Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93 results about "Stretch wrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stretch wrap or stretch film is a highly stretchable plastic film that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, shrink wrap is applied loosely around an item and shrinks tightly with heat.

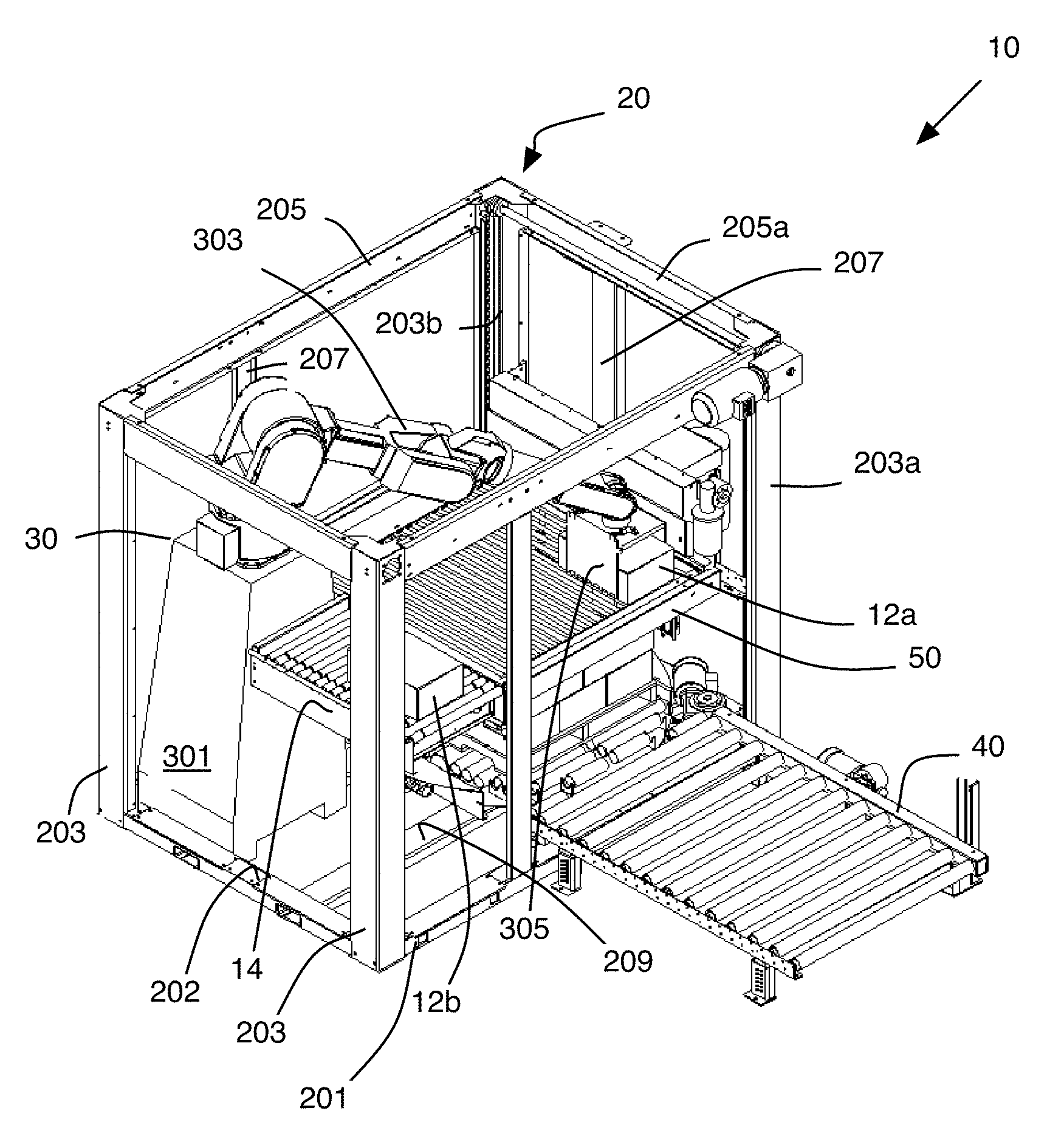

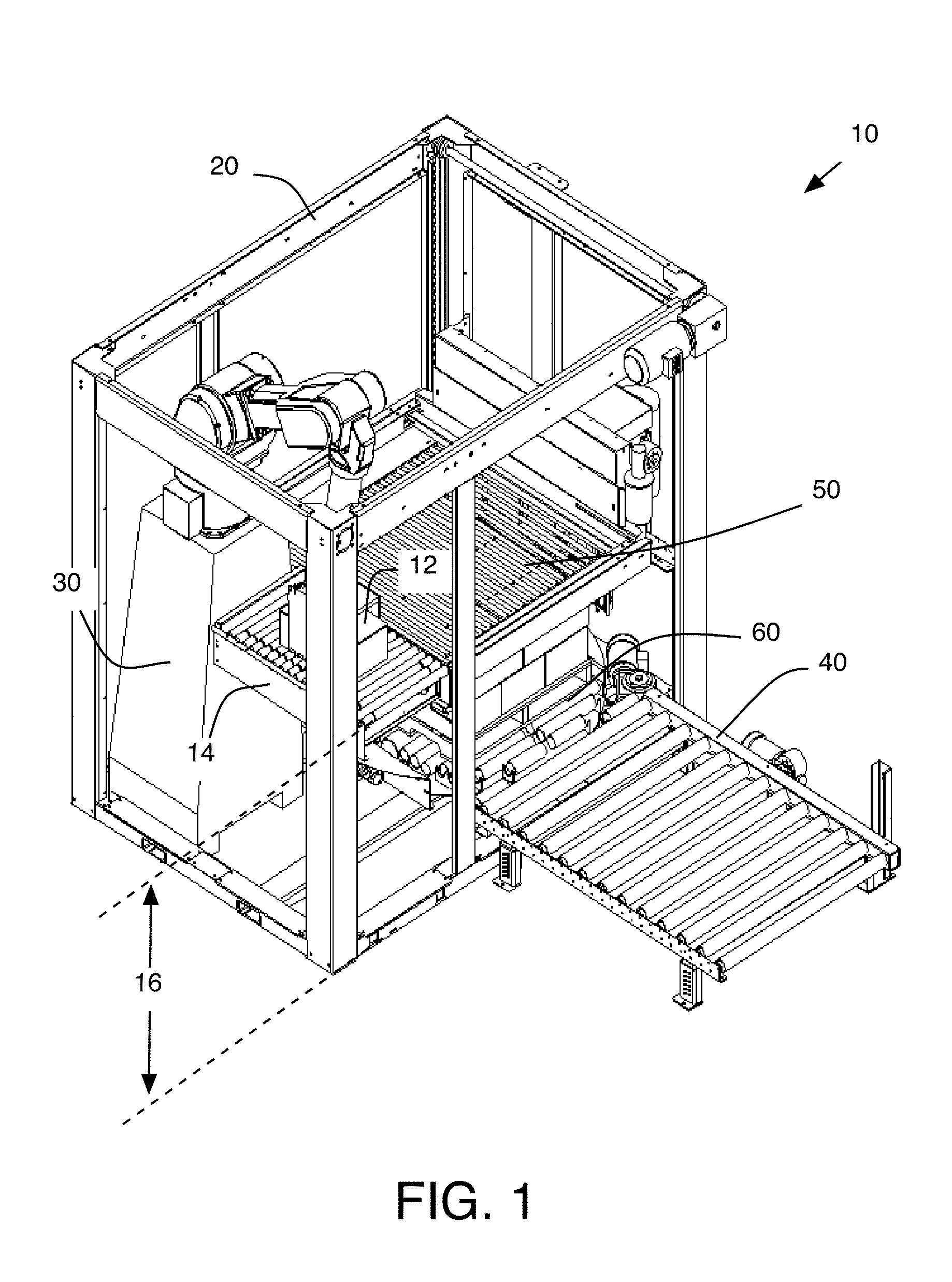

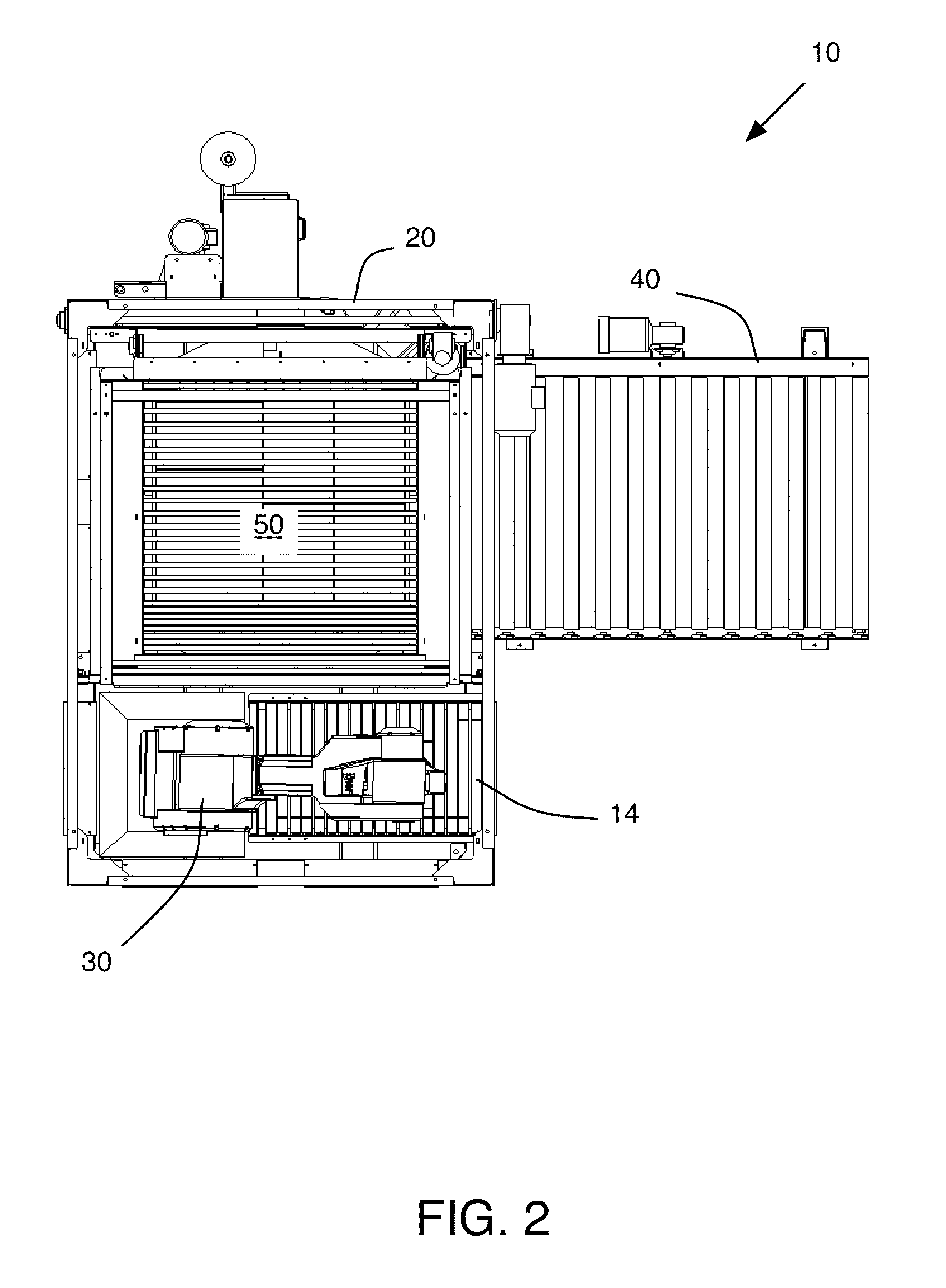

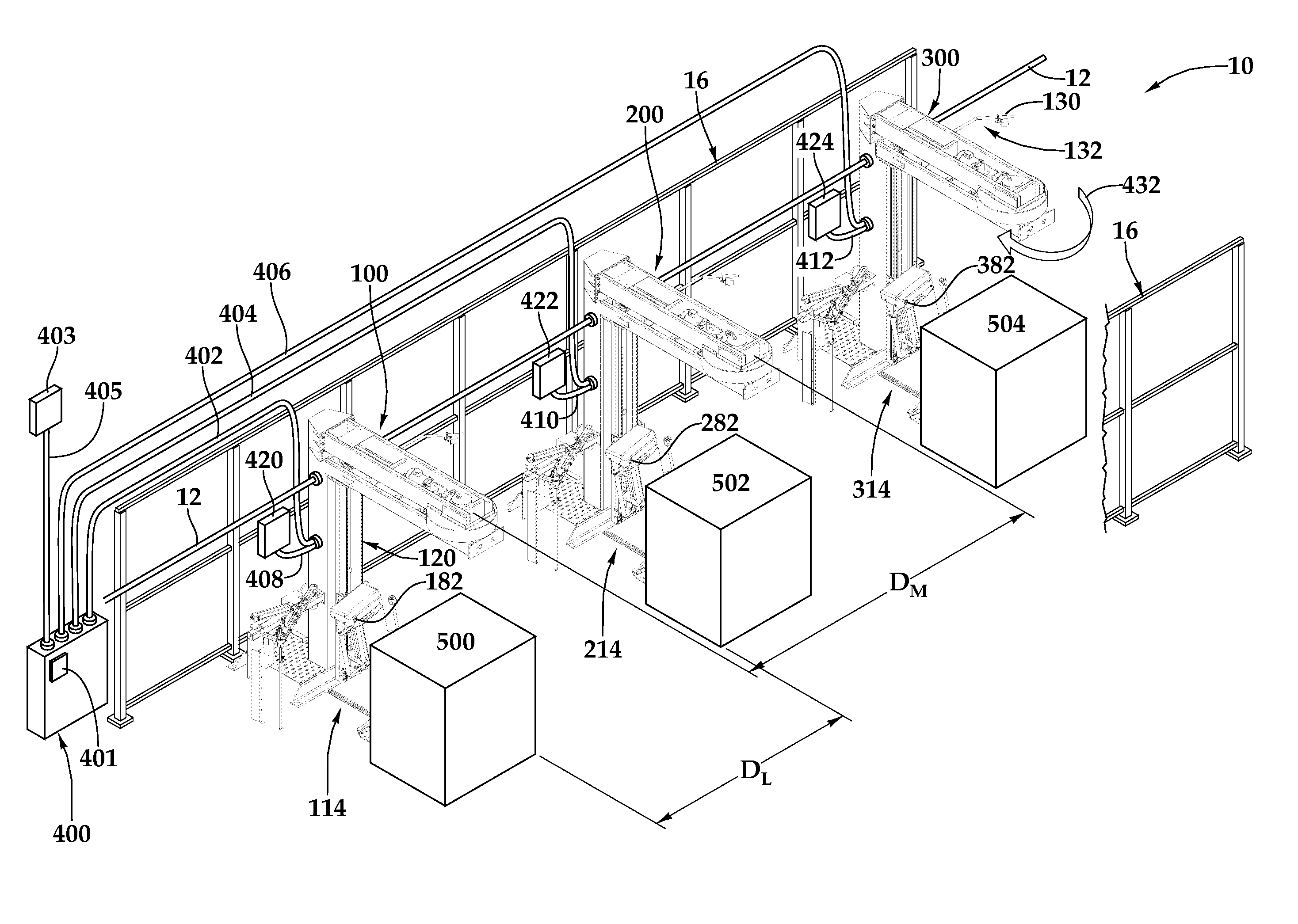

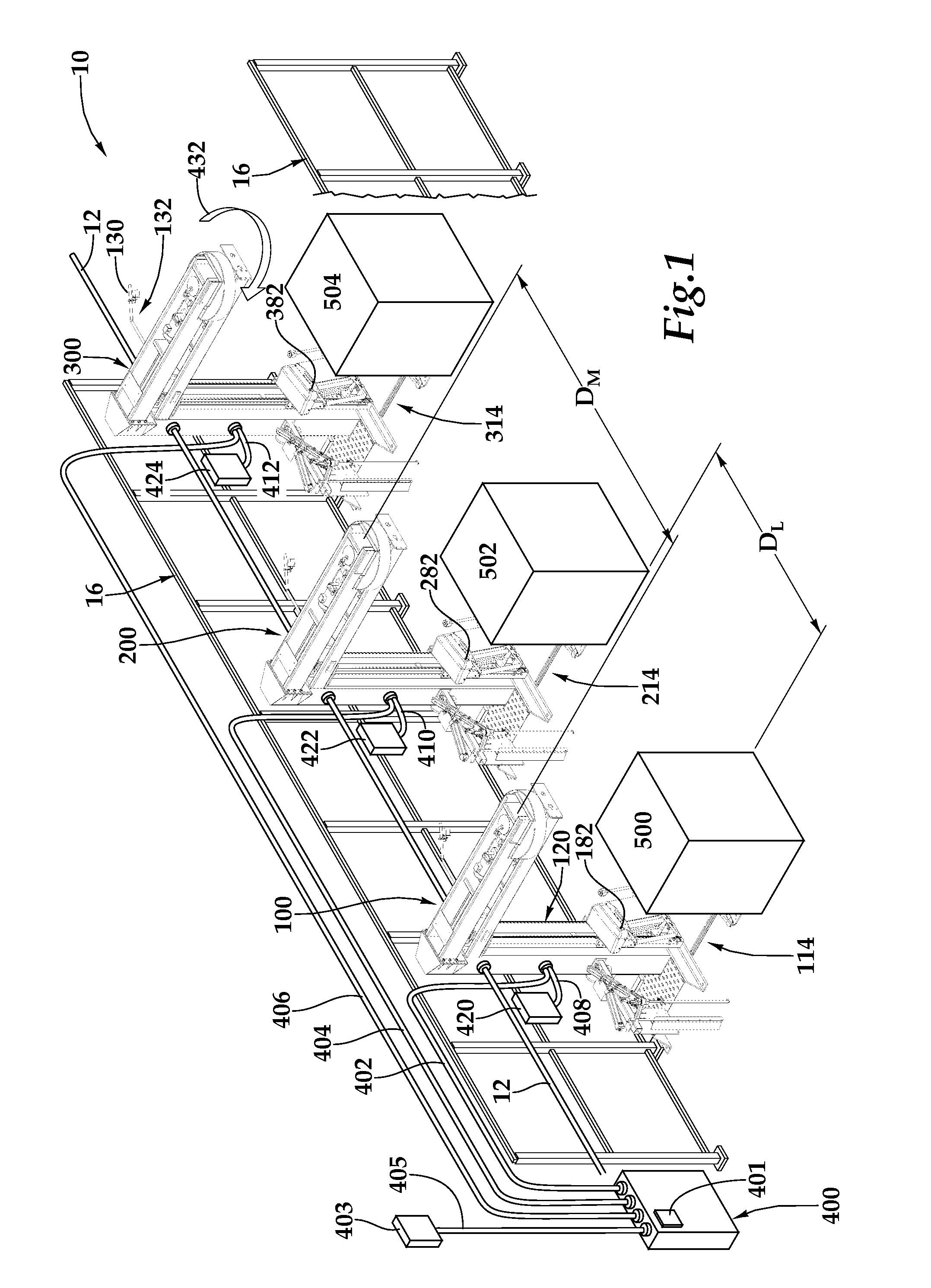

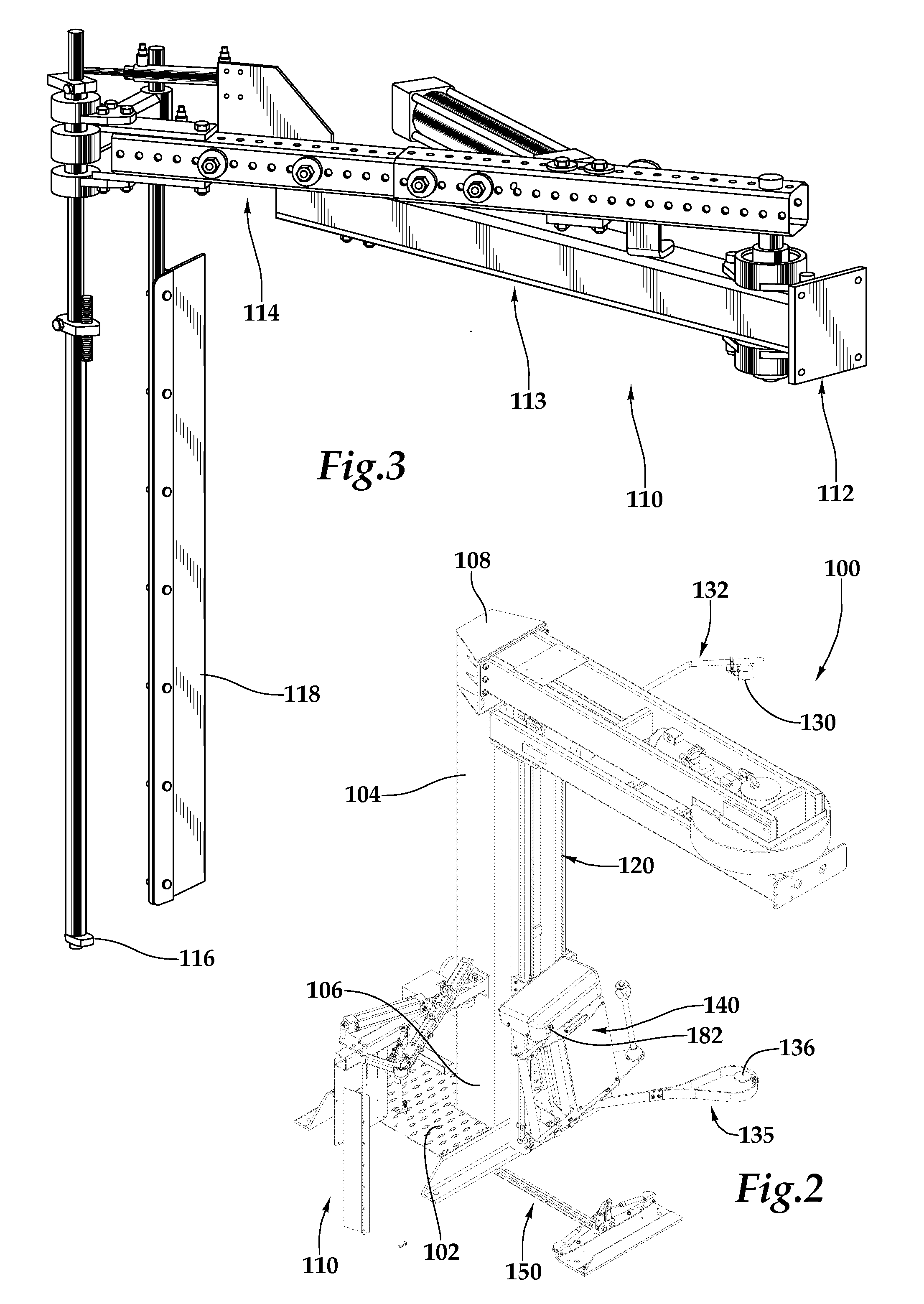

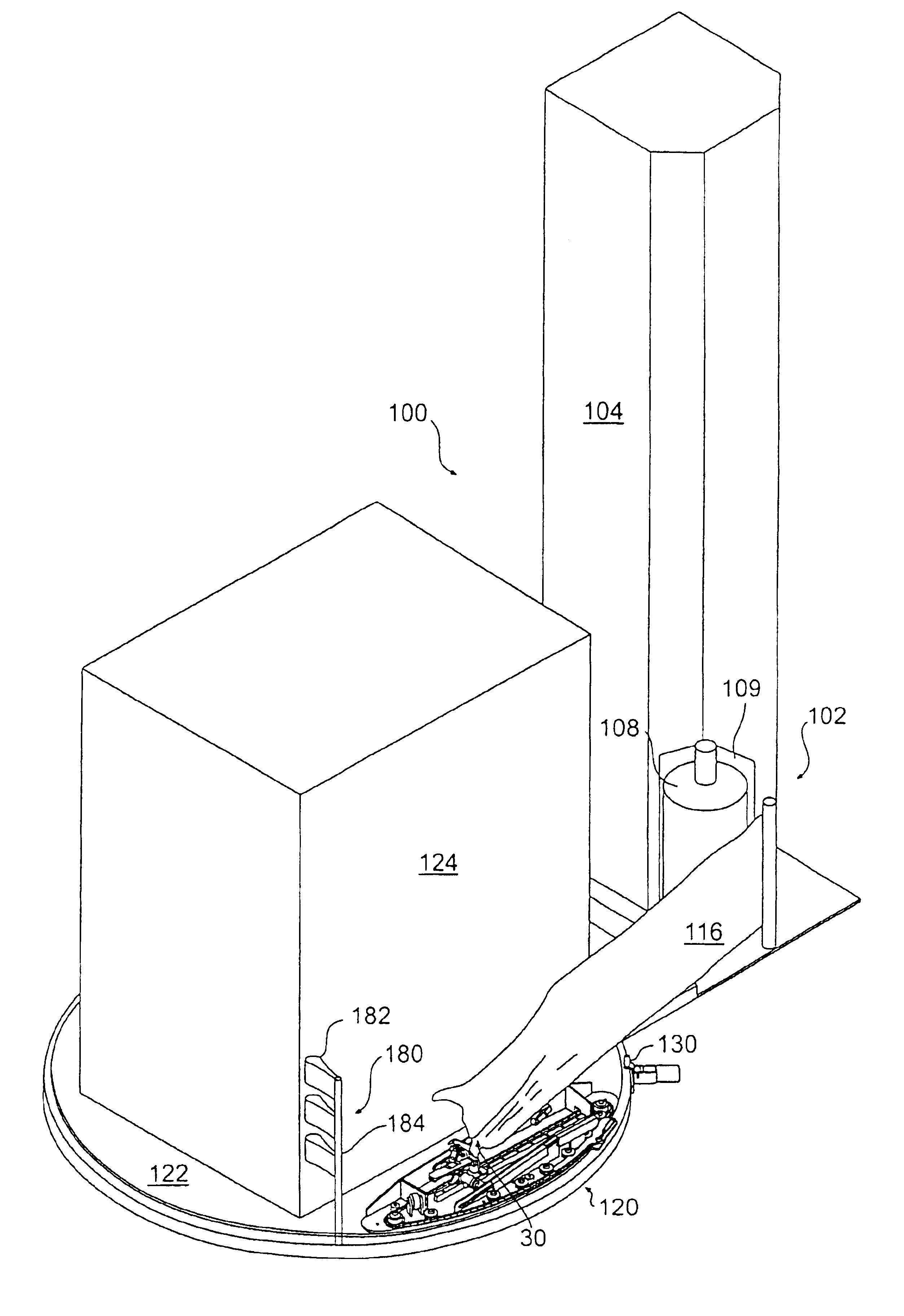

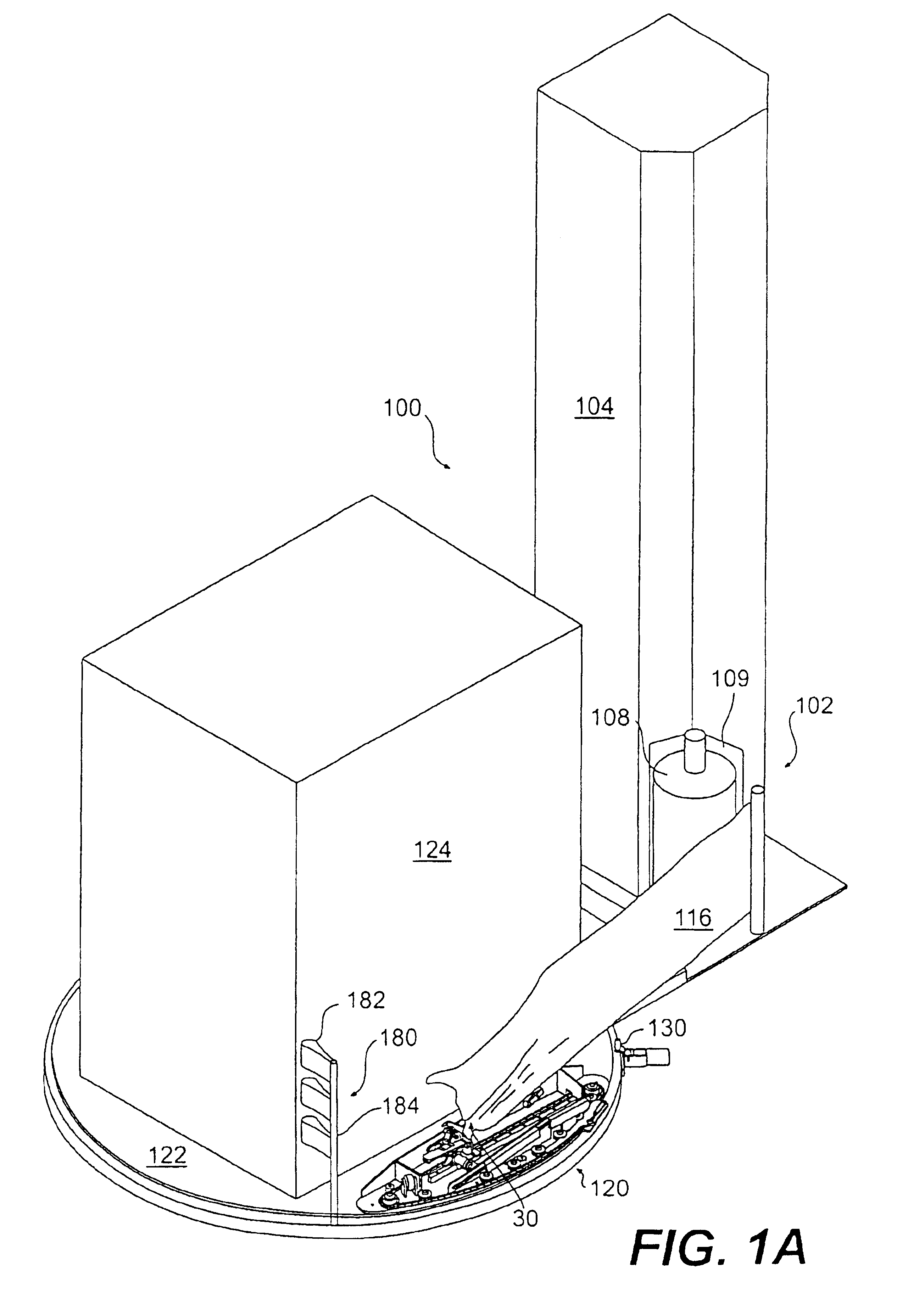

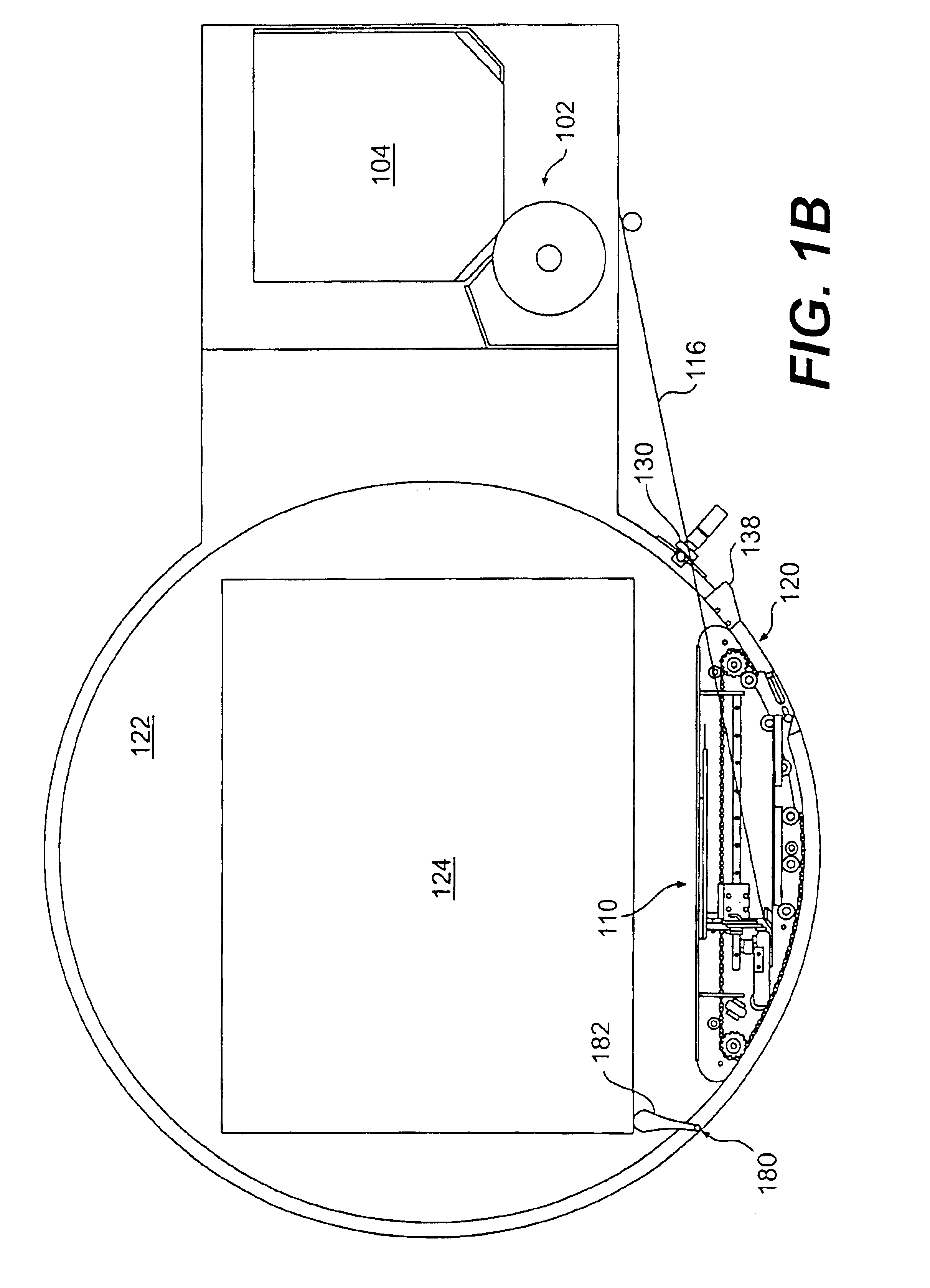

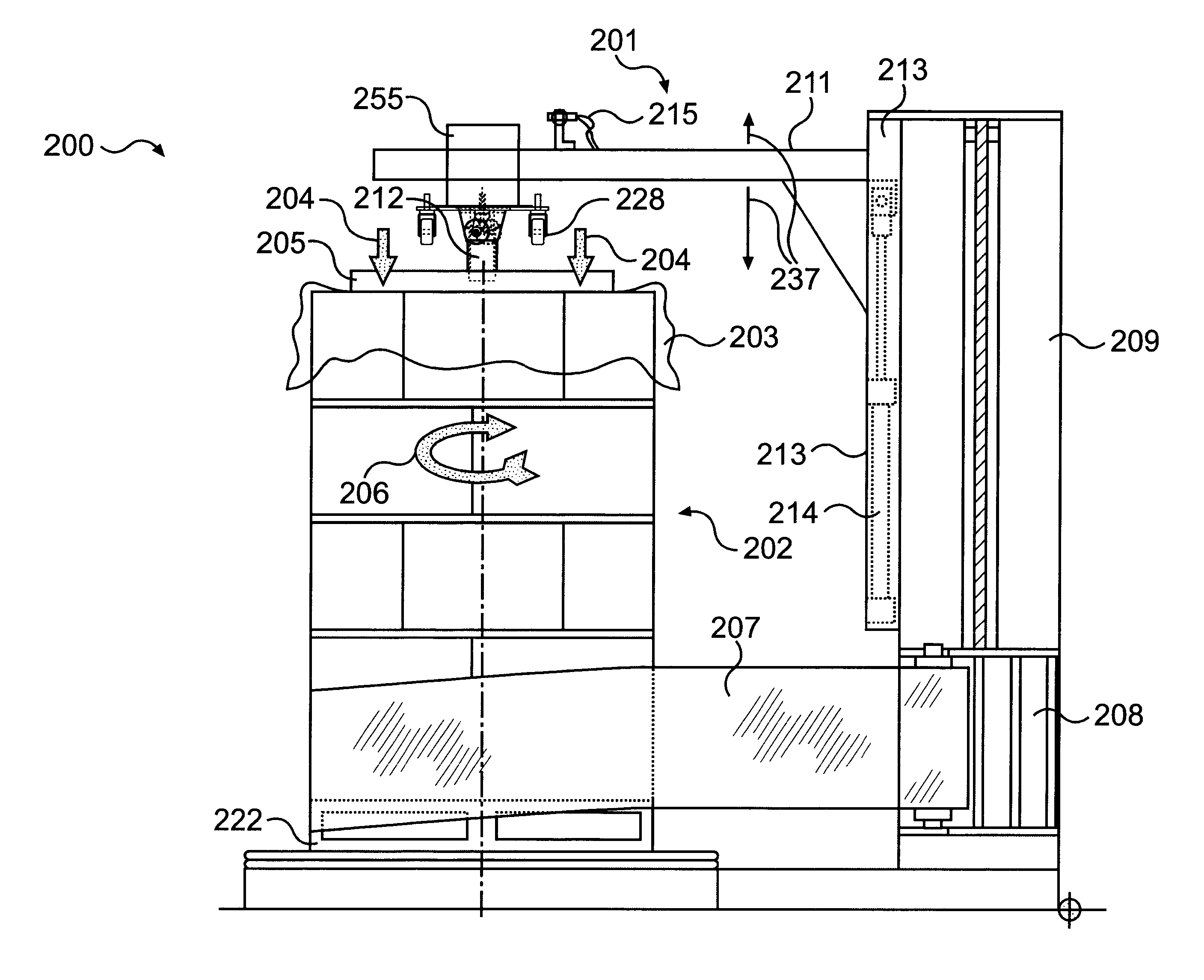

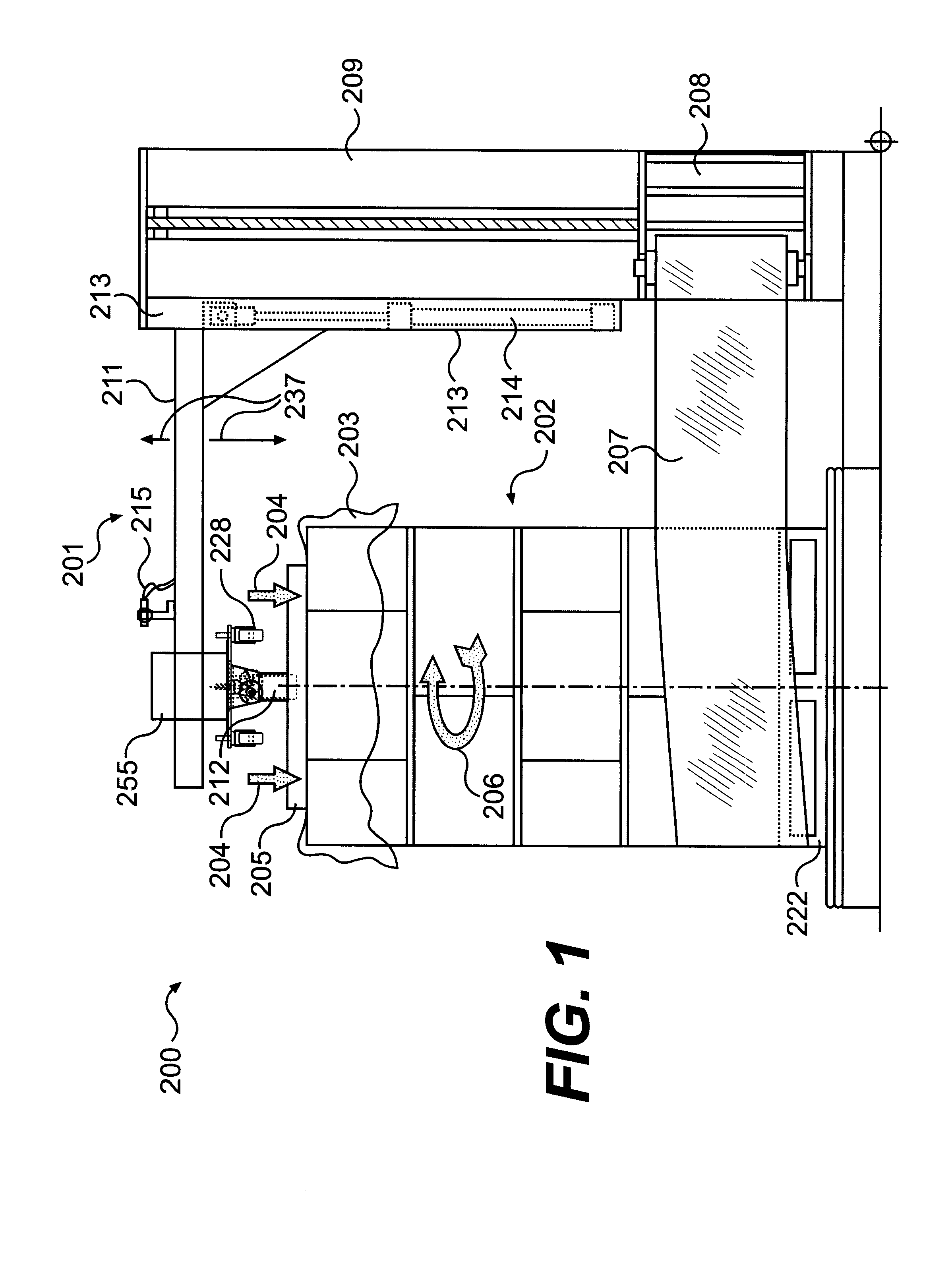

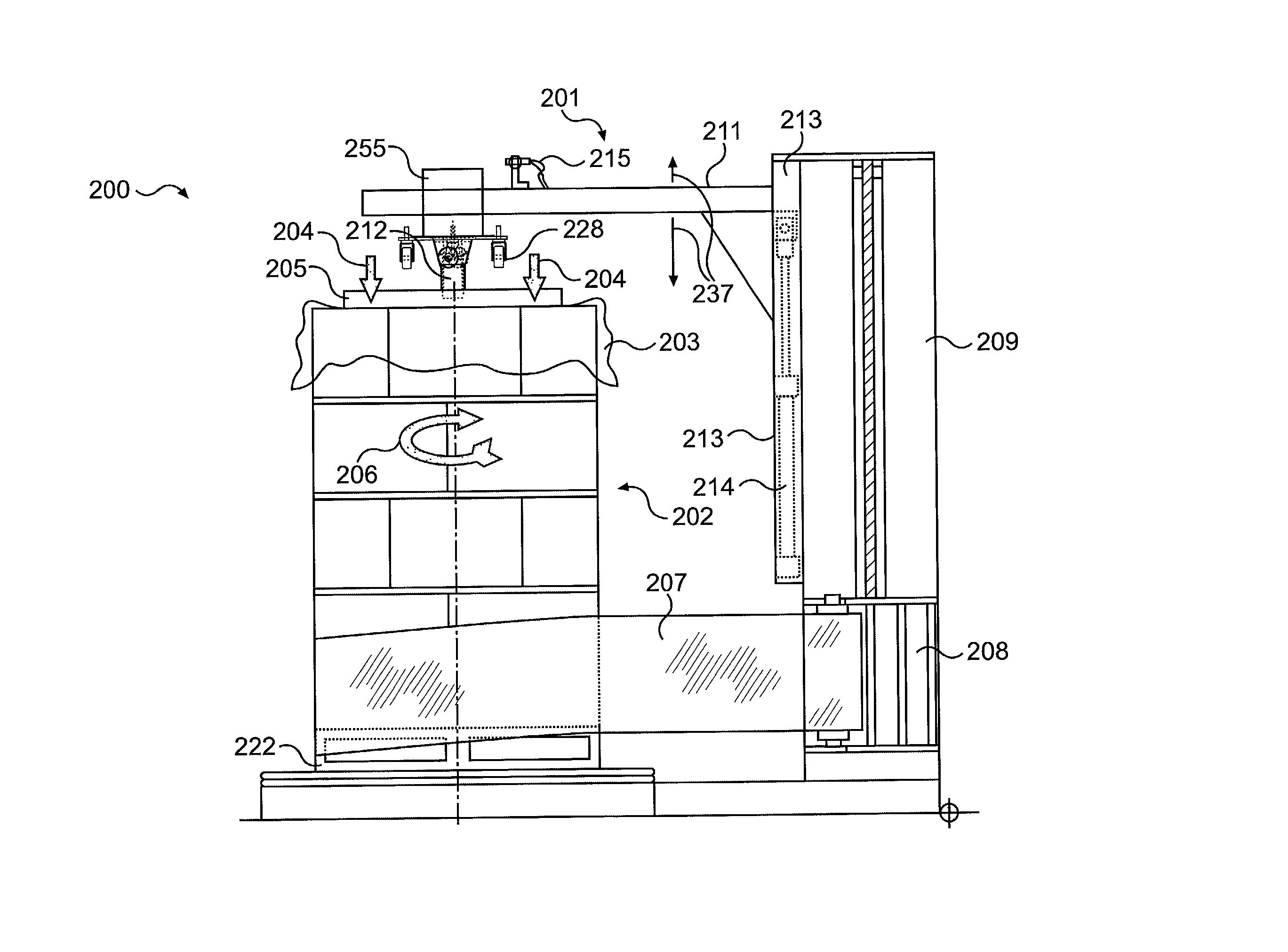

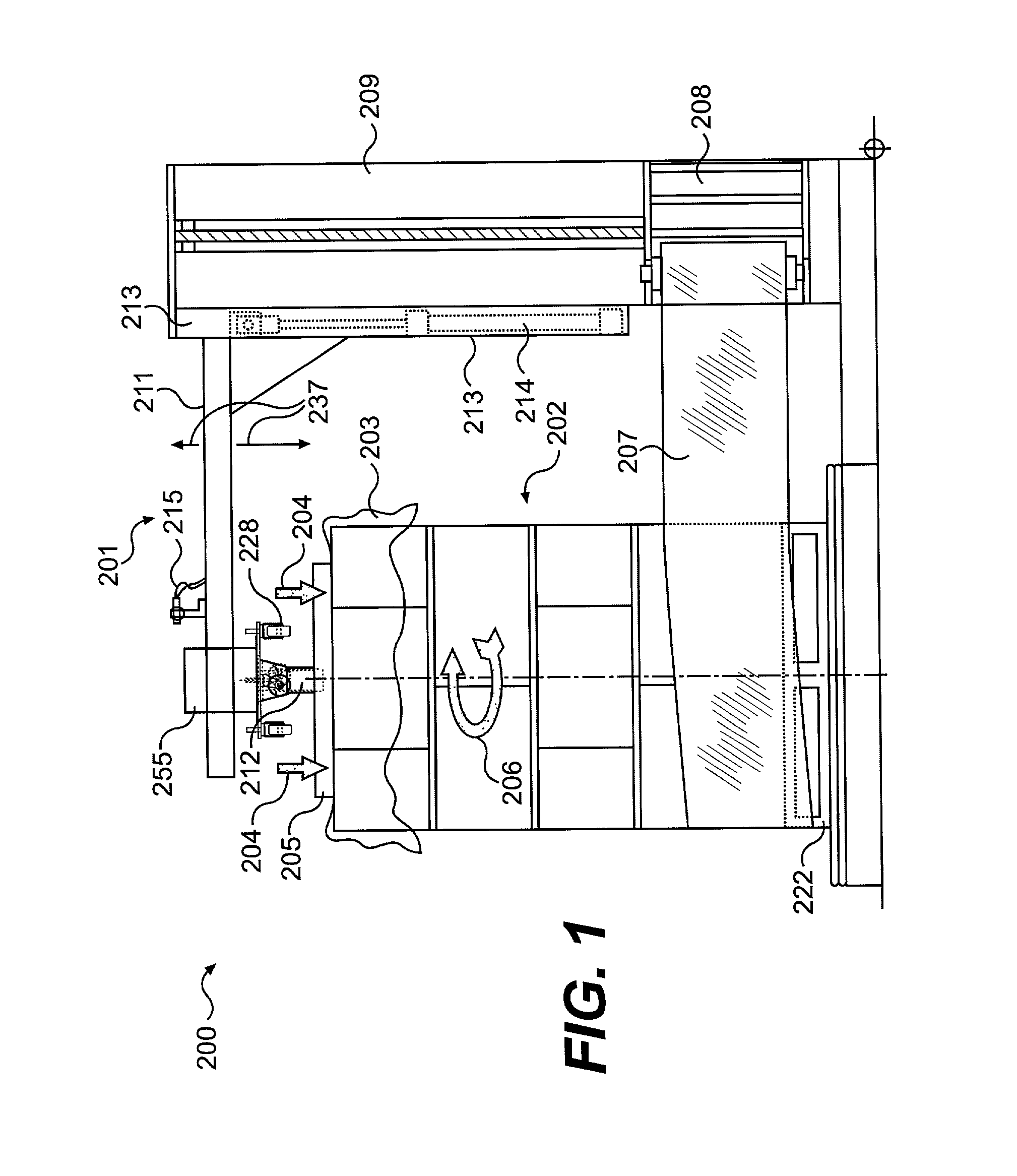

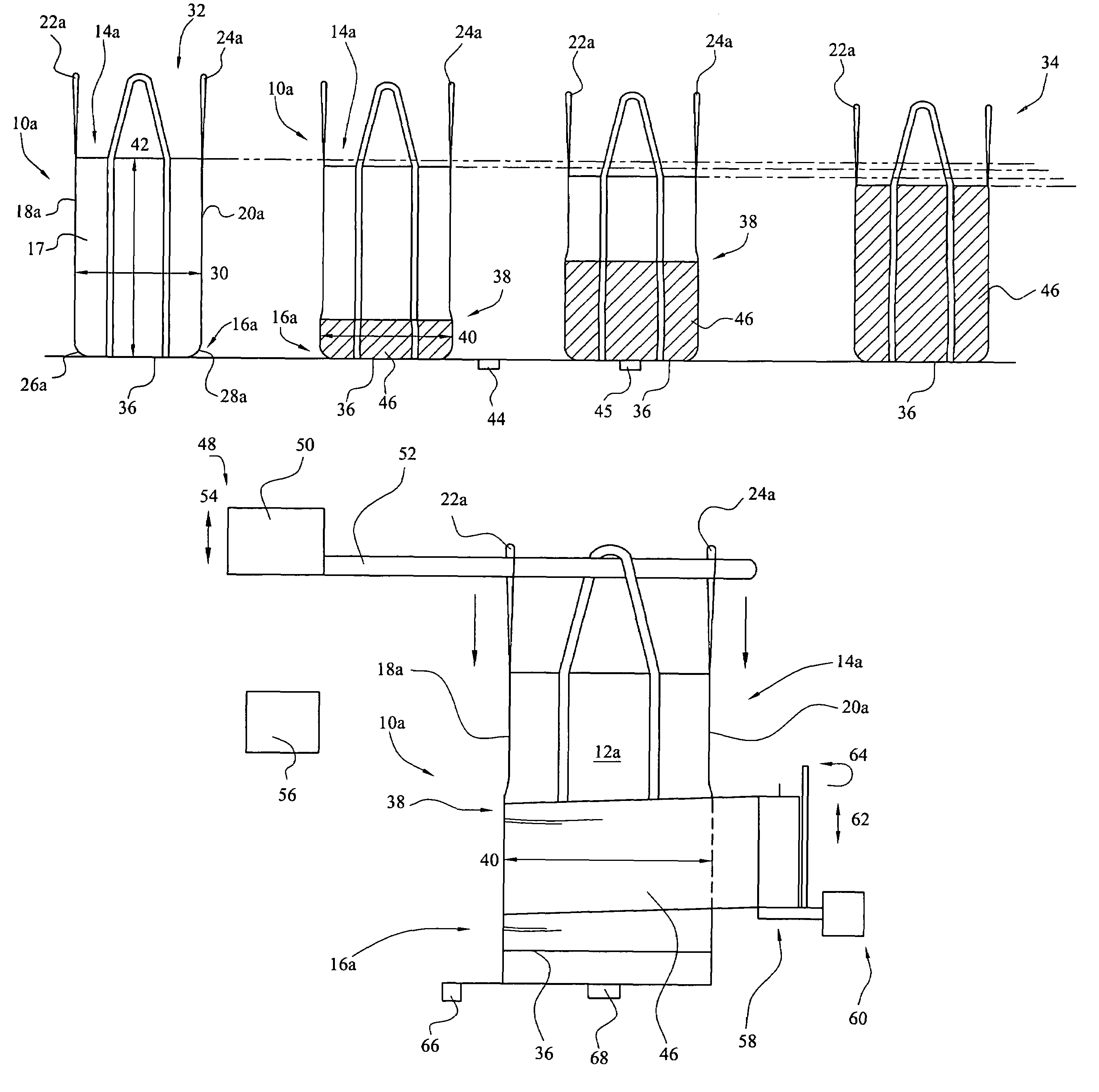

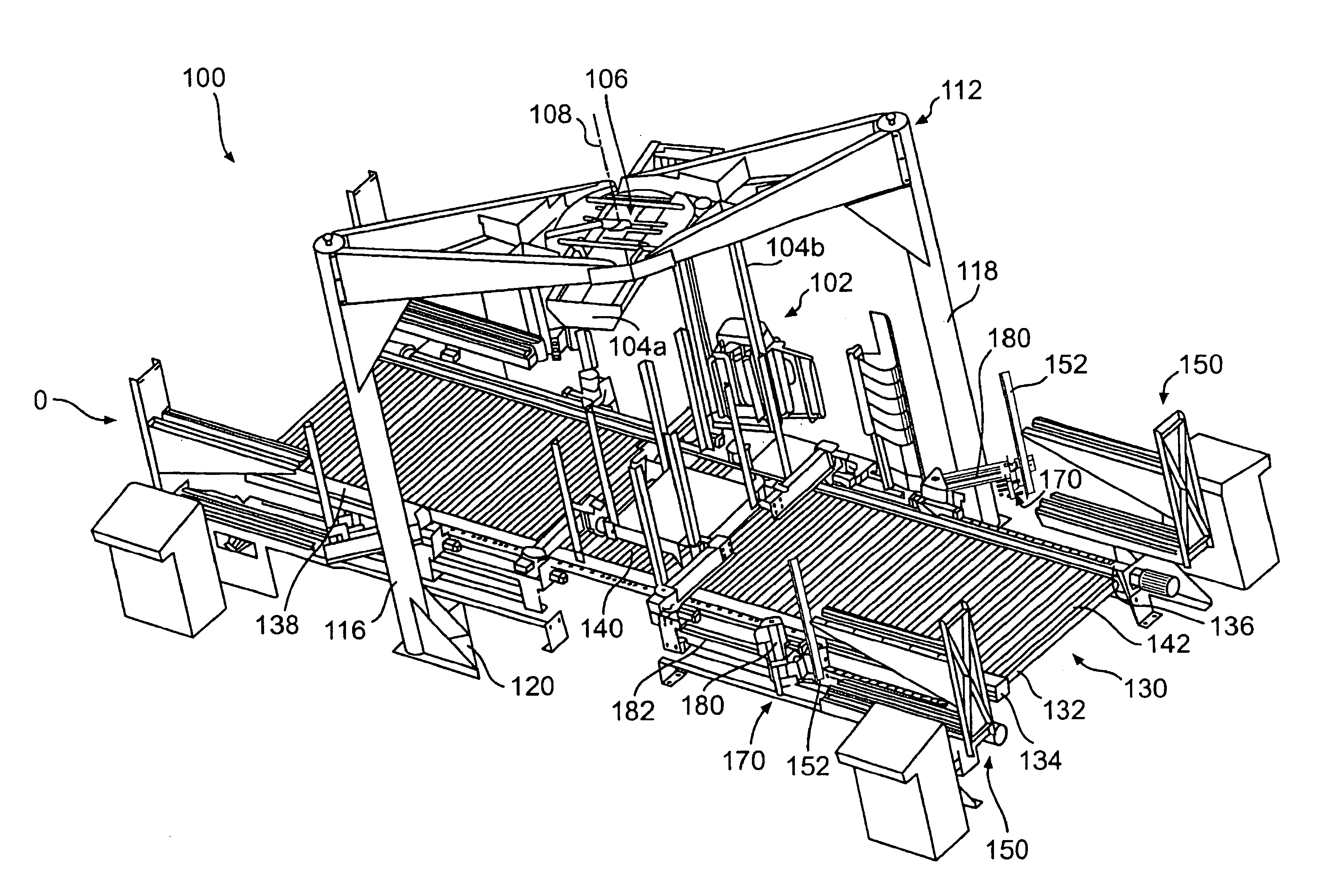

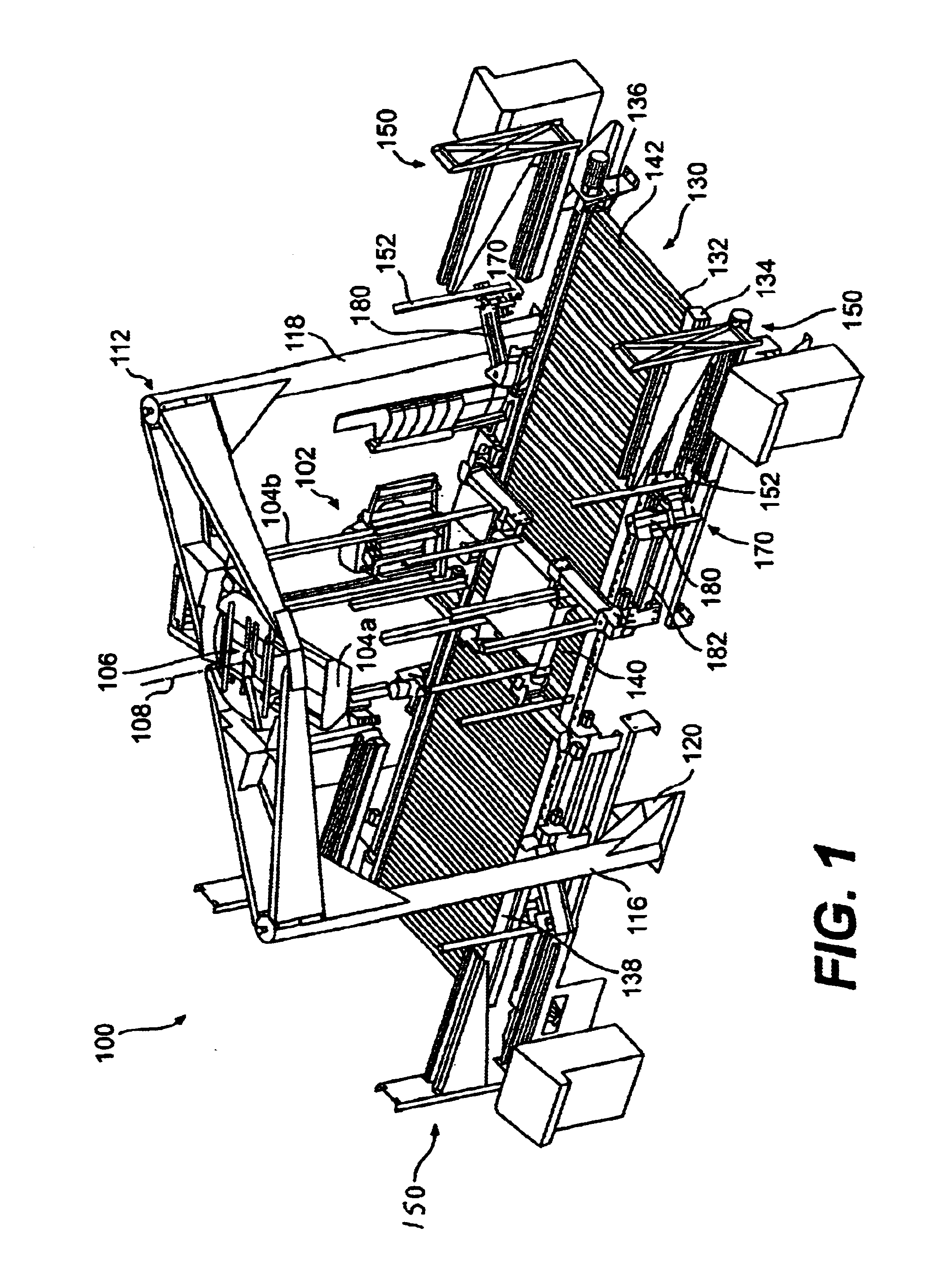

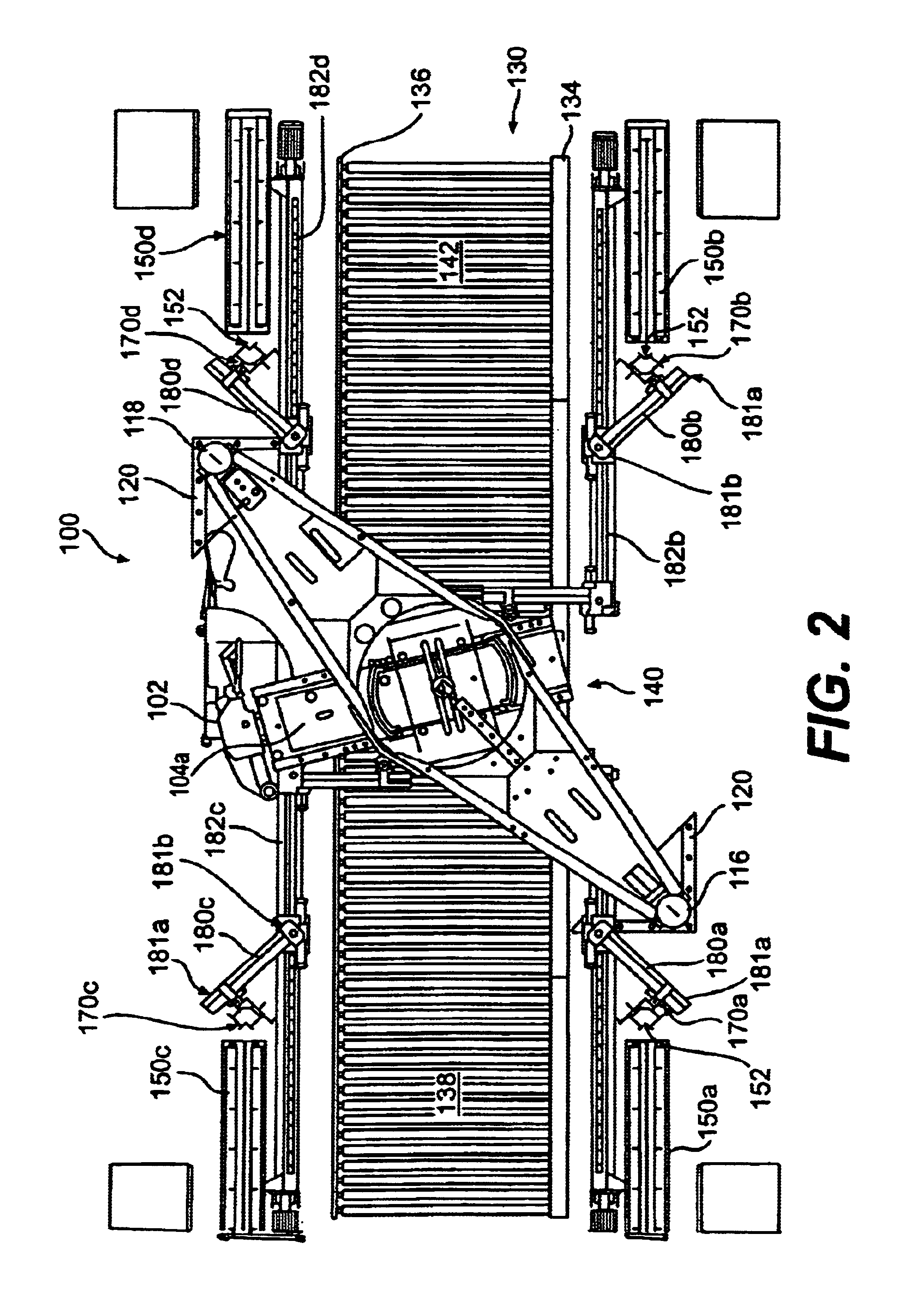

Hybrid palletizer

