Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5620results about "Gloves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

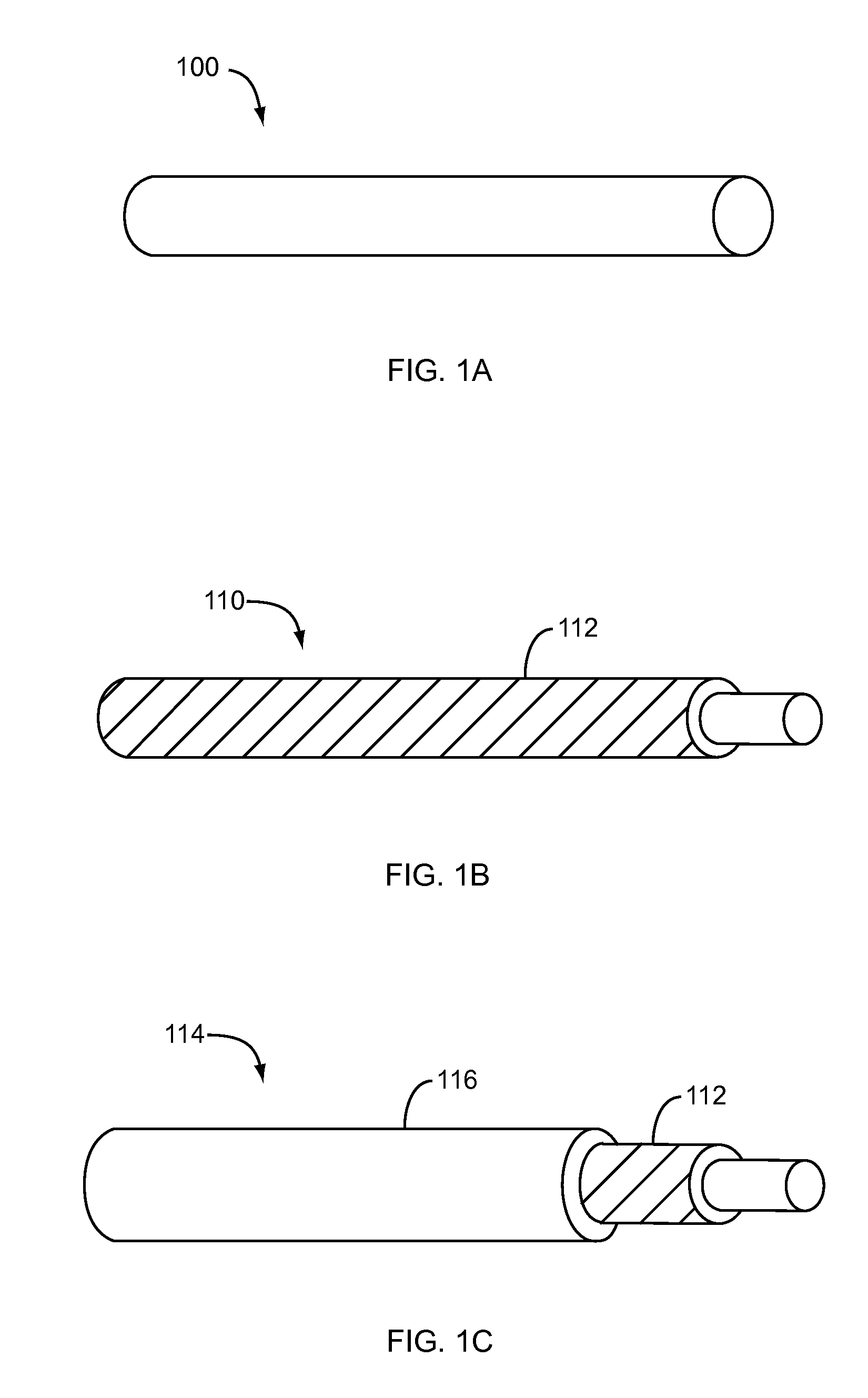

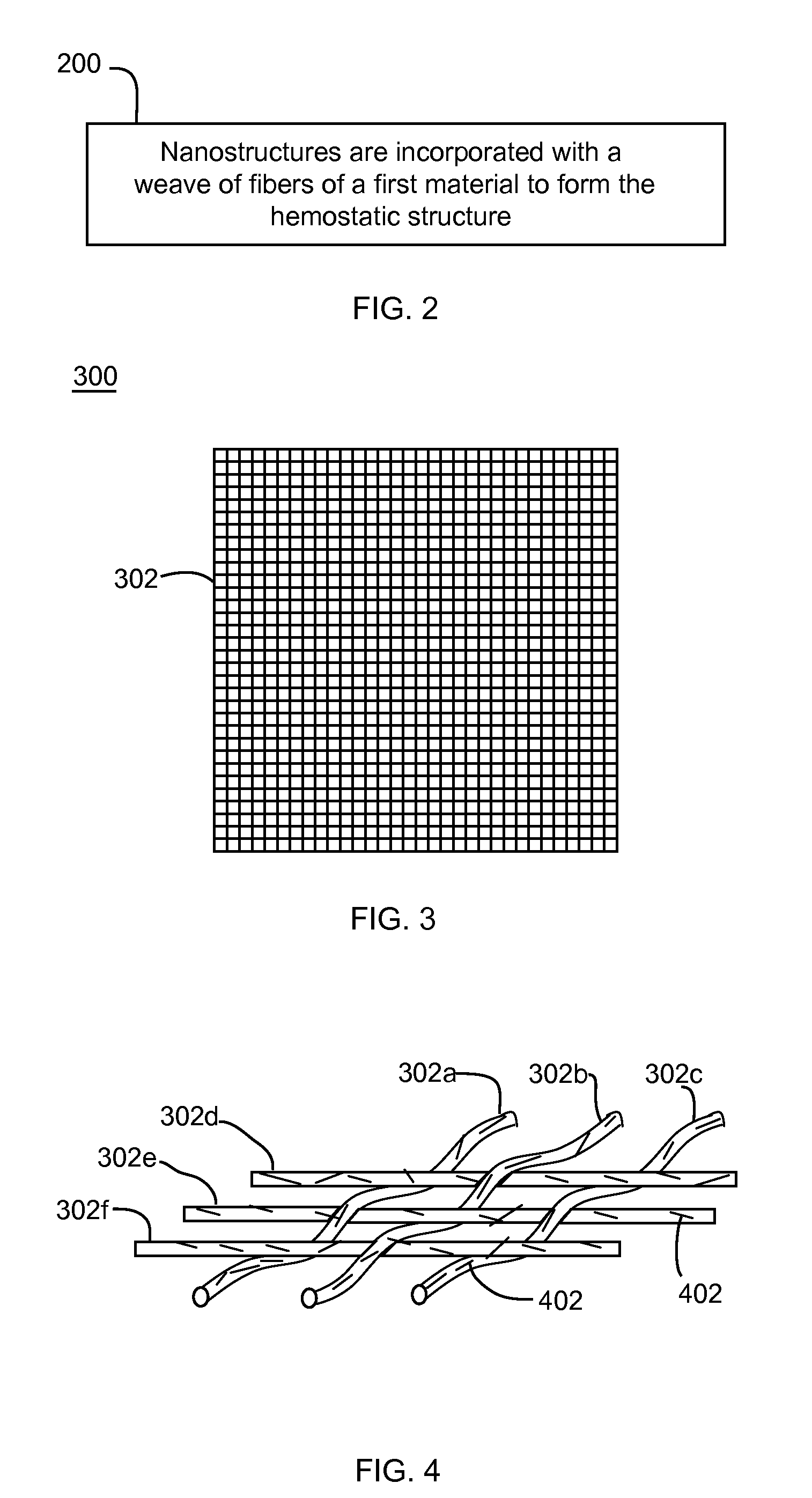

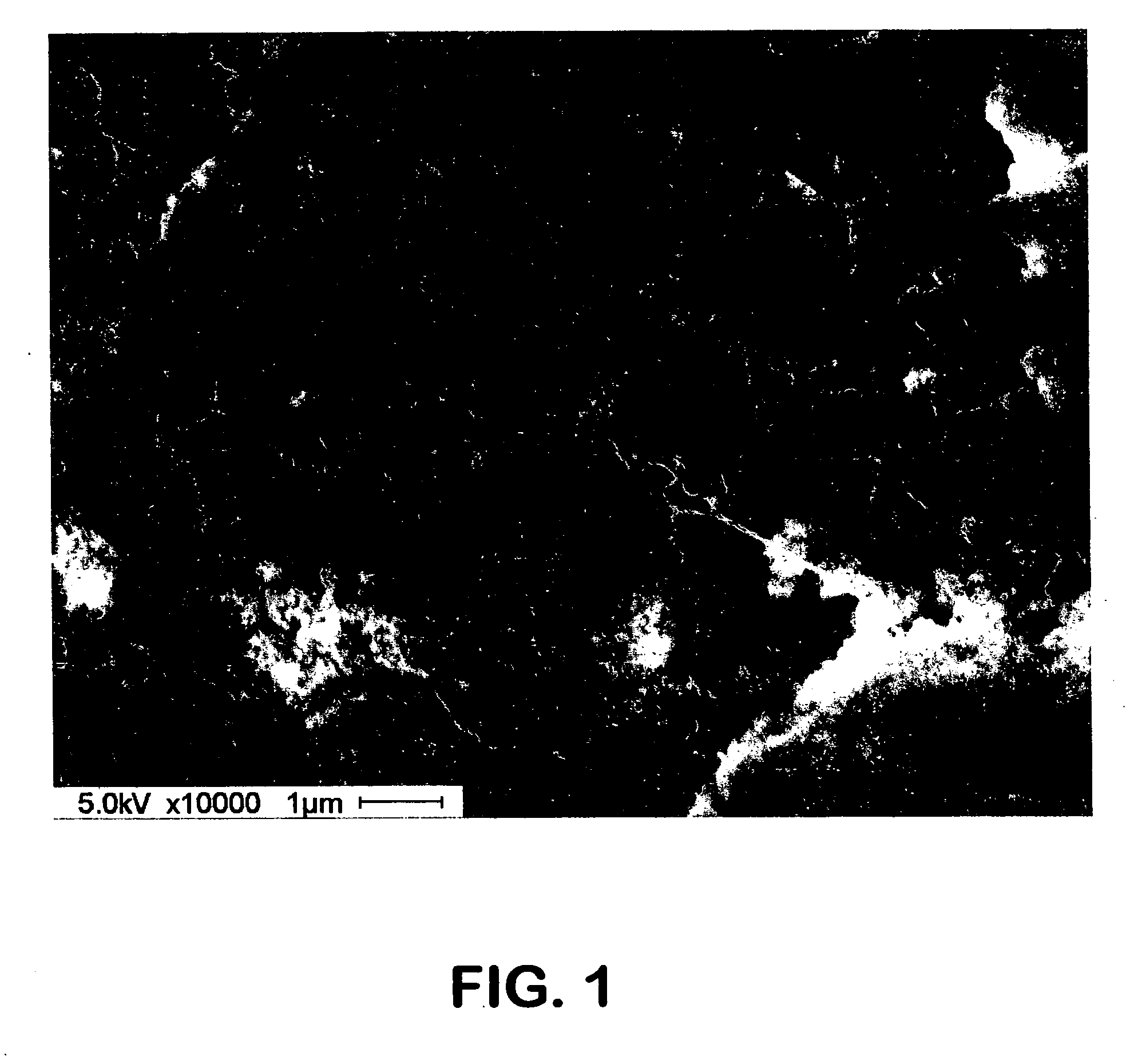

Nanostructure-enhanced platelet binding and hemostatic structures

InactiveUS8319002B2Enhancing overall rate and strengthInduce platelet binding and efficient hemostasisBiocideSurgical adhesivesPlateletNanofiber

Methods, systems, and apparatuses for nanomaterial-enhanced platelet binding and hemostatic medical devices are provided. Hemostatic materials and structures are provided that induce platelet binding, including platelet binding and the coagulation of blood at a wound / opening caused by trauma, a surgical procedure, ulceration, or other cause. Example embodiments include platelet binding devices, hemostatic bandages, hemostatic plugs, and hemostatic formulations. The hemostatic materials and structures may incorporate nanostructures and / or further hemostatic elements such as polymers, silicon nanofibers, silicon dioxide nanofibers, and / or glass beads into a highly absorbent, gelling scaffold. The hemostatic materials and structures may be resorbable.

