Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3444 results about "Directional Valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Directional control valves are one of the most fundamental parts in hydraulic machinery as well as pneumatic machinery. They allow fluid flow into different paths from one or more sources. They usually consist of a spool inside a cylinder which is mechanically or electrically controlled.

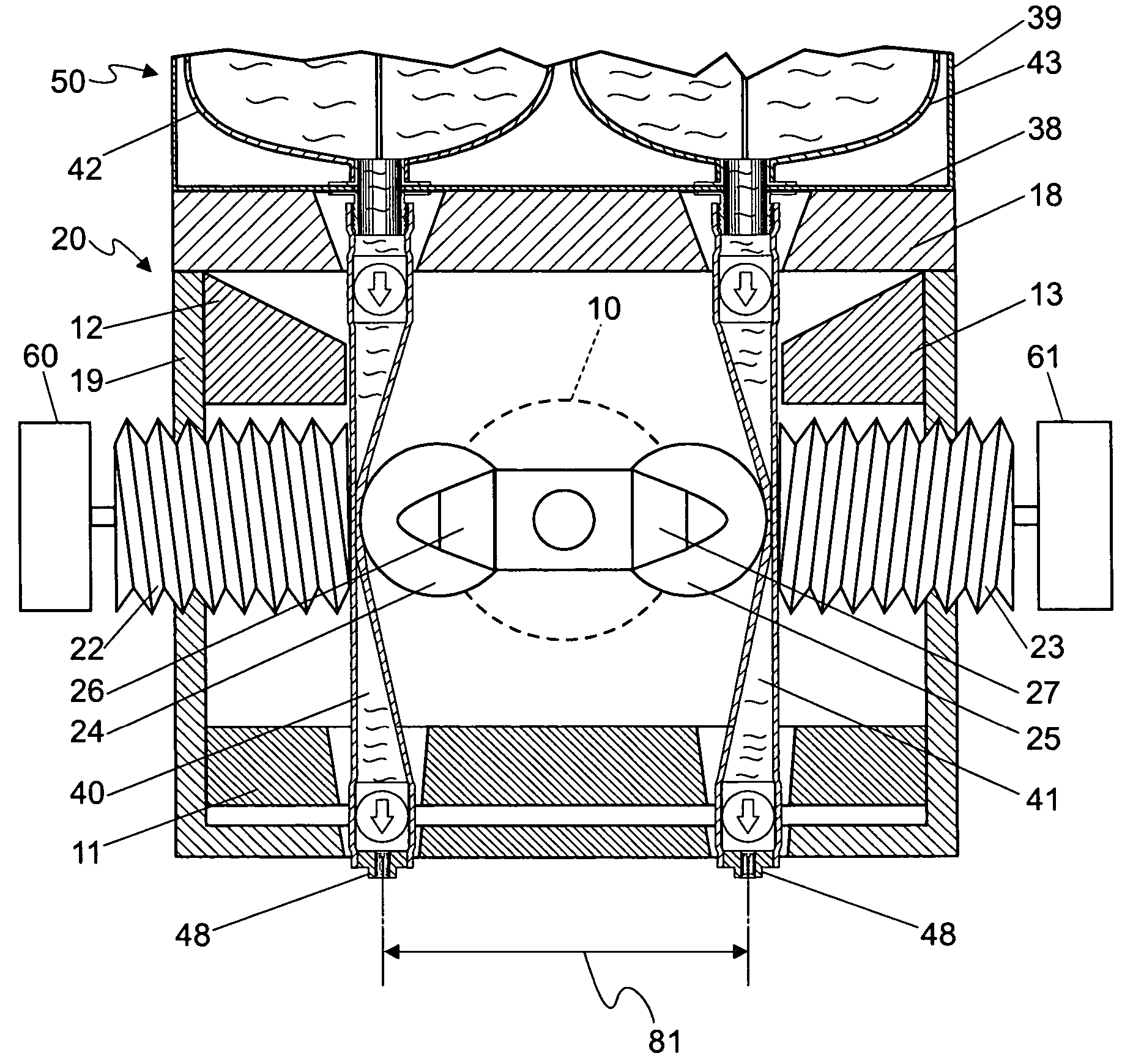

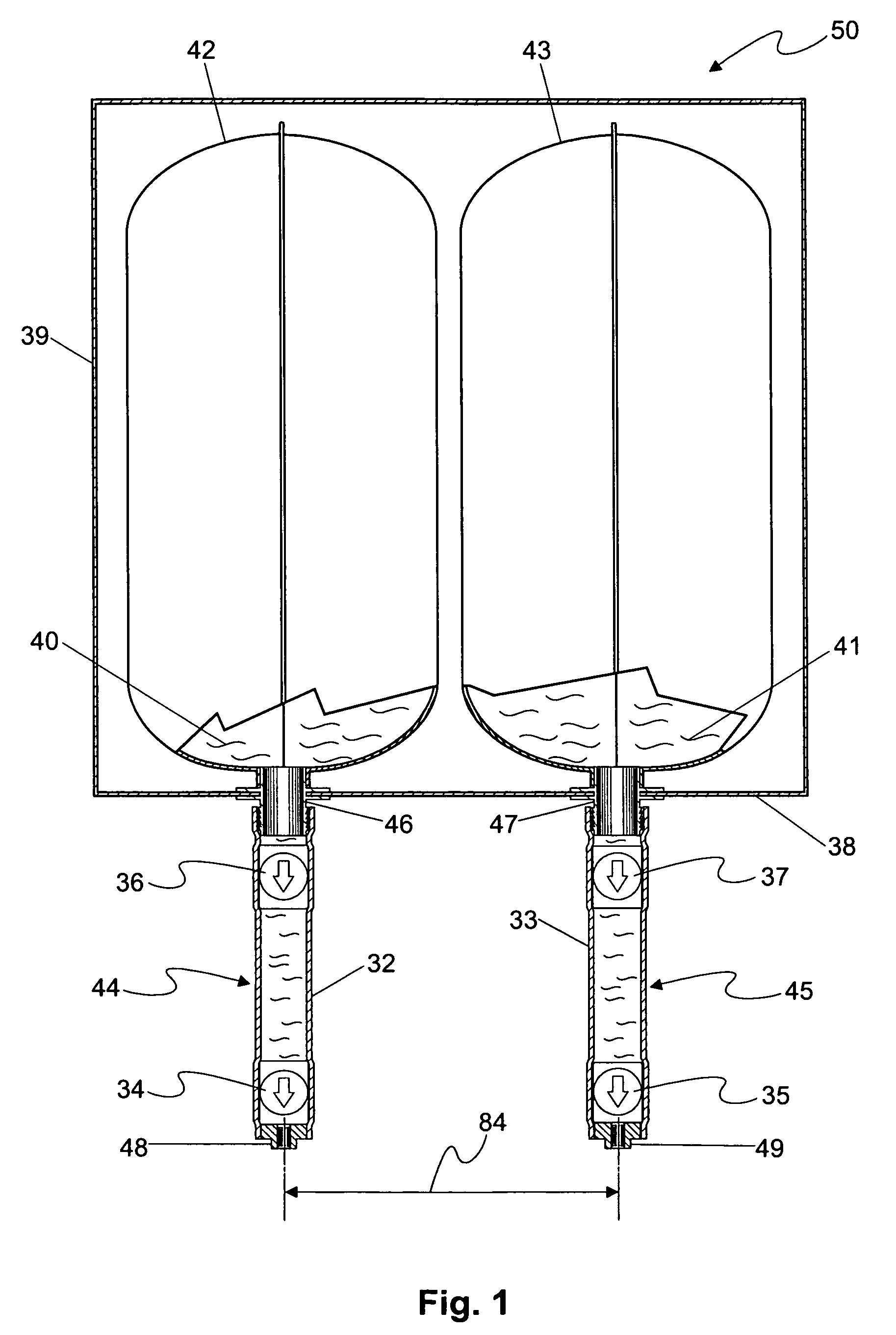

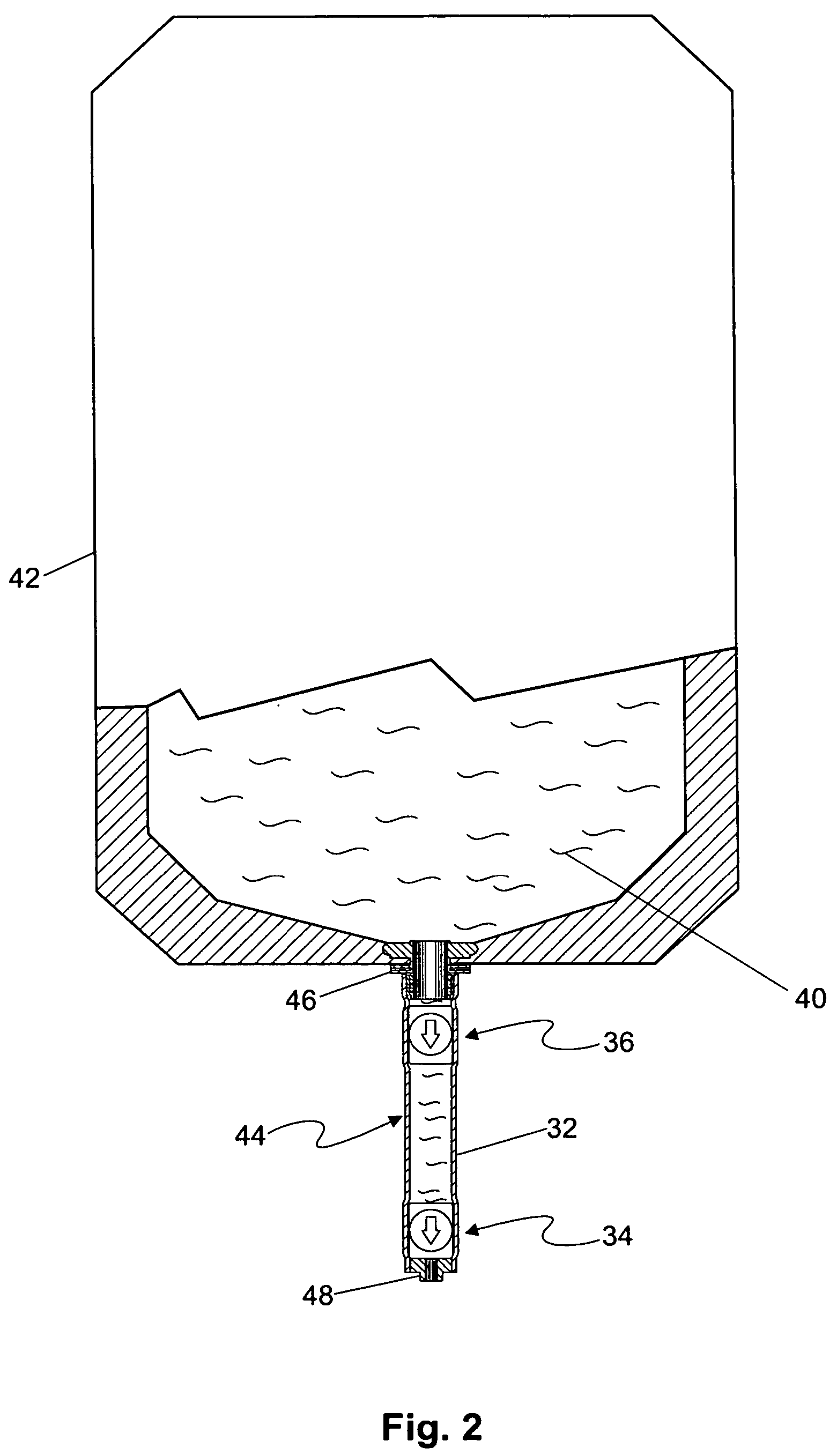

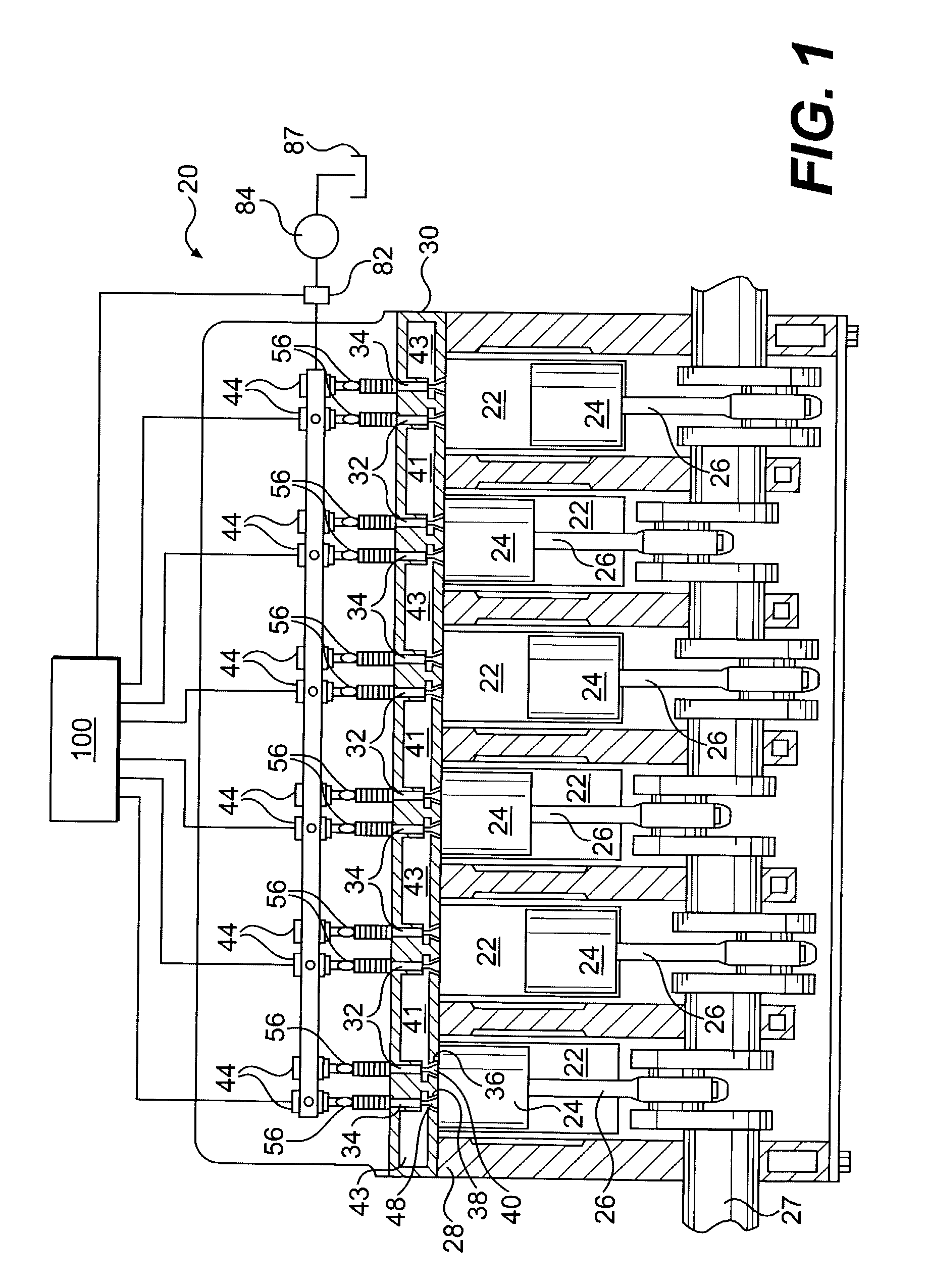

High frequency pressure swing adsorption

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

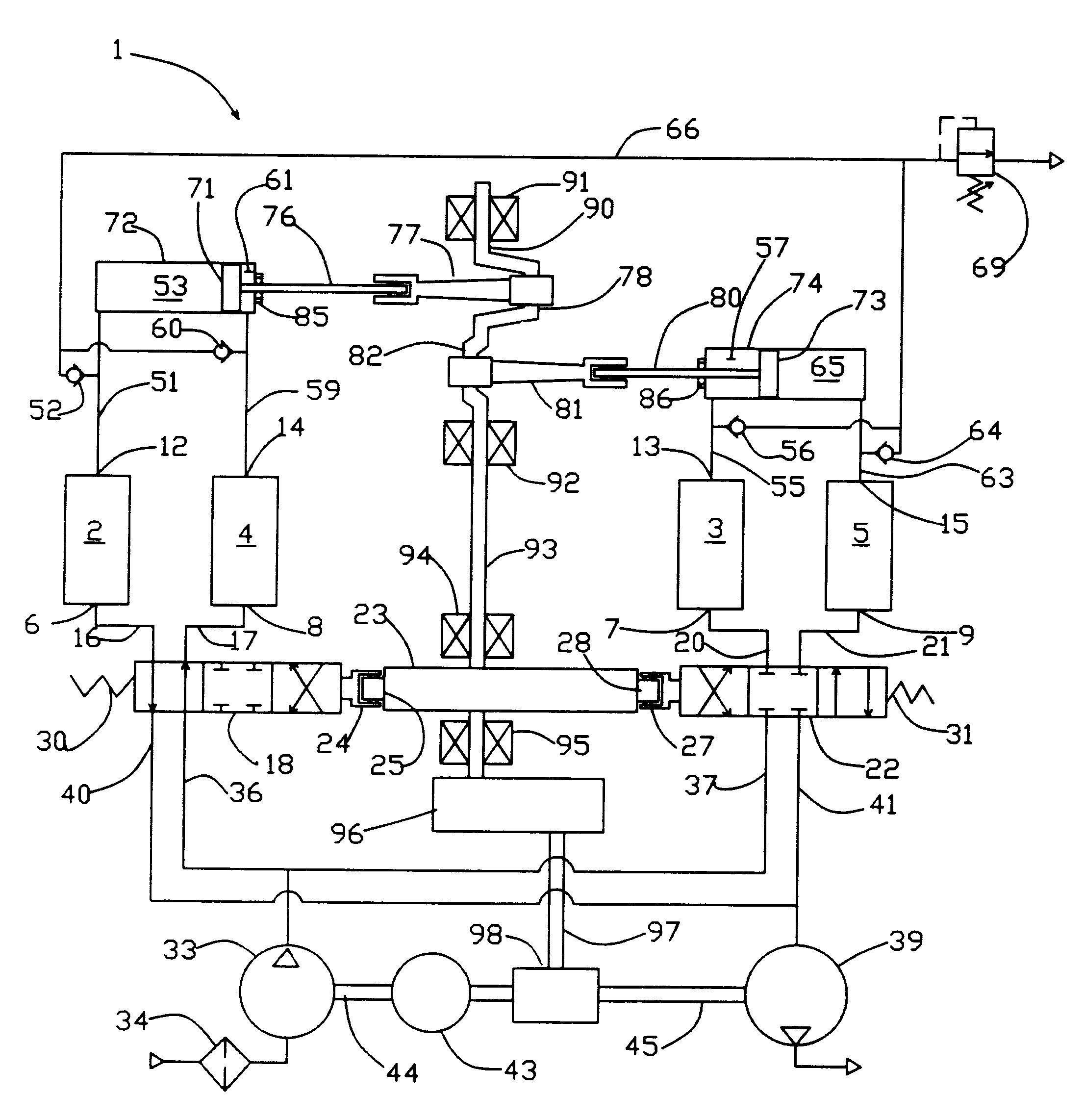

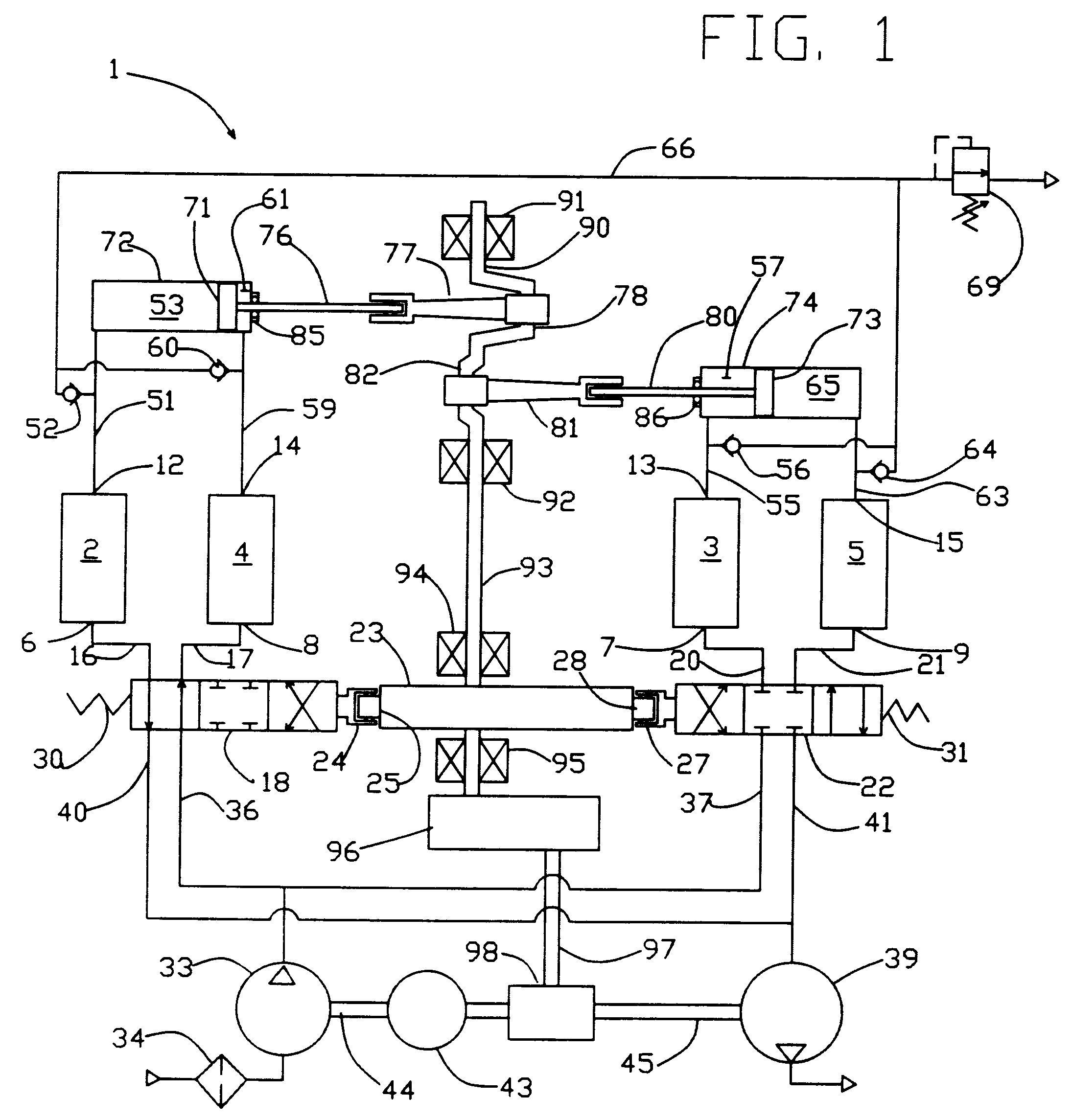

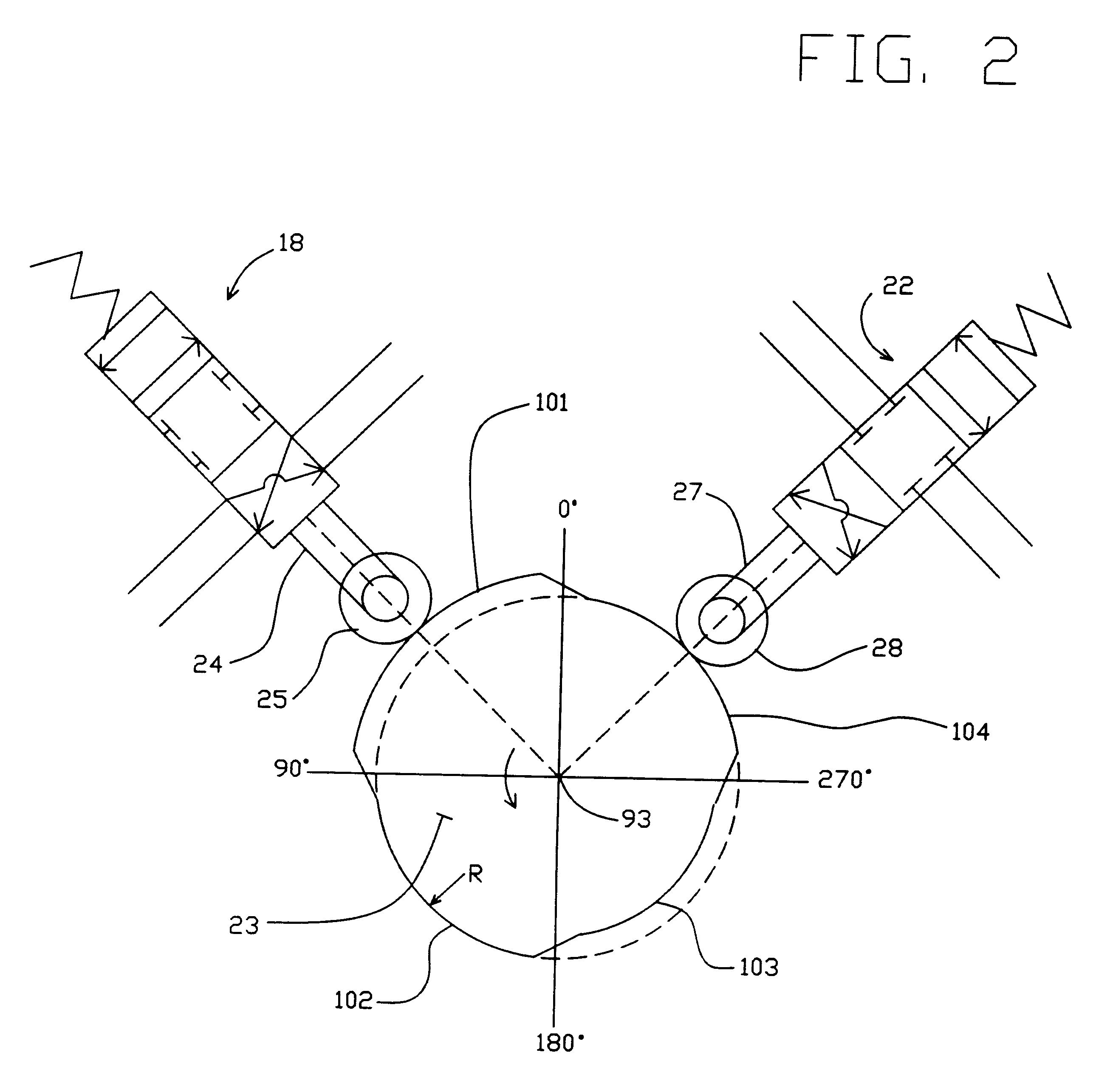

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

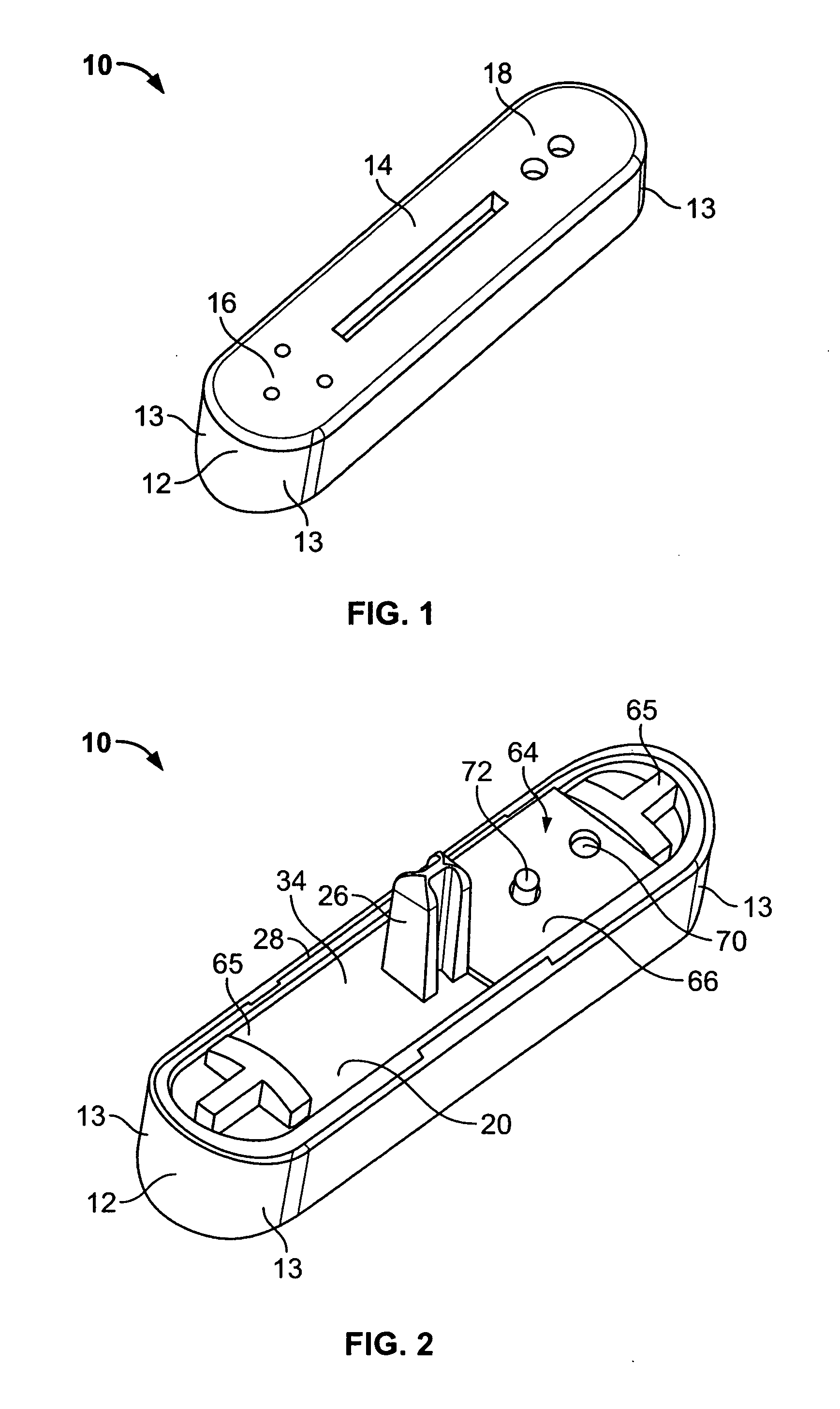

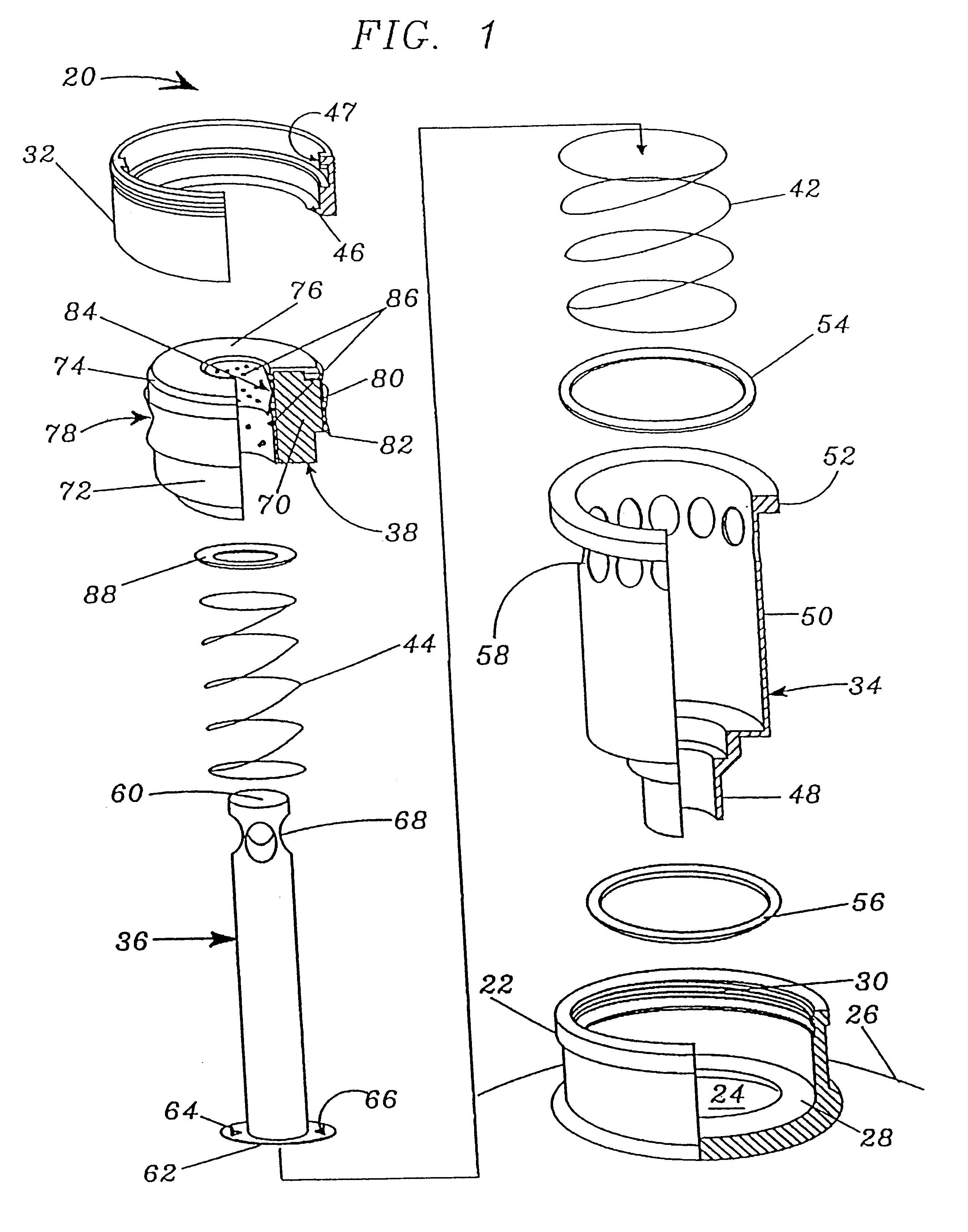

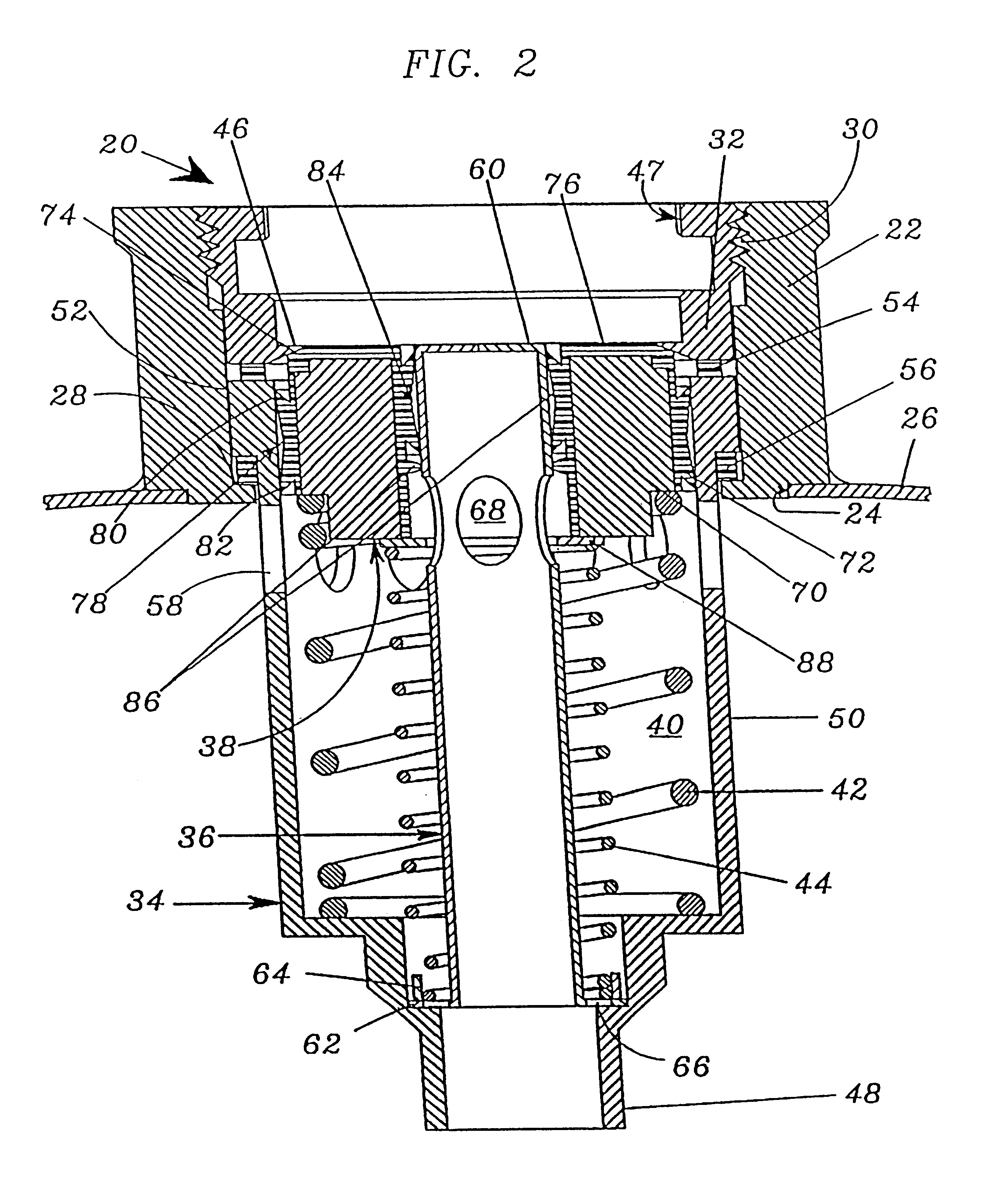

Artificial heart valve attachment apparatus and methods

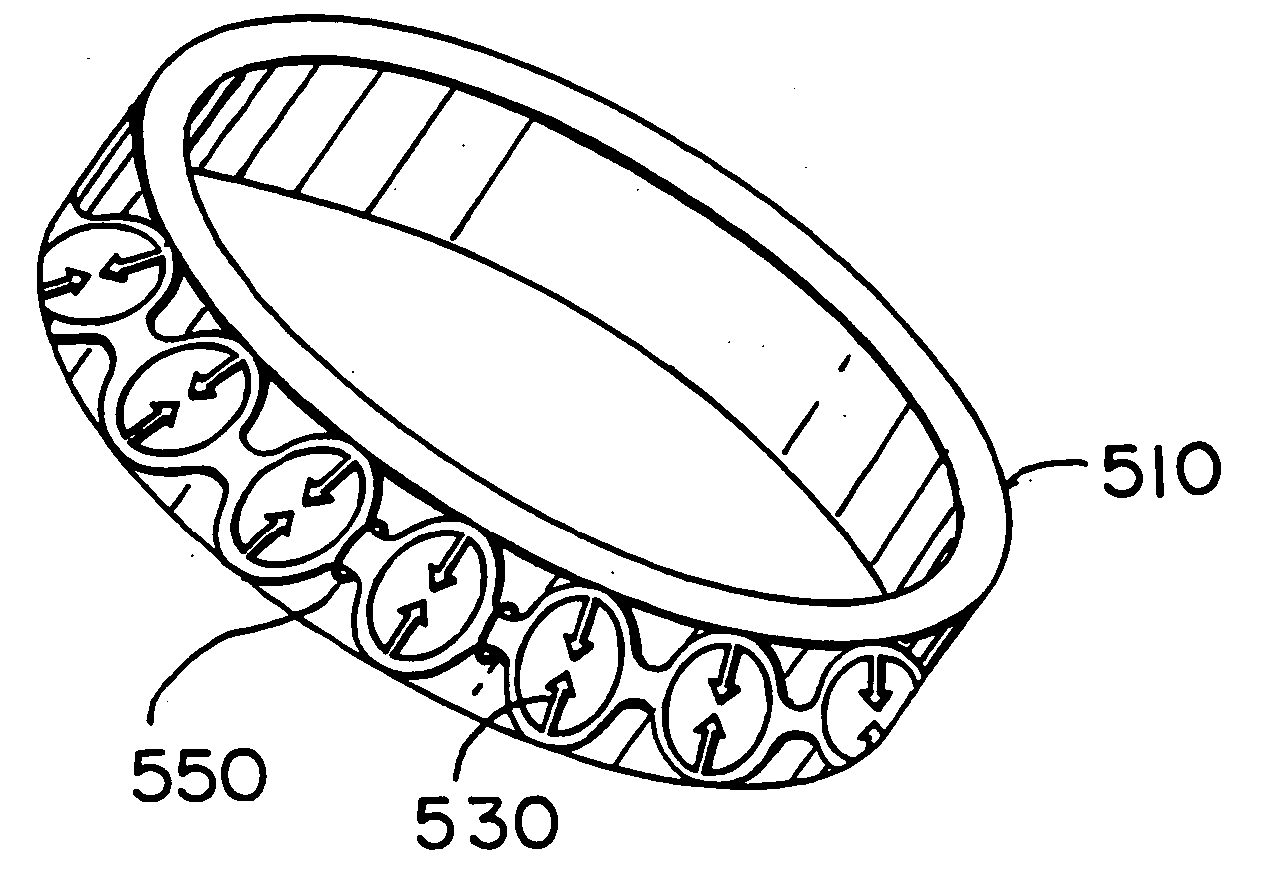

InactiveUS20060136054A1Eliminate needReduce attachment timeHeart valvesBlood vesselsBiomedical engineeringArtificial heart valve

