Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Hydraulic intensifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydraulic intensifier is a hydraulic machine for transforming hydraulic power at low pressure into a reduced volume at higher pressure.

Hydraulic intensifiers

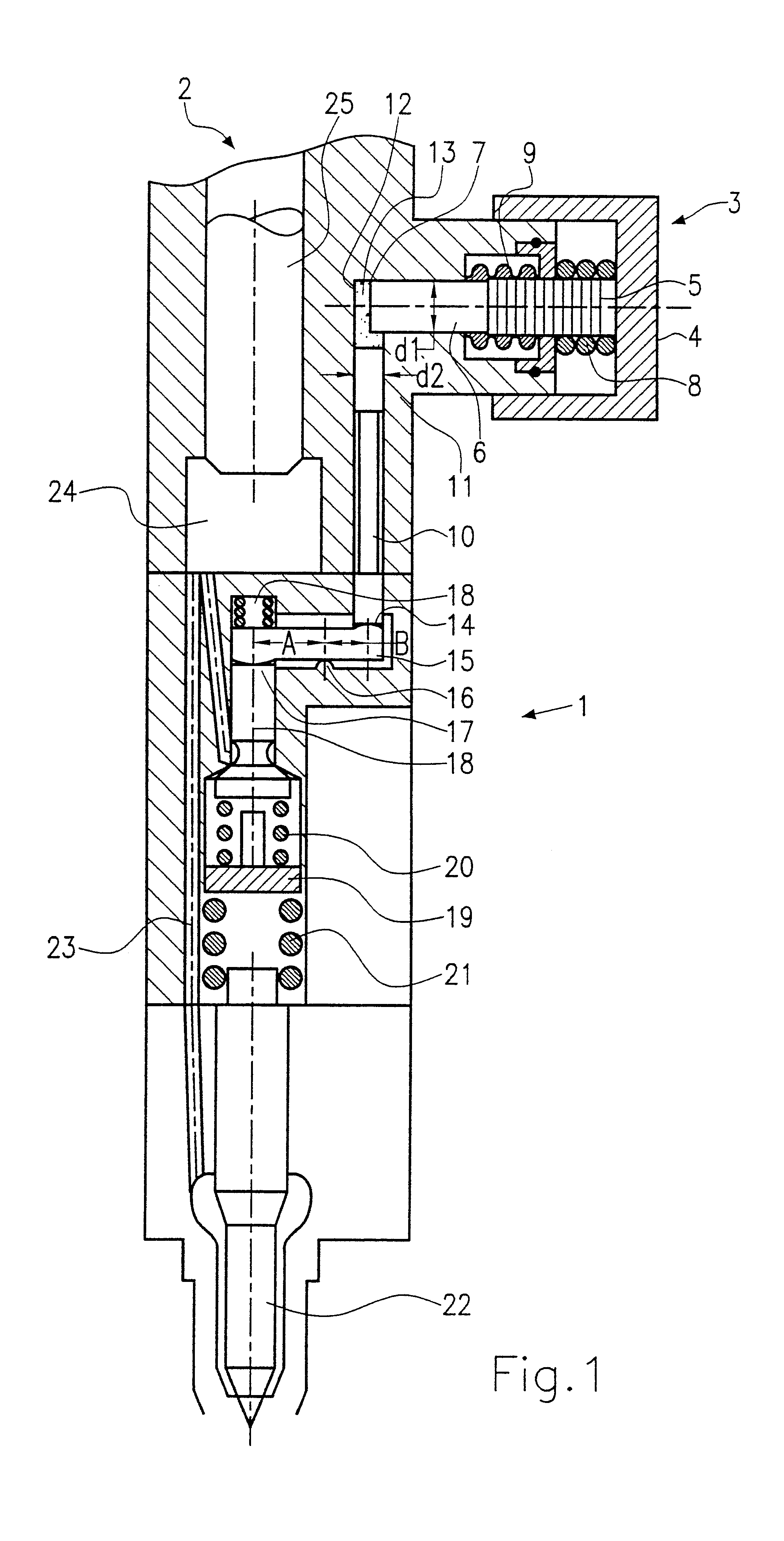

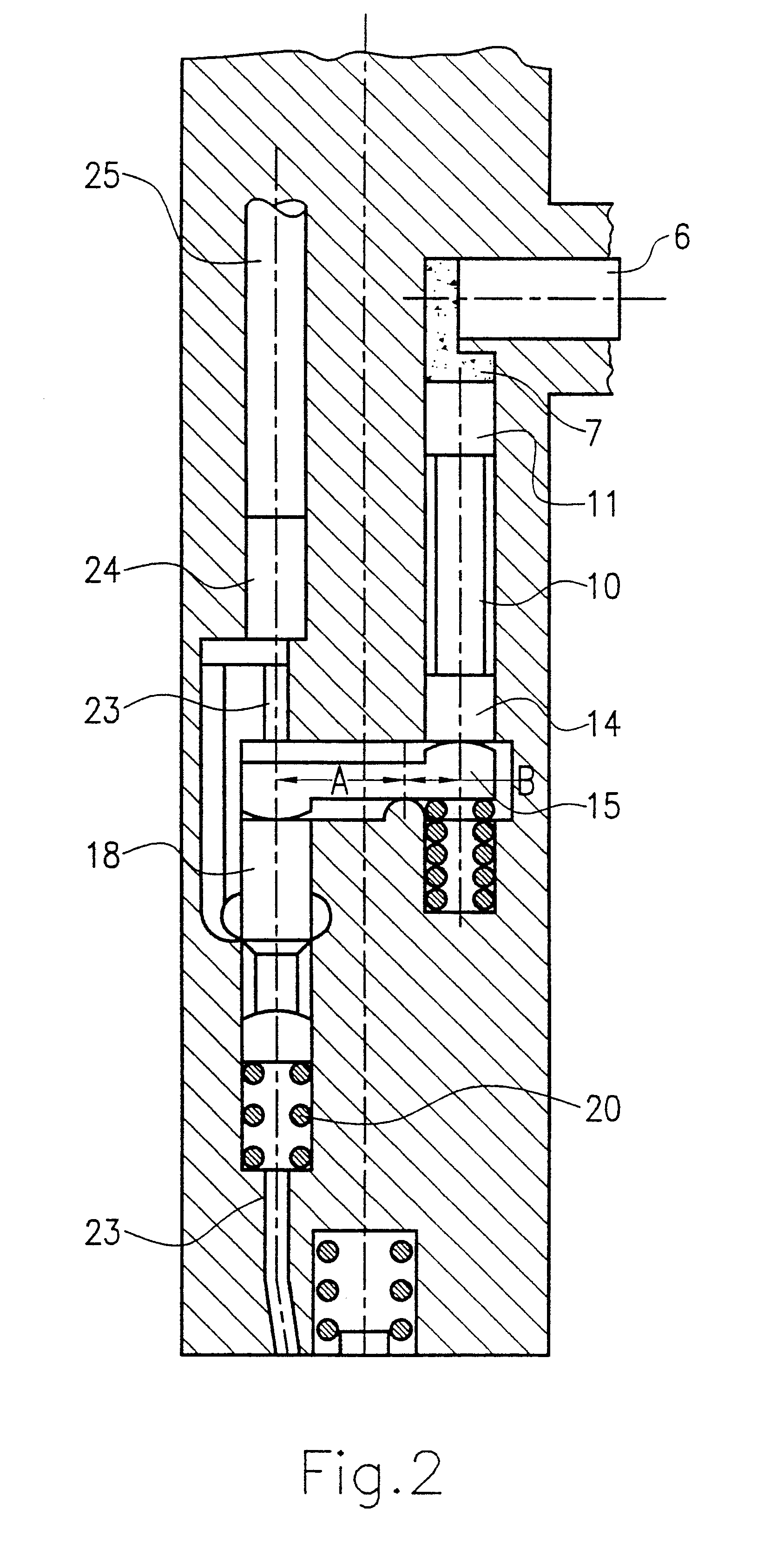

InactiveUS20090317267A1Increase the cross-sectional areaPositive displacement pump componentsFlexible member pumpsHigh pressureHydraulic fluid

A hydraulic intensifier with a piston and cylinder assembly (1) having a first piston (3) in a chamber (4) of low pressure cylinder and a second piston (7) in a chamber (8) of a high pressure cylinder. The first and second pistons are coupled together and the first piston has a larger cross-sectional area than the second piston. A high pressure output (19) is coupled to the chamber of the high pressure cylinder, there being; means (13) for supplying low pressure hydraulic fluid to the chamber of the low pressure cylinder; an electrically operated directional control valve (11) for controlling the supply of low pressure hydraulic fluid to the chamber of the low pressure cylinder; and electronic means (14) for controlling operation of the directional control valve.