ActiveUS8074431B1Increase speedShorten the timeWrappers shrinkageSolid materialIndividual itemRobotic arm

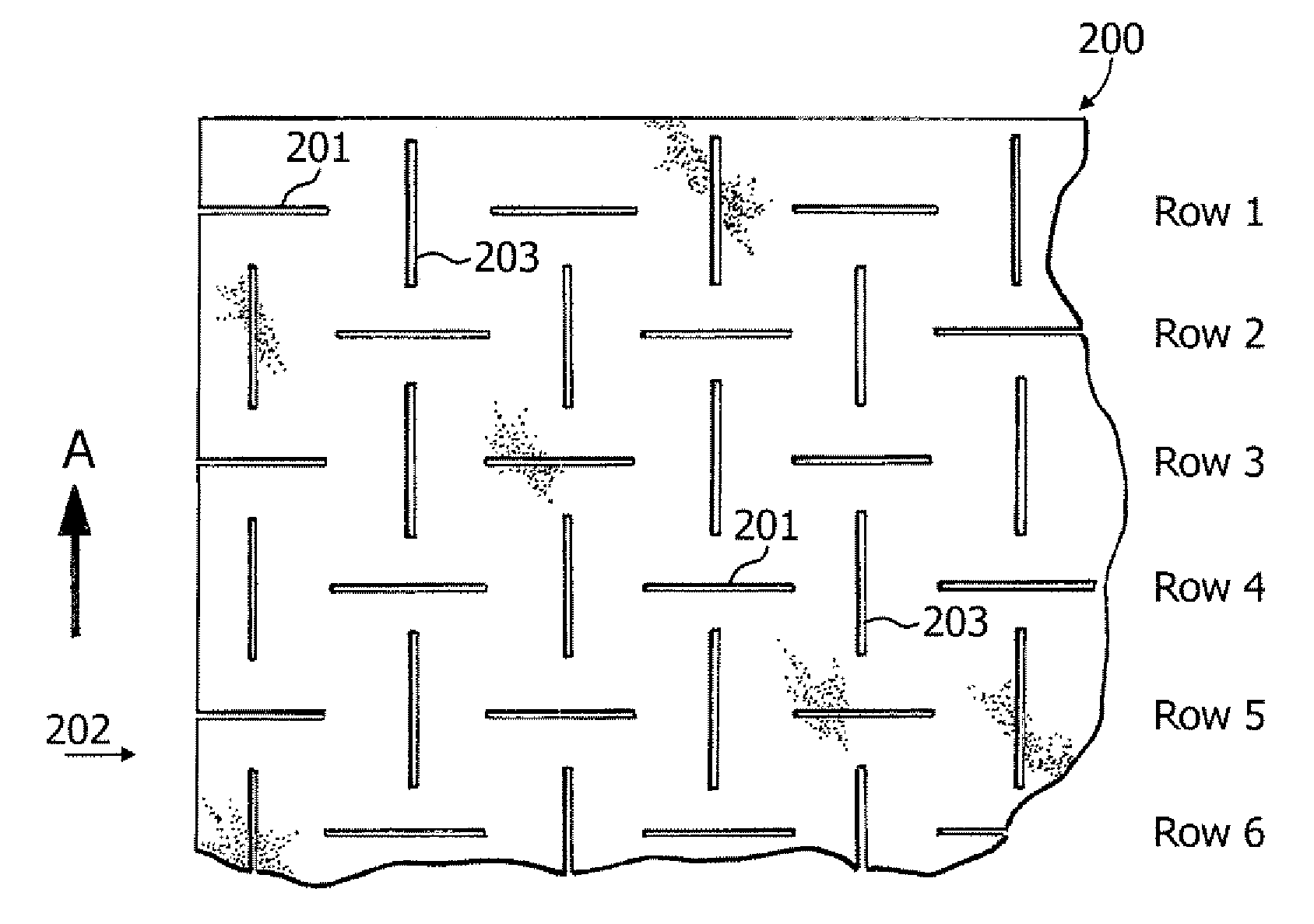

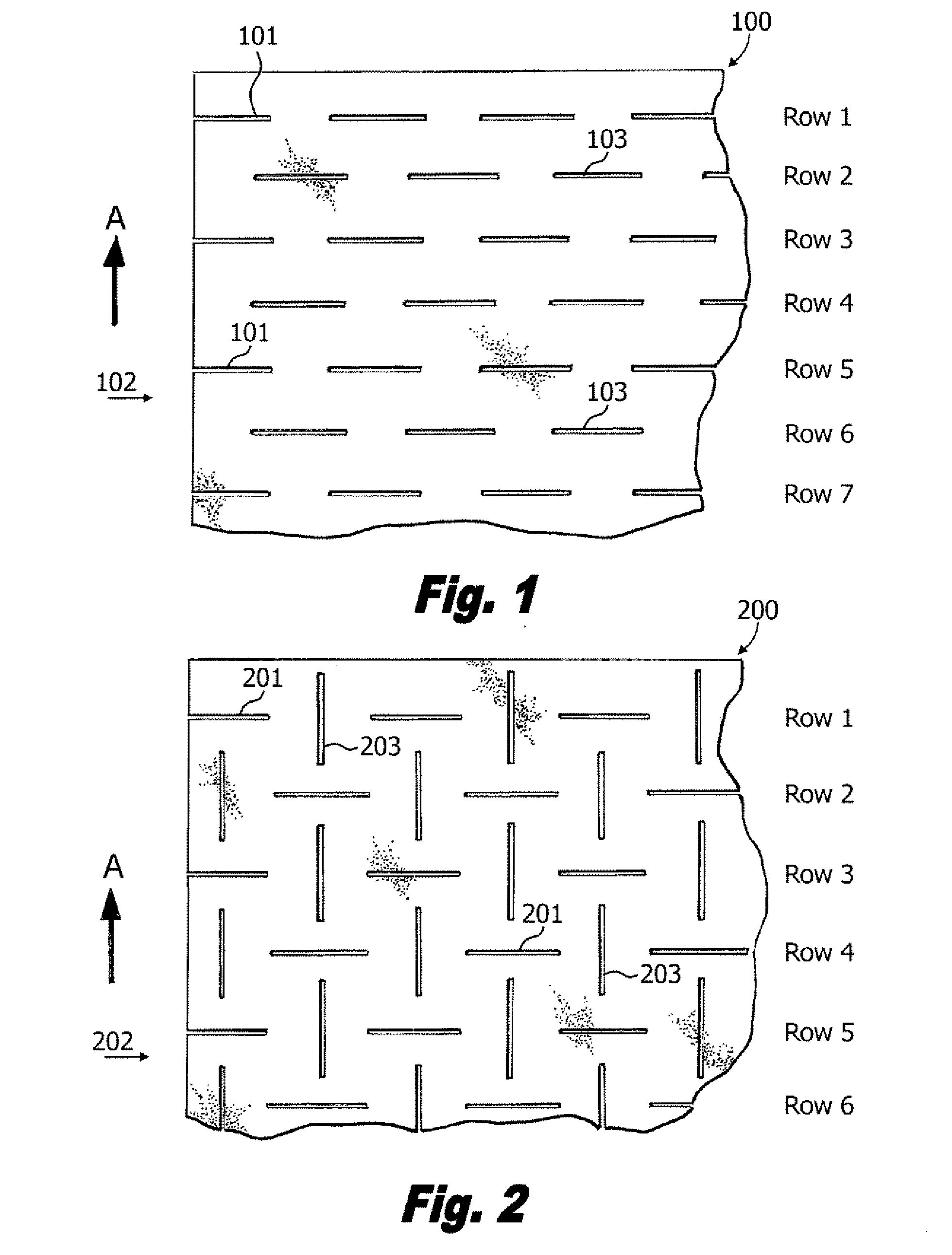

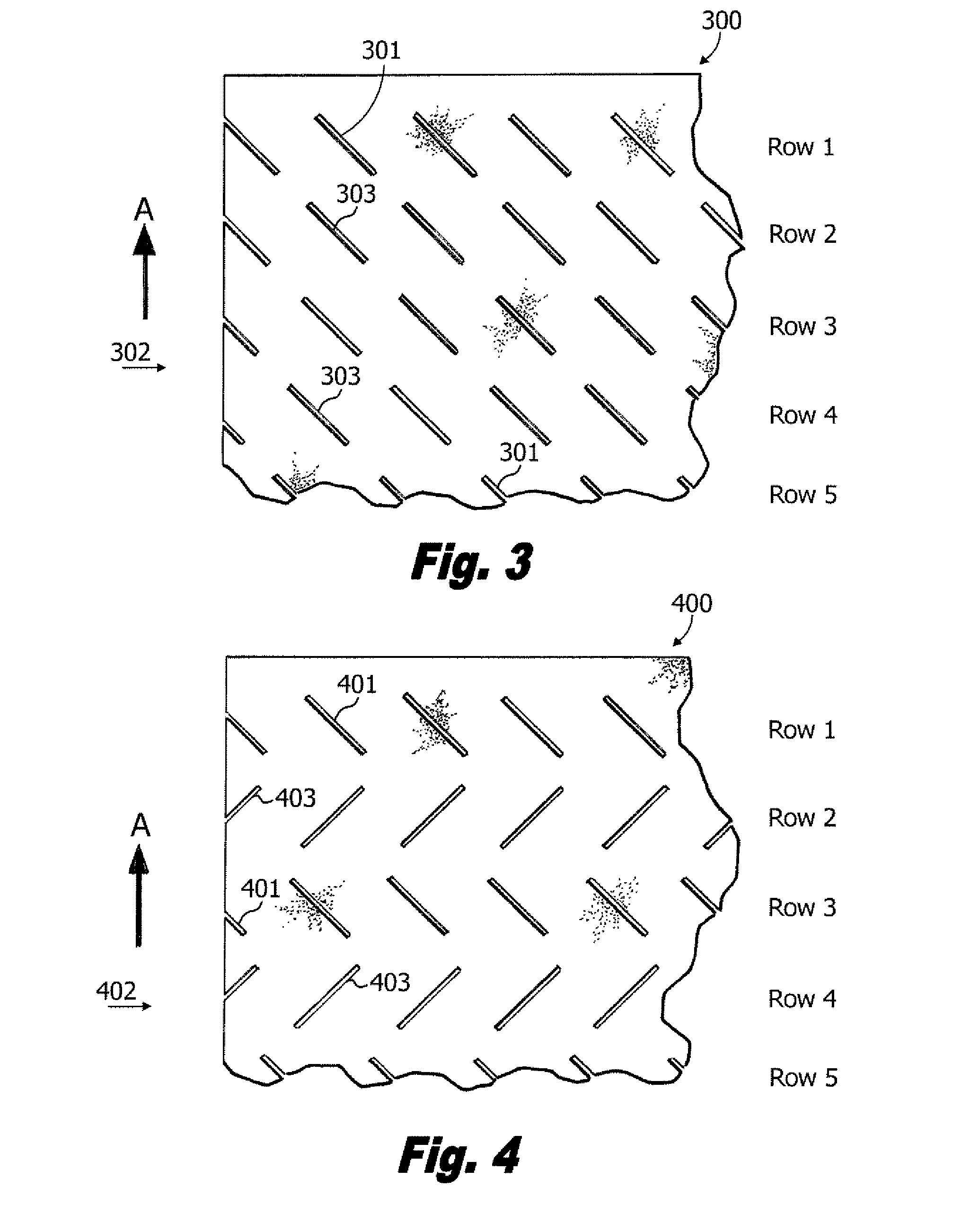

The present invention relates to compact palletizers that include a stretch-wrap operation as the pallet is built. Specifically, the present invention uses a robot to place items from a fixed infeed elevation either above or, alternatively, below the height of the finished load. A four-sided compression mechanism compresses the rough-built load to the final pallet size and then the entire layer is released to the pallet.Individual items or group of items are picked and placed onto a layer support device in a loose orientation. The loose orientation enables a much faster palletizing operation because the robotic arm that pick-and-places the item, the items, or the row of items, can travel much faster as it does not have to precisely locate the item, items, or row of items. During the time that a layer is being loosely constructed on the layer support device concurrent wrapping can occur.

