Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about How to "High economic feasibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

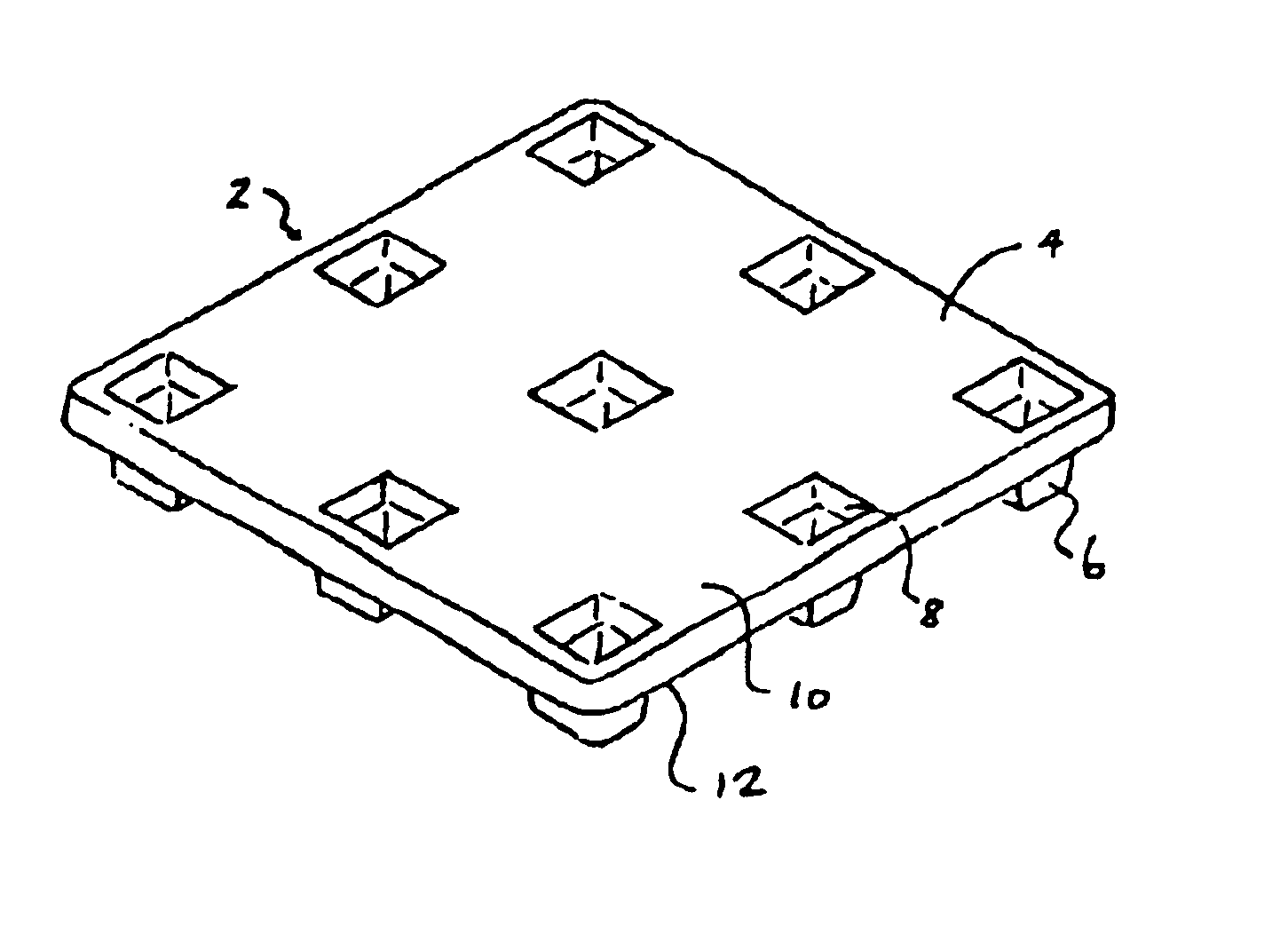

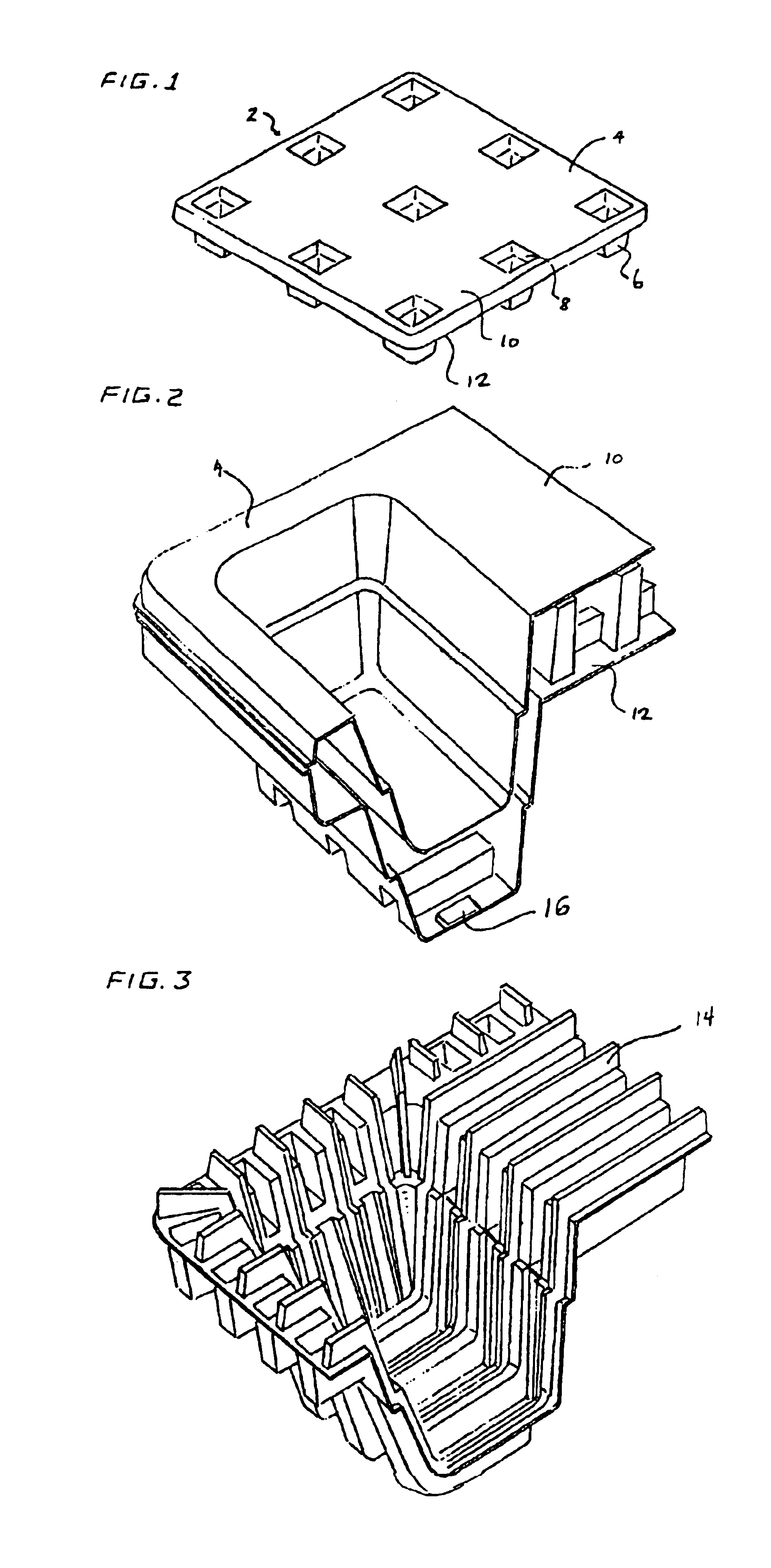

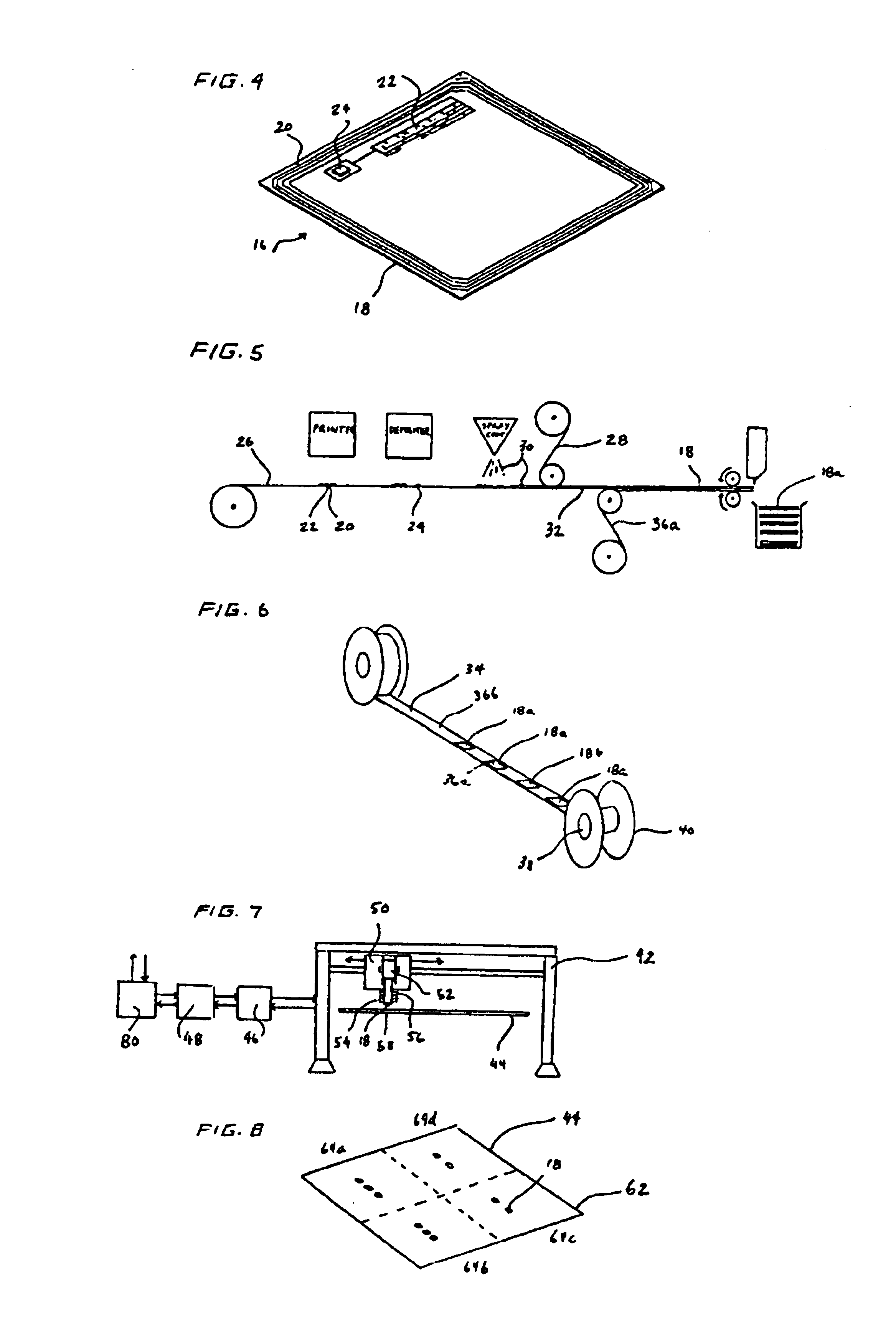

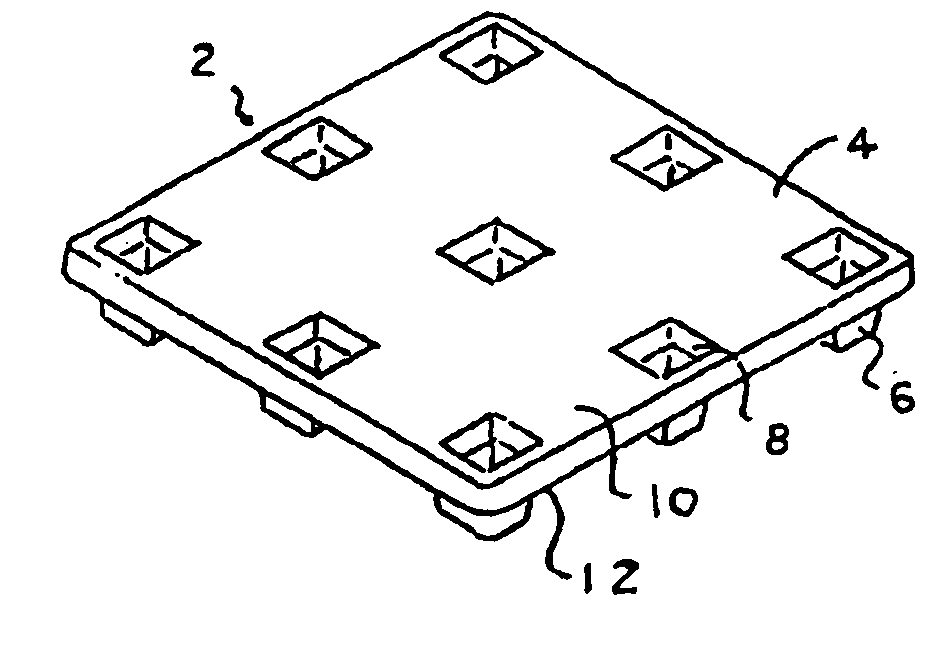

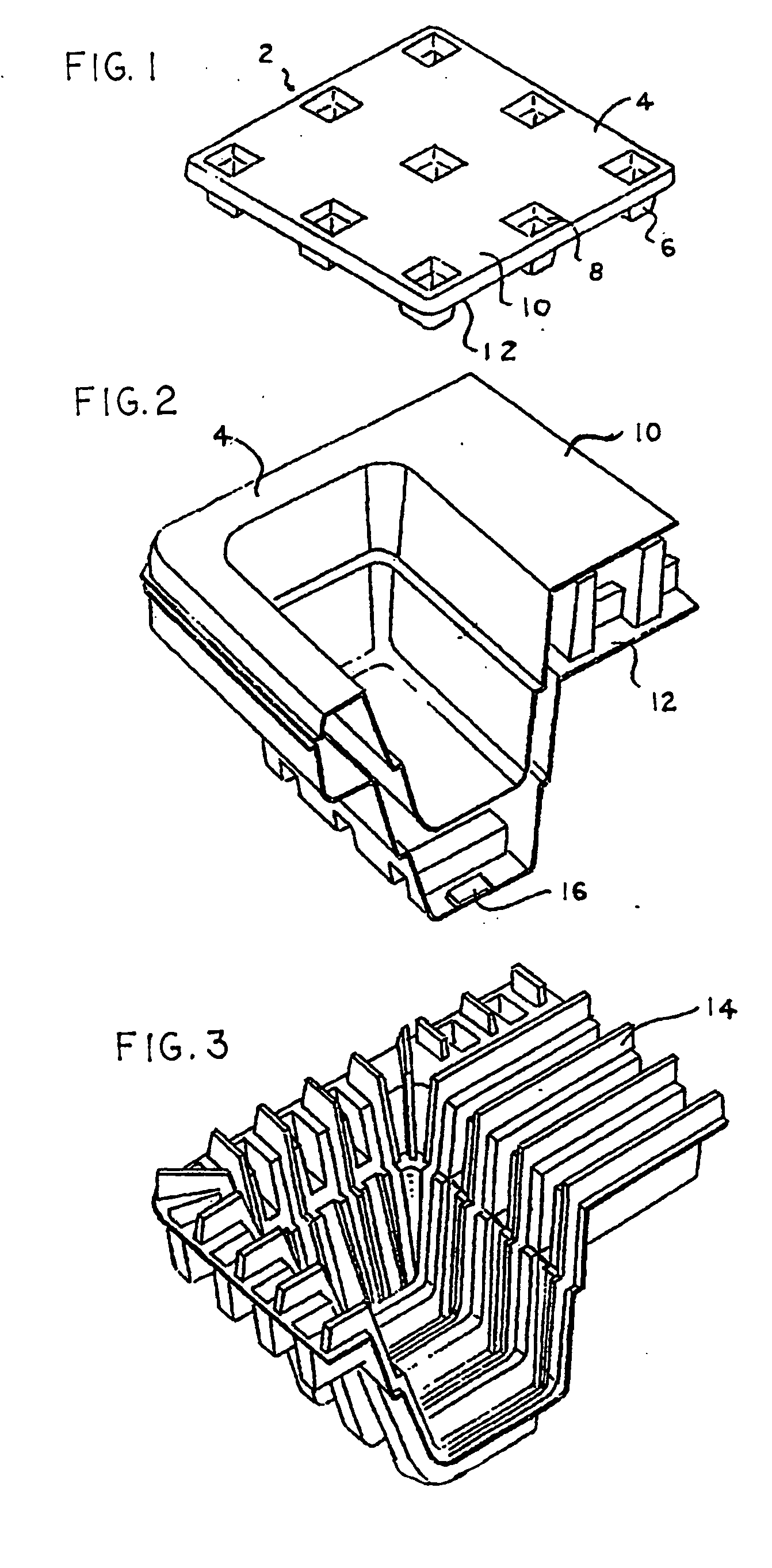

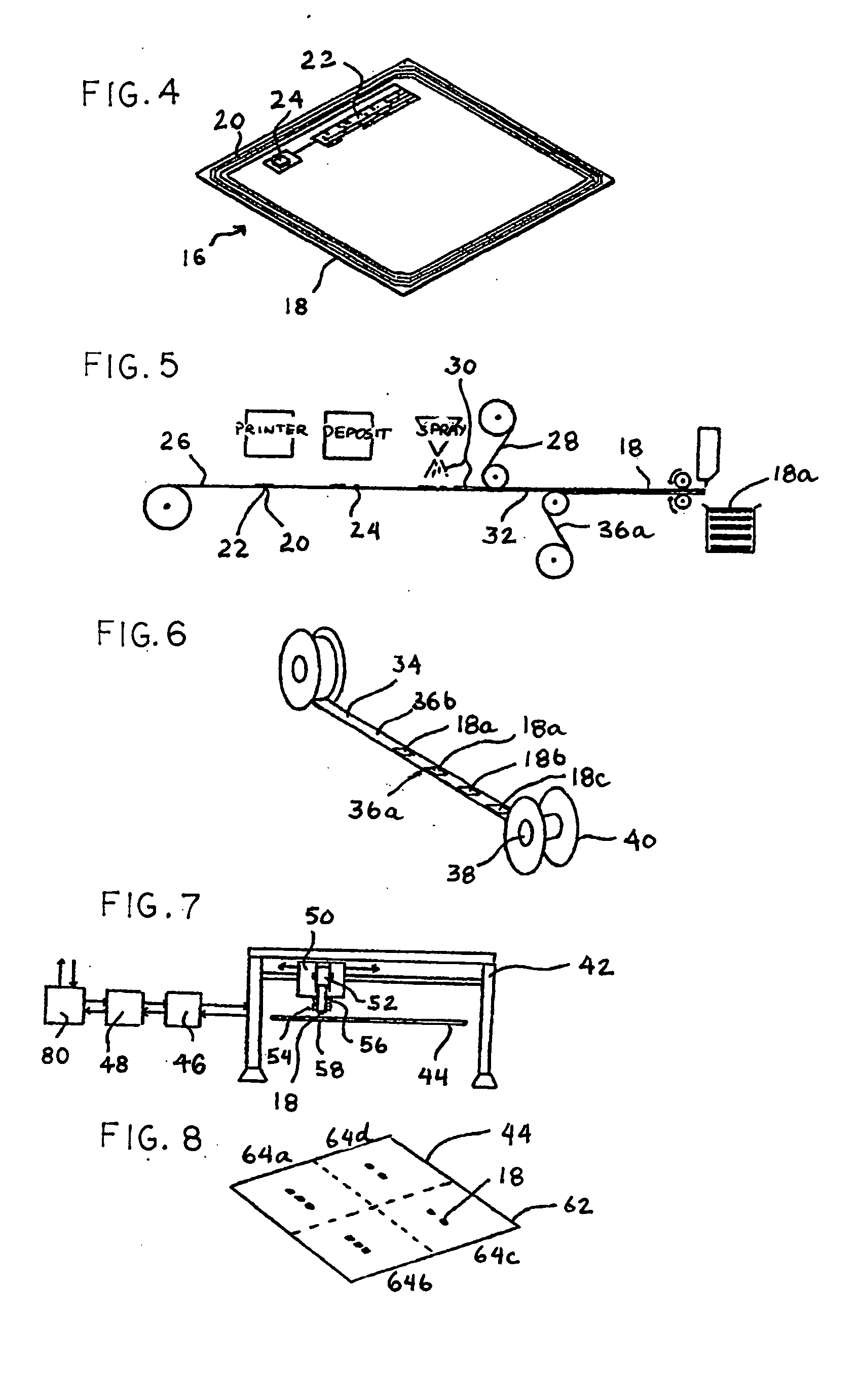

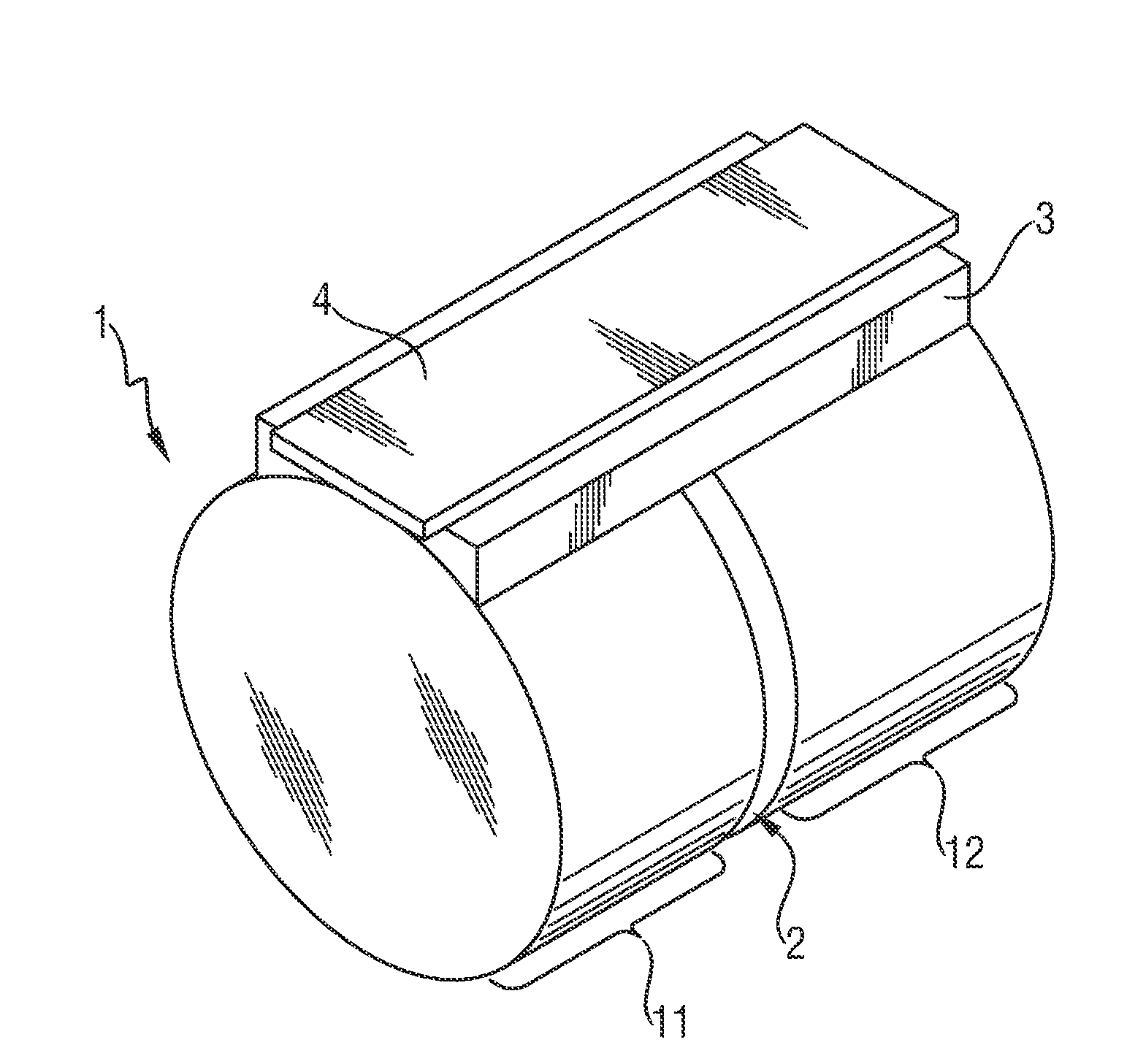

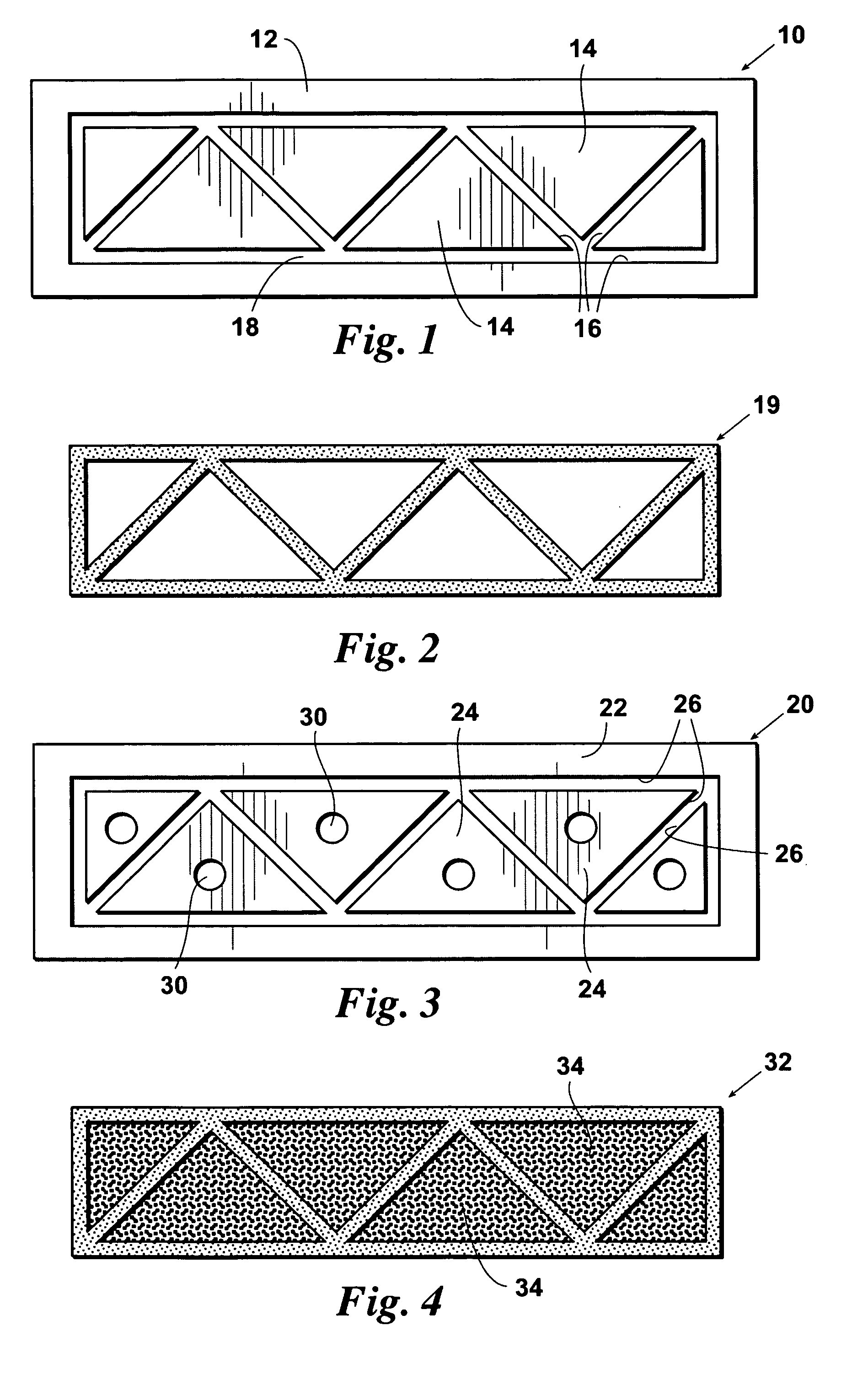

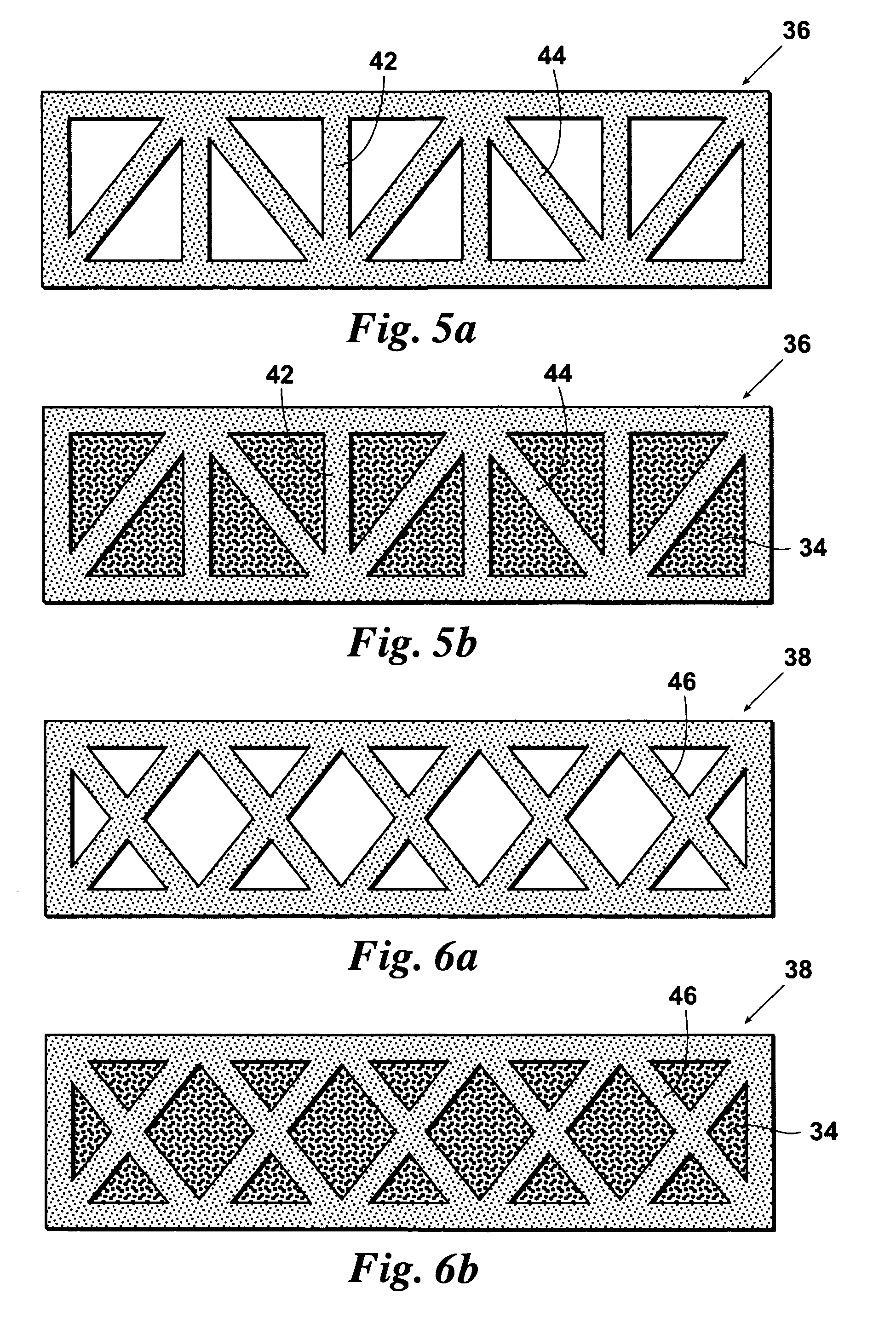

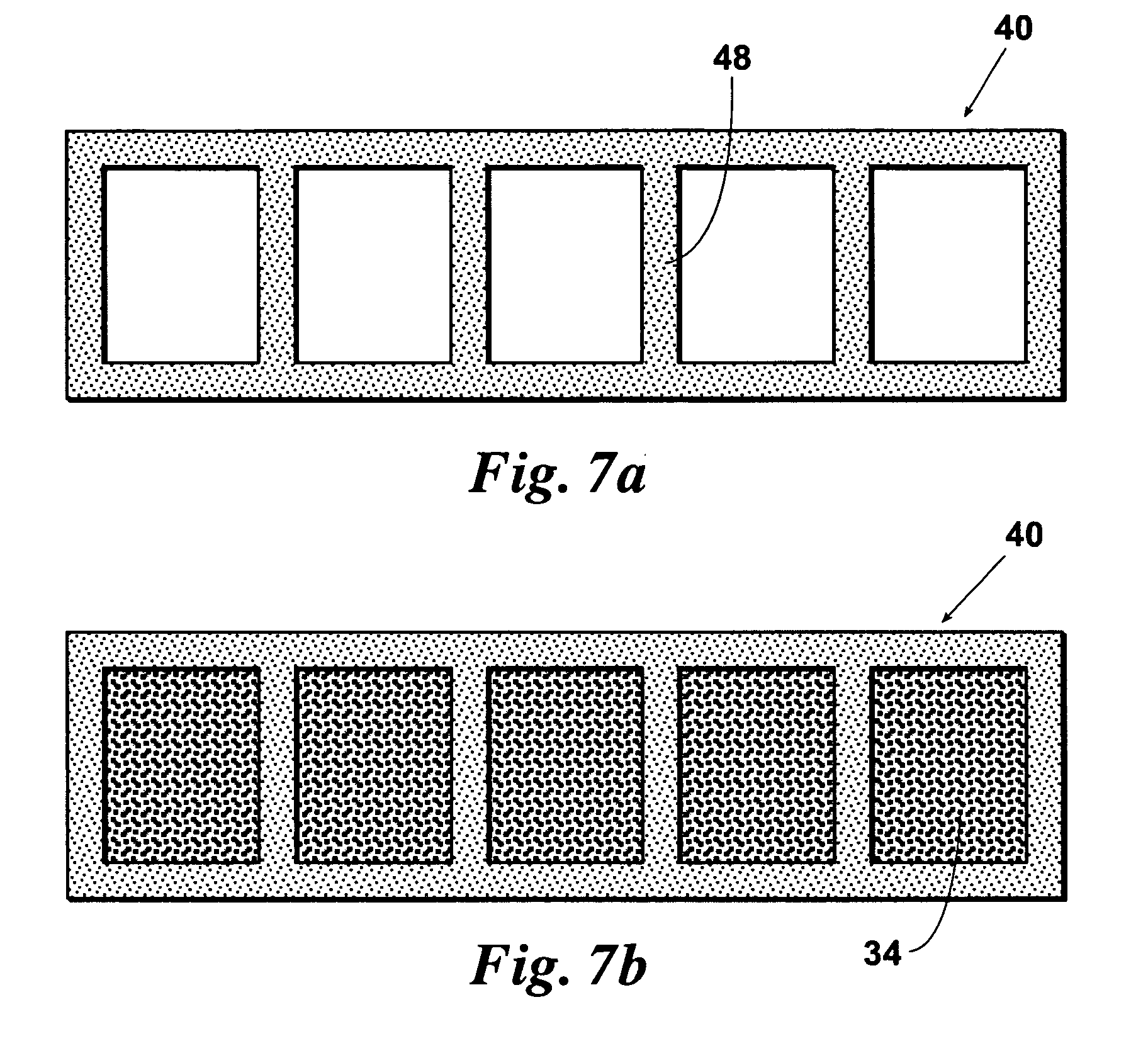

Thermoformed apparatus having a communications device

InactiveUS6943678B2Improve protectionIncreased durabilityRecord carriersDigital data processing detailsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

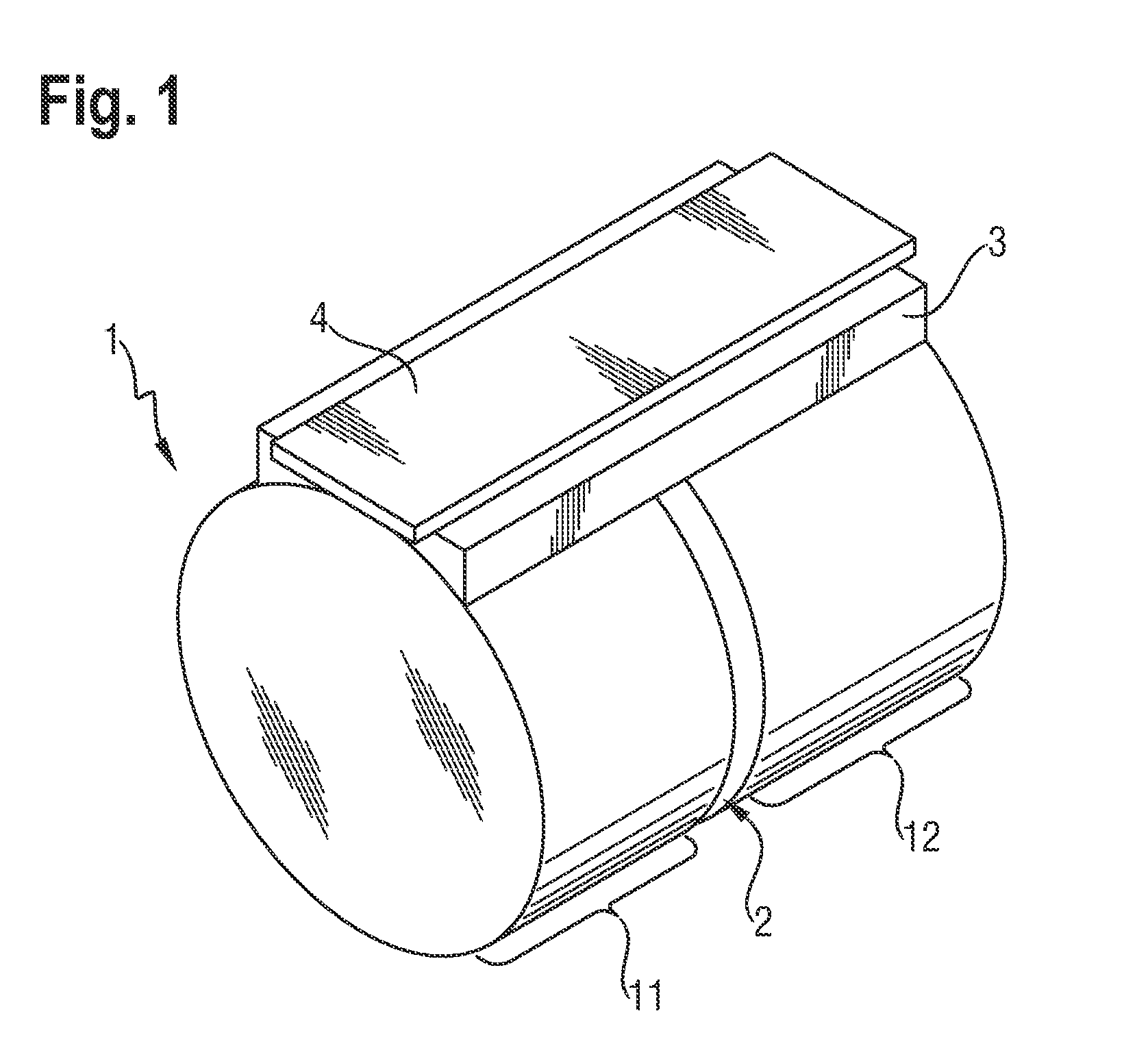

Thermoformed platform having a communications device

