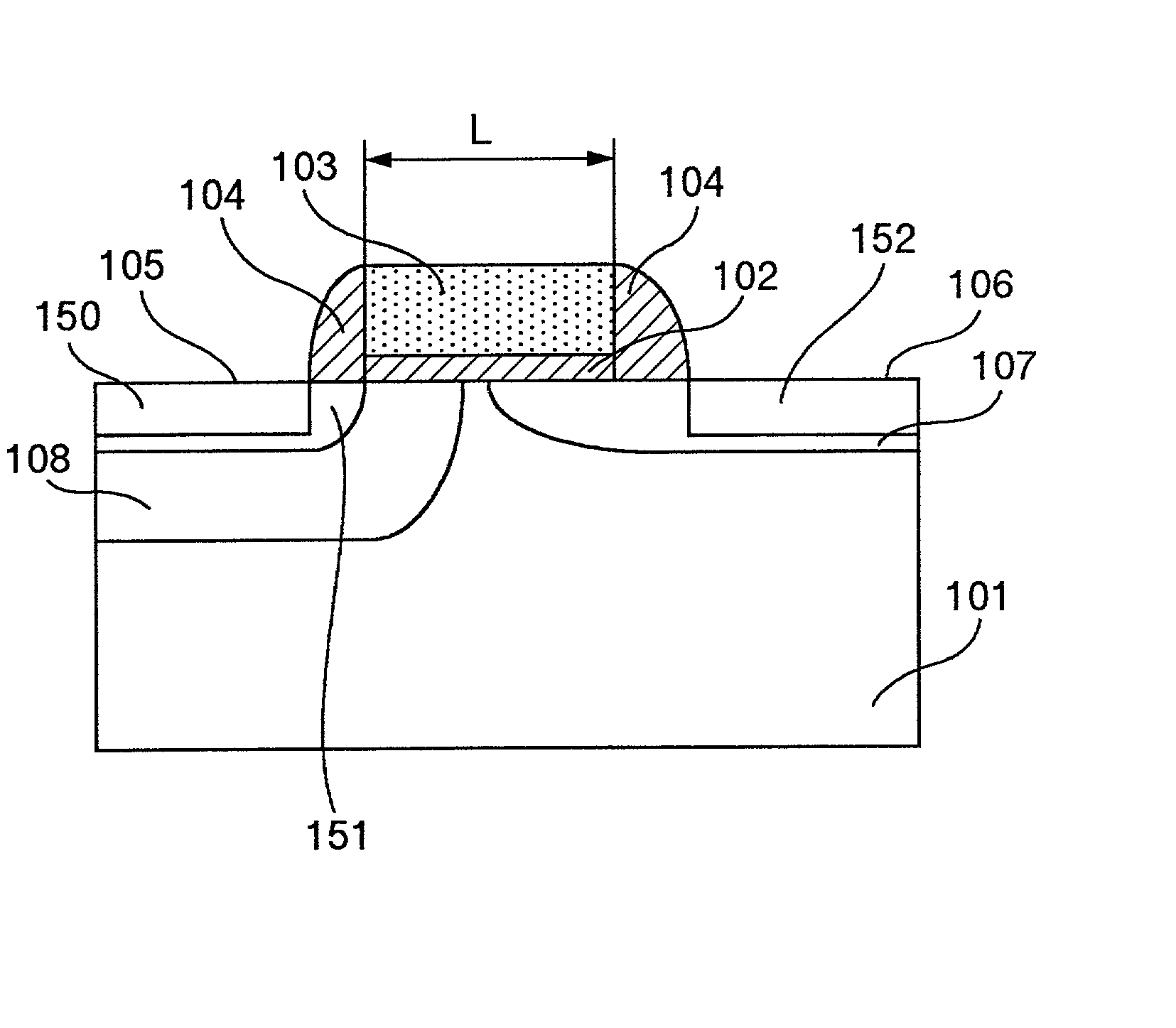

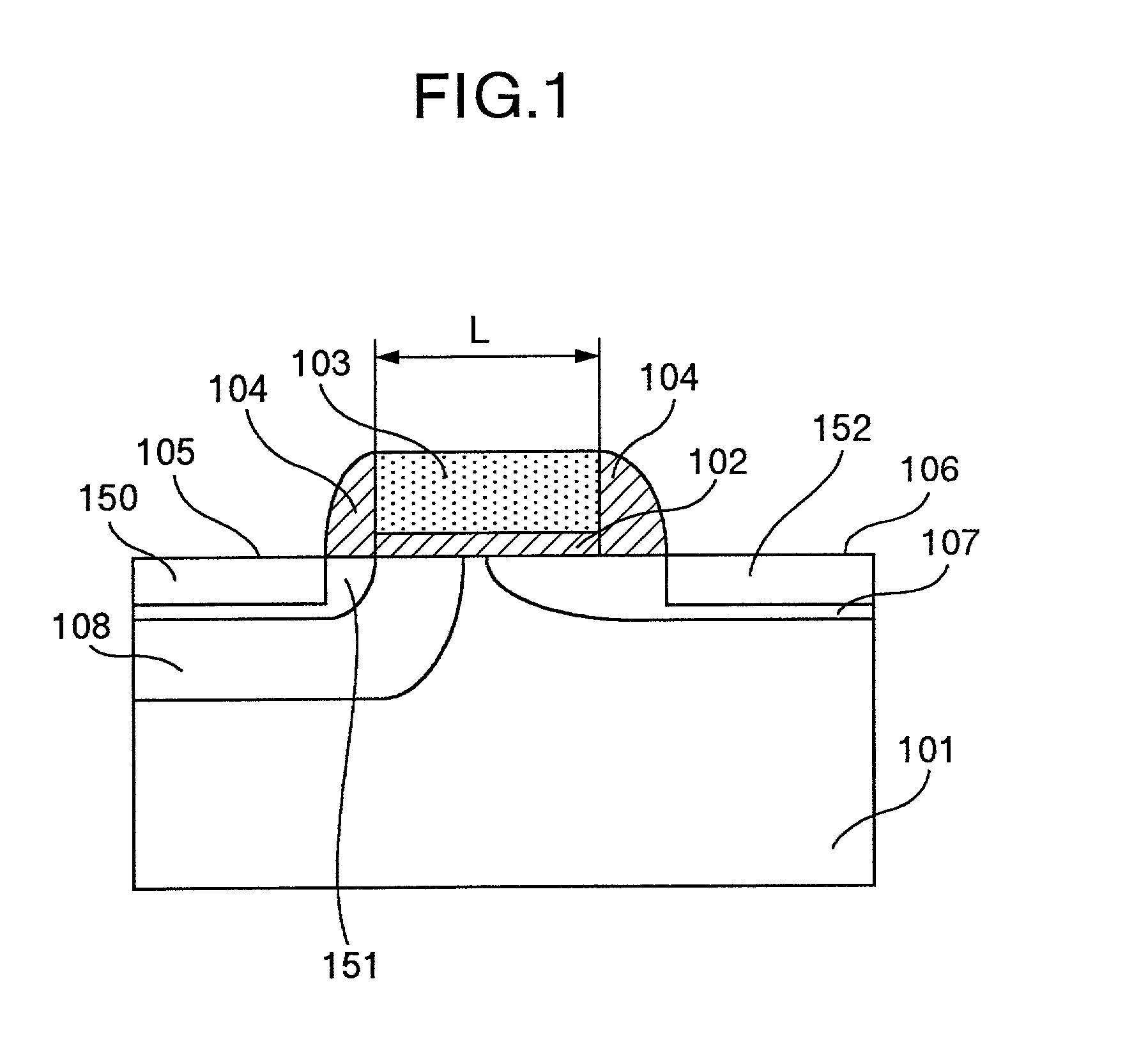

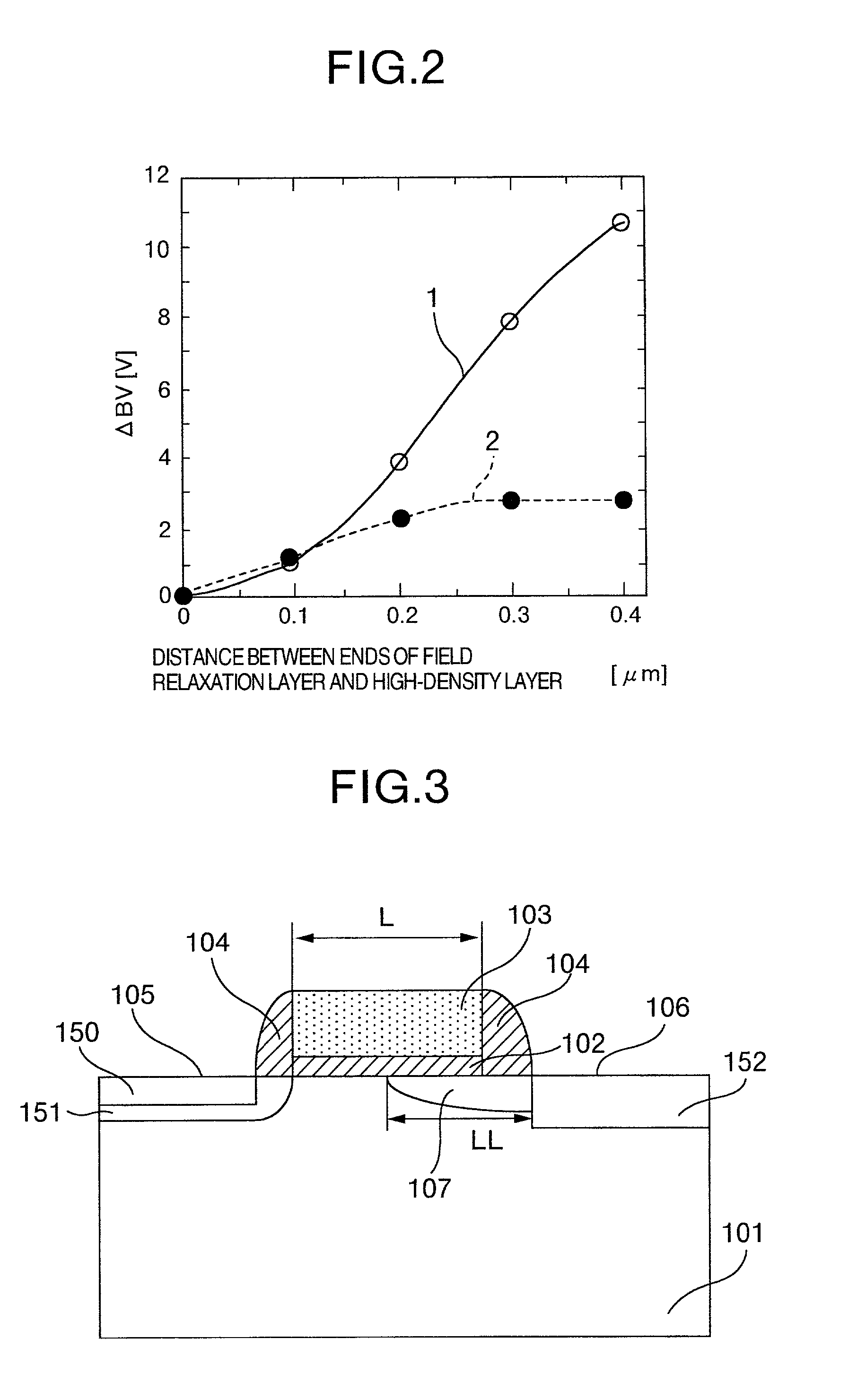

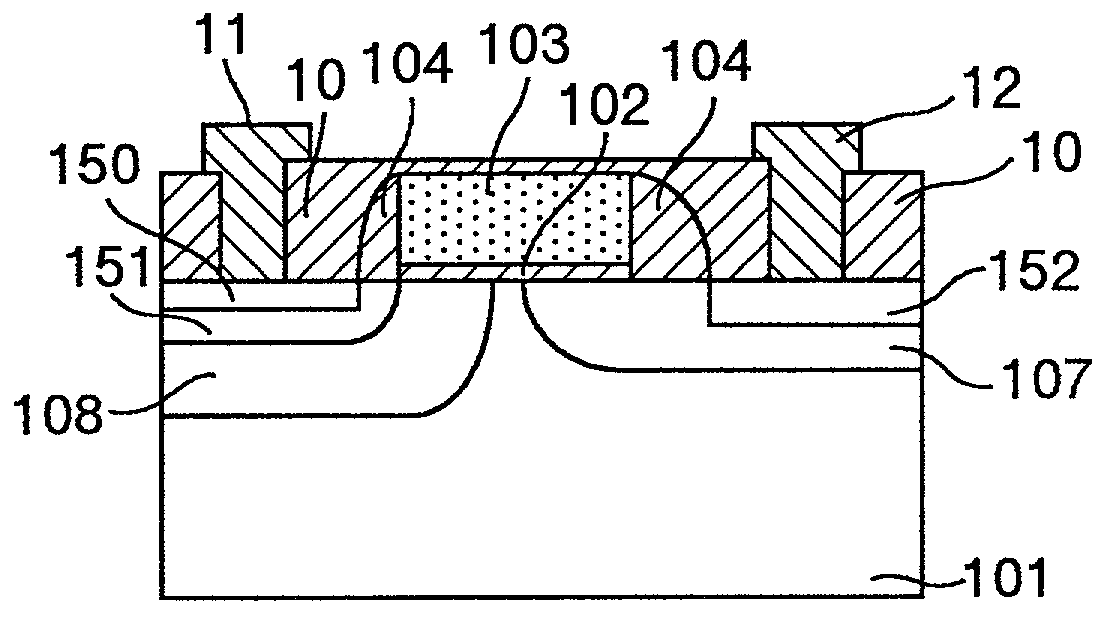

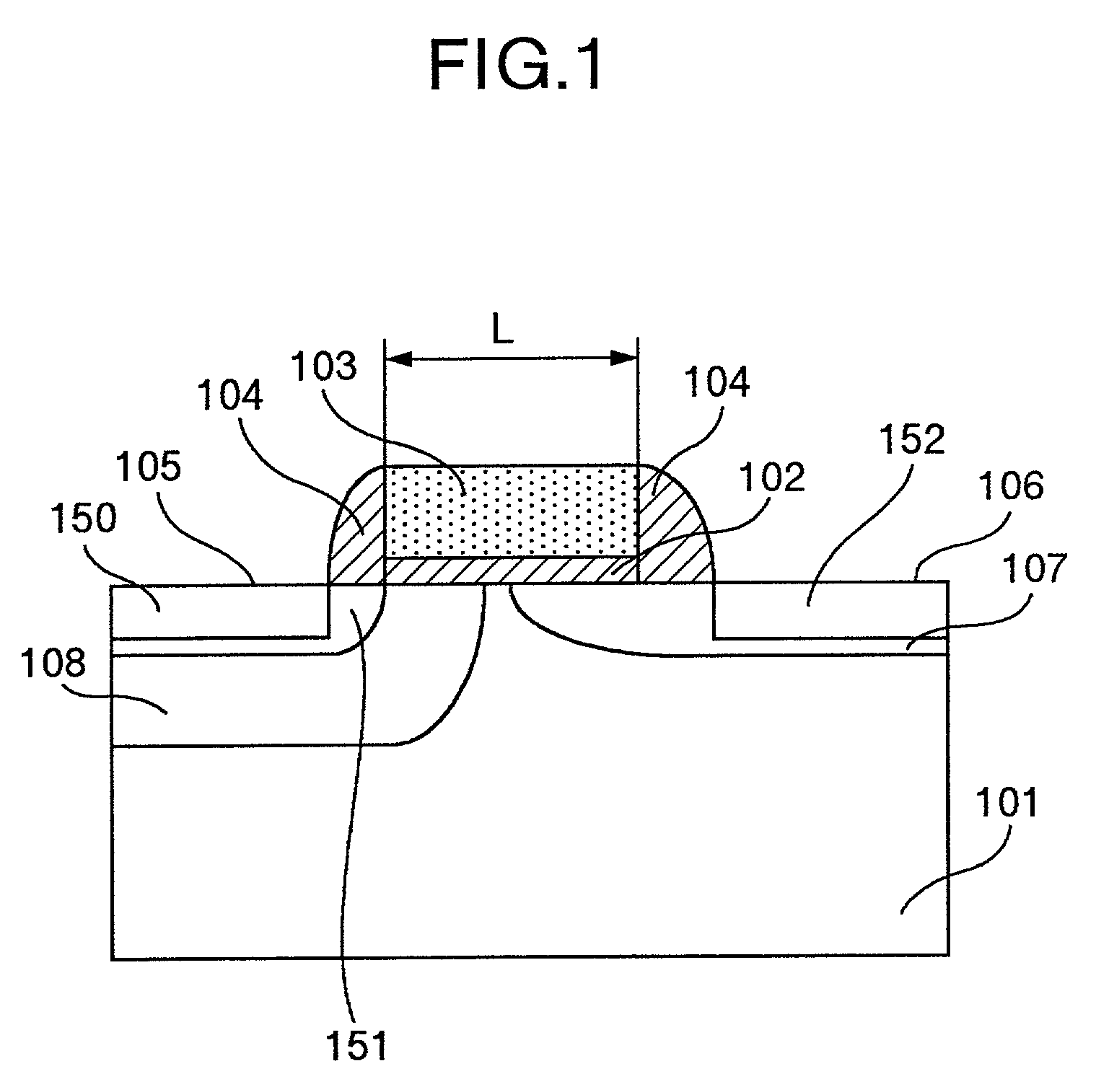

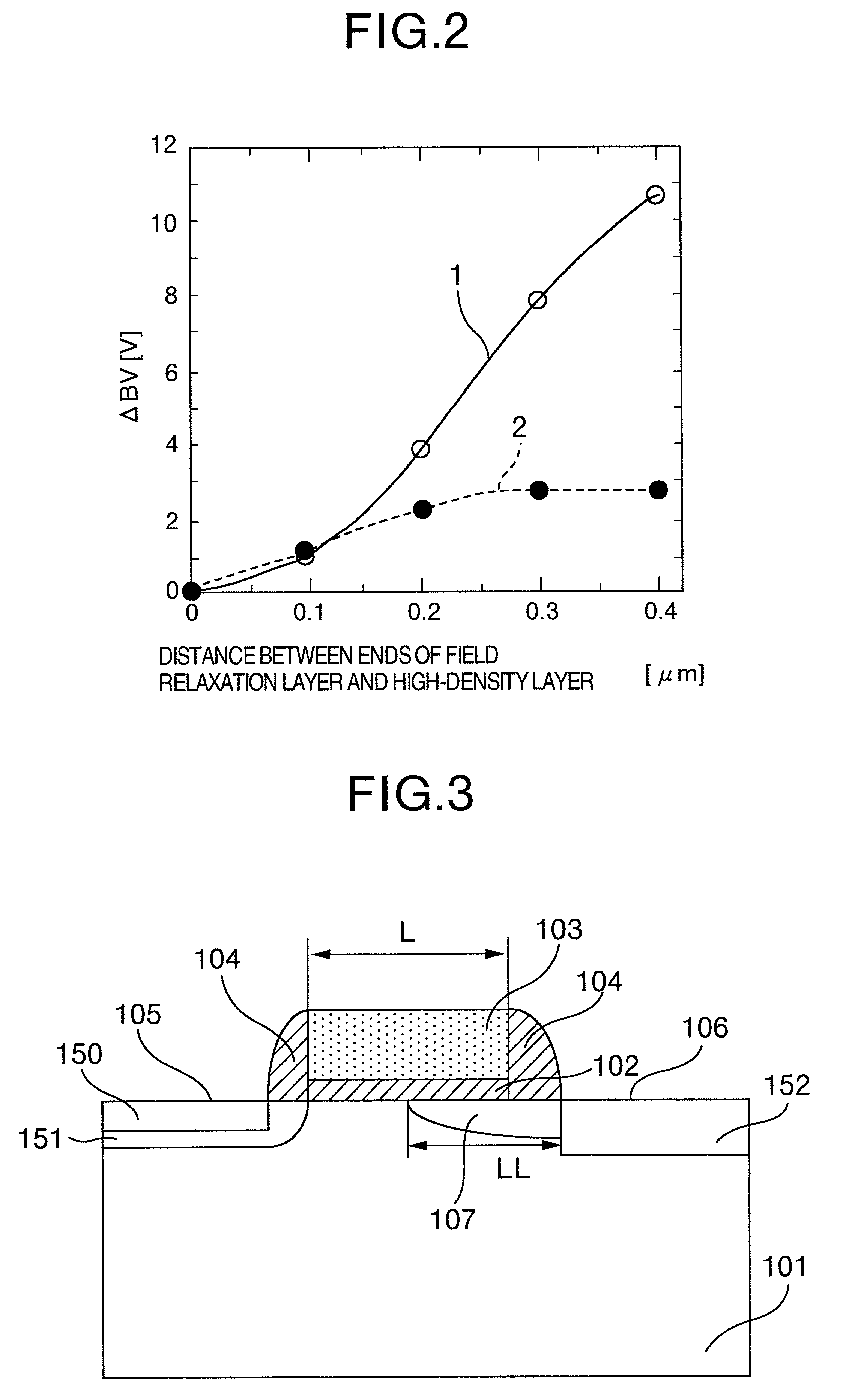

Field effect transistor and semiconductor device manufacturing method

InactiveUS20020125510A1DistanceShorten the lengthTransistorSemiconductor/solid-state device detailsHigh densityMiniaturization

A MOS field effect transistor. A field relaxation layer of a gate overlap structure is disposed in contact with a drain region for the purpose of relaxation of the electric field by increasing a distance between the field relaxation layer and a high-density layer. The electric field relaxation can further be promoted because the equipotential lines are bent by a gate insulation film. A punch-through stopper layer of a gate overlap structure is disposed in contact with a source region for suppressing spreading of a depletion layer toward the source region. The length of a gate electrode can be realized in a miniaturized size.

