Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

460results about "Proportioning devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

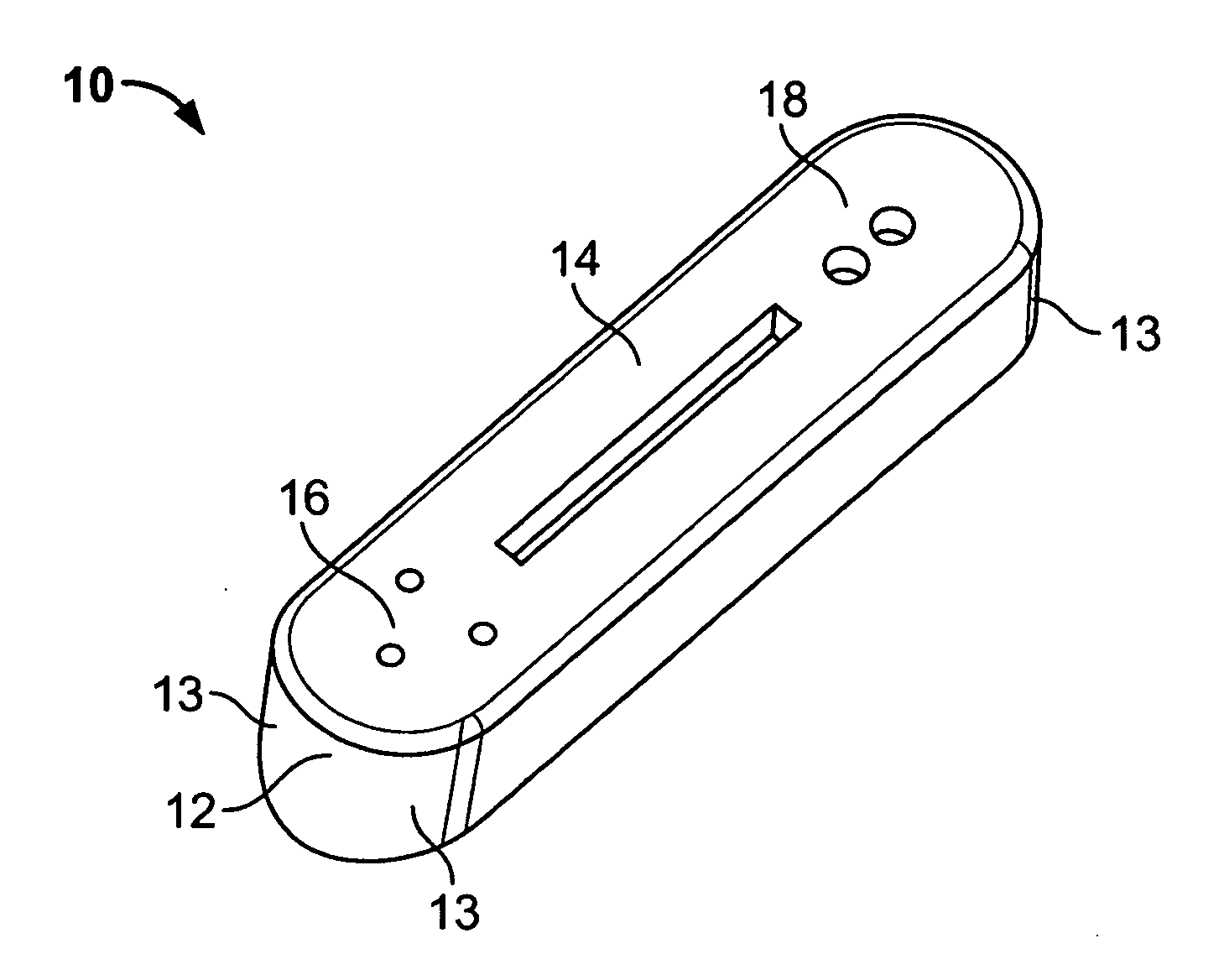

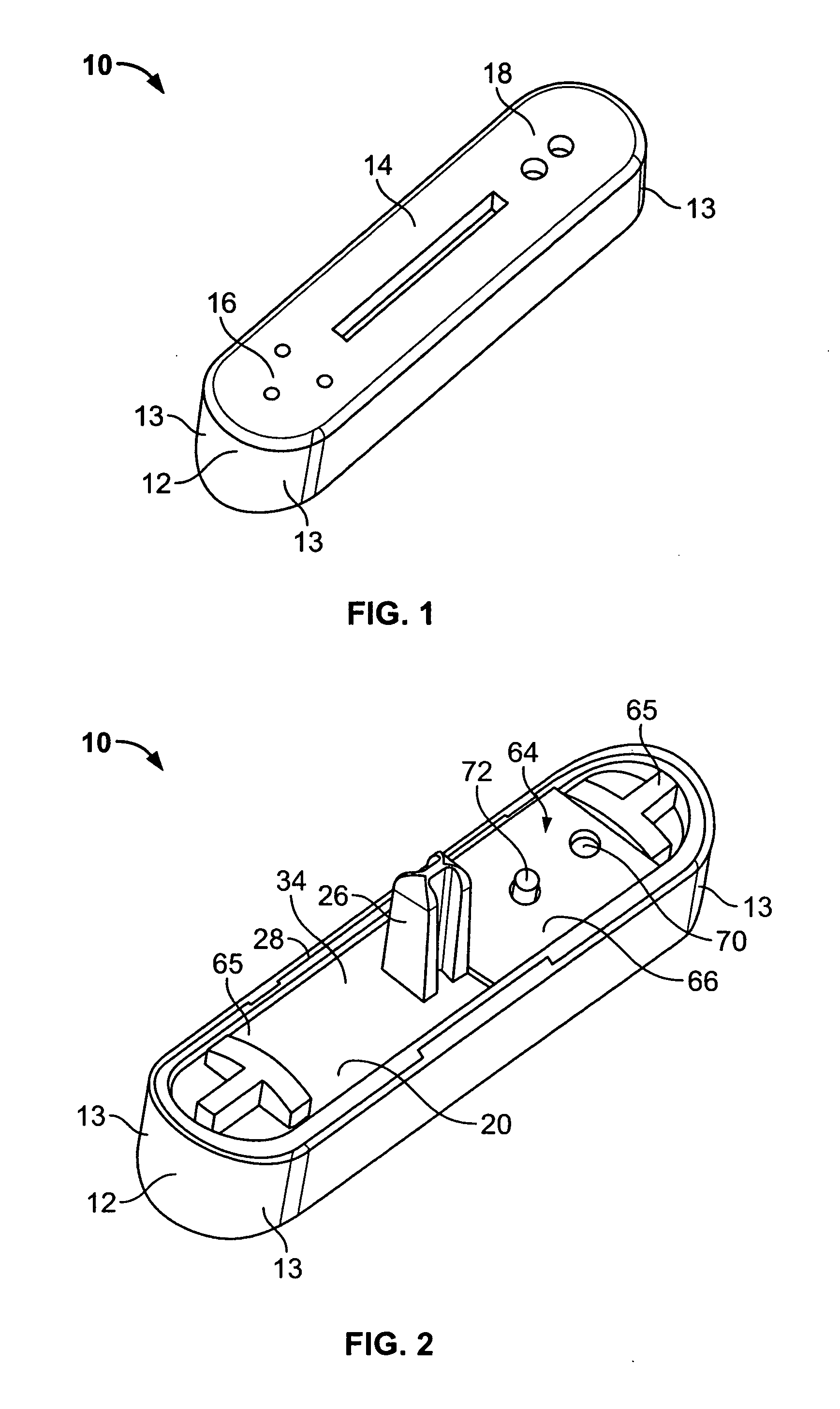

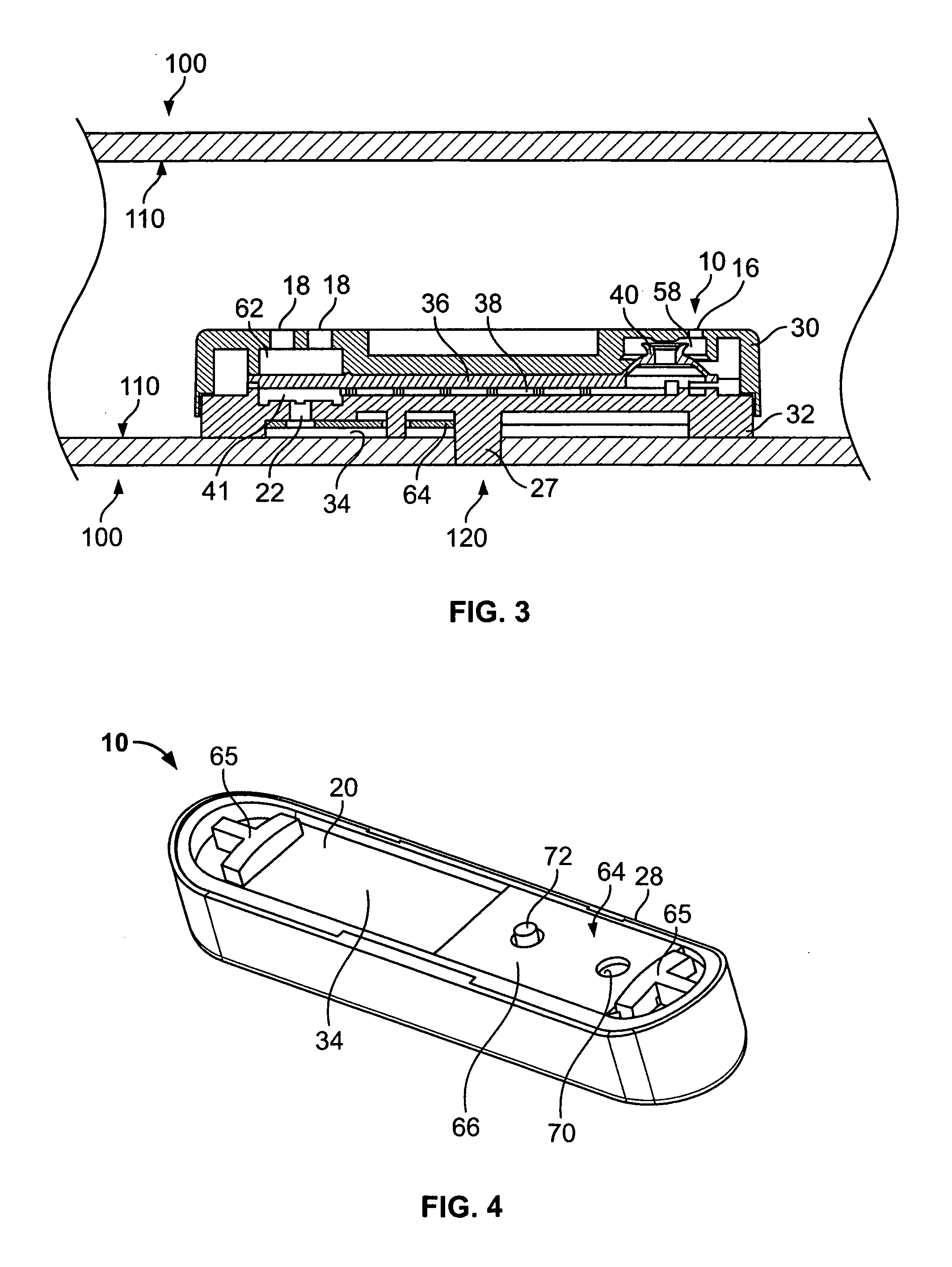

Drip emitter

A drip emitter is provided for delivering irrigation water from a supply tube to an emitter outlet at a reduced and relatively constant flow rate. Water enters the emitter through a first inlet and proceeds into a first chamber. When the water pressure is above a predetermined level, a one-directional valve opens to allow fluid flow past the first chamber, through a tortuous path flow channel, and through an emitter outlet. A second inlet is used to compensate for water pressure fluctuations in the supply tube to maintain output flow at a relatively constant rate. Water enters the second inlet and presses a flexible diaphragm toward a water metering surface to provide pressure-dependent control of the output flow. A copper member is mounted to the emitter over the emitter outlet to prevent plant root intrusion into the emitter outlet.

Owner:RAIN BIRD CORP

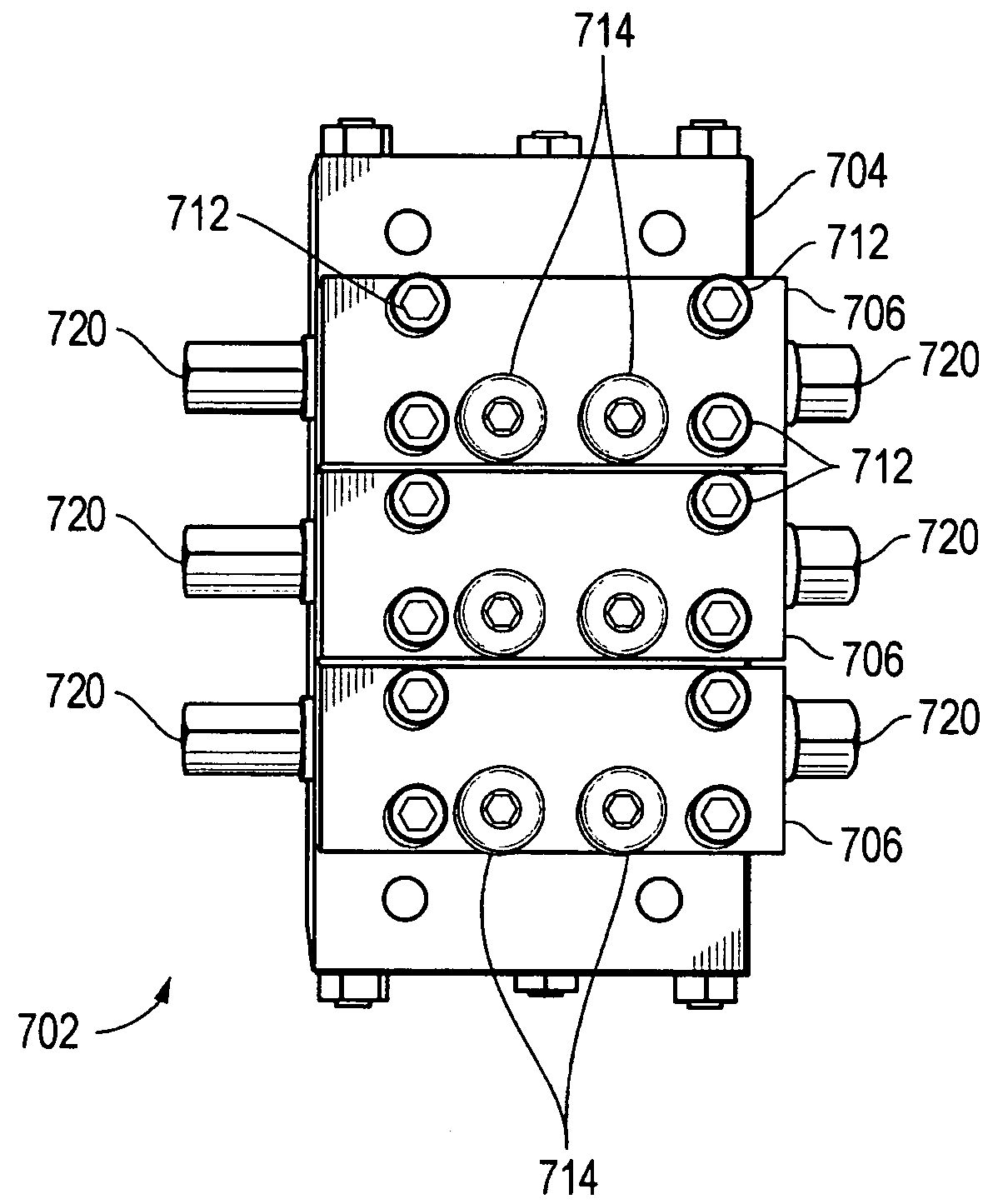

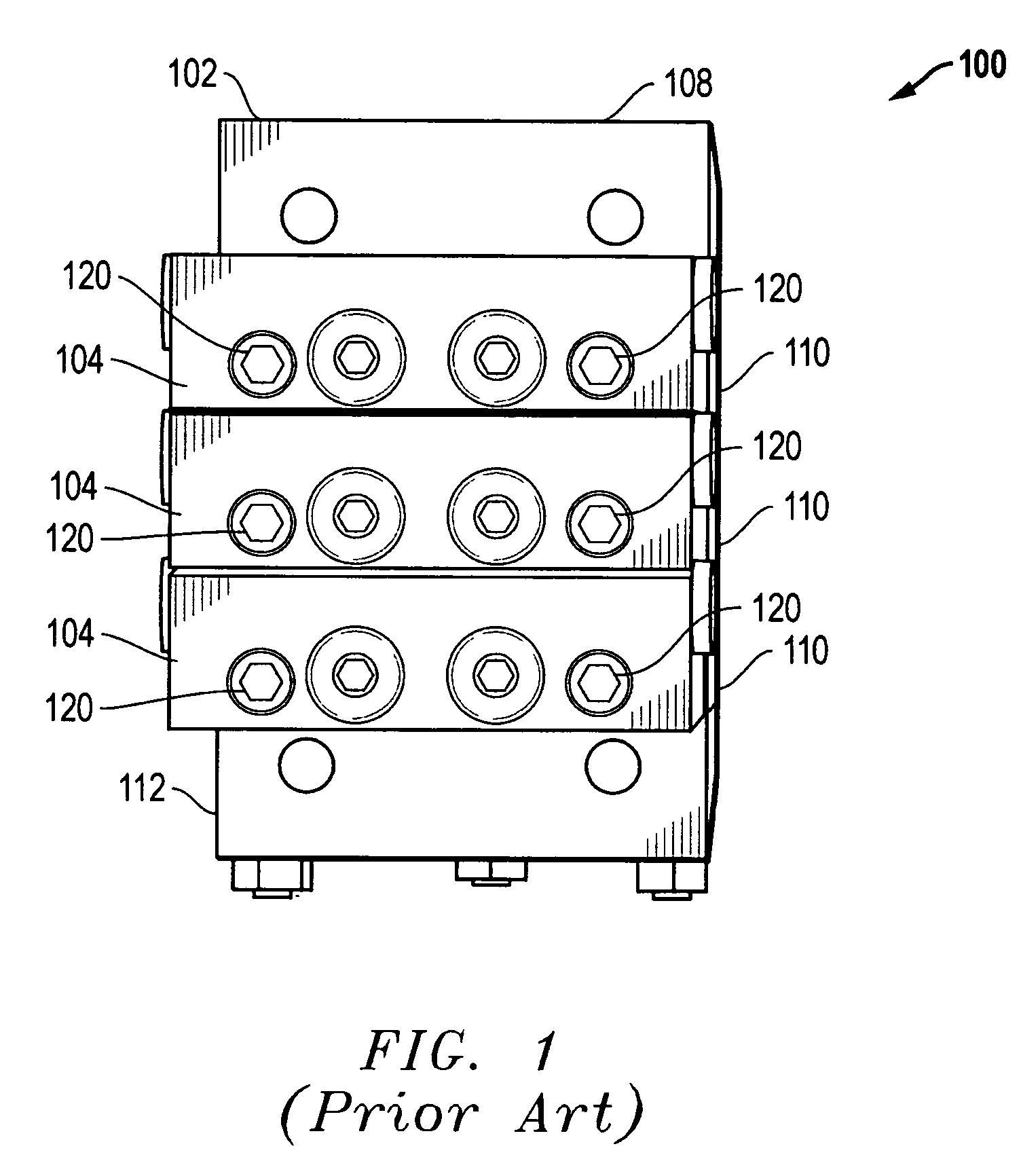

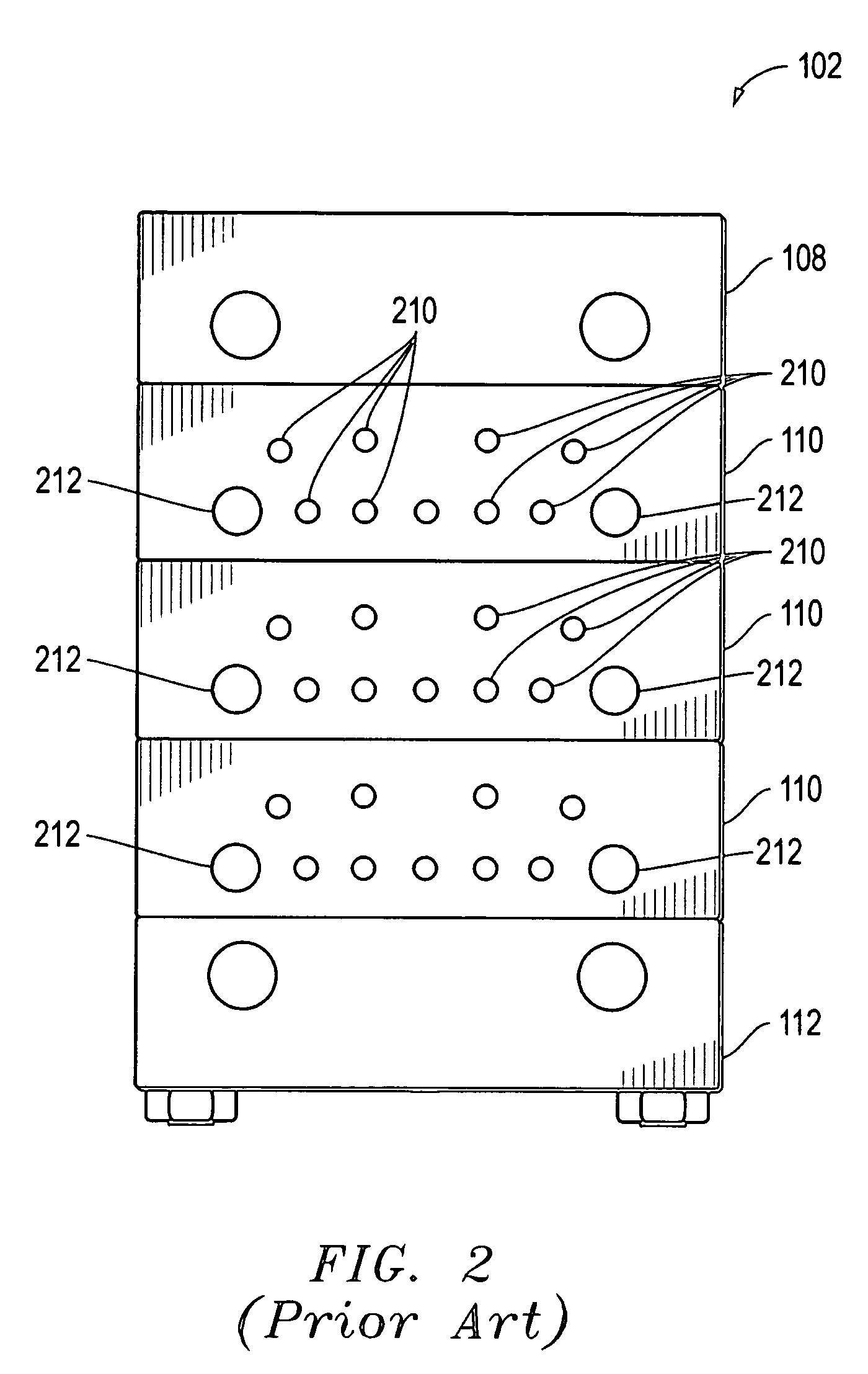

Fluid divider block suitable for use at high pressures

ActiveUS7096889B1Avoid distortionIncreased physical sizeProportioning devicesServomotor componentsEngineeringHigh pressure

The invention is a divider block assembly suitable for use at high fluid pressures. Applicant has found that divider blocks in common use deform sufficient at high pressures to have an adverse affect on accurate fluid delivery and component longevity. A preferred high pressure divider block uses divider block sections engineered for high pressure applications with substantially thicker material surrounding the piston bore, utilizing precise bolt placement on the divider block sections to ensure even pressure to prevent distortion of the piston bore, and engineered base plate inlet and end sections that allow mounting of divider blocks without the addition of extra intermediate sections to reduce leak paths and bolts to secure the base together more firmly, all bolts being torqued to prevent distortion while sealing fluid passages. The use of any of these aspects separately can improve performance, and not all are required in every embodiment.

Owner:COMPRESSOR PROD INT

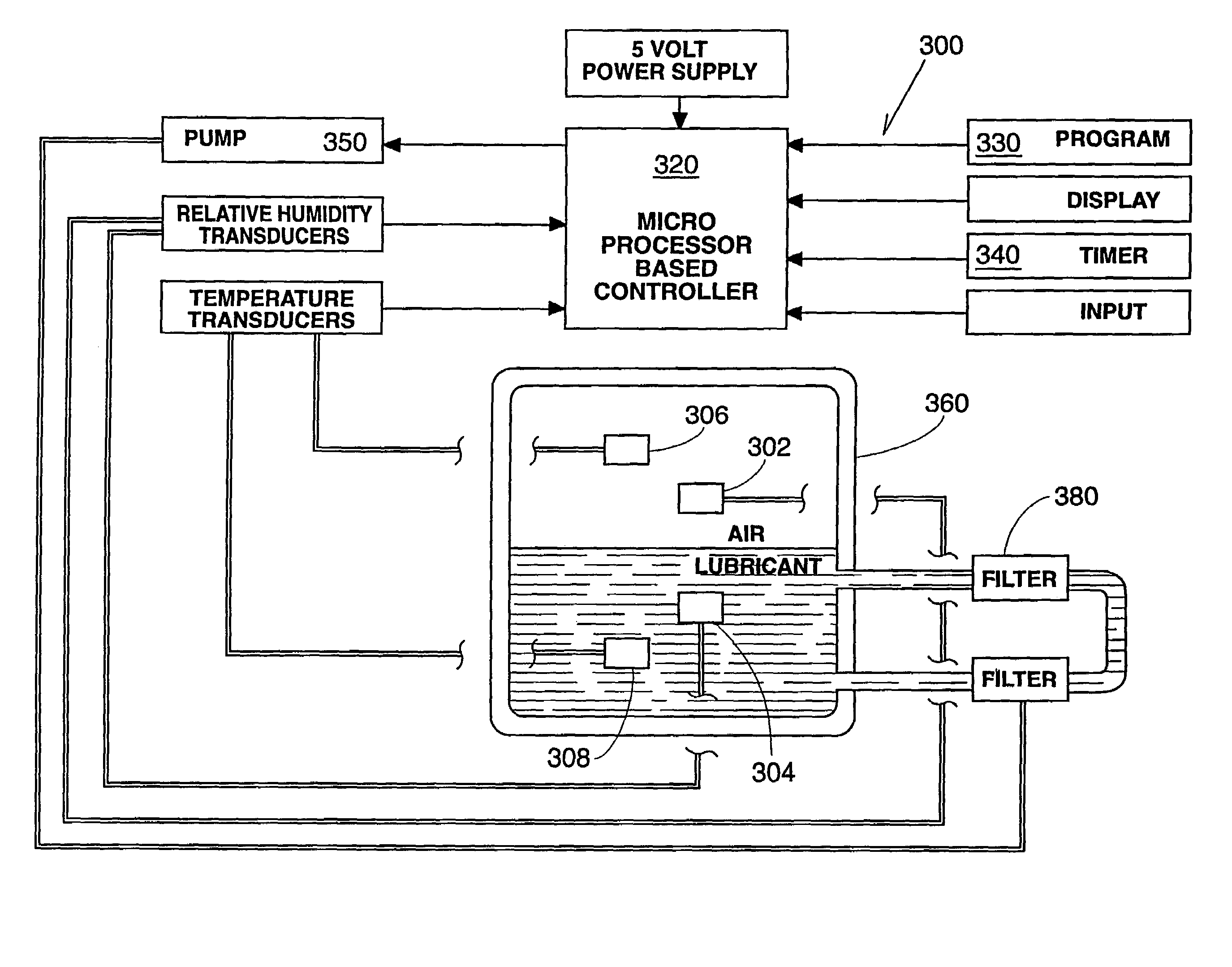

Apparatus and method for lubricant condition control and monitoring

InactiveUS7017712B1More and lessOvercome problemsEngine temperatureEngine pressureProcess engineeringKetone

A volumetric lubricant dispensing apparatus for delivering a precise volume of lubricant, such as oil, to a rotating machine element. The delivery mechanism includes a piston and cylinder assembly. A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. The output from each sensor is inputted into the microprocessor wherein an algorithm computes an responsive output. The responsive output is sent to the piston and cylinder assembly, which maintains an optimum lubricant condition within the reservoir wherein a rotating machine element located. Alternatively, for the purpose of qualitative control, the present invention may be described as a system intended for controlling lubricants, both mineral (natural) and synthetic based by measuring the condition characteristics of the lubricant. Some condition characteristics may include water or moisture content (the content could be any liquid, e.g., solvents like ketones are known to change condition characteristics like viscosity) and viscosity. Viscosity is related to temperature, therefore, temperature correlation to viscosity is helpful to provide relative indications for condition characteristics like lubricant flow.

Owner:TRICO CORP

Apparatus and method for lubricant condition control and monitoring

A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. A stand-alone humidity sensor mechanism is disclosed, in which signal process circuitry is electrically coupled to a humidity sensor, designed to be attached to the mechanism to be monitored so that it is juxtaposed in the atmosphere above the lubricant material that is being monitored.

Owner:TRICO CORP

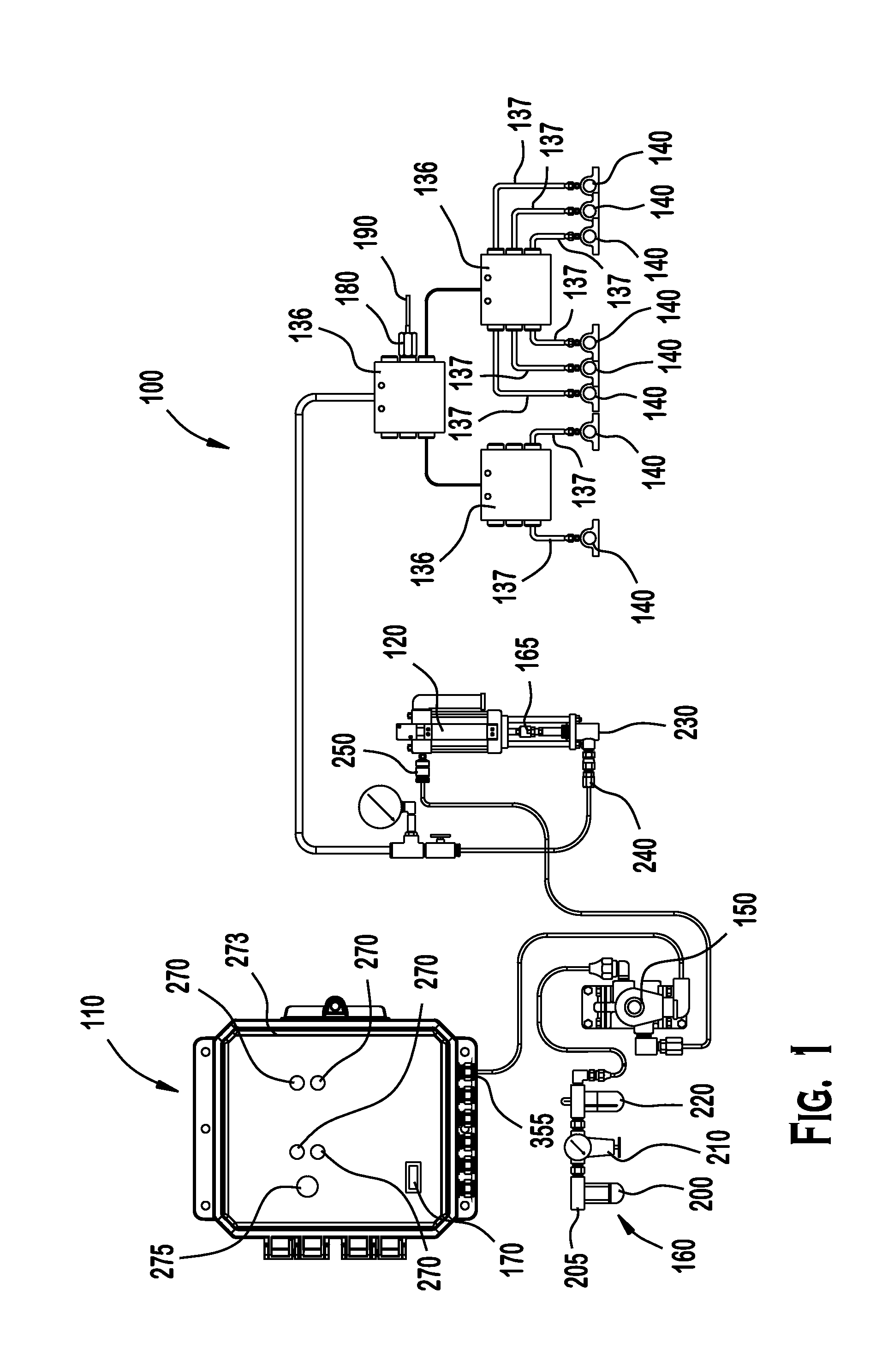

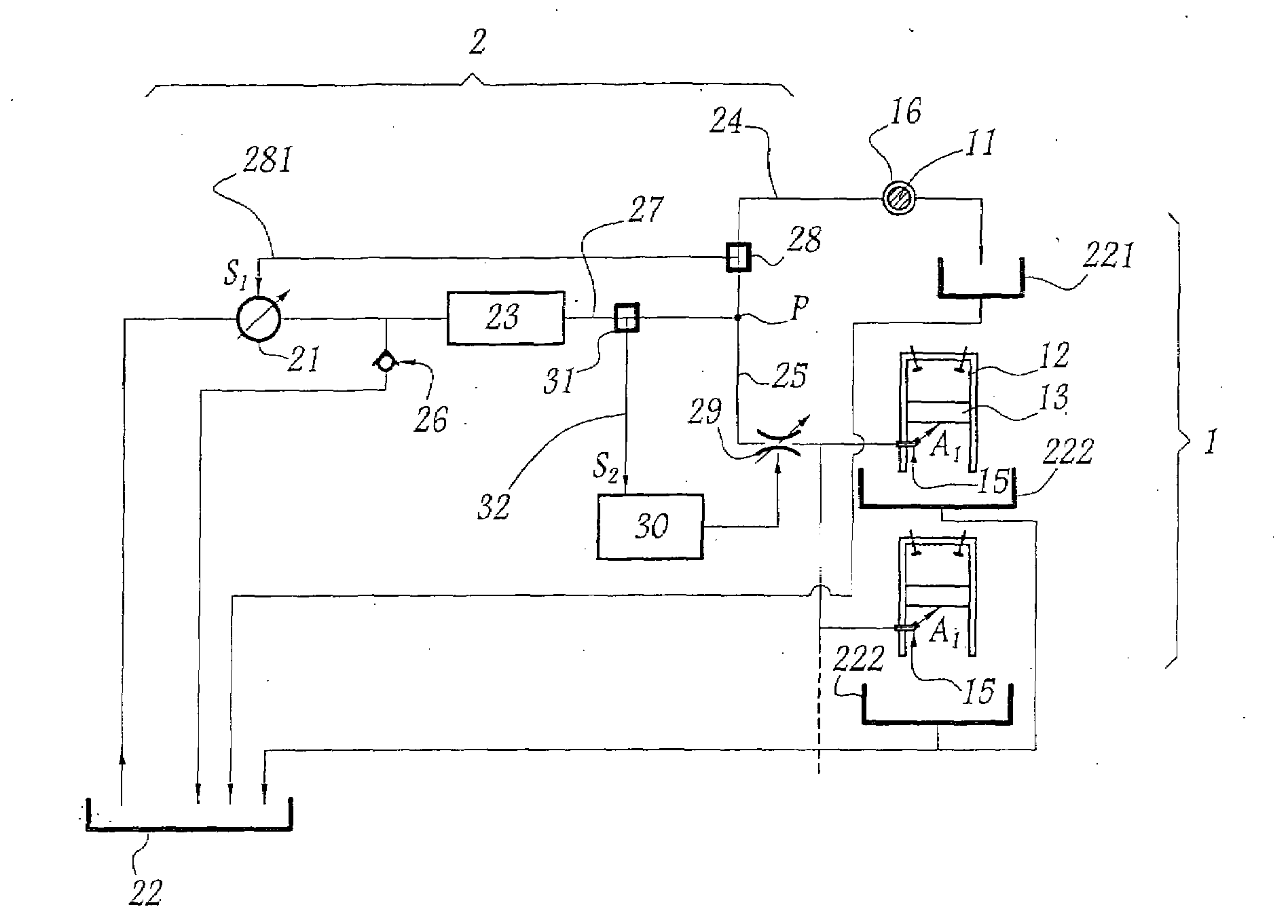

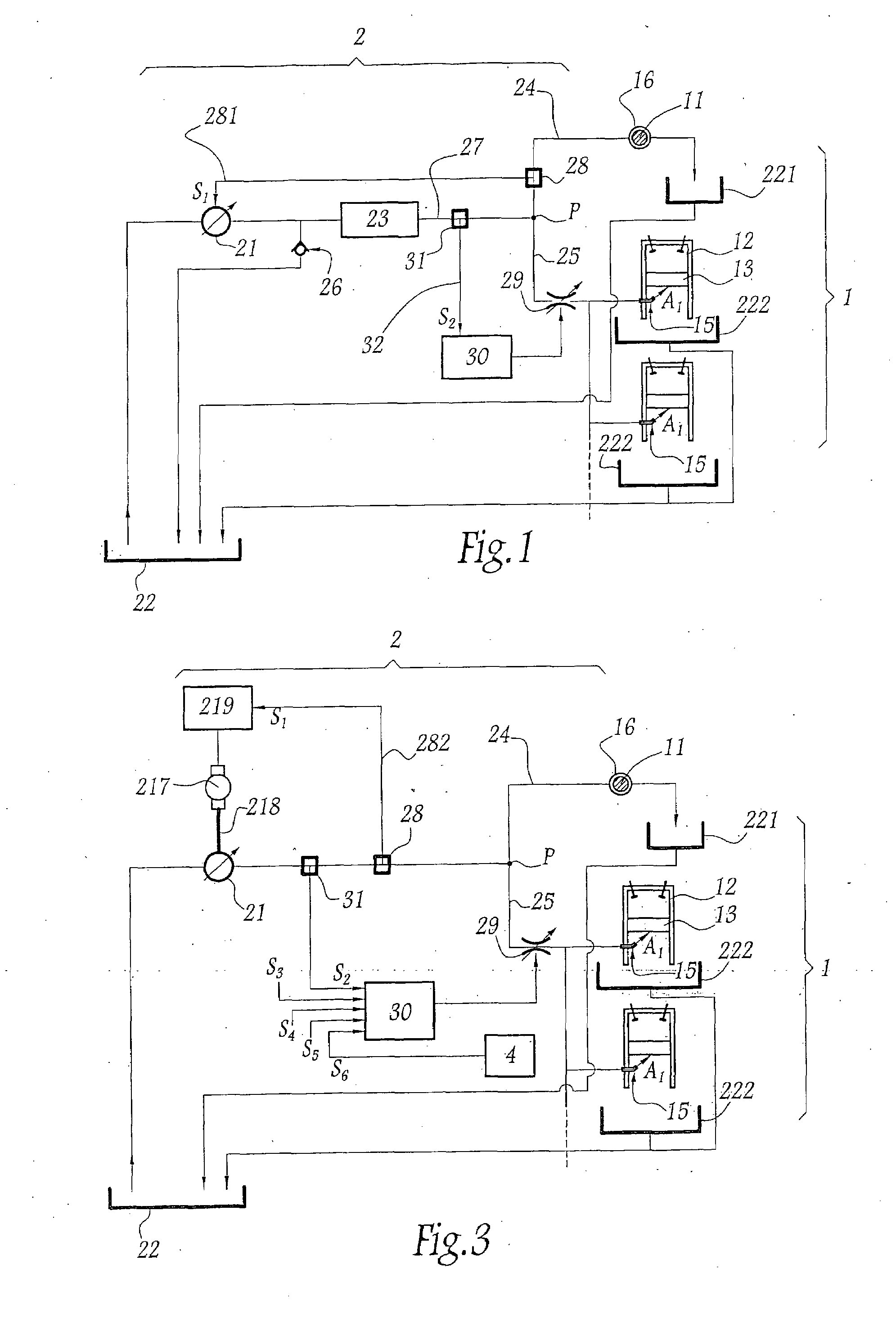

Lubrication system and controller

A lubrication system for lubricating bearings that includes at least one lubrication pump for pumping lubricant to the bearings and at least one metering valve for distributing the pumped lubricant throughout the lubrication system to the bearings. The system further includes a lubrication controller in communication with the at least one lubrication pump and at least one metering valve for controlling the lubrication system. The controller has firmware configured to provide a sequence of instructions to perform specified tasks and hardware that carries out the sequence of instructions to perform the specified tasks. In an unconfigured and unconnected state, the lubrication controller can be configured by reprogramming the firmware, to selectively control at least one of a series progressive lubrication system, a dual line lubrication system and a single line parallel lubrication system.