InactiveUS20050241548A1Improve protectionImprove reliability and durabilityContainer decorationsLevel indicationsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

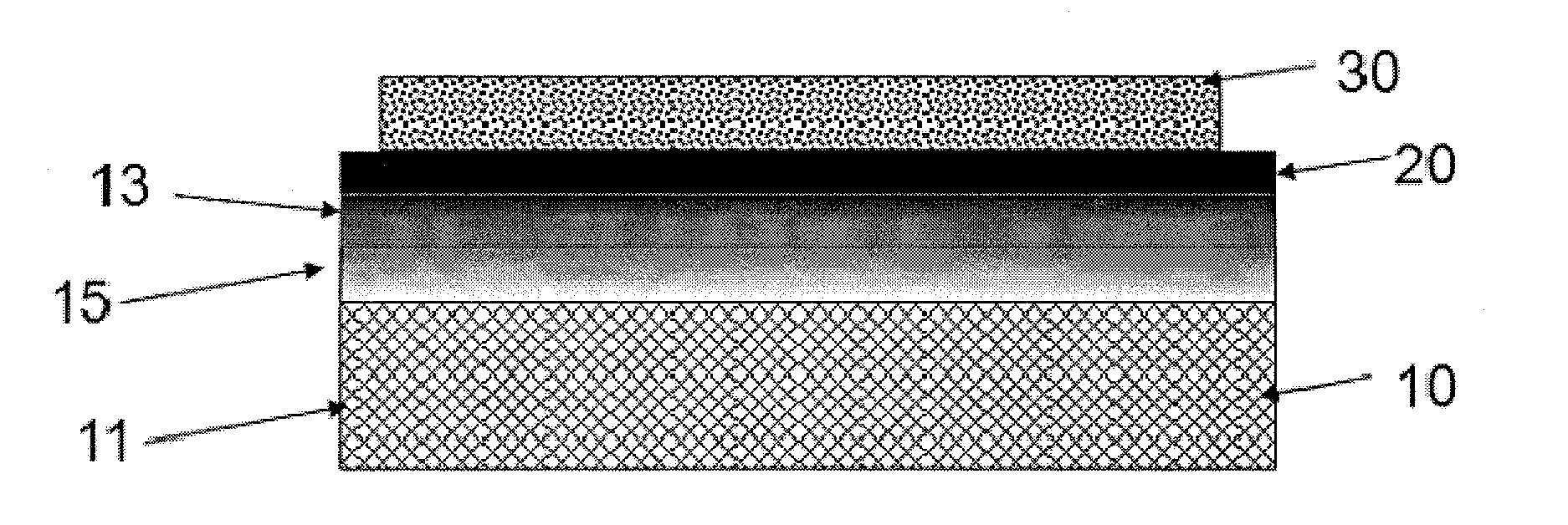

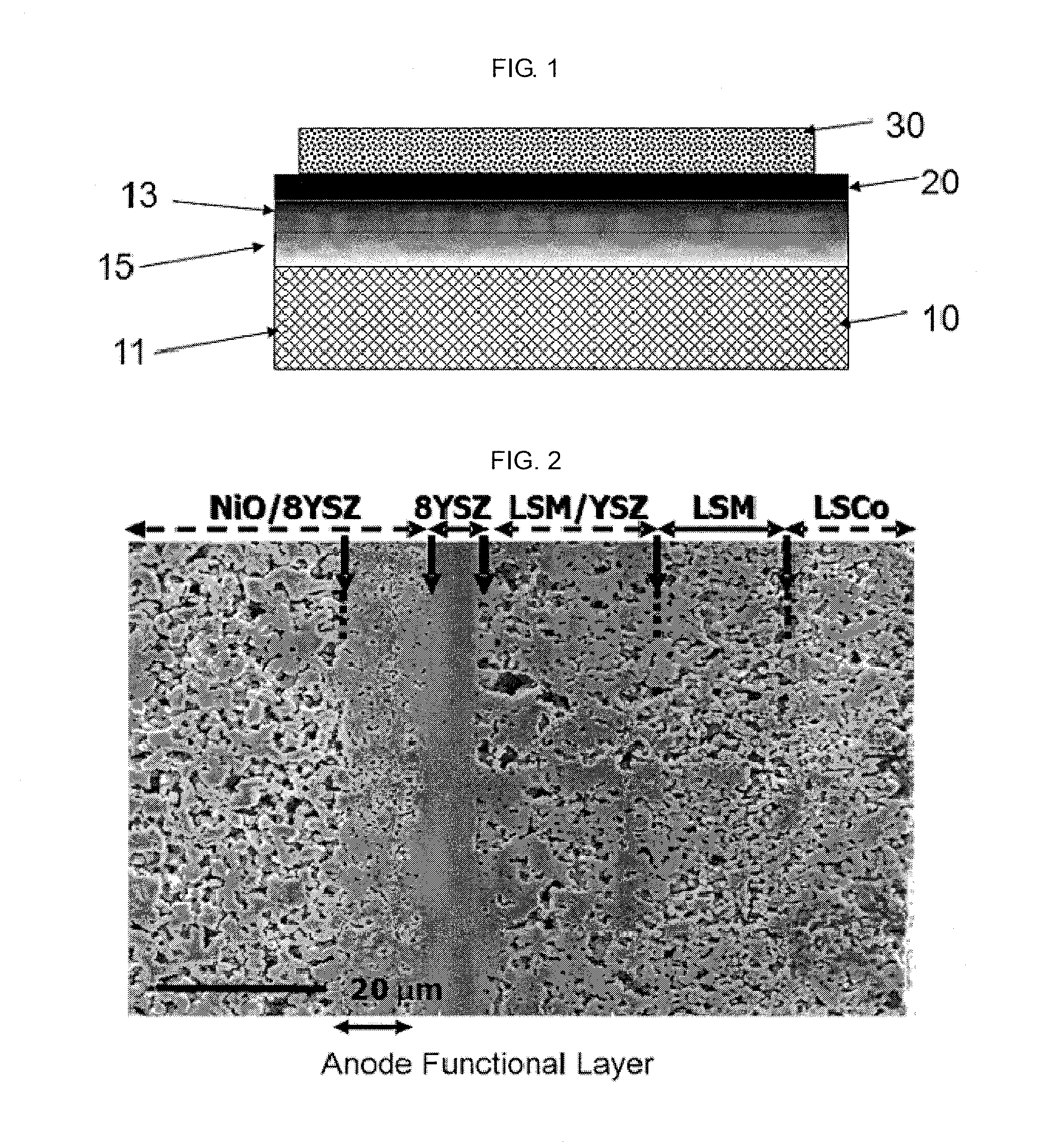

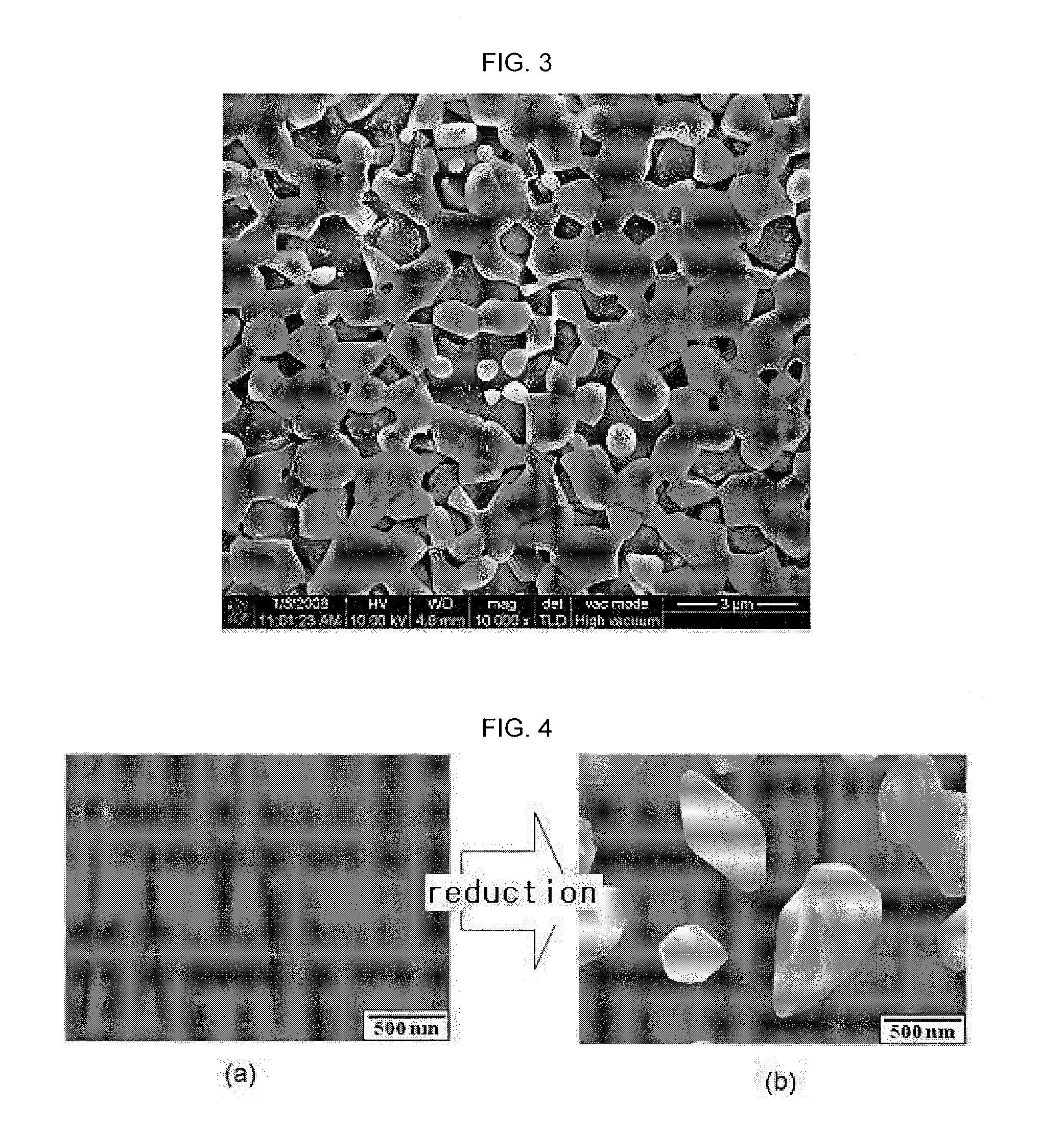

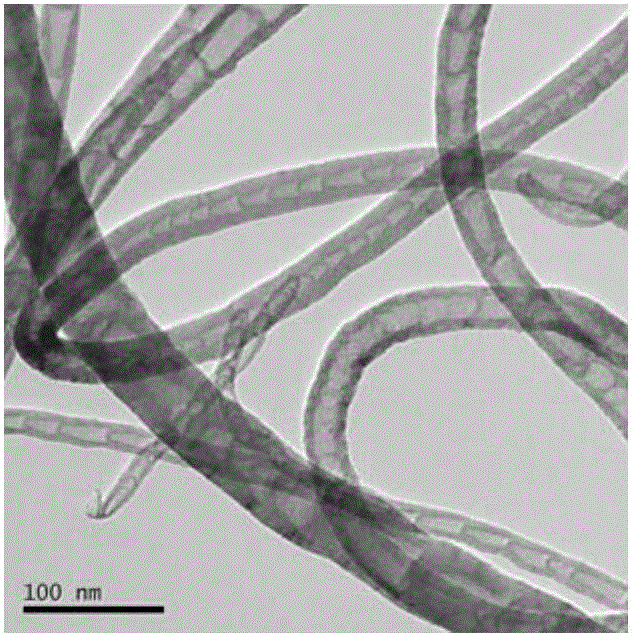

Anode-supported solid oxide fuel cell comprising a nanoporous layer having a pore gradient structure, and a production method therefor

ActiveUS20120003565A1Improve structural stabilityLow costMaterial nanotechnologyElectric discharge heatingFuel cellsPore diameter

The present invention relates to a solid oxide fuel cell having a gradient structure in which pore size becomes gradually smaller from a porous electrode to an electrolyte thin film in order to form a dense electrolyte thin film of less than about 2 microns and preferably less than 1 micron on the porous electrode.