Heart valve attachment apparatus and methods that significantly reduce attachment times are provided. The apparatus and methods utilize a connector band to form an interface between a uni-directional valve and a tissue annulus. The connector band is secured to the tissue annulus by retention fingers.

Owner:ST JUDE MEDICAL ATG

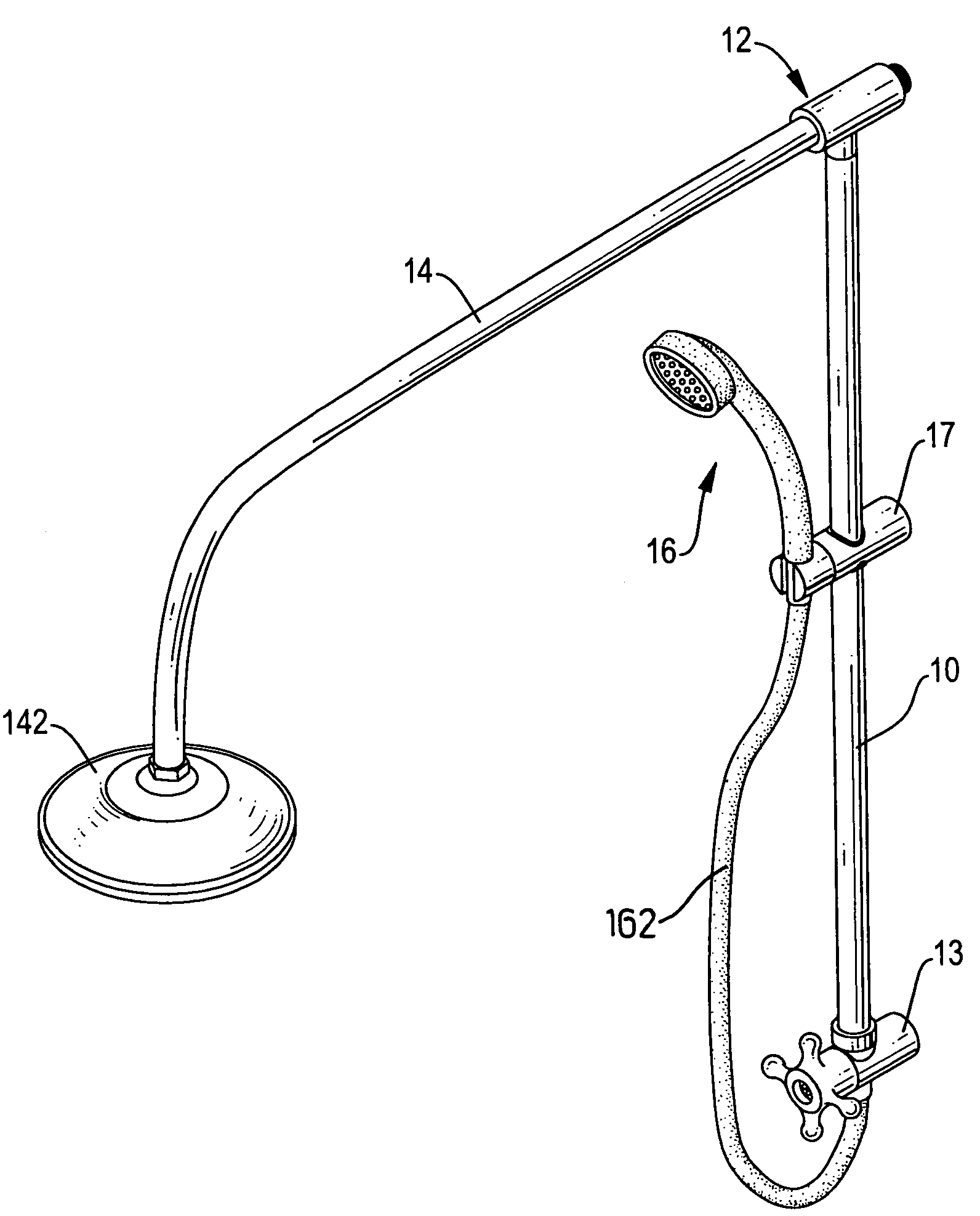

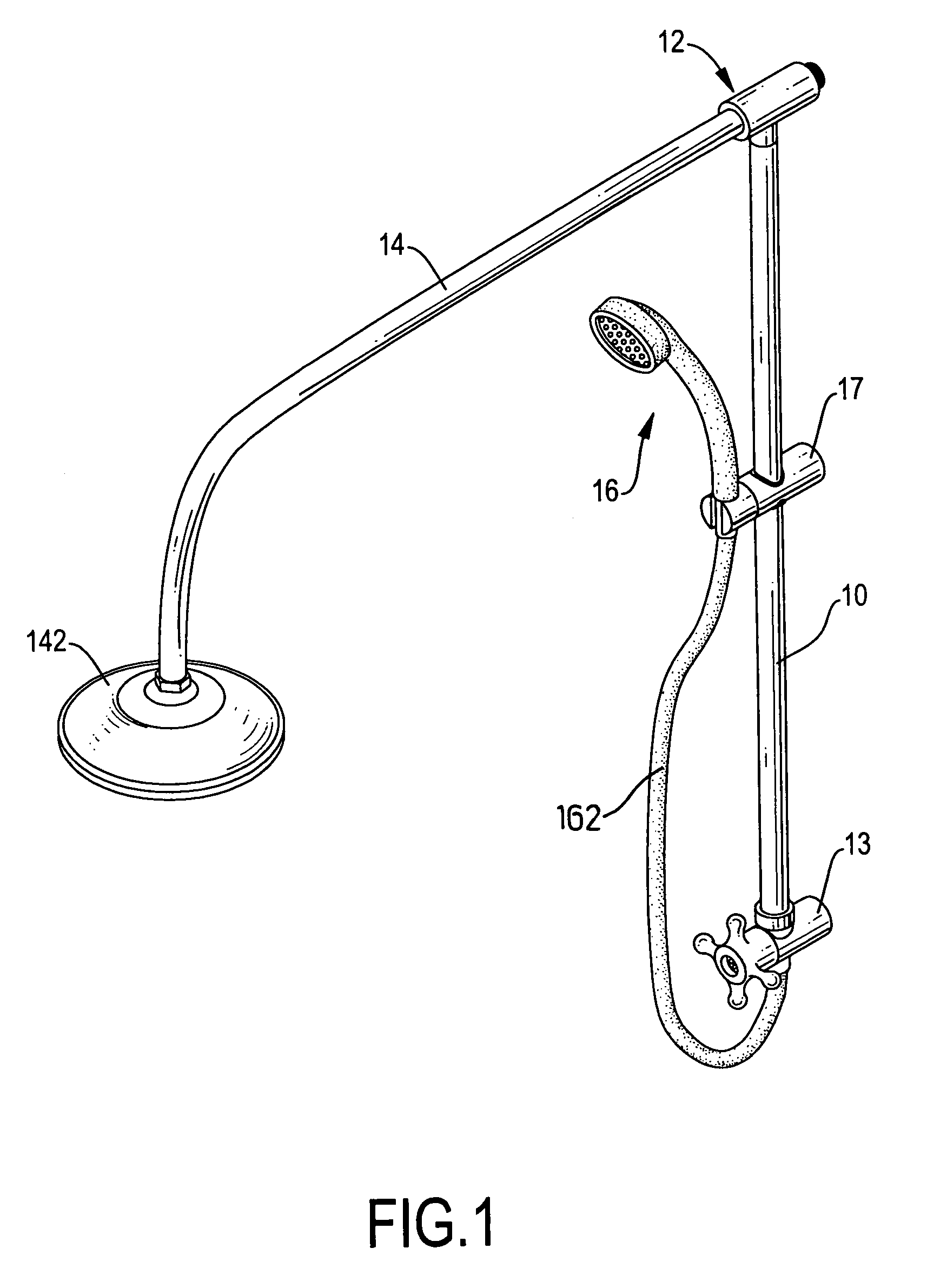

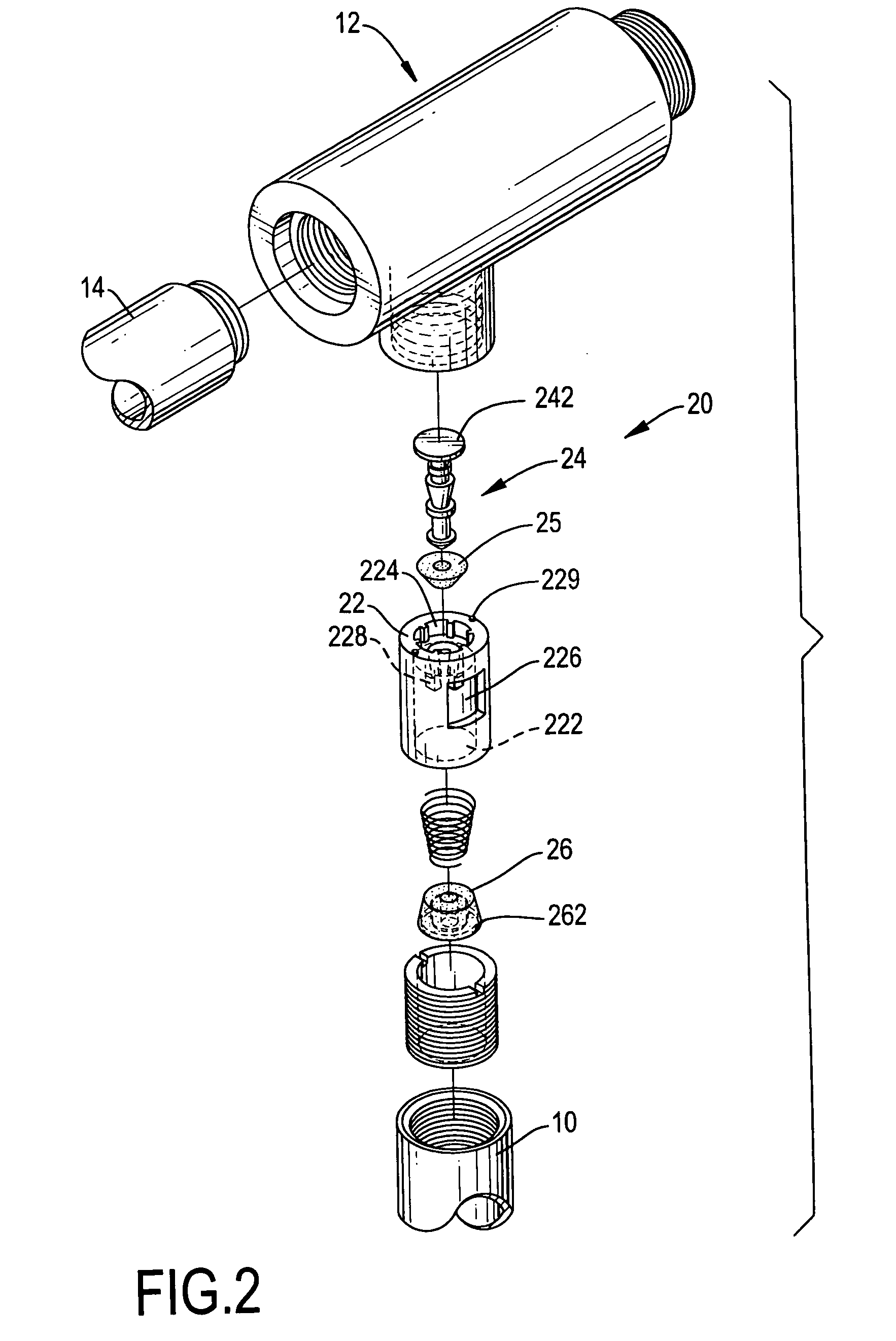

Shower assembly

A shower assembly has a standing pipe, a connector, an overhead pipe, a fixed overhead shower head, a control valve, a handheld showerhead, a handheld showerhead bracket and a directional valve. The connector has a three-way passage. The directional valve is mounted inside the passage to direct water to flow selectively into either the overhead pipe or the standing pipe and has a tubular valve body, a valve rod, a primary disk and a secondary disk. The tubular valve body has a top opening, a bottom opening and a side opening communicating respectively with three ends of the passage. The valve rod is moveably mounted in the valve body. The primary disk and the secondary disk are mounted on the valve rod to selectively close the top opening or the bottom opening.

