Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3065 results about "Polymer thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

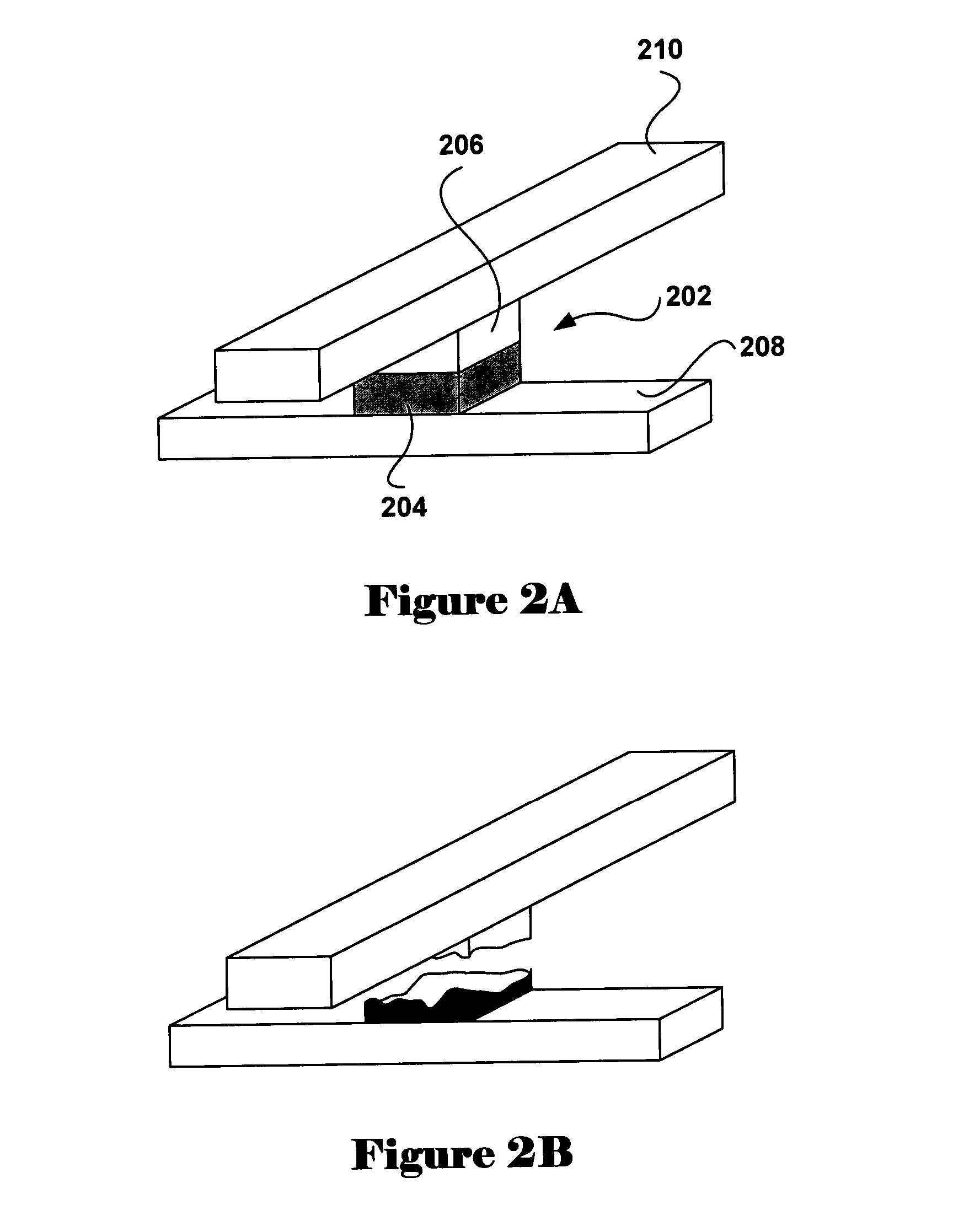

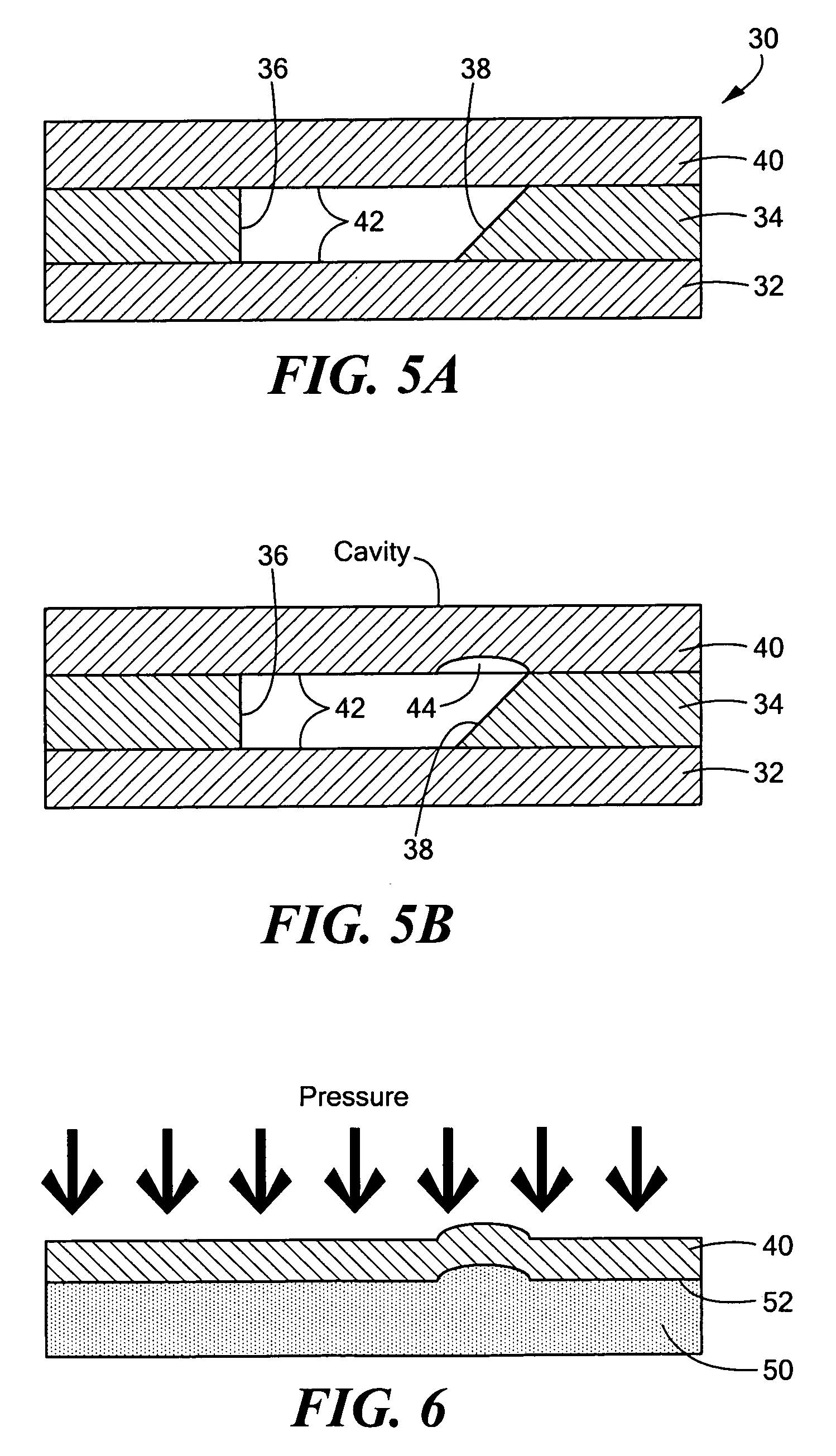

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

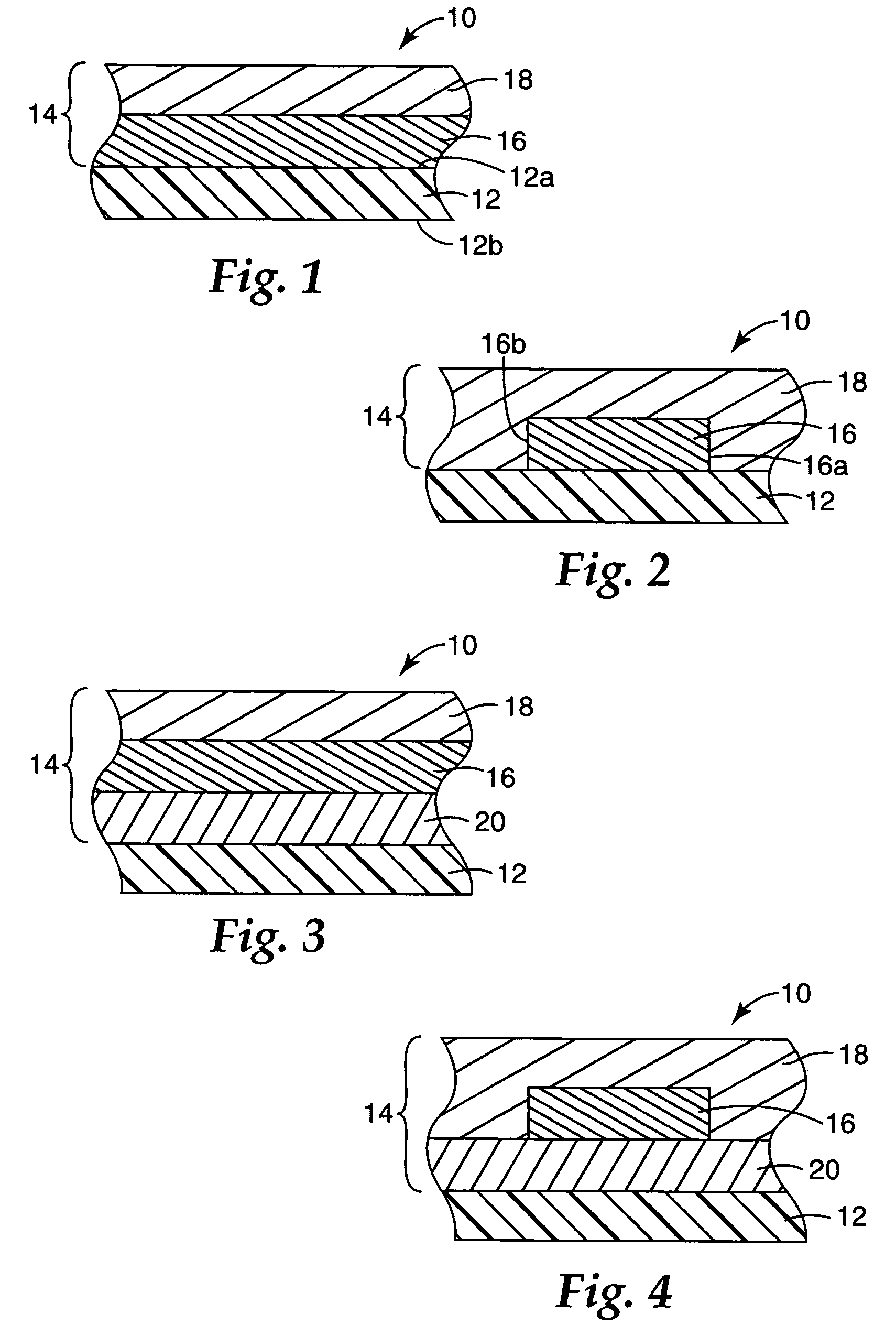

Frag shield

Fabric laminates having superior resistance to penetration of fragments, such as shrapnel. The fabrics are formed of high-strength fibers consolidated with from about 7% to about 15% by weight of an elastomeric matrix composition, and in combination with protective layers of a polymer film on each surface of the fabric. The fabrics achieve a significant improvement in fragment resistance compared to fabrics of the prior art, while also maintaining excellent ballistic resistant properties.

Owner:HONEYWELL INT INC

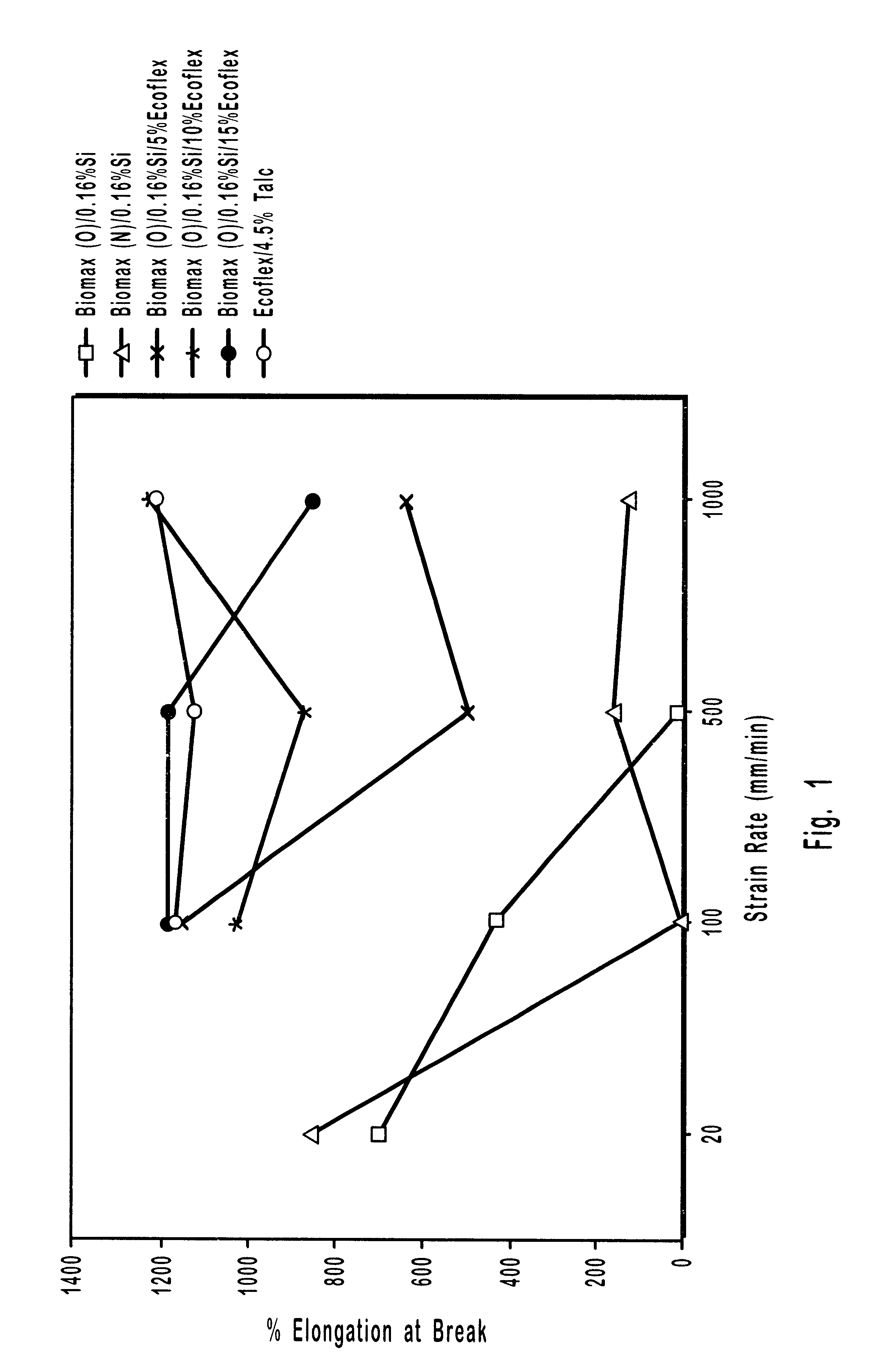

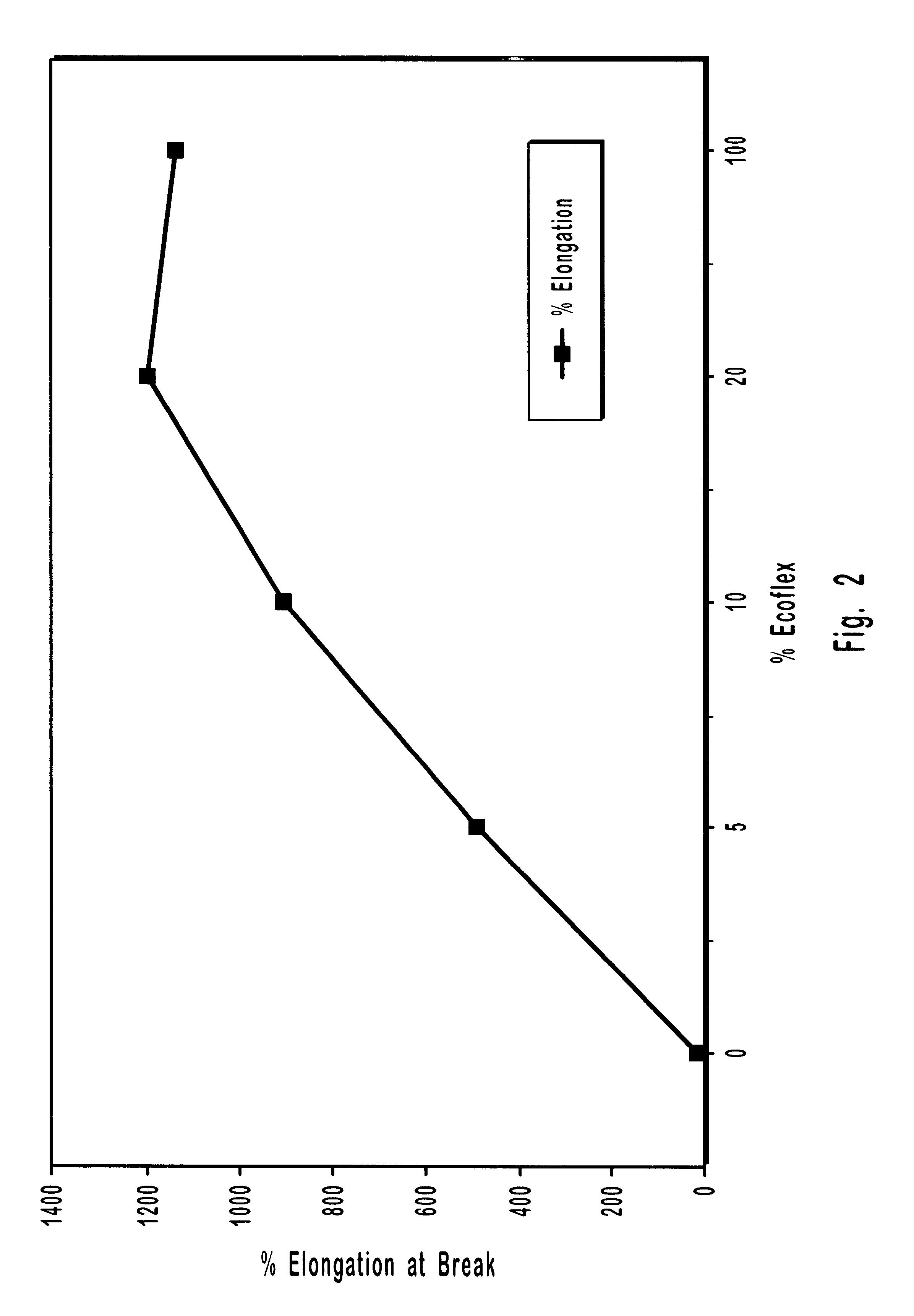

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

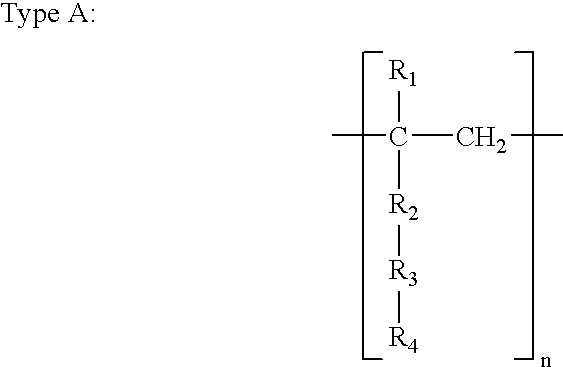

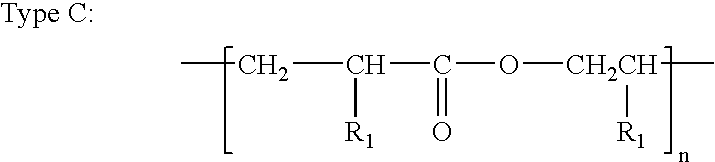

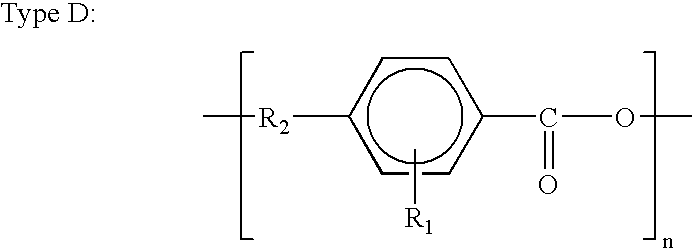

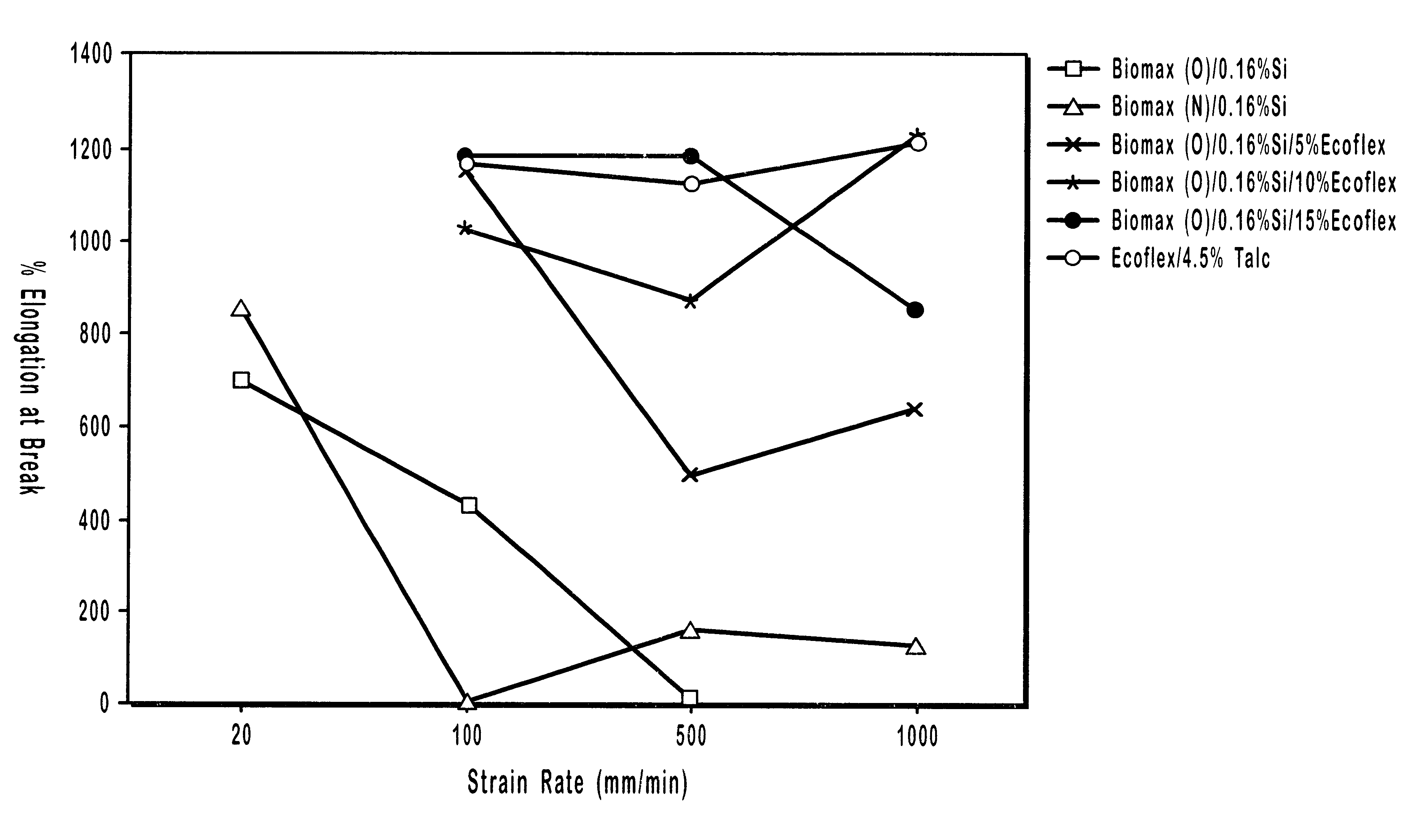

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

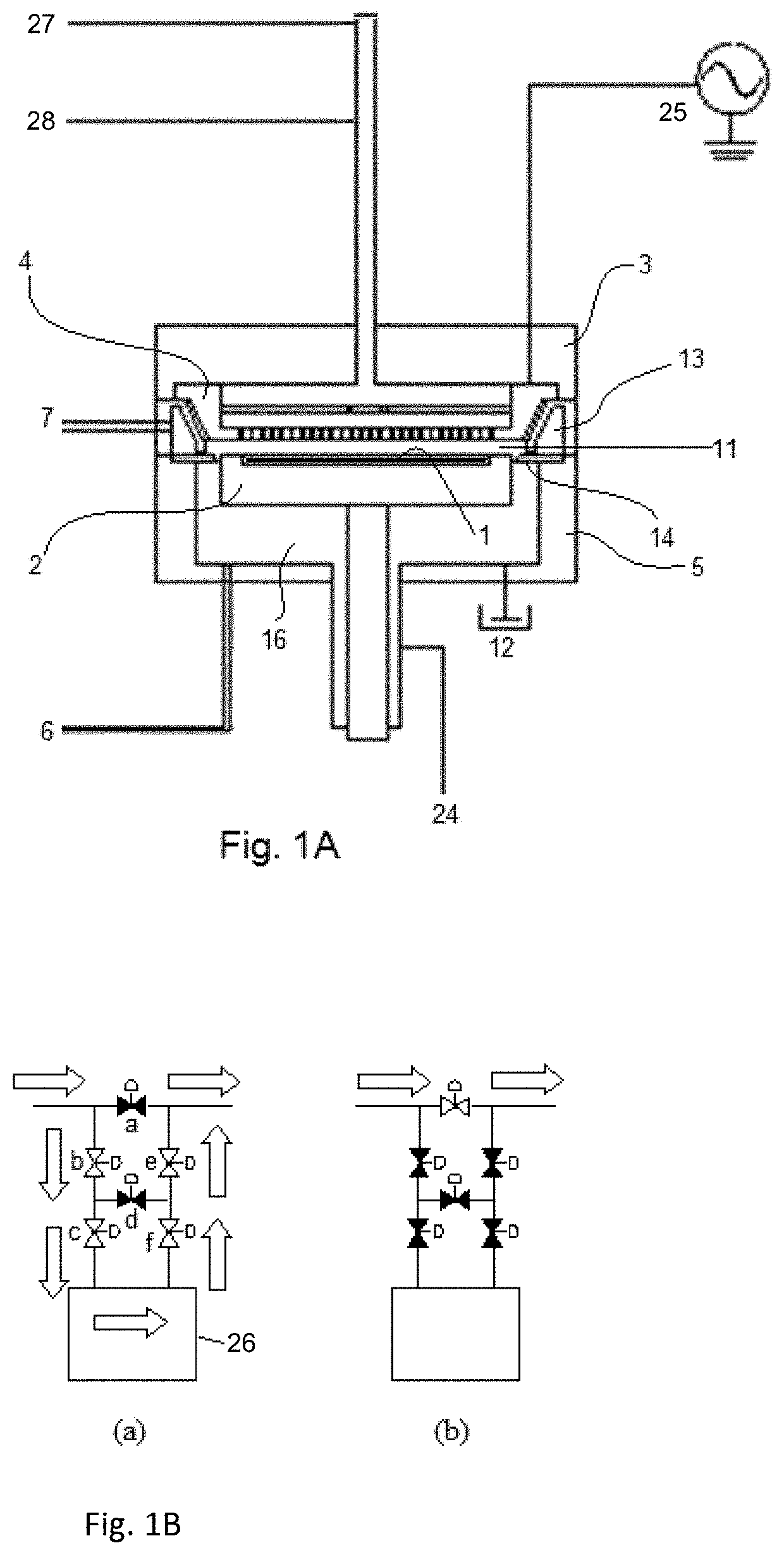

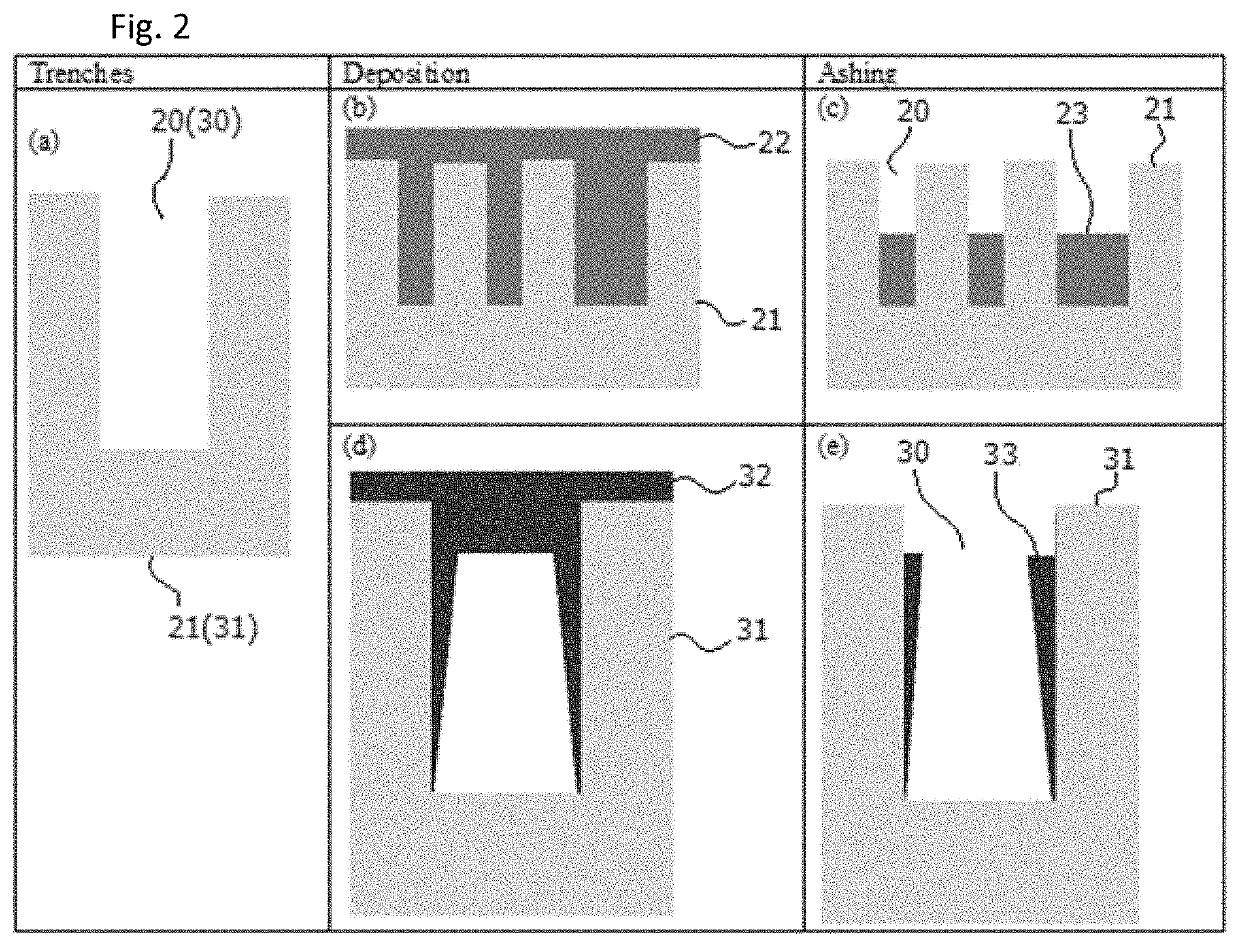

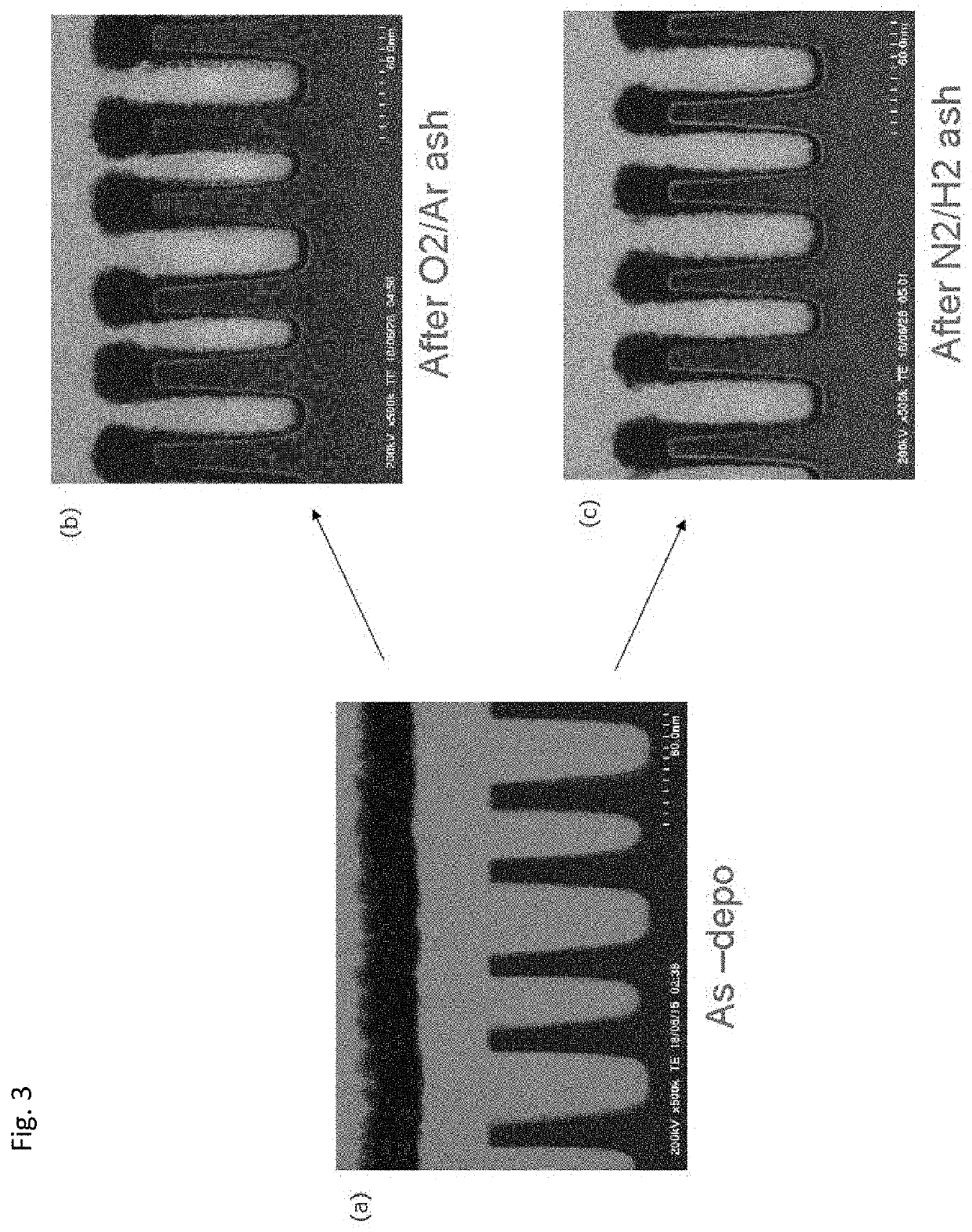

Method of forming topology-controlled amorphous carbon polymer film

ActiveUS20210020431A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAcid etchingPolymer science

A method of forming a topology-controlled layer on a patterned recess of a substrate, includes: (i) depositing a Si-free C-containing film having filling capability on the patterned recess of the substrate by pulse plasma-assisted deposition to fill the recess in a bottom-up manner or bottomless manner; and (ii) subjecting the bottom-up or bottomless film filled in the recess to plasma aching to remove a top portion of the filled film in a manner leaving primarily or substantially only a bottom portion of the filled film or primarily or substantially only a sidewall portion of the filled film.