Owner:RENESAS TECH CORP

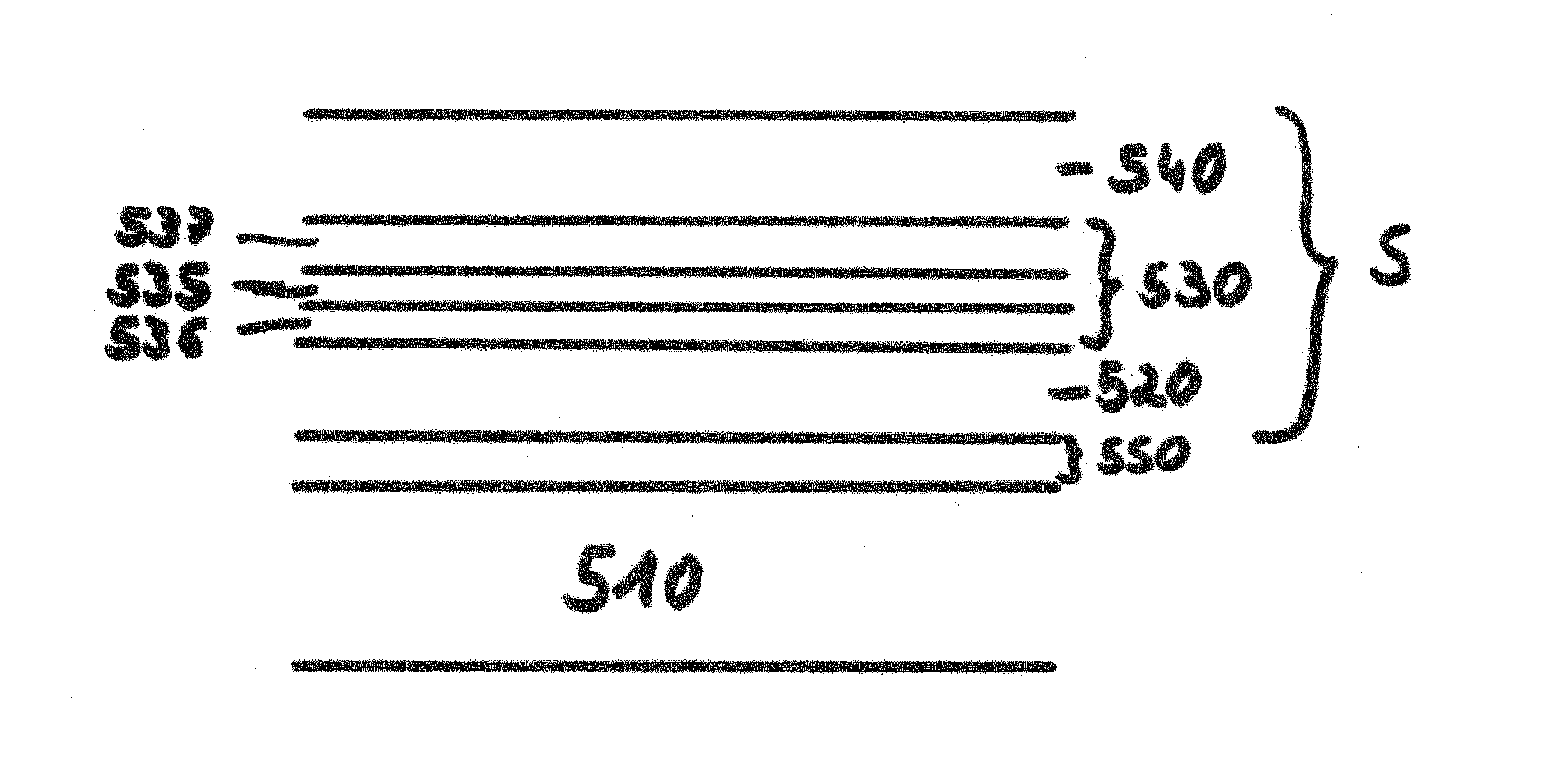

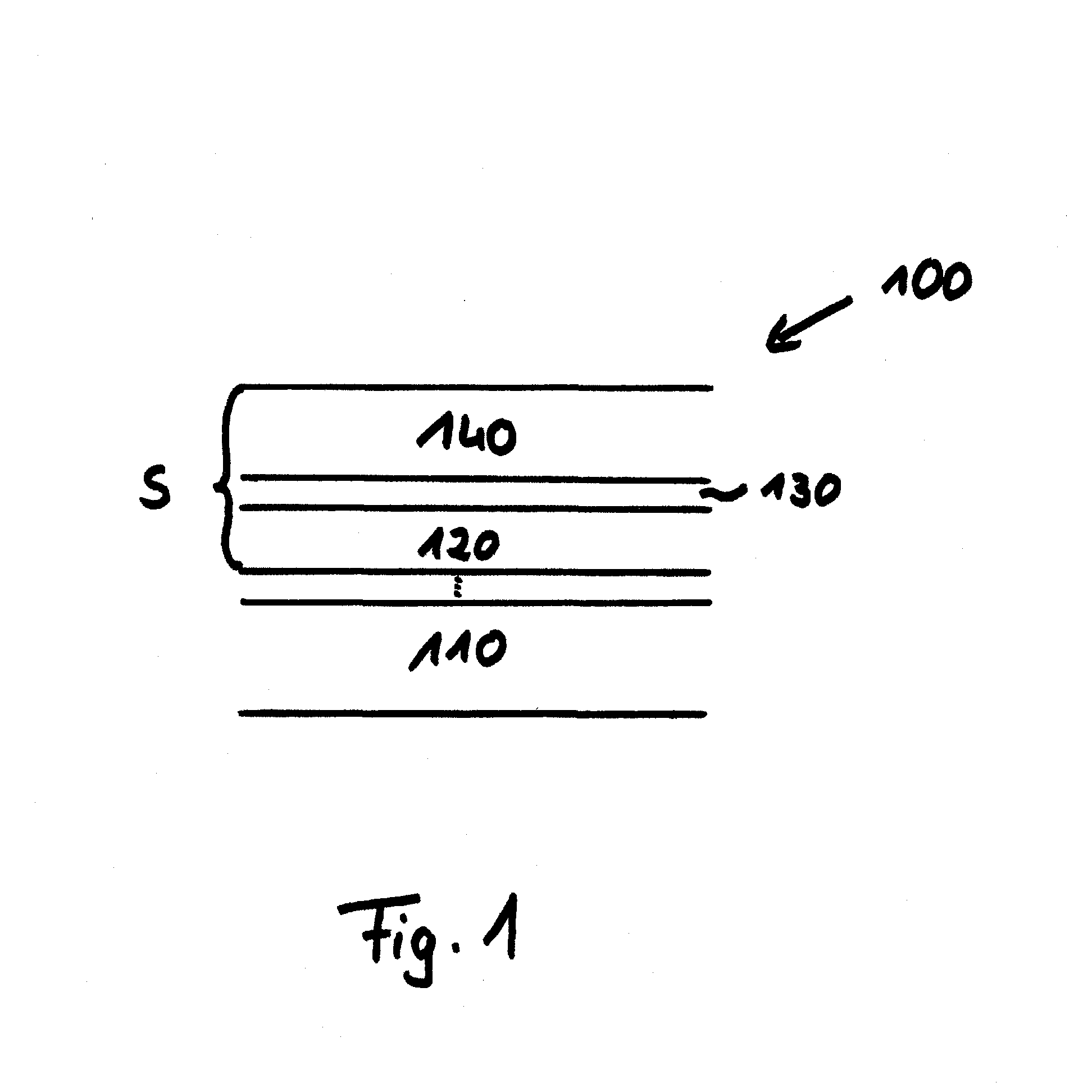

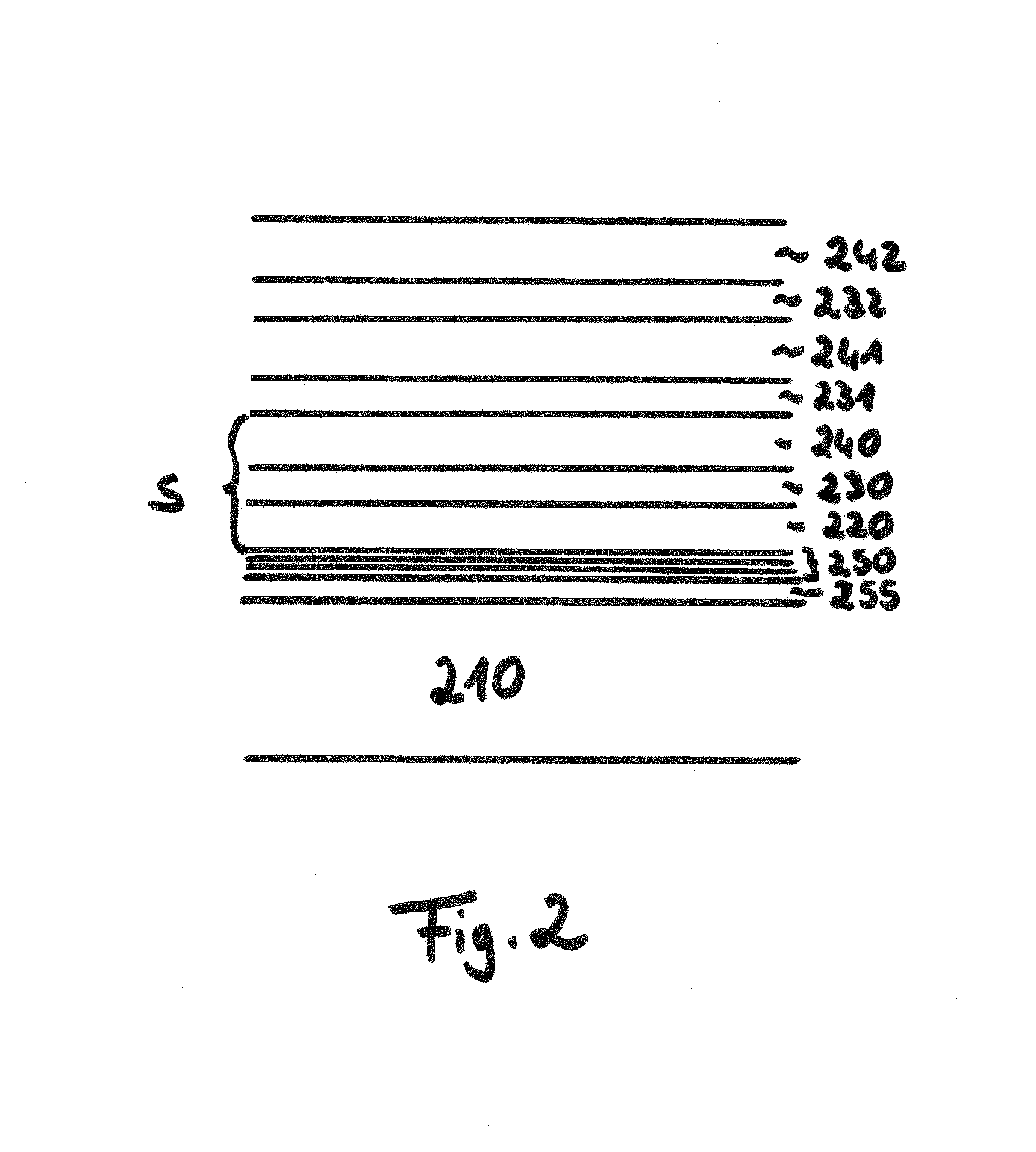

P-doping of group-iii-nitride buffer layer structure on a heterosubstrate

ActiveUS20150357419A1Highly resistive buffer layer structureInhibition formationTransistorSemiconductor/solid-state device manufacturingDopantInter layer

An epitaxial group-ill-nitride buffer-layer structure is provided on a heterosubstrate, wherein the buffer-layer structure has at least one stress-management layer sequence including an interlayer structure arranged between and adjacent to a first and a second group-ill-nitride layer, wherein the interlayer structure comprises a group-ill-nitride interlayer material having a larger band gap than the materials of the first and second group-ill-nitride layers, and wherein a p-type-dopant-concentration profile drops, starting from at least 1×1018 cm-3, by at least a factor of two in transition from the interlayer structure to the first and second group-ill-nitride layers.

Owner:AZUR SPACE SOLAR POWER

Nucleotide Analogs

ActiveUS20090061437A1Optimal for incorporationDetectable labelSugar derivativesMicrobiological testing/measurementNucleotideComputational biology

The invention provides for nucleotide analogs and methods of using the same, e.g., for sequencing nucleic acids.