Owner:WU CHAO CHANG

Drip emitter

A drip emitter is provided for delivering irrigation water from a supply tube to an emitter outlet at a reduced and relatively constant flow rate. Water enters the emitter through a first inlet and proceeds into a first chamber. When the water pressure is above a predetermined level, a one-directional valve opens to allow fluid flow past the first chamber, through a tortuous path flow channel, and through an emitter outlet. A second inlet is used to compensate for water pressure fluctuations in the supply tube to maintain output flow at a relatively constant rate. Water enters the second inlet and presses a flexible diaphragm toward a water metering surface to provide pressure-dependent control of the output flow. A copper member is mounted to the emitter over the emitter outlet to prevent plant root intrusion into the emitter outlet.

Owner:RAIN BIRD CORP

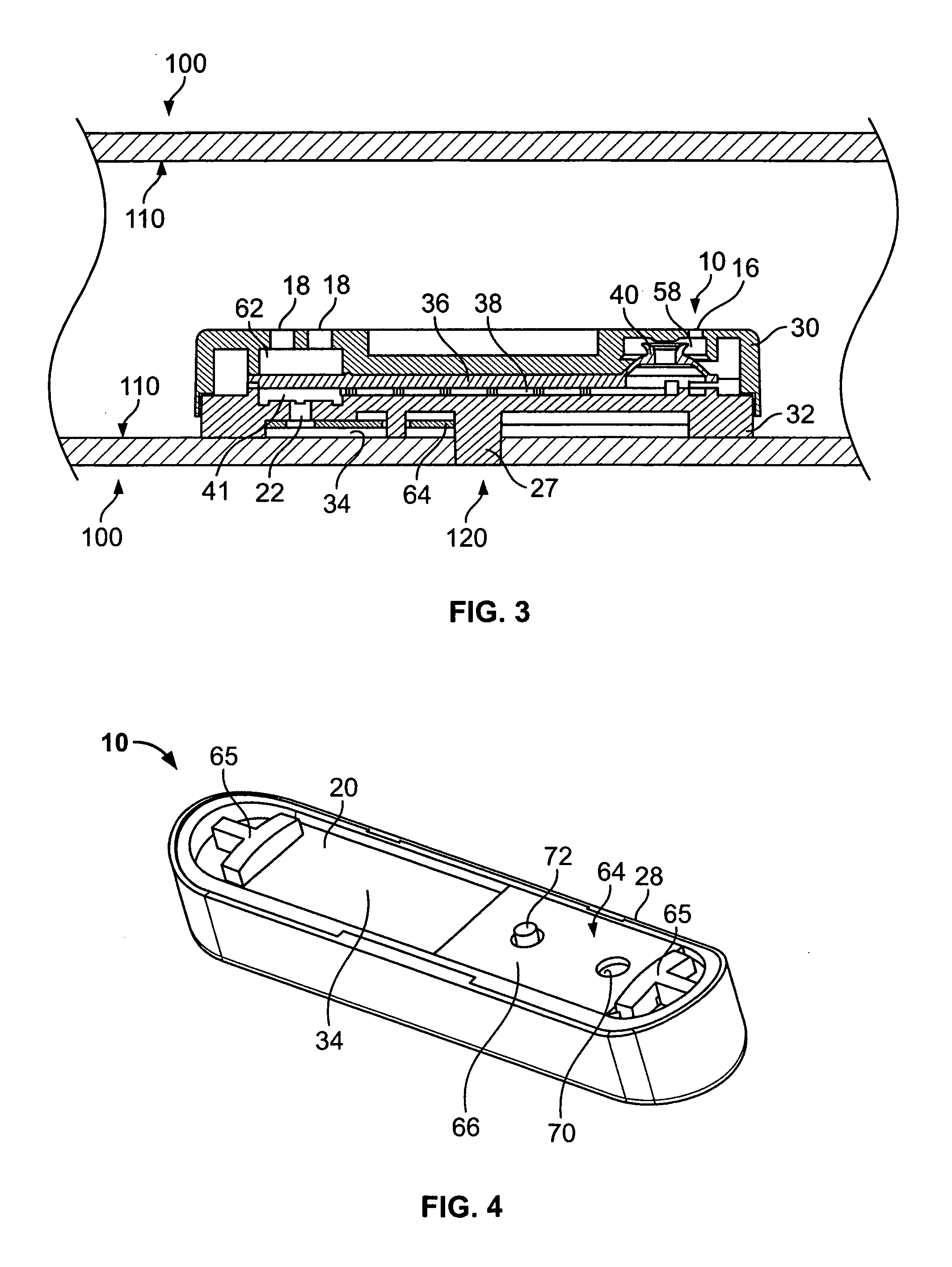

Hydraulic intensifiers

InactiveUS20090317267A1Increase the cross-sectional areaPositive displacement pump componentsFlexible member pumpsHigh pressureHydraulic fluid

A hydraulic intensifier with a piston and cylinder assembly (1) having a first piston (3) in a chamber (4) of low pressure cylinder and a second piston (7) in a chamber (8) of a high pressure cylinder. The first and second pistons are coupled together and the first piston has a larger cross-sectional area than the second piston. A high pressure output (19) is coupled to the chamber of the high pressure cylinder, there being; means (13) for supplying low pressure hydraulic fluid to the chamber of the low pressure cylinder; an electrically operated directional control valve (11) for controlling the supply of low pressure hydraulic fluid to the chamber of the low pressure cylinder; and electronic means (14) for controlling operation of the directional control valve.

Owner:VETCO GRAY CONTROLS

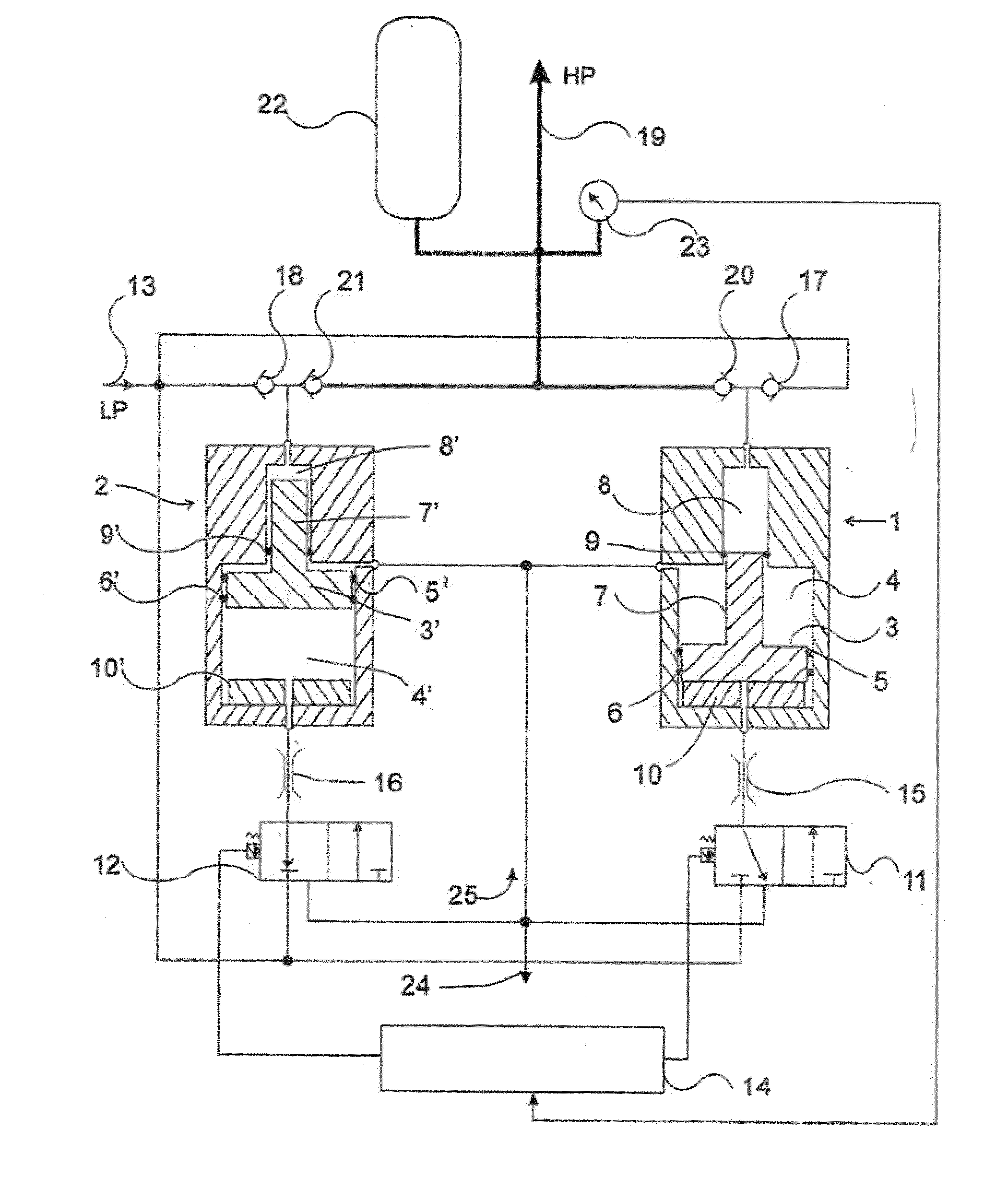

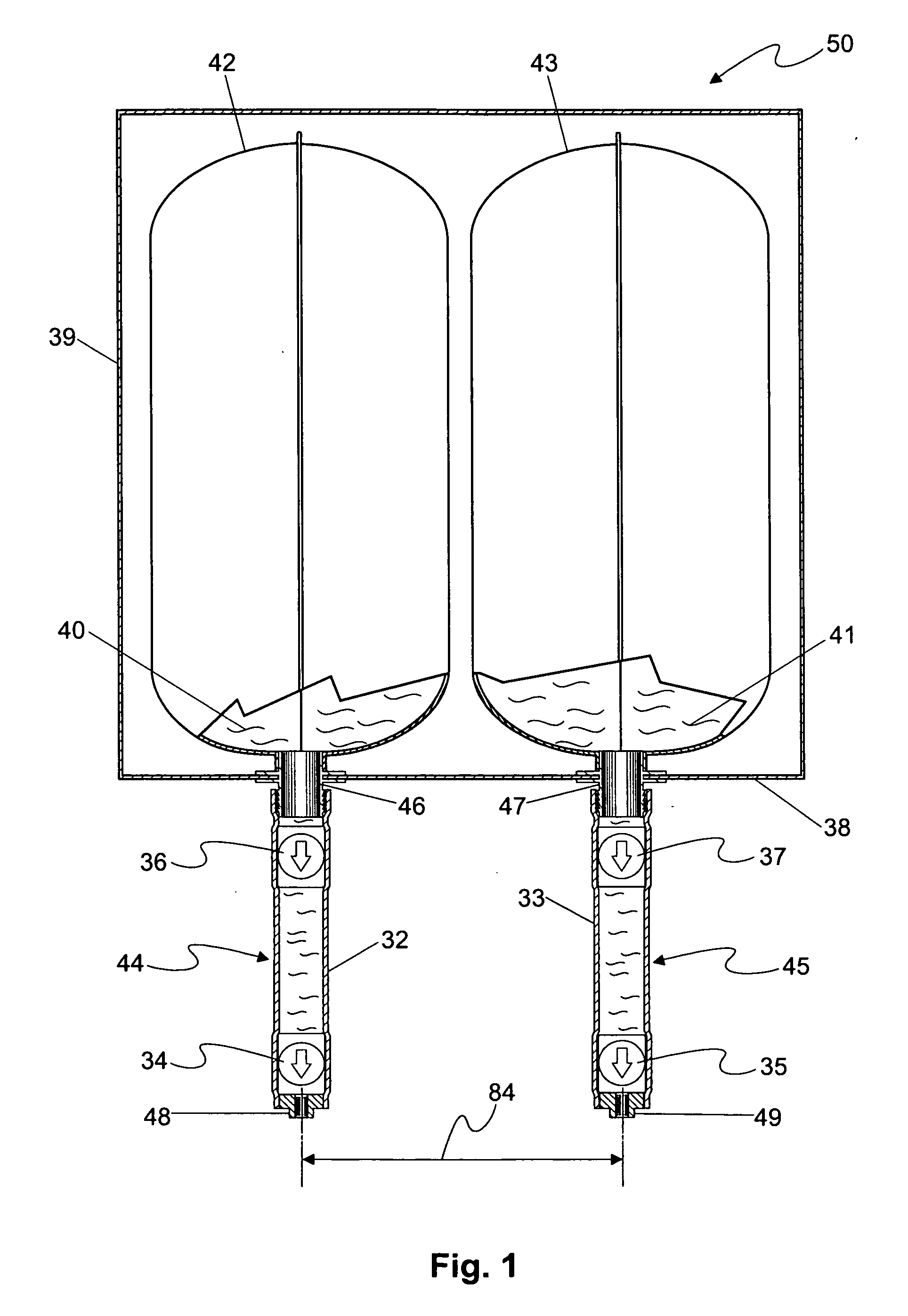

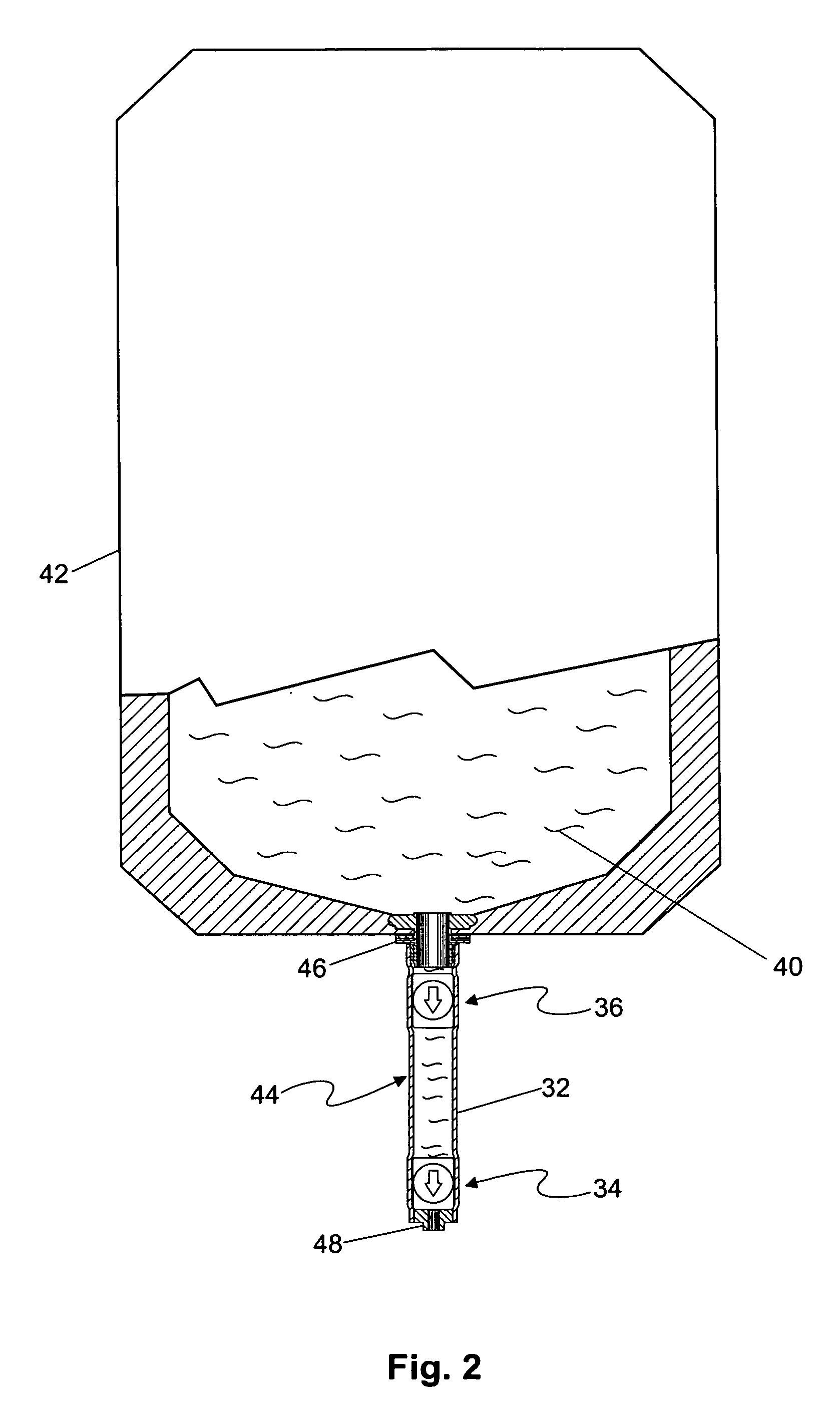

Food dispenser with pump for dispensing from a plurality of sources

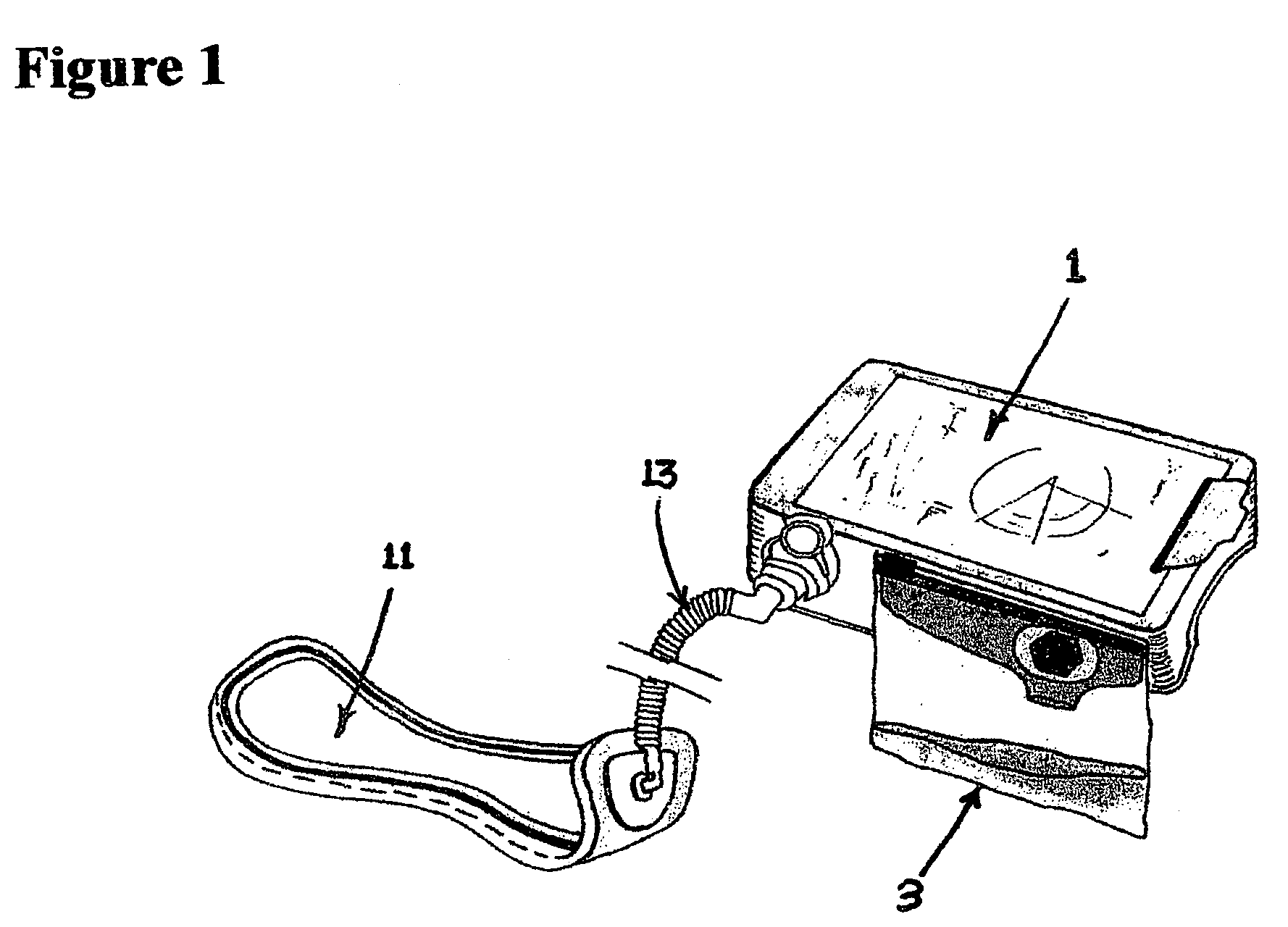

InactiveUS20070068969A1Easy loadingEasy to pumpFlexible member pumpsLiquid transferring devicesElastic compressionEngineering

The present invention relates generally to dispensing system configured for dispensing food product. The device includes a fluid container in fluid communication with a conduit having a compressible portion which is associable with a pumping mechanism for pumping a fluid therethrough. The compression portion contains an upstream uni-directional valve and a downstream uni-directional valve, so that when the compression portion is resiliently compressed, fluid is forced through the downstream valve, and upon decompression, fluid is drawn through the upstream valve. The present invention also relates to a method for dispensing a food product.

Owner:NESTEC SA

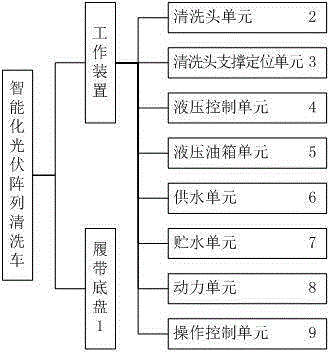

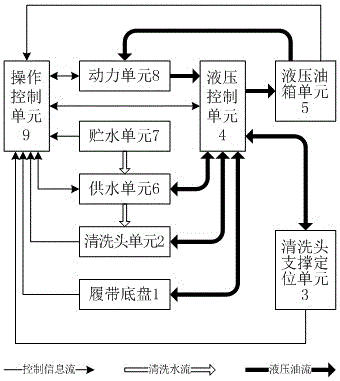

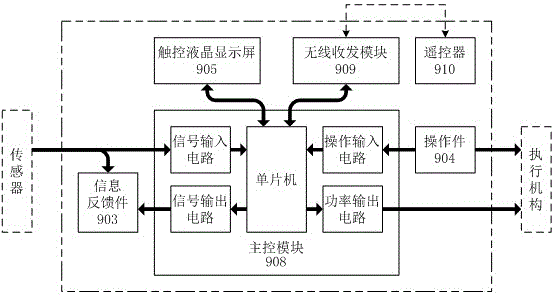

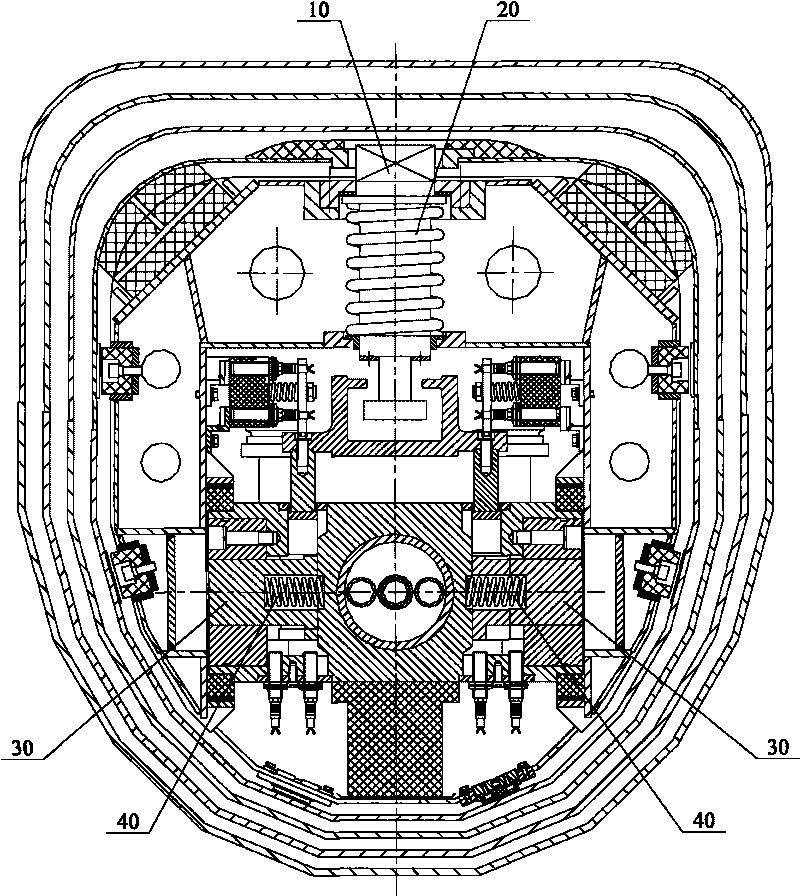

Intelligent photovoltaic array washing car

ActiveCN105107772AFunction increaseRegular shapeCleaning using toolsCleaning using liquidsWater storageHydraulic control unit

The invention provides an intelligent photovoltaic array washing car used for washing photovoltaic arrays of a large-scale ground photovoltaic power station. A washing head supporting and locating unit and a power unit are arranged on the head portion and the tail portion of a crawler base respectively, a water storage unit is arranged adjacent to the power unit, and a washing head unit is provided with range finder sensors used for measuring the distance between the washing head unit and solar cell panels; the washing head supporting and locating unit comprises a movable base capable of rotating and transversely moving and a working arm set provided with a main arm and an end arm, wherein the main arm and the end arm can pitch respectively; a water pump of a water supply unit is driven by a hydraulic motor; a computer is used as a control kernel of a main control module of an operation control unit; a pair of proportional directional valves of the hydraulic control unit controls two base crawler traveling motors, and other directional valves are electromagnetic directional valves controlled by the main control module. According to the intelligent photovoltaic array washing car, the position and the posture of the washing head unit relative to photovoltaic array panels and the position and the posture of a car body relative to the photovoltaic arrays can be automatically controlled, and the intelligent photovoltaic array washing car is intelligent, efficient, flexible in operation, high in adaptability, easy and convenient to operate, concise in structure and good in washing effect.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

Food dispenser with pump for dispensing from a plurality of sources

InactiveUS7651010B2Easy loadingEasy to pumpFlexible member pumpsLiquid transferring devicesElastic compressionGuide tube

The present invention relates generally to dispensing system configured for dispensing food product. The device includes a fluid container in fluid communication with a conduit having a compressible portion which is associable with a pumping mechanism for pumping a fluid therethrough. The compression portion contains an upstream uni-directional valve and a downstream uni-directional valve, so that when the compression portion is resiliently compressed, fluid is forced through the downstream valve, and upon decompression, fluid is drawn through the upstream valve. The present invention also relates to a method for dispensing a food product.

