Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2521 results about "Dual axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

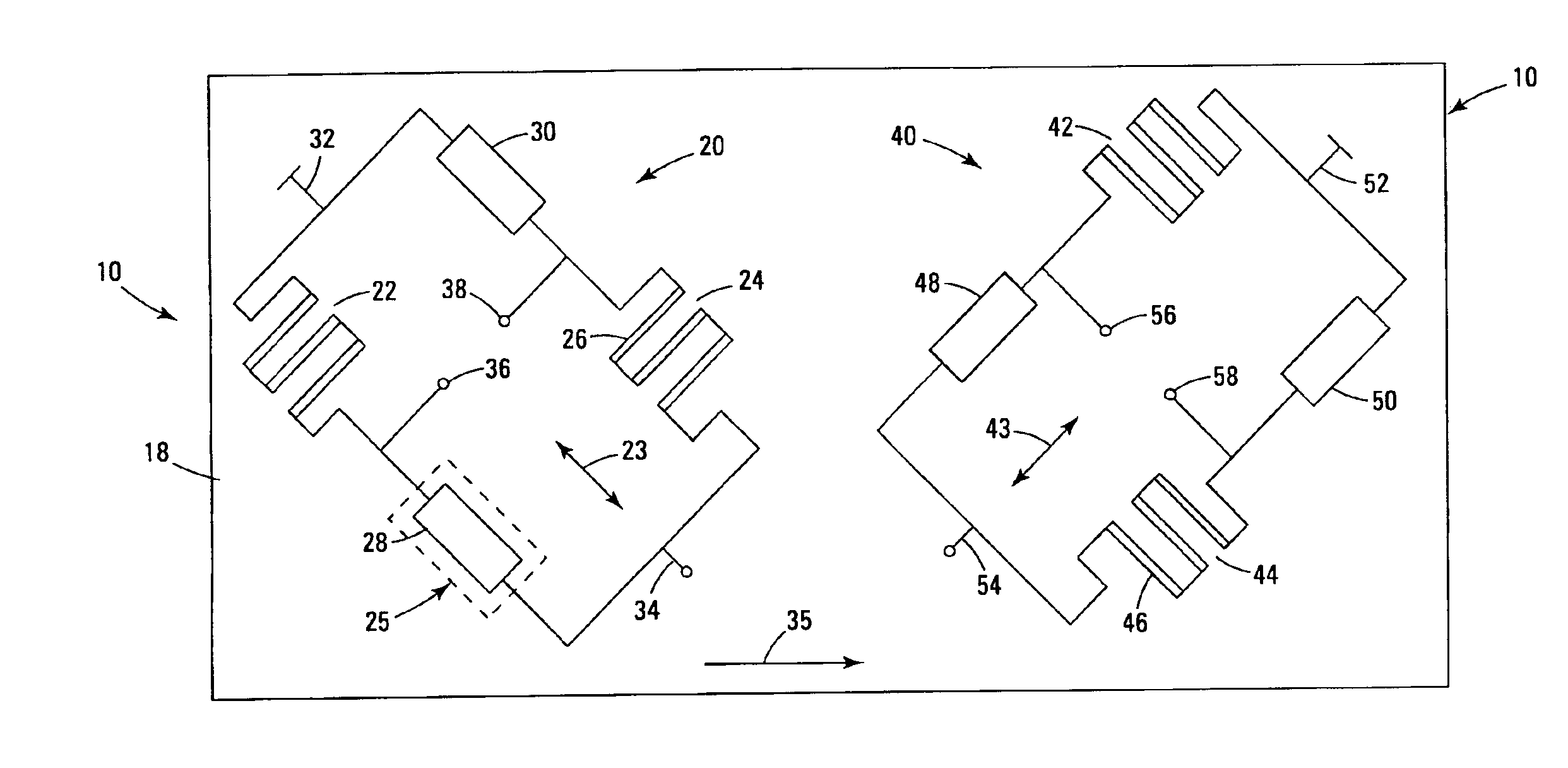

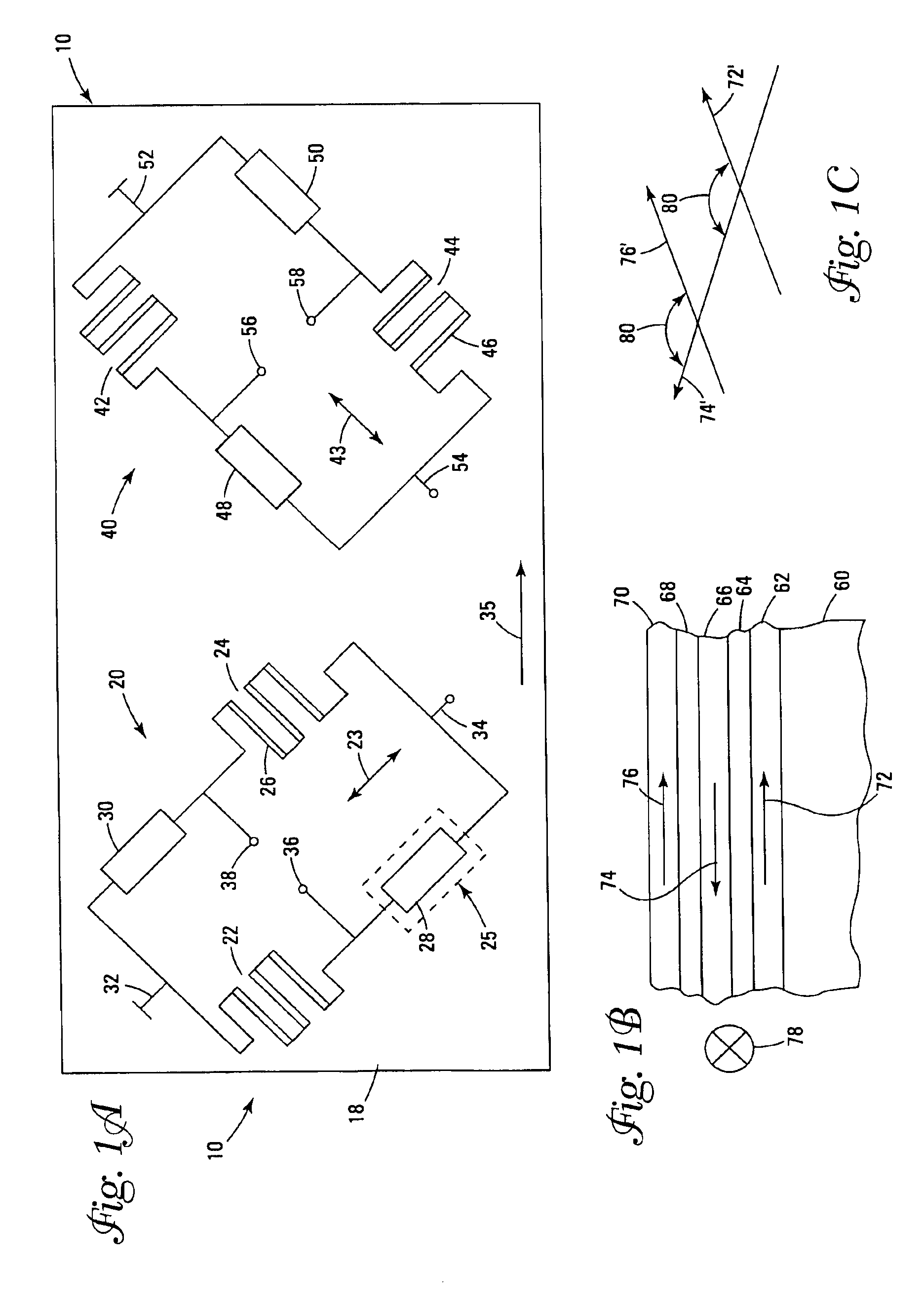

Mobile millimeter wave communication link

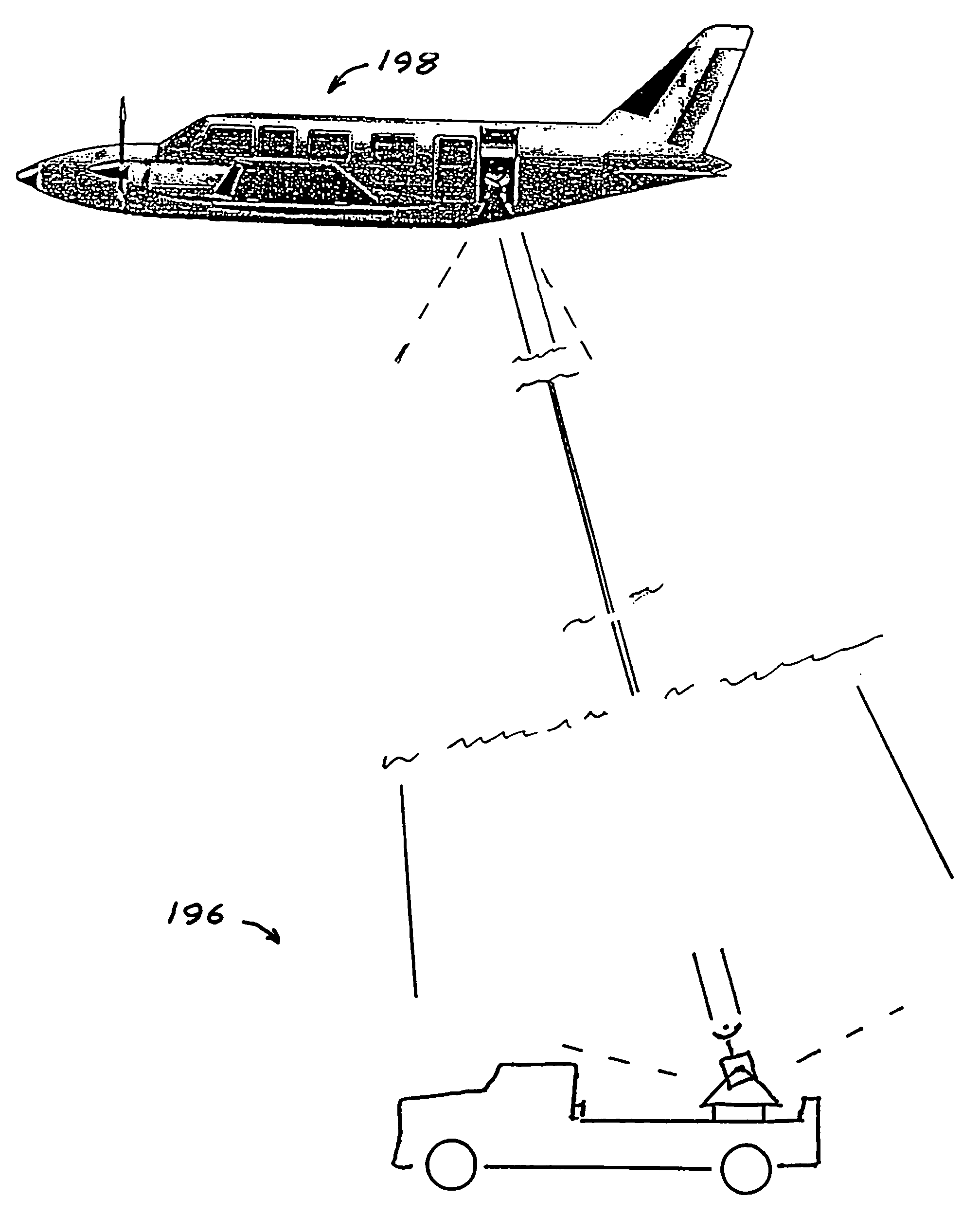

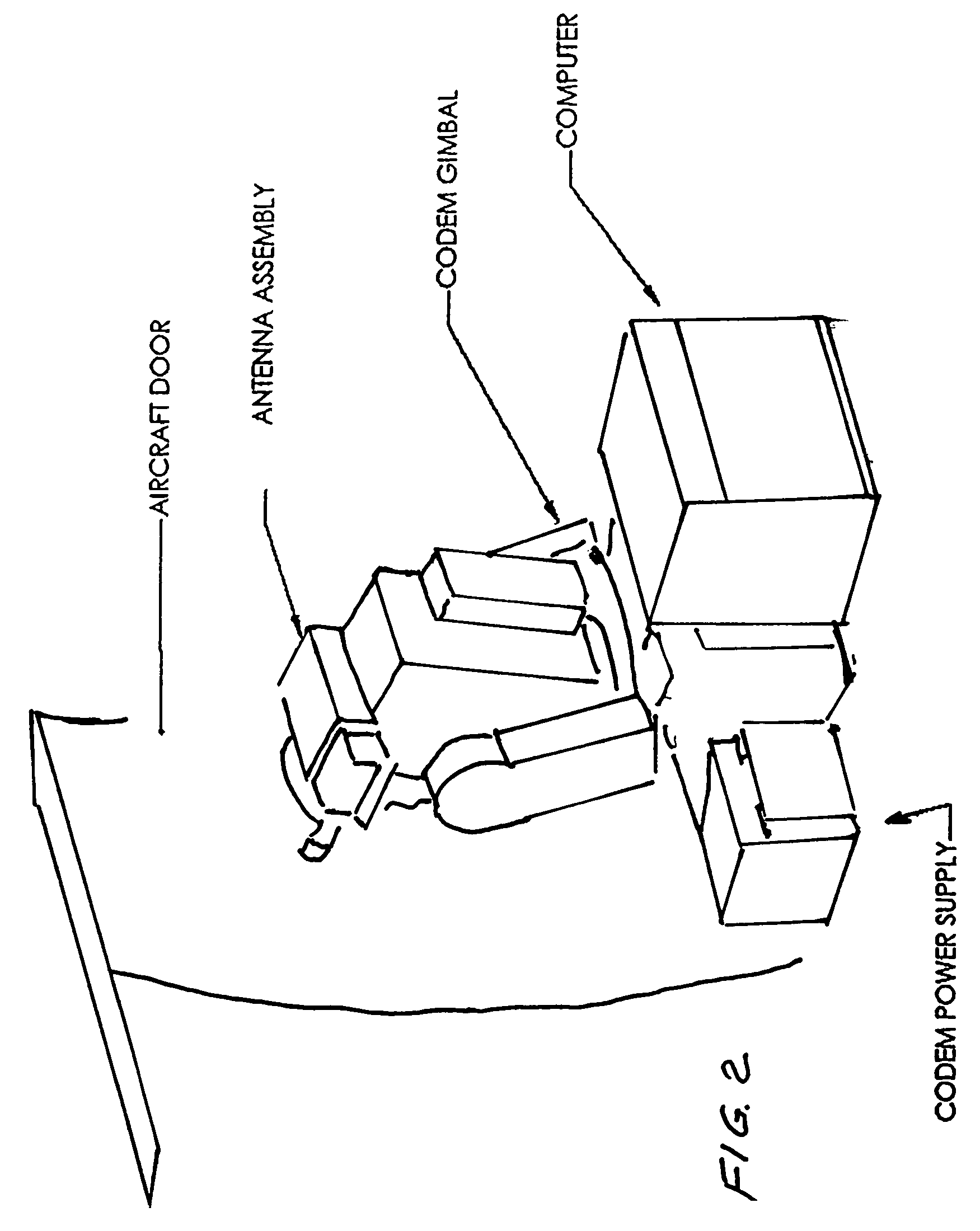

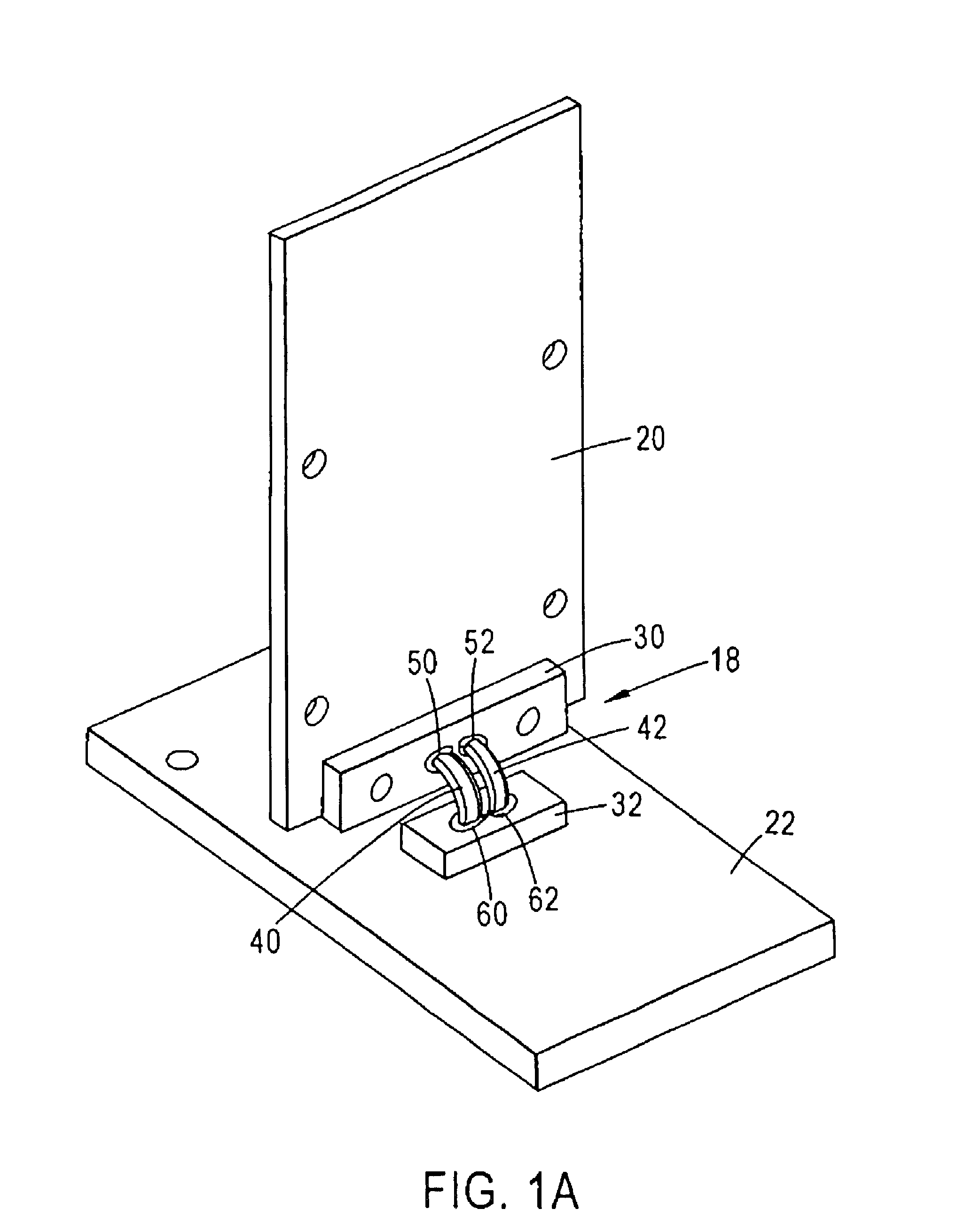

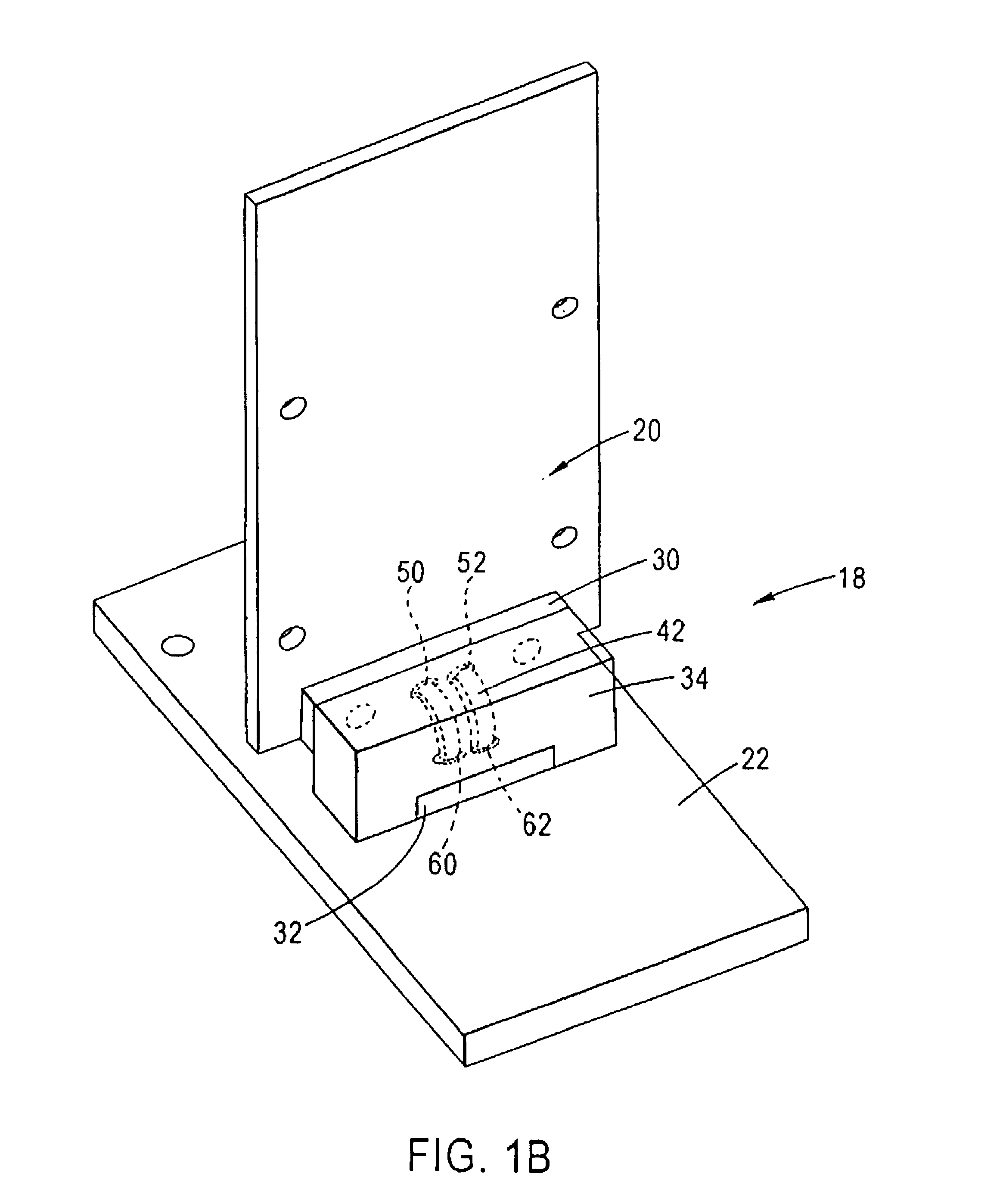

A point-to-point, wireless, millimeter wave communications link between two stations at least one of which is a mobile station. A millimeter wave transmitter system operating at frequencies higher than 57 GHz with a tracking antenna producing a beam having a half-power beam width of about 2 degrees or less and a millimeter wave receiver also with a tracking antenna having a half-power beam width of about 2 degrees or less. In preferred embodiments each mobile station has a global position system (GPS) and a radio transmitter and both tracking antennas are pointed utilizing GPS information from the mobile station or stations. The GPS information preferably is transmitted via a low frequency, low data rate radio. Each millimeter wave unit is capable of transmitting and / or receiving, through the atmosphere, digital information to / from the other station at rates in excess of 155 million bits per second during normal weather conditions. In preferred embodiments actually built and tested by Applicants digital information has been transmitted at rates of 1.25 gigabits per second. Preferred communication links described here are millimeter wave links operating at frequencies of 71-73 GHz and 74-76 GHz mounted on simple two-axis gimbals. Pointing information of the required accuracy is provided by GPS receivers and standard radio links which send the GPS calculated positions to the millimeter wave systems at the opposite end of the link. In these embodiments there is no need for any complicated closed loop pointing information derived from received signal intensity or phase. On moving platforms locally generated inertial attitude information is combined with the GPS positions to control pointing of the gimbaled transceivers.

Owner:TREX ENTERPRISES CORP

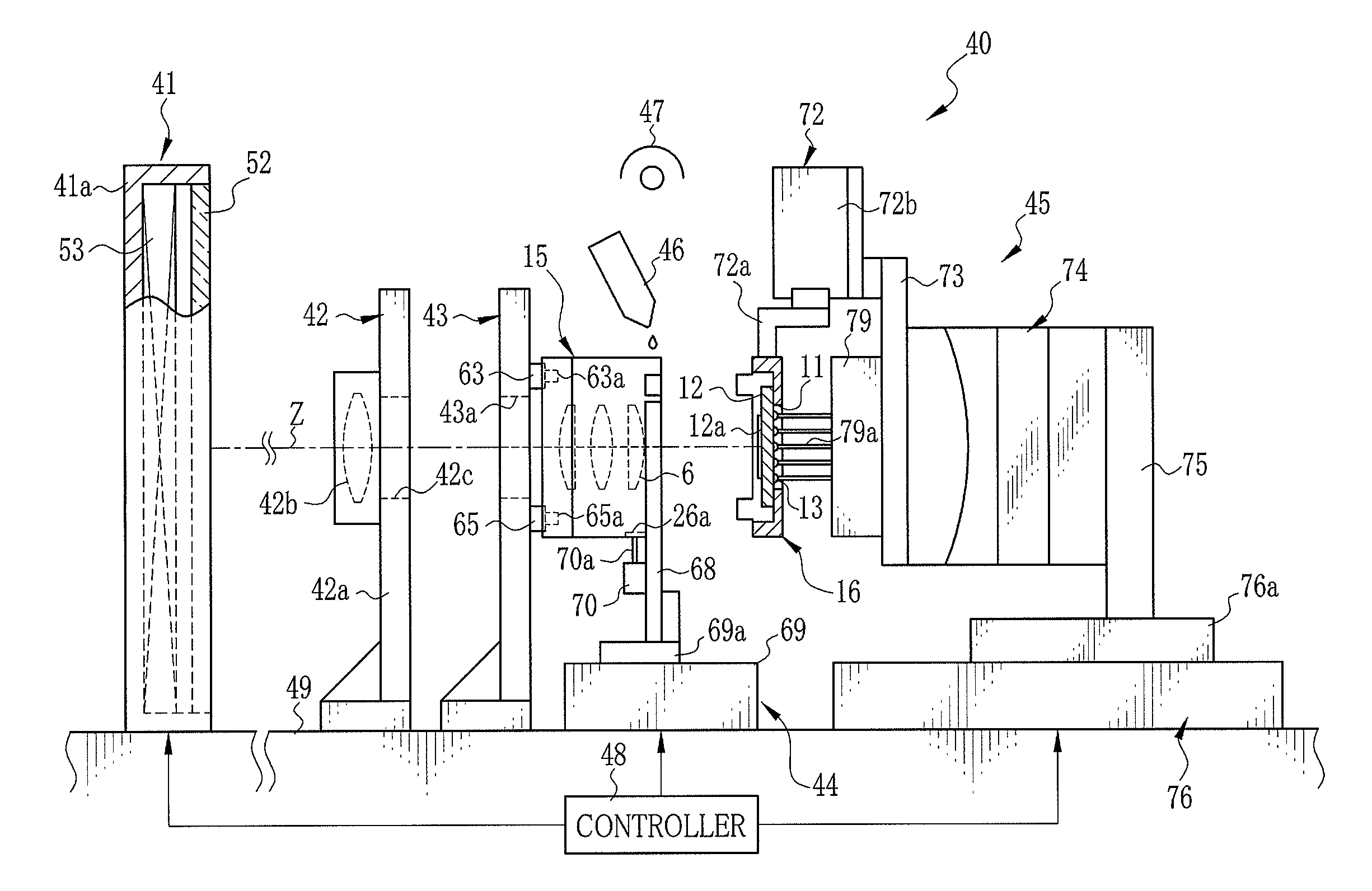

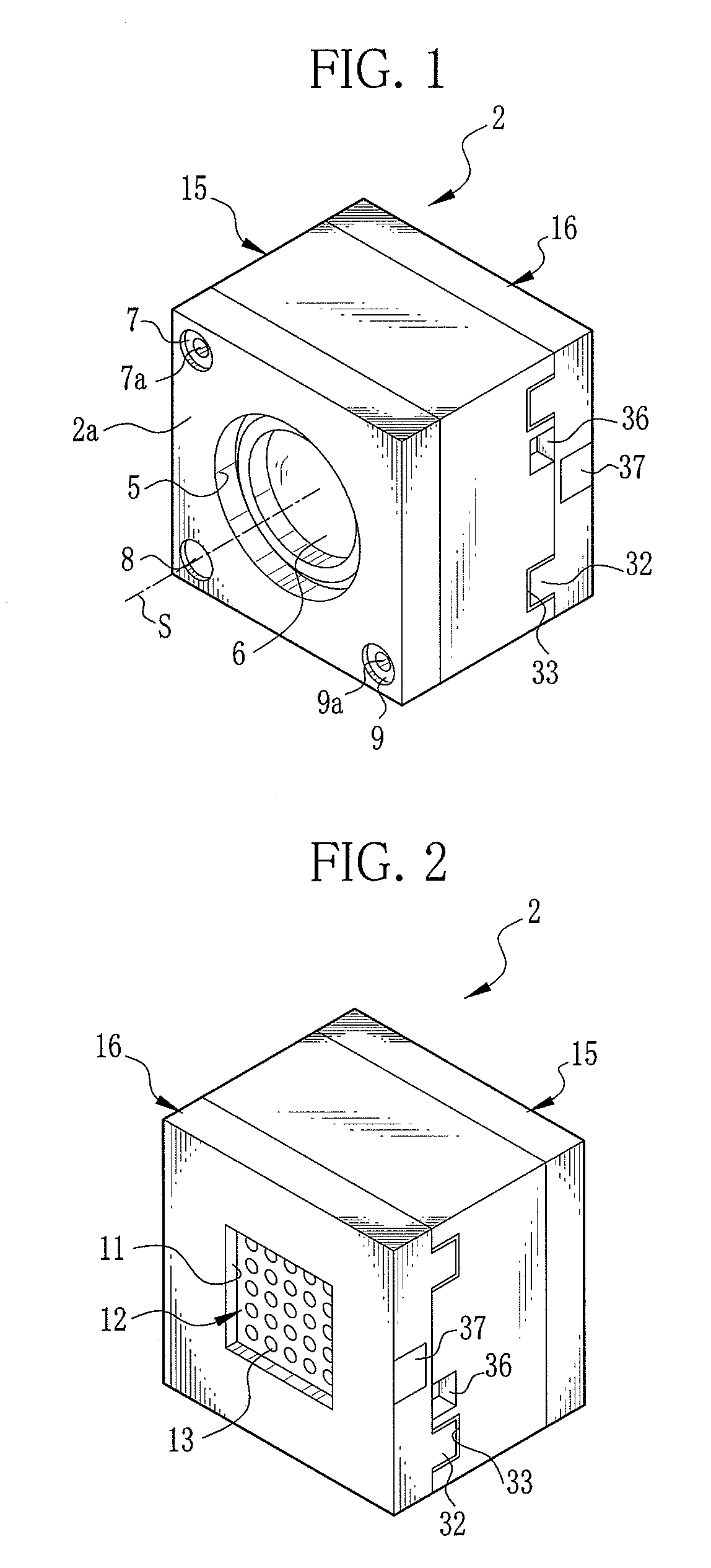

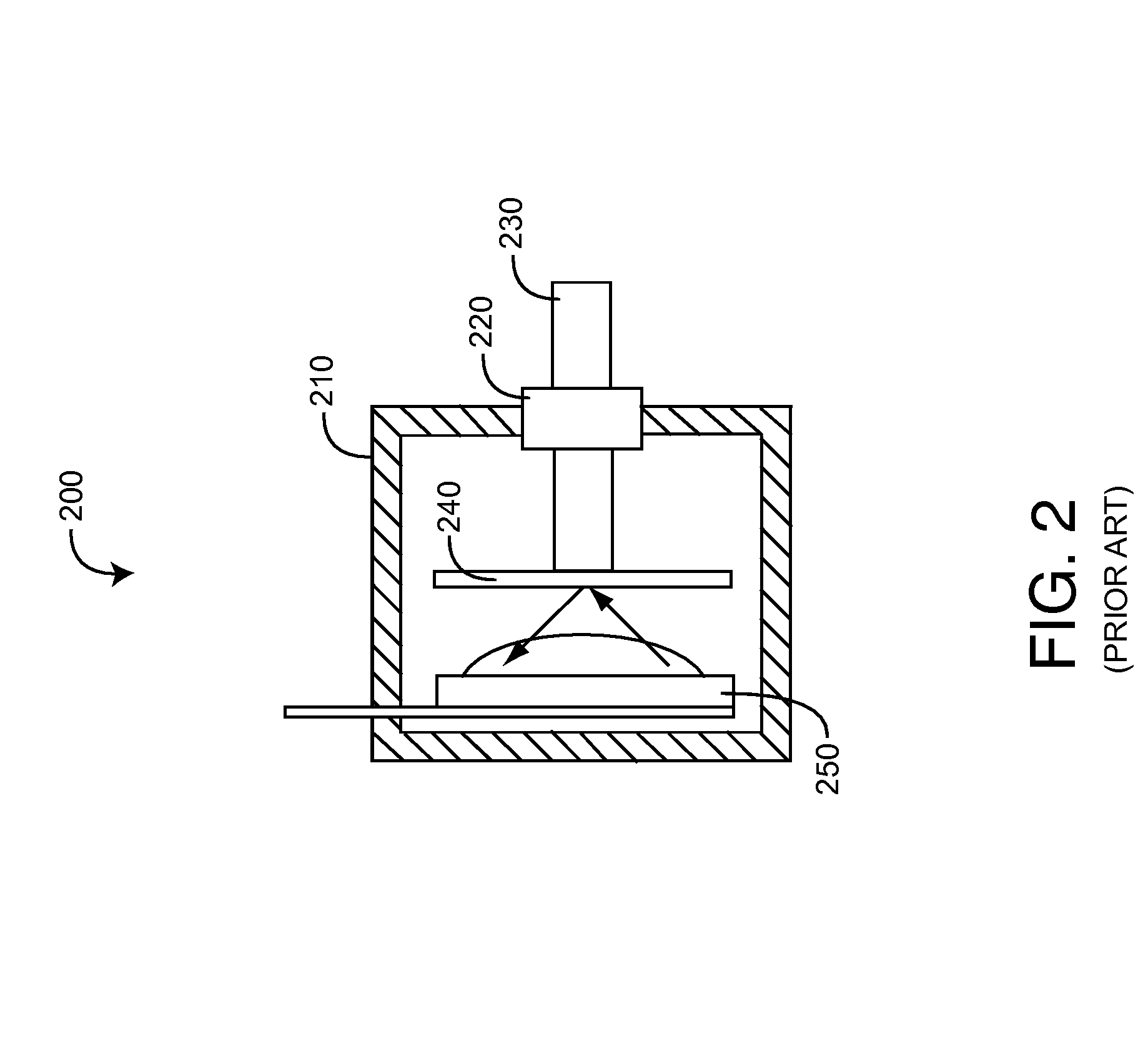

Method for adjusting position of image sensor, method and apparatus for manufacturing a camera module, and camera module

InactiveUS20090180021A1No longer be adjustedShort timeTelevision system detailsColor television detailsCamera lensRotary stage

A lens unit and a sensor unit are held by a lens holding mechanism and a sensor shift mechanism. As the sensor unit is moved in a Z axis direction on a second slide stage, a chart image is captured with an image sensor through a taking lens so as to obtain in-focus coordinate values in at least five imaging positions on an imaging surface. An approximate imaging plane is calculated from the relative position of plural evaluation points which are defined by transforming the in-focus coordinate value of each imaging position in a three dimensional coordinate system. The second slide stage and a biaxial rotation stage adjust the position and tilt of the sensor unit so that the imaging surface overlaps with the approximate imaging plane.

Owner:FUJIFILM CORP

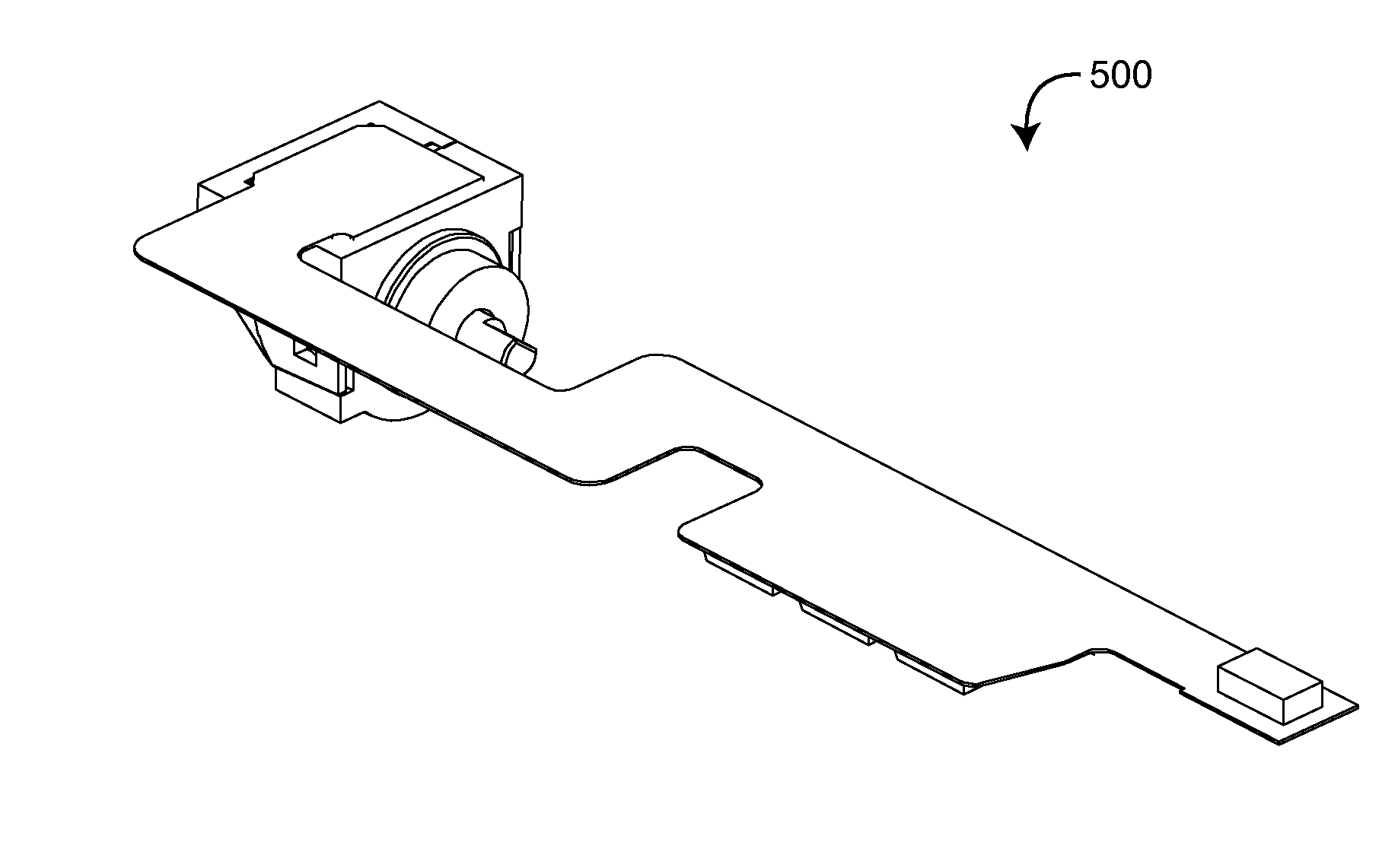

Double-bearing position encoder

ActiveUS20150045637A1Insufficient stabilityImprove stabilityDiagnostic recording/measuringSensorsEngineeringCam

A double-bearing position encoder has an axle stabilized within a housing via two bearings disposed on opposite walls of the housing. The axle is in communications with a rotating cam. The cam actuates a pulser so as to generate an active pulse at a tissue site for analysis by an optical sensor. The axle rotates a slotted encoder wheel or a reflective encoder cylinder disposed within the housing so as to accurately determine the axle position and, hence, the active pulse frequency and phase.

