Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

690 results about "Acid labile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the context of chemistry, acid labile means that an acidic proton is readily formed. For example, this can occur in molecules with a hydroxyl group with conjugated double bond capable of stabilising the anionic charge from extra electrons. This makes the acidic H+ easier to release, or more labile. Related QuestionsMore Answers Below.

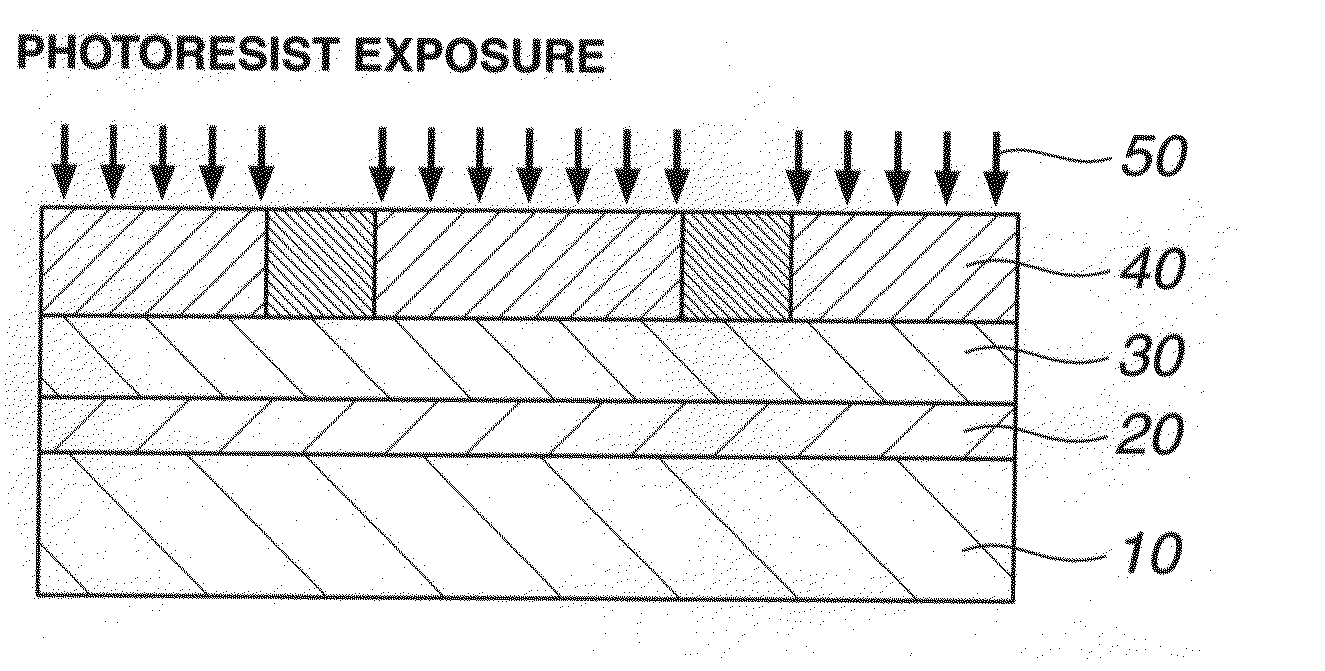

Photoresist composition for deep UV and process thereof

InactiveUS6447980B1Radiation applicationsSemiconductor/solid-state device manufacturingResistSide chain

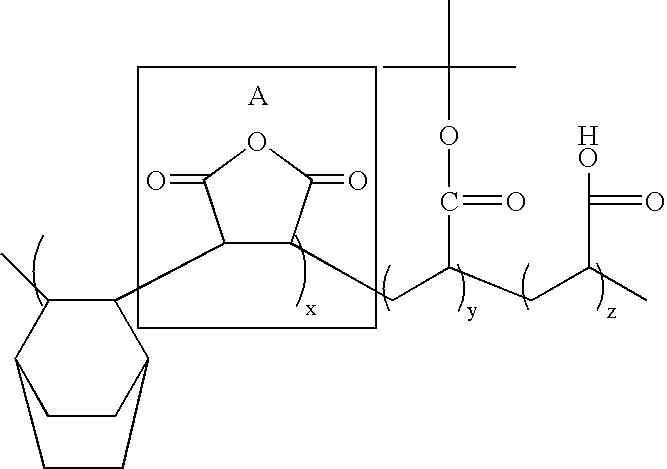

The present invention relates to a chemically amplified system, which is, sensitive to wavelengths between 300 nm and 100 nm, and comprises a) a polymer that is insoluble an aqueous alkaline solution and comprises at least one acid labile group, b) a compound capable of producing an acid upon radiation. The present invention comprises a polymer that is made from a alicyclic hydrocarbon olefin, an acrylate with a pendant cyclic moeity, and a cyclic anhydride. The present invention also relates to a process for imaging such a photoresist.

Owner:AZ ELECTRONICS MATERIALS USA CORP

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

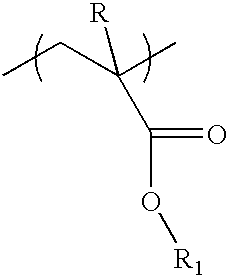

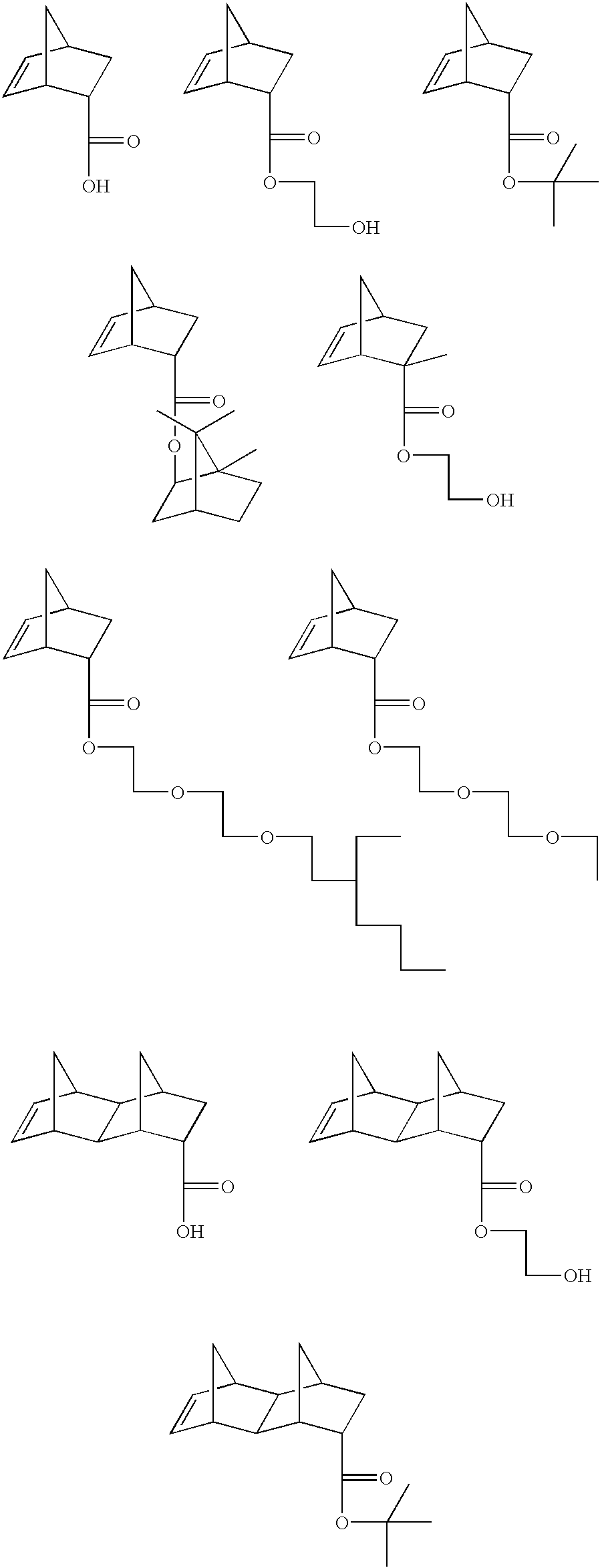

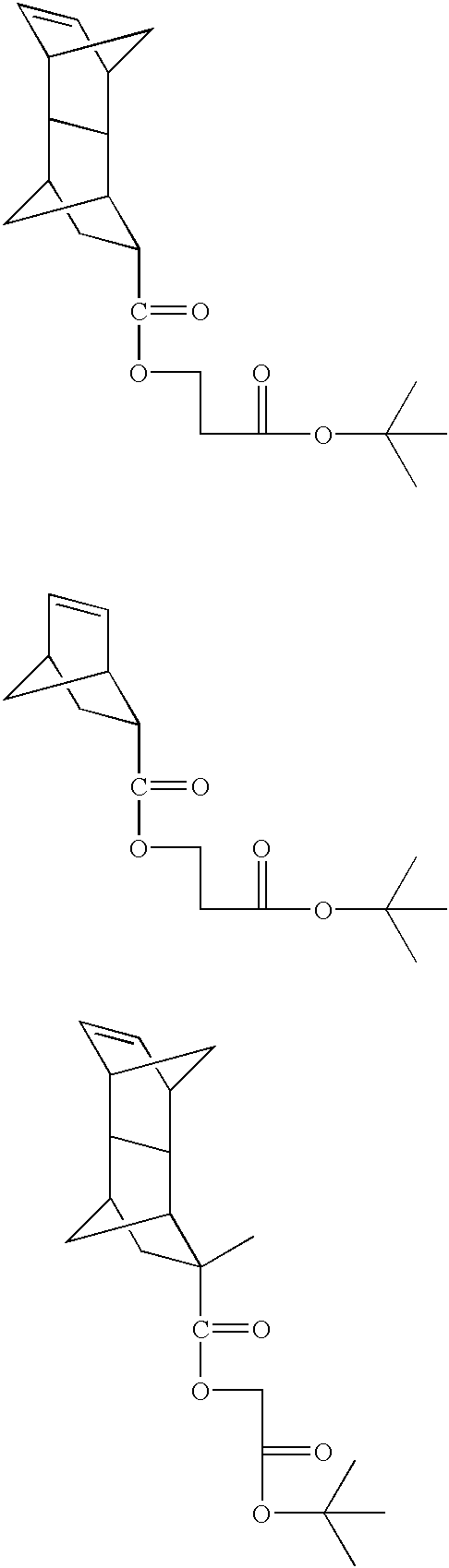

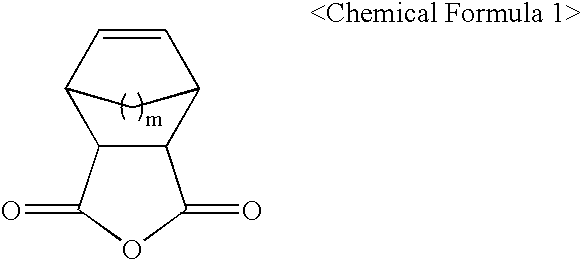

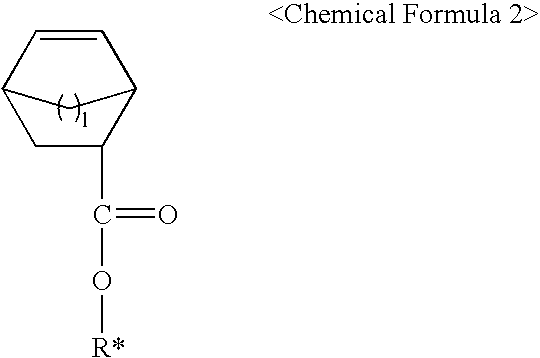

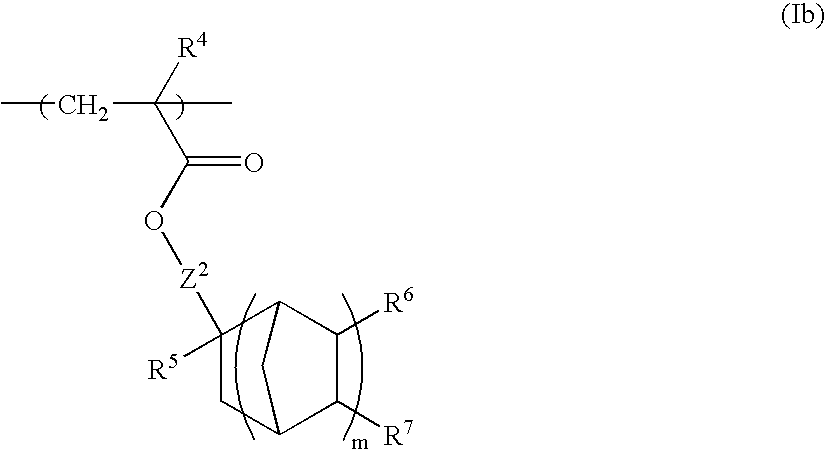

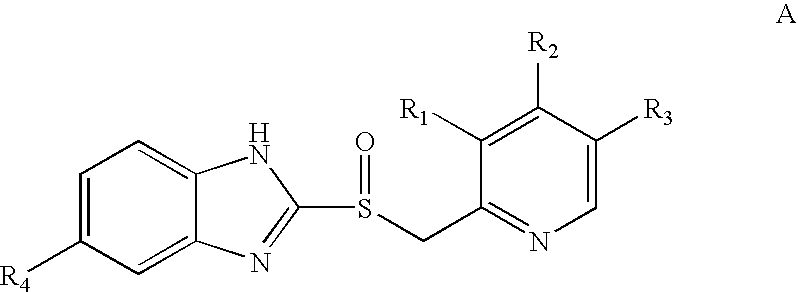

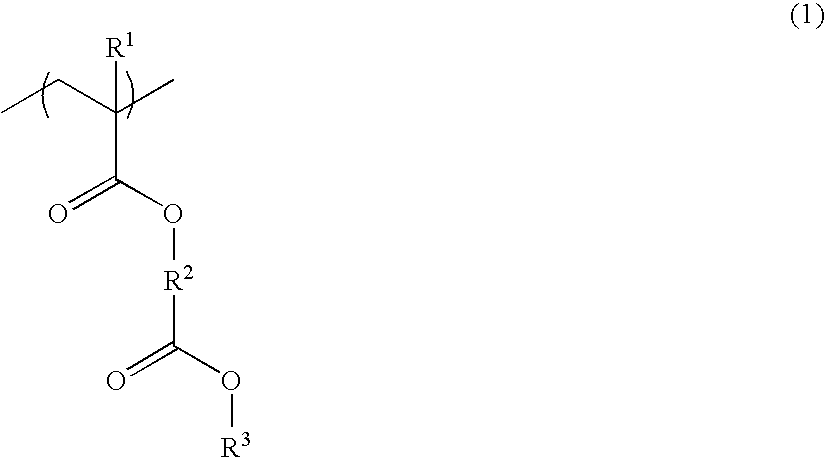

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

Photoresist composition for deep UV radiation containing an additive

InactiveUS6723488B2Reduce impactPrevent degradationPhotosensitive materialsElectric discharge tubesUltravioletAqueous solution

Owner:AZ ELECTRONICS MATERIALS USA CORP

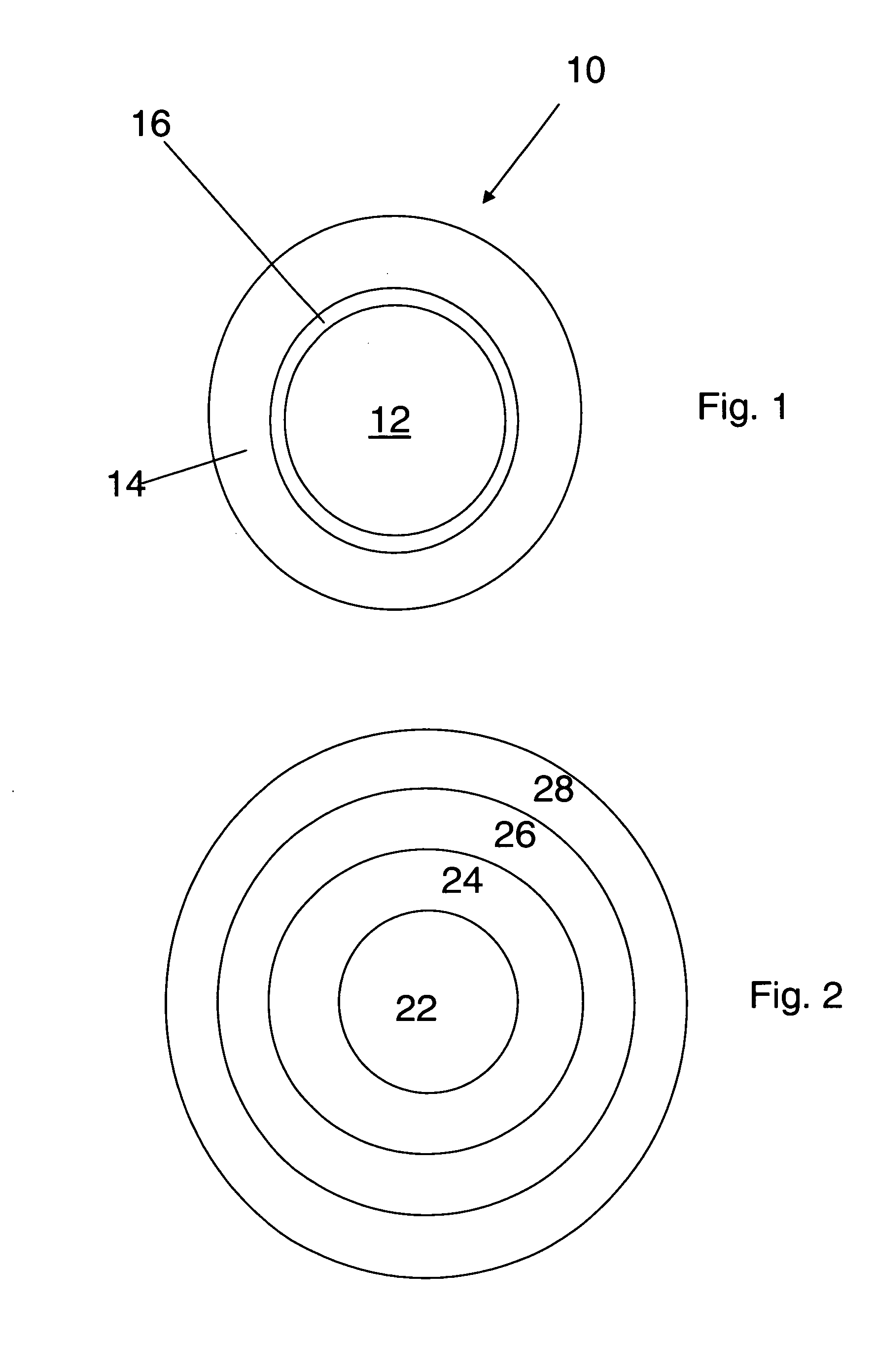

Orally disintegrable tablets

InactiveUS6328994B1Sufficient oral disintegrabilityHigh strengthOrganic active ingredientsPowder deliveryDiseaseOrally disintegrating tablet

An orally disintegrable tablet, of the present invention, which comprises (i) fine granules having an average particle diameter of 400 mum or less, which fine granules comprise a composition coated by an enteric coating layer, said composition having 10 weight % or more of an acid-labile physiologically active substance and (ii) an additive, has superior disintegrability or dissolution in the oral cavity so that it can be used for treatment or prevention of various diseases, as an orally disintegrable tablet capable of being administered to the aged or children and easily administered without water. Also, because the tablet of the present invention contains fine granules having the average particle diameter such that it will not impart roughness in mouth, it can be administered easily without discomfort at the administration.