Owner:TOP TIER

Stretch wrap films

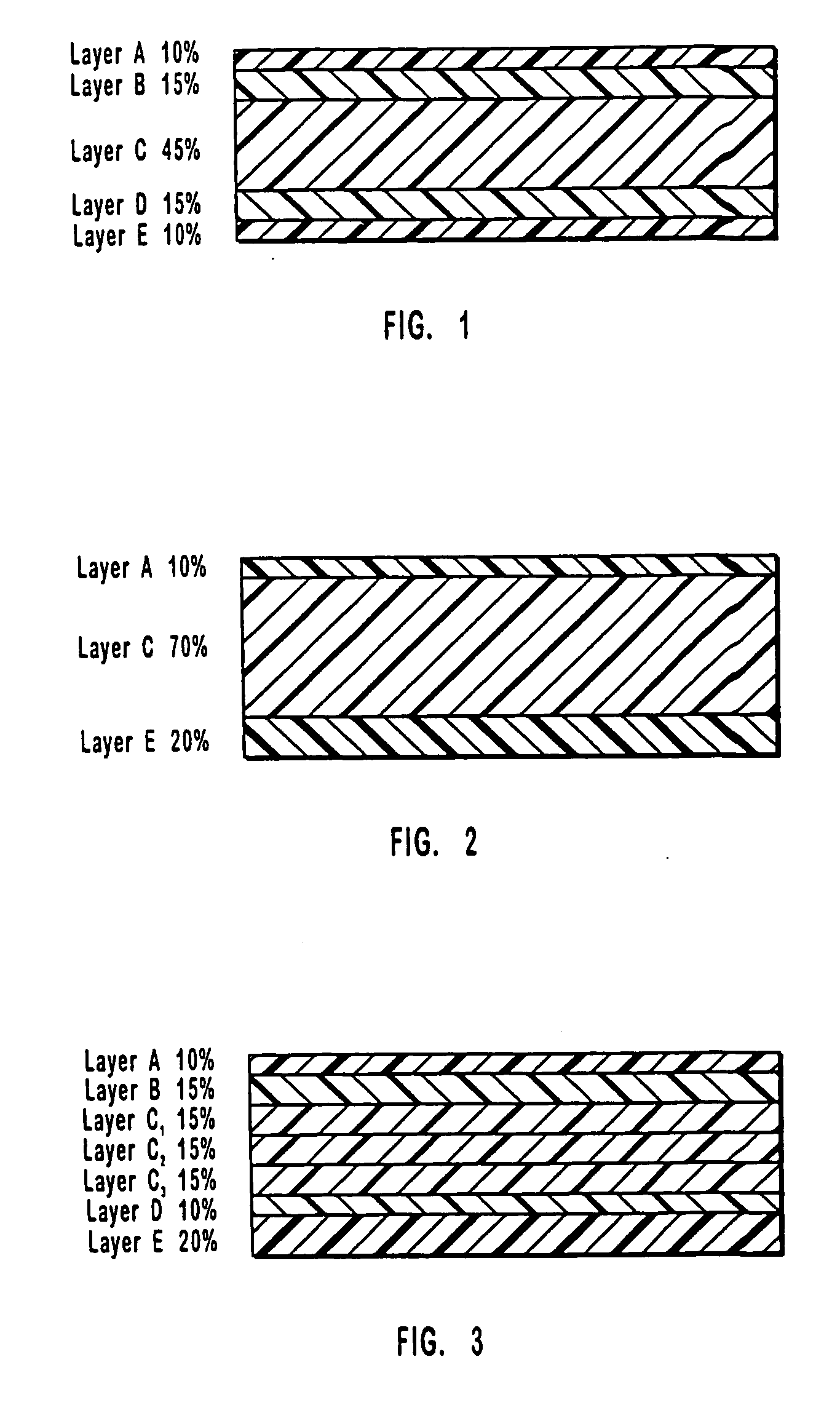

InactiveUS6093480AImprove clingImproved maximum stretchWrappers shrinkageSynthetic resin layered productsStretch wrapGram

A multilayer, thermoplastic stretch wrap film containing at least three polymeric film layers and comprised of a first layer and a second layer. The first and second layers may comprise a polymer of two or more monomers, wherein a first monomer is ethylene, in a major amount by weight, and a second monomer is an alpha olefin of from about 3 to about 12 carbon atoms, in a minor amount by weight. If the first and second layers are outer layers, they have a cling force to each other of at least about 140 grams / inch. The stretch wrap film also has at least one inner polymeric layer, located between the first and second layers. The inner polymeric layer comprises a low polydispersity polymer having a polydispersity of from about 1 to about 4, a melt index (I.sub.2) of from about 0.5 to about 10 g / 10 min., and a melt flow ratio (I.sub.20 / I.sub.2) of from about 12 to about 22. The inner layer(s) comprise(s) from about 5 wt. % to about 40 wt. % of the stretch wrap film so as to produce a film having a maximum stretch of at least 340%, a F-50 dart drop value of at least about 130 g / mil, a machine directional tear resistance of at least about 125 g / mil and a transverse directional tear resistance of at least about 500 g / mil. It is contemplated that additional outer layers may be added such an outer high cling layer or an outer slip layer, as well as additional inner layers.

Owner:BERRY PLASTICS CORP

Peel and stick stretch wrap

Owner:BMIC LLC

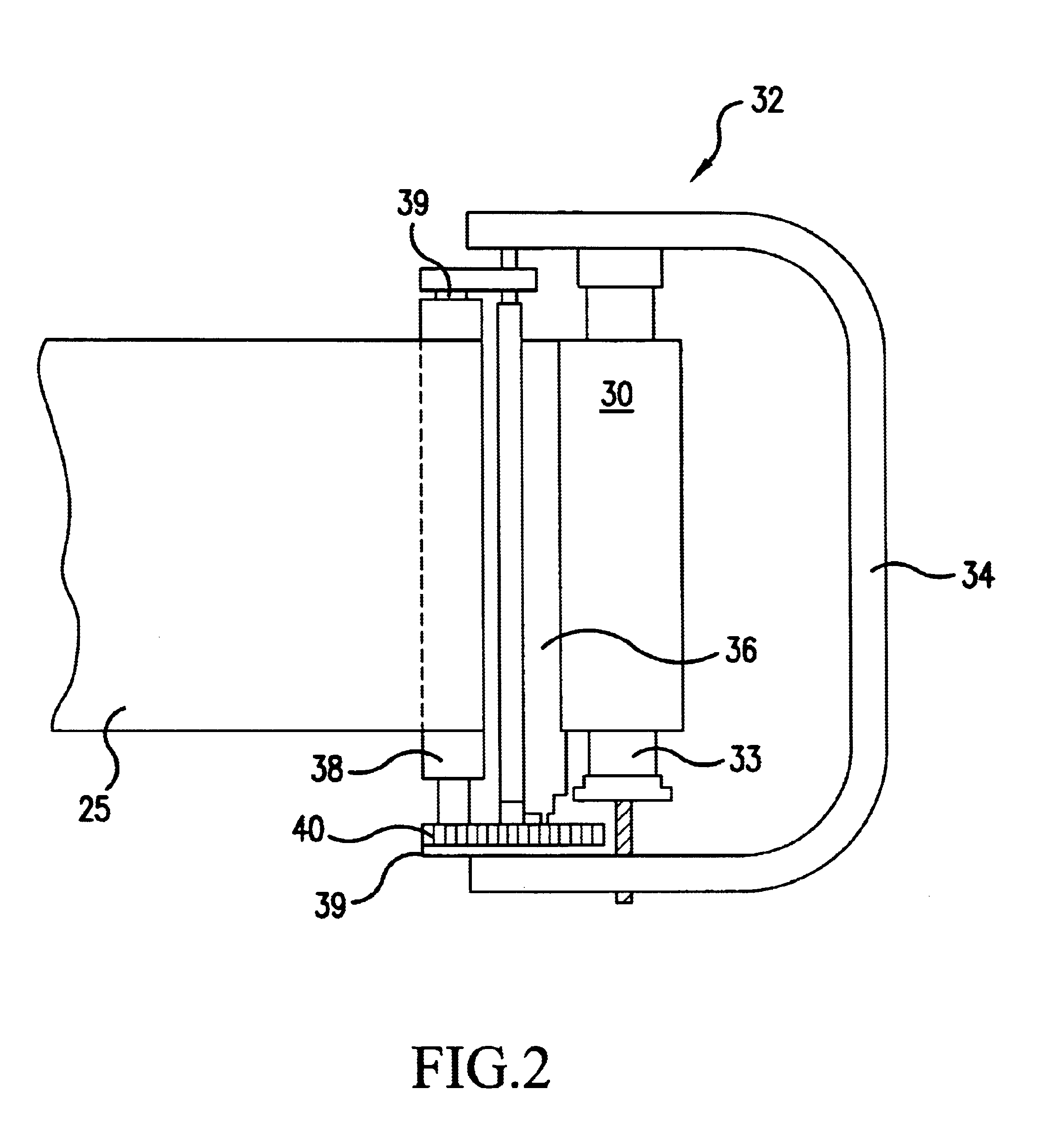

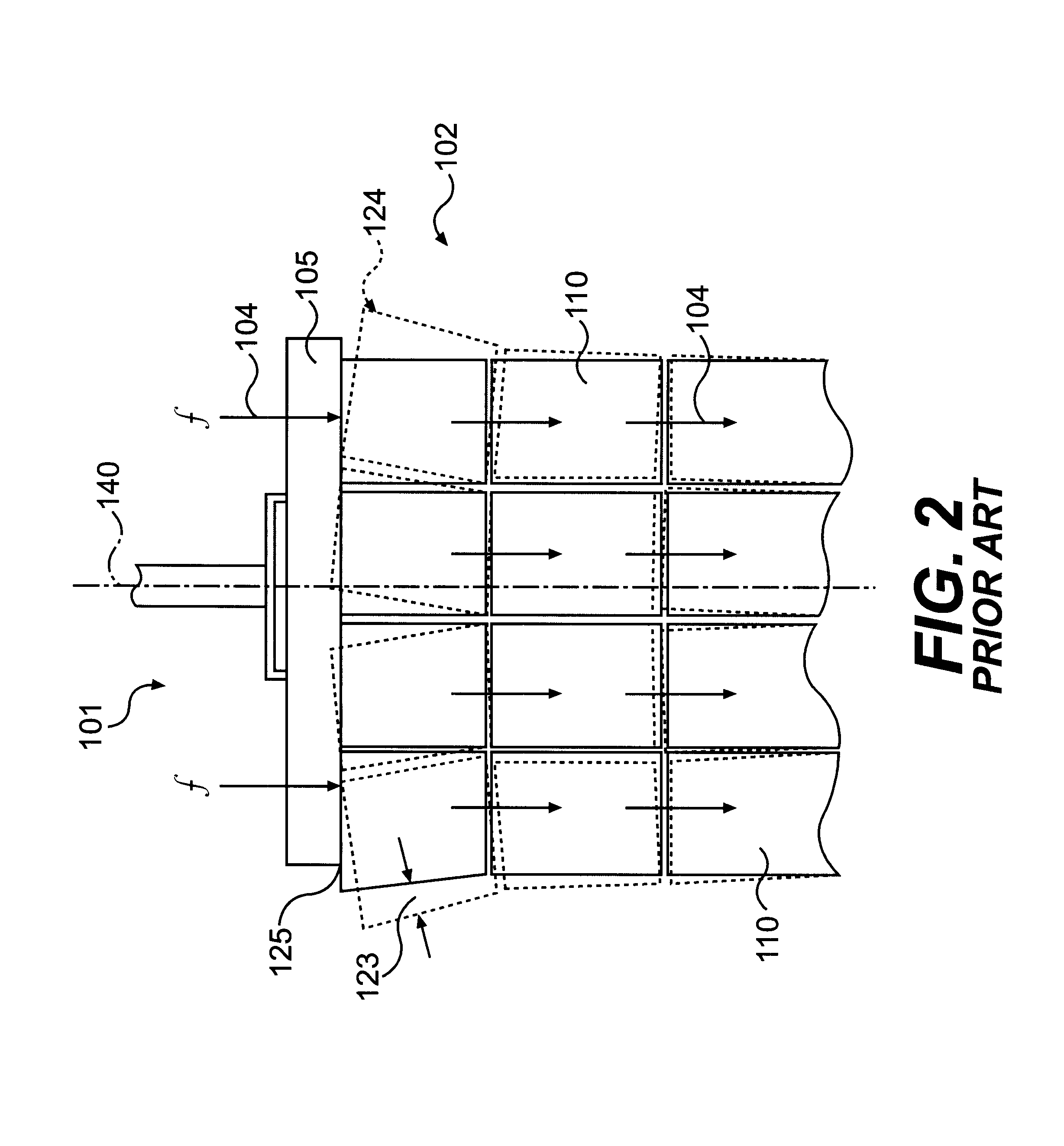

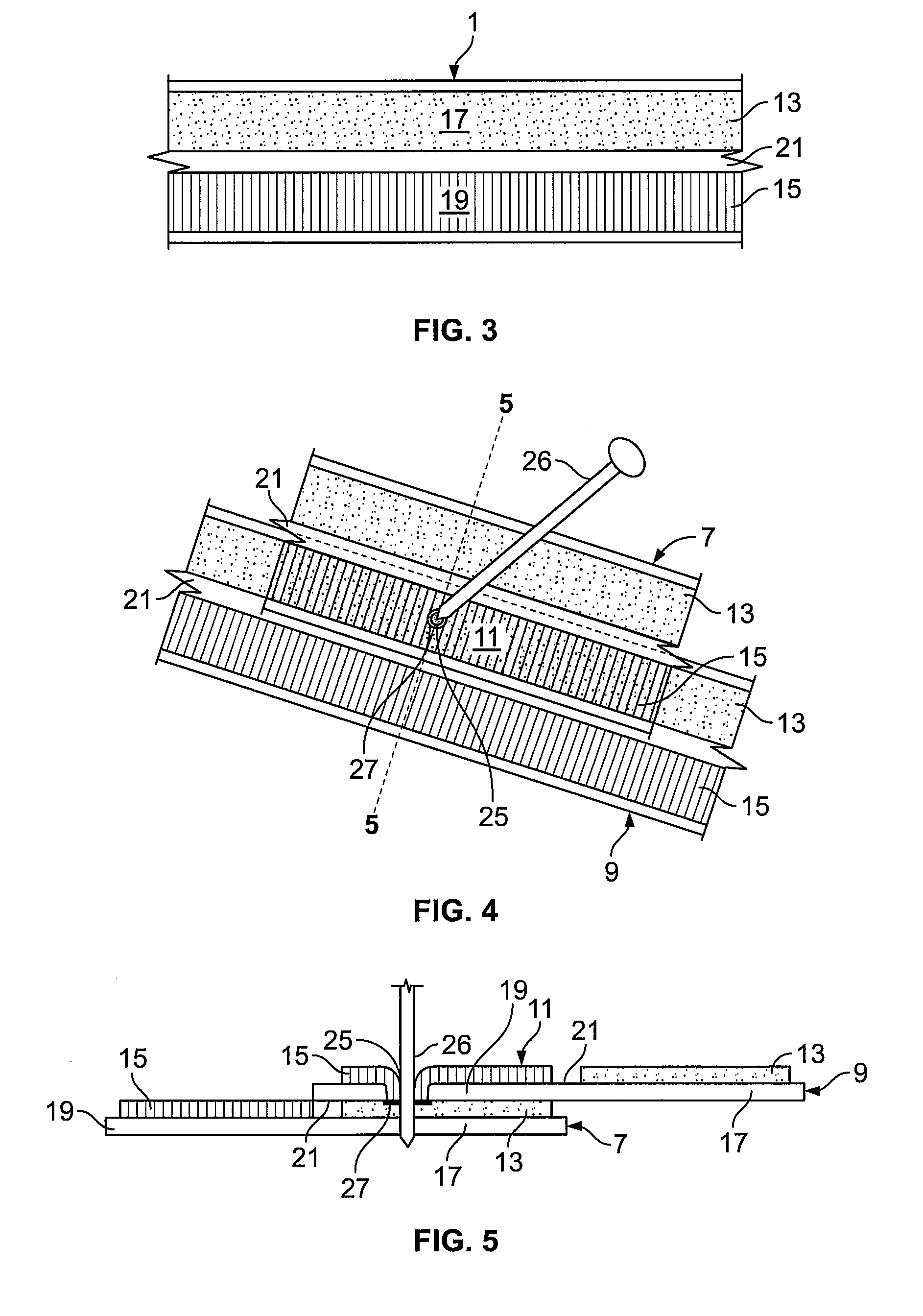

Method and apparatus for wrapping a load

InactiveUS6918229B2Eliminate the problemWrappers shrinkageWrapping material feeding apparatusStretch wrapEngineering

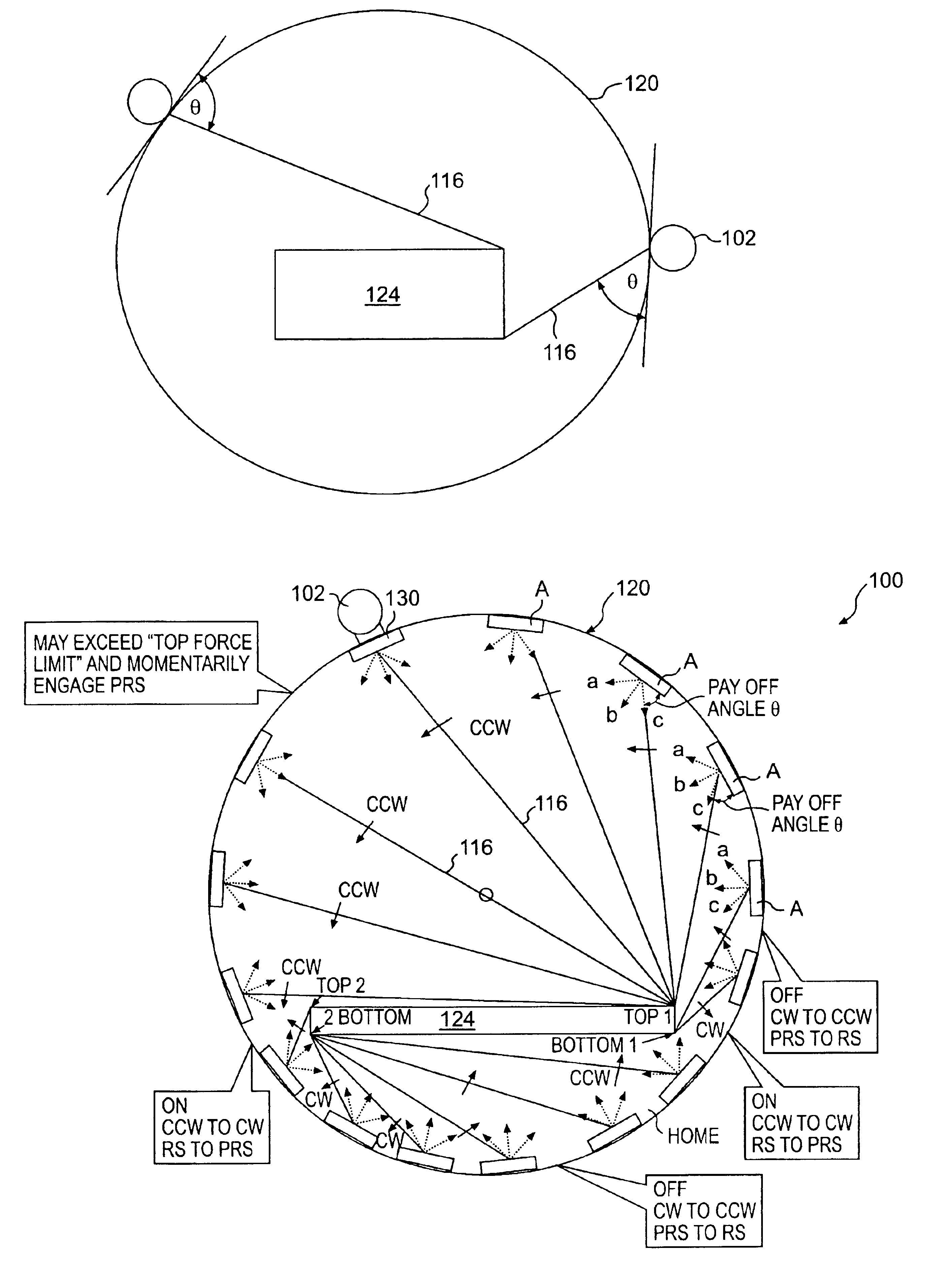

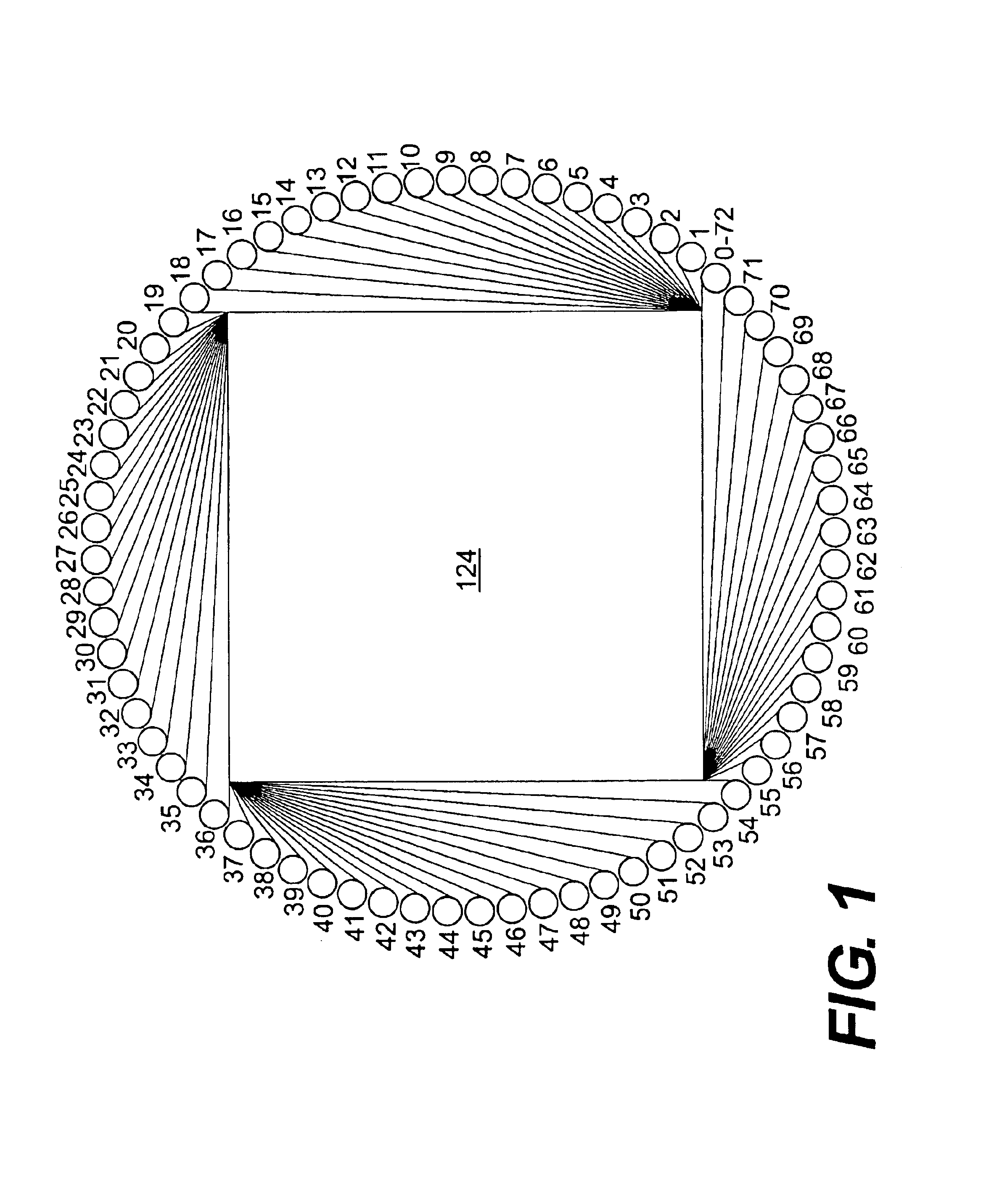

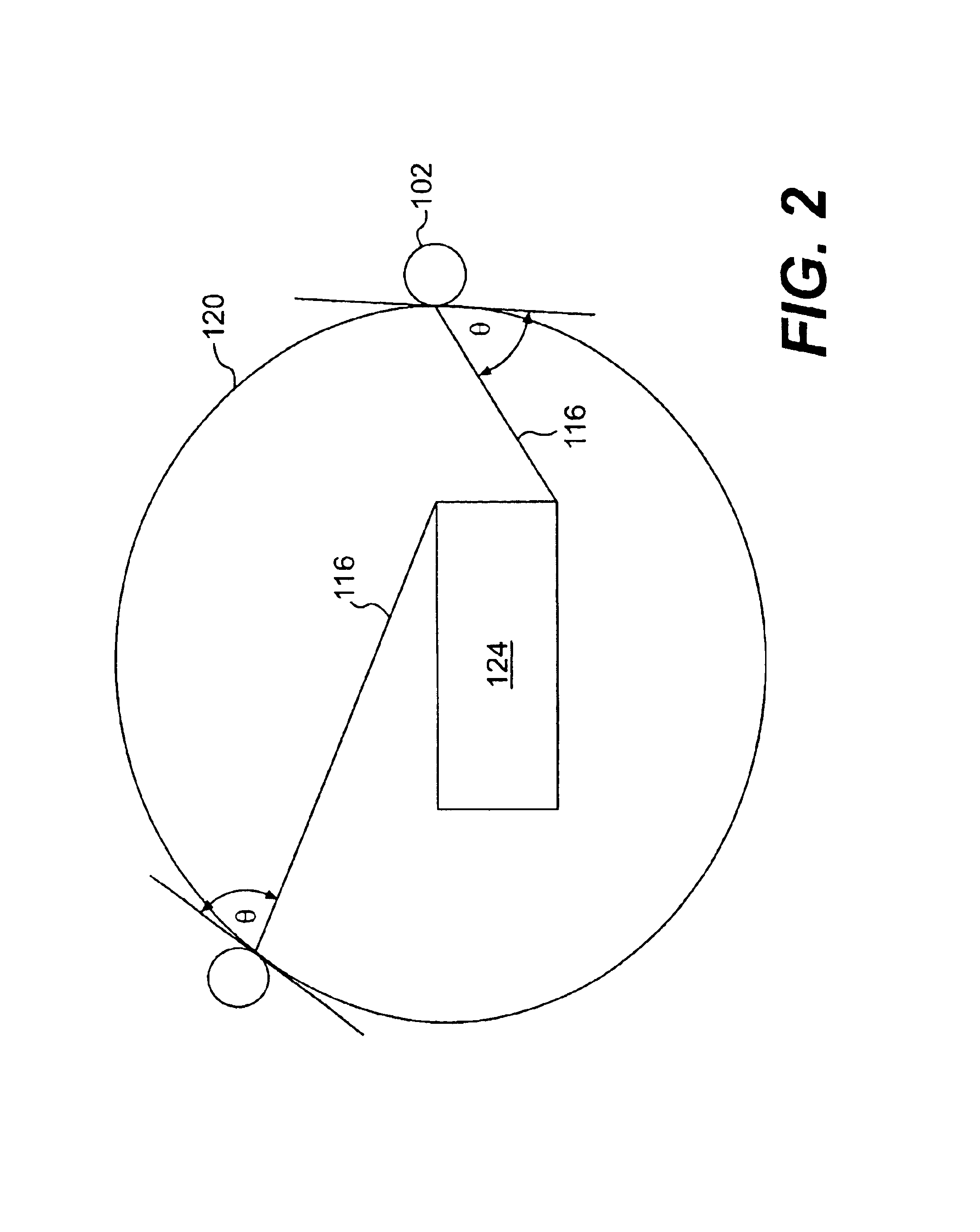

The present invention relates to an apparatus and method for stretch wrapping a load in an efficient manner so as to tightly and securely wrap the load at a desired tension without rupturing the packaging material. The method and apparatus compensate for variation in demand rate as the load is wrapped so as to apply the wrapping material to a load at a desired force, maintain the desired containment tension on the wrapping material on the load after wrapping, and prevent the wrapping material from rupturing during wrapping. The apparatus combines two systems, power assisted roller stretch (“PRS”) and roller stretch (“RS”) to vary the supply rate of the packaging material as the demand rate varies. The apparatus automatically switches between the two types of prestretch to achieve “high” and “low” wrapping force dependent upon the demand rate. Changes in the demand rate are sensed by monitoring changes in the payoff angle of the packaging material extending between the dispenser and the load.

Owner:LANTECH COM

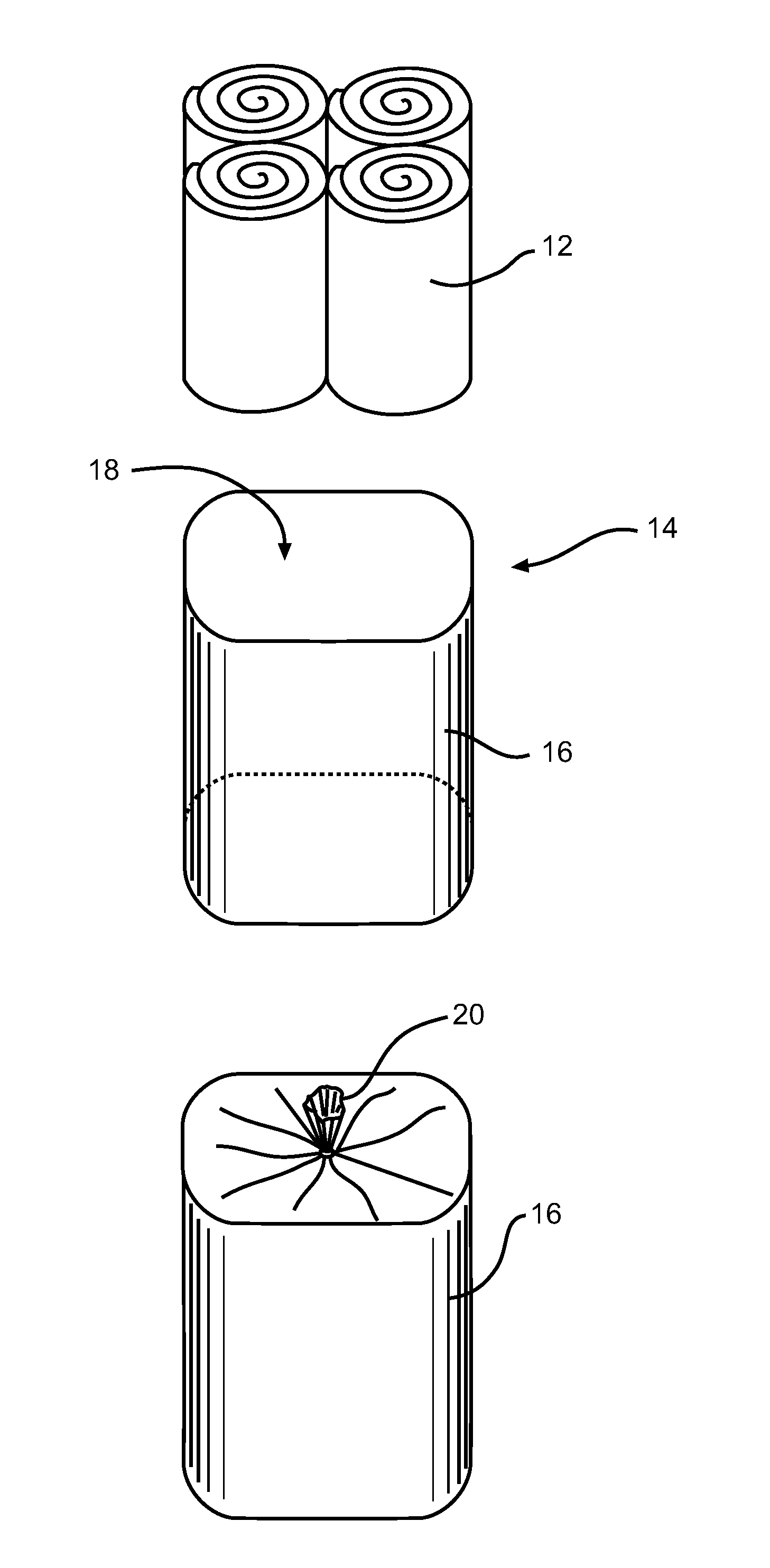

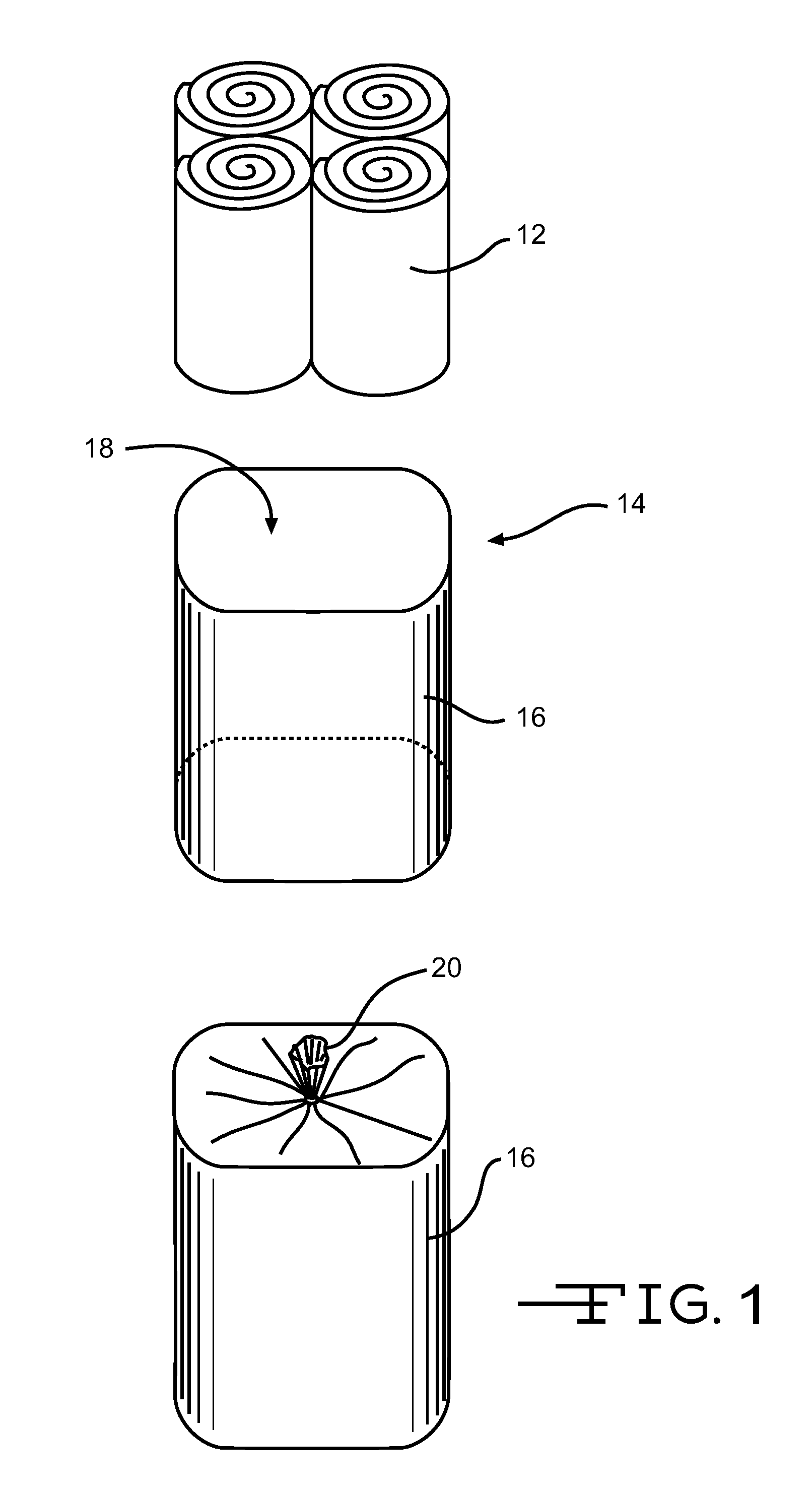

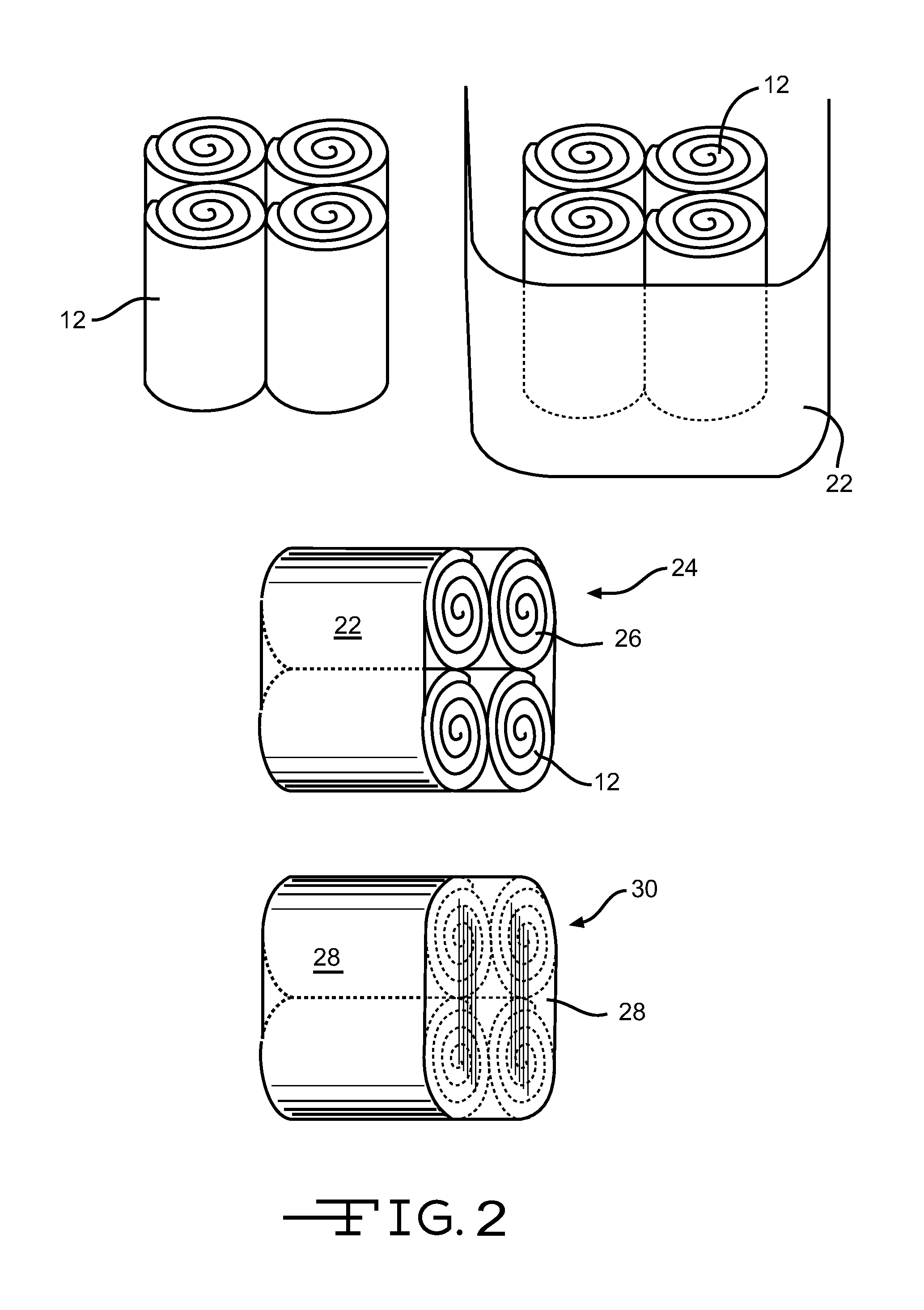

Packaging to improve shelflife of insulation products

InactiveUS20130067861A1Minimize degradationMinimizing recovery degradationContainers for flexible articlesWrappers shrinkageFiberAdditive ingredient

