Gearbox lubricating system and lubricating oil flow control method of gearbox lubricating system

A lubricating system and lubricating oil technology, applied in the direction of gear lubrication/cooling, engine flow, lubricating parts, etc., can solve the problems of low intelligence and automation, less application of sensors, and inability to accurately control the opening size of the one-way valve. , to achieve the effect of convenient operation, high degree of intelligence, improved service life and degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

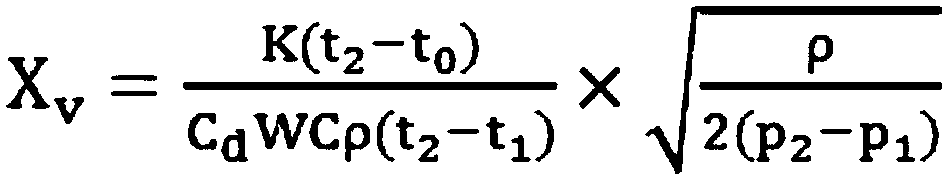

Method used

Image

Examples

Embodiment Construction

[0036] This embodiment takes a gearbox lubrication system applied to a wind power generating set as an example to describe the technical solution of the application in detail, which should not be construed as any limitation to the application. The details are as follows.

[0037] Refer to attached figure 1 As shown, the gearbox lubrication system of the wind power generating set in this embodiment includes a ring circuit formed by sequentially connecting the lubricating oil tank 1, the oil pump 2, the filter 4, the radiator 7 and the control valve, and the connection between the filter 4 and the control valve A straight-through passage is also provided, and the straight-through passage is arranged in parallel with the radiator 7 .

[0038] The control valve in this embodiment adopts an electronically controlled reversing valve 10 . Since the lubricating system is applied to the lubrication of the gearbox of the wind power generating set, the electronically controlled reversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com