Owner:MASIMO CORP

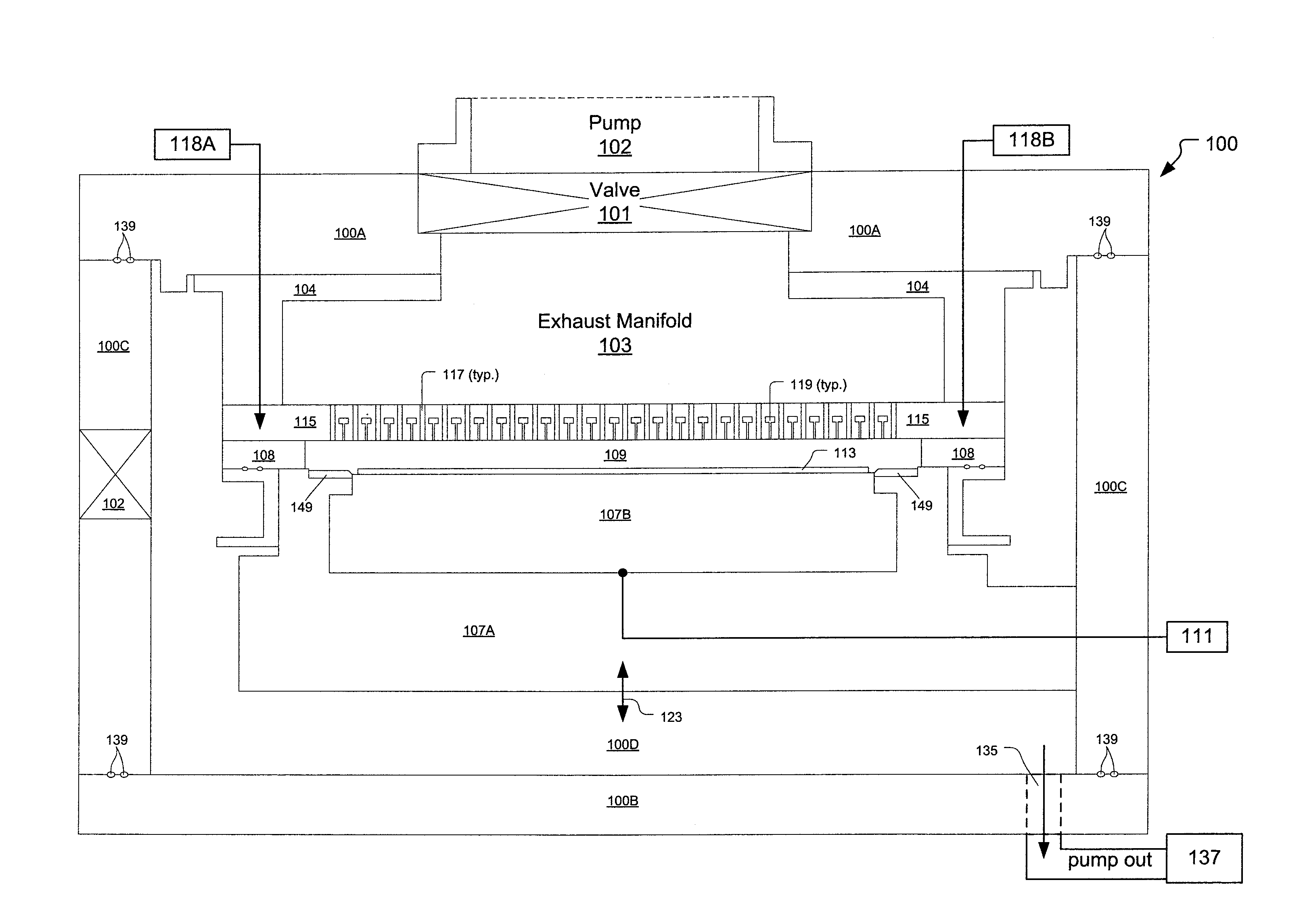

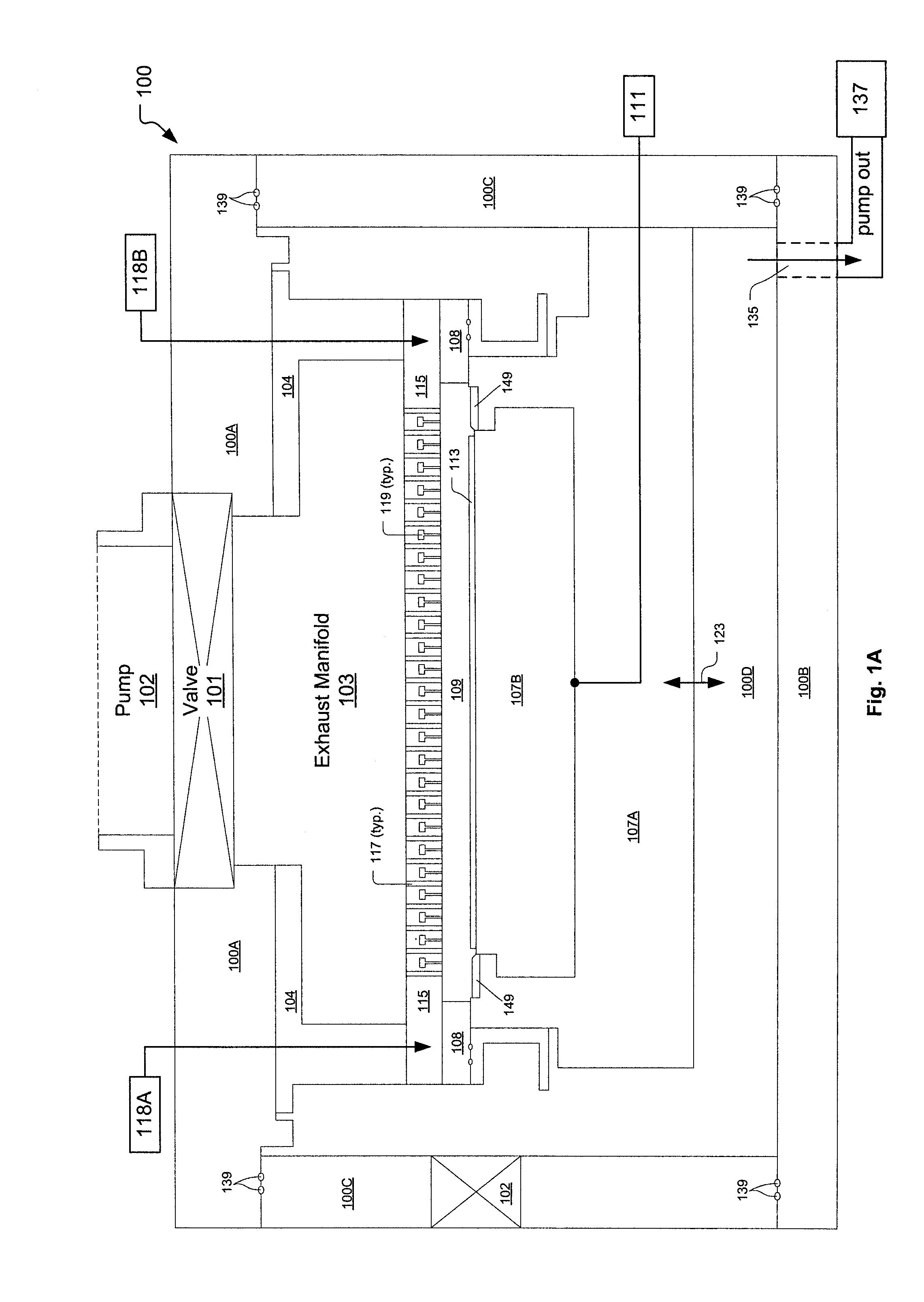

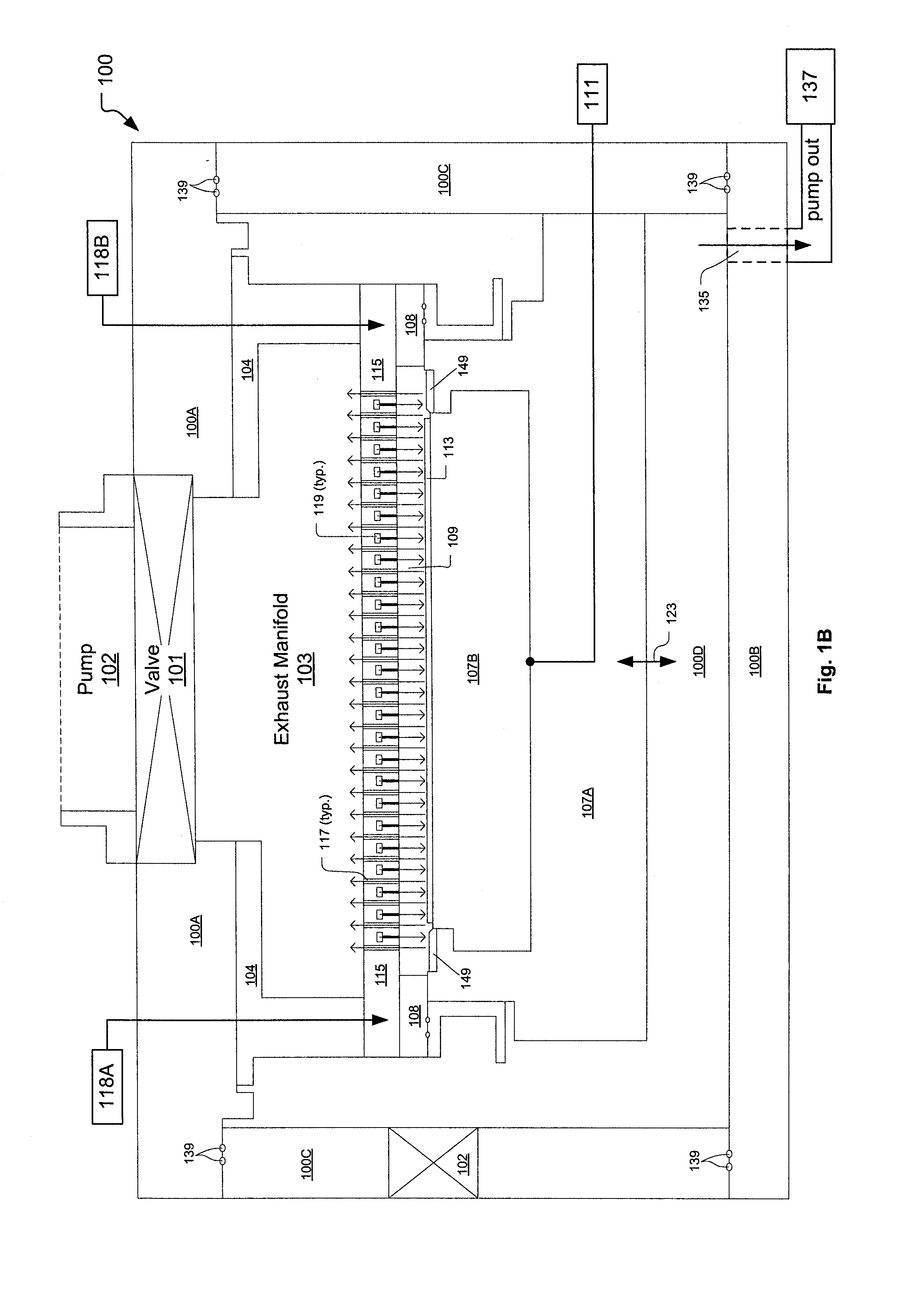

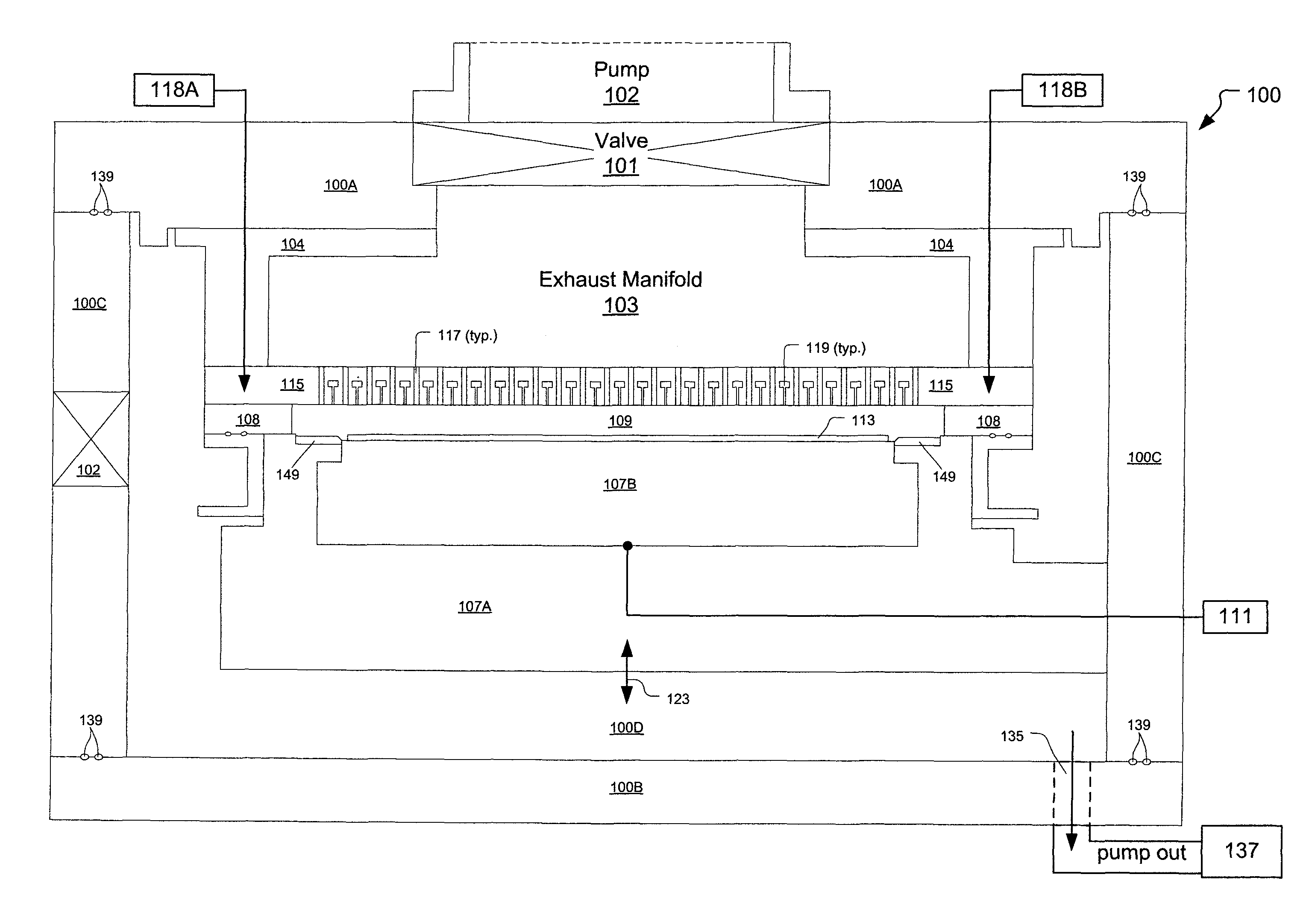

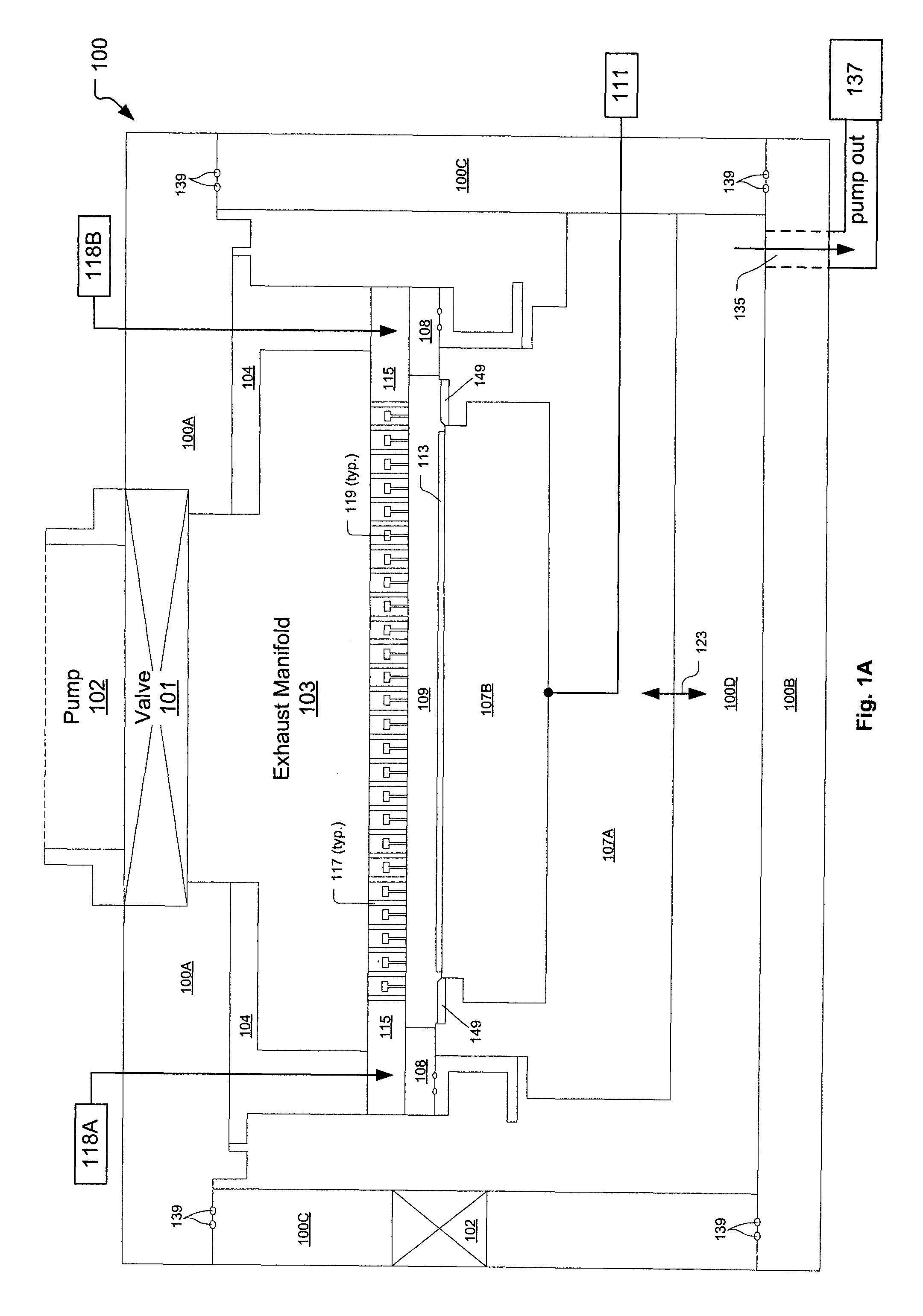

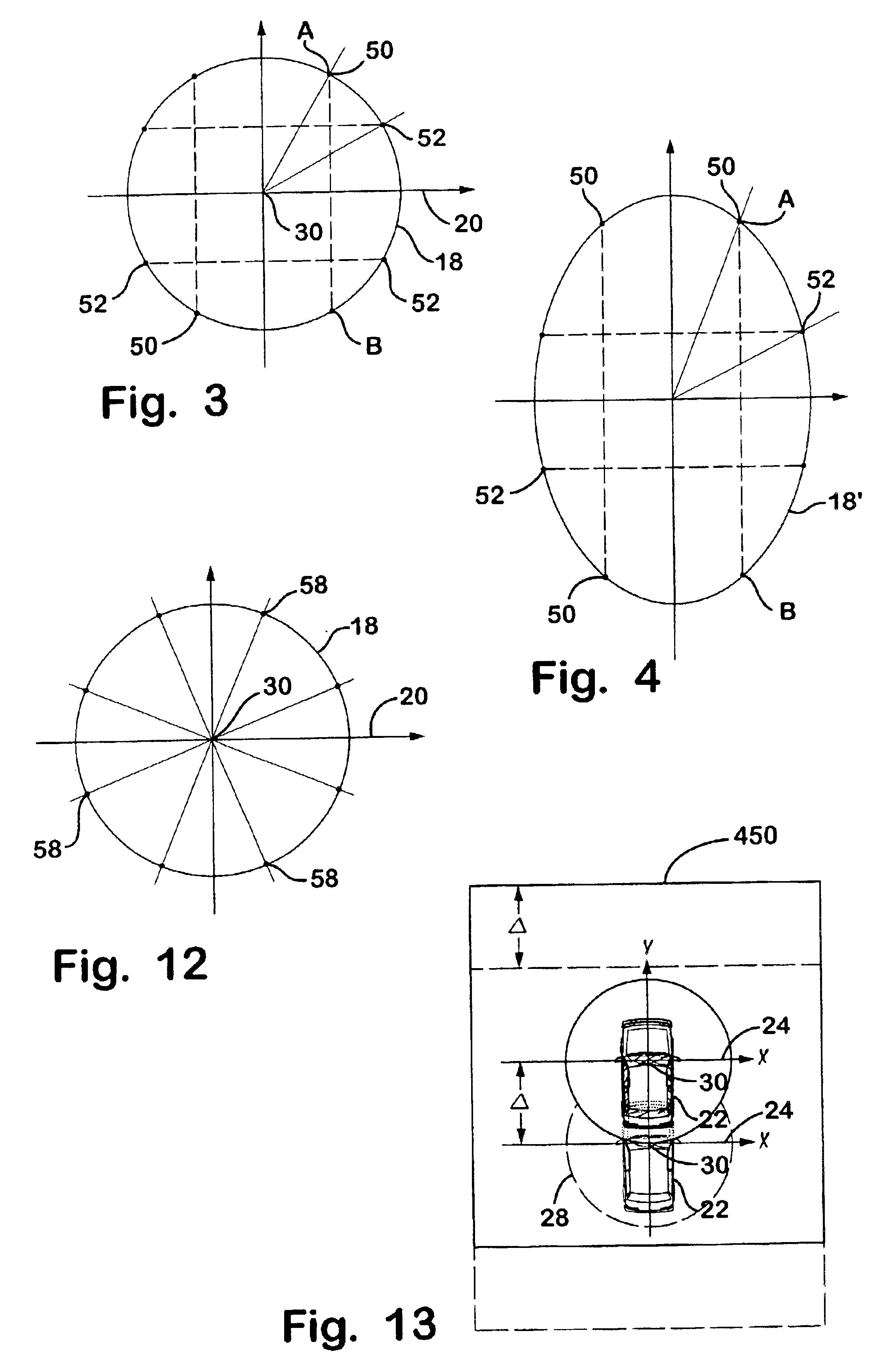

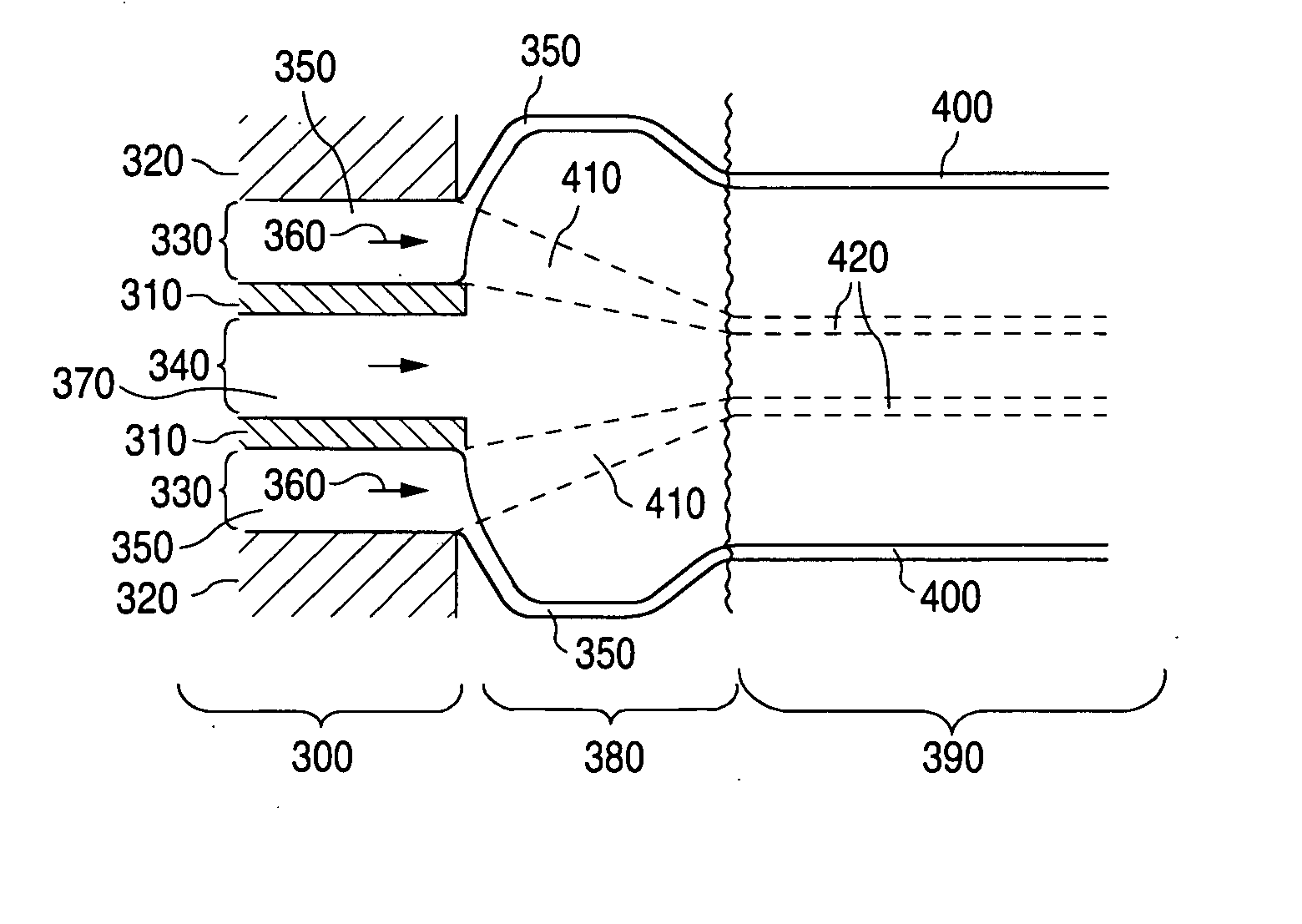

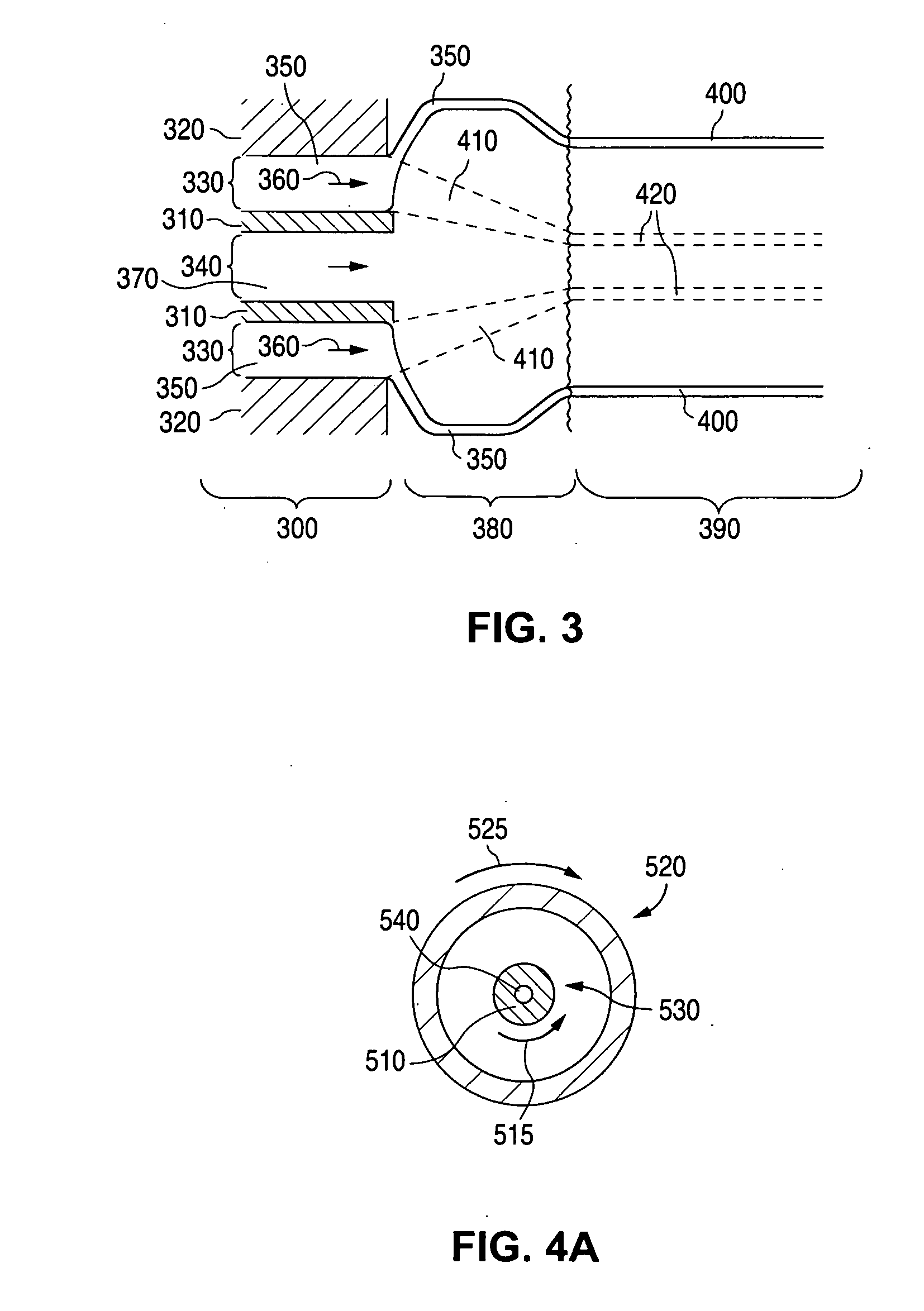

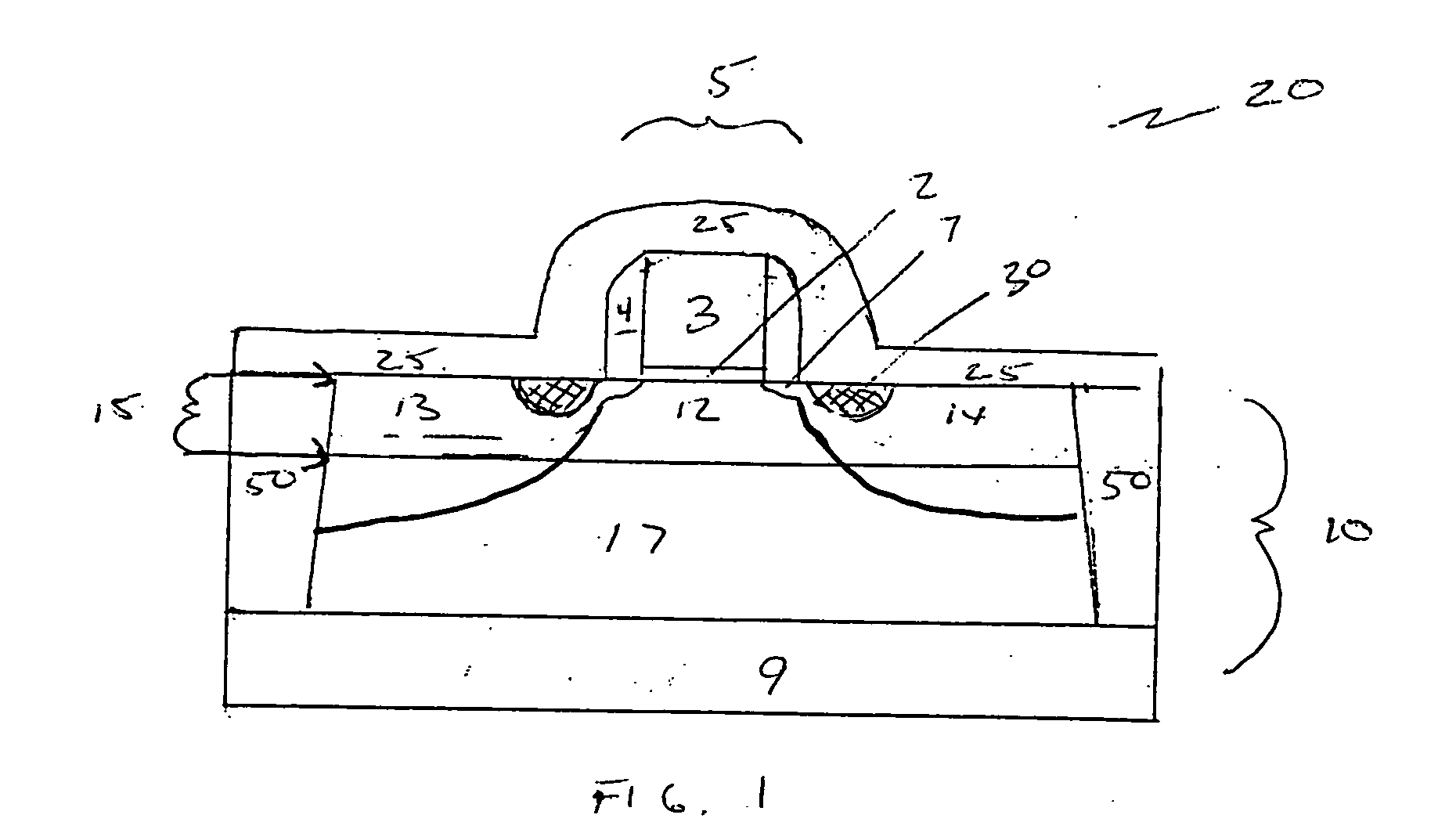

Plasma Processing Chamber with Dual Axial Gas Injection and Exhaust

ActiveUS20120034786A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDual axis

An electrode is exposed to a plasma generation volume and is defined to transmit radiofrequency power to the plasma generation volume, and includes an upper surface for holding a substrate in exposure to the plasma generation volume. A gas distribution unit is disposed above the plasma generation volume and in a substantially parallel orientation to the electrode. The gas distribution unit includes an arrangement of gas supply ports for directing an input flow of a plasma process gas into the plasma generation volume in a direction substantially perpendicular to the upper surface of the electrode. The gas distribution unit also includes an arrangement of through-holes that each extend through the gas distribution unit to fluidly connect the plasma generation volume to an exhaust region. Each of the through-holes directs an exhaust flow from the plasma generation volume in a direction substantially perpendicular to the upper surface of the electrode.

Owner:LAM RES CORP

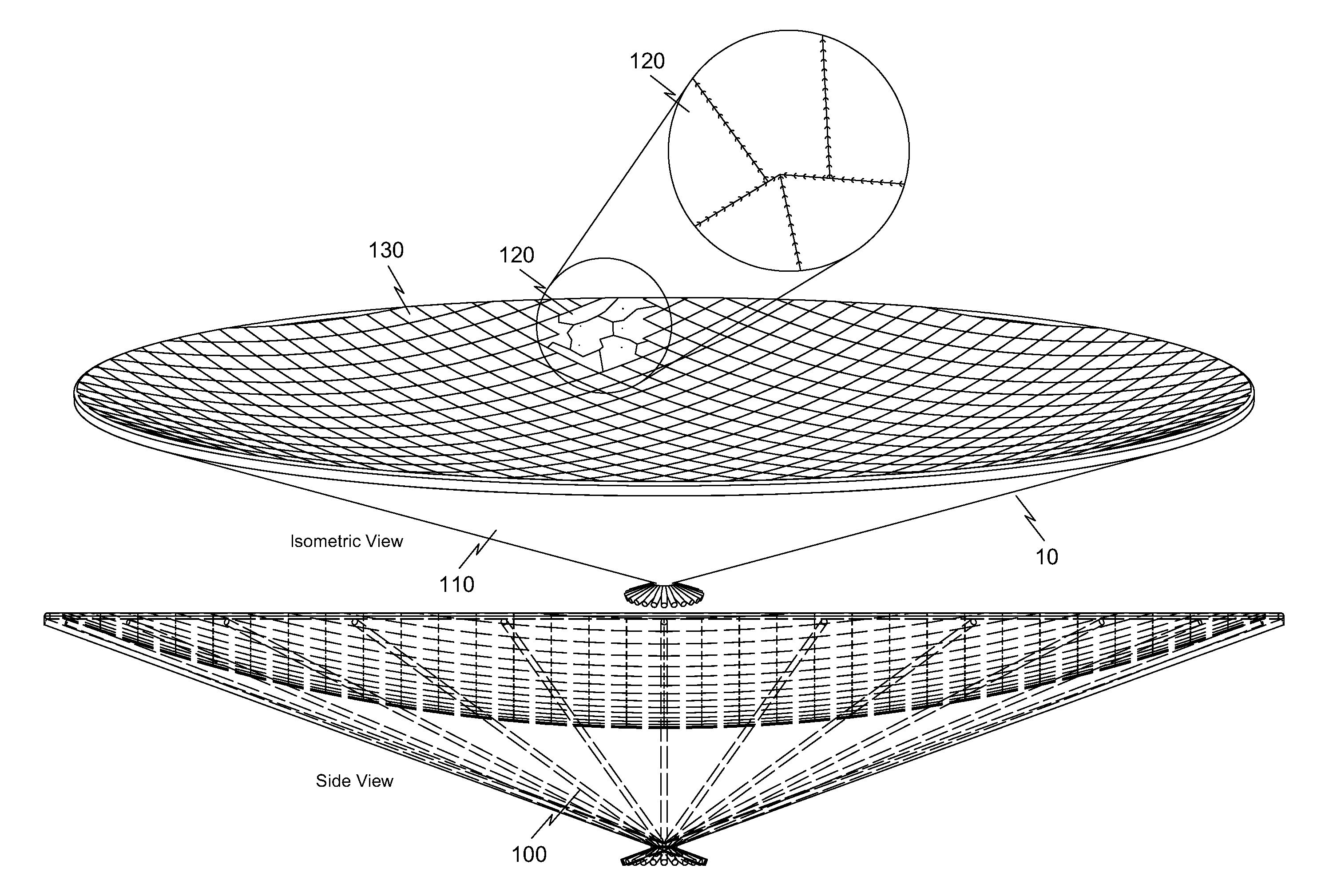

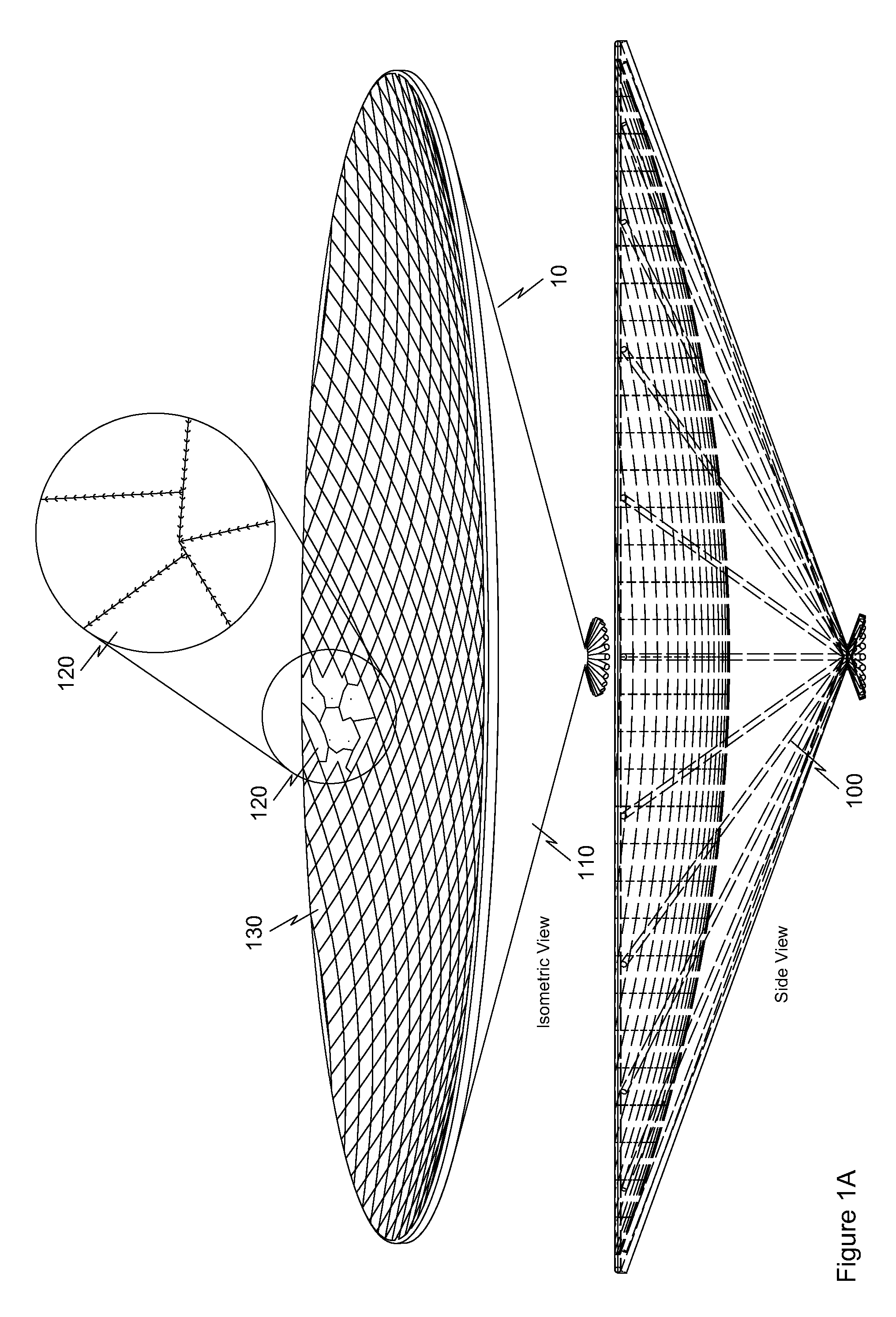

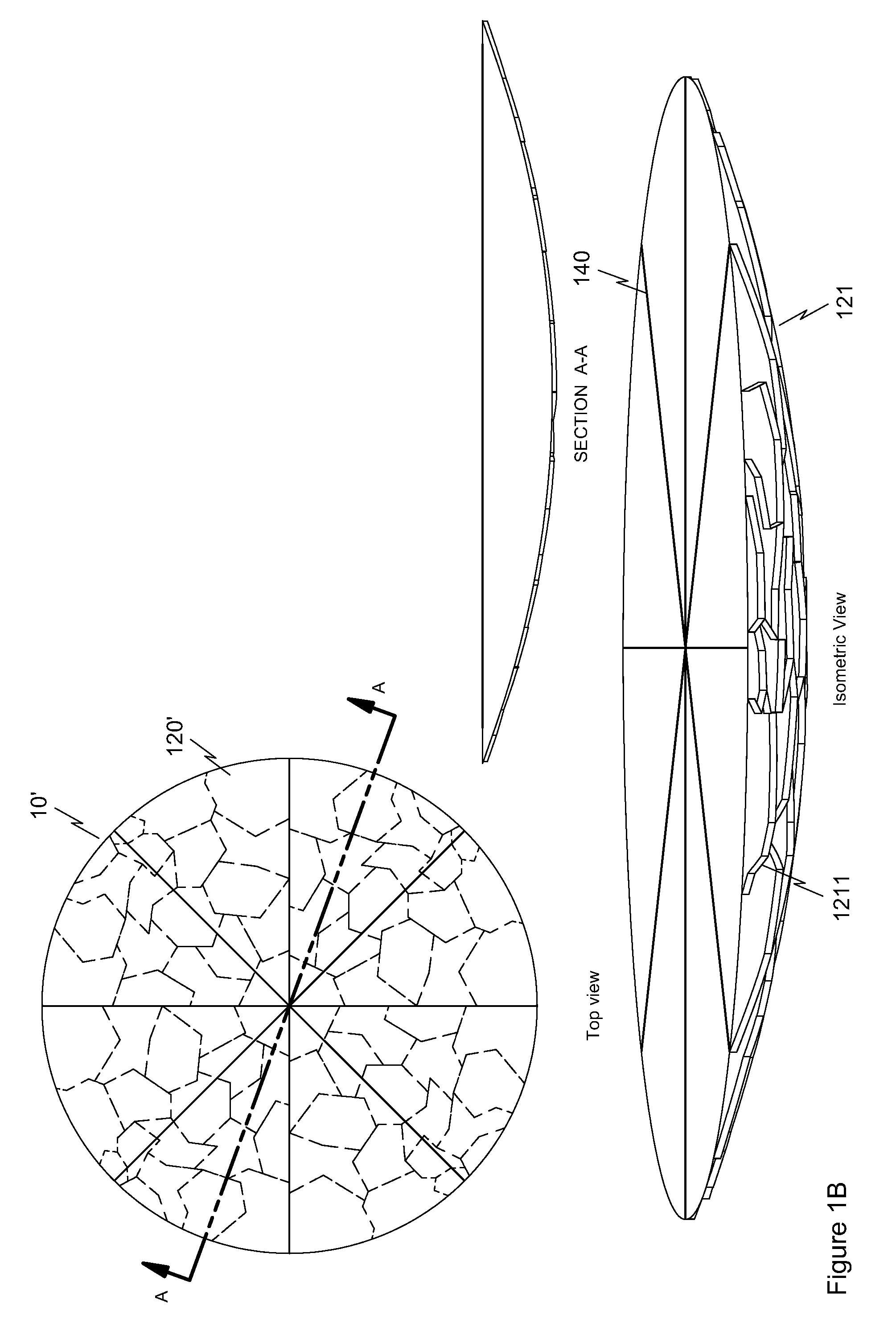

Systems for cost-effective concentration and utilization of solar energy

InactiveUS20100263709A1Increase concentrationSolar heating energySolar heat devicesSpace-based solar powerCombustion

The present invention is primarily directed to cost-effective systems for using large reflective elements that track the sun on two axes to concentrate solar energy onto a receiver that can convert the sun's optical energy to a form usable for extensive displacement of combustion of fossil fuels. The structures of the tracker frame, tracking mechanism and tracker supports are co-optimized with the optical elements and the receiver for high efficiency, low cost, and ease of assembly, making moderate and large-scale implementations cost-competitive with fossil fuels for peak power, and, with suitable storage, for base-load power and dispatchable peaking power in sunny locations. Improvement to small-tracker two-axis systems and one-axis tracking systems that focus in two dimensions are also included, as are improvements in systems for space-based solar power.

Owner:NORMAN RICHARD

Plasma processing chamber with dual axial gas injection and exhaust

ActiveUS8869742B2Electric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

An electrode is exposed to a plasma generation volume and is defined to transmit radiofrequency power to the plasma generation volume, and includes an upper surface for holding a substrate in exposure to the plasma generation volume. A gas distribution unit is disposed above the plasma generation volume and in a substantially parallel orientation to the electrode. The gas distribution unit includes an arrangement of gas supply ports for directing an input flow of a plasma process gas into the plasma generation volume in a direction substantially perpendicular to the upper surface of the electrode. The gas distribution unit also includes an arrangement of through-holes that each extend through the gas distribution unit to fluidly connect the plasma generation volume to an exhaust region. Each of the through-holes directs an exhaust flow from the plasma generation volume in a direction substantially perpendicular to the upper surface of the electrode.

