Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189results about "Engine temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

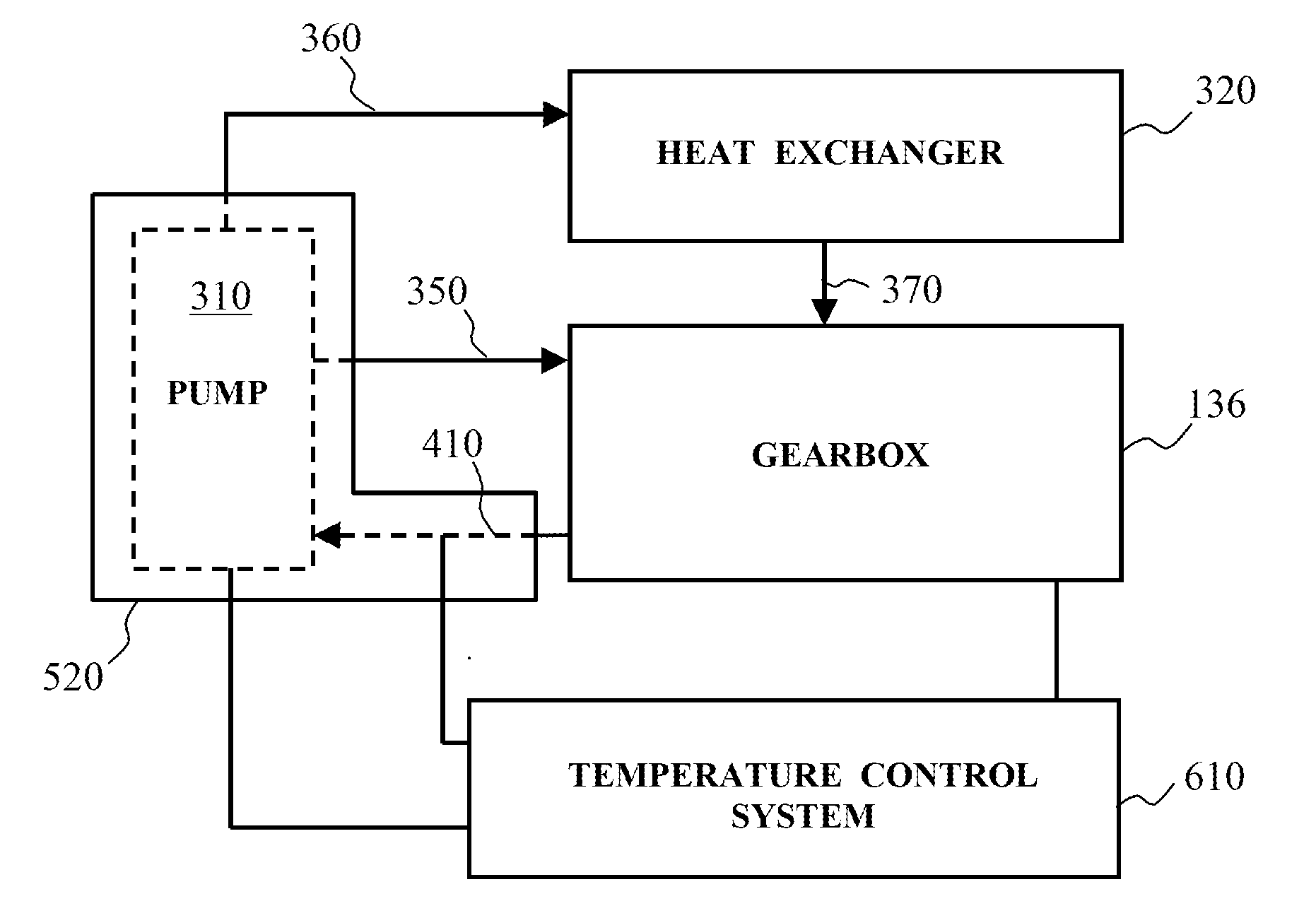

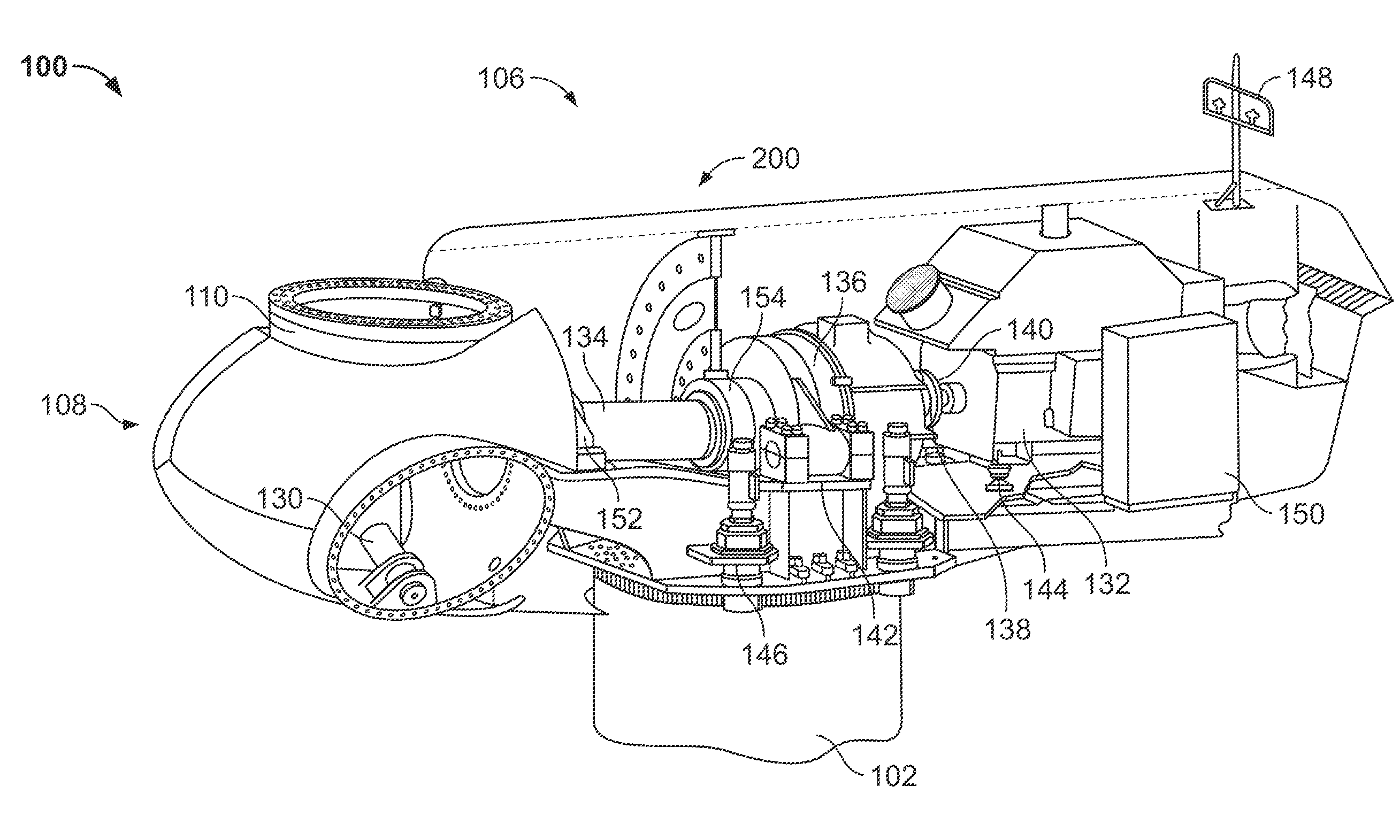

Lubrication heating system and wind turbine incorporating same

A wind turbine is provided having a gearbox containing a lubrication medium, a pump for circulating the lubrication medium. and a gearbox lubrication suction pipe for transporting the lubrication medium from the gearbox to the pump. A heater is in thermal connection to, at least a portion of, the gearbox lubrication suction pipe. This heater is used to heat the lubrication medium contained within the gearbox lubrication suction pipe to a temperature where damage to the pump is avoided.

Owner:GENERAL ELECTRIC CO

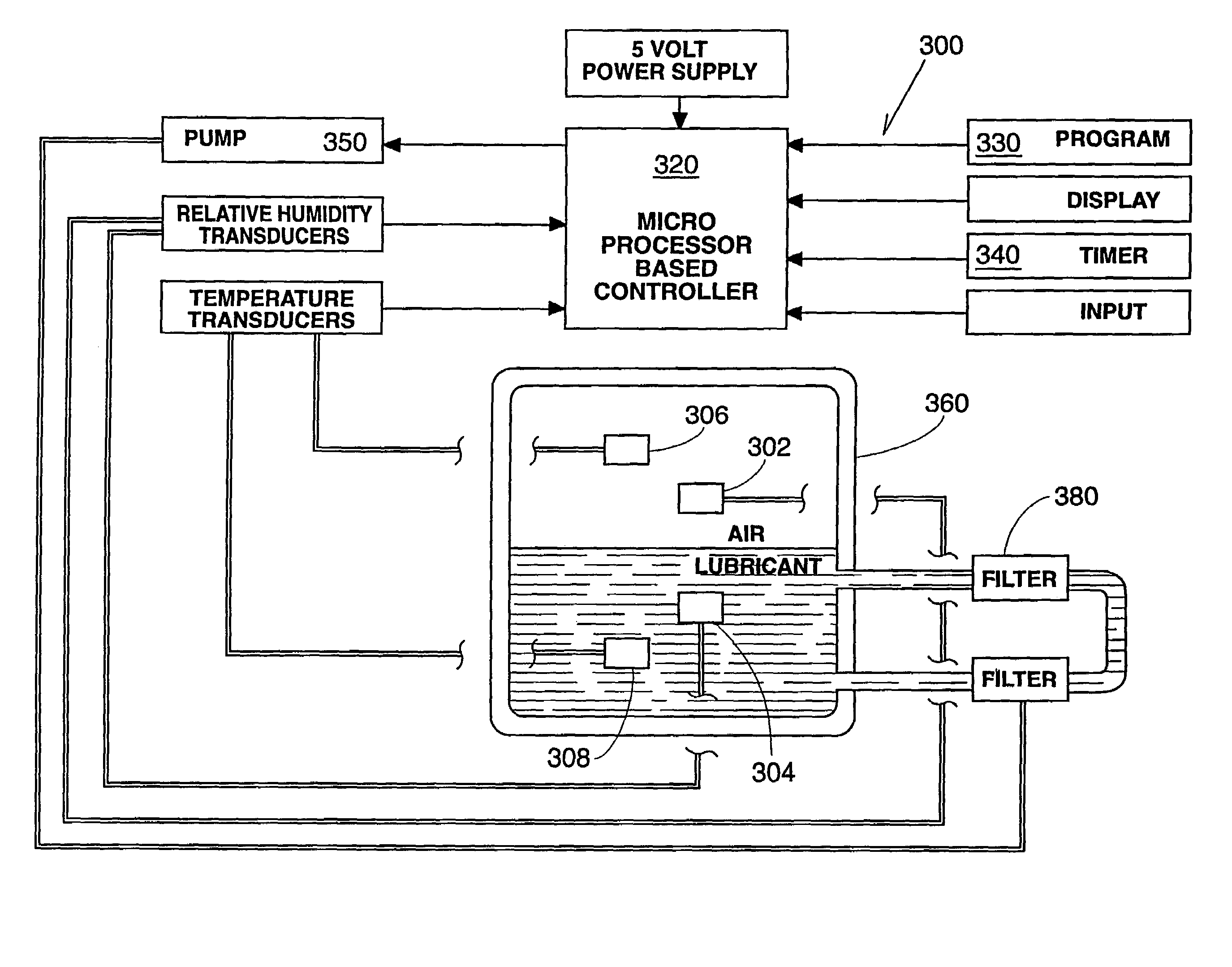

Apparatus and method for lubricant condition control and monitoring

InactiveUS7017712B1More and lessOvercome problemsEngine temperatureEngine pressureProcess engineeringKetone

