Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

437 results about "Proof mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A proof mass or test mass is a known quantity of mass used in a measuring instrument as a reference for the measurement of an unknown quantity. A mass used to calibrate a weighing scale is sometimes called a calibration mass or calibration weight.

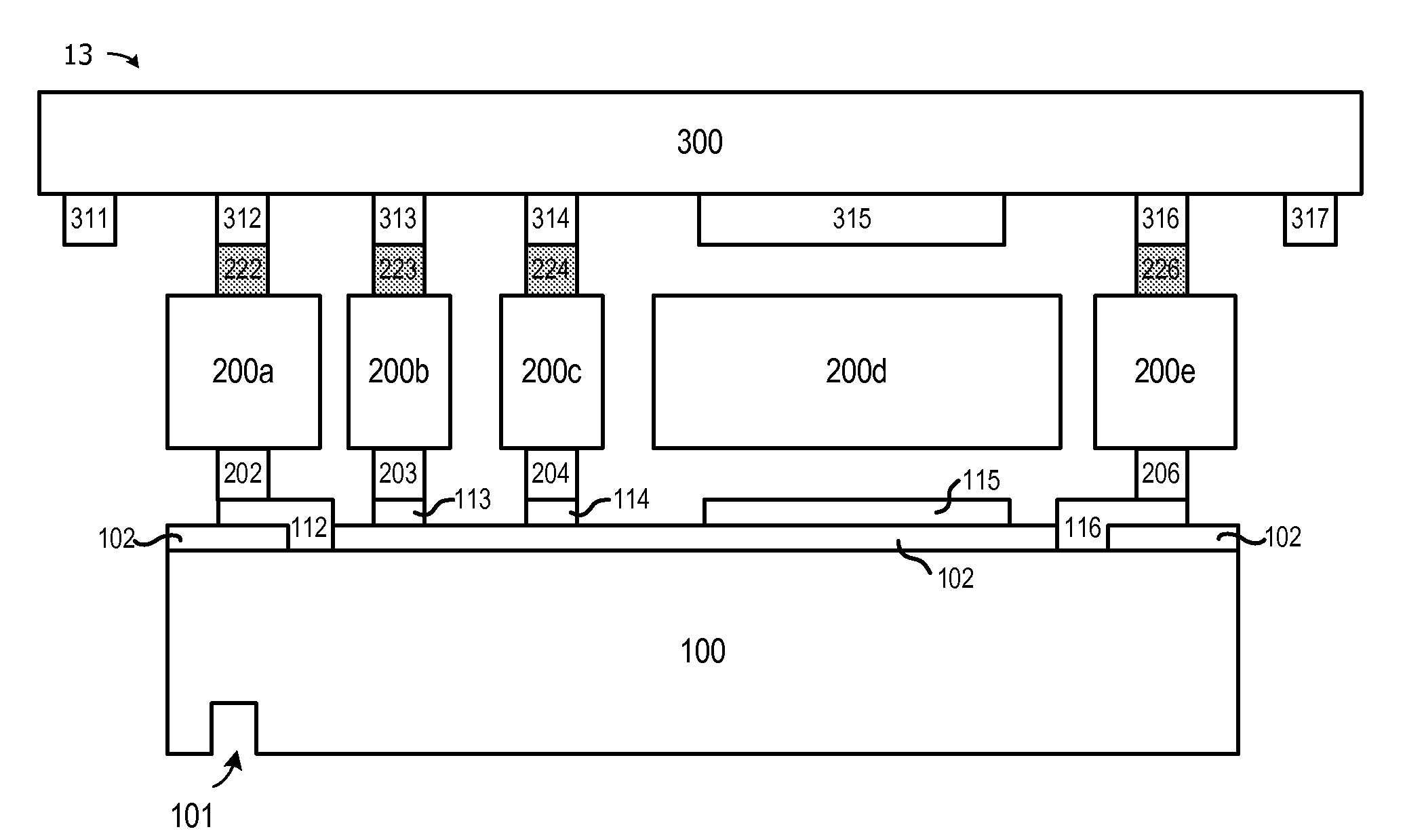

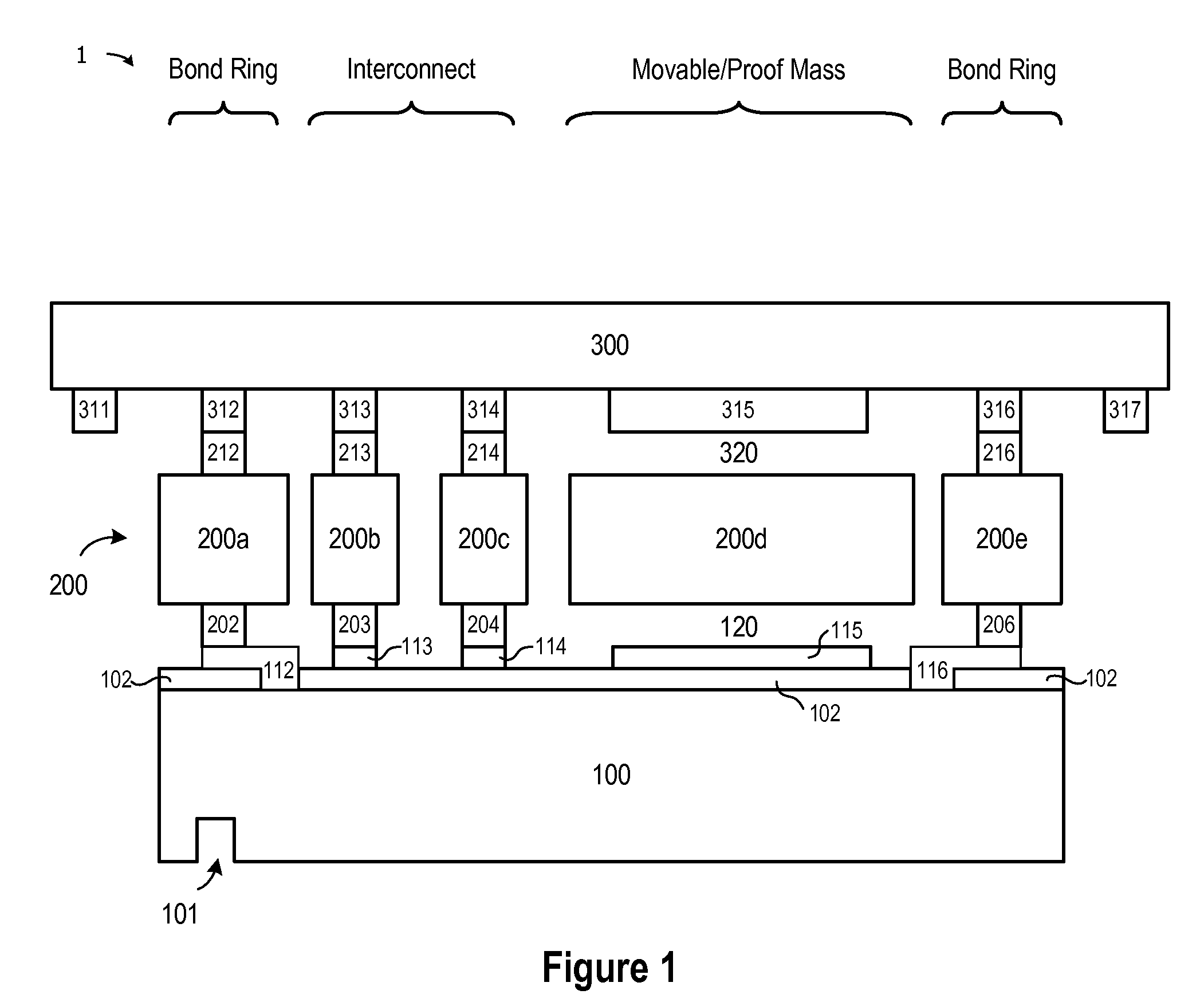

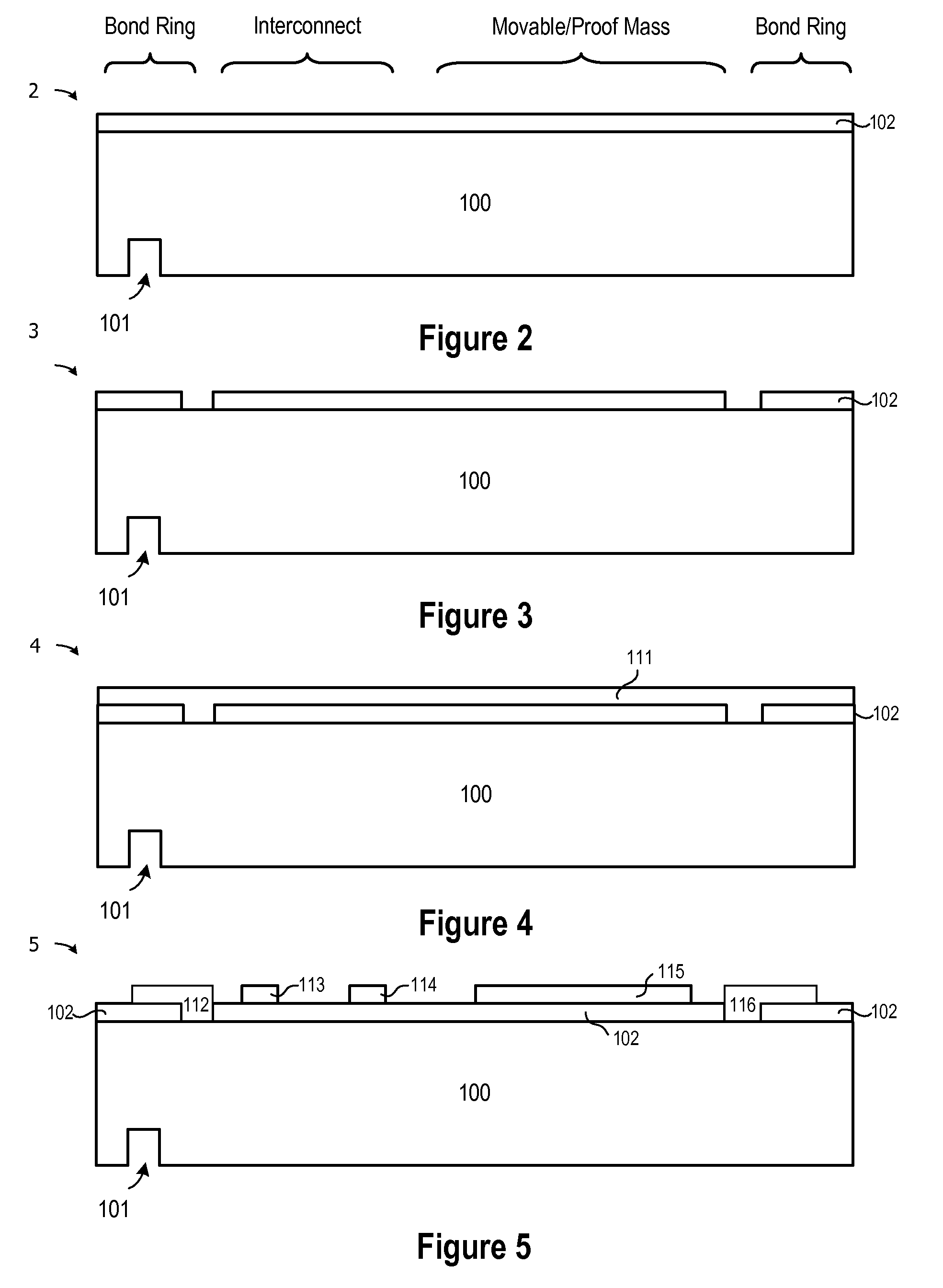

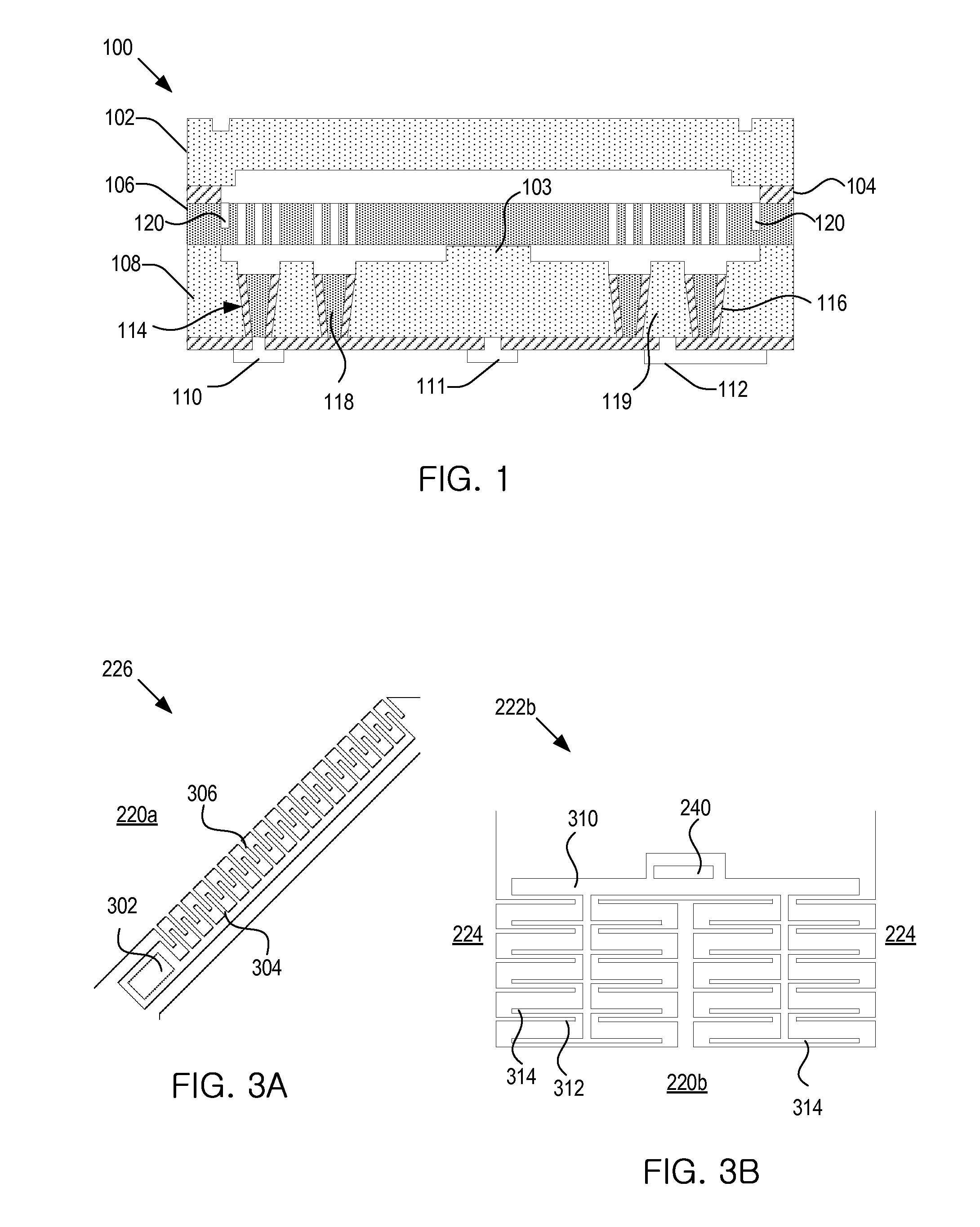

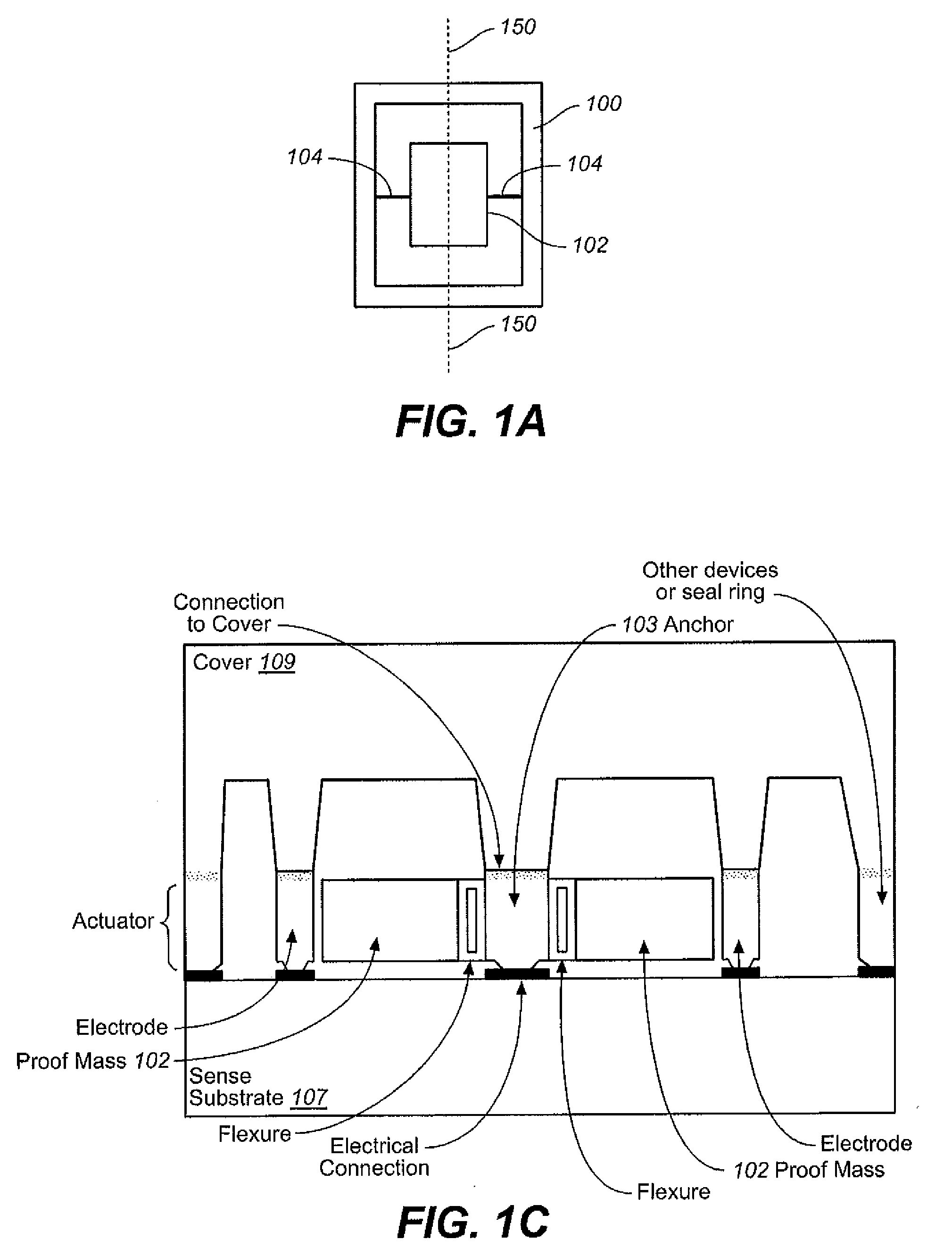

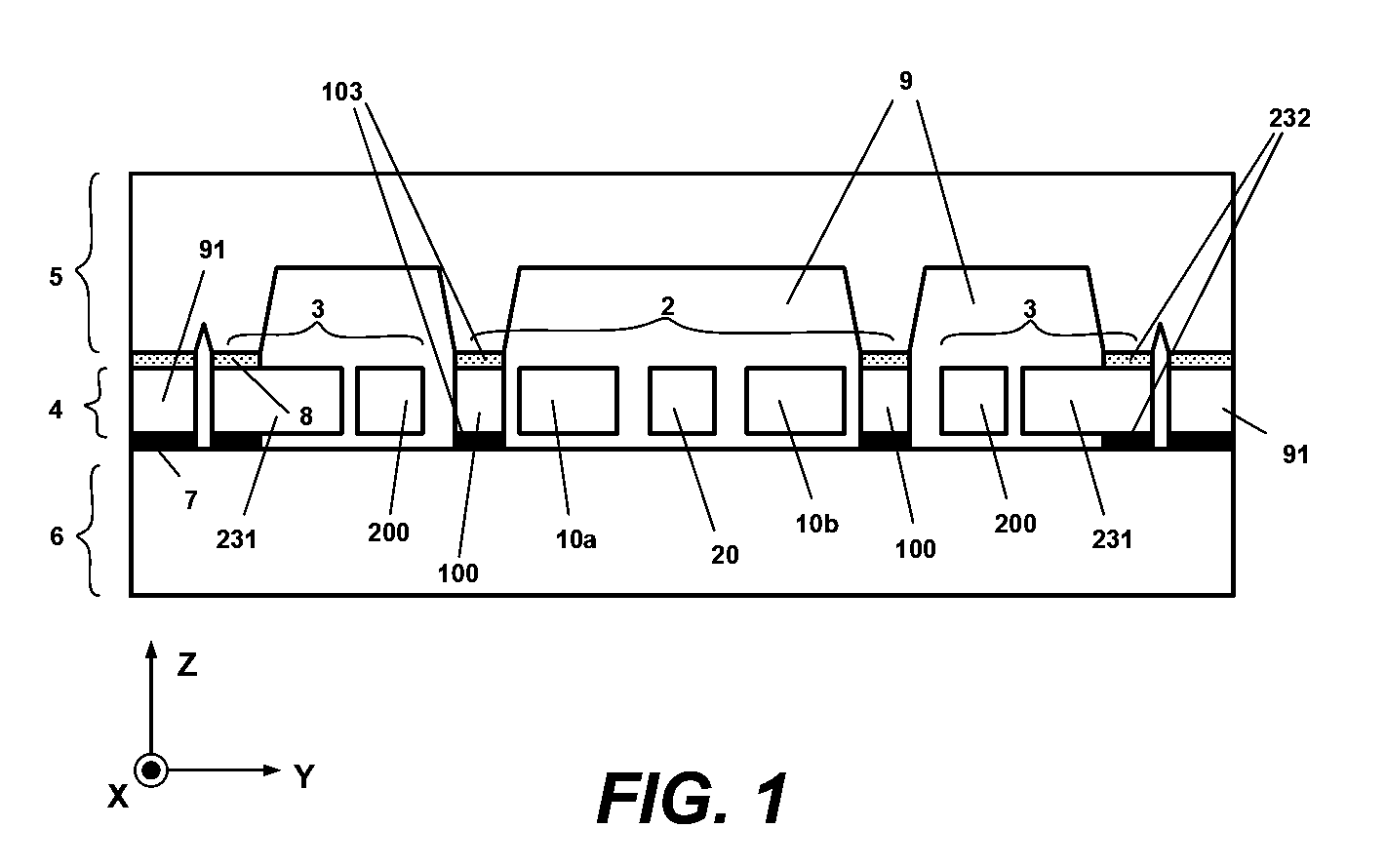

Method of Fabricating High Aspect Ratio Transducer Using Metal Compression Bonding

InactiveUS20100193884A1Television system detailsAcceleration measurement using interia forcesTransducerCapacitive sensing

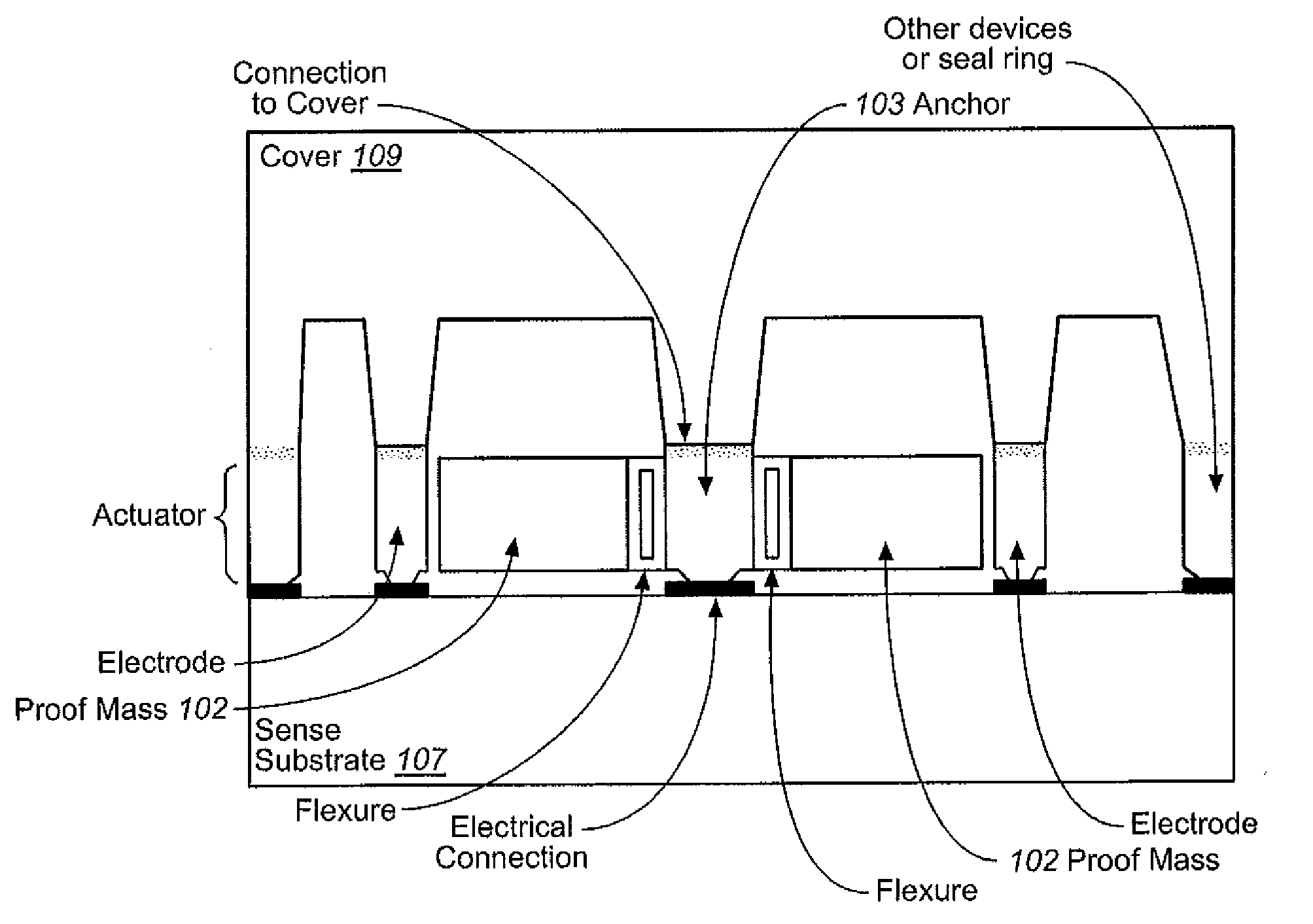

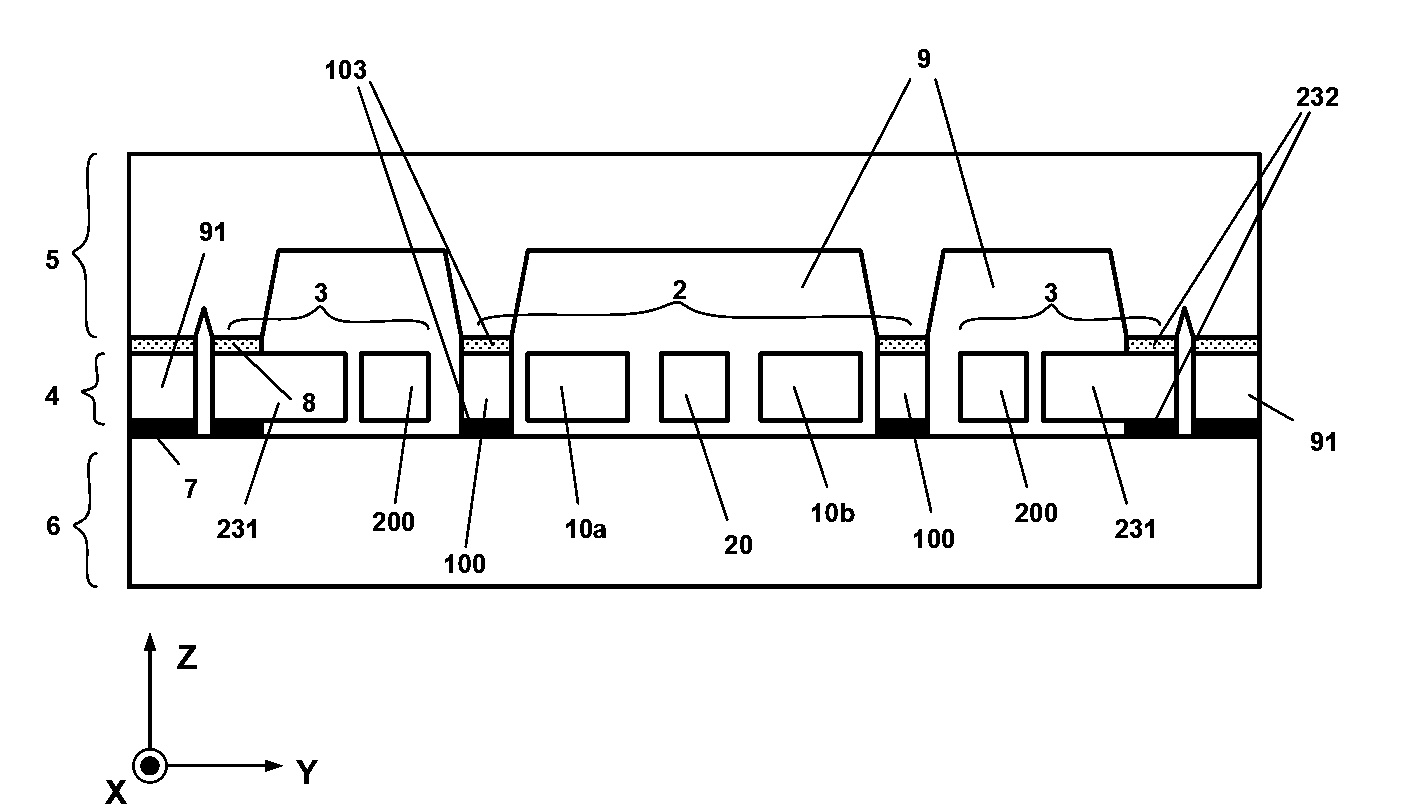

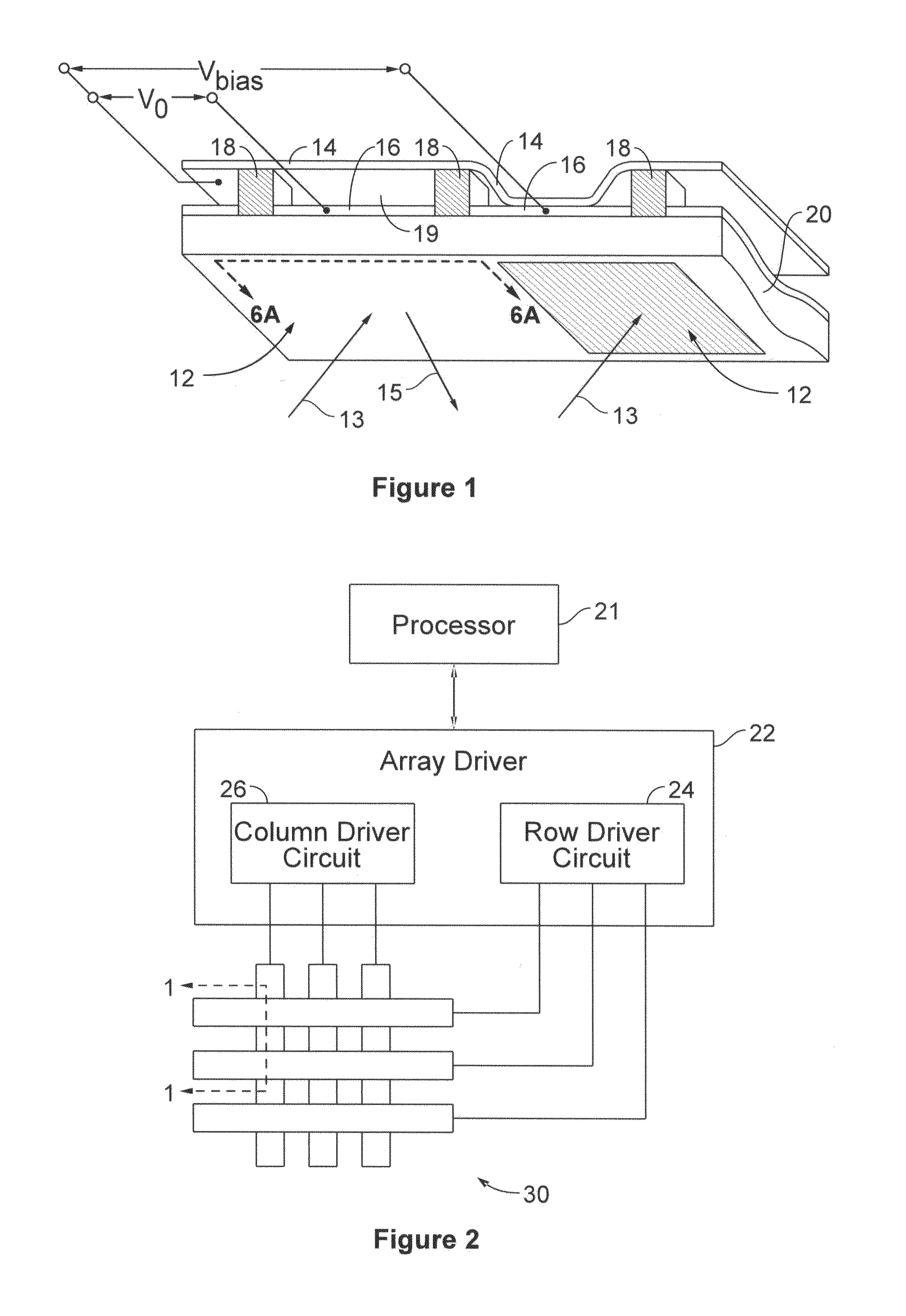

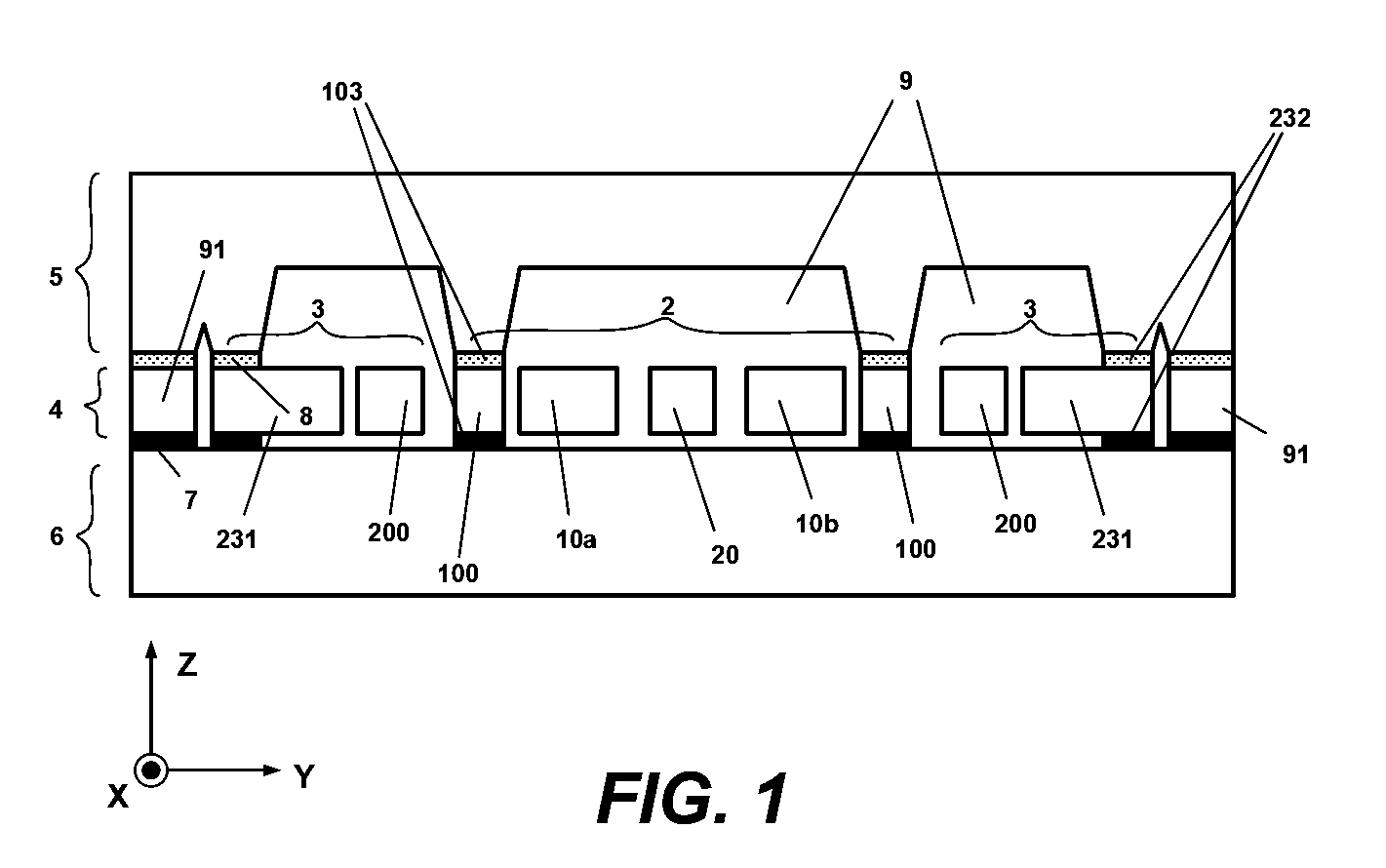

A method and apparatus are described for fabricating a high aspect ratio MEMS device by using metal thermocompression bonding to assemble a reference wafer (100), a bulk MEMS active wafer (200), and a cap wafer (300) to provide a proof mass (200d) formed from the active wafer with bottom and top capacitive sensing electrodes (115, 315) which are hermetically sealed from the ambient environment by sealing ring structures (112 / 202 / 200a / 212 / 312 and 116 / 206 / 200e / 216 / 316).