Owner:NANOSYS INC

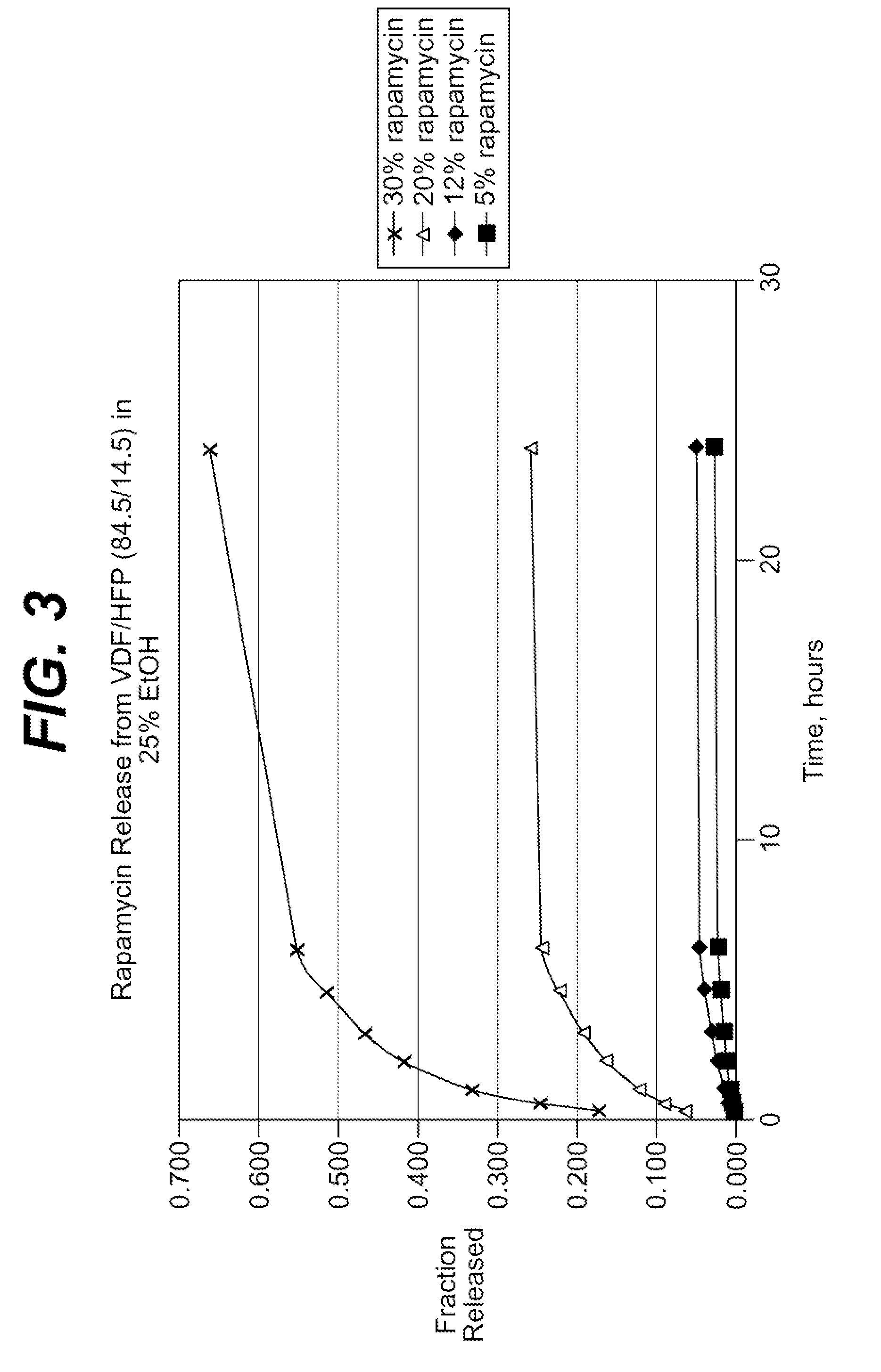

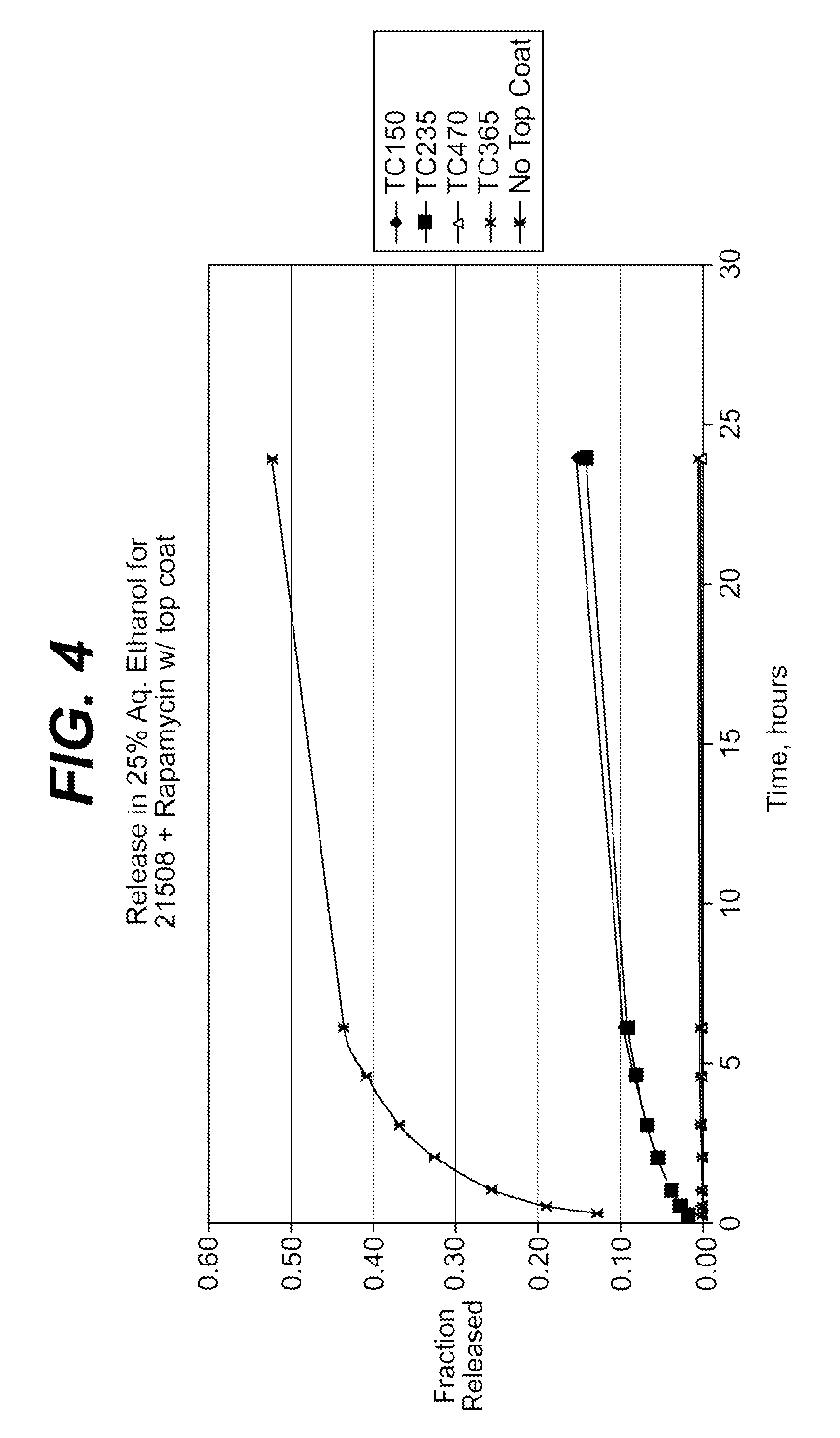

Extraction of solvents from drug containing polymer reservoirs

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

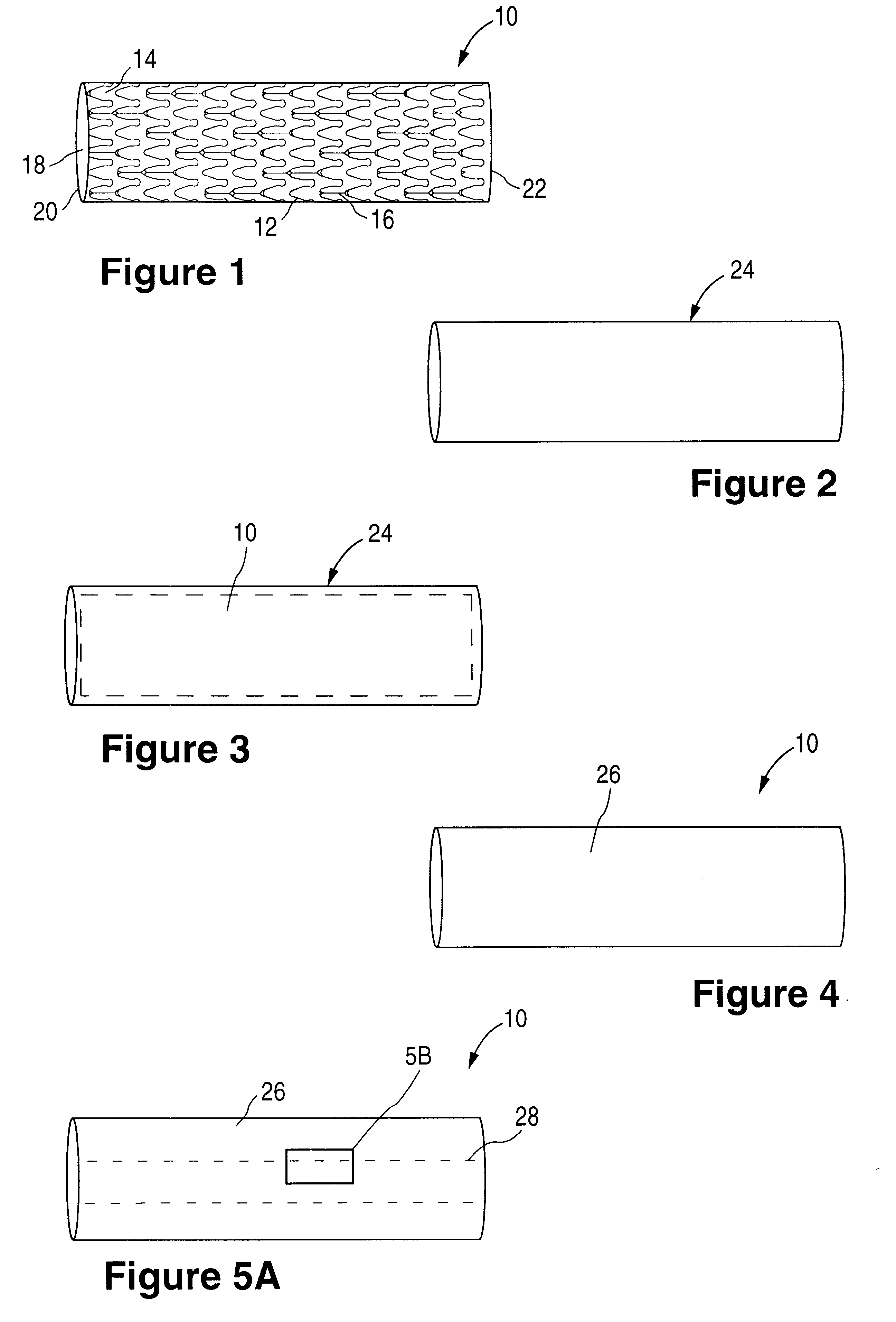

Methods of forming a coating for a prosthesis

InactiveUS6503556B2Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

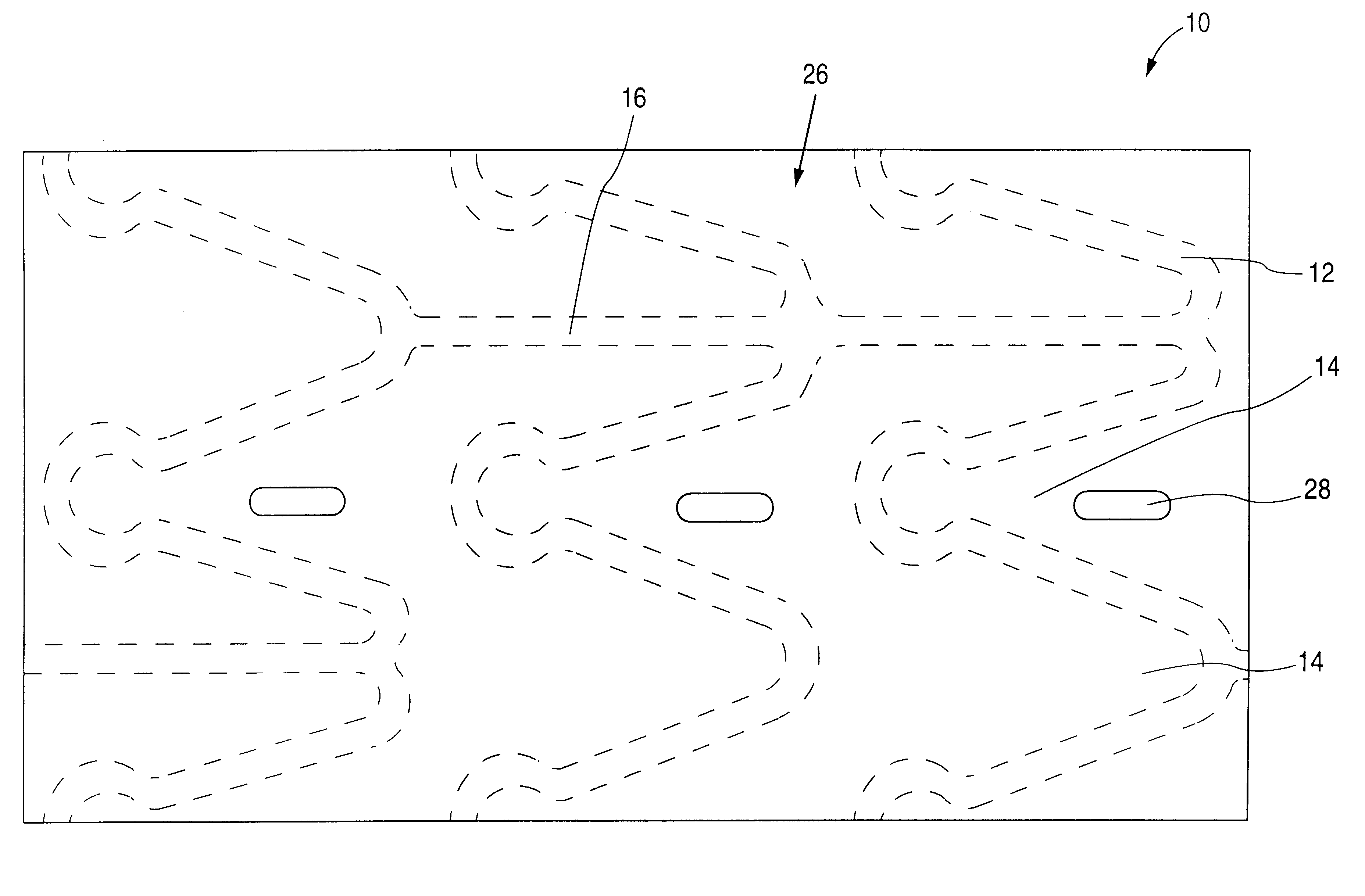

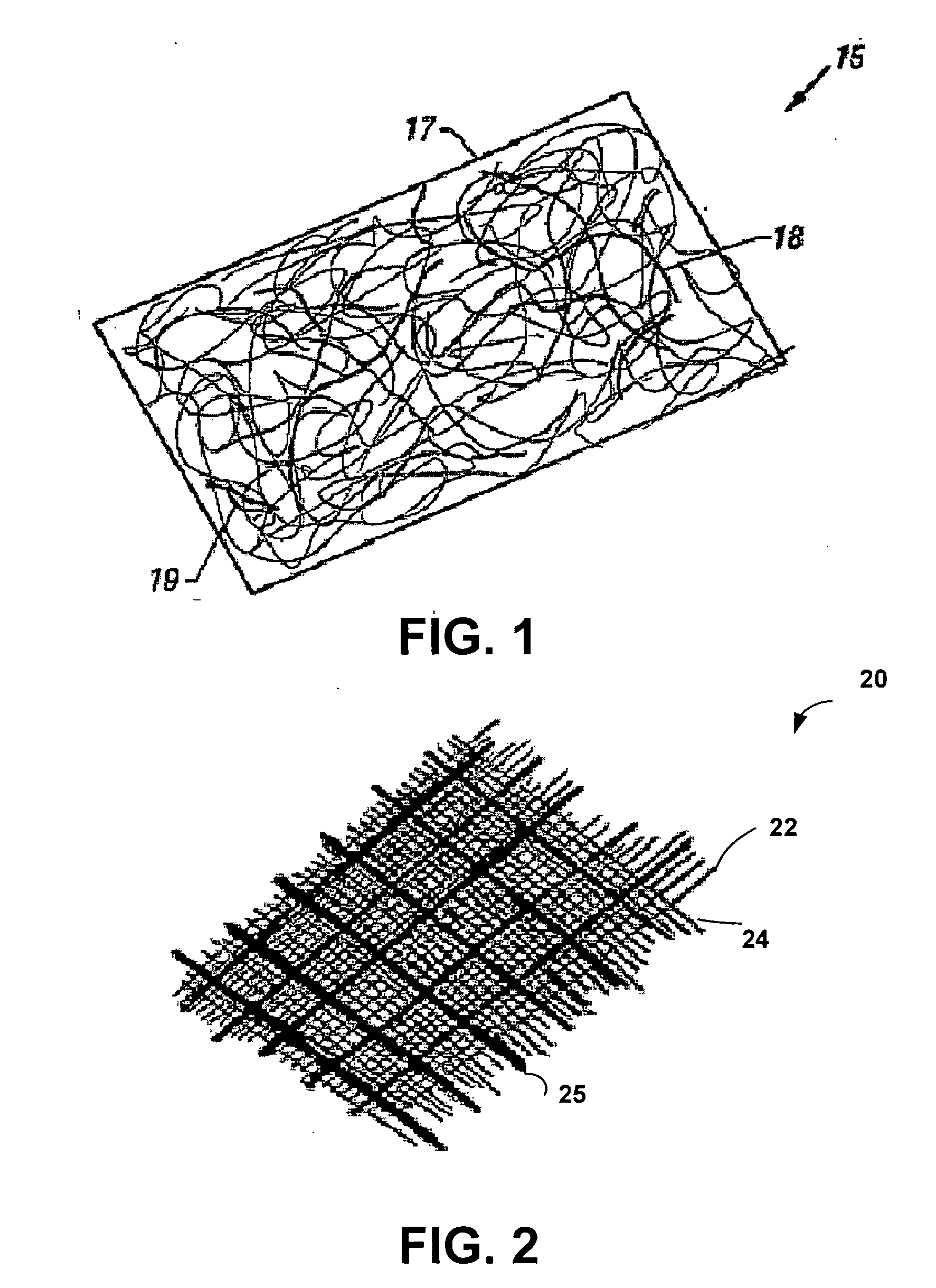

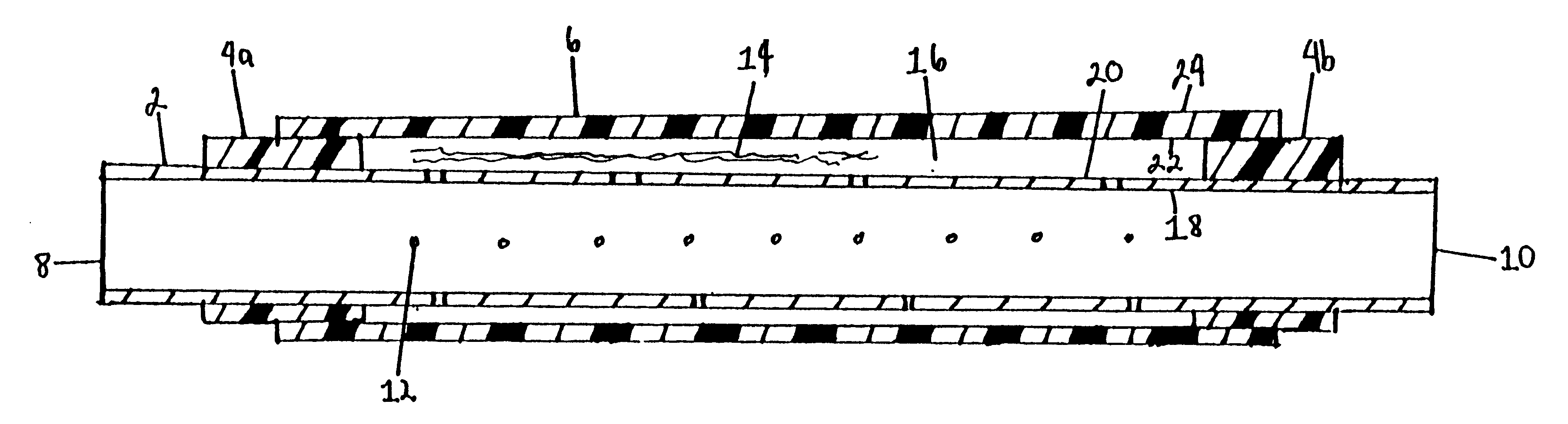

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

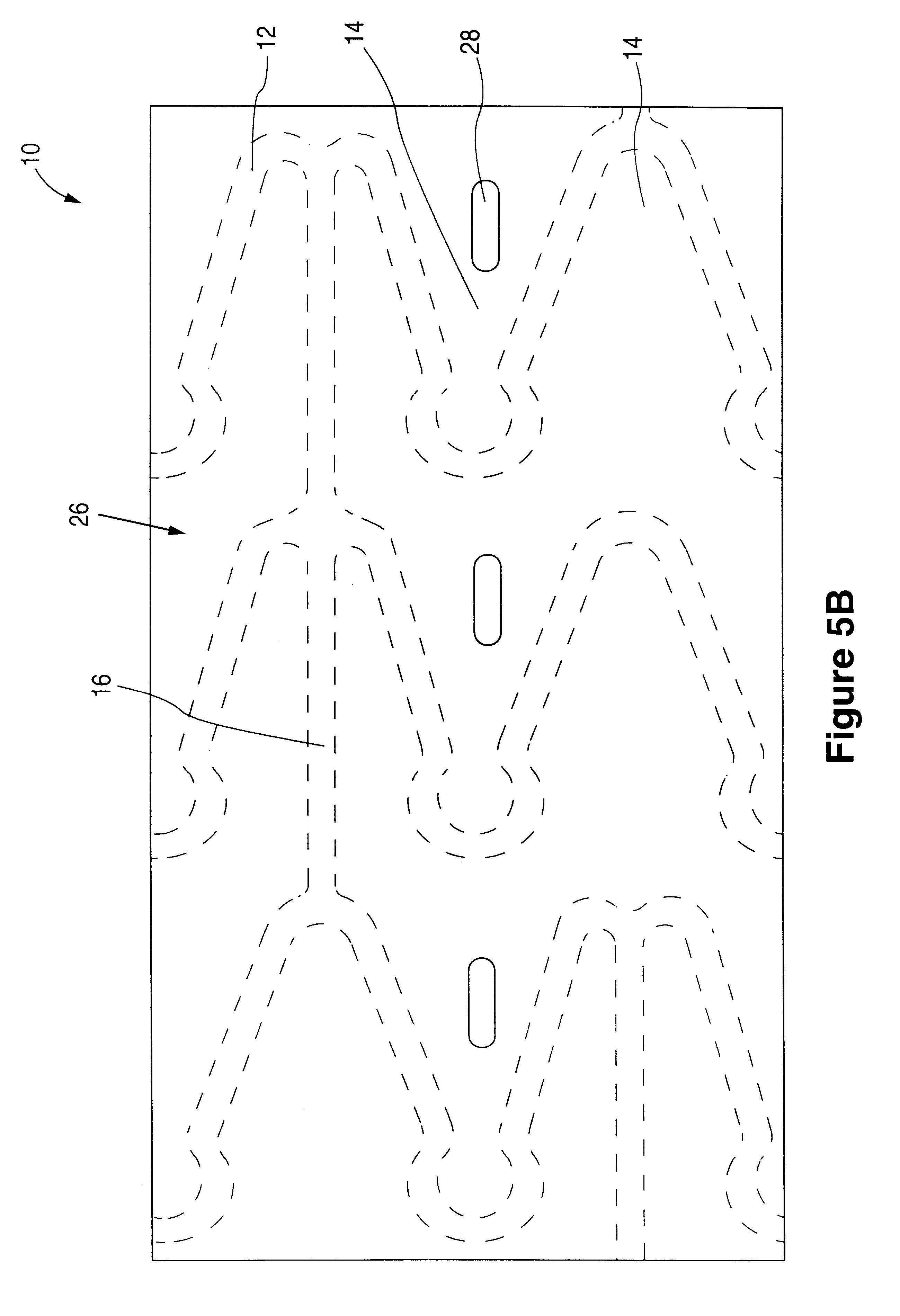

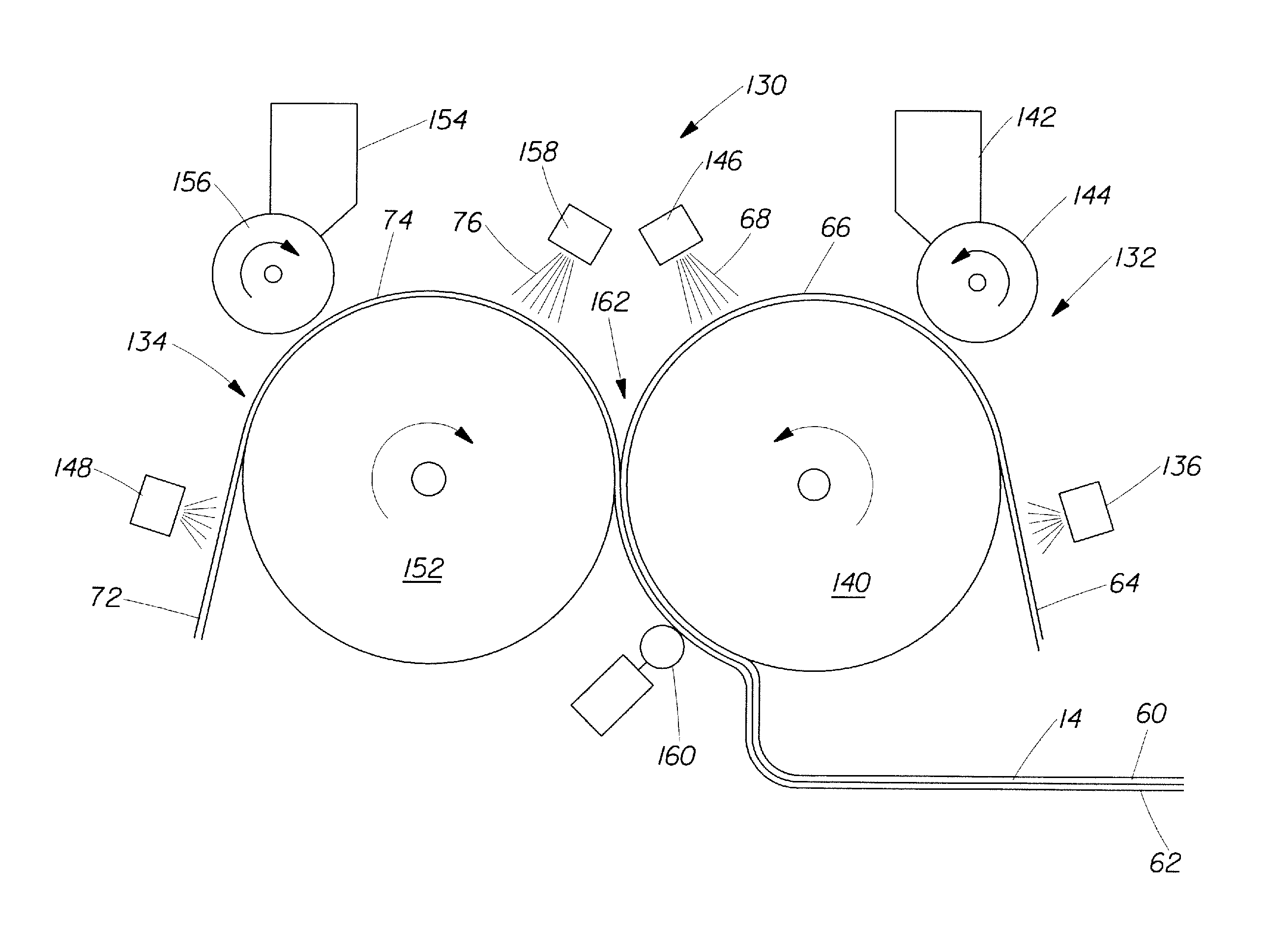

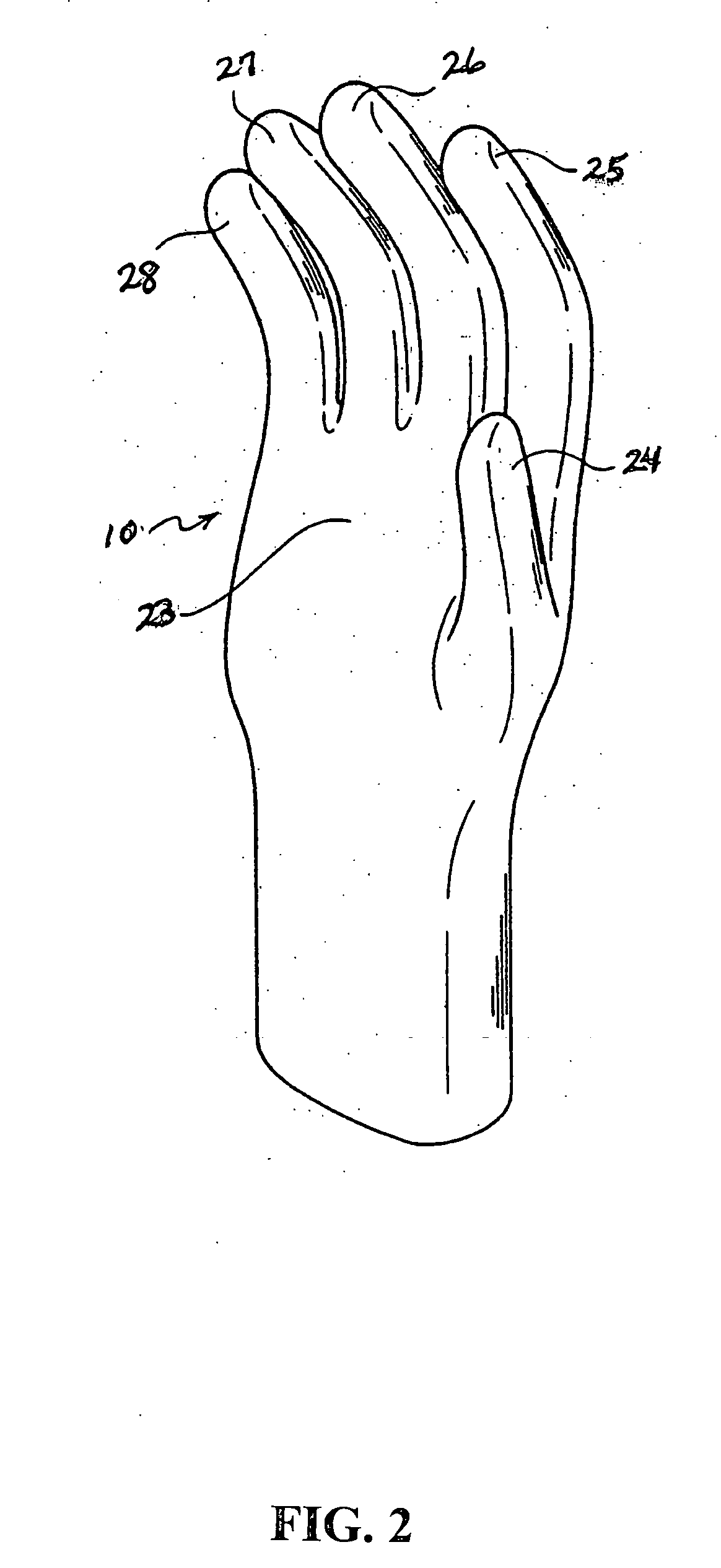

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

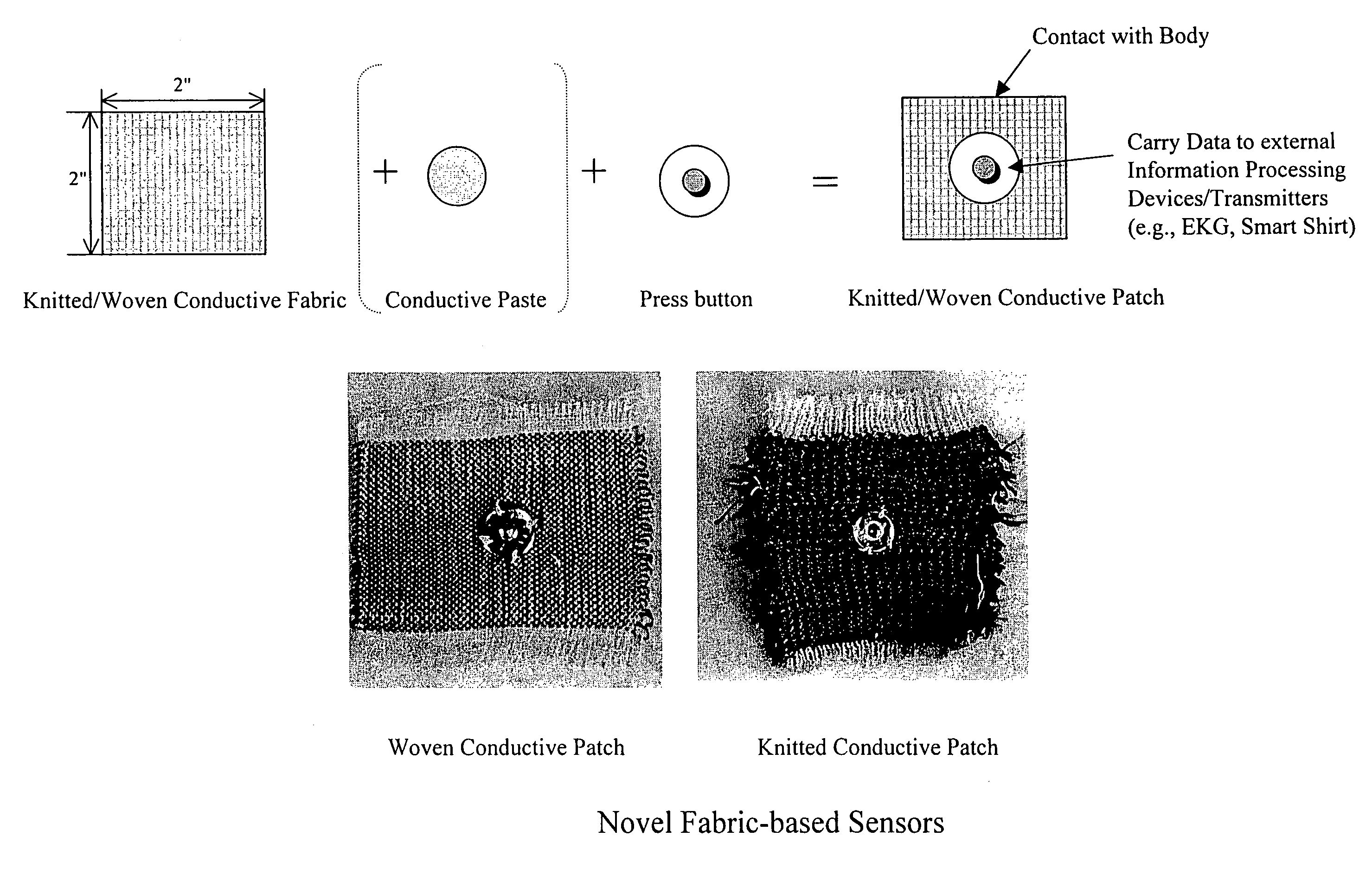

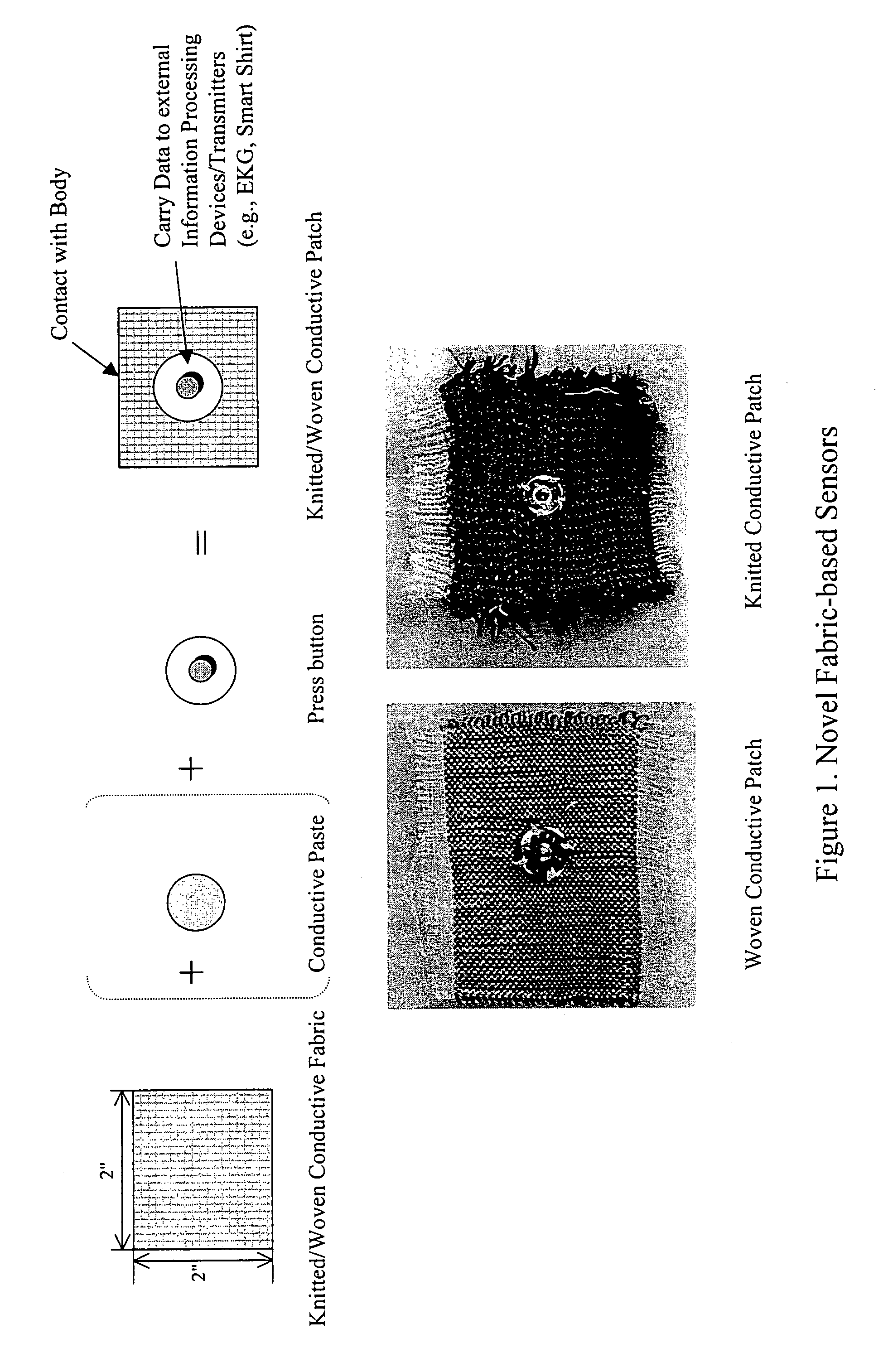

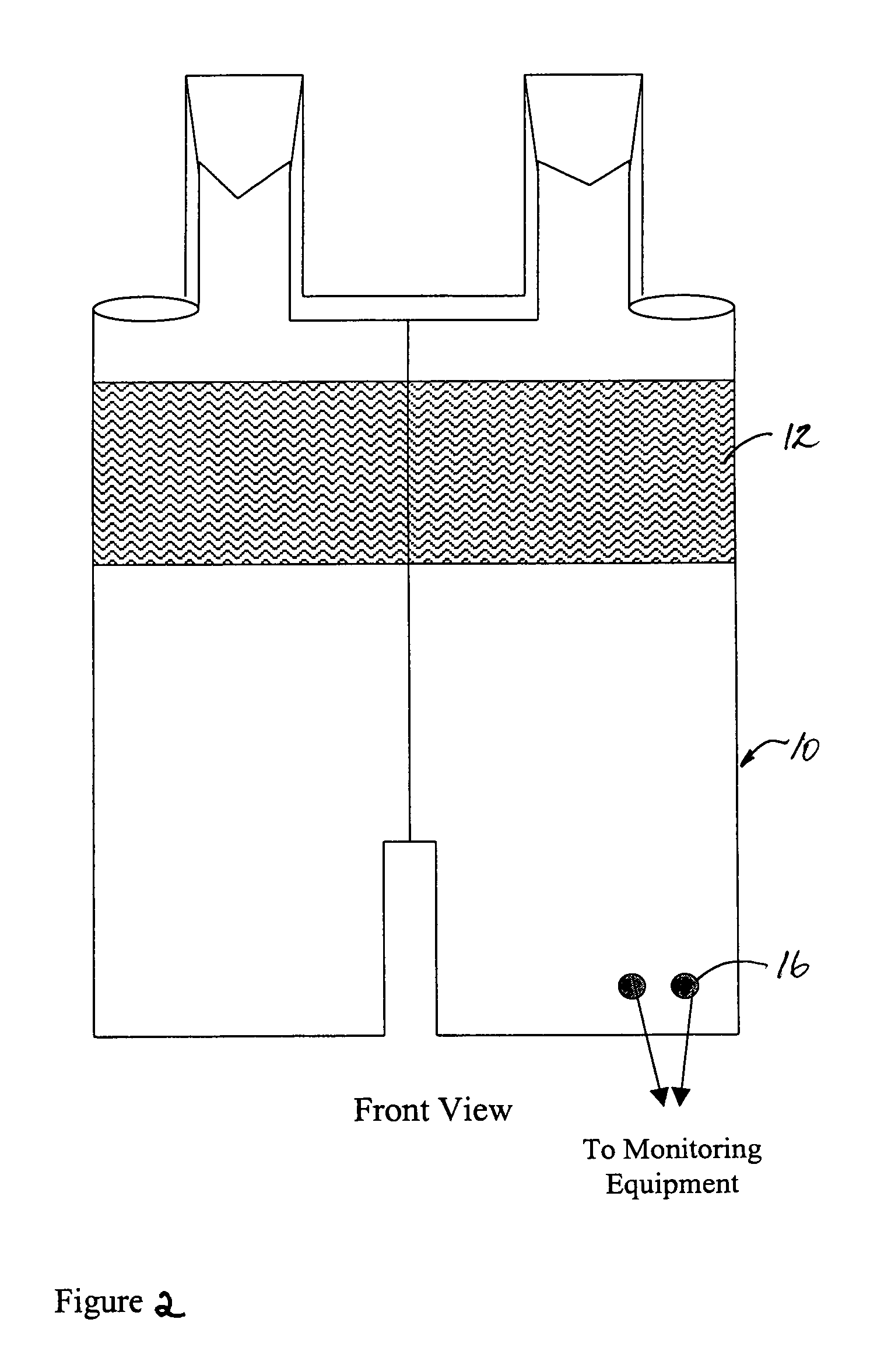

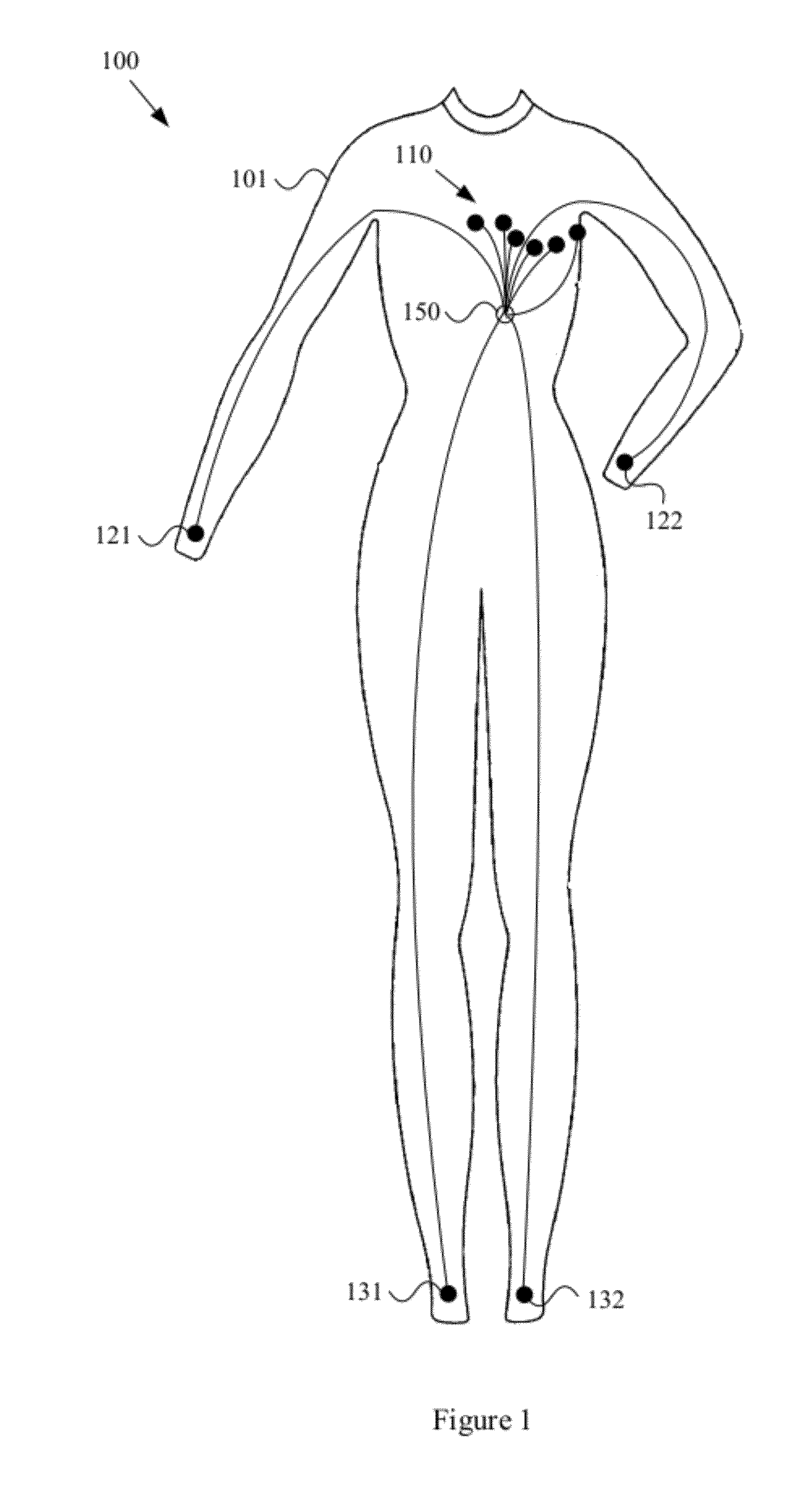

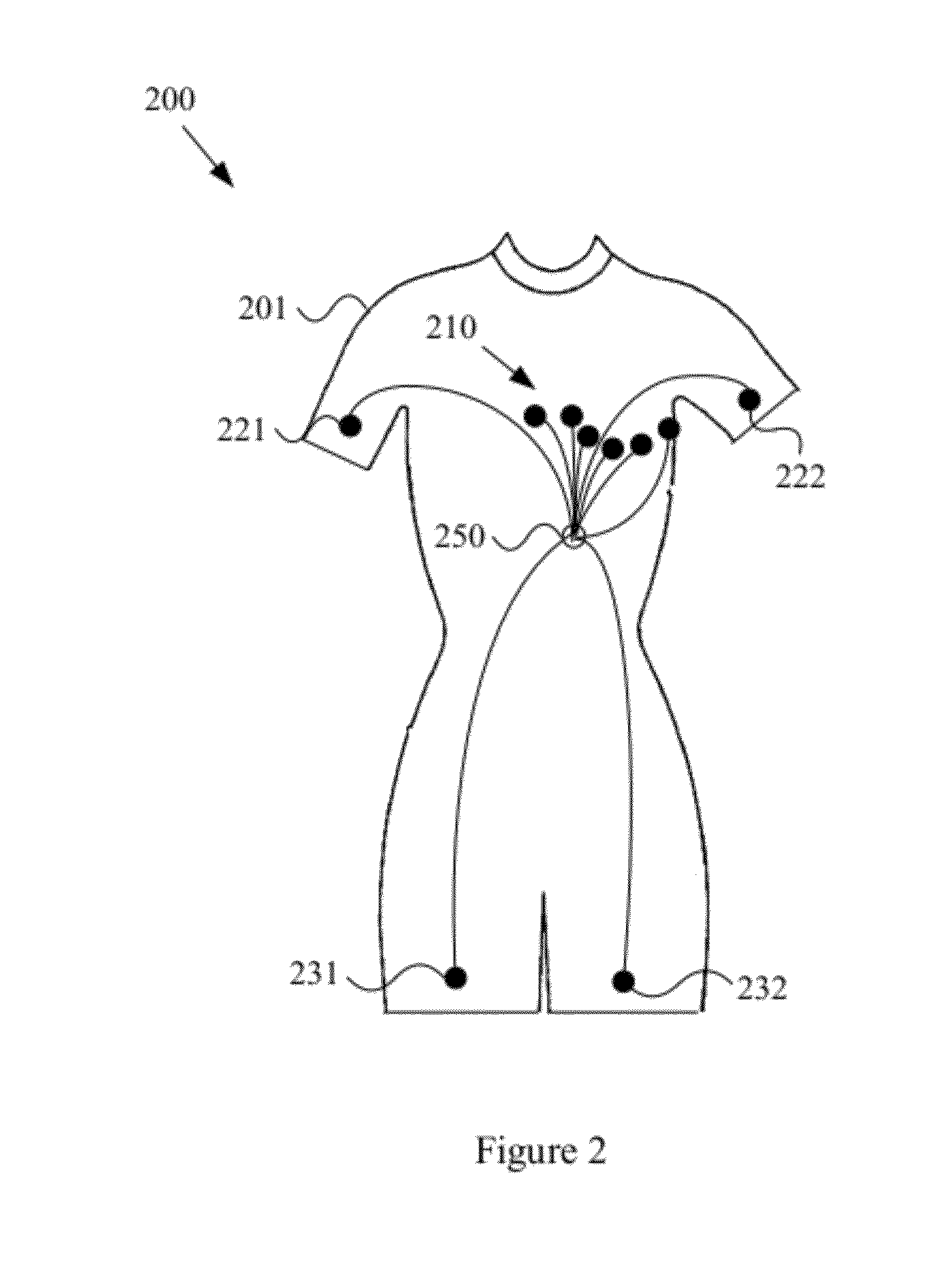

Fabric-based sensor for monitoring vital signs

The present invention comprises a fabric-based sensor for monitoring vital signs or other electrical impulses of a subject. The sensor is woven or knitted from conductive fibers and, when in contact with the body, receives signals from the wearer and transmits them to a processing or monitoring device through a data-output terminal. The sensor may be integrated into the fabric of a garment or used independently as a conductive patch. Additionally, the sensor may provide bi-directional communication by both monitoring electrical impulses and sending them.

Owner:GEORGIA TECH RES CORP

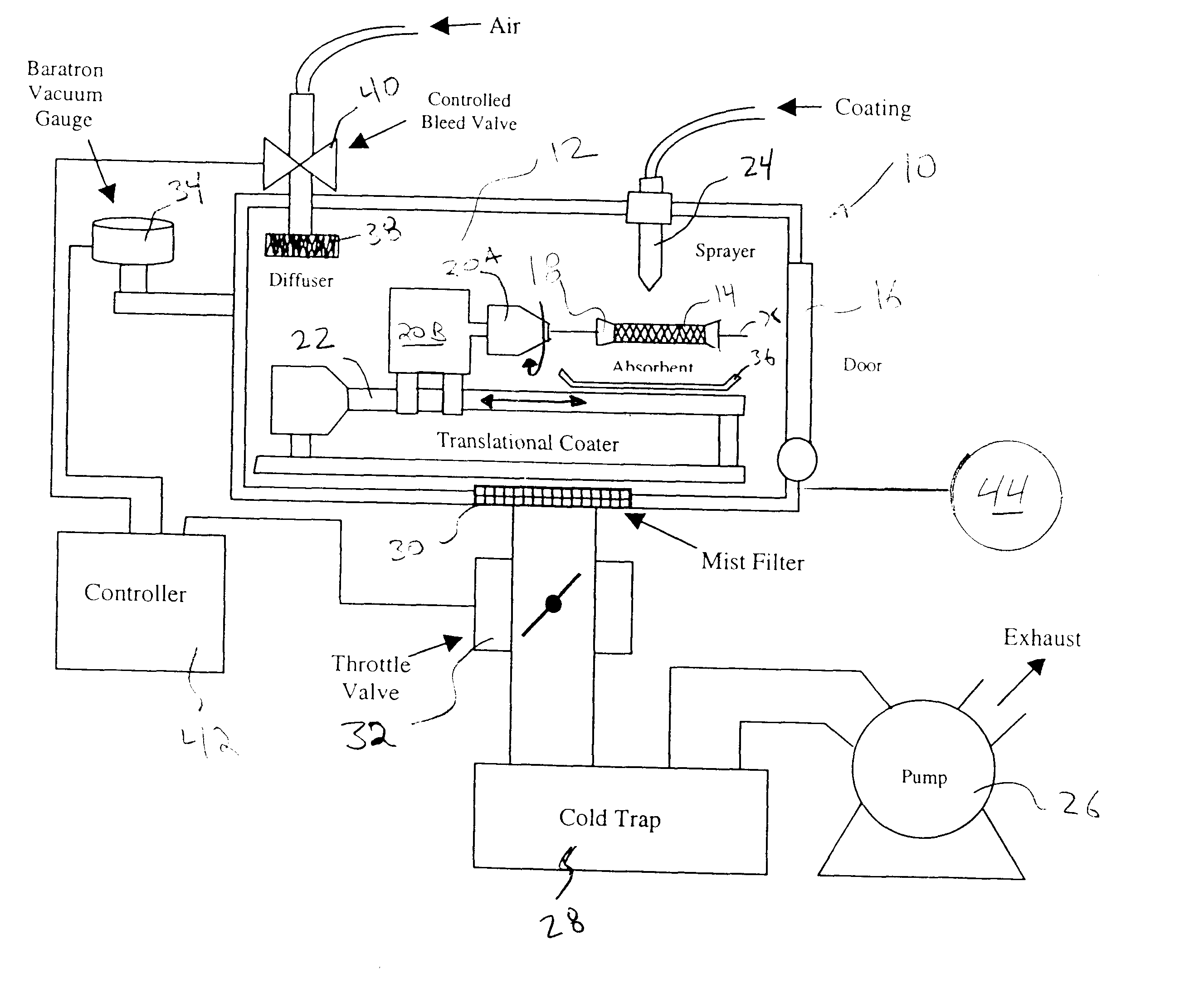

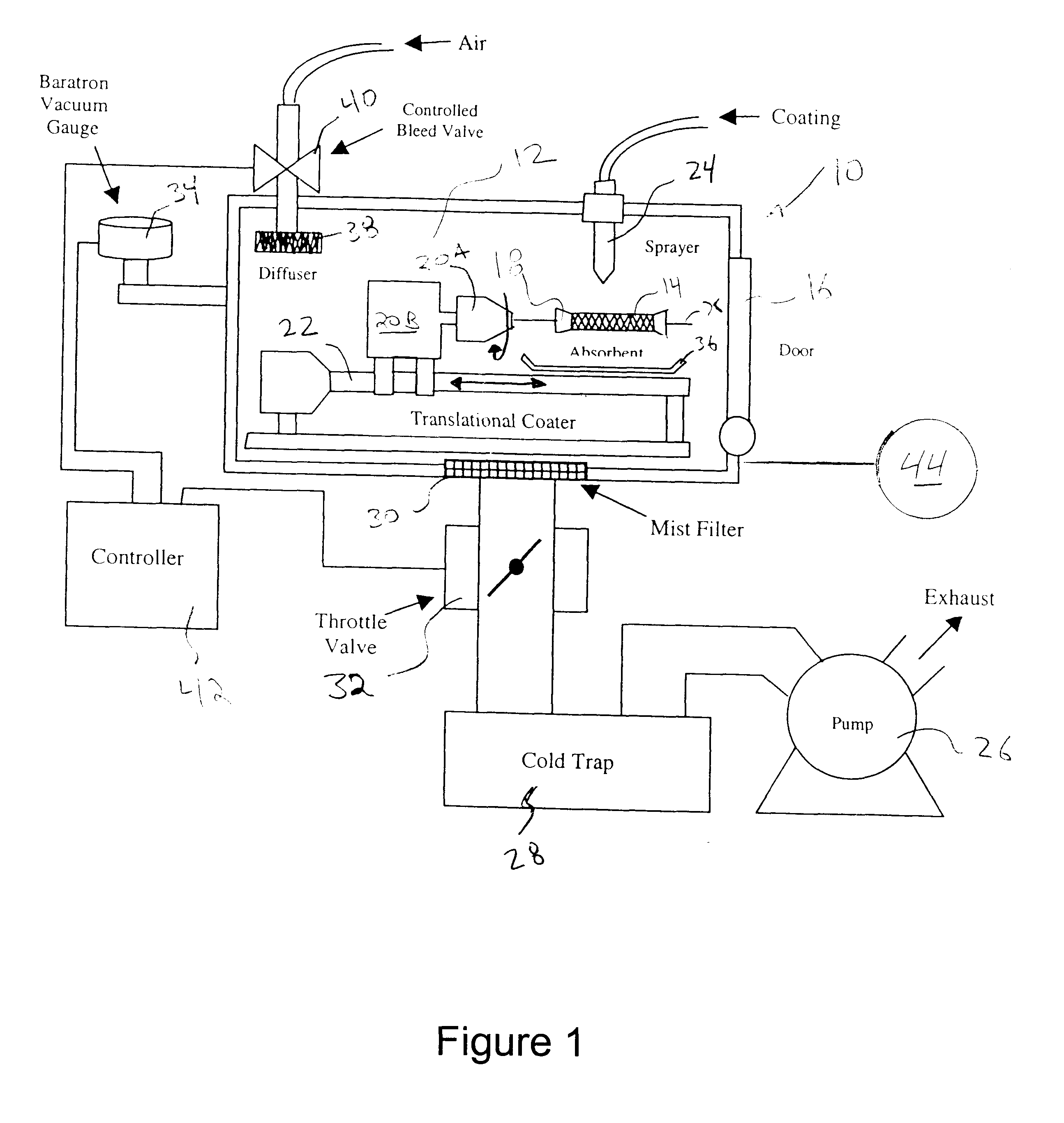

Apparatus and method for coating implantable devices

A method of forming a coating for an implantable medical device, such as a stent, is provided which includes applying a composition to the device in an environment having a selected pressure. An apparatus is also provided for coating the devices. The apparatus comprises a chamber for housing the device wherein the pressure of the chamber can be adjusted during the coating process.

