Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5311results about "Solid balls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

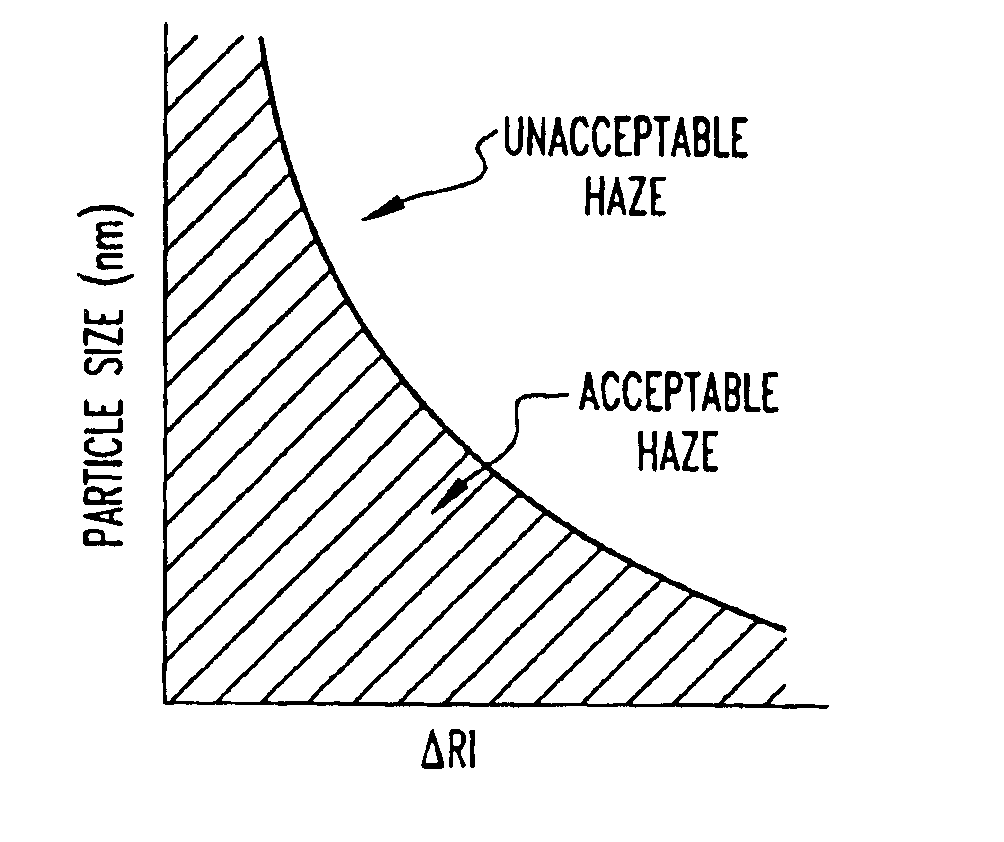

Use of nanoparticulate organic pigments in paints and coatings

A protective and decorative coating composition including about 2 to 10 different colorants which in combination with a resinous composition produce a desired visible coating. A majority of the colorants has a maximum haze of about 10% and exhibits an absorbance peak in the visible spectrum wherein at least about 50% of the total absorbance in the visible spectrum occurs at wavelengths within about 50 nm of the wavelength of the peak absorbance.