Owner:FLUIDIGM CORP

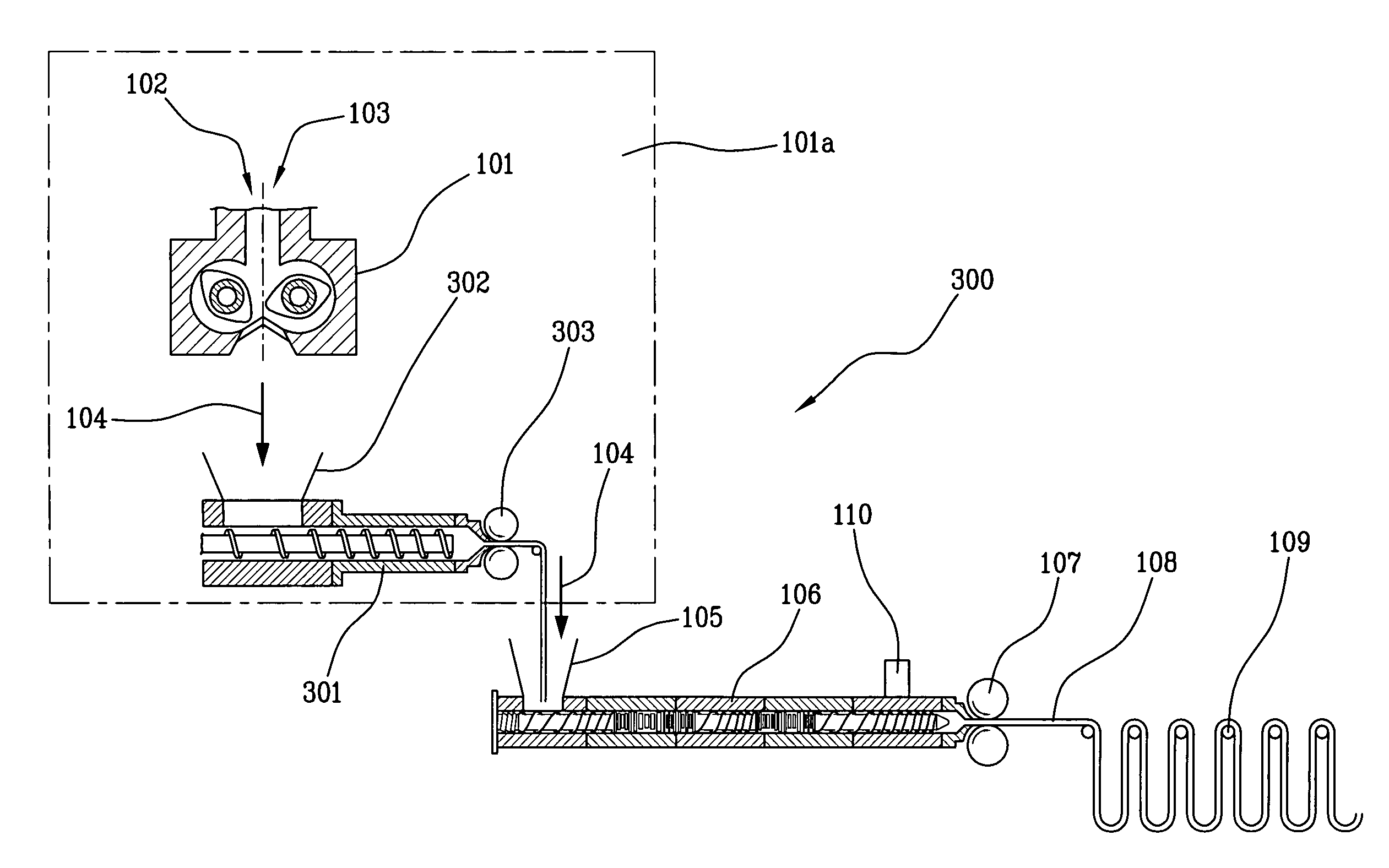

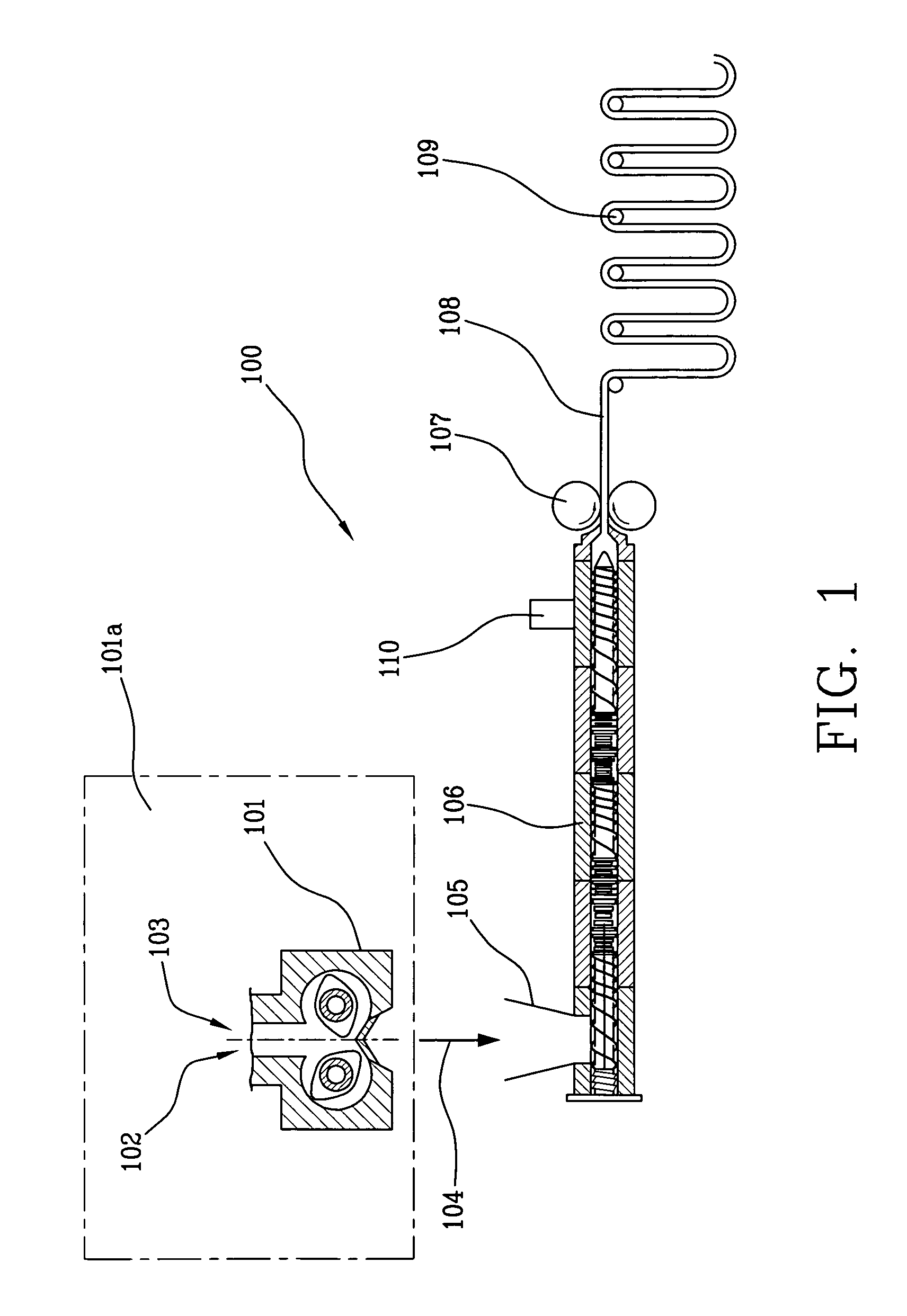

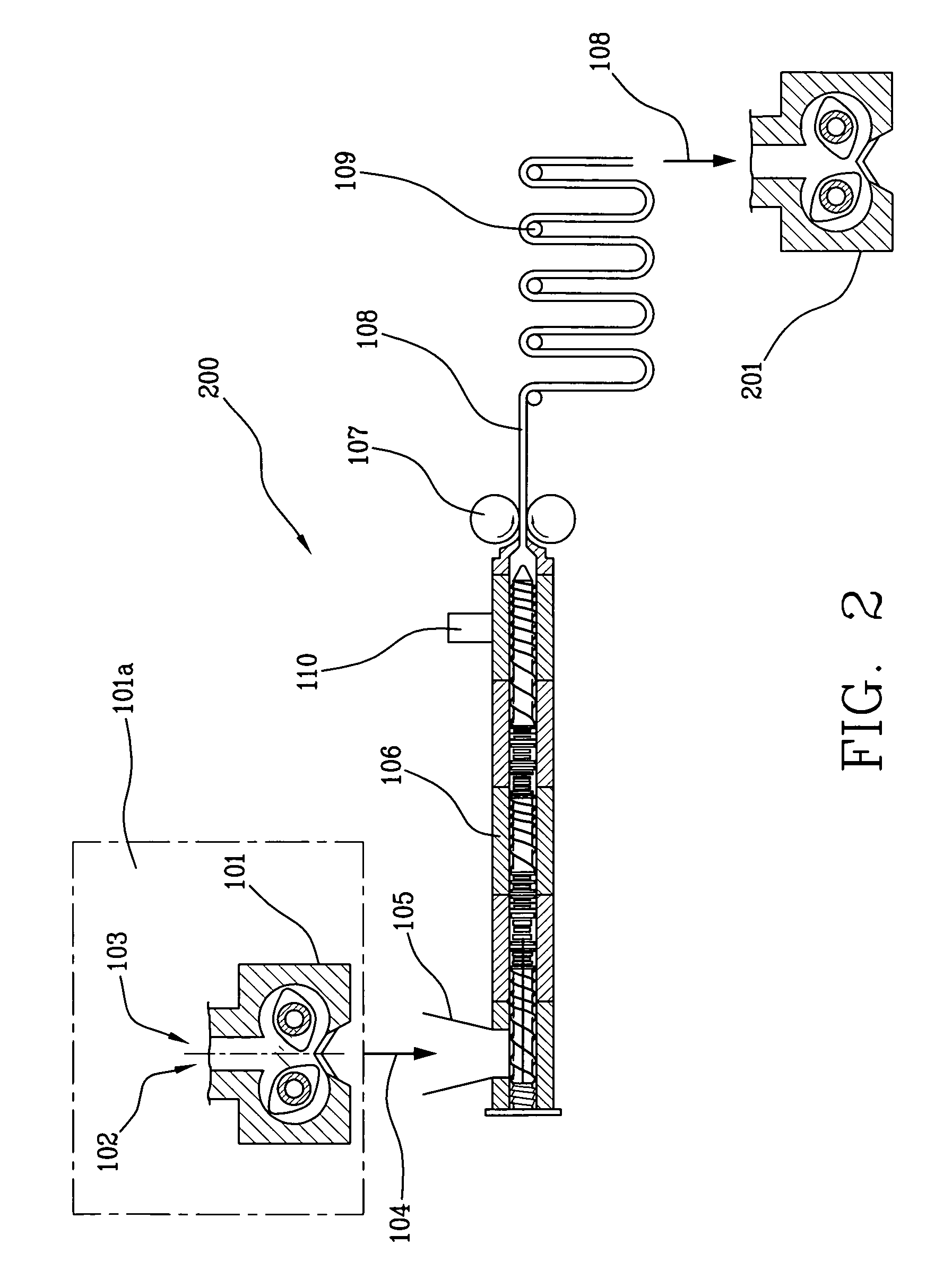

Process and plant for producing an elastomeric compound

A process for producing an elastomeric compound, includes: feeding at least one elastomeric polymer and at least one reinforcing filler to a mixing apparatus including at least one batch mixing device; mixing and dispersing, in the at least one mixing apparatus, the at least one reinforcing filler into the at least one elastomeric polymer, so as to obtain a first elastomeric compound; discharging the first elastomeric compound from the at least one mixing apparatus; feeding the first elastomeric compound to at least one continuous mixing device, said continuous mixing device including at least two rotating screws; mixing the first elastomeric compound in the at least one continuous mixing device, so as to obtain a second elastomeric compound; and discharging said second elastomeric compound from said at least one continuous mixing device.

Owner:PIRELLI TYRE SPA

High cis-1,4-polybutadiene rubber compounds

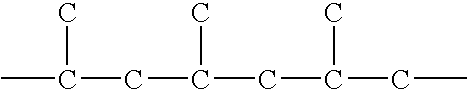

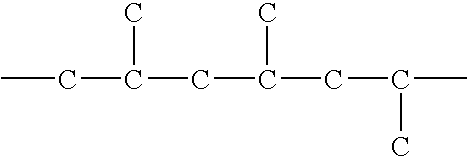

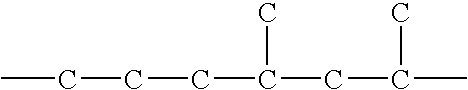

InactiveUSH2036H1Optimal for incorporationLittle in modulusSpecial tyresSolid ballsPolymer scienceNickel compounds

This invention relates to blends of a specific type of cis-l,4-polybutadiene rubber with other rubbery polymers, such as natural rubber, synthetic polyisoprene rubber, styrene-butadiene rubber, isoprene-butadiene rubber and / or styrene-isoprene- butadiene rubber. The cis-1,4-polybutadiene rubber utilized in the blends of this invention is synthesized by polymerizing 1,3-butadiene in the presence of (a) an organonickel compound, (b) an organoaluminum compound, (c) a fluorine containing compound and (d) para-styrenated diphenylamine; wherein the organoaluminum compound and the fluorine containing compound are brought together in the presence of the para-styrenated diphenylamine. The cis-1,4-polybutadiene rubber blends of this invention offer