Owner:KOREA INST OF SCI & TECH

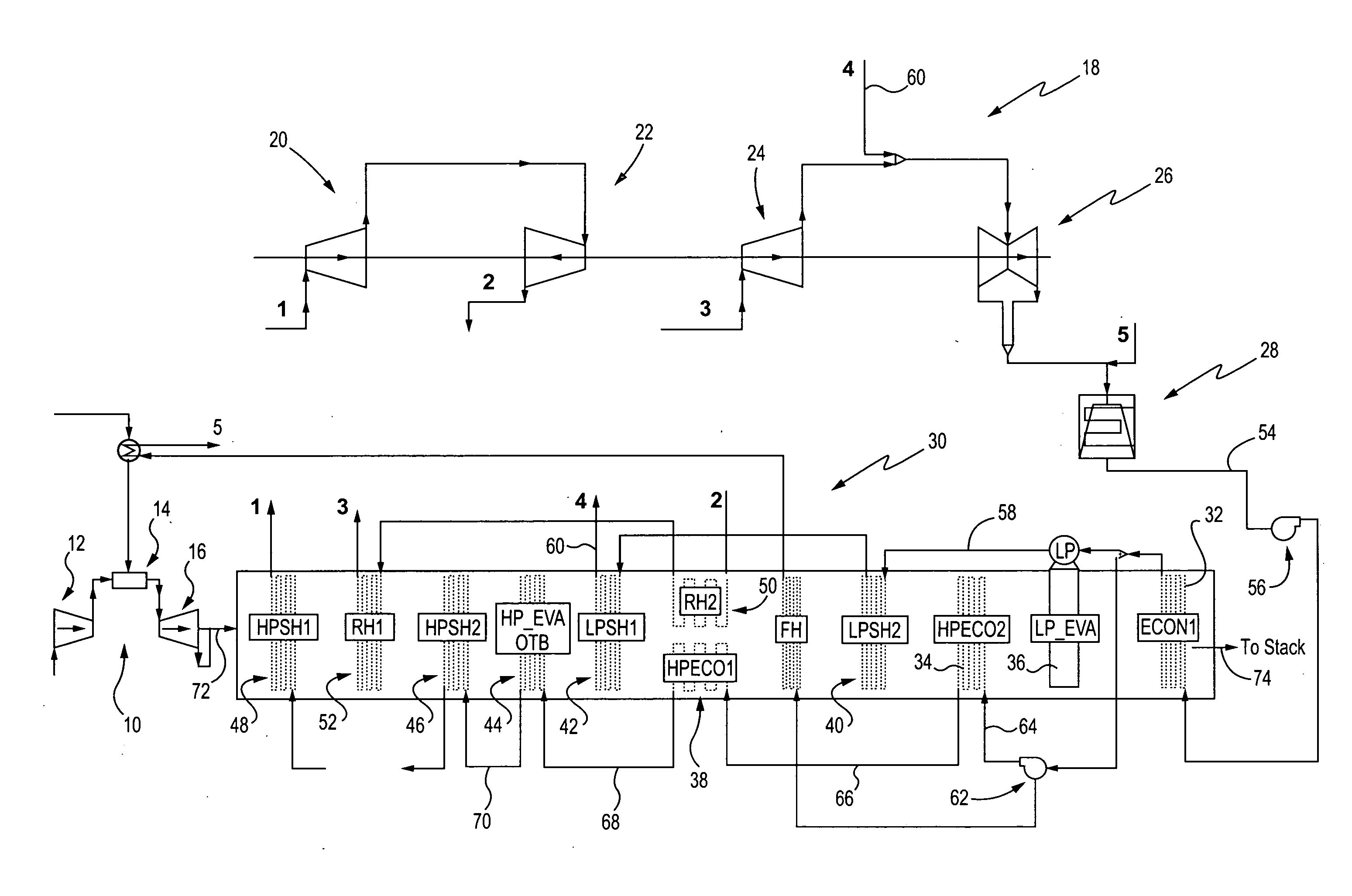

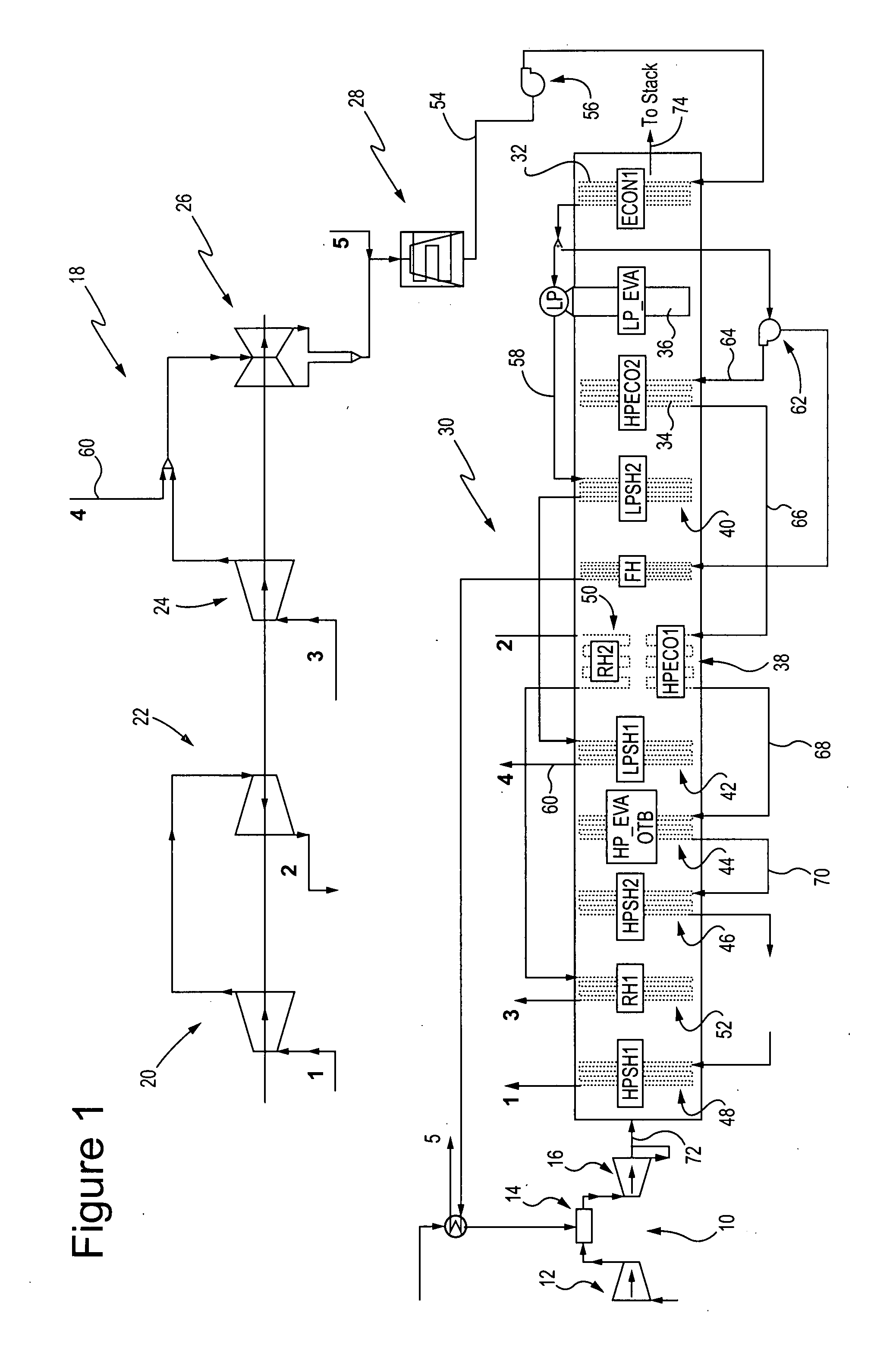

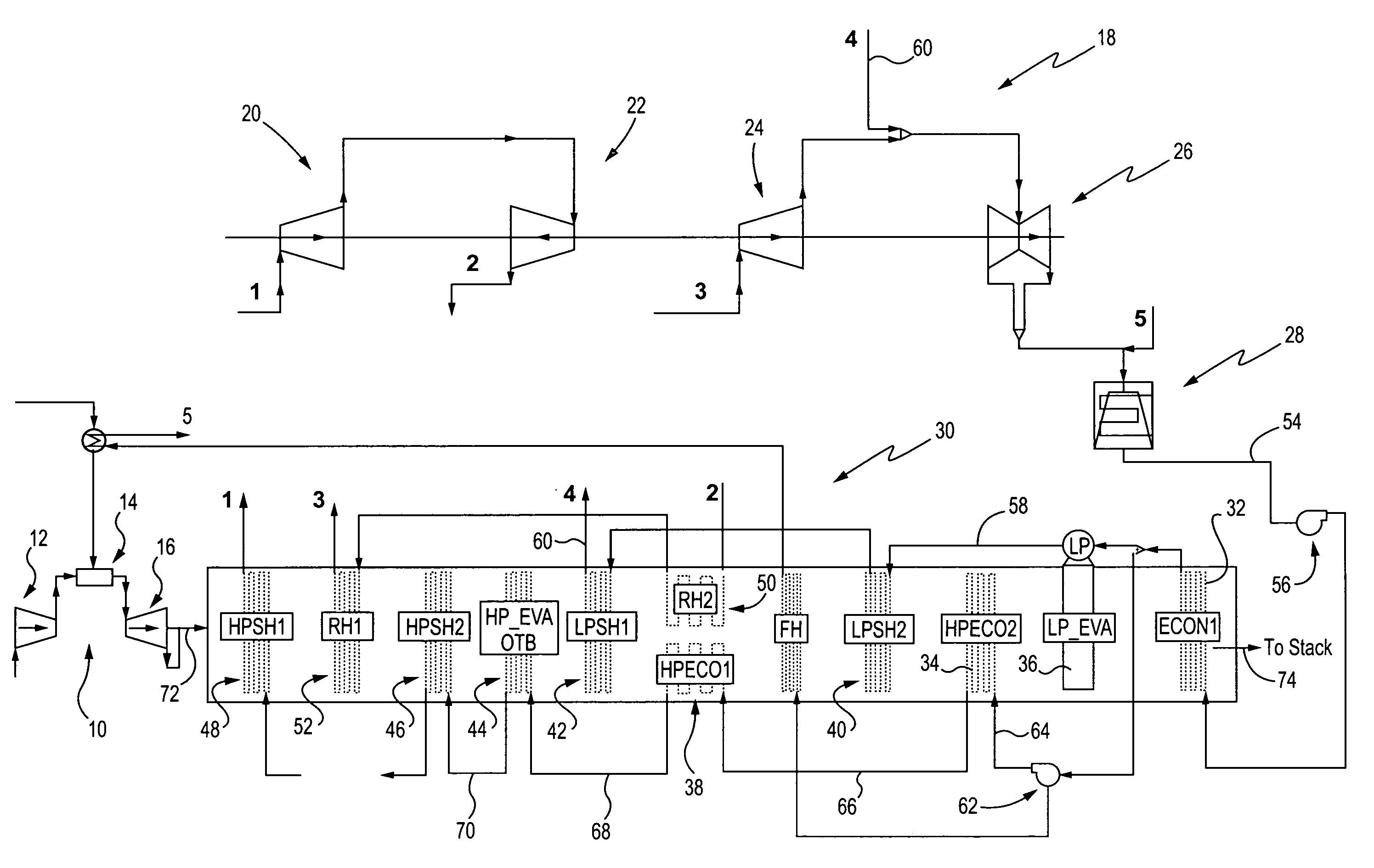

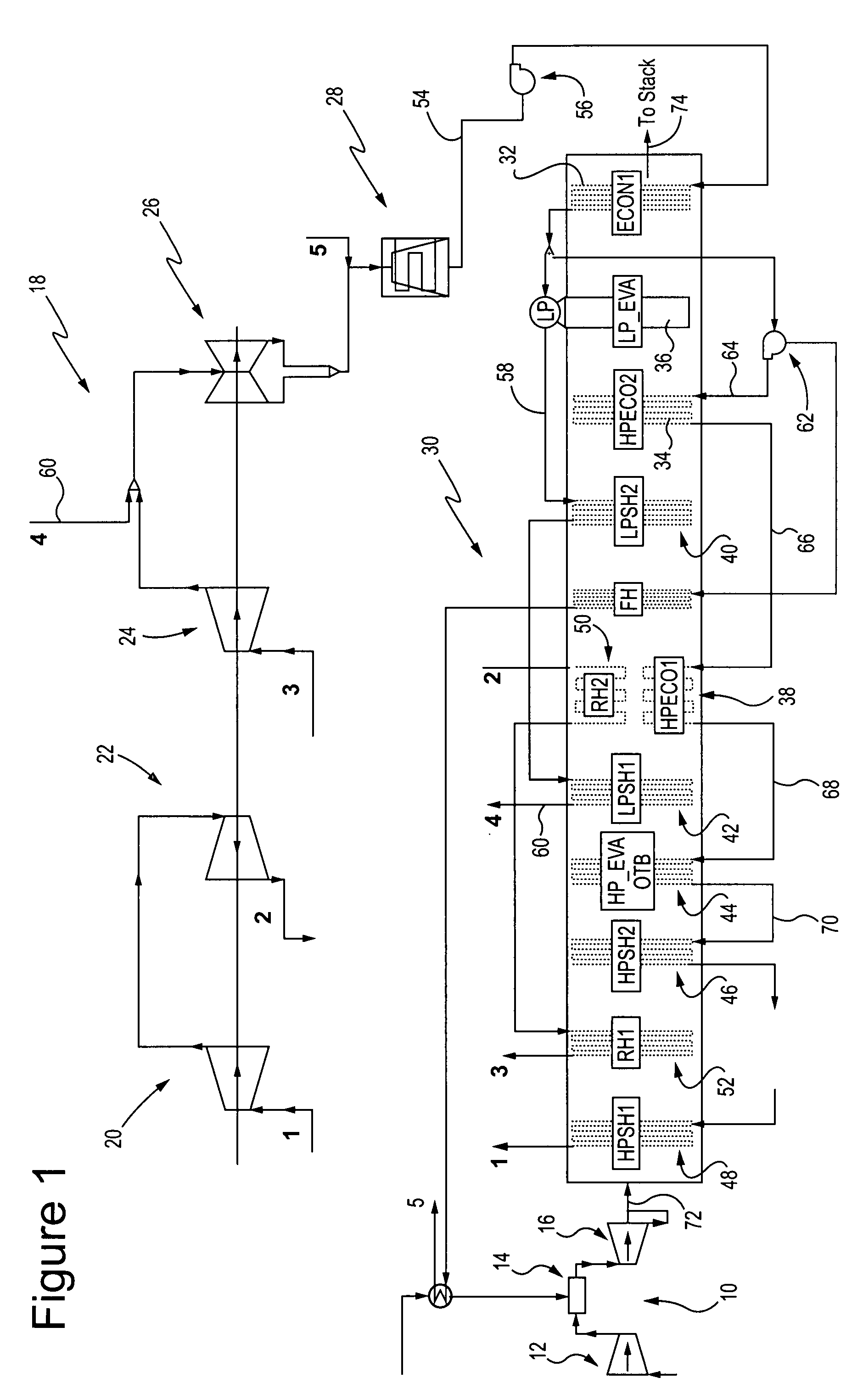

Supercritical steam combined cycle and method

ActiveUS20090090111A1Reduce irreversibilityCombined cycle performanceGas turbine plantsSteam engine plantsExhaust fumesEngineering

A supercritical steam combined cycle system including a gas turbine; a supercritical steam turbine system including a supercritical section, a high pressure section, an intermediate pressure section and at least one low pressure section; and a supercritical steam heat recovery steam generator (HRSG) for receiving exhaust gas from the gas turbine for heating fluid from the steam turbine system. The HRSG includes a supercritical evaporator arranged to supply steam to a superheater between the supercritical evaporator and the inlet of the HRSG and a reheater receiving cold reheat steam from and returning reheated steam to the steam turbine system. The reheater includes a first section disposed downstream of and a second section disposed upstream of the supercritical evaporator along the exhaust gas flow path. Cool reheat steam from the steam turbine system is received by the first reheater section and steam leaving the first reheater section is supplied to the second reheater section upstream of the supercritical evaporator.

Owner:GENERAL ELECTRIC CO

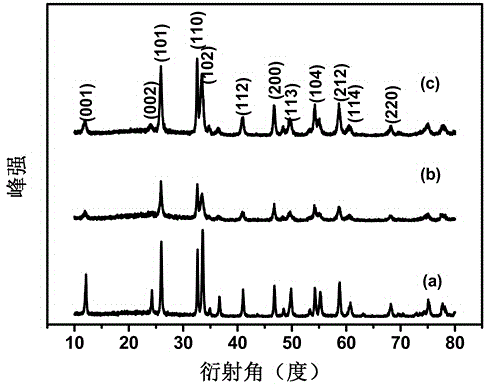

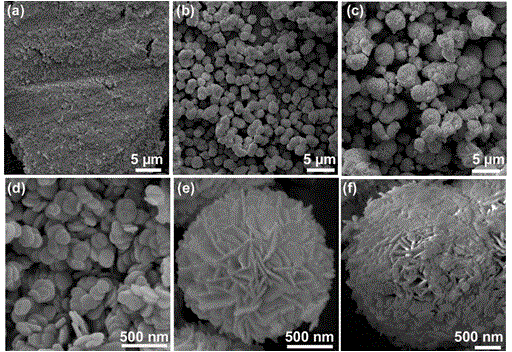

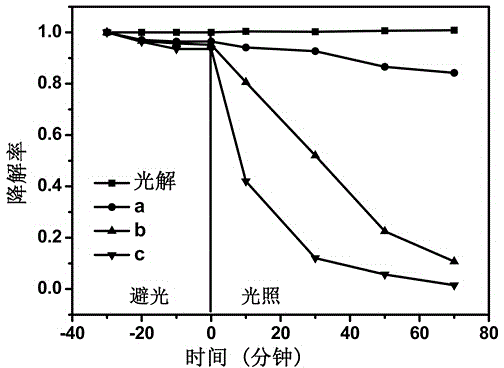

Multivariate controllable synthesis method of BiOCl photocatalyst

InactiveCN104014352AShort preparation cycleThe preparation process is simple and controllablePhysical/chemical process catalystsWater/sewage treatment by irradiationSynthesis methodsUltraviolet lights

The invention discloses a multivariate controllable synthesis method of a BiOCl photocatalyst, and belongs to the technical field of photocatalytic water treatment of environmental chemical engineering. The multivariate controllable synthesis method is characterized by comprising the following steps: adding BiCl3 with proper concentration to diethylene glycol or a mixed solvent of diethylene glycol and water; adding a urea precipitation agent, directly transferring sol or transferring sol subjected to ultrasonic pretreatment into a Teflon high-pressure reaction kettle to carry out solvothermal reaction at certain temperature to generate sediments after evenly mixing; and baking the sediments at 80 DEG C after washing with water and ethanol, so as to obtain BiOCl photocatalyst powder with different morphologies. The synthesis method disclosed by the invention has the characteristics that the preparation cycle of BiOCl is short, use of a surfactant is avoided, grains with controllable crystal faces (110 and 102) and controllable morphologies (two-dimensional flakes, three-dimensional flowers or spheres) can be conveniently achieved by controlling and ultrasonic pretreatment on the solvent. The catalyst is applied to photocatalytic degradation of carbamazepine medicine wastewater, displays the photocatalytic activity superior to that of TiO2(P25) under ultraviolet light and simulated sunlight, and has a practical application prospect.

Owner:TAIYUAN UNIV OF TECH

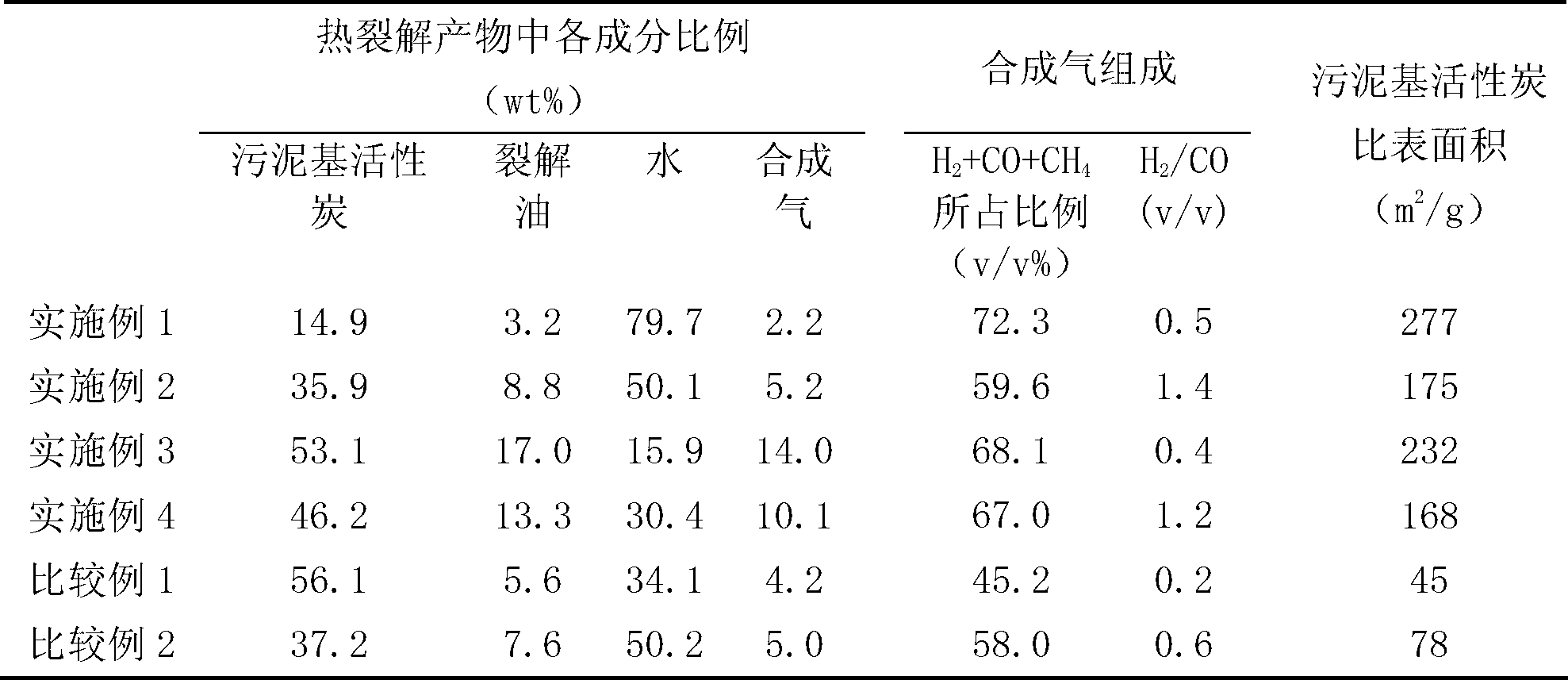

Method for preparing pyrolysis oil and synthesis gases by pyrolysis of sludge

InactiveCN102936087AReduce pyrolysis timeHigh economic feasibilitySludge treatment by pyrolysisByproduct vaporizationActivated carbonSludge

The invention provides a method for preparing pyrolysis oil and synthesis gases by pyrolysis of sludge. The method is characterized by comprising the following steps of evenly mixing activated carbon and a pyrolysis catalytic agent in dehydrated or air-dried sludge with over 60% of the dry basis organic content; loading an obtained mixture to a microwave heating device and performing pyrolysis reaction by microwave heating under an atmosphere of inert gases; and feeding gases generated by the pyrolysis reaction to a condenser to collect the pyrolysis oil, water and non-condensing gases used as the synthesis gases. By means of the method, pyrolysis of the sludge can be rapidly achieved, compared with traditional heat conduction heating sludge pyrolysis methods, the method has the advantages that sludge pyrolysis time is greatly shortened, energy consumption is saved, simultaneously, more pyrolysis oil and synthesis gases can be generated, generated sludge-based activated carbon can be recycled, and hardly any waste and pollutants are discharged.