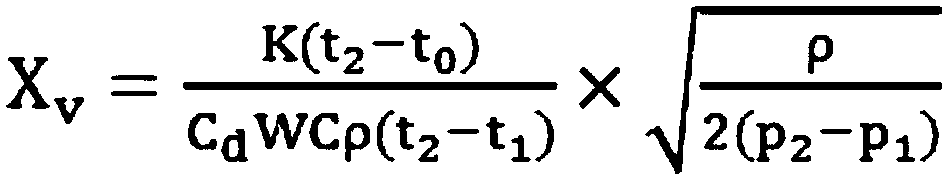

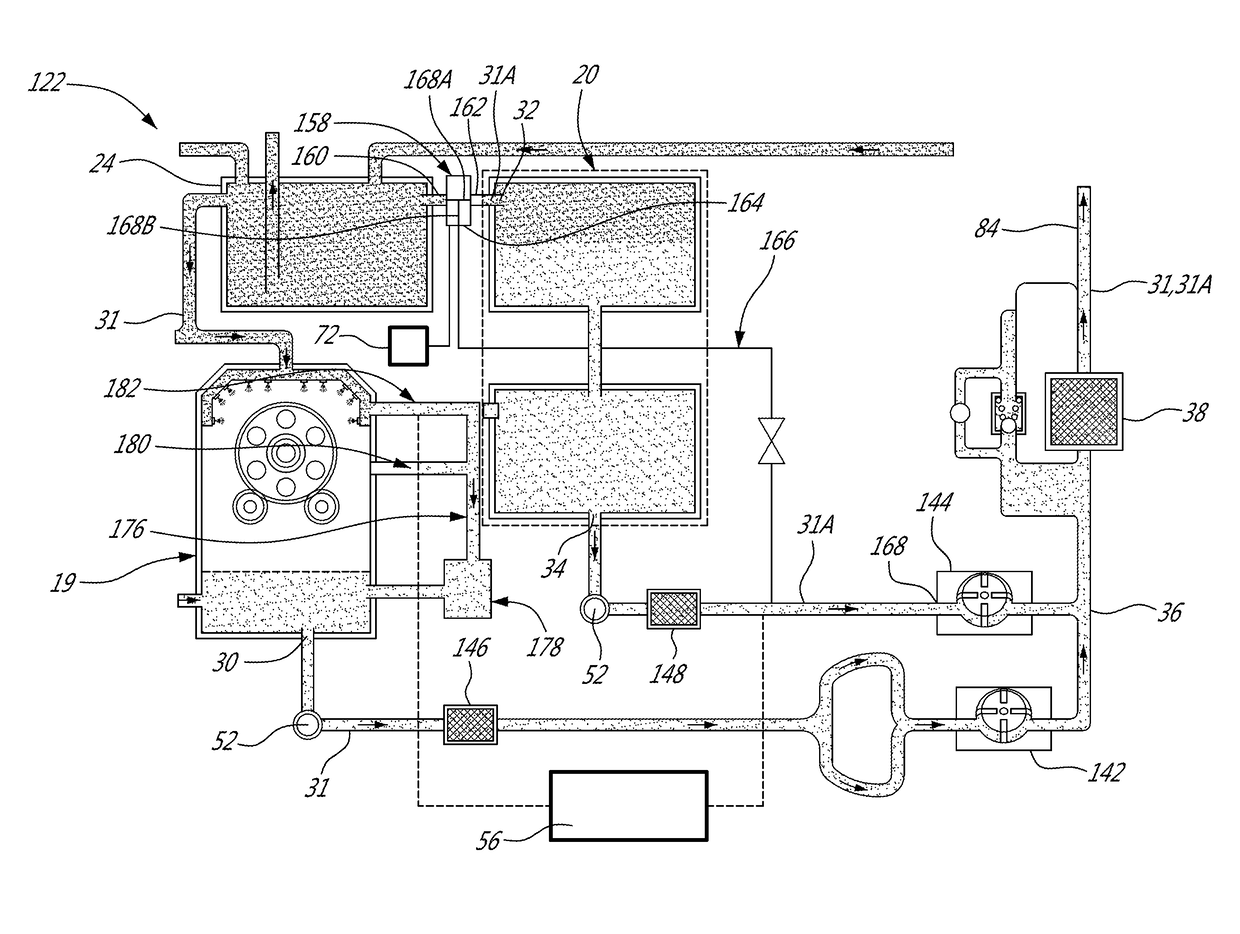

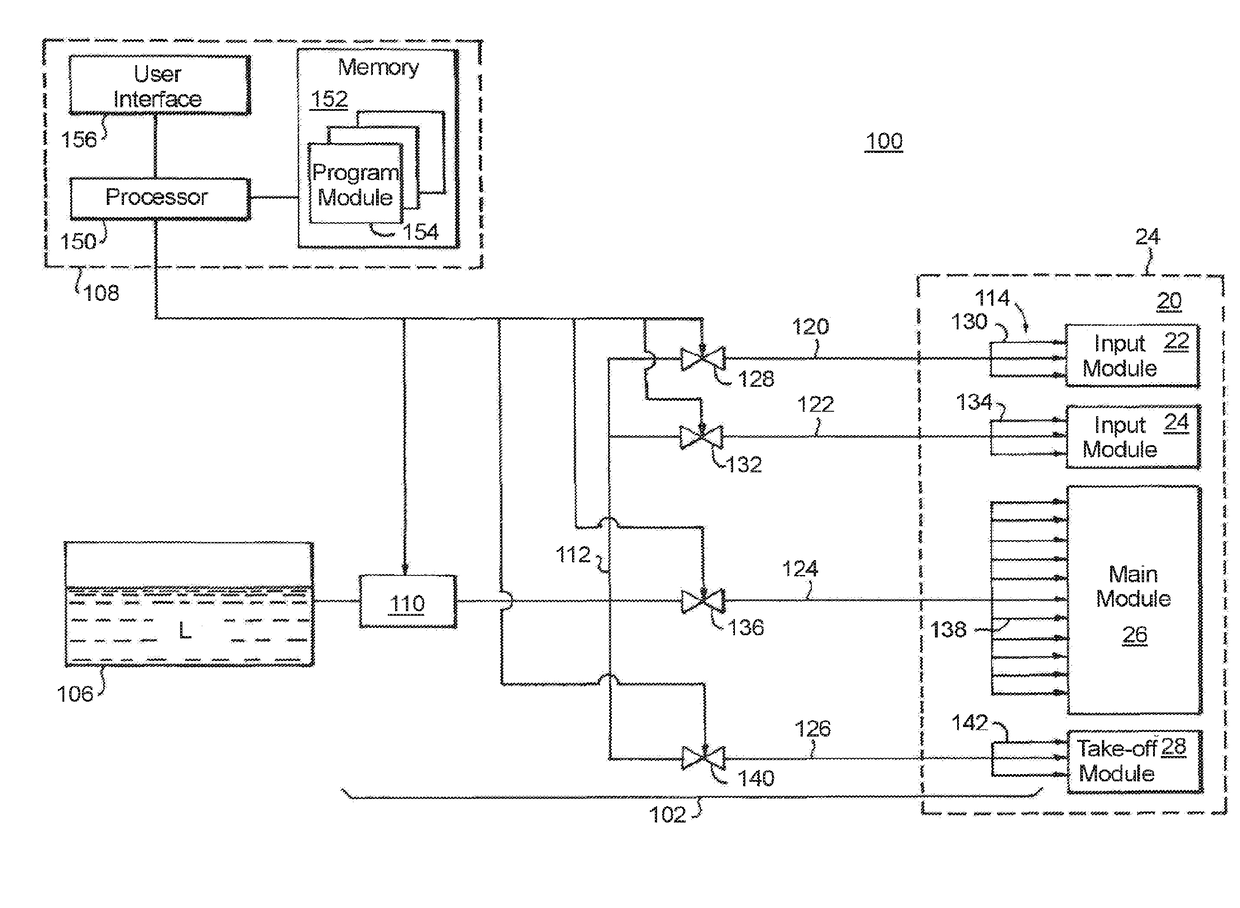

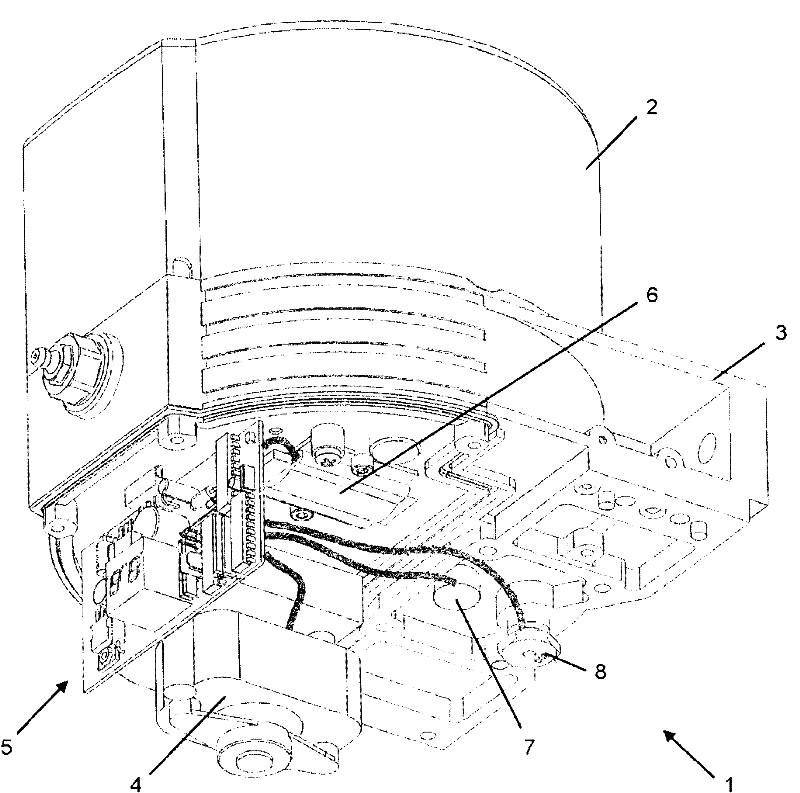

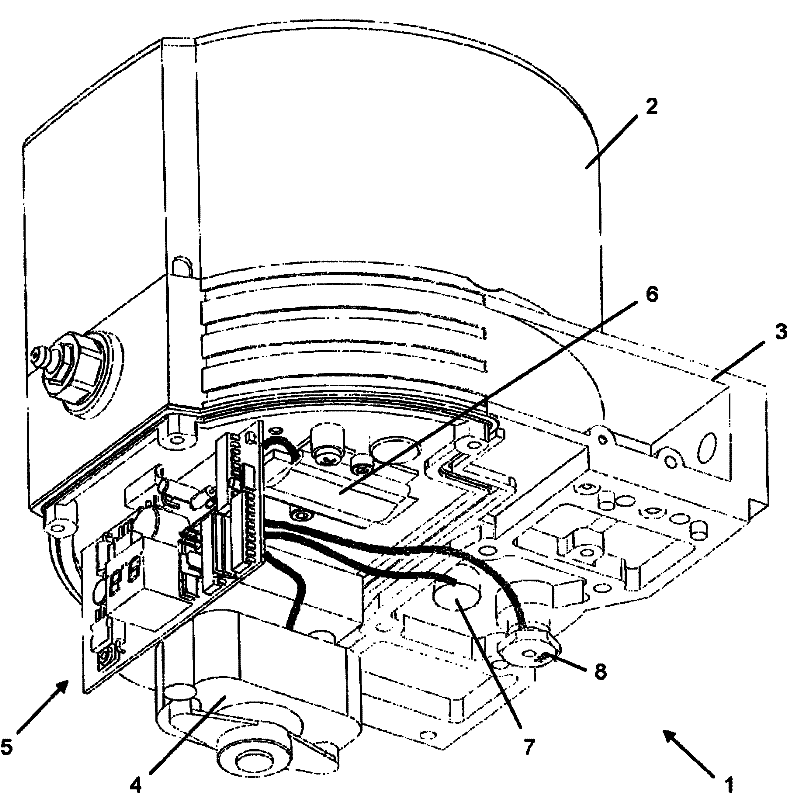

A volumetric lubricant dispensing apparatus for delivering a precise volume of lubricant, such as oil, to a rotating machine element. The delivery mechanism includes a piston and cylinder assembly. A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. The output from each sensor is inputted into the microprocessor wherein an algorithm computes an responsive output. The responsive output is sent to the piston and cylinder assembly, which maintains an optimum lubricant condition within the reservoir wherein a rotating machine element located. Alternatively, for the purpose of qualitative control, the present invention may be described as a system intended for controlling lubricants, both mineral (natural) and synthetic based by measuring the condition characteristics of the lubricant. Some condition characteristics may include water or moisture content (the content could be any liquid, e.g., solvents like ketones are known to change condition characteristics like viscosity) and viscosity. Viscosity is related to temperature, therefore, temperature correlation to viscosity is helpful to provide relative indications for condition characteristics like lubricant flow.

Owner:TRICO CORP

Apparatus and method for lubricant condition control and monitoring

A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. A stand-alone humidity sensor mechanism is disclosed, in which signal process circuitry is electrically coupled to a humidity sensor, designed to be attached to the mechanism to be monitored so that it is juxtaposed in the atmosphere above the lubricant material that is being monitored.