Owner:NESTEC SA

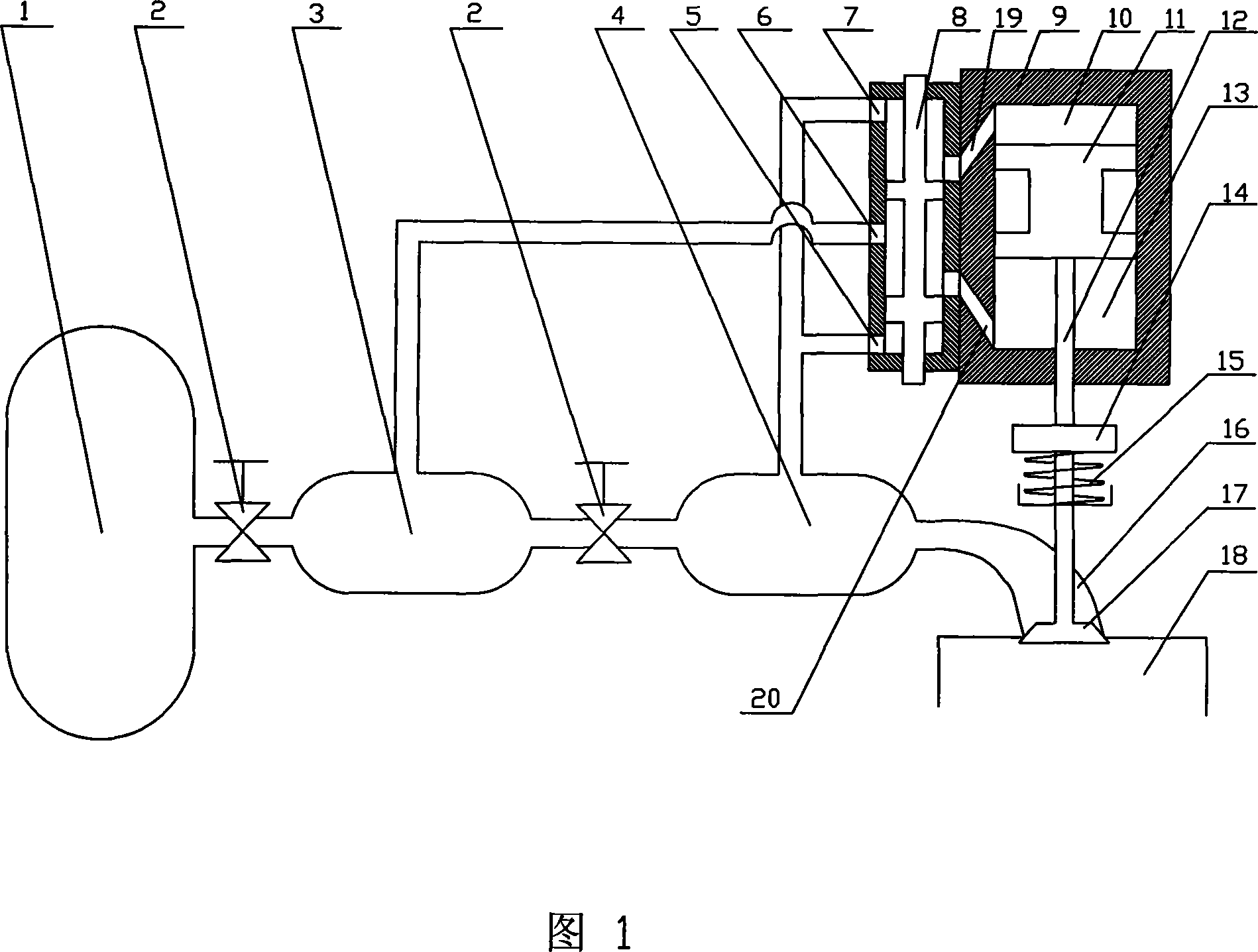

Compressed air engine electrically driven whole-variable valve actuating system

InactiveCN101149002AReduce throttling lossRealize time adjustmentReciprocating piston enginesNon-mechanical valveEngineeringEngine valve

The present invention relates to compressed air engine, and is especially one kind of variable air valve driving system for compressed air engine. The system includes one air valve spring, one shaft coupler, one piston rod and one piston inside a cylinder, connected successively to the air valve. There are two communication states between the air passage and the air exhaust electromagnetic directional valve based on the final position of the valve. The valve opening time may be controlled by means of controlling the power-on pulse duration. The present invention has the advantages of capacity of decoupling air valve motion and the crankshaft rotation speed of the pneumatic engine to optimize the air distributing phase, capacity of recovering the vehicle braking energy, convenient braking strength regulation, etc.

Owner:ZHEJIANG UNIV

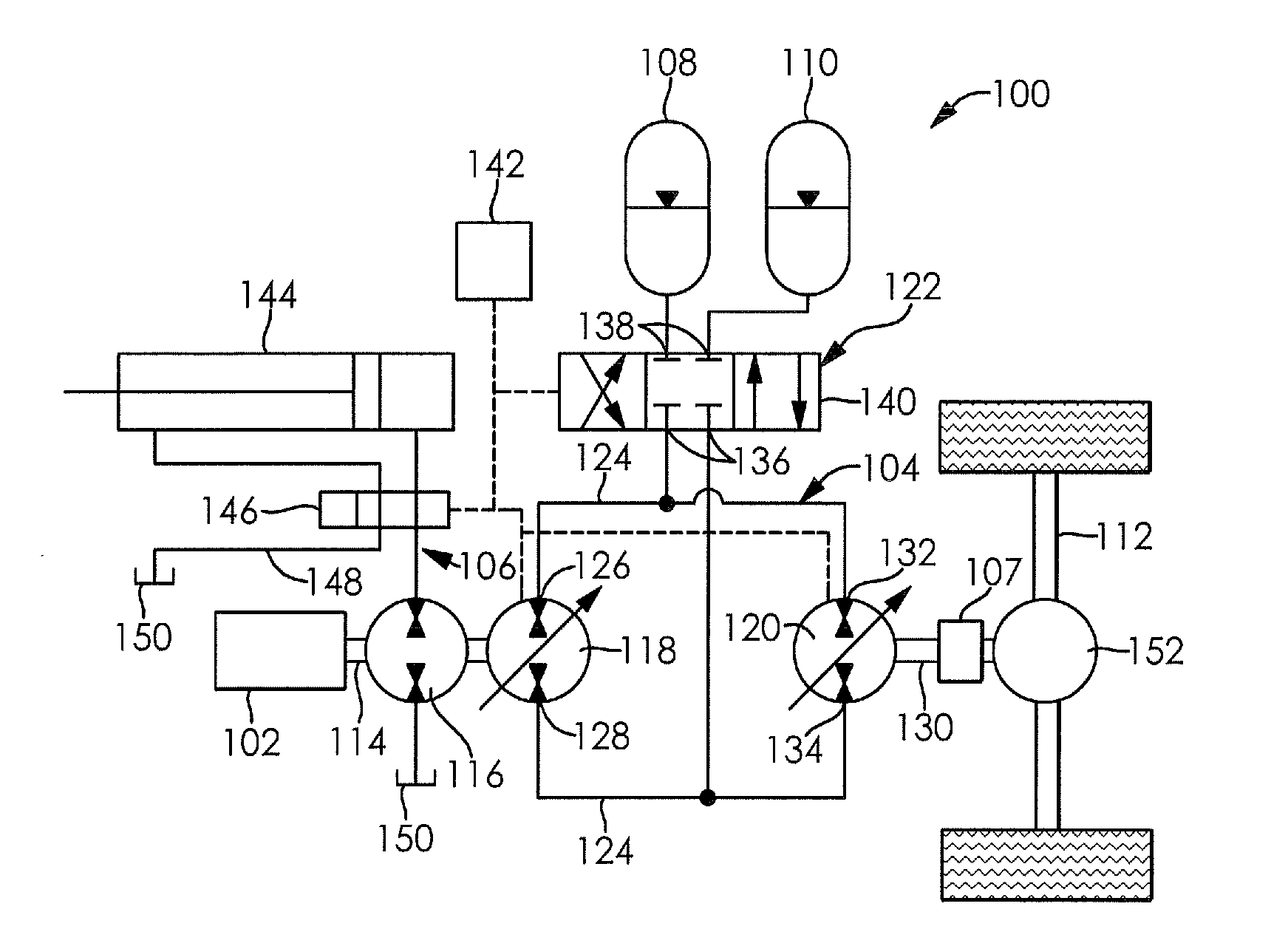

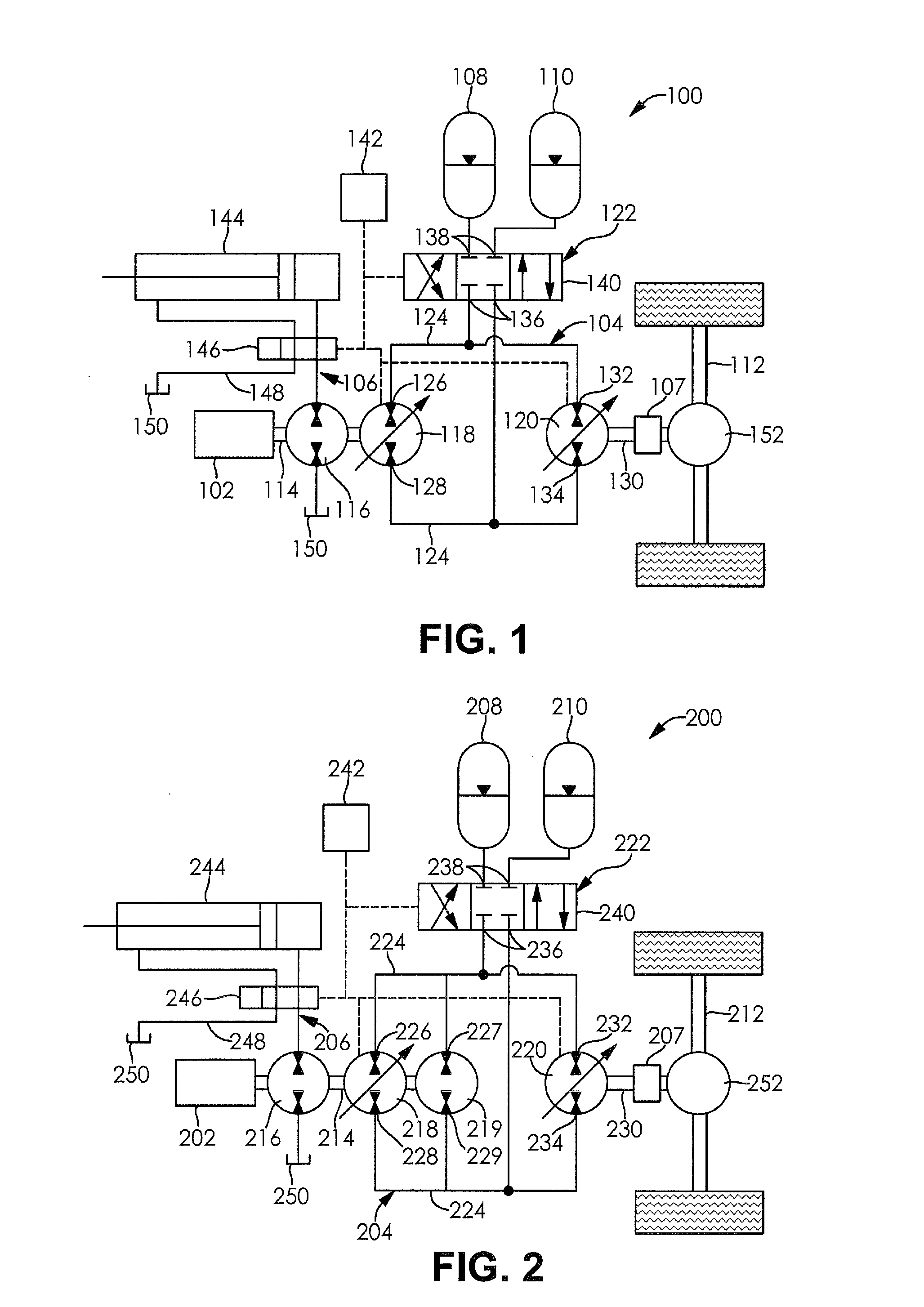

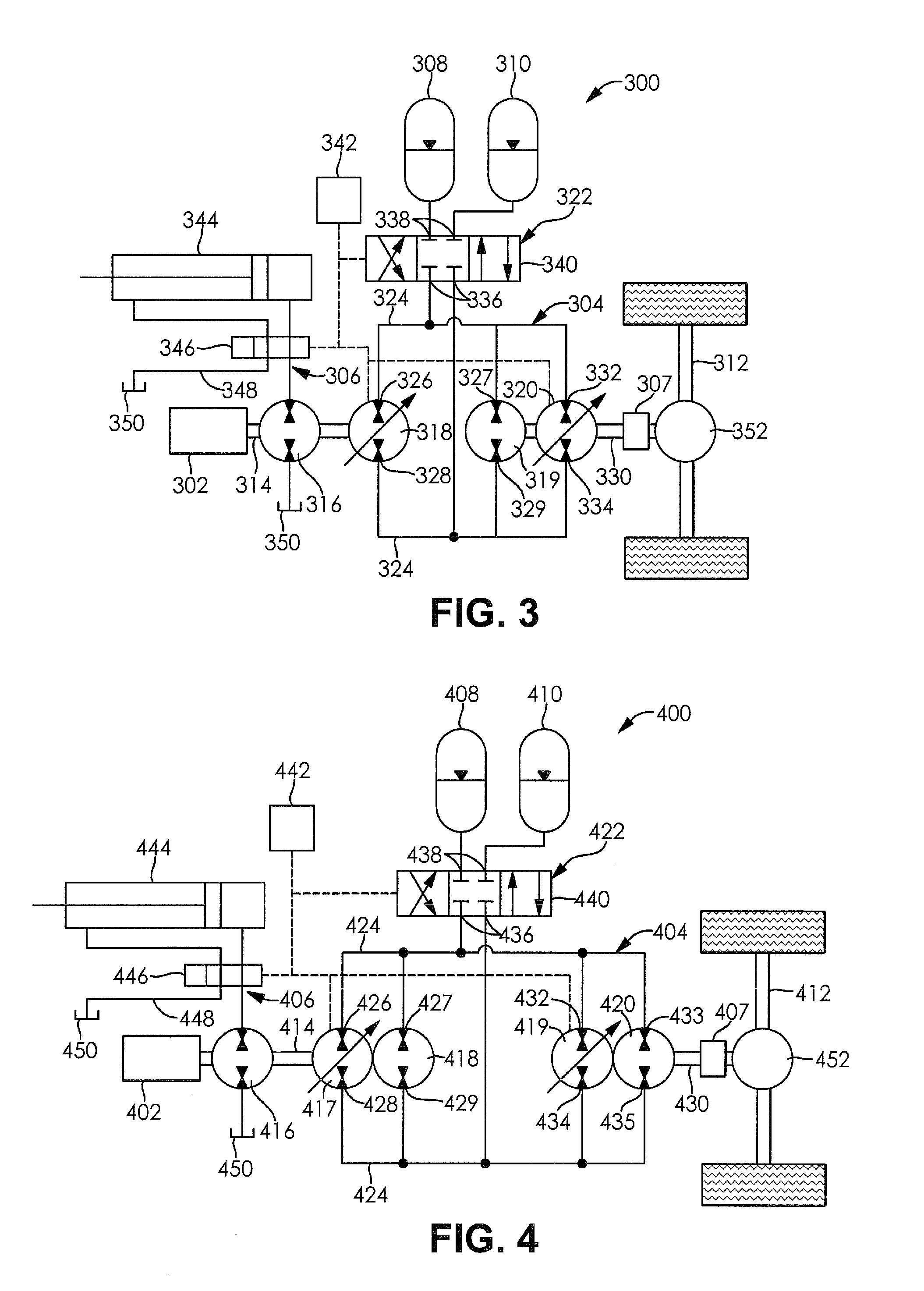

Accumulator assisted hydrostatic driveline and optimization method thereof

InactiveUS20120240564A1Easily procuredEasily servicedRotary clutchesAccumulator installationsState of chargeEngineering

A hydrostatic driveline for a vehicle, a method for minimizing a fuel consumption rate of the vehicle, and a method for tracking an optimal state of charge function for a hydrostatic accumulator are provided. The driveline includes a power source, a drive axle, a first fluid accumulator, a second fluid accumulator, an auxiliary circuit including a first pump drivingly engaged with the power source, and a drive circuit including a second pump drivingly engaged with the power source, a motor drivingly engaged with the drive axle, and a directional valve. The second pump is in fluid communication with the directional valve and the directional valve in fluid communication with the first fluid accumulator and the second fluid accumulator. The directional valve may be selectively controlled to direct fluid from the second pump and the motor to the first fluid accumulator and the second fluid accumulator.

Owner:DANA BELGIUM

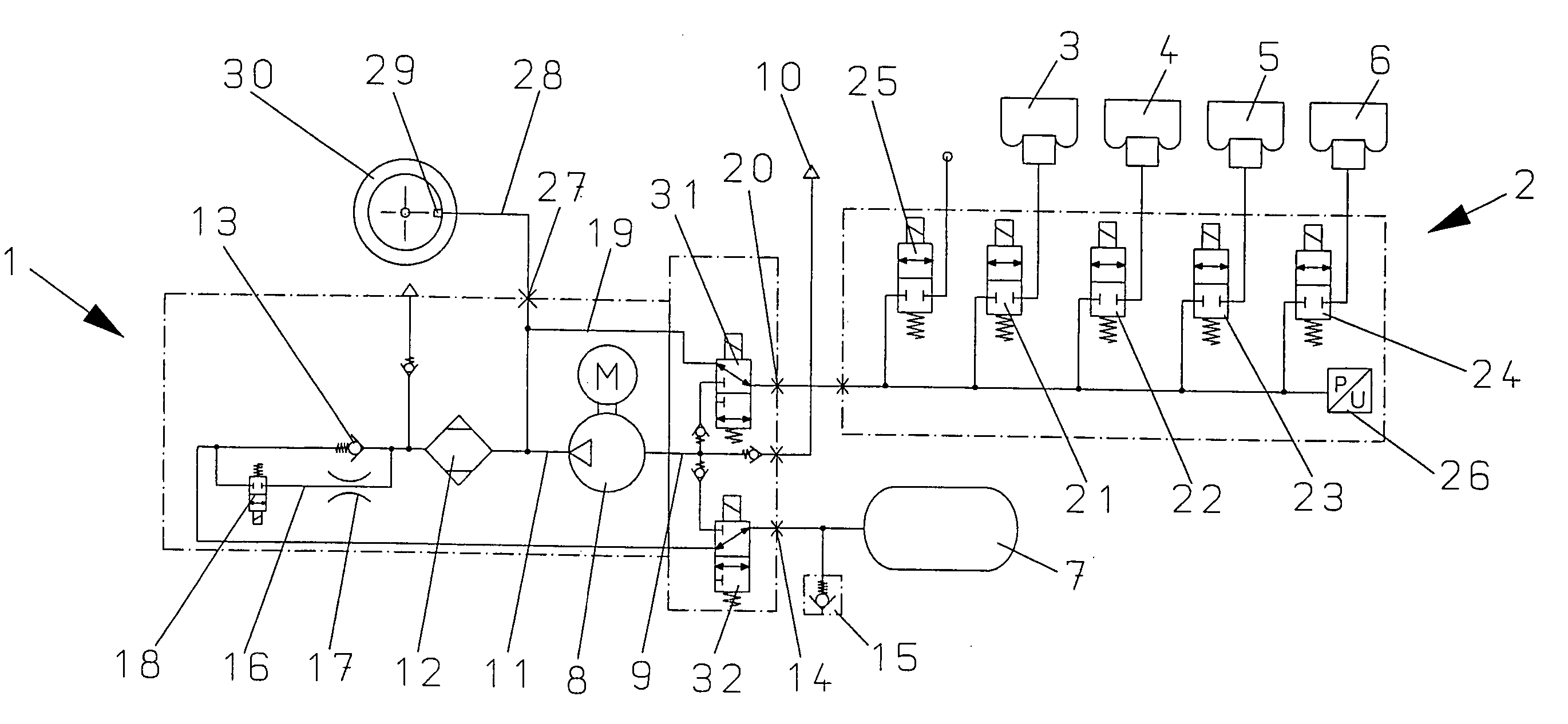

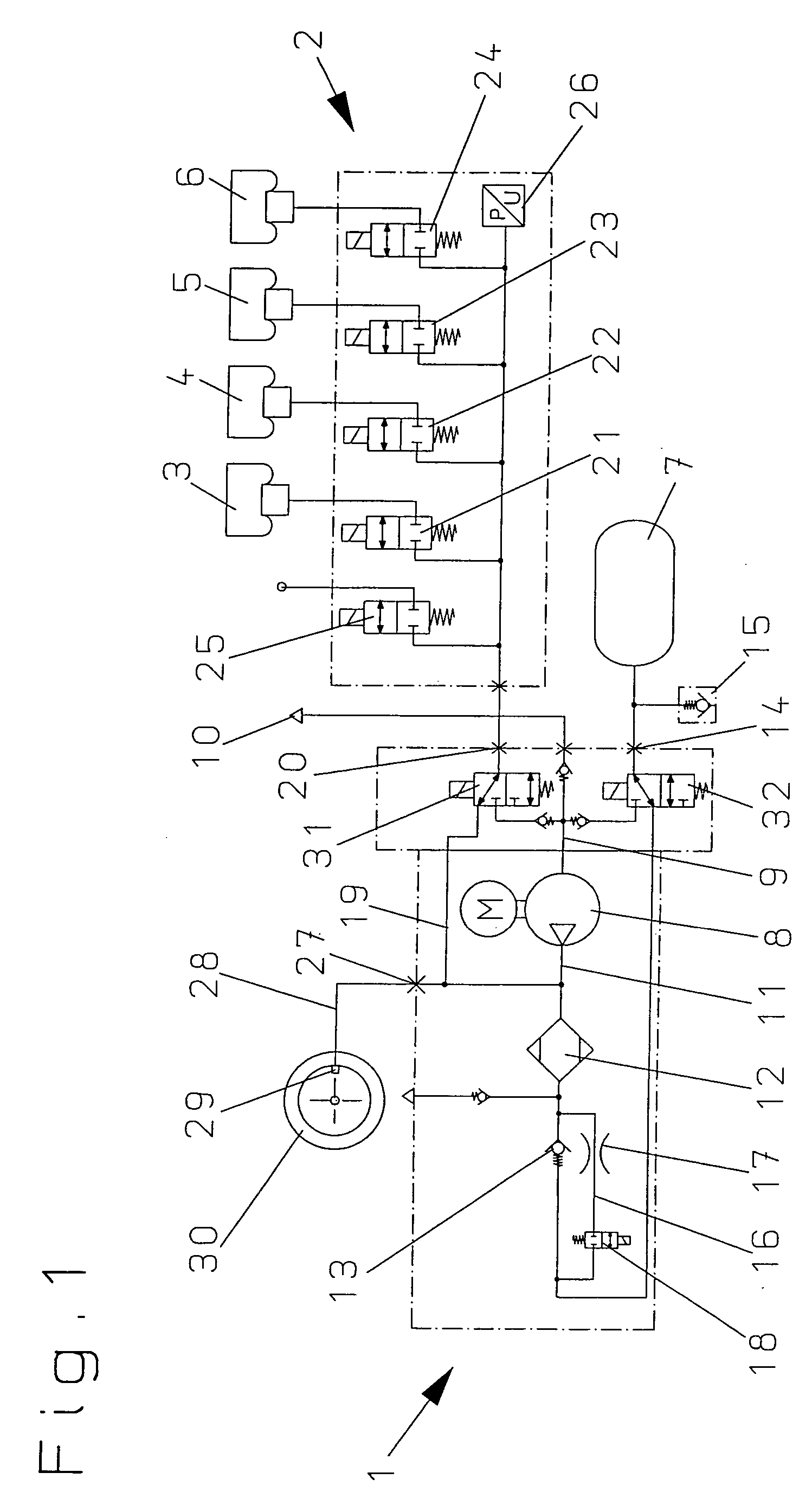

Closed level control system for a vehicle with the system having two pressure stores

