Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

850 results about "Load sensing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Load sensing is a term used to describe a type of pump control employed in open circuits.

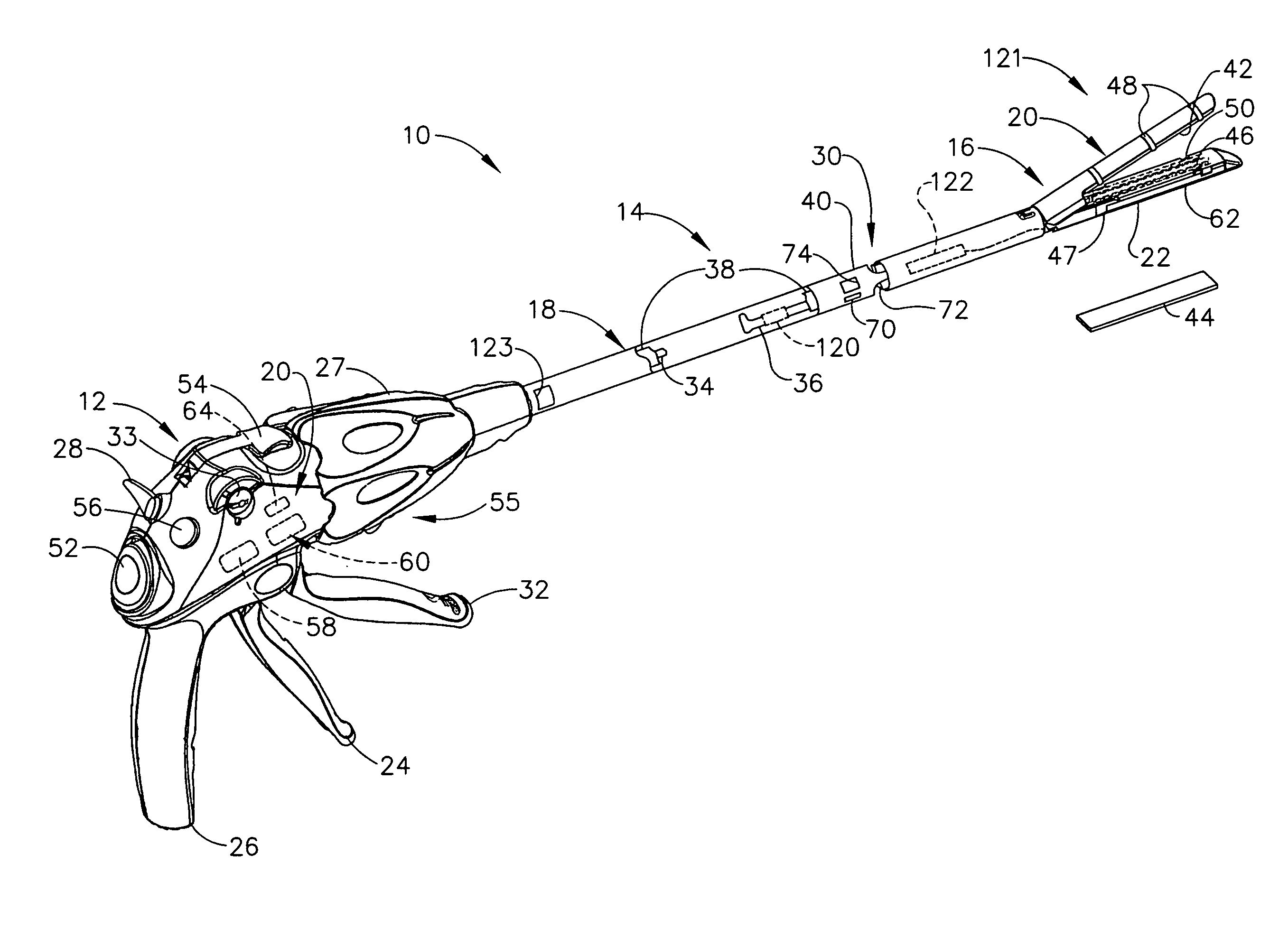

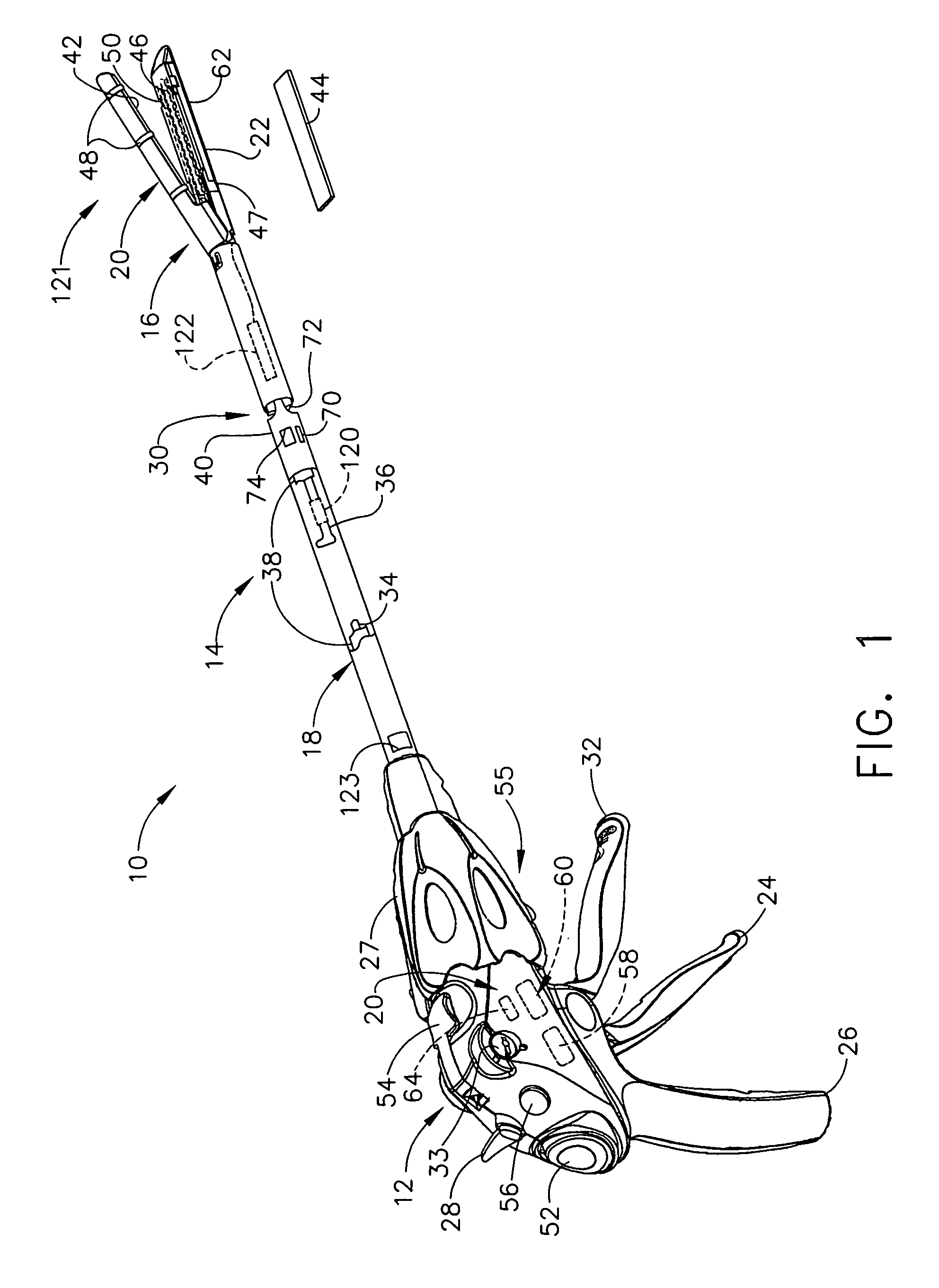

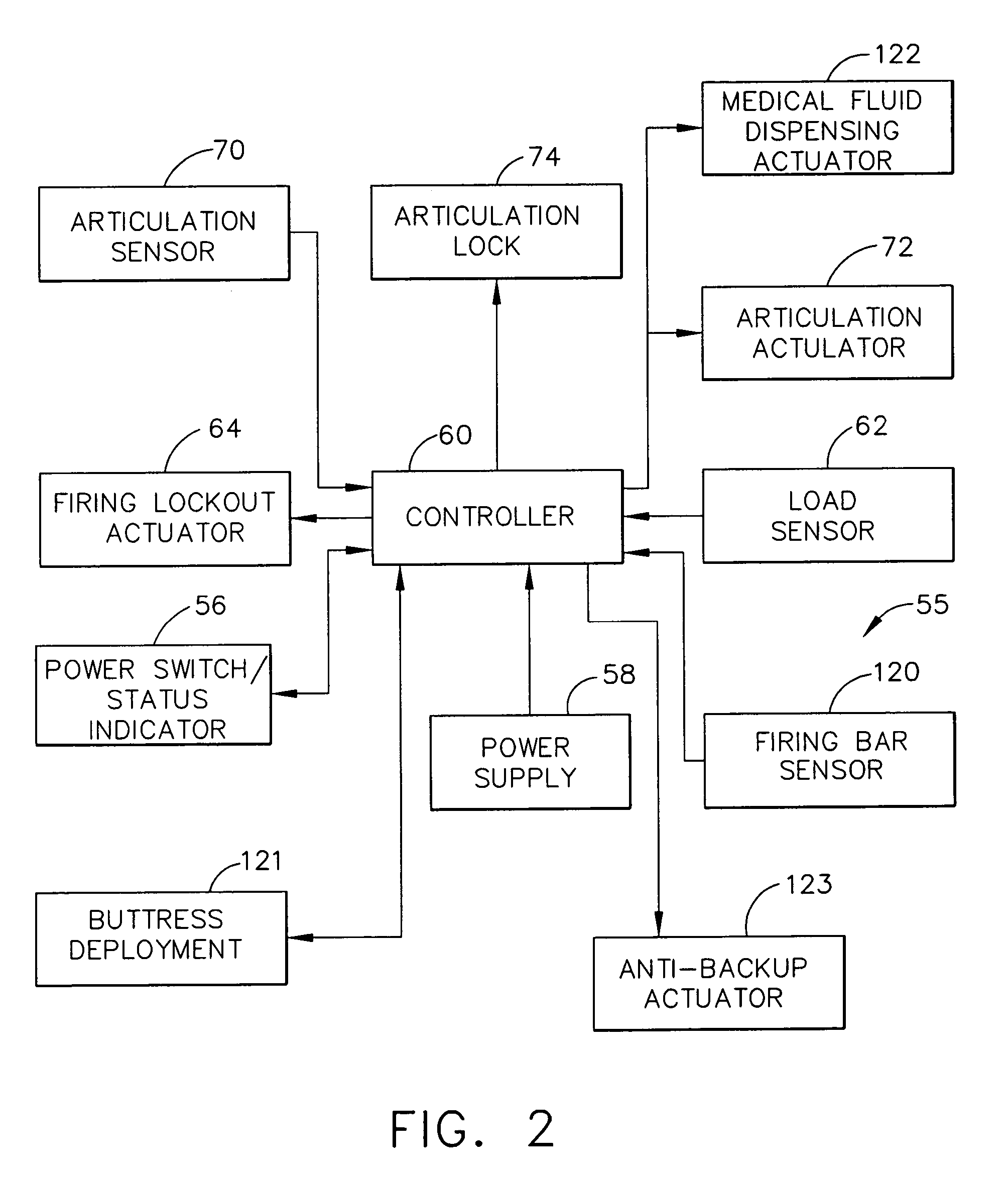

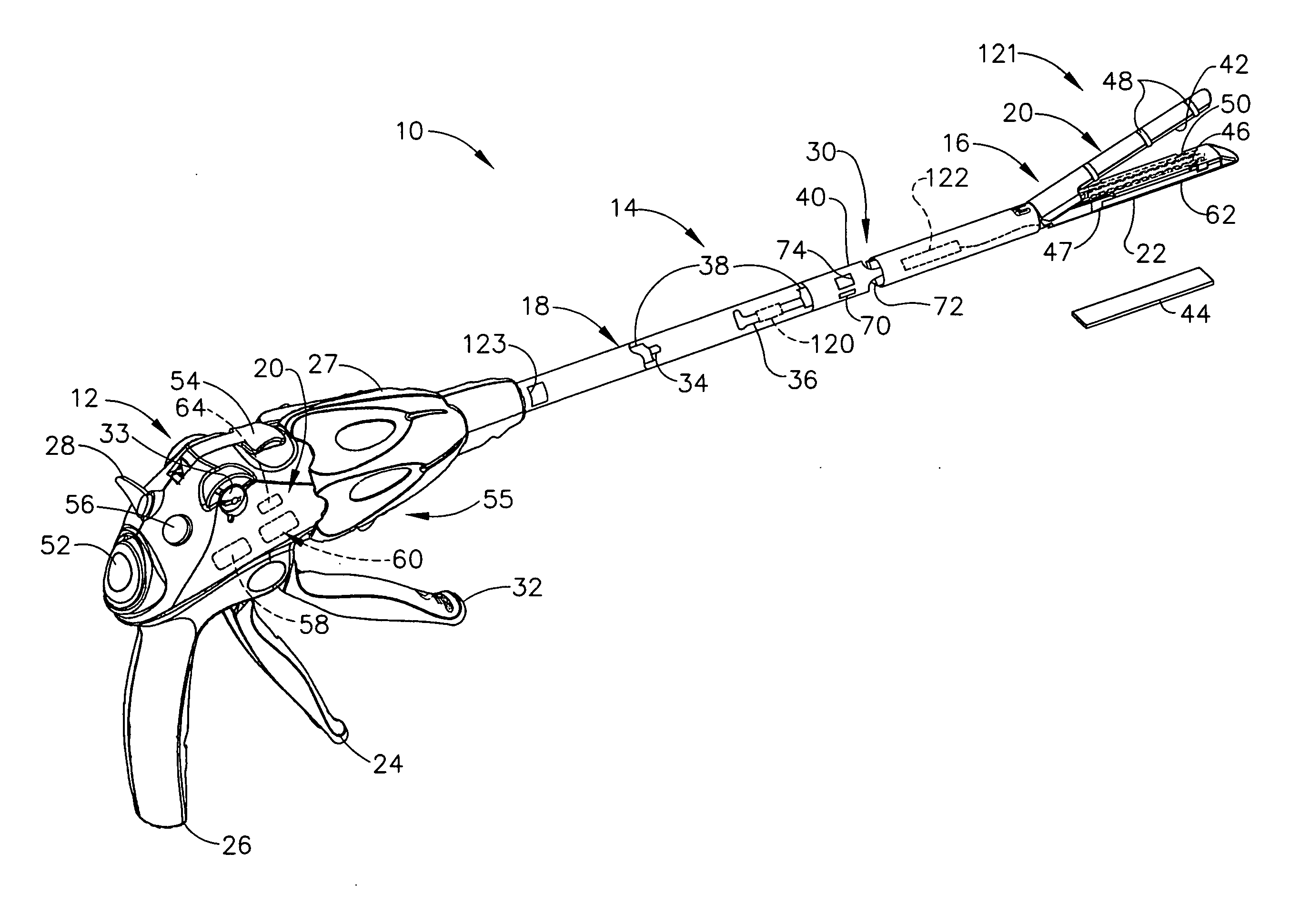

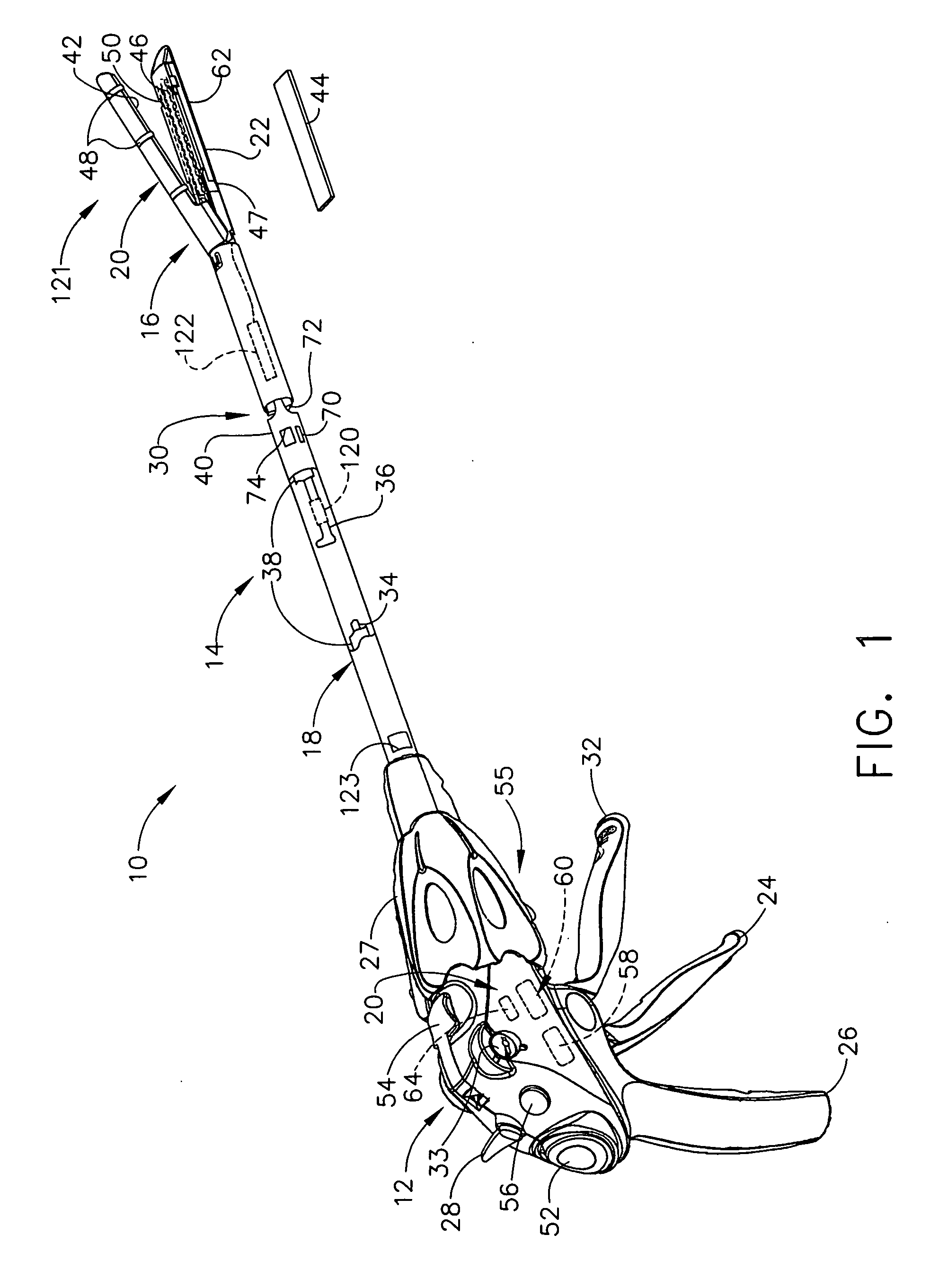

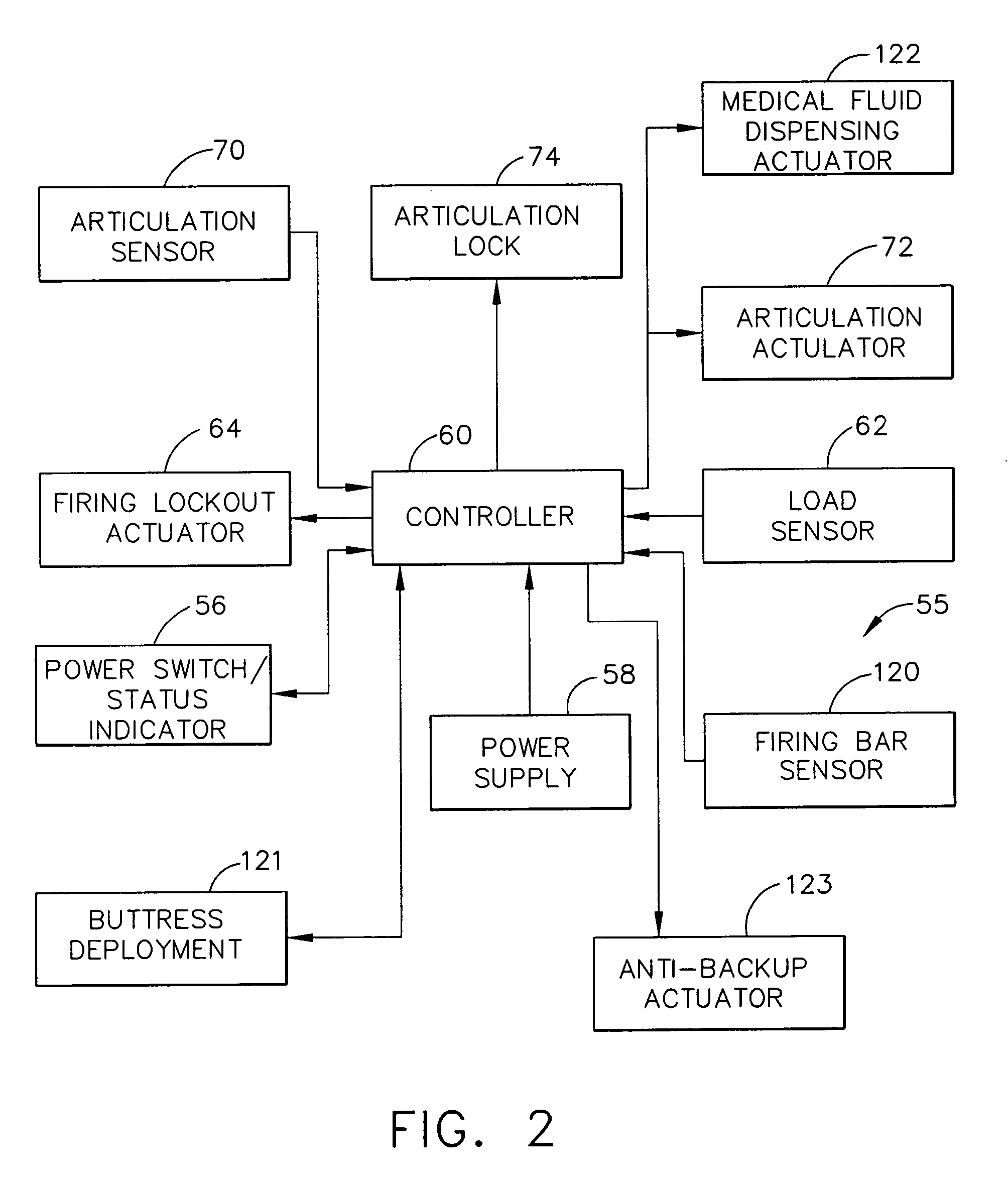

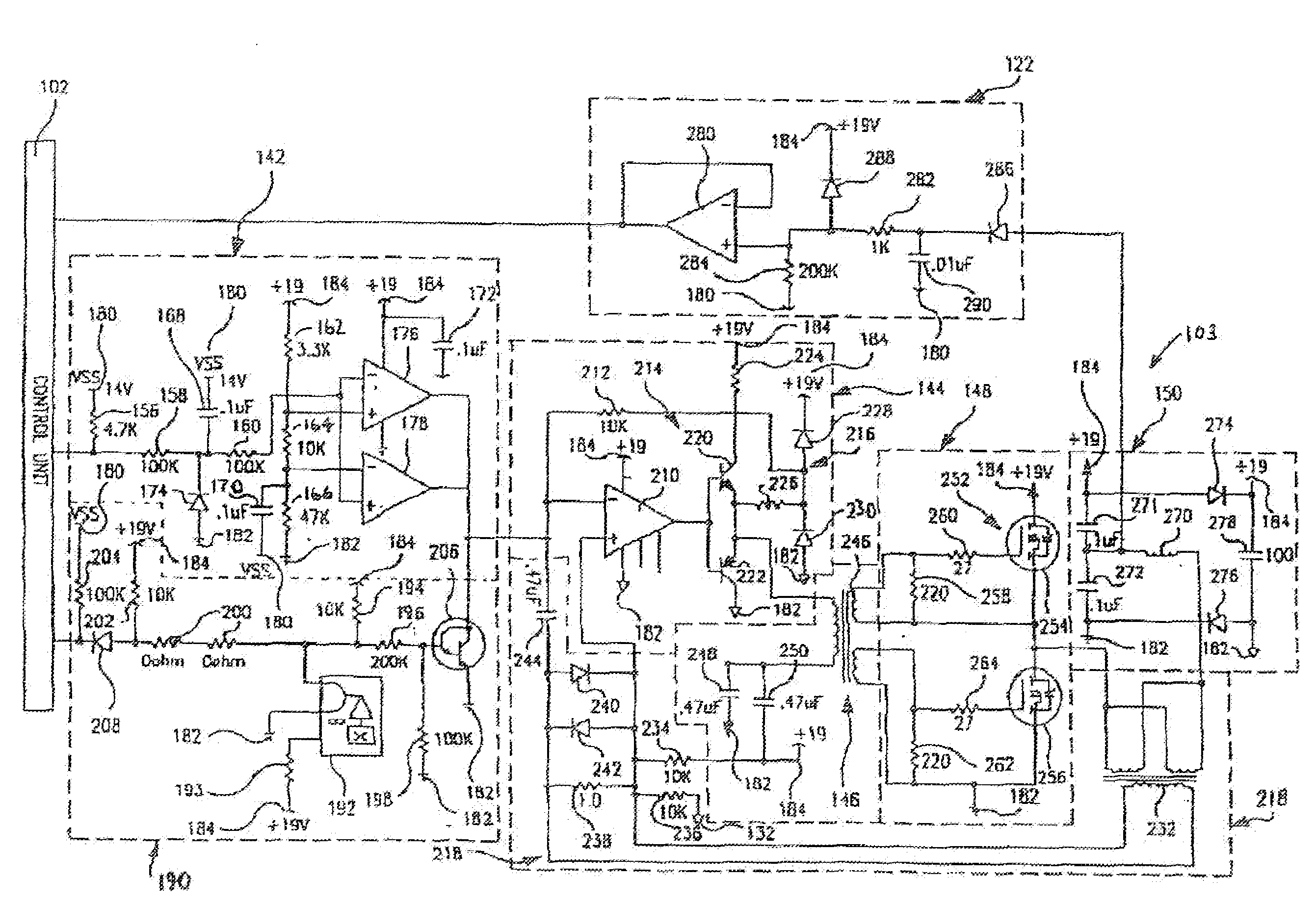

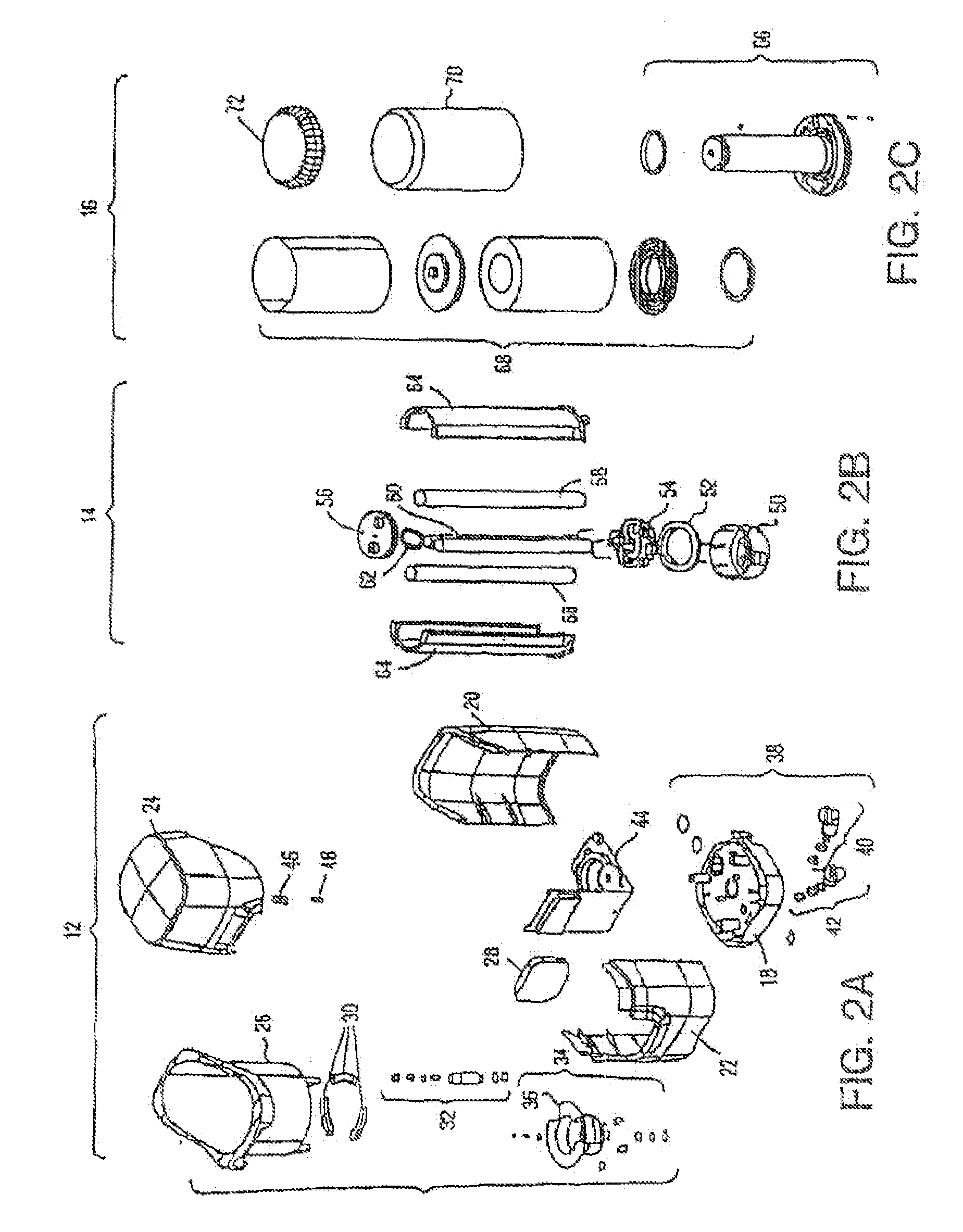

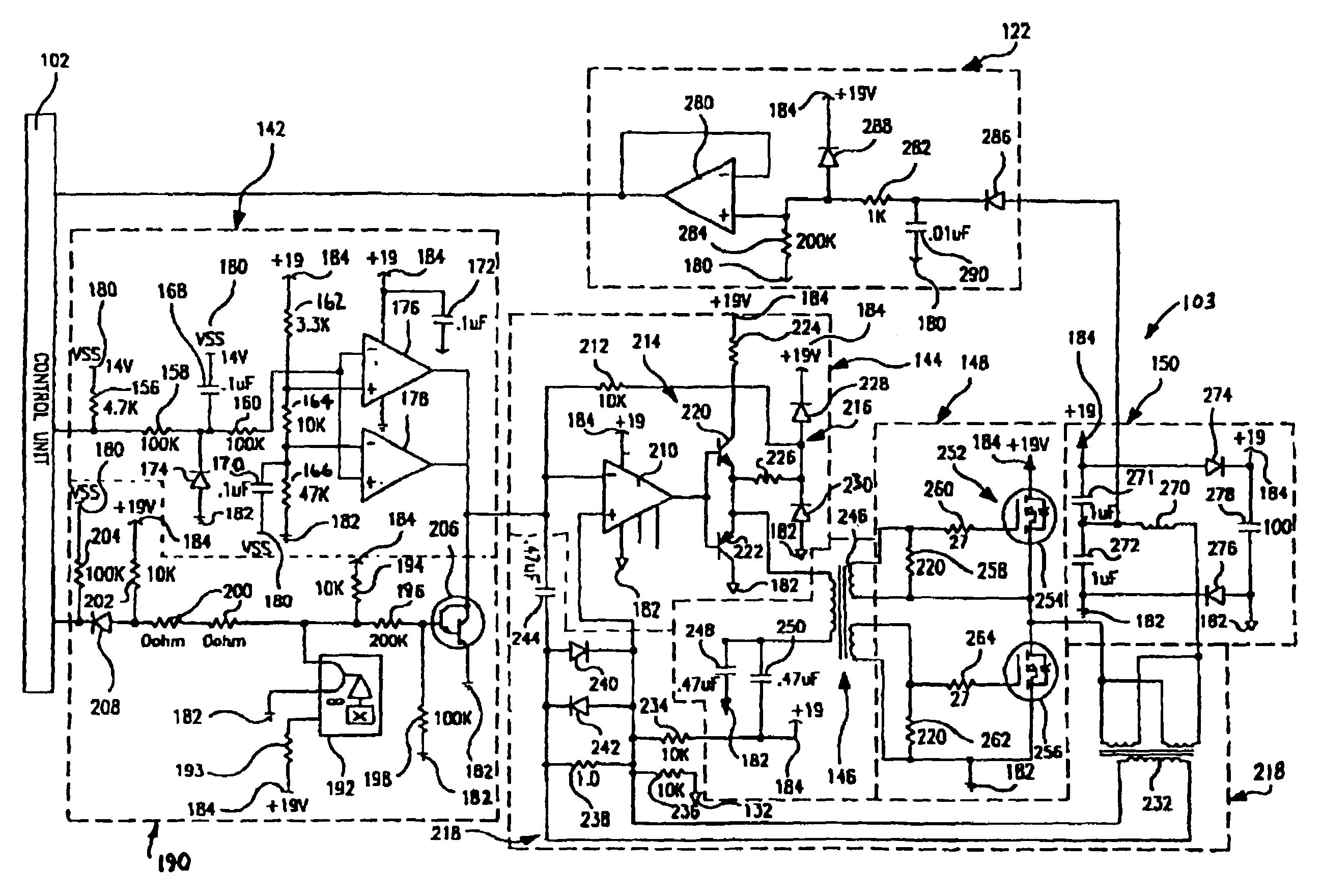

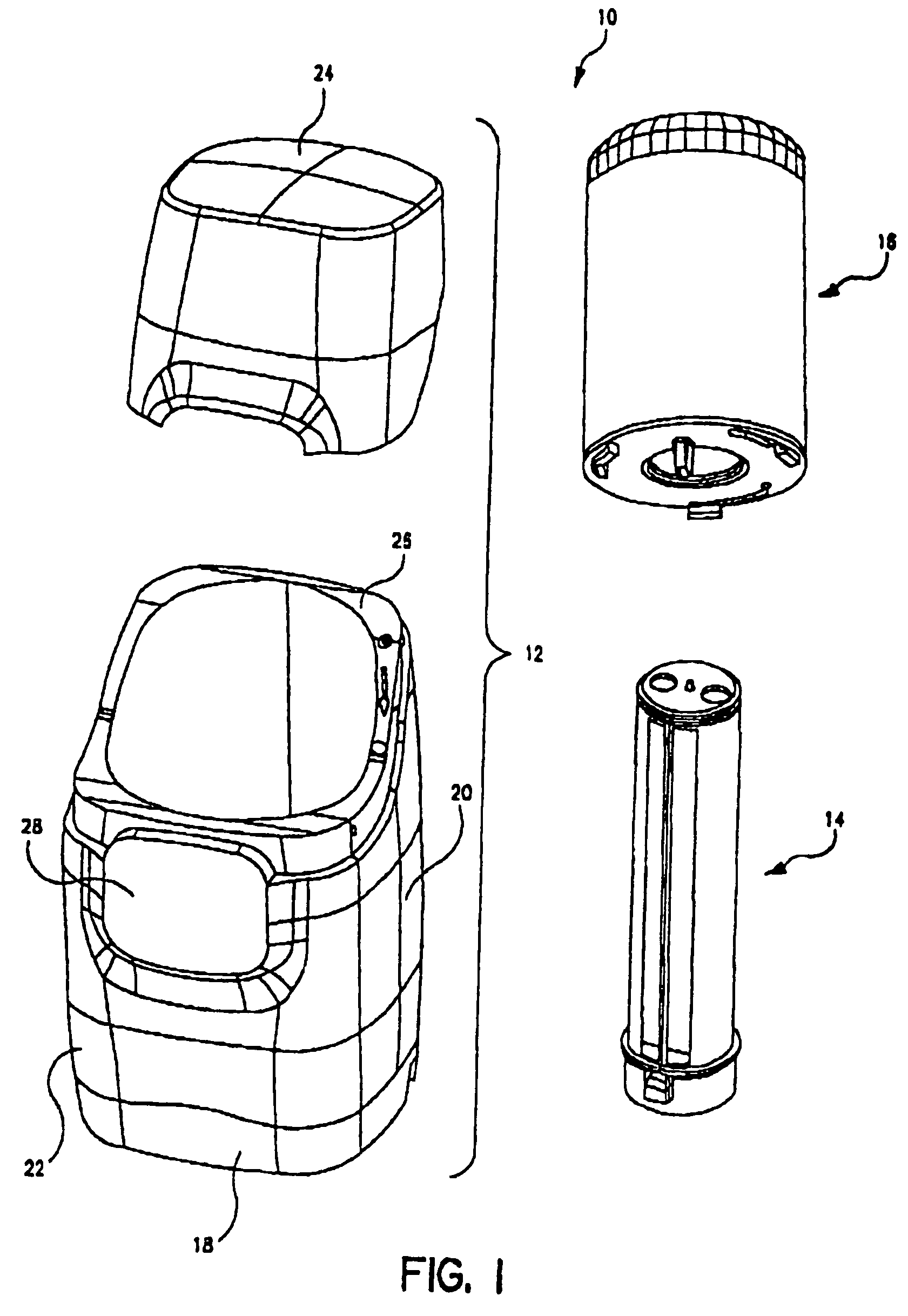

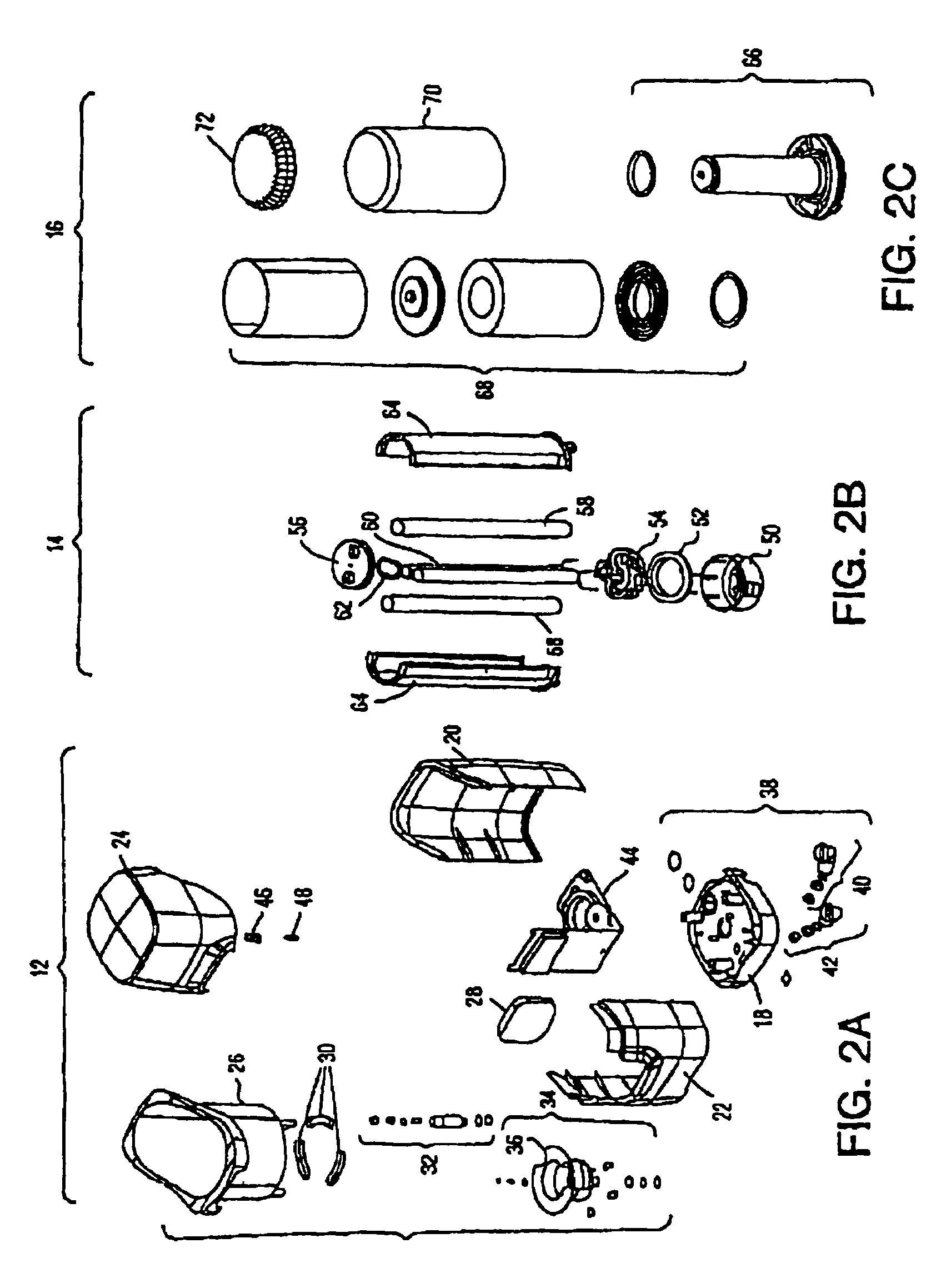

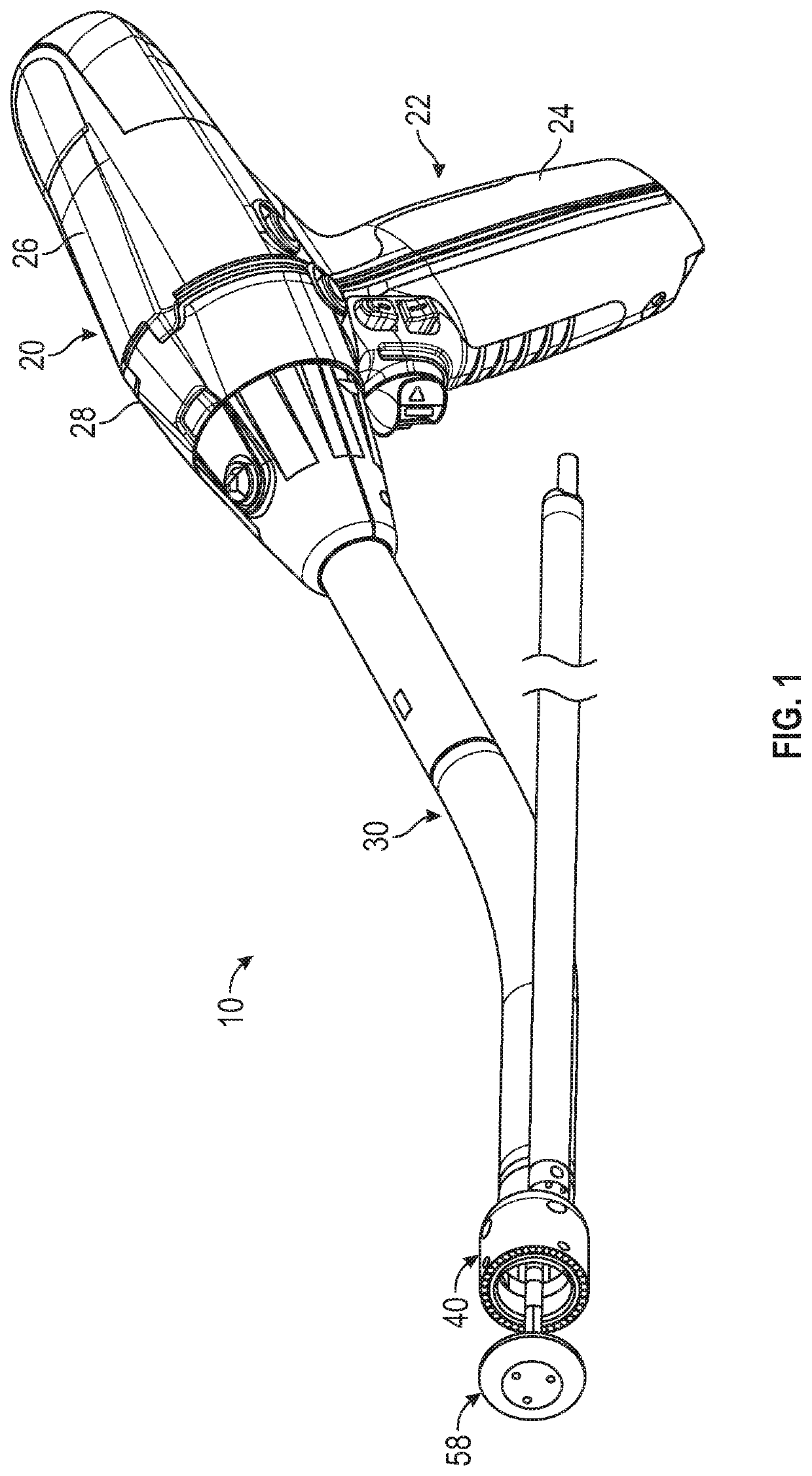

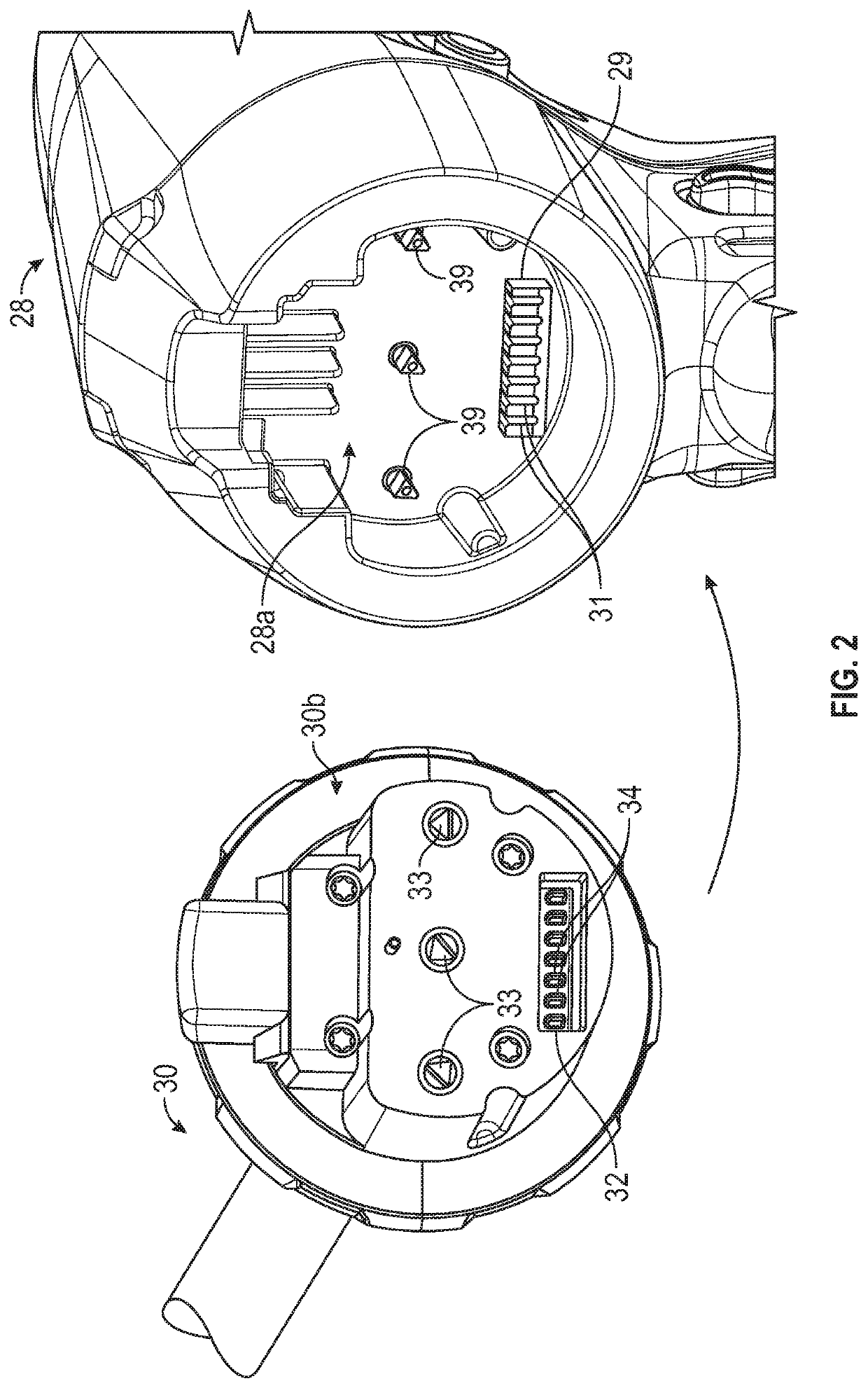

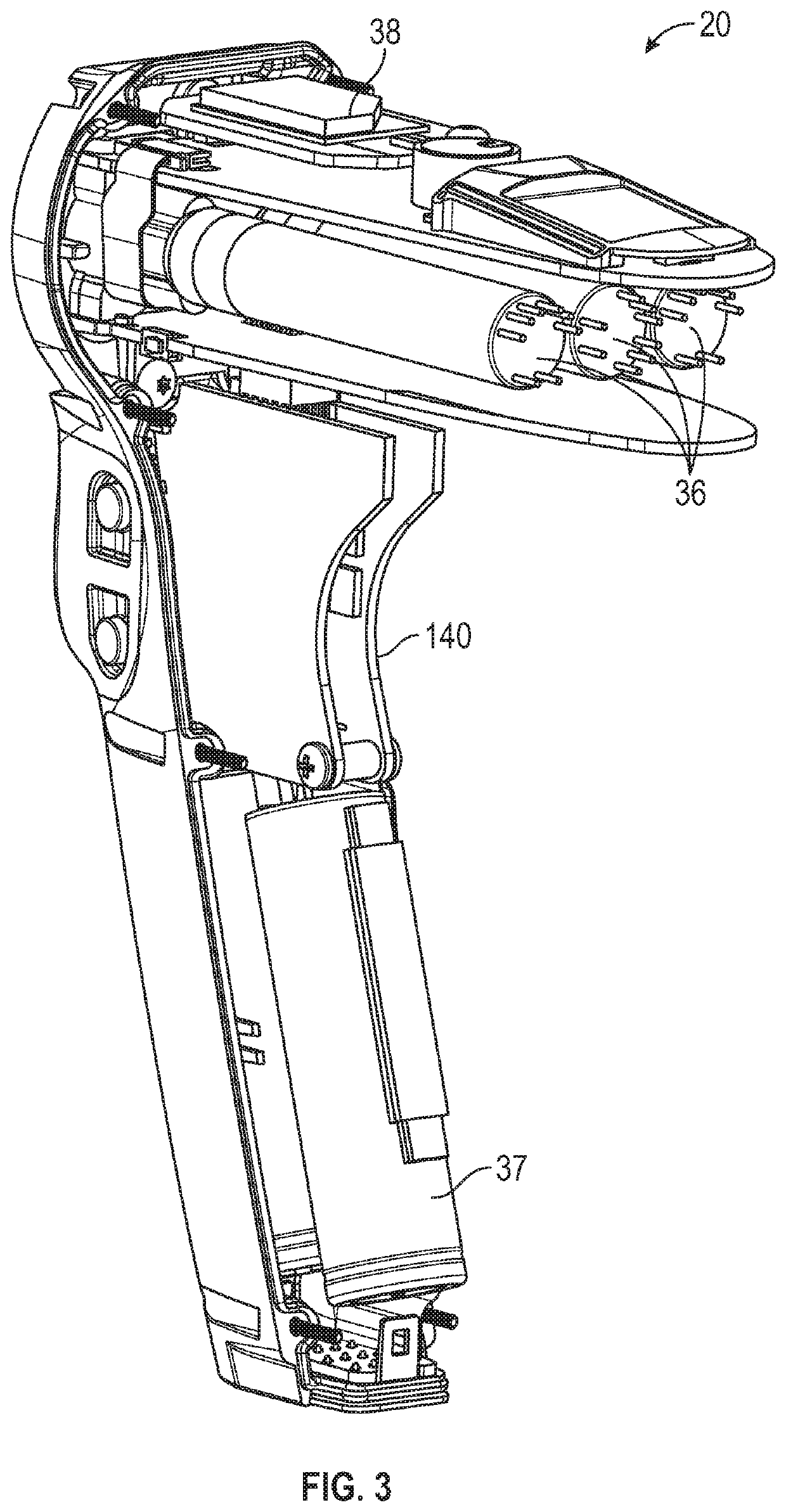

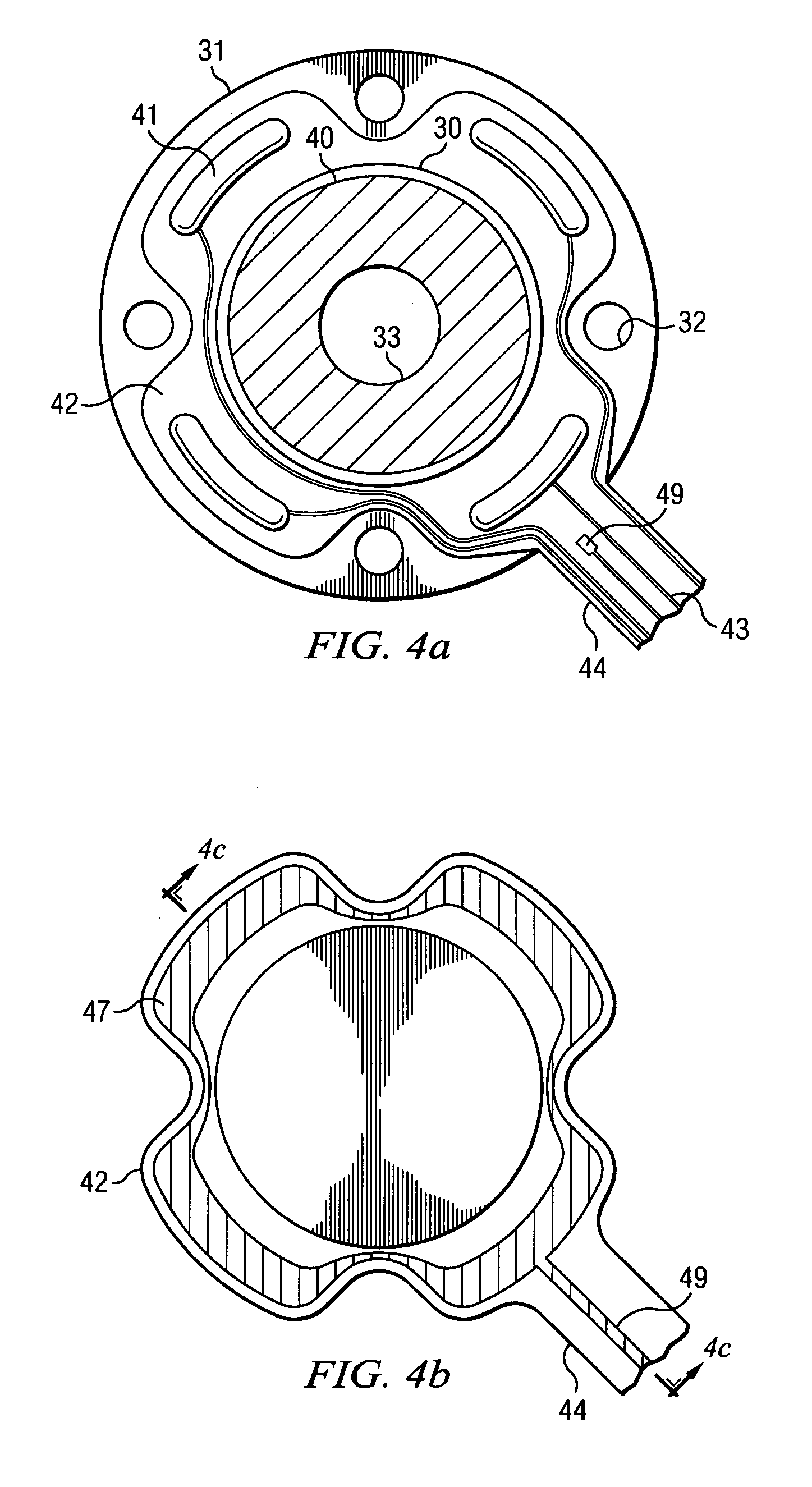

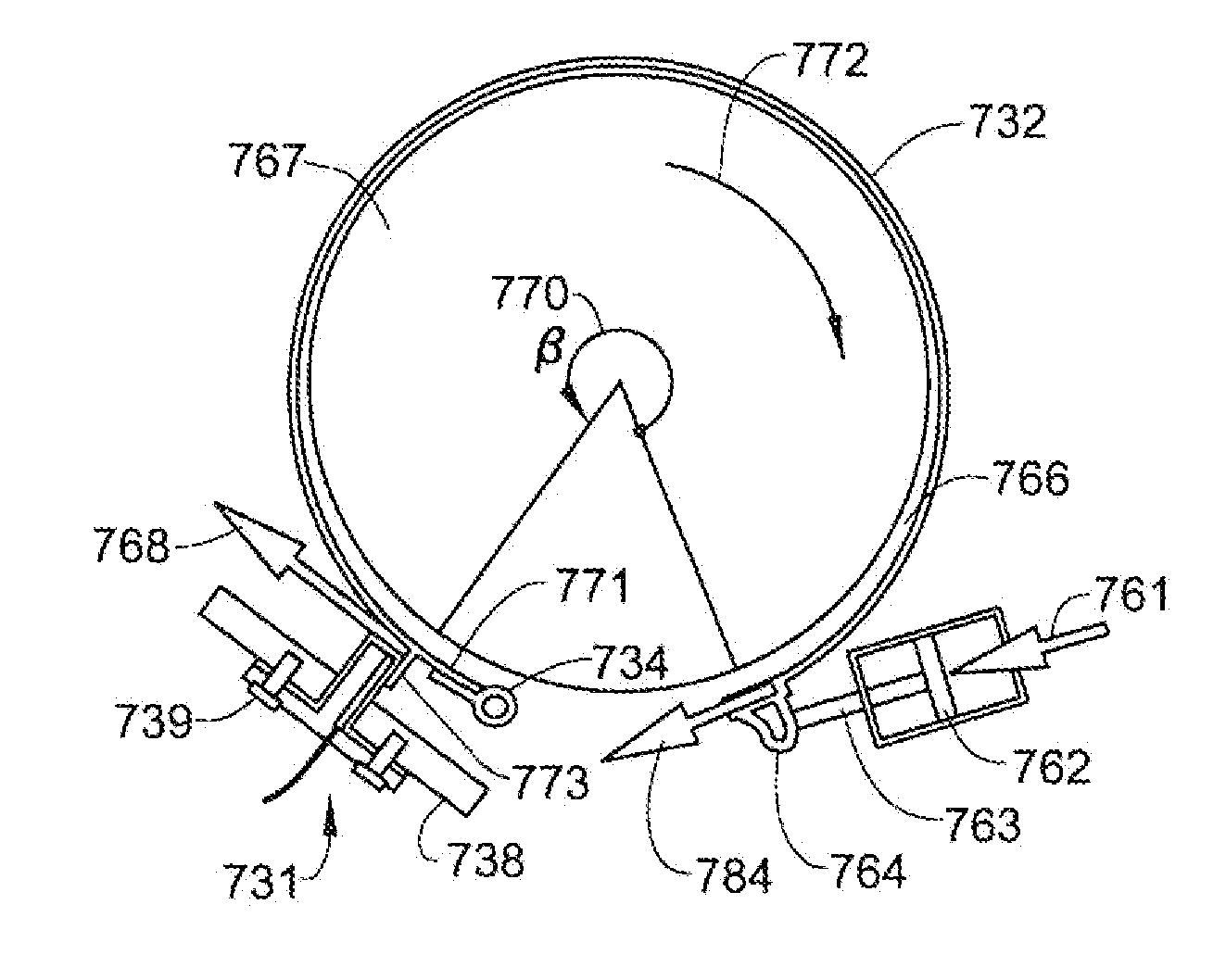

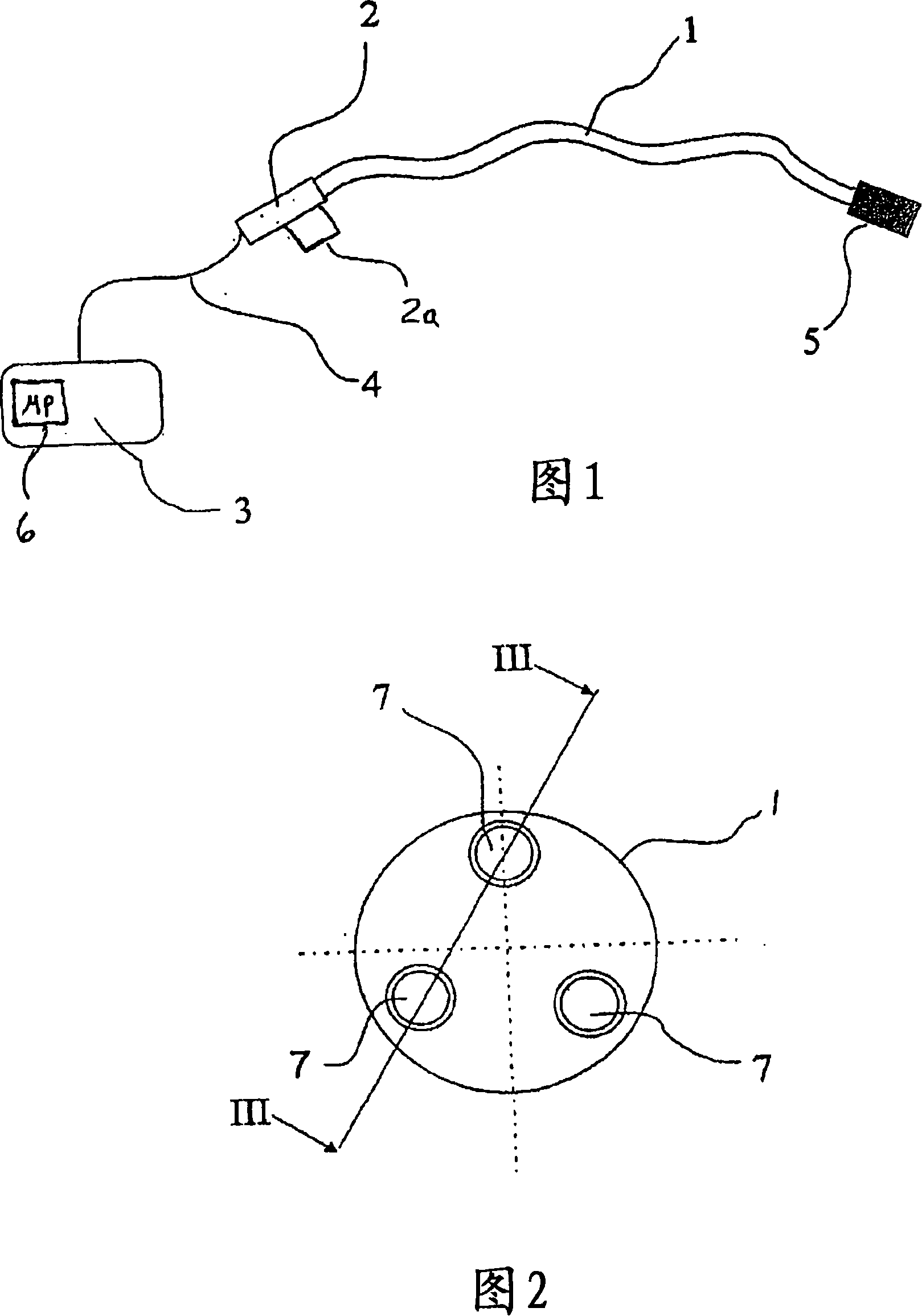

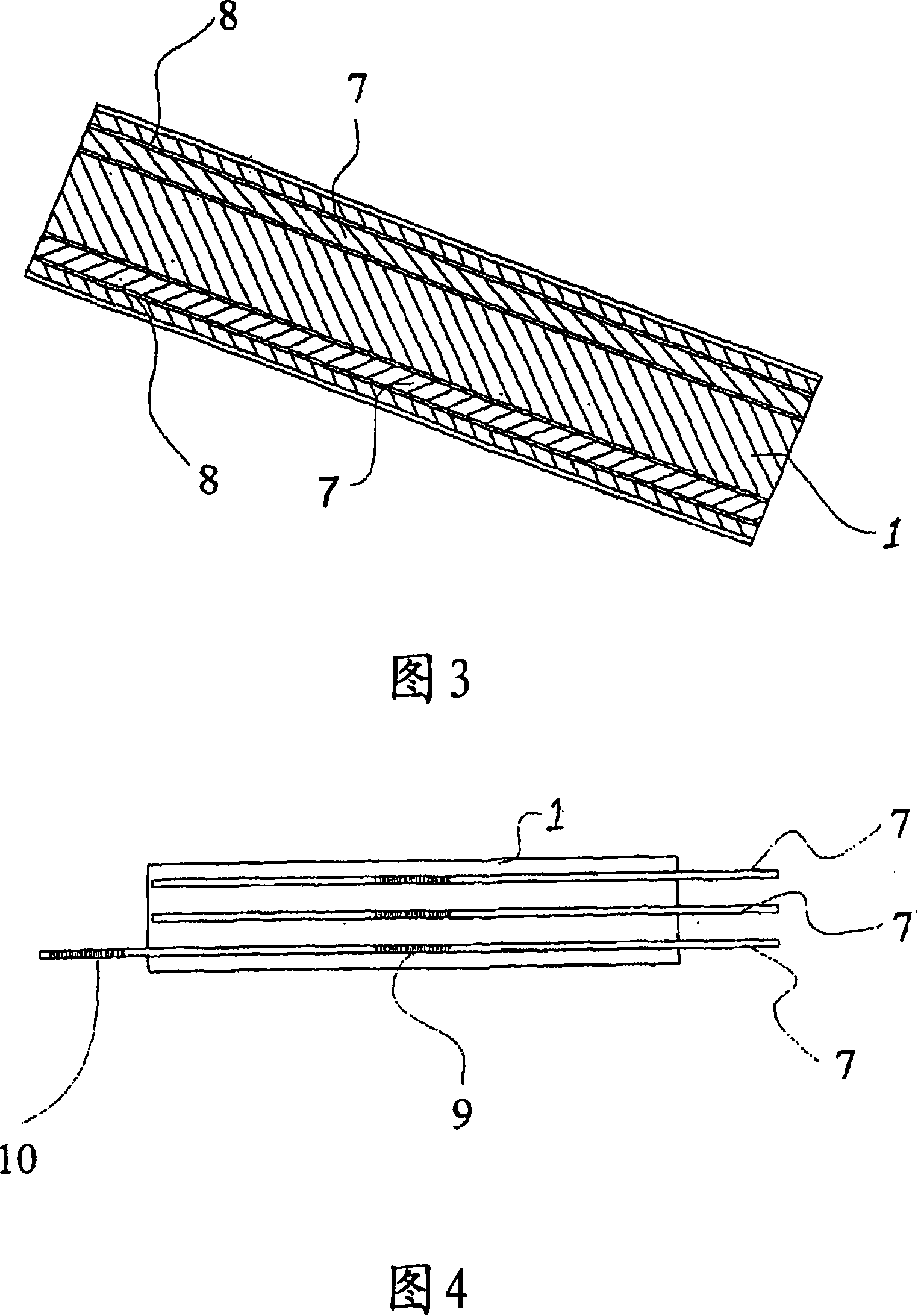

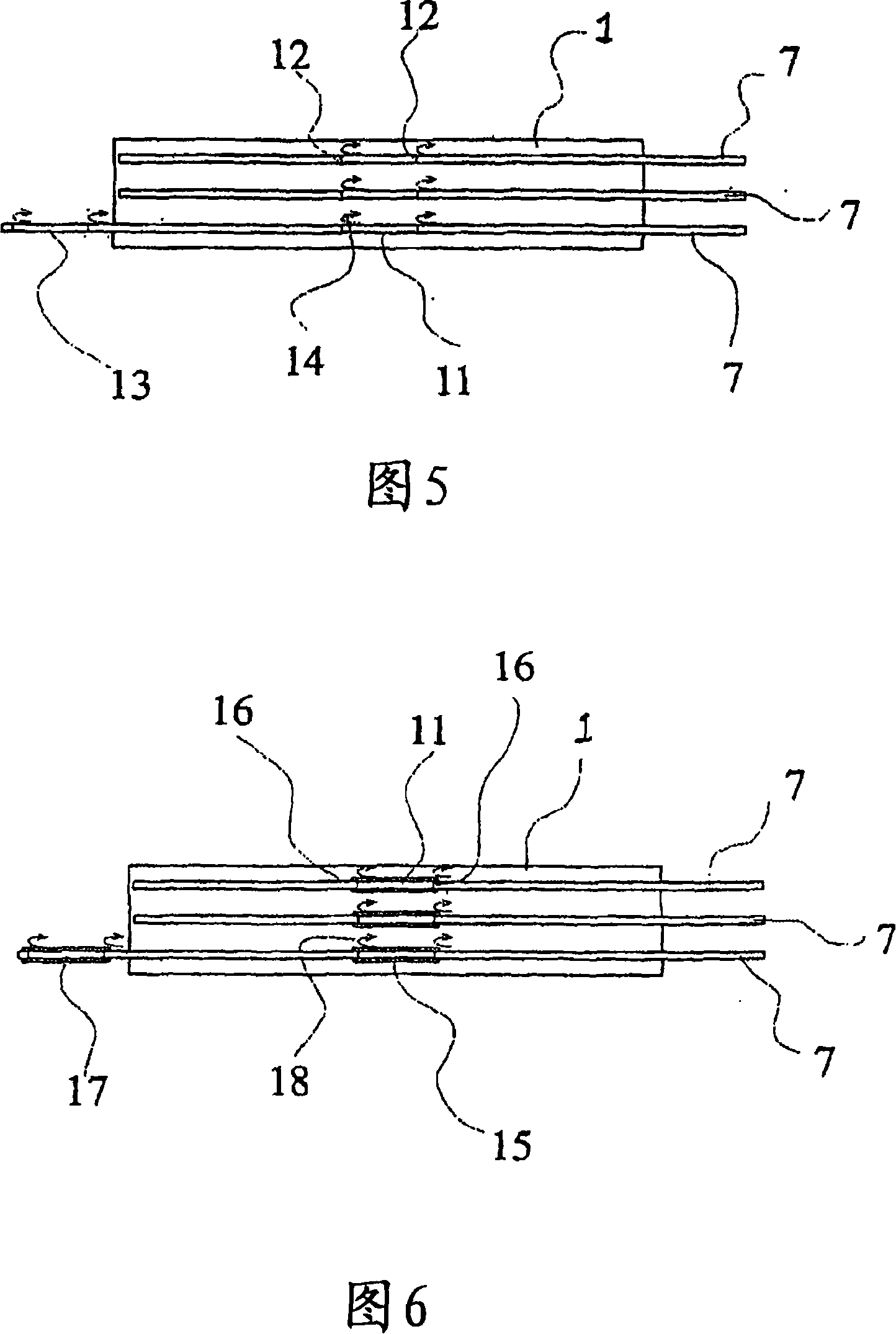

Surgical stapling instrument having load sensing control circuitry

A surgical instrument for being endoscopically or laparoscopically inserted into a surgical site for simultaneous stapling and severing of tissue includes load sensing pressure transducers strategically placed for closed loop control and monitoring. Load sensing within a staple applying assembly (end effector) may provide feedback for preventing firing with insufficient or too much tissue, or to sense appropriate presence buttress material, to deploy buttress material after firing is sensed.