Owner:ASM IP HLDG BV

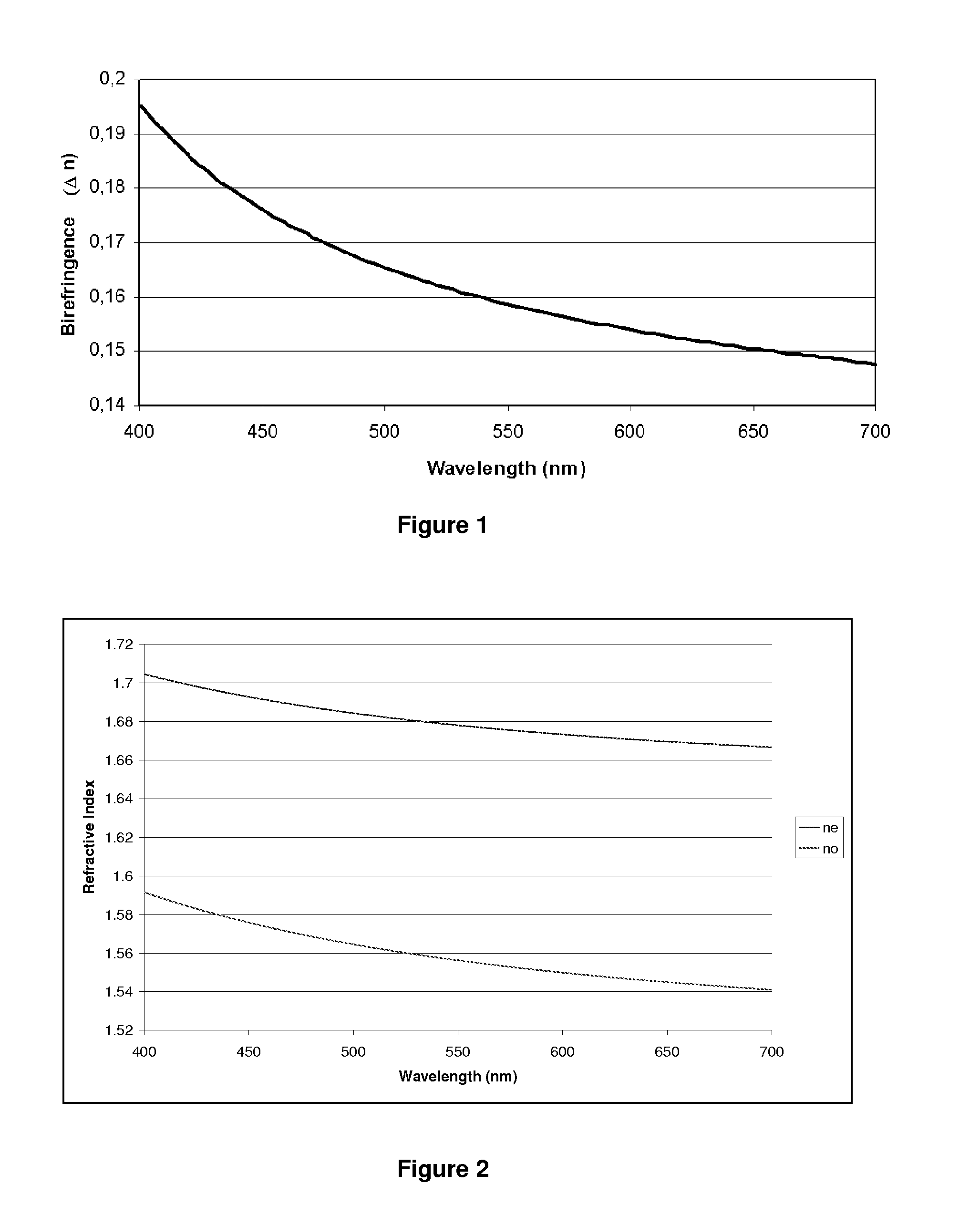

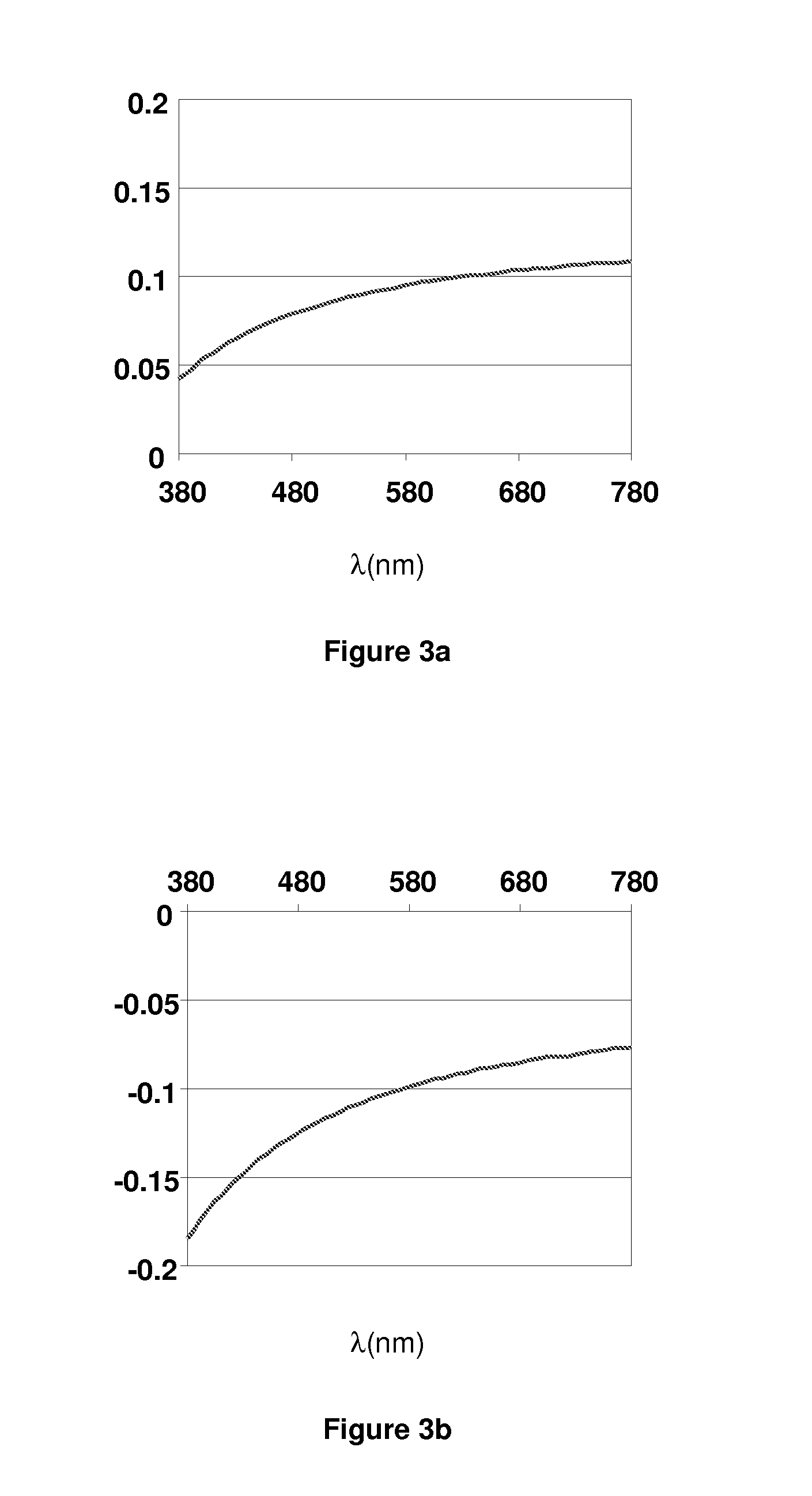

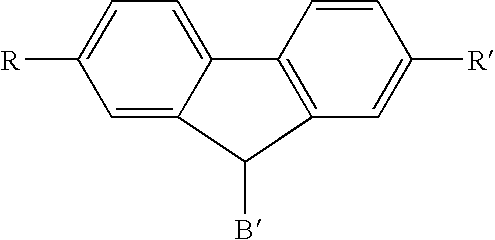

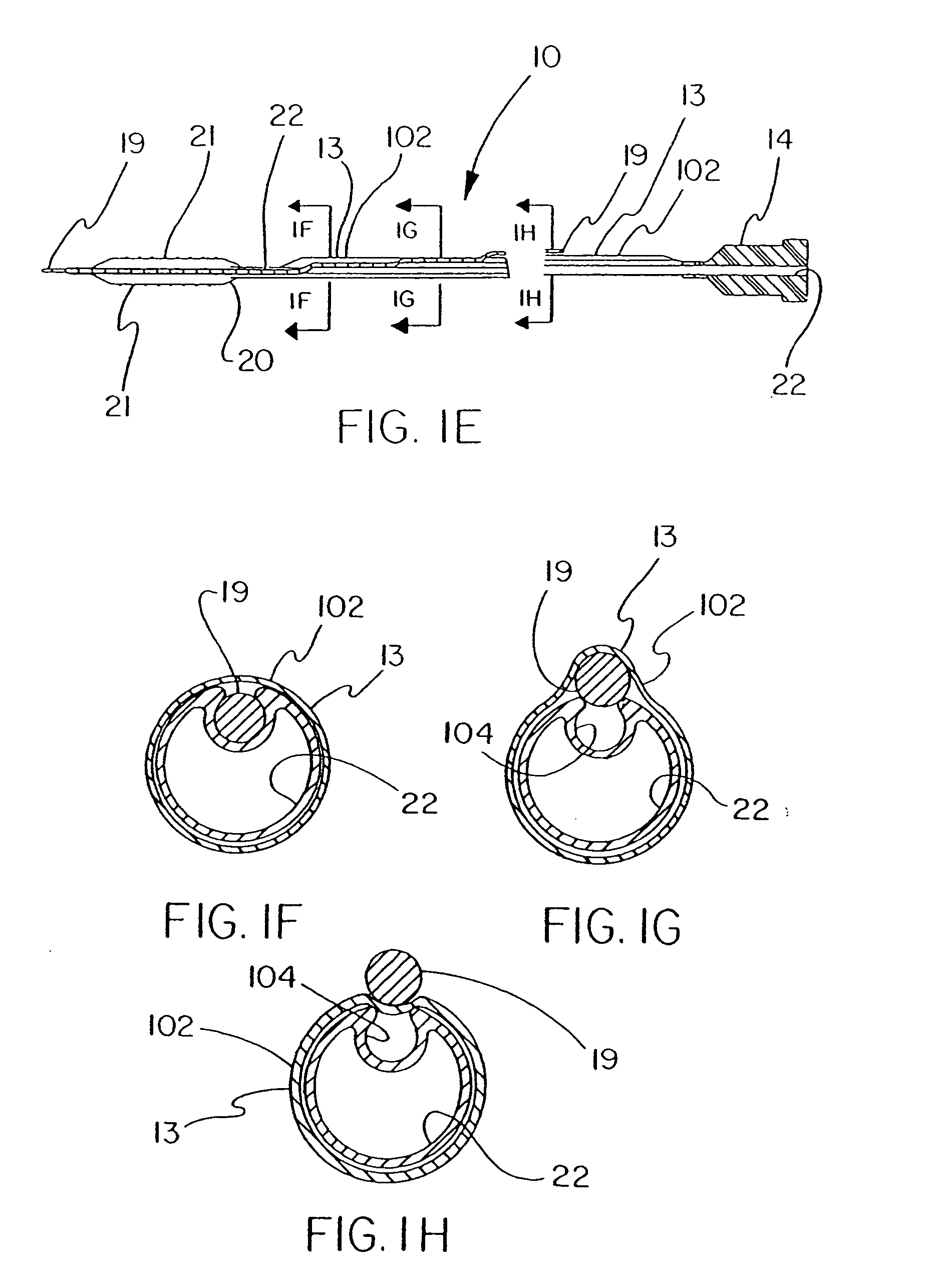

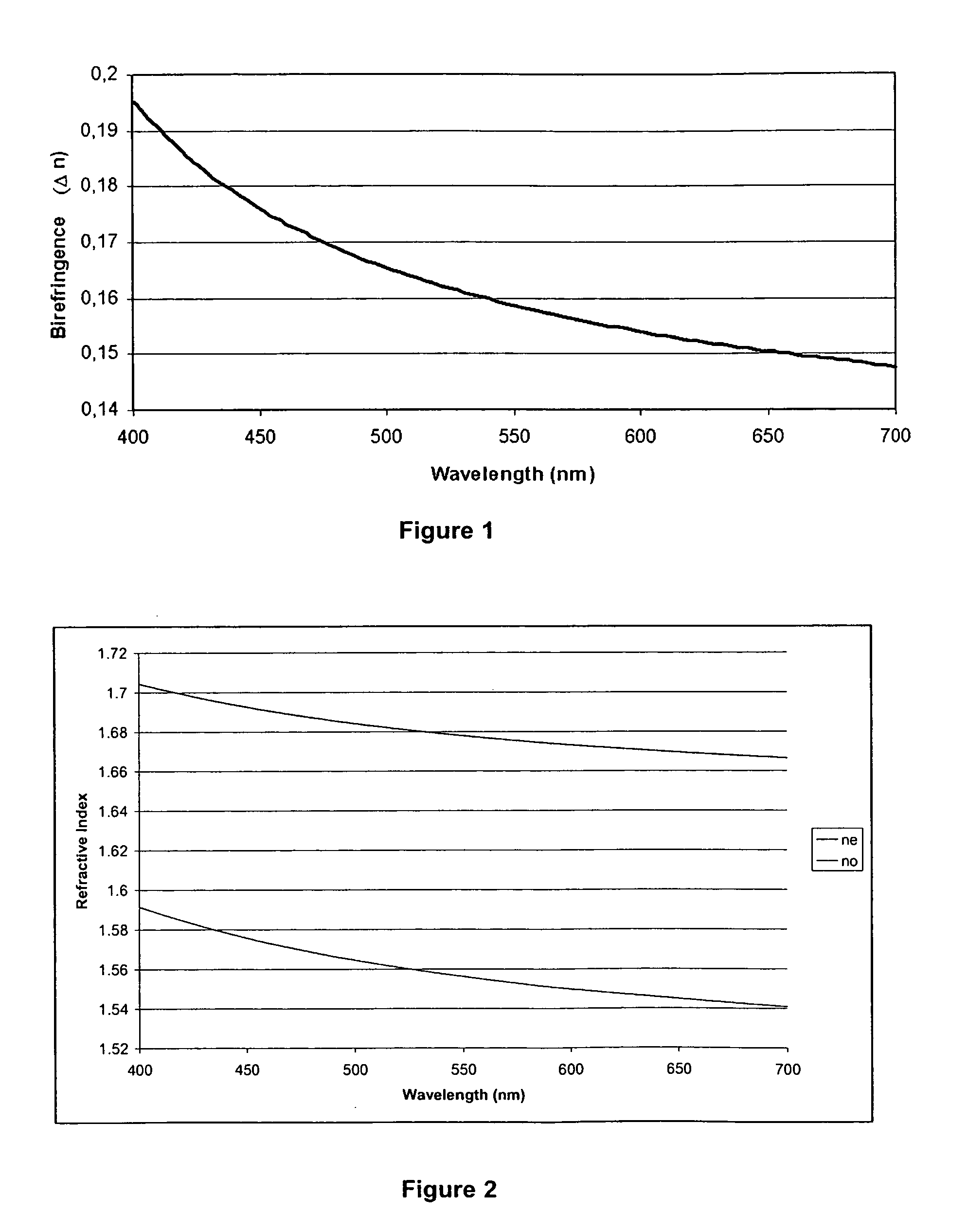

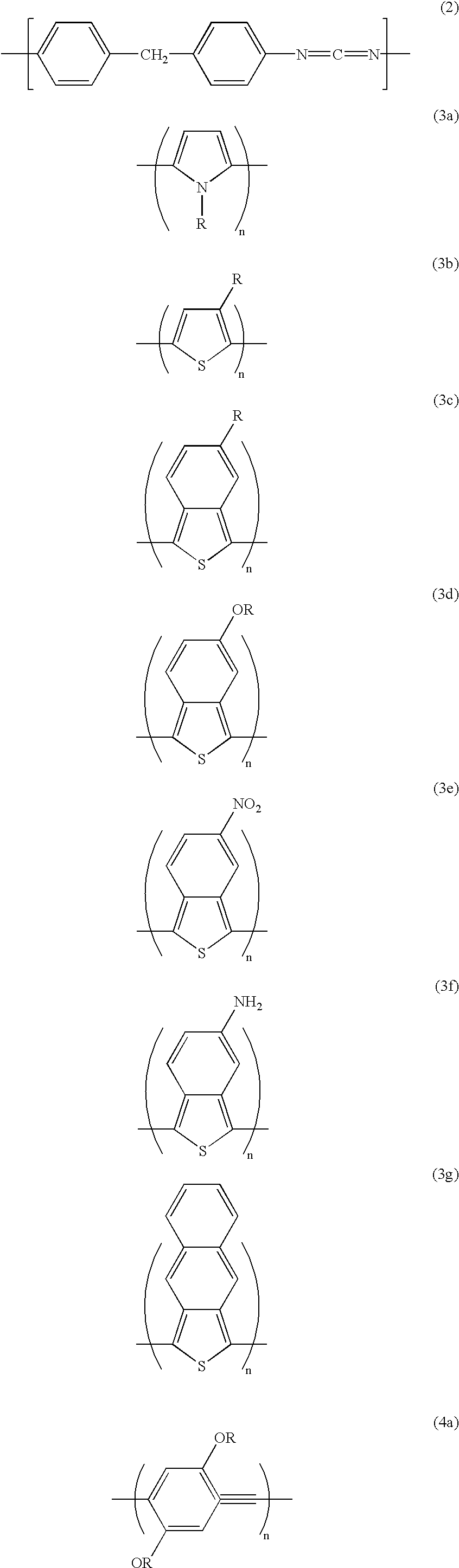

Fluorene derivatives

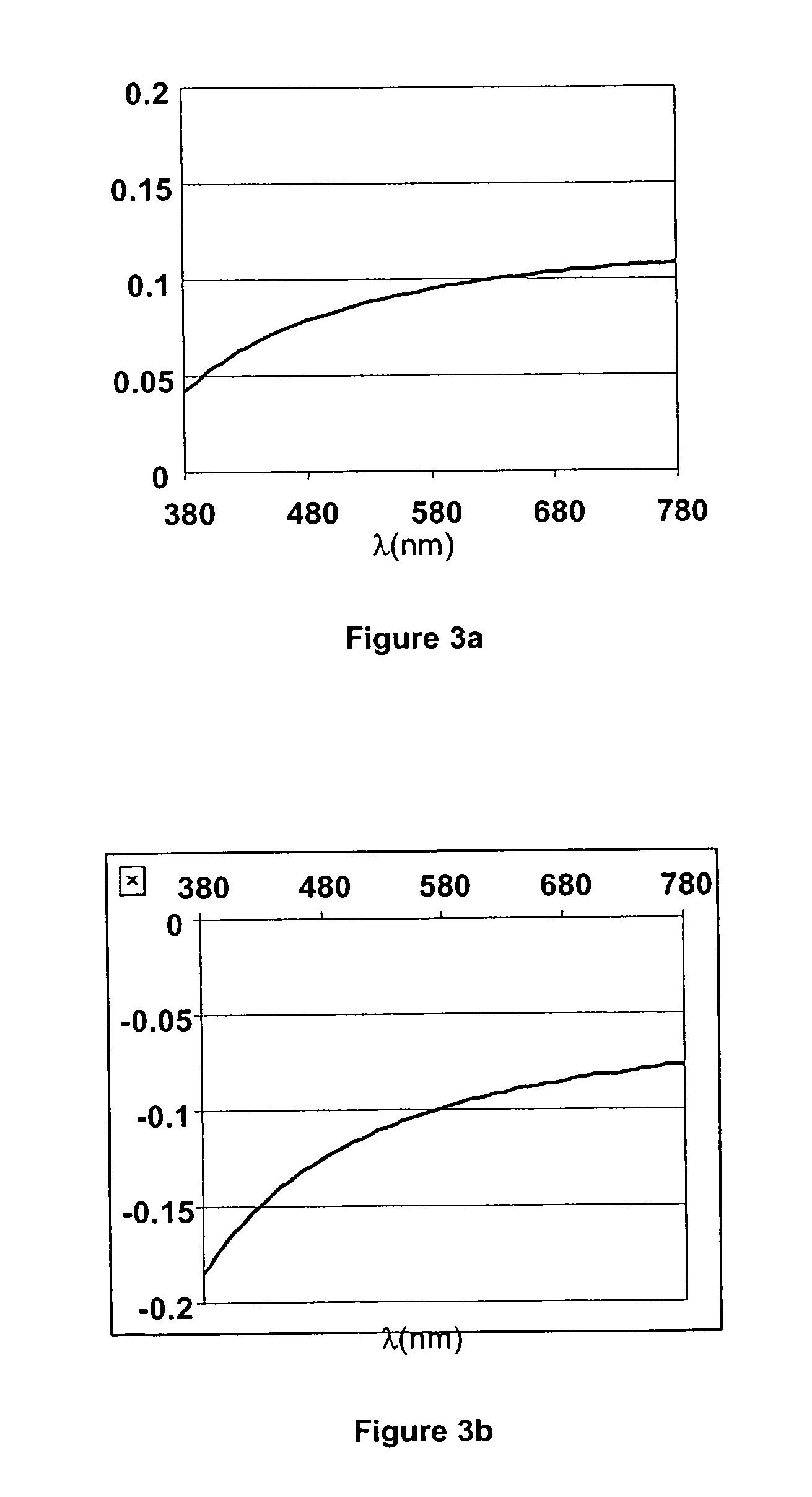

ActiveUS20100301271A1Increase polarizabilityLiquid crystal compositionsOrganic chemistryPolymer thin filmsSemiconductor

The invention relates to novel fluorene derivatives, which are especially suitable for use in birefringent films with negative optical dispersion, to novel liquid crystal (LC) formulations and polymer films comprising them, and to the use of the fluorene derivatives, formulations and films in optical, electrooptical, electronic, semiconducting or luminescent components or devices.