Owner:LINCOLN INDUSTRIES CORP

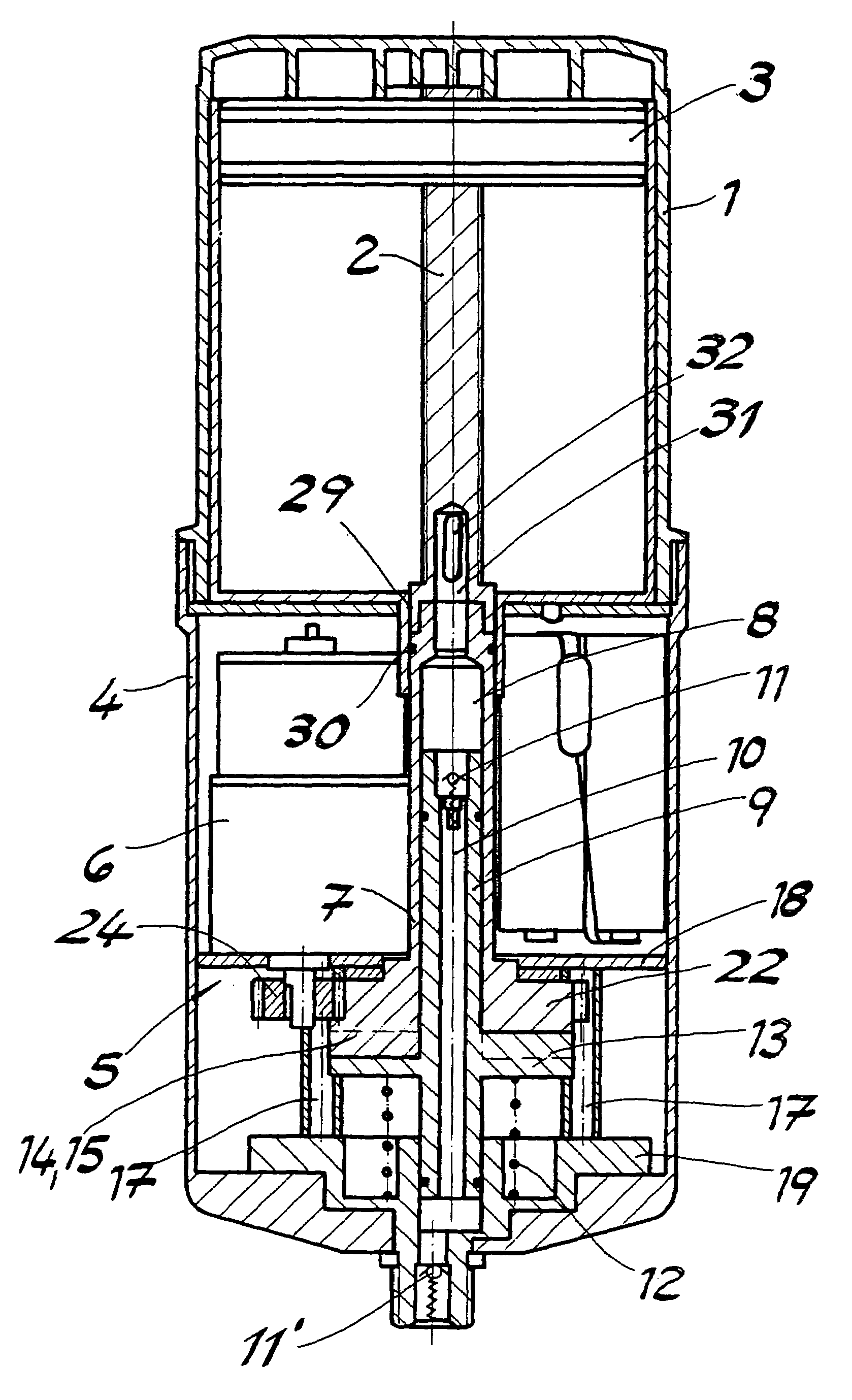

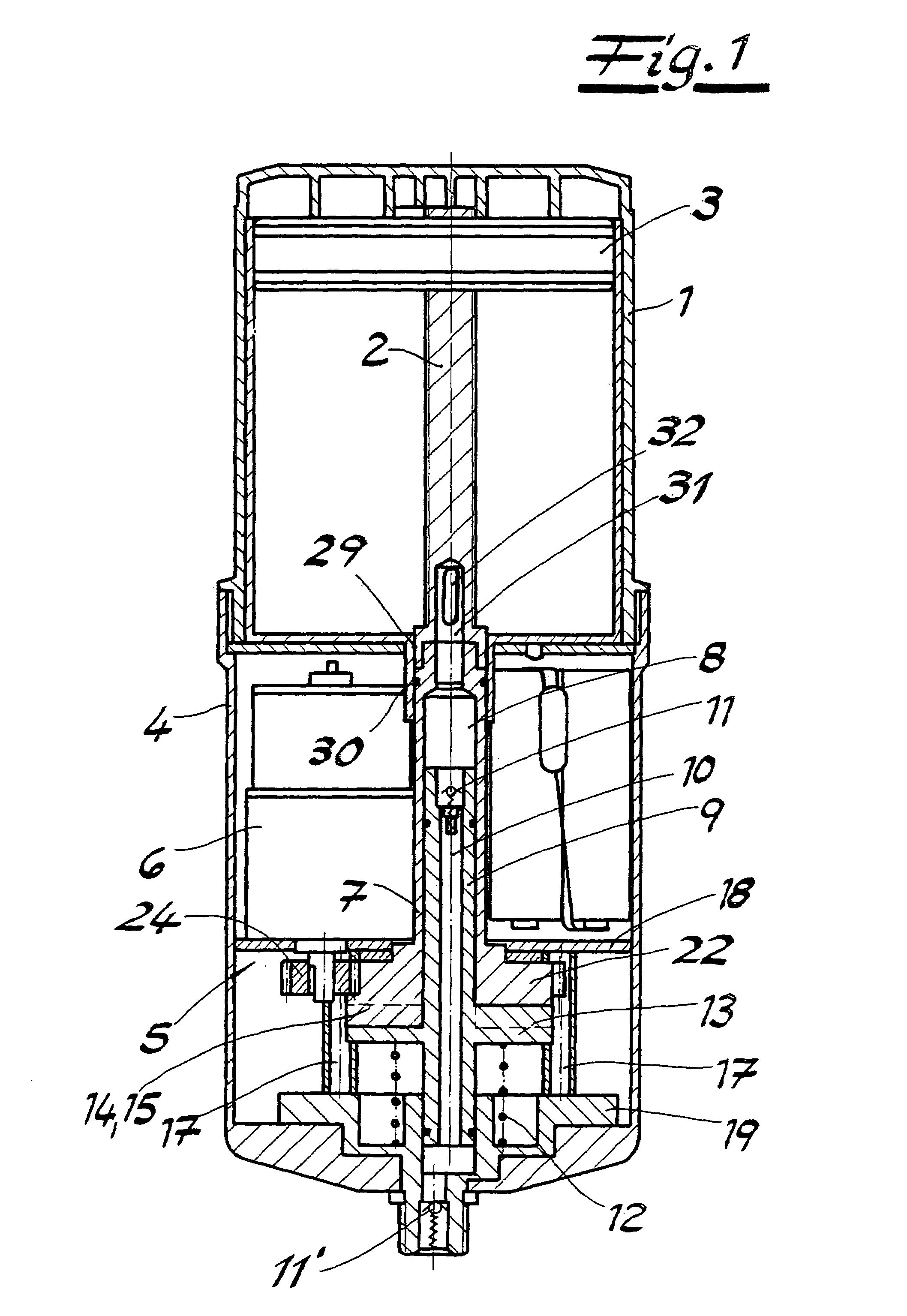

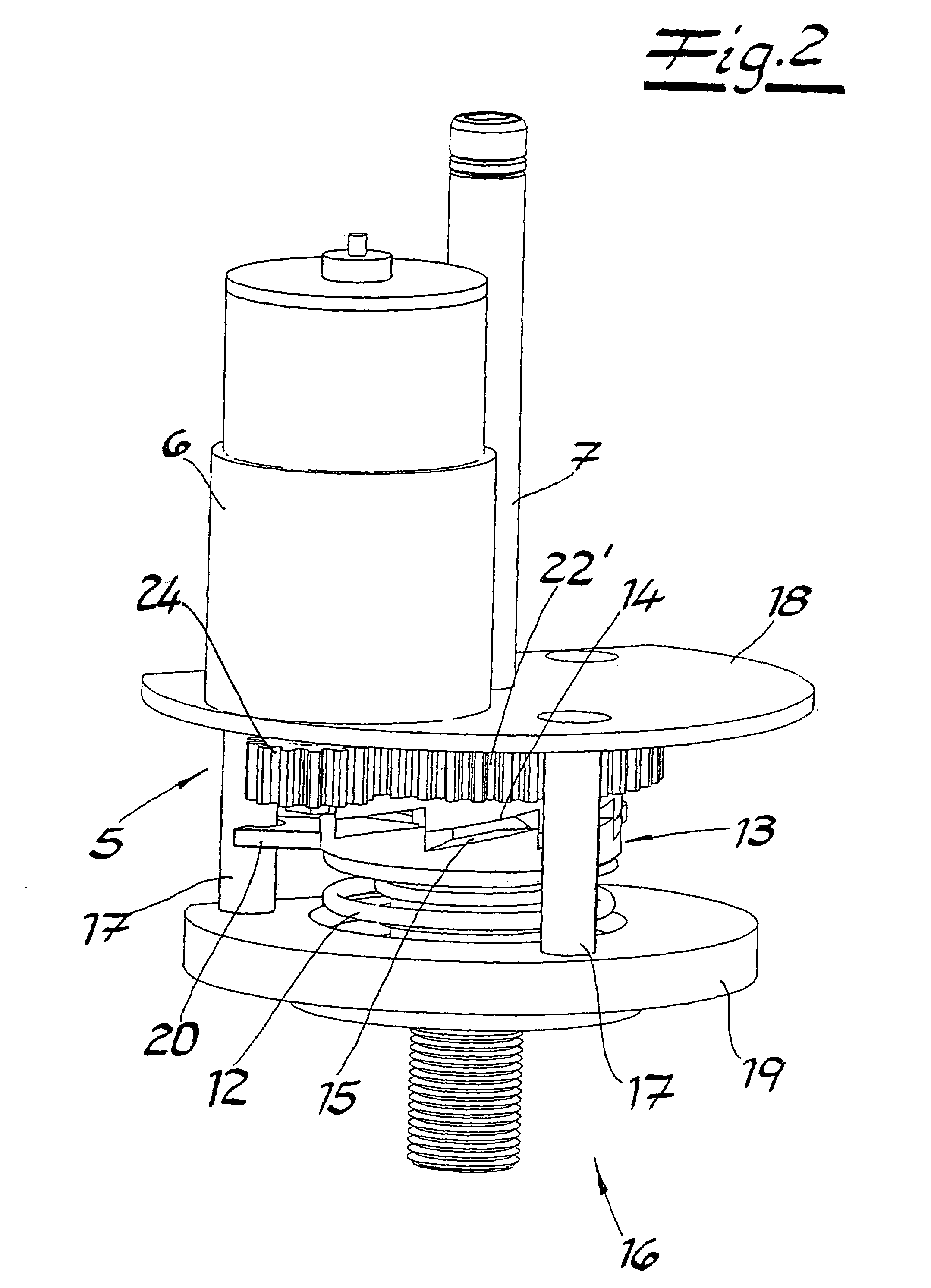

Metering device for lubricant

The invention relates to a metering device for lubricant having a lubricant reservoir (1), a piston (3), which is arranged on a threaded spindle (2), within the lubricant reservoir and a drive head 4, which has a drive shaft (7) connected to the threaded spindle (2) and an electromechanical drive (5) for actuating the drive shaft. The drive shaft (7) contains a lubricant passage duct (8) which opens into the lubricant storage space of the lubricant reservoir. A ram (9) is inserted into the lubricant passage duct (8) of the drive shaft, said ram having an axial bore (10) with a nonreturn valve (11) on the inlet side, and also a ram head (13) which is arranged in a rotationally fixed manner and is loaded by a compression spring (12). The ram head (13) bears under the effect of the compression spring (12) against a control surface (14) of the drive shaft (7). The control surface (14) and the associated contact surface of the ram head (13) are designed as slotted-guide surfaces which, when the control surface (14) rotates, bring about stroke movements of the ram (9), said movements conveying lubricant through the bore (10) in the ram (9) to a lubricant outlet at the end of the ram.