Fibrous insulation products have a binder composition that may include a carbohydrate and a crosslinking agent, and potentially other optional ingredients. The shelf life and physical properties of fibrous insulation products, particularly those having bio-based binders, can be improved by packaging that completely envelopes and seals the fibrous product from exposure to atmospheric conditions. Exemplary envelopes disclosed include sealed bags, double stretch wrap and stretch hoods. Properties that can be improved include recovery of loft, restoring force and tensile strength among others.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

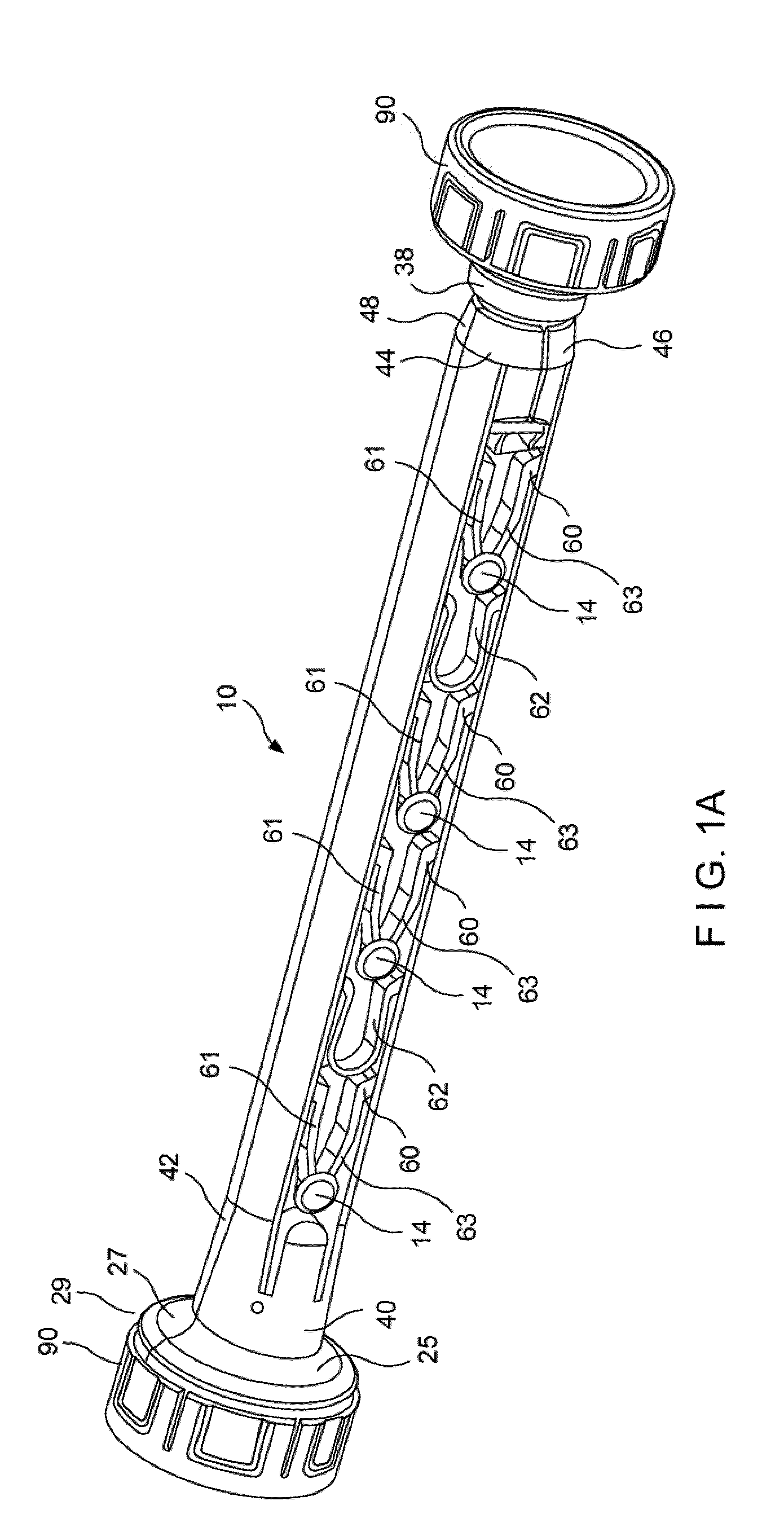

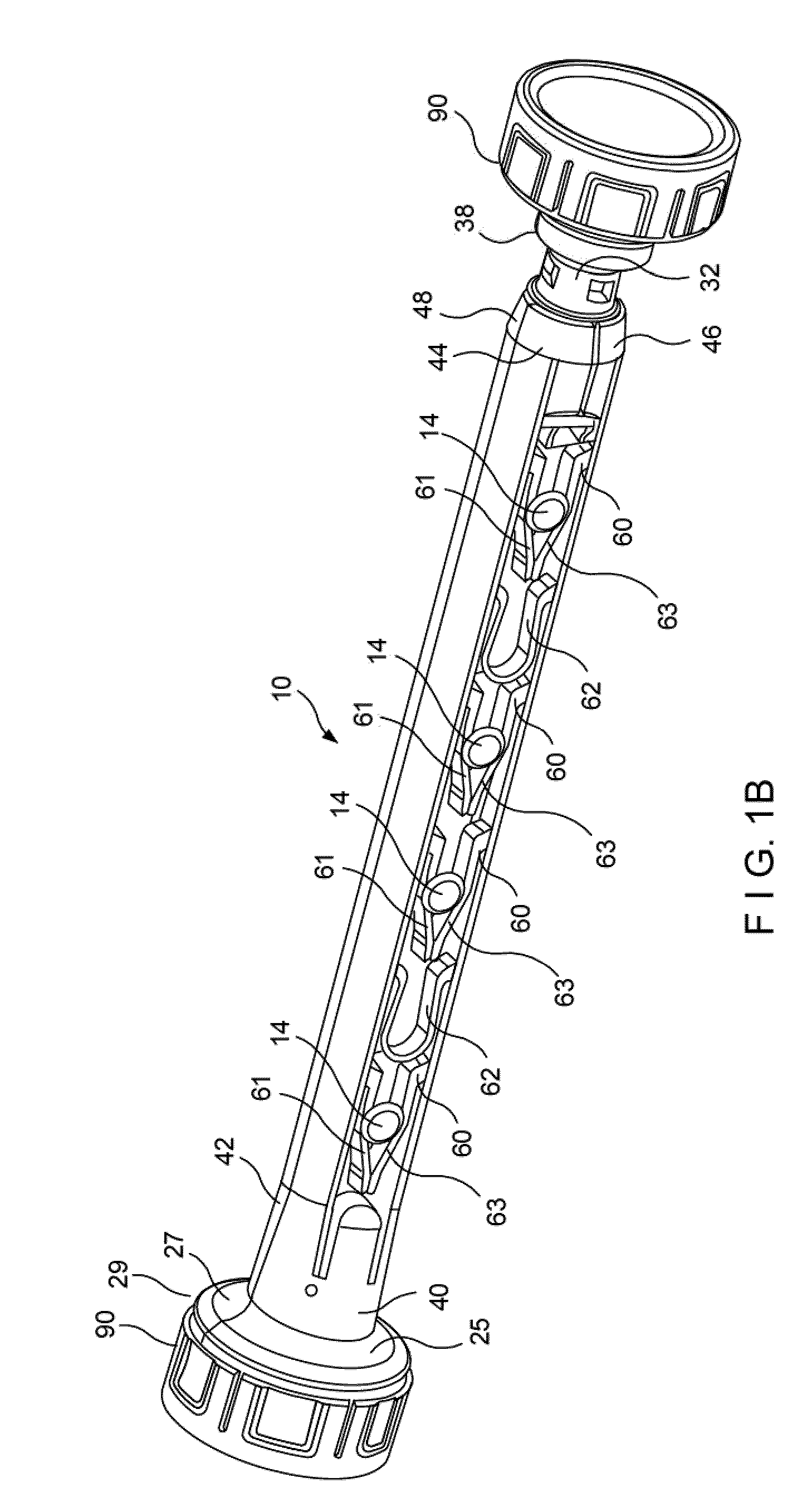

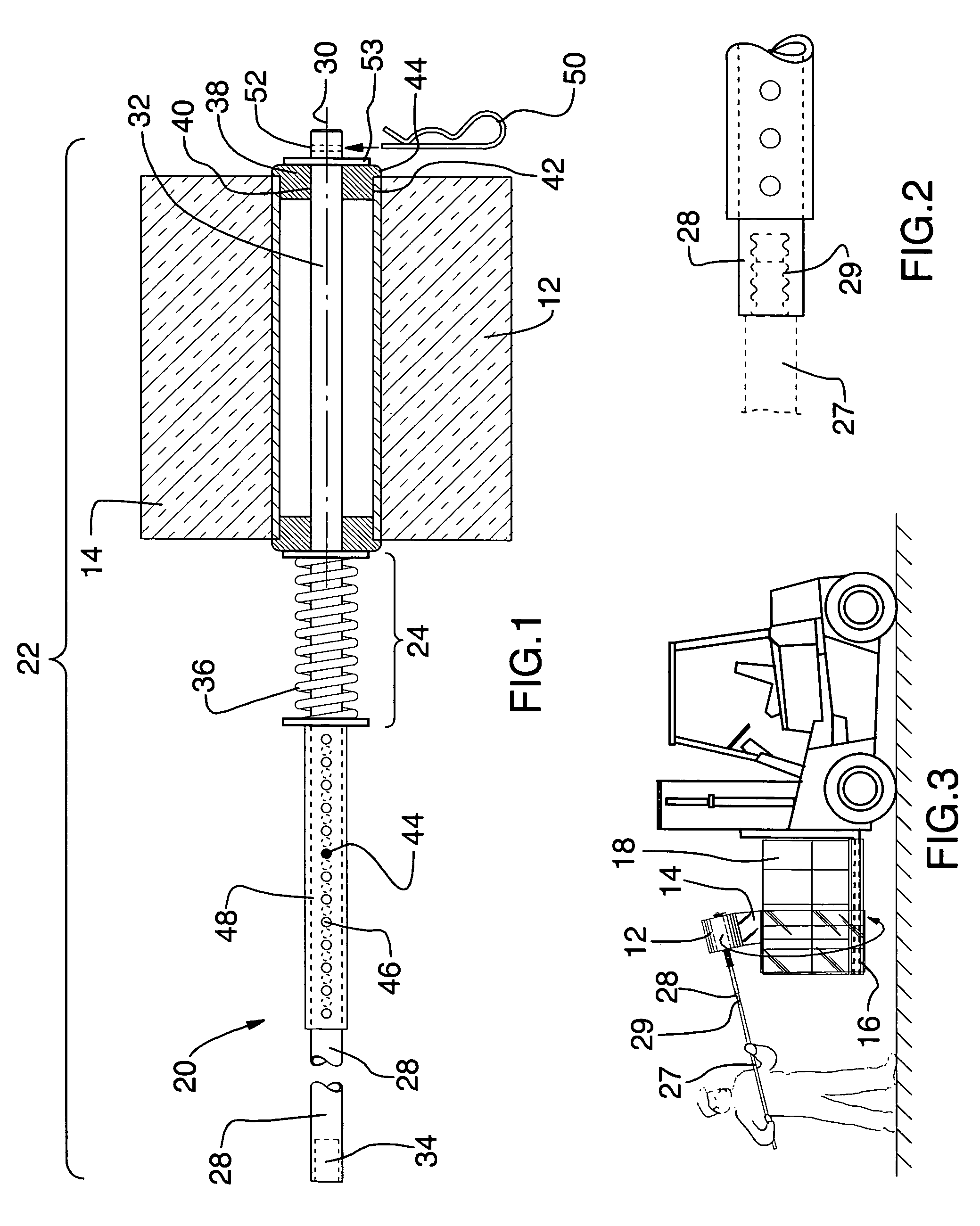

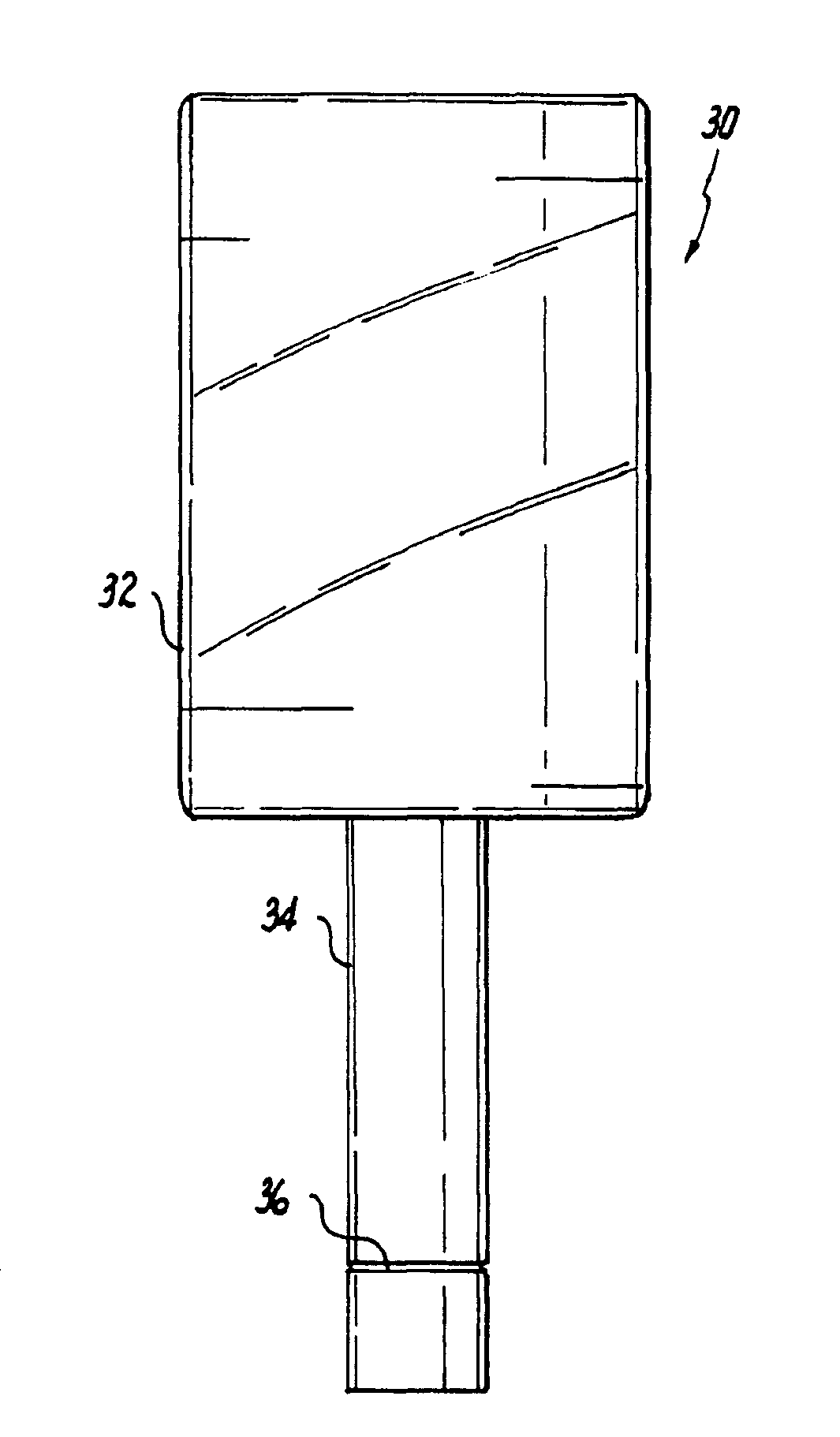

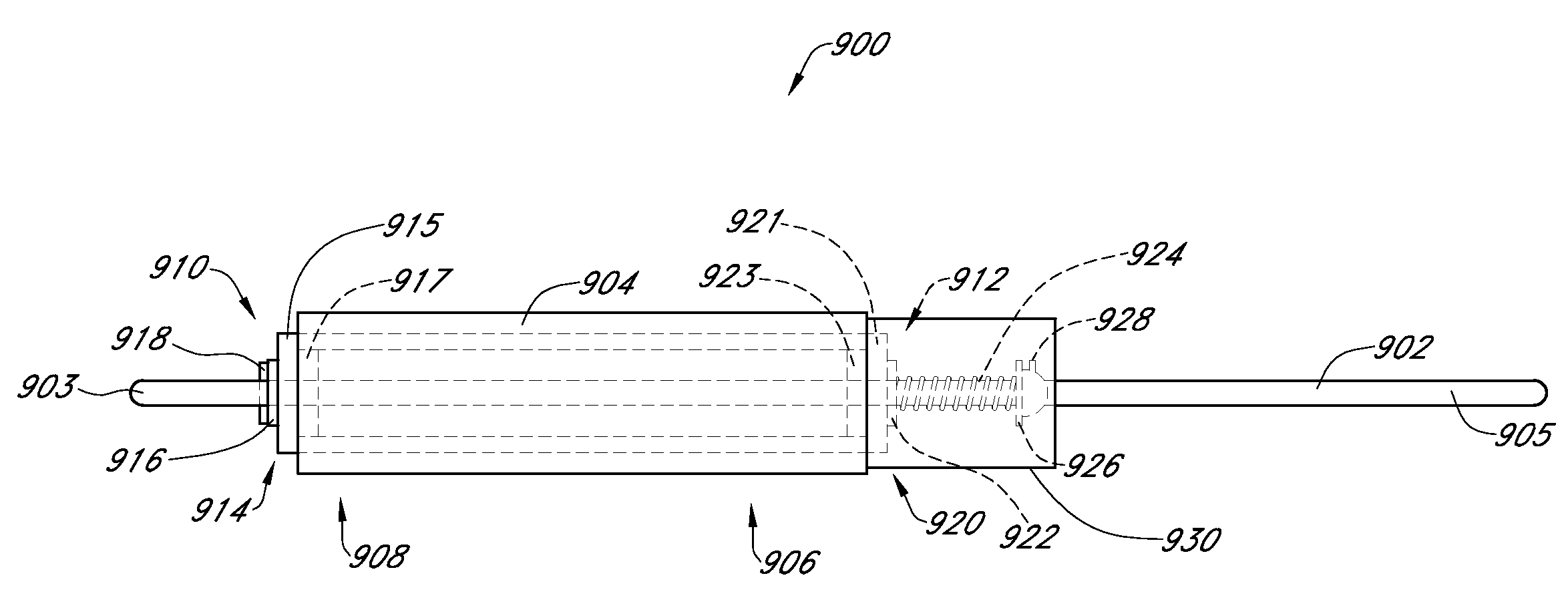

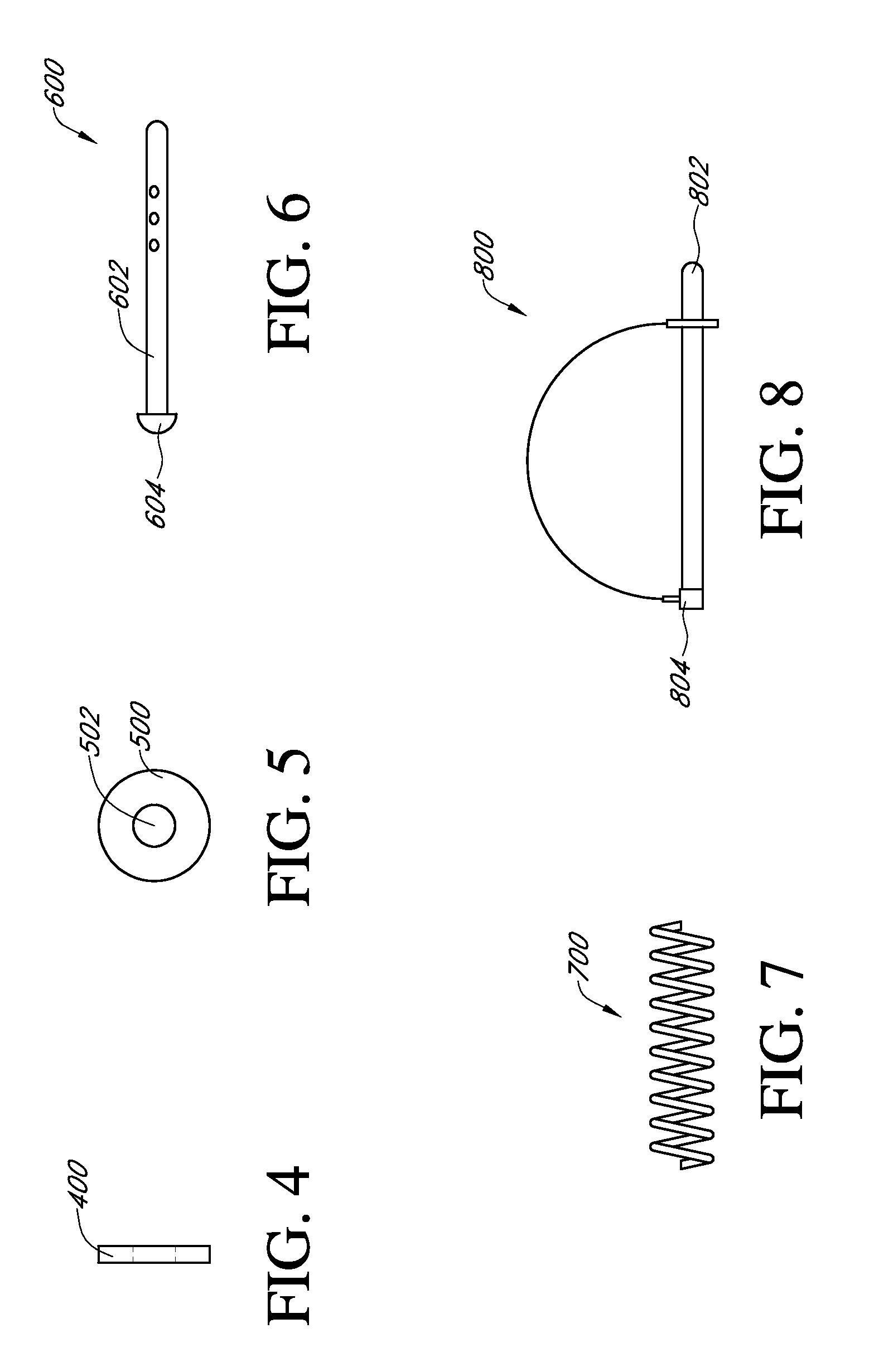

Push-to-expand mandrel for stretch-wrap hand tool

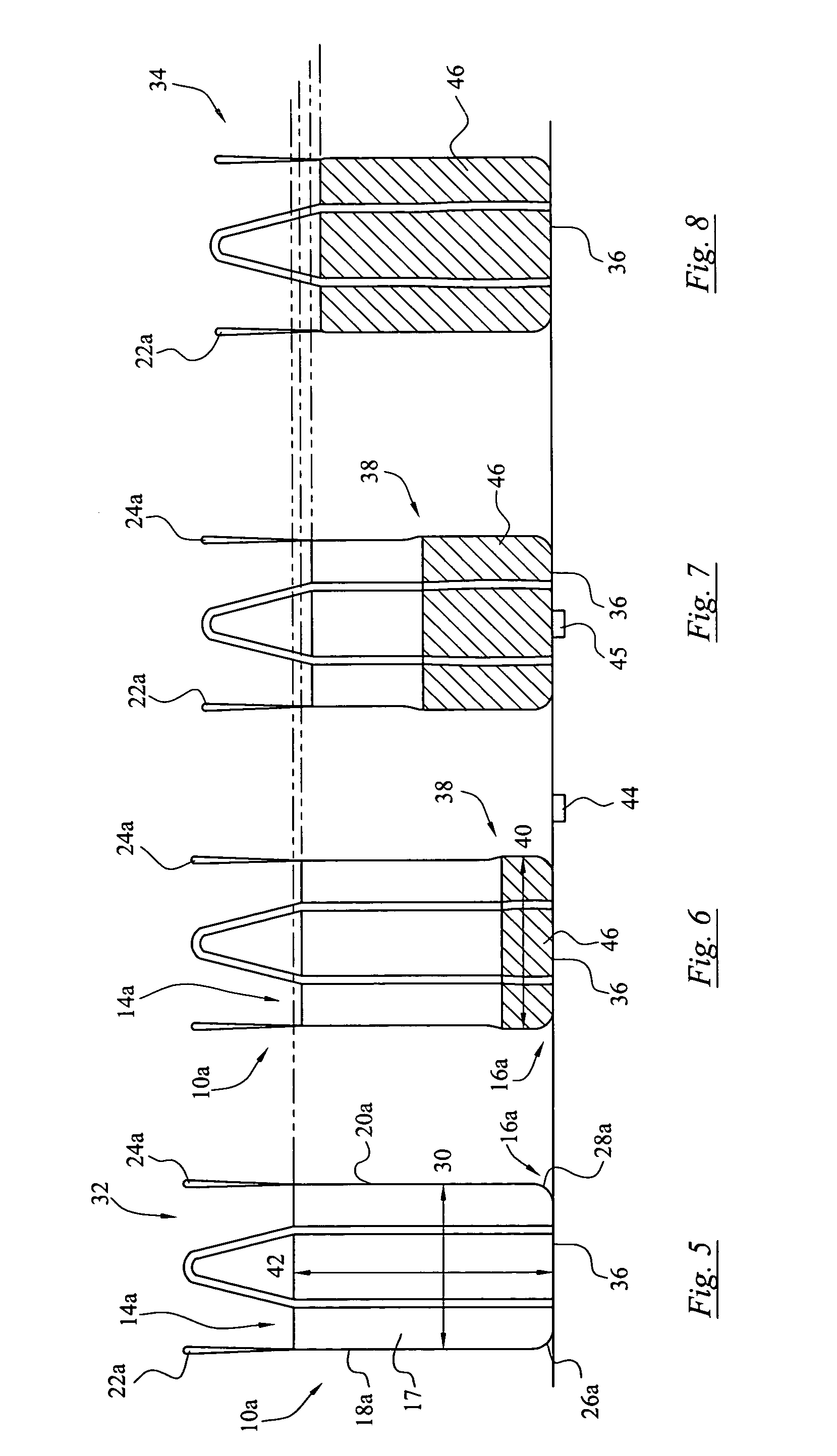

The present disclosure relates to a dispenser for use with rolls of film material, particularly coreless rolls. The mandrels of the dispenser can move between a retracted position wherein the dispenser has a reduced diameter, such as for when the dispenser is being inserted into a roll of film, and an increased diameter, such as for when the film is being dispensed from the dispenser. The mandrels have sections which are joined by various spring configurations and are formed as being axially slidable with respect to a central shaft with lug elements. As the mandrel is slid along the central shaft, the lug elements deflect the spring configurations outwardly so as move the mandrels radially outwardly and increase the radius of the dispenser.