Owner:TRICO CORP

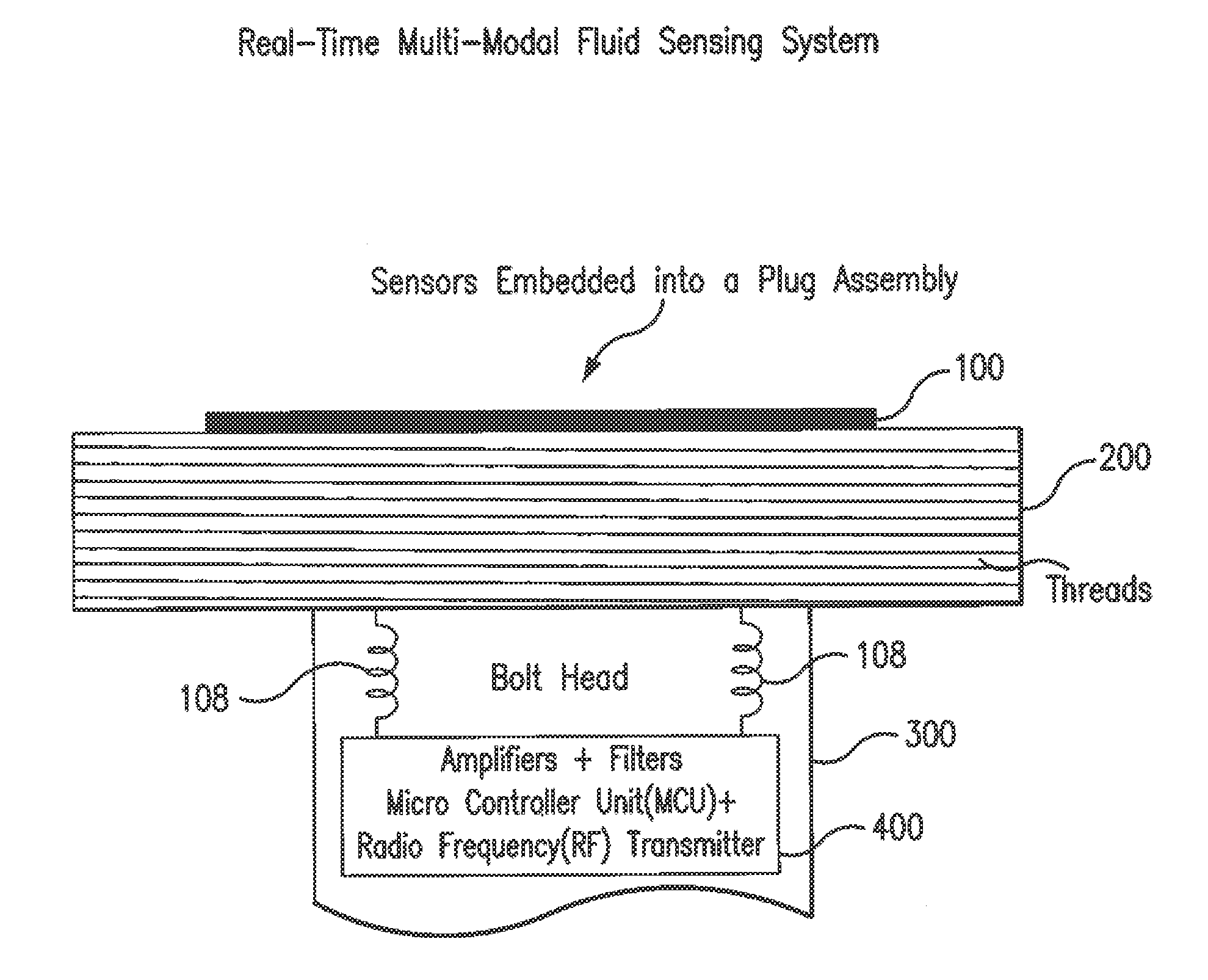

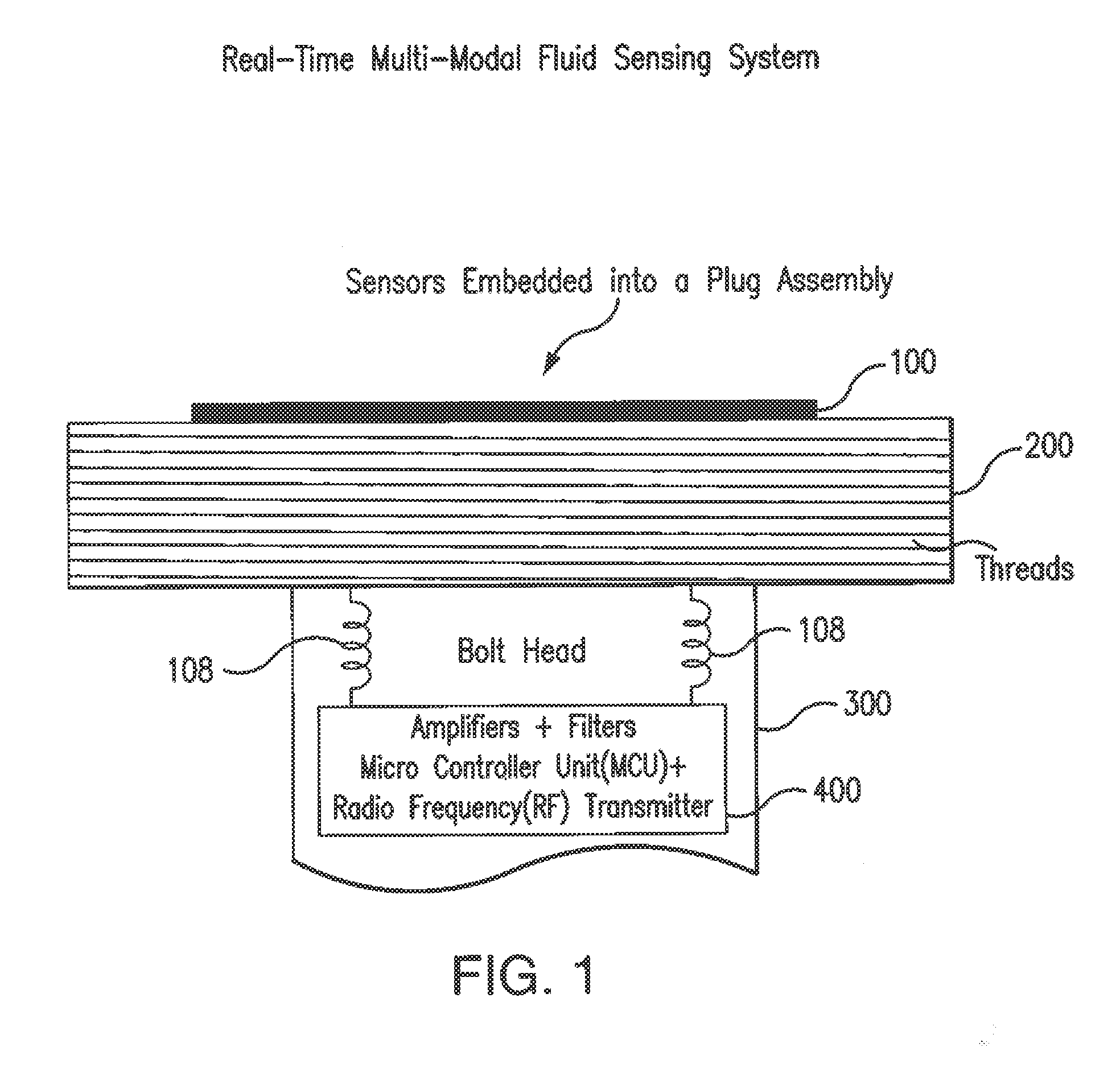

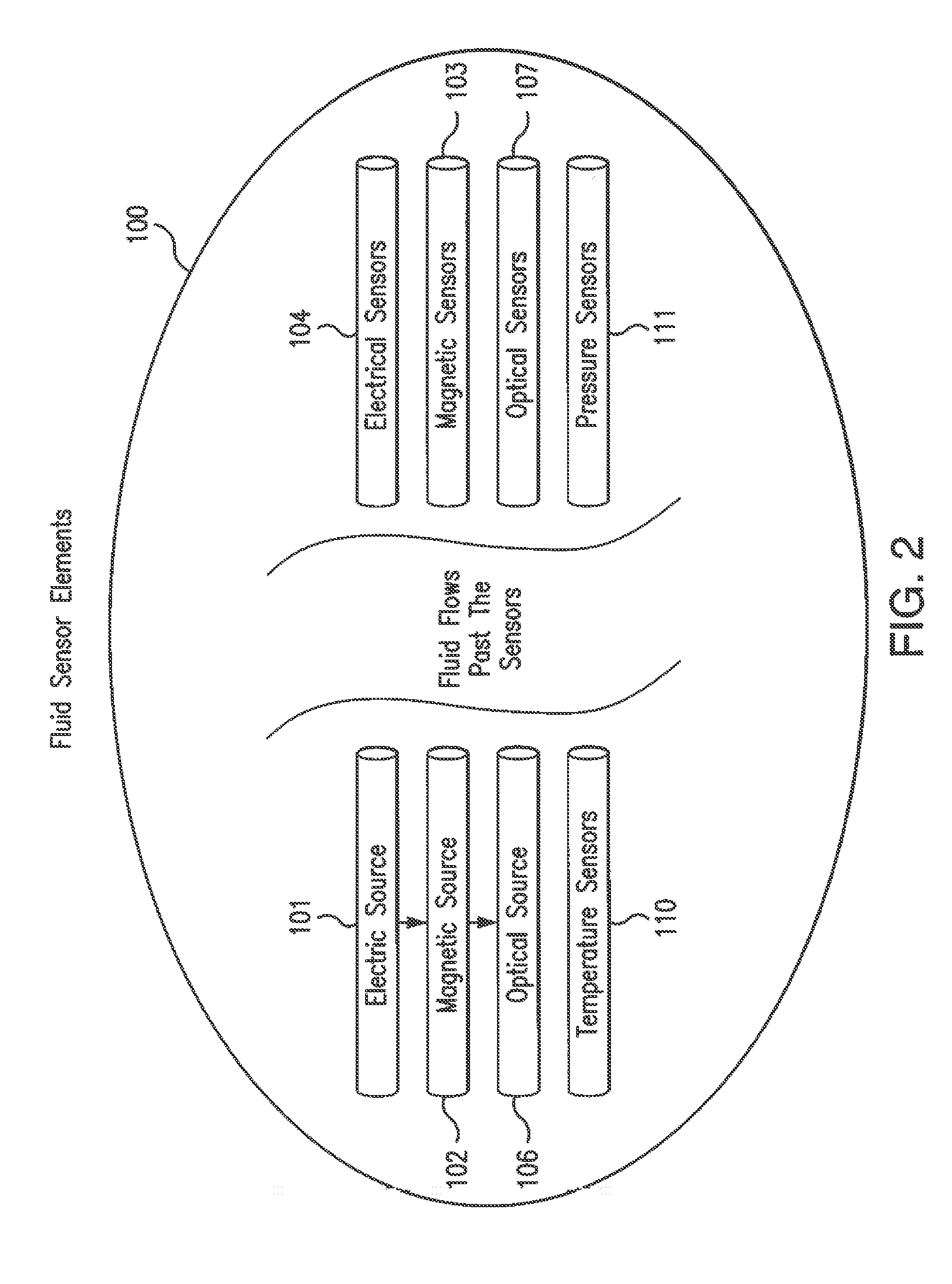

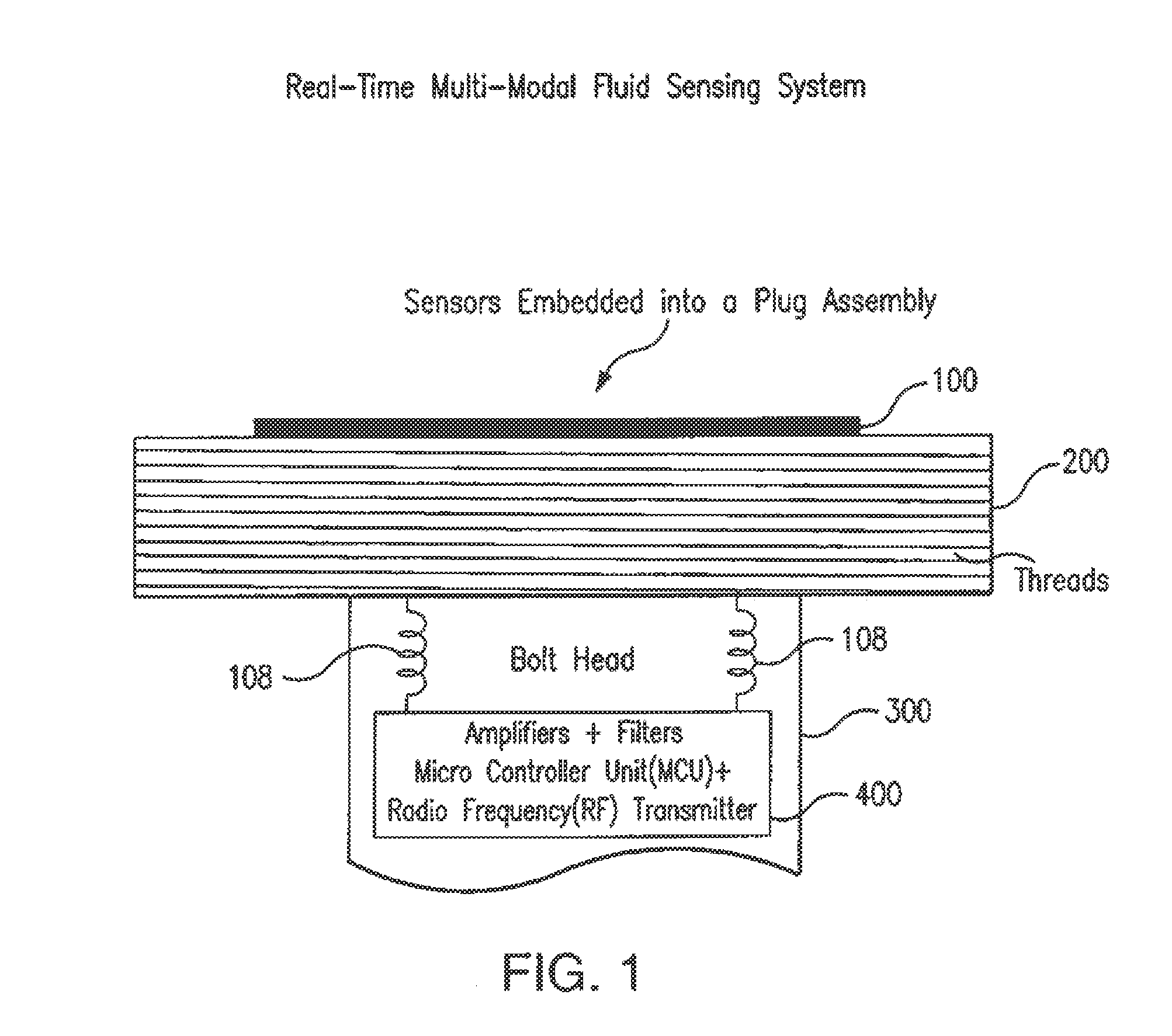

Multi-modal fluid condition sensor platform and system therefor

InactiveUS20140188404A1High pressure environmentEngine temperatureEngine pressureEngineeringLubrication

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

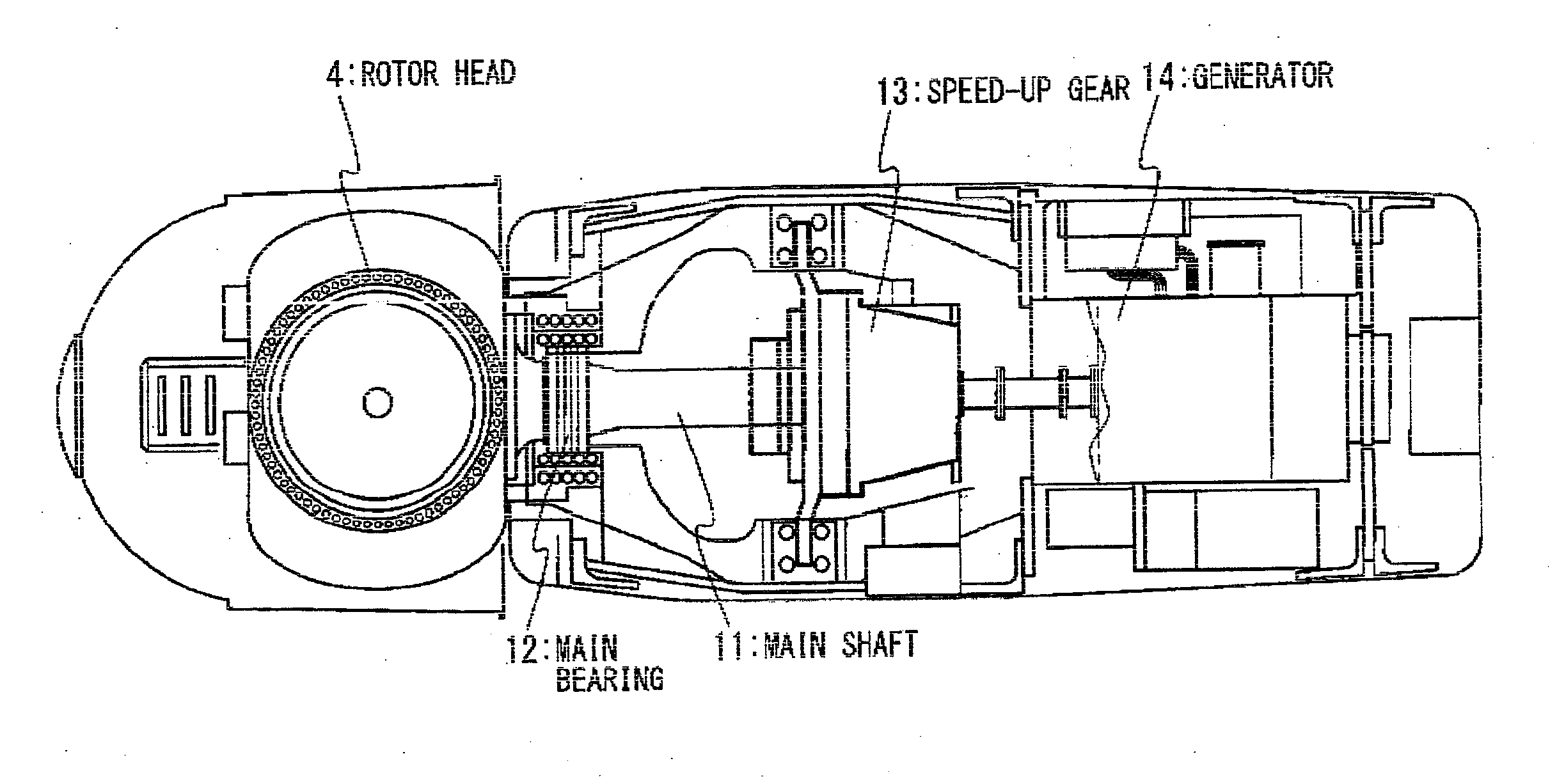

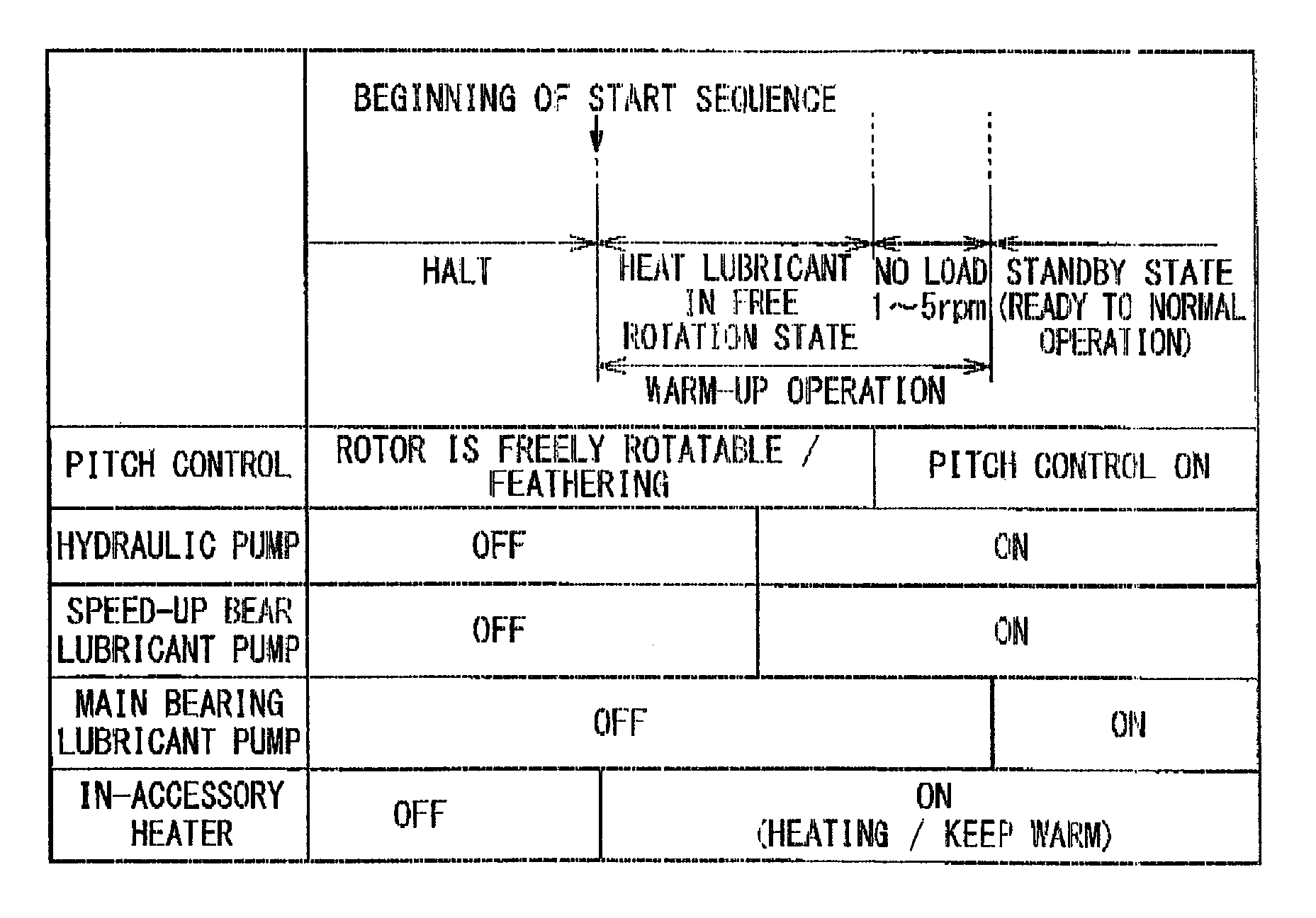

Starting method for rotating machine and starting method for wind turbine generator

A starting method is provided for a rotating machine which includes a main shaft, a main bearing rotatably supporting the main shaft and a main bearing lubricant pump circulating lubricant through the main bearing. The starting method includes steps of: rotating the main shaft to raise a temperature of the main bearing in a state in which the main bearing lubricant pump is not operated; and operating the main bearing lubricant pump to start supplying the lubricant to the main bearing after the step of raising the temperature of the main bearing.