Owner:MERCK PATENT GMBH

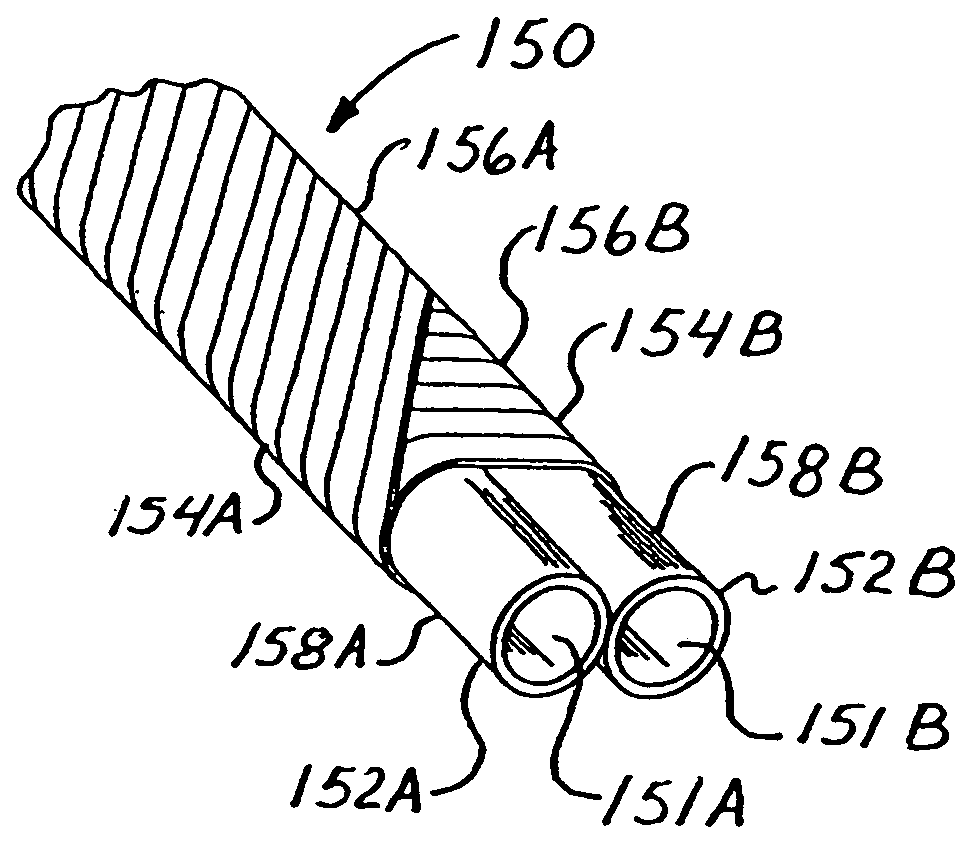

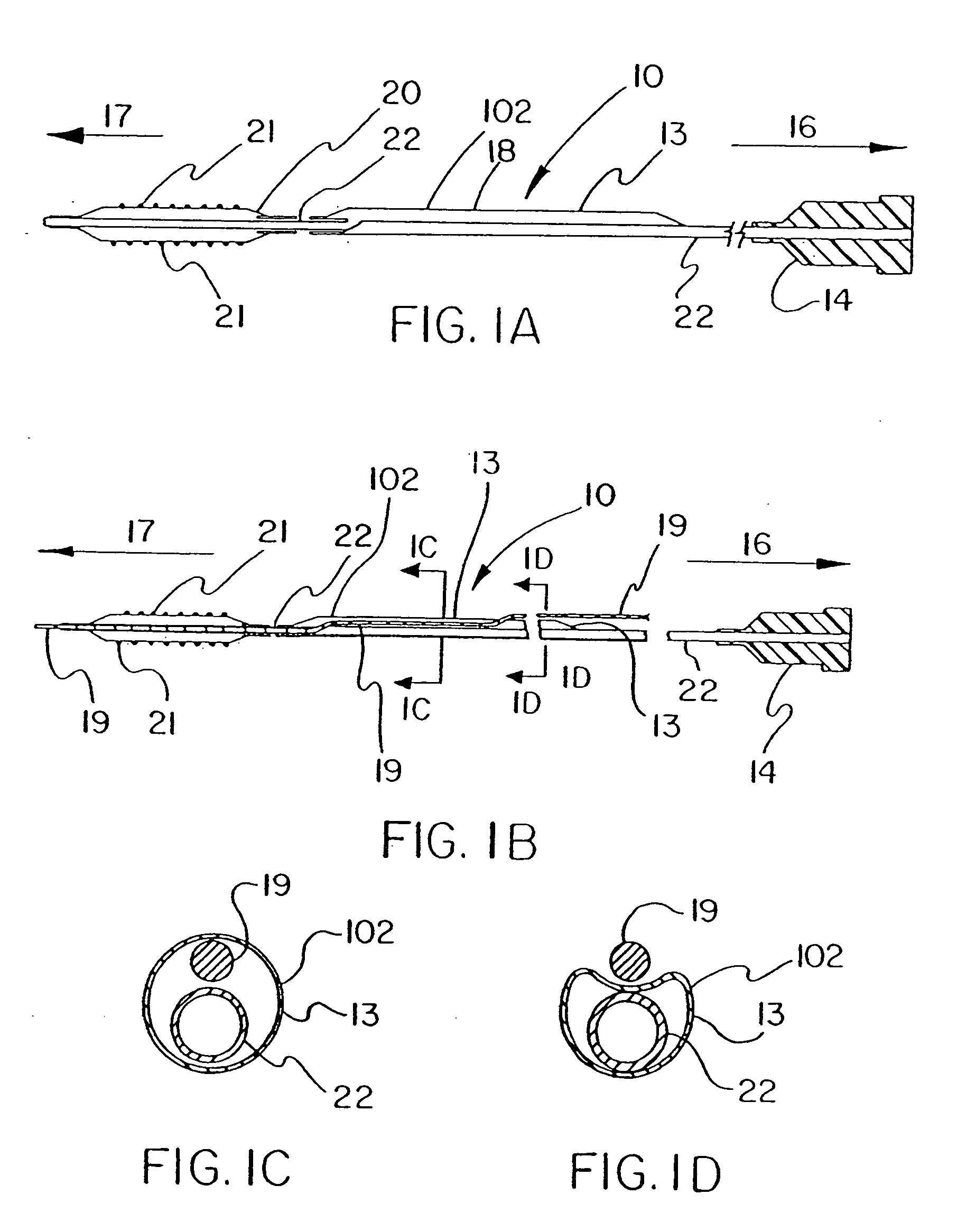

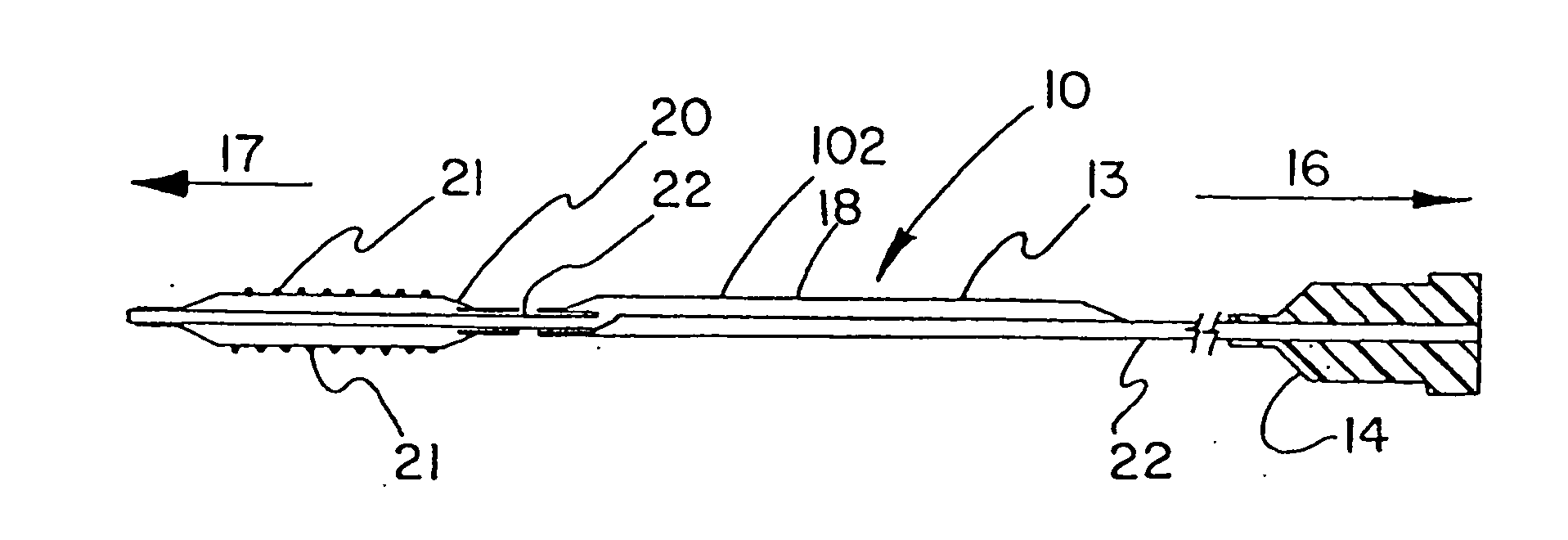

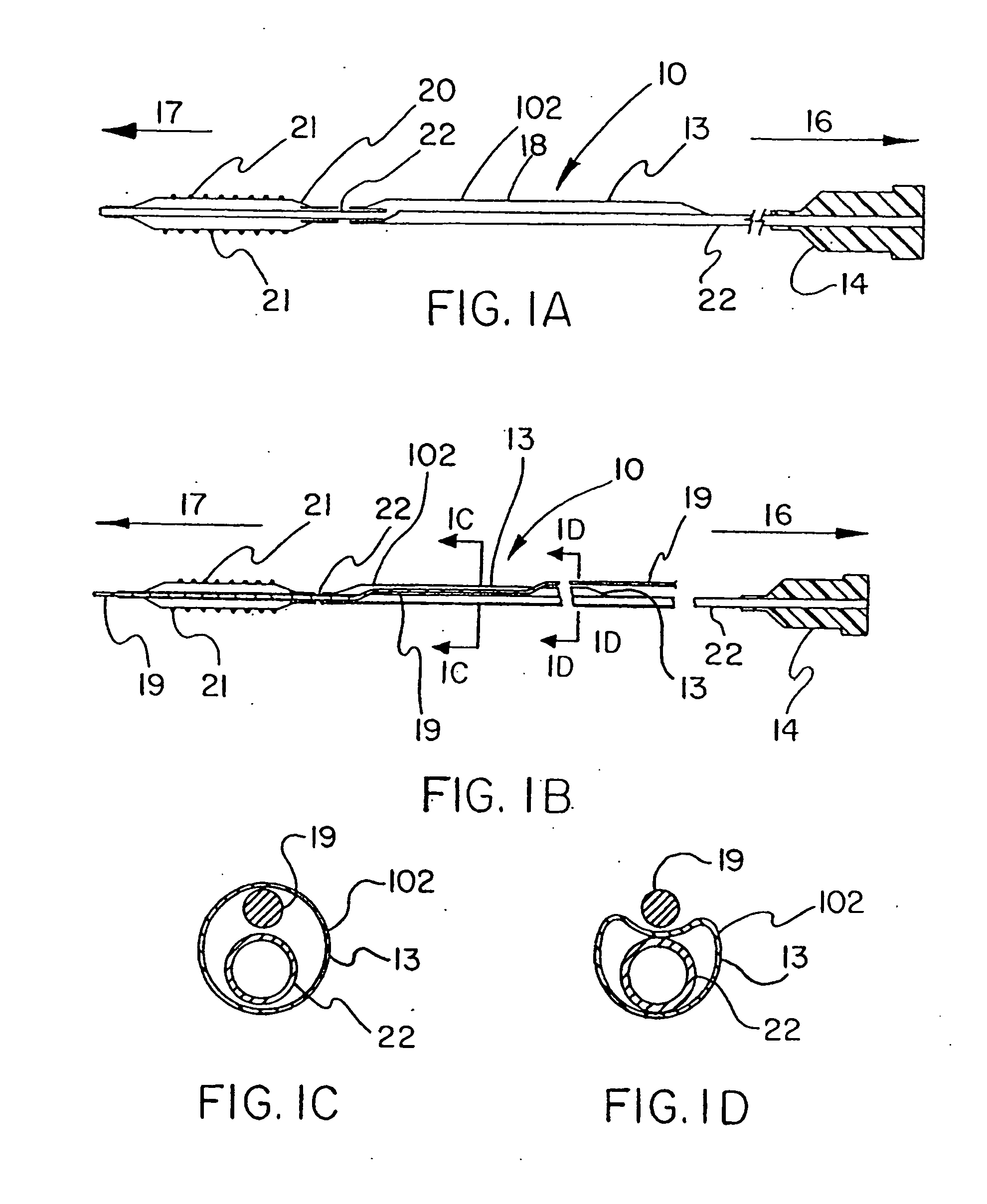

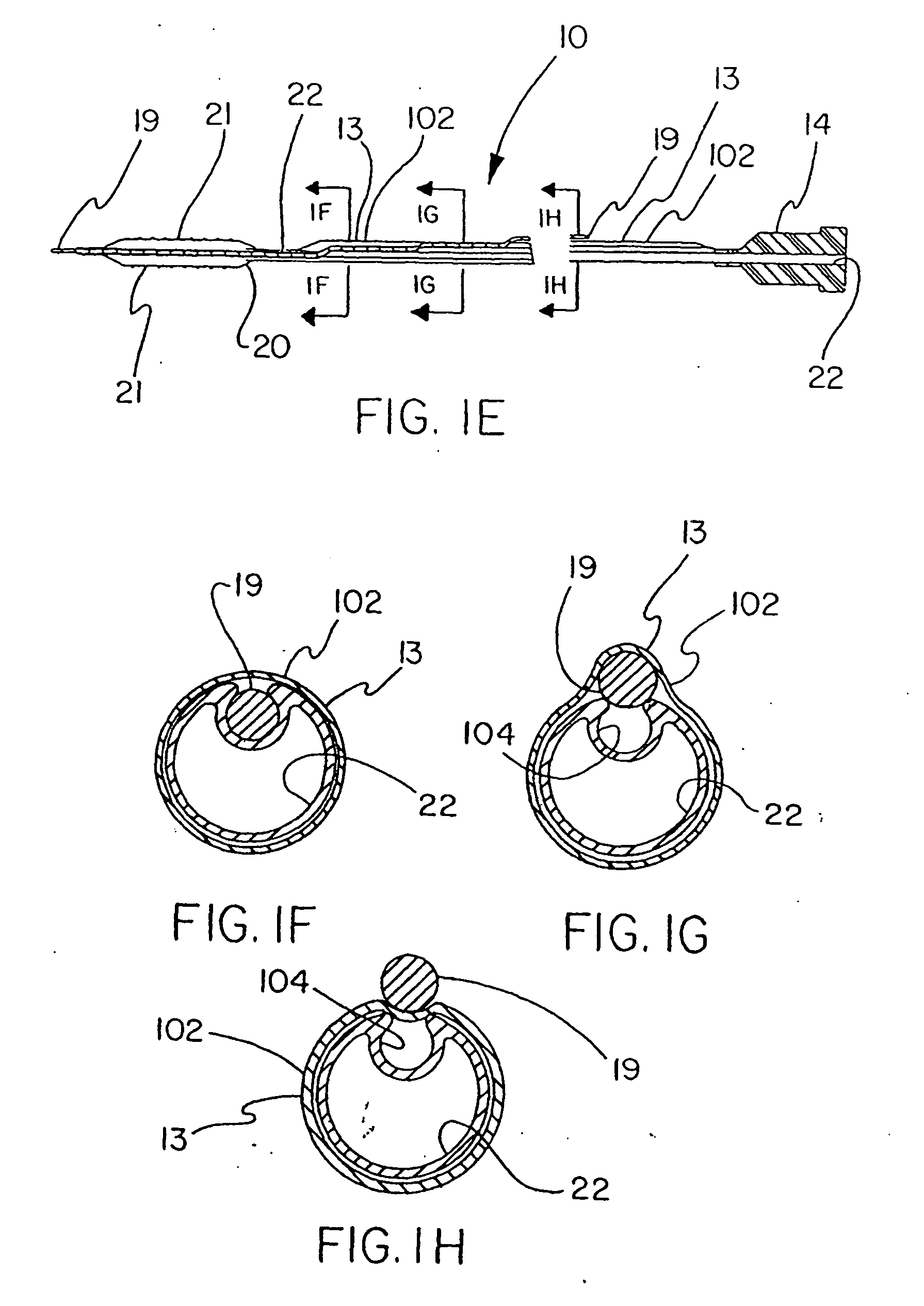

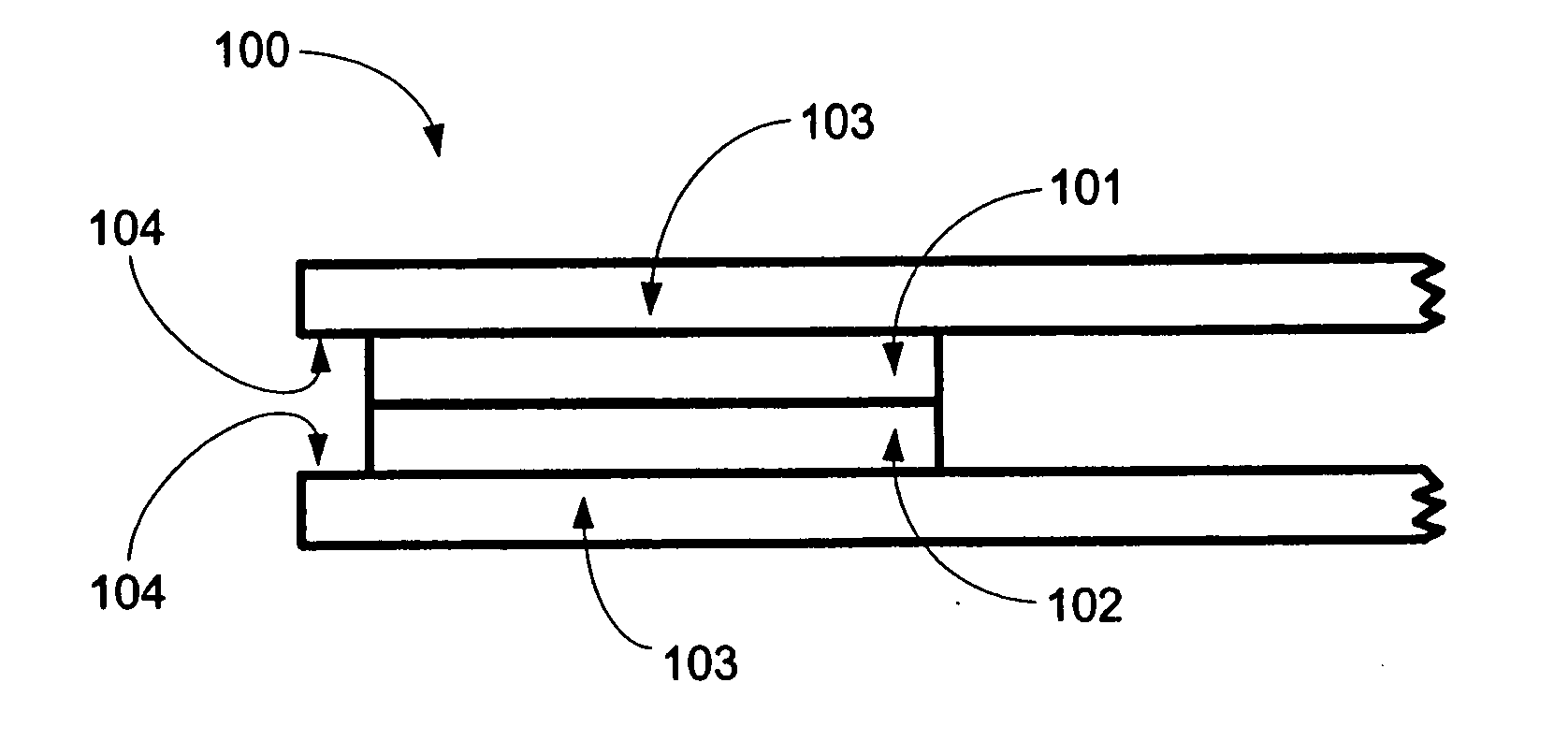

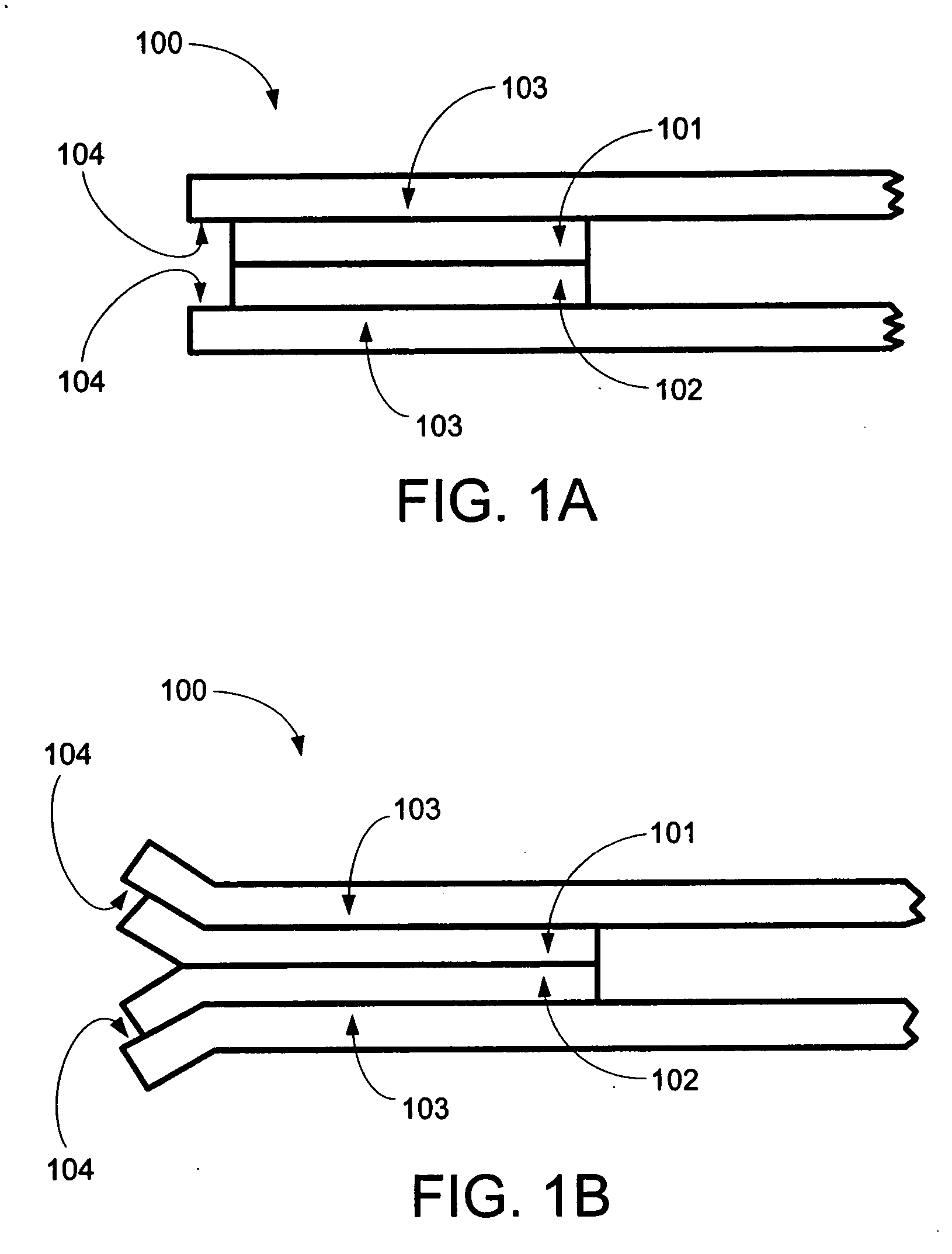

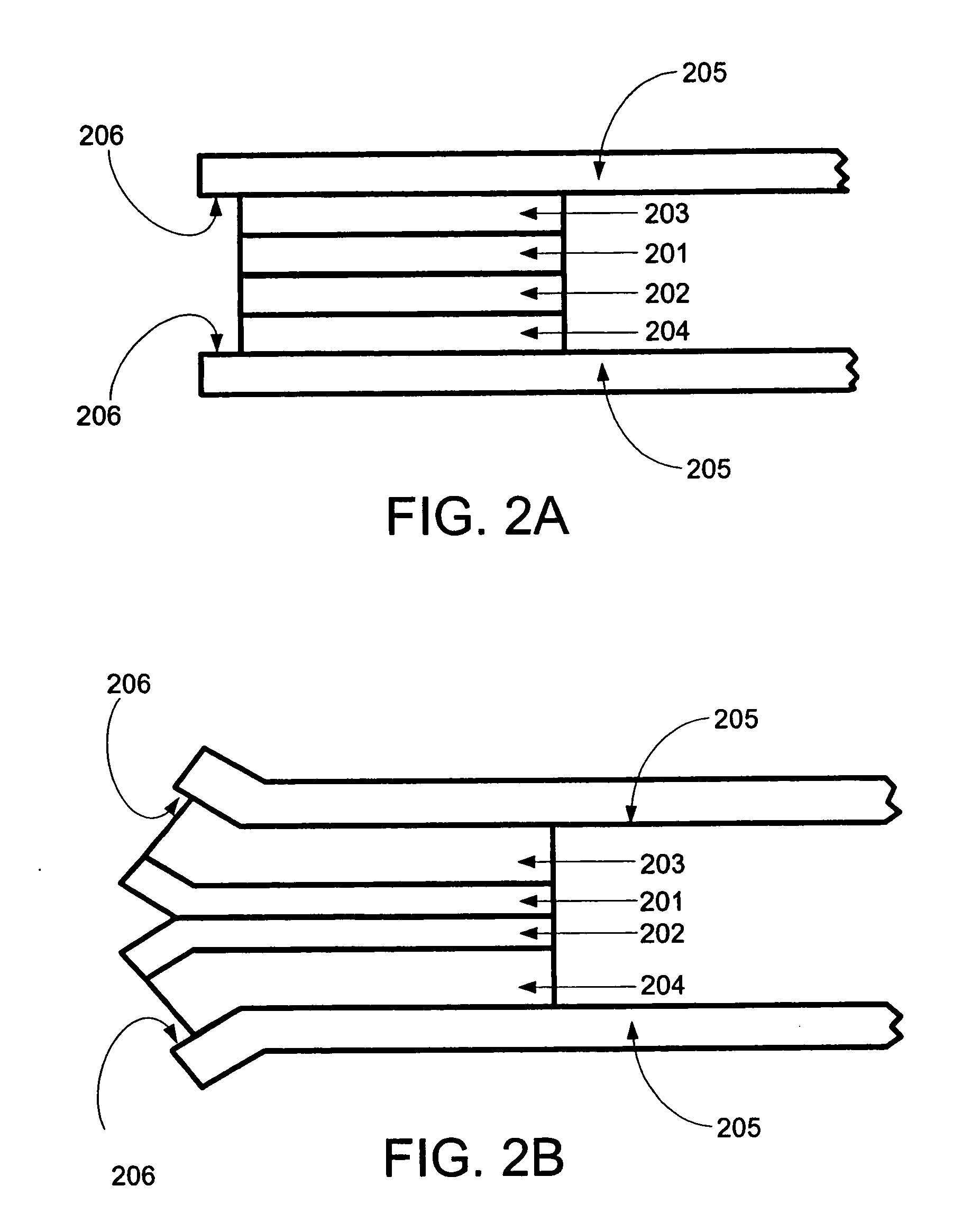

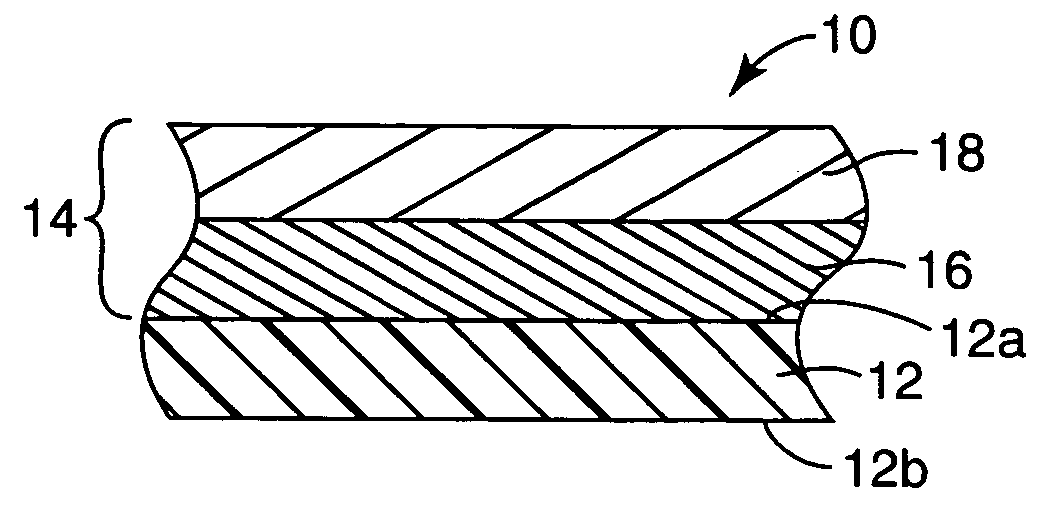

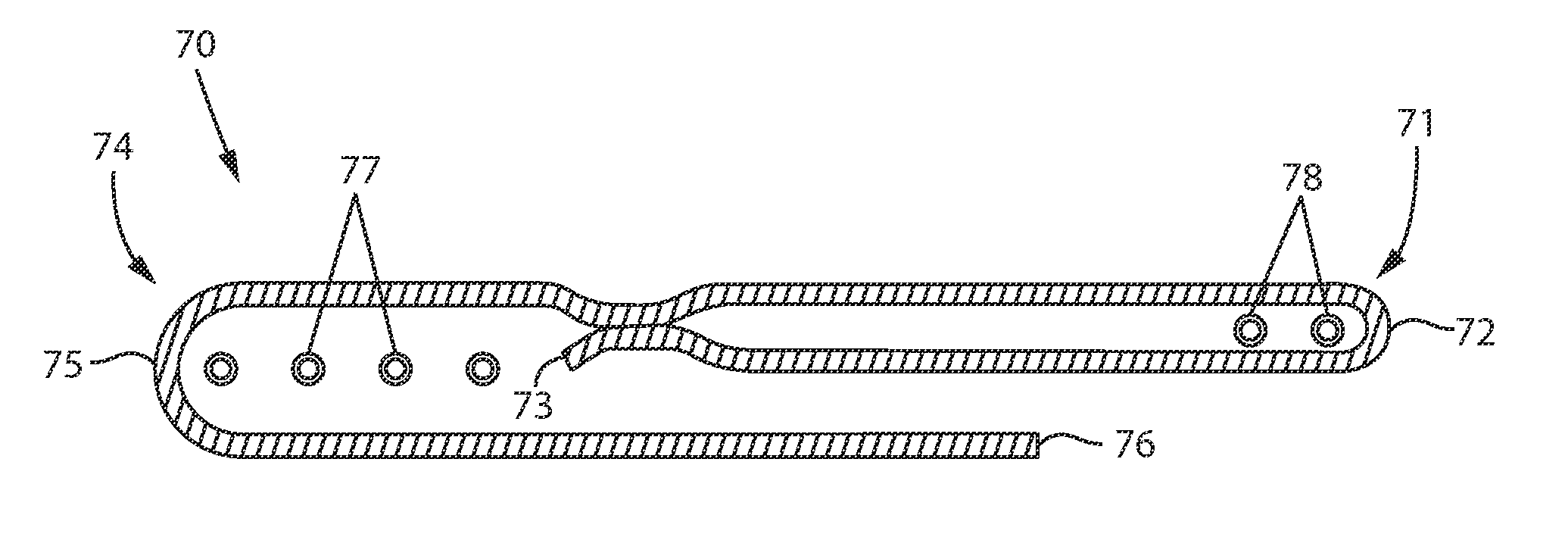

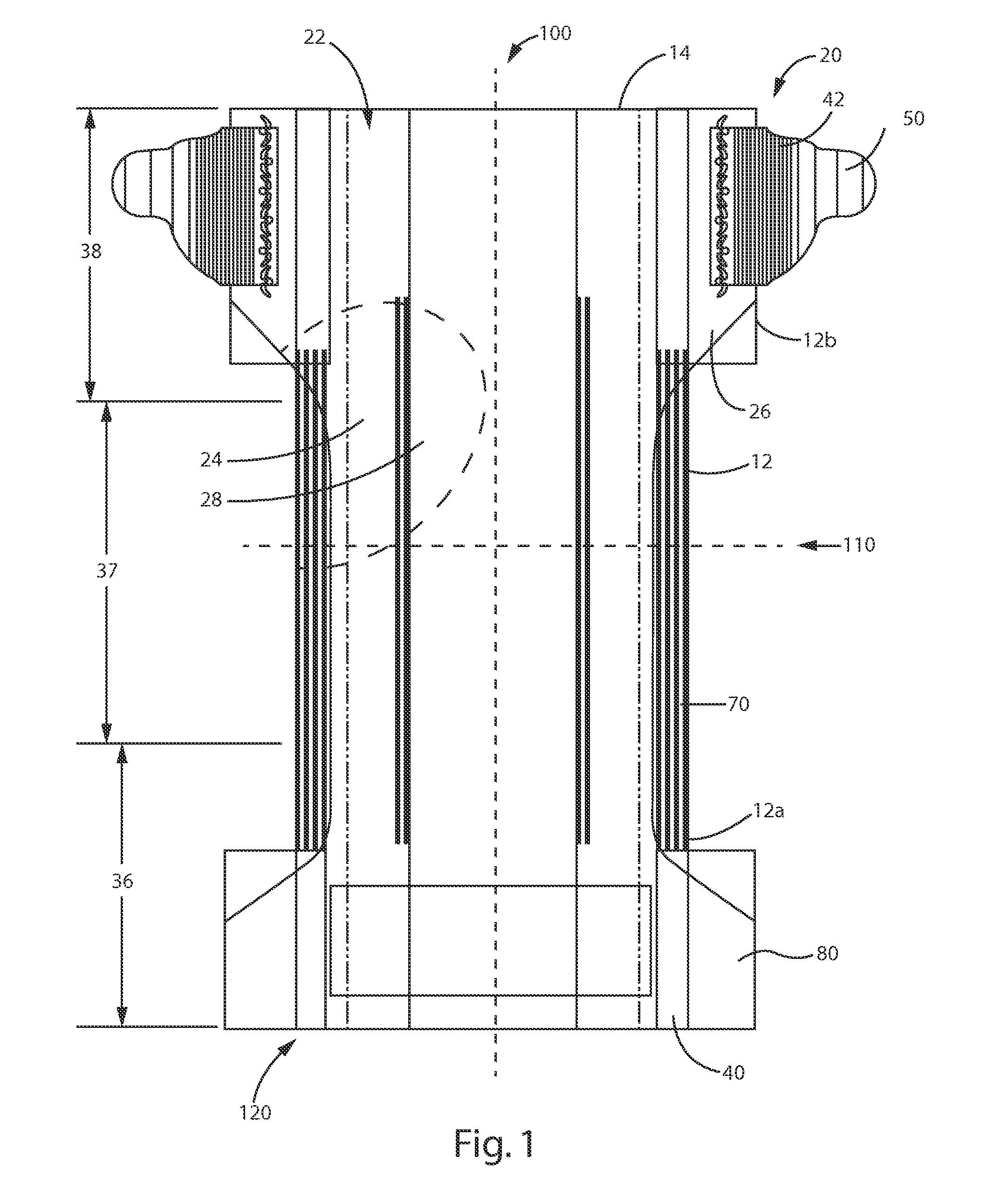

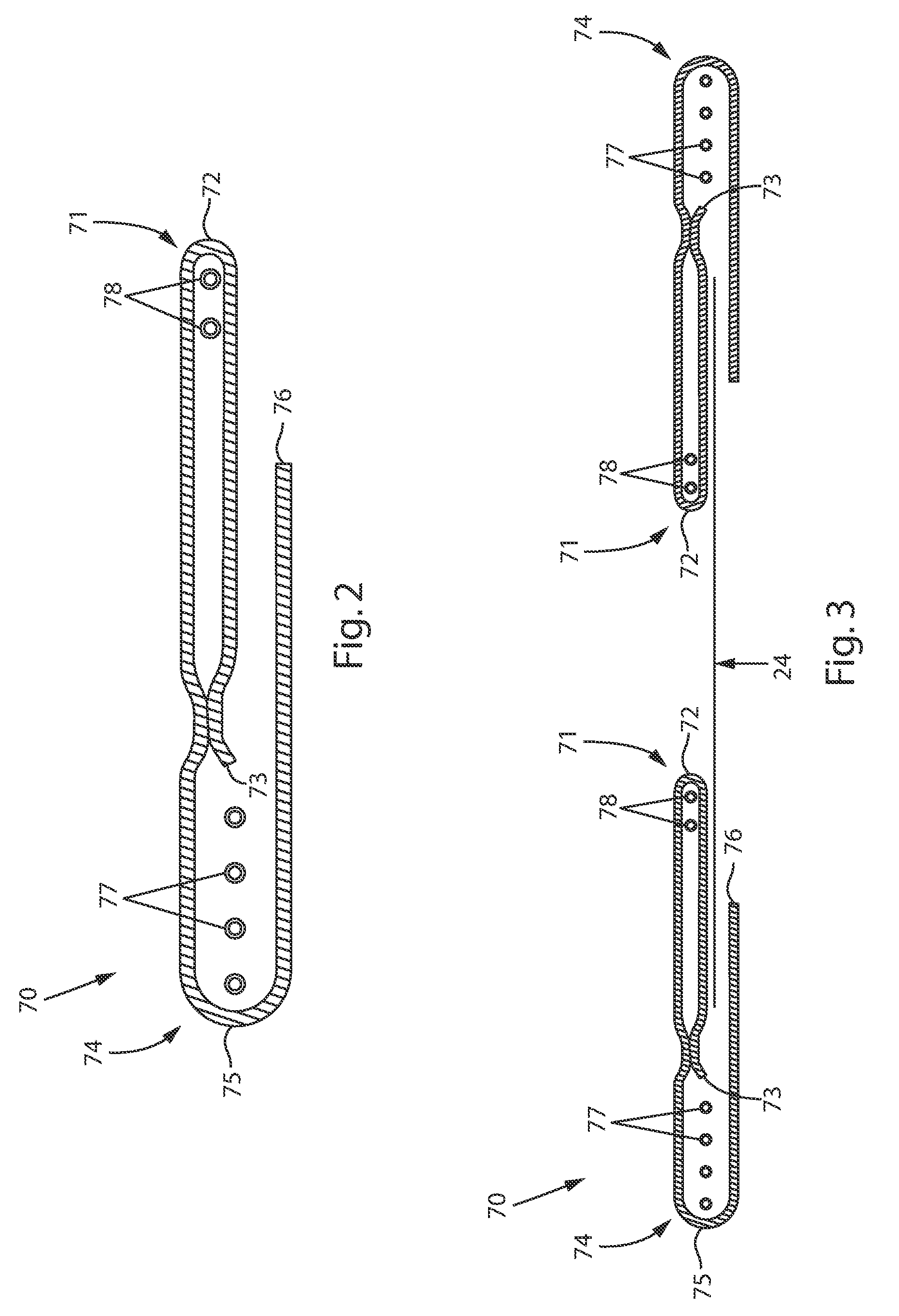

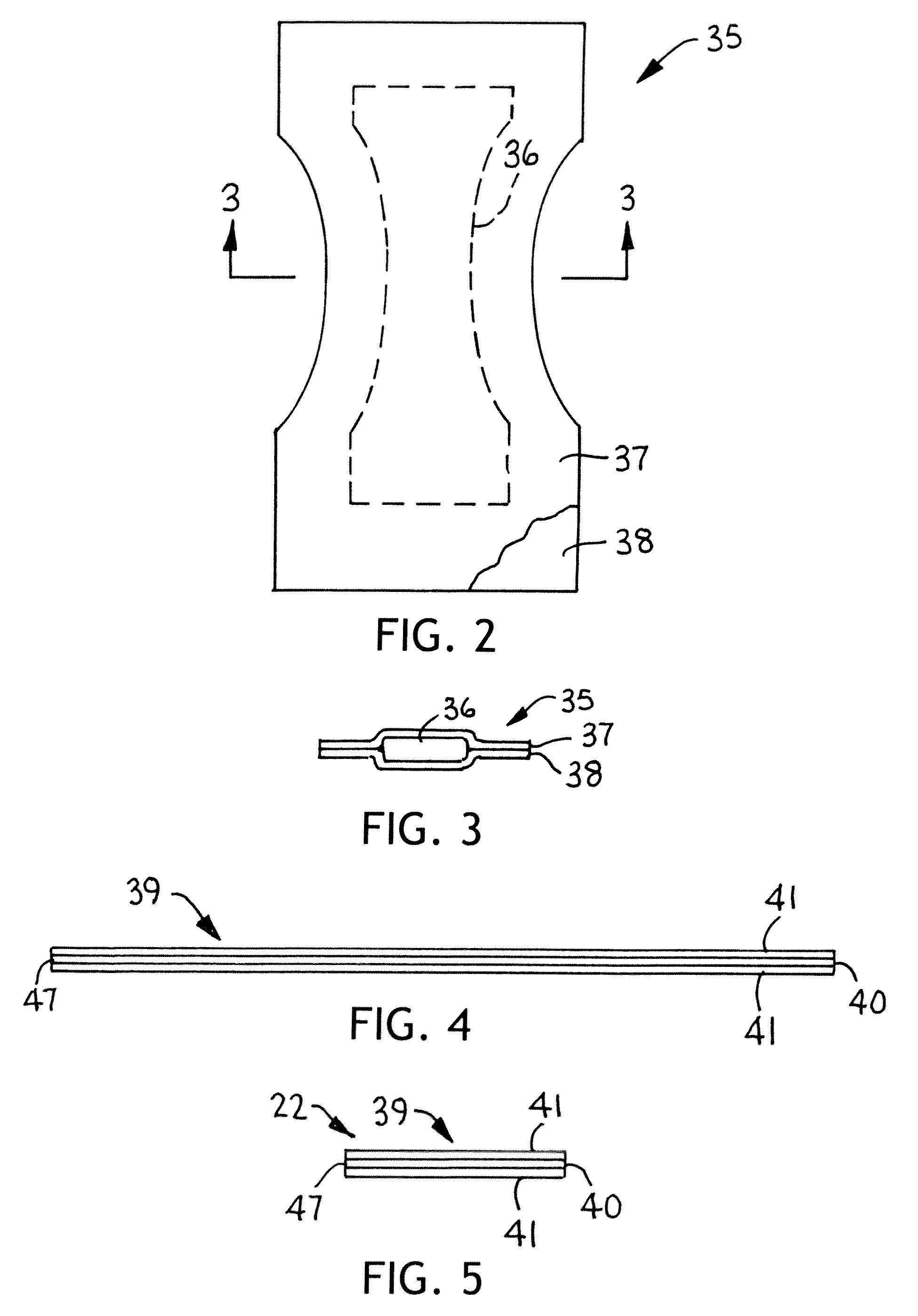

Catheter assembly

InactiveUS20050059957A1Efficient use ofEasily shortened in lengthStentsBalloon catheterCombined usePolymer thin films

Novel catheter constructions comprising thin covering or wrapping materials such as polymer films. A catheter provided with a guidewire catheter lumen having a thin covering that is easily punctured by a guidewire at virtually any desired point along the catheter length. The thin covering may be integral with the catheter shaft, or may be a separate component that covers only the portion of the catheter shaft immediately adjacent the outer portion of the guidewire lumen, or may be a thin tubular construct that surrounds the entire catheter shaft. Moreover, polymer film can be used in combination with one or more elements to produce novel catheter constructions.