Owner:PERMA TEC

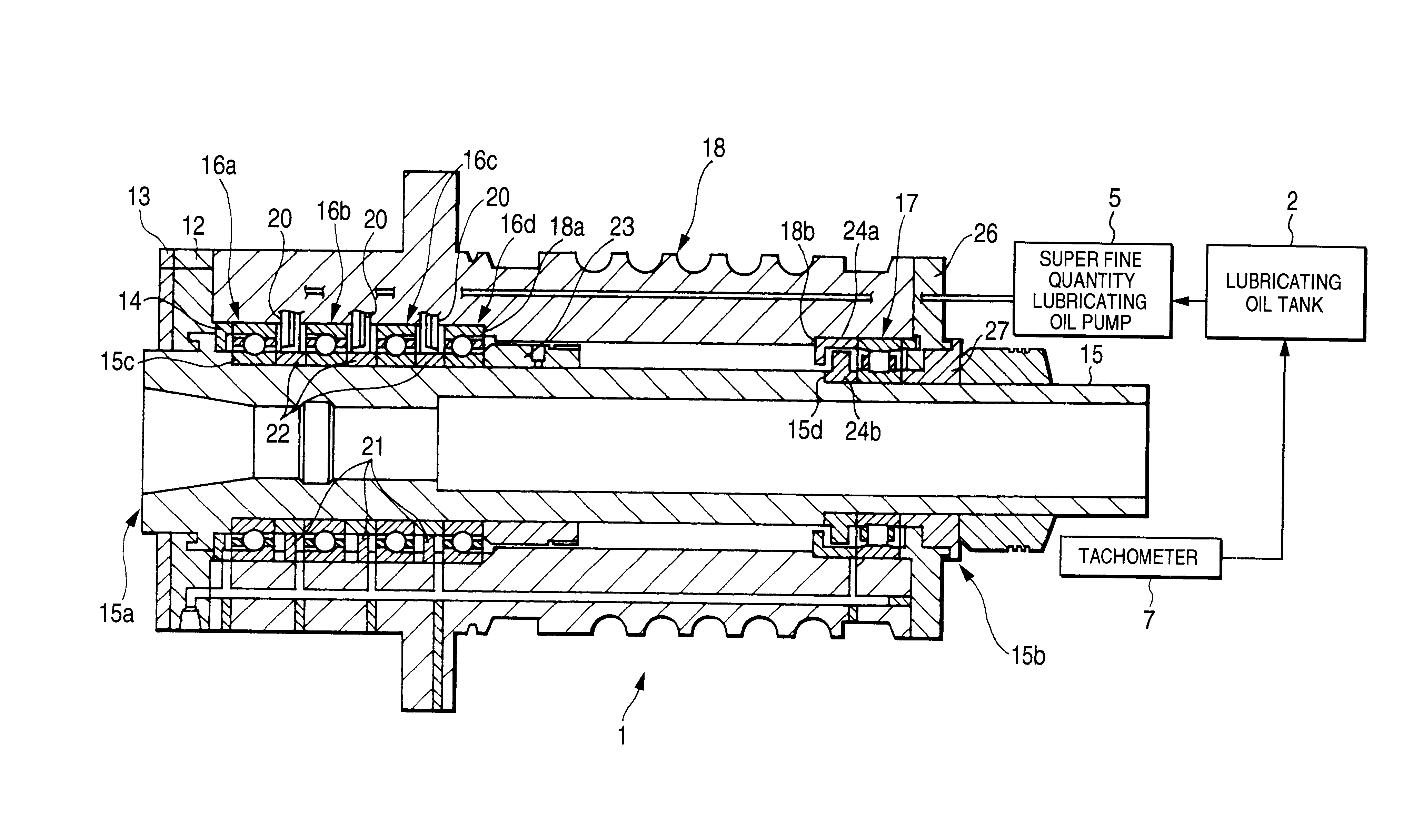

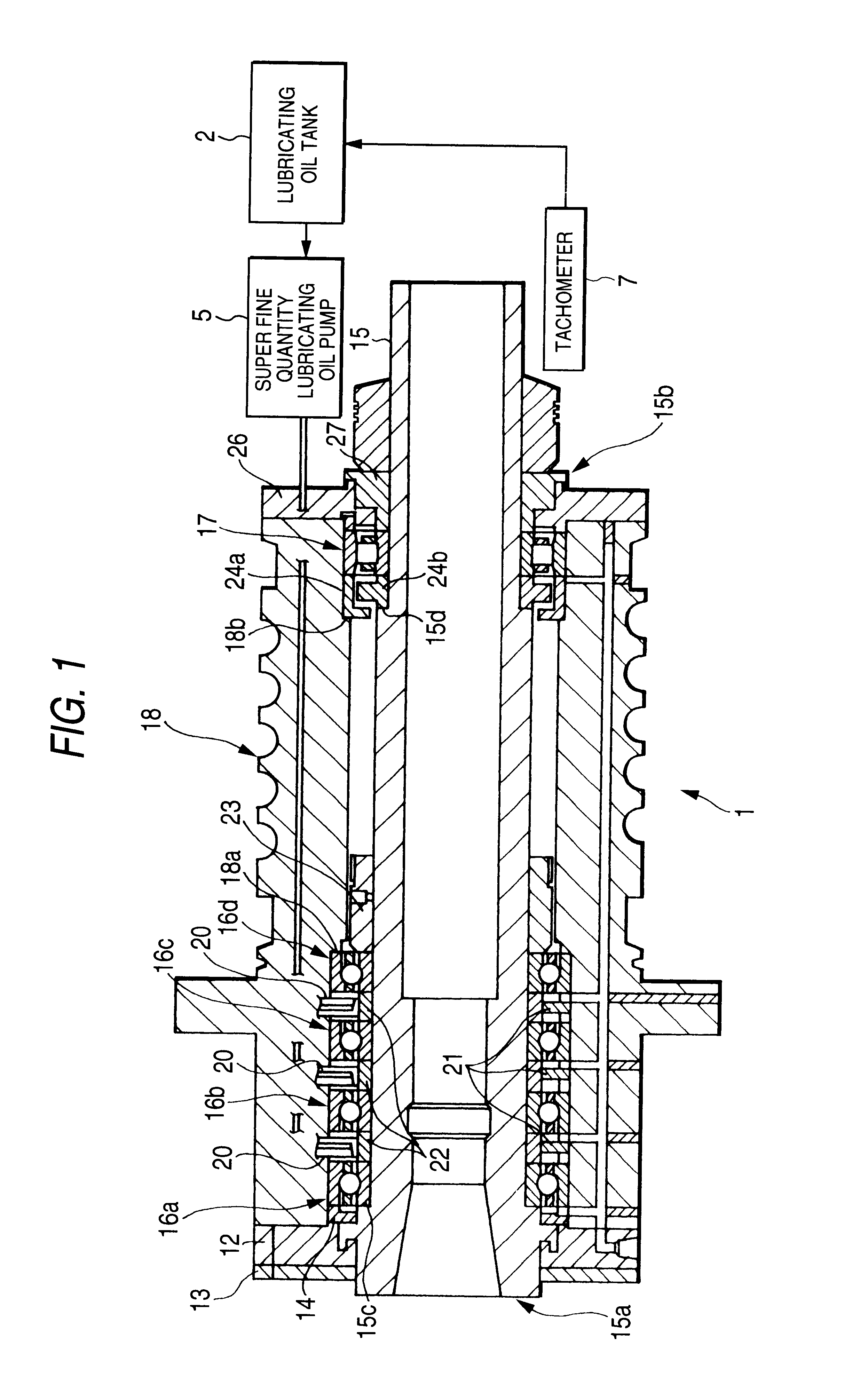

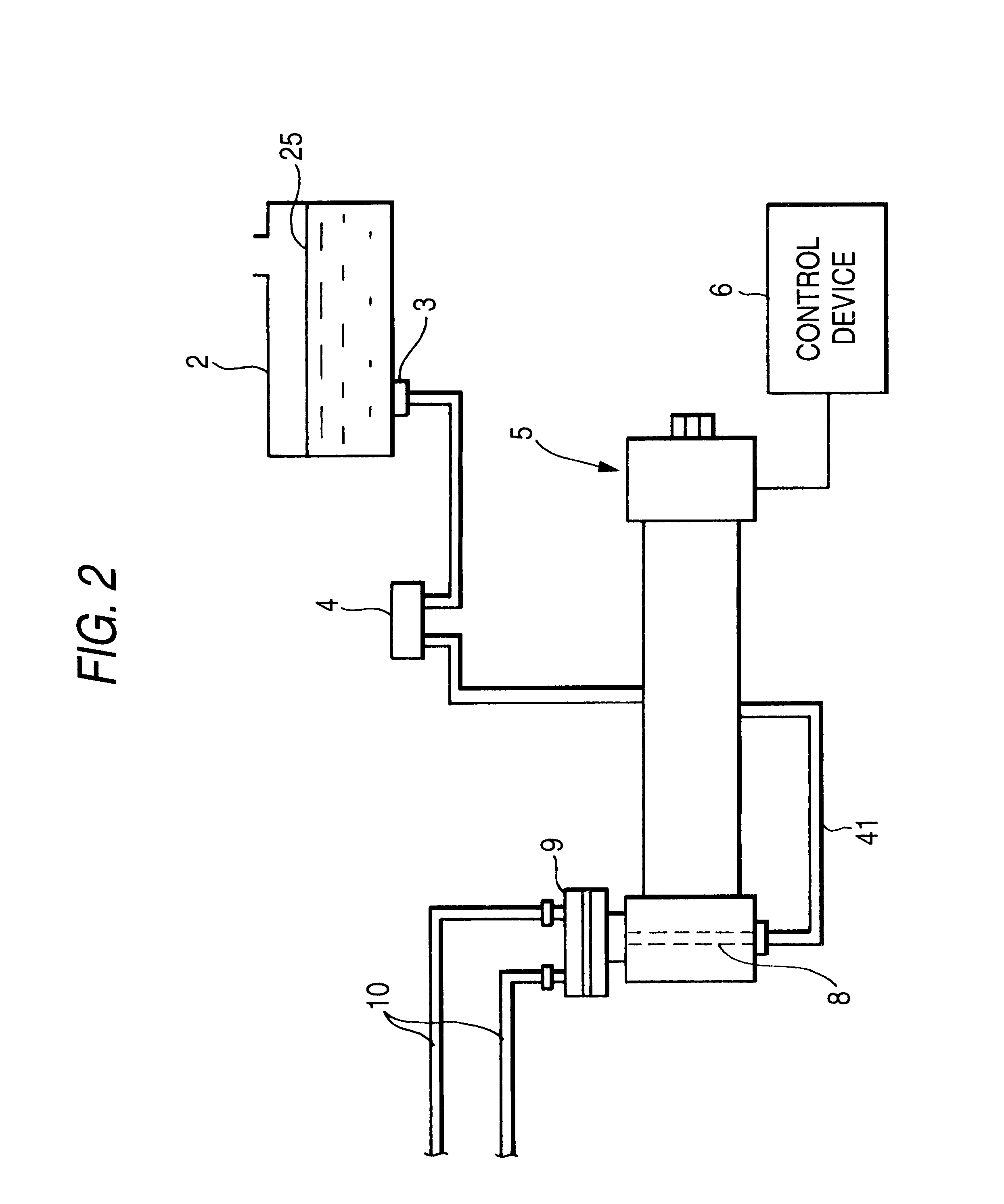

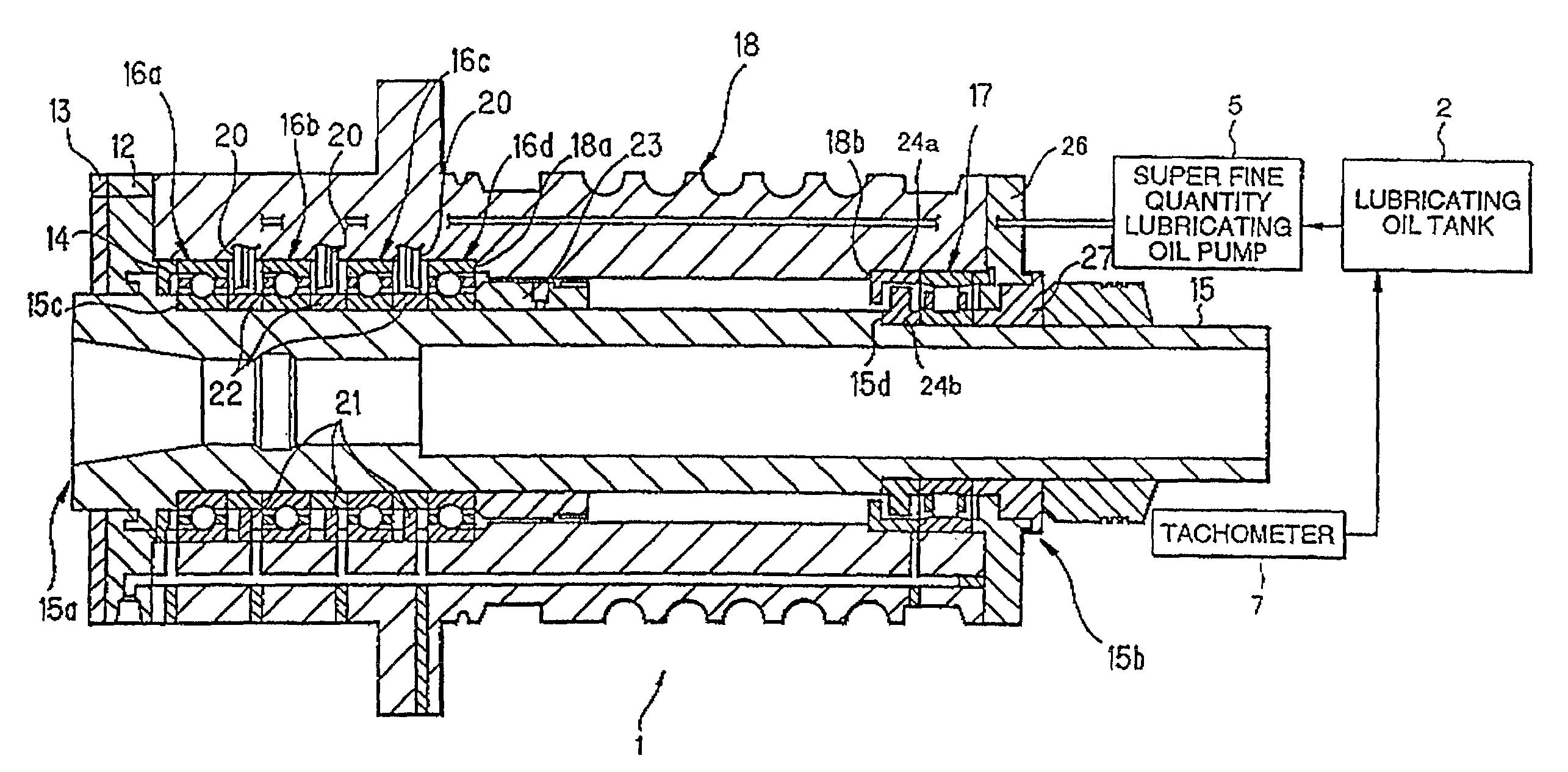

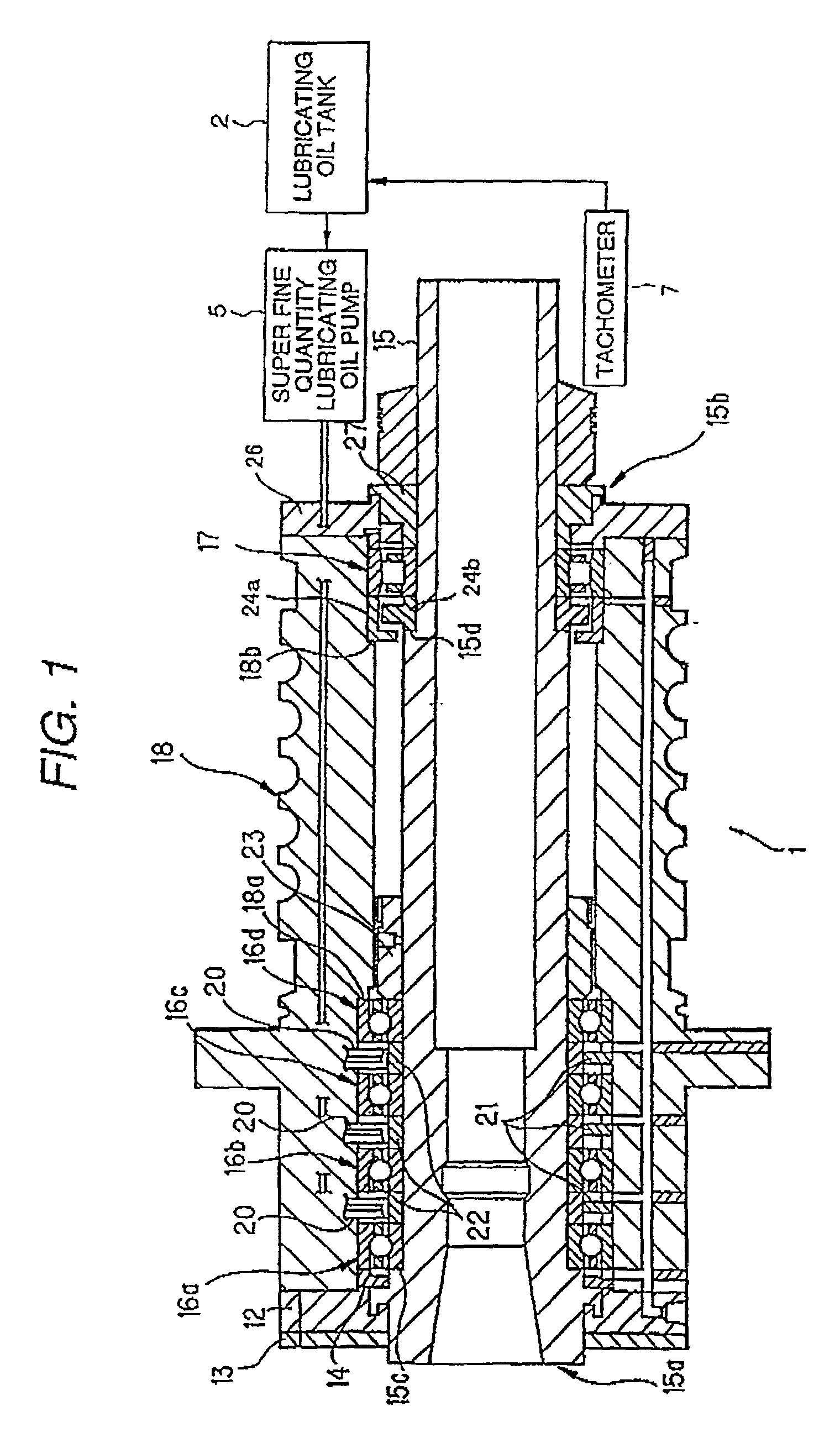

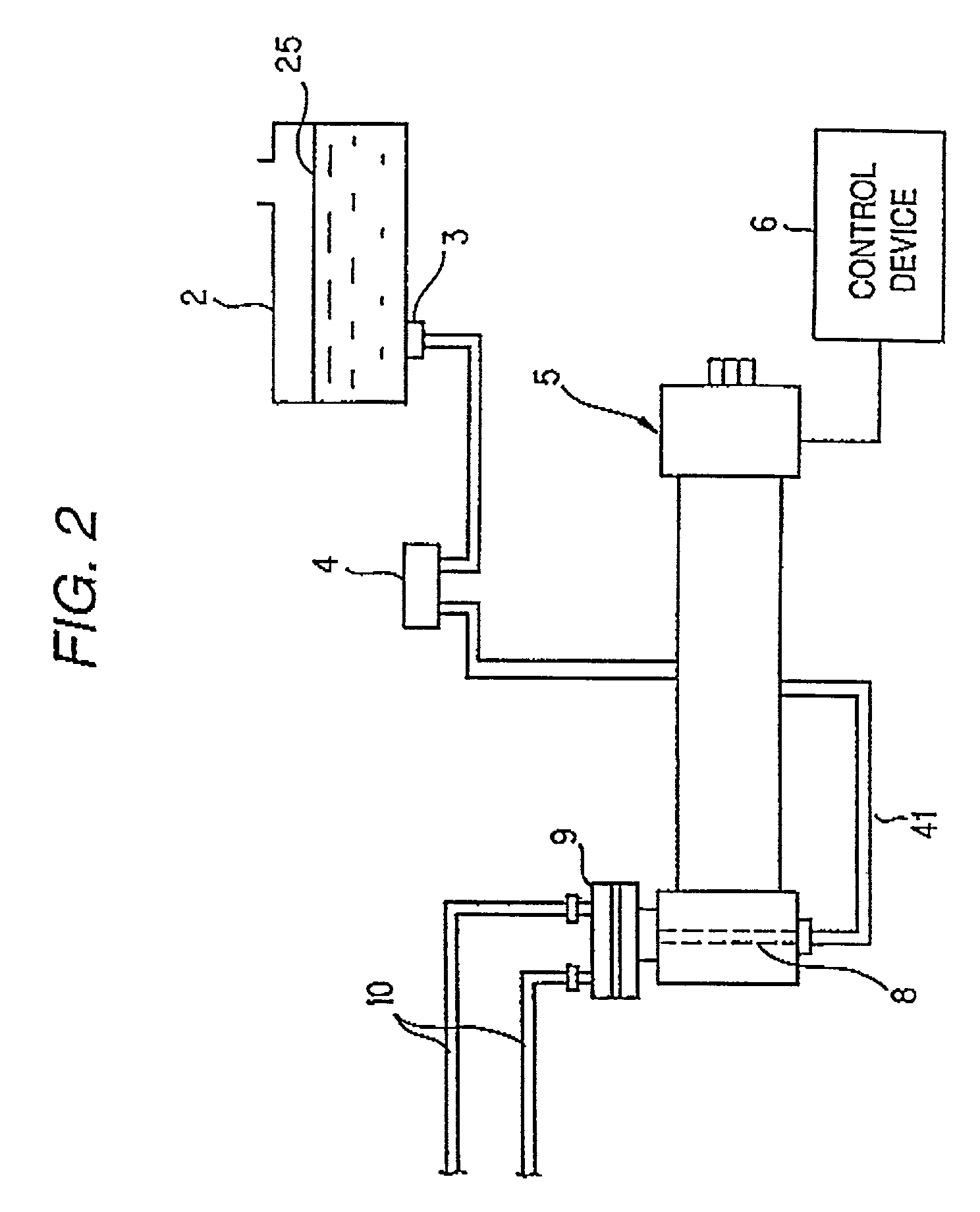

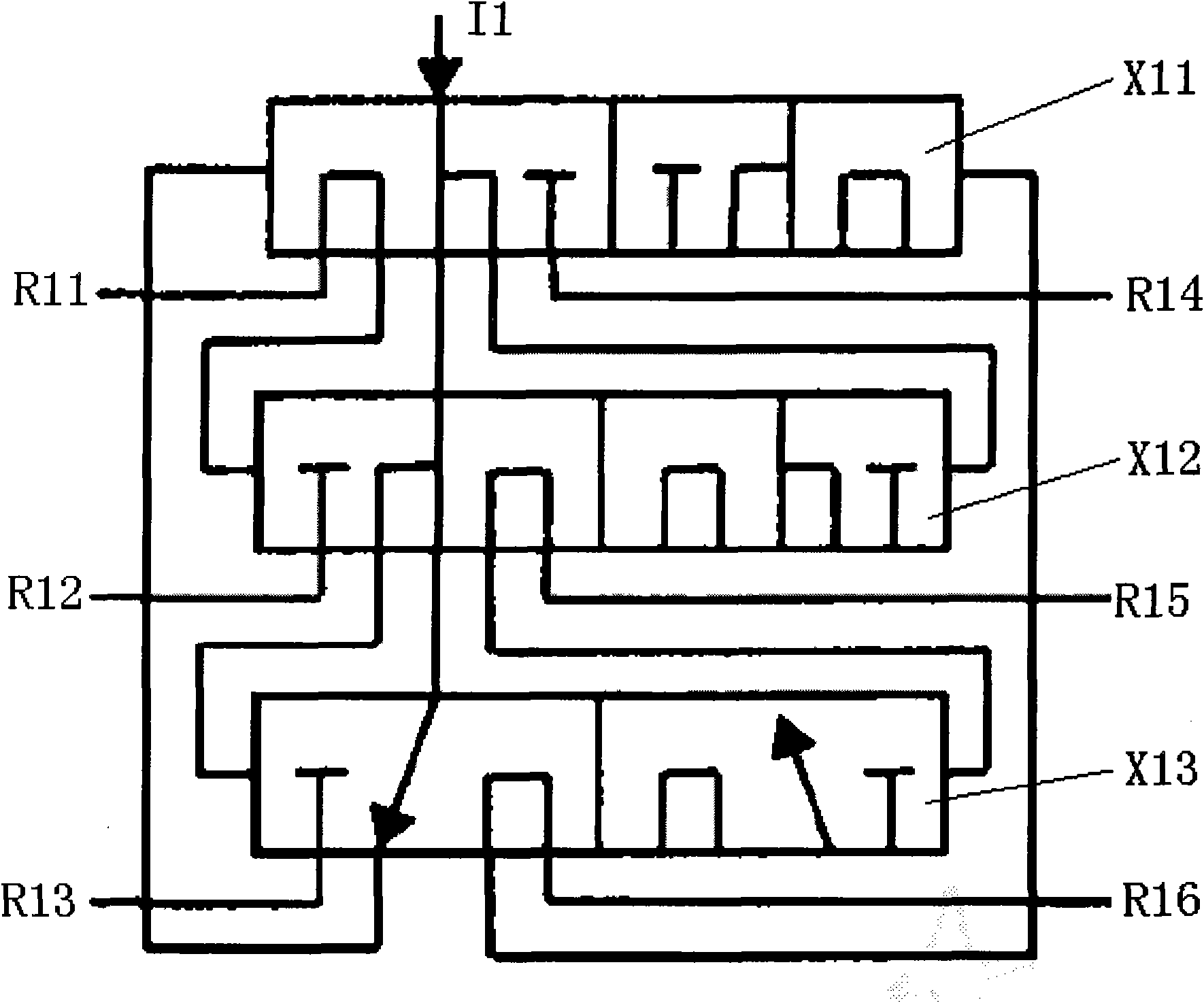

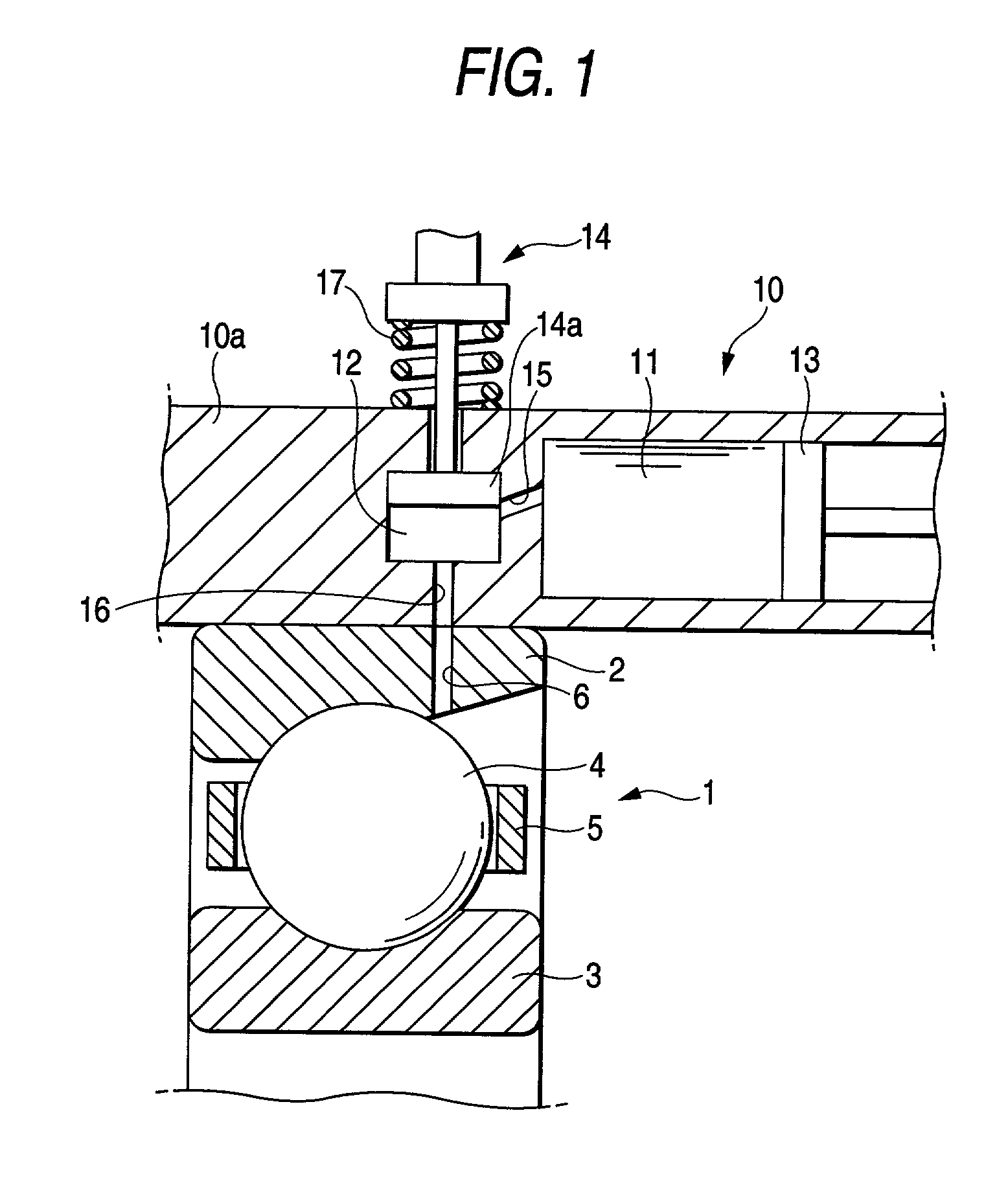

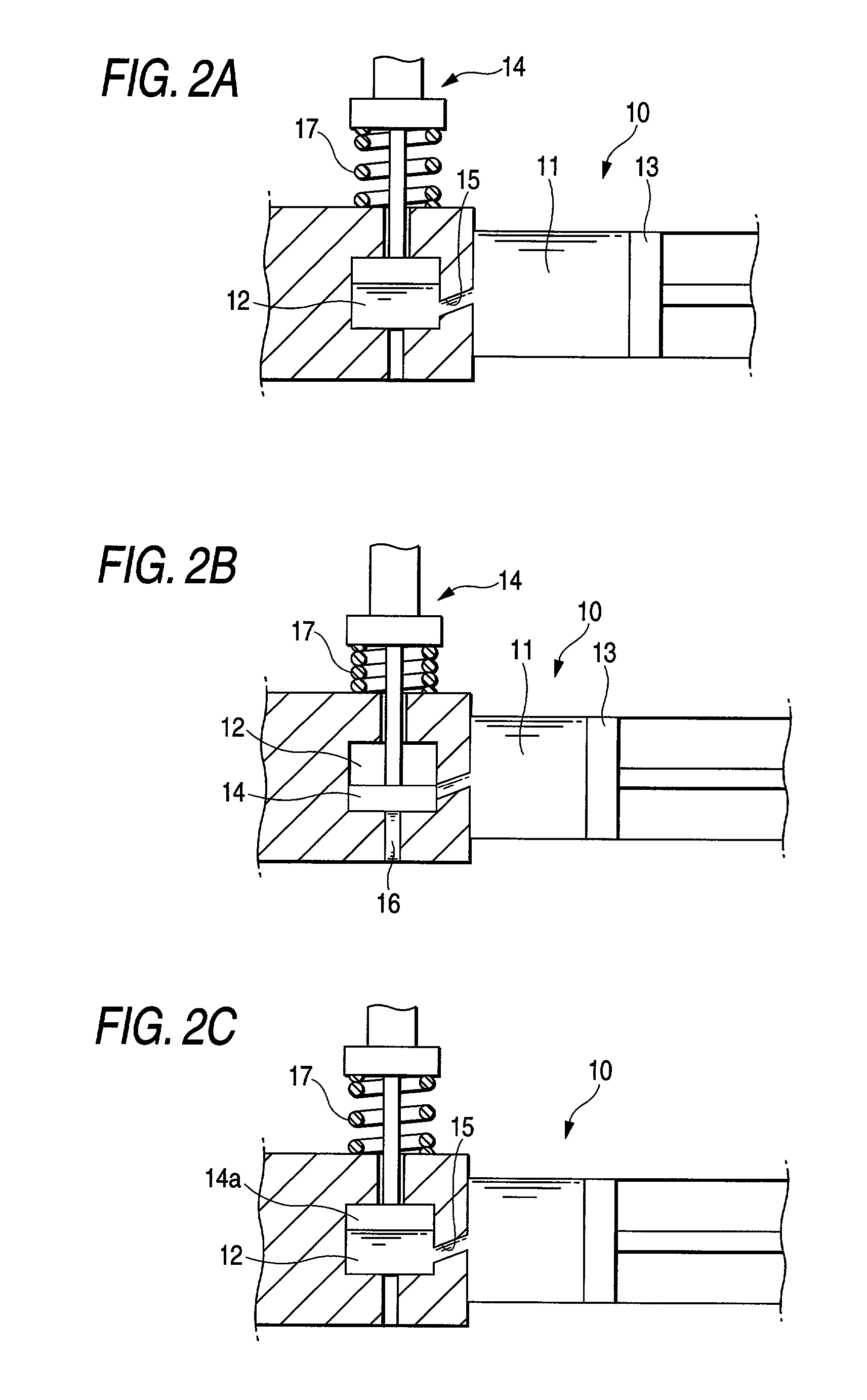

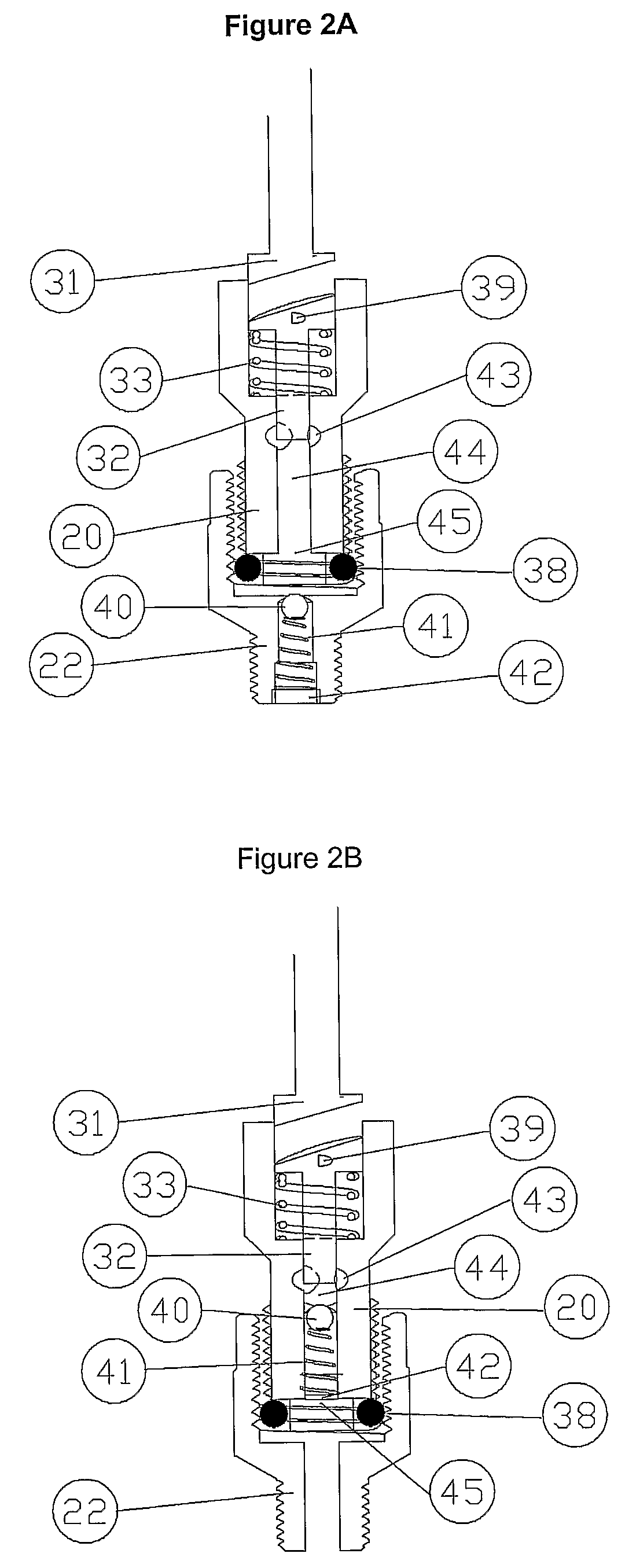

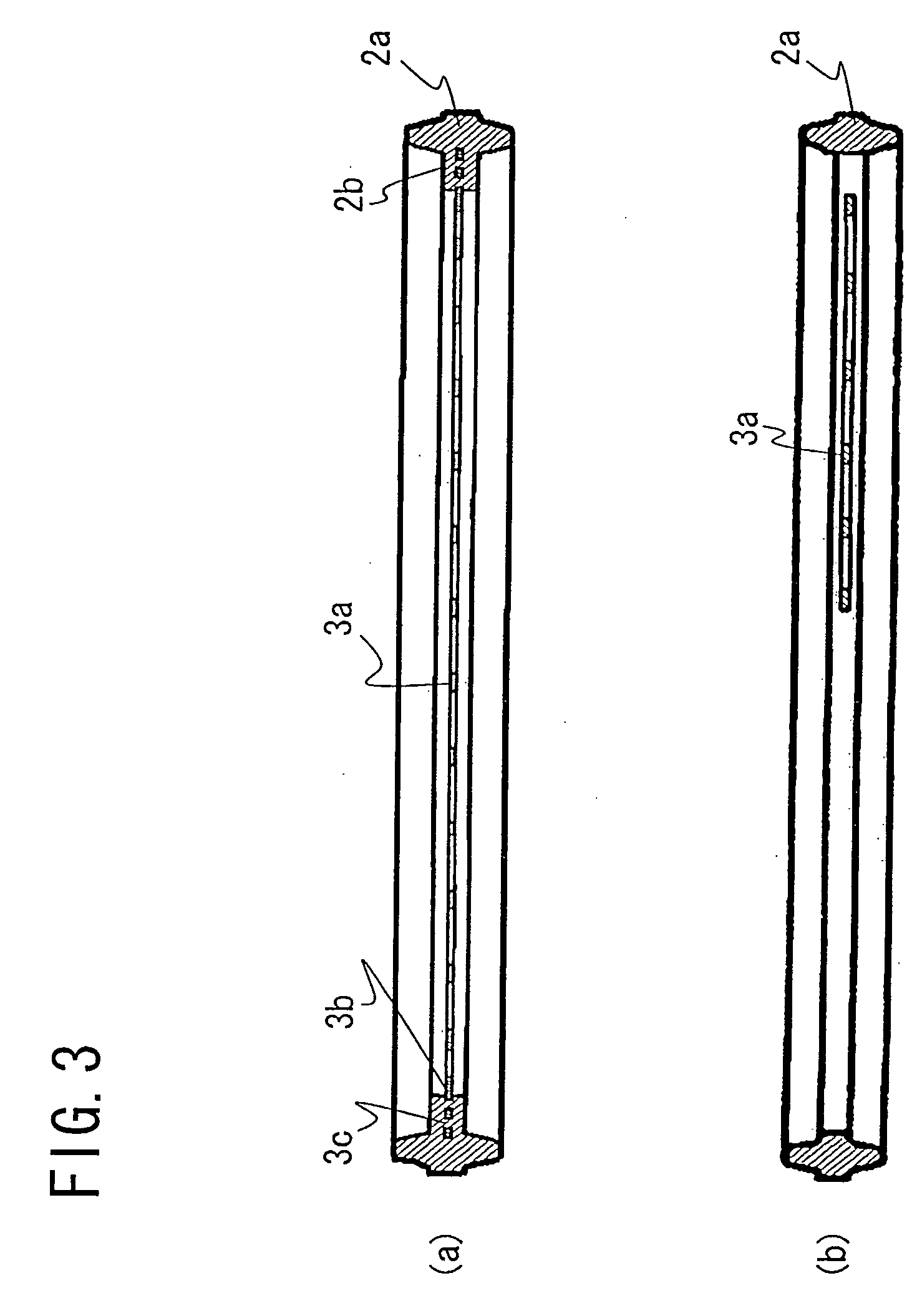

Spindle apparatus

InactiveUS6623251B2Reduce noiseMinimize an increase in torque and bearingPiezoelectric/electrostriction/magnetostriction machinesAttachable milling devicesPump chamberEngineering

A rod body (30) is formed of magnetostrictive material and includes one end portion (30a) fixed, and a piston (35) is fixed to the other end portion (35b) of the rod body (30). The piston (35) is slidably disposed within a cylinder (36) in which there is formed a pump chamber (37). A suction port (39) for sucking lubricating oil into the pump chamber (37) is formed in the cylinder (36), while a suction valve (40) for preventing the lubricating oil from flowing out from the suction port (39) is disposed in the suction port (39). In the cylinder (36), there is disposed a nozzle (20) which communicates with the pump chamber (37) and has a sectional area smaller than the lubricating oil passage sectional area of the suction valve (40). There is disposed a coil (43) outside the rod body (30) and, to the coil (43), there is connected a control device (6) for controlling the supply of a current to be supplied to the coil (43).

Owner:NSK LTD

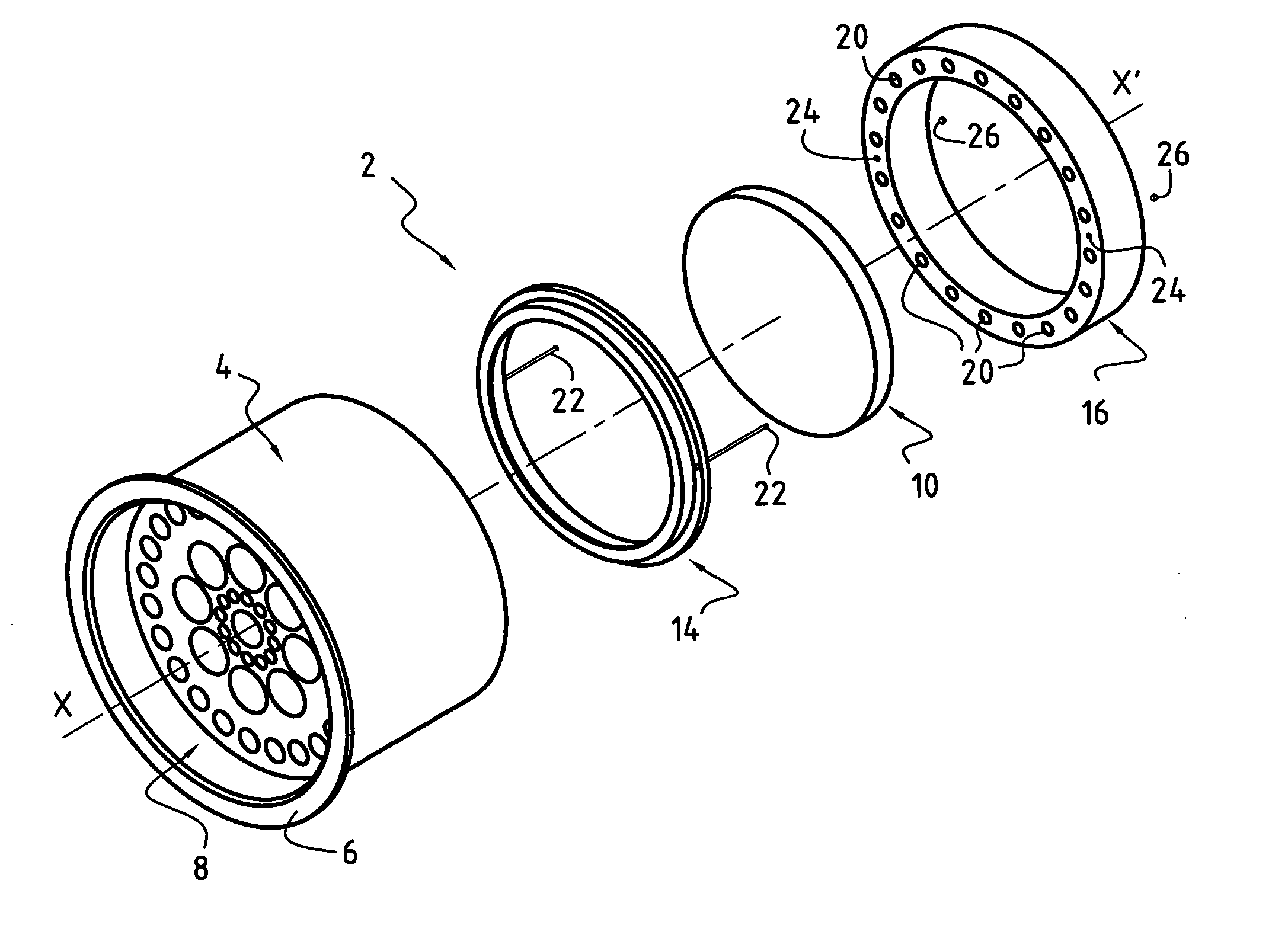

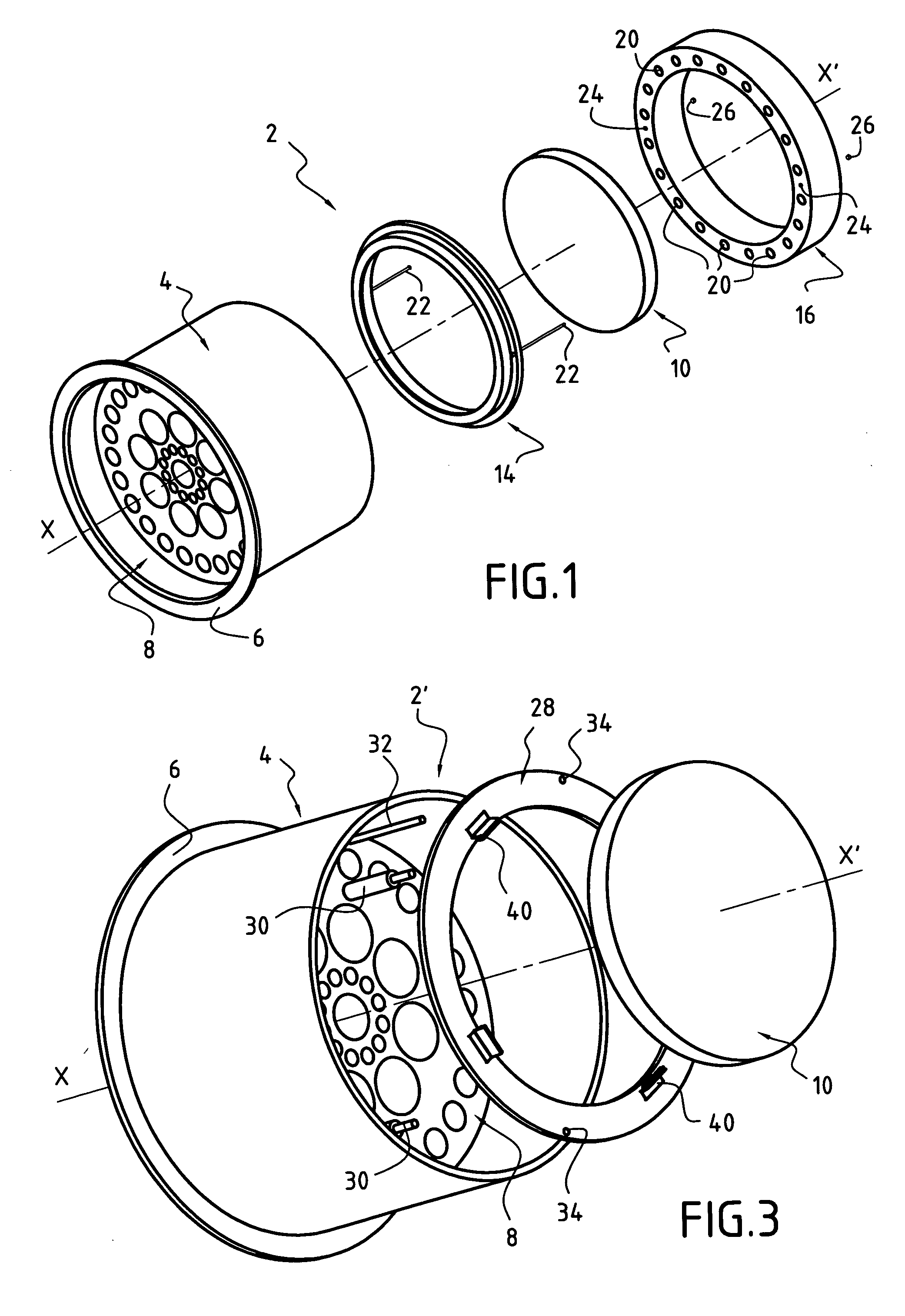

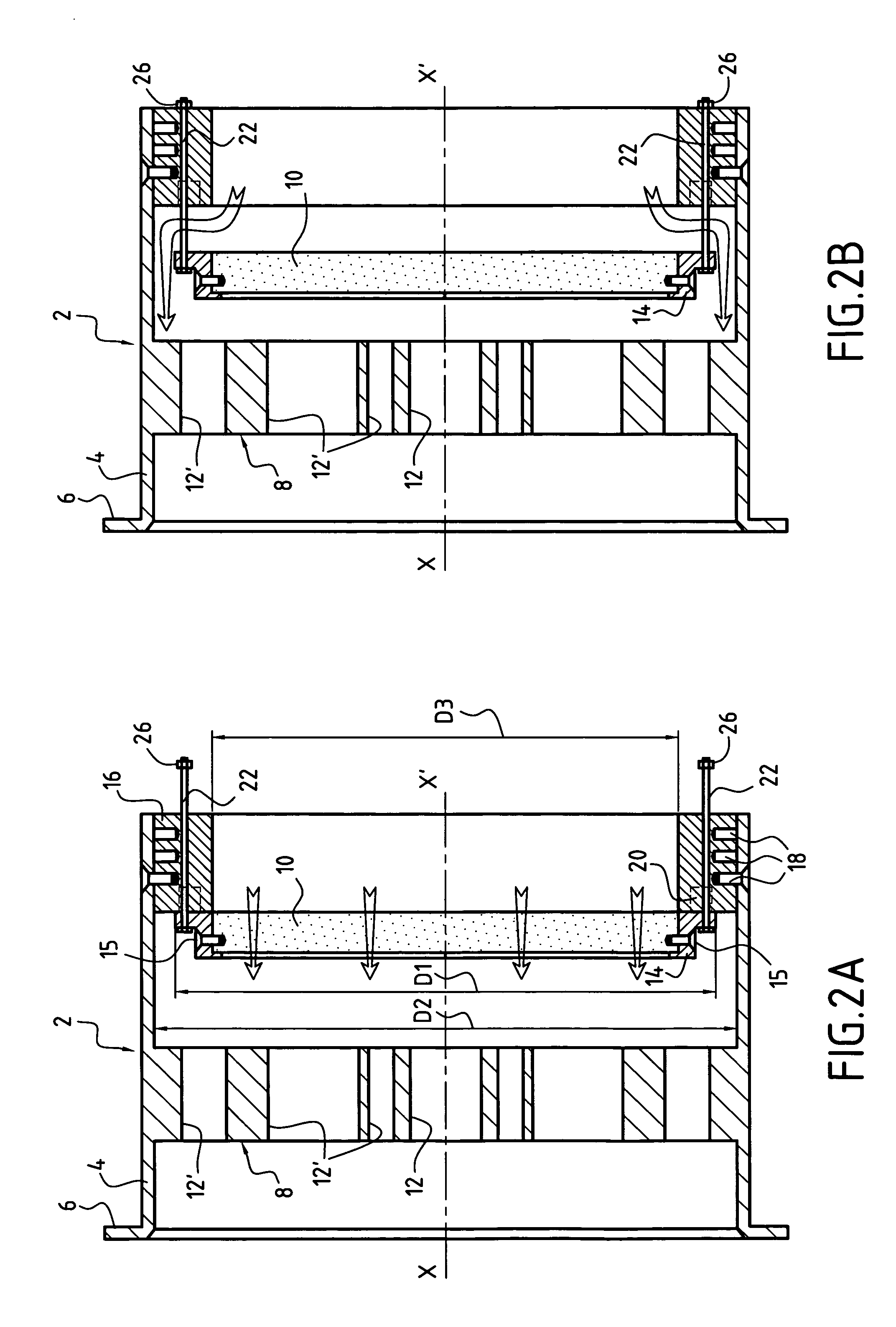

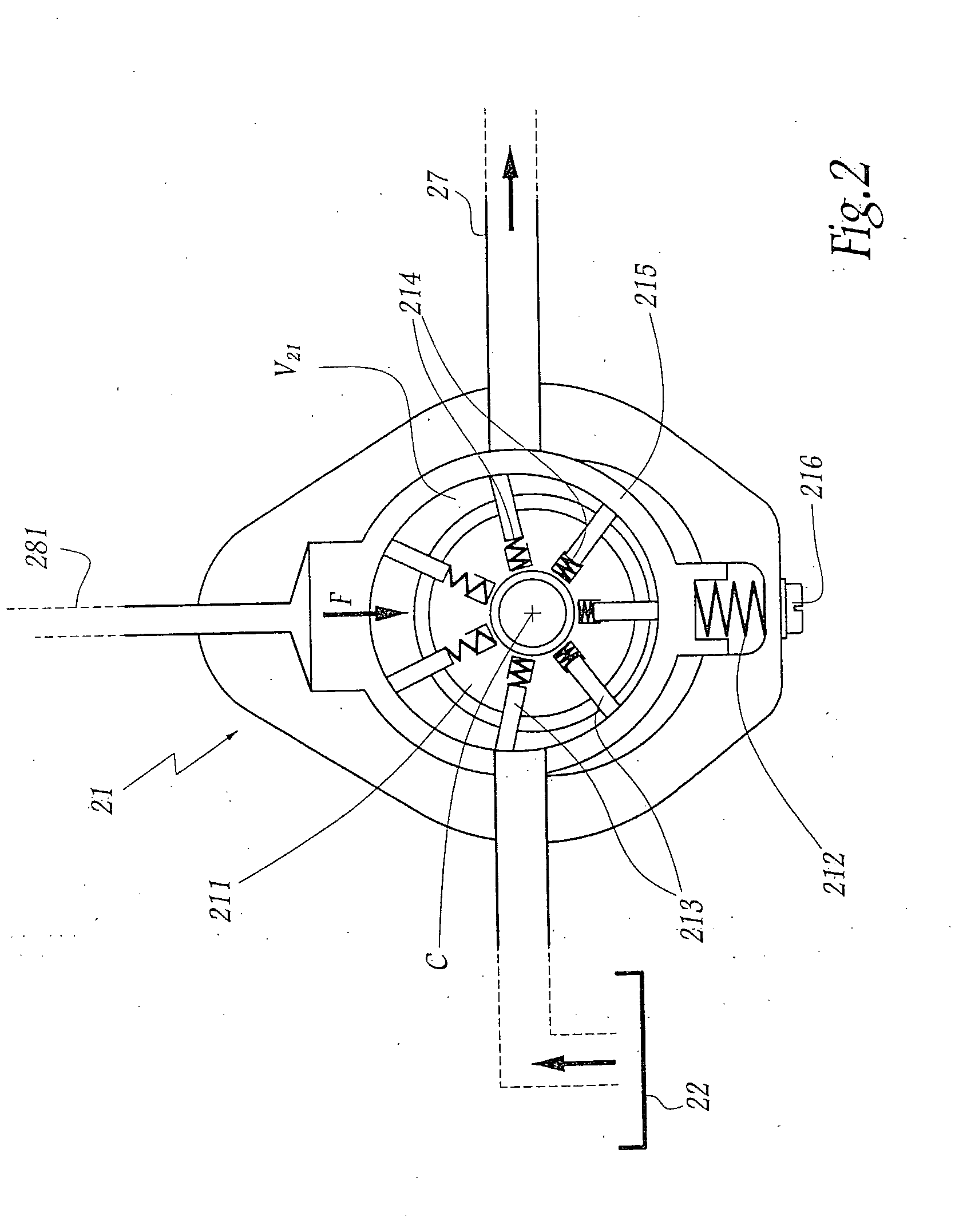

Flow conditioner for a fluid transport pipe

ActiveUS20050178455A1Reduce riskMitigate such drawbackFlow mixersFluid dynamicsFluid transportMechanical engineering