Owner:PPG IND OHIO INC

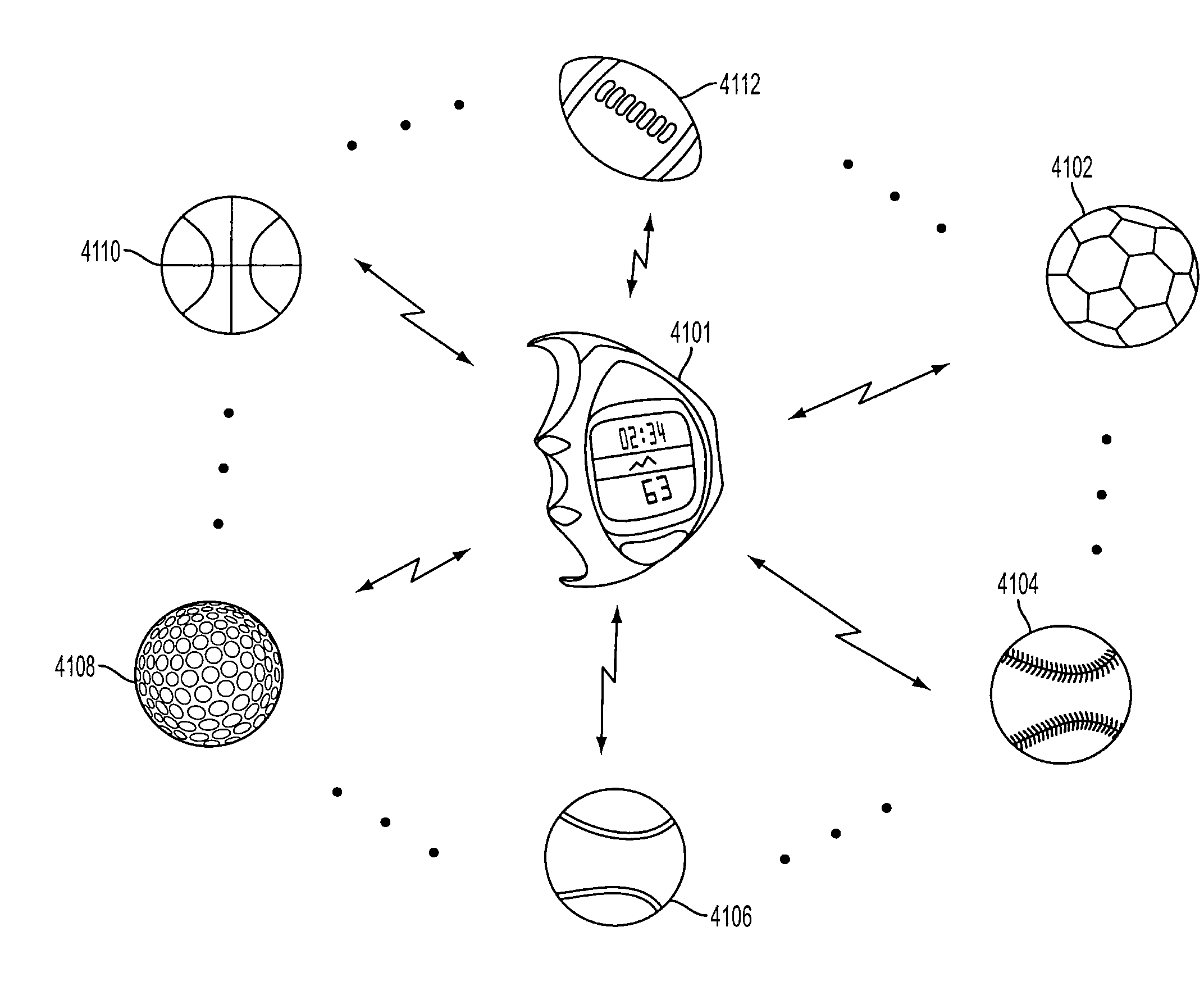

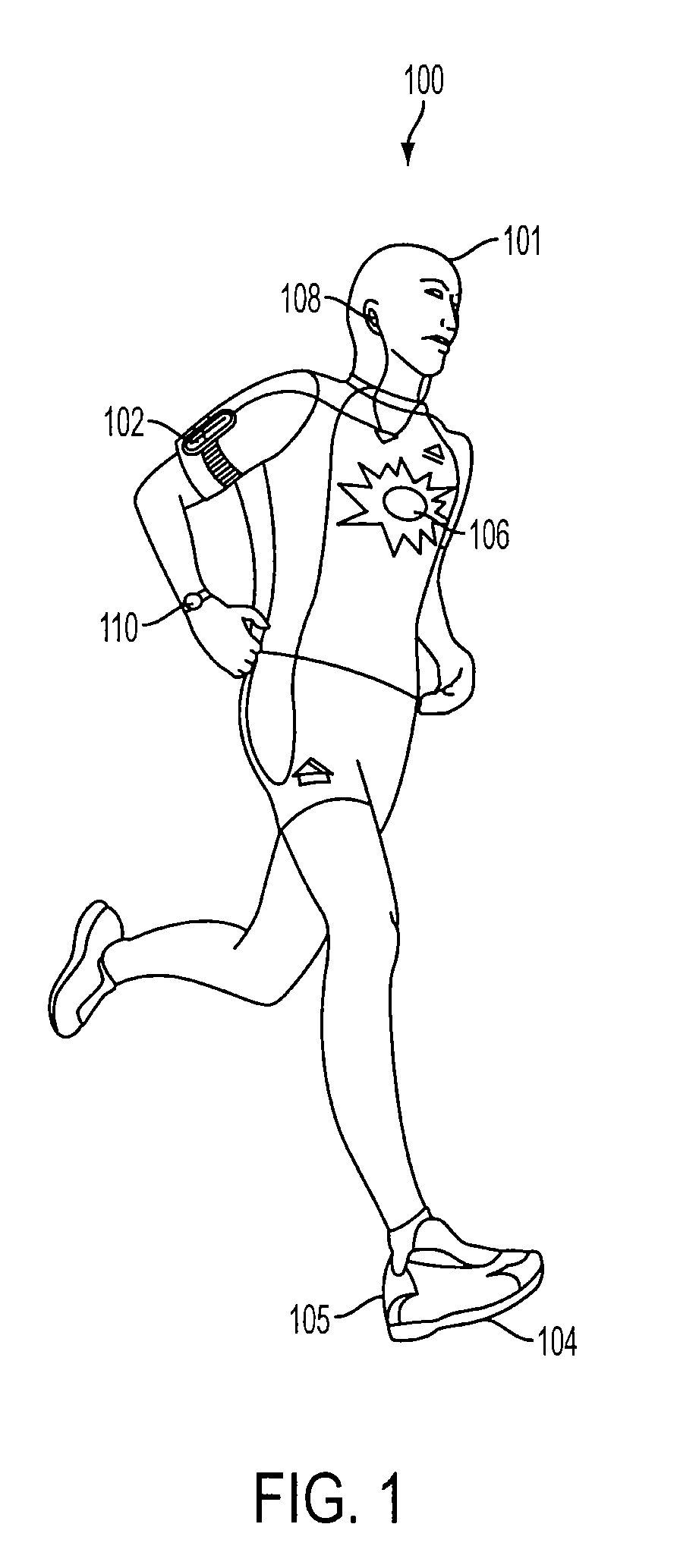

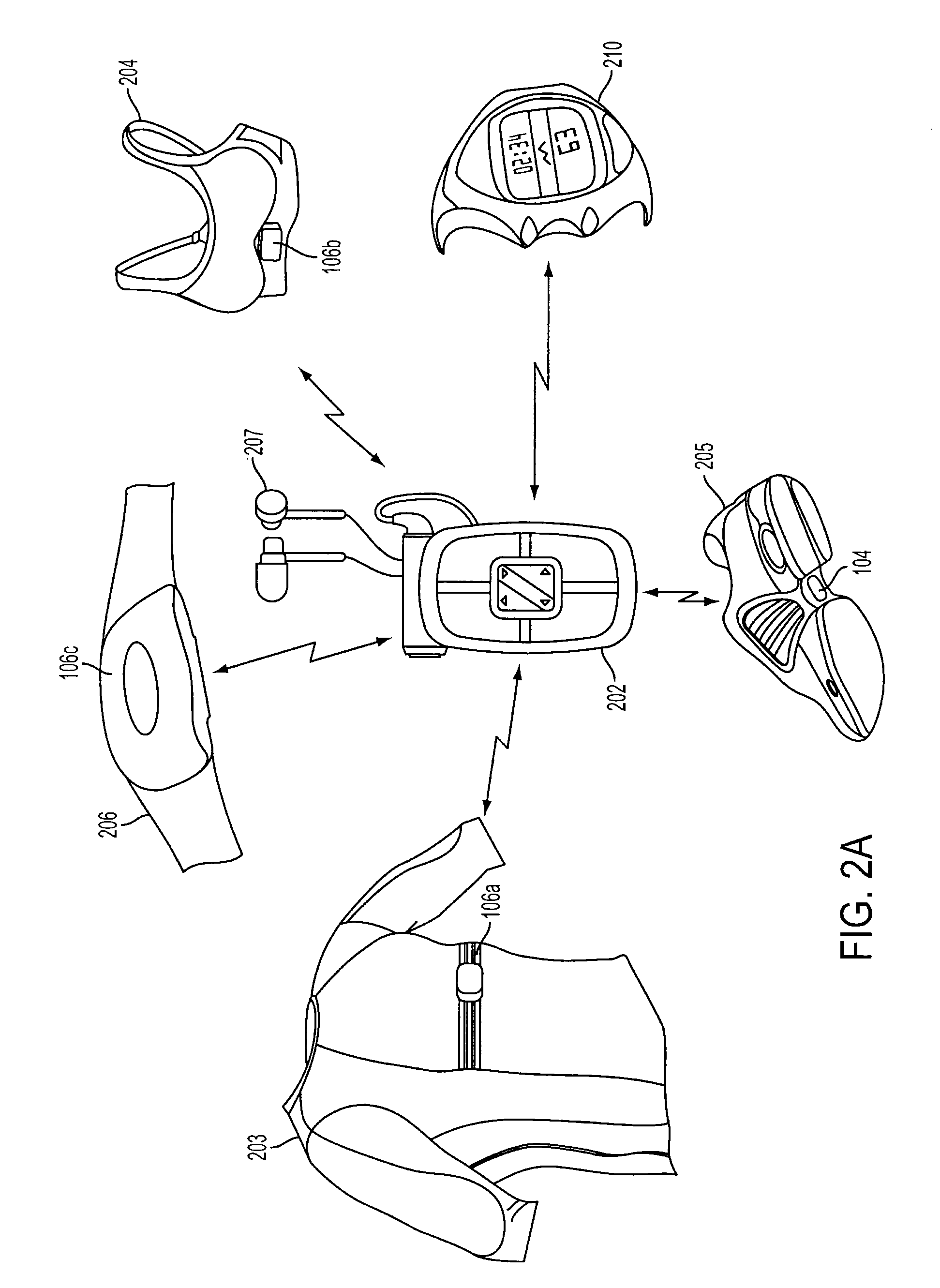

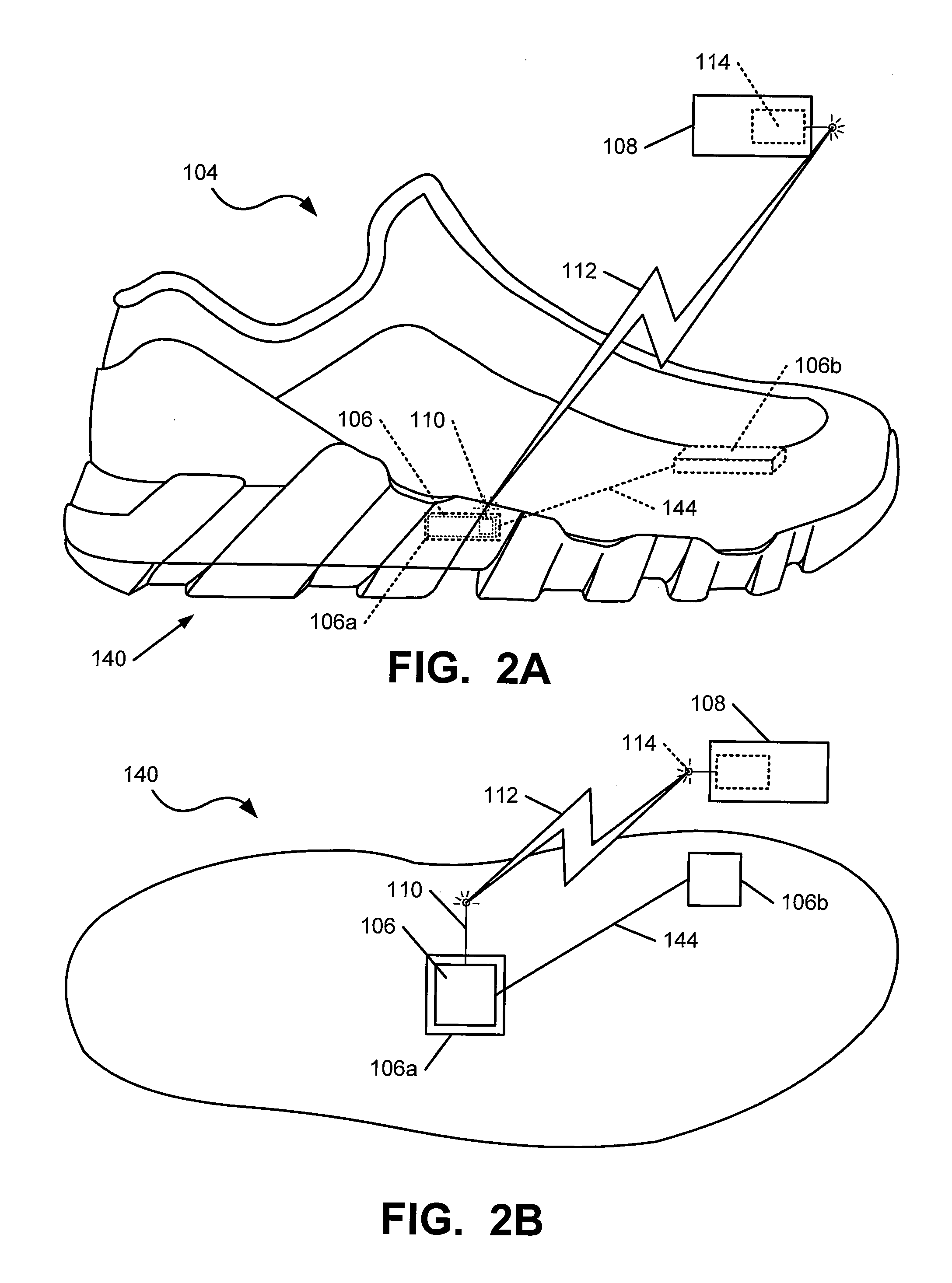

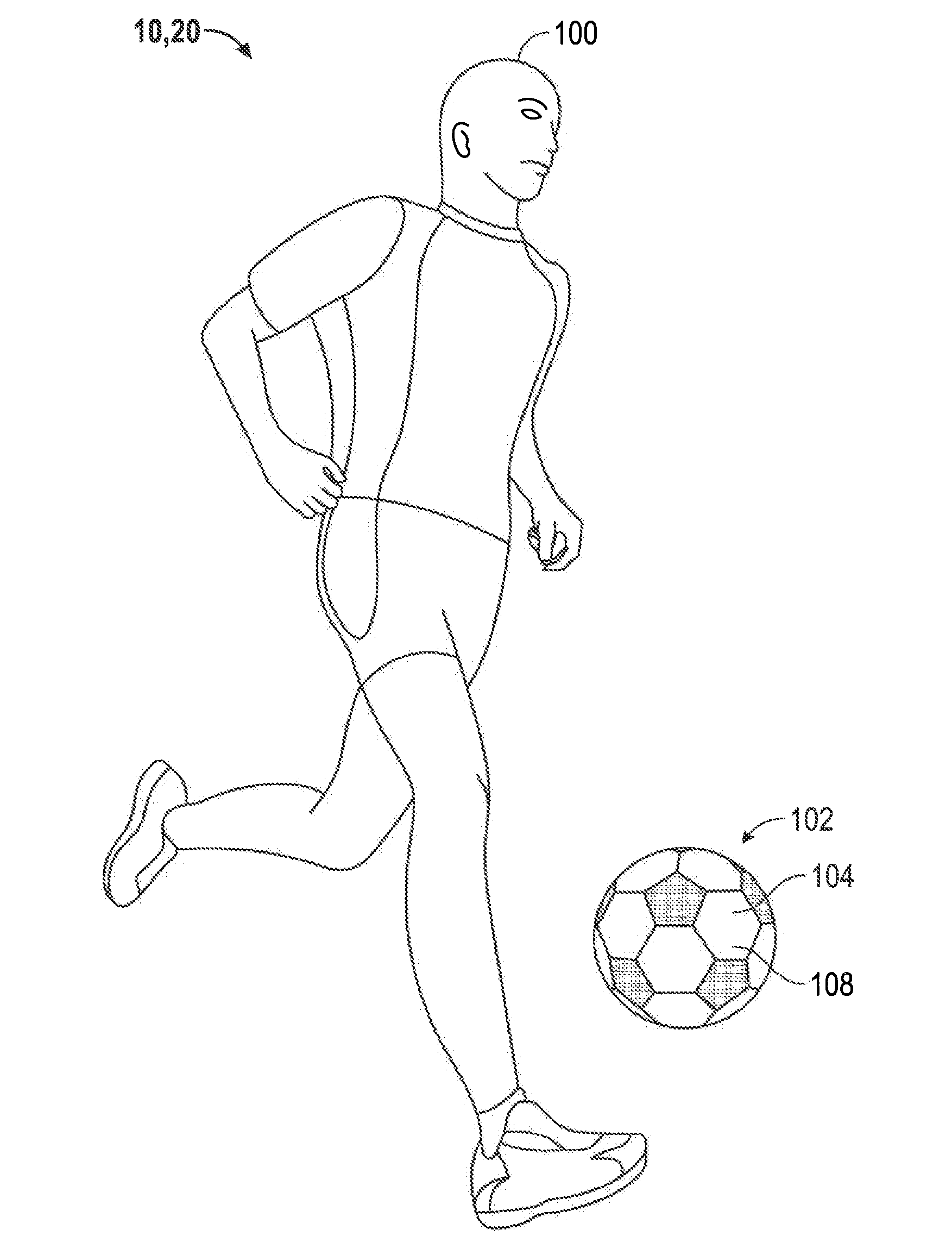

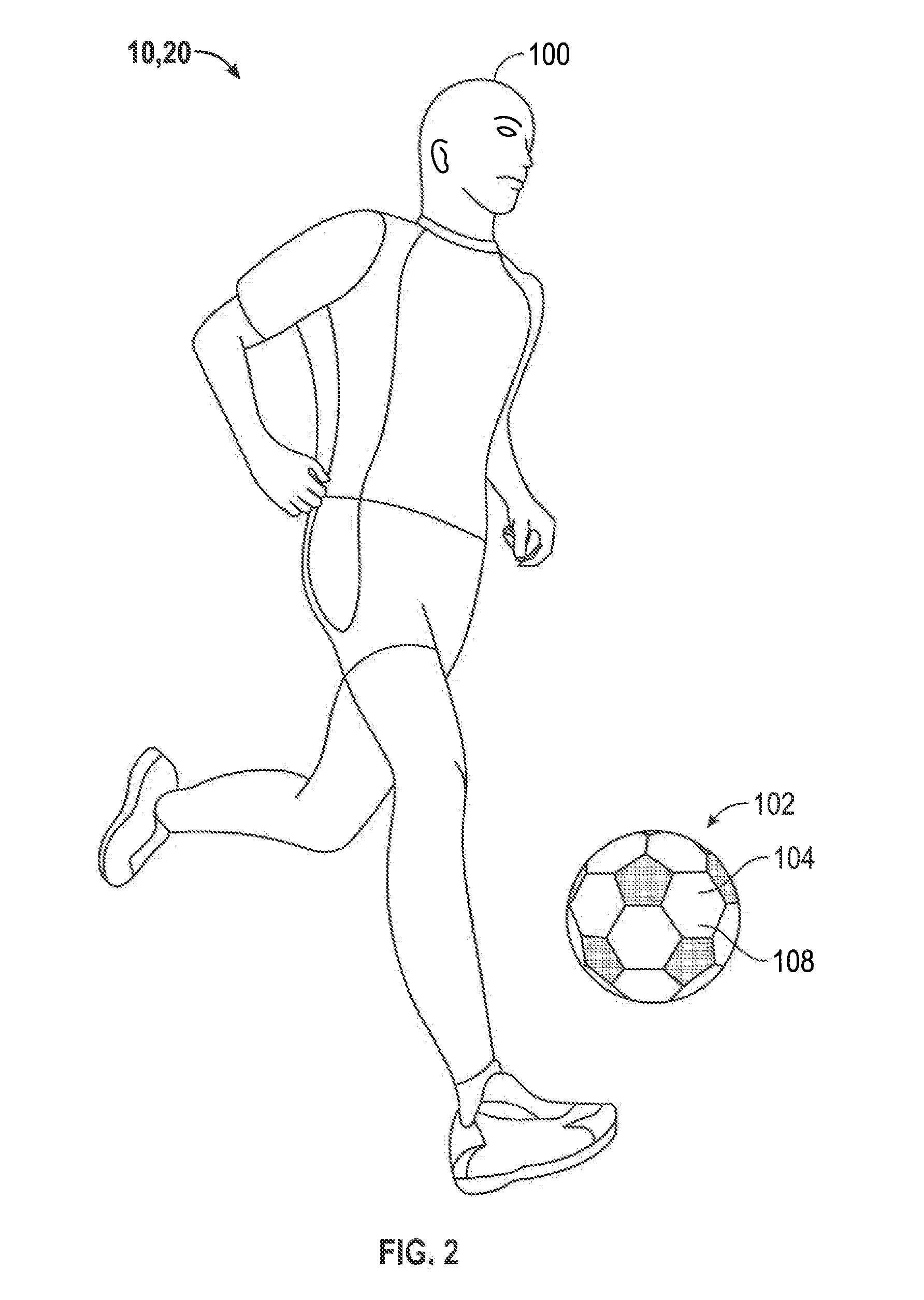

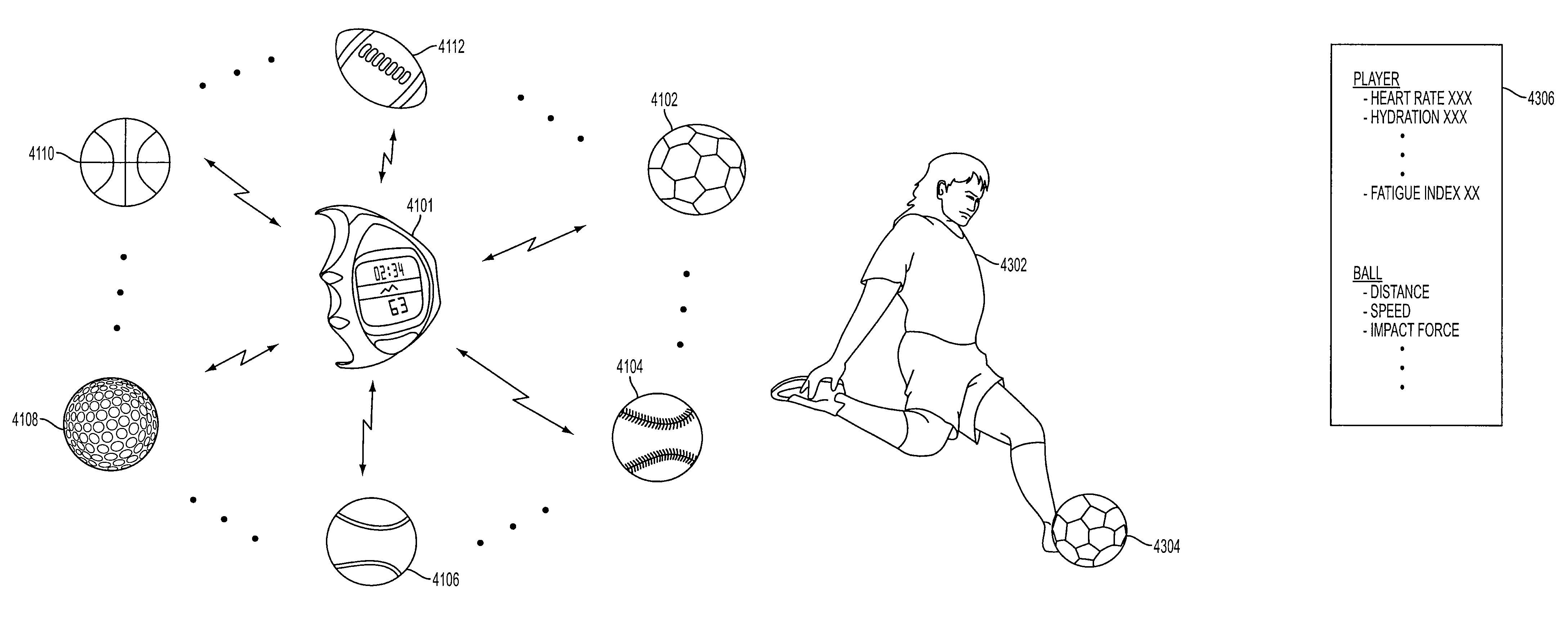

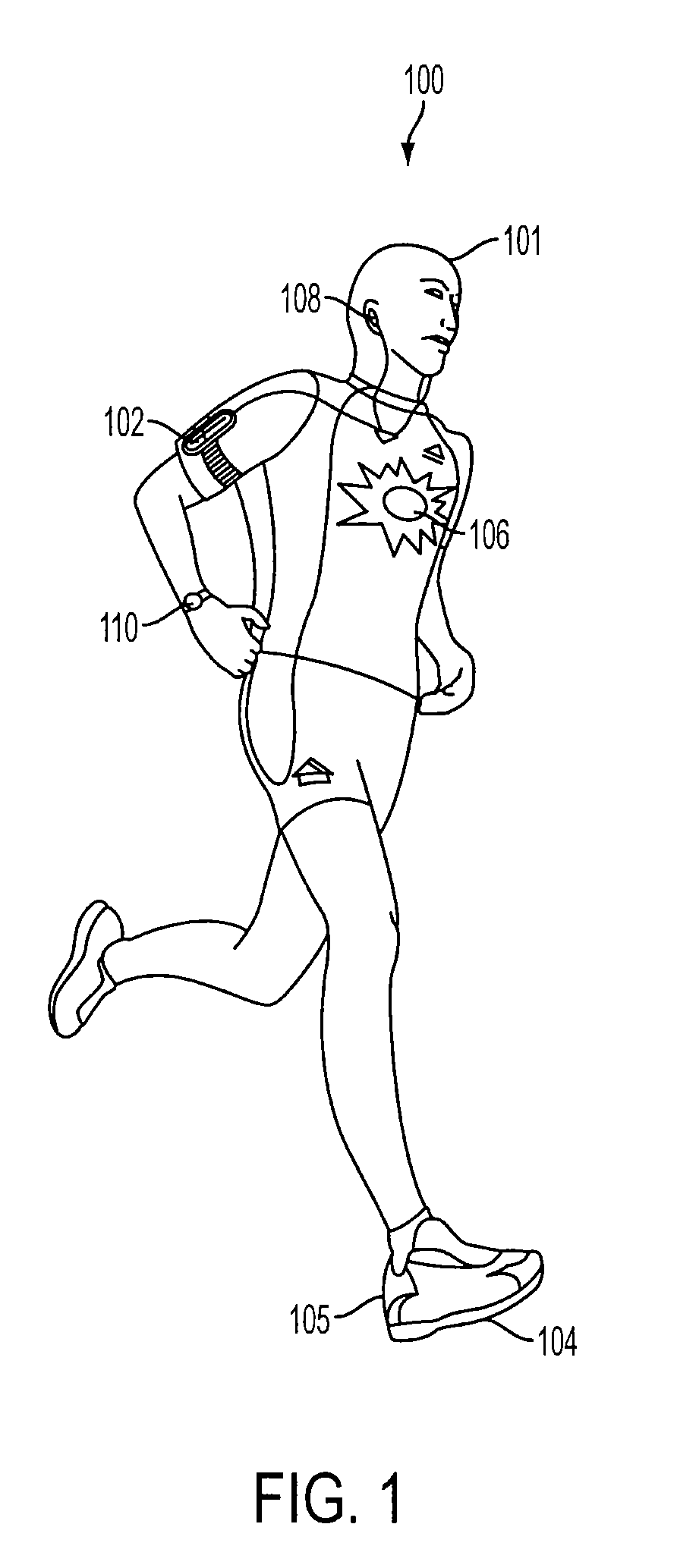

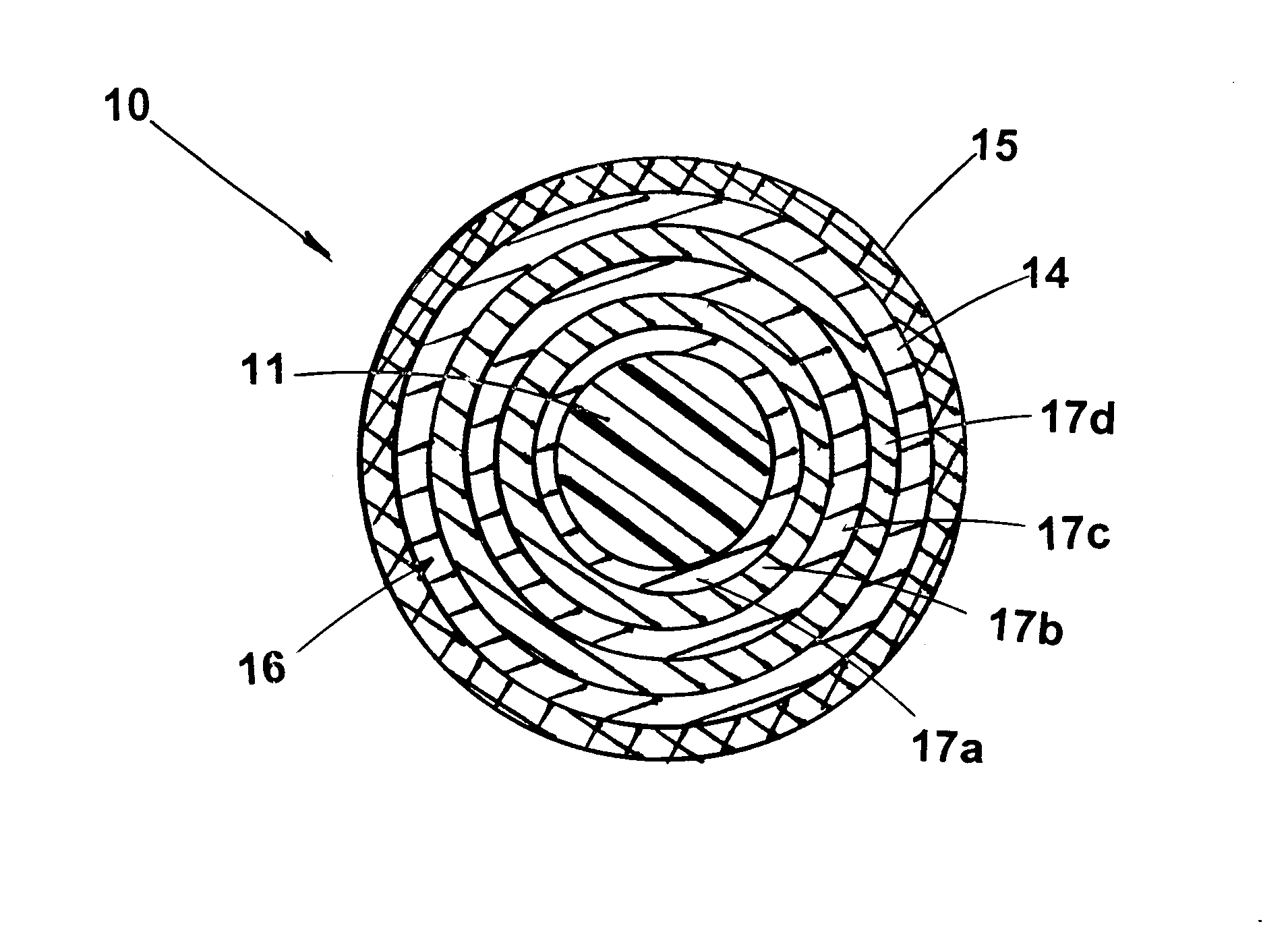

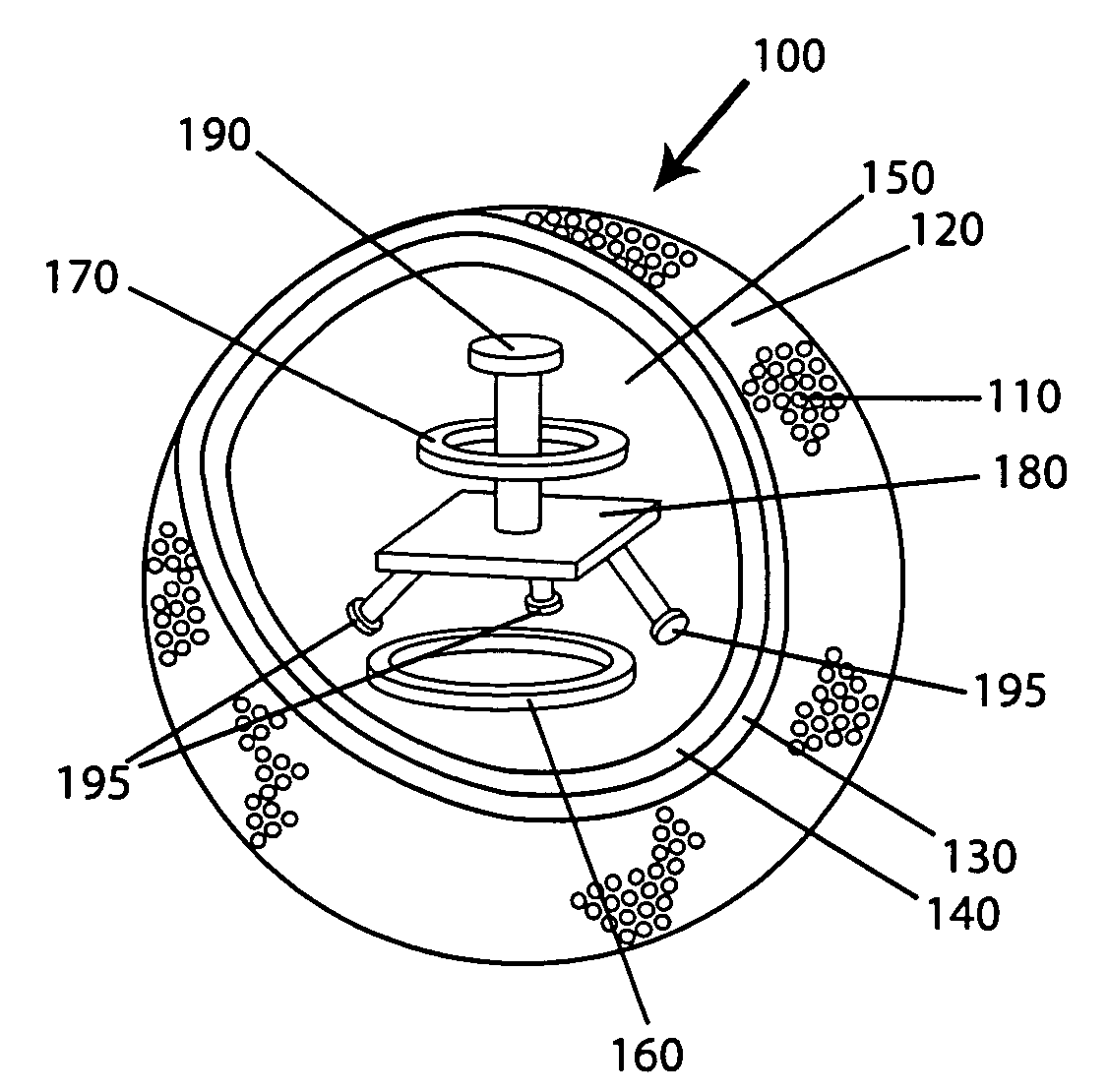

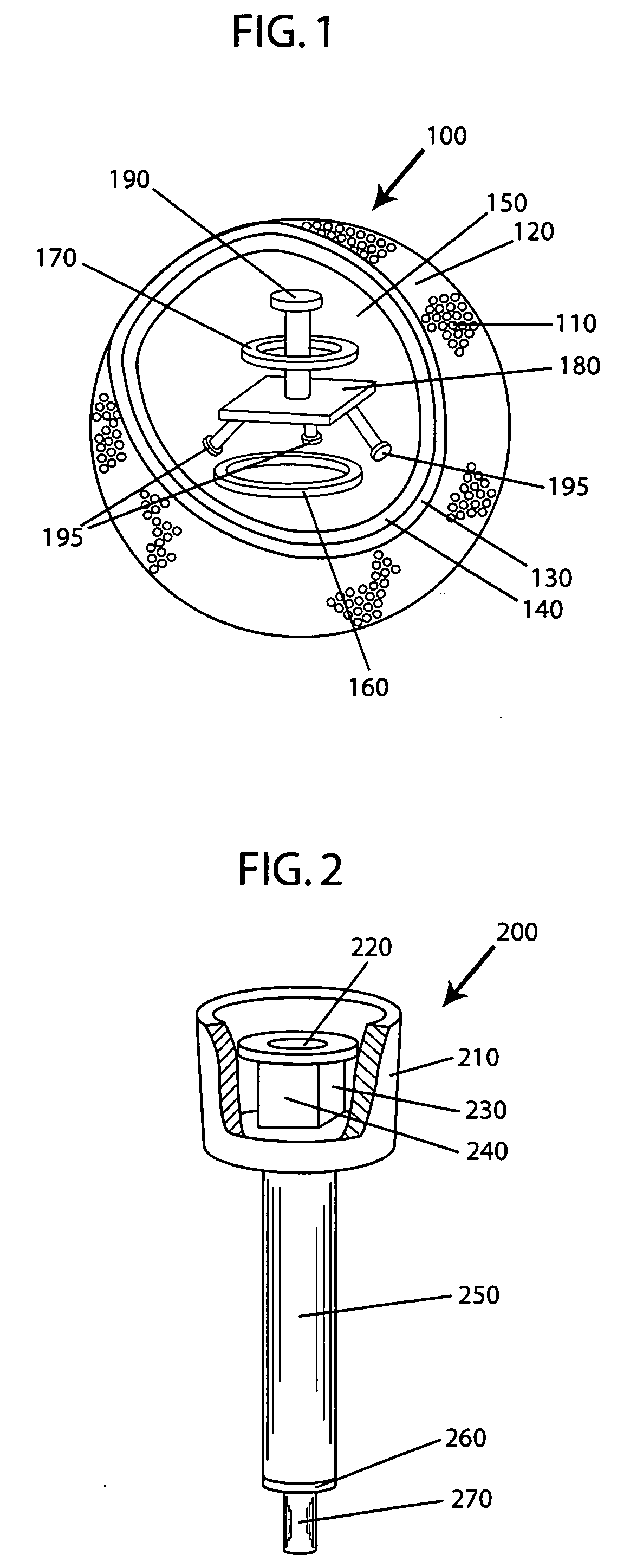

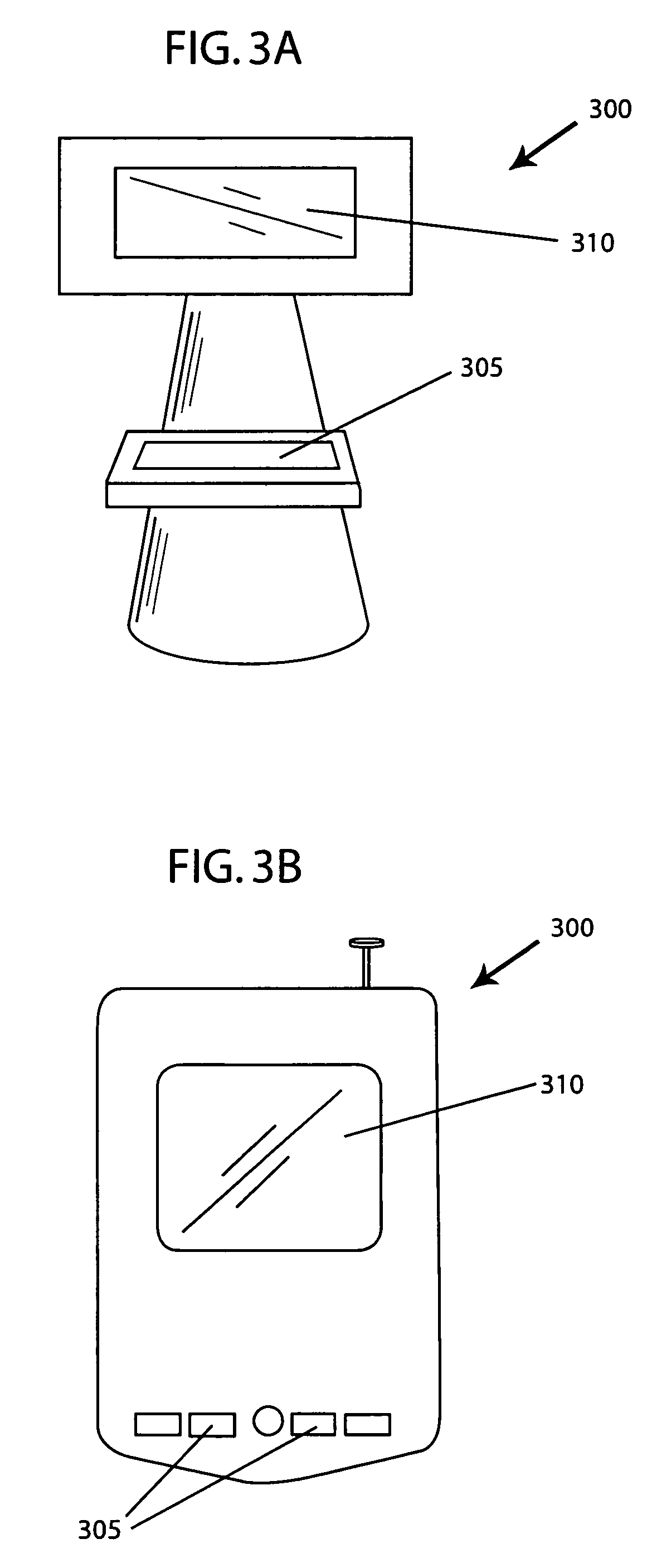

Sports electronic training system with sport ball, and applications thereof

ActiveUS20090048044A1Assess a fitness level for an individualPhysical therapies and activitiesSolesEngineeringHeart rate device

A sports electronic training system with sport ball, and applications thereof, are disclosed. In an embodiment, the system comprises at least one monitor and an electronic processing device for receiving data from the at least one monitor and providing feedback to an individual based on the received data. The monitor can be a motion monitor that measures an individual's performance such as, for example, speed, pace and distance for a runner. Other monitors might include a heart rate monitor, a temperature monitor, an altimeter, et cetera. In an embodiment, a sport ball that includes a motion monitor for monitoring motion of the sport ball stores an identification value received when a shoe that includes a motion monitor contacts the sport ball. The stored identification value serves as a record of the contact.

Owner:ADIDAS

Athletic Performance Monitoring Systems and Methods in a Team Sports Environment

ActiveUS20100184563A1Physical therapies and activitiesHollow inflatable ballsTeam sportExercise performance

Systems and methods for sensing and monitoring various athletic performance metrics, e.g., during the course of a game, a practice, a training session, training drills, and the like, are described. These systems and methods can provide useful metrics for players and coaches relating to athletic performances in various sports, including various team sports.