Owner:VETCO GRAY CONTROLS

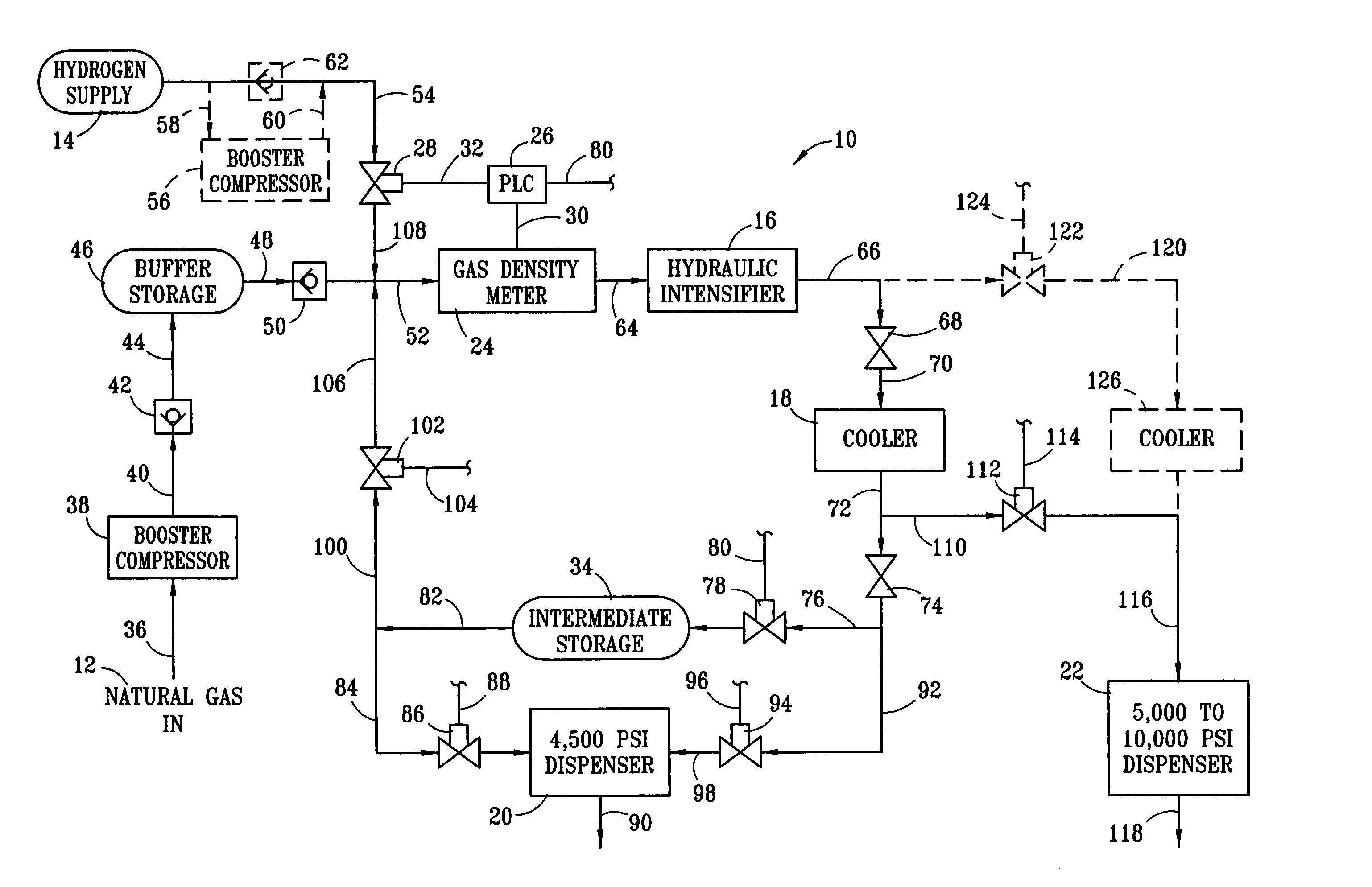

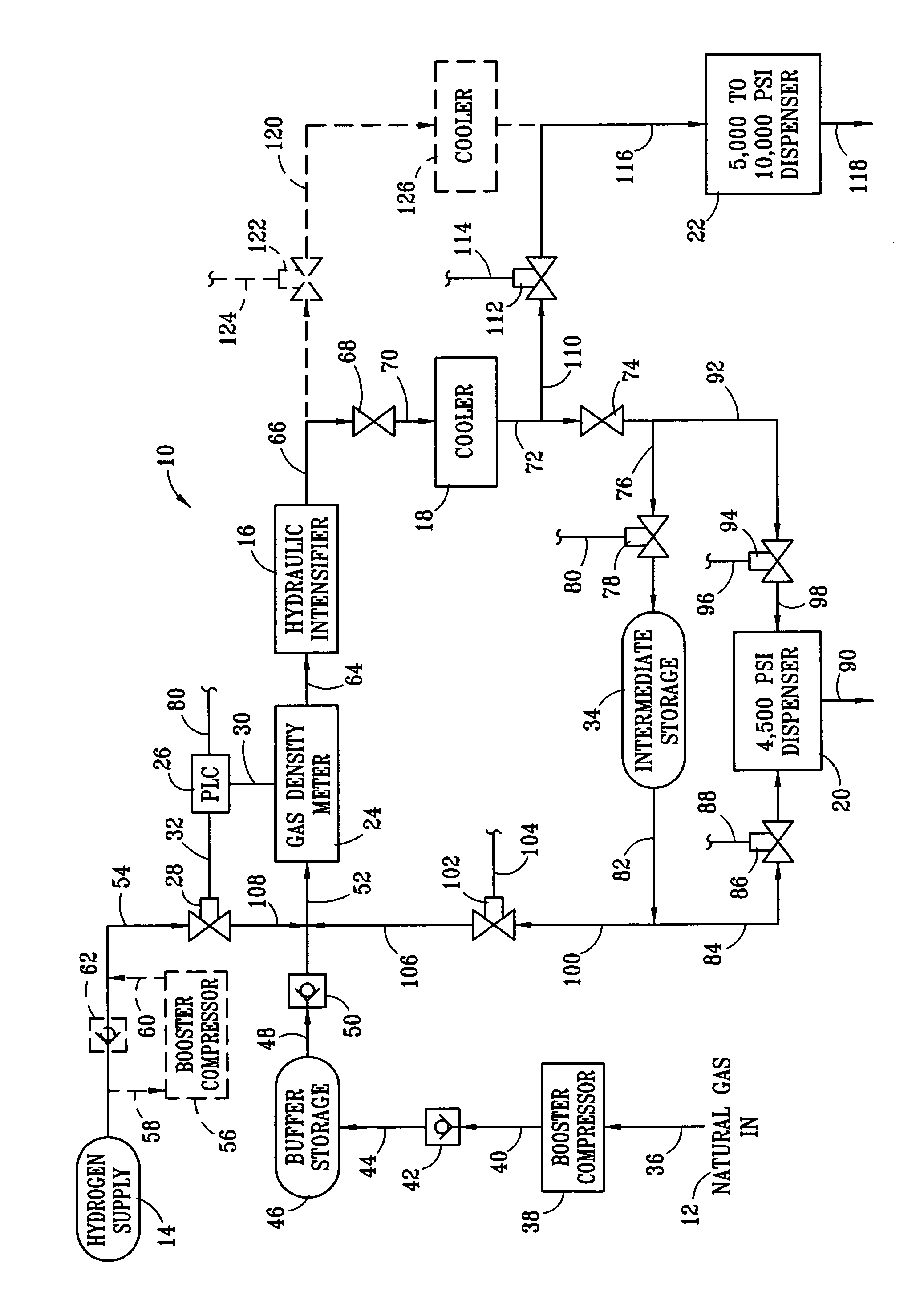

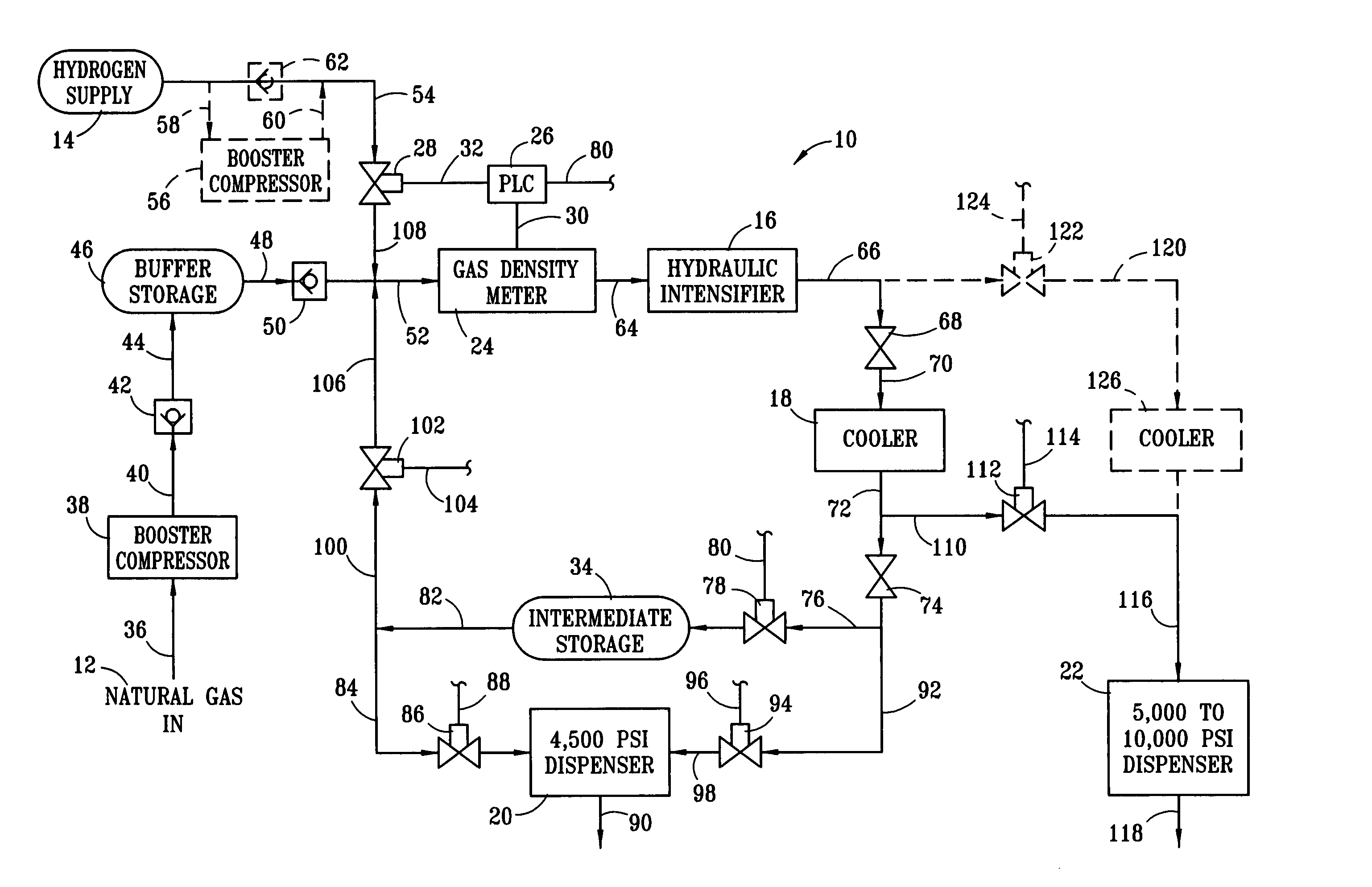

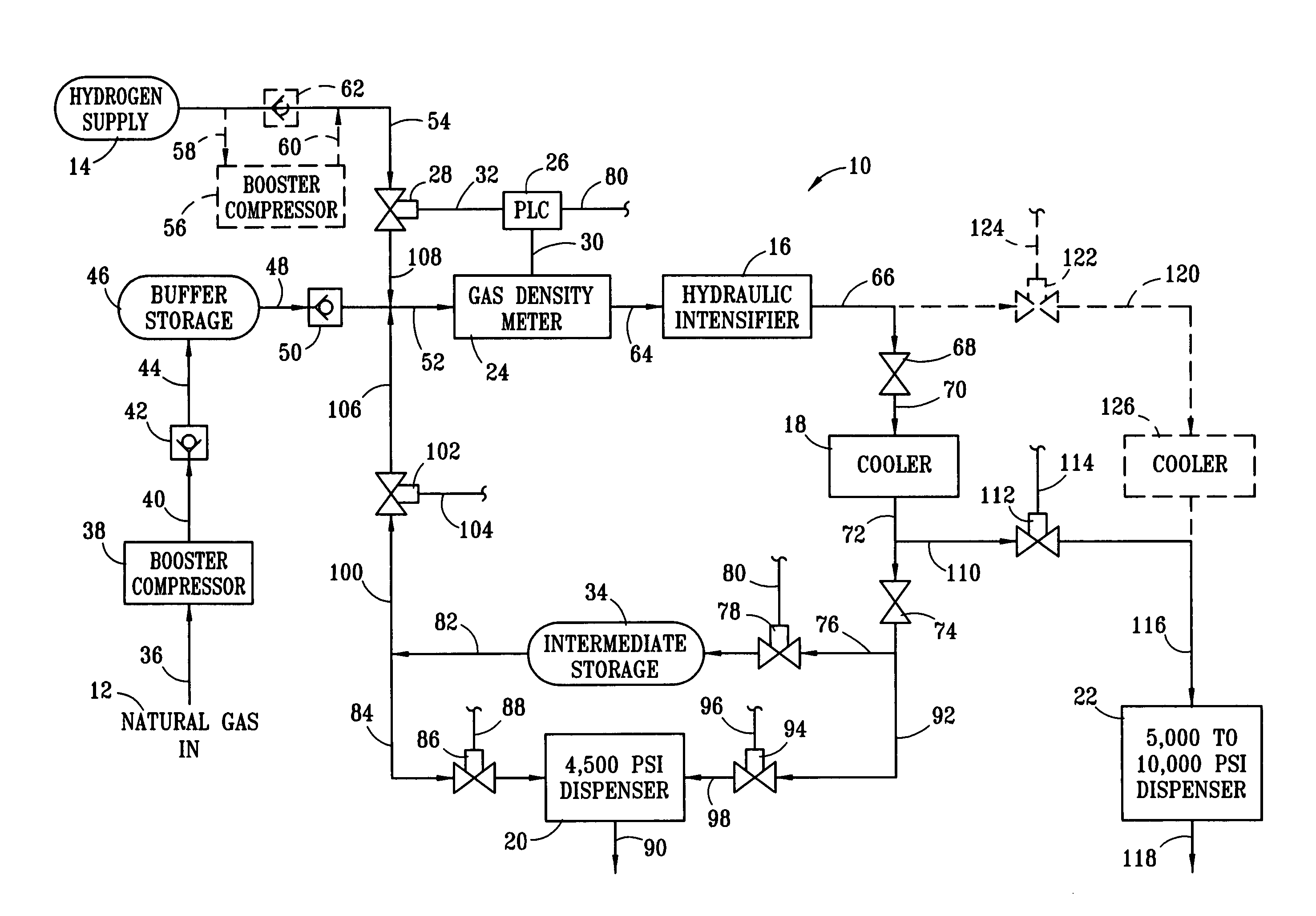

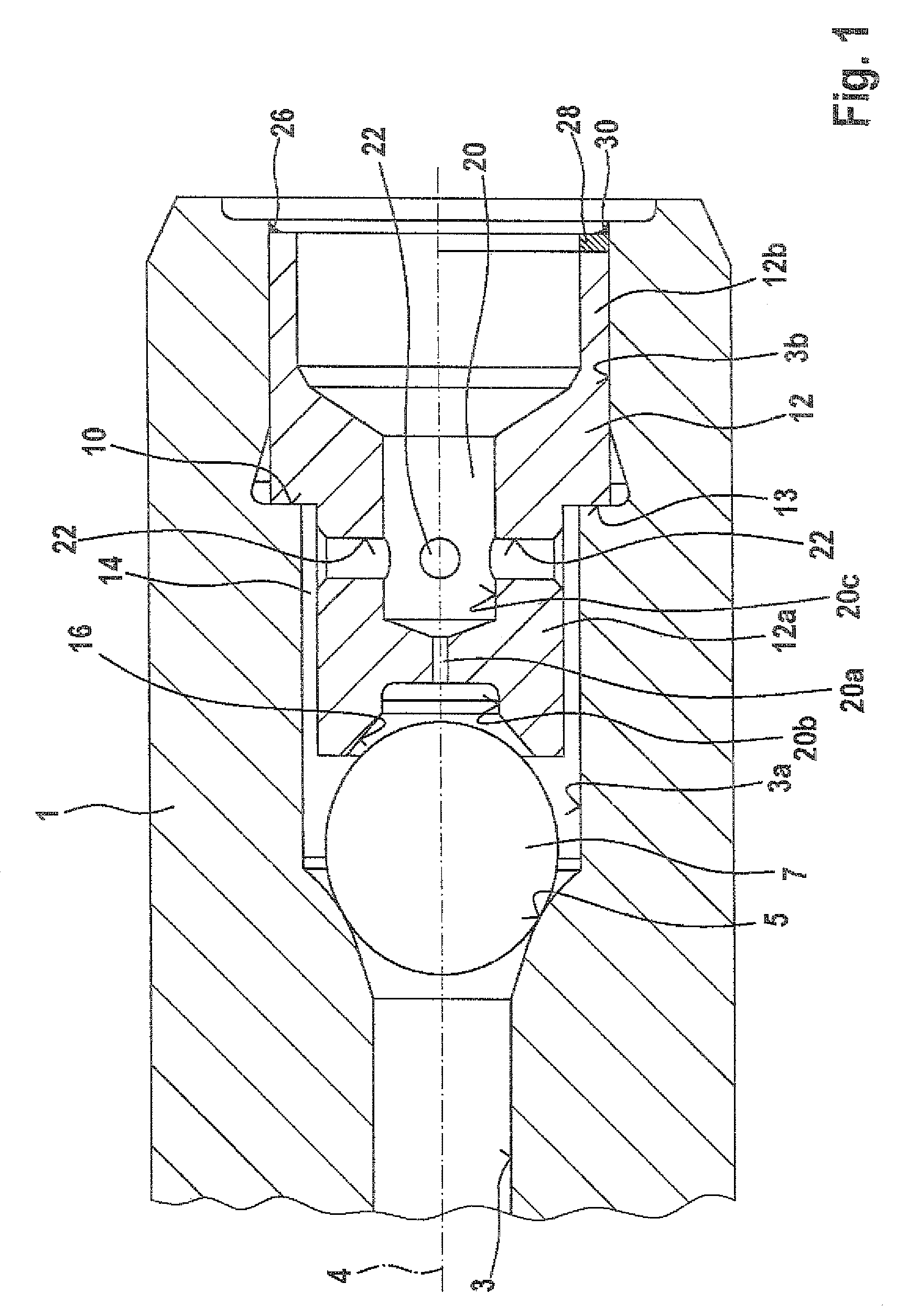

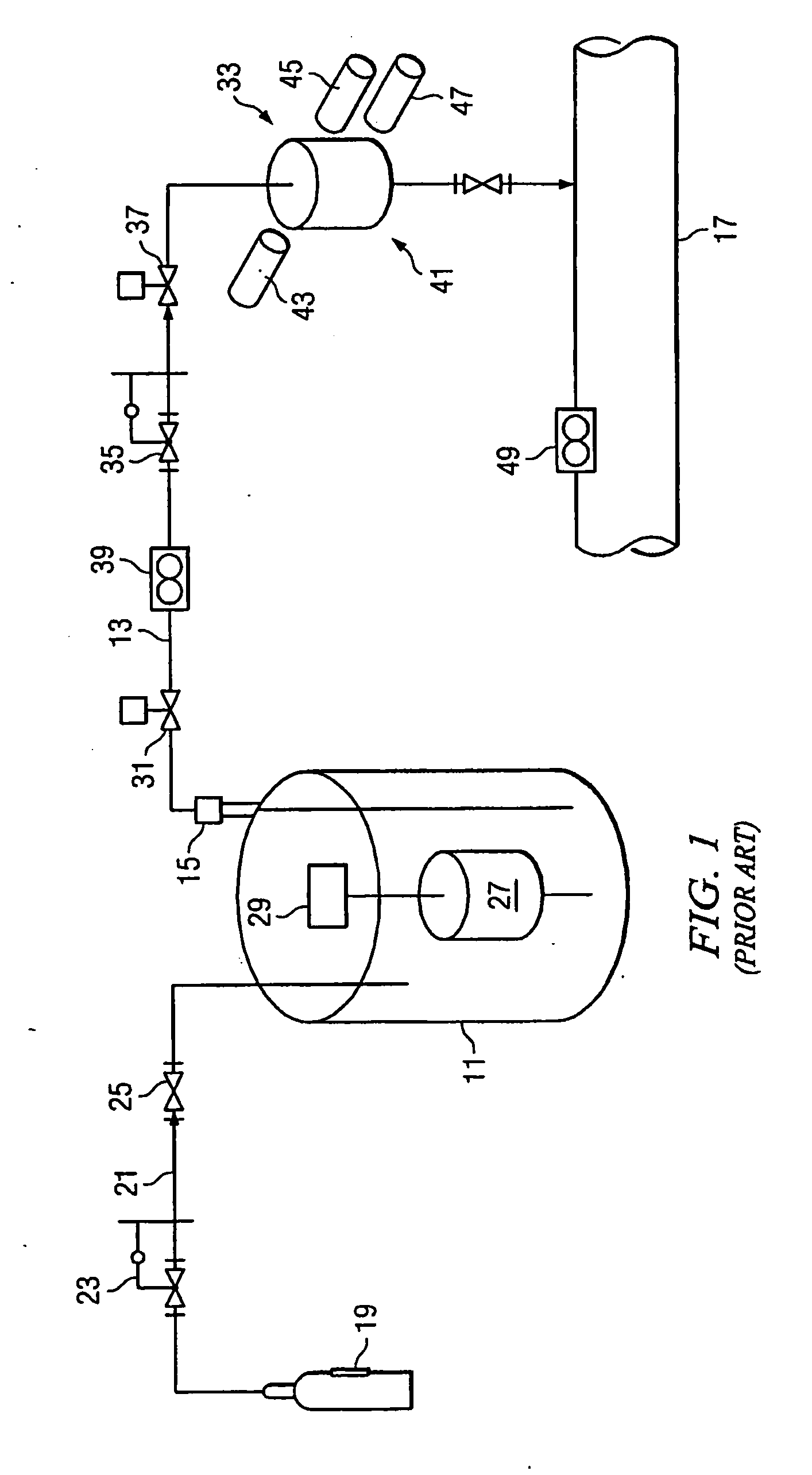

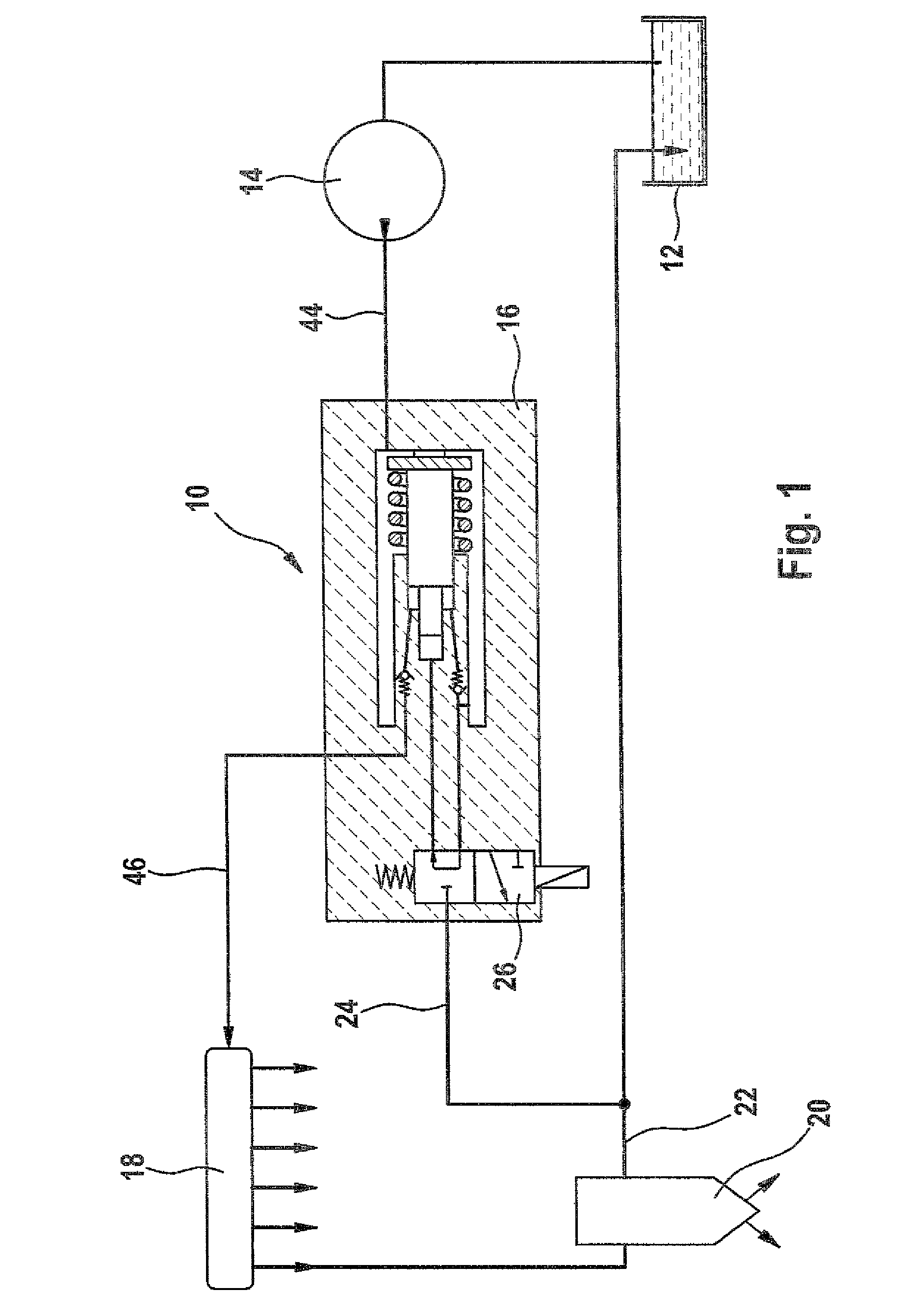

Dual-service system and method for compressing and dispensing natural gas and hydrogen

InactiveUS7168464B2Easy to switchFacilitate pressureLiquid fillingFrozen sweetsVolumetric Mass DensityGas cooler

A dual service system and method for selectively compressing and dispensing methane, hydrogen, and variable mixtures of methane and hydrogen for use as a gaseous fuel. The use of an in-line gas density meter, hydraulic intensifier, pressurized gas cooler, optional intermediate storage and multiple dispensers are disclosed. An inline gas density meter is used in combination with a programmable logic controller and a control valve on the hydrogen supply line to create a closed feedback loop for selectively controlling the hydrogen content of the resultant pressurized fuel gas.