Owner:WL GORE & ASSOC INC

Calamitic Mesogenic Compounds

ActiveUS20100201920A1Increase polarizabilityLiquid crystal compositionsOrganic chemistryCrystallographyPolymer thin films

The invention relates to novel calamitic mesogenic compounds which are especially suitable for use in birefringent films with negative optical dispersion, to novel liquid crystal (LC) formulations and polymer films comprising them, and to the use of the compounds, formulations and films in optical, electrooptical, electronic, semiconducting or luminescent components or devices.

Owner:MERCK PATENT GMBH

Catheter assembly

InactiveUS20070088323A1Efficient use ofEasily shortened in lengthStentsBalloon catheterPolymer thin filmsGuide wires

Novel catheter constructions comprising thin covering or wrapping materials such as polymer films. A catheter provided with a guidewire catheter lumen having a thin covering that is easily punctured by a guidewire at virtually any desired point along the catheter length. The thin covering may be integral with the catheter shaft, or may be a separate component that covers only the portion of the catheter shaft immediately adjacent the outer portion of the guidewire lumen, or may be a thin tubular construct that surrounds the entire catheter shaft. Moreover, polymer film can be used in combination with one or more elements to produce novel catheter constructions.

Owner:WL GORE & ASSOC INC

Cohesive reclosure systems and containers using same

This invention relates to resealable closure systems that are useful in containers, such as those used in packaging goods. The reclosure system features cohesive layers which are bonded to each other to provide a resealable closure. The cohesive bond layers are separable to provide opening of the container and access to the interior of the container and / or contents. The cohesive layers have low blocking characteristics. The reclosure systems are useful for flexible packaging, such as polymeric film and cloth packages, and rigid packaging, such as fiberboard, cardboard, paper, and polymeric foam. The reclosure systems may be opened and resealed multiple times. The closure system is resistance to contamination by oils, debris, solvents, and water. The reclosure is cold sealable with finger pressure.

Owner:AVERY DENNISON CORP

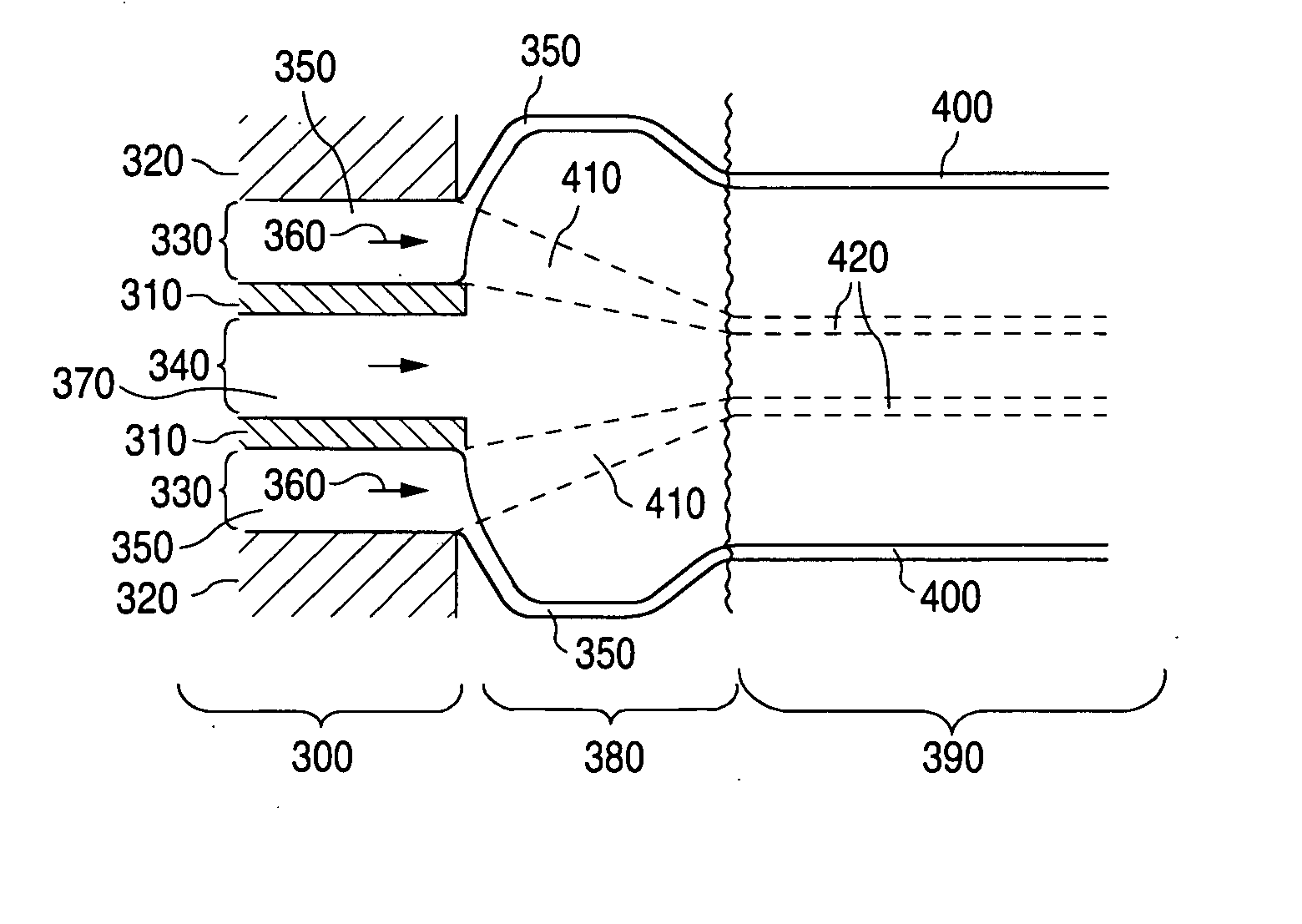

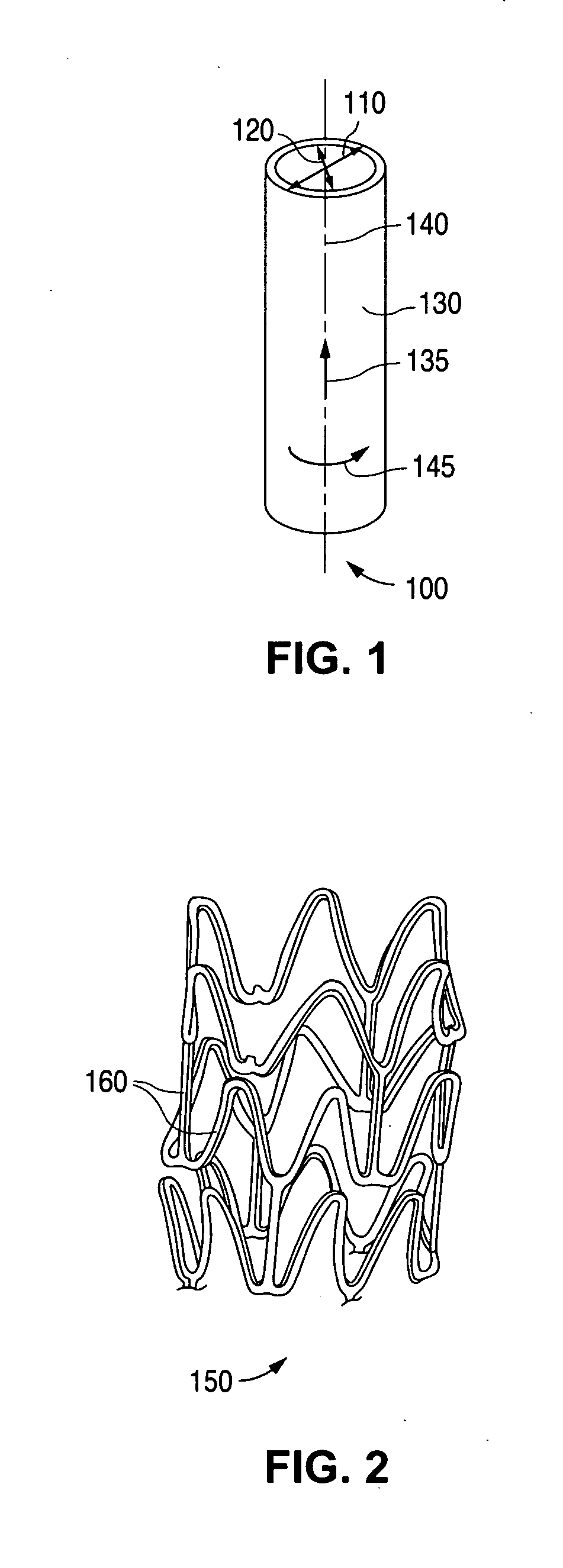

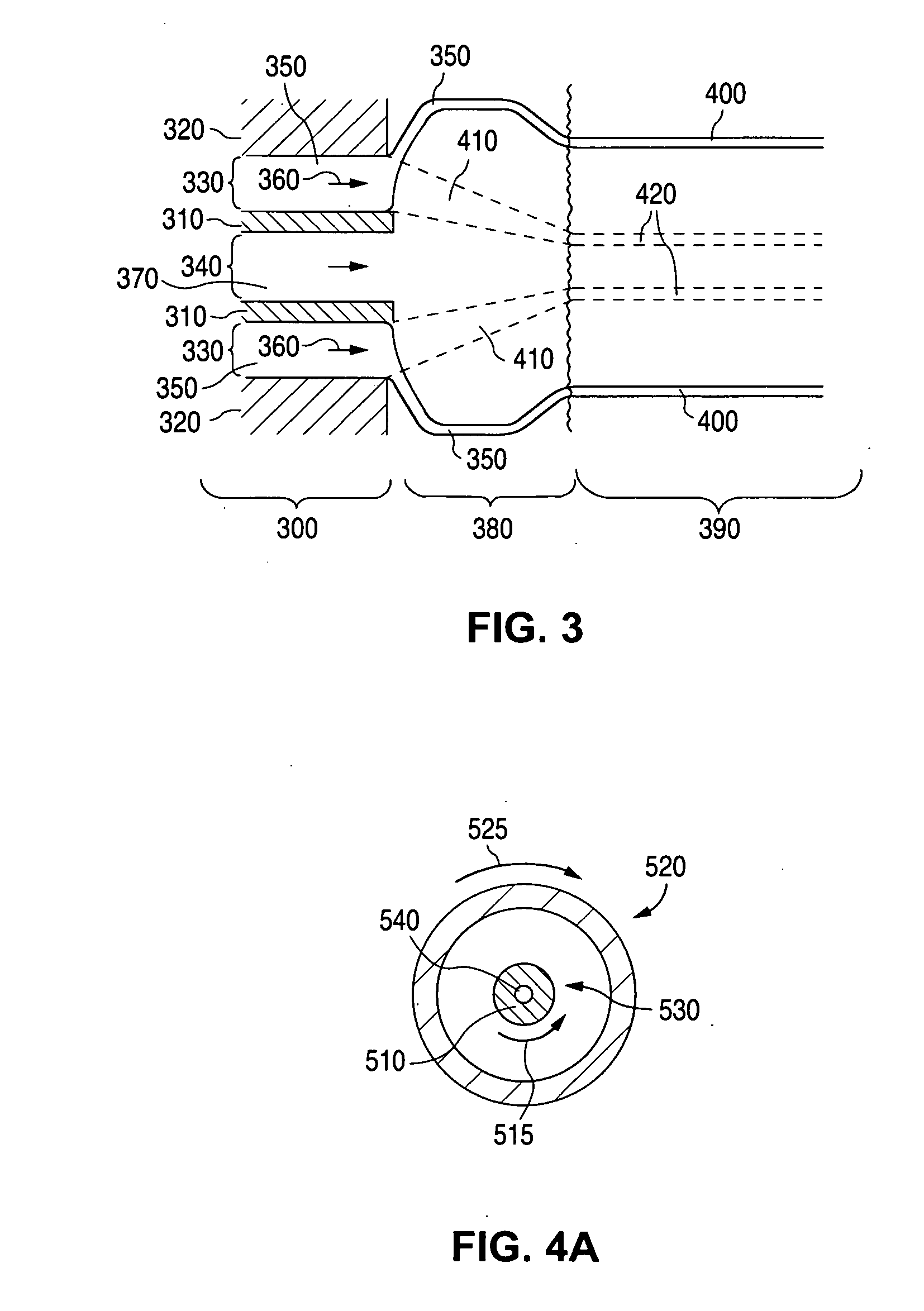

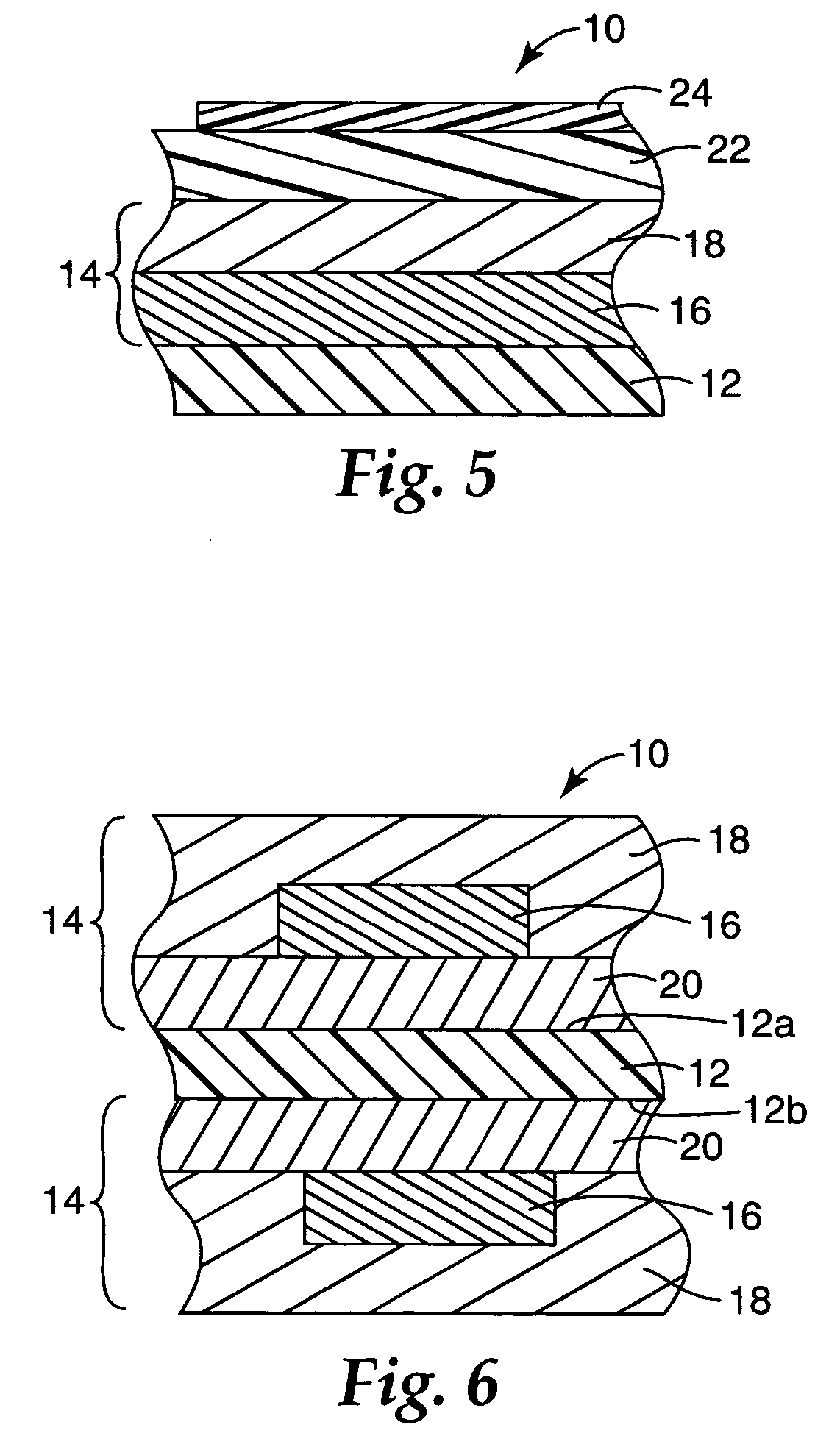

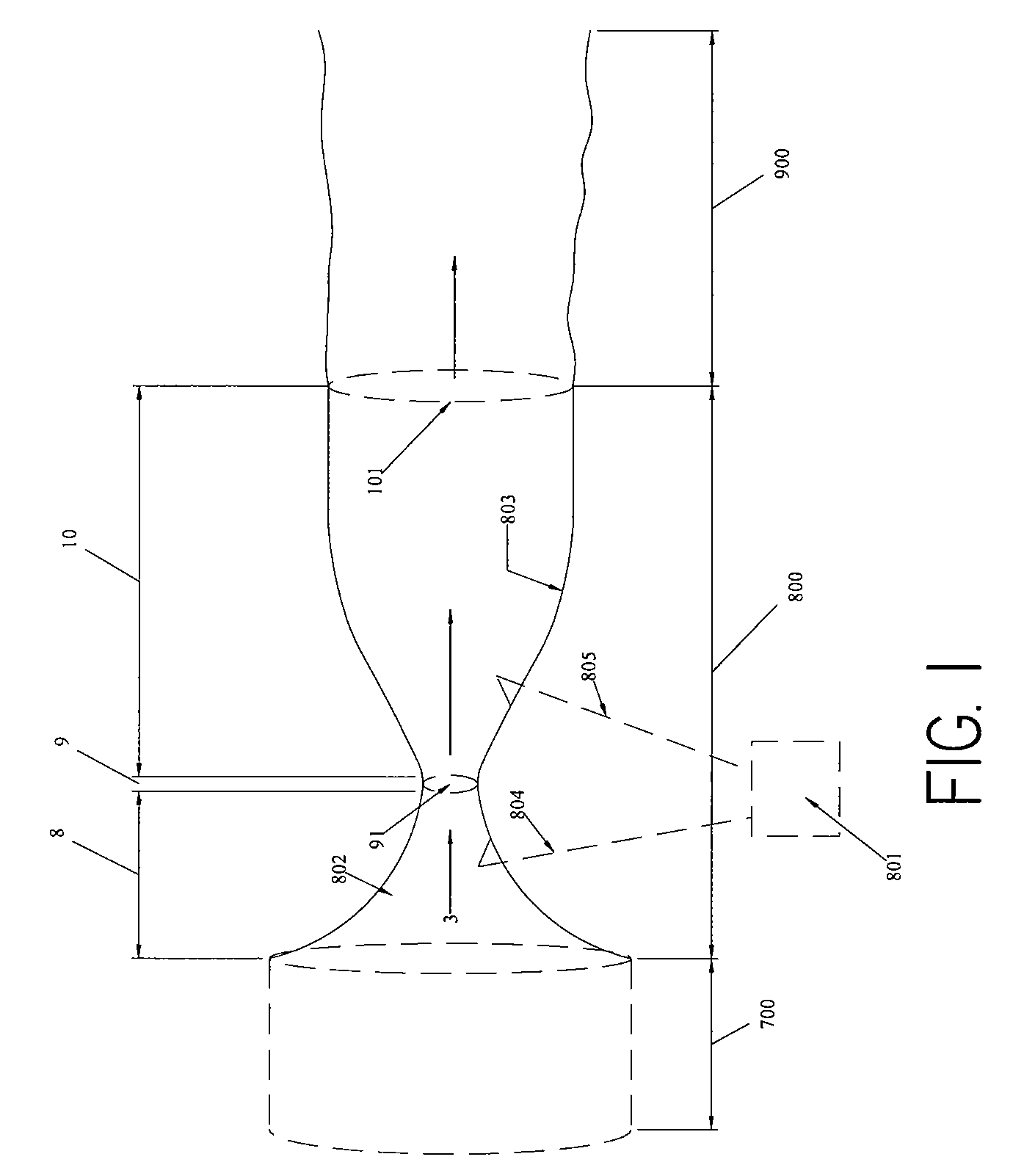

Method of fabricating an implantable medical device with biaxially oriented polymers

InactiveUS20060020330A1Desirable mechanical propertyImprove rigidityStentsSurgeryPolymer thin filmsUltimate tensile strength

Methods and systems for manufacturing an implantable medical device, such as a stent, from a tube with desirable mechanical properties, such as improved circumferential strength and rigidity, are described herein. Improved circumferential strength and rigidity may be obtained by inducing molecular orientation in materials for use in manufacturing an implantable medical device. Some embodiments may include inducing molecular orientation by expansion of a molten annular polymer film. Other embodiments may include inducing circumferential molecular orientation by inducing circumferential flow in a molten polymer. In certain embodiments, circumferential orientation may be induced by expansion of a polymer tube. Further embodiments may include manufacturing an implantable medical device from a biaxially oriented planar polymer film.

Owner:ABBOTT CARDIOVASCULAR

Protected polymeric film

InactiveUS20060063015A1Reduce inherentReduce but potentially undesirableSynthetic resin layered productsSolid-state devicesOptoelectronicsPolymer thin films

Owner:3M INNOVATIVE PROPERTIES CO

Cut resistant polymeric films

A polymeric film having increased cut resistance comprising a polymeric matrix having dispersed therein a plurality of cut resistance enhancing fibers. These films are preferably made into gloves, for example medical or industrial gloves.