Owner:CILAG GMBH INT

Surgical stapling instrument having load sensing control circuitry

A surgical instrument for being endoscopically or laparoscopically inserted into a surgical site for simultaneous stapling and severing of tissue includes load sensing pressure transducers strategically placed for closed loop control and monitoring. Load sensing within a staple applying assembly (end effector) may provide feedback for preventing firing with insufficient or too much tissue, or to sense appropriate presence buttress material, to deploy buttress material after firing is sensed.

Owner:CILAG GMBH INT

Inductively coupled ballast circuit

InactiveUS7385357B2Maximize power efficiencyMore currentCircuit arrangementsTreatment involving filtrationCurrent limitingLoad sensing

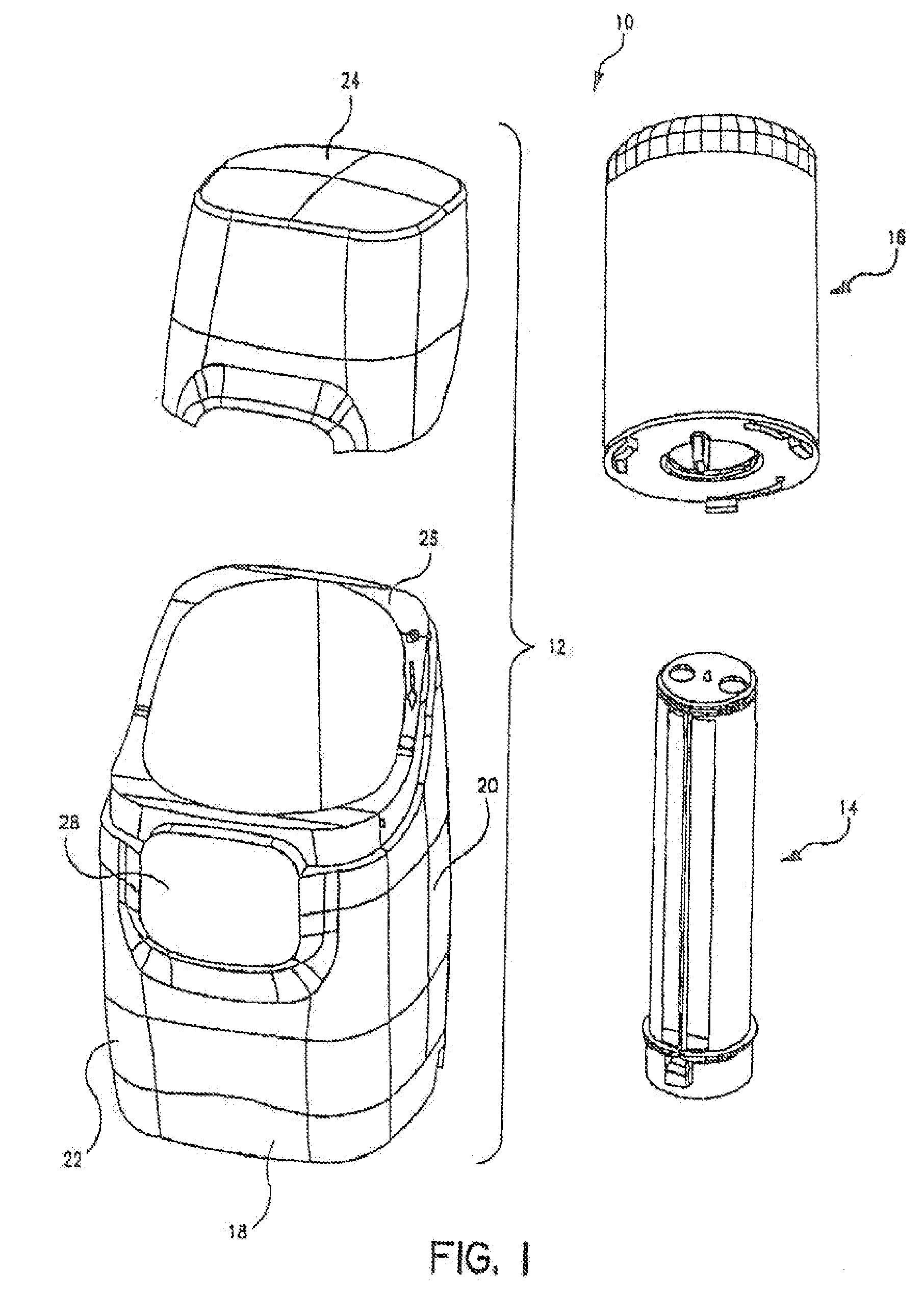

A ballast circuit is disclosed for inductively providing power to a load. The ballast circuit includes an oscillator, a driver, a switching circuit, a resonant tank circuit and a current sensing circuit. The current sensing circuit provides a current feedback signal to the oscillator that is representative of the current in the resonant tank circuit. The current feedback signal drives the frequency of the ballast circuit causing the ballast circuit to seek resonance. The ballast circuit preferably includes a current limit circuit that is inductively coupled to the resonant tank circuit. The current limit circuit disables the ballast circuit when the current in the ballast circuit exceeds a predetermined threshold or falls outside a predetermined range.