Owner:TAKEDA PHARMA CO LTD

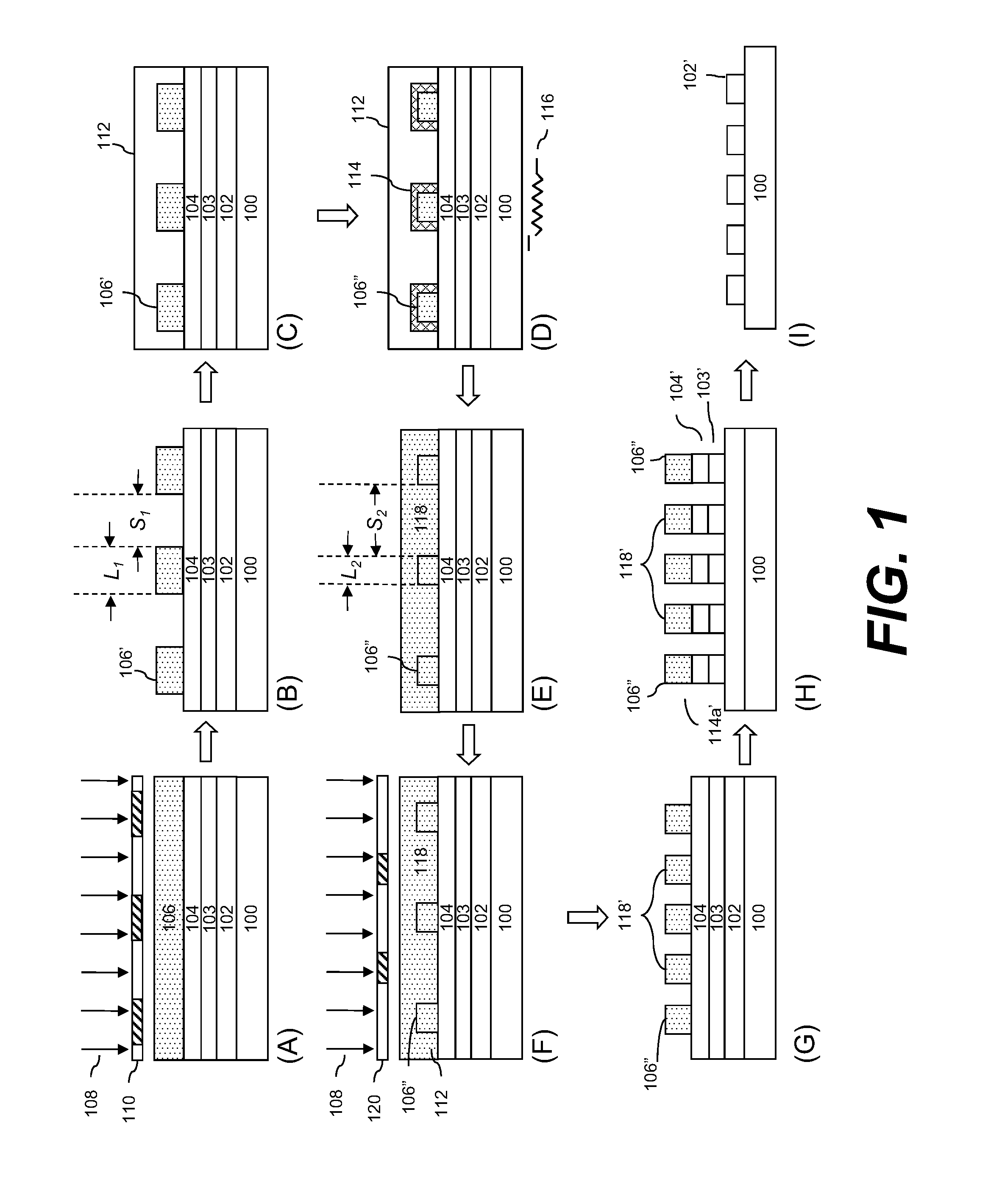

Photoresist pattern trimming methods

ActiveUS20140186772A1Increased process windowSemiconductor/solid-state device manufacturingPhotosensitive material processingResistPolymer science

Provided are methods of trimming a photoresist pattern. The methods comprise: (a) providing a semiconductor substrate; (b) forming a photoresist pattern on the substrate, wherein the photoresist pattern is formed from a chemically amplified photoresist composition comprising: a matrix polymer comprising an acid labile group; a photoacid generator; and a solvent; (c) coating a photoresist trimming composition on the substrate over the photoresist pattern, wherein the trimming composition comprises: a matrix polymer, an aromatic acid that is free of fluorine; and a solvent; (d) heating the coated substrate, thereby causing a change in polarity of the photoresist matrix polymer in a surface region of the photoresist pattern; and (e) contacting the photoresist pattern with a rinsing agent to remove the surface region of the photoresist pattern, thereby forming a trimmed photoresist pattern. The methods find particular applicability in the manufacture of semiconductor devices.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

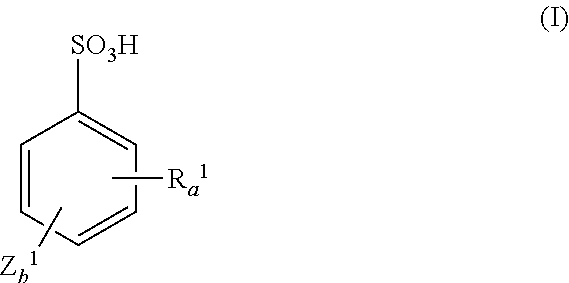

Sulfonium salt having polymerizable anion, polymer, resist composition, and patterning process

ActiveUS20080102407A1Feature size of to decreaseSmall feature sizeOrganic chemistryPhotosensitive materialsResistHigh energy

A sulfonium salt having a polymerizable anion generates a strong sulfonic acid upon exposure to high-energy radiation so that it facilitates effective scission of acid labile groups in chemically amplified resist compositions. It is useful as a monomer from which a base resin for use in radiation-sensitive resist compositions is derived.

Owner:SHIN ETSU CHEM IND CO LTD

Positive-working photoimageable bottom antireflective coating

The present invention relates to a novel absorbing, photoimageable and aqueous developable positive-working antireflective coating composition comprising a photoacid generator and a polymer comprising at least one unit with an acid labile group and at least one unit with an absorbing chromophore. The invention further relates to a process for using such a composition. The present invention also relates to a novel absorbing, photoimageable and aqueous alkali developable positive-working antireflective coating composition comprising a polymer comprising at least one unit with an acid labile group, a dye and a photoacid generator. The invention further relates to a process for using such a composition. The invention also relates to a novel process for forming a positive image with a positive photoresist and a novel photoimageable and aqueous developable positive-working antireflective coating composition, where the antireflective coating comprises a polymer comprising an acid labile group. The invention further relates to such a composition. The invention also relates to a process for imaging a photoimageable antireflective coating composition.

Owner:MERCK PATENT GMBH

Sulfonium salt having polymerizable anion, polymer, resist composition, and patterning process

ActiveUS7569326B2Improve featuresMask fidelityOrganic chemistryPhotosensitive materialsResistHigh energy

A sulfonium salt having a polymerizable anion generates a strong sulfonic acid upon exposure to high-energy radiation so that it facilitates effective scission of acid labile groups in chemically amplified resist compositions. It is useful as a monomer from which a base resin for use in radiation-sensitive resist compositions is derived.

Owner:SHIN ETSU CHEM IND CO LTD

Oral pharmaceutical composition with delayed release of active ingredient for pantoprazole

An oral pharmaceutical composition comprises an acid-labile irreversible proton pump inhibitor in pellet or tablet form, wherein the irreversible proton pump inhibitor is at least partly in slow-release form. On combined administration with an anti-microbially-active ingredient, the composition is distinguished by imparting an enhanced action of rapid onset against disorders caused by Helicobacter.

Owner:TAKEDA GMBH

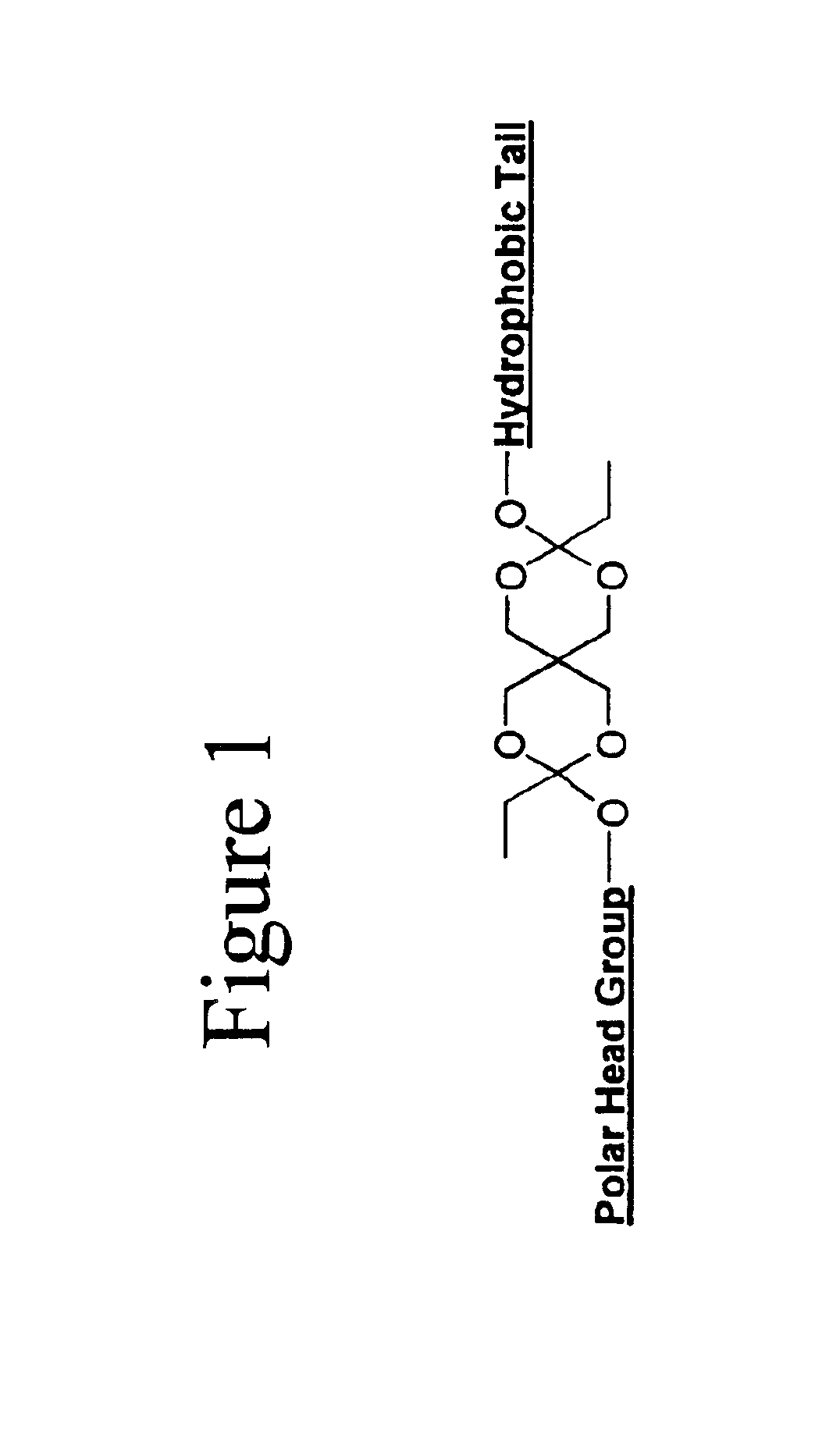

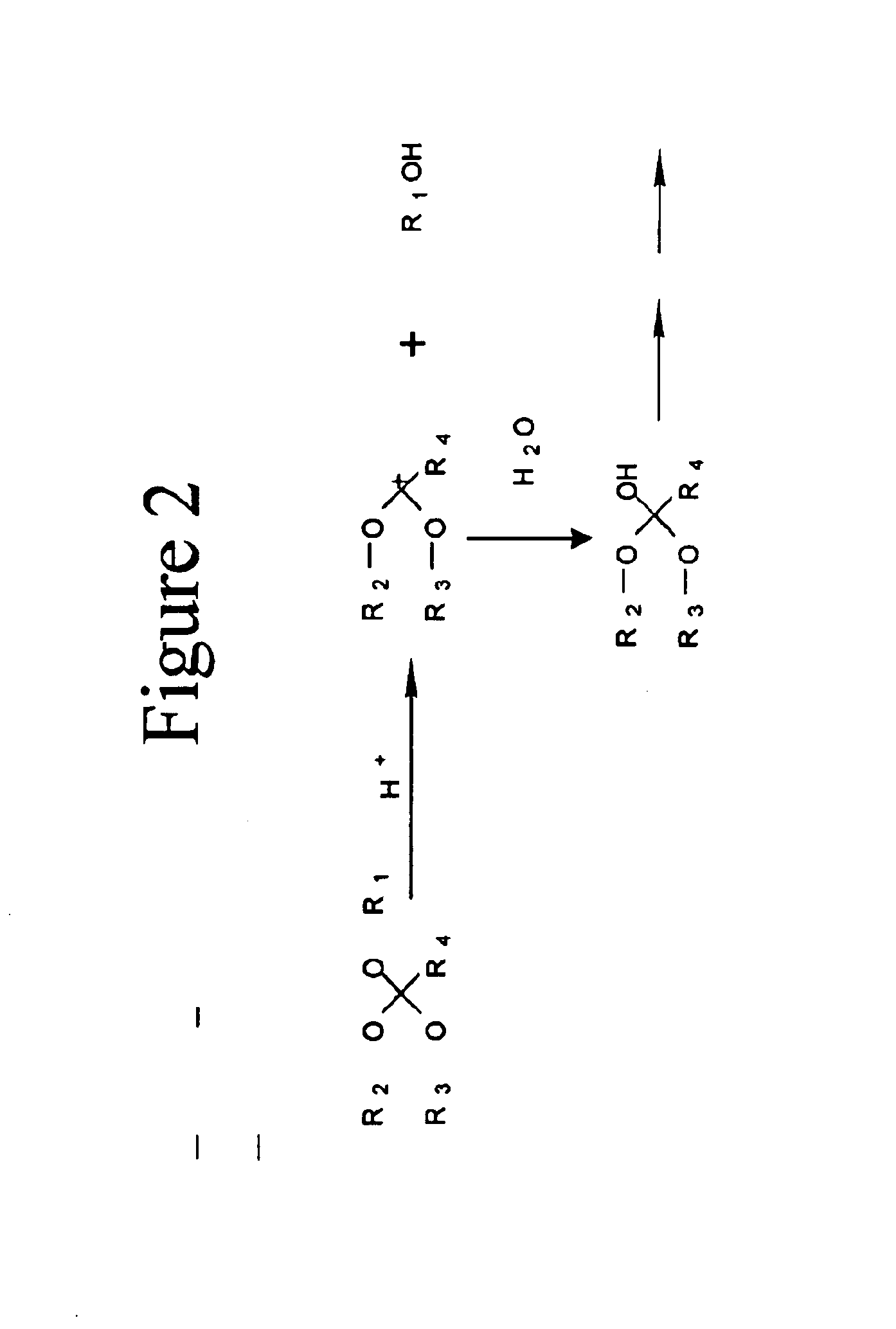

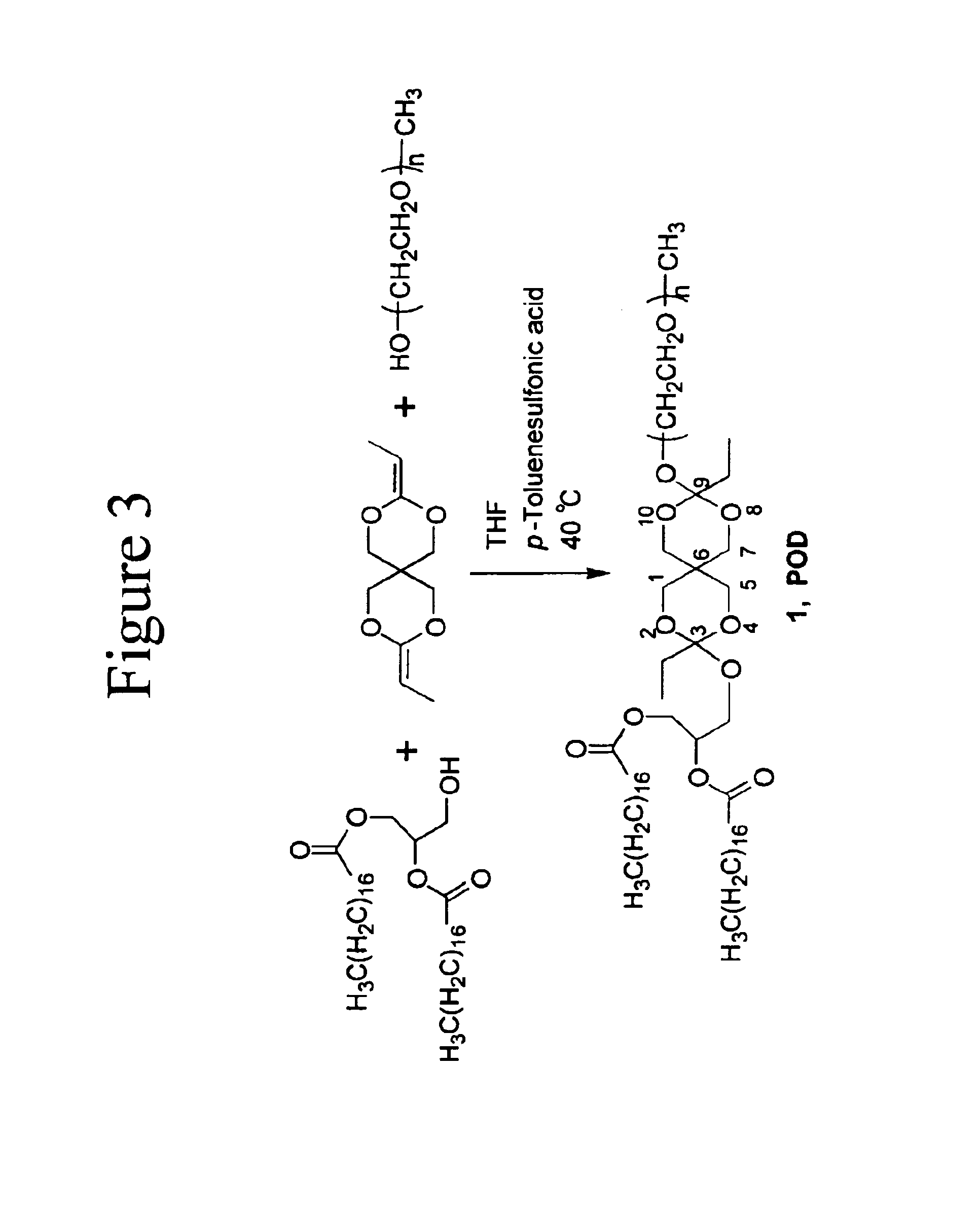

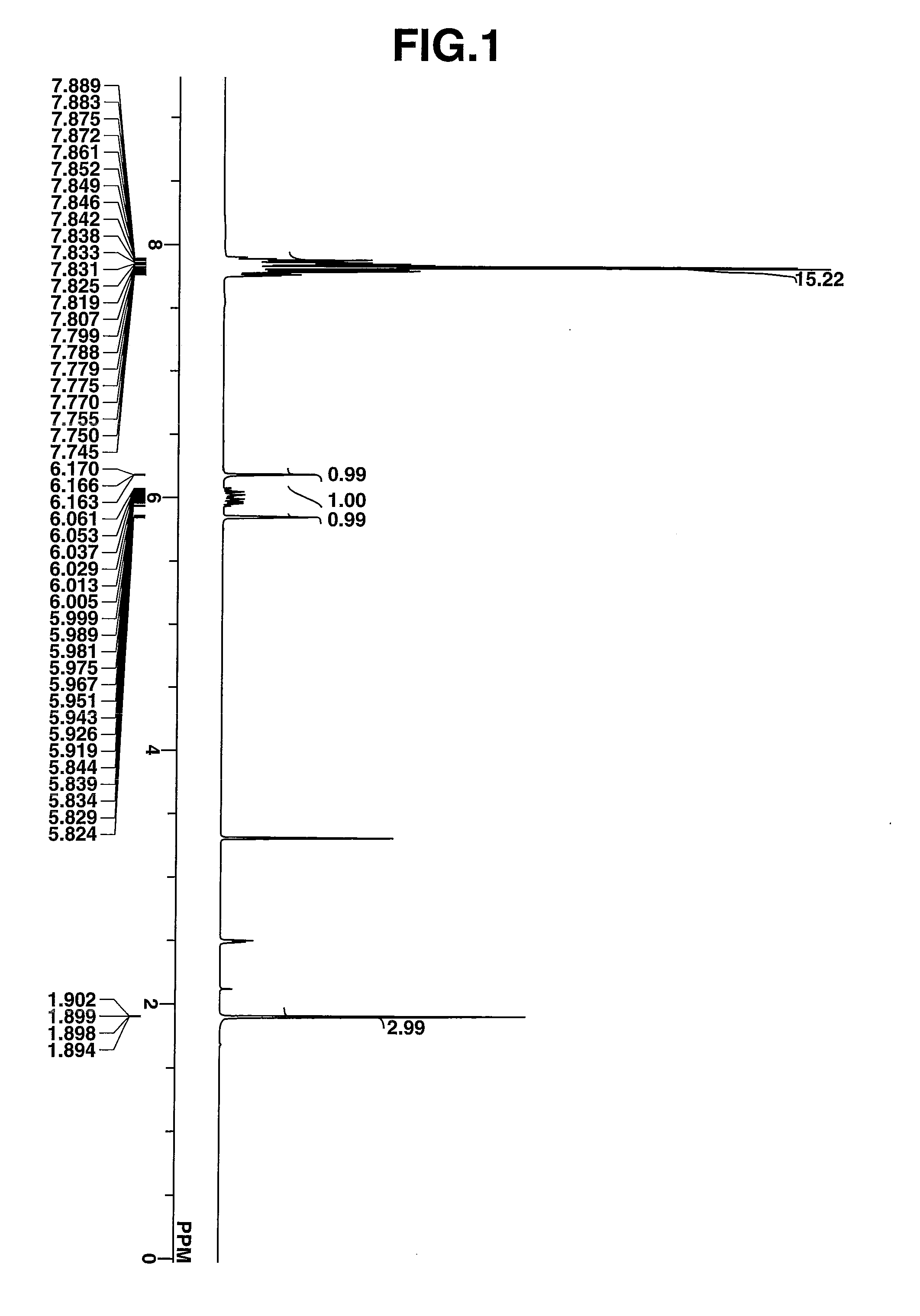

pH sensitive lipids based on ortho ester linkers, composition and method

InactiveUS6897196B1Improved endosome-disruptingOrganic active ingredientsBiocideLipid formationCycle time