Owner:LAM RES CORP

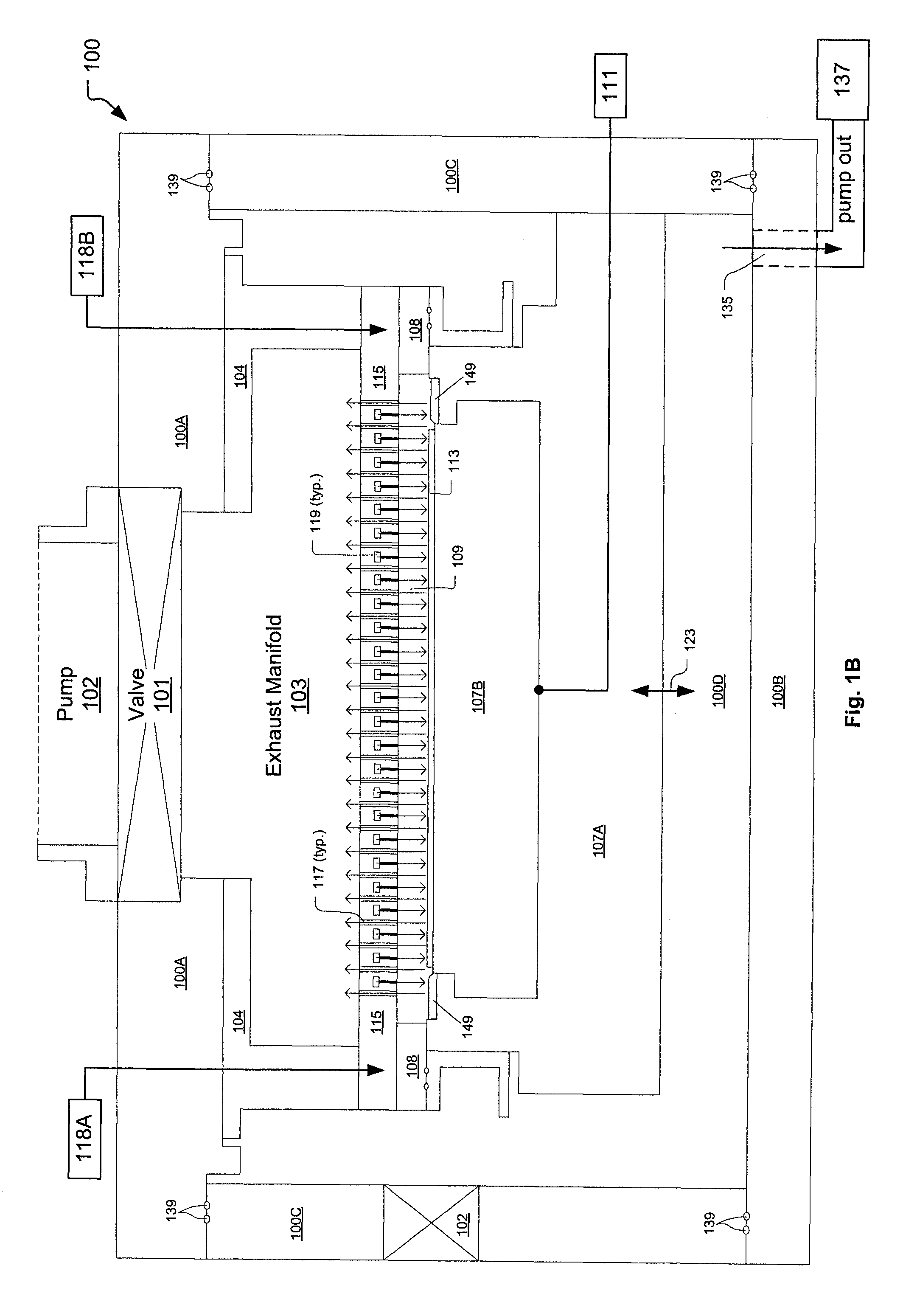

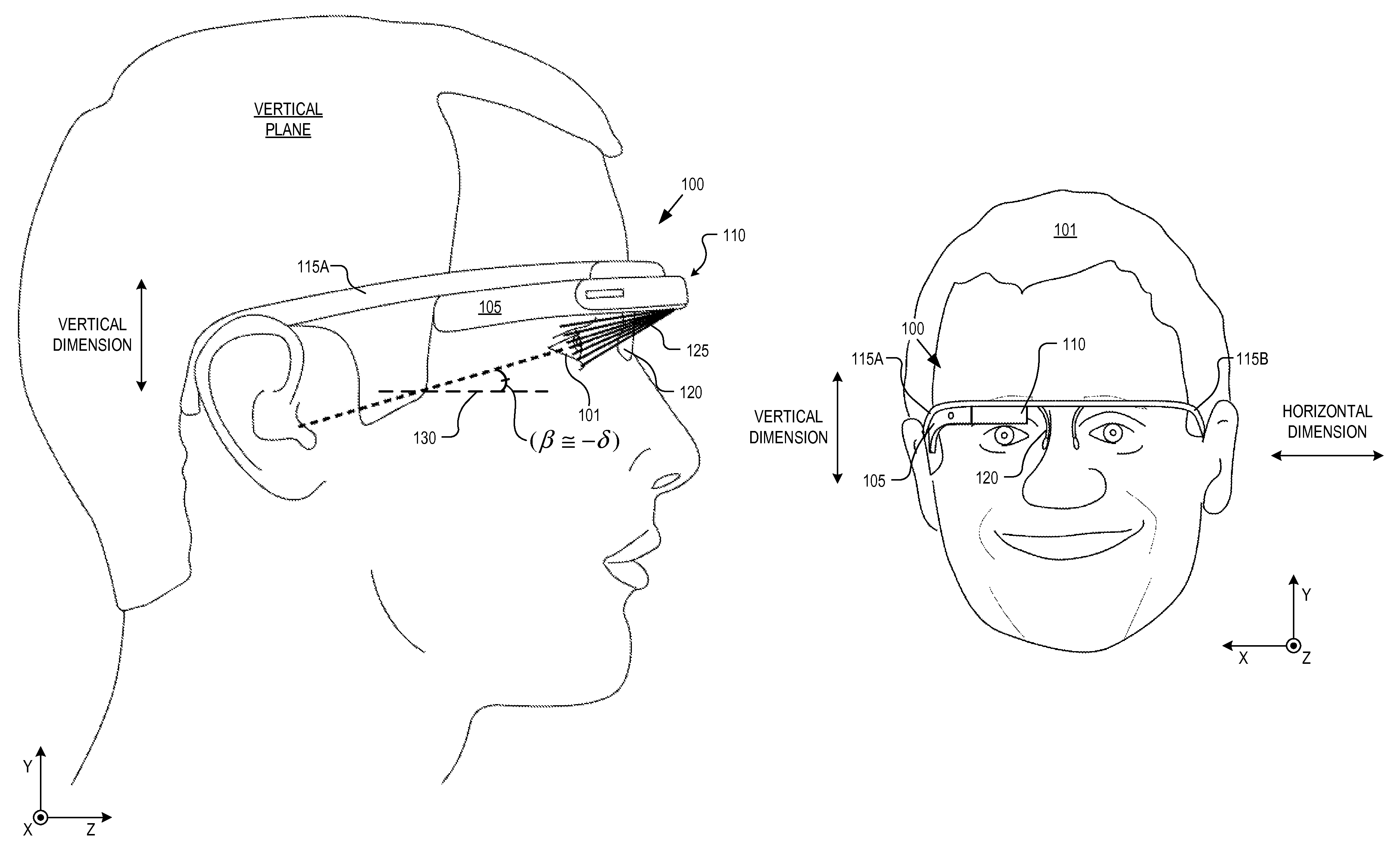

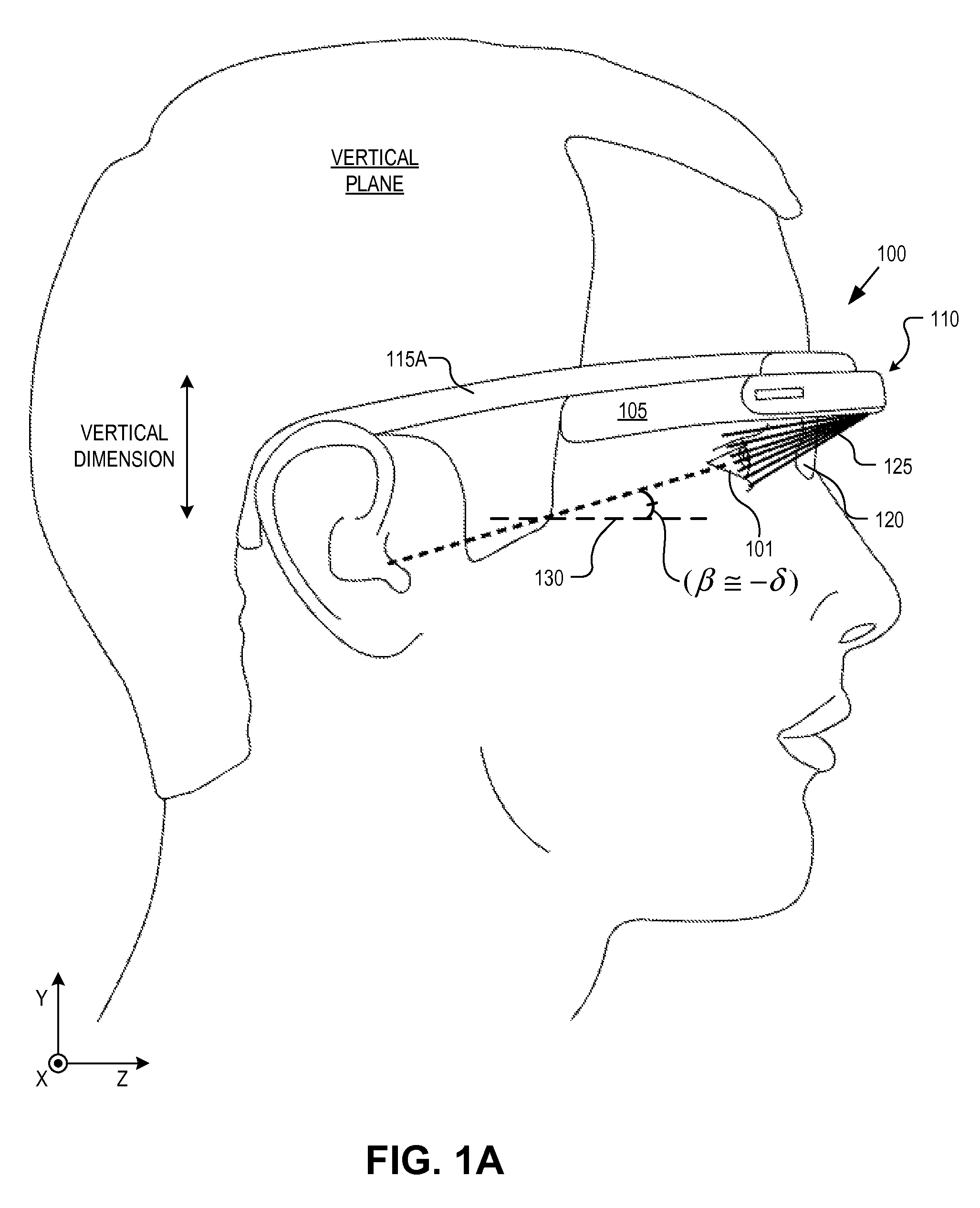

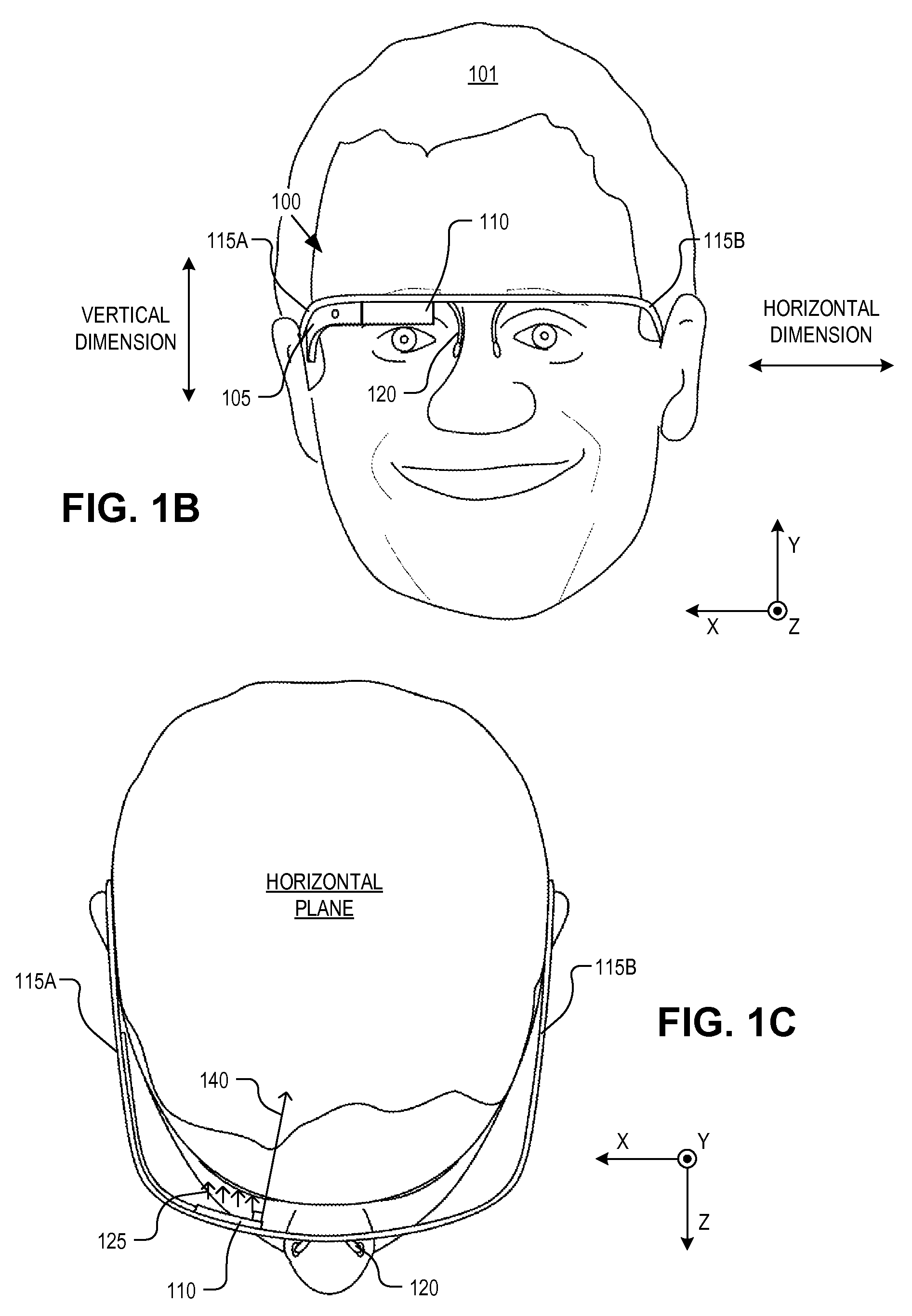

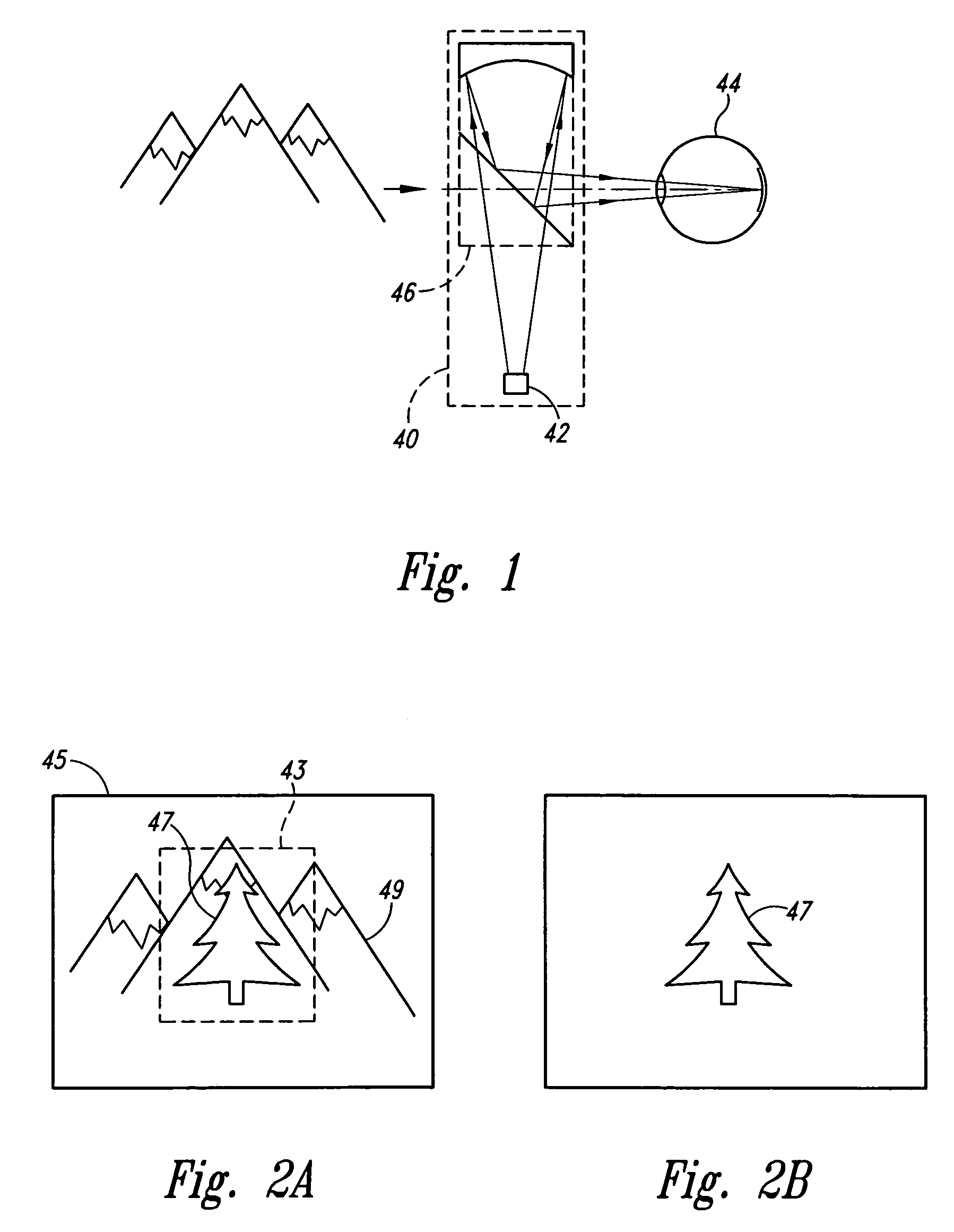

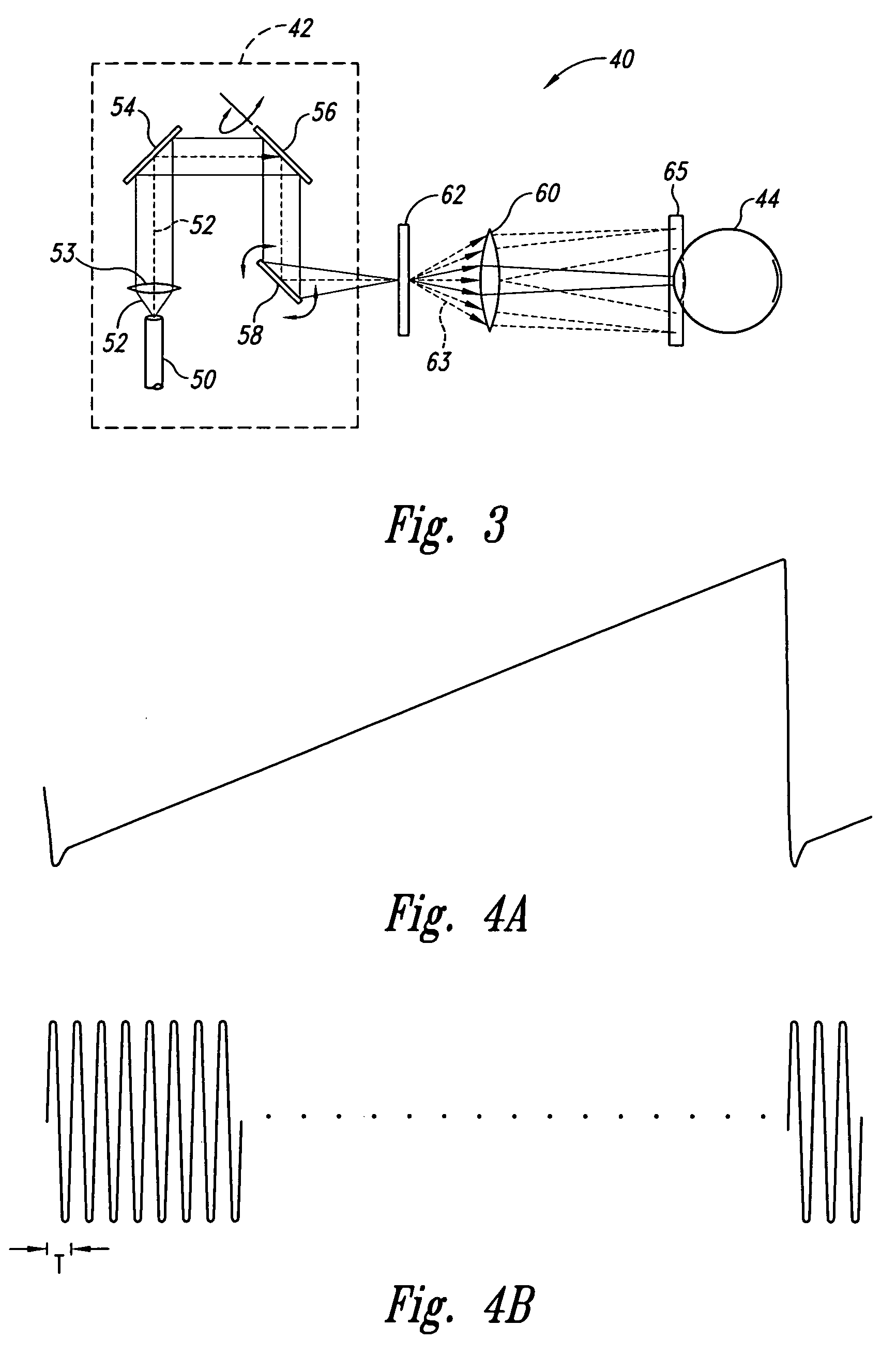

Dual axis internal optical beam tilt for eyepiece of an HMD

InactiveUS8867139B2Polarising elementsCathode-ray tube indicatorsPartially reflective surfaceEyepiece

An eyepiece includes a display module for providing display light, a concave end reflector, and a viewing region including a partially reflective surface to redirect at least a portion of the display light out of an eye-ward side of the eyepiece along an emission path. The partially reflective surface is obliquely angled with an offset from 45 degrees relative to the eye-ward side to cause the emission path to have a first oblique angle in a horizontal dimension relative to a first normal vector of the eye-ward side. The concave end reflector is tilted such that a second normal vector from a center point of the concave end reflector is obliquely angled relative to a top or bottom surface of the eyepiece to cause the emission path to have a second oblique angle in a vertical dimension relative to the first normal vector of the eye-ward side.

Owner:GOOGLE LLC

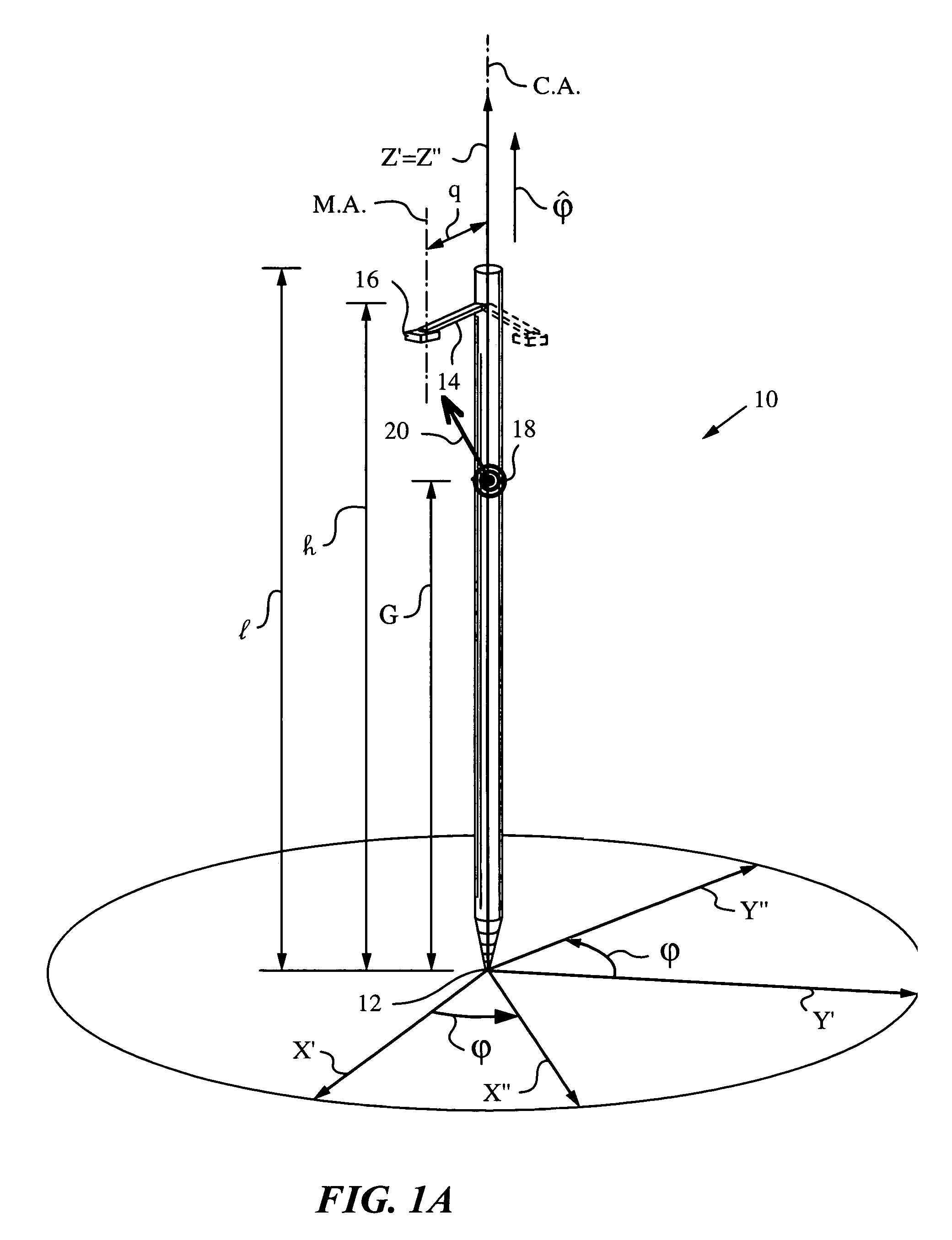

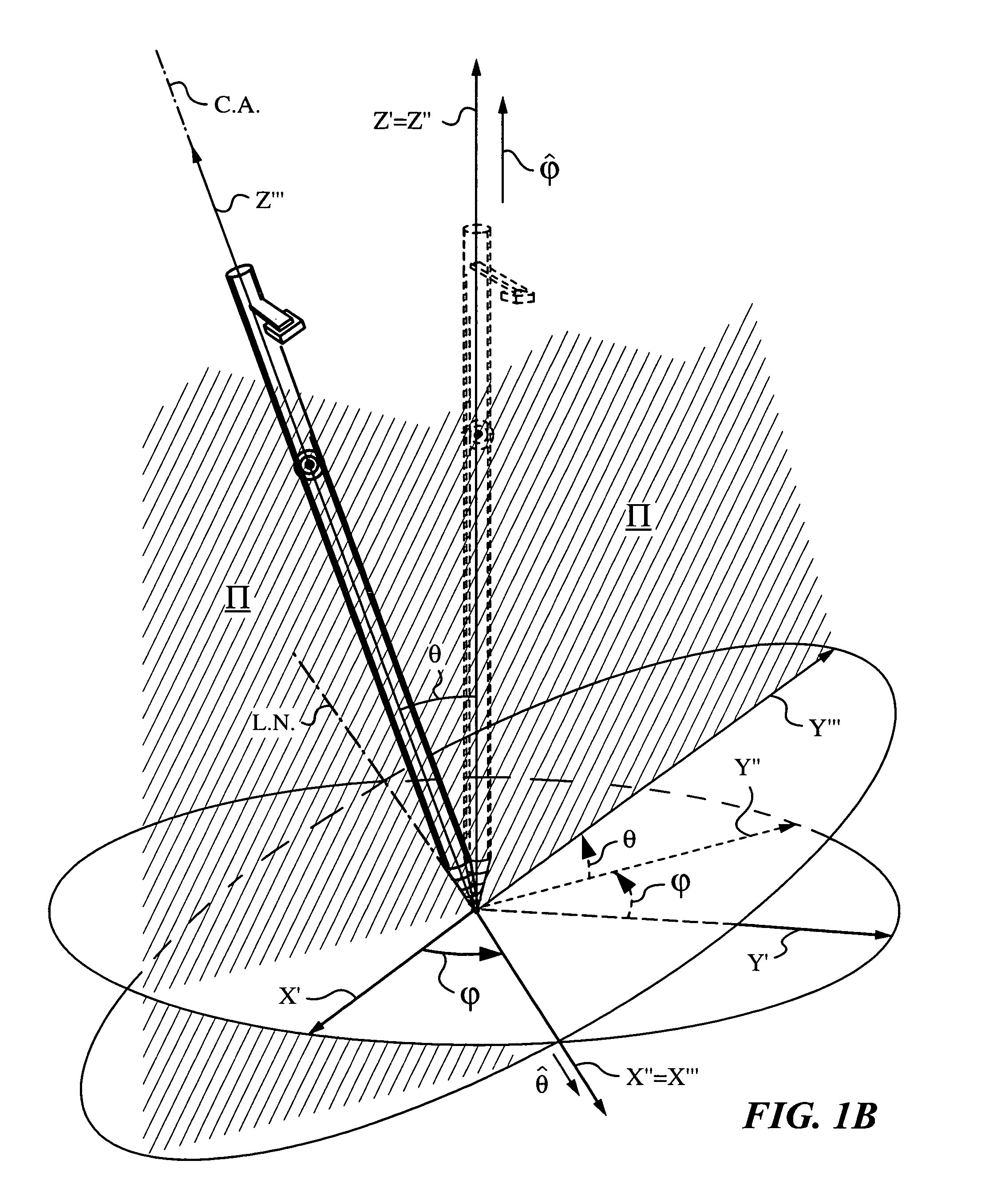

Apparatus and method for determining an inclination of an elongate object contacting a plane surface

An apparatus and method for determining an inclination angle θ between an axis of an elongate object such as a cane, a pointer or a jotting implement such as a pen, pencil, stylus or the like and a normal to a plane surface at times when a tip of the elongate object is contacting that plane surface. The apparatus has an emitter mounted on the object for illuminating the plane surface with a probe radiation at an angle σ with respect to the axis of the object. The apparatus also has a detector mounted on the elongate object for detecting a radiation characteristic of a scattered portion of the probe radiation returning from the plane surface and a computing unit for deriving the inclination angle θ from the radiation characteristic. A scanning arrangement, such as a uniaxial or biaxial scanner, or a light guiding optic can be used for varying angle σ, and the probe radiation can be emitted in the form of a scan beam. Preferably, the emitter and detector of the scattered portion of the probe radiation are integrated and the scattered portion of the probe radiation whose characteristic is being measured is the back-scattered portion. The radiation characteristic detected by the detector can be the intensity, polarization, time-of-flight or any combination thereof.

Owner:ELECTRONICS SCRIPTING PRODS

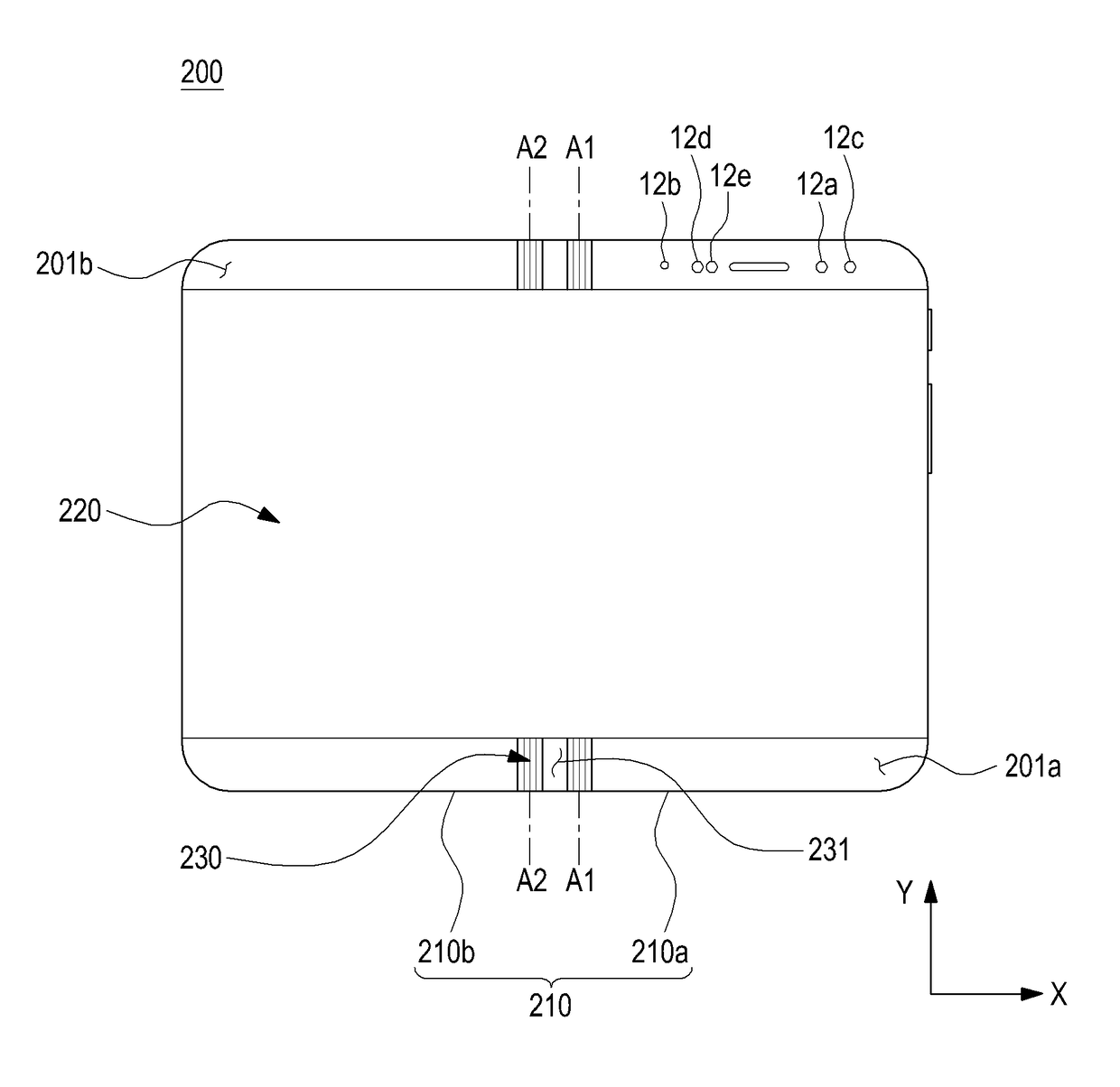

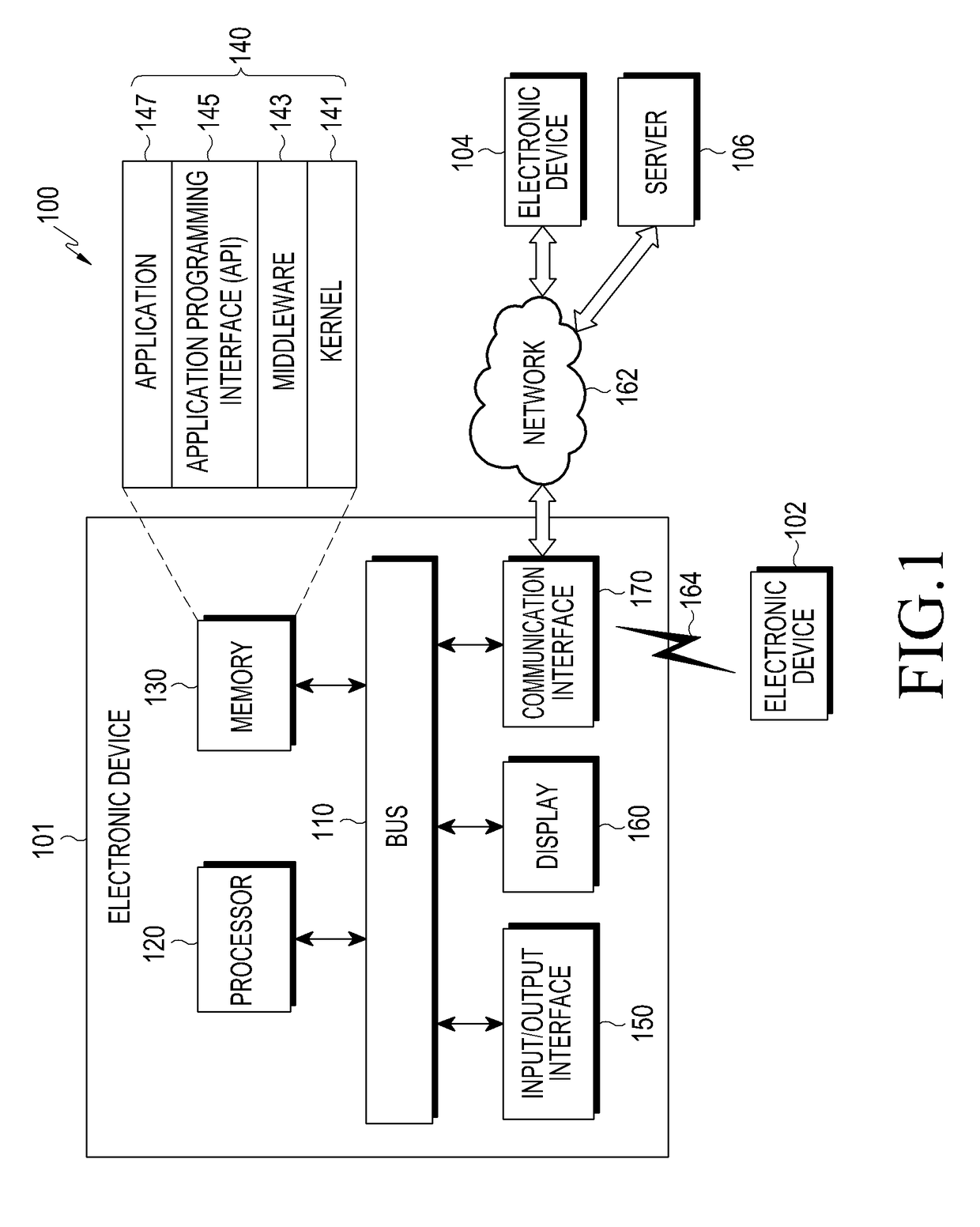

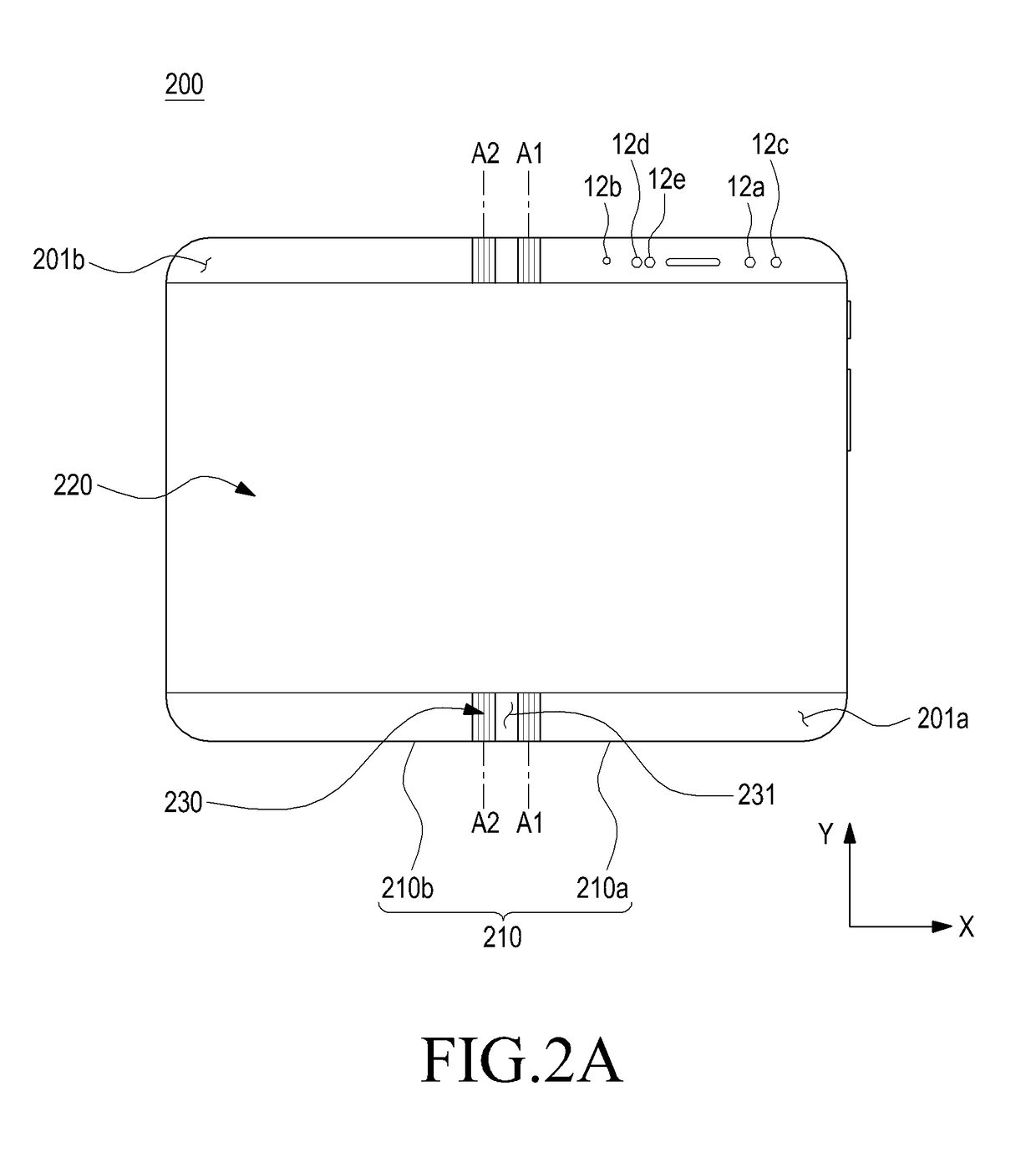

Electronic device including flexible display

ActiveUS20180324964A1Linear bearingsCasings with display/control unitsRotational axisFlexible display

According to an embodiment of the present disclosure, an electronic device may comprise a first housing including a first surface and a second surface facing in a direction opposite the first surface, a second housing including a third surface and a fourth surface facing in a direction opposite the third surface, a hinge disposed between the first housing and the second housing configured to provide rotational motion between the first housing and the second housing, and a flexible display disposed from the first surface of the first housing across the hinge to the third surface of the second housing, at least part of the flexible display configured to form a curved surface as the hinge structure is folded, wherein the hinge may include dual-axis hinges configured to provide a first rotational axis allowing the first housing to rotate about the second housing and a second rotational axis allowing the second housing to rotate about the first housing and slides coupled with the first housing and the second housing and configured to provide sliding motion perpendicular to a lengthwise direction of the first housing and the second housing.