Owner:THE UNIVERSITY OF AKRON

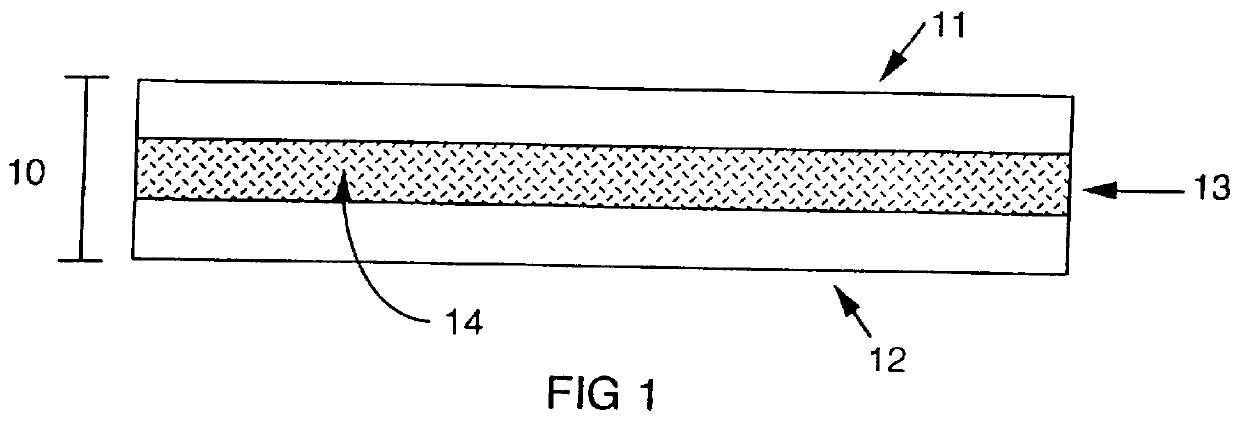

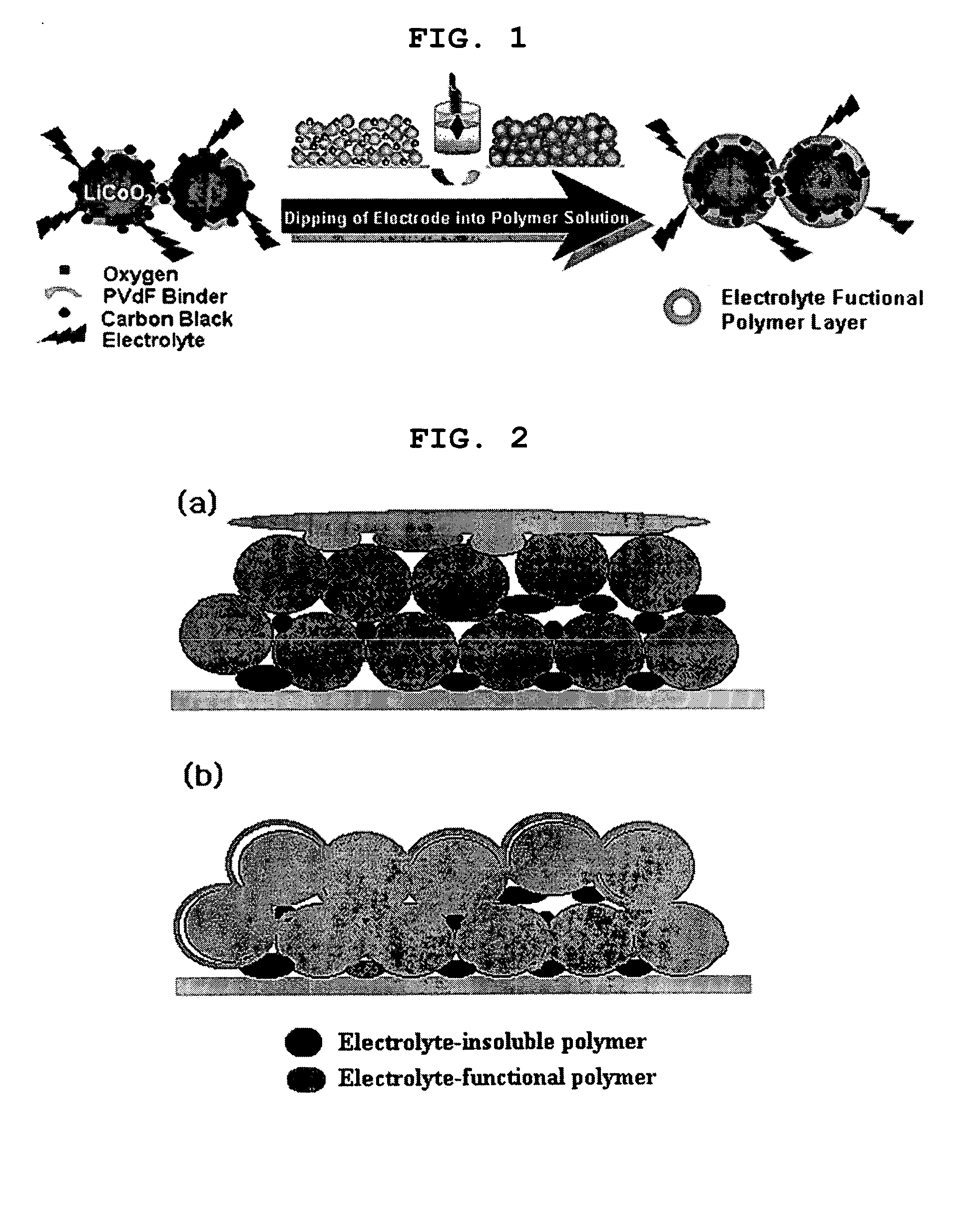

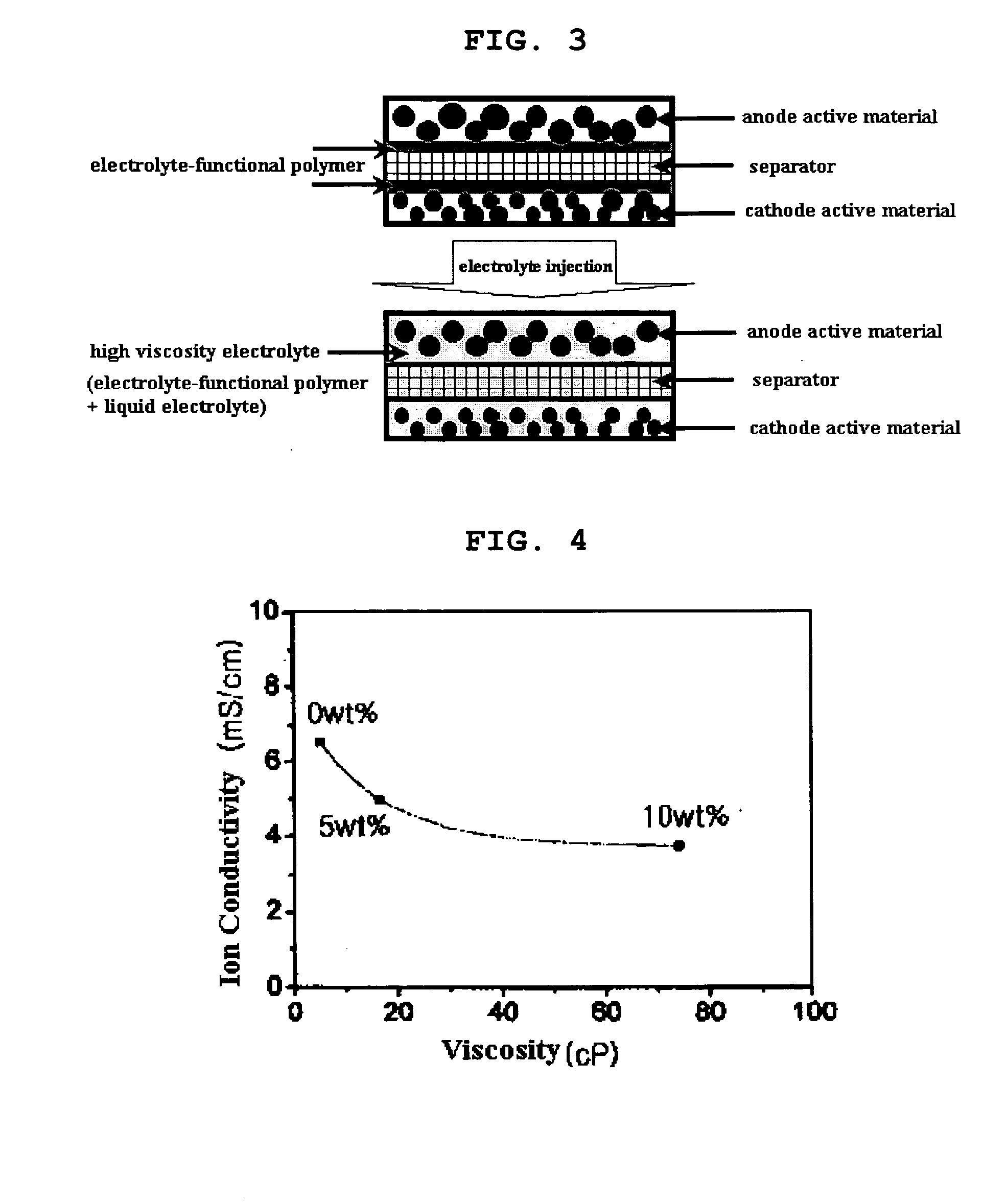

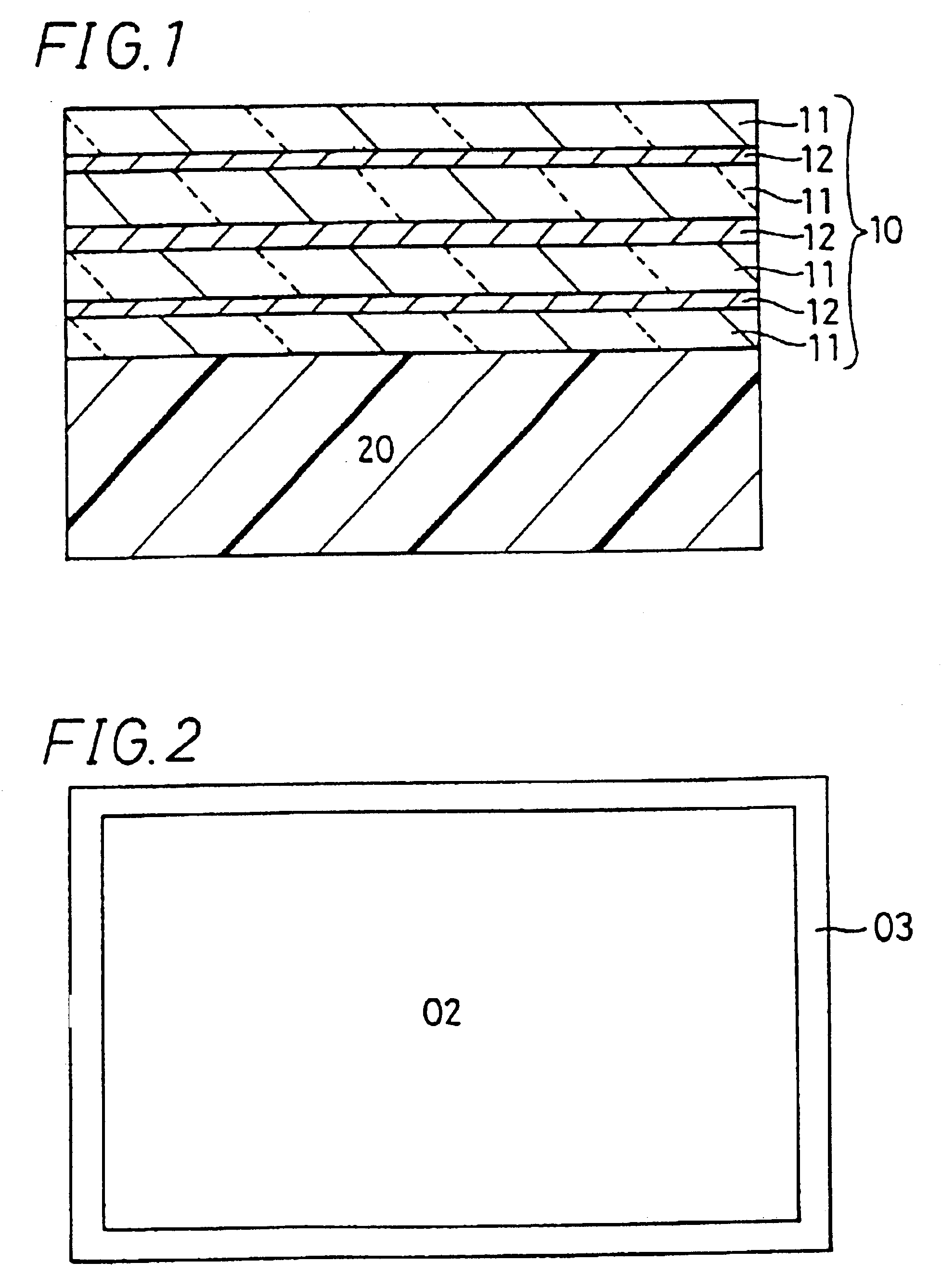

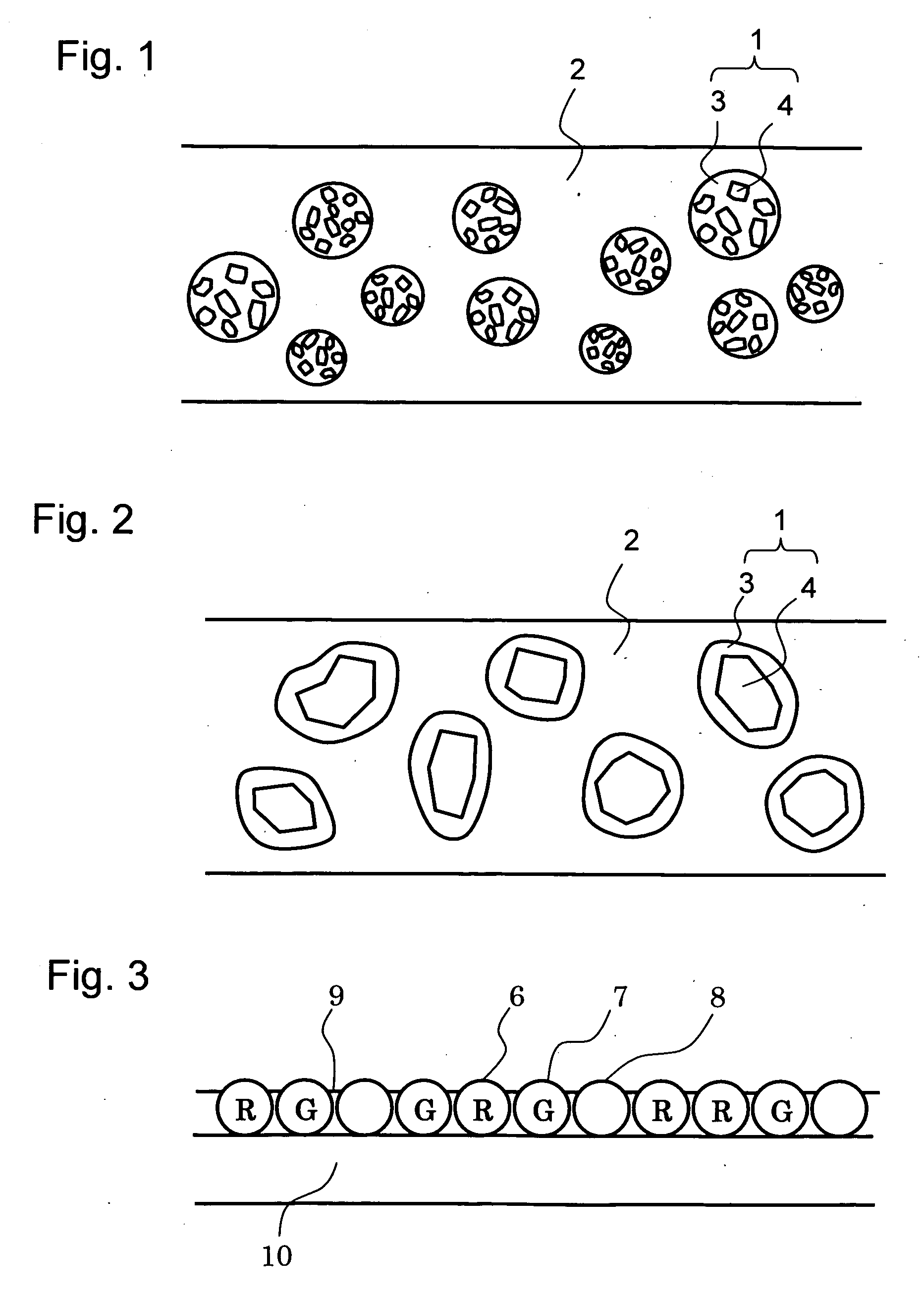

Functional polymer film-coated electrode and electrochemical device using the same

ActiveUS20050118508A1Lower performance requirementsImprove battery safetyGel electrodesElectrode carriers/collectorsSlurryPolymer thin films

The present invention provides an electrode in which an electrode active material particles as being interconnected are applied on current collector, wherein the interconnected surface of electrode active material particles is coated with a polymer, the polymer being present as an independent phase, while maintaining a pore structure formed among the interconnected electrode active material particles as well as an electrochemical device including the electrode. Also, the present invention provides a method for manufacturing an electrode coated with a polymer present on an interconnected surface of electrode active material as an independent phase, while maintaining a pore structure formed among the electrode active material particles, which comprises the steps of: (a) coating slurry for an electrode including an electrode active material on a current collector and drying it to form an electrode; and (b) dipping the electrode obtained from step (a) into a solution containing the polymer dissolved therein and a method for manufacturing an electrochemical device comprising the electrode obtained by the above method. The electrode coated with a polymer as an independent phase provides an electrochemical device with improved safety and prevents degradation of performance of an electrochemical device.

Owner:LG ENERGY SOLUTION LTD

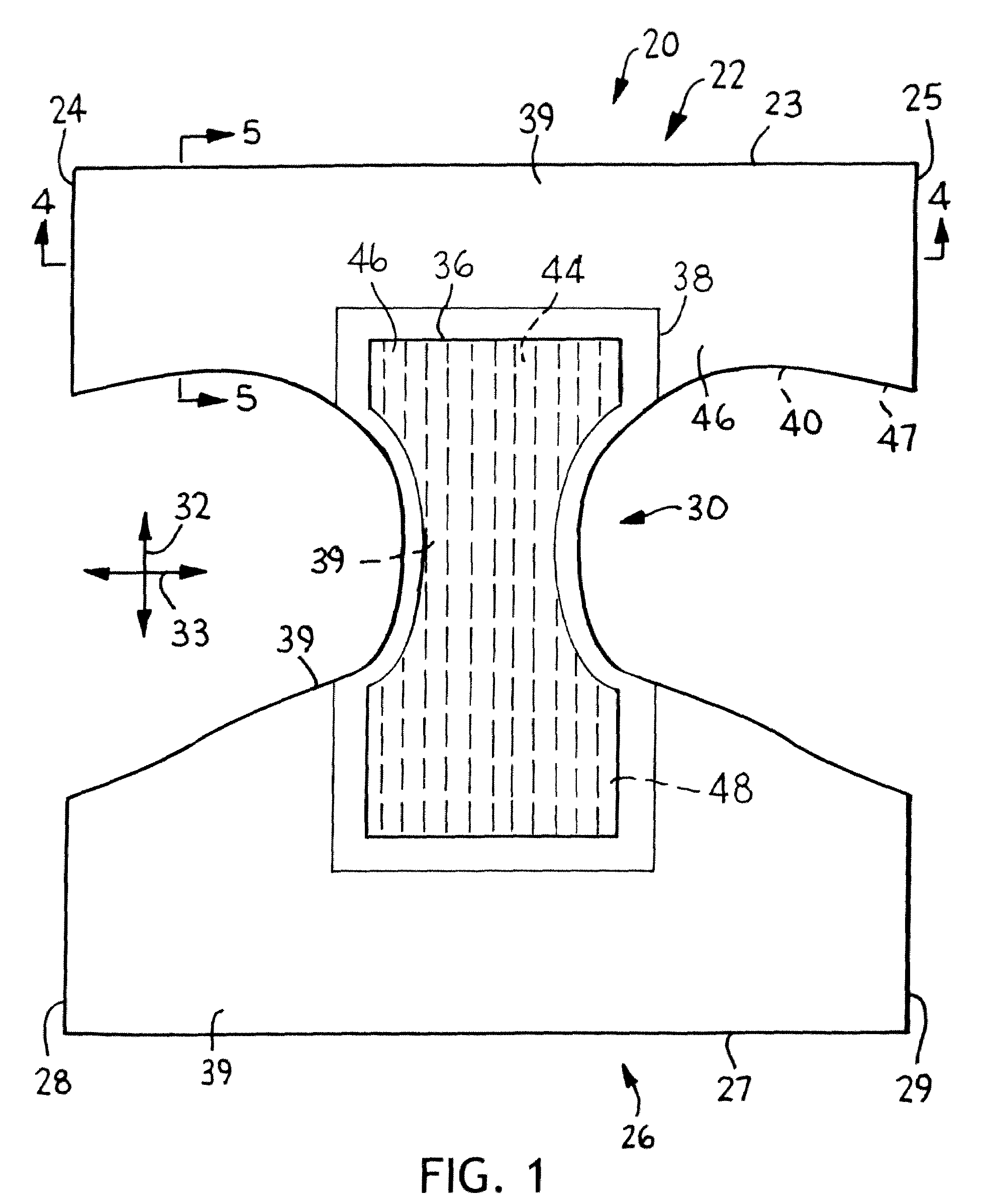

Absorbent Article With Narrow Polymeric Film And Opacity Strengthening Patch

InactiveUS20120277702A1Reduce strainStrengthMachines/enginesPump controlPolymer thin filmsEngineering

A disposable absorbent article for wearing about the lower torso of a wearer, the disposable absorbent article may include a first waist region, a second waist region, a crotch region disposed between the first and second waist regions; a first waist edge and a second waist edge; and a first longitudinal edge and a second longitudinal edge. The disposable absorbent article may include a chassis comprising a topsheet, a backsheet comprising a polymeric film, an absorbent core disposed between the topsheet and the backsheet. The polymeric film may be at least 20 mm more narrow than the chassis. An opacity strengthening patch may be disposed on the backsheet.

Owner:THE PROCTER & GAMBLE COMPANY

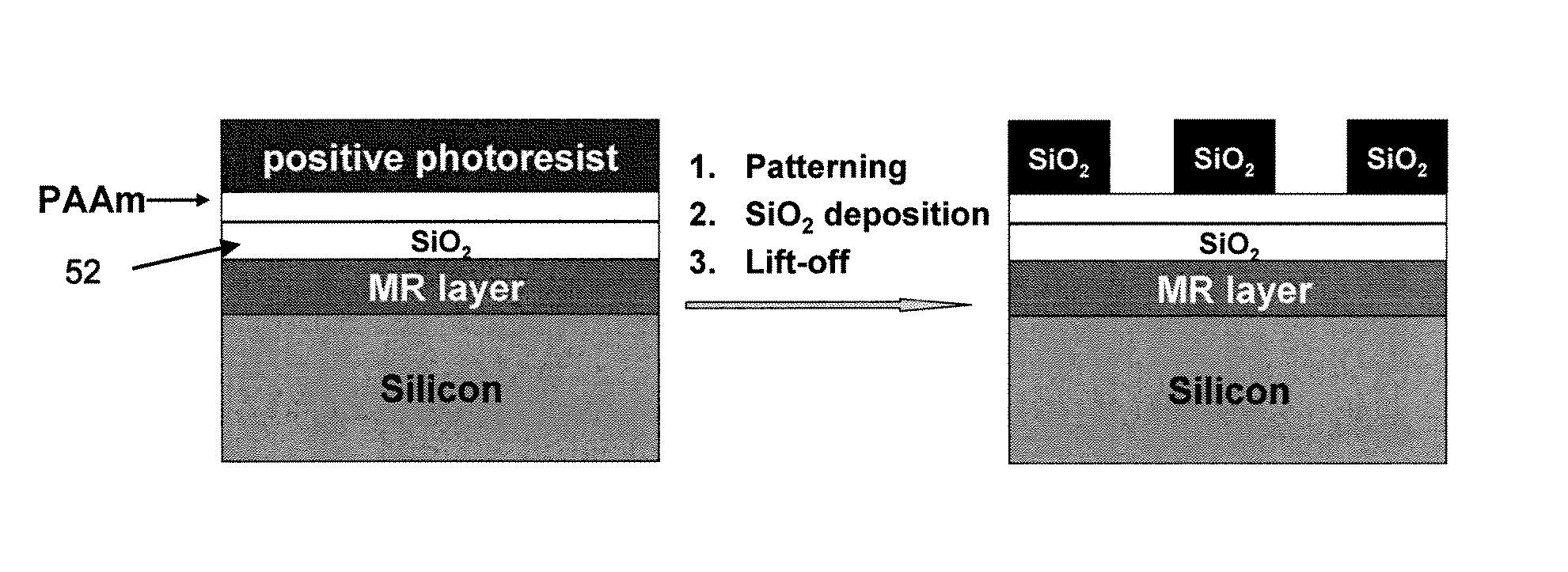

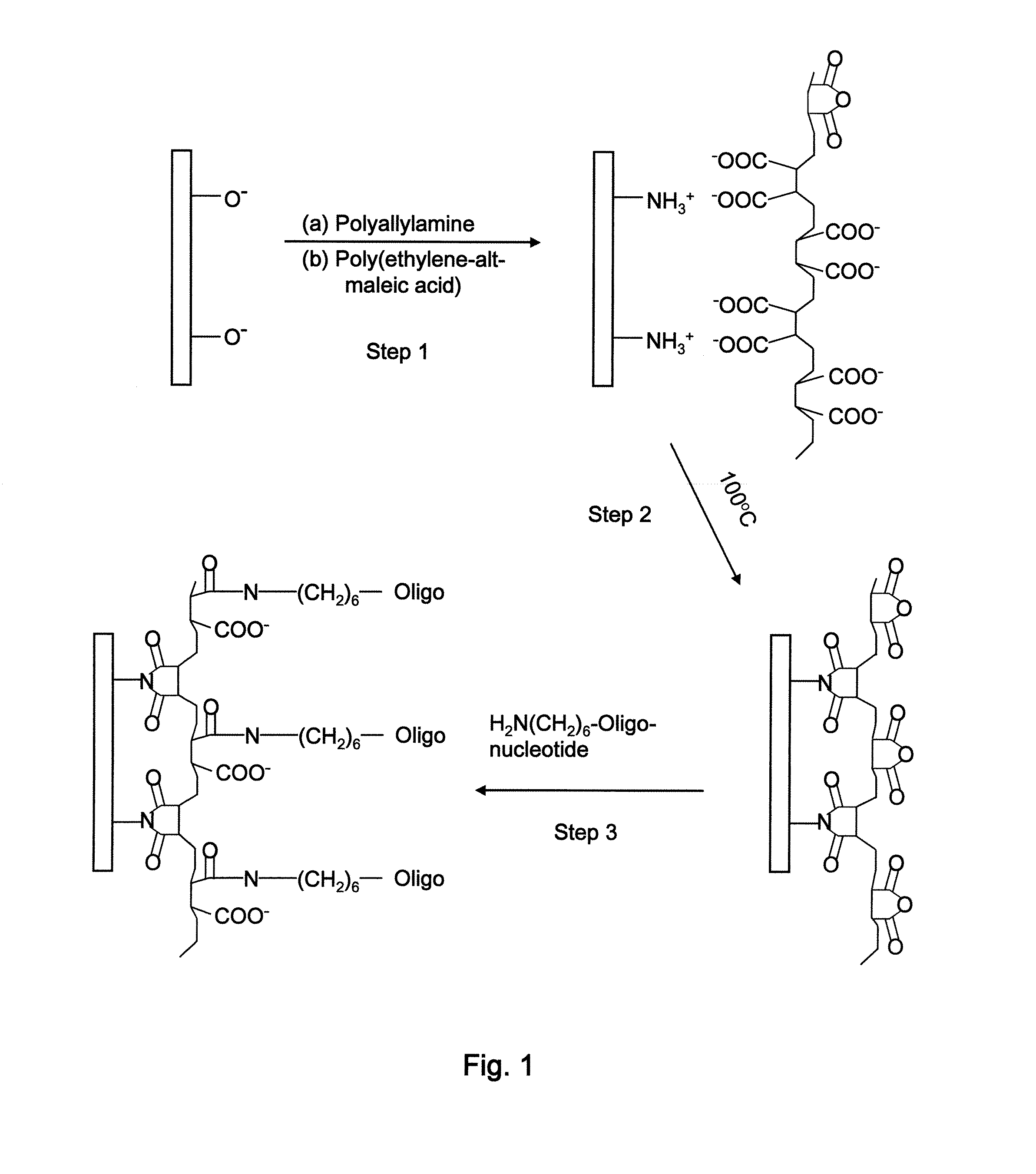

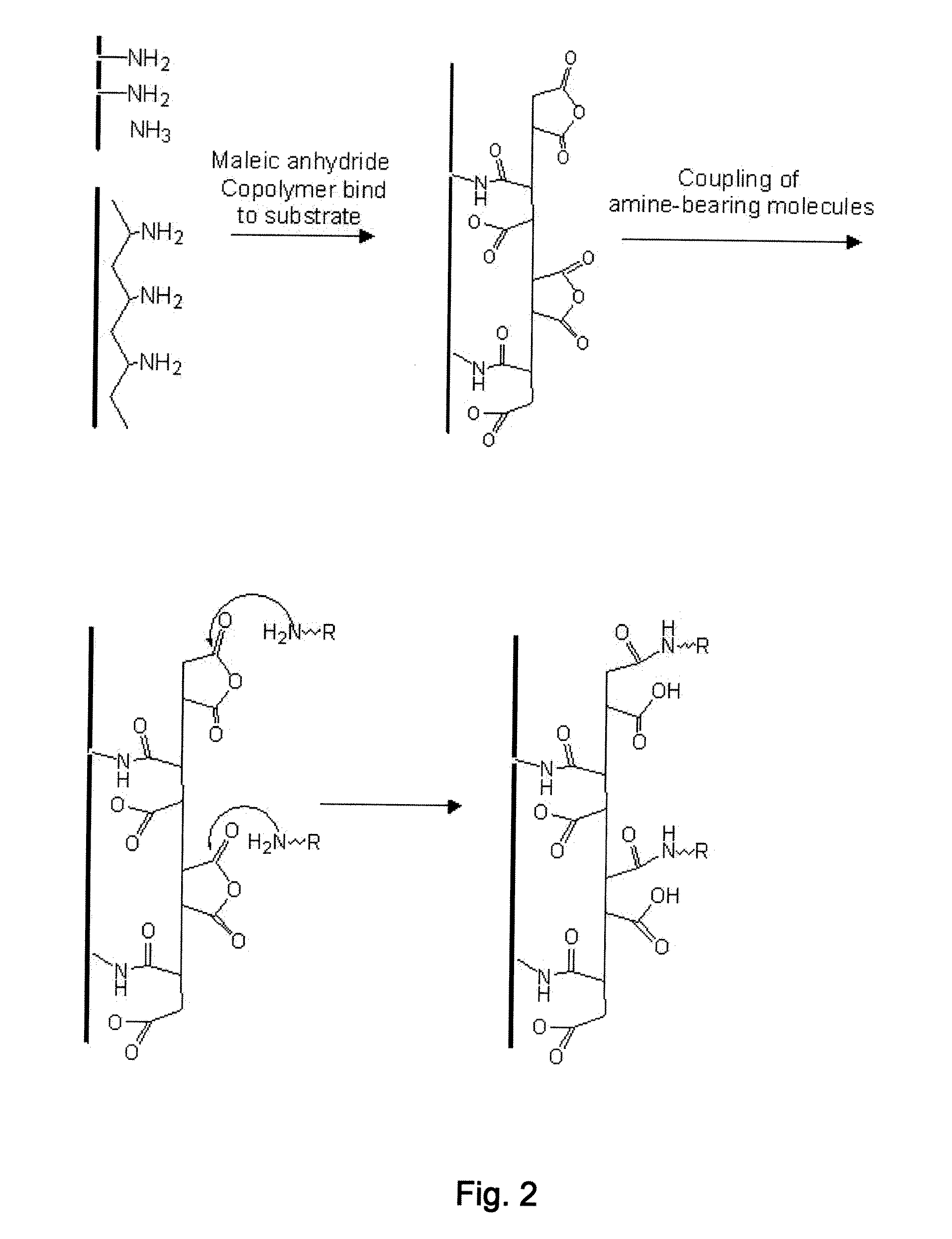

Biomolecule Immobilization on Biosensors

A highly specific and versatile surface chemistry for immobilization of amine-terminated probes is disclosed. A bi-layered polymer thin film serves as the platform for coupling the probes, which are preferably oligonucleotides. The process involves sequentially coating a substrate with polyamine and polyacid anhydride. Hydrolyzed polyacid anhydride groups may be converted to non-hydrolyzed groups at about 100° C. prior to probe attachment. The process of coating the substrate requires no harsh chemical pretreatment of substrates such as RCA or Piranha cleaning. In addition, simple thermal activation of the anhydride groups has a low requirement for storage, leading to a long shelf life of modified surfaces. The disclosed surface chemistry is especially compatible with microfabrication processes, and its effective application to magnetic biosensors is demonstrated.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

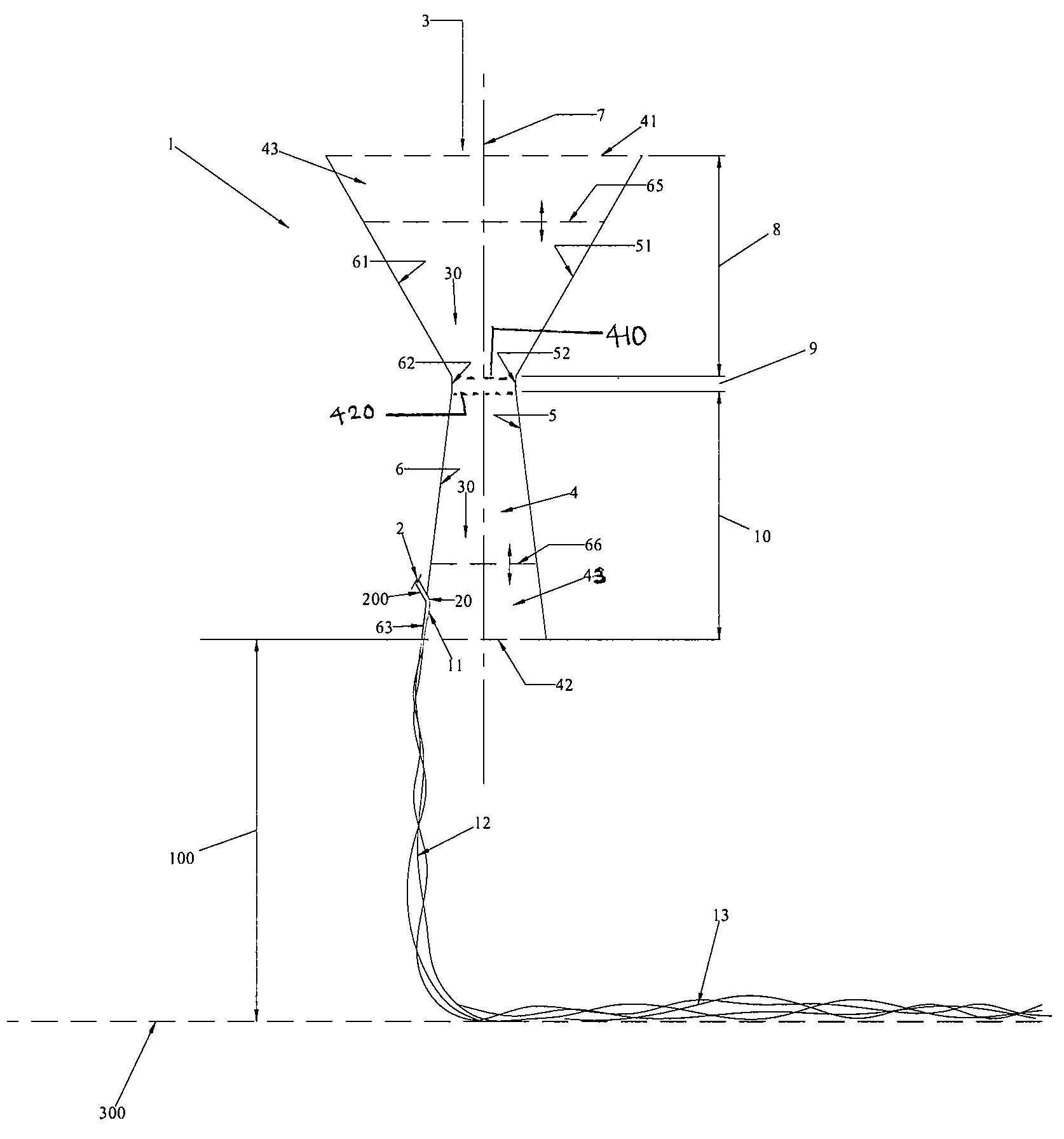

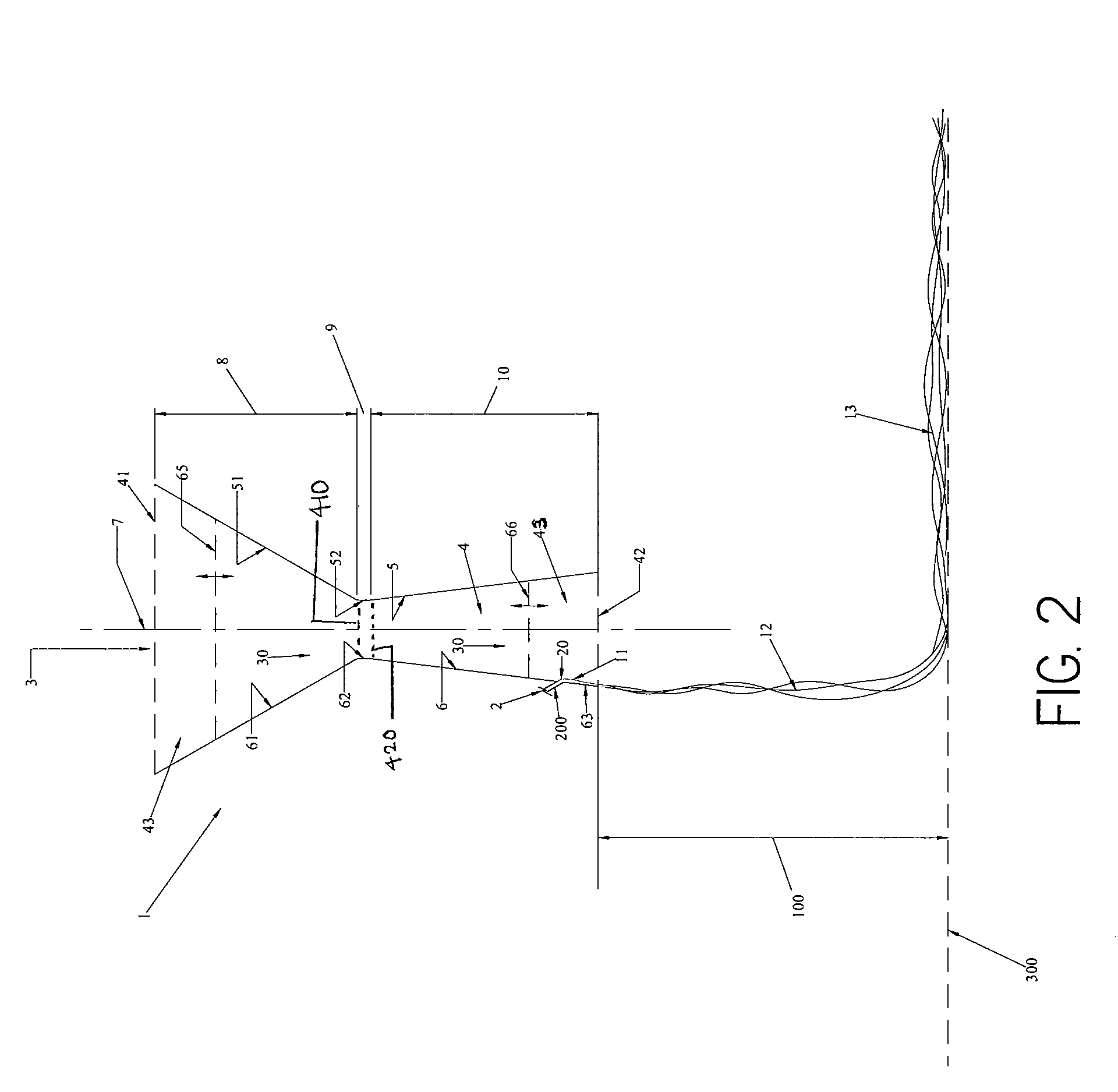

Process and apparatus for producing sub-micron fibers, and nonwovens and articles containing same

InactiveUS7666343B2Increase productionLower gas demandSpinnerette packsFilament/thread formingFiberPolymer science

A process and apparatus for producing sub-micron fibers, and more specifically a process and apparatus for effecting formation of sub-micron fibers by fibrillation of polymer films, and nonwoven materials and articles incorporating them.