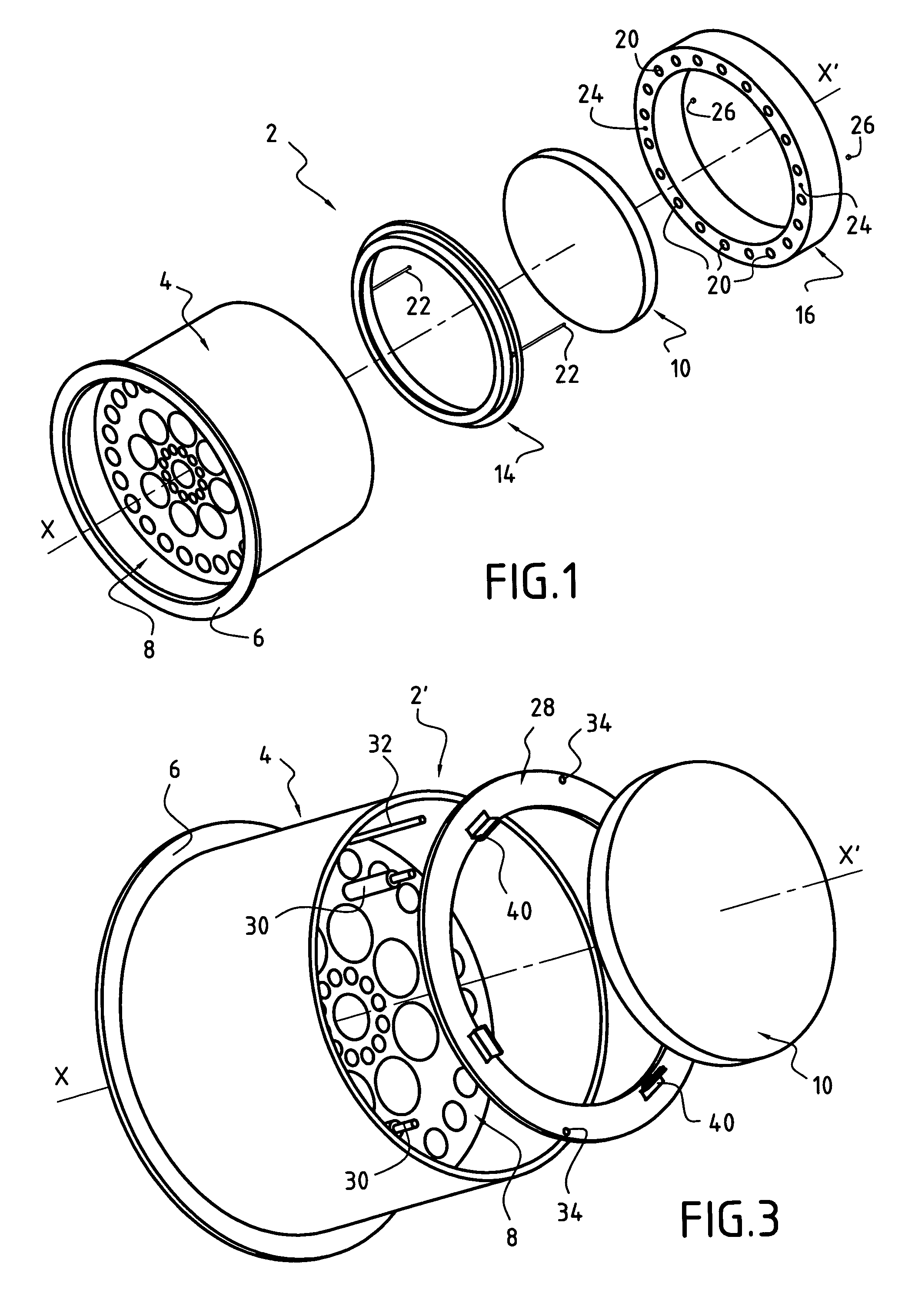

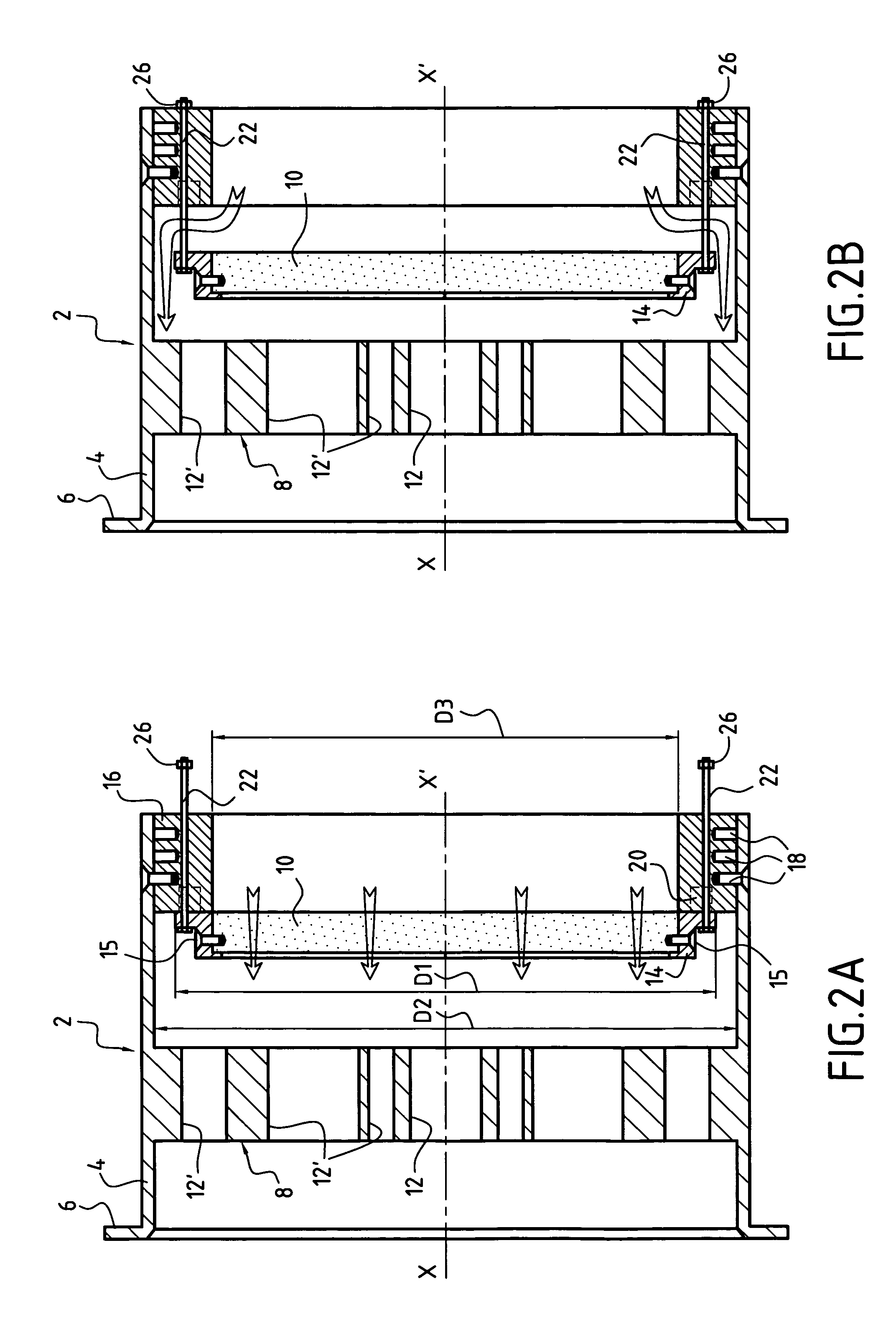

The flow conditioner for a fluid transport pipe, comprises a support-forming substantially tubular main body, at least one flow rectifier disposed inside the main body essentially perpendicularly to the axis XX′ thereof, and a porous plate disposed inside the main body upstream from the flow rectifier and parallel thereto. The elements of the conditioner are disposed in such a manner that a substantial fraction of the fluid flow passes through the flow rectifier and the porous plate in the absence of the porous plate becoming clogged. A bypass circuit is provided to ensure fluid flow continuity in the event of the porous plate becoming clogged.

Owner:GRTGAZ

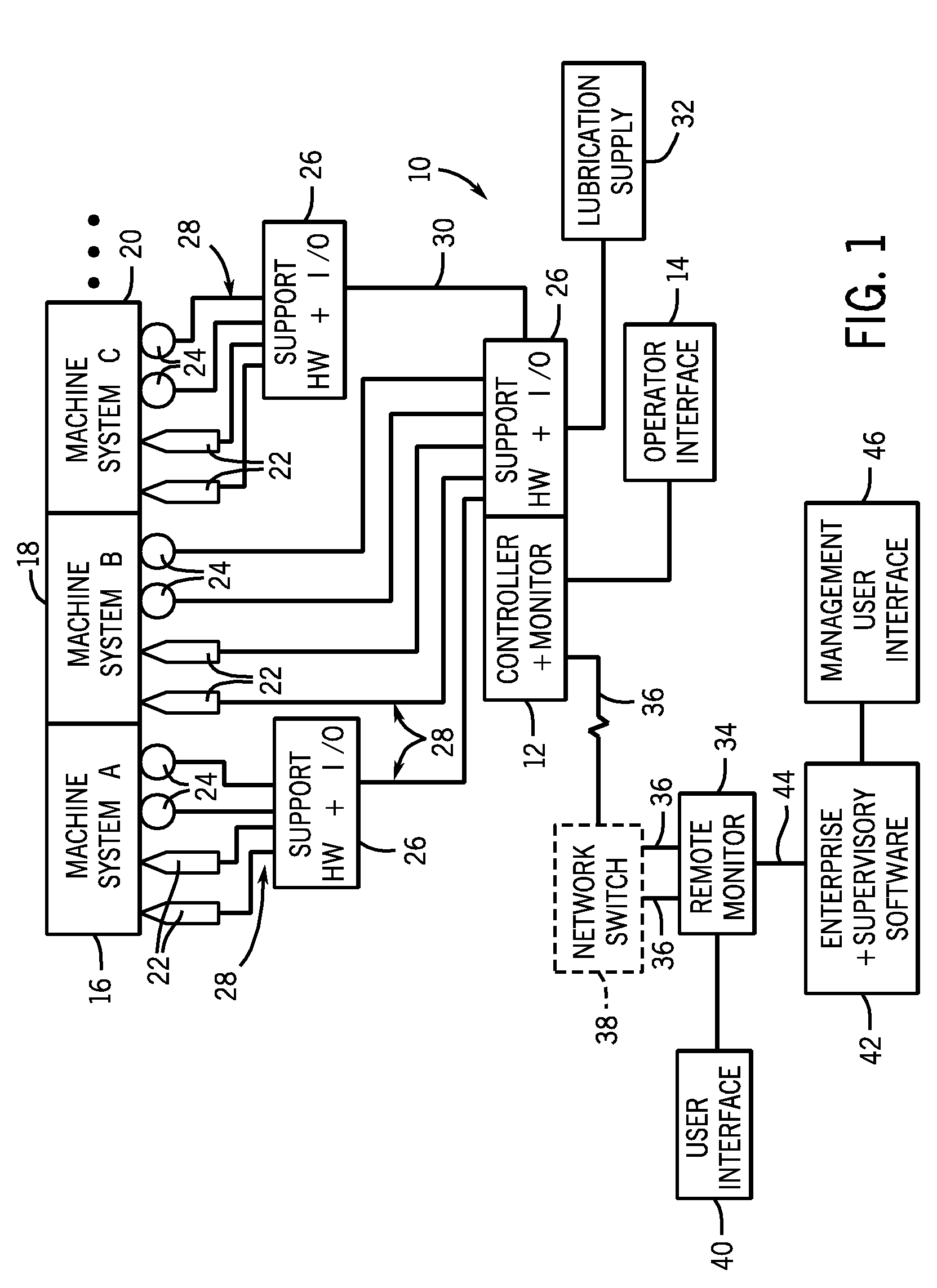

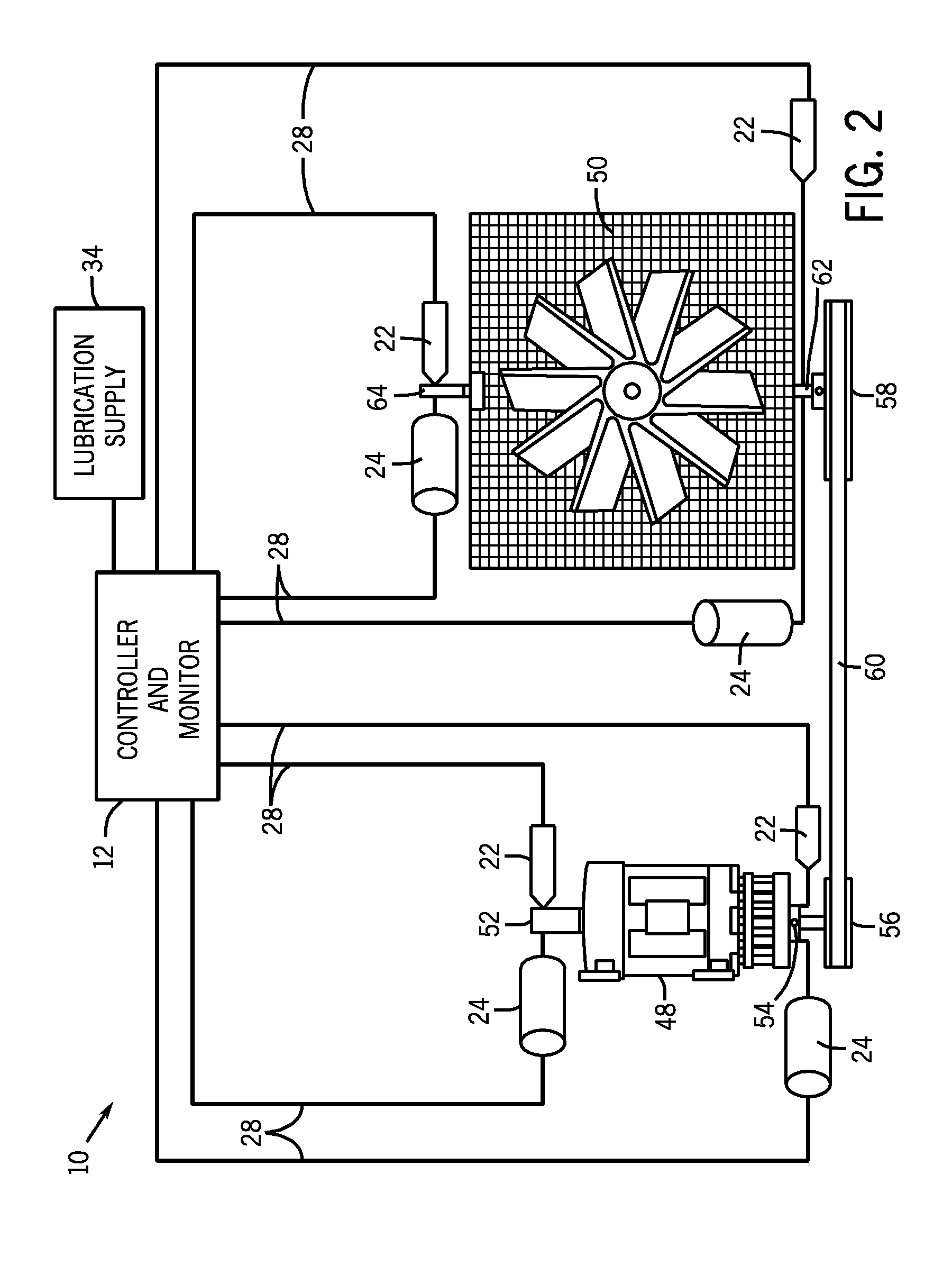

Machine conditioning monitoring closed loop lubrication system and method

ActiveUS20100147627A1Improve machine lifeReduce maintenanceVibration measurement in solidsProportioning devicesAccelerometerClosed loop

In one embodiment, the disclosed method for lubricating a machine bearing system includes monitoring a bearing system using a vibration sensor, such as an accelerometer, receiving a signal from the vibration sensor, calculating a parameter based on the signal; and adding a lubricant to the bearing system based upon the parameter. In another embodiment, a system may include a vibration sensor, a monitor configured to receive a signal from the vibration sensor and calculate a spike energy value, and a lubrication device configured to add a lubricant to a bearing system based on the spike energy value. The system and method help reduce maintenance and repair costs, while prolonging the life of the machine system components being monitored.

Owner:ROCKWELL AUTOMATION TECH

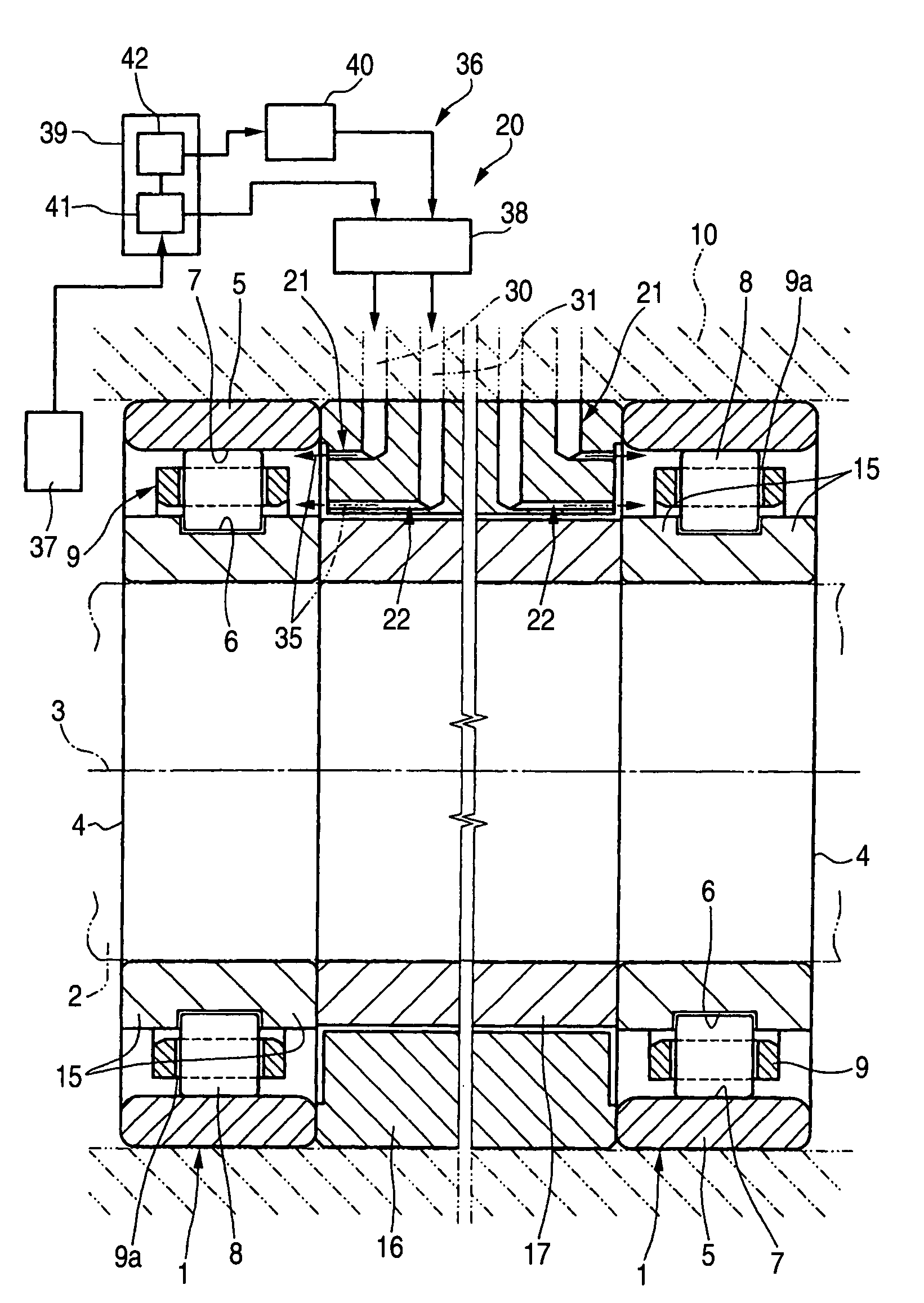

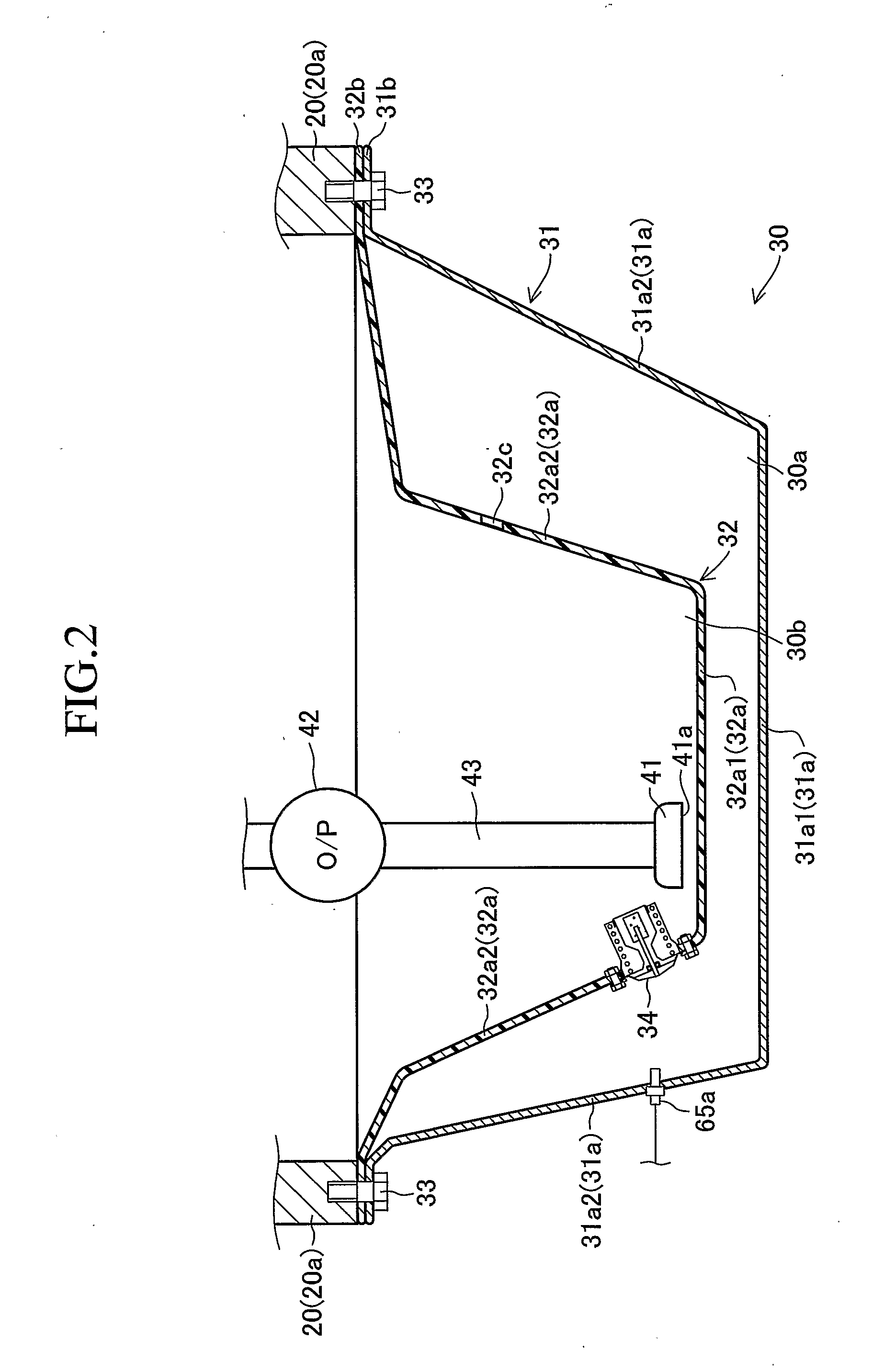

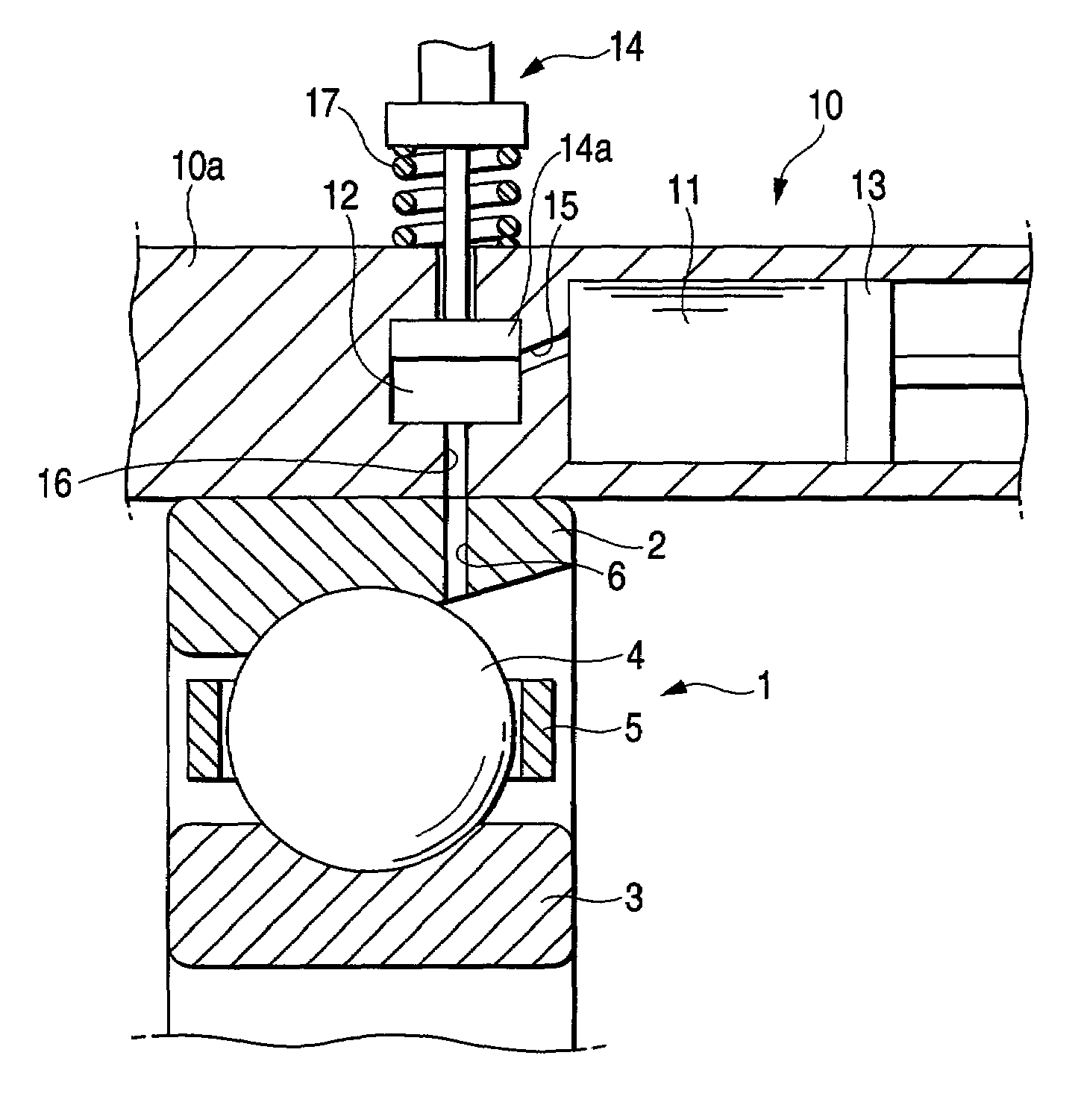

Spindle apparatus

InactiveUS20020048517A1Easy to assembleInsert smoothlyPiezoelectric/electrostriction/magnetostriction machinesAttachable milling devicesPump chamberEngineering

A rod body 30 is formed of magnetostrictive material and includes one end portion 30 fixed, and a piston 35 is fixed to the other end portion 30b of the rod body 30. The piston 35 is slidably disposed within a cylinder 36 in which there is formed a pump chamber 37. A suction port 39 for sucking lubricating oil into the pump chamber 37 is formed in the cylinder 36, while a suction valve 40 for preventing the lubricating oil from flowing out from the suction port 39 is disposed in the suction port 39. In the cylinder 36, there is disposed a nozzle 20 which communicates with the pump chamber 37 and has a sectional area smaller than the lubricating oil passage sectional area of the suction valve 40. There is disposed a coil 43 outside the rod body 30 and, to the coil 43, there is connected a control device 6 for controlling the supply of a current to be supplied to the coil 43.