Owner:RGT UNIV OF CALIFORNIA

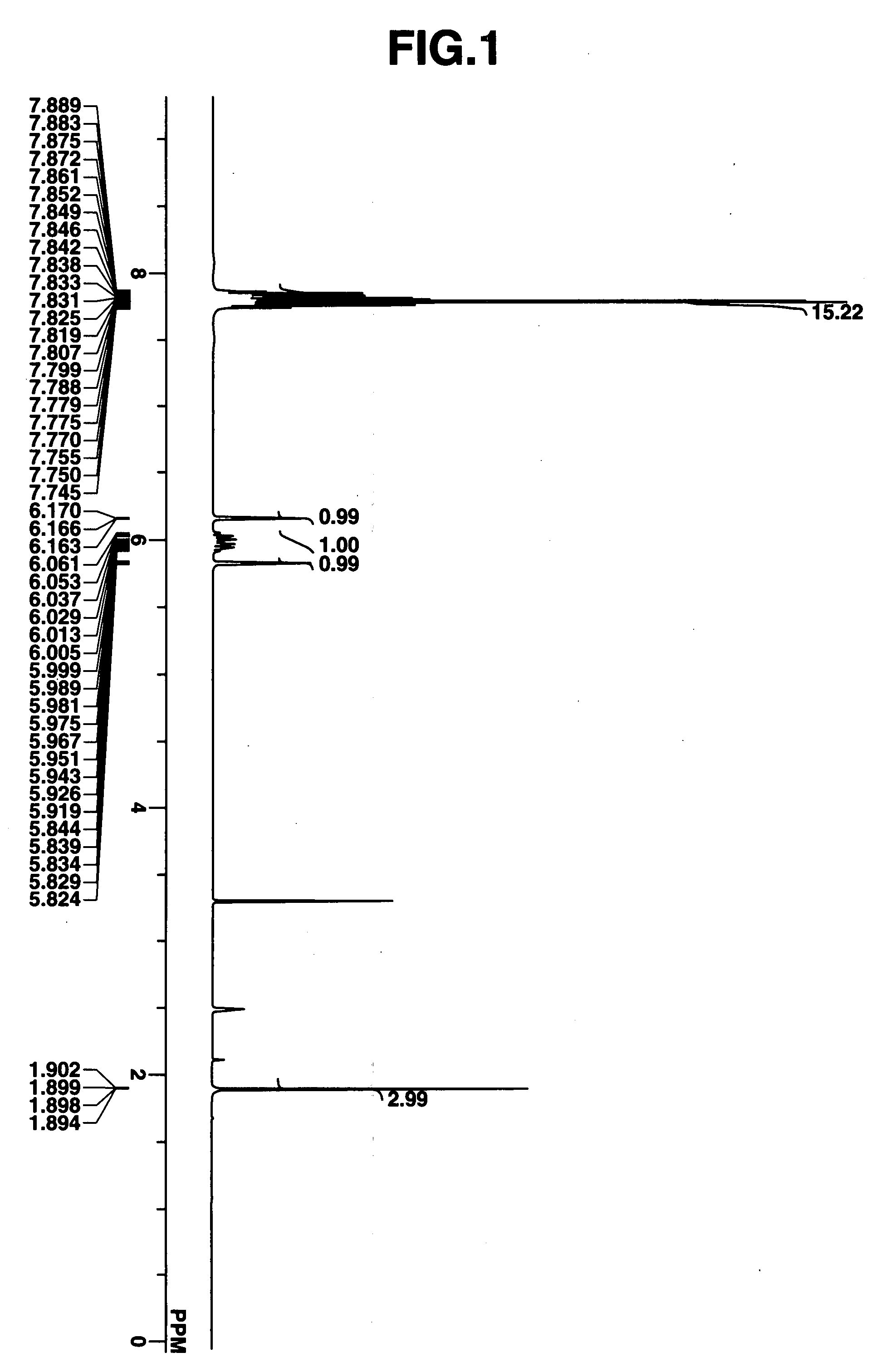

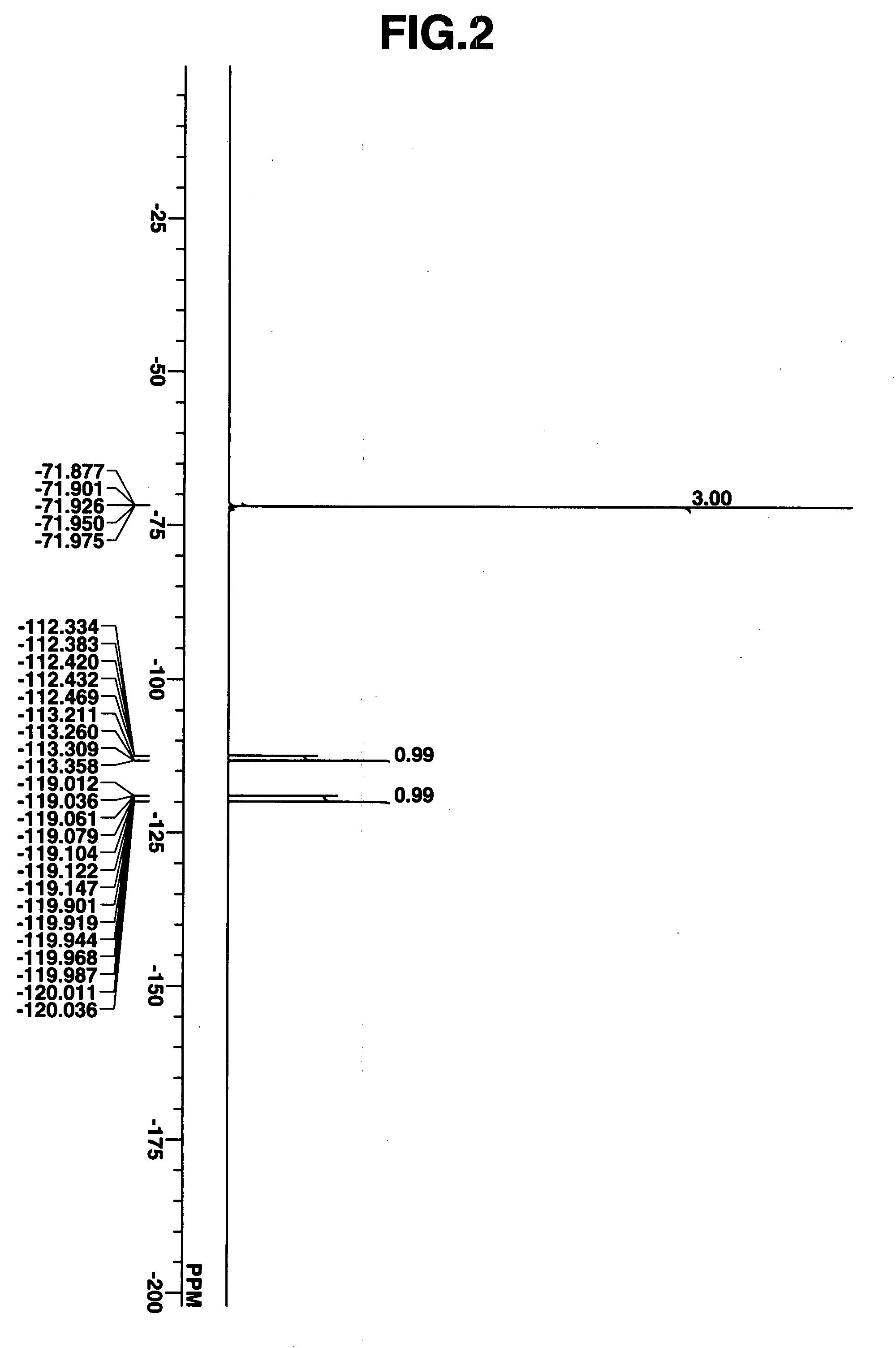

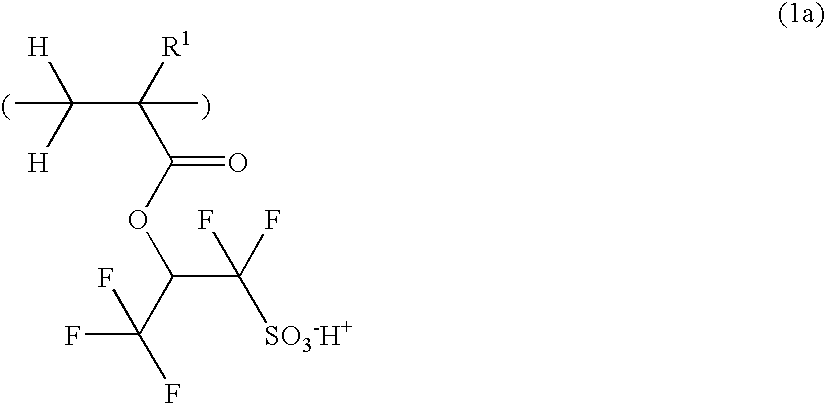

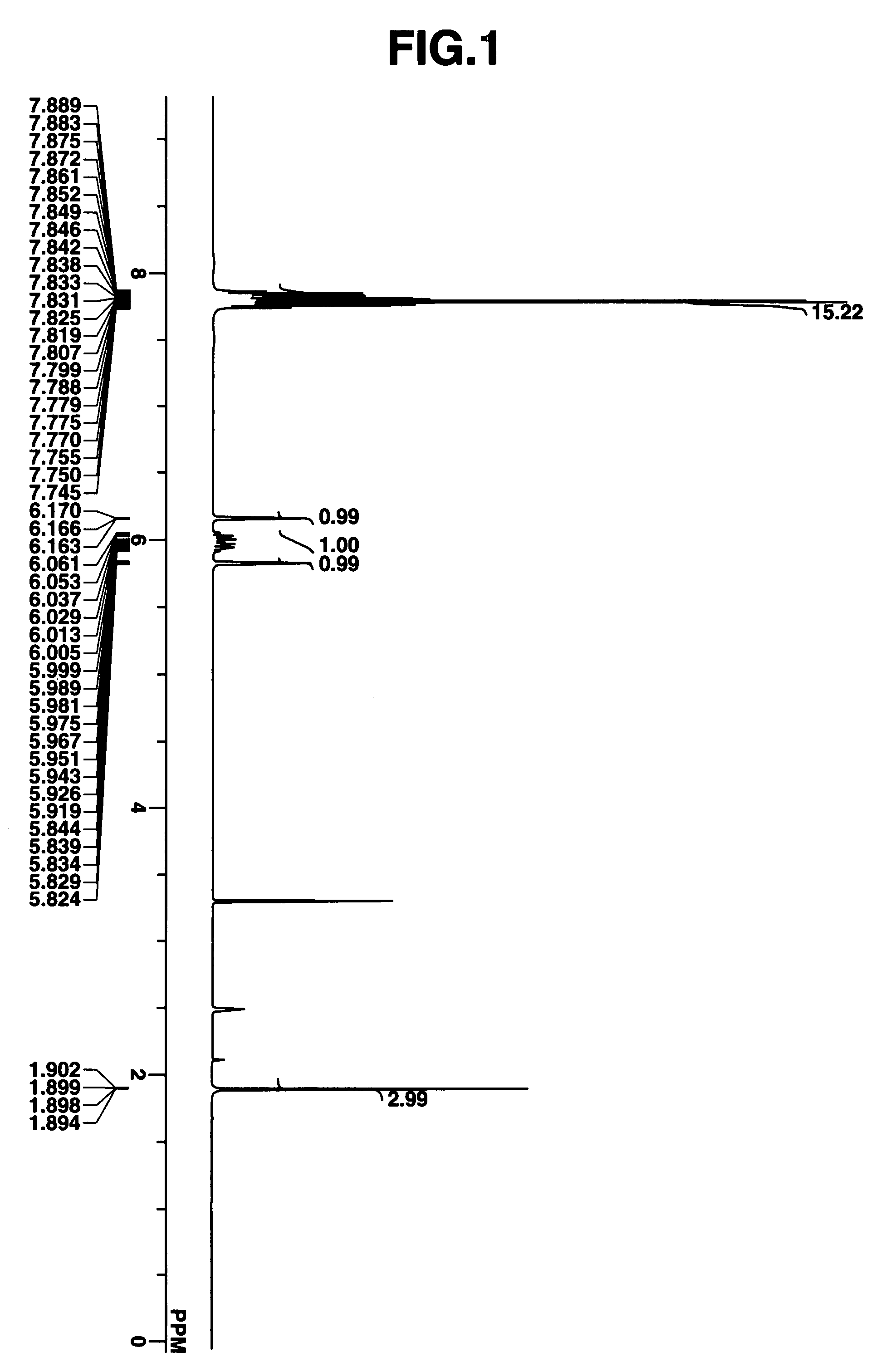

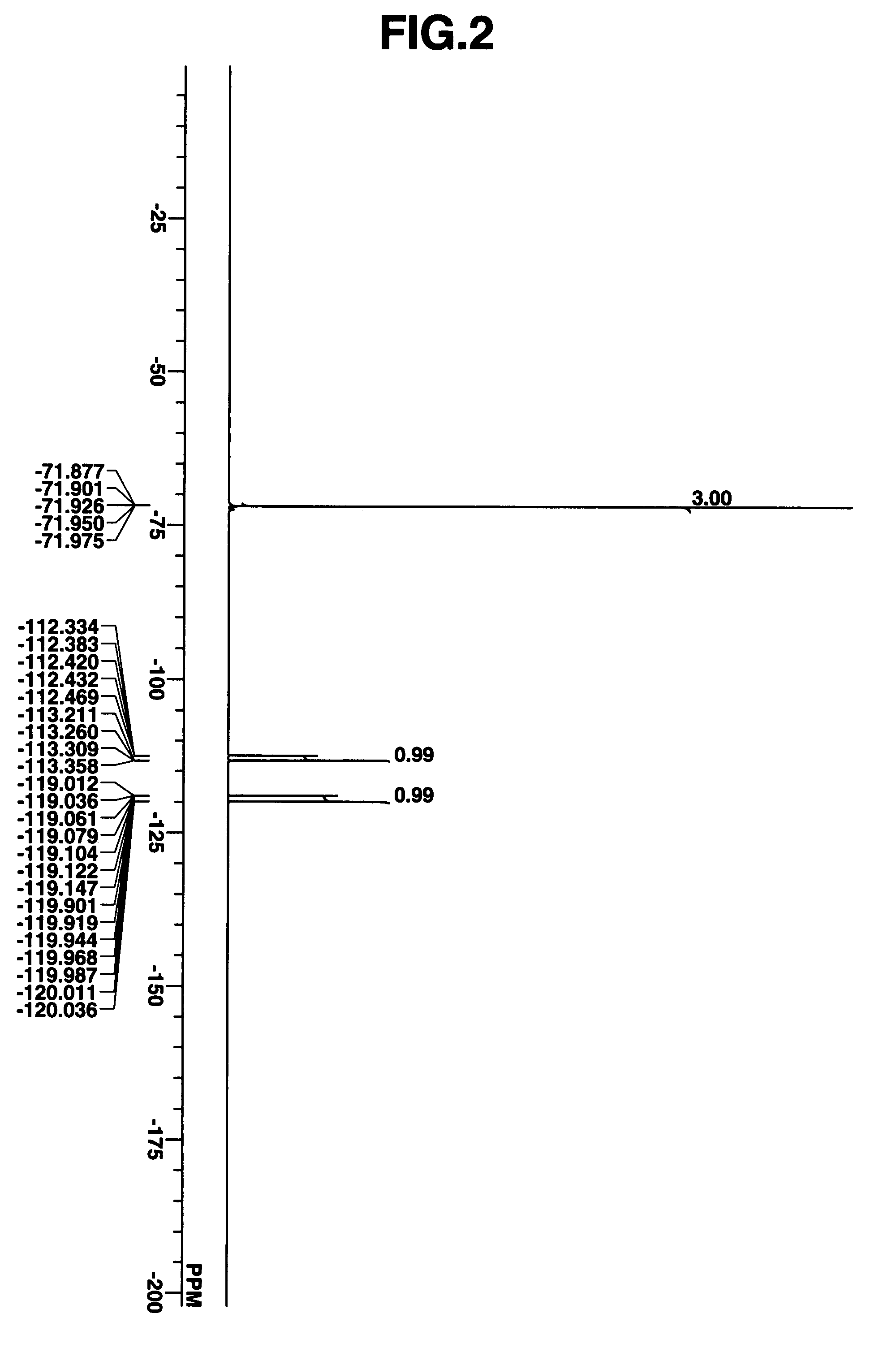

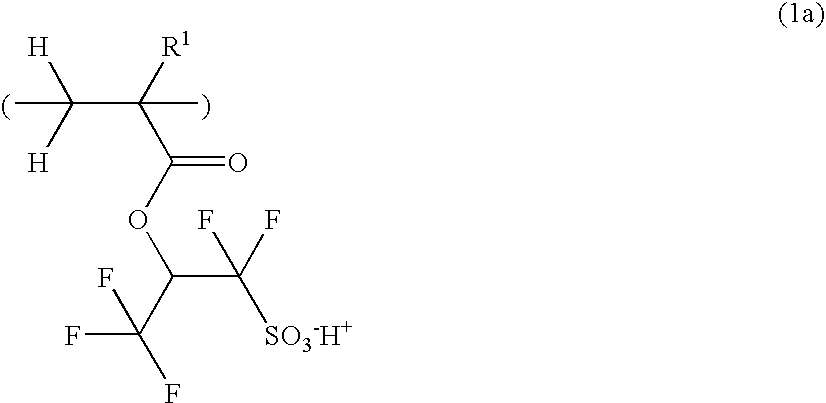

Sulfonium salt-containing polymer, resist composition, and patterning process

ActiveUS20090269696A1Promote divisionHigh sensitivity and resolutionPhotosensitive materialsRadiation applicationsResistAryl