Owner:DALIAN MARITIME UNIVERSITY

Treatment method for pulping black liquid and application method for product of pulping black liquid

The invention relates to a treatment method for pulping black liquid and an application method for a product of the pulping black liquid, and belongs to the field of alkaline pulping and cellulose and hemicellulose pulp extraction. Lignin and / or pectin and / or silicate which are smelted in the black liquid are converted into lignin calcium (magnesium) salt and / or pectate calcium (magnesium) salt and / or calcium (magnesium) silicate which are not smelted in water by using calcium sulfate or magnesium sulfate salt and can be separated out of the black liquid; due to filtration and separation, the black liquid in a pulping papermaking industry can be treated with low cost; and moreover, various useful chemicals can be obtained.

Owner:秦才东

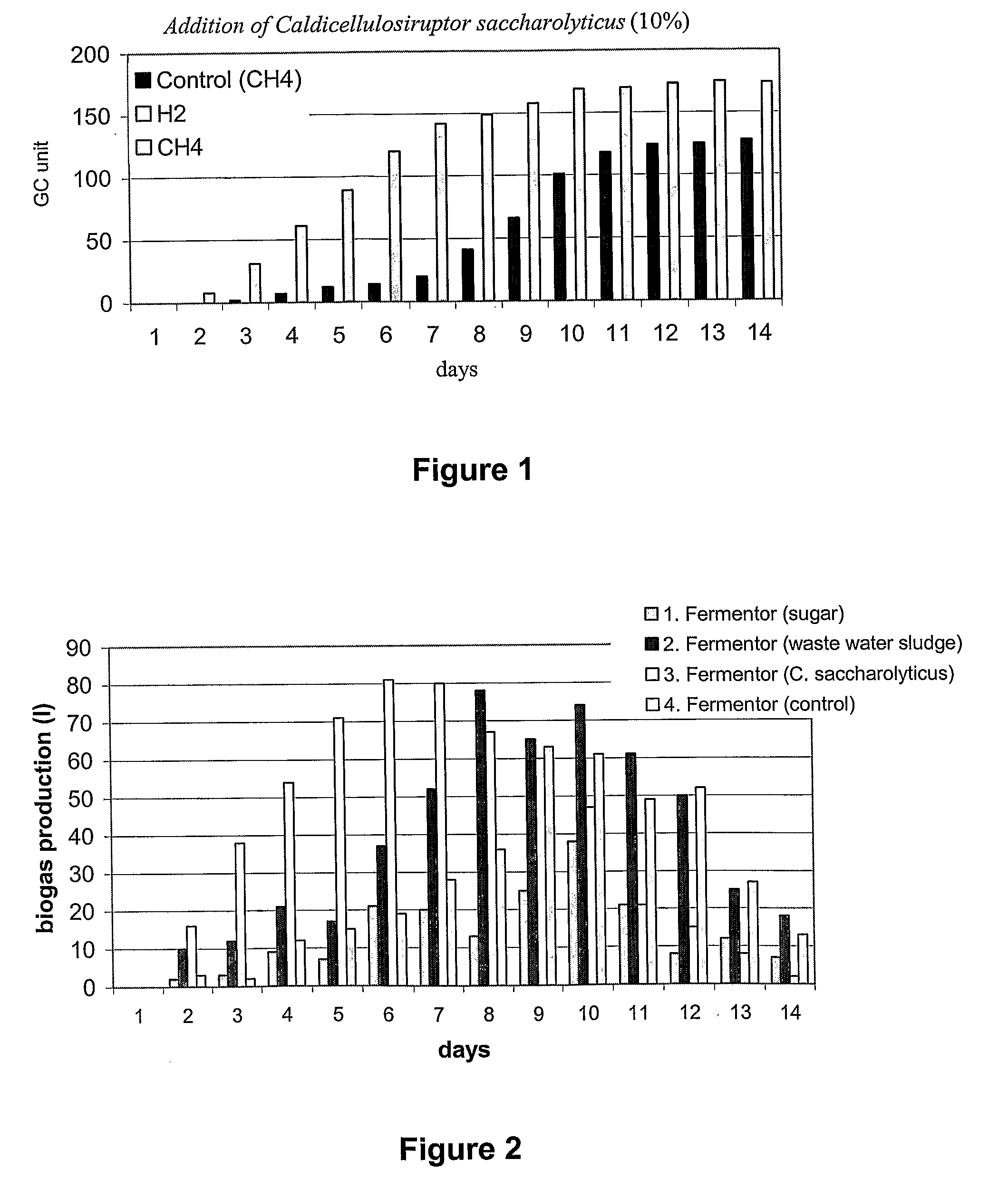

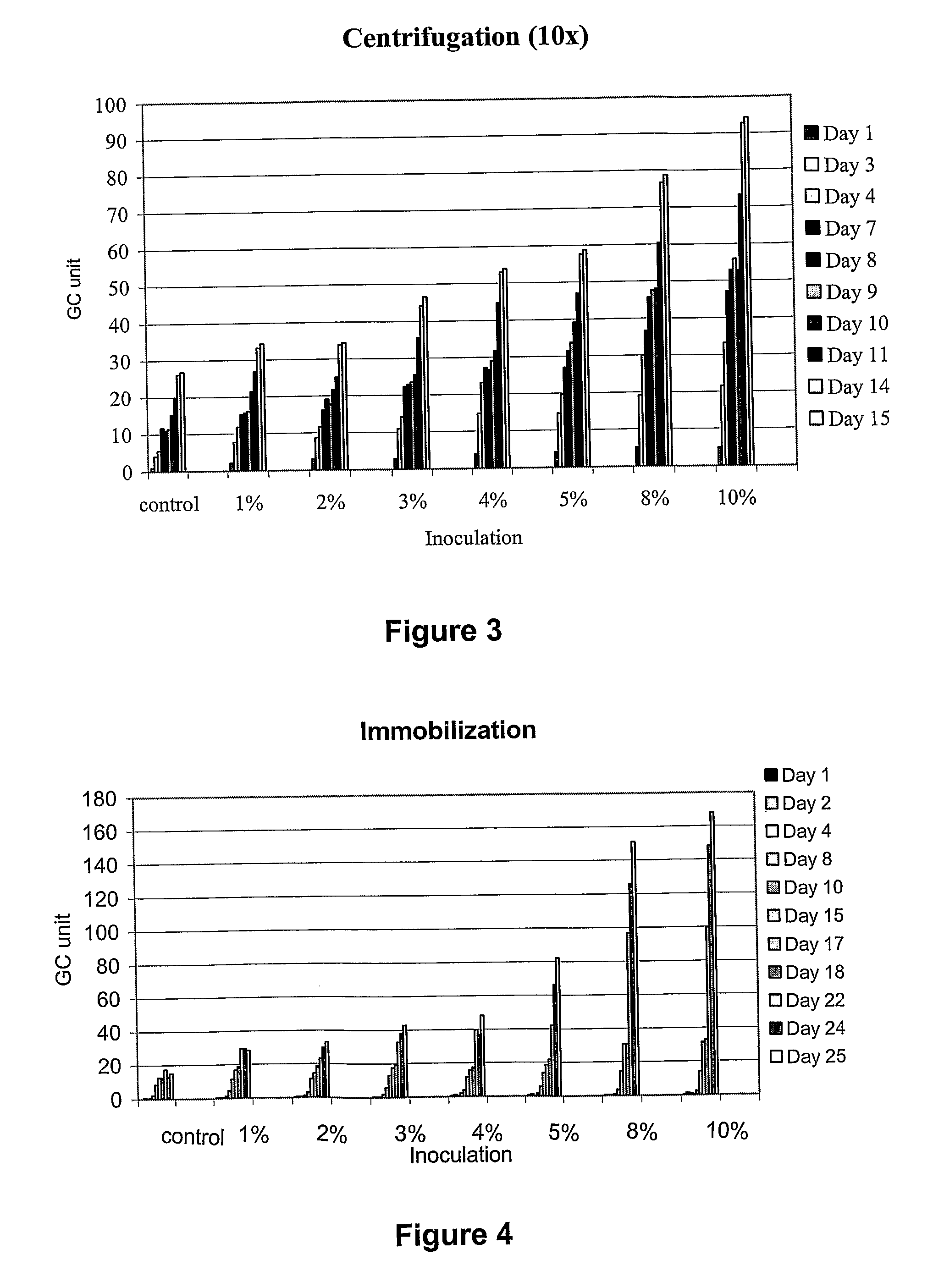

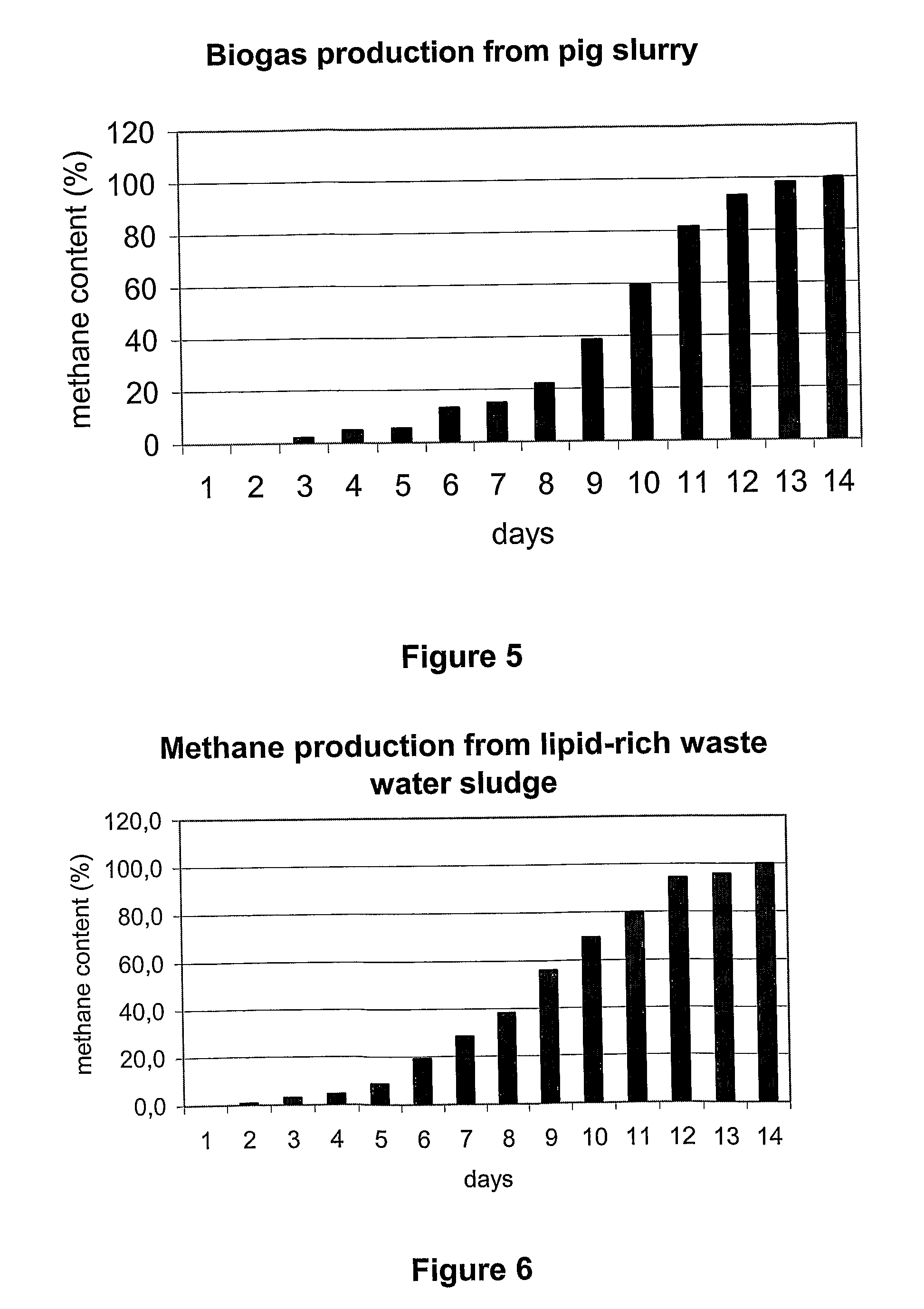

Method for Increased Production of Biogas

InactiveUS20080124775A1Improve overall utilizationGood curative effectManure treatmentMicrobiological testing/measurementMicroorganismAcetic acid

The invention relates to a method for increasing biogas production of thermophilic anaerobe systems. More closely, a biomass containing a consortium comprising polymer-degrading, acetogenic and methanogenic microorganisms is inoculated with a microorganism culture before the start of or during biogas production. Said microorganism is a thermophilic, acetogenic, hydrogen producing bacterium. As an example, Caldicellulosiruptor saccharolyticus is applied. According to the invention production if methane containing biogas is significantly increased.The invention is useful for intensifying biogas production and thereby increasing its feasibility.

Owner:SCHMACK BIOGAS GMBH

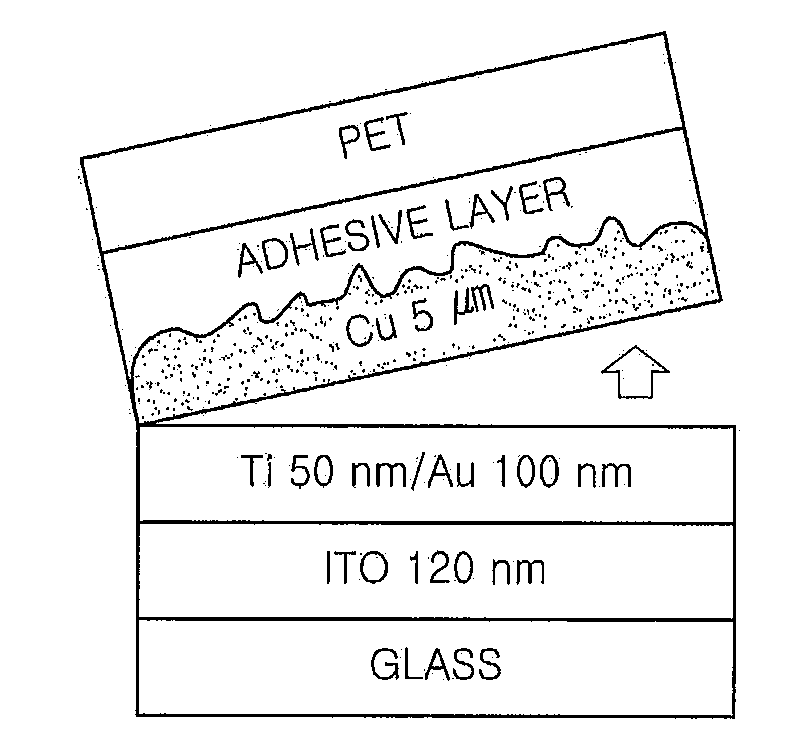

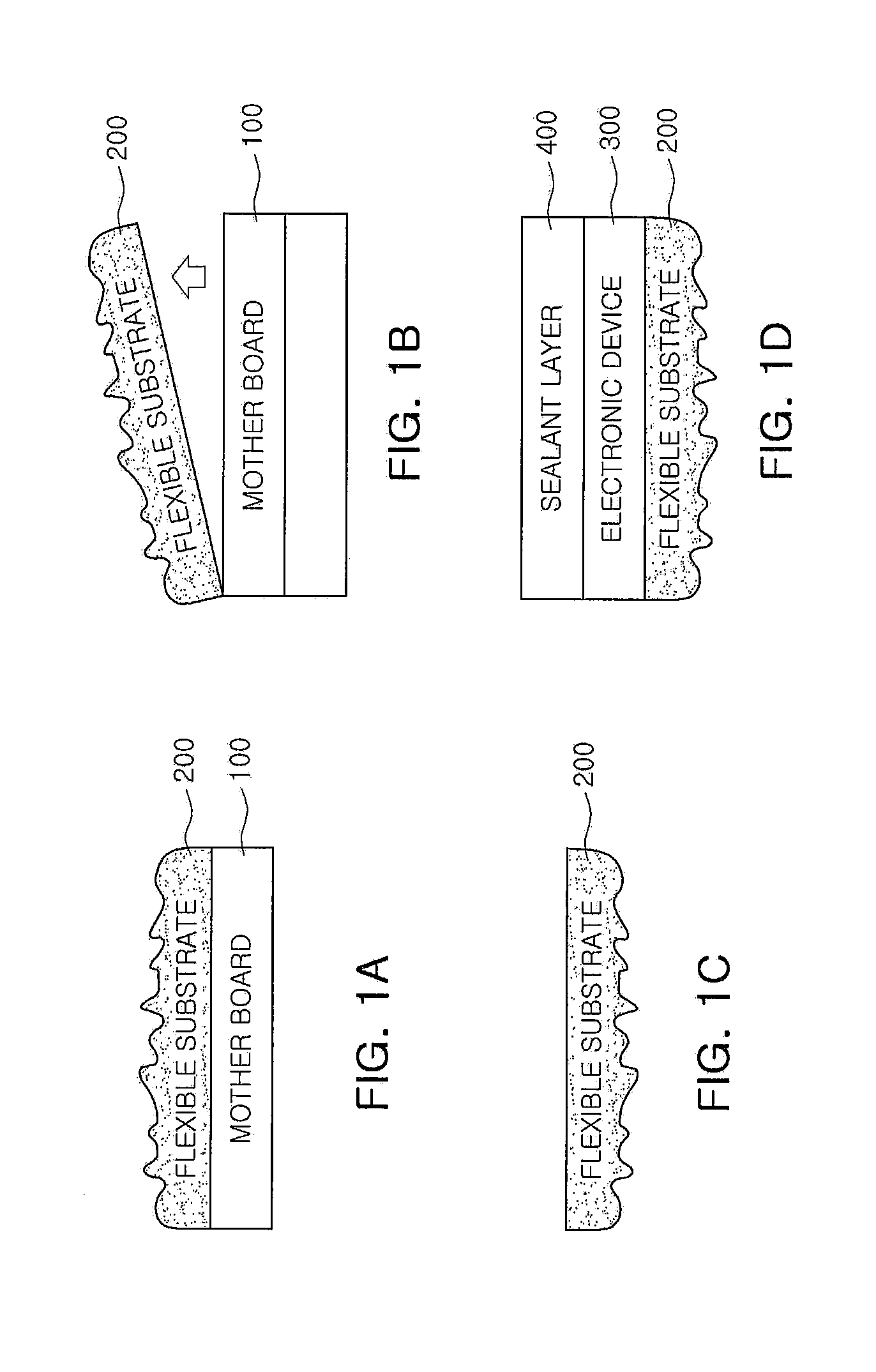

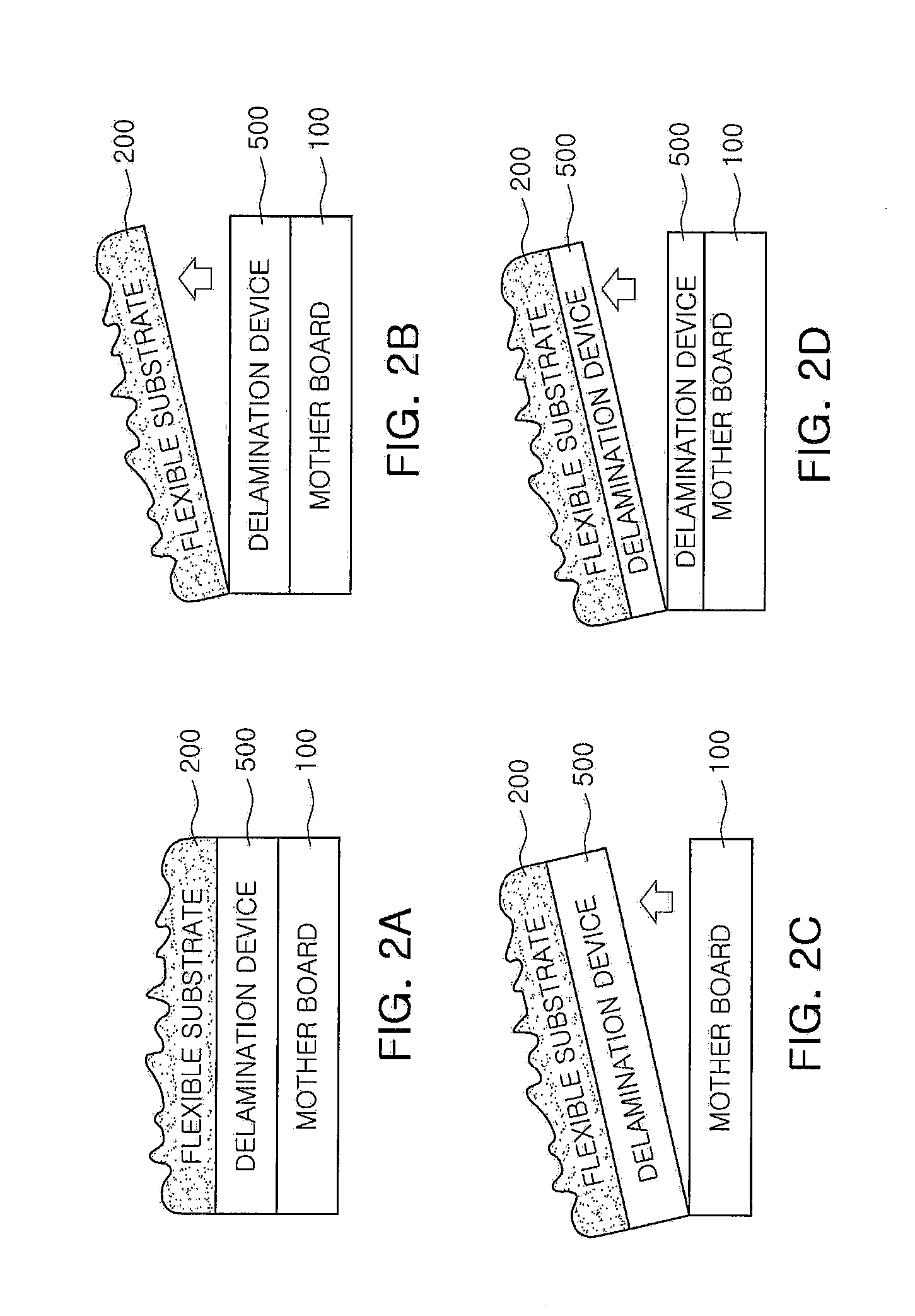

Flexible electronic device, method for manufacturing same, and a flexible substrate

InactiveUS20130105203A1Improve performanceLow costPrinted circuit assemblingCircuit bendability/stretchabilitySurface roughnessThermal expansion

The present invention relates to resolving issues concerning deterioration in the performance and yield of a flexible electronic device, caused by low manufacturing temperatures, high degrees of surface roughness, a high thermal expansion coefficients, and bad handling characteristics of typical flexible substrates. The method for manufacturing a flexible electronic device according to the present invention includes: forming a flexible substrate on a motherboard while physically separating the interface therebetween so that the interfacial bonding therebetween has a yield strength less than that of the flexible substrate; and forming an electronic device on the separated surface of the flexible substrate which had previously been in contact with the motherboard.

Owner:POHANG IRON & STEEL CO LTD

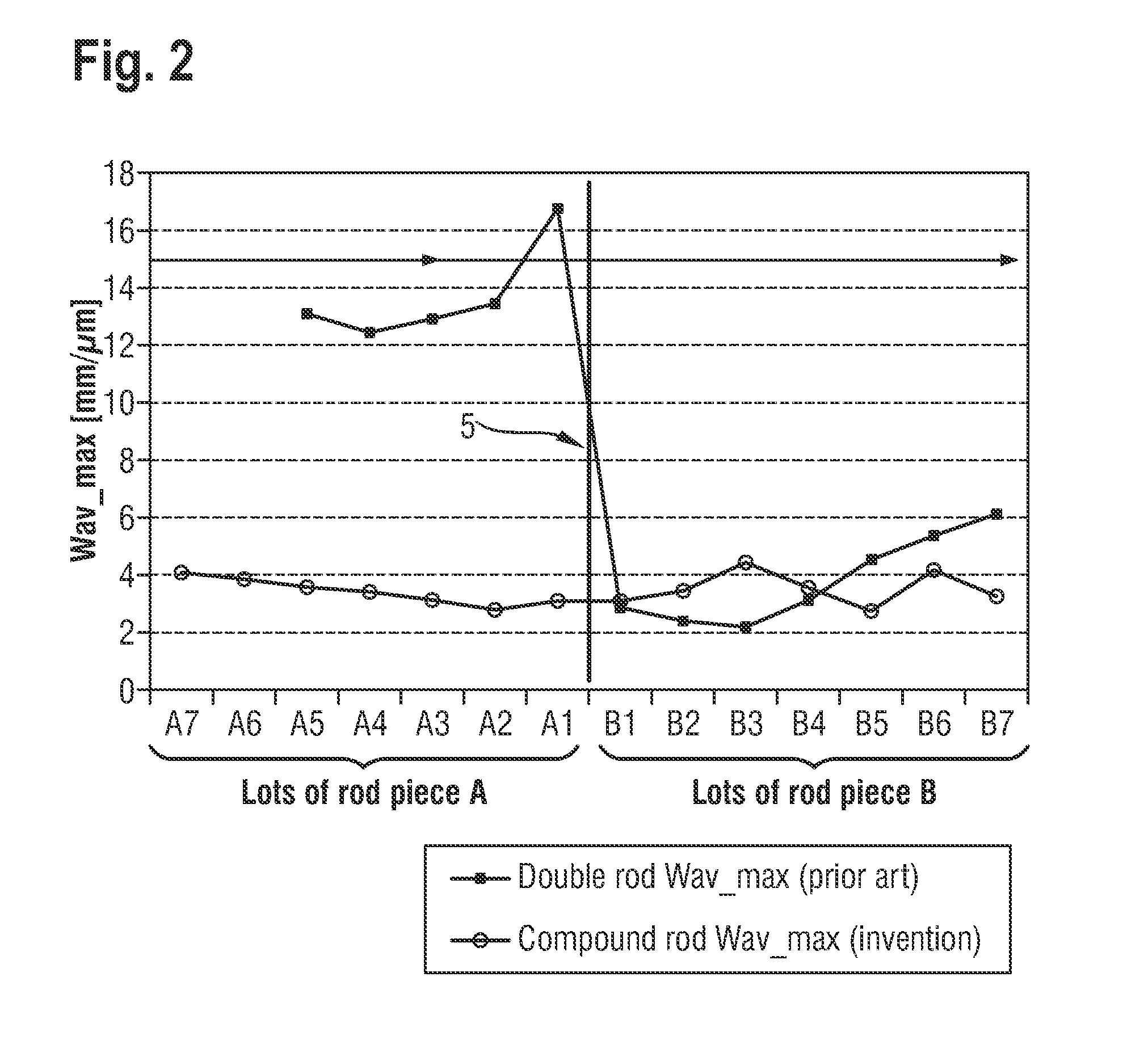

Method for simultaneously cutting a compound rod of semiconductor material into a multiplicity of wafers

ActiveUS20100089209A1Additional warpingSuppress mutationLamination ancillary operationsLaminationSemiconductor materialsEngineering

A method for simultaneously cutting a compound rod of semiconductor material into a multiplicity of wafers. The method includes selecting a first workpiece and a second workpiece, each having two end surfaces; grinding at least one of the two end surfaces of each workpiece so as to create a ground end surface on each workpiece; cementing the ground end surface of the first workpiece to the ground end surface of second workpiece using a fastener so as to produce a compound rod piece having a longitudinal axis, wherein the fastener is disposed between the workpieces so as create a distance between the workpieces; fixing the compound rod piece in a longitudinal direction on a mounting plate; clamping the mounting plate with the compound rod piece in a wire saw; and cutting the compound rod piece perpendicularly to the longitudinal axis using the wire saw.