Owner:ABBOTT CARDIOVASCULAR

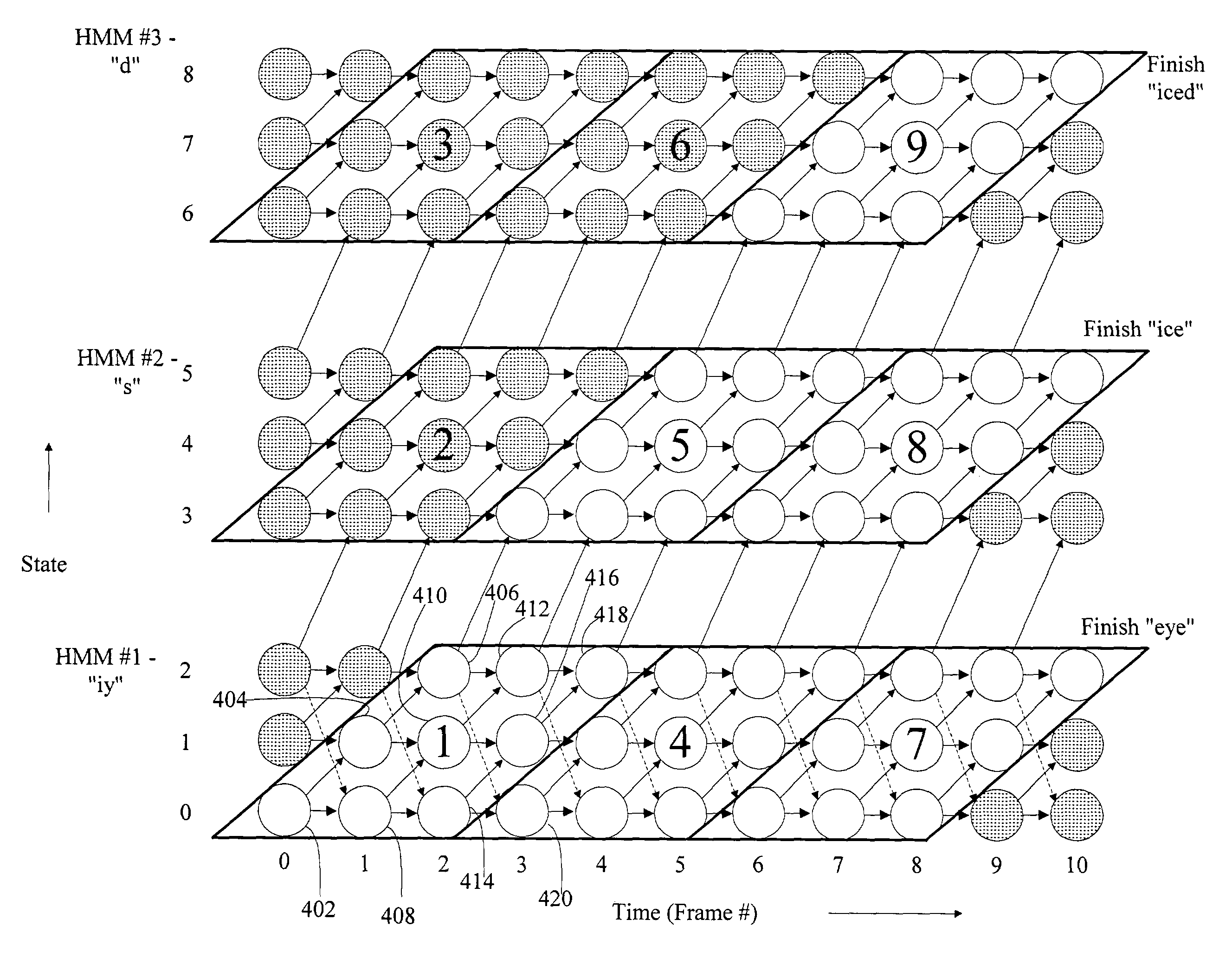

Block synchronous decoding

InactiveUS7529671B2Improved pattern recognition speedImprove cache localityKitchenware cleanersGlovesHide markov modelCache locality

A pattern recognition system and method are provided. Aspects of the invention are particularly useful in combination with multi-state Hidden Markov Models. Pattern recognition is effected by processing Hidden Markov Model Blocks. This block-processing allows the processor to perform more operations upon data while such data is in cache memory. By so increasing cache locality, aspects of the invention provide significantly improved pattern recognition speed.

Owner:MICROSOFT TECH LICENSING LLC

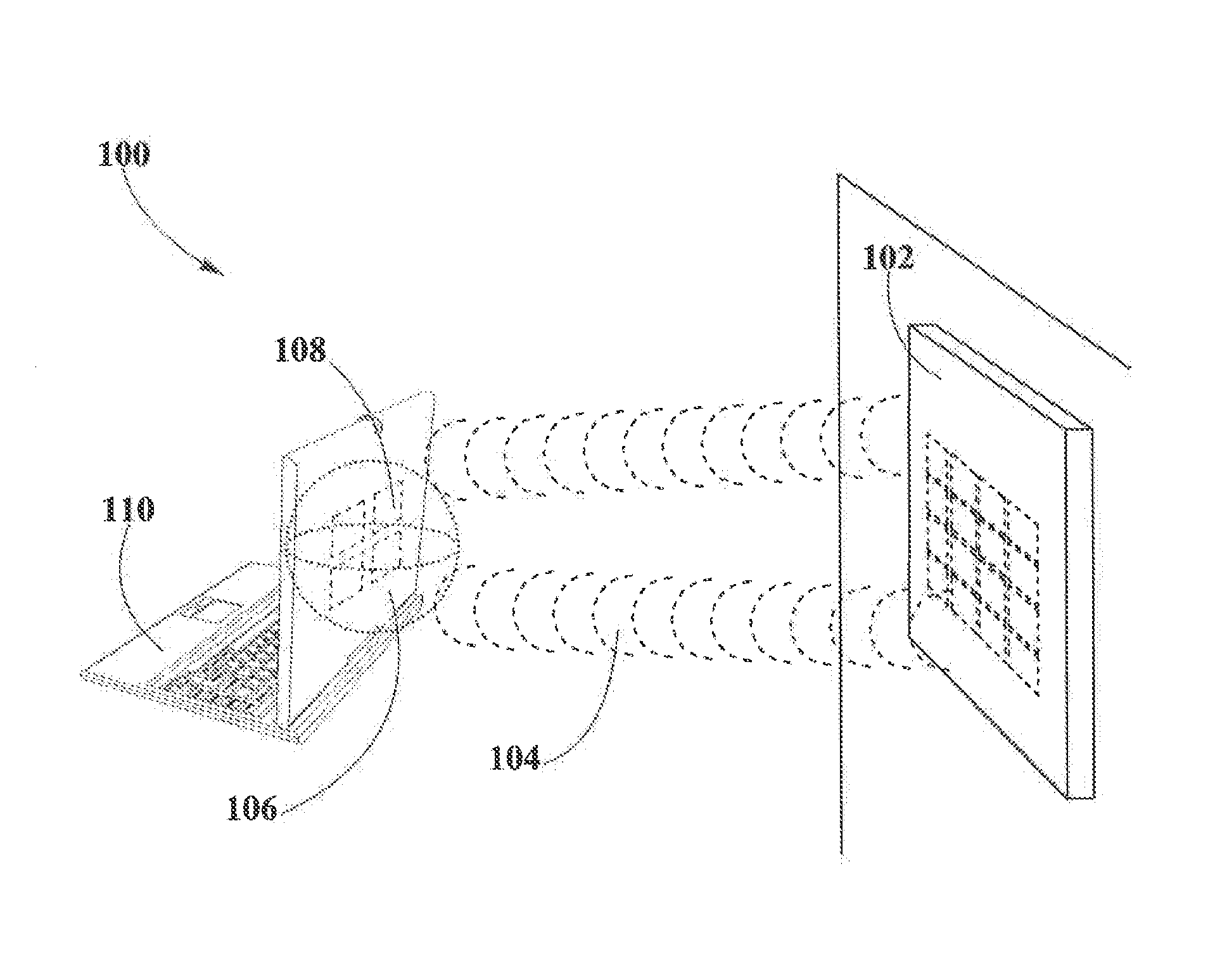

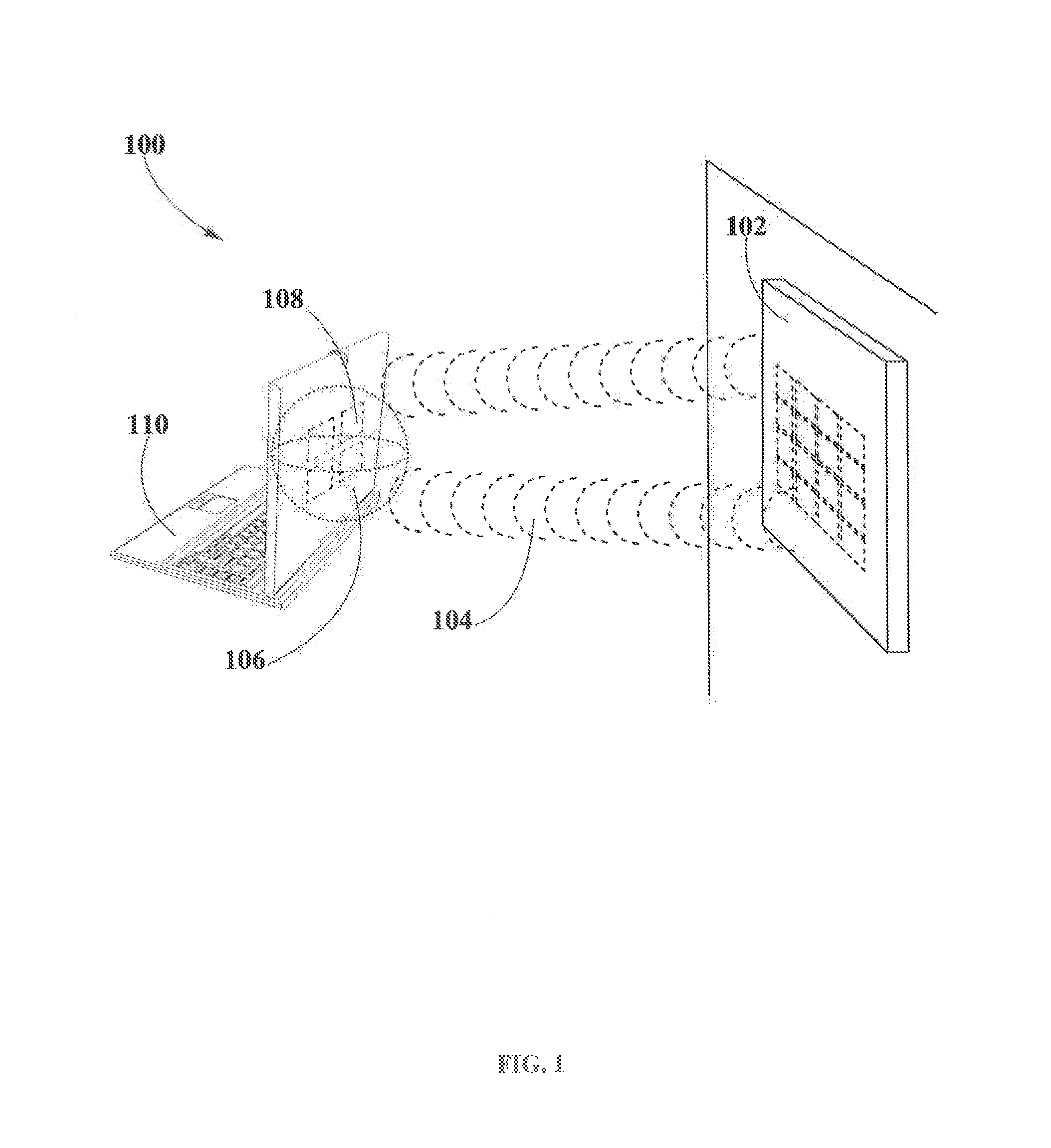

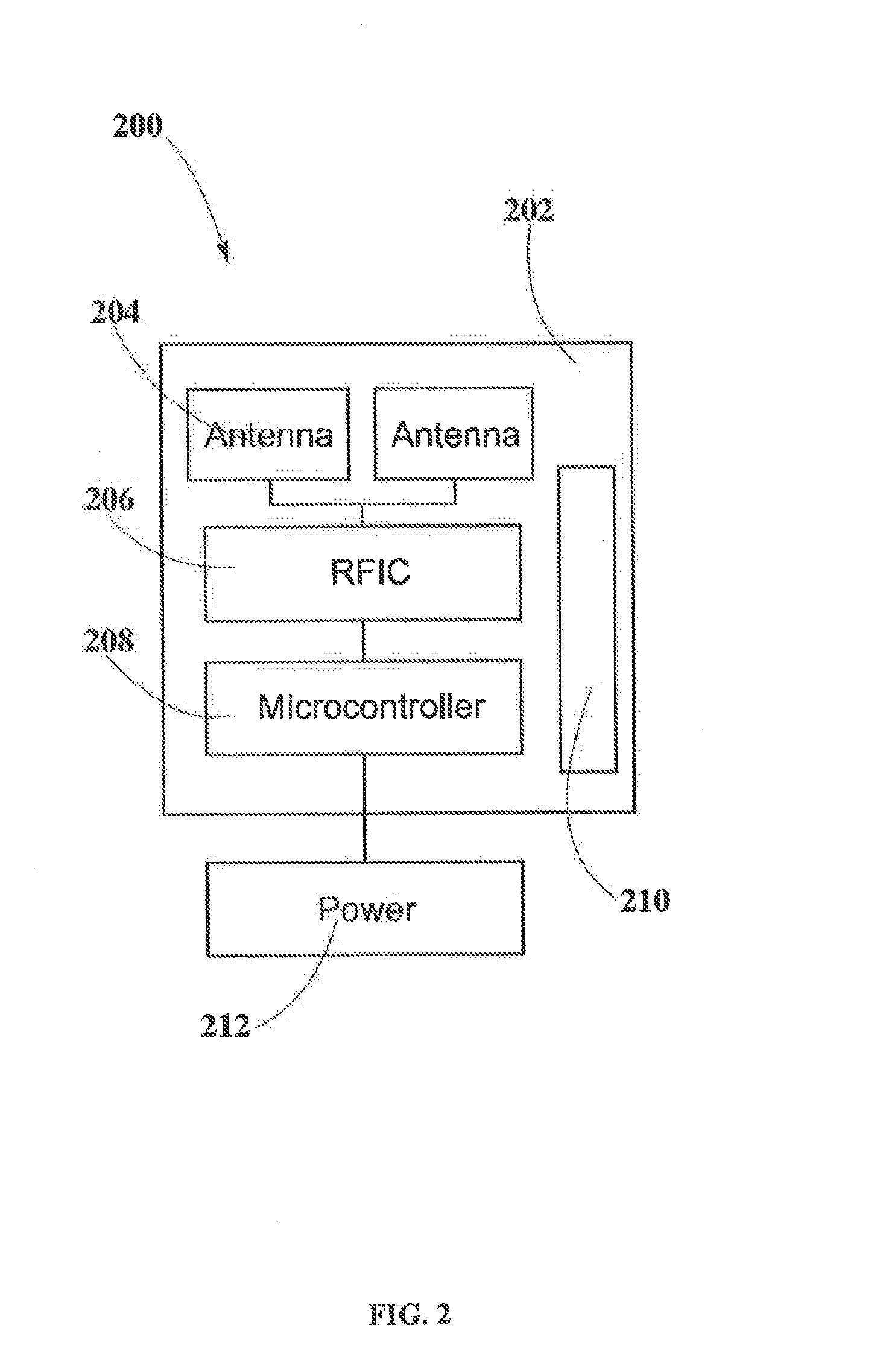

Wireless charging of clothing and smart fabrics

InactiveUS20150162751A1Improve experienceImprove user experienceInsolesGlovesElectric power transmissionElectricity

The present disclosure may provide various electric receiver arrangements included in clothing pieces that require electric current to perform tasks, such as warming, cooling and displaying. Suitable wireless power transmission techniques, like pocket forming, may be used to provide the clothing pieces with wireless power. In some embodiments, receivers may include at least one antenna connected to at least one rectifier and one power converter. In other embodiments, receivers including a plurality of antennas, a plurality of rectifiers or a plurality of power converters may be provided. In addition, receivers may include communications components which may allow for communication to various electronic equipment including transmitters.