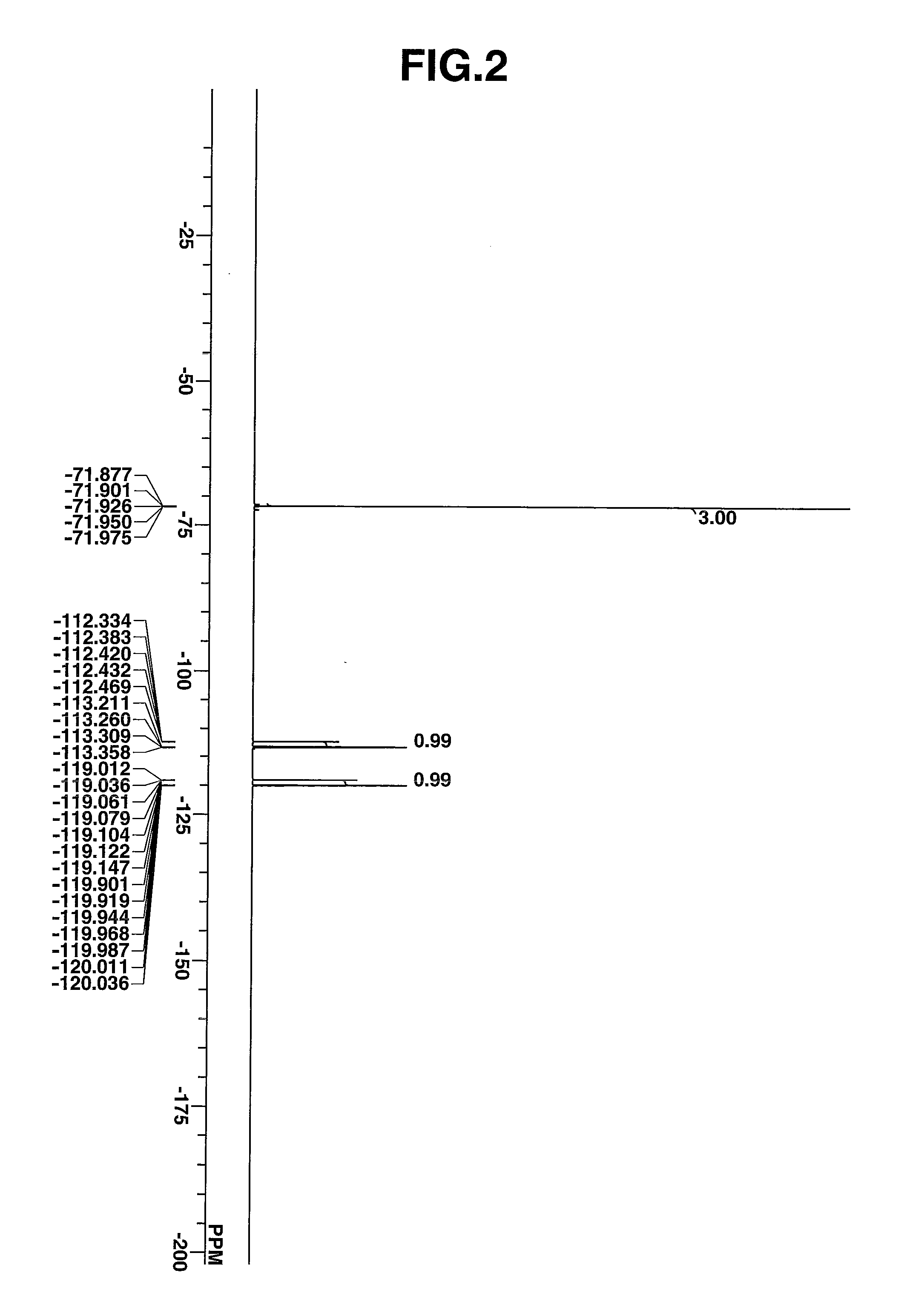

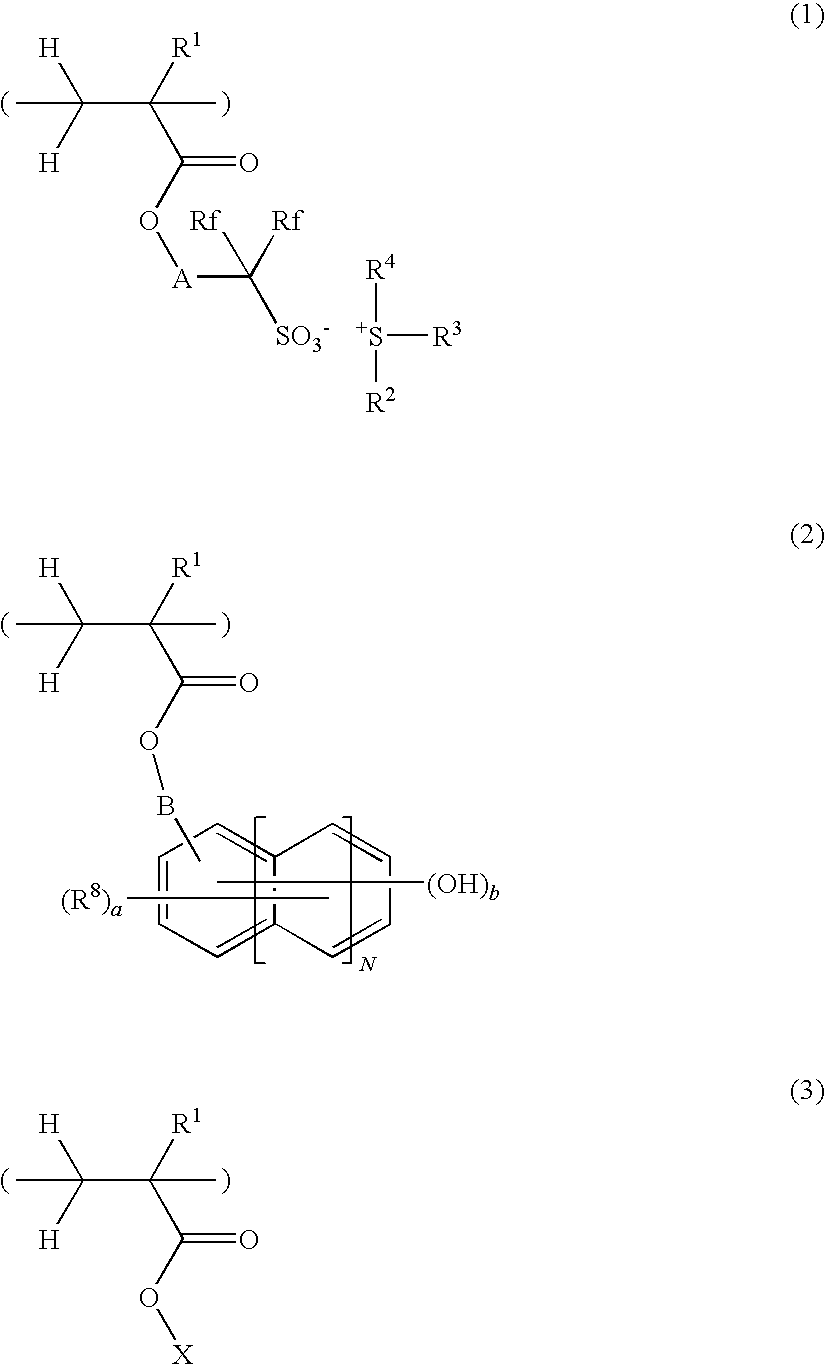

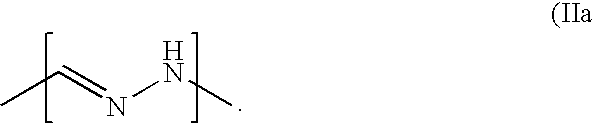

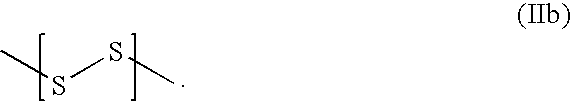

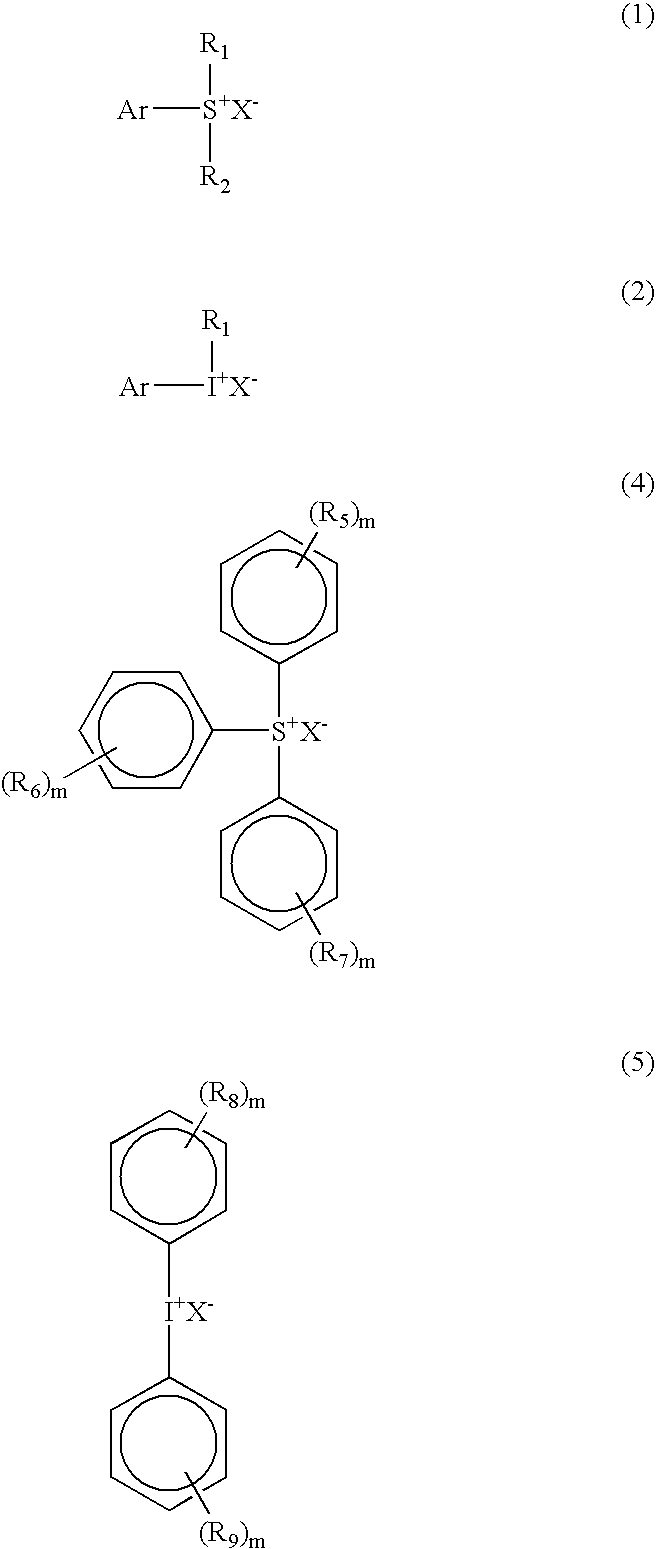

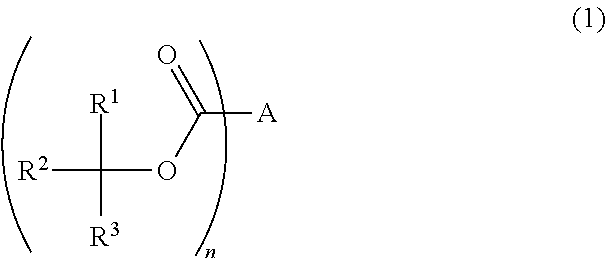

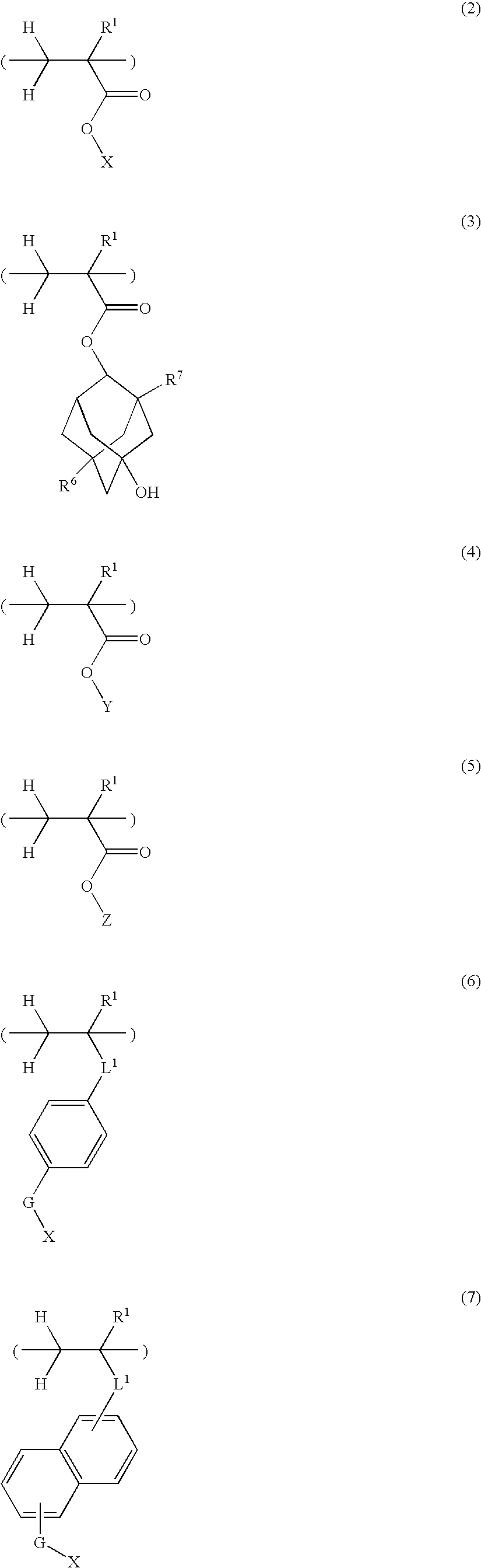

A polymer comprising recurring units having formulae (1), (2) and (3) is provided as well as a chemically amplified resist composition comprising the same. R1 is H, F, CH3 or CF3, Rf is H, F, CF3 or C2F5, A is an optionally fluorine or oxygen-substituted divalent organic group, R2, R3 and R4 are alkyl, alkenyl, oxoalkyl, aryl, aralkyl or aryloxoalkyl, or may form a ring with the sulfur atom, N=0-2, R8 is H or alkyl, B is a single bond or optionally oxygen-substituted divalent organic group, a=0-3, b=1-3, and X is an acid labile group. The polymer generates a strong sulfonic acid which provides for effective cleavage of acid labile groups in a chemically amplified resist composition.

Owner:SHIN ETSU CHEM IND CO LTD

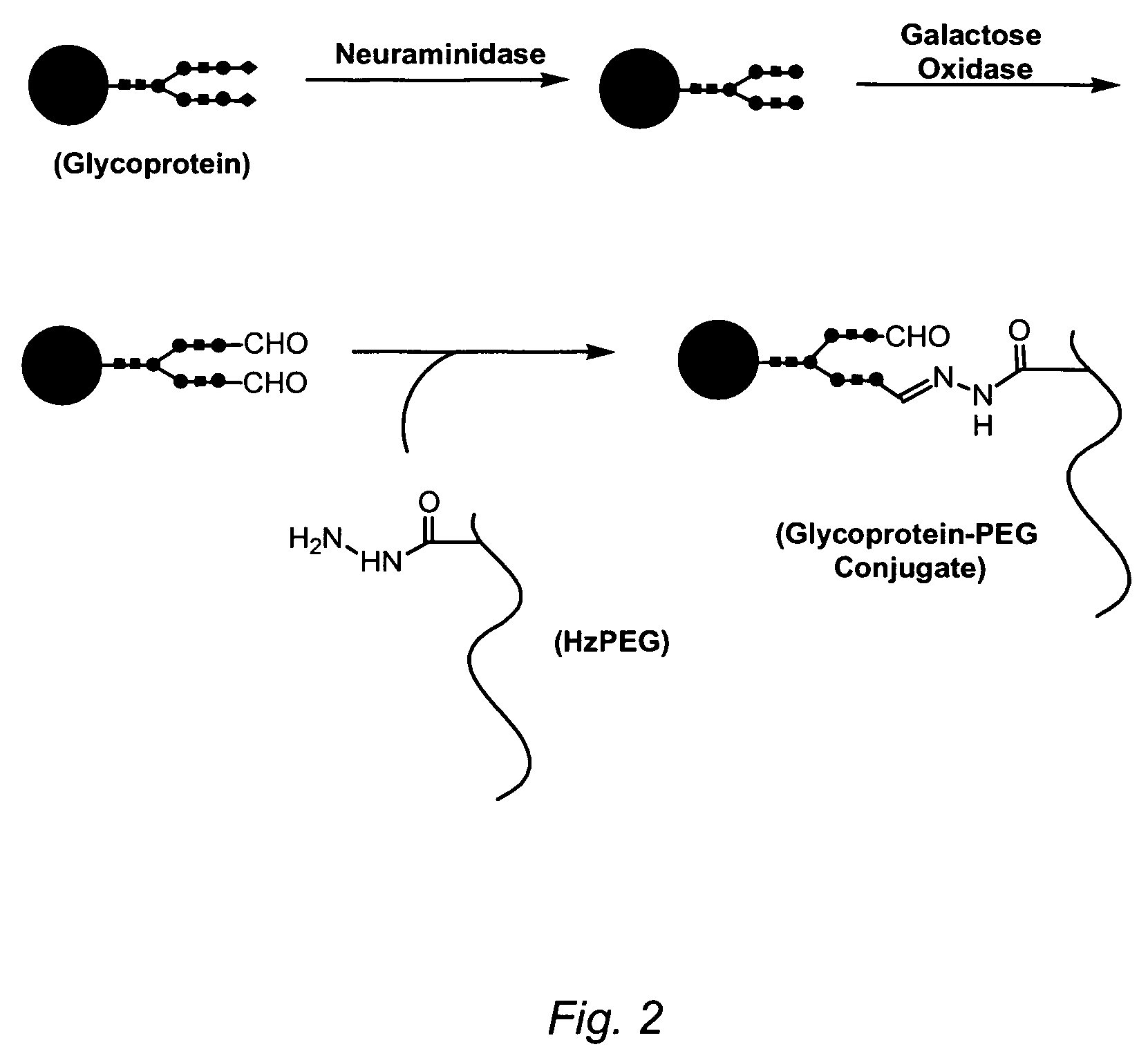

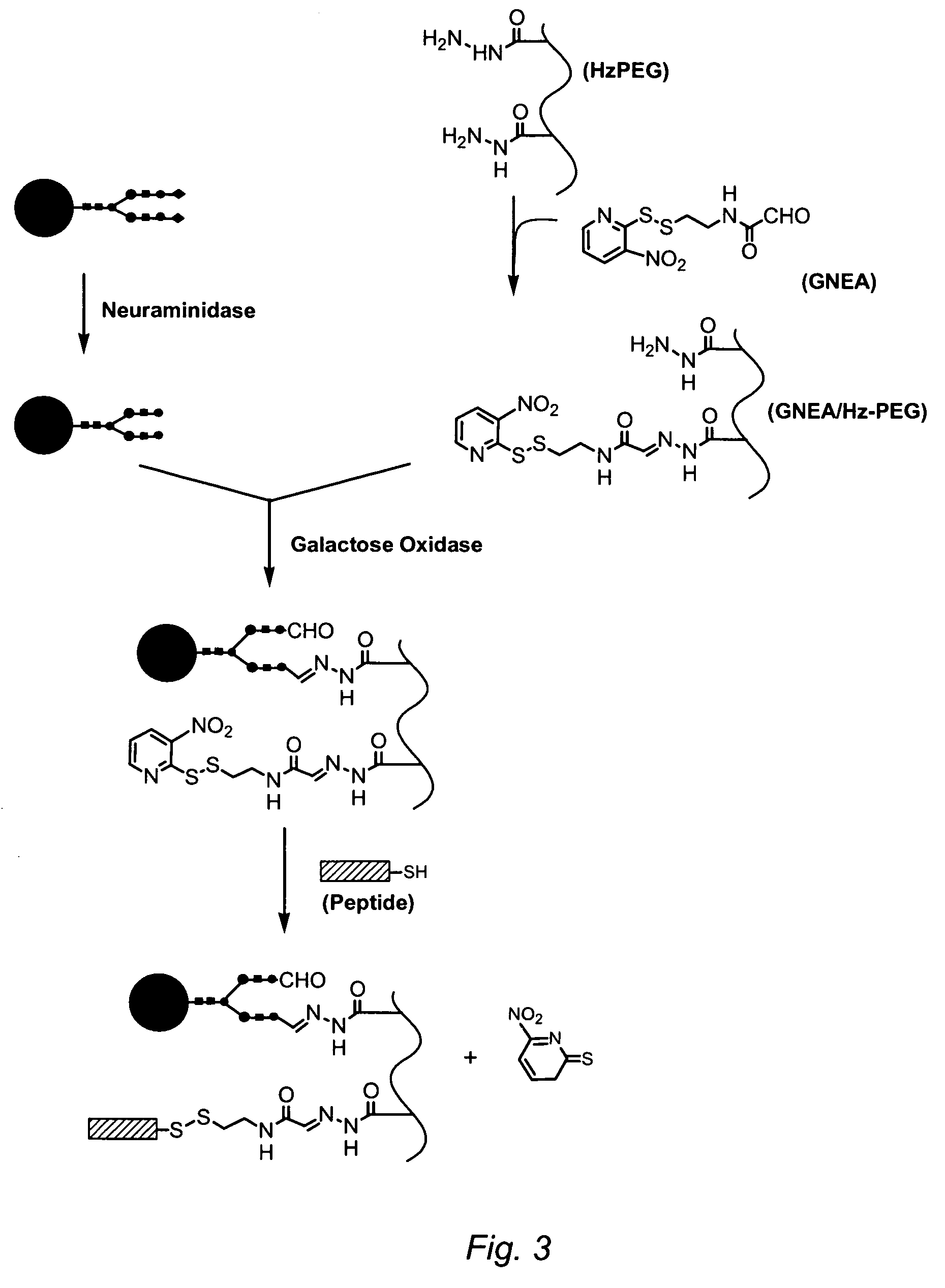

Targeting of glycoprotein therapeutics

Methods of making ligand-decorated polymer conjugates of therapeutic glycoproteins are described. Improved targeting of glycoproteins to specific tissues is achieved by masking the natural carbohydrate and other surface determinants with high molecular weight polymers, such as, e.g., PEG, polysialic acid, etc., which in turn are decorated with target-specific ligands. In some embodiments, acid-labile linkages in such conjugates or rapidly degradable masking groups allow for the intracellular release of the polymer from the glycoprotein, for example, under conditions found in lysosomes.