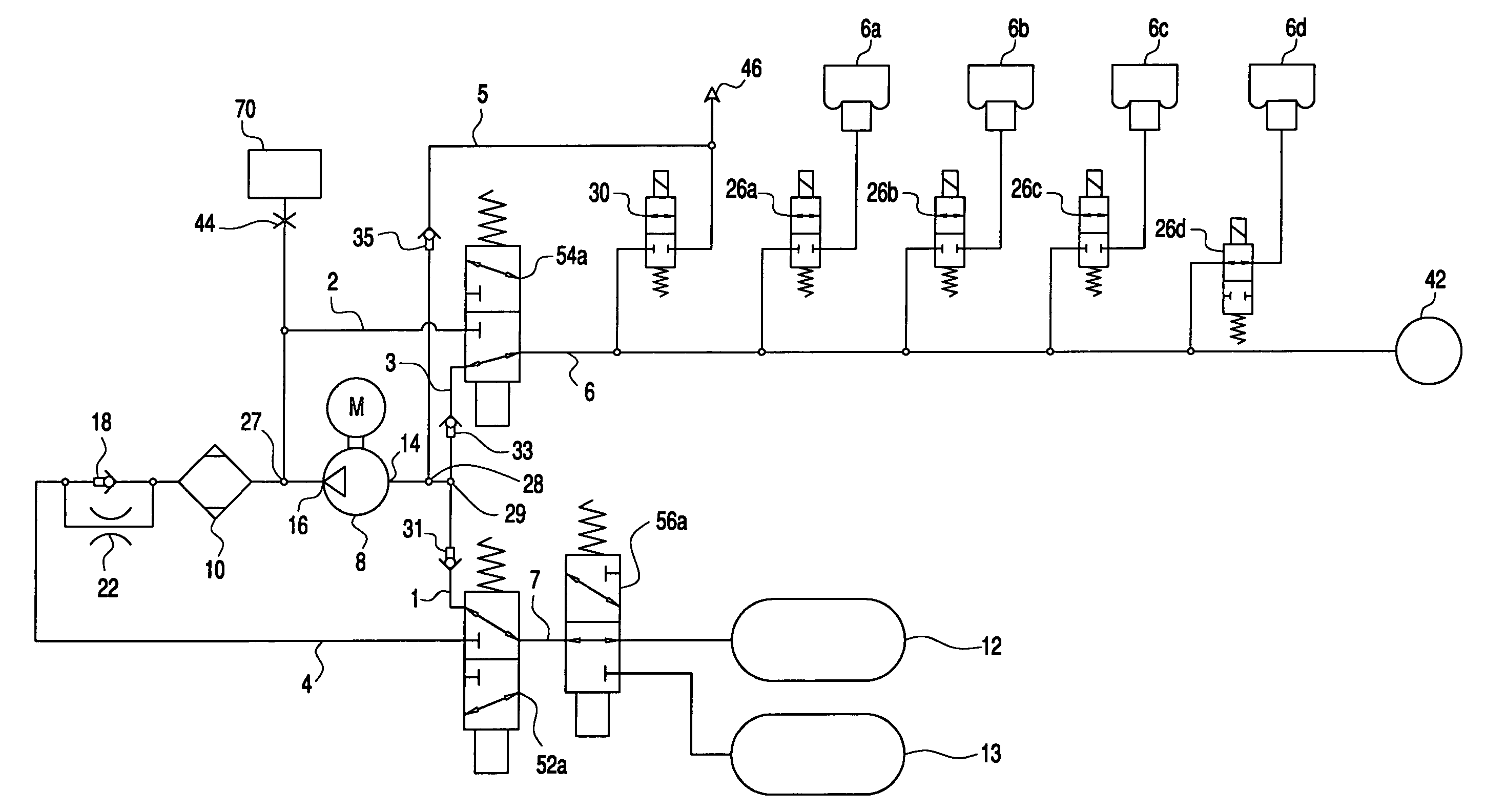

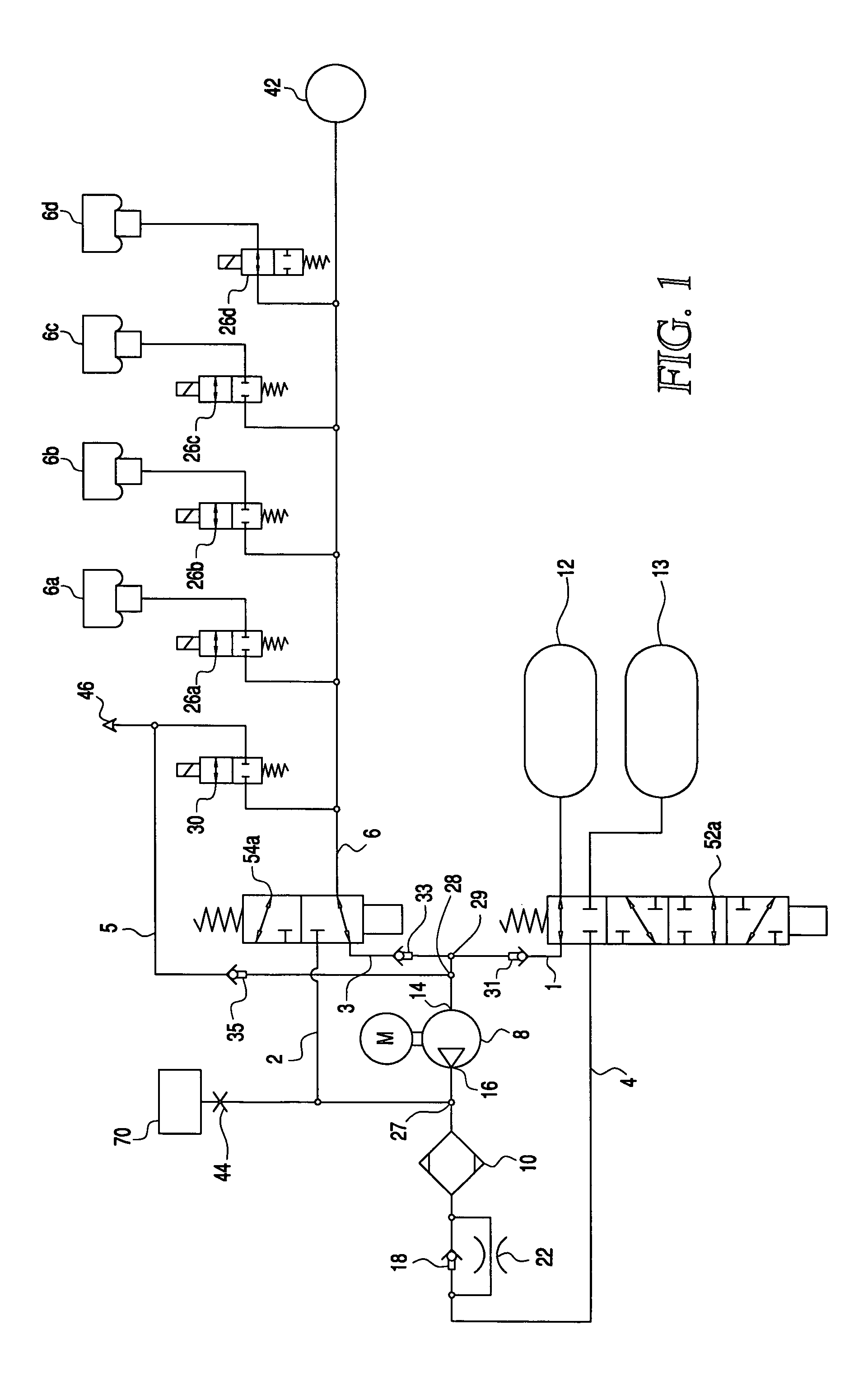

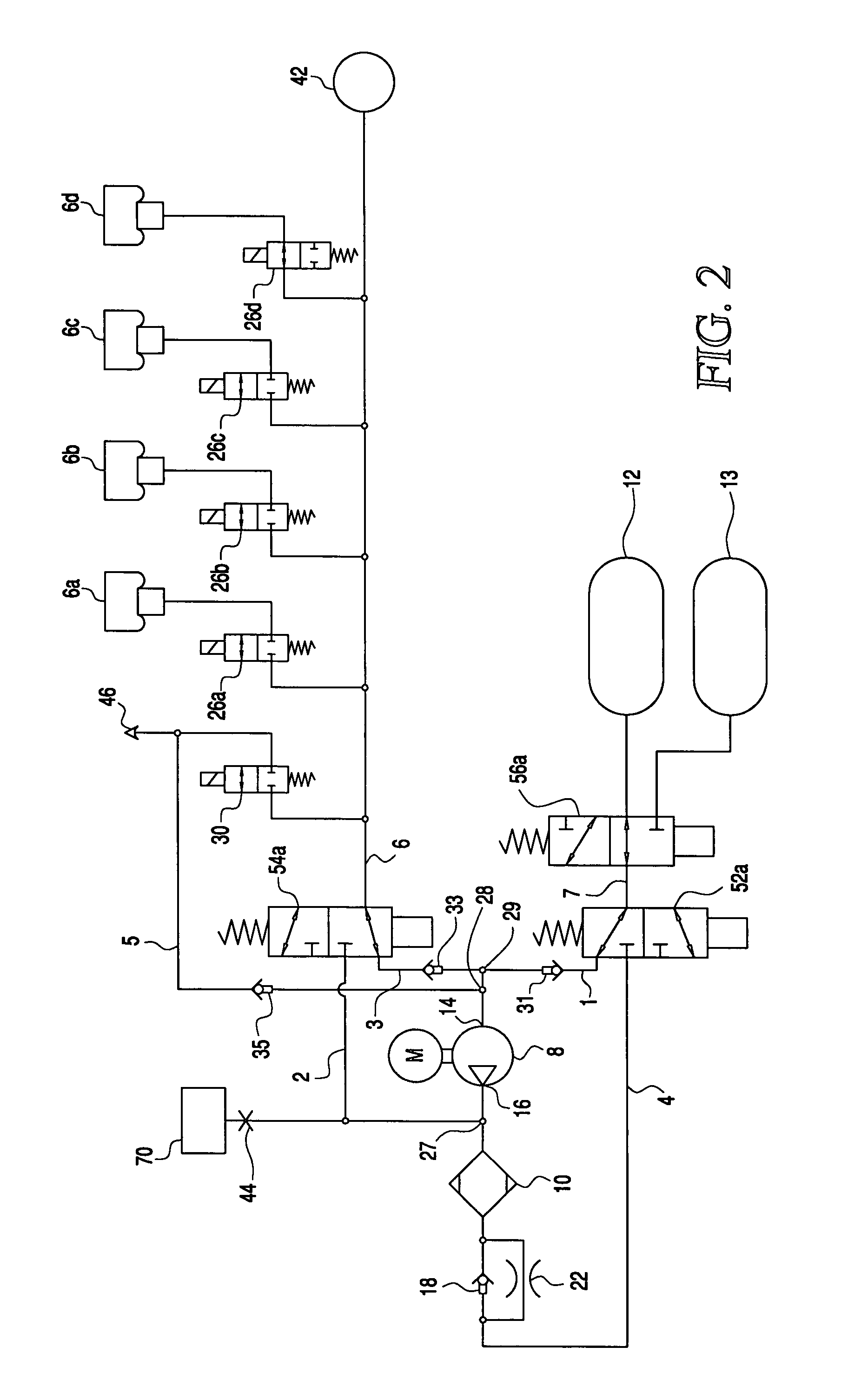

InactiveUS7032895B2Fast controlIncrease pressureLiquid springsResilient suspensionsControl systemAir dryer

In a closed level control system for vehicles, a vehicle body is suspended relative to at least one vehicle axle. The level control system includes pressurized medium chambers, a compressor, an air dryer and a pressurized medium supply vessel which is partitioned into first and second pressurized medium spaces. The two pressurized medium spaces have no direct connection. Either the first pressurized medium space or the second pressurized medium space can be connected to the compressor input or the compressor output via at least one common controllable directional valve so that the pressurized medium from the pressurized medium chambers can be transferred into the first or into the second pressurized medium space or pressurized medium can be transferred from the first or the second pressurized medium space into the pressurized medium chambers.

Owner:CONTINENTAL AG

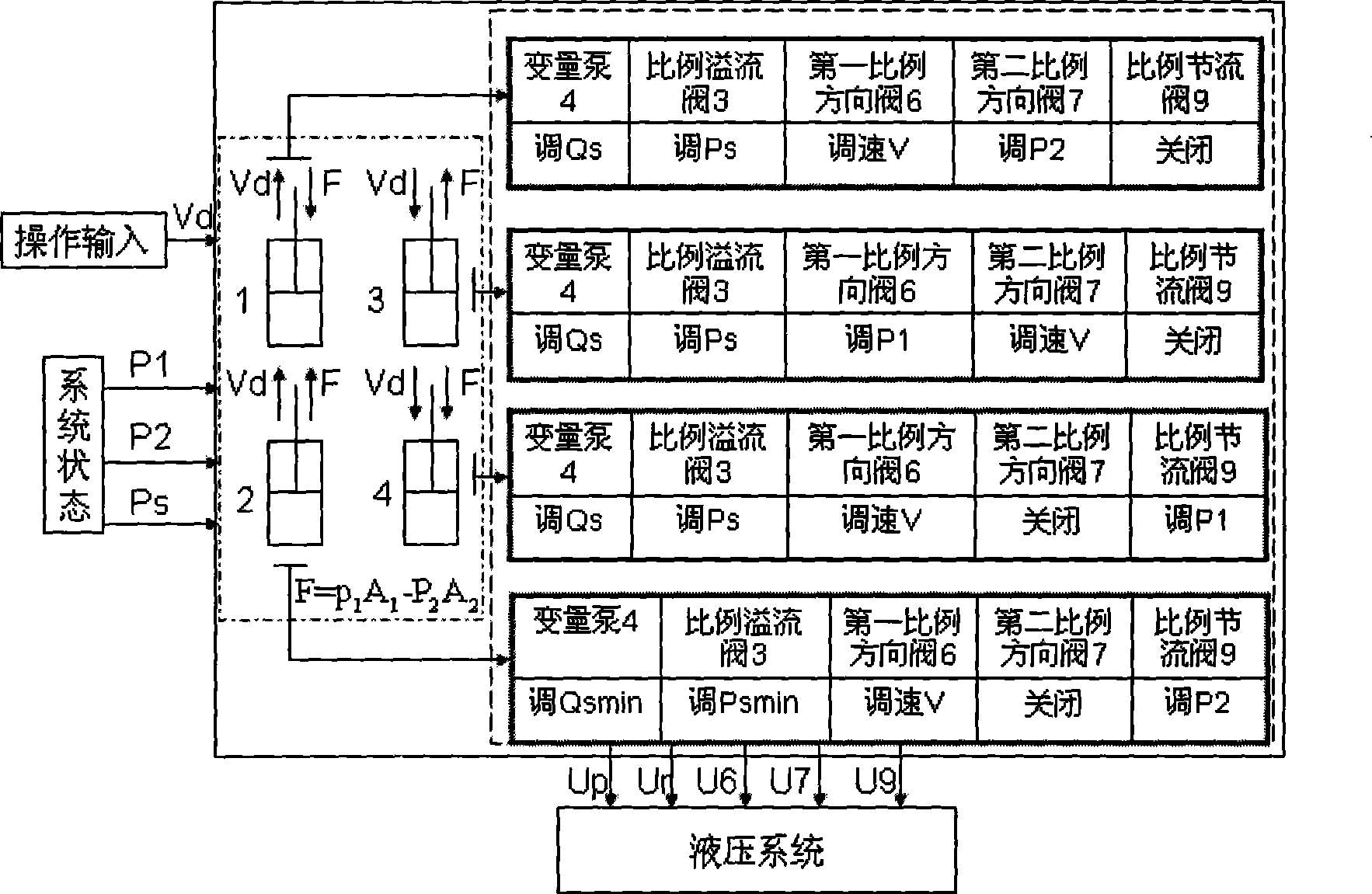

Independent electrohydraulic load sensitive energy regeneration hydraulic system of engineering machinery load port

InactiveCN101413522AAchieve regenerationReduce lossFluid-pressure actuator componentsLoad sensingElectrical connection

The invention discloses an independent electrohydraulic load sensing energy regeneration hydraulic system of an actuator port of an engineering machine. An oil outlet of a variable pump is connected with an oil inlet of a proportional relief valve, a first pressure sensor, an oil inlet of a first proportional directional valve, and an oil inlet of a second proportional directional valve respectively. An oil outlet of the first proportional directional valve is connected with a second pressure sensor, the oil inlet of a proportional throttle valve and a rodless cavity of a hydraulic cylinder respectively. An oil outlet of the second proportional directional valve is connected with an oil outlet of the proportional throttle valve, a third pressure sensor and a rod cavity of the hydraulic cylinder. A Controller is in electrical connection with a control handle, the variable pump, the proportional relief valve, two proportional directional valves, the proportional throttle valve and three pressure sensors. The system adopts the pressure sensors to detect working conditions, selects control policies according to the working conditions, reduces energy loss in flow restriction and realizes overload energy regeneration under the control of an actuator. Speed and energy-conservation control is realized through the combination of pump control and valve control.

Owner:ZHEJIANG UNIV

Engine valve actuation system

InactiveUS7004122B2Avoid oscillationElectrical controlInternal combustion piston enginesInlet valveEngineering

An engine valve actuation system is provided. The engine valve actuation system includes an intake valve that is moveable between a first position to prevent a flow of fluid and a second position to allow a flow of fluid. A cam assembly is configured to move the intake valve between the first position and the second position. A fluid actuator is configured to selectively prevent the intake valve from moving to the first position. A source of fluid is in fluid communication with the fluid actuator. A directional control valve is configured to control a flow of fluid between the source of fluid and the fluid actuator. A fluid passageway connects the directional control valve with the fluid actuator. An accumulator is in fluid communication with the fluid passageway. A restricted orifice is disposed between the accumulator and the fluid passageway to restrict a flow of fluid between the accumulator and the fluid passageway.

Owner:CATERPILLAR INC

Subsea choke control system

A choke actuator having an integrated choke control system enabling fast closure and opening of the choke. The choke control system includes integral electronics to receive signals from a surface or subsea control module and control directional control valves to regulate the flow of hydraulic fluid from a local hydraulic supply to the choke actuator. Response times for choke actuation are greatly reduced by locating the electronic control system and directional control valves in an integrated package with the choke actuator and providing a local hydraulic supply. Additional embodiments may also include other electronic sensing and instrumentation enabling the choke control system to monitor and adjust the choke to maintain selected flow characteristics or in accordance with a predetermined production scheme. Any or all of the components of the choke, the choke control system, or the choke actuator may also be retrievable separately from the other components so as to allow maintenance and replacement.

Owner:COOPER CAMERON CORP

Dual lumen syringe

InactiveUS20090062741A1Quickly and efficiently and reliably aspiratedReduce riskInfusion syringesIntravenous devicesBiomedical engineeringVALVE PORT

A dual lumen syringe includes a body having a pair of elongate cavities or lumens formed therein. A directional valve is associated with each lumen. The valve is alternated between the first position wherein the lumen is communicably connected to a fluid inlet and a second position wherein the lumen is connected with a fluid outlet. There are a pair of elongate plungers, which are fixedly interconnected by a handle. Each plunger is received and longitudinally slidable in a reciprocating manner through a respective lumen. The valves are switched to a first position wherein the lumens are interconnected with the fluid inlets and the plunger is retracted to aspirate fluids through the respective inlets and into the lumens. The valves are then switched to a second position to communicably interconnect the lumens with the outlets. The plungers are then simultaneously driven inwardly through the respective lumens to drive the fluids simultaneously through the outlets to a dispensing tip permanently connected to the body and in communication with the outlets.