Owner:INTEGRYS TRANSPORTATION FUELS

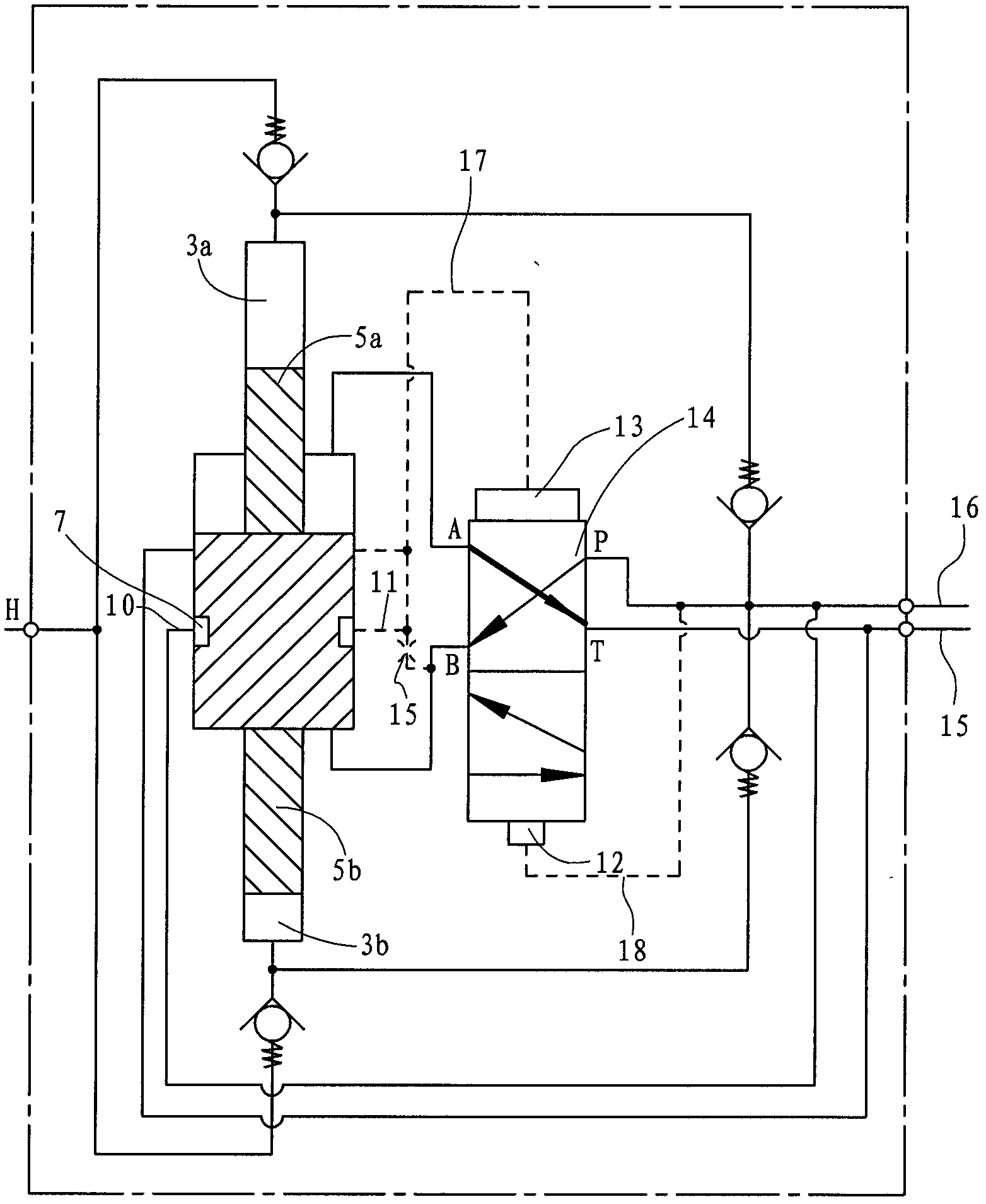

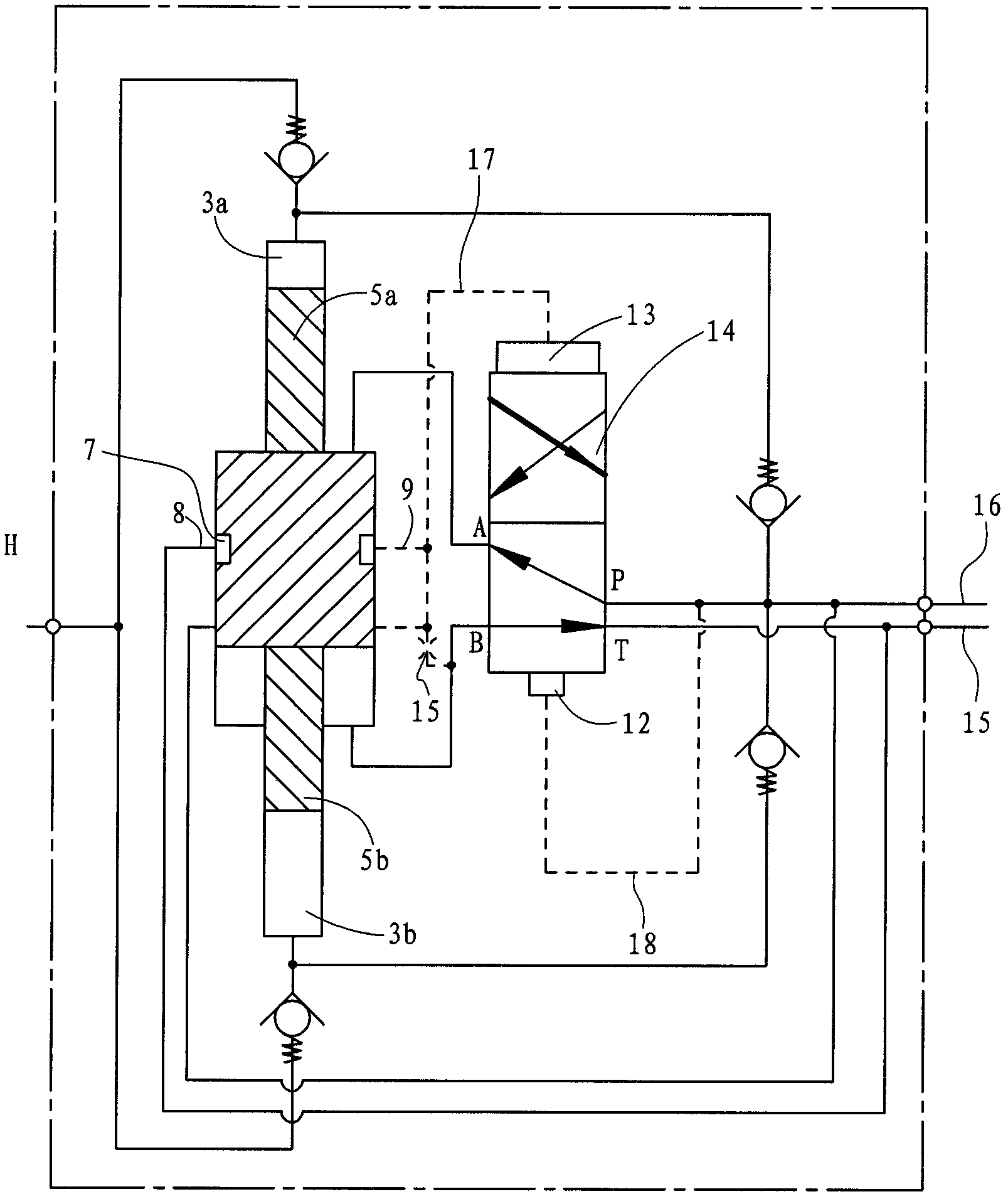

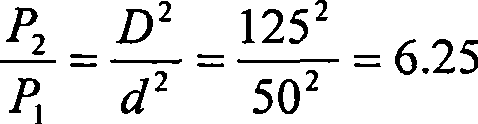

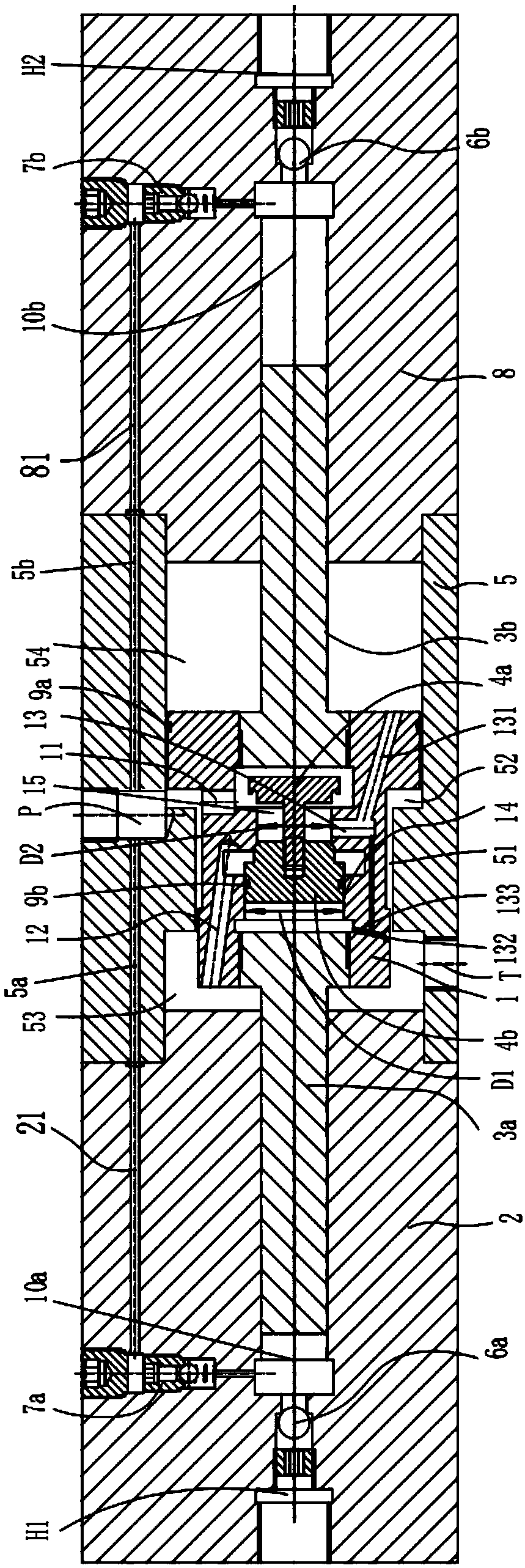

A double-acting reciprocating hydraulic pressure booster

InactiveCN102287407ANo boost frequency reductionSimple structureFluid-pressure convertersControl valvesHigh pressure

The invention relates to a double-action reciprocating hydraulic booster which comprises a boosting device and an automatic reversing control valve, and is characterized in that: the upper end and the lower end of the control valve core of the automatic reversing control valve are respectively connected with an upper piston and a lower piston; the cross sectional area of the upper piston is more than that of the lower piston; a first oil port of the automatic reversing control valve is communicated with a lower low-pressure cavity, a second oil port of the automatic reversing control valve is communicated with an upper low-pressure cavity, an oil return port of the automatic reversing control valve is communicated with an oil return channel, and a high-pressure oil port of the automatic reversing control valve is communicated with a high-pressure oil channel; the boosting part is also provided with an oil inlet runner, an oil return runner, a first control runner and a second control runner; a circular communicating groove is arranged on the peripheral surface of a low-pressure plunger; and the first control runner and the second control runner are communicated with an upper chamber of the upper piston through first bypass channels. Compared with an electromagnetic reversing valve, the automatic reversing control valve has a simpler structure, is controlled with a single pole, so that the boosting frequency is not reduced, the operation is reliable, and the purpose of high-frequency boosting can be achieved.