Owner:FREESCALE SEMICON INC

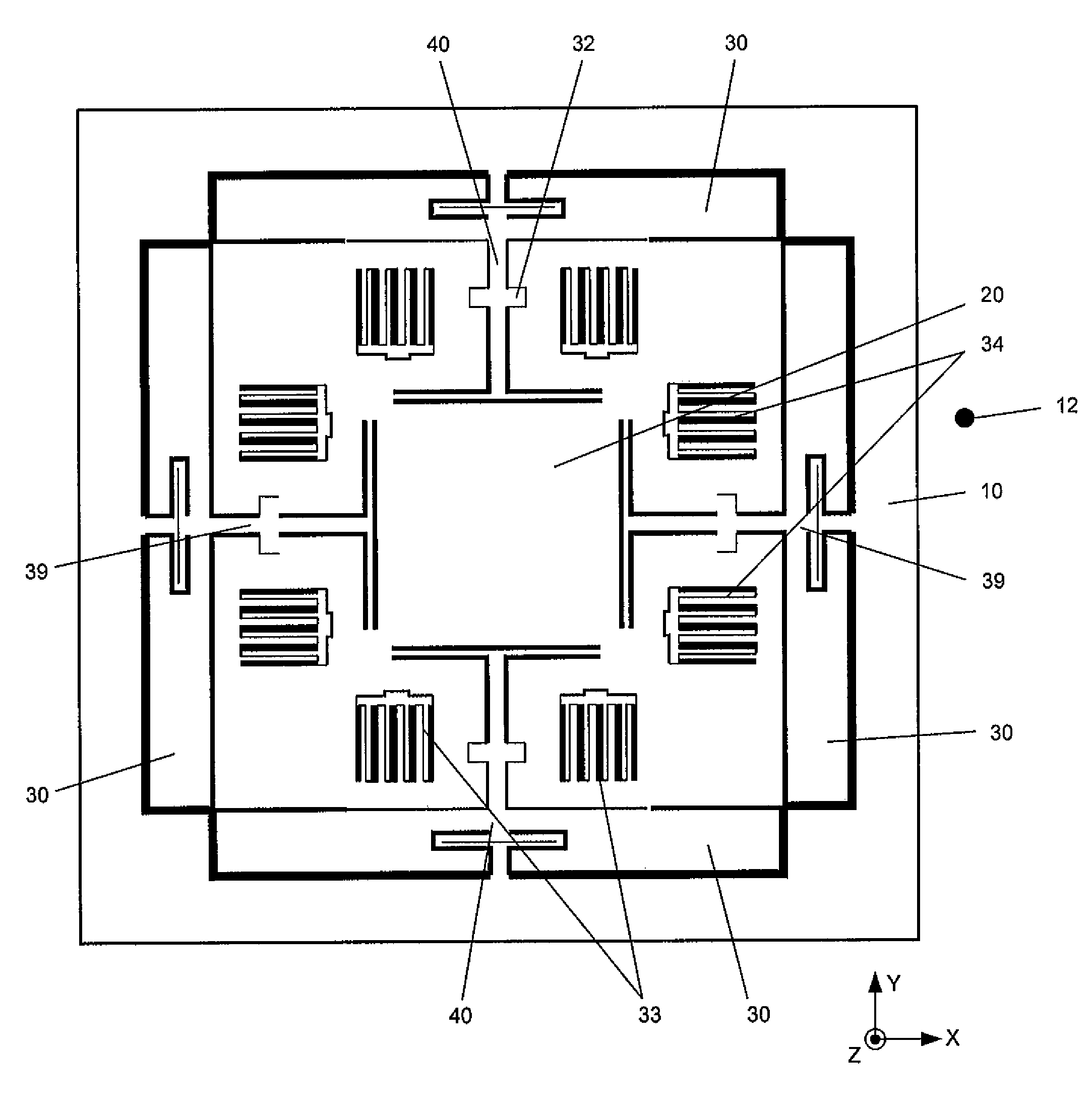

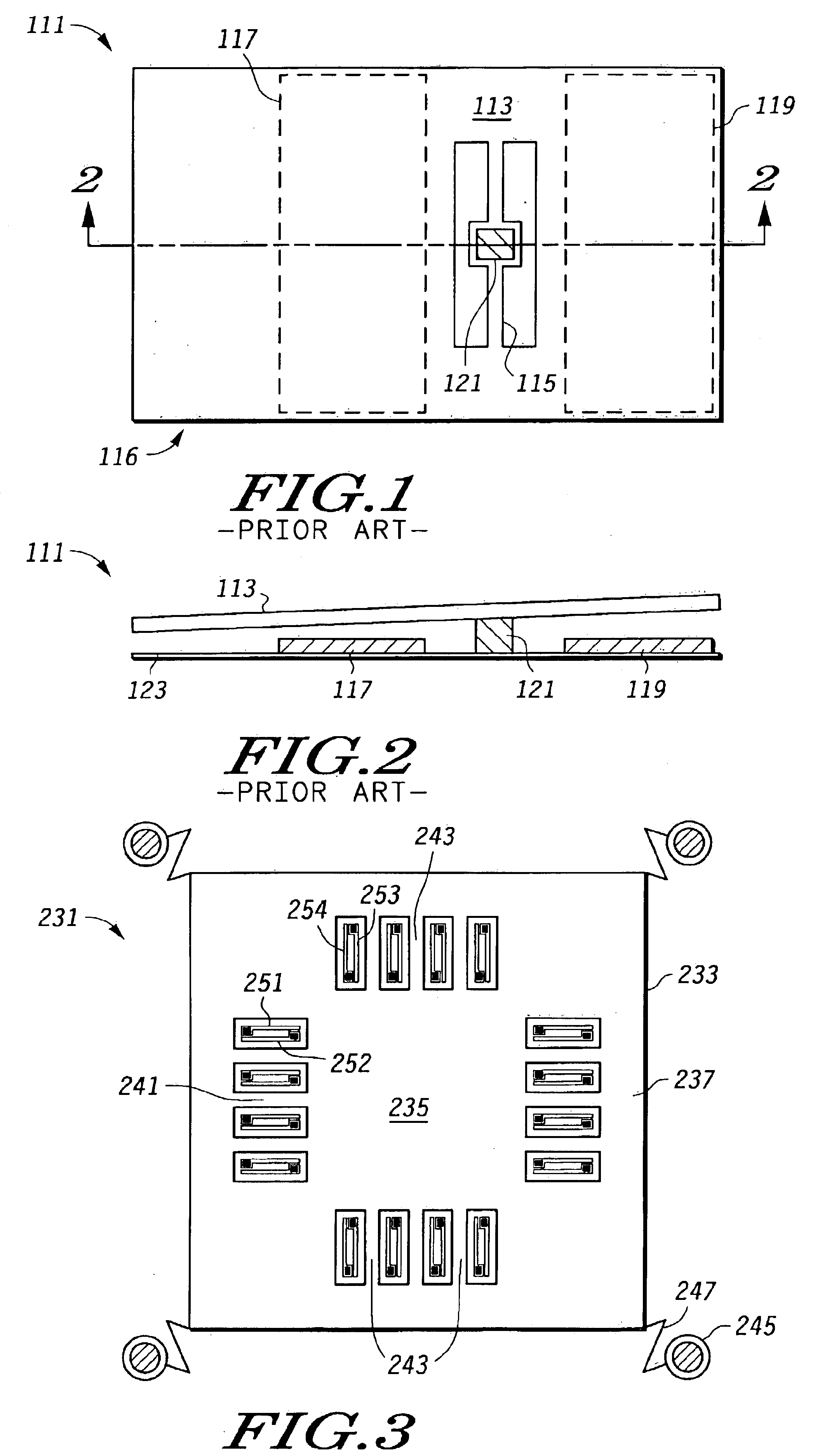

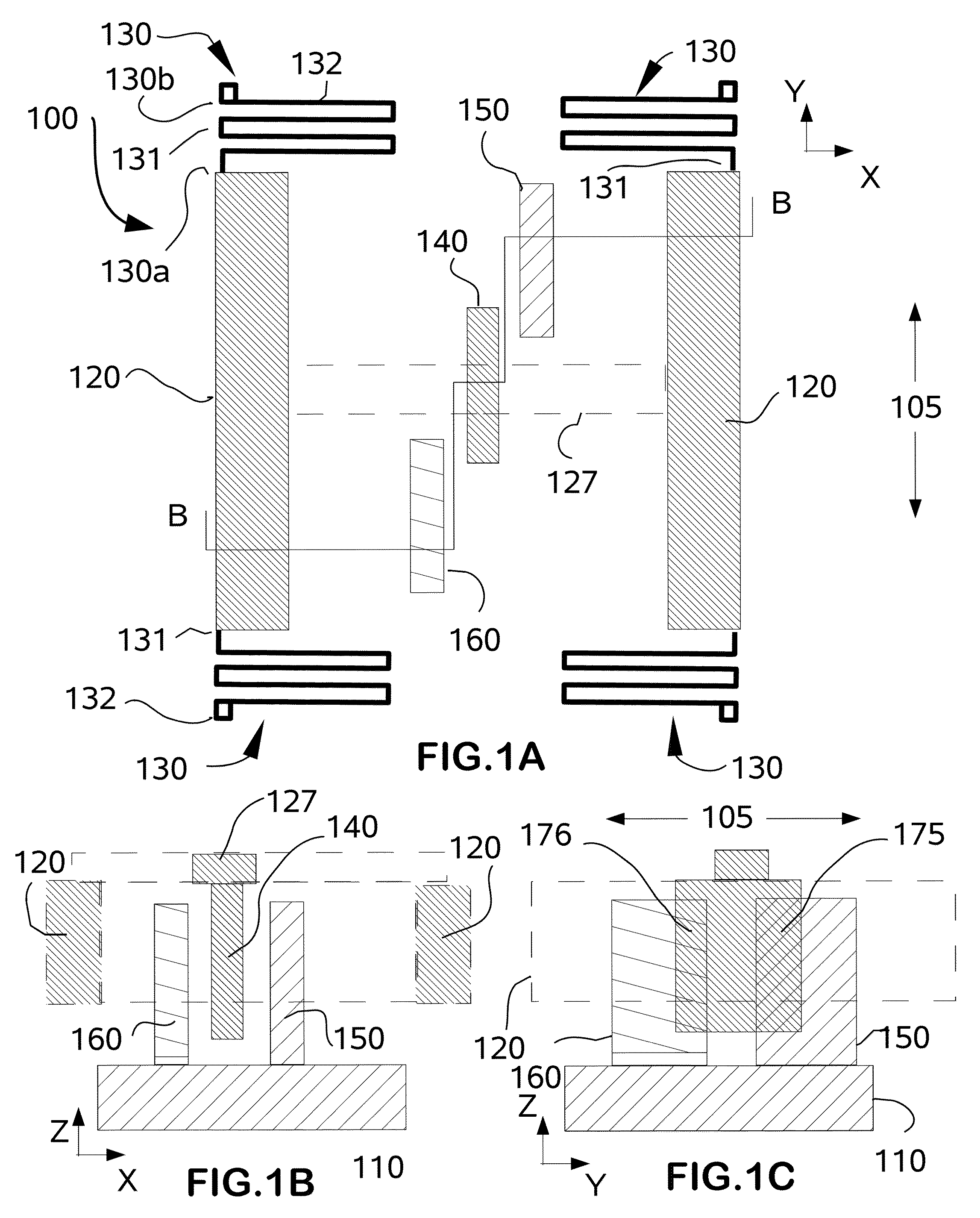

Multiple axis accelerometer

ActiveUS7258011B2Speed/acceleration/shock instrument detailsDevices characerised by mechanical meansTransducerAcceleration Unit

A sensor for measuring acceleration in three mutually orthogonal axes, X, Y and Z is disclosed. The sensor comprises a sensor subassembly. The sensor subassembly further comprises a base which is substantially parallel to the X-Y sensing plane; a proof mass disposed in the X-Y sensing plane and constrained to move substantially in the X, Y, and Z, about by at least one linkage and is responsive to accelerations in the X, Y and Z directions. The sensor includes at least one paddle disposed in the sensing plane; and at least one pivot on the linkage. Finally, the sensor includes at least one electrode at the base plate and at least one transducer for each sensing direction of the sensor subassembly responsive to the acceleration.

Owner:INVENSENSE

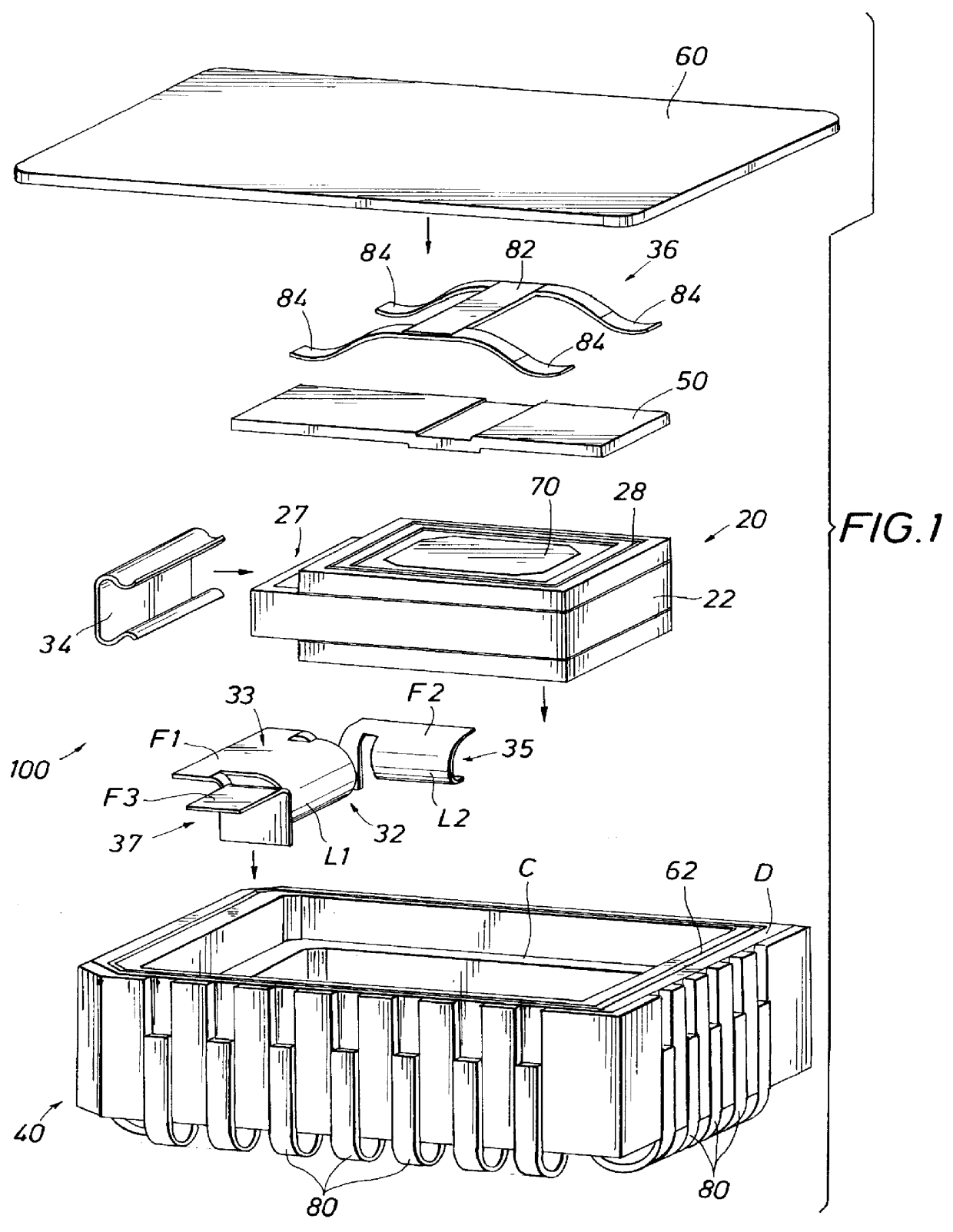

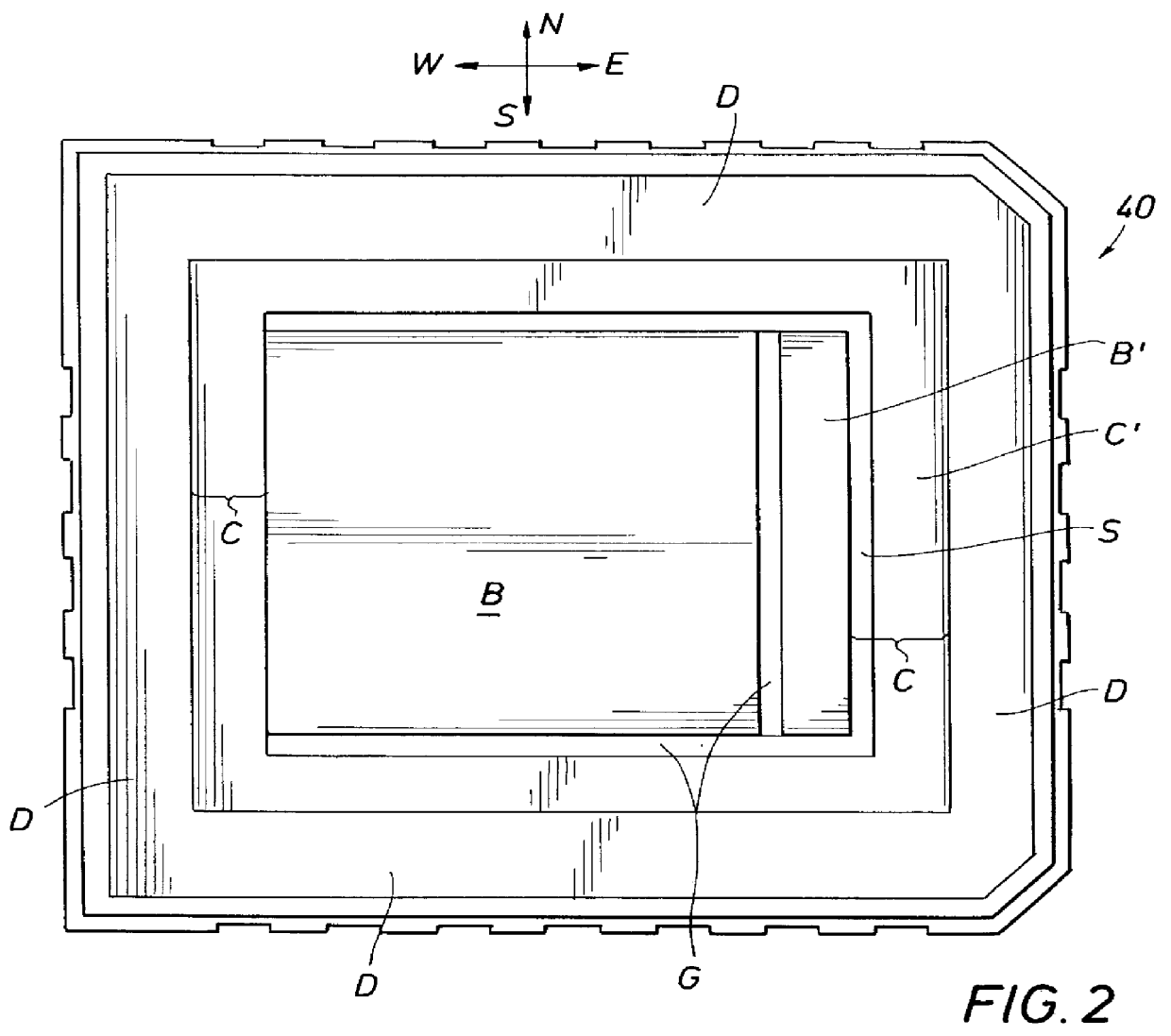

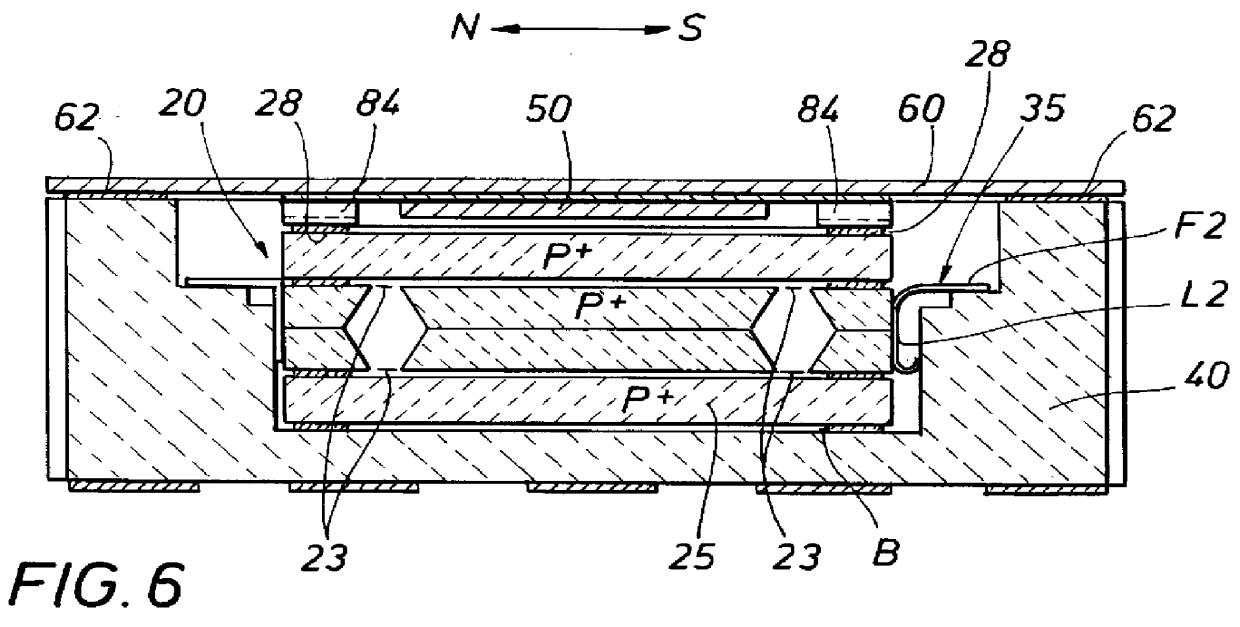

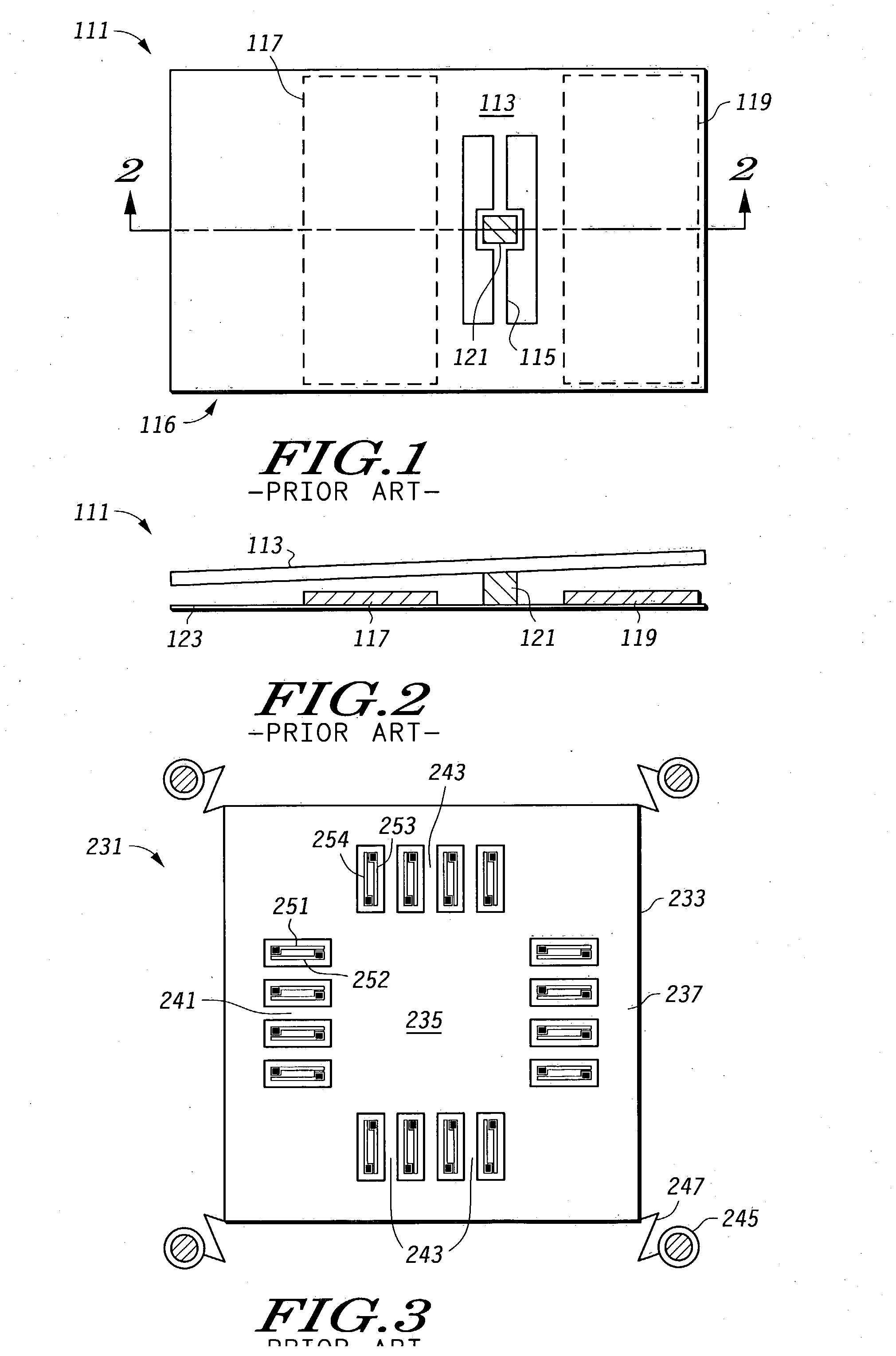

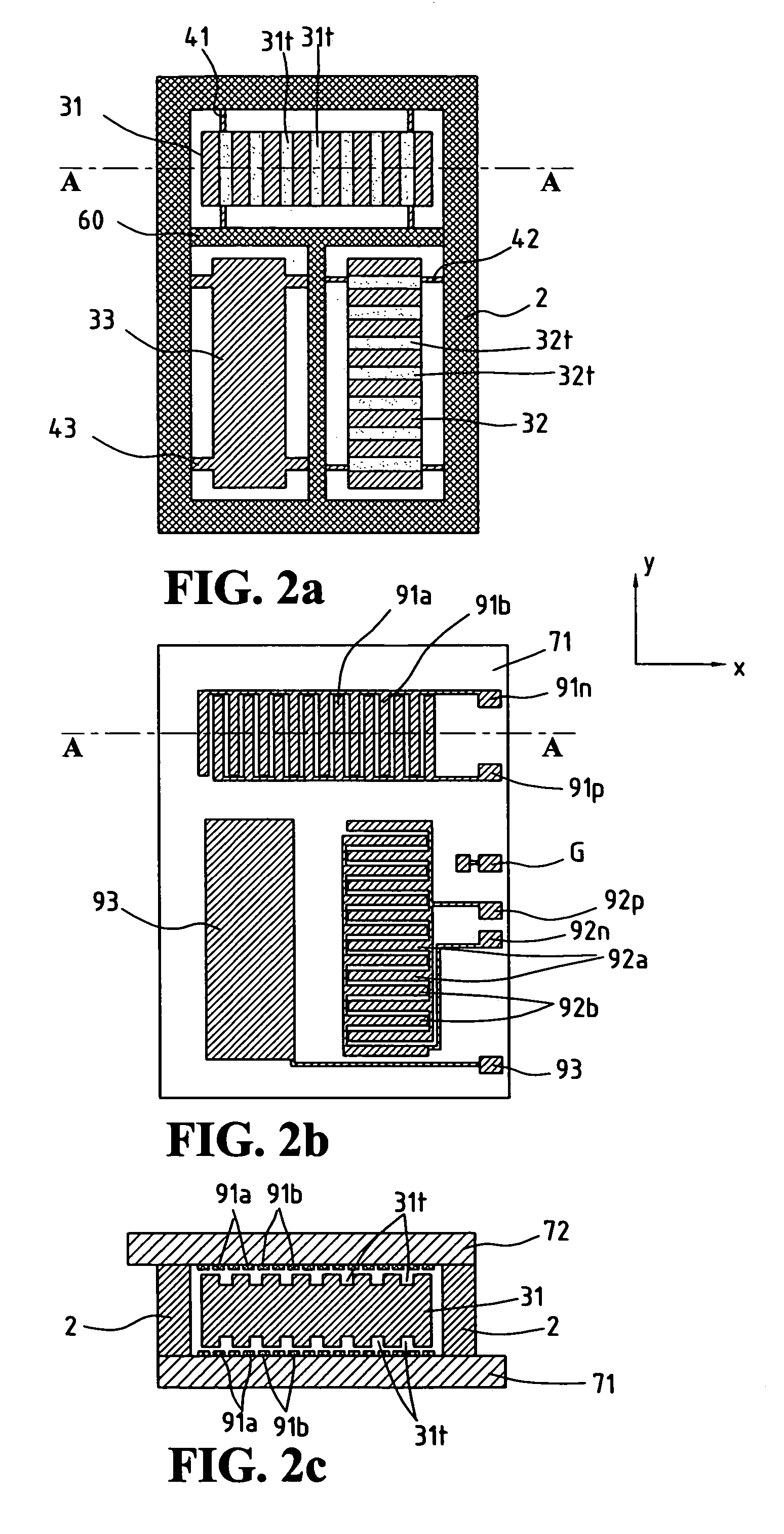

Sensor package arrangement

InactiveUS6040625AEasy to installMinimizing chance for outgassingSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical connection

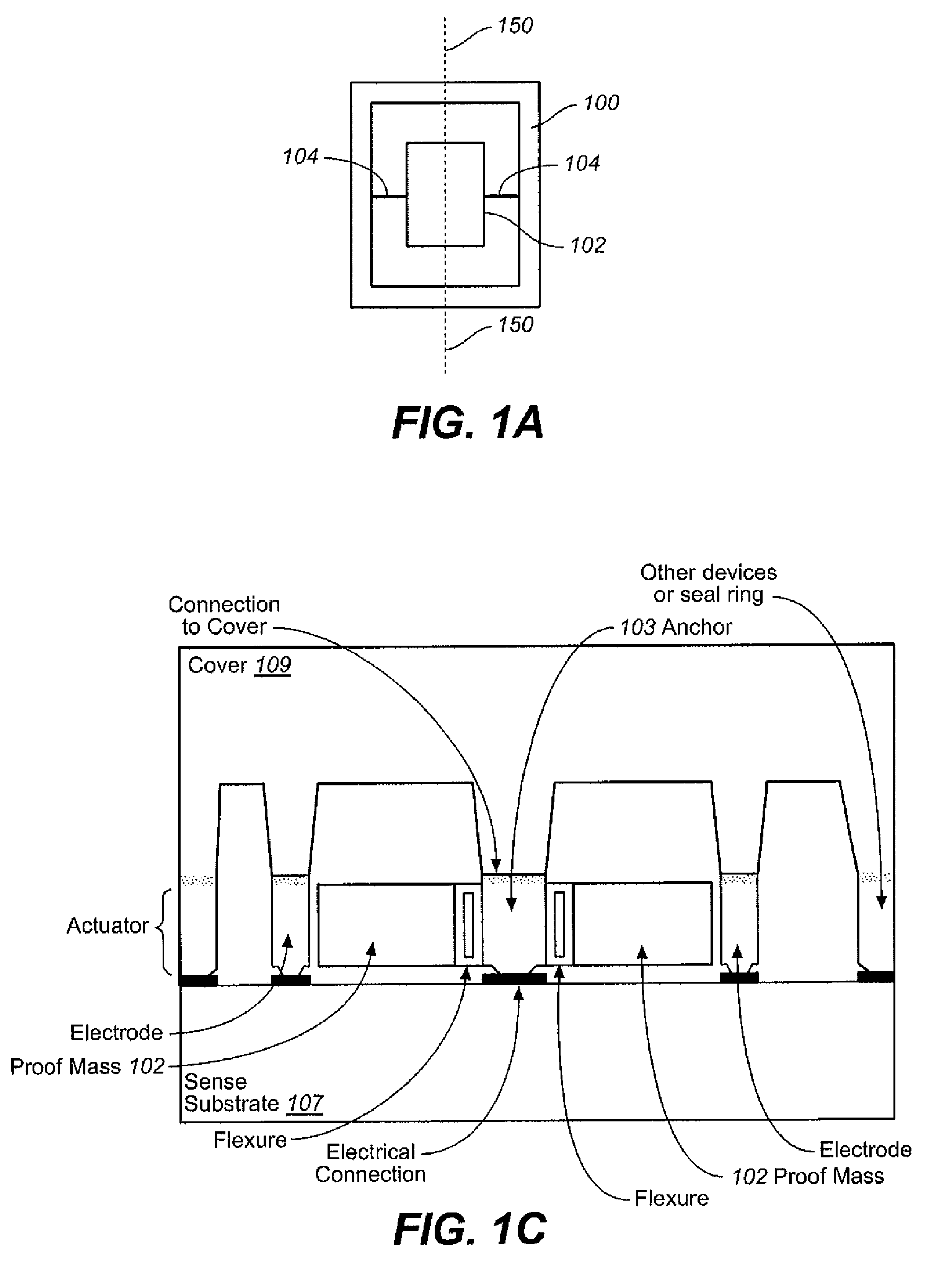

A highly sensitive silicon micro-machined sensor package is provided for use in a micro-g environment that can also resist high shock in excess of 5000 g. The sensor is provided to measure acceleration in cooperation with associated electronics which are required to have electrical contact with sensor elements. The sensor is sealed in a high vacuum environment, and is arranged and designed to be free of temperature induced stress to the sensor. The sensor die package assembly comprises a silicon micro-machined sensor die, a ceramic package, two contact springs, a shorting clip, solder preform, a metal lid and a getter foil for ensuring a good vacuum for an extended period. The sensor die comprises a moving mass with eight supporting flexures on both sides of the proof mass. The proof mass's movement is protected on both sides by a top and a bottom cap. Acceleration applied to the package and the die causes the proof mass to move vertically in relation with the adjacent caps. The changes in distance between the proof mass and the caps in turn generate a change in an electrical signal which corresponds to the capacitance changes between the gaps. The sensor die package arrangement provides that the sensor die be secured within an evacuated ceramic case. Electrical connections made between external contacts of the case and contacts of the sensor die within the case are made through conductive springs, thereby minimizing materials in the interior of the case which would outgass in the vacuum environment.

Owner:I O SENSORS

Micromachined inertial sensor devices

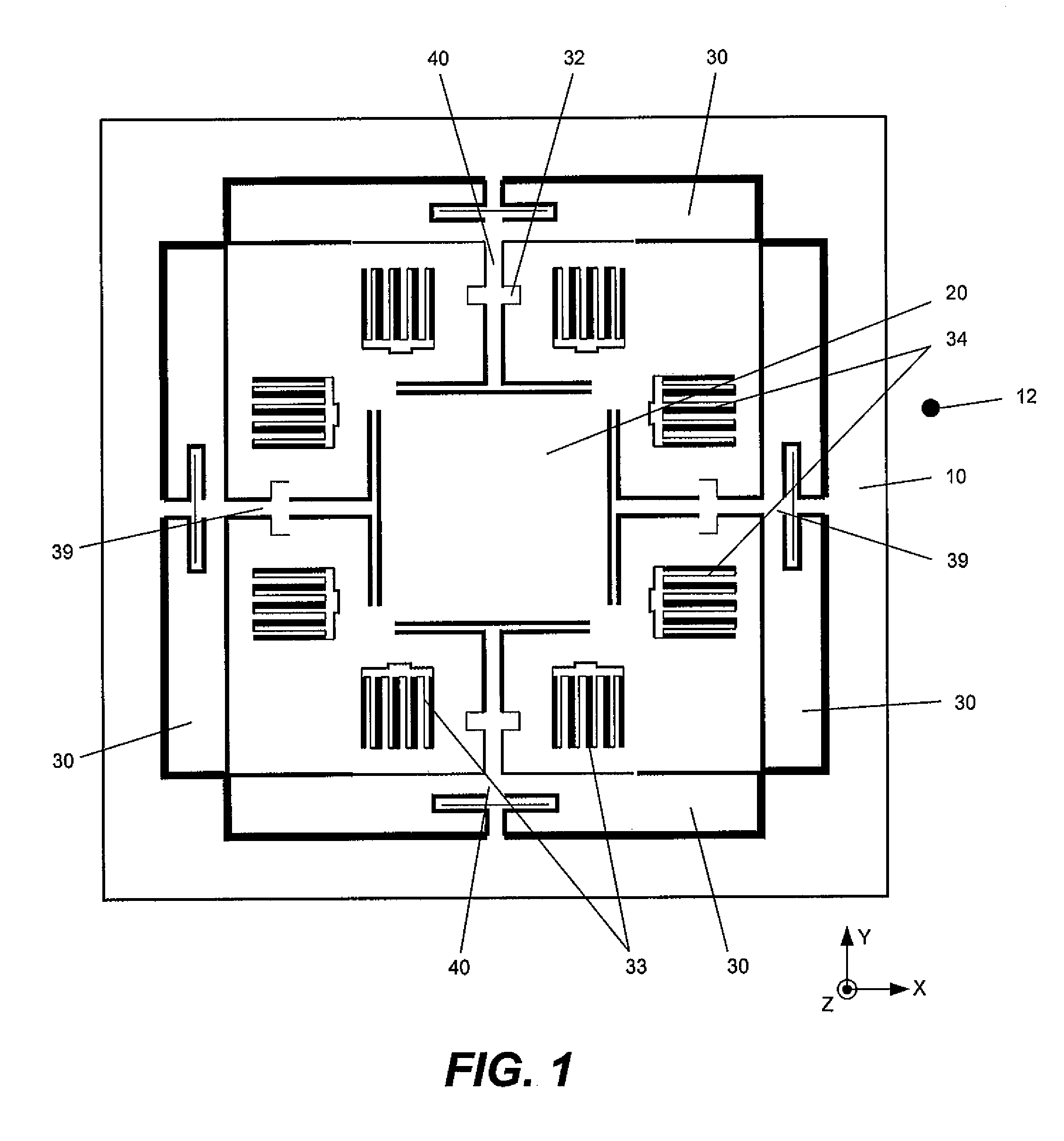

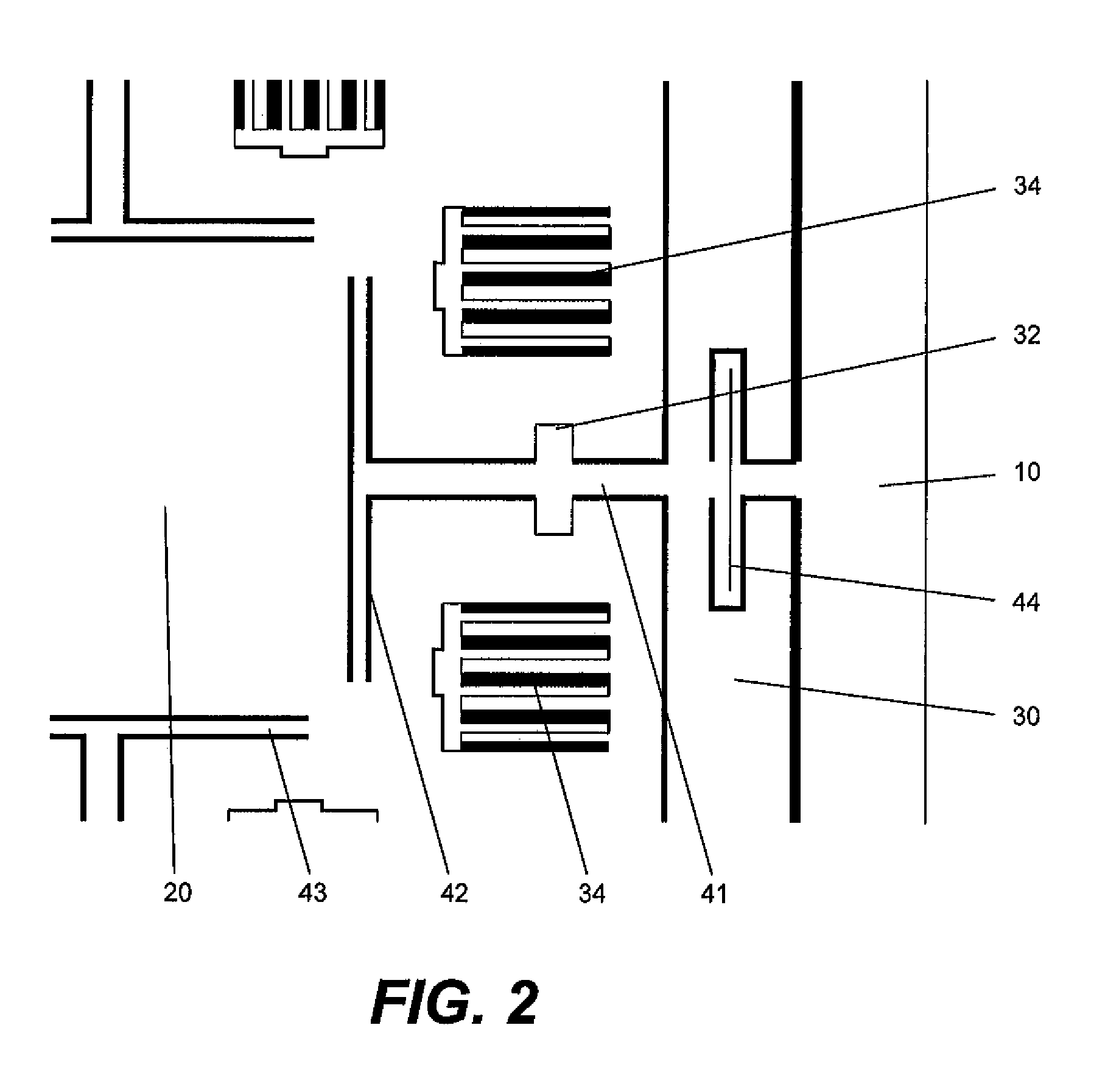

ActiveUS20110030473A1Acceleration measurement using interia forcesSolid-state devicesProof massLinear acceleration

A micromachined inertial sensor with a single proof-mass for measuring 6-degree-of-motions. The single proof-mass includes a frame, an x-axis proof mass section attached to the frame by a first flexure, and a y-axis proof mass section attached to the frame by a second flexure. The single proof-mass is formed in a micromachined structural layer and is adapted to measure angular rates about three axes with a single drive motion and linear accelerations about the three axes.