Owner:PERFUSION PARTNERS & ASSOC

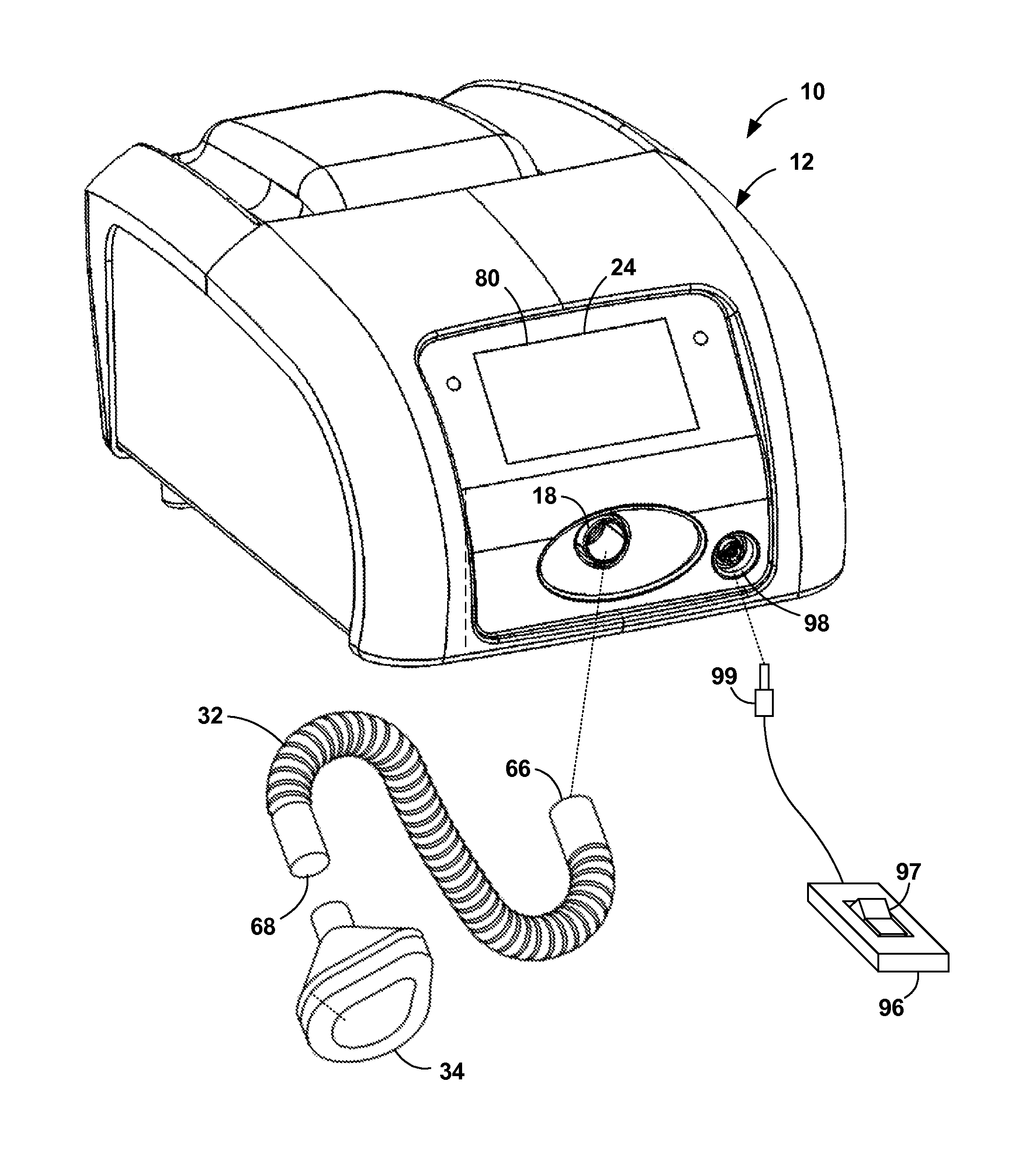

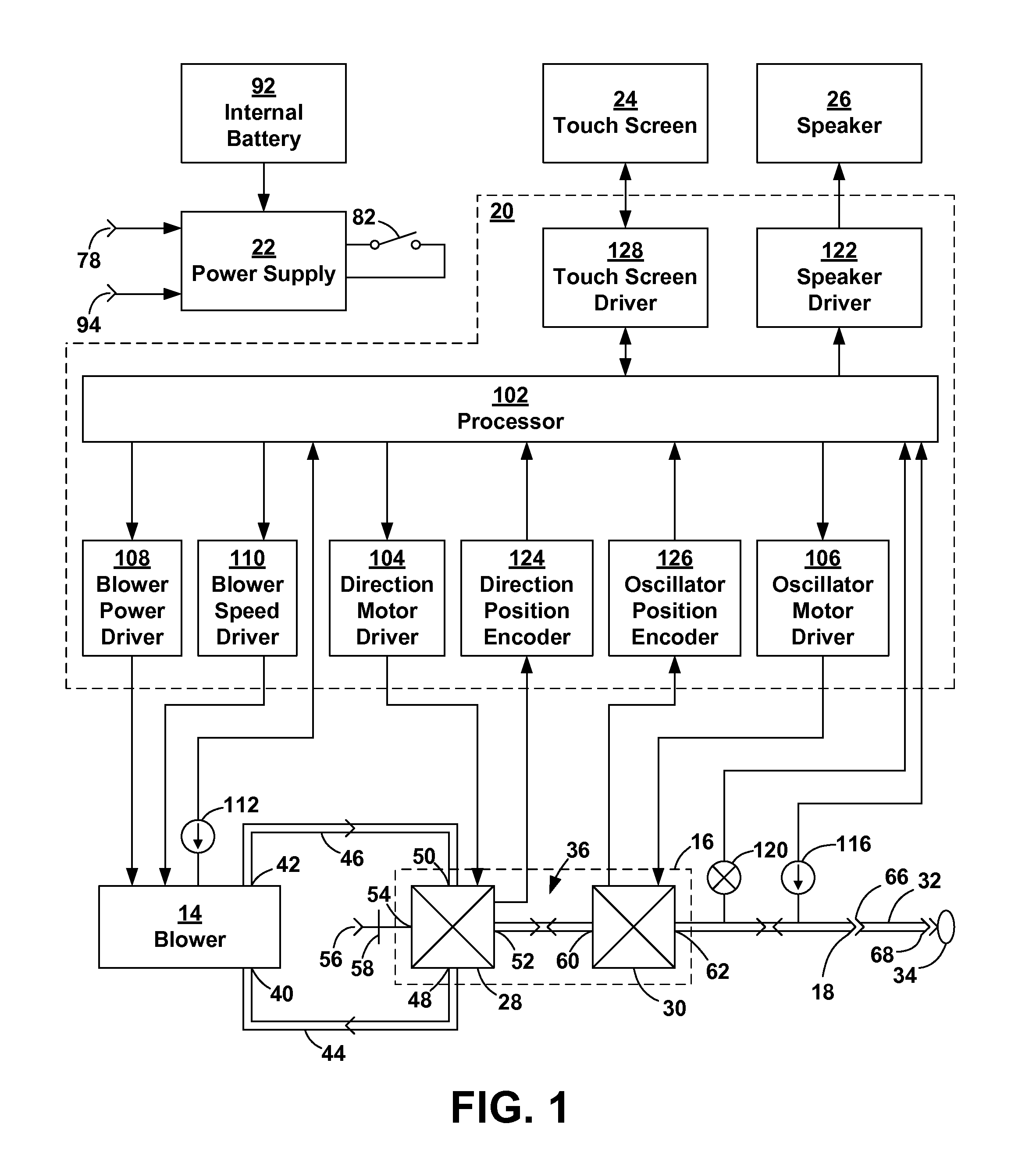

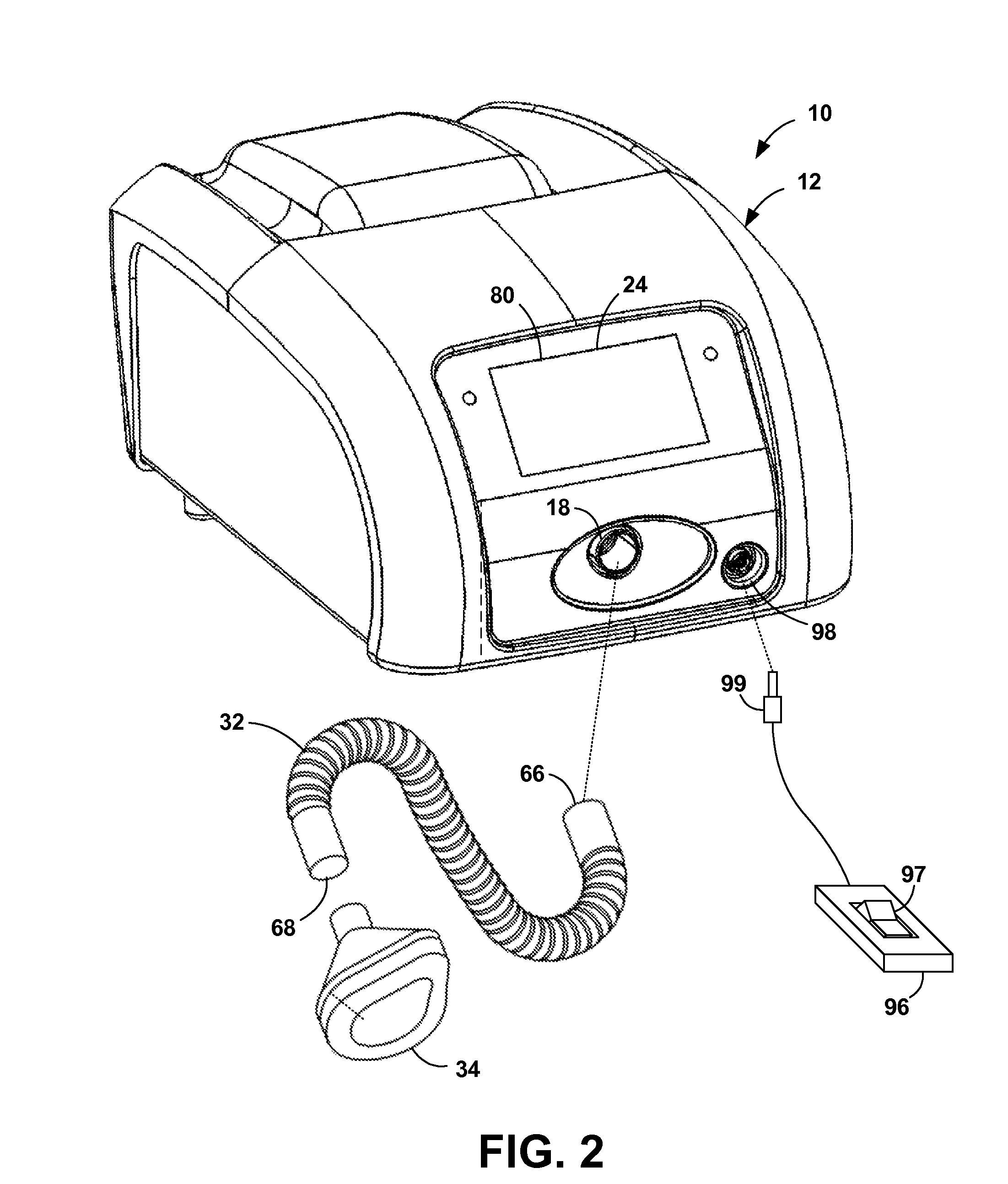

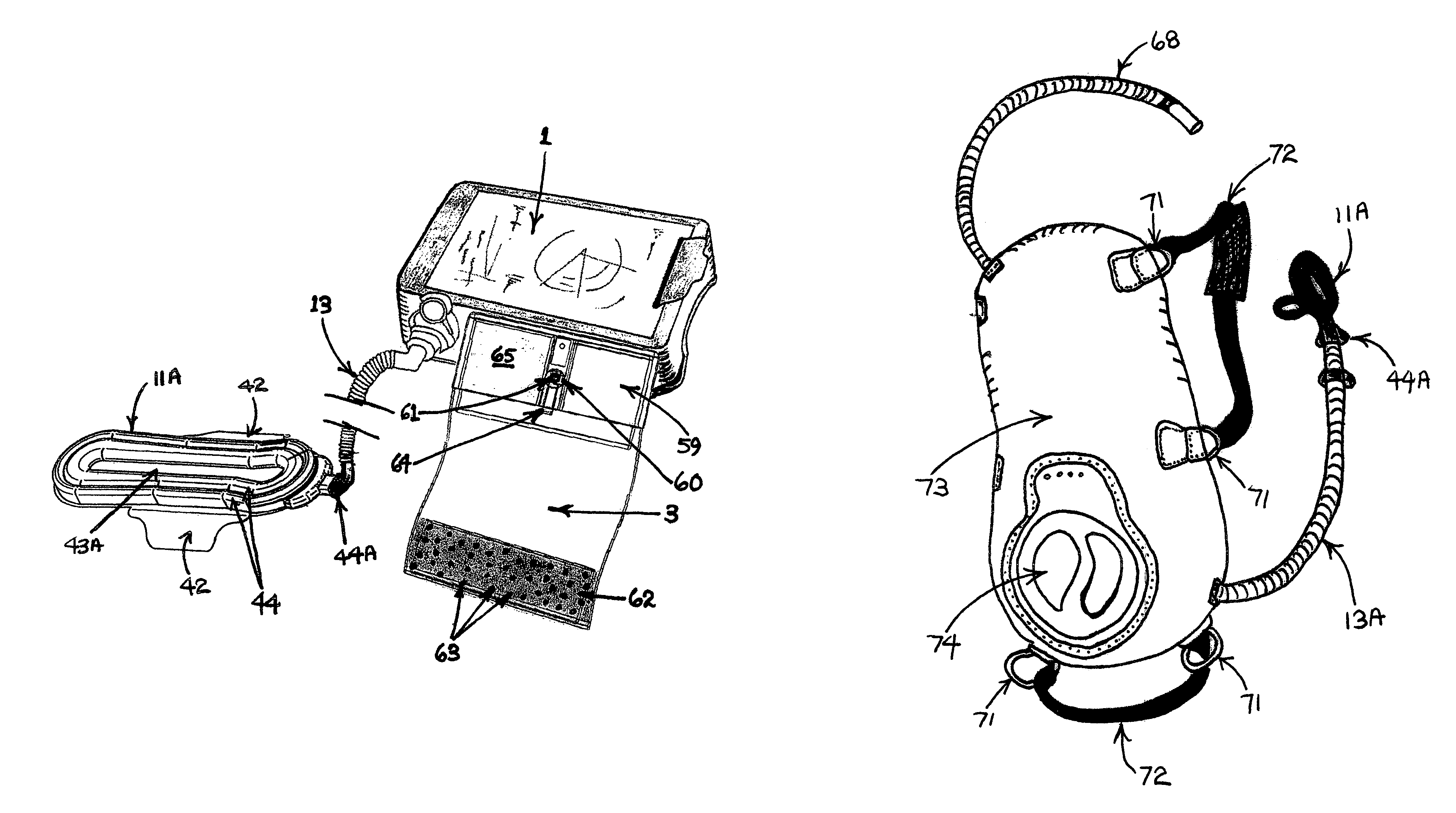

Mechanical insufflation/exsufflation airway clearance apparatus

ActiveUS8539952B2Operating means/releasing devices for valvesBreathing filtersPositive pressureEngineering

An MIE apparatus has a blower, a direction valve, an oscillator, and a mask hose connector. The blower is connected to the direction valve, which is connected to the oscillator, which is connected to the hose connector. During insufflation, a direction valve connects exhaust of a blower to an oscillator, causing positive pressure at the hose connector. During exsufflation, the direction valve connects the blower intake to the oscillator, causing negative pressure at the hose connector. The oscillator is a butterfly valve with a 360° rotating disc. During insufflation, the disc is fixed to steadily modulate the airflow. During exsufflation, the oscillator is inactive or in flutter mode. When inactive, the disc is fixed to allow maximum air flow. In flutter mode, the disc continuously rotates so that the air flow rapidly alternates between maximum and minimum.

Owner:HILL ROM SERVICES

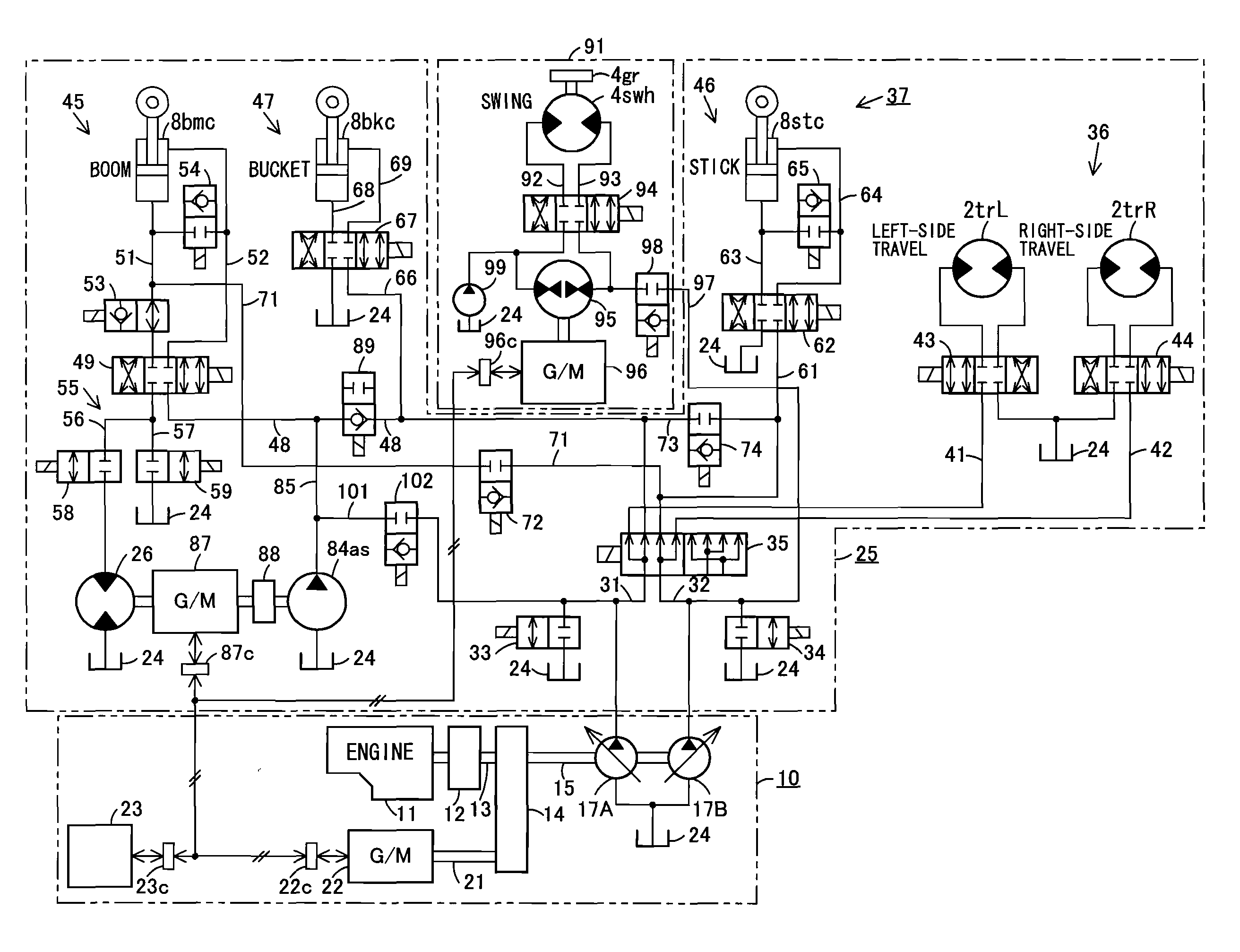

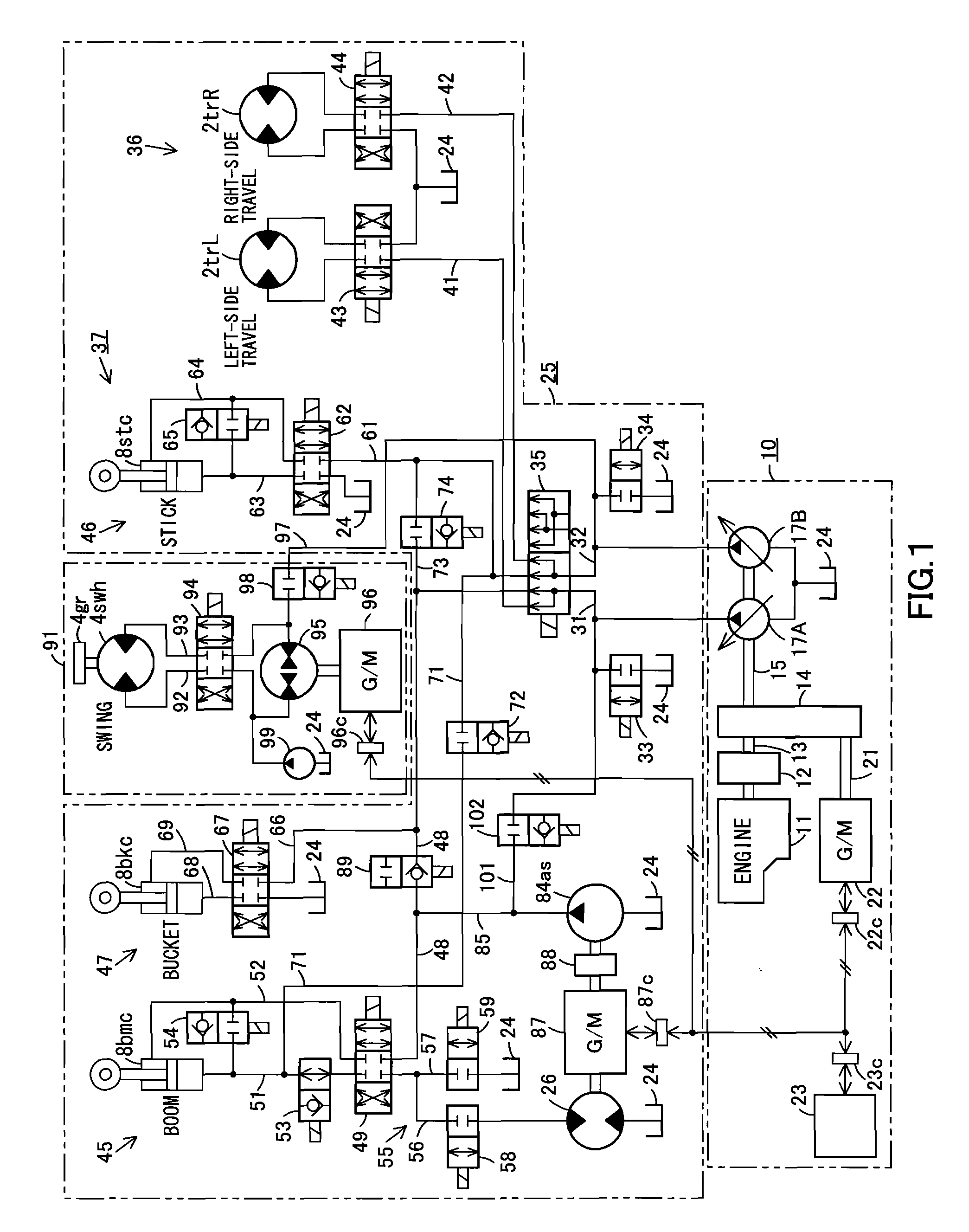

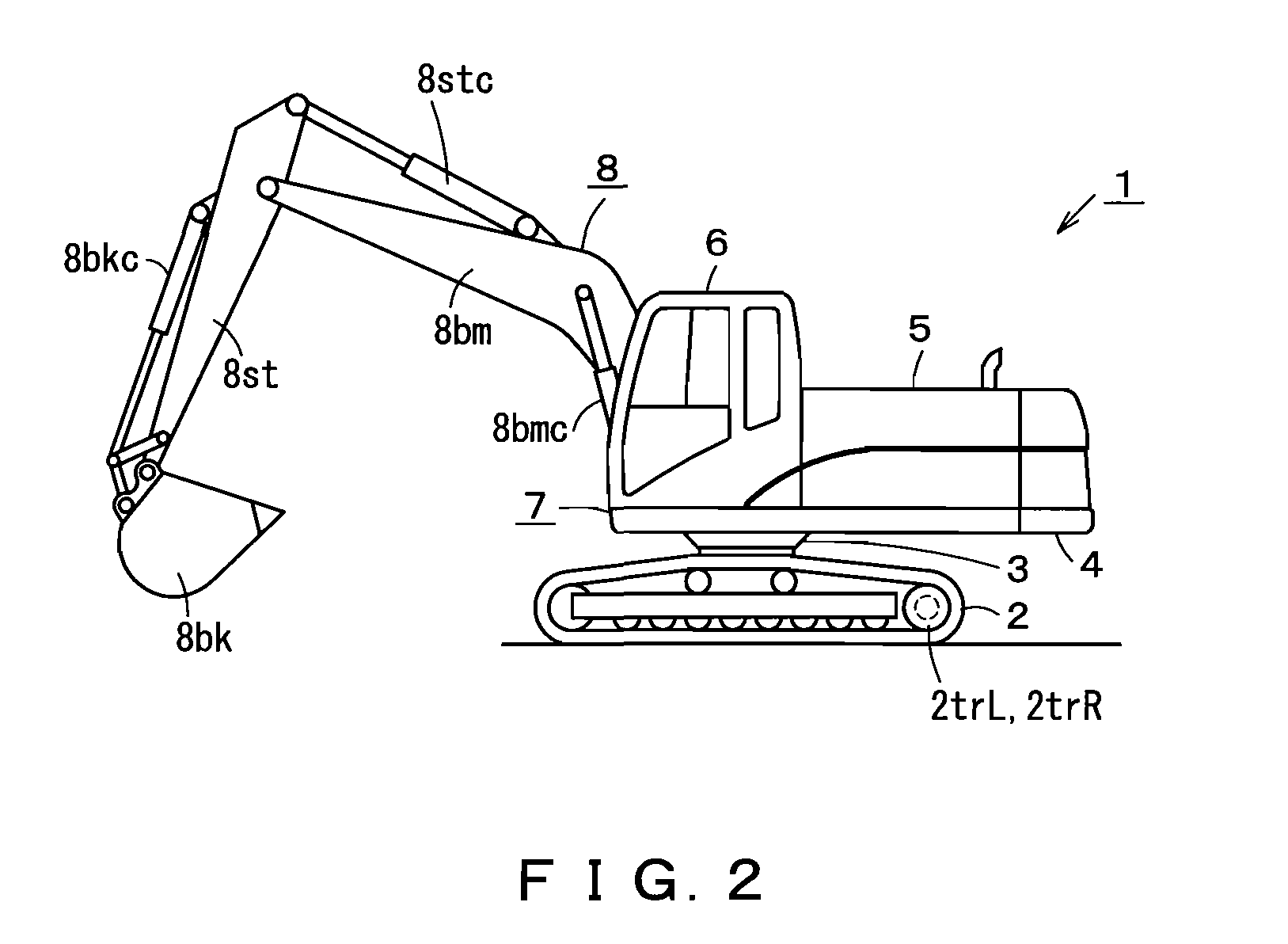

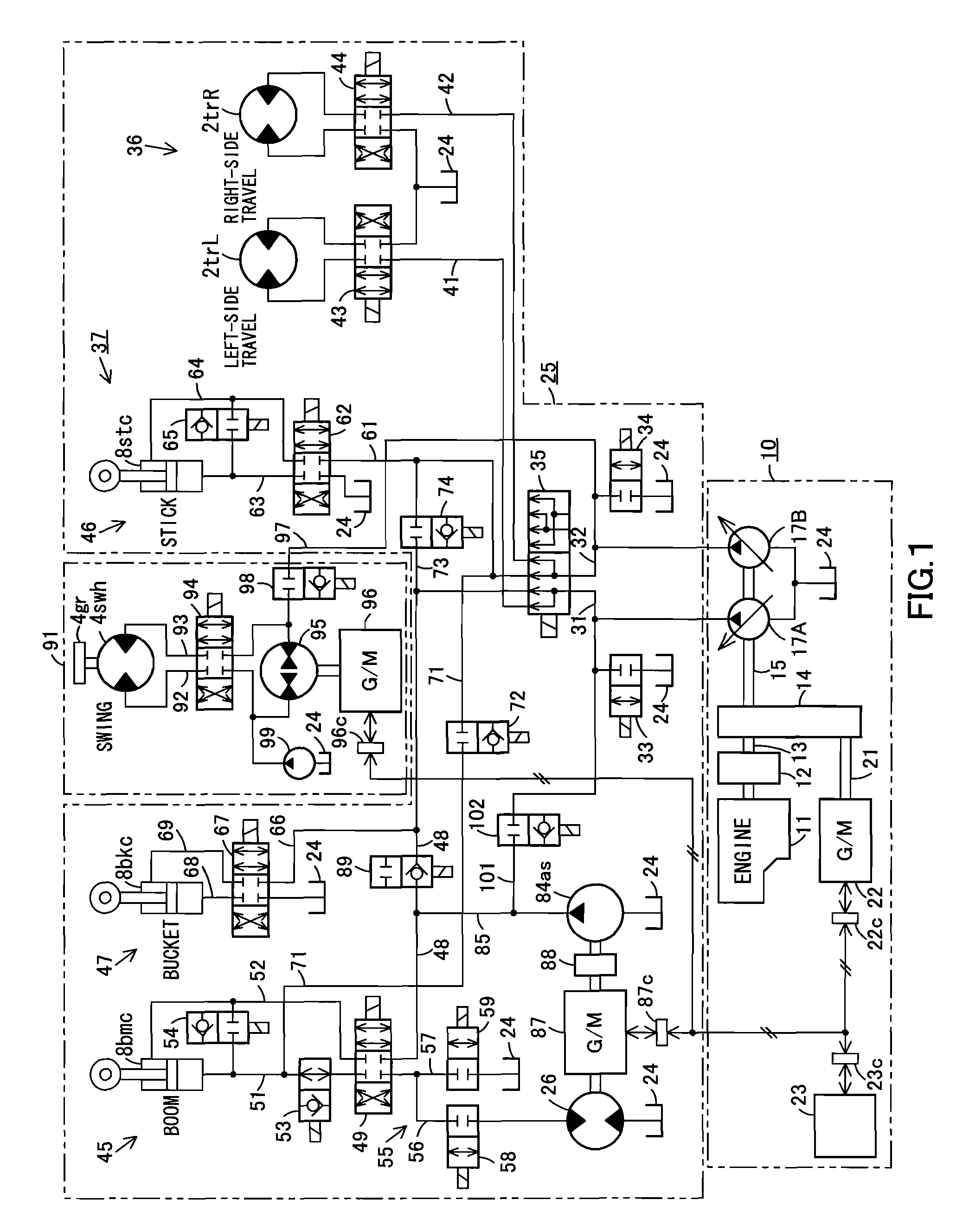

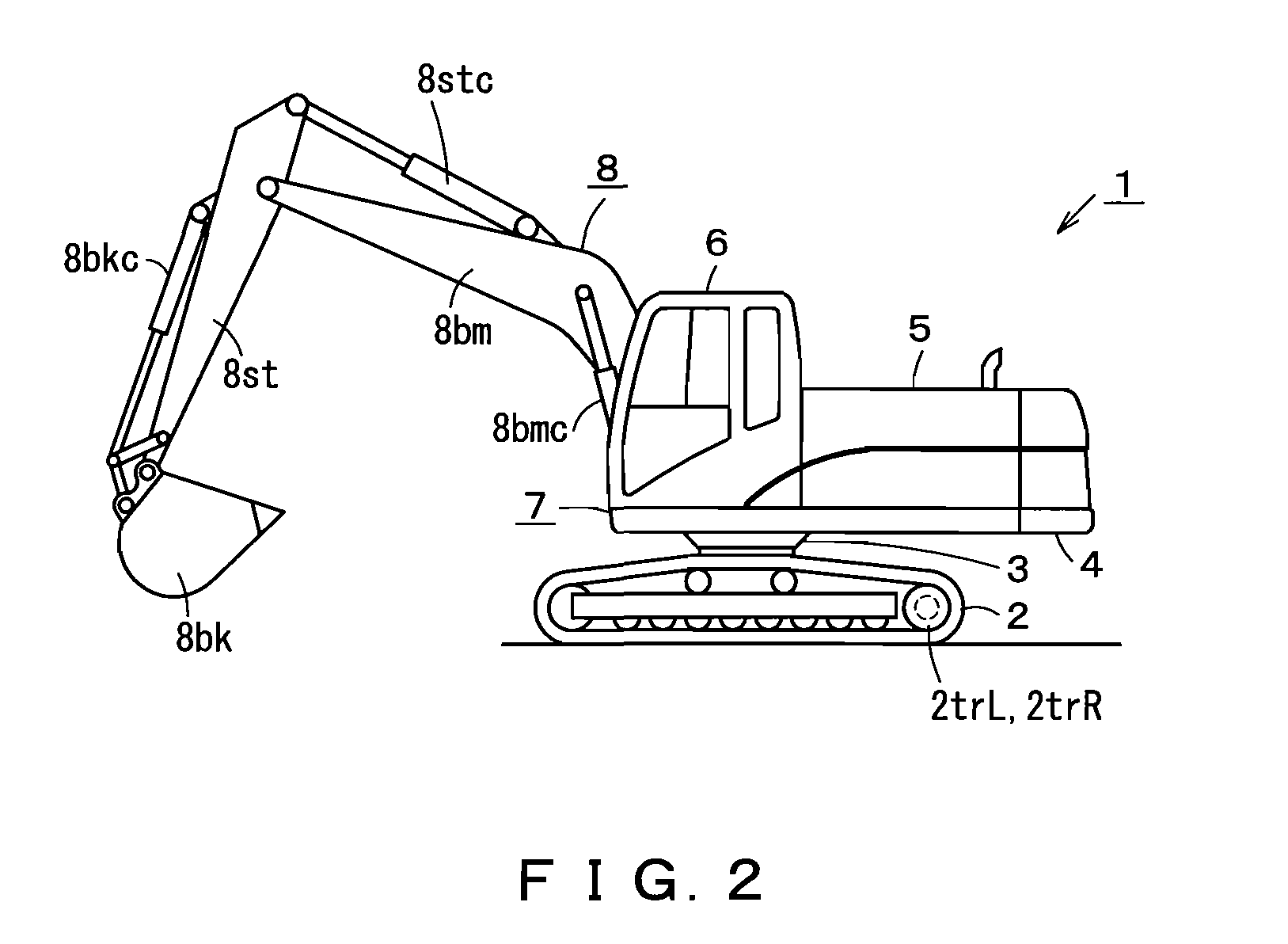

Swing Drive Device and Work Machine

InactiveUS20080314038A1Efficient inputRecovering energy efficientlyFluid couplingsServomotor componentsHybrid typeSolenoid valve

A swing control circuit is provided separately from a hydraulic actuator control circuit. The swing control circuit includes a swing pump motor connected to closed circuits of a swing motor through a solenoid valve that serves as a directional control valve. A swing motor generator is connected to the swing pump motor. The swing motor generator is connected to an electric power storage device of a hybrid type drive system. An exterior-connecting passage for feeding hydraulic fluid to hydraulic actuators of a lower structure and a work equipment is drawn from a pipeline between the swing pump motor and the solenoid valve. A connecting passage solenoid valve is disposed in the exterior-connecting passage. The invention enables hydraulic energy generated in the swing system to be directly fed to the outside of the swing system.