improved processability and enhanced physical properties. For instance, improved mixing which results in better incorporation of pigments and fillers, such as carbon black and silica, at lower levels of power consumption is realized. Additionally, improvements in extrusion characteristics and in tear resistance with little sacrifice in hysteretic properties, abrasion resistance and modulus are also attained with the rubber blends of this invention. The rubber blends of this invention can be used in manufacturing a wide variety of rubber products, such as tires, hoses, belts, golf balls, tennis balls, racquet balls, golf club grips, stoppers, plungers, tubing, straps, diaphragms, motor mounts, bushings, weather stripping, windshield wiper blades, shoe soles, other molded rubber products and adhesives.

Owner:THE GOODYEAR TIRE & RUBBER CO

Process for the production of thin layers of silicone, thin silicone and use

InactiveUS20060127588A1Produced very simply and quicklyProtection from damagePretreated surfacesSemiconductor/solid-state device manufacturingThin layerPolymer chemistry

Owner:INFIANA GERMANY GMBH & CO KG

Multi-layer biaxially oriented polypropylene film having an improved barrier, a method for the production thereof, and the use thereof

InactiveUS6811886B1Improve mechanical propertiesReliable runningWrappers shrinkageFlexible coversWaxPolypropylene

The invention relates to a multi-layer, sealable, biaxially oriented polypropylene film having improved barrier properties which is constructed of a base layer, of at least one sealable covering layer and of at least one intermediate layer. The intermediate layer contains a wax with an average molecular weight Mn ranging from 200 to 1200. The invention also relates to a method for producing the film and to the use thereof.

Owner:HOECHST TRESPAPHAN

Nucleotide analogs

ActiveUS8114973B2Optimal for incorporationDetectable labelSugar derivativesMicrobiological testing/measurementComputational biologyNucleic acid

The invention provides for nucleotide analogs and methods of using the same, e.g., for sequencing nucleic acids.