Owner:NSK LTD

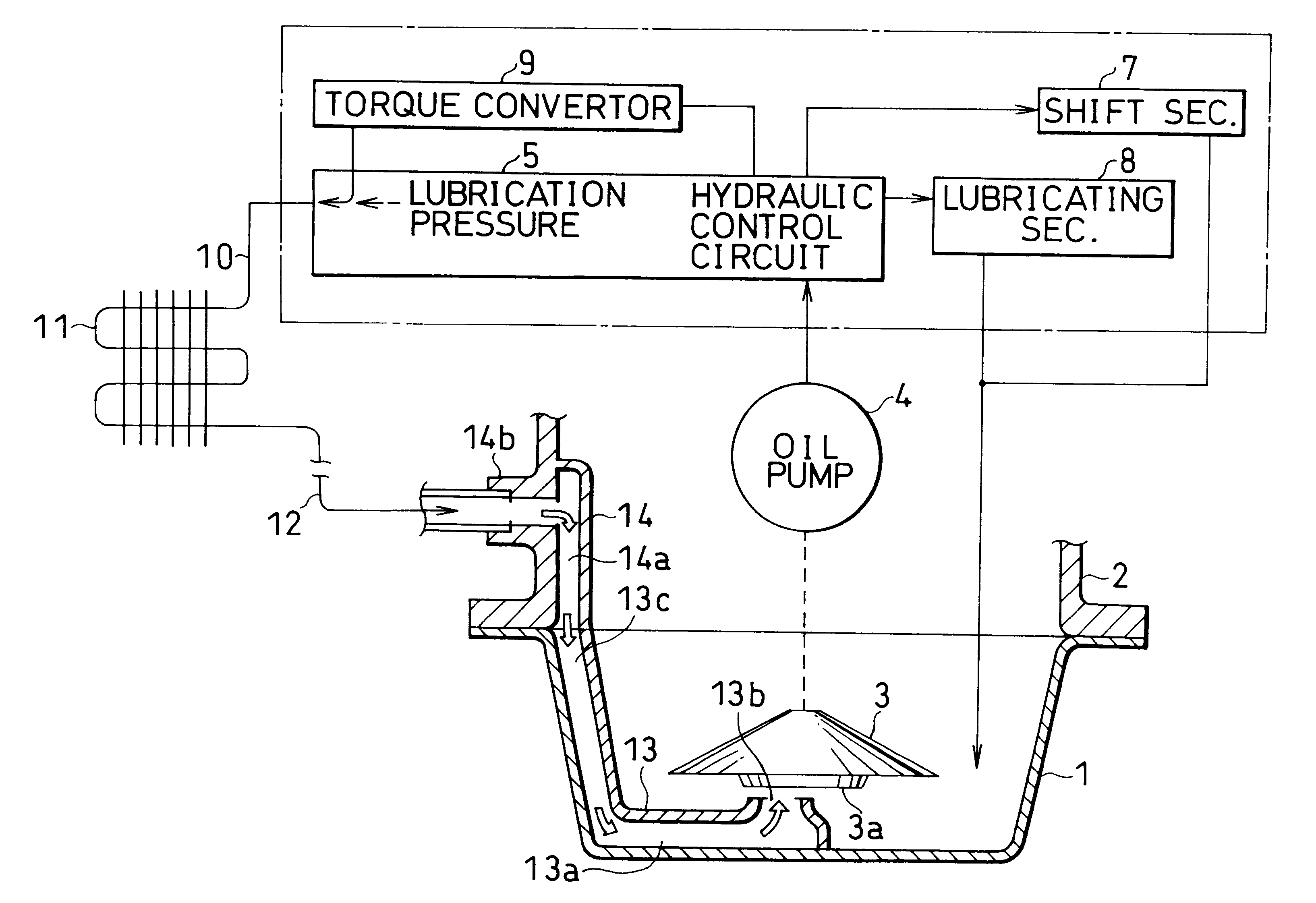

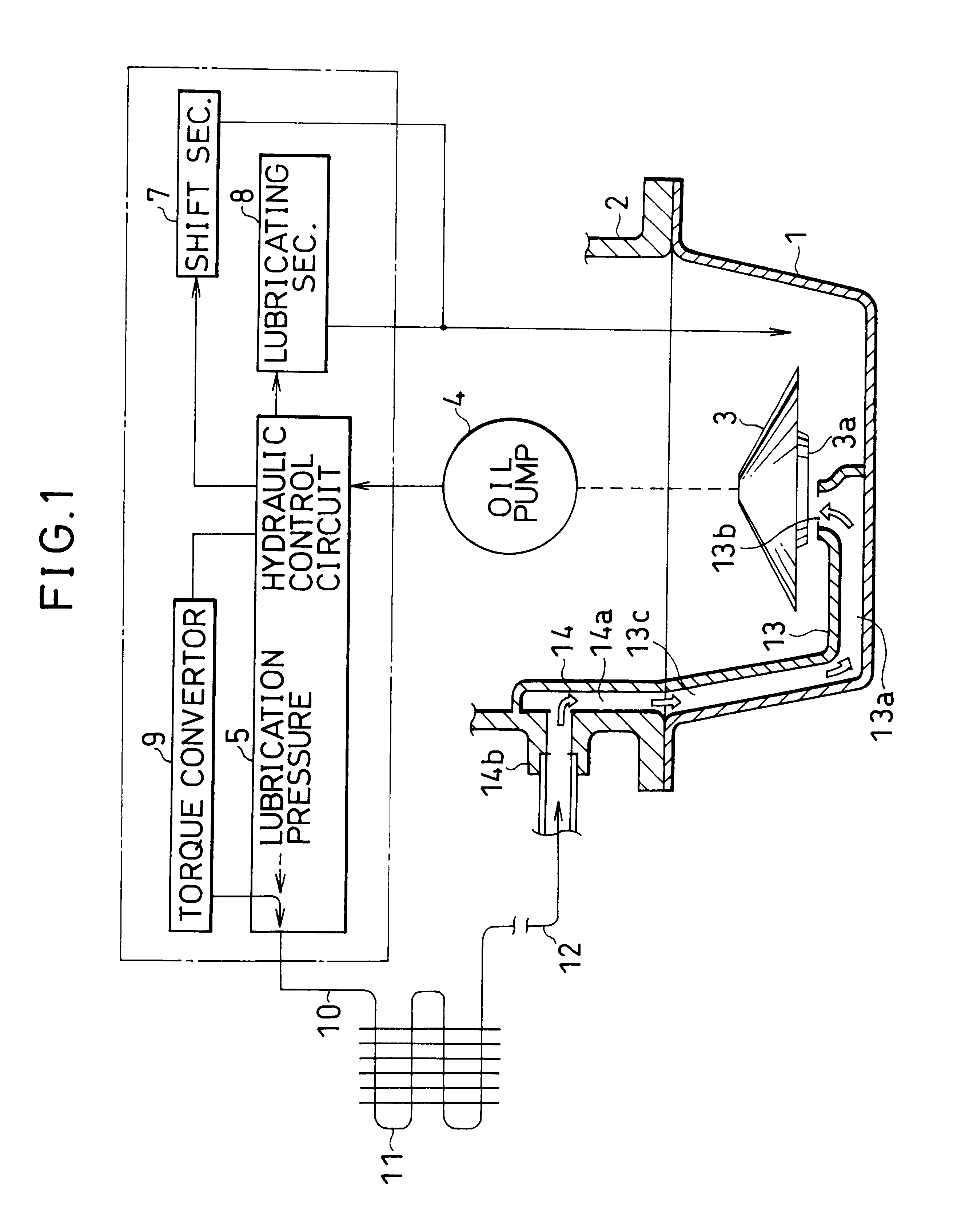

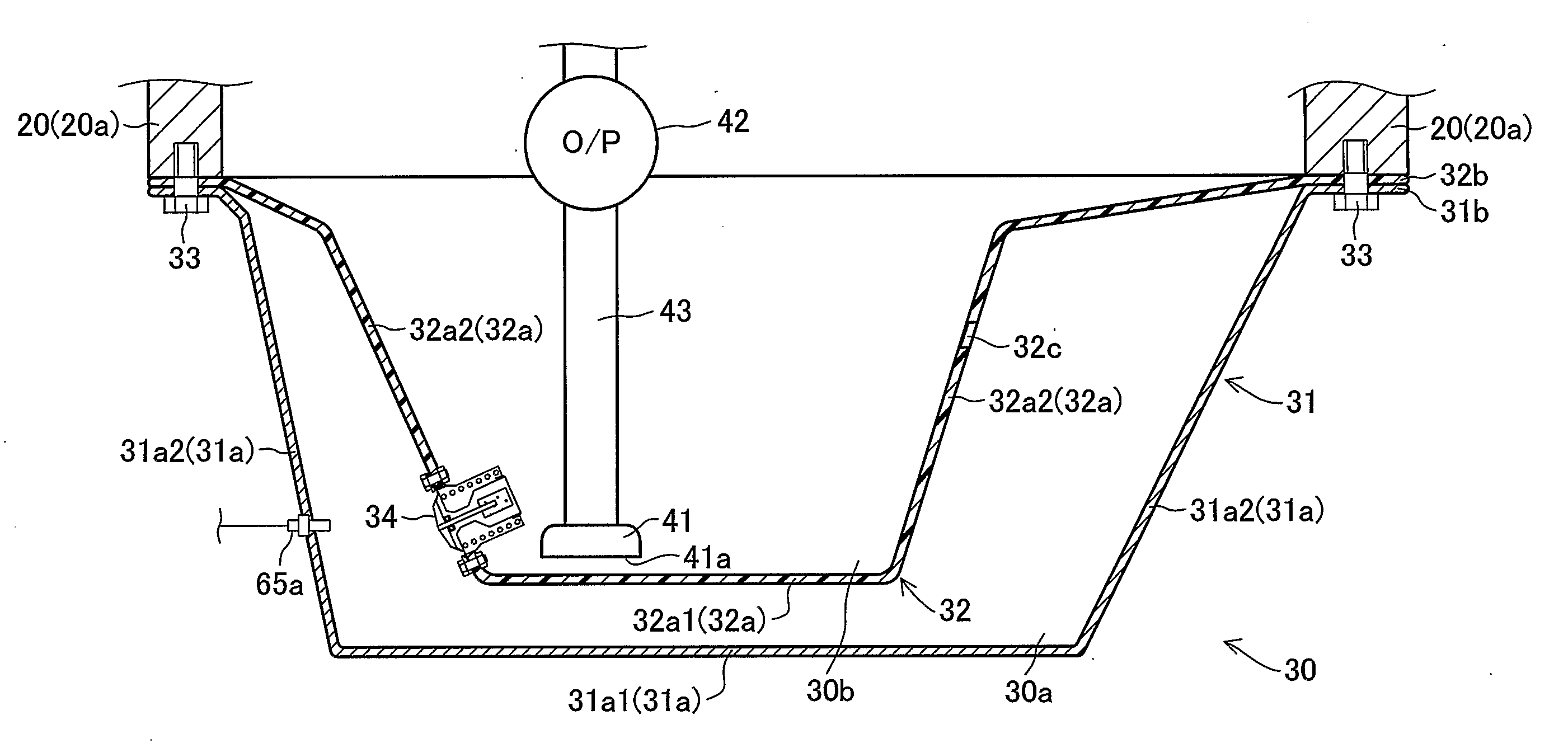

Oil circulating apparatus for automatic transmission

A part of oil sucked by an oil pump is circulated to an oil pan through a hydraulic control circuit, an oil cooler and an oil passage provided in a transmission case and the oil pan. The oil guided to the oil pan is gushed out from a discharge port of the oil passage toward a suction port of an oil strainer communicating with the oil pump. The discharge port of the oil passage is disposed opposite and adjacent to the suction port of the oil strainer so that only the oil containing a small number of bubbles is sucked by the oil pump.

Owner:FUJI JUKOGYO KK

Method of lubricating roller bearing

InactiveUS7500311B2Suppress feverAvoid resistanceProportioning devicesRoller bearingsEngineeringLubricant

A bearing device includes: an inner ring member through which a shaft is passed and which is supported rotatably about an axis of the shaft and includes an inner ring raceway surface; an outer ring member arranged concentrically with the inner ring member and including an outer ring raceway surface; a plurality of rollers arranged rollably between the inner ring raceway surface and the outer ring raceway surface; a lubricating path through which lubricant is supplied to at least one of the inner ring raceway surface and the outer ring raceway surface; and a lubricating device which supplies the lubricant to the lubricating path according to rotating speed of the inner ring member about the axis.

Owner:JTEKT CORP

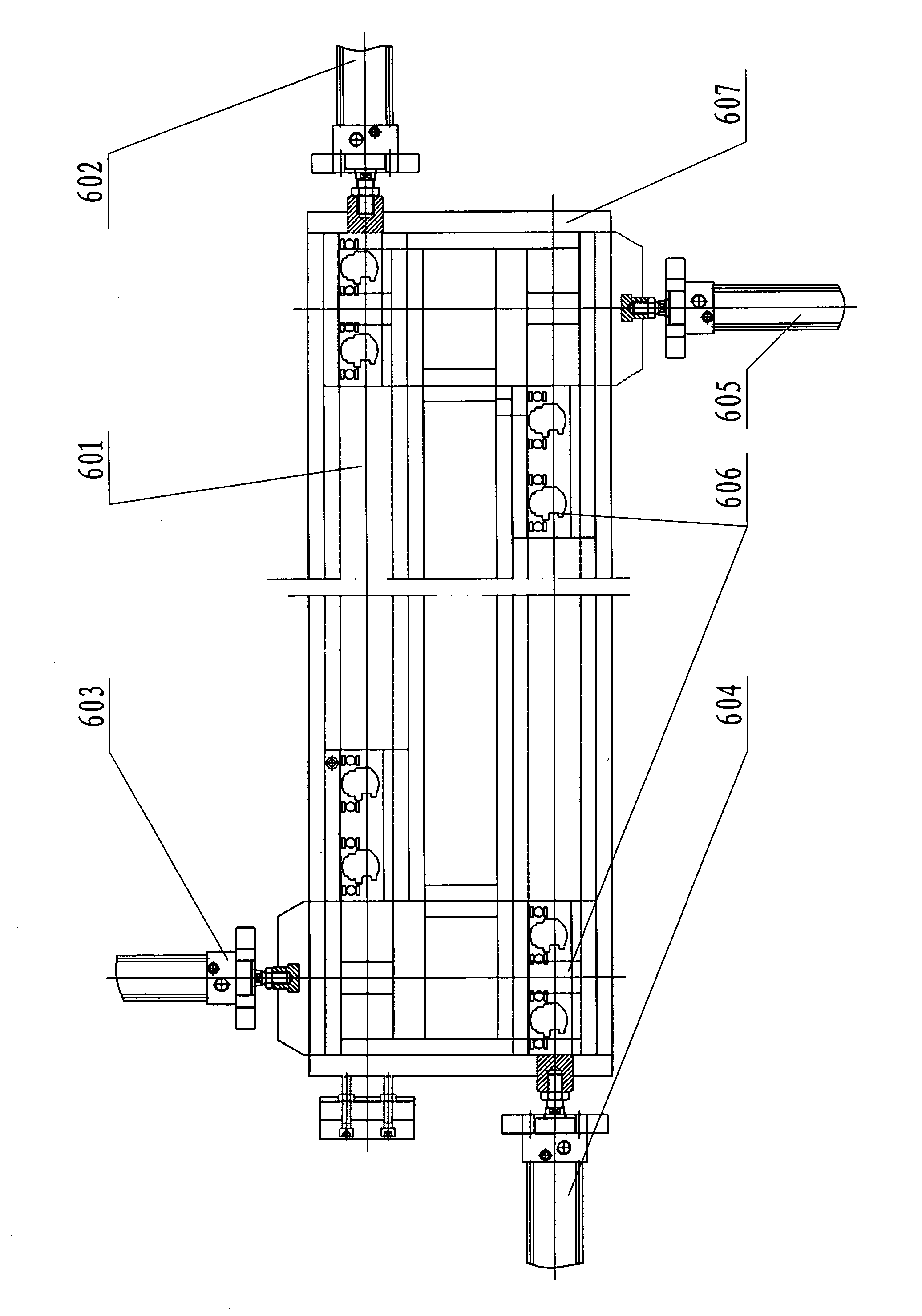

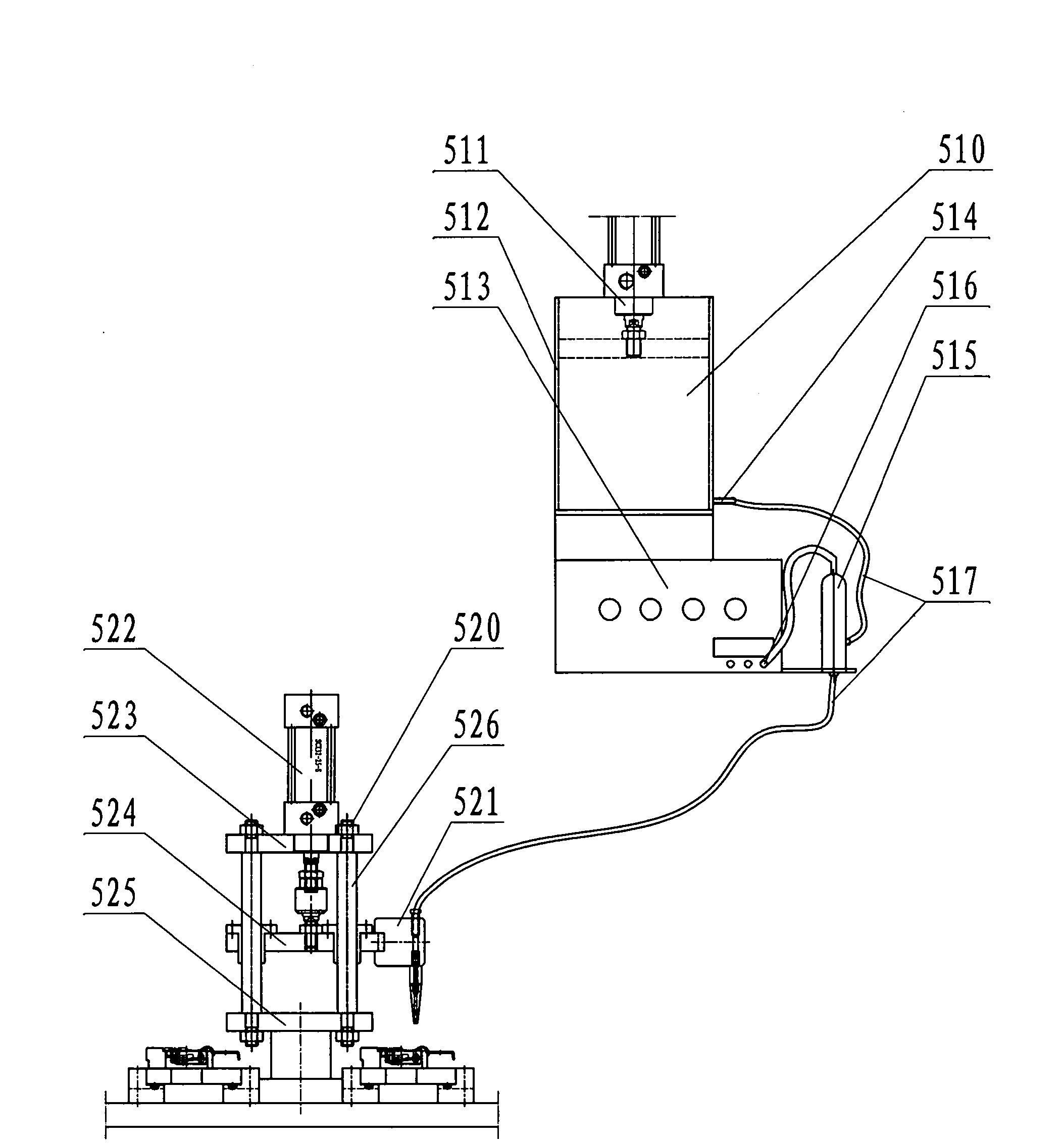

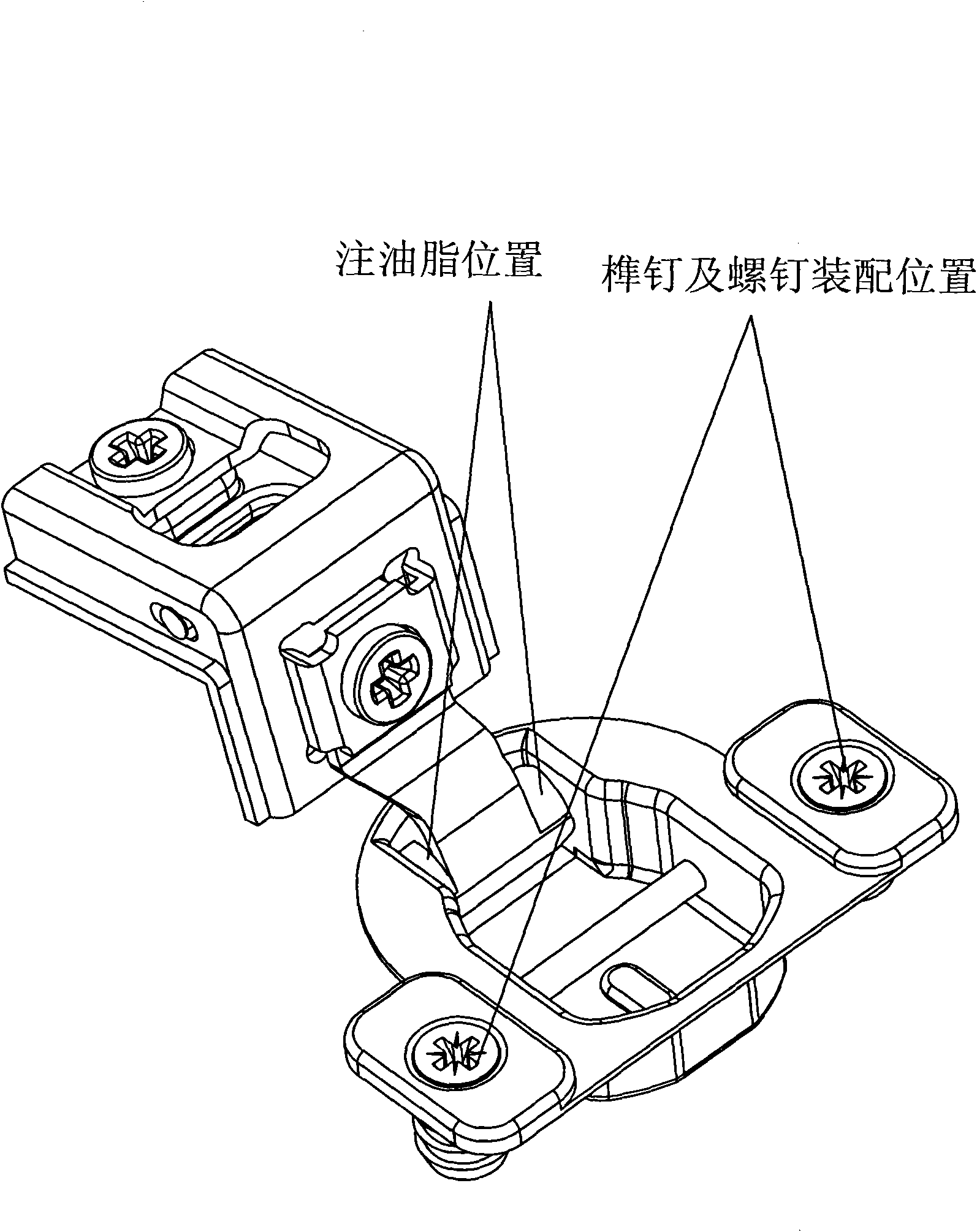

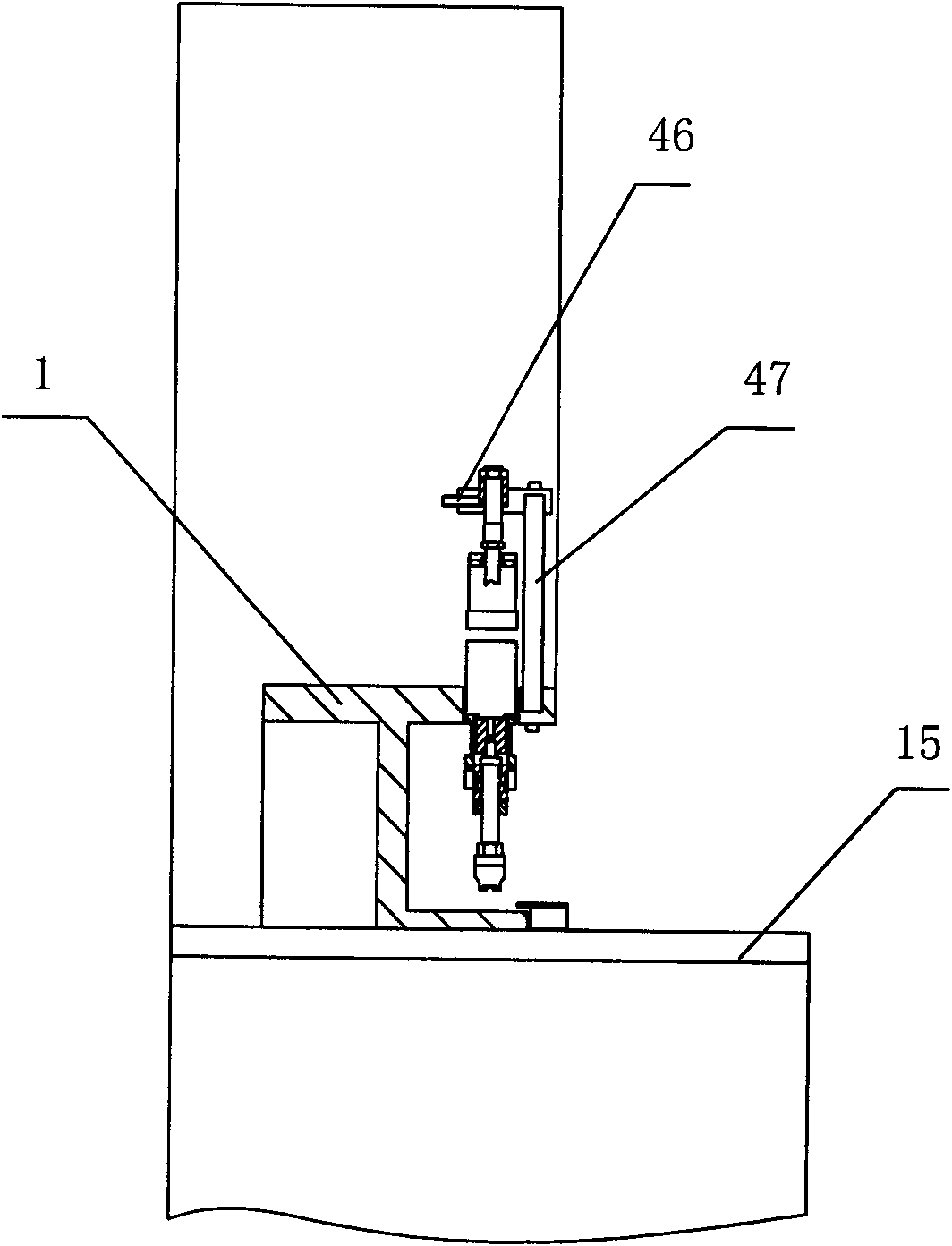

Automatic assembly equipment for hinge pre-installed tenon and oil injection process

InactiveCN102267047ARealize fully automatic assemblyImprove assembly productivityProportioning devicesLubricating pumpsSequence controlQuality assurance

The invention adopts the dowel pressing process, presses the metal screw into the center hole of the plastic dowel, the outer diameter of the screw is slightly larger than the diameter of the center hole of the dowel, and utilizes the elastic deformation and plastic deformation of the plastic dowel to make the screw and the dowel Tightly combined, so that it is firmly fixed on the fixed pocket of the hinge, and at the same time, the quantitative oil injection process is adopted to automatically inject the lubricating grease into the lubricating point quantitatively. The automatic assembly equipment of the present invention includes a dowel grasping mechanism, a dowel vibrating feeding mechanism, a dowel pre-installing mechanism, a screw vibrating feeding mechanism, a grease injection mechanism, a movable clamp cycle stepping and carrying mechanism and a microcomputer control system. Action sequence is controlled by microcomputer control system. The invention realizes the fully automatic assembly of dowel pre-installation and oil injection process, improves the assembly production efficiency and ensures the assembly quality.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

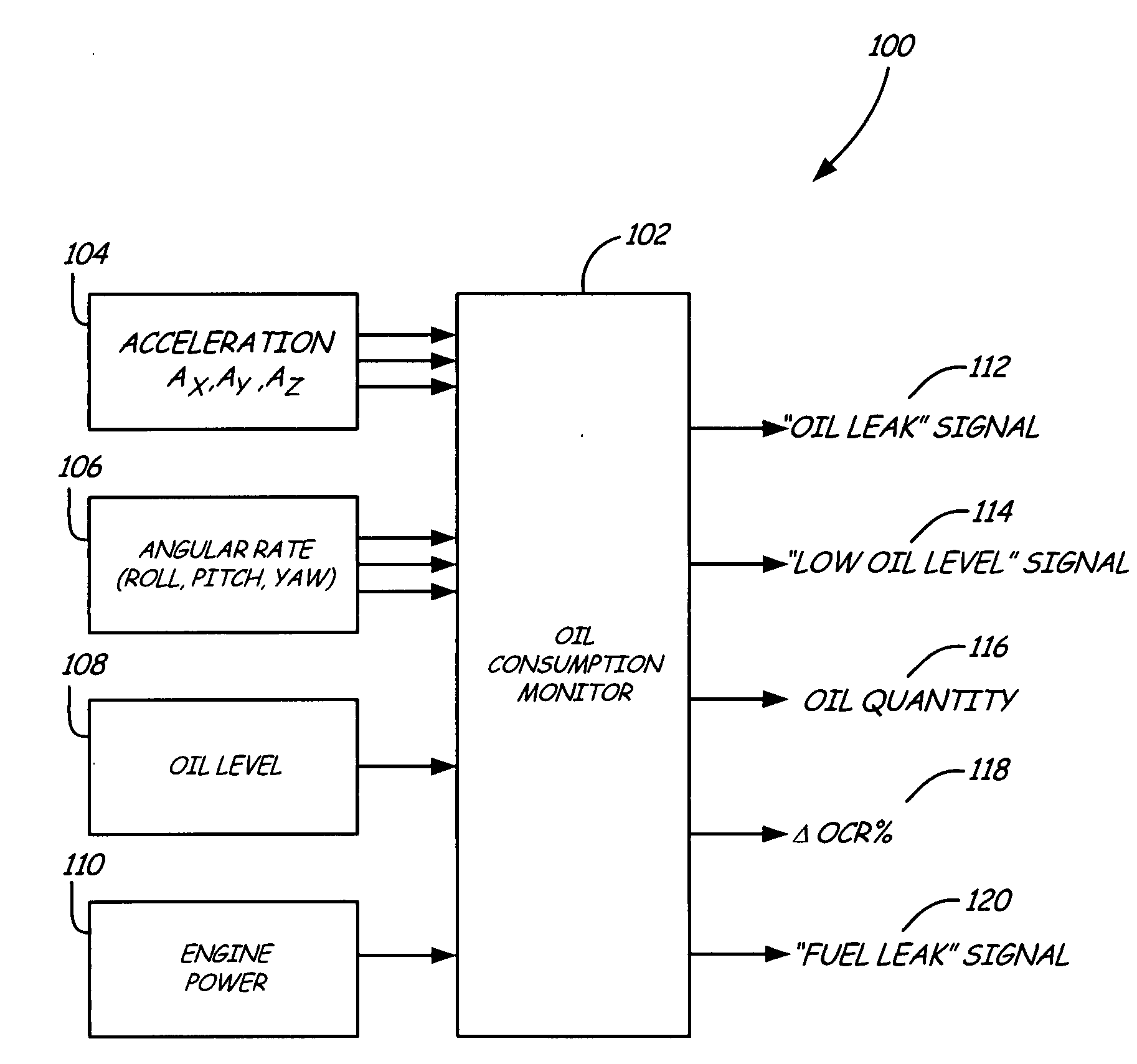

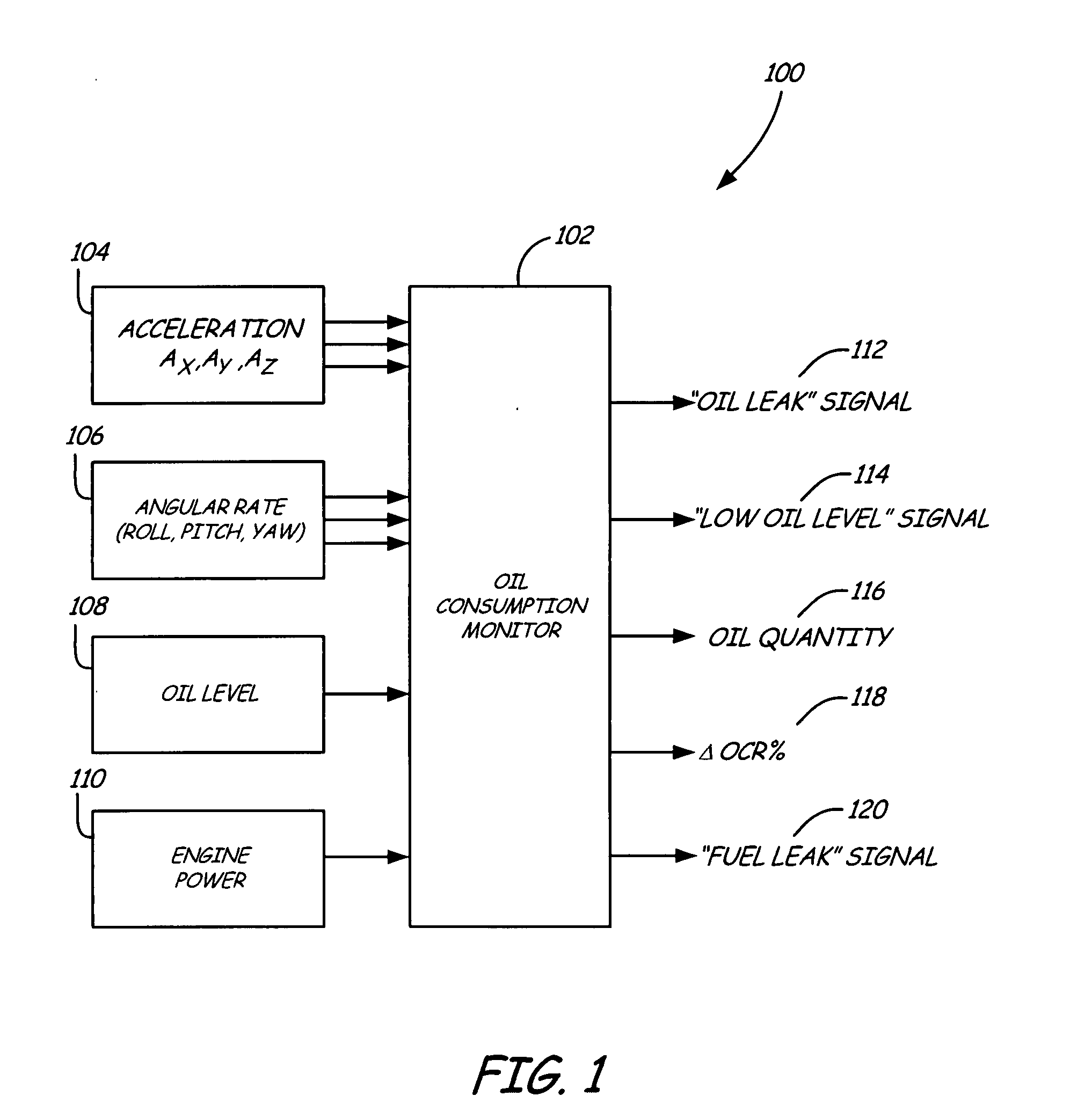

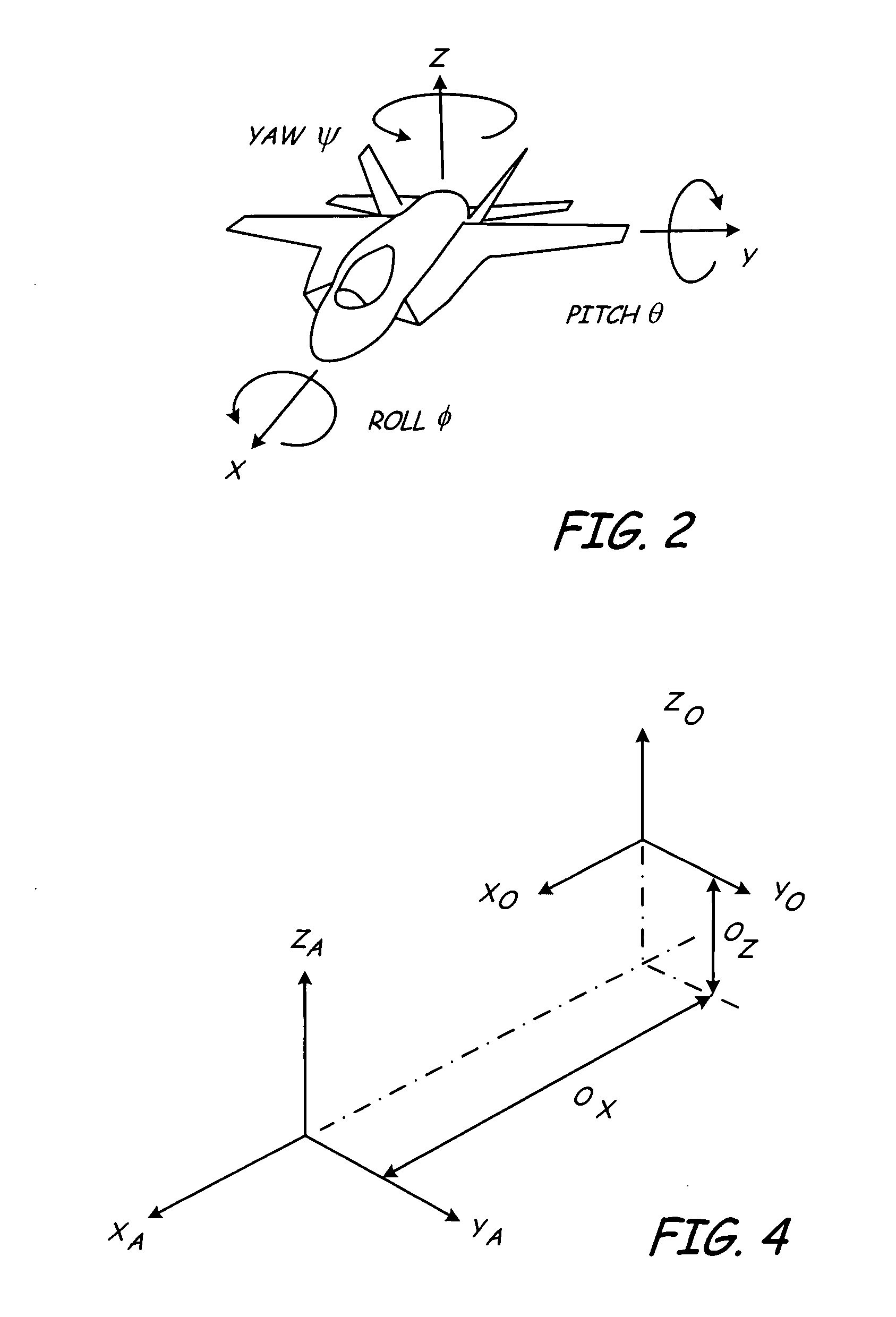

Oil consumption monitoring for aircraft engine

ActiveUS20090107771A1Accurately determineInternal-combustion engine testingProportioning devicesOil consumptionAirplane

A system and method for accurately calculating the oil quantity and oil consumption rate of an aircraft engine detects the level of oil in an oil tank, calculates the oil quantity in the oil tank by compensating for the acceleration of the aircraft, as well as changes in the pitch, yaw and roll of the aircraft. The oil consumption rate of the aircraft is also calculated by calculating the oil quantity at different times, and dividing the difference in oil quantity by the difference in times. The percentage change in oil consumption of the aircraft engine is also calculated. The oil quantity and oil consumption rate can be reported during and after the aircraft's flight.