Owner:GENZYME CORP

Photoresist composition for deep ultraviolet lithography comprising a mixture of photoactive compounds

InactiveUS6991888B2Reduce edge roughnessAcceptable photosensitivityOrganic chemistryOrganic compound preparationResistUltraviolet

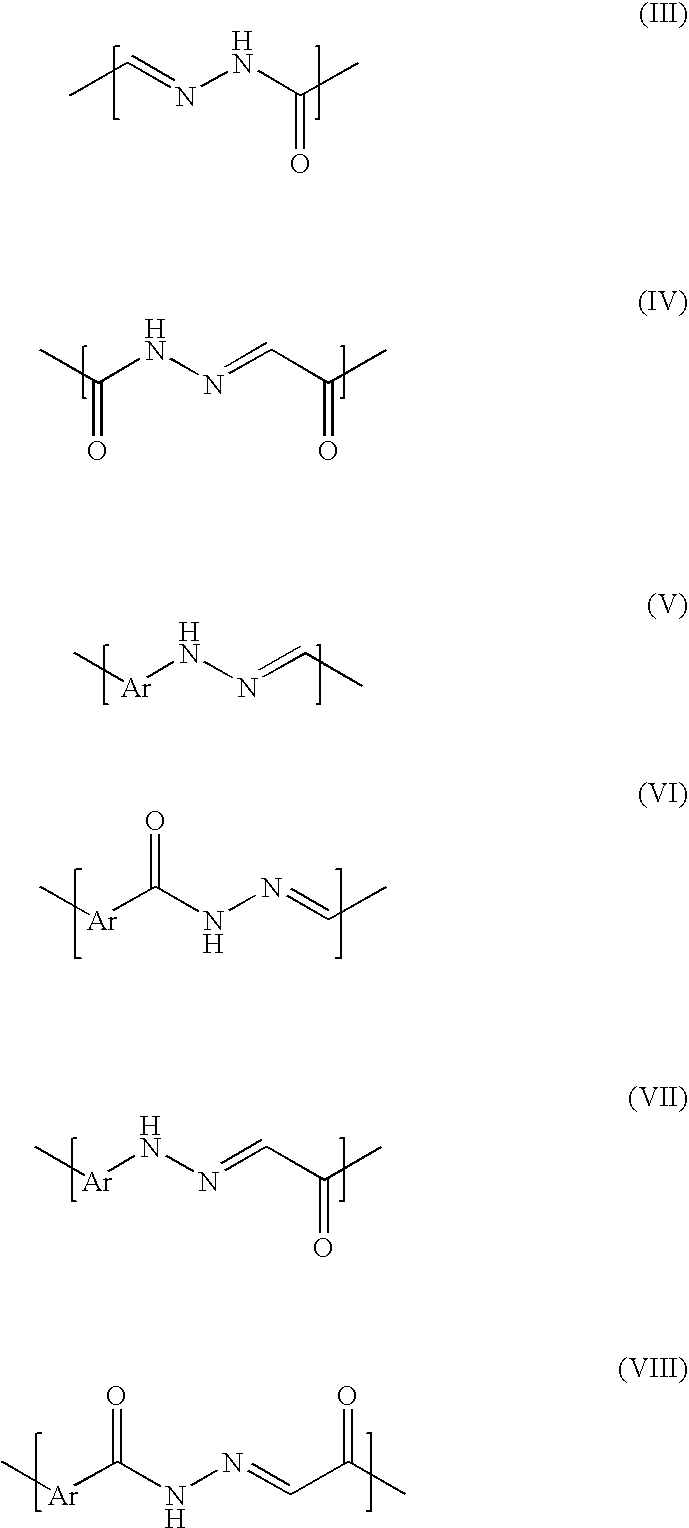

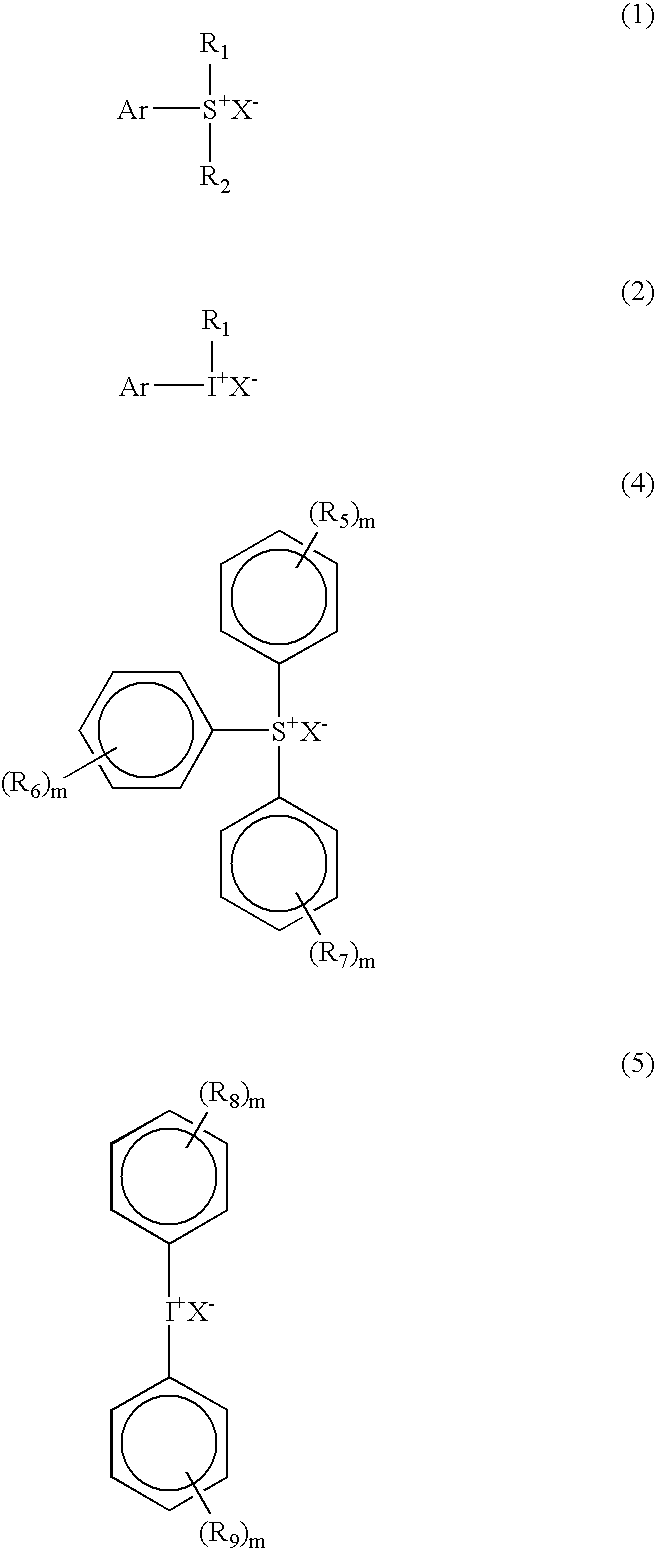

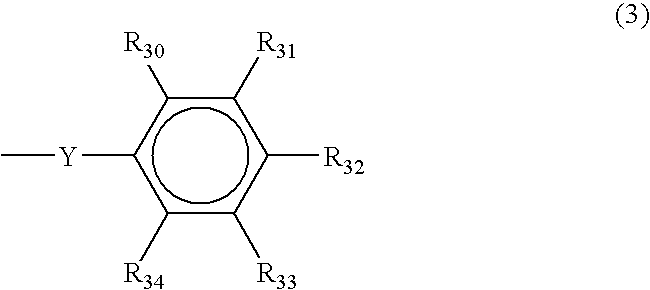

The present invention relates to a novel photoresist composition that can be developed with an aqueous alkaline solution, and is capable of being imaged at exposure wavelengths in the deep ultraviolet. The invention also relates to a process for imaging the novel photoresist as well as novel photoacid generators.The novel photoresist comprises a) a polymer containing an acid labile group, and b) a novel mixture of photoactive compounds, where the mixture comprises a lower absorbing compound selected from structure 1 and 2, and a higher absorbing compound selected from structure 4 and 5, where, R1 and R2 R5, R6, R7, R8, and R9 are defined herein; m=1–5; X− is an anion, and Ar is selected from naphthyl, anthracyl, and structure 3, where R30, R31, R32, R33, and R34 are defined herein.

Owner:MERCK PATENT GMBH

Targeting of glycoprotein therapeutics

Methods of making ligand-decorated polymer conjugates of therapeutic glycoproteins are described. Improved targeting of glycoproteins to specific tissues is achieved by masking the natural carbohydrate and other surface determinants with high molecular weight polymers, such as, e.g., PEG, polysialic acid, etc., which in turn are decorated with target-specific ligands. In some embodiments, acid-labile linkages in such conjugates or rapidly degradable masking groups allow for the intracellular release of the polymer from the glycoprotein, for example, under conditions found in lysosomes.

Owner:GENZYME CORP

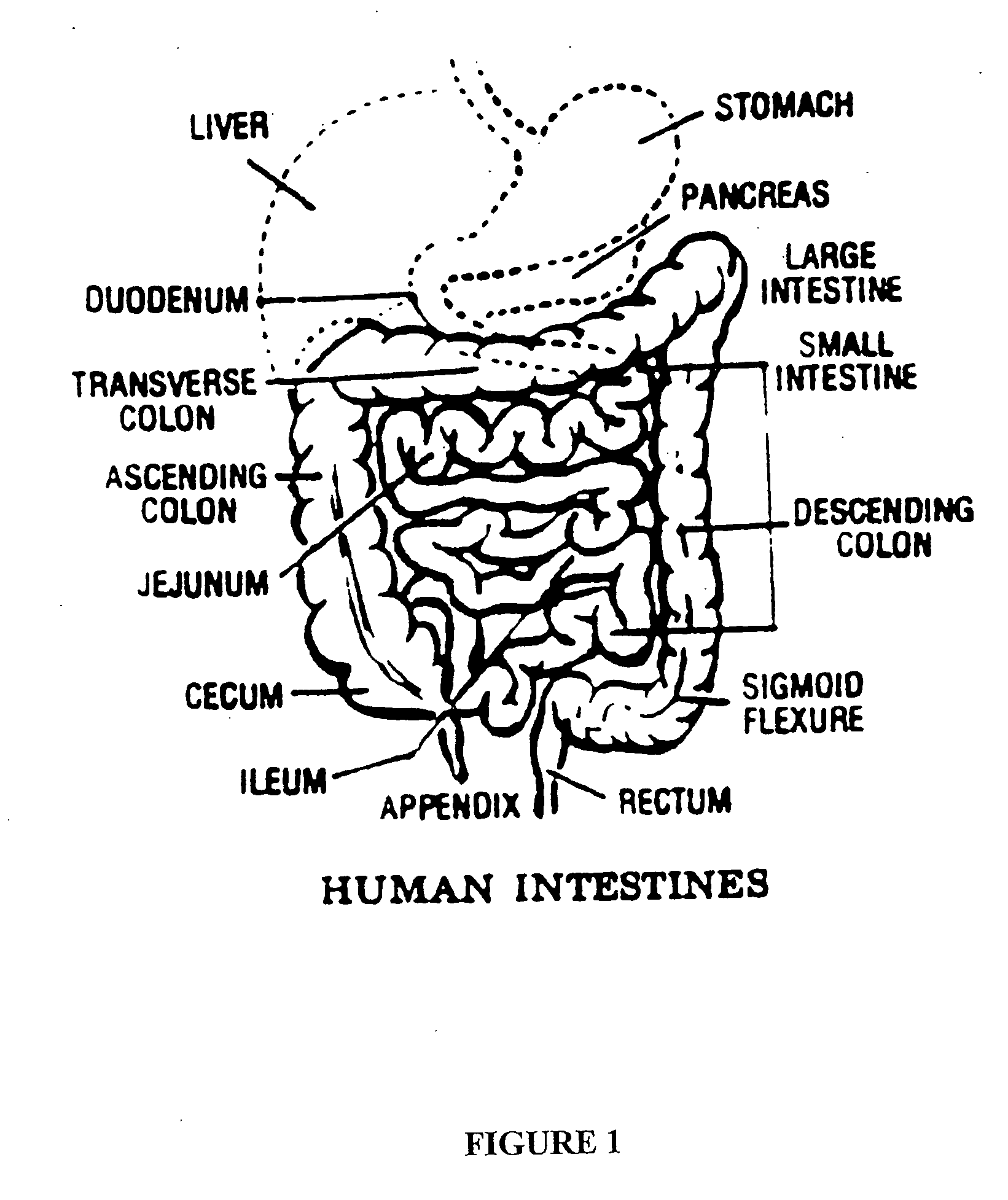

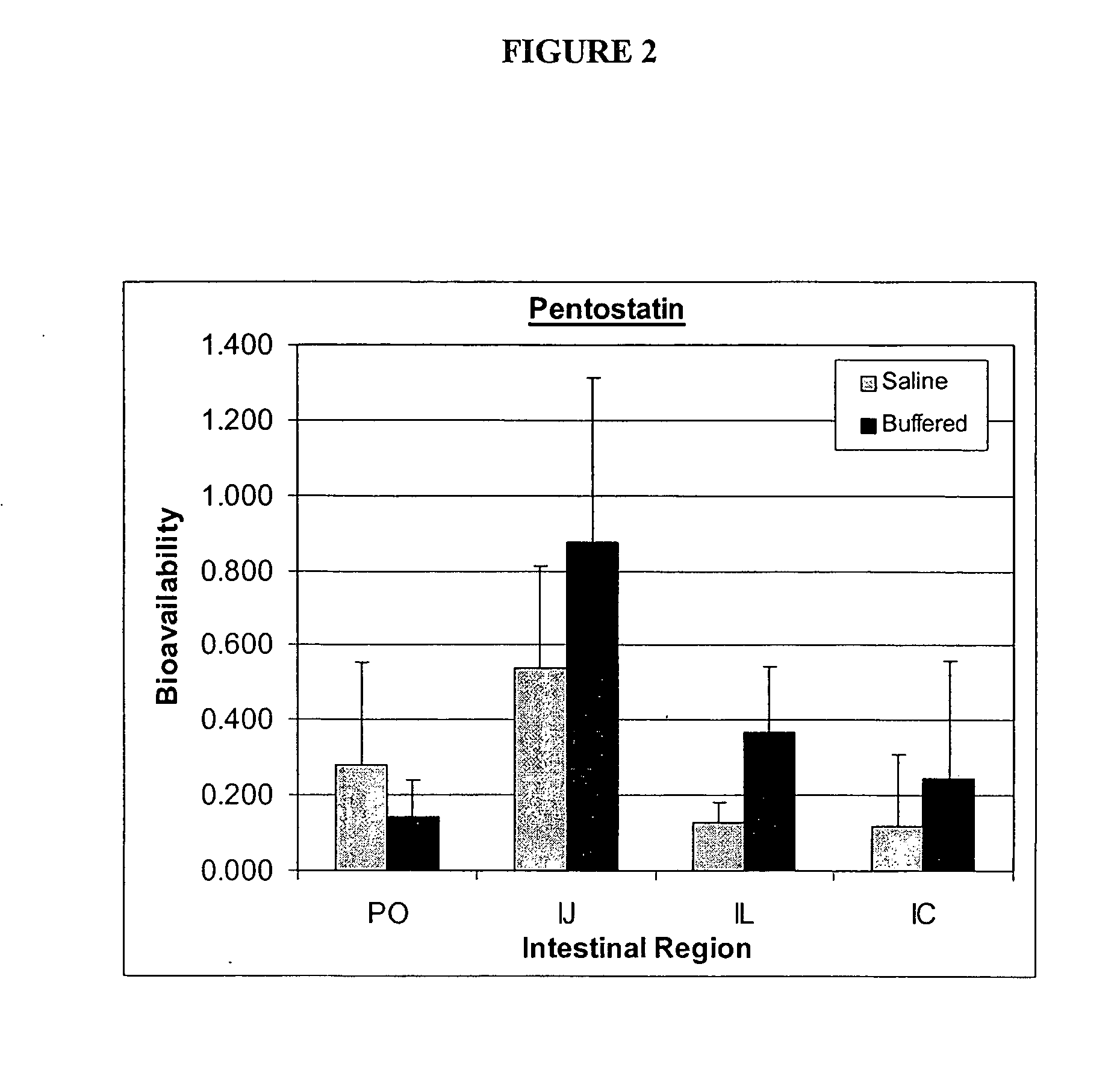

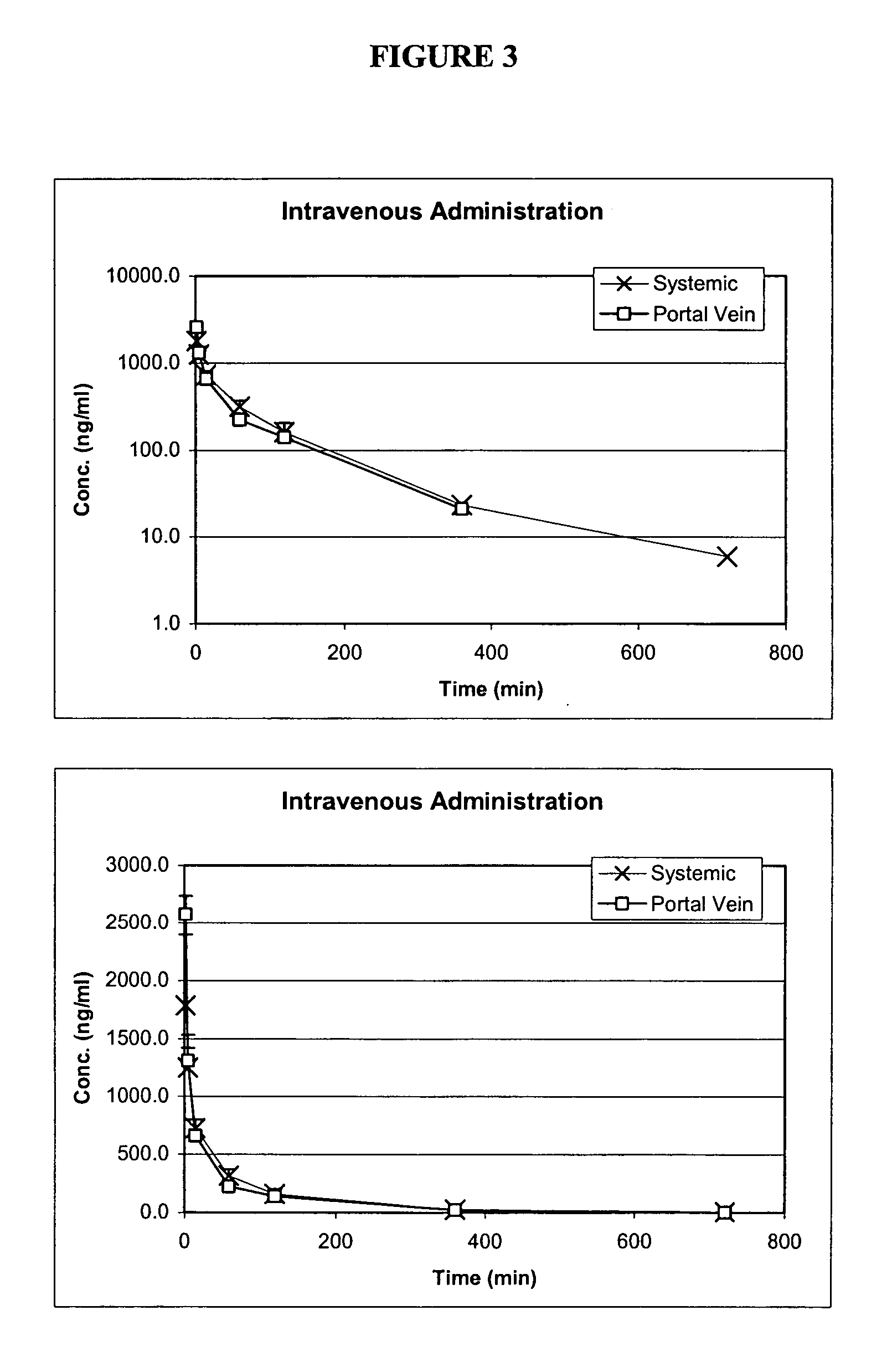

Pharmaceutical formulations targeting specific regions of the gastrointesinal tract

Oral formulations of pharmaceuticals are provided with enhanced bioavailability by targeting specific regions of the gastrointestinal tract. Particularly, water soluble and acid-labile drugs such as cytidine analogs (e.g., decitabine) and 2'-deoxyadenosine analogs (e.g., pentostatin) are formulated with pH-sensitive polymers so that these drugs are preferably absorbed in the upper regions of the small intestine, such as the jejunum. In addition, drugs with poor oral bioavailability such as camptothecin compounds (e.g., 9-nitro-camptothecin) can also be formulated using similar strategies in order to significantly improve their oral bioavailability. These formulations can be used to treat a wide variety of diseases or conditions, such hematological disorders, benign tumors, cancer, restenosis, inflammatory diseases, and autoimmune diseases.

