Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

212results about How to "Increased torque capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

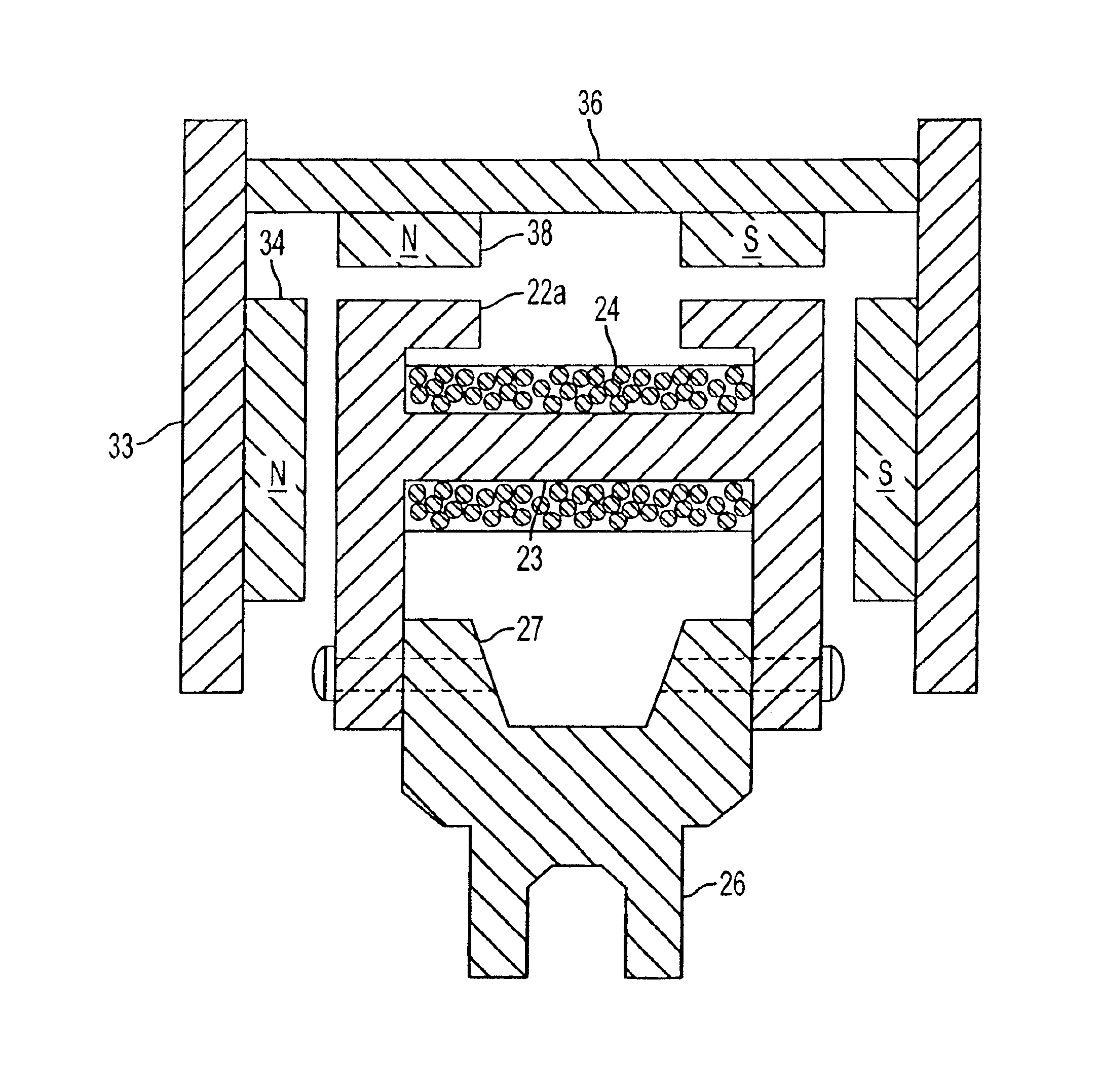

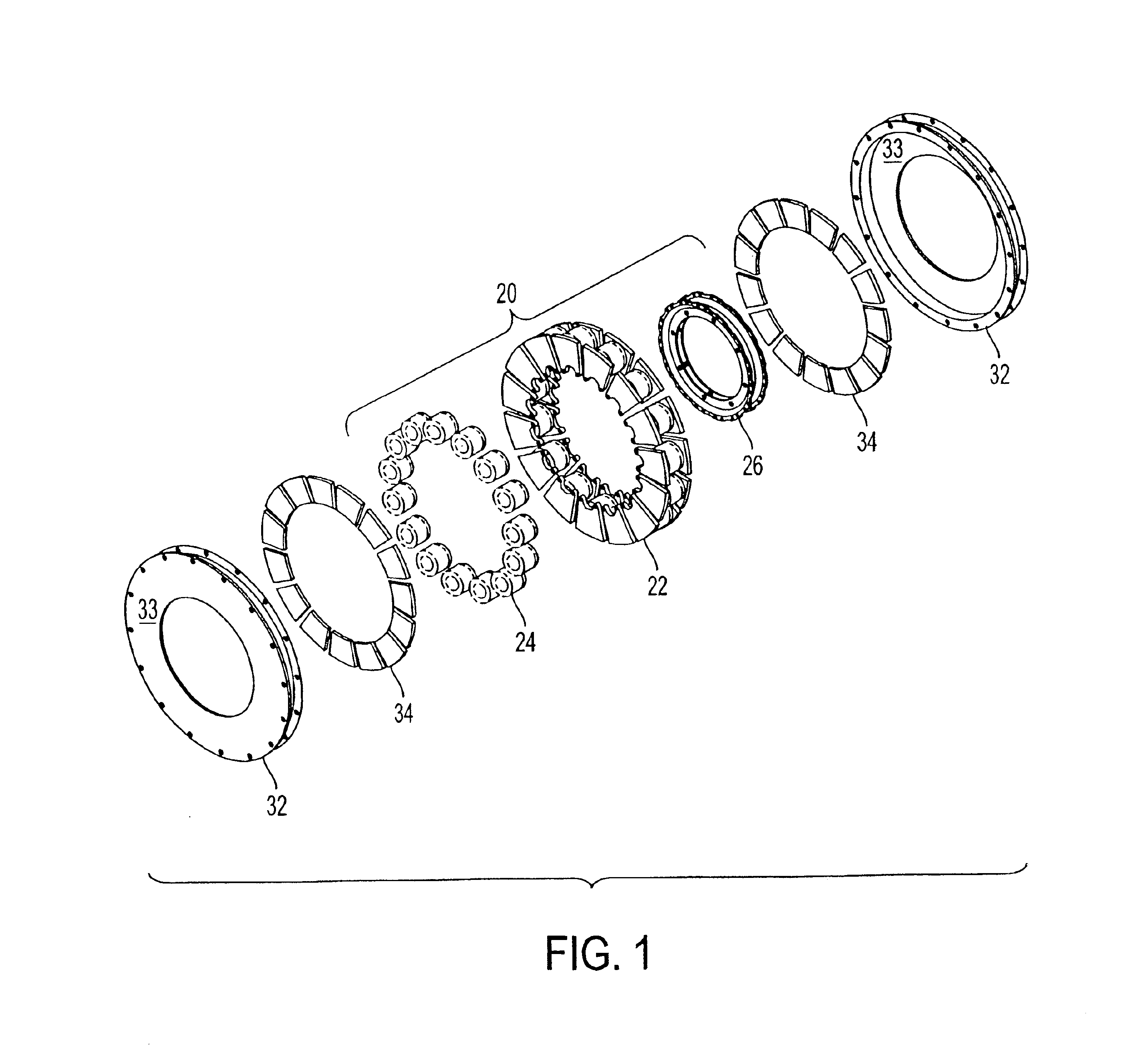

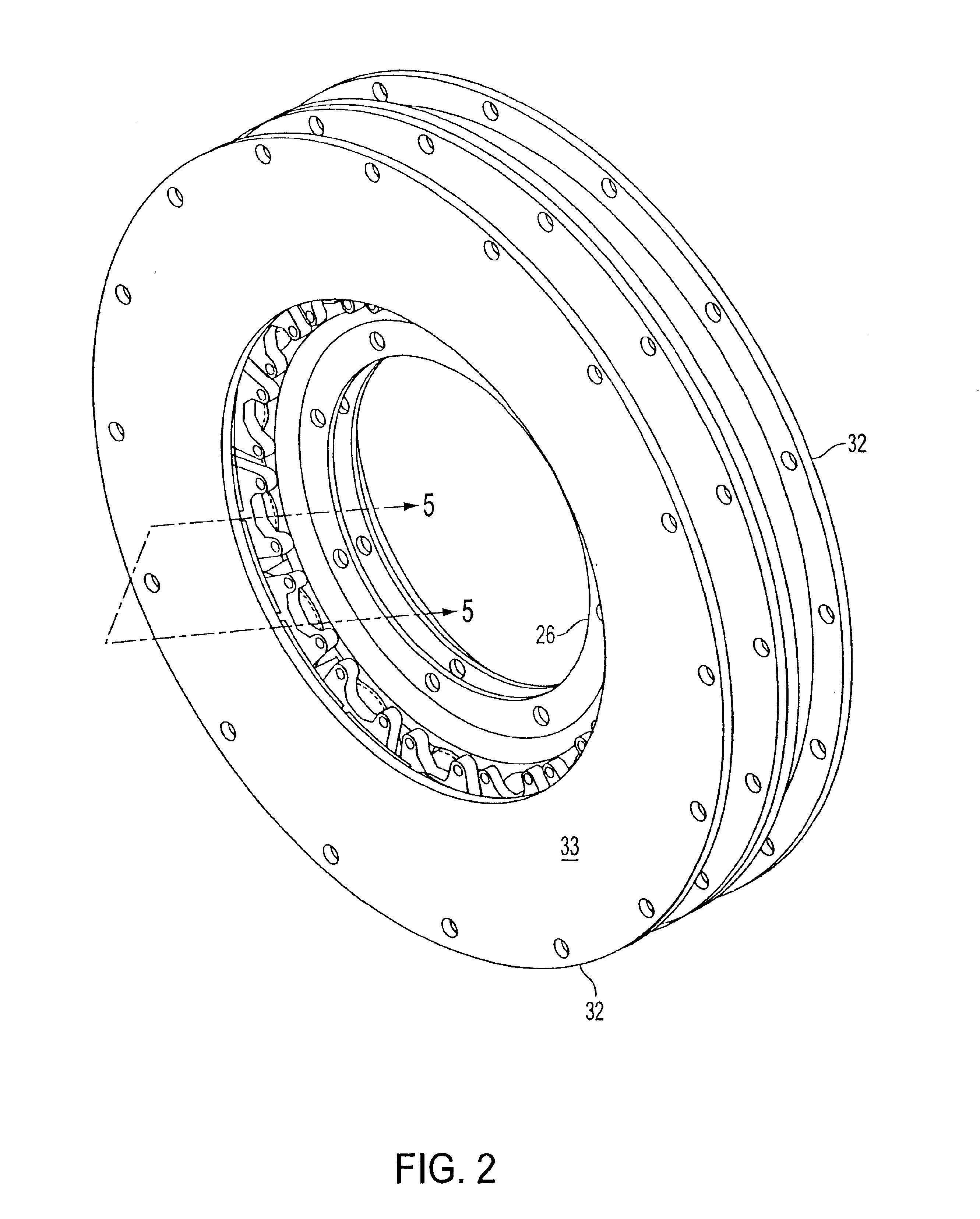

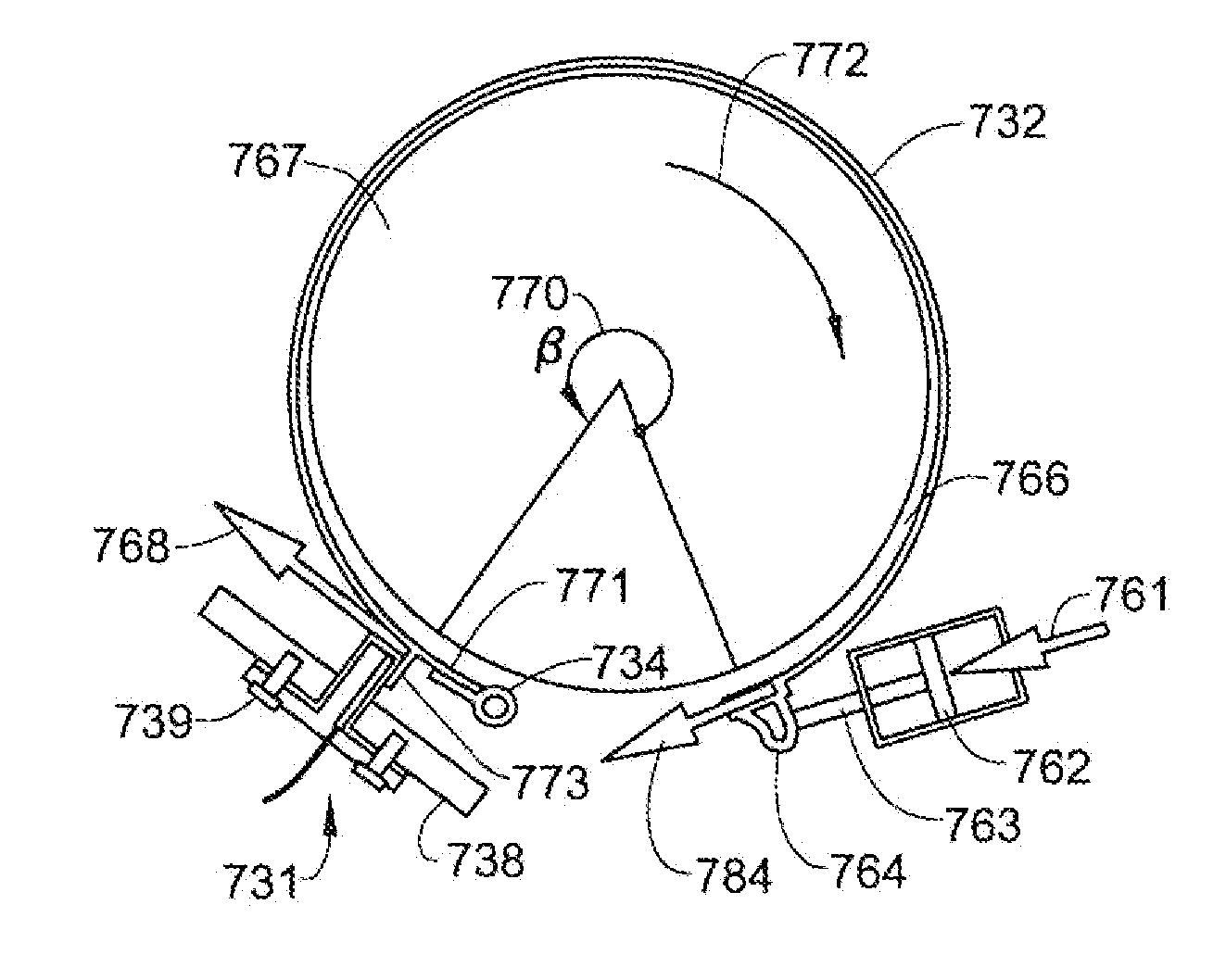

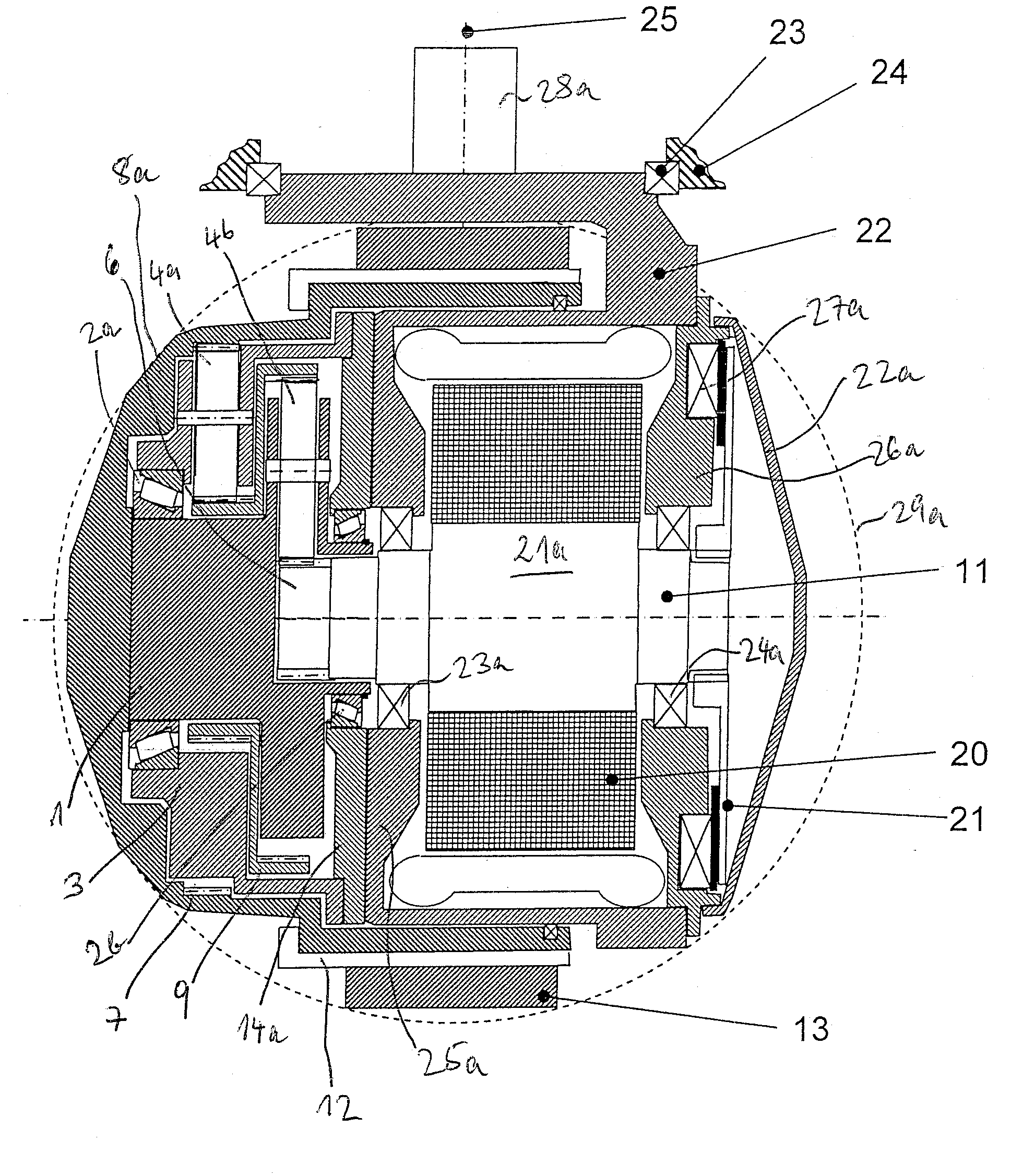

Rotary electric motor having both radial and axial air gap flux paths between stator and rotor segments

InactiveUS6891306B1Low flux lossEliminate the effects ofMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesElectrical polarity

In a rotary electric motor, a stator contains a plurality of separate electromagnet core segments disposed coaxially about an axis of rotation. The core segments are affixed, without ferromagnetic contact with each other, to a non-ferromagnetic support structure. The rotor is configured in a U-shaped annular ring that at least partially surrounds the annular stator to define two parallel axial air gaps between the rotor and stator respectively on opposite axial sides of the stator and at least one radial air gap. Permanent magnets are distributed on each inner surface of the U-shaped rotor annular ring that faces an air gap. A winding is formed on a core portion that links axially aligned stator poles to produce, when energized, magnetic poles of opposite polarity at the pole faces.