Owner:MITSUBISHI HEAVY IND LTD

Lubrication system with lubricant condition monitoring

Owner:LINCOLN INDUSTRIES CORP

Multi-modal fluid condition sensor platform and system therefor

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

Starting method for rotating machine and starting method for wind turbine generator

A starting method is provided for a rotating machine which includes a main shaft, a main bearing rotatably supporting the main shaft and a main bearing lubricant pump circulating lubricant through the main bearing. The starting method includes steps of: rotating the main shaft to raise a temperature of the main bearing in a state in which the main bearing lubricant pump is not operated; and operating the main bearing lubricant pump to start supplying the lubricant to the main bearing after the step of raising the temperature of the main bearing.

Owner:MITSUBISHI HEAVY IND LTD

Lubrication system for a frac pump

A lubrication system for a frac pump includes a lubrication system housing, a lubricant tank held by the lubrication system housing, a heating device held by the lubrication system housing, a cooling device held by the lubrication system housing, and a filtration device held by the lubrication system housing. The lubrication system housing is configured to be at least one of mounted to a frac pump housing of the frac pump or held within the frac pump housing.

Owner:SPM OIL & GAS INC

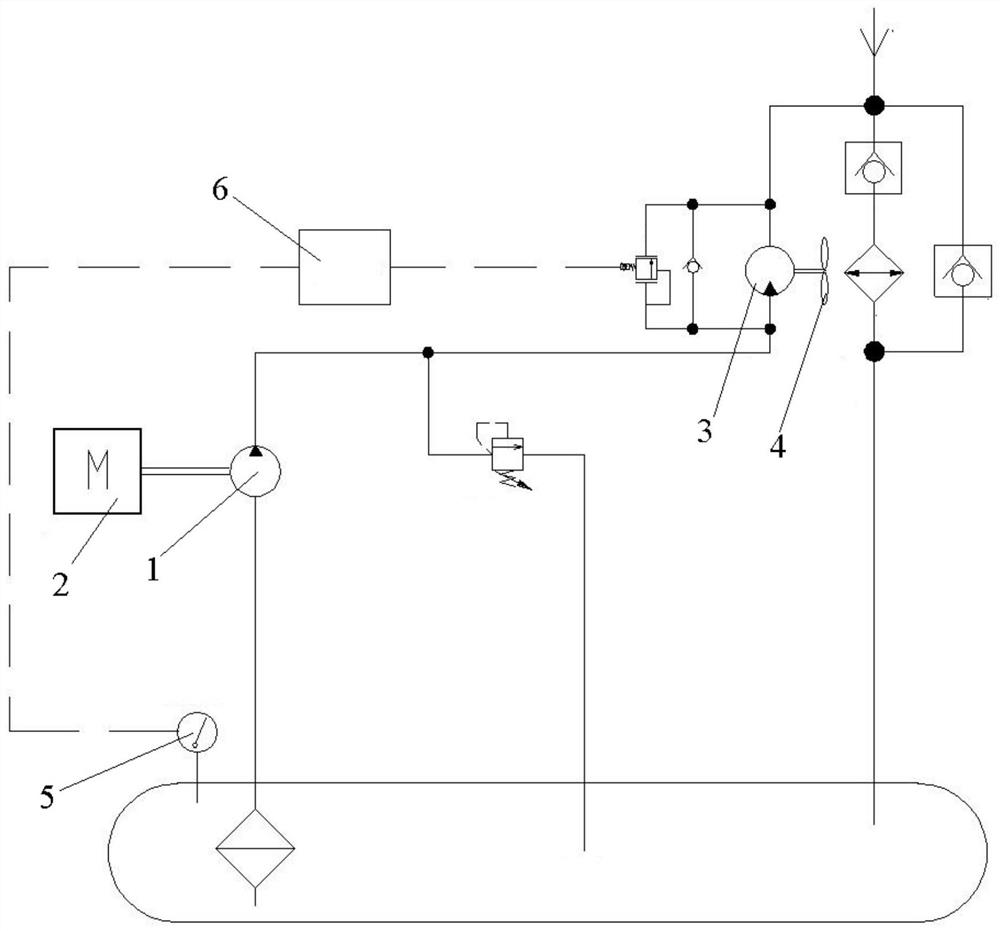

Gearbox lubricating system and lubricating oil flow control method of gearbox lubricating system

PendingCN108302188AEasy to operateEasy to controlTurbinesEngine temperatureElectric controlControl valves

The invention discloses a gearbox lubricating system. The system comprises an annular loop which is sequentially connected with a lubricating oil tank, an oil pump, a radiator and an electric controlreversing valve, wherein a through passage is further arranged between the oil pump and the control valve, and the through passage is arranged in parallel with the radiator; the system further comprises a PLC main controller, a first temperature sensor, a second temperature sensor, a first temperature sensor and a second temperature sensor, wherein the first temperature sensor, the second temperature sensor, the first temperature sensor and the second temperature sensor are connected with the PLC main controller; the electric control reversing valve is connected with the PLC main controller, the control of an open precision of the electric control reversing valve is realized through the PLC main controller according to the monitoring data of the first temperature sensor, the second temperature sensor, the first temperature sensor and the second temperature sensor. The invention further discloses a lubricating oil flow control method of the gearbox lubricating system. According to the system and method, the PLC main controller is additionally arranged, the electric control reversing valve, the temperature sensors and pressure sensors are connected with the PLC main controller, wherein the service life and the precision control of the electric control reversing valve are relatively high, so that the service life and the intelligent control degree of the gear box lubricating system can be greatly improved.

Owner:GUODIAN UNITED POWER TECH

Reciprocating engine lubricating oil analyzer system, computer program product and related methods