Owner:ENERGOUS CORPORATION

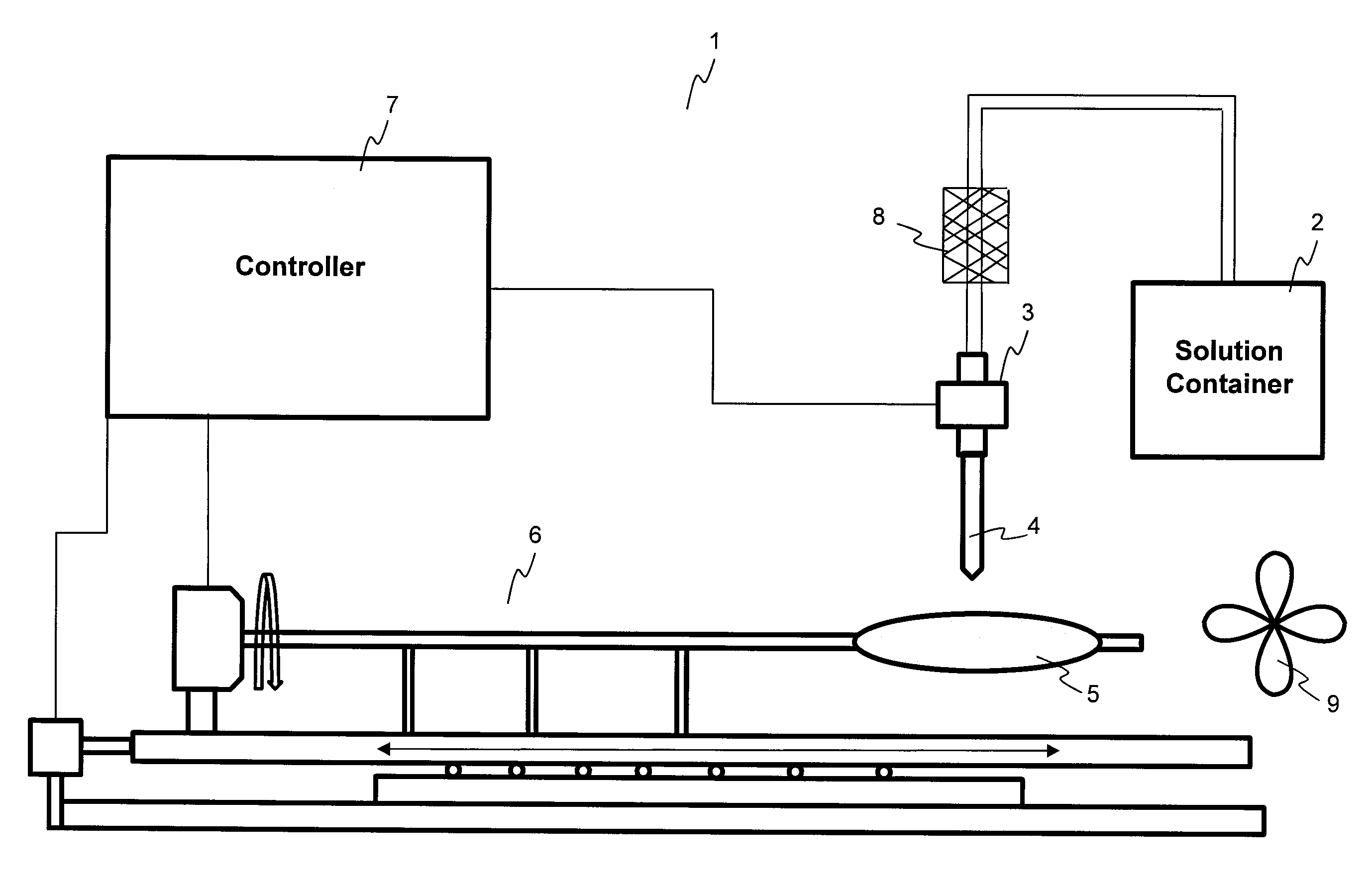

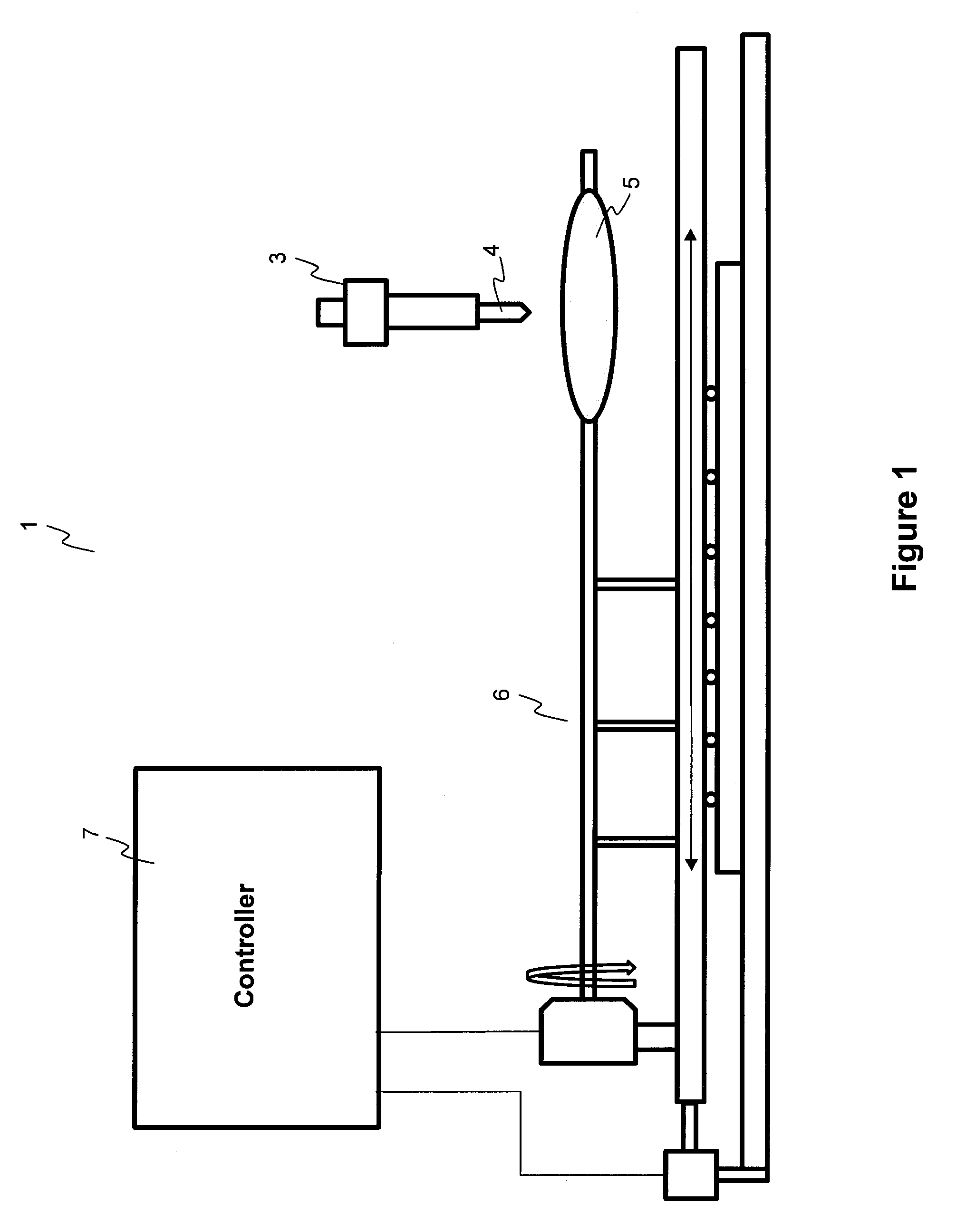

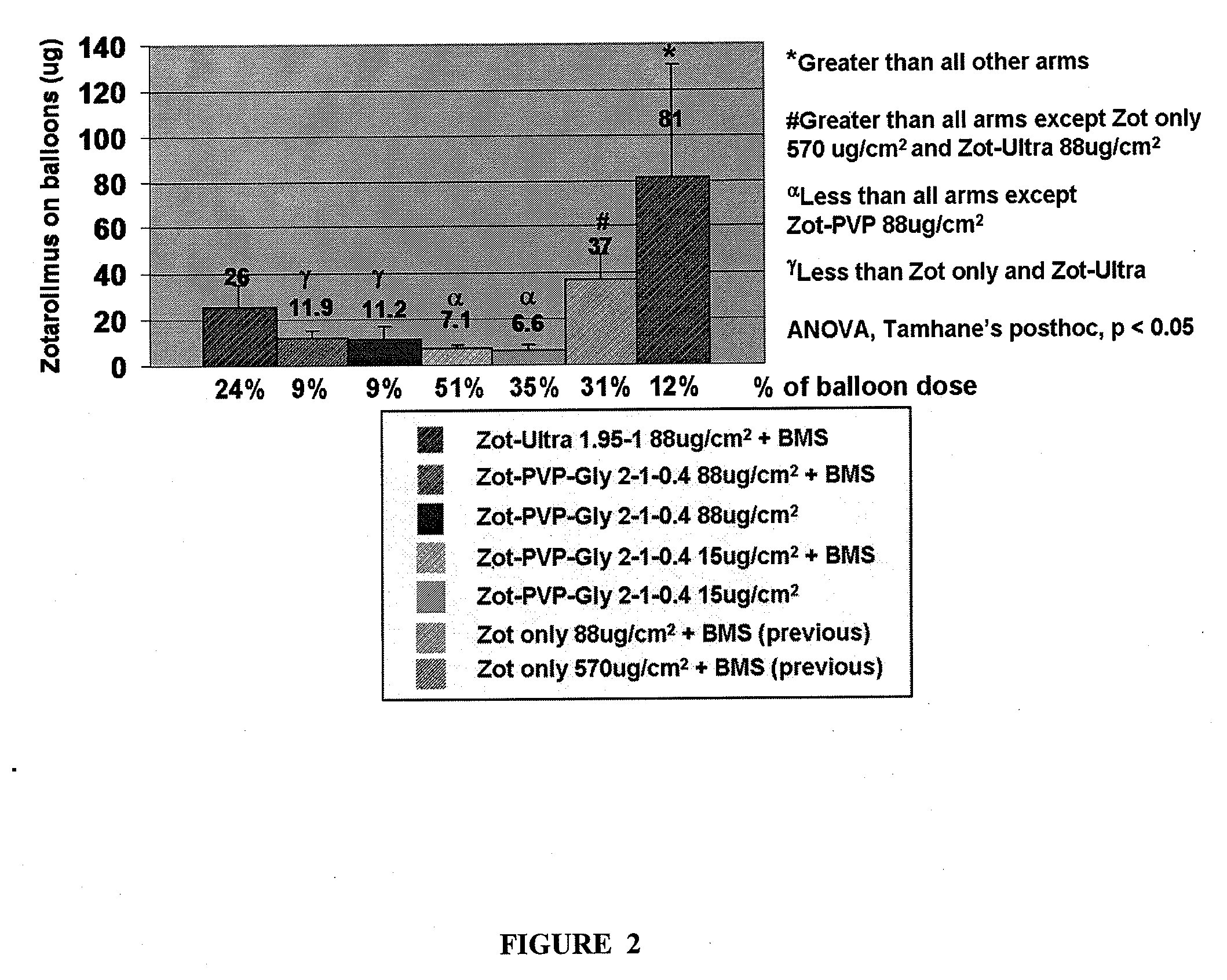

Methods and apparatuses for coating balloon catheters

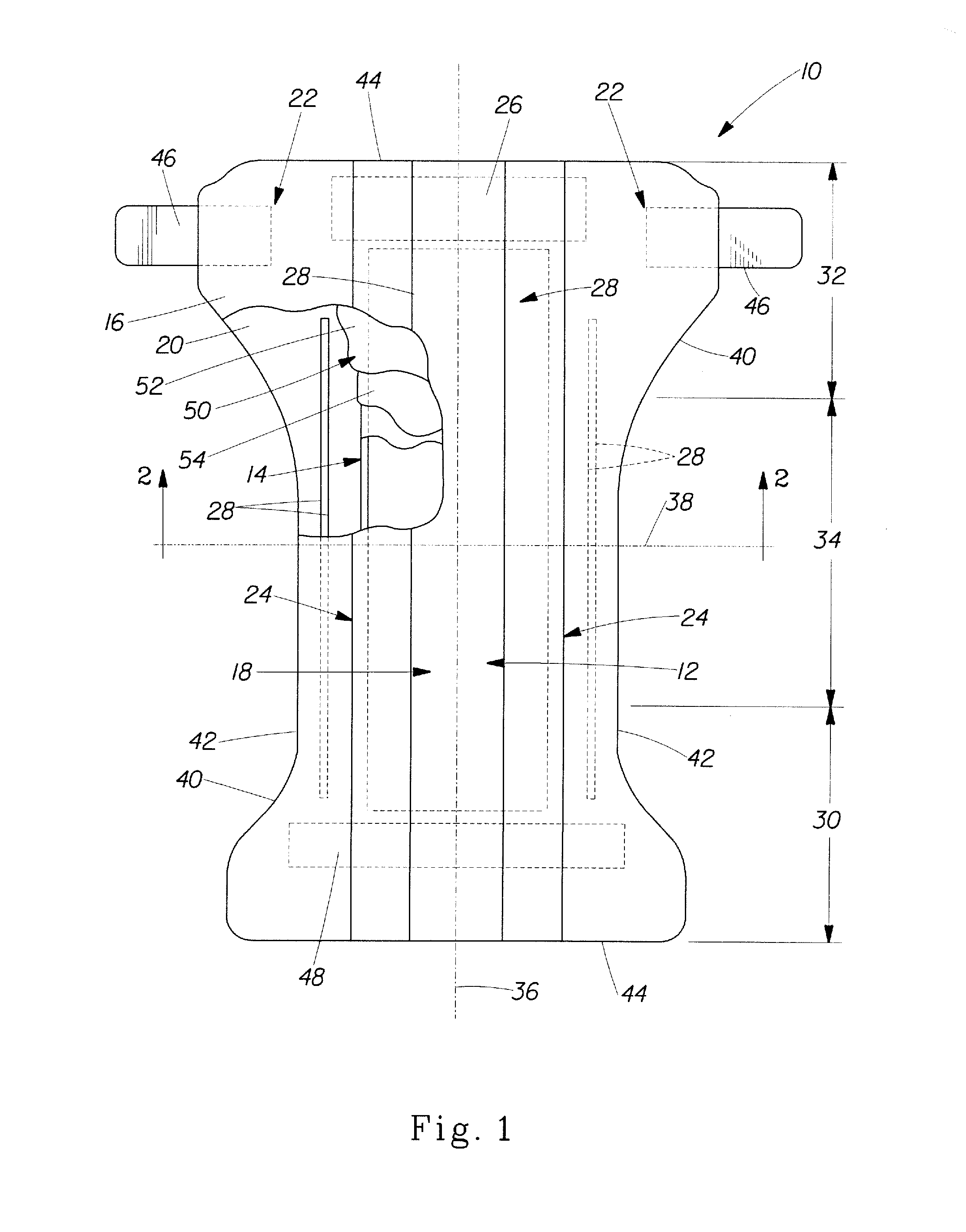

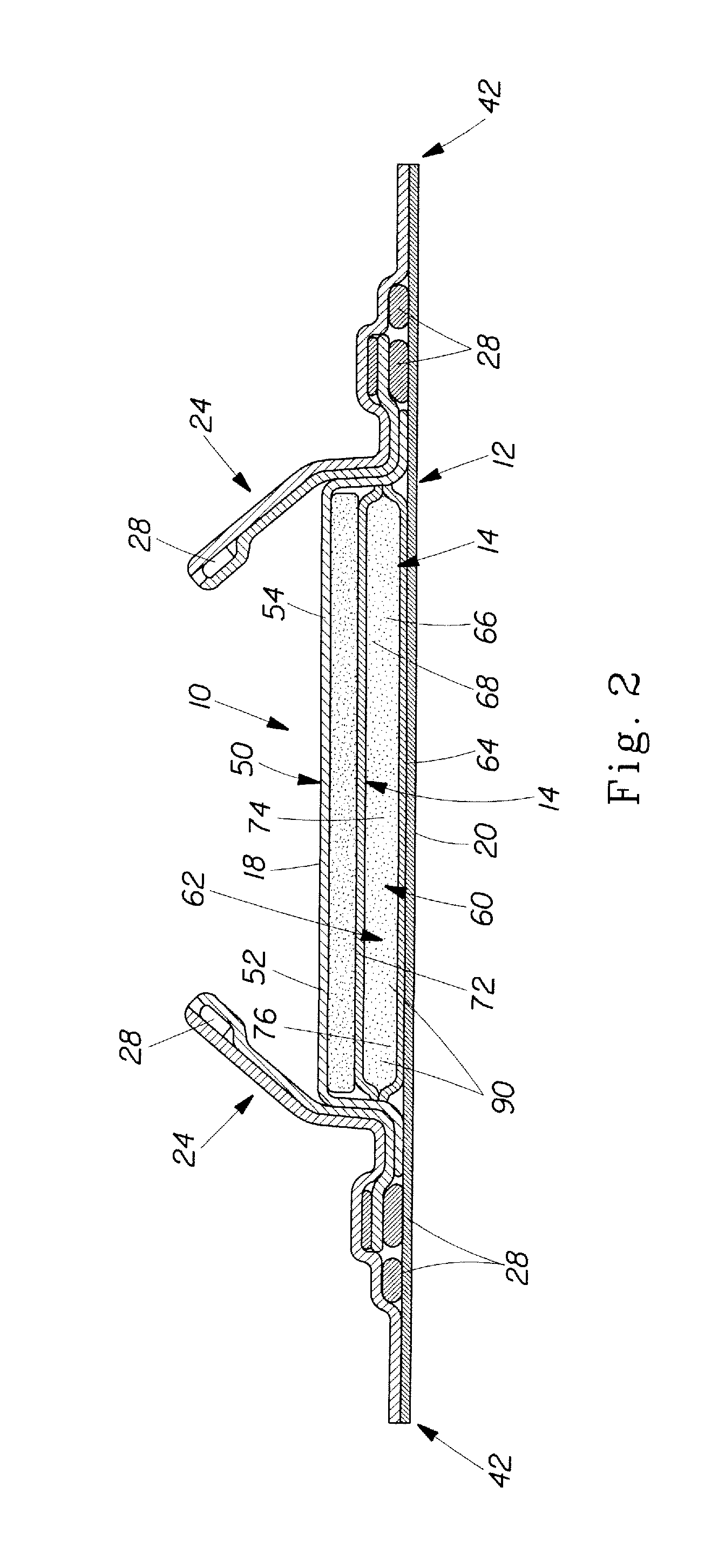

ActiveUS20100055294A1Destroy surface tensionUniform coatingBalloon catheterGlovesTransverse axisSolvent

Embodiments of the invention relate to a method and apparatus for coating a medical device. In one embodiment, the method for preparing a substantially uniform coated medical device includes (1) preparing a coating solution comprising a solvent, a therapeutic agent, and an additive; (2) loading a metering dispenser with the coating solution; (3) rotating the medical device about the longitudinal axis of the device and / or moving the medical device along the longitudinal or transverse axis of the device; (4) dispensing the coating solution from the metering dispenser onto a surface of the medical device and flowing the coating solution on the surface of the medical device while the medical device is rotating and / or linearly moving; and (5) evaporating the solvent, forming a substantially uniform coating layer on the medical device.

Owner:LUTONIX INC

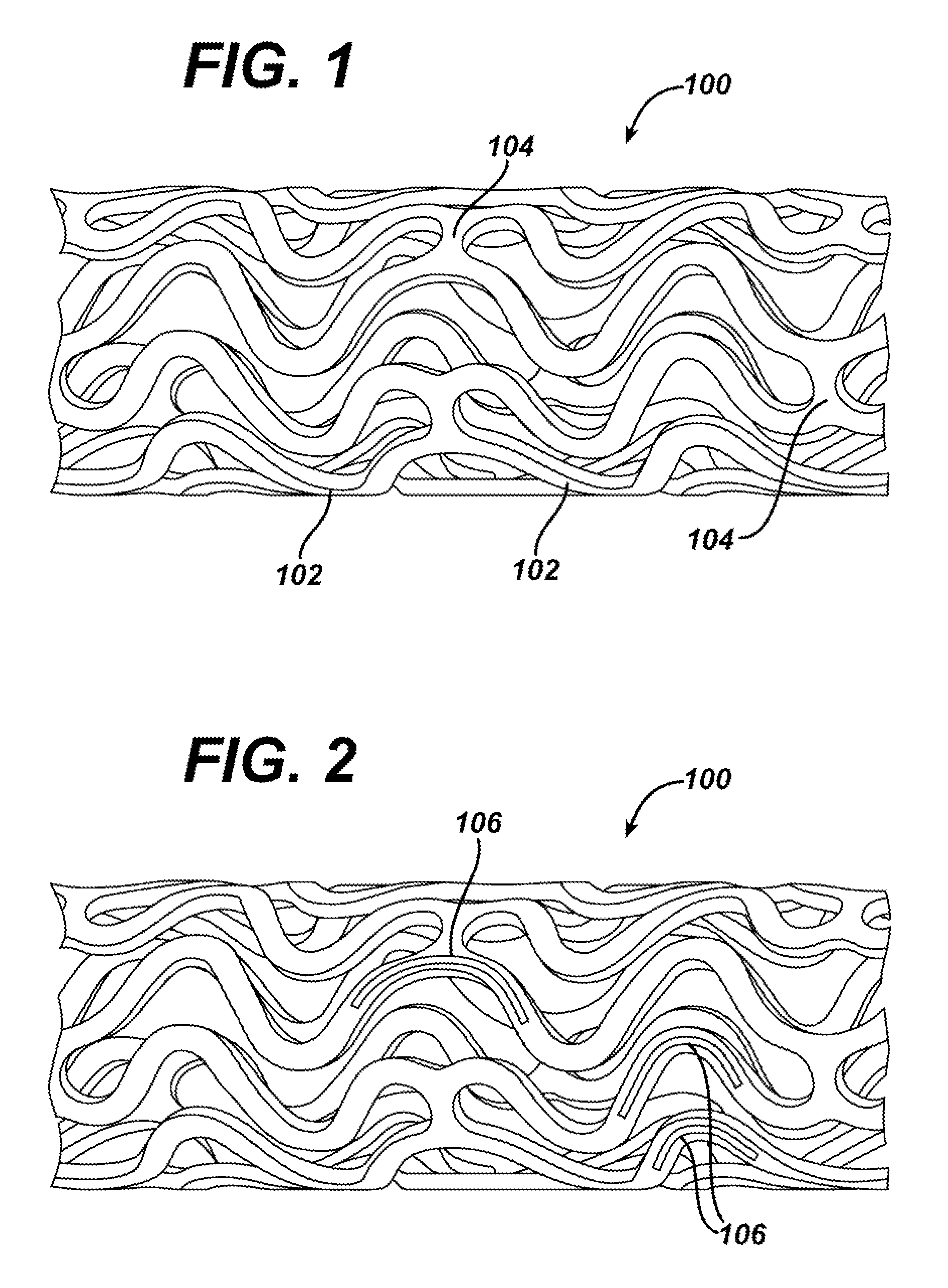

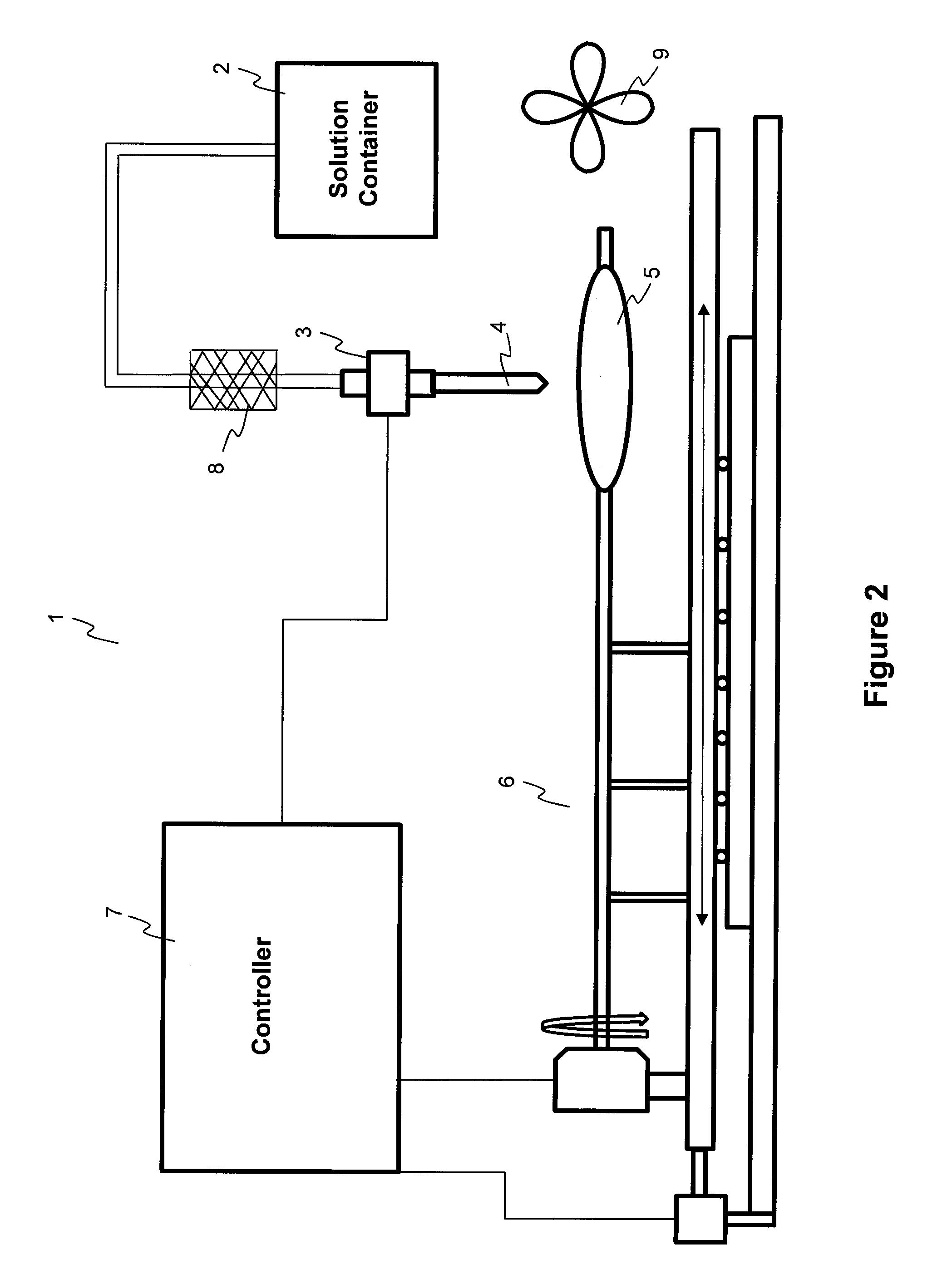

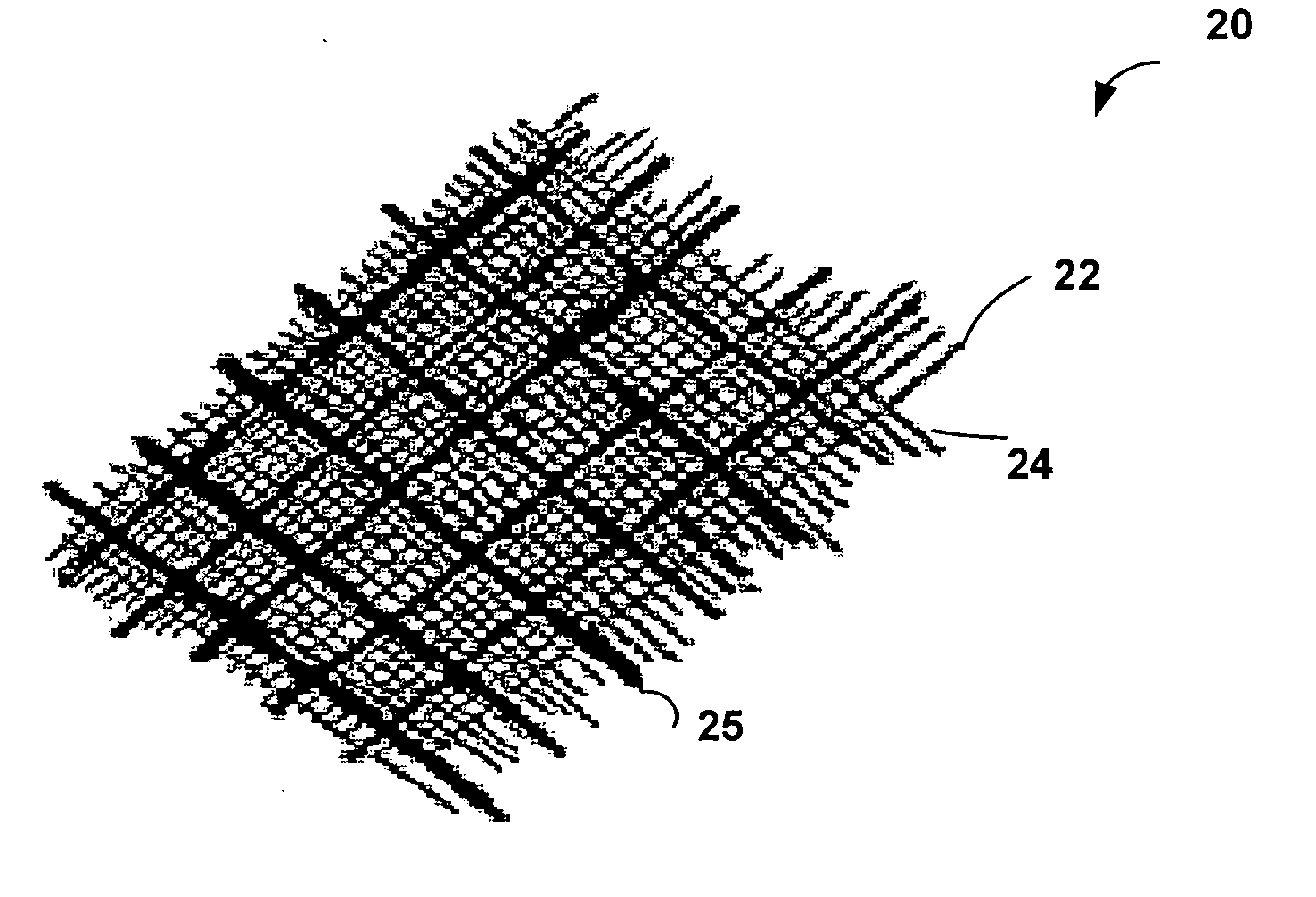

Carbon nanotube fabrics

The present invention provides fabrics that have unique chemical, electrical, and thermal properties. The fabrics comprise layers of yarns woven together wherein the yarns further comprise carbon nanotube fibers. These carbon nanotube fibers may be either single-walled or multi-walled carbon nanotubes. The use of carbon nanotube fibers allows the fabrics to insulate, semi-conduct or super-conduct electrical charges. Additionally, the thermal properties of carbon nanotubes allow thermal energy to flow efficiently between the fabric and a heat sink or source. Additional yarns of materials other than carbon nanotubes can be integrated or woven into the fabric to provide other unique properties for the fabric. These fabrics can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