Owner:BLUWAV SYST LLC

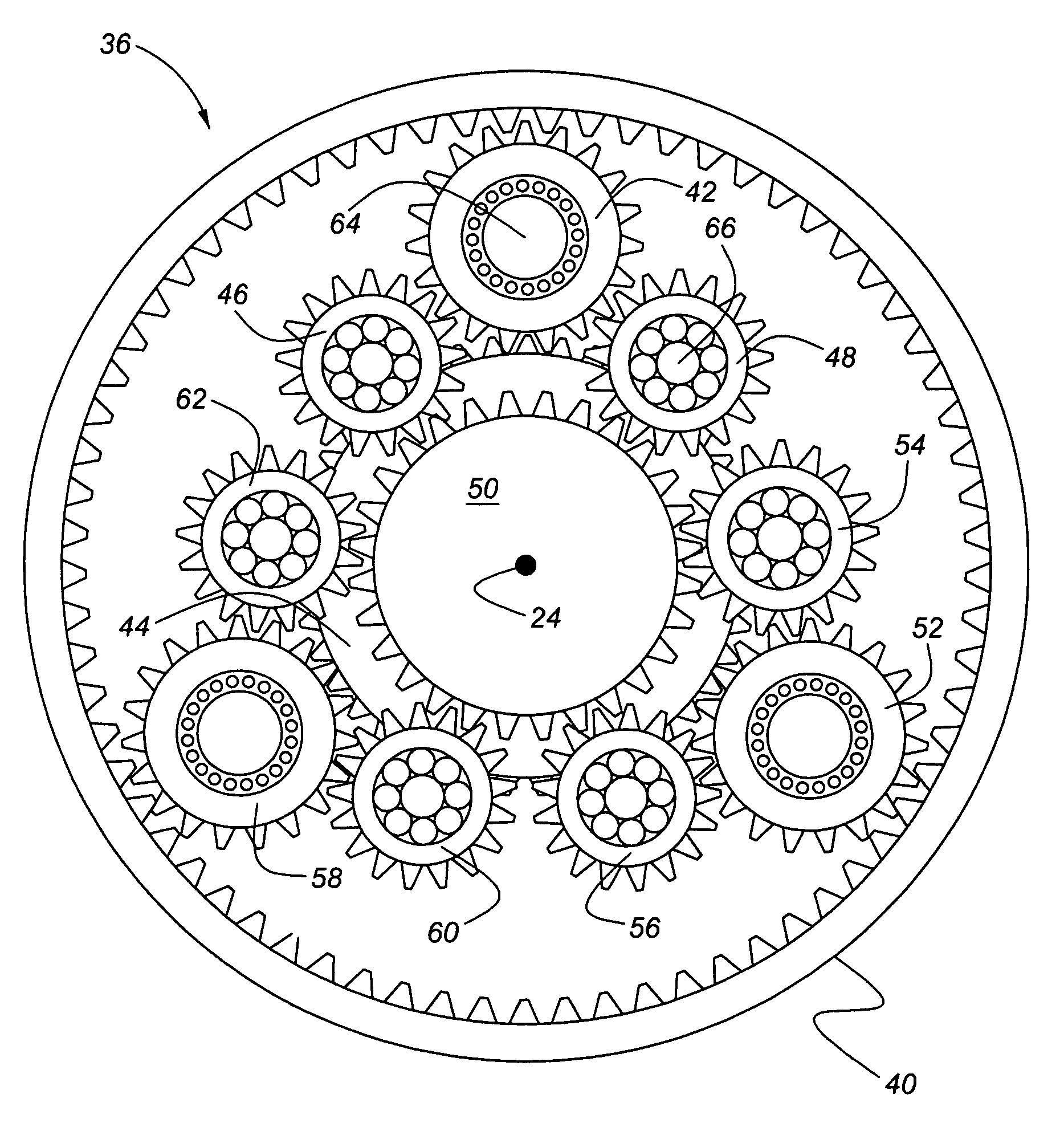

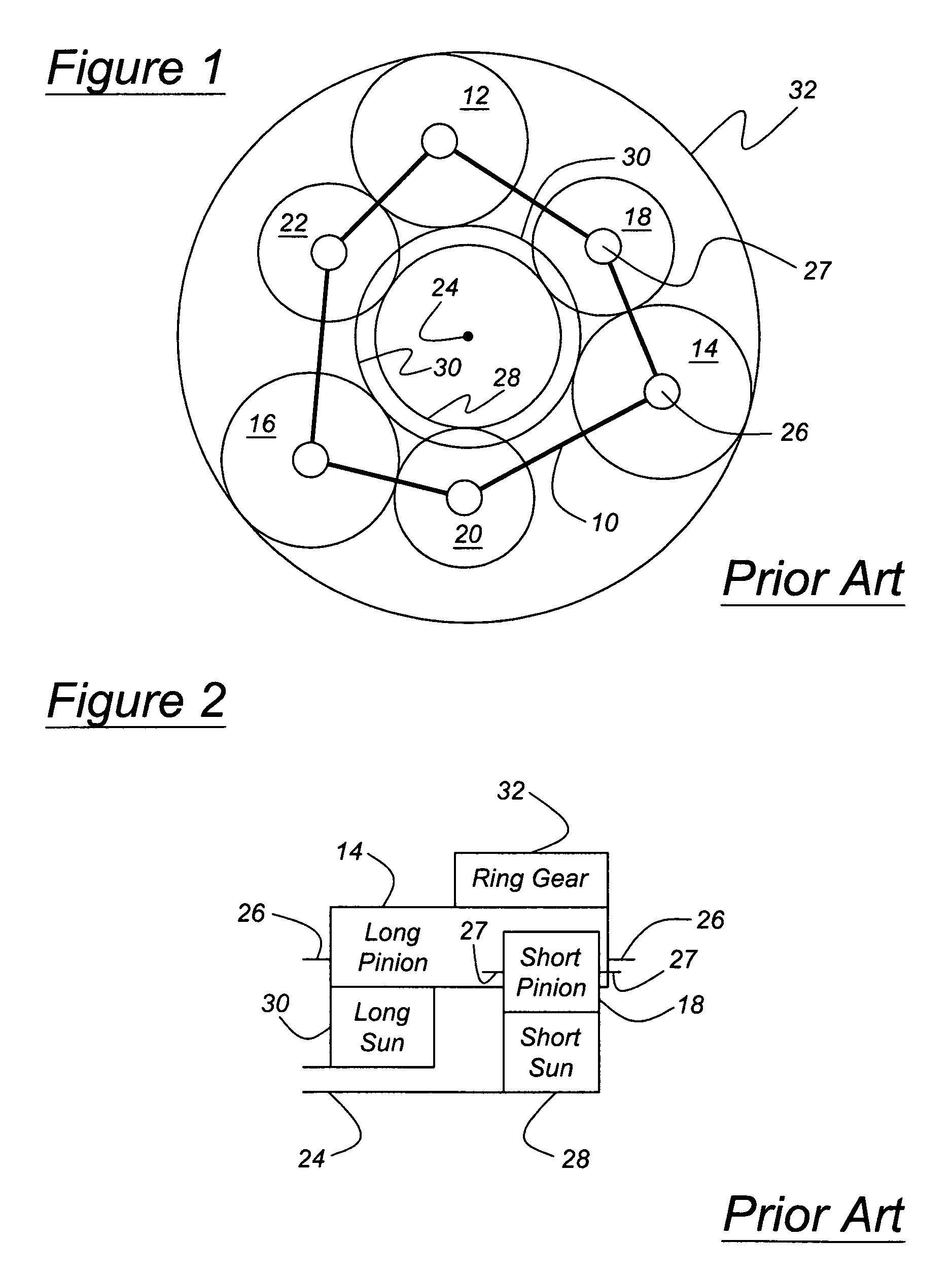

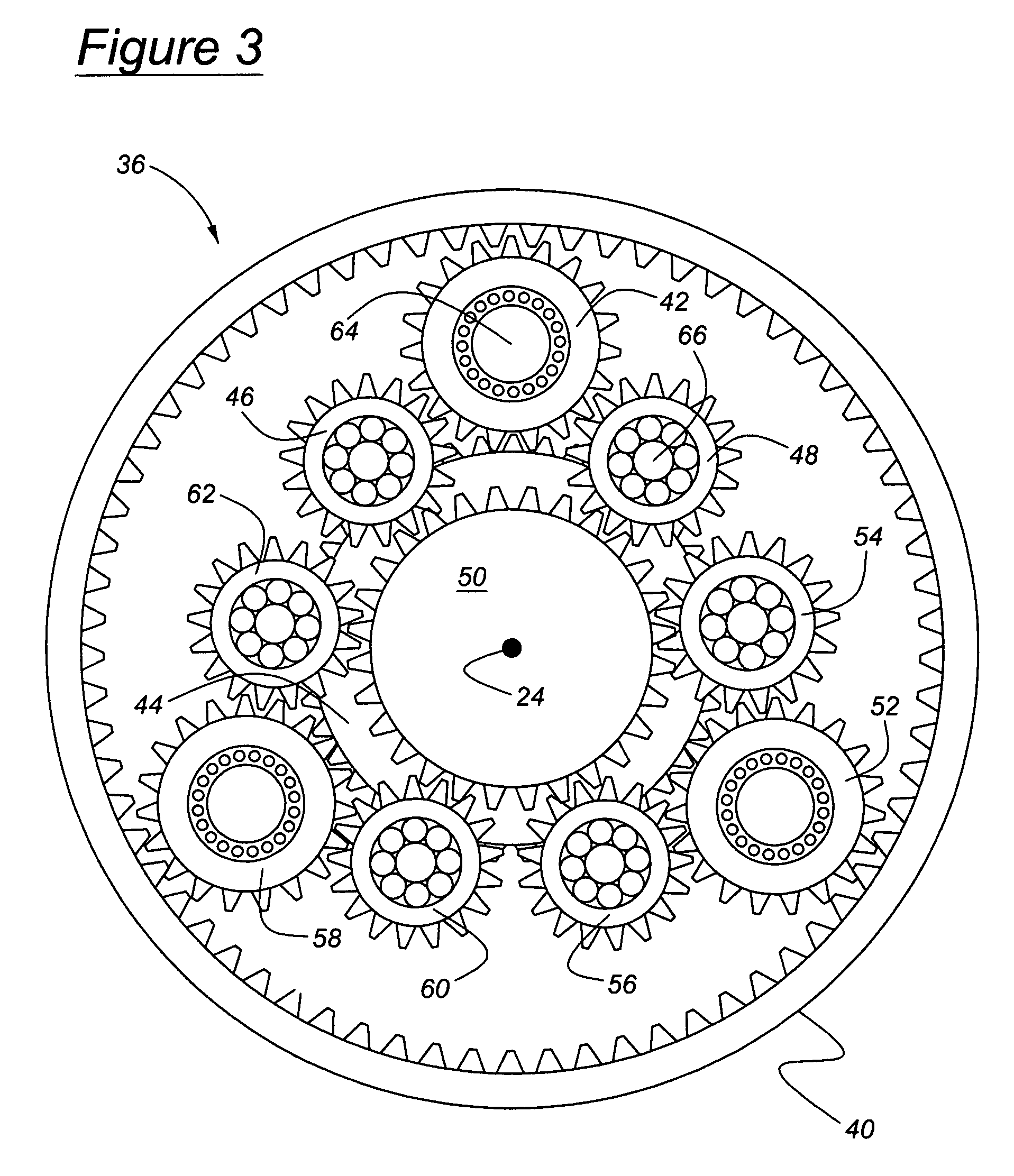

Planet pinion carrier assembly for Ravigneaux gearset

Owner:FORD GLOBAL TECH LLC

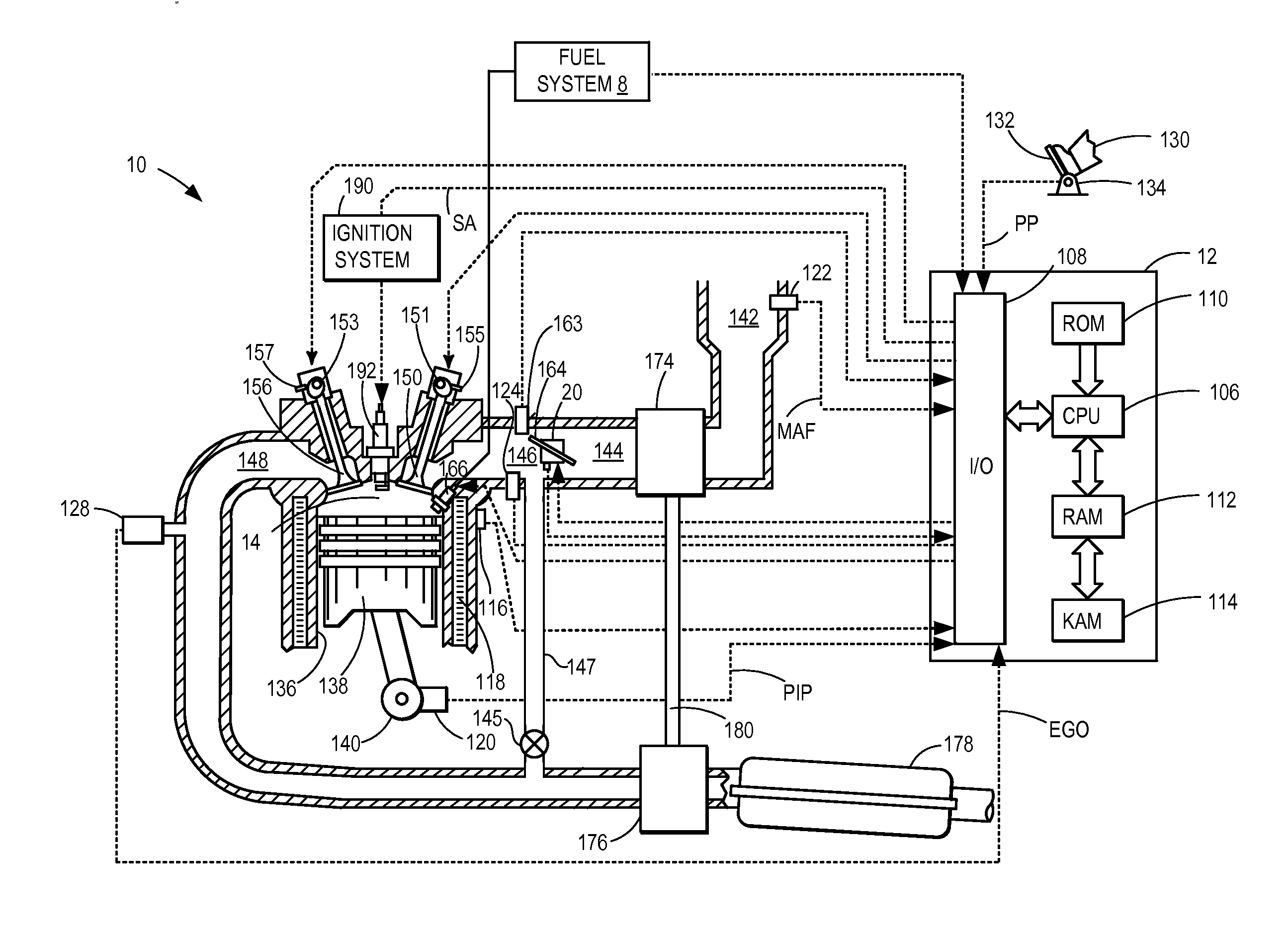

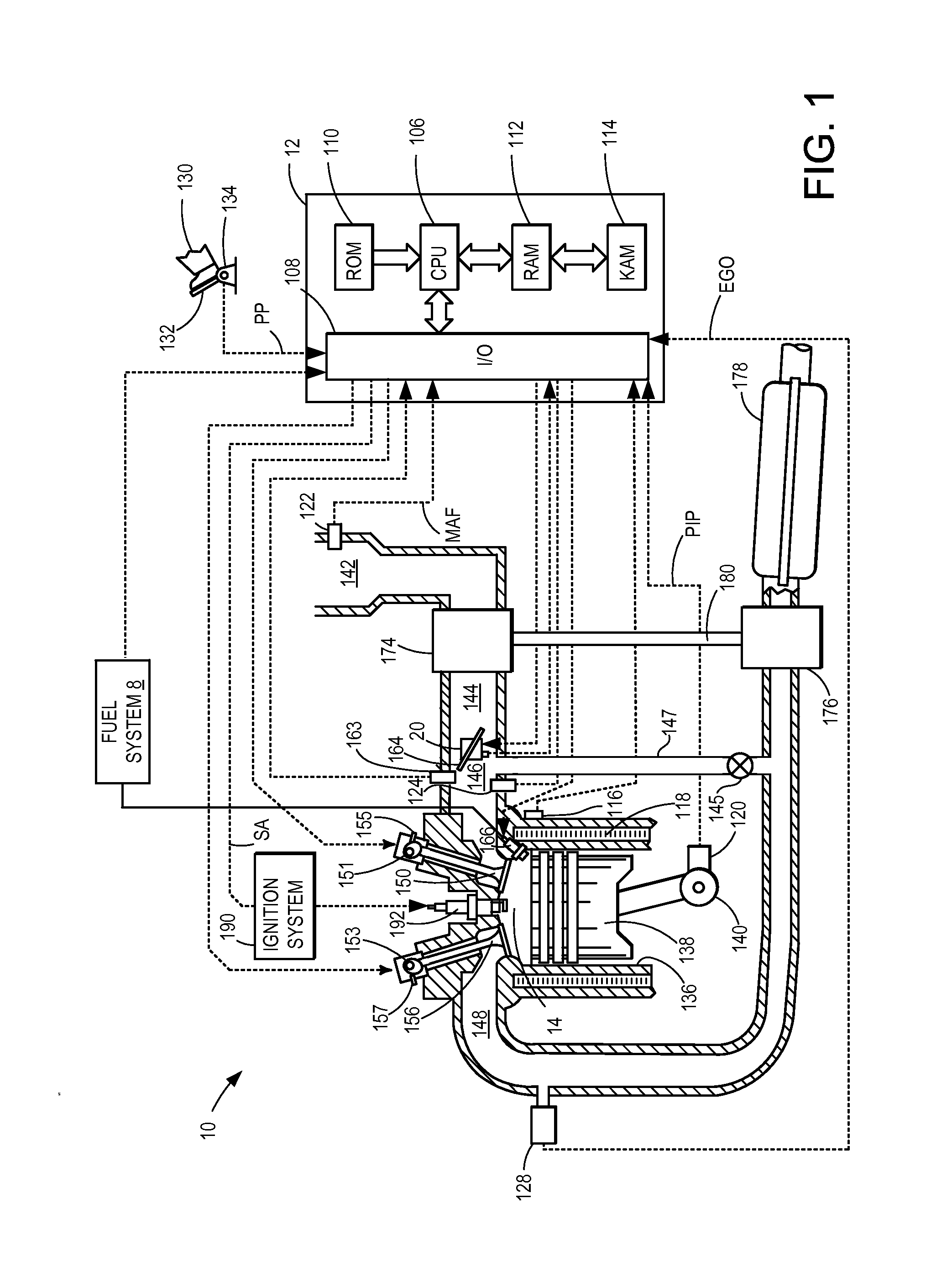

System and method for determining valve operation

InactiveUS20140360477A1Save fuelImprove efficiencyElectrical controlInternal combustion piston enginesEngineeringOxygen

Systems and methods for determining operation of a cylinder deactivating / reactivating device are disclosed. In one example, degradation of the cylinder deactivating / reactivating device is based on intake manifold oxygen concentration.