Owner:SILTRONIC AG

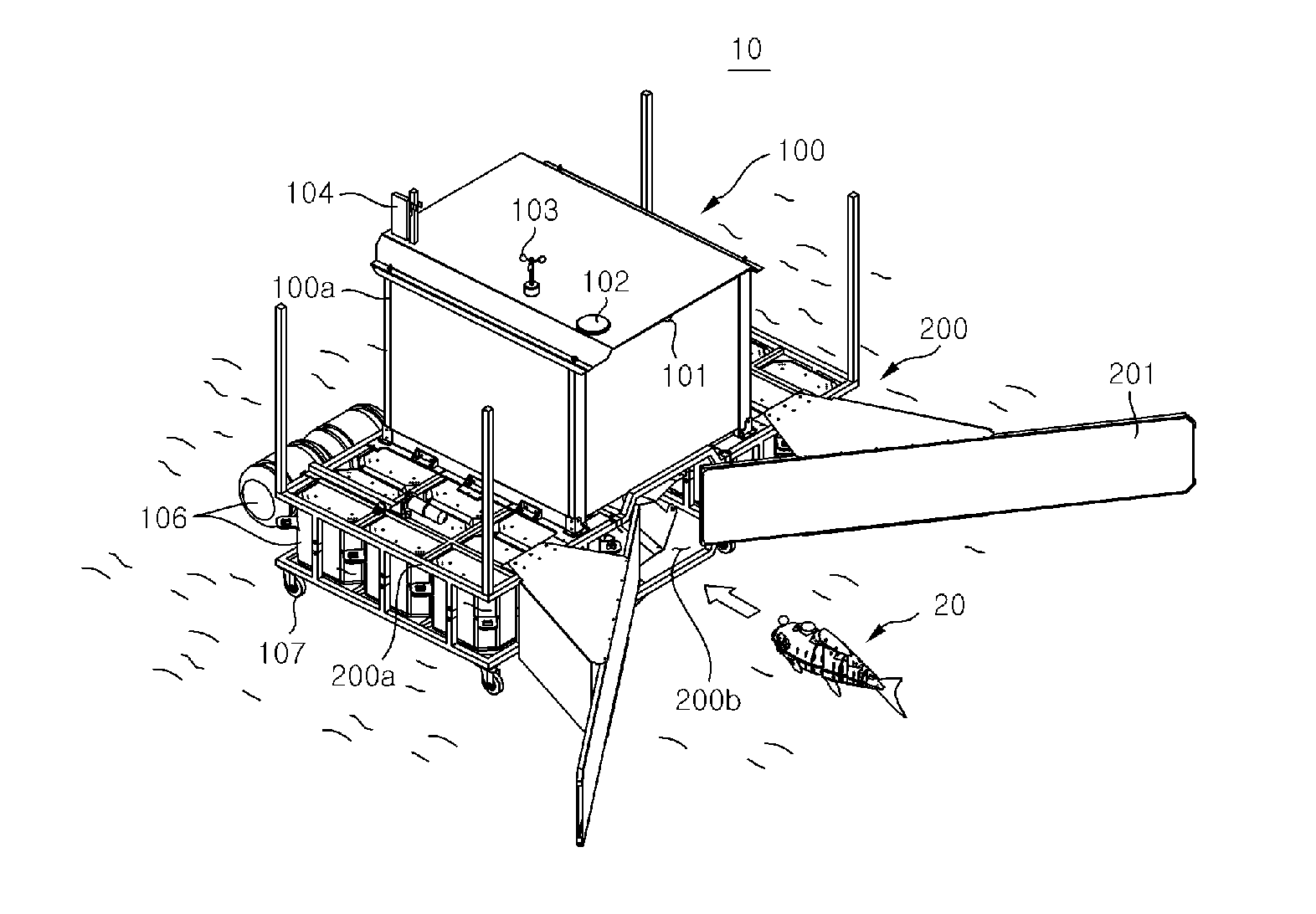

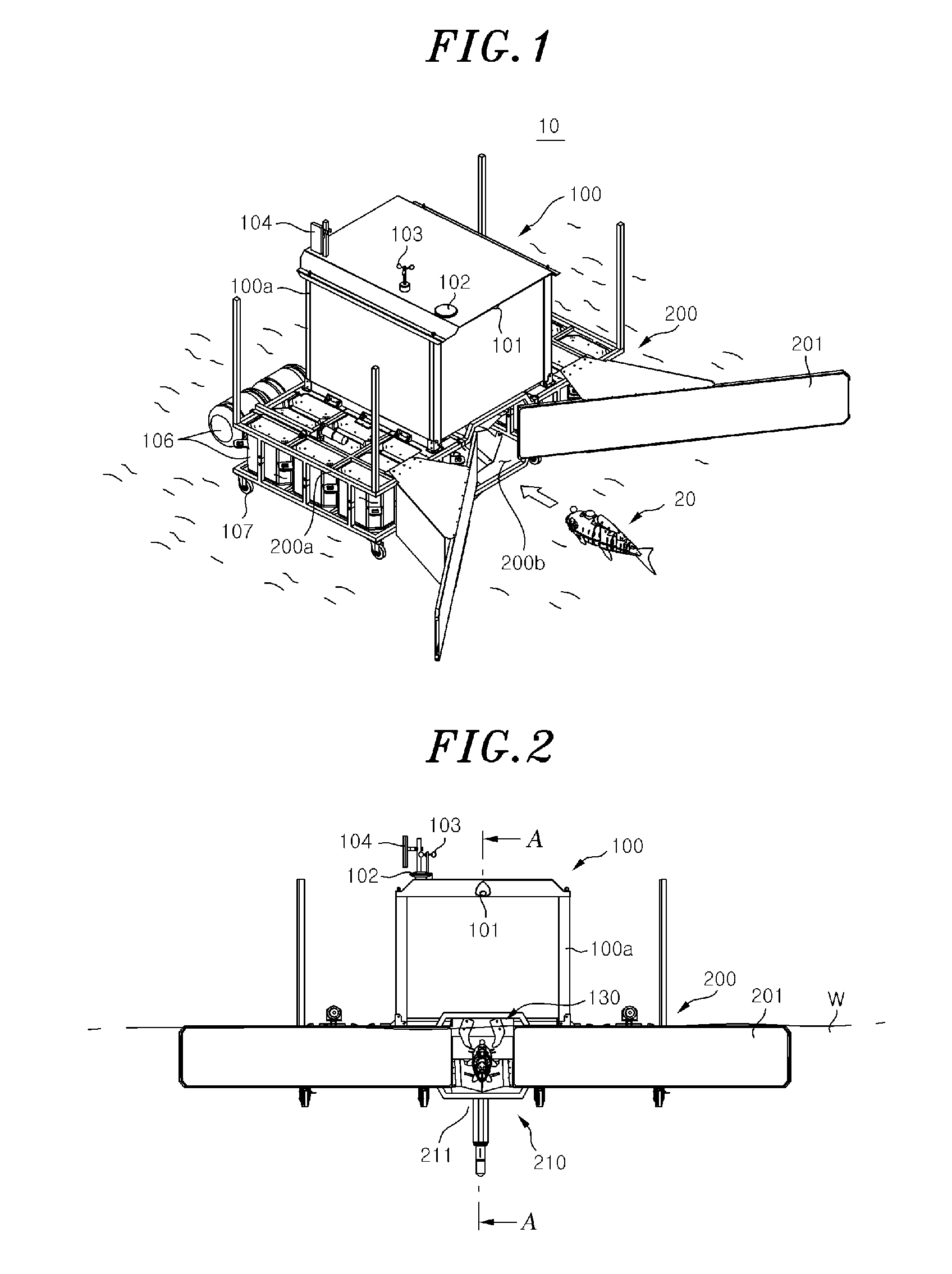

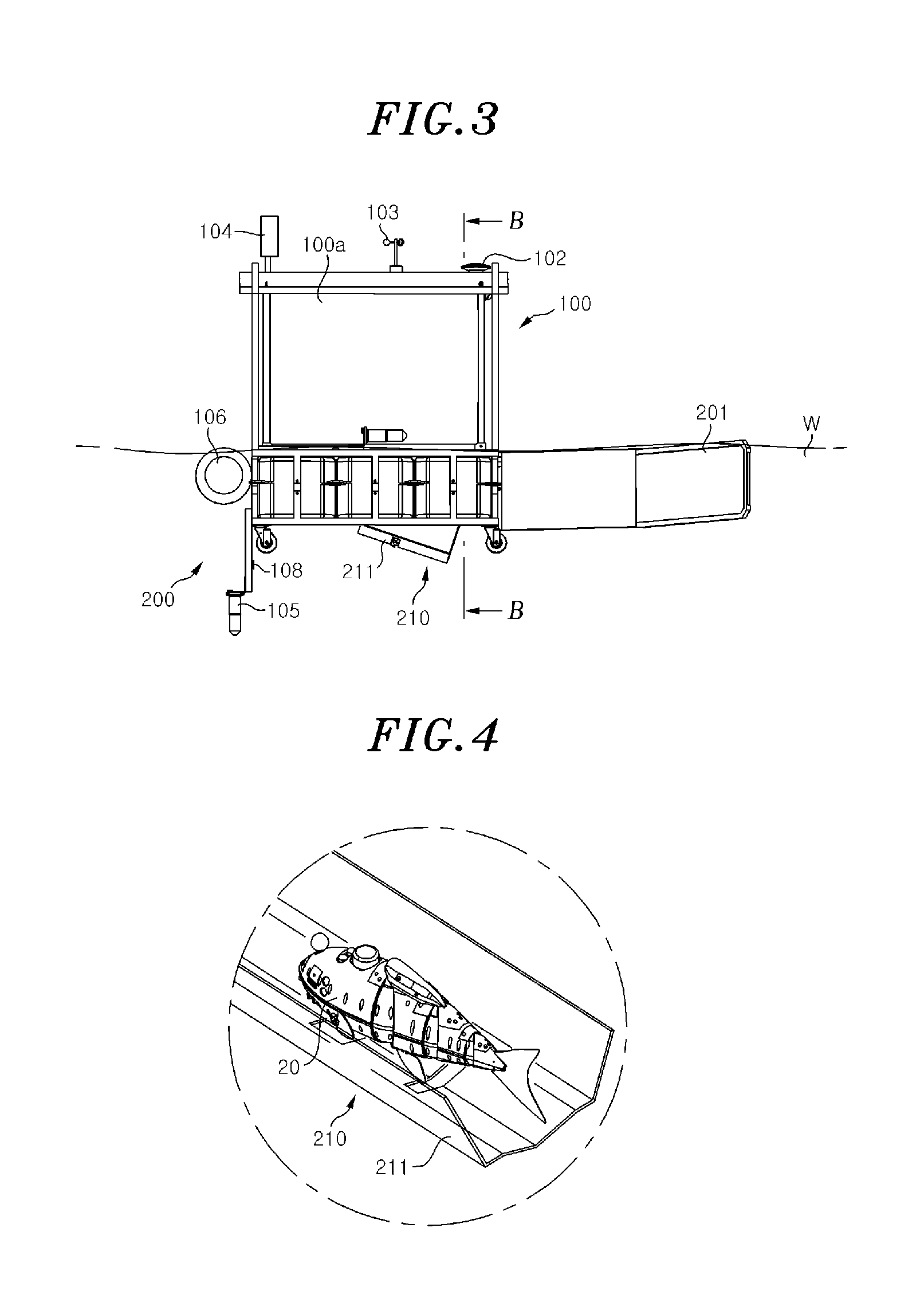

Docking station for underwater robot

ActiveUS20150251739A1Charging safetyKeep clean and dryCargo handling apparatusPassenger handling apparatusDocking stationMarine engineering

The present disclosure relates to a docking station whereby an underwater robot can be maintained, repaired and managed all the time. According to one aspect of the present disclosure, a docking station can be provided that may comprise: a receiving unit configured to receive an underwater robot therein and positioned under a surface of water; a maintenance unit provided on the receiving unit and positioned above the surface of the water; and a conveyor unit configured to convey the underwater robot from the receiving unit to the maintenance unit.

Owner:KOREA INST OF IND TECH

Method of producing composite members having increased strength

InactiveUS20070045886A1High compressive strengthLow compressive strengthPretreated surfacesLaminationPolymer chemistryStructural load

This invention relates to extruded composite materials specifically focusing on the increasing load bearing capacity and the overall strength of composites. Injectable conformable structural core materials are used to replace foam cells inside extruded composite materials thereby increasing the overall load bearing stability and strength. The core materials are tailored to have a desired CTE with respect to the structural materials. The core materials may also incorporate fibers and solid structural fillers for increasing the strength of the composite member. The objective is to enable composite materials to have the highest structural load bearing capability possible so that these technologies can be used as the replacement of wood, in aerospace applications and for other purposes.

Owner:ECOPURO LLC

Method for extracting phytosterol from waste residues generated in biodiesel production and product thereof

InactiveCN101942007AHigh economic feasibilityHigh crude extraction rateSteroids preparationPurification methodsBiodiesel

The invention discloses a method for extracting phytosterol from waste residues generated in biodiesel production, comprising the following steps of: converting phytosterol in a combined state into free phytosterol through deep saponification; extracting the phytosterol through an organic solvent to prepare mother liquor of crude sterine; recovering the solvent to obtain a crude sterine product, wherein the extraction rate of the crude sterine can reach 88.6 percent; recrystallizing the crude sterine product through absolute ethyl alcohol to obtain high-purity phytosterol, wherein the purity of the obtained phytosterol can reach 91.3 percent, and the prepared phytosterol contains campesterol, stigmasterol and sitosterol. The invention has simple extraction and purification method, changes the produced waste residues of biodiesel into valuables and has a good industrial application prospect.

Owner:领先生物农业股份有限公司

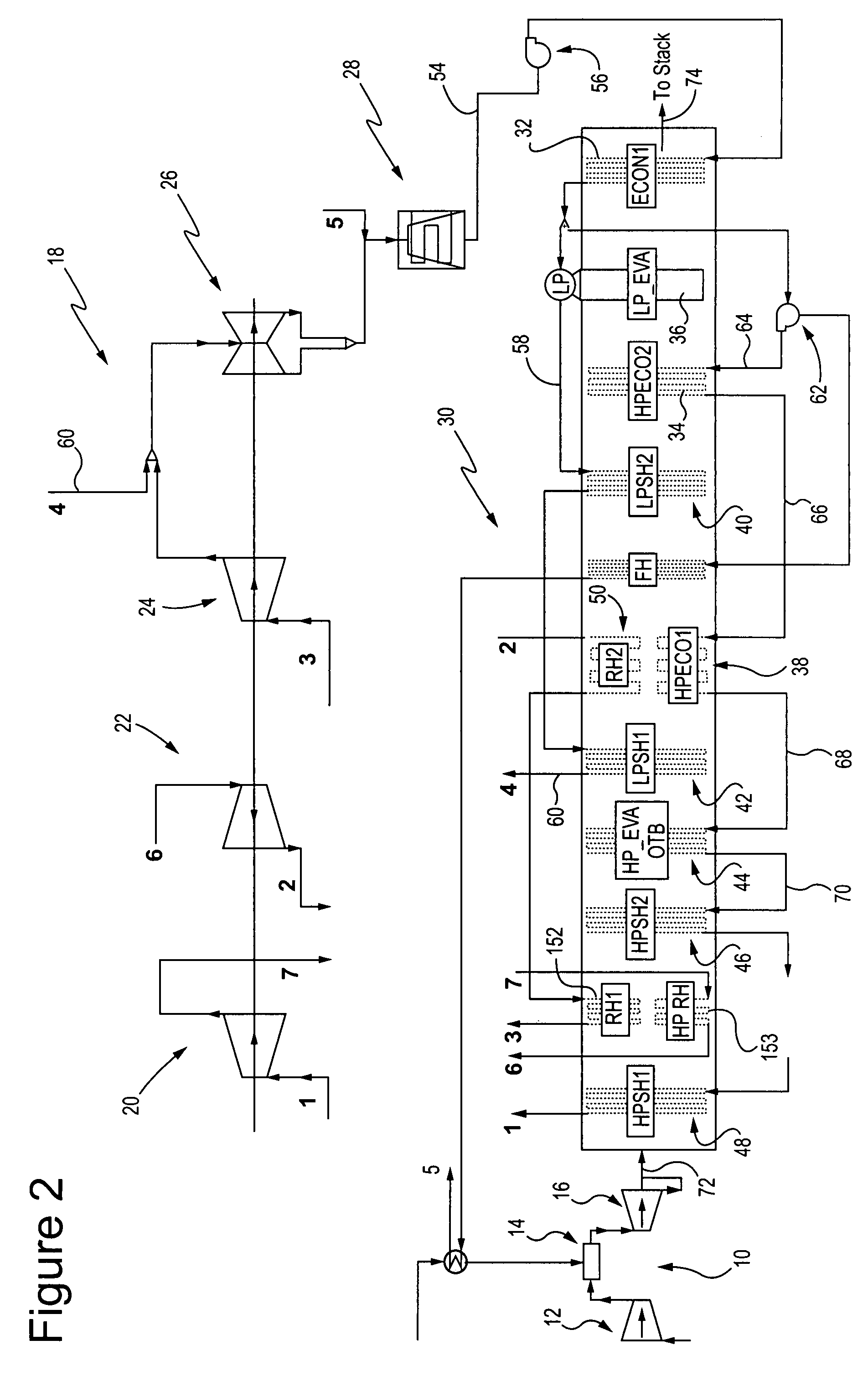

Supercritical steam combined cycle and method

ActiveUS7874162B2Reduce irreversibilityCombined cycle performanceGas turbine plantsSteam engine plantsExhaust fumesEngineering

A supercritical steam combined cycle system including a gas turbine; a supercritical steam turbine system including a supercritical section, a high pressure section, an intermediate pressure section and at least one low pressure section; and a supercritical steam heat recovery steam generator (HRSG) for receiving exhaust gas from the gas turbine for heating fluid from the steam turbine system. The HRSG includes a supercritical evaporator arranged to supply steam to a superheater between the supercritical evaporator and the inlet of the HRSG and a reheater receiving cold reheat steam from and returning reheated steam to the steam turbine system. The reheater includes a first section disposed downstream of and a second section disposed upstream of the supercritical evaporator along the exhaust gas flow path. Cool reheat steam from the steam turbine system is received by the first reheater section and steam leaving the first reheater section is supplied to the second reheater section upstream of the supercritical evaporator.