Owner:NIKE INC

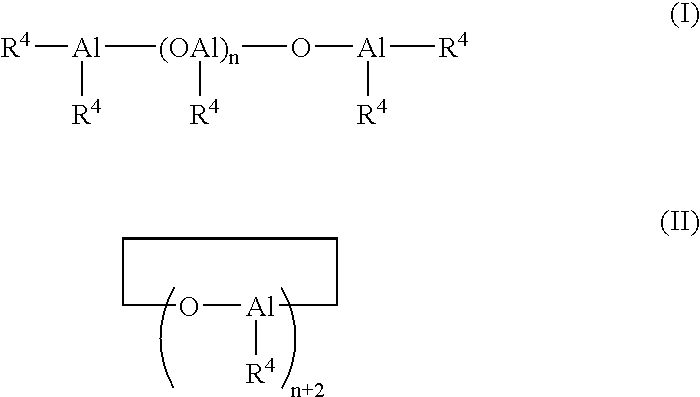

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

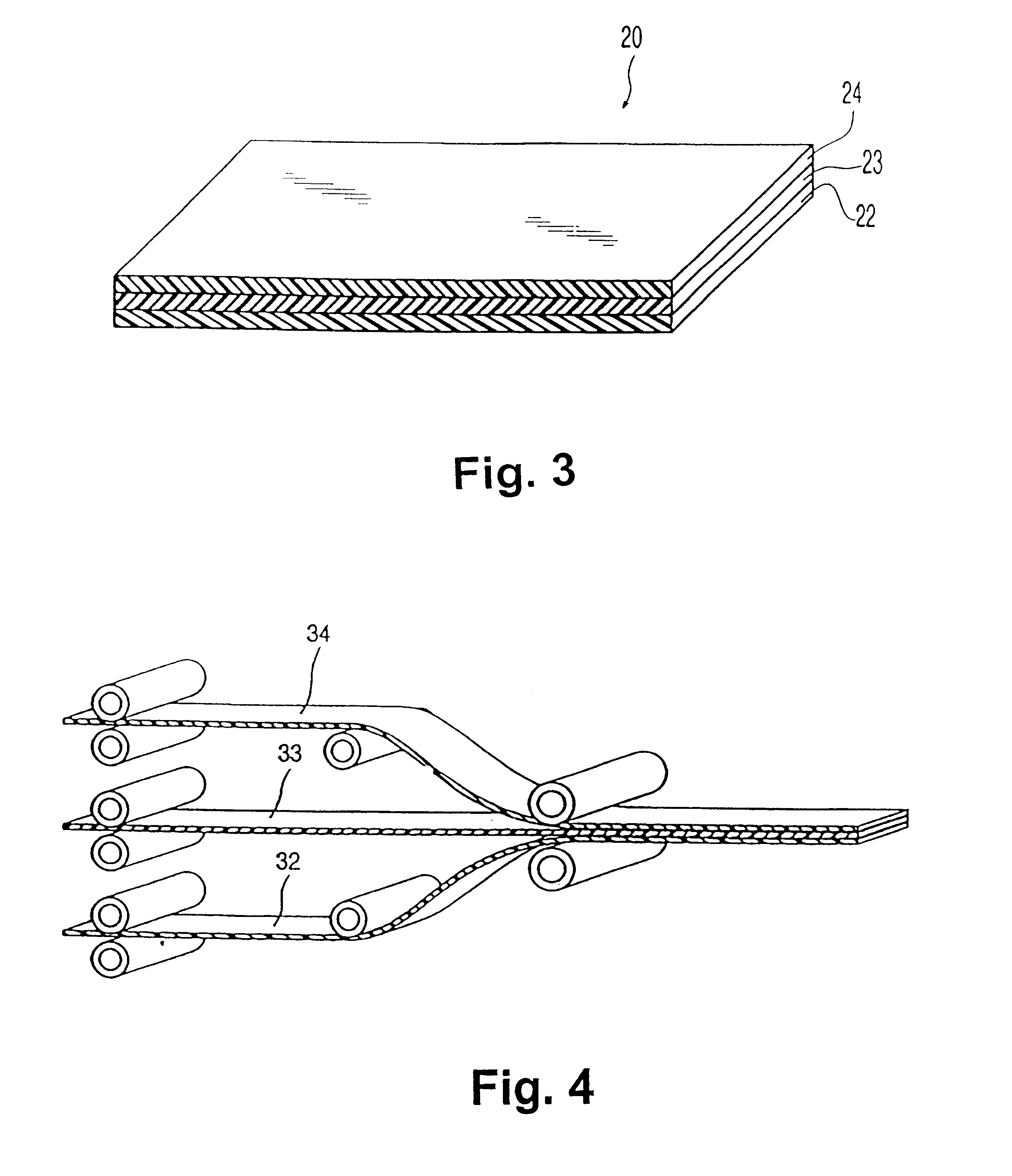

PVC nanocomposite manufacturing technology and applications

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

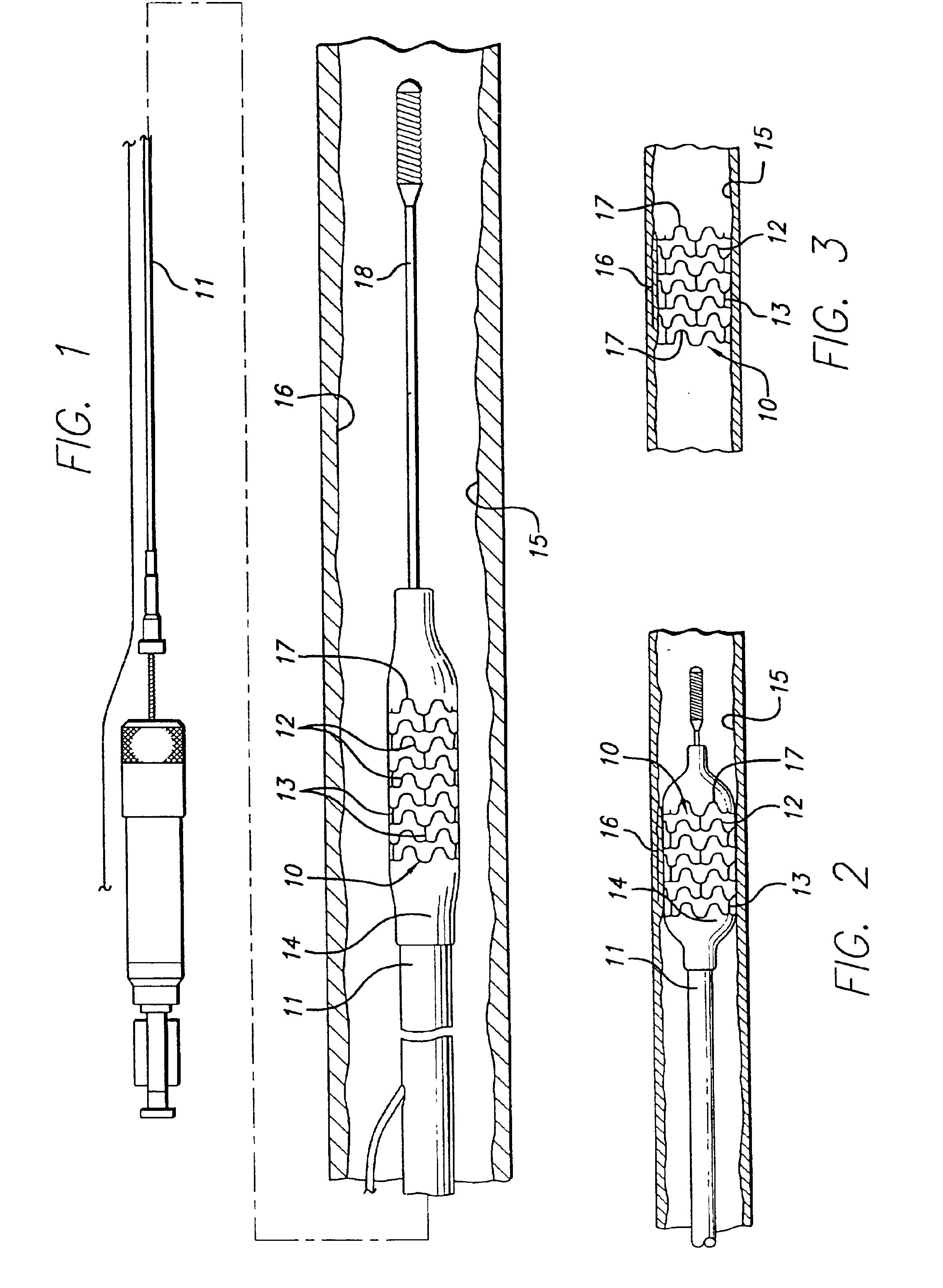

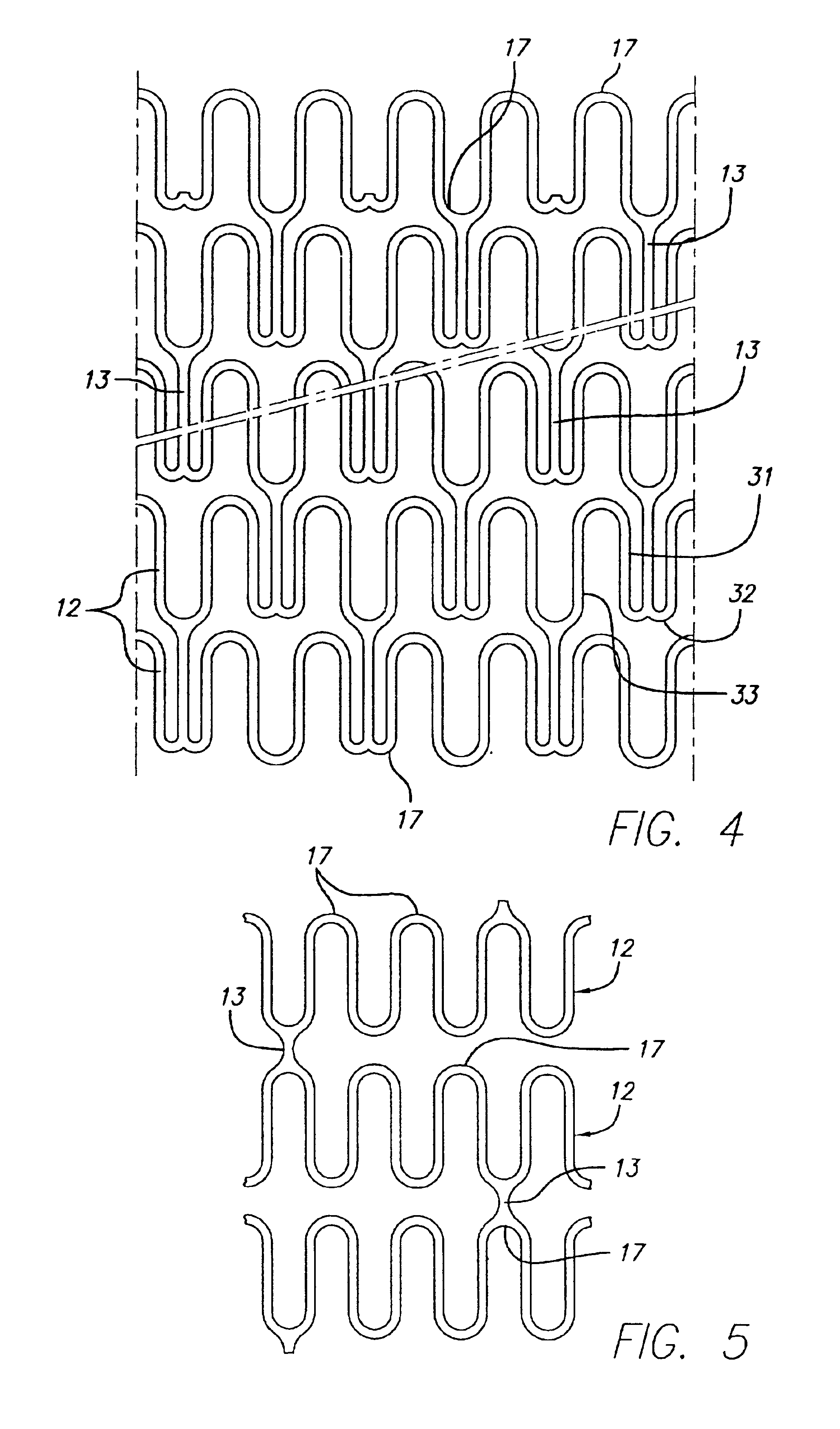

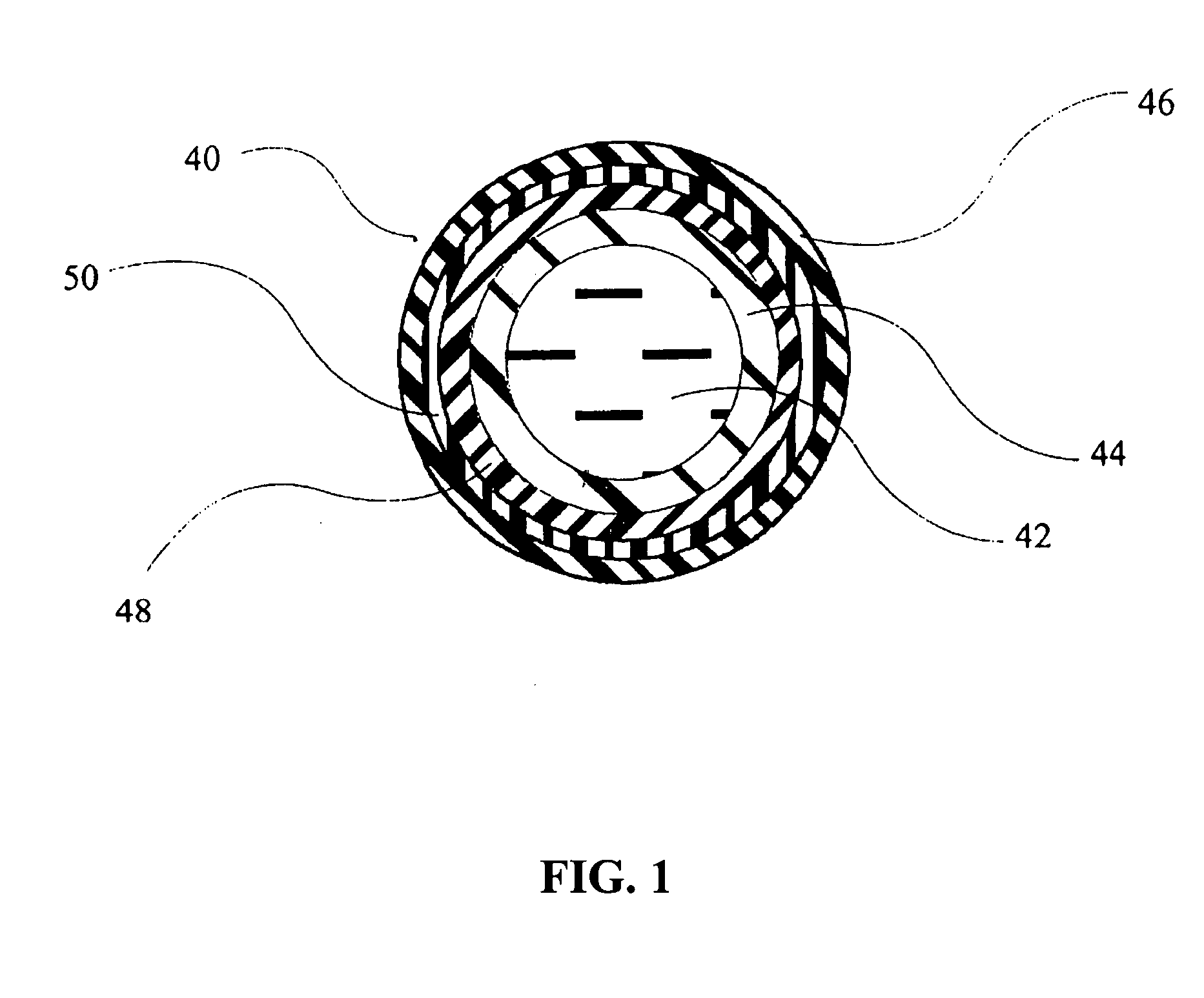

Hybrid intravascular stent

InactiveUS6866805B2Increase flexibilityImprove radial strengthStentsSurgeryCoronary arteriesIntravascular stent

A hybrid stent is formed which exhibits both high flexibility and high radial strength. The expandable hybrid stent for implantation in a body lumen, such as a coronary artery, consists of radially expandable cylindrical rings generally aligned on a common longitudinal axis and interconnected by one or more links. In one embodiment, a dip-coated covered stent is formed by encapsulating cylindrical rings within a polymer material. In other embodiments, at least some of the rings and links are formed of a polymer material which provides longitudinal and flexural flexibility to the stent. These polymer rings and links are alternated with metallic rings and links in various configurations to attain sufficient column strength along with the requisite flexibility in holding open the target site within the body lumen. Alternatively, a laminated, linkless hybrid stent is formed by encapsulating cylindrical rings within a polymer tube.

Owner:ABBOTT CARDIOVASCULAR

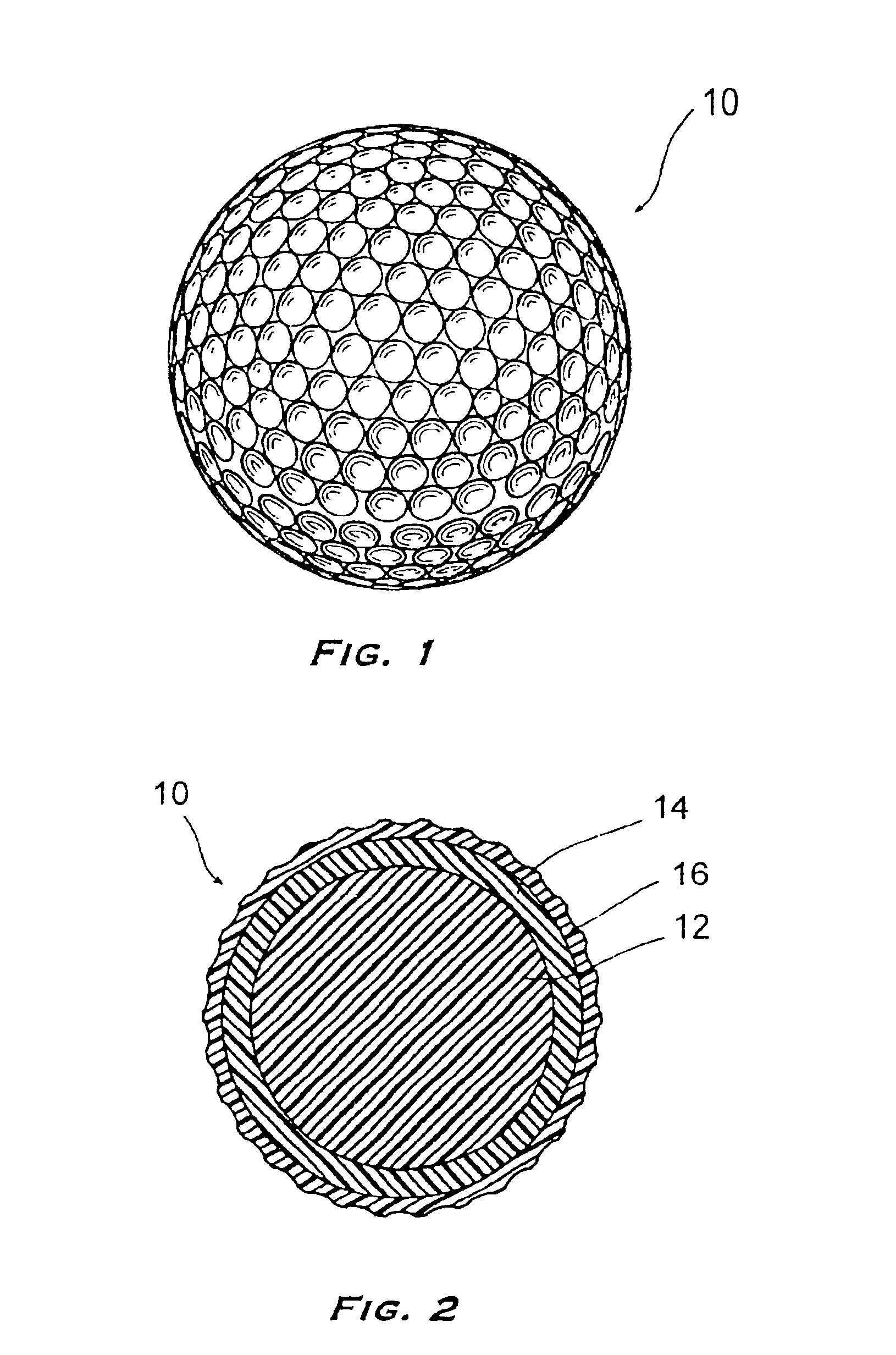

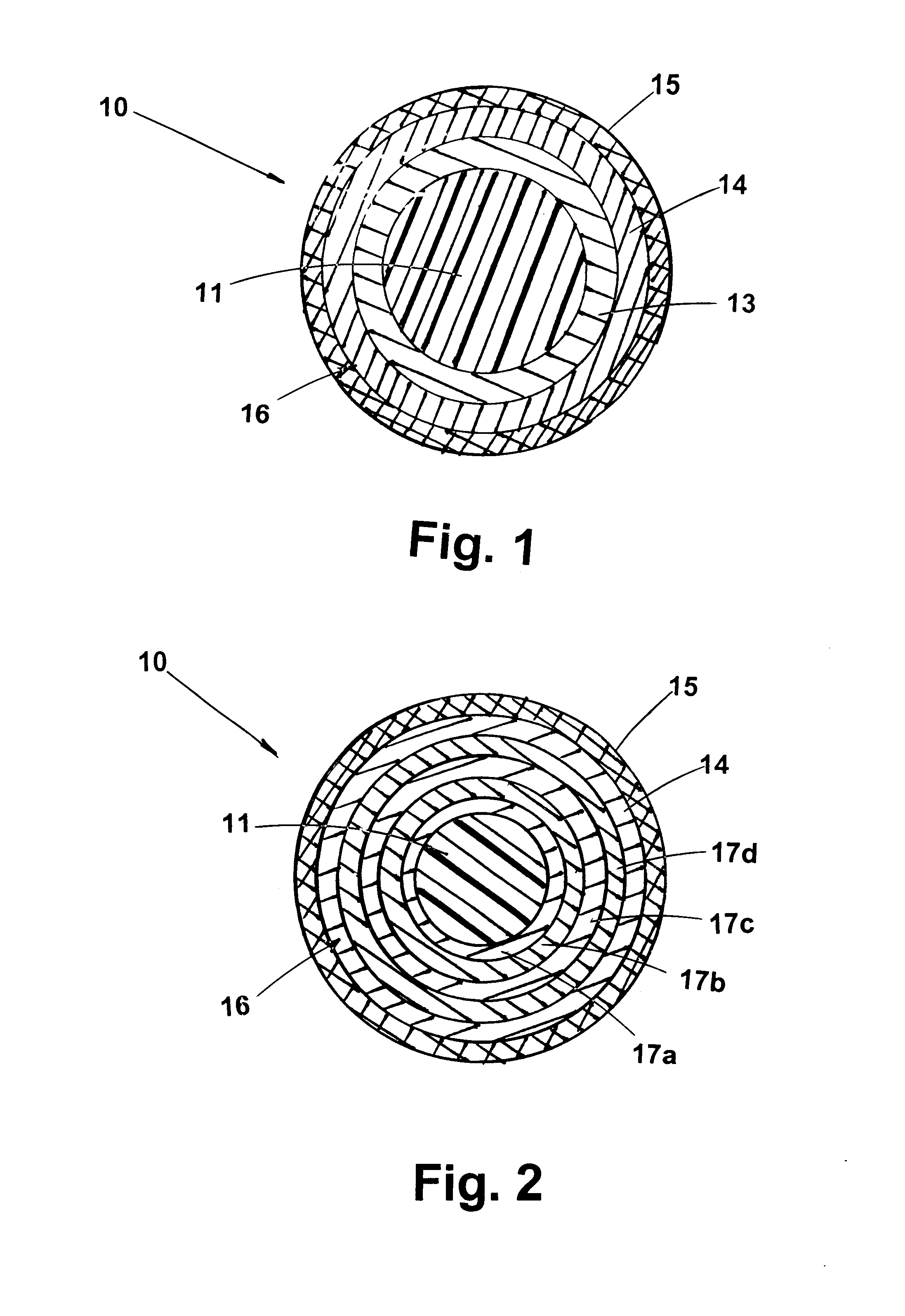

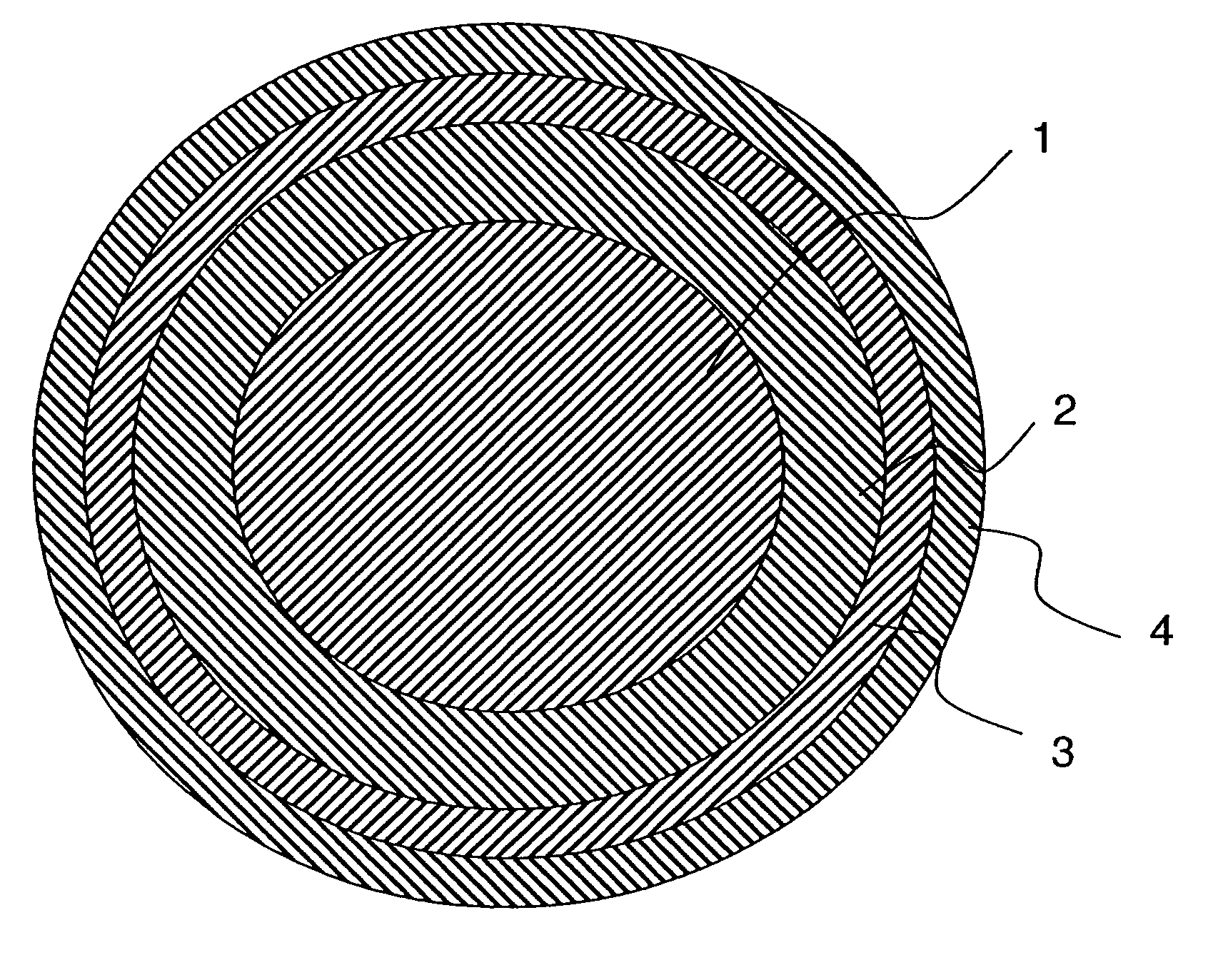

Golf ball with vapor barrier layer and method of making same

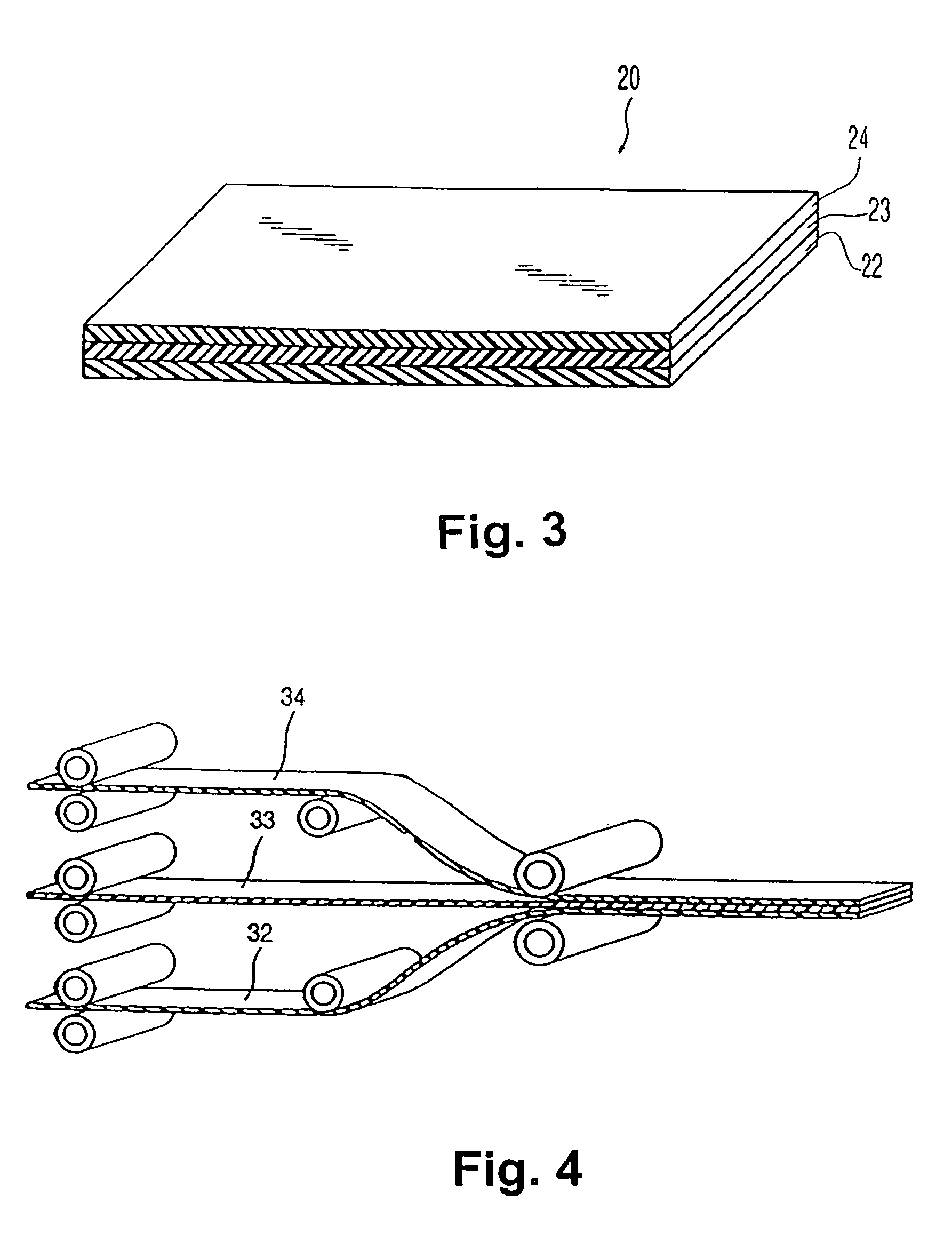

A golf ball comprising a core, a barrier layer enveloping the core, and a cover enveloping the barrier layer, wherein the barrier layer has a moisture vapor transmission rate less than that of the cover, and the barrier layer comprises a thermoplastic or thermoset composition of microparticles dispersed in a binder.