Owner:AVINTIV SPECIALTY MATERIALS INC

Disposable Absorbent Garments Employing Elastomeric Film Laminates With Deactivated Regions

Owner:KIMBERLY-CLARK WORLDWIDE INC

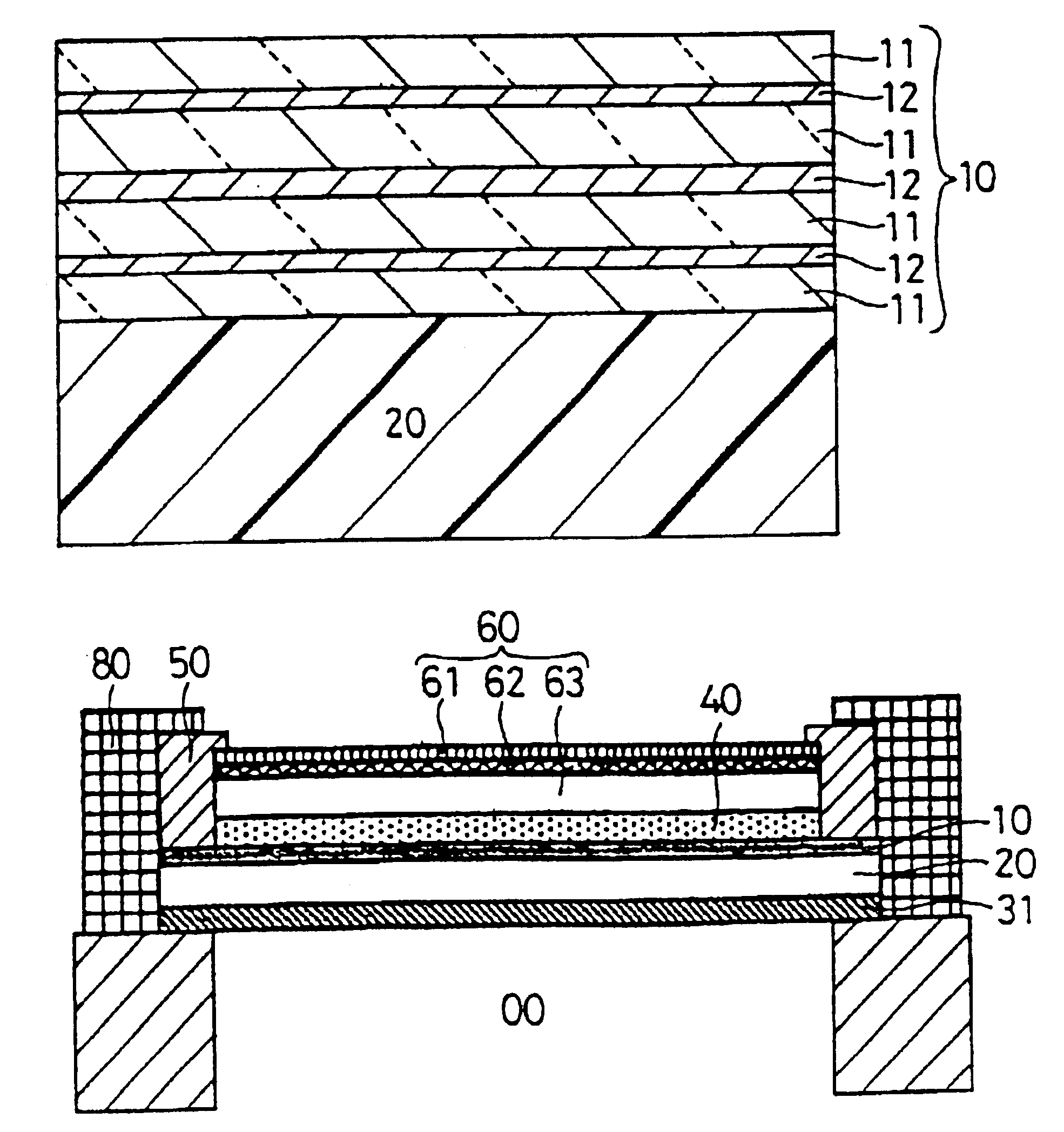

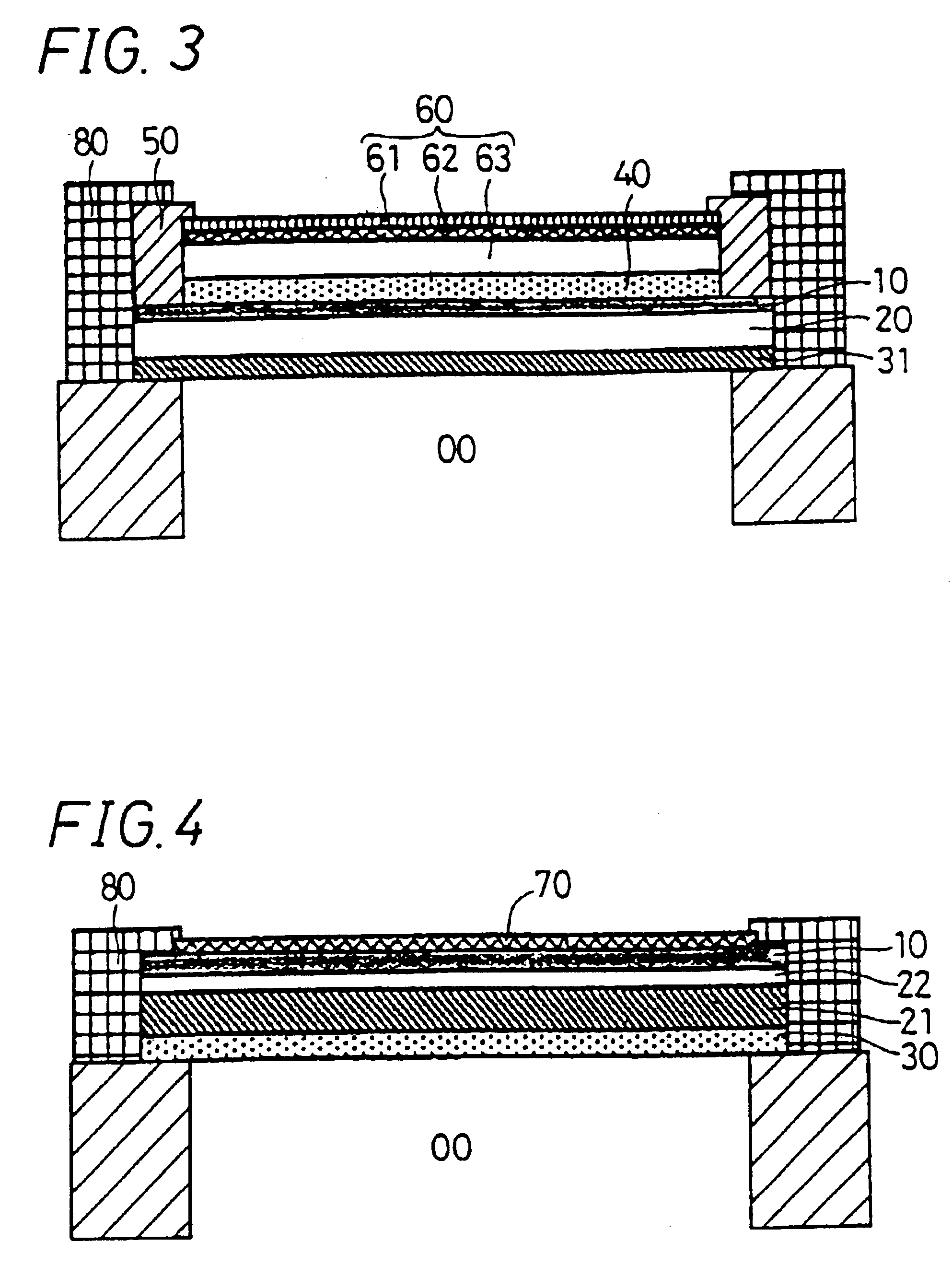

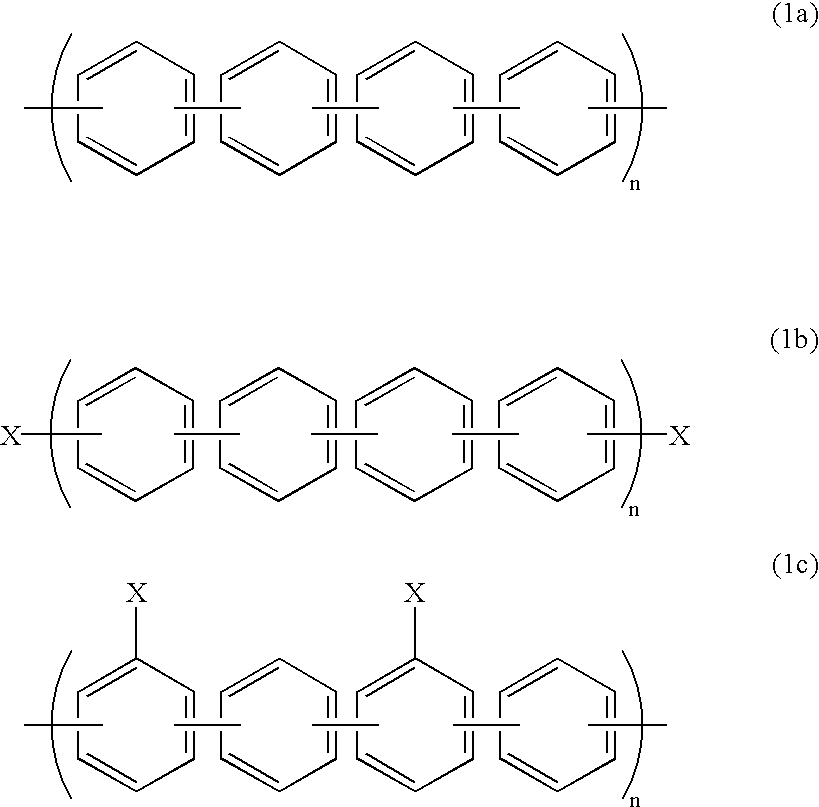

Display filter, display apparatus, and method for production of the same

InactiveUS6965191B2Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDisplay deviceEngineering

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

Polymer-based memory element

InactiveUS20050006640A1Increase and decrease resistanceNanoinformaticsSolid-state devicesElectrical resistance and conductanceChemical compound

Fuse-type and antifuse-type semiconducting-organic-polymer-film-based memory elements for use in memory devices are disclosed. Various embodiments of the present invention employ a number of different techniques to alter the electrical conductance or, equivalently, the resistance, of organic-polymer-film memory elements in order to produce detectable memory-state changes in the memory elements. The techniques involve altering the electronic properties of the organic polymers by application of heat or electric fields, often in combination with additional chemical compounds, to either increase or decrease the resistance of the organic polymers.

Owner:HEWLETT PACKARD DEV CO LP

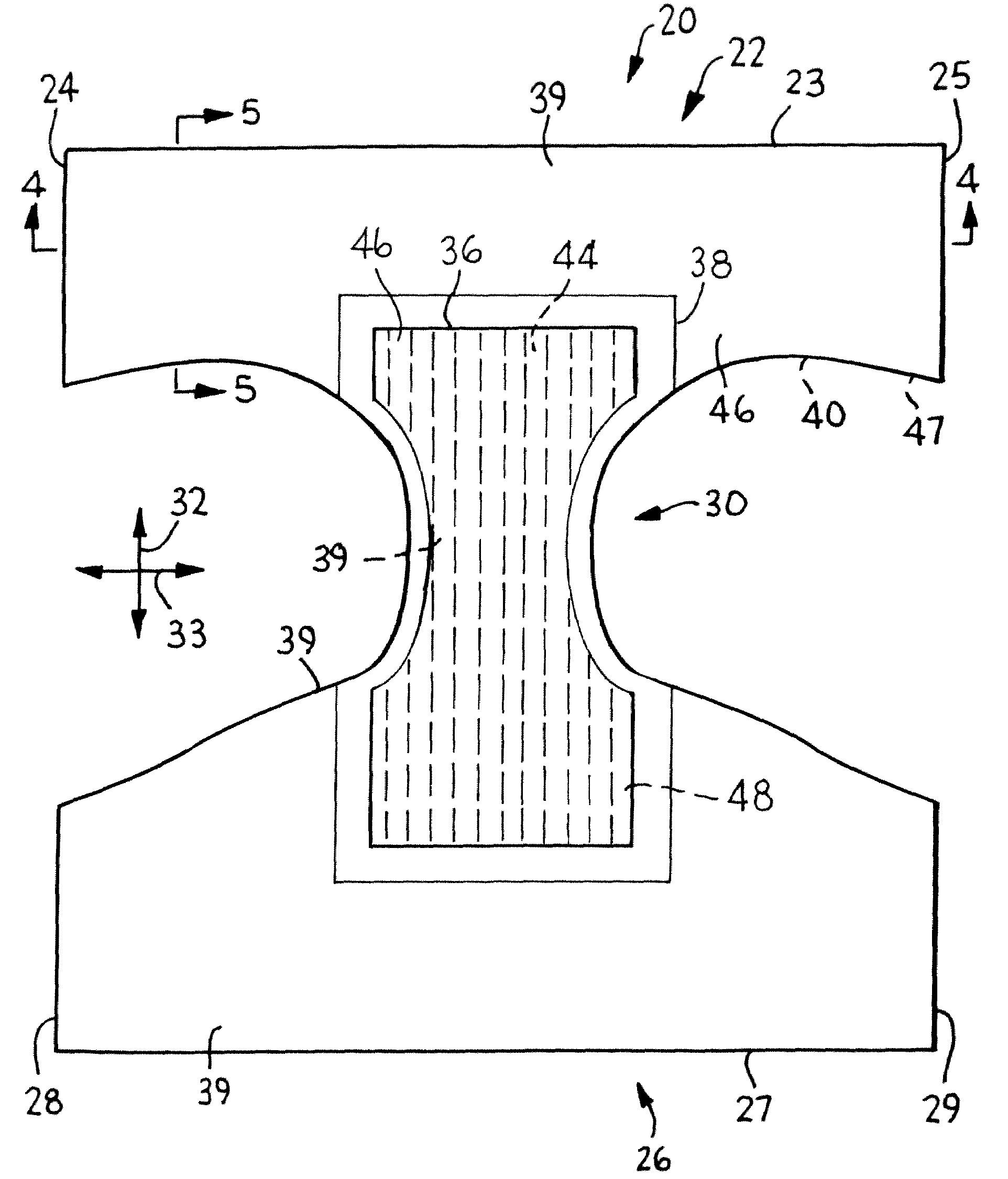

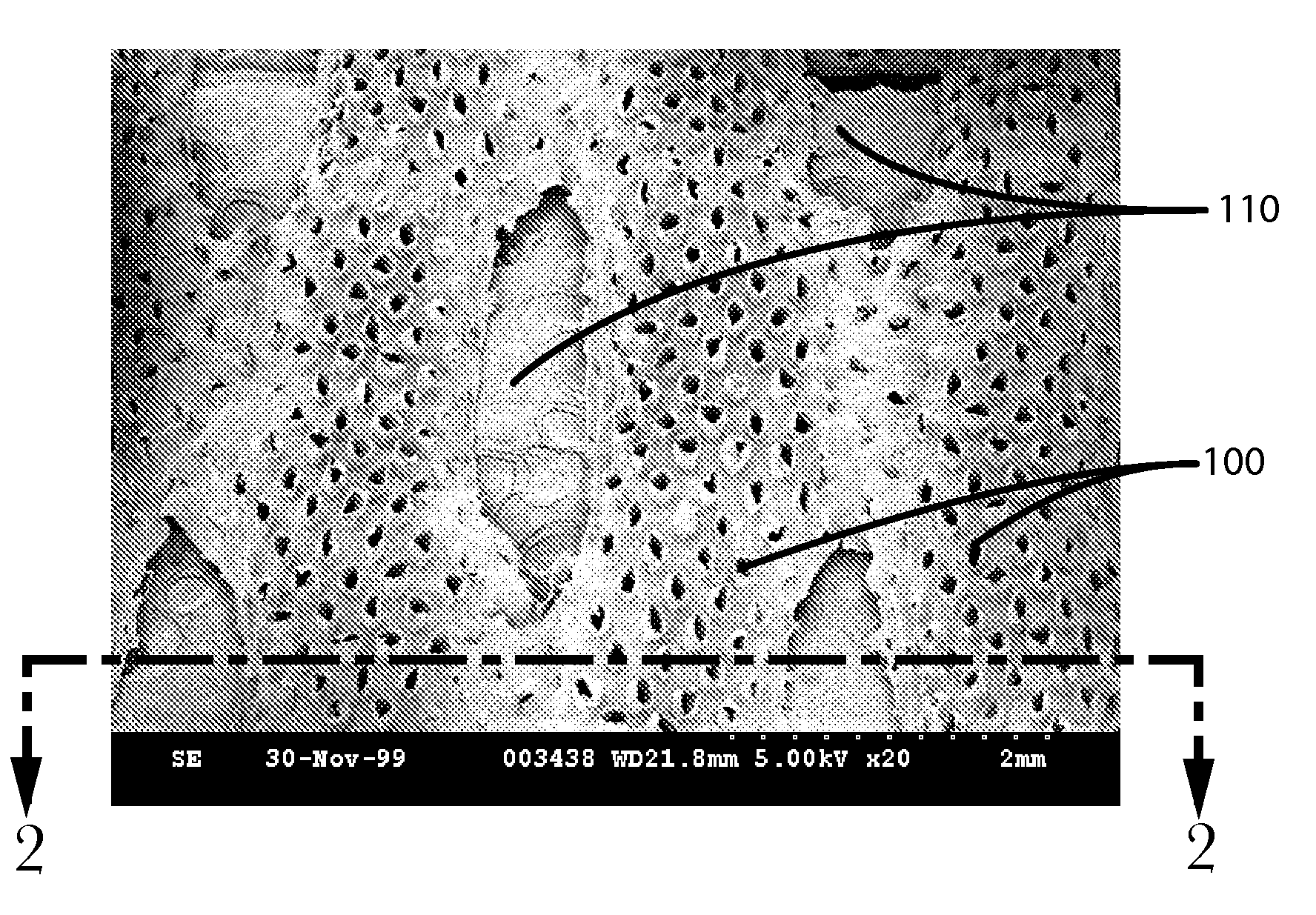

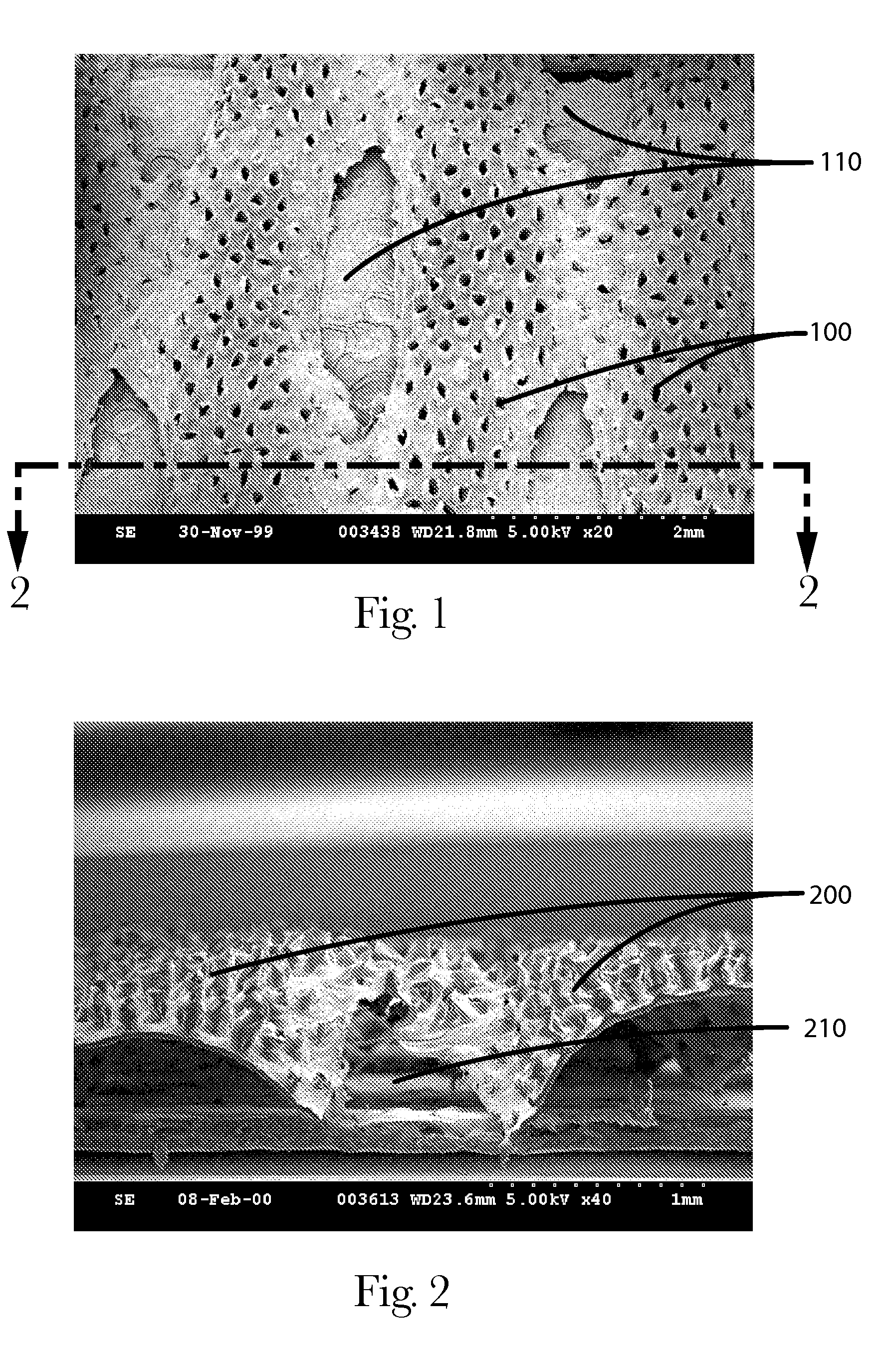

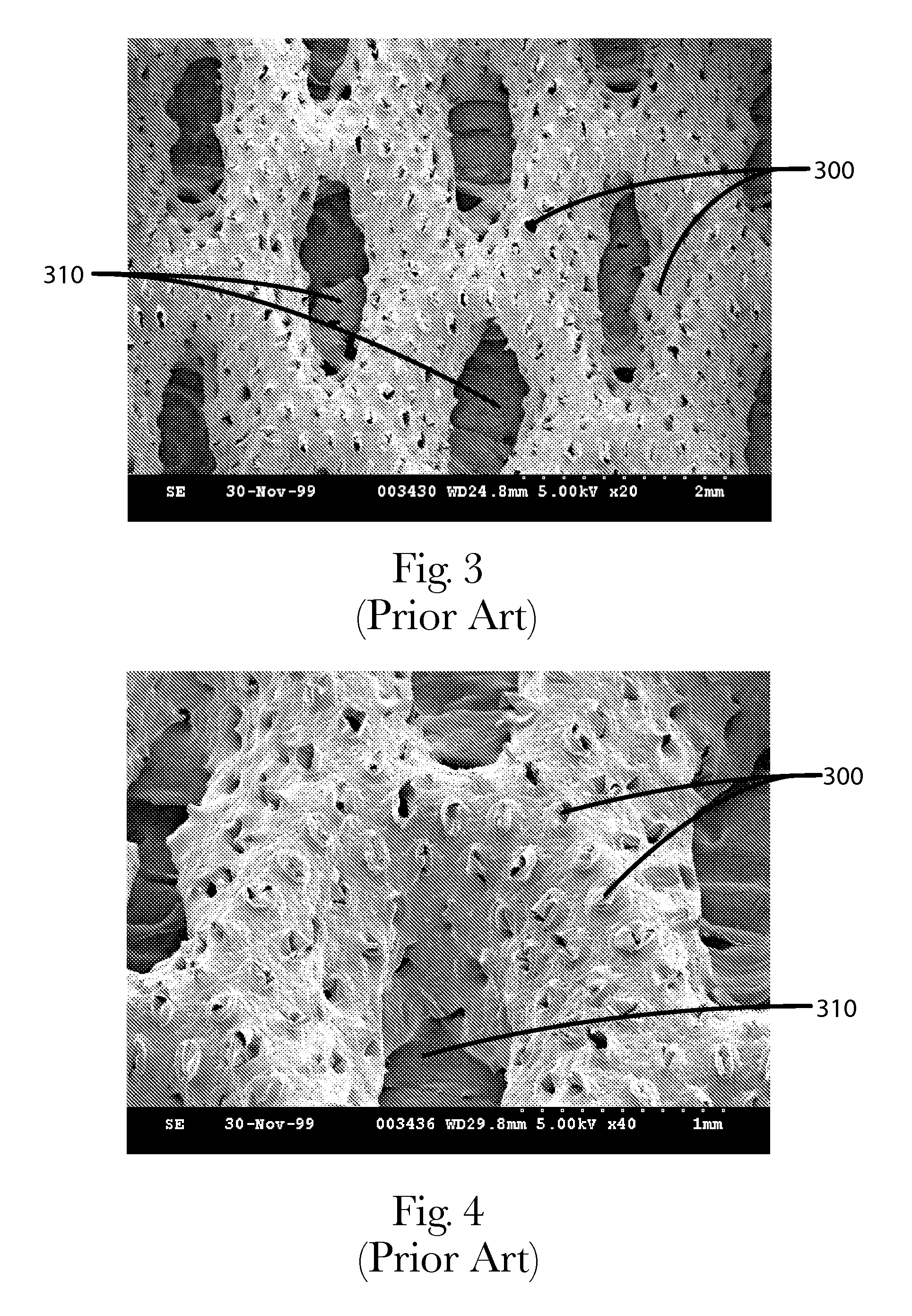

Apertured polymeric film webs and absorbent articles using such webs

A method for making an apertured polymeric film web, the method comprising the steps of:a. providing a polymeric film web;b. providing a first process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, flocking, ultrasonics, printed hair, brushing, and combinations thereof;c. providing a second process, different from the first process, the second process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, ultrasonics, stretch rupturing, hydrocutting, hydrosonics, slitting, ring-rolling, and combinations thereof;d. forming three dimensional surface structures in the polymeric film web by the first process; ande. forming fluid transport apertures in the polymeric film web by the second process.

Owner:THE PROCTER & GAMBLE COMPANY

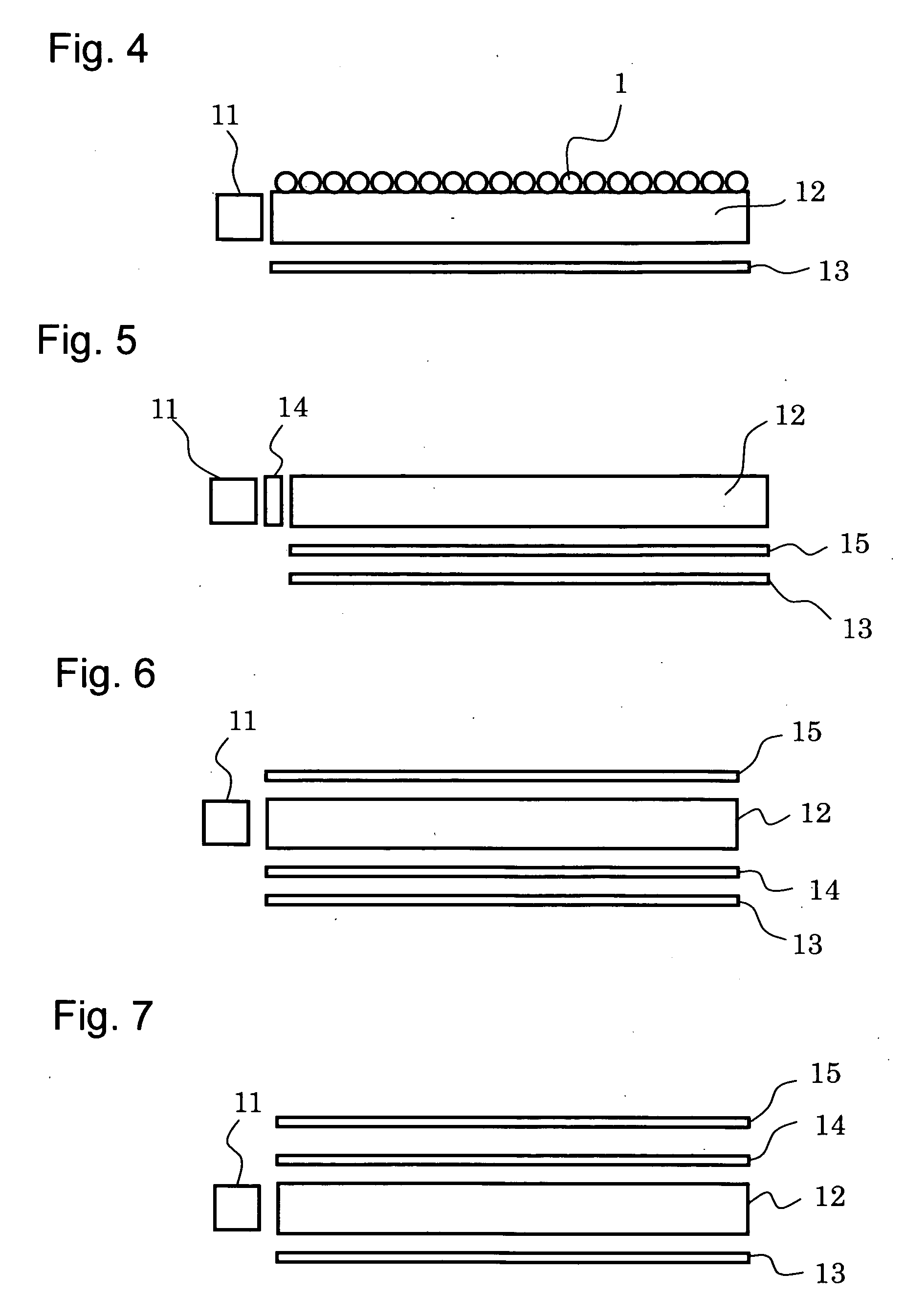

Lighting unit, display device, and phosphor film

ActiveUS20060255711A1Improve efficiencyLong life-timeDischarge tube luminescnet screensCathode ray tubes/electron beam tubesLight irradiationPhosphor

To provide a lighting unit which: does not greatly affect the design of a light guide plate; and has a long lifetime, high efficiency, and a wide color reproduction range by means of a phosphor. In view of the foregoing, the lighting unit of the present invention is constituted in such a manner that a phosphor bead or a phosphor film is arranged on at least one of the light irradiation plane of a light guide plate, the rear surface of the light guide plate, and the light incidence plane of the light guide plate. In addition, a phosphor film is constituted by using: a phosphor bead formed of a phosphor particle and a water-impervious material with which the phosphor particle is coated so that the particle is confined in the material; and a polymer film holding the phosphor bead.

Owner:DAWNCREST IP LLC

Flavoring of drug-containing chewing gums

ActiveUS20060275344A1Avoid problemsEnhanced release controlNervous disorderContainers for annular articlesAdditive ingredientPolymer thin films

A chewing gum comprising at least one active pharmaceutical ingredient (API) with a core onto which is applied at least one inner polymer film coating and thereafter onto which is applied at least one outer hard coating. A preferred API is nicotine. Flavoring agents may be incorporated in the core, in the at least one inner polymer film coating and / or in the at least one outer hard coating. The gums formed exhibit a long lasting effect of flavoring agent(s) and result in the domination of flavoring agents in the coating(s) over flavoring agent(s) in the core, thereby (a) avoiding problems of chemical or pharmaceutical incompatibility between an API in the core and flavoring agent(s) in the coating(s) and (b) achieving an increased control of the release of the API and of non-active excipients.

Owner:MCNEIL AB

Method of manufacturing a semiconductor device using a polymer film pattern

InactiveUS6465290B1Good pn junction characteristicImprove featuresTransistorSemiconductor/solid-state device manufacturingHydrogen contentPolymer thin films

Claimed and disclosed is a method of manufacturing a semiconductor device, the method comprising the steps of forming a dummy gate on a semiconductor substrate, forming a source-drain diffusion region by introducing an impurity into the semiconductor substrate having the dummy gate as a mask, removing the dummy gate to form an opening, and forming a gate electrode within the opening with a gate insulating film formed below the gate electrode. The dummy gate is further formed by coating the semiconductor substrate with a polymer having a higher carbon content than hydrogen content so as to form a polymer film, forming a photoresist pattern on the polymer film, and transferring the pattern shape of the photoresist pattern onto the polymer film.

Owner:KK TOSHIBA

Stretch wrap films

InactiveUS6093480AImprove clingImproved maximum stretchWrappers shrinkageSynthetic resin layered productsStretch wrapGram

A multilayer, thermoplastic stretch wrap film containing at least three polymeric film layers and comprised of a first layer and a second layer. The first and second layers may comprise a polymer of two or more monomers, wherein a first monomer is ethylene, in a major amount by weight, and a second monomer is an alpha olefin of from about 3 to about 12 carbon atoms, in a minor amount by weight. If the first and second layers are outer layers, they have a cling force to each other of at least about 140 grams / inch. The stretch wrap film also has at least one inner polymeric layer, located between the first and second layers. The inner polymeric layer comprises a low polydispersity polymer having a polydispersity of from about 1 to about 4, a melt index (I.sub.2) of from about 0.5 to about 10 g / 10 min., and a melt flow ratio (I.sub.20 / I.sub.2) of from about 12 to about 22. The inner layer(s) comprise(s) from about 5 wt. % to about 40 wt. % of the stretch wrap film so as to produce a film having a maximum stretch of at least 340%, a F-50 dart drop value of at least about 130 g / mil, a machine directional tear resistance of at least about 125 g / mil and a transverse directional tear resistance of at least about 500 g / mil. It is contemplated that additional outer layers may be added such an outer high cling layer or an outer slip layer, as well as additional inner layers.