Owner:SEMICON COMPONENTS IND LLC

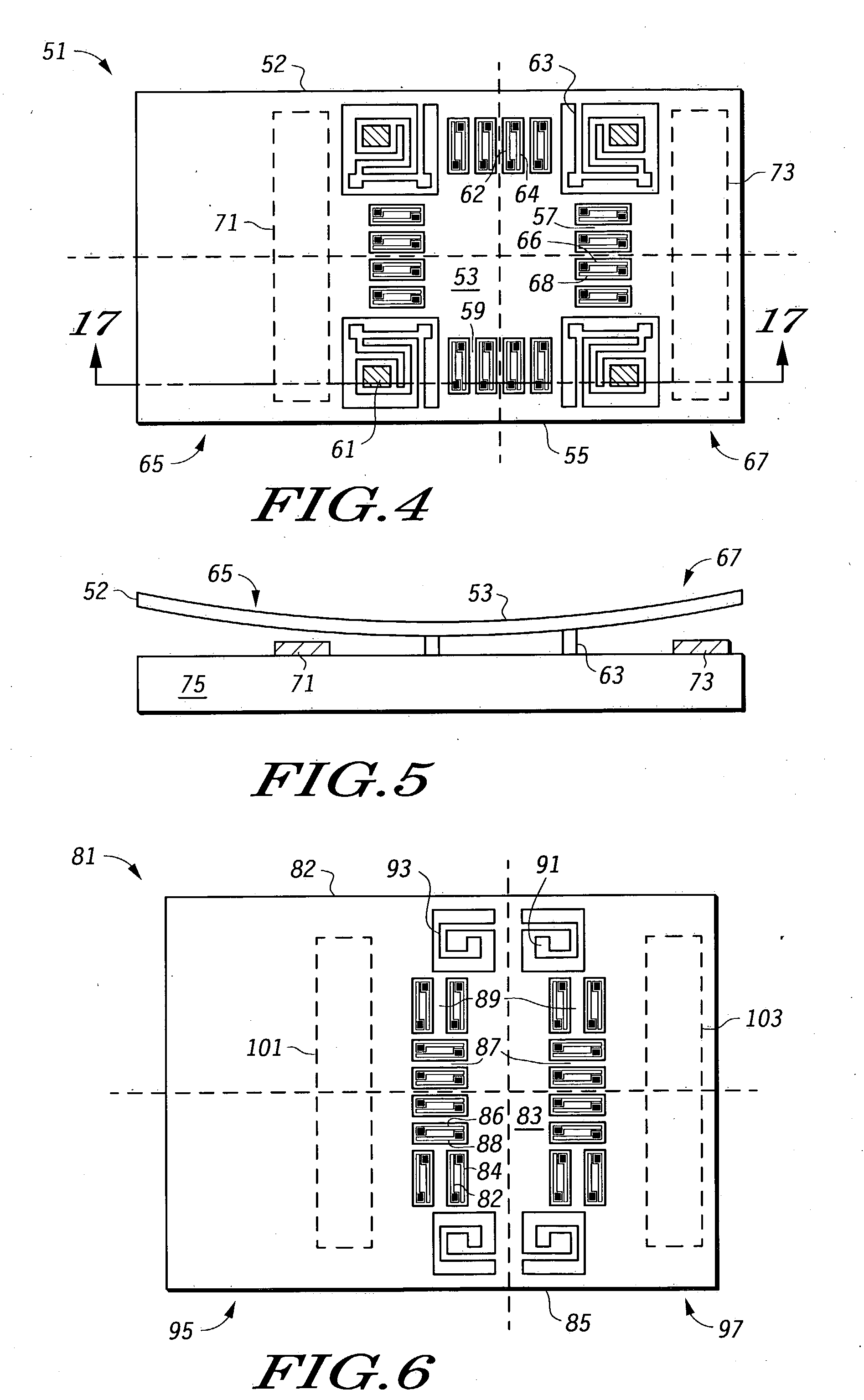

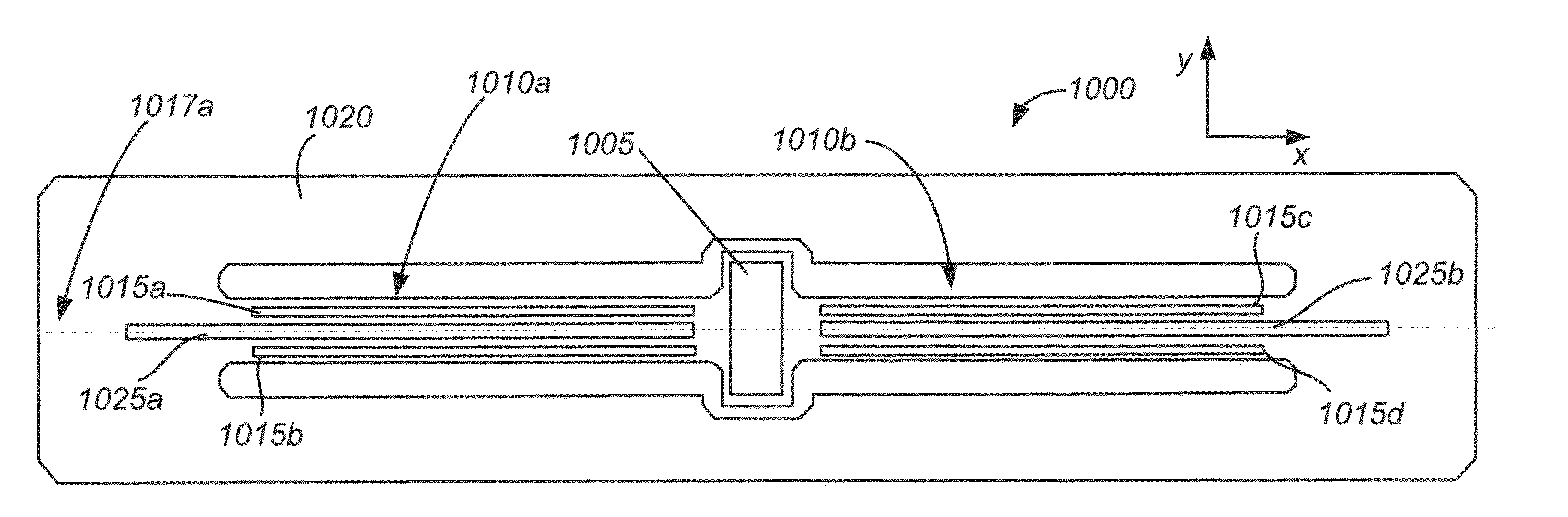

Single proof mass, 3 axis MEMS transducer

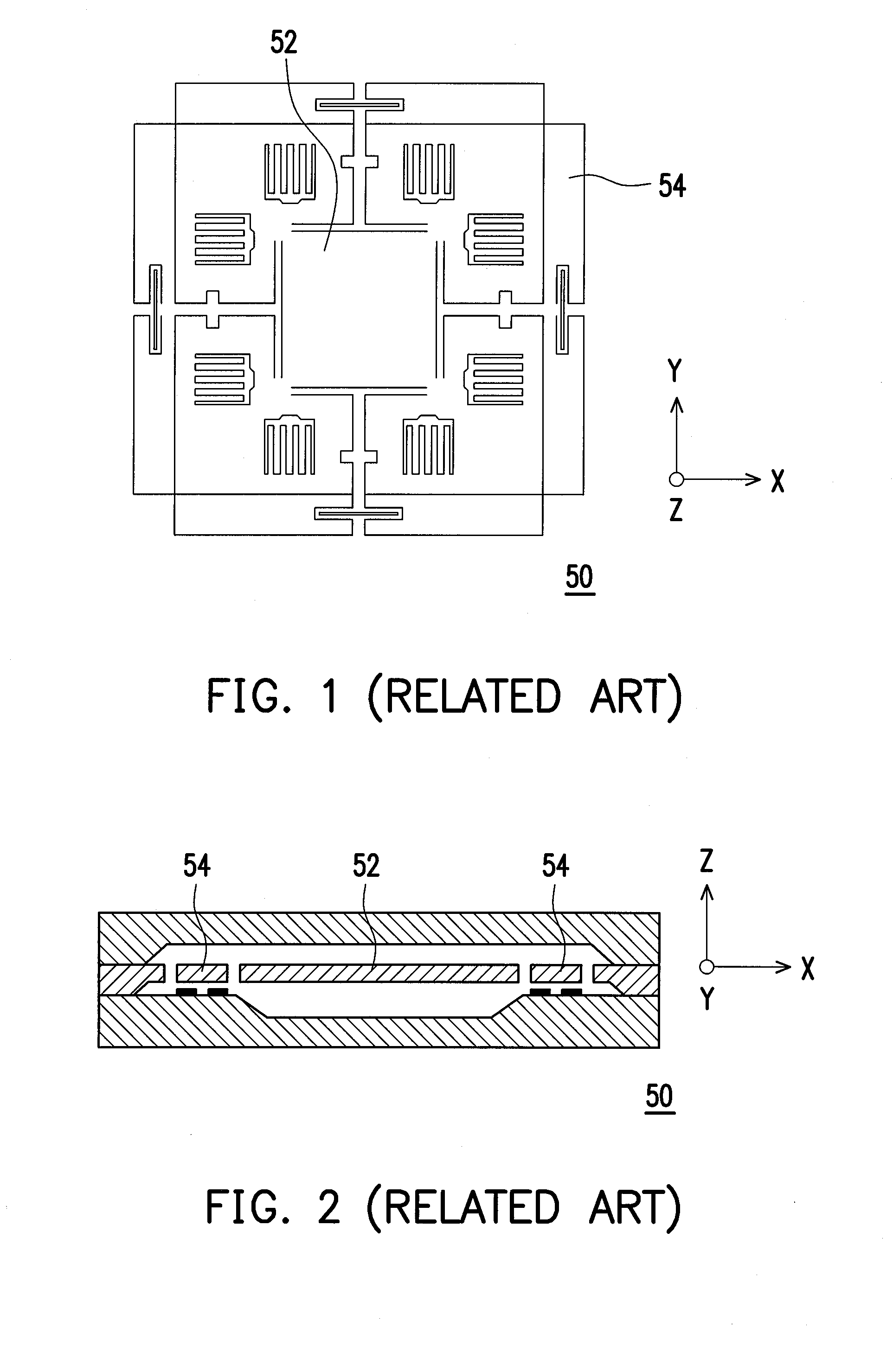

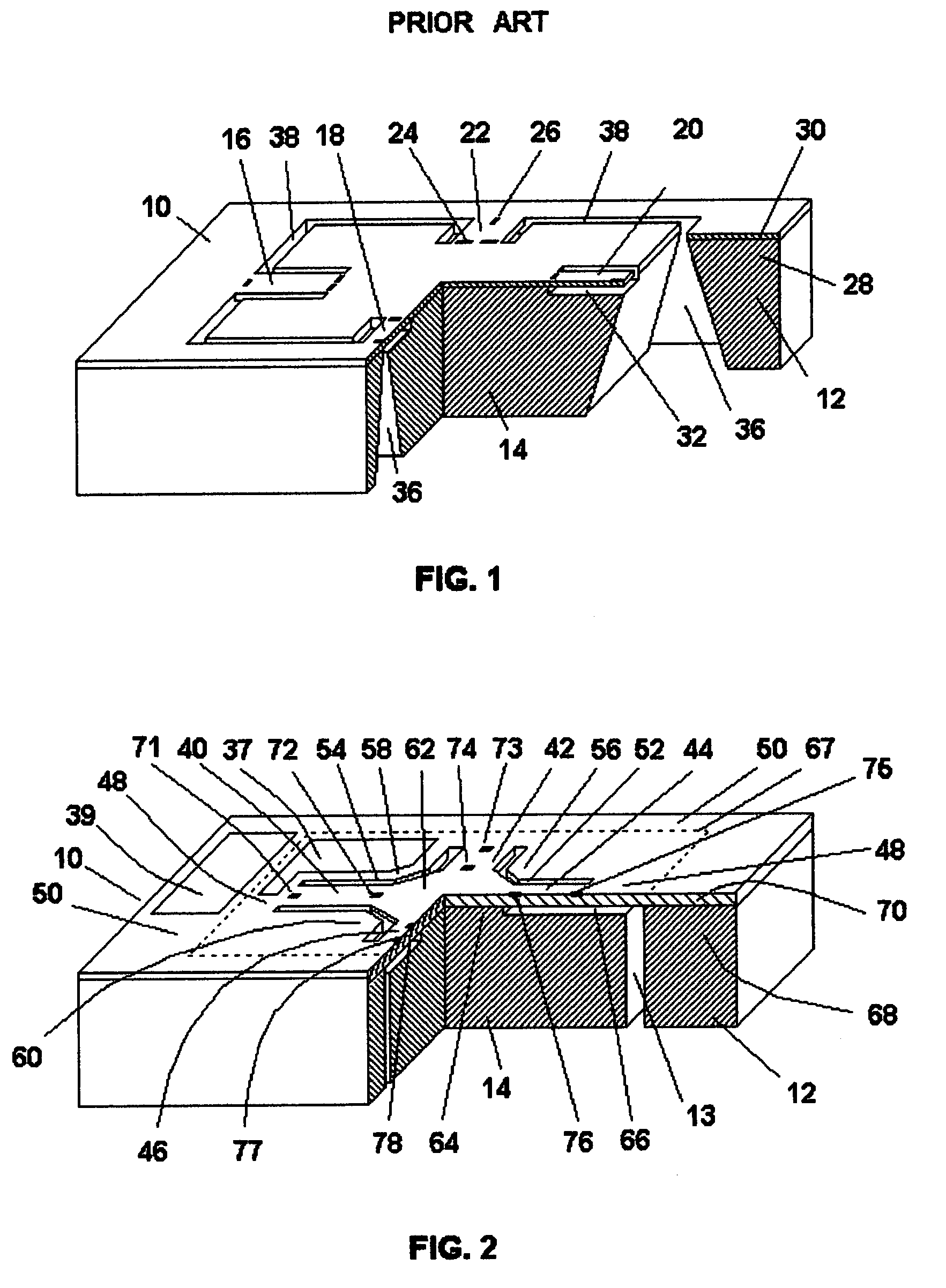

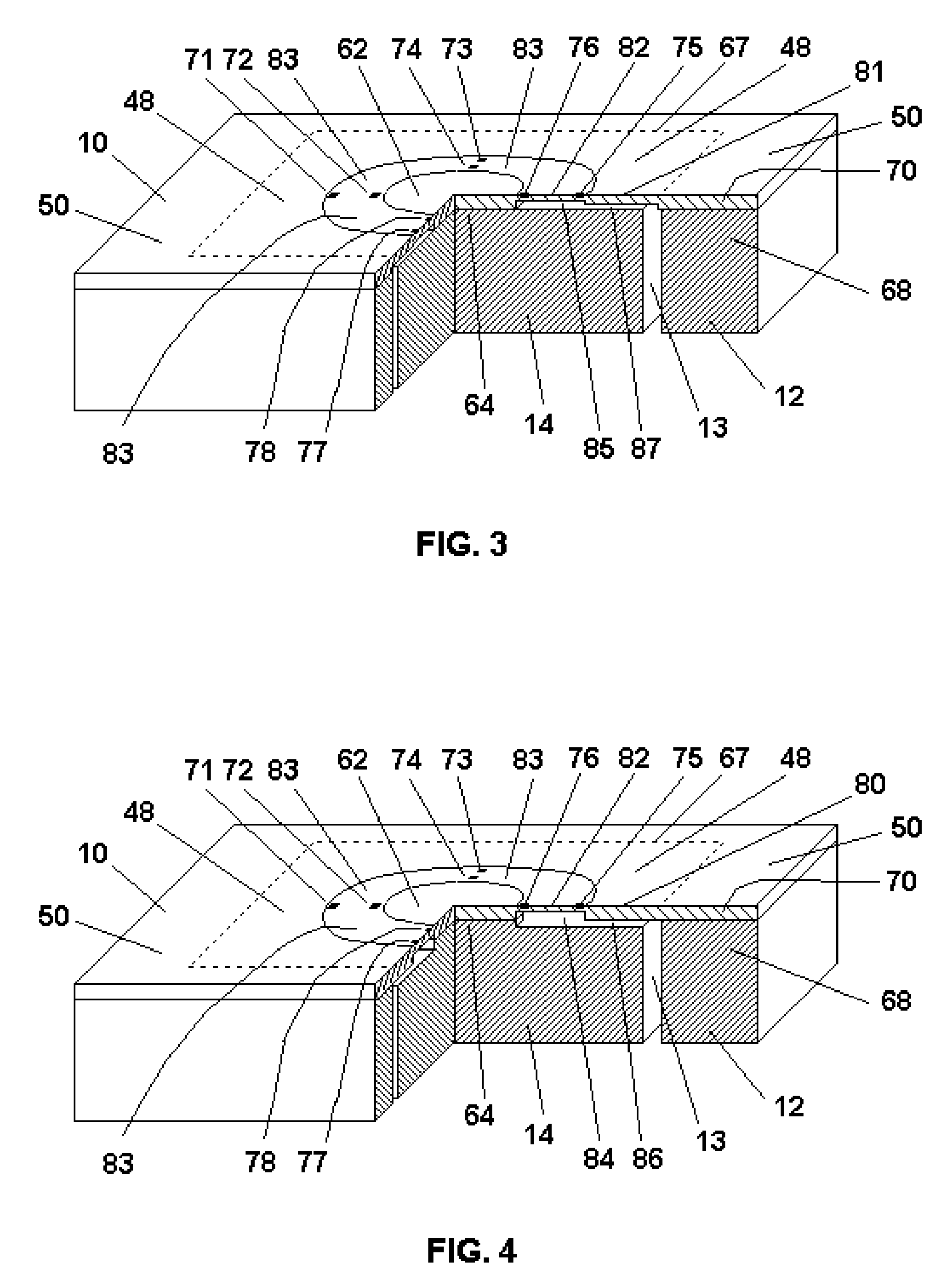

InactiveUS6845670B1Acceleration measurement using interia forcesDevices characerised by mechanical meansTransducerClassical mechanics

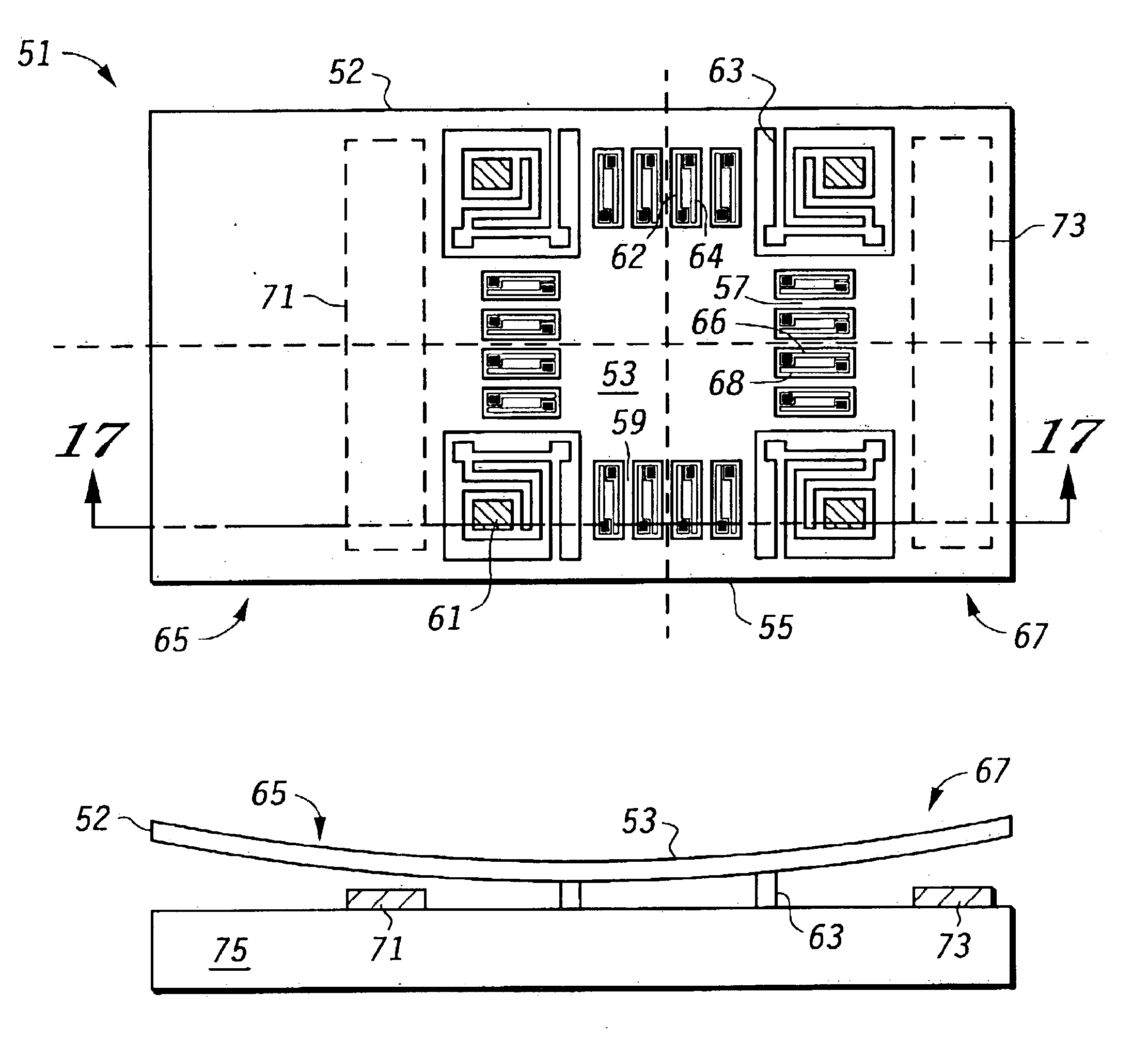

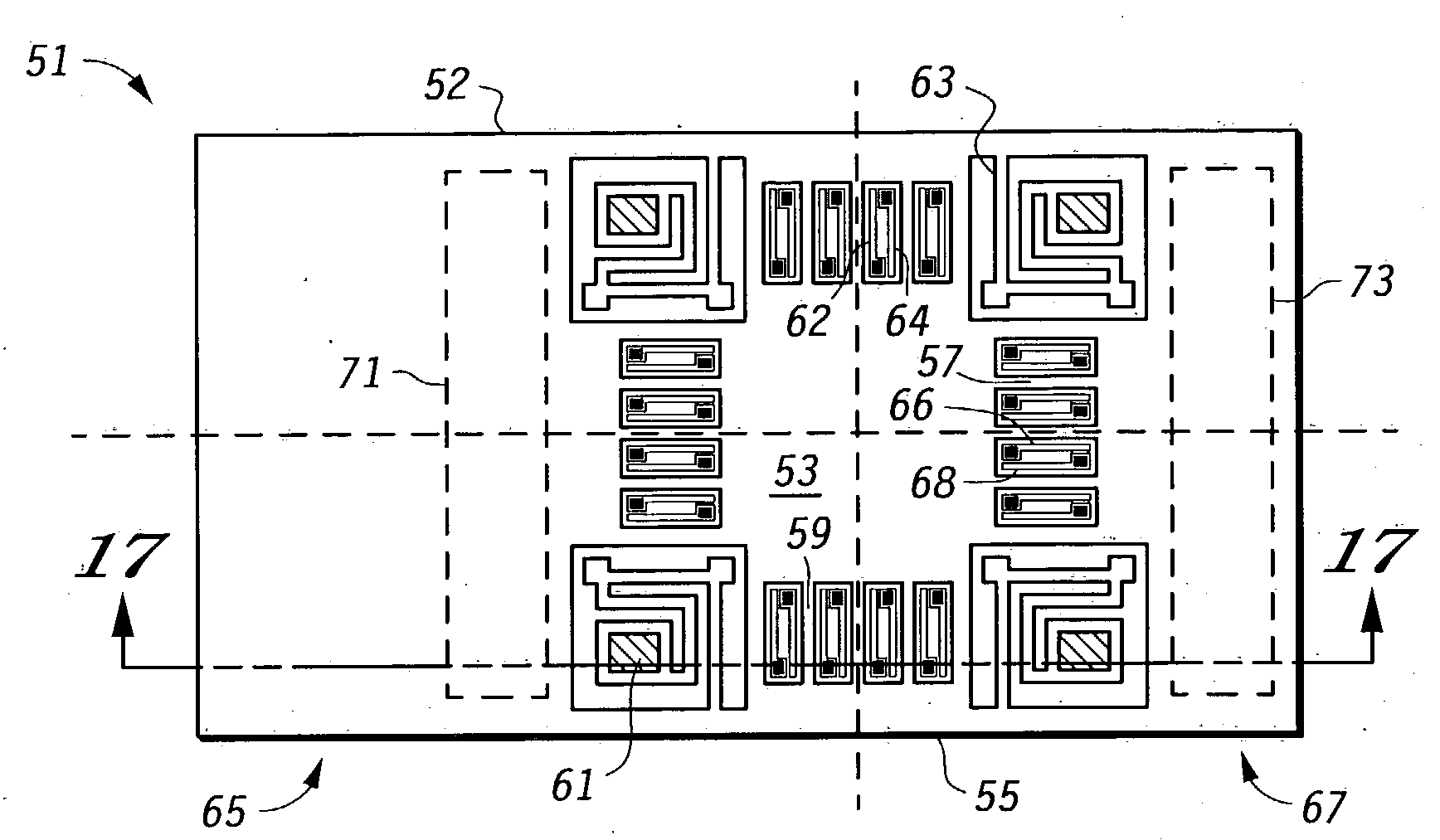

A transducer is provided herein which comprises an unbalanced proof mass (51), and which is adapted to sense acceleration in at least two mutually orthogonal directions. The proof mass (51) has first (65) and second (67) opposing sides that are of unequal mass.