Owner:RAYTHEON TECH CORP

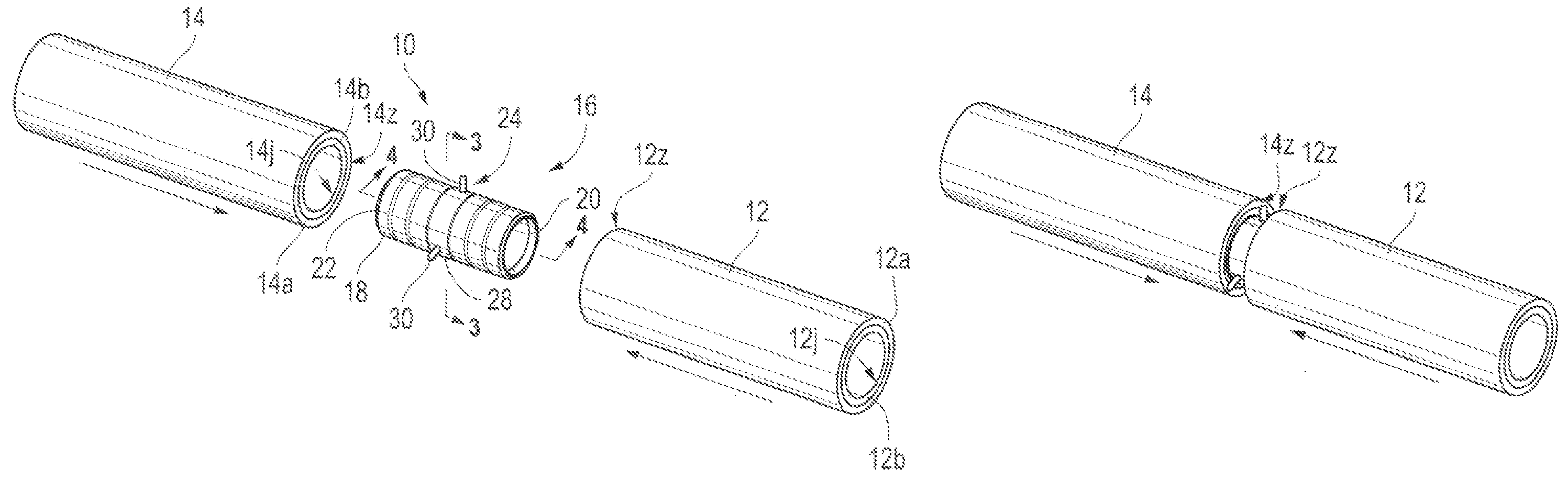

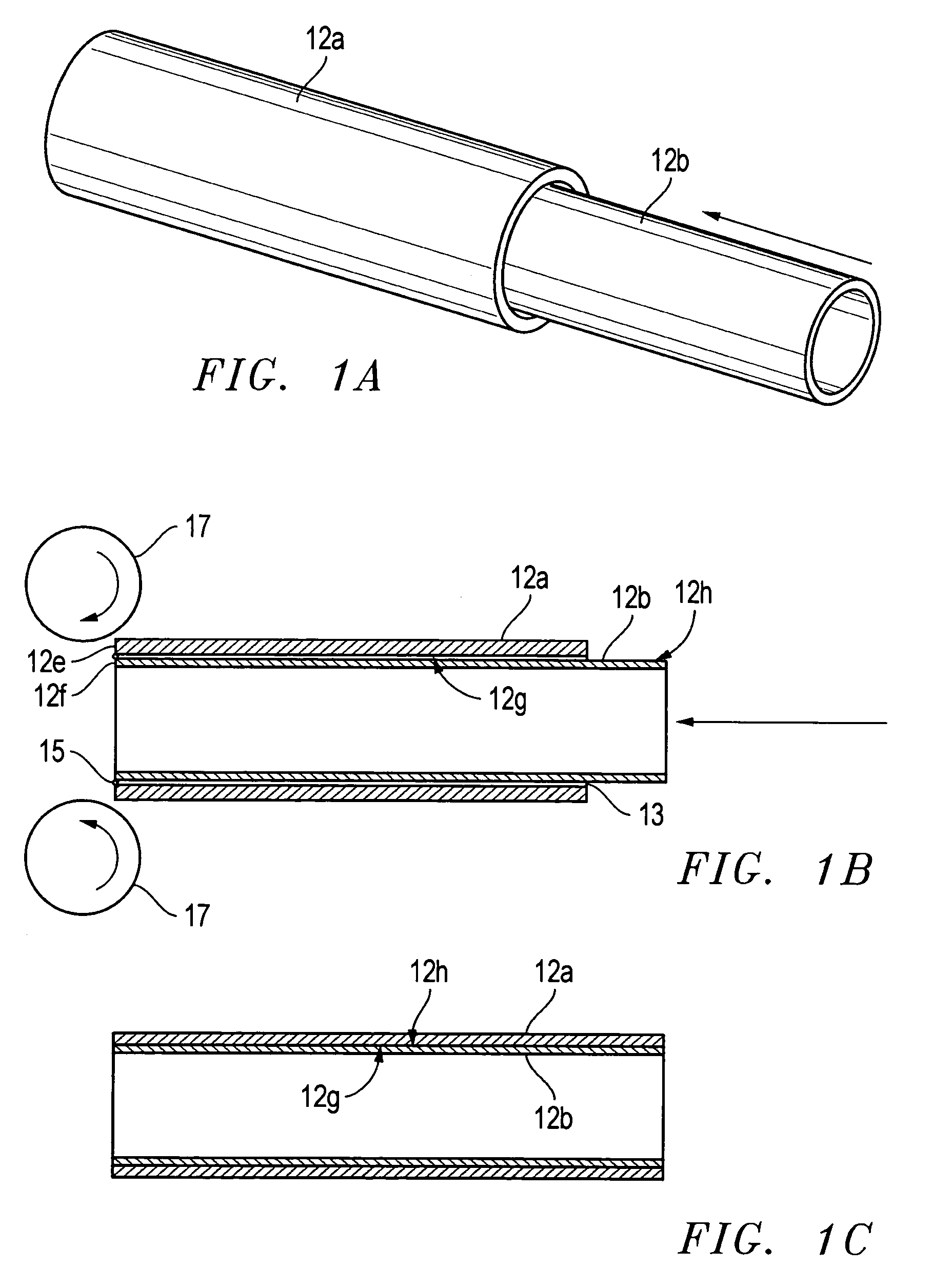

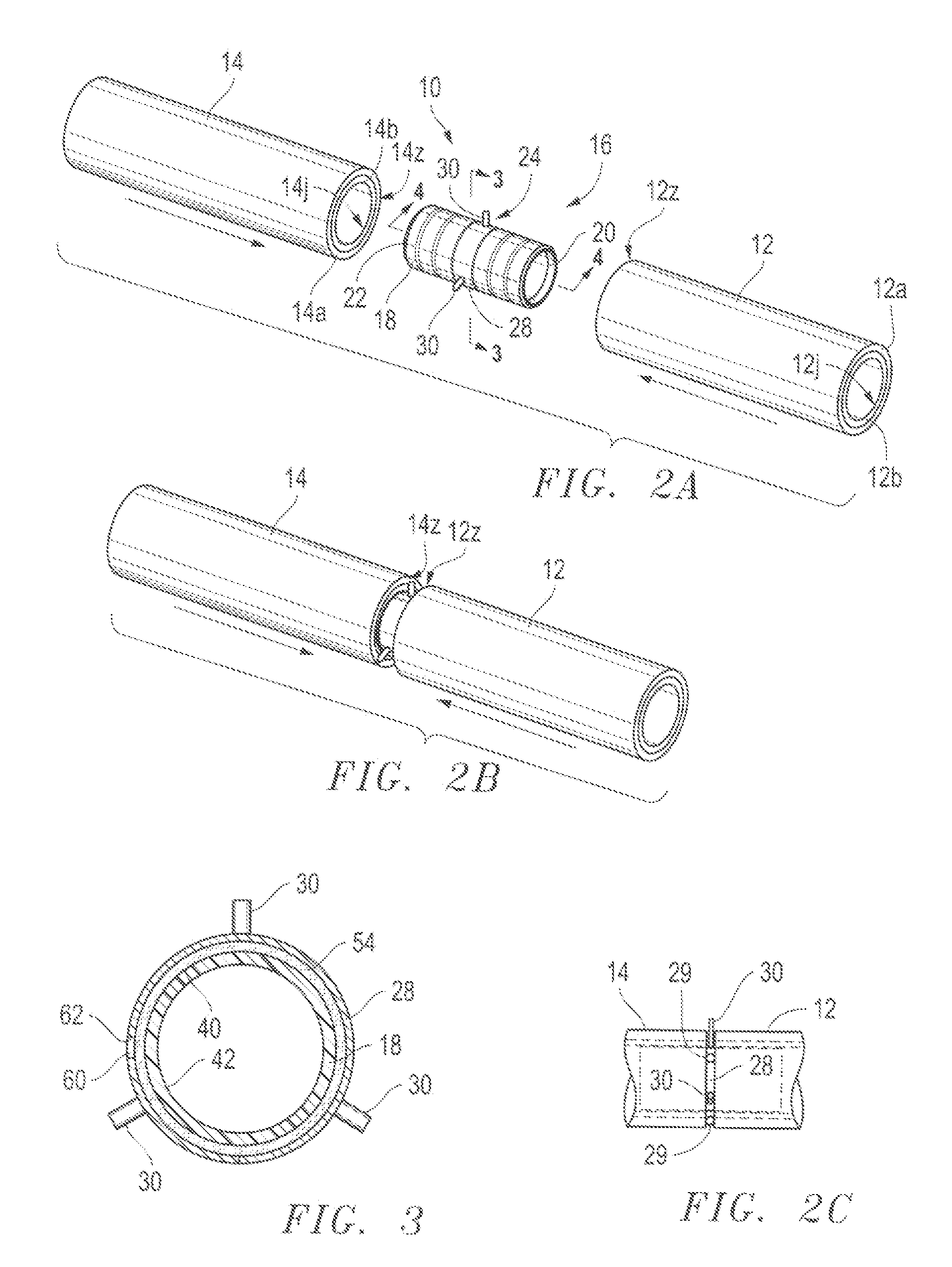

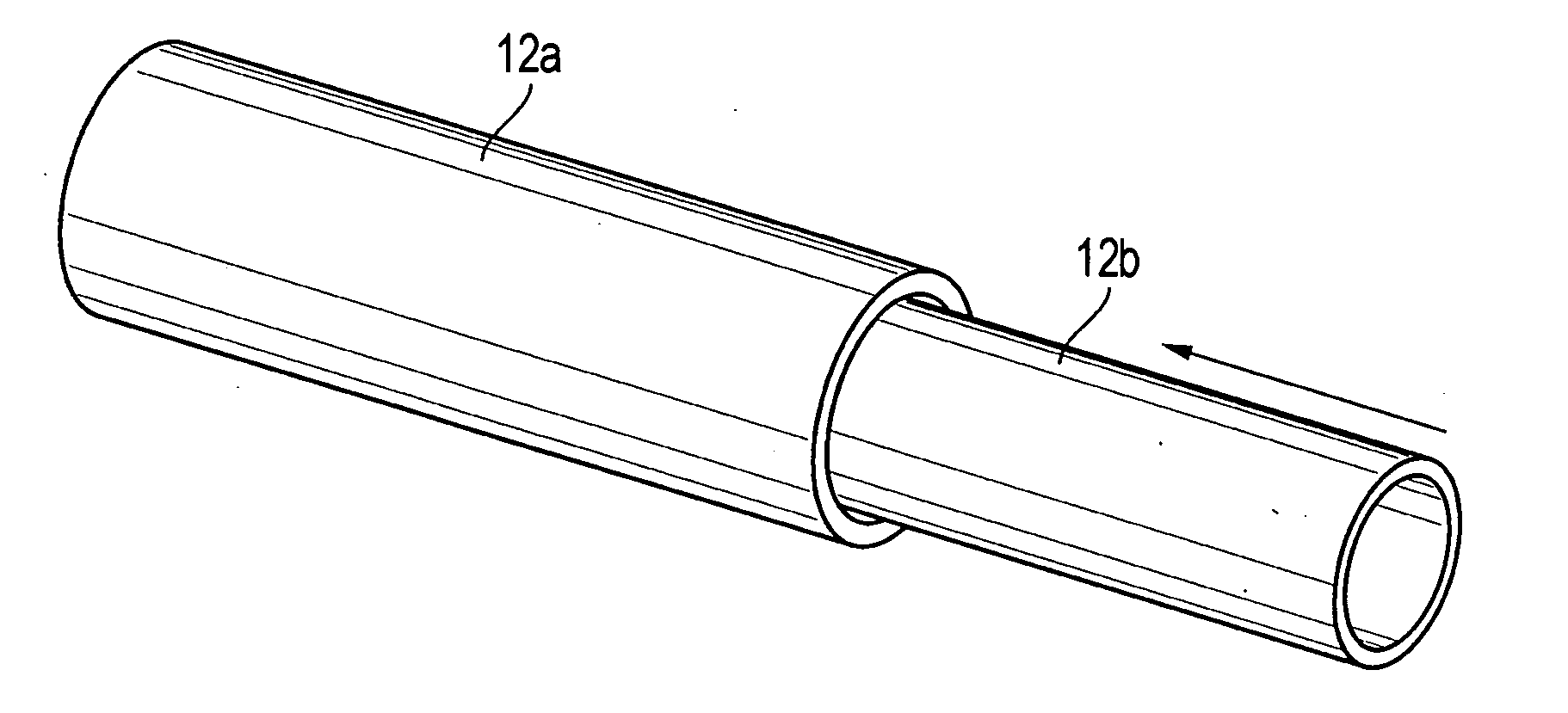

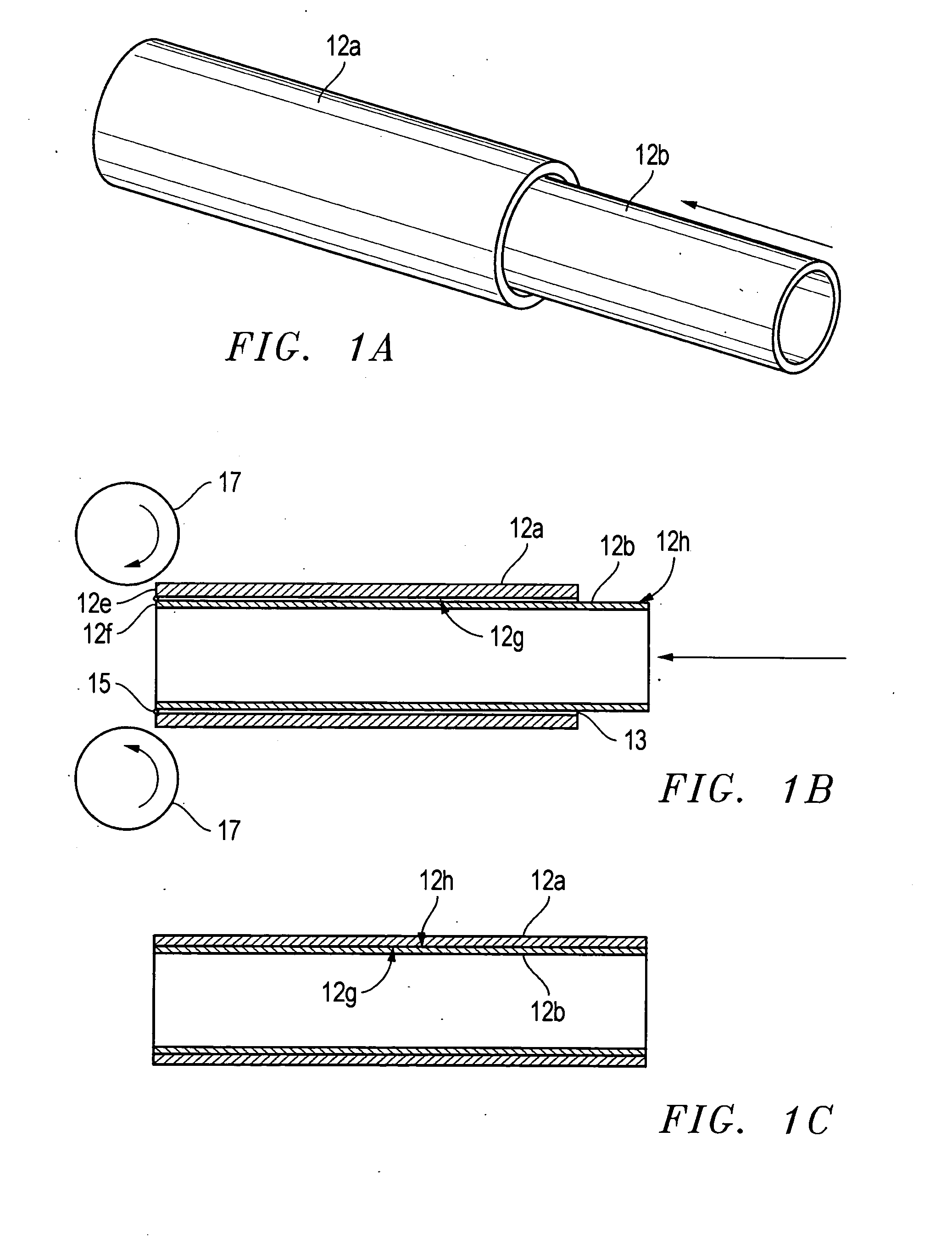

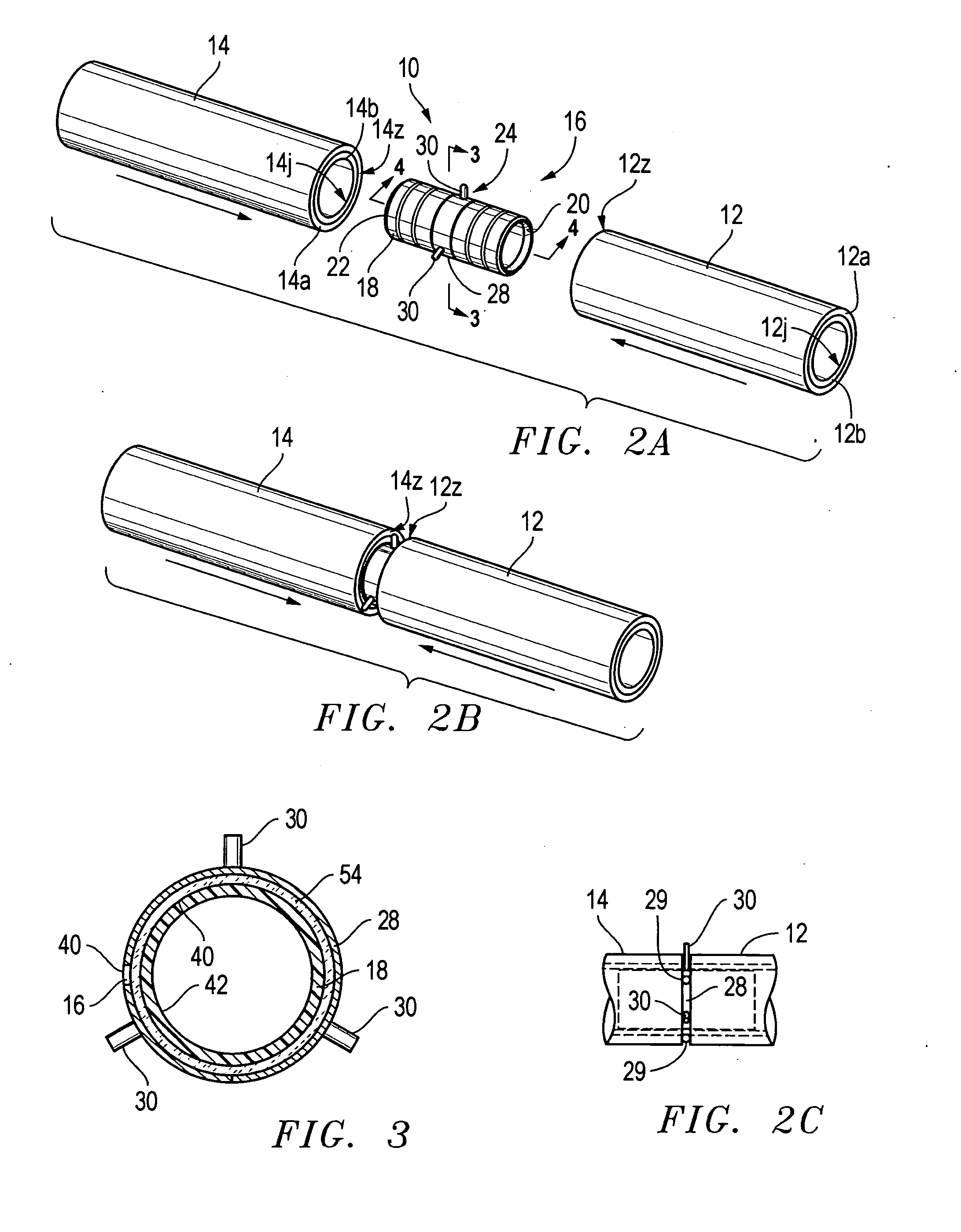

Weldable conduit method of forming

A composite conduit suitable for transporting corrosive and / or erosive fluids including gases, liquids or slurries, is formed by positioning a tube formed of a material having desirable corrosion and / or erosion resistant properties within a pipe formed of a commonly weldable material such that one end of the tube is aligned with one end of the pipe. The tube has an outer diameter slightly less than the inner diameter of the pipe. The tube is affixed to the pipe by connecting the aligned ends thereof, and the pipe is compressed in a reducing operation so that the inner diameter of the pipe is reduced to a diameter that is less than or equal to the outer diameter of the tube. Adjacent, end-to-end sections of the composite conduit are connected using a coupling that employs a cylindrical body formed of the same material as the tubes of the conduits. The coupling body has an outer diameter that is slightly less than the inner diameter of the tubes of the conduits, and preferably an inner diameter that varies to form a taper at each end of the body. The body further contains a circumferential recess intermediate the ends of the body, and a ring formed of the same material as the tubes of the conduits. The ring is positioned within the recess of the body and has a circumferential stop means for limiting movement of the ends of the body within the respective ends of the conduits by the ends of the conduits abutting the stop means. At least one circumferential seal is positioned intermediate the recess and each of the tapered ends of the body for sealing the interconnected conduits. An insulator is preferably positioned in the recess between the ring and the coupling body for inhibiting the transfer of heat produced by welding the ends of the conduits together, although the insulator is not essential in all embodiments.

Owner:HEAT PRO SYST

Weldable conduit and method

ActiveUS20050005983A1Reduce stepsPrevent heat transferProportioning devicesAssembly machinesCouplingEngineering

A composite conduit suitable for transporting corrosive and / or erosive fluids including gases, liquids or slurries, is formed by positioning a tube formed of a material having desirable corrosion and / or erosion resistant properties within a pipe formed of a commonly weldable material such that one end of the tube is aligned with one end of the pipe. The tube has an outer diameter slightly less than the inner diameter of the pipe. The tube is affixed to the pipe by connecting the aligned ends thereof, and the pipe is compressed in a reducing operation so that the inner diameter of the pipe is reduced to a diameter that is less than or equal to the outer diameter of the tube. Adjacent, end-to-end sections of the composite conduit are connected using a coupling that employs a cylindrical body formed of the same material as the tubes of the conduits. The coupling body has an outer diameter that is slightly less than the inner diameter of the tubes of the conduits, and preferably an inner diameter that varies to form a taper at each end of the body. The body further contains a circumferential recess intermediate the ends of the body, and a ring formed of the same material as the tubes of the conduits. The ring is positioned within the recess of the body and has a circumferential stop means for limiting movement of the ends of the body within the respective ends of the conduits by the ends of the conduits abutting the stop means. At least one circumferential seal is positioned intermediate the recess and each of the tapered ends of the body for sealing the interconnected conduits. An insulator is preferably positioned in the recess between the ring and the coupling body for inhibiting the transfer of heat produced by welding the ends of the conduits together, although the insulator is not essential in all embodiments.

Owner:HEAT PRO SYST

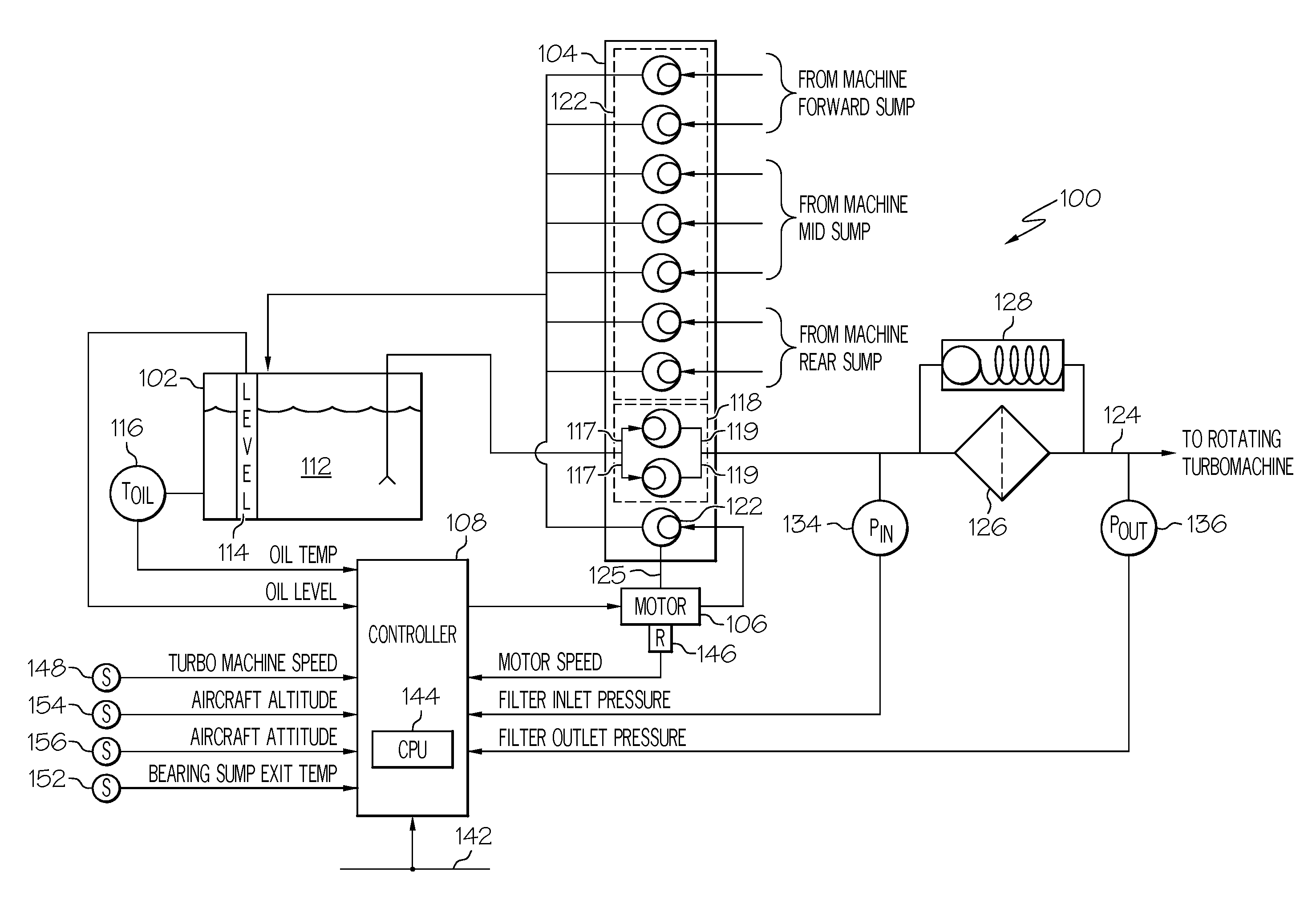

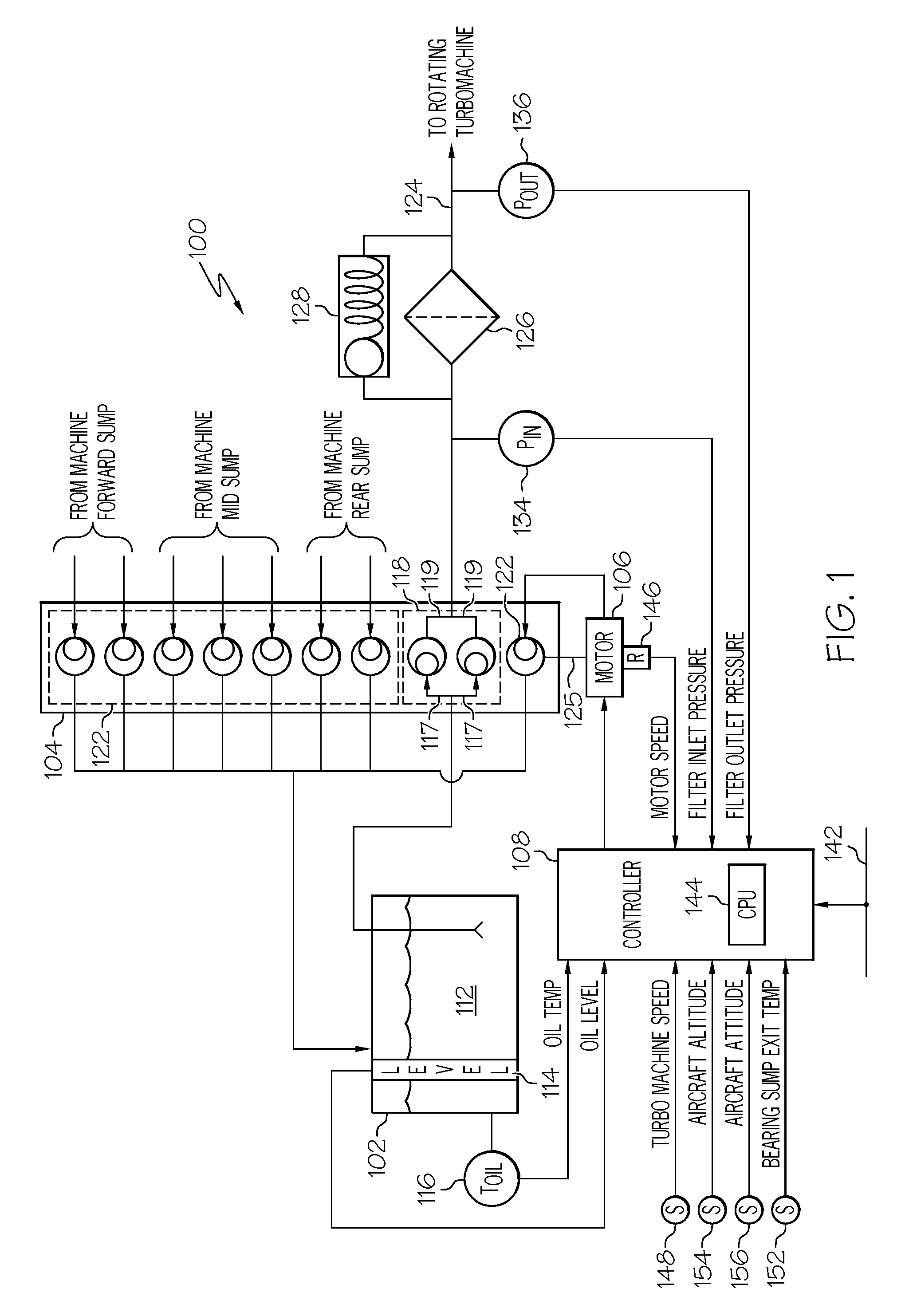

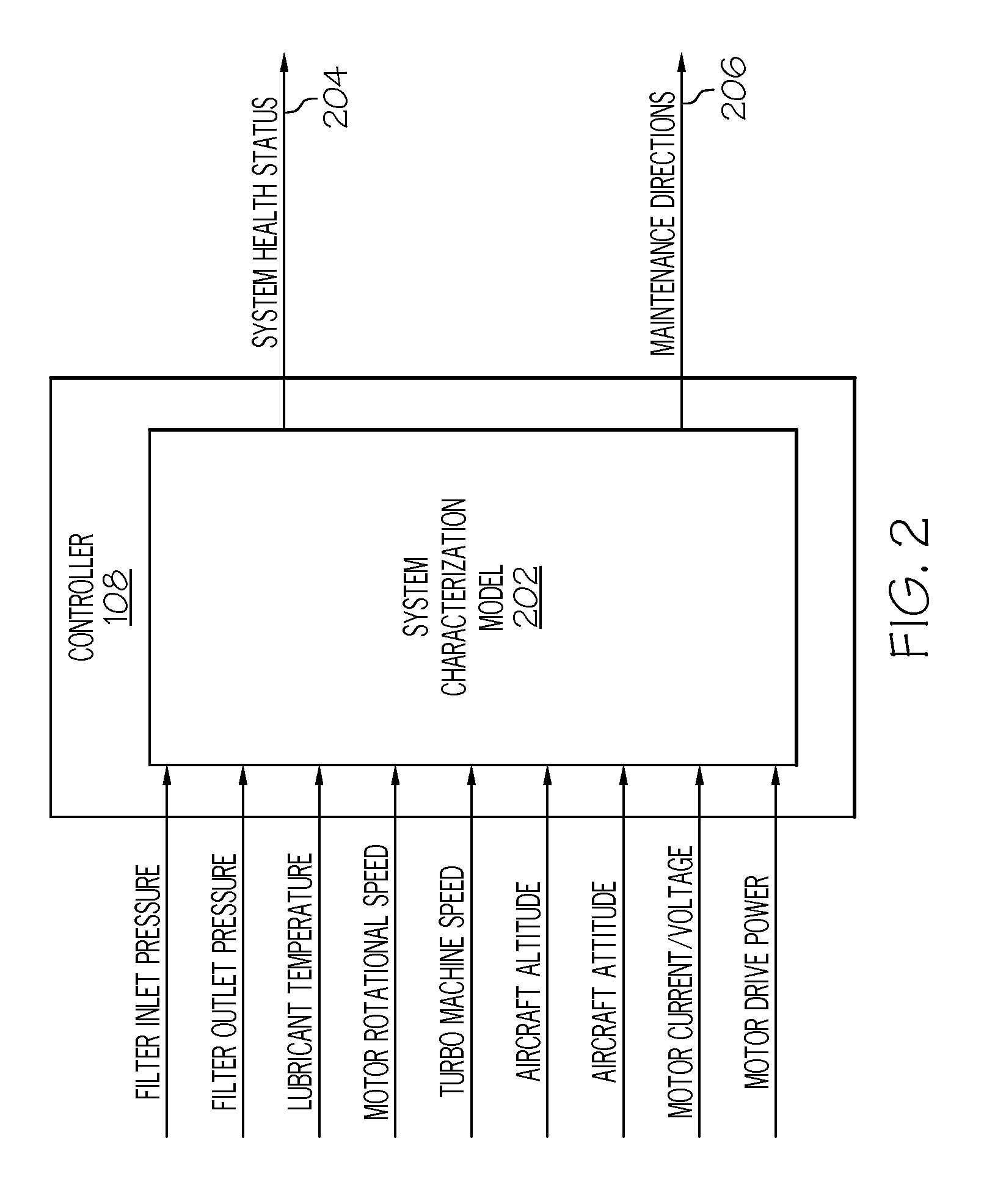

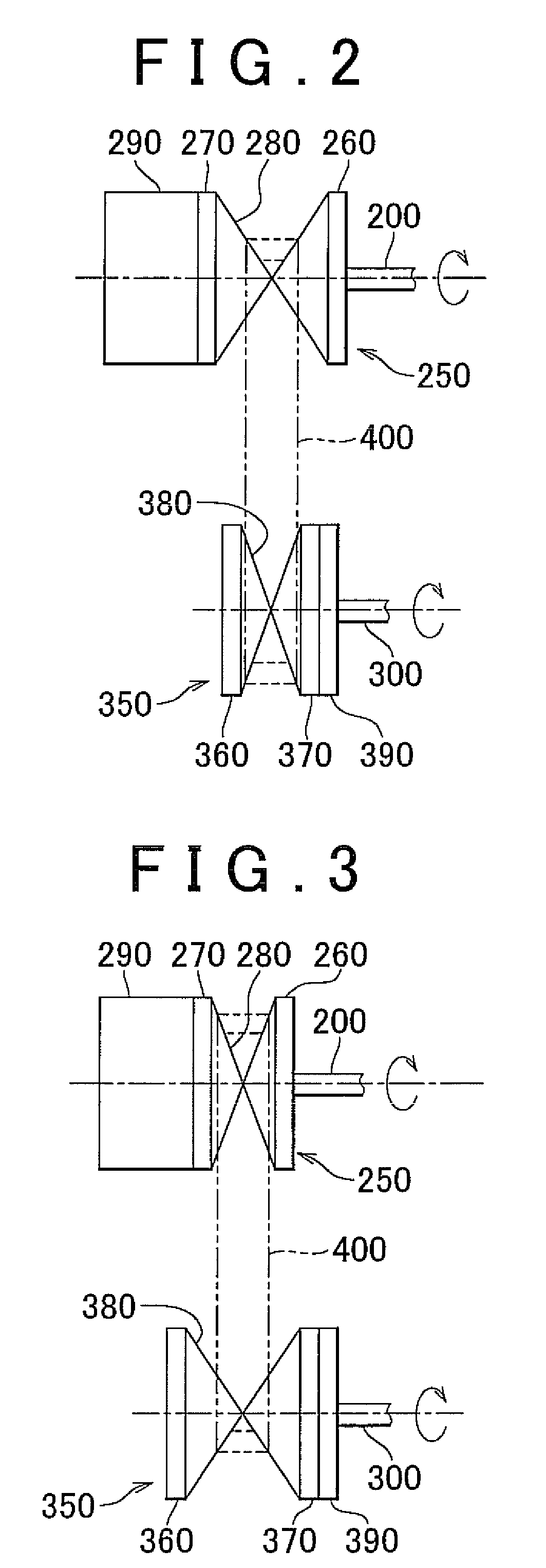

Electric motor driven lubrication pump and lubrication system prognostic and health management system and method

InactiveUS20090299535A1Proportioning devicesFlow control using electric meansSimulation basedPrediction system

An aircraft lubrication supply system health and prognostic system and method includes supplying a pressure signal representative of lubricant pressure, a temperature signal representative of lubricant temperature, a speed signal representative of motor rotational speed, and one or more aircraft condition signals representative of one or more aircraft operating conditions to a system characterization model of at least portions of the lubrication supply system. Simulation response data representative of at least the pressure signal, the temperature signal, and the speed signal are generated, and lubrication supply system health is determined based, at least in part, on the simulation response data.