Owner:FORD GLOBAL TECH LLC

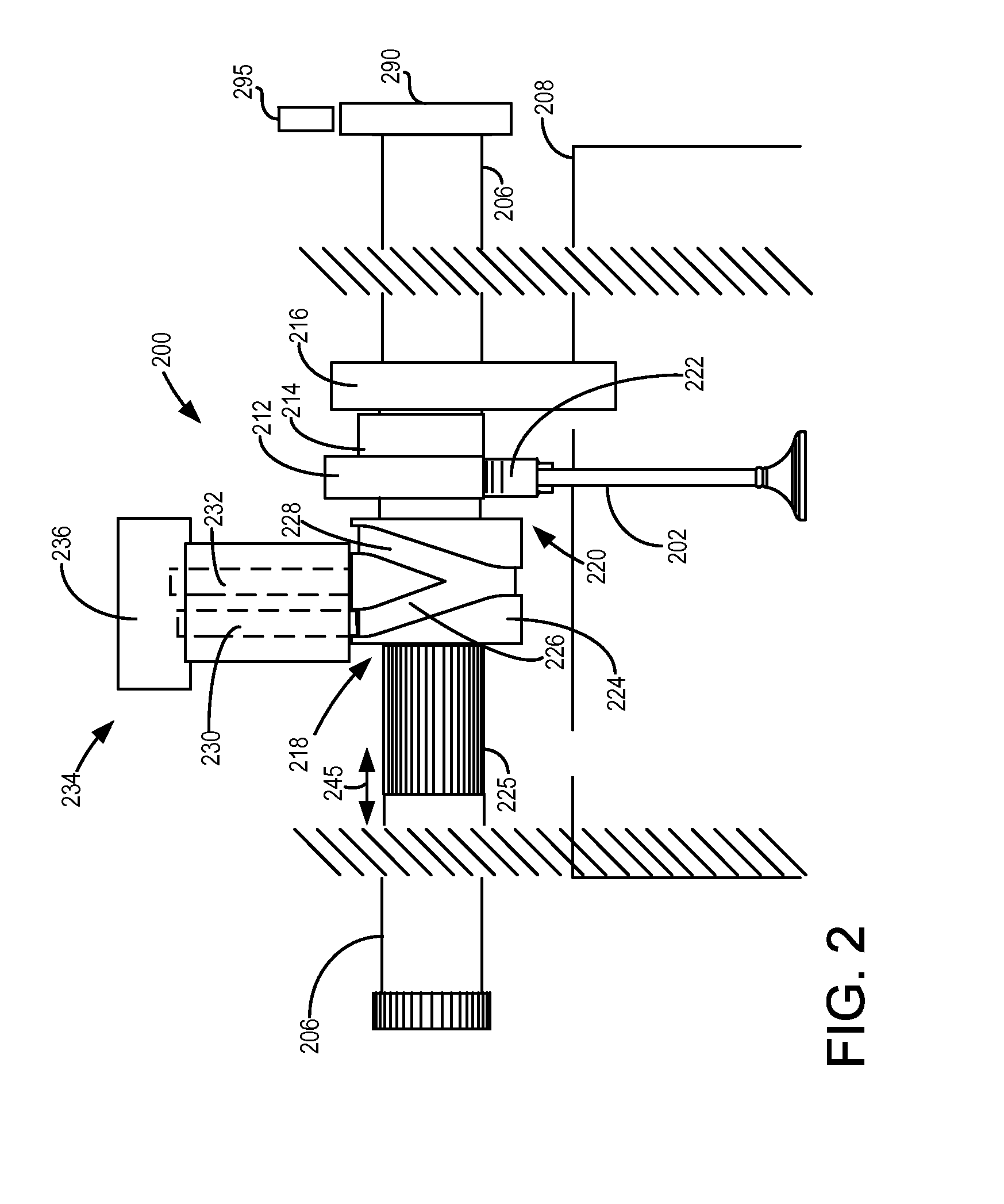

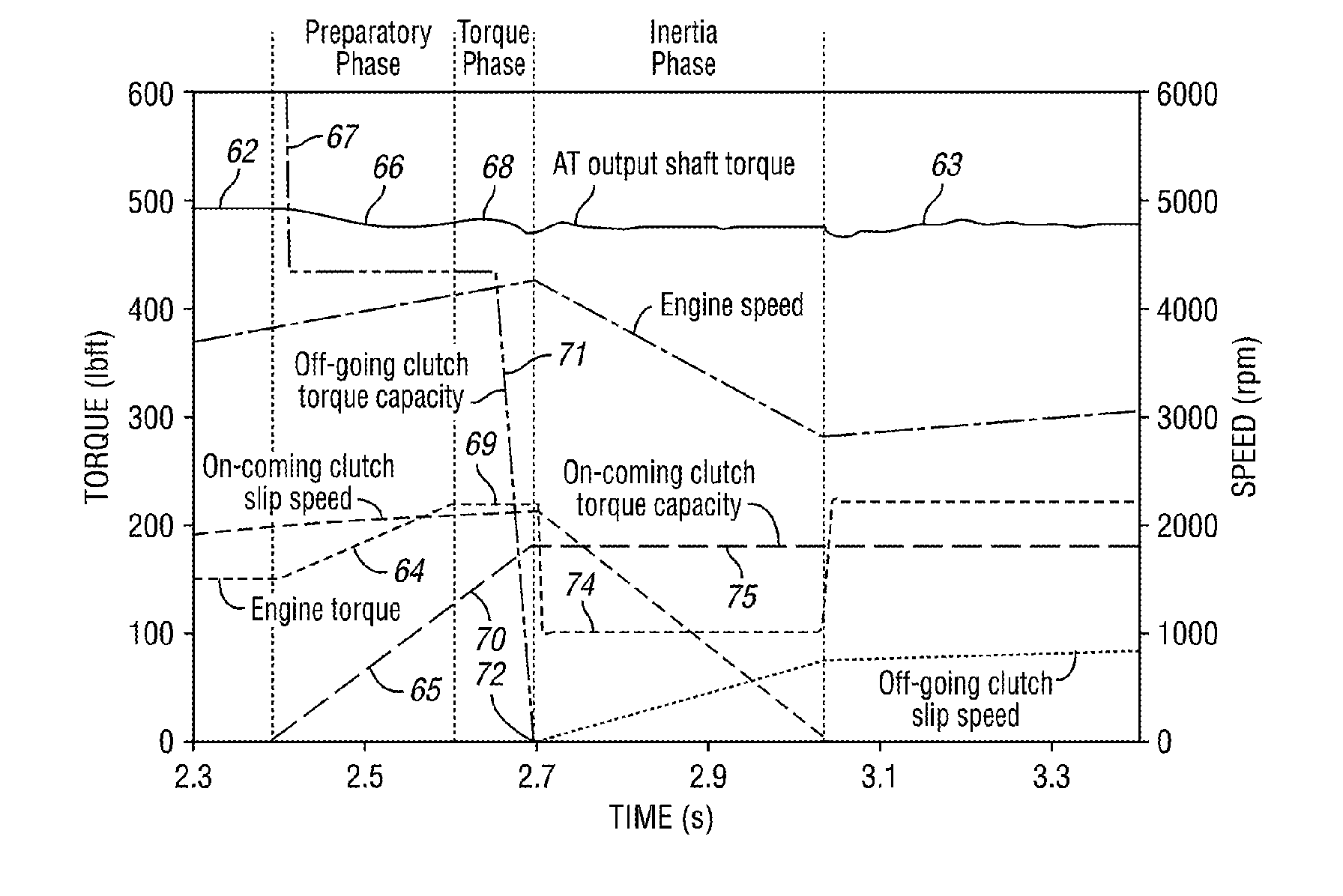

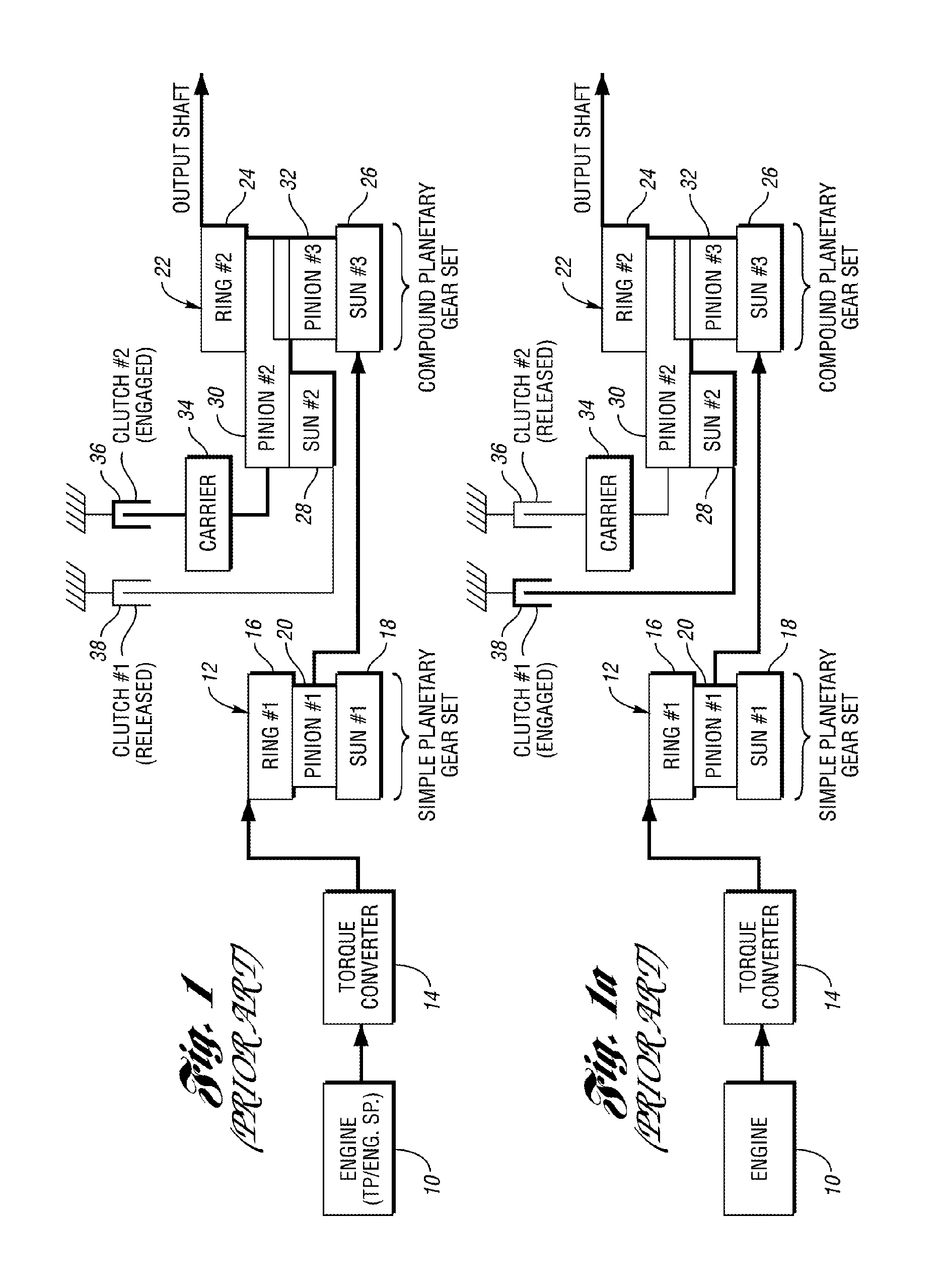

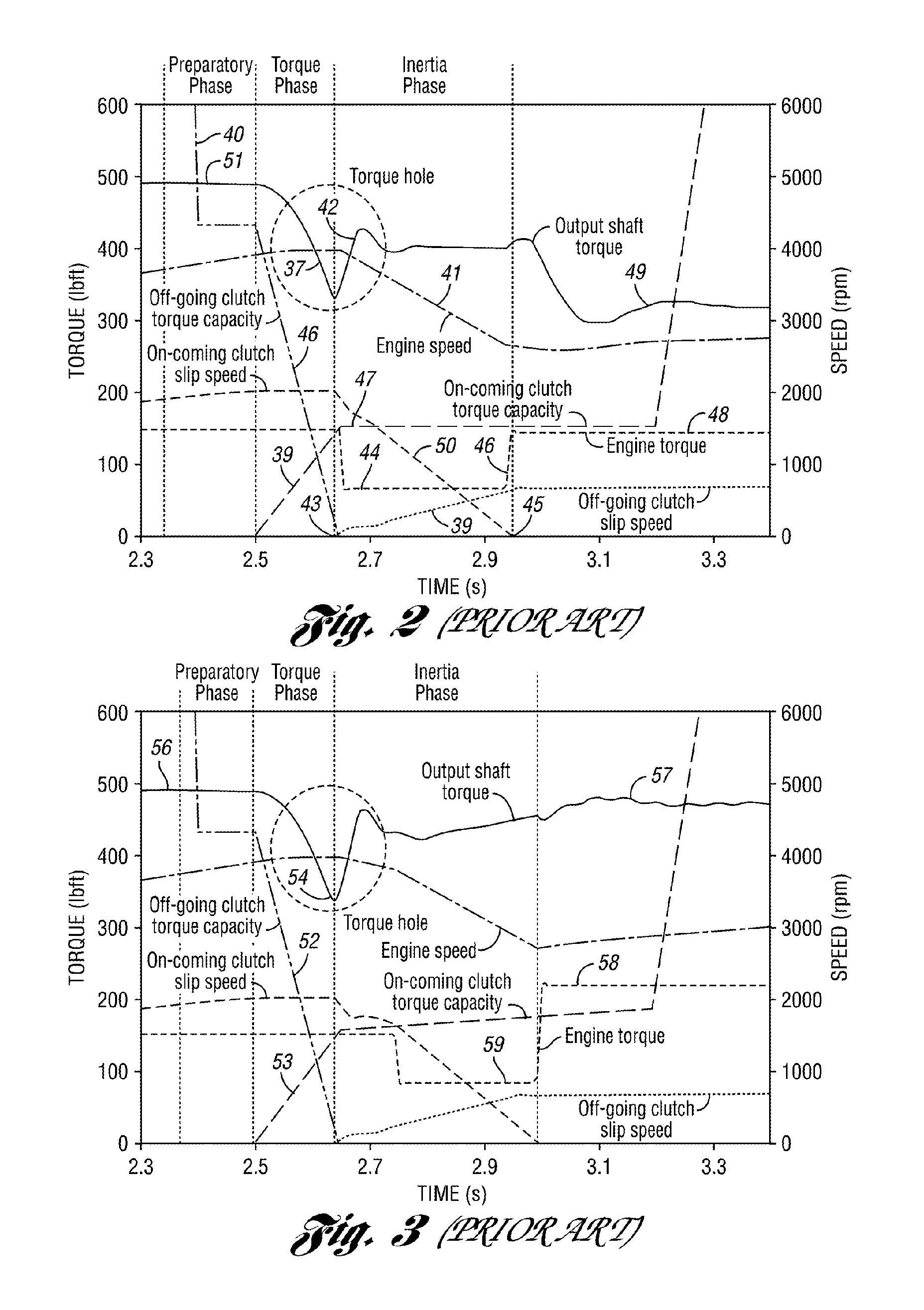

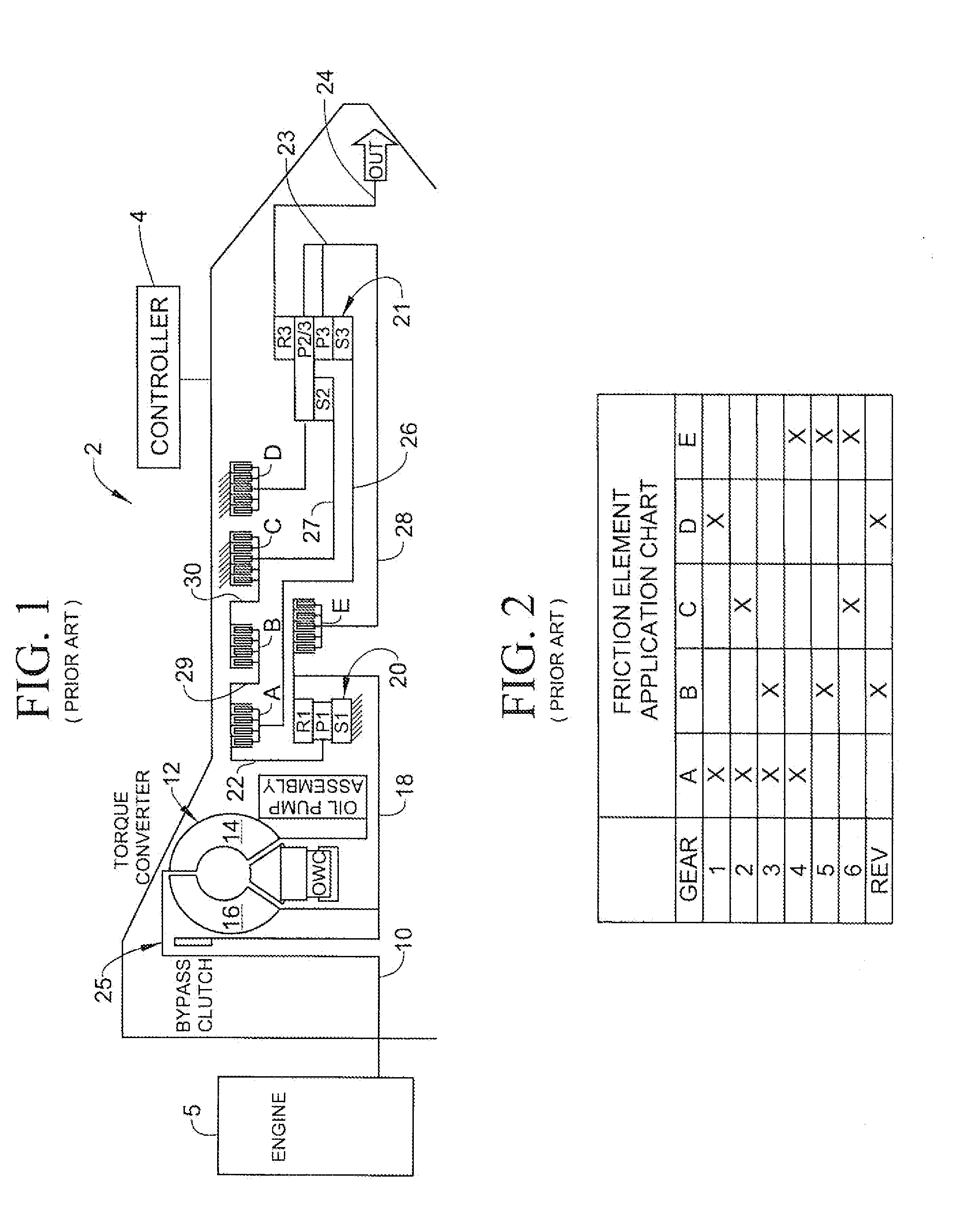

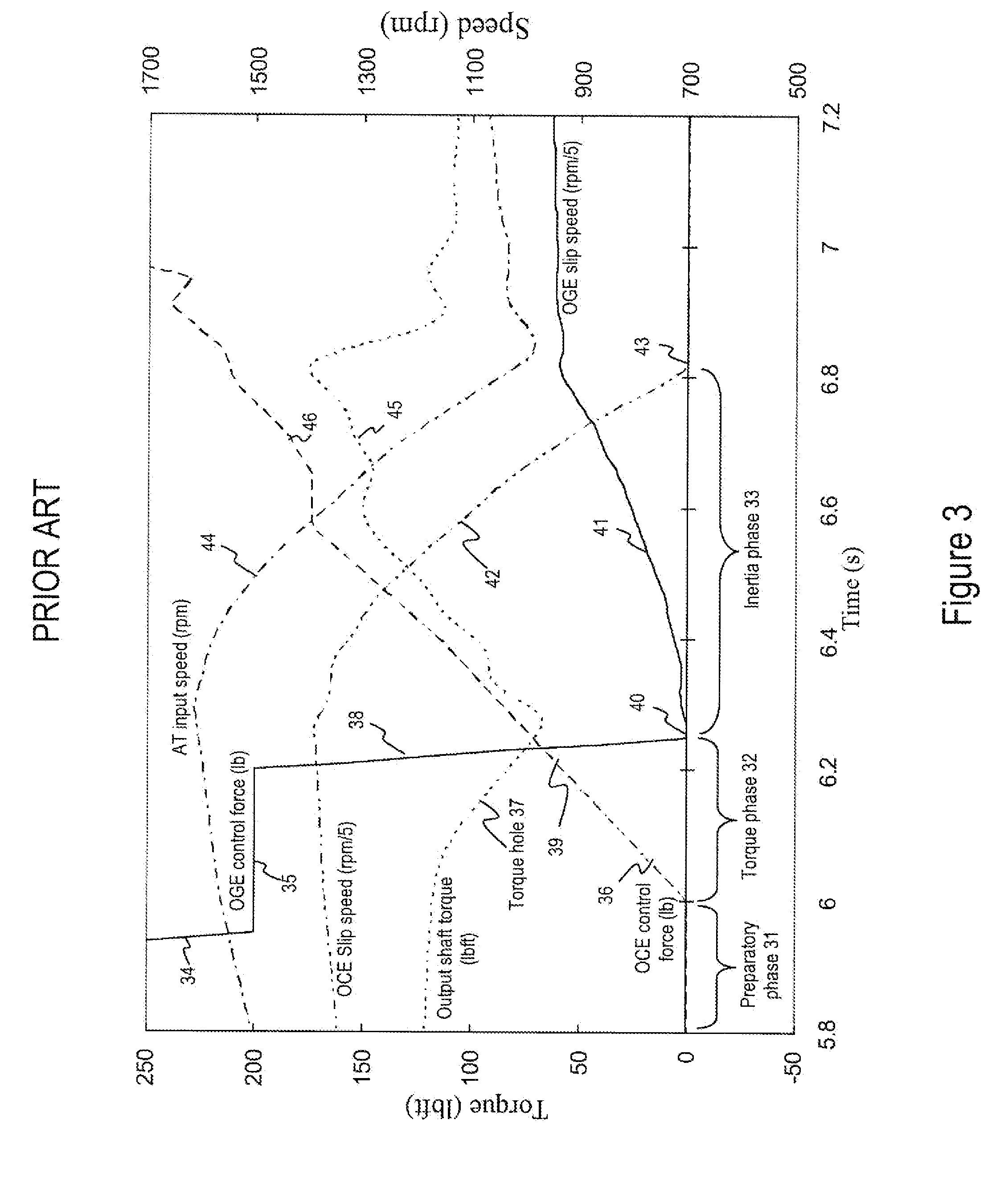

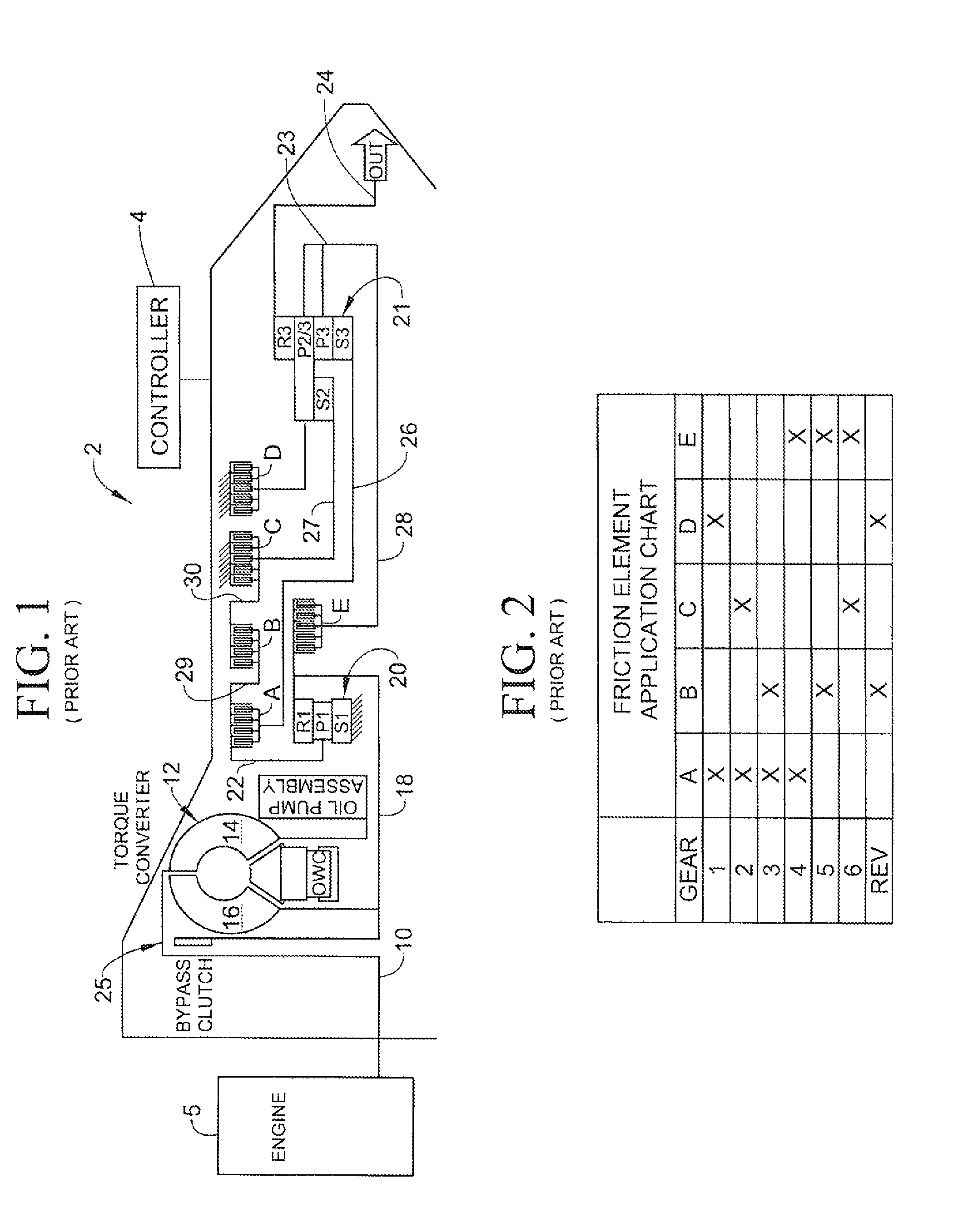

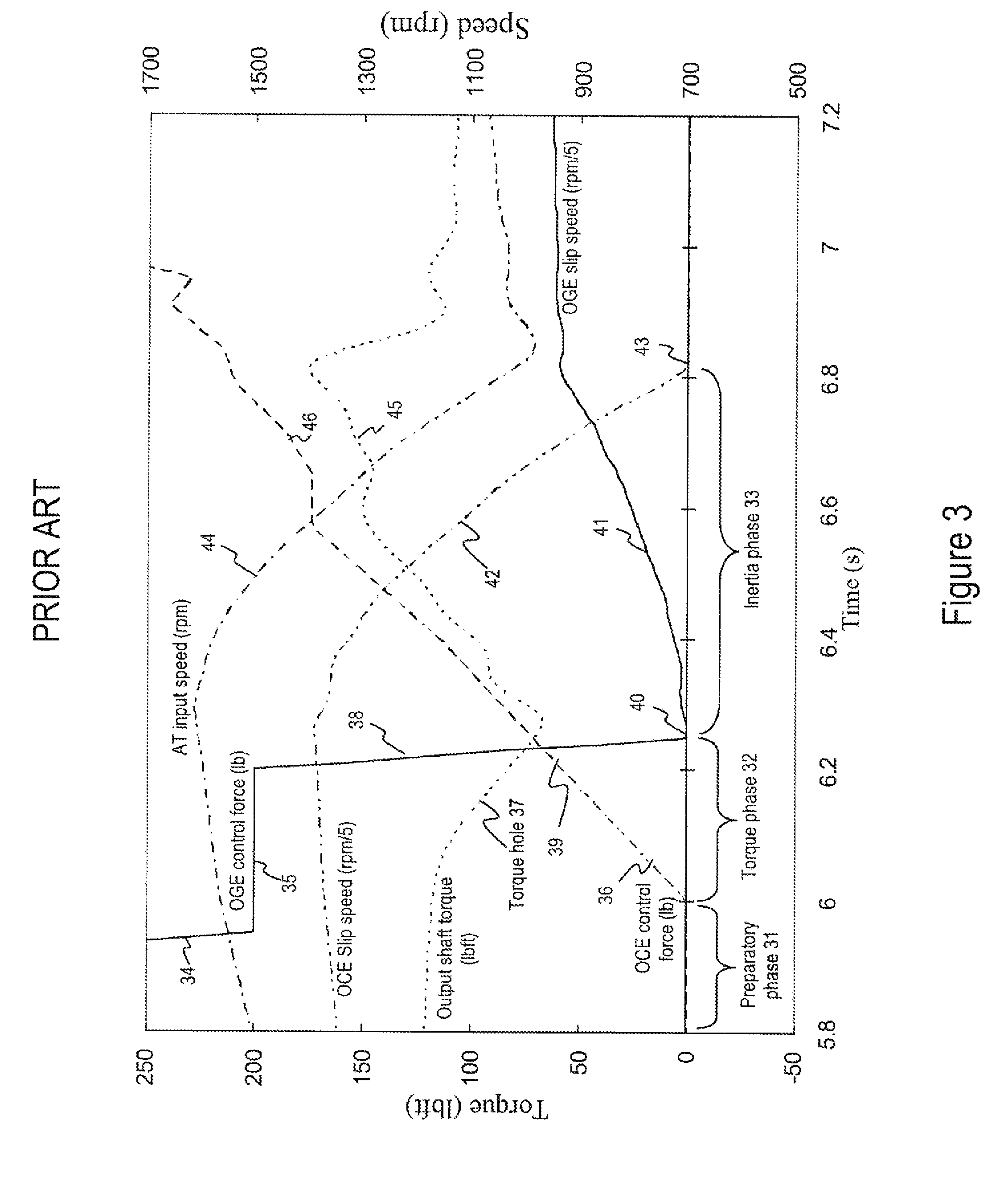

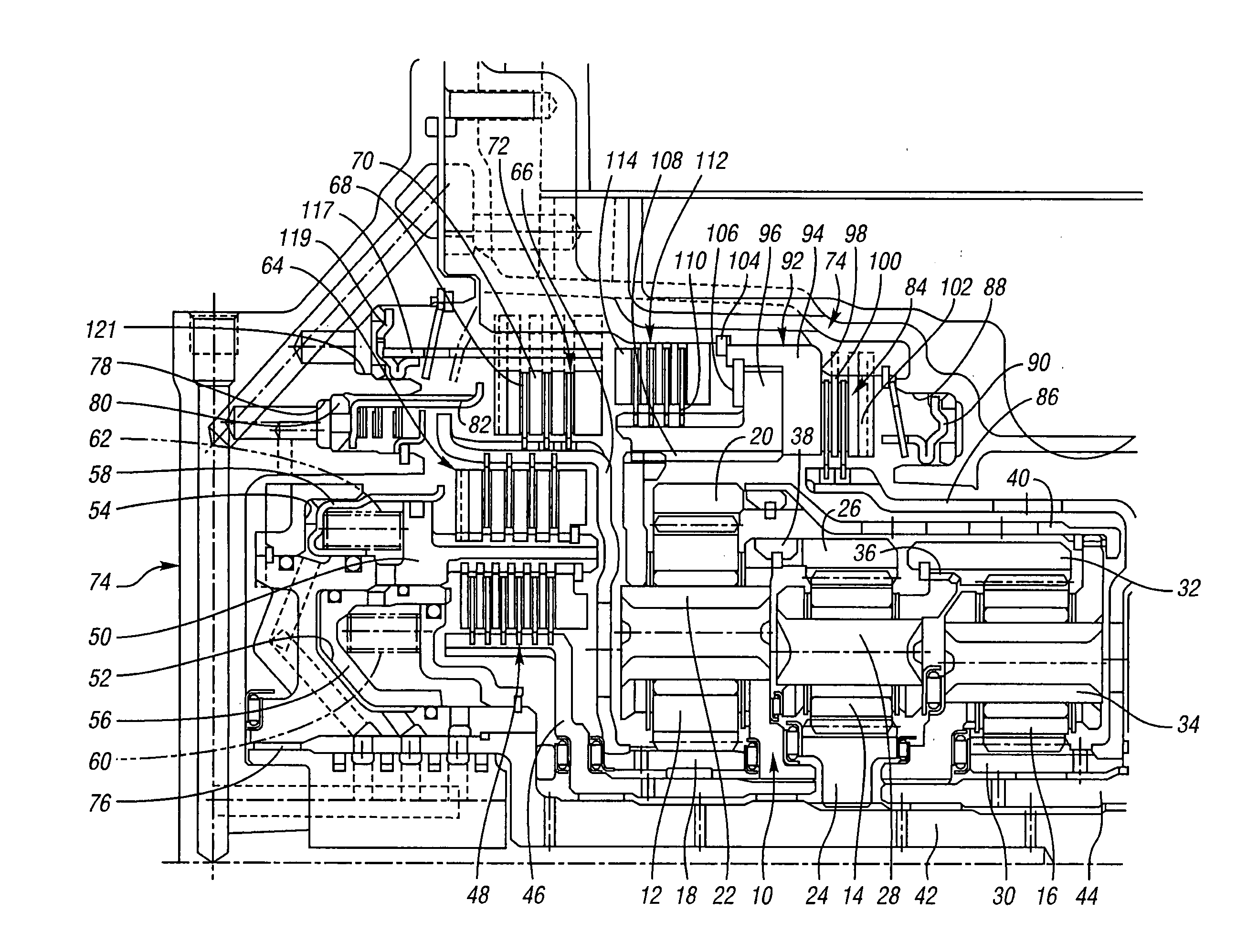

Ratio shift control for a multiple ratio automatic transmission

ActiveUS20060135316A1Eliminates and reduces output shaft torque oscillationReducing undesirable shift shockGearing controlEngine controllersAutomatic transmissionControl theory

A gear ratio shift control and control method controls gear ratio upshifts in a multiple-ratio transmission for an automotive vehicle. Pressure actuated friction elements establish torque flow paths in transmission gearing as they are selectively engaged and released. A net torque reduction at a transmission torque output shaft during an upshift event is reduced by increasing transmission input torque prior to the start of the inertia phase of the upshift event.

Owner:FORD GLOBAL TECH LLC

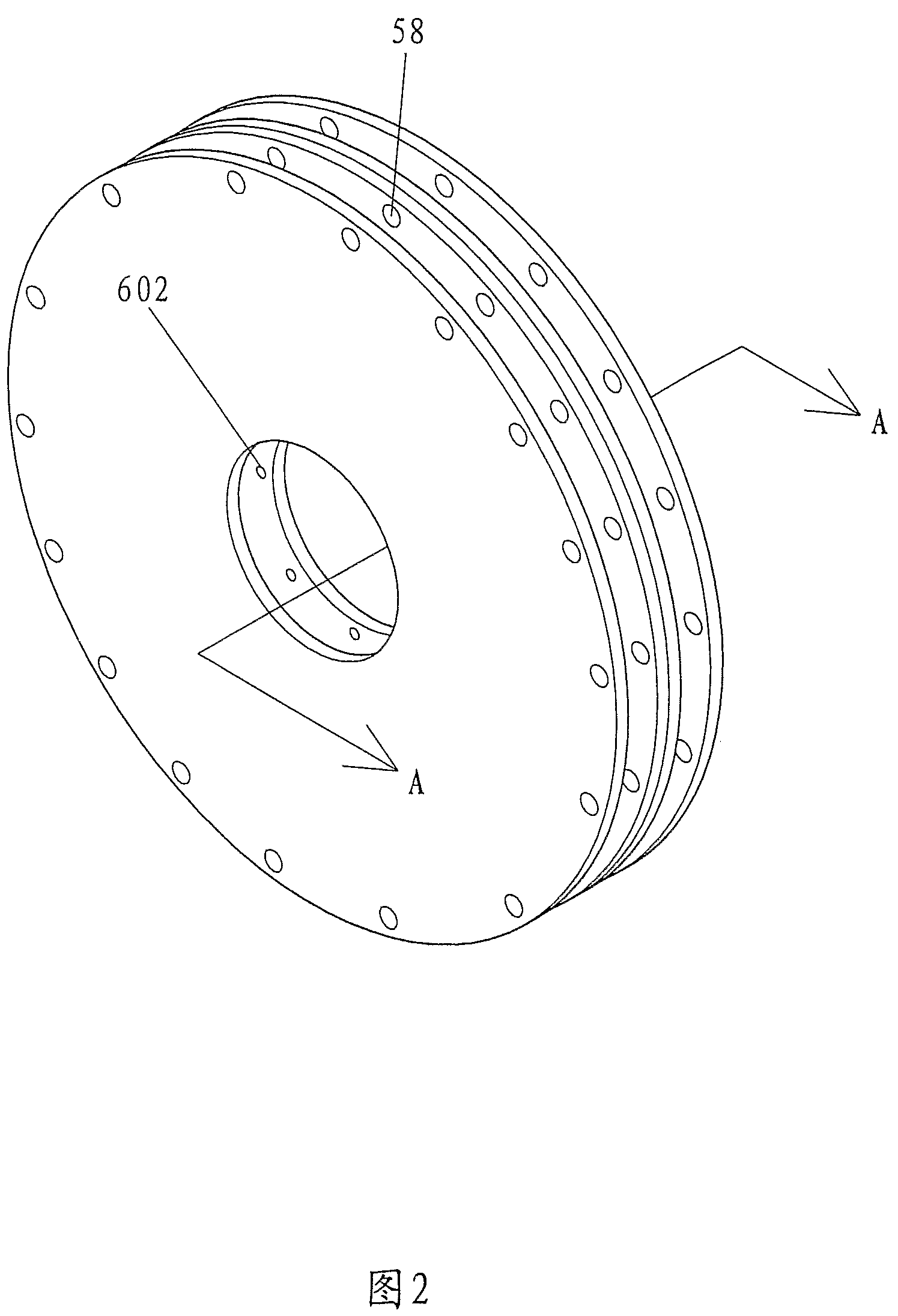

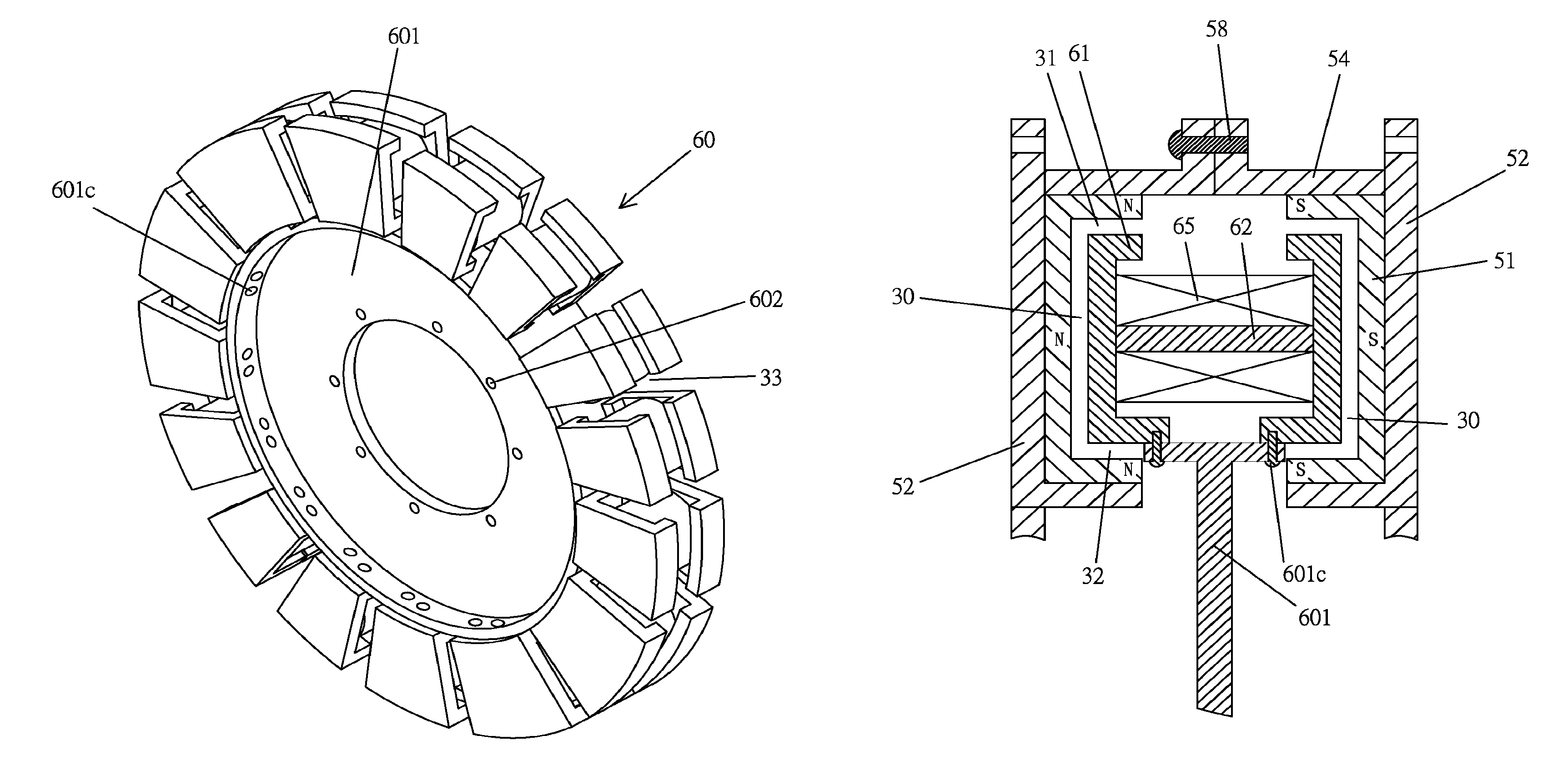

Magnetic Force Rotation Device

InactiveUS20080278019A1Improve efficiencyTorque pulsation can be reducedMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic tension forceMagnetic poles

A magnetic force rotation device includes a rotor and a stator. The rotor is provided with a plurality of magnetic assemblies containing permanent magnet. The plurality of magnetic assemblies are arranged along the circumferential direction of the rotating shaft to form a wheel-shaped ring, and each magnetic assembly is provided with two magnetic poles. The stator is provided with a plurality of magnetically isolated electromagnets coaxially arranged. The electromagnets form a wheel-shaped ring around the rotating shaft, and each electromagnet is provided with paired poles. The wheel-shaped ring of the stator is at least party surrounded by the wheel-shaped ring of the rotor, so that each pole of the paired poles of the electromagnets of the stator corresponds to one magnetic pole of the two magnetic poles of the magnetic assemblies of the rotor respectively. Two axial component air gaps are provided between the rotor and the stator. One of the above two axial component air gaps and two radial component air gaps are provided between one of the paired poles of the electromagnets of the stator and one corresponding magnetic pole of the two magnetic poles of the magnetic assemblies of the rotor.