Owner:MAYNE PHARMA USA

Oral administration form for an acid liable active proton pump inhibitor

Novel administration form for acid-labile active compounds are described. The novel administration forms have no enteric layers and are suitable for oral administration.

Owner:TAKEDA GMBH

Photoresist composition, resist pattern-forming method, acid diffusion control agent, and compound

ActiveUS20150004544A1High rectangularityReduced LWROrganic chemistryPhotosensitive materialsBinding siteAlicyclic Hydrocarbons

A photoresist composition containing: a polymer including an acid-labile group; a radiation-sensitive acid generator; and an acid diffusion control agent that contains a compound represented by a formula (1). In the formula (1), R1, R2 and R3 each independently represent a hydrogen atom or a monovalent hydrocarbon group having 1 to 10 carbon atoms. A represents a group having a valency of n that is obtained by combining: a hydrogen atom, a linear hydrocarbon group having 1 to 30 carbon atoms, an alicyclic hydrocarbon group having 3 to 30 carbon atoms or a combination thereof; —O—, —CO—, —COO—, —SO2O—, —NRSO2—, —NRSO2O—, —NRCO— or a combination thereof; and n nitrogen atoms as a binding site to the carbonyl group in the formula (1), in which a sum of atomic masses of the atoms constituting A is no less than 120. n is an integer of 1 to 4.

Owner:JSR CORPORATIOON

Chemically amplified positive resist composition

ActiveUS20070218401A1Excellent various resist abilityGood pattern profilePhotosensitive materialsRadiation applicationsResistFluorine containing

The present invention provides a chemically amplified resist composition comprising: a resin (A) which contains no fluorine atom and a structural unit (a1) having an acid-labile group, a resin (B) which contains a structural unit (b2) having a fluorine-containing group and at least one structural unit selected from a structural unit (b1) having an acid-labile group, a structural unit (b3) having a hydroxyl group and a structural unit (b4) having a lactone structure, and an acid generator.

Owner:SUMITOMO CHEM CO LTD

Pulsatile gastric retentive dosage forms

Dosage forms for delayed and pulsed release of therapeutic agents into the stomach are described. The dosage forms are gastric retentive dosage forms that achieve release of the therapeutic agent into the stomach and upper gastrointestinal tract subsequent to administration of the dosage form. The dosage forms find particular use in administration of acid-labile active agents such as proton pump inhibitors, and in treating gastric acid secretion such as gastro-esophageal reflux disease (GERD) and nocturnal acid breakthrough (NAB).

Owner:DEPOMED SYST INC

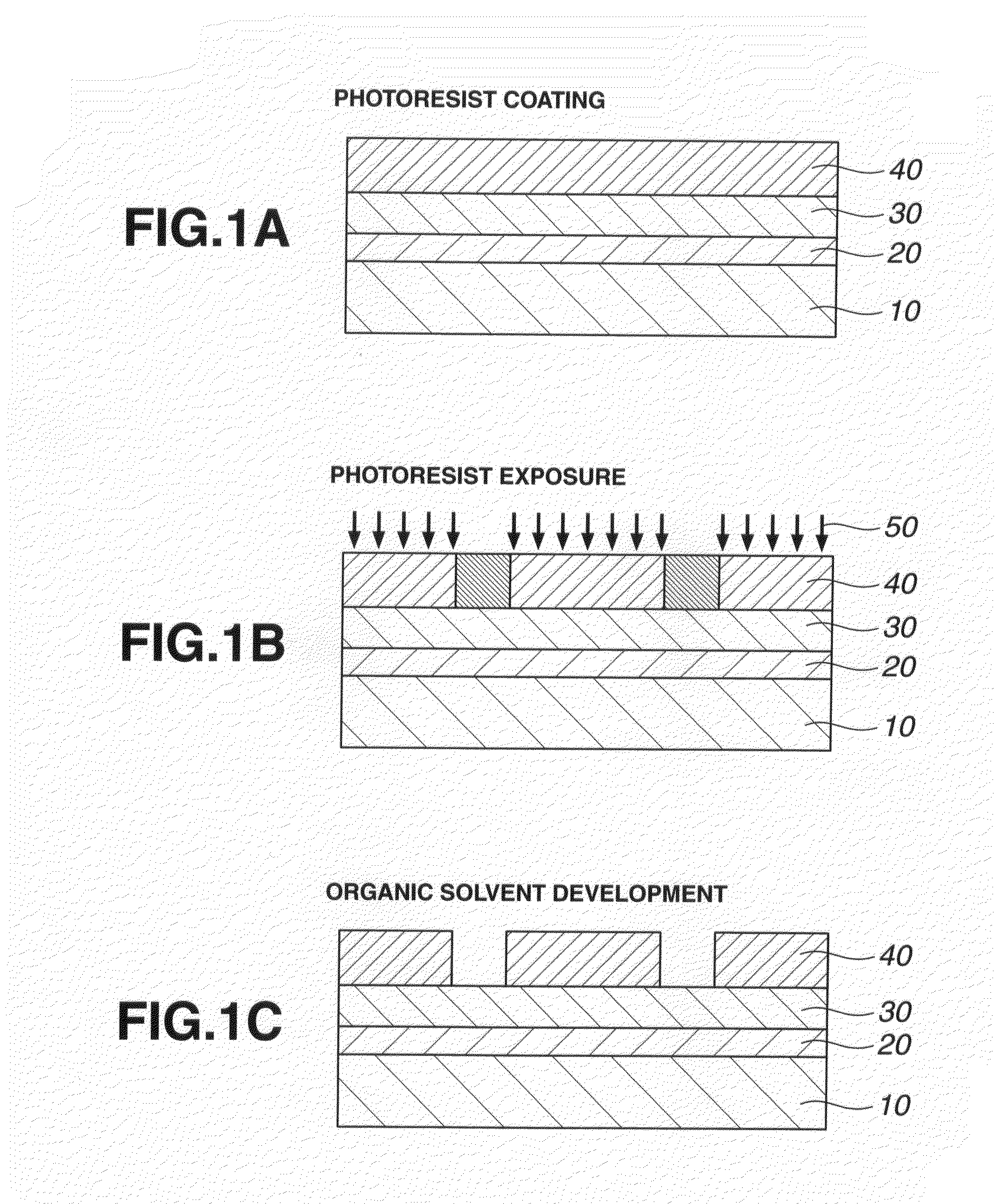

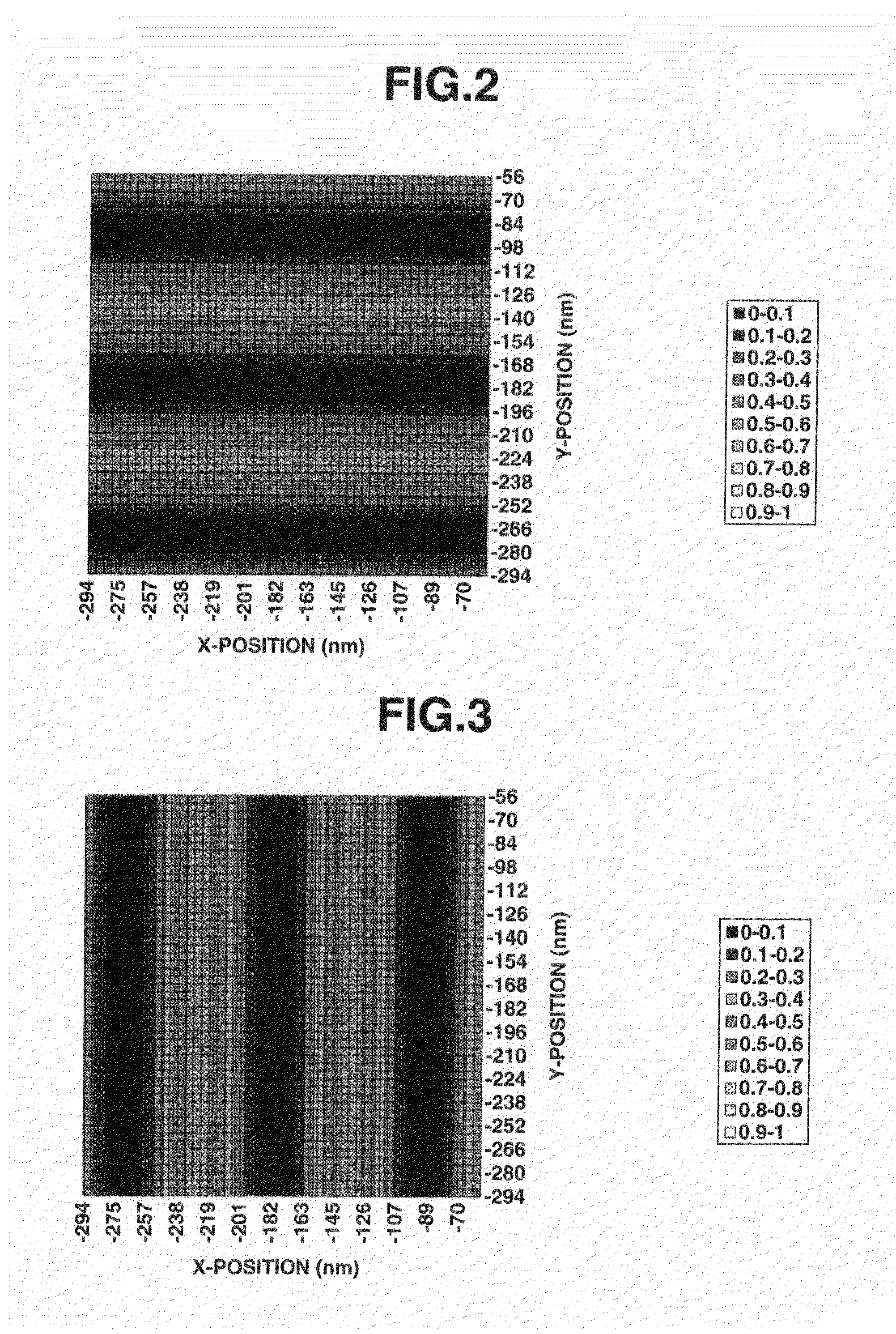

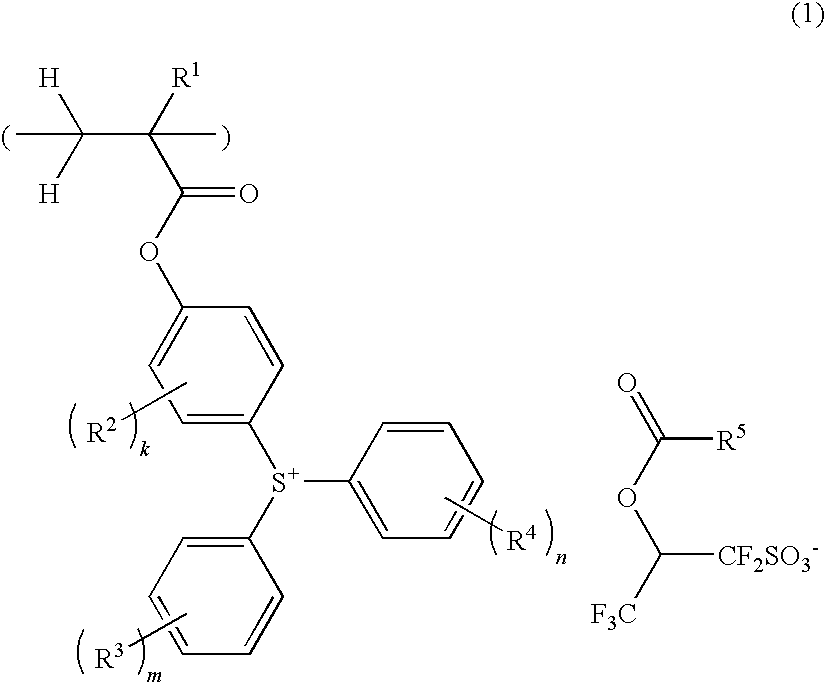

Patterning process

ActiveUS20110177462A1High dissolution contrastHigh dimensional control accuracyPhotosensitive materialsPhotomechanical exposure apparatusOrganic solventHigh energy

A pattern is formed by coating a resist composition comprising a polymer comprising recurring units having an optionally acid labile group-substituted naphthol group, an acid generator, and an organic solvent onto a substrate, baking to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with an organic solvent developer to form a negative pattern wherein the unexposed region of film is dissolved and the exposed region of film is not dissolved. In the process of image formation via positive / negative reversal by organic solvent development, the resist film has a high dissolution contrast and controlled acid diffusion. By subjecting the resist film to exposure through a mask having a lattice-like pattern and organic solvent development, a fine hole pattern can be formed at a high precision of dimensional control.

Owner:SHIN ETSU CHEM IND CO LTD

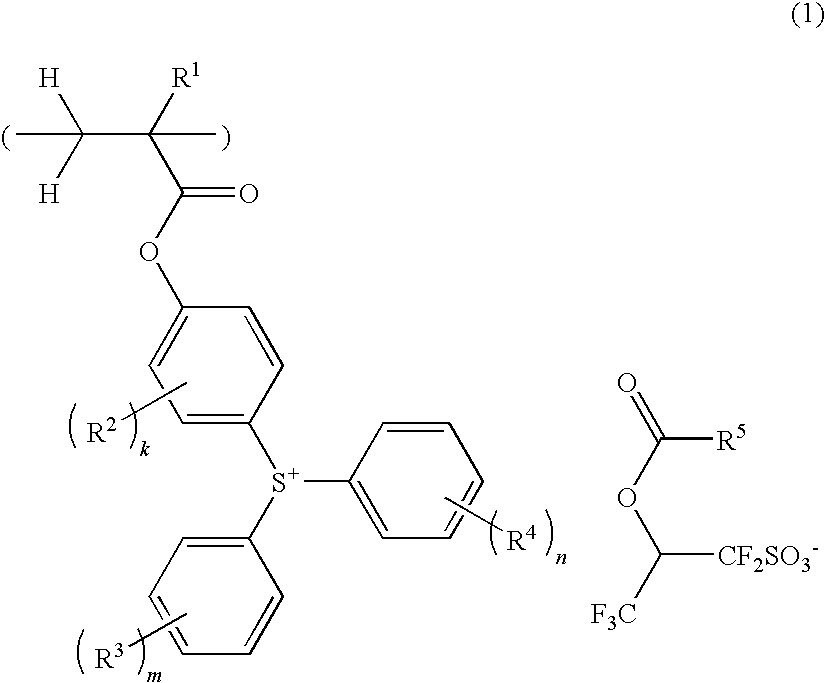

Sulfonium salt-containing polymer, resist composition, and patterning process

ActiveUS20090233223A1Promote divisionLow LERElectric discharge tubesPhotosensitive materialsResistHigh energy

A polymer comprising recurring units of a sulfonium salt represented by formula (1) is provided as well as a chemically amplified resist composition comprising the same. R1 is H, F, methyl or trifluoromethyl, R2 to R4 are C1-C10 alkyl or alkoxy, R5 is C1-C30 alkyl or C6-C14 aryl, k, m and n are 0 to 3. The recurring units generate a sulfonic acid upon exposure to high-energy radiation so as to facilitate effective scission of acid labile groups in the resist composition. The resist composition exhibits excellent resolution and a pattern finish with minimal LER.

Owner:SHIN ETSU CHEM IND CO LTD

Orally disintegrable tablets

InactiveUS20020142034A1High strengthGood disintegrationBiocidePowder deliveryDiseaseOrally disintegrating tablet

An orally disintegrable tablet, of the present invention, which comprises (i) fine granules having an average particle diameter of 400 mum or less, which fine granules comprise a composition coated by an enteric coating layer, said composition having 10 weight % or more of an acid-labile physiologically active substance and (ii) an additive, has superior disintegrability or dissolution in the oral cavity so that it can be used for treatment or prevention of various diseases, as an orally disintegrable tablet capable of being administered to the aged or children and easily administered without water. Also, because the tablet of the present invention contains fine granules having the average particle diameter such that it will not impart roughness in mouth, it can be administered easily without discomfort at the administration.