Owner:ILLINOIS TOOL WORKS INC

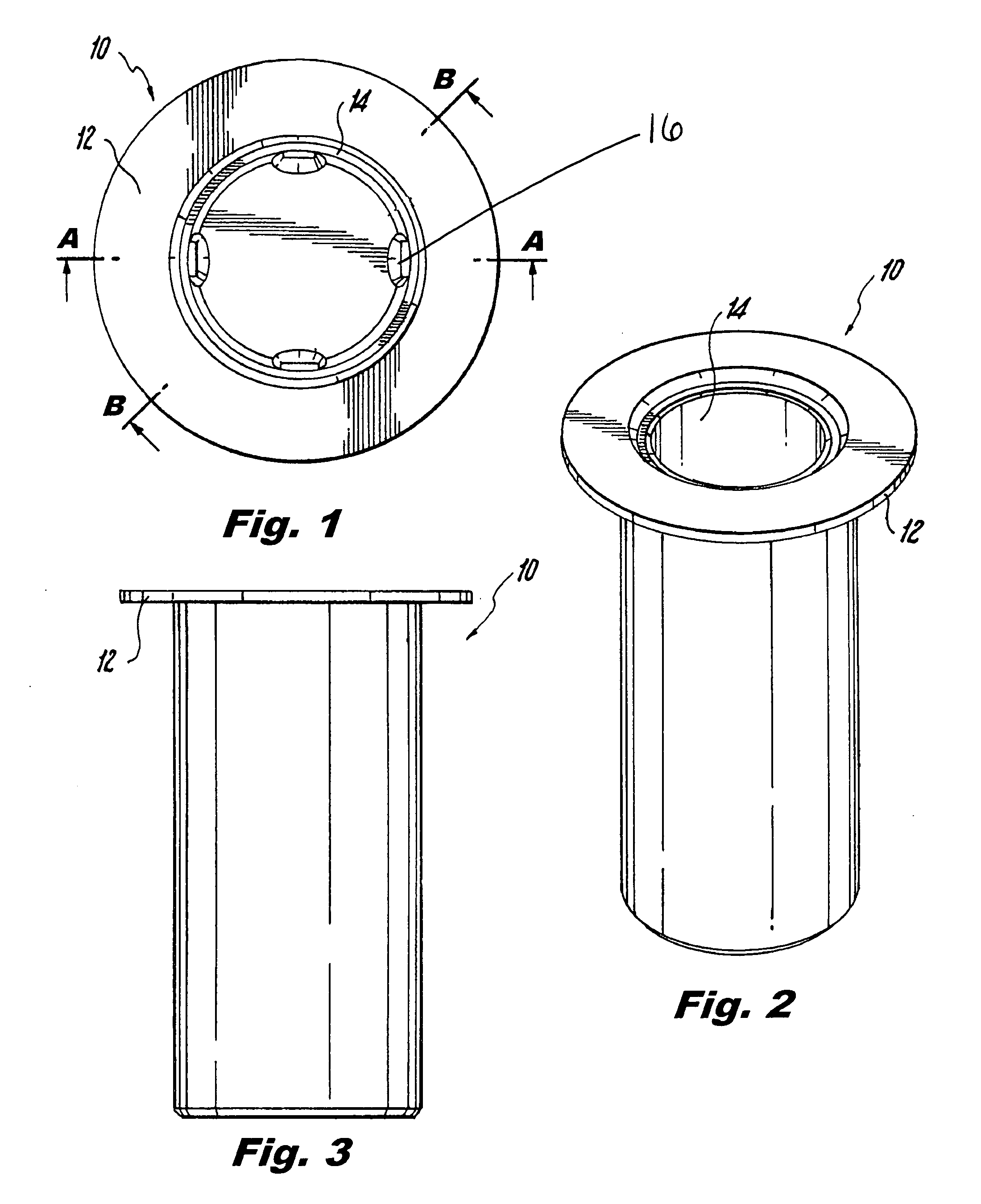

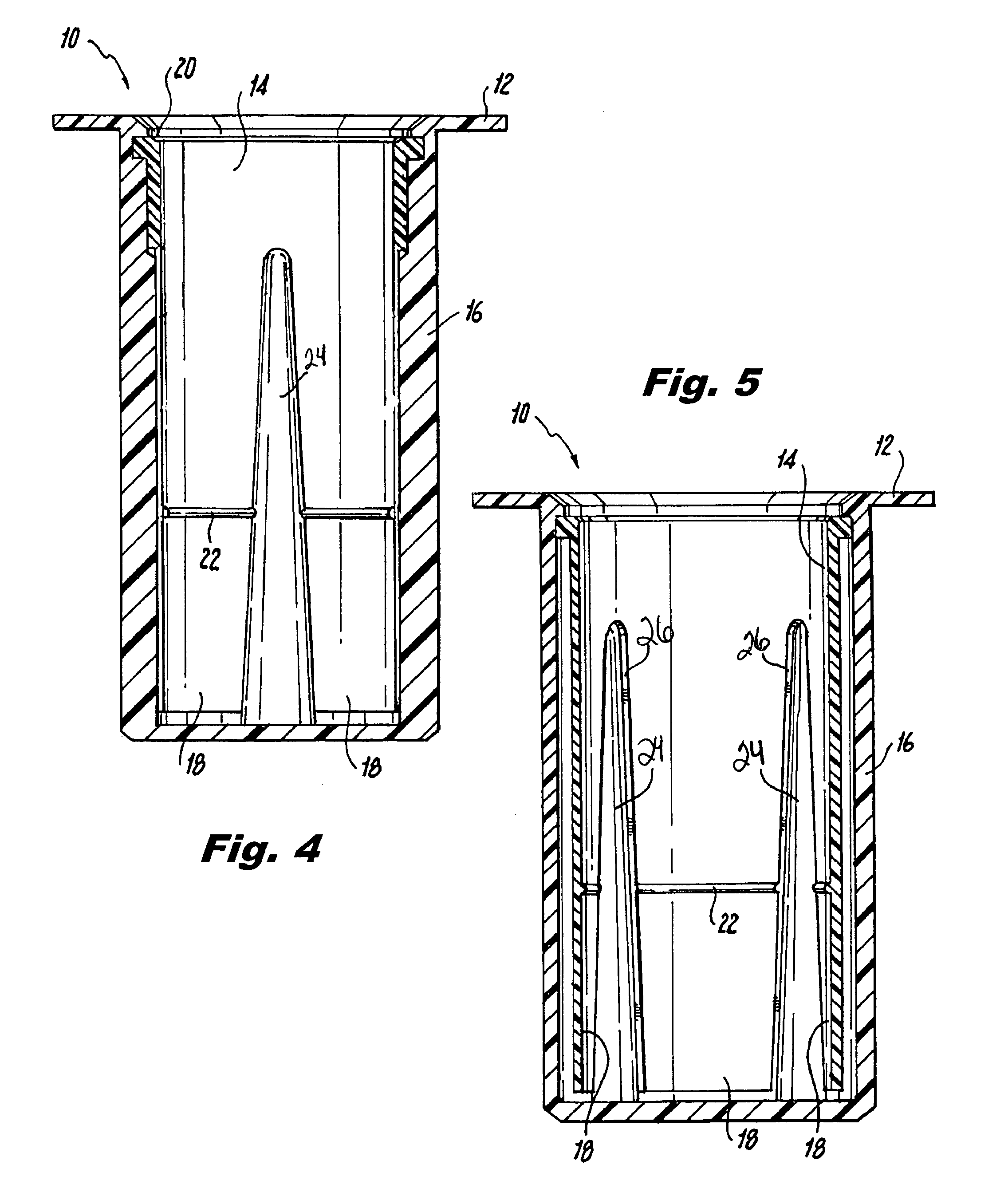

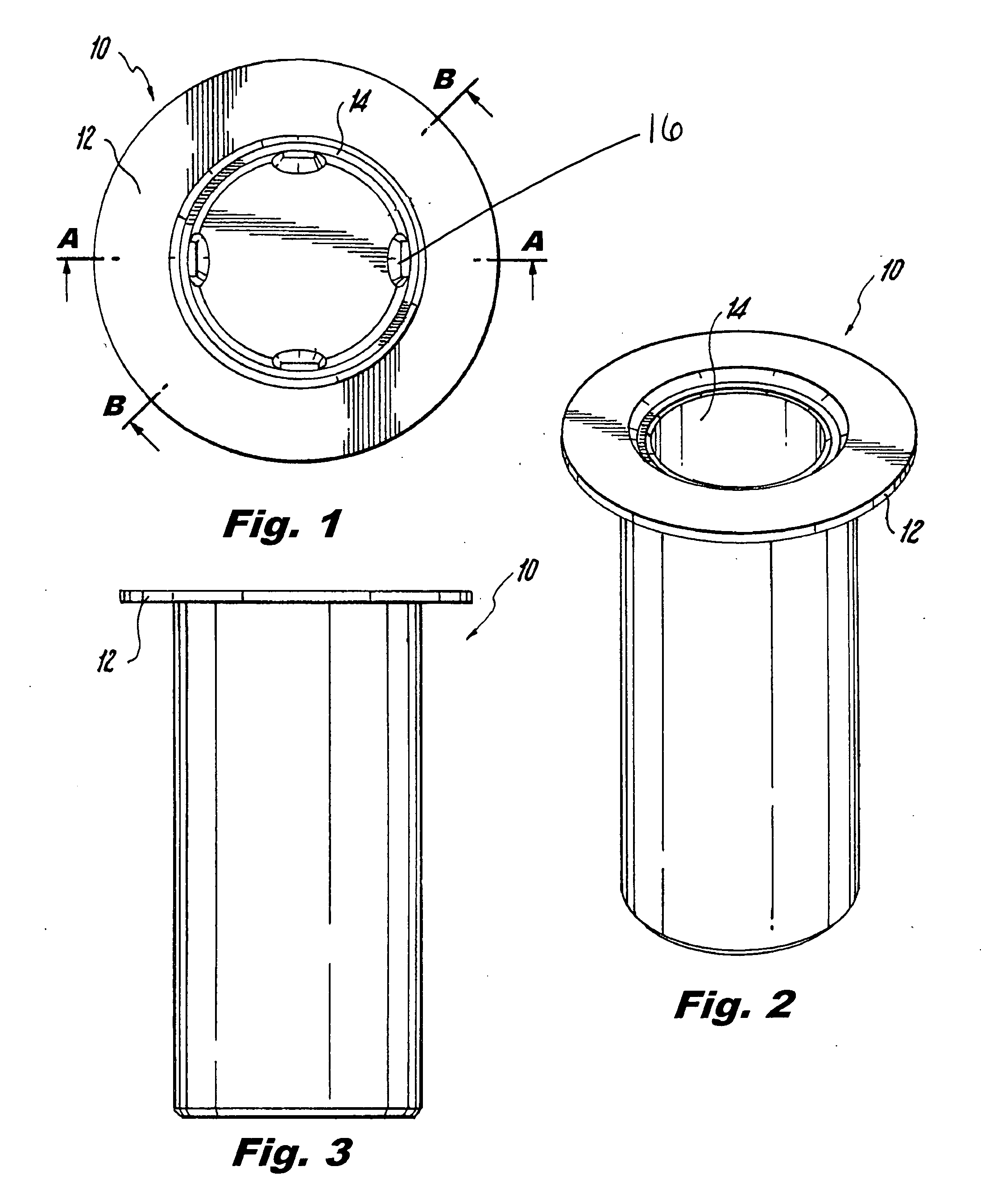

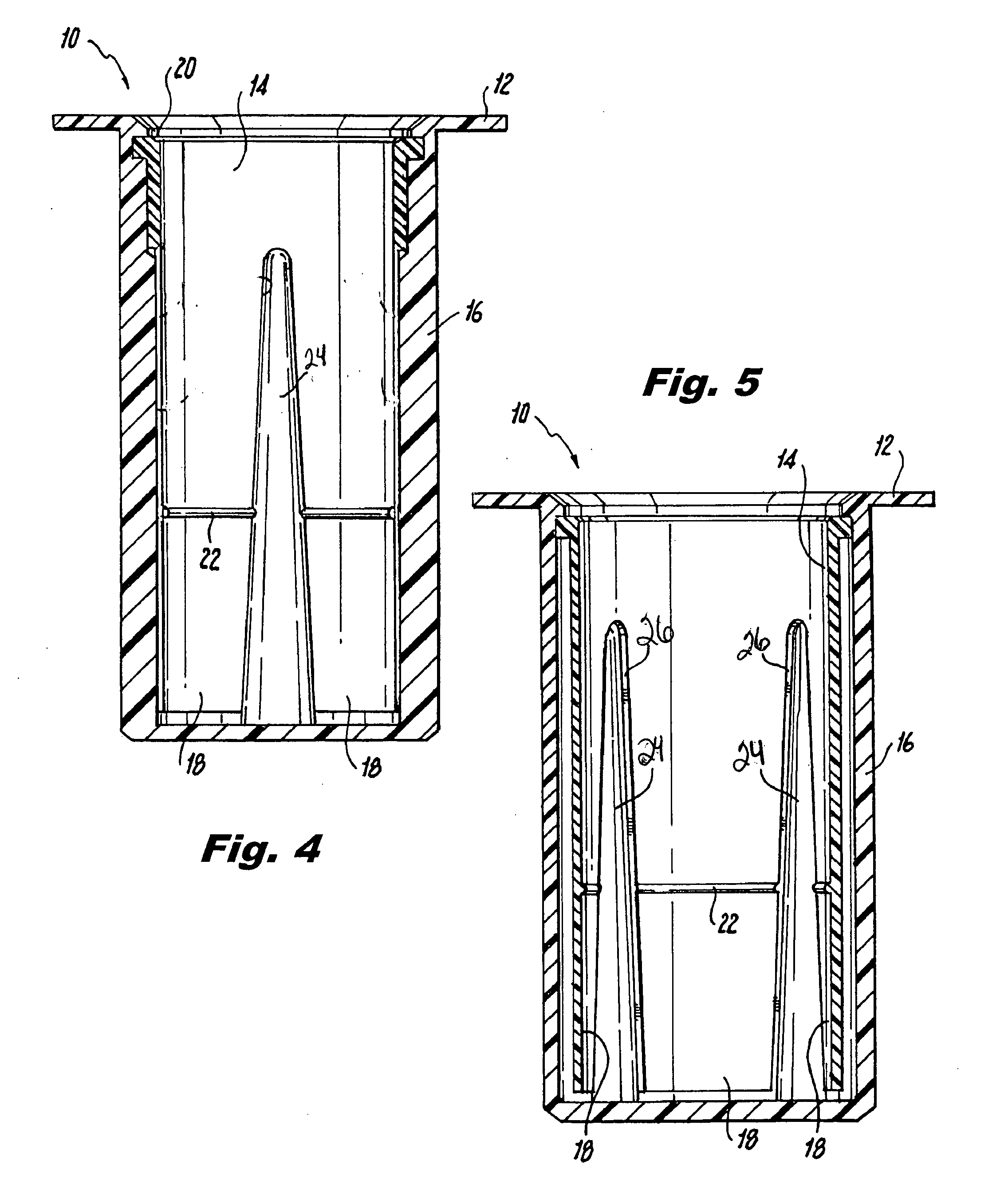

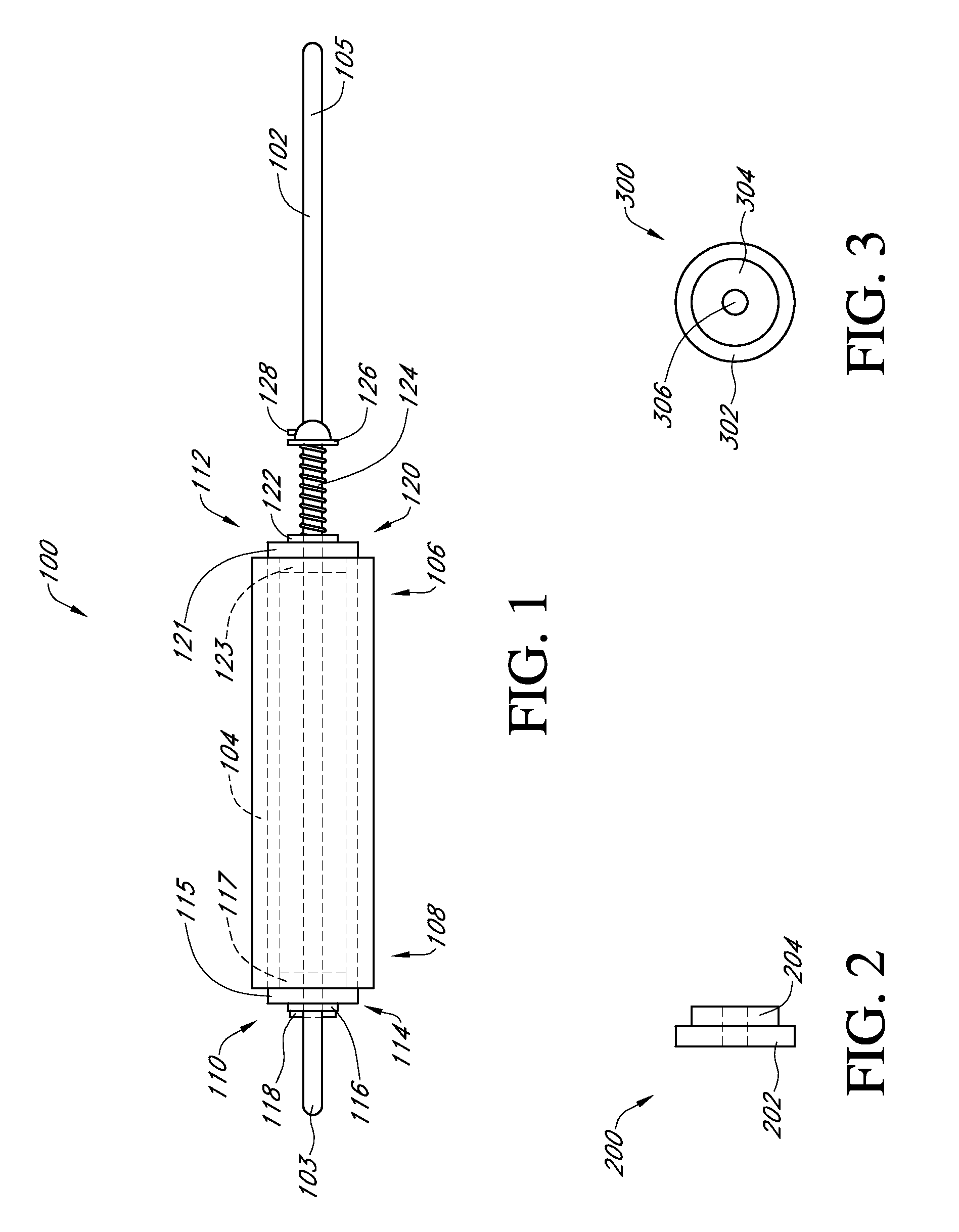

Hand dispenser for stretch wrap

ActiveUS8616490B2Increase coefficient of frictionReduce coefficient of frictionContainers for annular articlesFilament handlingStretch wrapBiomedical engineering

A film dispenser for dispensing stretch wrap or other flexible materials. The film dispenser is comprised of a separate inner and outer mold. The inner mold is comprised of slots and extensions, and a collar which fits into the outer mold, and inner ridges of said inner mold fit into a groove on an extended core. The outer mold is comprised of ribs which fit into the slots of the inner mold.

Owner:BROADWAY HLDG I

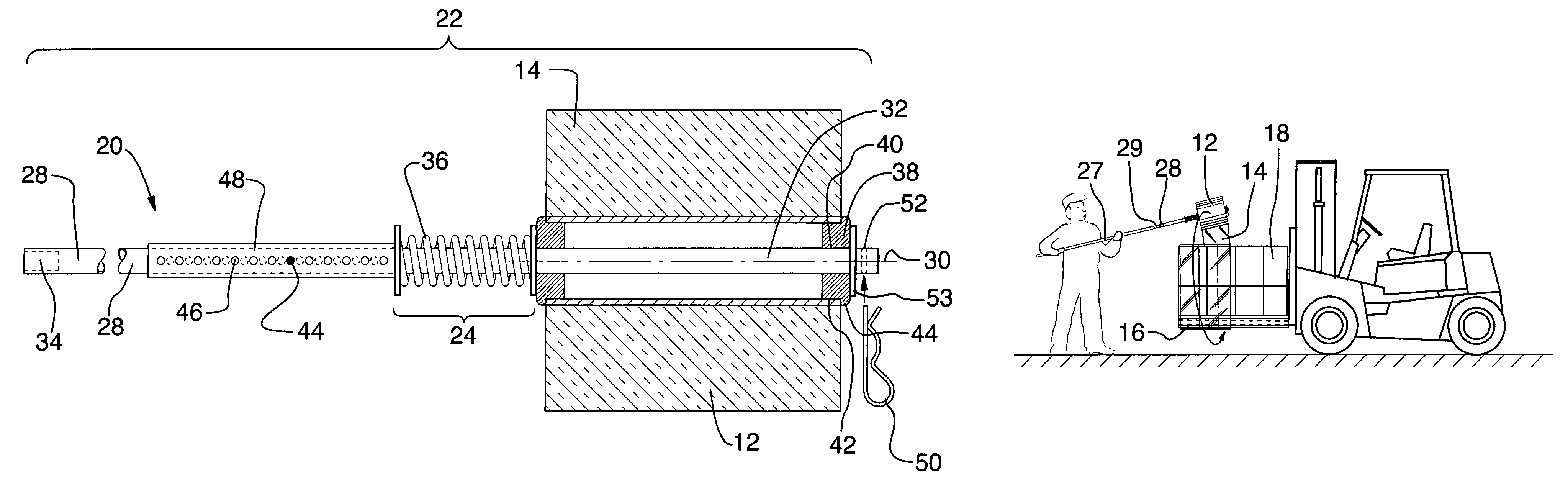

Apparatus and method for dispensing stretch wrap

InactiveUS7401449B2Risk minimizationFacilitates belly wrapping productWrappers shrinkageContainers for annular articlesPlastic packagingStretch wrap

An apparatus for covering goods, and goods stacked on a pallet with plastic wrap supplied in a roll comprises: a) a roll head adapted to rotatably carry the roll of plastic wrap, the roll head having a friction mechanism so that ease of rotation of the roll with respect to the head is controlled thereby facilitating stretching the wrap around the goods after an end portion of the wrap is initially secured adjacent to the goods; and, b) an elongate handle portion carrying the roll head and extending therefrom in a direction generally parallel to the axis of the roll of plastic wrap. A method of wrapping goods stacked on a pallet with plastic wrap supplied in a roll comprising the steps of: a) elevating the pallet and the goods stacked thereon so that there is sufficient clearance to readily pass the roll of plastic wrap beneath the pallet; b) providing a wrap apparatus as defined above; c) loading the roll head of the apparatus with a roll of plastic wrap; d) attaching an end portion of the plastic wrap to one of the pallet and the goods stacked thereon; and then, e) with the user standing adjacent to the elevated pallet having the goods stacked thereon, encircling the pallet and goods thereon with the roll head, by generally moving the handle in an outline of a cone, thereby encircling and securing the goods and pallet together with plastic wrap.

Owner:WATSON RANDY THOMAS +2

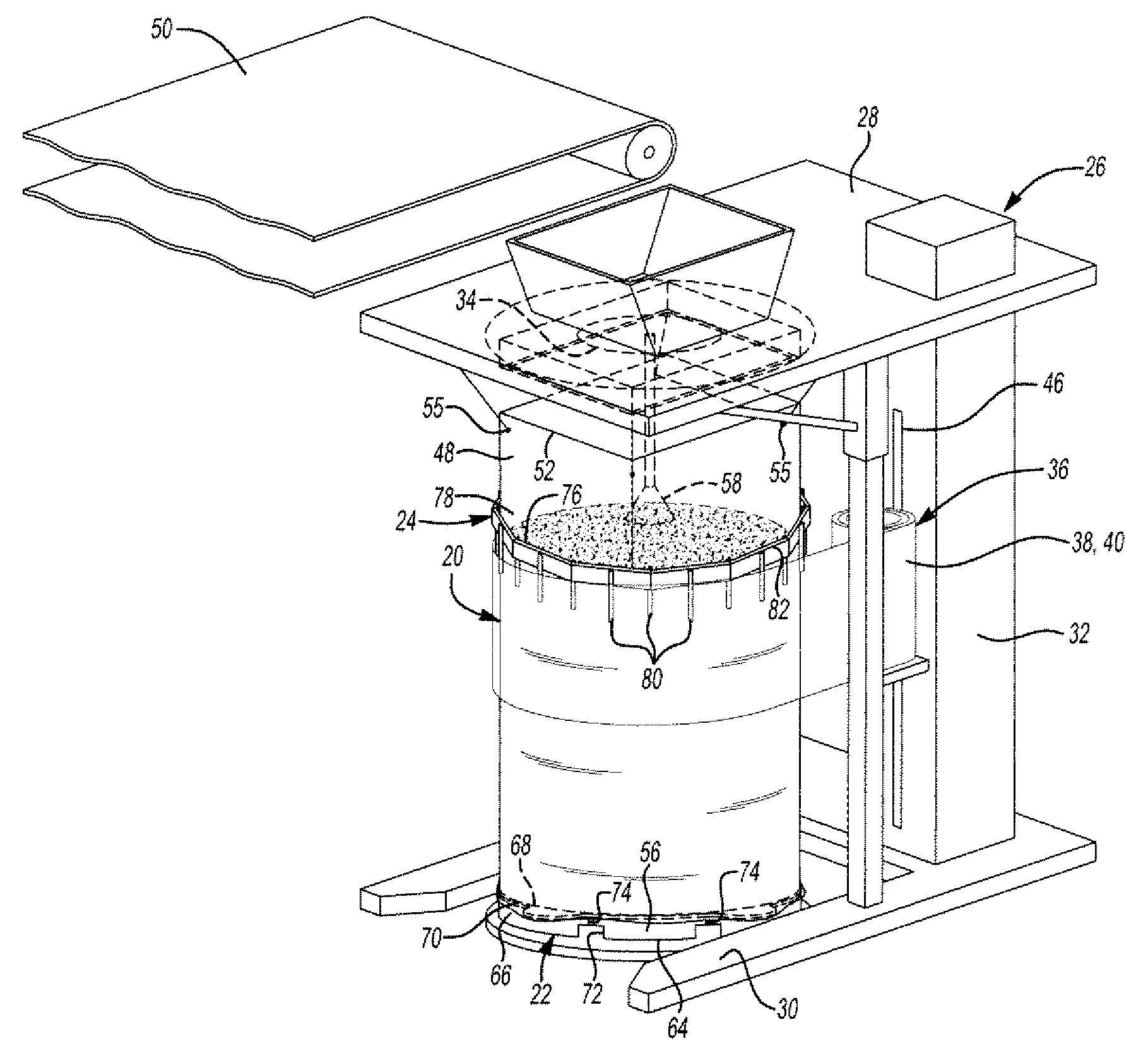

Unitary transporter base and shaper and slip frame former for forming a transportable container

The present invention relates to a method of producing a transportable container for bulk goods. A bag is placed through a former opening of a slip frame former which surrounds a portion of the bag. The bag receives the bulk goods from a feed source. A stretch wrap is disposed radially about a bottom support and a portion of the slip frame former to initially form the transportable container. At least one of the slip frame former and the bottom support moves relative to other in response to the fill level of the bulk goods in the bag. During filling, the slip frame former is maintained at a position surrounding the fill level of the bulk goods in the bag. As the fill level increases in the bag, previously disposed portions of stretch wrap are disengaged from the slip frame former to squeeze the filled portions of the bag and lock together the bulk goods as additional portions of stretch wrap are disposed around the slip frame former.

Owner:KELLOGG CO

Production process of single-head spin high modulus low shrinkage polyester industrial filament

The invention relates to a production technique of a single-head spinned high modulus low-shrink industrial polyester filament. The technique includes the steps: 1. the processing of high-viscosity polyester slices: firstly pre-crystallizing is carried out for the polyester slice and then solid phase polymerization is carried out for polyester slice and then the viscosity of the polyester slice can reach 1.25 to 1.35 dl / g; 2. melt spinning: the polyester slice is transferred to a high-flow spinning screw extrusion machine with screw-diameter of 125 to 160mm, fused mass is extruded out from the spinning screw extrusion machine, then the fused mass is distributed to fused mass branch pipes through a fused mass header pipe, and the fused mass enters a spinning element through a measuring pump and then is extruded out from a spinneret plate with diameter of 220 to 240mm; the extruded filaments are heated by a slow-cooling heating ring, are cooled for forming through an annular air-blowing device and then enter spinning shafts; 3. stretch-wrap forming: the surfaces of filaments are oiled, filaments are stretched at a two-level high speed with total stretching-multiple of 1.8 to 2.2; then the filaments are loosely formed under high temperature between 230 and 260 DEG C and are wrapped with the technique speed of 5200 to 6500 meters / minute to obtain the finished product.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