Owner:UNION PLASTIC HANGZHOU MACHINERY +1

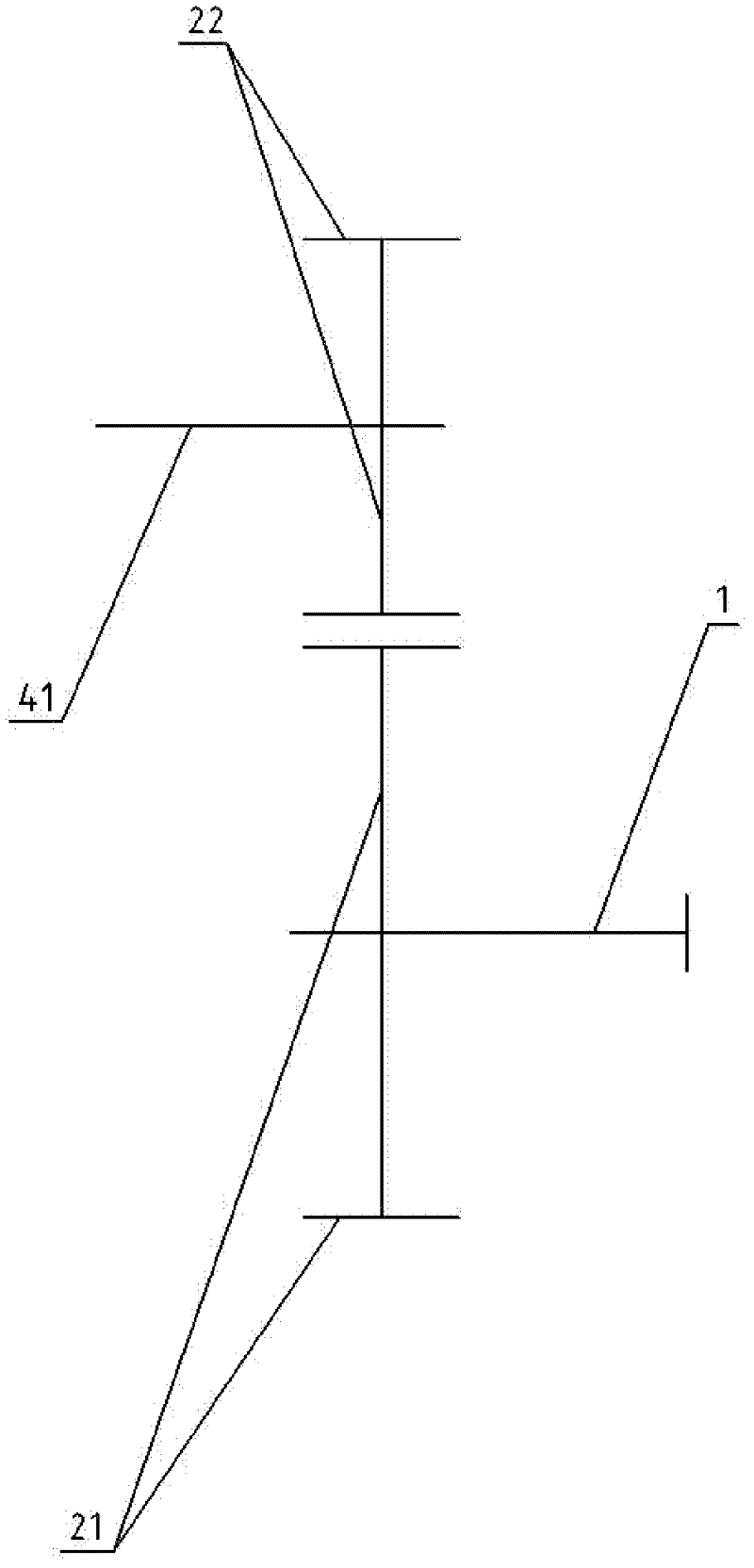

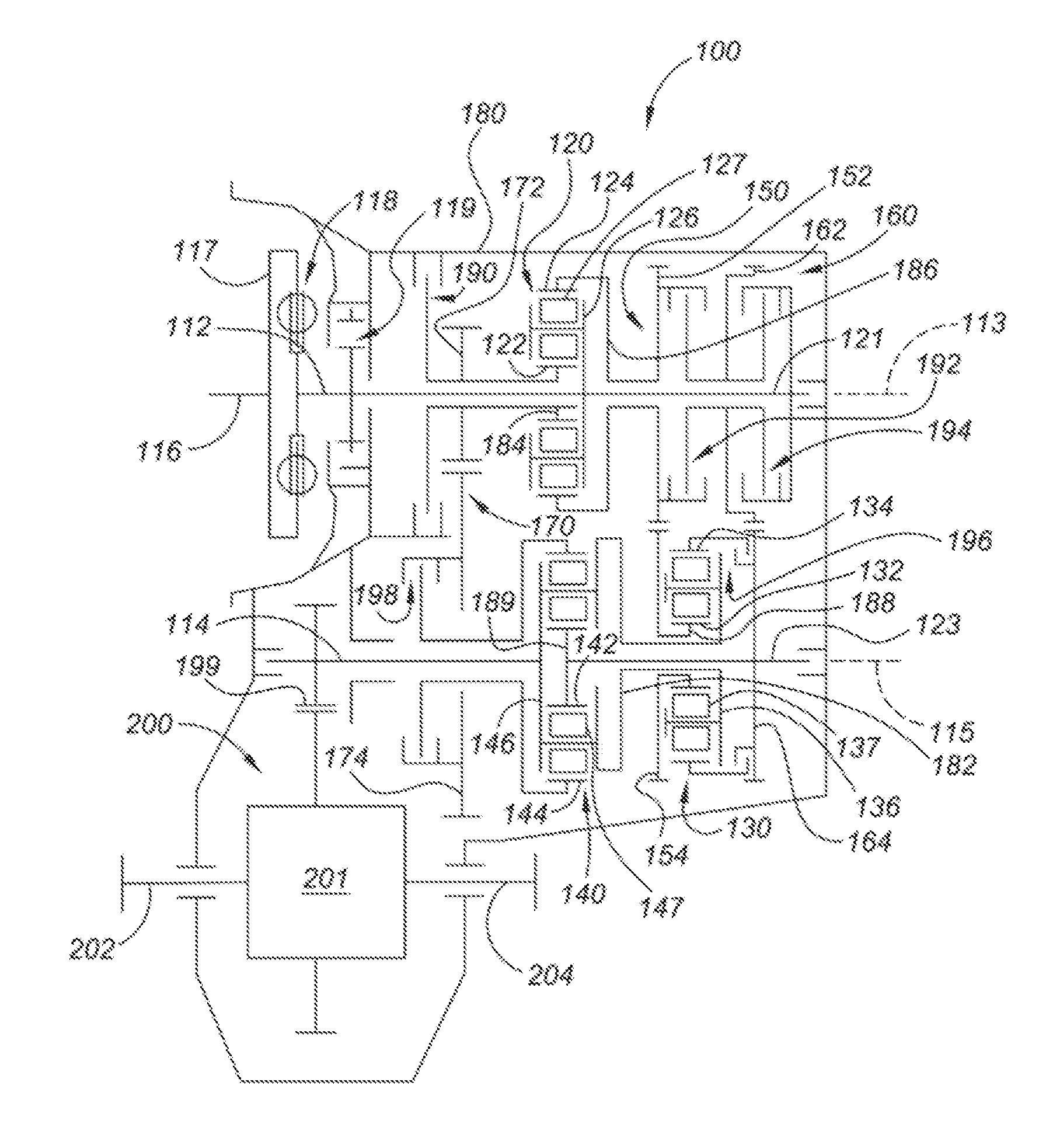

Automatic transmission assembly and automatic transmission vehicle

InactiveCN102297255AReduce layout widthIncrease layout lengthGearboxesFluid gearingsEngineeringAssembly line

The invention provides an automatic transmission assembly and an automatic transmission type automobile. The automatic transmission assembly includes an input shaft (1), a first-stage deceleration / speed-up mechanism (2), a continuously variable transmission mechanism (3), a two-stage deceleration / speed-up mechanism Speed-up mechanism (7), planetary mechanism (8) and output shaft (14), the automatic transmission assembly is distributed in-line, the input shaft (1) and output shaft (14) are arranged on the same axis, and the axis forms the automatic transmission The input-output main axis of the assembly The center of gravity of the entire transmission falls on or nearly falls on the input-output axis, which greatly enhances the balance performance of the transmission and the car.

Owner:HUNAN JIANGLU & RONGDA VEHICLE TRANSMISSION LIMITED

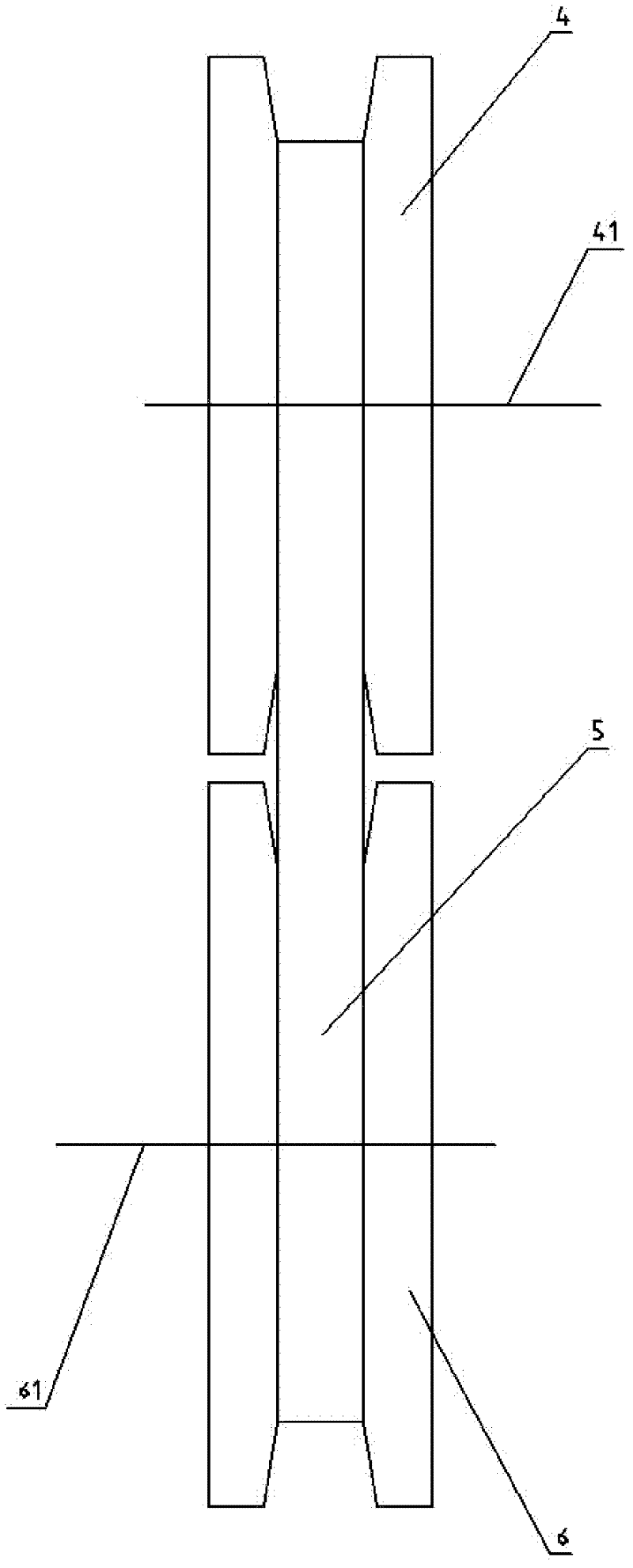

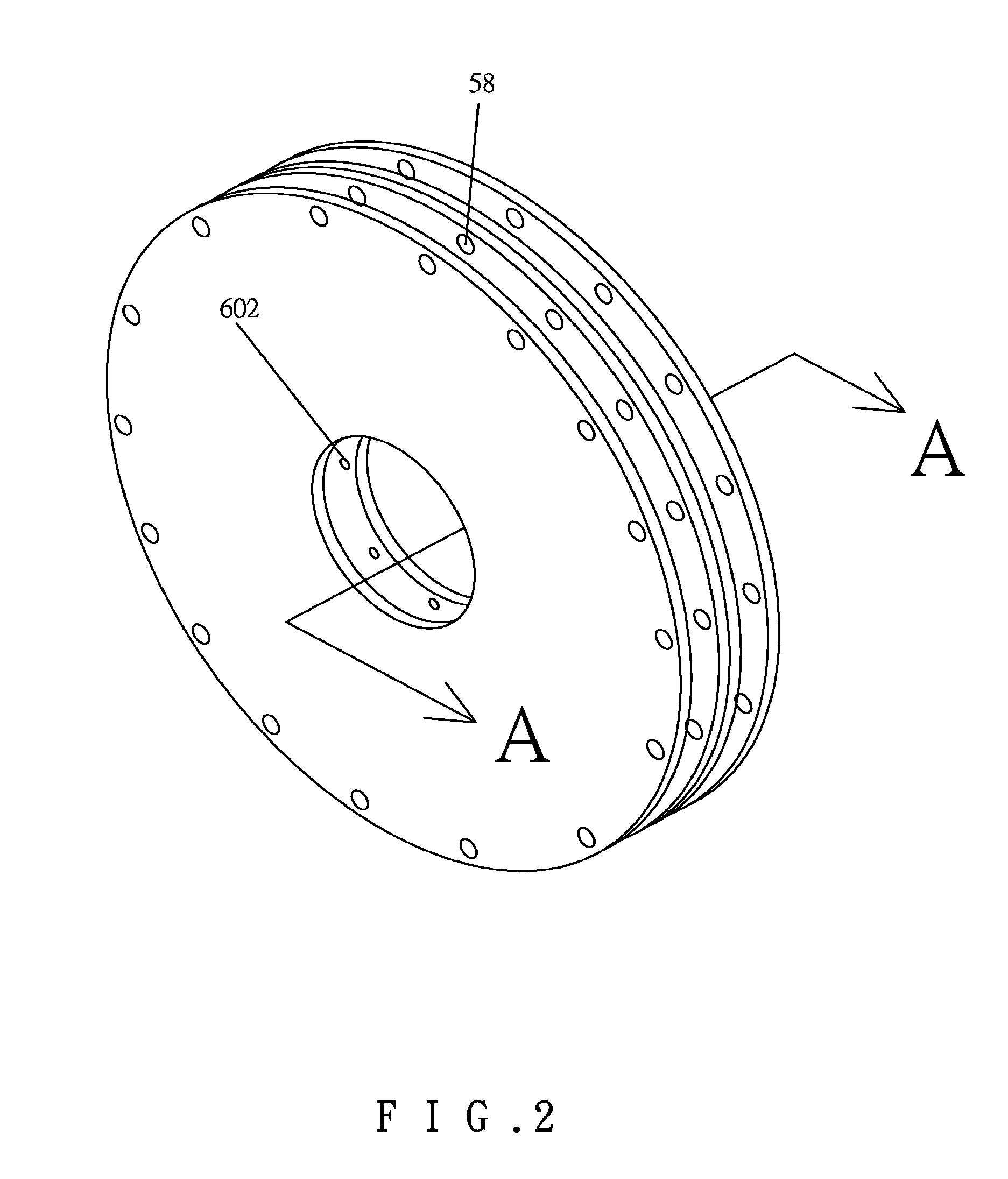

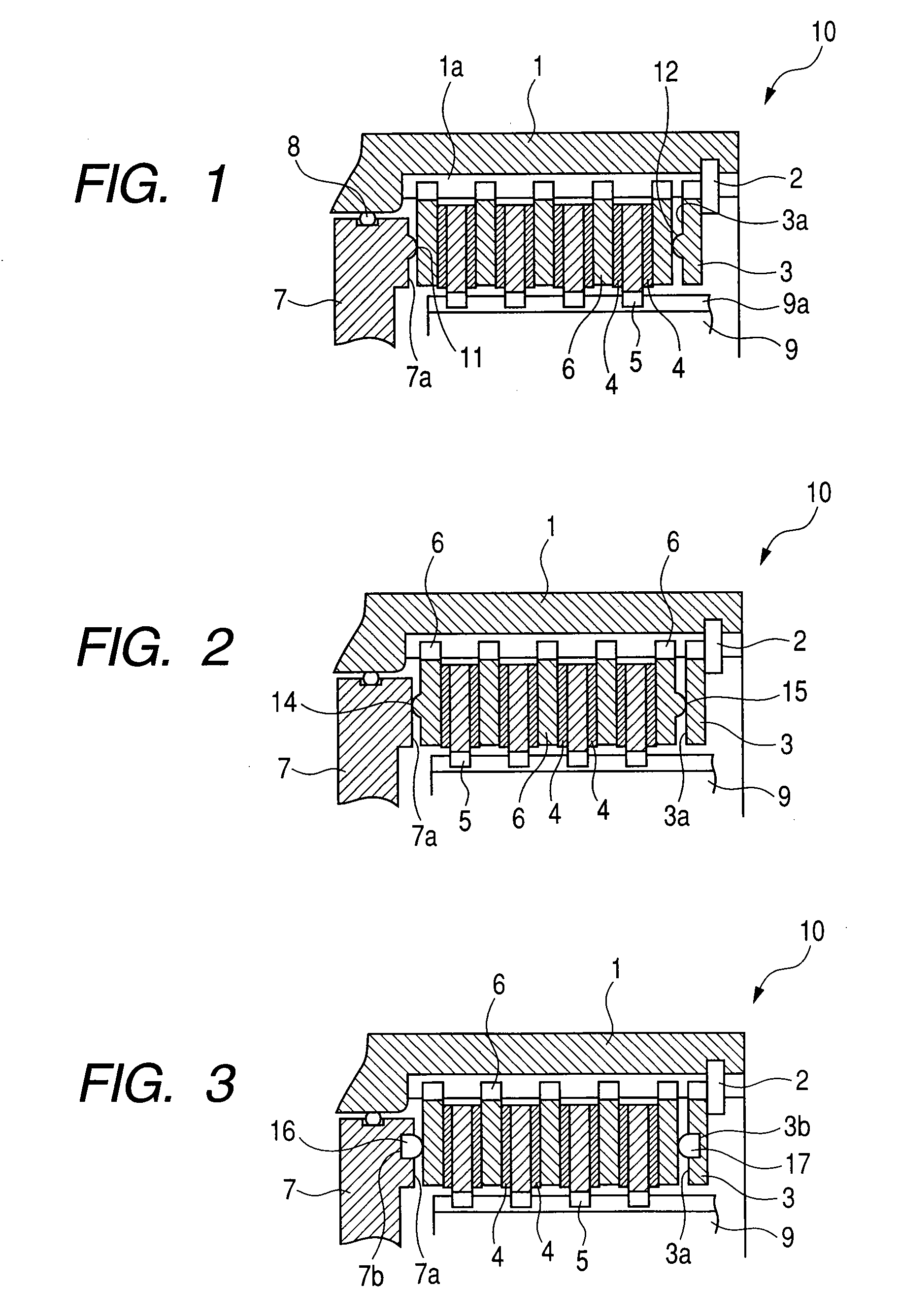

Brushless electric machine

InactiveUS20090102305A1Improve efficiencyTorque pulsation can be reducedWheelchairs/patient conveyancePropulsion by batteries/cellsBrushless motorsElectric machine

A brushless electric machine includes a rotor and a stator. Each of the twin poles of the stator electromagnetic members corresponds to one of the two magnetic poles of the rotor magnetic assembles. Two radial component air-gaps are arranged between the stator and the rotor to separate the stator and the rotor. Axial component air-gaps axially corresponding are arranged between the stator poles and the corresponding rotor poles to separate the stator poles and the rotor poles. The stator wheel-shaped ring is partly surrounded by the rotor wheel-shaped ring.

Owner:UNION PLASTIC HANGZHOU MACHINERY +2

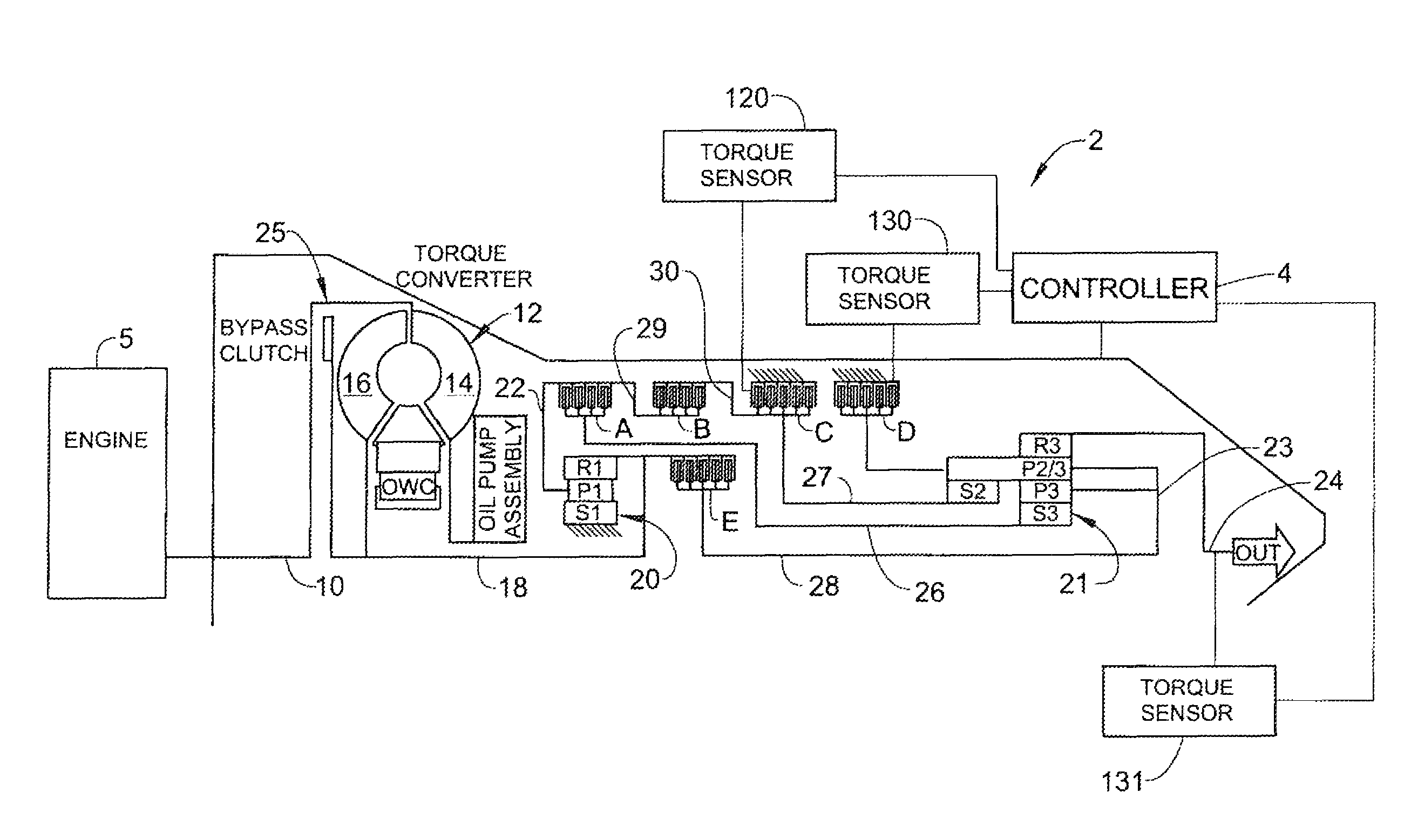

Closed-Loop Torque Phase Control for Shifting Automatic Transmission Gear Ratios Based on Friction Element Load Sensing

ActiveUS20100262344A1Improve shift feelIncreased torque capacityDigital data processing detailsGearing controlLoad sensingClosed loop

A closed loop shift control apparatus and method based on friction element load controls a torque transfer phase when shifting from a low gear configuration to a high gear configuration for an automatic transmission system. When pressure actuated friction elements are selectively engaged and released to establish torque flow paths in the transmission, measurements or estimates of torsional load exerted on the off-going friction element are used to predict the optimal off-going friction element release timing for achieving a consistent shift feel. The ideal timing to release the off-going friction element is uniquely defined when torque load exerted onto the off-going friction element becomes substantially zero. An on-coming clutch engagement process is controlled by a closed loop control based on measurements or estimates of on-coming clutch torque capacity for a constant shift feel under dynamically changing conditions.