Owner:BERRY PLASTICS CORP

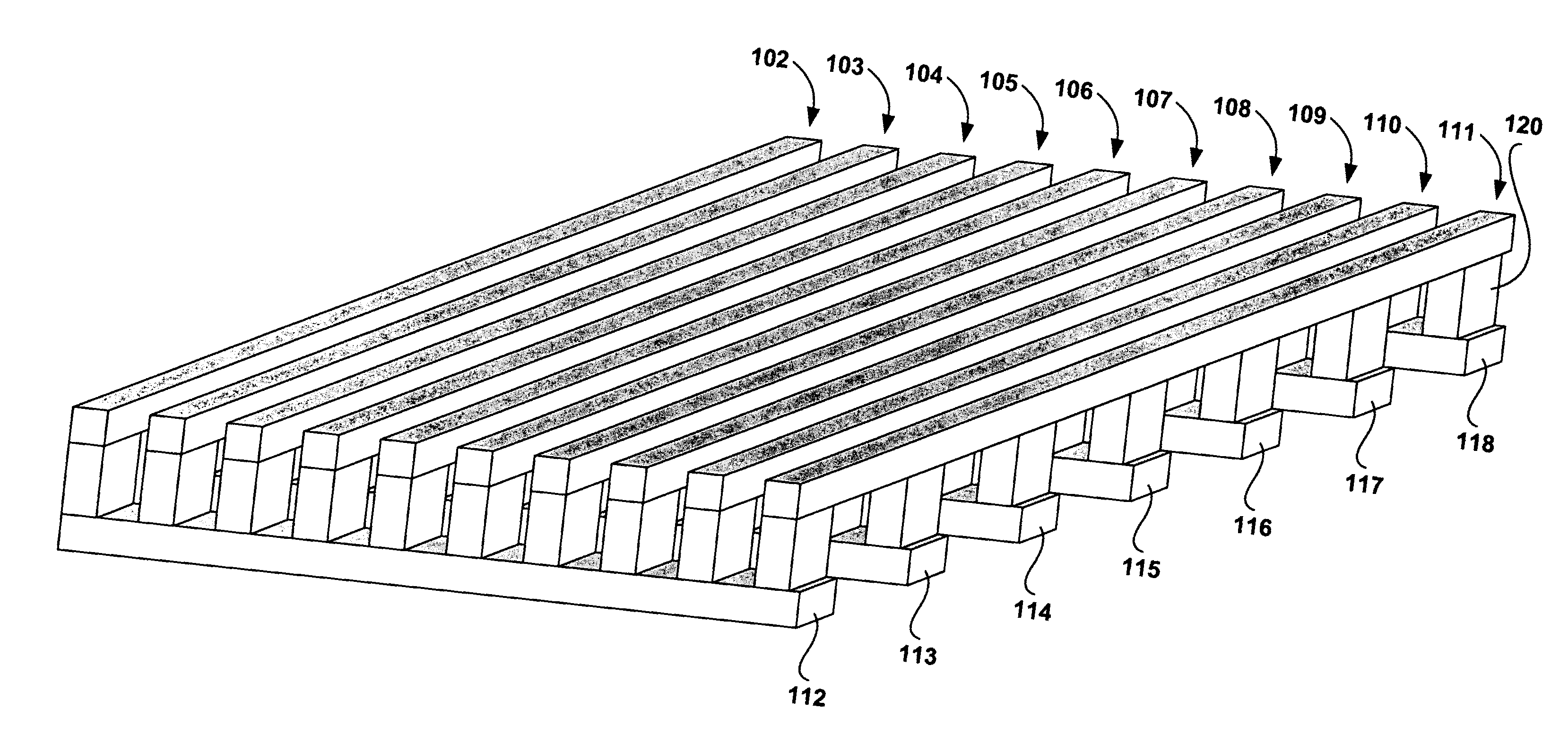

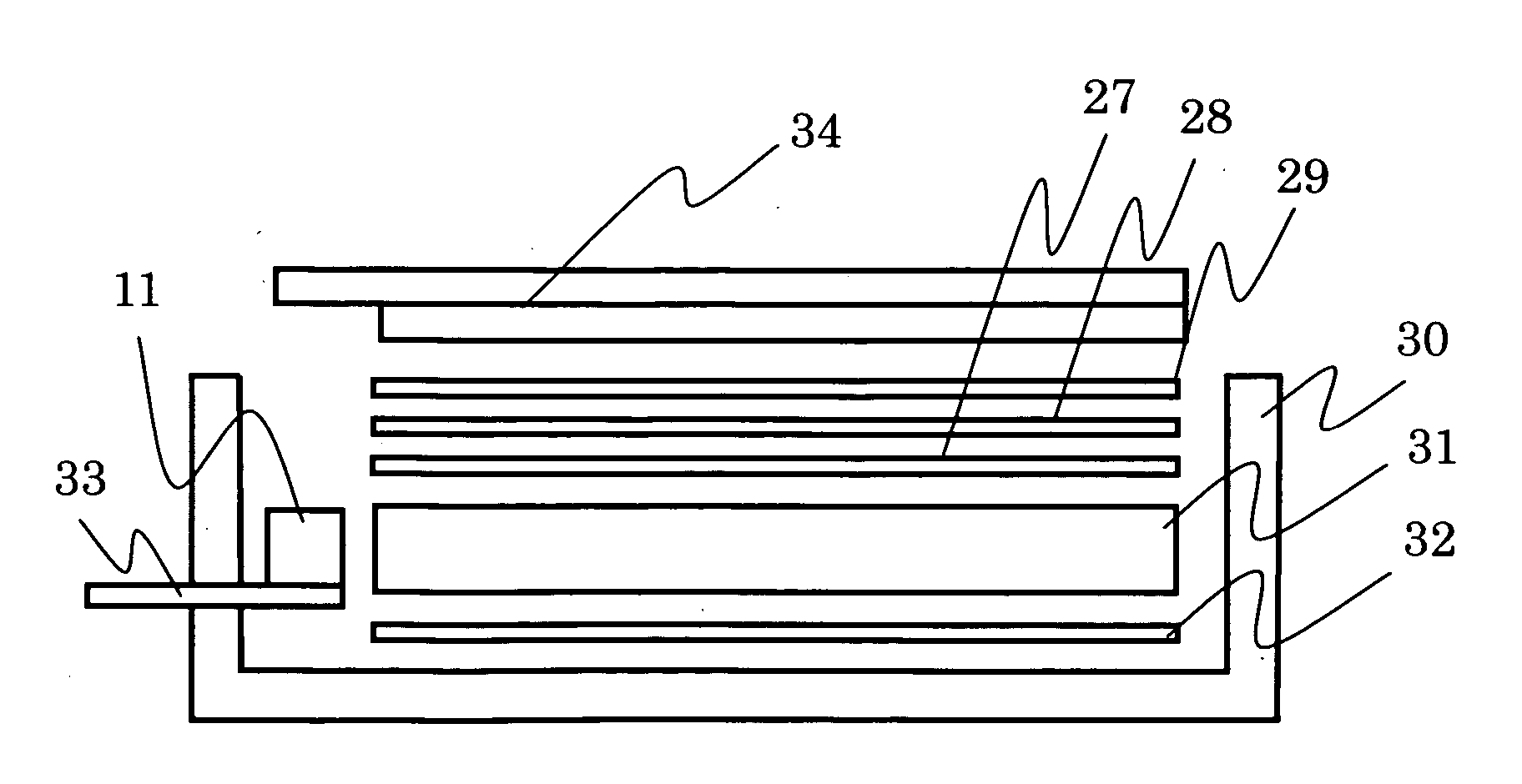

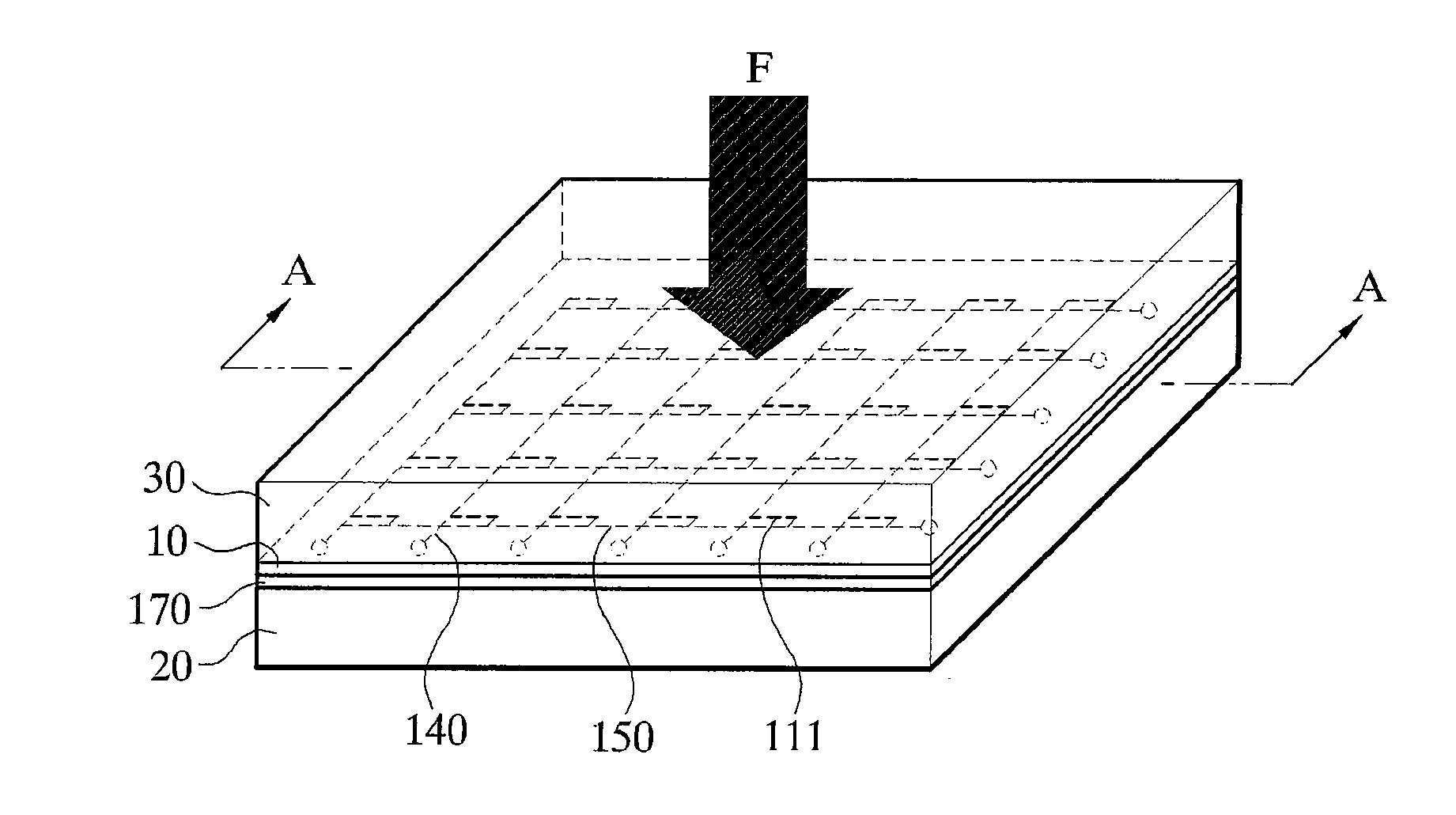

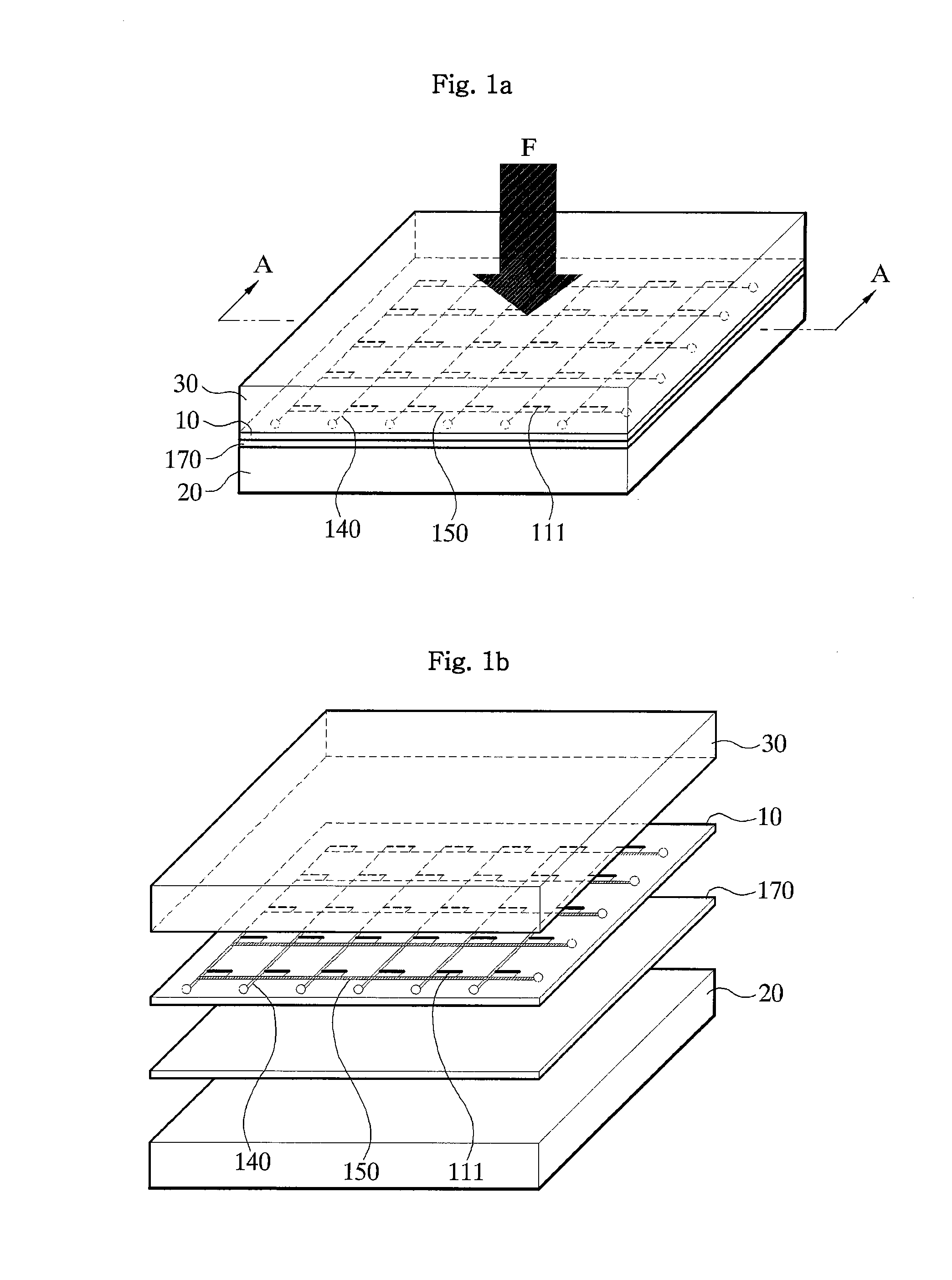

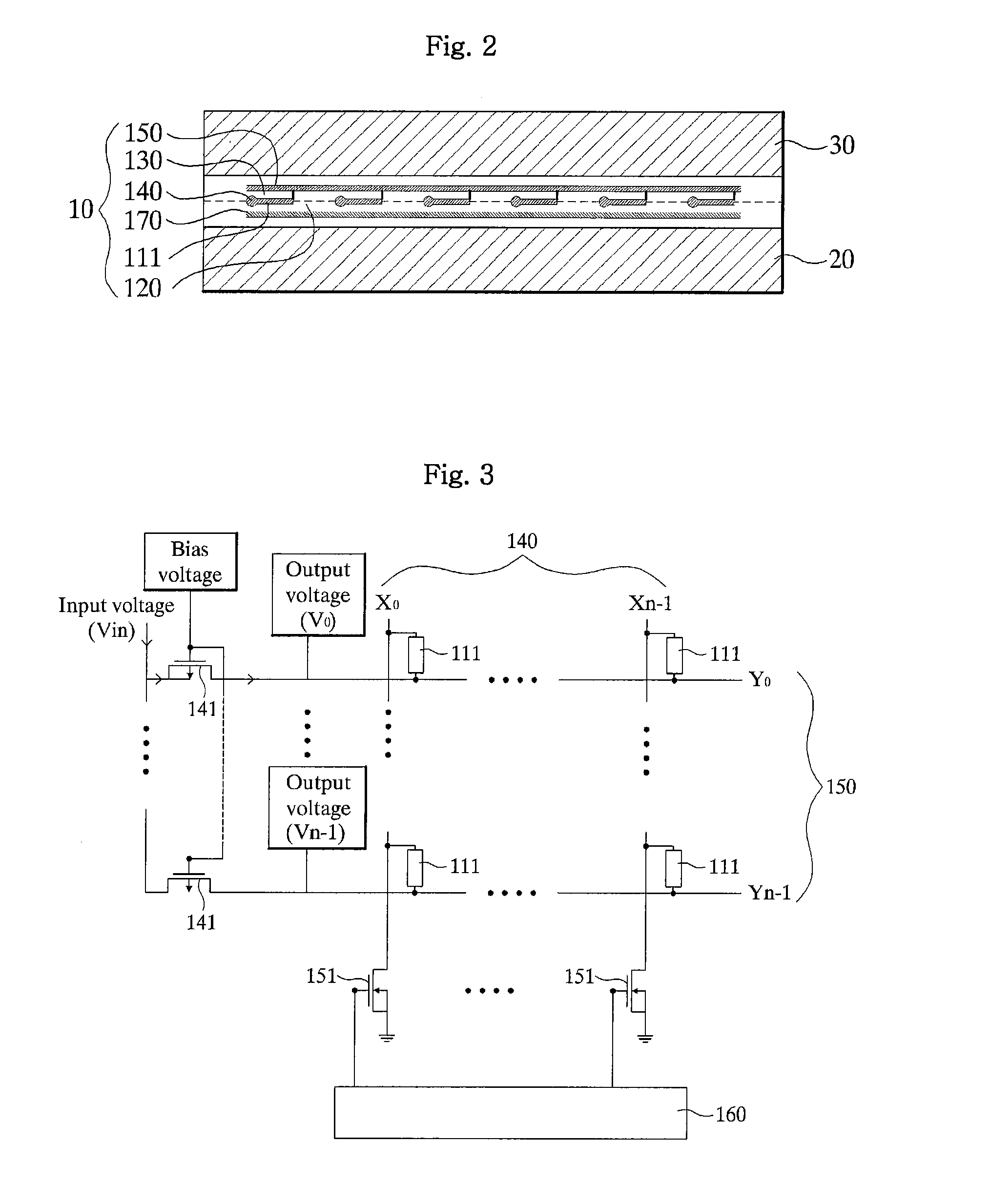

Flexible force or pressure sensor array using semiconductor strain gauge, fabrication method thereof and measurement method thereof

ActiveUS20110226069A1Simple and robust structureIncrease strainForce measurementSemiconductor/solid-state device manufacturingSensor arrayElastomer

The force or pressure sensor array of the present invention effectively has both flexibility and elasticity. Since the substrate itself is a kind of a polymer material, the substrate can be bent or expanded. Although silicon, which is a material of the semiconductor strain gauge, is easily broken and solid, mechanical flexibility can be secured if it is fabricated extremely thin. To this end, particularly, disclosed is a flexible force or pressure sensor array using semiconductor strain gauges 110, the sensor array comprising: a substrate 10 including: the semiconductor strain gauges 110 in which a plurality of elements formed in a certain array pattern is deformed by force or pressure, a pair of polymer film layers 120 and 130 having film surfaces contacted facing each other and containing the semiconductor strain gauge 110 between the film surfaces contacted with each other, and a pair of signal line layers formed on top and bottom surfaces of an insulating layer using either of the pair of polymer film layers 120 and 130 as the insulating layer and connected to the elements 111 of the array pattern to form electrodes, for fetching deformation signals outputted due to deformation of the elements 111 to outside; and a pair of elastomer layers 20 and 30 formed on both sides of the substrate 10 to contain the substrate 10 inside.

Owner:KOREA RES INST OF STANDARDS & SCI

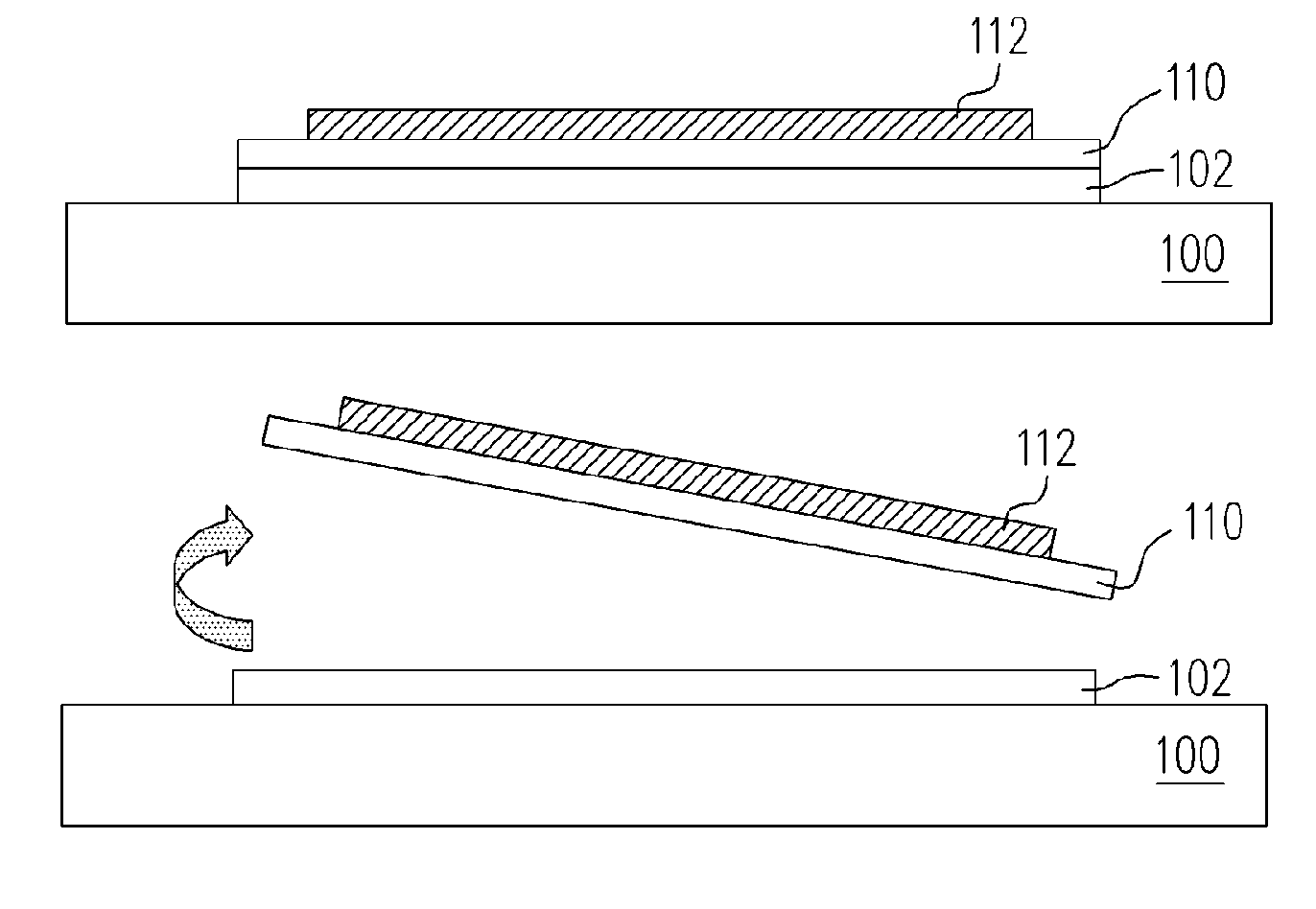

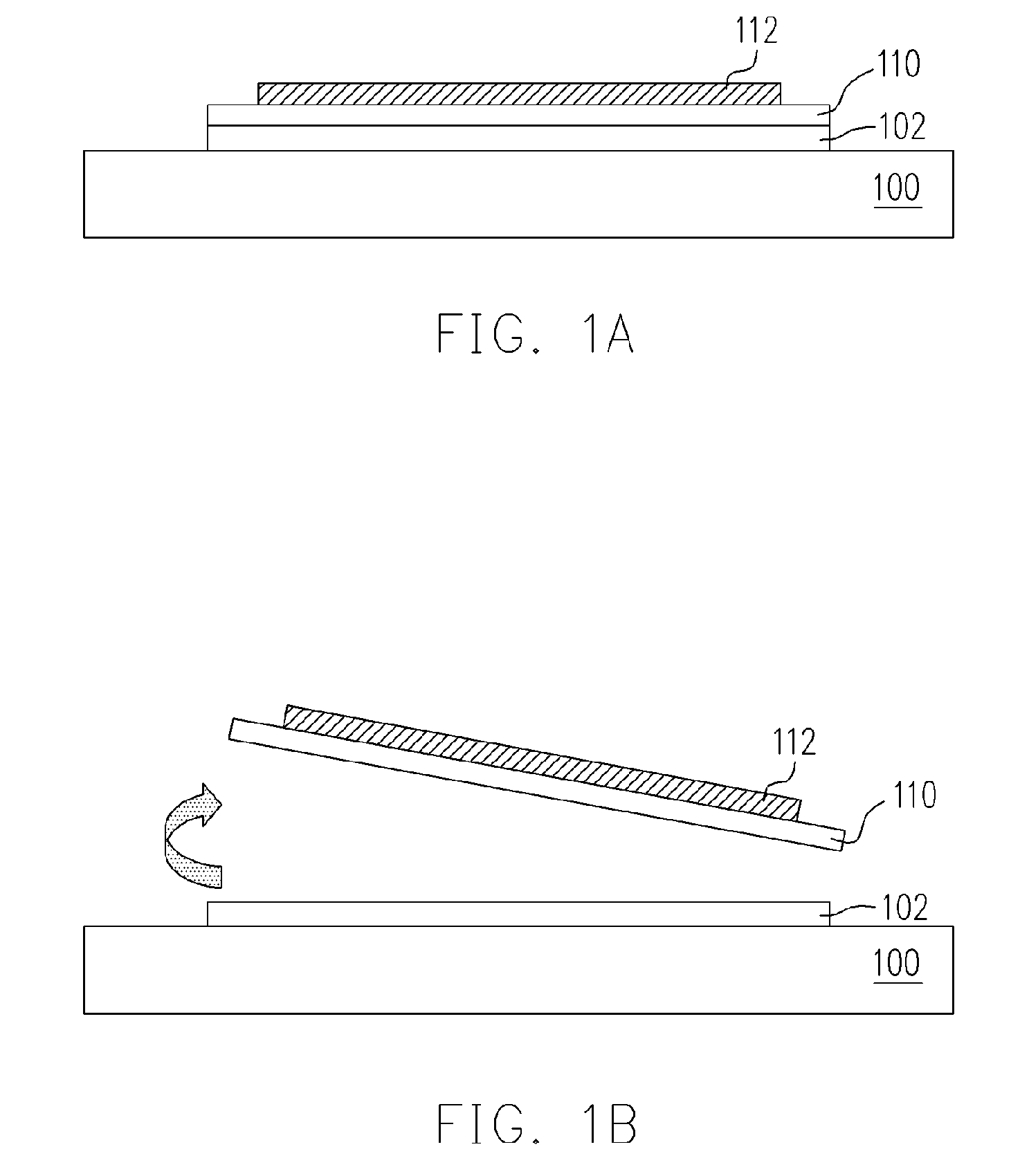

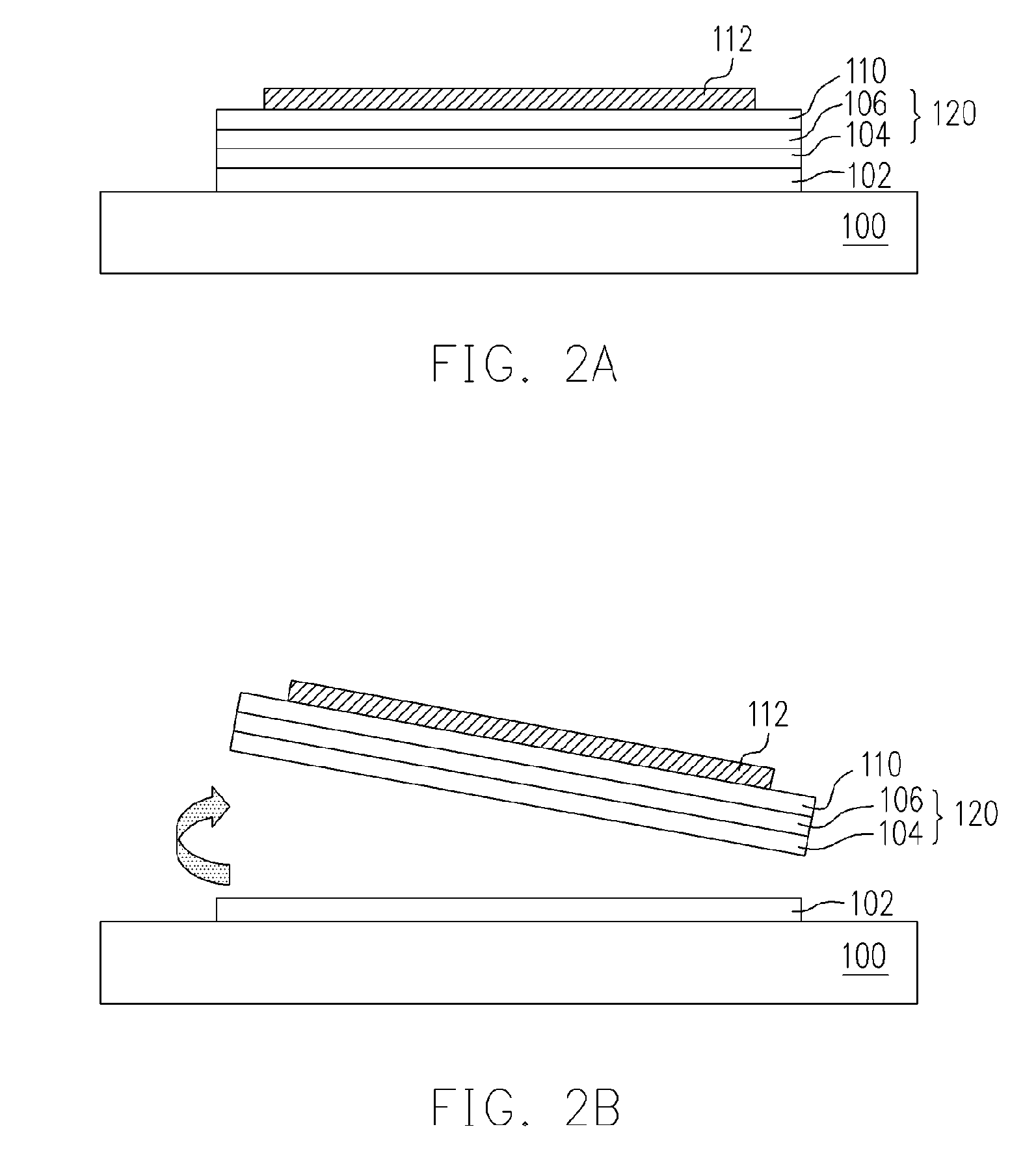

Flexible pixel array substrate and method for fabricating the same

ActiveUS20070059854A1Easy to separateHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingPolymer sciencePolymer thin films

The present invention provides a method for fabricating a flexible pixel array substrate as follows. First, a release layer is formed on a rigid substrate. Next, on the release layer, a polymer film is formed, the adhesive strength between the rigid substrate and the release layer being higher than that between the release layer and the polymer film. The polymer film is formed by spin coating a polymer monomer and performing a curing process to form a polymer layer. Afterwards, a pixel array is formed on the polymer film. The polymer film with the pixel array formed thereon is separated from the rigid substrate.

Owner:HANNSTAR DISPLAY CORPORATION

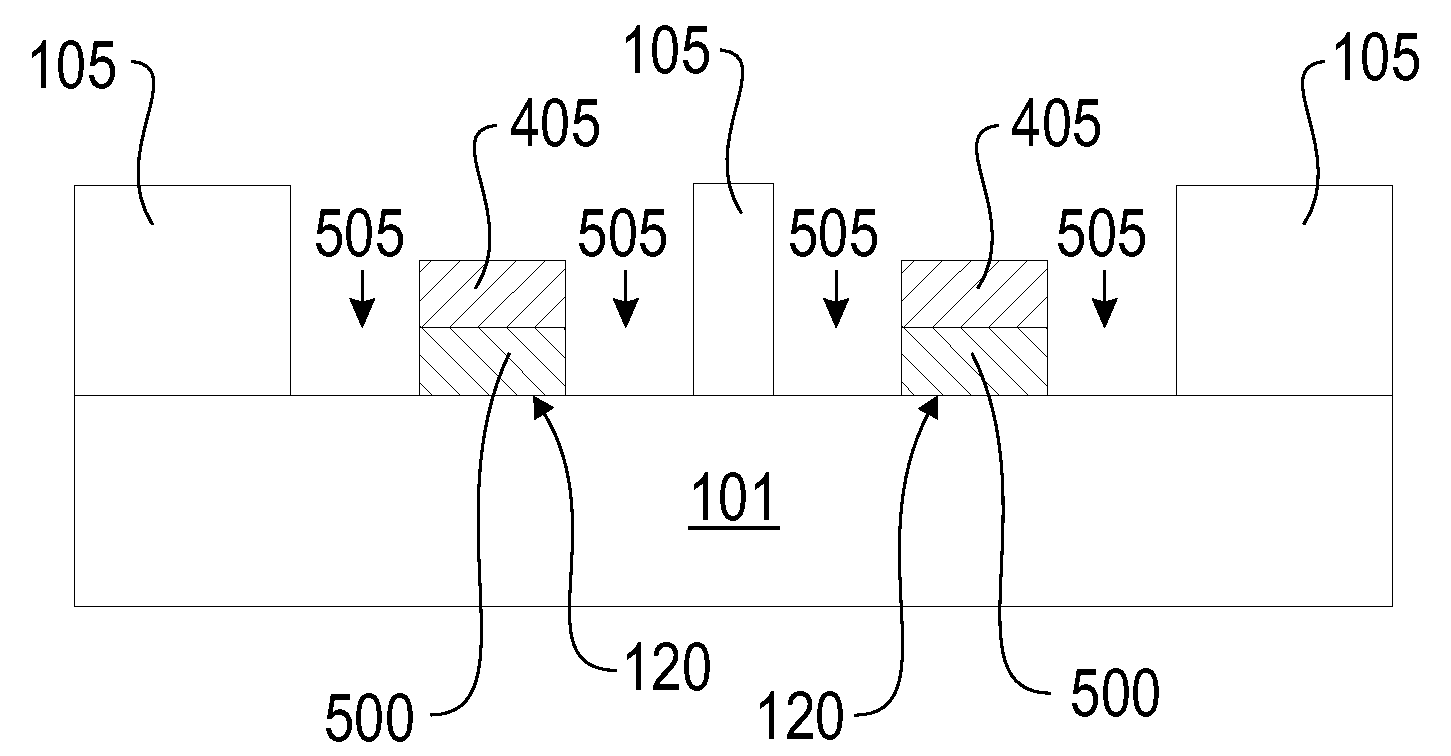

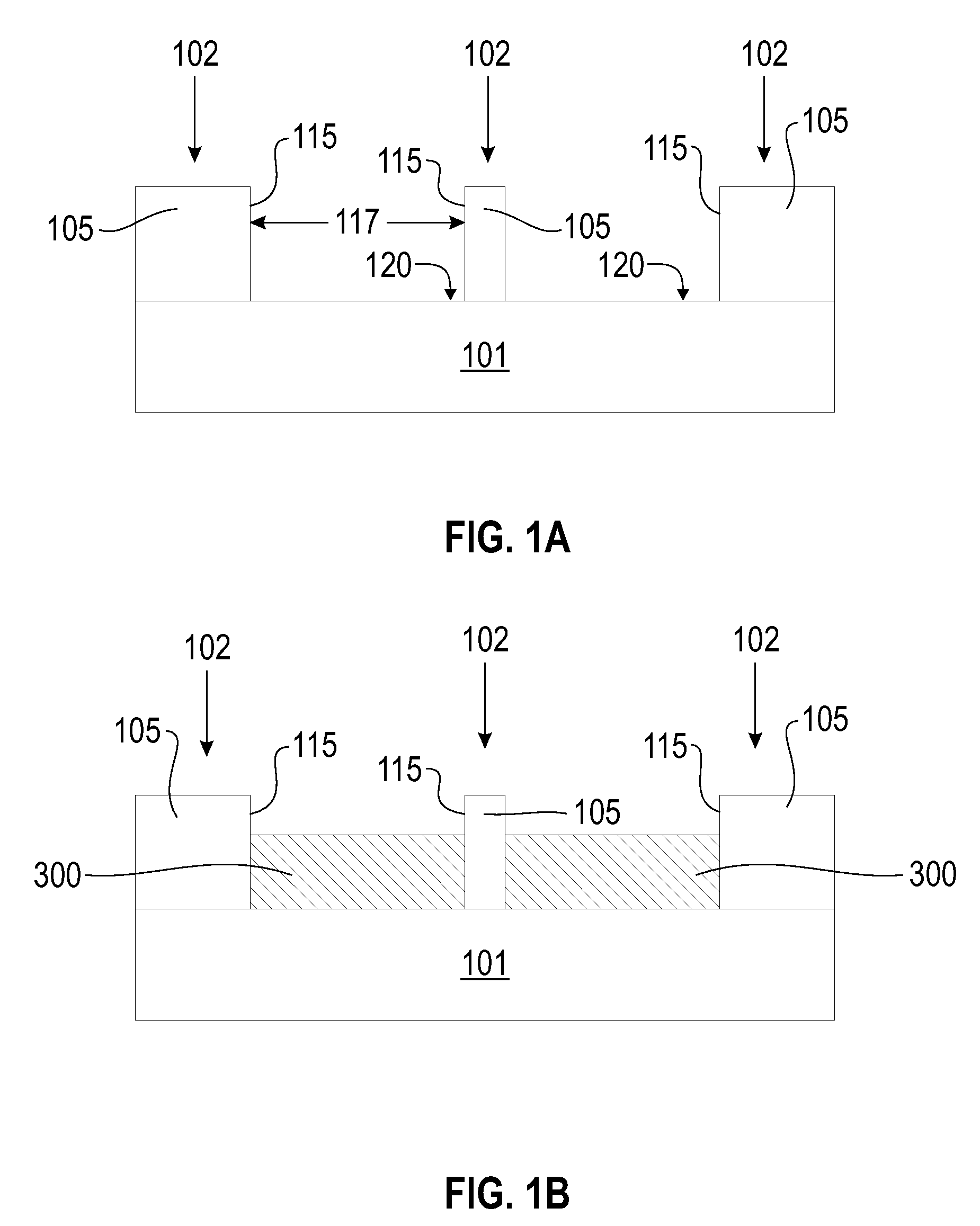

Aligning polymer films

InactiveUS20090212016A1Decorative surface effectsSemiconductor/solid-state device manufacturingPolymer thin filmsSubstructure

A Method. The method includes forming a substructure, on a substrate, including a feature having a sidewall of a first material and a bottom surface of a second material. Applying a solution including two immiscible polymers and third material to the substructure. The immiscible polymers include a first and second polymer. A selective chemical affinity of the first polymer for the material is greater than a selective chemical affinity of the second polymer for the material. The first polymer is segregated from the second polymer. The first polymer selectively migrates to the at least one sidewall, resulting in the first polymer being disposed between the at least one sidewall and the second polymer. The first polymer is selectively removed. The second polymer remains, resulting in forming structures including the substructure, the third material, and the second polymer. The substructure has a pattern. The pattern is transferred to the substrate.