Owner:GE INFRASTRUCTURE TECH INT LLC

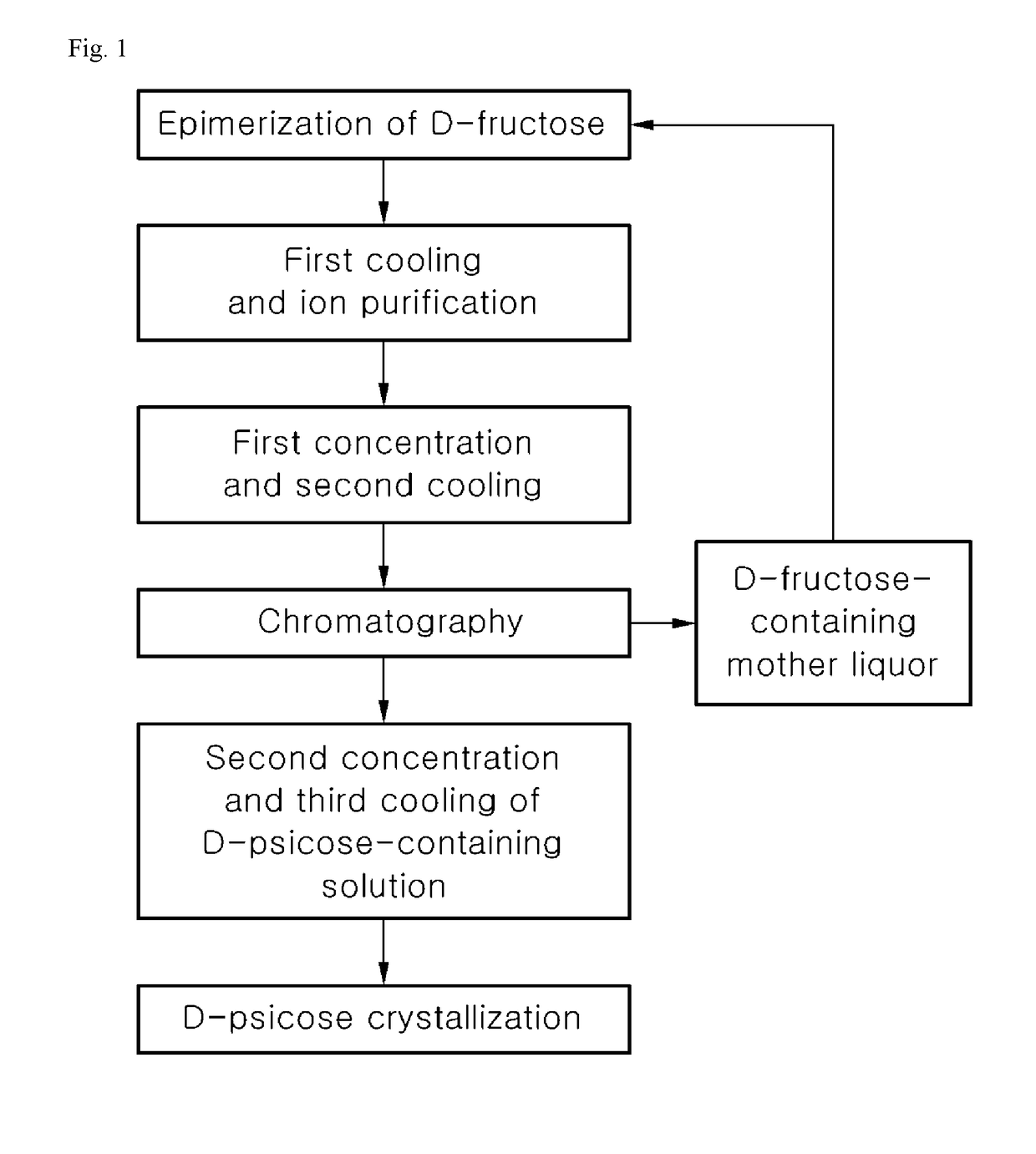

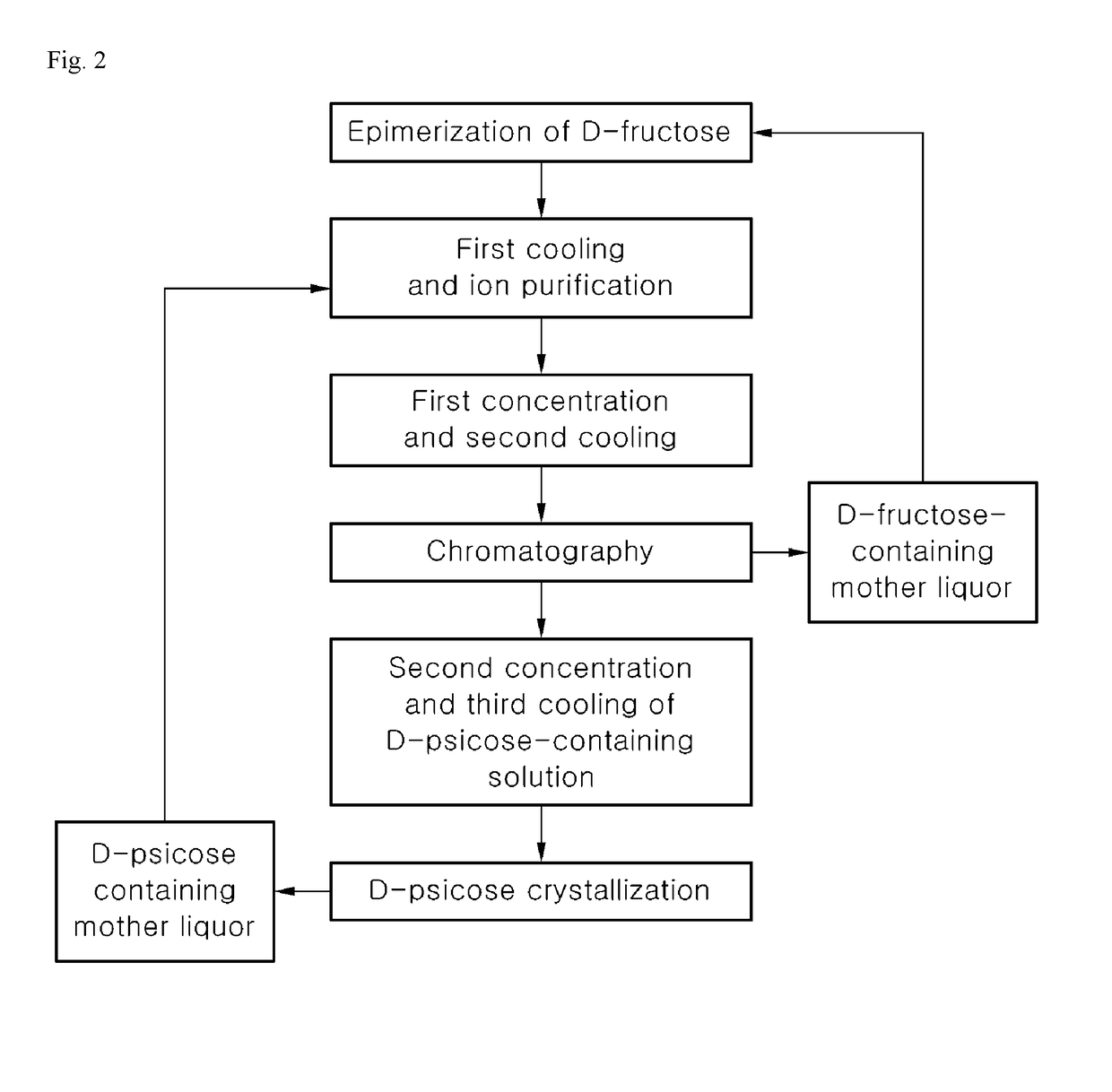

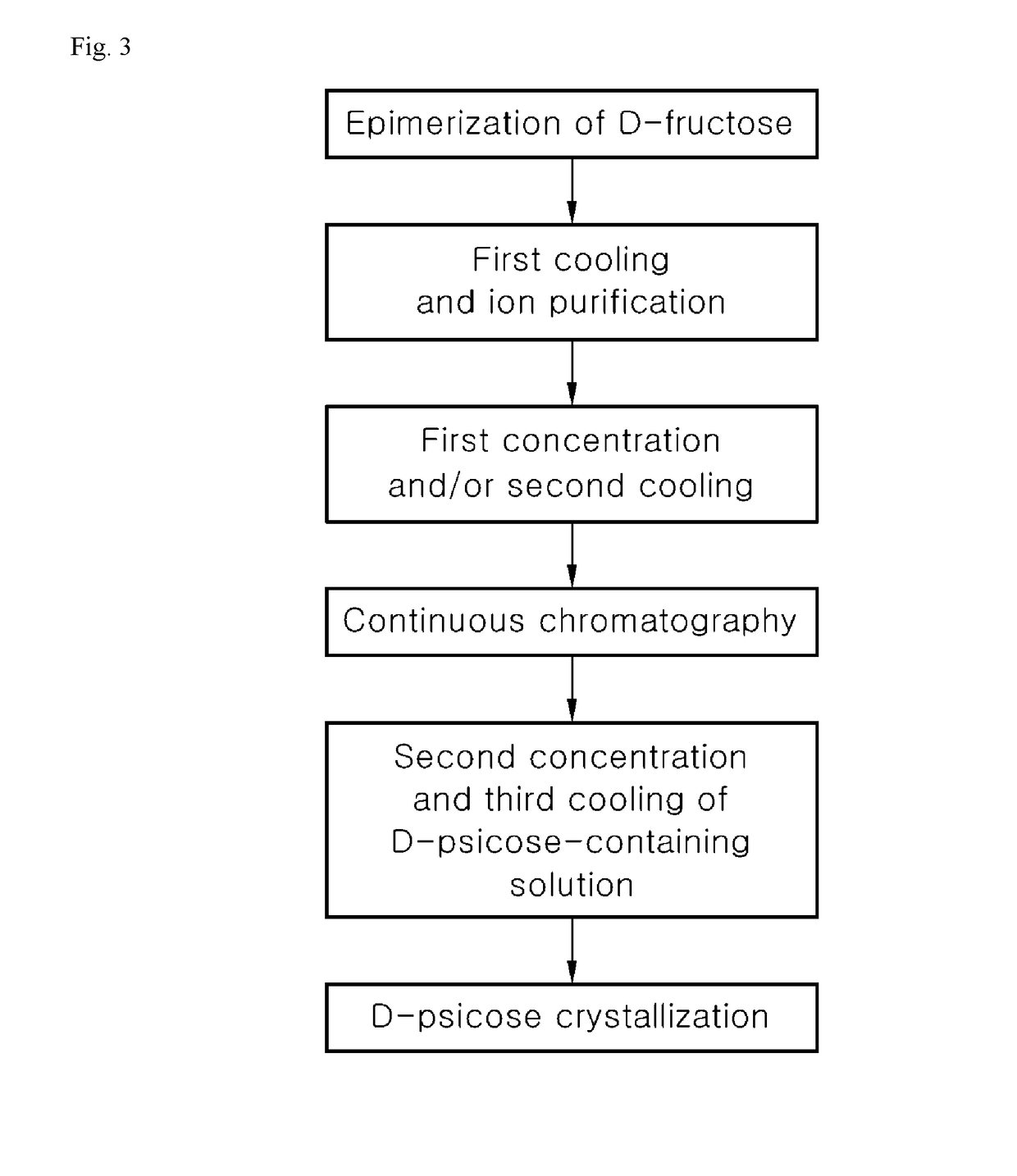

Method of producing high purity d-psicose

ActiveUS20180327796A1Prevent thermal deformationHigh yieldCation exchanger materialsOrganic anion exchangersChromatographic separationD fructose

Disclosed herein is a method of producing D-psicose. The method of producing D-psicose includes subjecting D-fructose to D-psicose epimerization to produce a D-psicose-containing solution, subjecting the D-psicose-containing solution to first cooling and ion purification, subjecting the purified D-psicose-containing solution to first concentration and second cooling, subjecting the D-psicose-containing solution, which has been subjected to first concentration and second cooling, to chromatography to obtain a D-fructose-containing mother liquor and a D-psicose-containing separated solution, and subjecting the D-psicose-containing separated solution to second concentration and third cooling to obtain D-psicose crystals, wherein the D-fructose-containing mother liquor produced by chromatography is reused in the D-psicose epimerization.

Owner:CJ CHEILJEDANG CORP

Method for reinforced ultrafiltration treatment of phenol-containing waste-water by ultrafiltration membrane

InactiveCN101157492AIncrease the amount of solubilizationHigh removal rateWater contaminantsWater/sewage treatment bu osmosis/dialysisFiltration membranePhenol

The invention discloses a method for ultra-filtration membrane strengthened ultra-filtration treatment of phenol-containing sewage. The method comprises: first adding cetylpyridinium chloride which is a cationic surfactant, and sodium carbonate into the phenol-containing sewage, stirring uniformly and standing for reaction where cetylpyridinium chloride monomer molecules produce micelles by self-assembly and then solubilize the phenol contained in the water; pumping the water to an ultra-filtration component for filtration where the cetylpyridinium chloride micelles with being solubilized the phenol contained in the water are intercepted by the ultra-filtration membrane so that the phenol contained in the water is removed. The phenol concentration in the sewage is 5mg / L-200mg / L; the addition of cetylpyridinium chloride is 20*10<-3>mol / L-30*10<-3>mol / L; the addition of sodium carbonate is 1*10<-3>mol / L-20*10<-3>mol / L; the weight of molecules intercepted by the ultra-filtration membrane is 6000-10000Dalton; the membrane operation pressure is 0.05MPa-0.20MPa. The method is carried out in an intermittent type, and the standing reaction time is 0.5-10h. In treating the phenol-containing sewage, the invention has excellent phenol removal performance, low energy consumption, simple operation, low surfactant consumption and low cost. In addition, the surfactant and the phenol can be recycled.

Owner:HUNAN UNIV

Device and method for accurately and visually testing soil displacement in seismic piping destroy

ActiveCN108169453AEasy to operateHigh economic feasibilityEarth material testingImaging processingEngineering

The invention discloses a device and method for accurately and visually testing soil displacement in seismic piping destroy. The device comprises a water supply device and a transparent model box. Thetransparent model box is lower than the water supply device. The bottom of the transparent model box is provided with an interface communicated with the water supply device. A plurality of pore pressure measuring devices are equidistantly disposed in the transparent model box. The device also comprises a shaking platform for storing the transparent model box, a water head adjustment mechanism foradjusting water head height of the water supply device, and a digital observing system. Through combination of saturated transparent soil samples and a particle image processing technology, the problem that the soil internal deformation and displacement field cannot be continuously measured and are invisible in soil piping destroy under action of earthquake is solved so that the piping destroy process visualization is realized under action of earthquake.

Owner:HOHAI UNIV

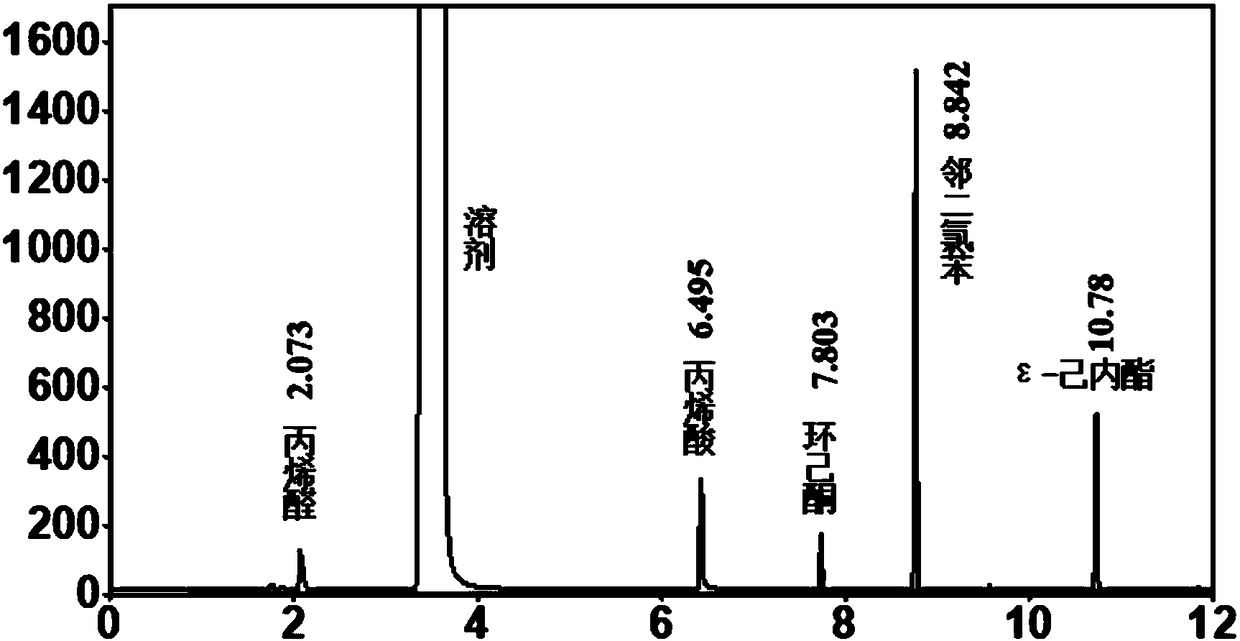

Method used for preparing epsilon-hexanolactone

ActiveCN106397386AHigh industrial valueReduce consumptionPhysical/chemical process catalystsCarboxylic acid ester formation/introductionCyclohexanoneOrganic solvent

The invention discloses a method used for preparing epsilon-hexanolactone. According to the method, cyclohexanone, an auxiliary oxidant, and a certain amount of a catalyst are added into a certain amount of an organic solvent, molecular oxygen is taken as an oxidizing agent, and stirring reaction is carried out for 0.1 to 24h at 60 to 100 DEG C under 0.1 to 2MPa, wherein the auxiliary oxidant is acrolein, and the catalyst is a carbon material. The method is high in auxiliary oxidant efficiency; the catalyst is simple, is easily available, and is convenient to recycle; the oxidizing agent is green, and is friendly to the environment; operation is simple; and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

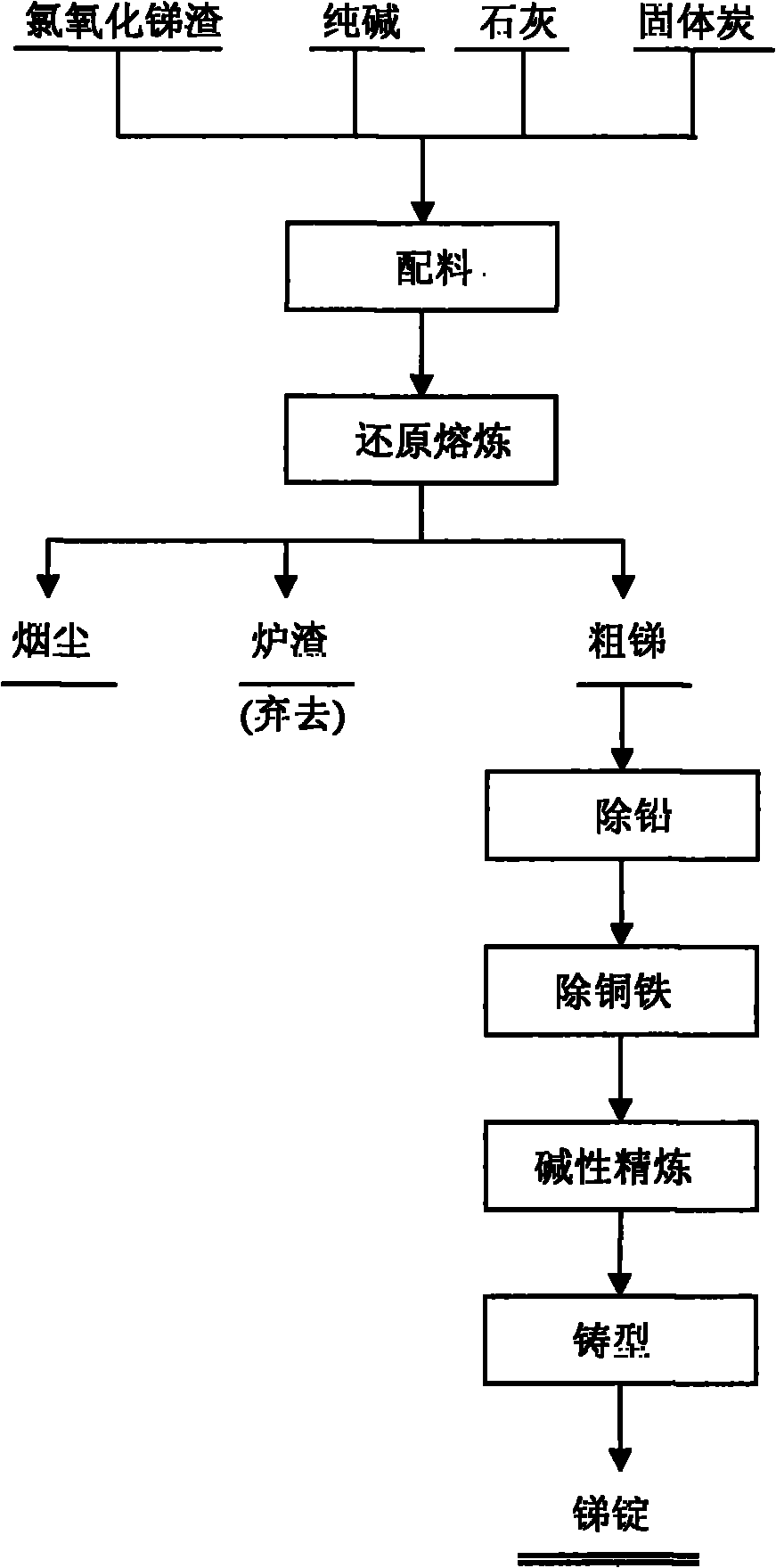

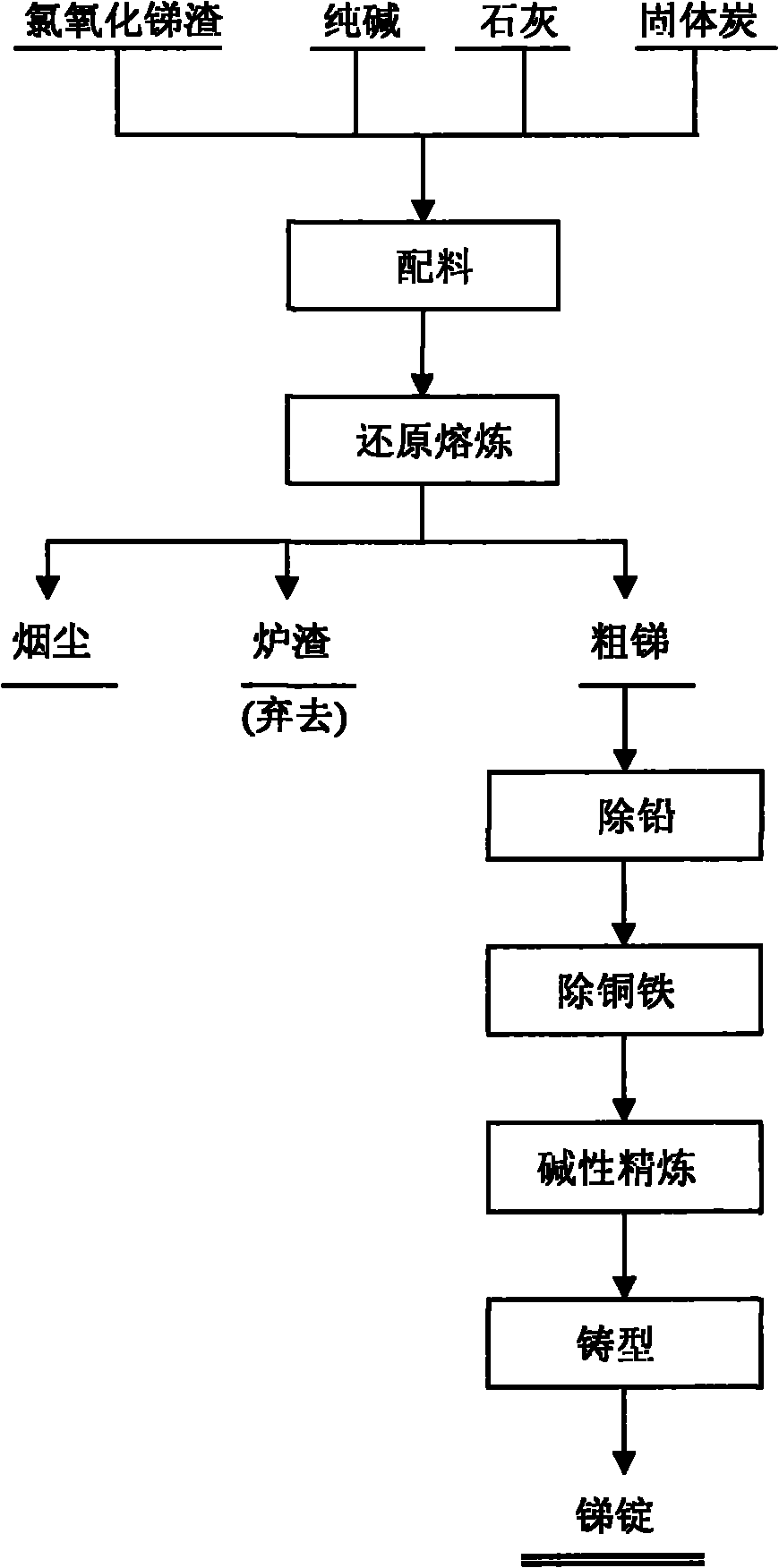

Production method for recovering antimony from antimonyoxychloride

ActiveCN101818266AHigh recovery rateHigh economic feasibilityProcess efficiency improvementReverberatory furnaceSulfide

The invention relates to a method for recovering antimony from antimonyoxychloride, which comprises the steps of furnace drying, reducing and smelting, coarse antimony refining and casting. The method is characterized in that in the step of reducing and smelting, antimonyoxychloride slag, soda ash, lime and solid carbon are mixed in a certain proportion, the mixture is added into a reverberatory furnace batch by batch, the temperature of the furnace is raised to 1,100 to 1,200 DEG C, the smelting time of each batch is 8 to 12 hours and the pressure in the furnace is kept between 20 and 50Pa. The step of coarse antimony refining comprises adding ammonium dihydrogen phosphate to remove lead, adding sulfur to remove copper and iron and alkaline refining, namely adding ammonium dihydrogen phosphate to remove lead according to a conventional method first, then adding antimony sulfide or sodium sulfide according to copper and iron content to remove the copper and iron, and finally adding soda ash and introducing compressed air to remove arsenic, copper, iron and sulfur and the like. Compared with the prior art, the method has the advantages of short process flow, relatively low cost and over 94 percent of antimony recovery rate.

Owner:ZHUZHOU SMELTER GRP

Method for improving lignocellulose raw material enzymolysis efficiency and lignose recovery rate

ActiveCN105755883AHigh economic feasibilitySolve recycling difficultiesLignin derivativesPaper material treatmentFiberEnvironmental resistance

The invention provides a method for improving lignocellulose raw material (especially bamboo reed fiber raw material) enzymolysis efficiency and lignose recovery rate. According to the method provided by the invention, through methods of ionic liquid dissolving, solid acid catalyzing and raw material regenerating by an acetone water solvent, compact cell wall structures of bamboo reeds are broken, and regenerative raw materials with rough fiber surface and II crystal form cellulose are obtained, so that the problem that liquid acid catalytic-ion liquid is difficult to recycle is solved, and the bamboo reeds can be utilized for high value; lignose powder is recycled with higher yield through heating, decompressing and distilling, so that the problem that ionic liquid lignose is difficult to recycle is solved, and the time for lignose recycle is shortened; a pre-processing and seperation method is simple and convenient to operate; the used reagents can be recycled and reused so as to be green and environmentally friendly; the recycle of acetone is favorable to environment protection and health of operators; the economic feasibility of ionic liquid pre-processing is improved.

Owner:山东银鹰化纤有限公司

Preprocessing method for measuring desaturase liveness of drinking water biological active carbon treatment process

InactiveCN101256147AEasy to get materialsReduce operating costsMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementPretreatment methodDesorption

The invention provides a dehydrogenase activity detection pretreatment method used in drinking water biological active carbon treatment technique, which is a mixed solution composed of three kinds of reagents, under the control of adding proportionment, adding time and operational condition, the pretreatment is finished, thereafter the measuring process is selected and the specification curve is drawn. The invention has the advantages that, from the chemical angle, using organic reagent to extract and elute the adsorbed microorganism, the desorption degree is high; testing the active carbon carried dehydrogenase activity with effective proportioning and oscillation mode, and confirming the optimum organic solvent combination and proportioning for achieving the maximum measuring effect; providing the reference for similar biological carrier activity test, which is suitable for biological activity test of biological carrier in drinking water treatment technique.