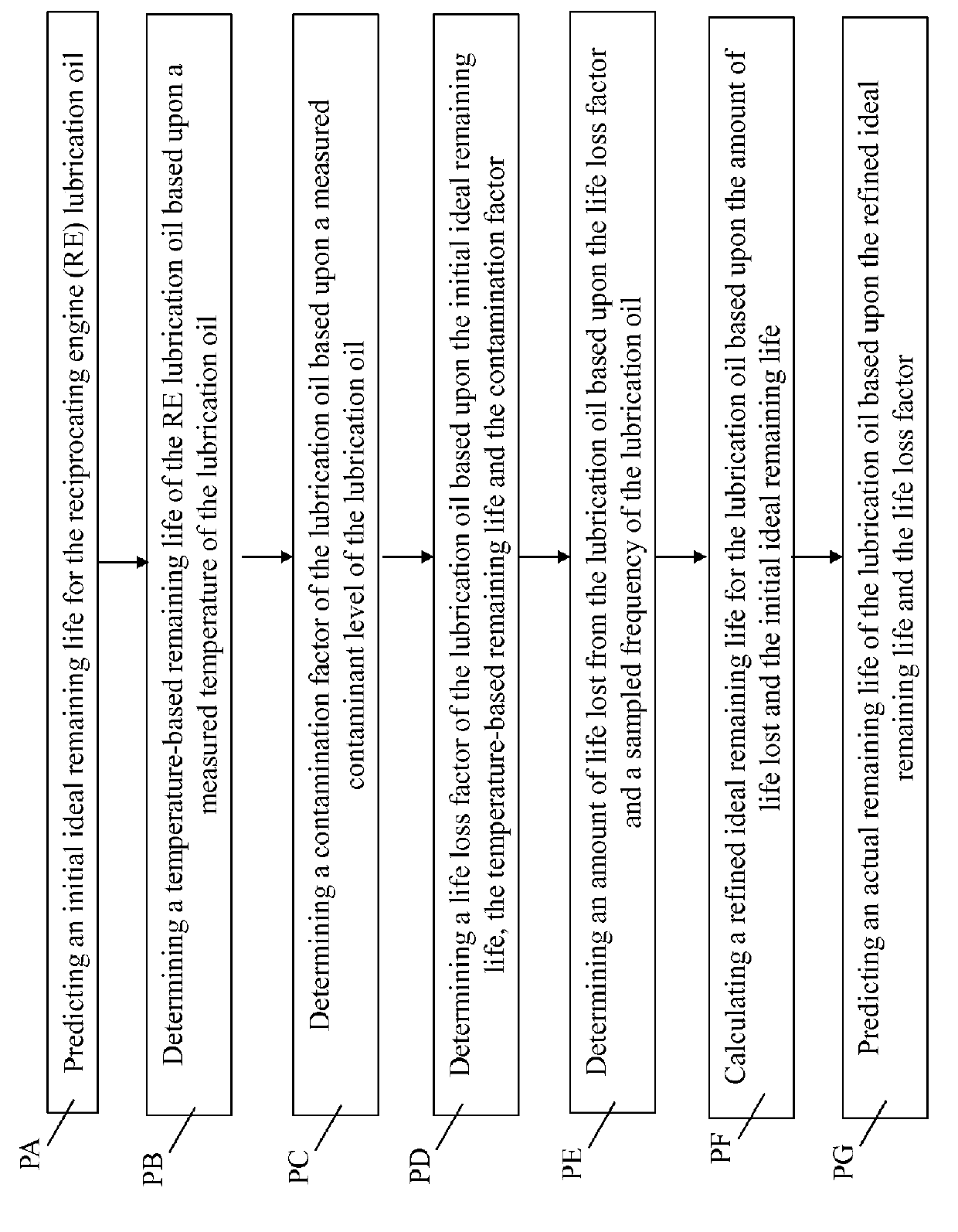

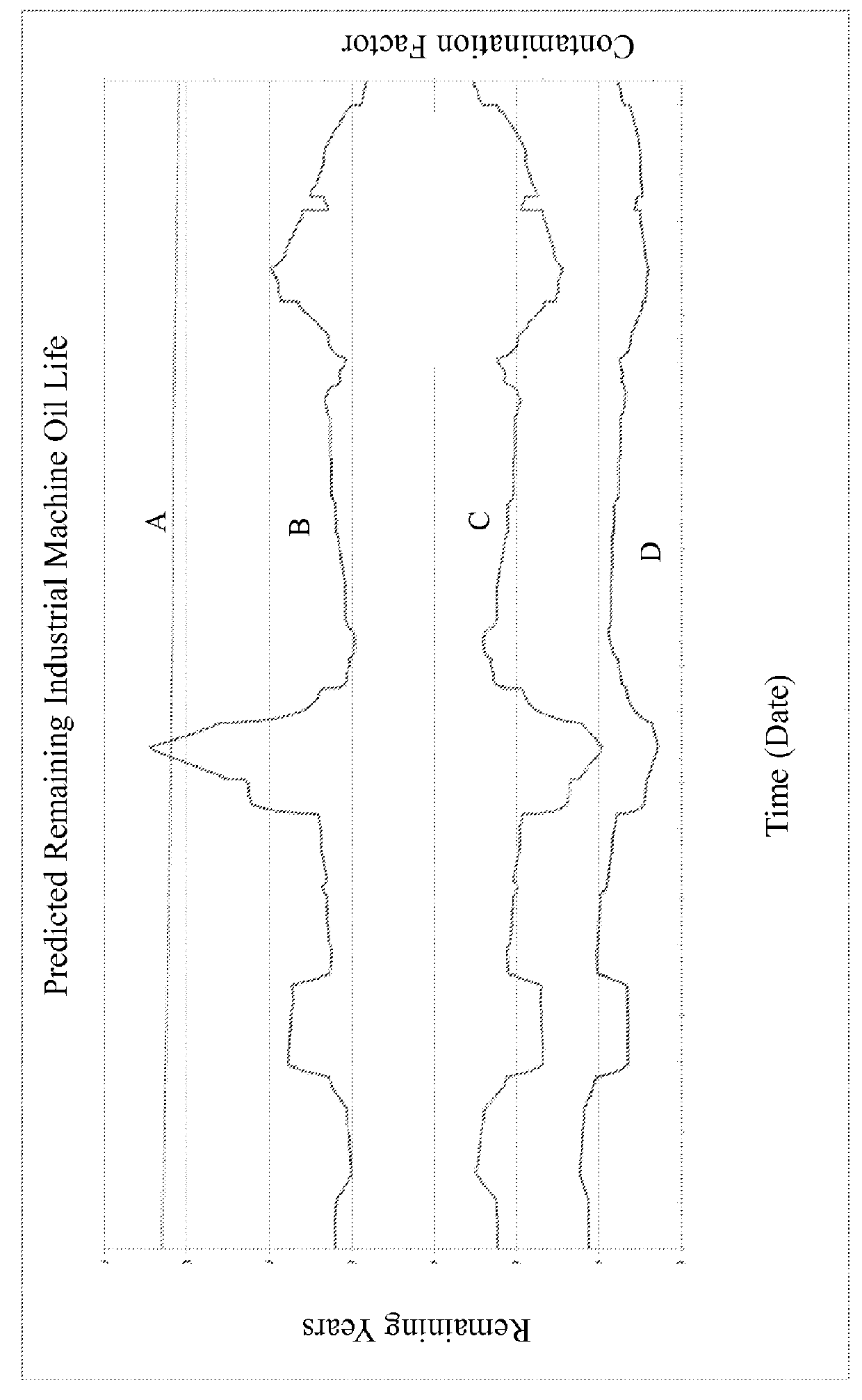

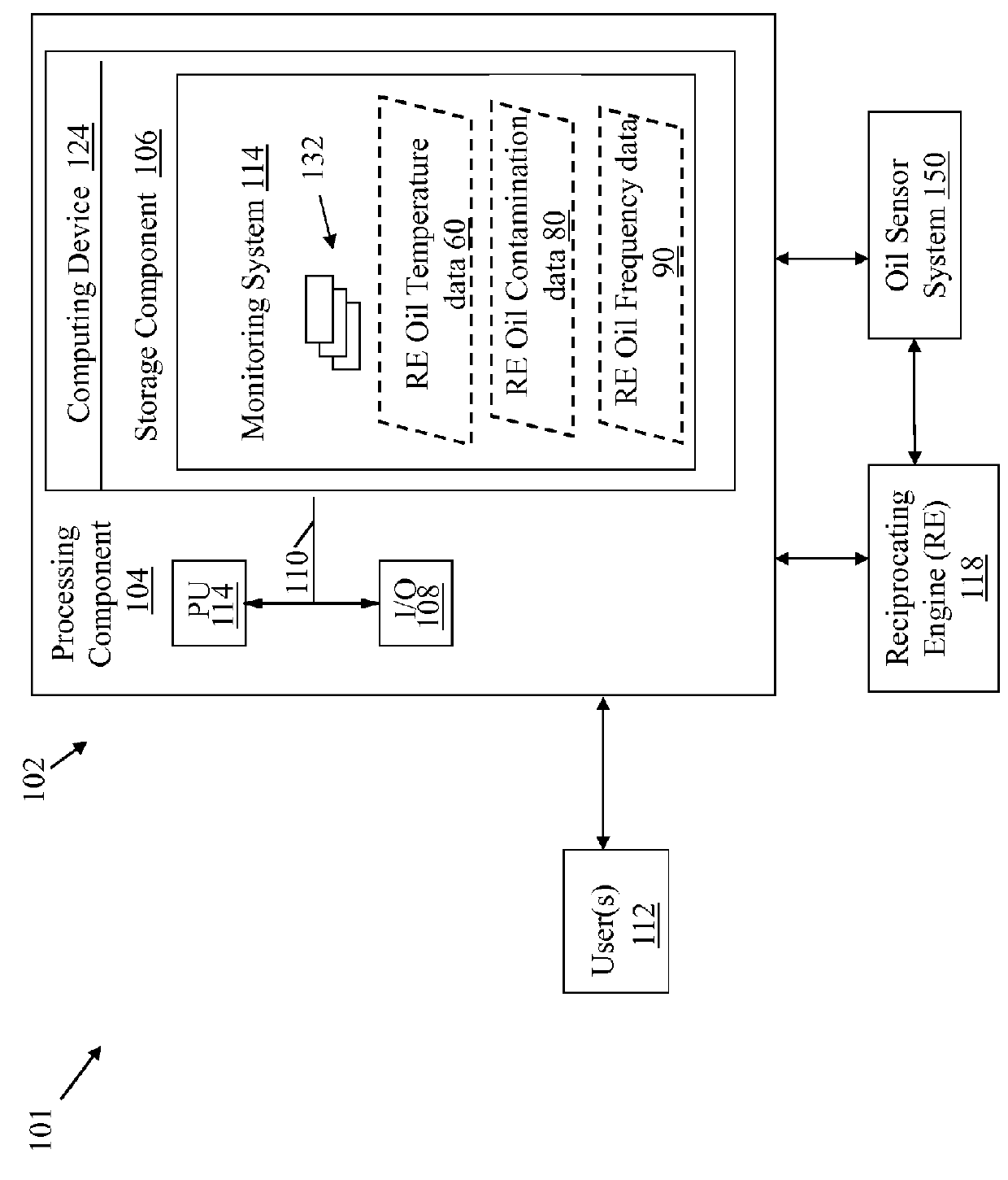

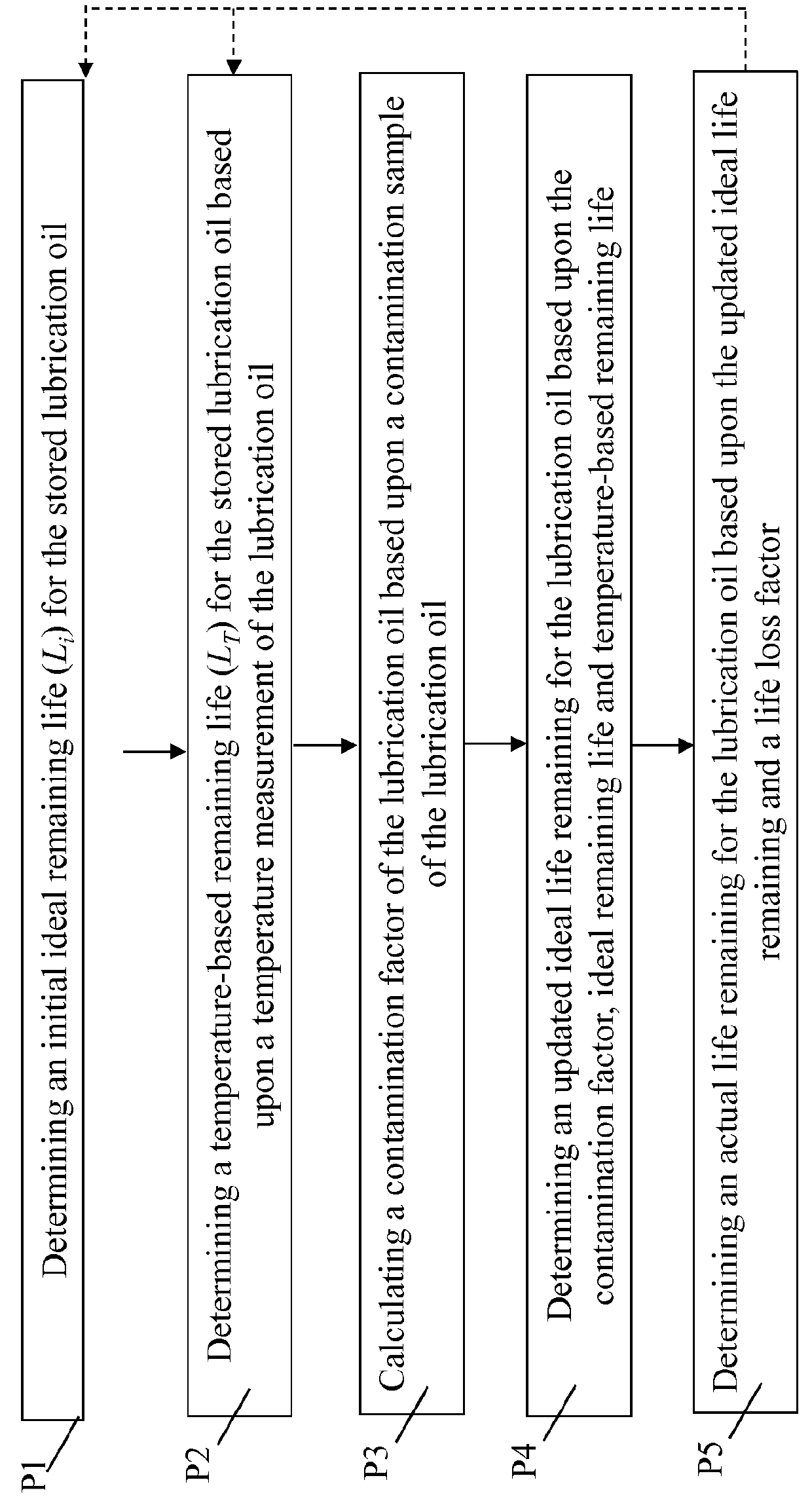

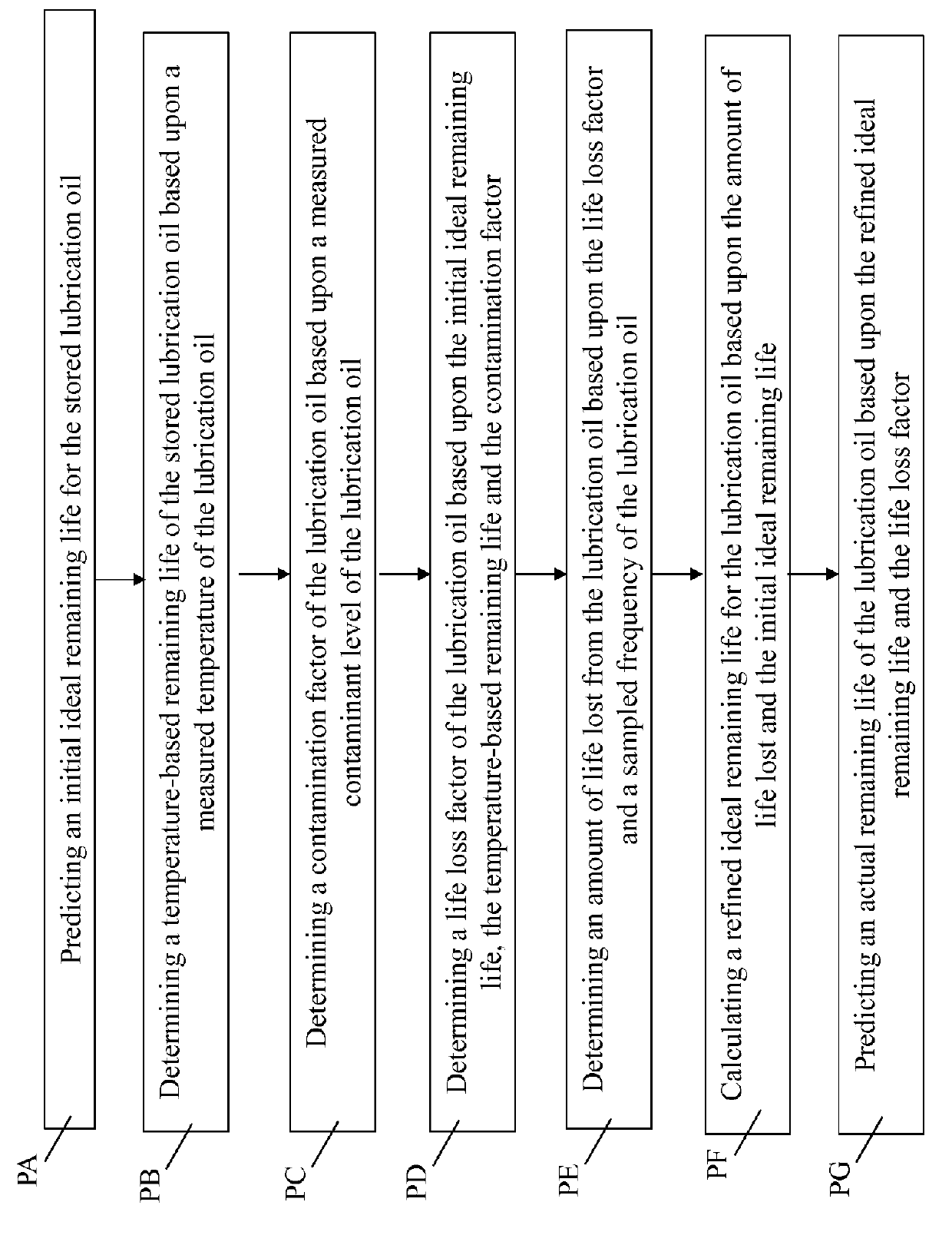

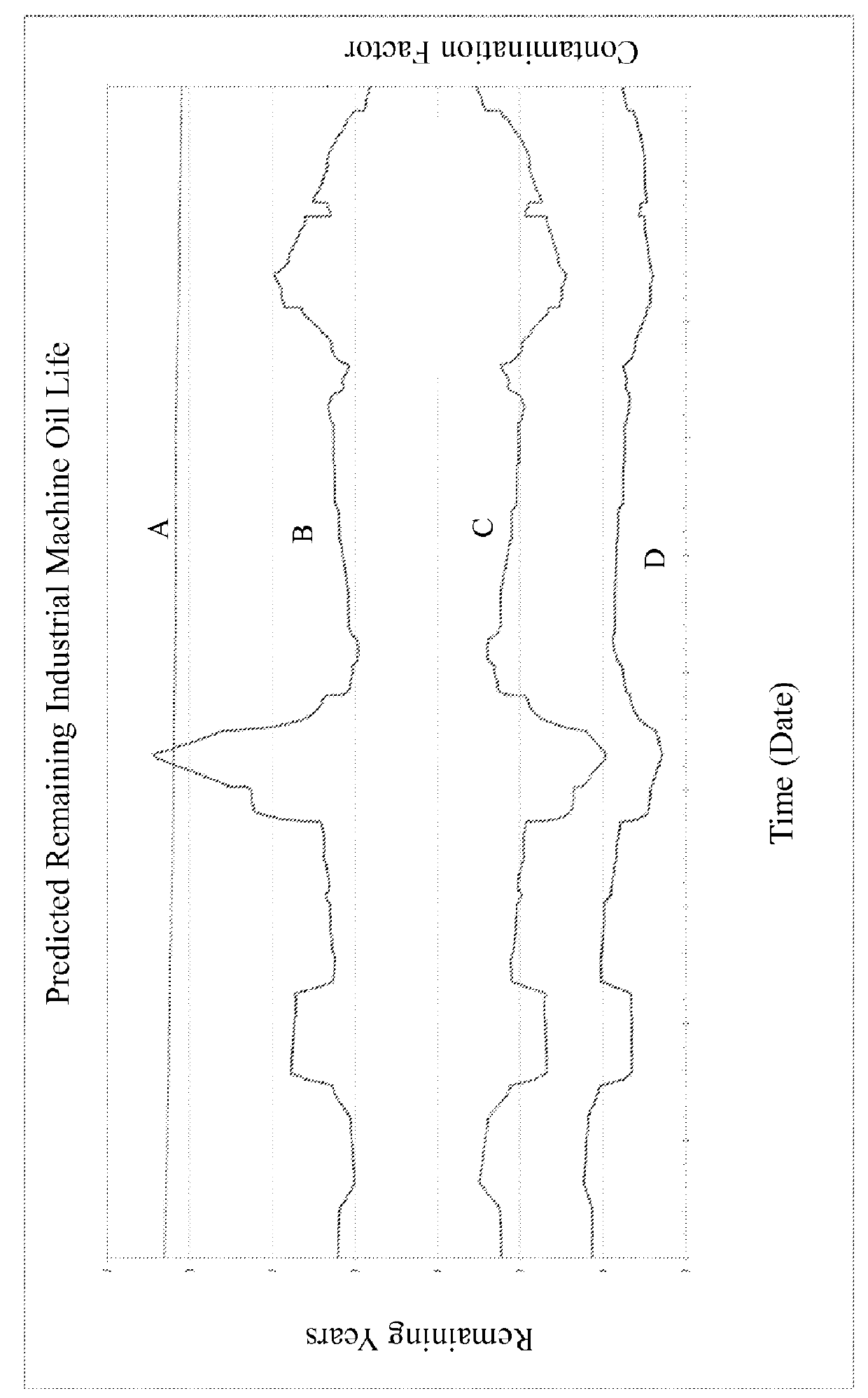

Various embodiments of the invention include a system having: at least one computing device configured to monitor a lubrication oil from a reciprocating engine by performing actions including: determining an initial ideal remaining life for the lubrication oil from the reciprocating engine; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a contamination sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Shared oil system arrangement for an engine component and a generator

A method of distributing oil to a component within a gas turbine engine includes directing a first oil flow from an oil source to an engine component and back to the oil source, directing a second oil flow from the oil source to a generator driven by the engine and back to the oil source, monitoring a parameter of the second oil flow downstream of the generator and upstream of the oil source, detecting a contaminant in the second oil flow based on the parameter, and reducing the second oil flow to the generator when the contaminant is detected without reducing the first oil flow to the engine component. A shared oil system for a component of a gas turbine engine and a generator driven by the gas turbine engine is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Lubricating device for supplying a tool with lubricant

InactiveCN103542246ATimely detection of wearAvoid damageEngine temperatureEngine pressureEngineeringLubricant

