Full-automatic bearing greasing and capping machine

A capping machine, fully automatic technology, applied in the direction of engine components, engine lubrication, conveyors, etc., can solve the problems of inconvenient maintenance, complex design, poor synchronization, etc., to achieve easy debugging and installation of tooling molds, high production qualification rate , The effect of accurate positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

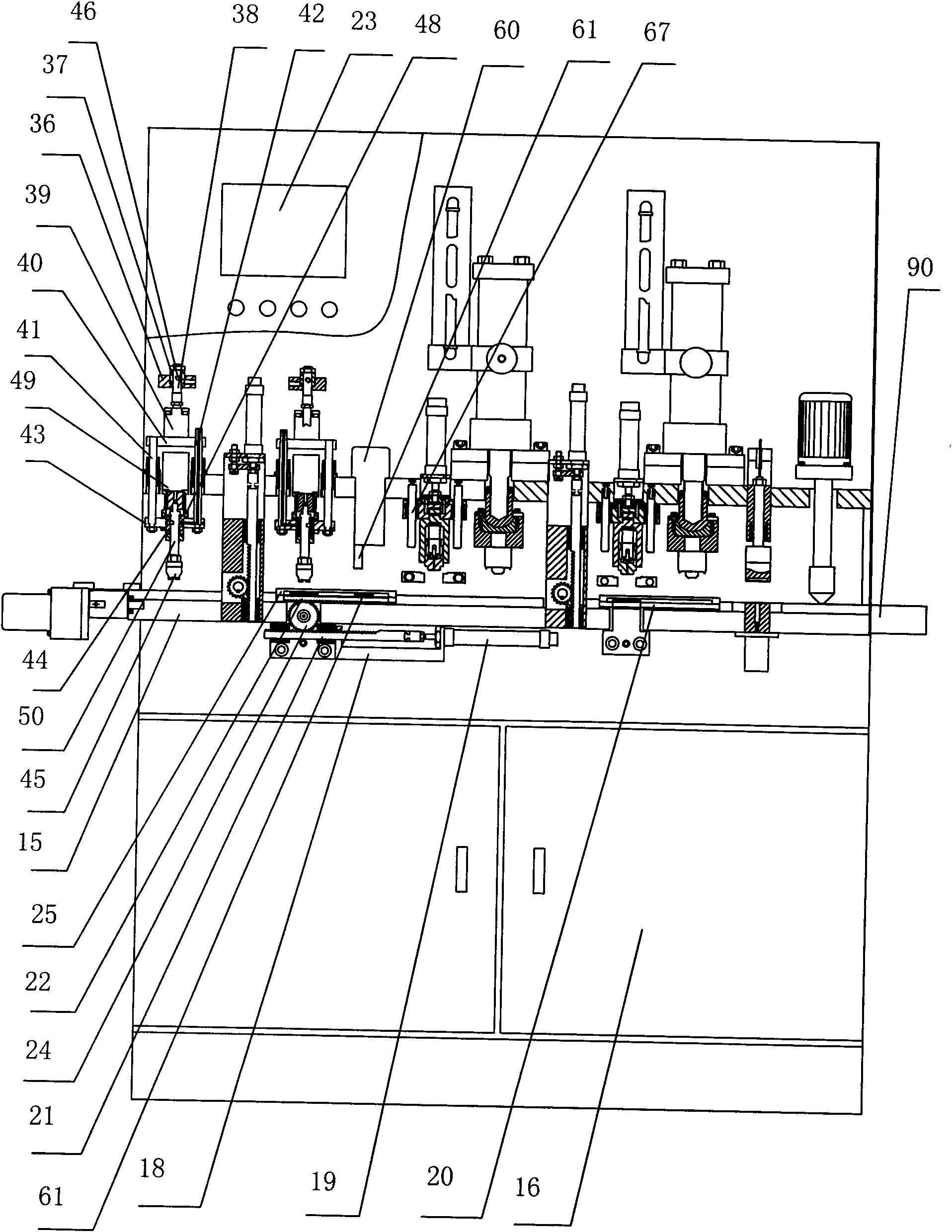

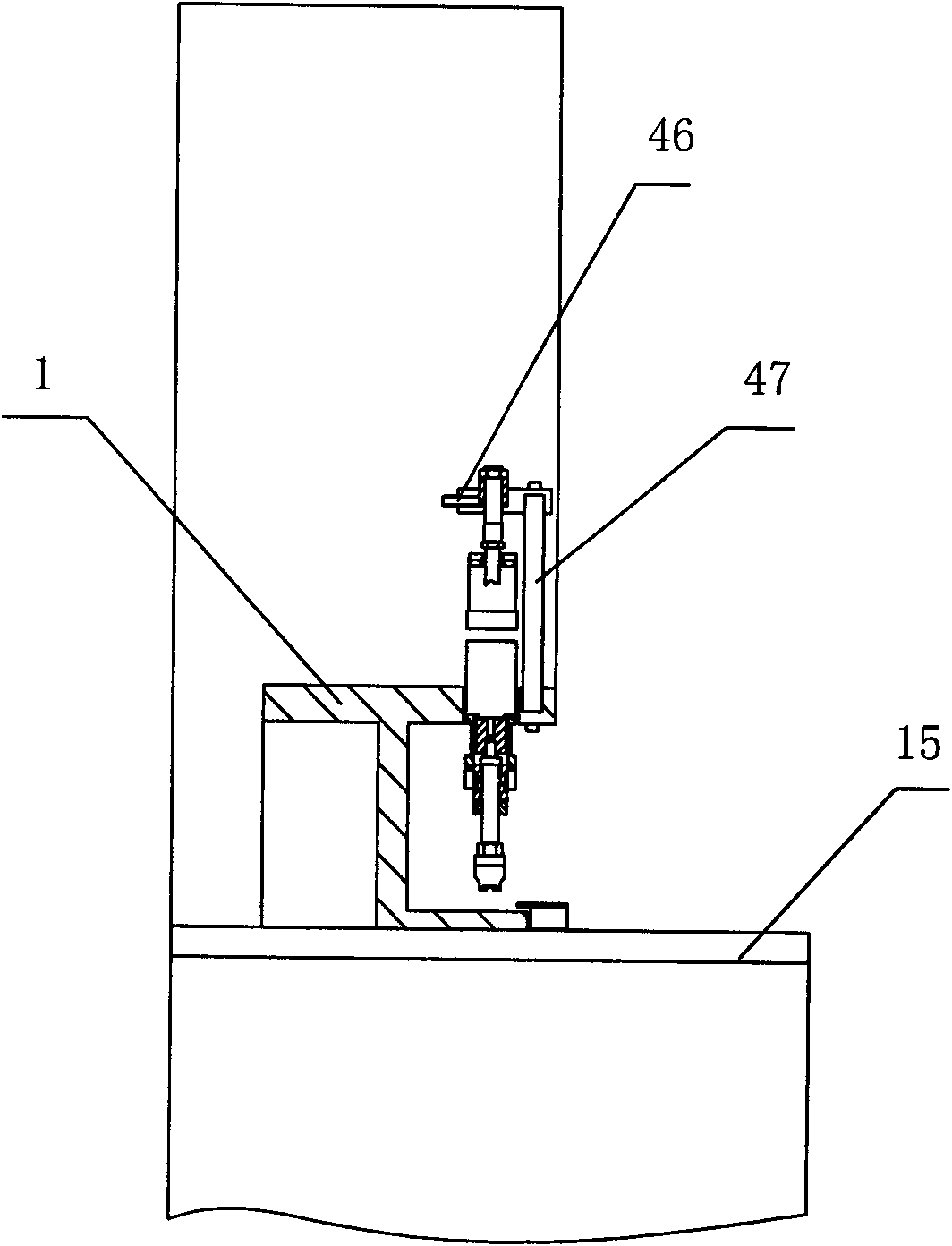

[0015] Such as figure 1 , figure 2As shown, a fully automatic bearing fatting and capping machine includes a frame 16, a control device 23, a workbench 15, a mounting seat 1, a raw material conveying device, a fatting device, a grease amount detection device, a capping device, and a capping device. device, stand-up device, dust cover height detection device, fat equalizing device and unqualified product rejecting device, it is characterized in that a workbench 15 is fixed on the frame 16, a mounting seat 1 is fixed on the workbench 15, and the front of the mounting seat 1 There is a supporting plate 17 at the bottom, a control device 23 is provided on the top of the mounting seat 1, a raw material conveying device is provided on the left side of the workbench 15, and a rejecting device is provided on the right side; The processing sequence is arranged from left to right: two grease adding devices, grease amount detection device, two capping devices and capping device, dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com