Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153 results about "Negative pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative thought patterns are repetitive, unhelpful thoughts. They directly cause what we could describe as ‘negative’ (unwanted or unpleasant) emotions like anxiety, depression, stress, fear, unworthiness, shame etc.

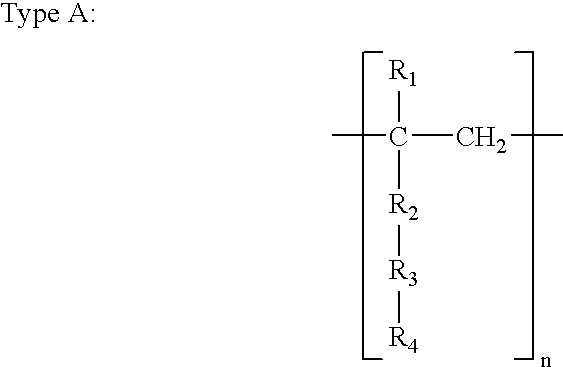

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

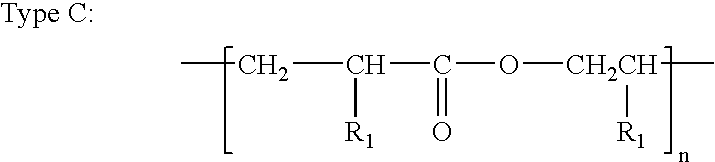

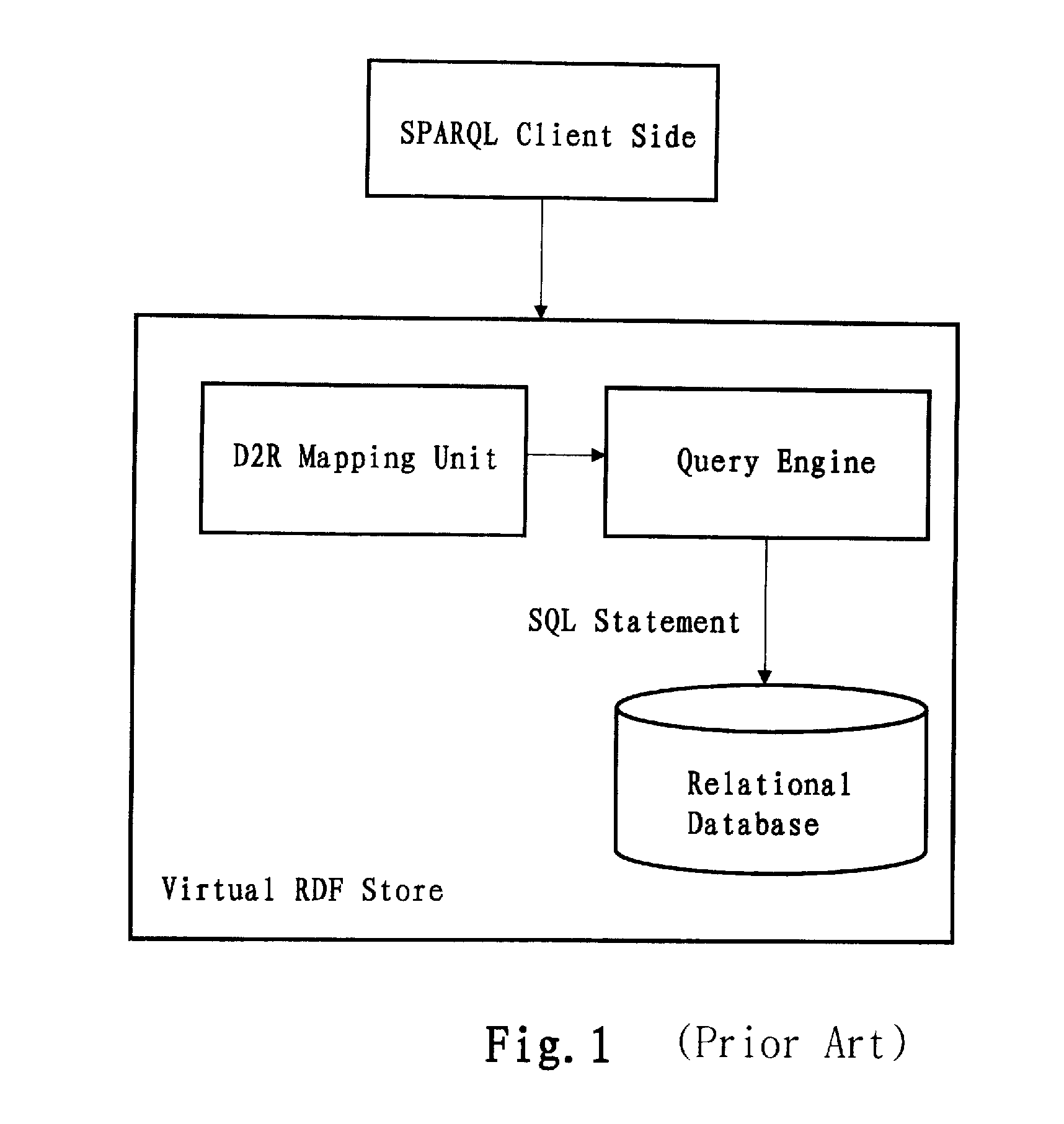

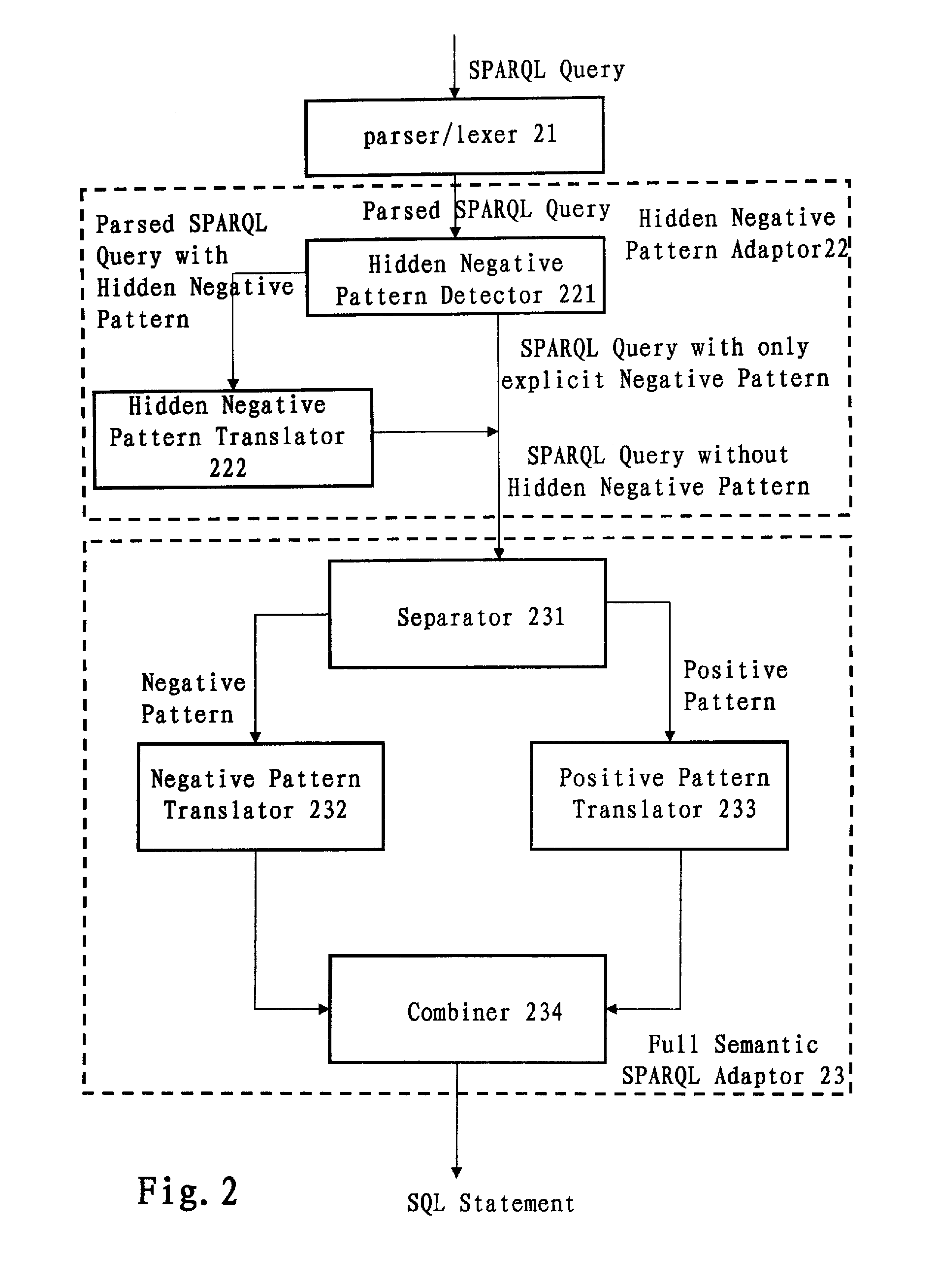

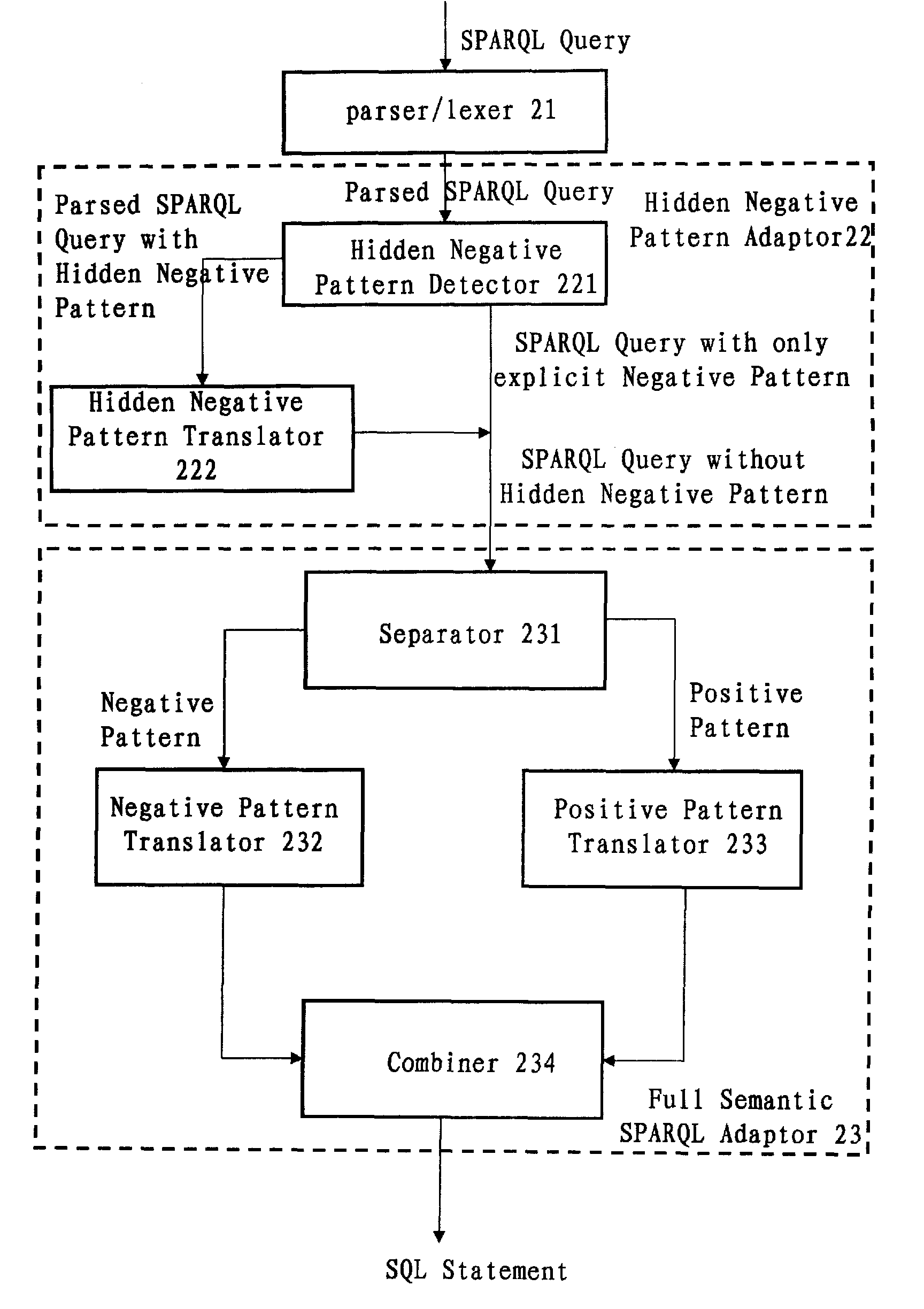

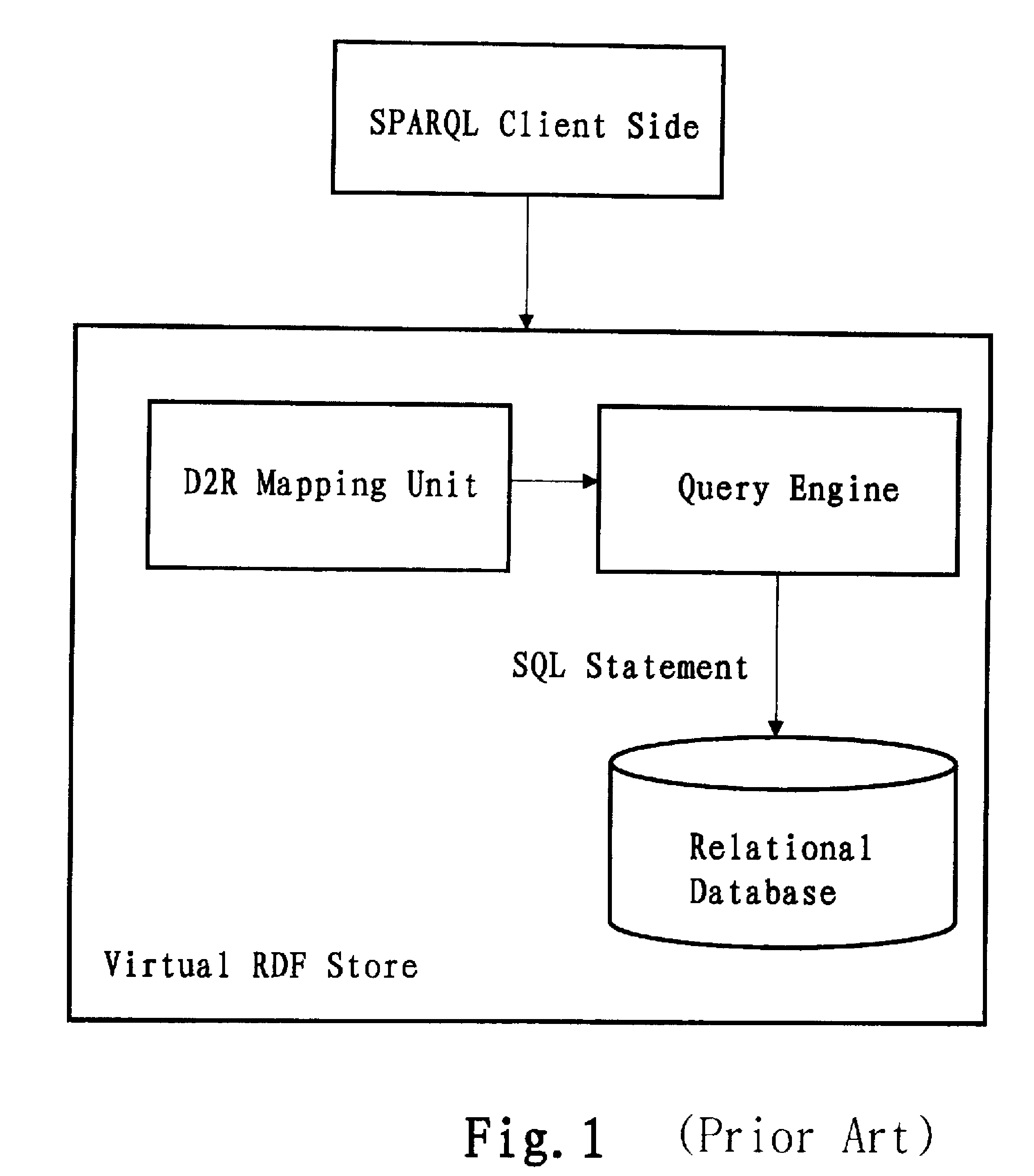

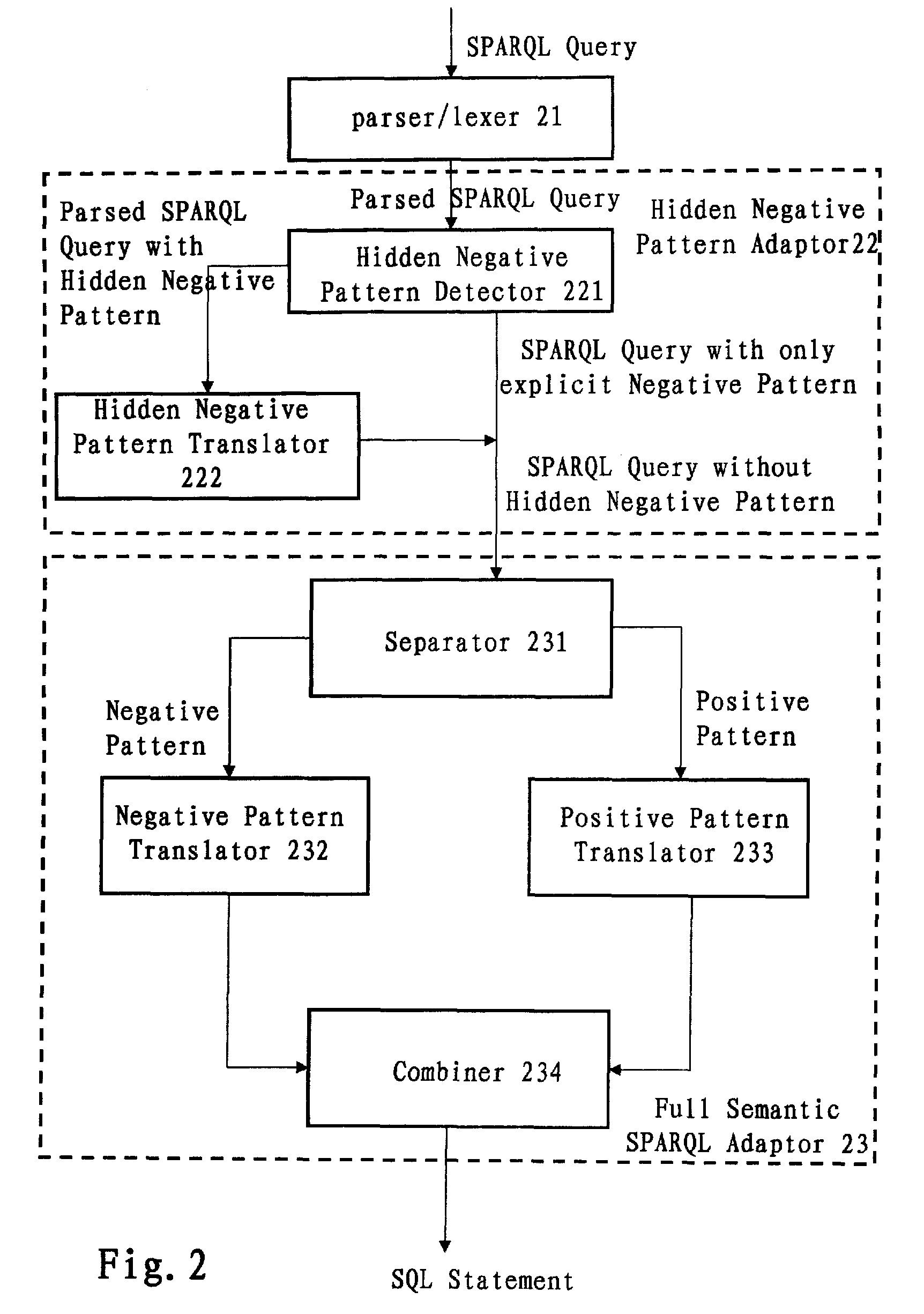

Translation system and method for sparql queries

InactiveUS20100250577A1Efficiently translatedDigital data information retrievalDigital data processing detailsLexical analysisPattern detection

A computer-implemented system and method for translating a SPARQL query. The system includes: a parser / lexer for parsing the SPARQL query; a hidden negative pattern detector for detecting a hidden negative pattern in the parsed SPARQL query; a hidden negative pattern translator for translating the detected hidden negative pattern into an explicit negative pattern; a separator for separating the explicit negative pattern from a positive pattern in the parsed SPARQL query; a negative pattern translator for translating the explicit negative pattern into a negative portion of an SQL statement; a positive pattern translator for translating the positive pattern into a positive portion of the SQL statement; and an SQL statement combiner for combining the negative portion of the SQL statement with the positive portion of the SQL statement.

Owner:IBM CORP

Translation system and method for SPARQL queries

InactiveUS8275784B2Efficiently translatedDigital data information retrievalDigital data processing detailsLexical analysisTheoretical computer science

A computer-implemented system and method for translating a SPARQL query. The system includes: a parser / lexer for parsing the SPARQL query; a hidden negative pattern detector for detecting a hidden negative pattern in the parsed SPARQL query; a hidden negative pattern translator for translating the detected hidden negative pattern into an explicit negative pattern; a separator for separating the explicit negative pattern from a positive pattern in the parsed SPARQL query; a negative pattern translator for translating the explicit negative pattern into a negative portion of an SQL statement; a positive pattern translator for translating the positive pattern into a positive portion of the SQL statement; and an SQL statement combiner for combining the negative portion of the SQL statement with the positive portion of the SQL statement.