Owner:FORD GLOBAL TECH LLC

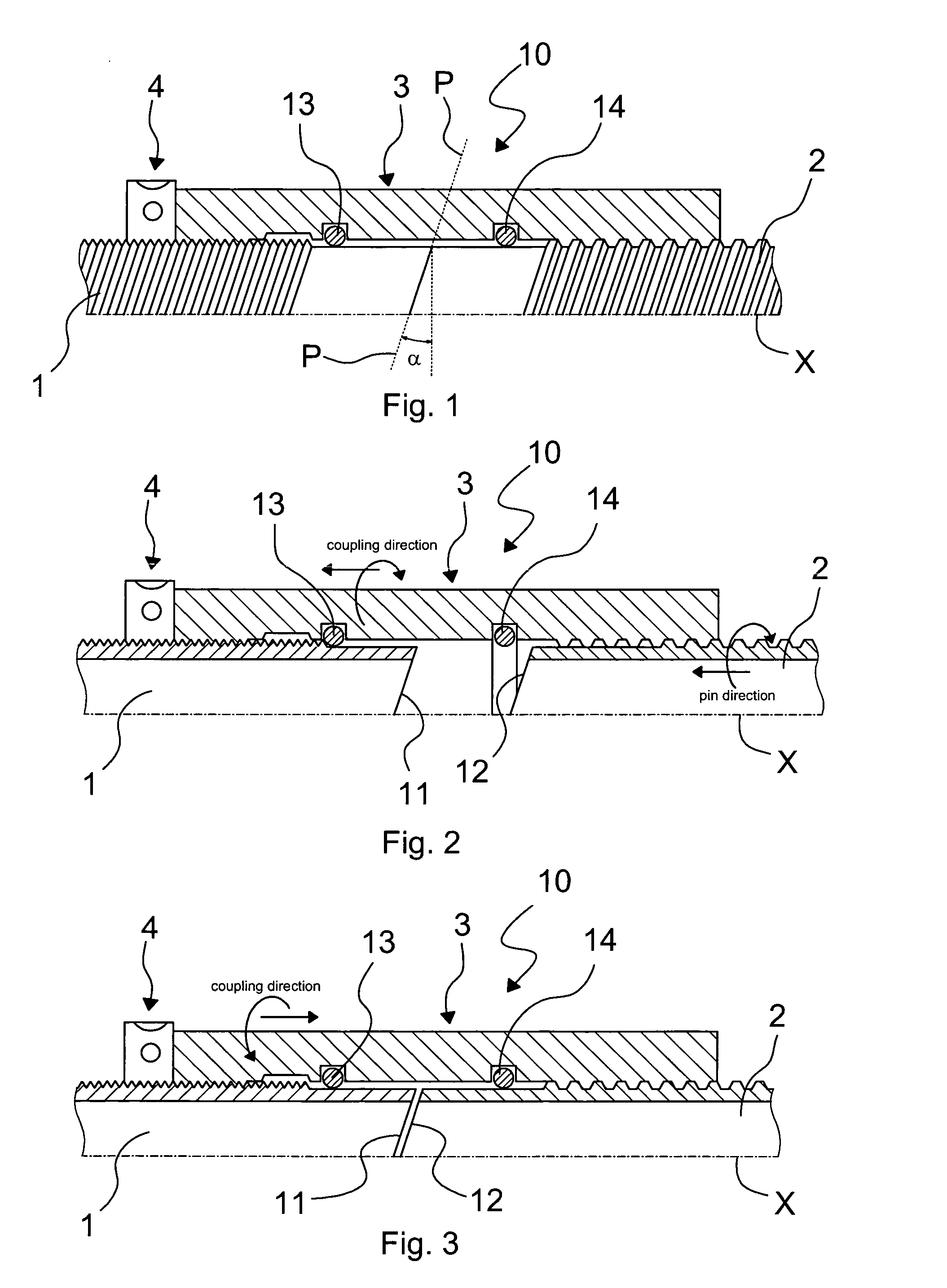

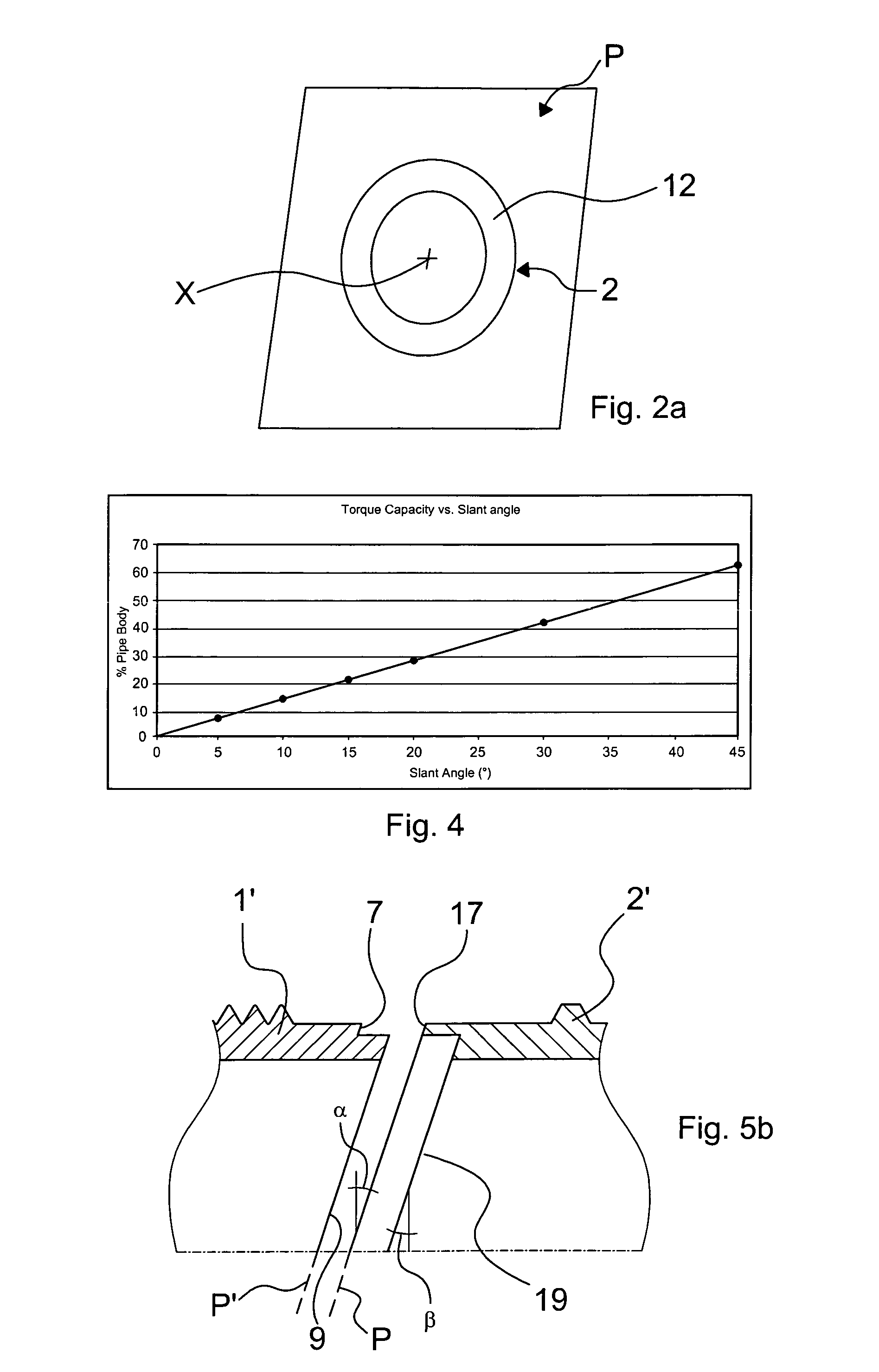

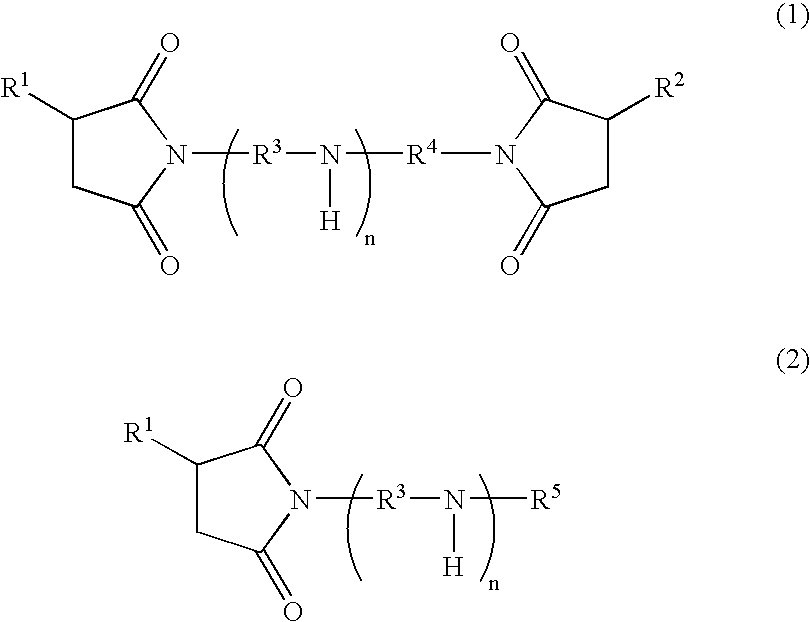

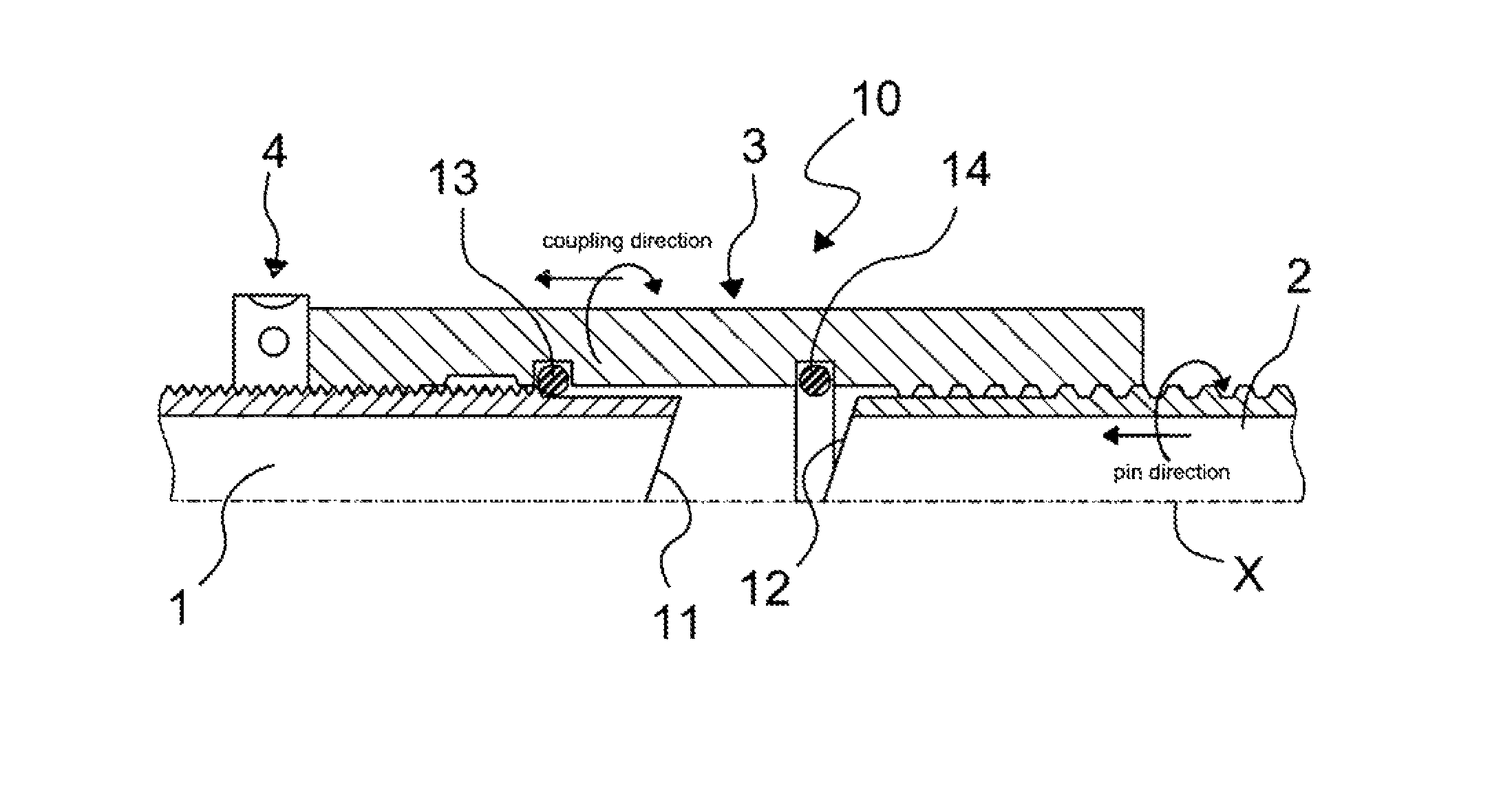

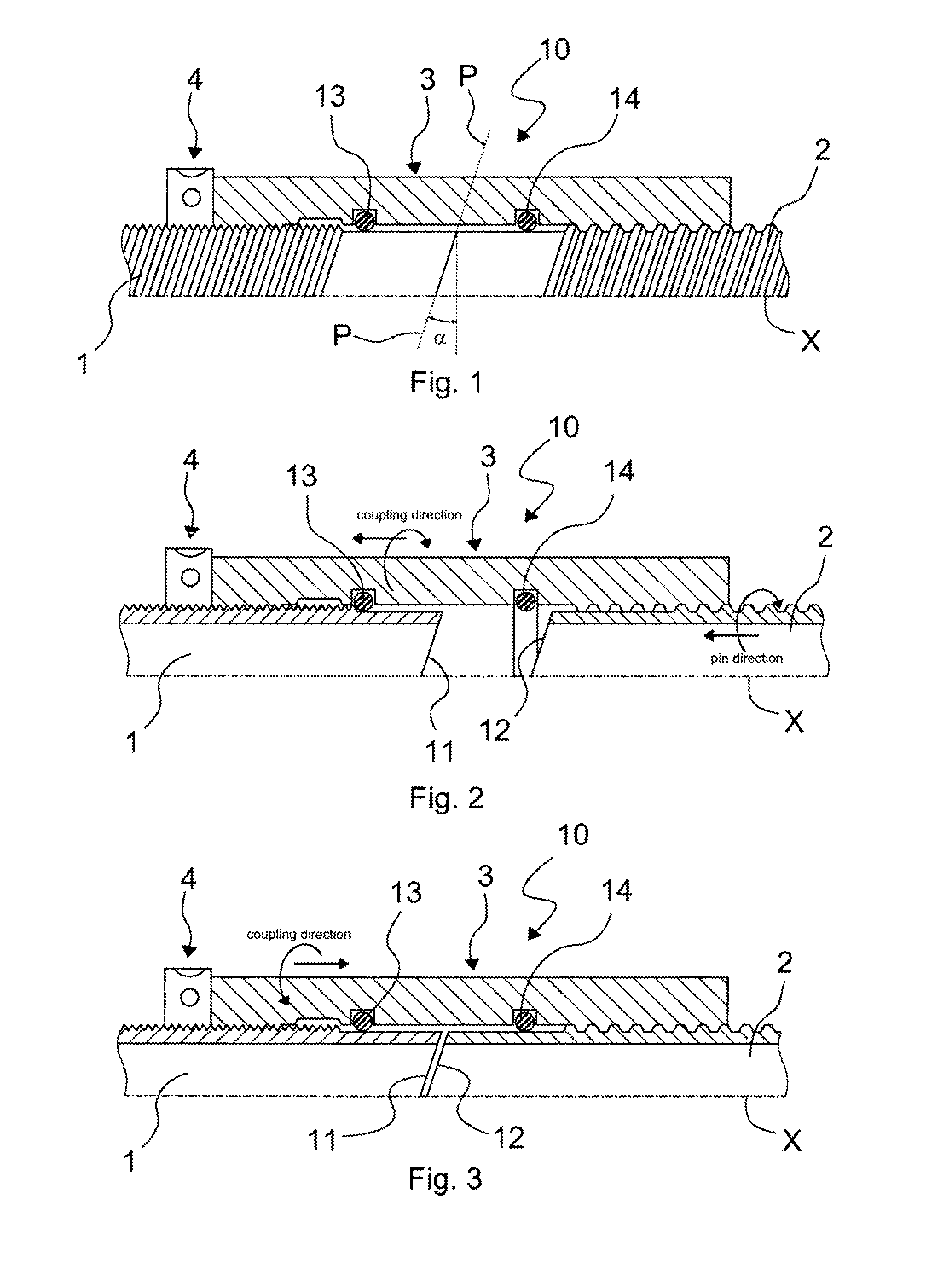

Threaded joint for tubes, pipes and the like

InactiveUS20120032435A1Improve sealingGuaranteed contactDrilling rodsFluid pressure sealed jointsCouplingEngineering

A threaded joint comprises a coupling, a first pin, and a second pin, wherein the thread of the first pin has a pitch different from the pitch of the thread of the second pin. The extremities of the pins have slanted contact surfaces of complementary shape that make mutual contact after make-up of the joint. The slanted common plane of contact of both pins has an angle to the plane perpendicular to the longitudinal axis of the joint which is greater than 0°. In an alternative embodiment the contact surfaces of the pins are split into two staggered planes and comprise a seal in-between.

Owner:TENARIS CONNECTIONS

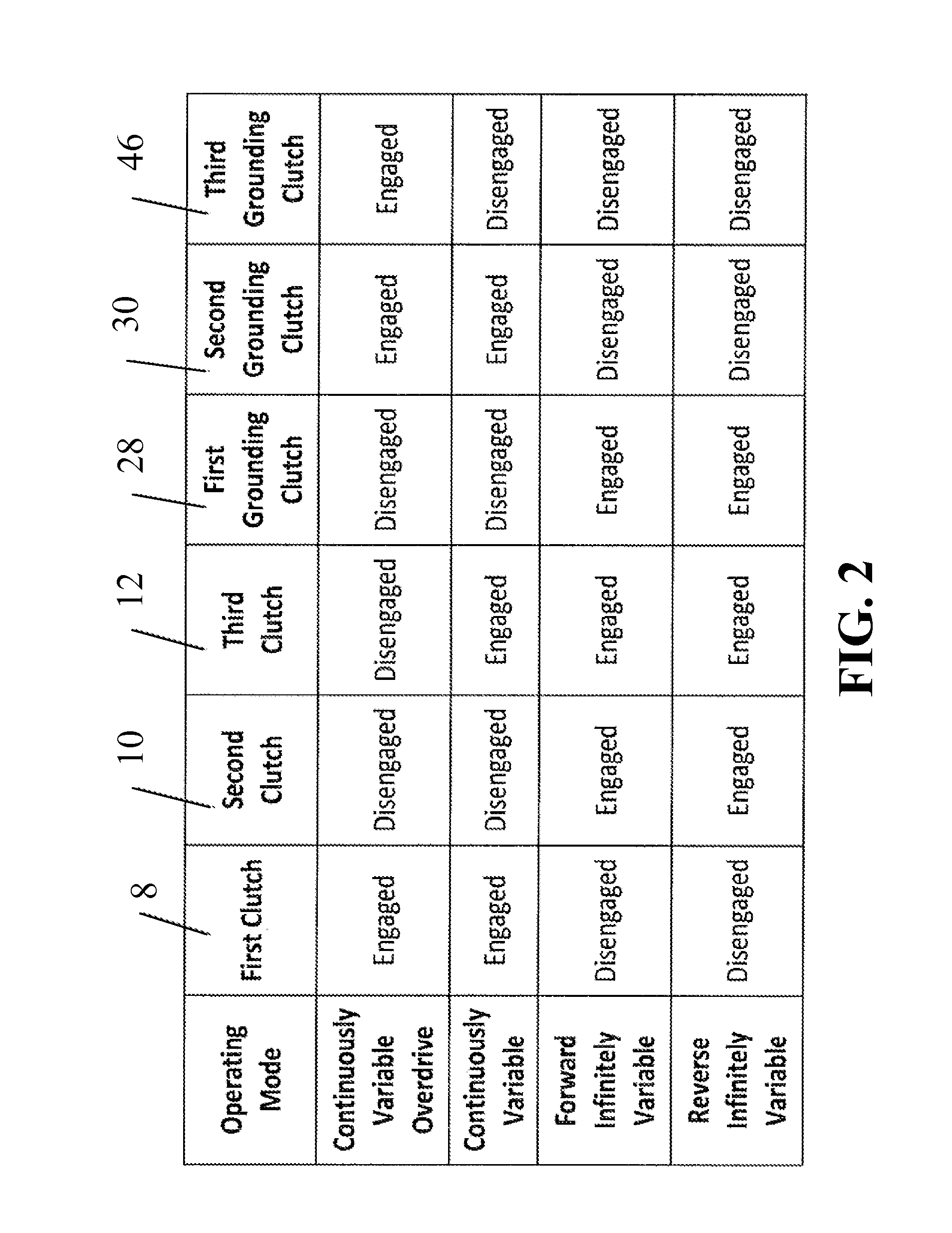

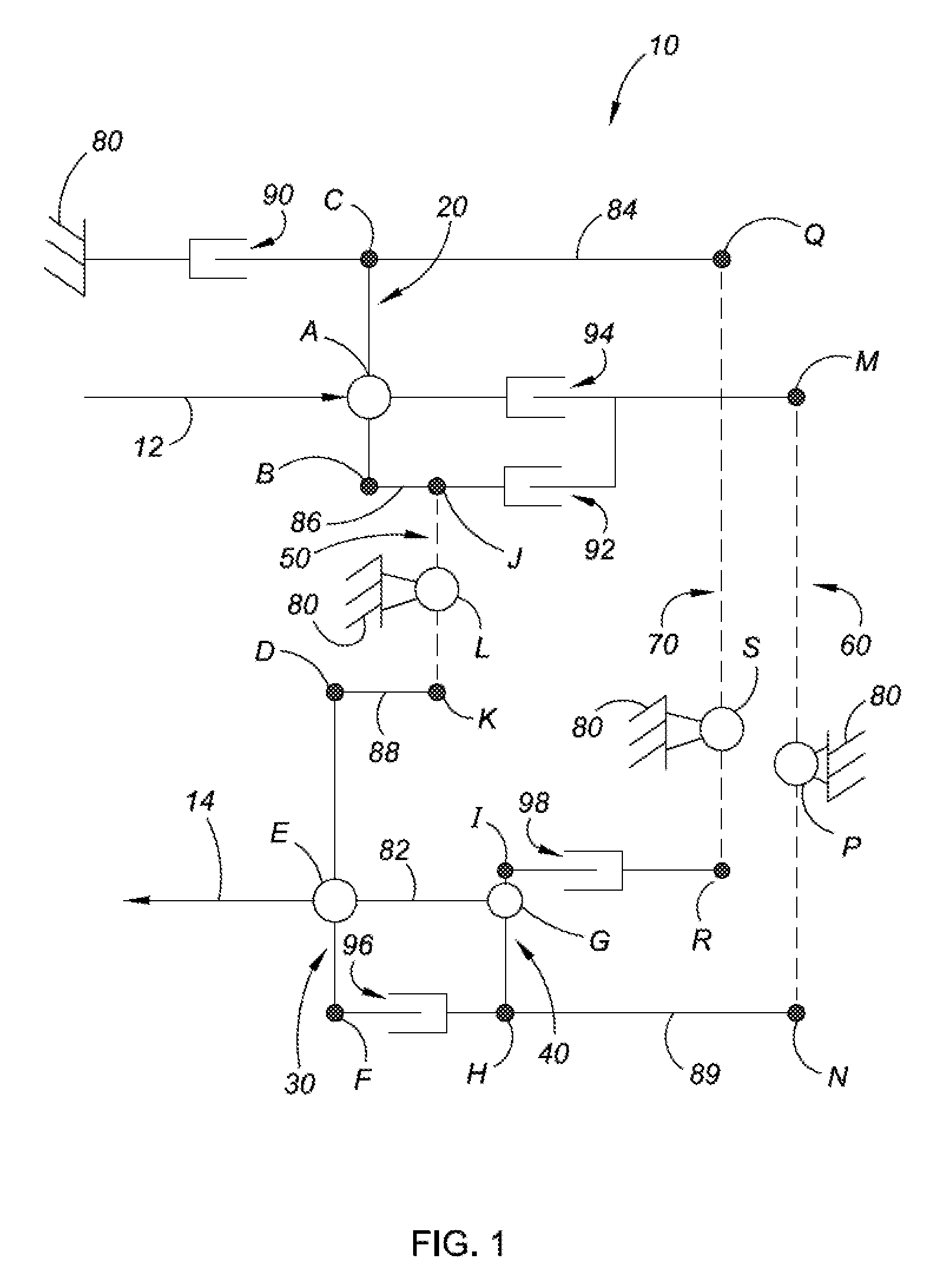

Transmission Having a Continuously or Infinitely Variable Variator Drive

InactiveUS20150226294A1Expand the ratio rangeIncreased power capacityTransmission elementsMultiple ratio transmissionControl theoryElectric power

A transmission having a variator drive capable of being placed in a continuously variable operating mode or an infinitely variable operating mode, capable of having a wide ratio range, and capable of transmitting large amounts of power. Variable transmissions comprising three clutches, three grounding clutches or brakes, and a variator comprising a plurality of tilting variators balls disposed between a first drive ring and a second drive ring allow a single variator to function as an infinitely variable transmission when power is inputted to the carrier assembly and as a continuously variable transmission when power is inputted through a first ring assembly. Certain embodiments include a differential that allows a parallel power path around the variator to improve the variator torque capacity and a direct drive mode to improve the efficiency of the variator.

Owner:DANA CORP

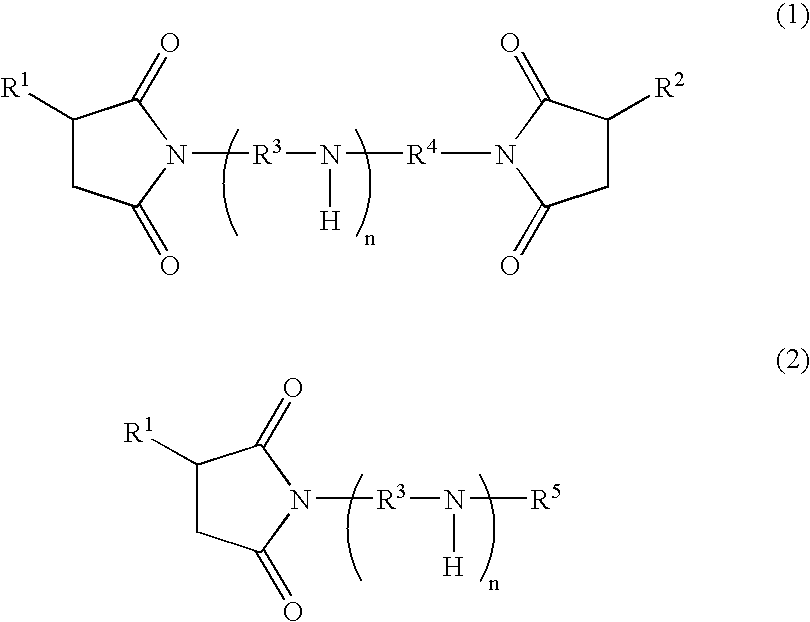

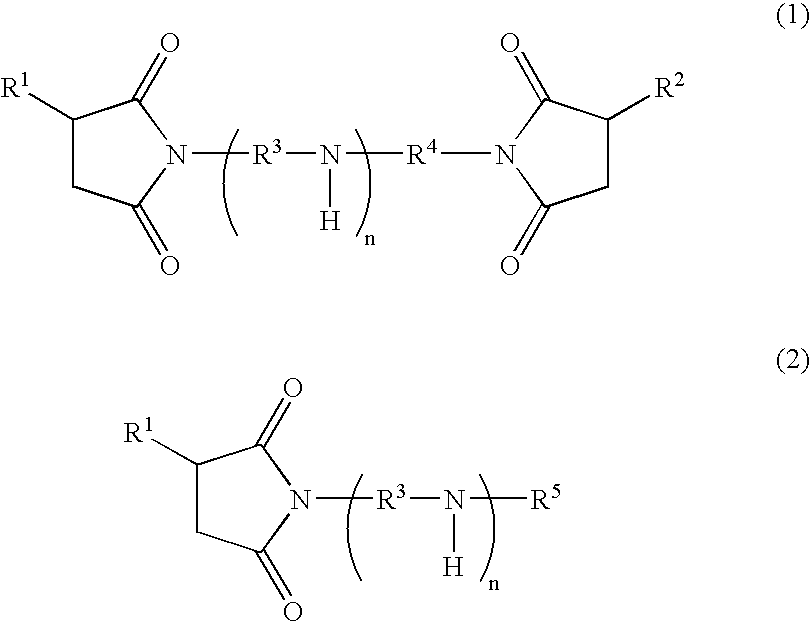

Lubricant compositions

InactiveUS20030220206A1Increased transfer torque capacityWell-balanced capacityOrganic compound preparationLiquid carbonaceous fuelsHydrogenBase oil

Lubricant compositions comprises a lubricant base oil and one or more compounds resulting the modification of a succinimide represented by formula (1) or (2) wherein R<1 >and R<2 >may be the same or different and are each independently a hydrocarbon group having 8 to 30 carbon atoms, R<3 >and R<4 >may be the same or different and are each independently a hydrocarbon group having 1 to 4 carbon atoms, R<5 >is hydrogen or a hydrocarbon group having 1 to 30 carbon atoms, n is an integer from 1 to 7. The lubricant compositions have a long-lasting anti-shudder property, an enhanced transmission capacity for a wet clutch, and an excellent shifting property.