Owner:PHILIPS IP VENTURES BV

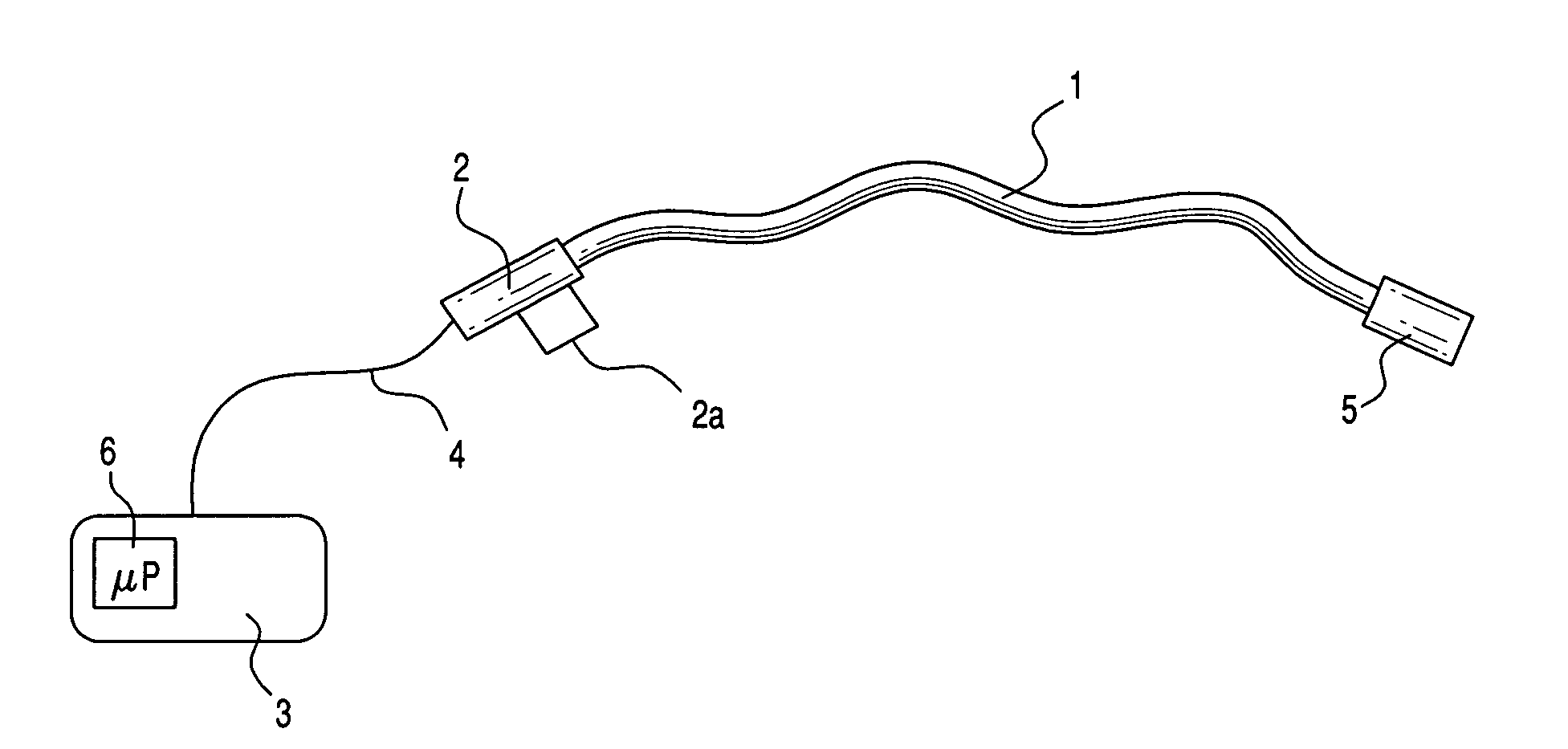

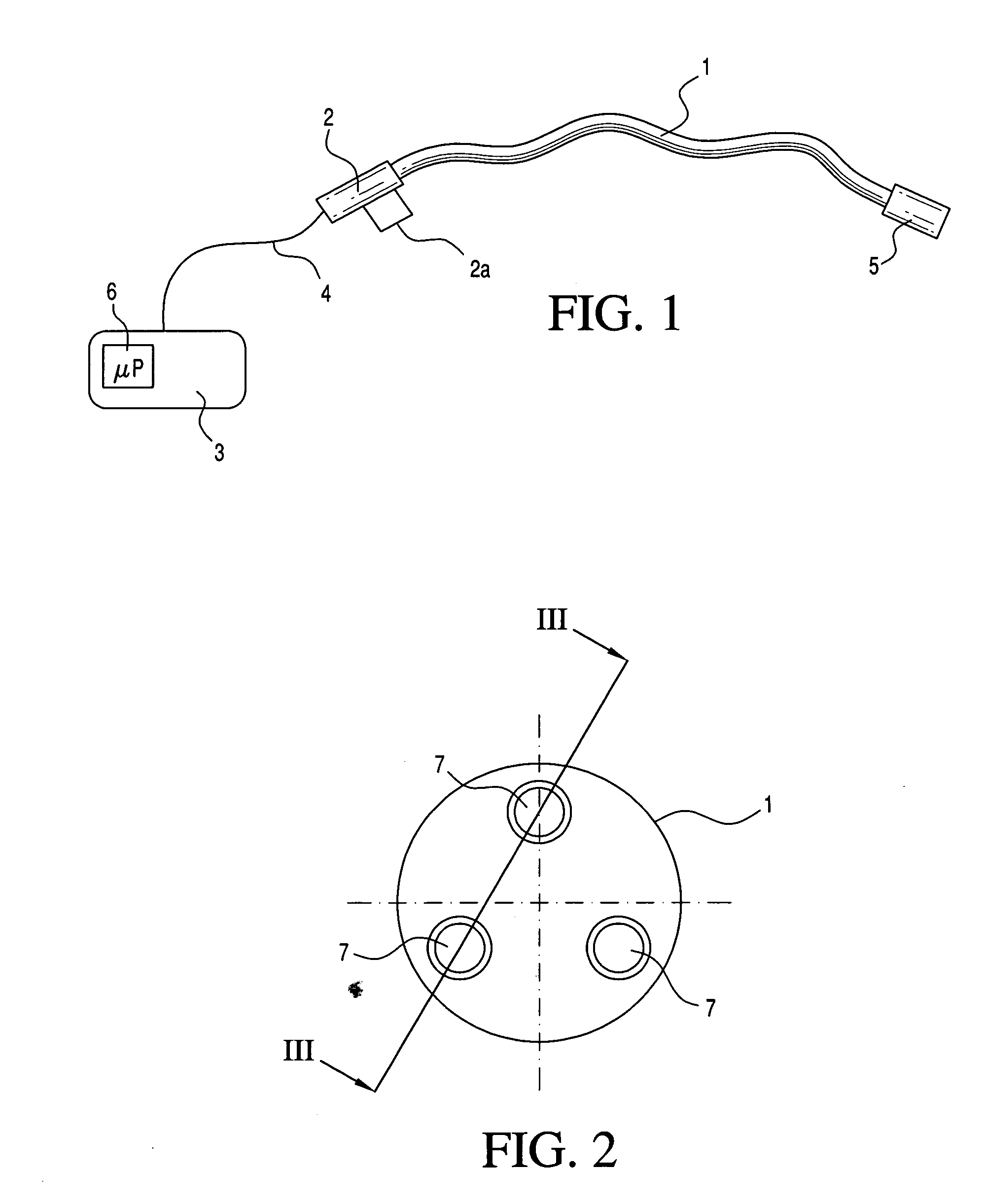

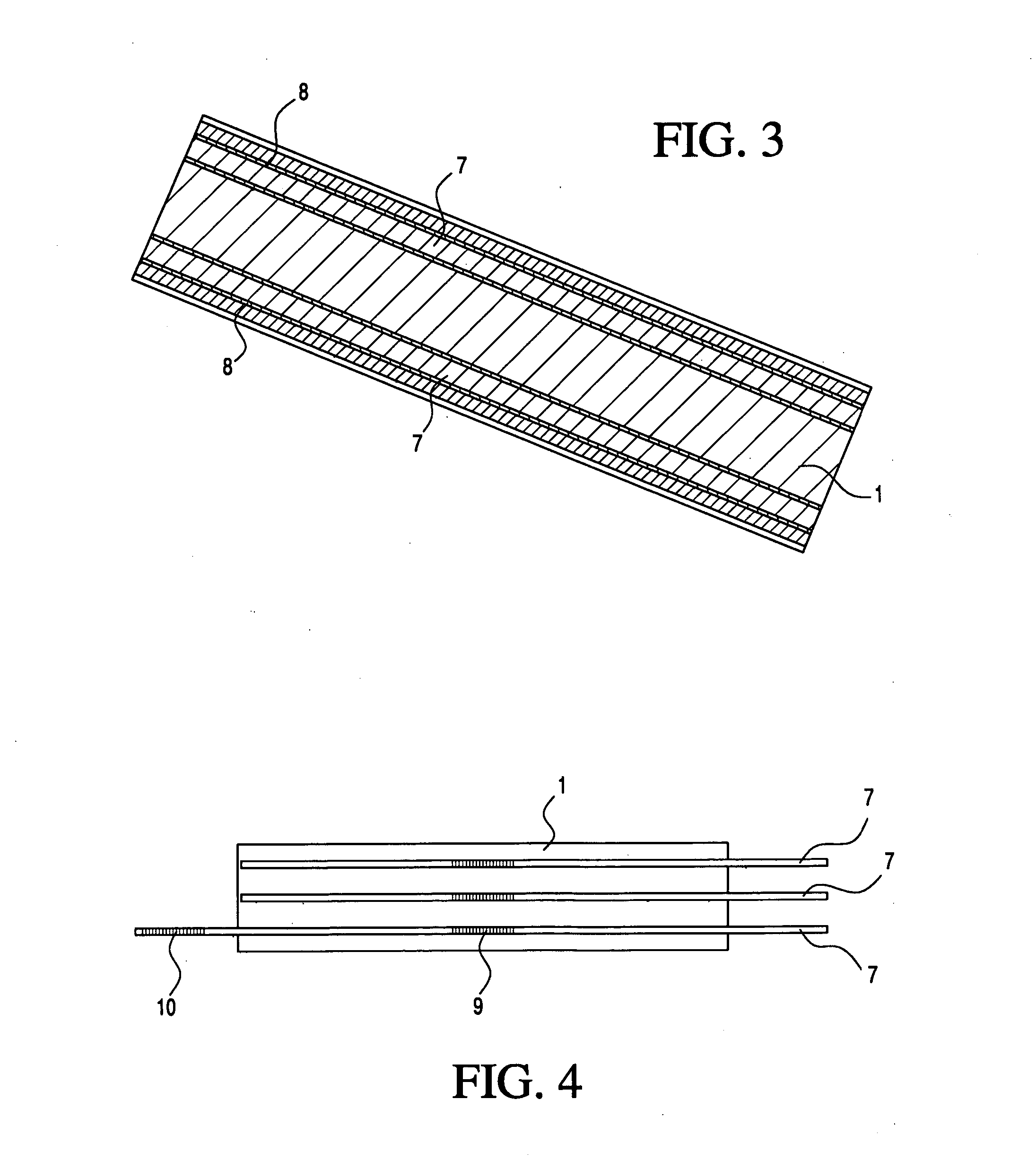

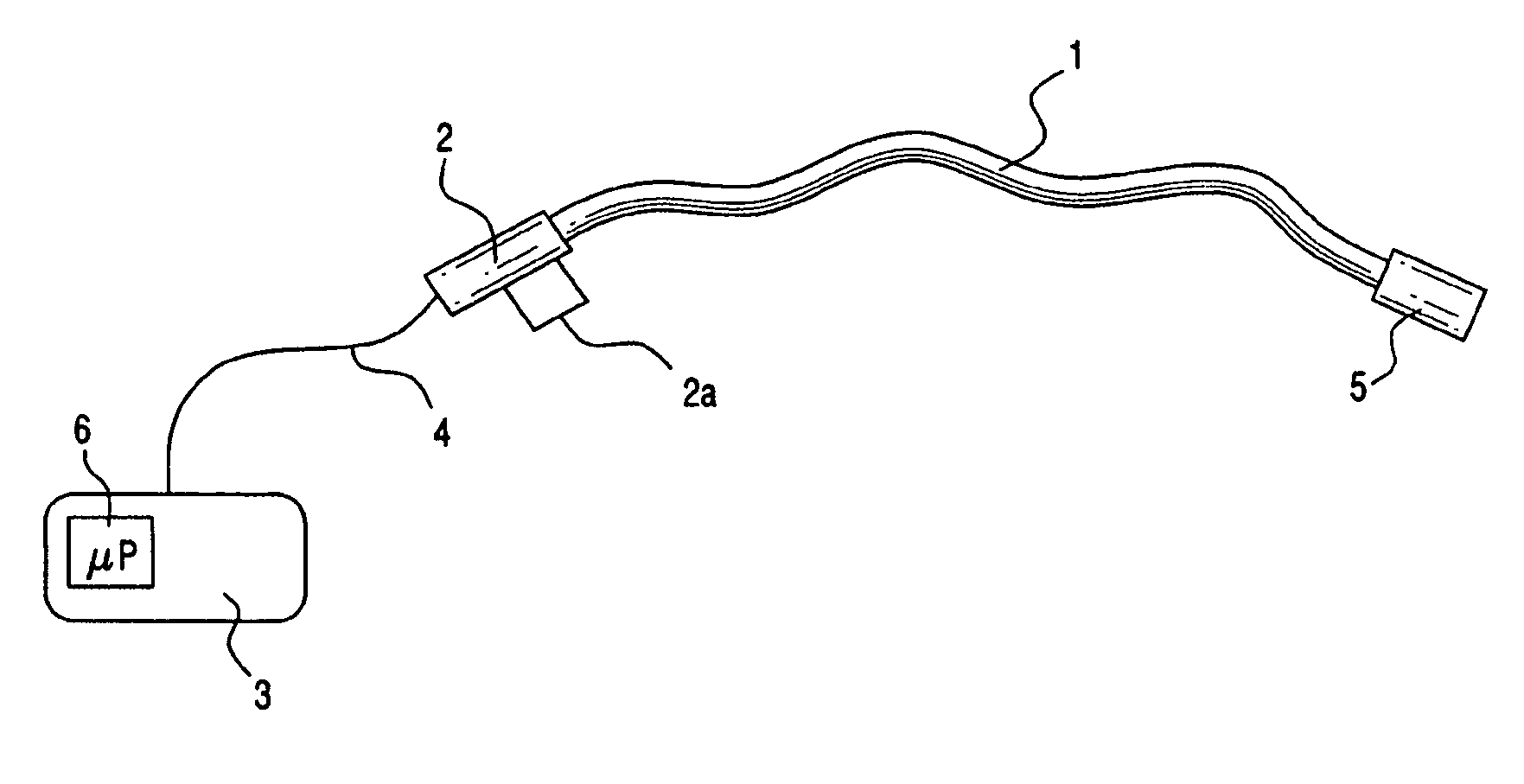

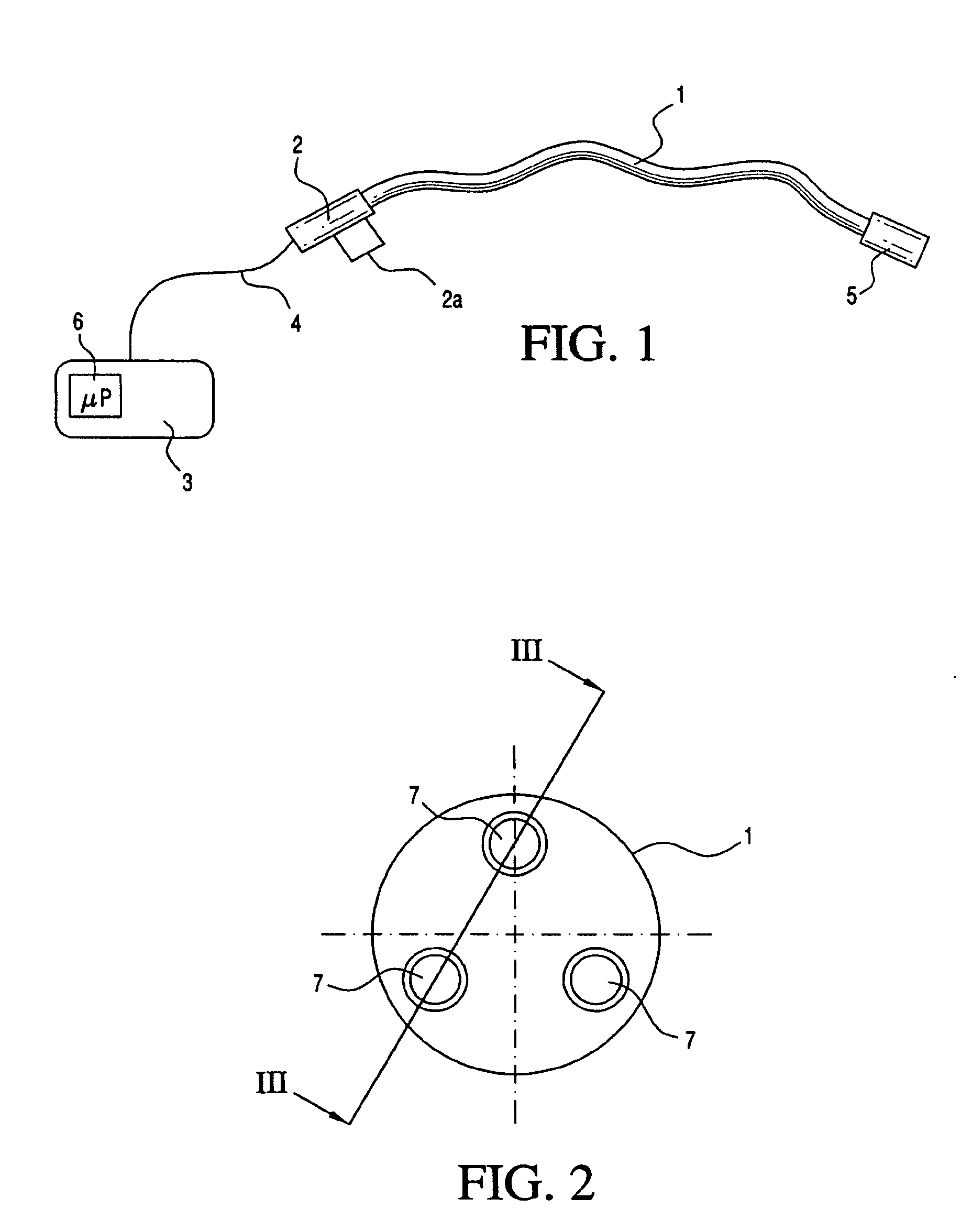

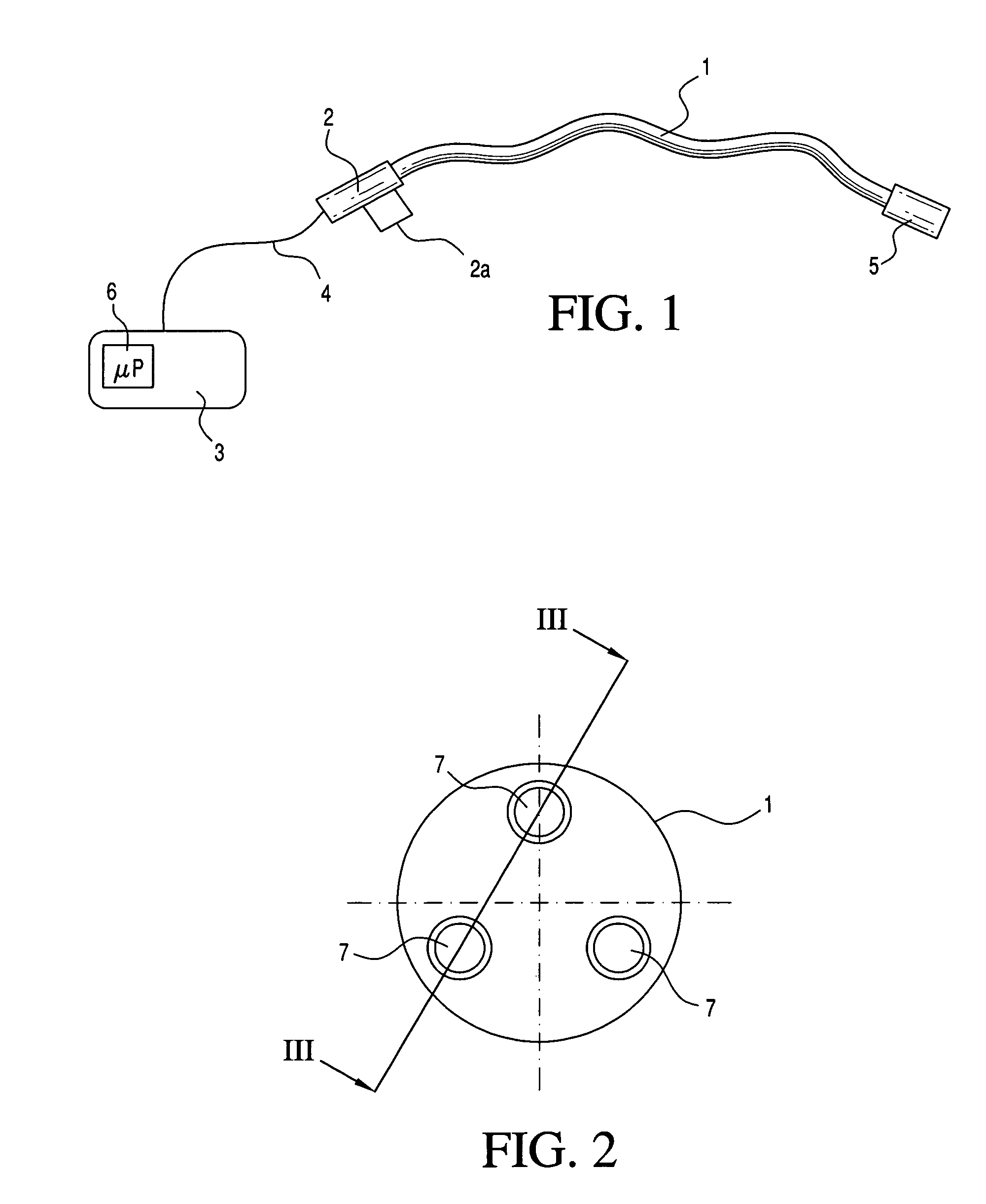

Medical apparatus system having optical fiber load sensing capability

ActiveUS20060200049A1Facilitate speedHelp accuracyStrain gaugePerson identificationRobotic systemsProcess logic

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a deformable body having at least two optical fiber sensors disposed in a distal extremity thereof is coupled to processing logic programmed to compute a multi-dimensional force vector responsive to detected changes in the optical characteristics of the optical fiber sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel. The force vector may be used to facilitate manipulation of the deformable body either directly or automatically using a robotic system.

Owner:ST JUDE MEDICAL INT HLDG SARL

Inductively coupled ballast circuit

InactiveUS7180248B2Maximize power efficiencyMore currentWater treatment parameter controlWater/sewage treatment by irradiationCurrent limitingLoad sensing

A ballast circuit is disclosed for inductively providing power to a load. The ballast circuit includes an oscillator, a driver, a switching circuit, a resonant tank circuit and a current sensing circuit. The current sensing circuit provides a current feedback signal to the oscillator that is representative of the current in the resonant tank circuit. The current feedback signal drives the frequency of the ballast circuit causing the ballast circuit to seek resonance. The ballast circuit preferably includes a current limit circuit that is inductively coupled to the resonant tank circuit. The current limit circuit disables the ballast circuit when the current in the ballast circuit exceeds a predetermined threshold or falls outside a predetermined range.

Owner:PHILIPS IP VENTURES BV

Medical apparatus system having optical fiber load sensing capability

ActiveUS20070060847A1Reduces sensor artifactReduction factorStrain gaugePerson identificationLoad sensingEngineering

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a device having at least two optical fiber sensors disposed in a distal extremity thereof is coupled to processing logic programmed to compute a multi-dimensional force vector responsive to detected changes in the optical characteristics of the optical fiber sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel. The force vector may be used to facilitate manipulation of the catheter either directly or automatically using a robotic system.

Owner:ST JUDE MEDICAL INT HLDG SARL

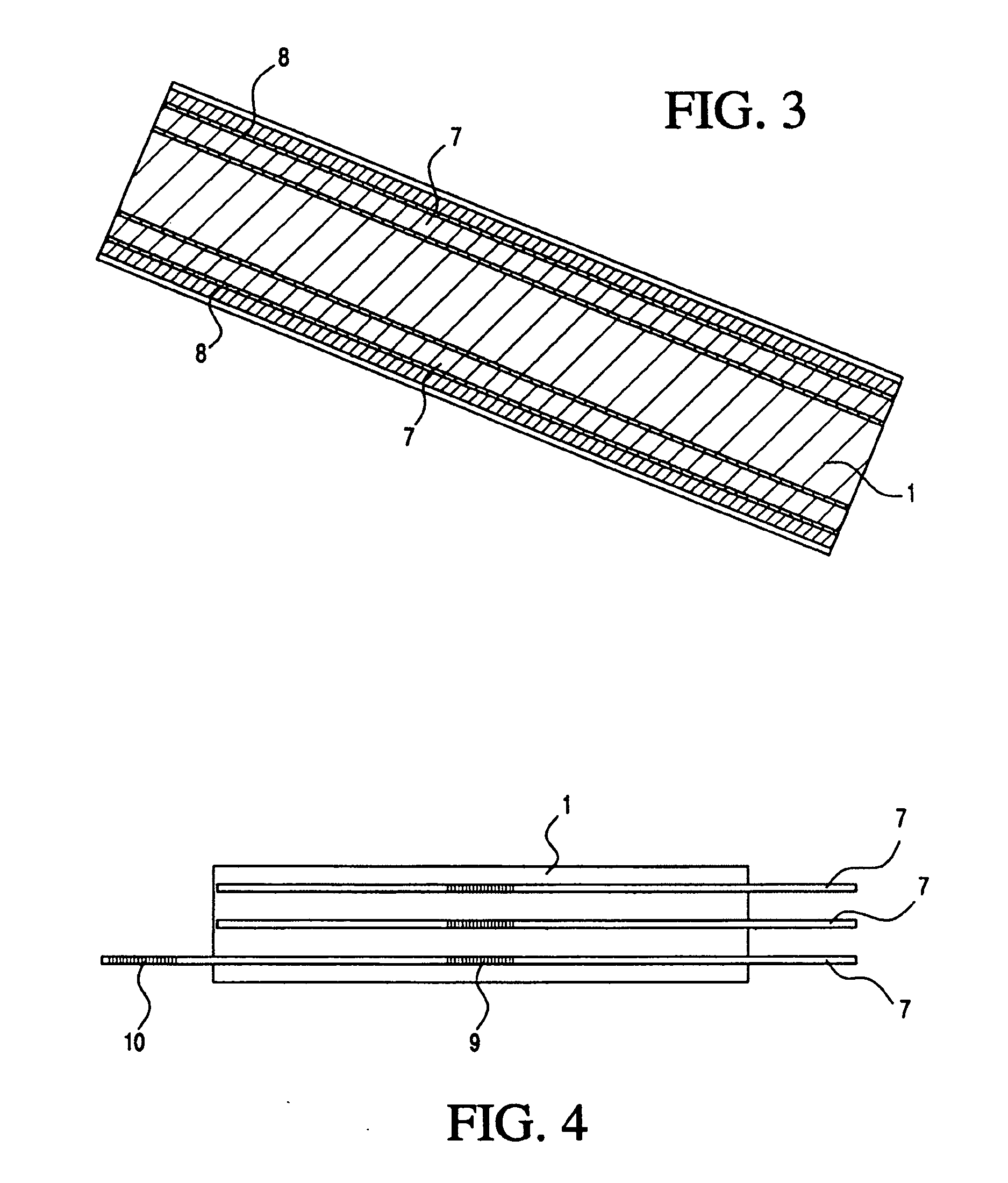

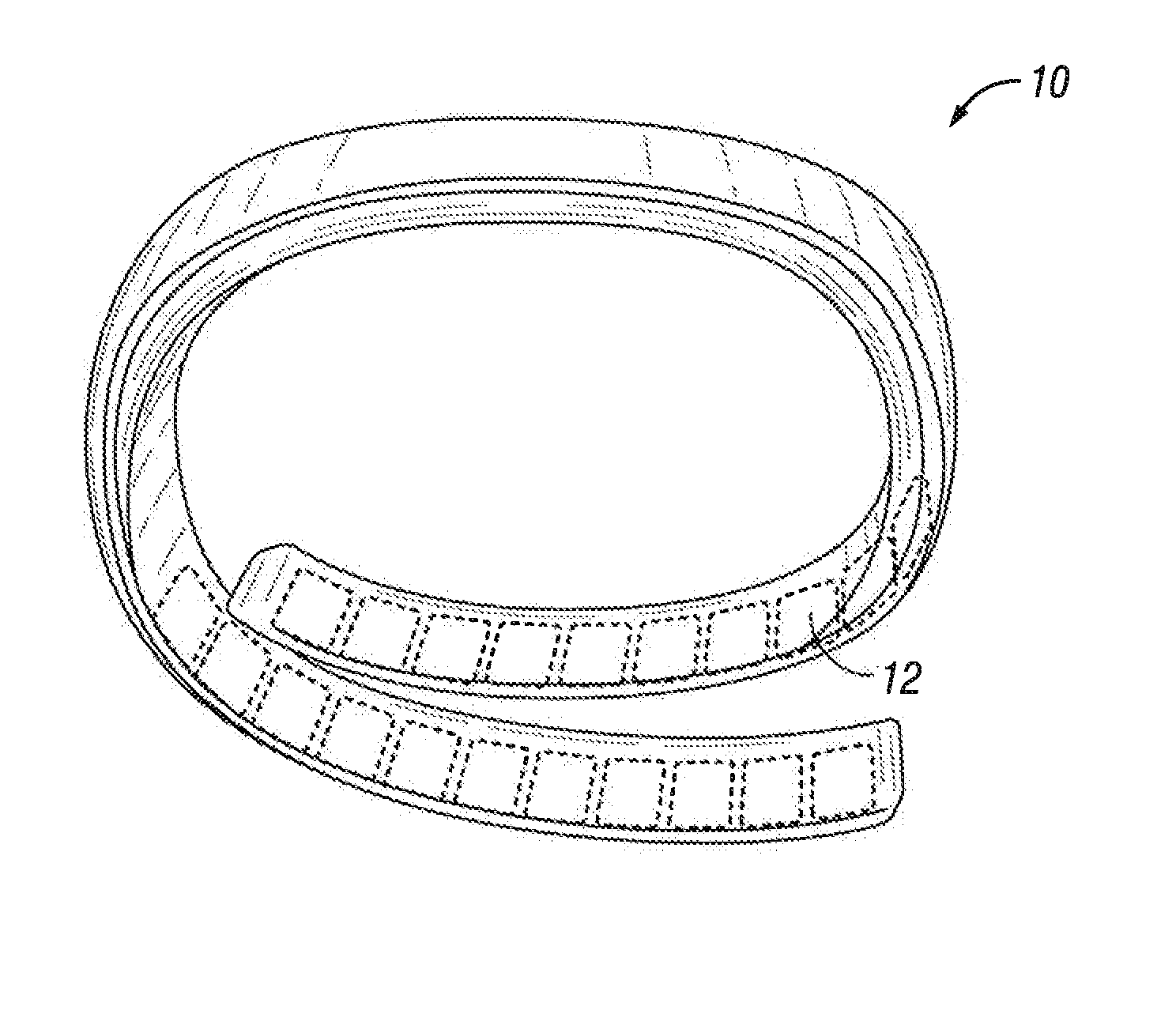

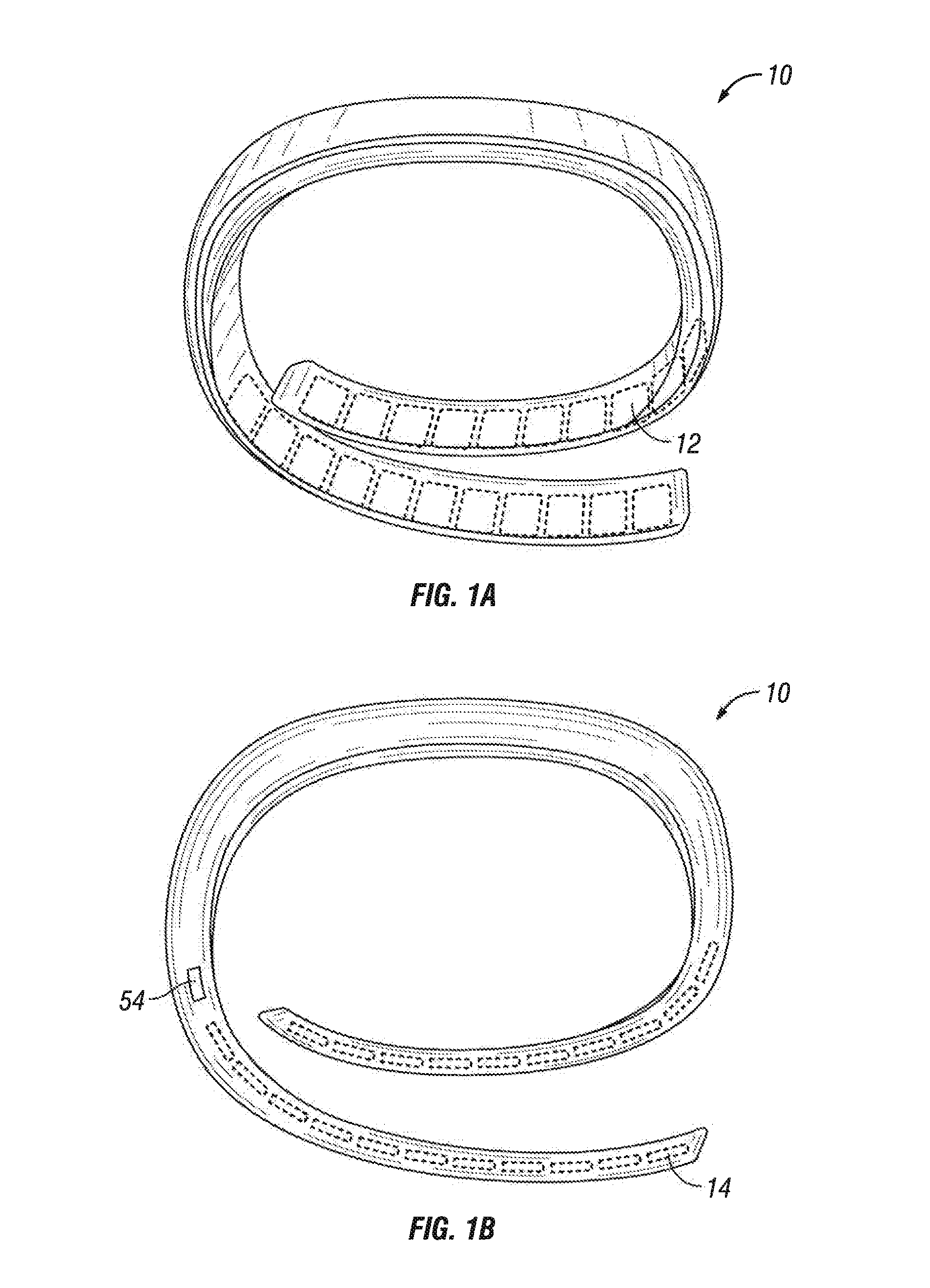

Telemetry system with tracking receiver devices

ActiveUS20140247152A1Improved wireless power transmissionElectric signal transmission systemsTelemetry/telecontrol selection arrangementsElectric power transmissionCommunication interface

A wireless power transmission system includes, a transmit antenna which in operation produces a wireless field, an amplifier coupled to the transmit antenna, a load sensing circuit coupled to the amplifier and a controller coupled to the load sensing circuit. A monitoring device has one or more sensors and a unique user ID. The one or more sensors acquire user information selected from of at least one of, a user's activities, behaviors and habit information. The monitoring device includes an ID circuitry. A communication interface receives information about the unique user ID when the load sensing circuit indicates the monitoring device is within the wireless field. The indication is created using at least a change in power consumption.

Owner:FITBIT INC

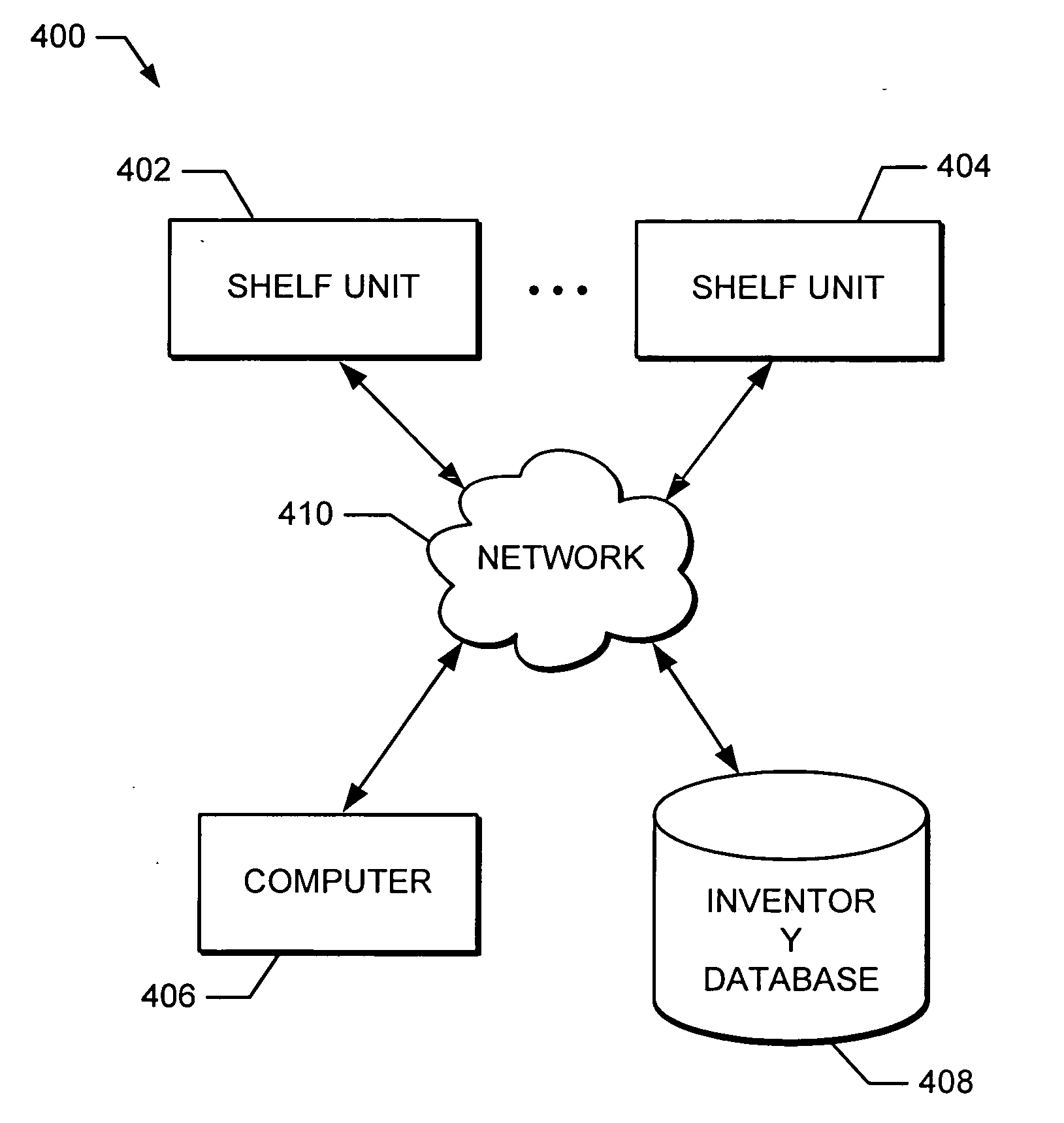

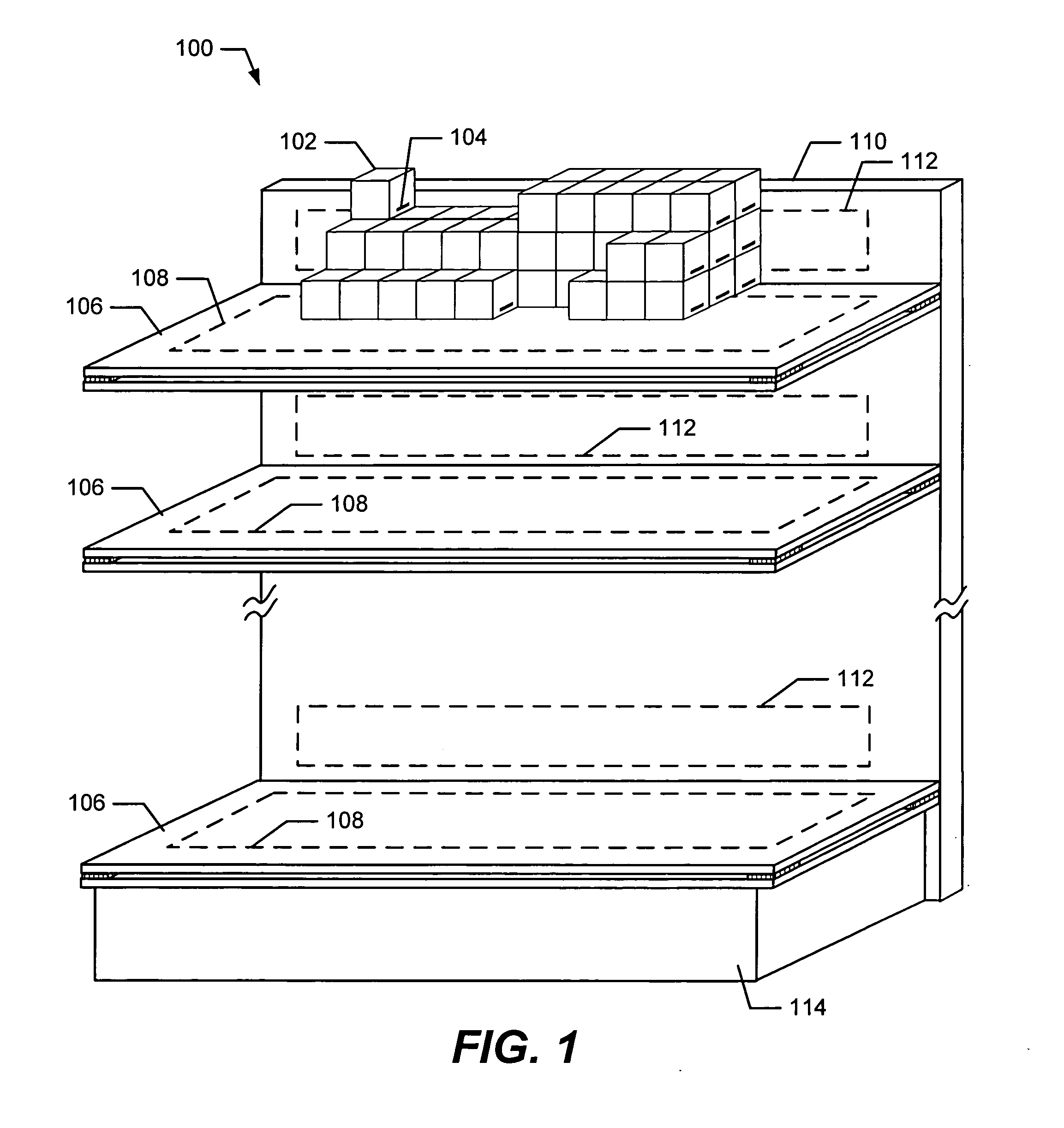

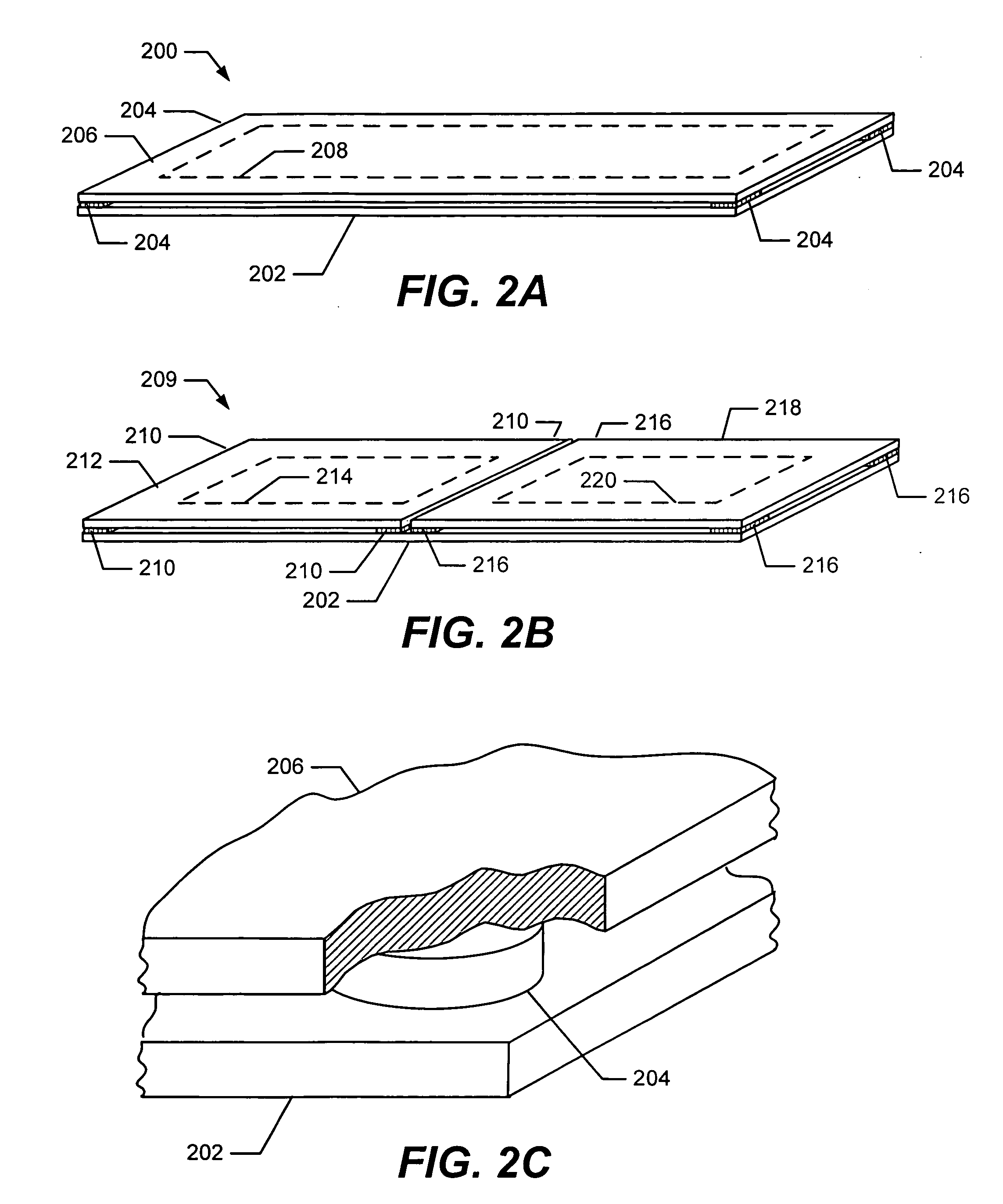

Load sensing inventory tracking method and system

Owner:HEWLETT PACKARD DEV CO LP

Medical apparatus system having optical fiber load sensing capability

ActiveUS8075498B2Facilitate speedHelp accuracyStrain gaugePerson identificationLoad sensingEngineering

Owner:ST JUDE MEDICAL INT HLDG SARL

Medical apparatus system having optical fiber load sensing

ActiveUS20110087112A1Reduces sensor artifactReduction factorStrain gaugeCatheterProcess logicOptical property

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a device having at optical fiber contact force sensors disposed in a distal extremity thereof and a deflection mechanism configured to deflect the elongate body at a location proximal of the distal extremity. The optical fiber contact force sensors are configured to be coupled to processing logic programmed which computes a force vector responsive to detected changes in the optical characteristics of the optical fiber contact force sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel.