Owner:SAMSUNG ELECTRONICS CO LTD

Dual axis magnetic sensor

A two-axis magnetic field sensor includes a substrate, a first sensor having at least one magnetoresistive element formed of GMR material on the substrate has a free layer having an easy axis of effective anisotropy field in a first direction. The first sensor is sensitive to magnetic field components perpendicular to the first direction. A current is caused to flow through the first sensor and variations in the resistivity of the first sensor due to the first magnetic field components are sensed. A second sensor having at least one magnetoresistive element formed of GMR material on the substrate has a free layer having an easy axis of effective anisotropy field in a direction substantially perpendicular to the first direction. The second sensor is sensitive to second magnetic field components perpendicular to its easy axis of effective anisotropy. A current is caused to flow through the second sensor and variations in the resistivity of the second sensor due to second magnetic field components are sensed.

Owner:HONEYWELL INT INC

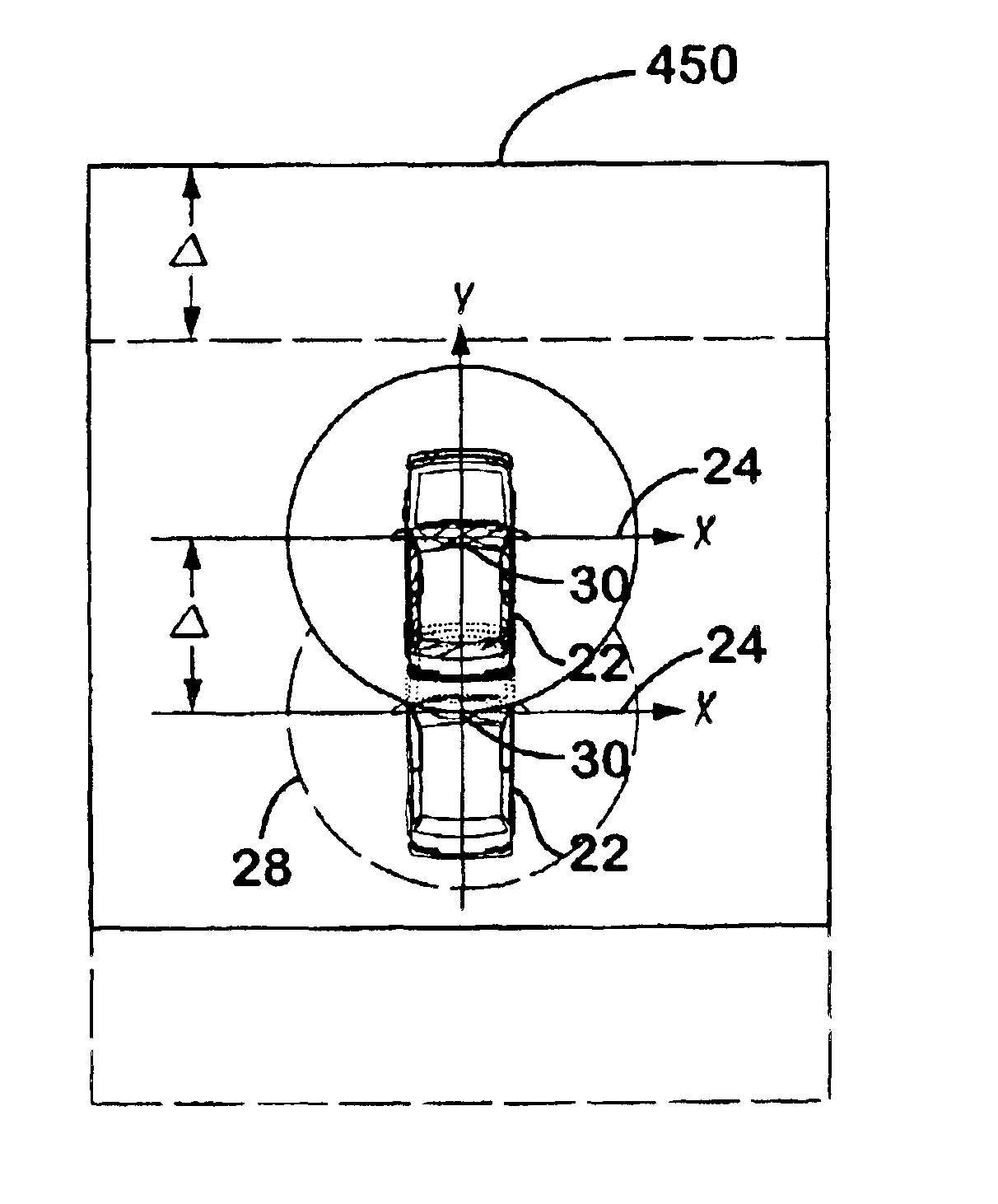

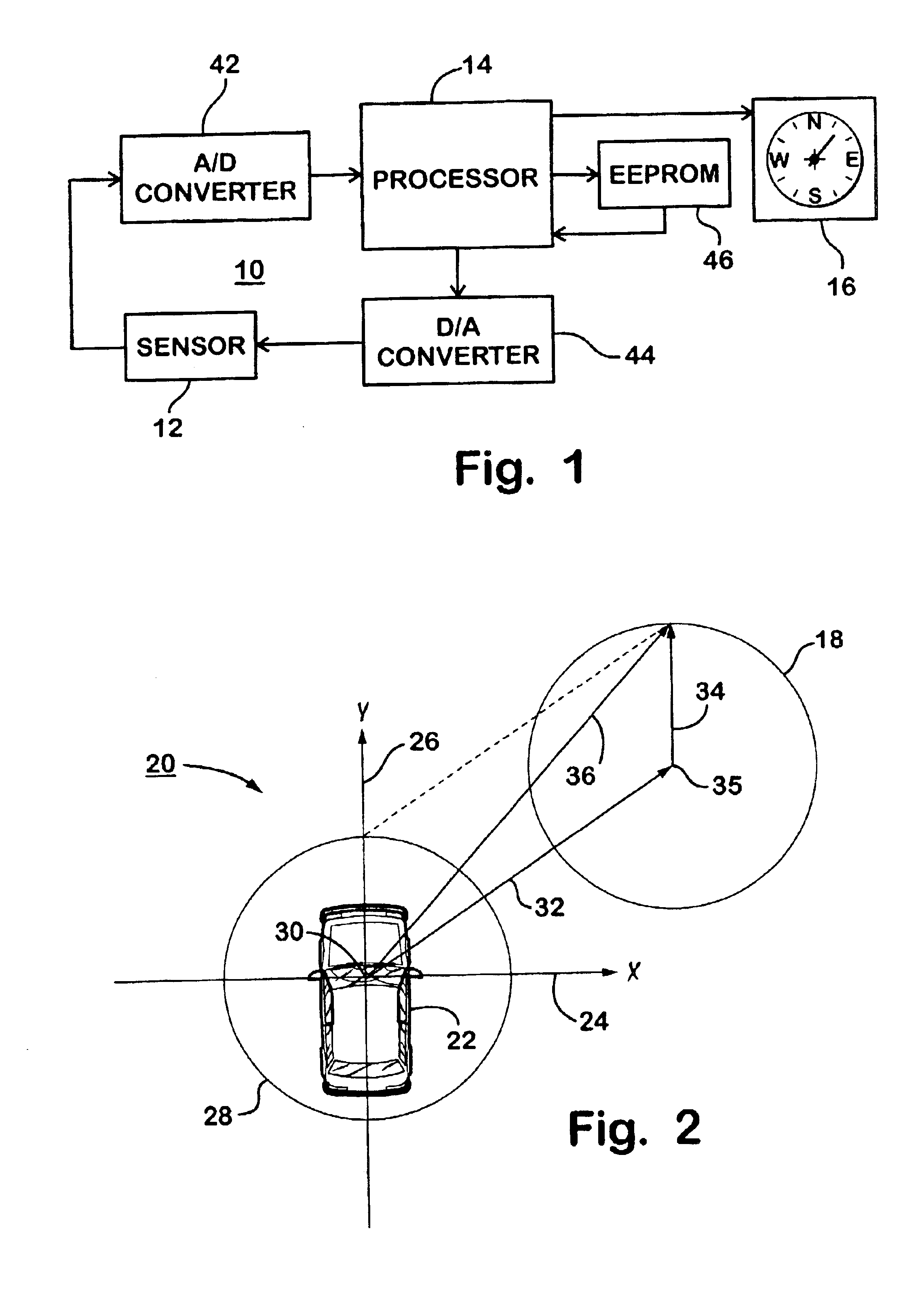

Vehicle compass compensation

A compass compensation system is provided for automatically and continuously calibrating an electronic compass for a vehicle, without requiring an initial manual calibration or preset of the vehicle magnetic signature. The system initially adjusts a two axis sensor of the compass in response to a sampling of at least one initial data point. The system further calibrates the compass by sampling data points that are substantially opposite to one another on a plot of a magnetic field and averaging an ordinate of the data points to determine a respective zero value for the Earth magnetic field. The system also identifies a change in magnetic signature and adjusts the sensor assembly.

Owner:DONNELLY CORP

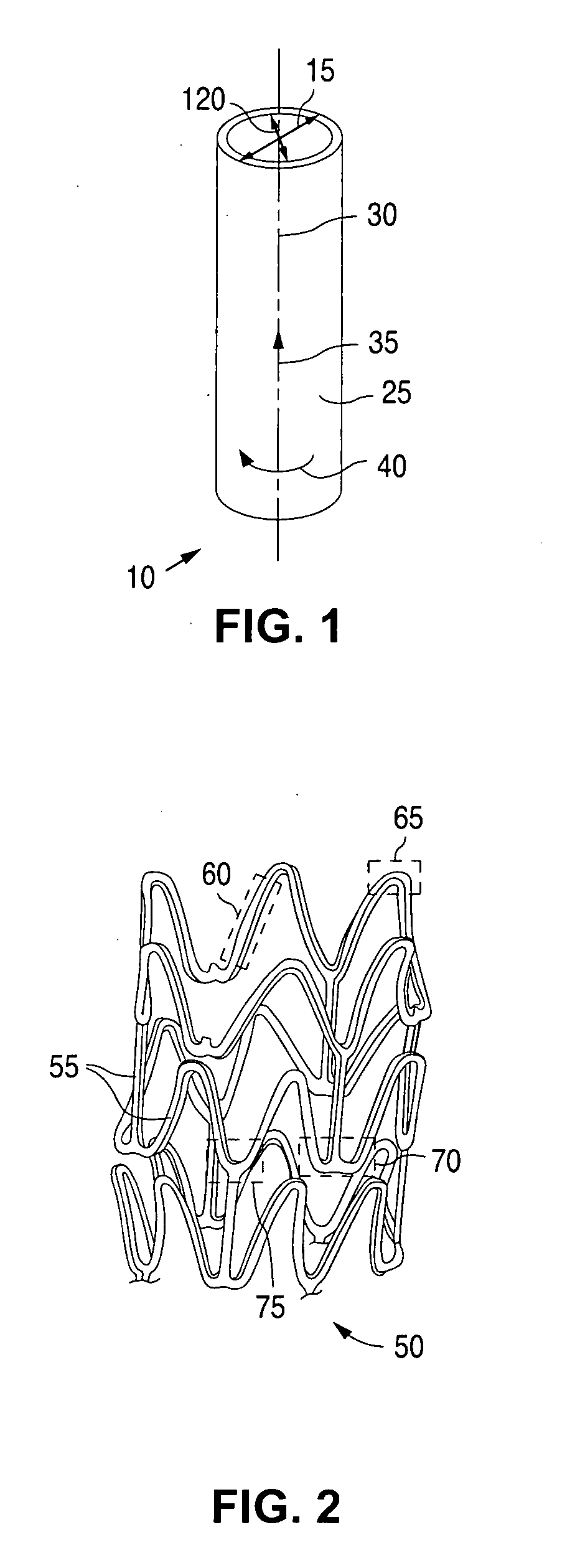

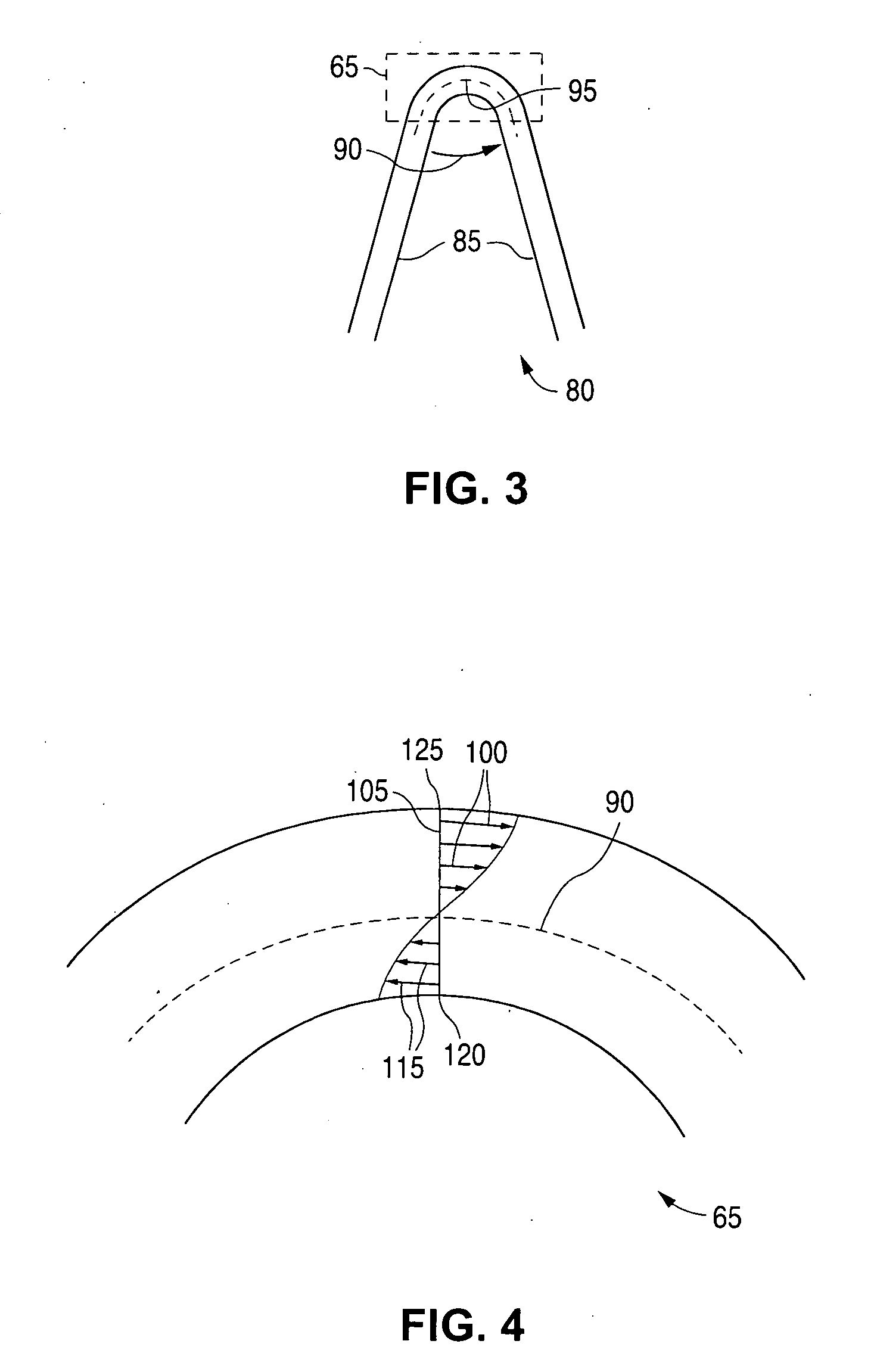

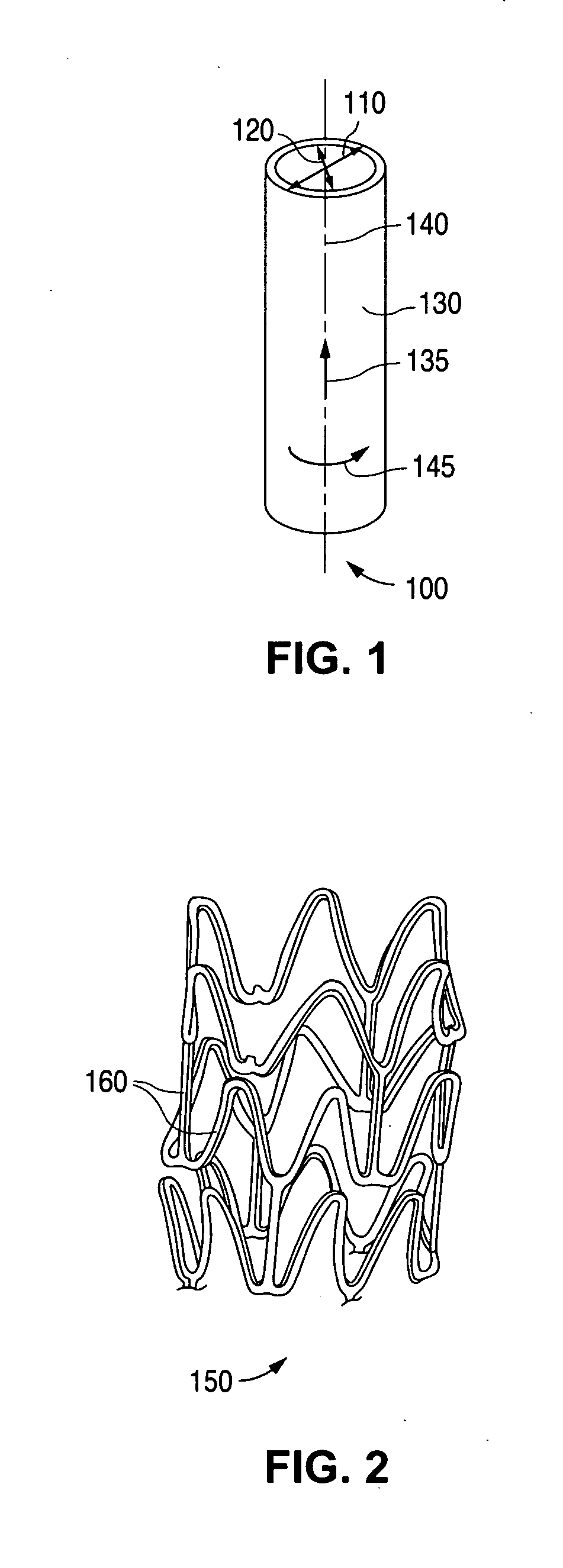

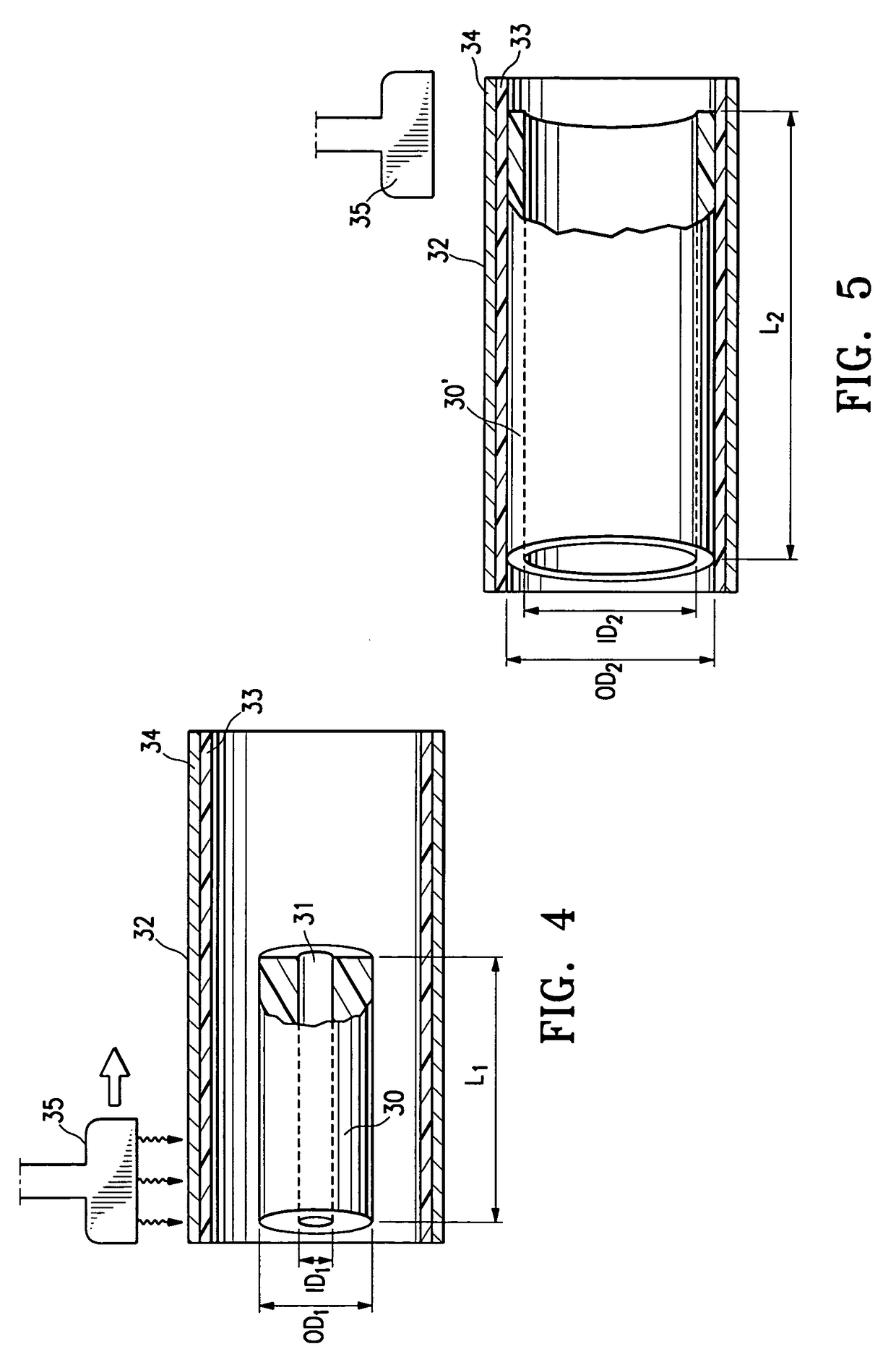

Method of fabricating a biaxially oriented implantable medical device

Methods of manufacturing a radially expandable stent, including radial expansion and axial elongation of a polymer tube, are disclosed.

Owner:ABBOTT CARDIOVASCULAR

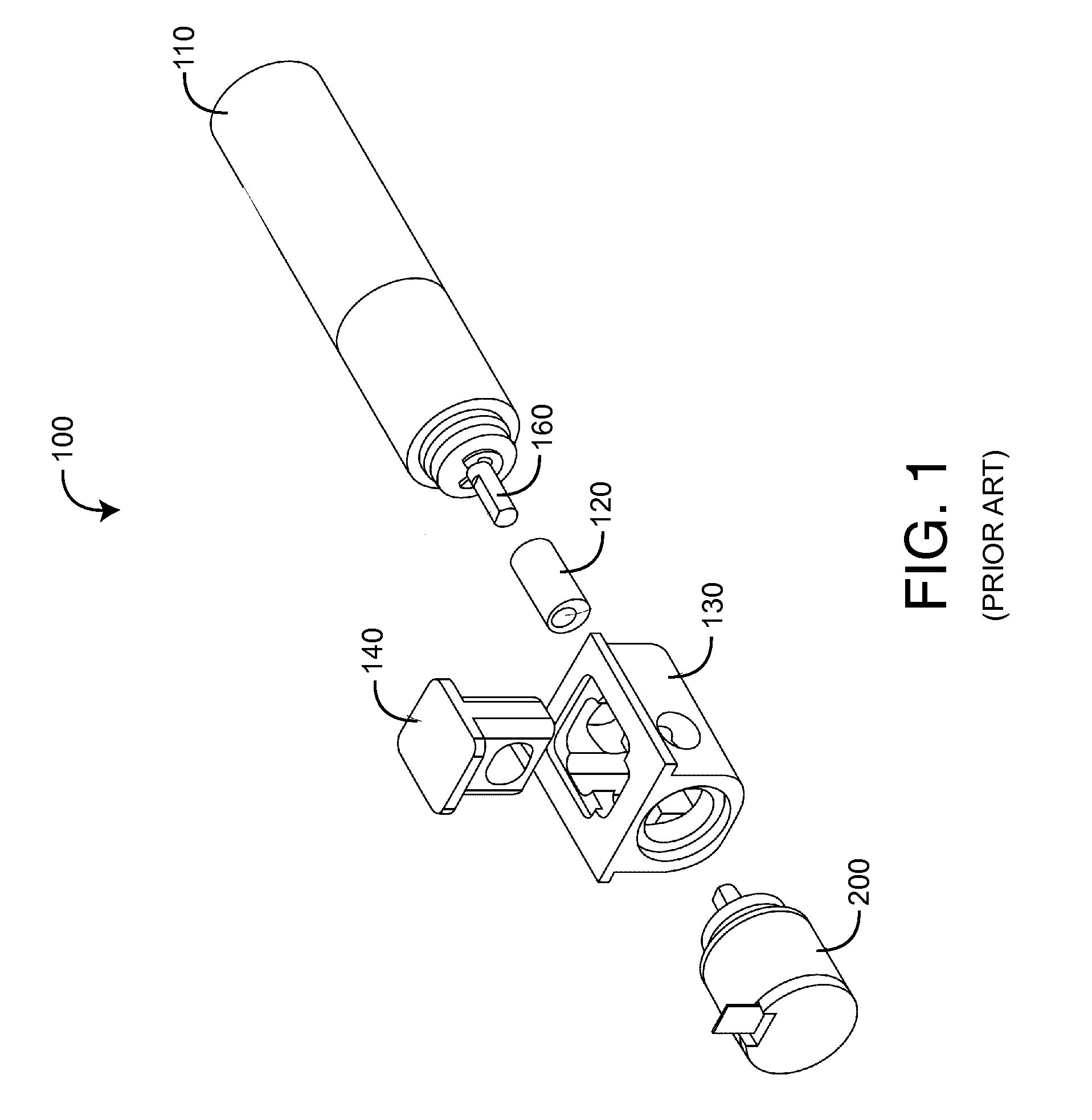

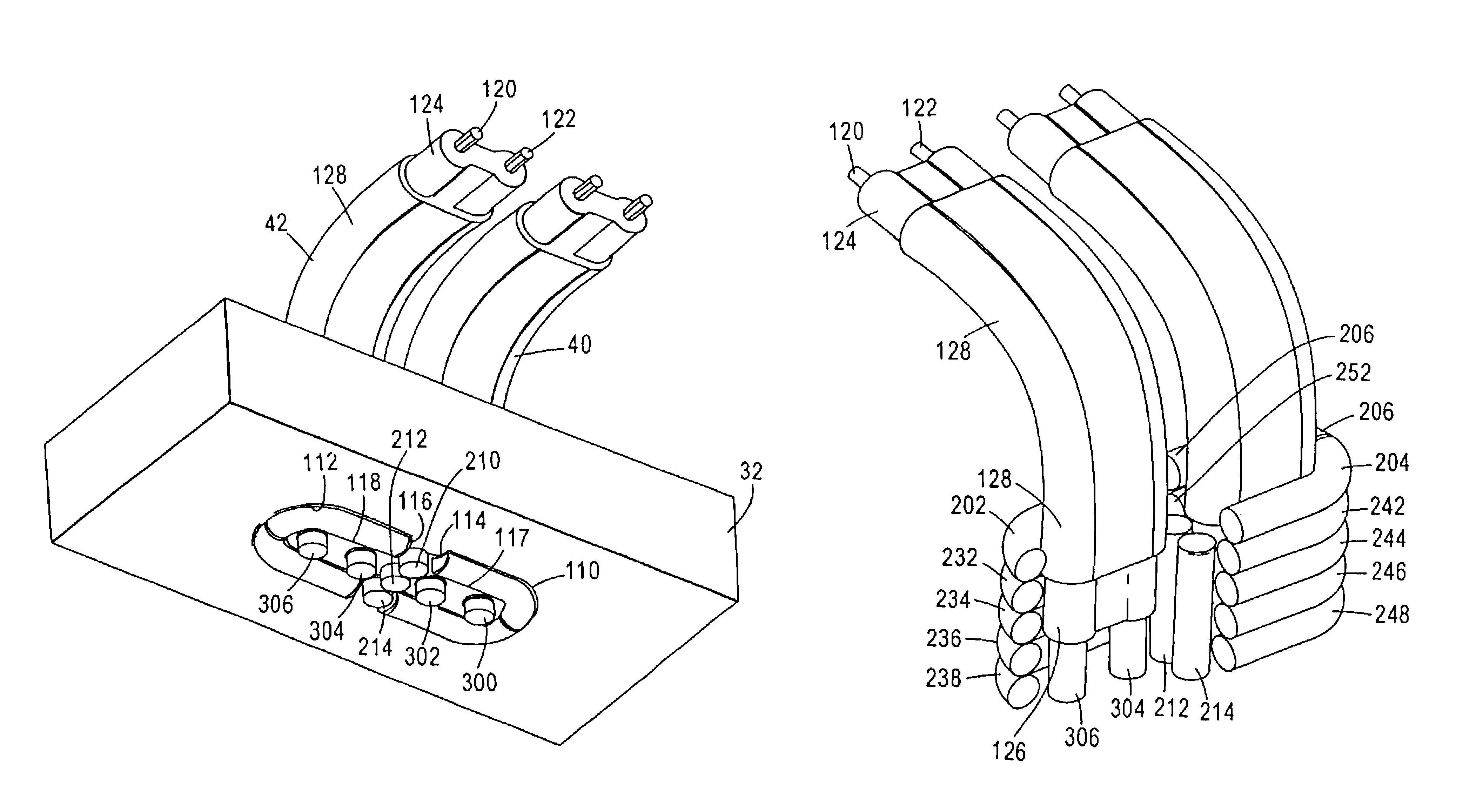

High speed, high density interconnect system for differential and single-ended transmission applications

InactiveUS6843657B2Simple and elegant latching mechanismEfficient use ofElectrically conductive connectionsCoupling contact membersHigh densityCoaxial cable

The present invention is directed to a high density electrical connector which can provide 80 or more twinax connections per linear inch in a 20 millimeter card slot. In a typical electronic system package, 20 millimeters is the spacing from center line to center line of the adjacent parallel daughtercards. Twinax cable is coaxial cable that contains two inner conducting wires rather than one. The two inner conducting wires provide two physical channels. Coaxial cable is called “coaxial” because it includes one physical channel that carries the signal surrounded (after a layer of insulation) by another concentric physical channel, both running along the same axis. The outer channel serves as ground.

Owner:WINCHESTER ELECTRONICS

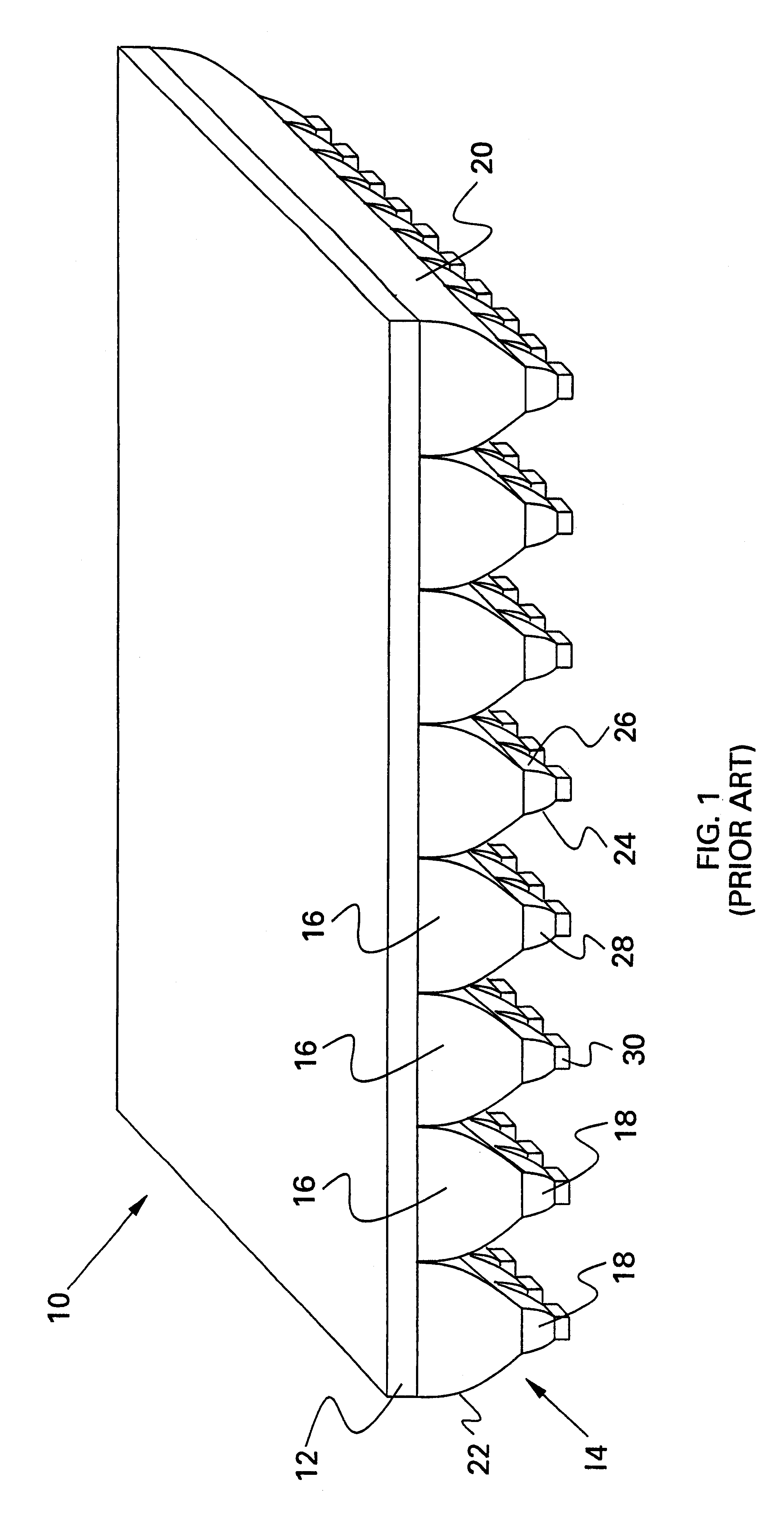

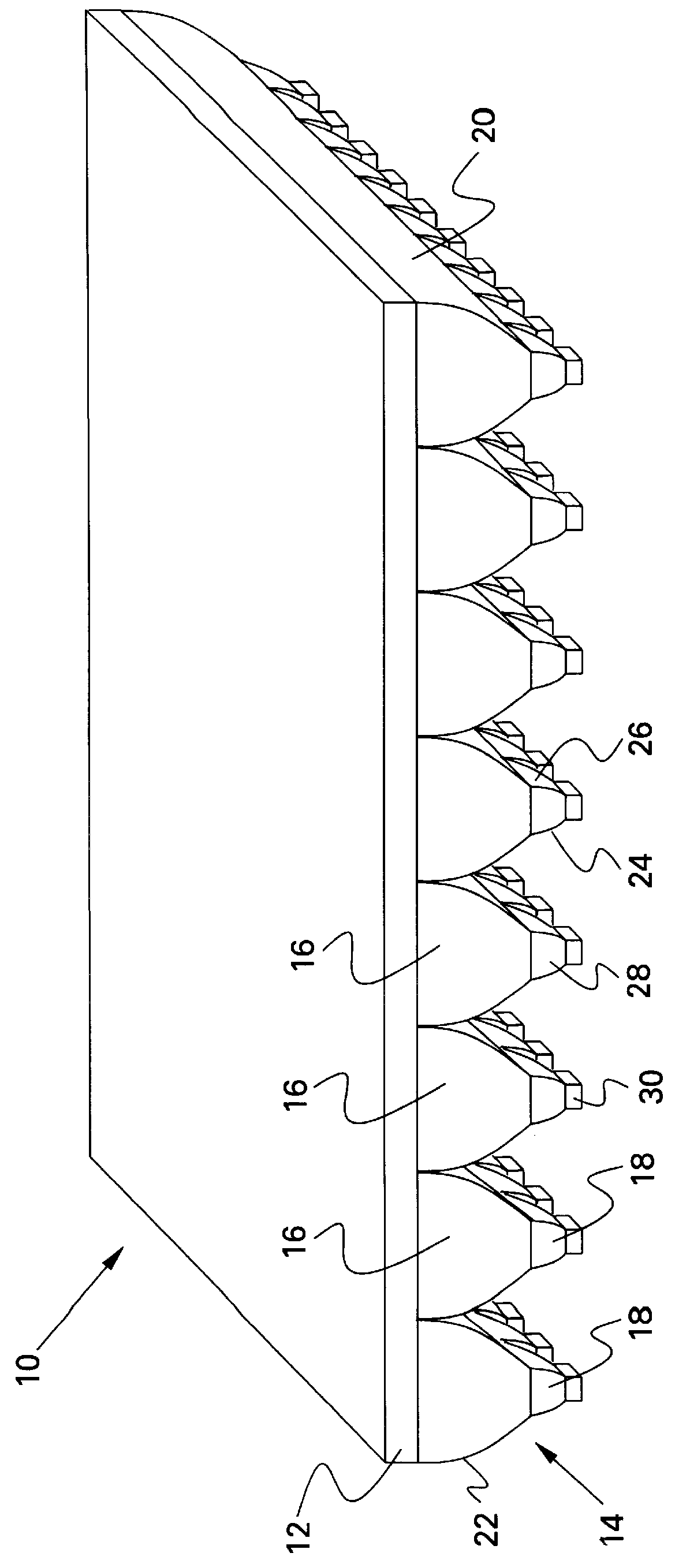

Space concentrator for advanced solar cells

InactiveUS6252155B1Reduce quality problemsImprove efficiencySolar heating energyMirrorsConcentration ratioRefractive index

A solar concentrator is provided that comprises two stages. The first stage comprises either a trough-shaped concentrator cusp unit having two major opposed sides joined by two ends. The inner surfaces of the first stage concentrator are mirrored. Further, the ends have two flat, angled surfaces, while the two sides have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The second stage comprises a bi-axial gradient refractive index (GRIN) element, in which two gradient refractive index materials, each having a high index surface and a low index surface, are joined together along their high index surfaces. The two ends of the bi-axial element are flat, while the two sides also have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The top surface of the bi-axial element is provided with a cylindrical surface, while the bottom, or exit, surface is ground flat. The high index boundary is parallel to the side surfaces of the first stage unit. A solar cell is bonded to the flat exit surface of the second stage of the concentrator of the present invention. An array of such concentrators and solar cells, in which the solar cells are electrically interconnected, may then be deployed for converting solar energy into useful electrical energy. The 2-D / 3-D concentrator evidences much lower mass than prior art concentrators. Further, as the array, or panel, of solar cells wobbles in space, the concentrator will continue to operate, even at lower efficiencies, due to the larger acceptance angle. Concentration ratios on the order of 50x are realized with the present concentrator. However, design studies allow concentration ratios in excess of 300x when used with 3-D versions of the same concept. The second stage can comprise mirrored surfaces. Or, the first stage can comprise a conical section and the second stage a radial GRIN element.

Owner:ORTABASI UGUR

Method of fabricating an implantable medical device with biaxially oriented polymers

InactiveUS20060020330A1Desirable mechanical propertyImprove rigidityStentsSurgeryPolymer thin filmsUltimate tensile strength

Methods and systems for manufacturing an implantable medical device, such as a stent, from a tube with desirable mechanical properties, such as improved circumferential strength and rigidity, are described herein. Improved circumferential strength and rigidity may be obtained by inducing molecular orientation in materials for use in manufacturing an implantable medical device. Some embodiments may include inducing molecular orientation by expansion of a molten annular polymer film. Other embodiments may include inducing circumferential molecular orientation by inducing circumferential flow in a molten polymer. In certain embodiments, circumferential orientation may be induced by expansion of a polymer tube. Further embodiments may include manufacturing an implantable medical device from a biaxially oriented planar polymer film.

Owner:ABBOTT CARDIOVASCULAR

Space concentrator for advanced solar cells

InactiveUS6057505AReduce weightReduce quality problemsSolar heating energyMirrorsConcentration ratioRefractive index

A solar concentrator is provided that comprises two stages. The first stage comprises either a trough-shaped concentrator cusp unit having two major opposed sides joined by two ends. The inner surfaces of the first stage concentrator are mirrored. Further, the ends have two flat, angled surfaces, while the two sides have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The second stage comprises a bi-axial gradient refractive index (GRIN) element, in which two gradient refractive index materials, each having a high index surface and a low index surface, are joined together along their high index surfaces. The two ends of the bi-axial element are flat, while the two sides also have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The top surface of the bi-axial element is provided with a cylindrical surface, while the bottom, or exit, surface is ground flat. The high index boundary is parallel to the side surfaces of the first stage unit. A solar cell is bonded to the flat exit surface of the second stage of the concentrator of the present invention. An array of such concentrators and solar cells, in which the solar cells are electrically interconnected, may then be deployed for converting solar energy into useful electrical energy. The 2-D / 3-D concentrator evidences much lower mass than prior art concentrators. Further, as the array, or panel, of solar cells wobbles in space, the concentrator will continue to operate, even at lower efficiencies, due to the larger acceptance angle. Concentration ratios on the order of 50x are realized with the present concentrator. However, design studies allow concentration ratios in excess of 300x when used with 3-D versions of the same concept. The second stage can comprise mirrored surfaces. Or, the first stage can comprise a conical section and the second stage a radial GRIN element.

Owner:ORTABASI UGUR

Strained-silicon CMOS device and method

ActiveUS20050285187A1High carrier mobilitySolid-state devicesSemiconductor/solid-state device manufacturingCMOSDevice material

The present invention provides a semiconductor device and a method of forming thereof, in which a uniaxial strain is produced in the device channel of the semiconductor device. The uniaxial strain may be in tension or in compression and is in a direction parallel to the device channel. The uniaxial strain can be produced in a biaxially strained substrate surface by strain inducing liners, strain inducing wells or a combination thereof. The uniaxial strain may be produced in a relaxed substrate by the combination of strain inducing wells and a strain inducing liner. The present invention also provides a means for increasing biaxial strain with strain inducing isolation regions. The present invention further provides CMOS devices in which the device regions of the CMOS substrate may be independently processed to provide uniaxially strained semiconducting surfaces in compression or tension.