Owner:GLOBALFOUNDRIES INC

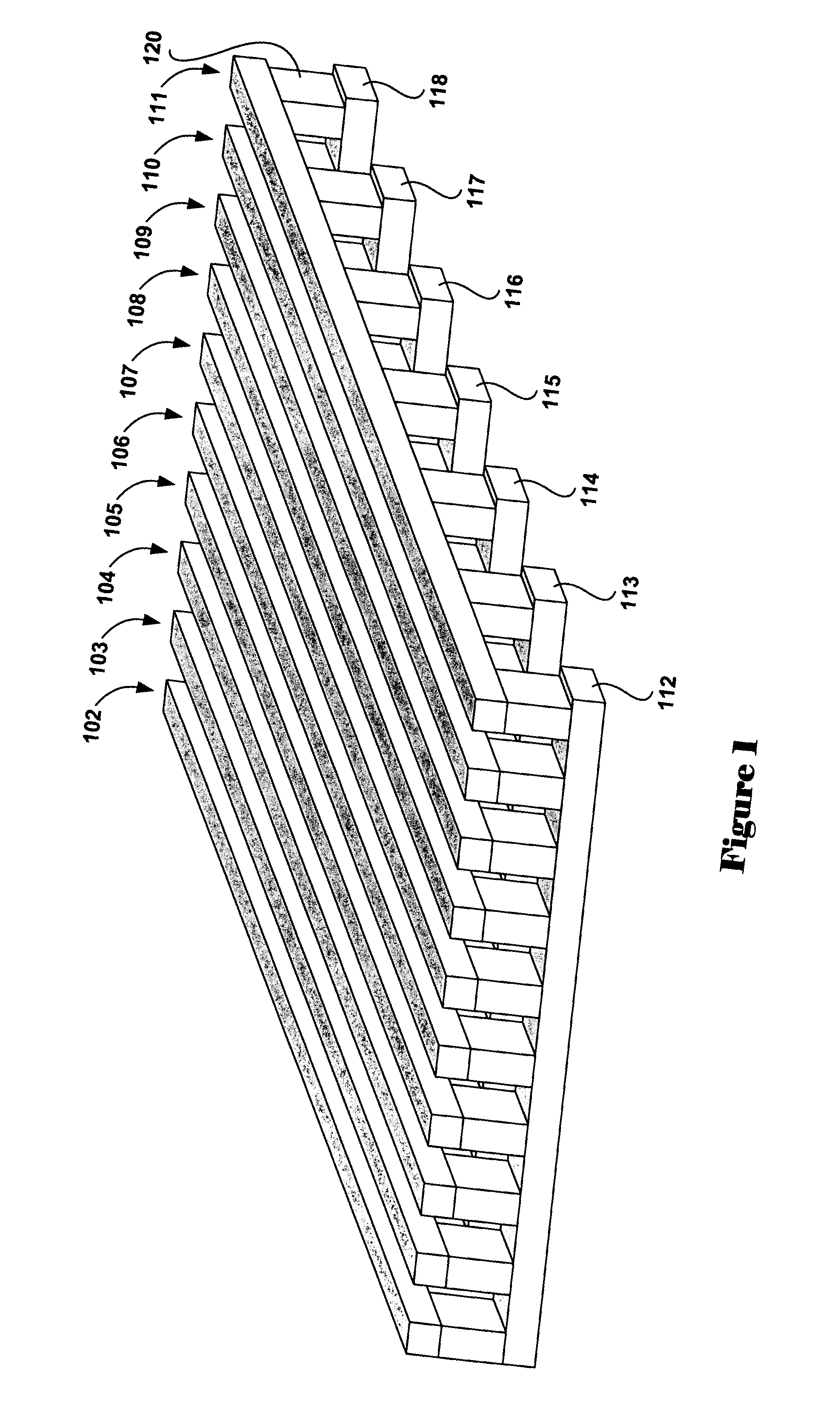

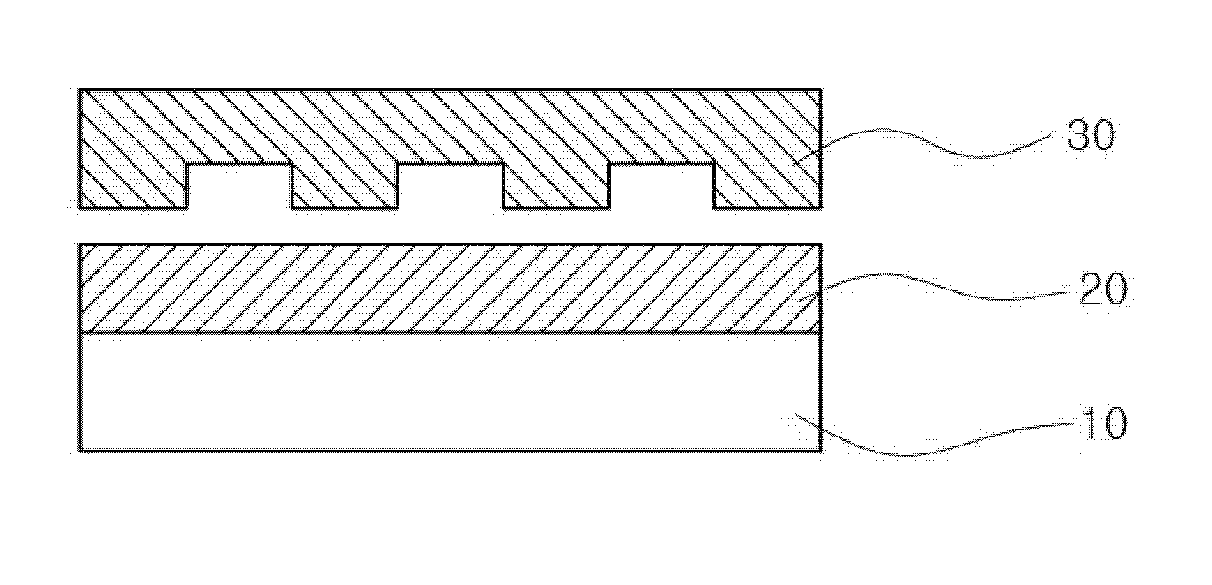

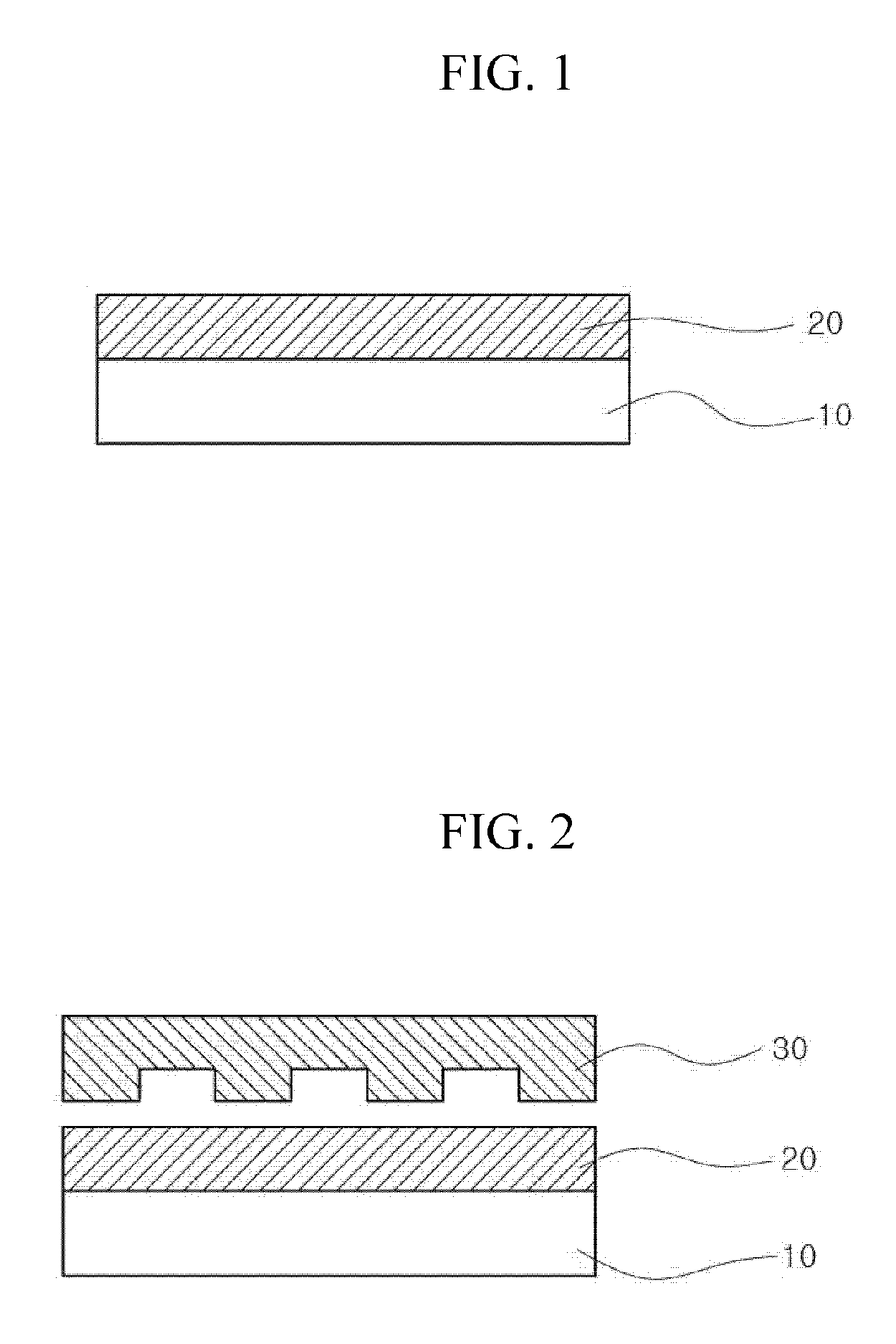

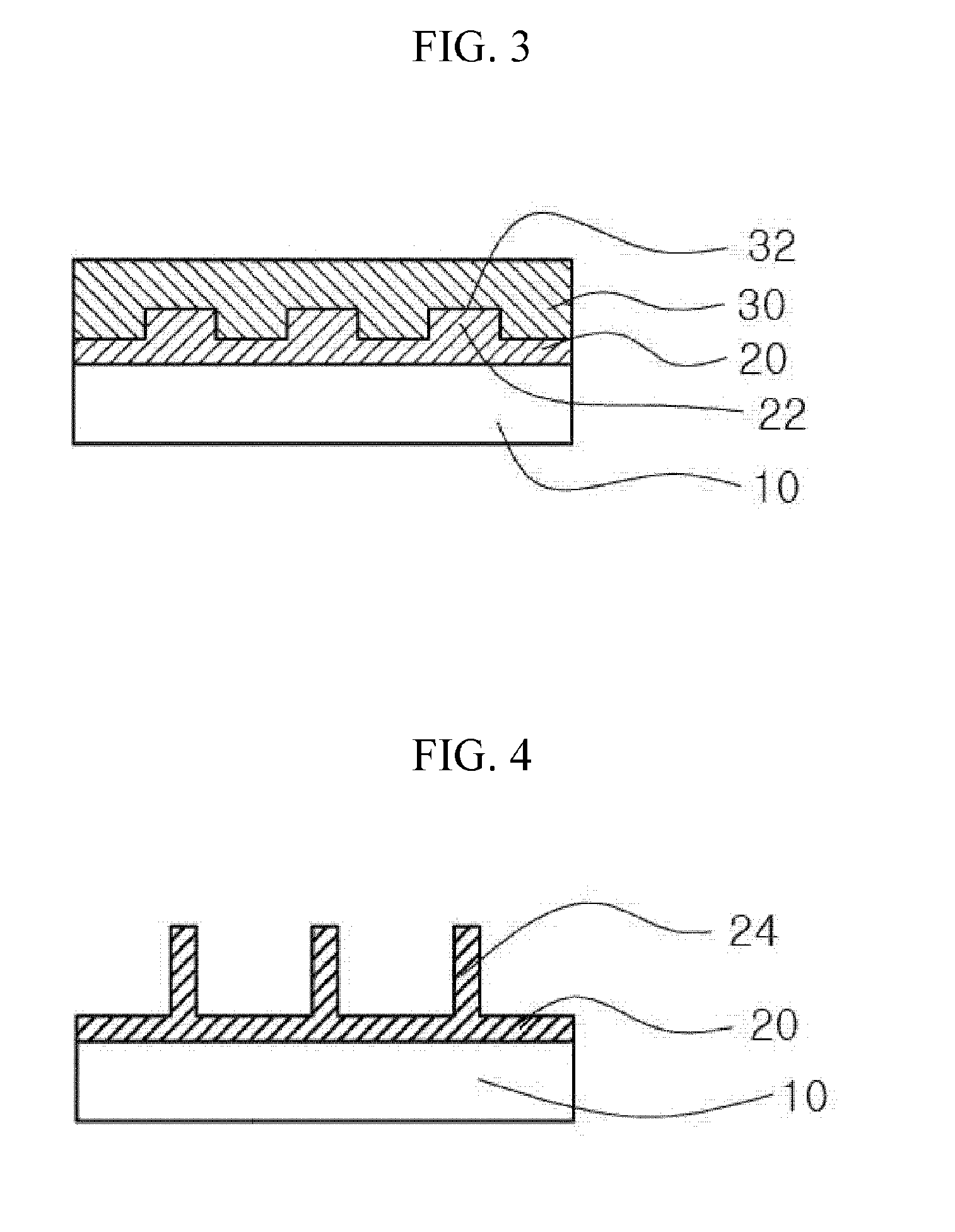

Method for forming nanostructure having high aspect ratio and method for forming nanopattern using the same

InactiveUS20080000871A1Simple and economical processHigh aspect ratioDecorative surface effectsIndividual molecule manipulationPolymer scienceCarbon nanotube

Provided is a method of forming a nanostructure having a nano-sized diameter and a high aspect ratio through a simple and economical process. To form the nanostructure, a polymer thin film is formed on a substrate and a mold is brought to contact the polymer thin film. Then, a polymer patterning is formed to contact the background surface of an engraved part of the mold, and then the polymer pattern is extended out by removing the mold out of the polymer thin film. The nanostructure forming method of the present research can reproduce diverse cilia optimized in the natural world. Also, it can be used to develop new materials with an ultra-hydrophobic property or a high adhesiveness. Further, it can be applied to a nanopattern forming process for miniaturizing electronic devices and to various ultra-precise industrial technologies together with carbon nanotube, which stands in the highlight recently.

Owner:SEOUL NAT UNIV R&DB FOUND

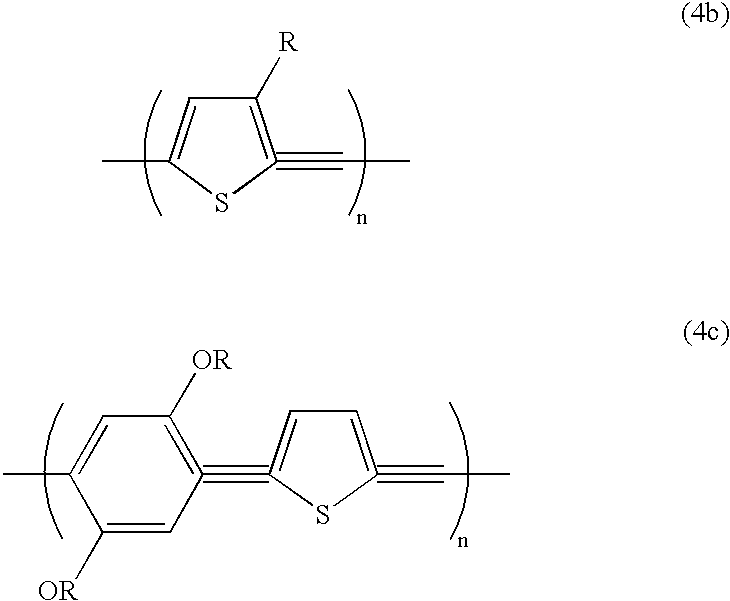

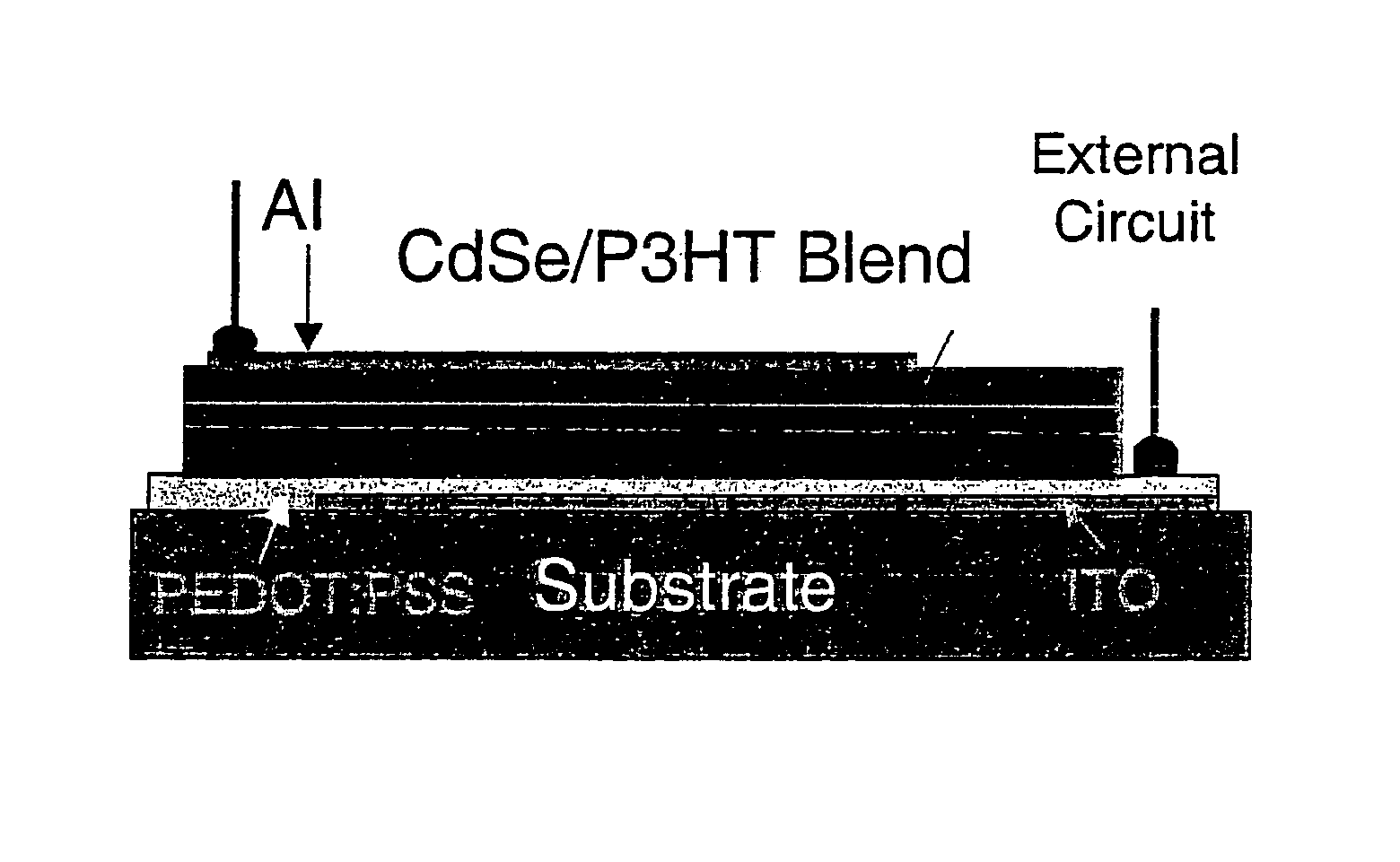

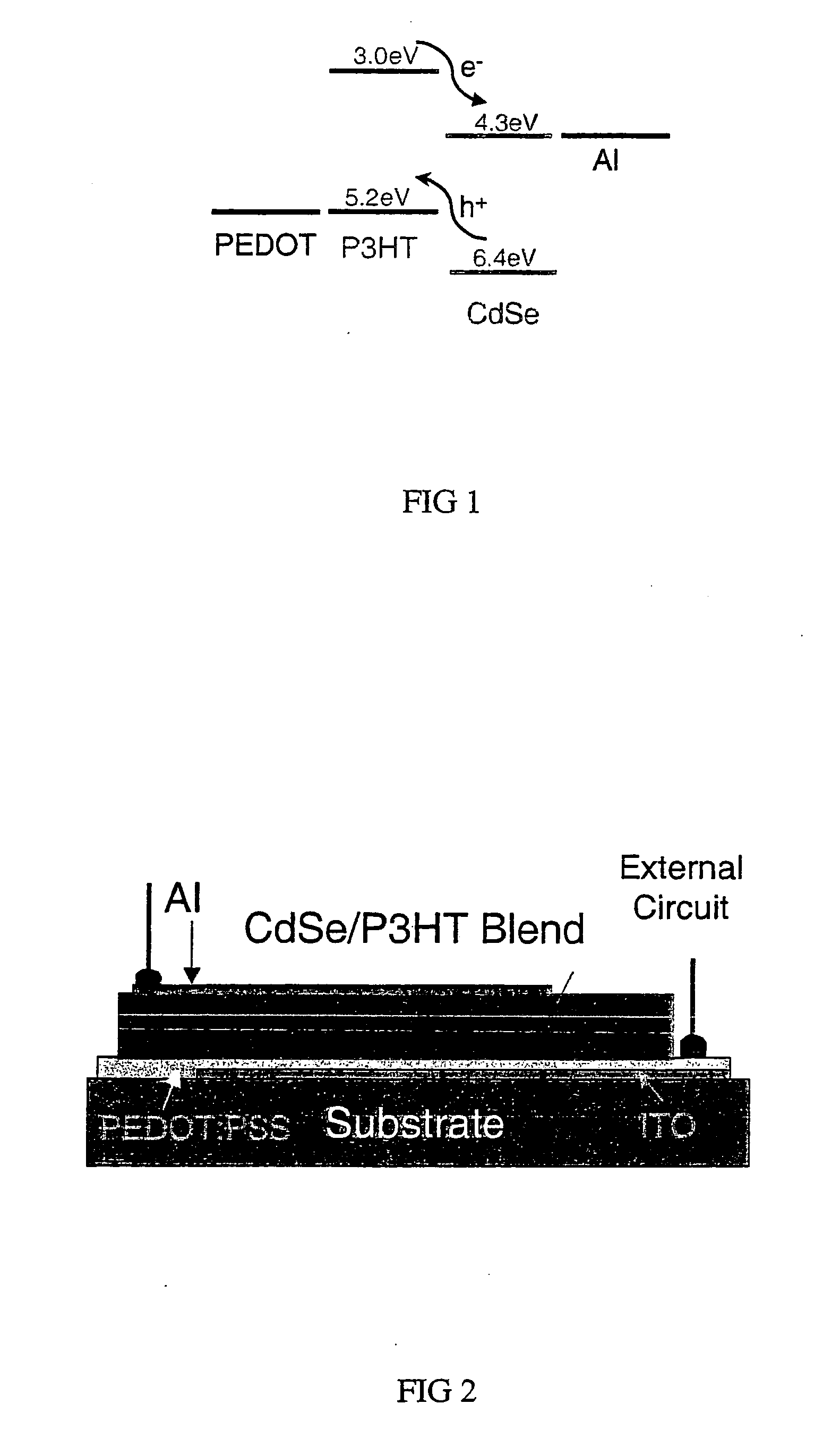

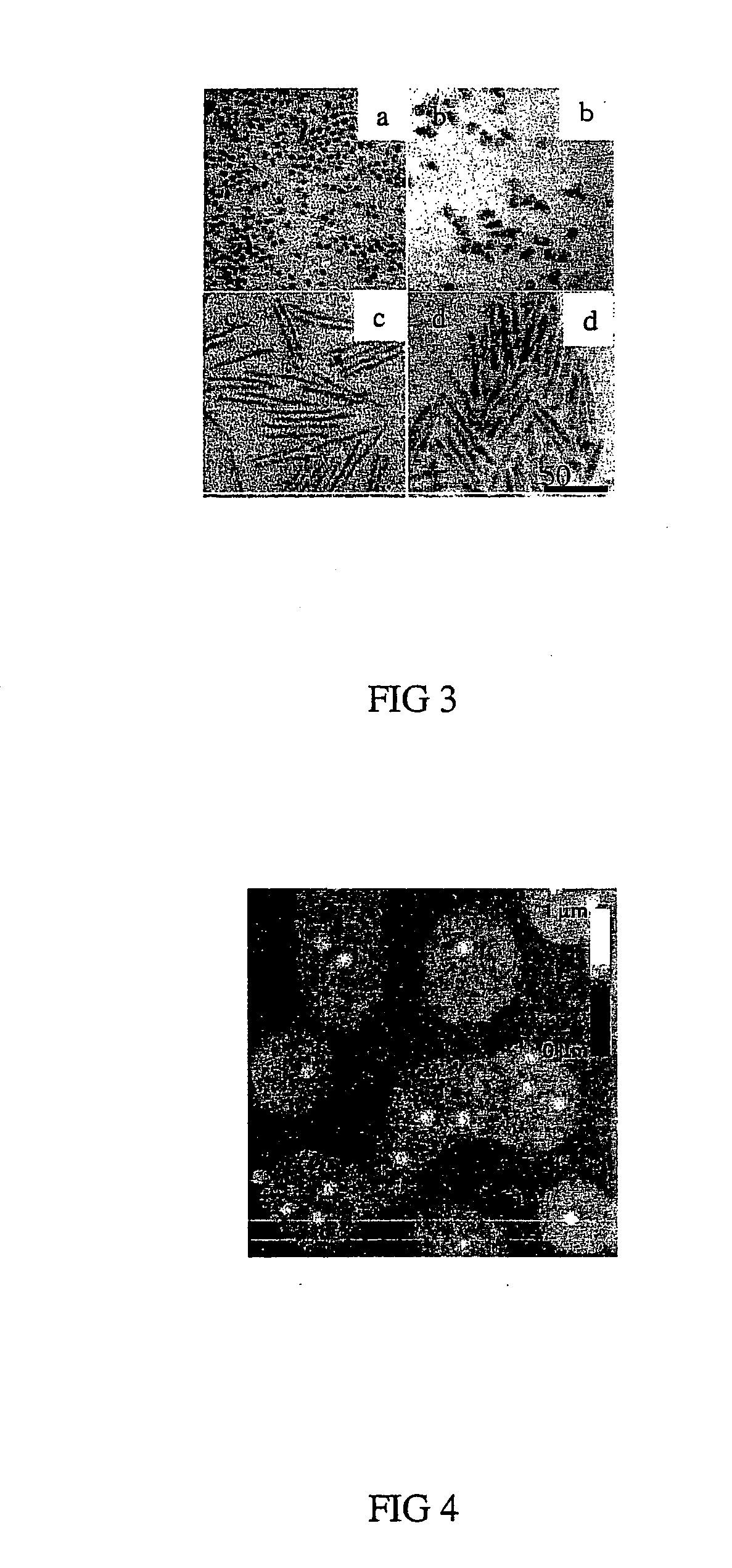

Semiconductor-nanocrystal/conjugated polymer thin films

ActiveUS20050133087A1Liquid crystal compositionsMaterial nanotechnologyPolymer thin filmsSemiconductor nanocrystals

The invention described herein provides for thin films and methods of making comprising inorganic semiconductor-nanocrystals dispersed in semiconducting-polymers in high loading amounts. The invention also describes photovoltaic devices incorporating the thin films

Owner:RGT UNIV OF CALIFORNIA

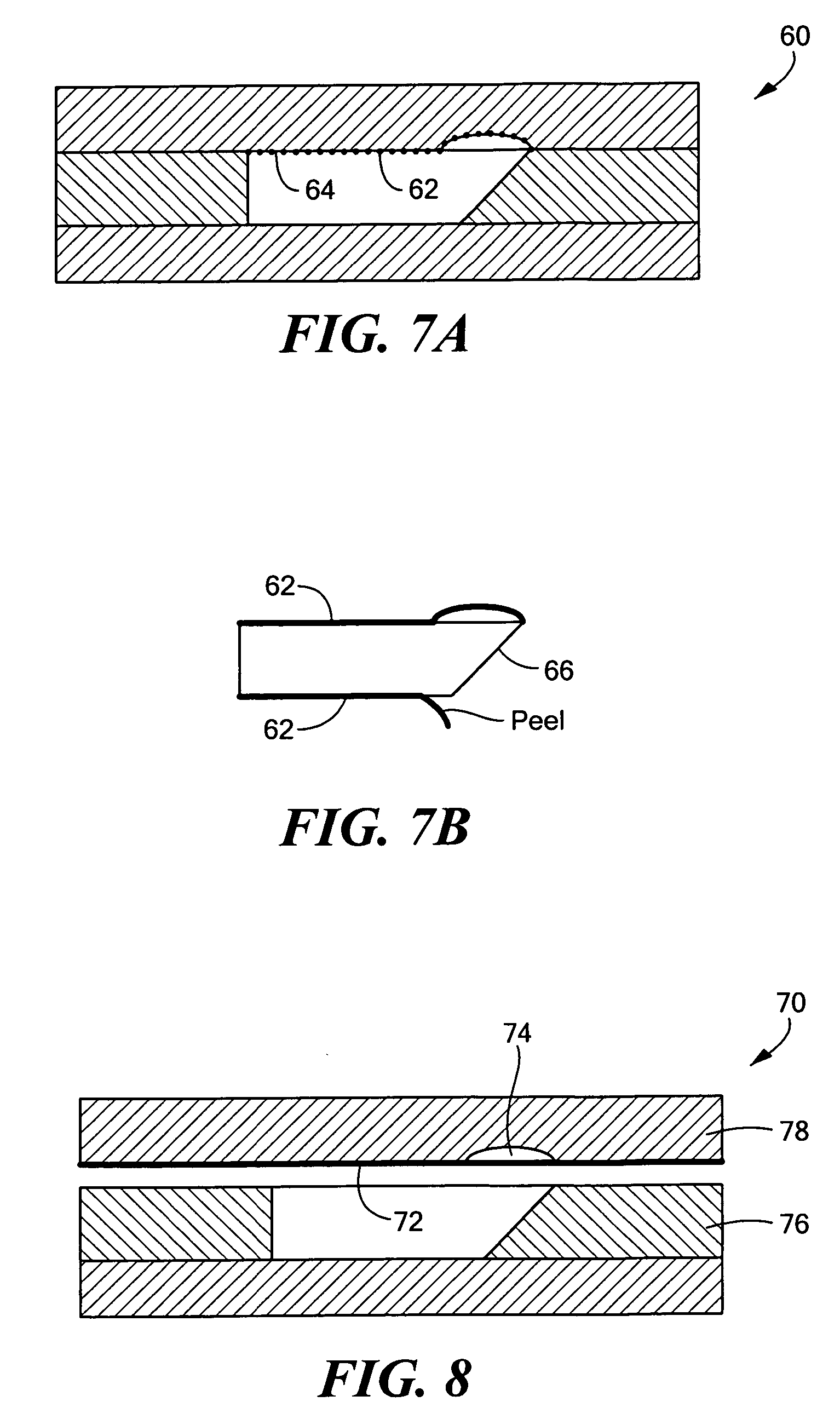

Method for producing high quality optical parts by casting

InactiveUS20060192307A1Quality improvementIncrease costOptical articlesPolymer sciencePolymer thin films

A casting method, rather than injection molding, to produce polymer optical components and systems is provided. The casting process controls shrinkage and stress, thus providing both high bulk uniformity and high quality, accurate surfaces, by incorporating polymer films into the mold. The films may remain incorporated into the part or may optionally be removed from the part after removal from the mold. In addition, the incorporation of separately produced components within the cast part is also provided, eliminating post-casting assembly manufacturing steps.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com