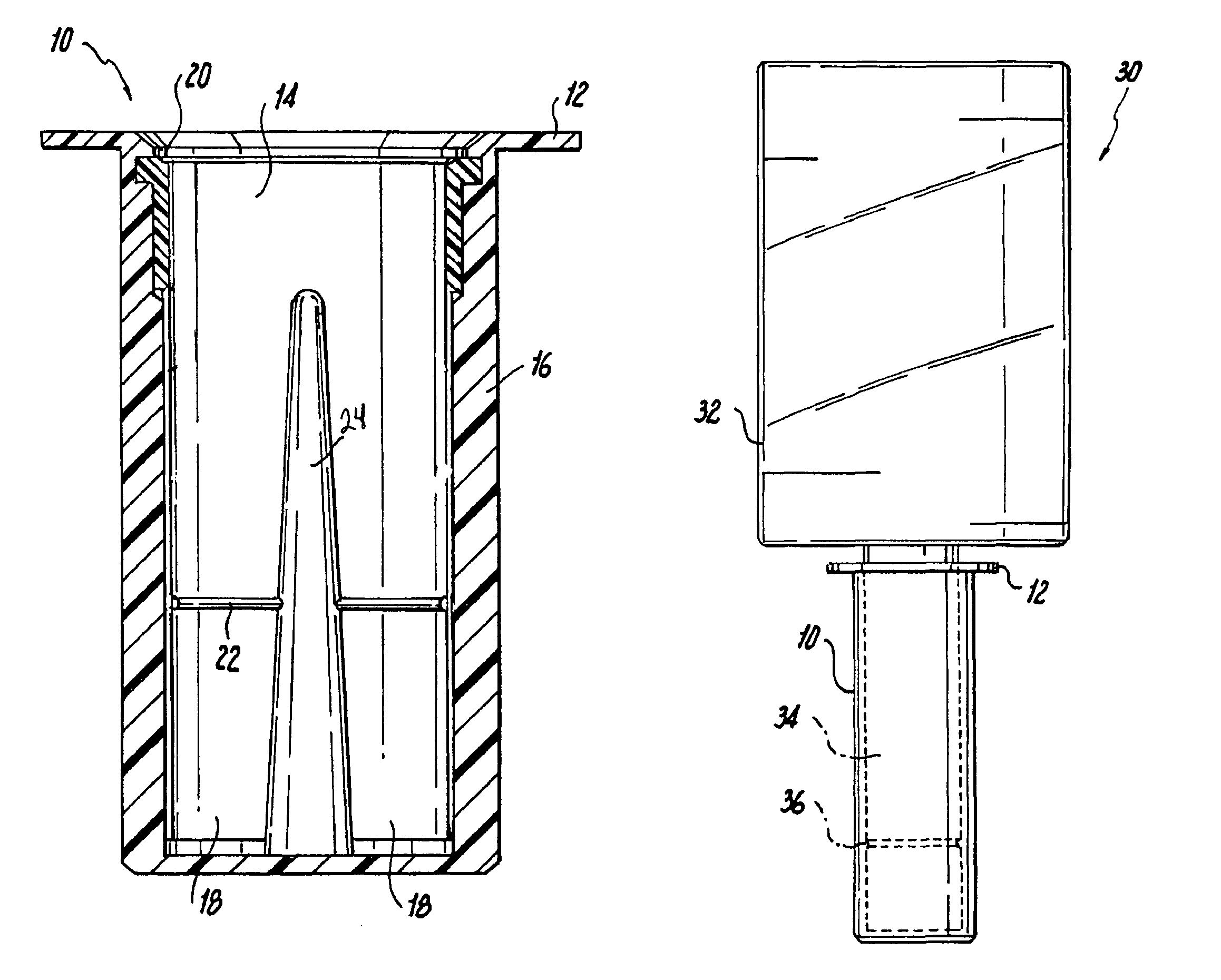

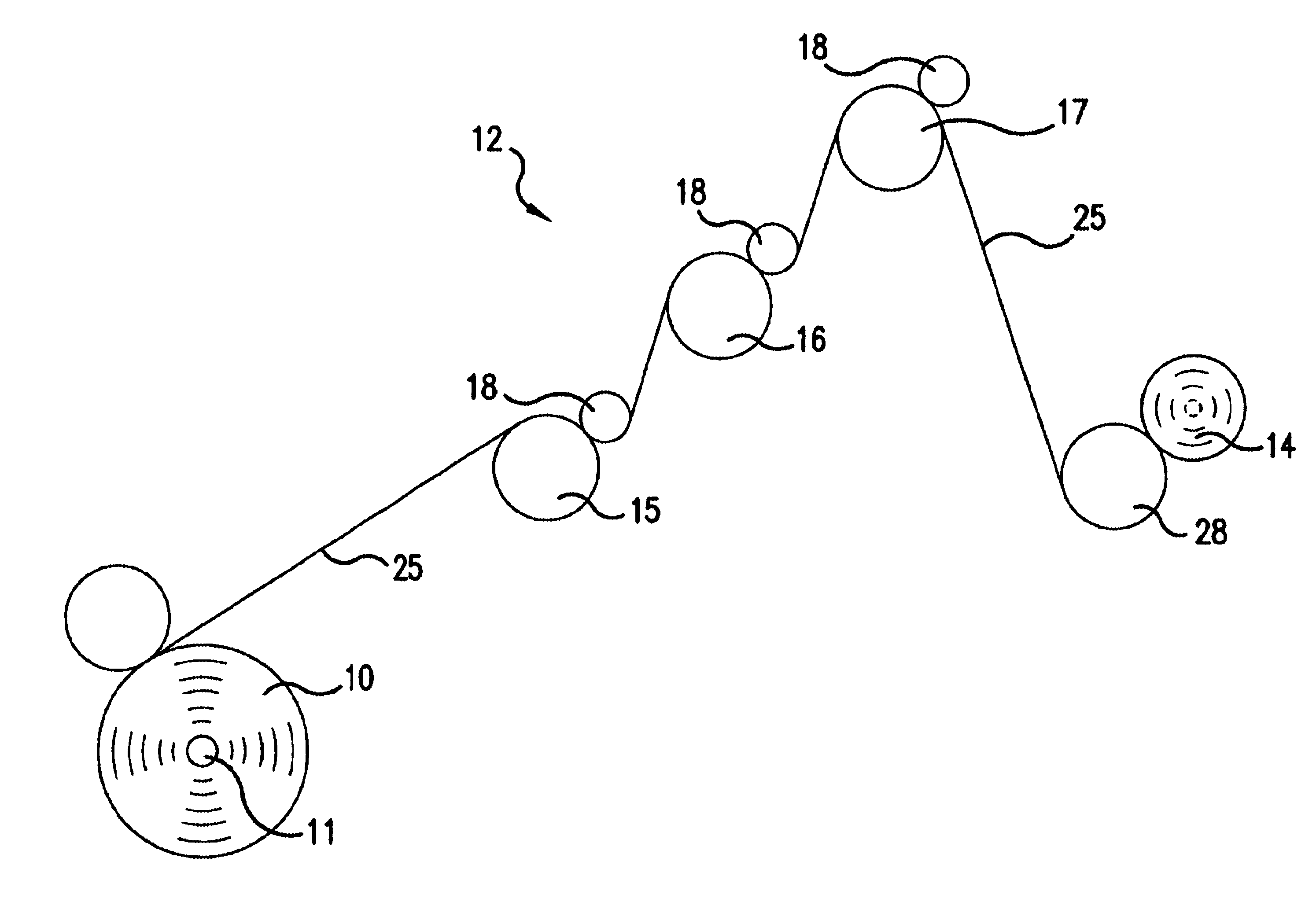

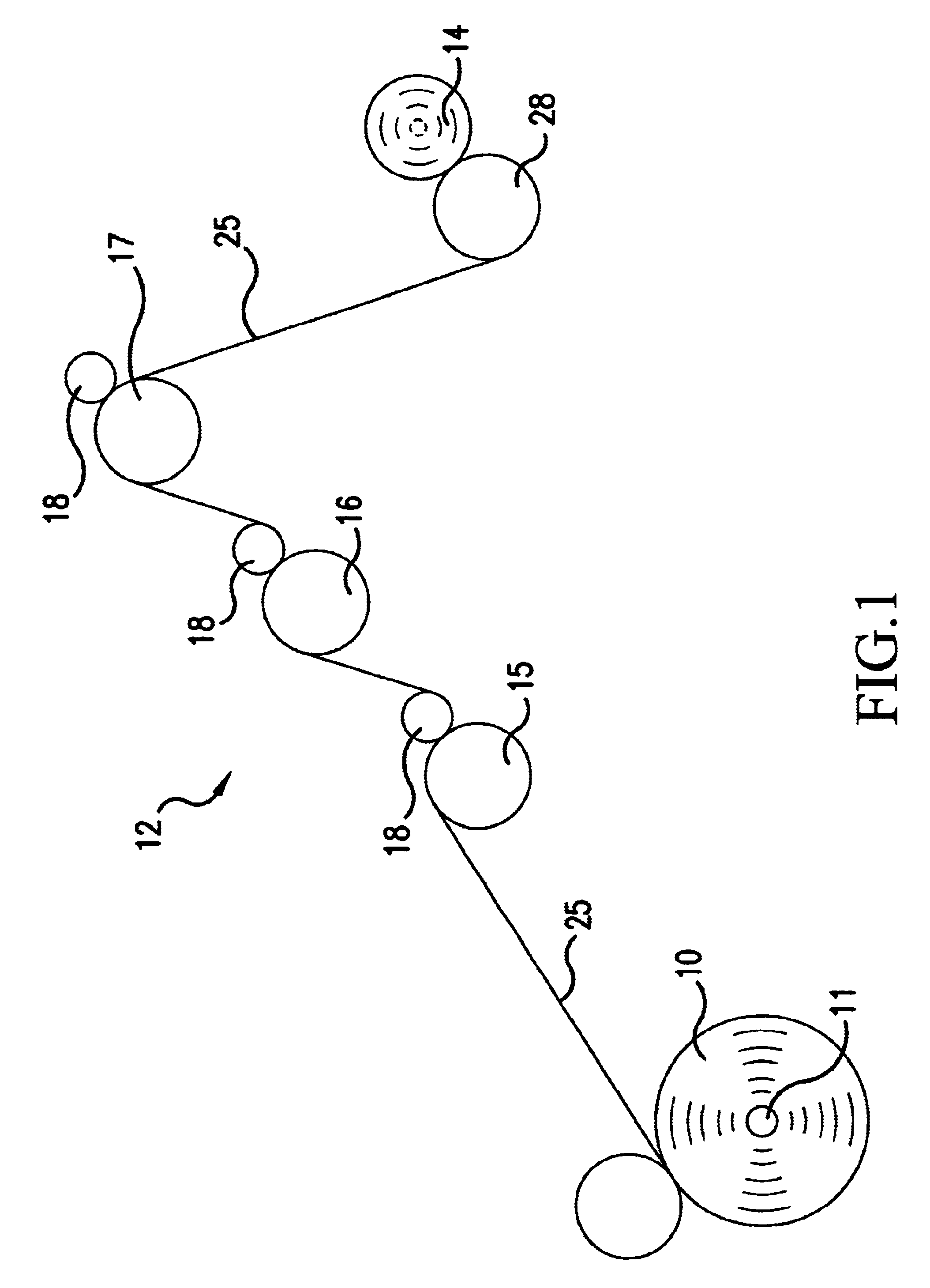

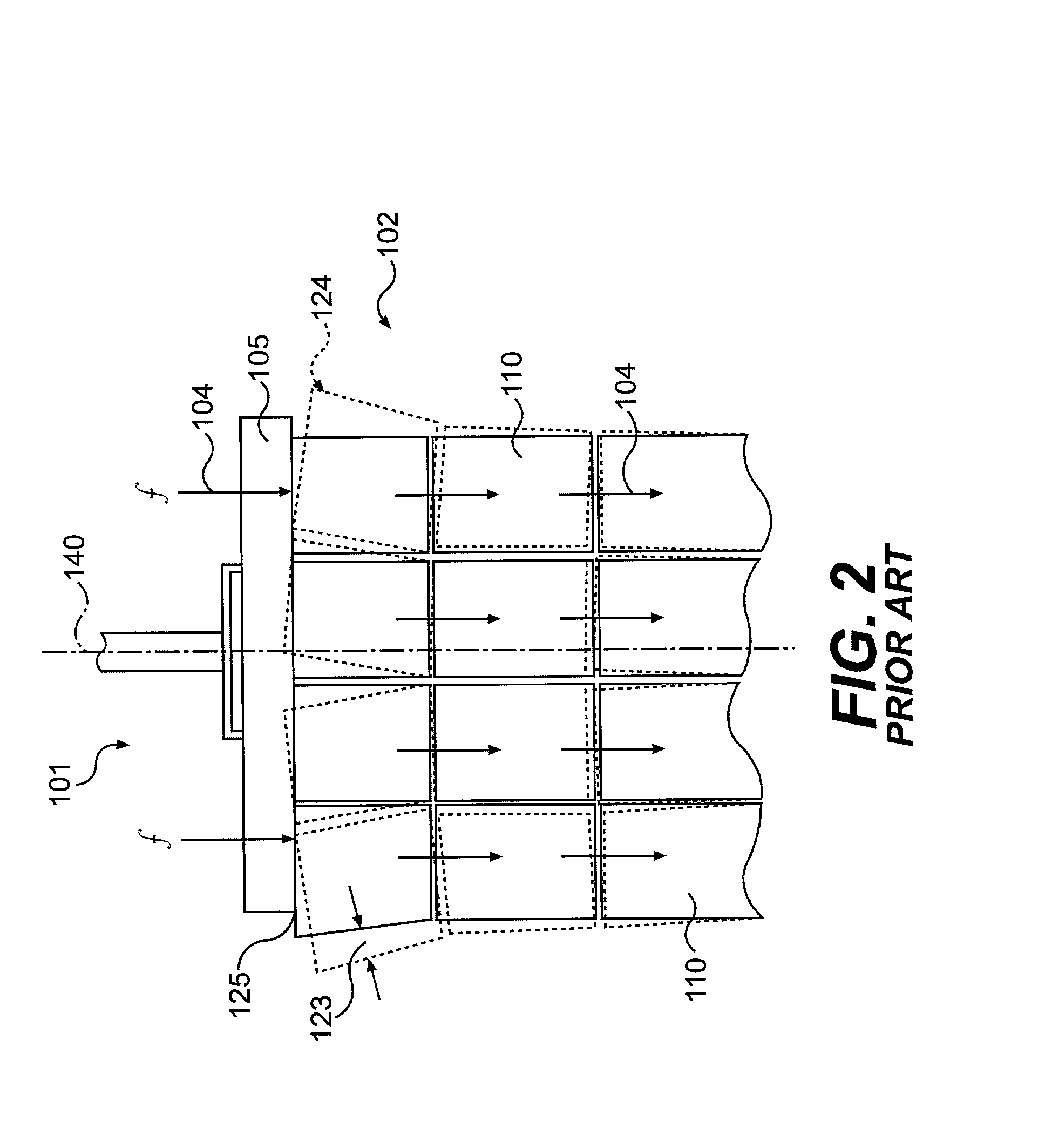

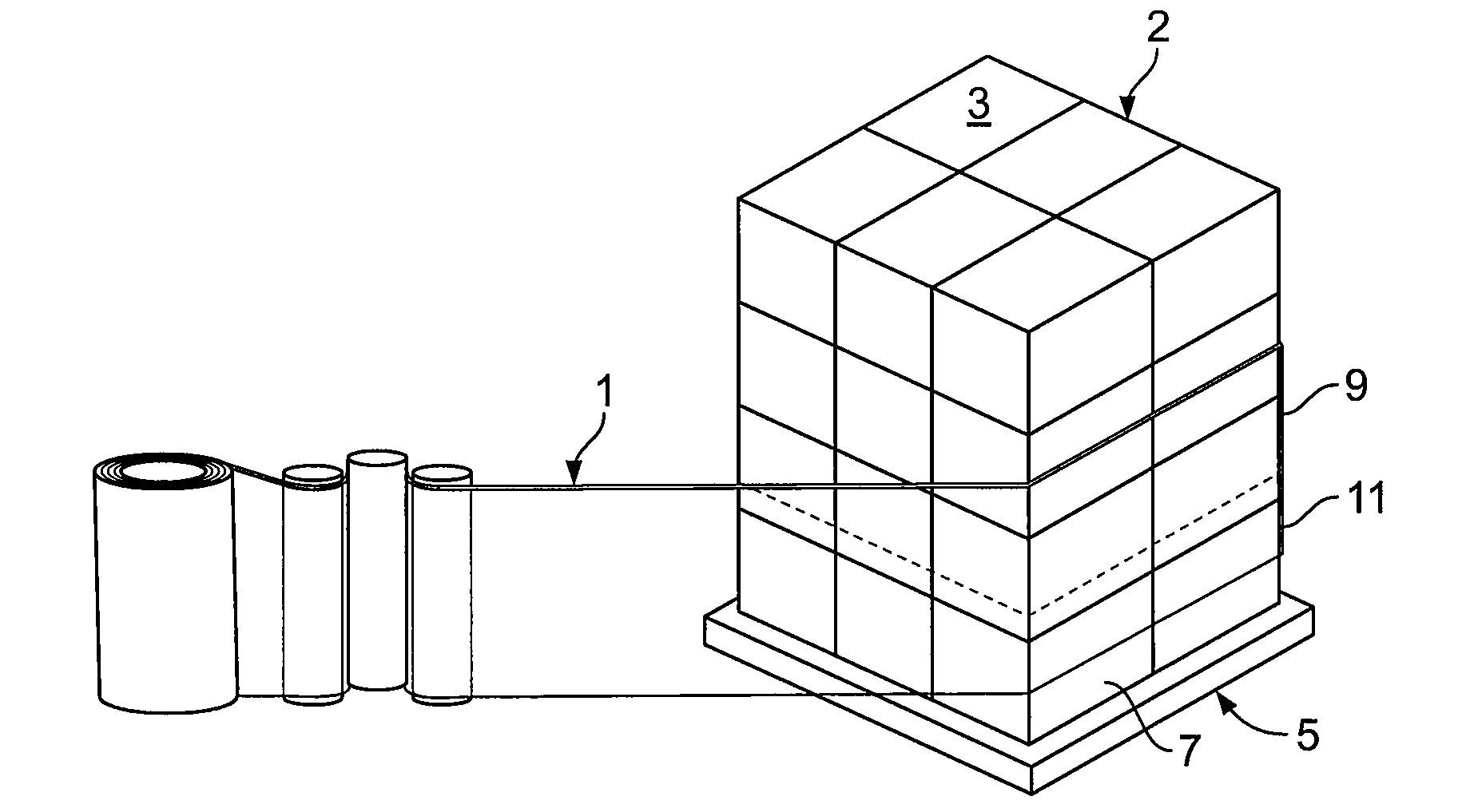

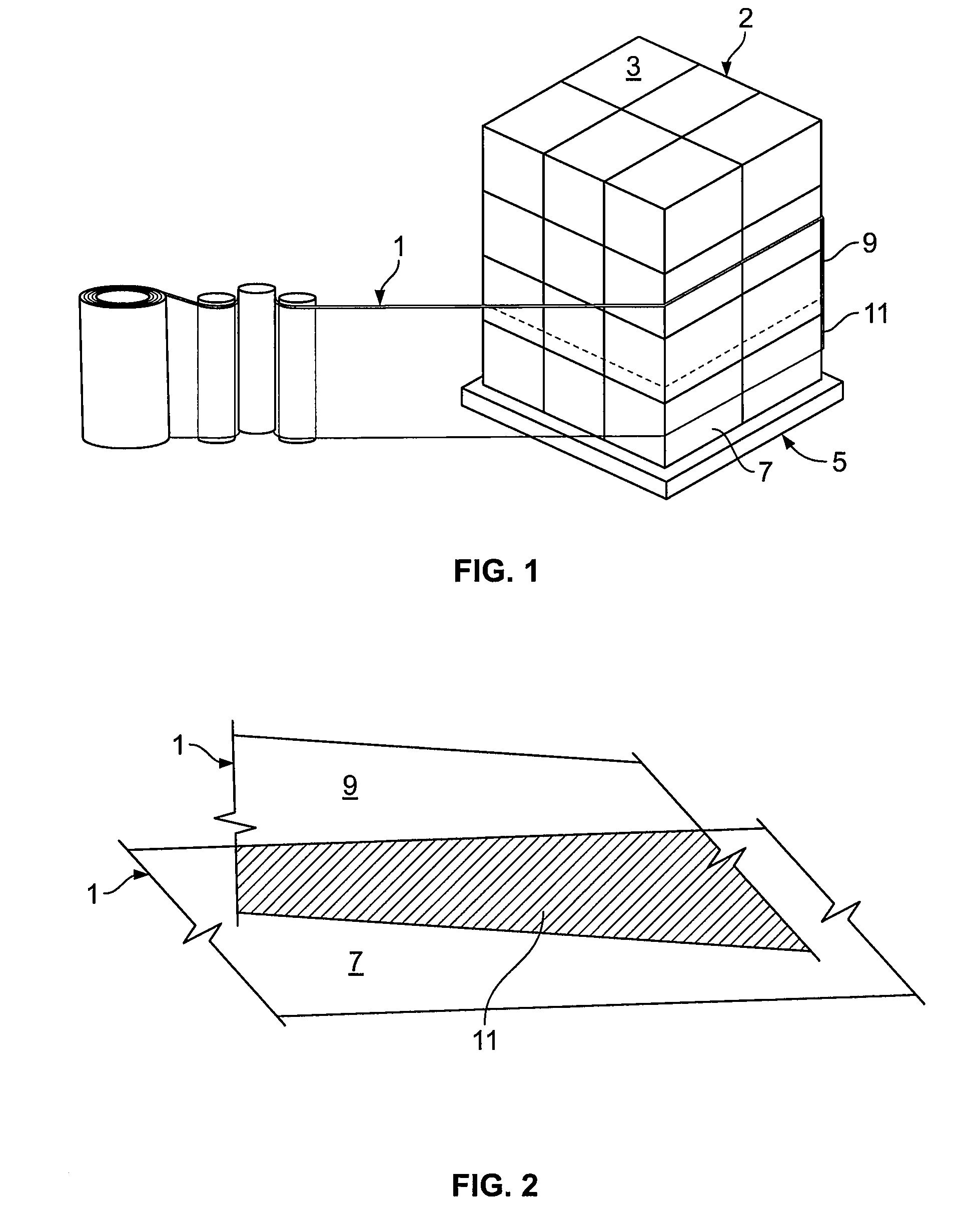

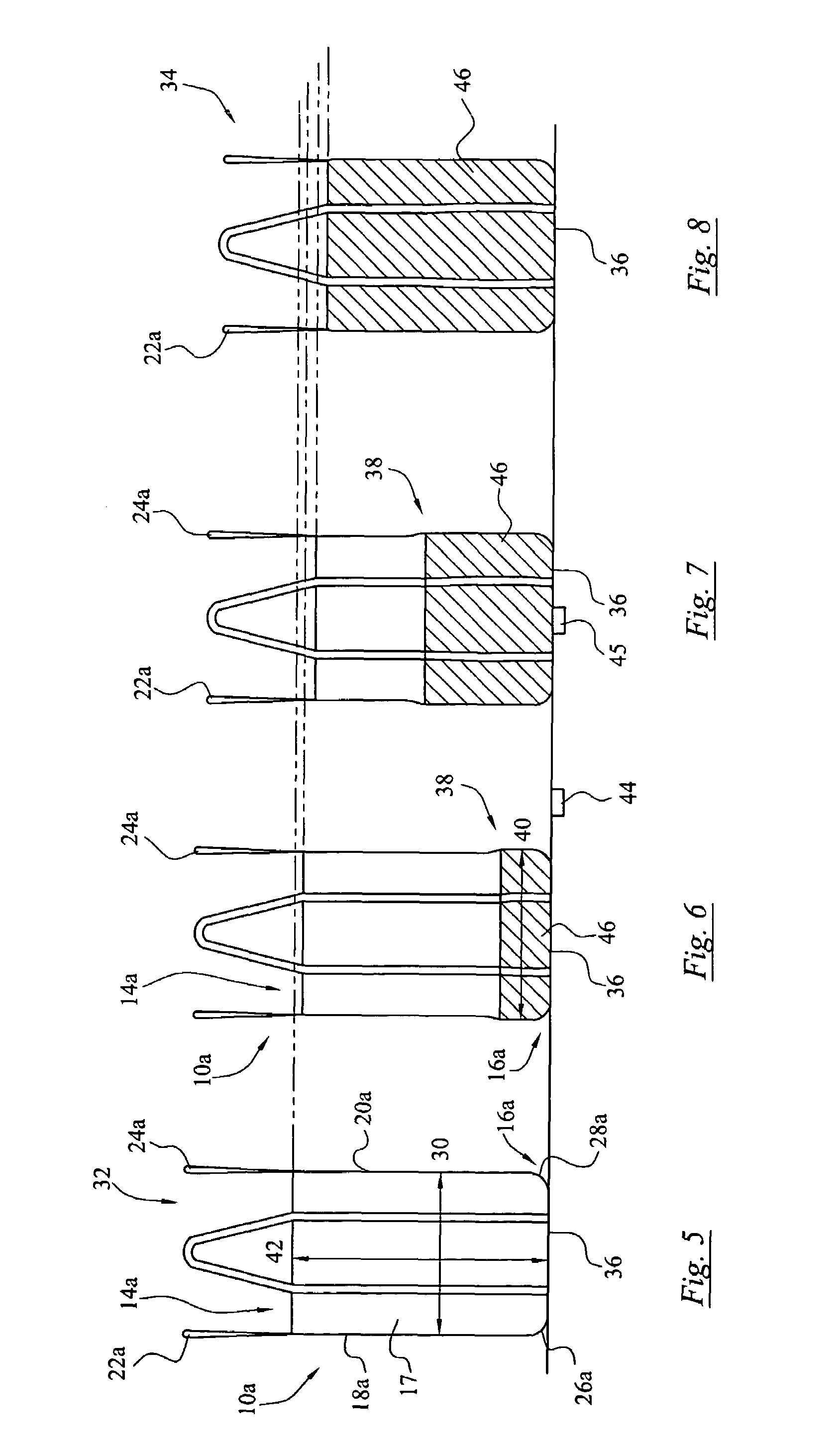

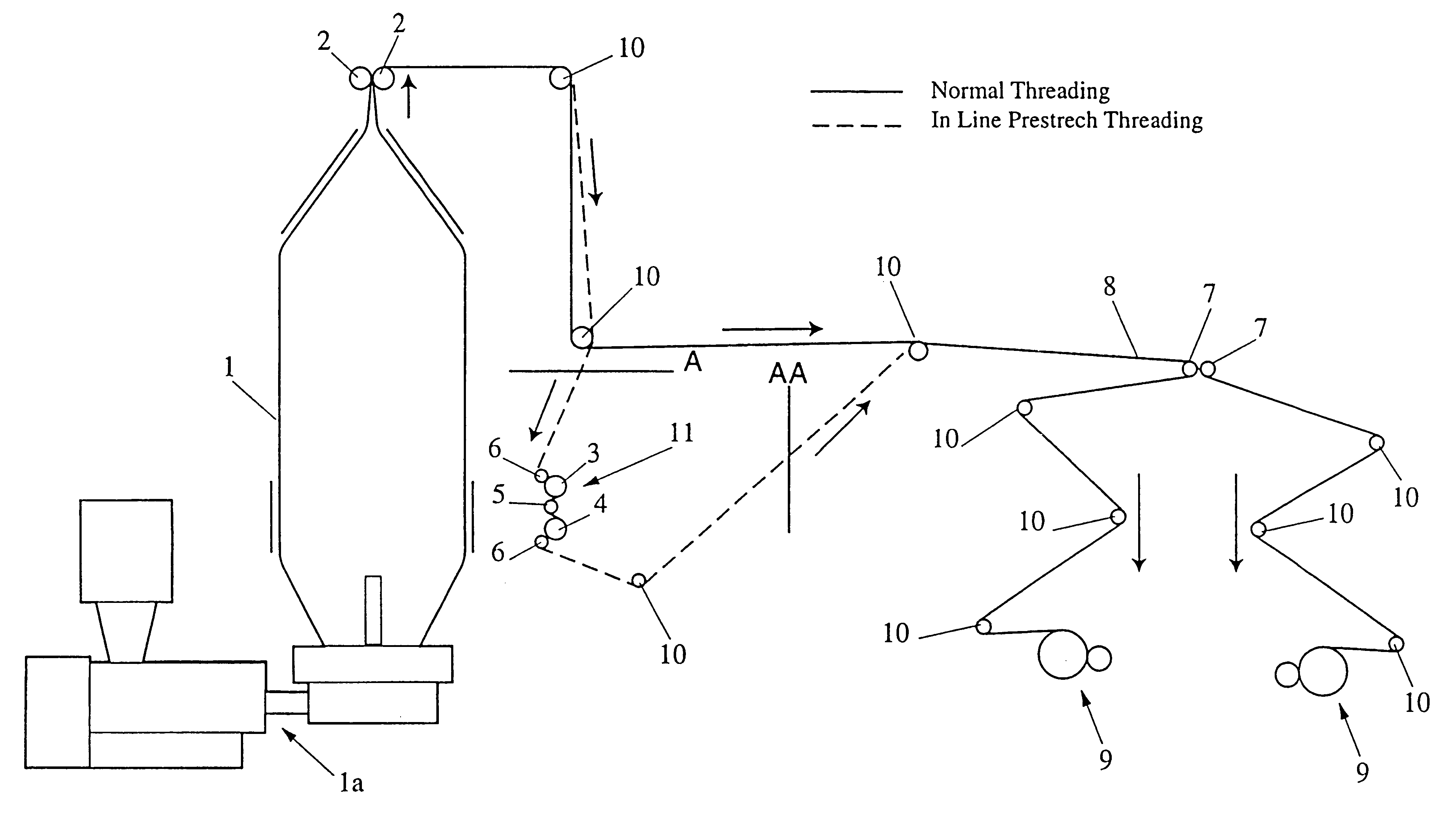

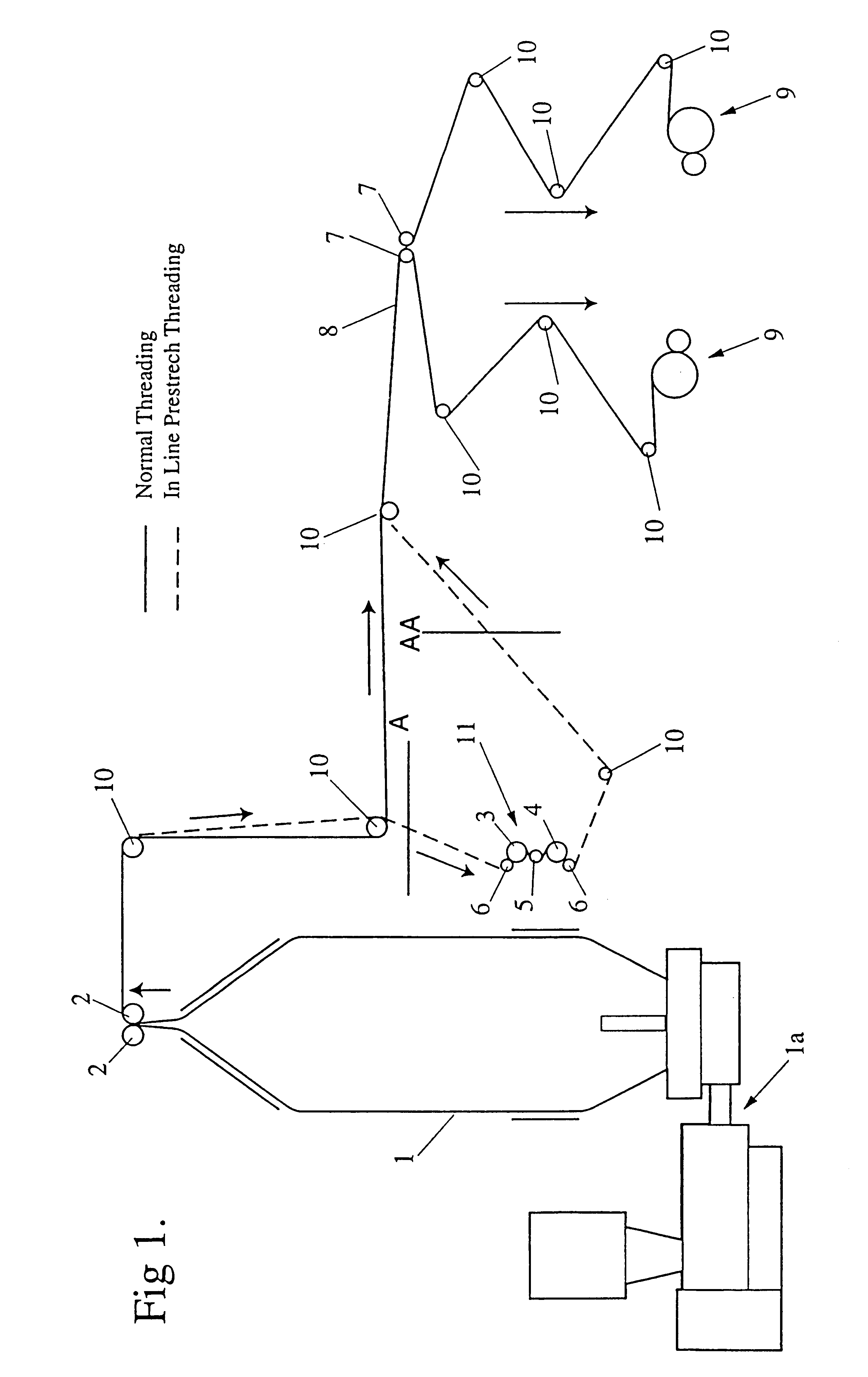

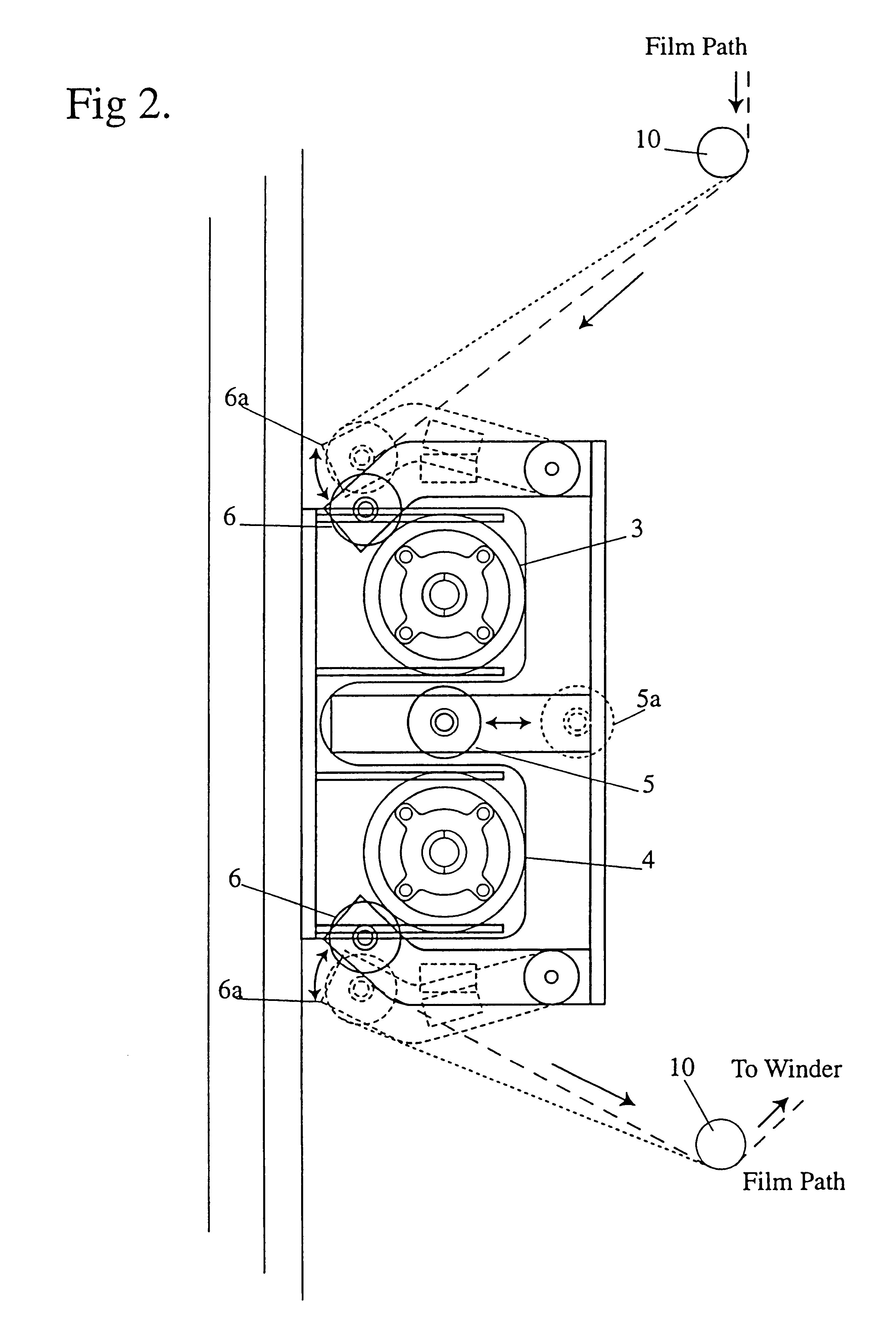

System for stretch-wrapping

InactiveUS6713010B1Promote resultsPrevent crashWrappers shrinkageTextiles and paperStretch wrapHand held

The invention provides a wrapping system for stretch-wrap plastic film. Plastic film (25) is partially pre-stretched by a selected amount and then relaxed prior to winding on a core (14). The film (25) is subsequently further stretched as it is drawn from the core (14) immediately prior to wrapping a load on a pallet, for example. The partial pre-stretching is preferably carried out in a number of steps by leading film (25) from a roll (10) over three rollers (15, 16, 17) in turn. These rollers (15, 16, 17) are driven at different speeds, the third roller (17) having a greater speed than the second roller (16) which in turn has a greater speed than the first roller (15). Thus, the film (25) is stretched in three steps prior to relaxing the film (25) and winding the relaxed film (25) on a core (14). The core (14) can be mounted on a hand-held dispenser which applies the final stretch to the film (25).

Owner:MARMIONS

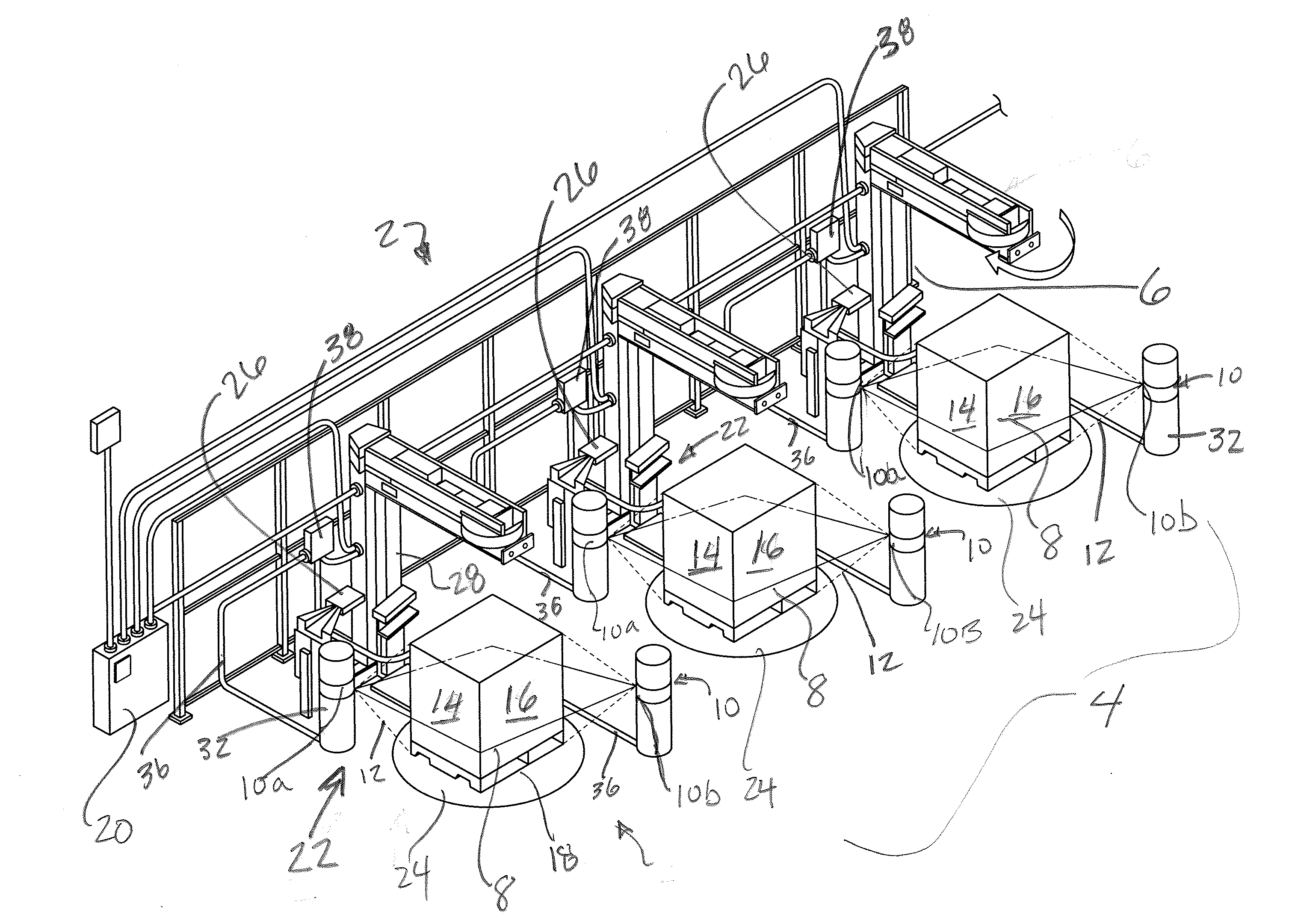

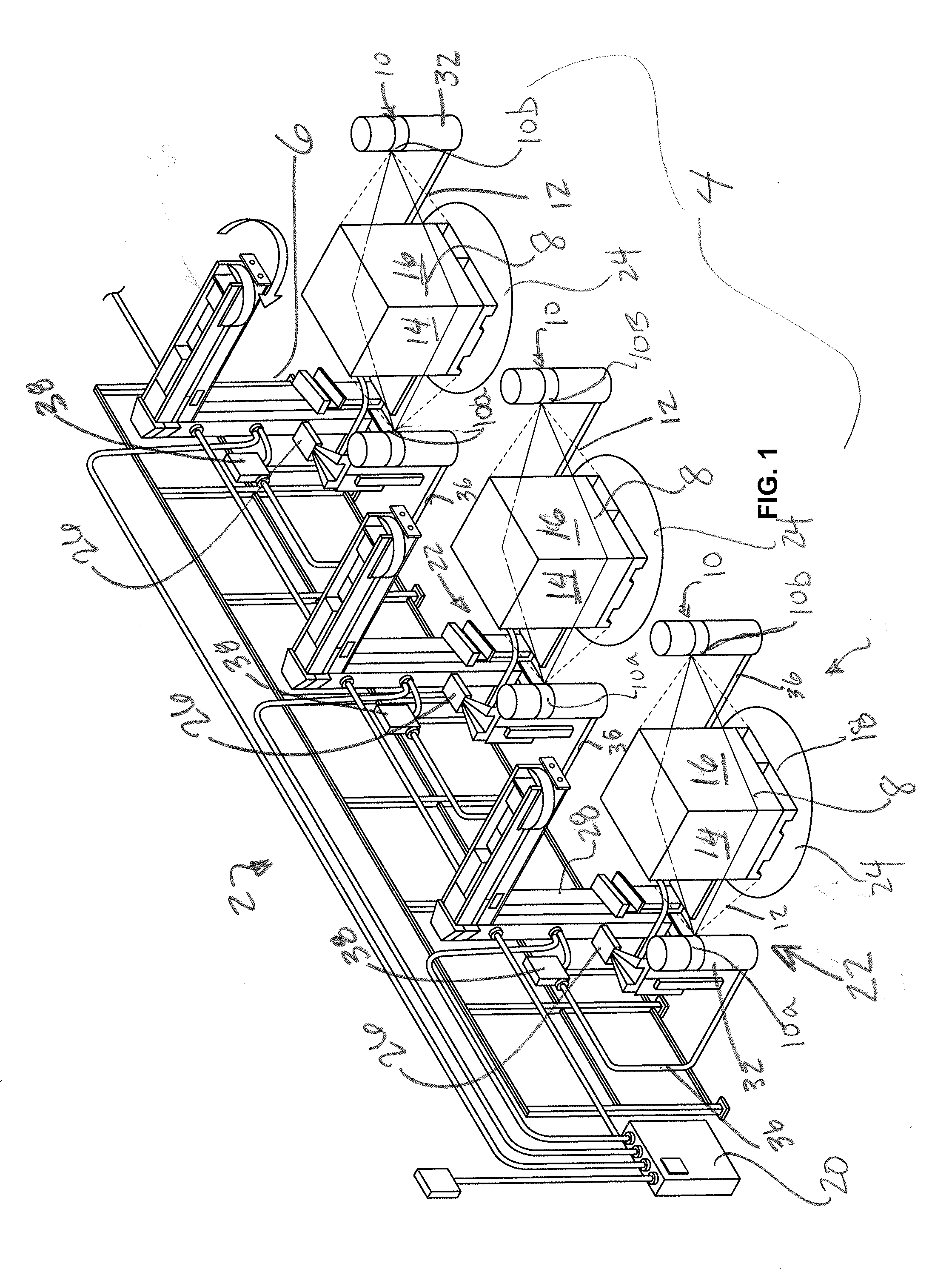

Stretch Wrapping System and Process

In one aspect, a stretch wrap system configured to separately wrap a plurality of loads in film comprising a plurality of stretch wrapping machines, each machine comprising at least one sensing mechanism configured to sense the presence of a load, and a control box electrically coupled to sensing mechanisms, the control box comprising a start button configured to start the machines when sensing mechanisms detect load. In another aspect, a process of operating a system for stretch wrapping comprising positioning at least one load to be wrapped in front of at least one of a first and second machine wherein the first machine includes a sensing mechanism electrically coupled to a control box and wherein the second machine includes a second sensing mechanism electrically coupled to the control box, inputting a start signal through the control box, transmitting a signal from the control box to each of the sensing mechanisms, determining the presence or absence of a load within an operational space of each of the plurality of stretch wrapping machines and wrapping each present load using a respective one of the plurality of stretch wrapping machines.

Owner:BEST PACKAGING

Method and apparatus for stretch wrapping a load

A leading end of packaging material is grasped in a packaging material holder while a load is wrapped. Packaging material is dispensed from a packaging material dispenser, and relative rotation is provided between the dispenser and a load to wrap packaging material around the load. The packaging material holder may be positioned on the rotating surface of a turntable but isolated from any electrical or fluid power source of a rotatable surface of the turntable. During the wrapping cycle, the packaging material holder moves downstream along the turntable, automatically releasing the leading end of the packaging material and automatically grasping a trailing end of the packaging material. The packaging material is weakened and then severed between the packaging material holder and the load. The packaging material holder is mounted to permit it to move upstream due to force exerted by the packaging material held in the holder.

Owner:LANTECH COM

Pallet load sensing system

InactiveUS20150101281A1Promote resultsPrecise positioningWeb rotation wrappingPackaging automatic controlStretch wrapLoad sensing

The present invention relates to a system for positioning pallets to be wrapped with a pallet stretch wrap machine and to adjust operation of the wrap machine according to measurements obtained from sensors, identify the relative size of the pallet load to be wrapped in stretch film, detect misalignment of the load and thereby control activation of the wrap sequence and the speed of the film applied.

Owner:BEST PACKAGING

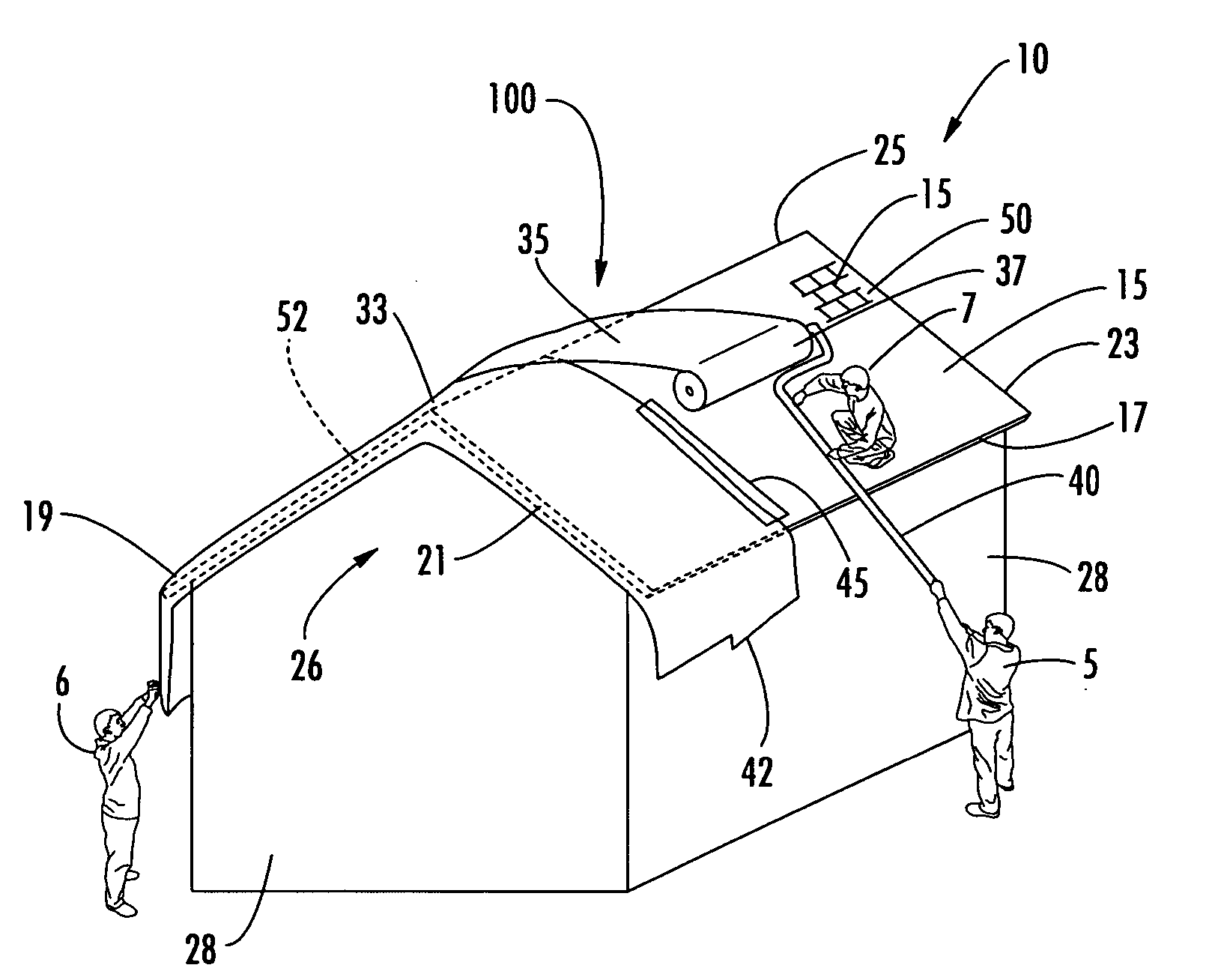

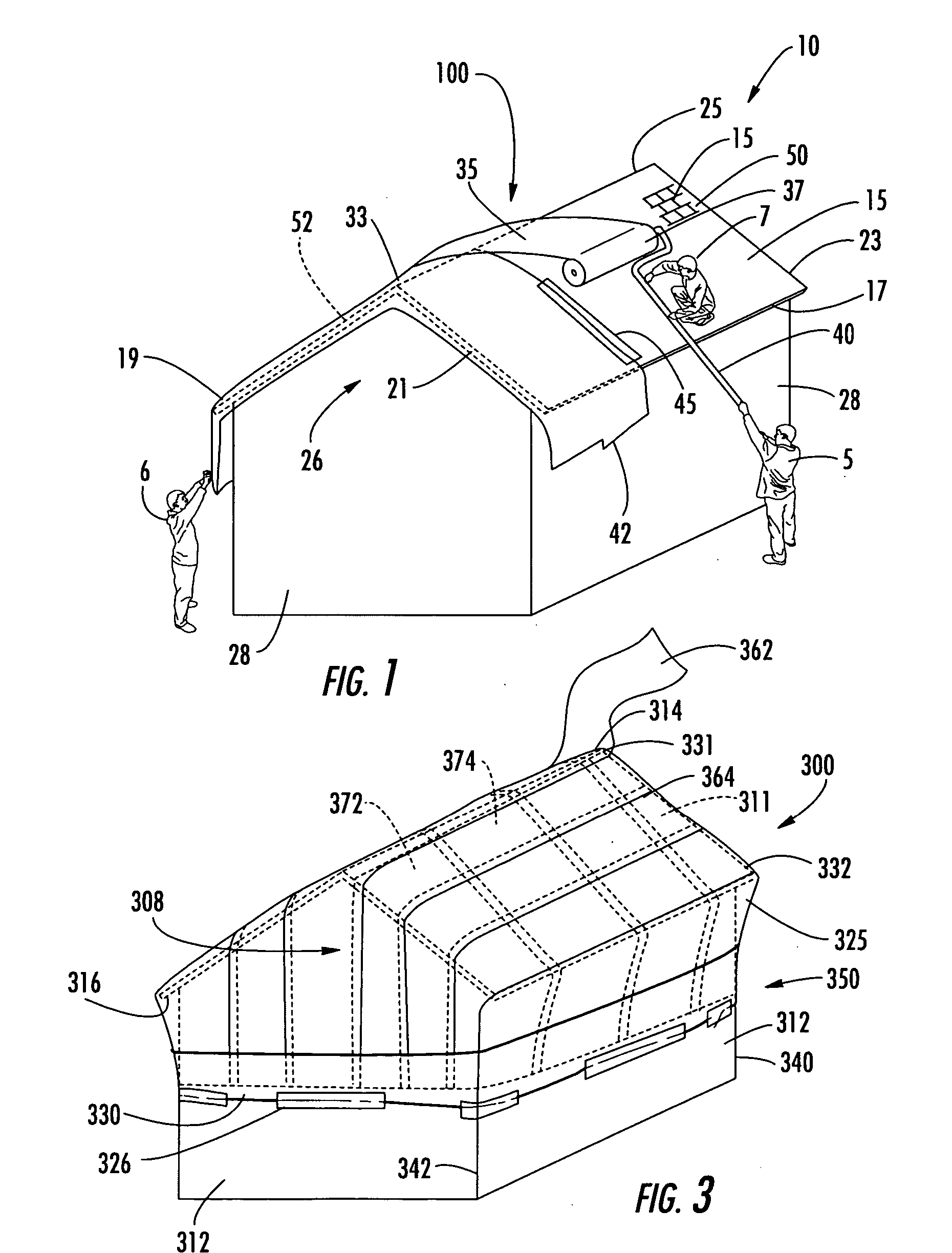

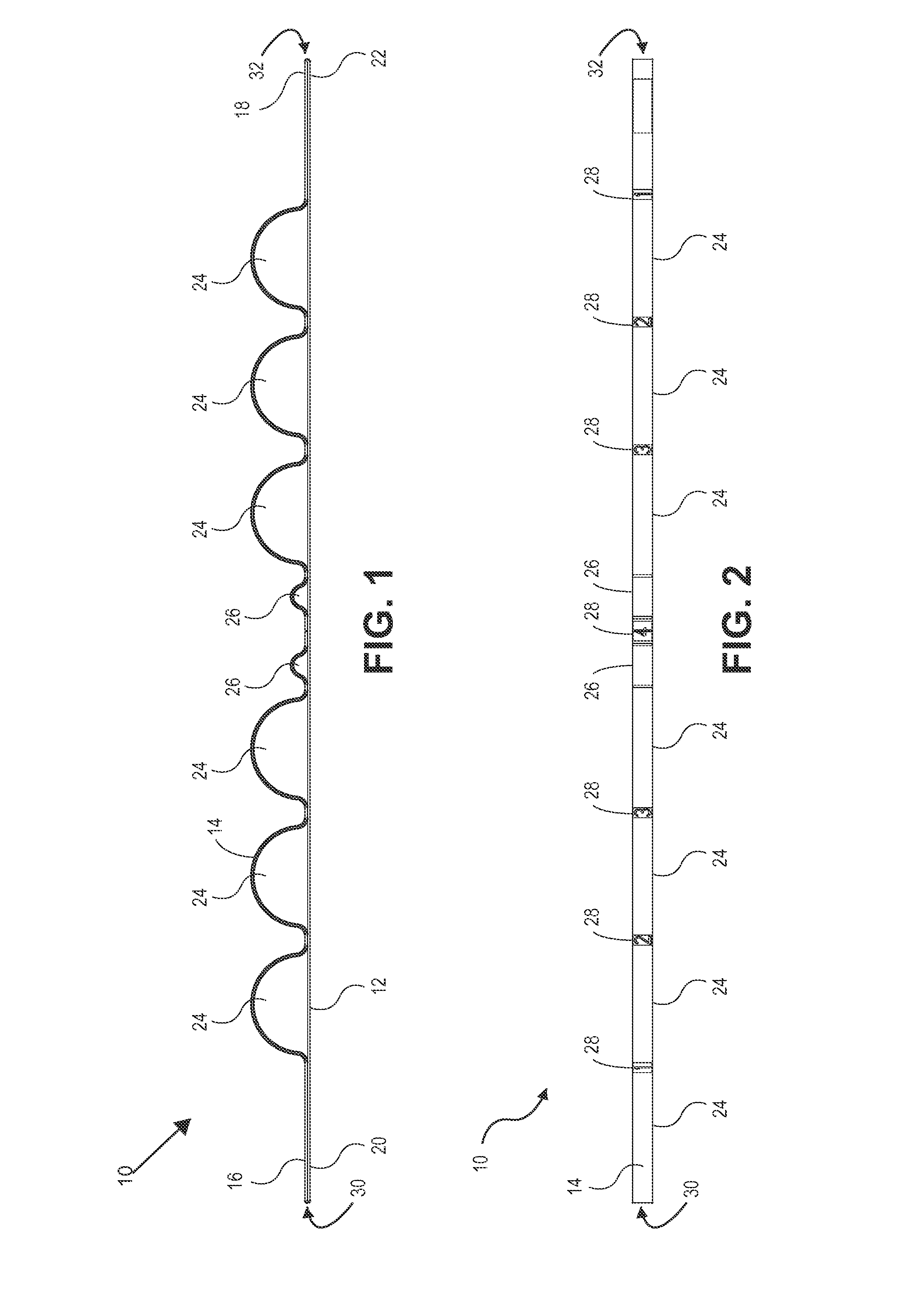

Roof protection systems for high wind zones

InactiveUS20050217202A1Prevent disengagementHuman health protectionRoof covering using slabs/sheetsStretch wrapEngineering

The present invention is directed to an improved cover for securing the roof a residential home or other building structure from the weather conditions that are associated with severe storms such as hurricanes. In one embodiment, the present invention comprises at least one protective membrane disposed adjacent the roof's upper surface. In a particular embodiment, the membrane is configured to cover substantially the entire roof surface. The membrane, which may comprise stretch wrap or shrink wrap, may be adhered in place, for example, using water resistant tape, an adhesive, mechanical fasteners, or a girdle sheet that is wrapped around the vertical walls of the building structure so as to capture the protective membrane between the girdle sheet and the vertical walls. Alternatively, the roof cover may be maintained adjacent the roof substantially entirely through its own physical properties, especially if the roof cover is comprised of stretch or shrink wrap.