Owner:NIPPON MITSUBISHI OIL CORP

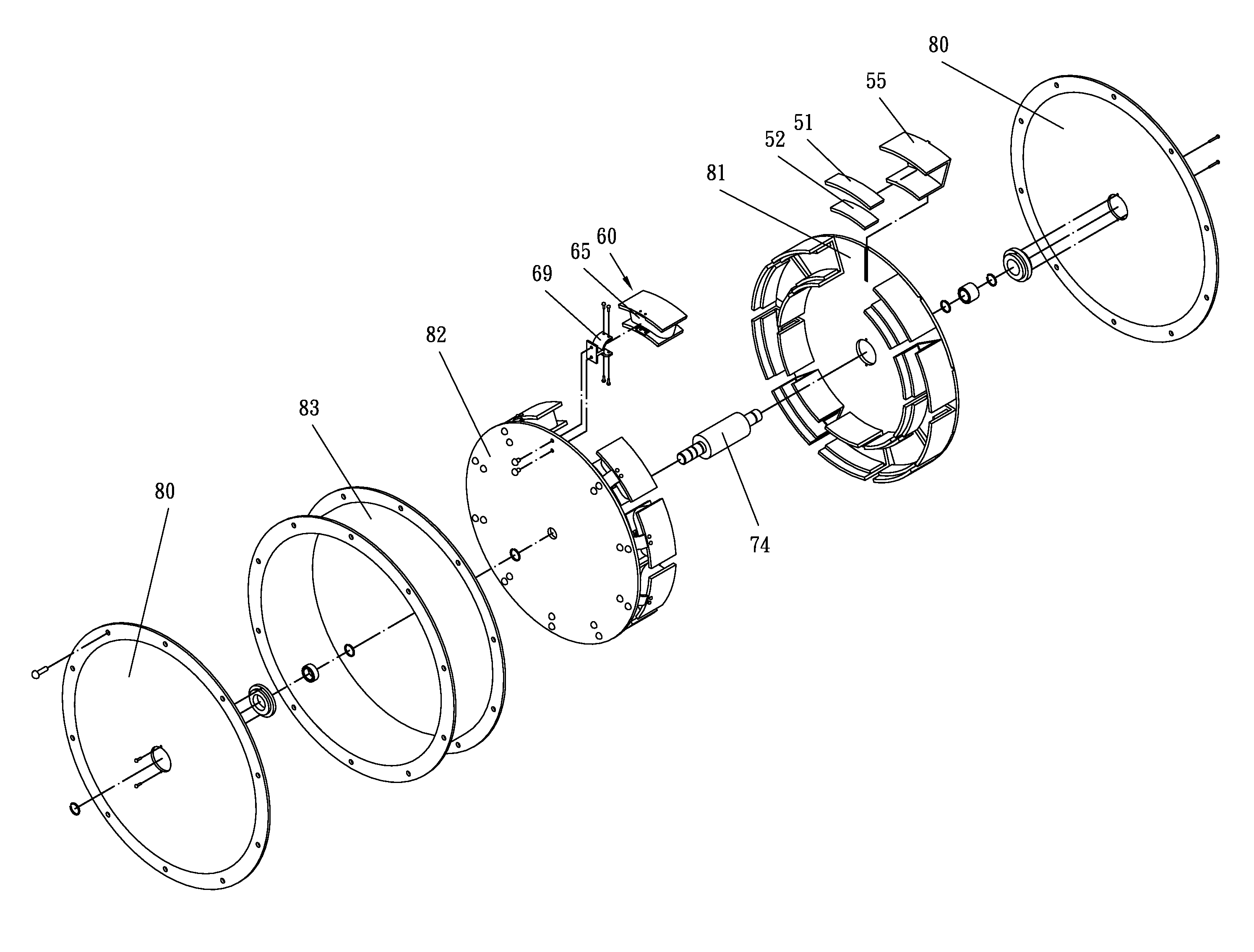

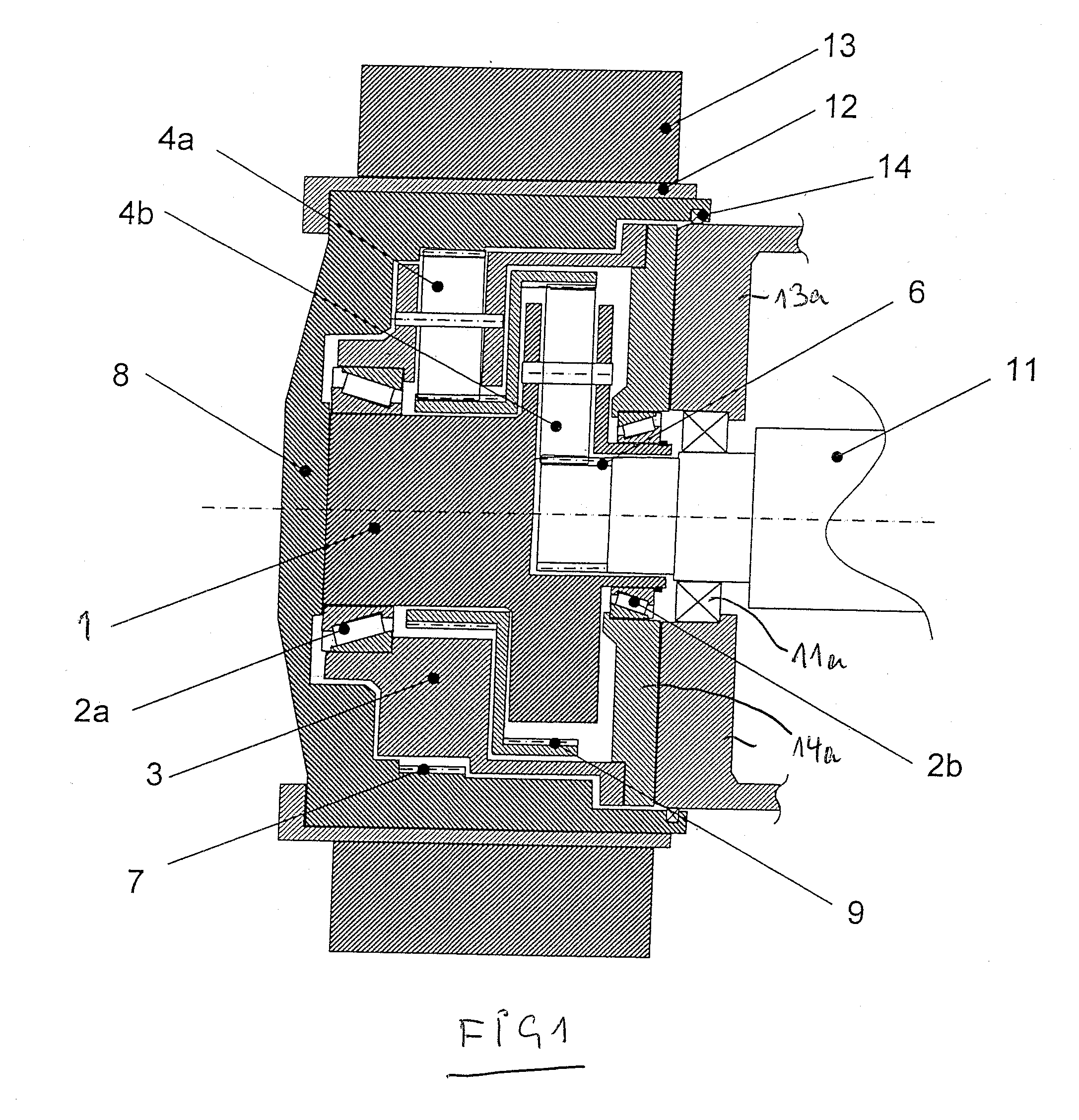

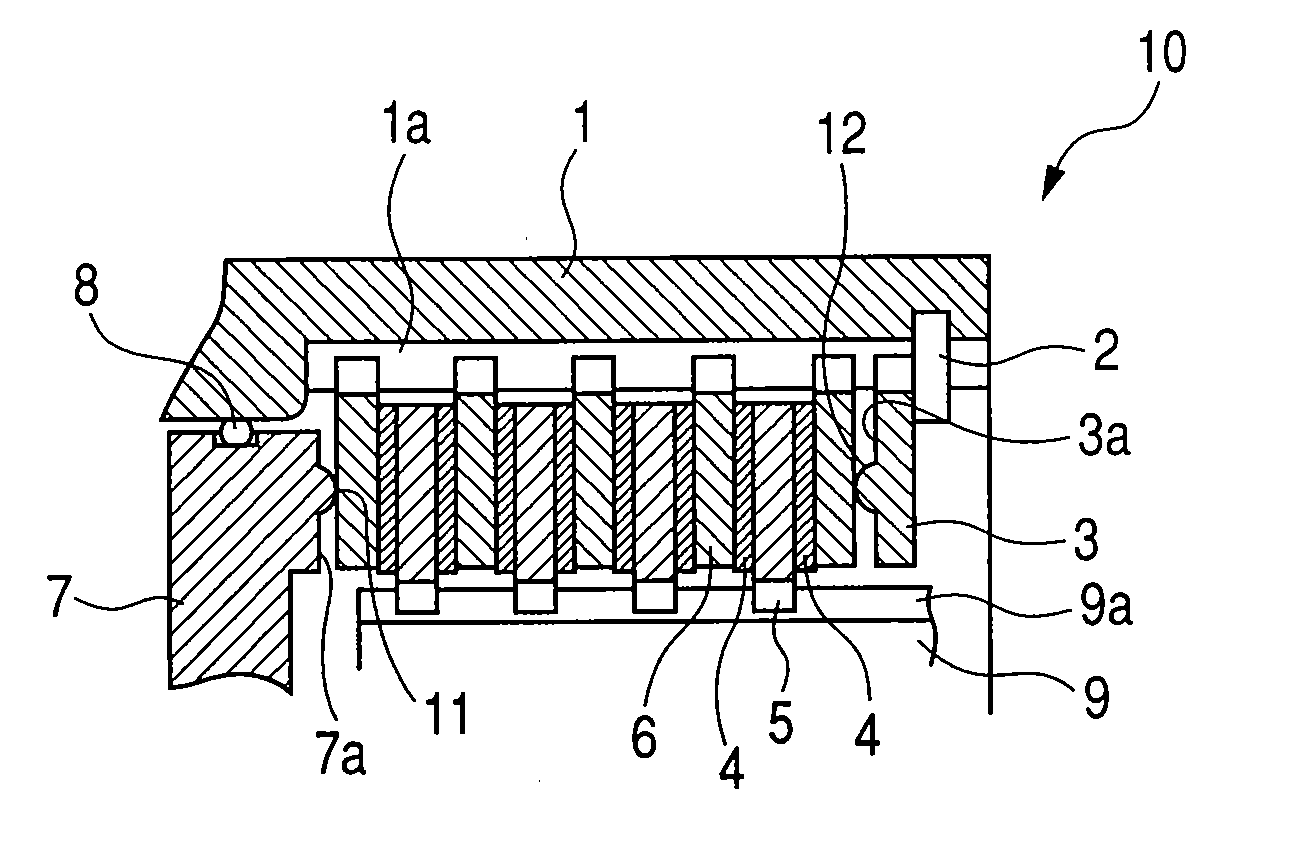

Magnetic force rotation device

InactiveUS7786646B2Improve efficiencySave, flexible operating characteristics during operationMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic tension forceMagnetic poles

A magnetic force rotation device includes a rotor and a stator. The rotor is provided with a plurality of magnetic assemblies containing permanent magnet. The plurality of magnetic assemblies are arranged along the circumferential direction of the rotating shaft to form a wheel-shaped ring, and each magnetic assembly is provided with two magnetic poles. The stator is provided with a plurality of magnetically isolated electromagnets coaxially arranged. The electromagnets form a wheel-shaped ring around the rotating shaft, and each electromagnet is provided with paired poles. The wheel-shaped ring of the stator is at least party surrounded by the wheel-shaped ring of the rotor, so that each pole of the paired poles of the electromagnets of the stator corresponds to one magnetic pole of the two magnetic poles of the magnetic assemblies of the rotor respectively. Two axial component air gaps are provided between the rotor and the stator. One of the above two axial component air gaps and two radial component air gaps are provided between one of the paired poles of the electromagnets of the stator and one corresponding magnetic pole of the two magnetic poles of the magnetic assemblies of the rotor.

Owner:UNION PLASTIC HANGZHOU MACHINERY +1

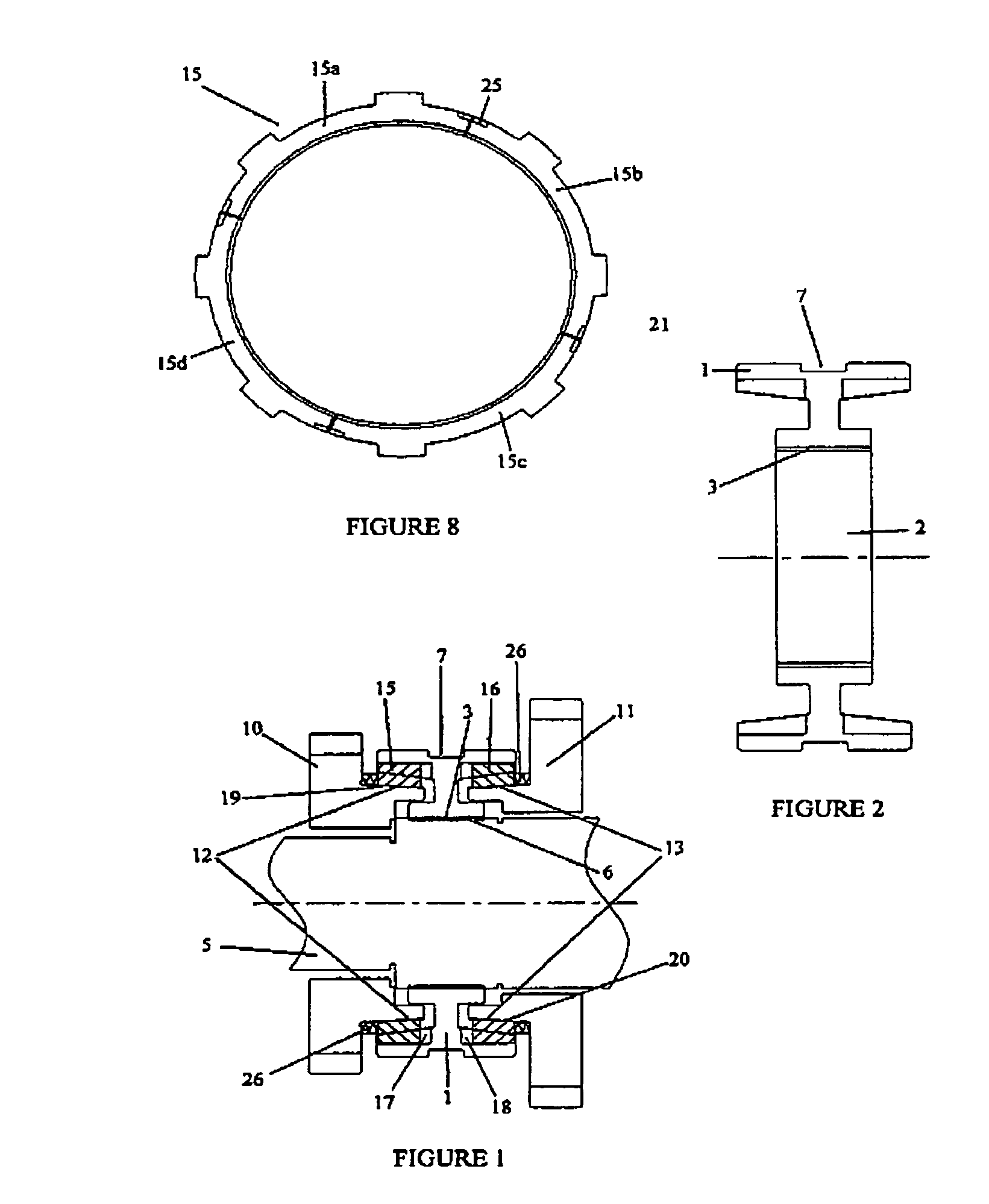

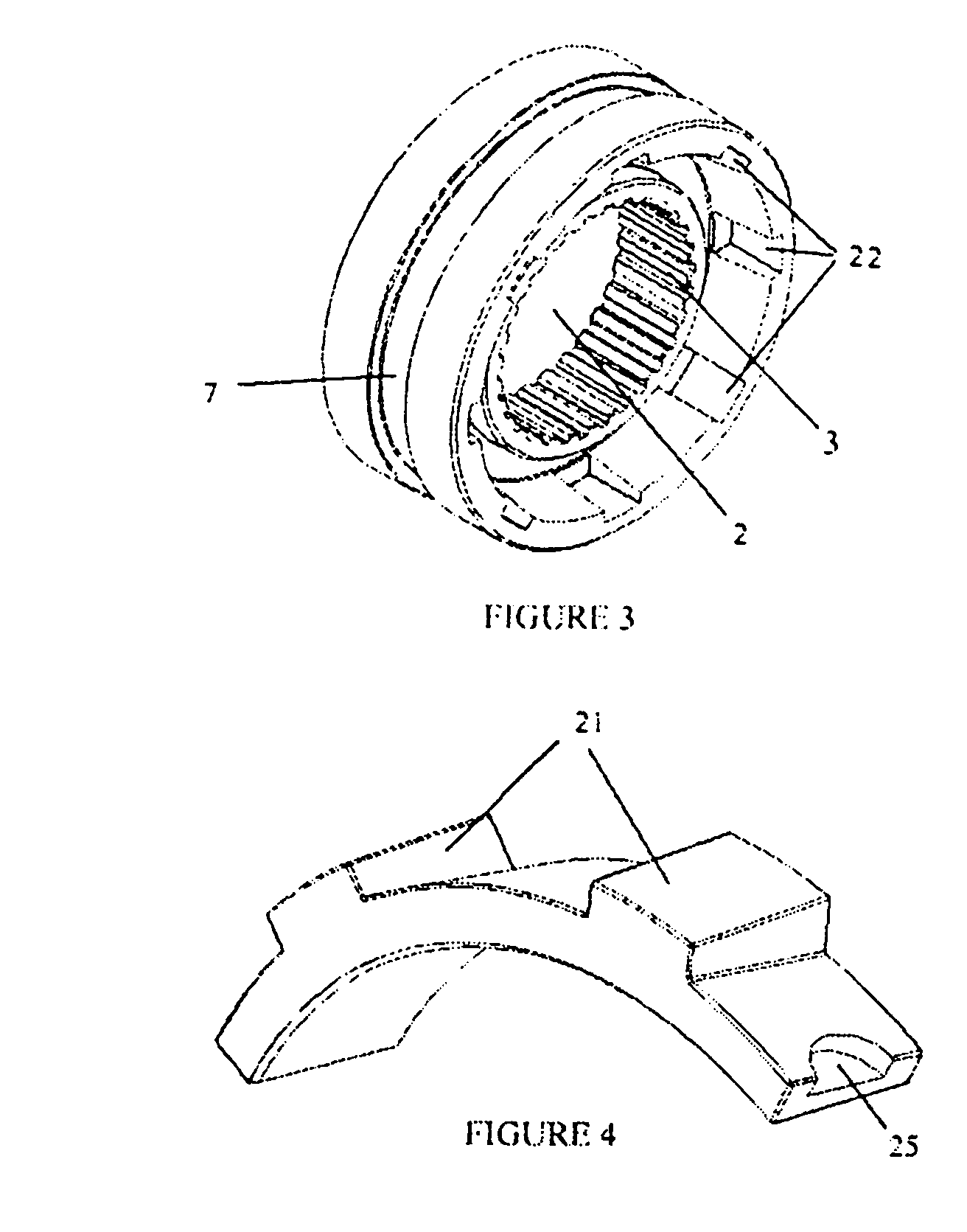

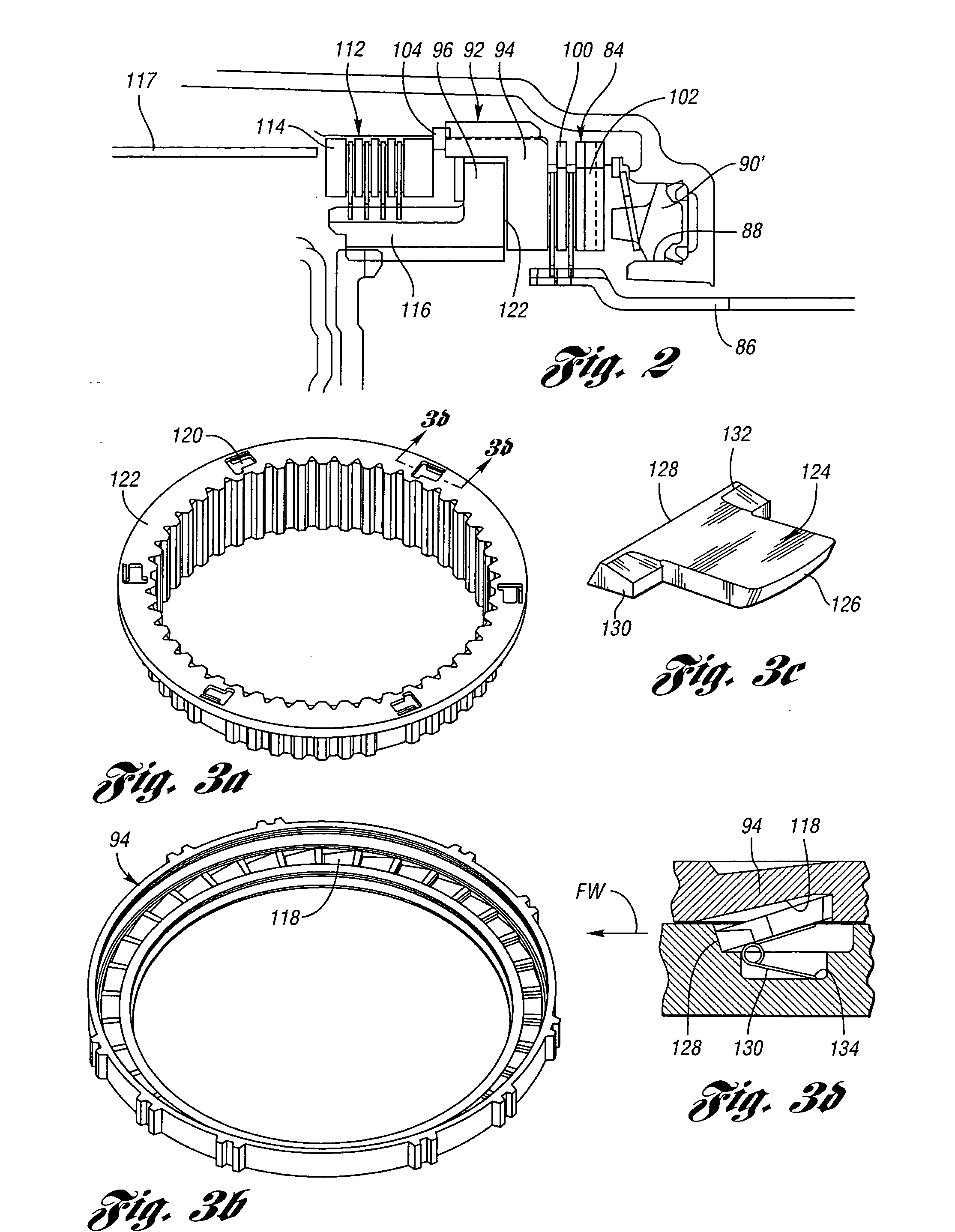

Segmented synchronizer clutch

ActiveUS7121393B1Easy to assembleReliable couplingFriction clutchesInterengaging clutchesEngineeringFriction force

A synchronizer clutch assembly includes a clutch hub which is axially movably mounted on a shaft, a gear which is axially spaced from the hub and which is journally mounted on the shaft and rotatable independent thereof, one of the hub or the gear having a conical friction surface formed thereon, and a synchronizer ring positioned between the hub and the gear. The synchronizer ring is coupled to the hub or the gear for rotation therewith and has a complementary conical friction surface formed thereon which is engageable with the conical friction surface on the hub or the gear. The synchronizer ring is composed of a plurality of separate arcuate segments arranged in a ring, which are movable between a first expanded configuration and a second, contracted configuration.

Owner:SULZER FRICTION SYST US

Variable valve timing control system of internal combustion engine

InactiveUS7219636B2Tendency increaseIncreased torque capacityValve drivesMachines/enginesWorking fluidVariable valve timing

A variable valve timing control system of an internal combustion engine includes a hydraulically-operated phase converter disposed between a sprocket and a camshaft, and having a phase-advance hydraulic chamber and a phase-retard hydraulic chamber for changing an angular phase of the camshaft relative to the sprocket. An electric pump is provided to supply working fluid selectively to one of the hydraulic chambers via a directional control valve. Also provided is a check valve disposed in a discharge line of the pump for permitting flow in a direction that the working fluid flows from the pump to the directional control valve and preventing any flow in the opposite direction, so as to prevent a pulse pressure arising from alternating torque exerted on the camshaft from being transmitted from either one of the hydraulic chambers via the discharge line to a discharge port of the pump.

Owner:HITACHI LTD

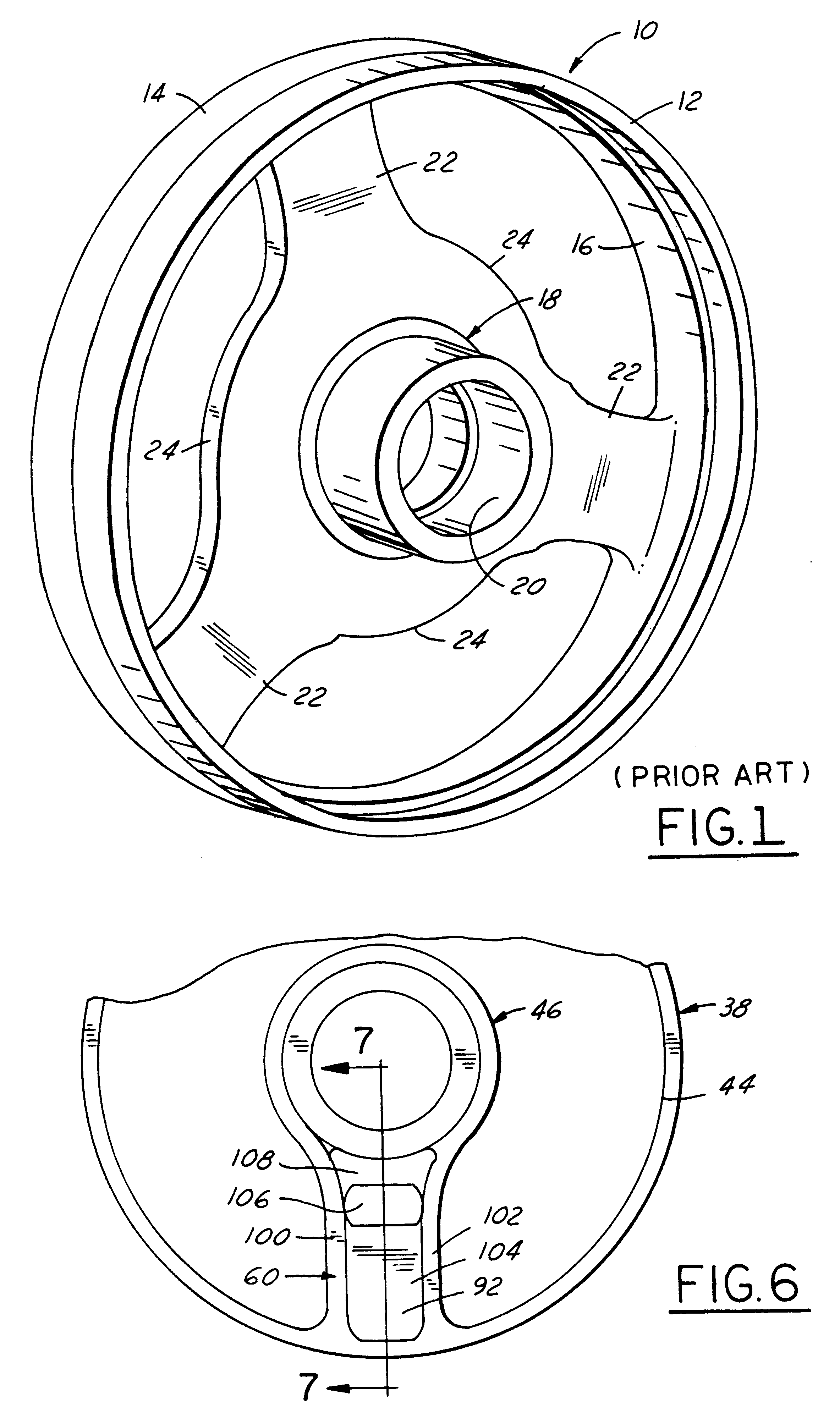

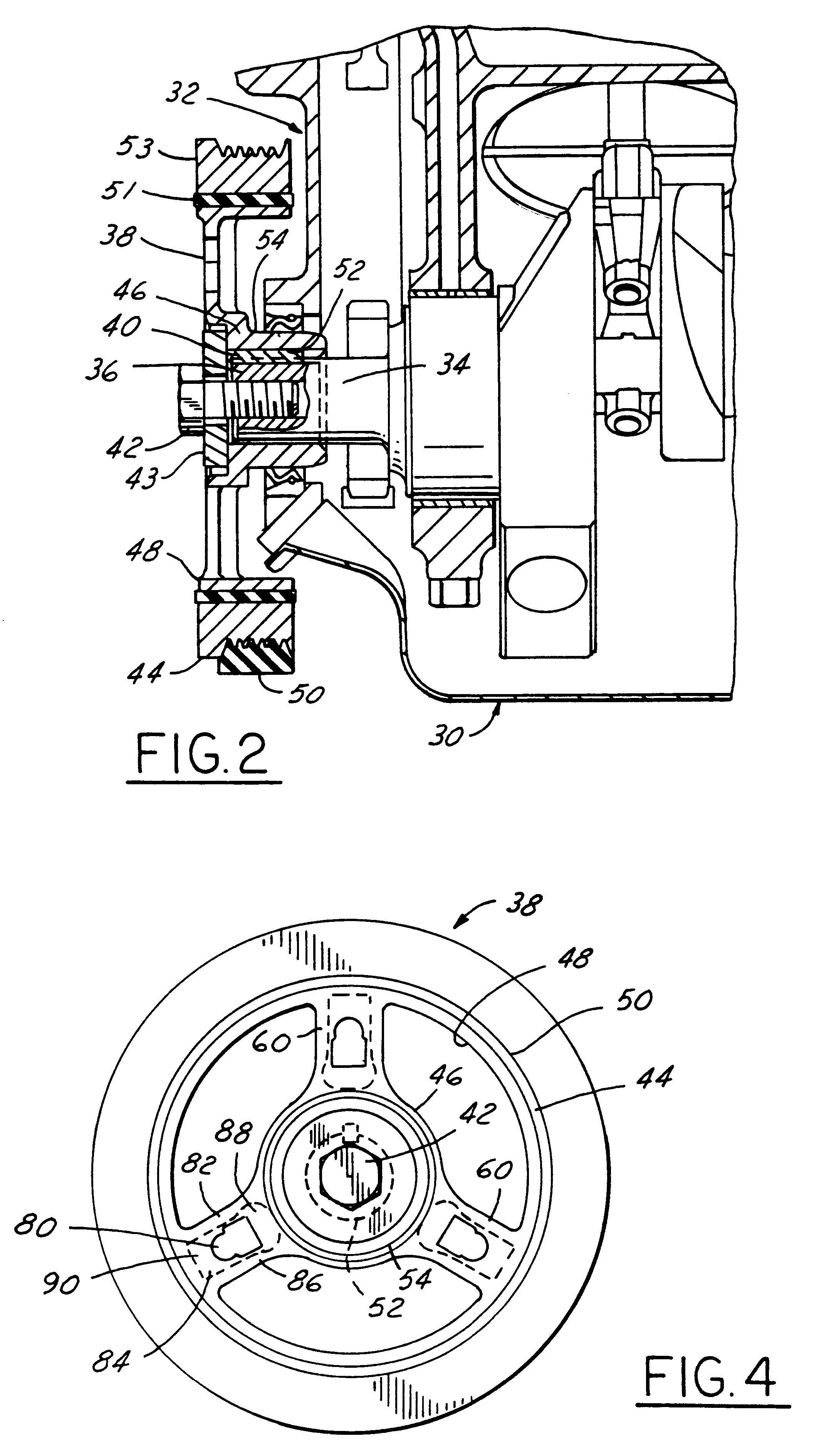

Spoke centered puller tab crankshaft damper hub

InactiveUS6216327B1Easy to disassembleDurable and strongFlywheelsMetal-working hand toolsEngineeringCrankshaft

A crankshaft damper hub (10) for attachment to an engine crankshaft (34) has an outer rim (44) and a center portion (46). The center portion (46) has a passageway (56) formed therethrough for receipt of an engine crankshaft (34). A plurality of spokes (60) extend between the outer rim (44) and the center portion (46). An opening (66) is formed in each of the plurality of spokes (60) with a tab (72) formed therein for engagement with a tool to facilitate removal of the hub (10) from the crankshaft (34).