Owner:TAKEDA PHARMA CO LTD

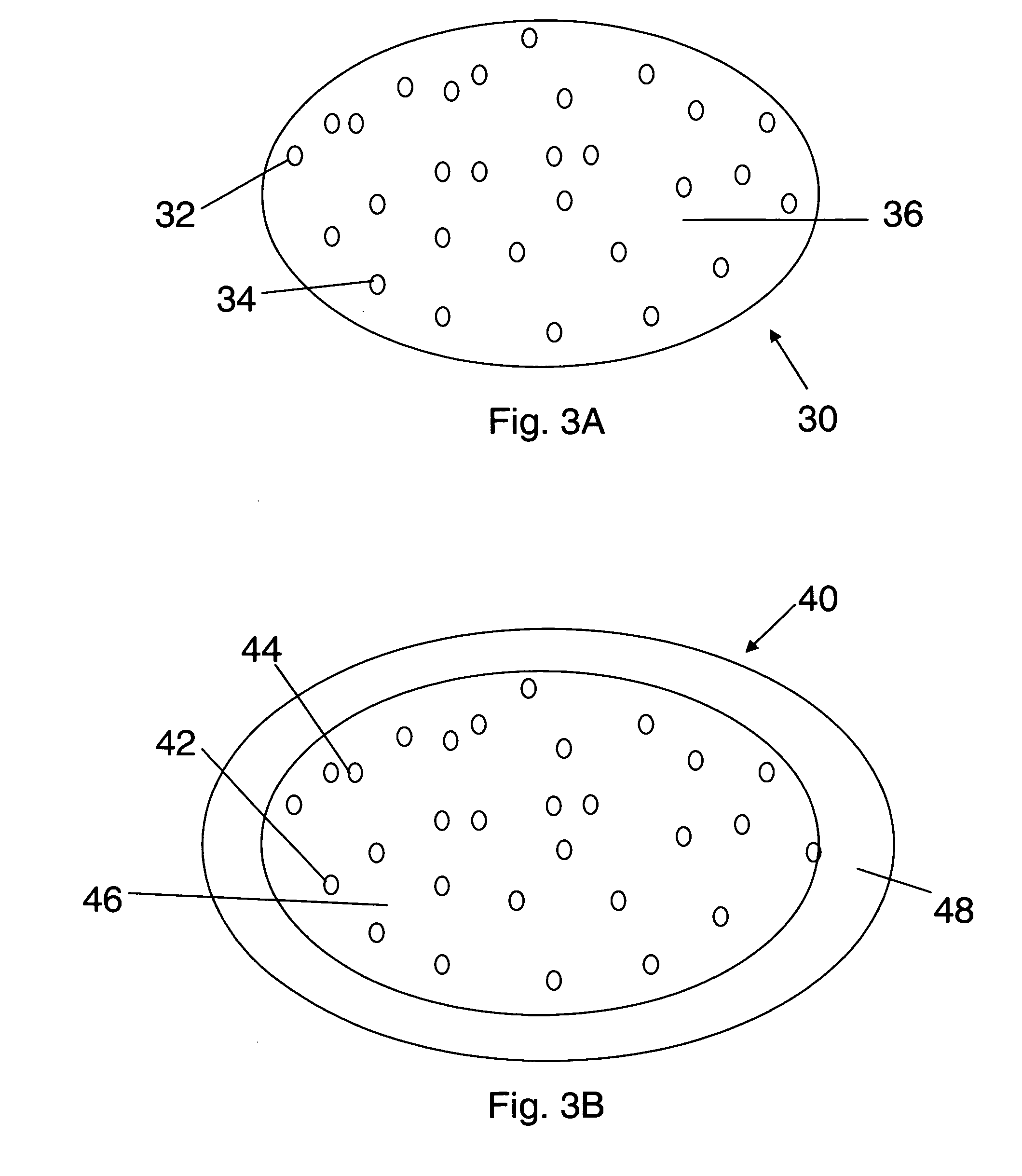

Solid dosage form for acid-labile active ingredient

InactiveUS20050281876A1Prevent and inhibit acid degradationPreserve bioavailabilityPowder deliveryMedical devicesBULK ACTIVE INGREDIENTSolid Dose Form

The present invention relates to solid, orally administrable dosage forms for acid-labile actives having at least one molded insert or core containing an acid-labile active ingredient, such as a proton pump inhibitor that is surrounded by barrier layer that is subsequently coated with an enteric layer. The present invention also relates to a dosage form that combines the barrier coated active ingredient containing insert with a second active ingredient.

Owner:MCNEIL PPC INC

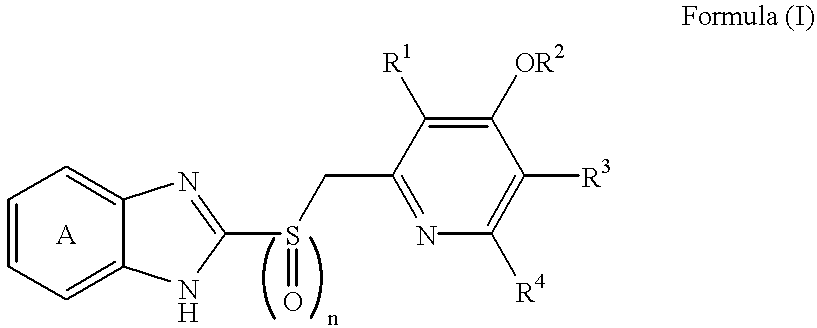

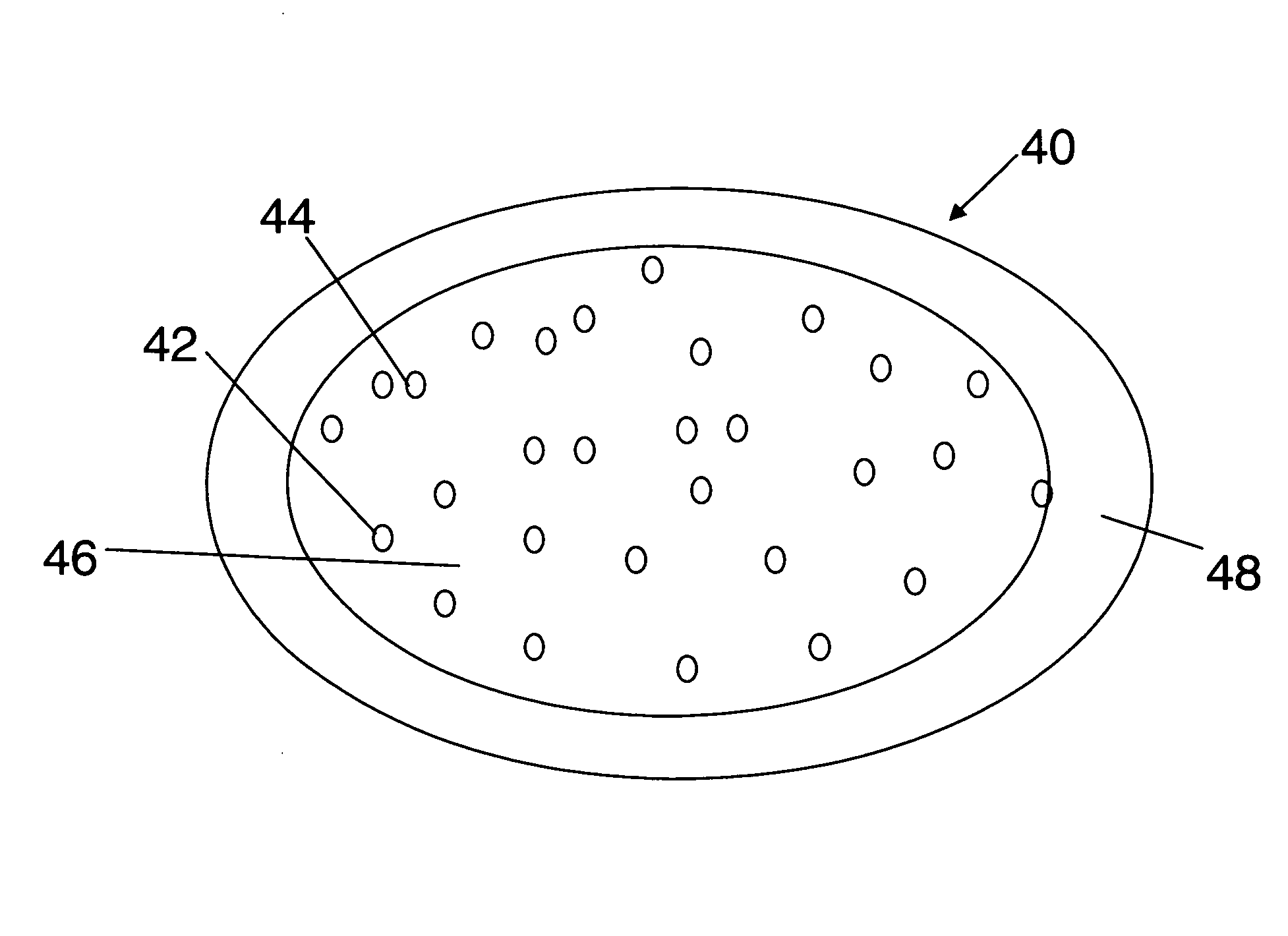

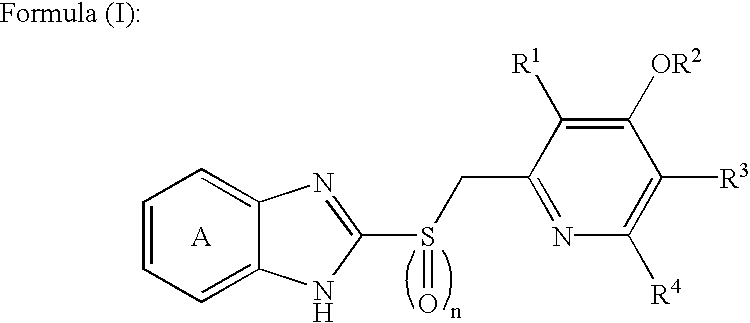

Stable pharmaceutical composition comprising an acid labile drug

The present invention provides a stable pharmaceutical composition of an acid labile drug such as a pharmaceutically active substituted benzimidazole compound, comprising: a) an inner core coated with the acid labile drug; b) a first intermediate coating devoid of an alkaline stabilizing agent and the benzimidazole compound; c) a second intermediate coating comprising an alkaline stabilizing agent; and, d) an outer enteric layer. The present invention also provides a method of preparing the same.

Owner:TEVA PHARM USA INC

Resist composition and patterning process

A resist composition comprising (A) an organic solvent; (B) at least two polymers with weight average molecular weights of 1,000-500,000, which have at least one type of acid labile group and are crosslinked within a molecule and / or between molecules with crosslinking groups having C-O-C linkages; and (C) a photoacid generator is sensitive to high-energy radiation, has excellent sensitivity, resolution, and plasma etching resistance, and provides resist patterns of outstanding thermal stability and reproducibility. Patterns obtained with this resist composition are less prone to overhanging and have excellent dimensional controllability. The resist composition is suitable as a micropatterning material for VLSI fabrication because it has a low absorption at the exposure wavelength of a KrF excimer laser, thus enabling the easy formation of a finely defined pattern having sidewalls perpendicular to the substrate.

Owner:SHIN ETSU CHEM IND CO LTD

Resist composition and patterning process

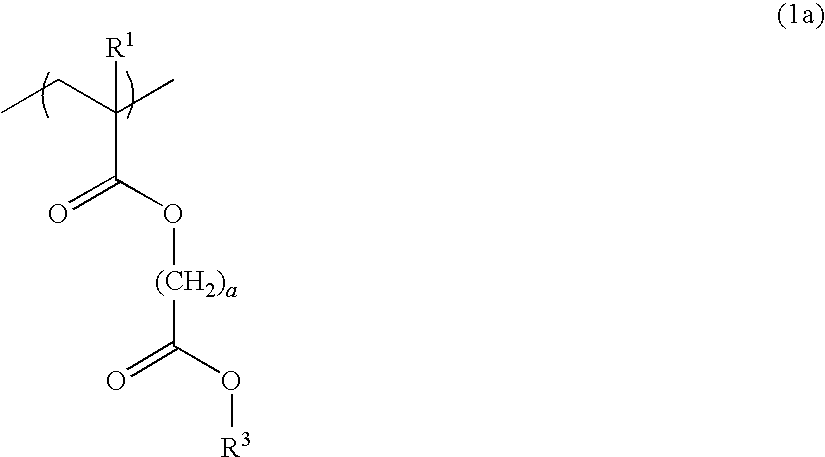

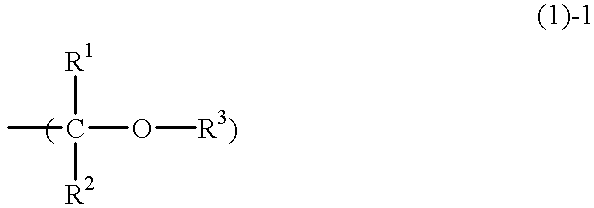

ActiveUS20100266957A1Readily availableEasy to handlePhotosensitive materialsElectric discharge tubesResistOrganic solvent

An additive polymer comprising recurring units of formula (1) is added to a resist composition comprising a base resin, a photoacid generator, and an organic solvent. R1 is hydrogen or methyl, R2 is alkylene or fluoroalkylene, and R3 is fluoroalkyl. The additive polymer is highly transparent to radiation with wavelength of up to 200 nm. Water repellency, water slip, acid lability, hydrolysis and other properties of the polymer may be adjusted by a choice of polymer structure.

Owner:SHIN ETSU CHEM IND CO LTD

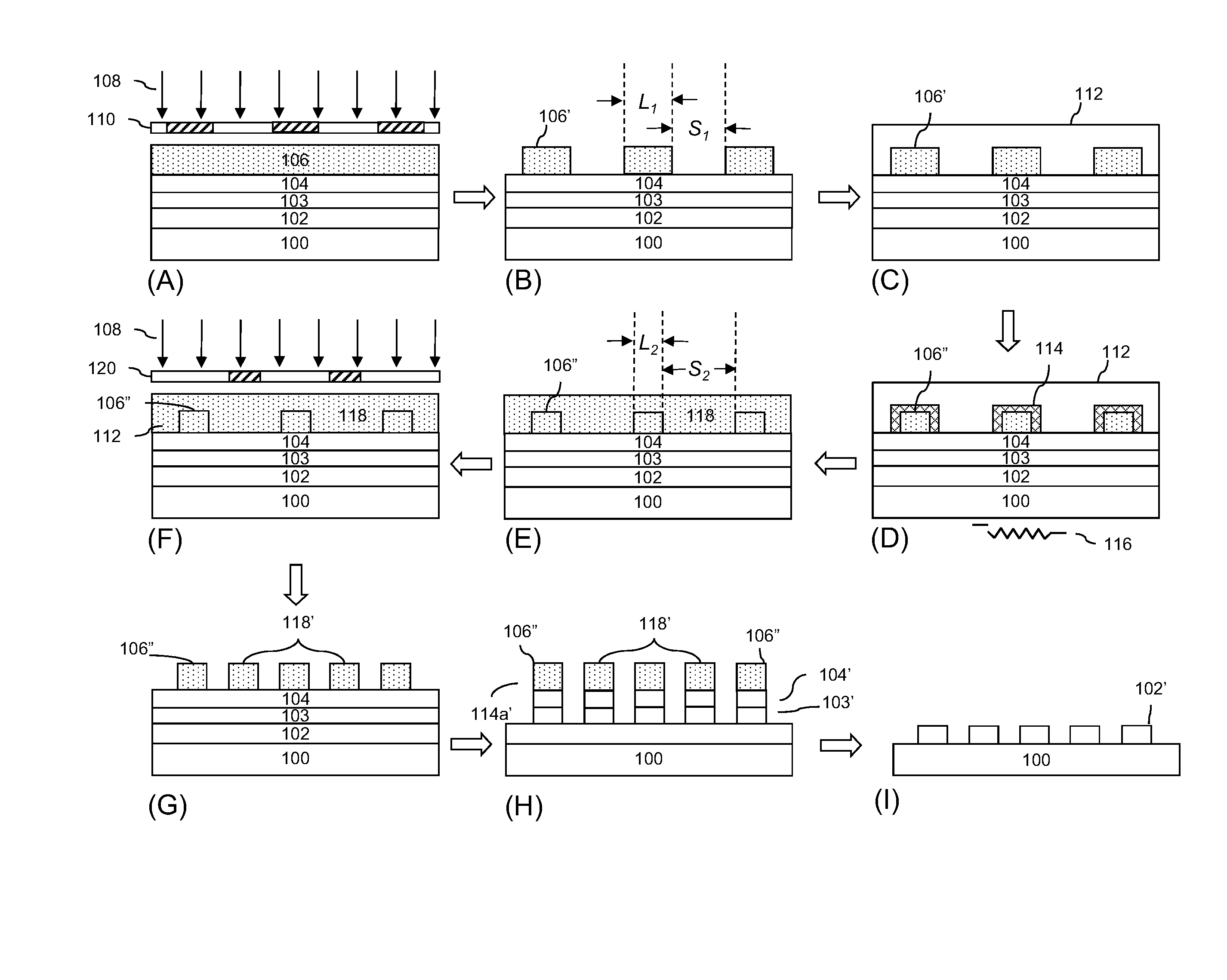

Patterning process and resist composition

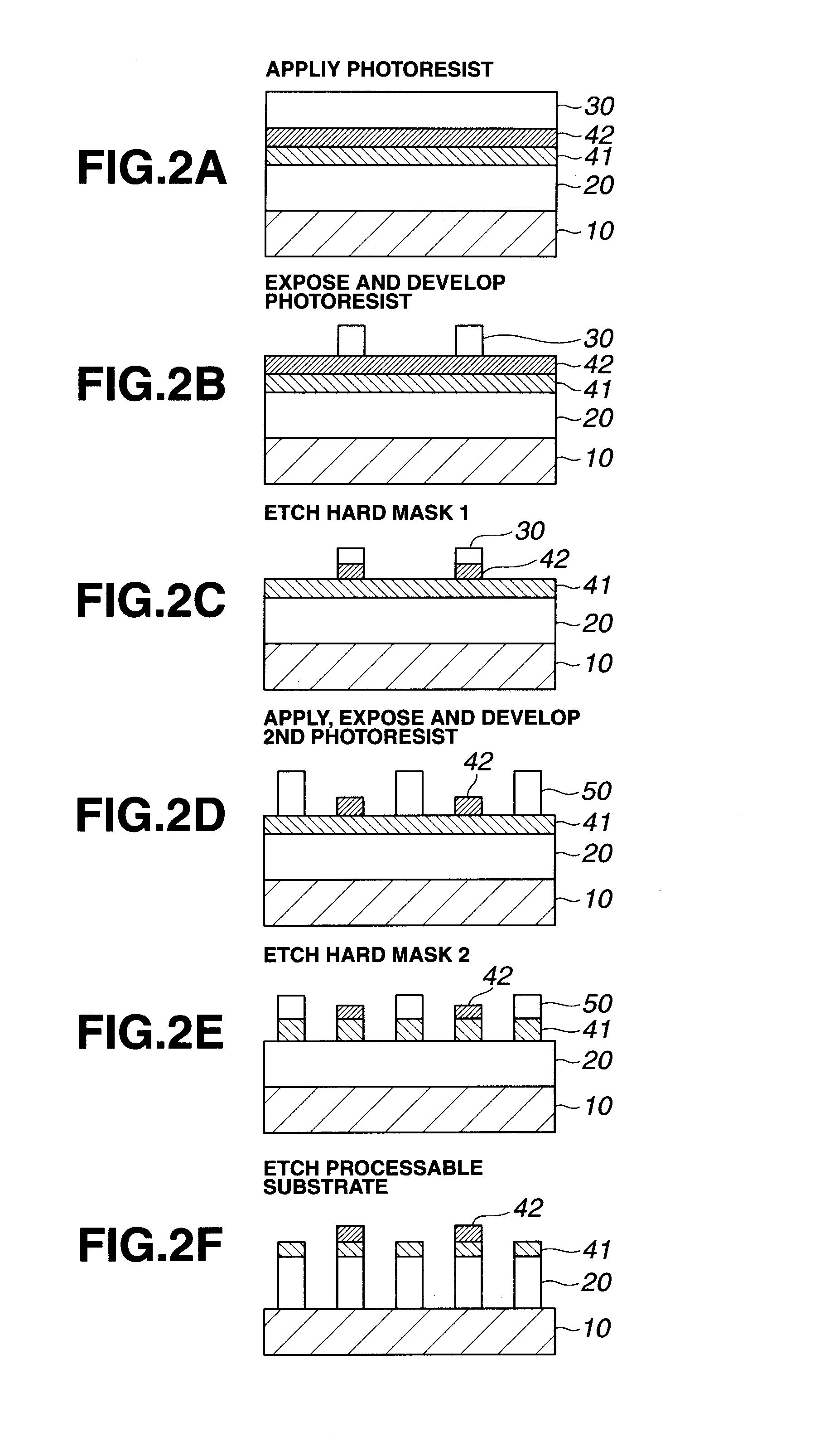

InactiveUS20080199806A1Avoid mixingPhotosensitive materialsRadiation applicationsNorbornaneNanotechnology

A pattern is formed by applying a positive resist composition comprising a polymer comprising 7-oxanorbornane ring-bearing recurring units and acid labile group-bearing recurring units and an acid generator onto a substrate to form a resist film, heat treating and exposing the resist film to radiation, heat treating and developing the resist film with a developer, and causing the resist film to crosslink and cure with the aid of acid and / or heat. A second resist pattern is then formed in the space area of the first resist pattern. The double patterning process reduces the pitch between patterns to one half.