Owner:GLOBALFOUNDRIES US INC

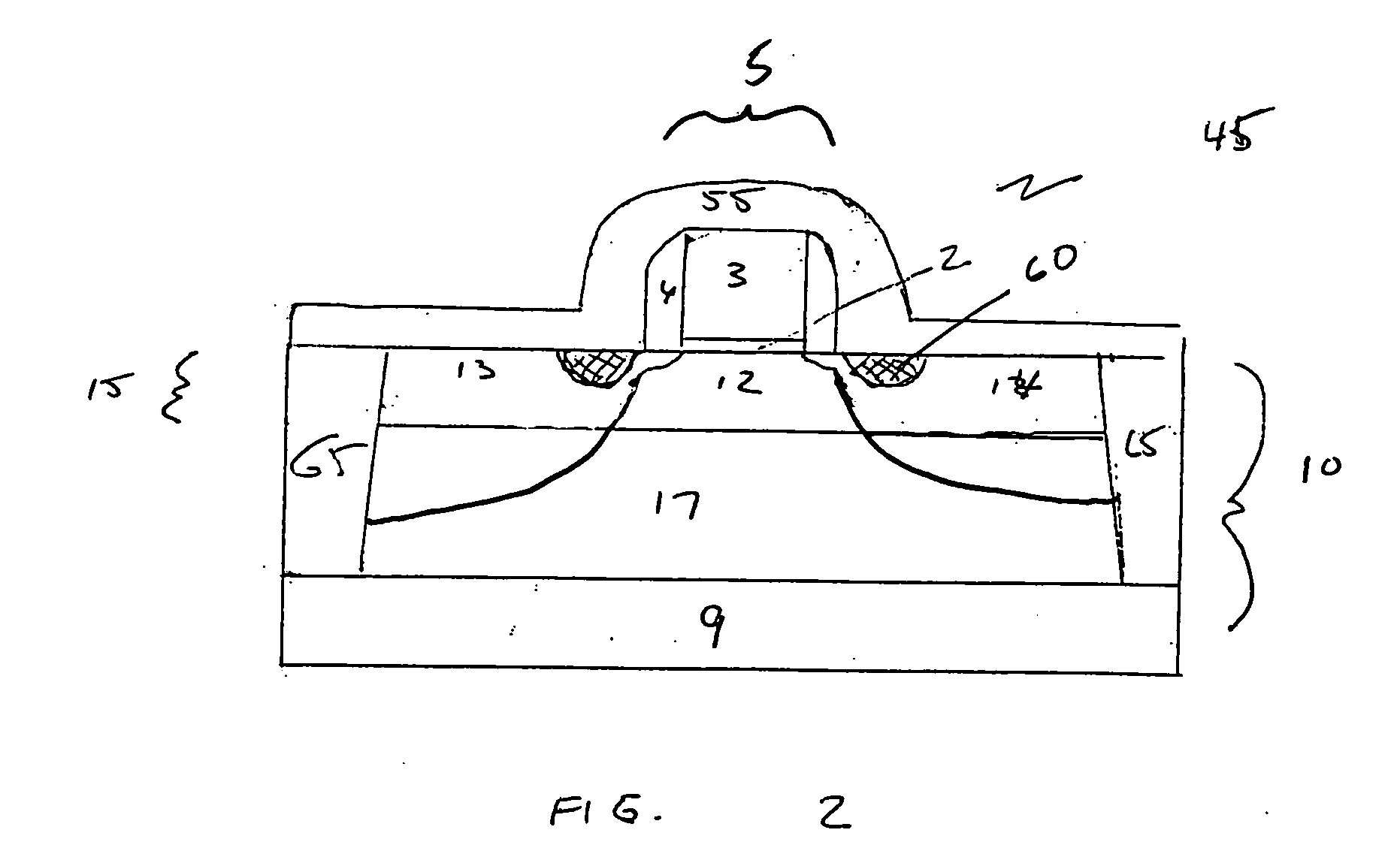

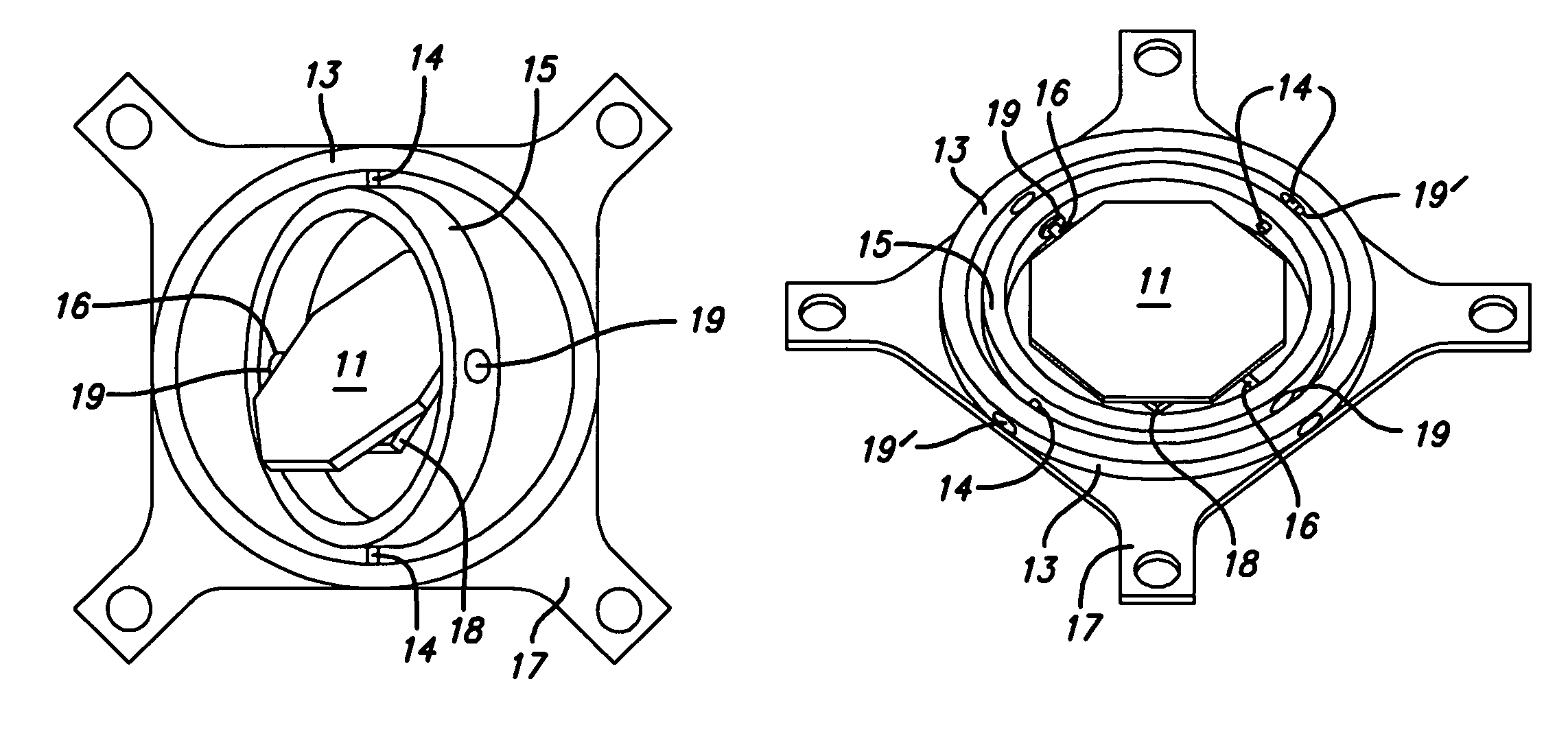

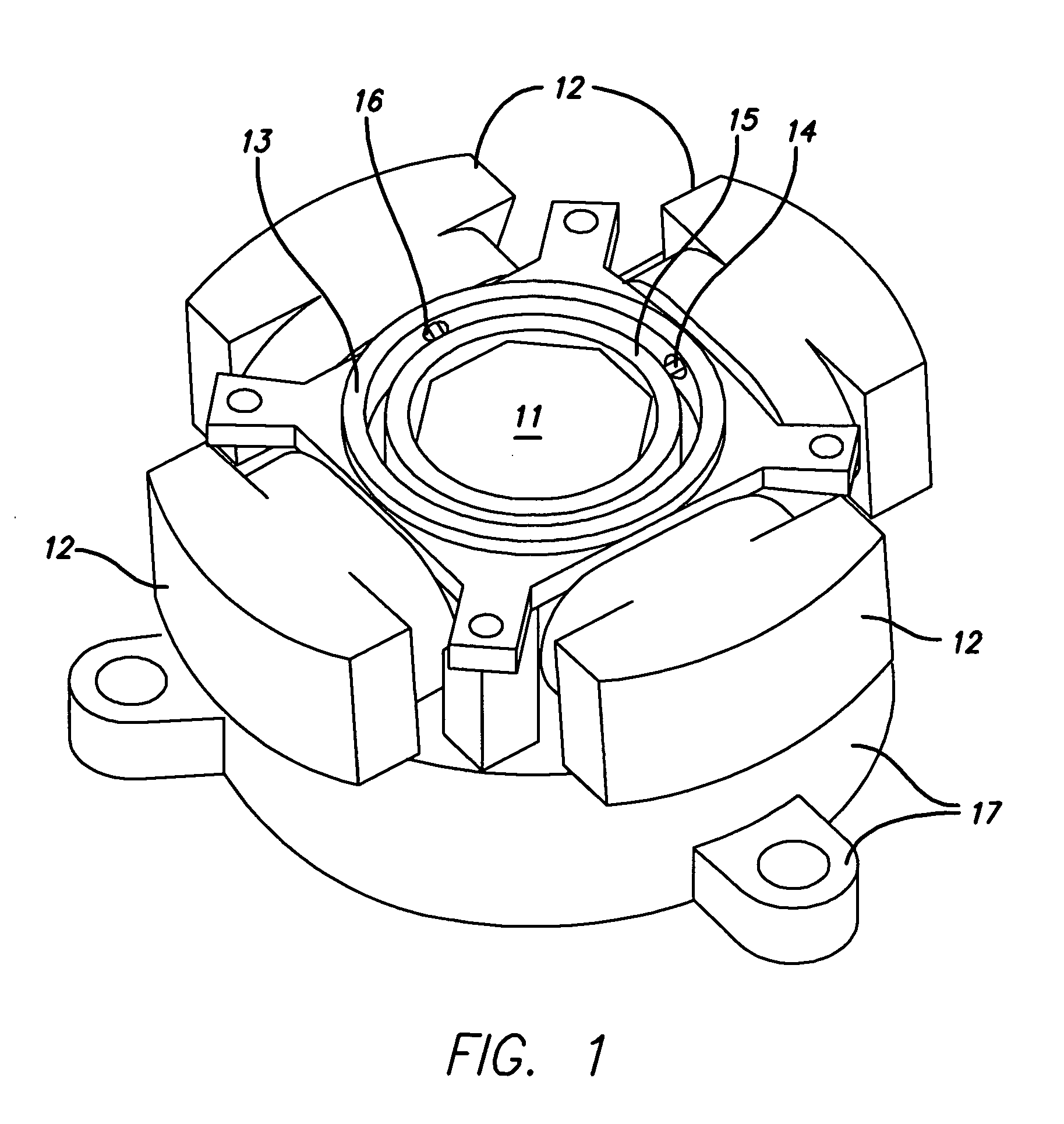

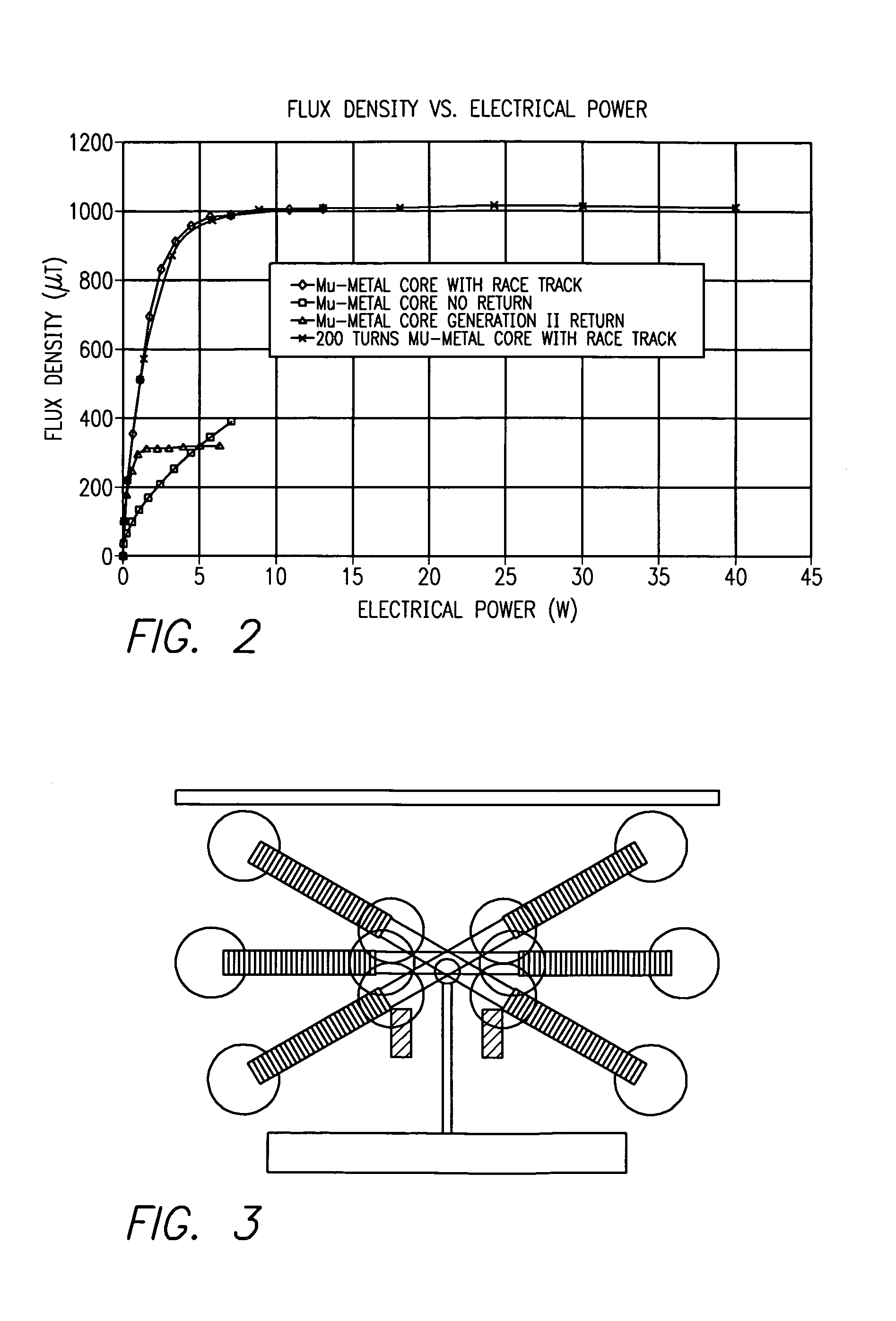

MEMS scanner with dual magnetic and capacitive drive

A MEMS scanning device includes more than one type of actuation. In one approach capacitive and magnetic drives combine to move a portion of the device along a common path. In one such structure, the capacitive drive comes from interleaved combs. In another approach, a comb drive combines with a pair of planar electrodes to produce rotation of a central body relative to a substrate. In an optical scanning application, the central body is a mirror. In a biaxial structure, a gimbal ring carries the central body. The gimbal ring may be driven by more than one type of actuation to produce motion about an axis orthogonal to that of the central body. In another aspect, a MEMS scanning device is constructed with a reduced footprint.

Owner:MICROVISION

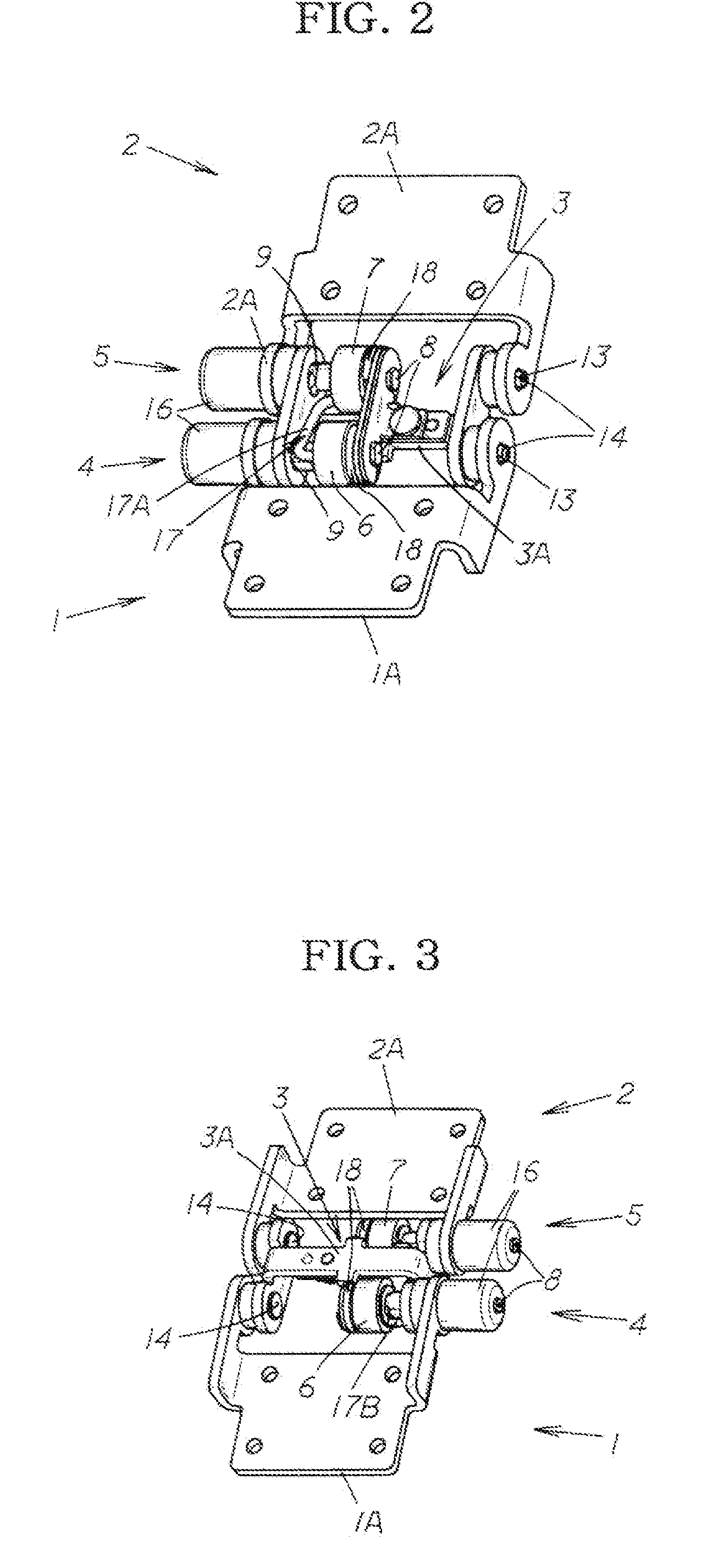

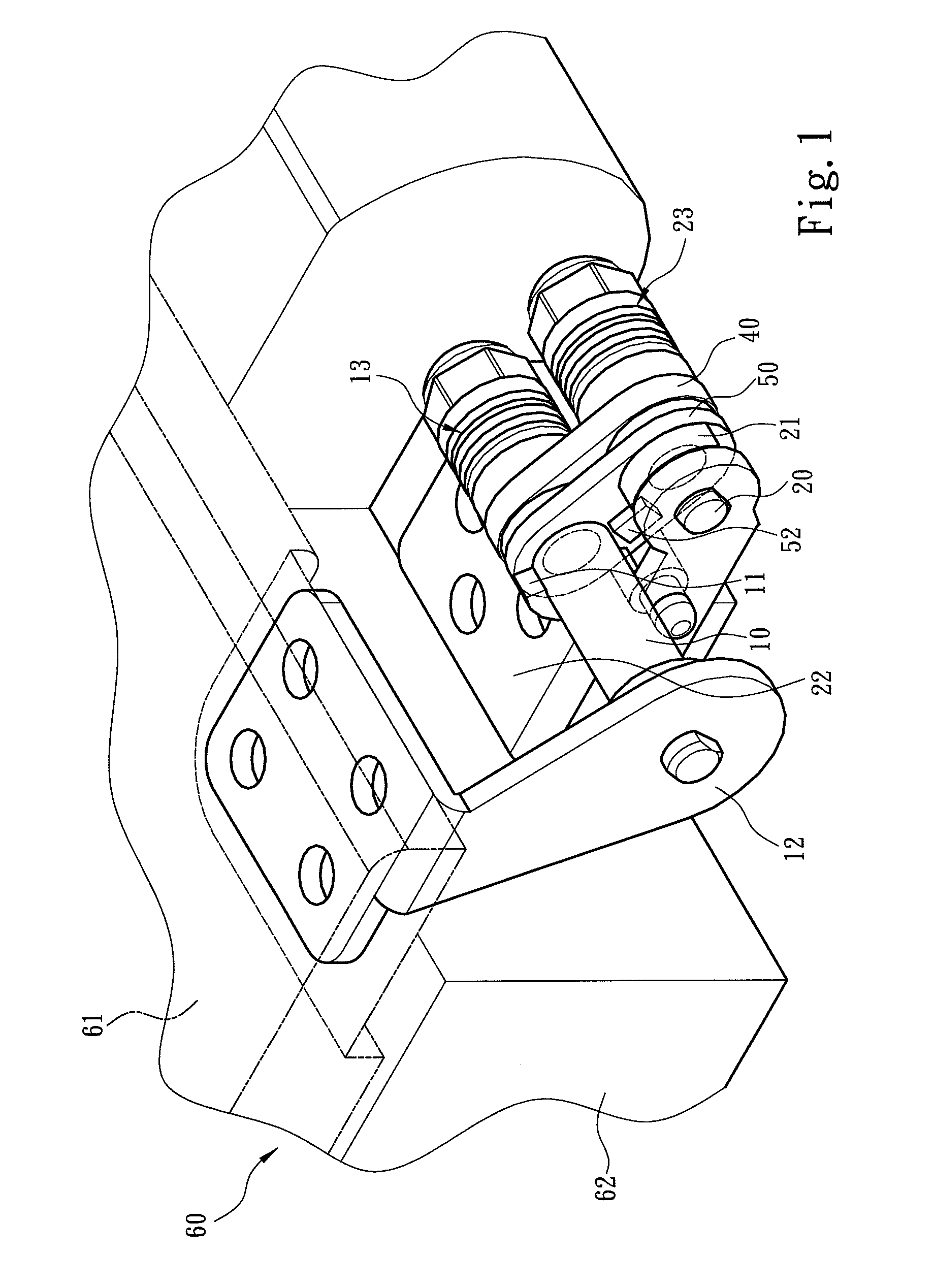

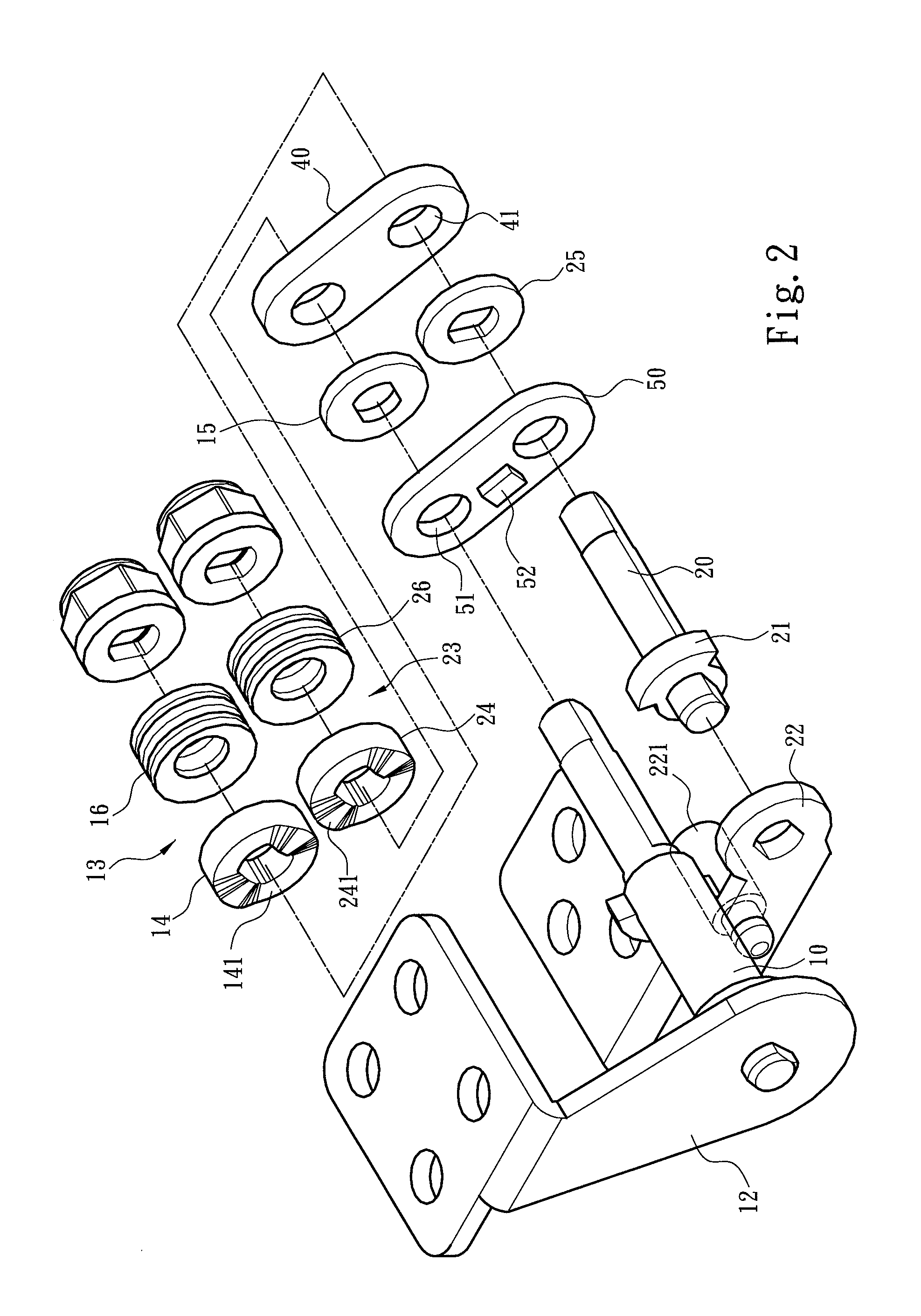

Hinge Device and Electronic Device Using Hinge Device

InactiveUS20090000062A1Smooth rotationOvercomes drawbackDetails for portable computersPin hingesEngineeringMechanical engineering

Owner:STRAWBERRY

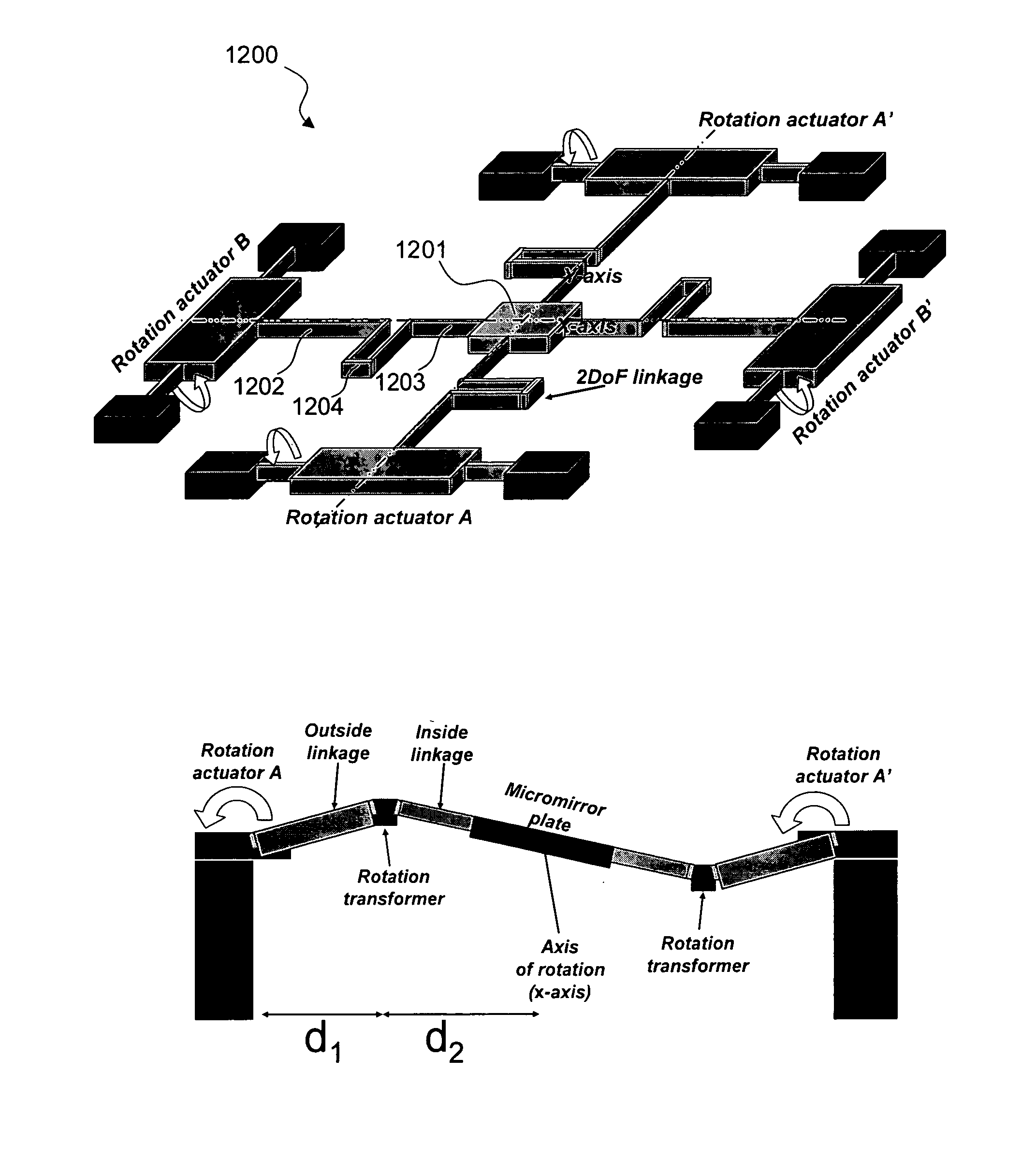

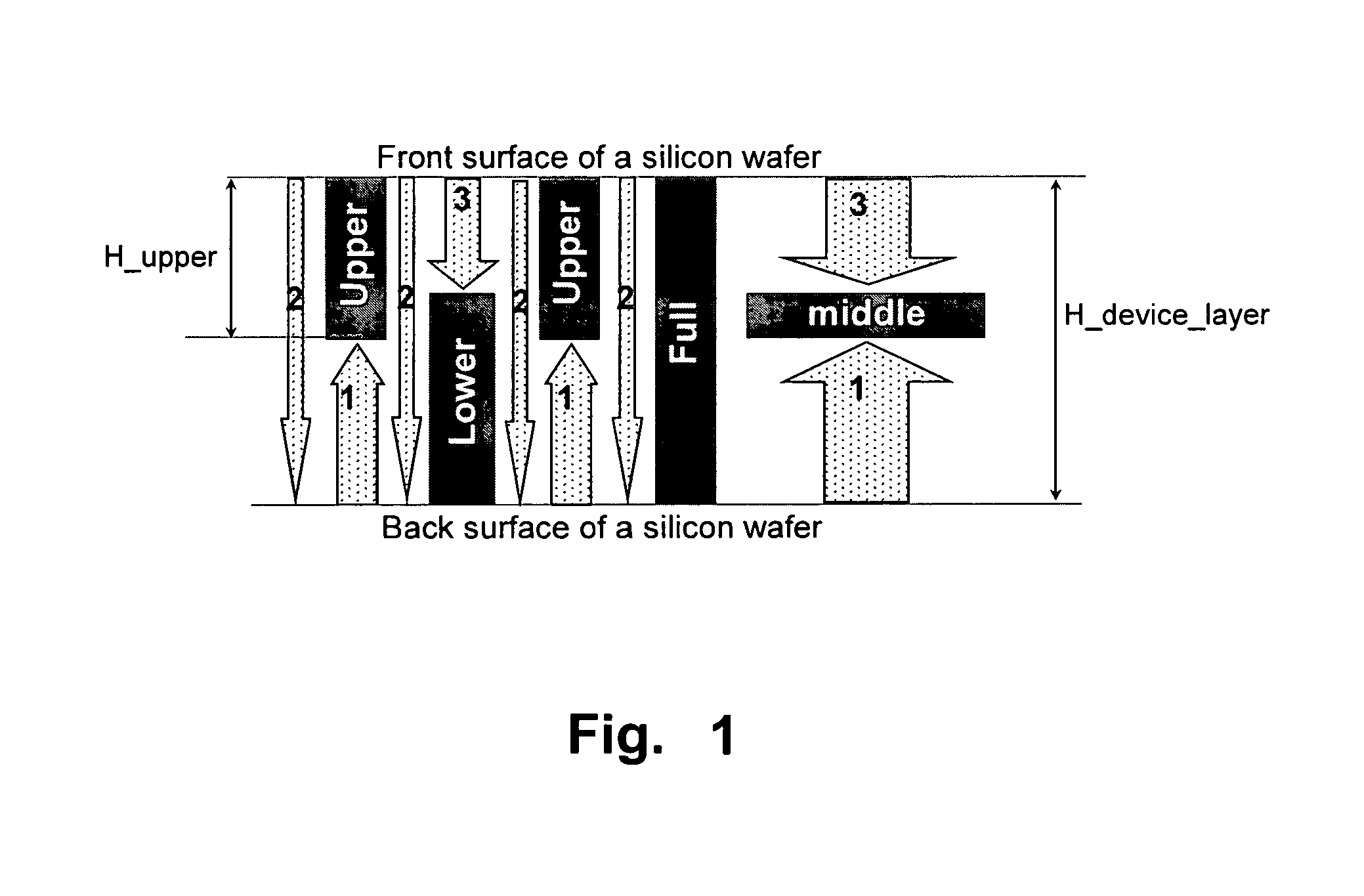

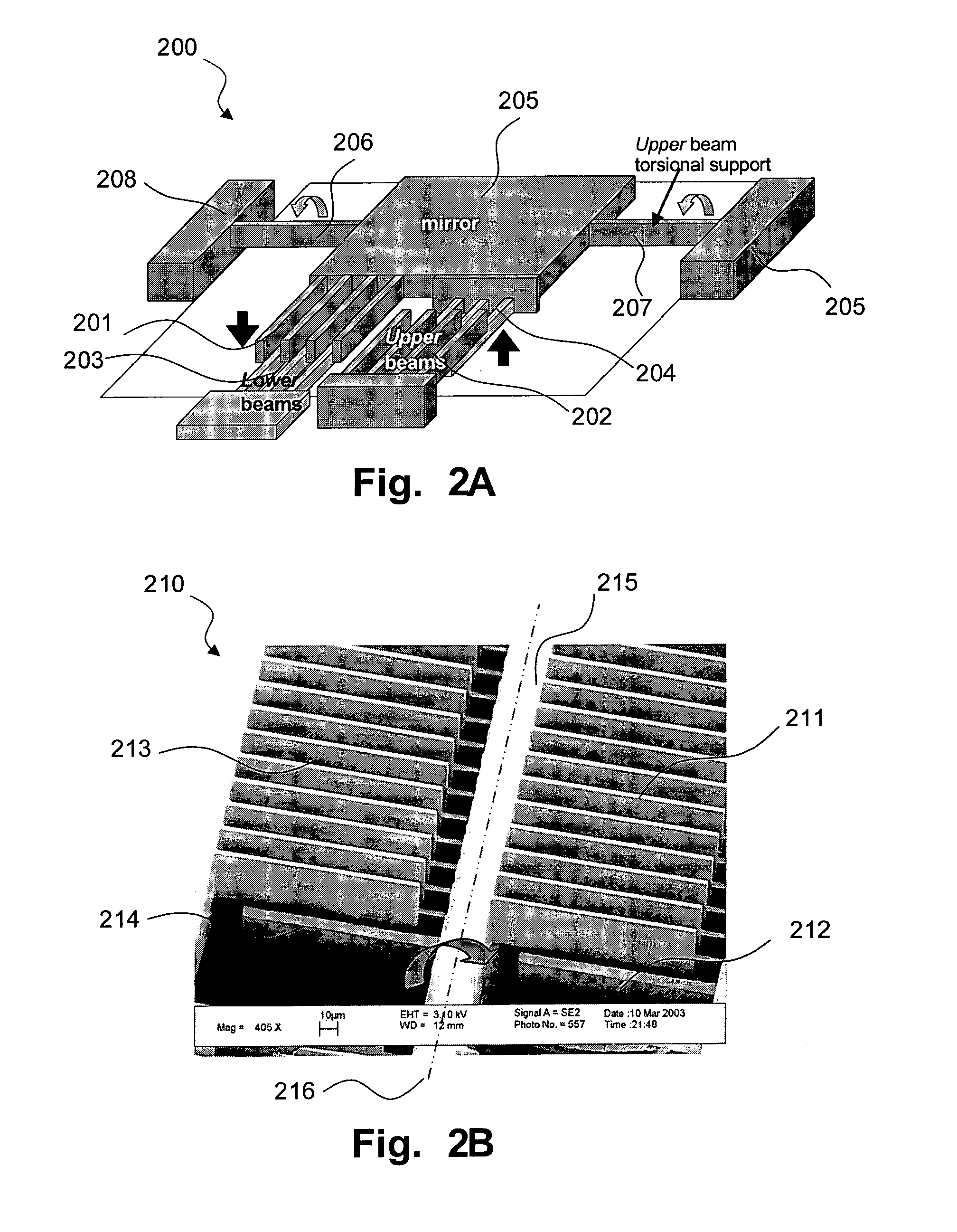

Gimbal-less micro-electro-mechanical-system tip-tilt and tip-tilt-piston actuators and a method for forming the same

Fully monolithic gimbal-less micro-electro-mechanical-system (MEMS) devices with large static optical beam deflection and fabrications methods are disclosed. The devices can achieve high speed of operation for both axes. Actuators are connected to a device, or device mount by linkages that allow static two-axis rotation in addition to pistoning without the need for gimbals, or specialized isolation technologies. The device may be actuated by vertical comb-drive actuators, which are coupled by bi-axial flexures to a central micromirror or device mount. Devices may be fabricated by etching an upper layer both from the top side and from the bottom side to form beams at different levels, The beams include a plurality of lower beams, a plurality of full-thickness beams, and a plurality of upper beams, the lower, full-thickness and upper beams That form vertical combdrive actuators, suspension beams, flexures, and a device mount.

Owner:ADRIATIC RES INST

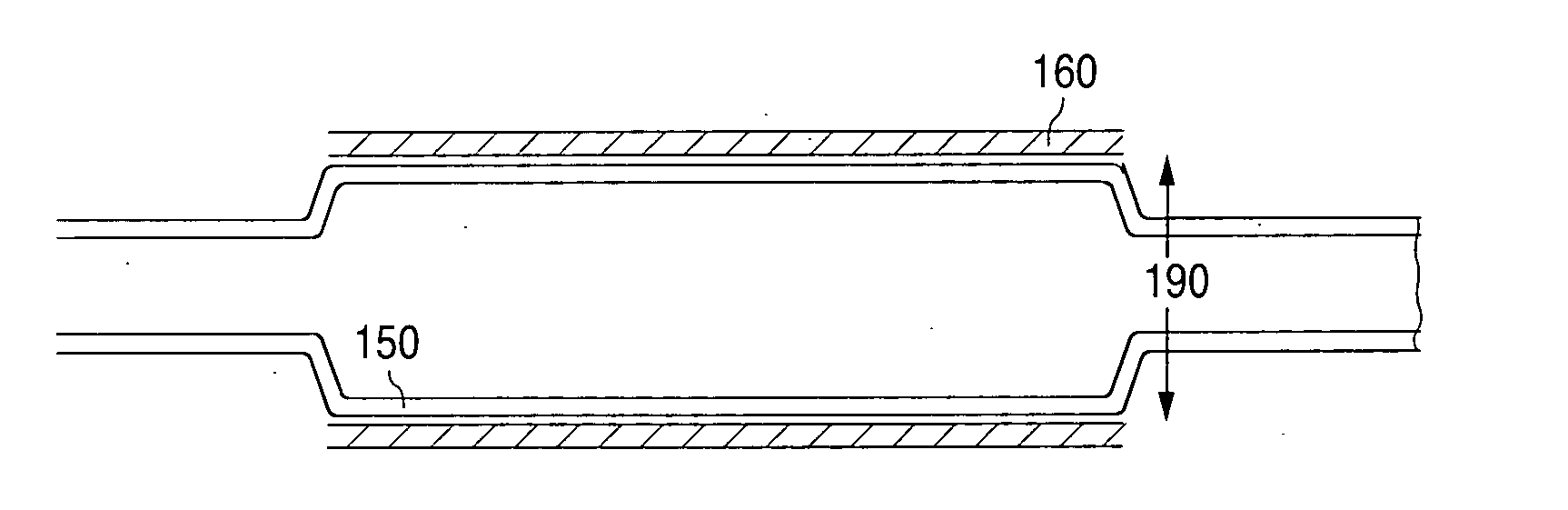

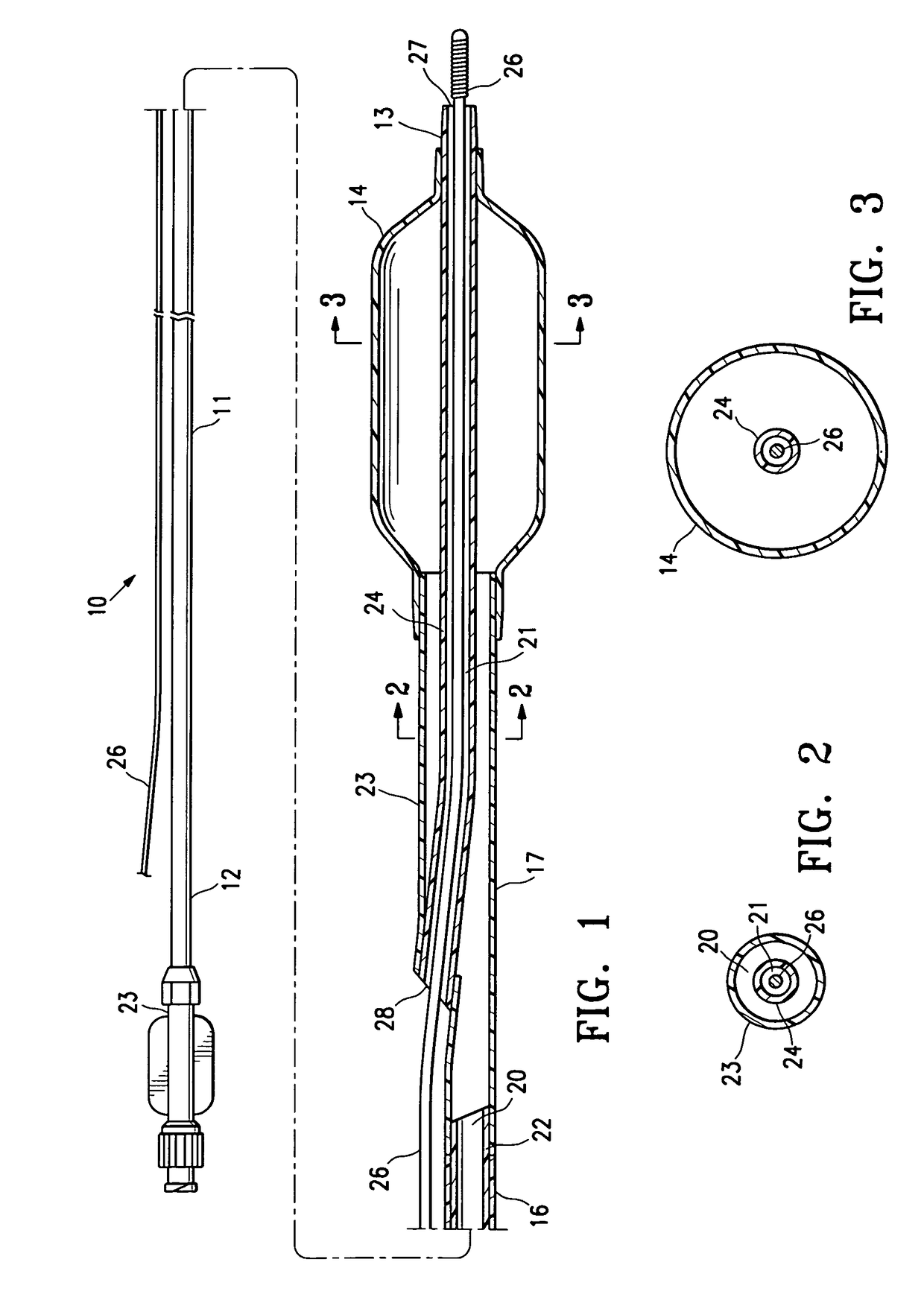

Method of making a balloon catheter shaft having high strength and flexibility

A catheter having an elongated shaft with a tubular member which forms at least a portion of the shaft and which is formed of a biaxially oriented thermoplastic polymeric material, and a method of forming the catheter shaft by radially and longitudinally expanding the tubular member to biaxially orient the polymeric material. A catheter of the invention has an improved combination of low bending stiffness, high rupture pressure, and high tensile strength, for improved catheter performance.