Owner:CROOK MICHAEL L

Hand dispenser for stretch wrap

ActiveUS20120181369A1Increase coefficient of frictionReduce coefficient of frictionContainers for annular articlesFilament handlingStretch wrapBiomedical engineering

A film dispenser for dispensing stretch wrap or other flexible materials. The film dispenser is comprised of a separate inner and outer mold. The inner mold is comprised of slots and extensions, and a collar which fits into the outer mold, and inner ridges of said inner mold fit into a groove on an extended core. The outer mold is comprised of ribs which fit into the slots of the inner mold.

Owner:BROADWAY HLDG I

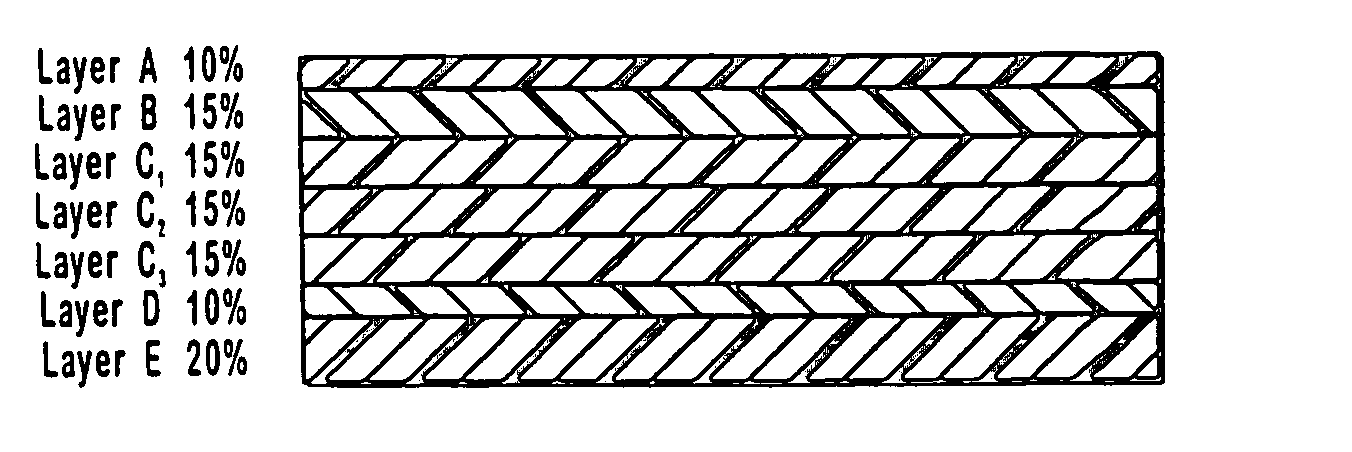

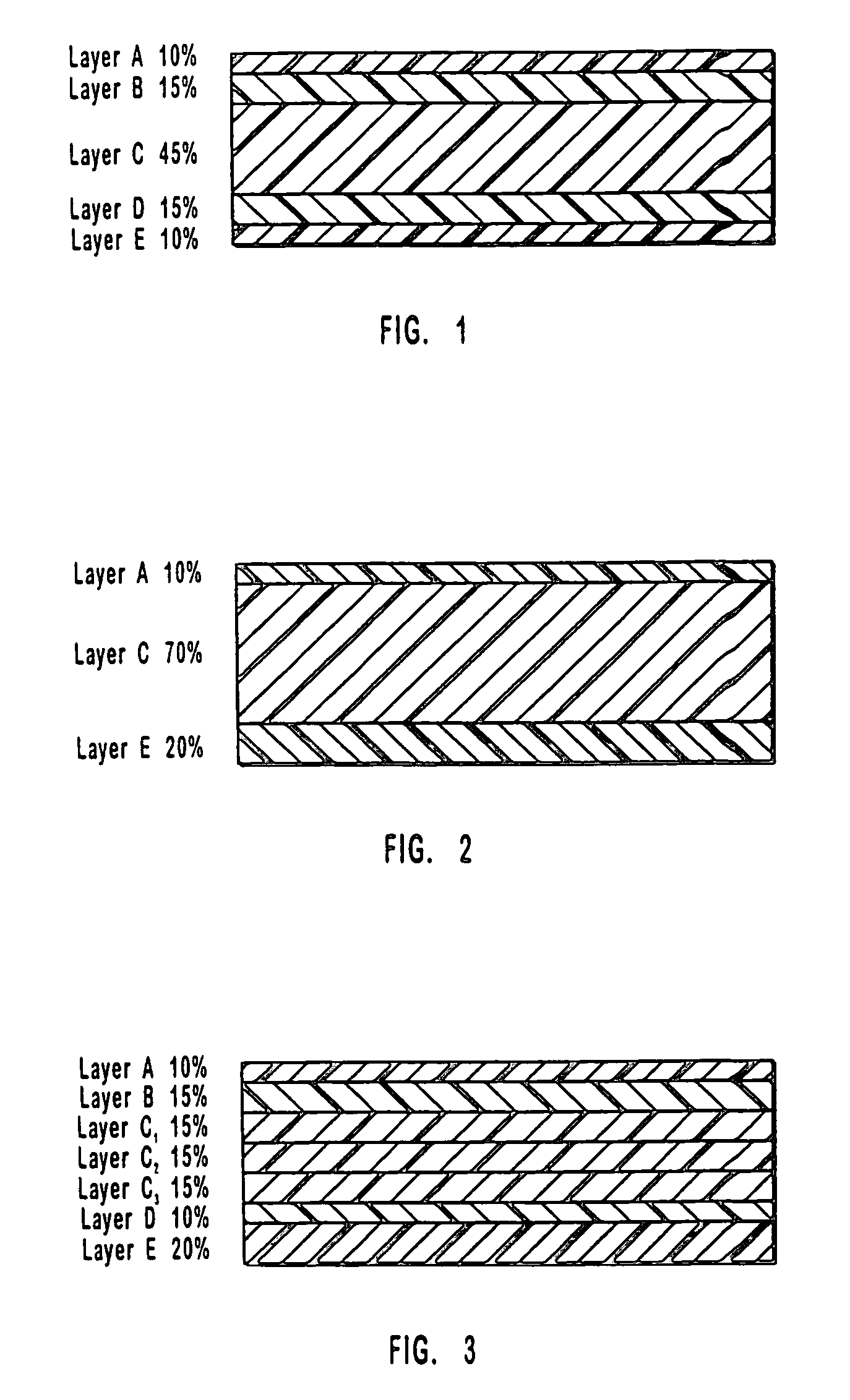

Stretch wrap films

InactiveUSRE38658E1Improve clingEasy to tearSynthetic resin layered productsBinding material applicationPolyolefinStretch wrap

The present invention provides for improved polyolefin stretch wrap films having superior cling force, load retention, tear resistance and puncture resistance properties and for the methods of using those stretch wrap films. The stretch wrap films generally have a thickness of from about 0.4 to about 3 mils, a cling force onto itself of at least 140 g / inch, an F-50 dart drop strength of at least about 150 g / mil. The stretch wrap films are constructed in a multilayer fashion having at least one outside cling polyethylene copolymer layer containing a polyethylene resin preferably produced through metallocene catalyst technology.

Owner:BERRY PLASTICS CORP

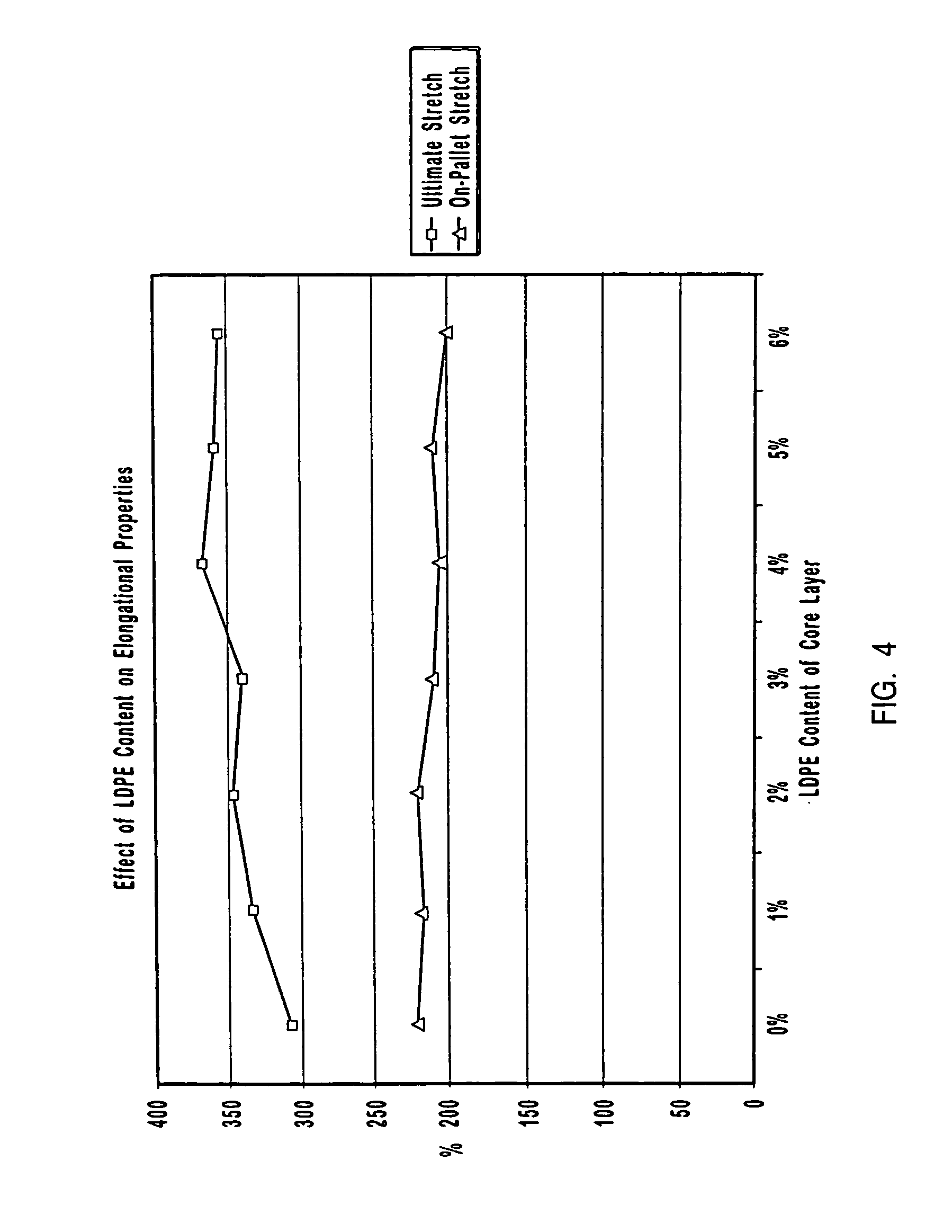

Low gauge stretch wrap film

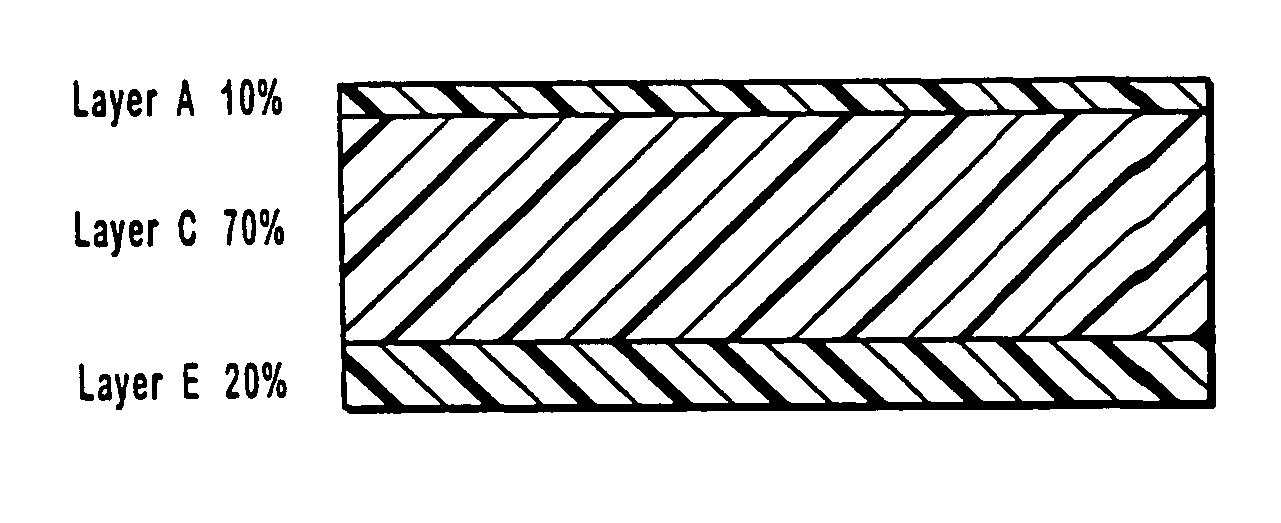

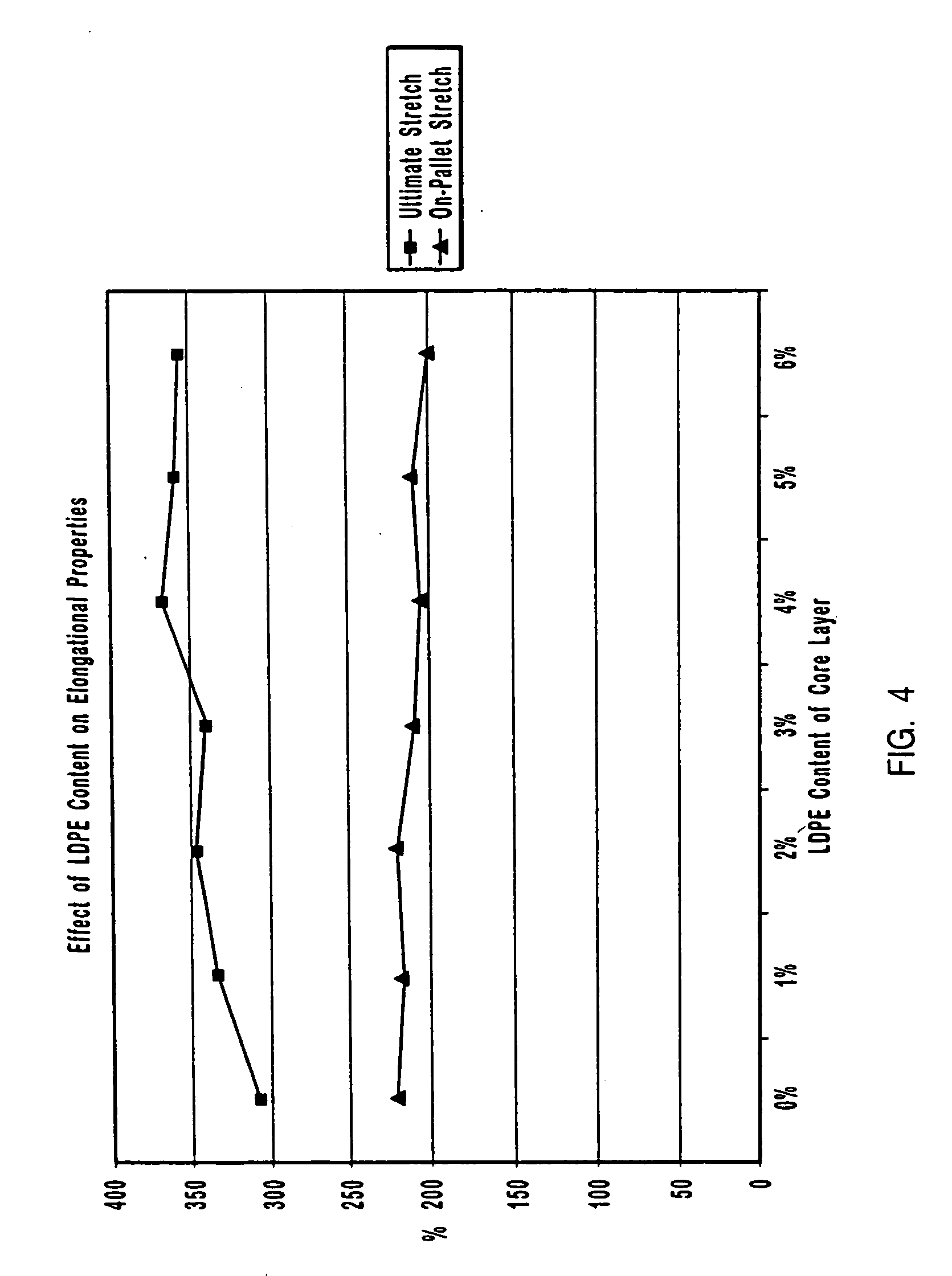

InactiveUS20070065650A1Improve puncture resistanceMaintain good propertiesSynthetic resin layered productsThin material handlingLow-density polyethyleneLinear low-density polyethylene

Stretch wrap films are used to hold goods to pallets during storage and shipping. Multilayer stretch wrap films are provided herein with at least one outer layer of polypropylene and other layers of blends of polyethylenes. In preferred embodiments, stretch wrap films comprise a cling layer comprising a heterogeneously branched ultra low density polyethylene, a non-cling layer, and at least one core layer comprising linear low density polyethylene and low density polyethylene. Preferred embodiments of films of the present technology optimize physical properties enabling the film to have sufficient cling while creating a tolerable noise level upon unwinding. The optimized properties can include good clarity, high load containment, high puncture resistance, high stretch and good tear resistance.

Owner:PLIANT CORP

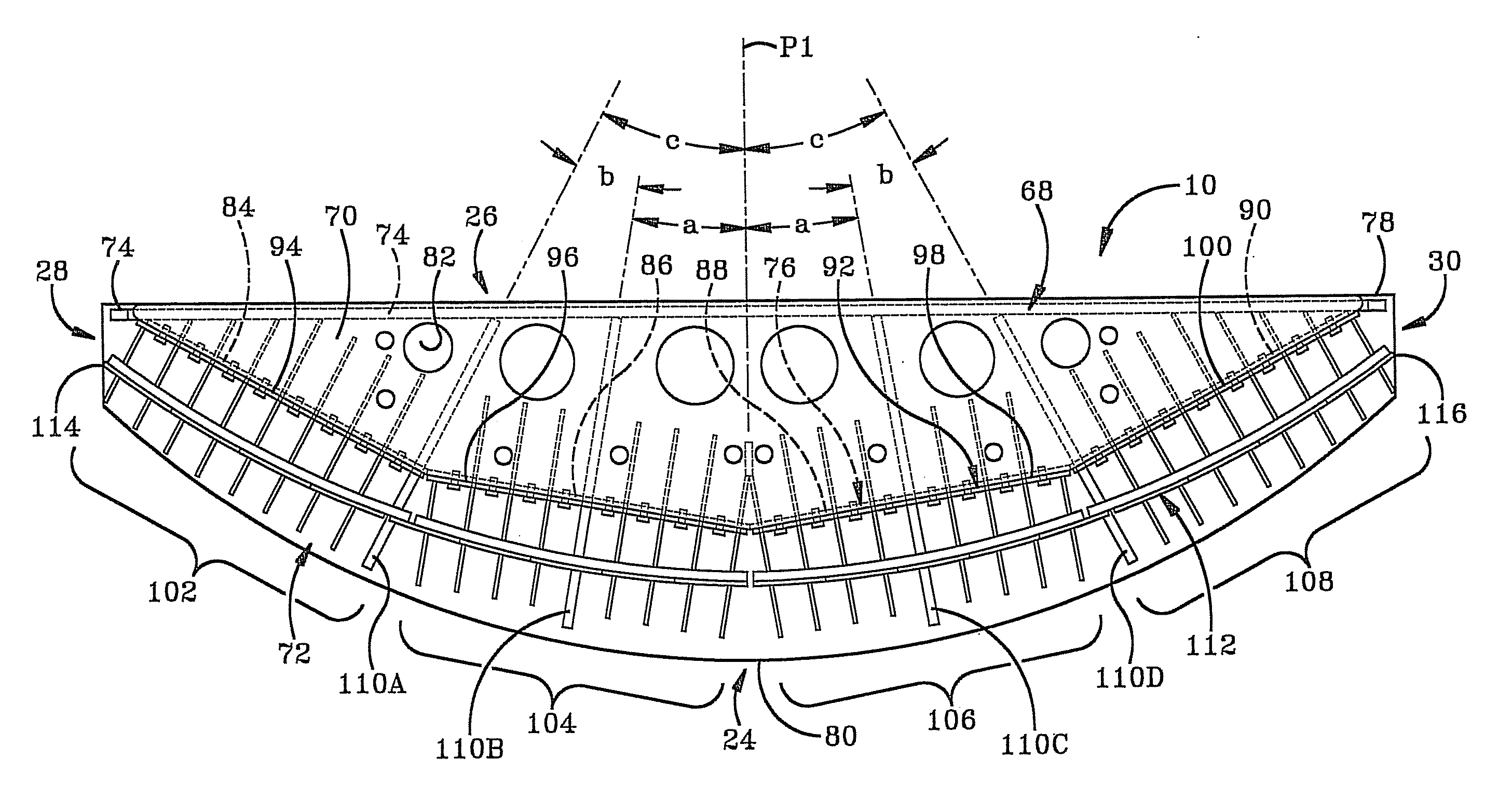

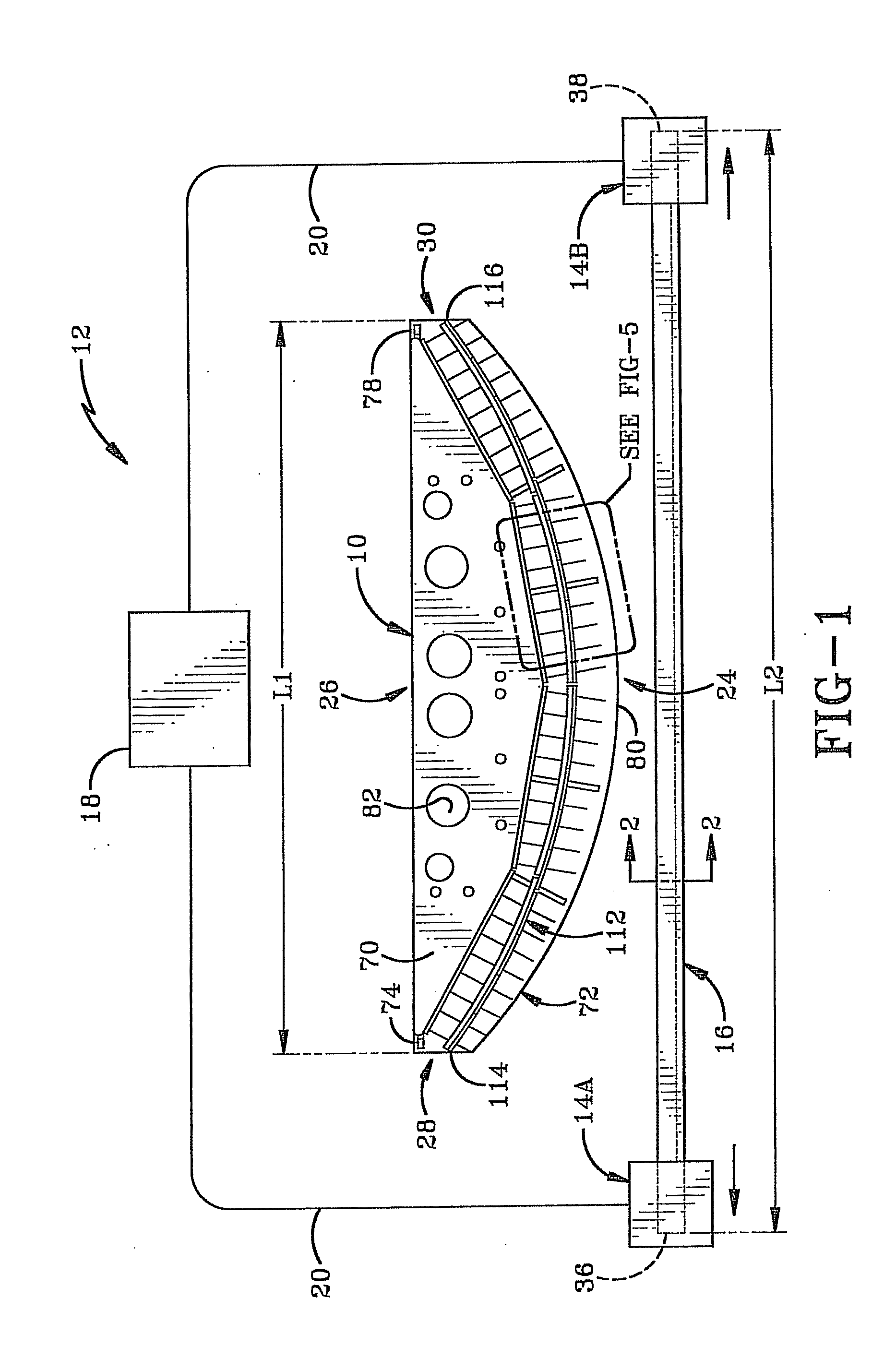

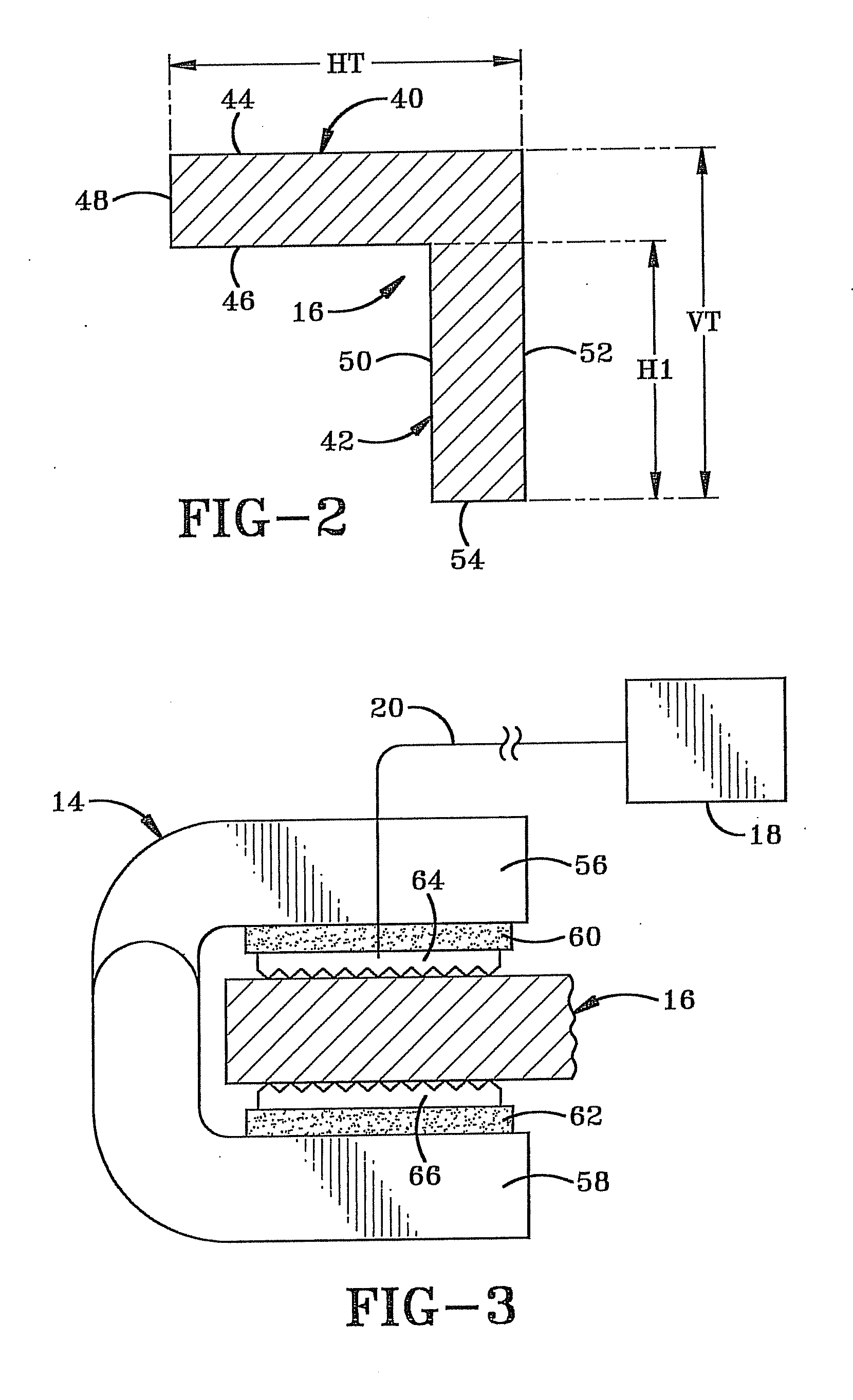

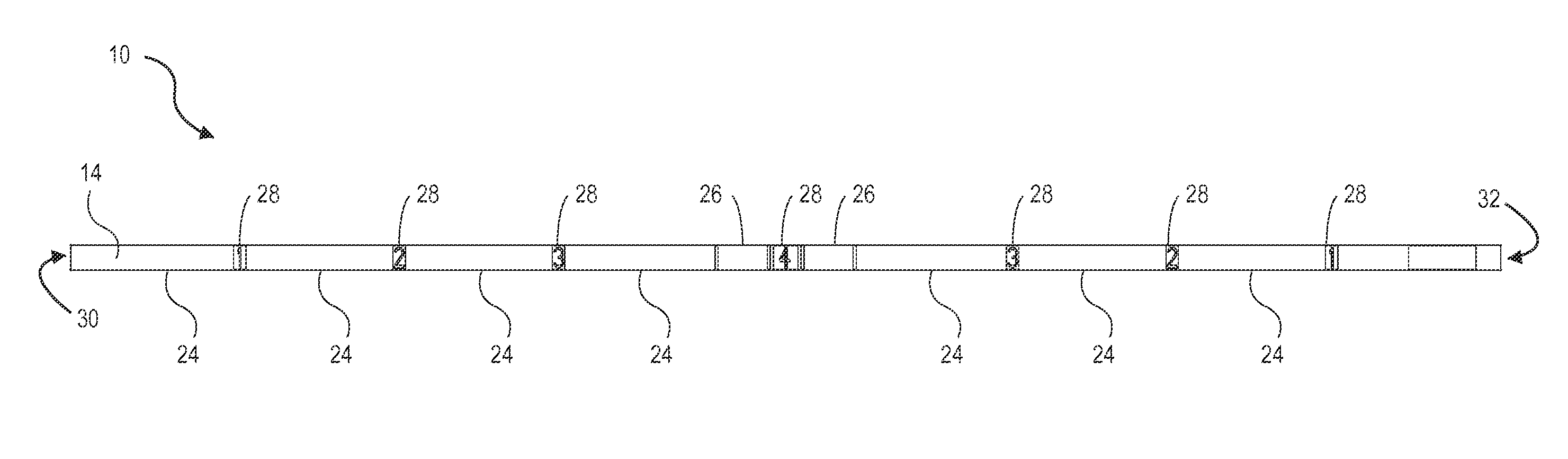

Hot stretch forming die having distortion-minimizing characteristics

A hot stretch wrap forming die typically includes a rigid backing section, a series of spaced ribs extending forward from the backing section, and an elongated face sheet secured to the ribs forward of the backing section with a convex forward-facing die face. The ribs elastically deflect during thermal expansion of the face sheet when a heated metal bar is forced against the die face so that the metal bar transfers heat to the face sheet. The die typically includes stiff ribs secured to the backing section and the face sheet which provide substantially fixed points for the face sheet during its thermal expansion. The face sheet may include several face sheet segments which together form the die face. The face sheet may also include contour plates which form respective portions of the die face and which may be used to adjust the specific contour of the die face.

Owner:HOWMET AEROSPACE INC

Stretch Strap

The present invention provides in some embodiments, a device for stretching muscles having a series of loops. The device can be formed from strips of elastic material periodically joined in order to form loops. More particularly, a top portion of elastic material can be laid on top of a bottom portion of elastic material. The top and bottom portions of materials can be joined in a variety of ways. A user of the device can engage different body parts with the loops and use the device to facilitate a dynamic stretch of a muscle. Dynamic stretching involves active contraction of the muscle prior to the stretch.

Owner:HYGENIC INTANGIBLE PROPERTY HLDG

Wrapping apparatus

InactiveUS20090044494A1Reduce riskLight-weightContainers for annular articlesFilament handlingBack injuryWork related injuries

An apparatus for applying a material, such as stretch wrap, to a pallet stacked with objects is provided. Conventional pallet wrapping is labor intensive, causes back injuries, repetitive stress injuries and other work related injuries to users / operators. By contrast, the apparatus of the present invention is portable, light-weight, easy to use and reduces the risk of work place injuries. The apparatus includes an elongated handle having a first end and a second end and a retaining mechanism mounted on the elongated handle for securing a roll of material to the handle. The retaining mechanism includes a first retaining member secured to the first end of the elongated handle and a second retaining member secured to the second end of the elongated handle, where the roll of material is located between the roll of material.