Owner:ST JUDE MEDICAL INT HLDG SARL

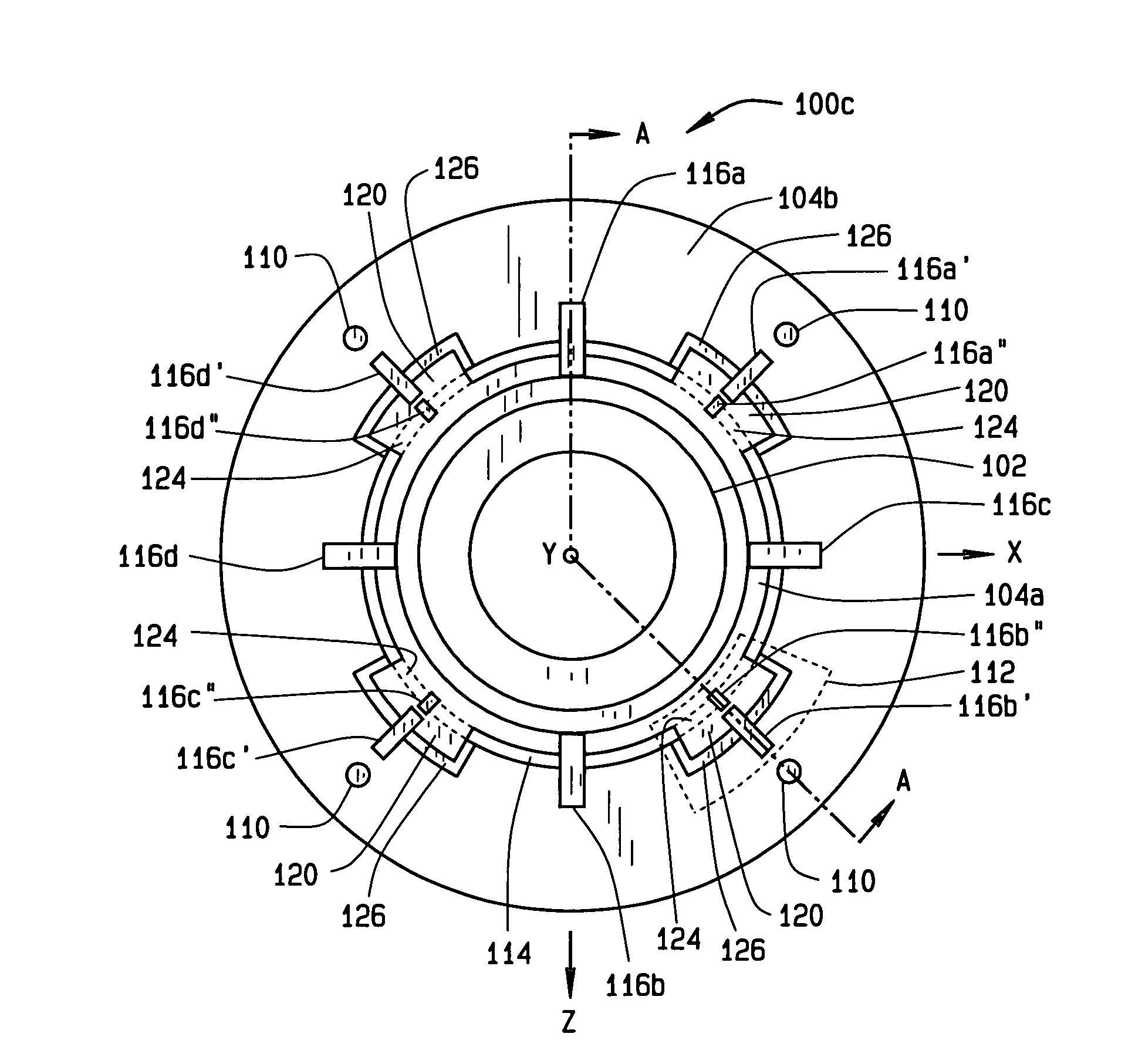

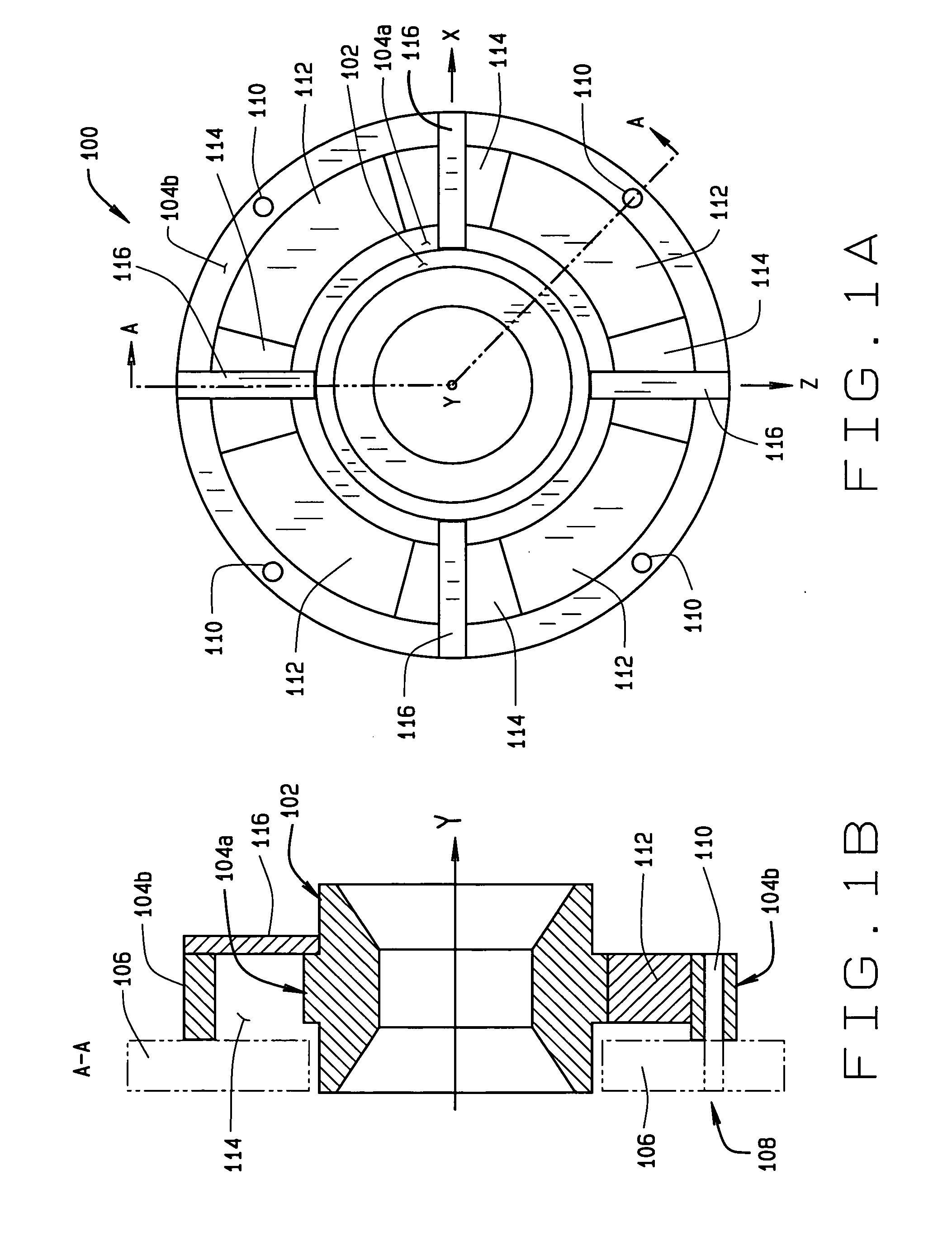

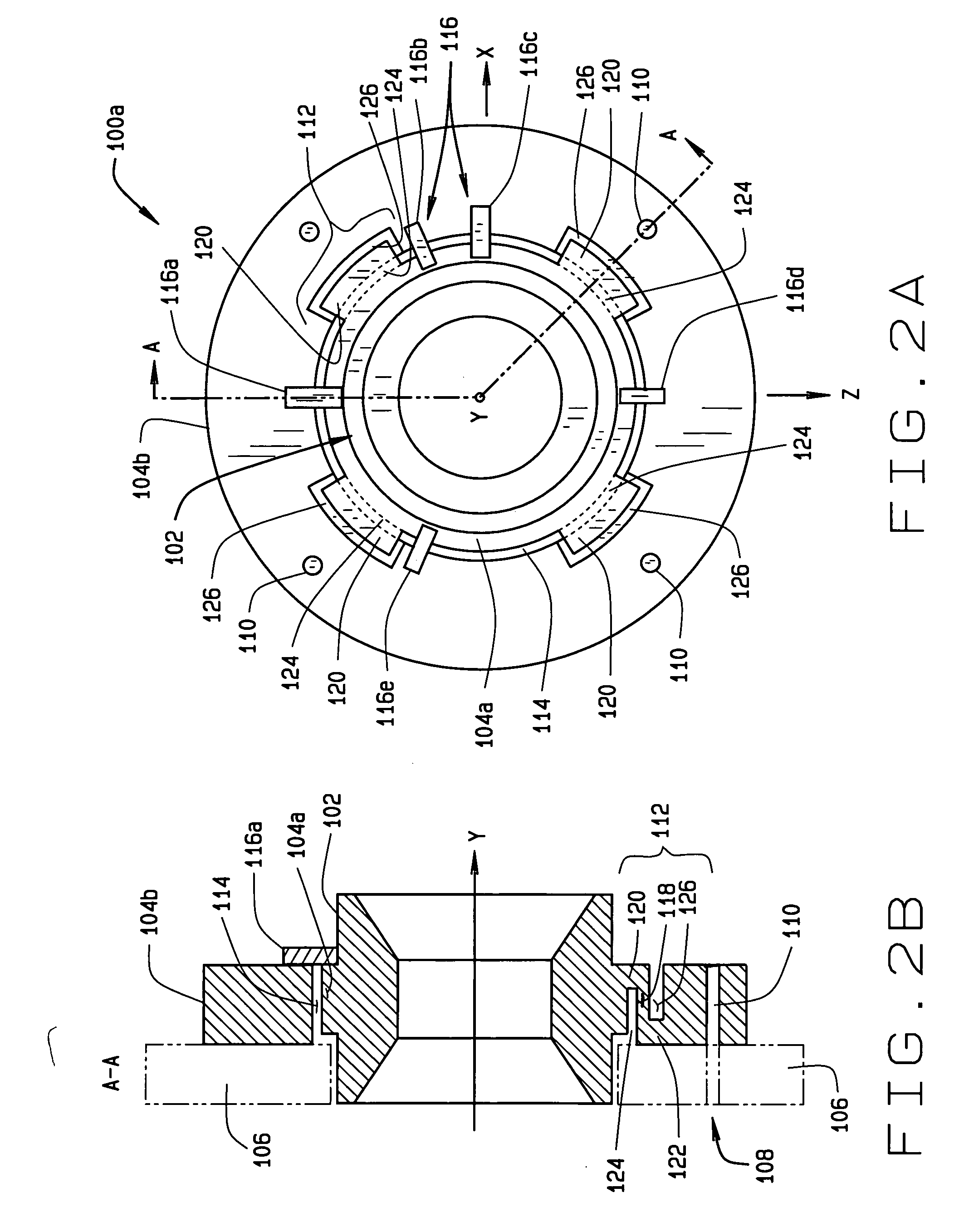

Load-sensing bearing

A load sensing bearing assembly comprises a bearing outer race secured to an application structure by a flange assembly incorporating a plurality of anisotropic spring regions which enable a limited range of displacement and / or rotation of the bearing outer race relative to the application structure in response to applied forces or moments. A set of sensor modules disposed through the bearing outer race and flange assembly acquire measurements from which the radial forces, thrust forces, and tilting moments exerted on the bearing outer race can be determined.