Owner:ACUSHNET CO

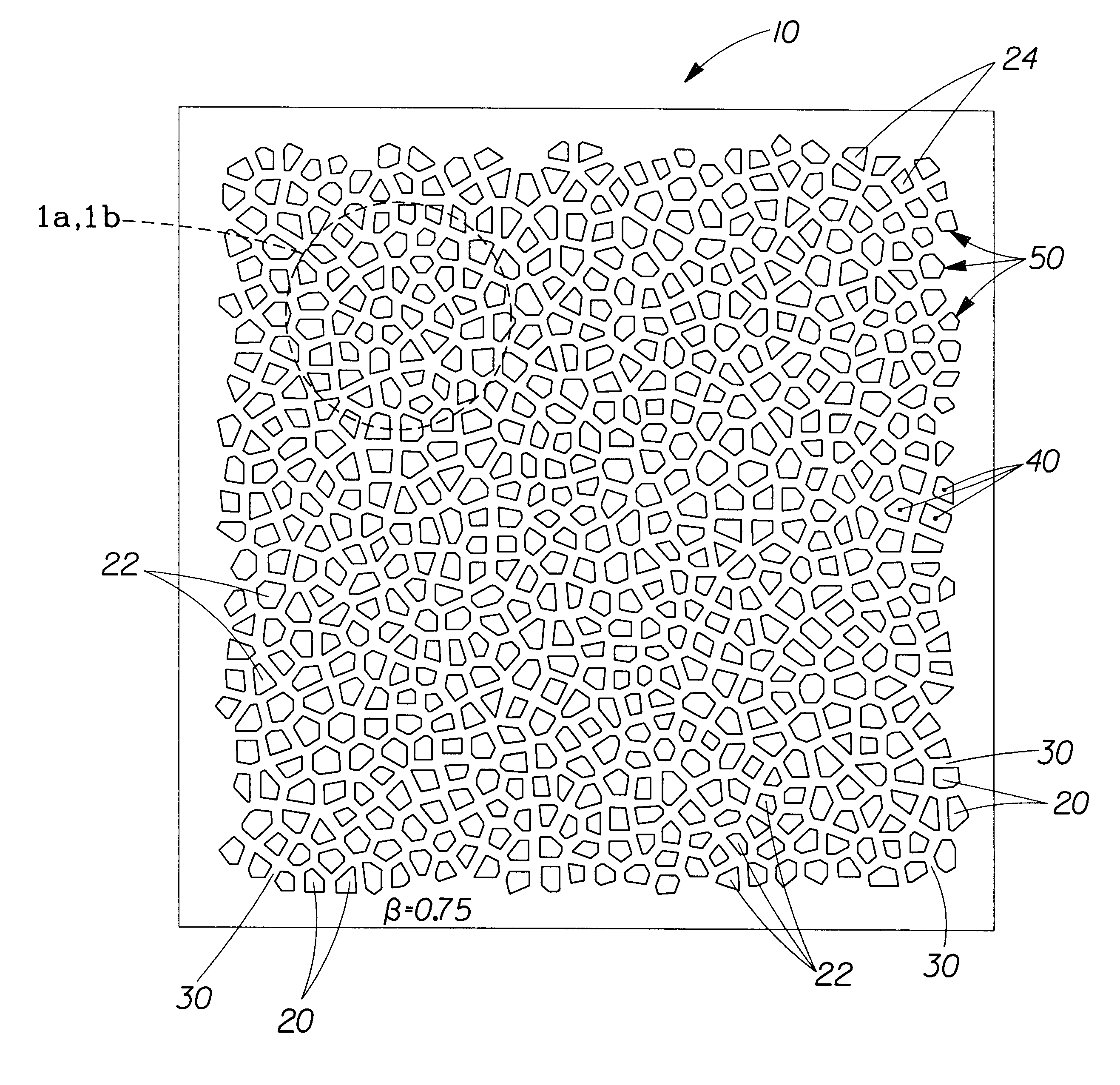

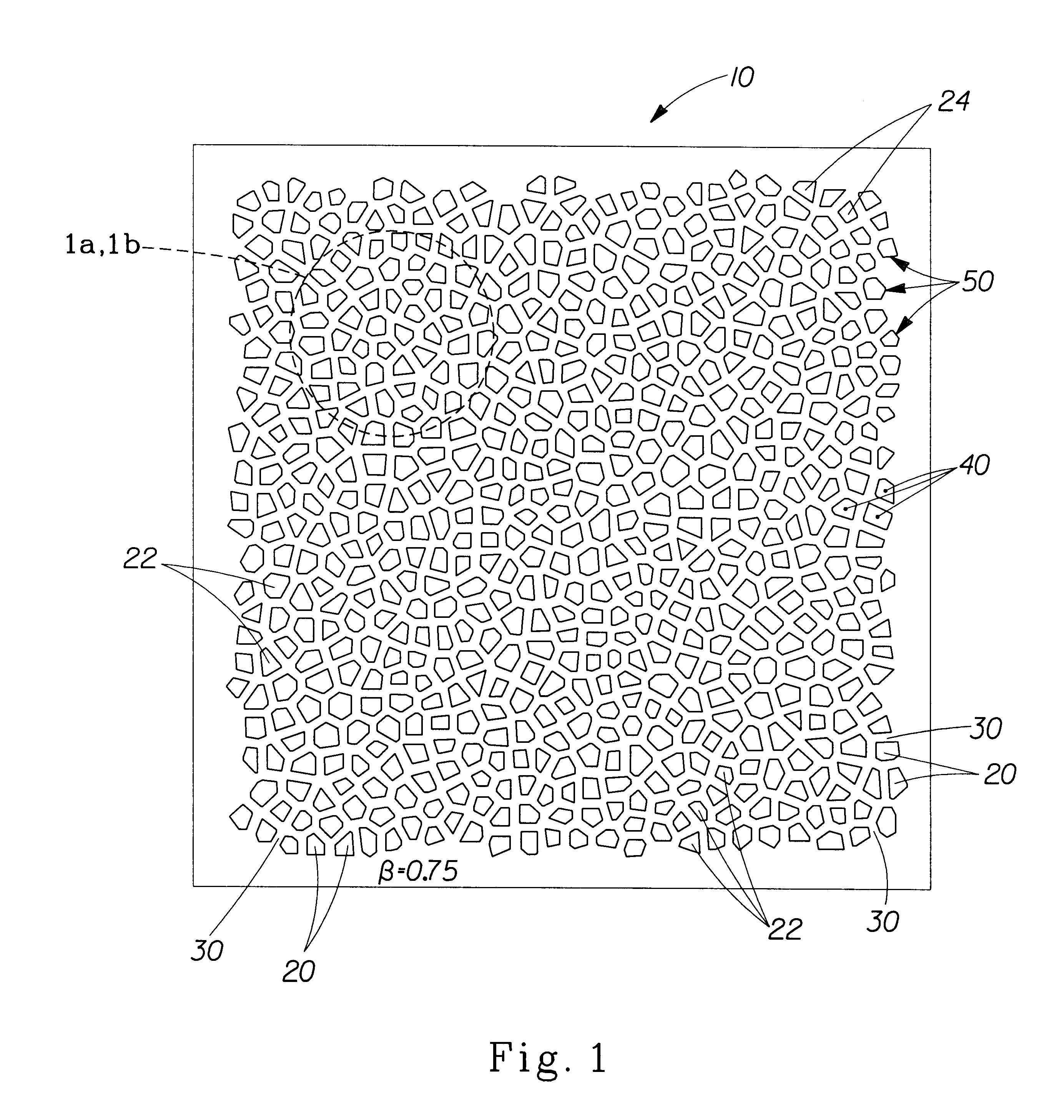

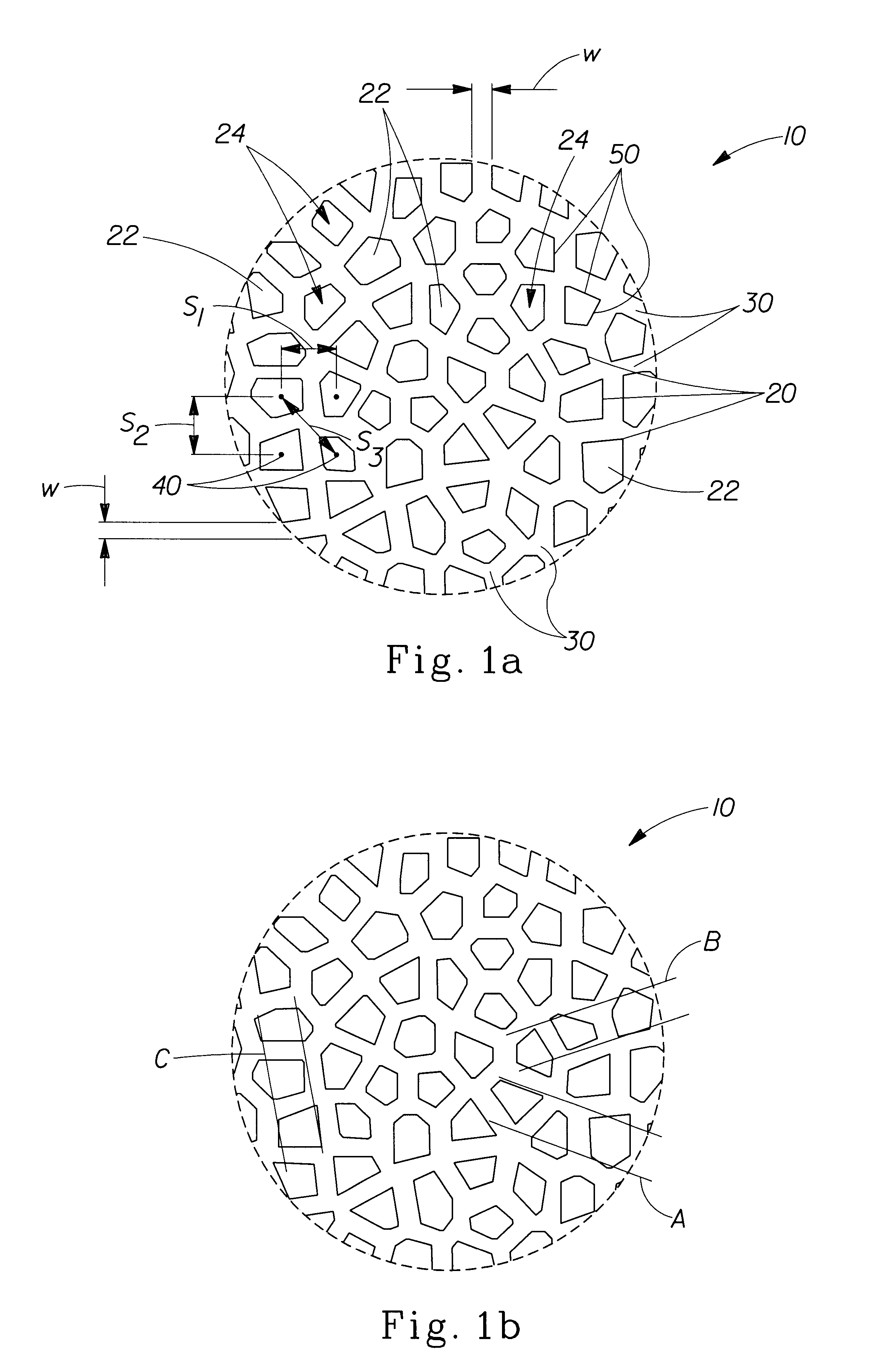

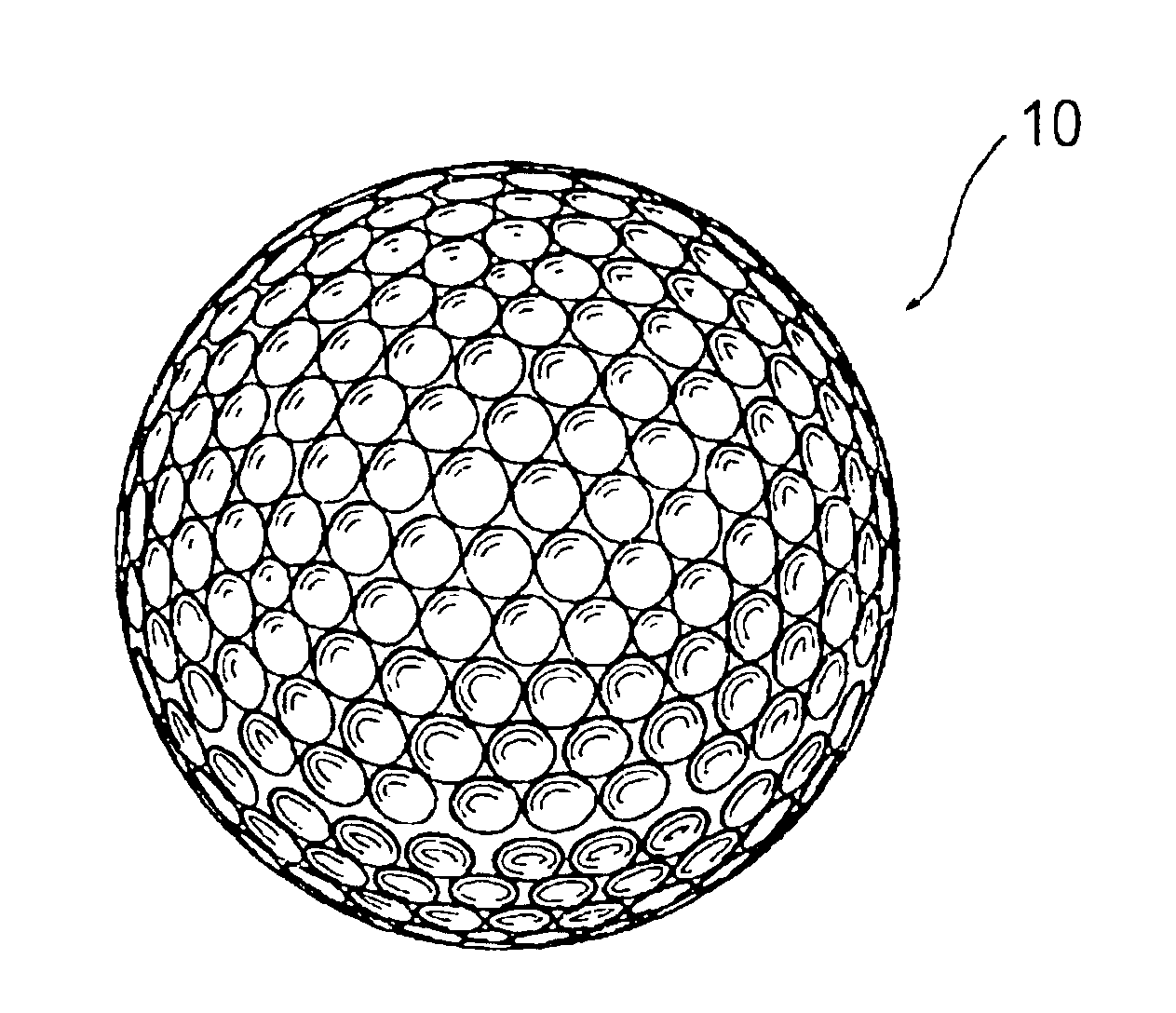

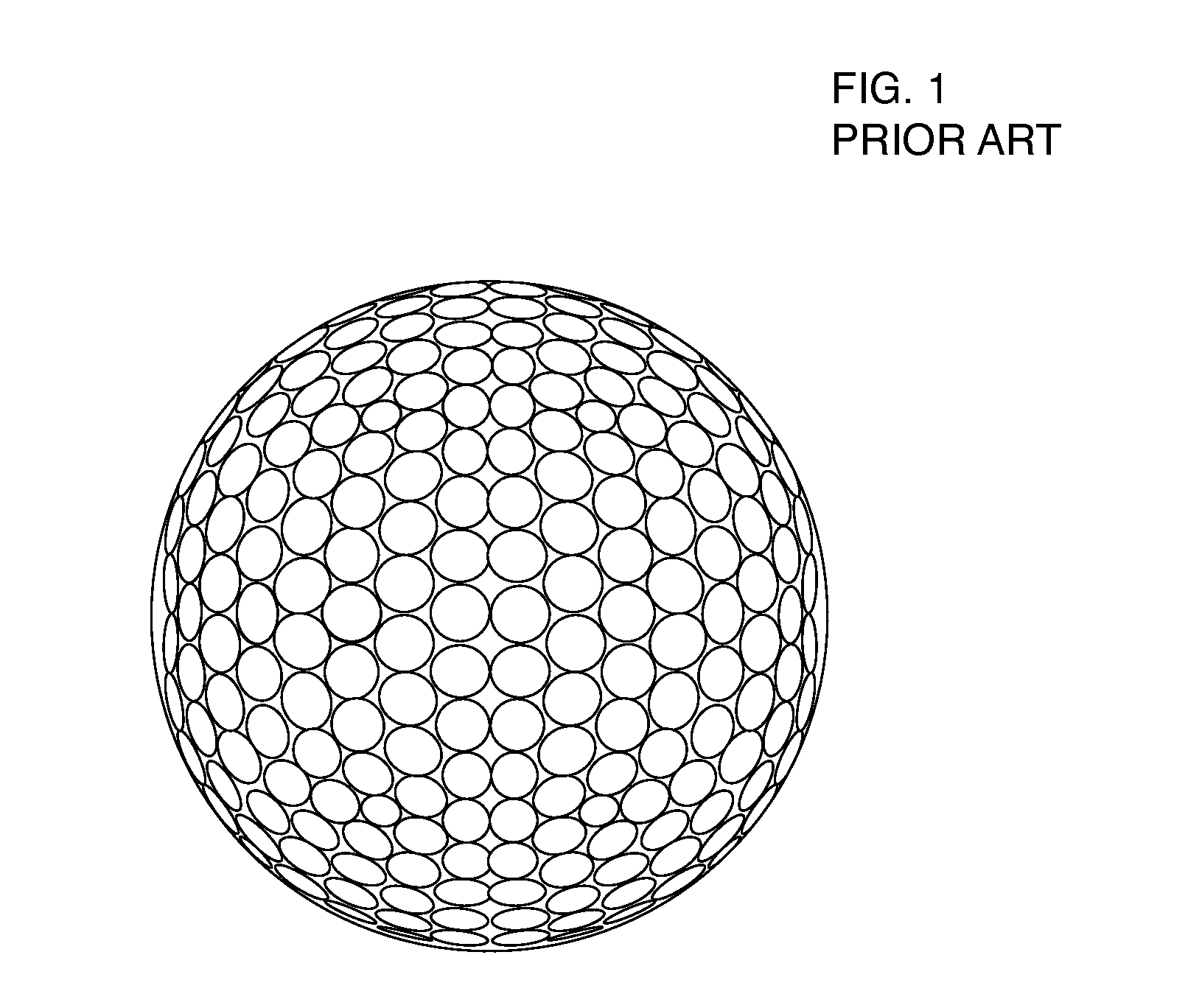

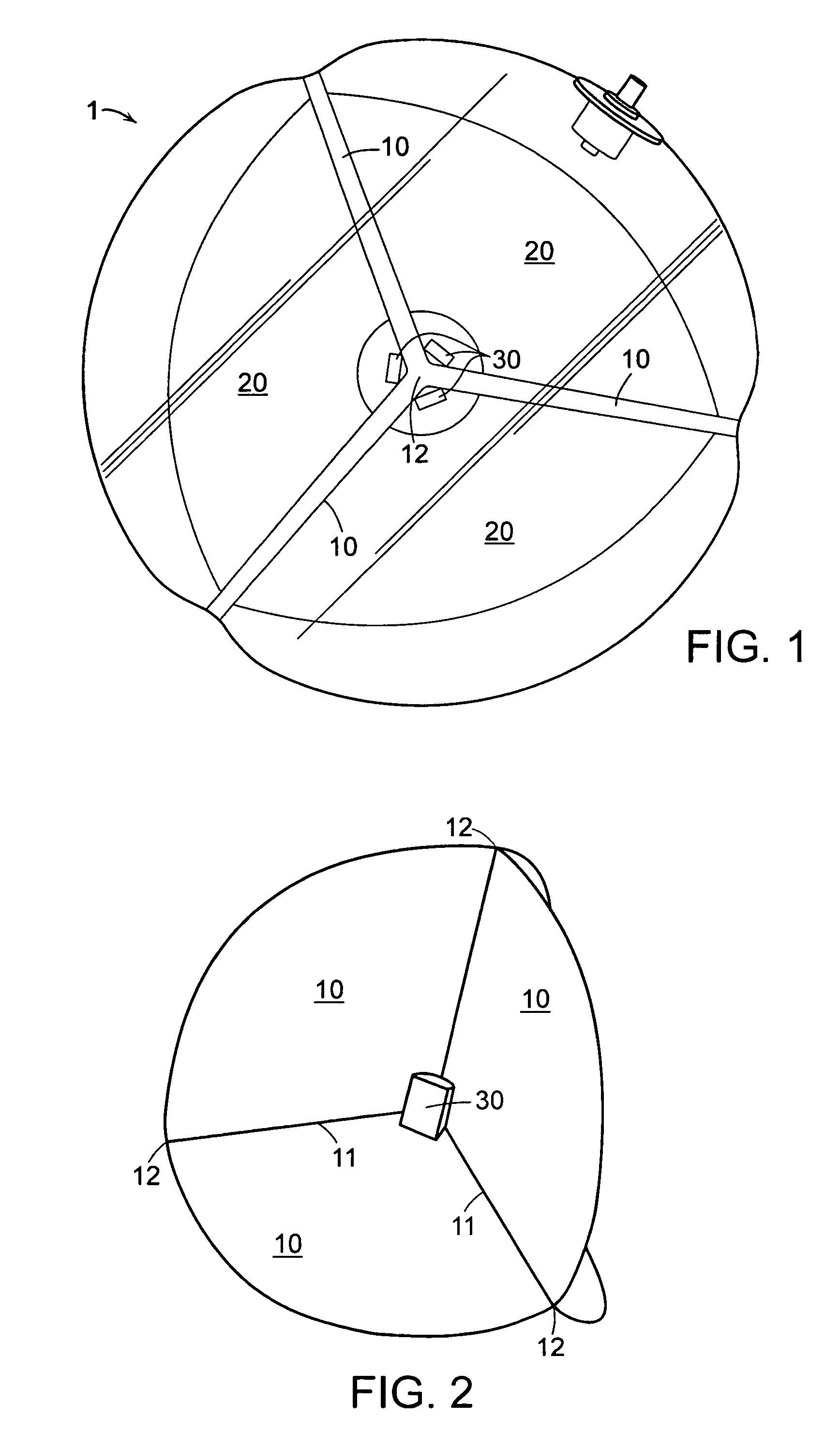

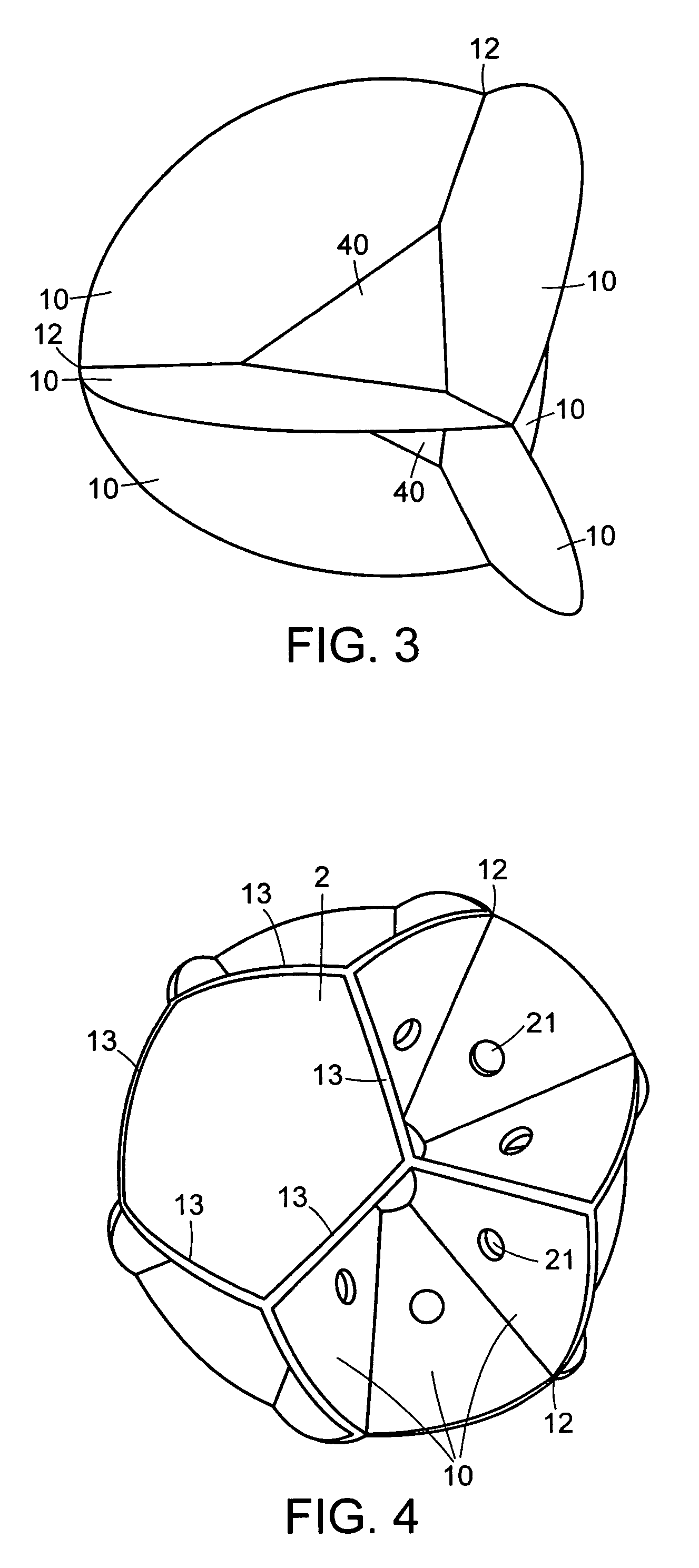

Golf ball with non-circular shaped dimples

In a non-limiting exemplary embodiment of the present invention, a golf ball has a surface comprising a plurality of dimples arranged in an amorphous pattern. In an additional embodiment of the invention, a golf ball has a surface comprising a plurality of spaced dimples, wherein the dimples each comprise a non-circular shape and are spaced by land portions having substantially uniform widths. In an additional embodiment of the present invention, a golf ball has a surface formed with a plurality of non-circular, multi-sided shaped dimples and interposed lands having substantially consistent widths between adjacent dimples. In yet another alternative embodiment of the present invention, an exemplary method of making a golf ball having a dimpled surface is provided. The process comprises generating an amorphous pattern of non-circular shaped dimples and then transferring the amorphous pattern to the surface of the golf ball.

Owner:THE PROCTER & GAMBLE COMPANY

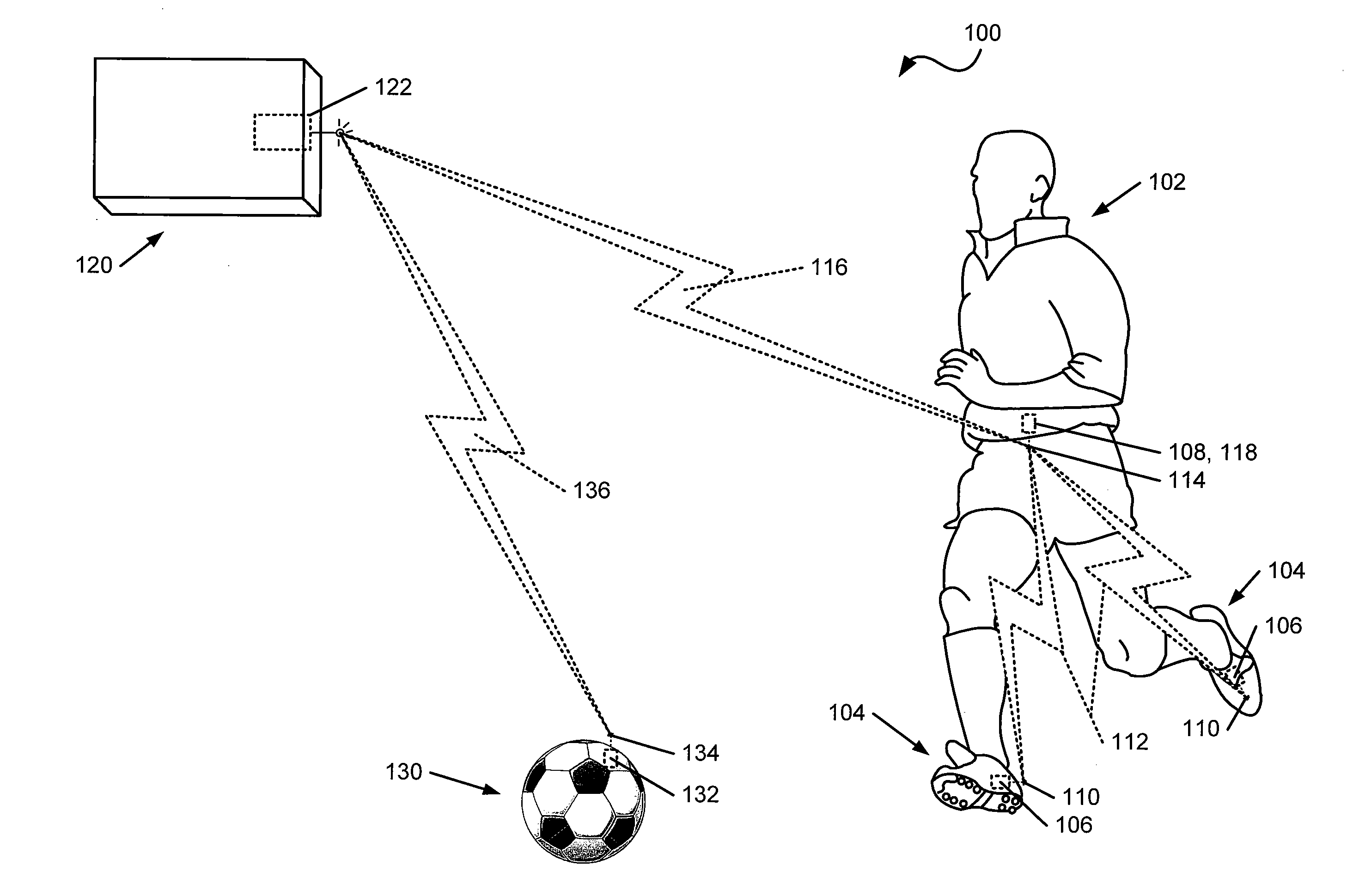

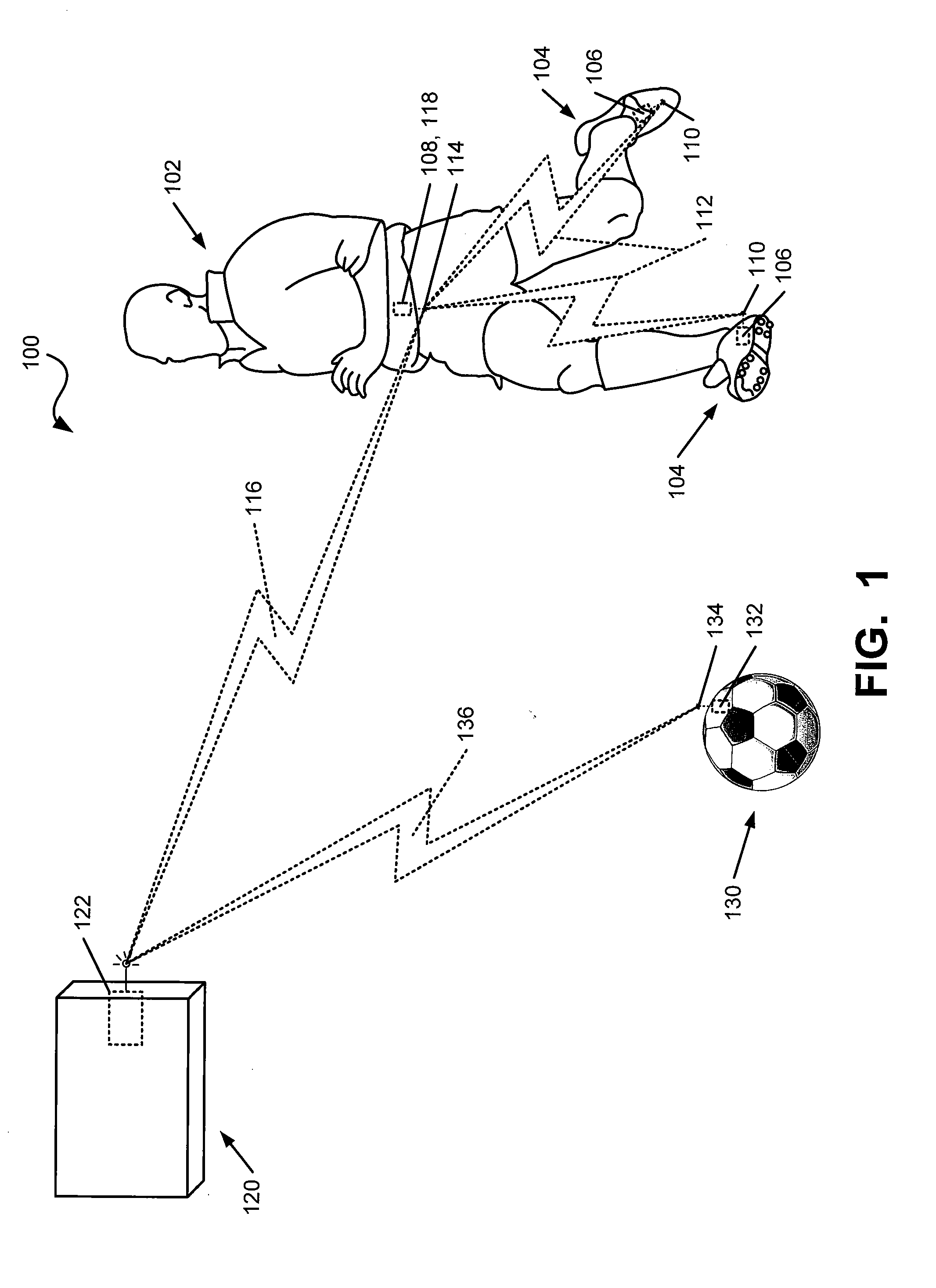

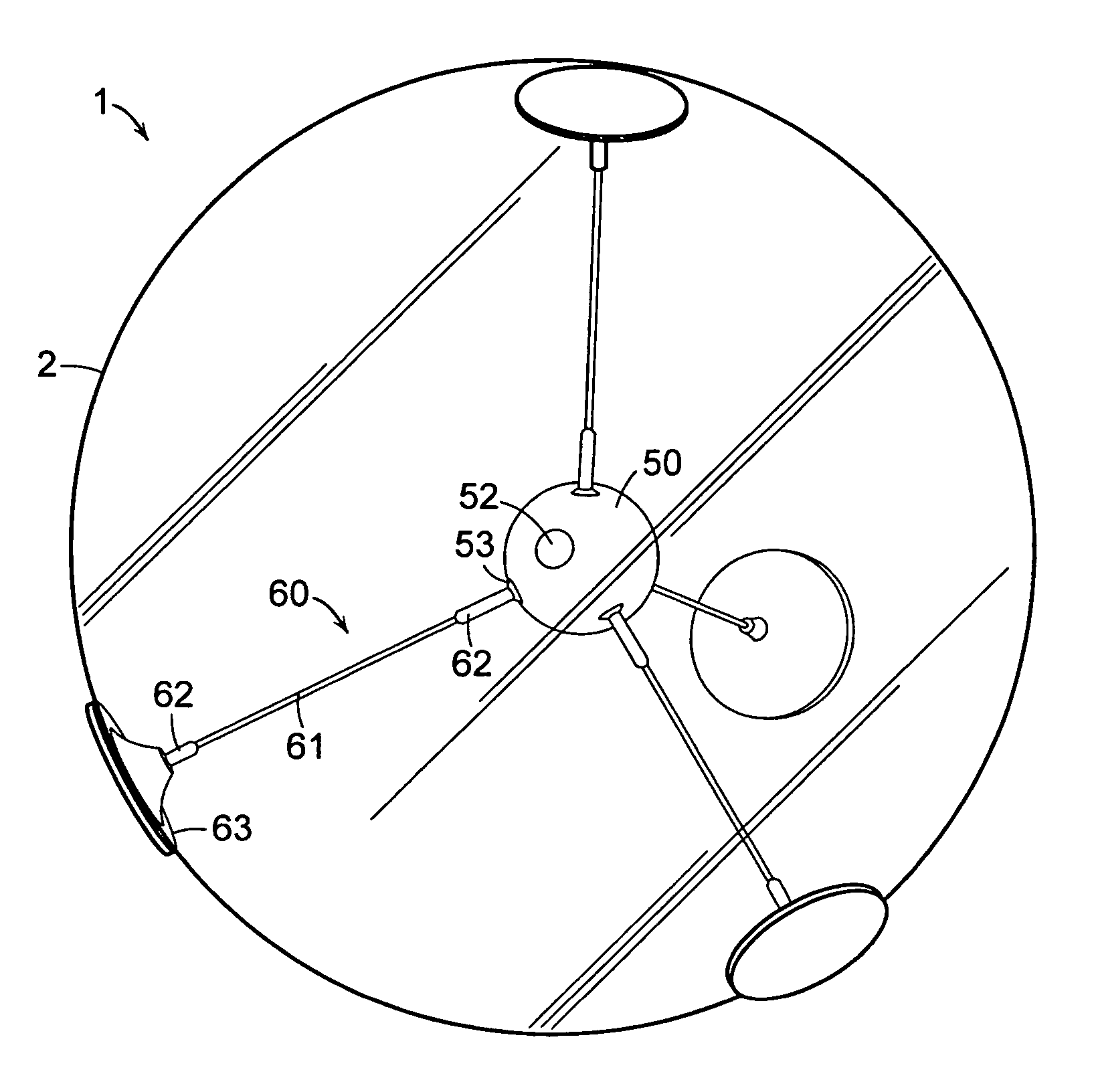

Sport Ball Athletic Activity Monitoring Methods And Systems

ActiveUS20130274040A1Improve abilitiesHollow inflatable ballsHollow non-inflatable ballsMovement activityEngineering

A method for monitoring a ball used for an athletic activity includes detecting movement of the ball at a first time, using a sensor module coupled to the ball, determining that the movement of the ball corresponds to a predetermined activation movement, entering an active state of the sensor module in response to the determination that the movement of the ball corresponds to the predetermined activation movement, and detecting movement of the ball at a second time, using the sensor module in the active state.