Owner:IBM CORP

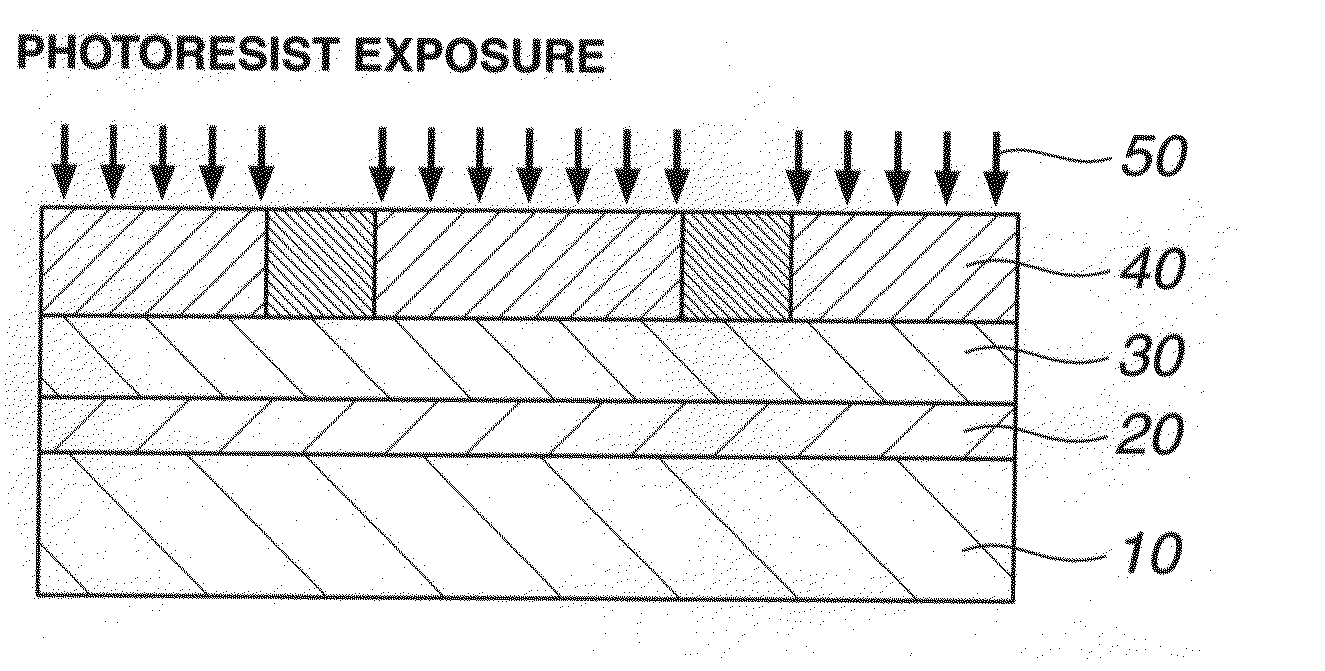

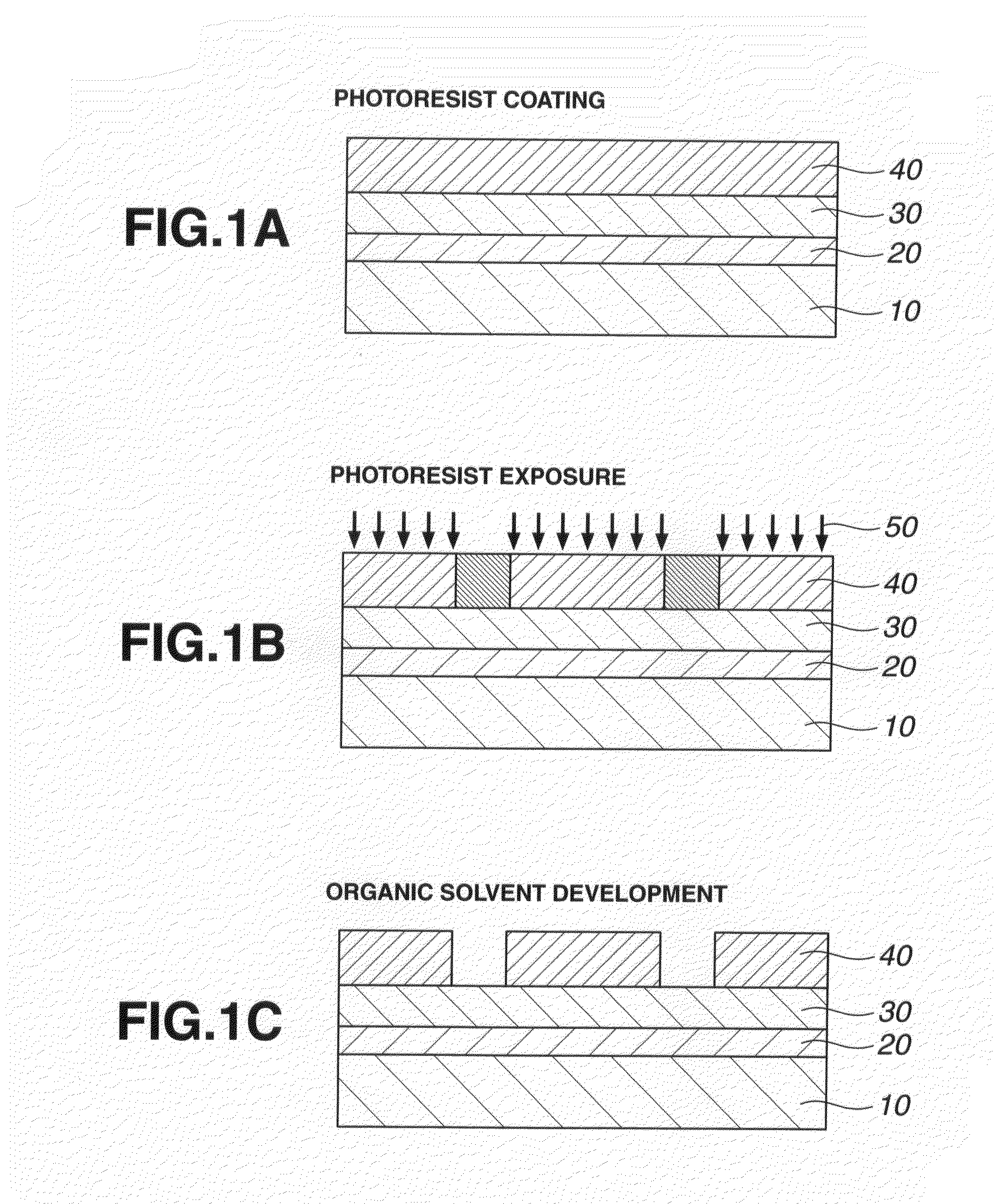

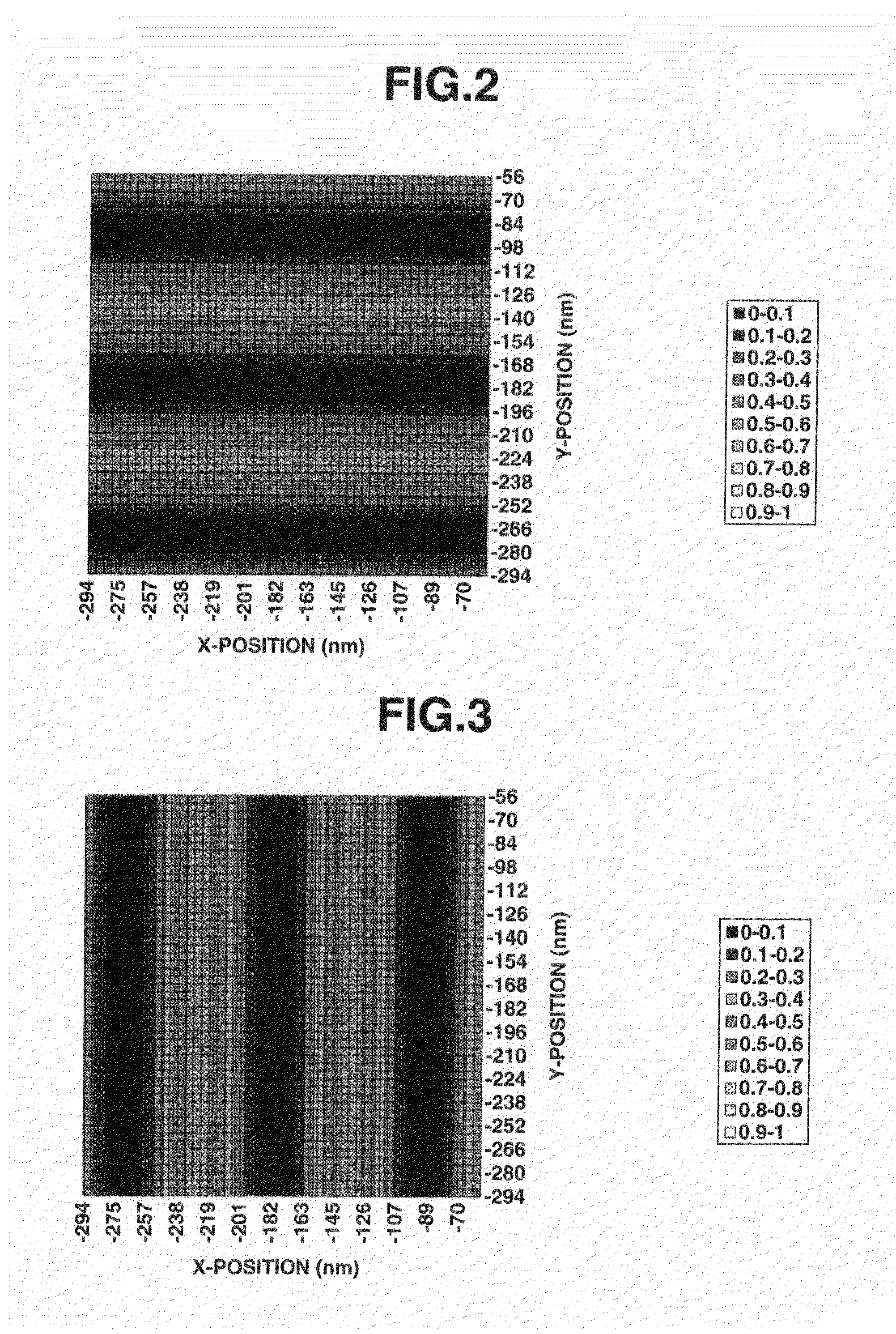

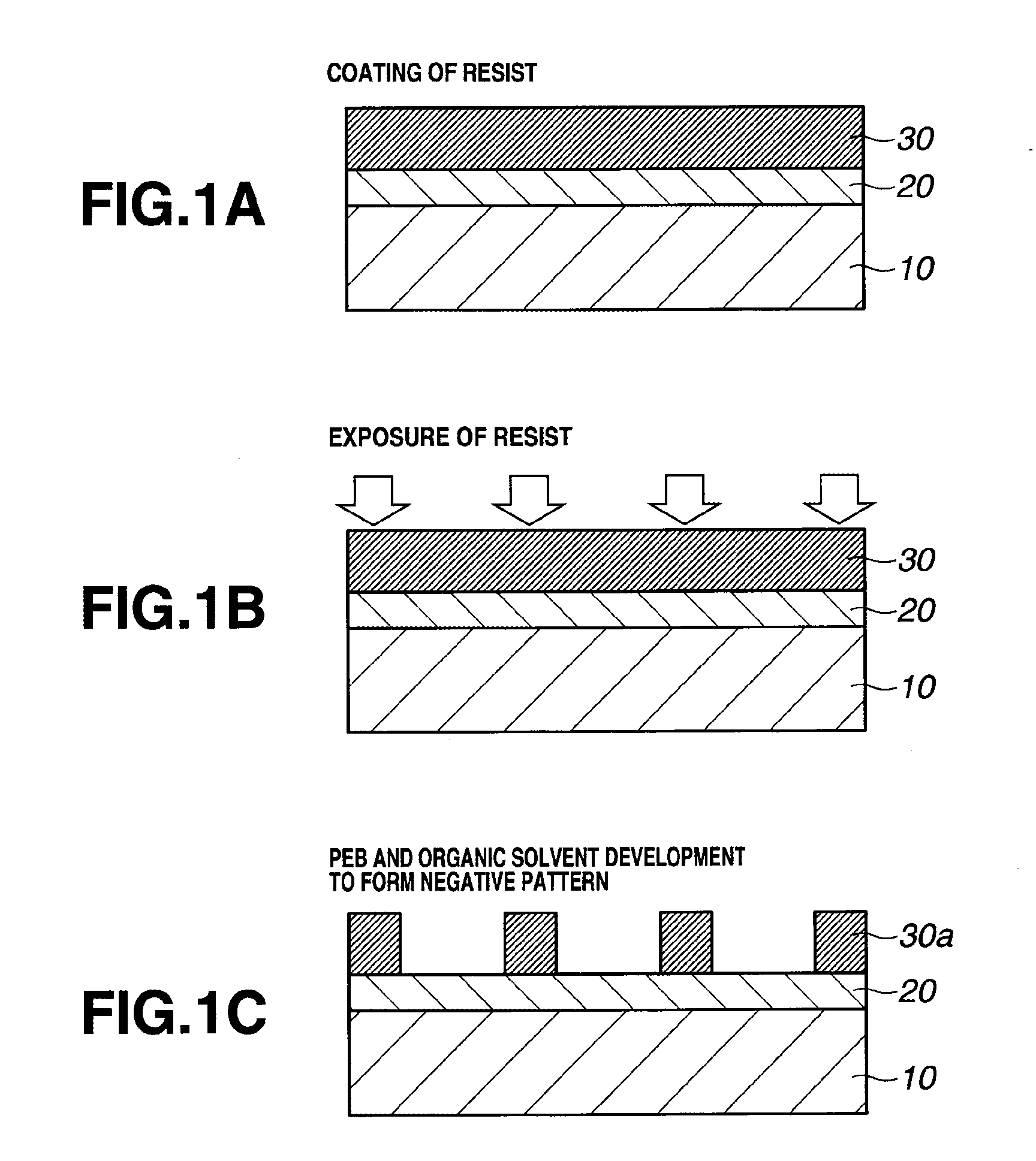

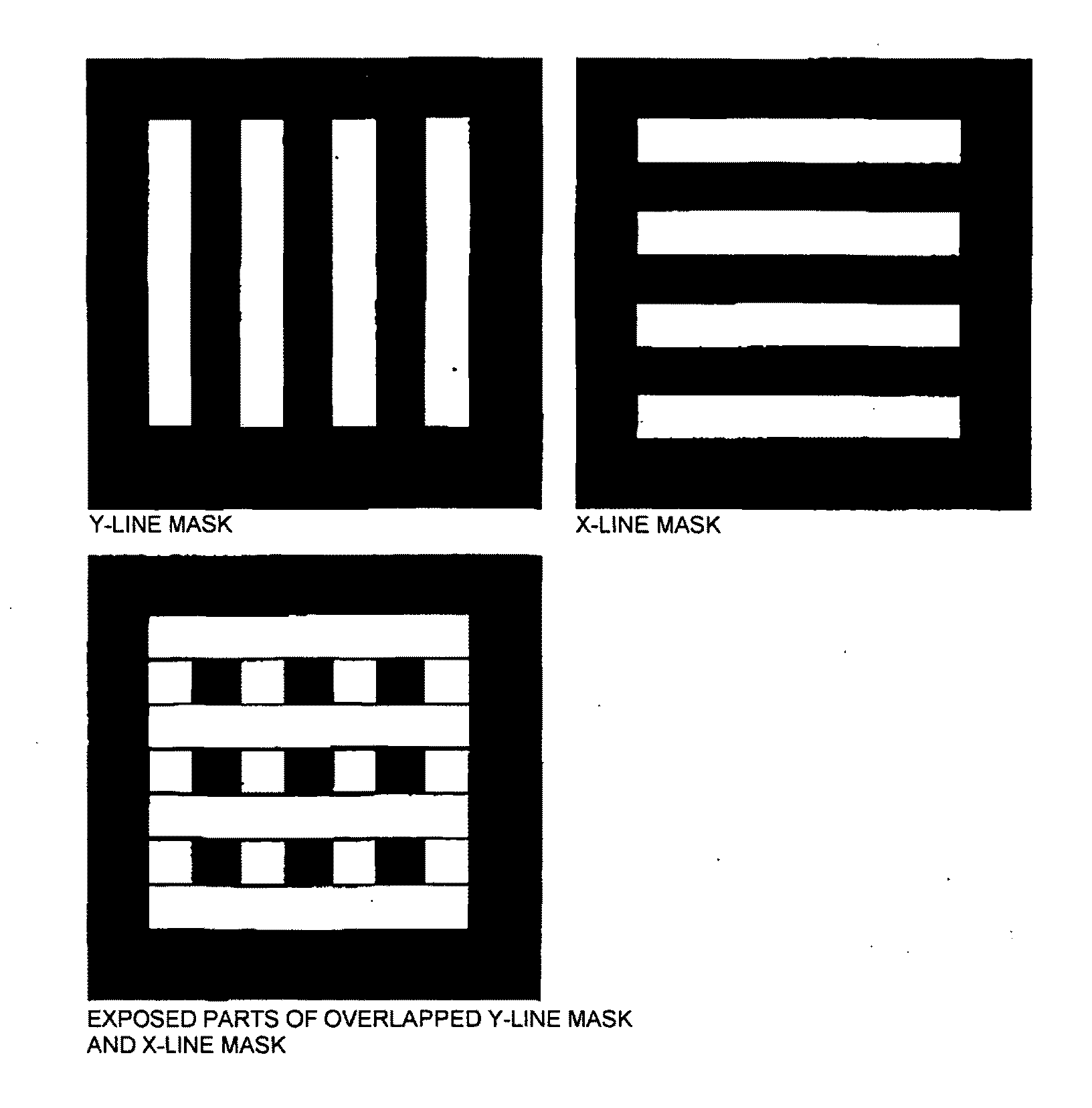

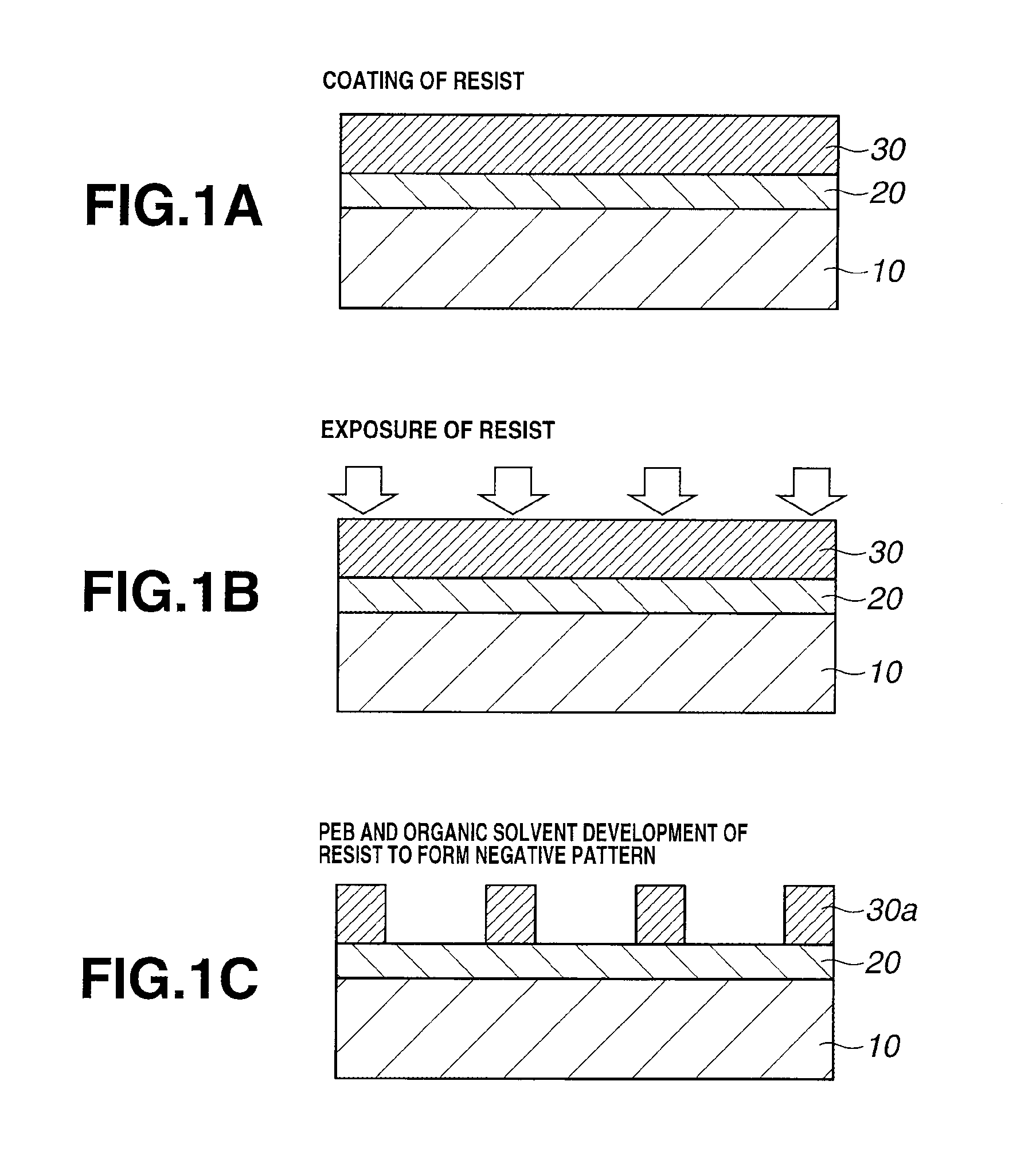

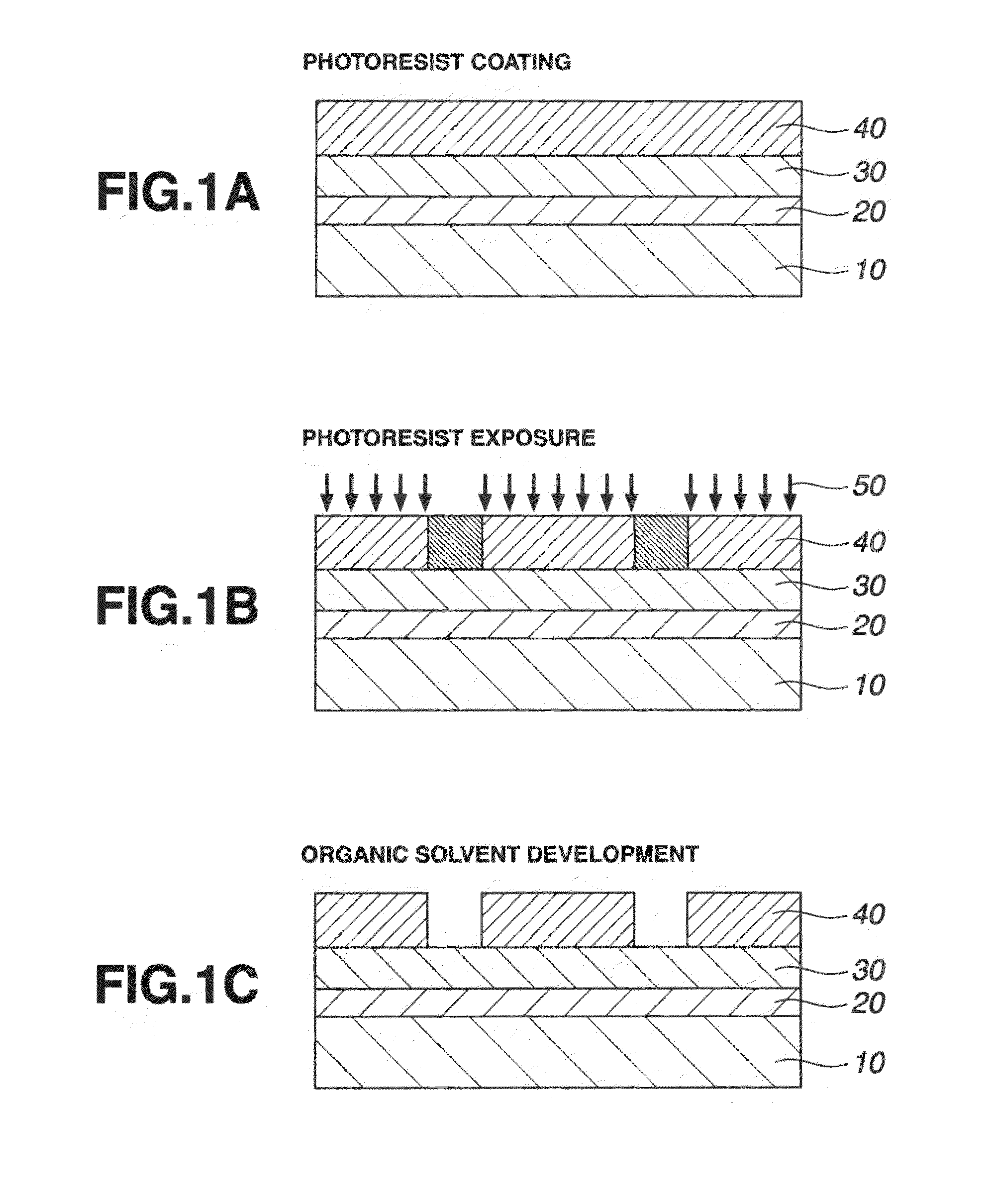

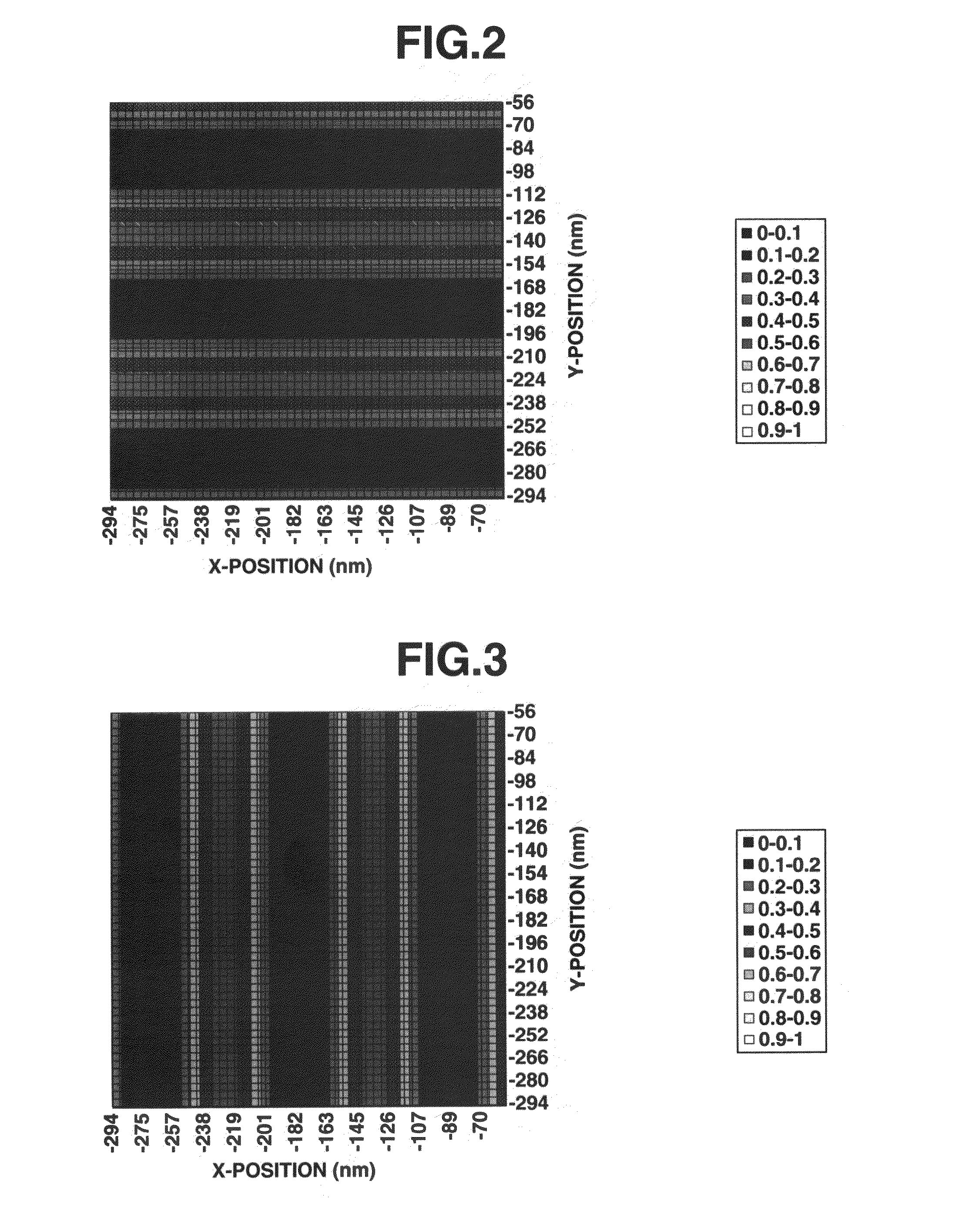

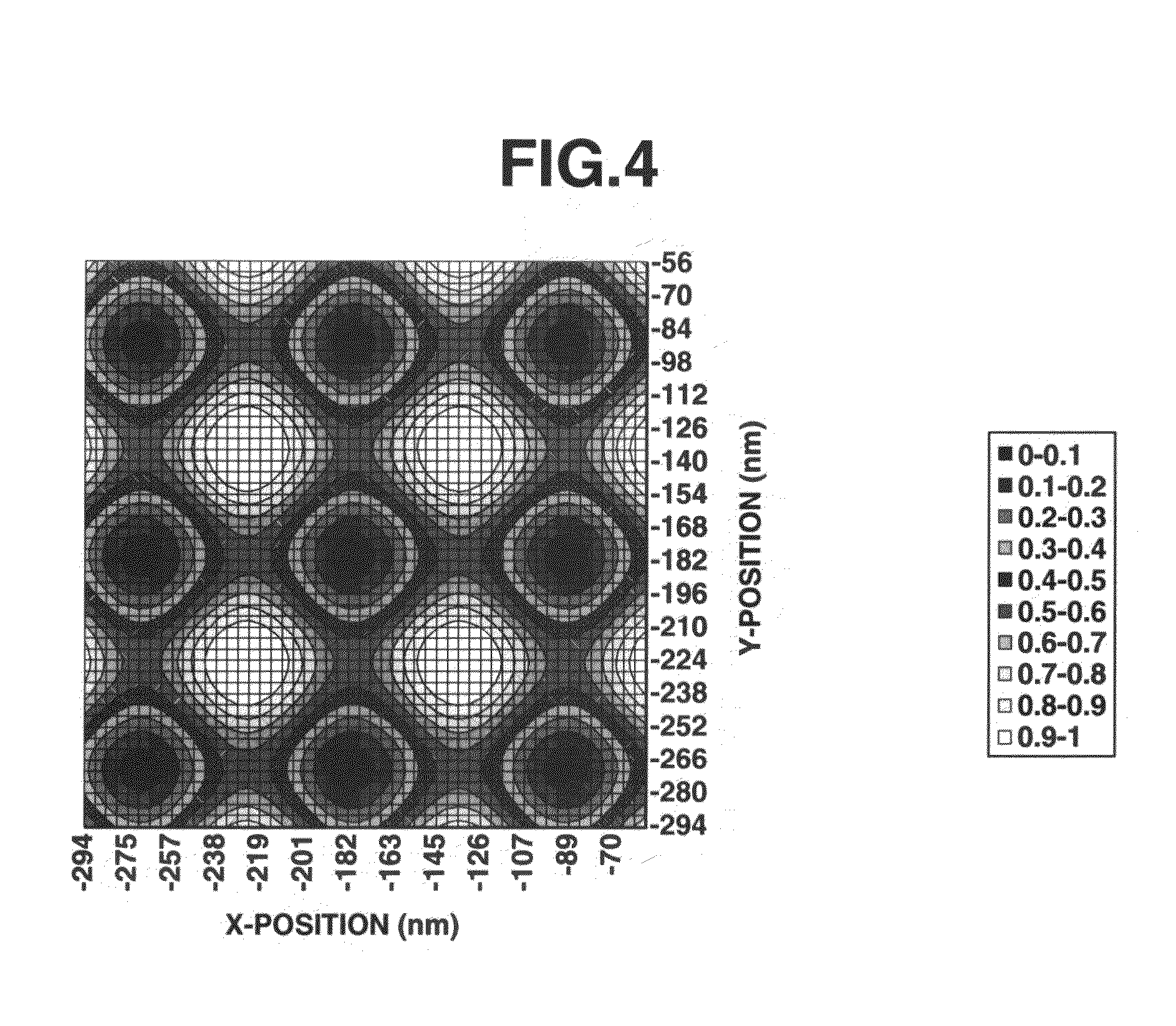

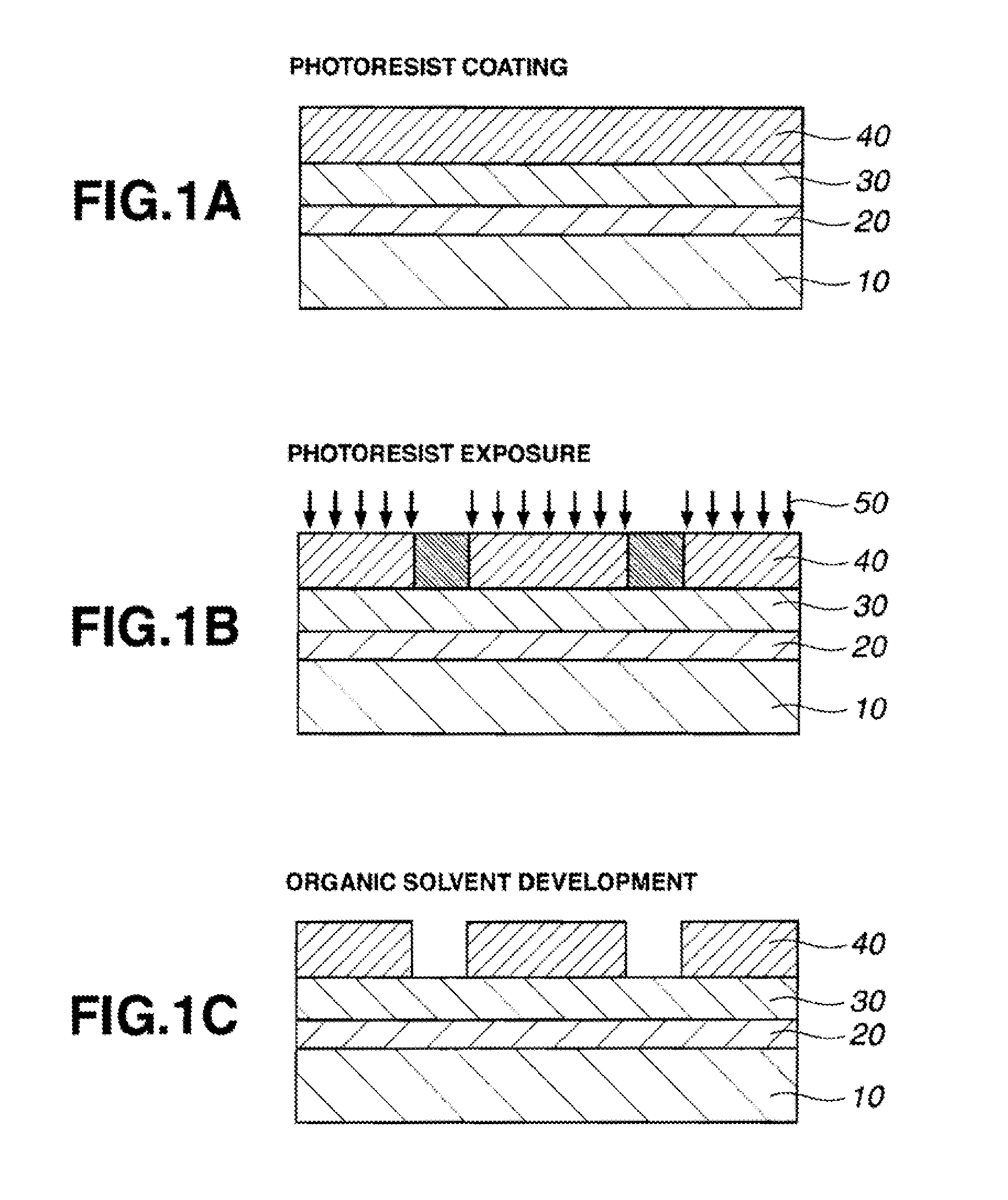

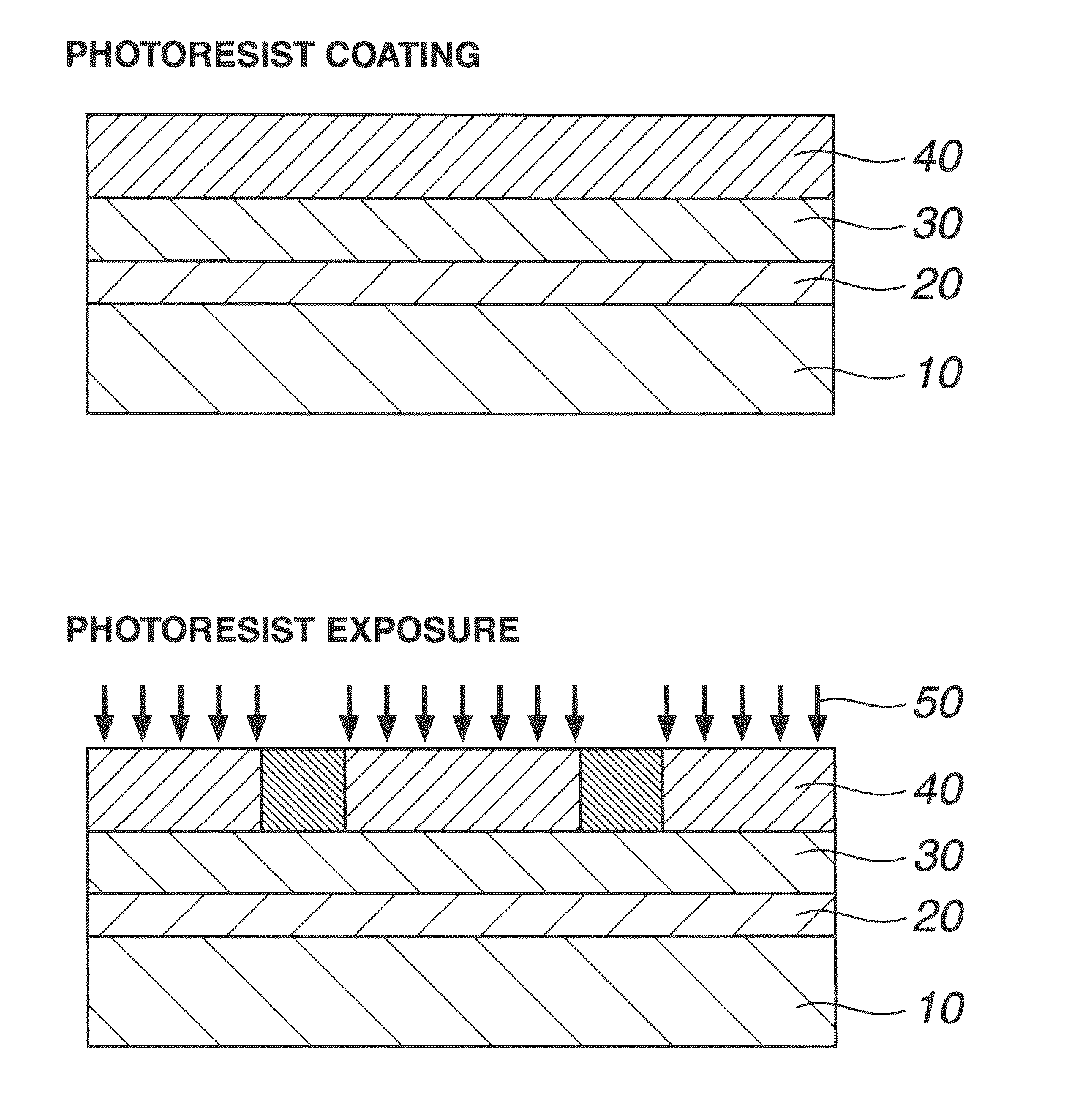

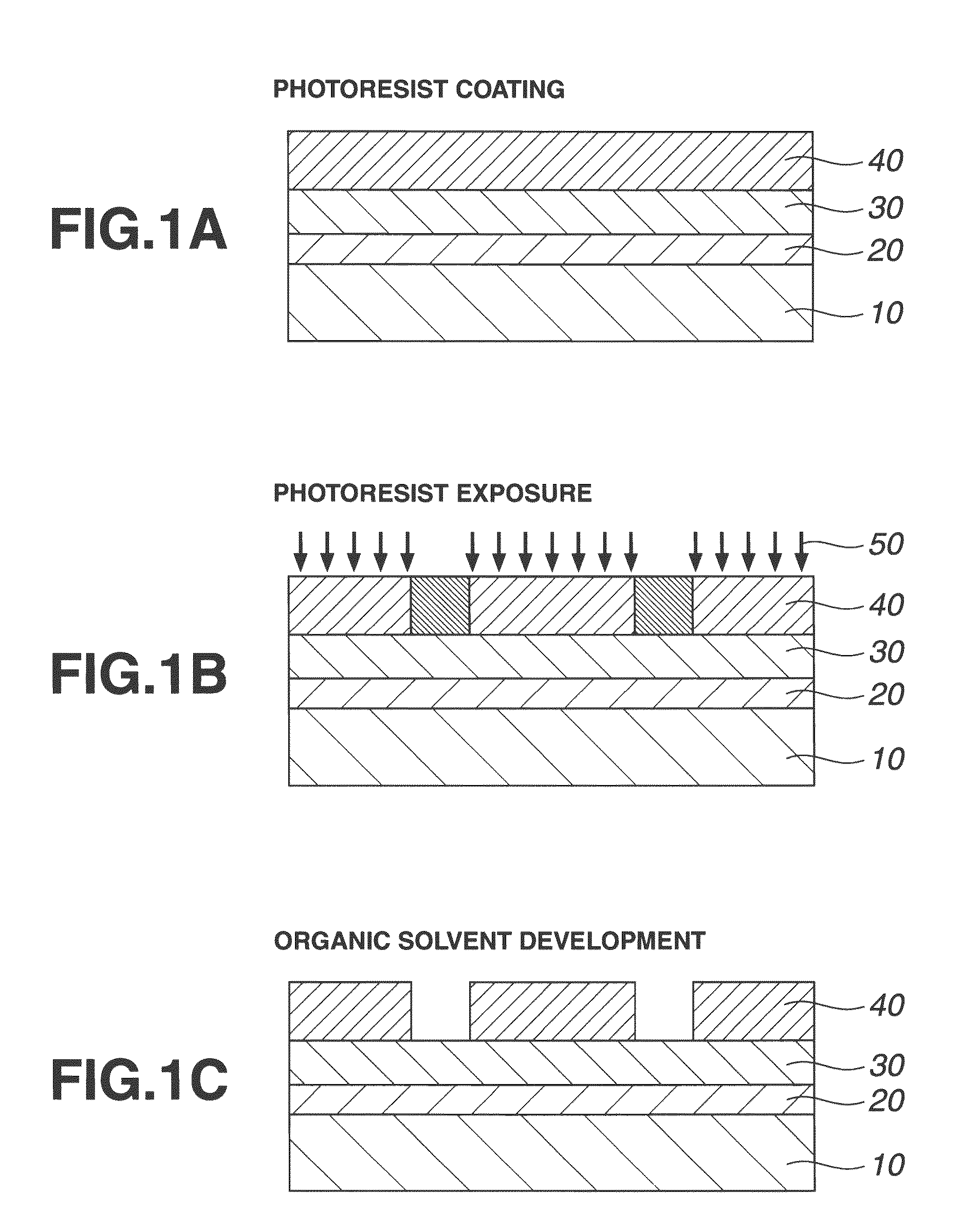

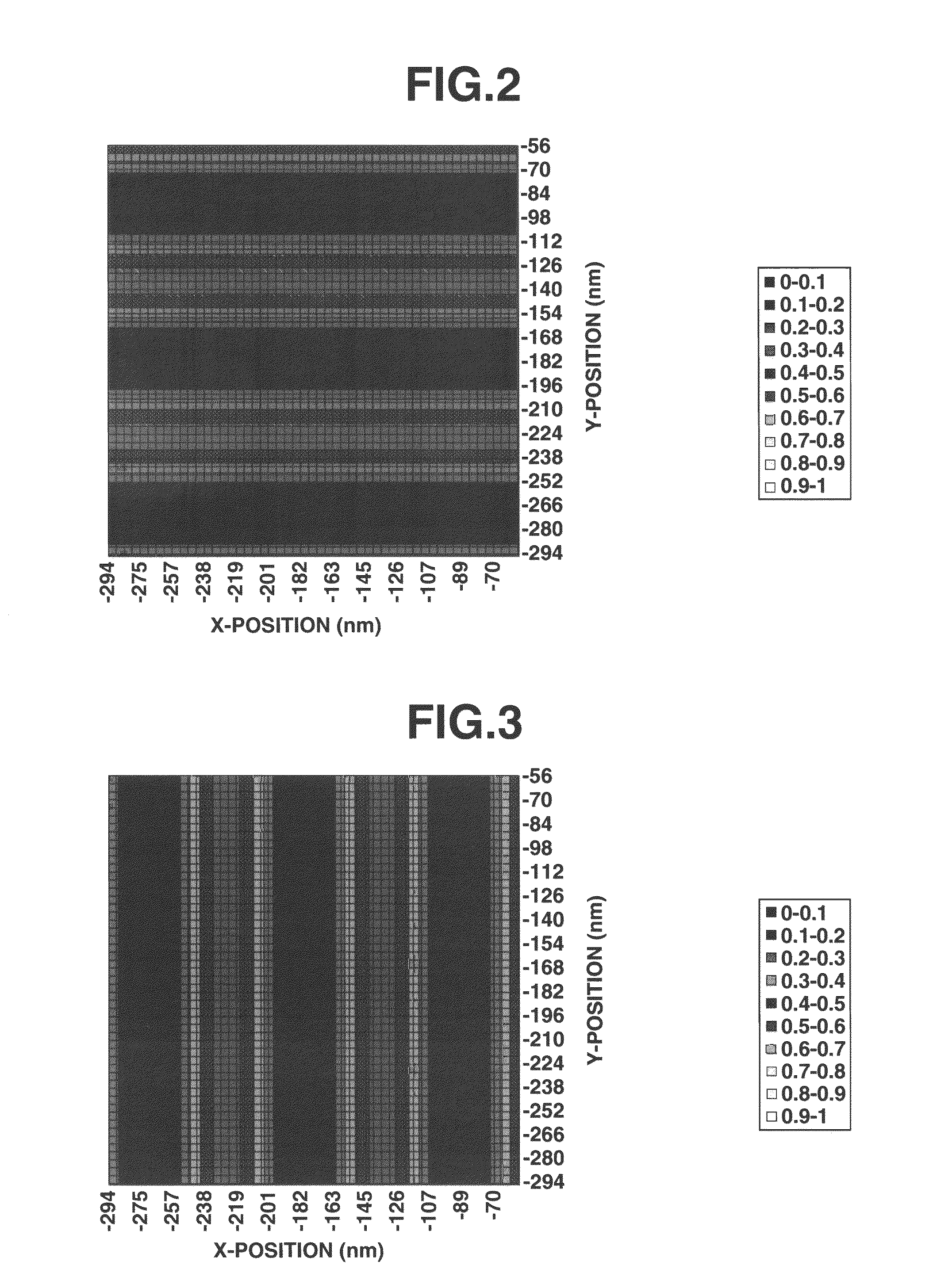

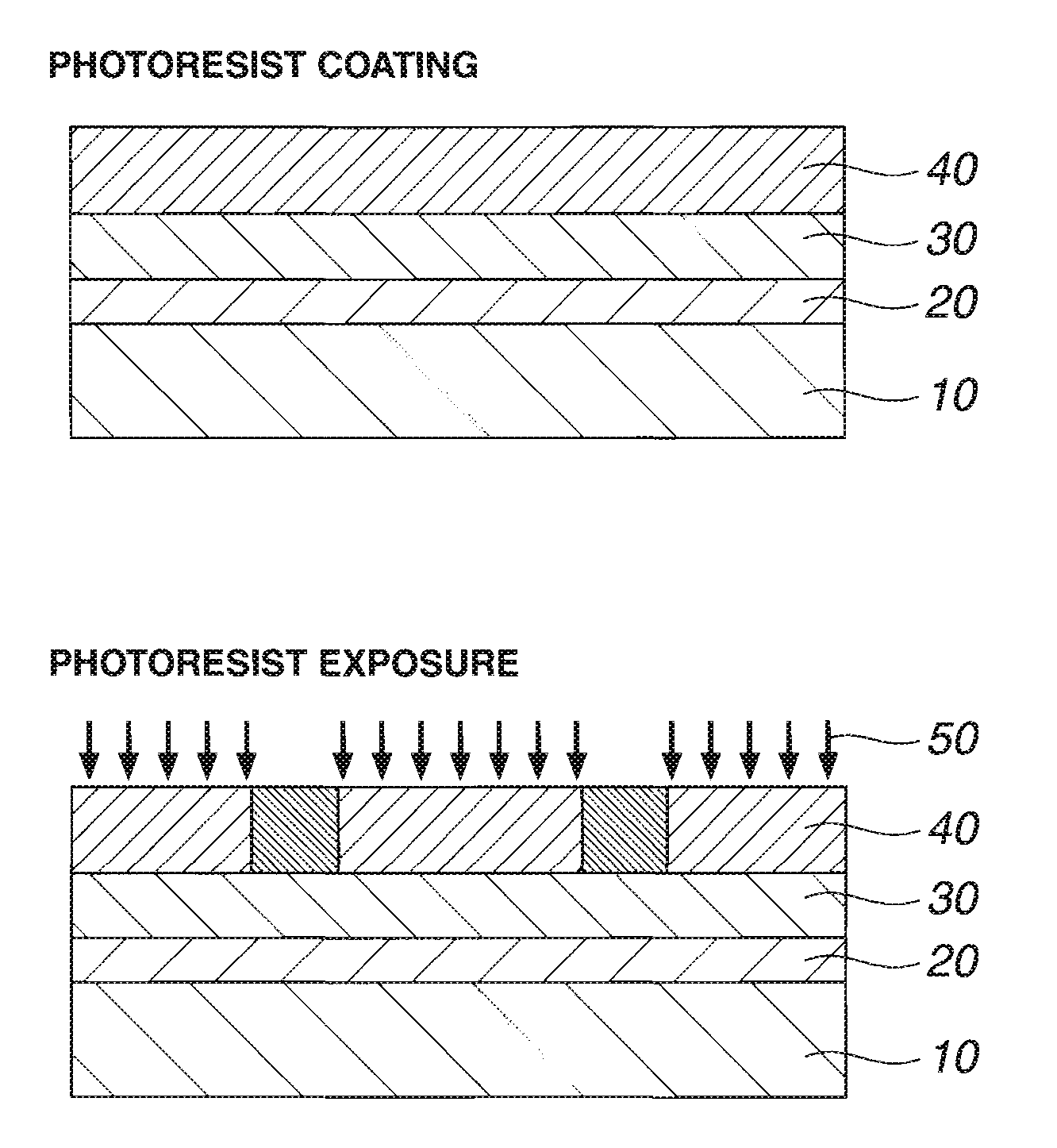

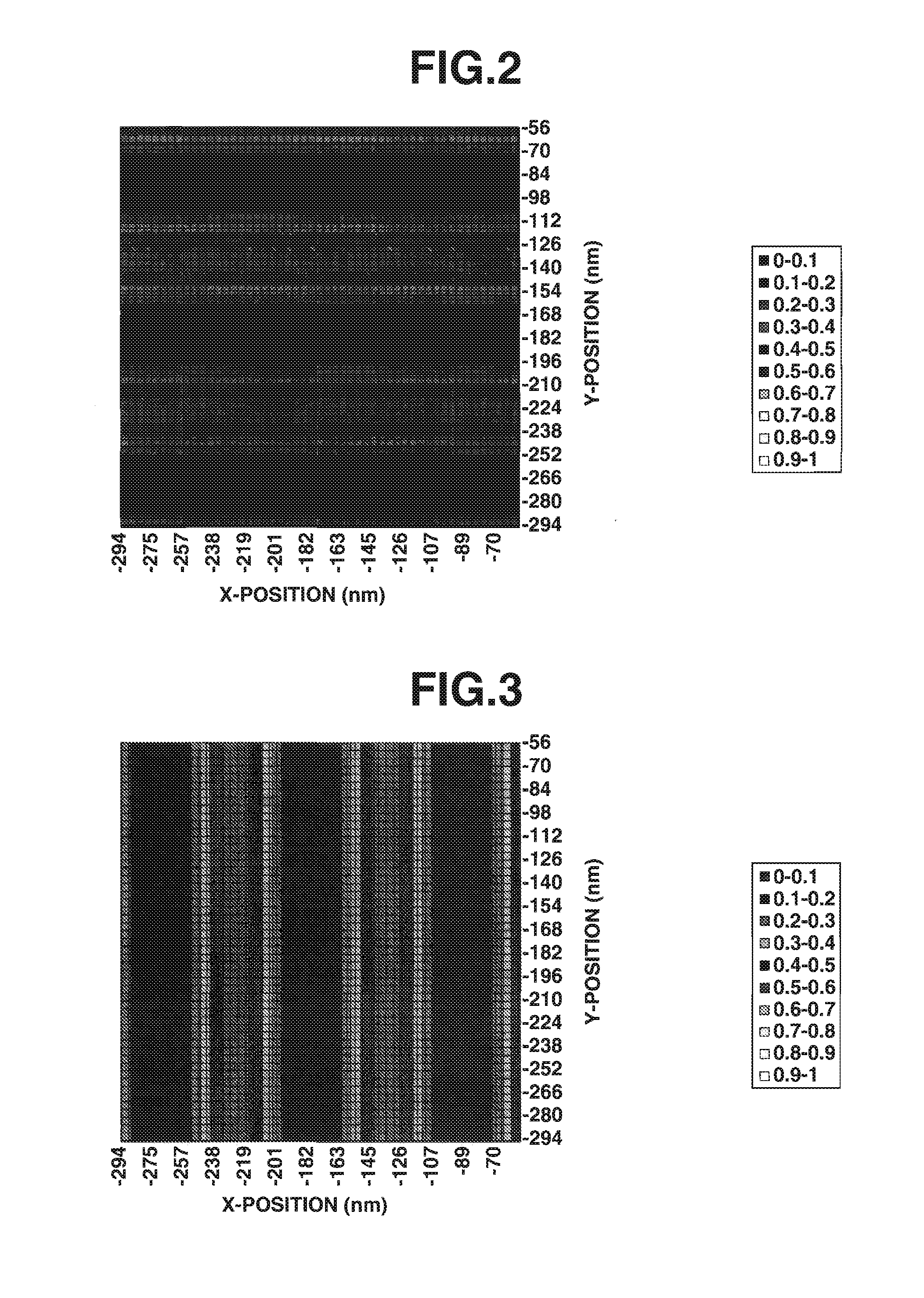

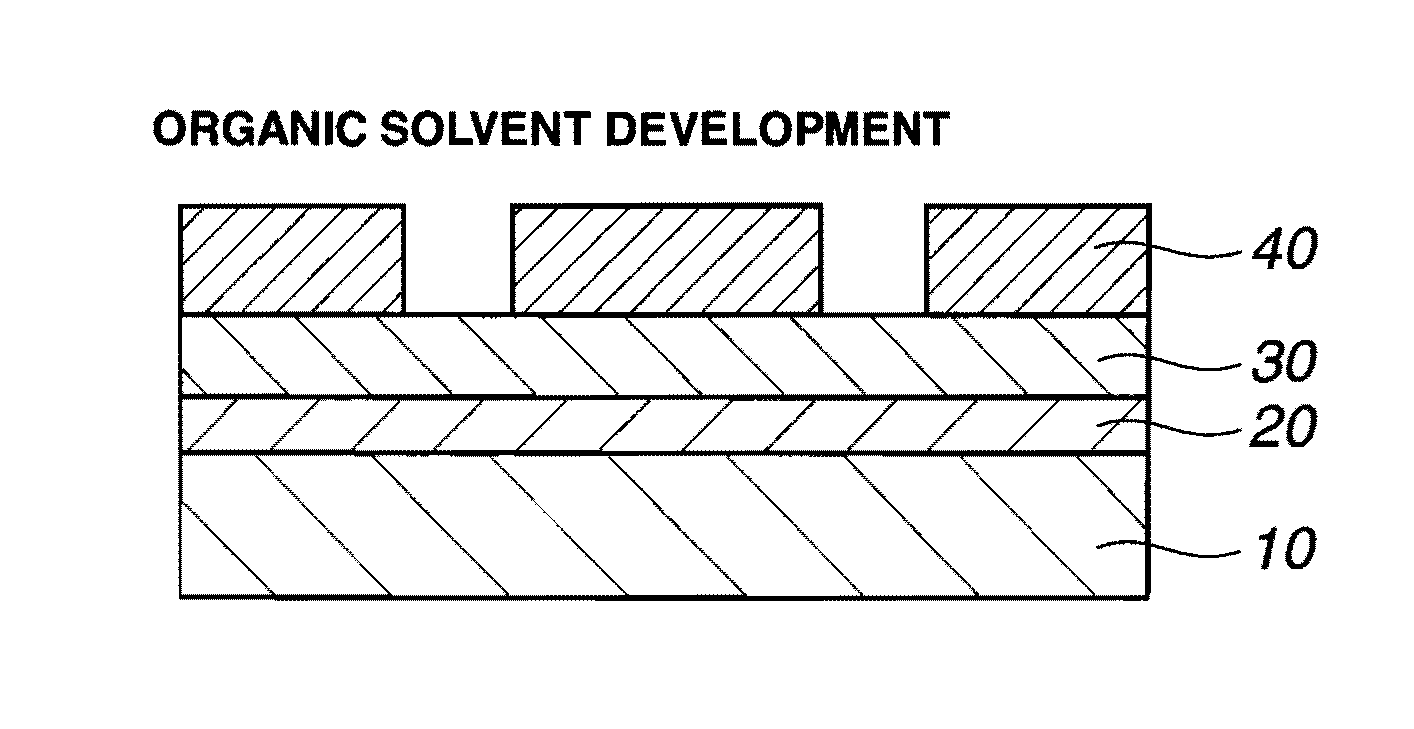

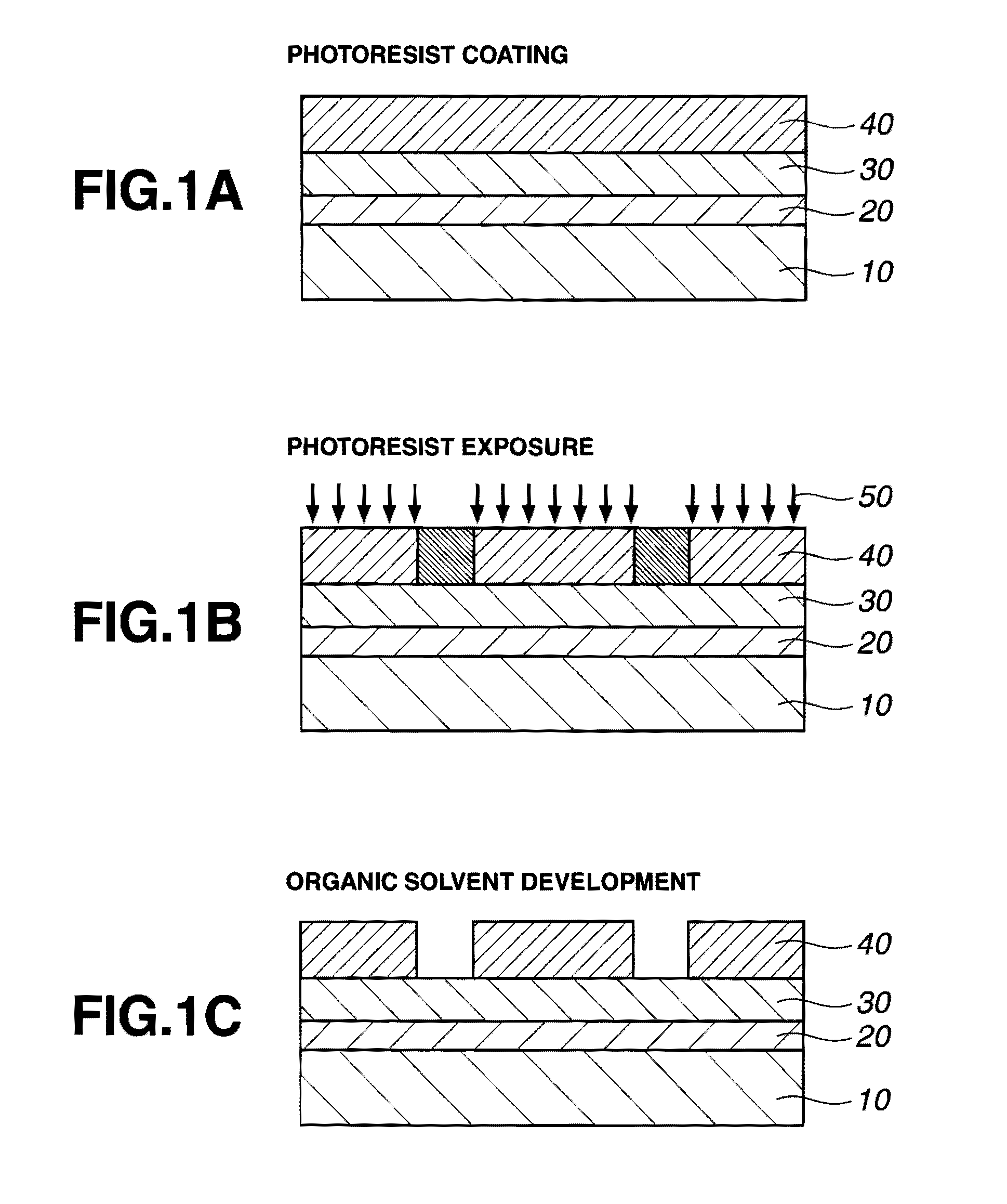

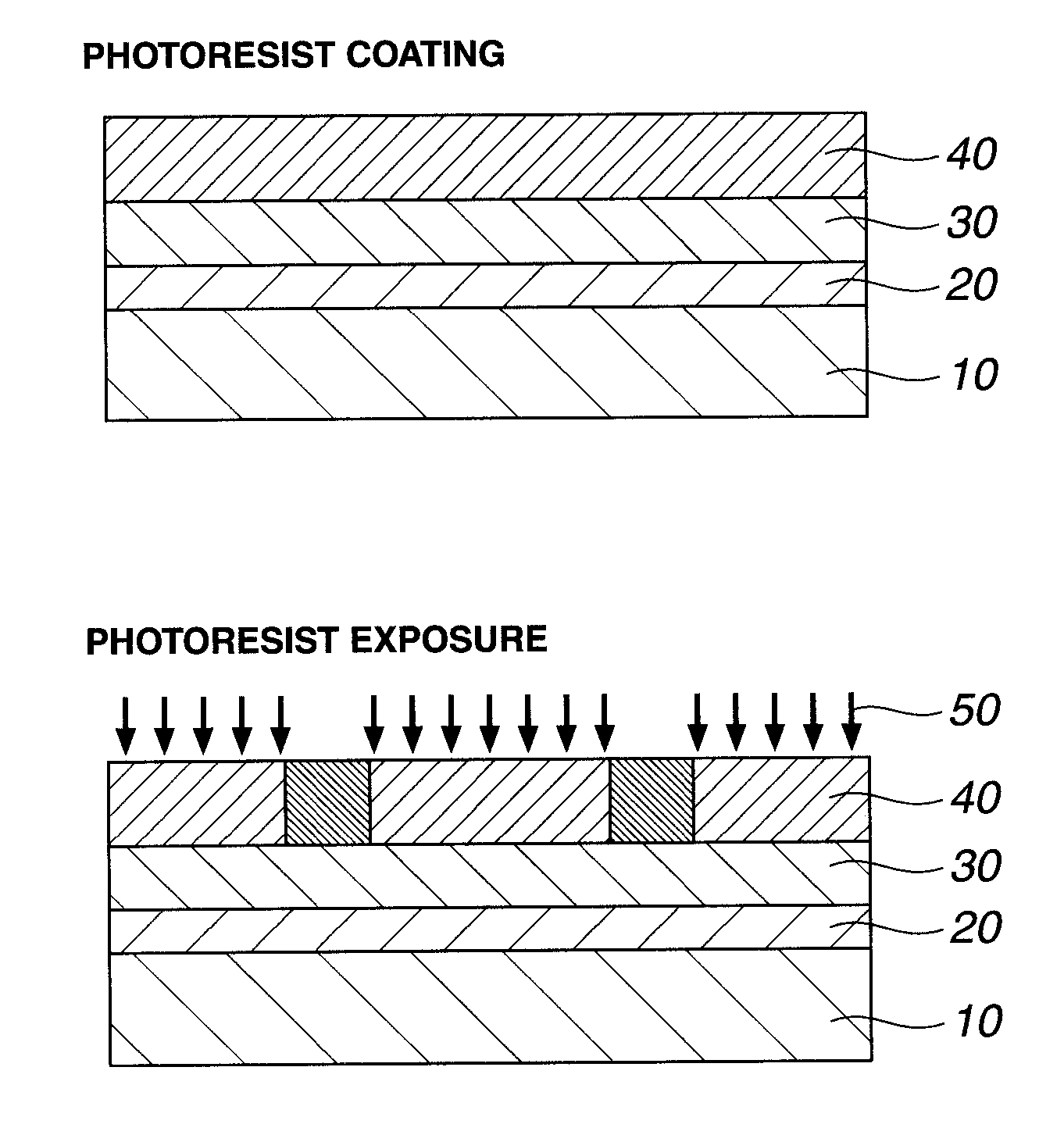

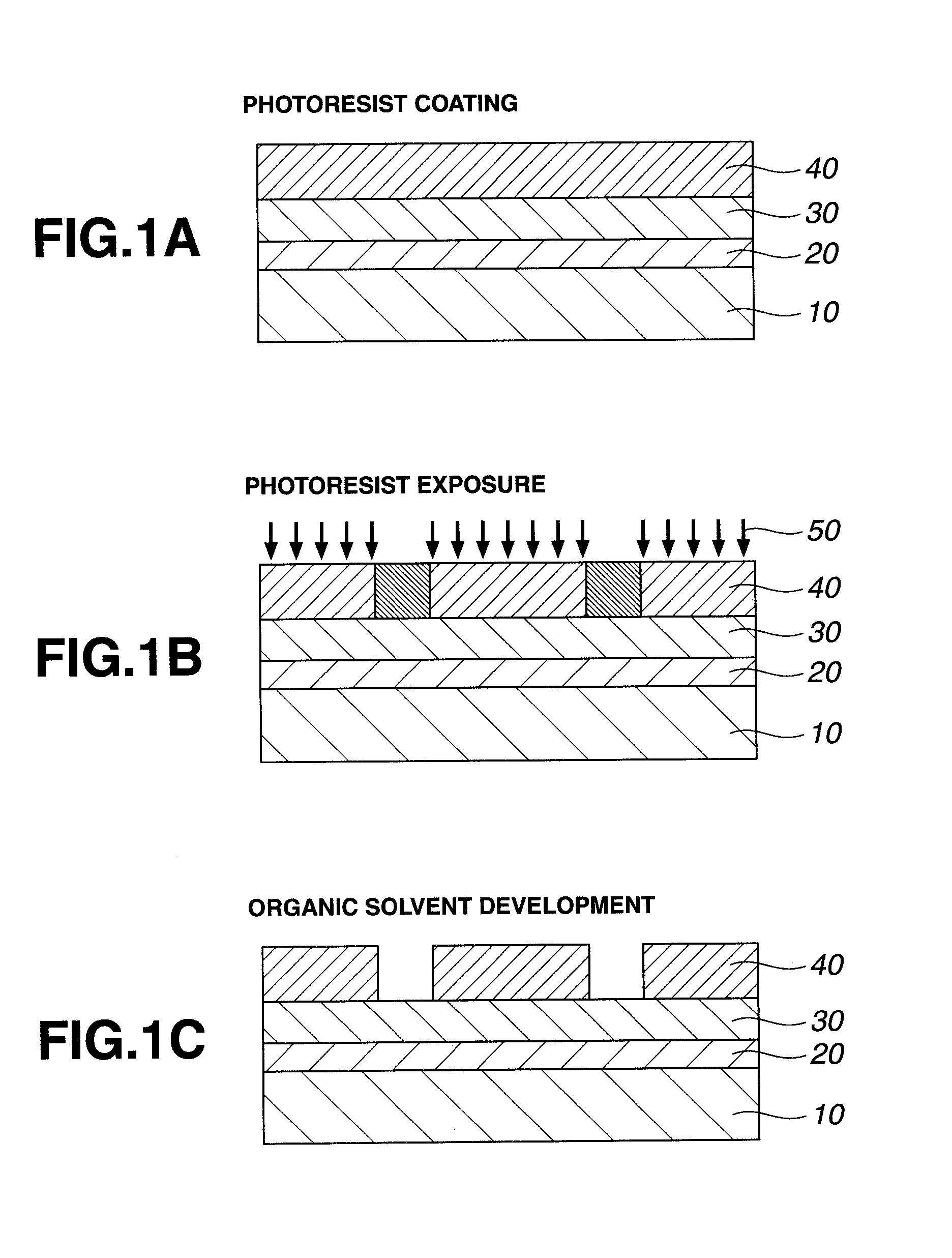

Patterning process

ActiveUS20110177462A1High dissolution contrastHigh dimensional control accuracyPhotosensitive materialsPhotomechanical exposure apparatusOrganic solventHigh energy