Owner:THE TIMKEN CO

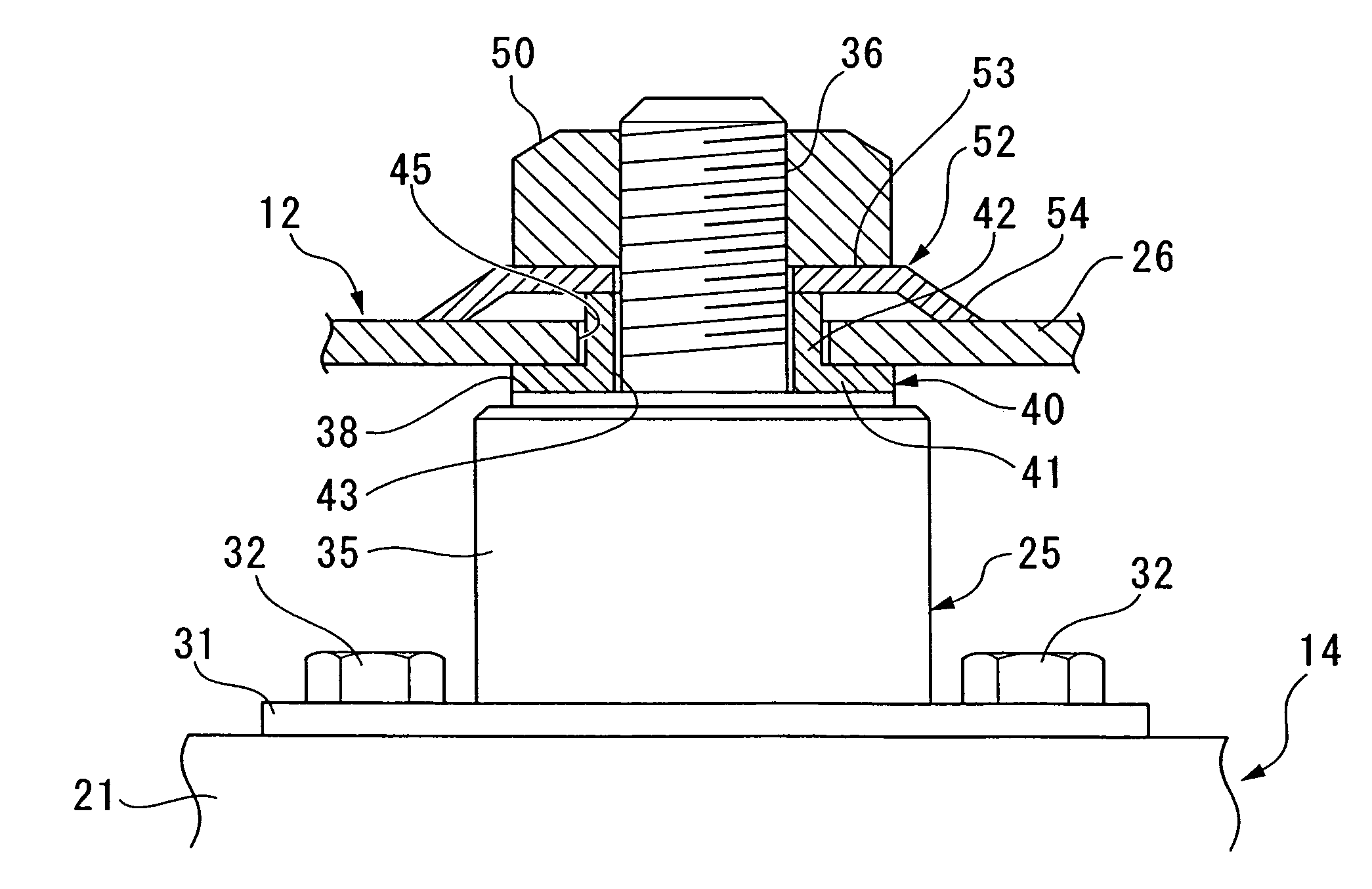

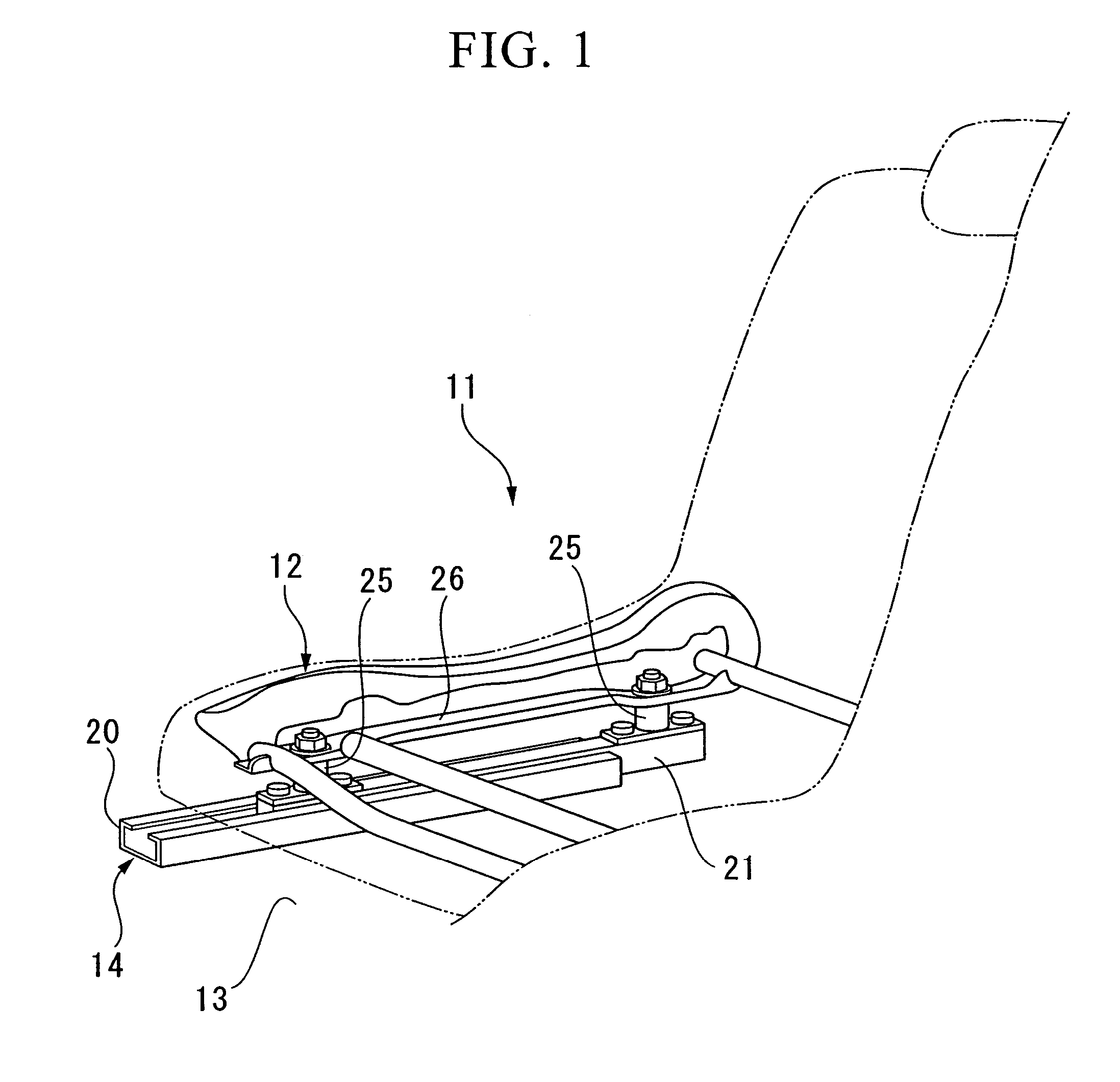

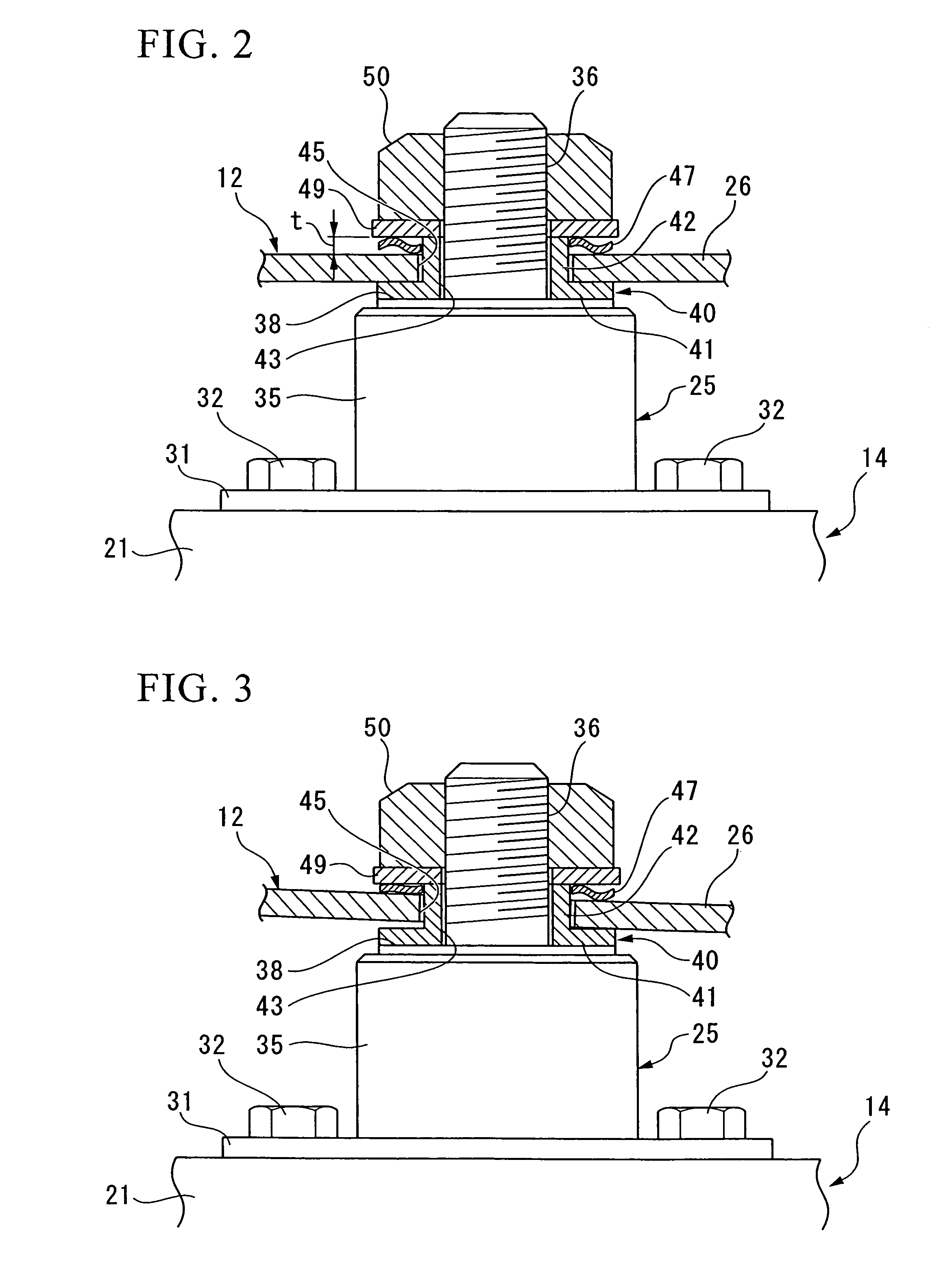

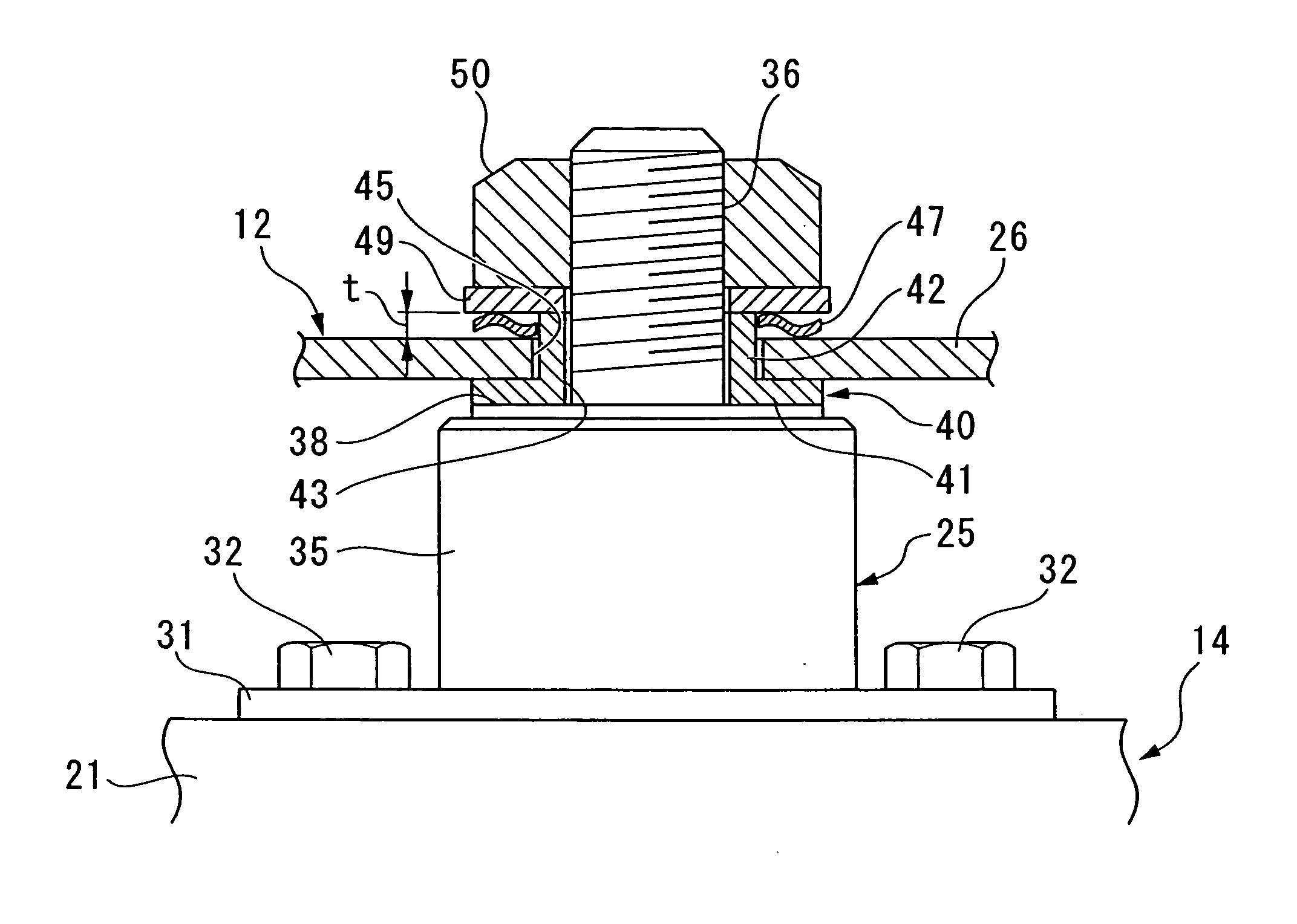

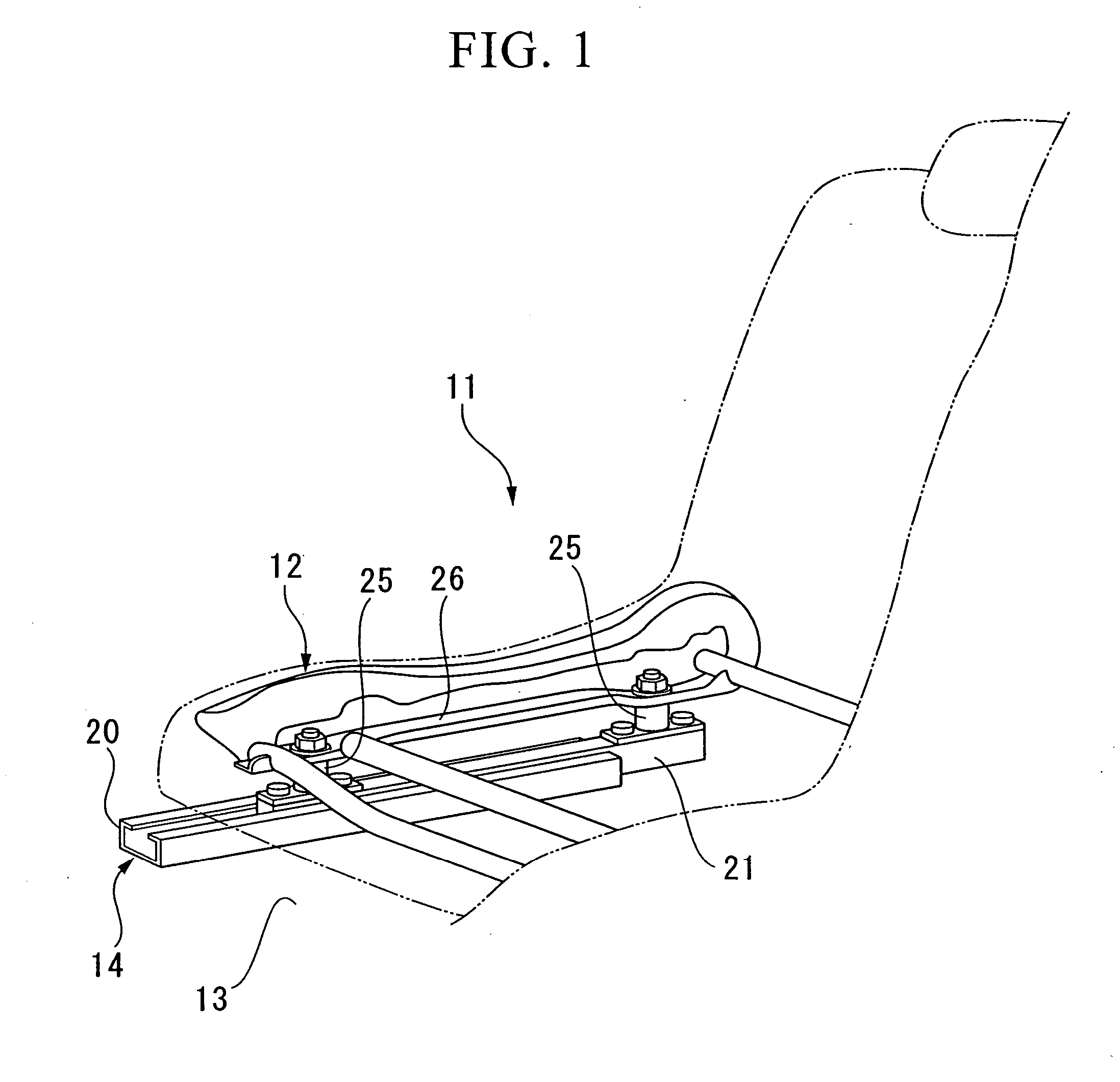

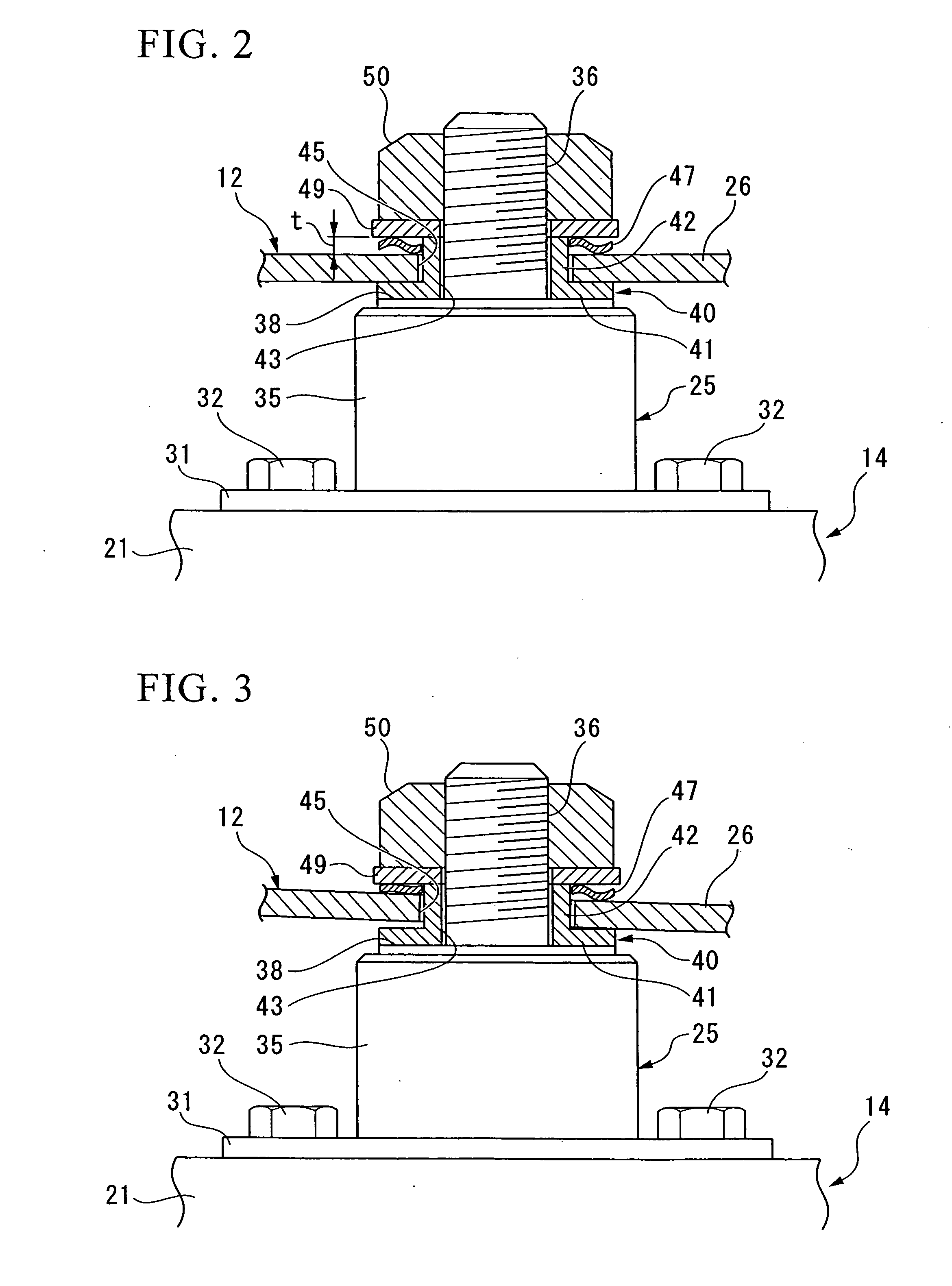

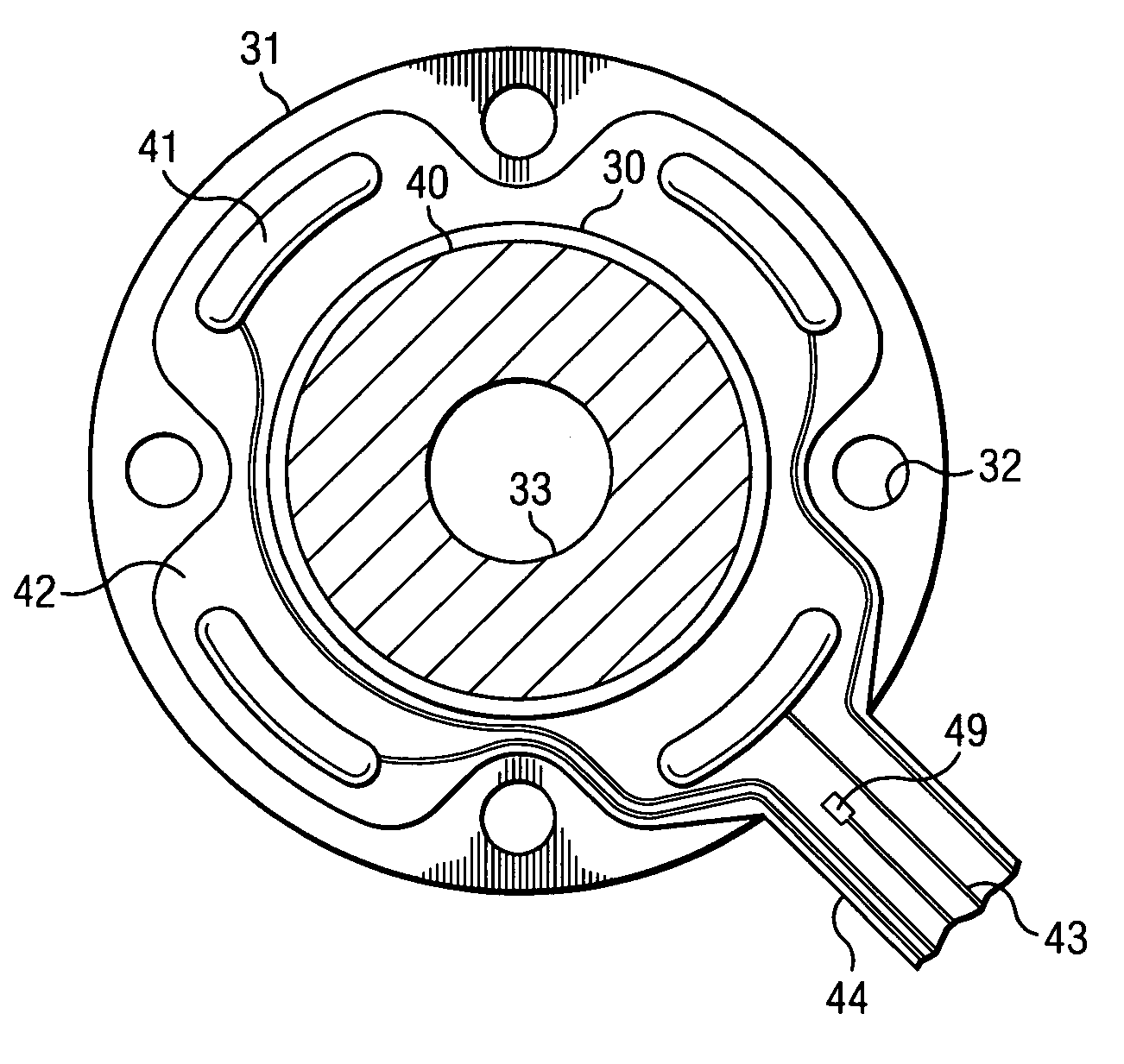

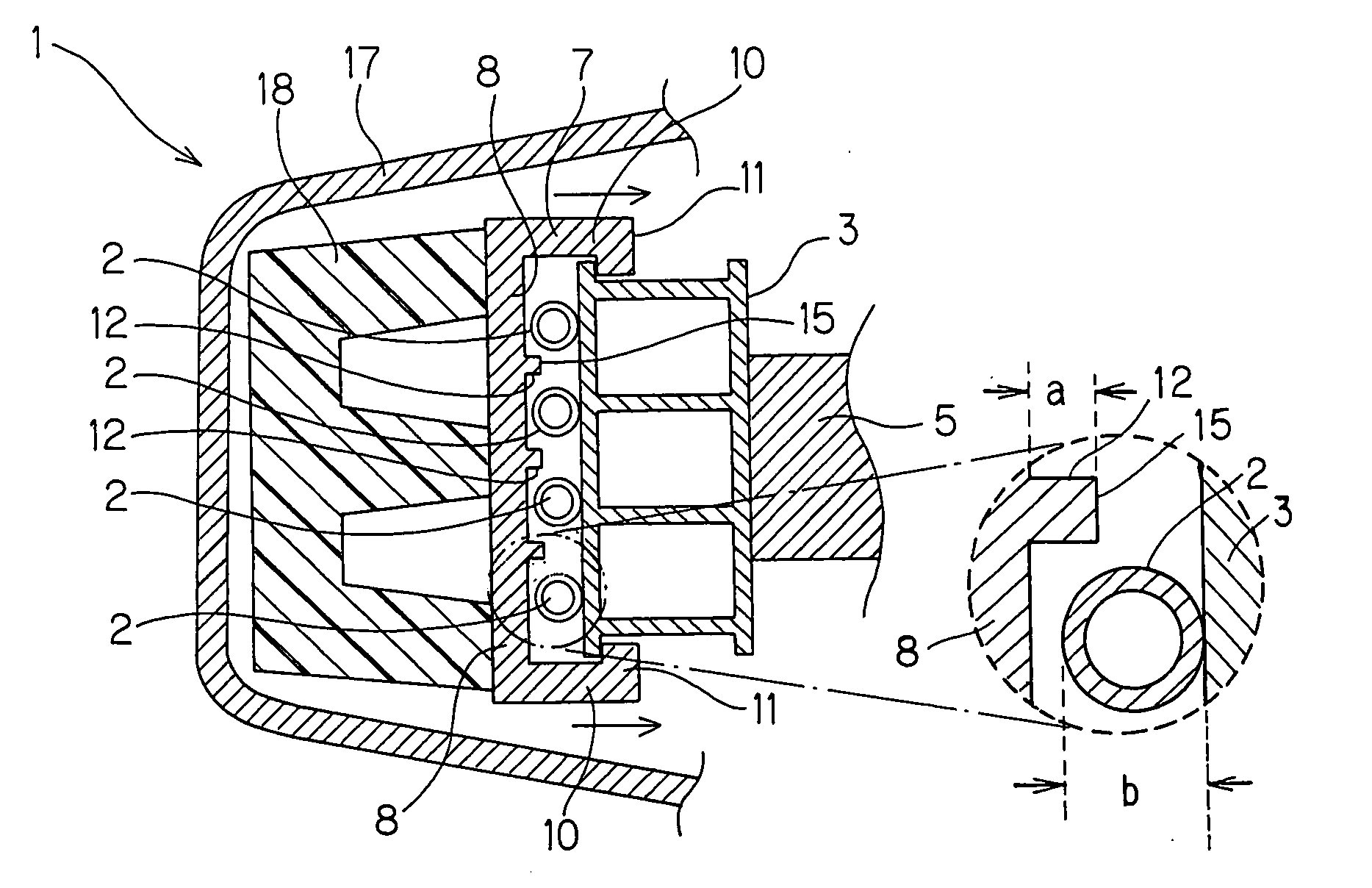

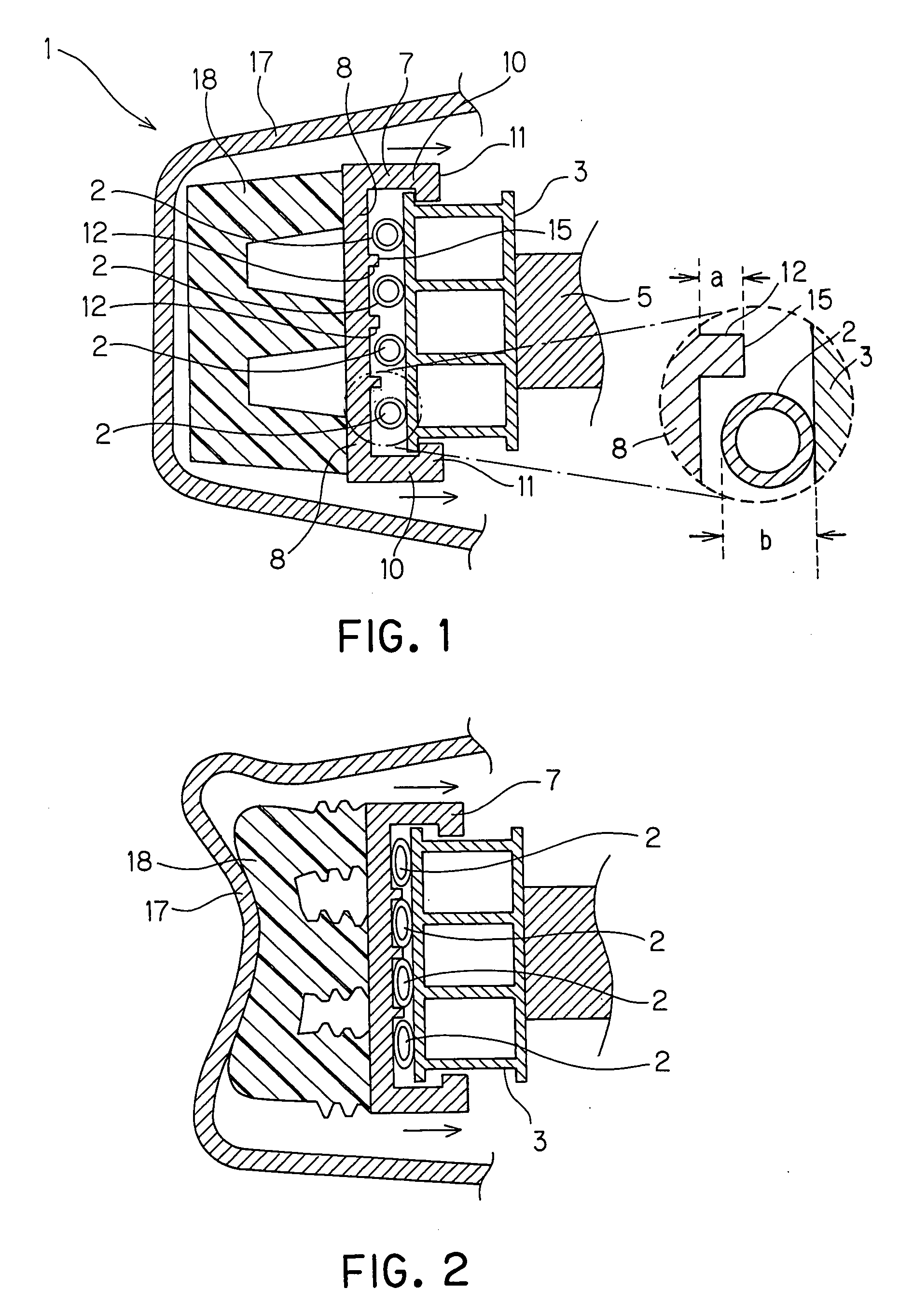

Load cell attachment structure

ActiveUS7373846B2Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

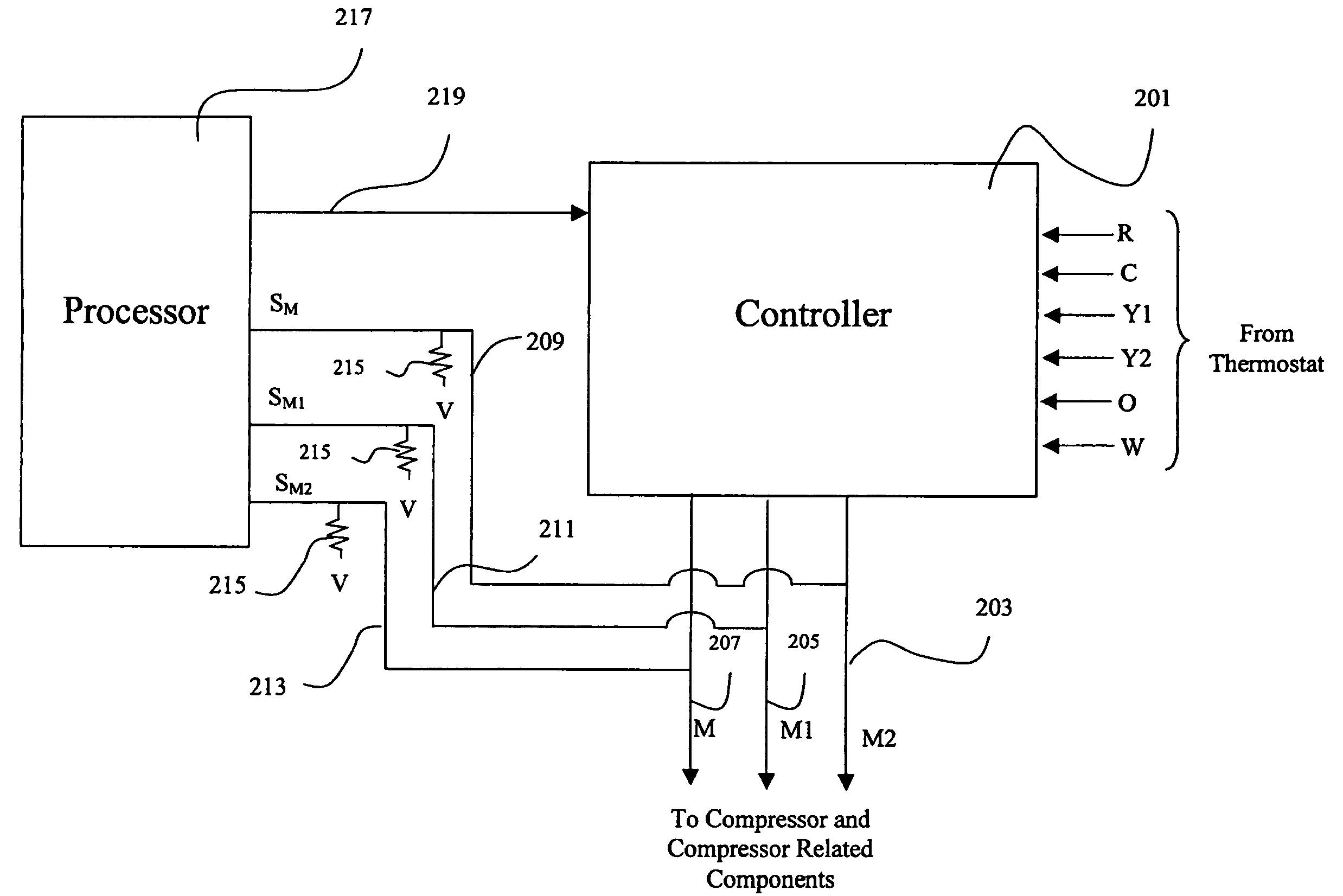

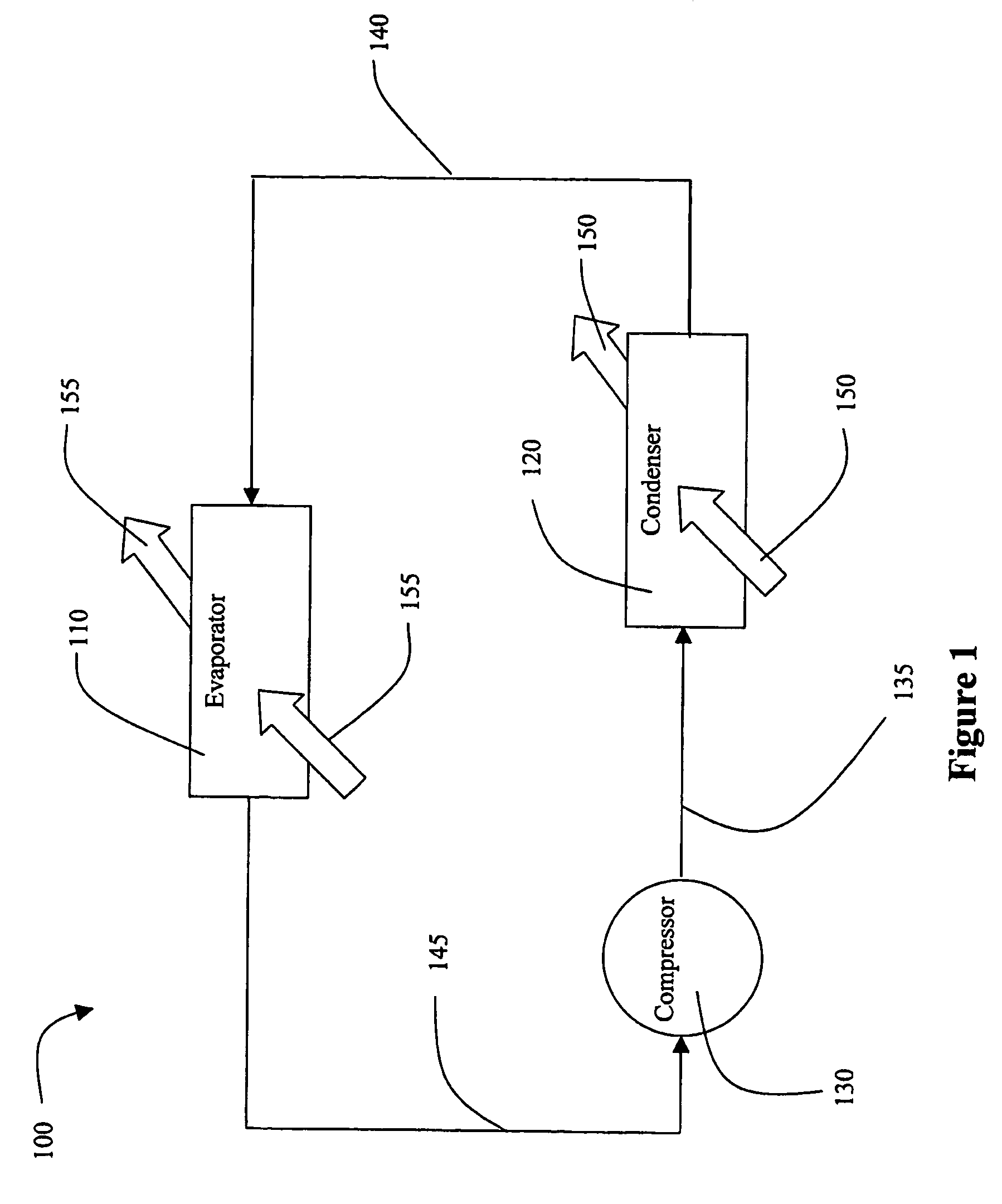

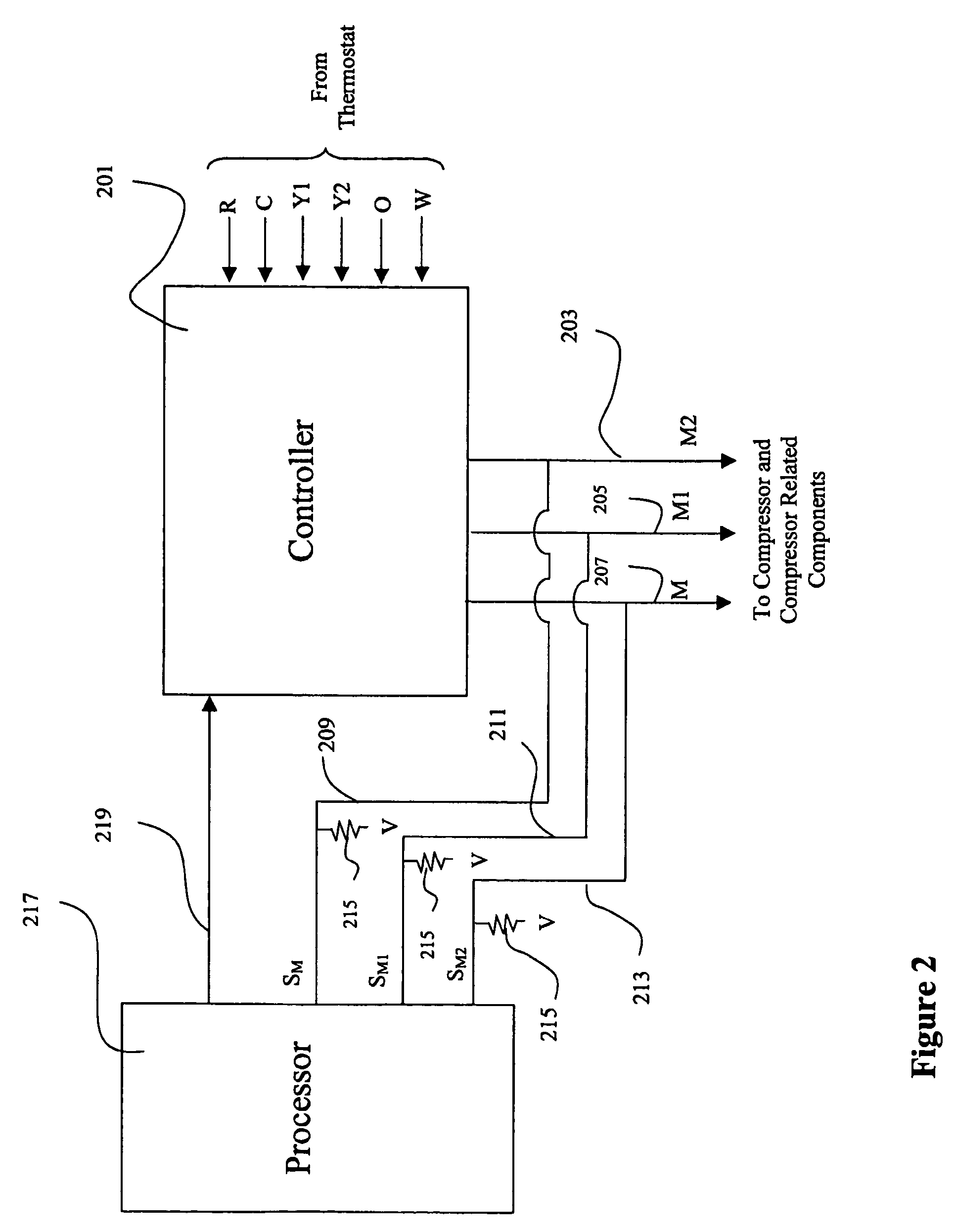

Method and apparatus to sense and control compressor operation in an HVAC system

ActiveUS7562536B2Reduce stepsCompression machines with non-reversible cycleElectric controllersLoad sensingControl theory

An HVAC system and method for configuring a controller to control a compressor including a detection system provided to determine a type of compressor. The detection system includes a processor; and a load sensing circuit connected between the processor and a controller. The controller has a plurality of output connections connectable to a compressor. The load sensing circuit senses whether a load is present on each output connection of the plurality of output connections and provides a load signal to the processor indicating whether a load is present on each output connection. The load signals are processed with the processor to determine the type of compressor is present. The controller is configured to control the compressor in response to the determined type of compressor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Medical apparatus system having optical fiber load sensing capability

ActiveUS8182433B2Facilitate speedHelp accuracyStrain gaugePerson identificationRobotic systemsProcess logic

Owner:ST JUDE MEDICAL INT HLDG SARL

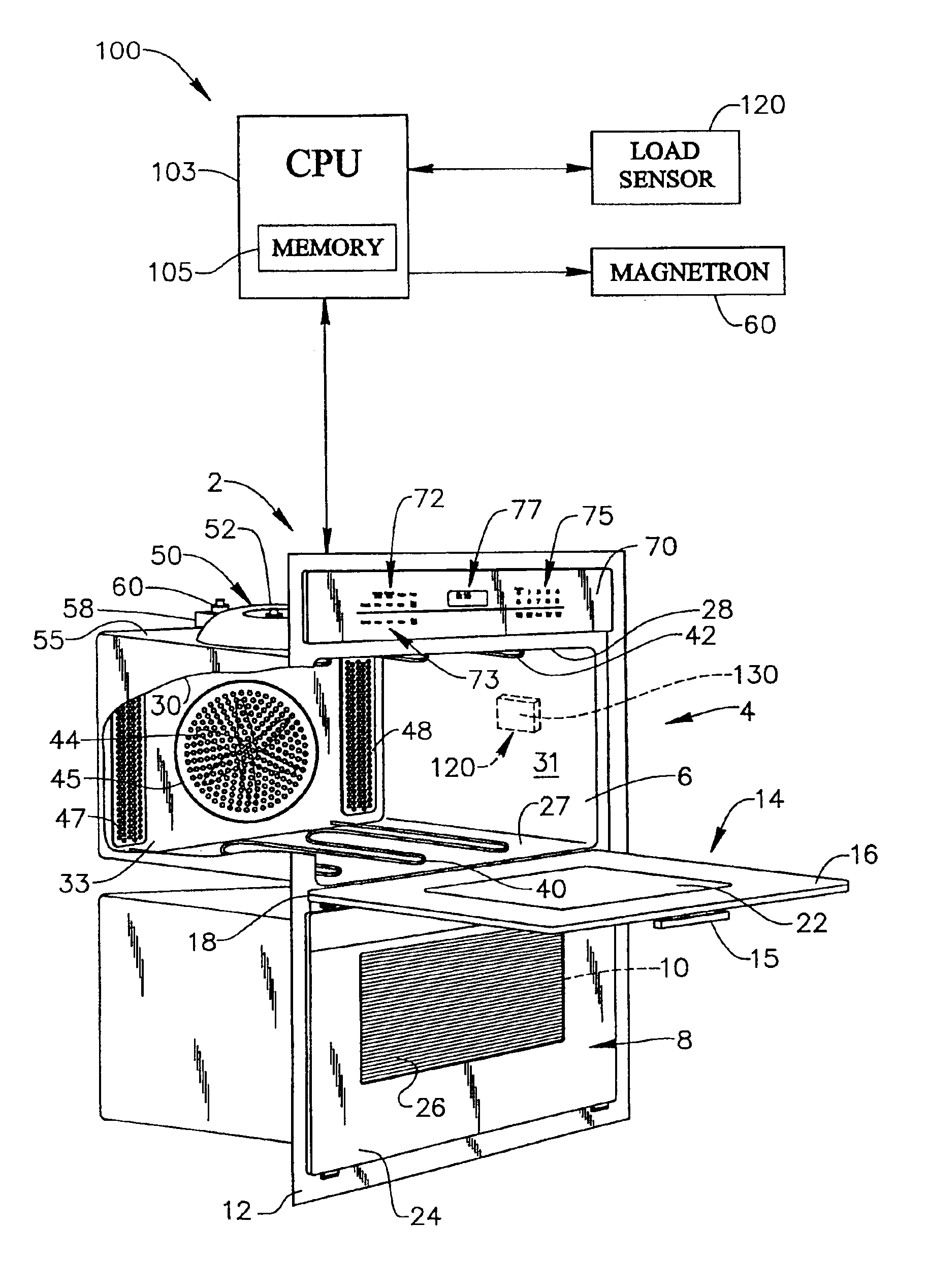

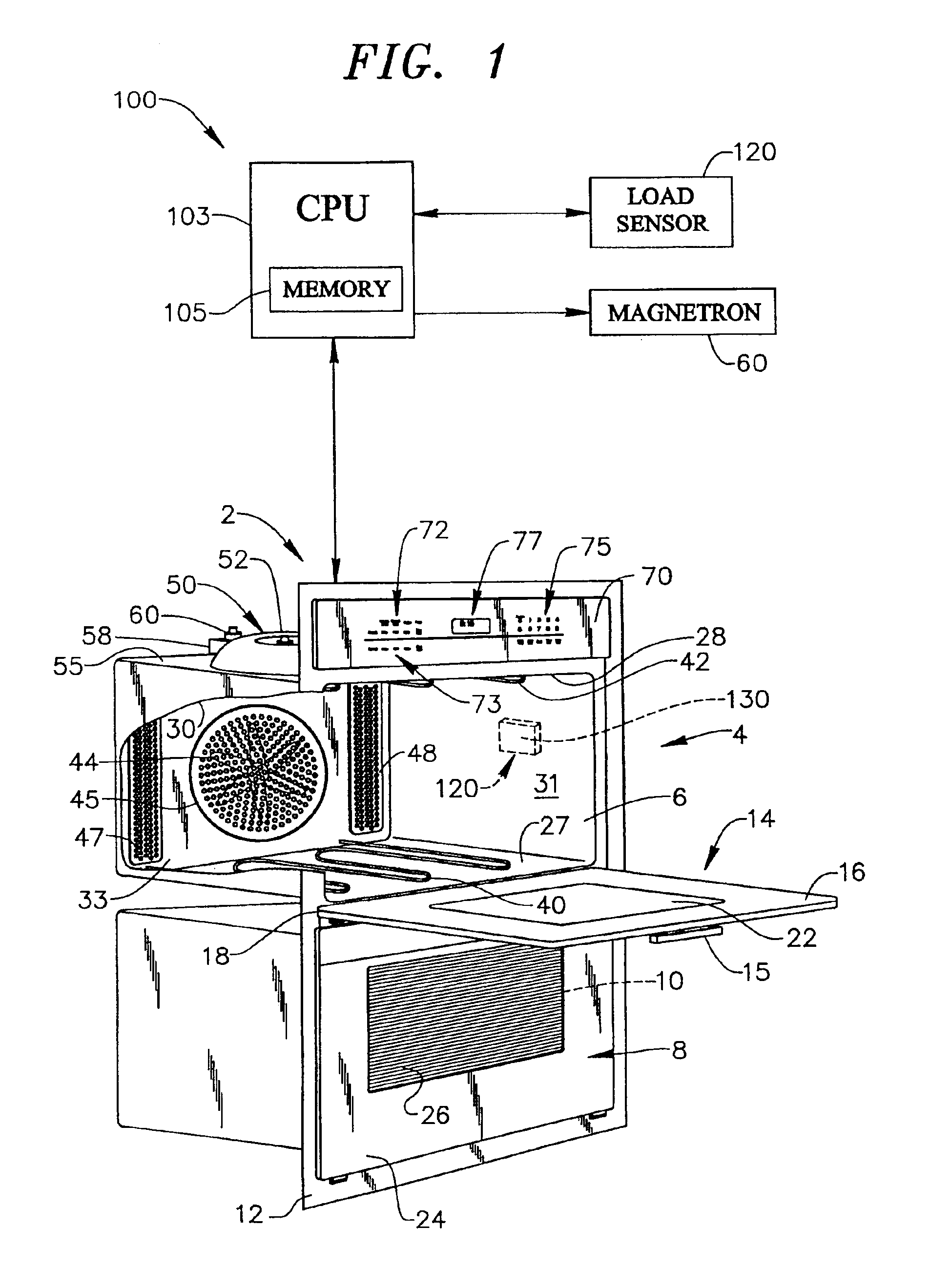

System for sensing the presence of a load in an oven cavity of a microwave cooking appliance

A microwave cooking appliance includes an oven cavity, a magnetron and a load sensing system. The load sensing system is used to detects the presence of a load in the oven cavity by introducing a high frequency energy burst into the oven cavity, with the energy burst being reflected back. A controller, based on a time period between emitted and reflected signals, determines whether a load is present in the oven cavity. If no load is present, operation of the magnetron is terminated. Preferably, the high frequency energy burst is an ultrasonic acoustic frequency energy burst in a range between approximately 10 kHz and 100 kHz.

Owner:ACP OF DELAWARE

Strain gauge stabilization in a surgical device

ActiveUS20200315623A1Minimizes strain gauge errorStable temperatureDiagnosticsStrain gaugeSurgical operationSignal processing circuits

A surgical device includes an adapter assembly including a tubular housing having a proximal end portion configured to couple to a handle assembly, and a load sensing assembly disposed with the tubular housing. The load sensing assembly is configured to measure a load exerted on the tubular housing and includes: a sensor body including a pocket defined therein; a load sensor circuit disposed within the pocket and coupled to the sensor body; a signal processing circuit disposed within the pocket and electrically coupled to the load sensor circuit; a cover defining a cavity and disposed over the pocket and enclosing the load sensor circuit and the signal processing circuit therein, the cover being coupled to the sensor body thereby forming a first hermetic seal therebetween; and a thermal management material disposed within the cavity and in contact with the load sensor circuit and the signal processing circuit.

Owner:TYCO HEALTHCARE GRP LP

Load cell attachment structure

ActiveUS20060048582A1Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

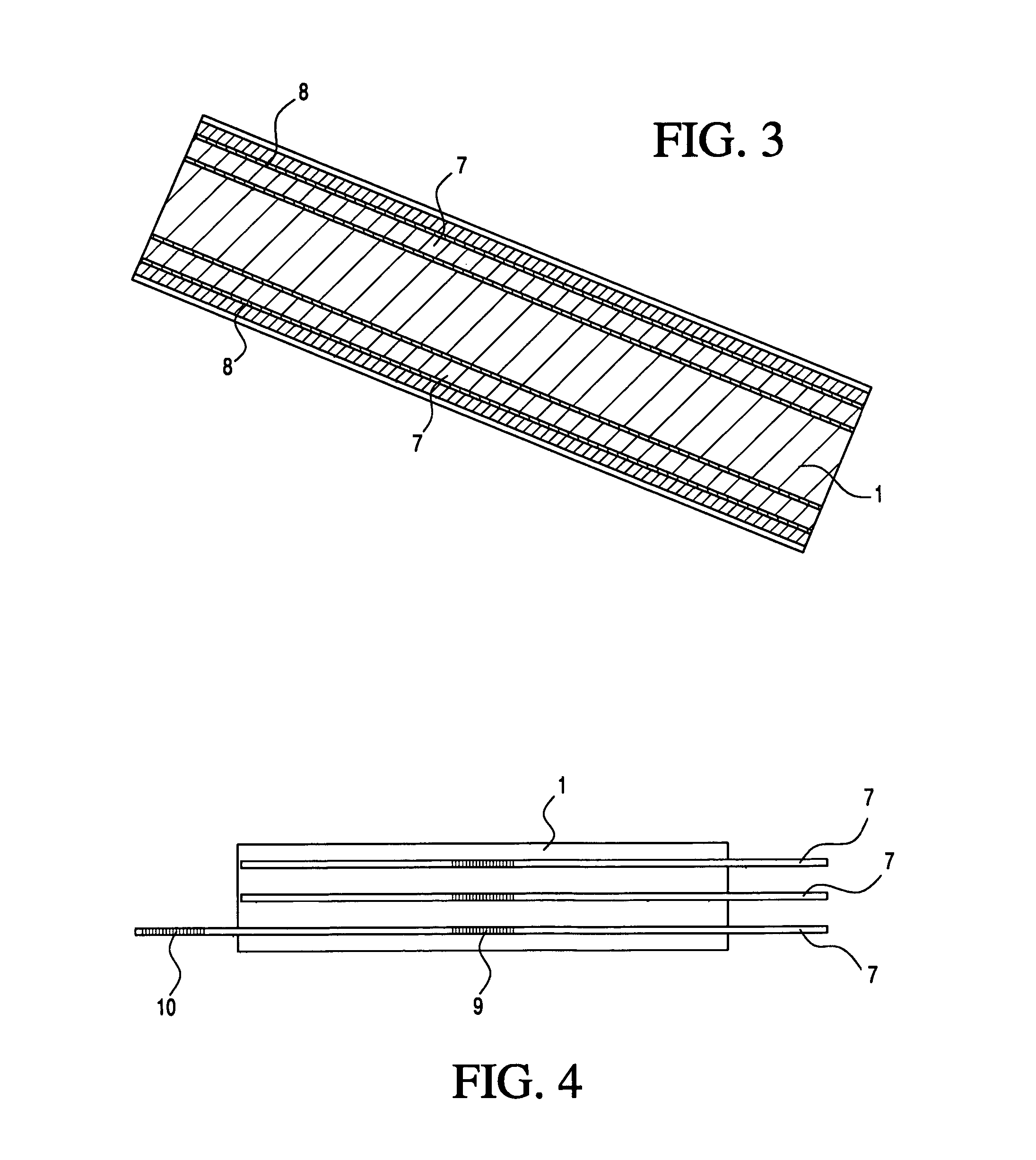

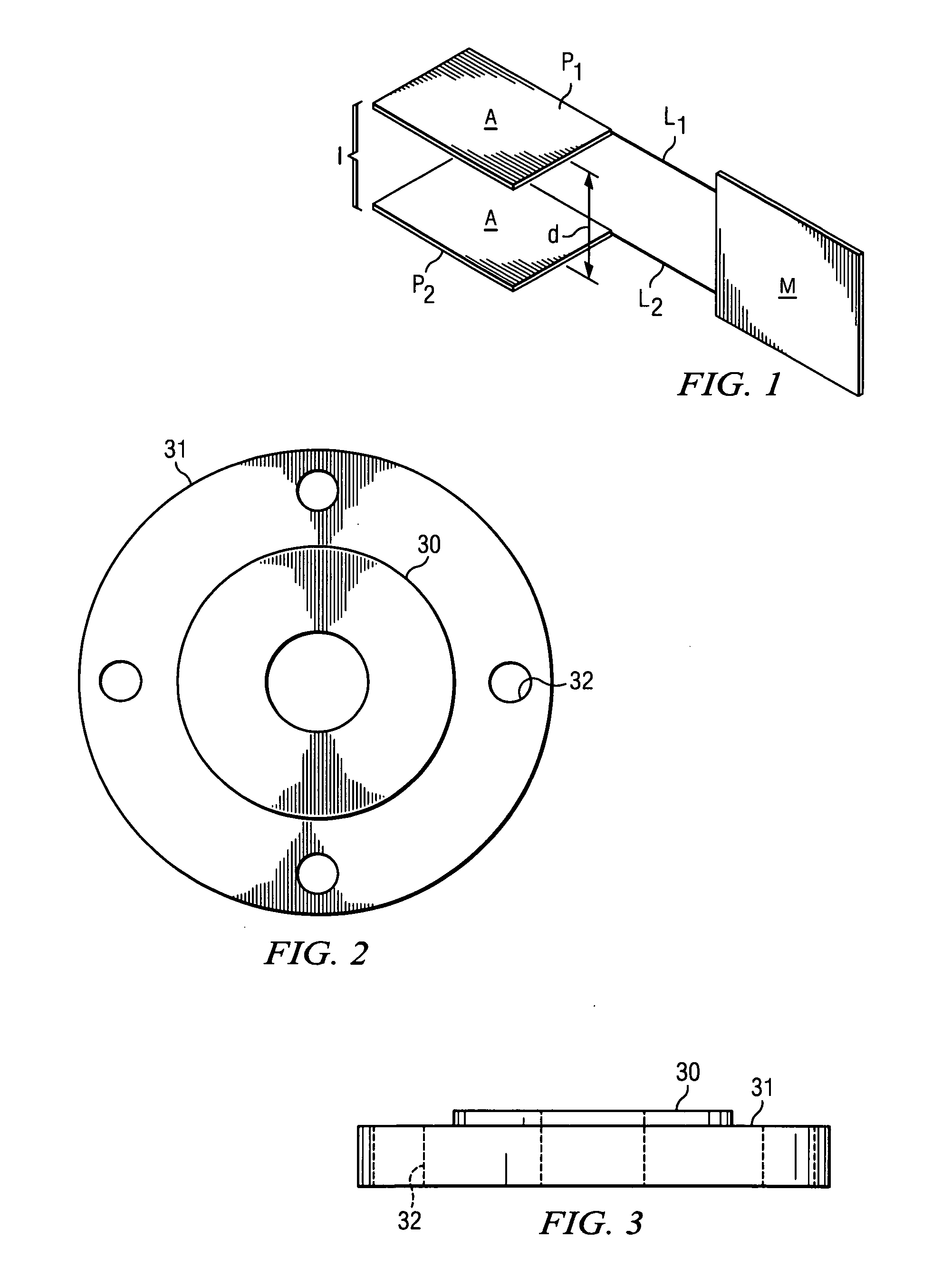

Compressive load sensor by capacitive measurement

InactiveUS20070193361A1Effectively measure parameterMaintain measurement accuracyForce measurementMachine sealing rings testingContinuous measurementElectricity

A thin, flat capacitive load sensor, such as of layered sandwich construction, having a variety of shapes, so as to provide a seal between two or more opposing surfaces. The load sensor includes a thin first and second insulating outer layer between which an inner layer is secured. The inner layer can be formed of dielectric material of a known dielectric constant, with at least one thin electrical conductor to accommodate load sensing disposed against a first face, and another thin electrical conductor to accommodate load sensing disposed against a second face. Electrical conductors connect the thin conductive areas on the first and second faces to the distal end of a tab extending beyond the load or connection measurement area. The distal end of the tab accommodates a connection with electrical measurement apparatus. As the inner layer is compressed, the spacing between the electrically conductive areas on the opposing faces is decreased such that compressive forces can be measured as a function of the changes in capacitance of the sensor. In this manner, proper compression can be achieved by monitoring capacitance during installation. Follow-up sampling or continuous measurement of sensor compression provides early detection prior to failure to allow corrective action.