Breathable protective articles

InactiveUS20060143767A1Improve gripImprove non-skidding propertyFinger bandagesNon-adhesive dressingsElastomerPliability

A protective article formed of a laminate between at least a layer of a liquid-impermeable, vapor-permeable barrier, and at least a layer of a stretchable or elastomeric, nonwoven fiber web is described. The barrier is reinforced at least on one side by the nonwoven fiber web, which remains elastic after being bonded to the barrier layer. The elasticity of both barrier and bonded fiber layers simulate the flexibility of natural or synthetic latex or other polymer films. The nonwoven fiber web includes at least about 75% of individual fibers with a length of over about 1 mm, and the fibers are substantially continuous. A second nonwoven web, a second barrier layer, or both may be attached to the exterior side of the breathable barrier. An elastomeric material coating, such as either a nature or synthetic latex or other polymers, may be applied over at least a portion of the article to provide for additional protection.

Owner:KIMBERLY-CLARK WORLDWIDE INC

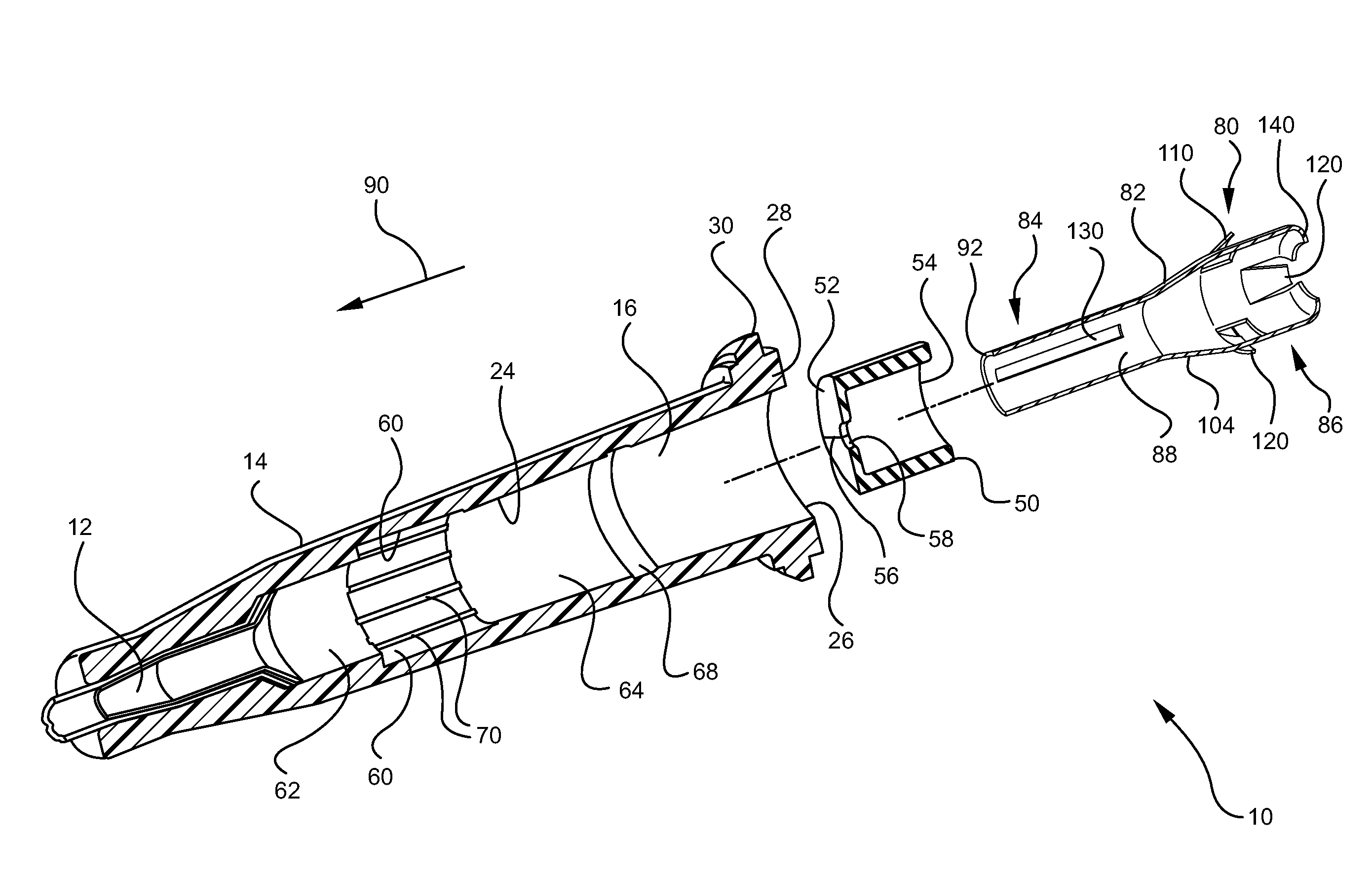

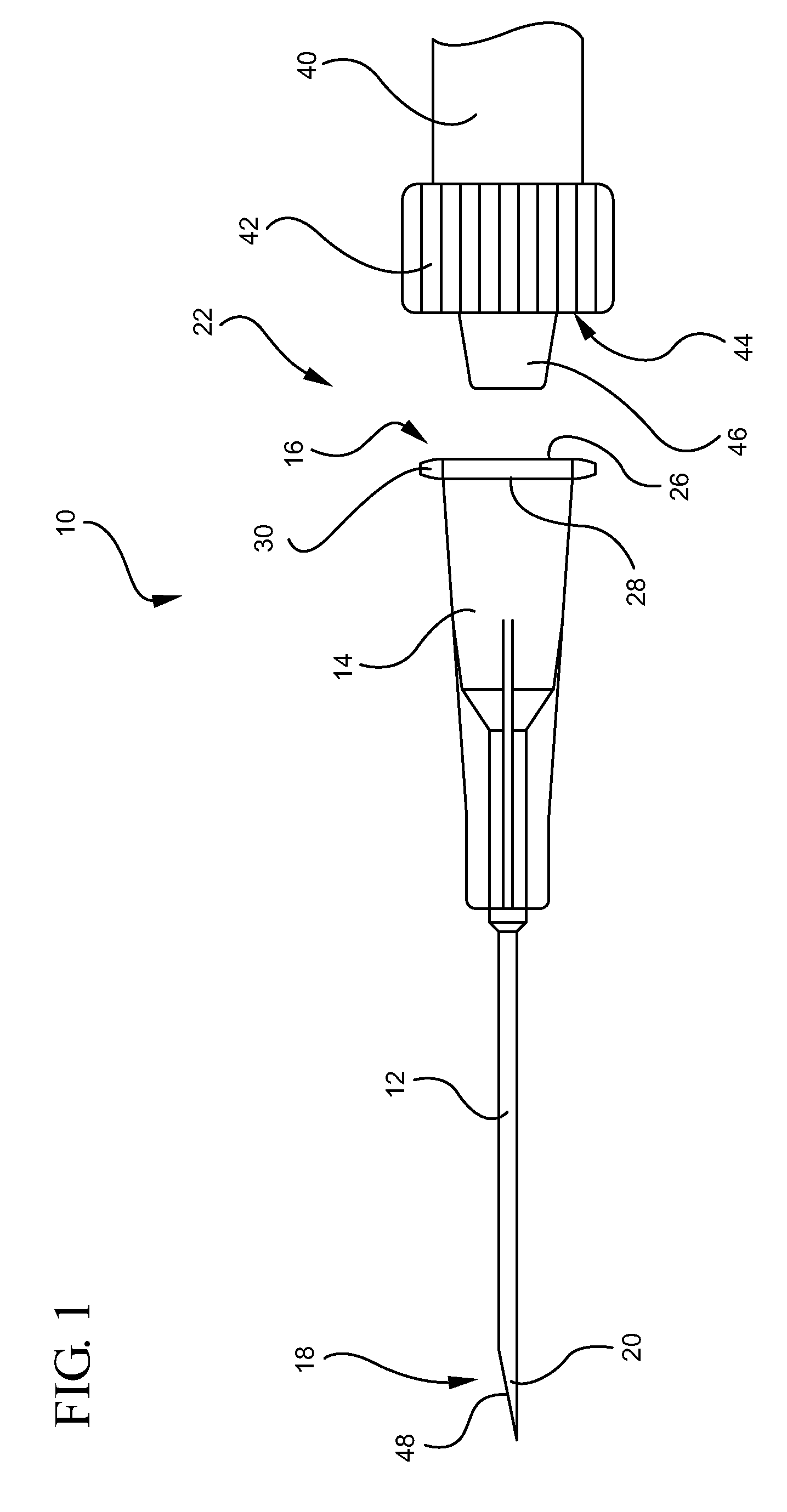

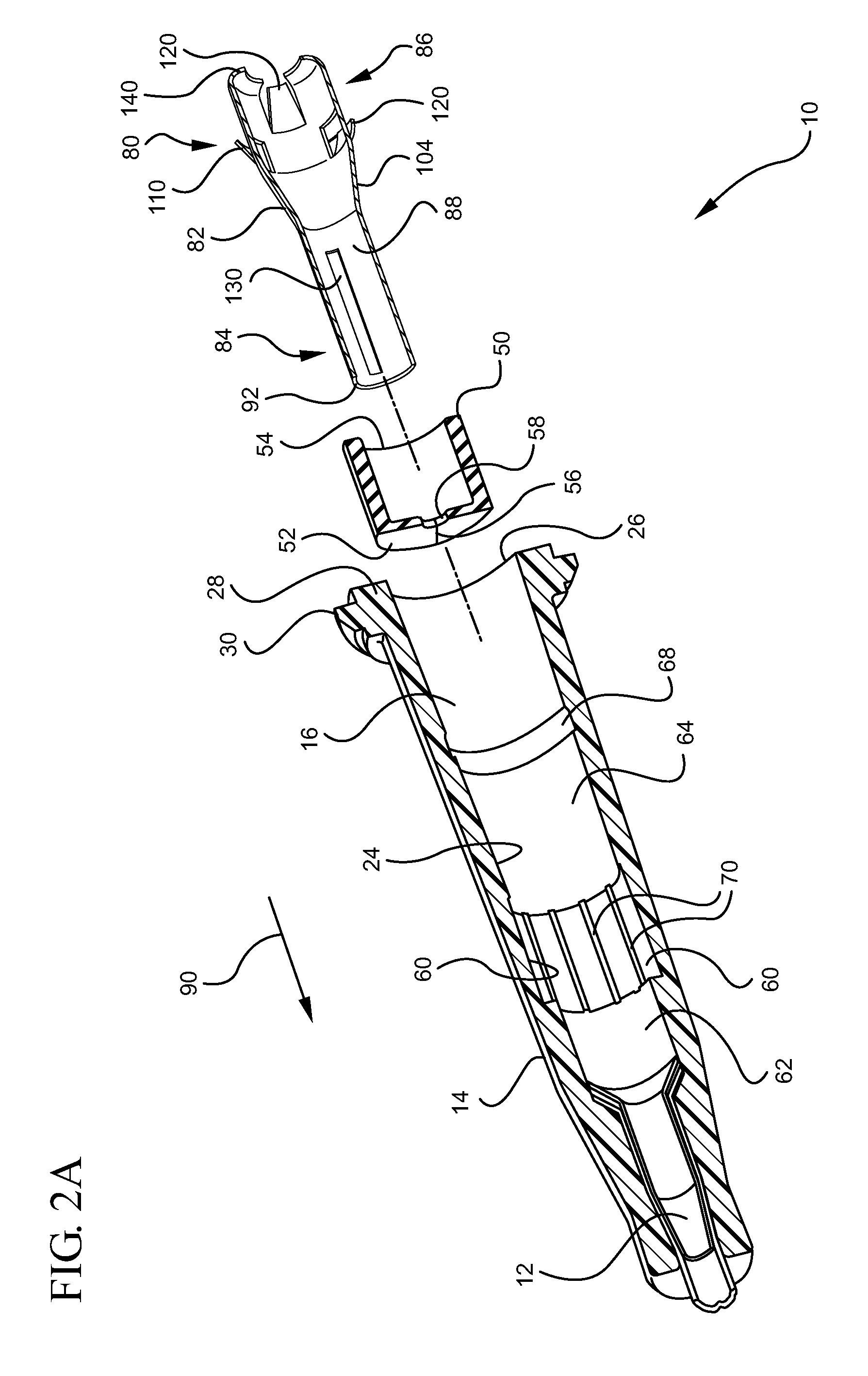

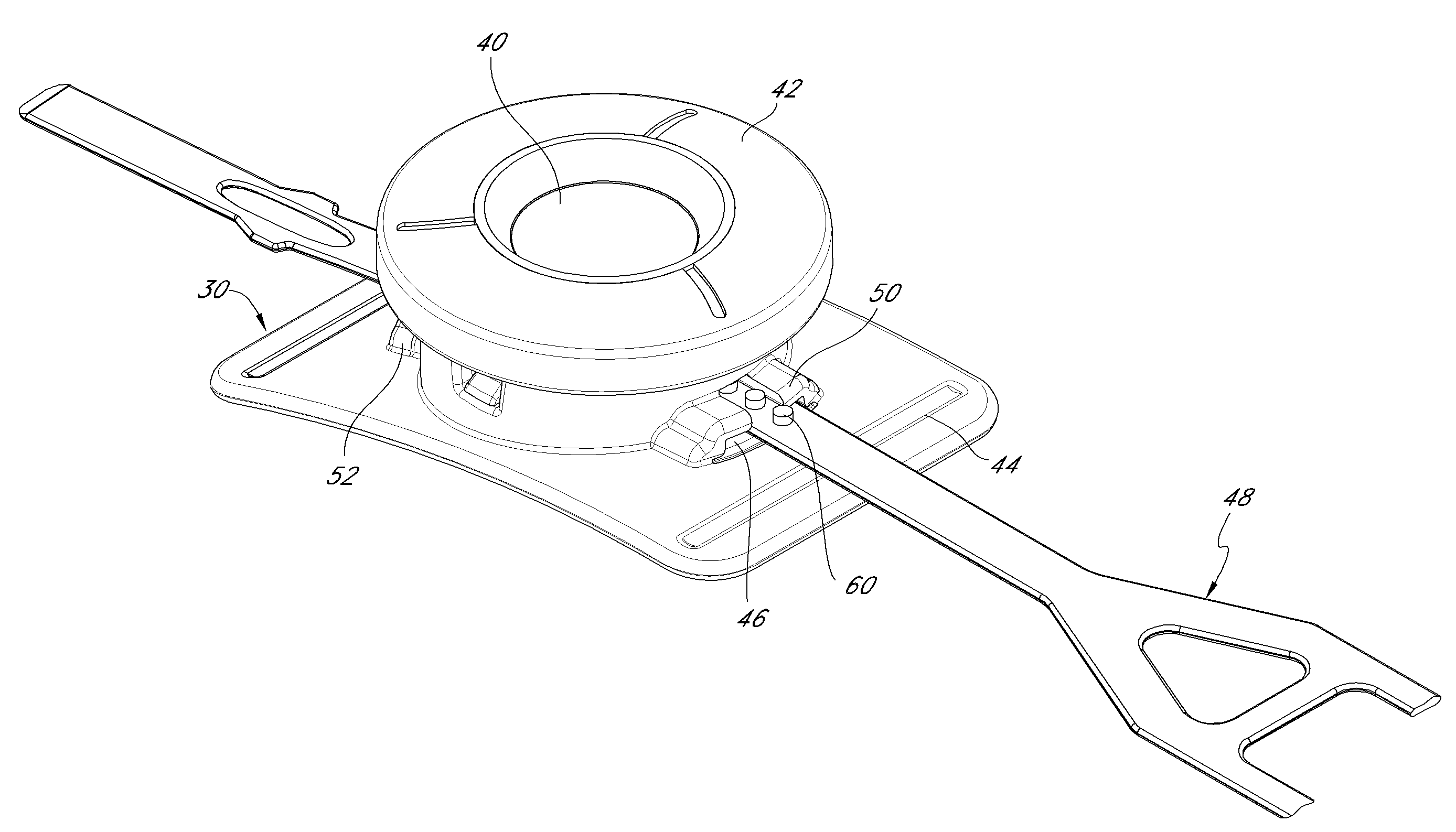

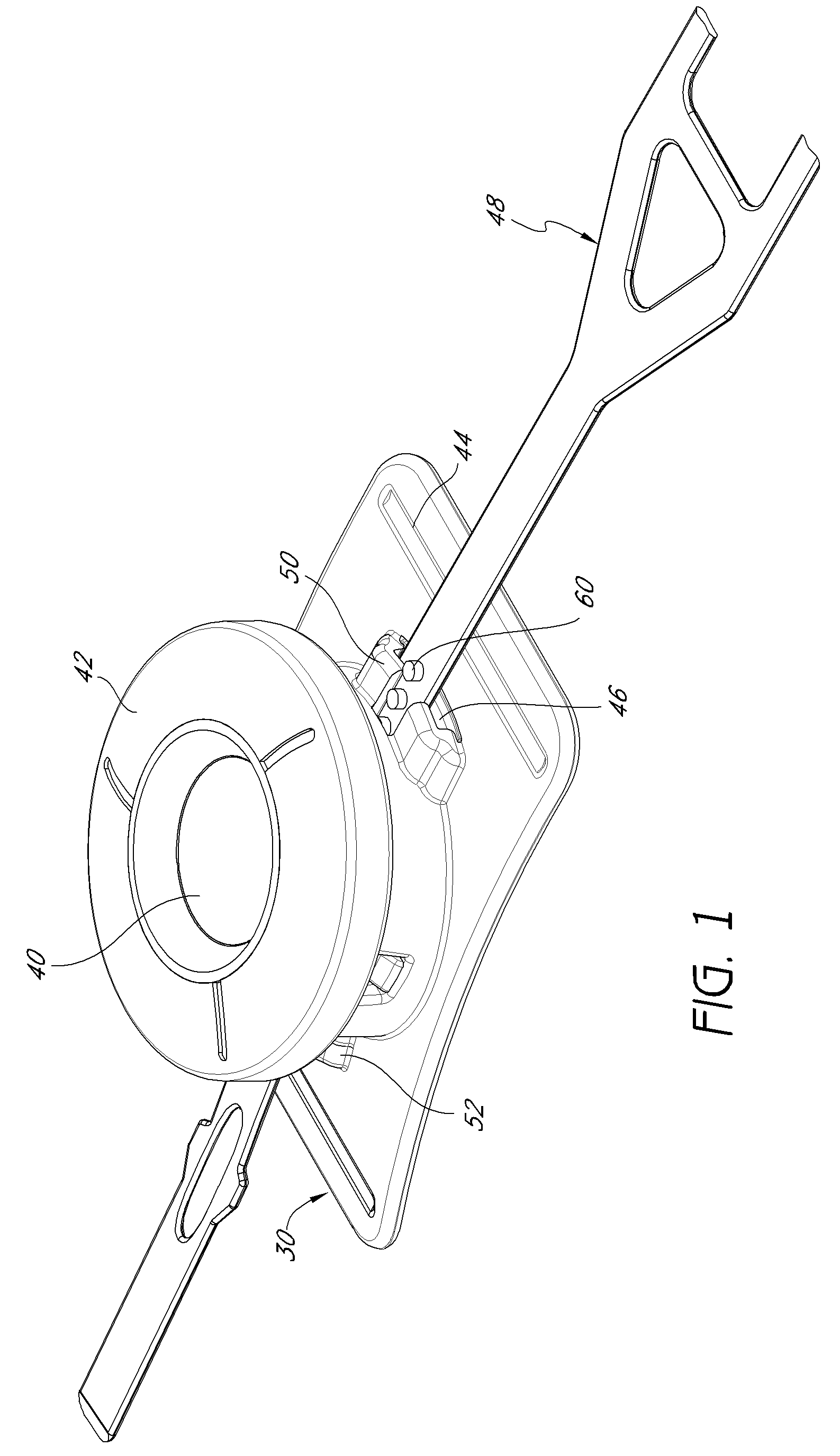

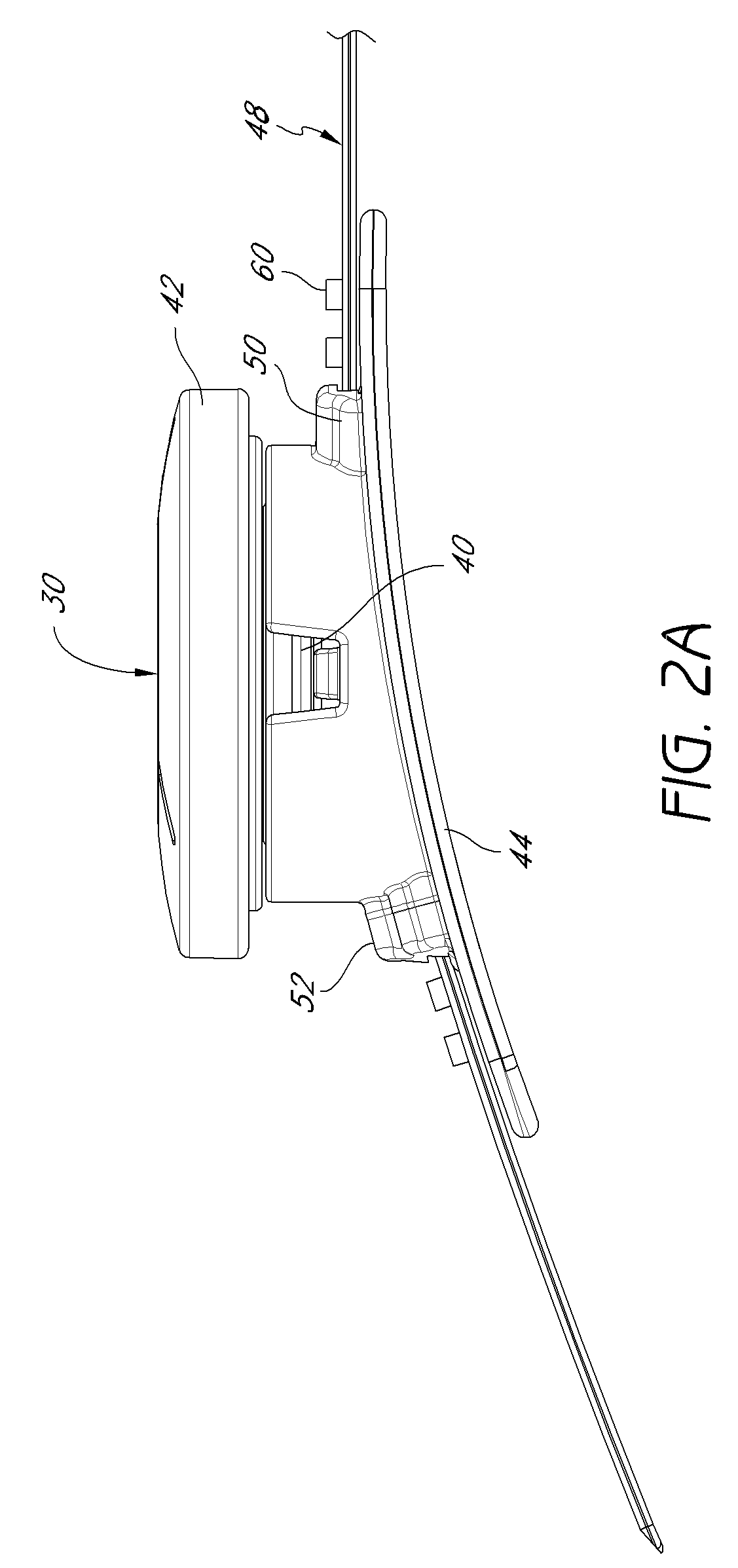

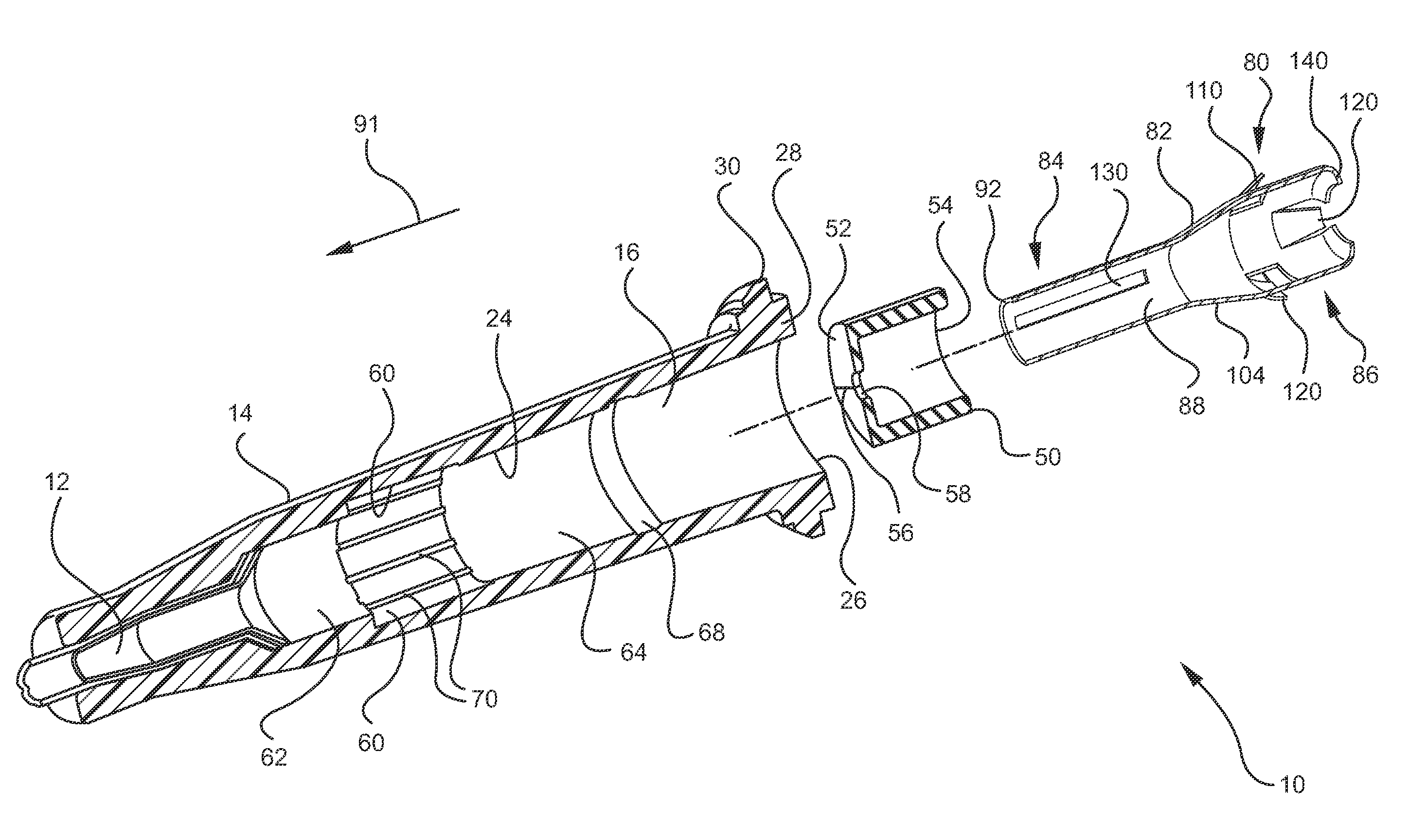

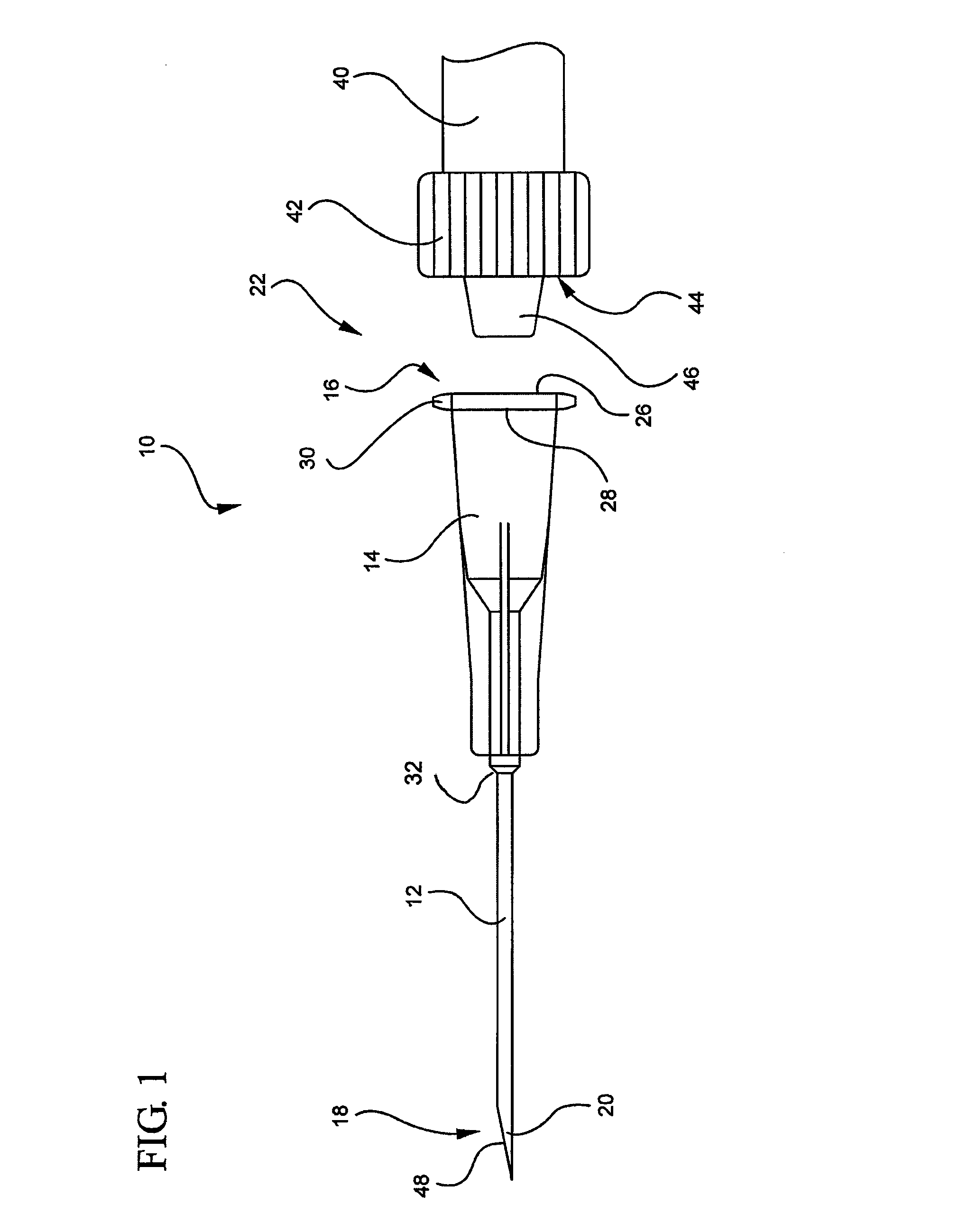

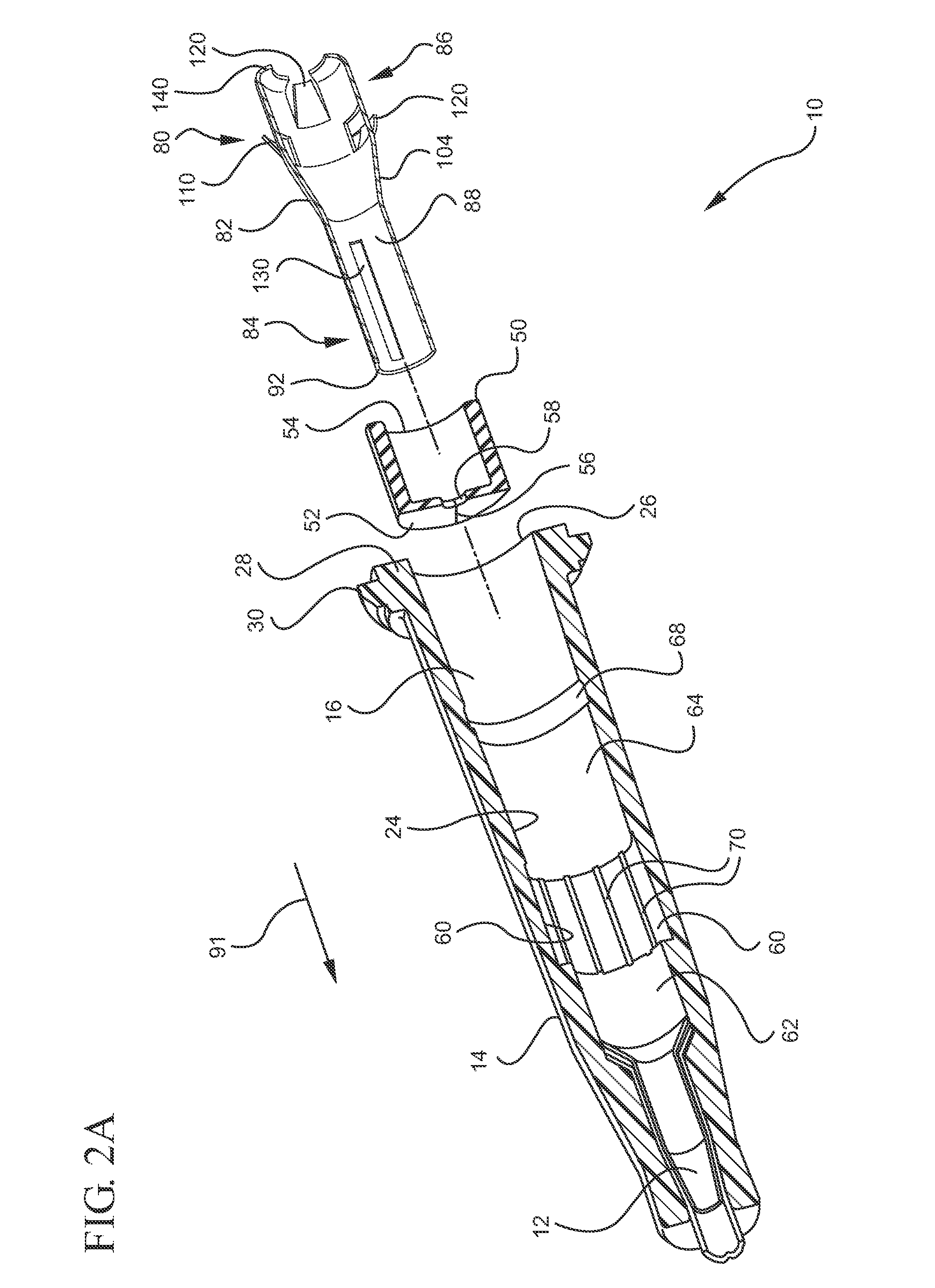

Systems and methods for providing a flushable catheter assembly

ActiveUS20110046570A1Maintain positionPrevent of positive pressureGlovesPretreated surfacesCATHETER ADAPTERBiological activation

A flushable catheter assembly having features to enable selective activation of fluid flow through the catheter assembly is disclosed herein. A septum is placed within the catheter adapter of the catheter assembly and includes a pathway that is closed prior to being biased open via a septum activator also positioned within the catheter adapter. A plurality of air vent channels is interposed between the septum and the inner surface of the catheter adapter to permit “flashback” of blood during insertion of the catheter into a patient. The septum activator is advanced through the pathway of the septum as a coupler is attached to a proximal opening of the catheter adapter.