Owner:NORTH STAR INNOVATIONS

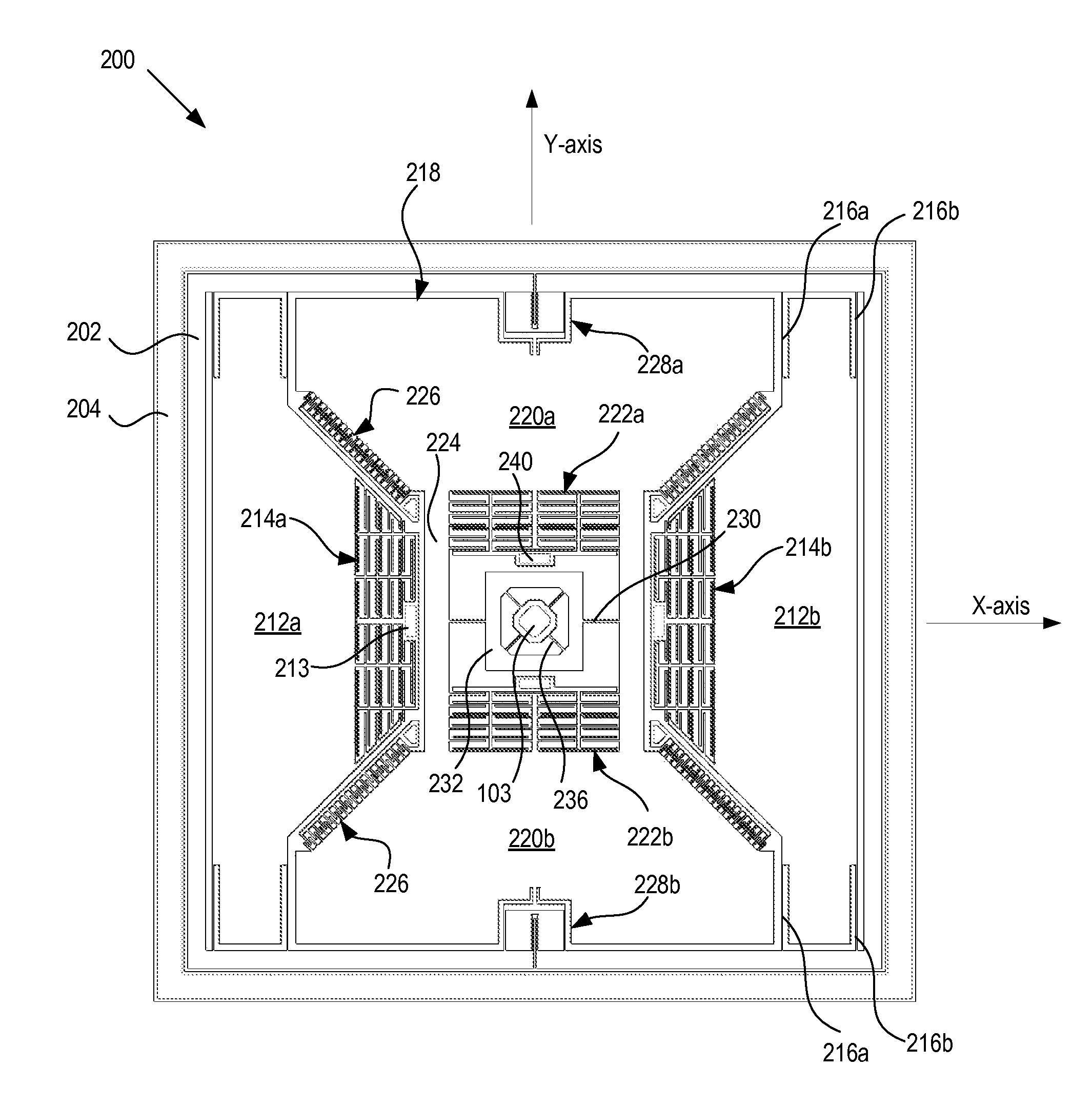

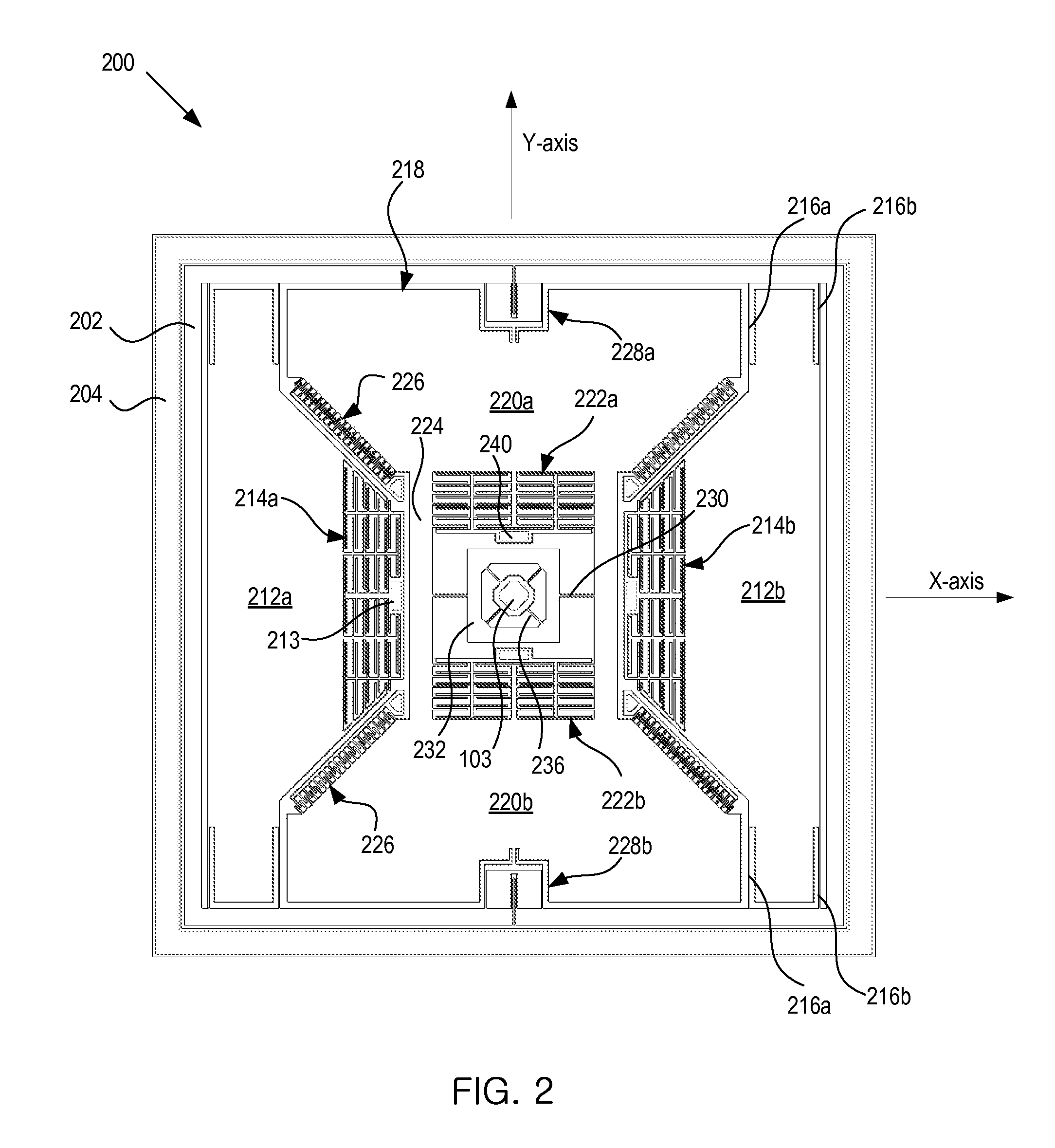

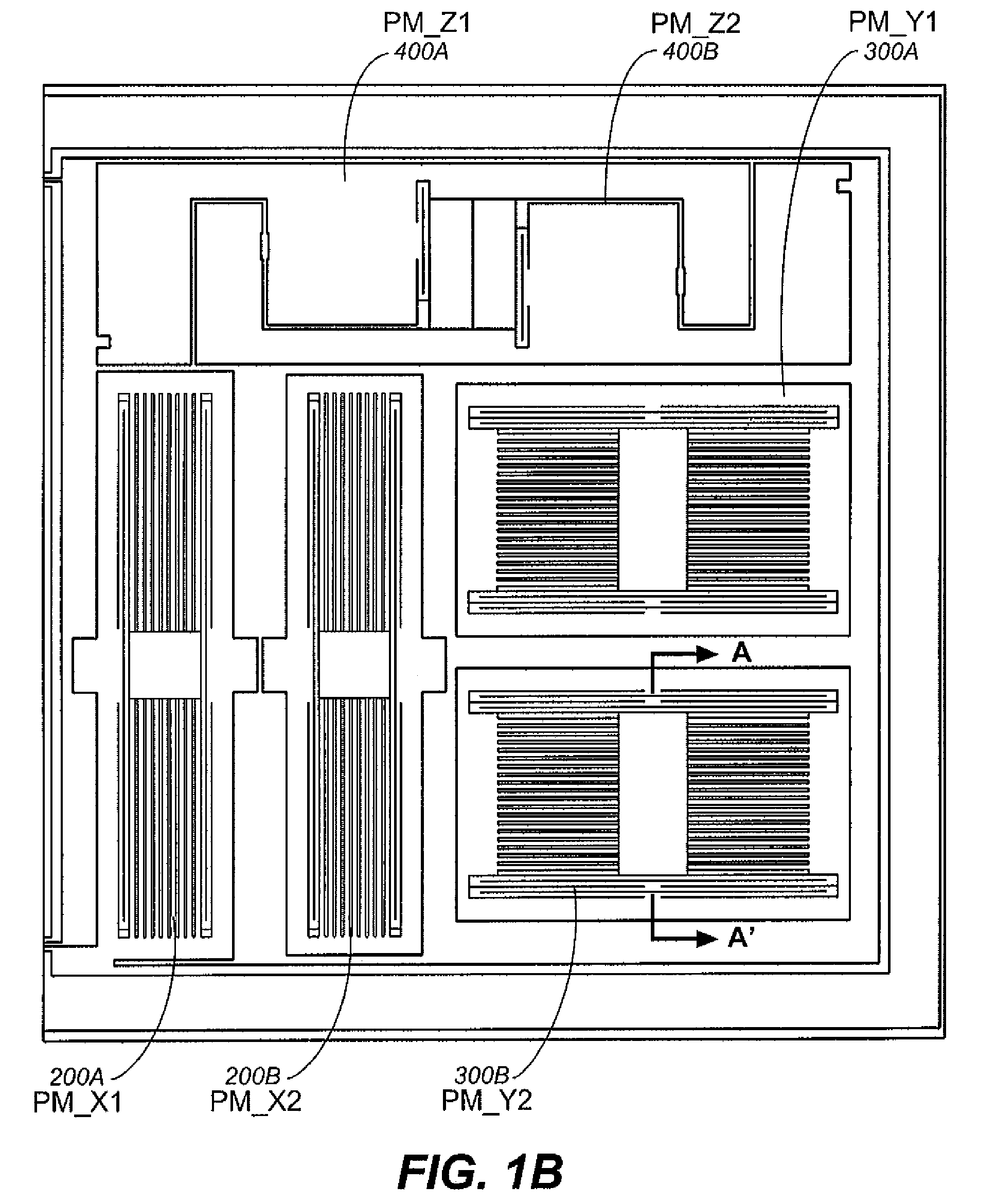

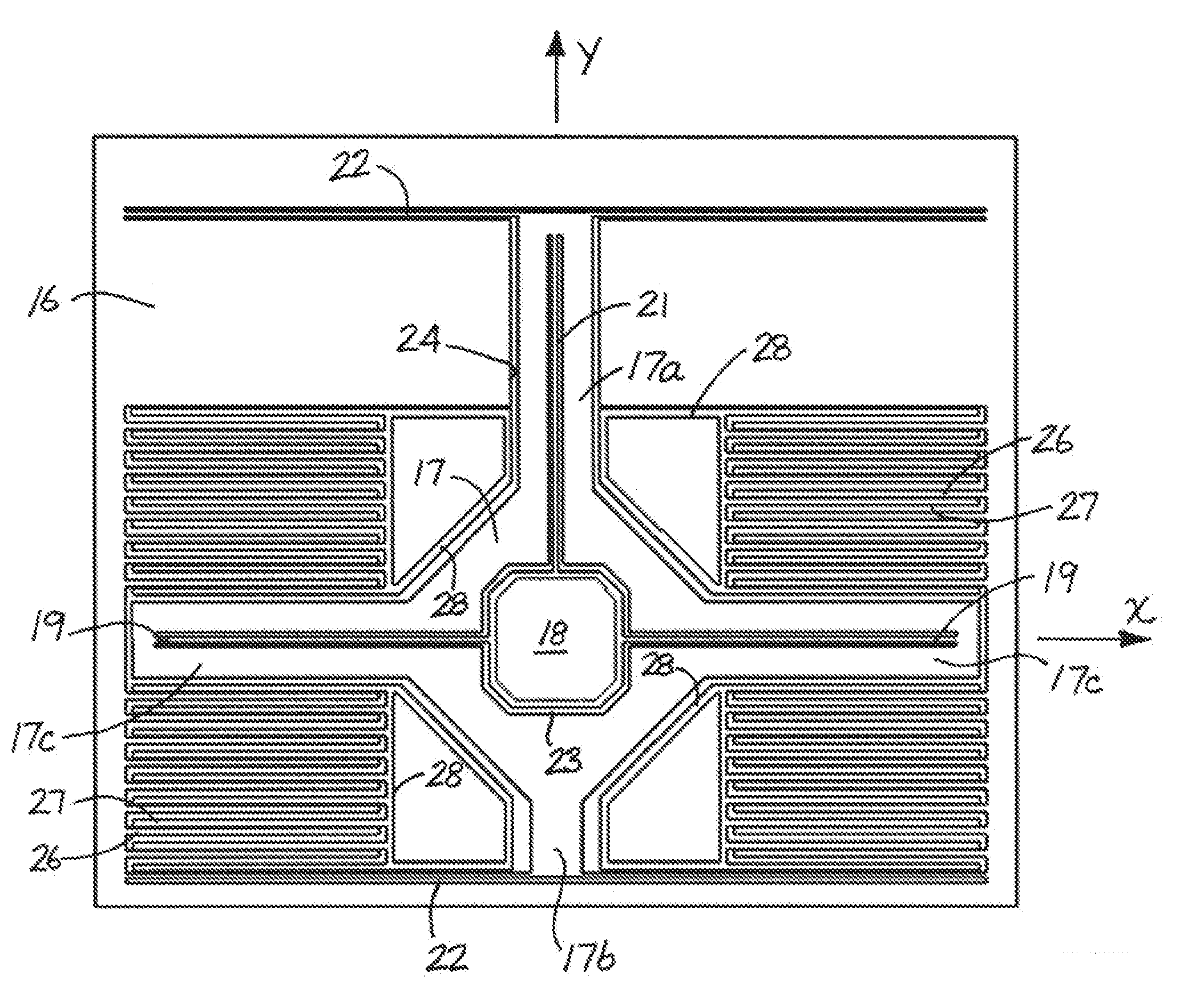

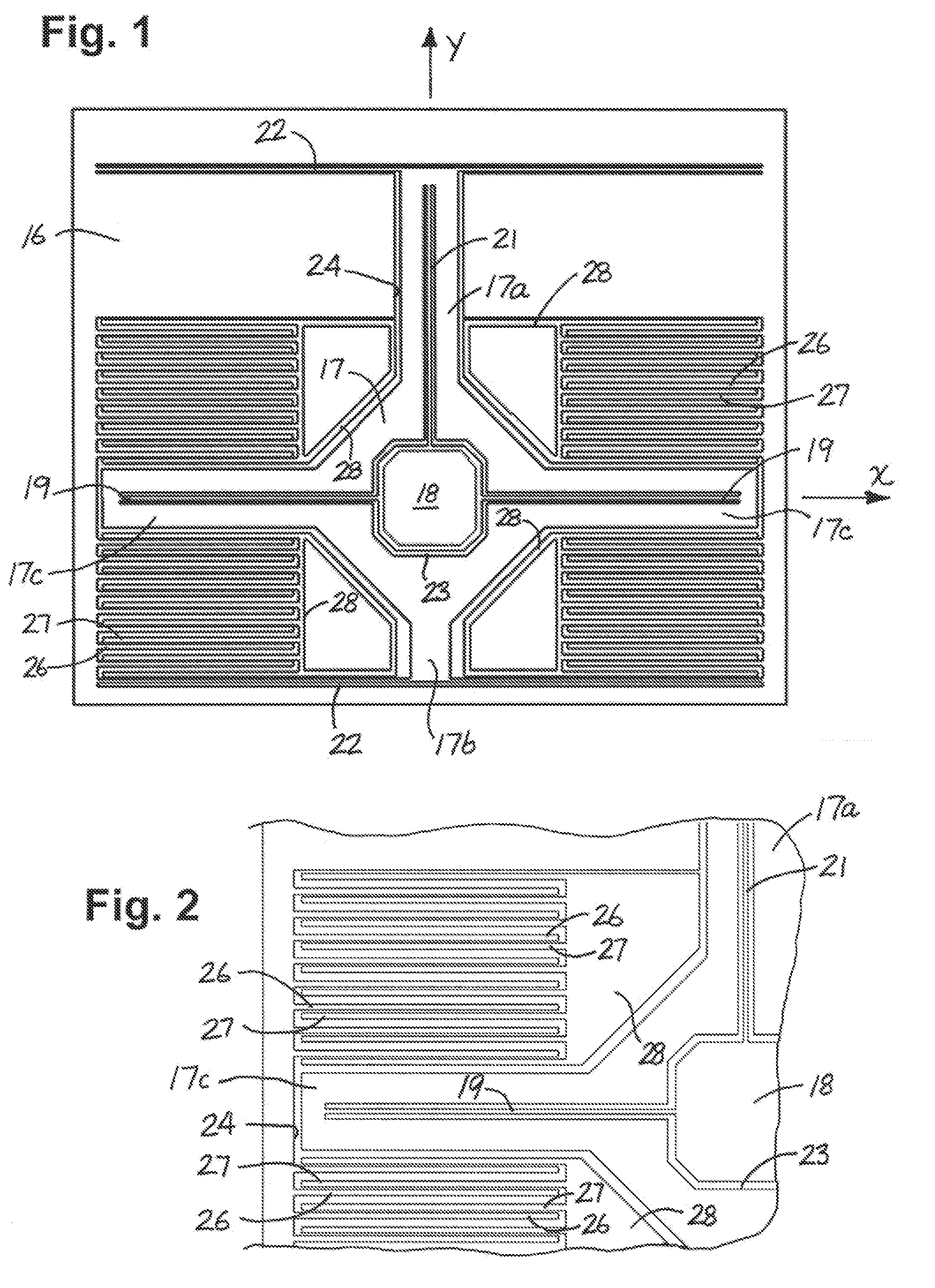

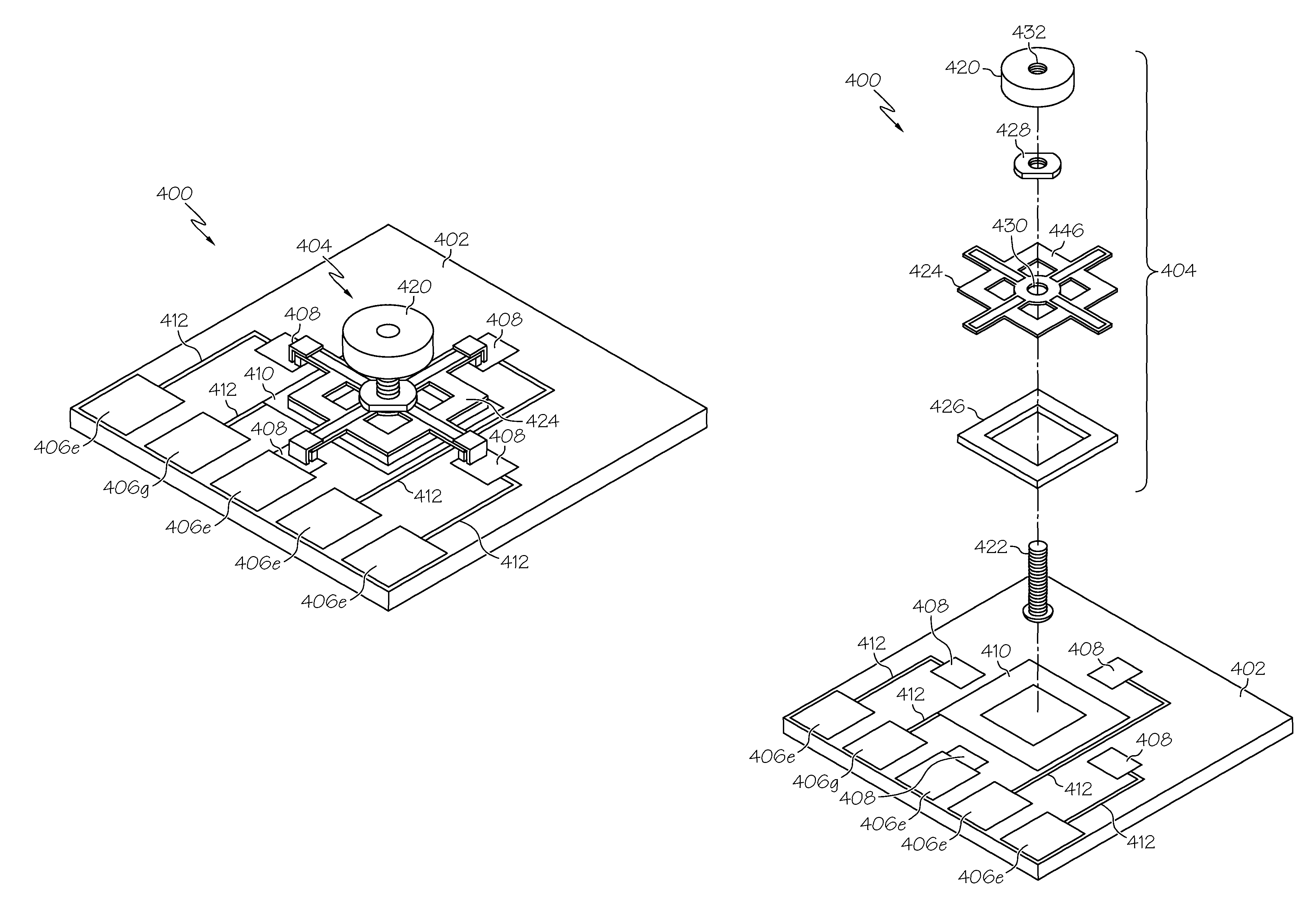

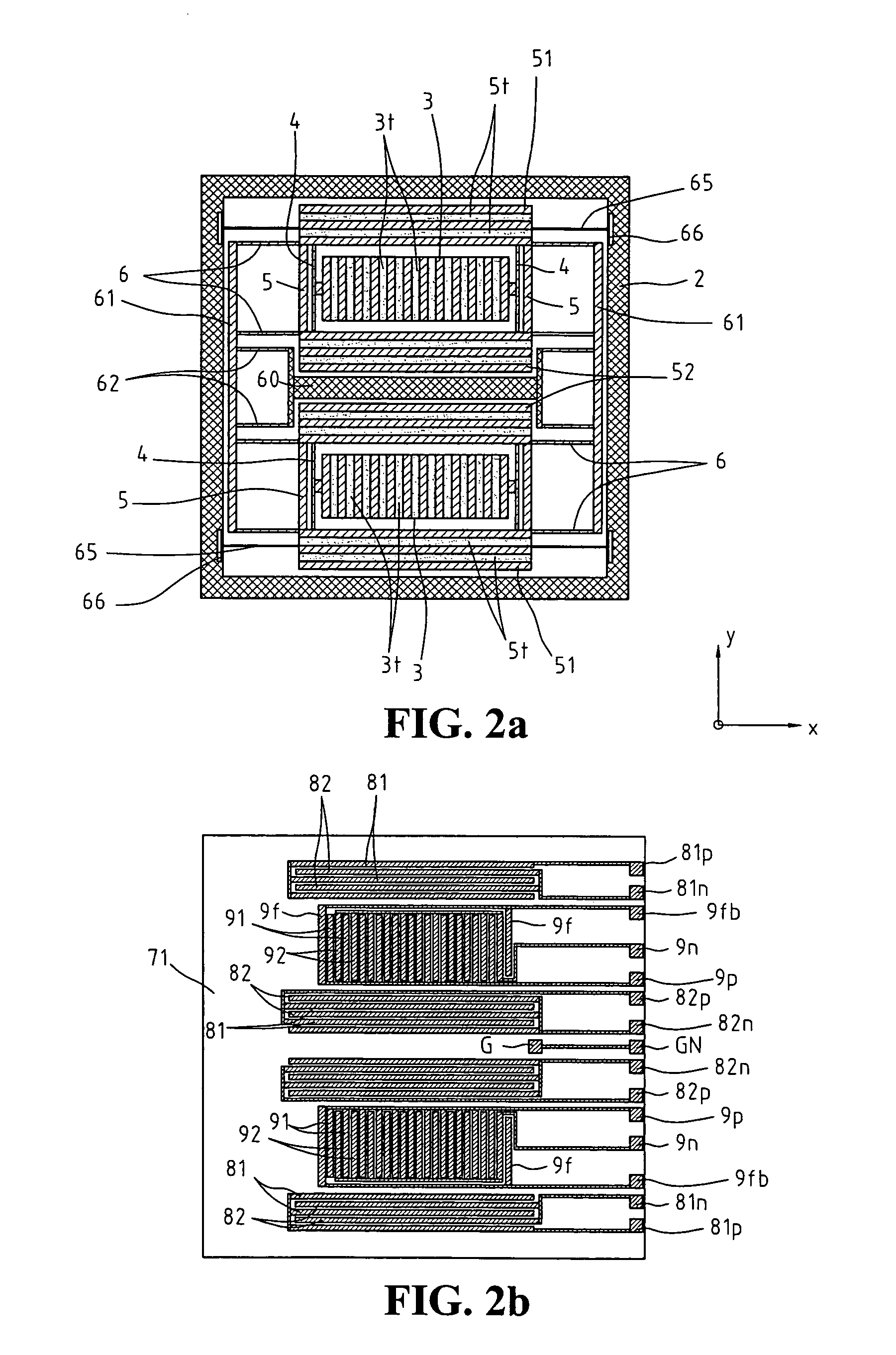

Vertically integrated 3-axis MEMS accelerometer with electronics

ActiveUS20080314147A1Reduce sensitivityReduce temperature changesDevices characerised by mechanical meansAcceleration measurement in multiple dimensionsFull bridgeResonance

A system and method in accordance with the present invention provides for a low cost, bulk micromachined accelerometer integrated with electronics. The accelerometer can also be integrated with rate sensors that operate in a vacuum environment. The quality factor of the resonances is suppressed by adding dampers. Acceleration sensing in each axis is achieved by separate structures where the motion of the proof mass affects the value of sense capacitors differentially. Two structures are used per axis to enable full bridge measurements to further reduce the mechanical noise, immunity to power supply changes and cross axis coupling. To reduce the sensitivity to packaging and temperature changes, each mechanical structure is anchored to a single anchor pillar bonded to the top cover.

Owner:INVENSENSE

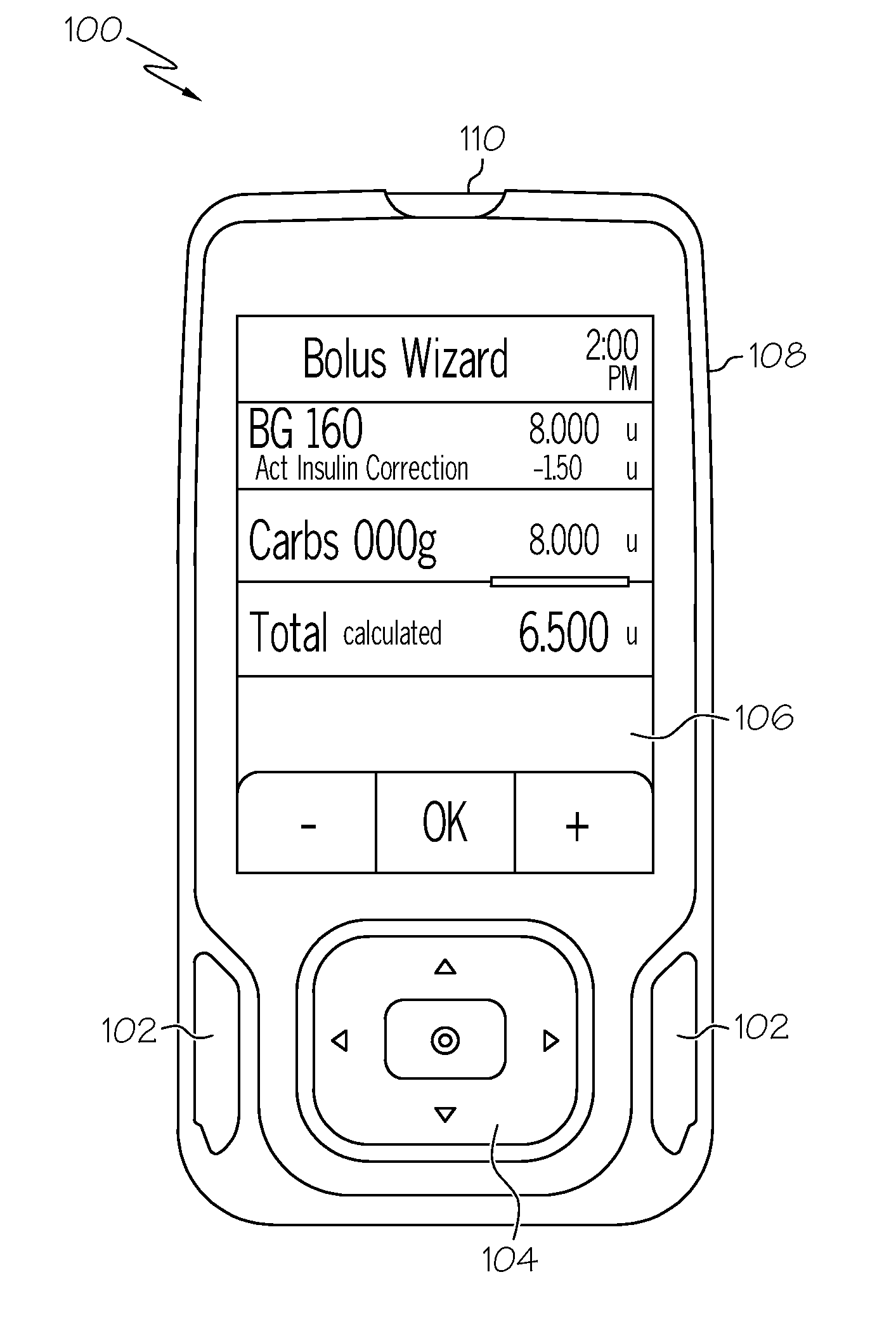

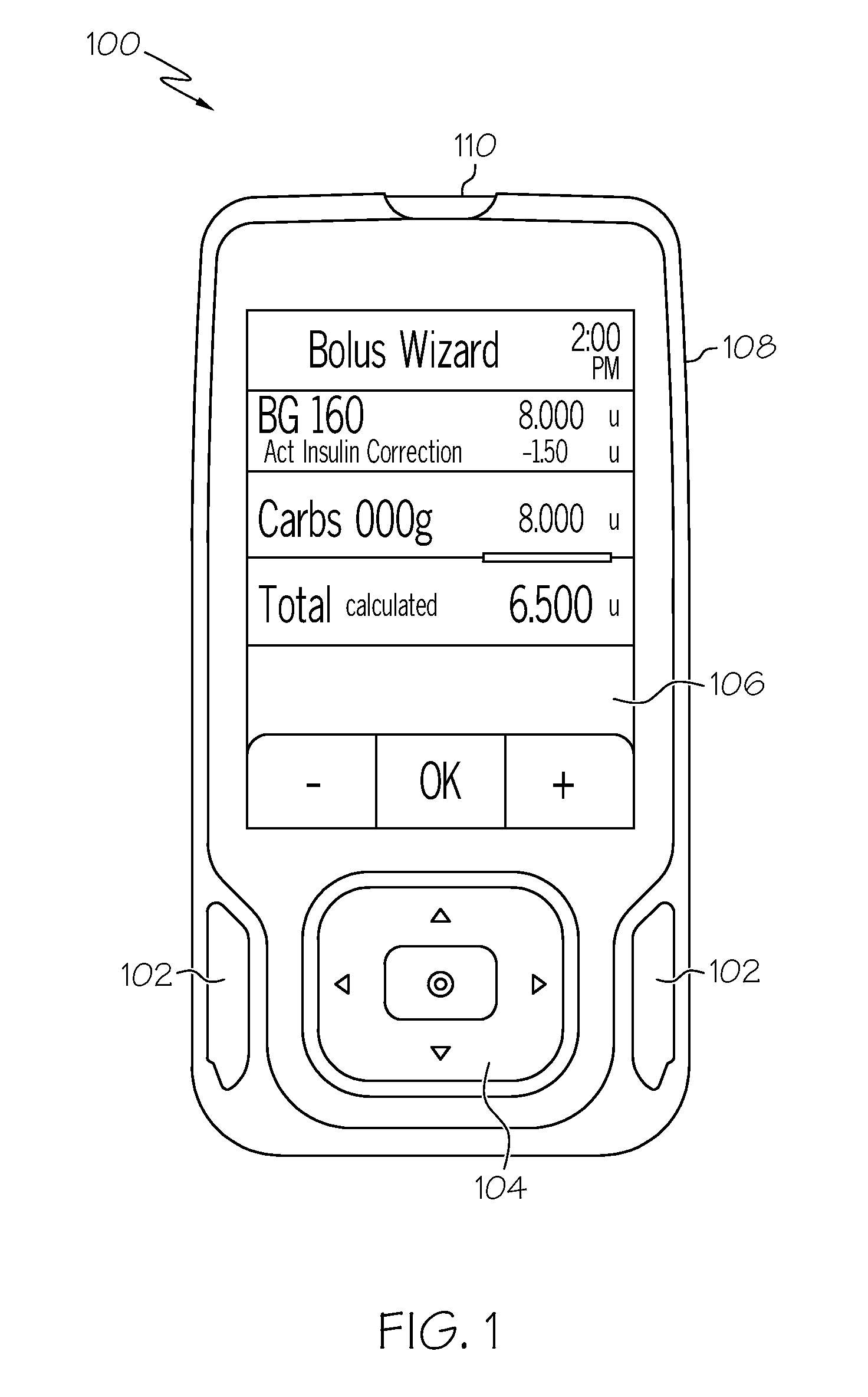

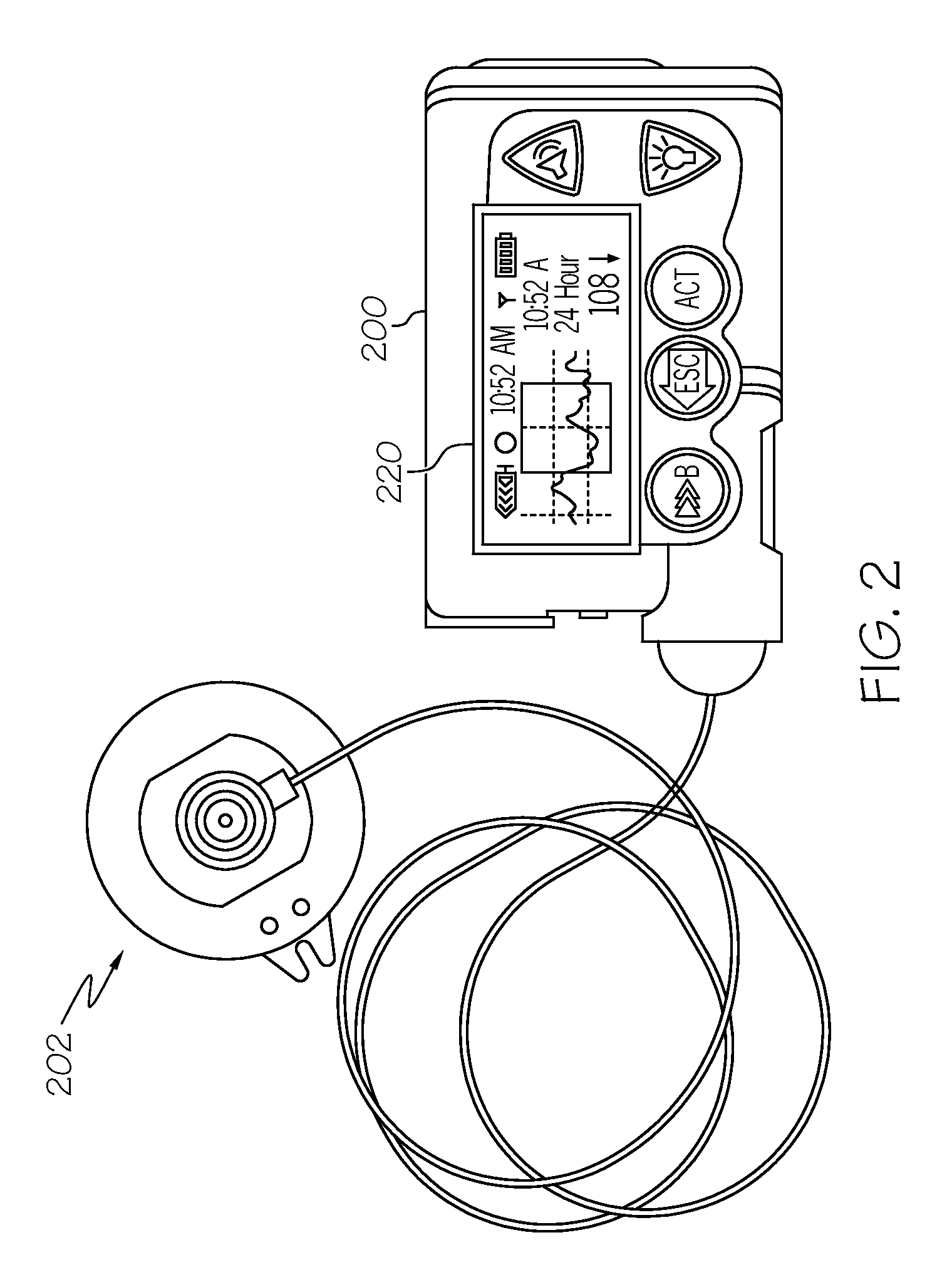

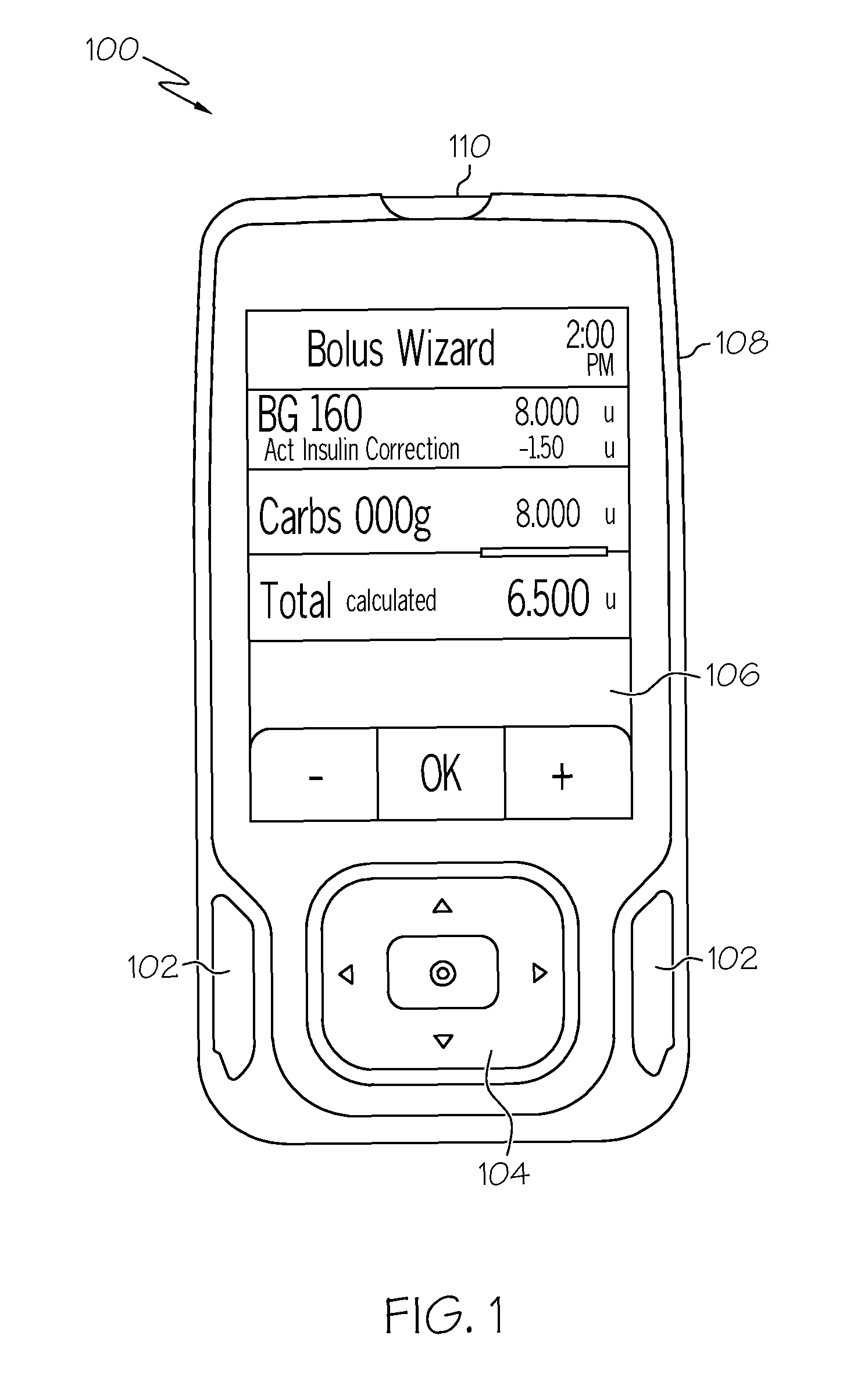

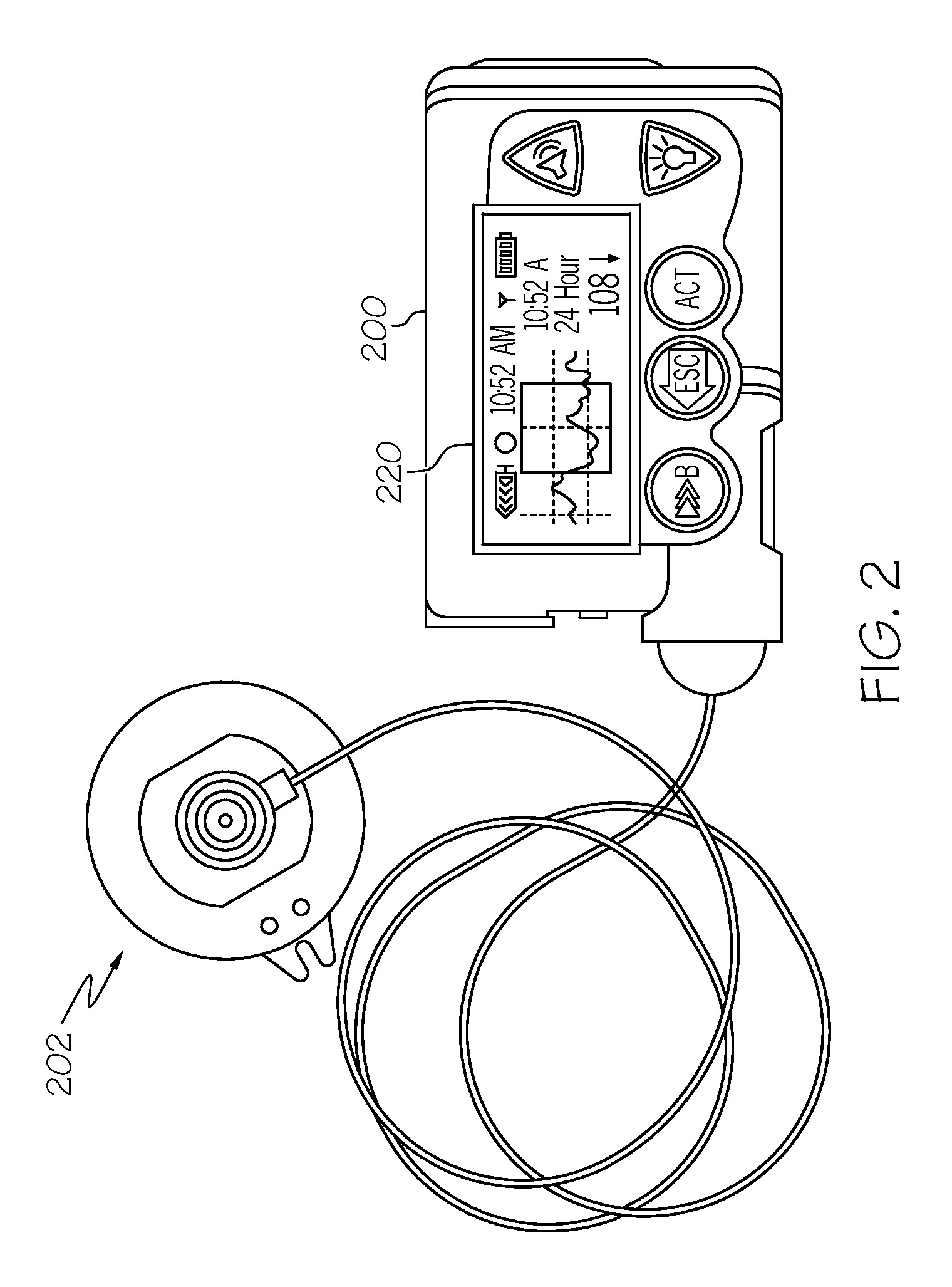

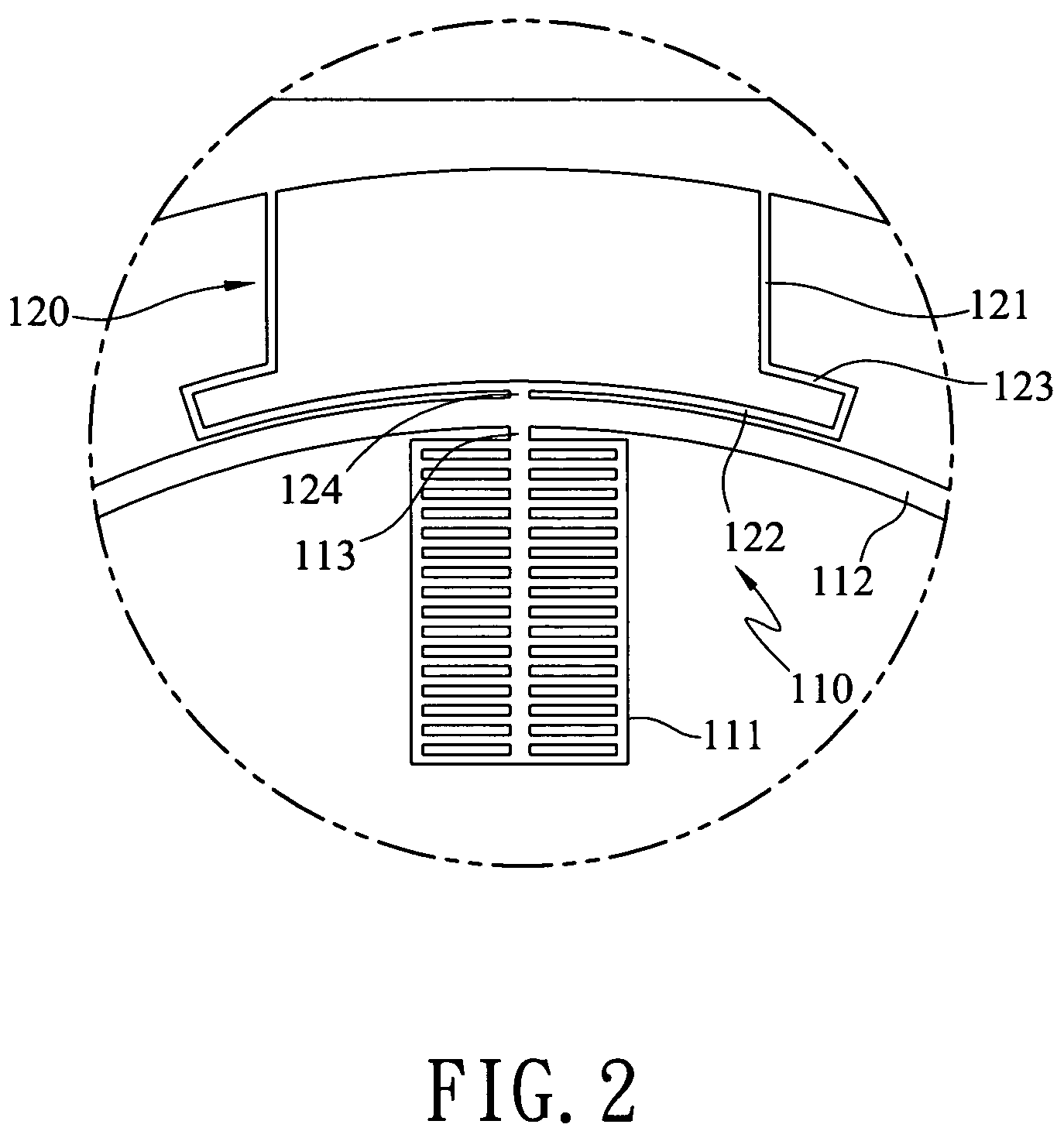

Omnidirectional accelerometer device and medical device incorporating same

ActiveUS20110105955A1Well formedAcceleration measurement using interia forcesElectrotherapyElectricityComputer module

A portable medical device is provided with an internal accelerometer device. The medical device includes a circuit board, the accelerometer device, and a response module coupled to the accelerometer device. The accelerometer device is mechanically and electrically coupled to the circuit board, and it includes a plurality of mass-supporting arms for a plurality of electrically distinct sensor electrodes, piezoelectric material for the mass-supporting arm, and a proof mass supported by the mass-supporting arms. Each of the mass-supporting arms has one of the sensor electrodes located thereon. Acceleration of the proof mass causes deflection of the piezoelectric material, which generates respective sensor signals at one or more of the sensor electrodes. The response module is configured to initiate an acceleration-dependent operation of the portable medical device in response to generated sensor signals present at the sensor electrodes.

Owner:MEDTRONIC MIMIMED INC

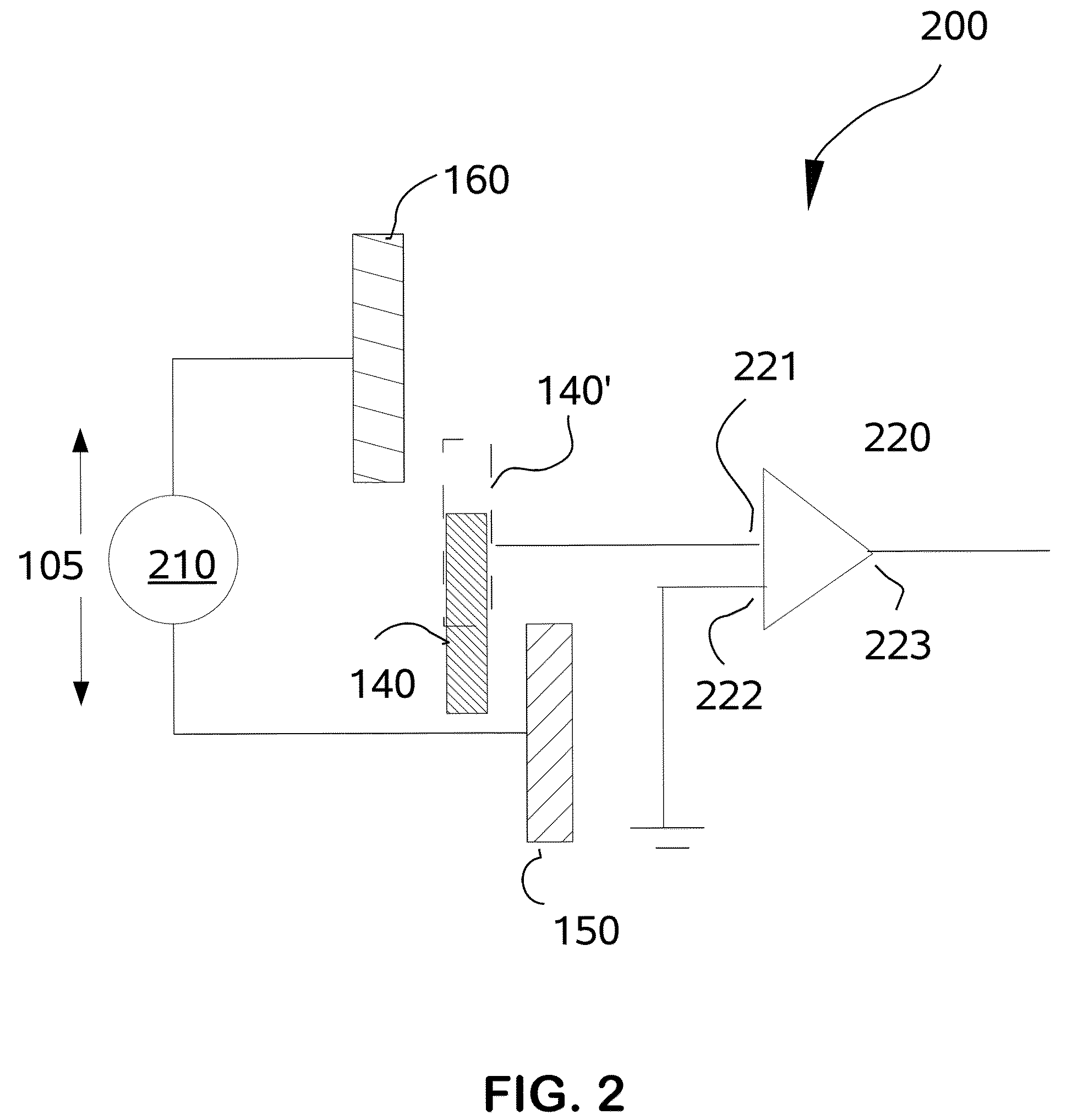

Accelerometer

ActiveUS7617729B2Cancel noiseQuality improvementAcceleration measurementCapacitanceClassical mechanics

An accelerometer is fabricated as a MEMS device and includes an array of capacitive electrode plates mechanically coupled to a common proof mass.The proof mass is constrained to move or vibrate in the plane parallel to the first array of plates. The capacitance between the first array of plates is measured with respect to additional arrays of capacitive plates inter-digitated in a comb like pattern.