Owner:ADIDAS

Golf ball with vapor barrier layer and method of making same

A golf ball with at least one moisture vapor barrier layer is disclosed. The moisture vapor barrier layer comprises an elastomer, and has a moisture vapor transmission rate of less than about 0.6 grams·mm / m2·day.

Owner:ACUSHNET CO

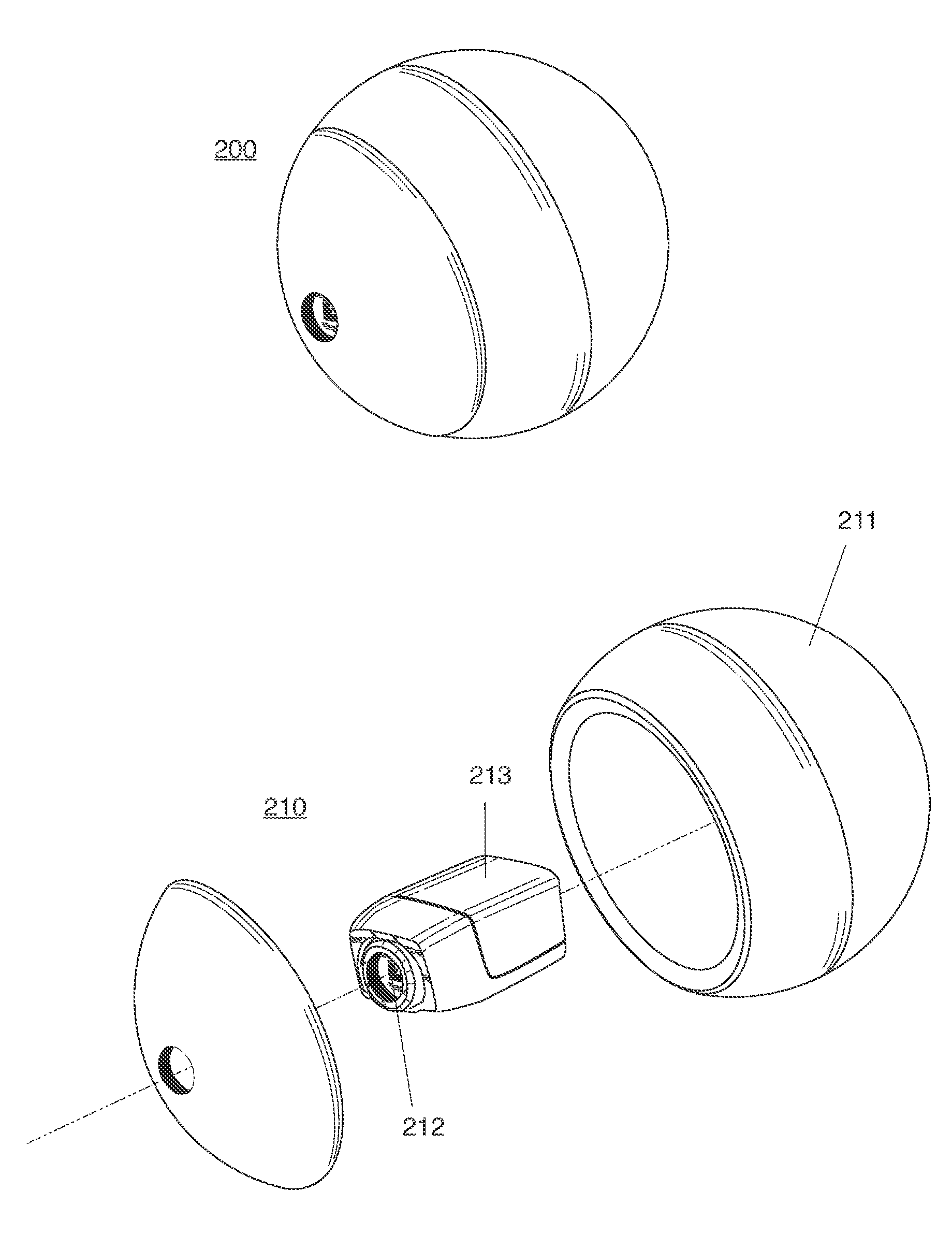

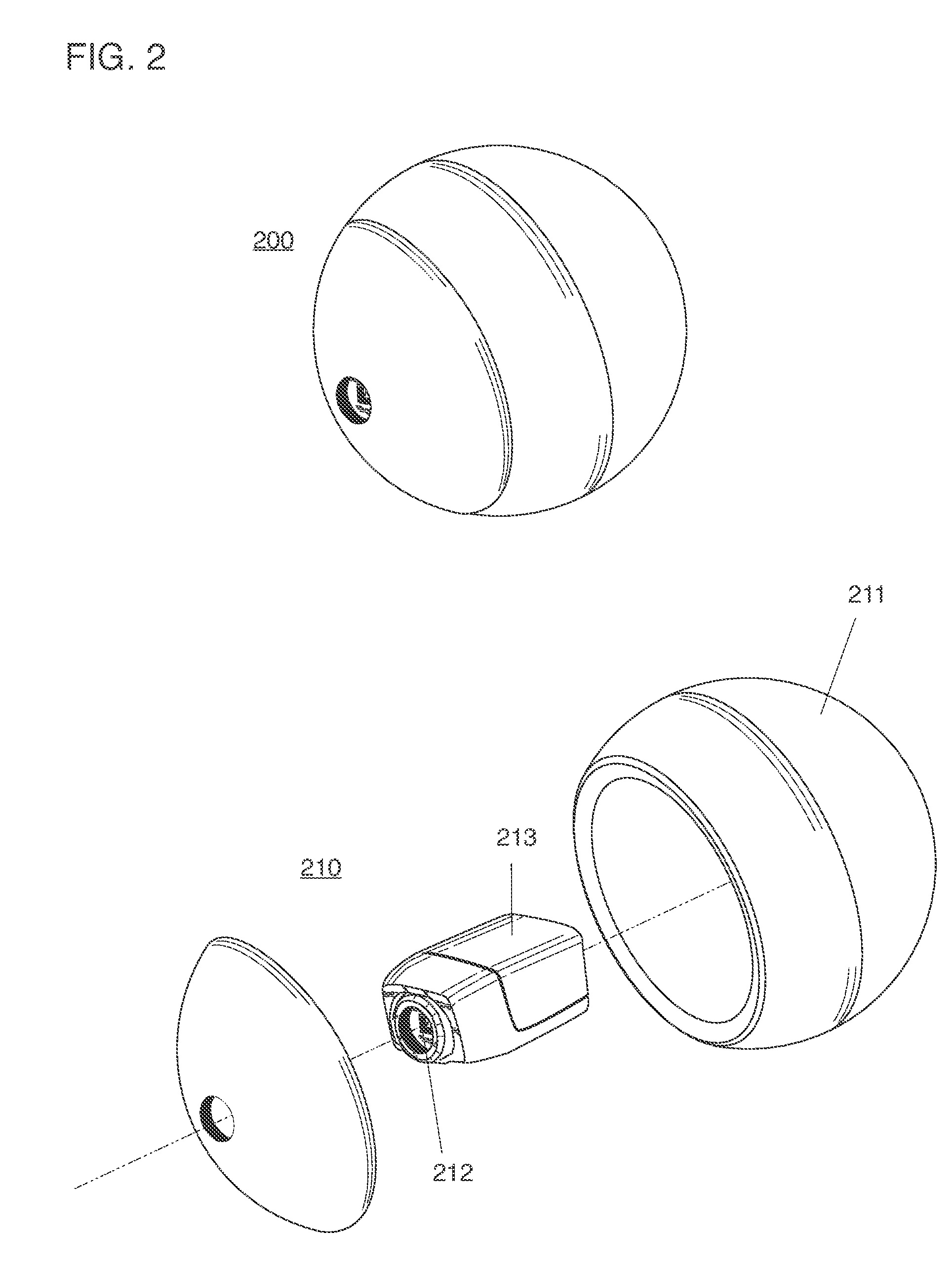

Ball with camera for reconnaissance or recreation and network for operating the same

ActiveUS20130210563A1Taking imageEasy to trackTelevision system detailsHollow inflatable ballsRecreationImage capture

A ball-shaped camera thrown or projected into an airborne trajectory, and an image capture system with network devices collaborating for the purpose of generating panoramic images and video sourced from network ball cameras, and ball cameras capable of capturing stable image and video while spinning, spiraling or precessing through a trajectory.

Owner:HOLLINGER STEVEN J

Golf ball

InactiveUS6921345B2Solid comfortable feelGood rebound characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

A golf ball includes a hot-molded product of a rubber composition comprising a base rubber composed of (a) 20-100 wt % of a polybutadiene having a high cis-1,4 content, a minimal 1,2 vinyl content, and a viscosity η of up to 600 mPa·s at 25° C. as a 5 wt % toluene solution, and satisfying a certain relationship between Mooney viscosity and polydispersity index Mw / Mn, in combination with (b) 0-80 wt % of another diene rubber, (c) an unsaturated carboxylic acid, (d) an organosulfur compound, (e) an inorganic filler, (f) an organic peroxide, and optionally, (g) an antioxidant. The hot-molded product has a difference in JIS-C hardness between the center and surface thereof of up to 15 units. The composition and hardness characteristics of the hot-molded product provide the golf ball with a solid comfortable feel upon impact and an excellent rebound.