Owner:FLUIDIGM CORP

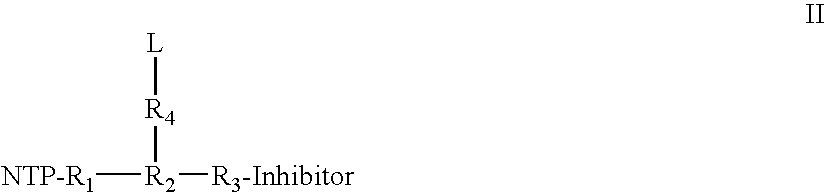

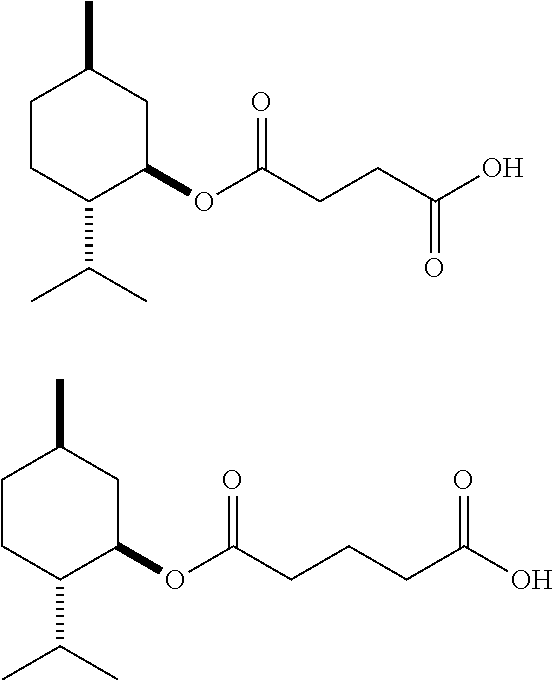

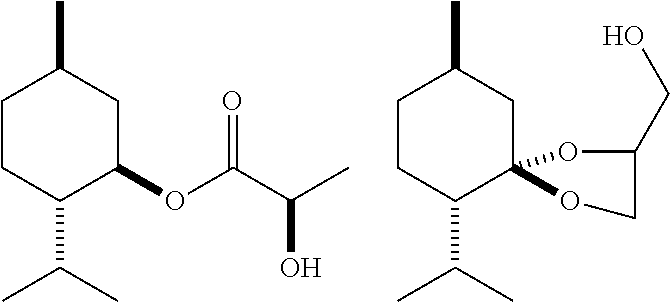

Cooling composition

PendingUS20140335224A1Imparting freshnessOptimal for incorporationCosmetic preparationsToilet preparationsFood industryAlcohol

The invention is rooted in the food industry and relates to a composition which provides a physiologically cooling effect for imparting freshness in the used preparations and comprises 2 to 10% cooling agent (A), 0 to 35% alcohol (6), 55 to 95% hydrophobic compound (C). Furthermore, the invention relates to the production and use of the composition according to the invention in oral preparations, in particular chewing gums and sweets.

Owner:SYMRISE GMBH & CO KG

Field effect transistor

InactiveUS7067878B2High blocking voltageSignificantly miniaturized structureTransistorSemiconductor/solid-state device detailsHigh densityMiniaturization

A MOS field effect transistor. A field relaxation layer of a gate overlap structure is disposed in contact with a drain region for the purpose of relaxation of the electric field by increasing a distance between the field relaxation layer and a high-density layer. The electric field relaxation can further be promoted because the equipotential lines are bent by a gate insulation film. A punch-through stopper layer of a gate overlap structure is disposed in contact with a source region for suppressing spreading of a depletion layer toward the source region. The length of a gate electrode can be realized in a miniaturized size.

Owner:RENESAS TECH CORP

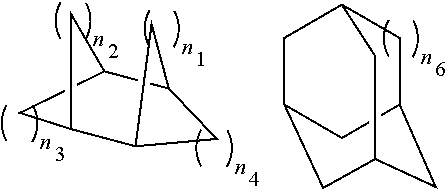

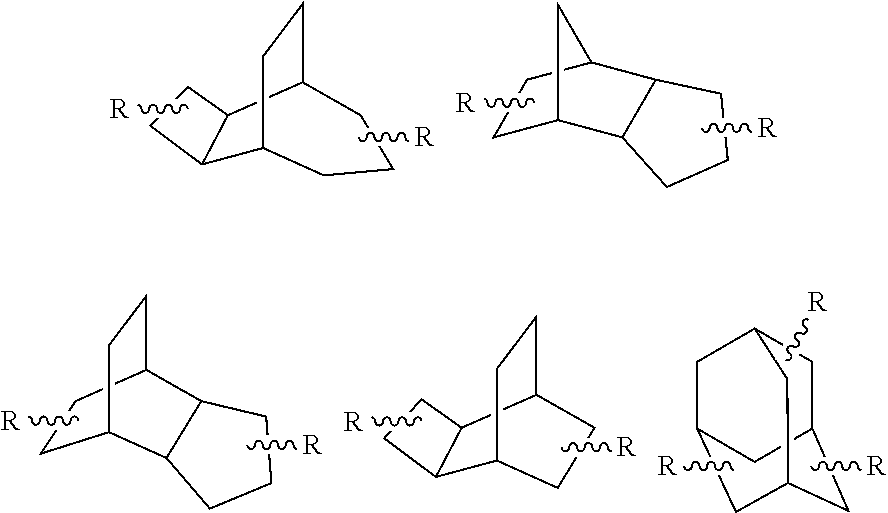

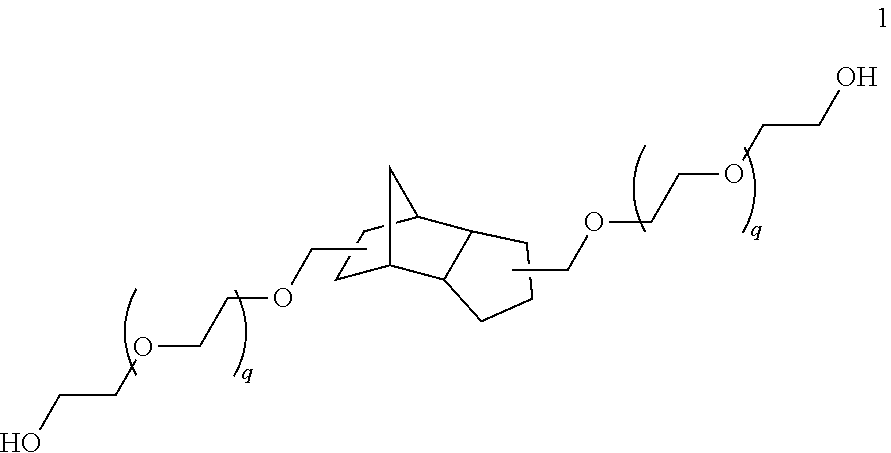

Dental composite materials comprising tricyclic plasticizers

ActiveUS20130203884A1Improve flexural strengthLow water absorptionImpression capsPhotomechanical apparatusPlasticizerDental composite

The present invention relates to dental polymerizable composite materials (curable dental compositions) comprising one or more plasticizers comprising a tricyclic structural element, to dental materials (polymers), obtainable by curing from the dental polymerizable composite materials comprising one or more plasticizers comprising a tricyclic structural element, to processes for producing a dental material and to dental curable composite materials for use in a therapeutic method in the production of a dental material.

Owner:VOCO

Metering dispensing system with one-piece pump assembly

ActiveUS8132696B2Not easily compressedManufacture easy and less-costlyOpening closed containersBottle/container closureEngineeringMechanical engineering

A liquid dispensing device includes a storage container having an opening and dome pump assembly attached thereto substantially over the opening for metered dispensing. The dome pump assembly is integrally formed with a dome button, top portion extension and valve to facilitate manufacture and reduce costs of the pump while improving performance thereof. The valve is employed to pull liquid from the storage container into the dome for metering. An exit passageway formed from the extension and container wall serves as an output valve. The user squeezes the dome and the opposite side of the container pouch concurrently to seal the flapper valve to urge liquid out through the exit passageway for actual dispensing.