Owner:PHYSICAL LOGIC LTD

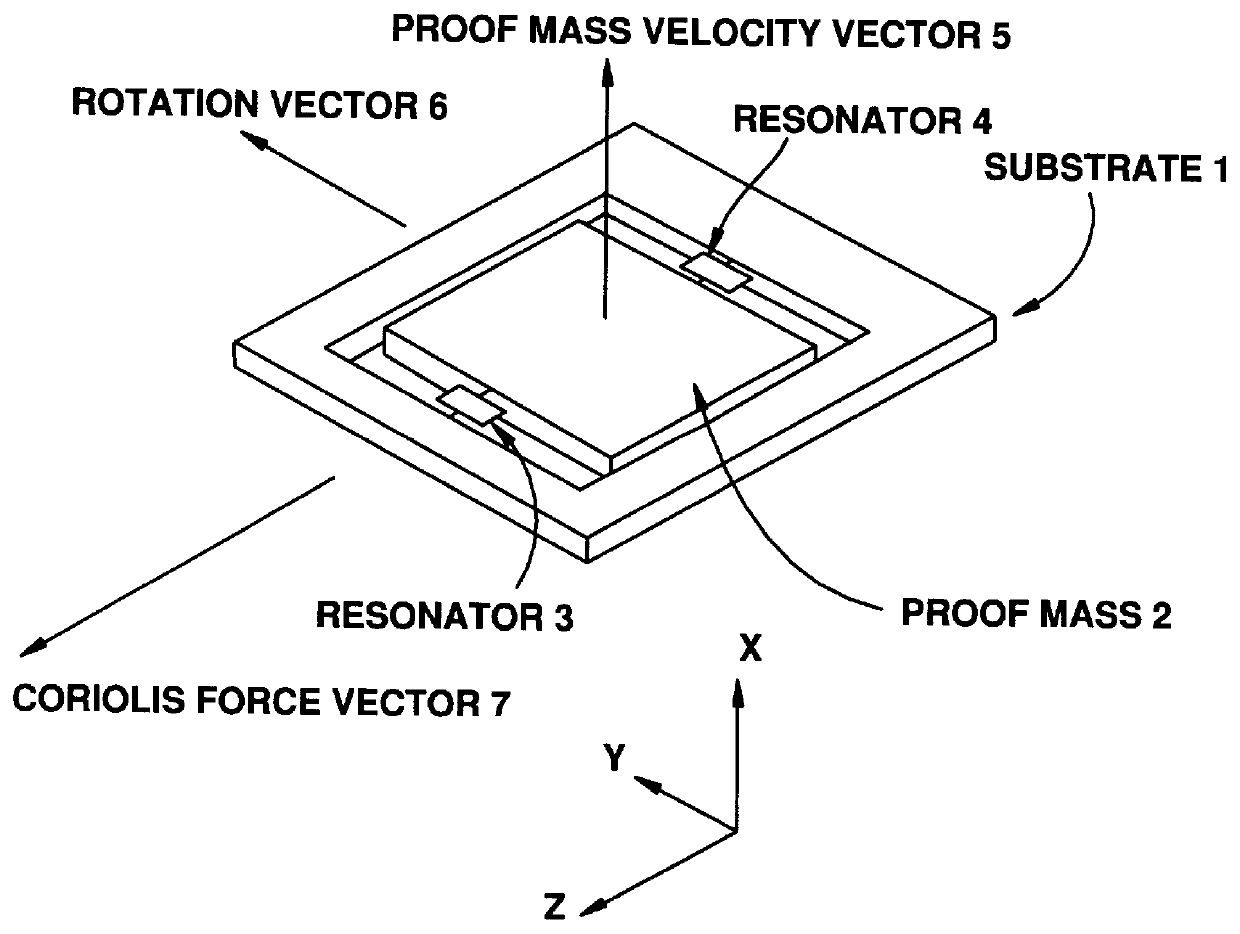

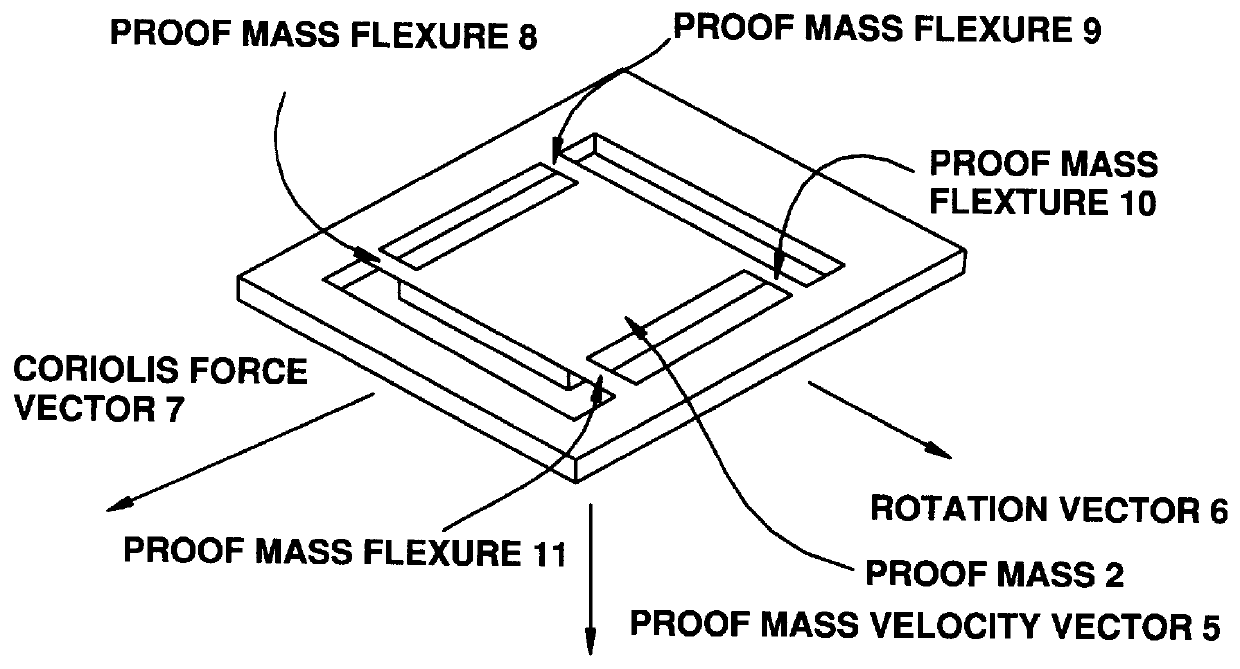

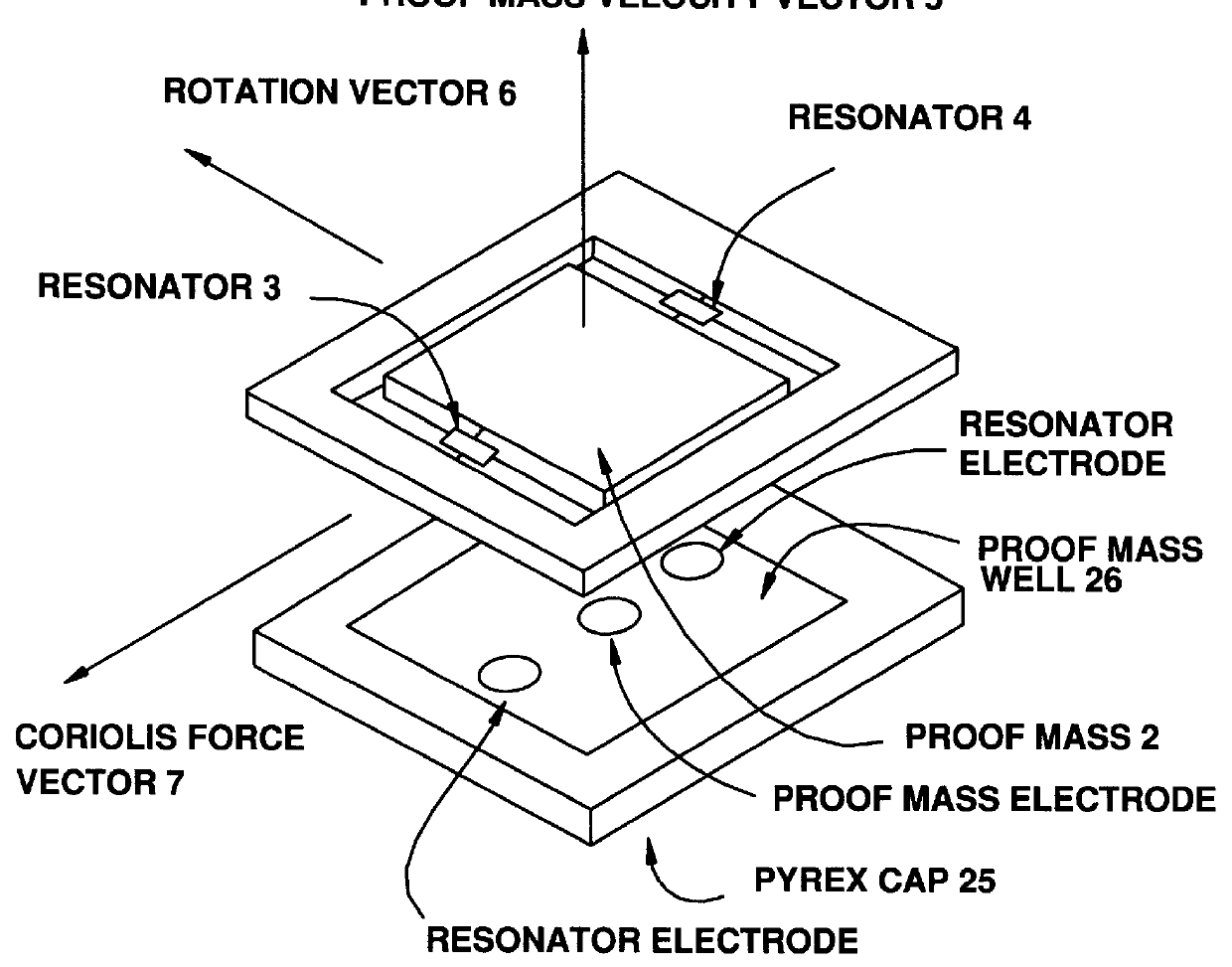

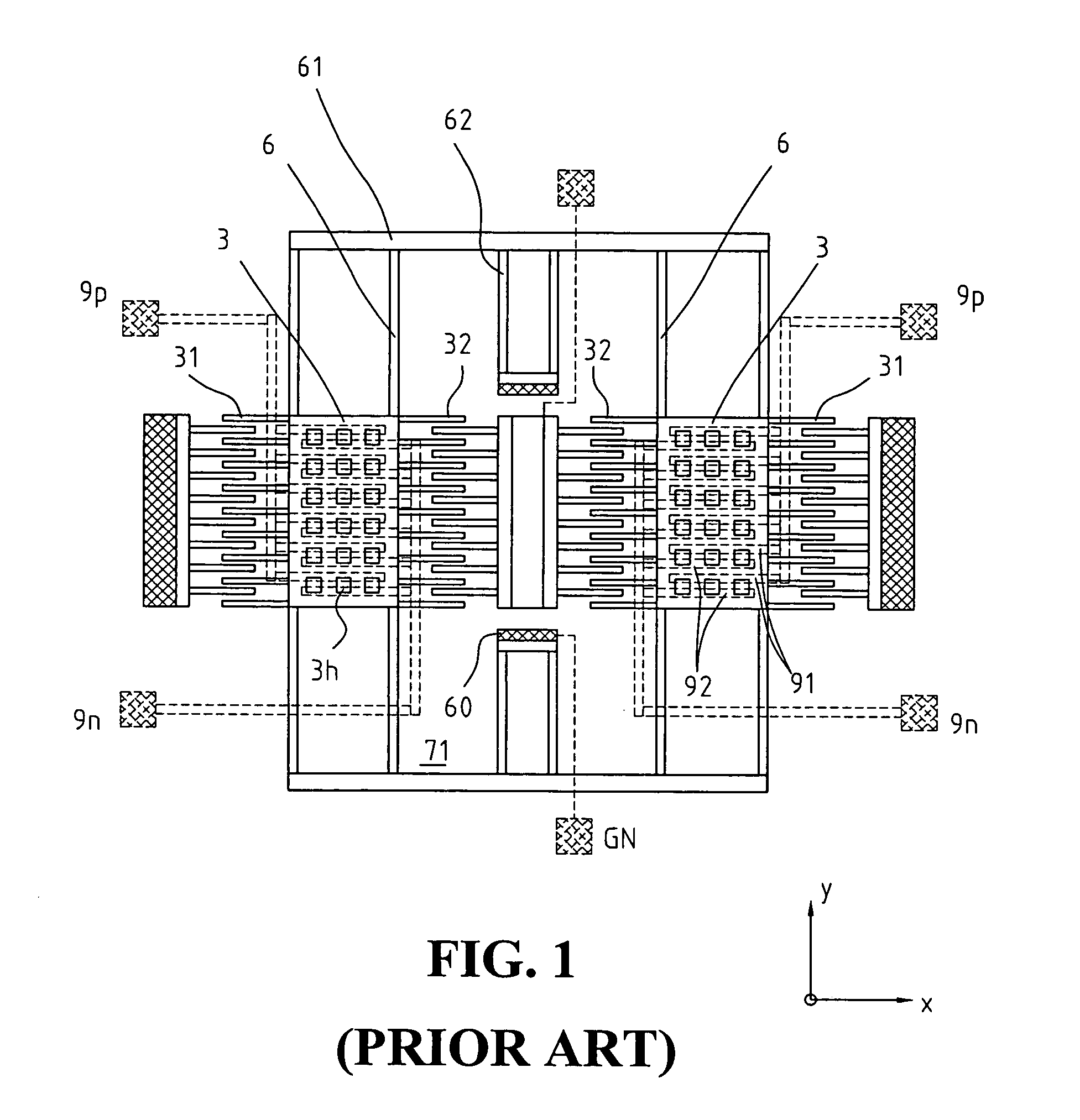

Micromachined acceleration and coriolis sensor

InactiveUS6032531AAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDual stageGyroscope

A solid state silicon micromachined acceleration and Coriolis (MAC) sensor that measures linear and angular motion. The MAC sensor is a single device that performs the functions of a conventional accelerometer and a gyroscope simultaneously. The MAC sensor is unique in that it is a differential dual stage device using only one micromachined proof mass to measure both linear and angular motions. The single proof mass is connected to opposing electromechanical resonators in a monolithic microstructure made from single crystal silicon. This unique design offers improvements in measurement performance and reductions in fabrication complexity that are beyond the state the art of earlier micromachined inertial sensors.

Owner:KEARFOTT

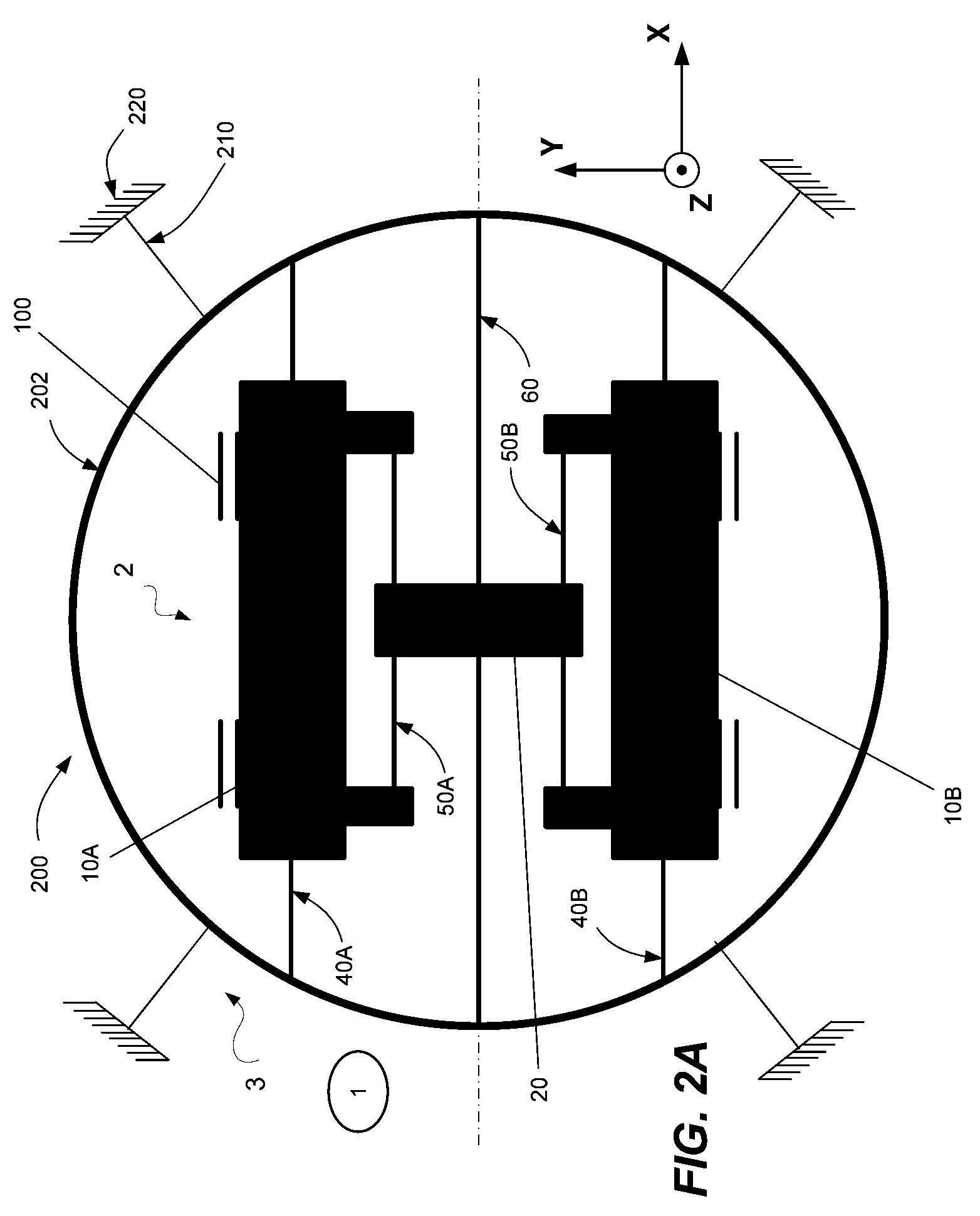

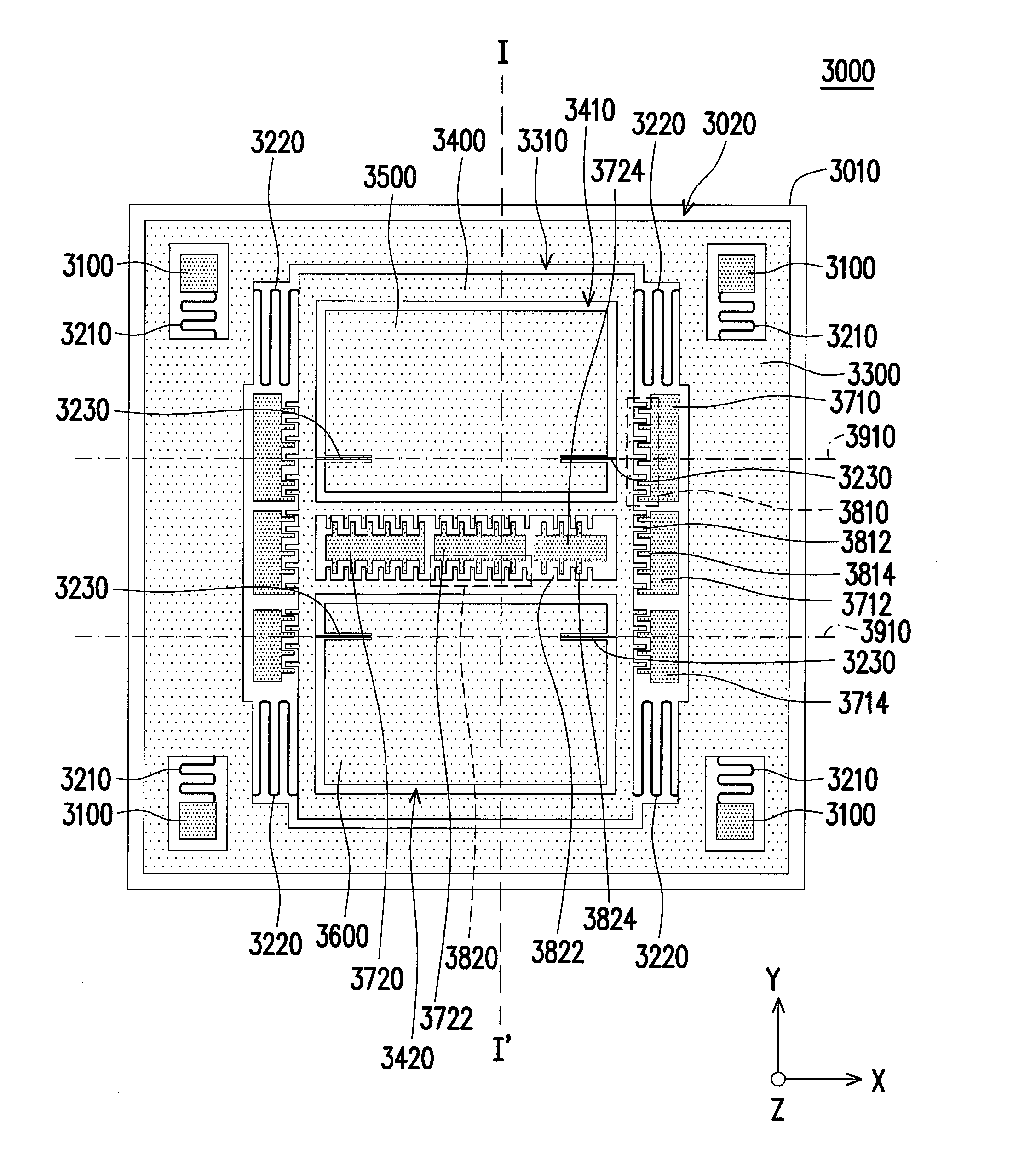

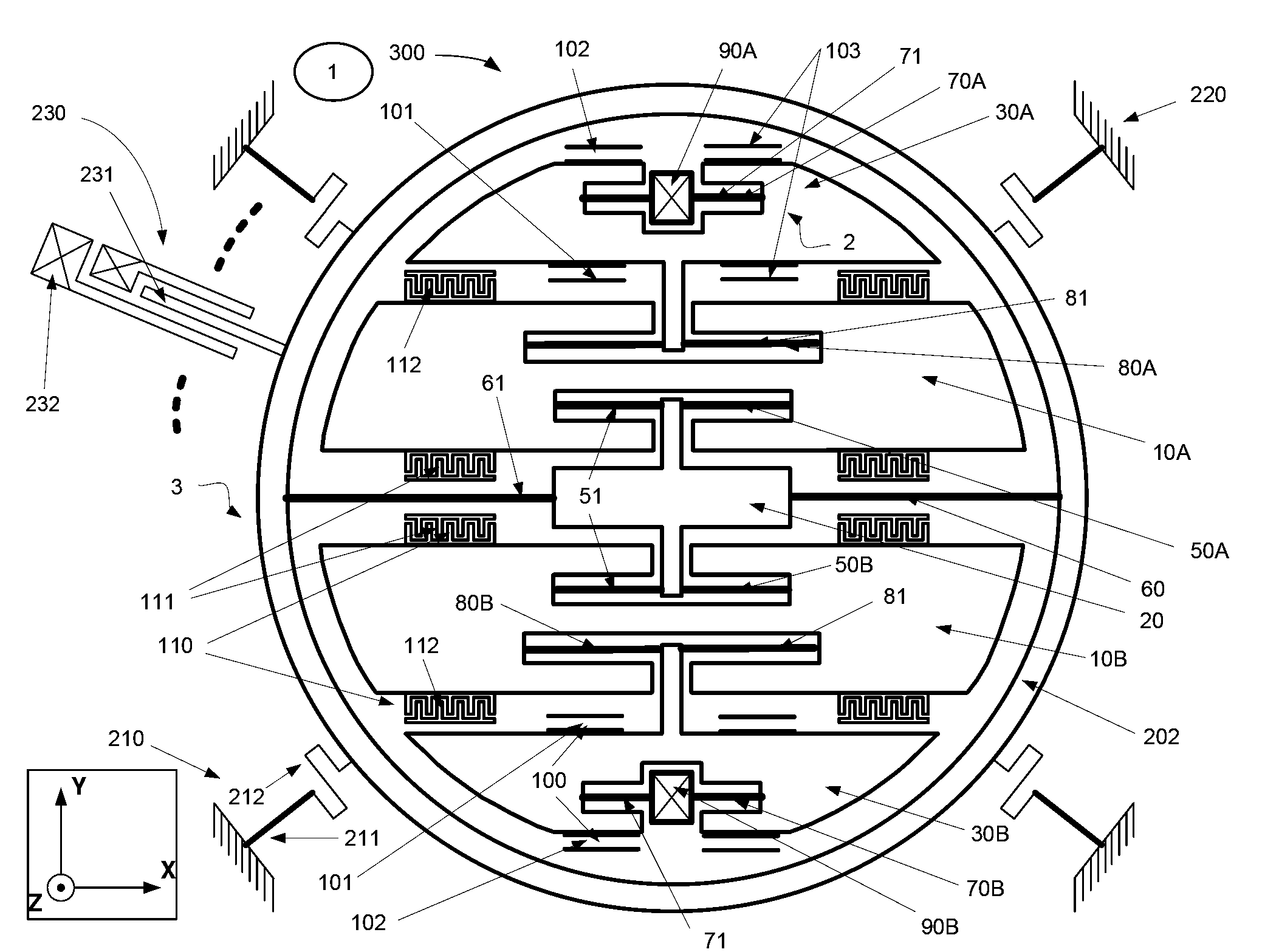

Integrated microelectromechanical systems (MEMS) vibrating mass z-axis rate sensor

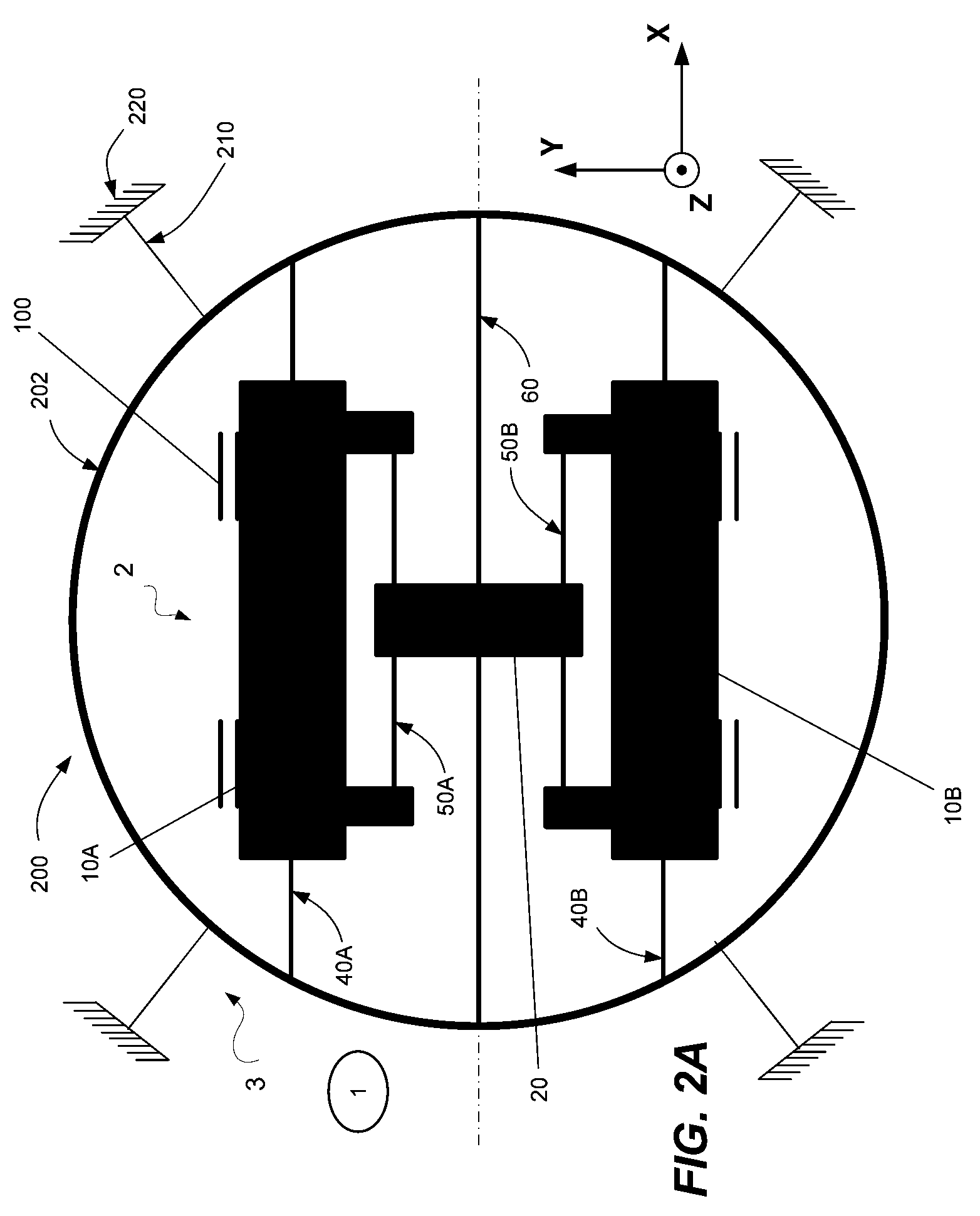

ActiveUS20090114016A1High yieldAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTransducerAngular velocity

A sensor that measures angular velocity about an axis that is normal to a sensing plane of the sensor. The sensor comprises a sensing subassembly that includes a planar frame parallel to the sensing plane, a first proof mass disposed in the sensing plane, a second proof mass disposed in the sensing plane laterally to the first proof mass, and a linkage within the frame and connected to the frame. The linkage is connected to the first proof mass and to the second proof mass. The sensor further includes actuator for driving the first proof mass and the second proof mass into oscillation along a drive axis in the sensing plane. The sensor further includes a first transducer to sense motion of the frame in response to a Coriolis force acting on the oscillating first proof mass and the oscillating second proof mass.

Owner:INVENSENSE

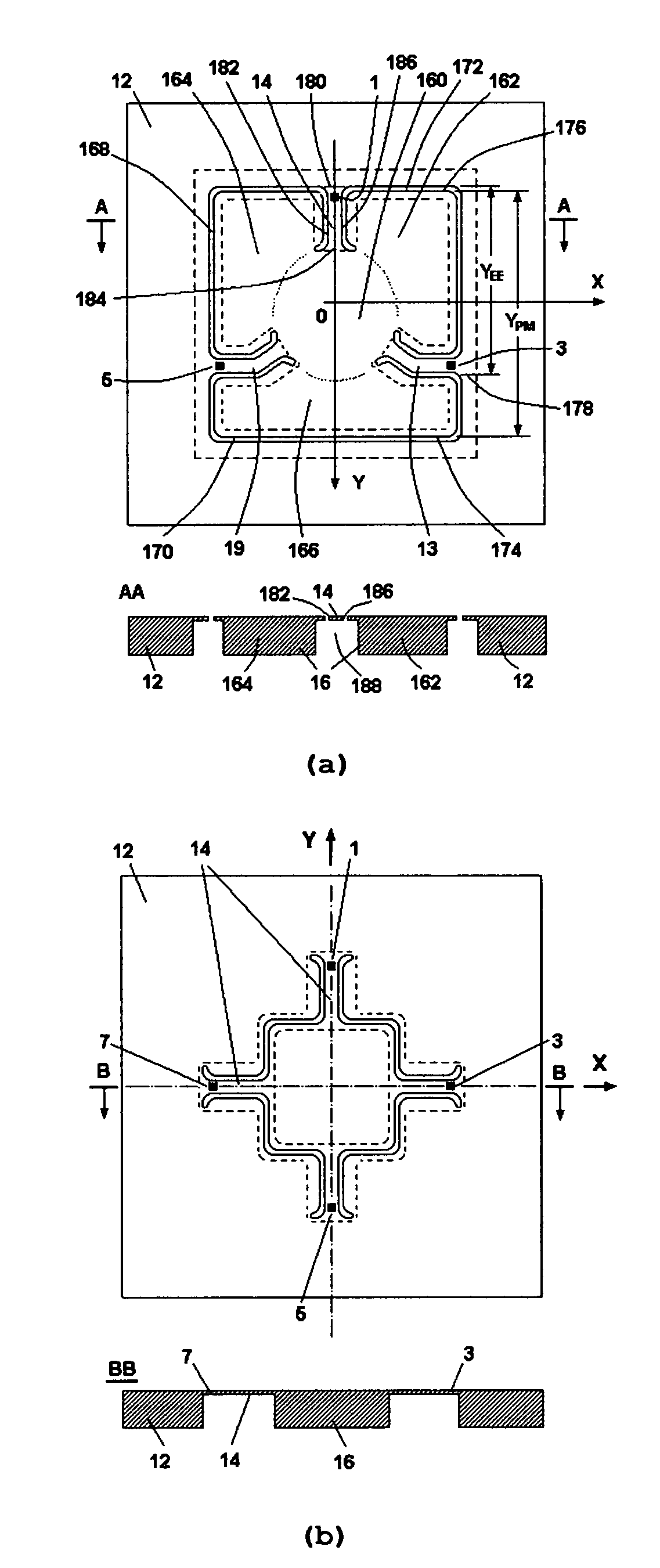

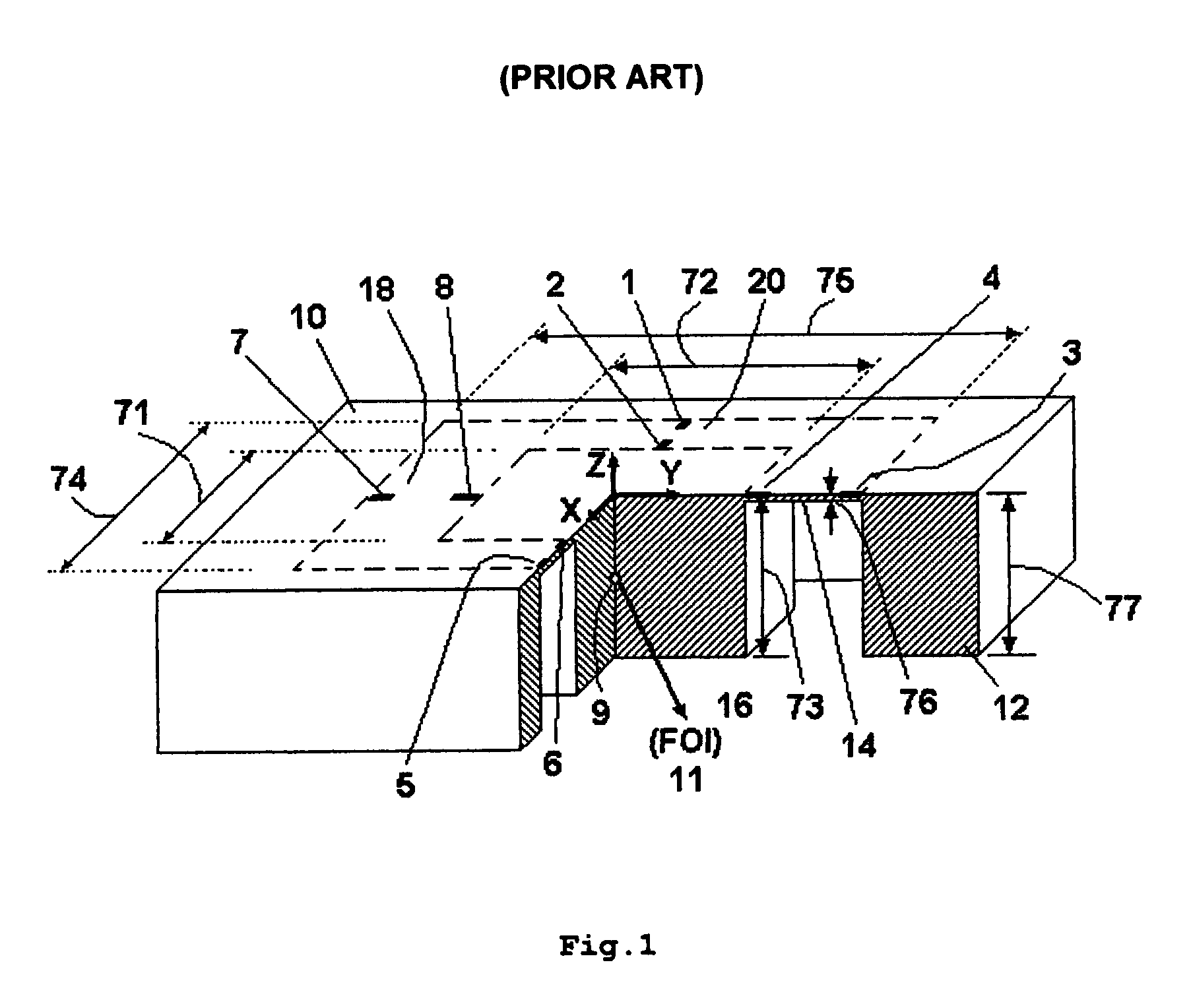

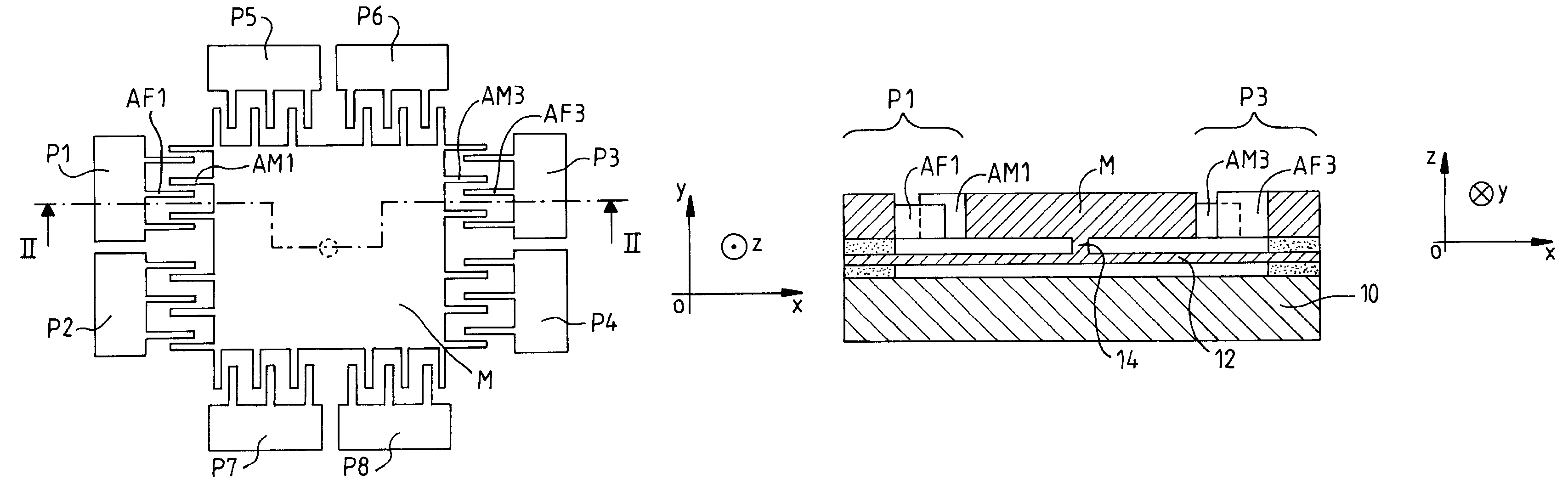

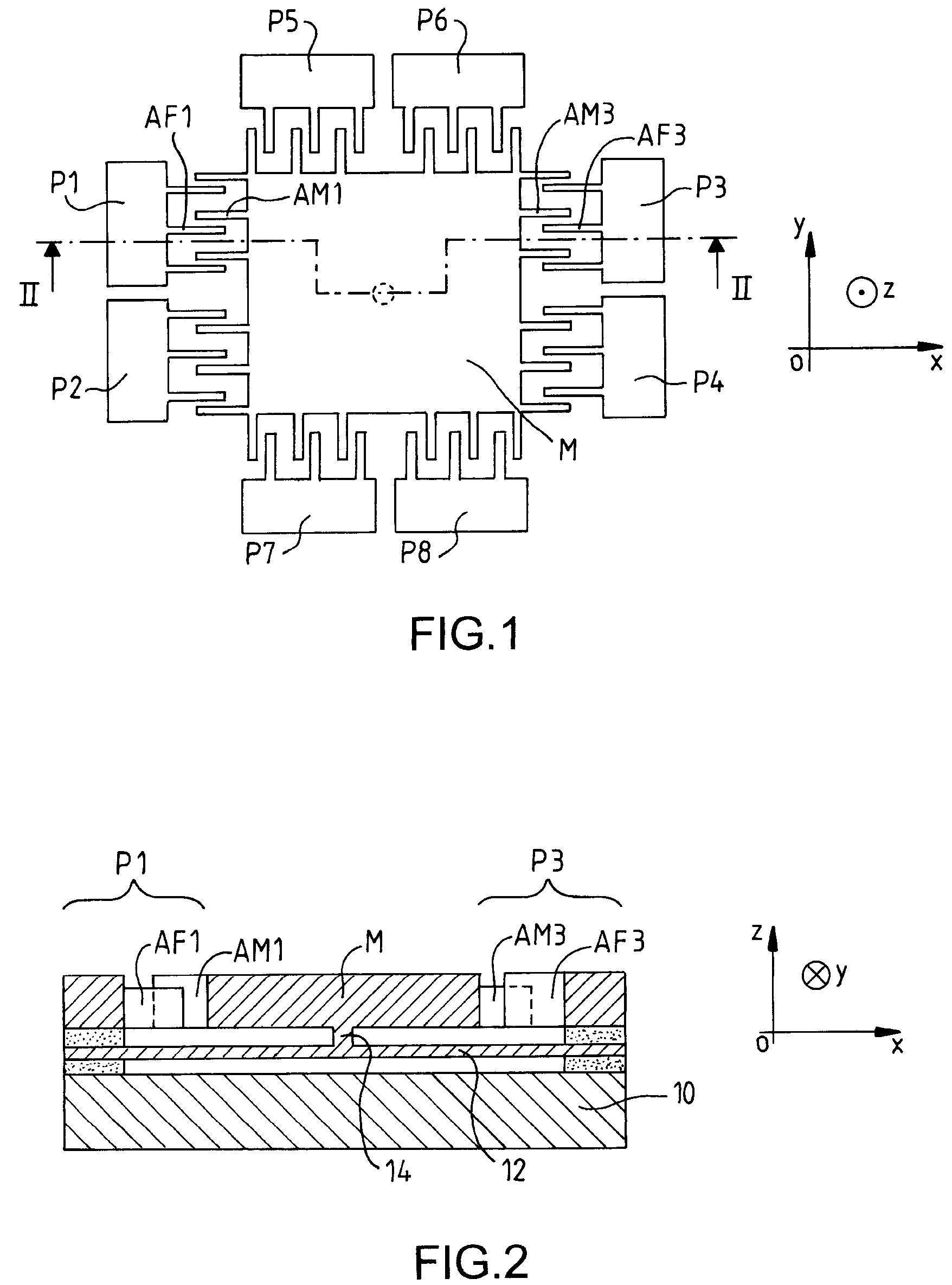

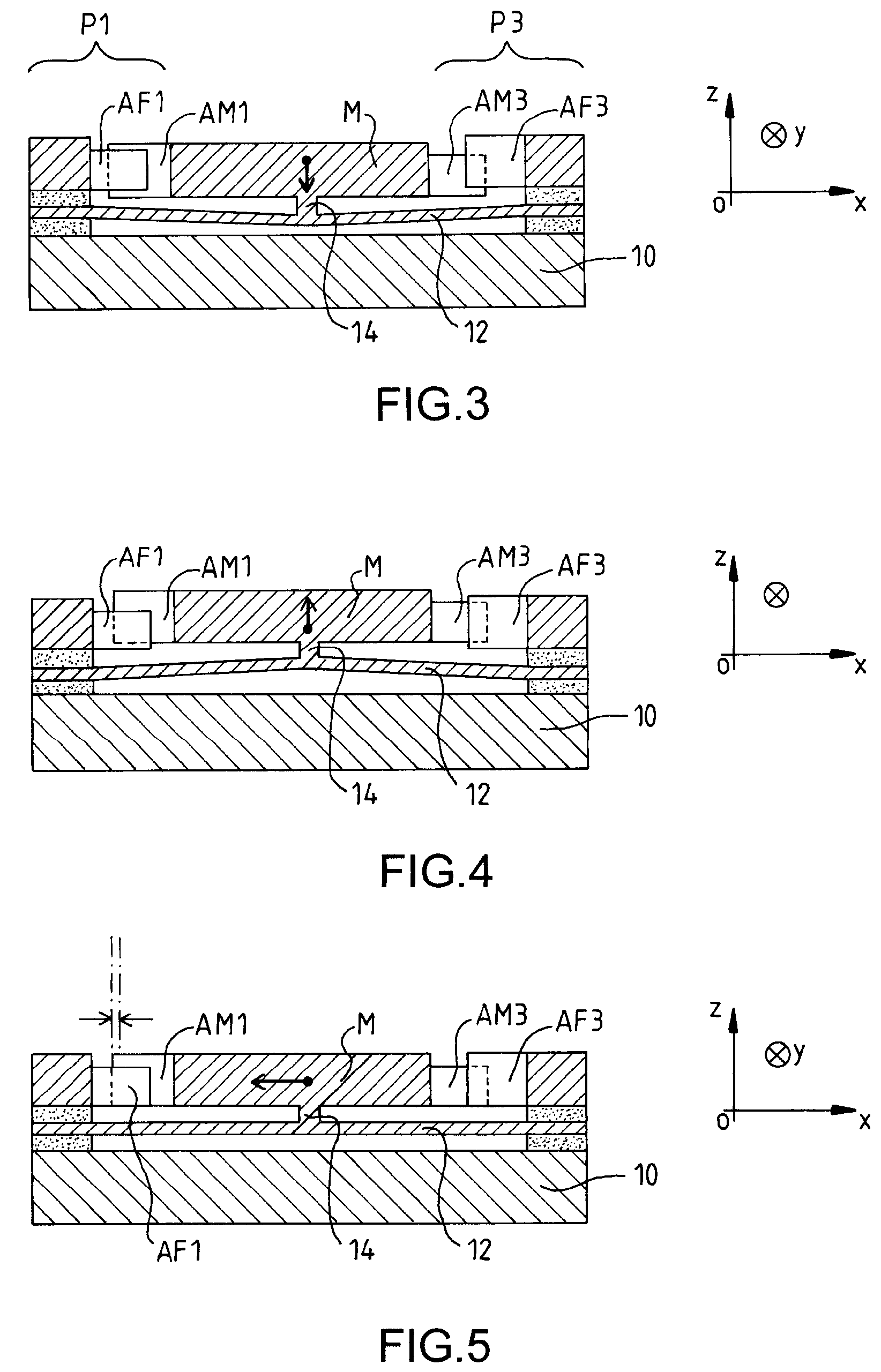

System and method for a three-axis MEMS accelerometer

InactiveUS7367232B2Low costHigh sensitivityAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElectricityOrthogonal coordinates

A system and method for inputting motion measurement data into a computationally based device are provided. In a first version three-axis accelerometer determines components of an inertial force vector with respect to an orthogonal coordinate system. The accelerometer includes a sensor die made of a semiconductor substrate having a frame element, a proof mass element, and an elastic element mechanically coupling the frame and the proof mass. The accelerometer also has three or more stress-sensitive IC components integrated into the elastic element adjacent to the frame element for electrical connectivity without metal conductor traversal of the elastic element.