Owner:BECTON DICKINSON & CO

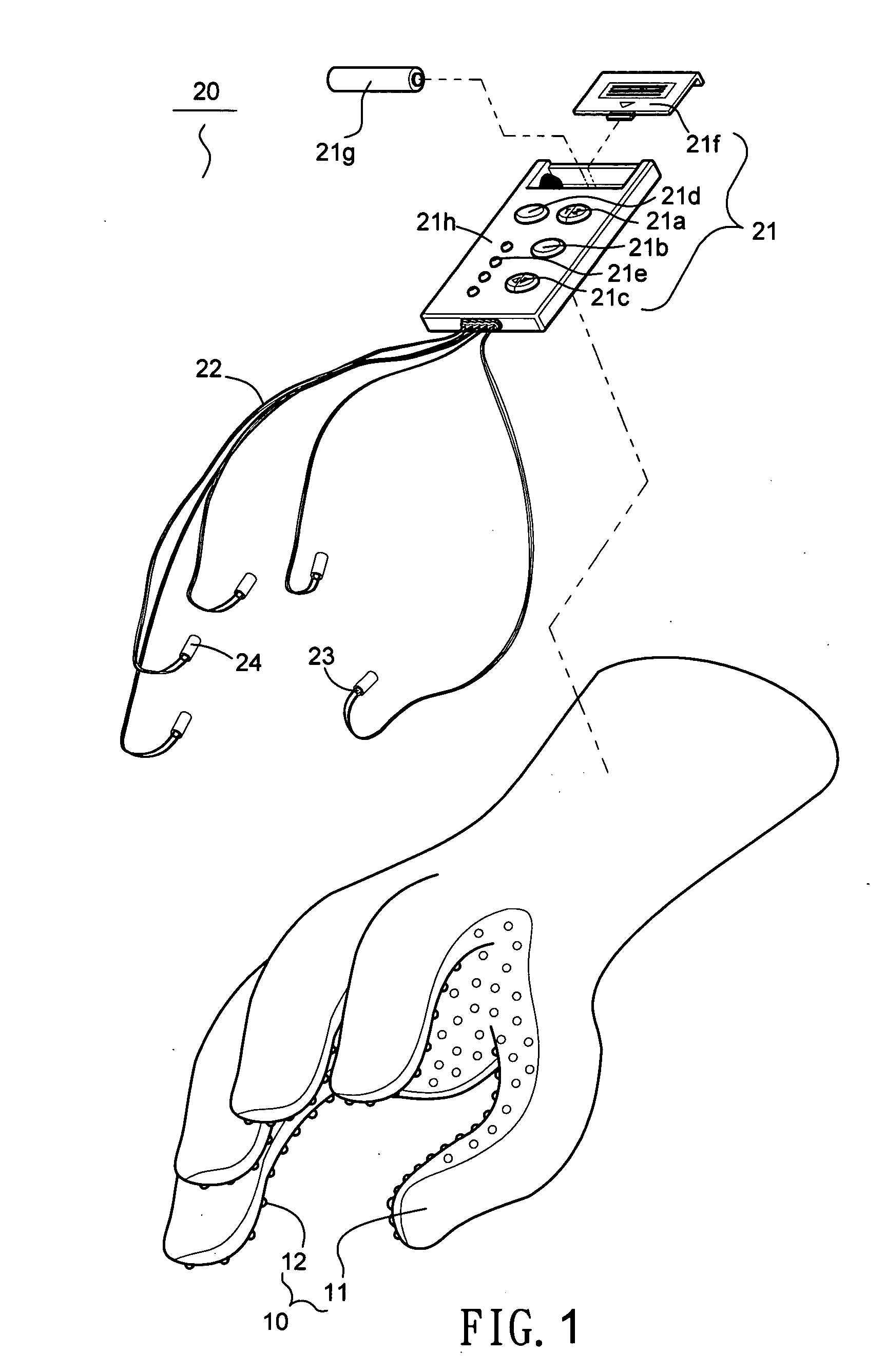

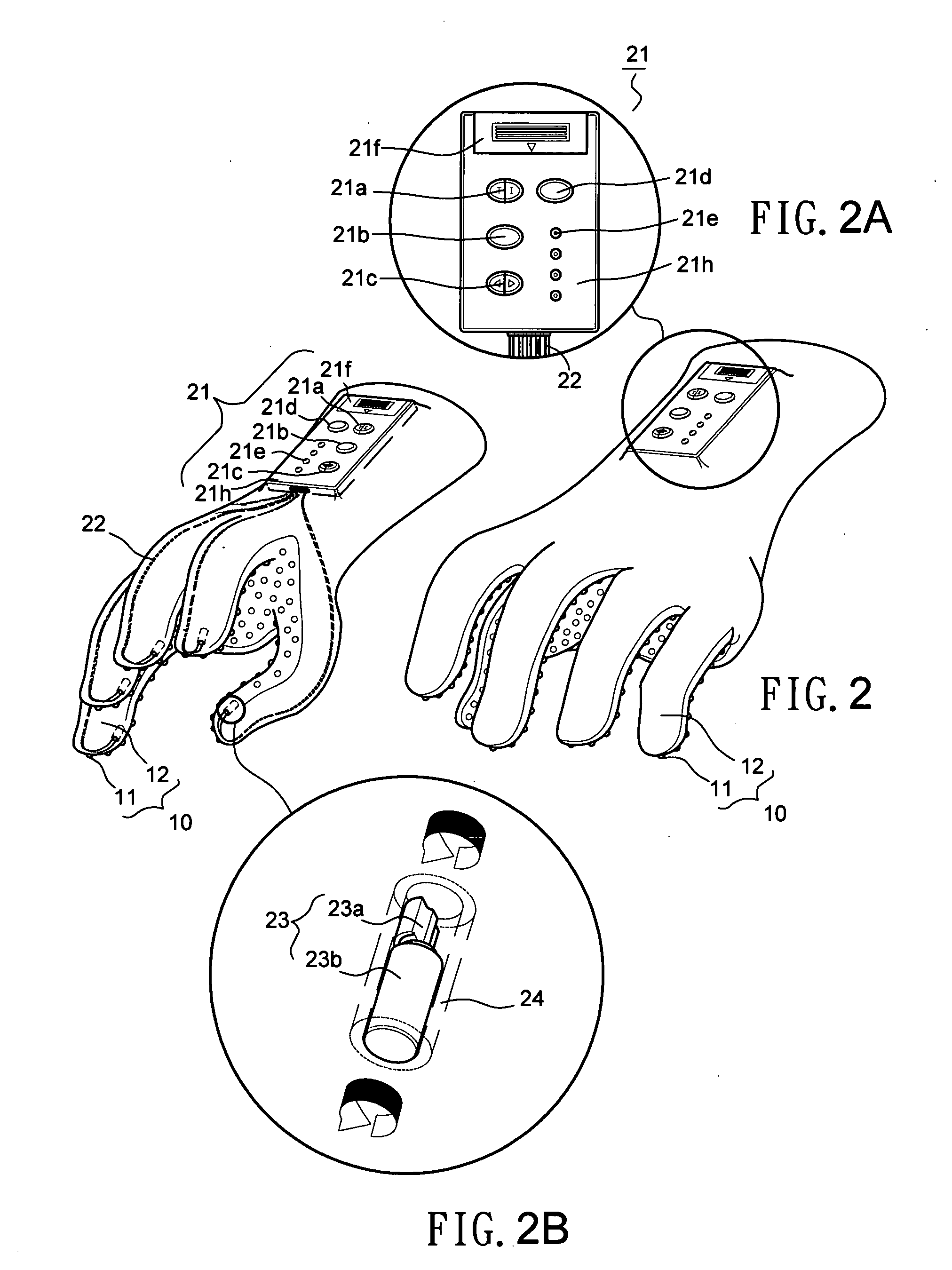

Finger pressing massage glove

Owner:TSAI SHEN HAI

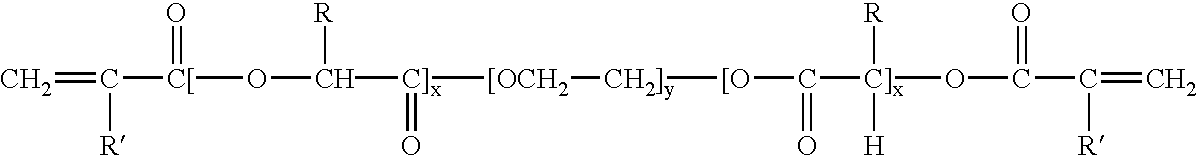

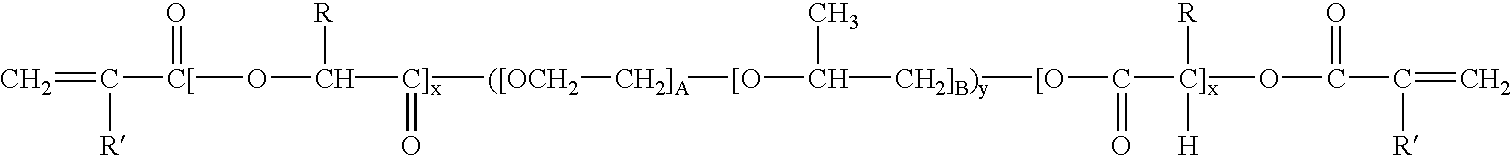

Process for preparing surface modification substances

InactiveUS6461665B1Improved nonthrombogenic activitySufficient non-thrombogenicitySuture equipmentsGlovesSurface modificationSurface modified

The present invention relates to a process for preparing surface modifications having an improved antithrombogenic activity, whereby the improvement is achieved by treating heparin at a temperature above 40° C. or a pH in the rage of 9-14 or in contact with nucleophilic catalysts before attaching said heparin to the surface to be modified.

Owner:CARMEDA AB

Process for impregnating a porous material with a cross-linkable composition

Owner:LIFESHIELD SCI

Closure system

ActiveUS20090184189A1Reduce in quantityTorque felt by the knob may be constantSnap fastenersGlovesFast releaseEngineering

In some embodiments, a cam assembly and strap based closure system using a spiral is configured for bringing two sides of an article together. In some embodiments, when the user inserts the strap into the cam assembly and turns a knob, the strap is driven into the cam assembly and the strap pins engage one or more cam spirals. In some embodiments, the system is configured such that strap pins may be engaged at a constant angle which may be self-locking. In some embodiments, the system may be infinitely adjustable and the torque felt by the knob may be constant. In some embodiments, the system may be configured to be a quick release system and may allow rapid insertion of the strap for faster operation.

Owner:BOA TECHNOLOGY

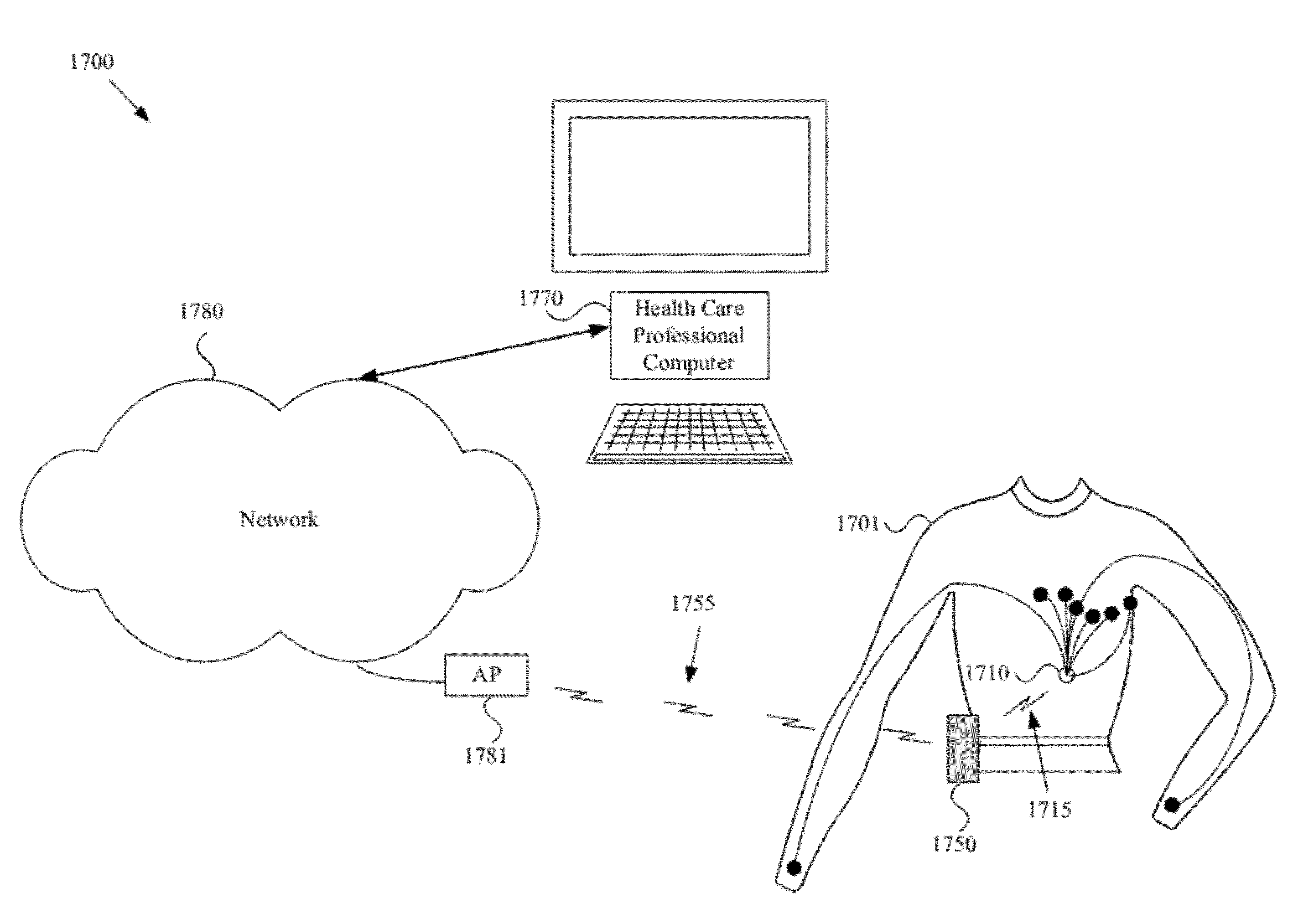

Wearable items providing physiological, environmental and situational parameter monitoring

A garment and / or garment system with health-monitoring (e.g., cardiovascular monitoring) capability, substantially as shown in and / or described in connection with at least one of the figures, as set forth more completely in the claims.