Owner:1TOUCH HLDG INC

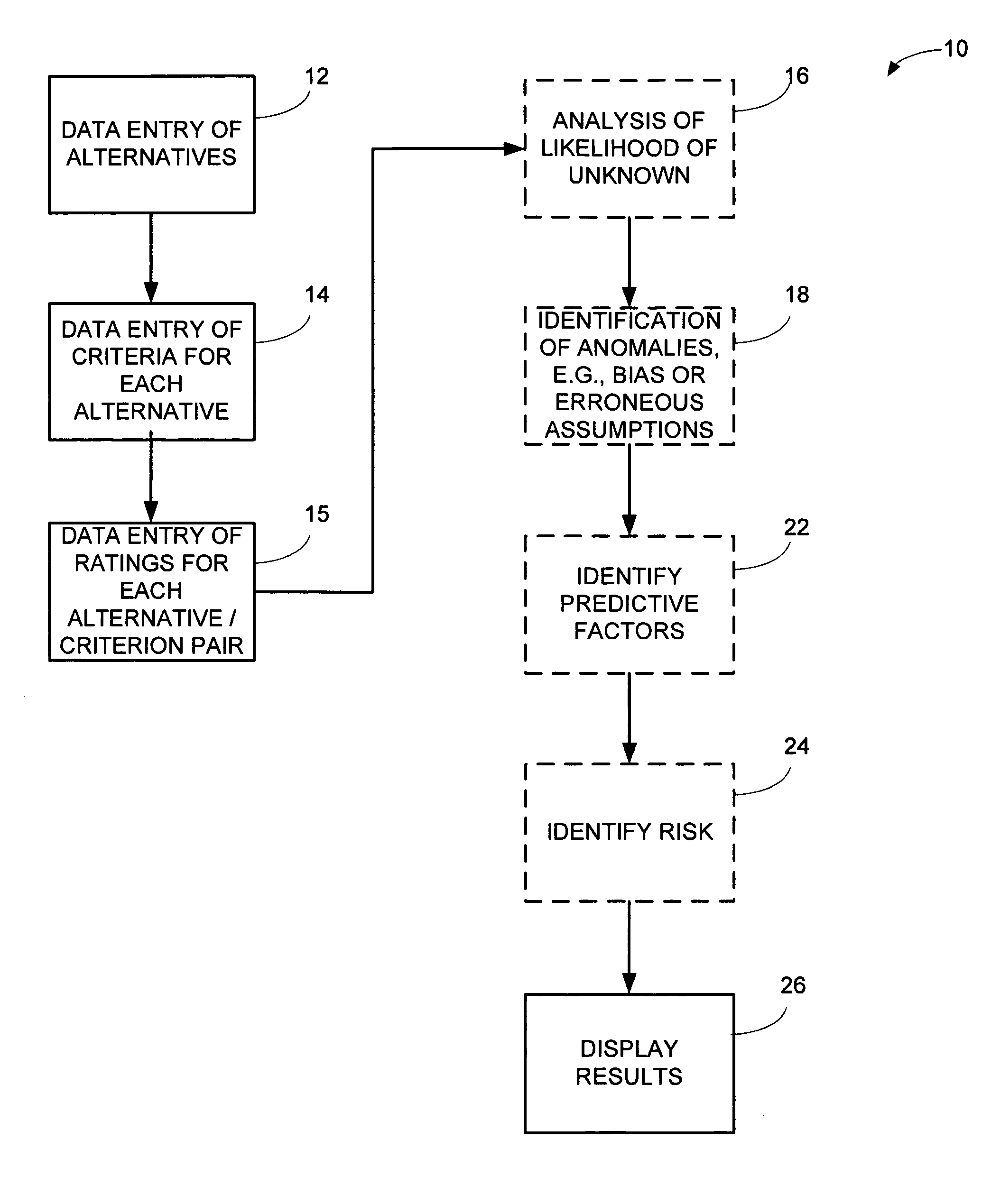

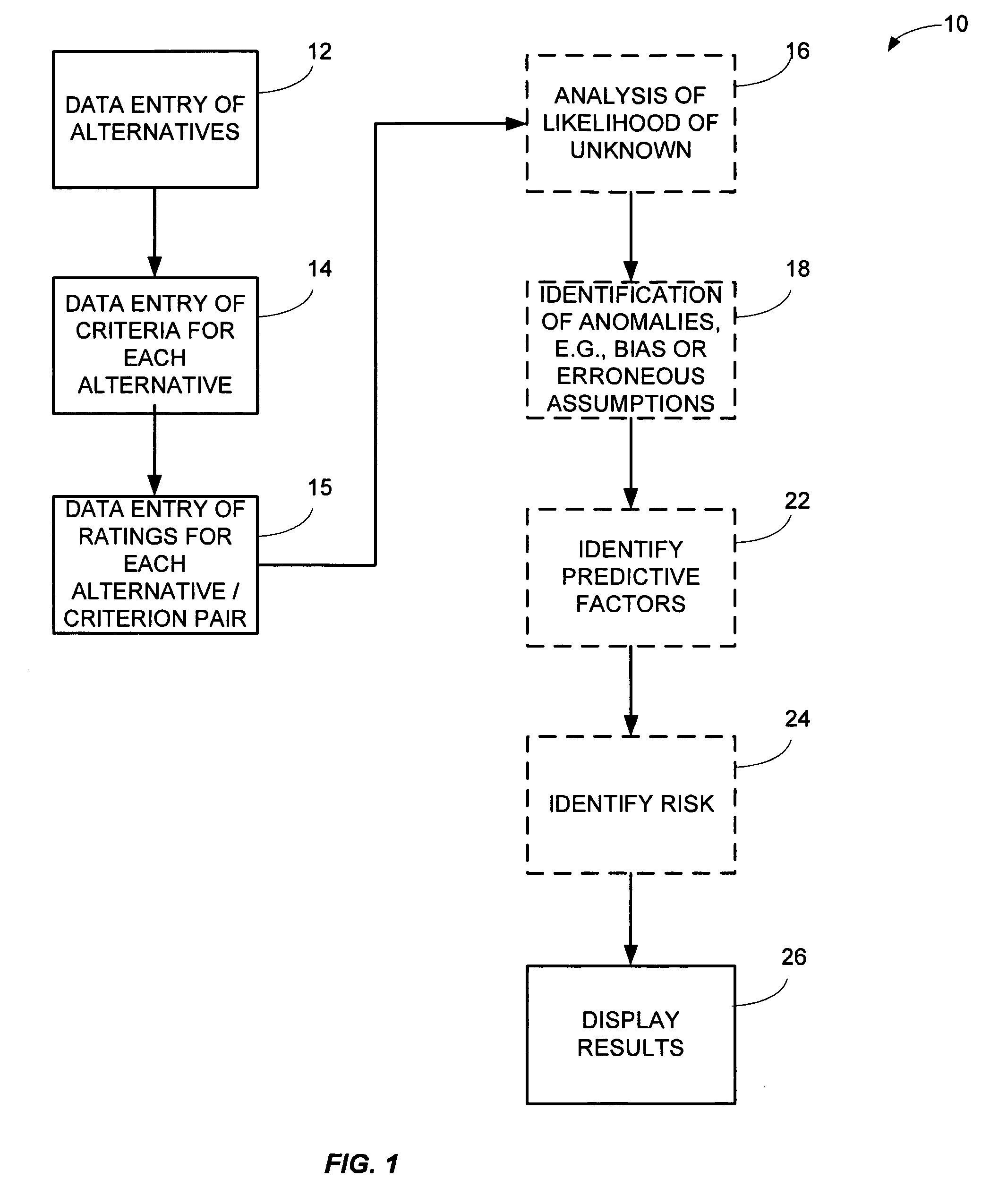

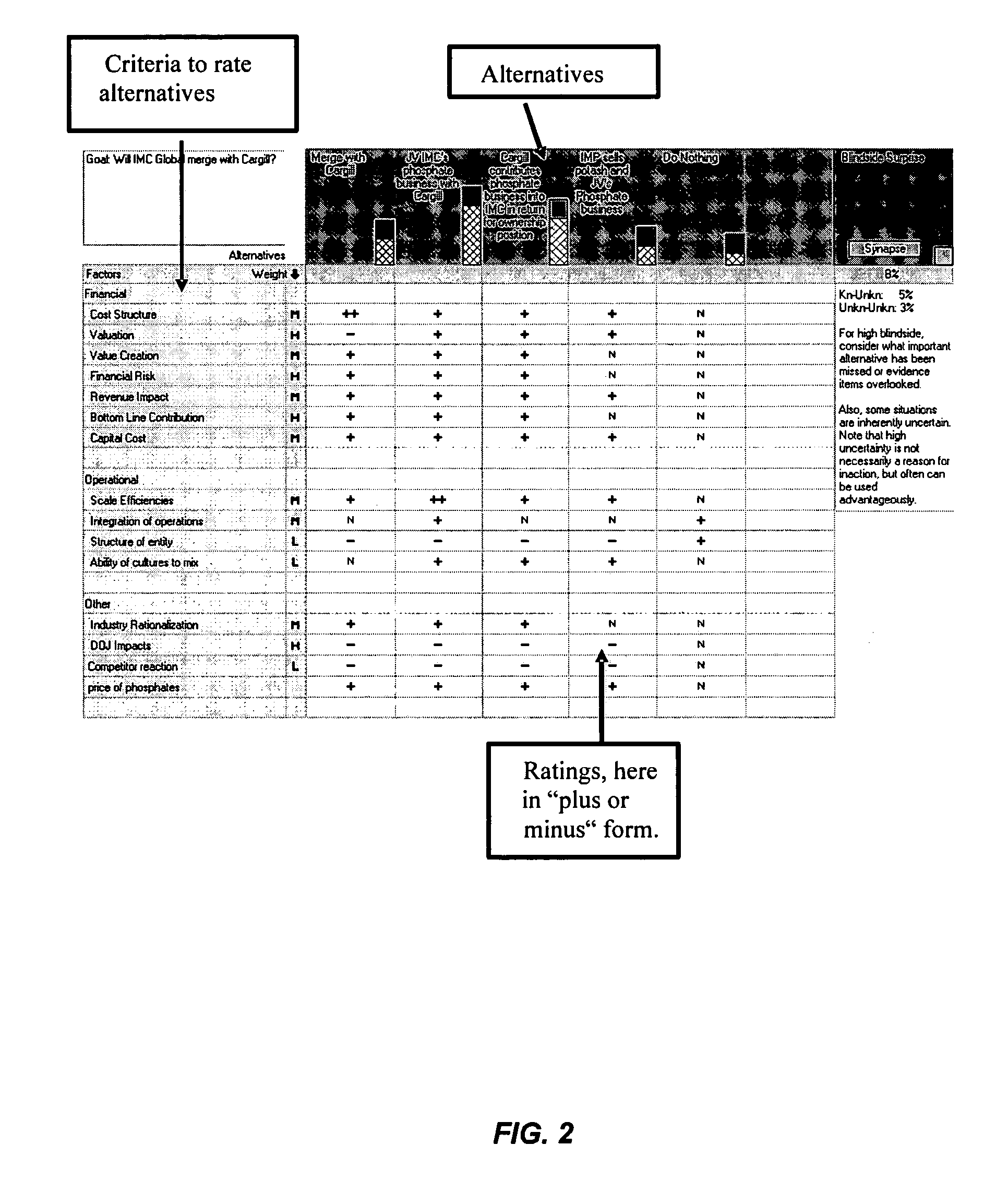

System and method for making decisions

InactiveUS7676446B2Improved insight and forecastingFacilitate discussionInference methodsSpecial data processing applicationsDecision systemError reduction

Systems and methods are disclosed to assist in making decisions. The systems and methods consider situations where the user is determining which of several alternatives is the best choice. The criteria to evaluate the decisions are input into a grid, and the user rates the different alternatives against the different criteria. Given several alternative choices or options, it provides the probability each alternative is the right selection. In one embodiment, the system implements a Bayesian approach. The systems and methods may estimate the chance some important consideration was missed thereby reducing the chance of being surprised or blindsided. The system and method may also examine the inputs to a decision analysis in order to detect entries that might reflect bias, assumptions or unusual reasoning, thereby increasing the chance of obtaining the correct answer. The systems and methods may also identify the factors that were predictive. The systems and methods do not accept information as valid and correct; rather, they allow cross-checking and verification, and further employ sub-systems and sub-methods to reduce mistakes. Systems and methods so disclosed may be employed in financial analyses, intelligence analysis, etc.

Owner:DECISION COMMAND

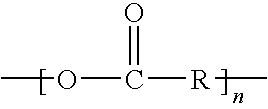

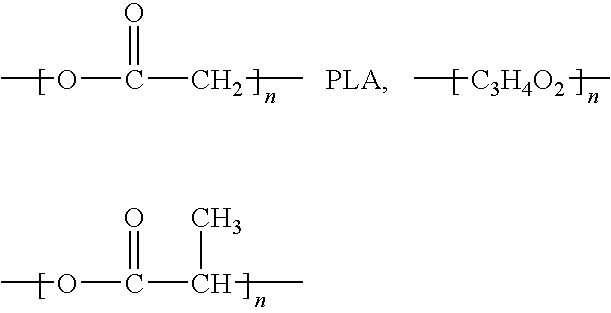

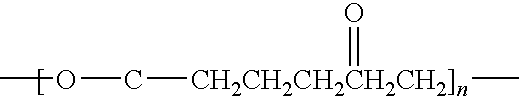

Totally Biodgradable Plastic Master Batch & Its Preparation

InactiveUS20090156713A1Low unit production costLow costPaper coatingCoatingsBiodegradable plasticMasterbatch

The present invention presents a totally biodegradable plastic master batch and its preparation methodology. Three main steps in preparation of the totally biodegradable plastic master batch include step (1): Refining and dehydration of starch, followed by step (2): mixing of multiple ingredients, followed by step (3): molding of product derived from previous step (2). Four preferred embodiments are introduced, while degradation performance of each preferred embodiment is given in terms of its degradation efficiency value.