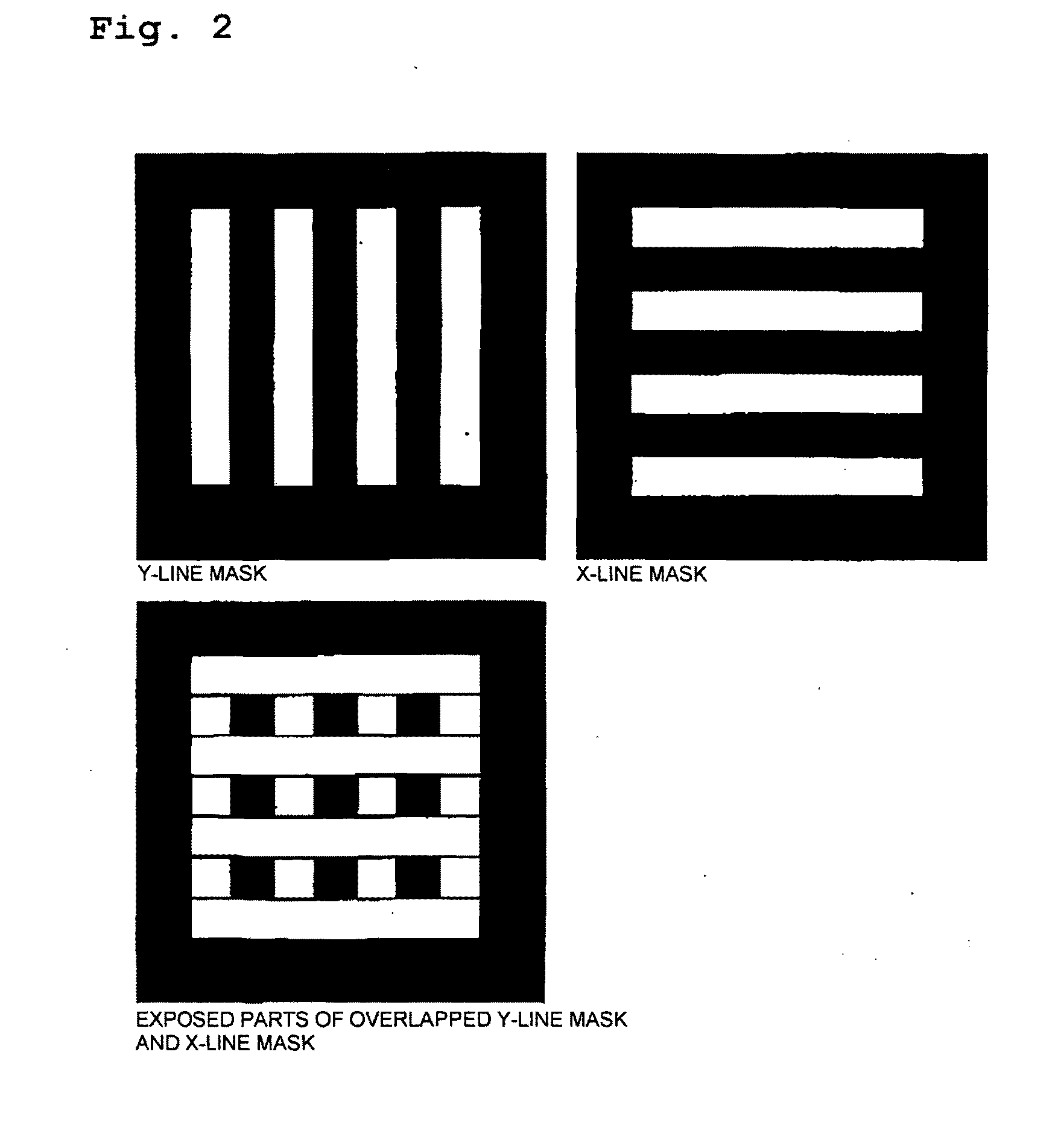

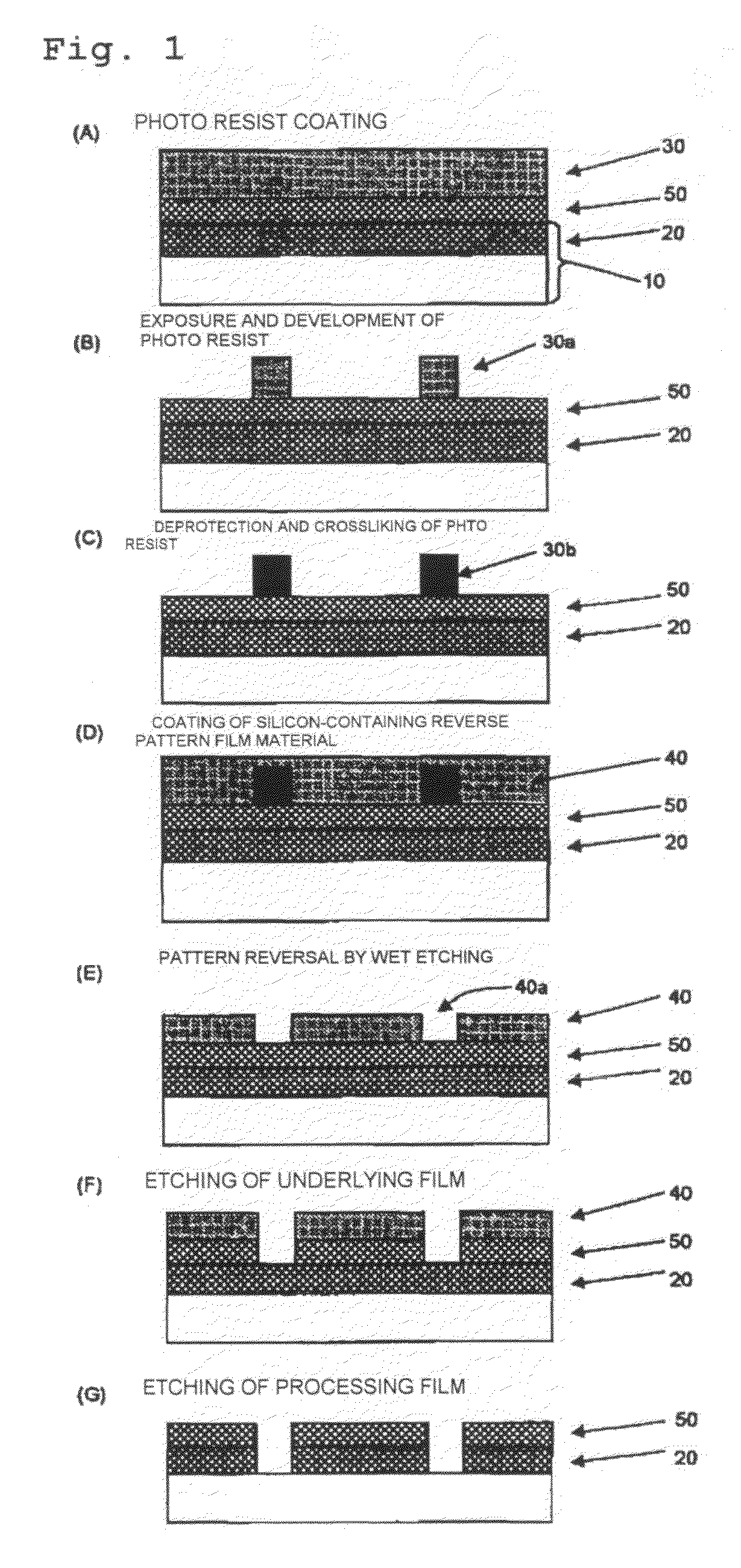

A pattern is formed by coating a resist composition comprising a polymer comprising recurring units having an optionally acid labile group-substituted naphthol group, an acid generator, and an organic solvent onto a substrate, baking to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with an organic solvent developer to form a negative pattern wherein the unexposed region of film is dissolved and the exposed region of film is not dissolved. In the process of image formation via positive / negative reversal by organic solvent development, the resist film has a high dissolution contrast and controlled acid diffusion. By subjecting the resist film to exposure through a mask having a lattice-like pattern and organic solvent development, a fine hole pattern can be formed at a high precision of dimensional control.