Owner:BRIDGESTONE SPORTS

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

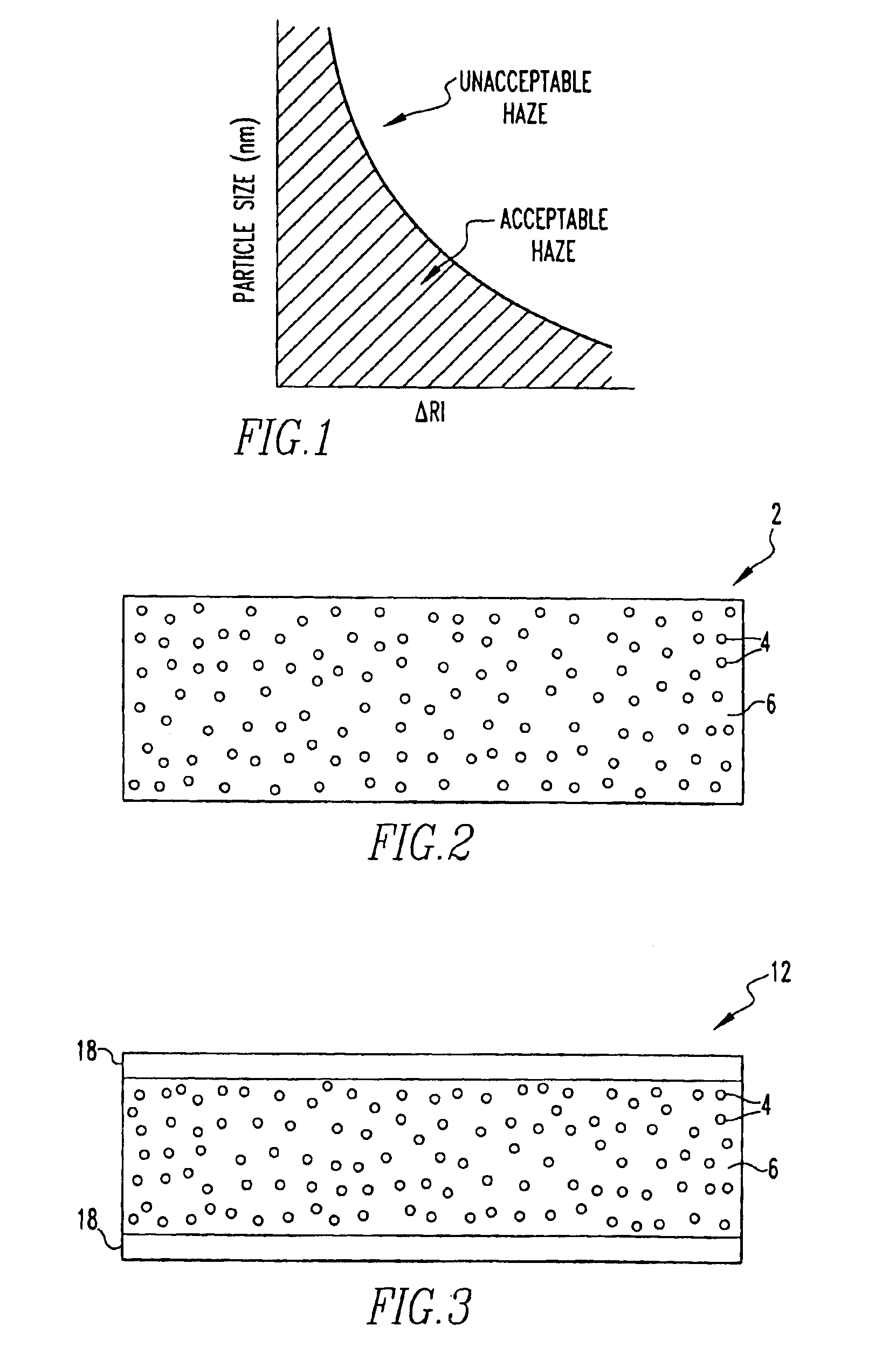

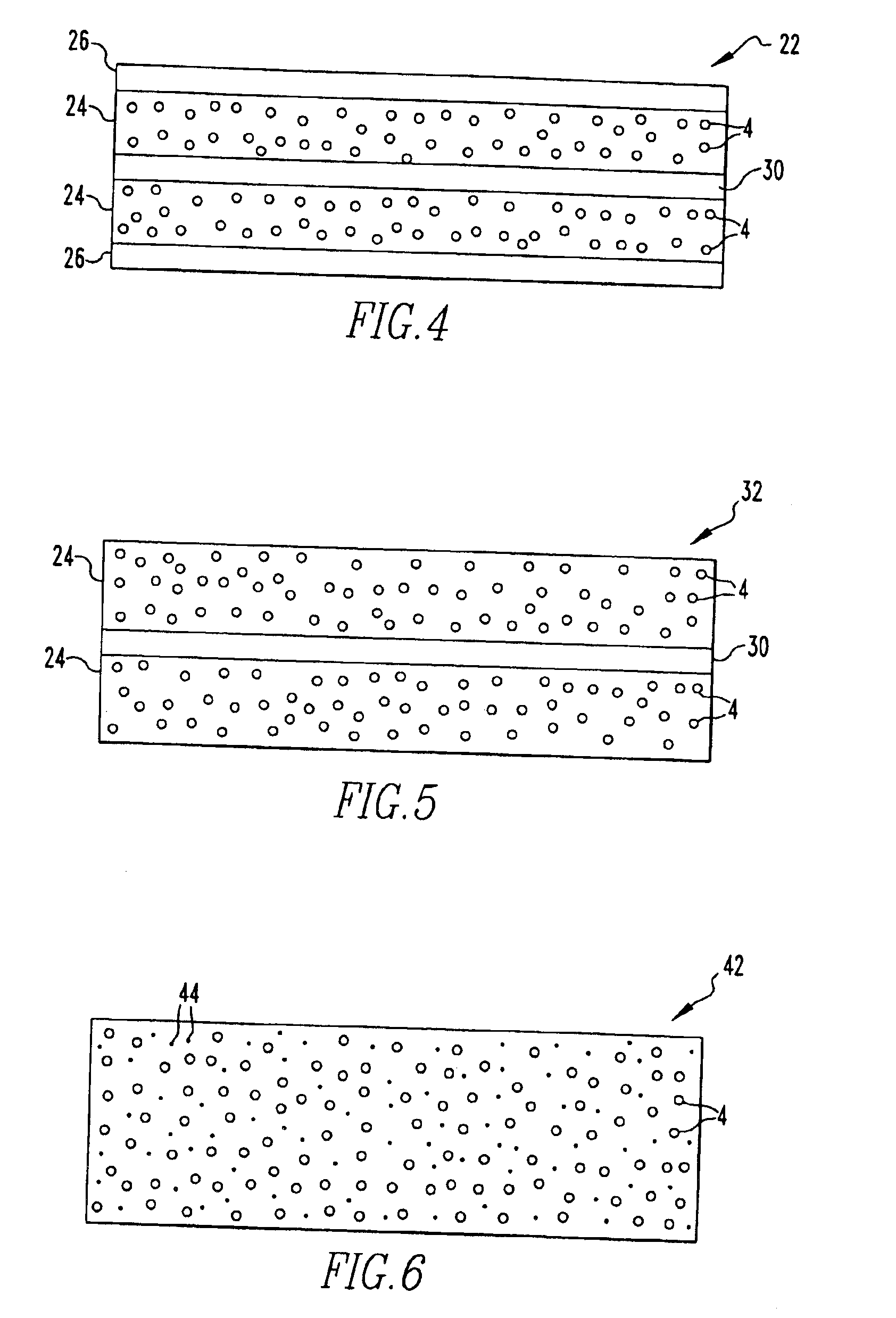

Optical element with nanoparticles

InactiveUS7046439B2Effective lightingBrighter backlit displaysDiffusing elementsProjectorsMicrometerNanoparticle

Owner:SKC HI TECH & MARKETING CO LTD CO REGISTRATION NO 161511 0225312

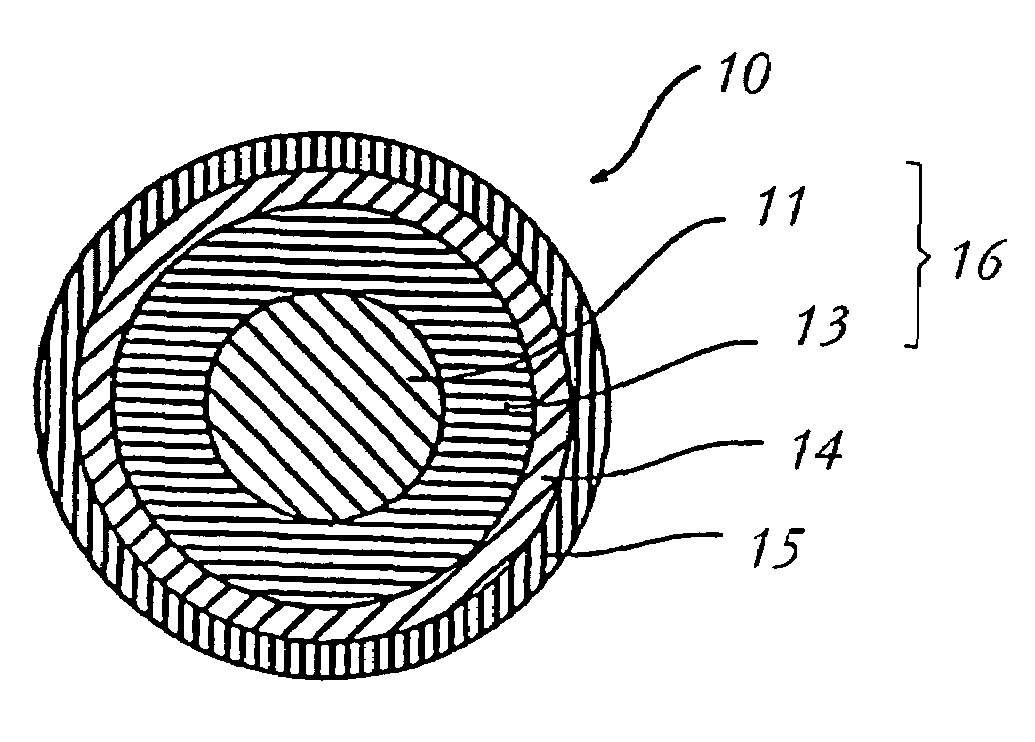

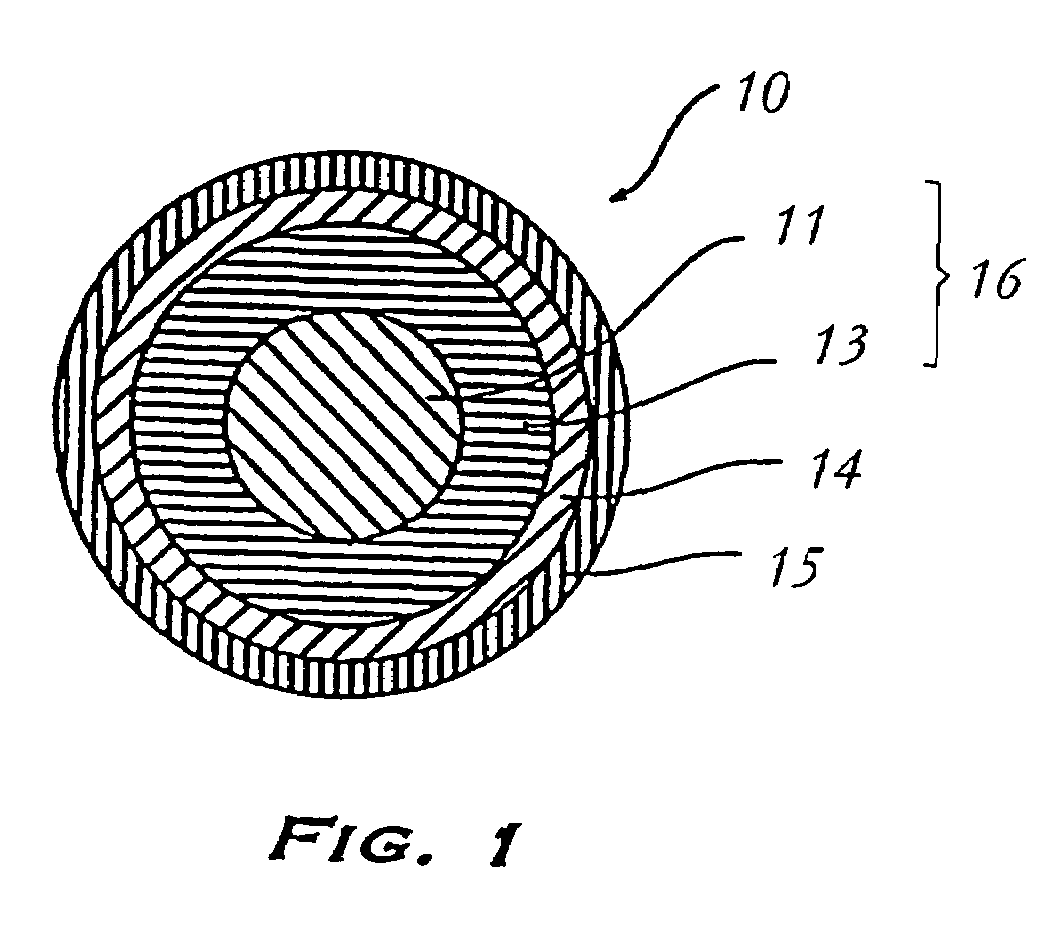

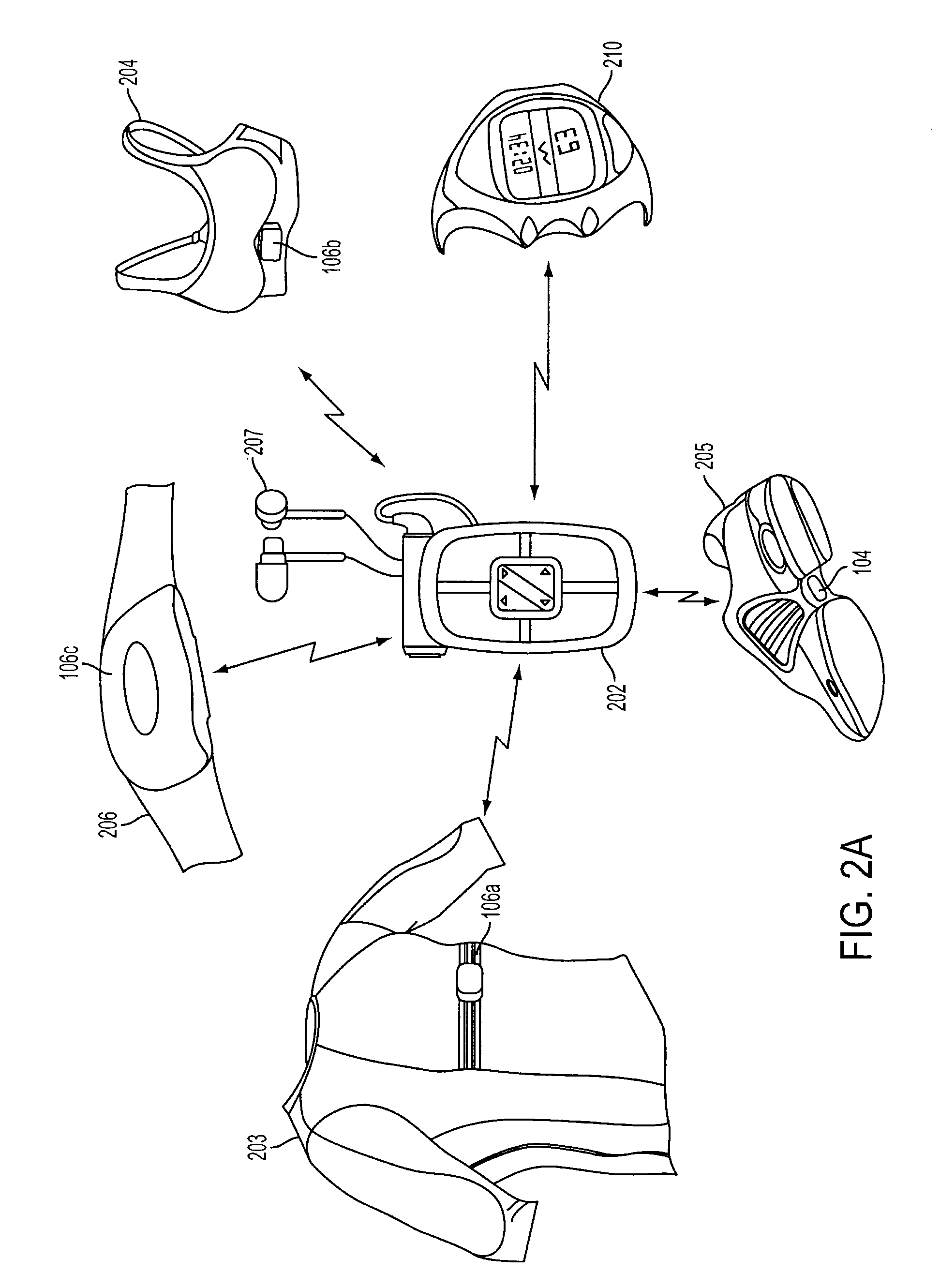

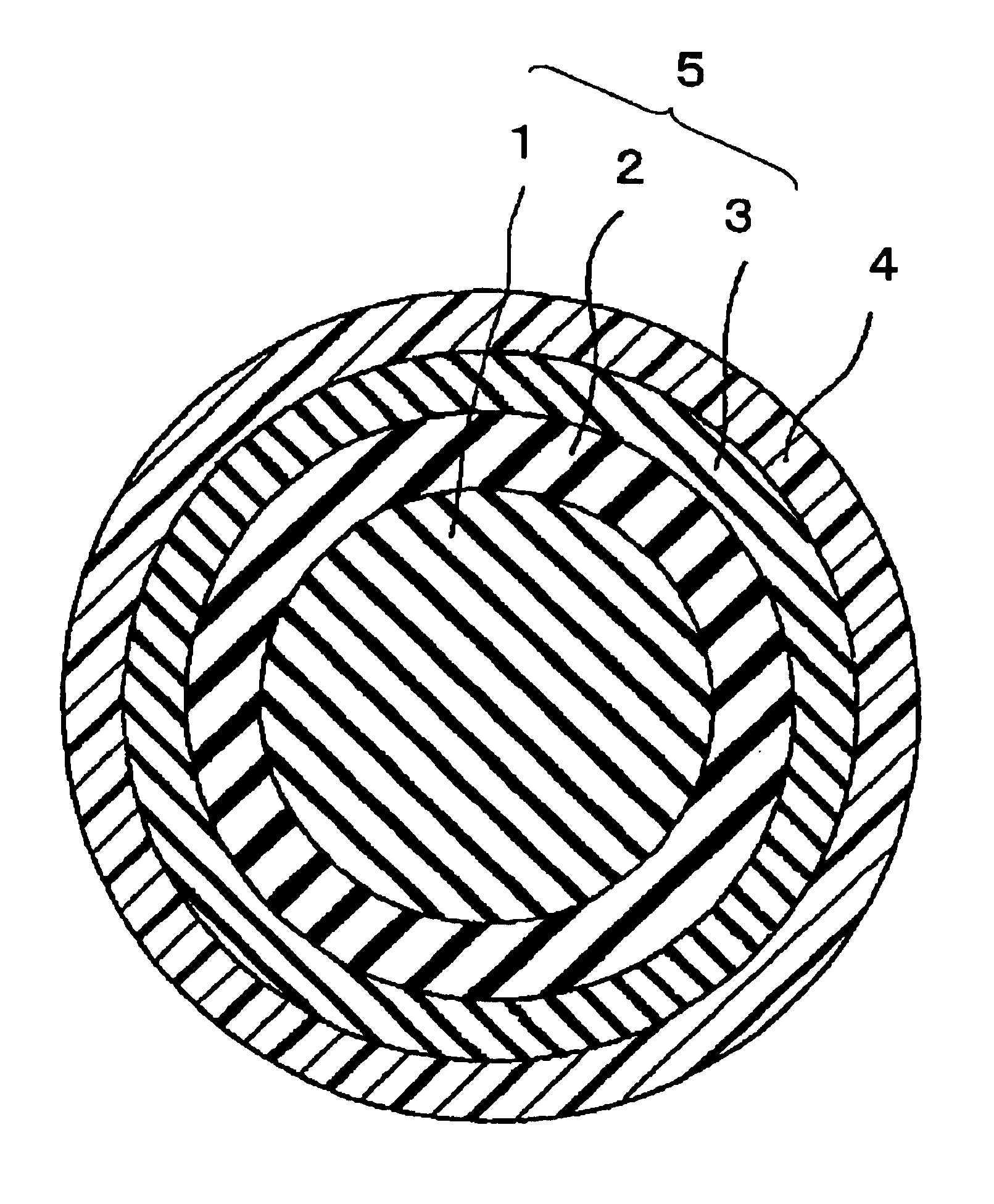

Multi-layer core golf ball

InactiveUS7255656B2Extended service lifeGolf ballsDomestic articlesMoisture vapor transmission rateEngineering

The present invention is directed to an improved golf ball displaying the desired spin profile and having a generally rigid, thermoset polybutadiene outer core surrounding a relatively soft, low compression inner core. In general, this golf ball has an inner core and at least one outer core layer surrounding the inner core. The inner core has a hardness less than a hardness of the outer core and a specific gravity less than or equal to the outer core specific gravity. Overall the inner core compression and outer core are formulated to provide a combined overall core compression of greater than about 50, preferably greater than about 70. A cover layer is provided to surround and to cover the outer core layer. A moisture barrier layer is provided between the outer core layer and the cover layer to protect the inner and outer cores from degradation due to exposure to water. The moisture vapor transmission rate of the moisture barrier layer is selected to be less than the moisture vapor transmission rate of the cover layer.

Owner:ACUSHNET CO

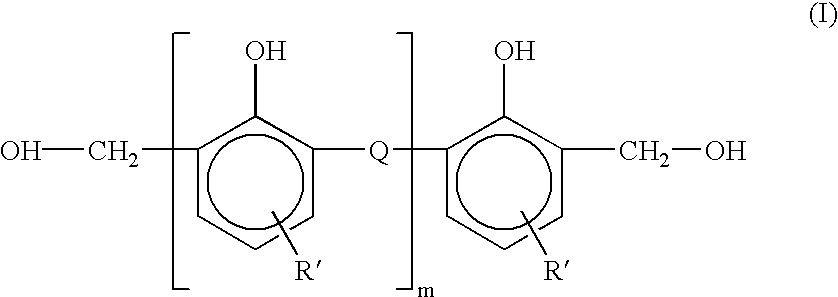

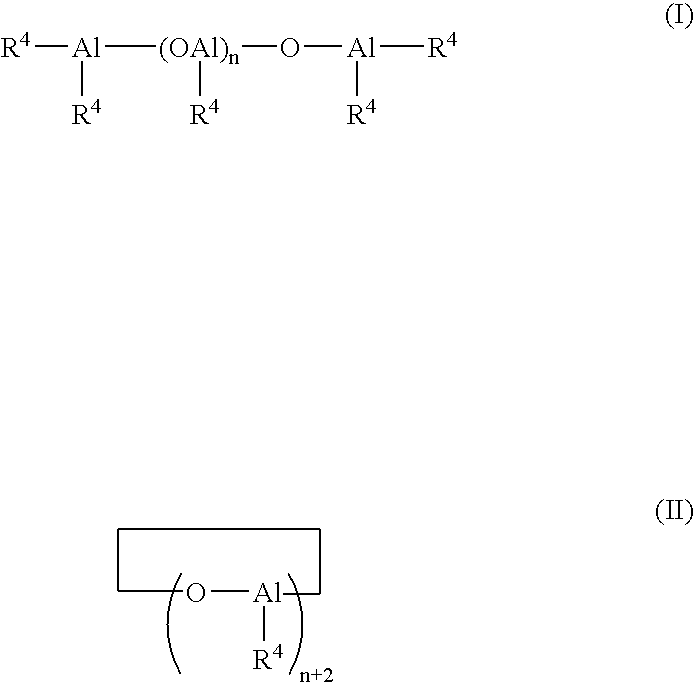

Thermoplastic vulcanizates and process for making the same

InactiveUS6437030B1Low hygroscopicityReduced halideSynthetic resin layered productsSolid ballsThermoplastic elastomerMetal halides

A process for forming a thermoplastic vulcanizate compromising the steps of dynamically vulcanizing a rubber within a blend that comprises the rubber and a thermoplastic polymer, where said step of vulcanizing is carried out by using a phenolic resin in the presence of a catalyst system formed by combining a metal halide and a metal carboxylate. Also, a thermoplastic vulcanizate having low moisture pick-up with a technologically useful cure.