Owner:NINGBO HANSHANG HYDRAULIC

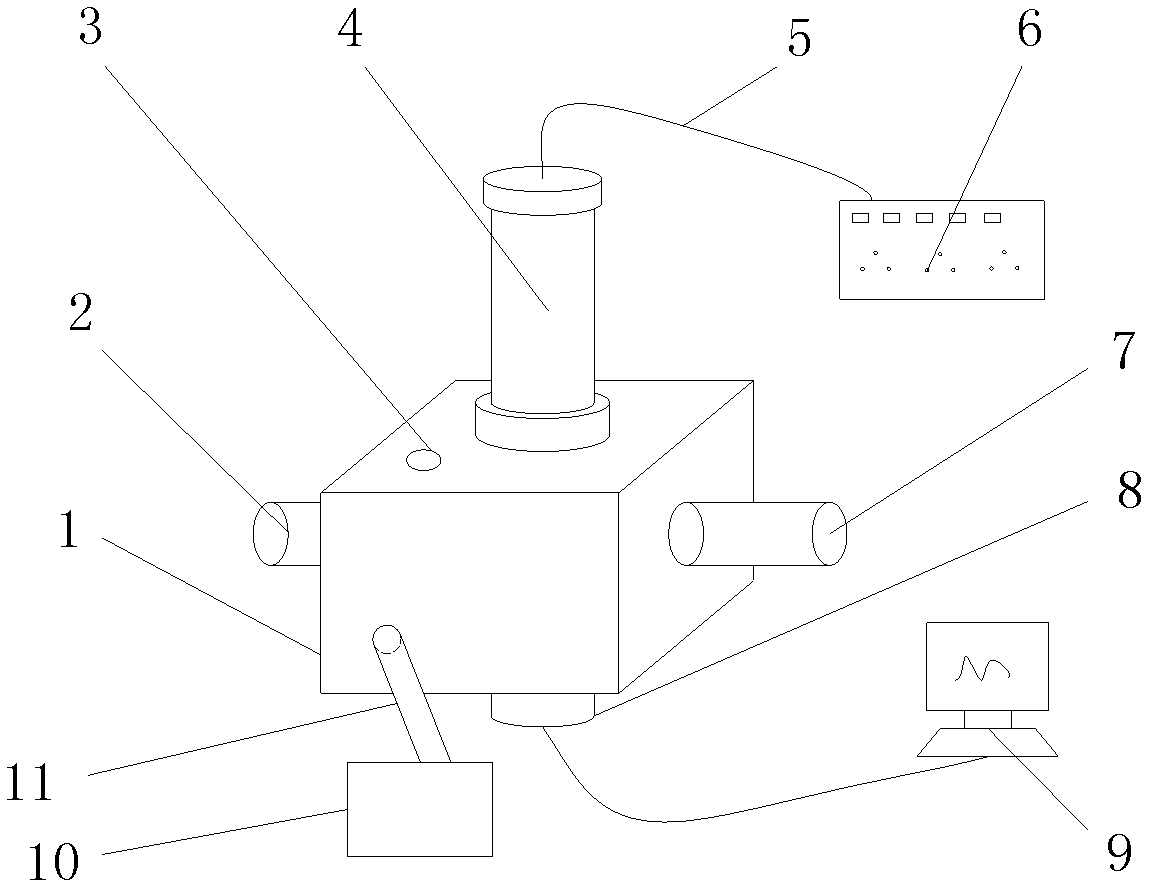

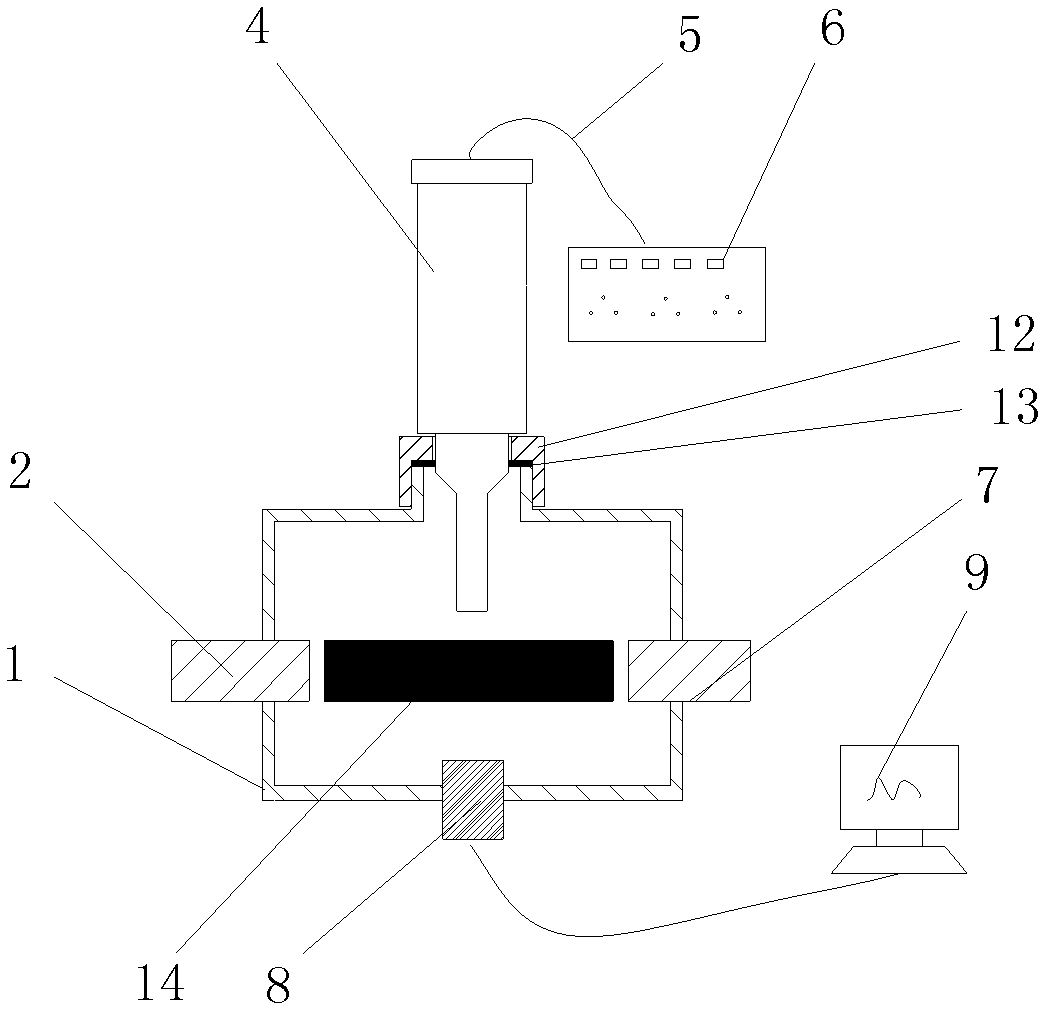

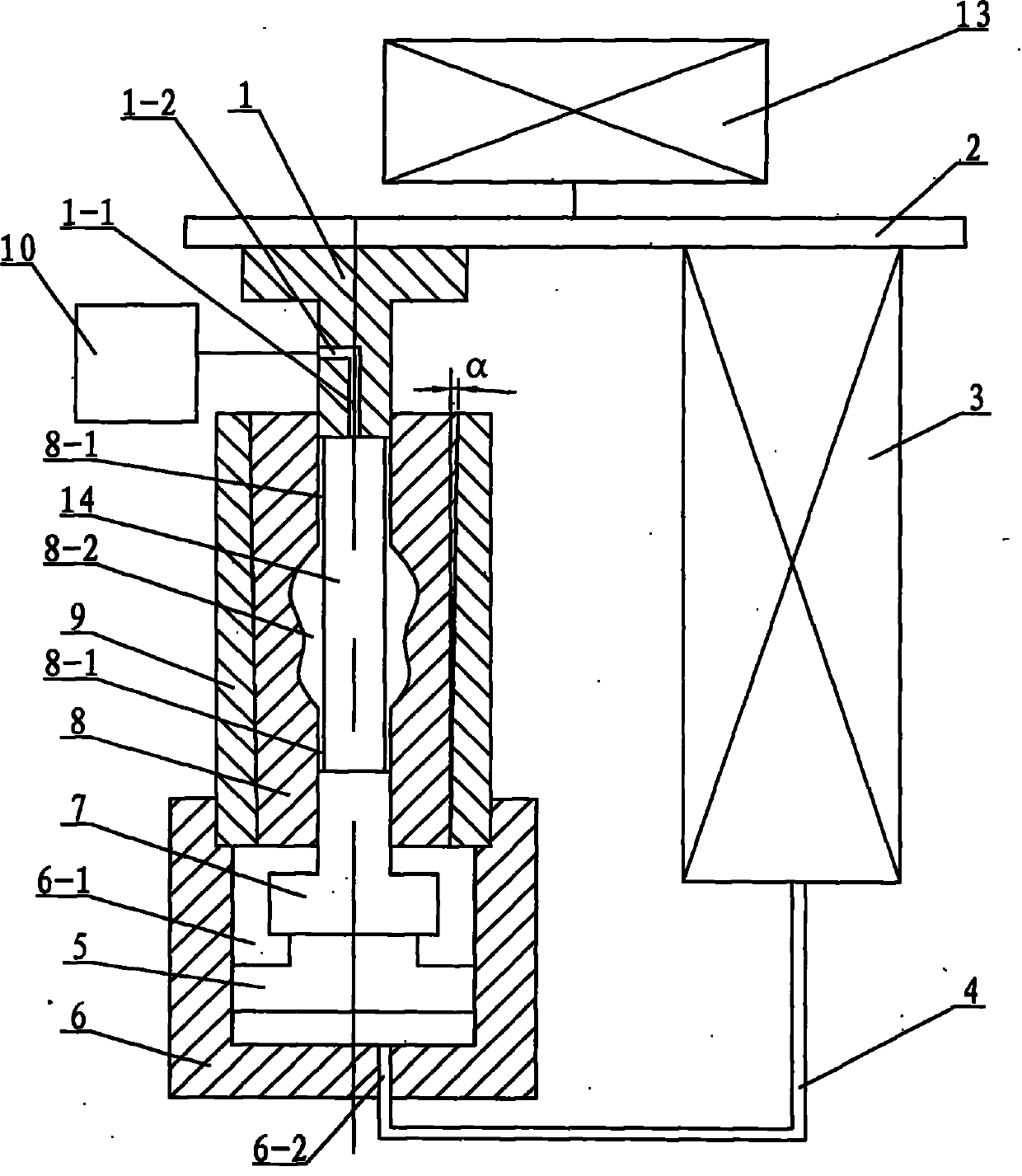

Experimental device and method for measuring rock mechanics parameters under action of ultrasonic wave and chemistry

ActiveCN102607959ASimple structureEasy to operatePreparing sample for investigationMaterial strength using tensile/compressive forcesExhaust valveMeasuring instrument

The invention discloses an experimental device and a method for measuring rock mechanics parameters under action of ultrasonic wave and chemistry. The experimental device comprises a closed box body for placing a rock core to be tested, a rock mechanics testing machine for symmetrically loading the rock core to be tested from a left side and a right side through a left side loading shaft and a right side loading shaft, an ultrasonic transducer, an ultrasonic generator, a hydraumatic pressurizer, a vent valve arranged on the upper part of the closed box body, a pressure measurement unit, an ultrasonic power detector, an ultrasonic amplitude measuring instrument and a display unit. The experimental method comprises the following steps of: 1, preparing an experiment; 2, adding a chemical reagent; 3, carrying out ultrasonic treatment; and 4, booting loading and simultaneously carrying out rock mechanics parameter measurement in a loading process. The experimental device has a reasonable design, is convenient to install and arrange, has complete functions, is simple and convenient to use, has good use effect, and can be used for efficiently and quickly finishing a rock mechanics parameters measuring experiment of the rock core to be tested under the joint action of the ultrasonic wave and the chemical reagent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