Owner:MARKEL GAL

Balloon coating with drug transfer control via coating thickness

InactiveUS20100285085A1Improved coating transfer efficiencyPromote absorptionBiocideGlovesMedical deviceBlood vessel

Owner:ABBOTT CARDIOVASCULAR

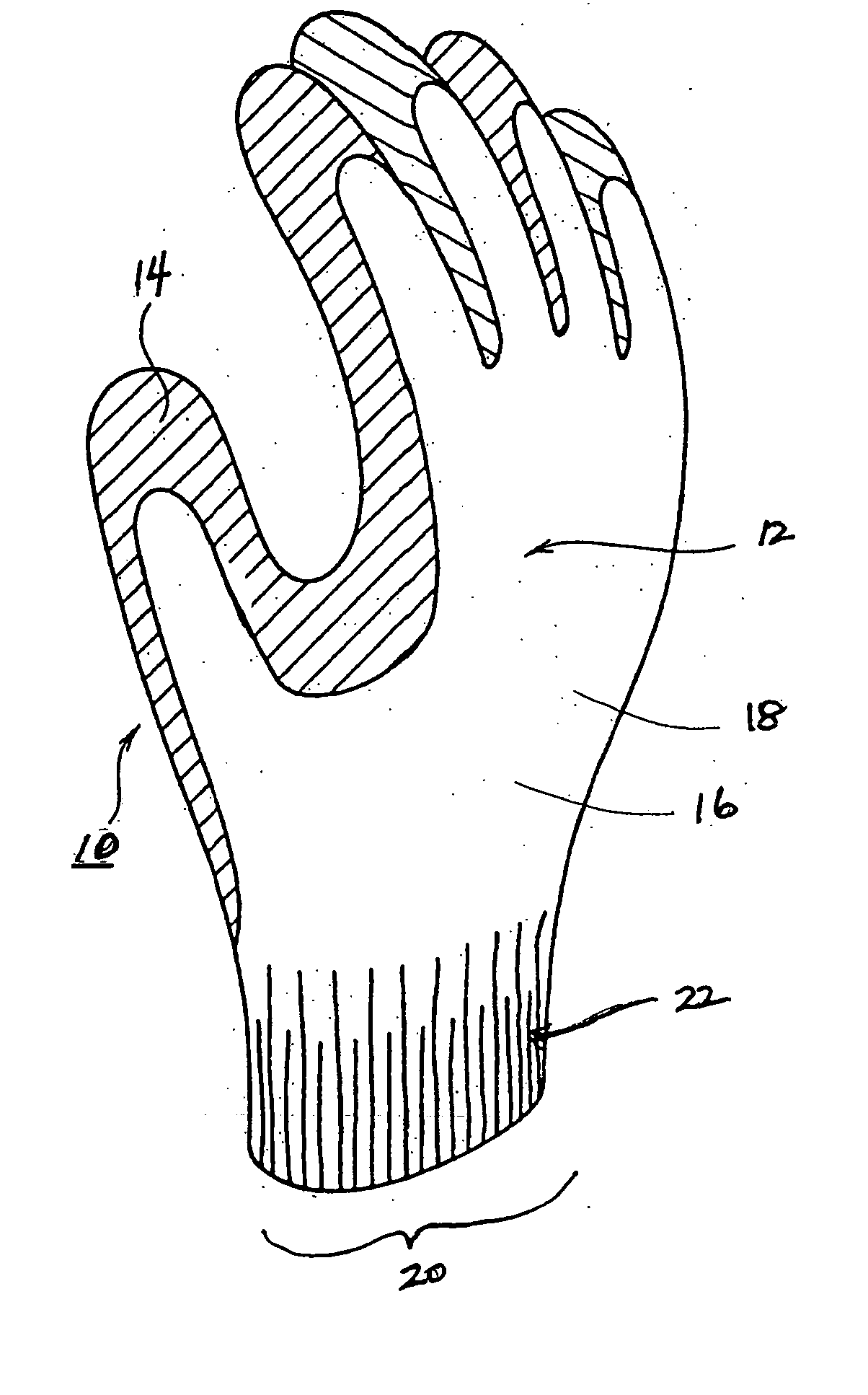

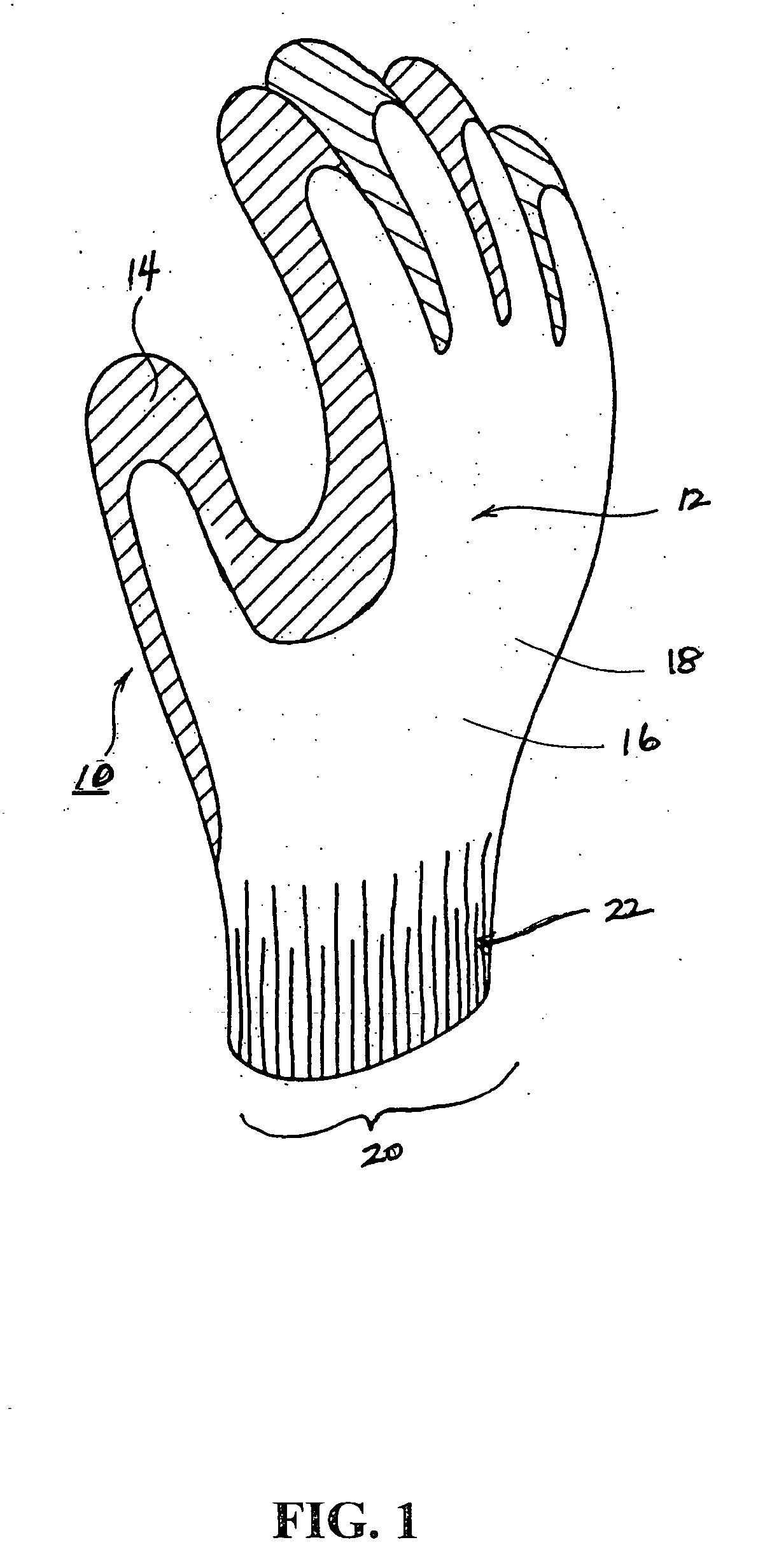

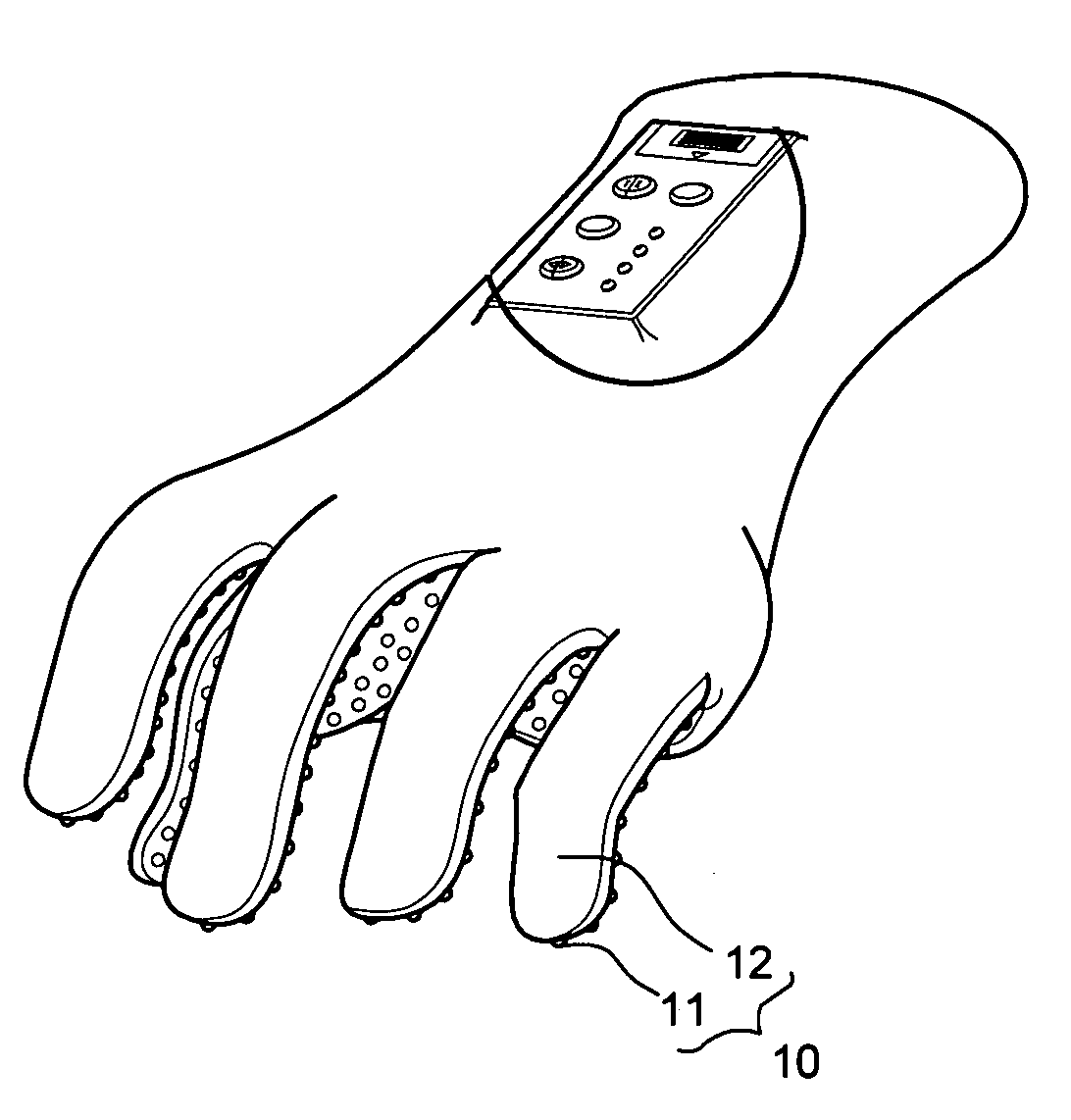

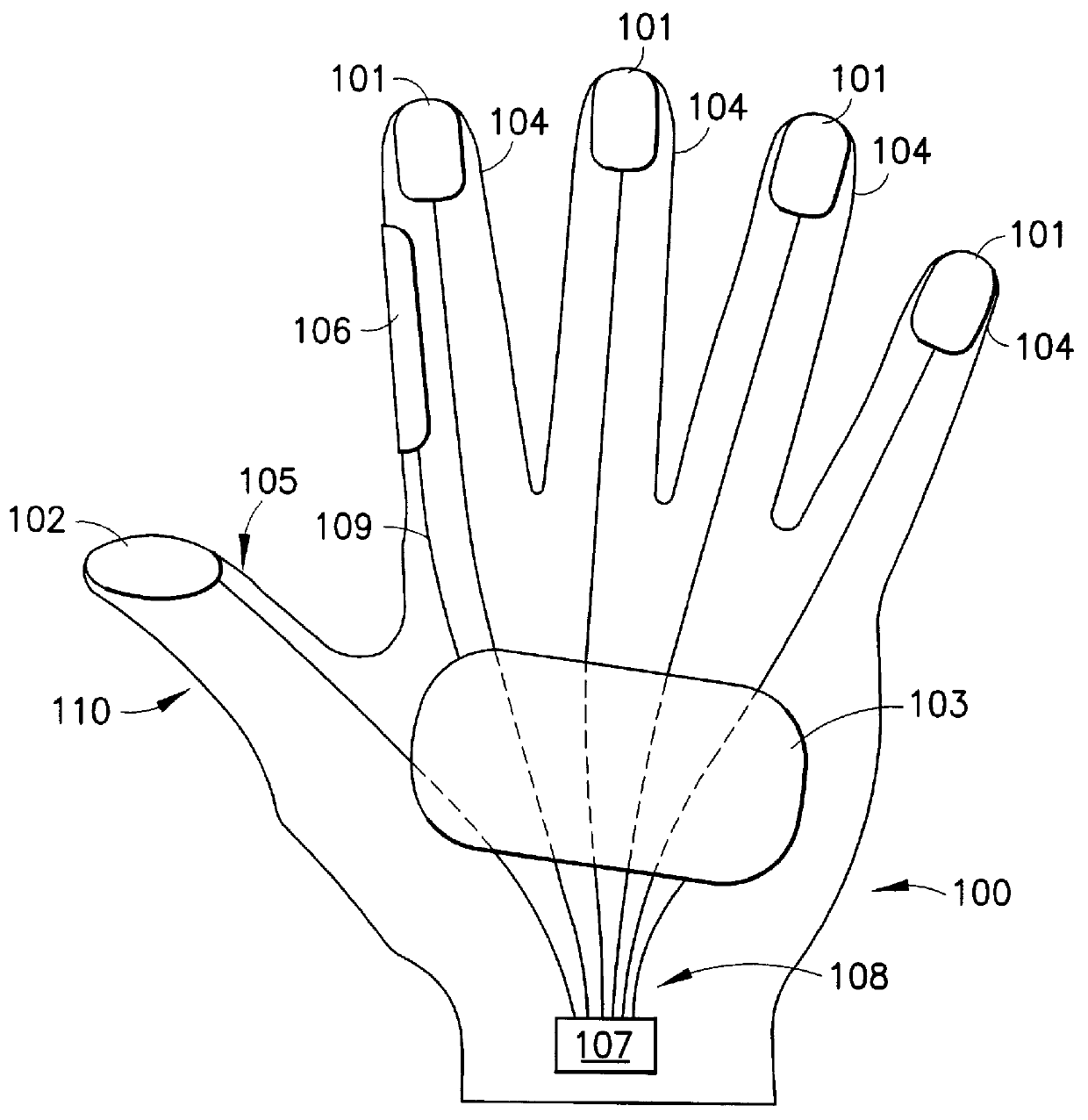

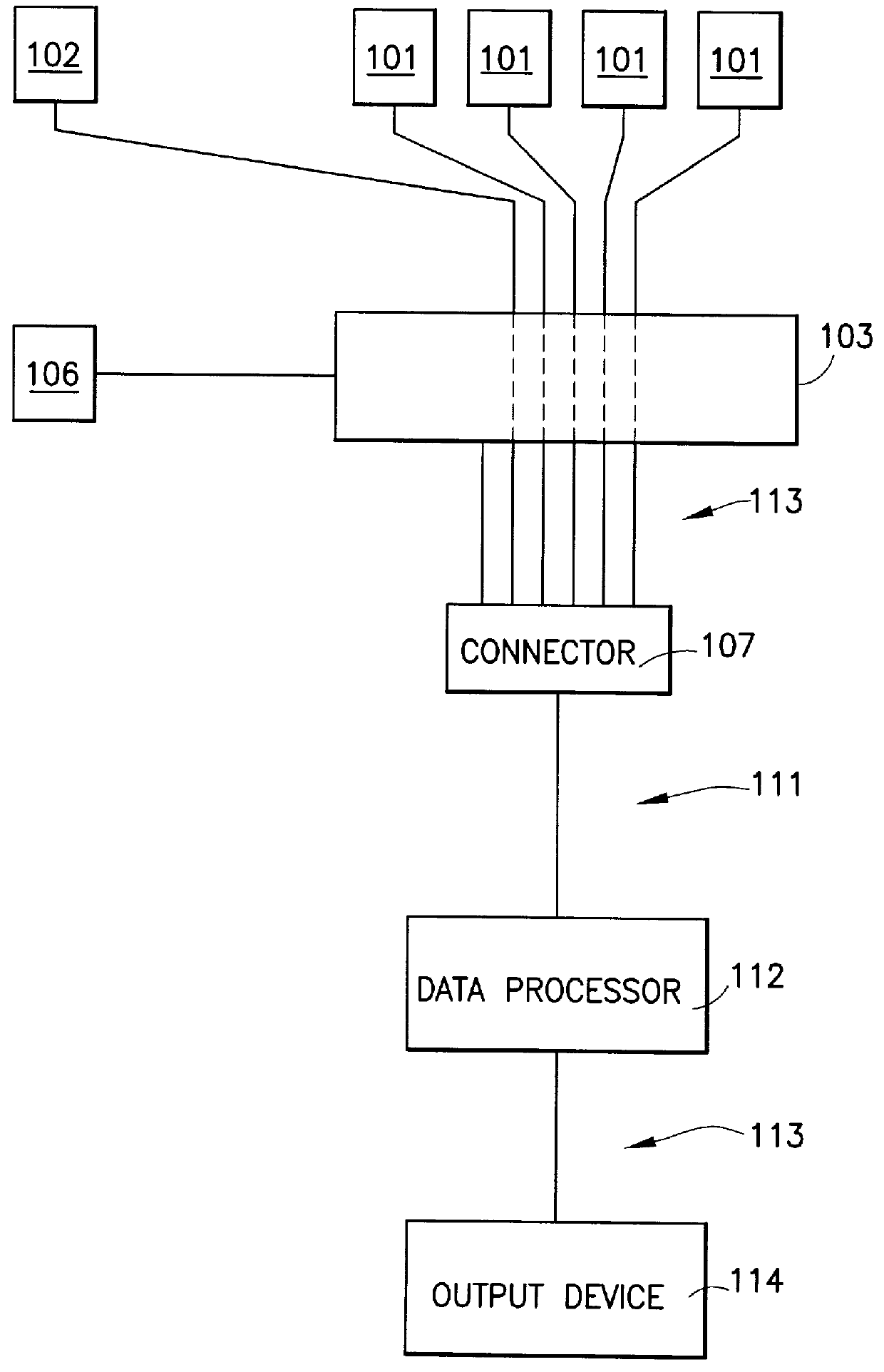

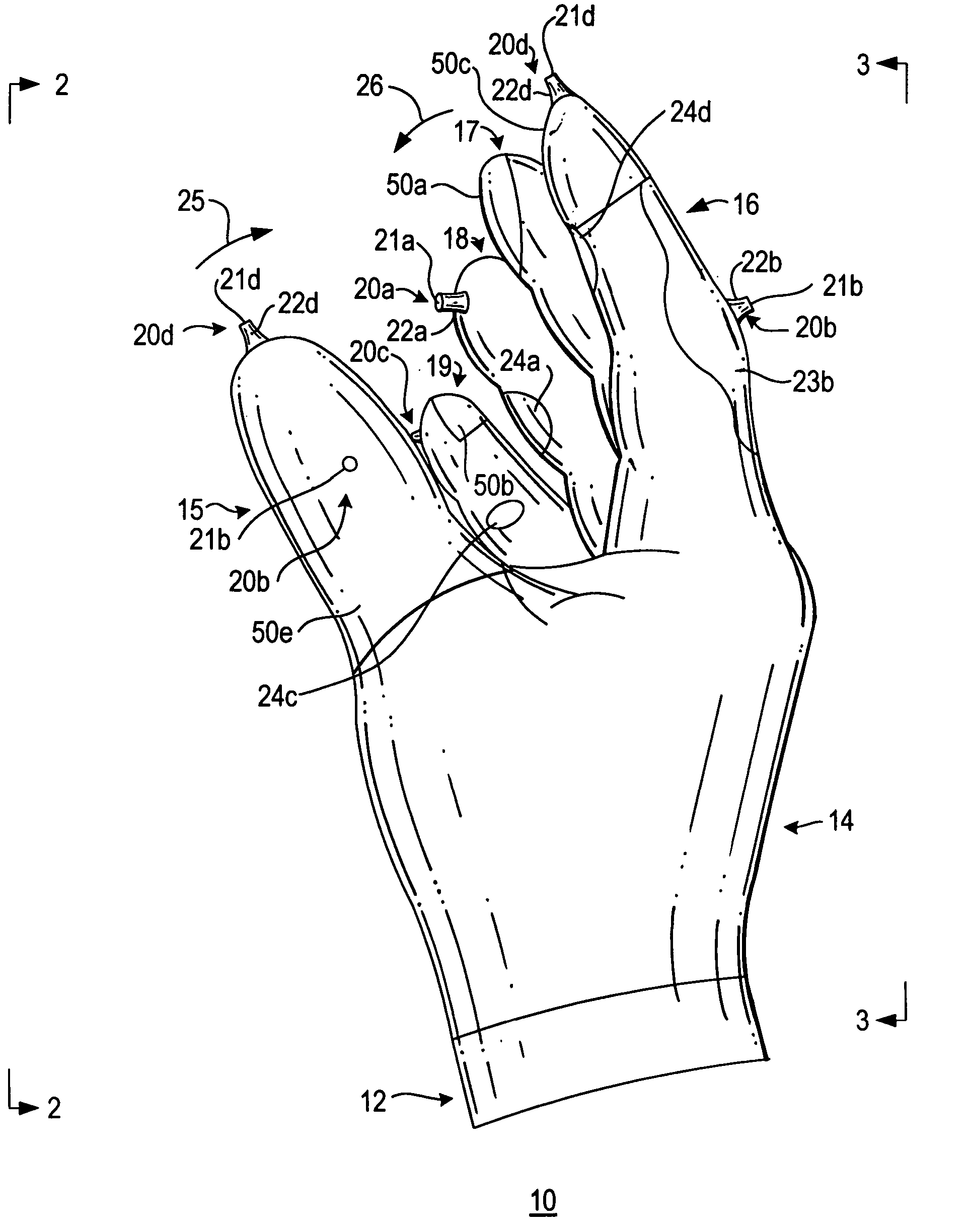

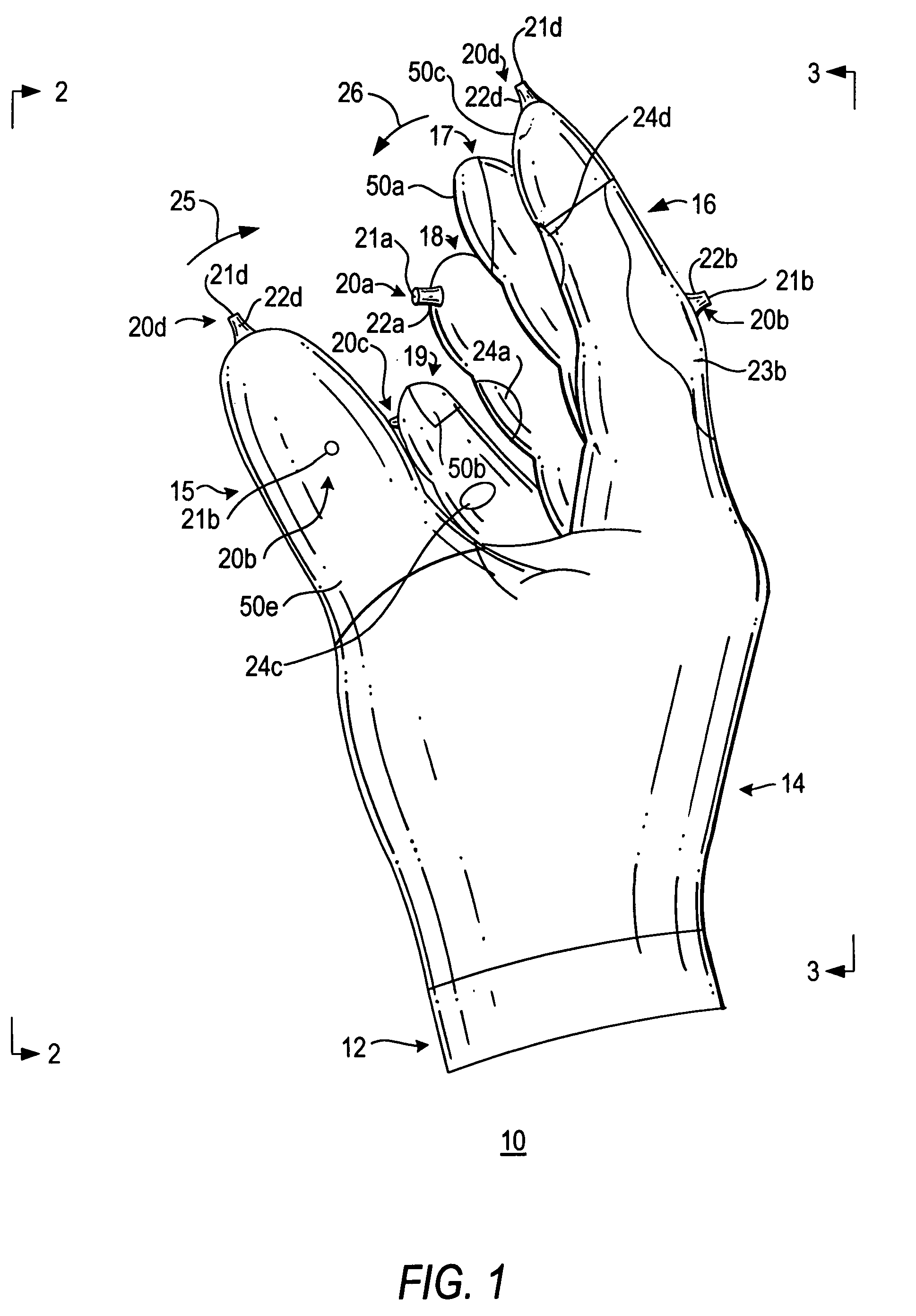

Data input glove having conductive finger pads and thumb pad, and uses therefor

A data input glove including a gloved body at least some of whose fingertip portions have conductive fingertip pad elements thereon, operatively connected to an output connector, and at least one conductive palm pad positioned on a palm portion of the gloved body and operatively connected to an output connector, wherein contact between a finger pad and a palm pad generates a signal. The signal may be processed by computer processor to provide a desired output, e.g., synthesized speech or other analogue or digital output in a suitable medium. The data glove is useful for inputting data in a covert manner, as well as communicationally enabling disabled persons with the aid of a computer, such as a handheld, wearable, or desktop computer.

Owner:HARMON STEVE

Waterborne polyurethane having film properties comparable to rubber

InactiveUS6017997ASimply and economically manufacturedMaintain good propertiesMale contraceptivesSynthetic resin layered productsFiberElastomer

A waterborne dispersion of a polyurethane polymer is disclosed, which is useful as a film having improved mechanical properties. More particularly, the film has properties comparable to rubber; including, a percentage elongation greater than 700%; a tensile strength greater than 3500 psi; a 100% modulus below 450 psi; a 300% modulus below 700 psi; and, a 500% modulus below 1500 psi. The film can be prepared in the absence of a solvent, thus making it attractive for a variety of protection products for medical and industrial applications such as gloves, condoms, catheters, and the like. The polymer is useful as a coating for textiles, such as backcoatings, fabric or fiber saturants, finishes, or transfer coatings, or other textile and non-textile applications where good elastomeric properties would be useful.

Owner:NOVEON INC

Microspheres containing condensed polyanionic bioactive agents and methods for their production

The invention describes improved methods for incorporating nucleic acids into polymeric microspheres and / or nanospheres through the use of a condensing agent.

Owner:RGT UNIV OF MICHIGAN

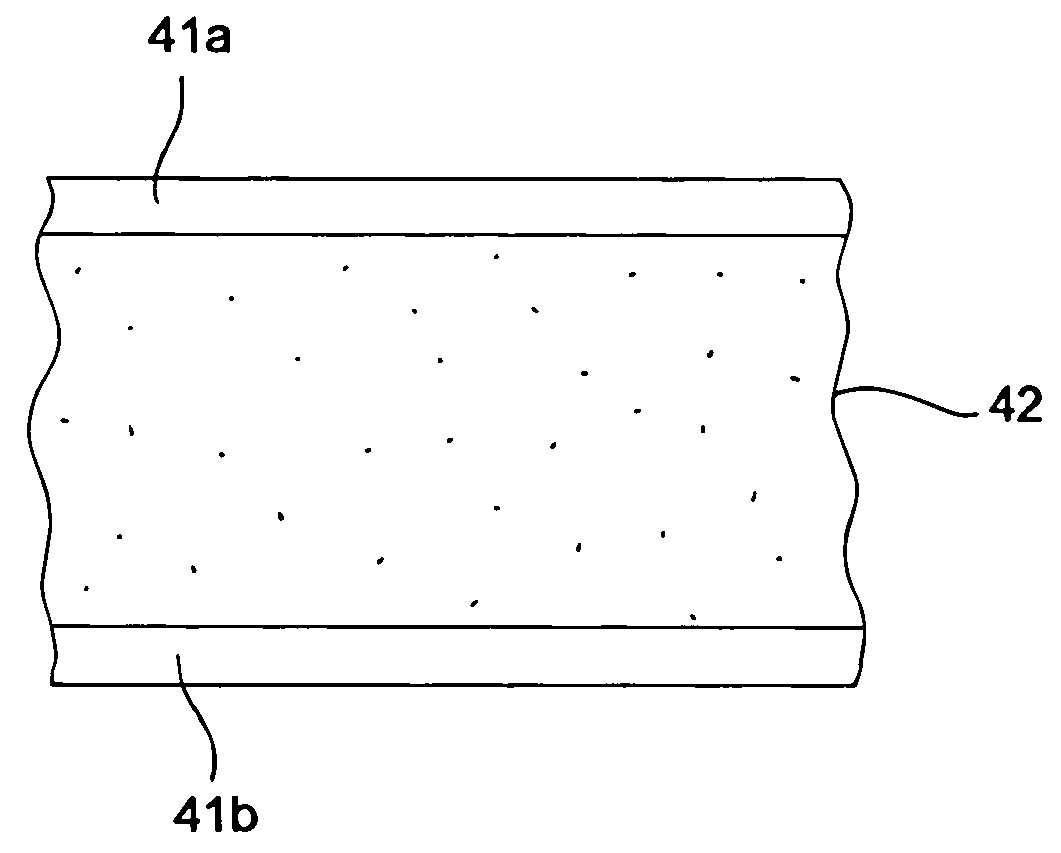

Aerogel/PTFE composite insulating material

ActiveUS20050100728A1Increase flexibilityHigh strengthDigital data processing detailsAdhesive articlesInto-structureMaterials science

A material comprising aerogel particles and a polytetrafluoroethylene (PTFE) binder is formed having a thermal conductivity of less than or equal to 25 mW / m K at atmospheric conditions. The material is moldable or formable, having little or no shedding of filler particles, and may be formed into structures such as tapes or composites, for example, by bonding the material between two outer layers. Advantageously, composites may be flexed, stretched, or bent without significant dusting or loss of insulating properties.