Owner:NORTHRUP BILL THOMAS

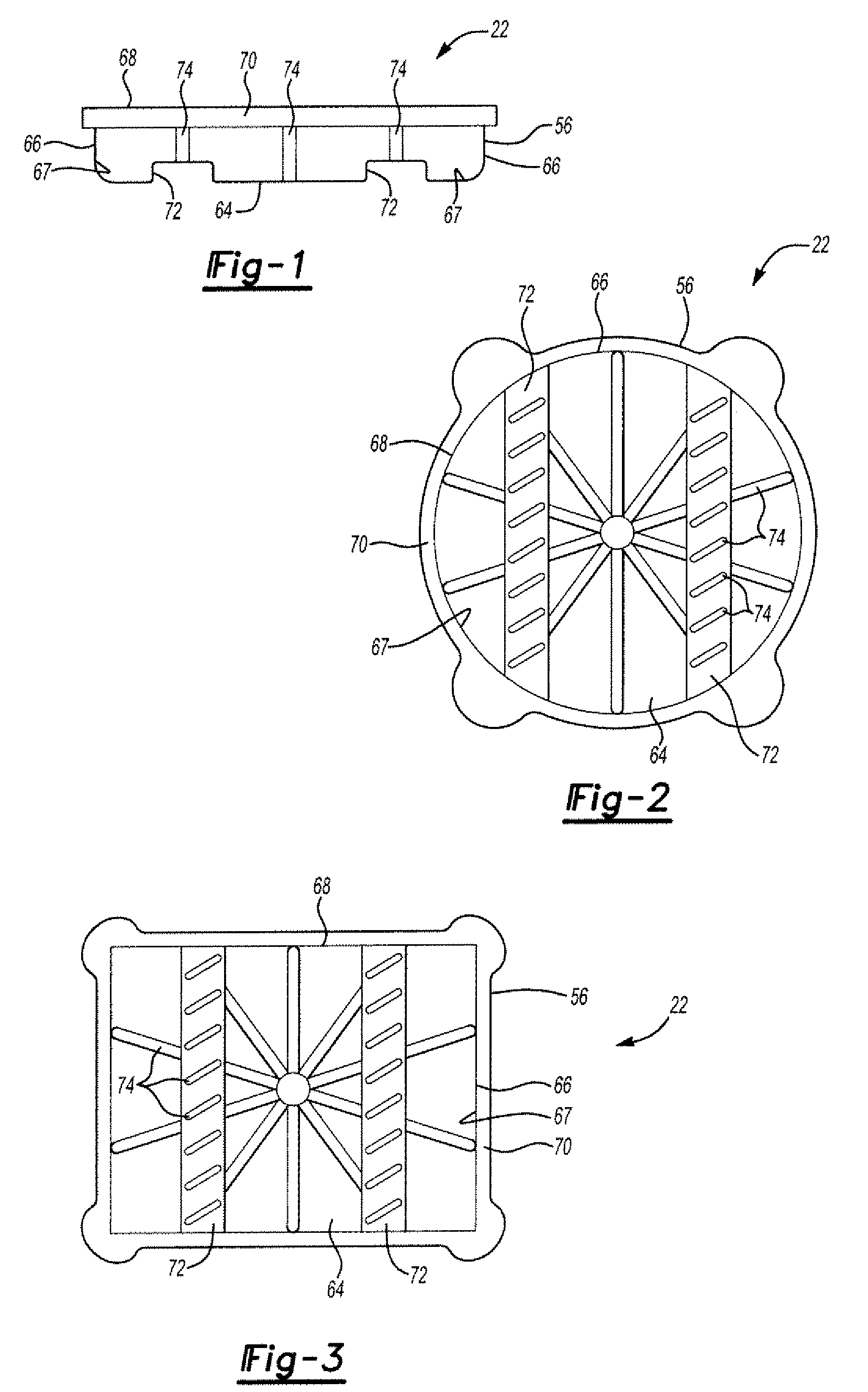

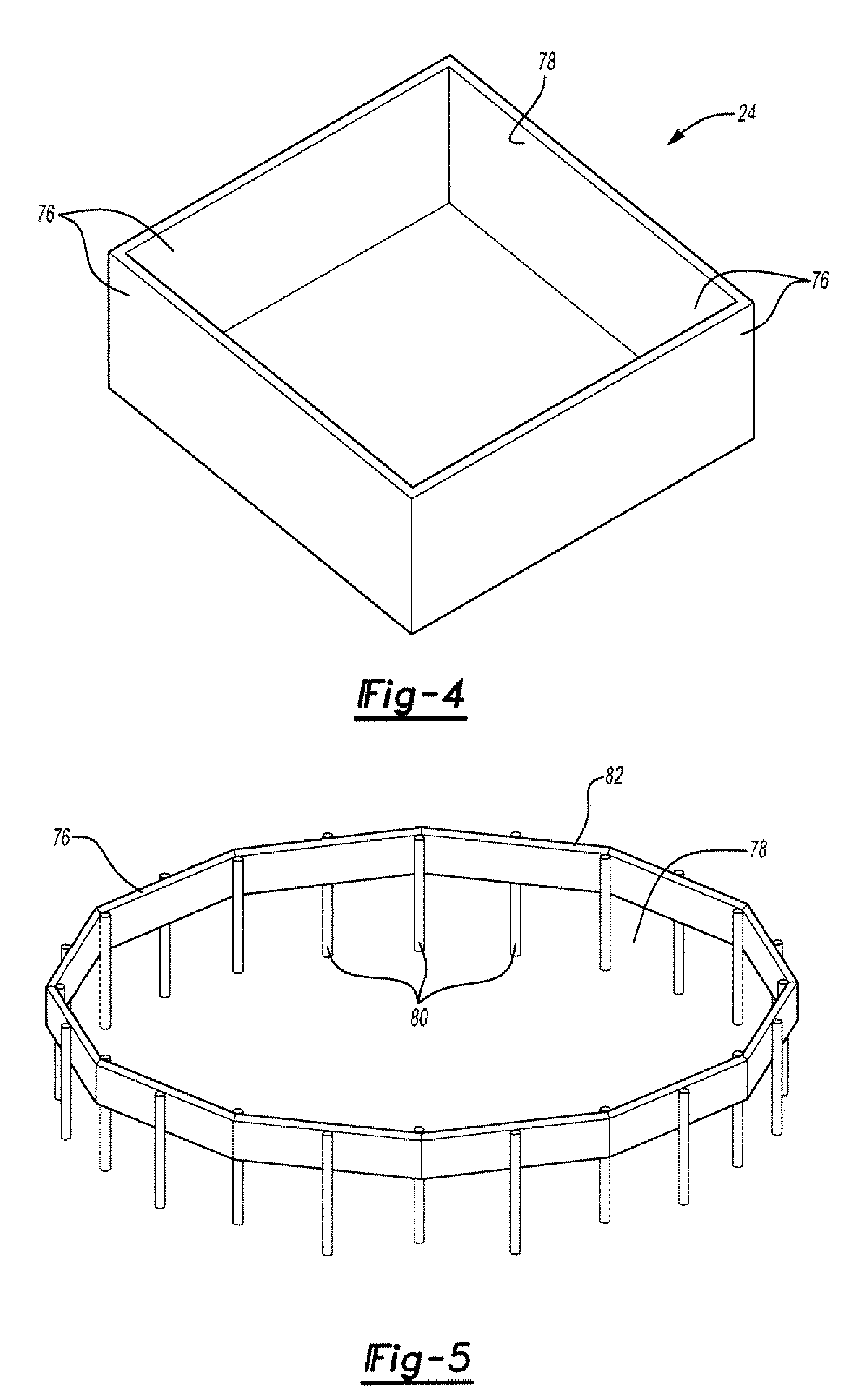

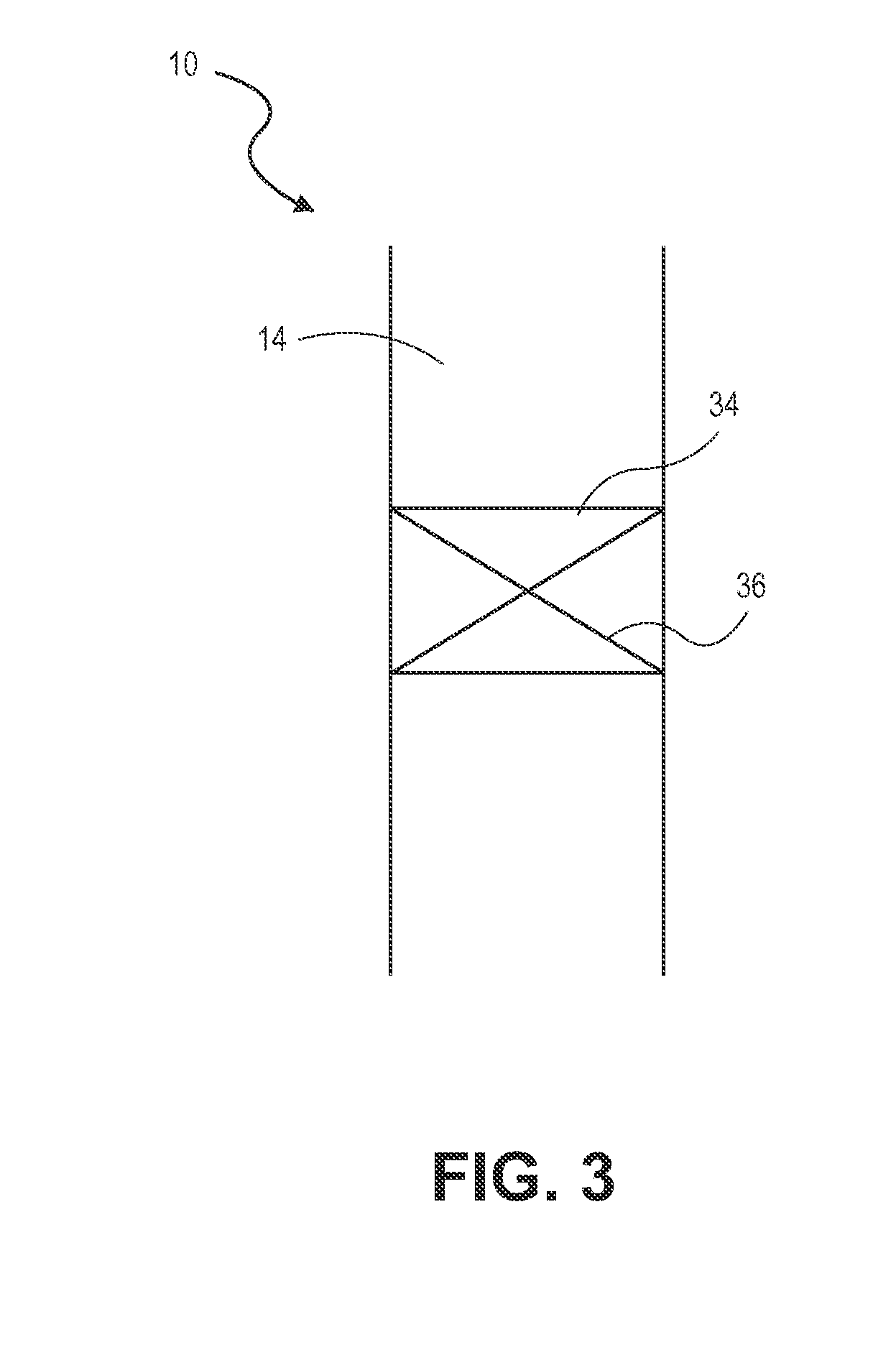

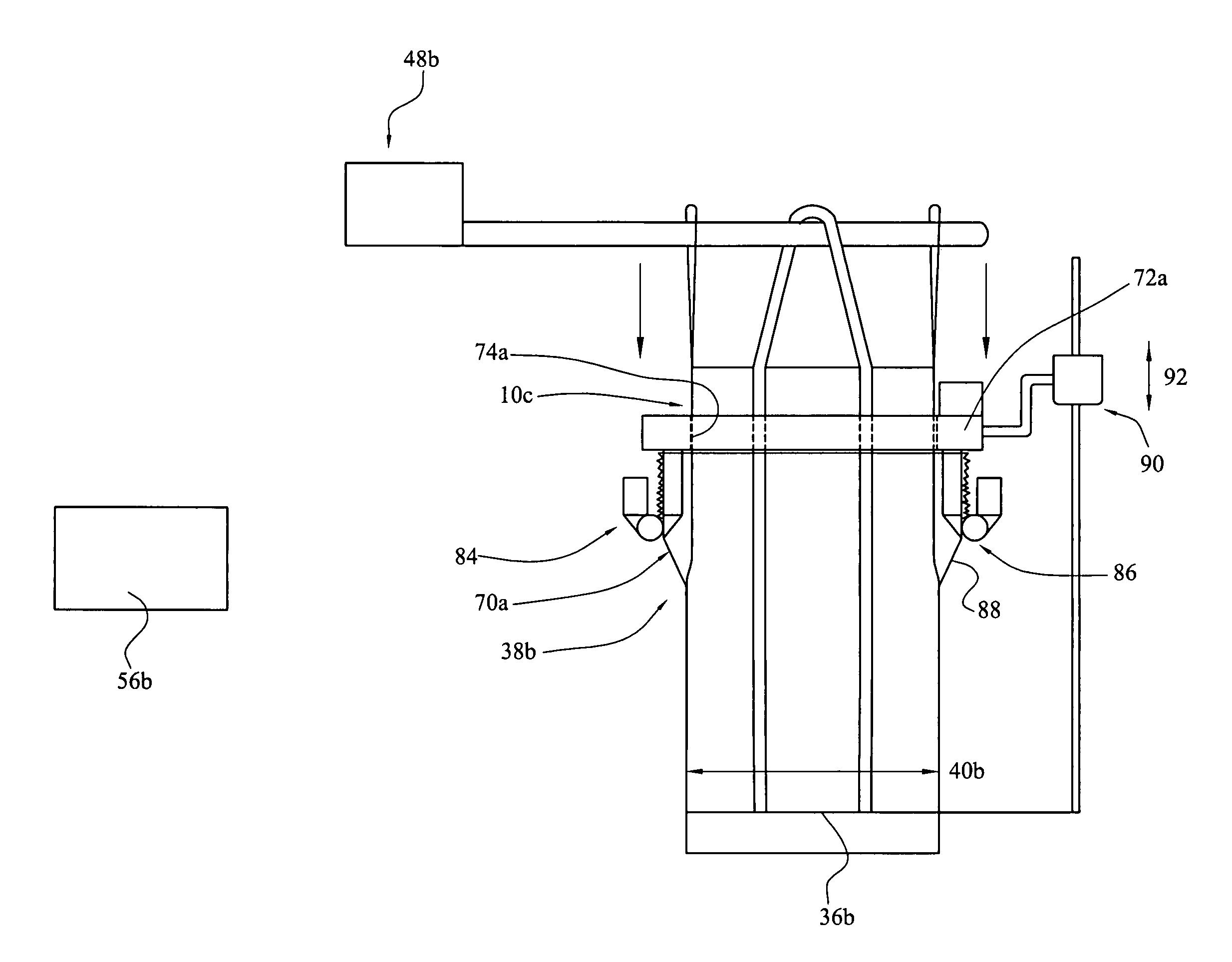

Method and apparatus for stretch wrapping a load, including a top platen

Loads on pallets are often wrapped with a plastic film for shipping. The present invention relates to top platen devices used to maintain stability in loads while the load is wrapped for shipping. The top platen device applies a compressive force to the load to stabilize the load while it is being wrapped. The top platen includes a shaft supporting platen pad which is placed on top of the load. The shaft and platen pad are configured to rotate eccentrically with respect to the geometric center of the top platen in order to rotate with the load about the load's center of rotation.

Owner:LANTECH MANAGEMENT

Low gauge stretch wrap film

InactiveUS7172815B2Improve carrying capacityImprove puncture resistanceSynthetic resin layered productsRecord information storageStretch wrapCLARITY

Stretch wrap films are used to hold goods to pallets during storage and shipping. A multilayer stretch wrap film with at least one outer layer of polypropylene and other layers of blends of polyethylenes. The film of the present invention optimizes physical properties enabling the film to have sufficient cling while creating a tolerable noise level upon unwinding. The optimized properties include good clarity, high load containment, high puncture resistance, high stretch and good tear resistance.

Owner:PLIANT LLC

Peel and stick stretch wrap

Owner:BMIC LLC

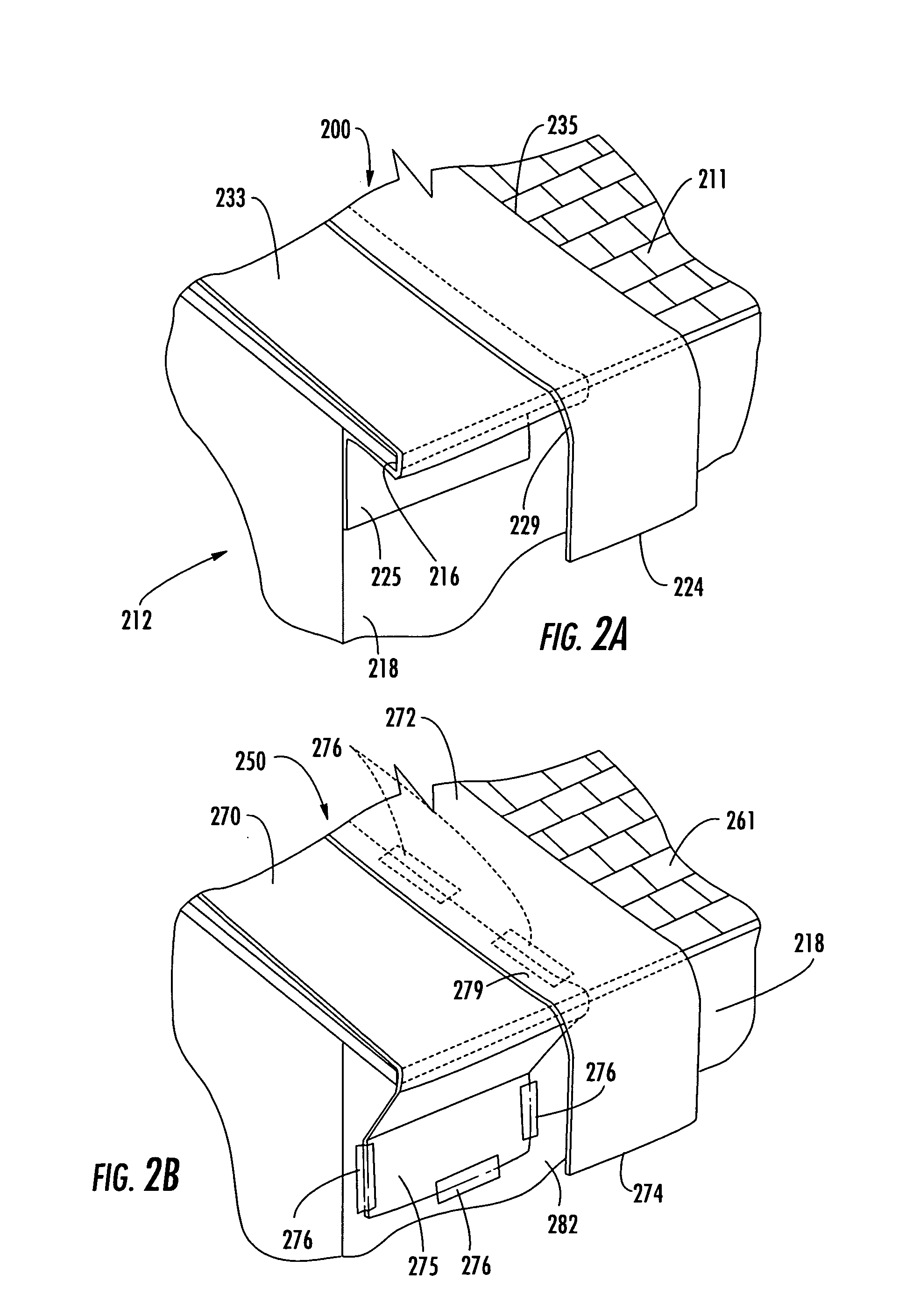

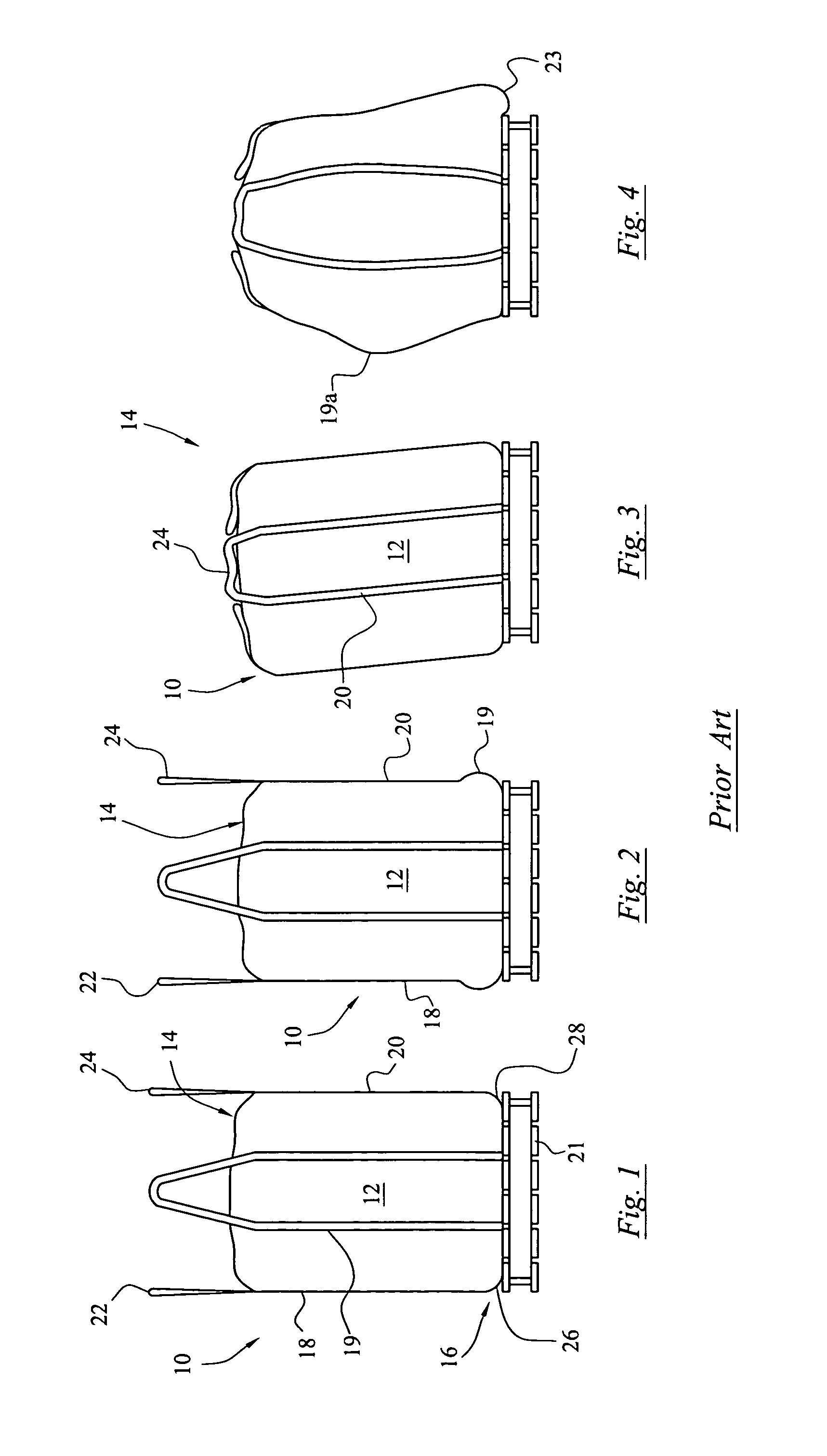

Bulk transportable container

ActiveUS20060037285A1Wrappers shrinkageWrapping material feeding apparatusStretch wrapCompound (substance)

A method for filling a flexible container with a flowable material is provided, including the steps of filling the flexible container, suspending the flexible container, transferring the weight of the flexible container from being suspended to being supported by a support surface, and applying a hoop force to the flexible container to substantially maintain a configuration of the flexible container. The flexible container can be a bag-type container for containing flowable material such as chemicals, food products, agricultural products, and plastic pellets. As the container is lowered from the suspended position to a bottom-supported position, the hoop force is applied around the perimeter as the perimeter changes during transfer of the flexible container from being suspend to being bottom-supported. The hoop force can be applied by stretch wrap. Alternatively, the first flexible container can be lowered into a second flexible container. The second flexible container can be formed from a heat shrinkable material and the second flexible container can be shrunk at the perimeter as the perimeter changes. Alternatively, the second flexible container can be a stretchable bag. A stretched portion of the stretchable bag can be released substantially at the perimeter to generate the hoop force.

Owner:KELLOGG CO

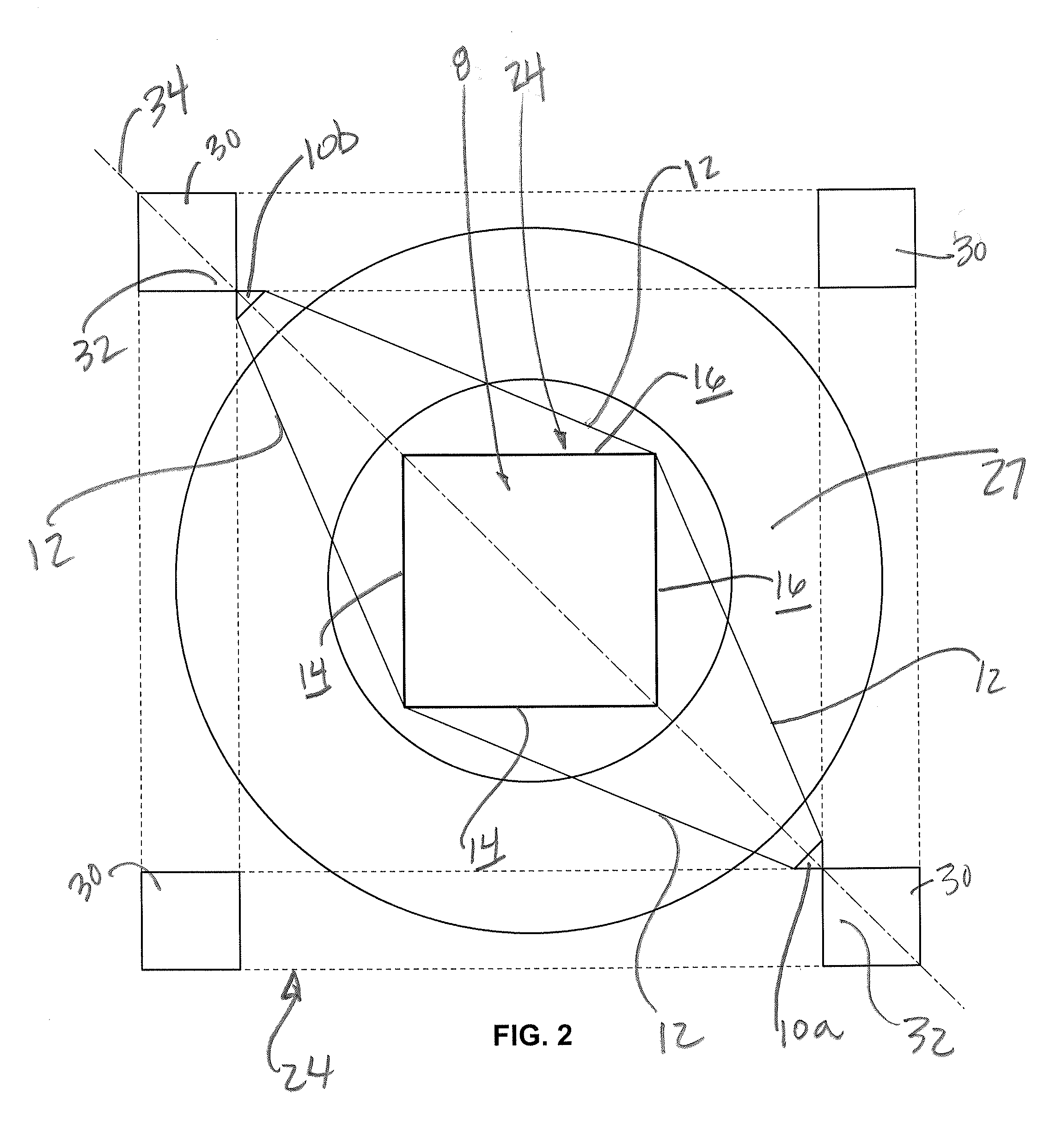

Method and apparatus for stretch wrapping a load, including a top platen

Loads on pallets are often wrapped with a plastic film for shipping. The present invention relates to top platen devices used to maintain stability in loads while the load is wrapped for shipping. The top platen device applies a compressive force to the load to stabilize the load while it is being wrapped. The top platen includes a shaft supporting platen pad which is placed on top of the load. The shaft and platen pad are configured to rotate eccentrically with respect to the geometric center of the top platen in order to rotate with the load about the load's center of rotation.

Owner:LANTECH MANAGEMENT

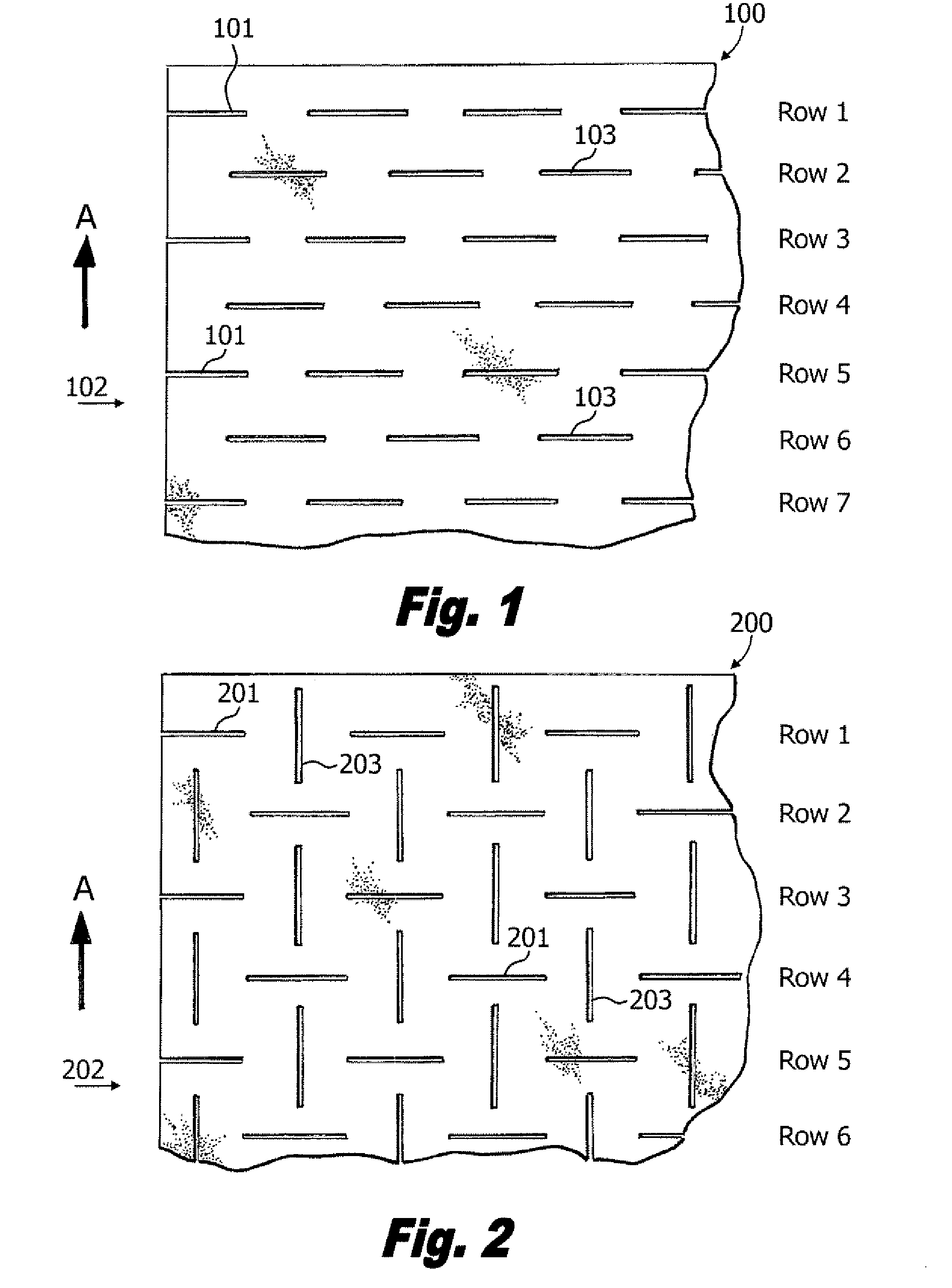

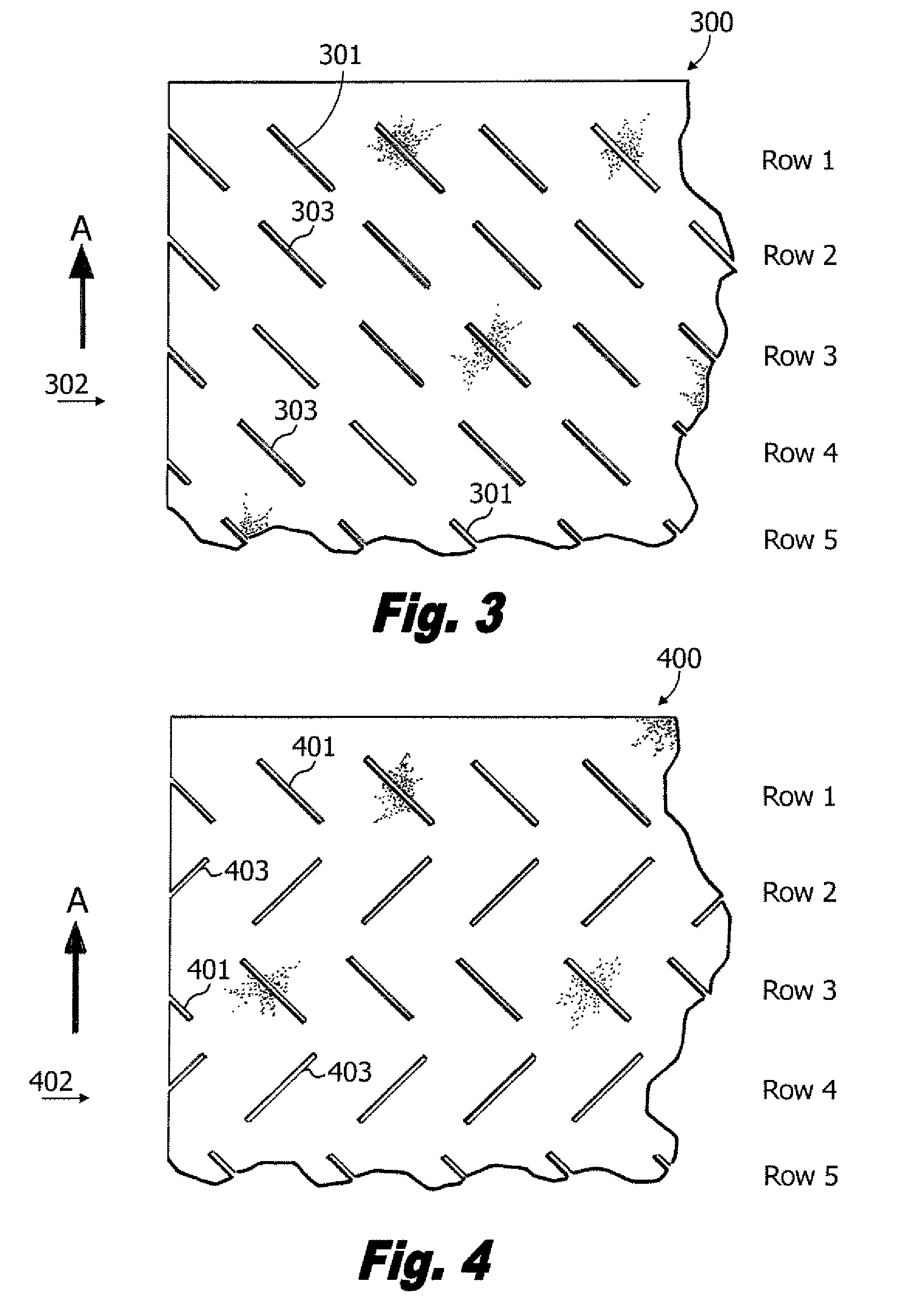

Films and Methods for Making Tampering Events Evident

Films and methods for making tampering events obvious are disclosed. In one embodiment, a tamper evident film includes a coating containing a first substance, and an observable change occurs when the first substance comes into contact with a second substance. In another embodiment, a tamper evident stretch wrap includes an inner portion, an outer portion, and a substance between the inner and outer portions that is adapted to escape from between the portions when the outer portion is breached. In another embodiment, a tamper evident stretch wrap includes a first layer of film having a first pattern and a second layer of film having a second pattern that overlap to form a predetermined third pattern. In yet another embodiment, a stretch wrap is exposed to ultraviolet light and checked for a change in a fluorescent signature to determine whether the stretch wrap has been breached.

Owner:PLIANT LLC

Bulk transportable container

A method for filling a flexible container with a flowable material is provided, including the steps of filling the flexible container, suspending the flexible container, transferring the weight of the flexible container from being suspended to being supported by a support surface, and applying a hoop force to the flexible container to substantially maintain a configuration of the flexible container. The flexible container can be a bag-type container for containing flowable material such as chemicals, food products, agricultural products, and plastic pellets. As the container is lowered from the suspended position to a bottom-supported position, the hoop force is applied around the perimeter as the perimeter changes during transfer of the flexible container from being suspend to being bottom-supported. The hoop force can be applied by stretch wrap. Alternatively, the first flexible container can be lowered into a second flexible container. The second flexible container can be formed from a heat shrinkable material and the second flexible container can be shrunk at the perimeter as the perimeter changes. Alternatively, the second flexible container can be a stretchable bag. A stretched portion of the stretchable bag can be released substantially at the perimeter to generate the hoop force.

Owner:KELLOGG CO

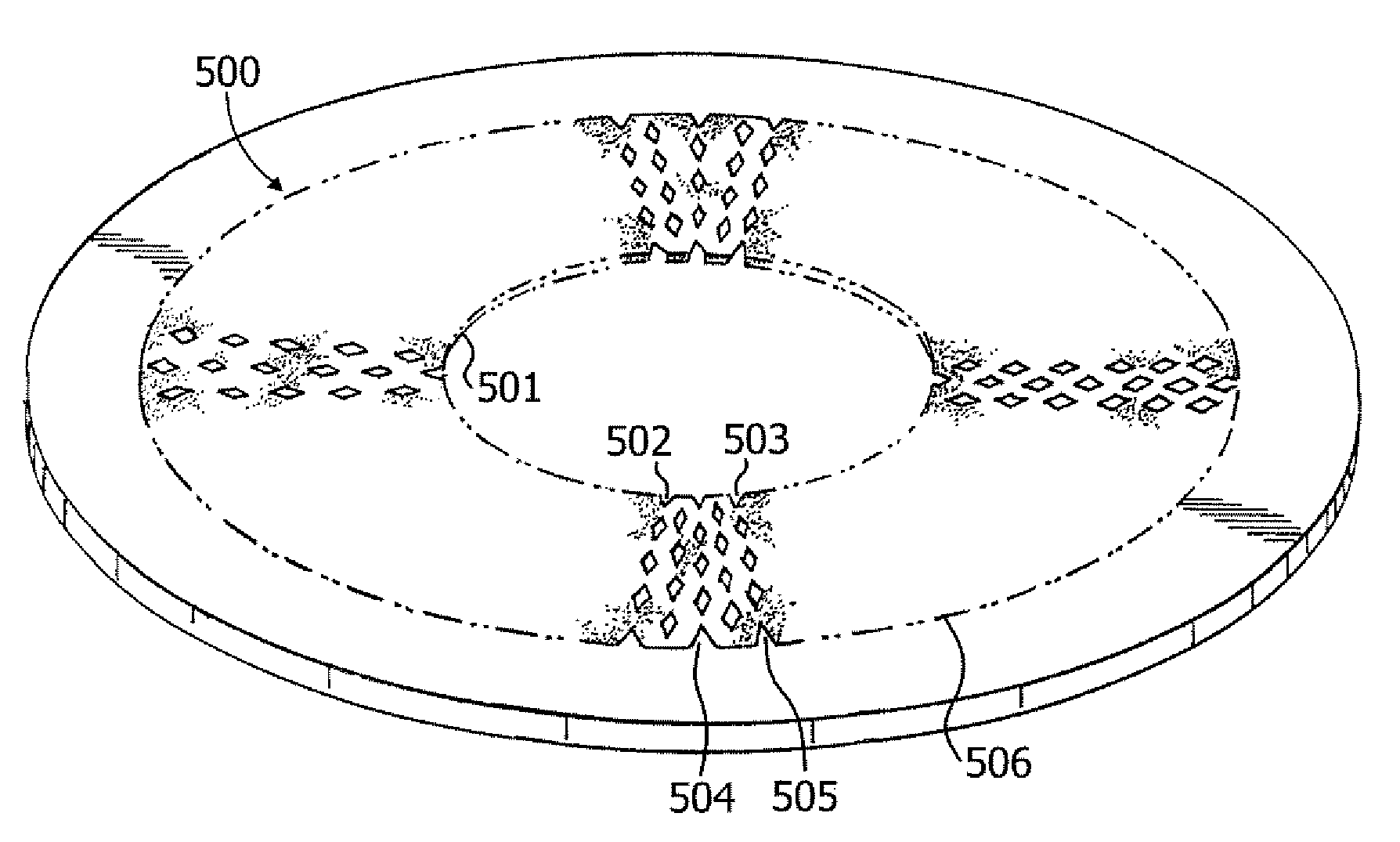

Apparatus and method for applying cornerboards to a load

InactiveUS6883293B2Quickly and reliably and inexpensively placeWeb rotation wrappingBinding material applicationStretch wrapEngineering

A method and apparatus for providing corners of a load with cornerboards prior to wrapping the load is provided. The method may include providing a load on a load transport surface, removing a cornerboard from within a magazine by a gripper, and transporting the cornerboard to a corner of the load with the gripper. Relative rotation may be provided between the stretch wrap packaging material dispenser and the load to wrap the stretch wrap packaging material around the cornerboard and the load. If the cornerboard is not pre-formed, it is folded prior to transport to the load. The cornerboard is secured to the corner of the load with the stretch wrap packaging material. In a preferred embodiment, four magazines and four grippers are provided, such that four cornerboards can be carried to the load at the same time.

Owner:LANTECH

Method for producing stretch wrap plastic film

InactiveUS6383430B1Avoid unwinding and recoilingHigh tensionWrappers shrinkageSynthetic resin layered productsStretch wrapPlastic materials

Owner:INTEGRATED PACKAGING AUSTRALIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com