Owner:ADVANCED ELASTOMER SYST LP

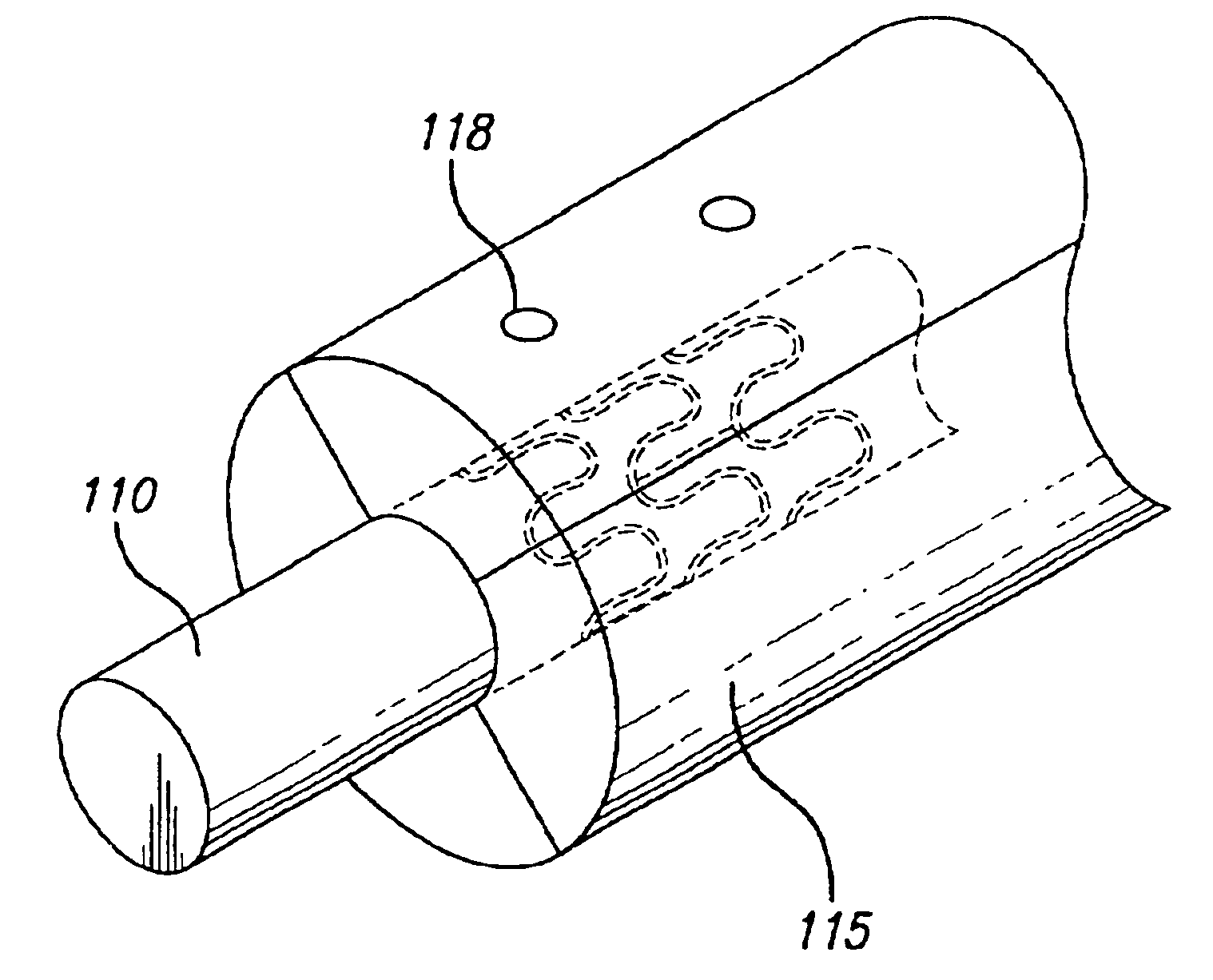

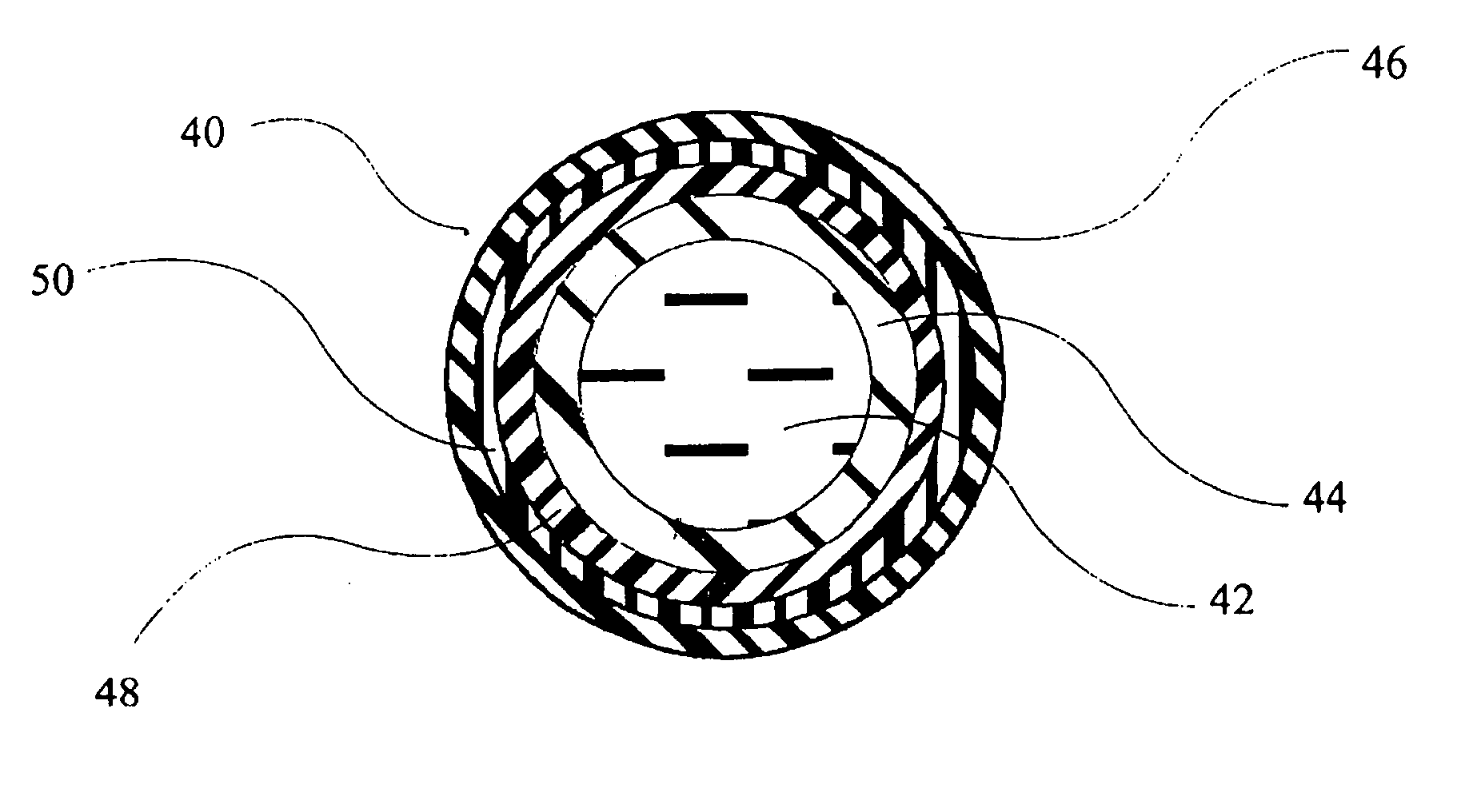

Bladder

ActiveUS7740551B2Maintain positionEasy to produceHollow inflatable ballsHollow non-inflatable ballsCushioningEngineering

Owner:ADIDAS

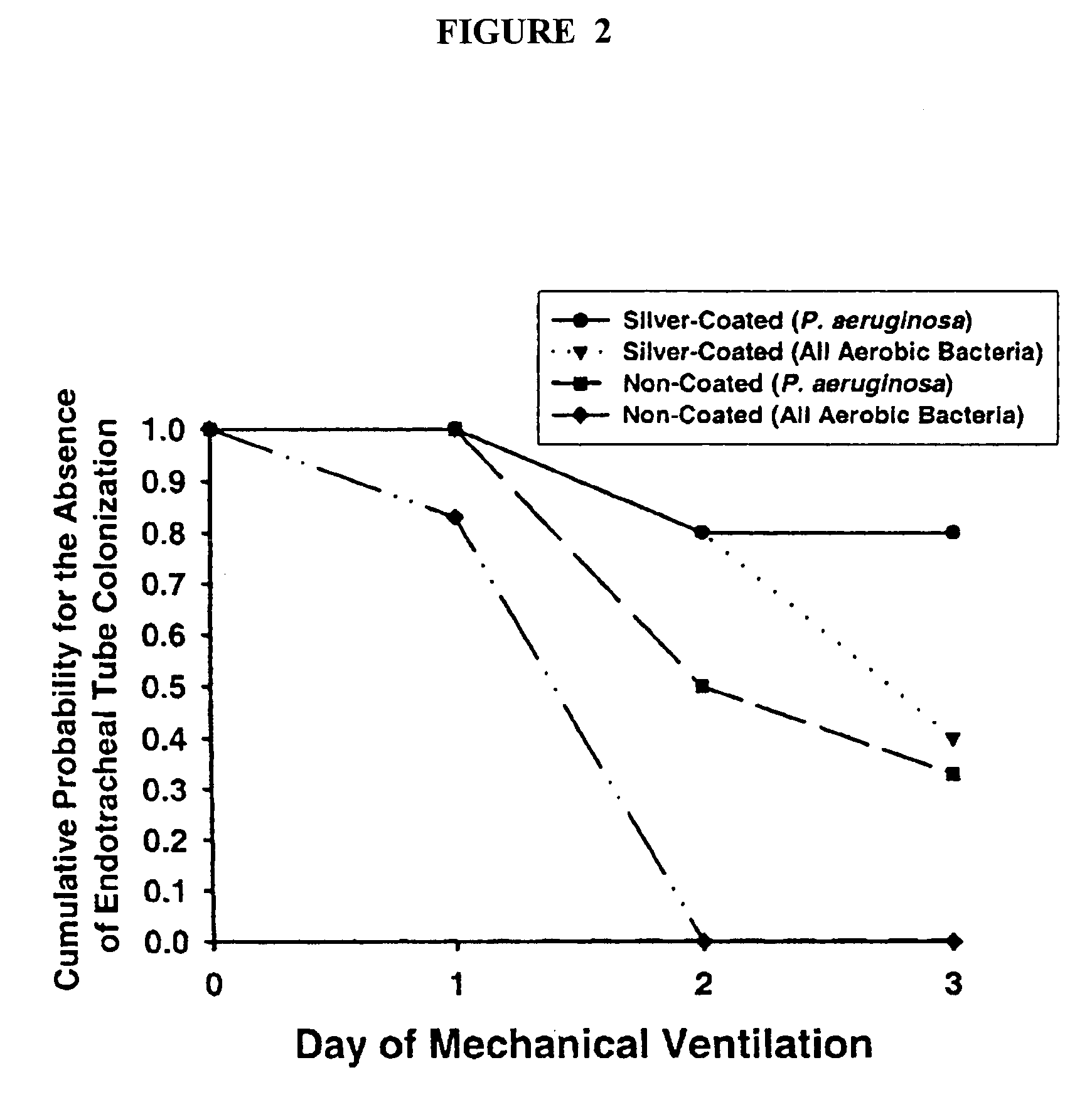

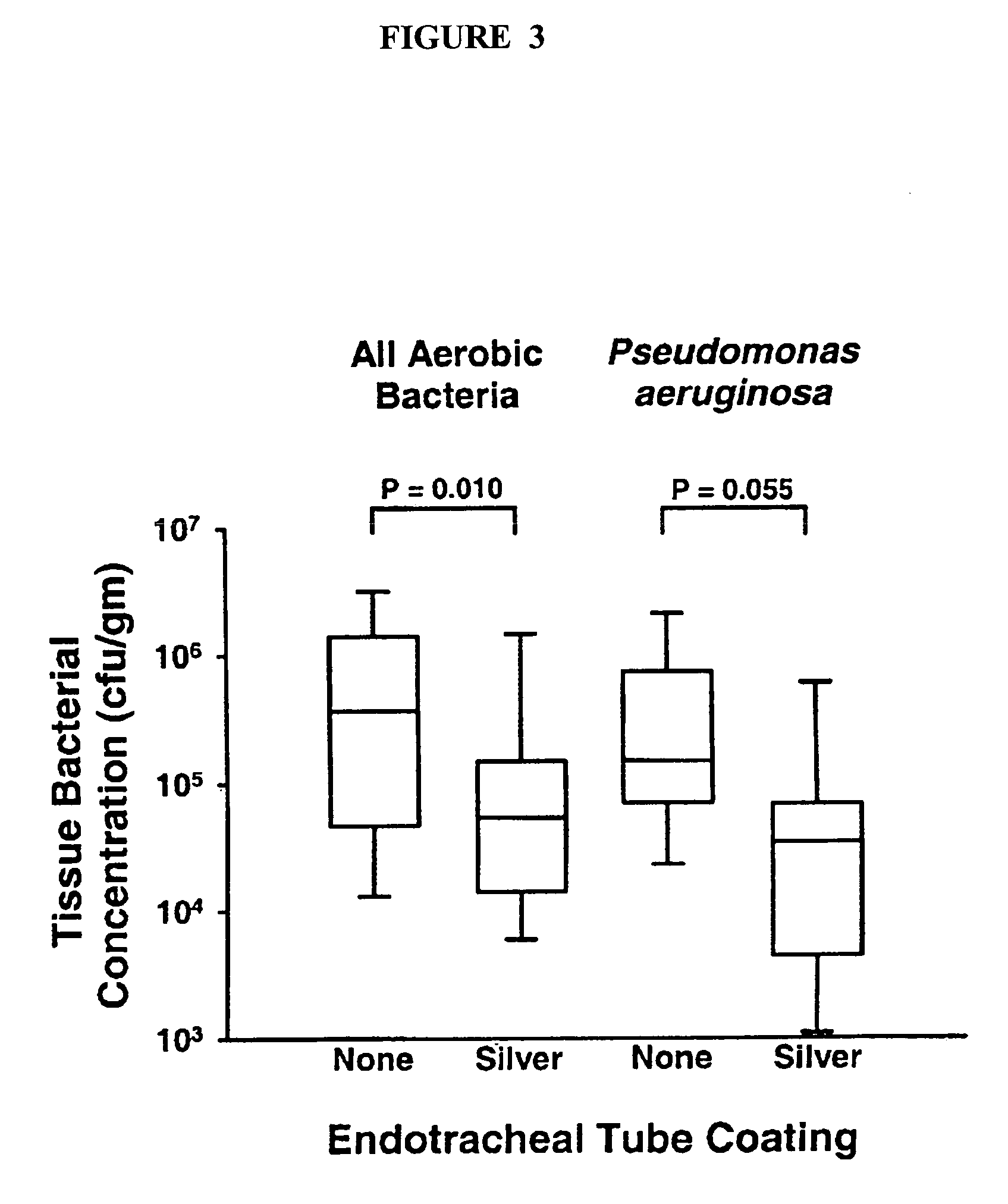

Antimicrobial compositions containing colloids of oligodynamic metals

InactiveUS7179849B2Reduced settlingReduce agglomerationOrganic active ingredientsPretreated surfacesSolubilityCatheter

Owner:CR BARD INC

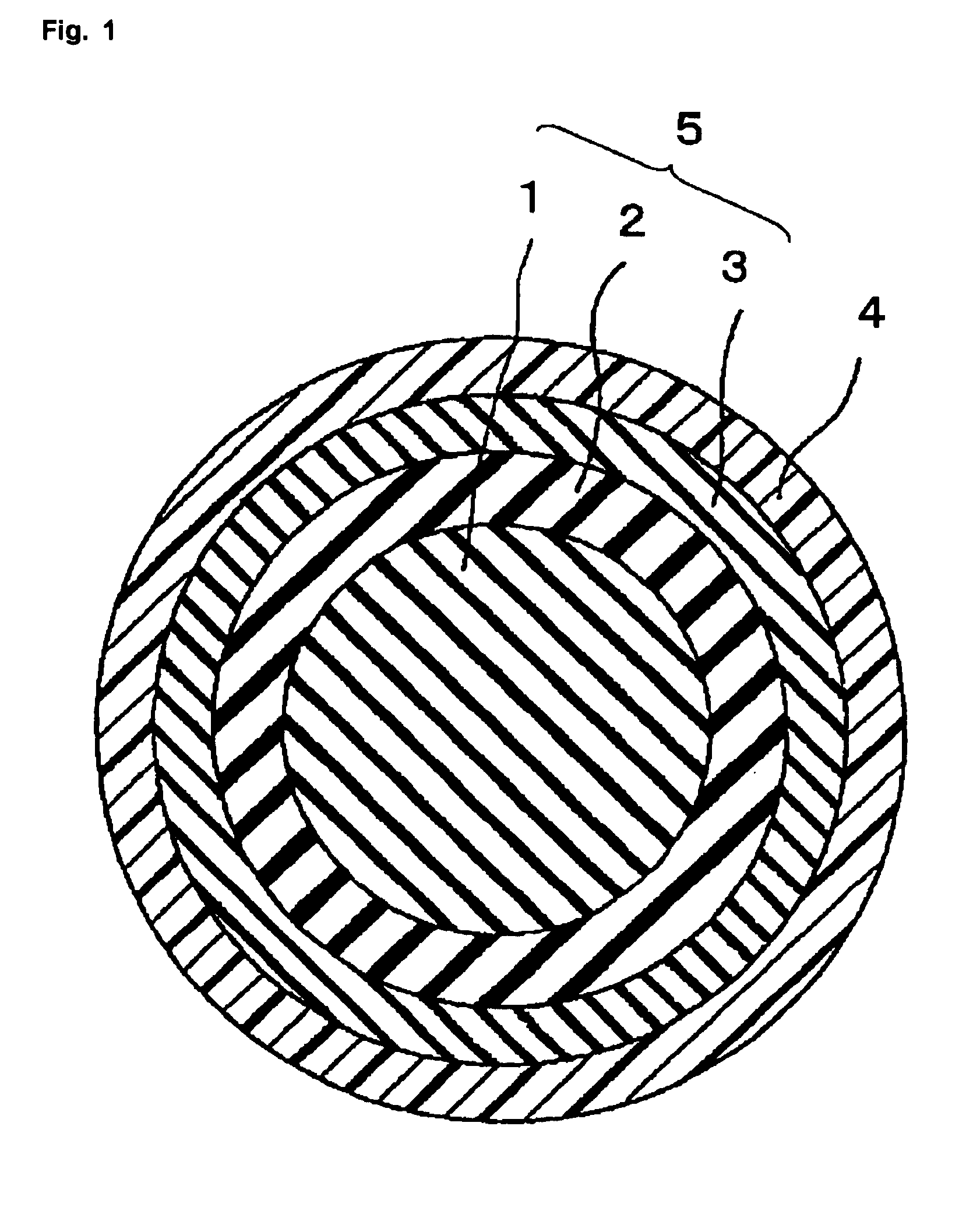

Multi-piece solid golf ball

InactiveUS6739986B2Stretching flight performanceExtended driving distancePolyurea/polyurethane coatingsGolf ballsLow speedHardness

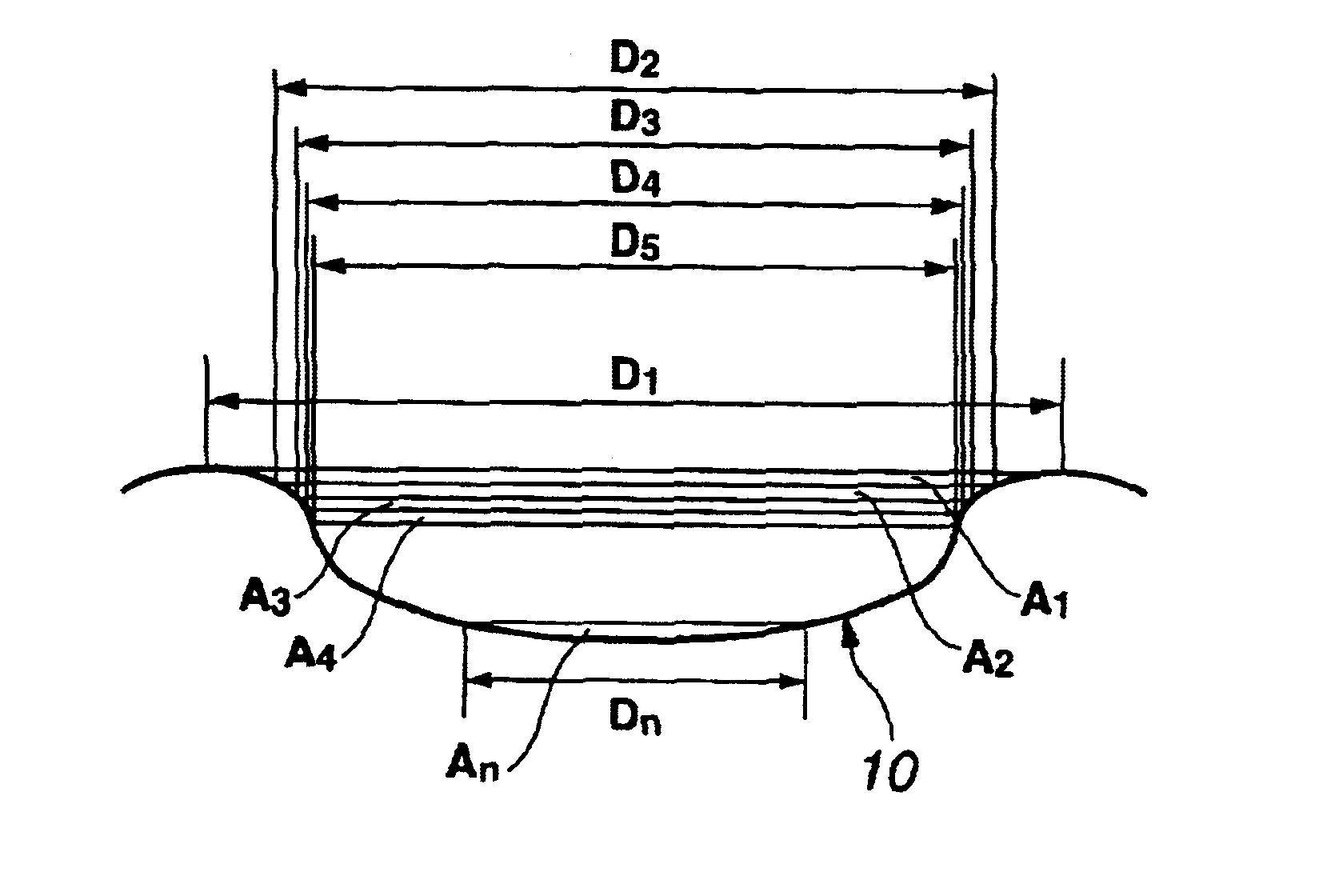

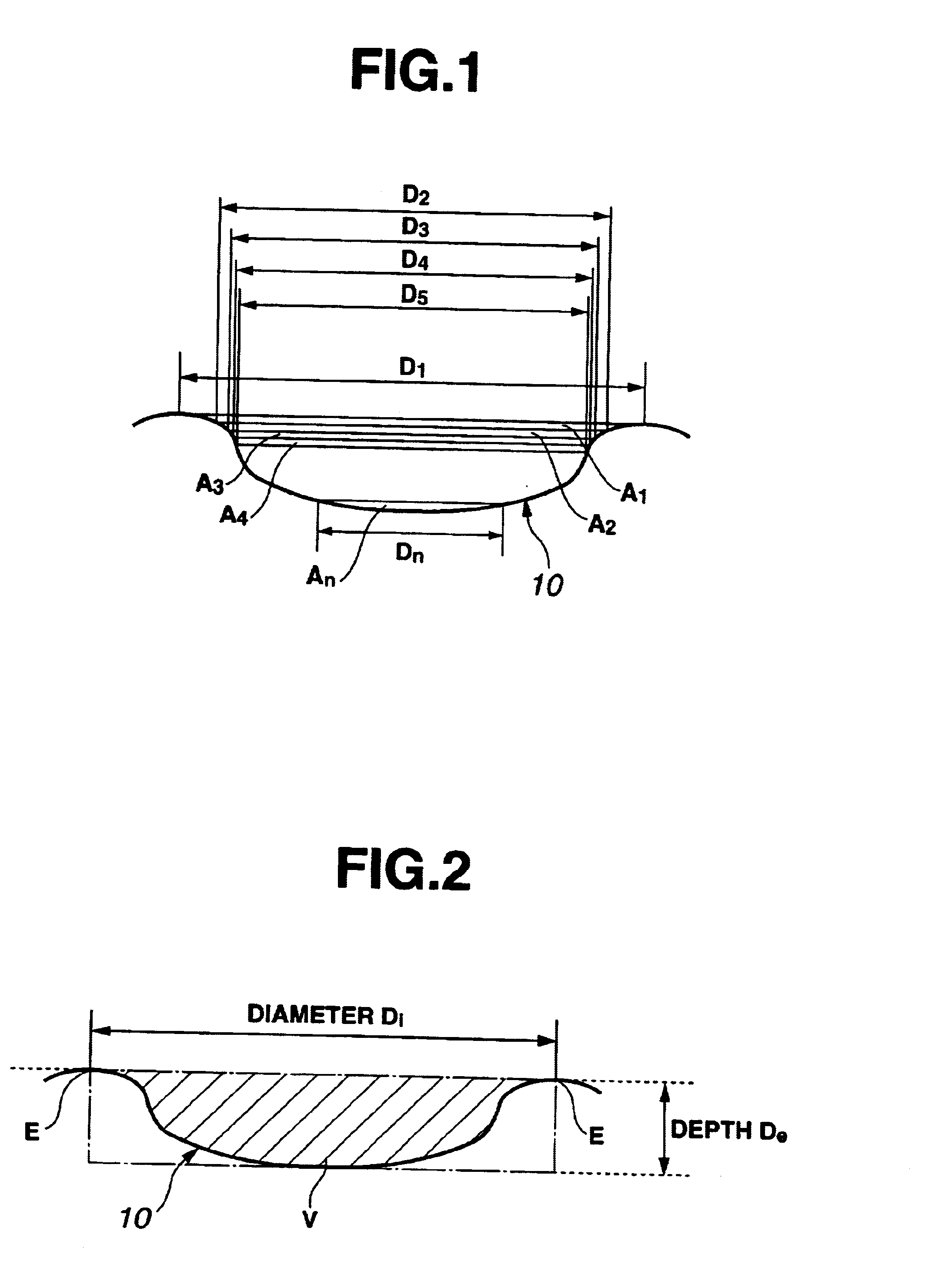

In a multi-piece solid golf ball comprising a solid core and a cover of two inner and outer layers enclosing the solid core and formed on the surface with a plurality of dimples, the solid core in its entirety has a hardness distribution falling within the range of JIS-C hardness 50-85, the difference between maximum and minimum JIS-C hardnesses in the solid core falls within 5%, the cover inner layer has a JIS-C hardness of 70-90, the cover outer layer has a JIS-C hardness of 60-80, the sum of high-speed region dimple operative volumes HDOV of respective dimples is 170-310, the sum of low-speed region dimple operative volumes of respective dimples LDOV is 200-310, and the overall dimple volume is 260-360 mm<3>.