Owner:SHIN ETSU CHEM IND CO LTD

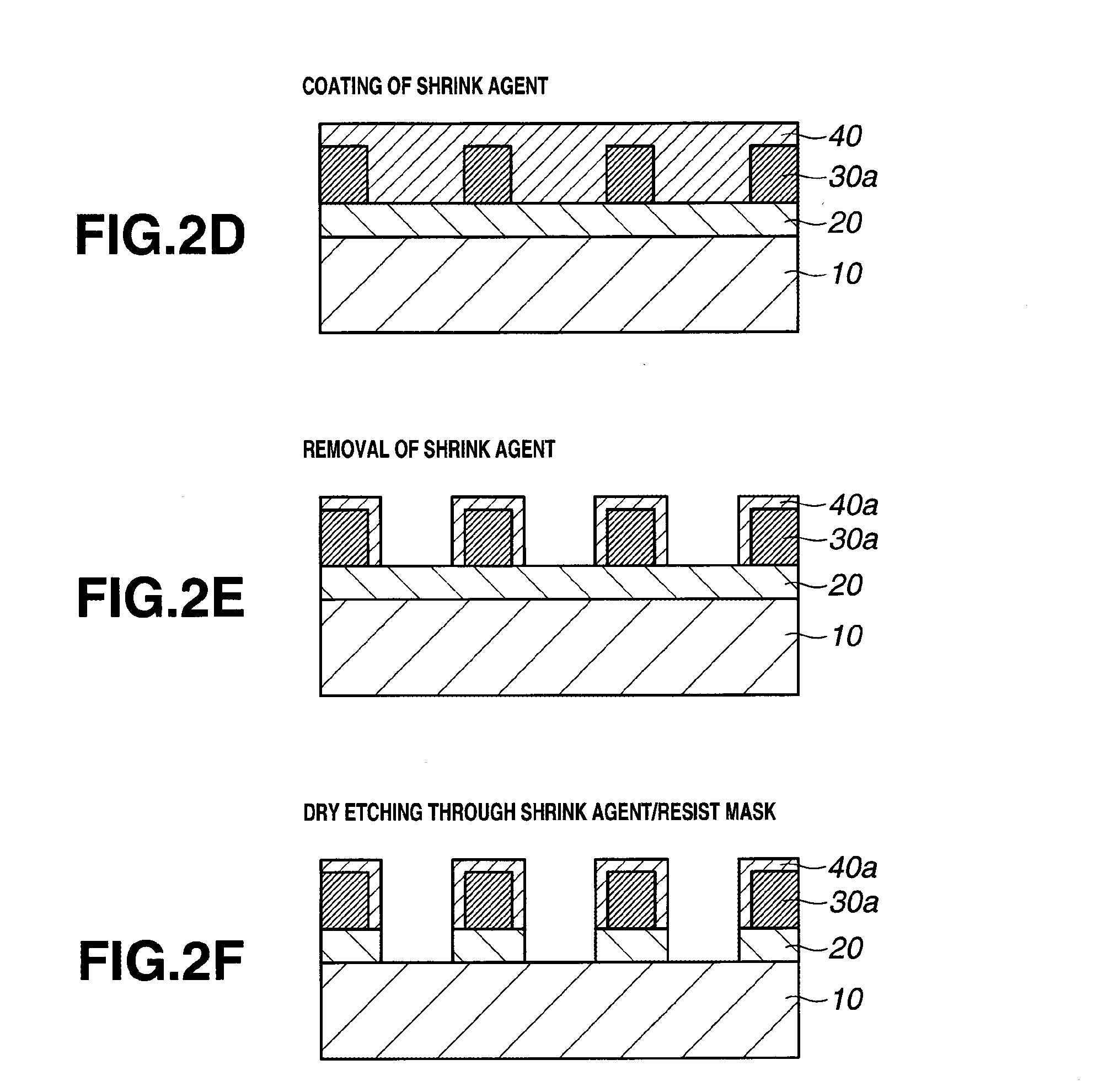

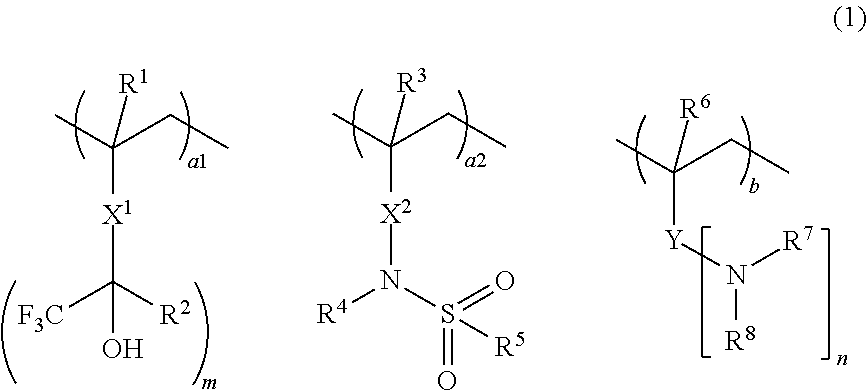

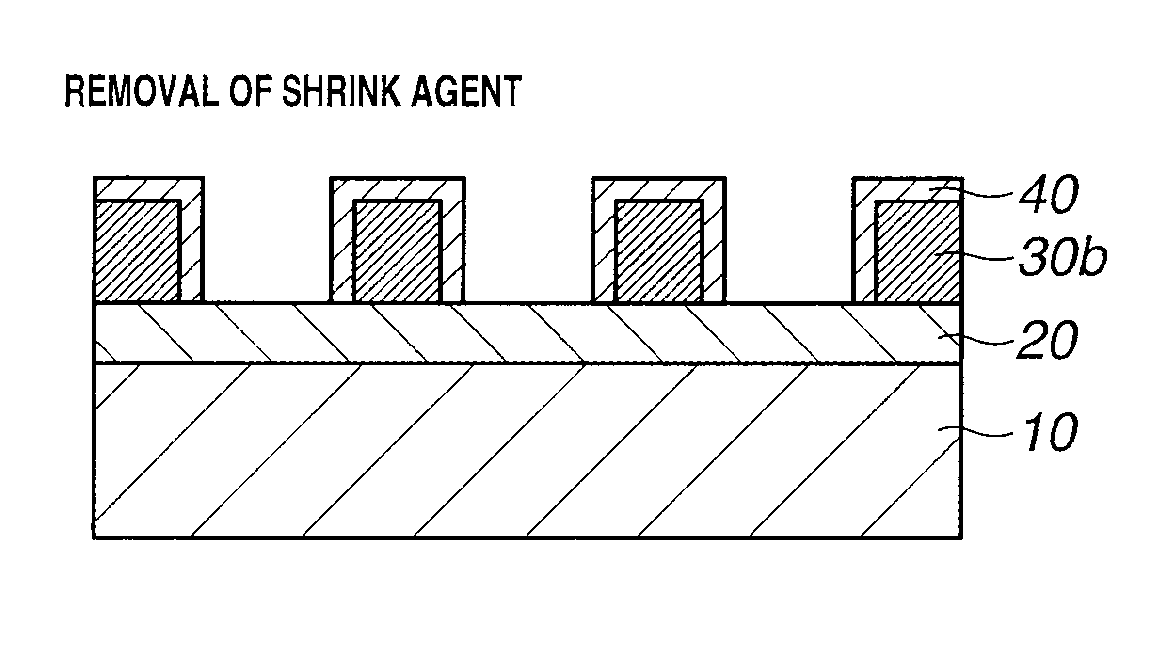

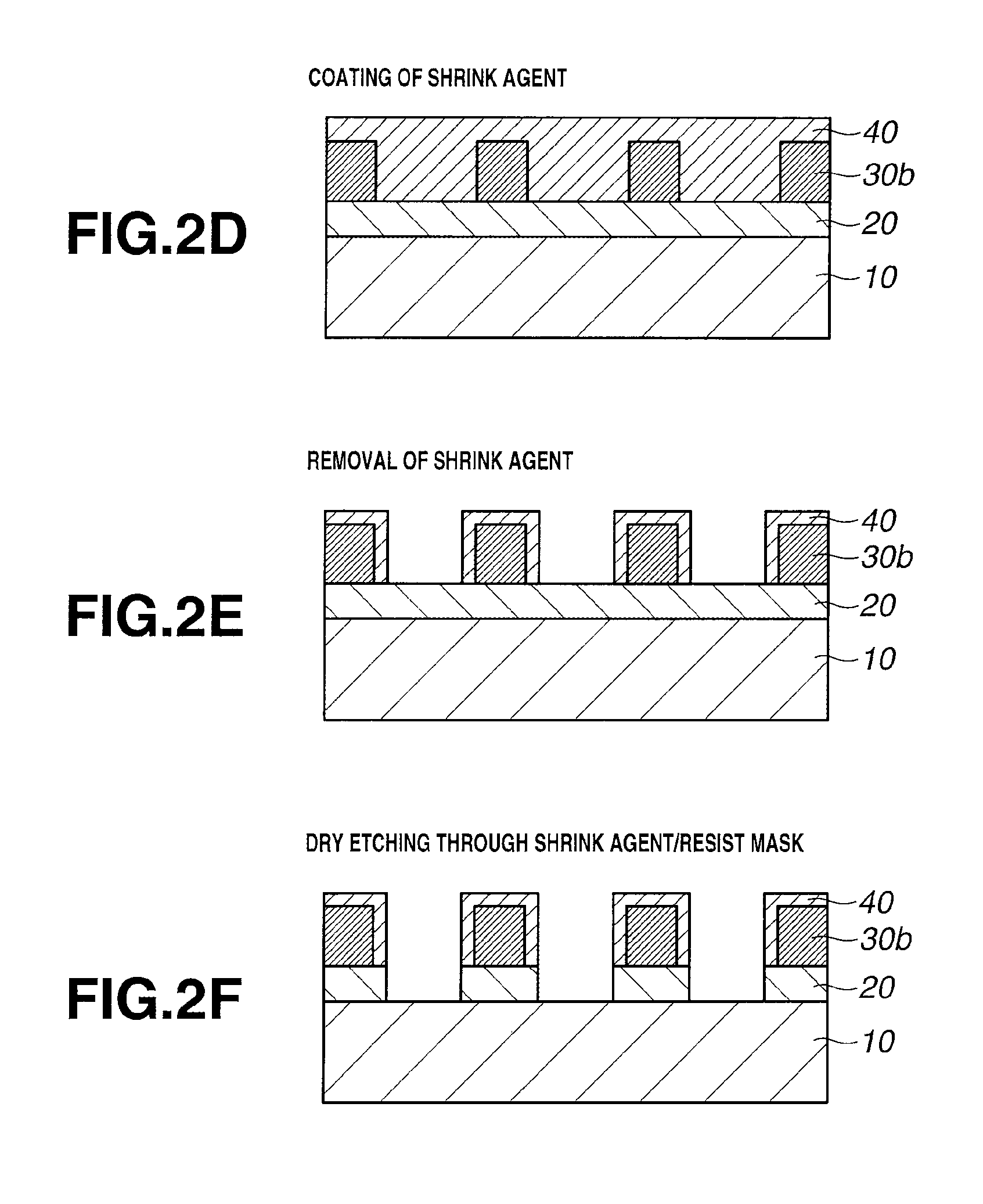

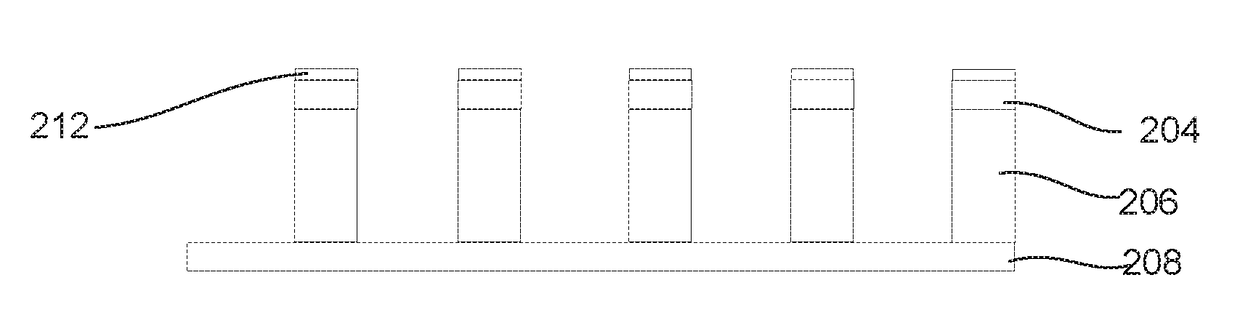

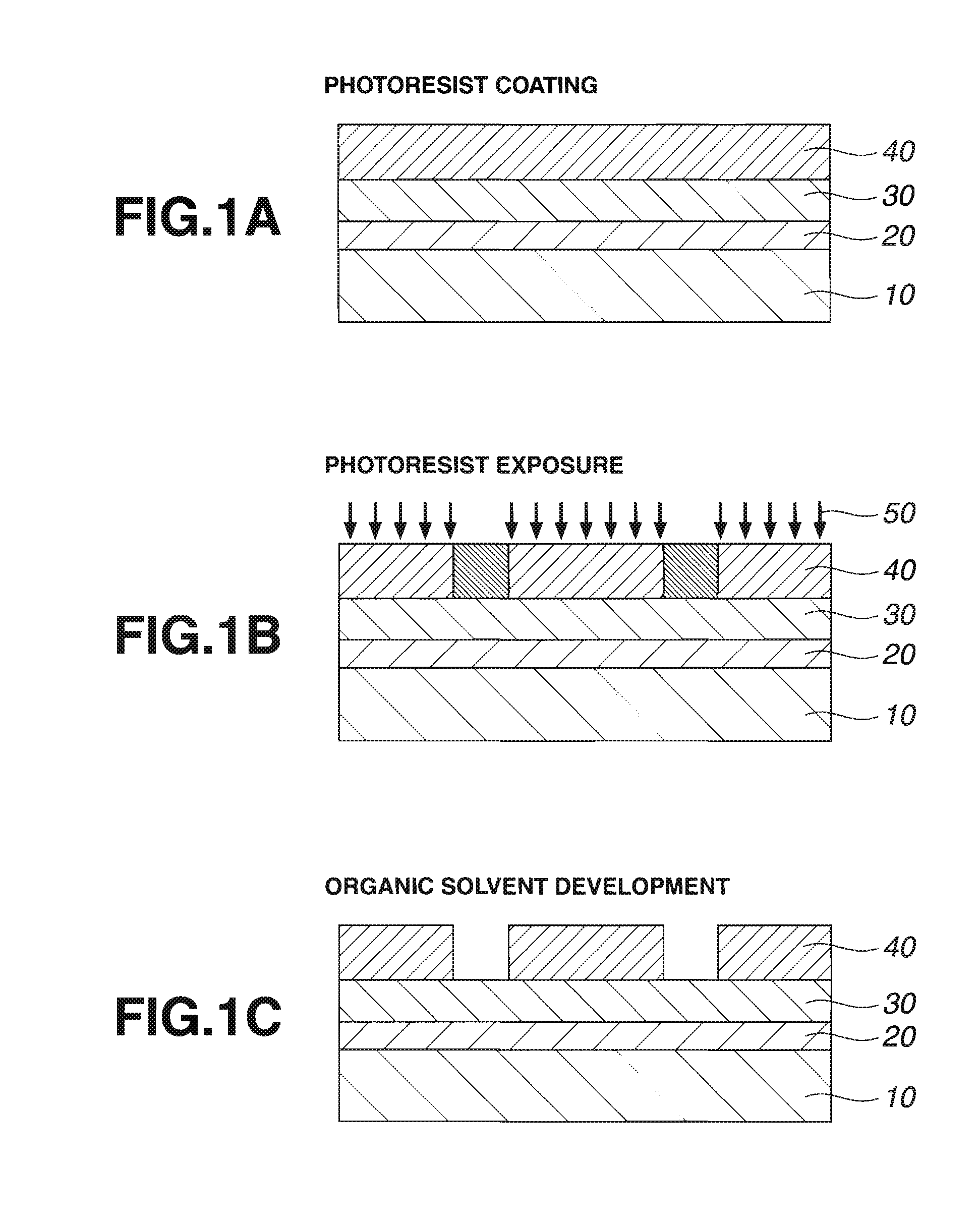

Pattern forming process and shrink agent

ActiveUS20150086929A1Photosensitive material processingOriginals for photomechanical treatmentOrganic solventAlcohol

A negative pattern is formed by applying a resist composition onto a substrate, exposing the resist film, and developing the exposed resist film in an organic solvent developer. The process further involves coating the negative pattern with a shrink agent solution of a copolymer comprising recurring units having an α-trifluoromethylhydroxy or fluoroalkylsulfonamide group and recurring units having an acid labile group-substituted amino group in a C6-C12 ether, C4-C10 alcohol, C6-C12 hydrocarbon, C6-C16 ester or C7-C16 ketone solvent, baking the coating, and removing the excessive shrink agent for thereby shrinking the size of spaces in the pattern.

Owner:SHIN ETSU CHEM IND CO LTD

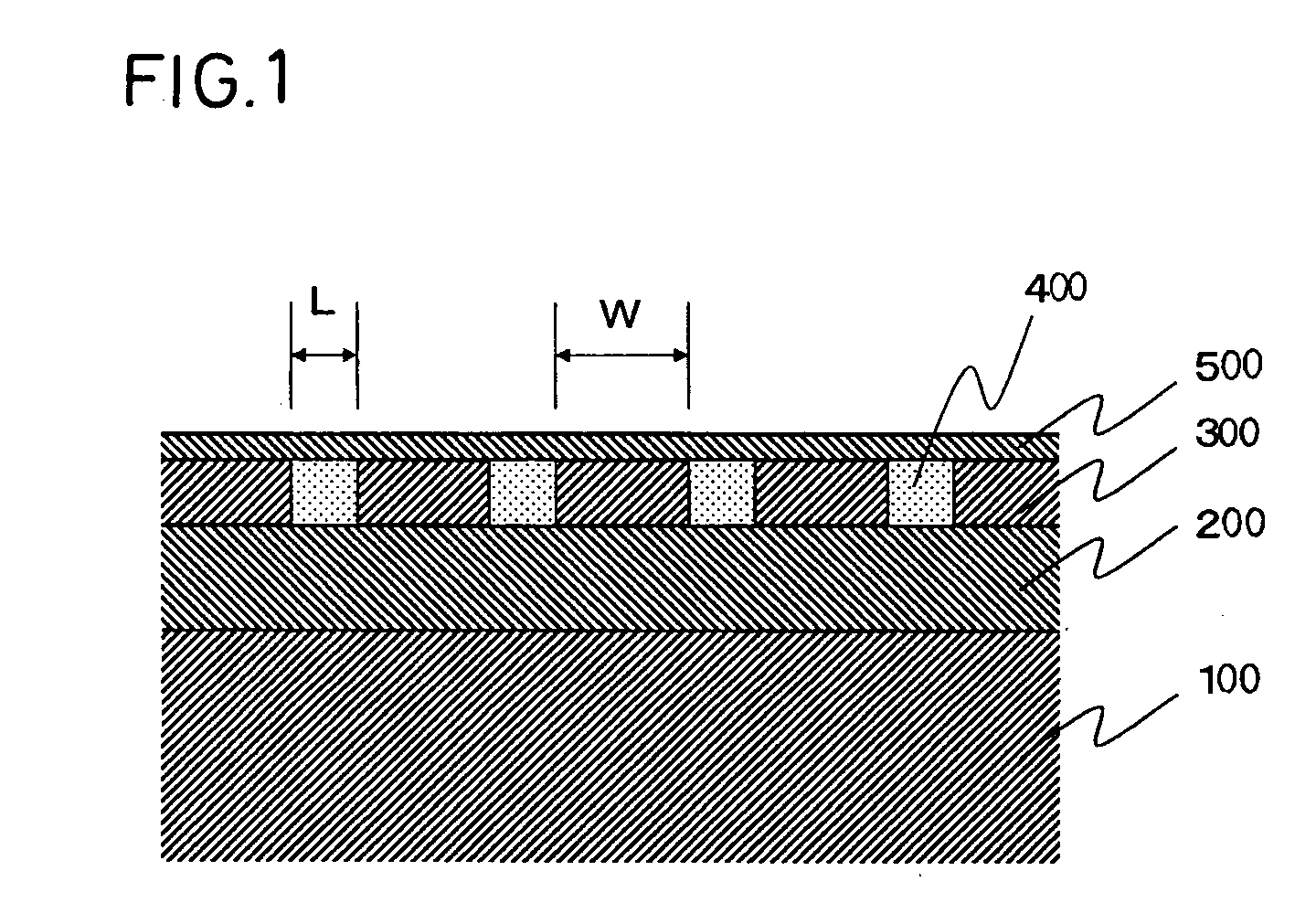

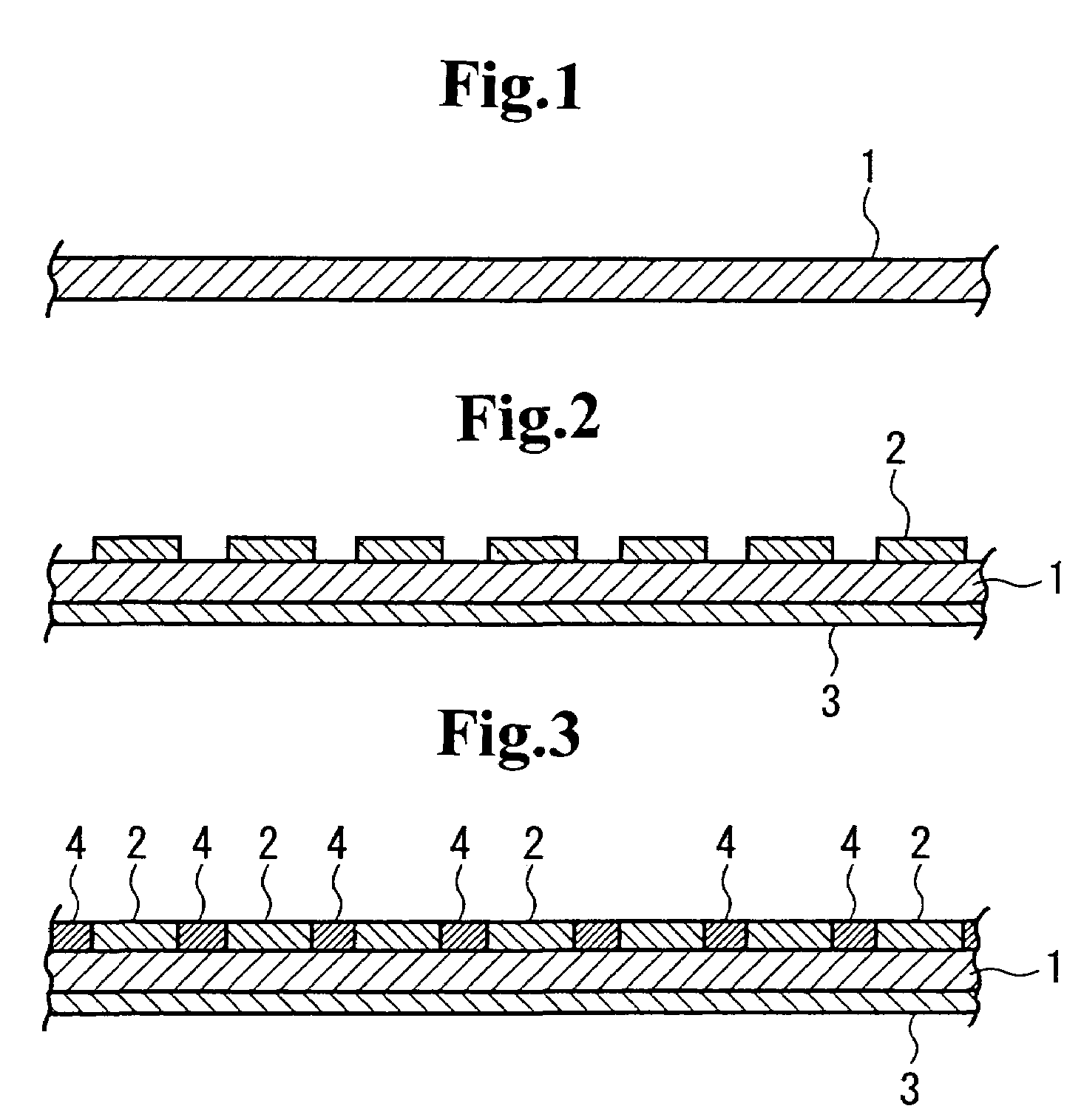

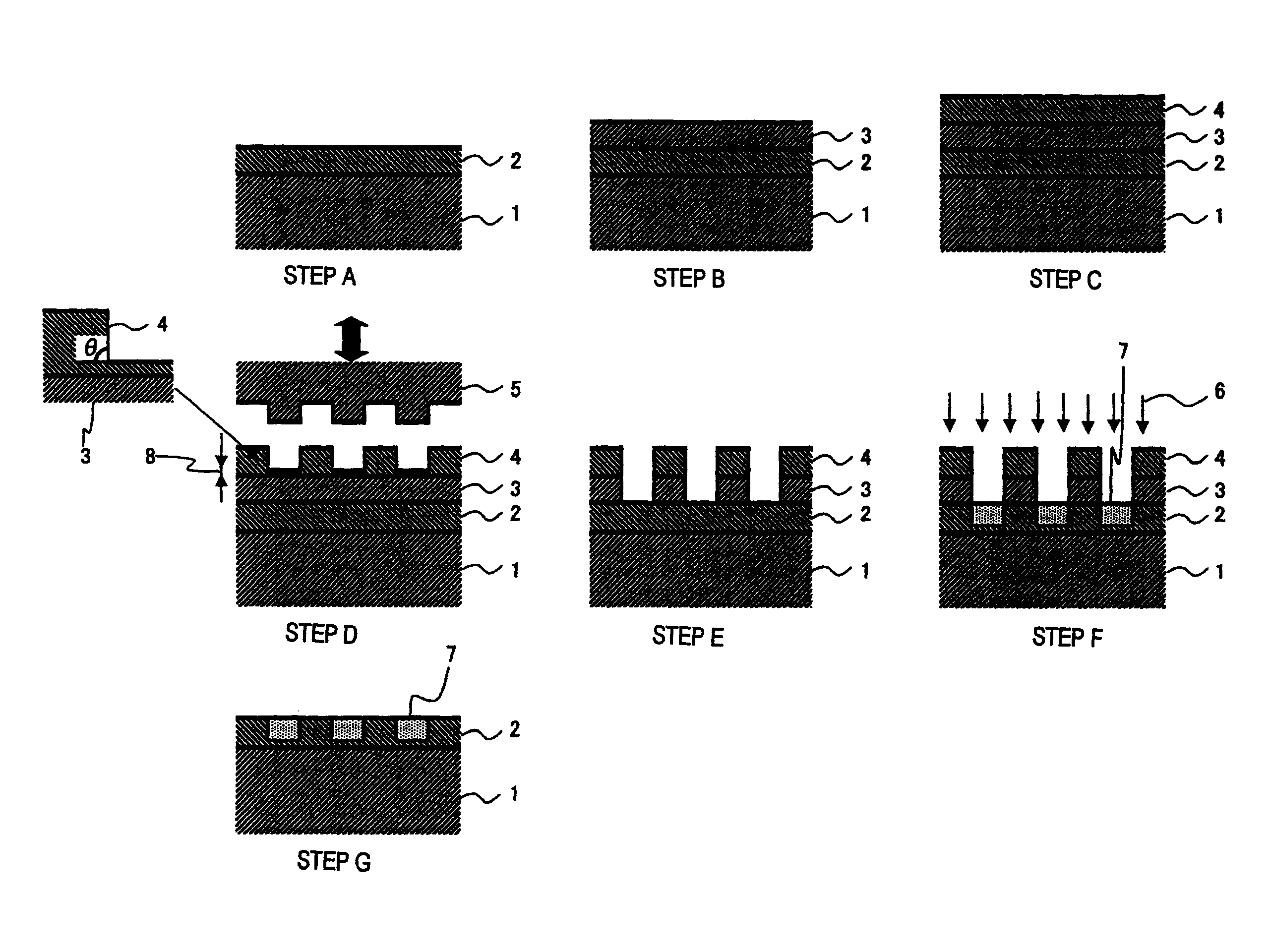

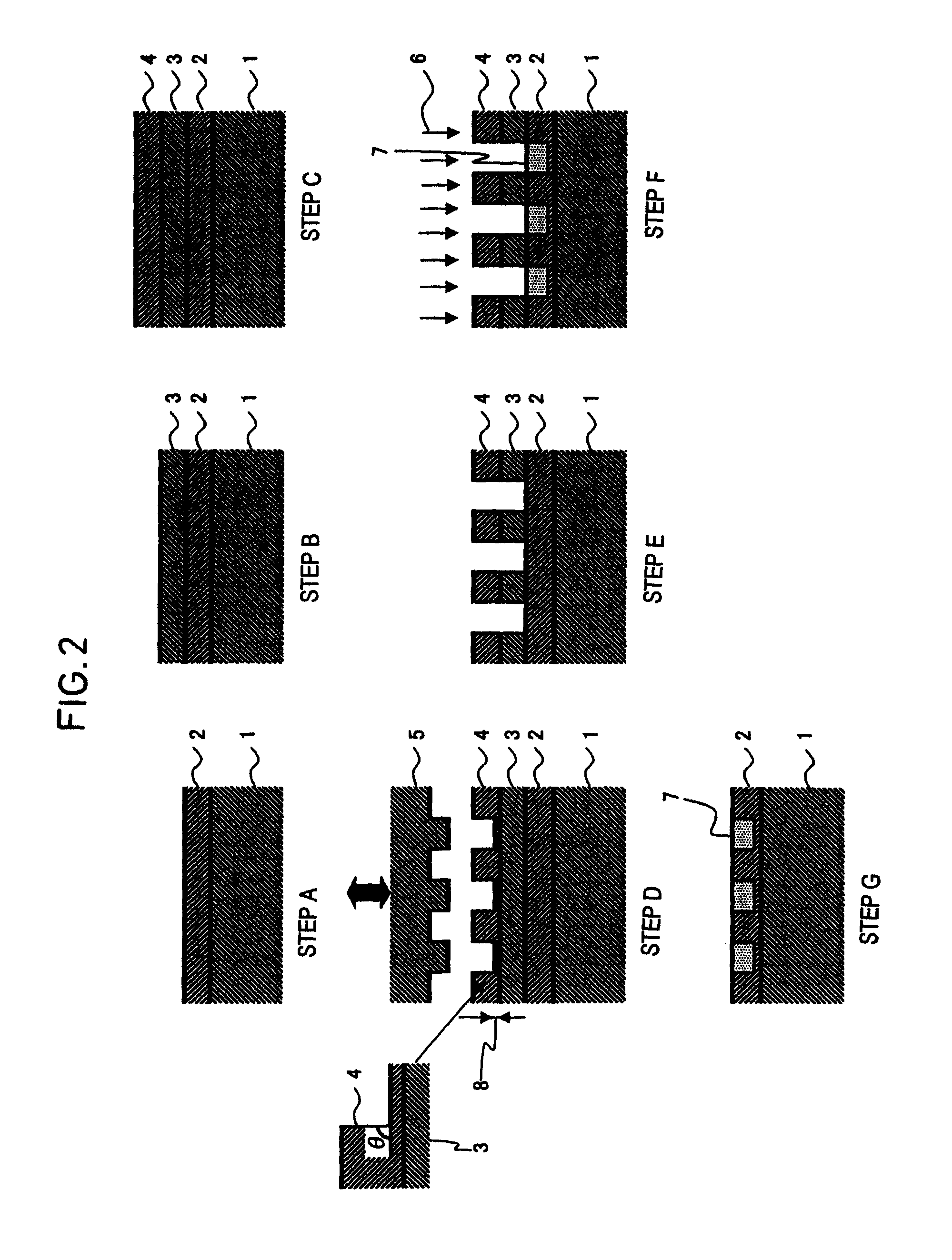

Method for manufacturing magnetic recording medium and magnetic recording and reproducing apparatus