Owner:VAGANOV VLADIMIR +1

System and method for a three-axis MEMS accelerometer

InactiveUS20050160814A1Low cost productionLow-cost functional testingAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElectricityOrthogonal coordinates

A system and method for inputting motion measurement data into a computationally based device are provided. In a first version three-axis accelerometer determines components of an inertial force vector with respect to an orthogonal coordinate system. The accelerometer includes a sensor die made of a semiconductor substrate having a frame element, a proof mass element, and an elastic element mechanically coupling the frame and the proof mass. The accelerometer also has three or more stress-sensitive IC components integrated into the elastic element adjacent to the frame element for electrical connectivity without metal conductor traversal of the elastic element.

Owner:VAGANOV VLADIMIR +1

Single proof mass, 3 axis MEMS transducer

ActiveUS20050005698A1Acceleration measurement using interia forcesDevices characerised by mechanical meansTransducerClassical mechanics

A transducer is provided herein which comprises an unbalanced proof mass (51), and which is adapted to sense acceleration in at least two mutually orthogonal directions. The proof mass (51) has first (65) and second (67) opposing sides that are of unequal mass.

Owner:NORTH STAR INNOVATIONS

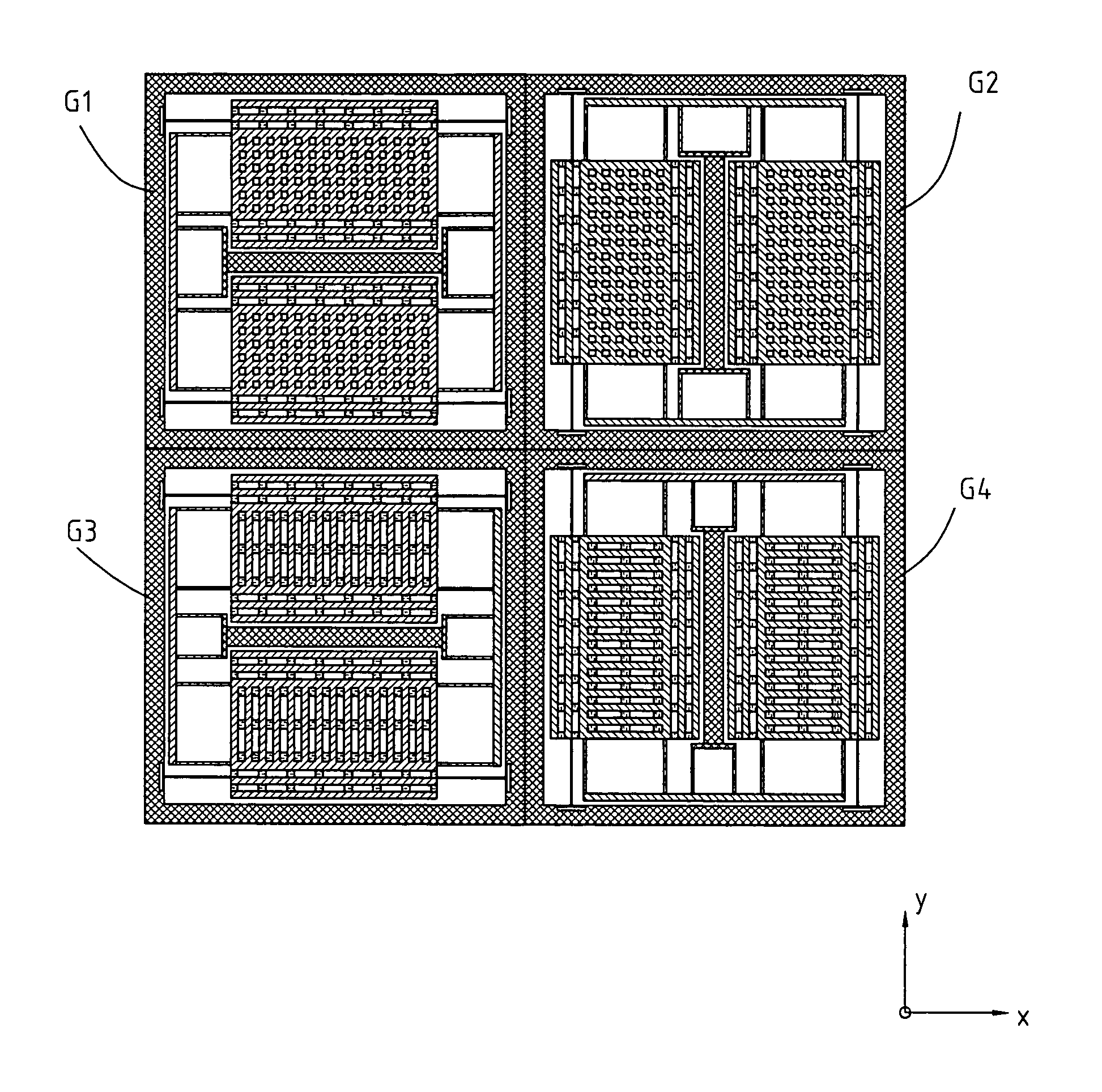

Multi-axis capacitive accelerometer

ActiveUS20100122579A1Improve linearityEliminate relative rotationAcceleration measurement in multiple dimensionsIn planeClassical mechanics

A multi-axis accelerometer is consisted of a substrate with sensing electrodes and a structure layer. The structure layer includes anchor bases fixed on the substrate. A first proof mass is disposed over the substrate and has a first opening and a second opening symmetric to each other. The first proof mass is suspended to the anchor bases. Fixed sensing blocks are disposed on the substrate, and capacitors are formed between each fixed sensing block and the first proof mass for sensing acceleration along two in-plane directions. A second proof mass and a third proof mass are disposed in the first opening and the second opening and are asymmetrically suspended. Separate electrodes are disposed on the substrate and form two differential capacitors with the second proof mass and the third proof mass for sensing the out-of-plane acceleration.

Owner:IND TECH RES INST

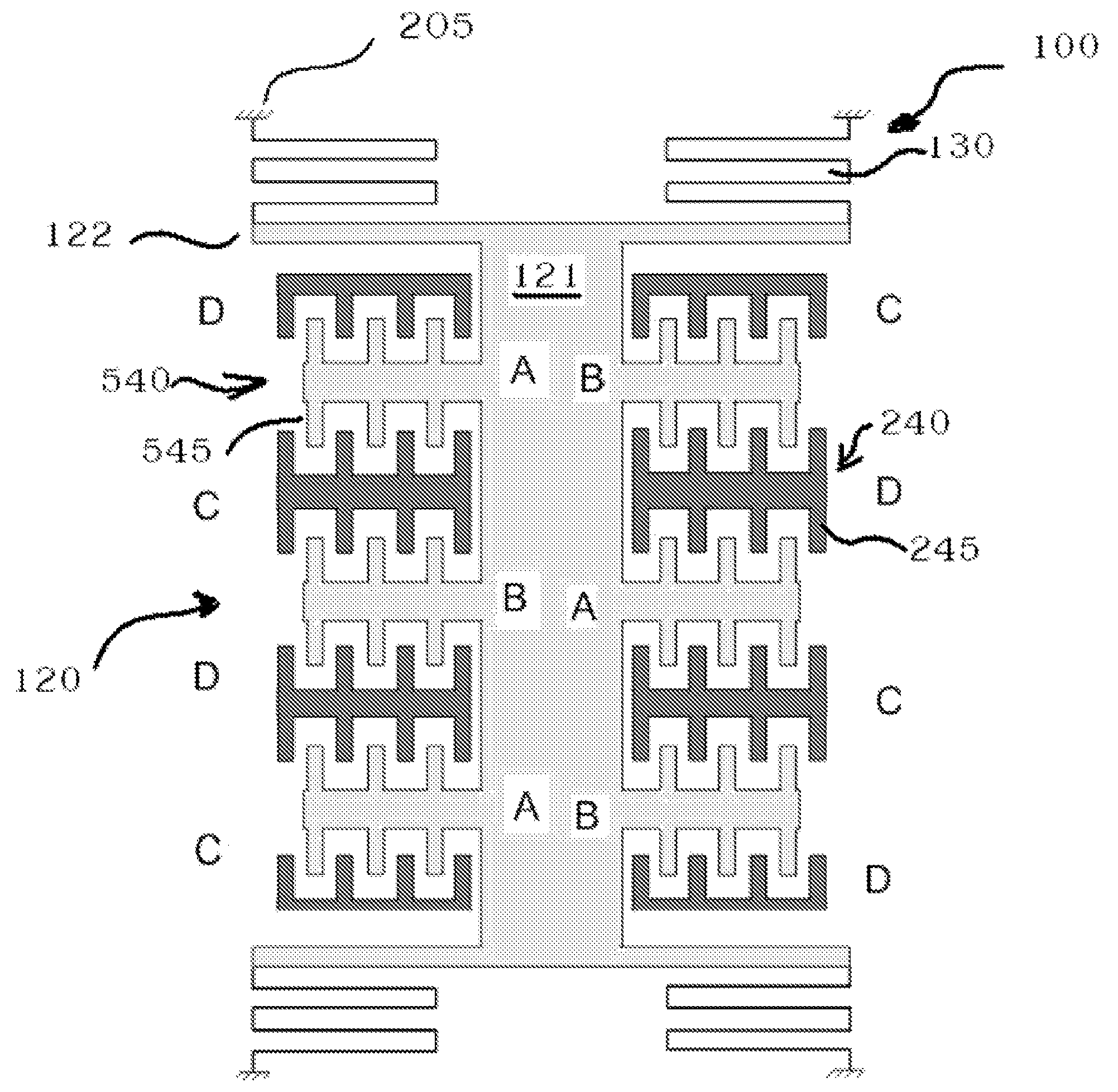

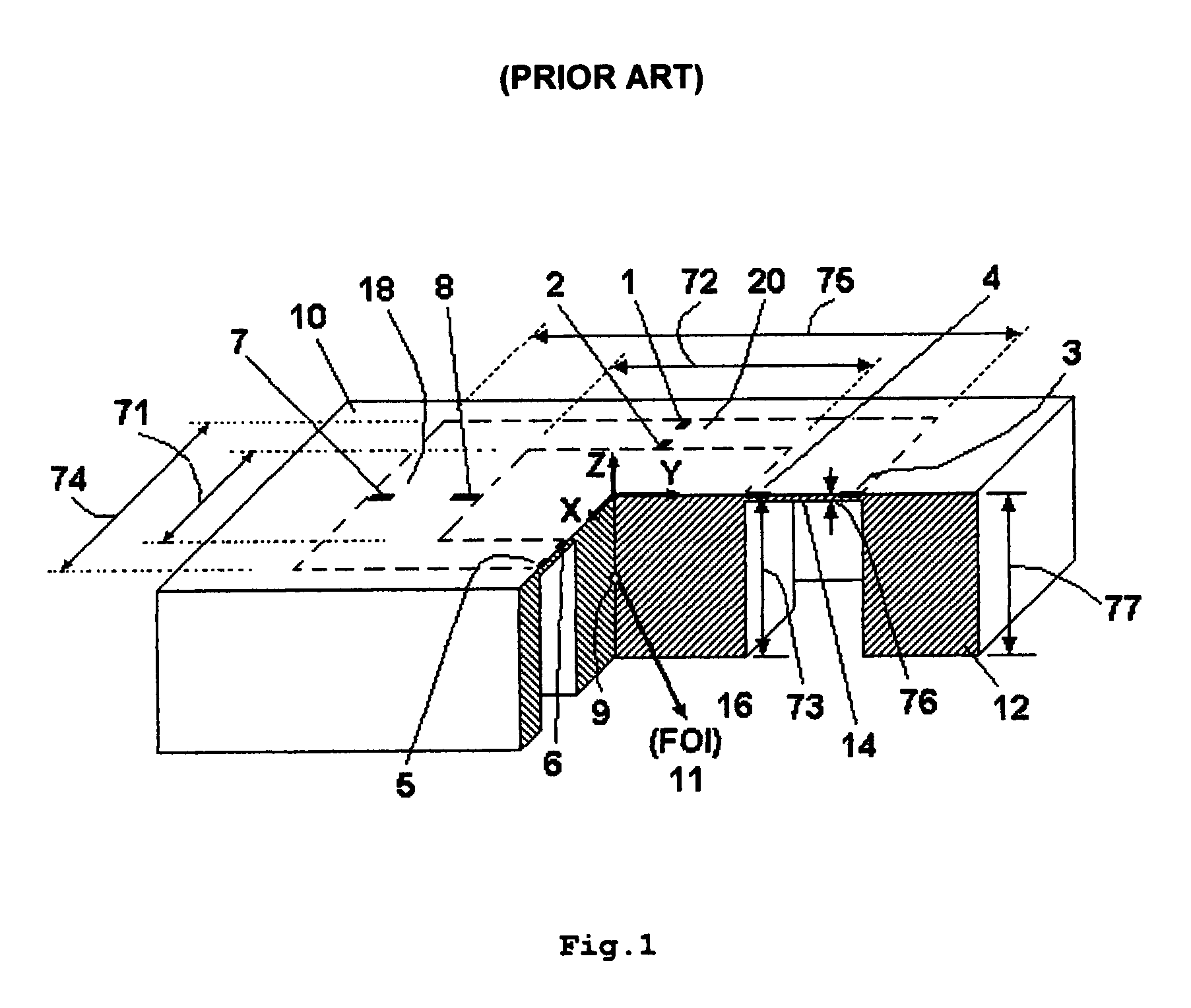

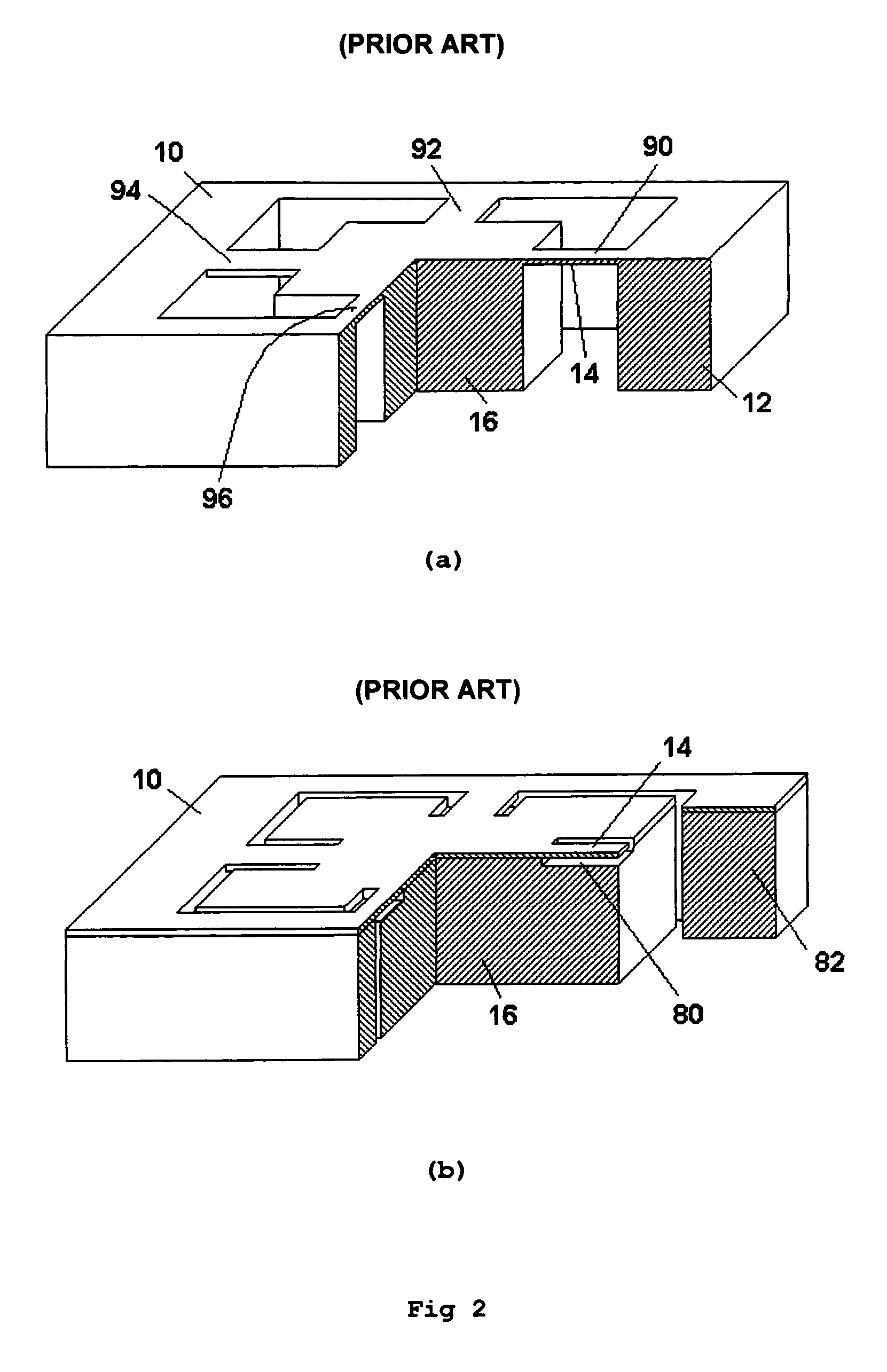

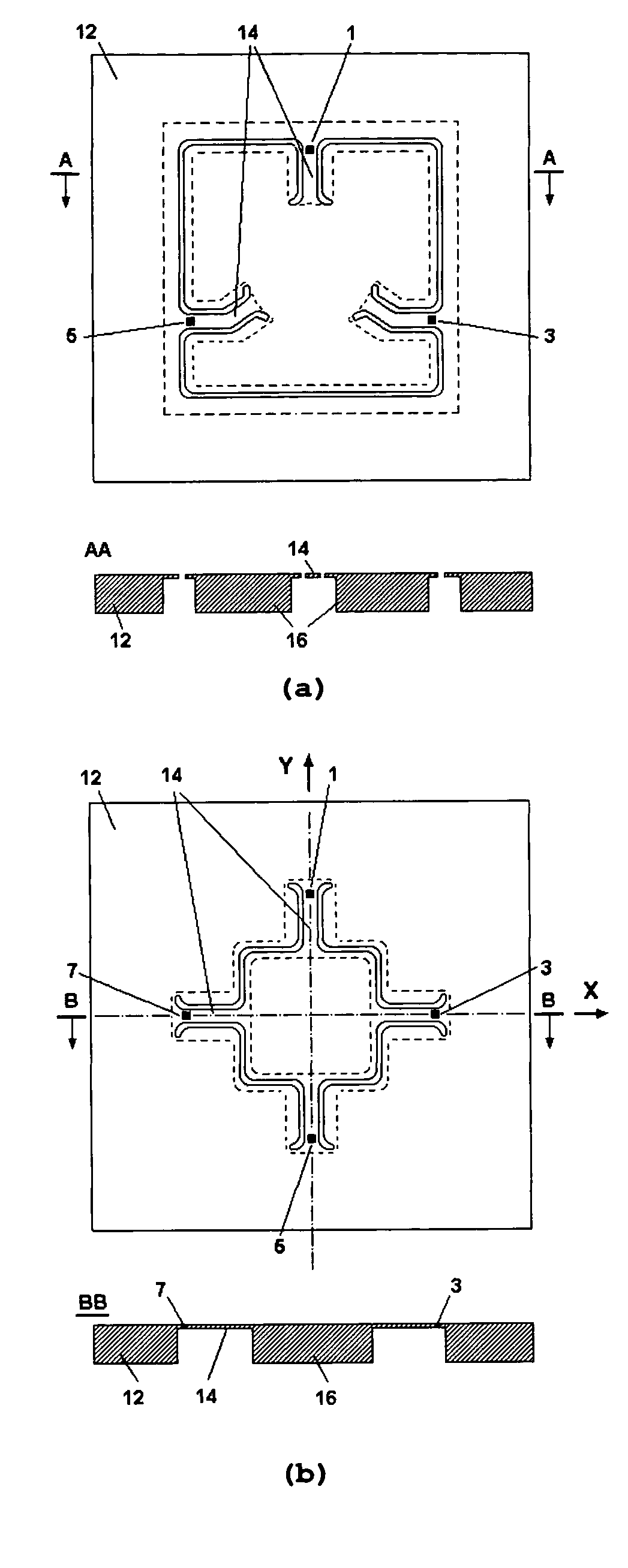

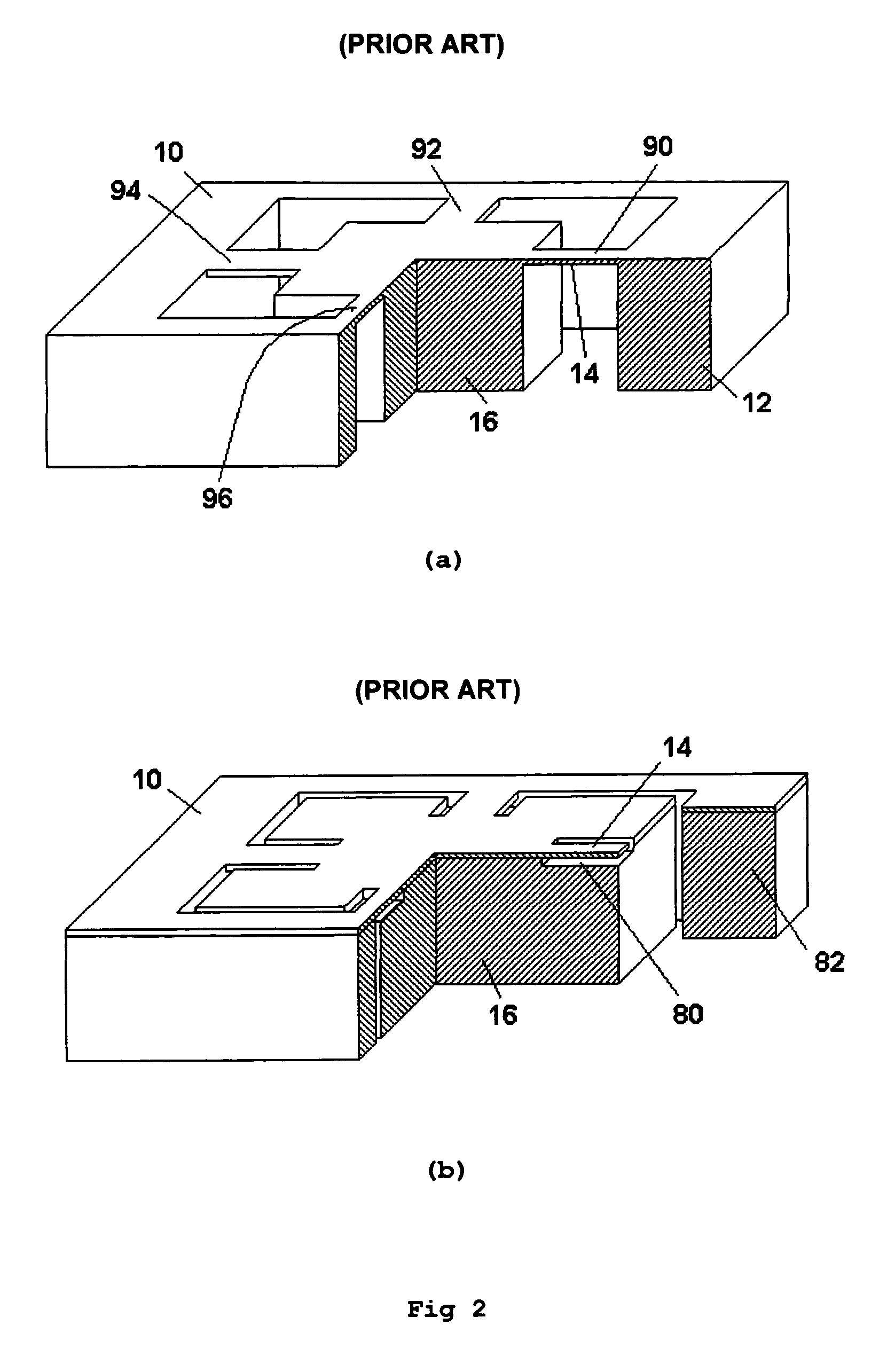

Micromachined cross-differential dual-axis accelerometer

InactiveUS20090183570A1Acceleration measurement in multiple dimensionsCapacitanceClassical mechanics

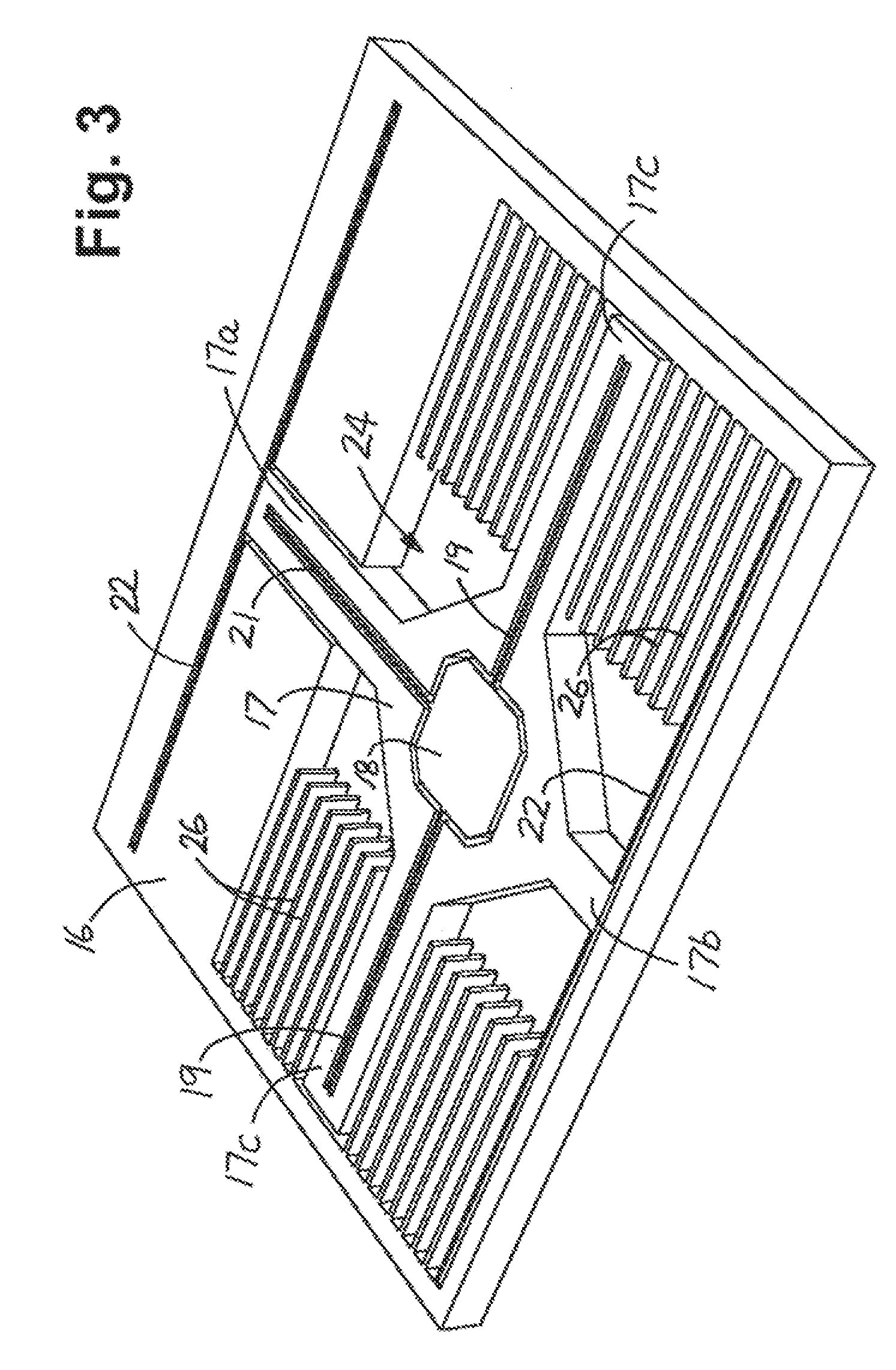

Micromachined accelerometer having one or more proof masses (16, 36, 37, 71, 72) mounted on one or more decoupling frames (17, 38, 39) or on a shuttle (73) such that the proof mass(es) can move along a first (y) axis in response to acceleration along the first axis while being constrained against movement along a second (x) axis and for torsional movement about a third (z) axis perpendicular to the first and second axes in response to acceleration along the second axis. Electrodes (26, 53, 54, 78, 79) that move with the proof mass(es) are interleaved with stationary electrodes (27, 56, 57, 81, 82) to form capacitors (A-D) that change in capacitance both in response to movement of the proof mass(es) along the first axis and in response to torsional movement of the proof mass(es) about the third axis, and circuitry (31-34) connected to the electrodes for providing output signals corresponding to acceleration along the first and second axes. The capacitances of two capacitors on each side of the second axis change in the same direction in response to acceleration along the first axis and in opposite directions in response to acceleration along the second axis. Signals from the capacitors that change capacitance in opposite directions both in response to acceleration along the first axis and in response to acceleration along the second axis are differentially combined to provide first and second difference signals, and the difference signals are additively and differentially combined to provide output signals corresponding to acceleration along the first and second axes.

Owner:CUSTOM SENSORS & TECH INC

Three-axis integrated MEMS accelerometer

InactiveUS7318349B2Low costHigh sensitivityAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsOrthogonal coordinatesAcceleration Unit

3D accelerometer for measuring three components of inertial force (or acceleration) vector with respect to an orthogonal coordinate system, which has high sensitivity due to a big proof mass located within a cavity beneath the surface of the sensor die. The size of the cavity and the size of the proof mass exceed the corresponding overall dimensions of the elastic element. The sensor structure occupies a very small area at the surface of the die increasing the area for ICs need to be integrated on the same chip.

Owner:VAGANOV VLADIMIR +1

Micromachined piezoelectric x-axis gyroscope

InactiveUS20110265564A1Acceleration measurement using interia forcesSolid-state devicesElectricityGyroscope

This disclosure provides systems, methods and apparatus, including computer programs encoded on computer storage media, for making and using gyroscopes. Such gyroscopes may include a sense frame, a proof mass disposed outside the sense frame, a pair of anchors and a plurality of drive beams. The plurality of drive beams may be disposed on opposing sides of the sense frame and between the pair of anchors. The drive beams may connect the sense frame to the proof mass. The drive beams may be configured to cause torsional oscillations of the proof mass substantially in a first plane of the drive beams. The sense frame may be substantially decoupled from the drive motions of the proof mass. Such devices may be included in a mobile device, such as a mobile display device.

Owner:SNAPTRACK

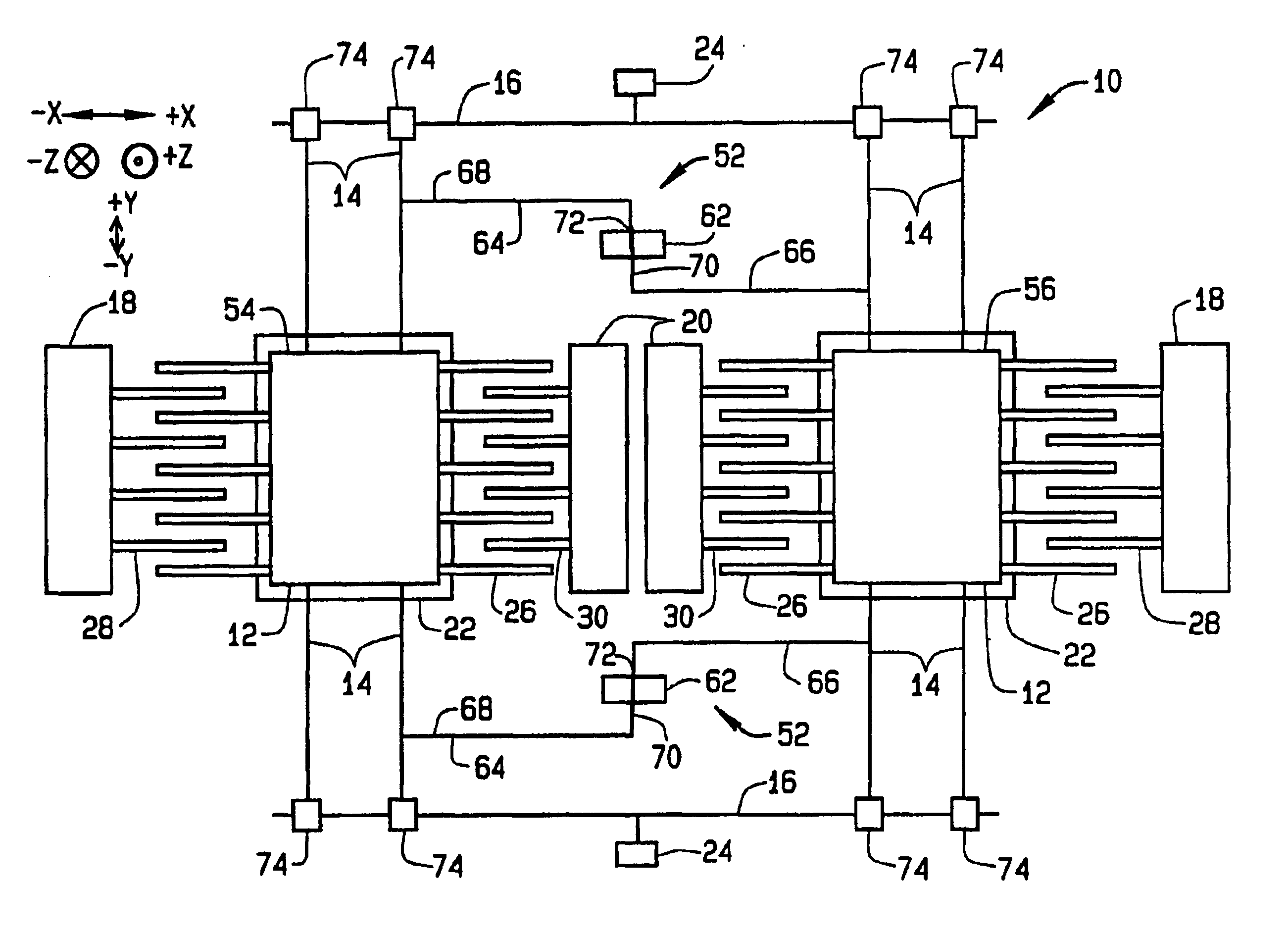

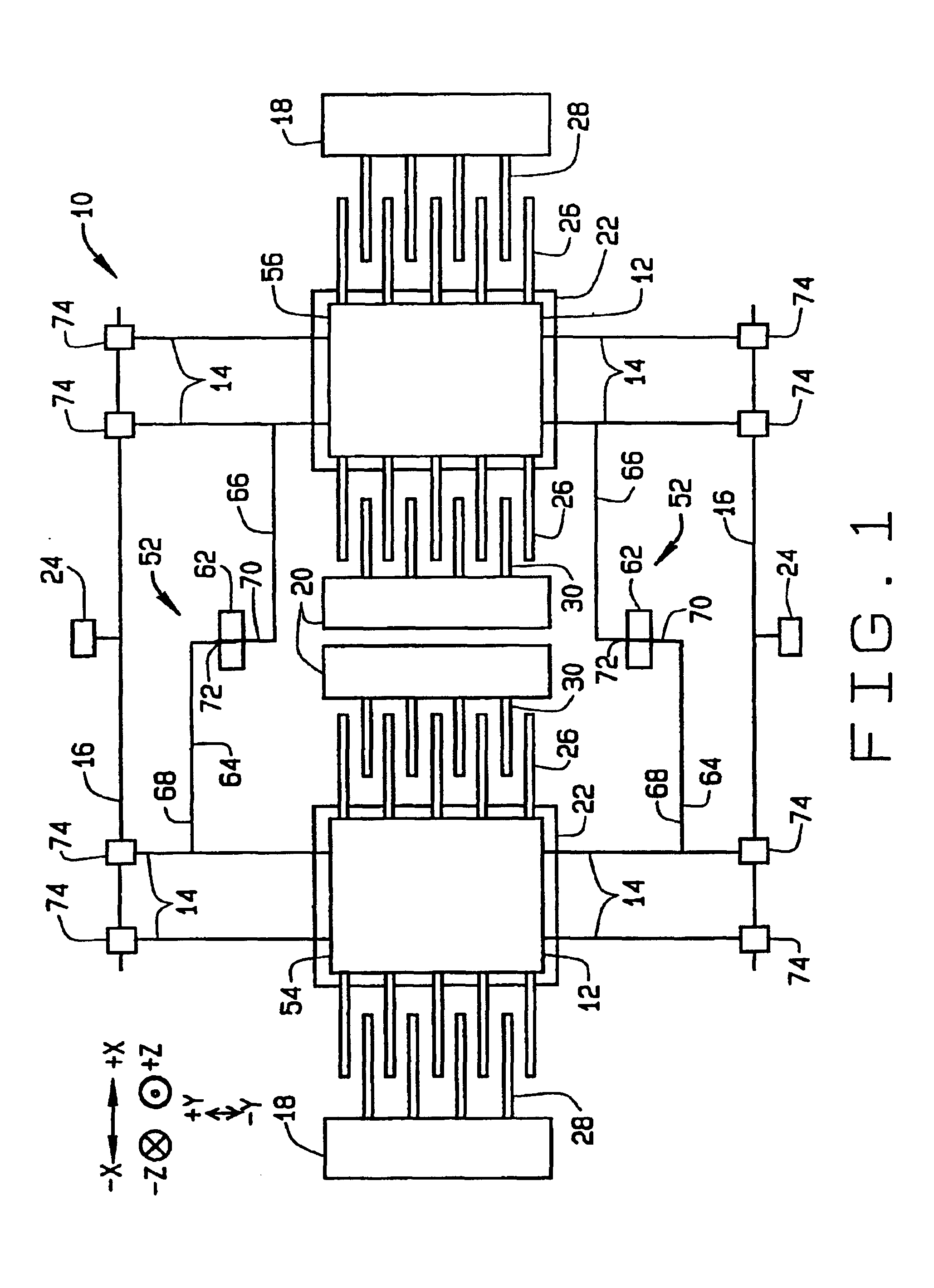

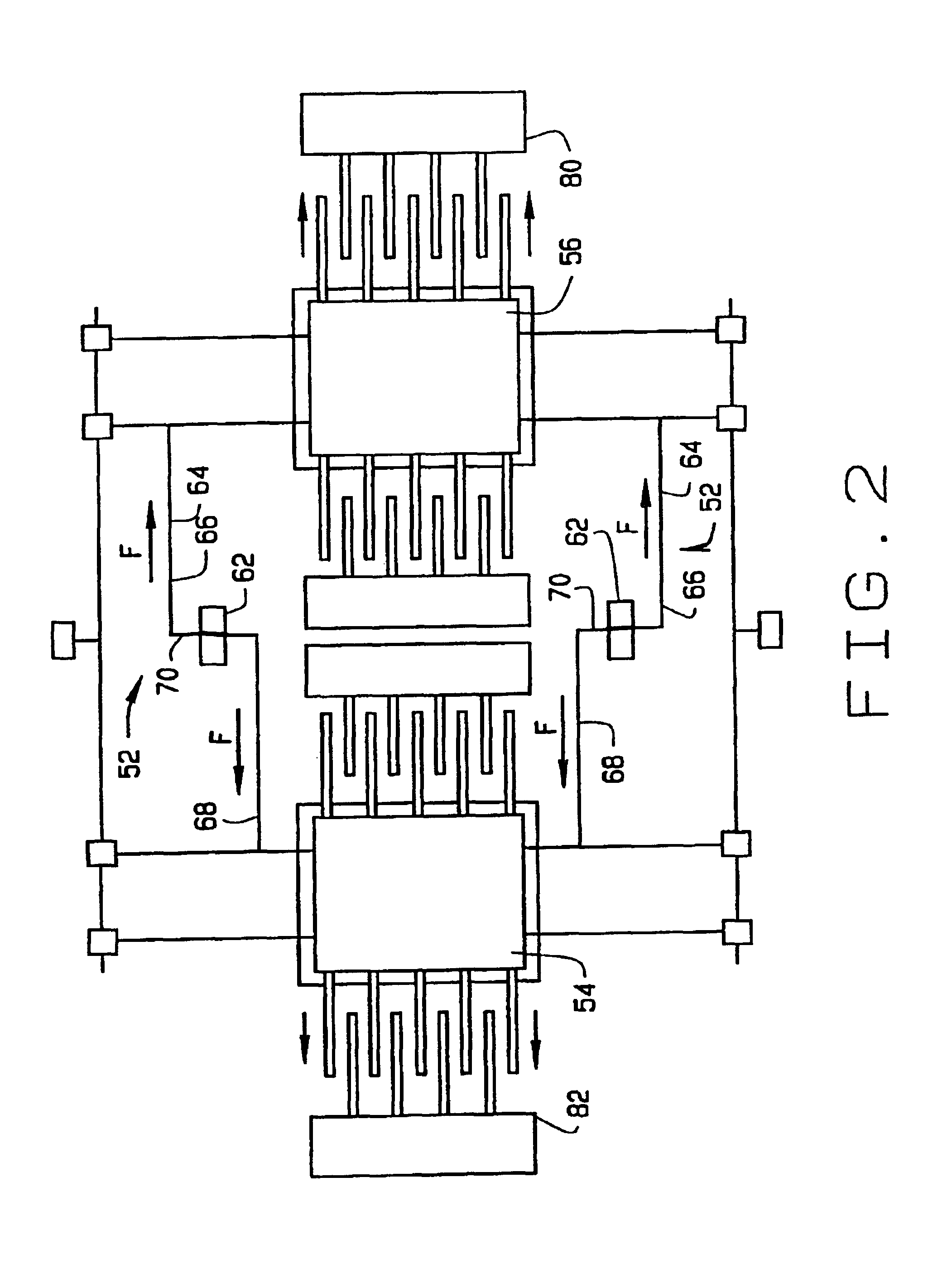

Integrated microelectromechanical systems (MEMS) vibrating mass Z-axis rate sensor

ActiveUS7677099B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocityTransducer

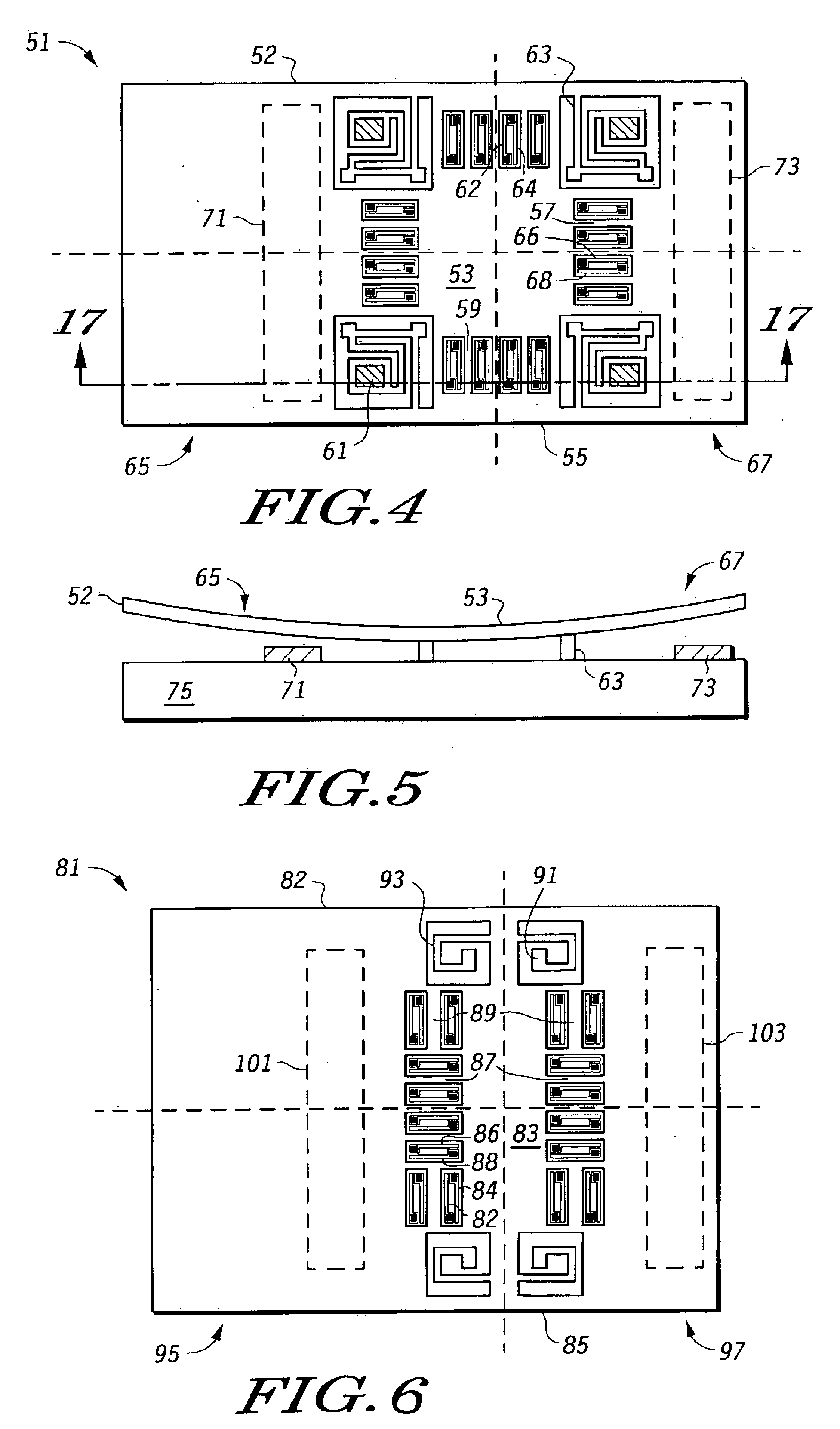

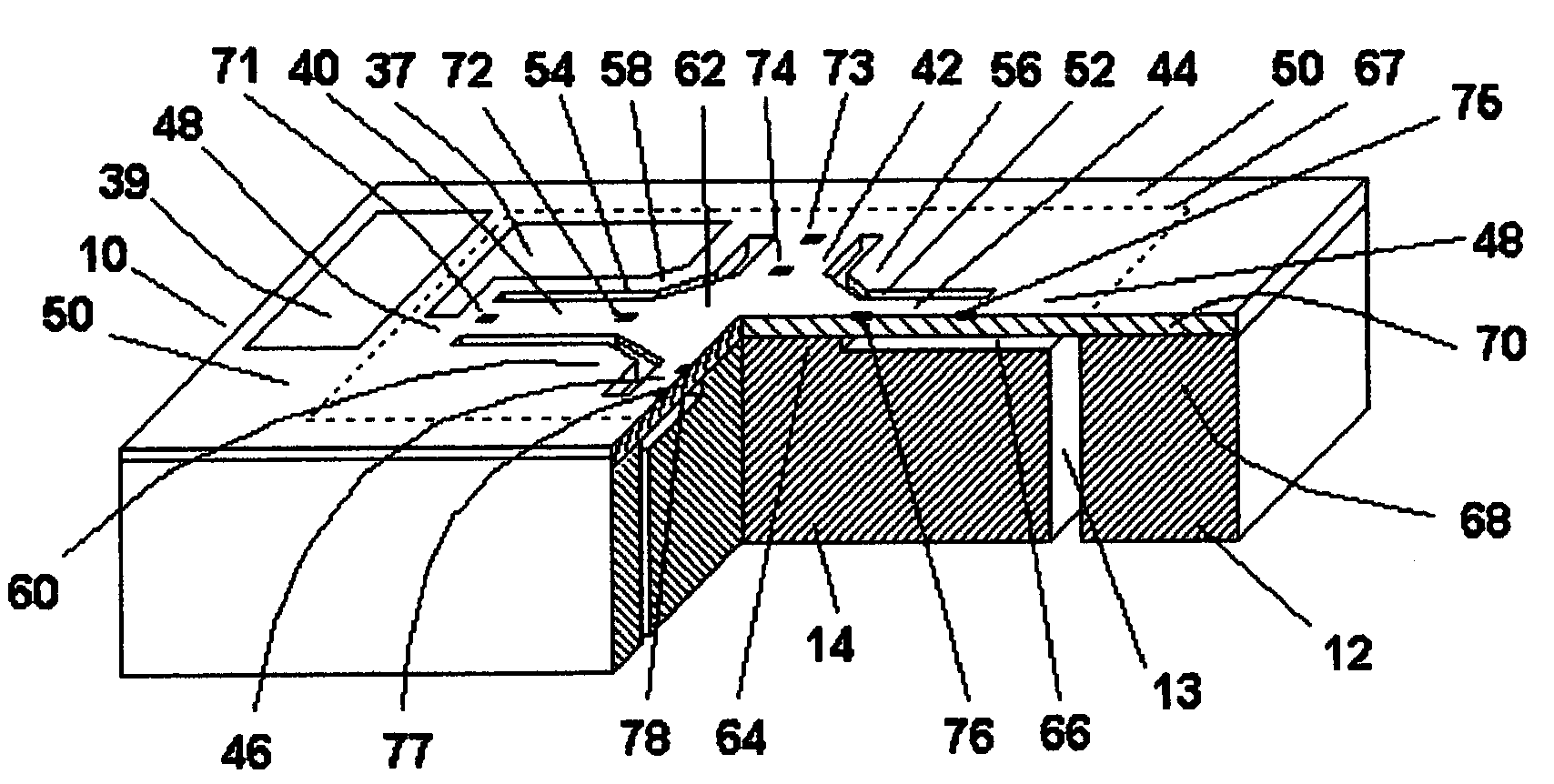

A sensor that measures angular velocity about an axis that is normal to a sensing plane of the sensor. The sensor comprises a sensing subassembly that includes a planar frame parallel to the sensing plane, a first proof mass disposed in the sensing plane, a second proof mass disposed in the sensing plane laterally to the first proof mass, and a linkage within the frame and connected to the frame. The linkage is connected to the first proof mass and to the second proof mass. The sensor further includes actuator for driving the first proof mass and the second proof mass into oscillation along a drive axis in the sensing plane. The sensor further includes a first transducer to sense motion of the frame in response to a Coriolis force acting on the oscillating first proof mass and the oscillating second proof mass.

Owner:INVENSENSE

Vertically integrated 3-axis MEMS accelerometer with electronics

ActiveUS8047075B2Reduce changesReduce complexityDevices characerised by mechanical meansAcceleration measurement in multiple dimensionsFull bridgeResonance

A system and method in accordance with the present invention provides for a low cost, bulk micromachined accelerometer integrated with electronics. The accelerometer can also be integrated with rate sensors that operate in a vacuum environment. The quality factor of the resonances is suppressed by adding dampers. Acceleration sensing in each axis is achieved by separate structures where the motion of the proof mass affects the value of sense capacitors differentially. Two structures are used per axis to enable full bridge measurements to further reduce the mechanical noise, immunity to power supply changes and cross axis coupling. To reduce the sensitivity to packaging and temperature changes, each mechanical structure is anchored to a single anchor pillar bonded to the top cover.

Owner:INVENSENSE

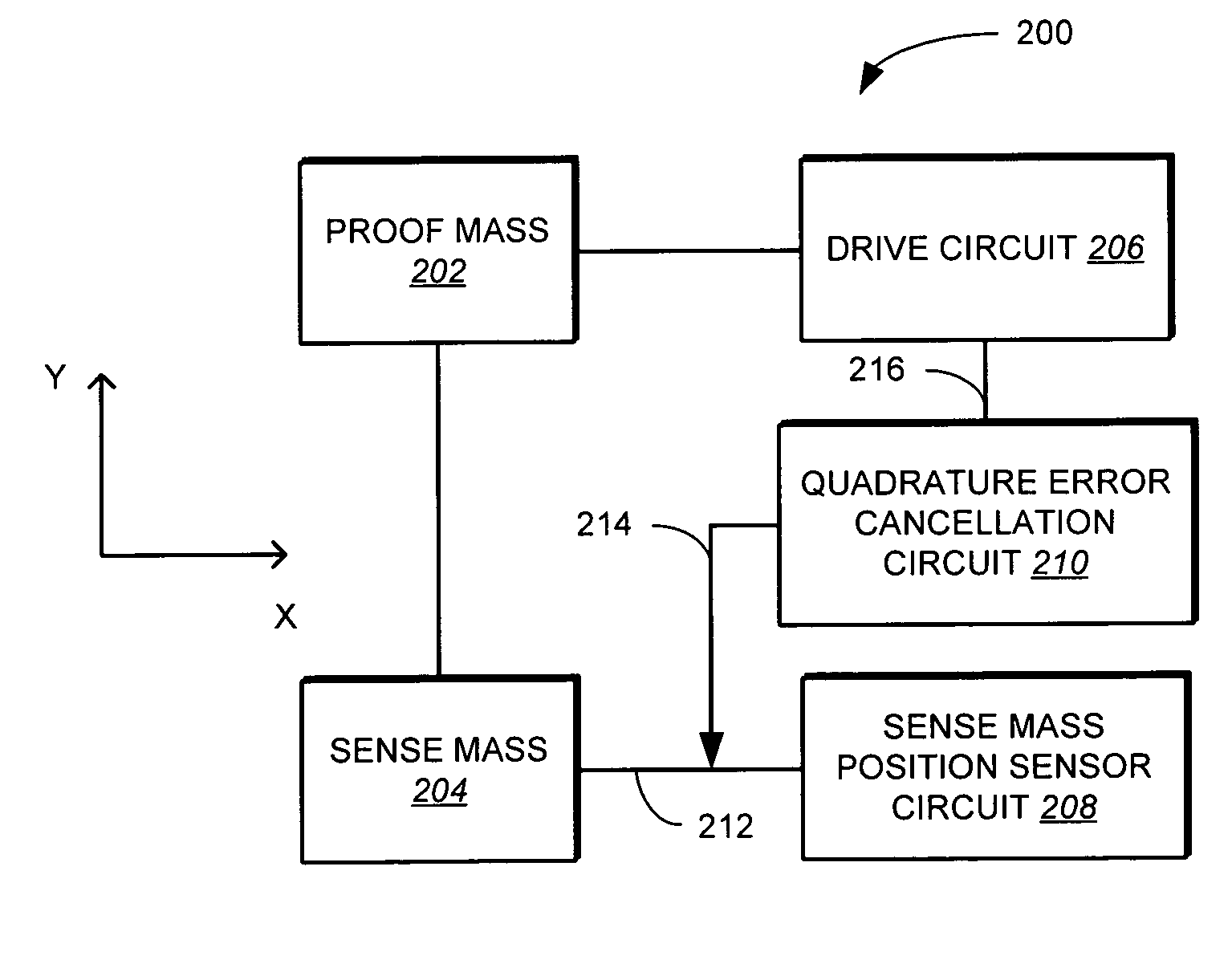

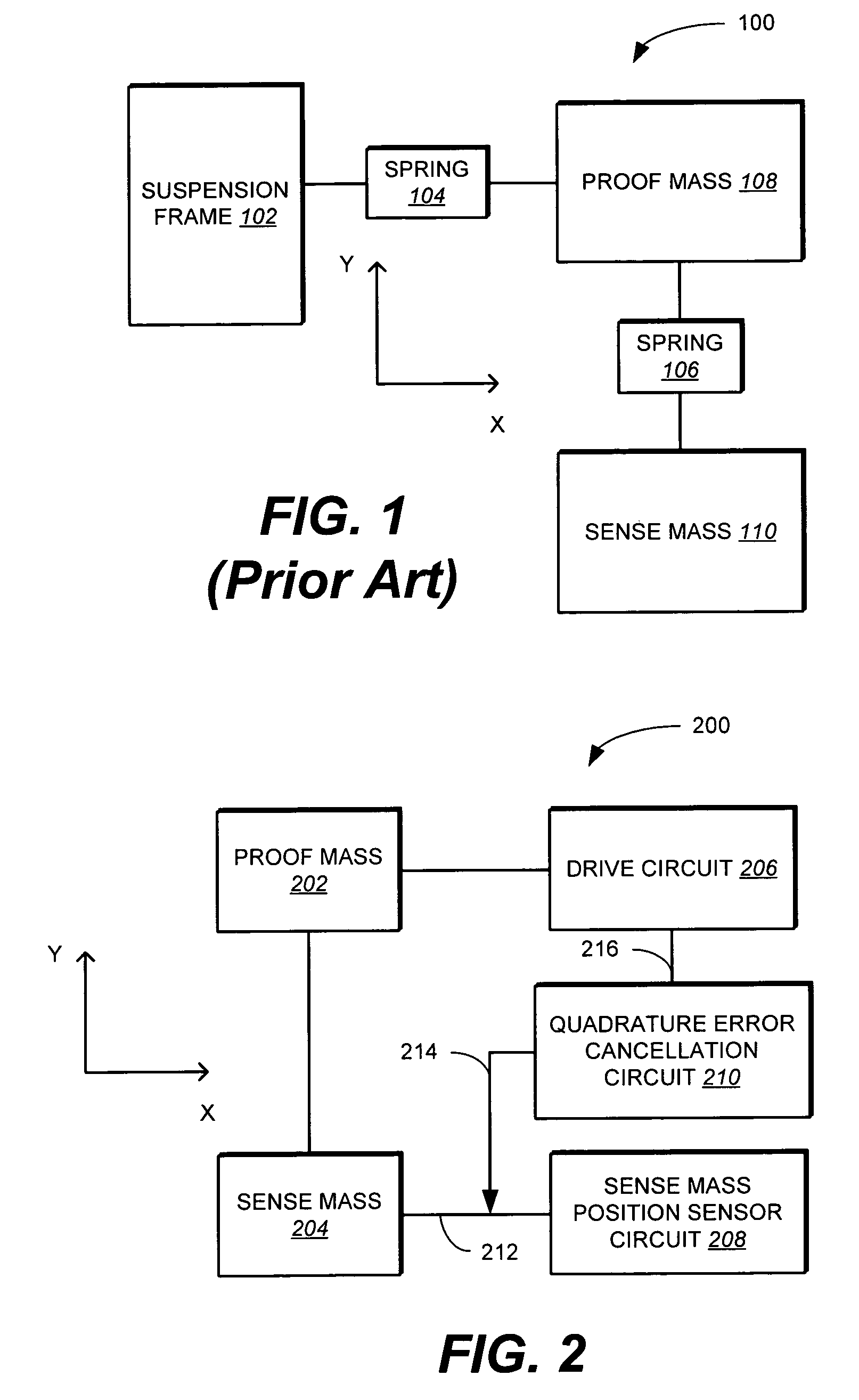

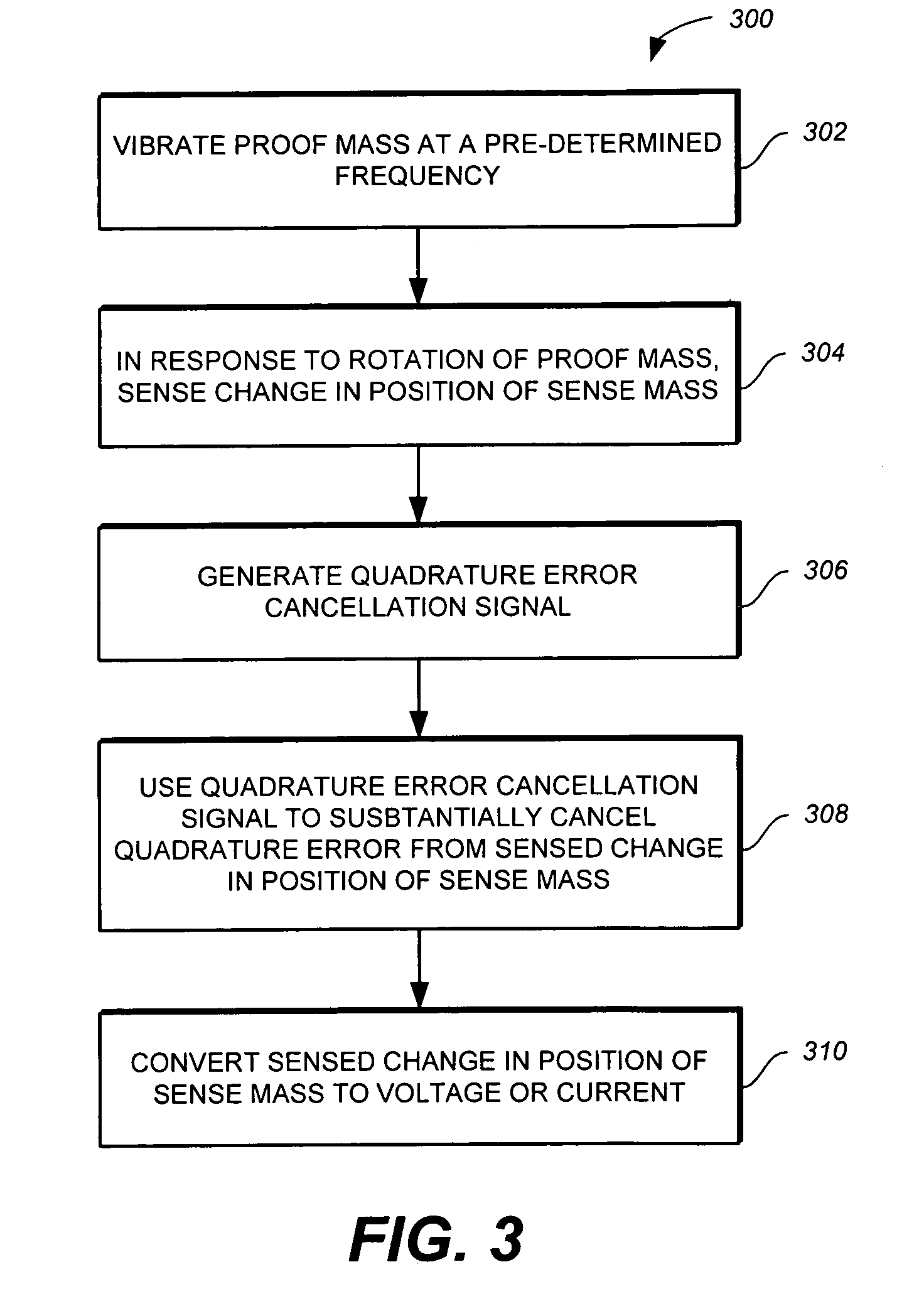

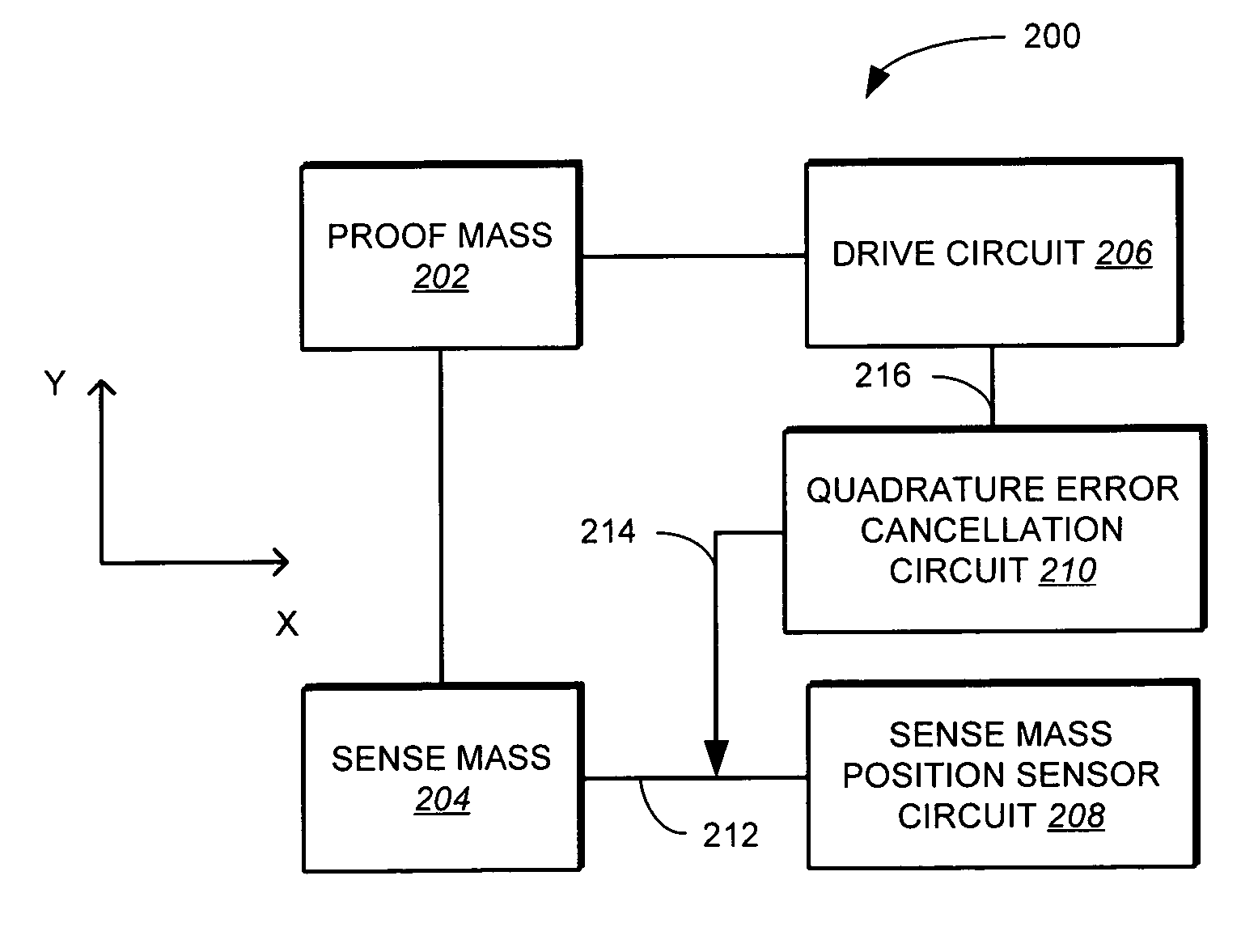

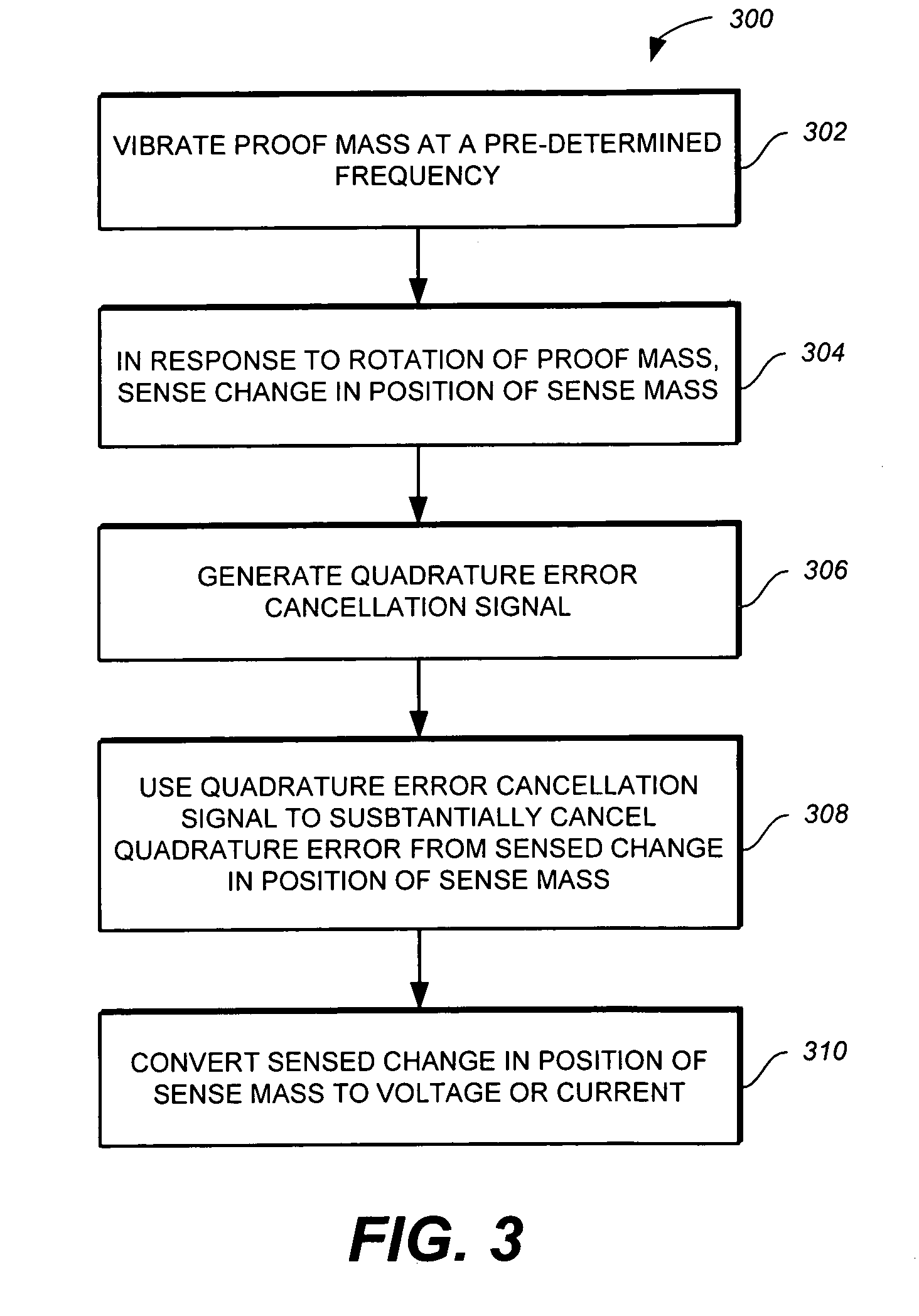

Method and apparatus for electronic cancellation of quadrature error

ActiveUS7290435B2Error minimizationImprove signal-to-noise ratioAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsEngineeringProof mass

Methods and apparatus are provided for detecting a rate of rotation. In one implementation, the method includes vibrating a proof mass at a pre-determined frequency in a drive axis. In response to a rotation, sensing an amount of deflection of the proof mass in an axis orthogonal to the drive axis, in which the amount of deflection is sensed as a change in charge. The method further includes generating a quadrature error cancellation signal to substantially cancel quadrature error from the sensed change in charge.

Owner:INVENSENSE

Multi-axis solid state accelerometer

InactiveUS6981416B2Easy to makeHigh aspect ratioAcceleration measurement using interia forcesDevices characerised by mechanical meansCapacitanceElectricity

Owner:MIN OF NAT DEFENSE

Triaxial membrane accelerometer

ActiveUS7600428B2Acceleration measurement using interia forcesDevices characerised by mechanical meansThin layerEngineering

The invention relates to accelerometer structures micro-machined according to micro-electronics technologies. The accelerometer according to the invention comprises a substrate, an elastically deformable thin-layer membrane suspended above the substrate and secured to the substrate at its periphery, a proof mass suspended above the membrane and linked to the latter by a central stud, and capacitive interdigitated combs distributed about the mass, having movable plates secured to the mass and fixed plates secured to the substrate. The fixed plates and movable plates of the various combs are of differentiated heights to help in the discrimination of the upward and downward vertical accelerations.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

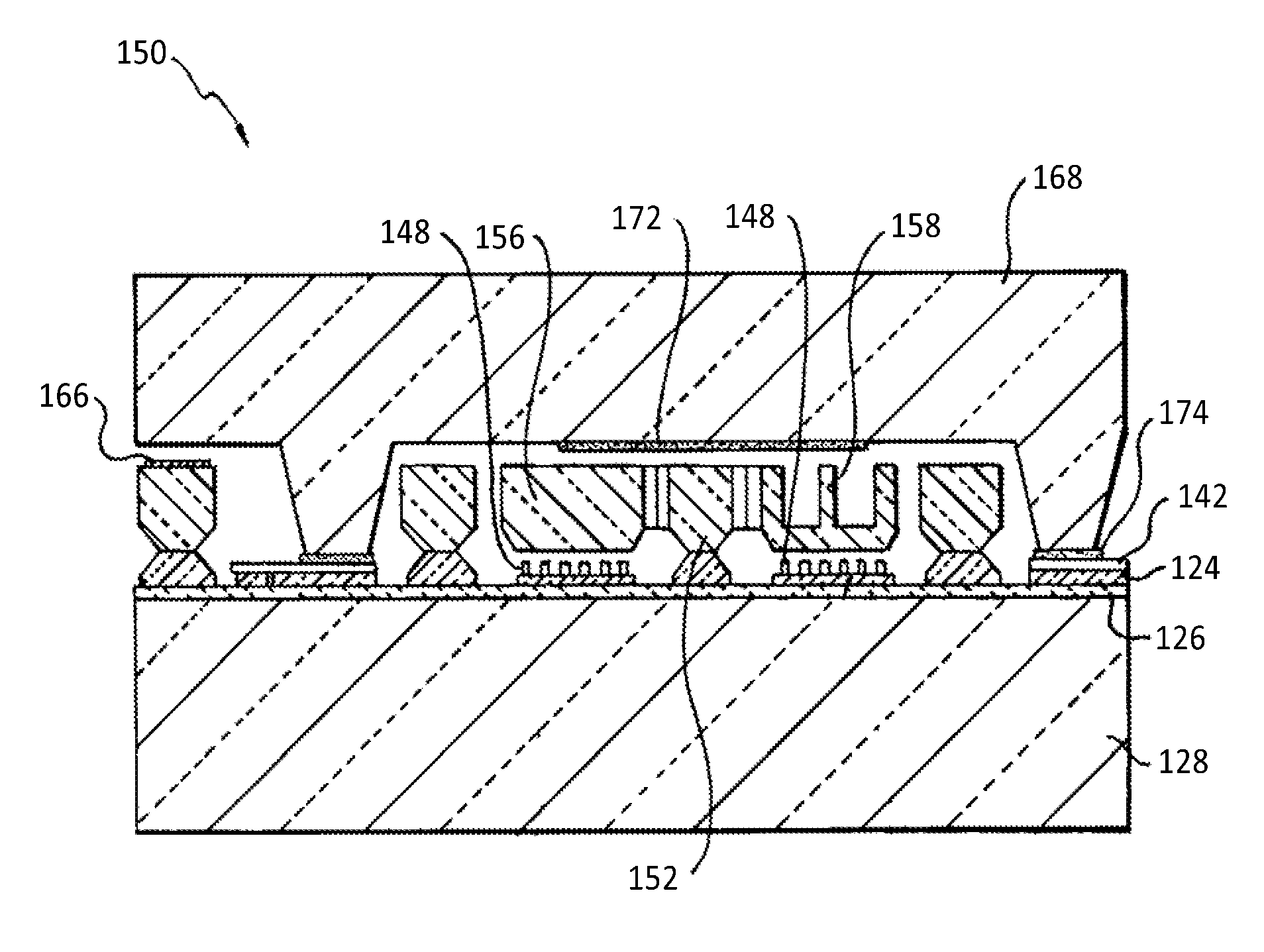

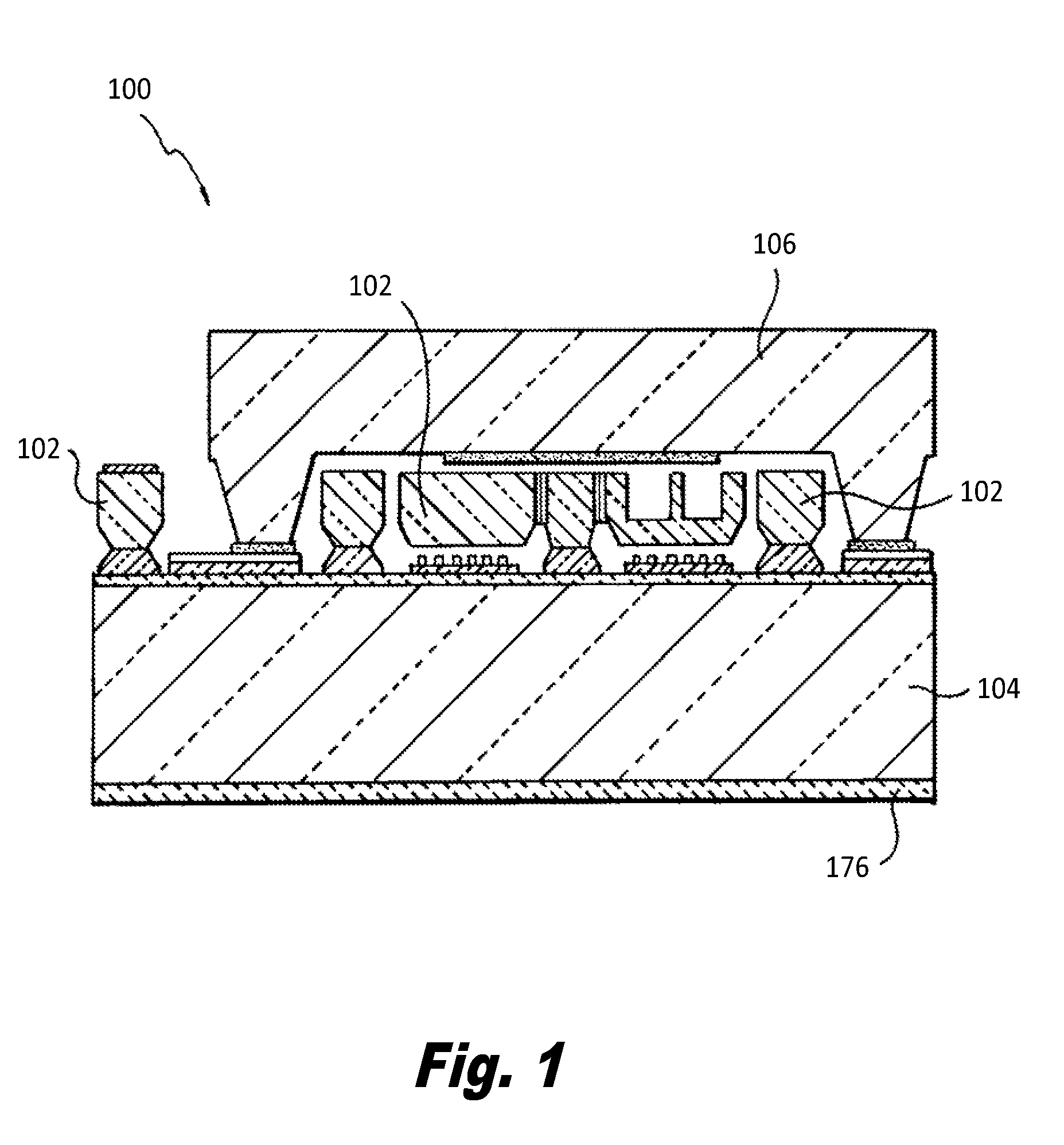

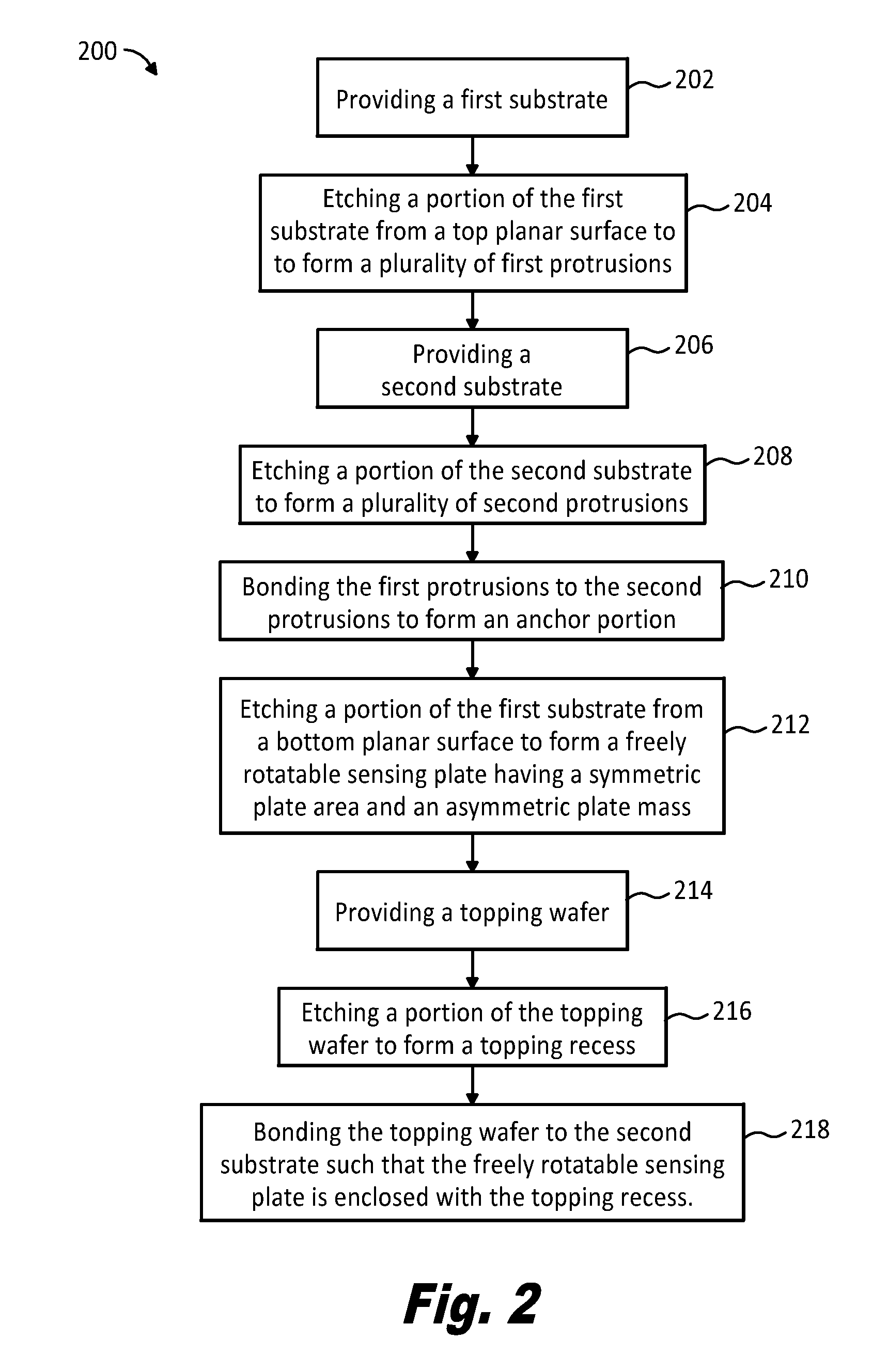

Wafer process flow for a high performance MEMS accelerometer

InactiveUS7736931B1Acceleration measurement using interia forcesSemiconductor/solid-state device manufacturingFree rotationEngineering

A process for fabricating a pendulous accelerometer, including the steps of: providing a first substrate having a top planar surface, etching a portion of the first substrate to a first predetermined depth from the top planar surface to form a plurality of first protrusions, providing a second substrate, etching a portion of the second substrate to a second predetermined depth to form a plurality of second protrusions, bonding planar surfaces of the first protrusions to planar surfaces of the second protrusions, and etching a portion of the first substrate from an opposite side of the first substrate to a third predetermined depth equal to or greater than the difference between the total thickness of the first substrate and the first predetermined depth to form a freely rotatable sensing plate that includes a substantially hollow proof mass.