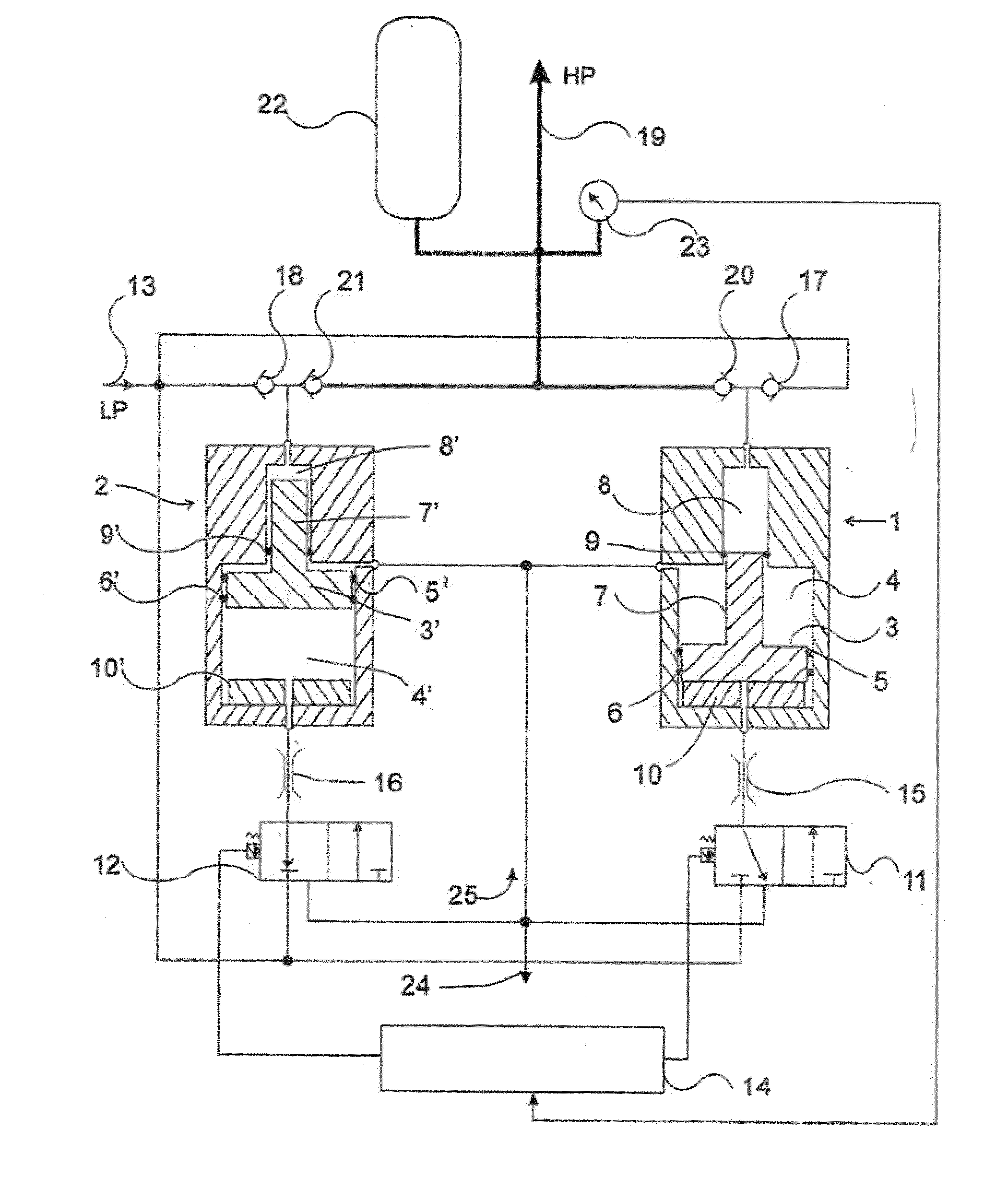

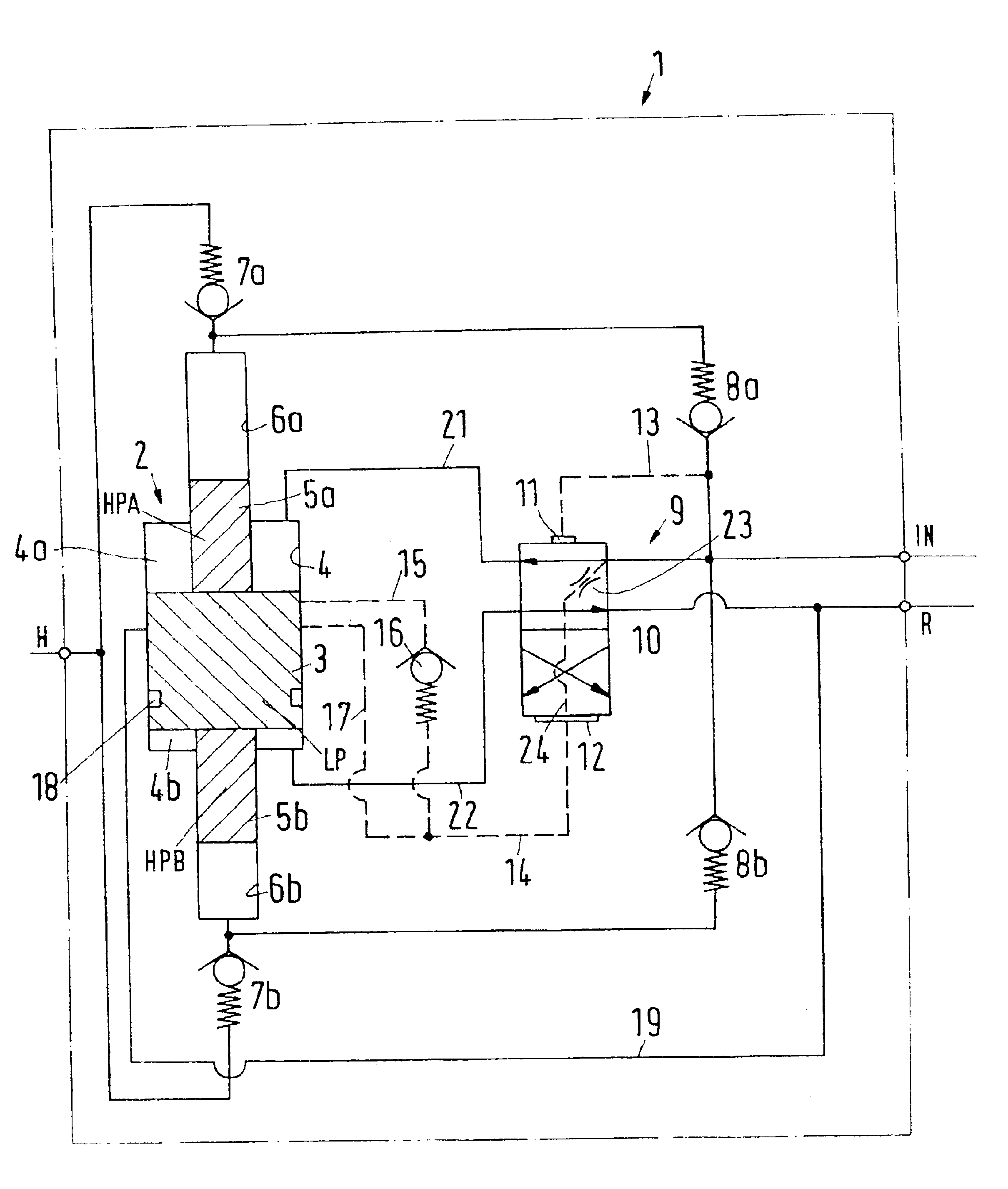

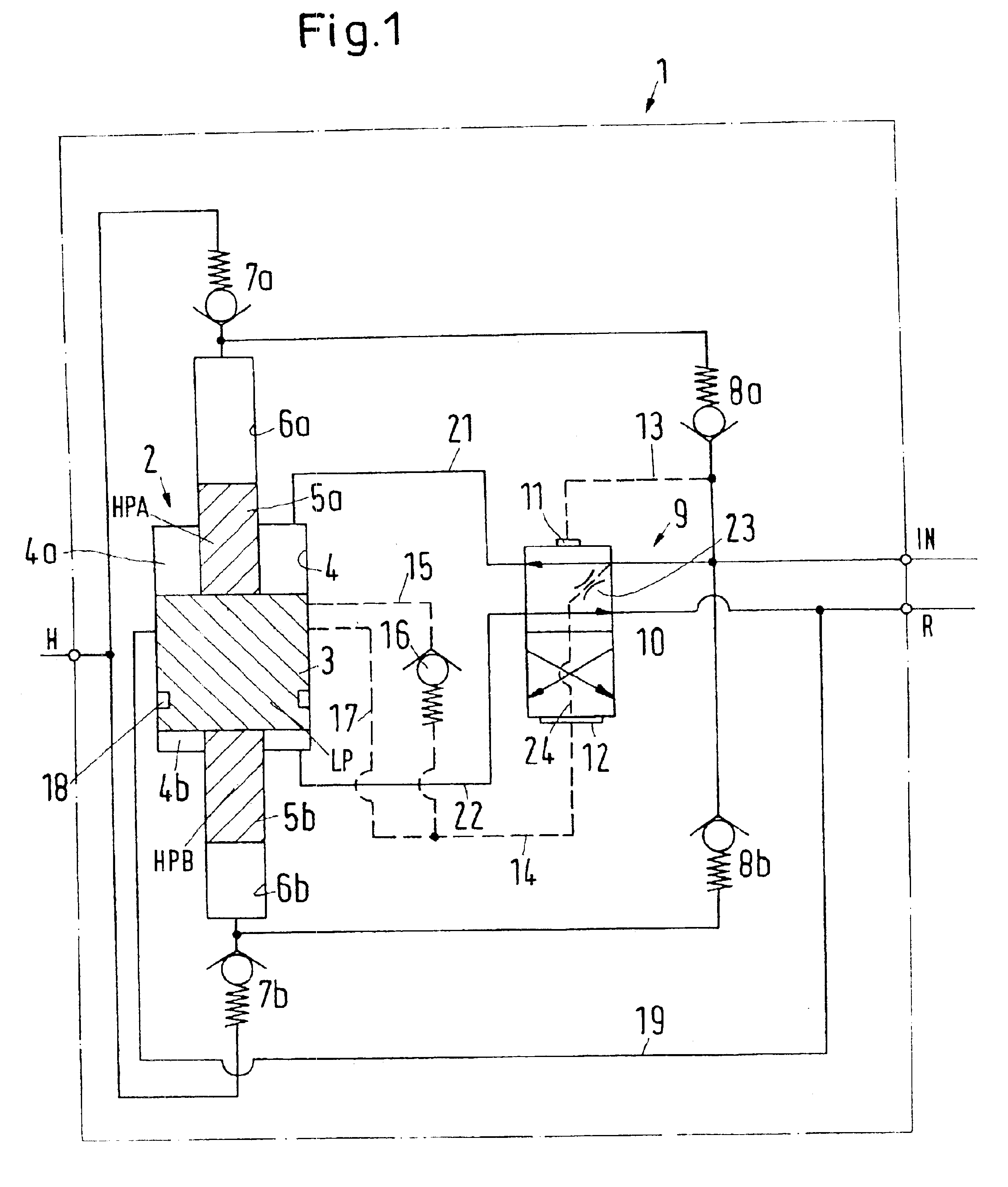