Owner:HONEYWELL INT INC

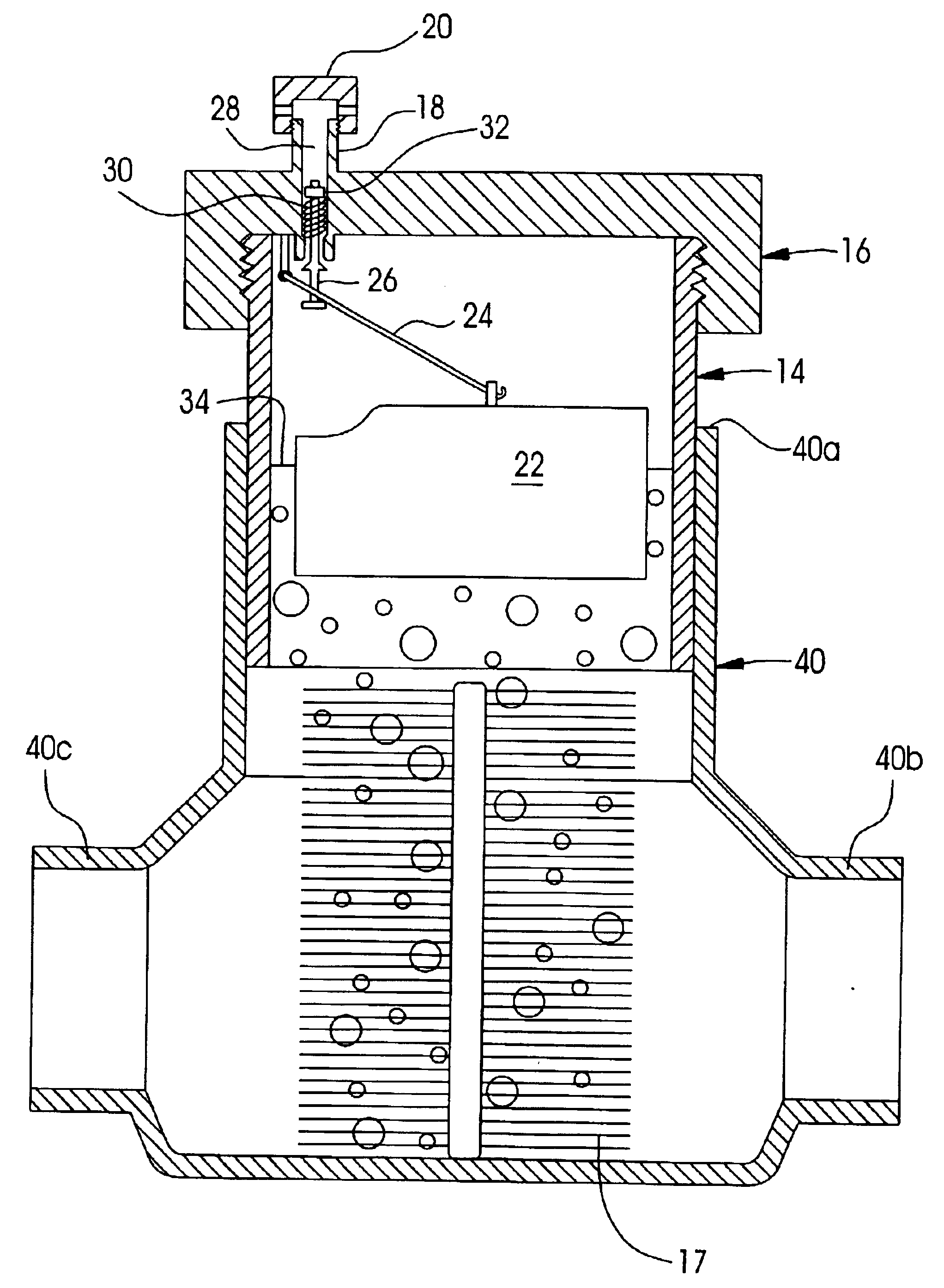

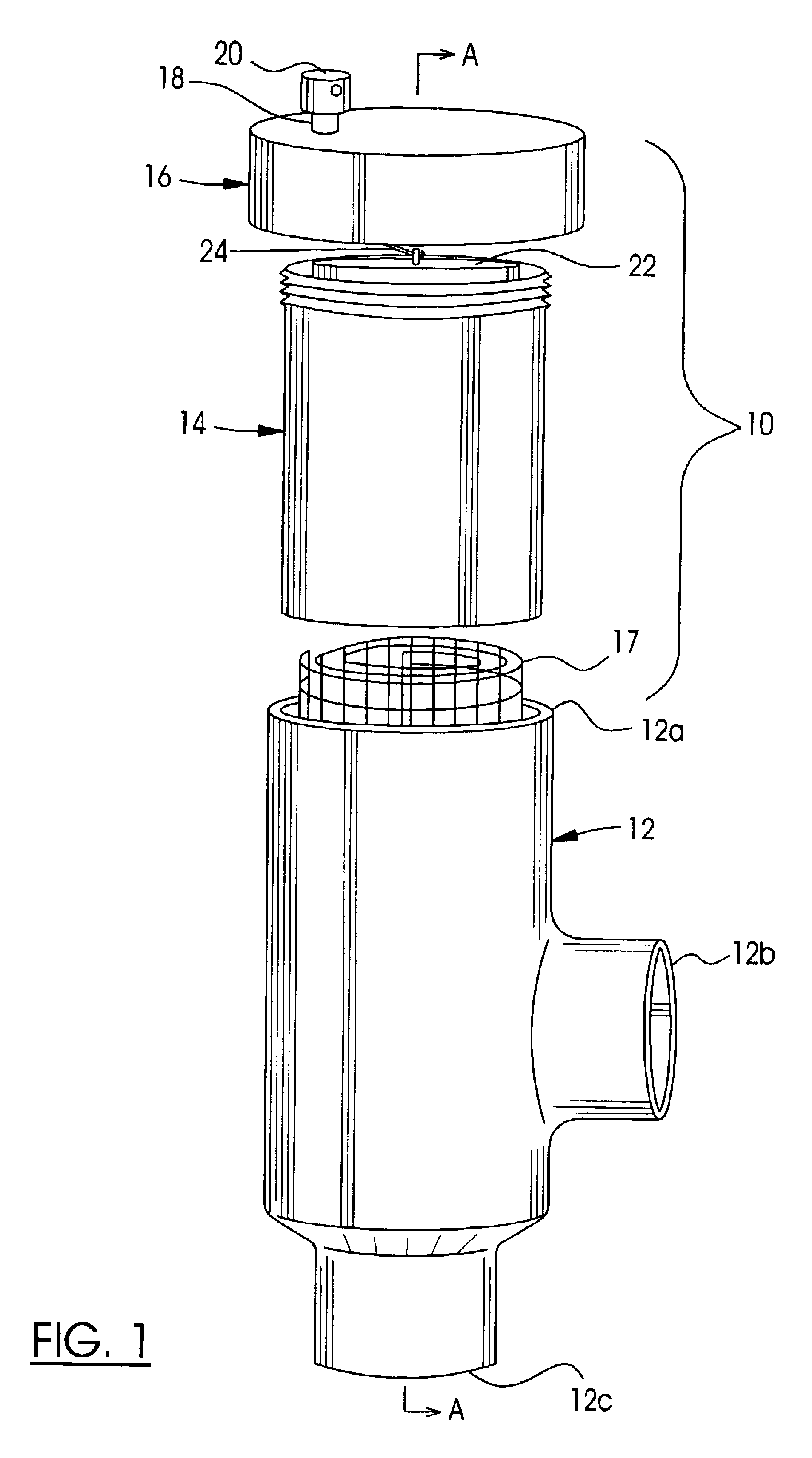

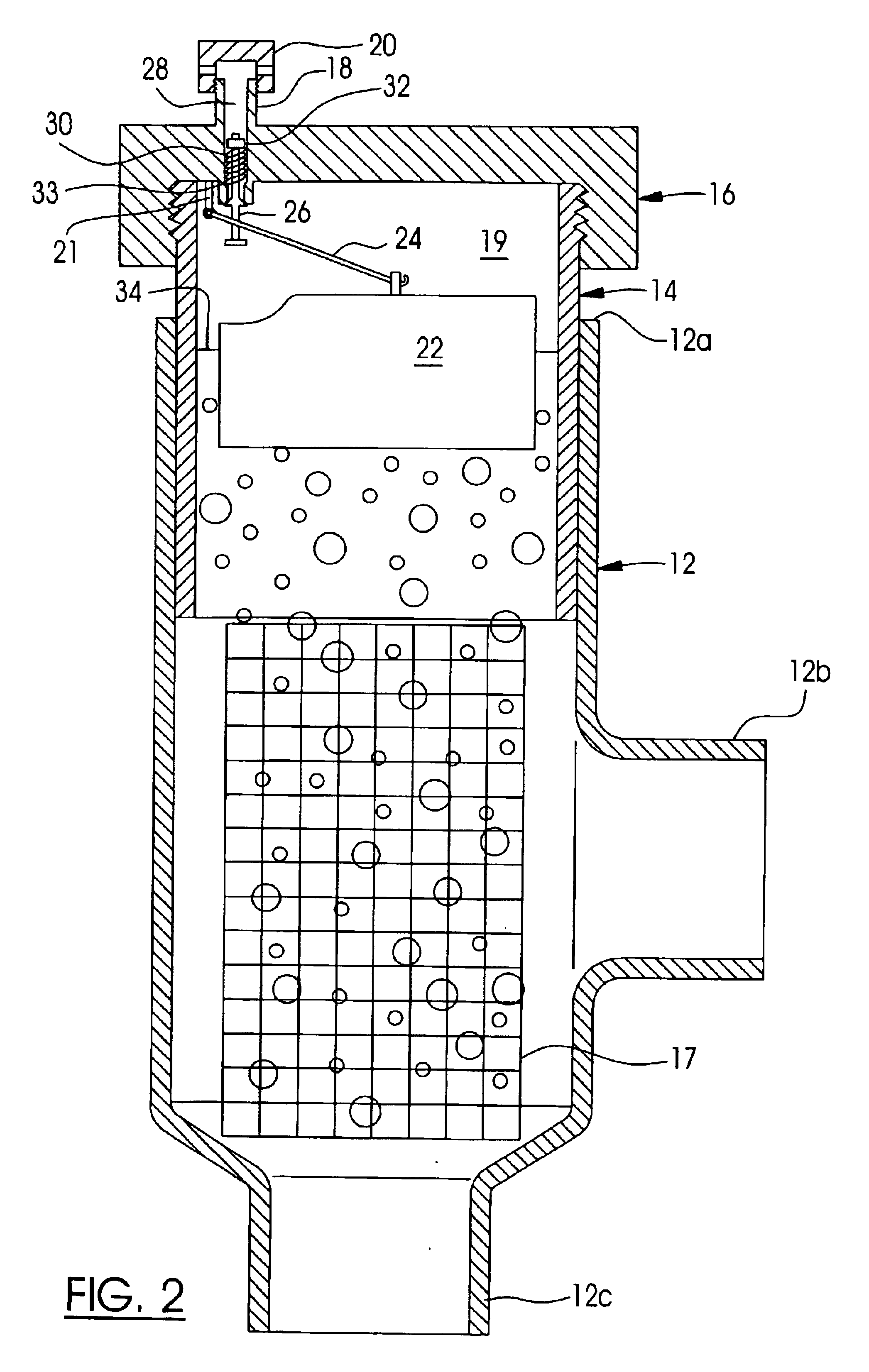

Method and kit for use with standard pipe couplings to construct a de-aerator

InactiveUS6893485B2Easy constructionQuick installationSleeve/socket jointsProportioning devicesBiomedical engineeringConcentrator

A kit for constructing a de-aerator that includes a concentrator is adapted to be connected to a standard pipe coupling. The concentrator is inserted in the path of liquid conveyed through the pipe coupling for aggregating gas, and directing the gas to a cavity. The cavity is encased by the fitting which is a vertical, cylindrical sheath with one end adapted to be inserted into standard pipe couplings, and the other end adapted to be connected with the cap. The cap includes a vent adapted to open and shut in response to lowering and raising of the level of the liquid in the cavity below / above a threshold, respectively.

Owner:SWABEY OGILVY RENAULT

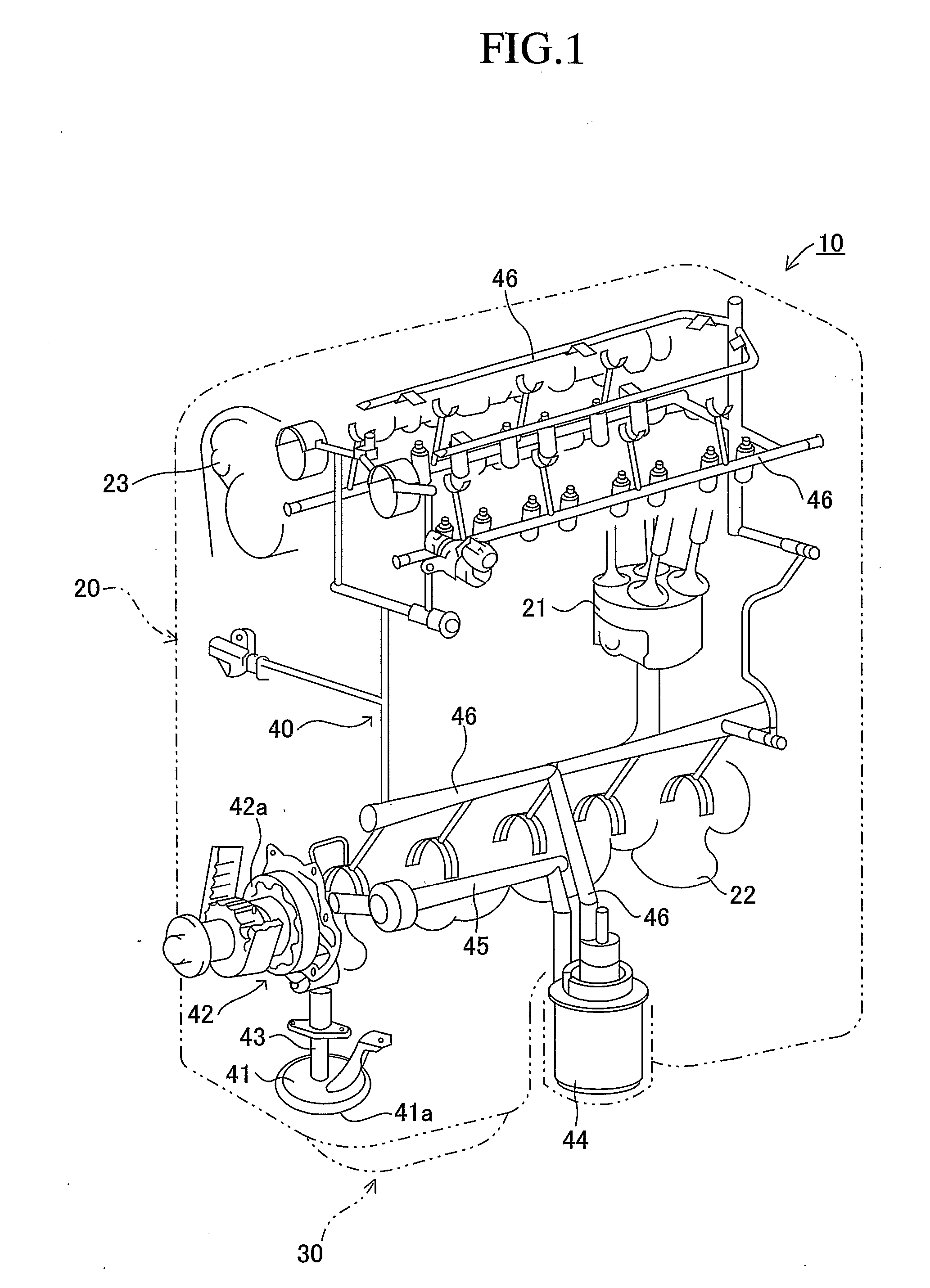

Lubrication System and Internal Combustion Engine Comprising Such a System

This lubrication system includes a pump feeding a main line which provides oil to a support interface for a crank shaft of oil engine and an auxiliary line connected to at least one piston cooling jet. The pump is a variable flow pump controlled on the basis of oil pressure in the main line. A proportional means is mounted on the auxiliary line. This means is adapted to control oil flow in the auxiliary line depending on the working conditions of the engine, e.g. oil temperature, torque to be delivered or rotational speed of the engine.

Owner:RENAULT TRUCKS

Flow conditioner for a fluid transport pipe

ActiveUS7370675B2Reduce riskMitigate such drawbackFlow mixersFluid dynamicsFluid transportMechanical engineering

Owner:GRTGAZ

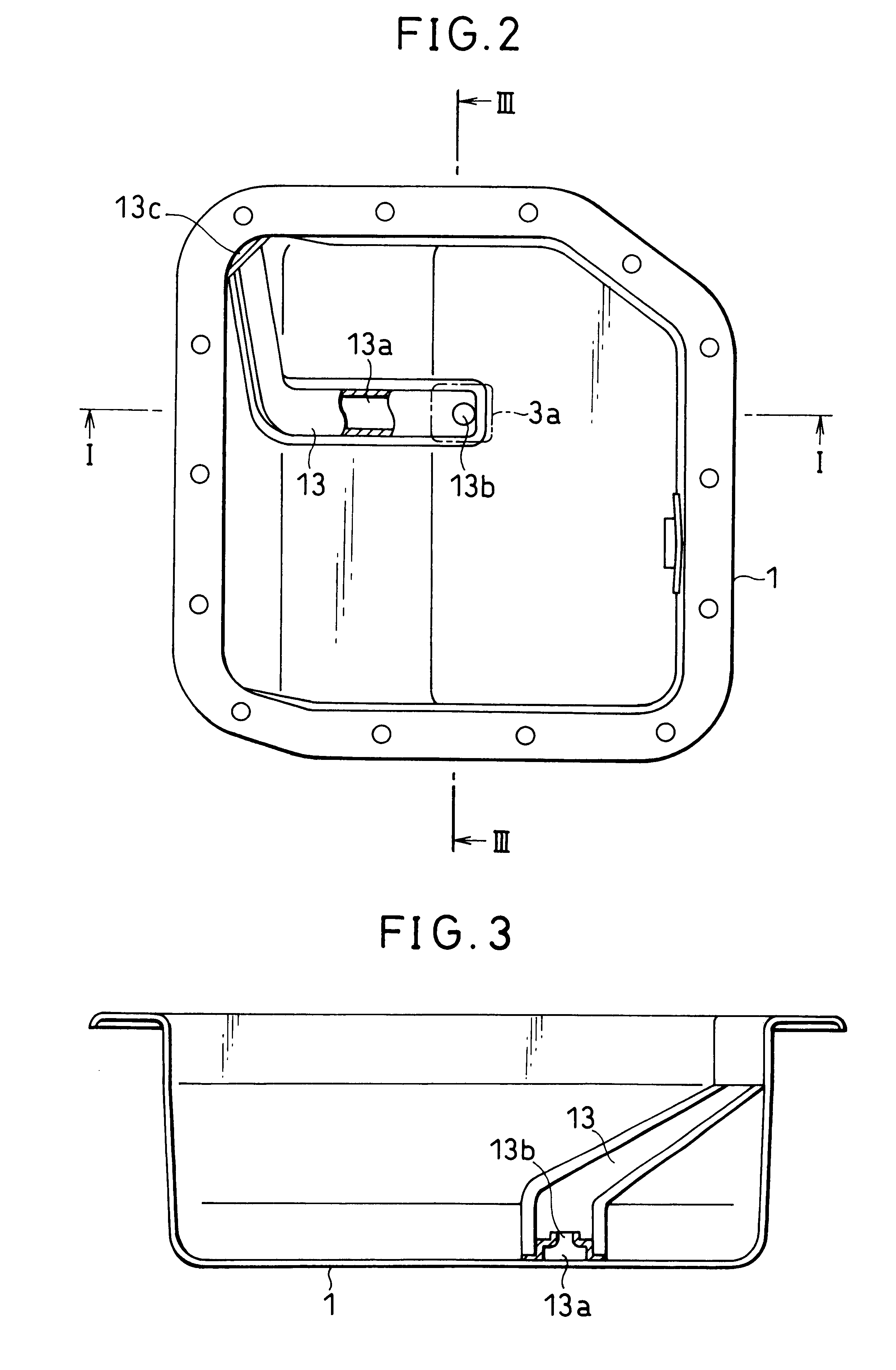

Oil Pan Apparatus

InactiveUS20080083586A1Problem is exacerbatedCrankshaftsProportioning devicesThermostatOil temperature

An oil temperature sensor is externally mounted on a side plate of an oil pan cover that constitutes an external cover for an oil pan apparatus. The oil temperature sensor can output a signal in accordance with the oil temperature prevailing near a thermostat valve apparatus in a second chamber. If the second chamber oil temperature rises immediately after startup of an engine, a CPU judges that an open valve failure has occurred, that is, the thermostat valve apparatus is stuck open. If the oil temperature of the second chamber is not raised when an adequate amount of time has elapsed after the end of a warm-up operation, the CPU judges that a closed valve failure has occurred, that is, the thermostat valve apparatus is stuck closed.

Owner:TOYOTA JIDOSHA KK

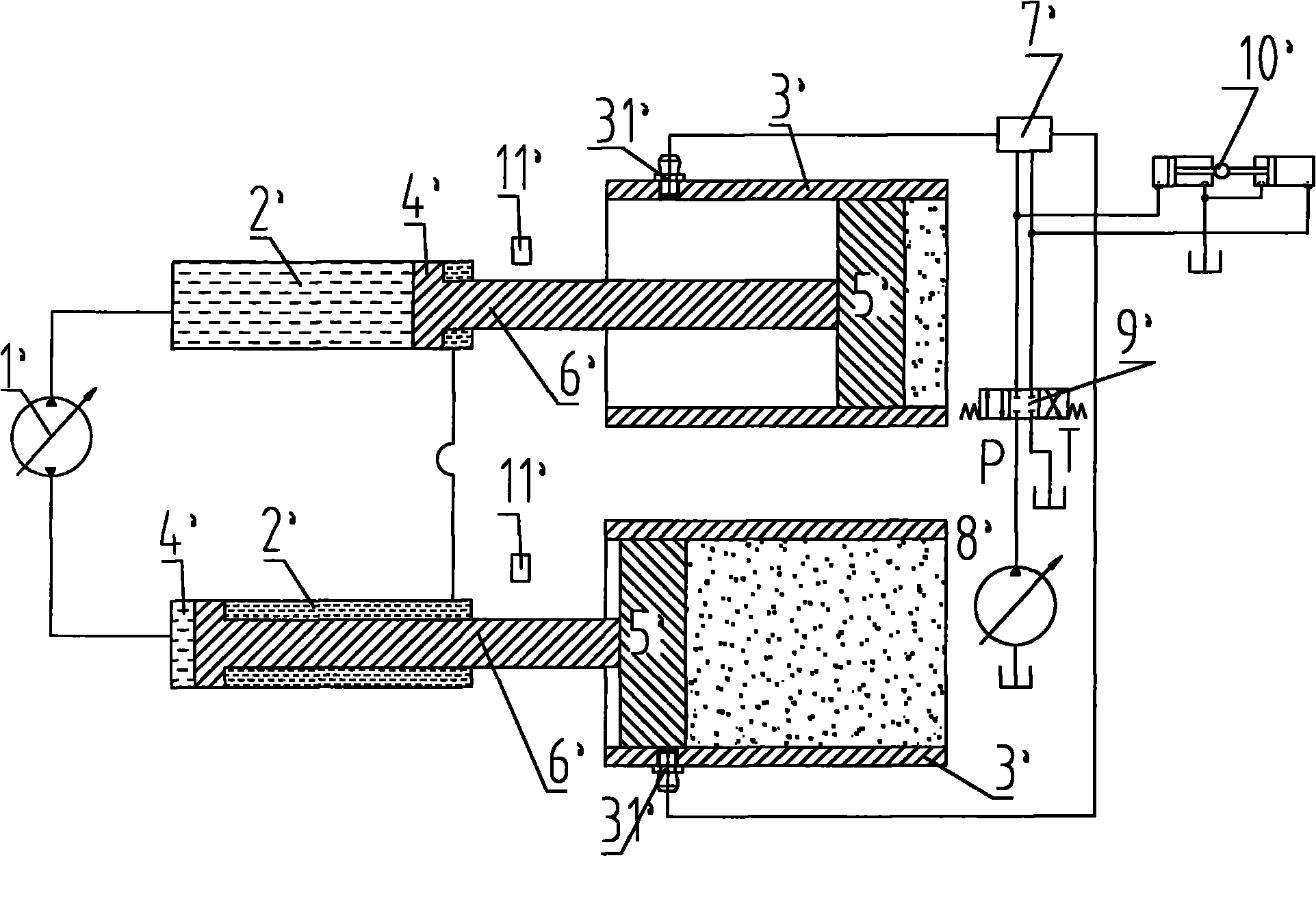

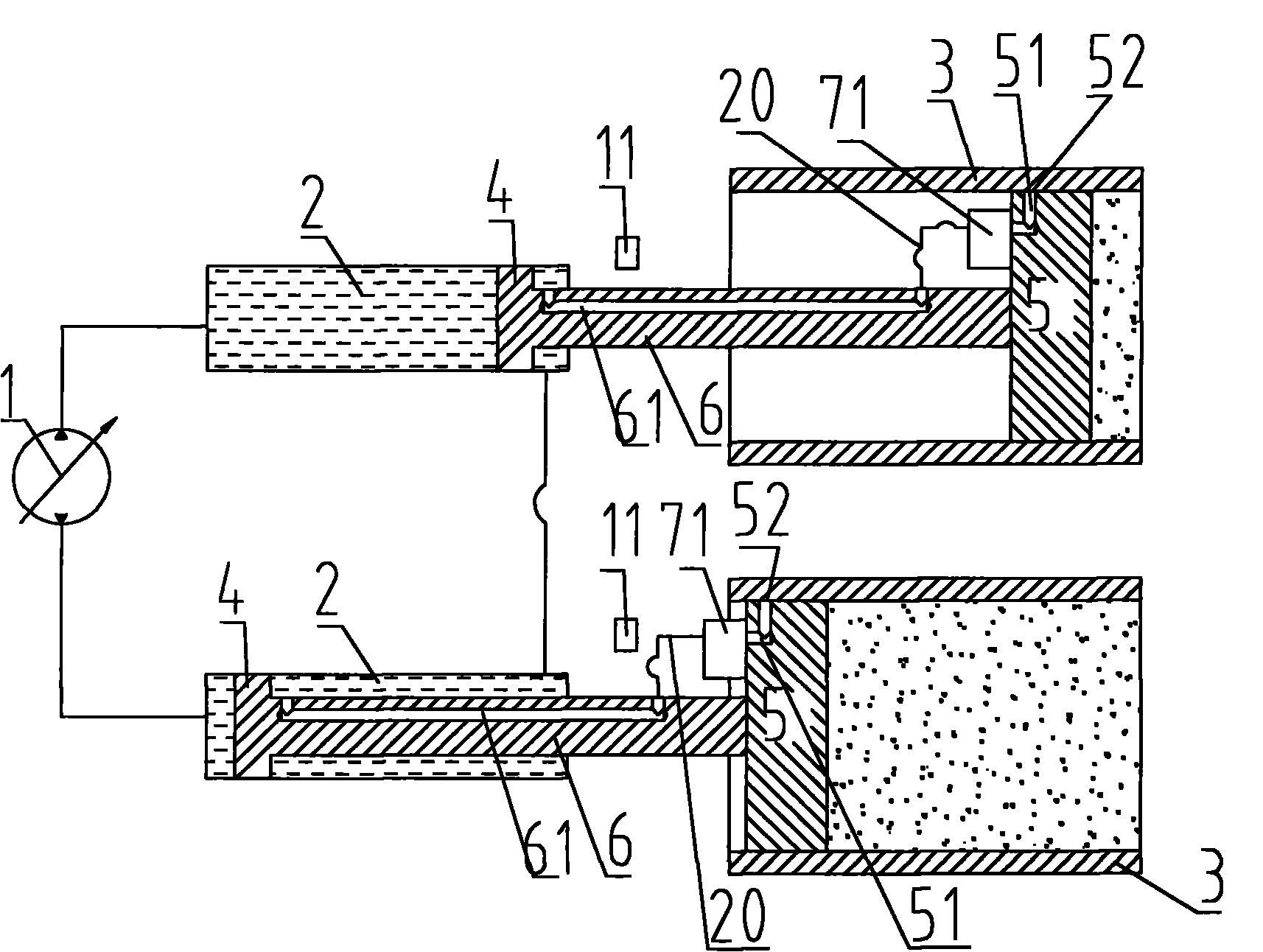

Piston lubricating system for concrete cylinder

ActiveCN102042217AReduce wastePrecise applicationProportioning devicesPositive displacement pump componentsHydraulic pumpEngineering

The invention discloses a piston lubricating system for concrete cylinders, comprising a hydraulic pump (1), main oil cylinders (2), concrete cylinders (3), oil cylinder pistons (4) positioned in the main oil cylinders, concrete pistons (5) positioned in the concrete cylinders, piston rods (6), and a hydraulic lubricating device. Piston rod channels (61) are formed on the piston rods, lubricatingchannels (51) are formed on the concrete pistons, the oil inlet ends of the piston rod channels are communicated with a cavity with piston rod or a cavity without piston rod of the main oil cylinders, the oil outlet ends of the piston rod channels are communicated with the oil inlets of the hydraulic lubricating device, the oil outlets of the hydraulic lubricating device are communicated with theoil inlet ends of the lubricating channels, the oil outlets of the lubricating channels are communicated with the lubricating holes (52) formed in the circumferential walls of the concrete pistons. The lubricating system can accurately apply lubricating oil on the pistons of the concrete cylinders, so that lubrication effect is good and the waste of the lubricating oil is reduced.

Owner:ZOOMLION HEAVY IND CO LTD

Grease replenishing device

InactiveUS6994473B2Extended service lifeSlow heatingProportioning devicesRolling contact bearingsRolling-element bearingEngineering

A grease replenishing device replenishes a grease-lubricated rolling bearing with a grease. The grease replenishing device has a storage chamber portion and a pressing member. The storage chamber portion stores the grease. The pressing member pushes the grease out of the storage chamber into an interior of the rolling bearing.