Owner:HOHAI UNIV

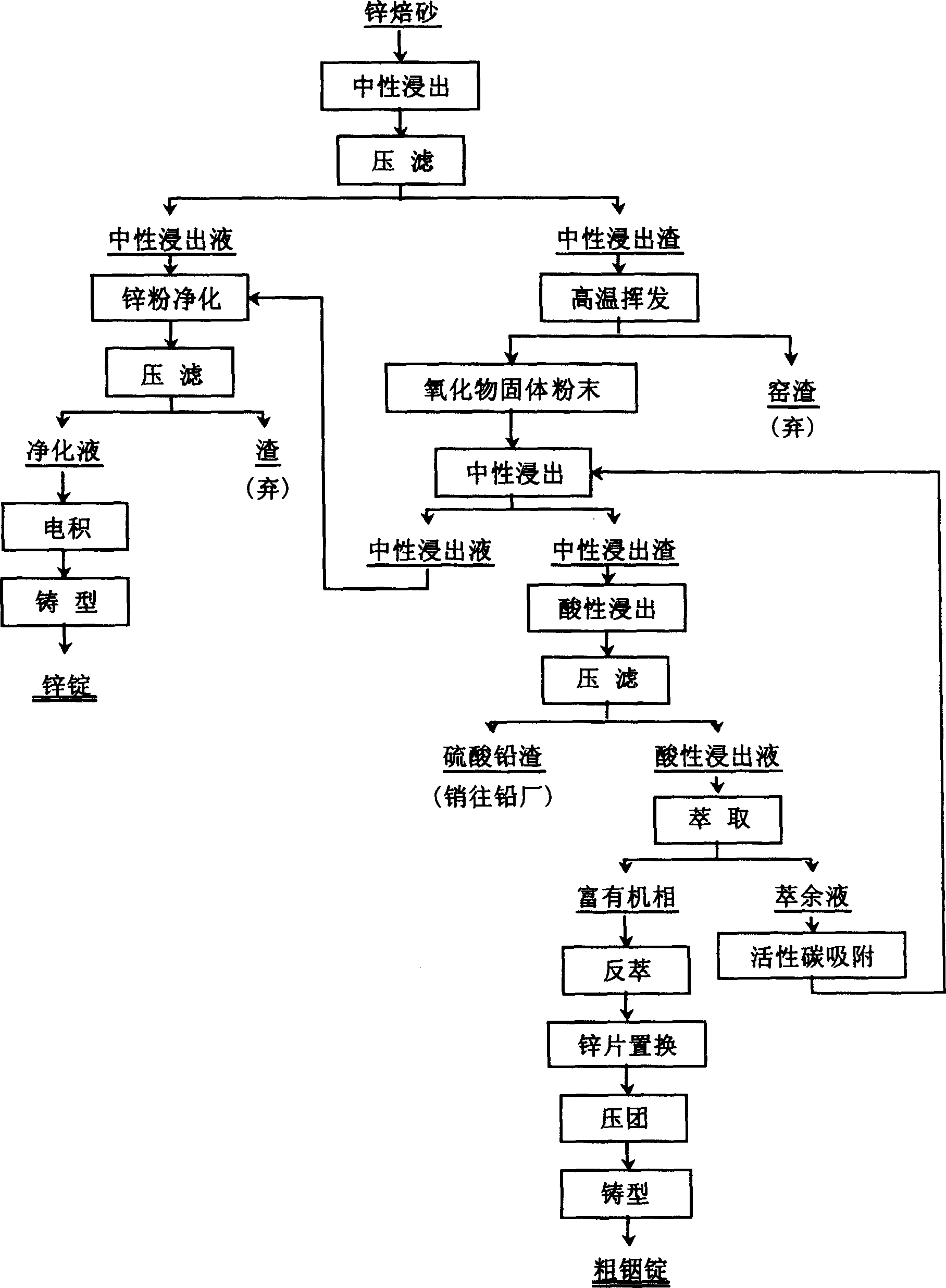

High Iron zinc calcine process method

ActiveCN1730683AReduce material handlingReduce manufacturing costProcess efficiency improvementSlagIndium

The invention relates to a method for smelting zinc, more specifically a method for processing zinc roasting-sand comprising the following steps, dissolving most of the easy-recovering, zinc oxide form zinc into solution through the conventional neutral extraction method, subjecting the neutral lixiviated slag to high-temperature volatilization processing, so as to separate zinc and ferrum, and as a result, the zinc oxide, lead oxide, and indium oxide can be separated in sequence.

Owner:株洲冶炼集团有限责任公司

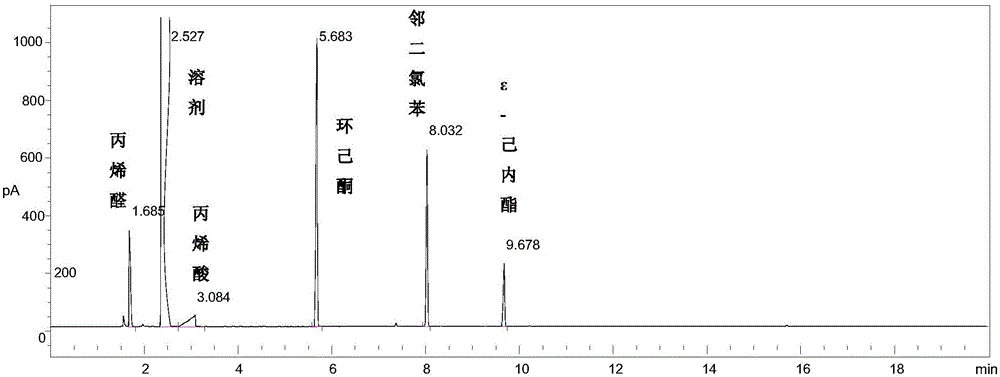

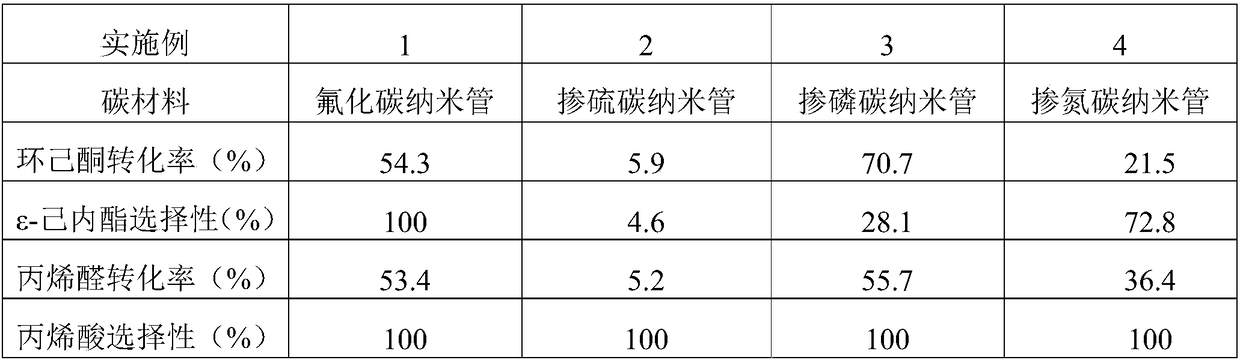

Method for preparing epsilon-caprolactone by using carbon nanotube

InactiveCN108558819AReduce consumptionEasy to separatePhysical/chemical process catalystsOrganic compound preparationCyclohexanoneOrganic solvent

The invention discloses a method for preparing epsilon-caprolactone by using a carbon nanotube. In the method, cyclohexanone, a pro-oxidant and a certain amount of catalyst are added into a certain amount of organic solvent, the molecular oxygen is taken as the oxidizing agent, the pro-oxidant is acrolein, the catalyst is a carbon material, and the mixture is stirred and reacted for 0.1-24 hours at the pressure of 0.1-2 MPa at the temperature of 50-90 DEG C. The method has the advantages that the efficiency of the pro-oxidant is high, the selectivity of the epsilon-caprolactone and crylic acidis high, the catalyst is easy to recycle, the oxidizing agent is green and environmentally friendly, the operation is simple, and the cost is low.

Owner:SOUTH CHINA UNIV OF TECH

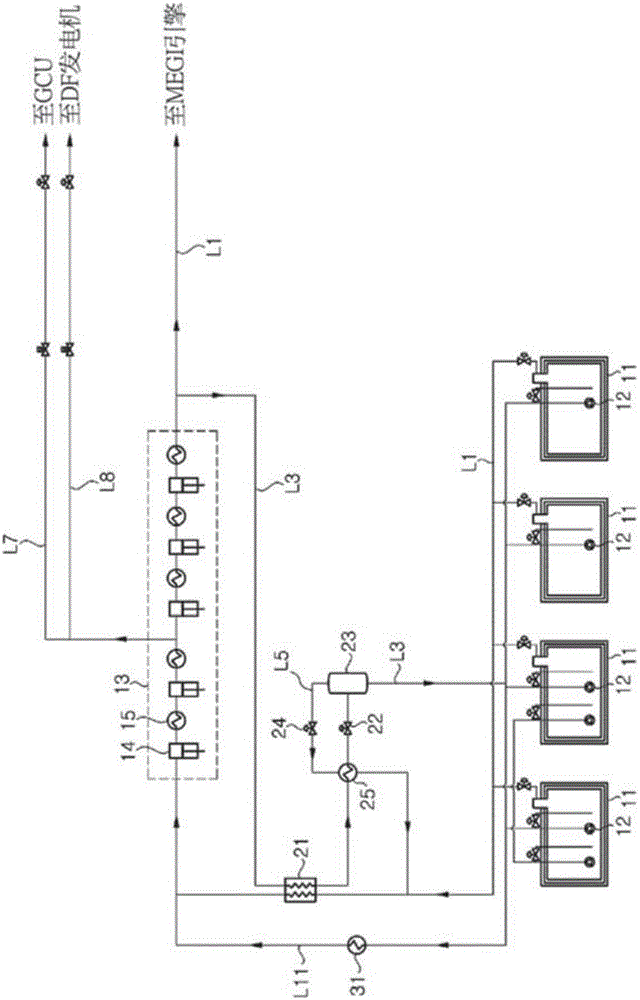

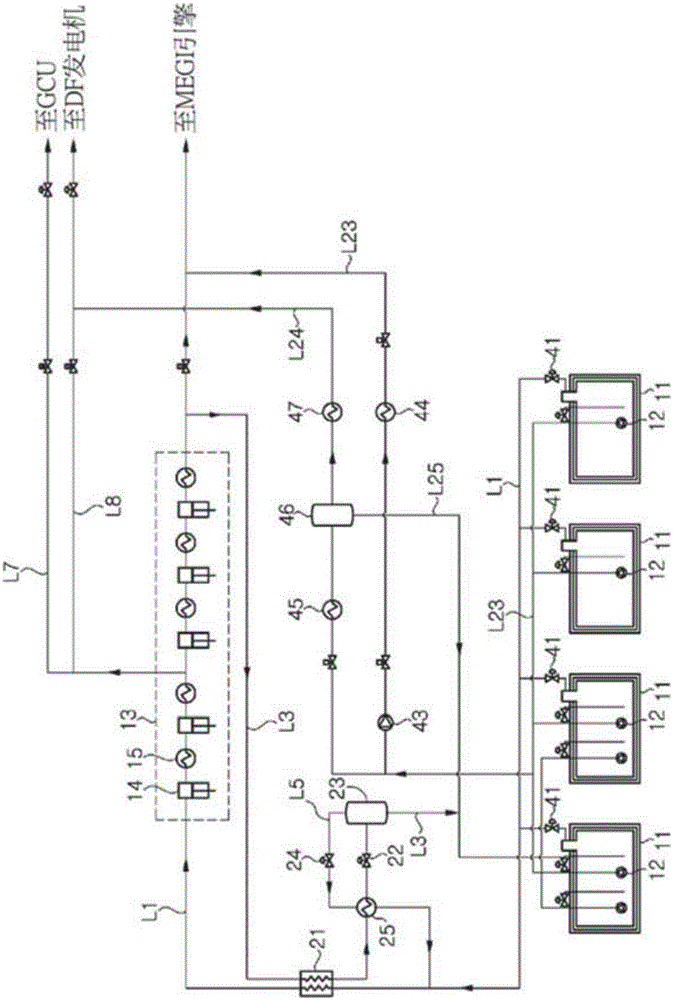

Boil-off gas treatment system

ActiveCN106029491ALower initial installation costsReduce equipment sizeSolidificationLiquefactionProcess engineeringEngineering

A boil-off gas treatment system is disclosed. The boil-off gas treatment system according to the present invention comprises: a compressor which compresses boil-off gas that is generated in an LNG storage tank of a ship or floating structure; a heat exchanger which cools the boil-off gas that has been compressed in the compressor using boil-off gas that is to be introduced into the compressor by means of exchanging heat therebetween; an expansion means which adiabatically expands the boil-off gas that was cooled in the heat exchanger; a gas-liquid separator which separates the boil-off gas that was adiabatically expanded in the expansion means into gas and liquid, and supplies liquefied natural gas to the LNG storage tank; and a bypass line which supplies the adiabatically-expanded boil-off gas from the downstream of the expansion means to the downstream of the gas-liquid separator.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

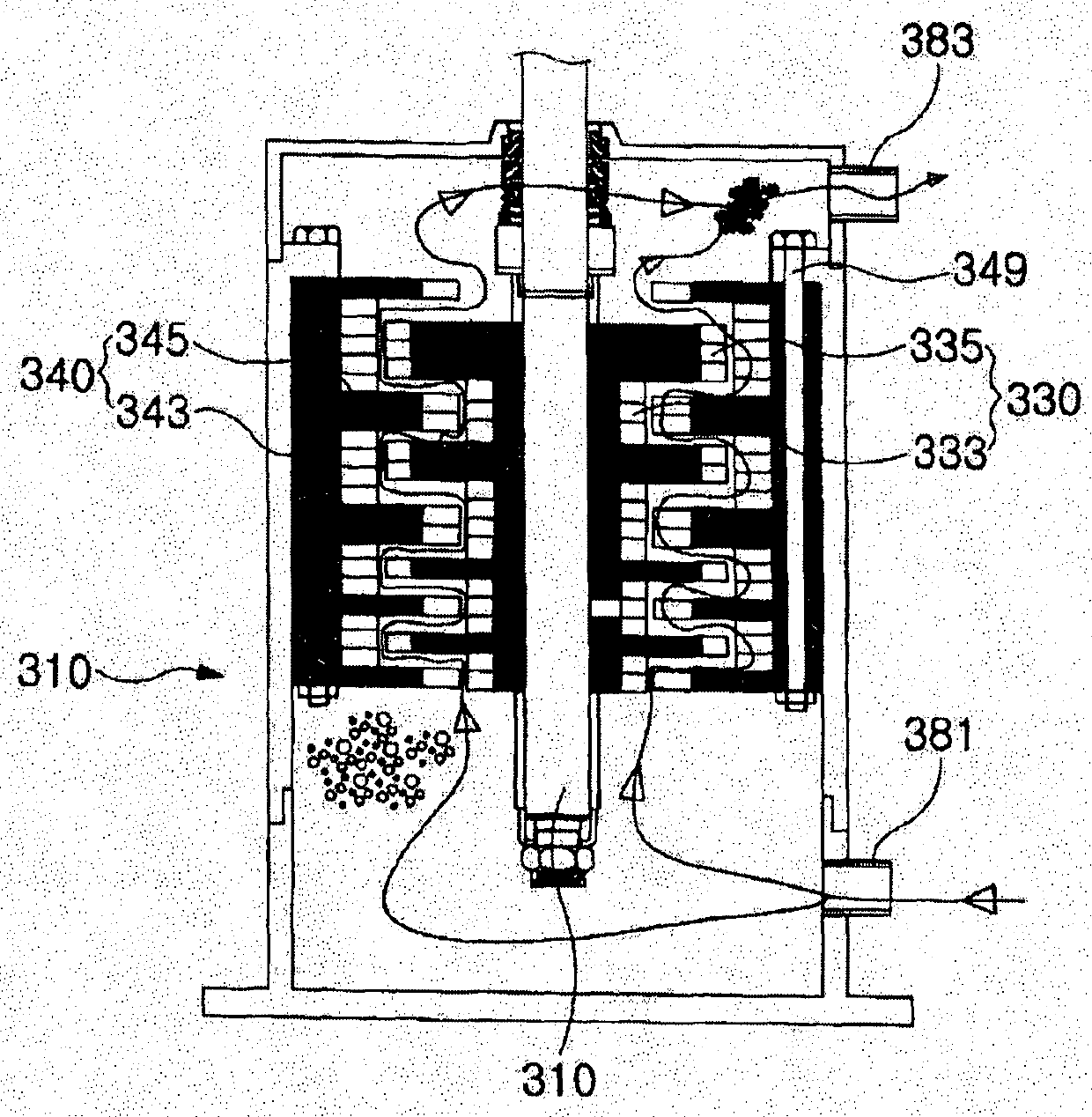

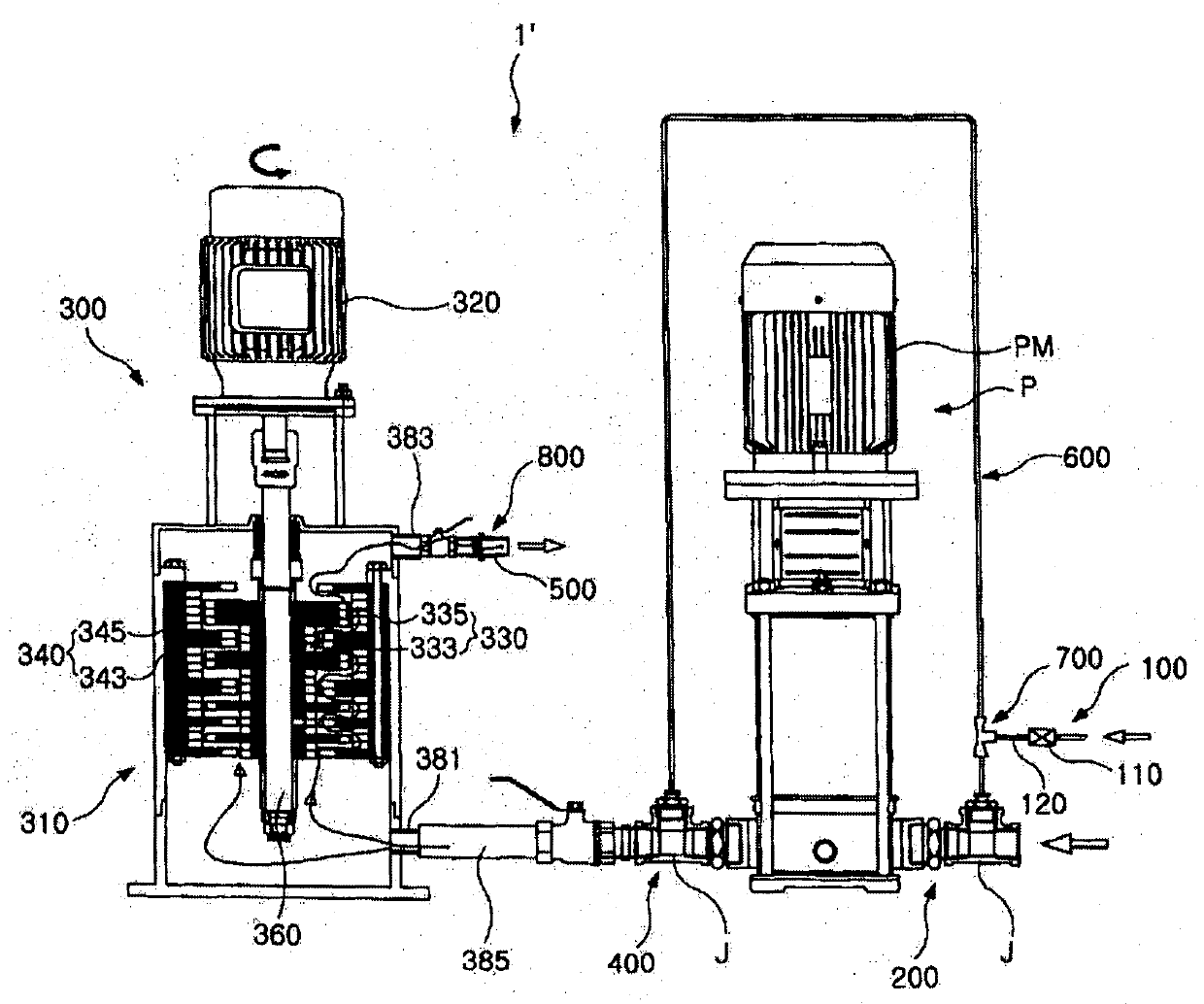

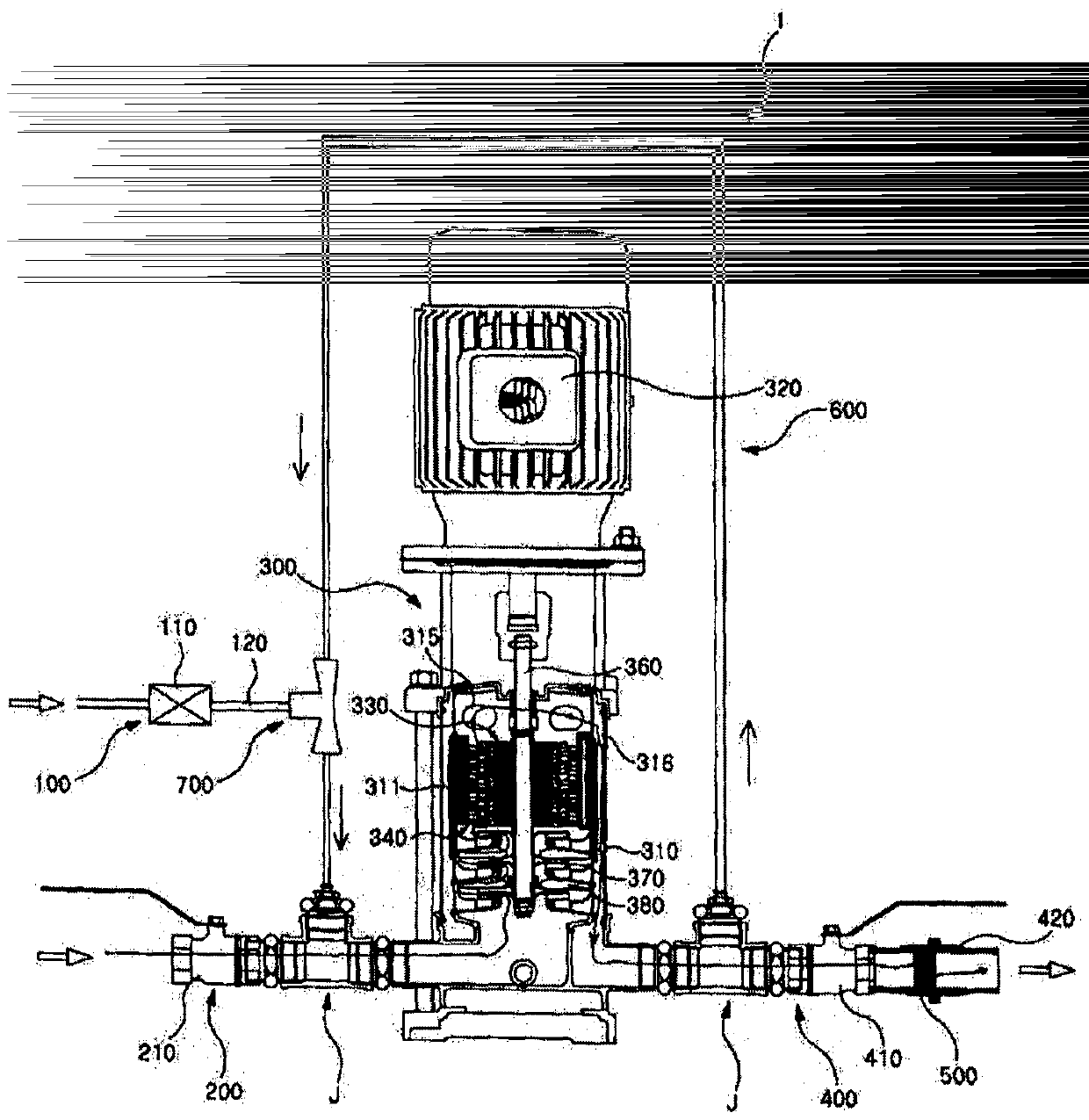

Nanobubble-and-hydroxyl-radical generator and system for processing polluted water without chemicals using same

InactiveCN107922226AEnhanced mixing processImprove dissolution rateFlow mixersWater treatment compoundsDrive shaftEnvironmental engineering

Owner:NABAS GRP INC

Treating method for pulping black liquor

InactiveCN102953286AImprove economic viability and industrial applicabilityReduce manufacturing costRegeneration of alkali lyePollutantChemistry

The invention relates to a treating method for pulping black liquor. According to the invention, a novel process of separating the pulping black liquor from an aqueous solution containing acid by using a diaphragm is utilized, wherein the diaphragm comprises a cation permselective membrane, a filter cloth or a filter screen, a variety of by products with a high added-value such as lignin, white carbon black, salt, sugar, reusable water and the like are separated from the pulping black liquor, so economic feasibility and industrial applicability of process flow are improved, particularly the problem of great consumption of acid in a traditional acid precipitation method is overcome, production cost is reduced, and secondary pollution of acidic waste water is avoided, e.g., waste of acid and cost of lime during neutralization of waste water produced in acid precipitation by using lime in a traditional method are avoided; moreover, the purpose of economical and effective neutralization treatment of acidic waste water without bringing of new pollutants is achieved.