Owner:WL GORE & ASSOC INC

Antimicrobial coating for dermally invasive devices

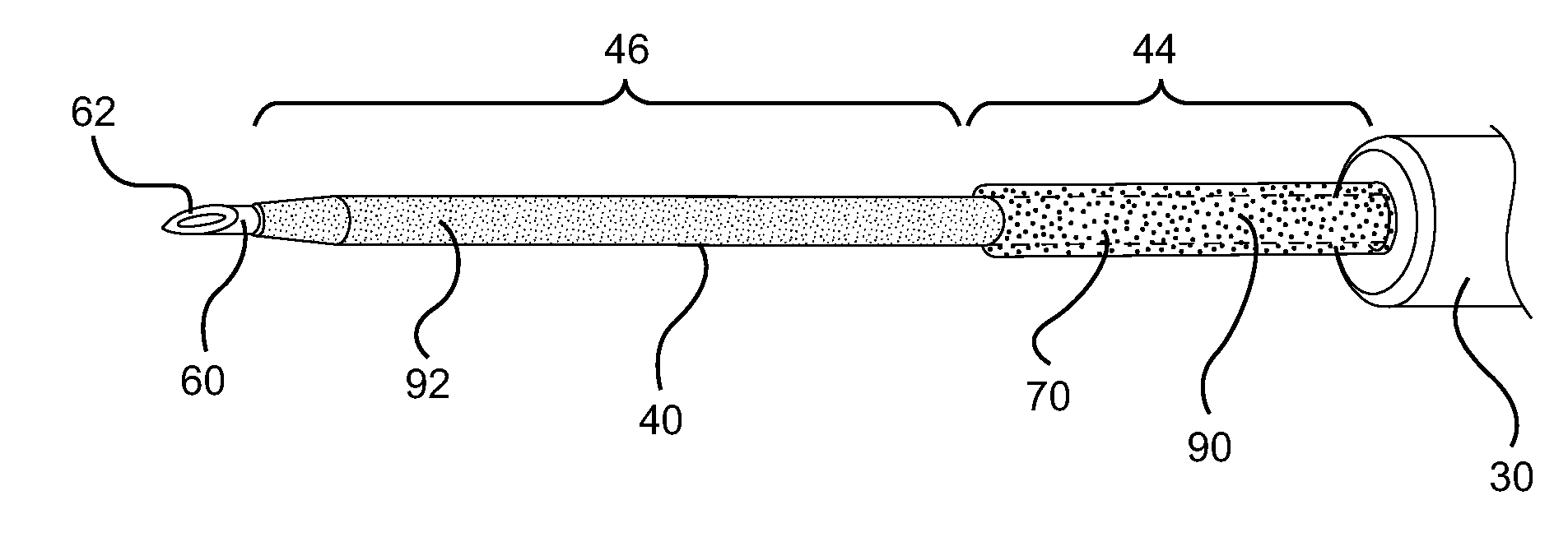

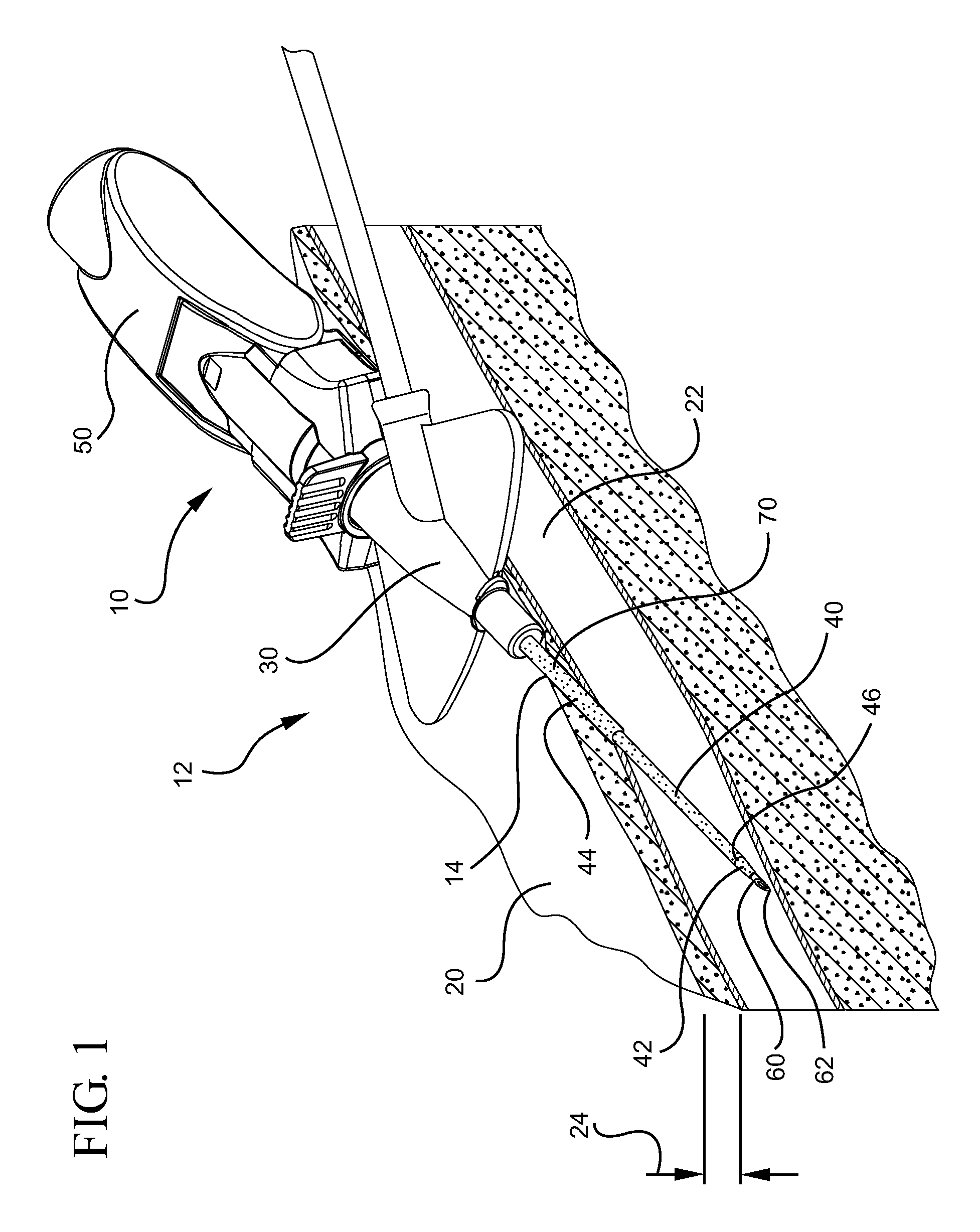

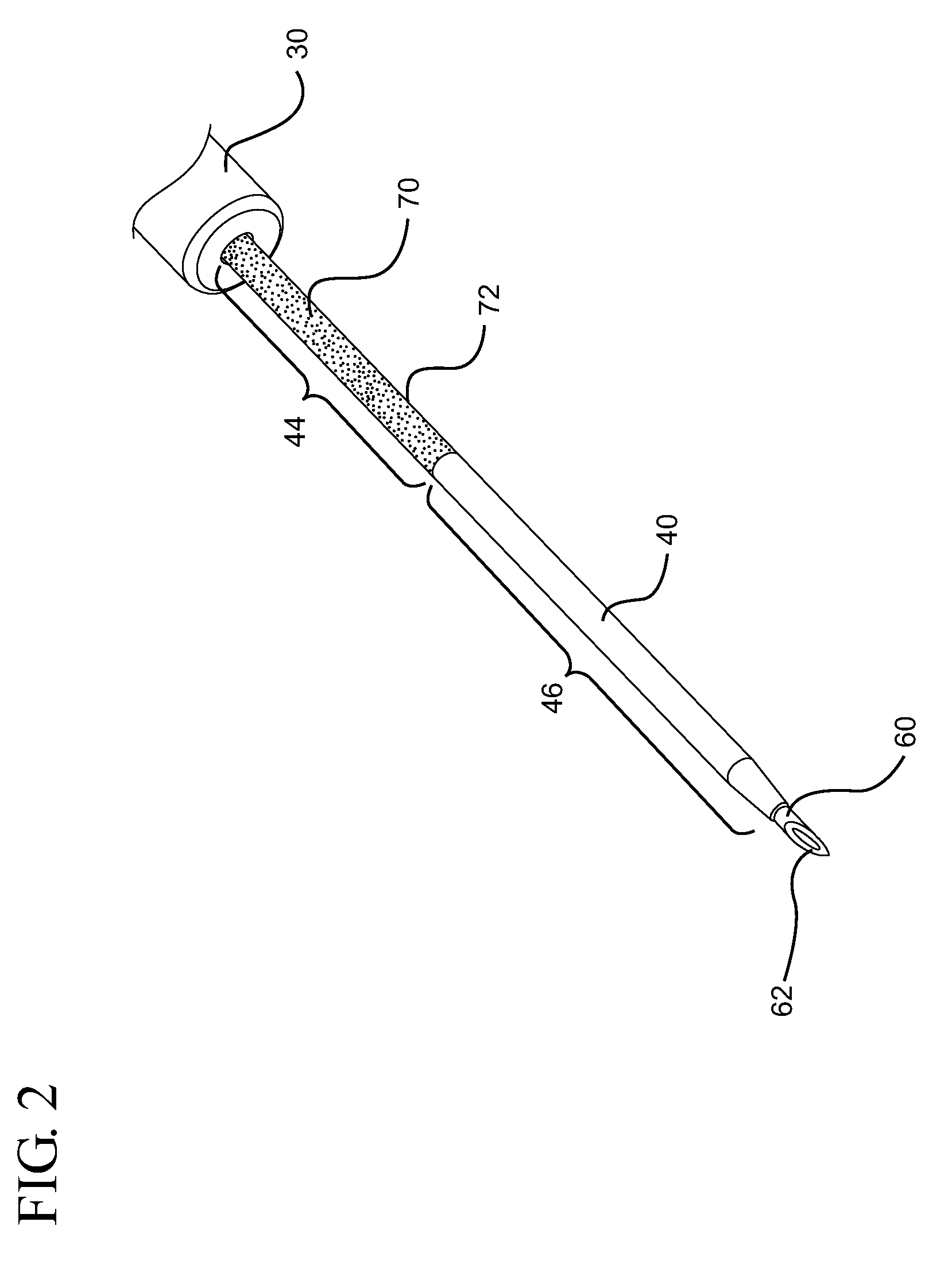

ActiveUS20110009831A1Raise the possibilityAvoid contactAntibacterial agentsBiocideCatheterBiomedical engineering

An antimicrobial coating applied to a transdermal surface of a catheter device. An antimicrobial coating applied to catheter device such that when the catheter device is fully inserted, the antimicrobial coating is interposed between the catheter device and the dermal layers of the patient.

Owner:BECTON DICKINSON & CO

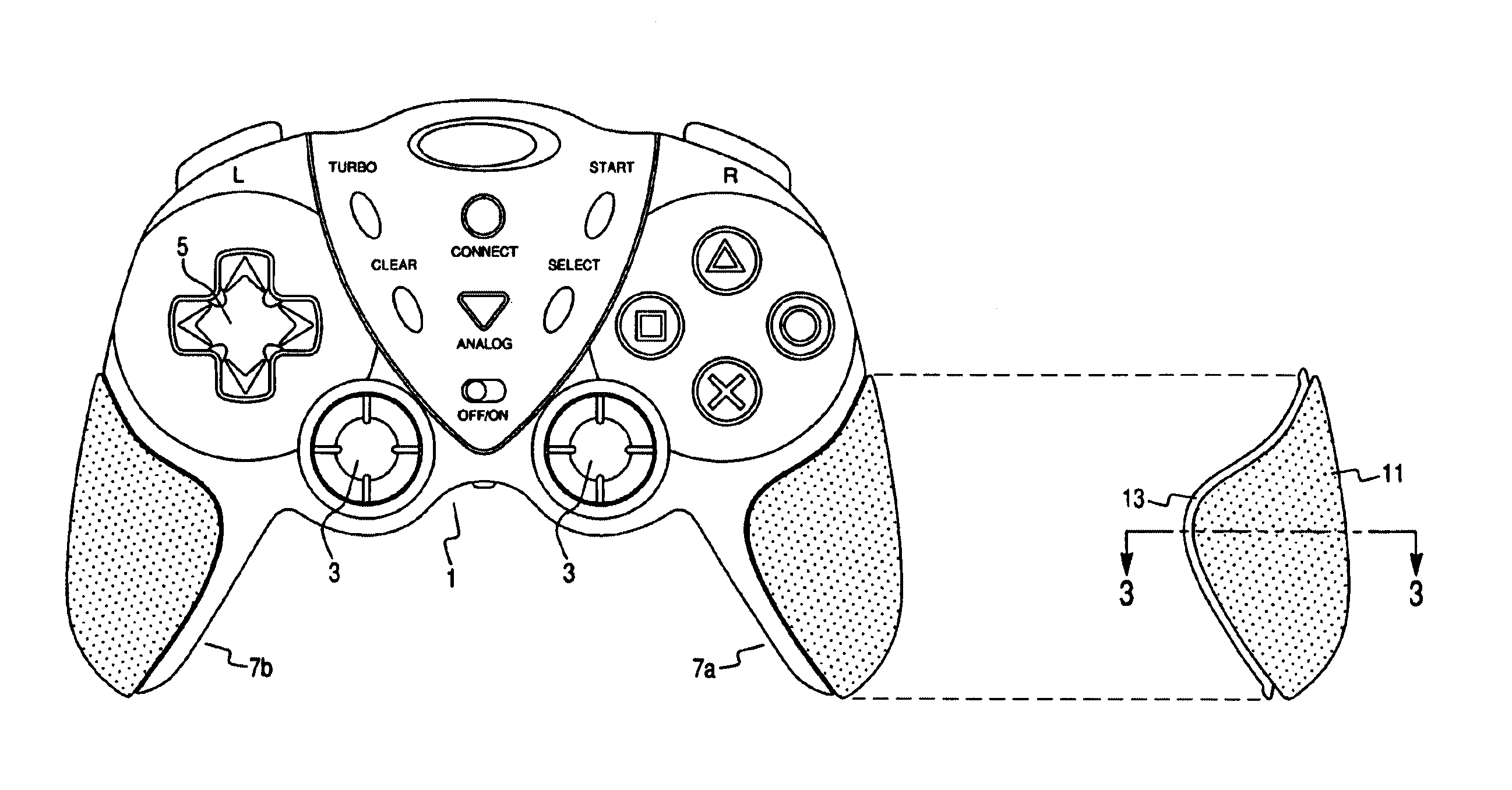

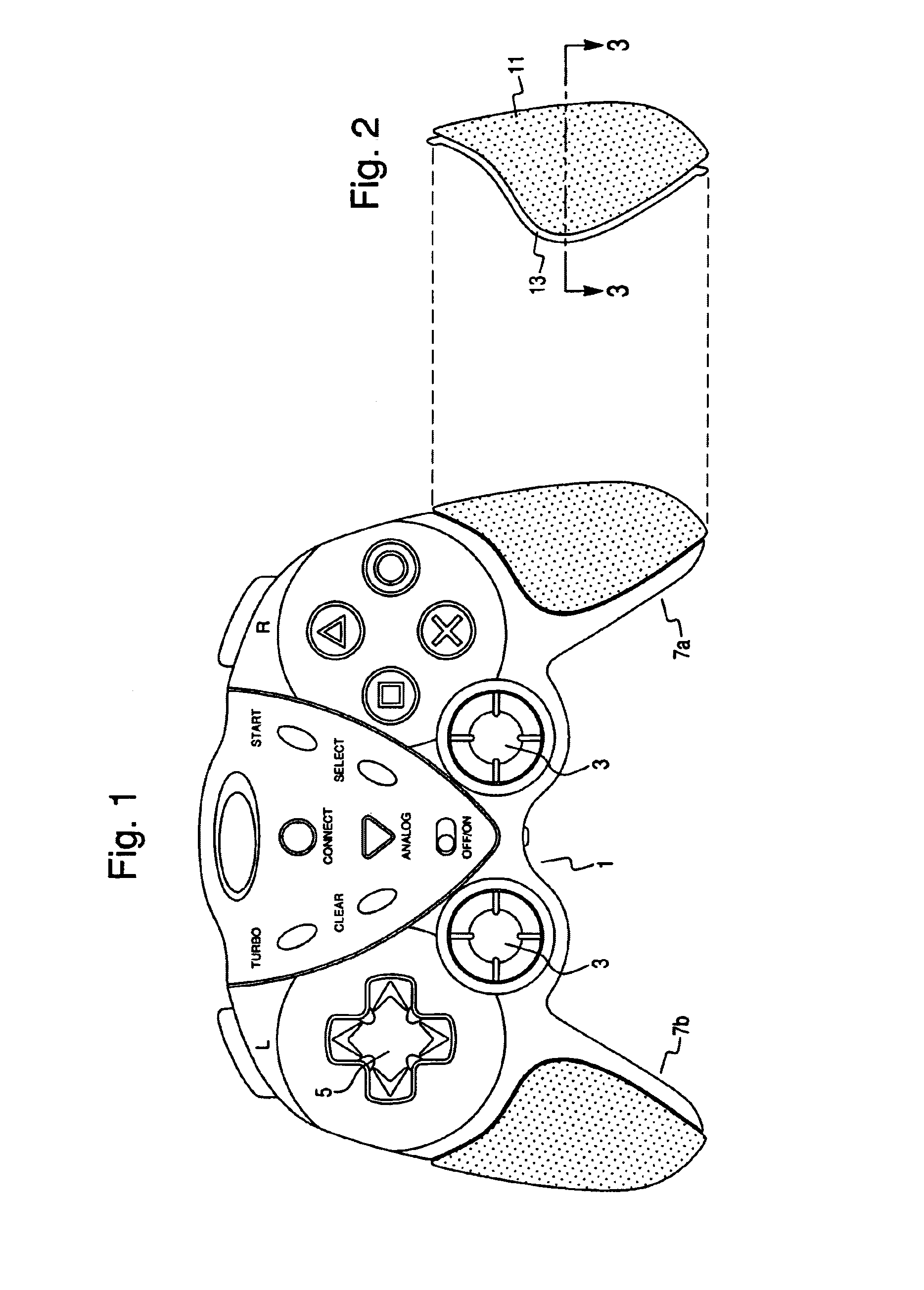

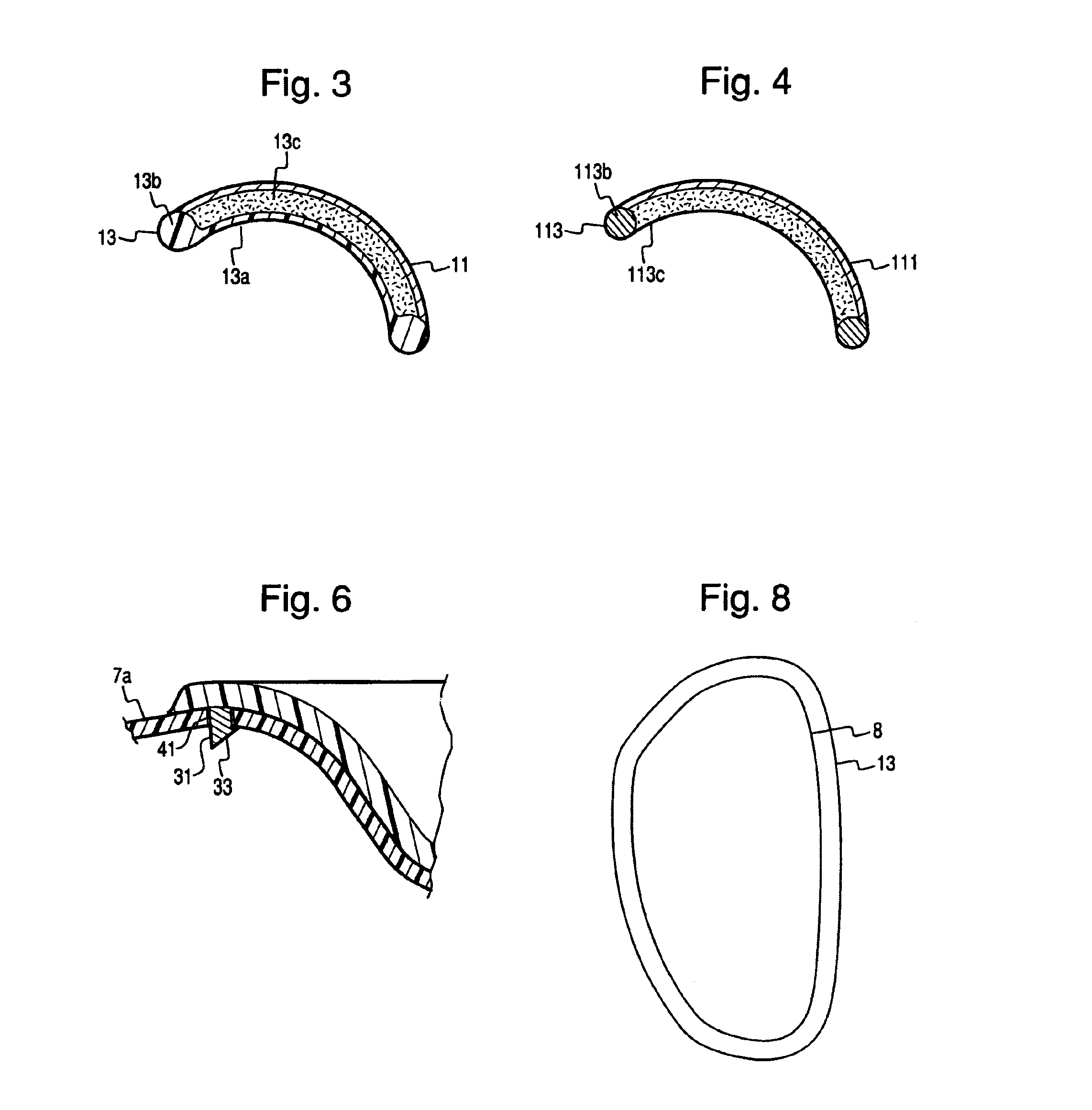

Gel grip controller

The present invention is directed to a controller having a gel-gripping surface for engagement with a user's hand. The controller includes a housing having a plurality of operation members logistically positioned for manipulation by a user's hand. A handle portion adapted to be grasped by the hand of a user includes a deformable gel-grip extending over a substantial portion of the handle. The gel grip includes a flexible external exposed surface containing a semi-liquid flowable material within a cavity portion of the gel-grip. Such an arrangement provides a multi-directional deforming gripping surface with a comfortable feel.

Owner:INTEC INC

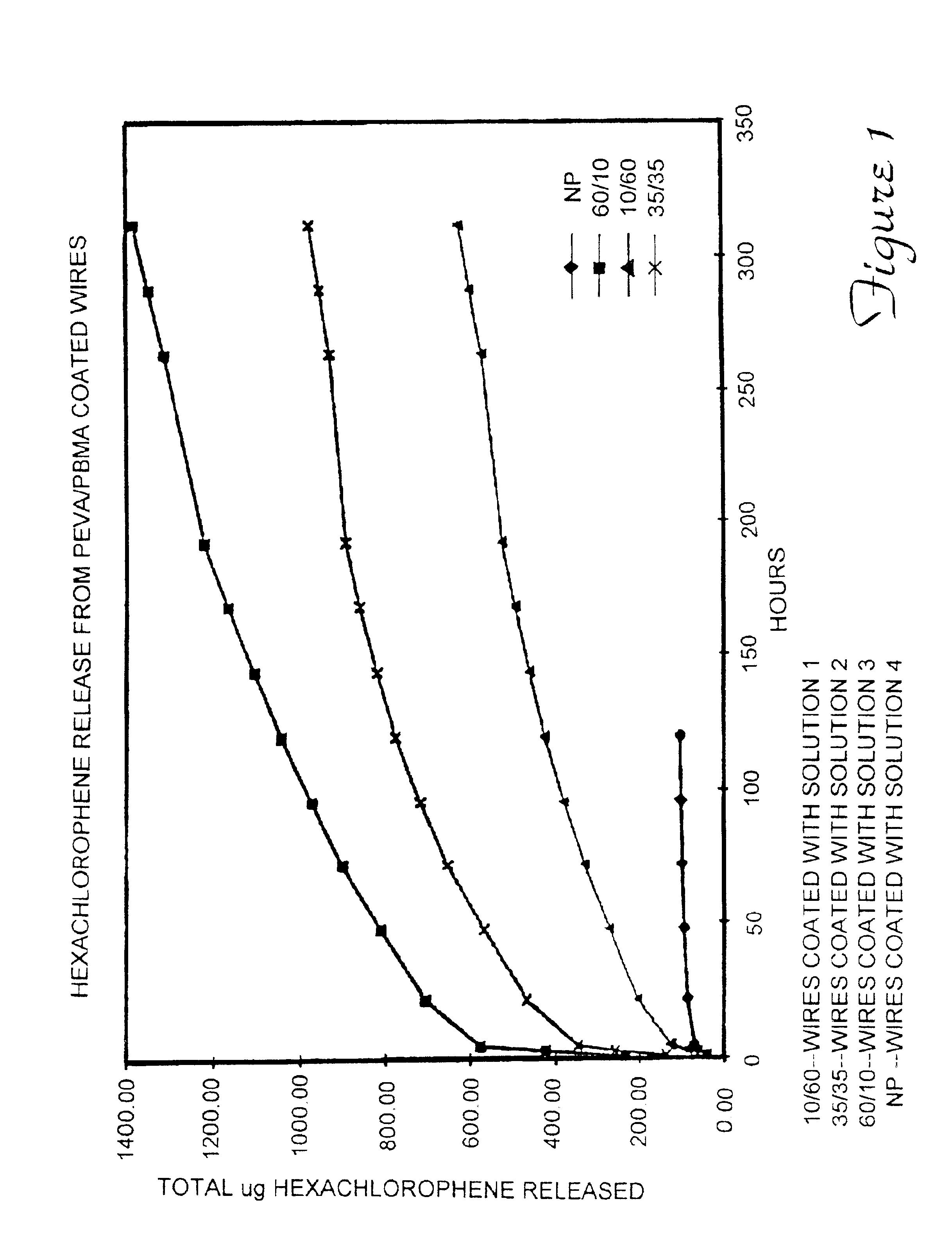

Bioactive agent release coating

A coating composition for use in coating implantable medical devices to improve their ability to release bioactive agents in vivo. The coating composition is particularly adapted for use with devices that undergo significant flexion and / or expansion in the course of their delivery and / or use, such as stents and catheters. The composition includes the bioactive agent in combination with a mixture of a first polymer component such as poly(butyl methacrylate) and a second polymer component such as poly(ethylene-co-vinyl acetate).

Owner:SURMODICS INC

Systems and methods for providing a flushable catheter assembly

ActiveUS8388583B2Maintain positionPrevent buildupGlovesPretreated surfacesCATHETER ADAPTERBiological activation

A flushable catheter assembly having features to enable selective activation of fluid flow through the catheter assembly is disclosed herein. A septum is placed within the catheter adapter of the catheter assembly and includes a pathway that is closed prior to being biased open via a septum activator also positioned within the catheter adapter. A plurality of air vent channels is interposed between the septum and the inner surface of the catheter adapter to permit “flashback” of blood during insertion of the catheter into a patient. The septum activator is advanced through the pathway of the septum as a coupler is attached to a proximal opening of the catheter adapter.

Owner:BECTON DICKINSON & CO

Combination of antimicrobial agents and bacterial interference to coat medical devices

This invention relates to a method for coating a medical device comprising the steps of applying to at least a portion of the surface of said medical device, an antimicrobial coating layer and a non-pathogenic bacterial coating layer, wherein the antimicrobial and non-pathogenic bacterial coating layers inhibit the growth of pathogenic bacterial and fungal organisms. The non-pathogenic bacterium used in the bacterial coating layer is resistant to the antimicrobial agent. Furthermore, the non-pathogenic bacterium layer includes at least one of the following: viable whole cells, non-viable whole cells, or cellular structures or extracts. The antimicrobial agent and non-pathogenic bacterium are used to develop a kit comprising these compositions in one container or in separate containers. The kit is used to coat a catheter prior to implantation in a mammal.

Owner:BAYLOR COLLEGE OF MEDICINE

Method of selective coating of articles

InactiveUS6106889AConvenient coatingImprove production efficiencyGlovesPharmaceutical containersWater soluble polymersWater soluble

Articles such as medical devices are selectively coated with a lubricious coating. A temporary coating, formed from an aqueous solution of a water-soluble polymer of low to moderate molecular weight, is painted onto those portions of the article which are to remain free of any coating in the final product. Then, the entire article is coated with a material which forms a lubricious coating. The article is then soaked in water to loosen the coatings at the locations at which the temporary coating was applied. The coatings are cleanly removed from those locations, leaving an article with a lubricious coating in some portions, and which is uncoated in the remaining portions. The process can be used in coating portions of catheters, surgical gloves, contact lenses, and any other articles which require a lubricious coating only on a portion of the surface of the article.

Owner:BIOCOAT

Method for fabricating a coating for a medical device

Methods for fabricating coatings for implantable medical devices are disclosed. The coatings include blends of hydrophilic and hydrophobic polymers. The methods provide for treatment of the coatings to cause enrichment a region close to the outer surface of the coating with the hydrophilic polymers.

Owner:ABBOTT CARDIOVASCULAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com