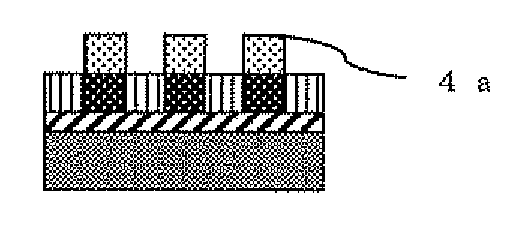

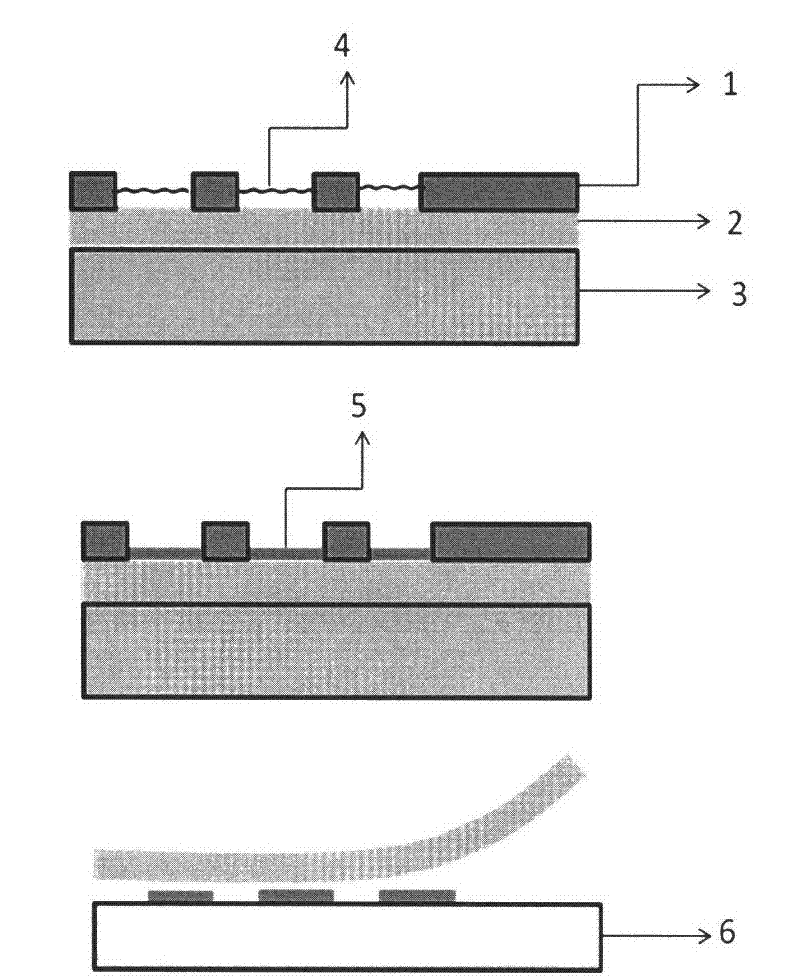

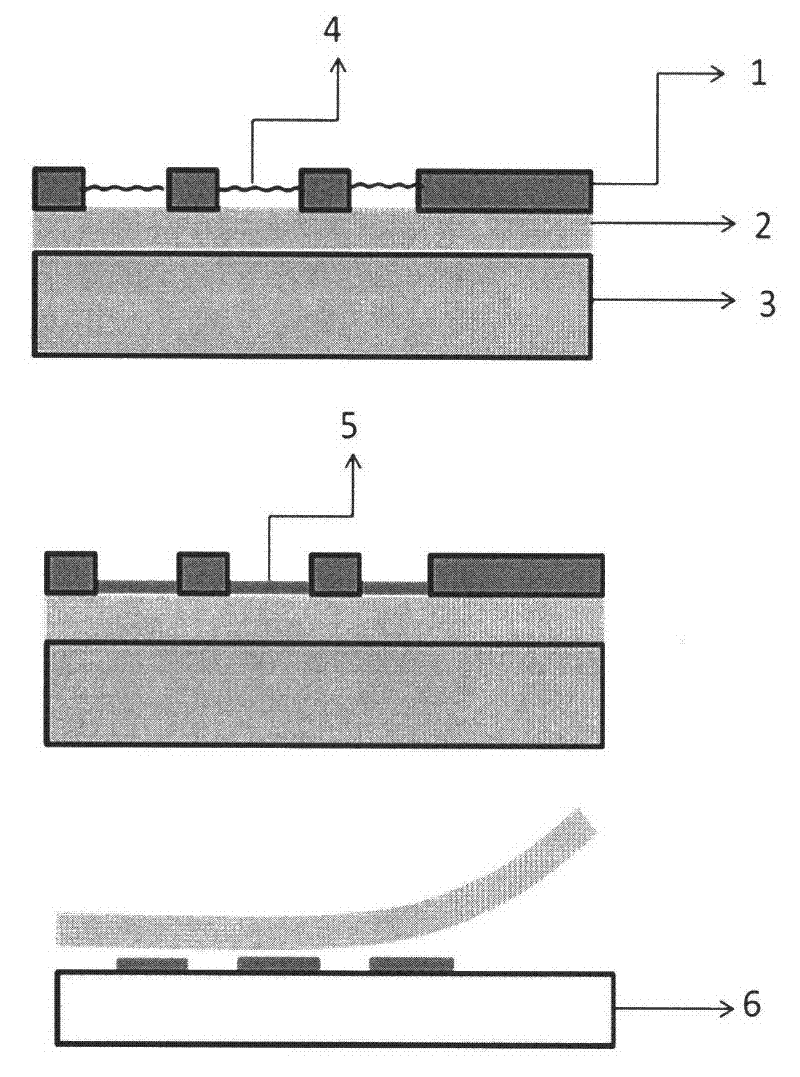

InactiveUS20100053813A1Excellent recording density propertyImprove productivityDifferent record carrier formsDecorative surface effectsMagnetic beadEngineering

A method for manufacturing a magnetic recording medium (30) having magnetically separate magnetic recording patterns on at least one surface of a nonmagnetic substrate (1), includes the steps of forming a magnetic layer (2) on the nonmagnetic substrate, forming a mask layer (3) on the magnetic layer, forming a resist layer (4) on the mask layer, transferring negative patterns of the magnetic recording patterns to the resist layer using a stamp (5), removing portions of the mask layer which correspond to the negative patterns of the magnetic recording patterns, implanting ions in the magnetic layer from a resist layer-side surface to partly demagnetize the magnetic layer, and removing the resist layer and the mask layer. A magnetic recording and reproducing apparatus includes the above magnetic recording medium (30), a driving section (11) that drives the magnetic recording medium in a recording direction, a magnetic head (27) including a recording section and a reproducing section, a device (28) for moving the magnetic head relative to the magnetic recording medium, and recording and reproducing signal processing device (29) for inputting a signal to the magnetic bead and reproducing an output signal from the magnetic head.

Owner:SHOWA DENKO KK

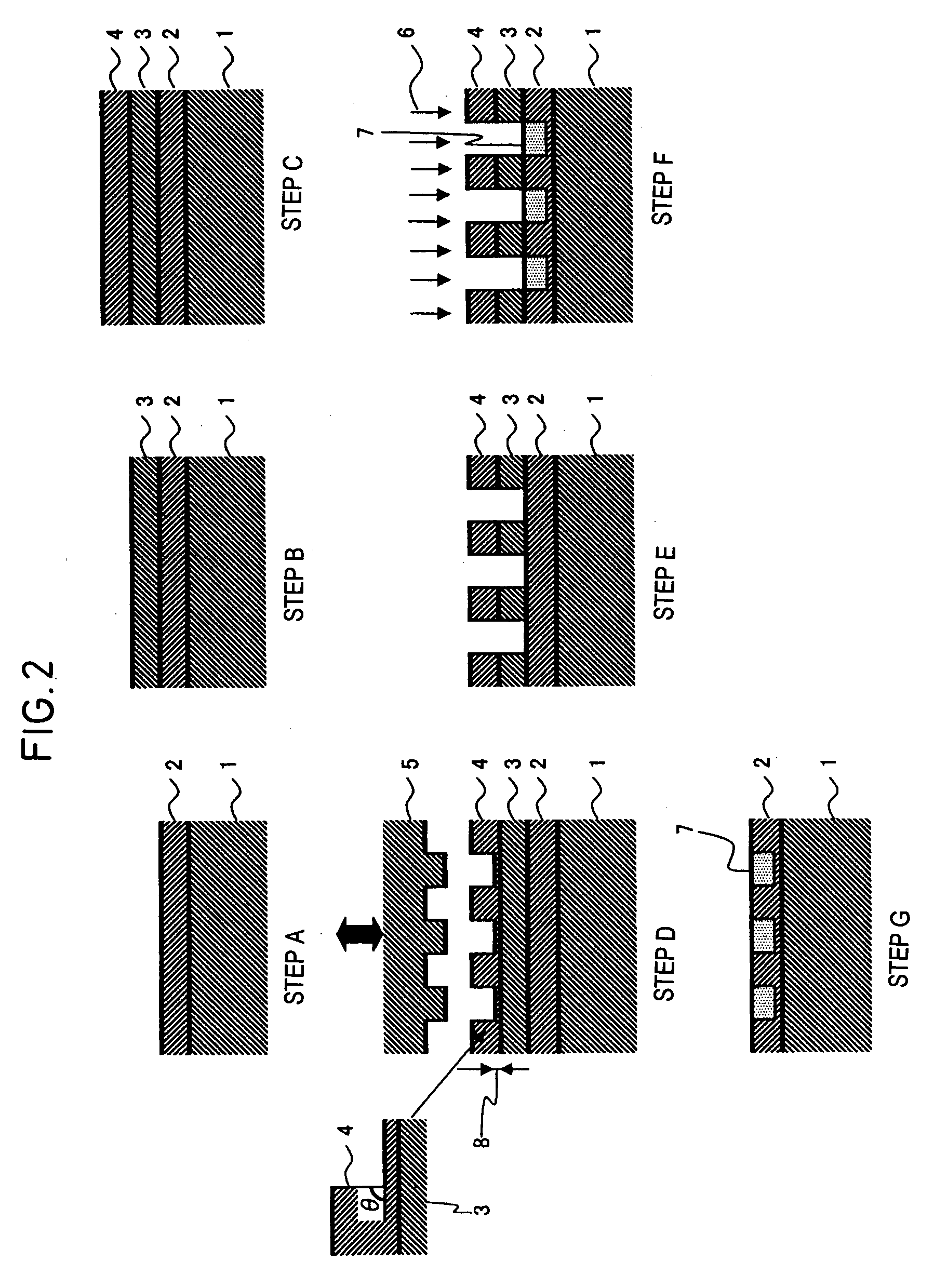

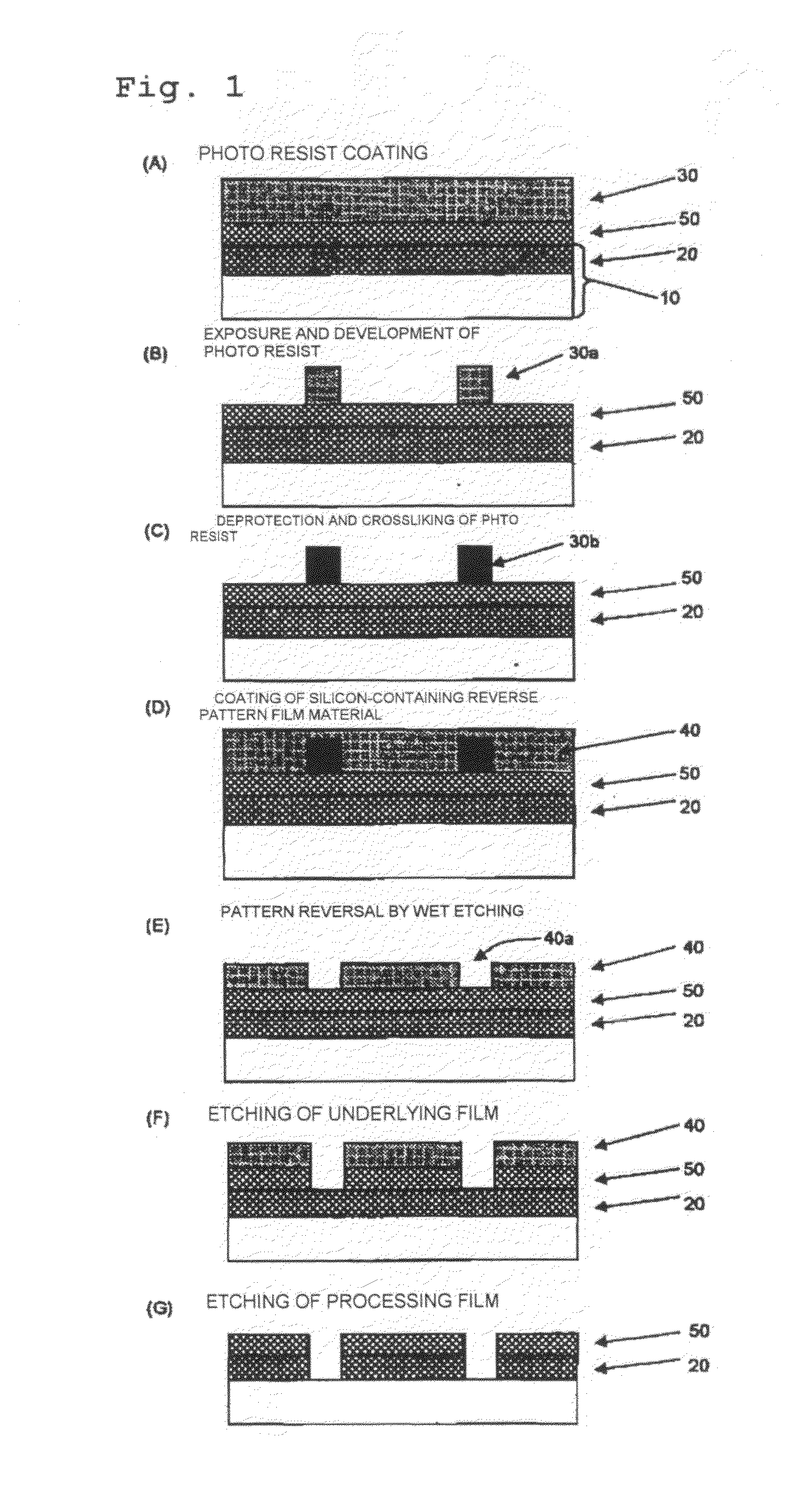

Patterning process

ActiveUS20090286188A1High resolutionSolve the real problemPhotosensitive materialsRadiation applicationsSolubilityOrganic solvent

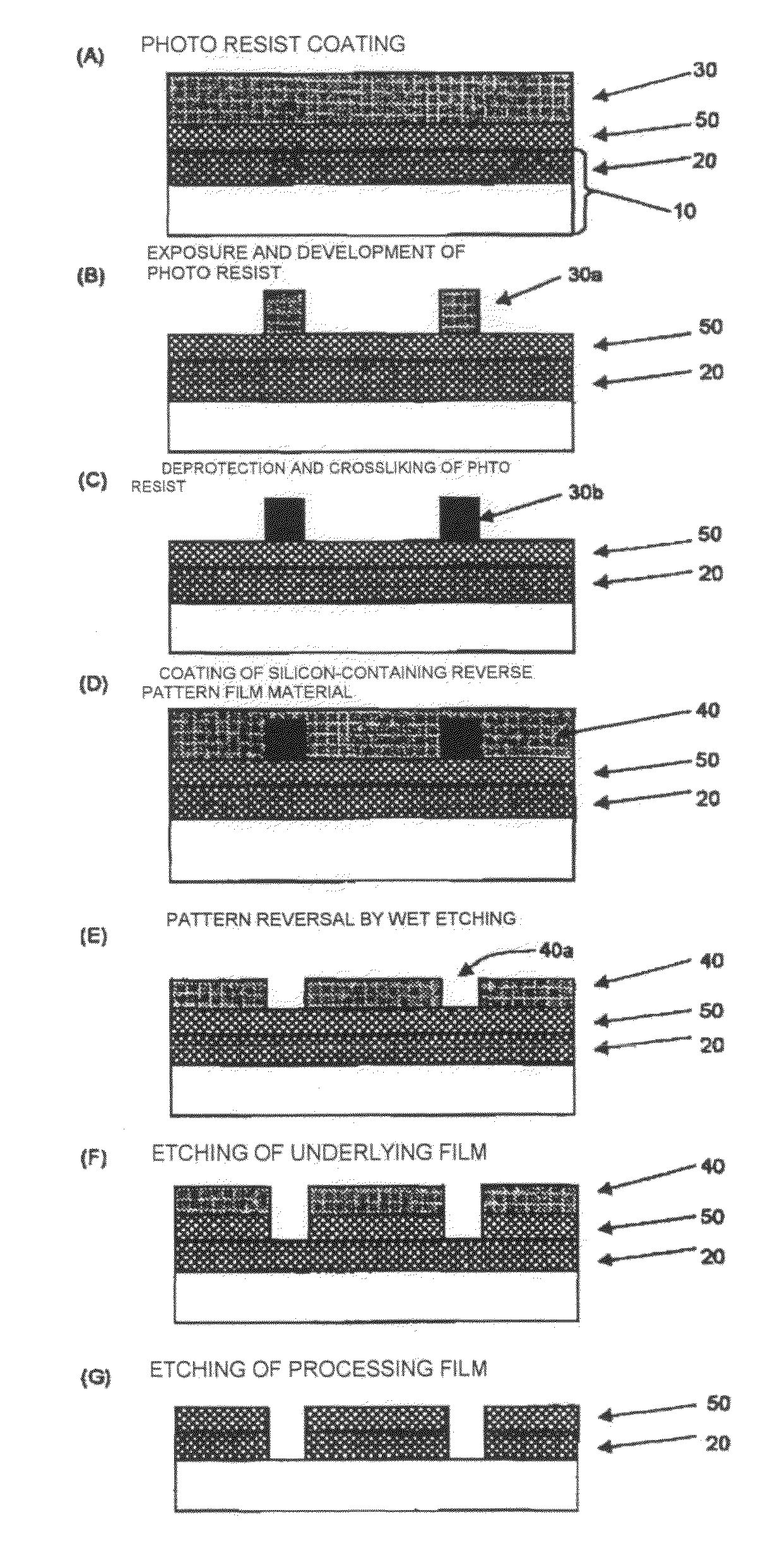

The present invention provides a patterning process, in which a resistance with regard to an organic solvent used for a composition for formation of a reverse film is rendered to a positive pattern to the degree of necessity and yet solubility into an alkaline etching liquid is secured, thereby enabling to finally obtain a negative image by a positive-negative reversal by performing a wet etching using an alkaline etching liquid.A resist patterning process of the present invention using a positive-negative reversal comprises at least a step of forming a resist film by applying a positive resist composition; a step of obtaining a positive pattern by exposing and developing the resist film; a step of crosslinking the positive resist pattern thus obtained; a step of forming a reverse film; and a step of reversing the positive pattern to a negative pattern by dissolving into an alkaline wet-etching liquid for removal.

Owner:SHIN ETSU CHEM IND CO LTD

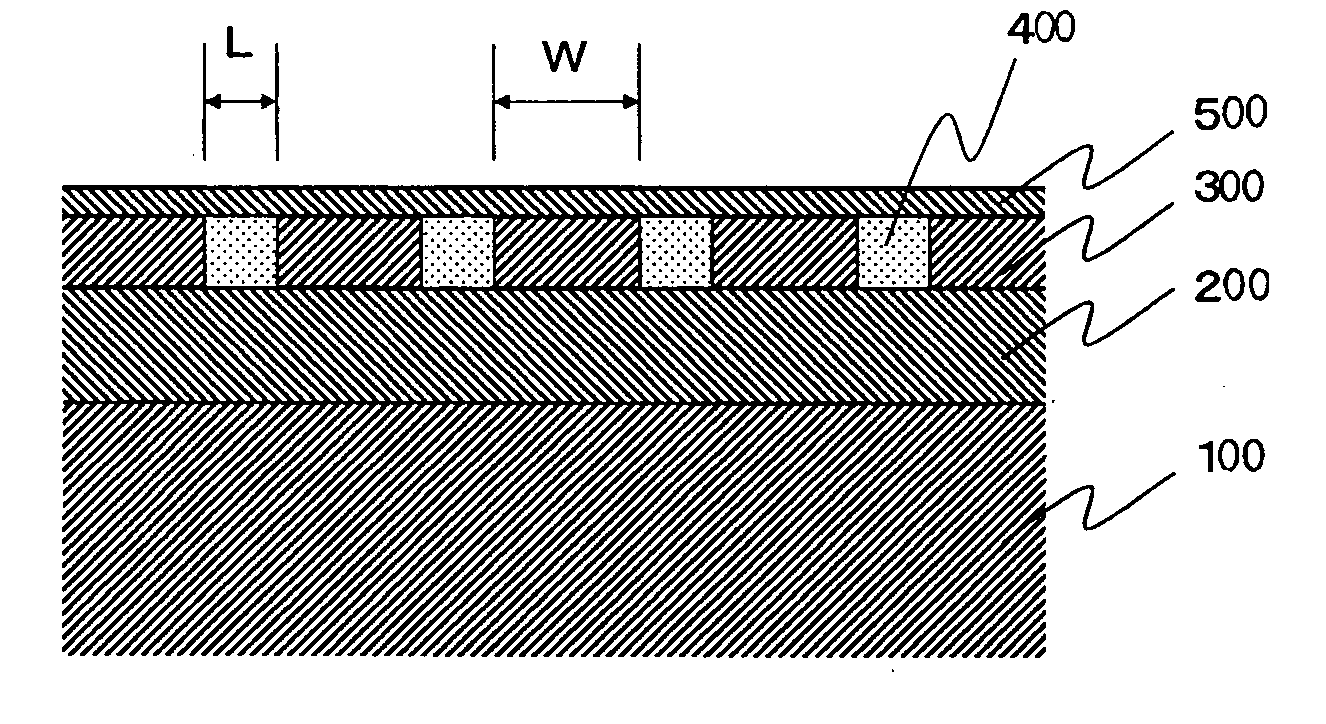

Pattern forming process and shrink agent

ActiveUS20150338744A1Reduce space sizeSemiconductor/solid-state device manufacturingPhotosensitive material processingAlcoholOrganic solvent

A negative pattern is formed by applying a resist composition onto a substrate, exposing the resist film, and developing the exposed resist film in an organic solvent developer. The process further involves coating the negative pattern with a shrink agent solution of a polymer comprising recurring units having a tertiary amino group in a C6-C12 ether, C4-C10 alcohol, C6-C12 hydrocarbon, C6-C16 ester or C7-C16 ketone solvent, baking the coating, and removing the excessive shrink agent for thereby shrinking the size of spaces in the pattern.

Owner:SHIN ETSU CHEM IND CO LTD

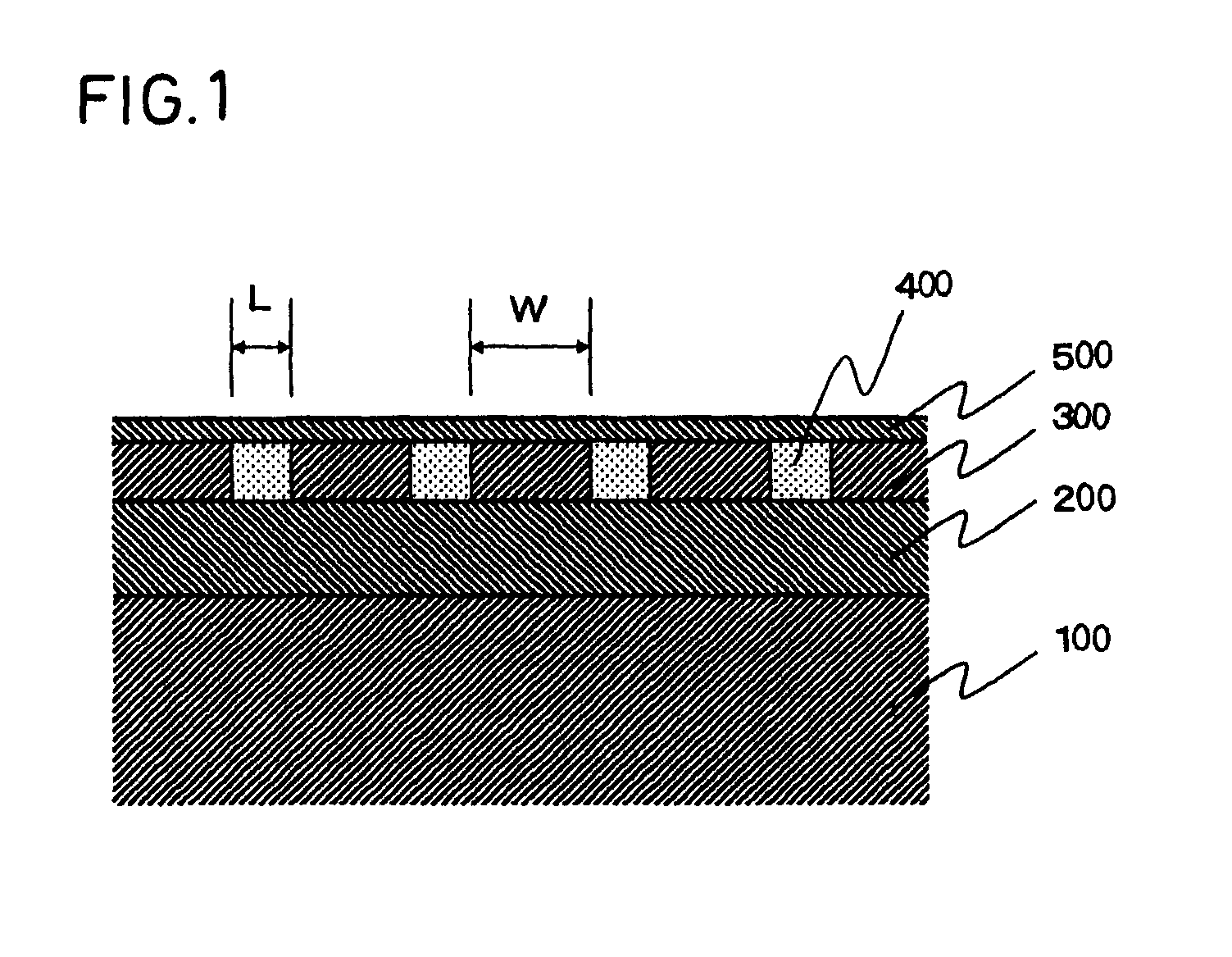

Patterning process

ActiveUS20120276483A1Improve adhesionReduce surface roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOrganic solventPhotoresist

The invention provides a patterning process, comprising at least a step of forming a silicon-containing film on a body to be processed by using a composition for the silicon-containing film, a step of forming, on the silicon-containing film, a photoresist film by using a resist composition, a step of exposing to the photoresist film after heat treatment thereof, and a step of forming a negative pattern by dissolving an unexposed area of the photoresist film by using a developer of an organic solvent; wherein a composition giving the silicon-containing film whose pure-water contact angle in the part corresponding to the exposed area of the photoresist film becomes in the range of 35° or more to lower than 70° after exposure is used as the composition. There can be optimum patterning process as a patterning process of a negative resist pattern to be formed by adopting organic solvent-based development.