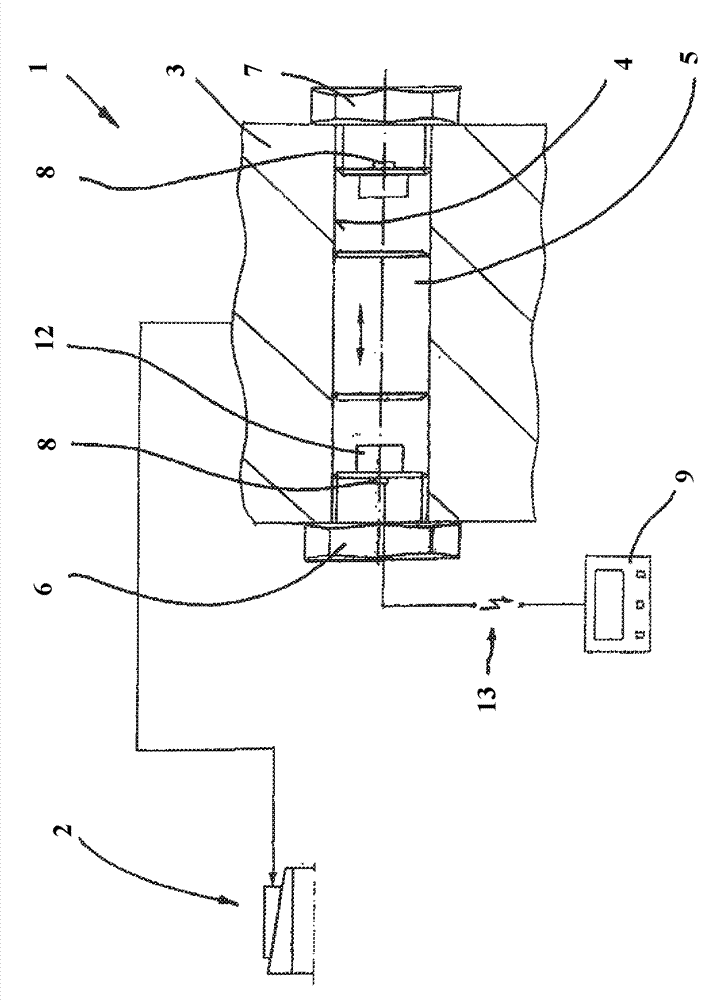

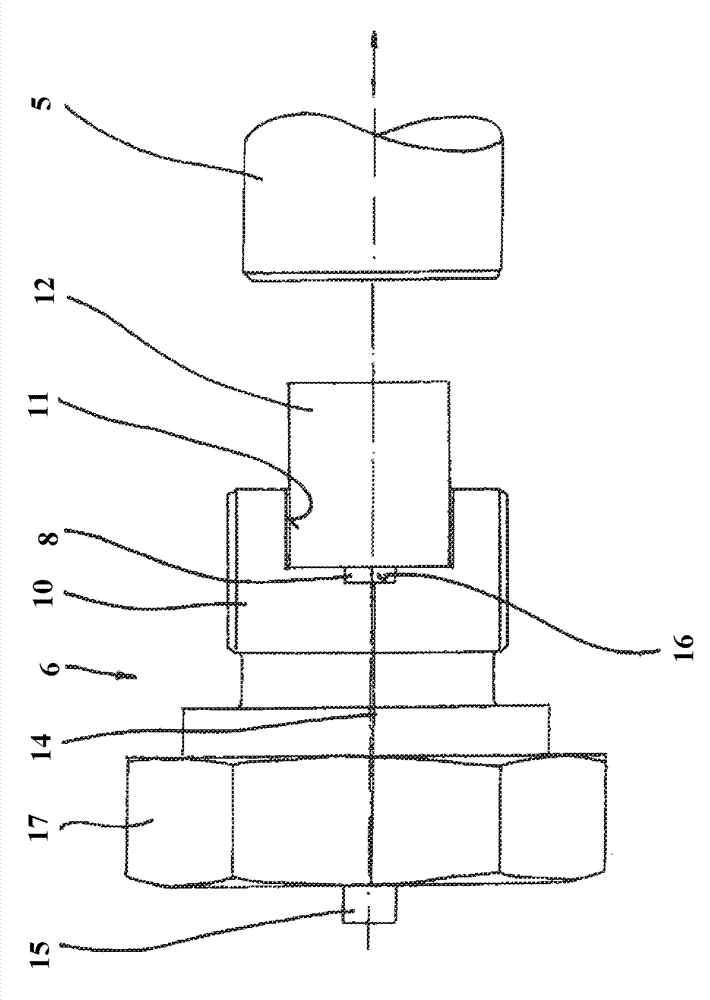

The invention relates to a lubricating device (1) supplying lubricating agents, especially lubricating grease or lubricating oil to a tool (2). The lubricating device (1) comprises a lubricating distributor (3). At least one piston hole (4) is introduced into the lubricating distributor. A piston (5) which can move back and forth is arranged inside the piston hole. The piston hole (4) parts in the axial end part areas can be locked respectively through locking bolts (6, 7). In order to guarantee the monitoring of a lubricating system especially when used in a pipe expanding tool, the invention has at least one sensor (8) arranged in or beside at least one locking bolt (6). The sensor is connected with a monitoring device (9) so as to detect and monitor at least one running parameter of the lubricating distributor (3).

Owner:SMS MEER

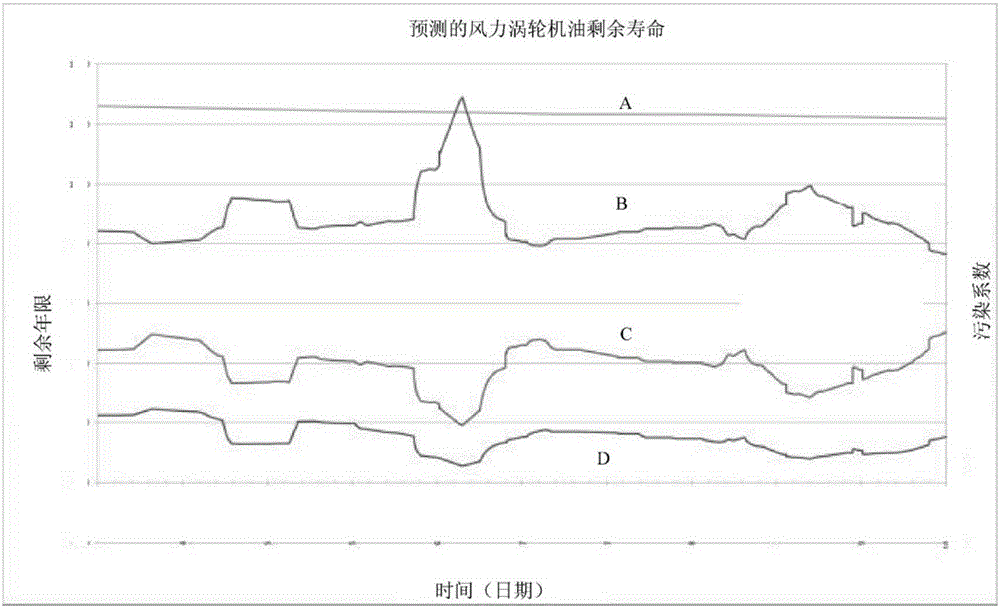

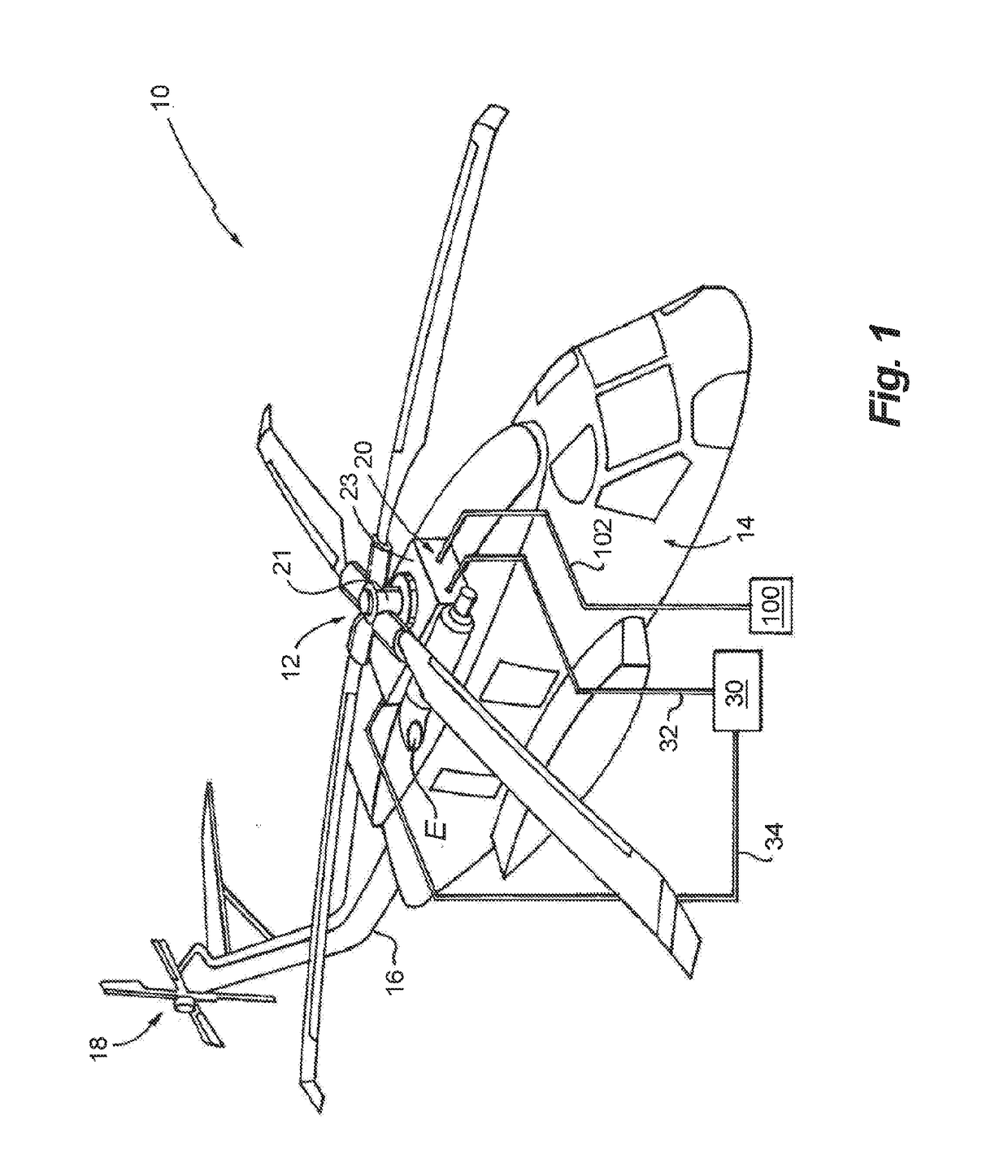

Wind turbine lubricating oil analyzer system, computer program product and related methods

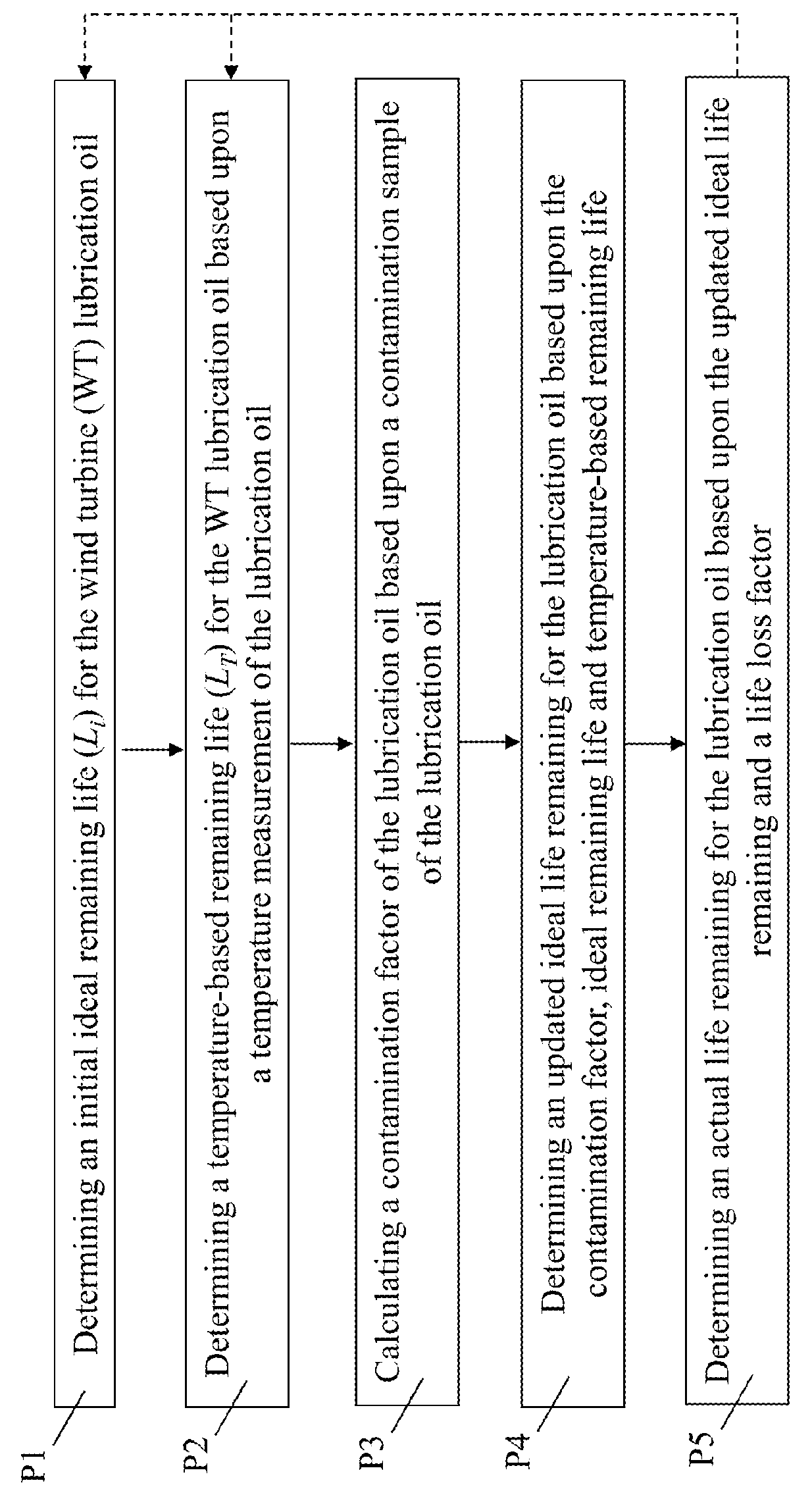

Various embodiments of the invention include a system having: at least one computing device configured to monitor a lubrication oil from a wind turbine by performing actions including: determining an initial ideal remaining life for the lubrication oil from the wind turbine; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a contamination sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Lubrication system with supply line monitoring

A lubrication system includes a lubricant supply reservoir, a supply line connecting the reservoir with one or more dispenser valves, a return valve and a pump. A control is operatively connected with a pump and with the return valve, the control being configured to operate the pump and the return valve such that a quantity of lubricant within the supply line flows out of the supply line and into the reservoir when a period of storage within the supply line of the quantity of lubricant exceeds an estimated period of effectiveness of the quantity of lubricant or a predetermined portion of the estimated lubricant effectiveness period.