Owner:ABBOTT CARDIOVASCULAR

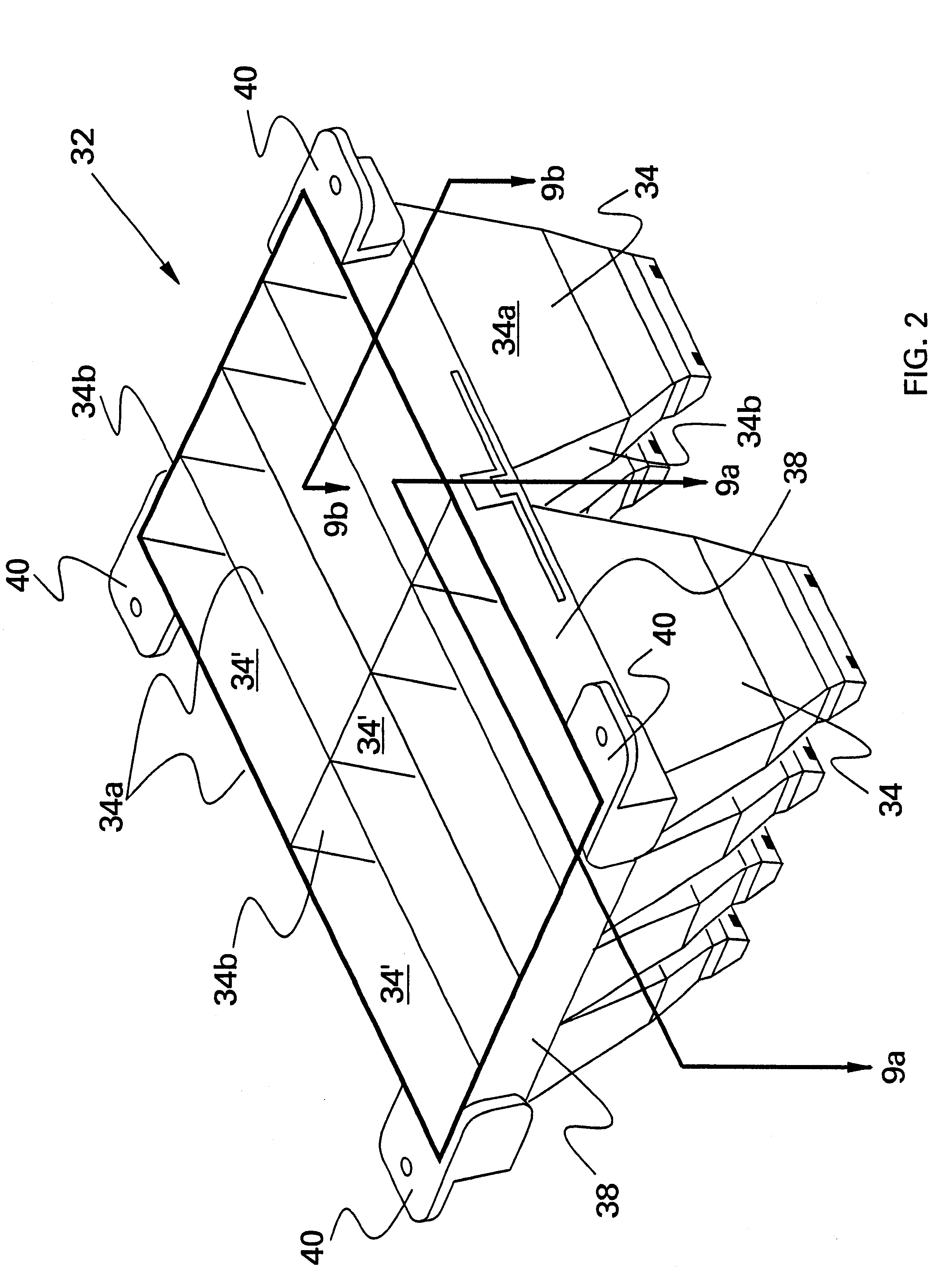

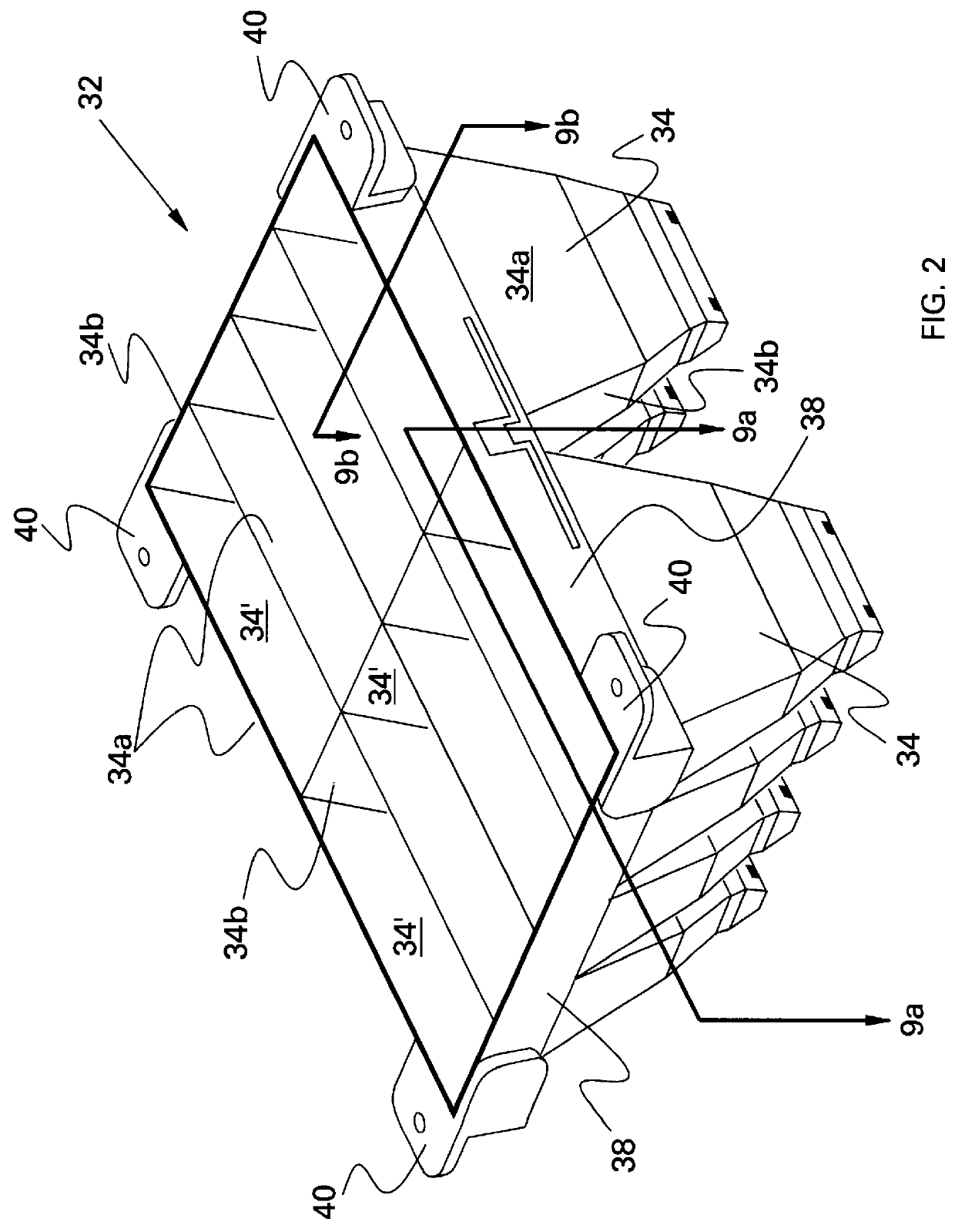

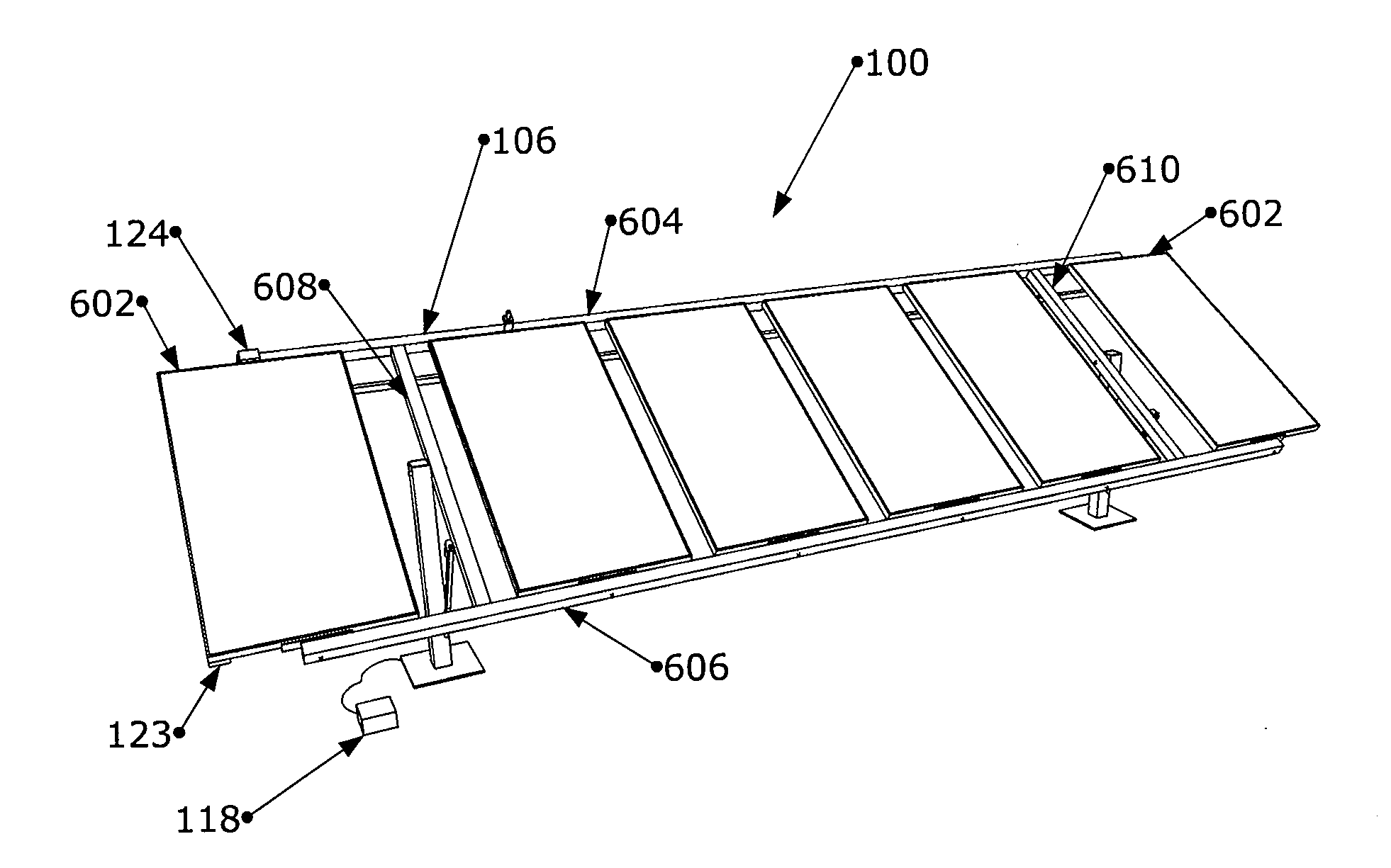

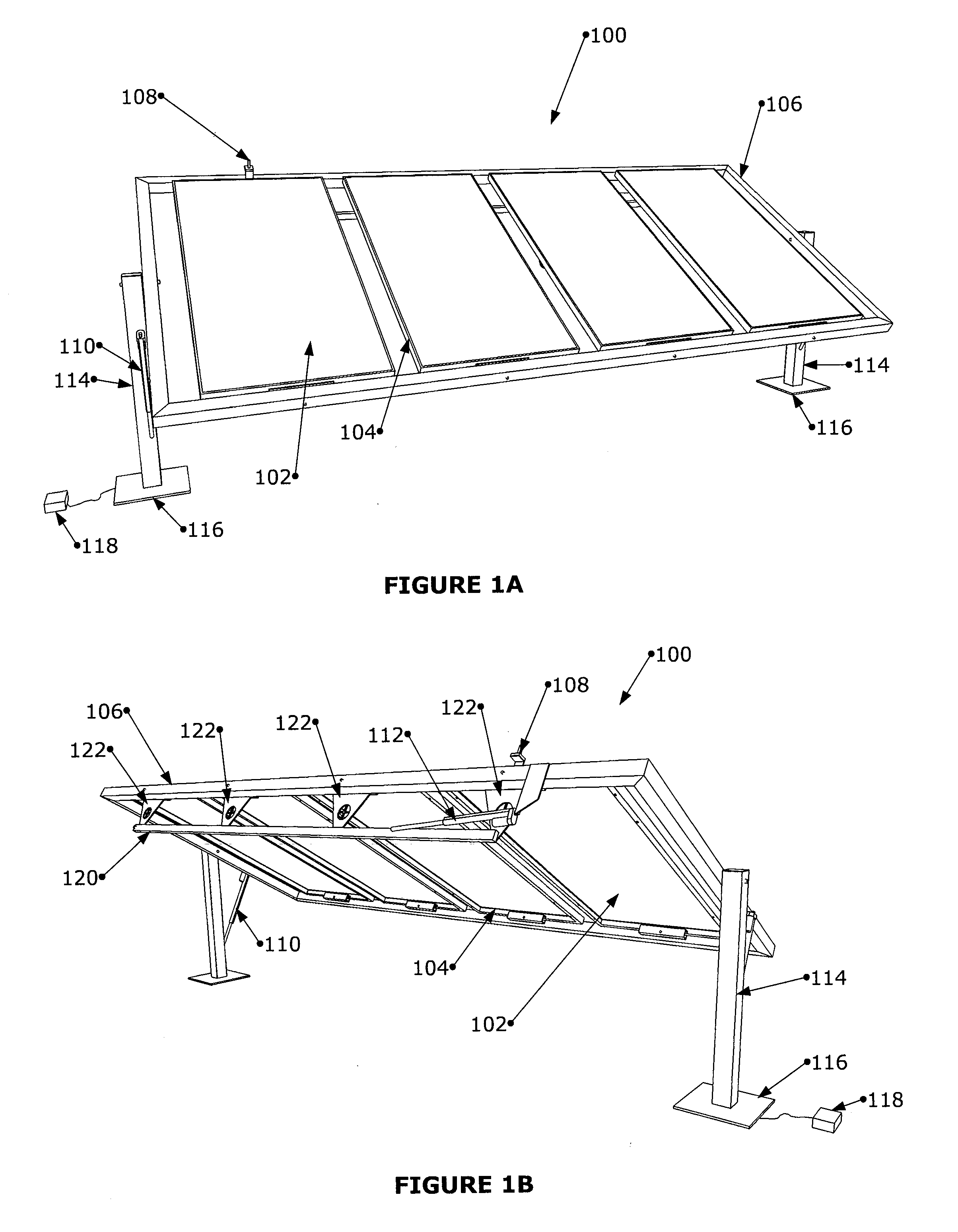

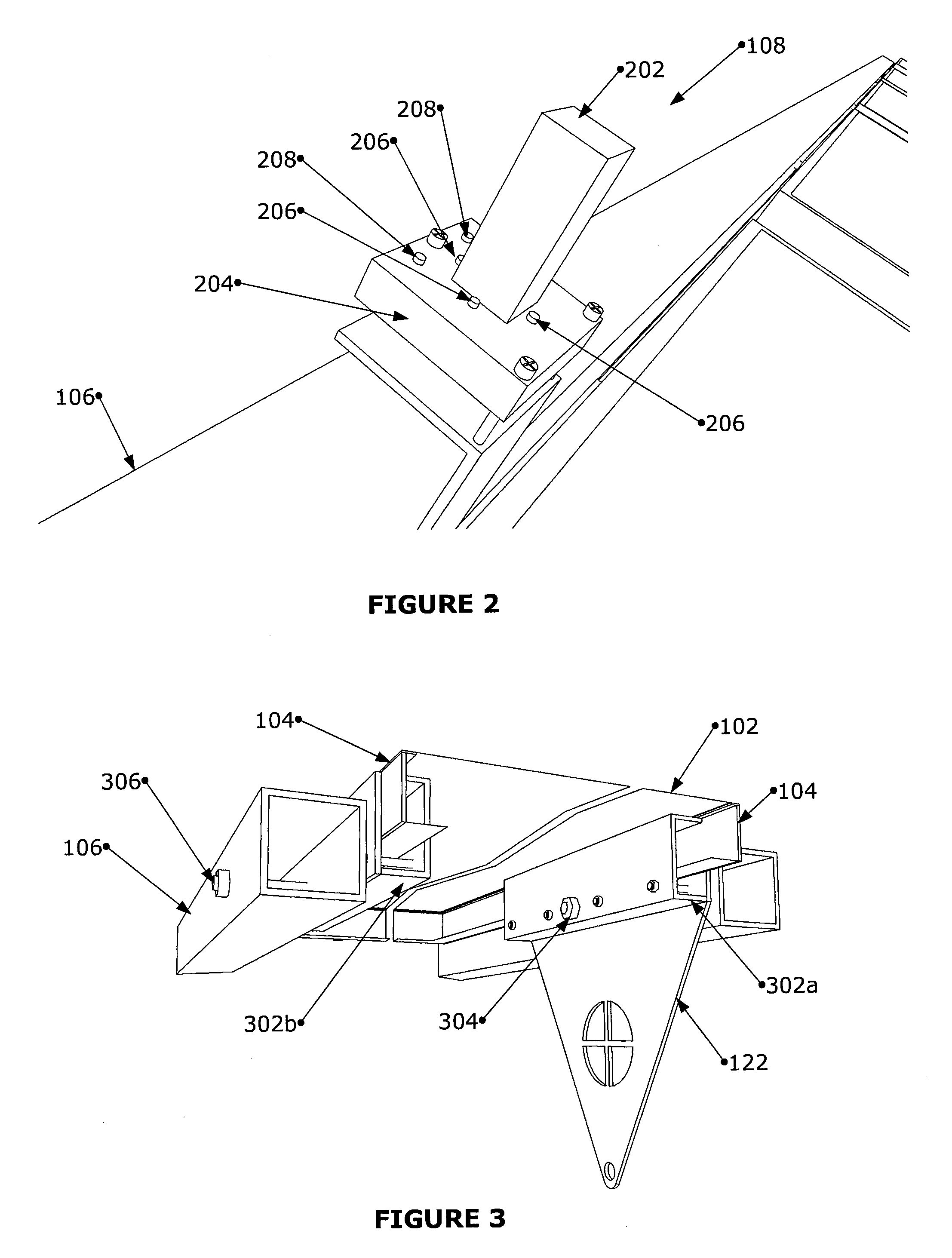

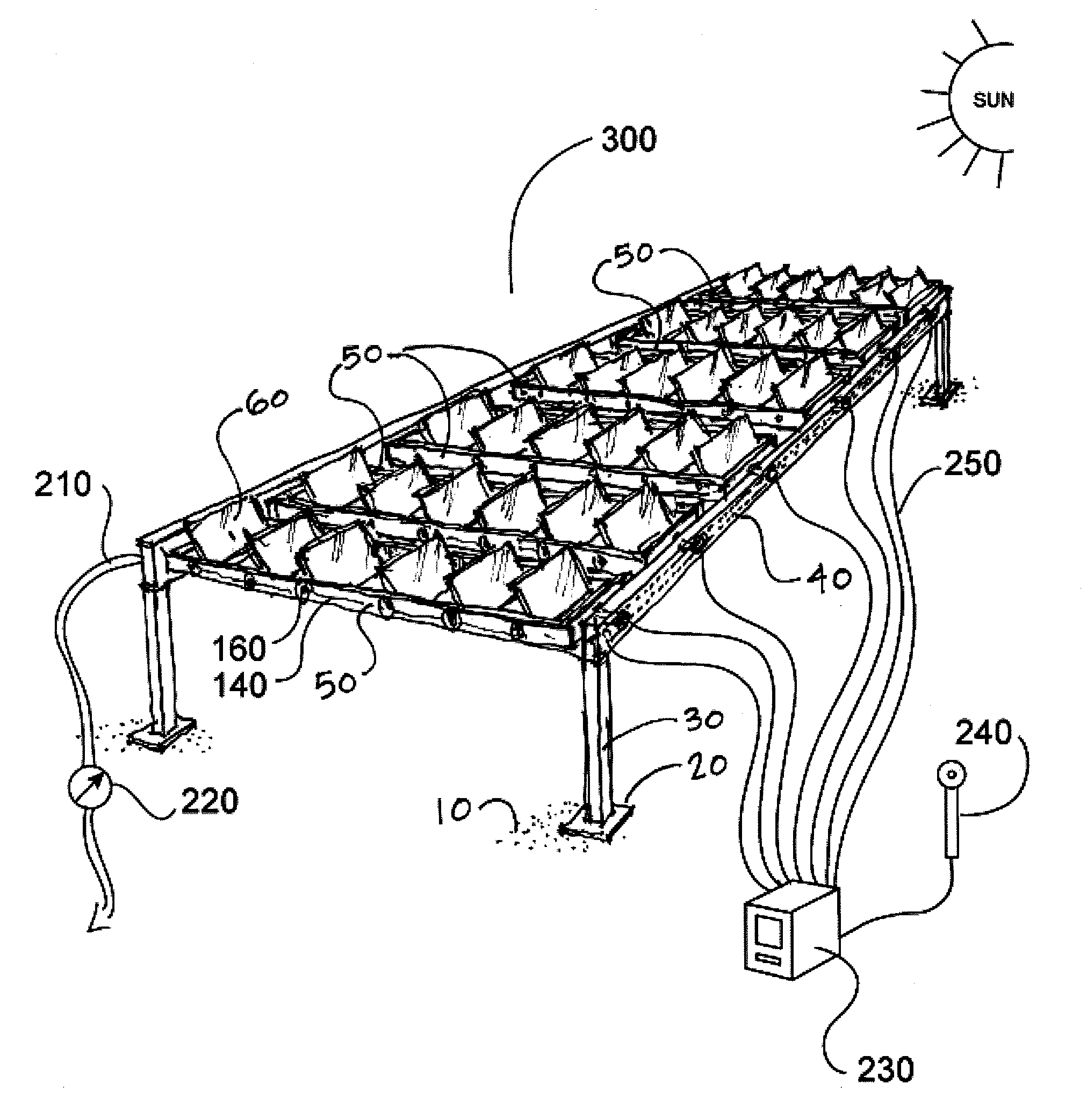

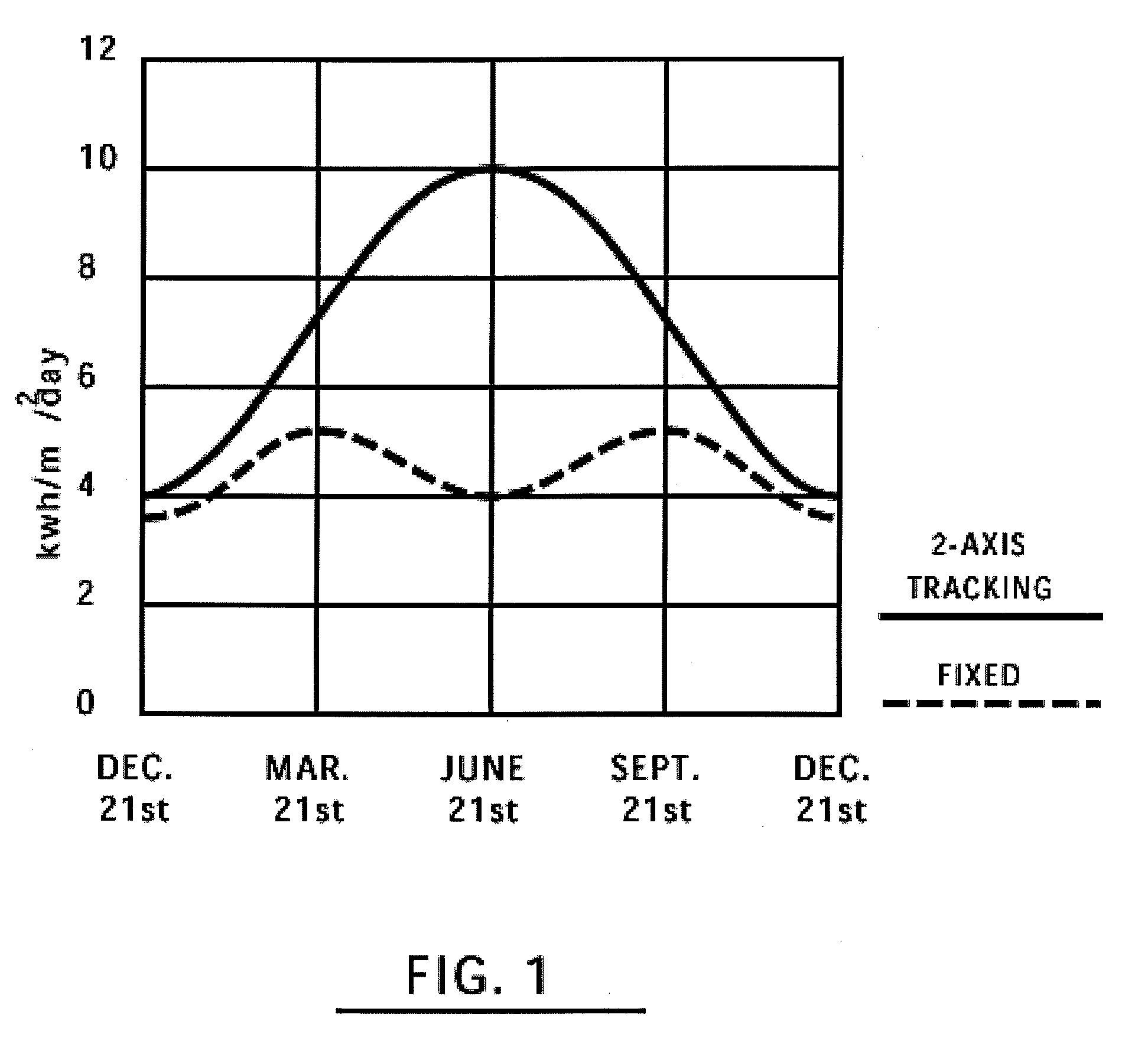

High efficiency counterbalanced dual axis solar tracking array frame system

ActiveUS20110073161A1Minimizes wind loadingReduce windOptical radiation measurementSolar heating energyPhotovoltaic solar energyShadowings

A high efficiency, environmentally friendly system comprising a plurality of photovoltaic solar collecting panels (PV panels) is disclosed. The system comprises an outer frame to which a plurality of inner frames are mounted to which the plurality of PV panels are attached. To minimize shadowing by the outer frame upon one or more PV panels, at least one PV panel may extend beyond an endpoint of the main frame. The system also comprises an outer frame rotation actuator that rotates the outer frame and an inner frame rotation actuator that rotates the inner frames and the plurality of PV panels. The solar tracking array frames disclosed herein help to improve the quality of the environment by conserving a variety of energy resources (e.g., fossil fuels, hydroelectric energy, etc.) The solar tracking array frames disclosed herein also help to reduce greenhouse gas emissions, as solar tracking array frames do not produce carbon dioxide byproducts.

Owner:SCANLON MARK +1

Method of operating a fast scanning mirror

ActiveUS8752969B1Reduce frictionRapid responseAngle measurementAdditive manufacturing apparatusObject structureLight beam

The mirror has a base, inner stage, reflector, controller, and mechanical subsystems pivotally supporting stage and reflector: subsystem #1, the stage (about one rotation axis, relative to the base); subsystem #2, the reflector (about another axis, relative to the stage). Stage and reflector each rotate on respective jewel, ceramic or other refractory bearings. Controller establishes stage / base and reflector / stage angles. Subsystems include respective bearings. The method includes (1) using the two-axis mechanism to receive, and measure an incident angle of, incident rays from an external object; (2) then using that mechanism to direct a radiation beam from a laser source toward the external object, responsive to incident rays. Optionally step (1) operates the mirror at peak acceleration, or minimum response time, as function of mirror thickness; and provides two- to three-millimeter mirror thickness. Optionally step (2) directs the beam to disrupt object function or impair object structure.

Owner:ARETE ASSOCIATES INC

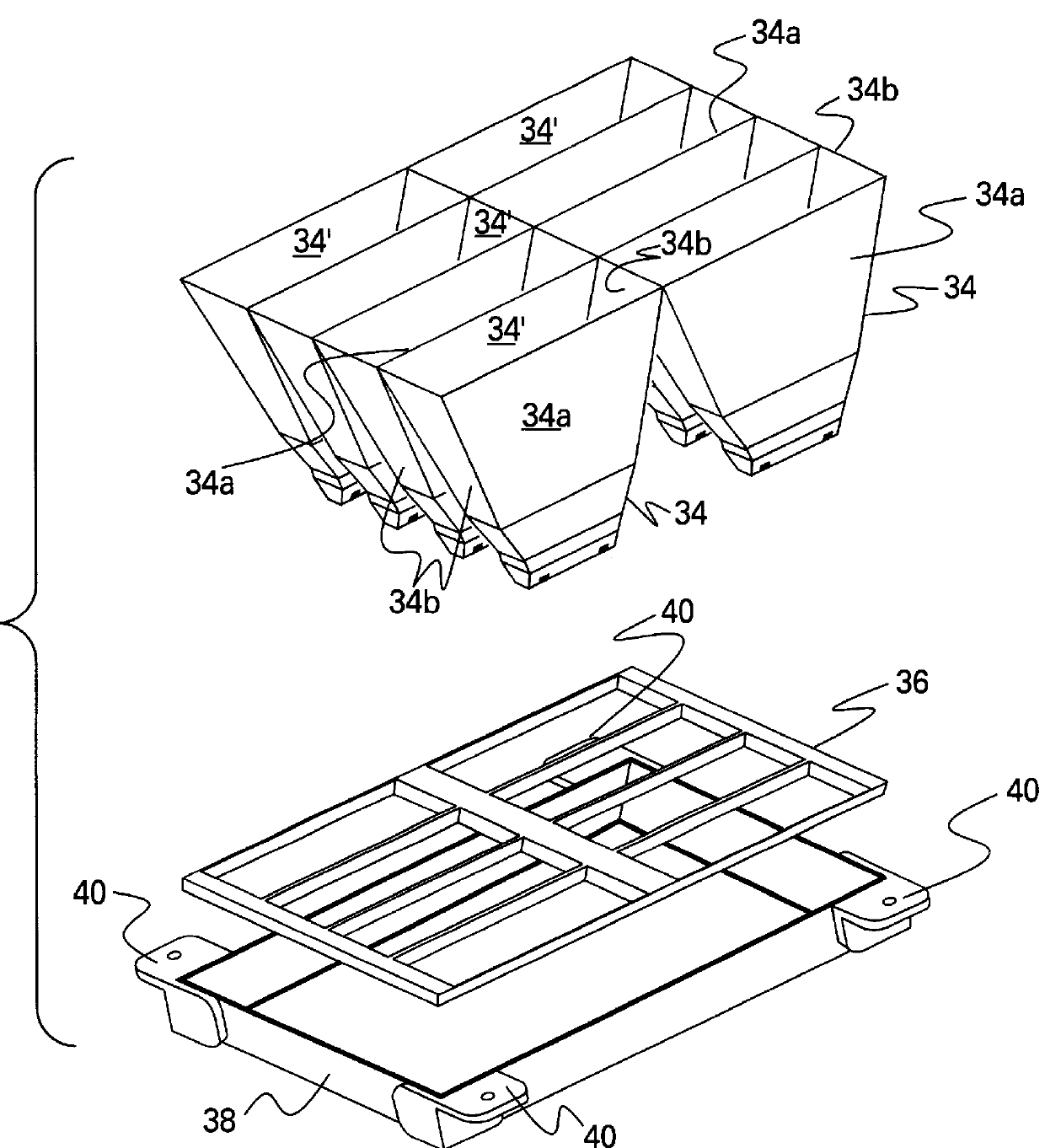

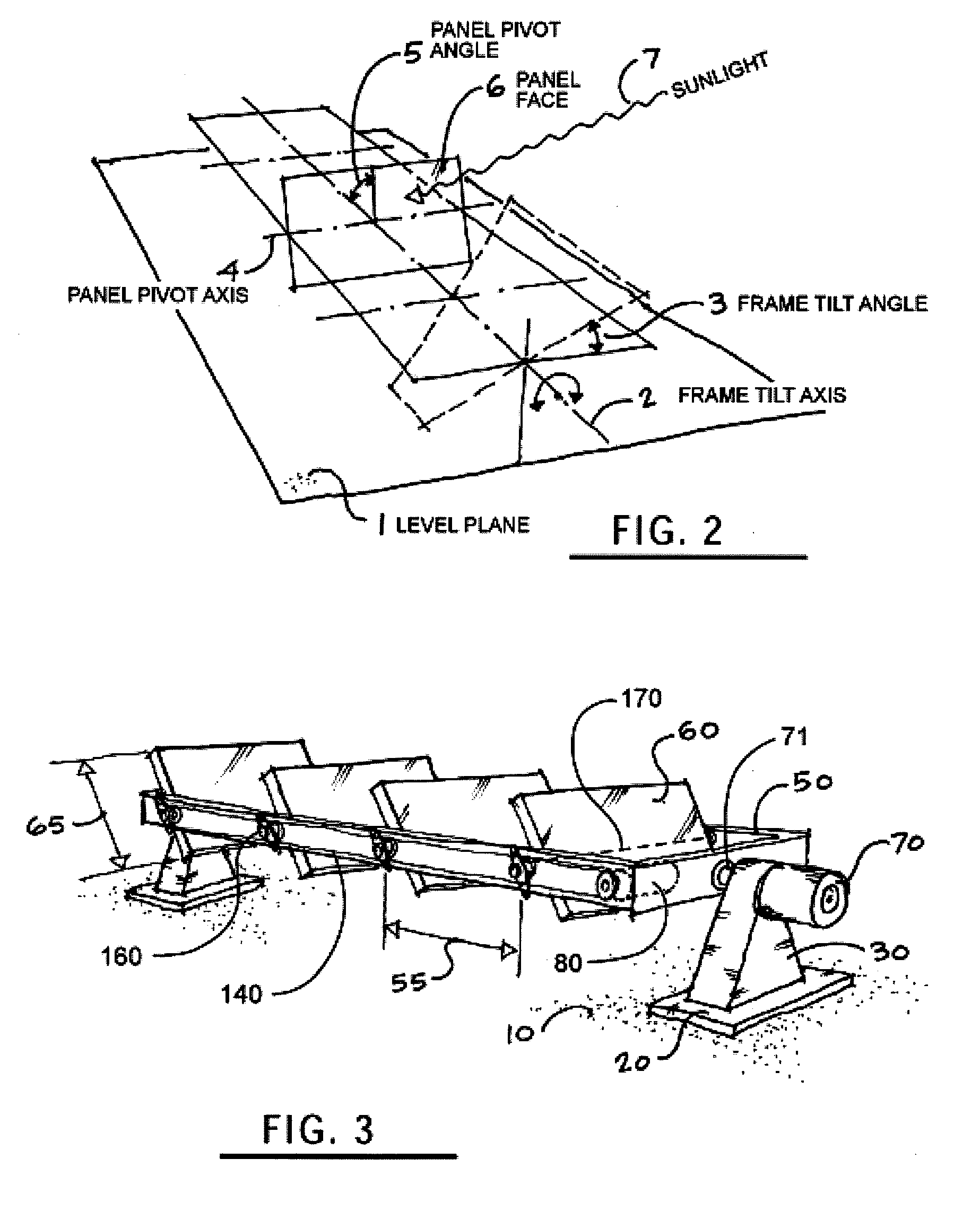

Dual Axis Sun-Tracking Solar Panel Array

Apparatuses are disclosed for adjusting the position of the photovoltaic panels. The adjustments of the photovoltaic panels can be performed in two axes: pivot and tilt. The photovoltaic panels can be pivotably mounted along the longitudinal axis of rotatable frames. The substantially parallel photovoltaic panels in a frame can be simultaneously pivoted by a pivoting drive mechanism attached to the frame. Multiple tiltable frames can be arranged in parallel to each other, thus creating a 2-D matrix of the photovoltaic panels. The tiltable frames can be supported by an elevated structure permitting the unobstructed rotation of both the frames and the panels inside the frames. A controller can synchronize the tilt and pivot, such that the combined rotation of the photovoltaic panels results in the photovoltaic panels of the entire array being substantially perpendicular to the incident solar radiation.