Owner:BRIDGESTONE SPORTS

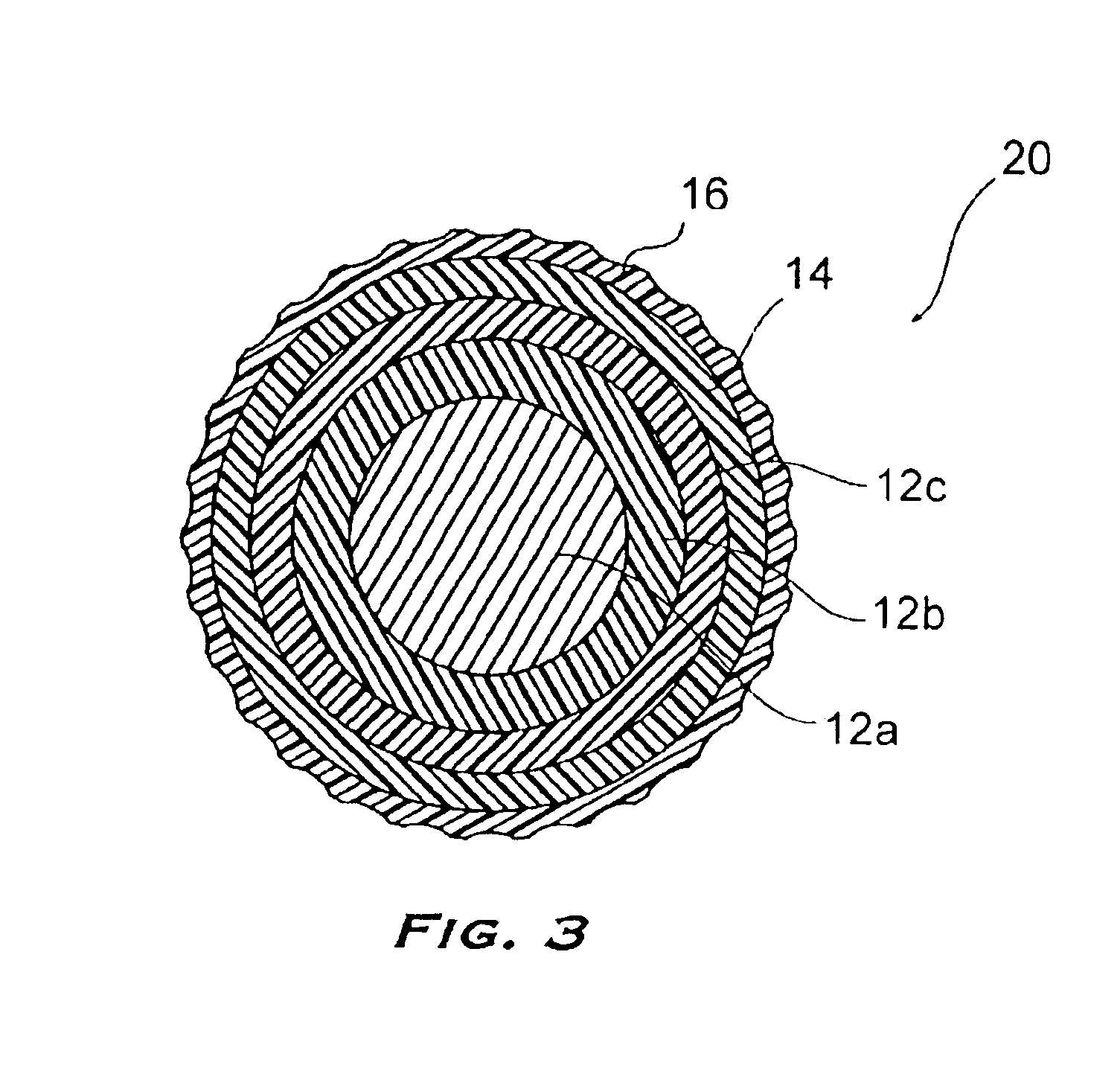

Multi-layered core golf ball

InactiveUS6988962B2Increasing moment of inertiaSlow down the spin rateGolf ballsDomestic articlesEngineeringGolf Ball

The present invention is directed towards a multi-layered core golf ball that comprises a center, a cover and at least two core layers formed around the center to create an inner ball, wherein the outermost core layer is relatively stiff and hard relative to the center. At least the center or / and one core layer is comprised of an ionomer resin having a fully neutralized acid moiety.

Owner:ACUSHNET CO

Two-piece solid golf ball

InactiveUS6494793B1Excellent shot feelingImprove flight performanceGolf ballsSolid ballsHardnessGolf Ball

Owner:SUMITOMO RUBBER IND LTD

Sports electronic training system with sport ball, and applications thereof

ActiveUS8360904B2Assess a fitness level for an individualPhysical therapies and activitiesSolesEngineeringHeart rate device

Owner:ADIDAS

Multi-layered core golf ball

InactiveUS6852044B2High partial wedge spinIncreased durabilityGolf ballsDomestic articlesVapor barrierEngineering

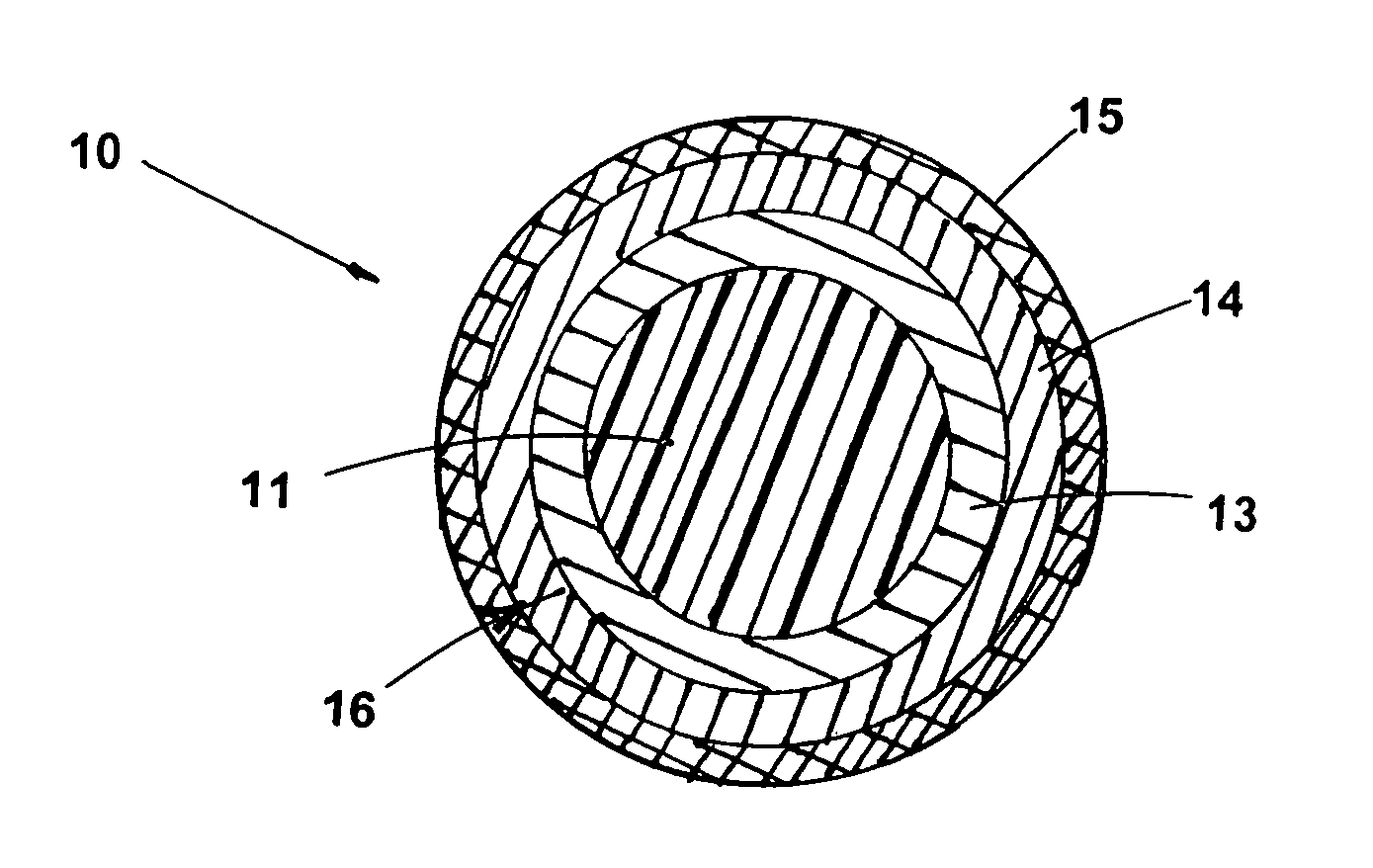

The present invention is directed towards a multi-layered core golf ball that comprises a center, a cover and at least two core layers formed around the center to create an inner ball, wherein the outermost core layer is relatively stiff and hard relative to the center. One outermost core layer is heavily filled with a density increasing material and at least one core layer functions as a moisture vapor barrier. One core layer may serve to provide all the functions in a single layer.

Owner:ACUSHNET CO

Method of determining a flight trajectory and extracting flight data for a trackable golf ball

A method for determining a shot trajectory of a trackable golf ball is disclosed, wherein substantially real-time position information transmitted by the ball for a time period is received and processed to determine a shot trajectory for a golf shot, wherein a velocity value and an acceleration value is determined, and wherein an initial and final location of the shot trajectory is determined based on at least one of the acceleration and velocity values. Also disclosed is a method for determining a spin rate of a trackable golf ball, wherein the shot trajectory and a profile of the shot trajectory are determined, wherein at least one of an initial velocity, a maximum height, an initial shot angle, a curvature of the trajectory, and an in-air shot distance are calculated using the shot trajectory, and wherein the spin rate is determined based on the calculated values.

Owner:HBL

Multi-piece solid golf ball

InactiveUS6855074B2Superior in flight distance and spin performance and shot feelGolf ballsSolid ballsHardnessEngineering

The present invention provides a multi-piece solid golf ball, which is superior in flight distance, spin performance and shot feel. The present invention relates to a multi-piece solid golf ball comprising a core consisting of a center, an intermediate layer formed on the center and an outer layer formed on the intermediate layer, and a cover covering the core, whereinthe center has a diameter of 10 to 20 mm and a central point hardness in JIS-A hardness of 30 to 85,the intermediate layer has a surface hardness in Shore D hardness of 30 to 55,the outer layer has a hardness in Shore D hardness of 55 to 70, andthe cover has a Shore D hardness of 35 to 55 and a thickness of 0.3 to 1.5 mm.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

InactiveUS6837803B2Excellent in preventing burnReduced characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

A golf ball includes, as a composing element, a hot-molded product of a rubber composition. The rubber composition contains a polybutadiene having 60 wt % or more of cis-1,4-bonds and 40 or more of a Mooney viscosity (ML1+4(100° C.)), unsaturated carboxylic acid and / or a metal salt thereof, an organic peroxide, and a monophenol based antioxidant. The golf ball can be produced with good workability because of no burn at the time of kneading the rubber composition, while preventing a reduction in rebound characteristic.

Owner:BRIDGESTONE SPORTS

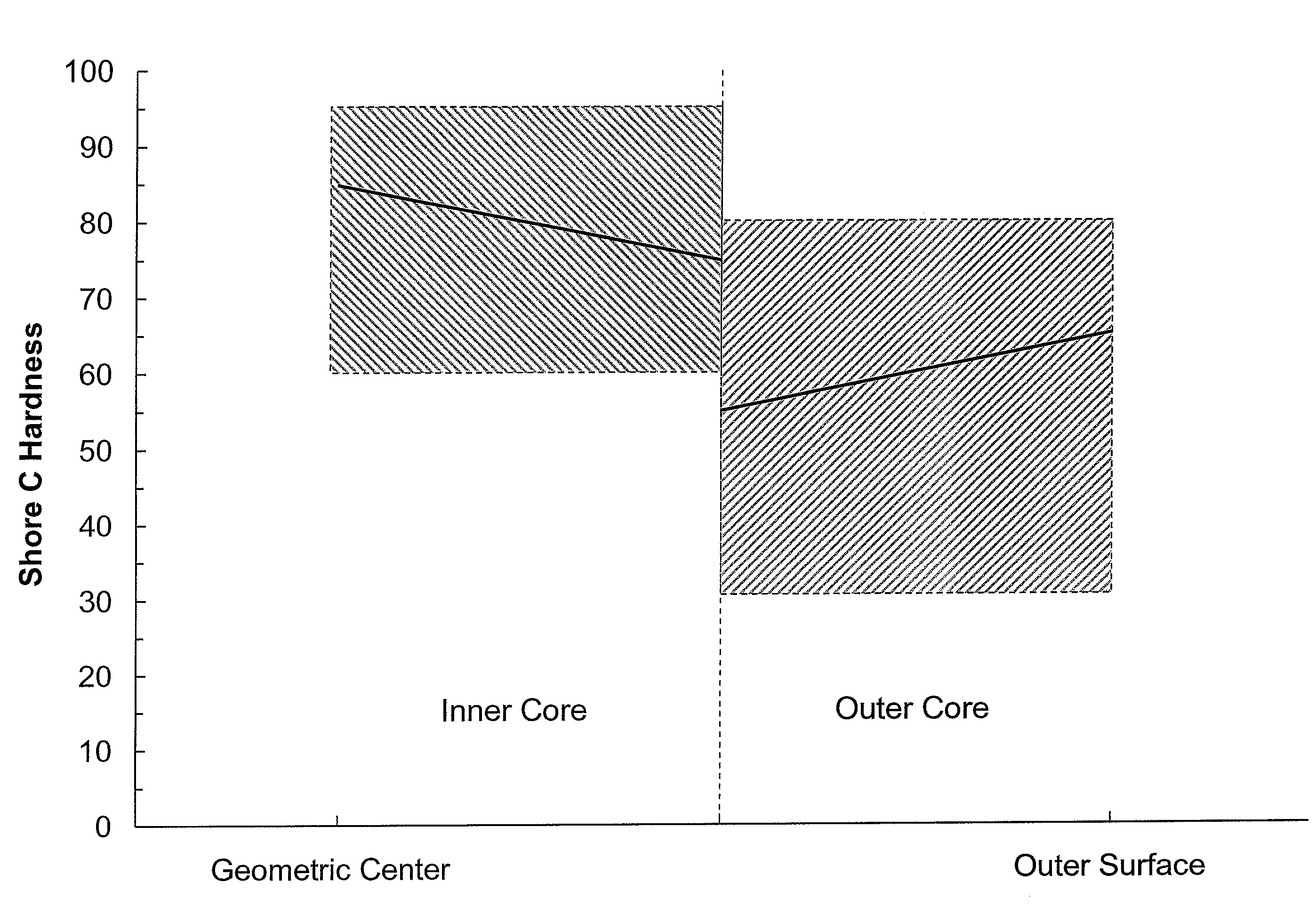

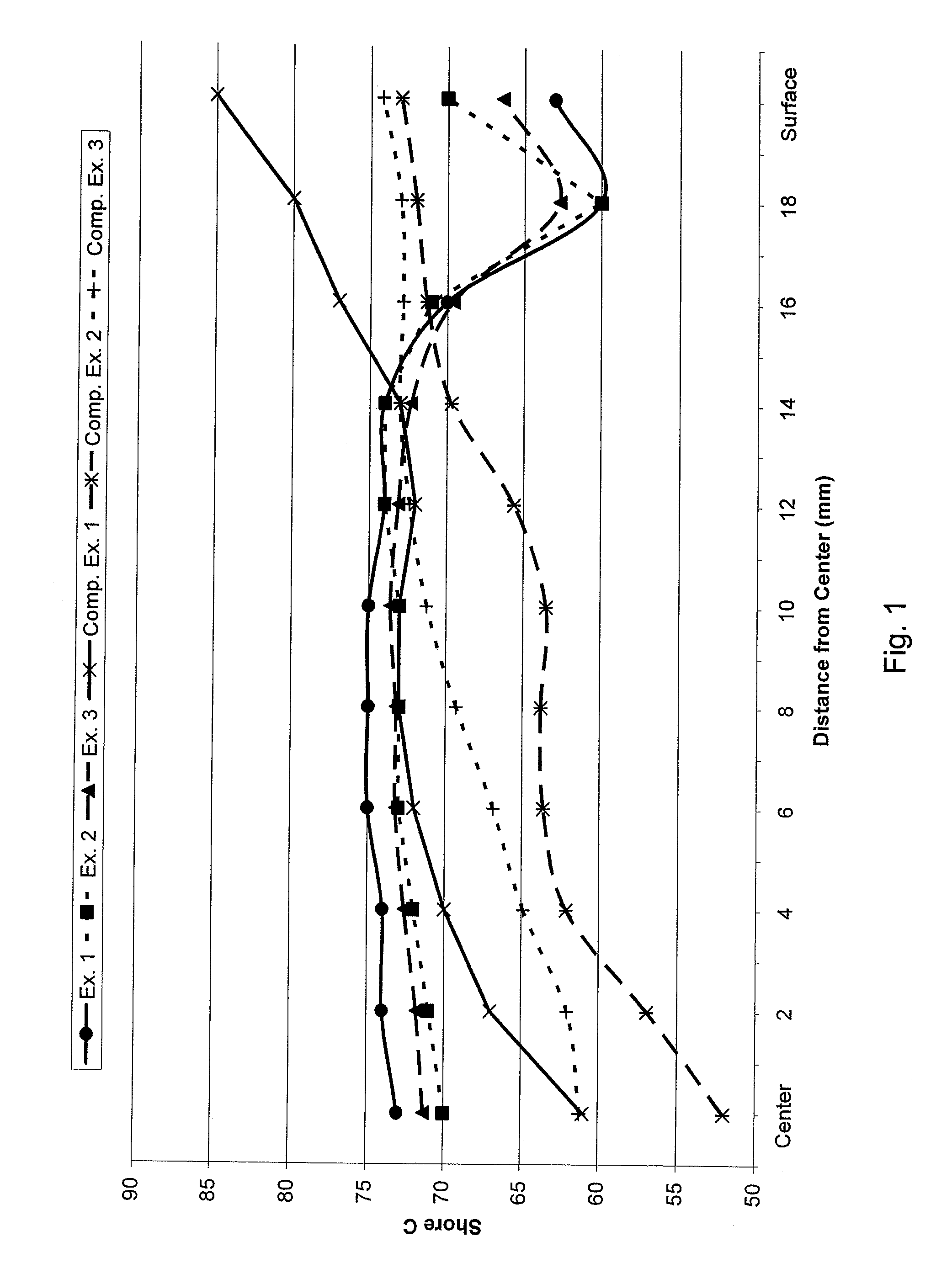

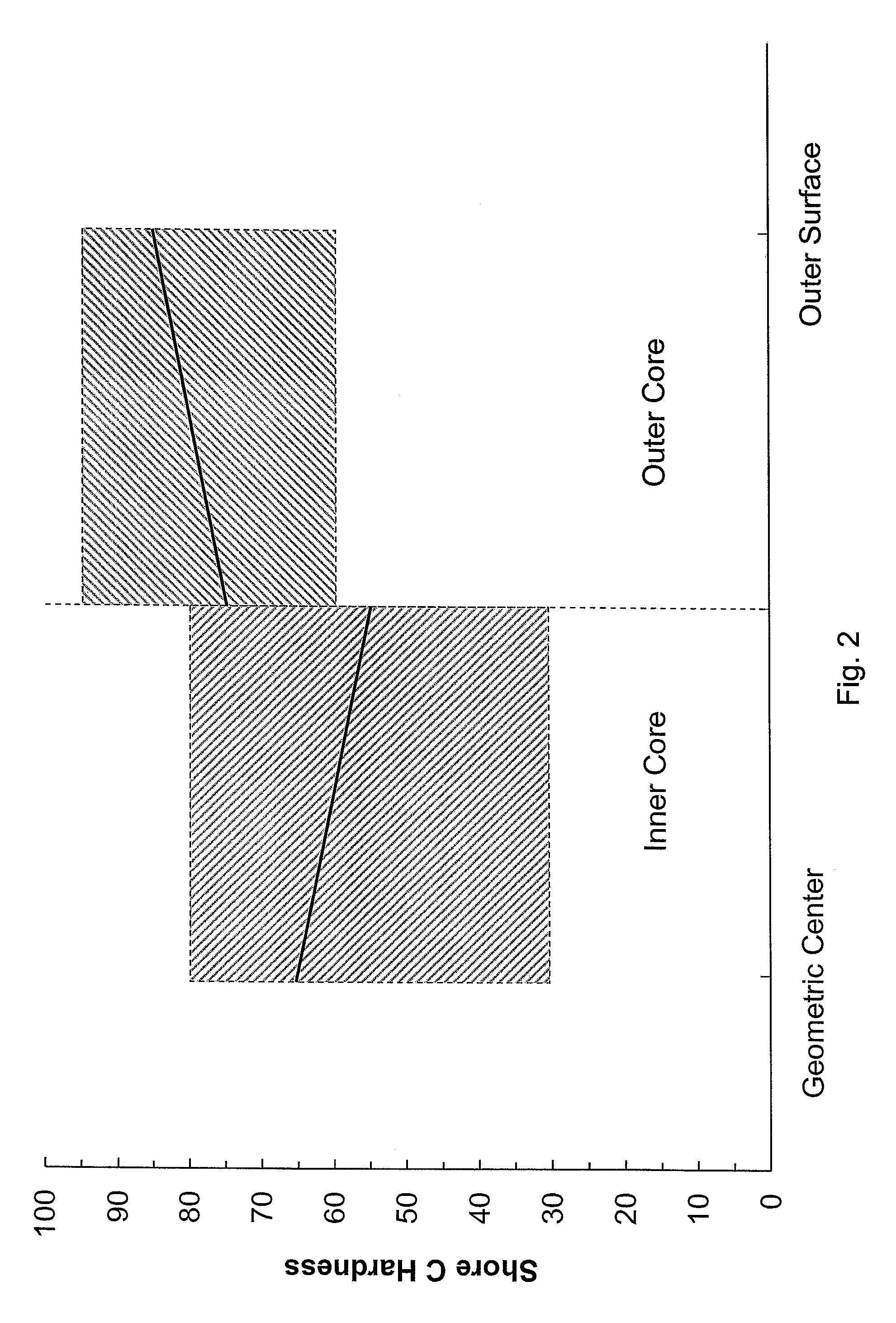

Negative hardness gradient inner core for dual core golf ball

A golf ball having an inner core having a first outer surface and a geometric center and being formed from a substantially homogenous formulation such that the inner core has a hardness of 45 Shore C to 65 Shore C; an outer core layer disposed about the inner core having a second outer surface and an inner surface and being formed from a substantially homogenous formulation such that the outer core layer has a hardness of 55 Shore C to 90 Shore C. A cover is disposed about the outer core layer. The hardness of the first outer surface is the same as or lower than the hardness of the geometric center to define a “negative hardness gradient” and the hardness of the second outer surface is greater than the hardness of the inner surface to define a “positive hardness gradient.”

Owner:ACUSHNET CO

Multi-piece solid golf ball

InactiveUS7086969B2Improve spin performanceIncrease total distance traveledGolf ballsSolid ballsPtru catalystSulphur compound

Owner:BRIDGESTONE SPORTS

Foam-core golf balls

InactiveUS7452291B2Reduce decreaseIncrease in moment of inertiaGolf ballsSolid ballsEngineeringGolf Ball

A golf ball with a controlled moment of inertia and controlled spin rate is disclosed. The increase in moment of inertia is preferably accomplished by a reduction in the specific gravity or weight of the core, e.g., by foaming. Preferably, this reduction is less than about 15% in specific gravity or less than about 25% in weight to minimize the reduction in the coefficient of restitution of the core.

Owner:ACUSHNET CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com