Owner:CATEPILLAR SARL

Hydraulic working machine

ActiveUS20060162543A1Reduce consumptionImprove energy efficiencyServomotor componentsServomotorsHydraulic circuitBottom pressure

A hydraulic circuit for a hydraulic working machine is composed of a main pump 21, a boom cylinder 11 arranged for extension or contraction by pressure oil from the main pump 21, a directional control valve 22 for controlling flows of pressure oil to be fed from the main pump 21 to a bottom chamber 11a and rod chamber 12b of the boom cylinder 11, a control unit 23 for performing a change-over control of the directional control valve 22, a pilot pump 24, a jack-up selector valve 25 for controlling a flow of pressure oil delivered from the pilot pump 24, a flow control valve 26 connected on an upstream side of the directional control valve 22 to a meter-in port of the directional control valve 22 such that the flow control valve 26 can be changed over by the jack-up selector valve 25, and a center bypass selector valve 27 connected on a downstream side of the directional control valve 22 to a center bypass port of the directional control valve 22 such that the center bypass selector valve 27 can be changed over by the jack-up selector valve 25. The hydraulic circuit performs a change-over of the jack-up selector valve 25 in accordance with a bottom pressure on the boom cylinder 11.

Owner:NIHON KENKI CO LTD

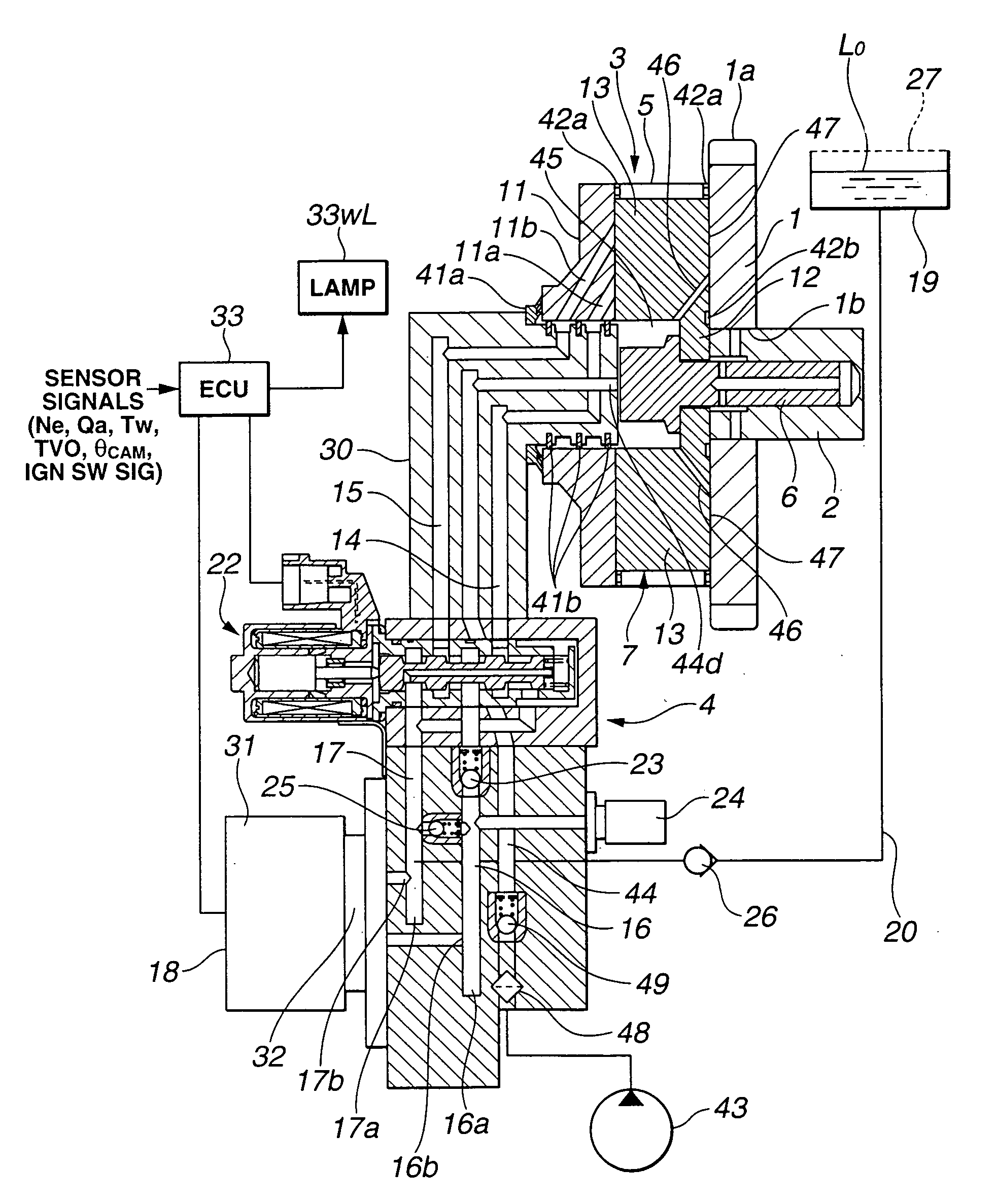

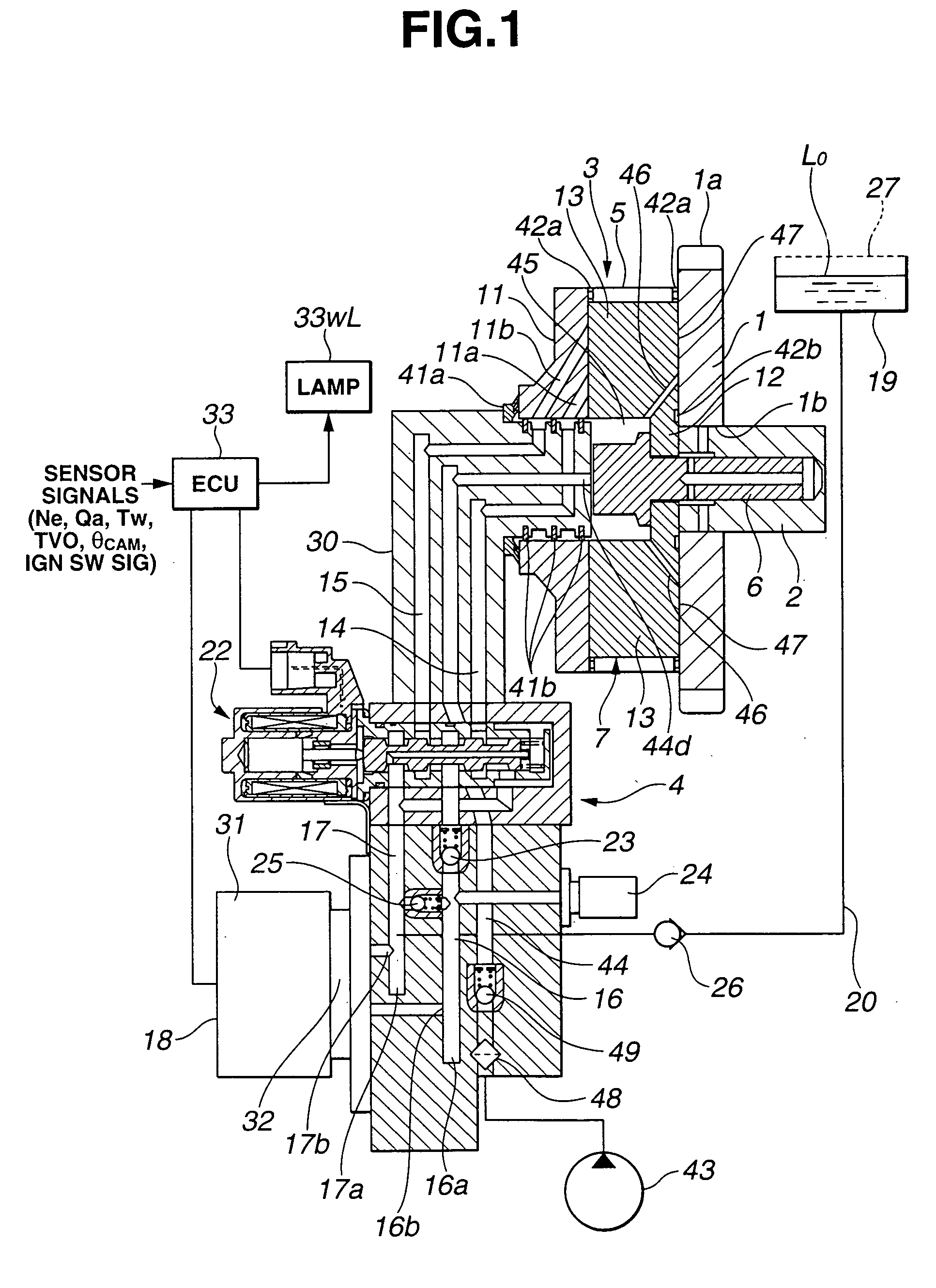

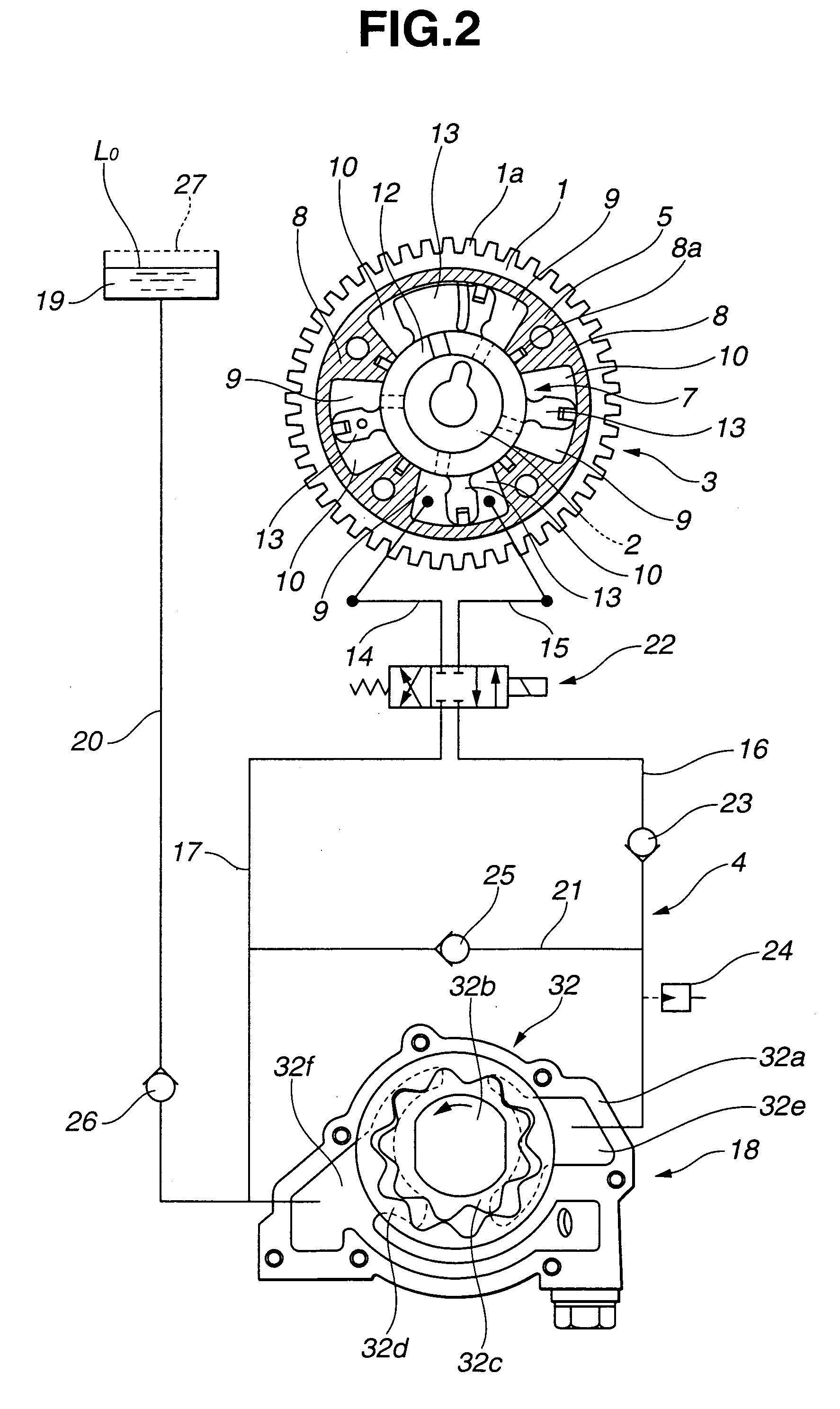

Variable valve timing control system of internal combustion engine

InactiveUS20050257762A1Tendency increaseIncrease system costValve drivesMachines/enginesWorking fluidVariable valve timing

A variable valve timing control system of an internal combustion engine includes a hydraulically-operated phase converter disposed between a sprocket and a camshaft, and having a phase-advance hydraulic chamber and a phase-retard hydraulic chamber for changing an angular phase of the camshaft relative to the sprocket. An electric pump is provided to supply working fluid selectively to one of the hydraulic chambers via a directional control valve. Also provided is a check valve disposed in a discharge line of the pump for permitting flow in a direction that the working fluid flows from the pump to the directional control valve and preventing any flow in the opposite direction, so as to prevent a pulse pressure arising from alternating torque exerted on the camshaft from being transmitted from either one of the hydraulic chambers via the discharge line to a discharge port of the pump.

Owner:HITACHI LTD

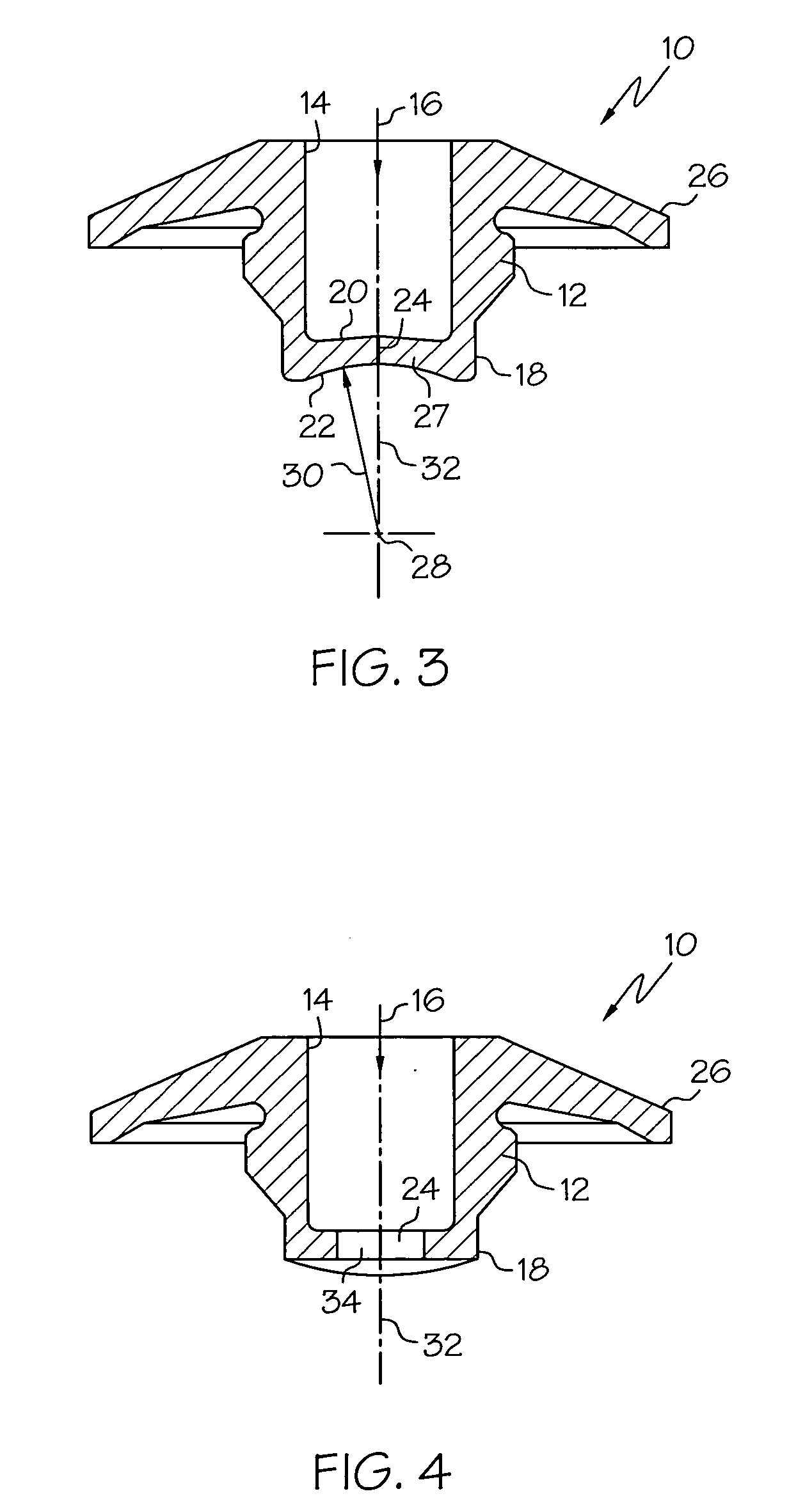

Combination umbrella and inverted bi-directional valve

ActiveUS7243676B2Inhibit transferSufficient pressureClosuresCheck valvesEngineeringMechanical engineering

A combination valve including a valve body having an inverted bi-directional valve portion and an umbrella portion is disclosed. In accordance with one aspect of the invention, a combination valve includes a valve body with a substantially cylindrical portion defining a flow path, a resilient umbrella valve portion extending annularly from the valve body and an inverted bi-directional valve portion provided in the flow path. The inverted bi-directional valve portion includes an interior surface, an exterior surface and at least one normally closed slit extending therebetween, wherein the exterior surface of the inverted bi-directional valve portion includes a generally concave curved portion when the slit is closed.

Owner:VERNAY LAB

Swing drive device and work machine

InactiveUS7565801B2Increase speedIncrease pressureFluid couplingsServomotorsHybrid typeSolenoid valve

A swing control circuit is provided separately from a hydraulic actuator control circuit. The swing control circuit includes a swing pump motor connected to closed circuits of a swing motor through a solenoid valve that serves as a directional control valve. A swing motor generator is connected to the swing pump motor. The swing motor generator is connected to an electric power storage device of a hybrid type drive system. An exterior-connecting passage for feeding hydraulic fluid to hydraulic actuators of a lower structure and a work equipment is drawn from a pipeline between the swing pump motor and the solenoid valve. A connecting passage solenoid valve is disposed in the exterior-connecting passage. The invention enables hydraulic energy generated in the swing system to be directly fed to the outside of the swing system.

Owner:CATEPILLAR SARL

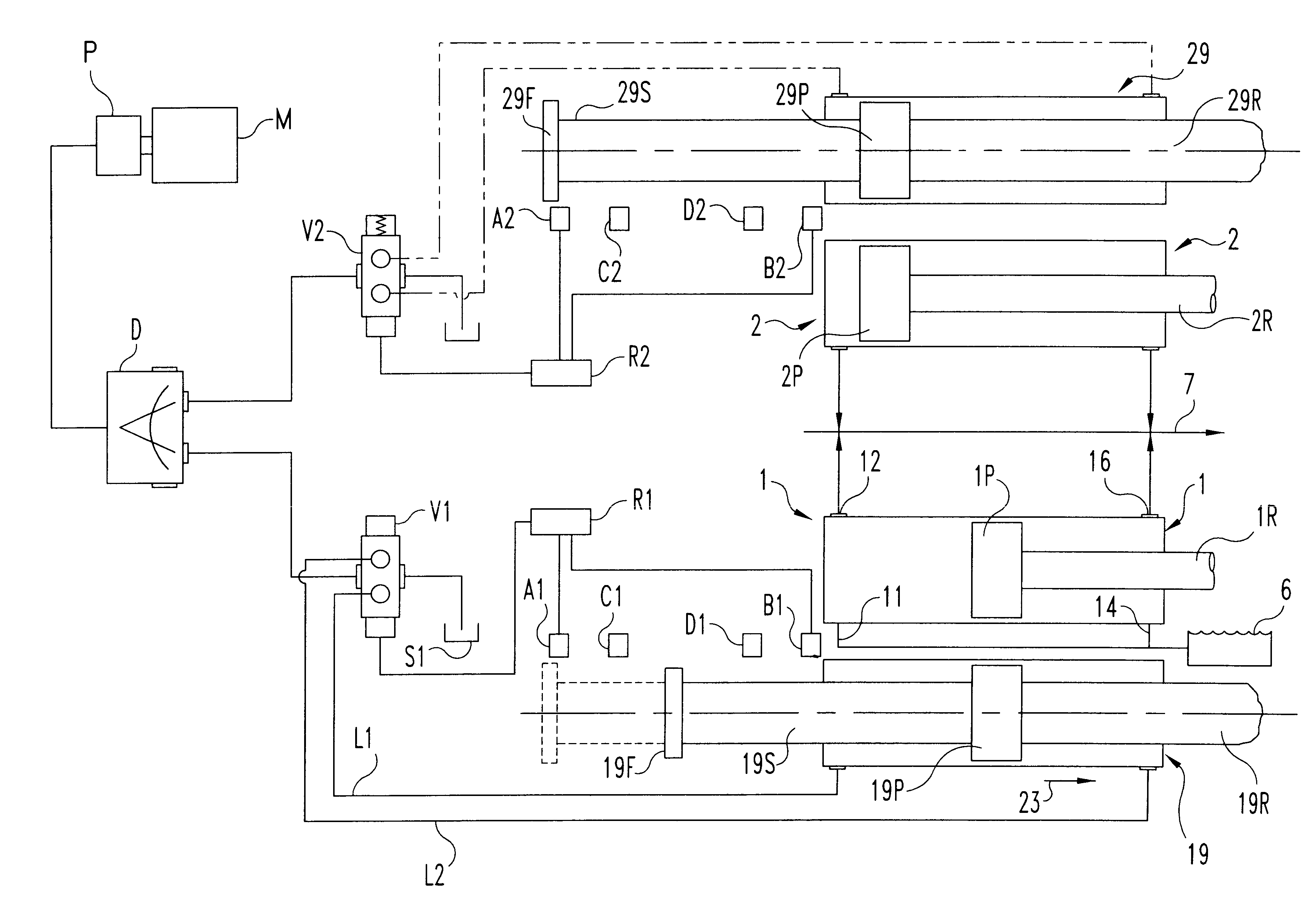

Hydraulic cylinder powered double acting duplex piston pump

A mud pump is provided with two cylinders for pumping mud in connection with water well drilling, and two sets of hydraulic oil cylinders with pistons connected to and driving the pistons of the mud pump by piston rod connecting plates. A flow divider located downstream from a hydraulic oil power supply pump applies hydraulic power evenly to two sets of mud pump driving cylinders, but the flow divider accommodates re-routing of hydraulic oil to one driving cylinder during a directional valve shift for the other driving cylinder. Rod position sensing switches coupled to an electro-hydraulic control system coordinates the action of the sets of pump driving cylinders and thereby of the mud pumping cylinders, to control and phase the mud driving pistons produce a steady mud pump output simulating the effect of constant velocity pistons.