Owner:DAVIE COFFEY TECH L L C

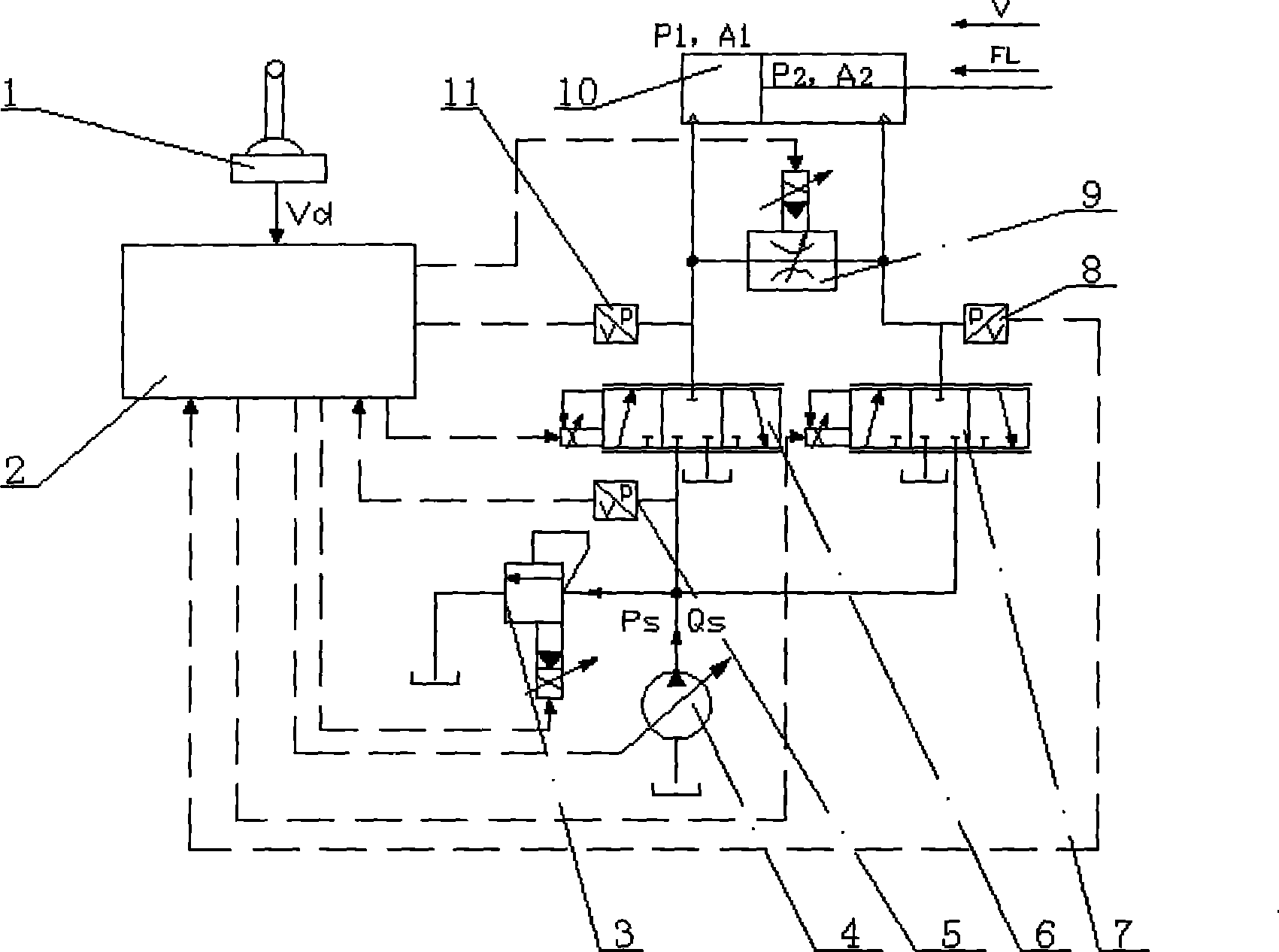

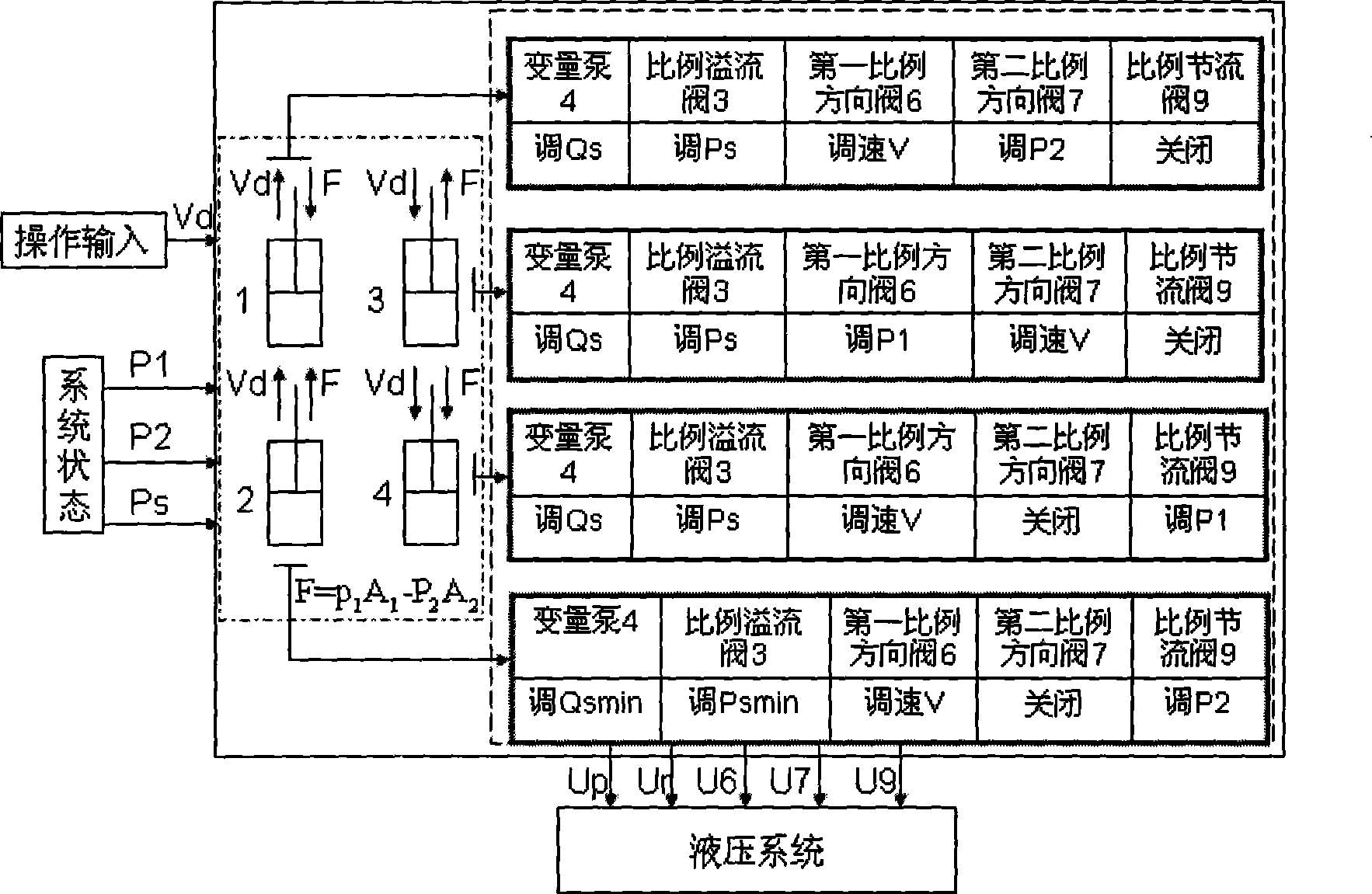

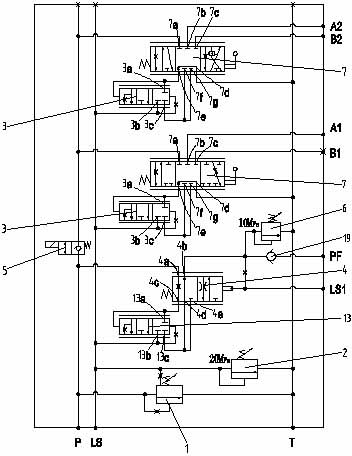

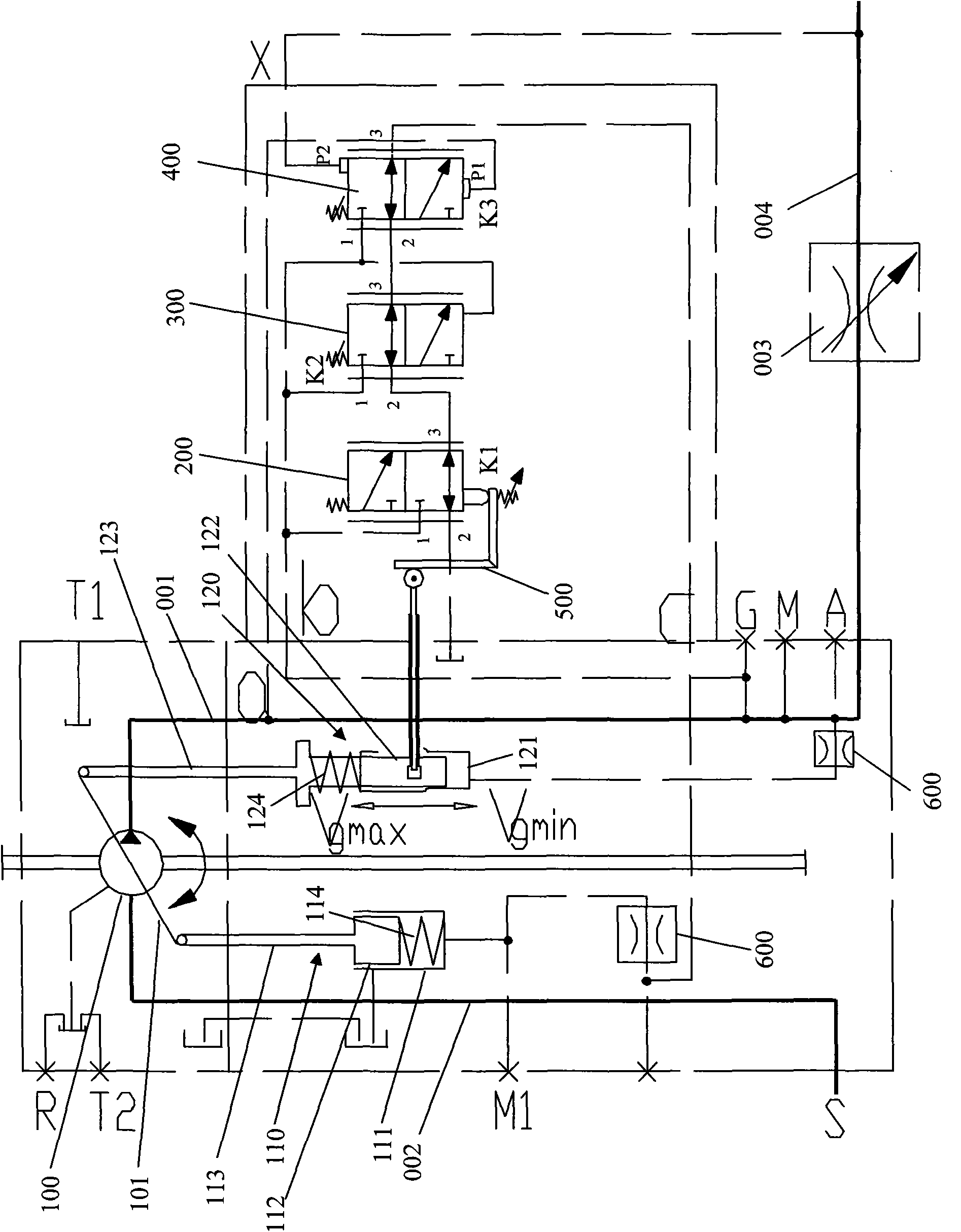

Independent electrohydraulic load sensitive energy regeneration hydraulic system of engineering machinery load port

InactiveCN101413522AAchieve regenerationReduce lossFluid-pressure actuator componentsLoad sensingElectrical connection

The invention discloses an independent electrohydraulic load sensing energy regeneration hydraulic system of an actuator port of an engineering machine. An oil outlet of a variable pump is connected with an oil inlet of a proportional relief valve, a first pressure sensor, an oil inlet of a first proportional directional valve, and an oil inlet of a second proportional directional valve respectively. An oil outlet of the first proportional directional valve is connected with a second pressure sensor, the oil inlet of a proportional throttle valve and a rodless cavity of a hydraulic cylinder respectively. An oil outlet of the second proportional directional valve is connected with an oil outlet of the proportional throttle valve, a third pressure sensor and a rod cavity of the hydraulic cylinder. A Controller is in electrical connection with a control handle, the variable pump, the proportional relief valve, two proportional directional valves, the proportional throttle valve and three pressure sensors. The system adopts the pressure sensors to detect working conditions, selects control policies according to the working conditions, reduces energy loss in flow restriction and realizes overload energy regeneration under the control of an actuator. Speed and energy-conservation control is realized through the combination of pump control and valve control.

Owner:ZHEJIANG UNIV

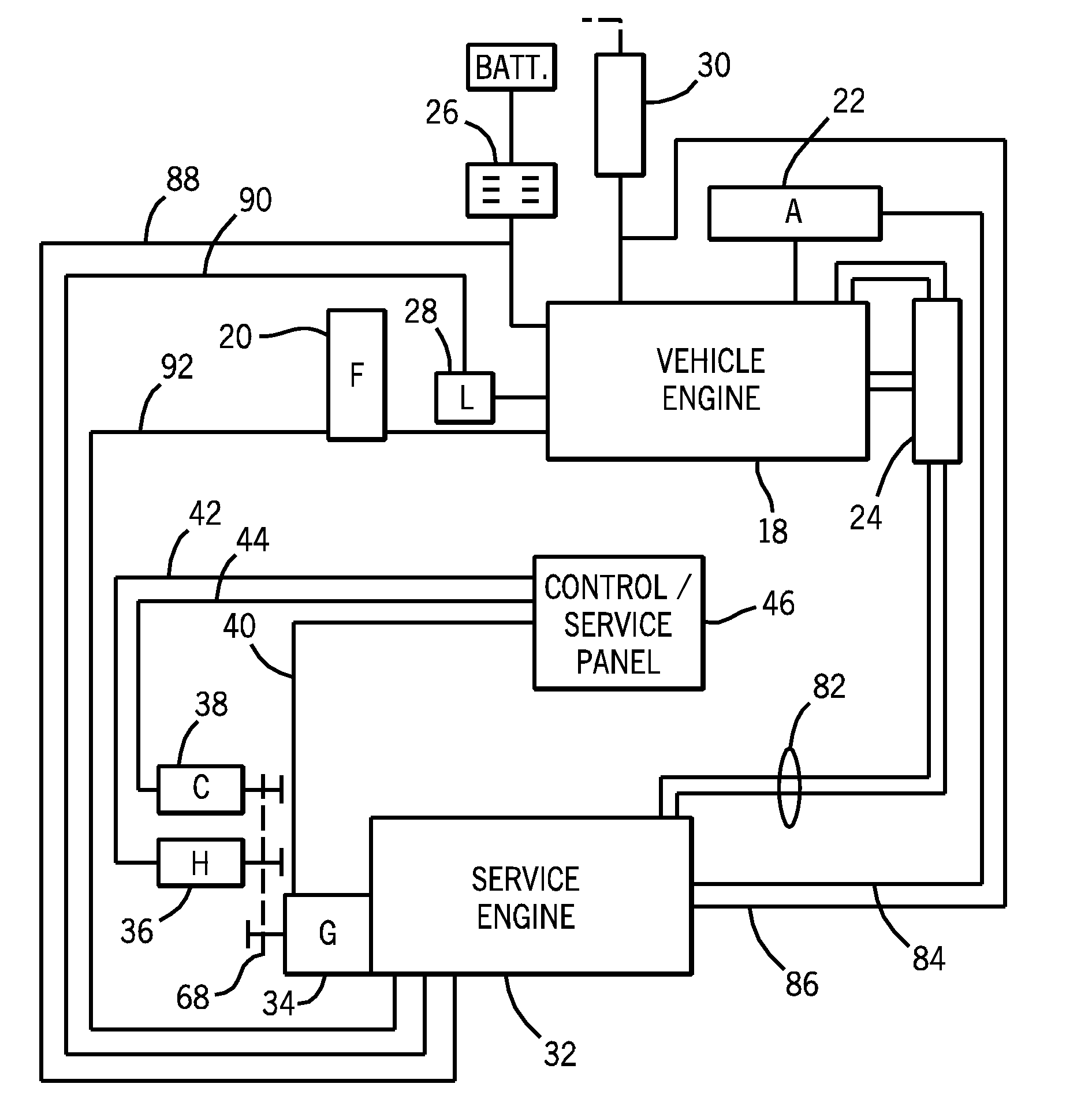

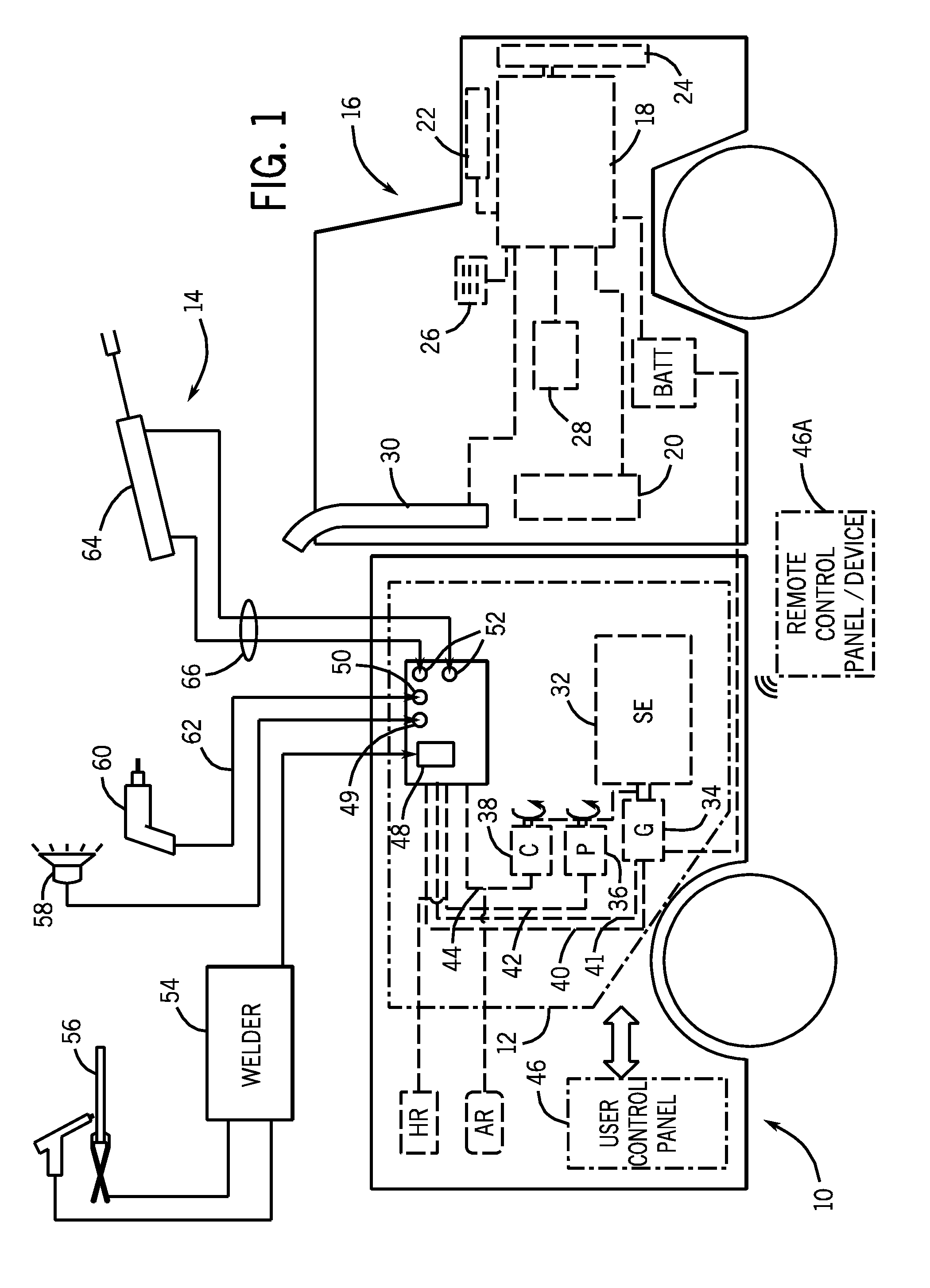

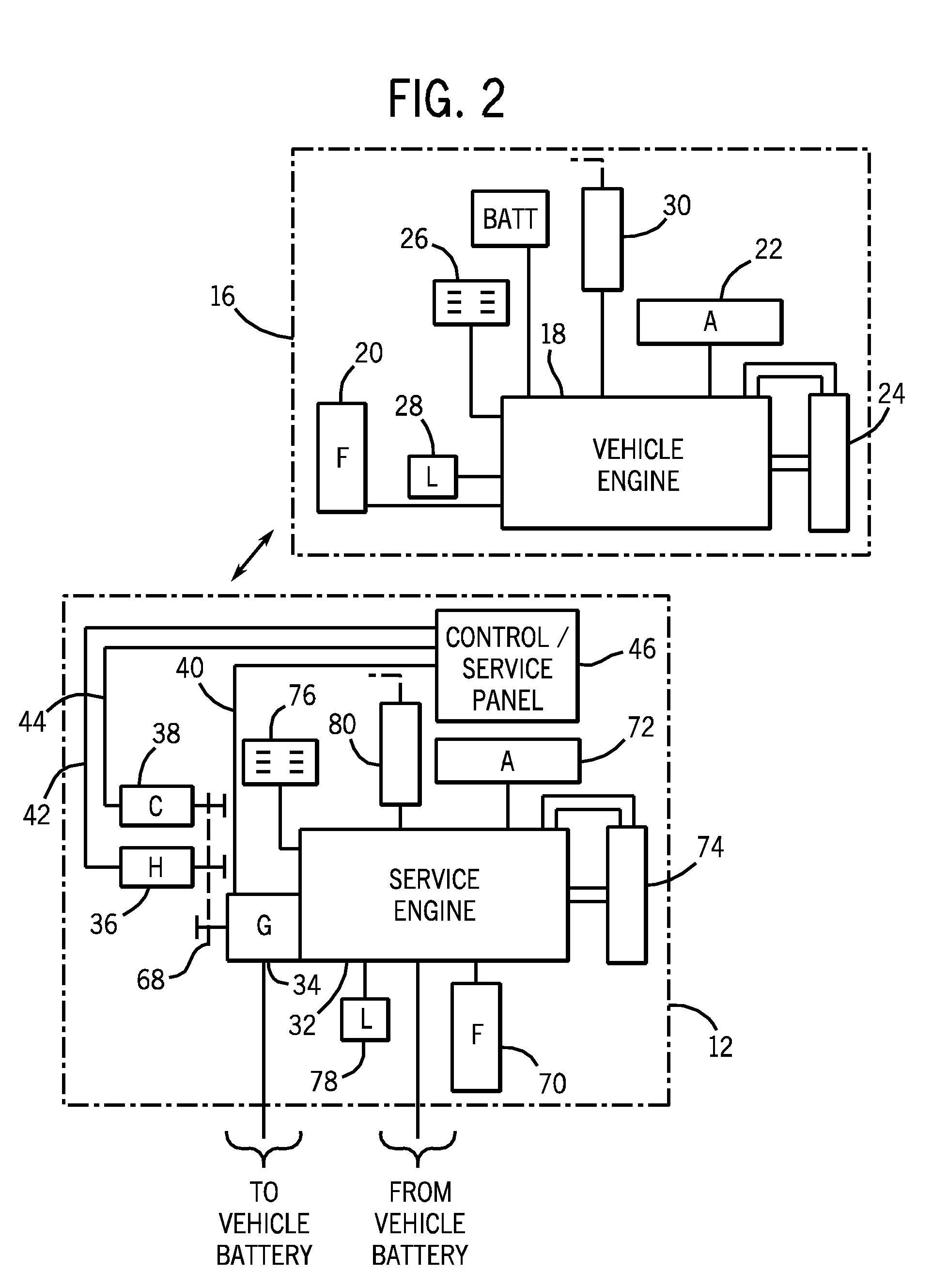

Service pack power management

ActiveUS20090194067A1Reducing the possibility of overloading the prime moverEasy to manageAnalogue computers for vehiclesElectrical controlLoad sensingSet point

A power management system, in certain aspects, may utilize direct load sensing feedback from the prime mover (e.g., engine), thereby reducing the possibility of overloading the prime mover. The use of direct load sense feedback from the prime mover can then be used with additional feedback, such as prime mover RPM feedback and individual output load sensing feedback, to directly control the output loads and set the primary power sources rpm set-point to better manage the power available and reduce the possibility of overloading the primary power source.