Owner:DING SHAOZHONG

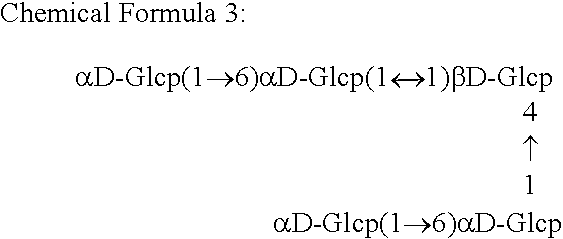

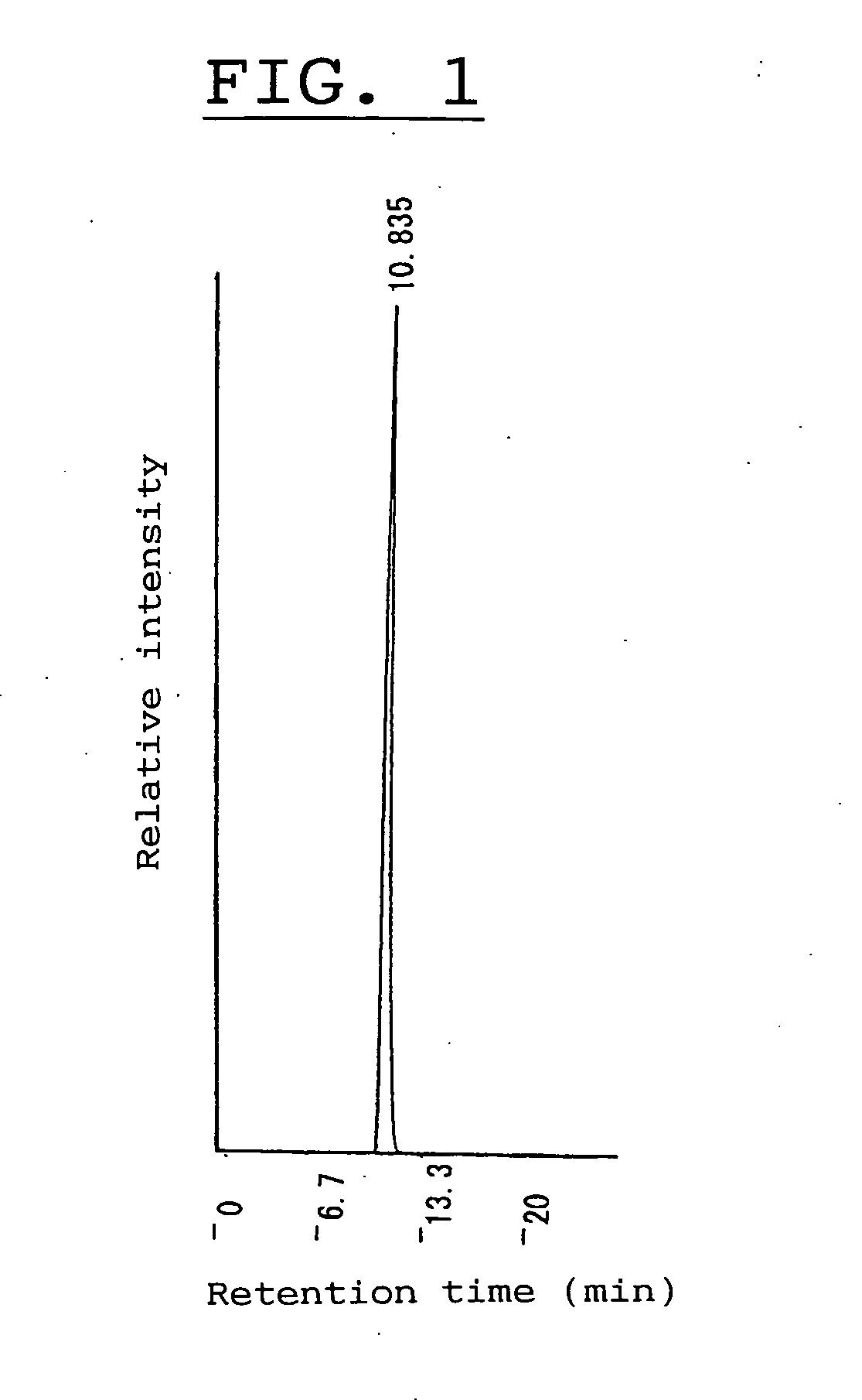

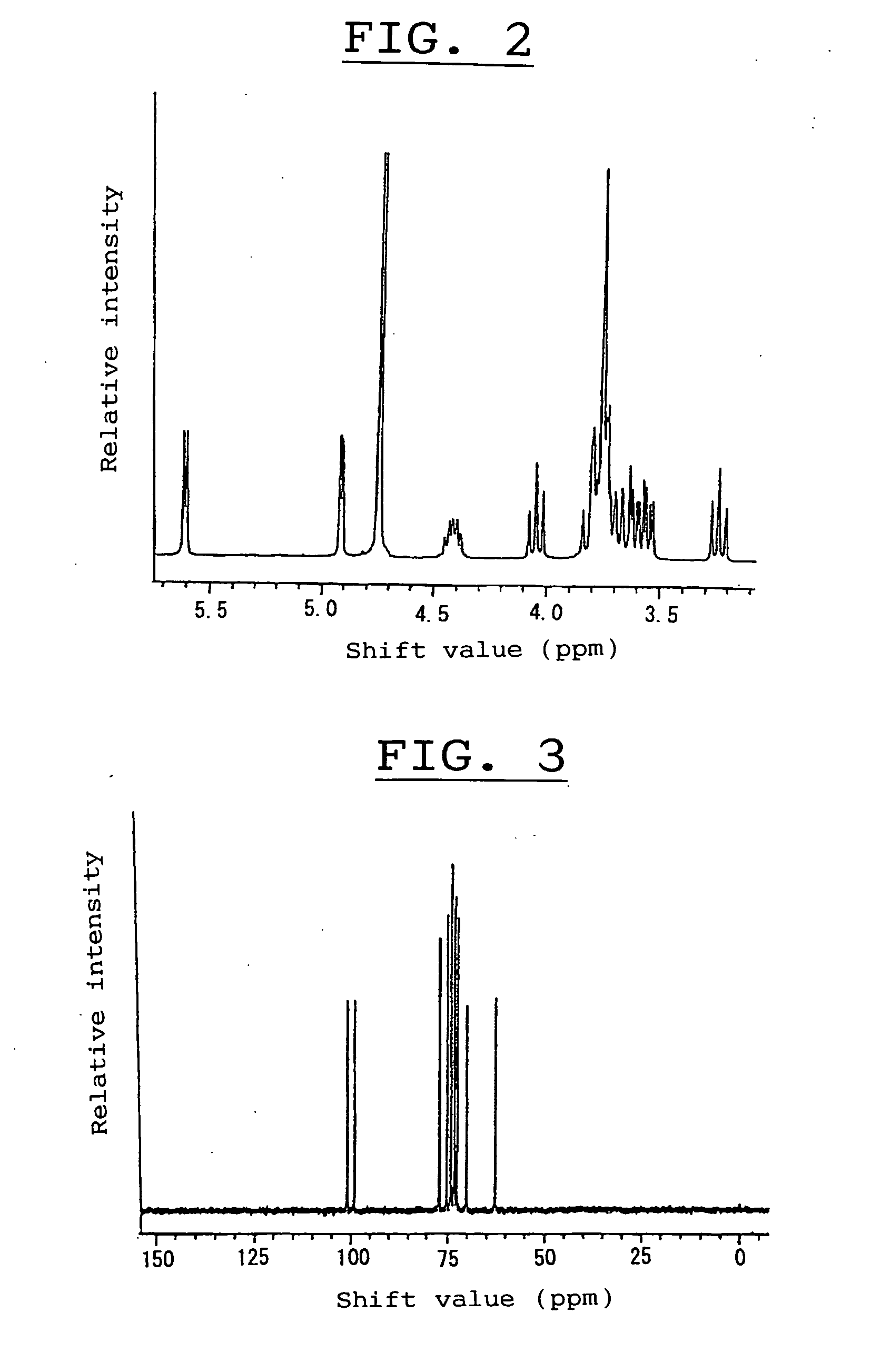

Alpha-isomaltosyltransferase, process for producing the same and use thereof

InactiveUS20050009017A1Improve taste preferenceEasy to prepareCosmetic preparationsDough treatmentMicroorganismIsomaltose

The object of the present invention is to provide an alpha-isomaltosyl-transferring enzyme which forms a cyclotetrasaccharide having the structure of cyclo{->6)-alpha-D-glucopyranosyl-(1->3)-alpha-D-glucopyranosyl-(1->6)-alpha-D-glucopyranosyl-(1->3)-alpha-D-glucopyranosyl-(1->} from a saccharide having a glucose polymerization degree of at least three and having both the alpha-1,6 glucosidic linkage as a linkage at the non-reducing end and the alpha-1,4 glucosidic linkage other than the linkage at the non-reducing end; microorganisms which produce the enzyme; process for producing the enzyme; cyclotetra-saccharide or saccharide compositions comprising the same; and uses thereof.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

Pigment granules

InactiveUS20110251303A1Optimal for incorporationHeating safetyNon-fibrous pulp additionInorganic pigment treatmentMasterbatchPolymer science

Pigment granules comprise one or more flake-form effect pigments, polymer particles or polymer particle mixtures, adhesion promoters, antioxidants and optionally additives. A process for the preparation of pigment granules comprises mixing one or more flake-form effect pigments, one or more polymer particles, at least one adhesion promoter, at least one antioxidant and optionally one or more additives with one another simultaneously or successively. The pigment granules may be used for the pigmentation of powder coatings, plastics and for the preparation of masterbatches. The pigment granules may be employed as a mixture with plastic powders or as a mixture with plastic granules for use in masterbatch applications.

Owner:MERCK PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com