Owner:LINCOLN INDUSTRIES CORP

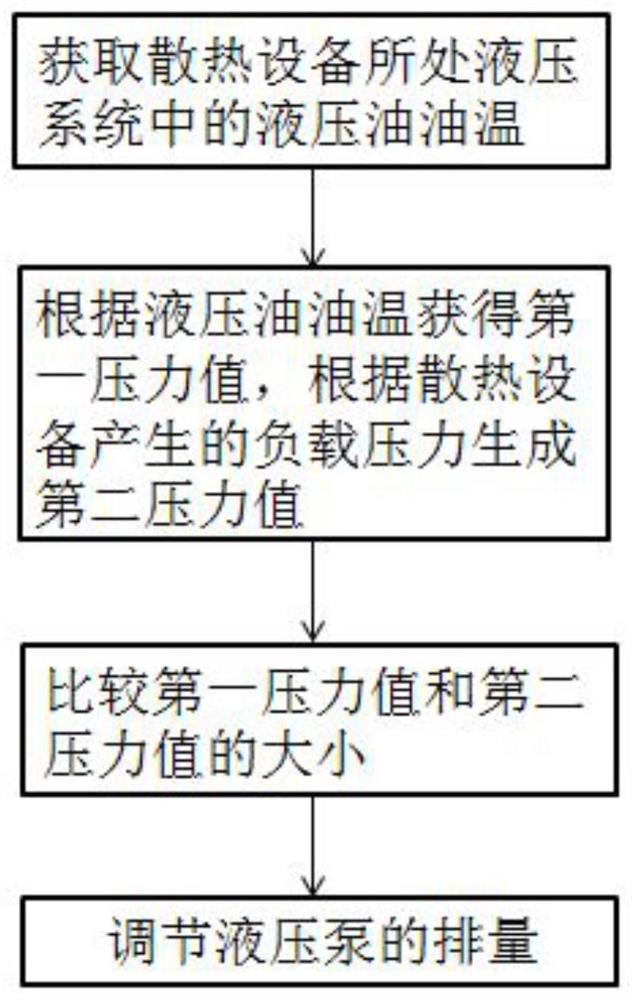

Pressure compensation type hydraulic pump, rotating speed control system, rotating speed control method and engineering machinery

PendingCN112128178AStable speedStable jobServomotor componentsServomotorsSpeed control systemControl system

The invention relates to engineering machinery, and specifically discloses a pressure compensation control type hydraulic pump. The hydraulic pump comprises an electric proportional pressure compensator, a hydraulic pump, a hydraulic control reversing valve and a servo piston, the electric proportional pressure compensator can be electrically connected with a controller, a first hydraulic controlport of the hydraulic control reversing valve is connected with an internal oil drainage oil way through the electric proportional pressure compensator, the first hydraulic control port is connected to an internal output oil way through a hydraulic control oil-inlet oil way provided with a first throttling valve, a second hydraulic control port of the hydraulic control reversing valve is connectedwith the internal output oil way, and the pressure difference between the opening pressure of the electric proportional pressure compensator and the pressure of an oil outlet of the hydraulic pump can drive the hydraulic control reversing valve to reverse. In this way, a rodless cavity of the servo piston selectively communicates with the internal output oil way or the internal oil drainage oil way. In addition, the invention further discloses a rotating speed control method, a rotating speed control system and engineering machinery. According to the hydraulic pump, the output flow of the hydraulic pump can be stabilized at a required value.

Owner:ZOOMLION HEAVY IND CO LTD +1

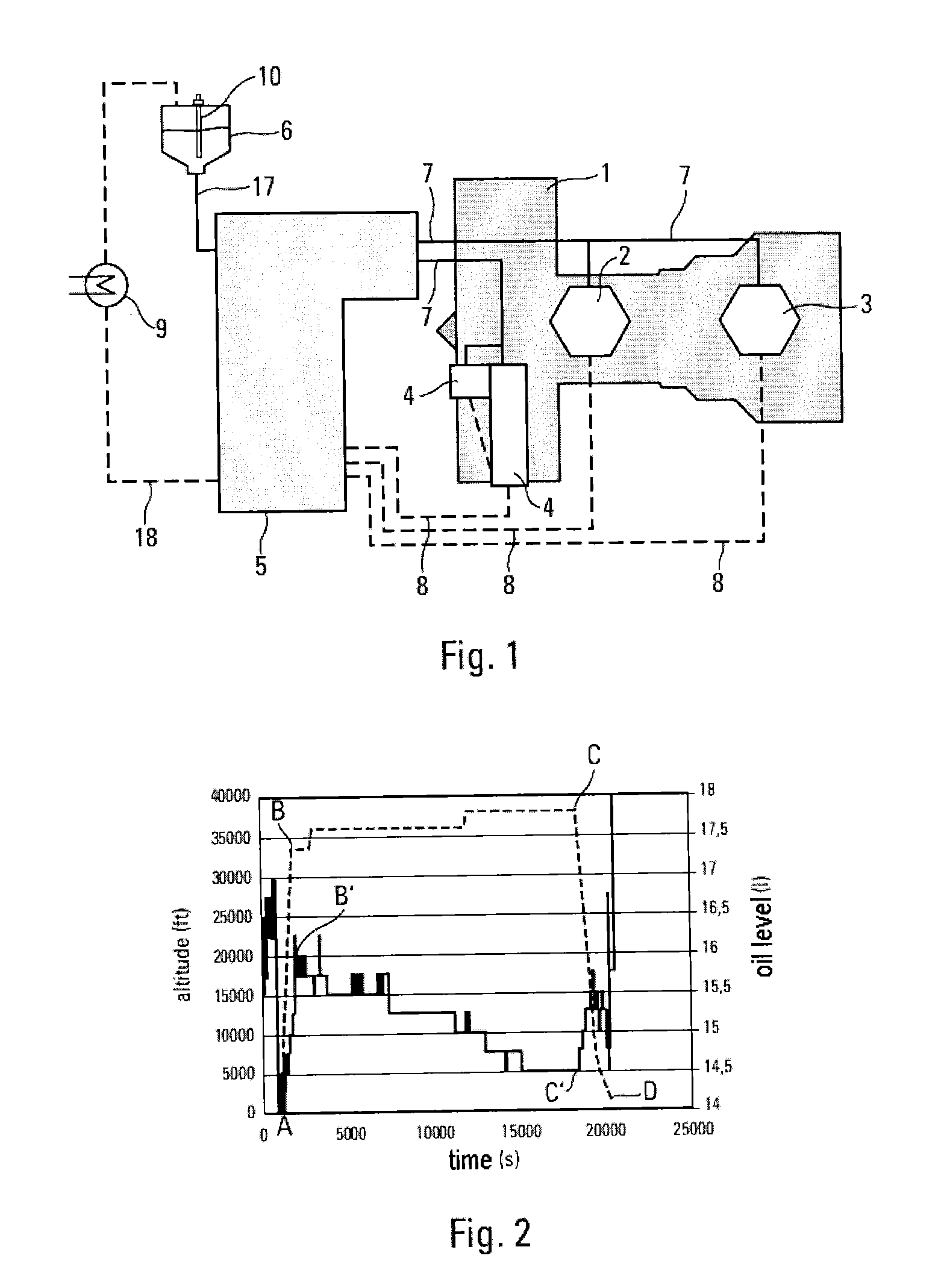

Method and device for detection of contamination by fuel of the oil circuit of a turbine

InactiveUS20130073171A1Reduce weightEliminate disadvantagesAnalogue computers for vehiclesEngine temperatureFuel tankTurbine

A method for detection of contamination, by another fluid, of the oil circuit of a turbomachine fitted on an aircraft, the oil circuit including a tank provided with a device for measuring its oil level, piping which connects the tank to the various units of the turbomachine to be lubricated, and a device for putting the oil into circulation between the tank and the units, the turbomachine including a device for measuring its engine speed and a device for measuring the temperature of the oil at one point at least of the oil circuit. The oil level in the tank is monitored, an alert is triggered if the decrease in the oil level, measured over a given interval of time, becomes lower than a set minimum decrease. The decrease can be replaced by a simple increase in the oil level, without taking a duration of the monitoring into account.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

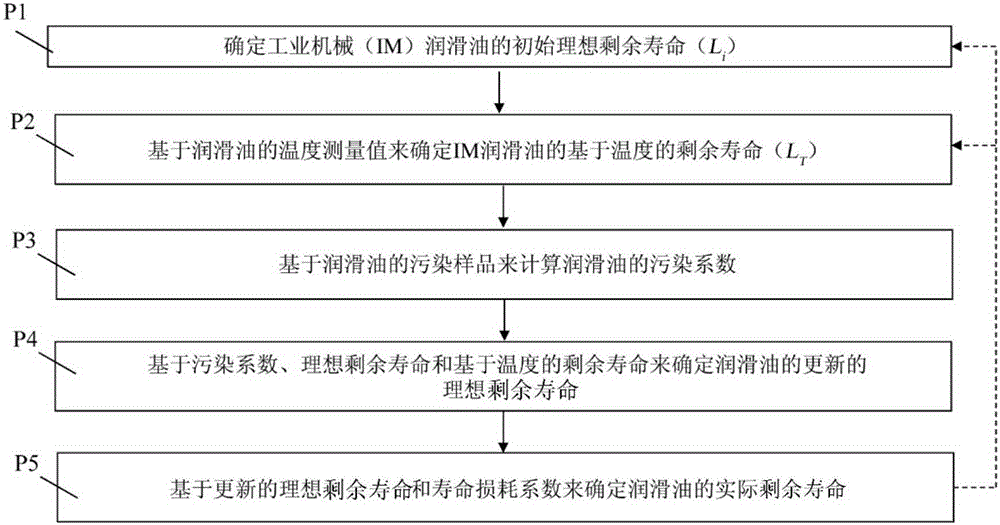

Industrial machine lubricating oil monitoring system, and related methods

Owner:GENERAL ELECTRIC CO

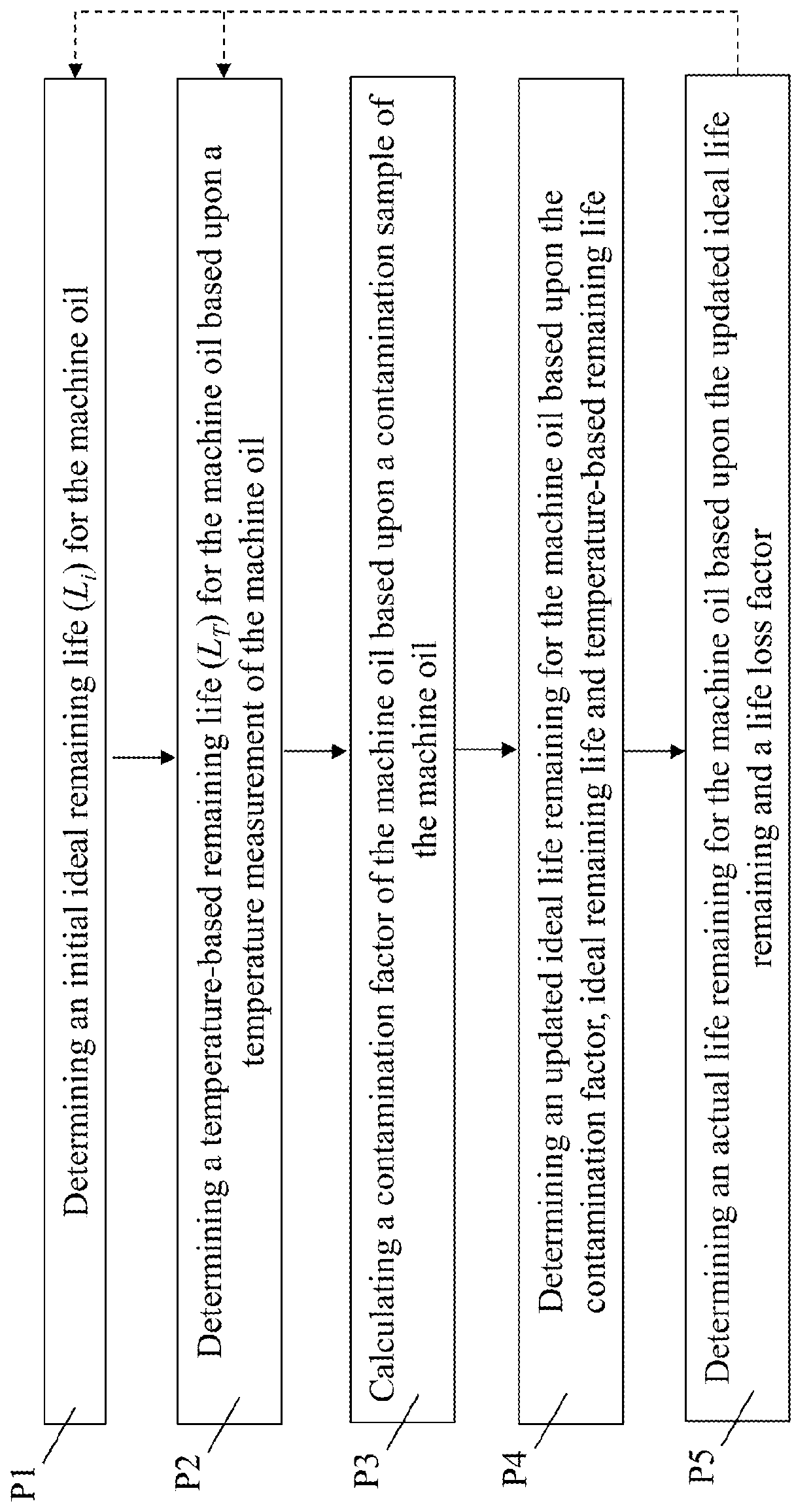

Machine oil analyzer system and related methods

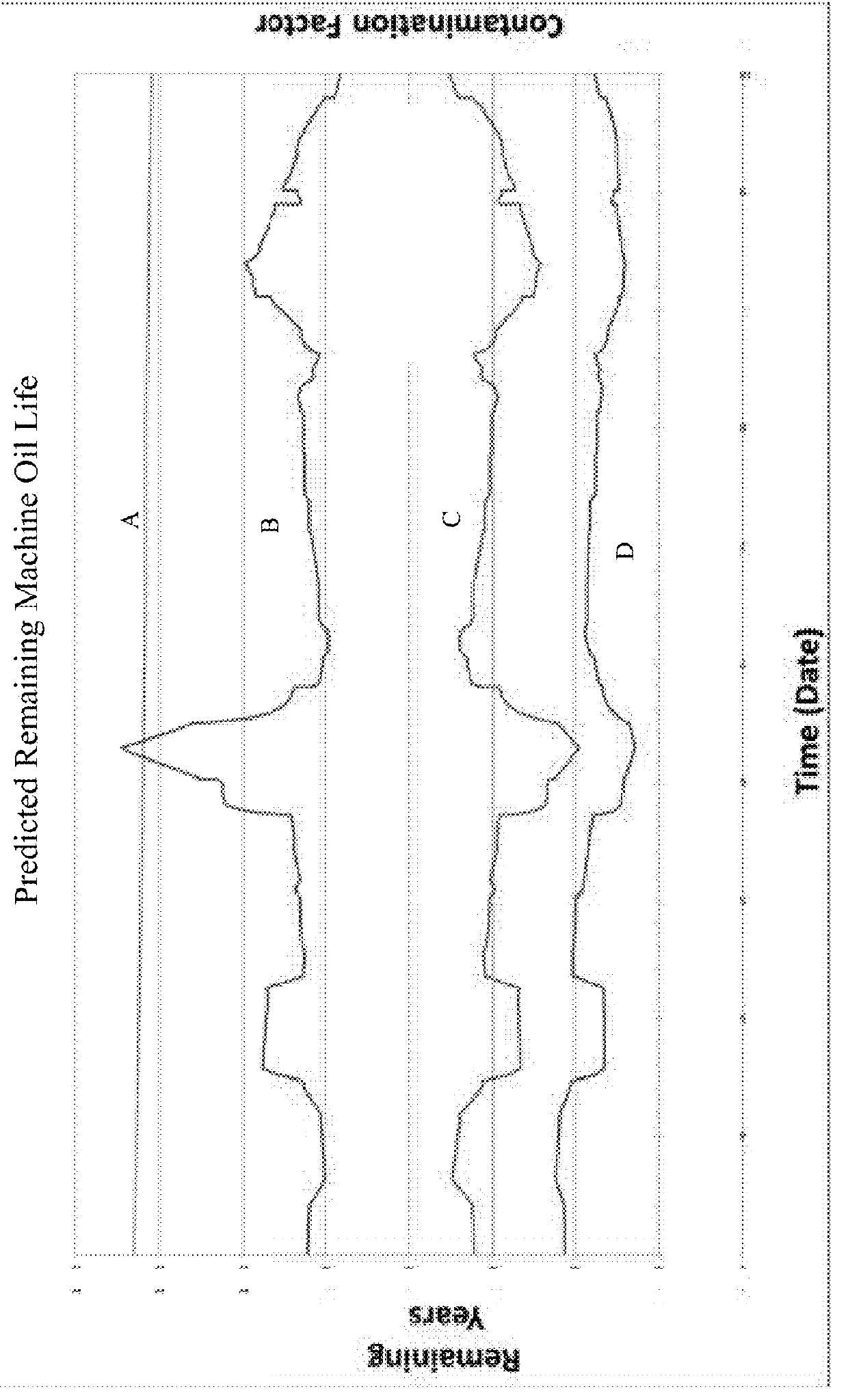

Various embodiments of the invention include a system having: at least one computing device at least one computing device configured to monitor a machine oil by performing actions including: determining an initial ideal remaining life for the machine oil; determining a temperature-based remaining life for the machine oil based upon a temperature measurement of the machine oil; calculating a contamination factor of the machine oil based upon a contamination sample of the machine oil; determining an updated ideal life remaining for the machine oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the machine oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Machine oil analyzer system, computer program product and related methods

Various embodiments of the invention include a system having: at least one computing device at least one computing device configured to monitor a machine oil by performing actions including: determining an initial ideal remaining life for the machine oil; determining a temperature-based remaining life for the machine oil based upon a temperature measurement of the machine oil; calculating a contamination factor of the machine oil based upon a contamination sample of the machine oil; determining an updated ideal life remaining for the machine oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the machine oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Wind turbine lubricating oil analyzer system, and related methods

Various embodiments of the invention include a system having: at least one computing device configured to monitor a lubrication oil from a wind turbine by performing actions including: determining an initial ideal remaining life for the lubrication oil from the wind turbine; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a contamination sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Lubrication systems for transmissions

A lubrication system for a transmission includes a flow-metering device and a controller. The controller is operatively associated with the flow-metering device to cause the flow-metering device to intermittently issue lubricant from the flow-metering device into a transmission based on an operating parameter of the transmission.