Owner:ILLINOIS TOOL WORKS INC

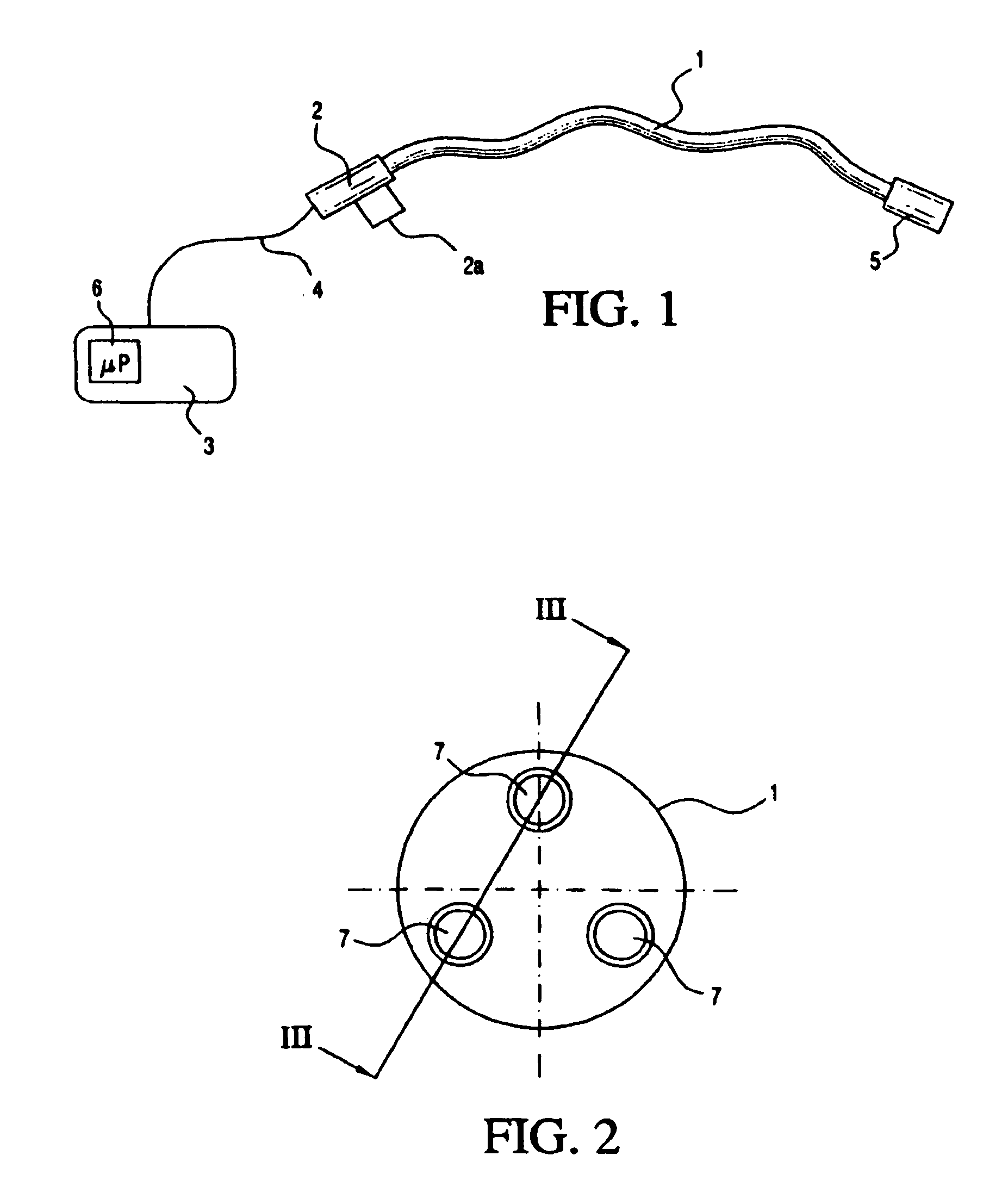

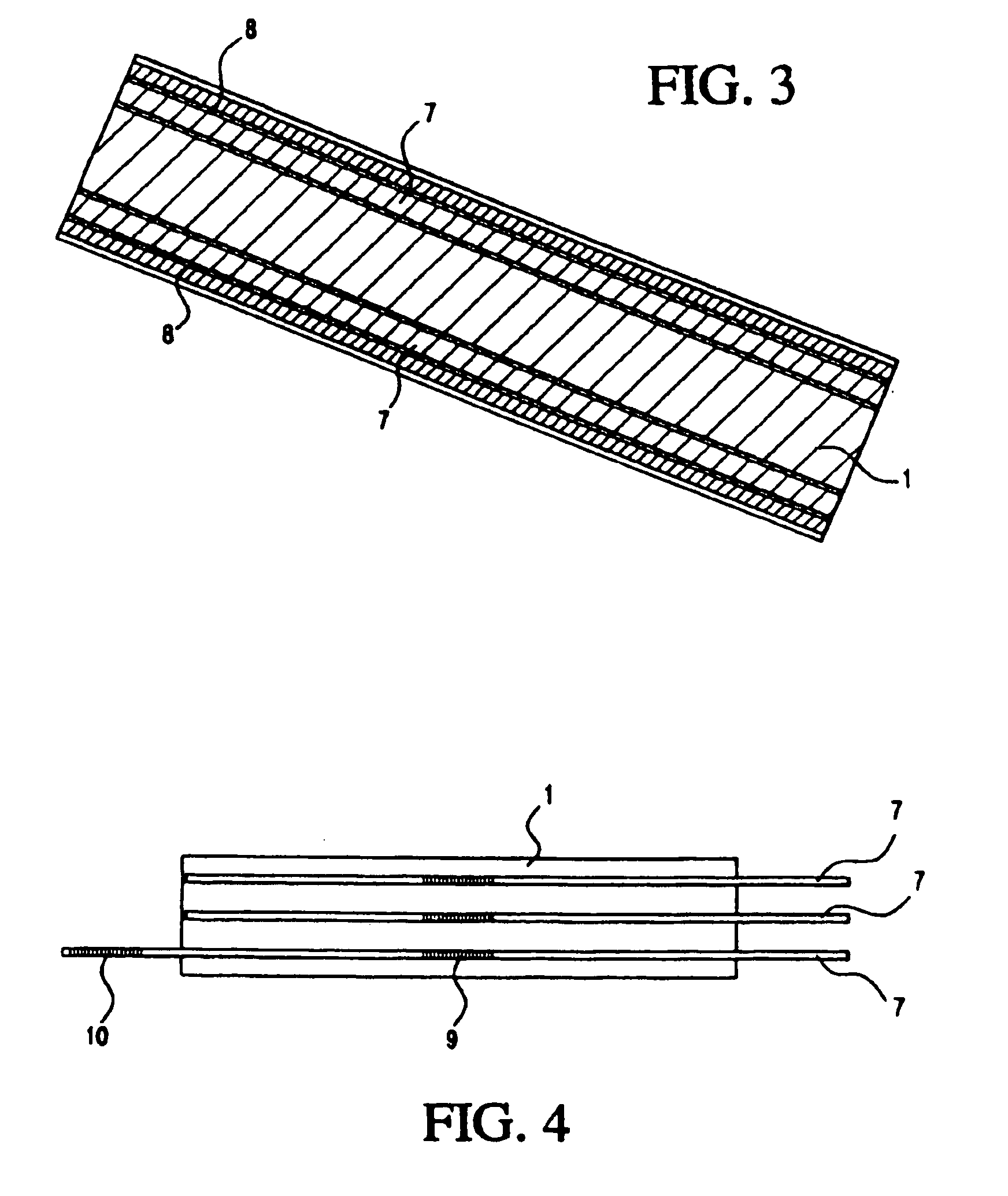

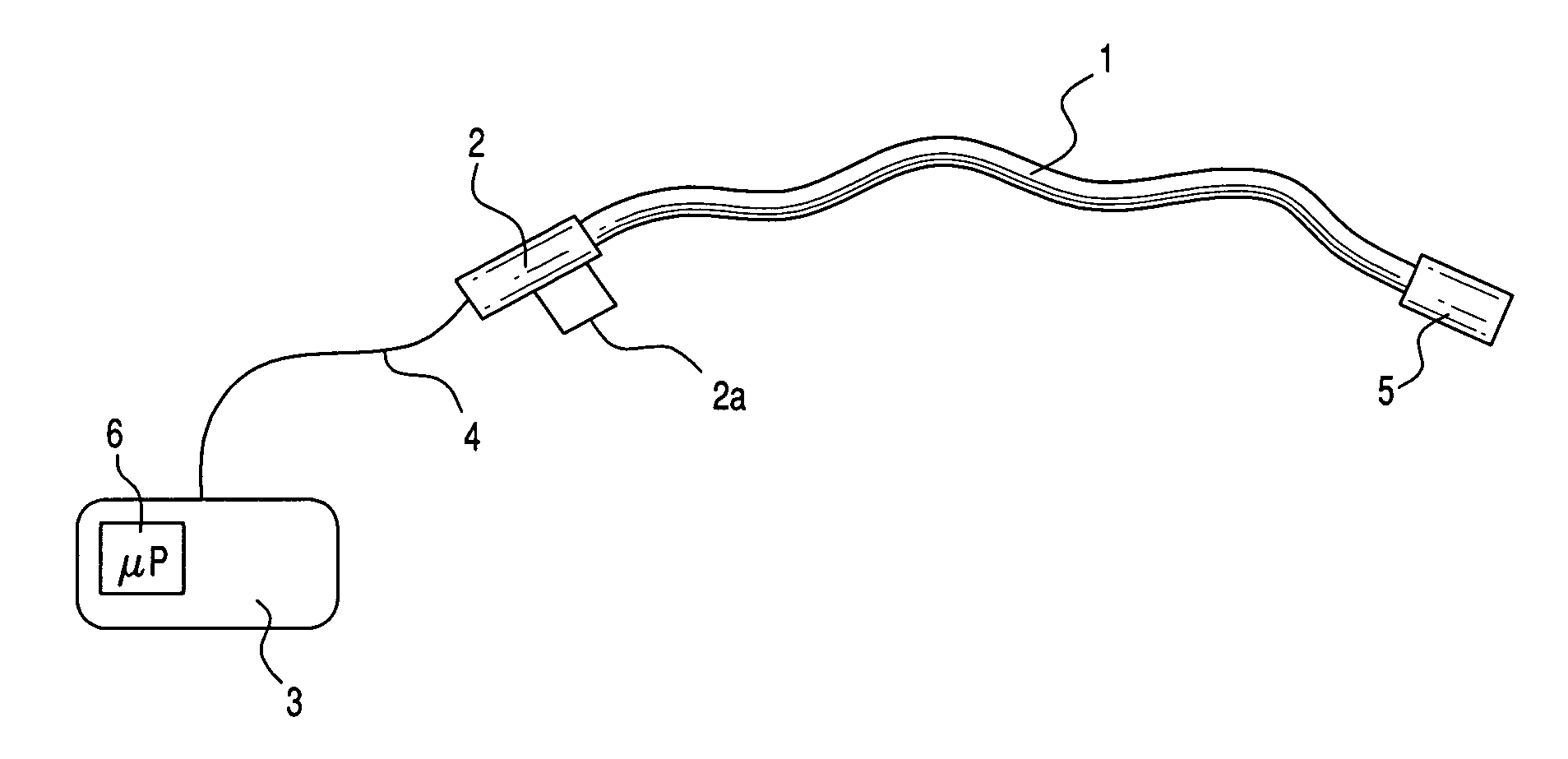

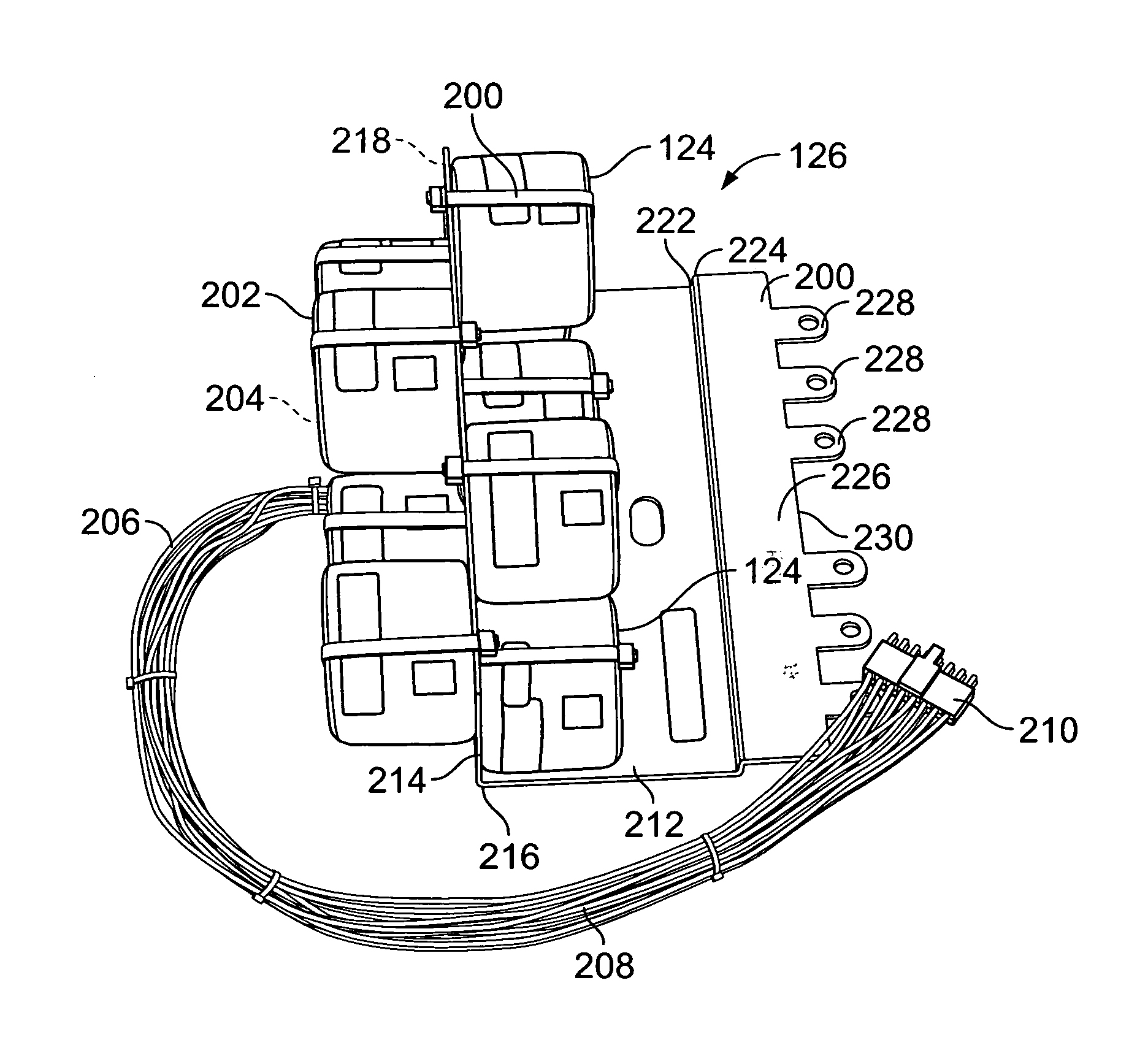

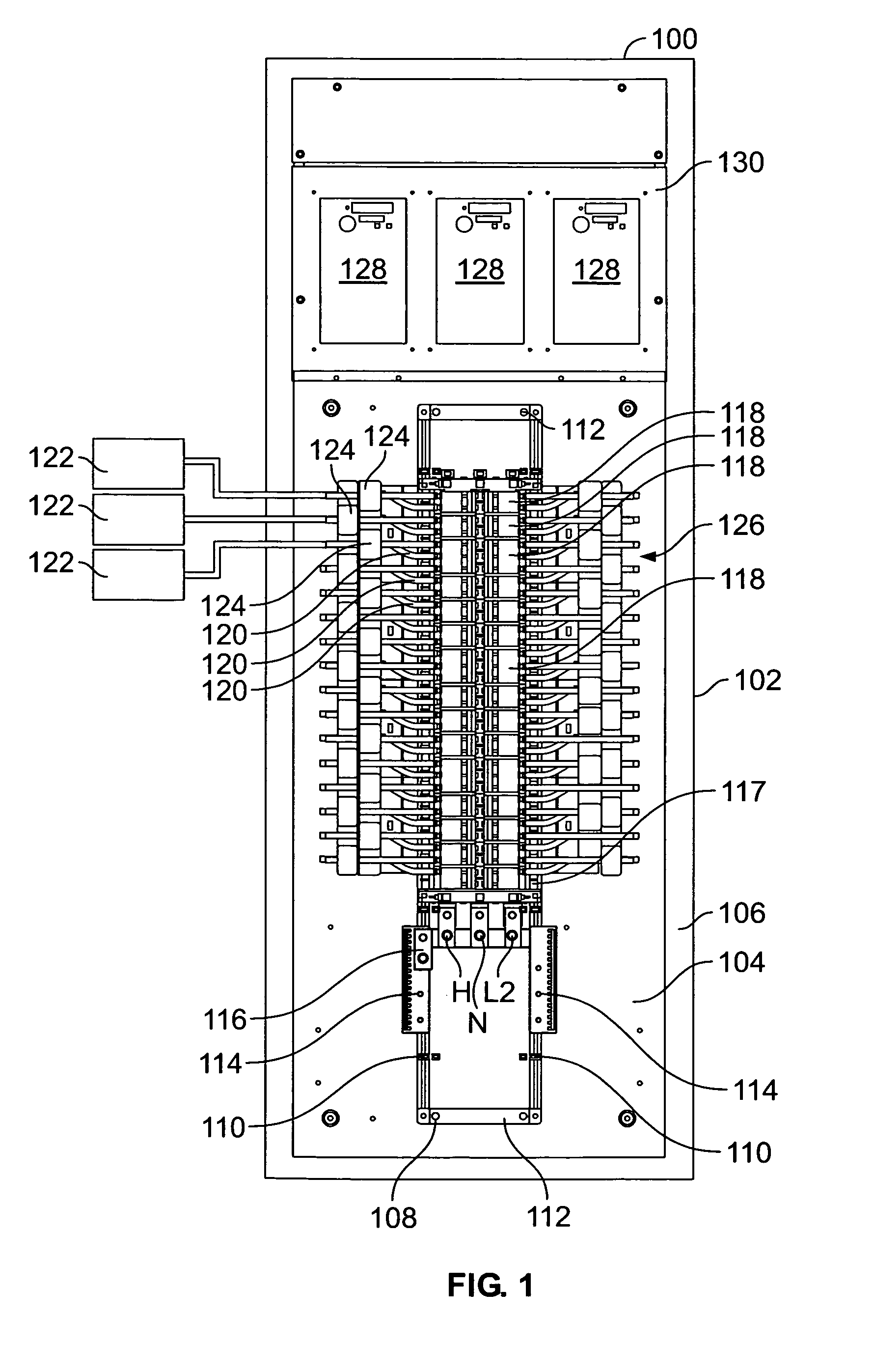

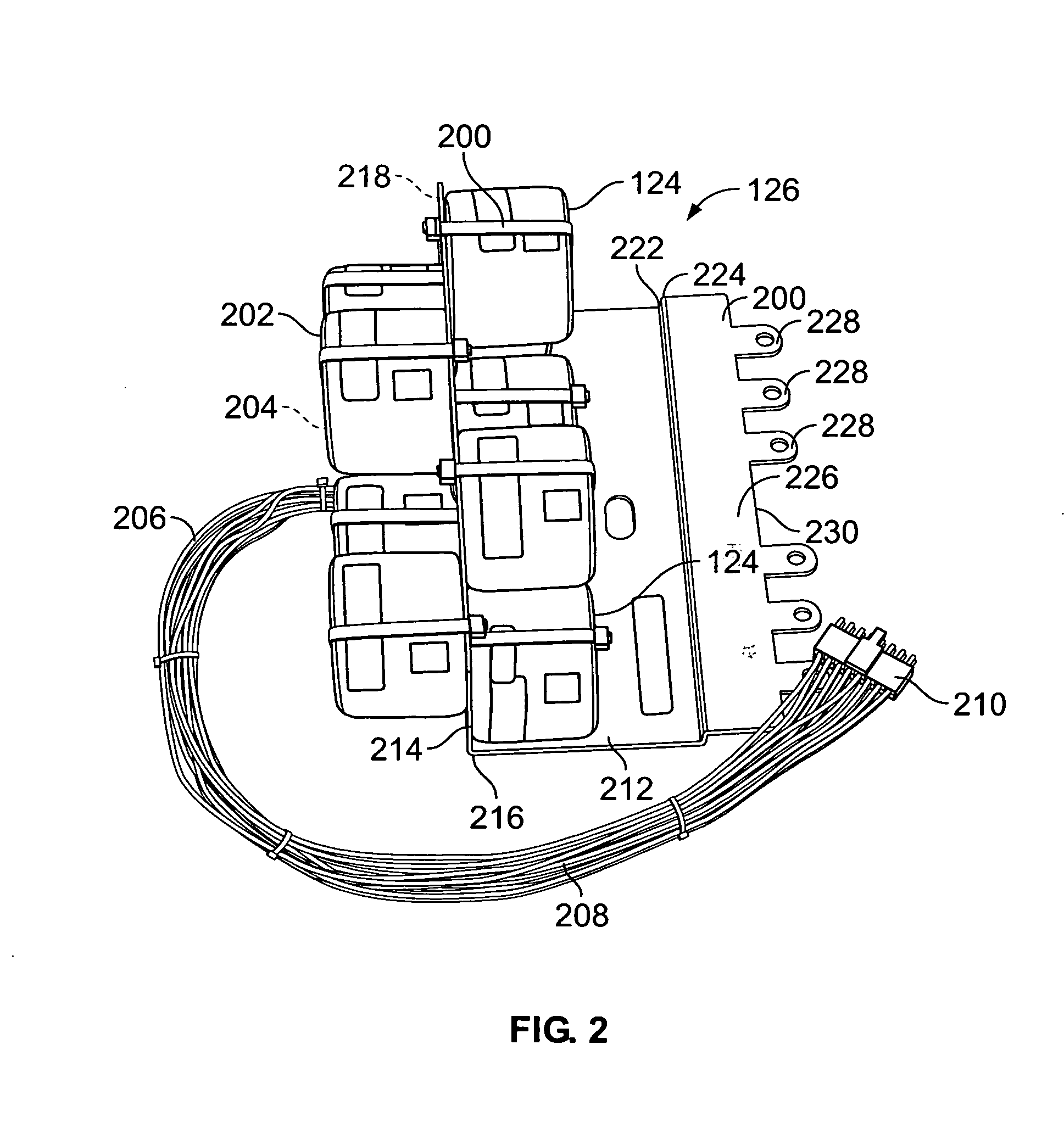

Methods and systems for electric power sub-metering

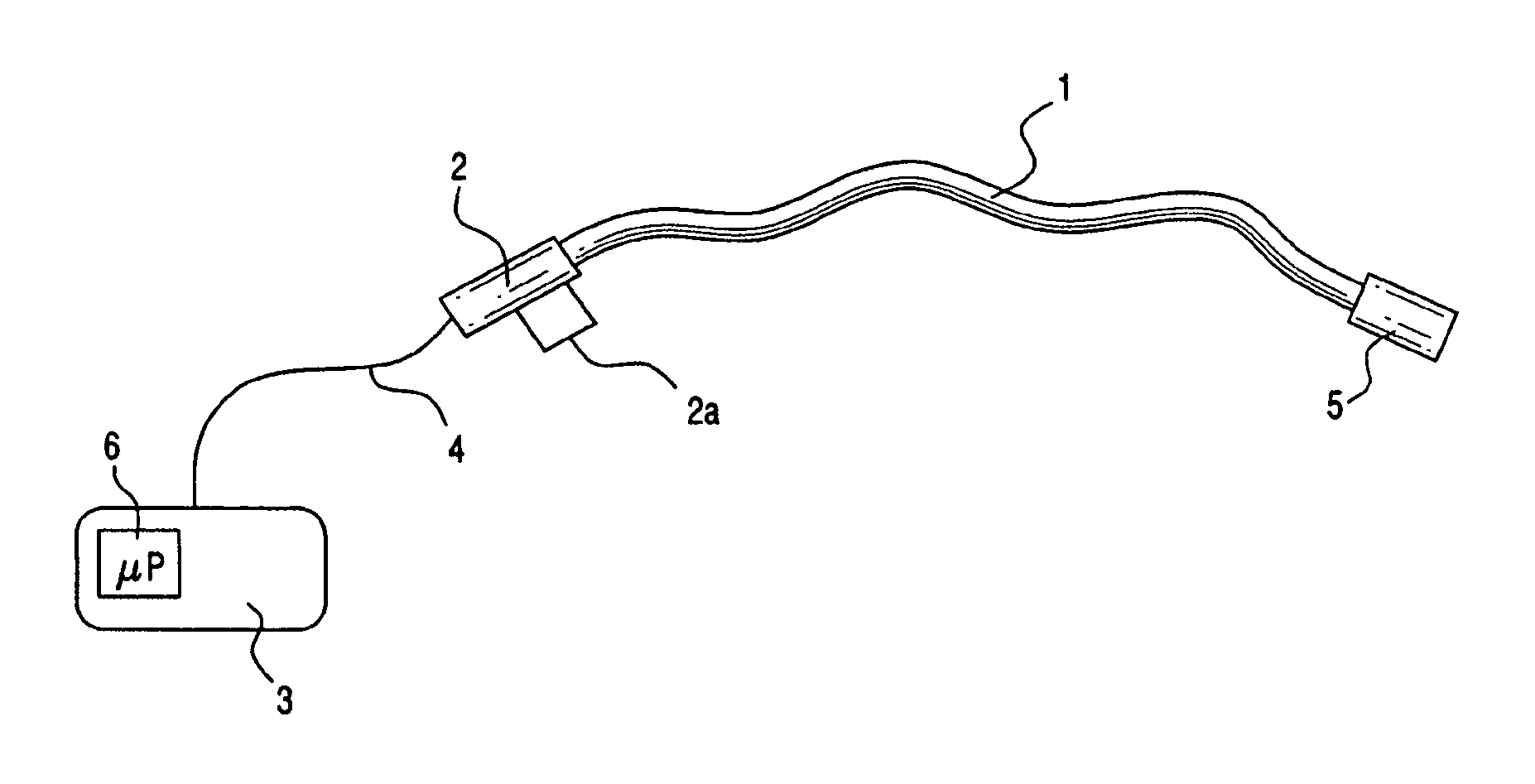

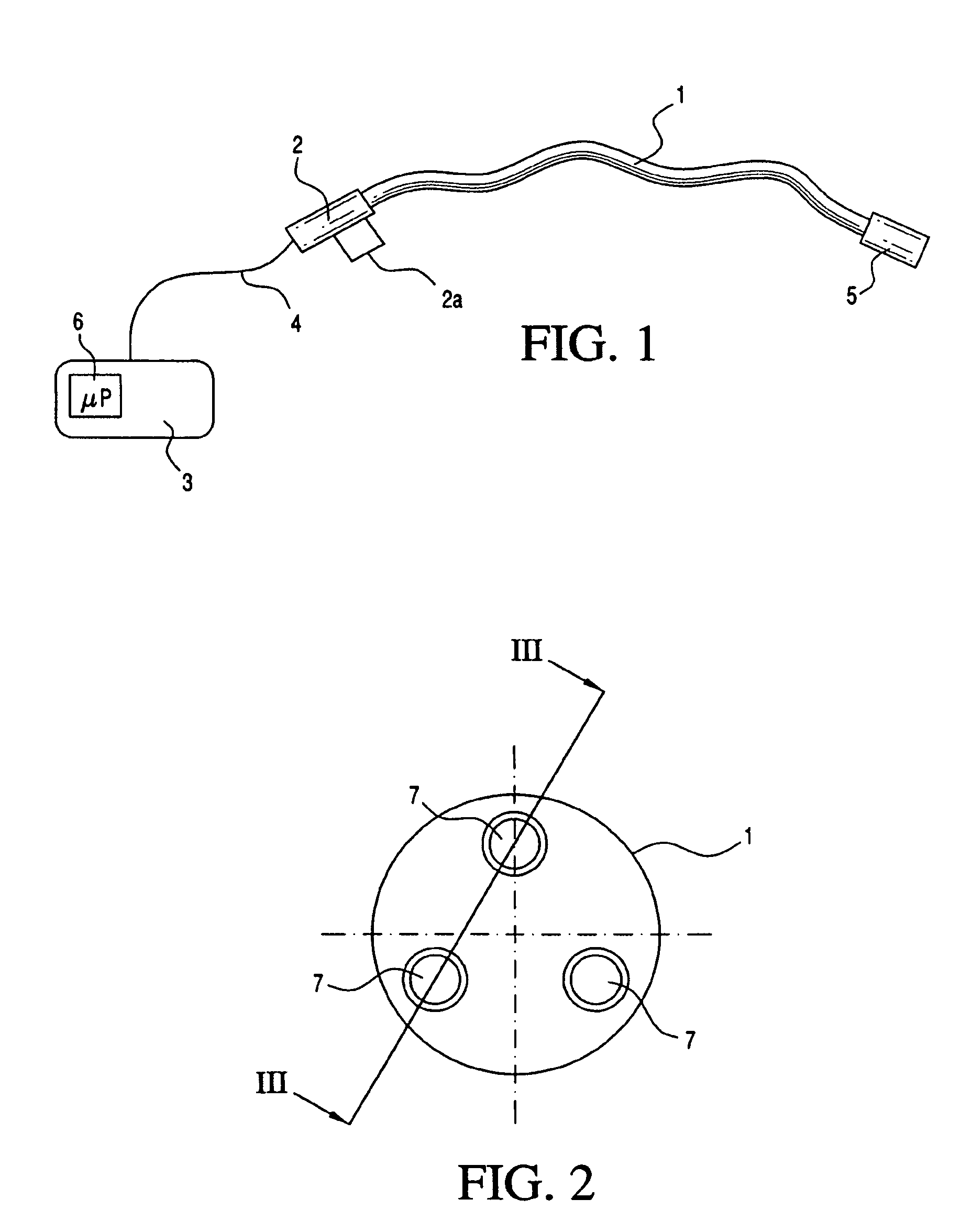

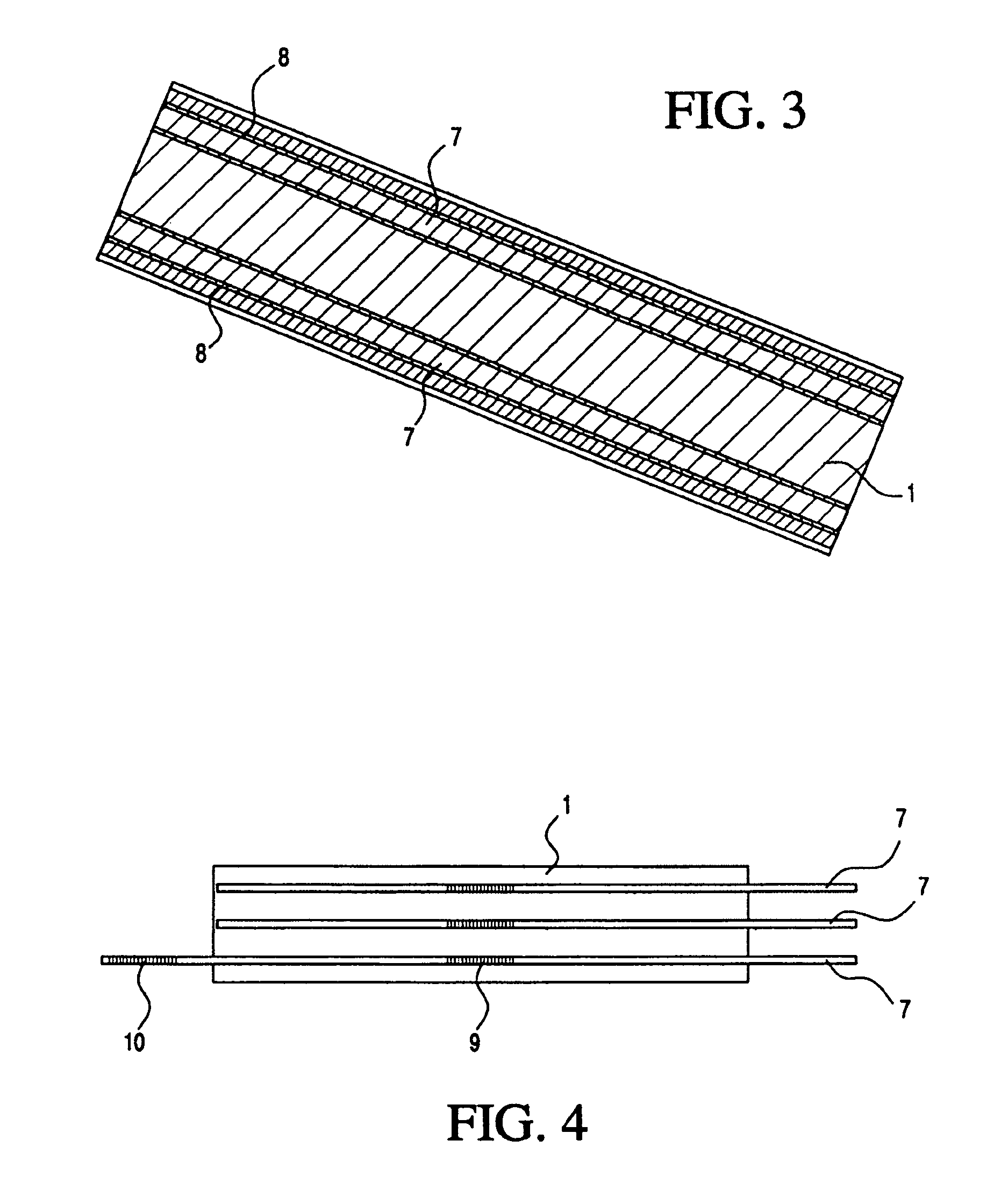

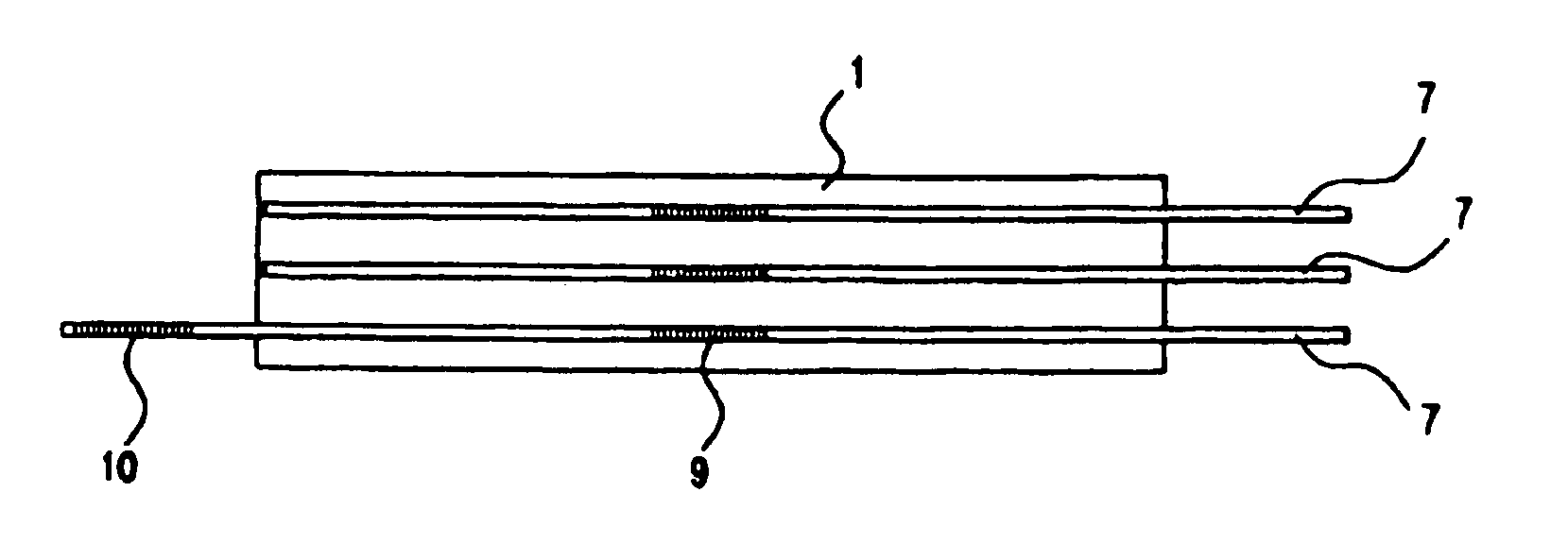

ActiveUS20060121785A1Coupling device connectionsElectrically conductive connectionsElectricityLoad sensing

Methods and systems for electrical distribution submetering are provided. The electrical distribution submetering system includes a modular load sensing assembly including a plurality of load sensors. The load sensing assembly further includes a first cable having a first cable termination connector, an interface board including a plurality of electrical terminations, at least some of the terminations electrically coupled to a second cable having a second cable termination connector coupled to at least one conductor of the second cable, the second cable termination connector being complementary to the first cable termination connector such that the first cable termination connector and the second cable termination connector are configured to be electrically coupled. The submetering system also includes a modular sub metering electronics communicatively coupled to the interface board, the modular sub metering electronics configured to determine a branch circuit load in the electrical distribution system using the detected electrical load.

Owner:ABB (SCHWEIZ) AG

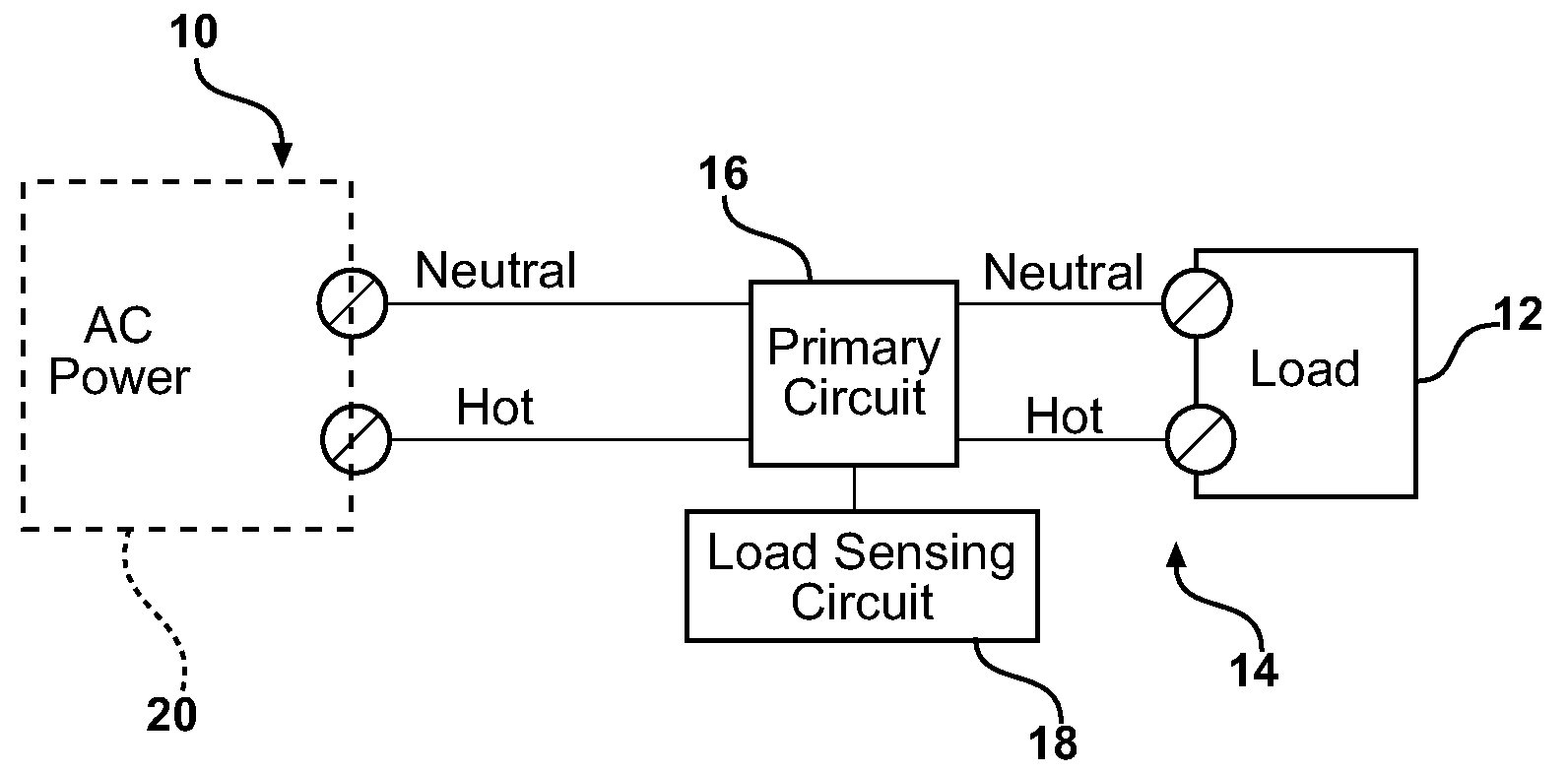

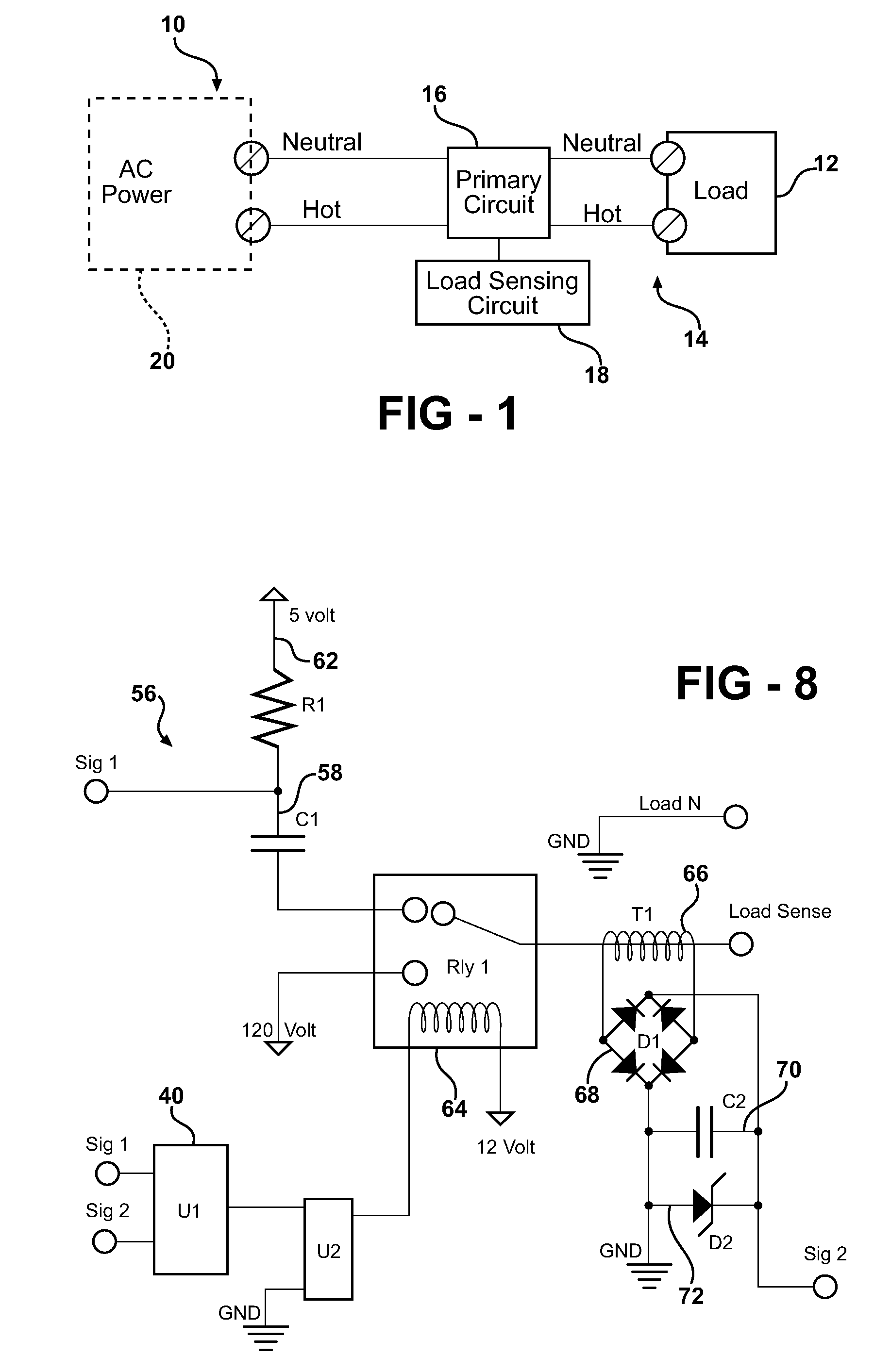

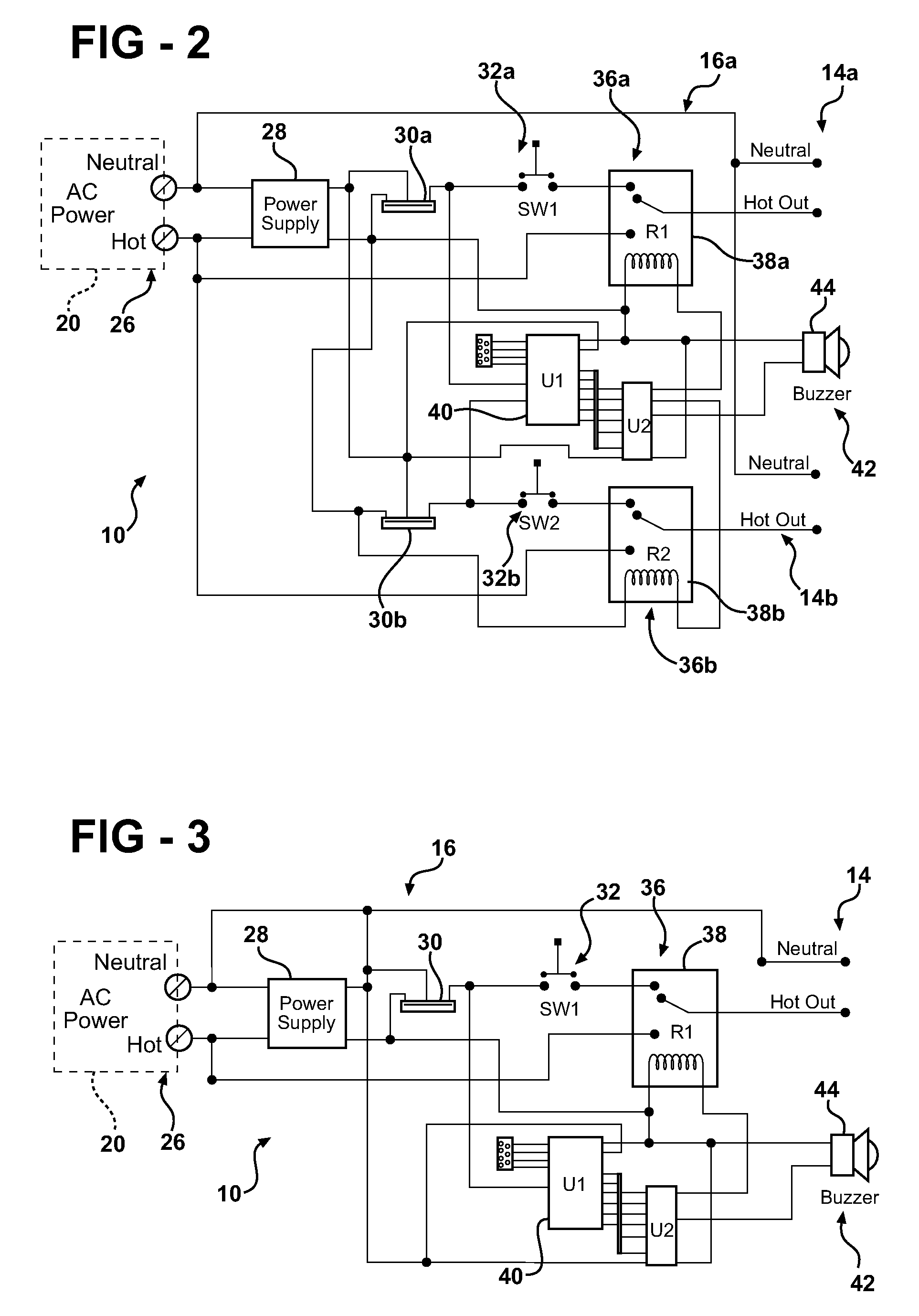

Current Sensing Load Demand Apparatus and Methods

InactiveUS20080049367A1Boards/switchyards circuit arrangementsProtective switchesElectricityElectrical resistance and conductance

An apparatus supplies AC power to a load. The apparatus includes a set output terminals, a primary circuit, and a load sensing circuit. The primary circuit is electrically coupled to a source of AC power and to the output terminals for selectively providing power at a low voltage at the output terminals or electronically coupling the source of AC power directly to the output terminals. The load sensing circuit coupled to the primary circuit and the source of AC power for determining a resistance associated with the load at initial application of the load and controlling the primary circuit to electronically couple the source of AC power directly to the output terminals if a proper load is detected.