Owner:NSK LTD

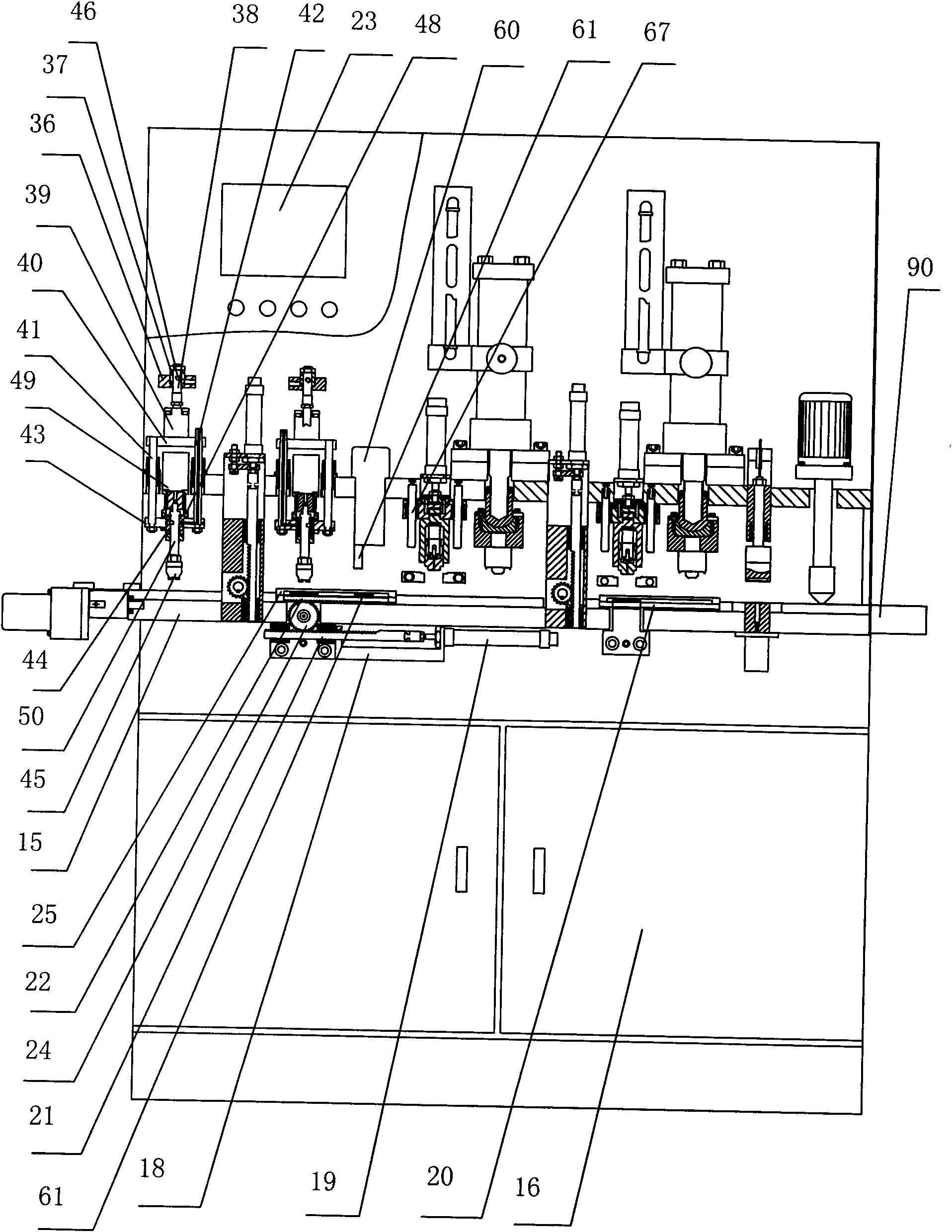

Full-automatic bearing greasing and capping machine

InactiveCN101982699ACompact structureEasy to debugProportioning devicesConveyorsFailure rateEngineering

The invention discloses a full-automatic greasing and capping machine, relating to a device for adding grease and a dust cap to a bearing. A workbench is fixed on a machine frame; a mounting base is fixed on the workbench; the front part of the mounting base is provided with a material support plate; the upper part of the mounting base is provided with a control device; the left side of the workbench is provided with a material conveyor, and the right side of the workbench is provided with an unacceptable product removing device; according to the processing sequence, two greasing devices, a grease quantity detection device, two capping devices, a dust cap height detection device and a grease equalizer are sequentially arranged on the mounting base from left to right; turning devices are respectively arranged between the two greasing devices and between the two capping devices; and a front reciprocating device and a rear reciprocating device are respectively arranged below the workbench. The full-automatic greasing and capping machine disclosed by the invention integrates the stations and the mounting base into a whole, is high in positioning accuracy and facilitates debugging and installation of a fixture mold; and the total seal shell is convenient for cleaning and maintenance, thus, the invention has the advantages of strong dustproof capacity, low danger coefficient, low failure rate and high product qualification rate.

Owner:SHANDONG XUNJIE PRECISION EQUIP

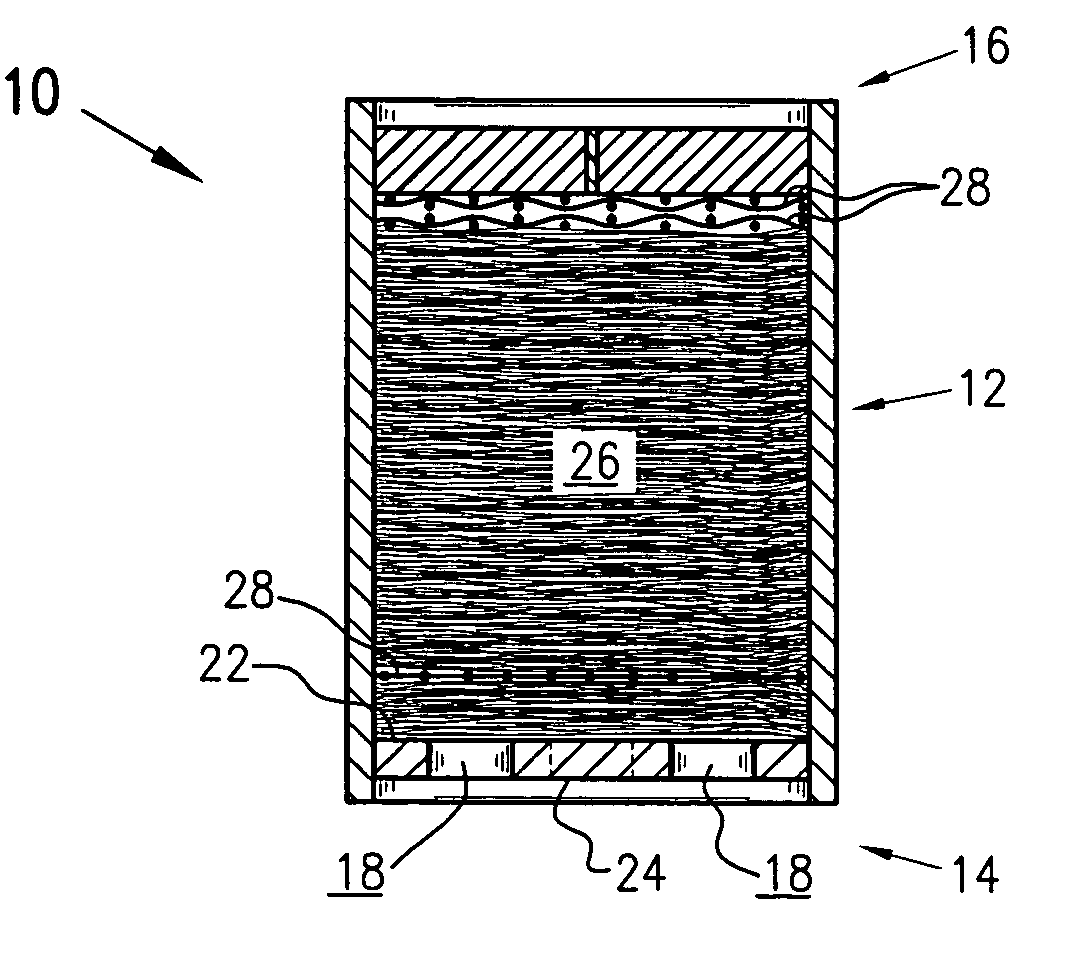

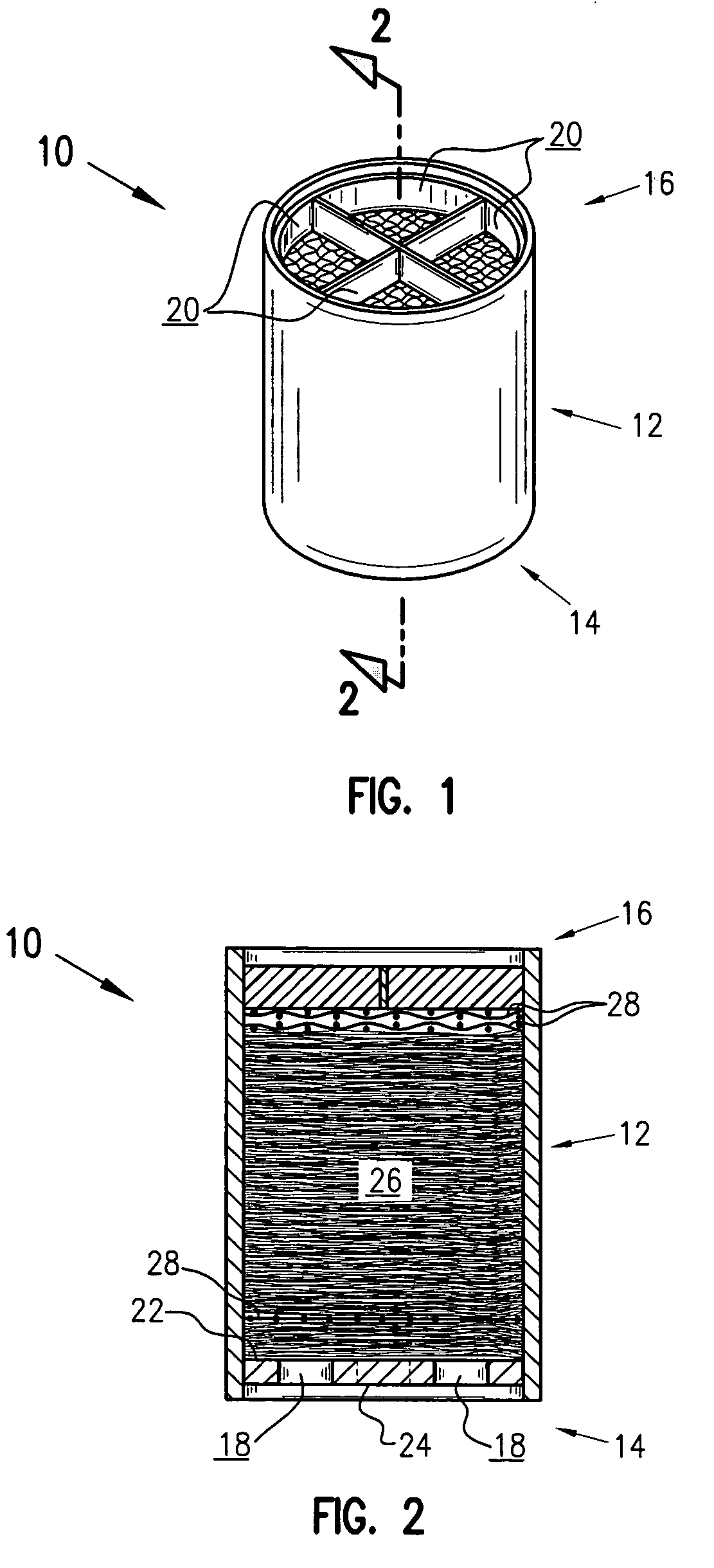

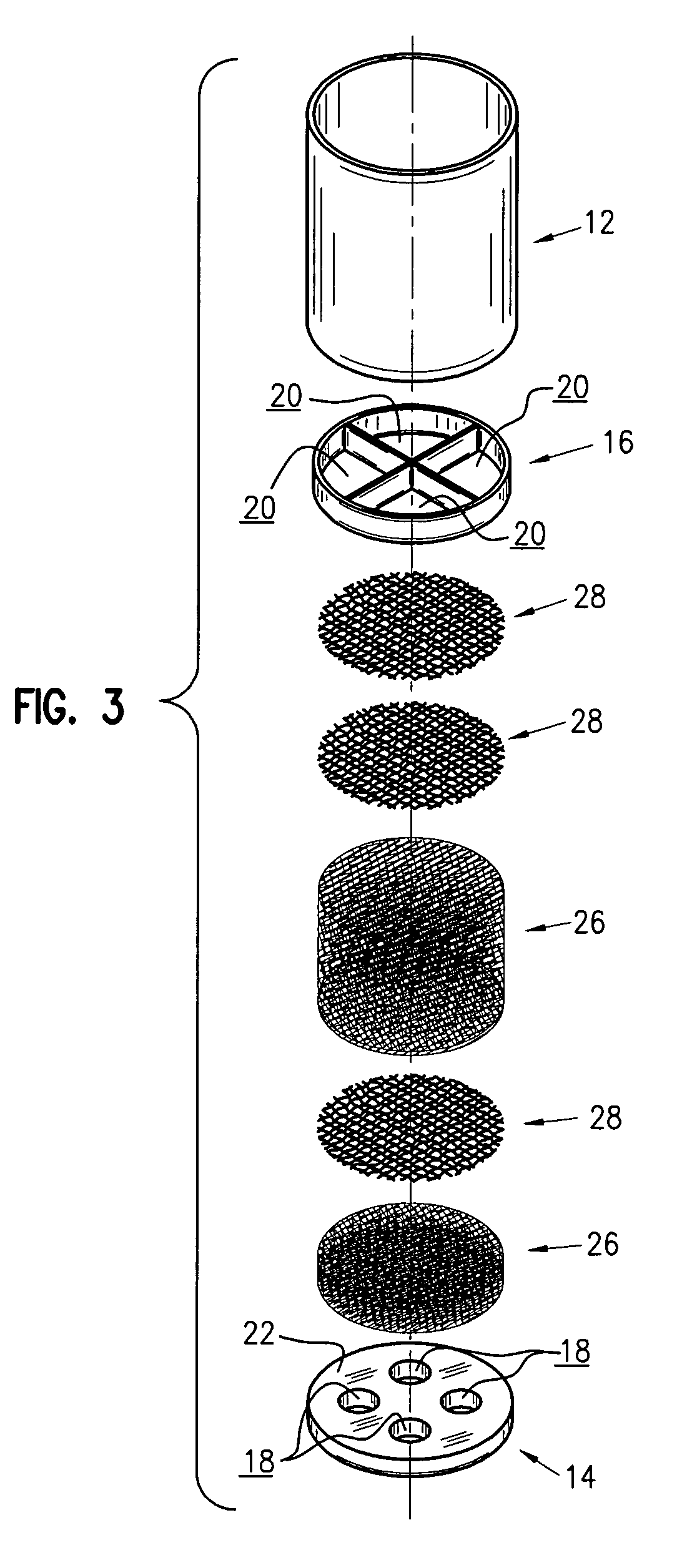

Orifice plate diffuser

ActiveUS7185678B1Reduce noiseKeep in touchProportioning devicesEngine fuctionsVena contracta diameterPack material

A noise reducing device for a pressurized fluid stream, i.e., a gas, includes a housing. An inlet end and an outlet end of the housing each have at least one orifice for passing a fluid therethrough. The inlet end orifice includes an inlet face and an outlet face and the inlet end orifice is configured for maintaining a backpressure upstream of the inlet end orifice. A diffusing pack material is disposed within the housing. One or more stiffeners may be disposed within the diffusing pack material to ensure that the diffusing pack material maintains contact with the outlet face of the inlet end orifice and / or to prevent the migration of the diffusing pack material within the housing, thereby maintaining a homogeneous distribution of the pack material.

Owner:CECO ENVIRONMENTAL IP INC

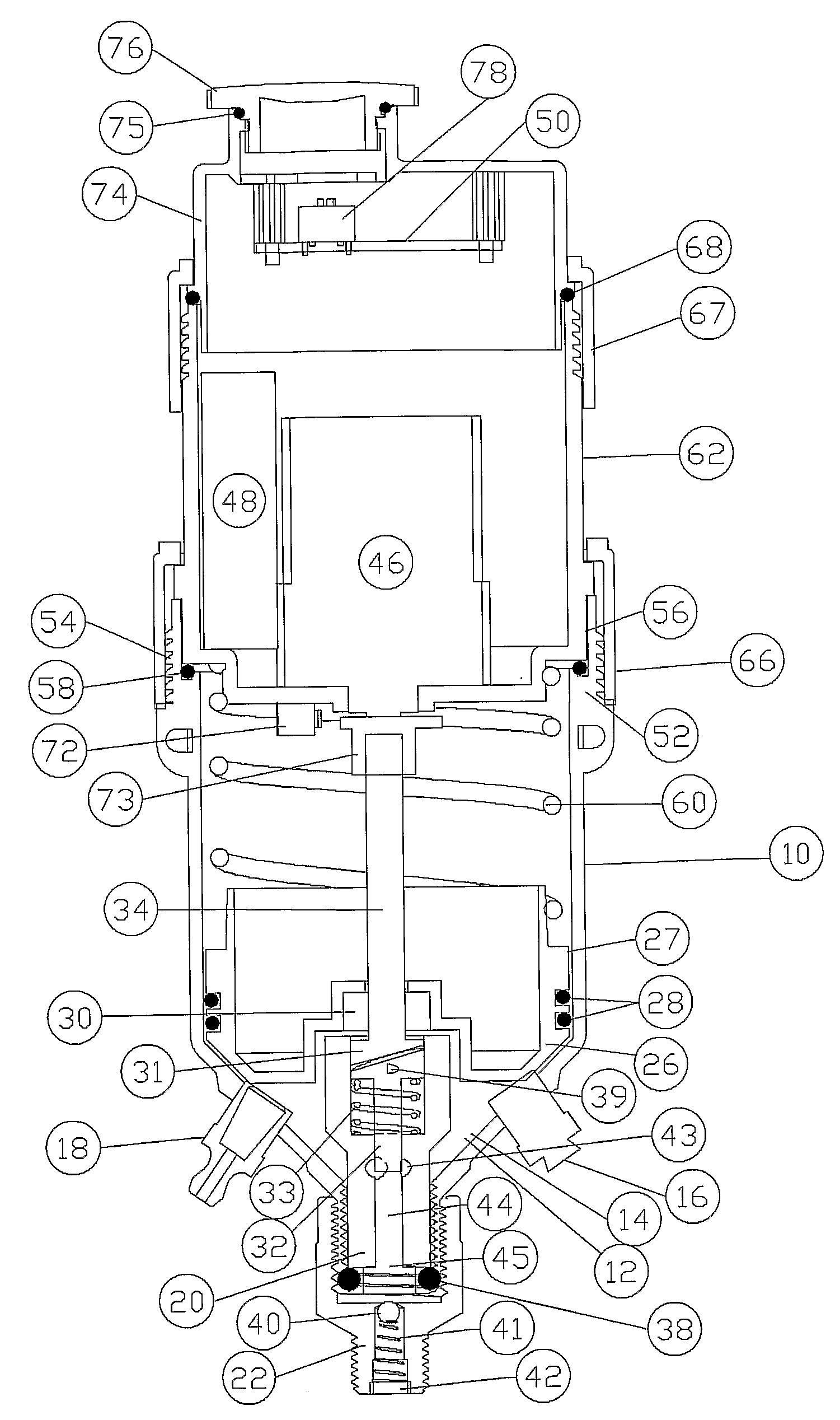

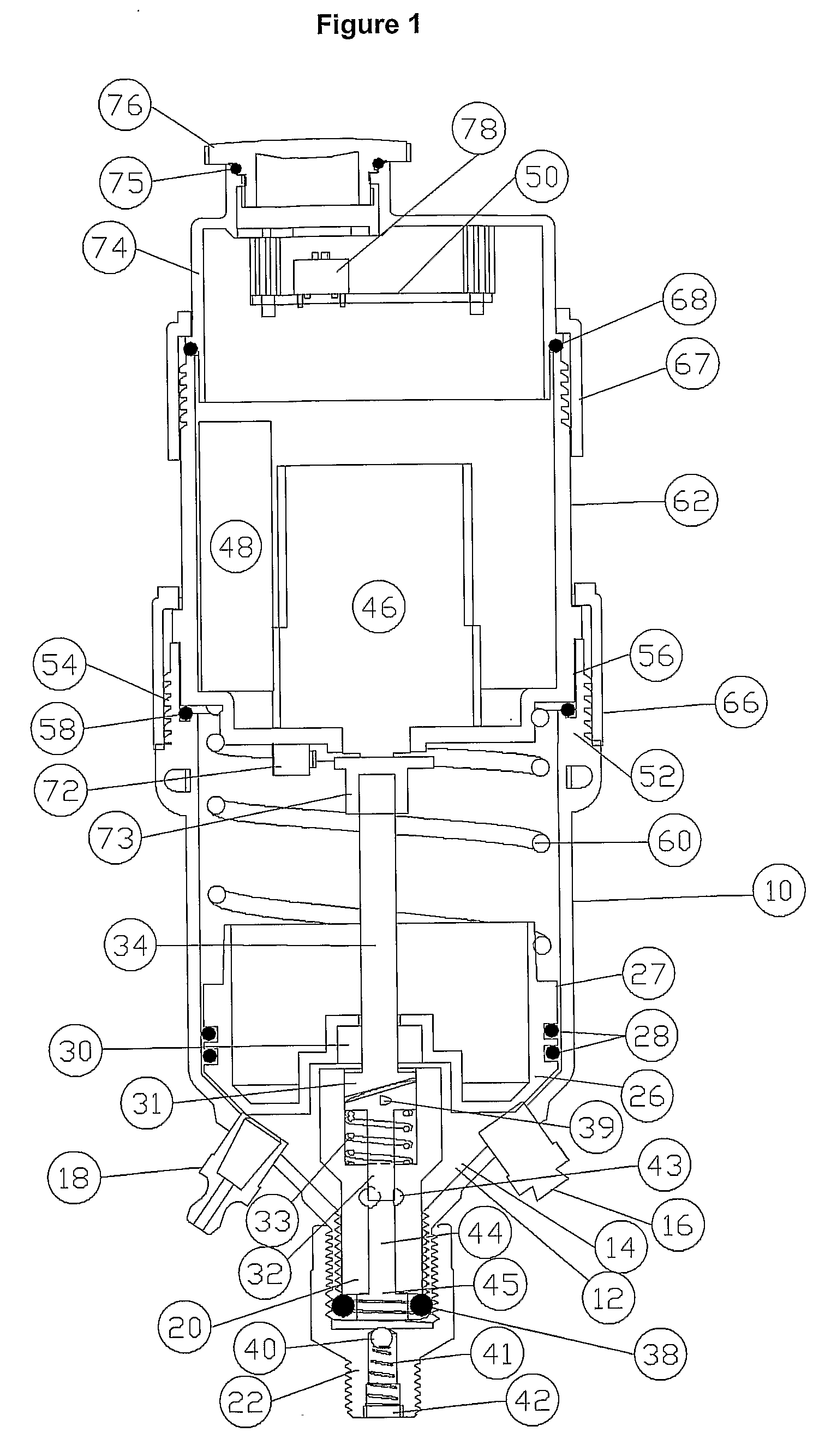

Automatic motor driven in-line piston pump lubricator

In various embodiments, the invention provides a lubricator comprising a housing defining a main lubricant chamber adapted to contain a fluid lubricant. A piston pump in fluid communication with the main lubricant chamber may be adapted to be driven to discharge the lubricant from a pump chamber through a lubricant outlet in the housing. A check valve may be mounted on the lubricant outlet, to check the discharge of lubricant from the lubricator. The lubricator may include a motor having a drive shaft adapted to rotate a swash plate to act as a cam to drive reciprocating motion of the pump piston in the pump chamber. The drive shaft may be in axial alignment with the piston, the swash plate being set obliquely on the drive shaft to revolve when the motor is activated to give reciprocating motion to the piston in a direction parallel to the drive shaft. The piston may be biased in the pump chamber against the swash plate, so that the swash plate rides on the piston.

Owner:STEPHANIA HLDG

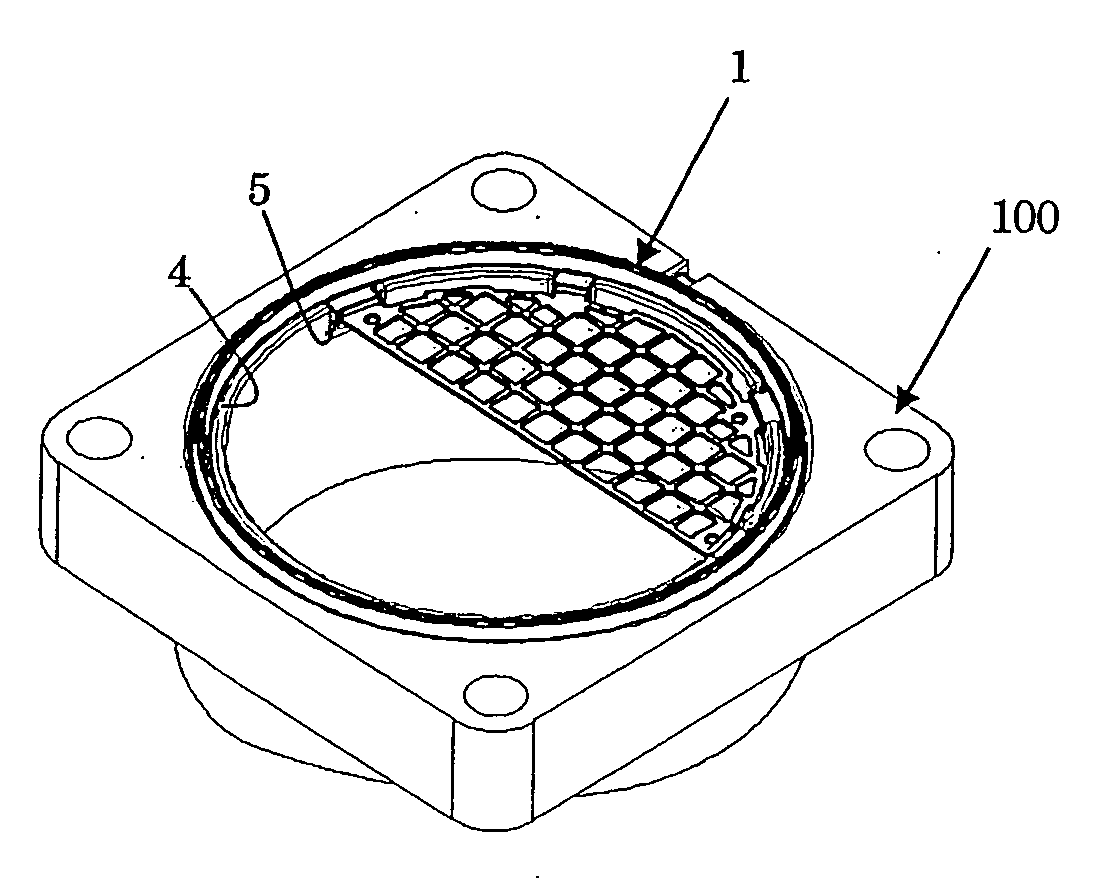

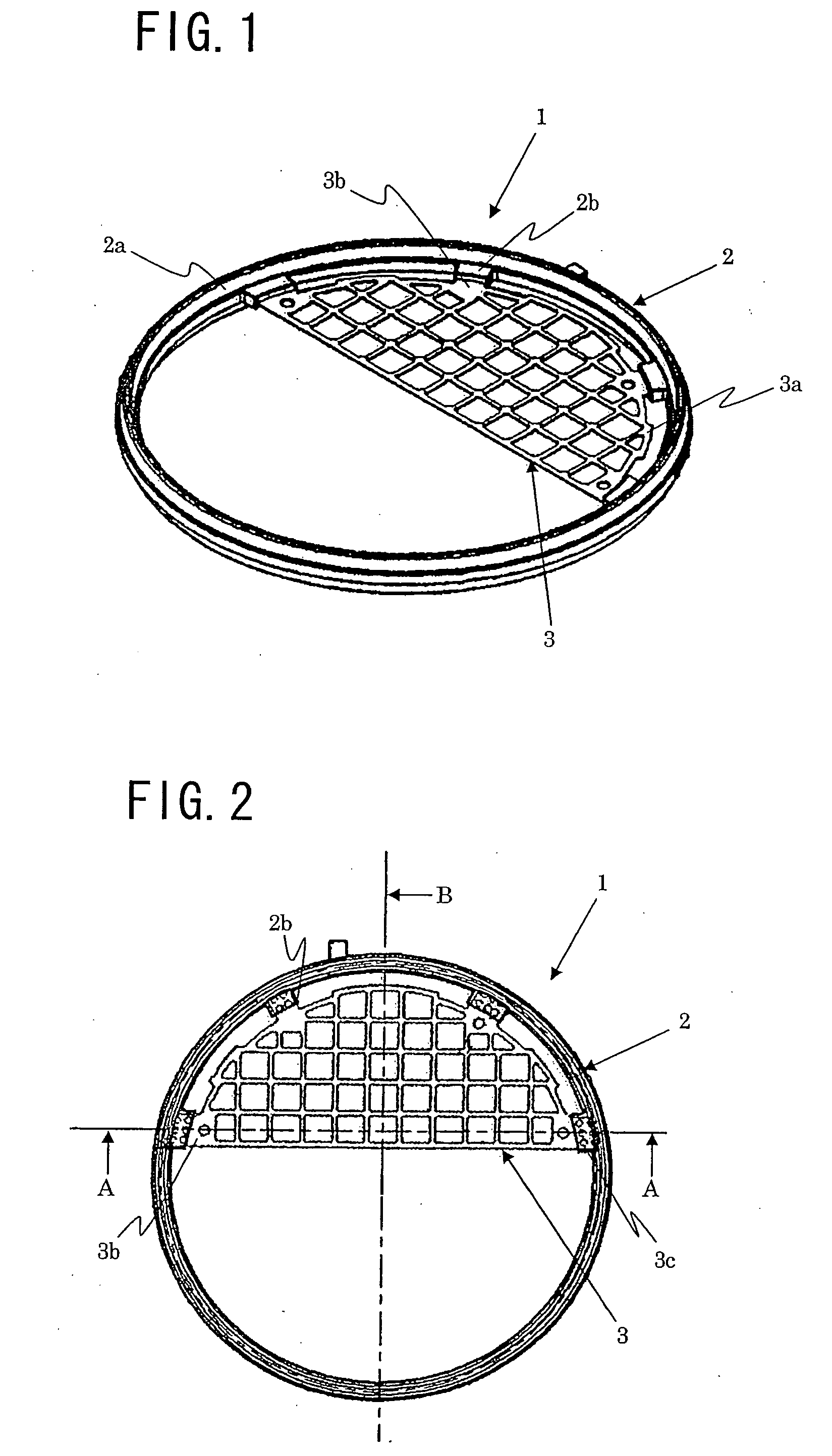

Air Intake Noise Reducing Device, Internal Combustion Engine Fitted with the Same and Structure for Fitting the Same to the Internal Combustion Engine

ActiveUS20090038880A1Less assembling man-hoursReduce intake noiseProportioning devicesSilencing apparatusMan-hourEngineering

The present invention provides an air intake noise reducing device, an internal combustion engine fitted with the air intake noise reducing device and a structure for fitting the air intake noise reducing device to the internal combustion engine. The air intake noise reducing device comprises a gasket (2) comprising a ring member (2a) held by connecting surfaces of an air intake passage (100) and protrusion holding portions (2b) extending from the ring member (2a) toward a center of the air intake passage (100); and a net member (3) comprising a net (3a) for rectifying intake air and connecting protrusions (3b) extending outward from the net (3). The connecting protrusions (3b) are held in the protruding holding portions (2b) such that the ring member (3) is firmly secured to the gasket (3). The air intake noise reducing device constituted by in the above-mentioned manner can reduce assembly man-hours without deteriorating a sealing property of the air passage.

Owner:KOKOKU INTECH CO LTD

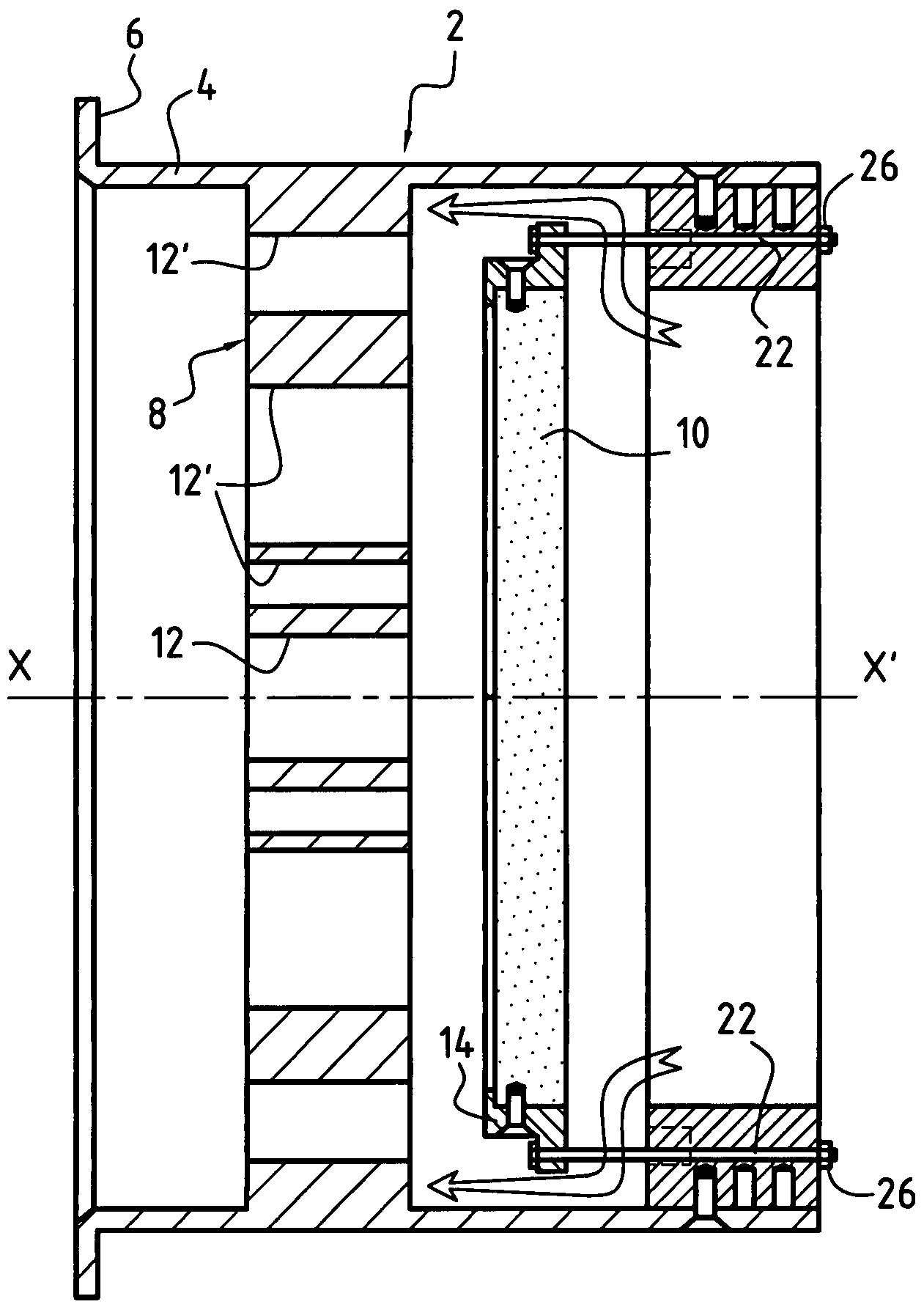

System for automatic lubrication

ActiveUS20120145482A1Prevent returnAvoid accidental rotationProportioning devicesDomestic plumbingInjection pressureExhaust valve

A system for automatically delivering lubricant to at least one bearing (16) has a lubricant pump (1) feeding lubricant under pressure through a supply line (3) to an injector (4). The injector, driven by the lubricant, sends a measured amount of lubricant down feed line (14) to bearing (16). A pressurising valve (15) maintains injection pressure in the feed line (14) enabling any failure of supply to be detected as a pressure drop at pressure switch (2). Preferred features include the incorporation of a second pressurising valve (12) at the injector end of the feed line (14), a blocked-line vent valve (13) to enable detection of a blocked or crushed feed line, and check valves (10) and (11). The injector (4) is preferably configured to produce a higher pressure at the outlet than the inlet, and various versions of this intensifying injector are described and claimed.

Owner:IFIELD ENG

Continuously variable transmission

ActiveUS8100791B2Precise positioningReduce internal pressureProportioning devicesPortable liftingPulleyPetroleum engineering

Owner:TOYOTA JIDOSHA KK

Sealing assembly for lubricant injector

InactiveUS6986407B2Exhaust fastImprove performanceProportioning devicesPiston ringsEngineeringHigh pressure

Owner:LINCOLN INDUSTRIES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com