Owner:ROSEMOUNT AEROSPACE

Omnidirectional accelerometer device and medical device incorporating same

ActiveUS8386042B2Acceleration measurement using interia forcesElectrotherapyElectricityComputer module

Owner:MEDTRONIC MIMIMED INC

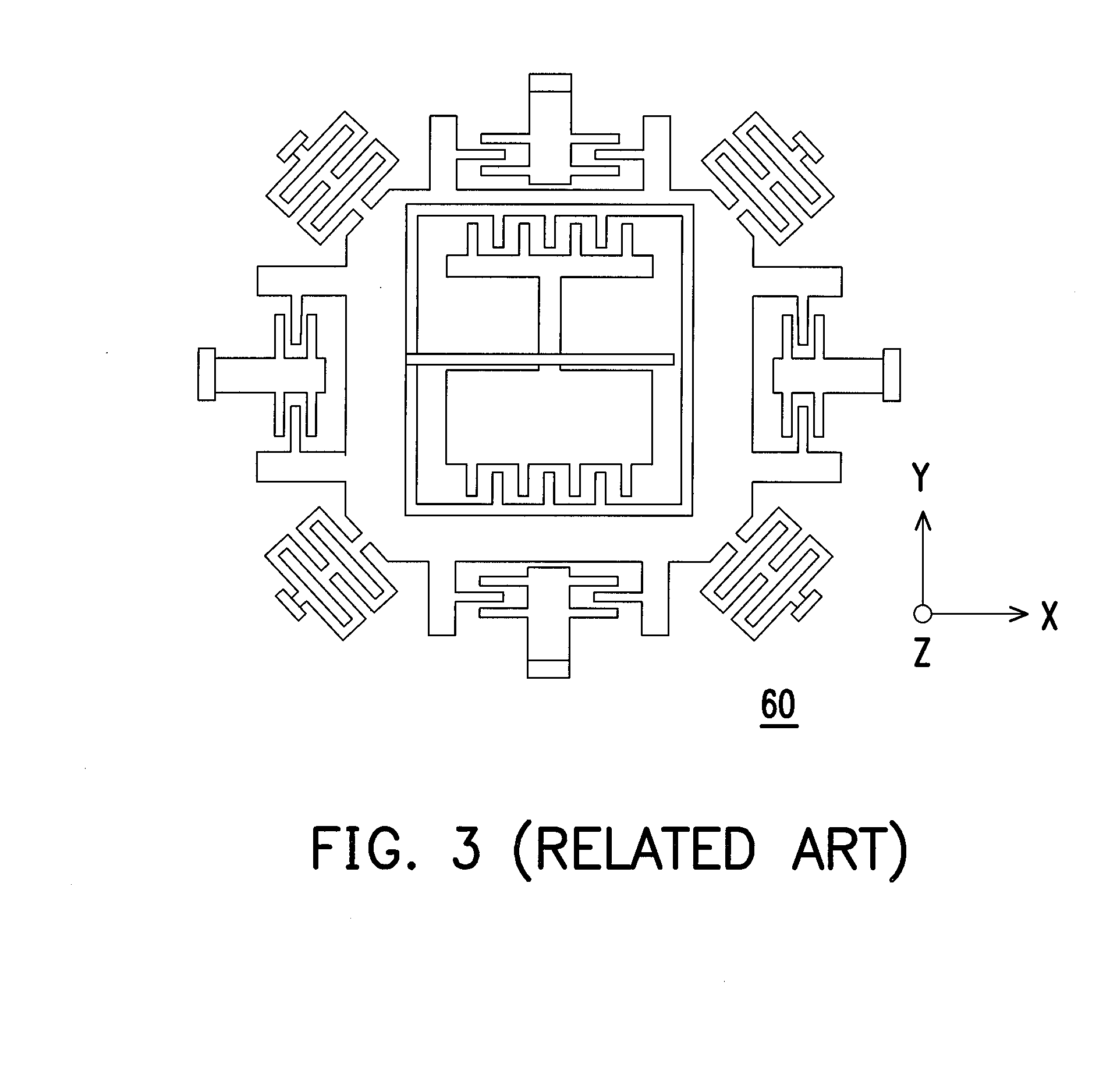

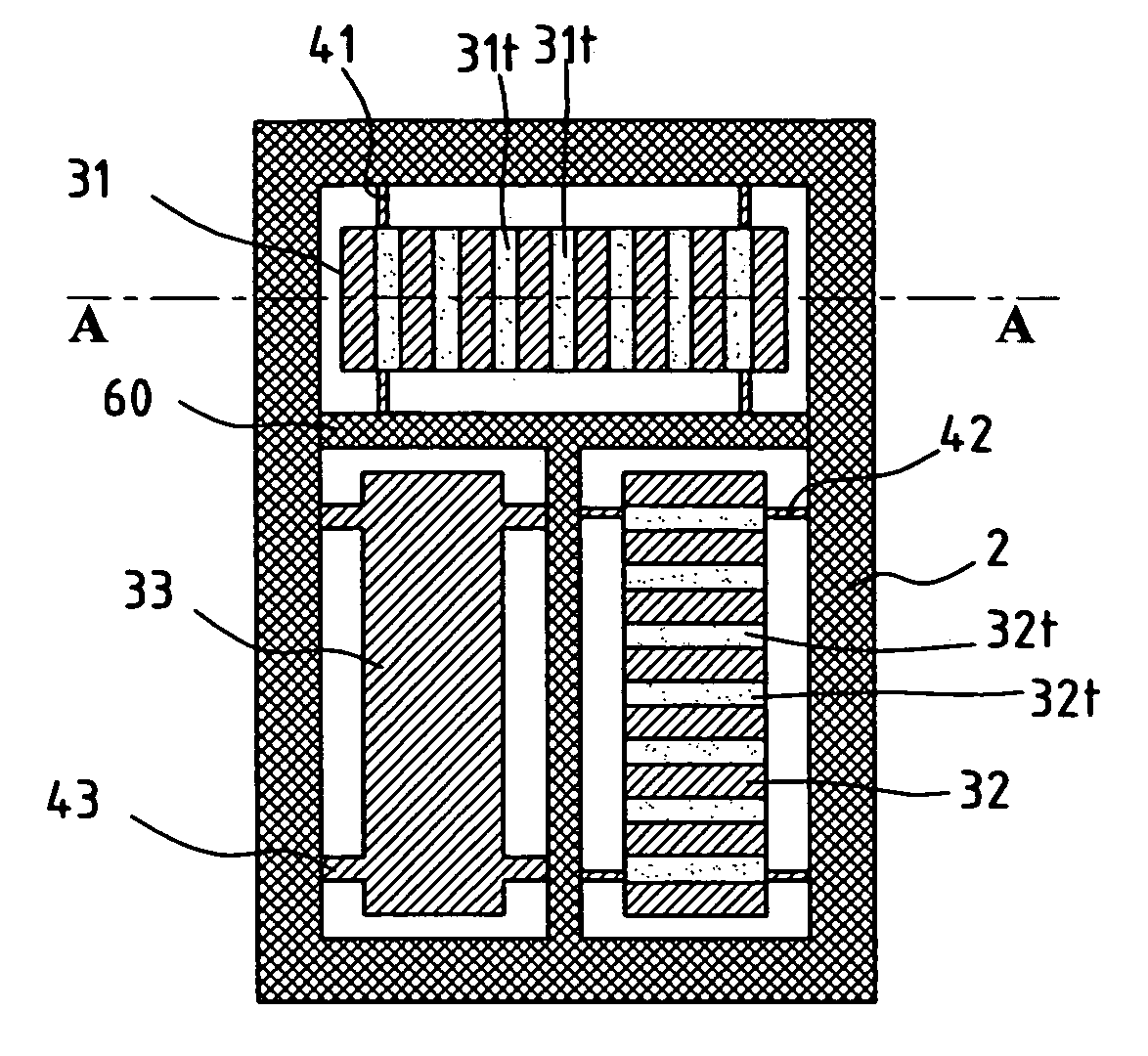

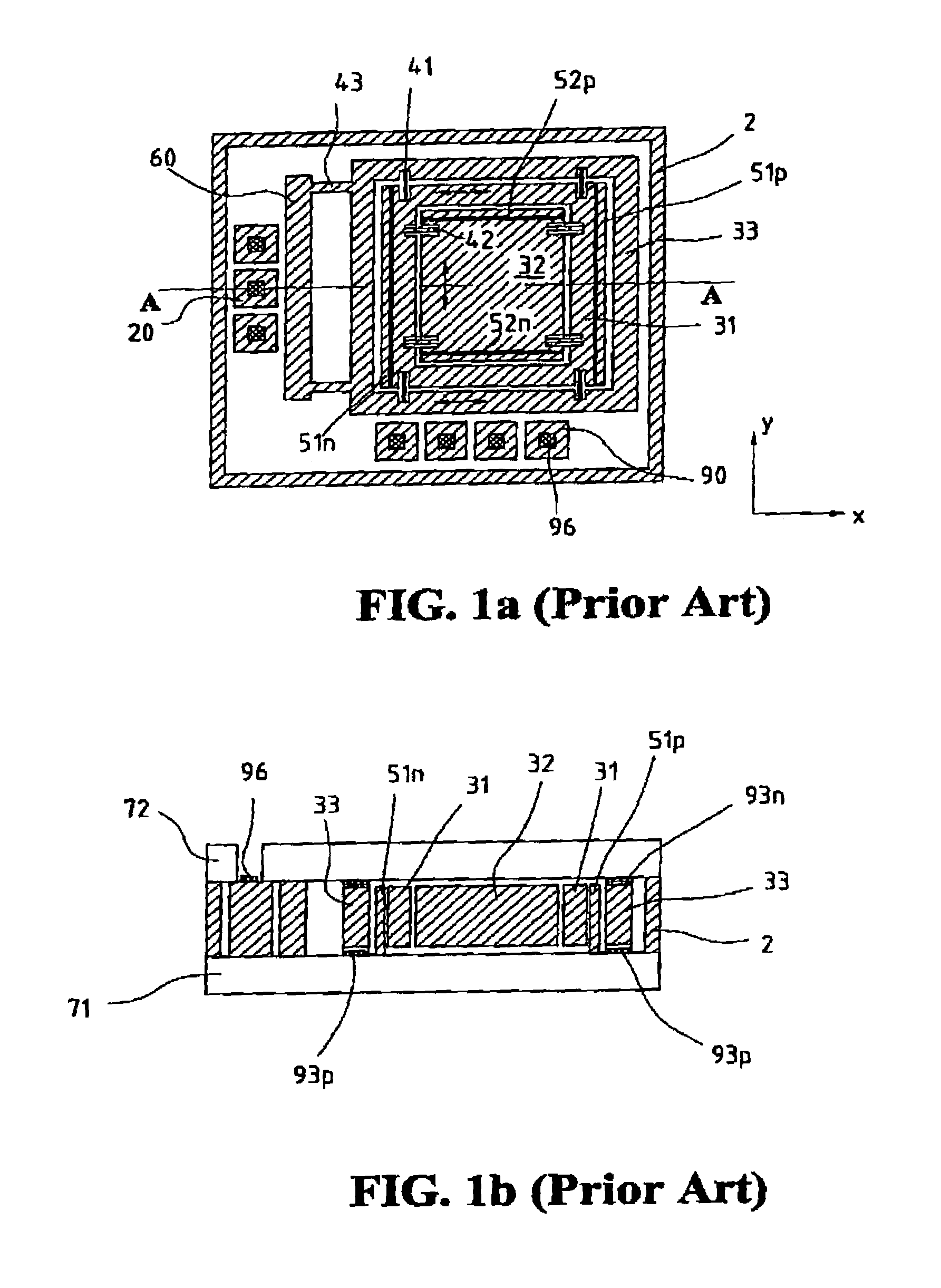

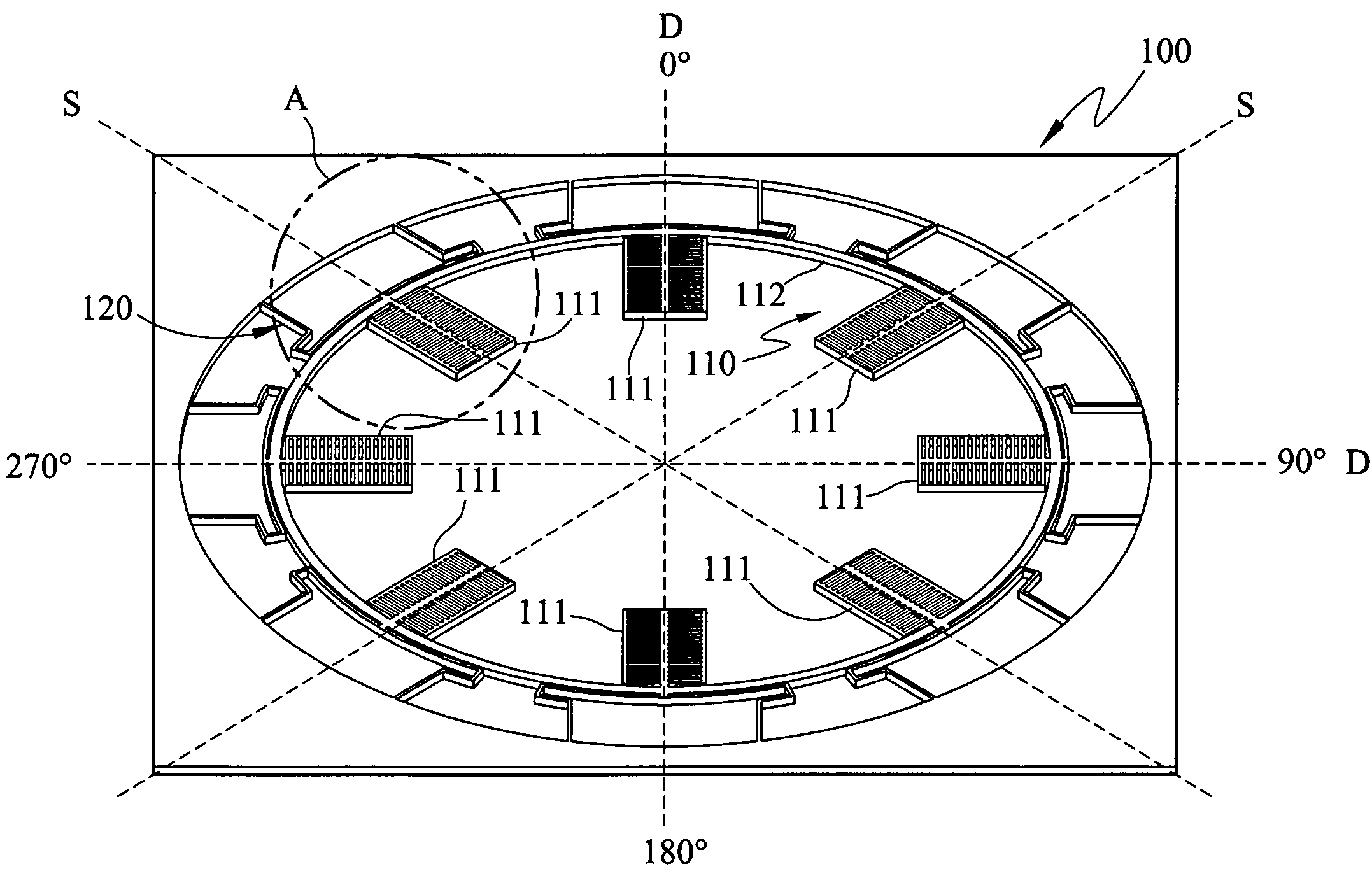

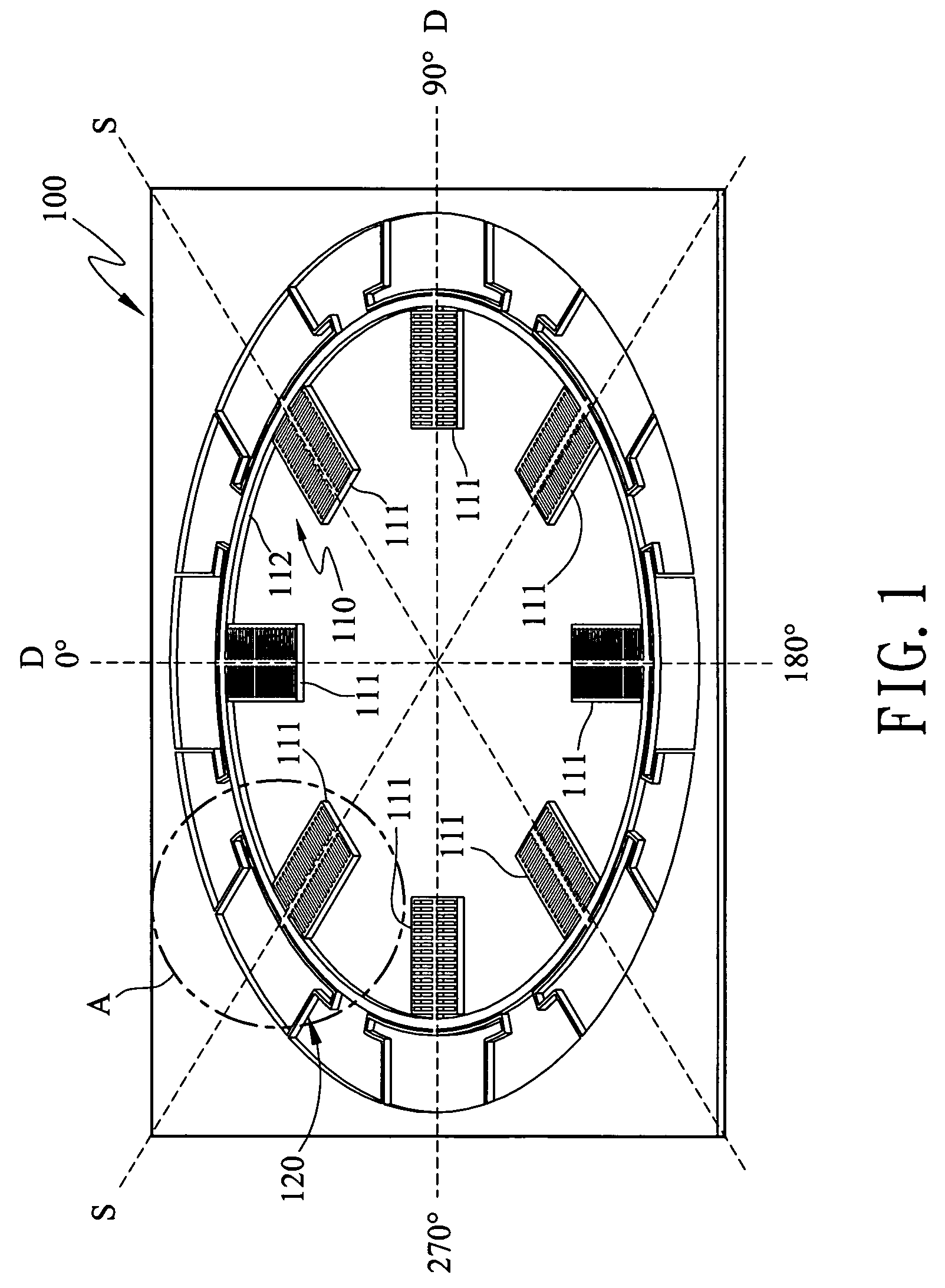

Micro angular rate sensor

InactiveUS7155978B2Great massIncrease the areaAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitancePlanar electrode

A micro angular rate-sensing device is provided. A vibrator, having a plurality of proof masses connected to a ring, is arranged in a first base. Flexible supporting members connect to the vibrator to suspend the vibrator in the first base. Electrodes drive the vibrator to oscillate and control the oscillation mode of the vibrator in driving mode. Planar electrodes are arranged relative to the proof masses on a second base. The motion of the proof masses relative to the planar electrodes is sensed through the capacitance between the proof masses and the planar electrodes. The resonant structure with greater mass of the device generates greater Coriolis force and increases the sensing area. Thus, the intensity of sensed signals and noise-signal ratio are greatly increased. Furthermore, the device does not rely much on high aspect ratio manufacturing technology. Thus the manufacturing cost is reduced and the yield rate is increased.

Owner:NAT CHUNG SHAN INST SCI & TECH +1

Planar 3-axis inertial measurement unit

ActiveUS7168317B2Simple manufacturing processLow costAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsIn planeCapacitance

The present invention relates to a z-axial solid-state gyroscope. Its main configuration is manufactured with a conductive material and includes two sets of a proof mass and two driver bodies suspended between two plates by an elastic beam assembly. Both surfaces of the driver bodies and the proof masses respectively include a number of grooves respectively perpendicular to a first axis and a second axis. The surfaces of the driver bodies and the proof masses and the corresponding stripe electrodes of the plates thereof are respectively formed a driving capacitors and a sensing capacitors. The driving capacitor drives the proof masses to vibrate in the opposite direction along the first axis. If a z-axial angular velocity input, a Coriolis force makes the two masses vibrate in the opposite direction along the second axis. If a first axial acceleration input, a specific force makes the two masses move in the same direction along the first axis. If a second axial acceleration input, a specific force makes the two masses move in the same direction along the second axis. Both inertial forces make the sensing capacitances change. One z-axial solid-state gyroscopes and two in-plane axial gyroscopes can be designed on a single chip to form a complete three-axis inertial measurement unit.

Owner:MIN OF NAT DEFENSE

Method and apparatus for electronic cancellation of quadrature error

ActiveUS20070180908A1Minimize quadrature errorImprove signal-to-noise ratioAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsEngineeringProof mass

Methods and apparatus are provided for detecting a rate of rotation. In one implementation, the method includes vibrating a proof mass at a pre-determined frequency in a drive axis. In response to a rotation, sensing an amount of deflection of the proof mass in an axis orthogonal to the drive axis, in which the amount of deflection is sensed as a change in charge. The method further includes generating a quadrature error cancellation signal to substantially cancel quadrature error from the sensed change in charge.

Owner:INVENSENSE

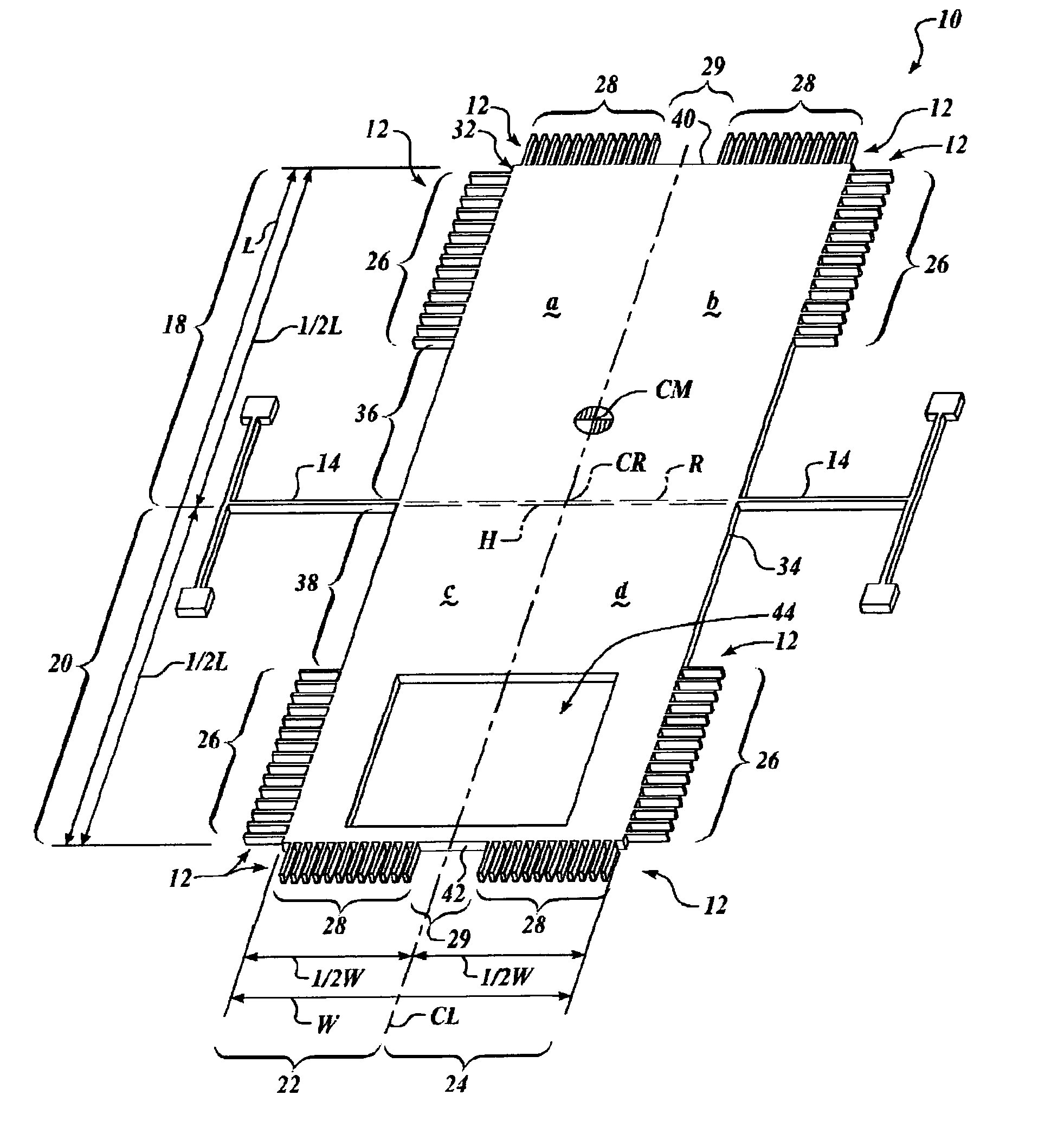

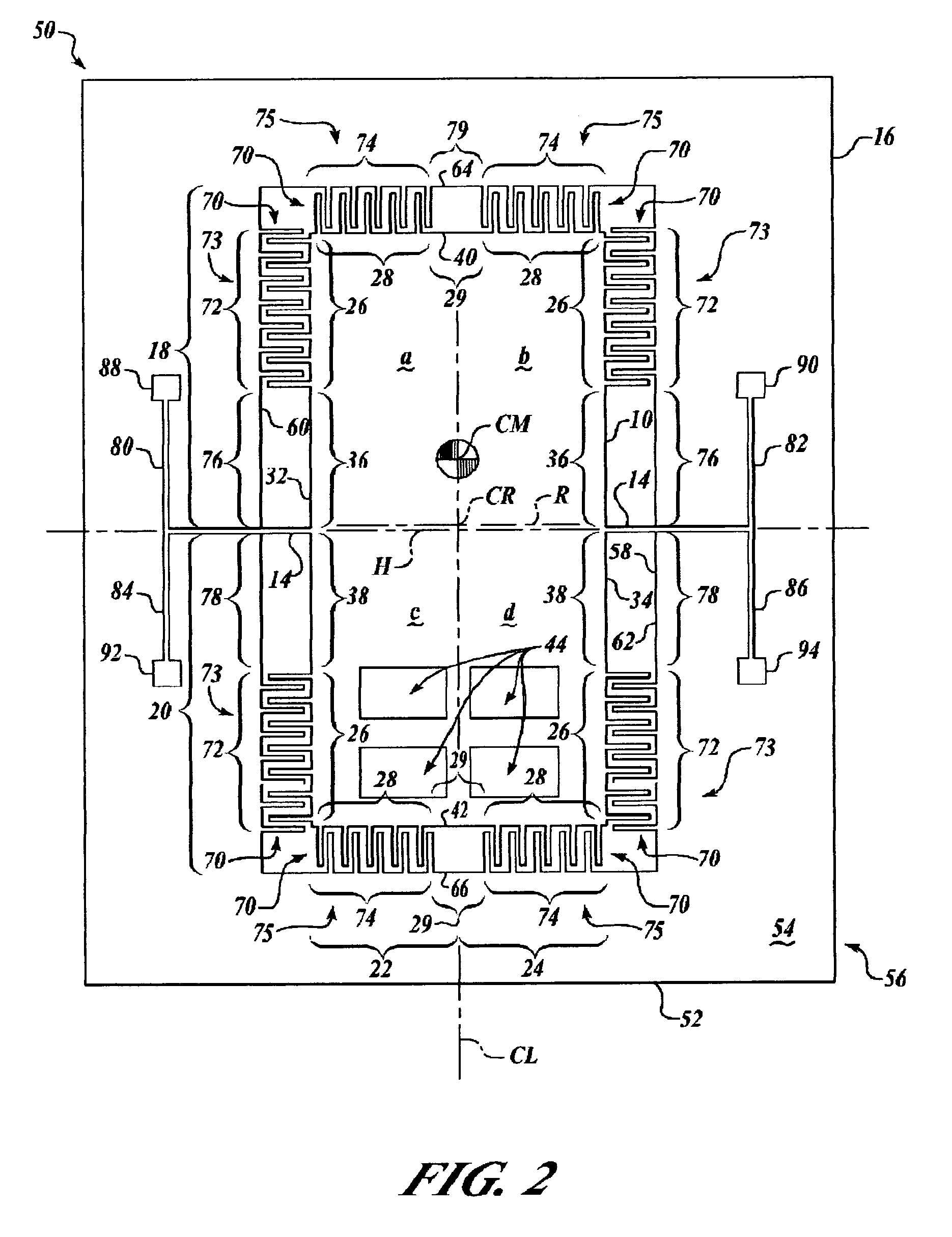

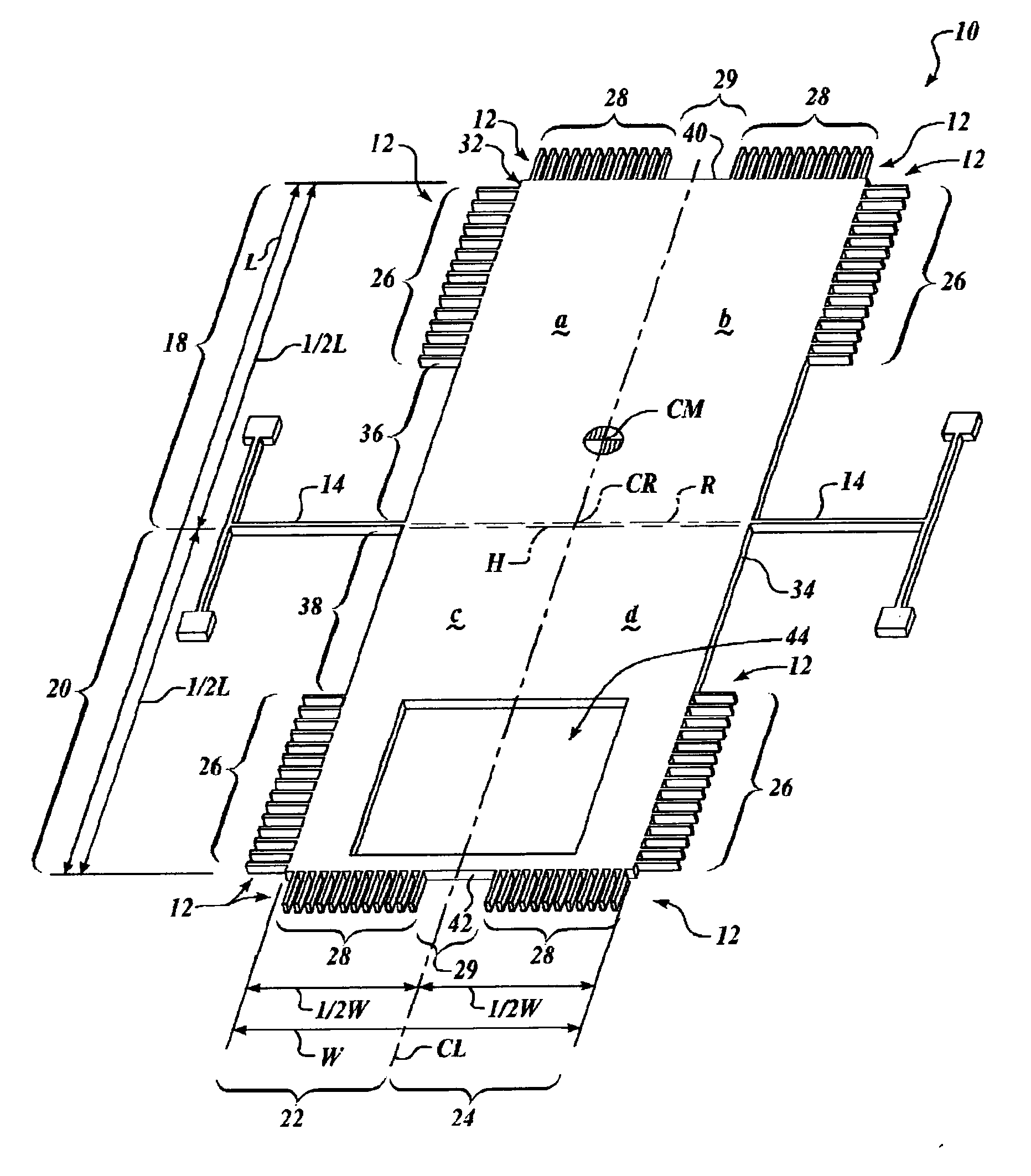

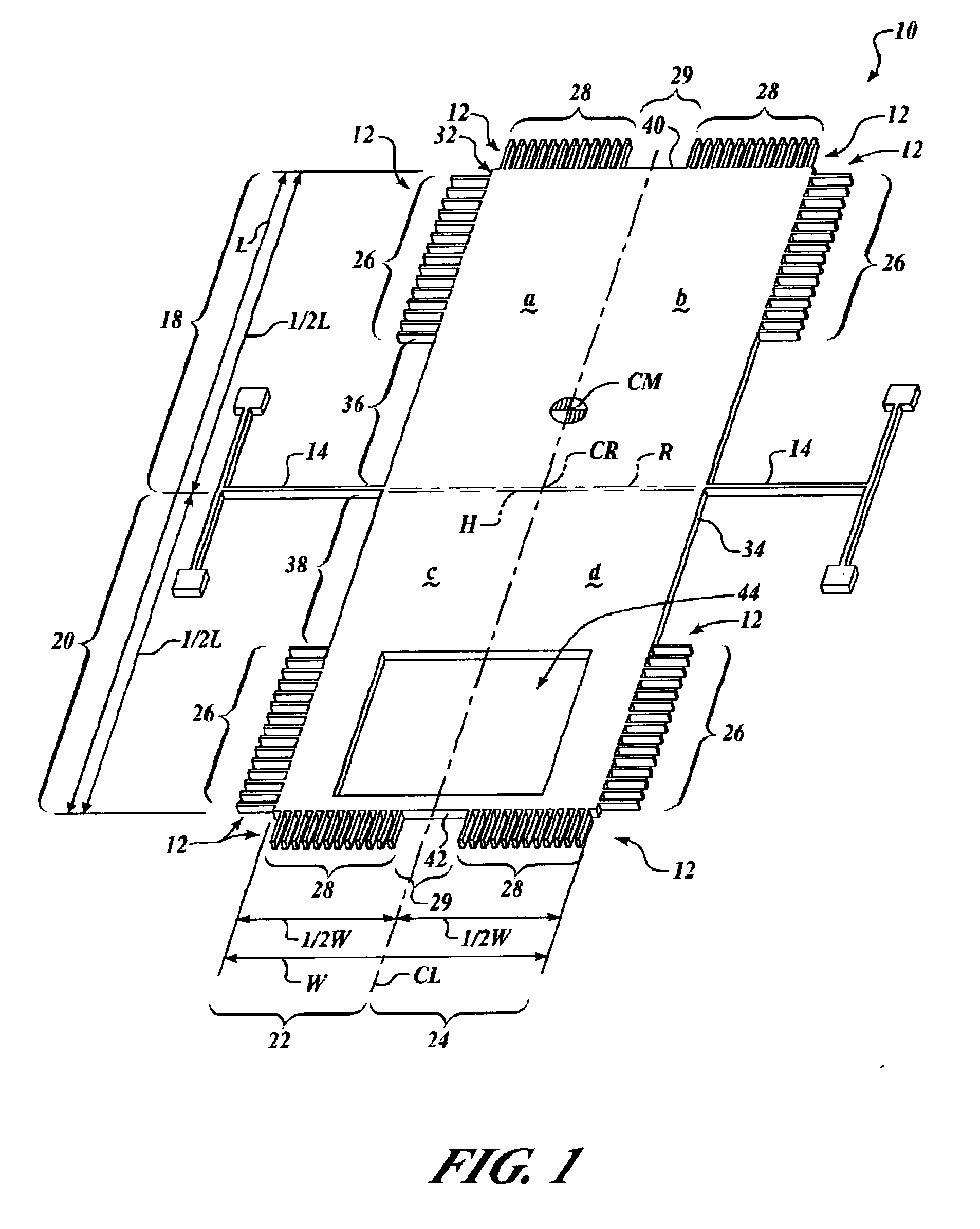

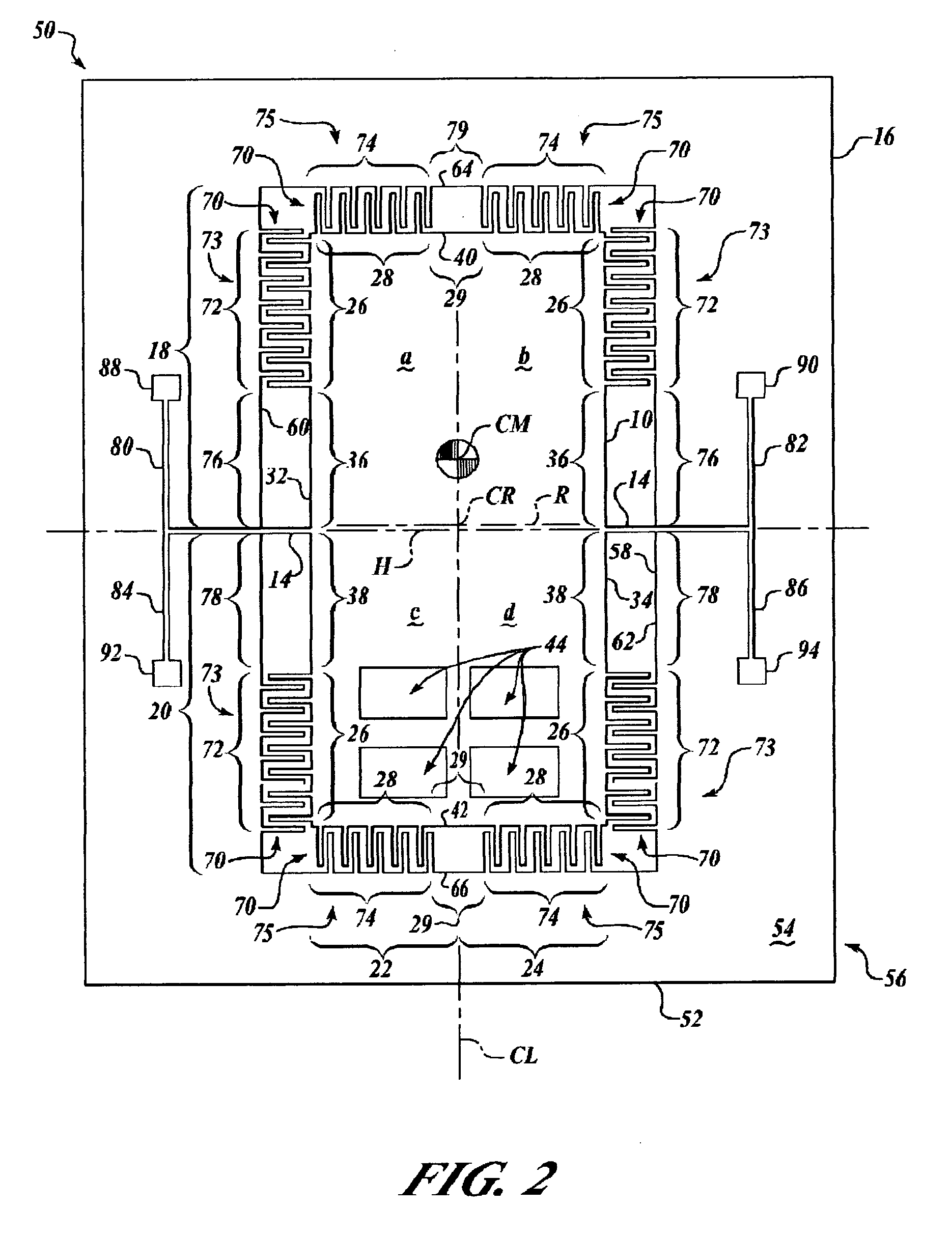

MEMS teeter-totter accelerometer having reduced non-linearty

ActiveUS7140250B2Improve accuracyLow costAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsRotational axisEngineering

An apparatus and method for force sensing device having a pendulous mechanism proof mass formed in a silicon semiconductor substrate and structured for rotation about an intermediate rotational axis, the proof mass being substantially rectangular in shape with opposing first and second lateral peripheral edges and opposing first and second endwise peripheral edges. A plurality of capacitor comb teeth are formed symmetrically along the opposing first and second endwise peripheral proof mass edges and along the opposing first and second lateral peripheral proof mass edges adjacent to the first and second endwise peripheral edges, and one or more mass reduction apertures are formed in an interior portion of the proof mass on one side of the intermediate hinge axis.

Owner:HONEYWELL INT INC

MEMS teeter-totter accelerometer having reduced non-linearty

ActiveUS20060185433A1Reduce non-linearityImprove accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsRotational axisEngineering

An apparatus and method for force sensing device having a pendulous mechanism proof mass formed in a silicon semiconductor substrate and structured for rotation about an intermediate rotational axis, the proof mass being substantially rectangular in shape with opposing first and second lateral peripheral edges and opposing first and second endwise peripheral edges. A plurality of capacitor comb teeth are formed symmetrically along the opposing first and second endwise peripheral proof mass edges and along the opposing first and second lateral peripheral proof mass edges adjacent to the first and second endwise peripheral edges, and one or more mass reduction apertures are formed in an interior portion of the proof mass on one side of the intermediate hinge axis.

Owner:HONEYWELL INT INC

Methods and systems for controlling movement within MEMS structures

InactiveUS6860151B2Reducing undesired movementAcceleration measurement using interia forcesMechanical apparatusClassical mechanicsProof mass

A method for reducing undesired movements of proof masses in micro-electromechanical systems (MEMS) devices is described where the proof masses are suspended above a substrate by one or more suspensions. The method includes providing an anchor on the substrate substantially between a first proof and suspensions for the first proof mass and a second proof mass and suspensions for the second proof mass, coupling a first portion of a beam to the first proof mass, coupling a second portion of the beam to the second proof mass, and attaching a third portion of the beam to the anchor, the third portion extending between the first portion and second portion of the beam, the anchor and the third portion configured to allow for rotation about an axis perpendicular to the substrate.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com