Owner:LAIBE CORP

Air conditioner and control method thereof

InactiveCN102721149AReasonable designEasy to controlSpace heating and ventilation safety systemsSpace heating and ventilation control systemsFour-way valveControl theory

The invention discloses an air conditioner and a control method thereof. The air conditioner comprises an indoor heat exchanger (1), a first electromagnetic valve (2), a throttling gear (3), a second electromagnetic valve (4), a one-way valve (5), a throttling gear (6), a two-position three-way directional control valve (7), a third electromagnetic valve (8), a fourth electromagnetic valve (9), two outdoor heat exchangers (10 and 11), a compressor (13) and a four-way valve (14). The invention provides an air conditioner by which people enjoy a more comfortable environment. The air conditioner is reasonable in design, convenient and practical. The control method of the air conditioner is simple and convenient. The air conditioner which adopts hot gas bypass and independent defrosting mode linked with indoor air supply temperature and indoor coil temperature and operates at a rise frequency in a defrosting process and the control method of the air conditioner are provided.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

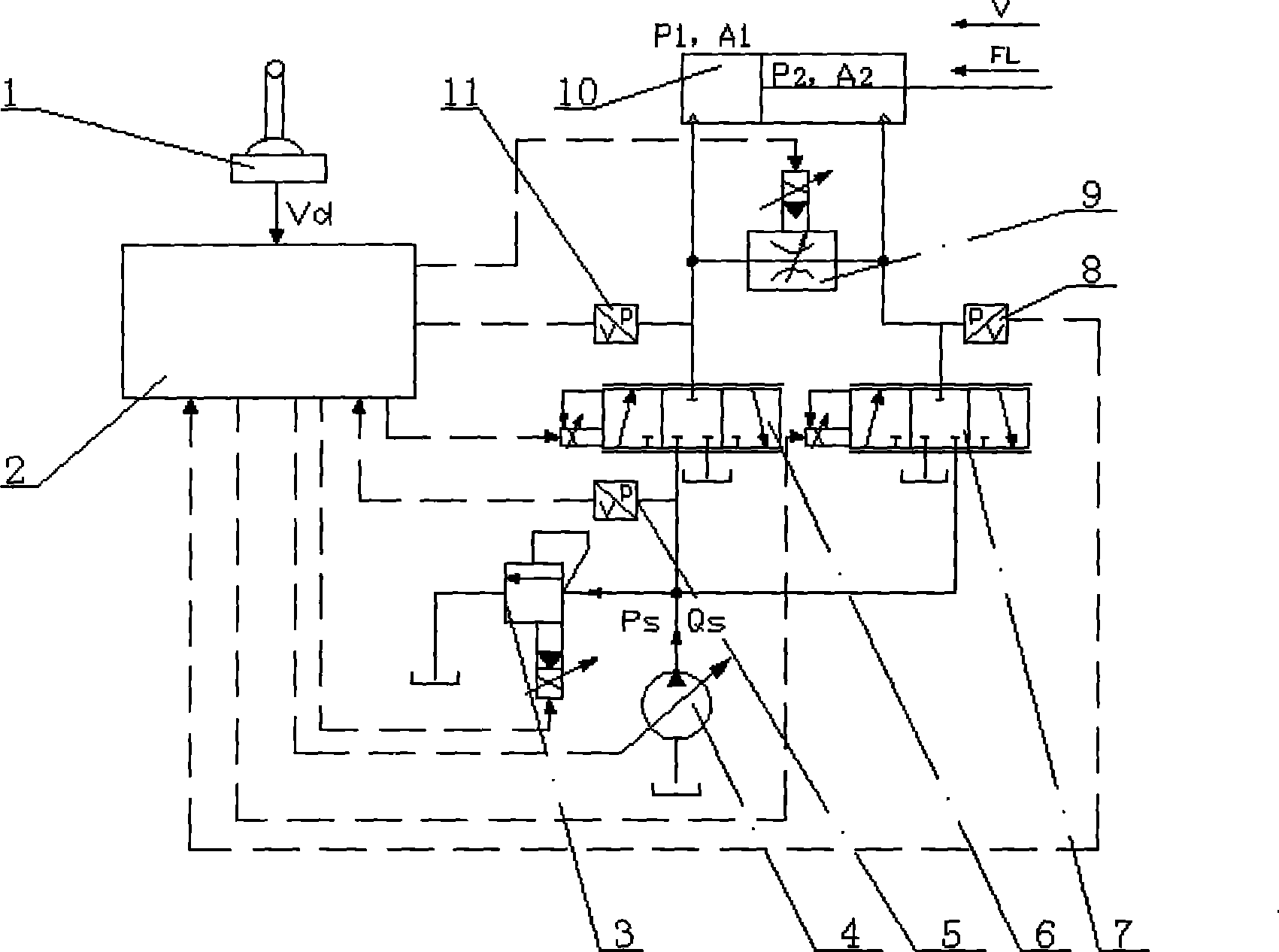

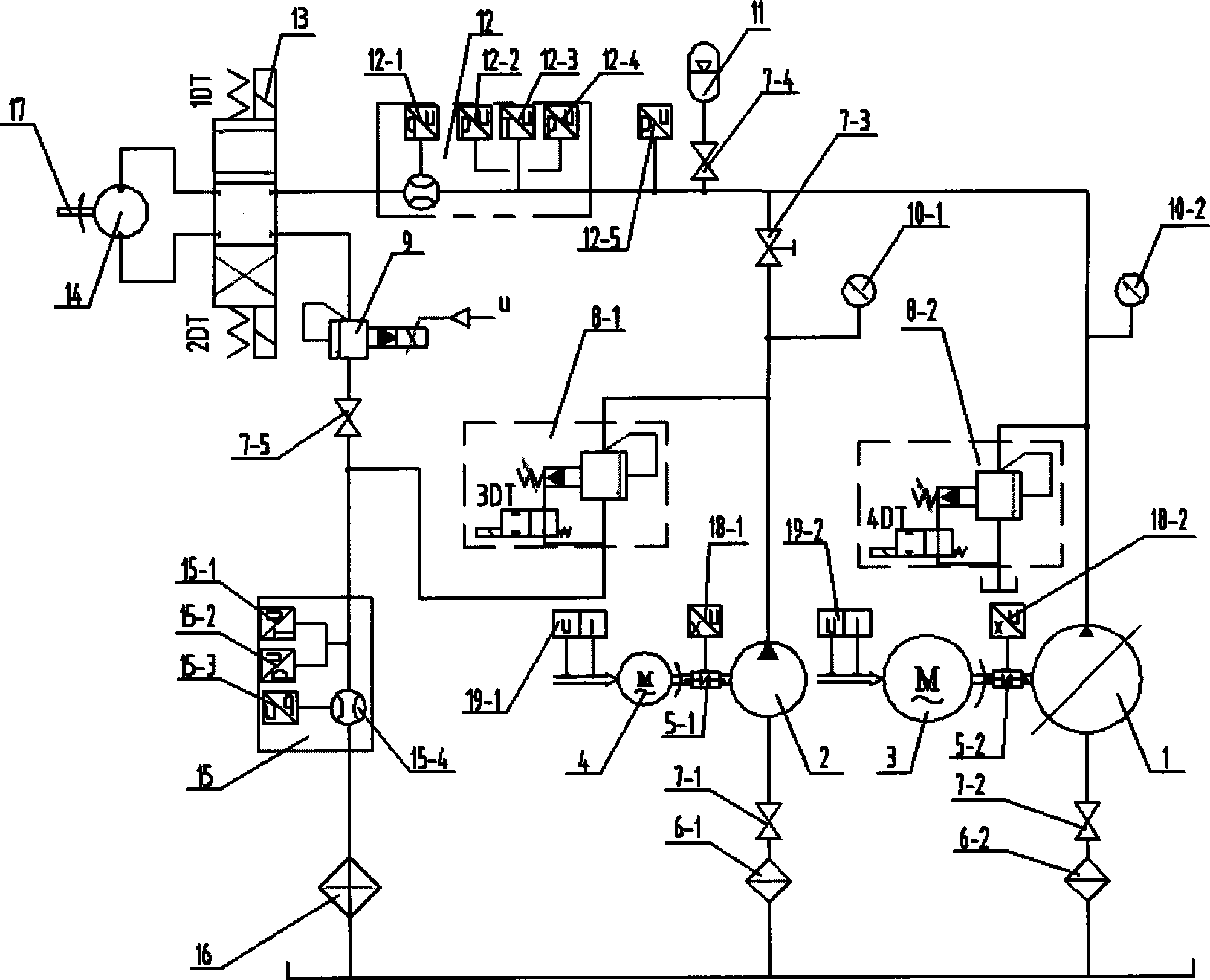

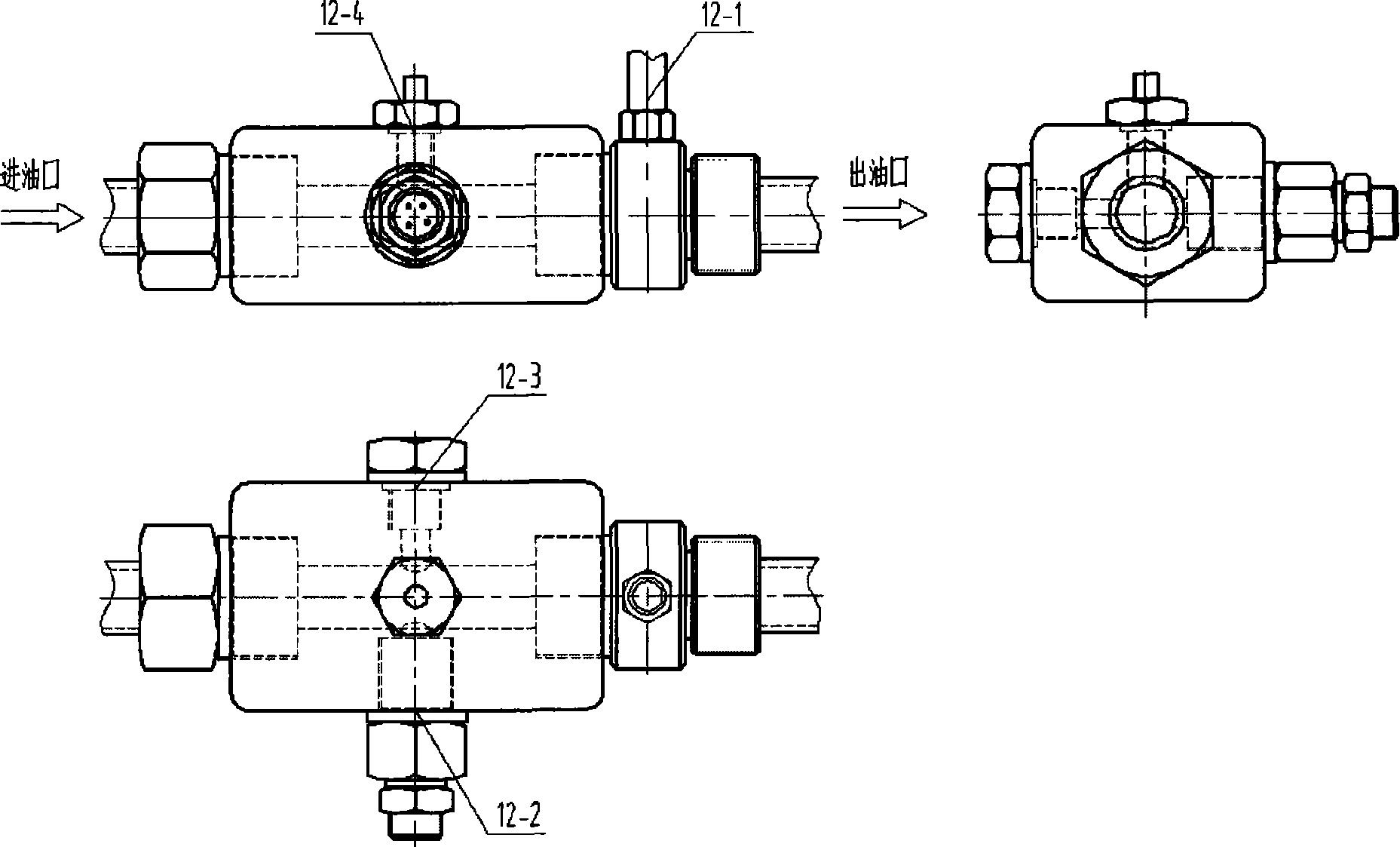

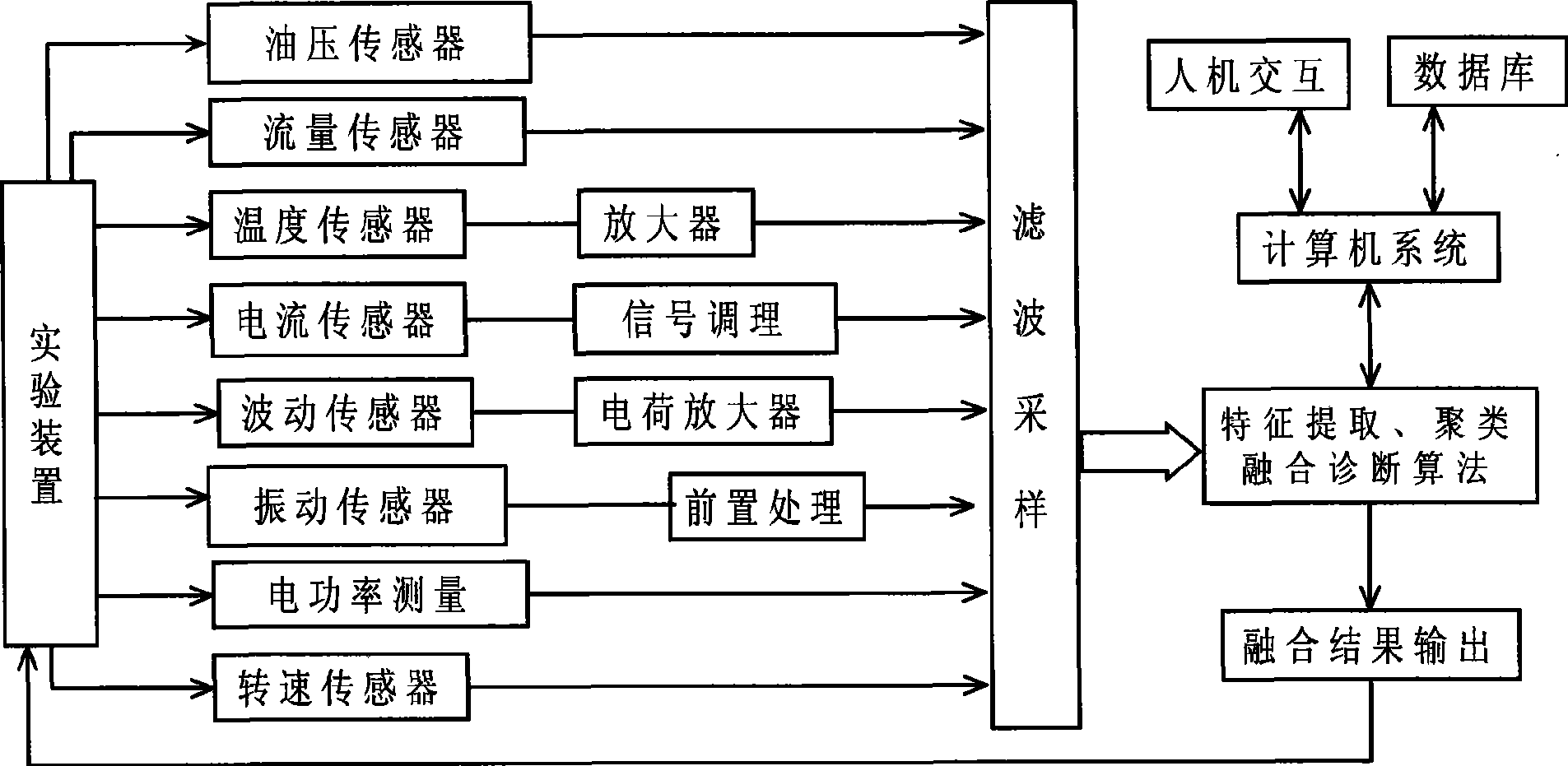

Experimental apparatus and method for obtaining multi-source diagnostic information of hydraulic equipment

InactiveCN101413521ALow efficiencySimple and fast operationFluid-pressure actuator testingSelf organizing map neural networkGear pump

The invention relates to an experimental device and an experimental method for multi-source information fusion for fault diagnosis of a hydraulic device. The device comprises the following elements: a variable plunger pump, a gear pump, two motors, two suction filters, five throttle and stop valves, two electromagnetic relief valves, an electromagnetic proportional relief valve, two pressure meters, an energy accumulator, two sets of combined sensors, a three-position four-way electromagnet directional valve, a hydraulic motor and a cooler. The experimental device can simulate eight typical running states (faults) of the hydraulic device, including low efficiency, oil and liquid pollution, air suction, leakage, oil pump fault, relief valve failure, motor failure and mechanical failure and can perform cluster analysis and fusion diagnosis to characteristics of the eight faults through a self organizing maps neural network.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Valve assembly for controlling fluid ingress and egress from a transportable container which stores and distributes liquid under pressure

InactiveUS6286730B1Enhance self-threading natureLow costPressure pumpsLiquid transferring devicesDetentSlide plate

A valve assembly has (1) a riser pipe including a valve cup housing and portals blockable, and (2) a central tower which communicates with blockable pathways that pass both liquid and gas, and (3) a bi-directional valve member which controls separation of gas and liquid and directional flow in the chamber. A retainer assembly is provided on the outer peripheral surface of the valve cup so as to facilitate insertion of the valve cup into the container but so as to prevent the unintended removal of the valve cup from the container while still permitting selective valve cup removal when it is desired to do so. The retainer assembly preferably includes a protrusion and a pair of centering skids spaced about the outer periphery of the valve cup. The protrusion includes a radially tapered, vertical extending detent portion and a radially tapered, circumferentially extending ramp portion. The centering skids taper radially inwardly from vertically central portions thereof to the vertical end portions thereof. Upon simultaneous twisting and tilting of the valve cup relative to an annular member on the container such as the shoulder of a stub, the centering skids engage the annular member so as to take up the clearance between the valve cup and the annular member, and the protrusion ramps onto the annular member in a self-threading manner so as to circumferentially distort the valve cup and to permit the valve cup to be turned out of the container.

Owner:VENT MATIC +1

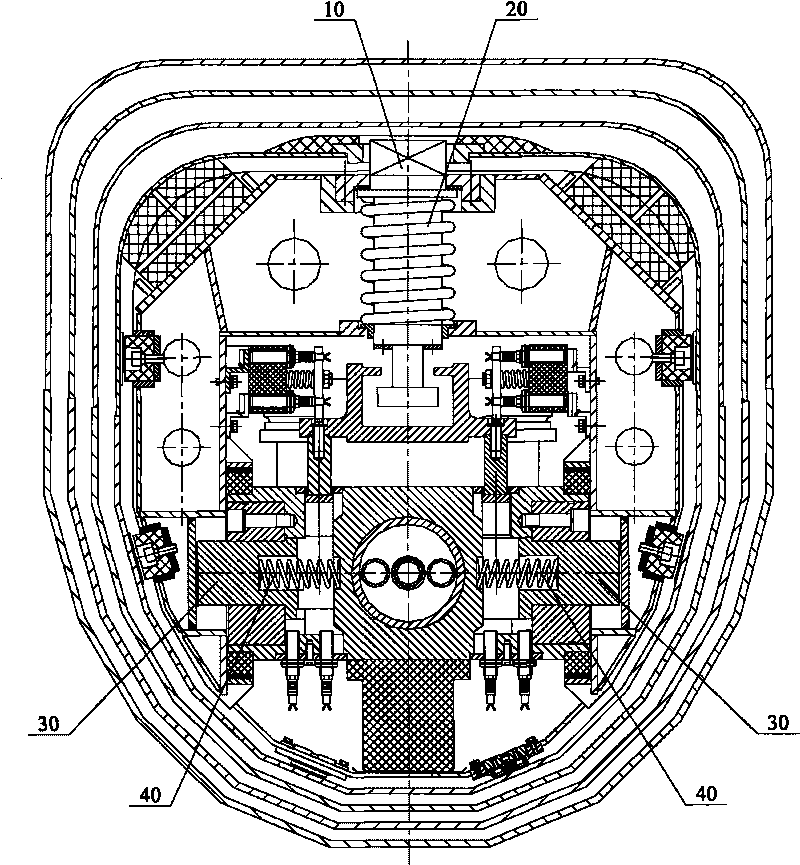

Control system of telescopic boom bolt mechanism

The invention discloses a control system of a telescopic boom bolt mechanism, which comprises an oil tank, a hydraulic pump, a motor and a second directional control valve which are arranged on a telescopic boom, wherein the oil tank is used for storing hydraulic oil; the hydraulic pump is used for outputting the hydraulic oil in the oil tank into a hydraulic circuit; the motor is used for driving the hydraulic pump; and the second directional control valve is used for controlling the route between the hydraulic circuit and the hydraulic pump or the oil tank to be turned on. Preferably, the control system also comprises a third one-way valve, an energy accumulator and a pressure relay; when a pressure value detected by the pressure relay is more than a preset maximum pressure value, the pressure relay outputs control signals to the motor, and the motor is switched off; and when a pressure value detected by the pressure relay is less than the maximum pressure value, the pressure relay outputs control signals to the motor, and motor is switched on. The system has simple and reasonable design, and can effectively avoid the problem that hydraulic volume in a large chamber influences the control response speed, so as to ensure the sensitive and reliable motions of an arm pin hydro cylinder and a cylinder pin hydro cylinder.

Owner:XUZHOU HEAVY MASCH CO LTD

Air supply system for a motor vehicle

InactiveUS7097166B2Simple configurationReduce manufacturing costLiquid springsBraking componentsMobile vehicleClosed loop

In addition to the consumers of a closed loop, known air supply systems also can supply an external consumer with fresh pressurized air. These systems are very complex with respect to apparatus and furthermore have the disadvantage that already improved pressurized air can escape from the pressurized air store during the supply of the external consumer. A switchable 3 / 2-directional valve (31) is arranged in the first consumer pressure line (19) of the drive unit (1) and a switchable 3 / 2-directional valve (32) is mounted in the store pressure line (11) of the drive unit (1) and a switchable check valve is mounted in the bypass line (16) of the store pressure line (11). This check valve disables the throttle function of the bypass throttle (17).

Owner:CONTINENTAL AG

Automatic self cleaning bladder relief and hydration system

InactiveUS7141043B2Minimizing bulkMinimize discomfortNon-surgical orthopedic devicesSuction devicesSemi automaticUrine Collections

Owner:HARVIE MARK R

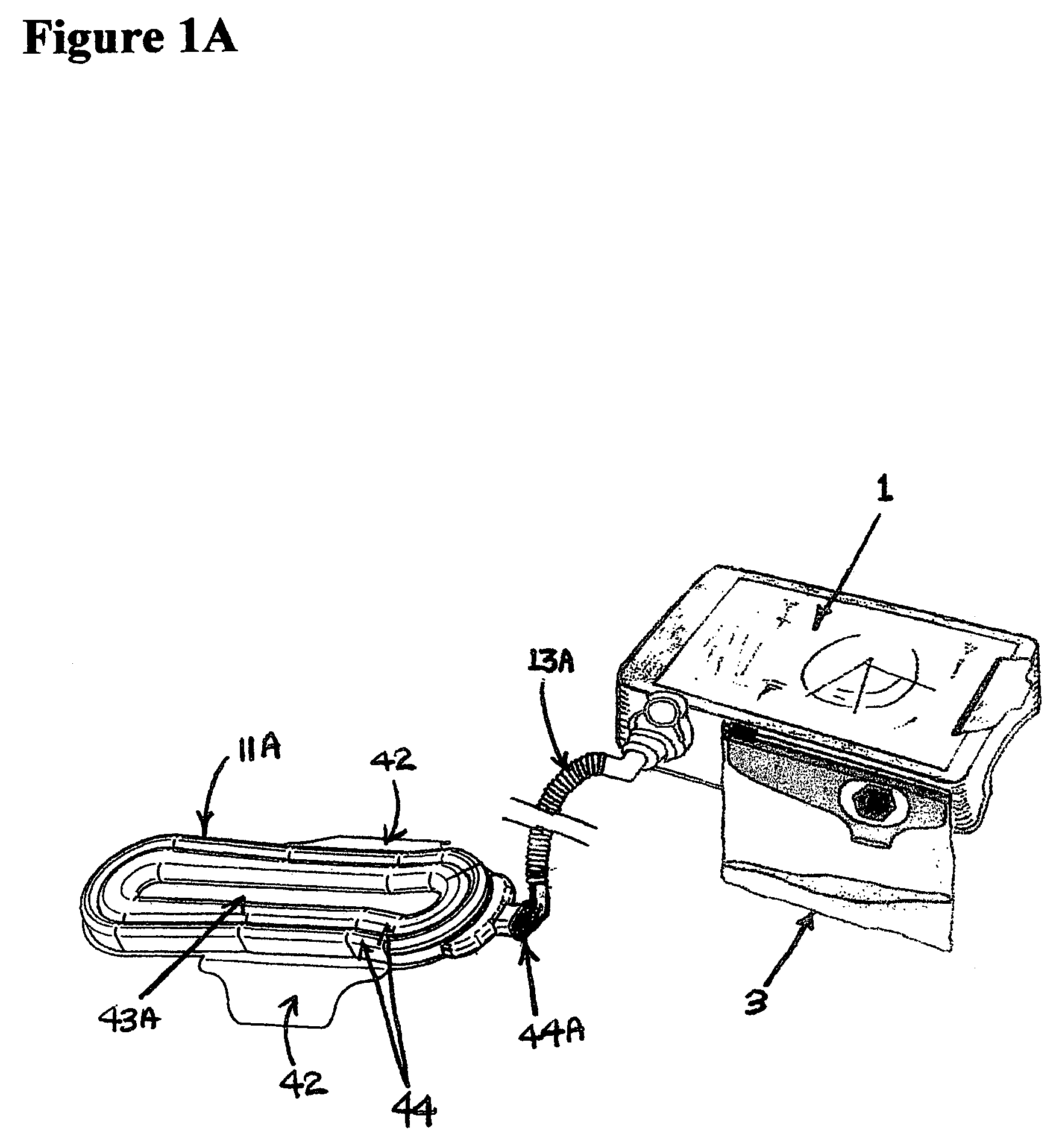

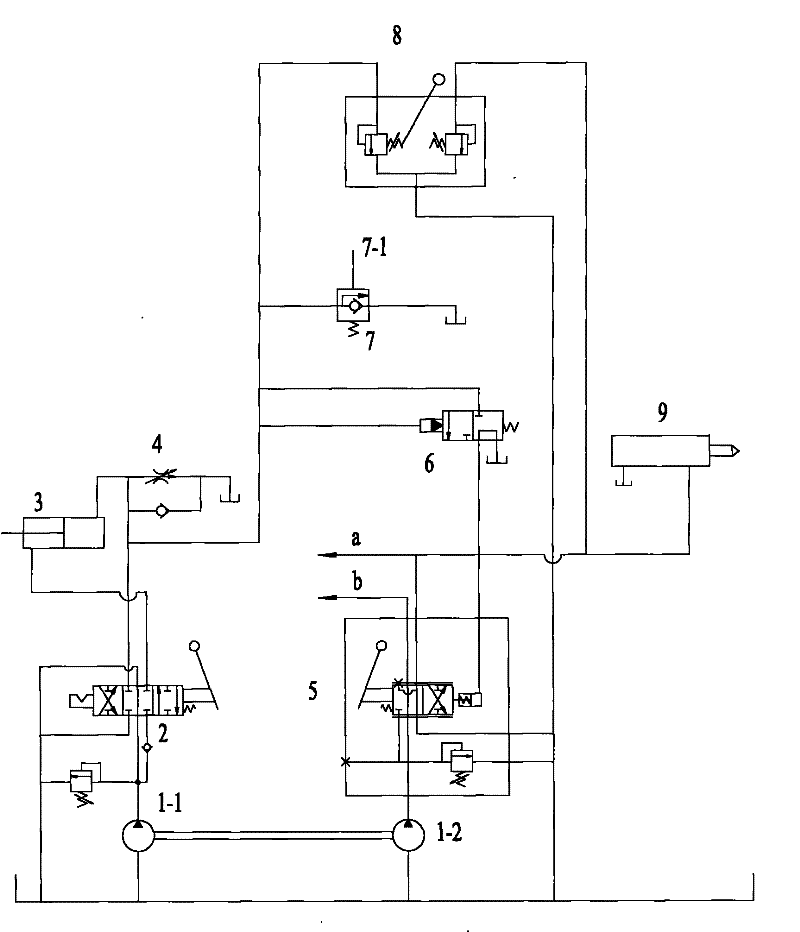

Hydraulic control loop used for jackdrill and control system thereof

InactiveCN101748969AReduce manufacturing costReduce labor intensityServomotorsDrilling drivesPunchingControl system

The invention relates to the technical field of jackdrill and discloses a hydraulic control loop used for jackdrill and control system thereof. The hydraulic control loop used for jackdrill includes a hydraulic pump, a drill rod thrust cylinder, a drill rod spin motor, a solenoid directional valve, a directional valve, an unloading valve and a sequence valve. In the hydraulic control loop used for jackdrill provided by the invention, control valves needing controlling all adopt solenoid valves, and the reversing or flux control of the control valves can be realized by transmitting solenoid control signals to the solenoid valves, and the operation staff do not heed to directly operate the control valves; therefore, the work intensity of the operation staff is smaller, the control performance is good and the defect of inaccurate locating and punching of manual operation can be overcome. One hydraulic pump can simultaneously supply oil to the drill rod thrust cylinder and the jackdrill, can simultaneously implement two motions including boosting and drilling, thus reducing the manufacture cost of the jackdrill. The invention also provides a control system for hydraulic control loop used for jackdrill.

Owner:SANY HEAVY EQUIP

Combination umbrella and inverted bi-directional valve

ActiveUS20050257837A1Inhibit transferSufficient pressureClosuresCheck valvesEngineeringMechanical engineering

A combination valve including a valve body having an inverted bi-directional valve portion and an umbrella portion is disclosed. In accordance with one aspect of the invention, a combination valve includes a valve body with a substantially cylindrical portion defining a flow path, a resilient umbrella valve portion extending annularly from the valve body and an inverted bi-directional valve portion provided in the flow path. The inverted bi-directional valve portion includes an interior surface, an exterior surface and at least one normally closed slit extending therebetween, wherein the exterior surface of the inverted bi-directional valve portion includes a generally concave curved portion when the slit is closed.

Owner:VERNAY LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com