Owner:秦才东

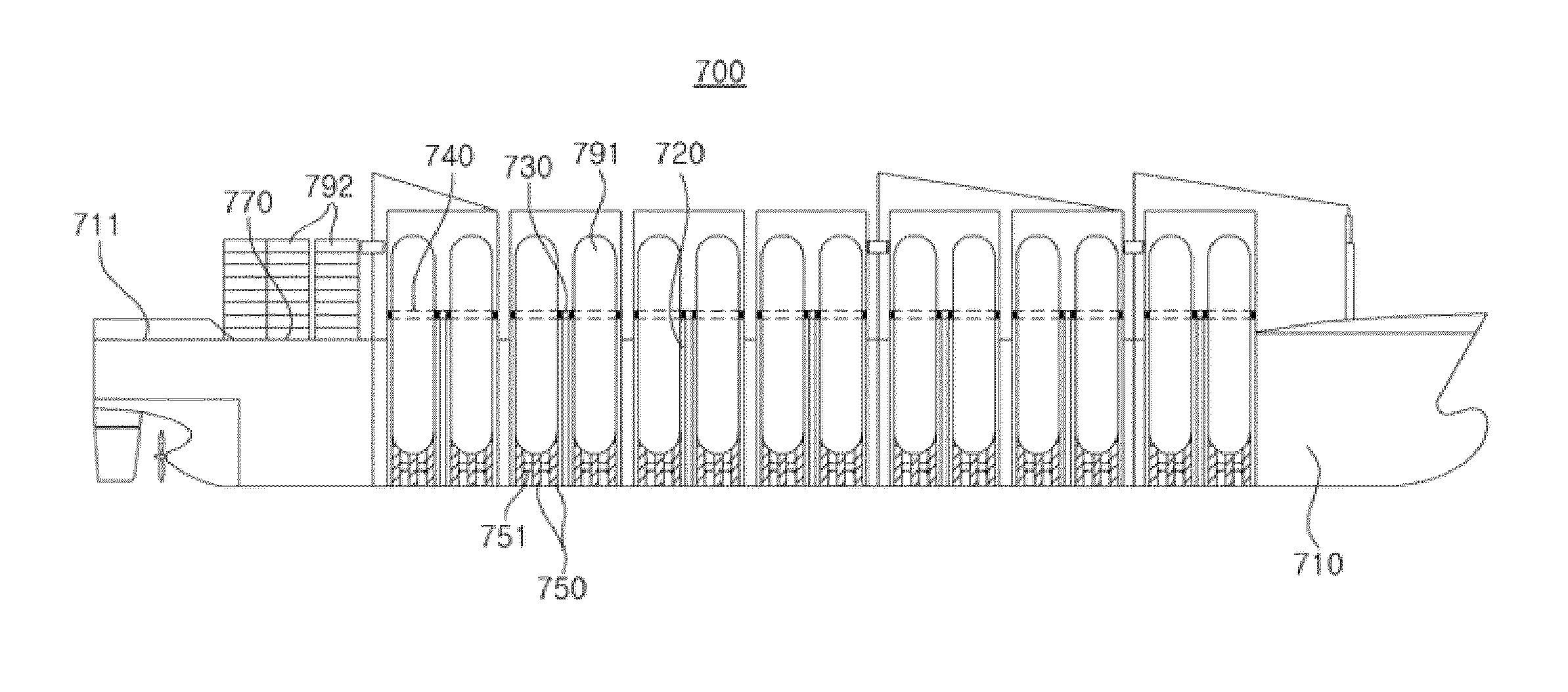

Ship for transporting a liquefied natural gas storage container

InactiveUS20130192510A1Efficiently and stably transportEfficient and stable transportationHull interior subdivisionContainer filling methodsLiquefied natural gasMarine engineering

An LNG storage container carrier includes: one or more cargo holds provided on a hull such that upper portions thereof are opened; a plurality of first and second upper supports installed on the cargo holds in a width direction and a length direction to partition the upper portions of the cargo holds into a plurality of openings, wherein storage containers are vertically inserted into the openings and supported; and a lower support installed under the cargo holds and supporting the bottoms of the storage containers inserted into the openings. Accordingly, it is possible to efficiently and stably transport the storage containers storing LNG or PLNG pressurized at a predetermined pressure. Such storage containers may be transported through simple modification of the existing container carrier.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

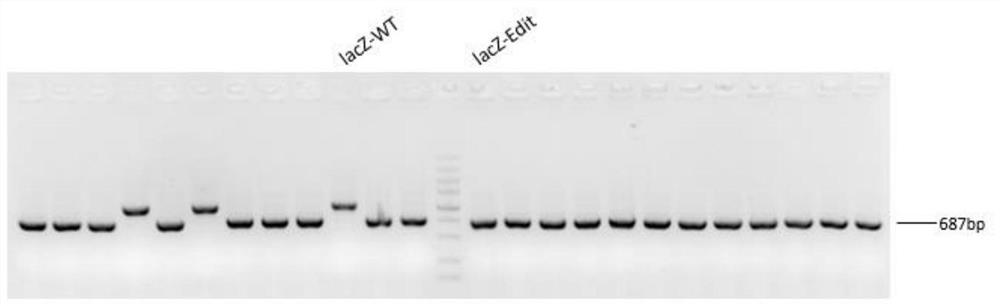

Recombinant escherichia coli for synthesizing 2'-fucosyllactose and construction method thereof

ActiveCN112625990AEfficient Genome Editing SolutionFermentation does not affectBacteriaMicroorganism based processesEnzyme GeneColanic acid

The invention provides a recombinant escherichia coli for synthesizing 2'-fucosyllactose and construction method thereof, and the recombinant Escherichia coli is obtained by knocking out a beta-galactosidase gene in the genome of Escherichia coli, synthesizing a key enzyme gene of colanic acid from guanosine diphosphate fucose, enhancing expression key enzyme genes of lactose permease genes and a guanylate diphosphate fucose denovo synthesis route and expressing exogenous fucosyltransferase genes. According to the scheme, lactose hydrolysis can be reduced, and the rate of transferring exogenous lactose into cells is increased, so that the concentration of lactose in the cells is effectively increased; meanwhile, the consumption of the guanosine diphosphate fucose is reduced, and the concentration of the guanosine diphosphate fucose in cells is effectively improved; through codon optimization, the expression of an exogenous fucosyltransferase gene is improved, and synthesizing of the 2'-fucosyllactose is effectively promoted.

Owner:量子高科(广东)生物有限公司

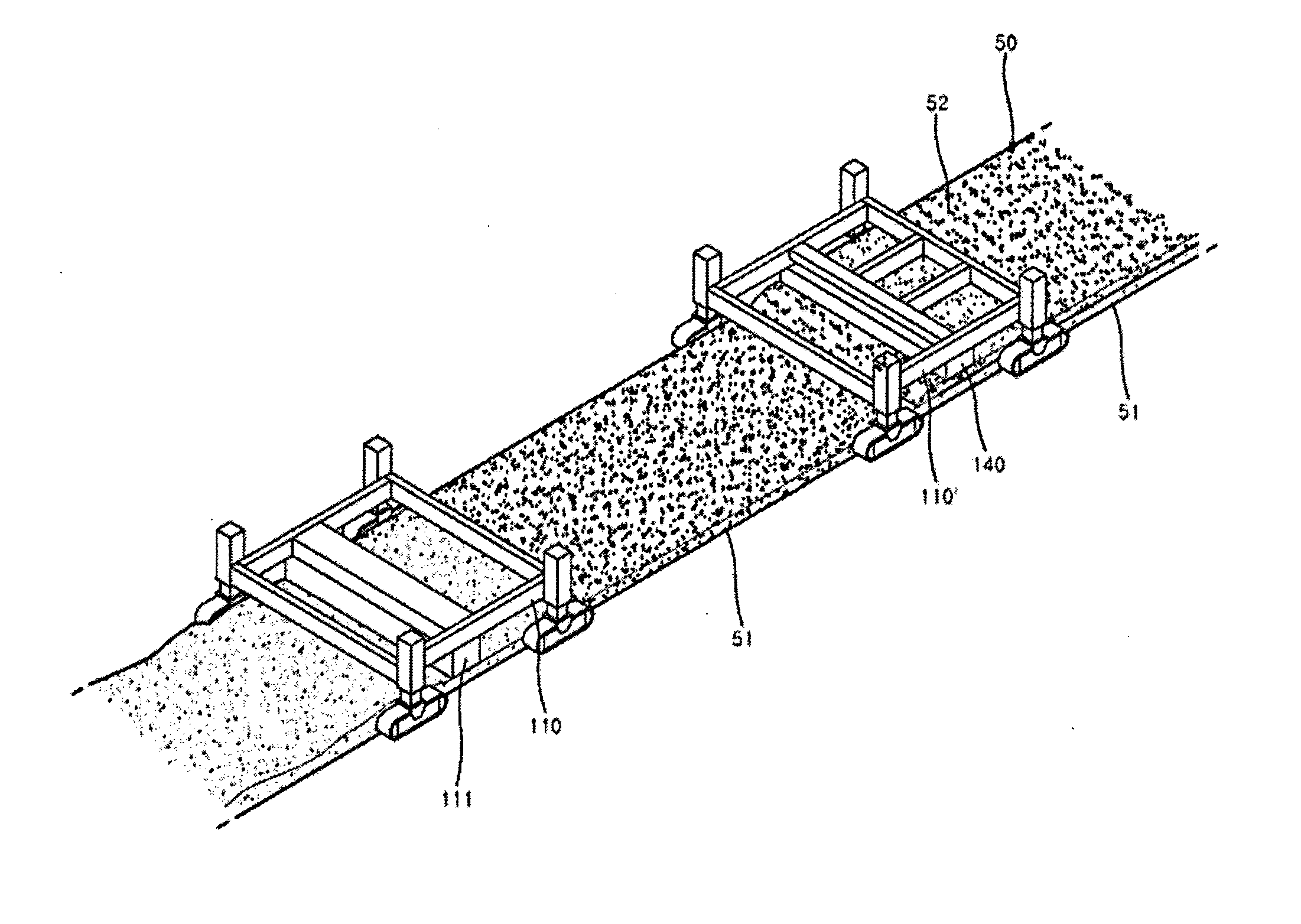

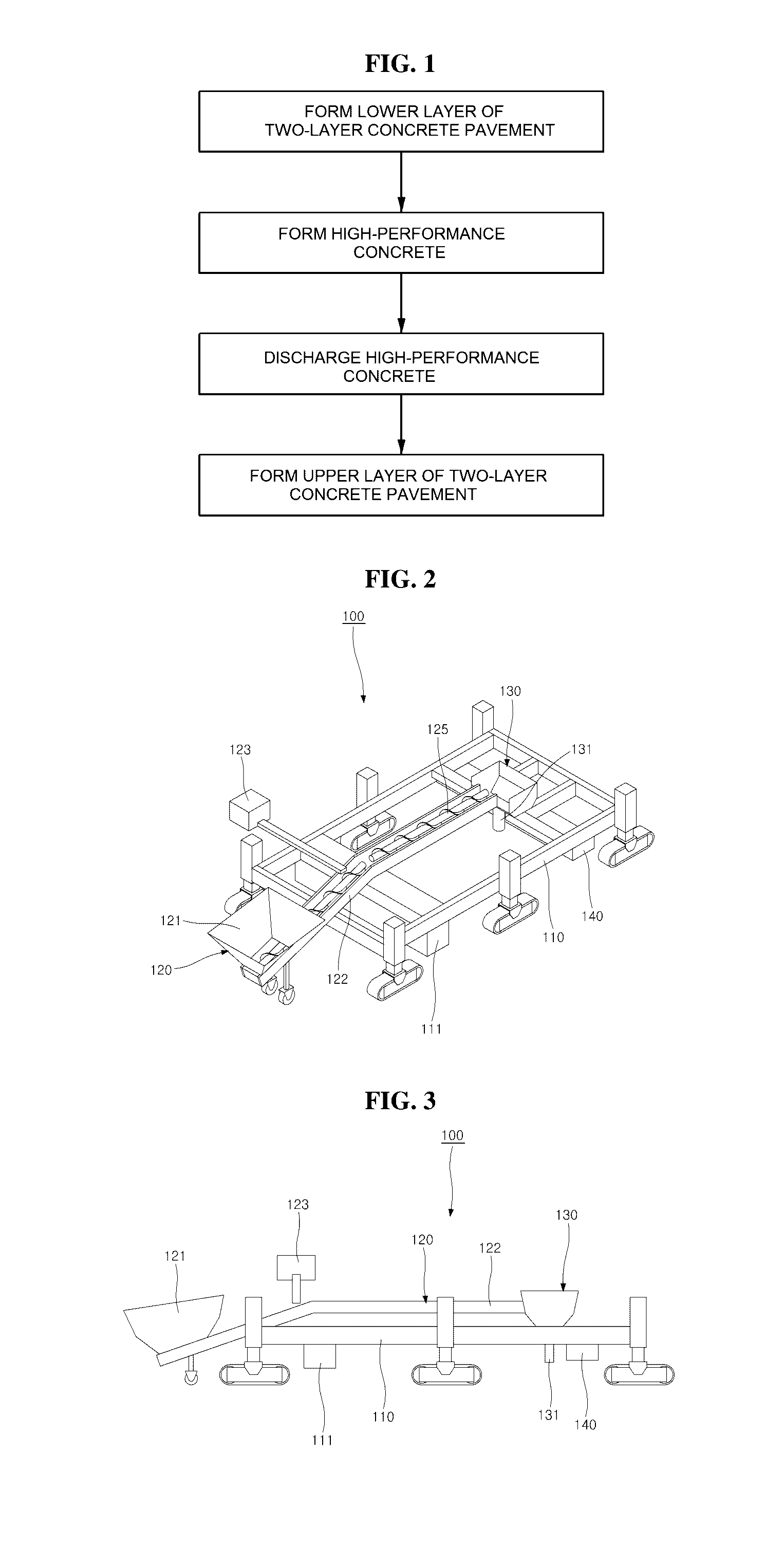

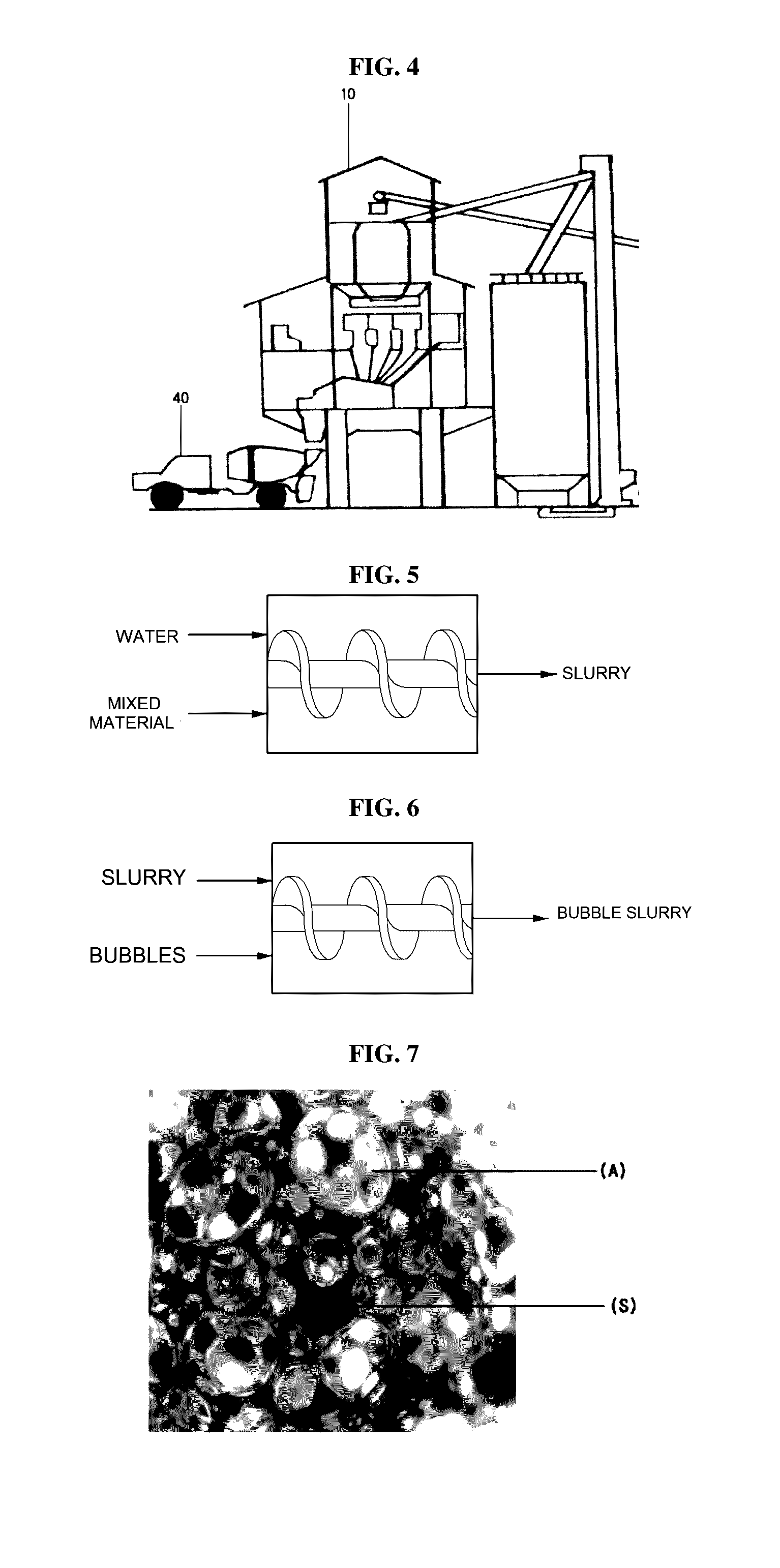

Two-layer concrete pavement device and pavement method using normal concrete and high-perpormance concrete

ActiveUS20160340840A1Shorten the timeHigh strengthIn situ pavingsSolid waste managementShotcreteSlag

The present invention relates to a method for reinforcing an assembly-type slope by using high-performance shotcrete and a reinforcing member, the method, after producing, at a batch plant, normal concrete having a compressive strength of 21-30 MPa and transporting the normal concrete to a construction site: forms a normal-strength shotcrete by mixing either fly ash or slag fine powder or low-grade mixed material in which fly ash or slag fine powder is mixed, in an increased fluidity state by mixing 20-40% of bubbles of the total volume; forms a high-performance shotcrete by mixing silica fumes and metakaolin or high-grade mixed material in which either silica fumes or metakaolin are mixed; and forms a color shotcrete by mixing coloring materials of iron oxide or carbon black, so as to sequentially construct an inner layer section, an outer layer section, and a surface layer section on the slope.

Owner:KNU IND COOPERATION FOUND

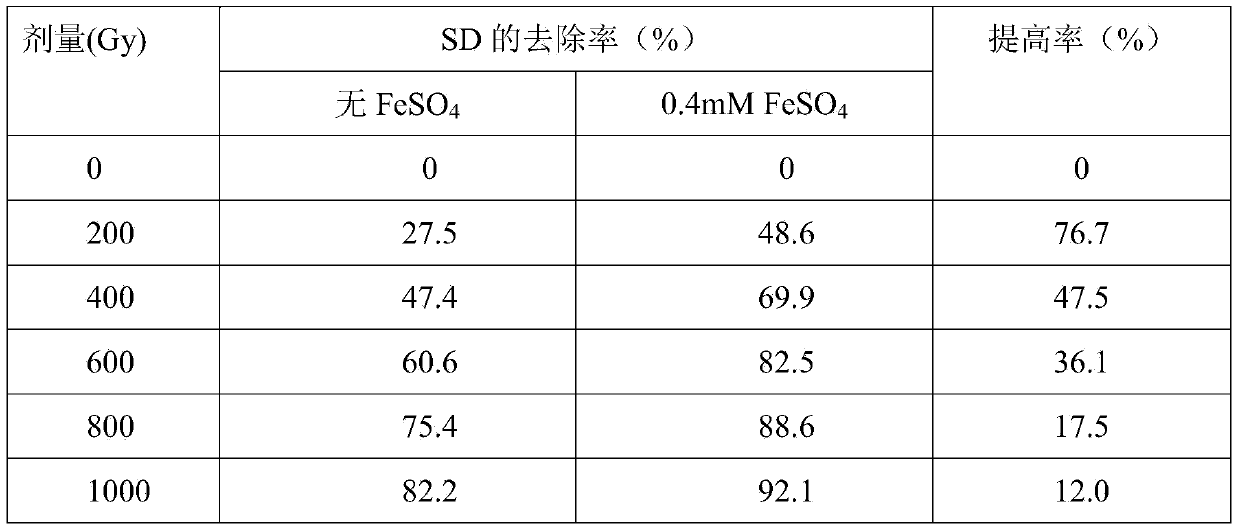

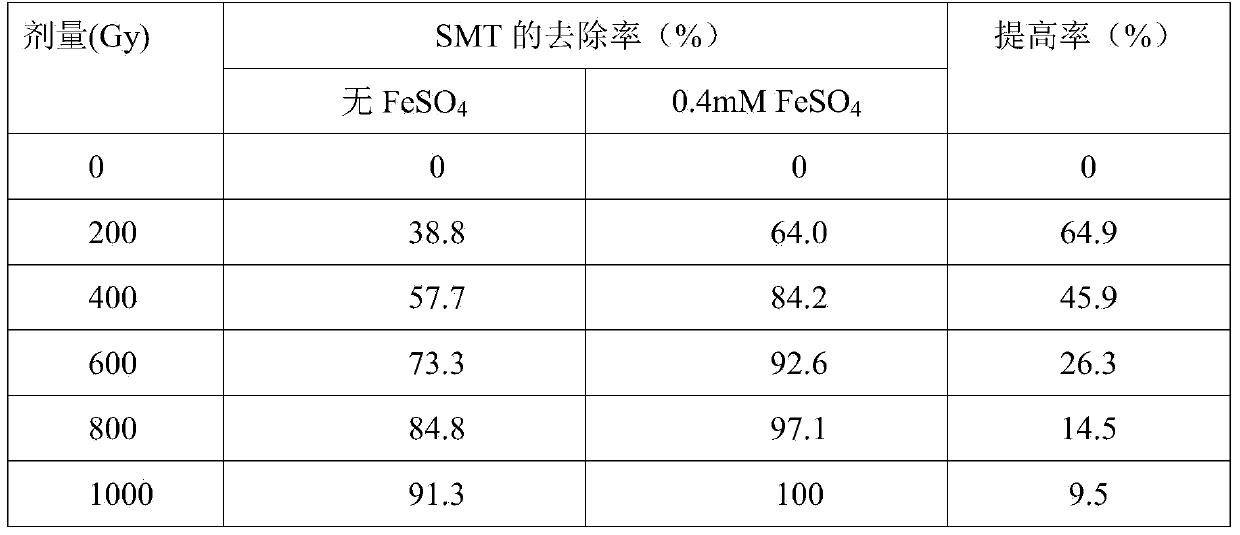

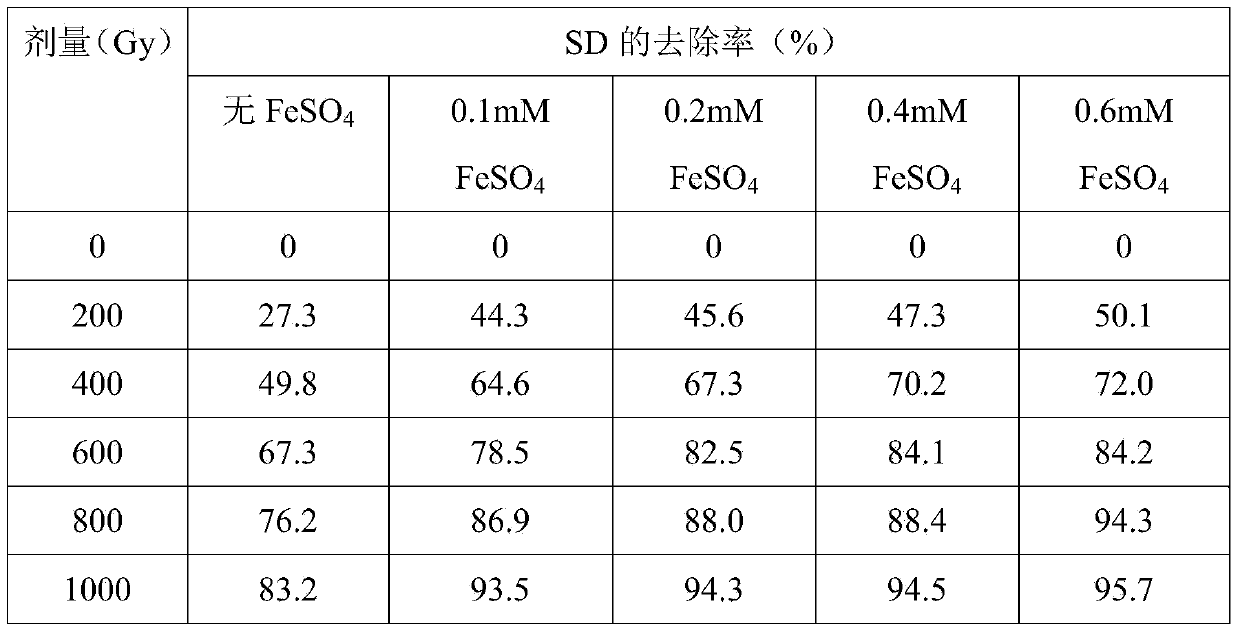

Method for facilitating removal of radiation of sulfanilamide antibiotic in waste water by utilizing ferrous ions

ActiveCN103466745AIncrease profitEasy to operateWater/sewage treatment by irradiationWater contaminantsDecompositionSulfanilamide

The invention belongs to the field of nuclear technology application and environmental technology protection, and discloses a method for facilitating removal of irradiation of organic pollutants in waste water by adding ferrous ions. The method is applied to treatment of sulfanilamide antibiotic waste water. The method applies an ionizing radiation technique, adds the ferrous ions, and combines a Fenton oxidation method, so that the generation quantity of .OH is increased, the reaction efficiency is improved, the absorption dose required by the removal of the irradiation of antibiotic is reduced, and the energy consumption is reduced greatly. In addition, the method utilizes H2O2 generated in a water radiation decomposition process, and additional addition is not required, so that the cost is lowered. The method is simple in technology, easy and simple to operate, low in energy consumption and low in cost; the method is high-efficiency, rapid, economically feasible, and free from secondary pollution when the method is used for treating the sulfanilamide antibiotic waste water; and the method has wide application prospects in waste water treatment and environmental protection.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com