Owner:DANHAKL JOHN

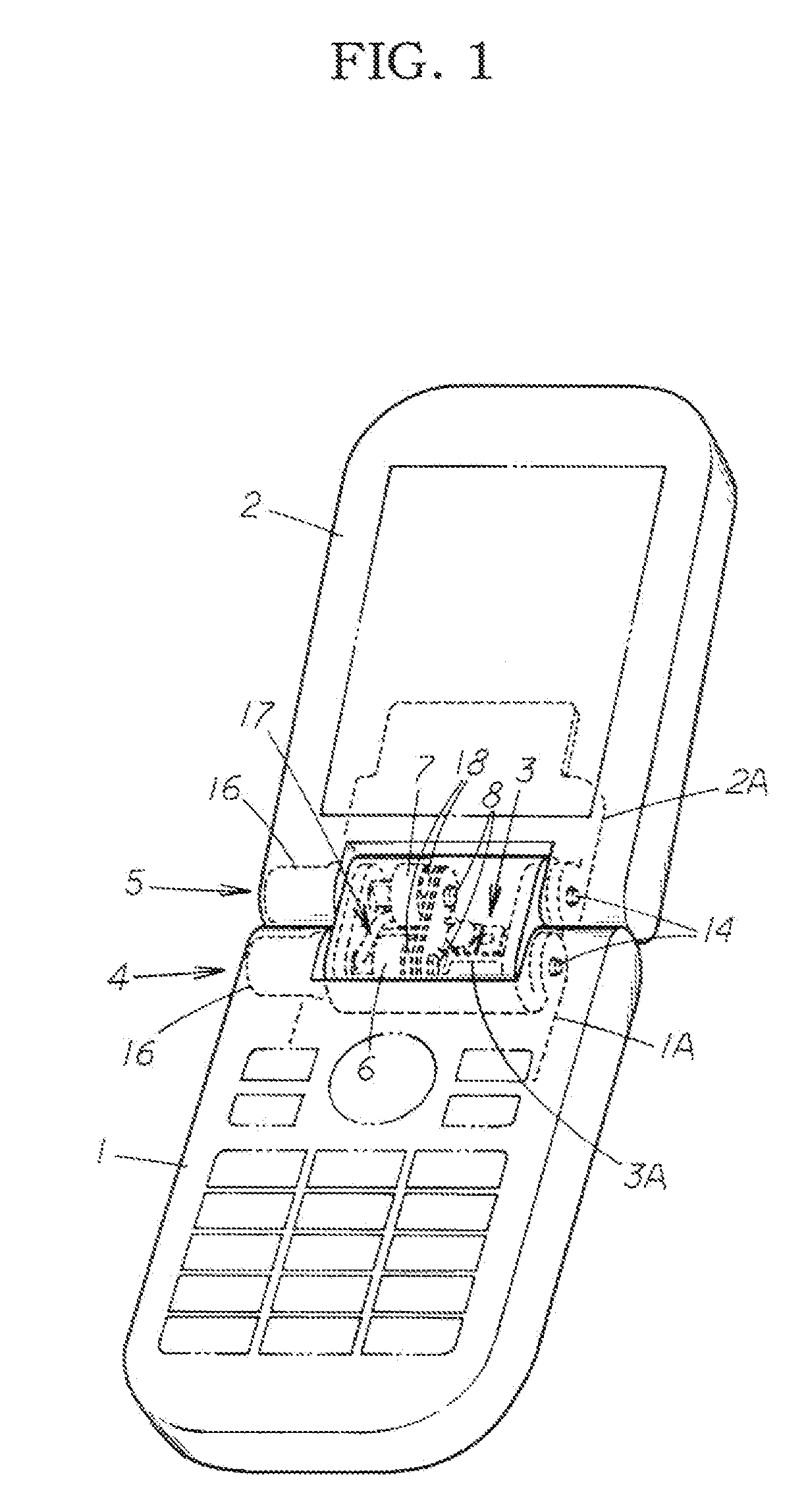

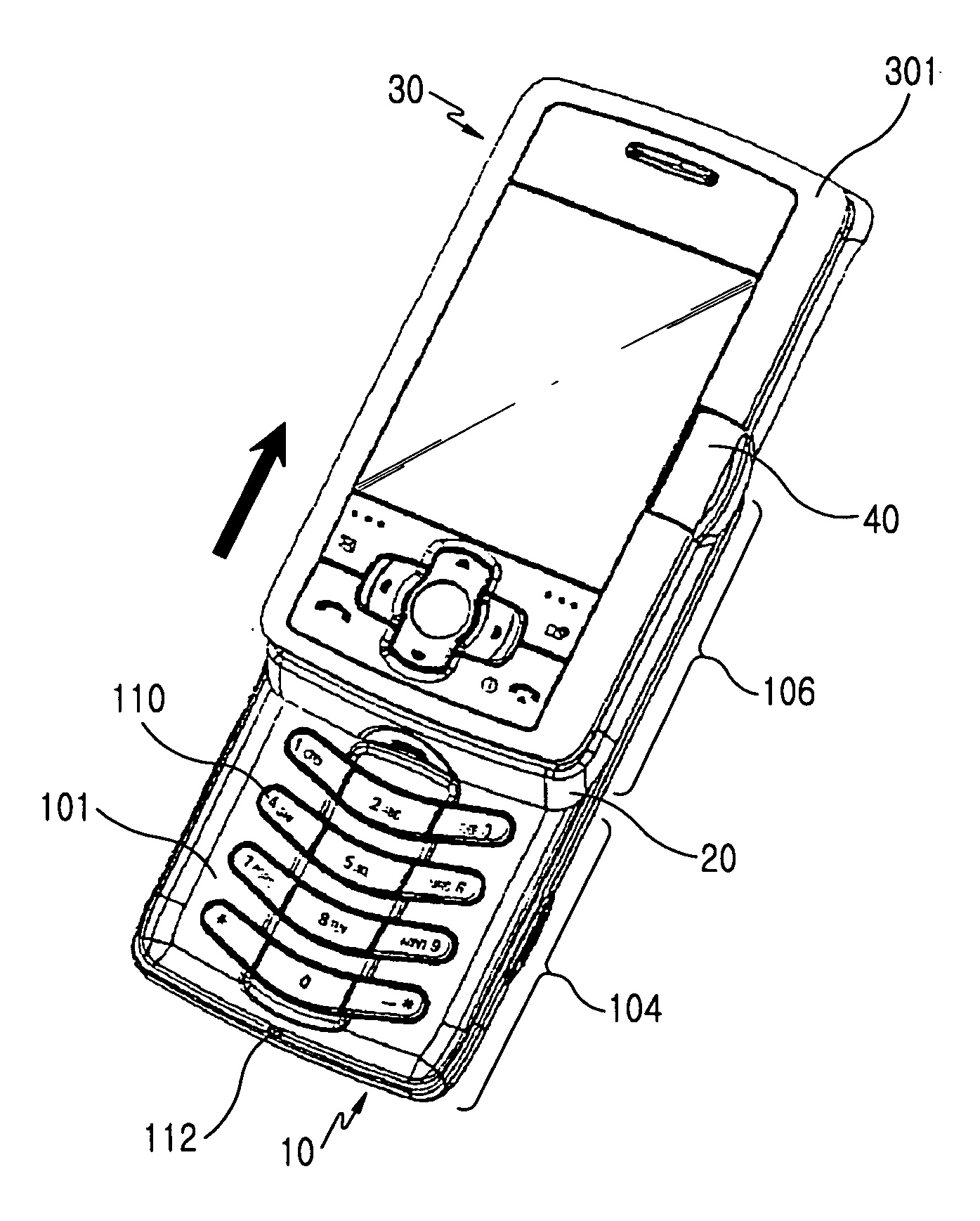

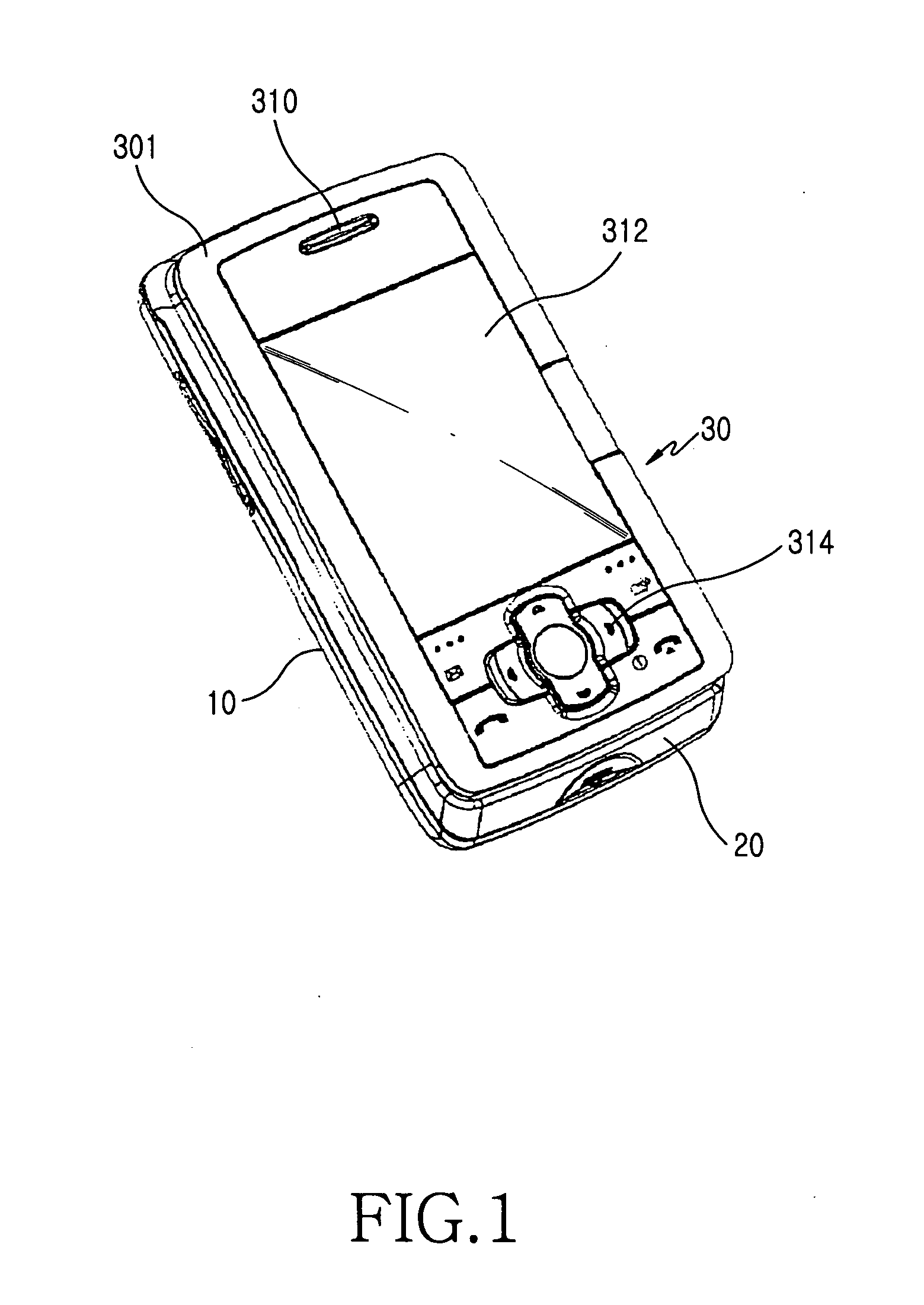

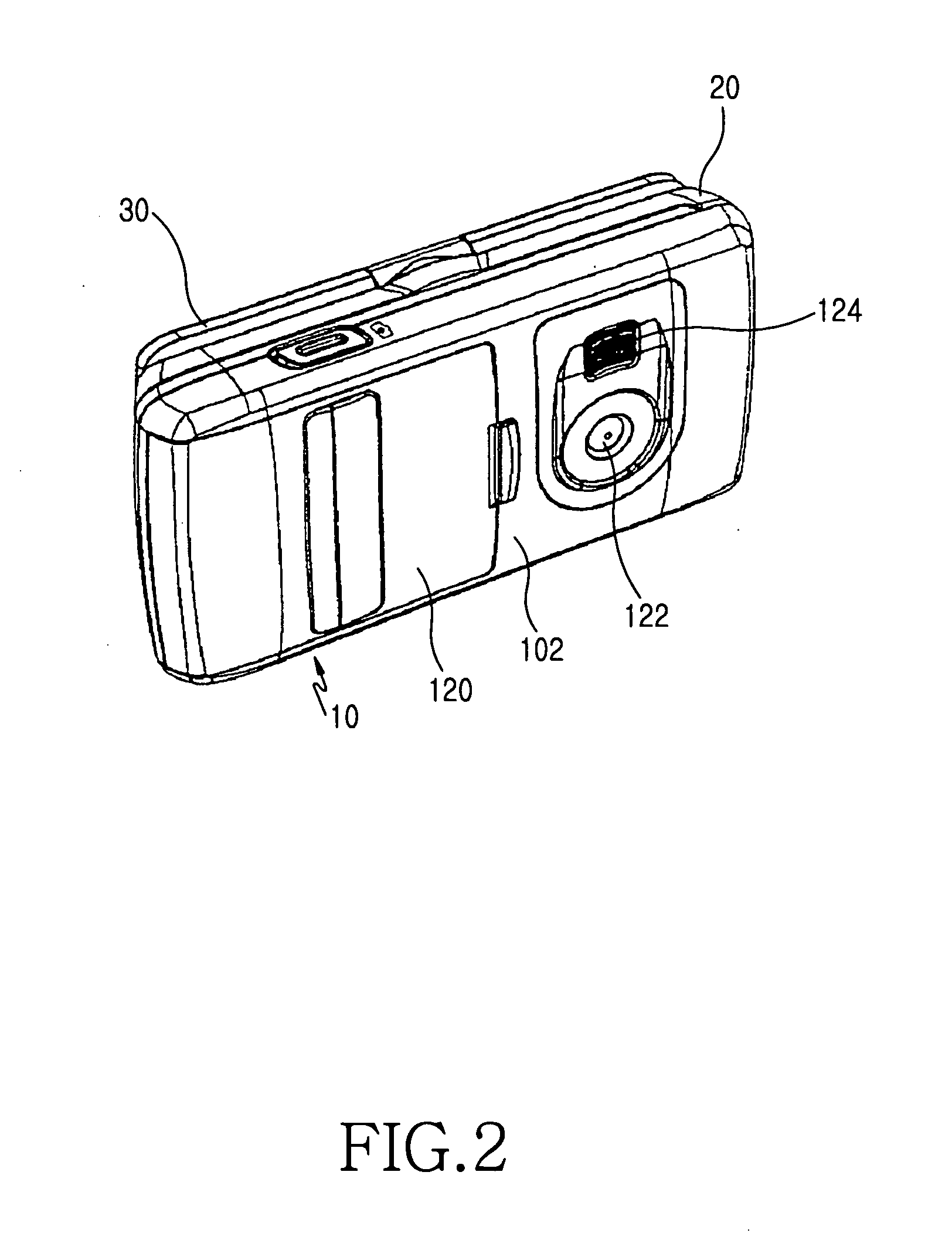

Sliding/folding-type portable apparatus

InactiveUS20050266897A1Wider display deviceConvenience in key operationDevices with multiple keyboard unitsTransmissionEngineeringMechanical engineering

A sliding / folding-type portable apparatus includes a body housing; a sliding housing adapted to travel along the longitudinal direction of the body housing while continuously facing it to expose or hide the top surface of the body housing; a folding housing adapted to rotate about a first hinge axis to fold on or unfold from the sliding housing and to rotate about a second hinge axis, which is perpendicular to the first hinge axis, to reverse the top and bottom surfaces thereof; and a dual-axis hinge sliding module connected between the sliding housing and the folding housing to provide the folding housing with the first and second hinge axes.

Owner:SAMSUNG ELECTRONICS CO LTD

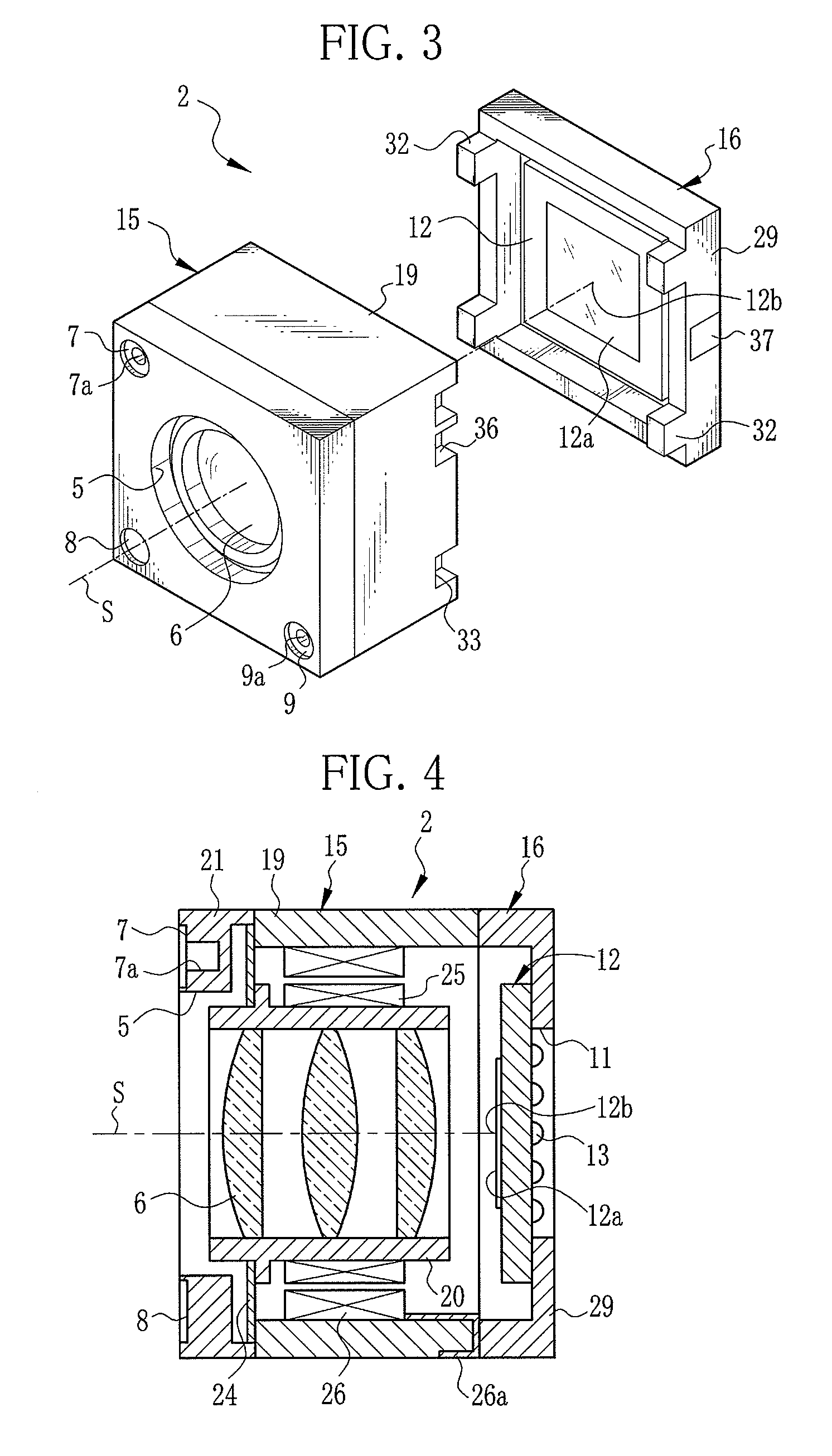

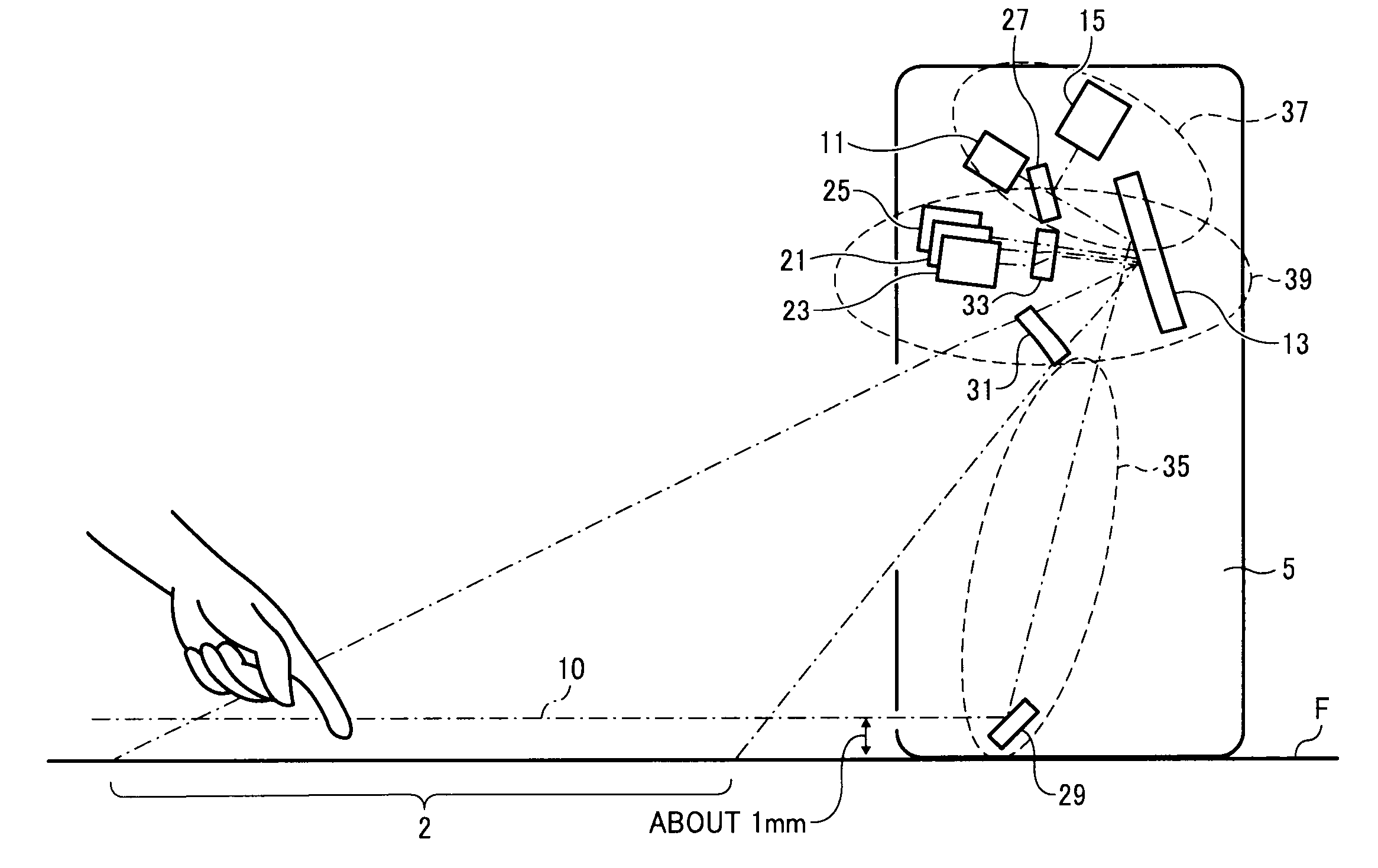

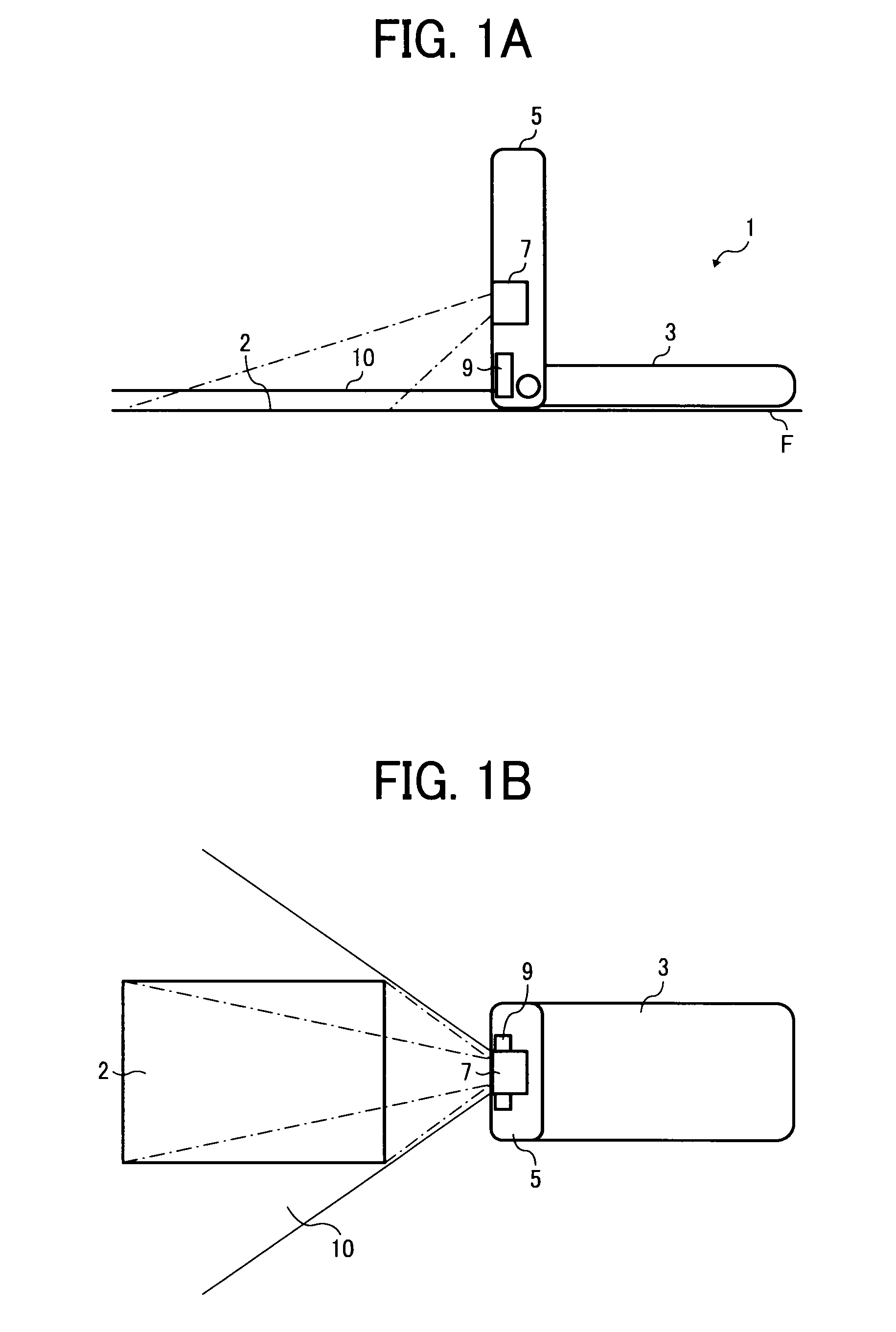

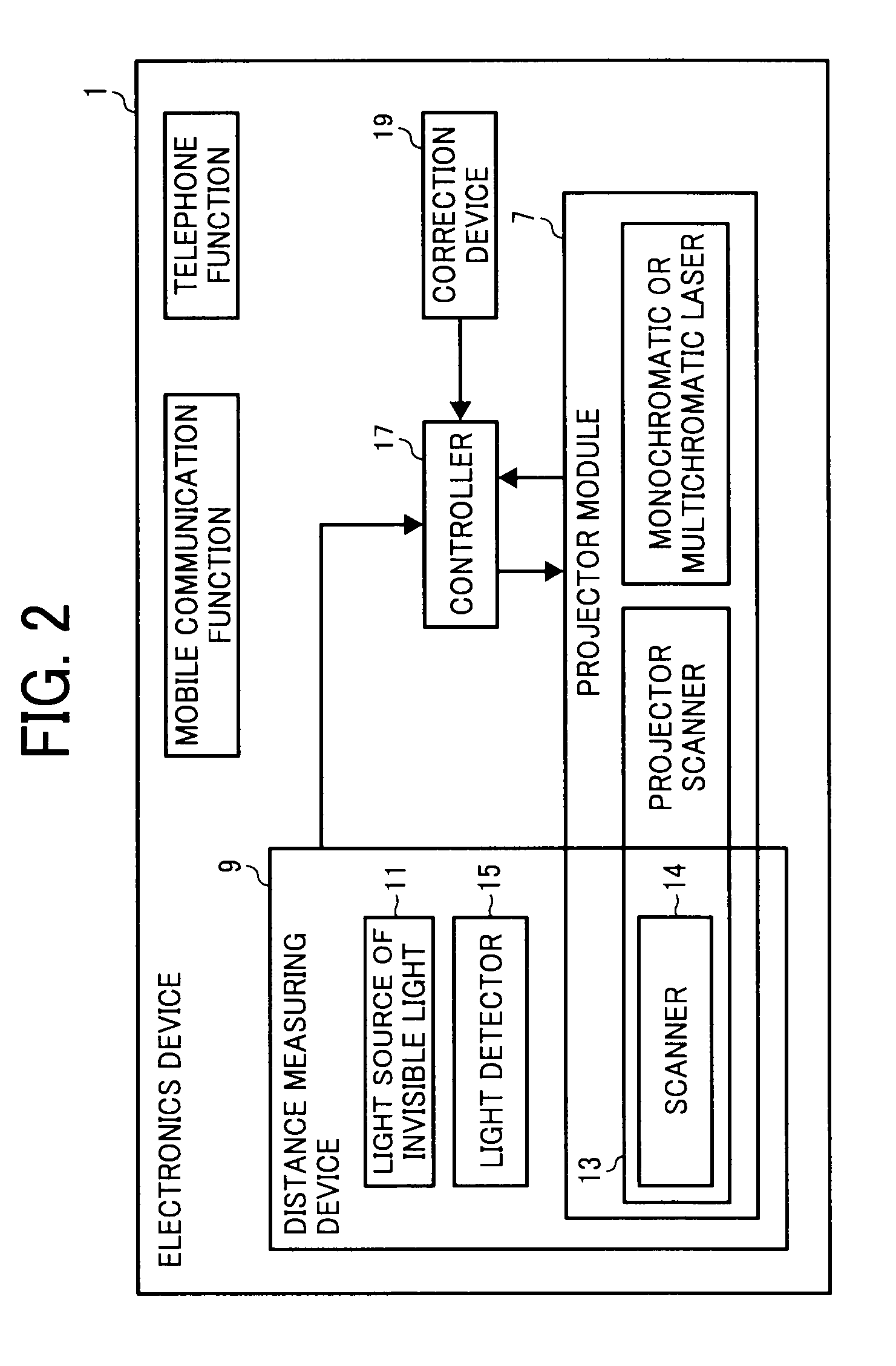

Electronics device having projector module

An electronics device having a projector module including a first light source, and a first scanner scanning an image projection surface in a biaxial direction; a distance measuring device performing one-dimensional scanning on a plane over the image projection surface to determine the position of an optical interceptor and including a second light source, a second scanner performing scanning with the second light beam, and a light detector detecting the second light beam reflected from the optical interceptor; and a controller. The uniaxial-scanning component of the first scanner is shared with the second scanner. The positional data are compared with two-dimensional coordinate data of the projected image to determine the position of the optical interceptor on the projected image. The controller inputs a signal to the electronics device when determining that the optical interceptor performs optical interception on the projected image.