Owner:SHIN ETSU CHEM IND CO LTD

Patterned transparent electrode fabrication method

ActiveCN102543303AEnsure controllabilityEfficient removalConductive layers on insulating-supportsCable/conductor manufactureMaterials scienceNanomaterials

The invention discloses a patterned transparent electrode fabrication method. The method comprises the steps of (1) depositing a conductive nanoparticle dispersion solution on a porous filter membrane with a negative pattern mask to obtain a patterned transparent conductive film adhered on the porous filter membrane; and (2) removing the mask, transferring the patterned transparent conductive film on the porous filter membrane onto a transparent substrate, and removing the porous filter membrane to obtain the patterned transparent electrode; wherein the dispersion solution contains conductive nanoparticles 0.015wt% to 5wt%, dispersing agent 0.15wt% to 20wt%, and water in balance; and the dispersing agent is selected from arbitrary one or the combination of a surfactant, organic acid, high-molecular polysaccharide and DNA macromolecules. The method has the advantages of simple process, low cost and large material selection range, and can accurately design and control the formed pattern according to requirement.

Owner:浙江暖科能源技术有限公司

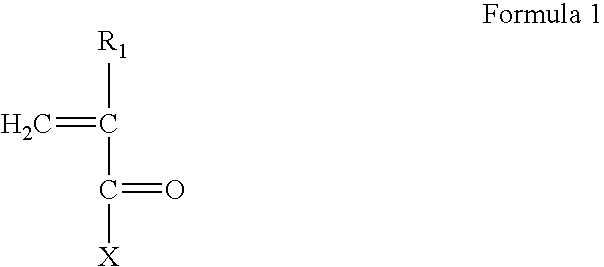

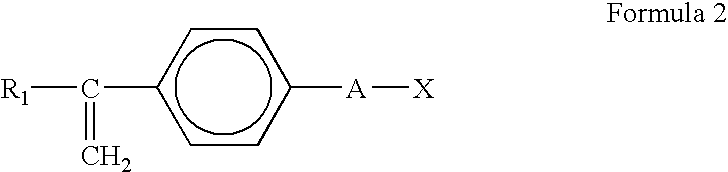

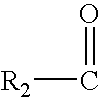

Method of forming a patterned film of surface-modified carbon nanotubes

Disclosed herein is a method of forming a negative pattern of carbon nanotubes through: modifying the surfaces of carbon nanotubes to have double bond-containing functional group capable of participating in radical polymerization; coating a substrate with a liquid coating composition prepared by dispersing the surface-modified carbon nanotubes in an organic solvent along with a photoinitiator; exposing the film to UV light through a photomask to induce radical polymerization of the carbon nanotubes; and developing the film. By virtue of the present invention, desired patterns of carbon nanotubes can be easily made on the surfaces of various substrates according to the conventional photolithography procedure.

Owner:SAMSUNG ELECTRONICS CO LTD

Pattern forming process

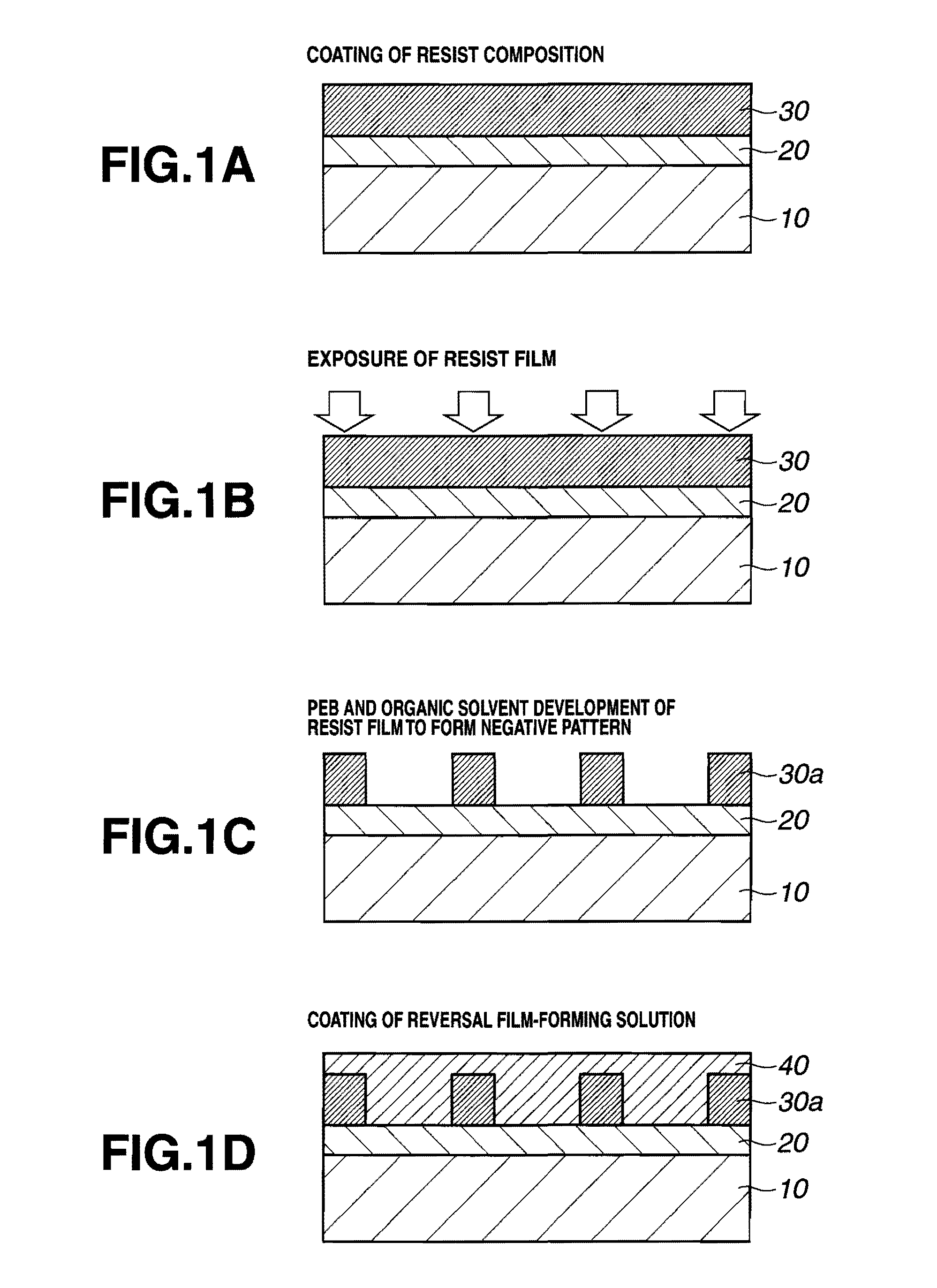

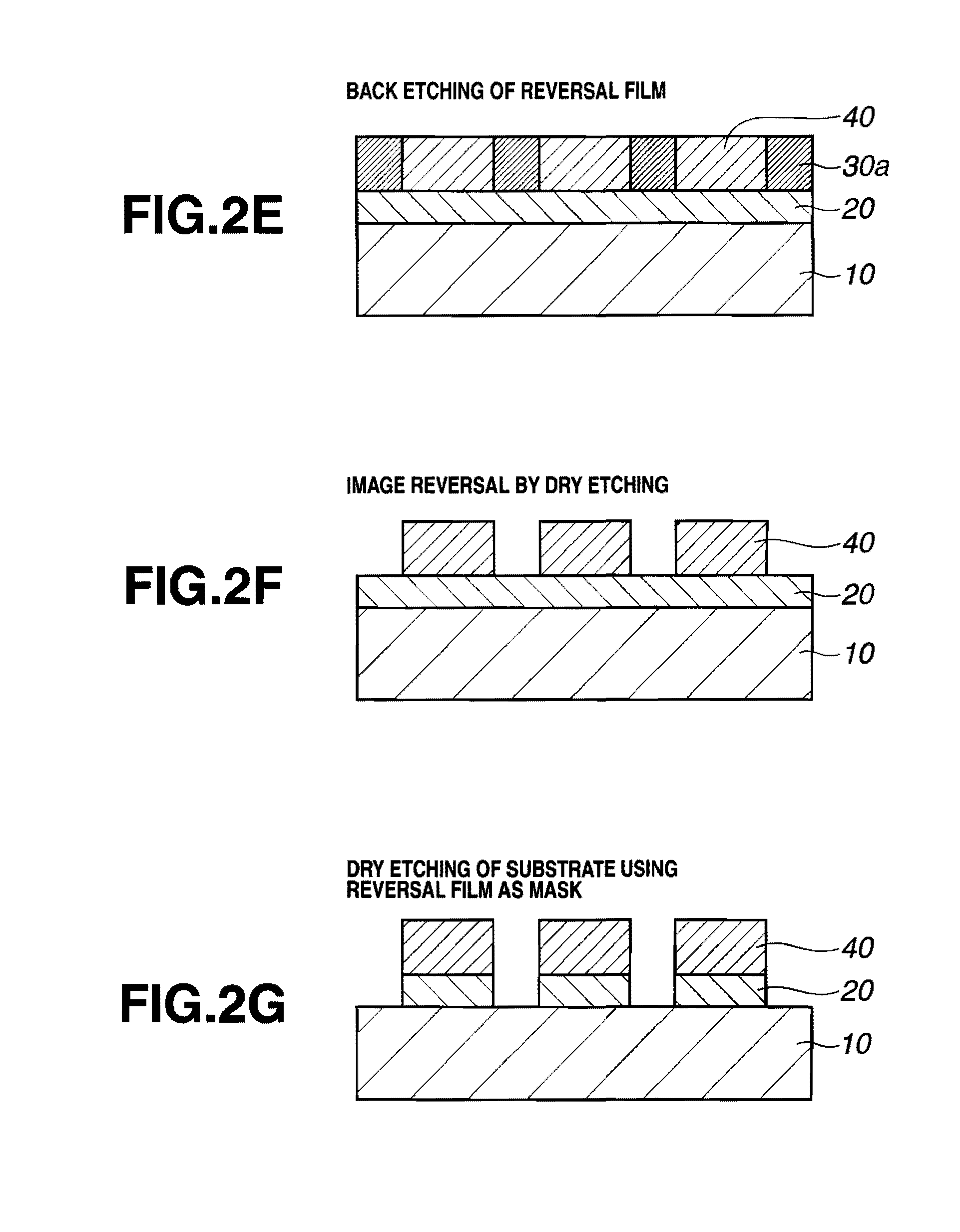

InactiveUS20140234785A1Without riskHigh aspect ratioImpression capsSemiconductor/solid-state device detailsOrganic solventDry etching

A pattern is formed by coating a chemically amplified resist composition comprising a resin having a dissolution rate in an organic solvent developer that lowers under the action of acid onto a processable substrate, prebaking, exposing the resist film, PEB, developing in an organic solvent developer to form a negative pattern, coating a solution comprising Si, Ti, Zr, Hf or Al, prebaking, and dry etching to effect image reversal for converting the negative pattern into a positive pattern.

Owner:SHIN ETSU CHEM IND CO LTD

Method of making carbon nanotube patterned film or carbon nanotube composite using carbon nanotubes surface-modified with polymerizable moieties

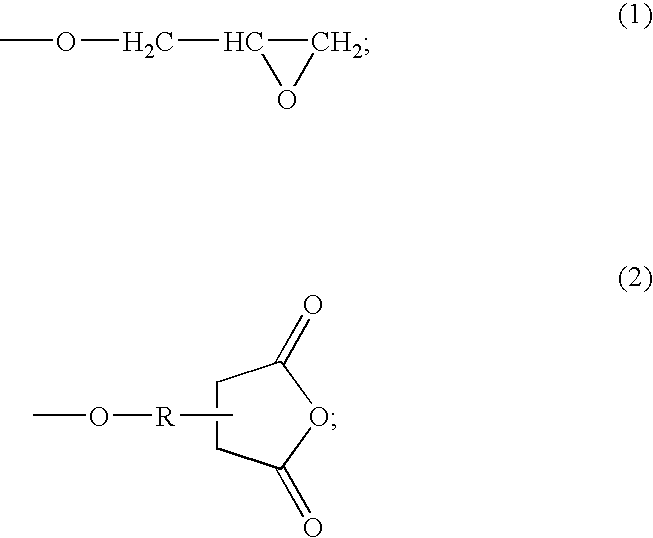

Disclosed herein are methods of making a negative pattern of carbon nanotubes or a polymerized carbon nanotube composite having an interpenetrating polymer network (IPN) by modifying the surfaces of the carbon nanotubes with polymerizable functional groups such as oxirane and anhydride groups and subjecting the surface-modified carbon nanotubes either to a photolithography process or to a heatcuring process. By virtue of the present invention, desired patterns of carbon nanotubes can be easily made on the surfaces of various substrates, and polymerized carbon nanotube composites improved in hardening properties can be made without additional polymers.

Owner:SAMSUNG ELECTRONICS CO LTD

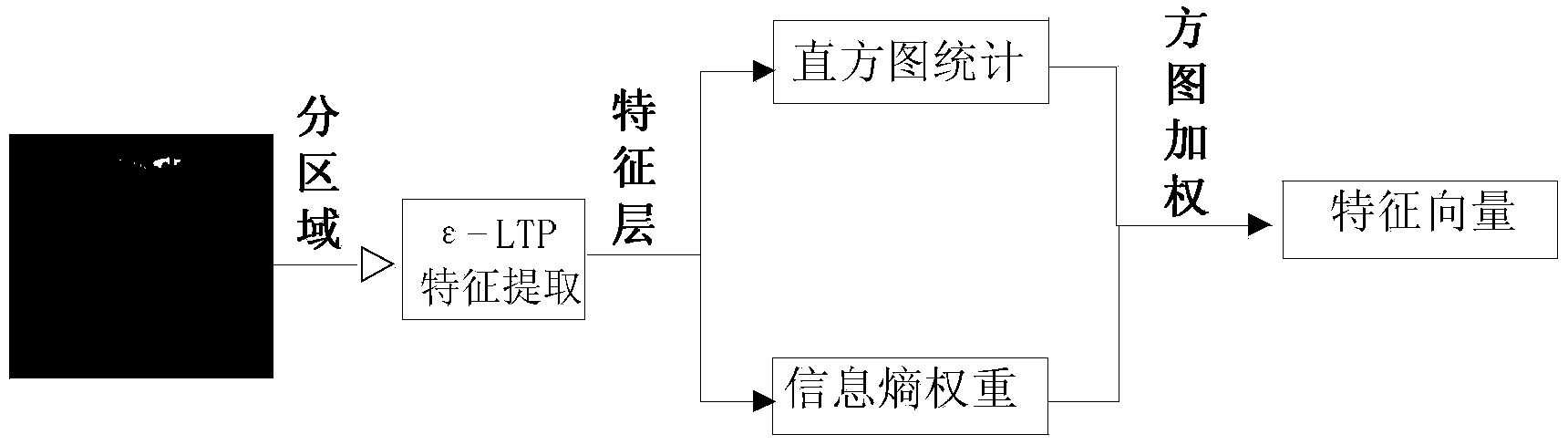

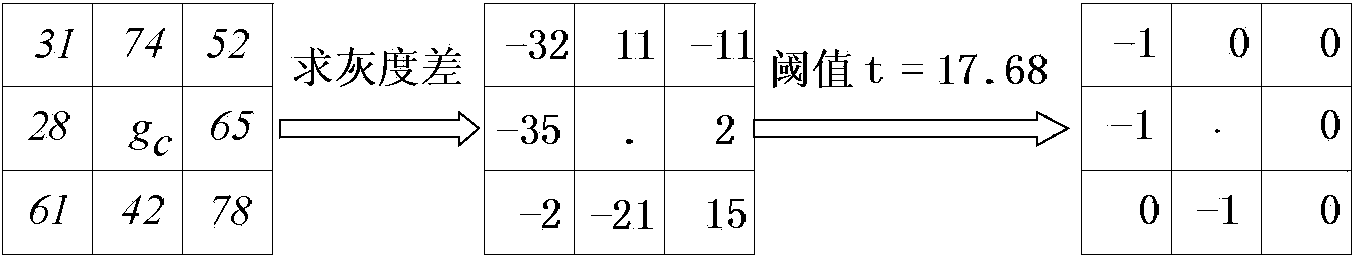

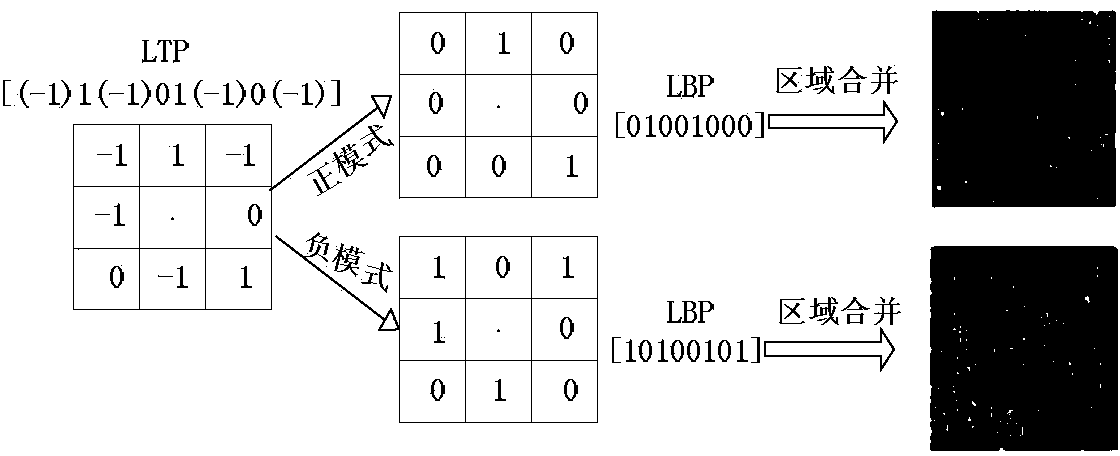

Face recognition method based on local ternary pattern adaptive threshold

InactiveCN103778412AImprove recognition accuracyCharacter and pattern recognitionMatrix decompositionNeighbor classifier

The invention discloses a face recognition method based on a local ternary pattern adaptive threshold, and pertains to the technical field of pattern recognition. The method comprises the following steps: at first, segmentation treatment is performed on face database images; epsilon-LTP characteristics in segmented regions are calculated for training set and test set images separately; the obtained epsilon-LTP characteristic matrix is decomposed into two layers including positive and negative pattern layers; information entropy weight is solved and obtained according to the characteristics of each layer; the characteristics of each layer are converted into the form of a weighted histogram by combining with the information entropy weight; the chi<2> (chi-square) distance function is adopted in the histogram to calculate the characteristic similarity between test samples and training samples; and classification recognition is performed on the test samples through a third-order neighbor classifier. The method of the invention has the advantage of good face recognition accuracy.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

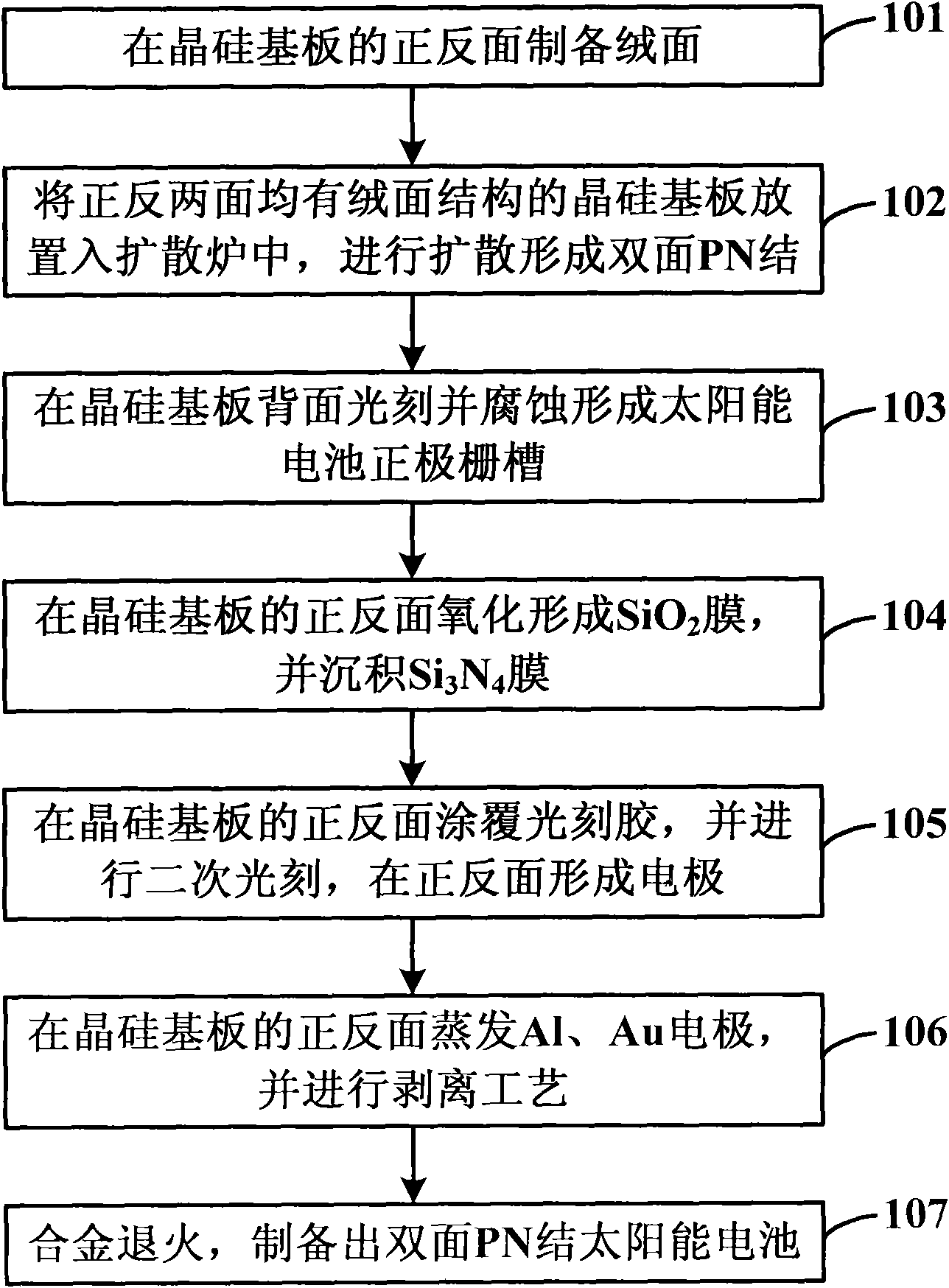

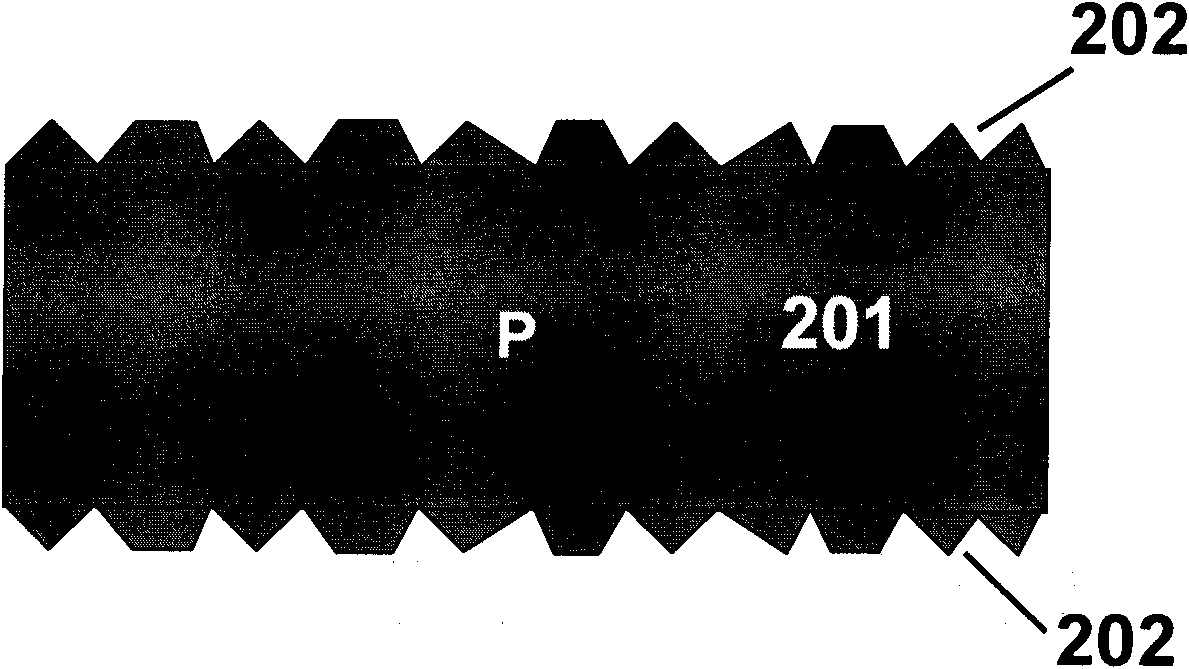

Method for preparing double-sided PN junction solar battery

ActiveCN101840952AReduce process stepsThe process steps are simpleFinal product manufactureSemiconductor devicesProduction lineAlloy

The invention discloses a method for preparing a double-sided PN junction solar battery, which comprises the following steps of: preparing matte structures on the front side and the back side of a crystal silicon substrate; placing the crystal silicon substrate of which the front side and the back side are provided with the matte structures in a diffusion furnace to perform diffusion so as to form a double-sided PN junction structure; photoetching and corroding the back side of the crystal silicon substrate to form a positive electrode gate groove of the solar battery; oxidizing the front side and the back side of the crystal silicon substrate to form SiO2 films, and depositing Si3N4 films; coating a photoresist on the front side and the back side of the crystal silicon substrate, and performing photoetching exposure and development to form positive and negative patterns on the back side of the battery and negative electrode patterns on the front side of the battery; evaporating metal electrodes on the front side and the back side of the crystal silicon substrate, and performing a stripping process; and performing alloy annealing to prepare the double-sided PN junction solar battery. The method uses two PN junctions of a crystal silicon battery for work to finally fulfill the aim of efficient conversion, has fewer process steps, is simple, can be compatible with a process on a large-scale production line, and can realize large-scale production easily.

Owner:锐立平芯微电子(广州)有限责任公司

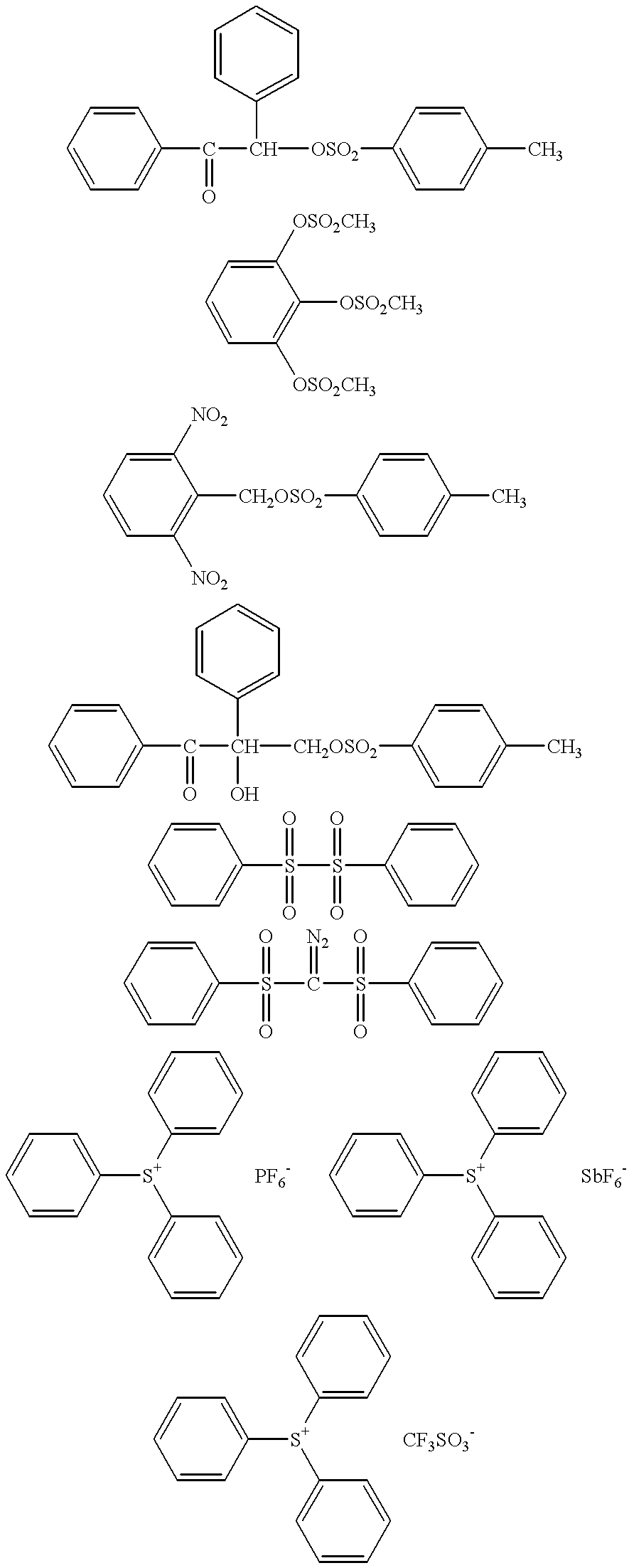

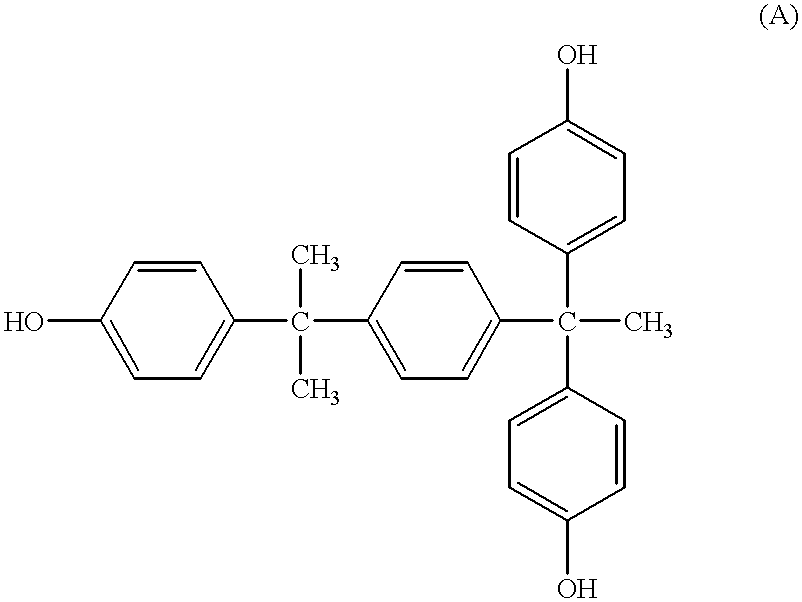

Photosensitive resin composition and process for producing the same

InactiveUS6440632B2Promote absorptionHard surfaceSemiconductor/solid-state device manufacturingDiazo compound compositionsImage resolutionLength wave

A photosensitive resin composition comprises a base resin (e.g., novolak resins, polyvinylphenol-series polymers), a first photoactive ingredient (e.g., diazobenzoquinone derivatives, diazonaphthoquinone derivatives) and a second photoactive ingredient (e.g., mixtures with azide compounds) each having an absorption range at wavelength lambd1 or lambd2, the wavelengths thereof being different from each other. Between the first and second photoactive ingredients, at least one photoactive ingredient is substantially inert at the absorption wavelength of the other. After exposing the photosensitive resin composition to a light to form a pattern, the whole surface of the photosensitive layer is exposed to a light of the other wavelength to make the surface hardly soluble (in the case a positive pattern is formed) or readily soluble (in the case a negative pattern is formed) in a developer, and developed, thereby forming a pattern of high resolution. Utilizing an existing exposure system, there can be obtained photosensitive resin compositions (especially, resists for semiconductor production) having improved sensitivity and resolution.