Owner:METALDYNE MACHINING & ASSEMBLY

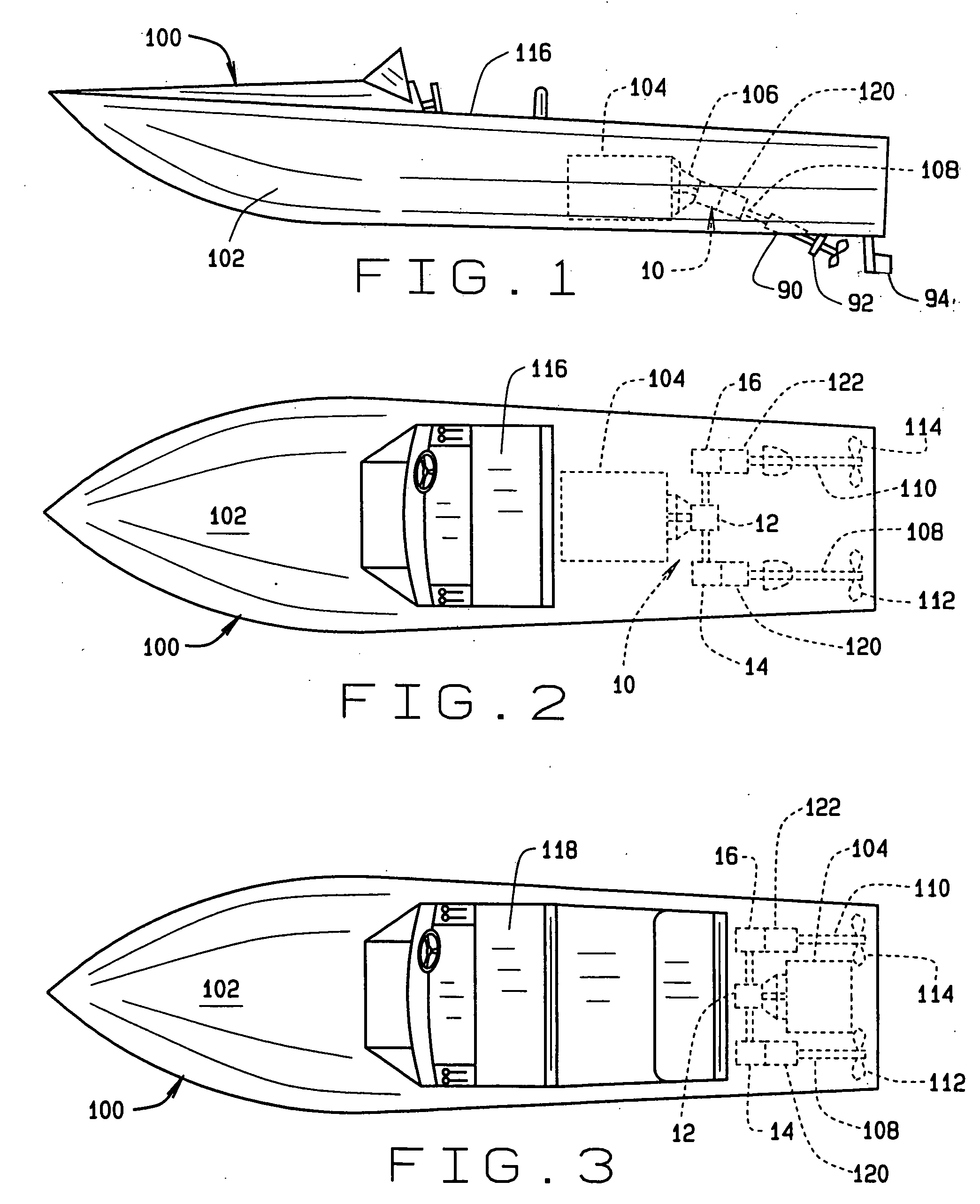

Power boat drive system with multiple gearboxes

InactiveUS20060089062A1Easy to installIncreased torque capacityMechanical apparatusPropulsion power plantsPropellerEngineering

A boat drive system is provided for a power boat which includes an engine having a drive shaft, connected to a pair of propeller shafts. The drive system includes a primary gearbox and opposed outboard gearboxes. The primary gearbox includes a housing and a gear arrangement connected to the engine shaft and the outboard gearboxes, which are connected to the primary gearbox by a transverse shaft, include a housing and a gear arrangement connected to associated propeller shafts. A cooling system is provided including a cooling pad for each gearbox. A support system is provided for each outboard gearbox including a cradle connected to the bearing points on the hull. The engine includes an adapter plate attached to the primary gearbox for movement of the primary gearbox with the engine. In a modified drive system only one outboard gearbox is used in conjunction with a single engine. In another modified drive system a single engine and propeller are used in conjunction with a gearbox having a take-off shaft.

Owner:SUPERIOR GEAR BOX CO

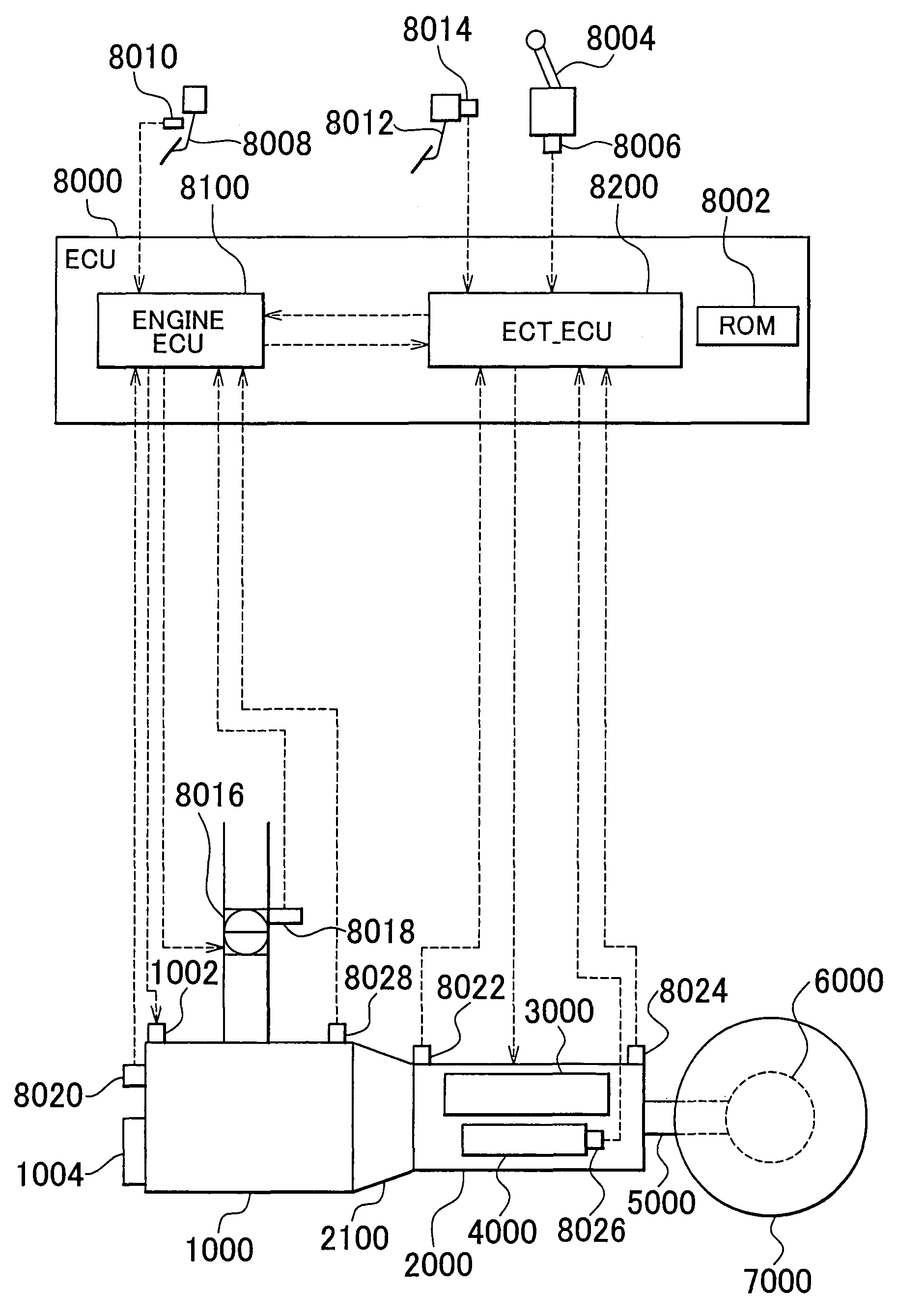

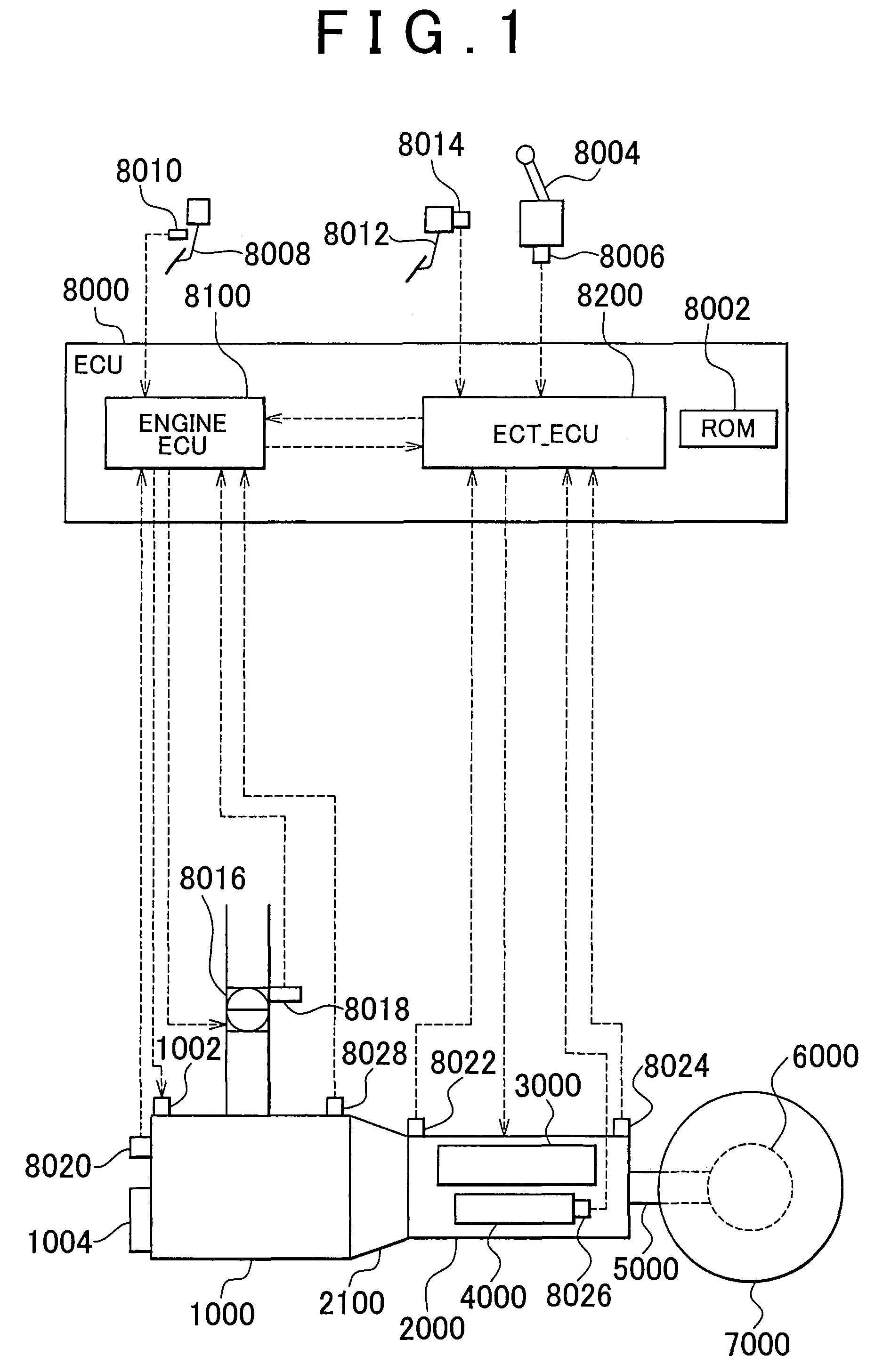

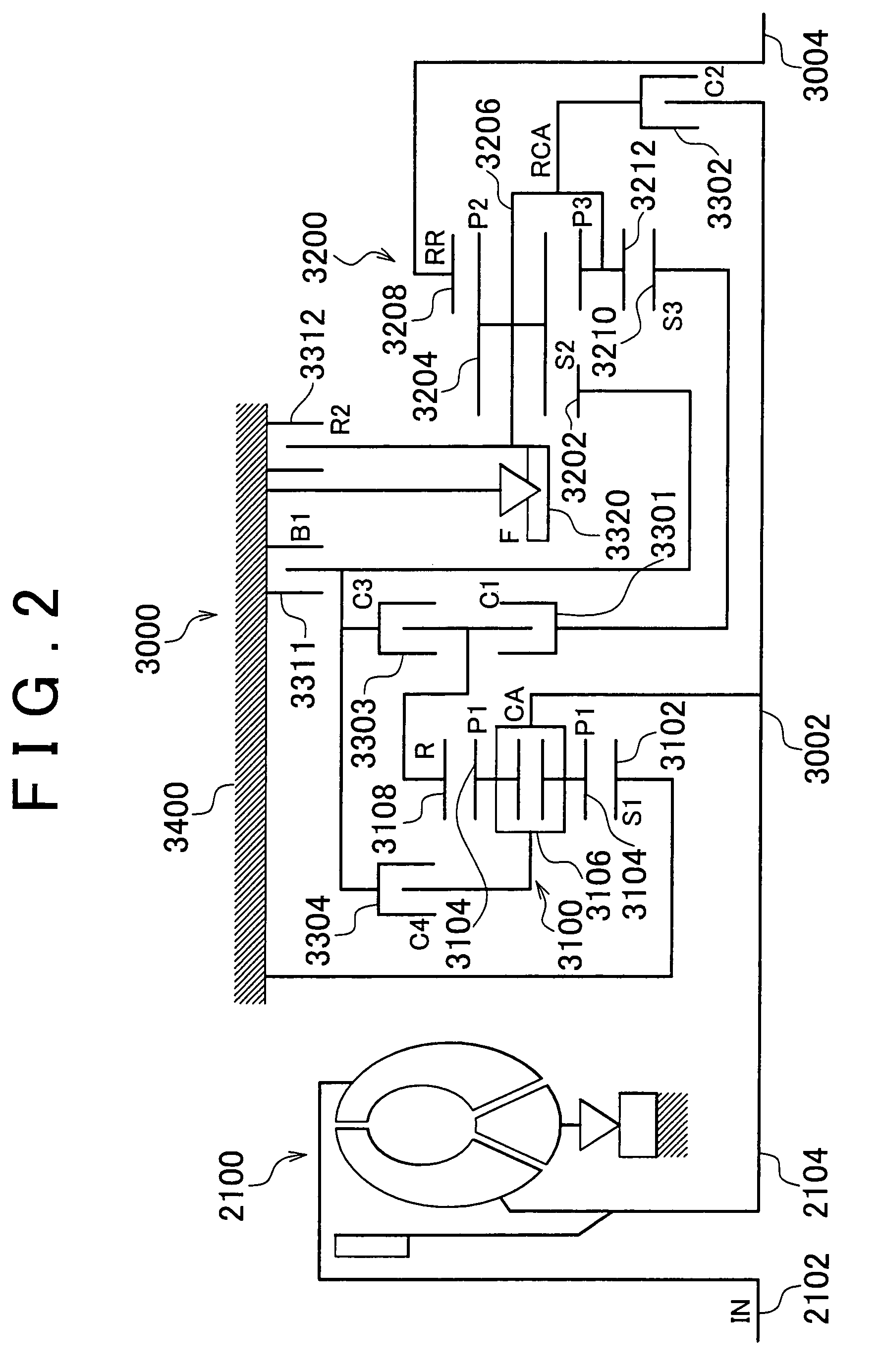

Apparatus for and method of controlling power train, and storage medium storing program for implementing the method

InactiveUS7780570B2Reduce the shock that can occurReduce capacityDigital data processing detailsGearing controlControl powerAutomatic transmission

An ECU executes a program for implementing a method that includes: a step of performing control so that torque capacity Tch of a frictional engagement device that is brought from an engaged state into a disengage state by a downshift operation is gradually reduced to start an inertia phase when a power-on downshift is performed; and a step of stopping the gradual reduction of the torque capacity Tch when the rate of change in an input shaft rotation speed NI of an automatic transmission has reached a desired rate of change ΔN(1). Variation in output torque is kept small, and the shock that can occur at the time of a shift is thus reduced.