Owner:RICOH KK

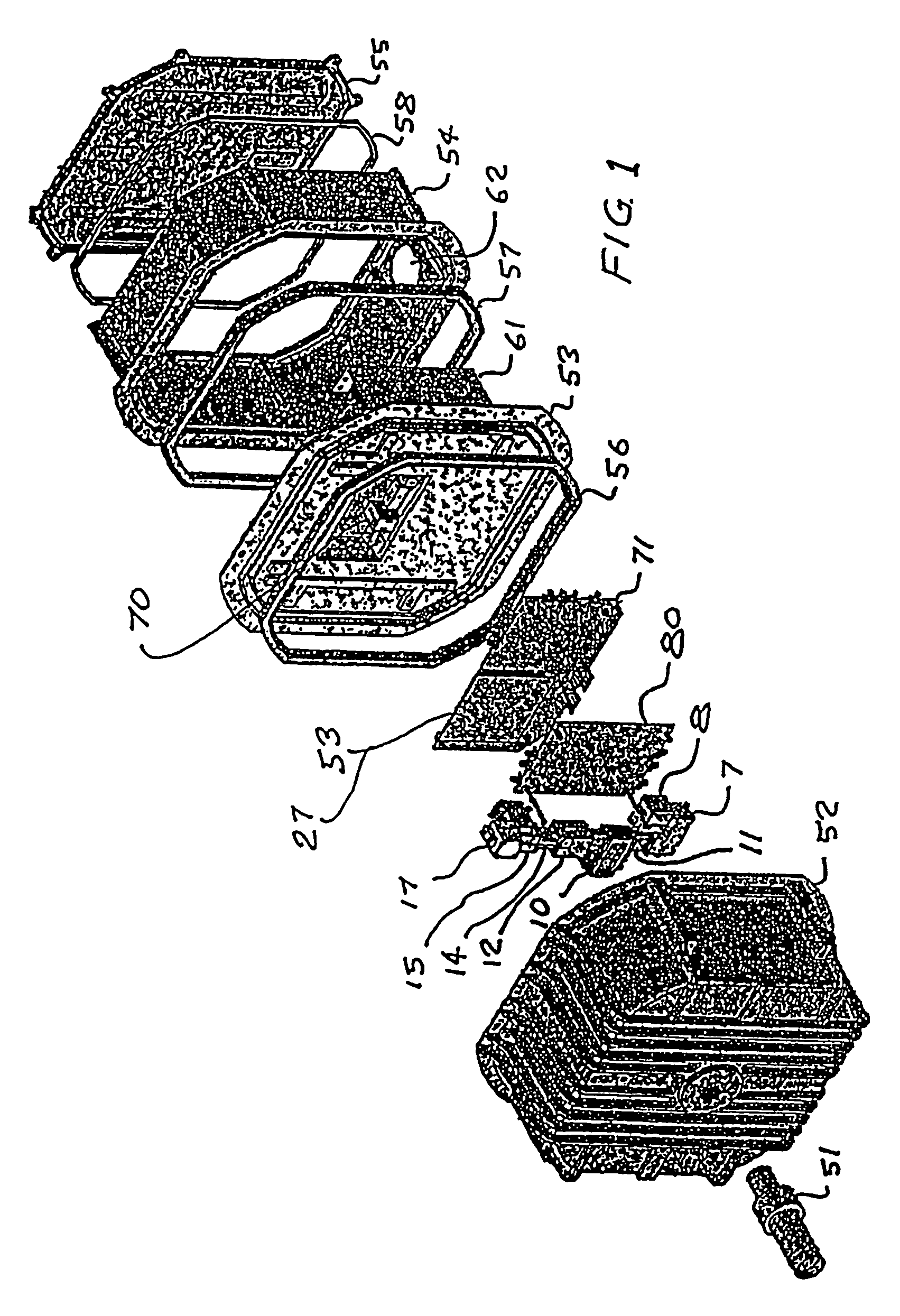

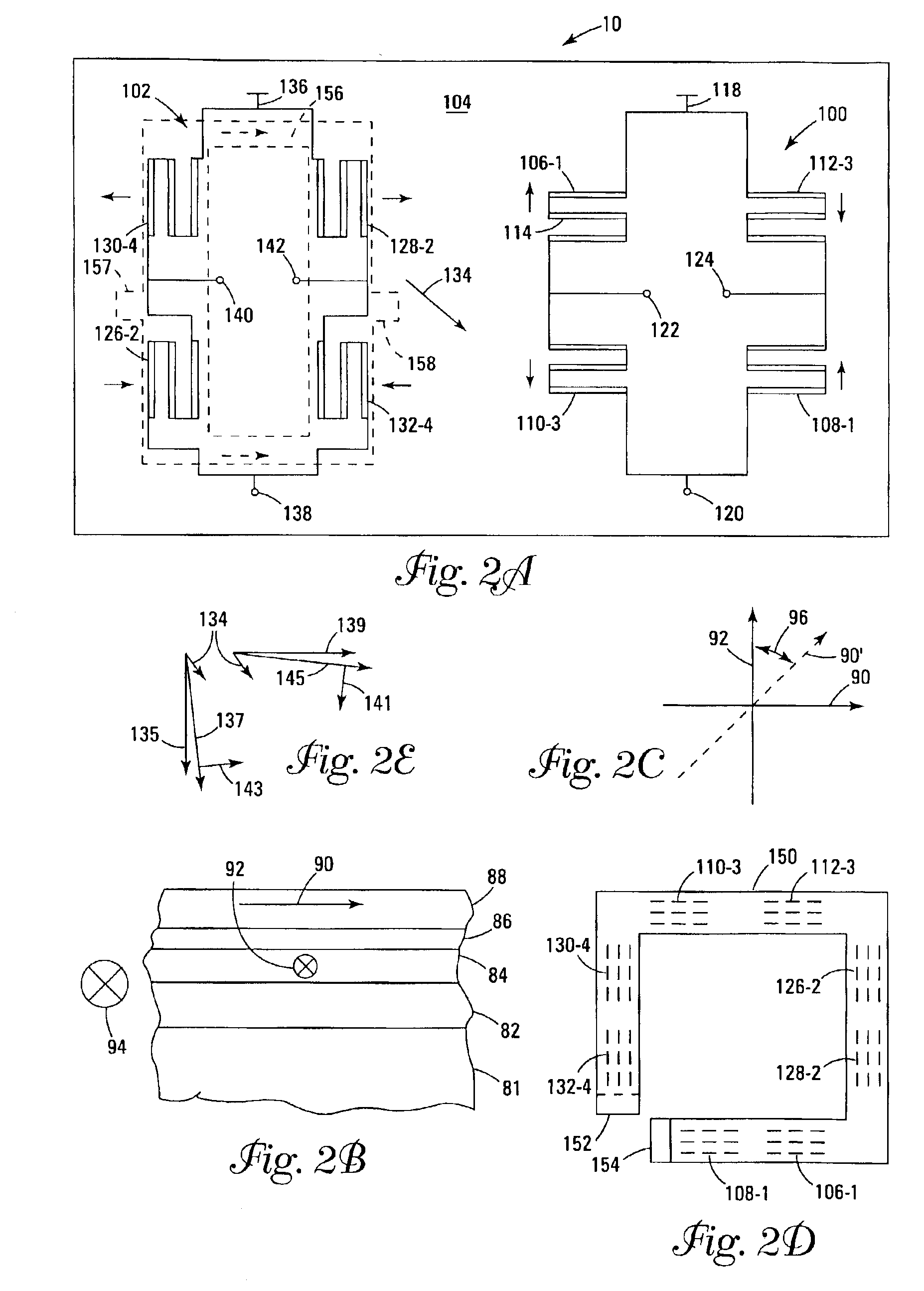

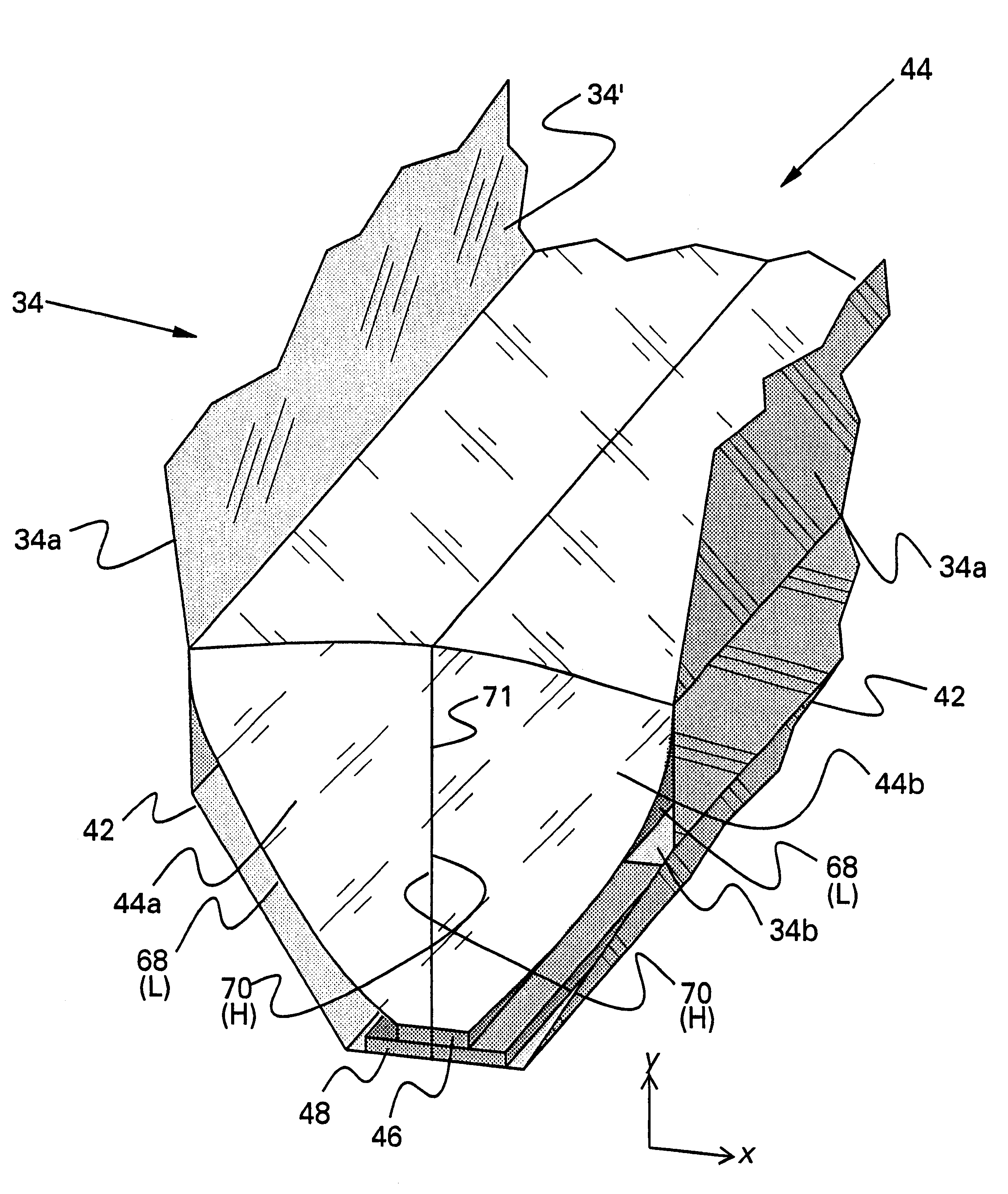

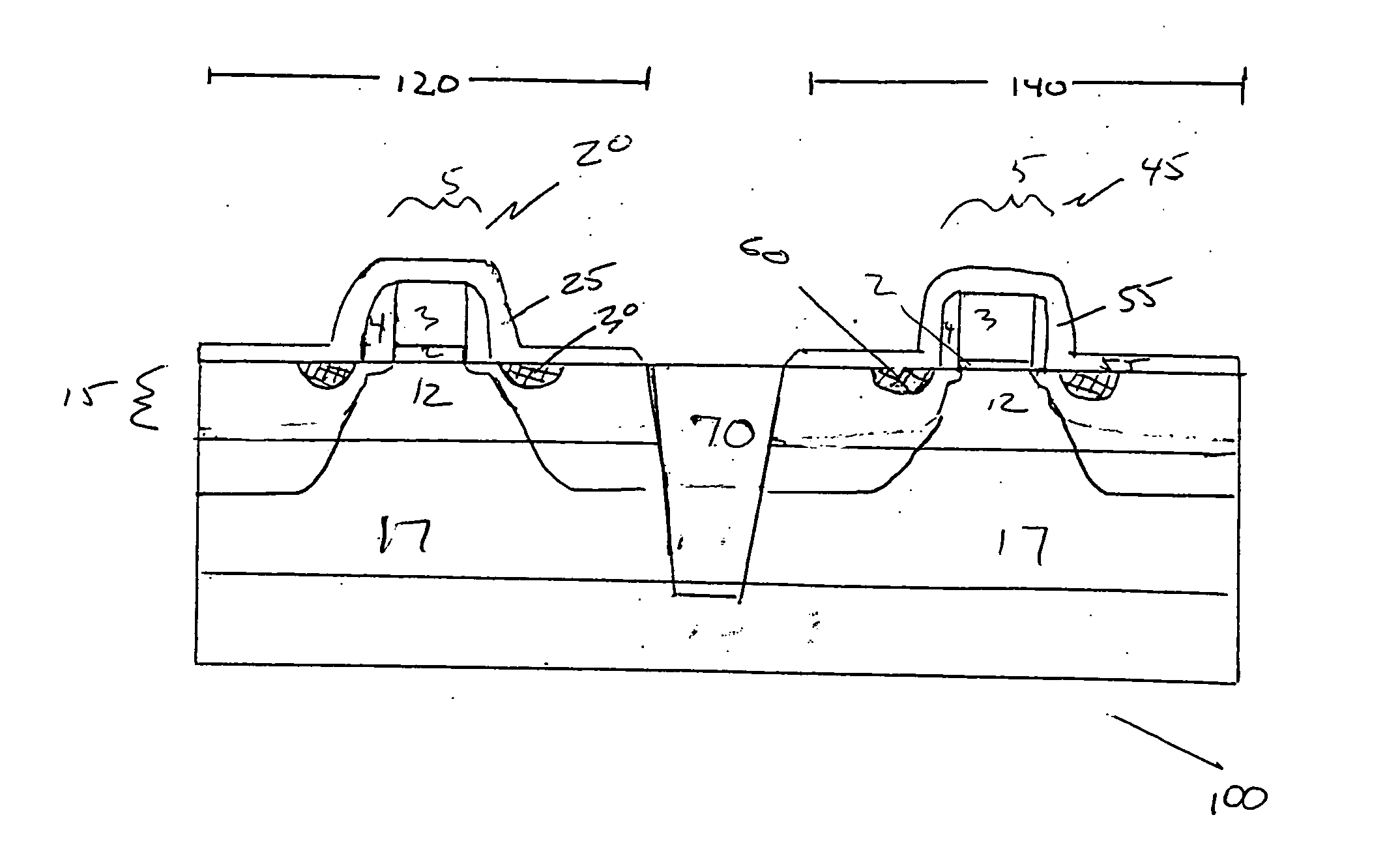

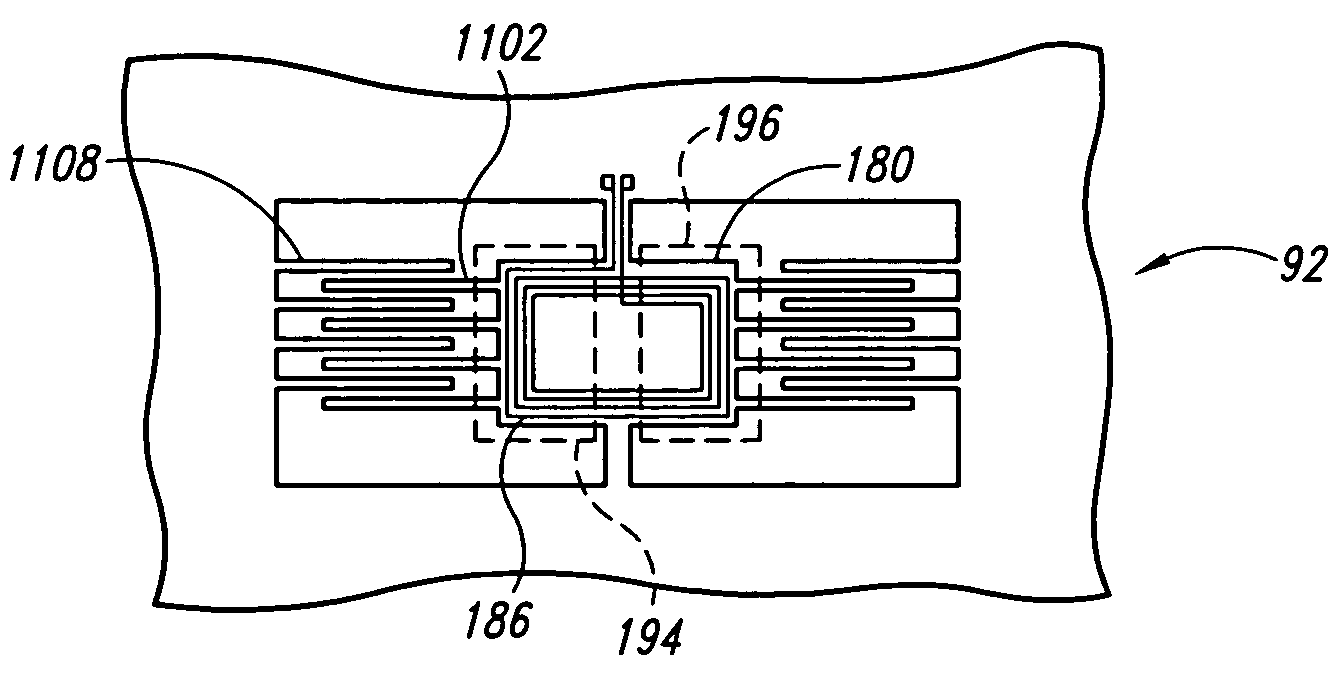

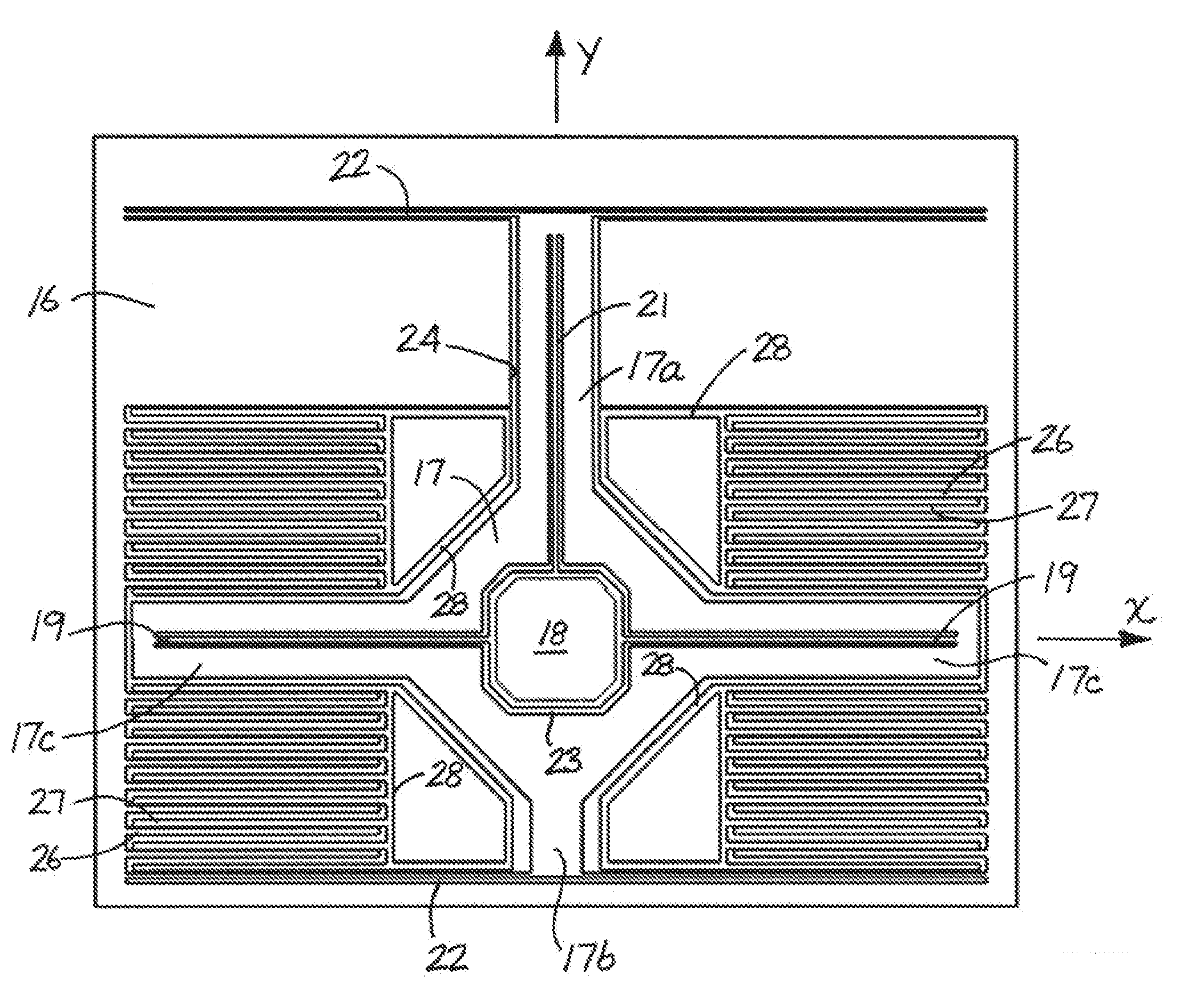

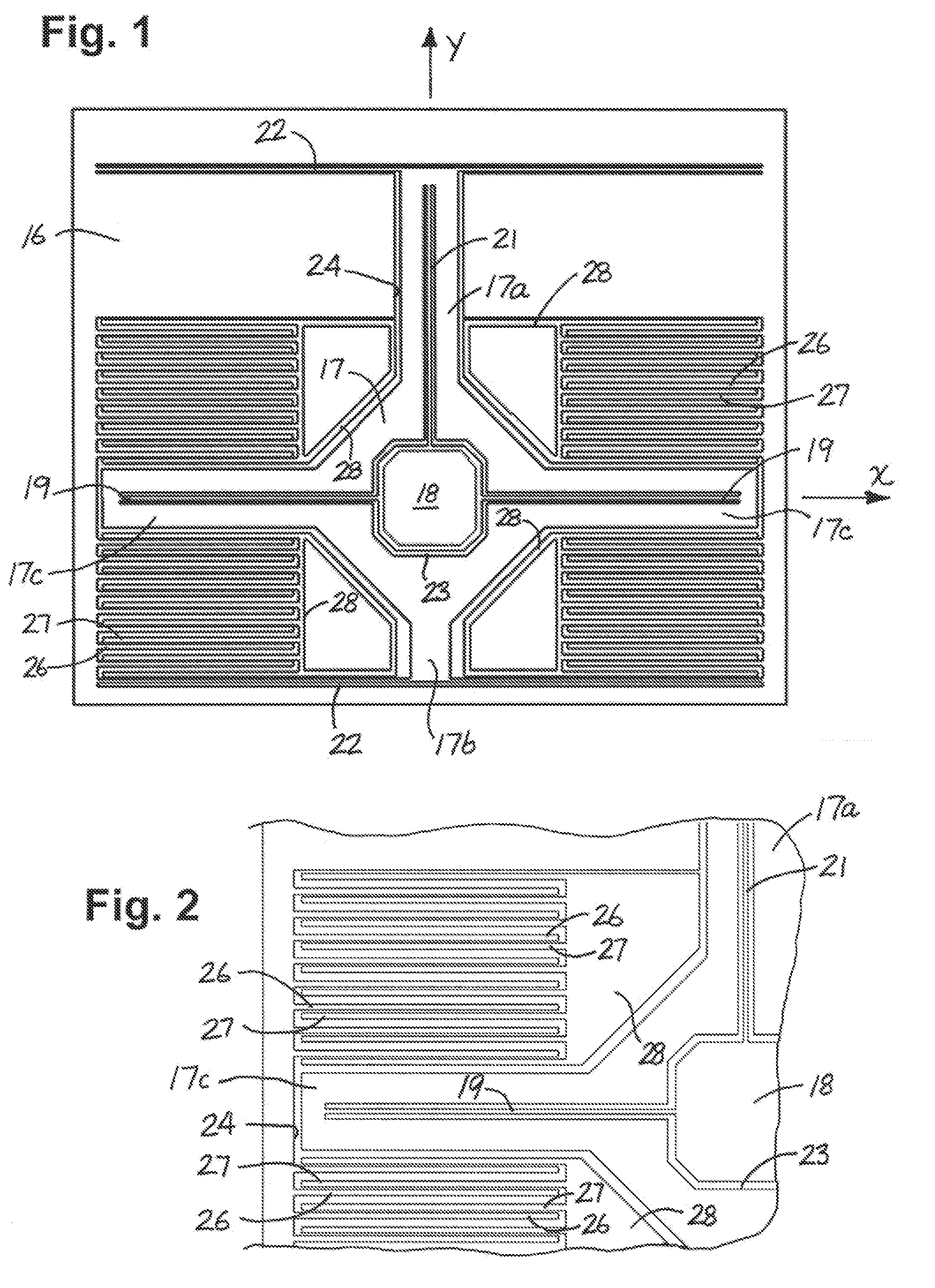

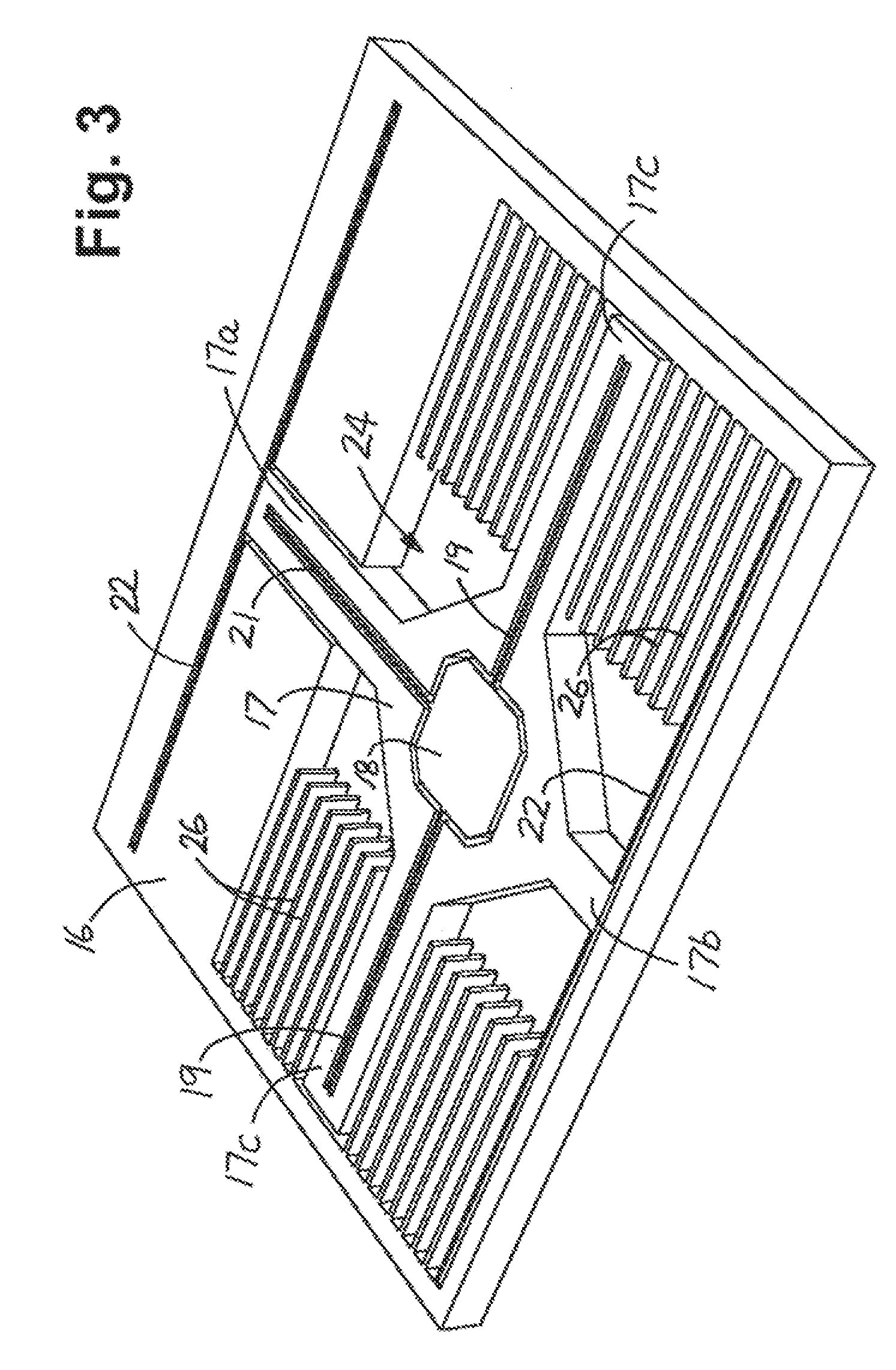

Micromachined cross-differential dual-axis accelerometer

InactiveUS20090183570A1Acceleration measurement in multiple dimensionsCapacitanceClassical mechanics

Micromachined accelerometer having one or more proof masses (16, 36, 37, 71, 72) mounted on one or more decoupling frames (17, 38, 39) or on a shuttle (73) such that the proof mass(es) can move along a first (y) axis in response to acceleration along the first axis while being constrained against movement along a second (x) axis and for torsional movement about a third (z) axis perpendicular to the first and second axes in response to acceleration along the second axis. Electrodes (26, 53, 54, 78, 79) that move with the proof mass(es) are interleaved with stationary electrodes (27, 56, 57, 81, 82) to form capacitors (A-D) that change in capacitance both in response to movement of the proof mass(es) along the first axis and in response to torsional movement of the proof mass(es) about the third axis, and circuitry (31-34) connected to the electrodes for providing output signals corresponding to acceleration along the first and second axes. The capacitances of two capacitors on each side of the second axis change in the same direction in response to acceleration along the first axis and in opposite directions in response to acceleration along the second axis. Signals from the capacitors that change capacitance in opposite directions both in response to acceleration along the first axis and in response to acceleration along the second axis are differentially combined to provide first and second difference signals, and the difference signals are additively and differentially combined to provide output signals corresponding to acceleration along the first and second axes.

Owner:CUSTOM SENSORS & TECH INC

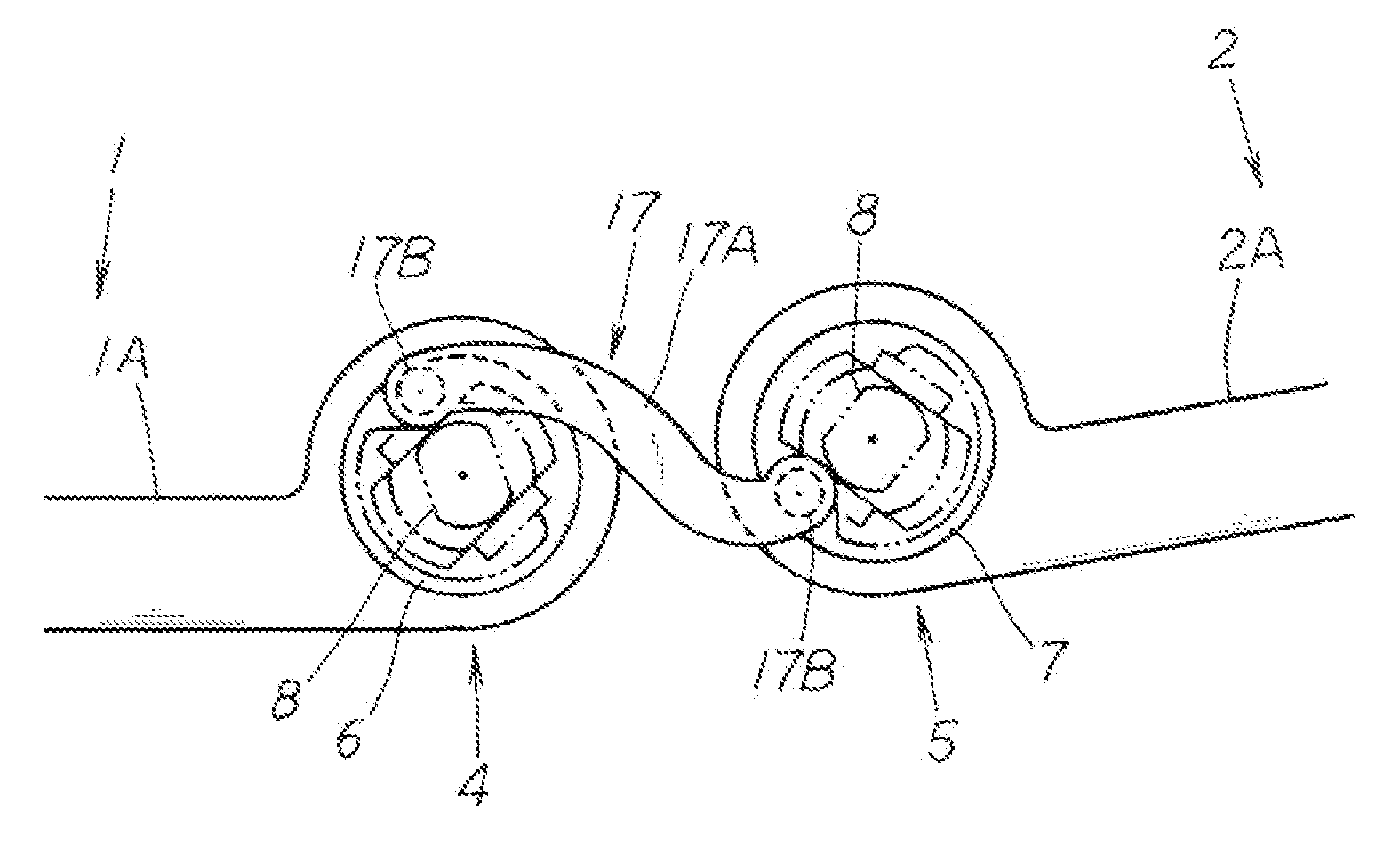

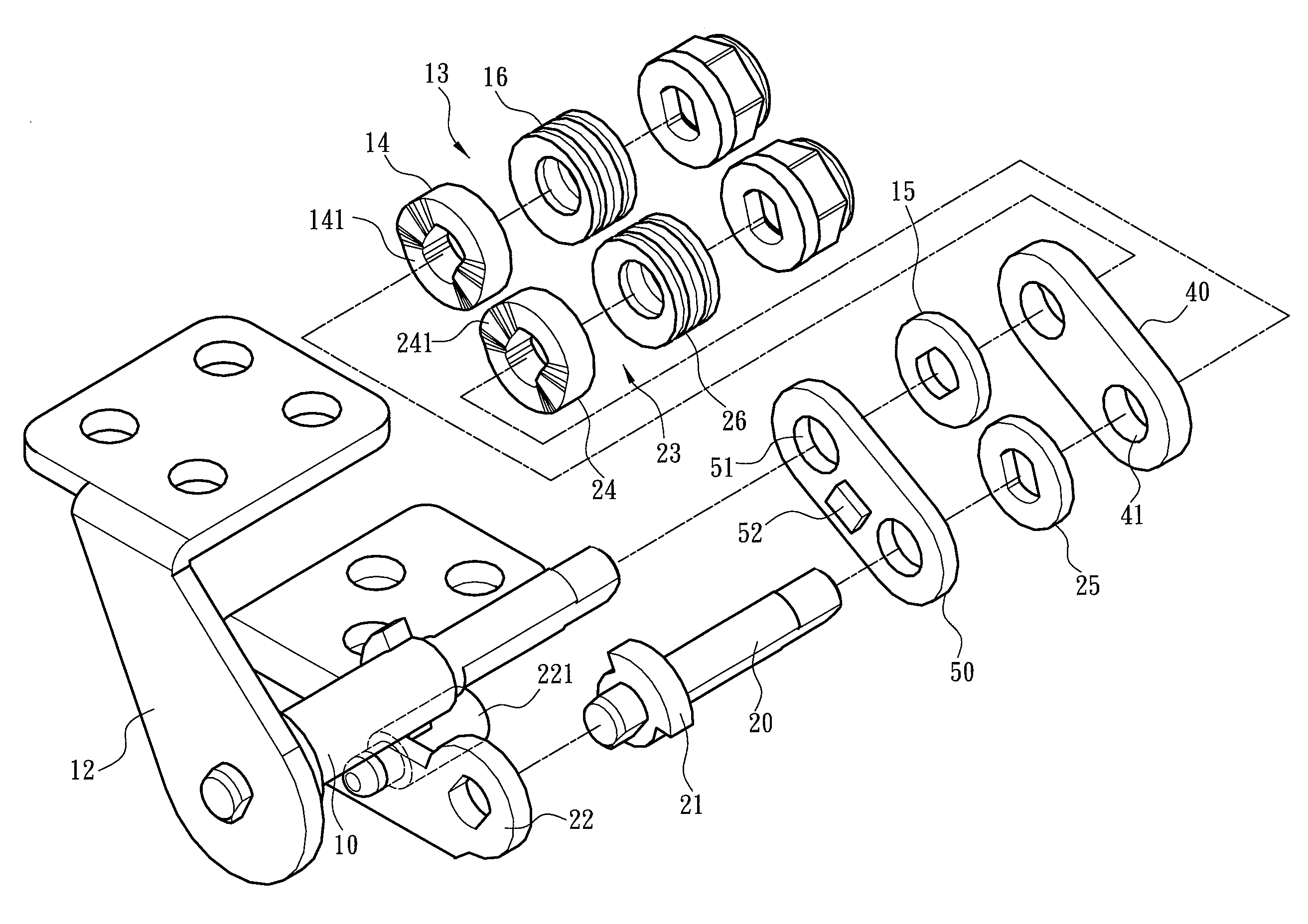

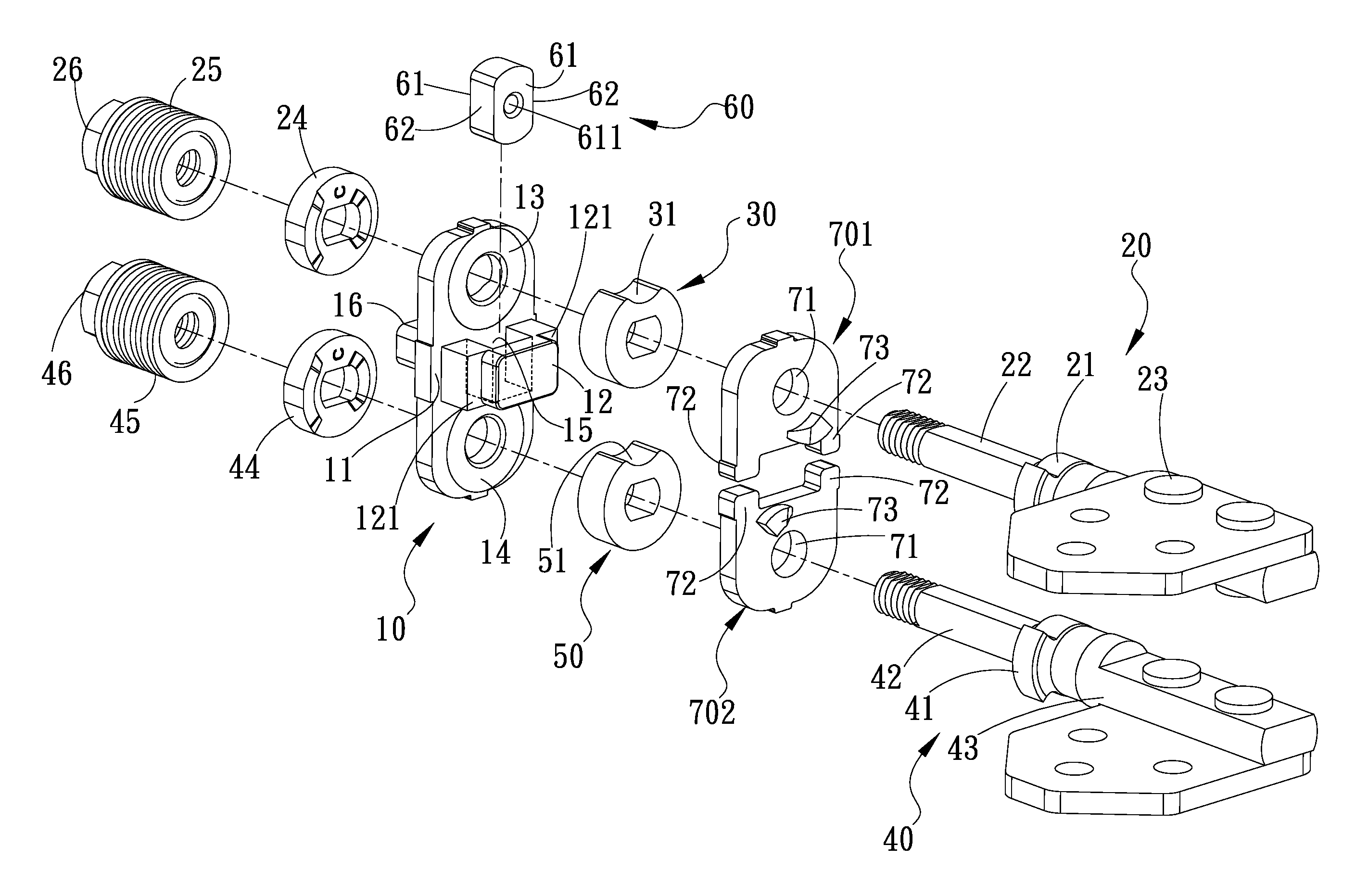

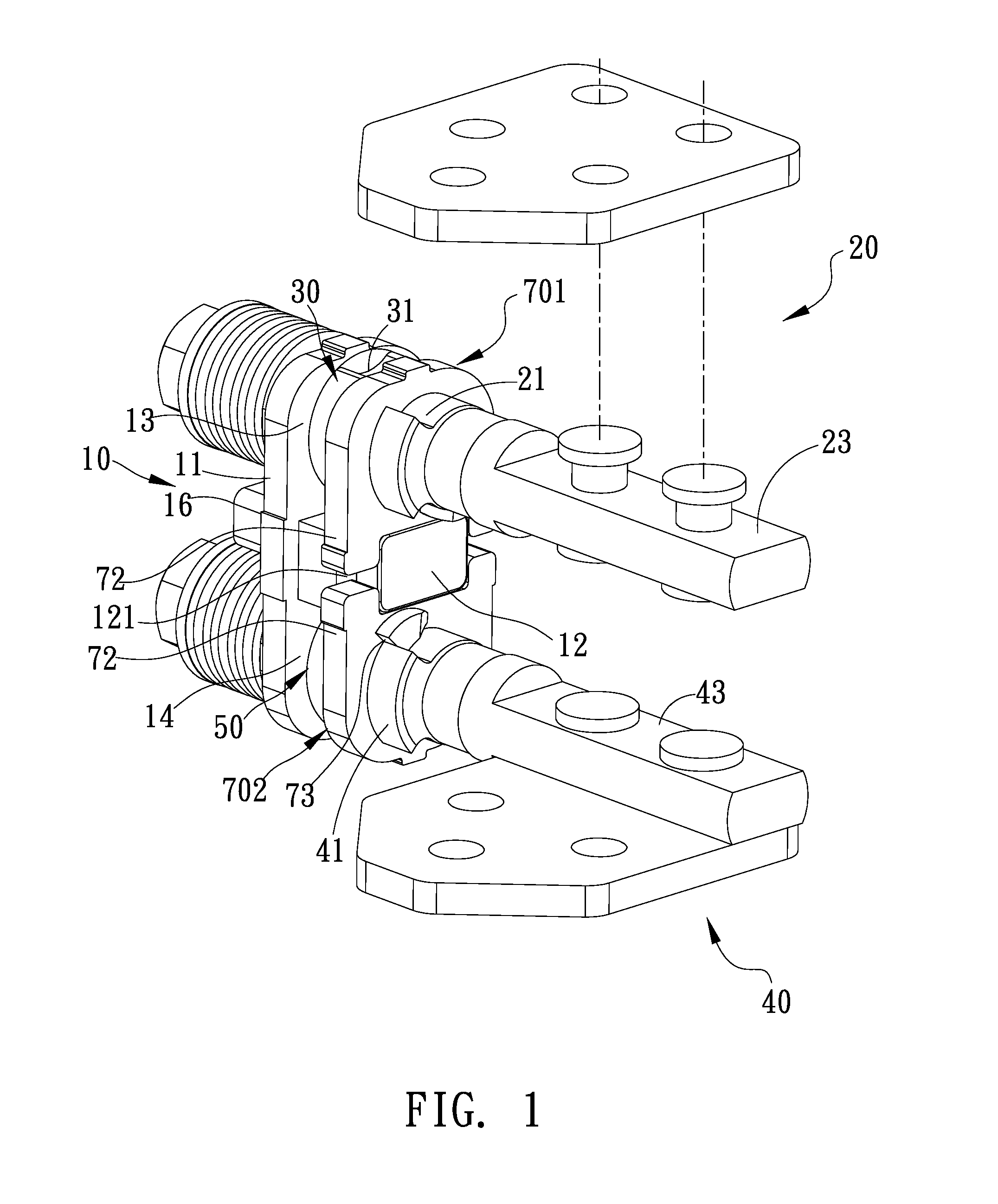

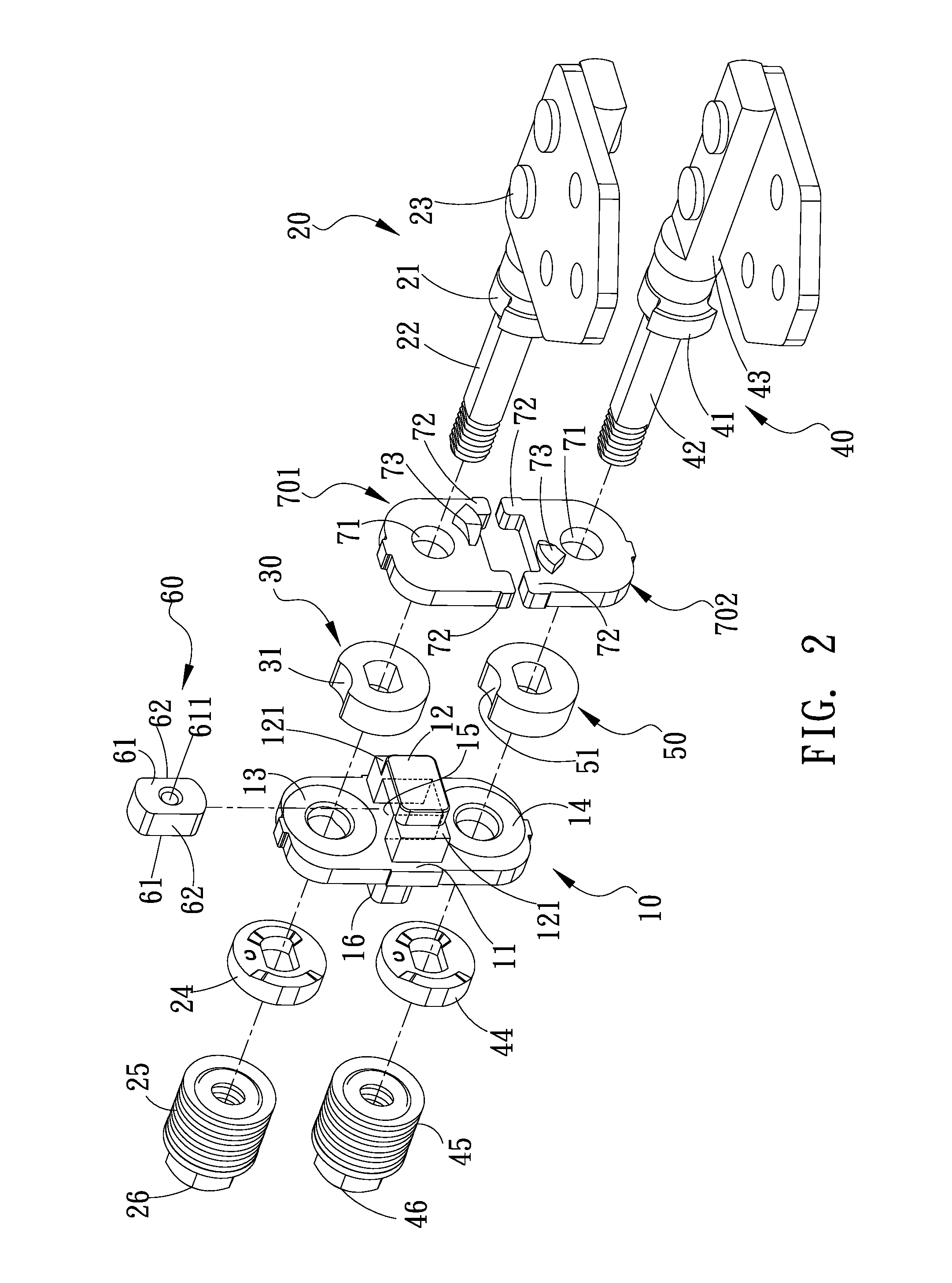

Two-stage dual-pintle hinge

InactiveUS20110265288A1Extend your lifeDigital data processing detailsWing fastenersDual axisEngineering

Owner:SINHER TECH INC

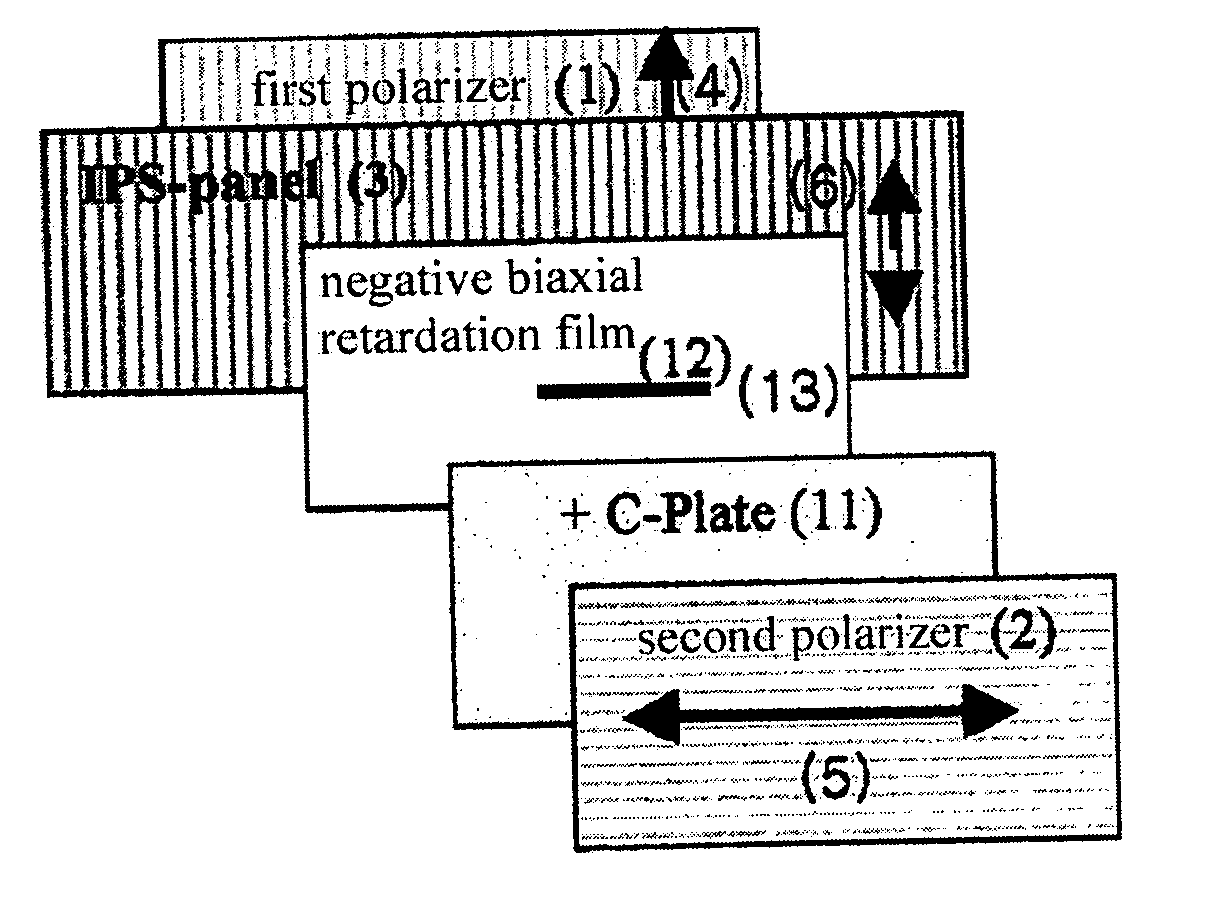

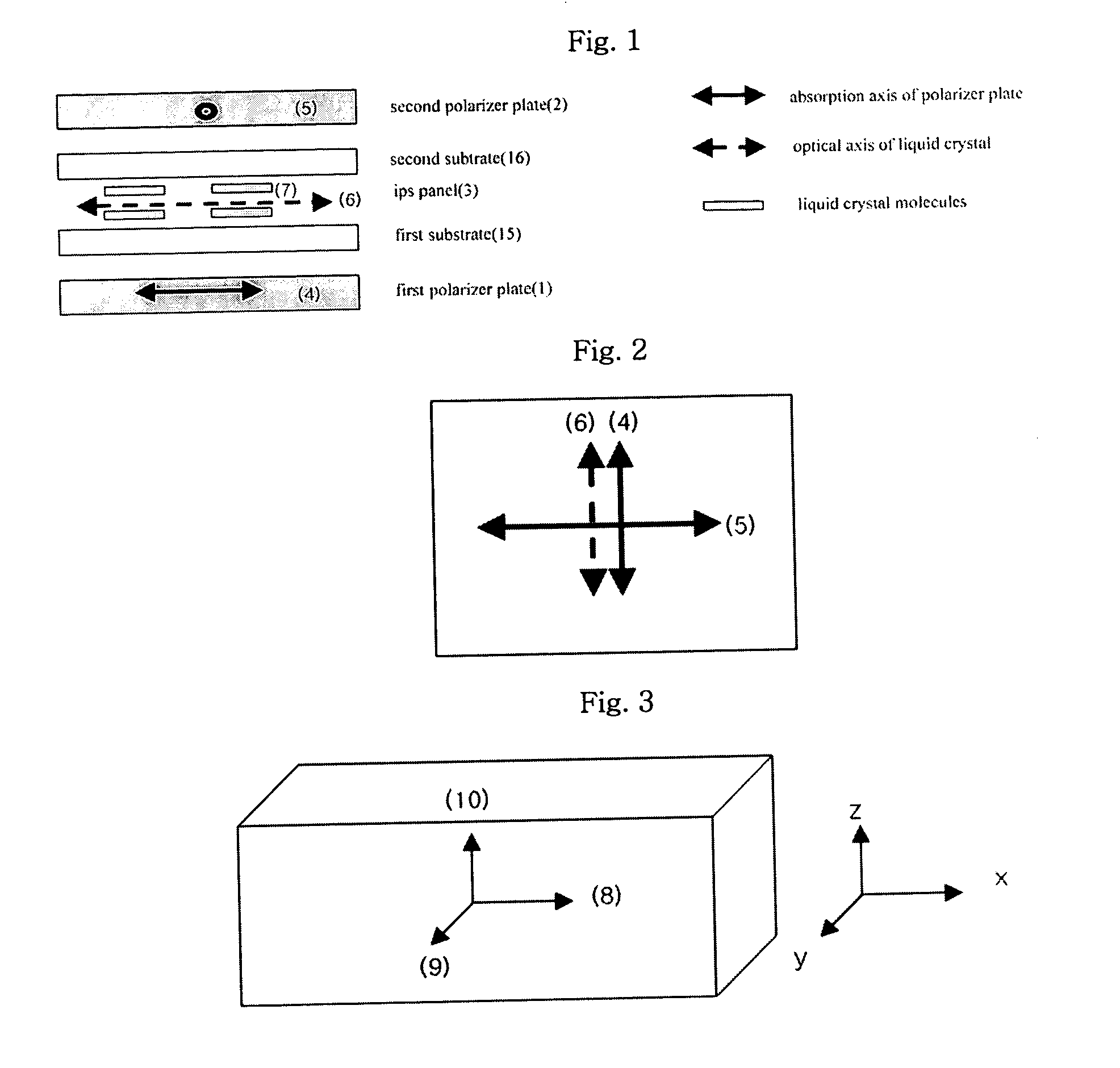

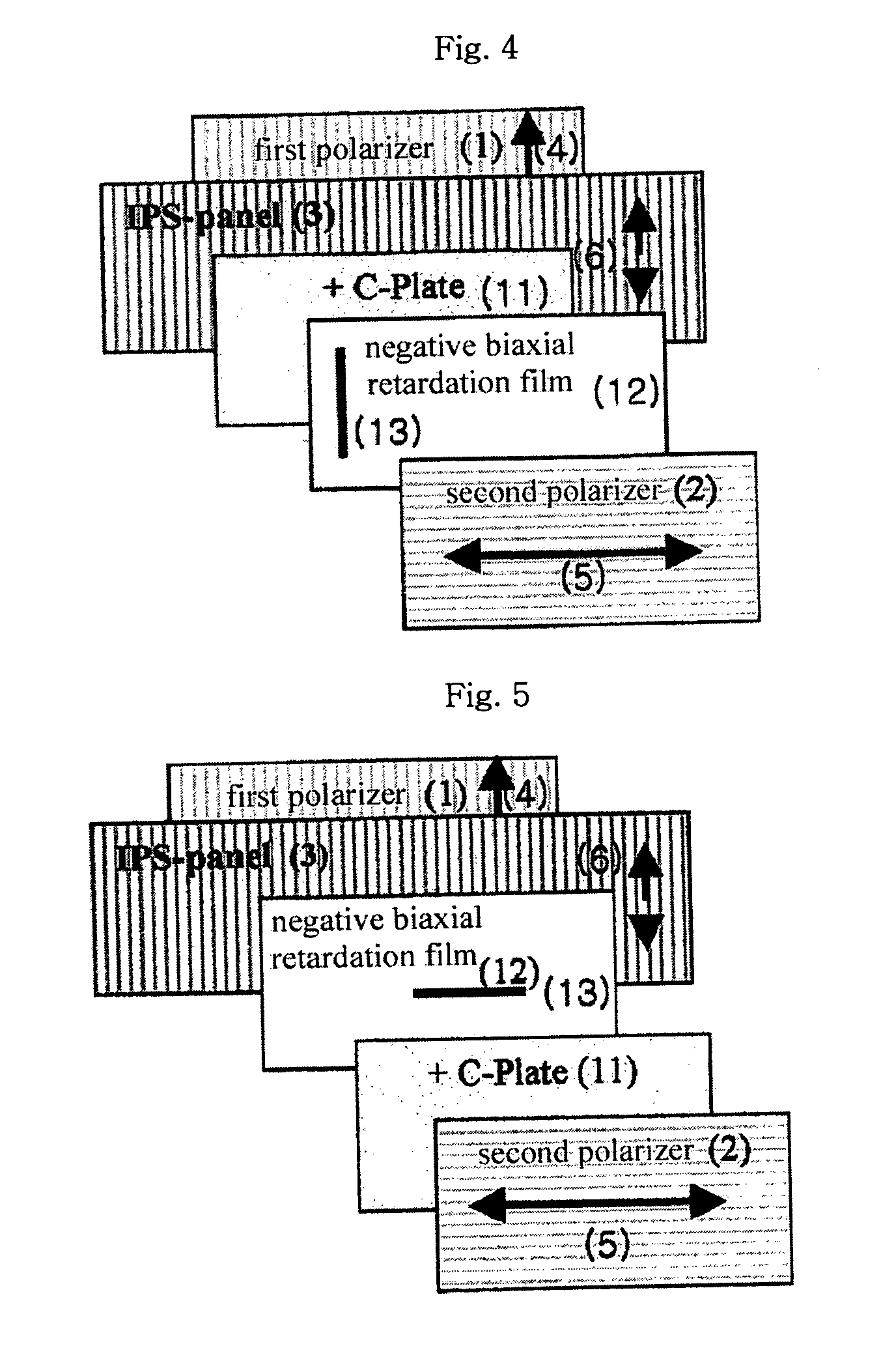

In-plane switching liquid crystal display comprising compensation film for angular field of view using negative biaxial retardation film and (+) C- plate

The present invention relates to an in-plane switching liquid crystal display comprising a negative biaxial retardation film and a positive C-plate, as viewing-angle compensation films. By the use of such viewing-angle compensation films, the contrast characteristics at the front side and inclination angle of the in-plane switching liquid crystal display can be improved and color shift with viewing angle in the dark state can be minimized.

Owner:LG CHEM LTD

Pin locking dual shaft hinge

ActiveUS8776319B1Simple designEasy to modifyDigital data processing detailsWing fastenersEngineeringCam

The present invention relates to a pin locking dual shaft hinge, including a connecting support, a first core shaft and a second core shaft parallel to each other, a first engaging cam, a second engaging cam and an insertion pin. The connecting support includes a main body and a first connecting member disposed between an upper and a lower end thereof, the first connecting member is penetrated with a penetrated hole. The first core shaft and the second core shaft are respectively pivoted at the upper and lower end of the main body. The first engaging cam is sleeved and engaged on the first core shaft, the periphery of the first engaging cam is formed with at least a first engaging part. The second engaging cam is sleeved and engaged on the second core shaft, the periphery of second engaging cam is formed with at least a second engaging part.

Owner:JARLLYTEC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com