Owner:KRI INC

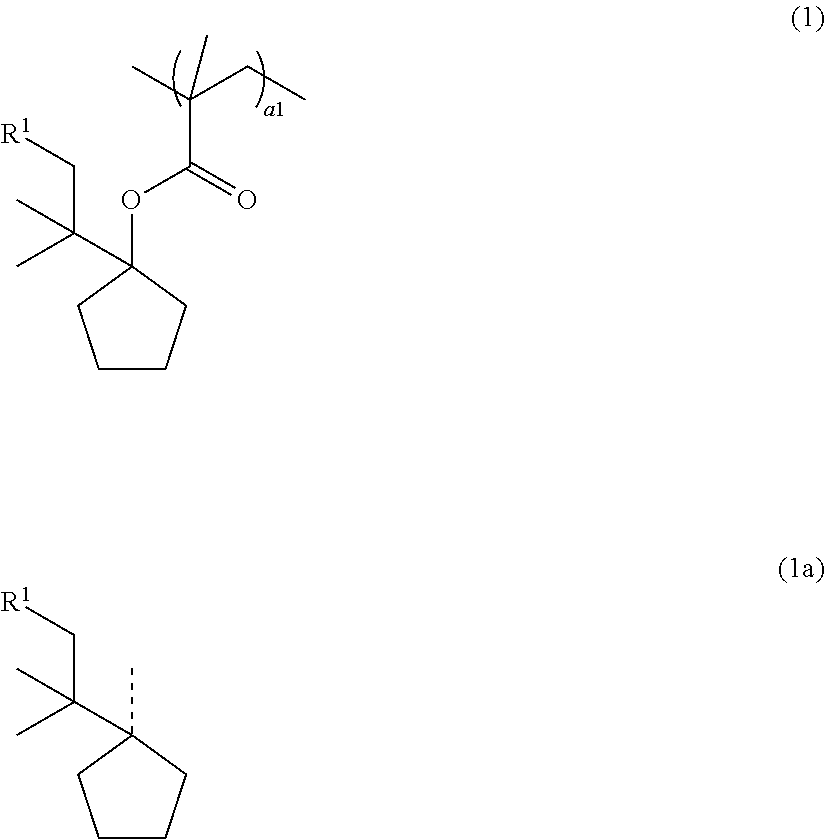

Negative pattern forming process

ActiveUS20130130183A1Inhibition formationPhotosensitive material processingOriginals for photomechanical treatmentCooking & bakingOrganic solvent

A negative pattern is formed by applying a resist composition comprising (A) a polymer comprising recurring units (a1) having a carboxyl group protected with an acid labile group and recurring units (a2) having an amino group, amide bond, carbamate bond or nitrogen-containing heterocycle, (B) a photoacid generator, and (C) an organic solvent onto a substrate, prebaking, exposing, baking, and selectively dissolving an unexposed region of the resist film in an organic solvent-based developer.

Owner:SHIN ETSU CHEM IND CO LTD

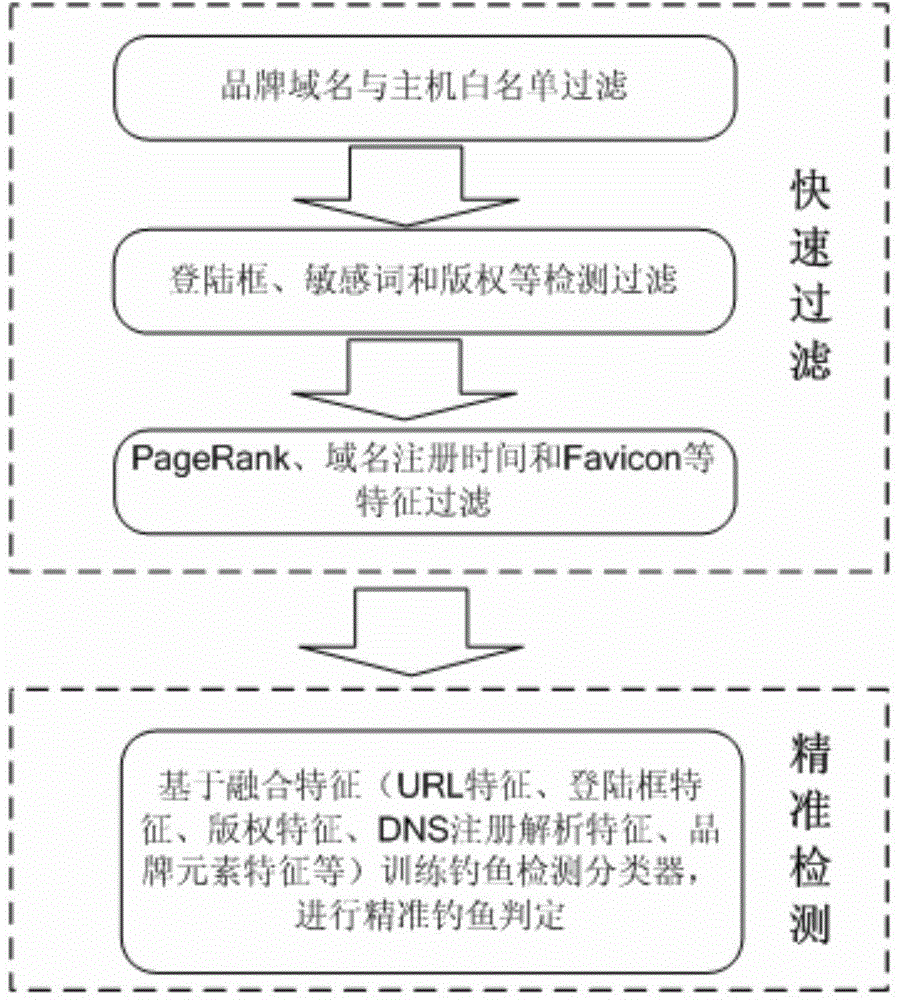

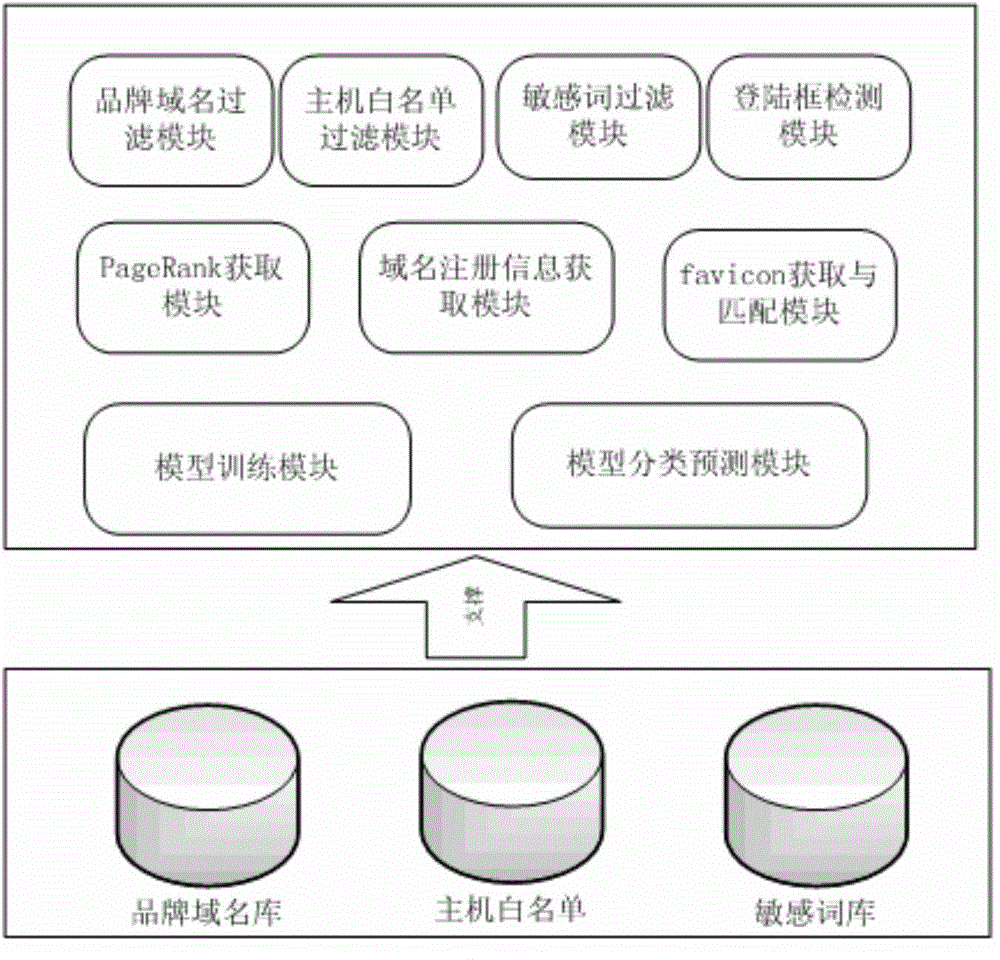

Multistage phishing website detecting method and system

ActiveCN104899508AQuick judgmentAccurate judgmentPlatform integrity maintainanceNarrow rangeWeb site

The invention provides a multistage phishing website detecting method and system. The core concept includes that rapid filtration is integrated with precision filtration. Suspected phishing websites are controlled within a narrow range by multistage rapid filtration. Further, an accurate judgment model is trained by analyzing statistical characteristics of positive and negative patterns within a narrow range. The method includes the steps: selecting websites to be detected within a range, rapidly filtering the websites and eliminating obvious non-phishing websites; accurately judging whether the rest websites after rapid filtration are phishing websites. The system comprises a rapid filtration module and an accurate judgment module, wherein the rapid filtration module is used for selecting the websites to be detected within the range, rapidly filtering the websites and eliminating the obvious non-phishing websites, and the accurate judgment module is used for accurately judging the rest websites to be detected after rapid filtration.

Owner:CHINA INTERNET NETWORK INFORMATION CENTER

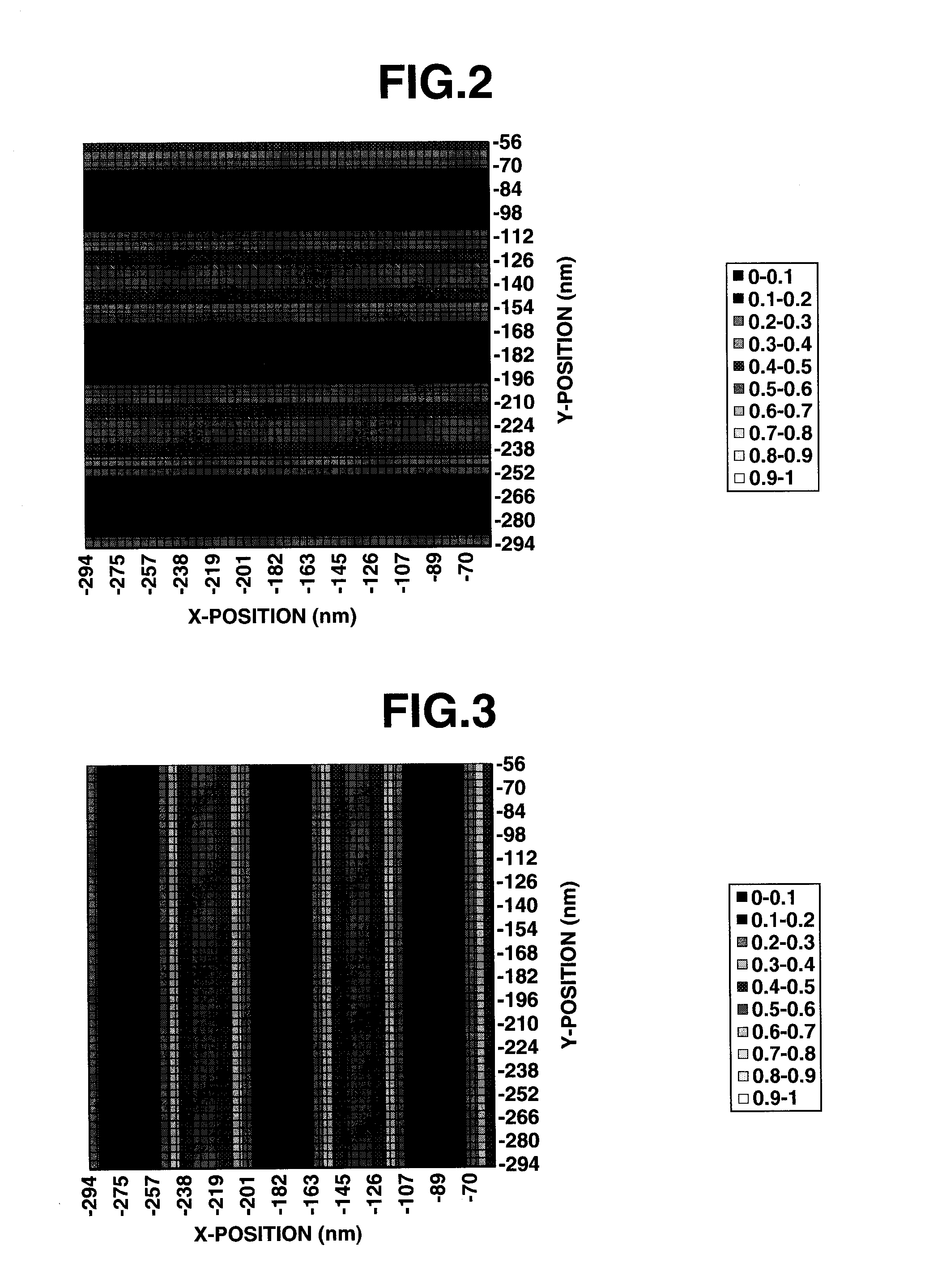

Patterning process and resist composition

InactiveUS20140212808A1High dissolution contrastGood size controlPhotosensitive materialsPhotosensitive material processingOrganic solventHigh energy

A resist composition comprising a polymer comprising recurring units having an acid labile group of cyclopentyl with tert-butyl or tert-amyl pendant is coated onto a substrate, baked, exposed to high-energy radiation, PEB and developed in an organic solvent to form a negative pattern. A fine hole pattern can be formed from the resist composition with advantages including high dissolution contrast, good size control and wide depth of focus.

Owner:SHIN ETSU CHEM IND CO LTD

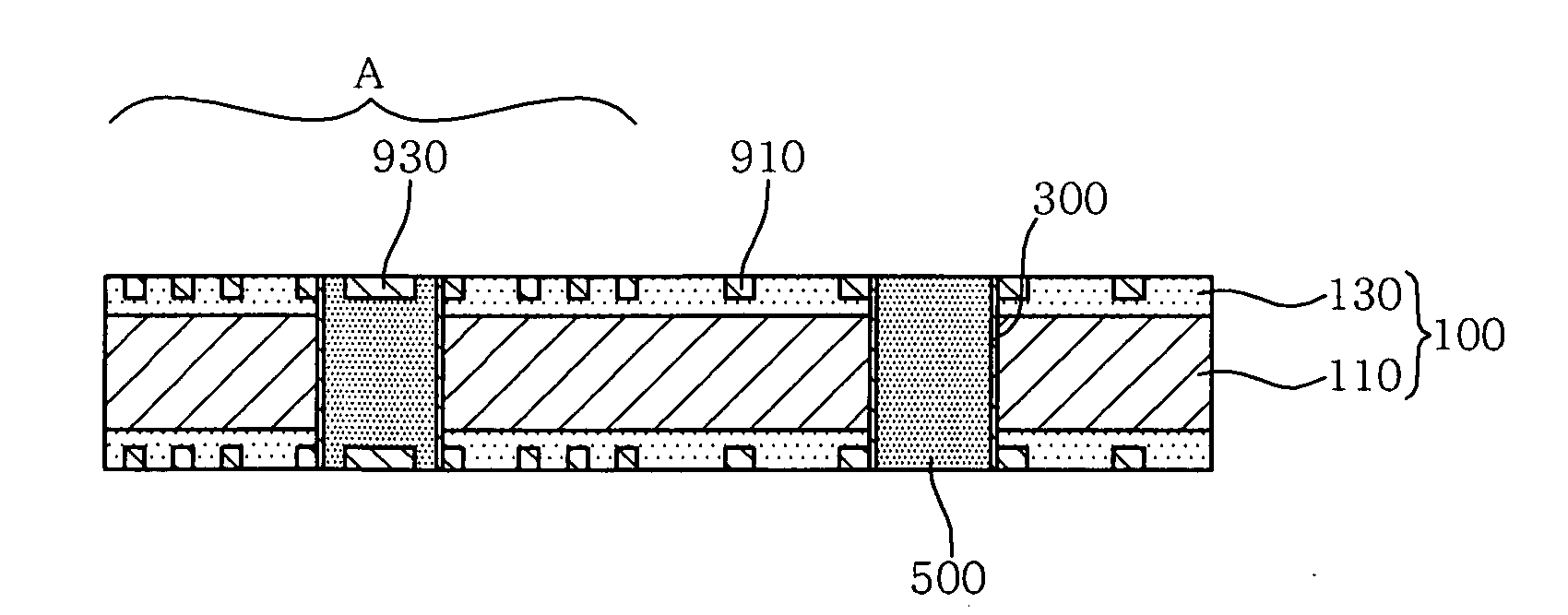

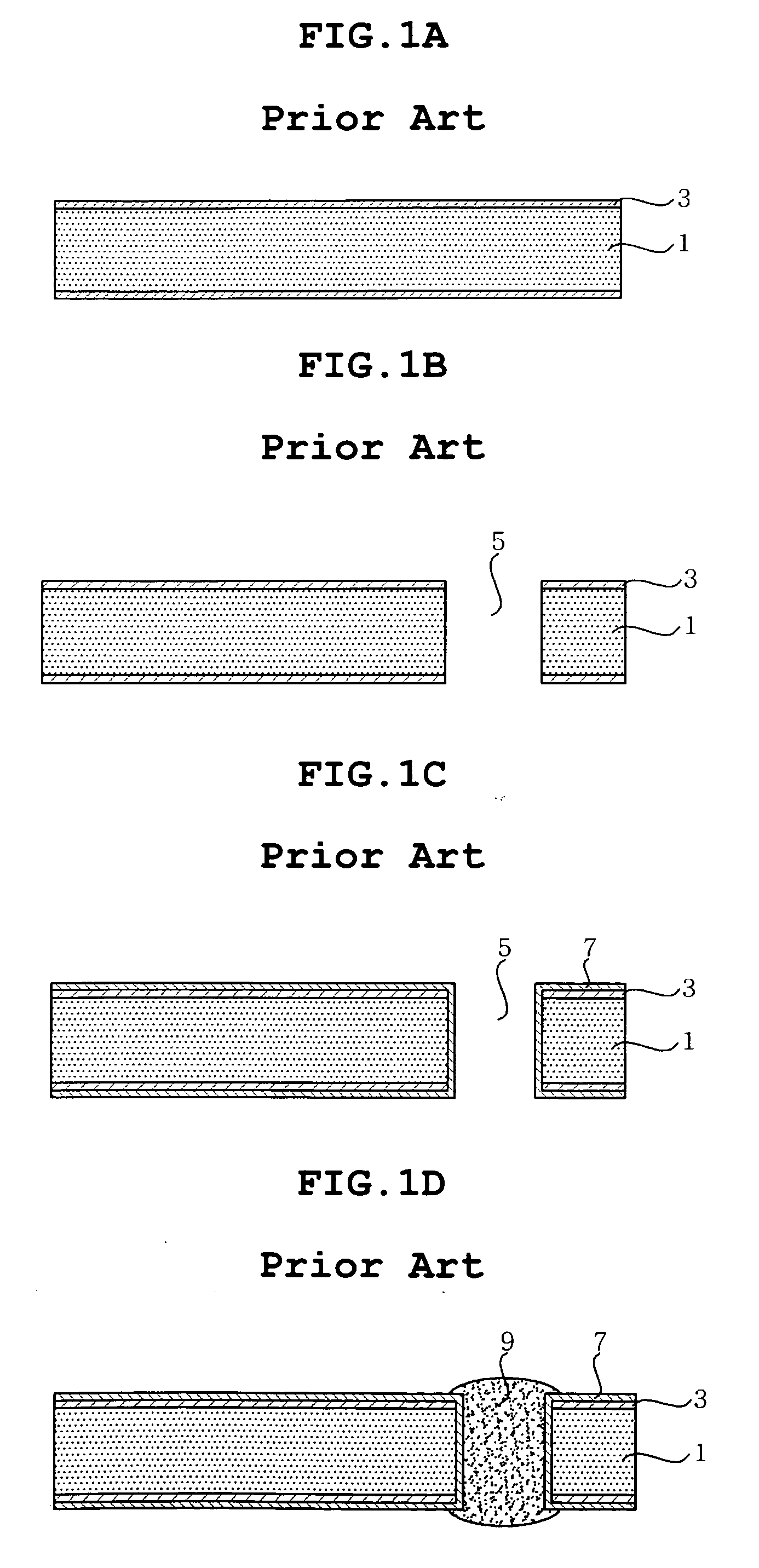

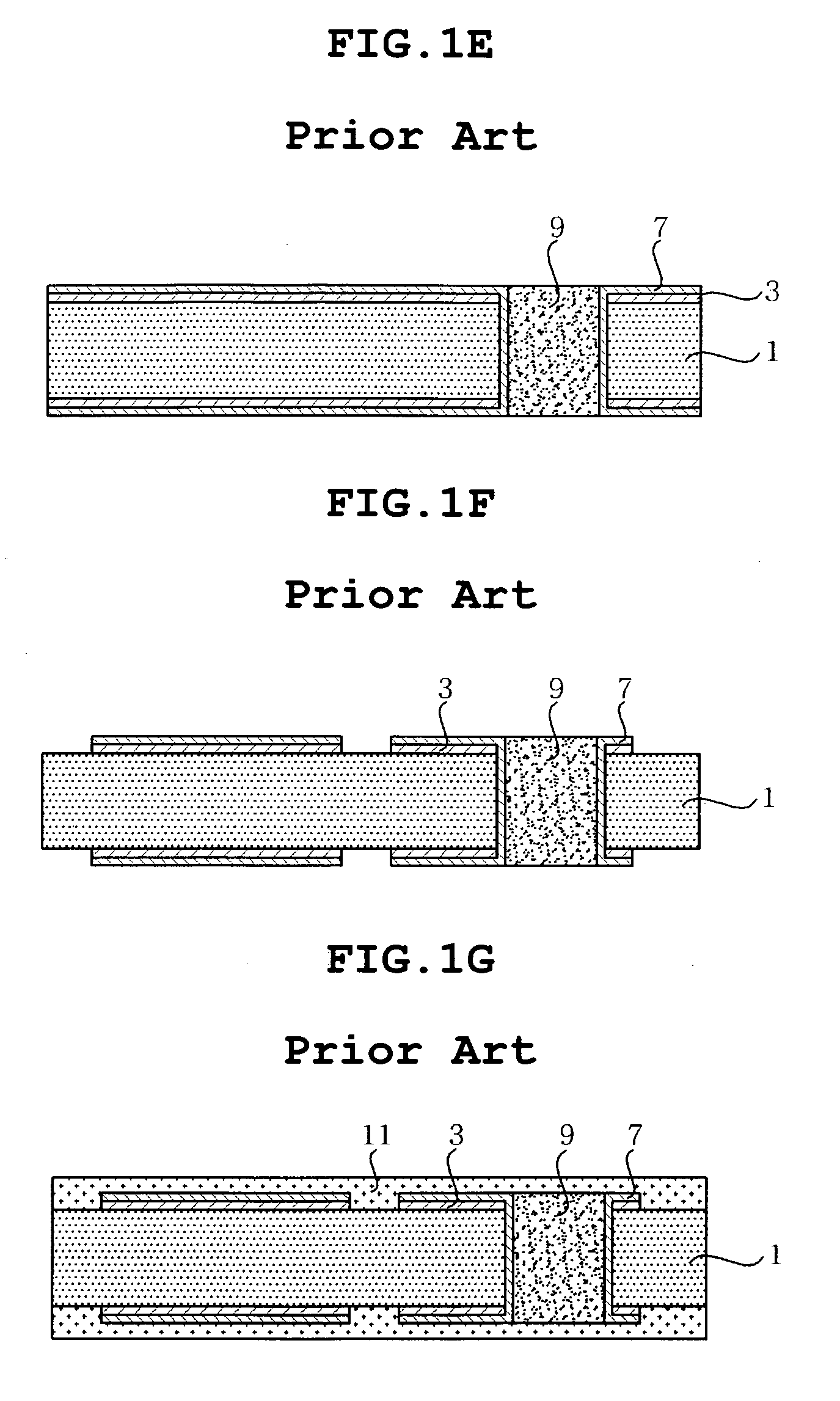

Printed circuit board having plating pattern buried in via and method of manufacturing the same

InactiveUS20100139960A1MinimizationMinimize biasRadiation applicationsPretreated surfacesPrinted circuit boardElectroplating

Disclosed is a printed circuit board having a plating pattern buried in a via and a method of manufacturing the same. The method of manufacturing the printed circuit board includes forming a negative pattern for forming a plating pattern, thus remarkably reducing the generation of plating thickness deviation in a plating process for forming a circuit pattern, and the printed circuit board has improved electrical signal transmission properties.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Patterning process and resist composition

ActiveUS20130108960A1High dissolution contrastHigh sensitivityPhotosensitive materialsElectric discharge tubesOrganic solventEther

A negative pattern is formed by coating a resist composition onto a substrate, the resist composition comprising a polymer comprising recurring units having an acid labile group-substituted hydroxyl group, an acid generator, an onium salt of perfluoroalkyl ether carboxylic acid, and an organic solvent, prebaking, exposing, baking, and developing in an organic solvent such that the unexposed region of film is dissolved away and the exposed region of film is not dissolved. In image formation via positive / negative reversal by organic solvent development, the resist film is characterized by a high dissolution contrast between the unexposed and exposed regions.

Owner:SHIN ETSU CHEM IND CO LTD

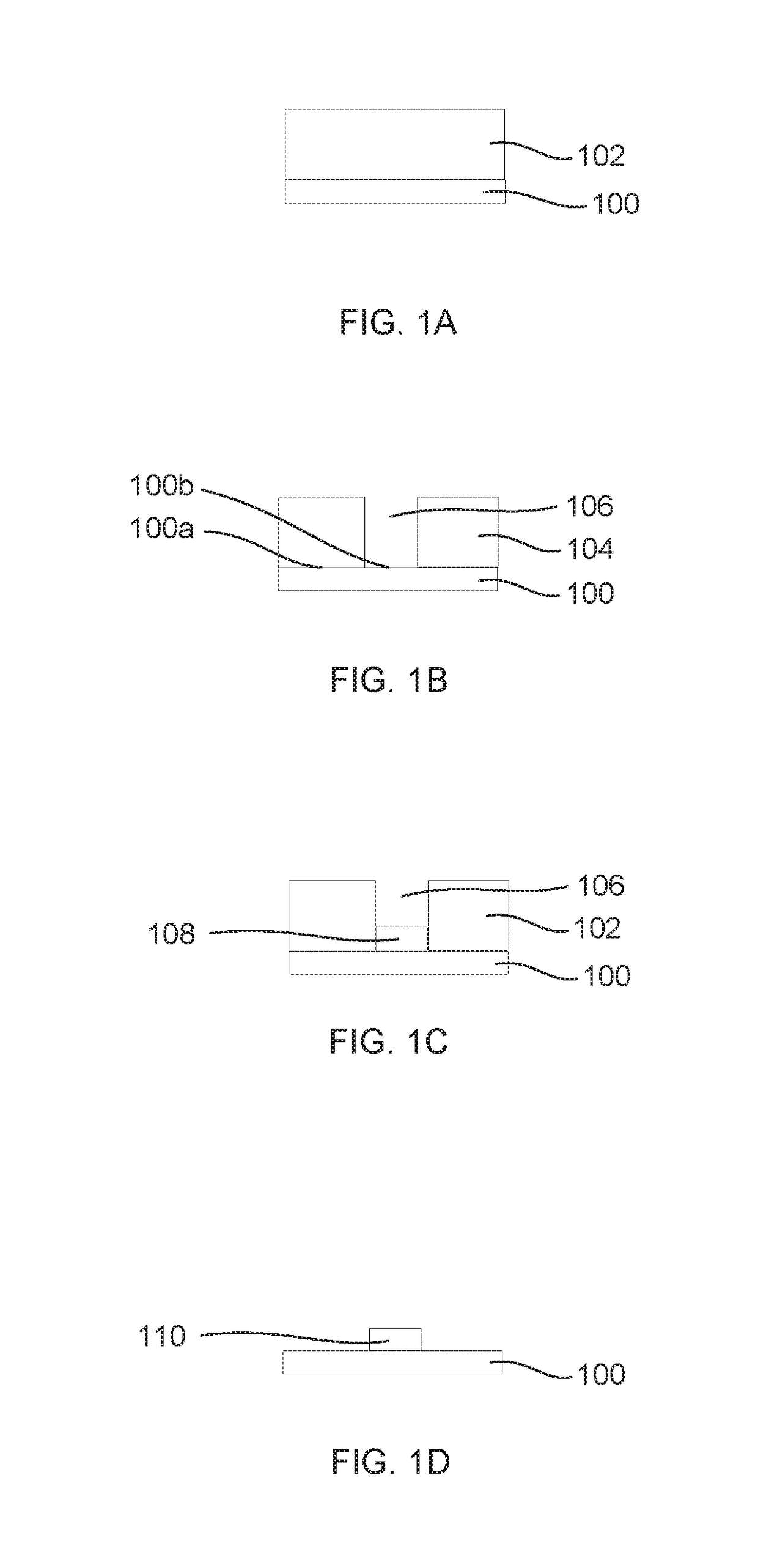

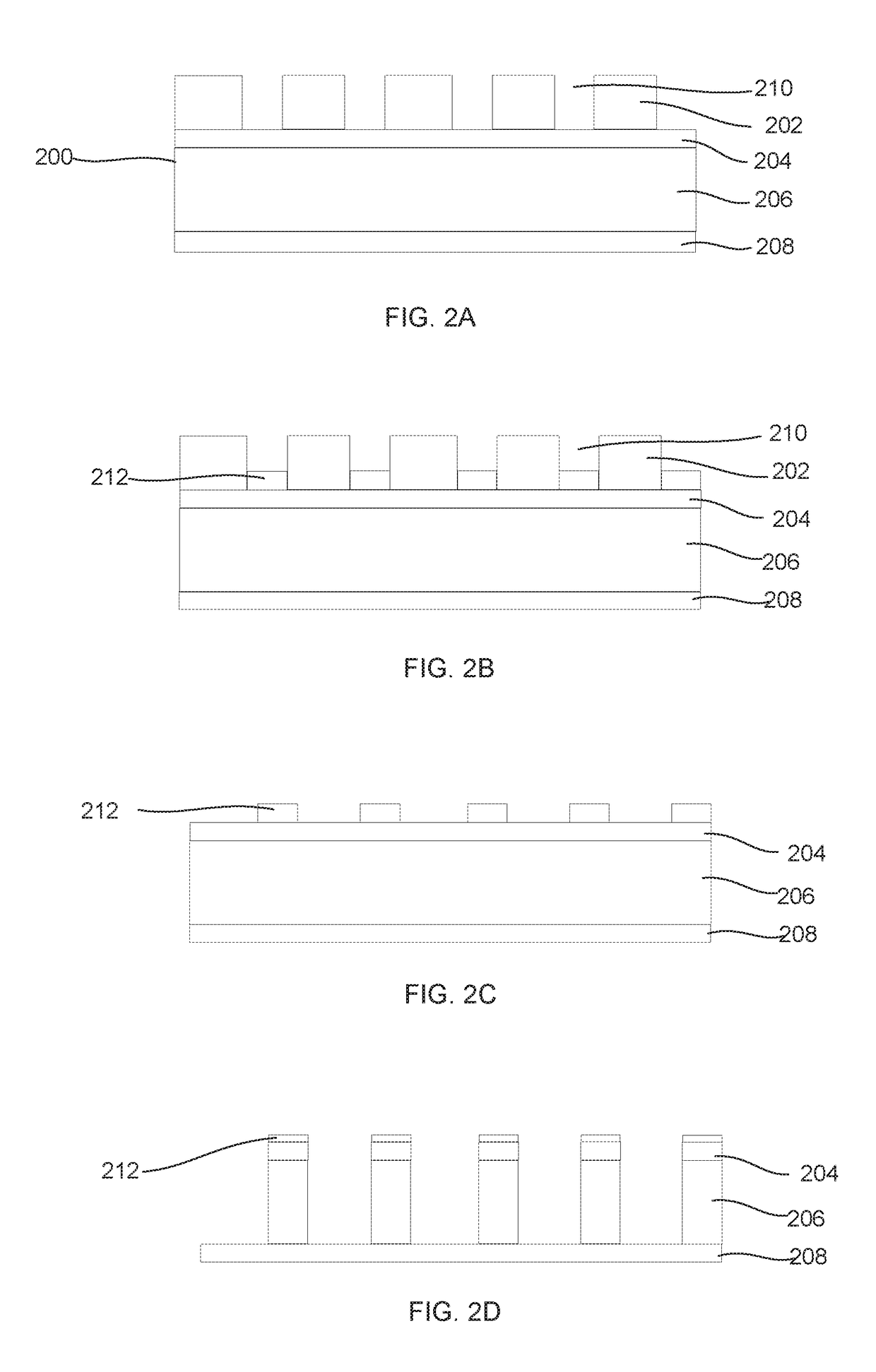

EUV photopatterning and selective deposition for negative pattern mask

InactiveUS20180308687A1Resist budgetEliminate needSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSelective depositionNitride

Process and apparatus for forming a negative patterning mask in the context of EUV patterning uses a selective deposition process to deposit a metal oxide or metal nitride thin film in a feature defined in an EUV resist to prepare a negative image for patterning. The method to produce the “negative” image does not involve an etch back step and therefore accommodates the small resist budget. The material forming the “negative” image is significantly more etch resistant than resist which eliminates the need for an additional hard mask transfer layer.