Owner:SIKORSKY AIRCRAFT CORP

Stored lubricating oil analyzer system, computer program product and related methods

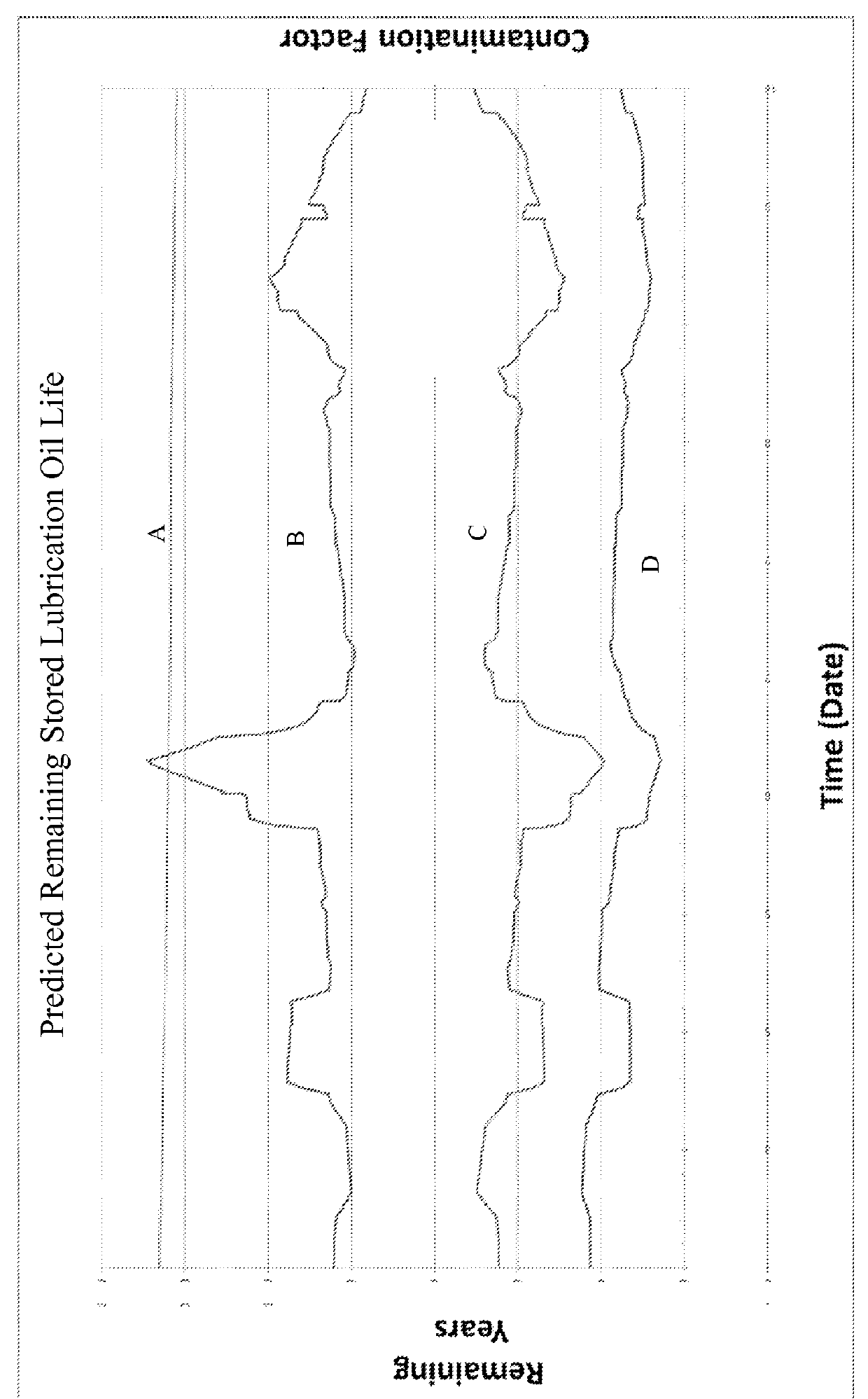

Various embodiments of the invention include a system having: at least one computing device configured to monitor a lubrication oil from a lubrication oil storage system by performing actions including: determining an initial ideal remaining life for the lubrication oil from the lubrication oil storage system; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a contamination sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Transportation machine lubricating oil monitoring system and related methods

The invention discloses a transportation machine lubricating oil monitoring system and related methods. The system is provided with at least one computing device configured to monitor a lubrication oil from a transportation machine by performing actions including: determining an initial ideal remaining life for the lubrication oil from the transportation machine; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a contamination sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

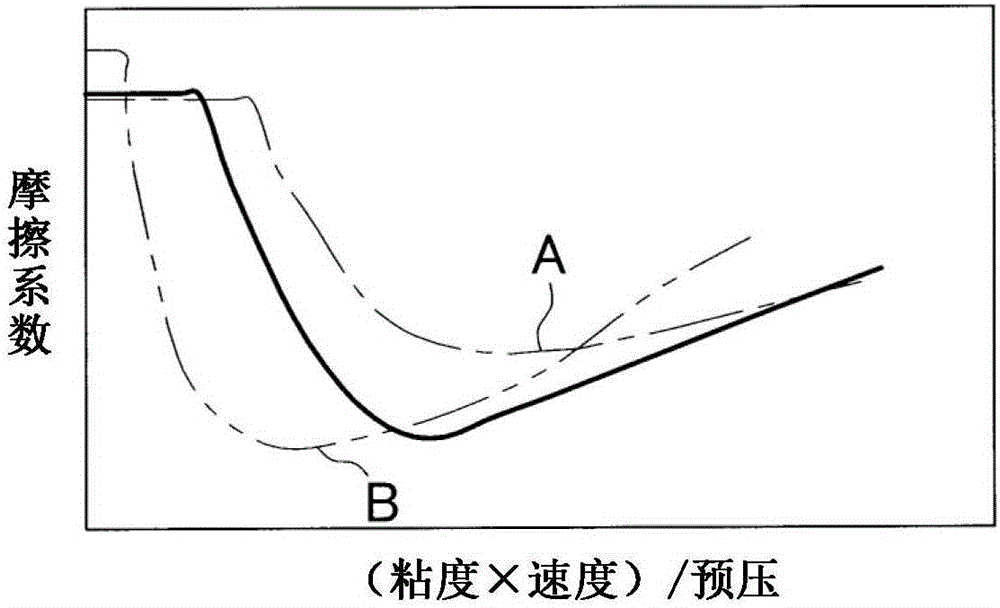

Bearing diagnostic device for machine tool

The invention provides a bearing diagnostic device for a machine tool. The device is capable of detecting abnormality of a bearing in a precise and low-cost manner at an early time prior to possible damage to a machine tool. The bearing diagnostic device includes a rotation speed detector and a calculating apparatus which detect the rotation speed of a spindle at a certain specific rotation speed; a temperature sensor and a calculating apparatus which detect the temperature of the spindle; a friction torque calculating part which calculates a friction torque of the bearing; a rolling speed calculating part which calculates the rolling sped of the bearing; a bearing pre-pressing estaimation part which estimates the pre-pressing of the bearing; a lubricant viscosity estimation part which estimate the lubricant viscosity of the bearing; a bearing characteristics calculating part which, based on the friction torque, the rolling speed, the pre-pressing, and the lubricant viscosity, calculates bearing characteristics; a storage apparatus which stores a reference bearing characteristics; and a determination apparatus which compares the bearing characteristics calculated by the bearing characteristics calculating part and the reference bearing characteristics stored in the storage apparatus, and determines the presence of abnormality.

Owner:OKUMA CORP

Industrial machine lubricating oil analyzer system, computer program product and related methods

InactiveUS20160054289A1Engine temperatureMaterial testing goodsProcess engineeringIndustrial machine

Various embodiments of the invention include a system having: at least one computing device configured to monitor a lubrication oil from an industrial machine by performing actions including: determining an initial ideal remaining life for the lubrication oil from the industrial machine; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a contamination sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and a life loss factor.

Owner:GENERAL ELECTRIC CO

Lubricant pump and lubricating system with pump heater

InactiveCN102537629AEliminate the cause of the failureReduce usageEngine temperatureEngine pressureEngineeringLubricant

A lubricant pump is disclosed for delivering lubricant to at least one lubricating point. The pump features a lubricant container (2), a pump unit, a drive (4) assigned to the pump unit, and at least one lubricant outlet and a control unit (5) assigned to the drive (4). At least one heating element (6) is also provided and can be actuated by the control unit and / or another control unit (5). In addition, the invention further relates to a lubricating system with the lubricant pump.

Owner:LINCOLN GMBH

Lubrication heating system and wind turbine incorporating same

Owner:GE INFRASTRUCTURE TECH INT LLC

Multi-modal fluid condition sensor platform and system therefor

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

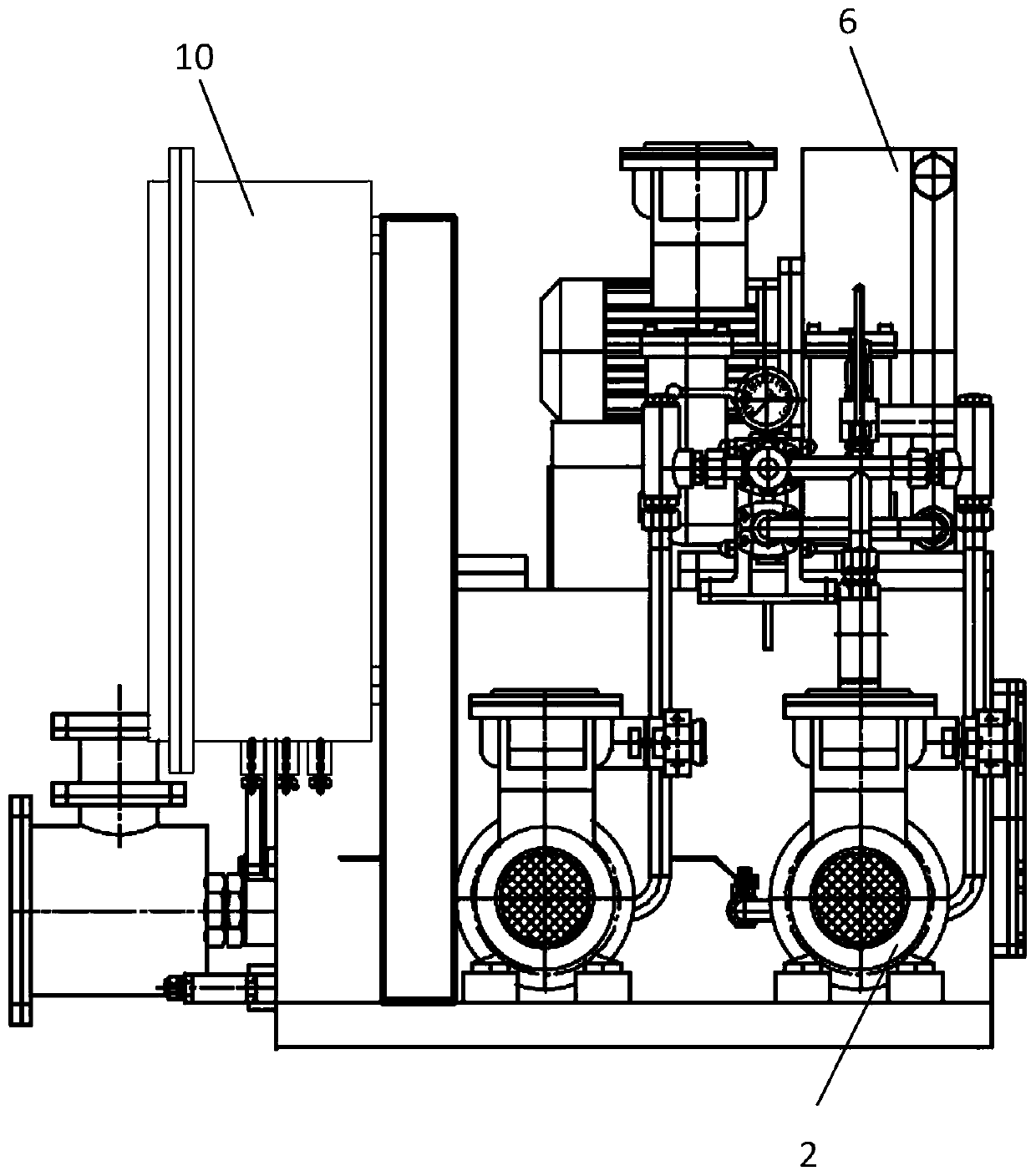

Mining explosion-proof type thin oil lubrication station

PendingCN110778902AEasy to installLow costEngine temperatureEngine pressureElectric controlLubrication

The invention provides a mining explosion-proof type thin oil lubrication station. The station comprises an oil tank, an oil outlet pipeline, an oil return pipeline, an oil pump, a one-way valve, a safety valve, a double-barrel filter, a cooler and an electric control box, wherein the oil return position of the oil tank is provided with a magnetic filtering device, the oil outlet pipeline comprises a first pipeline, a second pipeline and a third pipeline, wherein one end of the first pipeline and one end of the second pipeline communicate with the oil tank, the other end of the first pipelineand the other end of the second pipeline communicate with the input end of the double-barrel filter, one end of the third pipeline communicates with the output end of the double-barrel filter, the other end of the third pipeline is branched into a fourth pipeline with a first oil outlet and a fifth pipeline with a second oil outlet, one end of the oil return pipeline communicates with the magneticfiltering device, the other end of the oil return pipeline is branched into a sixth pipeline with a first oil return port and a seventh pipeline with a second oil return port, the cooler is an air cooler, and a shell of the electric control box is a metal closed explosion-proof type panel.

Owner:南通信仁润滑液压设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com