Owner:SHIN ETSU CHEM IND CO LTD

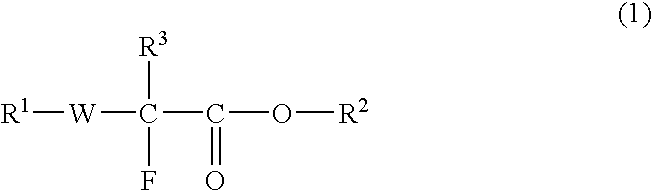

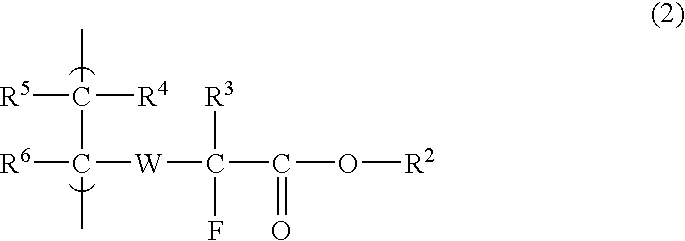

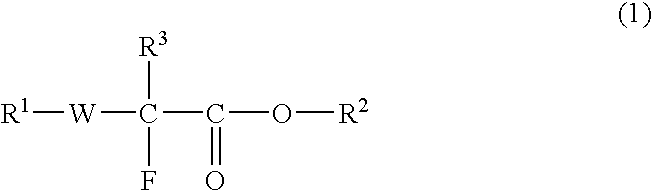

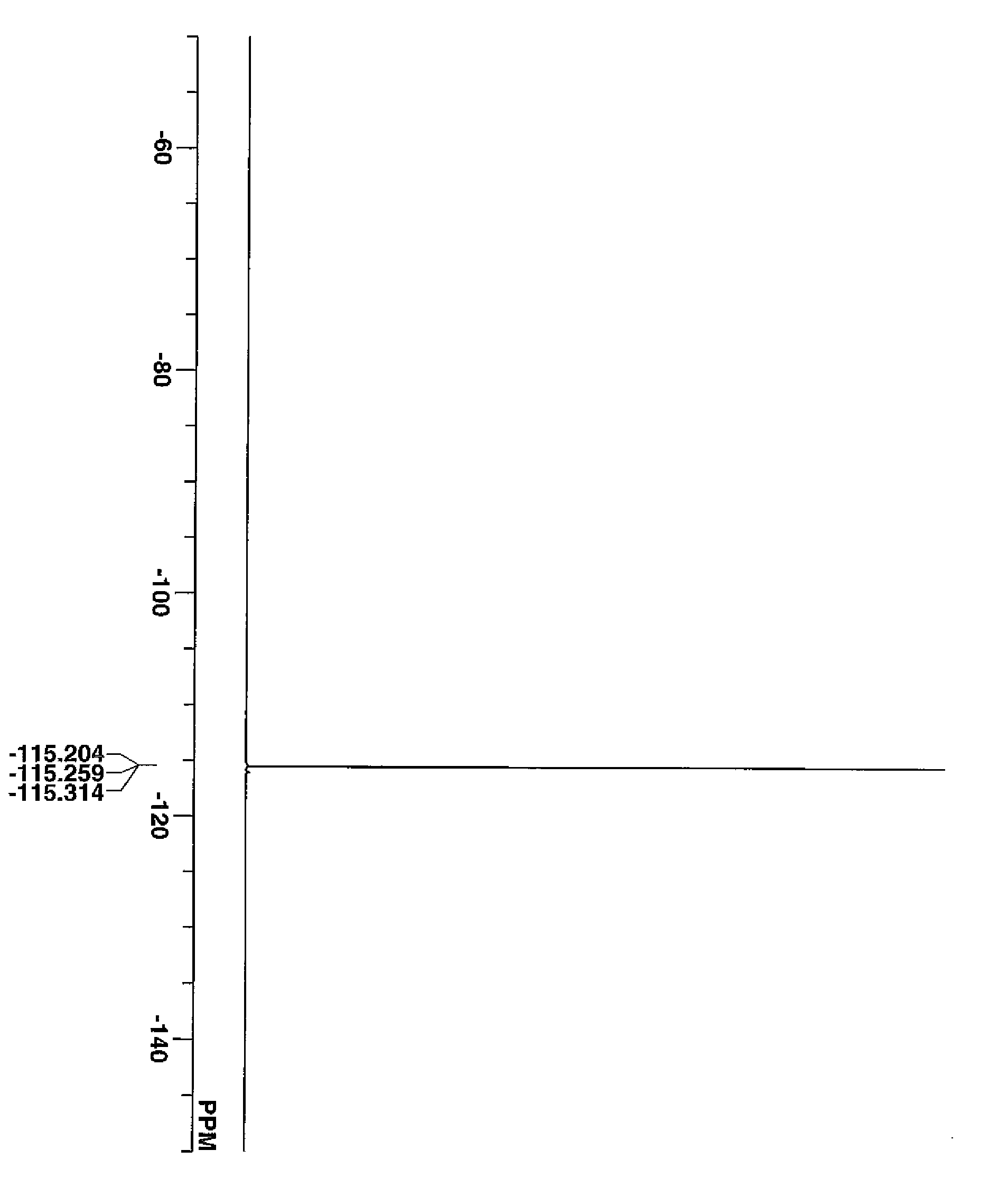

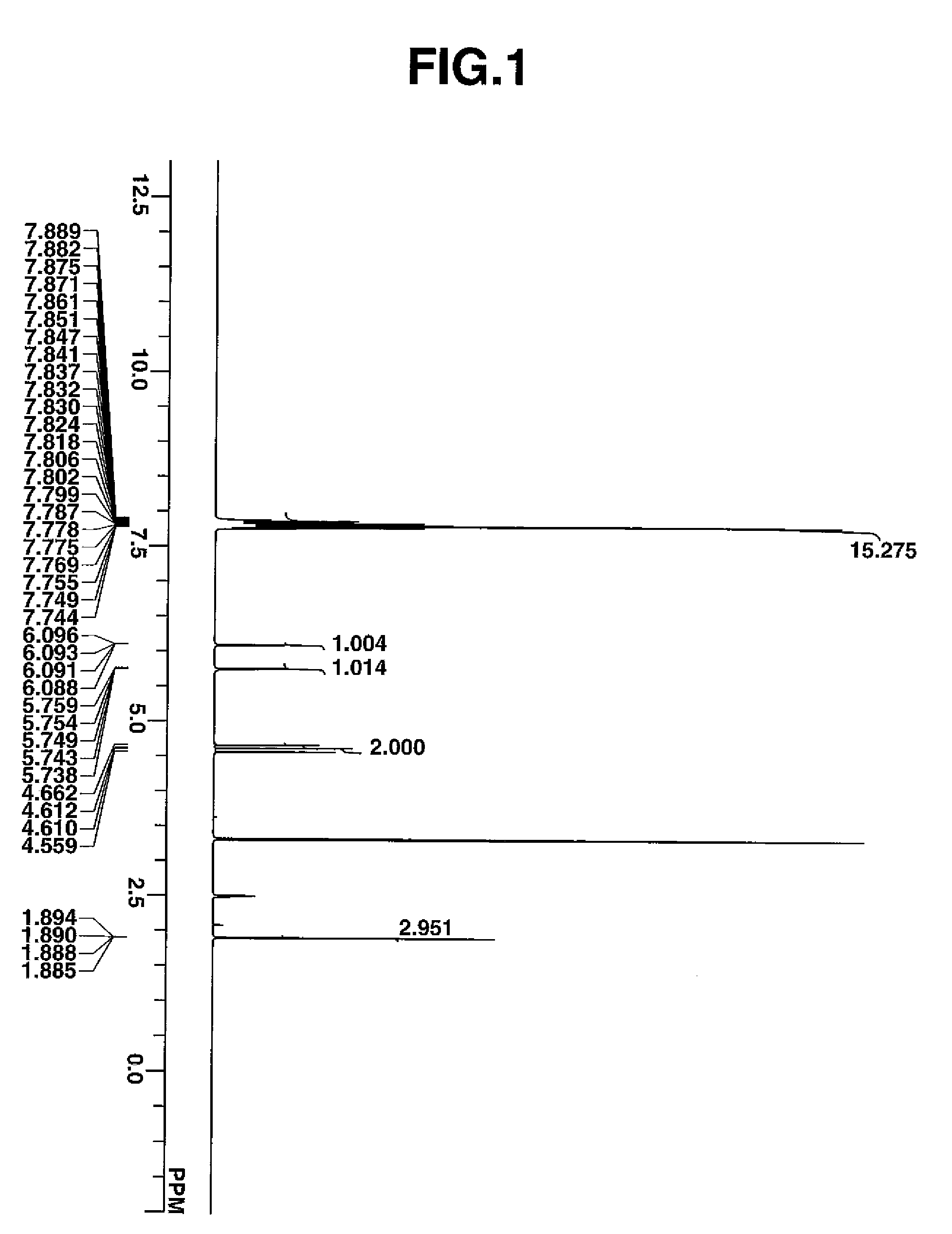

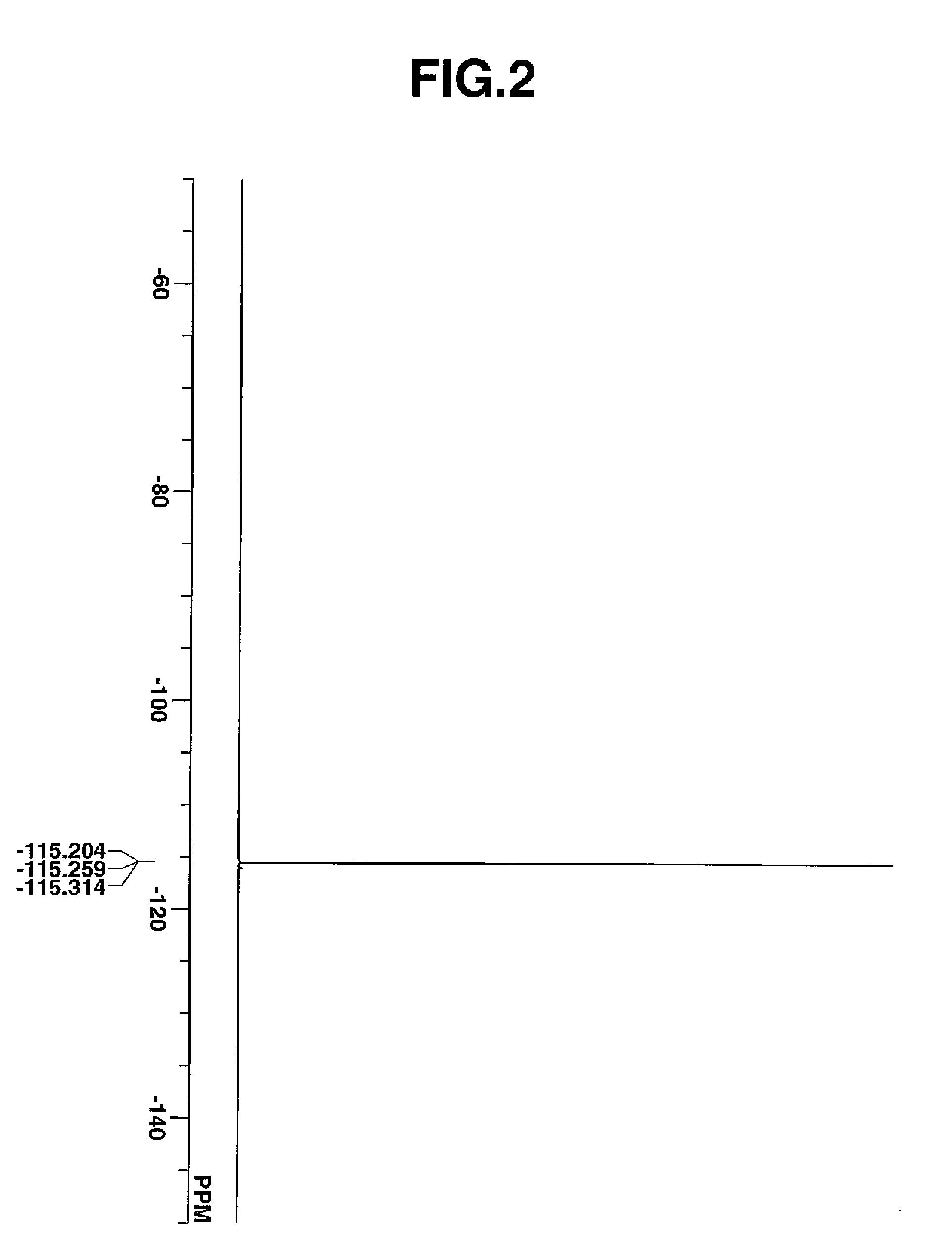

Fluorine-Containing Compound, Fluorine-Containing Polymer, Postive-Type Resist Composition, And Patterning Process Using Same

InactiveUS20080311507A1High rectangularityIncrease acidityOrganic chemistryPhotosensitive materialsPolymer scienceOrganic group

Disclosed is a fluorine-containing compound represented by formula (1),wherein R1 represents a polymerizable double-bond containing group, R2 represents an acid-labile protecting group, R3 represents a fluorine atom or fluorine-containing alkyl group, and W represents a bivalent linking group. This compound can provide a fluorine-containing polymer compound that has a weight-average molecular weight of 1,000-1,000,000 and contains a repeating unit represented by formula (2),wherein R2, R3 and W are defined as above, each of R4, R5 and R6 independently represents a hydrogen atom, fluorine atom or monovalent organic group, at least two of R4, R5 and R6 may be combined to form a ring. This polymer compound can provide a resist composition capable of forming a pattern that is transparent to exposure light and superior in rectangularity.

Owner:CENT GLASS CO LTD

Positive resist composition and patterning process

ActiveUS20090202943A1Feature size of to decreaseSmall feature sizePhotosensitive materialsRadiation applicationsResistHigh energy

A positive resist composition comprises a polymer comprising recurring units having a sulfonium salt incorporated therein as a base resin which becomes soluble in alkaline developer under the action of acid. The polymer generates a strong sulfonic acid upon exposure to high-energy radiation so as to facilitate effective scission of acid labile groups in the resist composition.

Owner:SHIN ETSU CHEM IND CO LTD

Chemically amplified positive resist composition

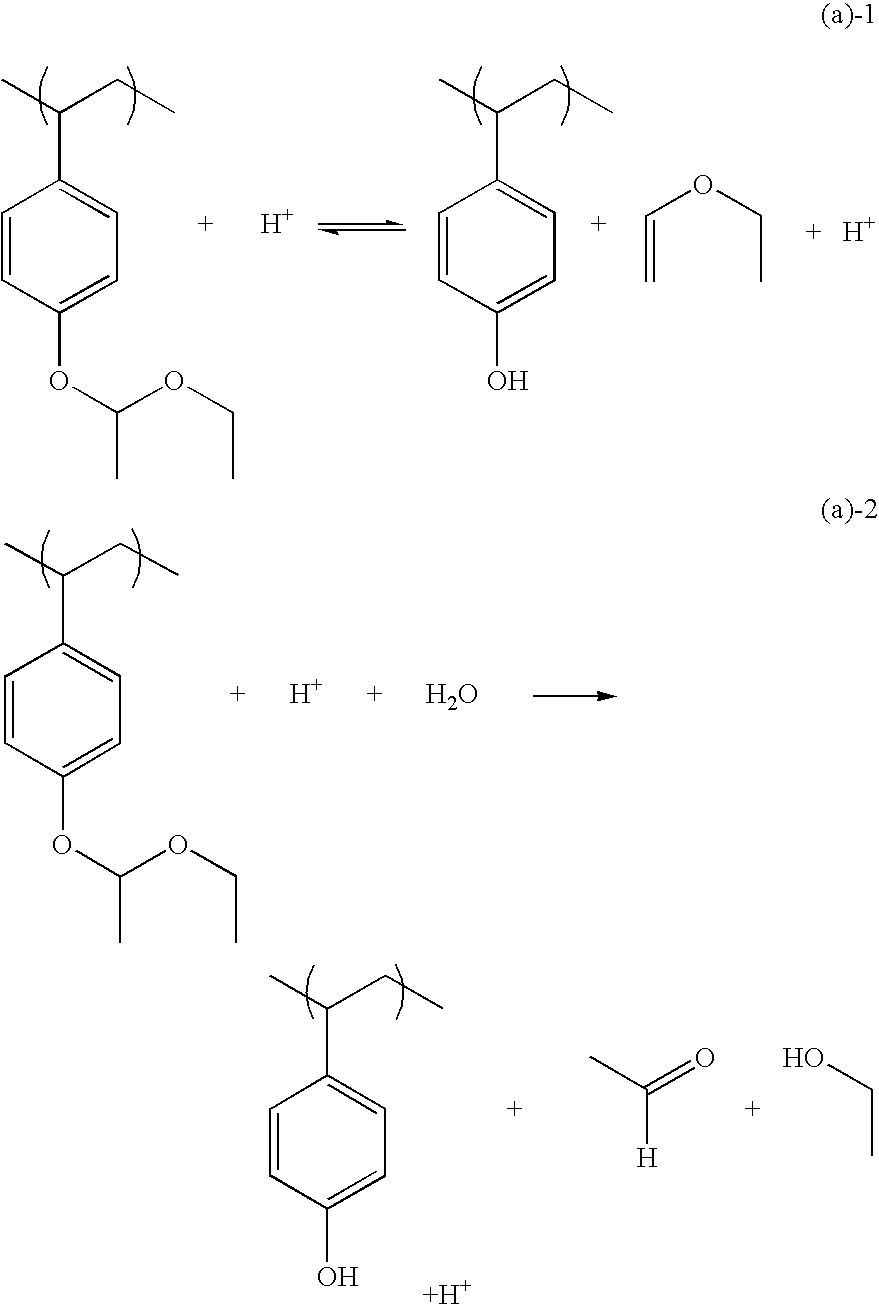

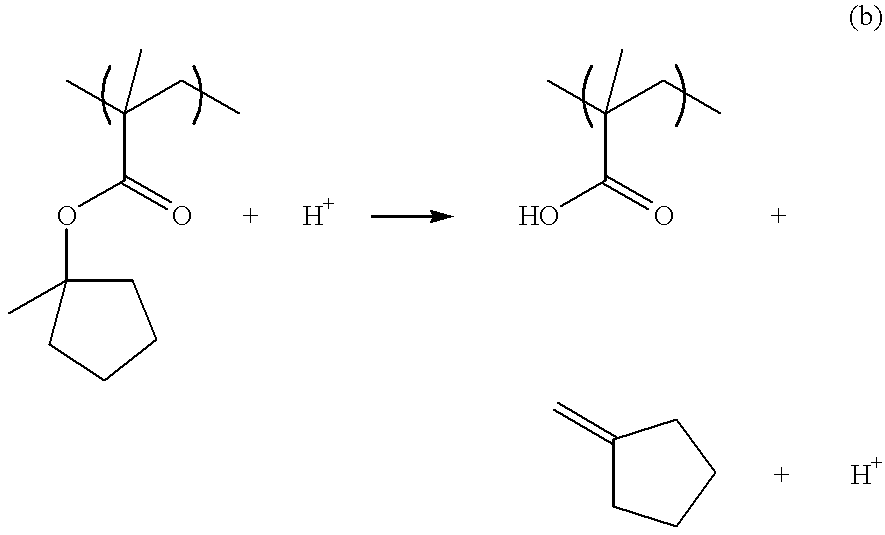

InactiveUS6869744B2Minimized change of sensitivityMinimize changesElectric discharge tubesPhotosensitive materialsResistCarboxylic group

A chemically amplified positive resist composition contains as a base a carboxyl or phenolic hydroxyl group-containing resin soluble in aqueous alkaline solution, in which acid labile groups are incorporated into at least some of the hydrogen atoms on the carboxyl or phenolic hydroxyl groups so that the resin becomes insoluble or substantially insoluble in alkali, wherein the resin contains acid labile groups of at least two types, acid labile groups of one type are acetal or ketal groups, and acid labile groups of the other type are tertiary hydrocarbon groups or tertiary hydrocarbon group-containing substituents. The resist composition remains stable during vacuum standing after exposure to electron beams or soft x-rays, leaves minimal footings on chromium substrates, has an excellent sensitivity and resolution, and is thus suited as a micropatterning material for use in the processing of mask substrates.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com