Owner:LAM RES CORP

Patterning process and resist composition

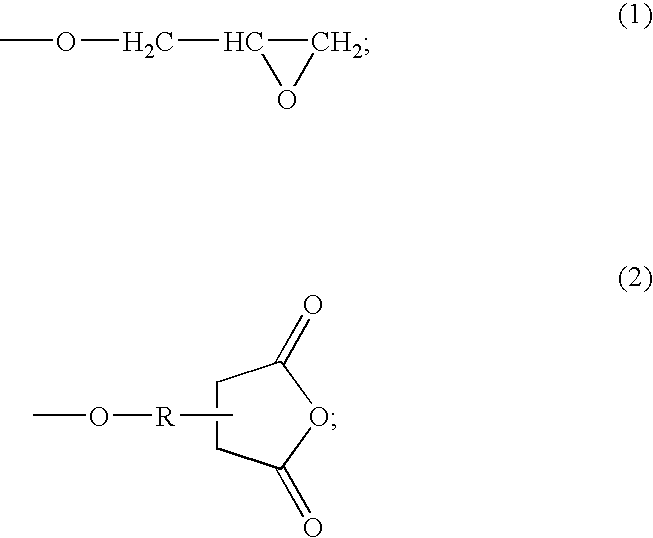

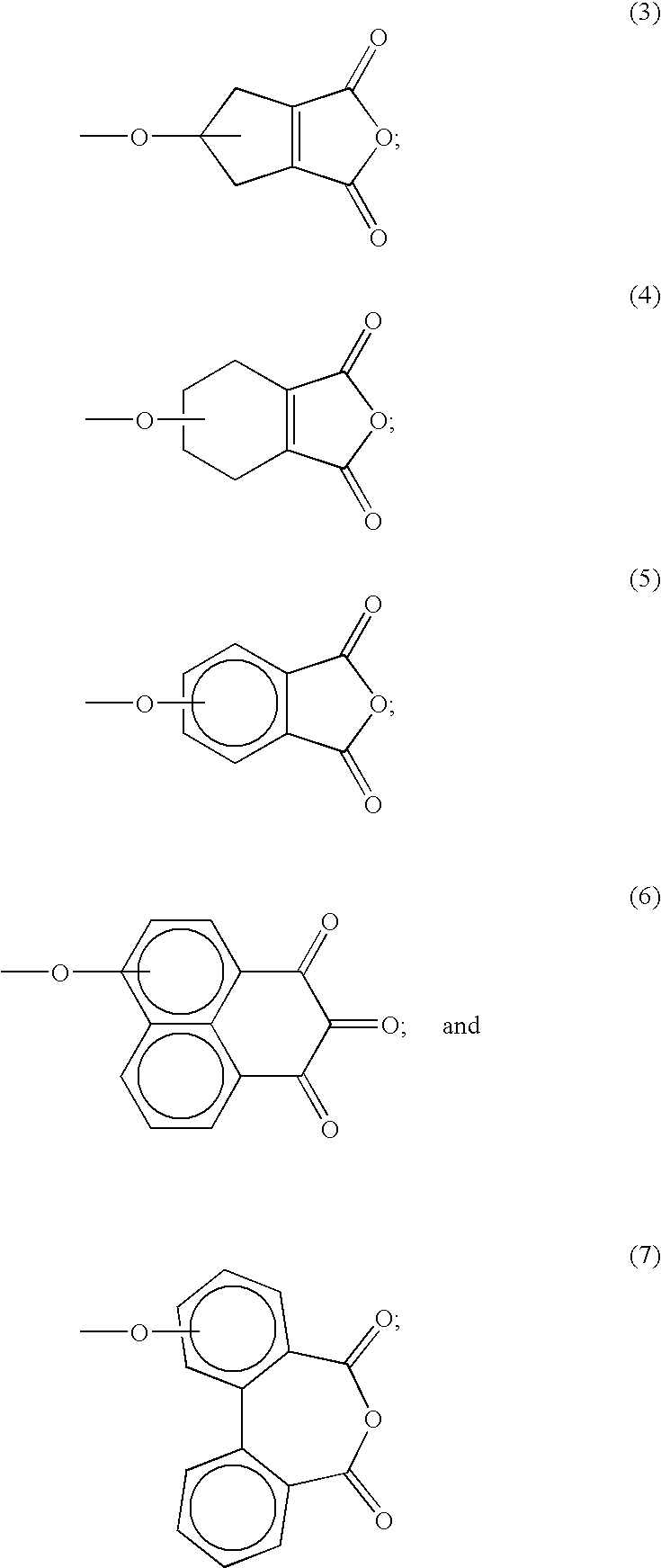

InactiveUS20130071788A1Increase contrastHigh sensitivityPhotosensitive materialsElectric discharge tubesOrganic solventHigh energy

A negative pattern is formed by coating a resist composition comprising a polymer comprising recurring units of acid labile group-substituted vinyl alcohol and maleic anhydride and / or maleimide, an acid generator, and an organic solvent onto a substrate, prebaking, exposing to high-energy radiation, and developing in an organic solvent developer such that the unexposed region of resist film is dissolved away and the exposed region of resist film is not dissolved. In image formation via positive / negative reversal by organic solvent development, the resist film is characterized by a high dissolution contrast between the unexposed and exposed regions.

Owner:SHIN ETSU CHEM IND CO LTD

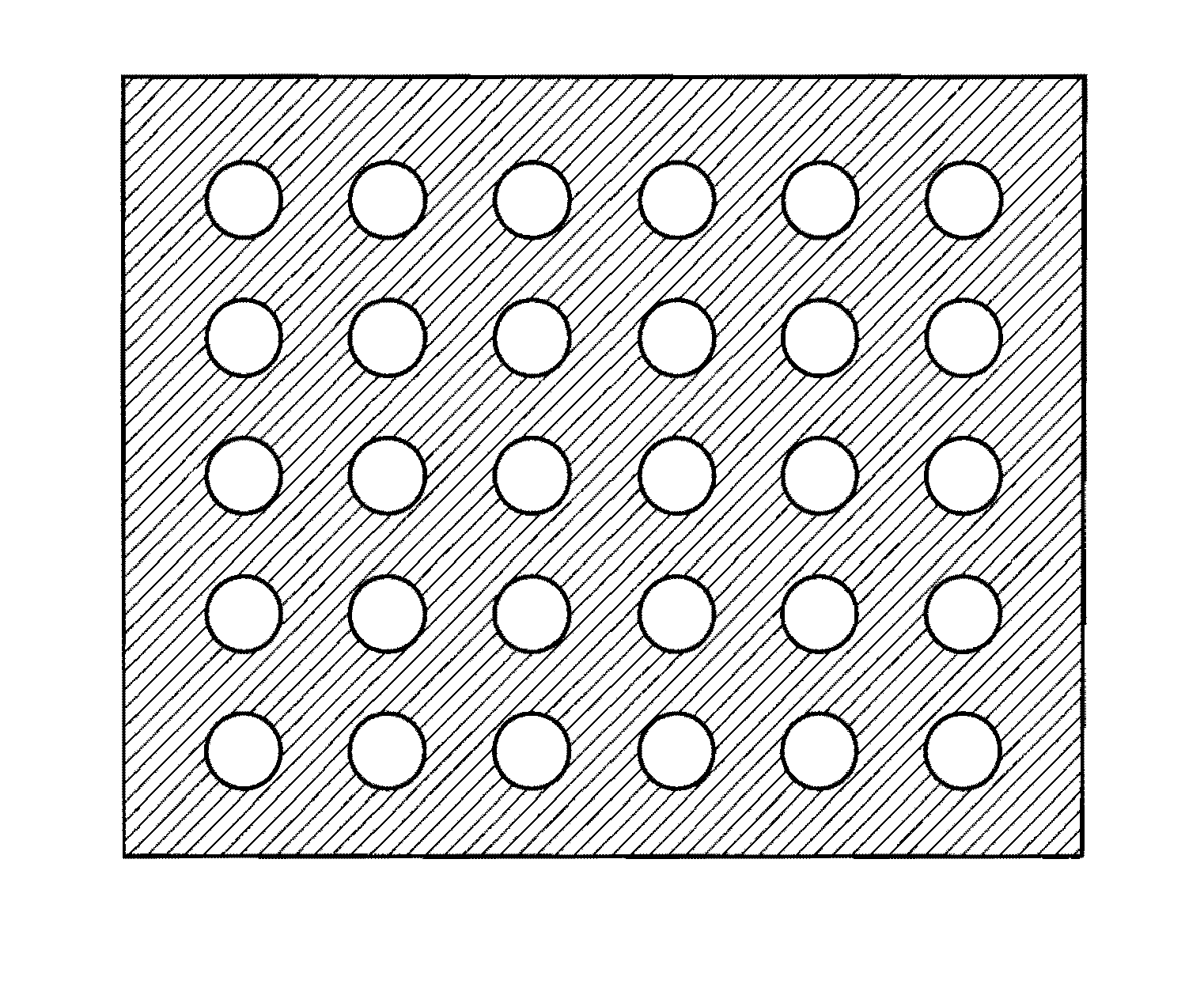

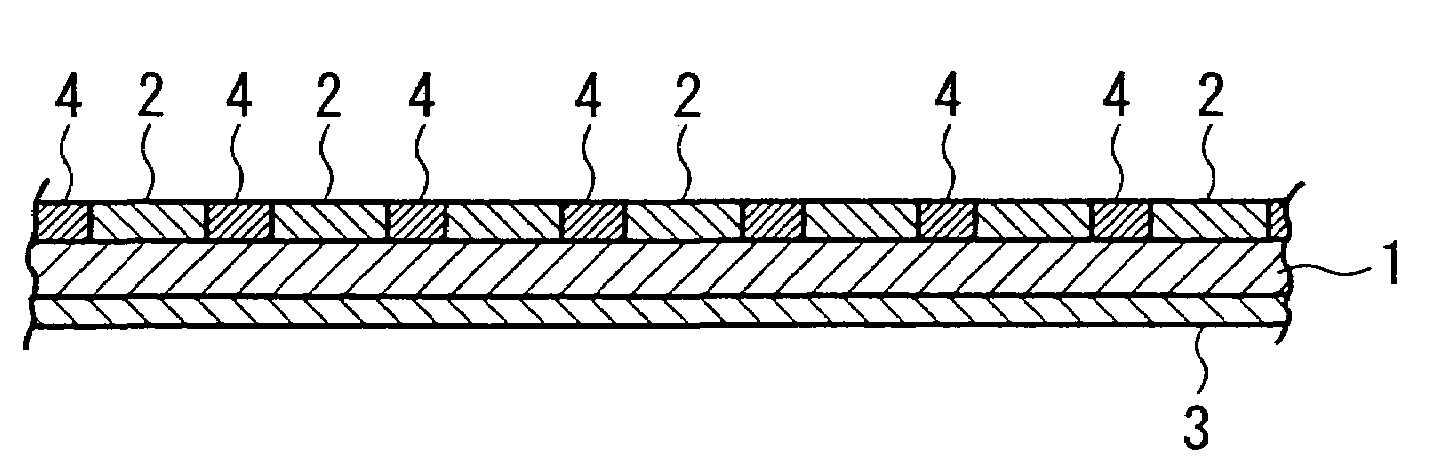

Electromagnetic-wave shielding and light transmitting plate and manufacturing method thereof

InactiveUS7560135B2Good surface smoothnessMagnetic/electric field screeningLiquid/solution decomposition chemical coatingConductive materialsEngineering

To manufacture an electromagnetic-wave shielding and light transmitting plate having a conductive pattern of which line width is narrow and open area ratio is high, a negative pattern 2 composed of dots is printed on a transparent film 1 having a high affinity for a plated layer of a conductive material by using a transparent resin having a low affinity for the plated layer and a backside coating layer 3 is formed by printing a transparent resin on the entire back surface of the transparent film 1. Then, a conductive material layer is formed by electroless plating to cover the film exposed surface not covered by the negative pattern 2 of the film 1, thereby forming the conductive pattern 4. After that, the blackening treatment is conducted, thereby obtaining the electromagnetic-wave shielding and light transmitting plate.

Owner:BRIDGESTONE CORP

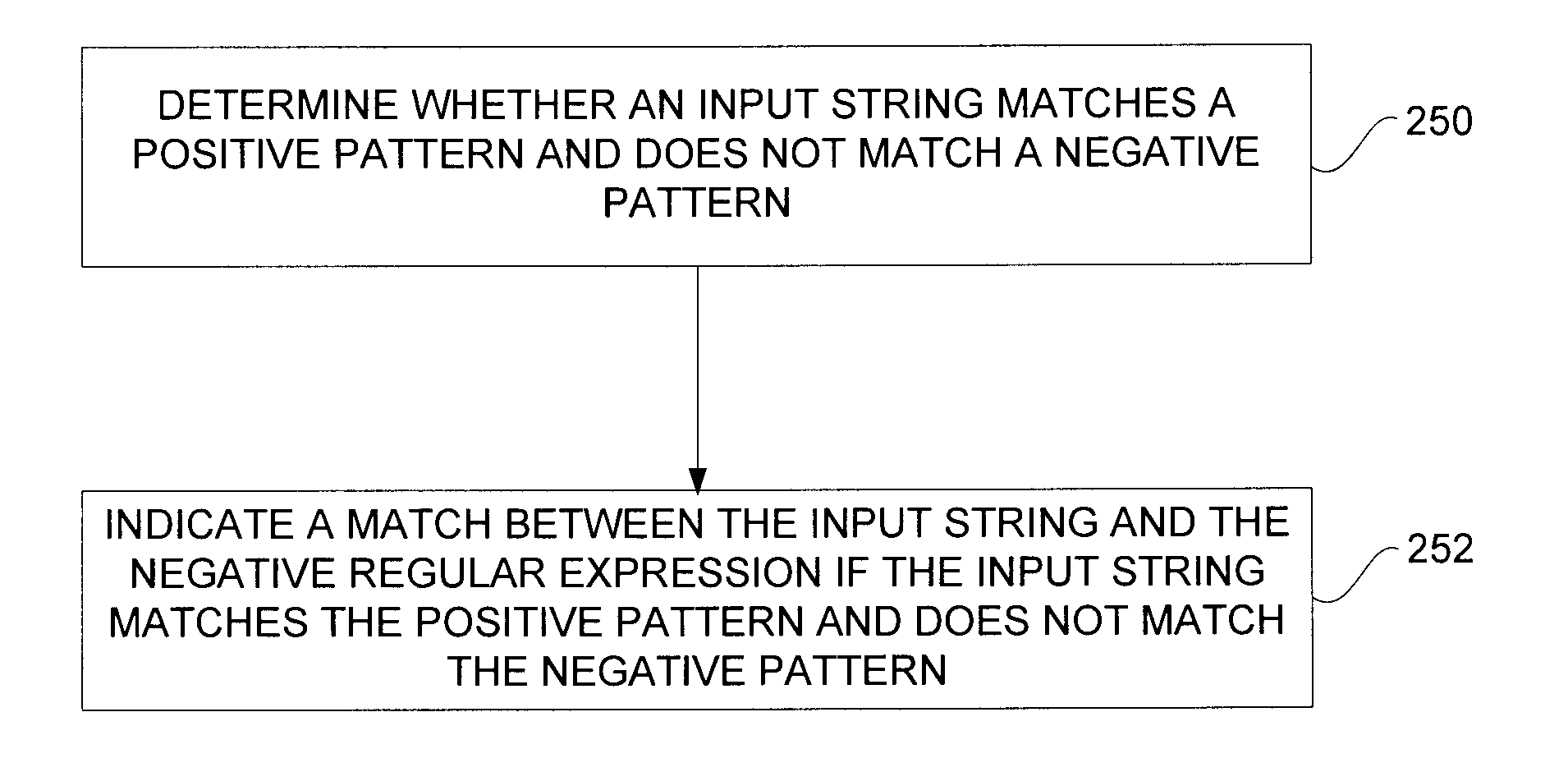

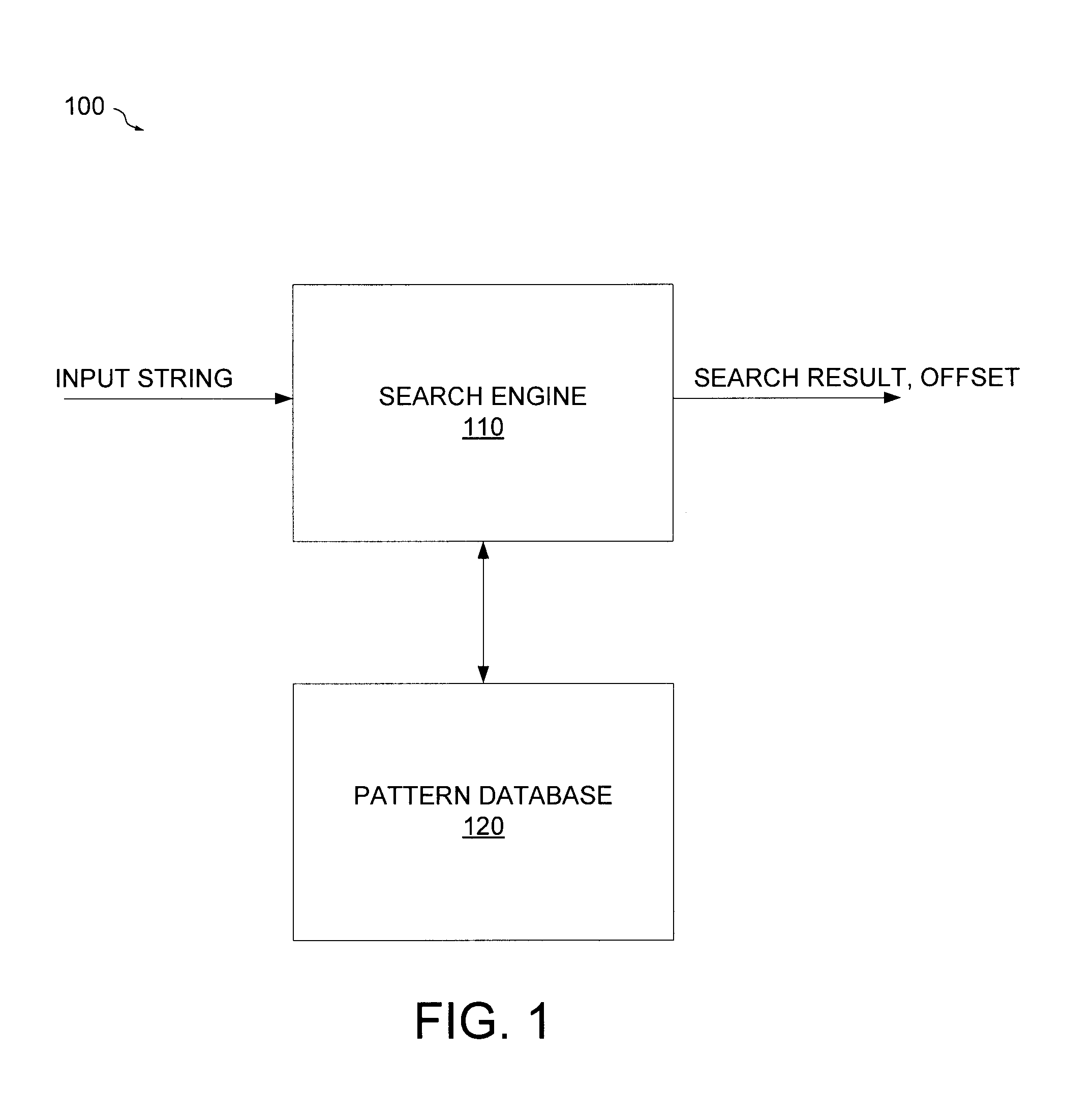

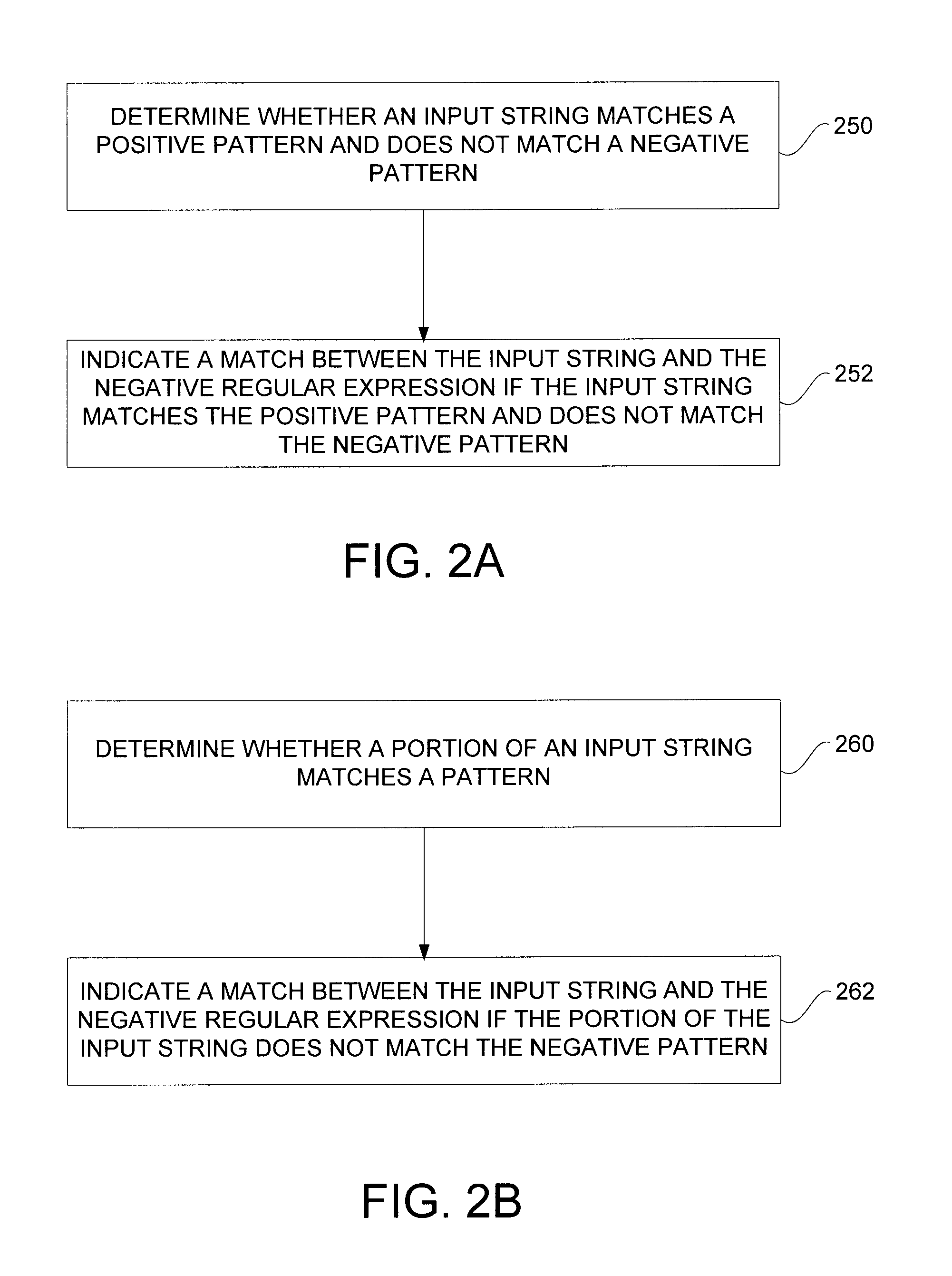

Negative regular expression search operations

InactiveUS8527488B1Digital data information retrievalDigital data processing detailsPattern matchingNetwork packet

A content search system determines whether an input string matches a negative regular expression that includes a negative pattern and an optional positive pattern. If the input string matches the positive pattern and does not match the negative pattern, a match between the input string and the negative regular expression is indicated. The positive pattern and the negative pattern may be compared to the input string in a single pass of the input string. The content search system may be implemented in a content addressable memory (CAM) device. The negative regular expression may specify a particular portion of the input string, such as a range of characters or bytes of a data packet, in which the negative pattern should not match for a match between the negative regular expression and the input pattern to be indicated.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

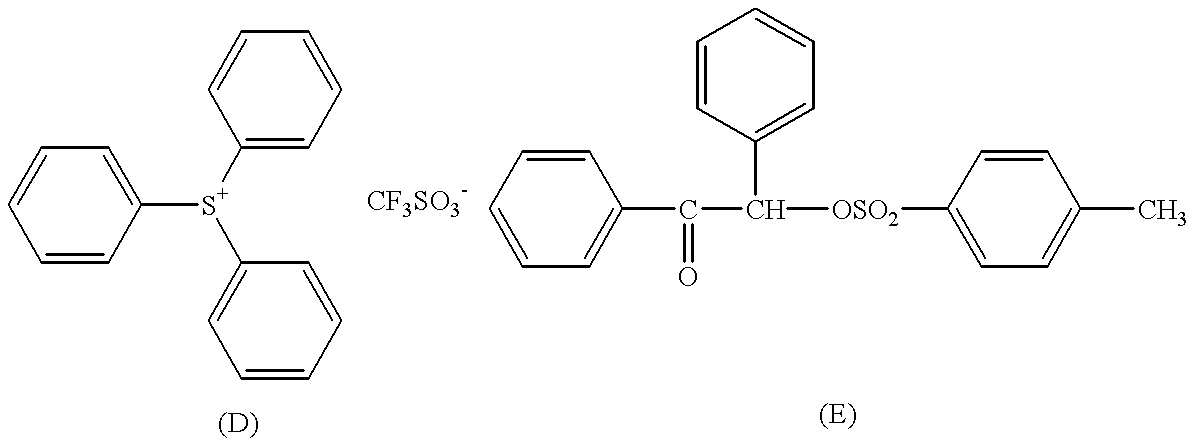

Patterning process and resist composition

ActiveUS20140255843A1Minimized edge roughnessPattern collapse is mitigatedPhotosensitive materialsPhotosensitive material processingCooking & bakingAryl

A negative pattern is formed by coating a resist composition comprising (A) a polymer having an acid labile group, adapted to change its polarity under the action of acid, (B) a photoacid generator, and (C) an organic solvent onto a substrate, baking, exposing the resist film to high-energy radiation, PEB, and developing in an organic solvent-based developer to selectively dissolve the unexposed region of resist film. The photoacid generator has the formula: R1—COOC(CF3)2—CH2SO3−R2R3R4S+ wherein R1 is a monovalent hydrocarbon group, R2, R3 and R4 are an alkyl, alkenyl, oxoalkyl, aryl, aralkyl or aryloxoalkyl group, or may bond together to form a ring with the sulfur atom.

Owner:SHIN ETSU CHEM IND CO LTD

Patterning process

ActiveUS8198016B2High resolutionSolve the real problemPhotosensitive materialsRadiation applicationsSolubilityOrganic solvent

The present invention provides a patterning process, in which a resistance with regard to an organic solvent used for a composition for formation of a reverse film is rendered to a positive pattern to the degree of necessity and yet solubility into an alkaline etching liquid is secured, thereby enabling to finally obtain a negative image by a positive-negative reversal by performing a wet etching using an alkaline etching liquid.A resist patterning process of the present invention using a positive-negative reversal comprises at least a step of forming a resist film by applying a positive resist composition; a step of obtaining a positive pattern by exposing and developing the resist film; a step of crosslinking the positive resist pattern thus obtained; a step of forming a reverse film; and a step of reversing the positive pattern to a negative pattern by dissolving into an alkaline wet-etching liquid for removal.

Owner:SHIN ETSU CHEM CO LTD

Bootstrapping weak learning method based on random fern and classifier thereof

InactiveCN102708384AImprove accuracyReal-time processingCharacter and pattern recognitionNODALGraphics

The invention provides a bootstrapping weak learning method based on a random fern and a classifier thereof, which belong to the technical field of computer graphic identification. In graphic identification, positive and negative patterns are generally judged by adopting the mean value distances of weighting and Gaussian probability distribution of a weak classifier. Or classification trees are taken as weak learners, nodes are partitioned by using the partitioning rule of error metric reduction maximization, and the weak classifiers are improved into strong classifiers. However, the weak learning methods have the defects of low convergence rate, poor accuracy and low computing efficiency. Through steps for selecting image characteristics, constructing a random fern and a weak learning method based on a random fern, establishing a weak classifier and a result classifier and the like, the image mode identification problems of complexity of an imaging environment and strict requirement on the operand can be well solved, a rapidly-converging and efficient bootstrapping weak learning method is realized, and a high-accuracy classifier for real-time processing is obtained. The method and the classifier are mainly applied to identification occasions in various modes.

Owner:SOUTHWEST JIAOTONG UNIV

Patterning process and resist composition

ActiveUS20130052587A1High dissolution contrastHigh sensitivityElectric discharge tubesPhotosensitive materialsOrganic solventHigh energy

A negative pattern is formed by coating a resist composition comprising a methylol-substituted urea, amide or urethane compound, a polymer comprising recurring units having an acid labile group-substituted hydroxyl group, and an acid generator onto a substrate, prebaking, exposing to high-energy radiation, and developing in an organic solvent developer such that the unexposed region of resist film is dissolved away and the exposed region of resist film is not dissolved. In image formation via positive / negative reversal by organic solvent development, the resist film is characterized by a high dissolution contrast between the unexposed and exposed regions.

Owner:SHIN ETSU CHEM IND CO LTD

Method for manufacturing magnetic recording medium and magnetic recording and reproducing apparatus

InactiveUS8048323B2Easy to separateHead stabilizationDifferent record carrier formsDecorative surface effectsNon magneticSignal processing

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com