Owner:TOYOTA JIDOSHA KK

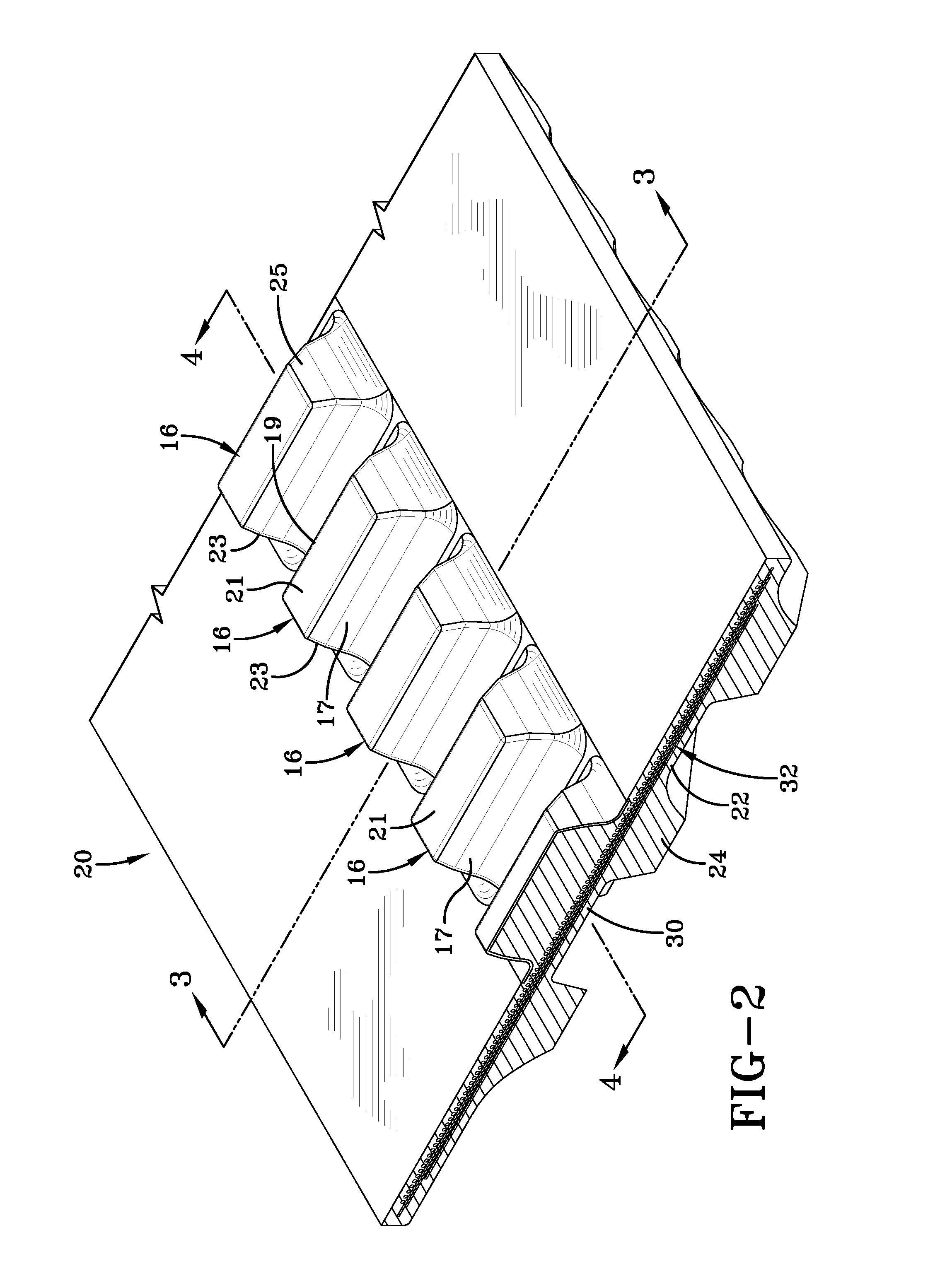

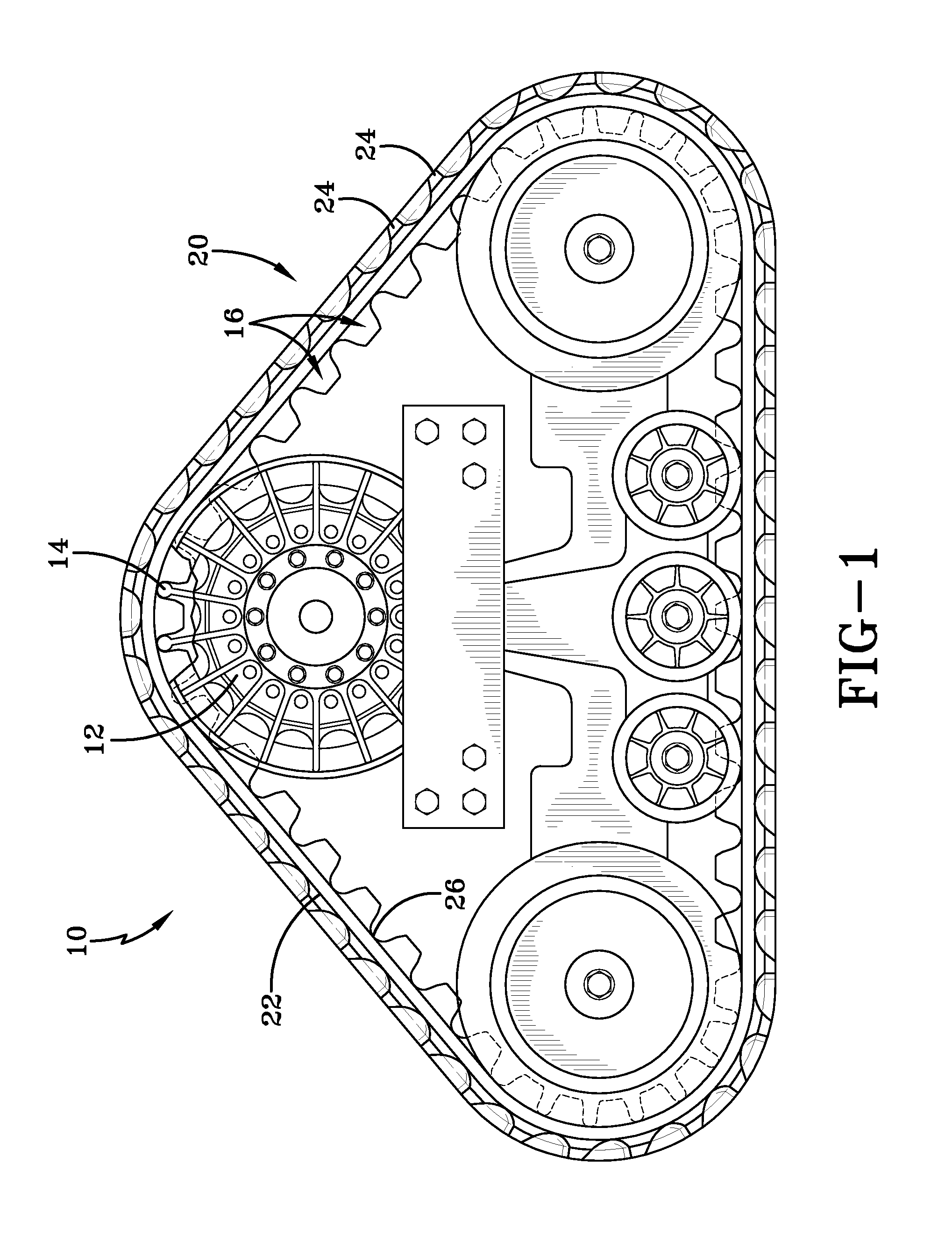

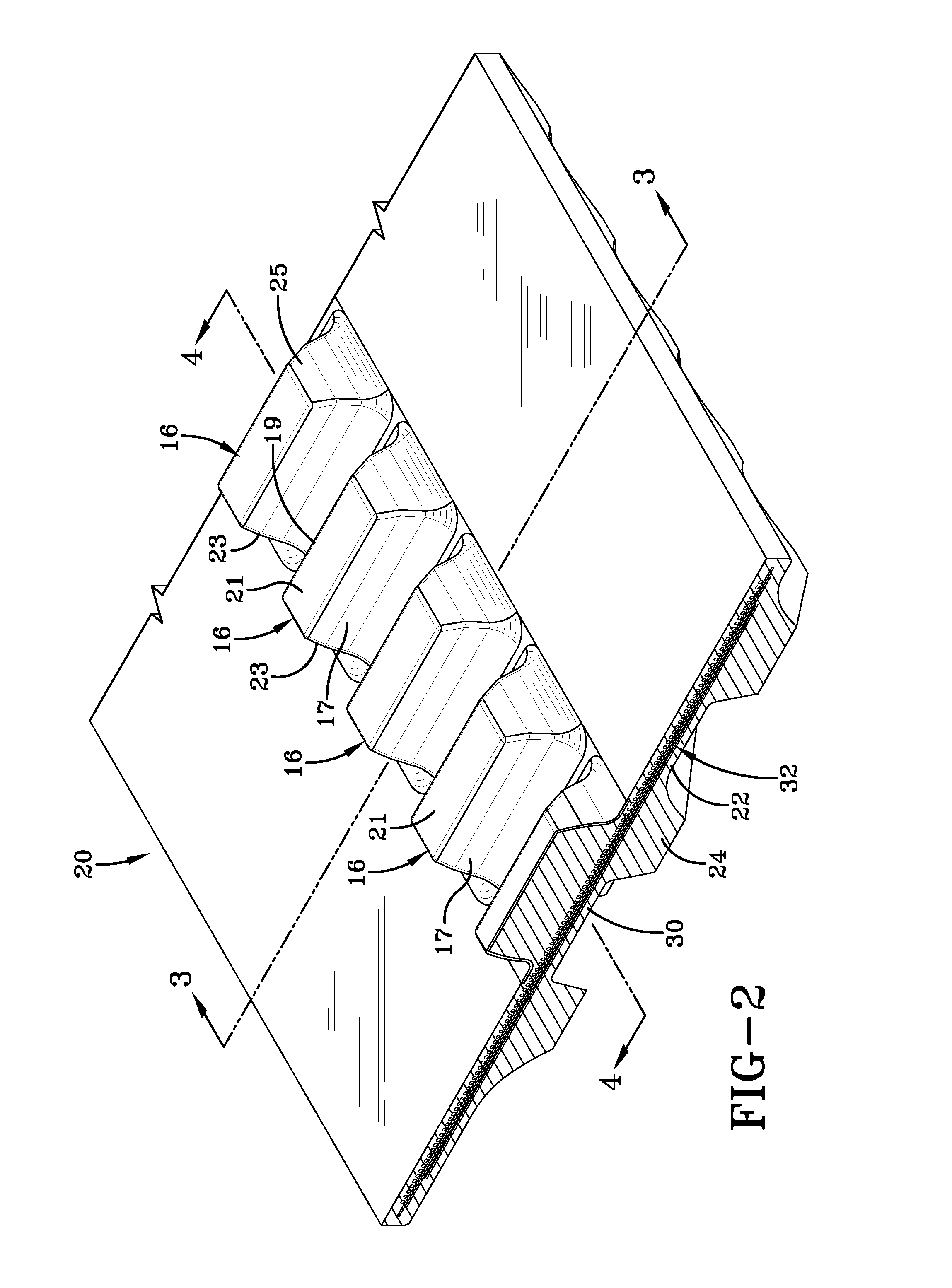

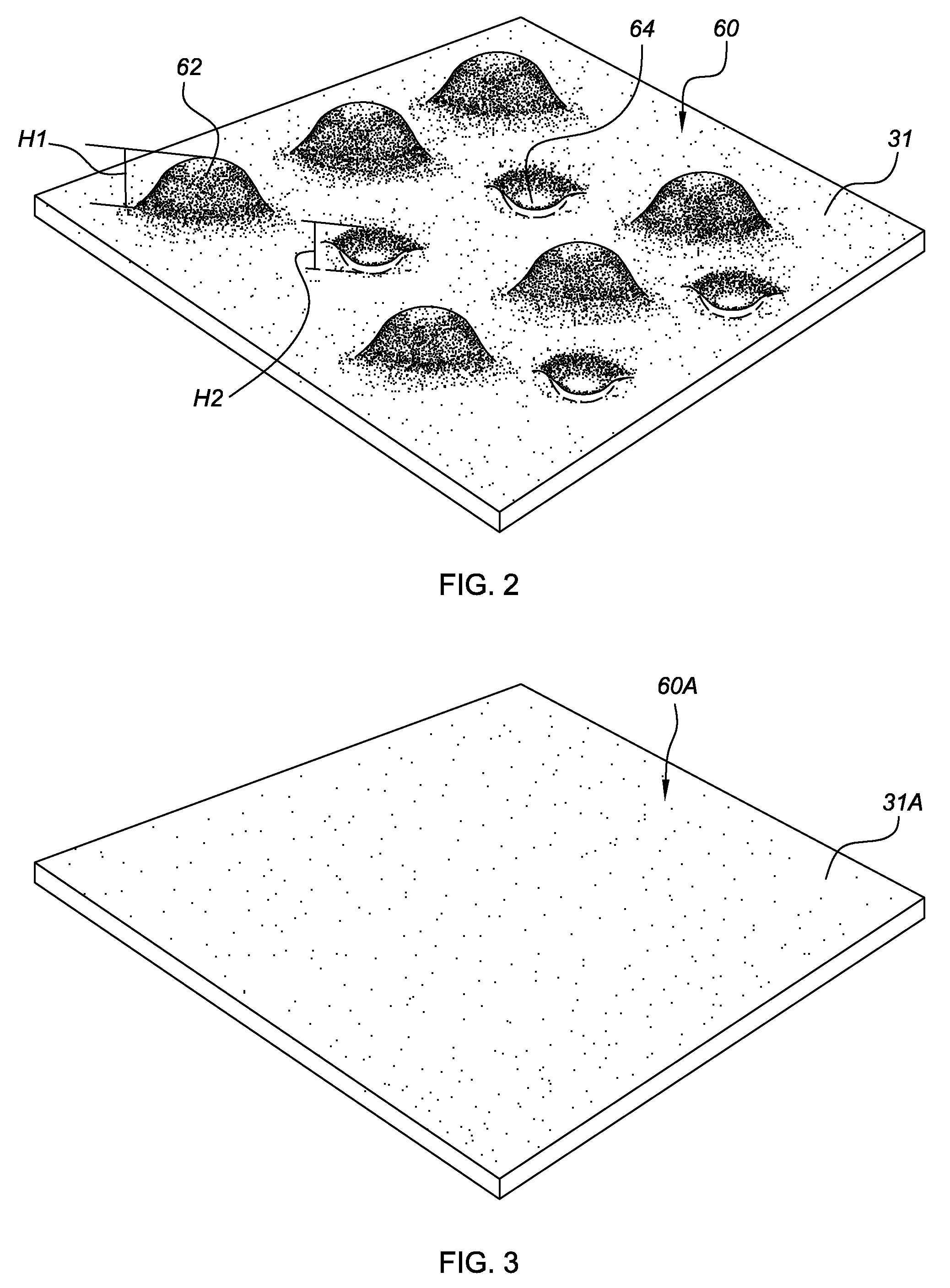

Vehicle track

The tracks of the present invention utilize cut pieces of reinforcement which are associated with each individual drive lug. By using individual pieces the lugs can be easily built up with multiple layers of rubber and reinforcement. The cut pieces can be strategically shaped and placed to optimize their effect to realize improved performance and durability of the track. Incorporation of such inner fabric reinforcement layers adds stiffness to the lugs and thereby increases the torque capacity of the track. Additional layers also provide increased damage resistance after the outer layers of fabric are worn away, and added layers improve wear resistance on the sides of the lugs due to undercarriage misalignment and track-to-wheel contact when the vehicle turns during normal operations.

Owner:LOC PERFORMANCE PROD LLC

Closed-loop torque phase control for shifting automatic transmission gear ratios based on friction element load sensing

ActiveUS8255130B2Improve shift feelIncreased torque capacityDigital data processing detailsGearing controlLoad sensingClosed loop

Owner:FORD GLOBAL TECH LLC

Lubricating oil composition for automatic transmissions

ActiveUS20050124506A1Increased transfer torque capacityProlonged shudder inhibitionOrganic compound preparationCarboxylic acid amides preparationChemical compositionCombustion

An additive compound comprising a non-borated and / or borated reaction product, in which the reaction product is obtained by reacting a linear or branched, saturated or unsaturated monovalent aliphatic acid having 8 to 22 carbon atoms, urea, and polyalkylenepolyamine, when employed in a lubricating oil composition is favorably employable as an automatic transmission fluid of internal combustion engines.

Owner:CHEVRONTEXACO JAPAN

Vehicle track

ActiveUS8567876B2Easy to assembleImproved performance and durabilityV-beltsDriving beltsWear resistanceMultiple layer

The tracks of the present invention utilize cut pieces of reinforcement which are associated with each individual drive lug. By using individual pieces the lugs can be easily built up with multiple layers of rubber and reinforcement. The cut pieces can be strategically shaped and placed to optimize their effect to realize improved performance and durability of the track. Incorporation of such inner fabric reinforcement layers adds stiffness to the lugs and thereby increases the torque capacity of the track. Additional layers also provide increased damage resistance after the outer layers of fabric are worn away, and added layers improve wear resistance on the sides of the lugs due to undercarriage misalignment and track-to-wheel contact when the vehicle turns during normal operations.

Owner:LOC PERFORMANCE PROD LLC

Eight speed transmission with planetary and layshaft gearing

InactiveUS7857726B2Low spin lossesIncreased torque capacityToothed gearingsTransmission elementsForward speedHigh torque

A transmission is provided that utilizes three planetary gear sets and three layshaft gear sets, as well as four rotating-type clutches and one brake that are engagable in different combinations to provide eight forward speed ratios between an input member and an output member of the transmission. By combining features of a layshaft transmission with those of a planetary transmission, the low spin losses and packaging convenience typical of a layshaft transmission are available while still achieving the high torque capacity typical of a planetary transmission.

Owner:GM GLOBAL TECH OPERATIONS LLC

Wheel hub drive for industrial trucks

ActiveUS20070267234A1Increased torque capacityReduce expenditureBraking element arrangementsSteering linkagesRotational axisCoupling

A wheel hub drive with drive motor and drive gear system for industrial trucks, with the following features: driving and output axis of the drive gear system, rotation axis of the wheel and driving axis of the drive motor are disposed coaxially; the drive gear system is a single step or multi step planetary stepping gear system or a two or more step planetary coupler mechanism gear system, two horizontally spaced wheel bearings are located inside the drive gear system, wherein, a first wheel bearing is disposed between a first bearing portion, connected with the wheel hub, and a frame-fixed planet carrier, and a second wheel bearing is disposed between the first bearing portion and a frame-fixed second bearing portion or the frame-fixed planet carrier.

Owner:JUNGHEINRICH AG

Lubricant compositions

InactiveUS6828286B2Increased transfer torque capacityWell-balanced capacityOrganic compound preparationLiquid carbonaceous fuelsHydrogenBase oil

Owner:NIPPON MITSUBISHI OIL CORP

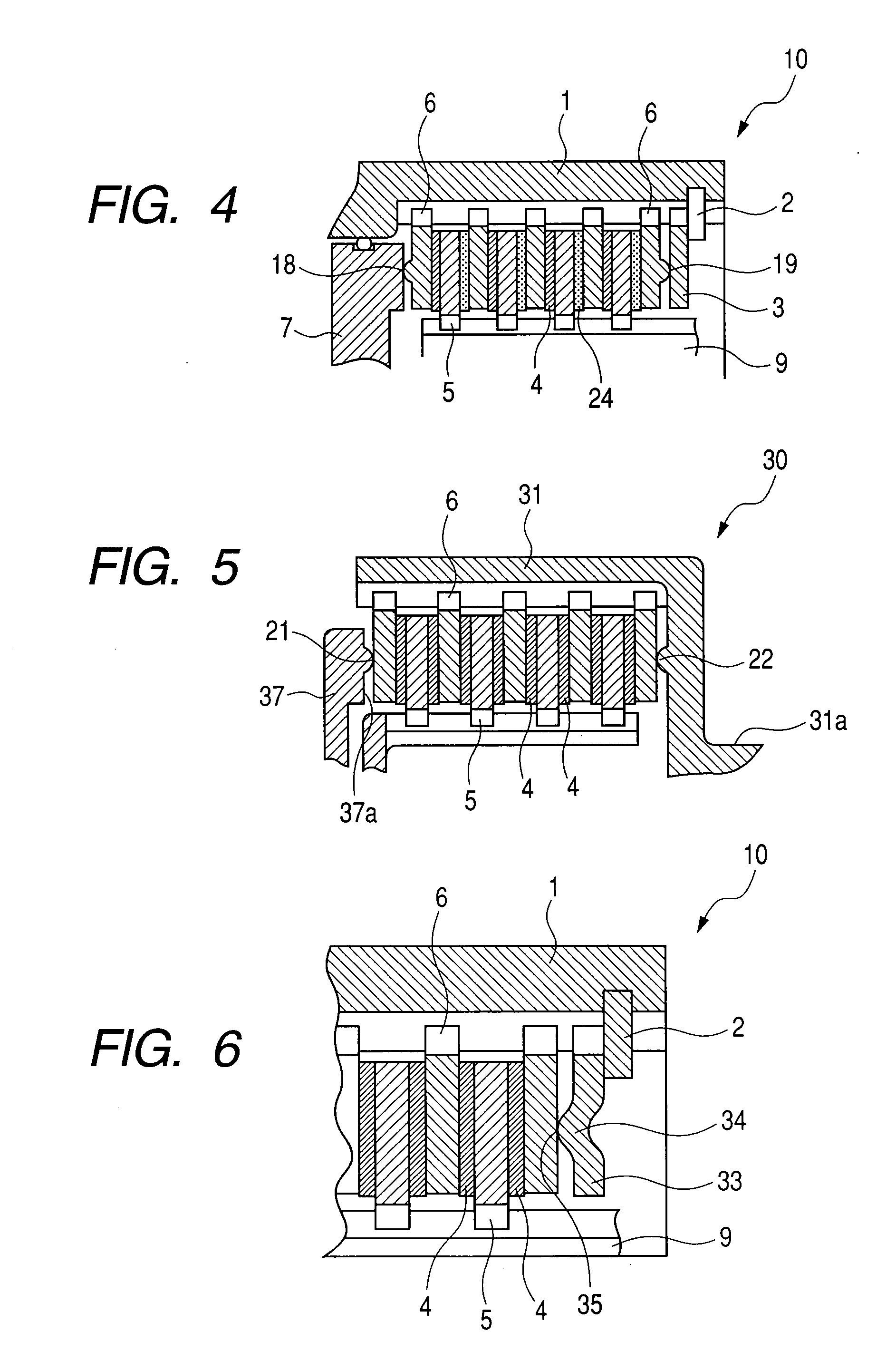

Planar coupling assembly for an automatic transmission

InactiveUS20060249345A1Improve freewheeling abilityImprove retentionToothed gearingsFriction clutchesAutomatic transmissionCoupling

Owner:MEANS IND INC

Apparatus with active material surface in contact with rheological fluid and method of enhancing performance thereof

InactiveUS8056687B2Increased torque capacityOverheating of the stator and/or rotor is avoidedSpringsNon-rotating vibration suppressionEngineeringSurface geometry

An apparatus is provided having an active material forming a surface thereof in contact with a rheological fluid. The active material is controllable to vary a surface geometry thereof between a rough or nonsmooth surface geometry to increase drag, and achieve an increase in stress transmitted through the fluid, when a field is applied, while allowing a smooth surface geometry and an associated reduction in stress transmitted through the fluid when the field is removed. A method of enhancing performance of an apparatus that includes a rheological fluid is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

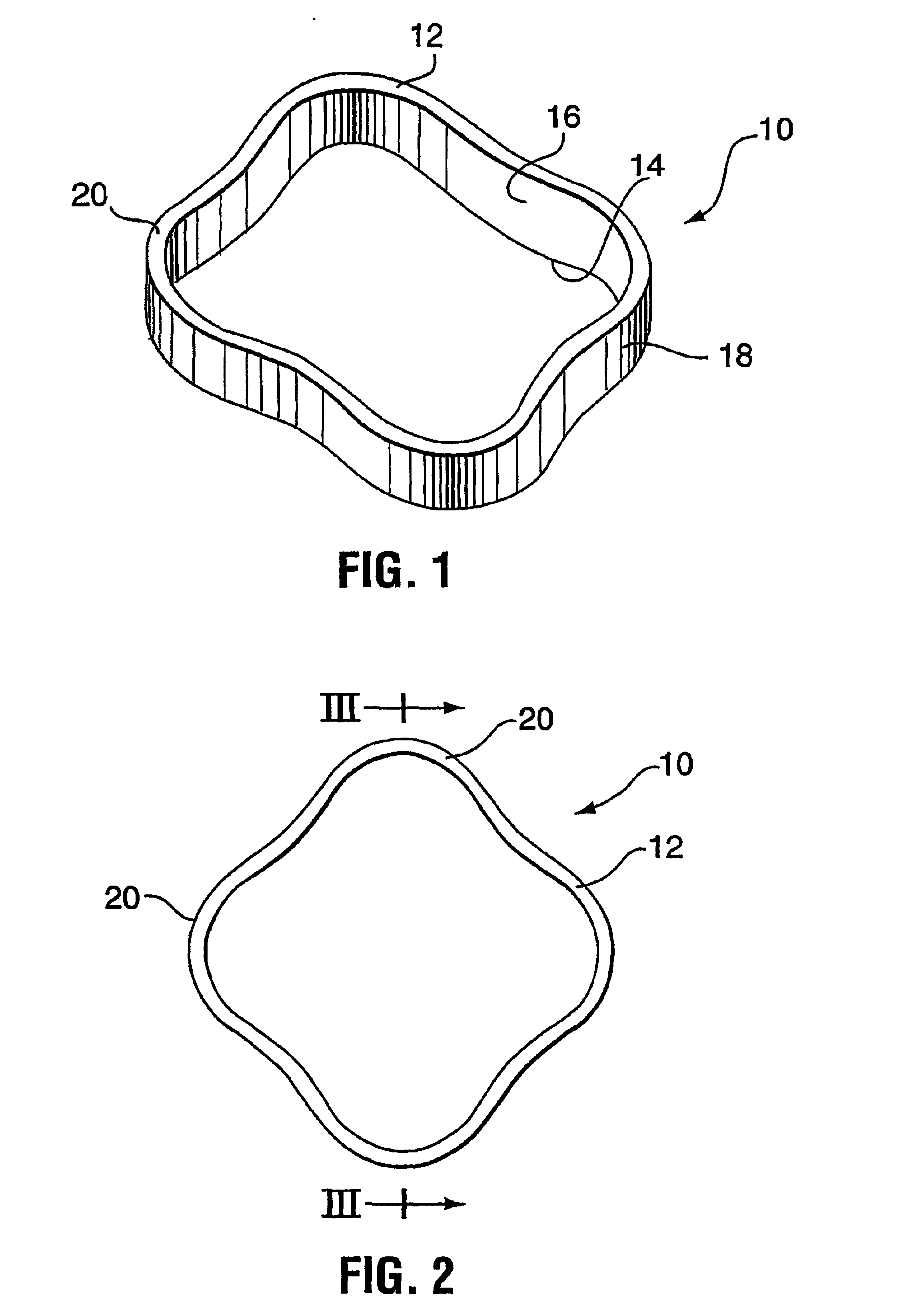

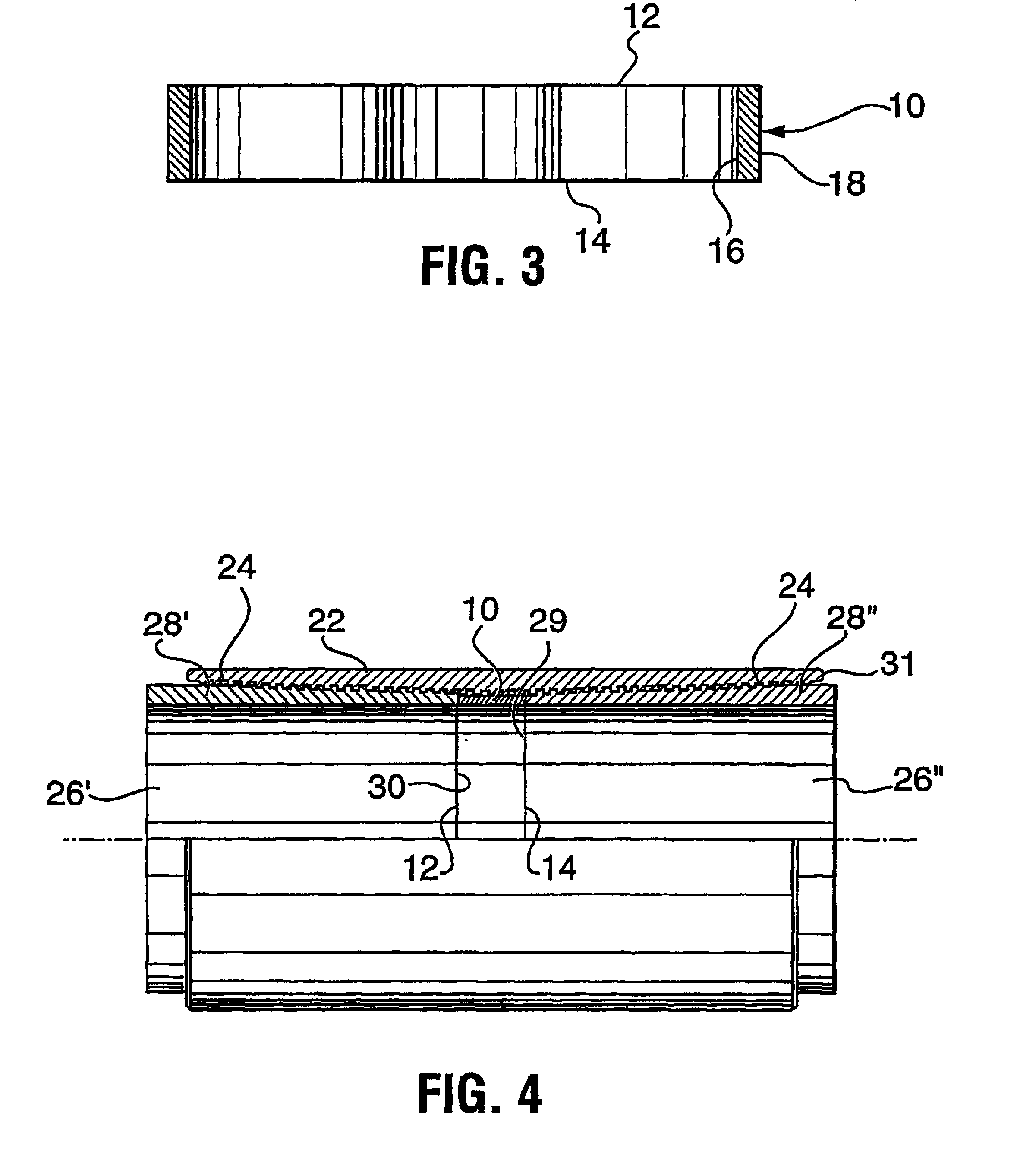

Tubular connection floating shoulder ring

InactiveUS6899356B2Improve abilitiesEnhancing connection torque capacityPipe elementsHose connectionsShaft collarBiomedical engineering

A shoulder ring (10) for installing in the J-space between the installed pin ends within a coupling collar is taught having a body with a central opening therethrough, a first end face (12) on the body, an opposite end face (14) on the body, an inner surface (16) adjacent the central opening and extending between the first end face and the opposite end face and an outer surface (18) extending between the first end face and the opposite end face, the body having a substantially uniform cross sectional shape between the first end face, the opposite end face, the inner surface and the outer surface and the ring shaped such that its radius to the outer surface varies around the outer surface circumference to form a plurality of lobes (12).

Owner:NABORS DRILLING TECH USA INC

Wet-type multi-plate friction engaging apparatus

ActiveUS20080217133A1Improve abilitiesAvoid offsetFluid actuated clutchesFriction clutchesEngineeringPiston

The present invention provides a wet-type multi-plate friction engaging apparatus comprising a clutch portion including internally toothed plates and a piston adapted to apply an urging force for engaging the internally toothed plates and wherein load acting portions acting on the clutch portion are arranged on both sides of the clutch portion, and a contact area of the load acting portion through which the load acting portion is contacted with the clutch portion is located in a predetermined range between about 20% of a radial width of a friction engaging portion from a central position of the friction engaging portion in an outer diameter direction and about 20% of the radial width of the friction engaging portion in an inner diameter direction, and a radial width of the contact area is smaller than about 10% of the radial width of the friction engaging portion.

Owner:NSK WARNER

Threaded joint for tubes, pipes and the like

InactiveUS9004544B2Increase resistanceEasy to manufactureDrilling rodsFluid pressure sealed jointsCouplingEngineering

A threaded joint comprises a coupling, a first pin, and a second pin, wherein the thread of the first pin has a pitch different from the pitch of the thread of the second pin. The extremities of the pins have slanted contact surfaces of complementary shape that make mutual contact after make-up of the joint. The slanted common plane of contact of both pins has an angle to the plane perpendicular to the longitudinal axis of the joint which is greater than 0°. In an alternative embodiment the contact surfaces of the pins are split into two staggered planes and comprise a seal in-between.

Owner:TENARIS CONNECTIONS

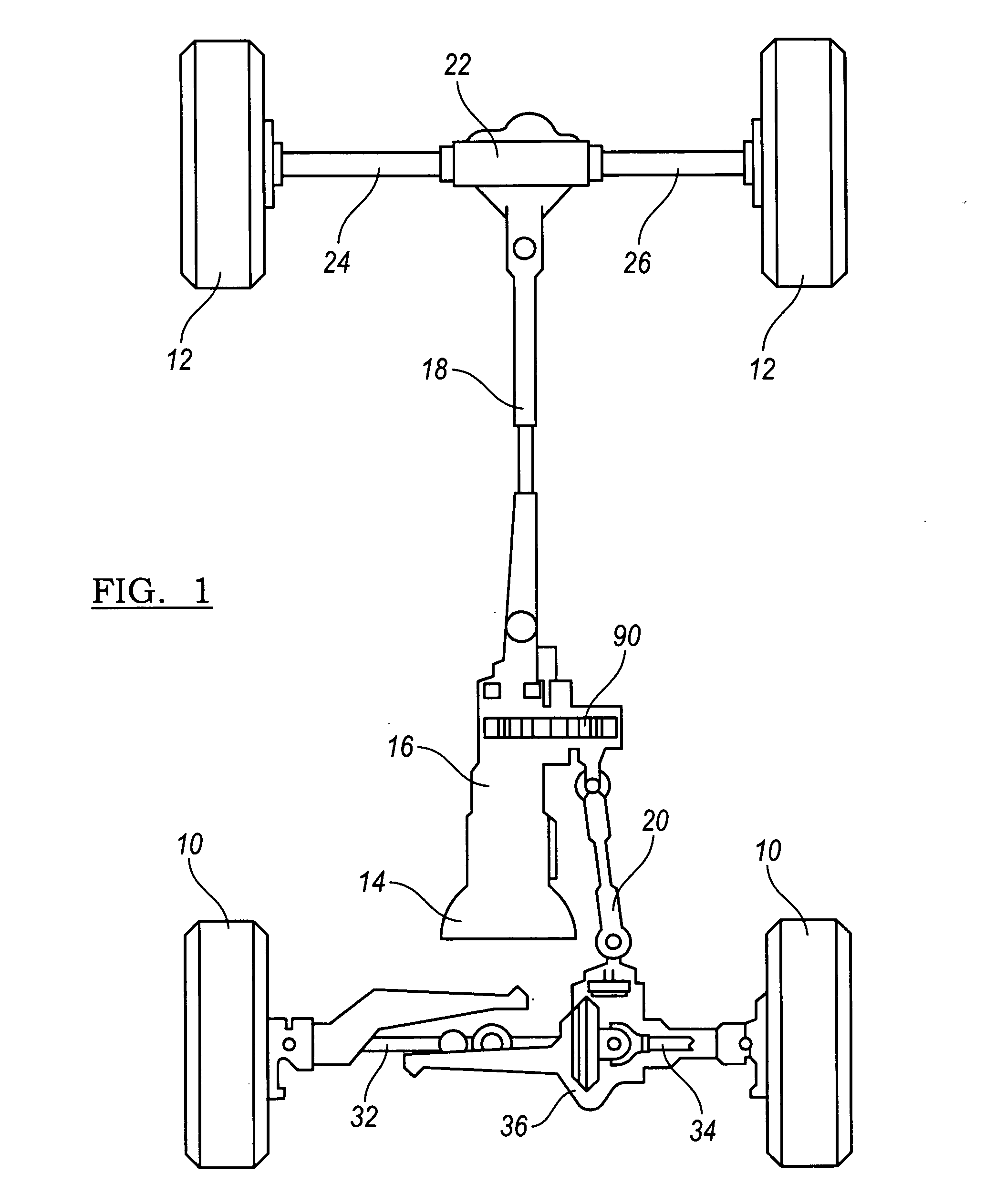

Prevention of inadvertent inertial engagement of a transfer case clutch

InactiveUS20070295548A1Minimal effectIncreased torque capacityClutchesDigital data processing detailsMobile vehicleTransfer case

A method for controlling operation of a transfer case in a motor vehicle driveline that includes by an engine controlled by a throttle having a variable position, and a transmission driveably connected to the engine for producing multiple ratios of the speed of a transmission input relative to the speed of a transmission output. The transfer case transmitting rotating power in response to an electric signal applied to a clutch. The method includes determining that the engine throttle position is less than a first reference throttle position during a period of predetermined length; determining that a speed of the vehicle speed is in a predetermined range; determining that the transmission is operating in a speed ratio greater than a reference speed ratio; determining that the engine throttle position is greater than a first reference throttle position; and increasing the torque capacity of the clutch for a predetermined period.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com