Owner:TECH MAVERICKS

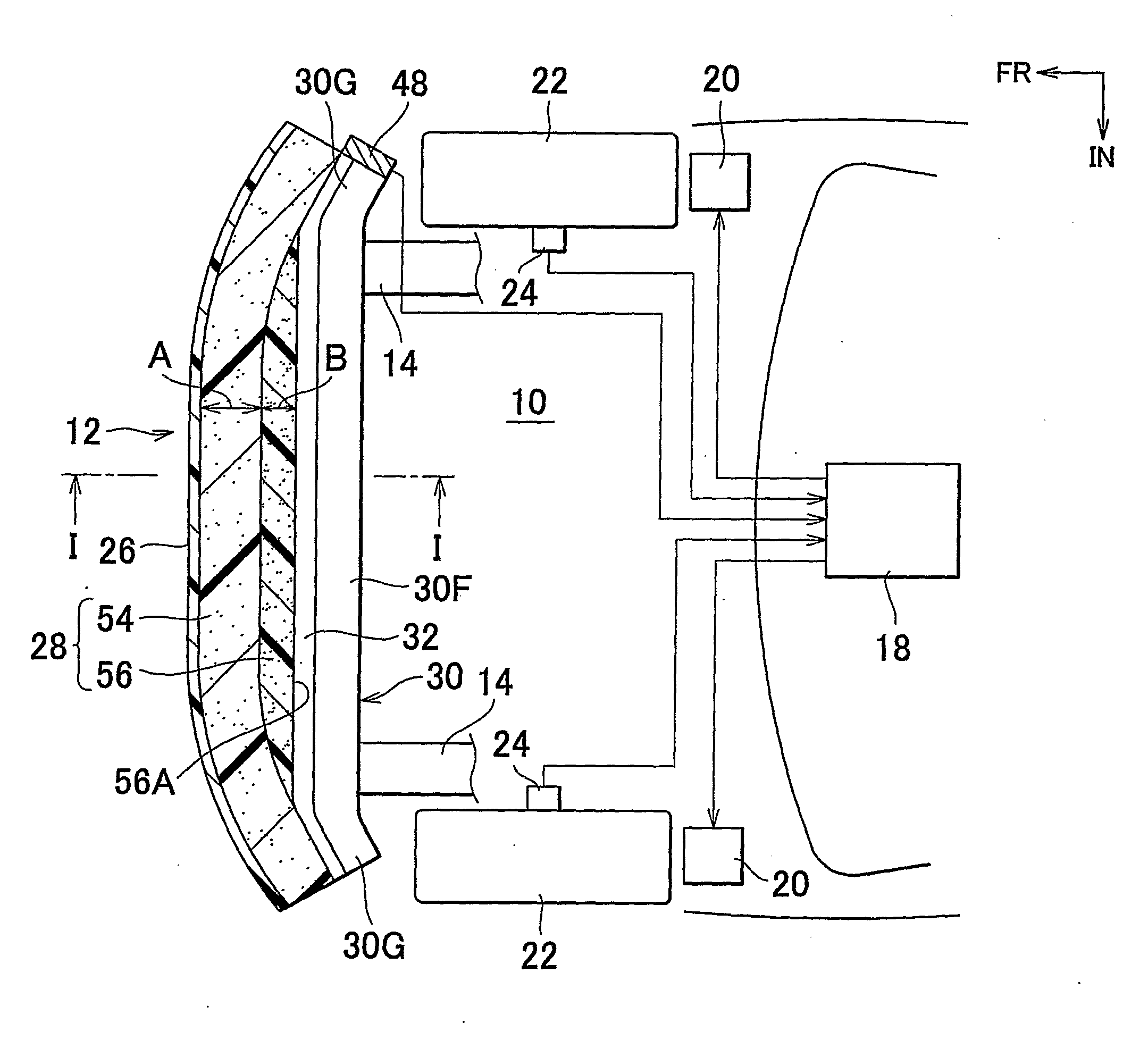

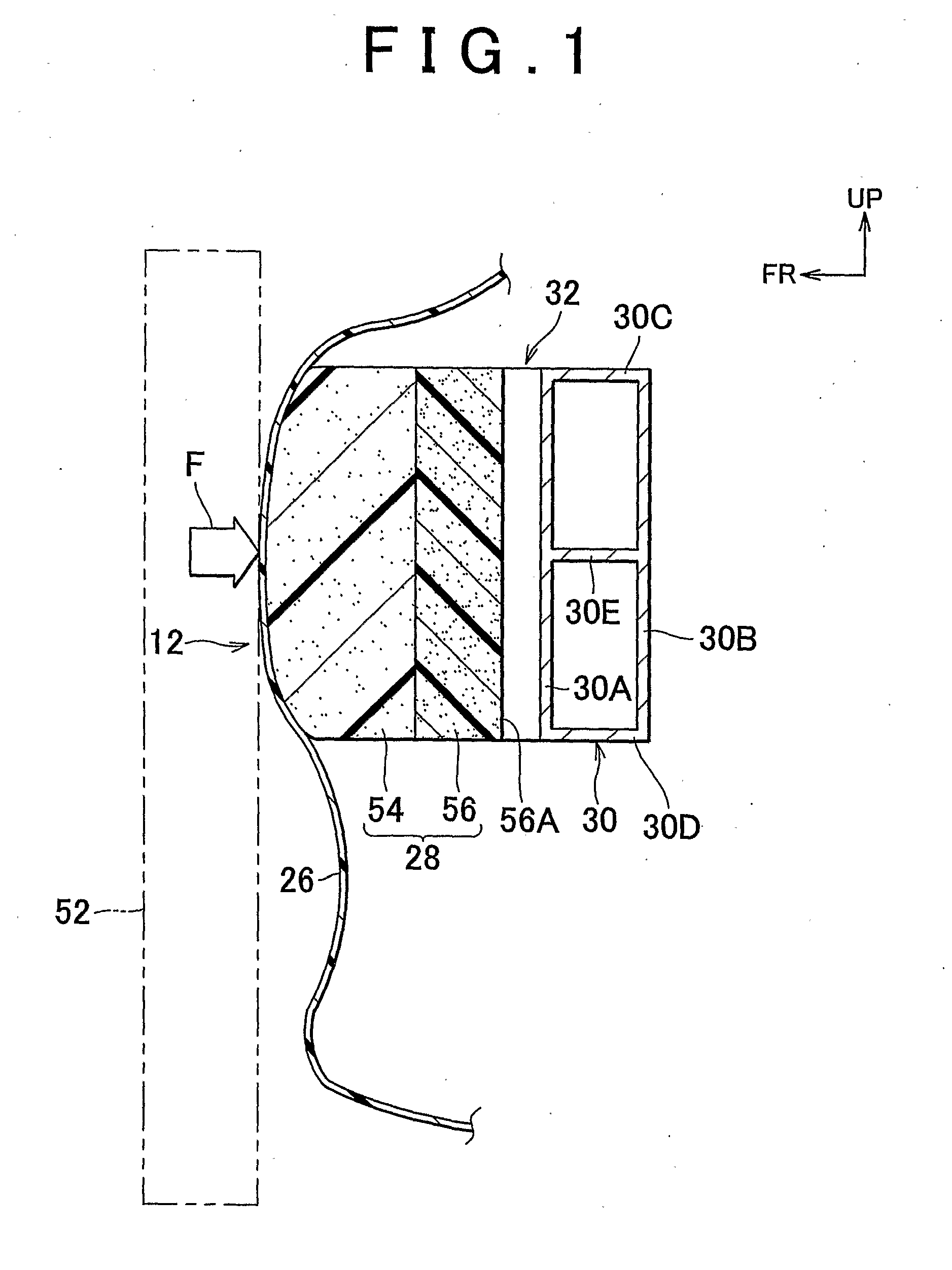

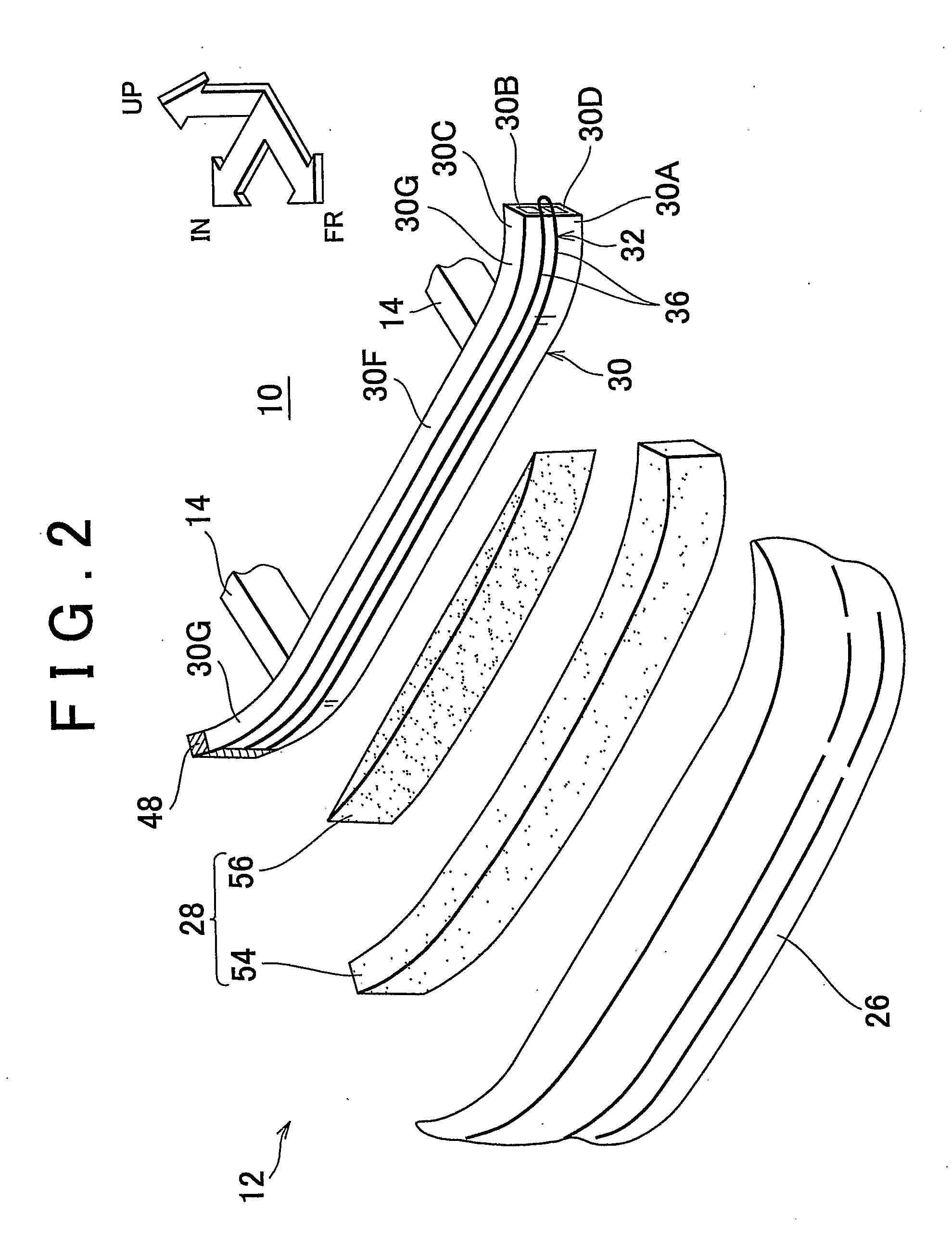

Vehicle bumper structure

InactiveUS20090322107A1Variation in outputReduce variationSuspensionsPedestrian/occupant safety arrangementLoad sensingEngineering

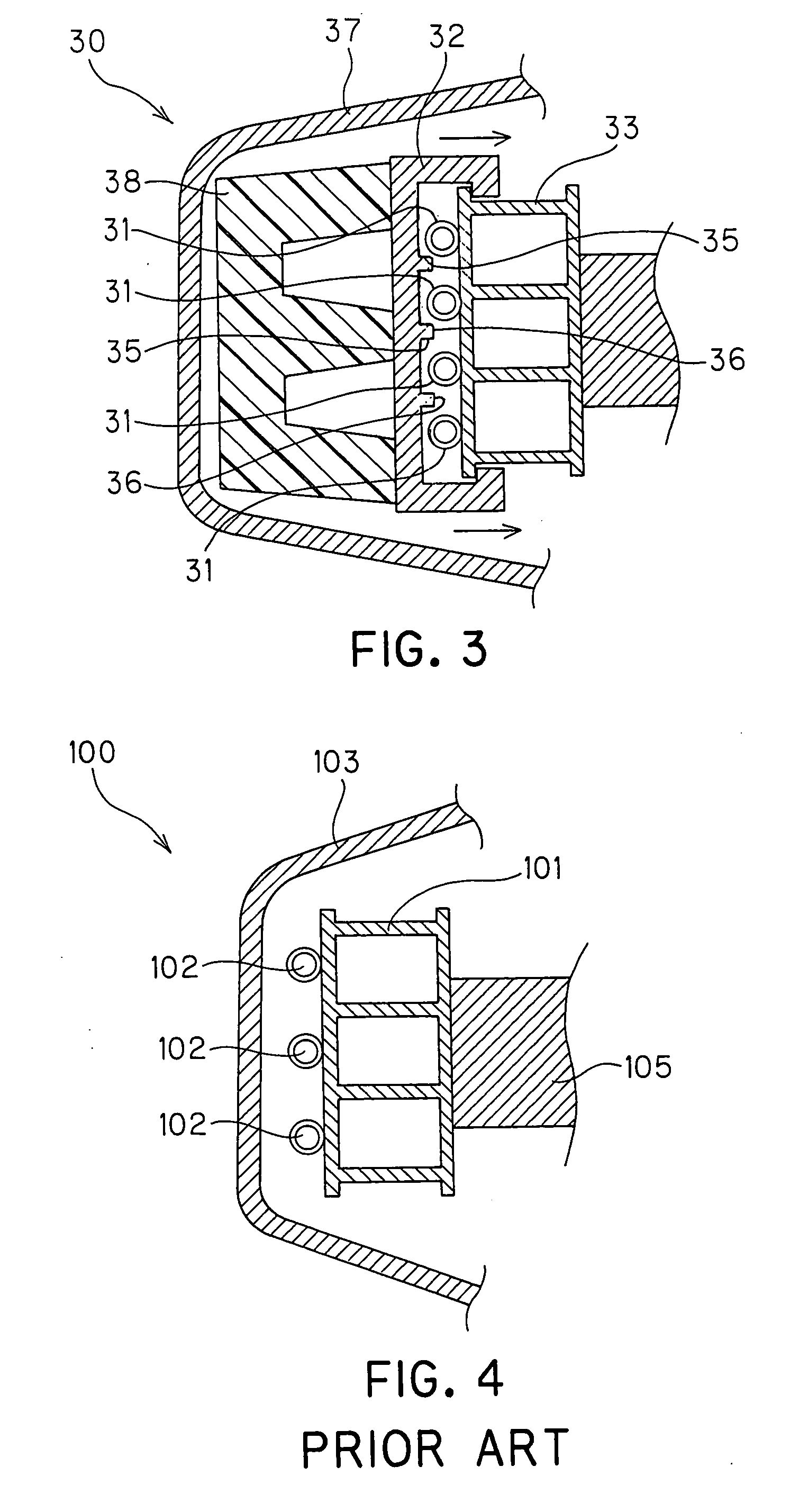

In a vehicle bumper structure, an optical fiber sensor (32) is provided in a vehicle width direction on the front surface of a front-bumper reinforcement (30). A front-bumper absorber (28) is provided in front of the optical fiber sensor (32), the front-bumper absorber (28) formed of a soft absorber (54) and a hard absorber (56). The hard absorber is disposed at the bumper center region where the thickness of the bumper is increased. Accordingly, the thickness of the soft absorber (54) becomes substantially uniform in the vehicle width direction, so that a substantially uniform load is inputted to the optical fiber sensor (32) regardless of the collision position of the bumper with an object. As a result, variations in the output of the load-sensing unit are reduced.

Owner:TOYOTA JIDOSHA KK +2

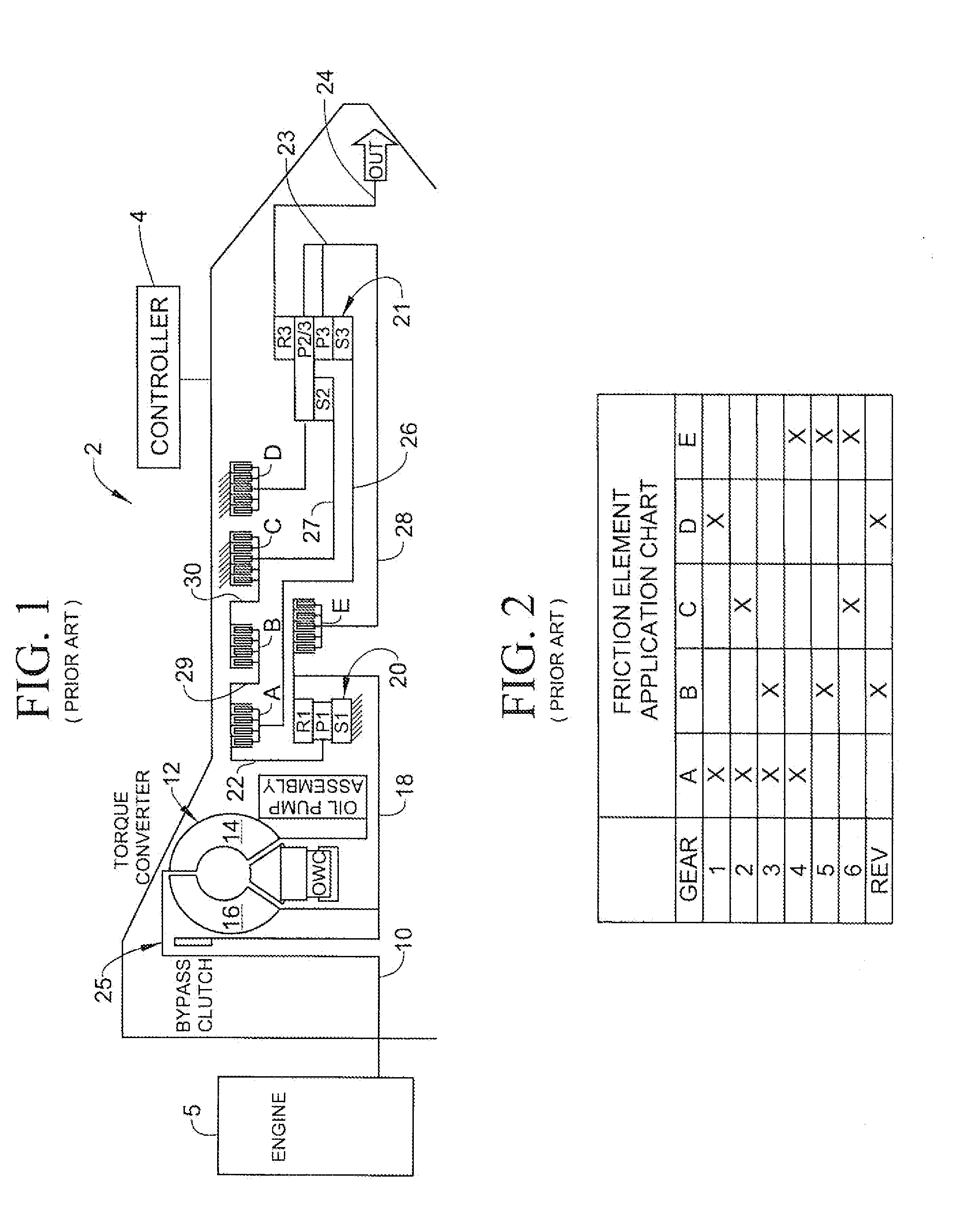

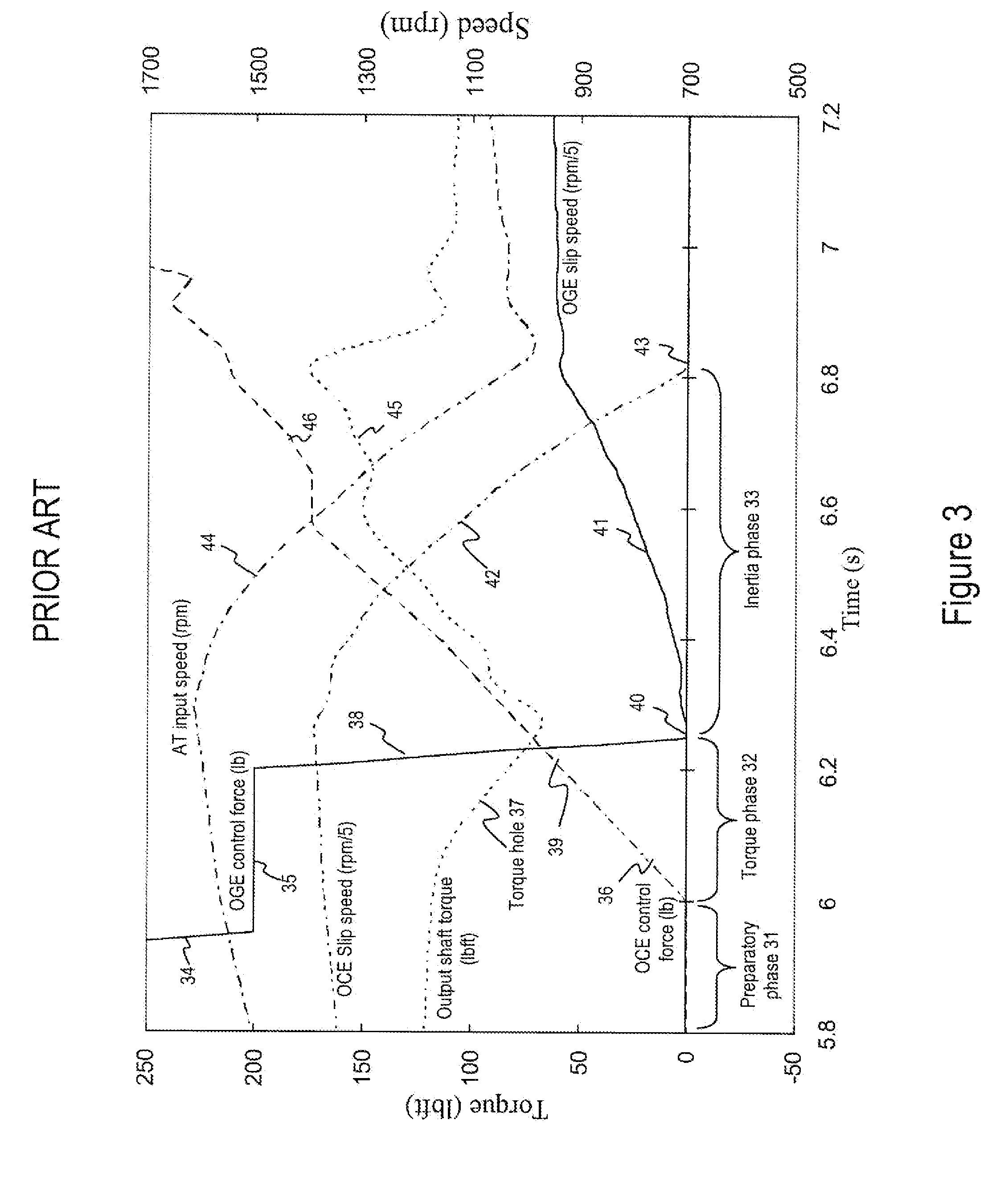

Closed-Loop Torque Phase Control for Shifting Automatic Transmission Gear Ratios Based on Friction Element Load Sensing

ActiveUS20100262344A1Improve shift feelIncreased torque capacityDigital data processing detailsGearing controlLoad sensingClosed loop

A closed loop shift control apparatus and method based on friction element load controls a torque transfer phase when shifting from a low gear configuration to a high gear configuration for an automatic transmission system. When pressure actuated friction elements are selectively engaged and released to establish torque flow paths in the transmission, measurements or estimates of torsional load exerted on the off-going friction element are used to predict the optimal off-going friction element release timing for achieving a consistent shift feel. The ideal timing to release the off-going friction element is uniquely defined when torque load exerted onto the off-going friction element becomes substantially zero. An on-coming clutch engagement process is controlled by a closed loop control based on measurements or estimates of on-coming clutch torque capacity for a constant shift feel under dynamically changing conditions.

Owner:FORD GLOBAL TECH LLC

Load sensing device for automobiles

InactiveUS20050200139A1Easy to transformReliable transmissionPedestrian/occupant safety arrangementForce measurement by measuring optical property variationLoad sensingEmbedded system

A load sensing device comprise an inner member provided at a front part of a vehicle and a load sensor provided at a position before a front of the inner member, in addition to an outer member and a load transfer member. The outer member is provided at the front part of the vehicle so as to be located more frontward than the load sensor so that a space is formed between the outer member and the load sensor. The outer member is in charge of allowing the load sensor to sense, via the outer member, a load applied to a front of the vehicle. The load transfer member, made of a hard material, is disposed adjacently to the load sensor within the space between the outer member and the load sensor. The load sensor is allowed to move along the inner member in the back-and-forth direction of the vehicle.

Owner:TOYOTA JIDOSHA KK

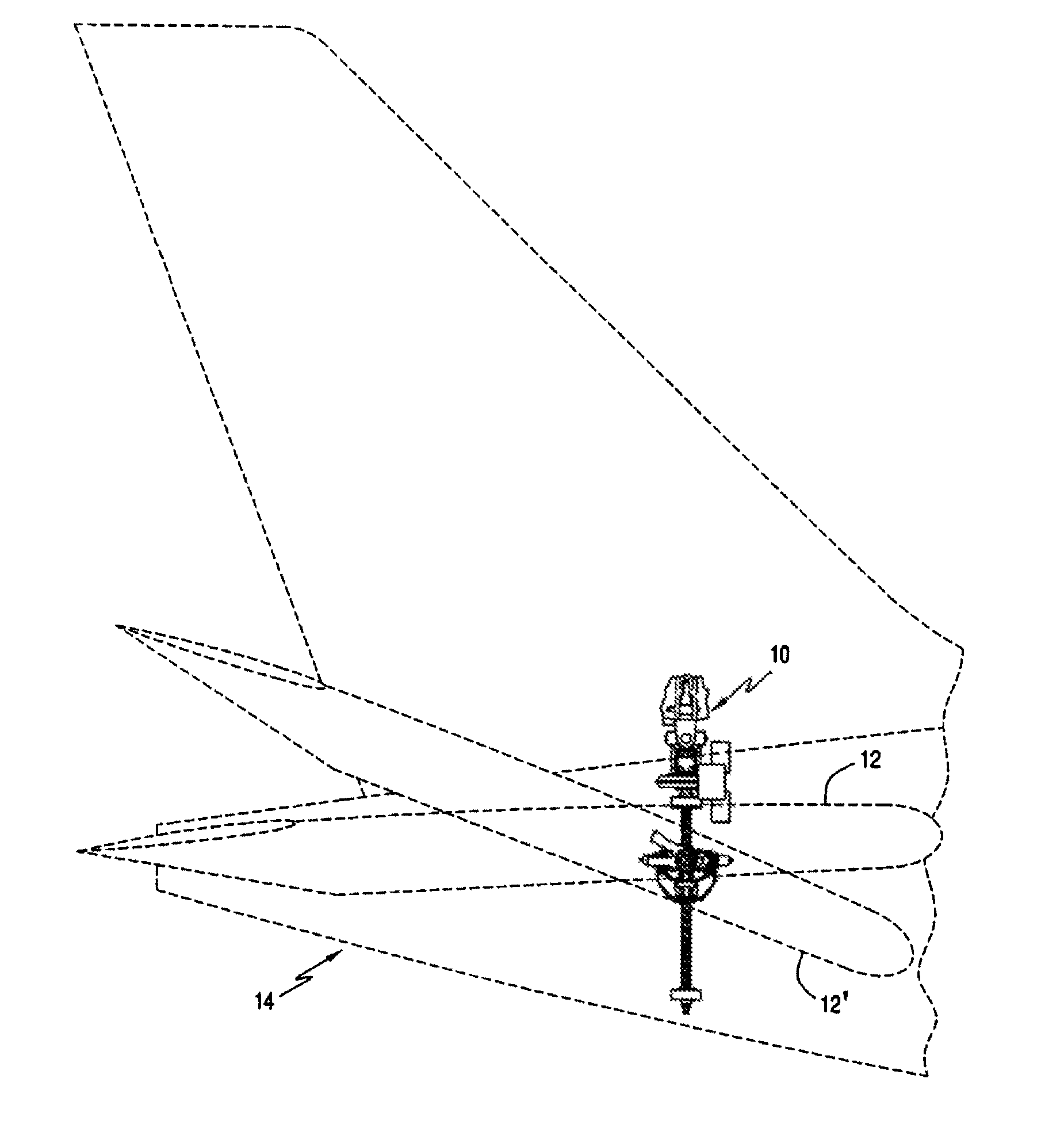

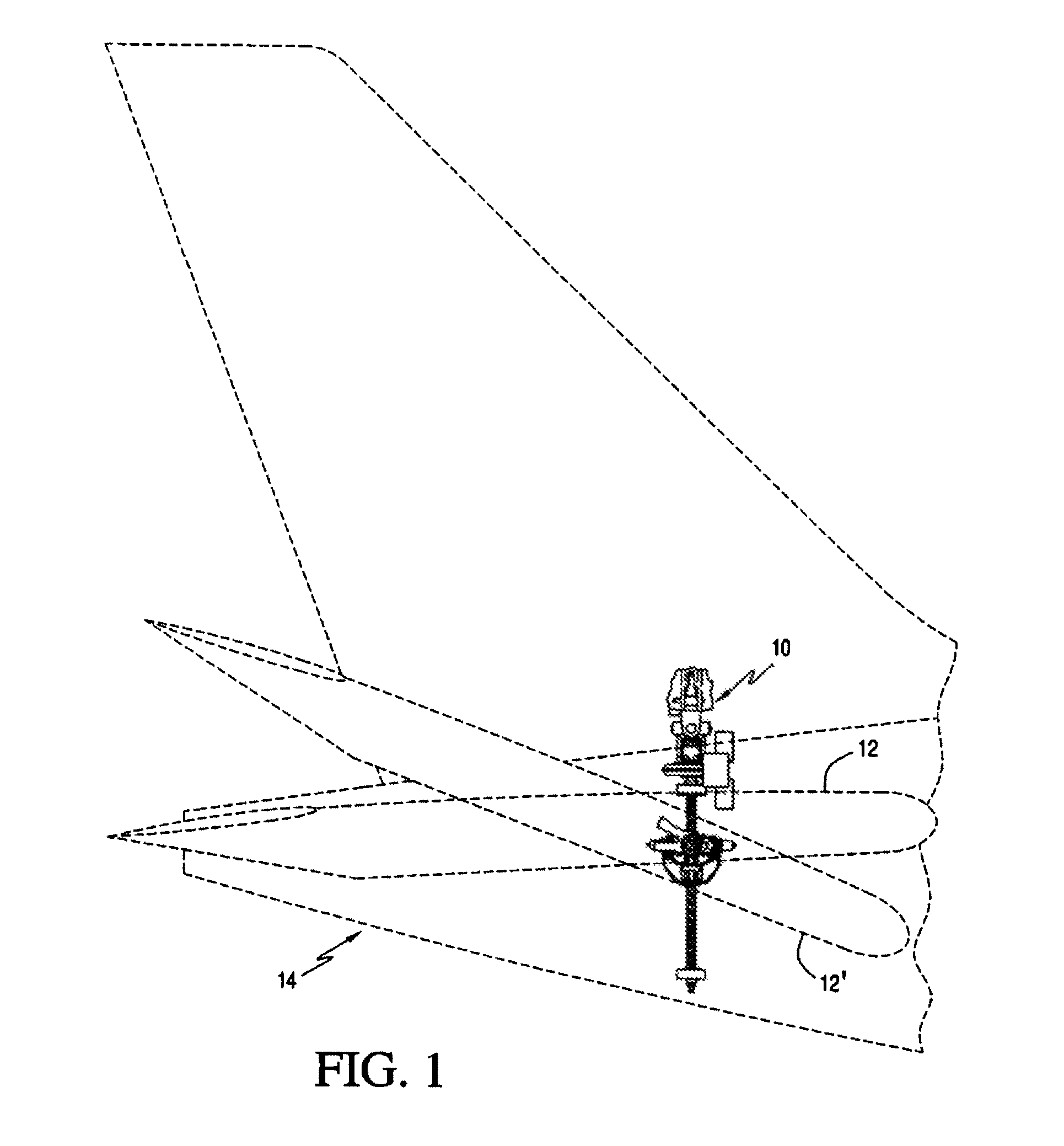

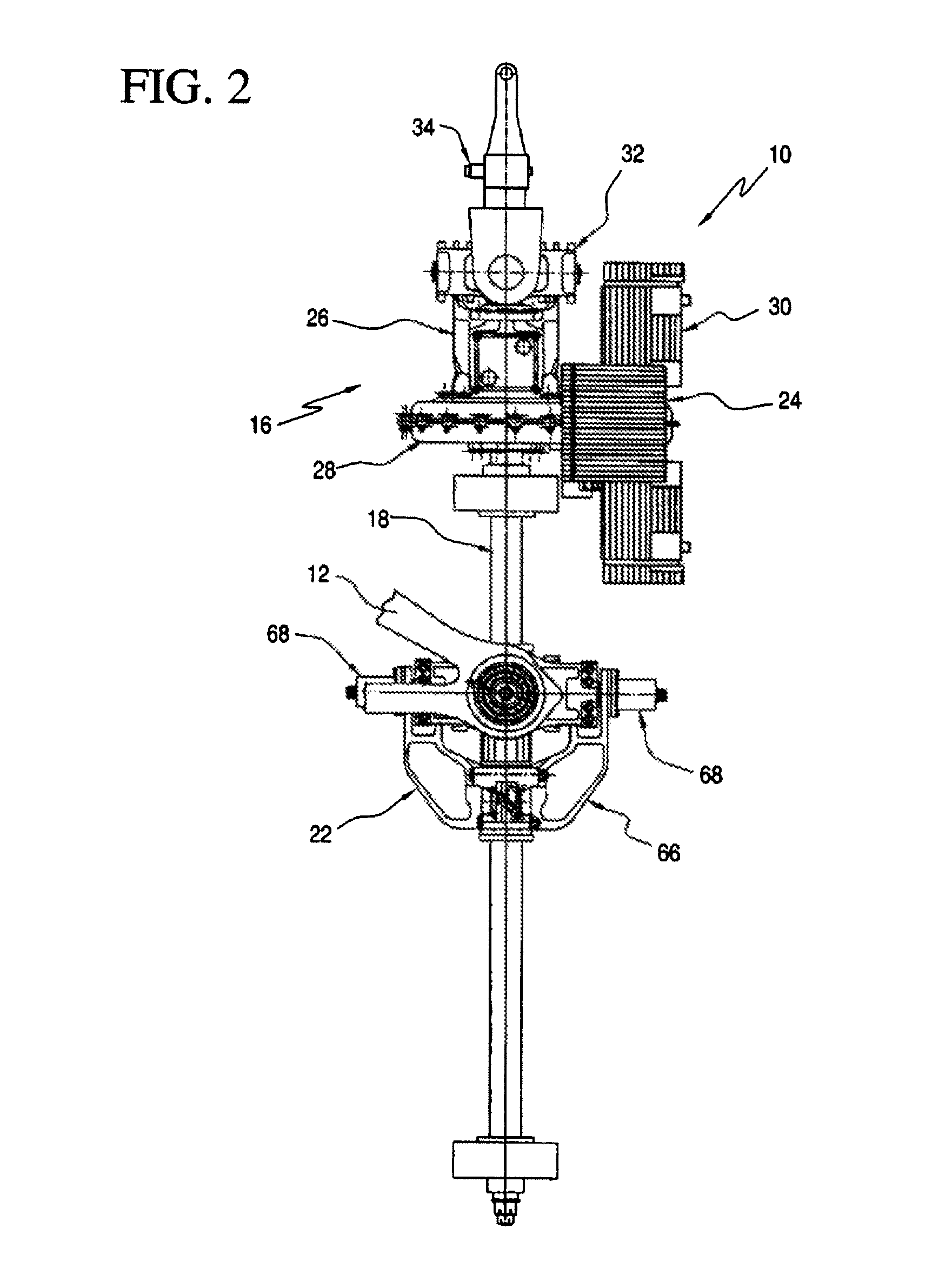

Actuator load path monitoring system

ActiveUS8033500B1Fast response timeEasy field replacementAircraft stabilisationWithout power ampliicationBall screwLoad sensing

An actuator load path monitoring system for an aircraft having an aircraft structure, a control surface, and, an actuator connected between the aircraft structure and the control surface to support and position the control surface as desired relative to the aircraft structure. The actuator is of a type including a) an upper actuator assembly securely connected to the aircraft structure, including a motor assembly and gear assembly; b) a ball screw assembly operatively connected to the gear assembly; c) a tie-rod assembly positioned within the ball screw assembly; and, d) a lower actuator assembly securely connected to the control surface, wherein actuation of the ball screw provides selected positioning of the control surface. The actuator load path monitoring system includes an upper load sensing assembly positioned in an upper load path between the upper actuator assembly and the aircraft structure. The upper load sensing assembly provides upper indications of the applied forces in the upper load path when the upper load path is disconnected. A lower load sensing assembly is positioned in a lower load path between the lower actuator assembly and the control surface. The lower load sensing assembly provides upper indications of the applied forces in the lower load path when the lower load path is disconnected. A computer system receives the upper and lower indications of applied forces and analyzes the upper and lower indications, thereby monitoring the structural integrity and safety of the upper and lower load paths by annunciating the detection of a failed portion thereof.

Owner:ROCKWELL COLLINS INC

System for mapping and intervention of an organ within the human or animal body

ActiveCN101132730AStrain gaugeForce measurement by measuring optical property variationLoad sensingContact force

Apparatus is provided for diagnosing or treating an organ or vessel, wherein a device having at optical fiber contact force sensors disposed in a distal extremity thereof and a deflection mechanism configured to deflect the elongate body at a location proximal of the distal extremity. The optical fiber contact force sensors are configured to be coupled to processing logic programmed which computes a force vector responsive to detected changes in the optical characteristics of the optical fiber contact force sensors arising from deflection of the distal extremity resulting from contact with the tissue of the wall of the organ or vessel.

Owner:ST JUDE MEDICAL INT HLDG SARL

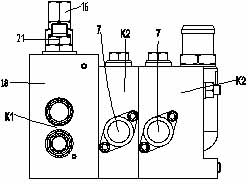

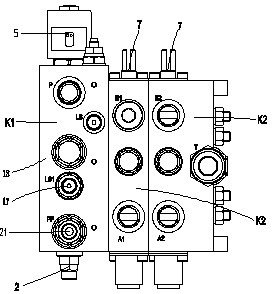

Proportional multi-way valve with steering load feedback

The invention discloses a proportional multi-way valve with a turning load feedback function, comprising an oil inlet control joint valve body and a unit operation control joint valve body which are sequentially overlapped; a three-way flow valve core, a main overflow valve, and a turning valve core and a first pressure compensation valve which are integrated and matched are arranged in the oil inlet control joint valve body; an oil inlet of the three-way flow valve core is communicated with a pressure oil duct, and an oil return port of the three-way flow valve core is communicated with an oil return channel; the oil inlet of the main overflow valve is communicated with a load sensing port oil duct, and the oil return port of the main overflow valve is communicated with the oil return channel; the load sensing port oil duct is also communicated with a spring cavity control end of the three-way flow valve core; a unit control valve core and a second pressure compensation valve which are integrated and matched are arranged in the unit operation control joint valve body; the three-way flow valve core is arranged, so that the immediate discharge of real-time flow is realized, the action is flexible, and the control performance is improved; a turning auxiliary load feedback function is added, so that the operation efficiency of a whole machine and the actual operability are improved; and a two-position two-way electromagnetic valve is added, two operation modes, i.e. electrification and non-electrification are designed, so that the operation safety in configuration is improved.

Owner:卢宇

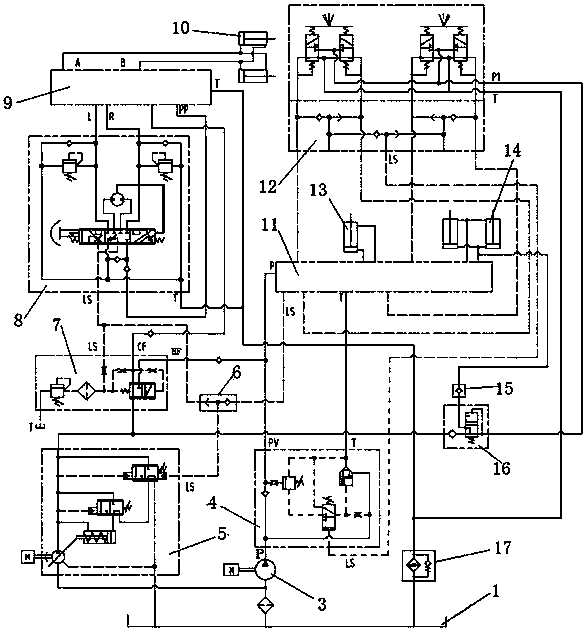

Quantitative and variable hydraulic system of loading machine

ActiveCN104032792AReduce lossesReduce the temperatureSoil-shifting machines/dredgersLoad sensingEngineering

The invention relates to a quantitative and variable hydraulic system of a loading machine. The shortcomings that a quantitative hydraulic system in an existing loading machine hydraulic system is high in energy consumption, and a variable hydraulic system in the existing loading machine hydraulic system is high in cost are overcome. The quantitative and variable hydraulic system is characterized in that a load sensing steering gear and a load sensitive flow amplification valve are connected to control a steering oil cylinder; a pilot valve and a load sensitive distribution valve are connected to control a working oil cylinder; an oil outlet of a load sensitive variable pump passes through a pressure-gradient control valve to be respectively communicated with an opening P of the load sensitive flow amplification valve and an opening P of the load sensitive distribution valve, a metering pump passes through an unloading valve to be communicated with the opening P of the load sensitive distribution valve, an opening LS of the unloading valve obtains a pilot oil pressure signal from the pilot valve, and an opening LS of the load sensing steering gear and an opening LS of the pressure-gradient control valve are communicated to provide a loading pressure signal for the load sensitive variable pump through a shuttle valve with the load sensitive distribution valve. By means of the quantitative and variable hydraulic system, overflowing losses, medium-position opening losses and high-pressure unloading losses are avoided, the energy consumption and the cooling power are low, and the oil liquid service life is long.

Owner:GUANGXI LIUGONG MASCH CO LTD

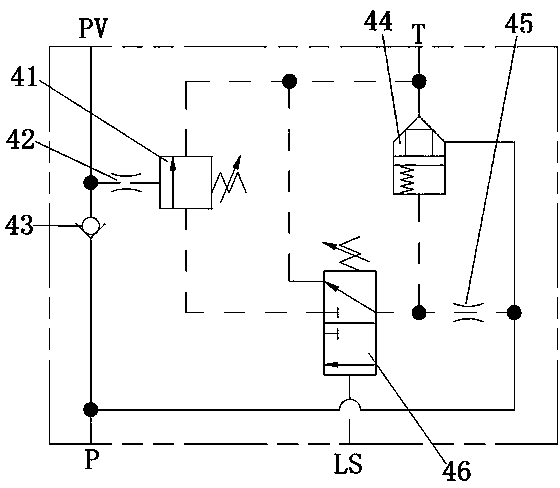

Variable control system of plunger variable pump

InactiveCN101550921AImprove job stabilityEnergy savingServomotorsPositive-displacement liquid enginesConstant powerLoad sensing

The invention discloses a variable control system of plunger variable pump, comprising a plunger variable pump having an output main oil way supplying oil to load of a hydraulic system, a left variable oil cylinder component and a right variable oil cylinder component used for regulating swash plate tilt angle change, also having a constant power valve, a pressure stop valve and a load sensitive valve. The system realizes three control functions at the same time: constant power, pressure stop and load sensing, not only has simple structure, but also can greatly improve work stability of the plunger variable pump, and has advantage of saving energy.

Owner:SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com