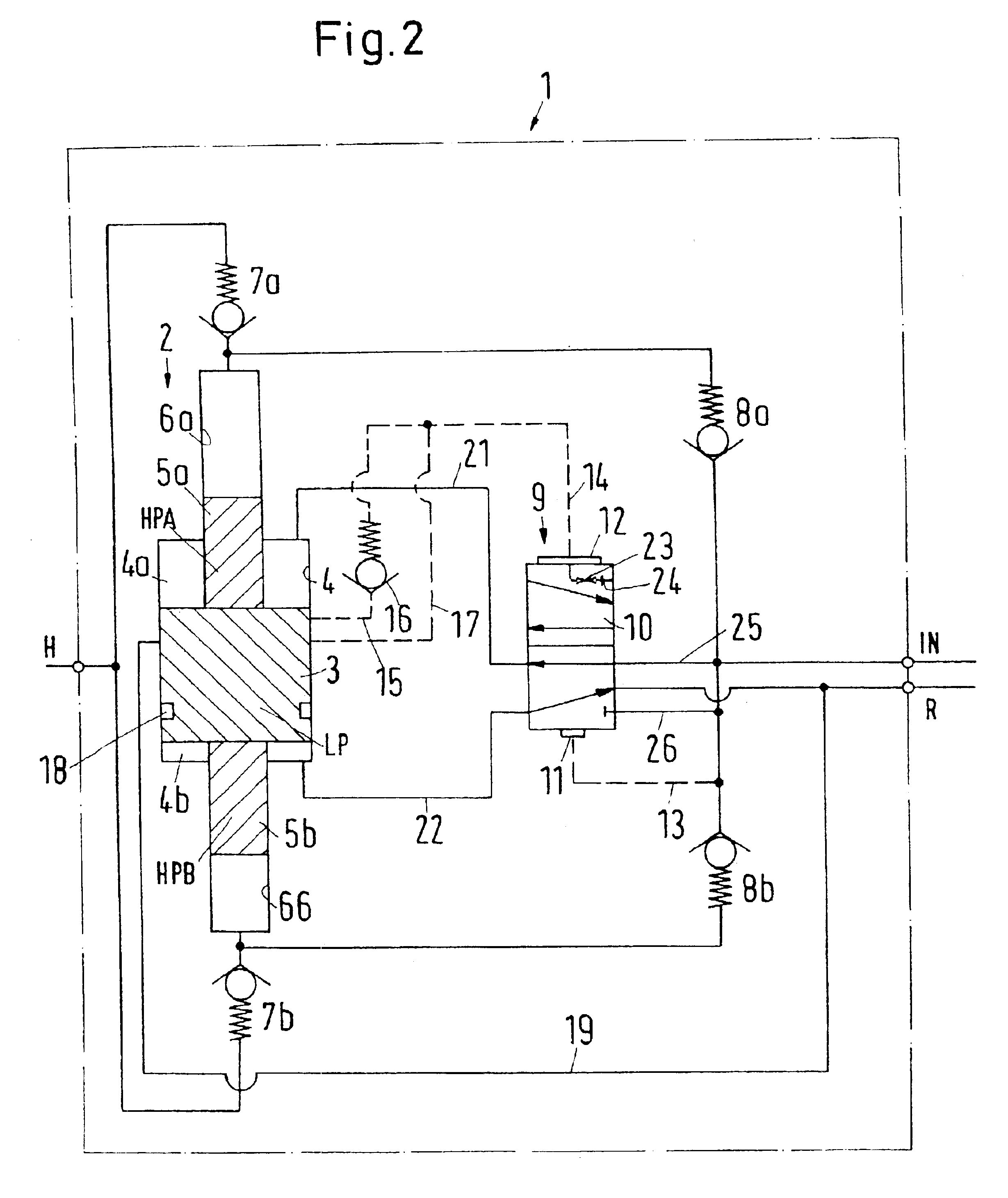

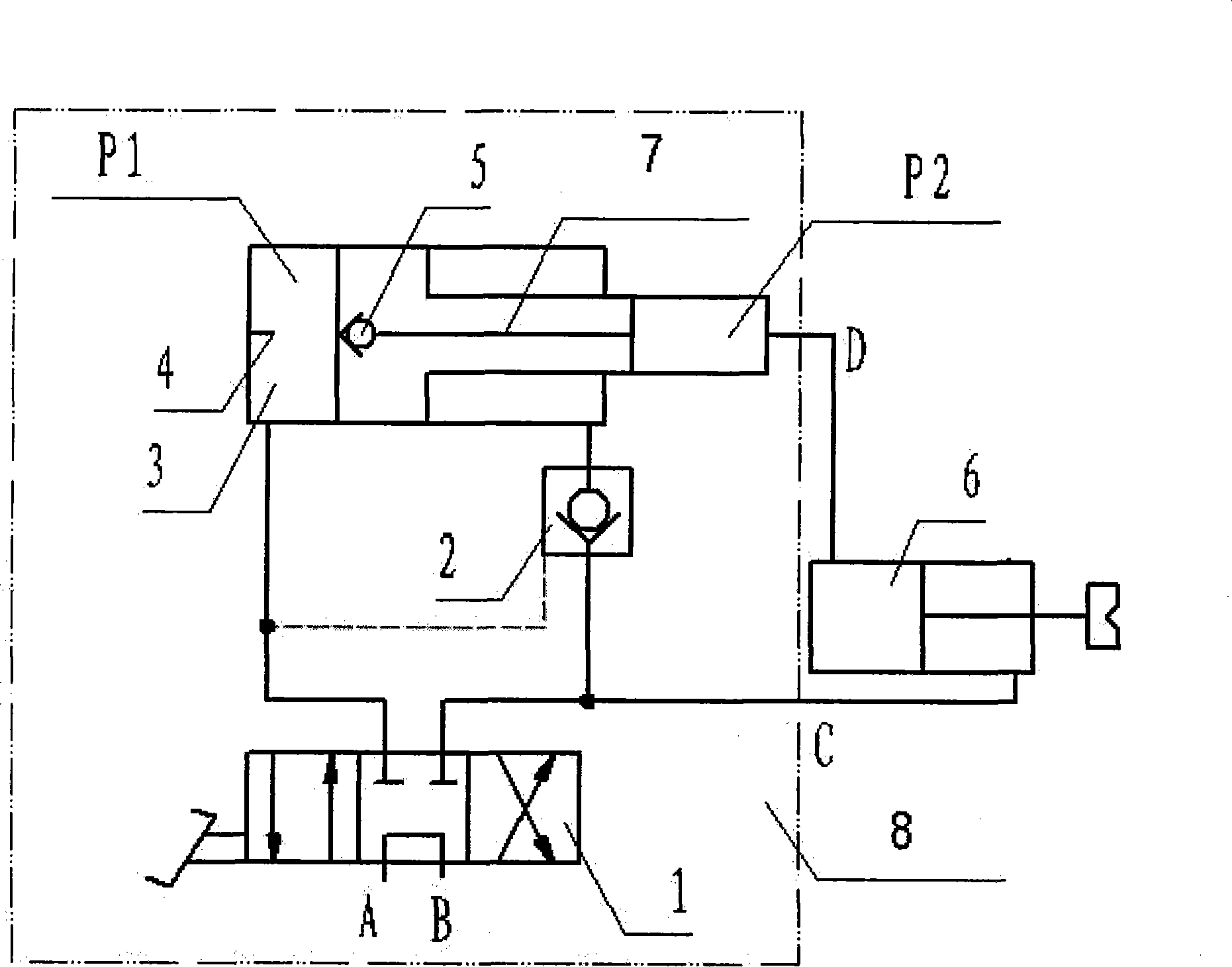

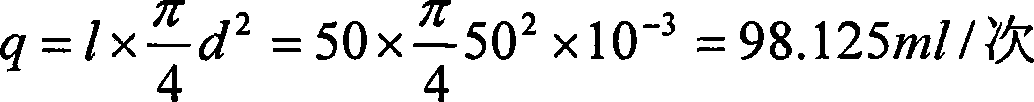

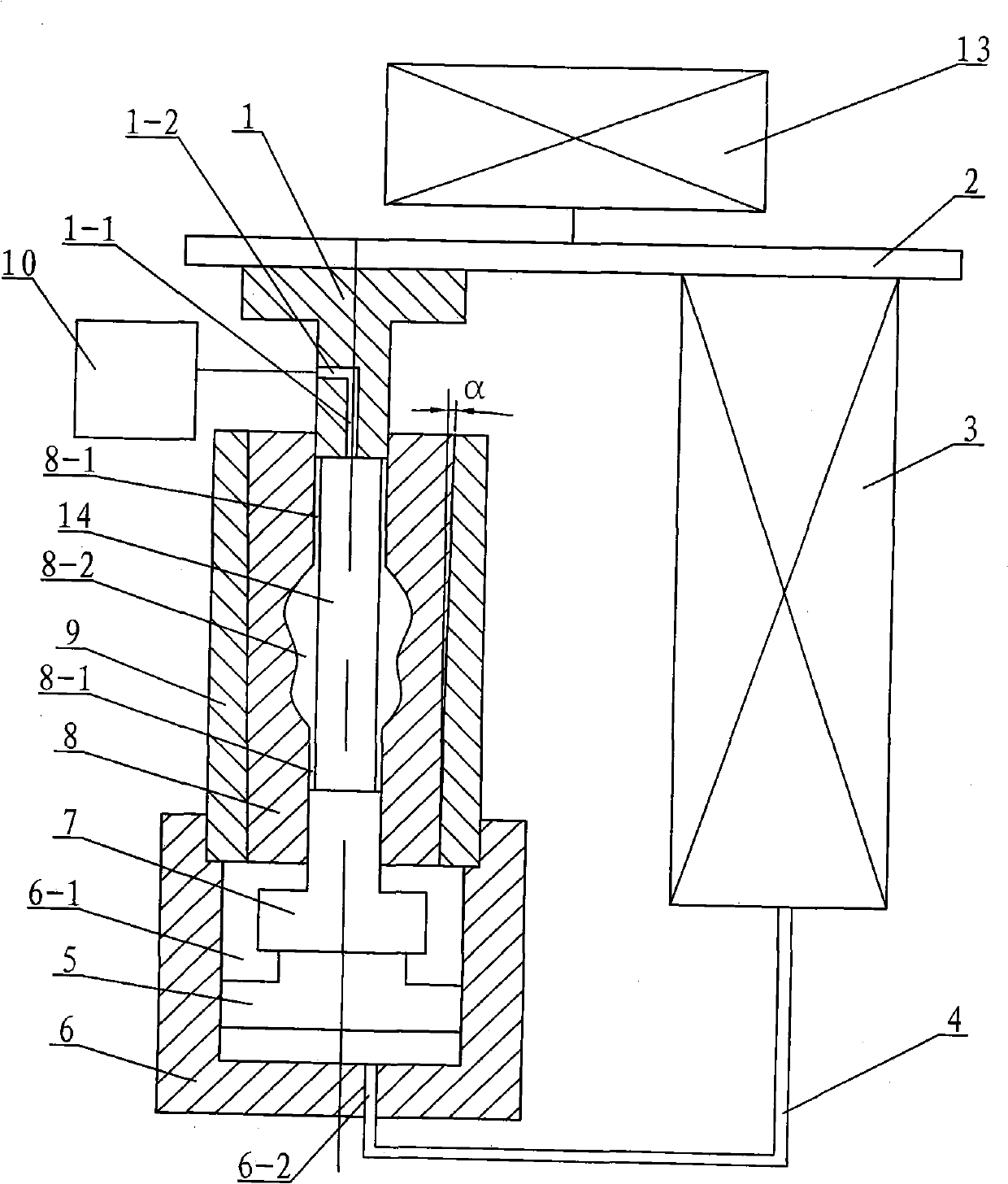

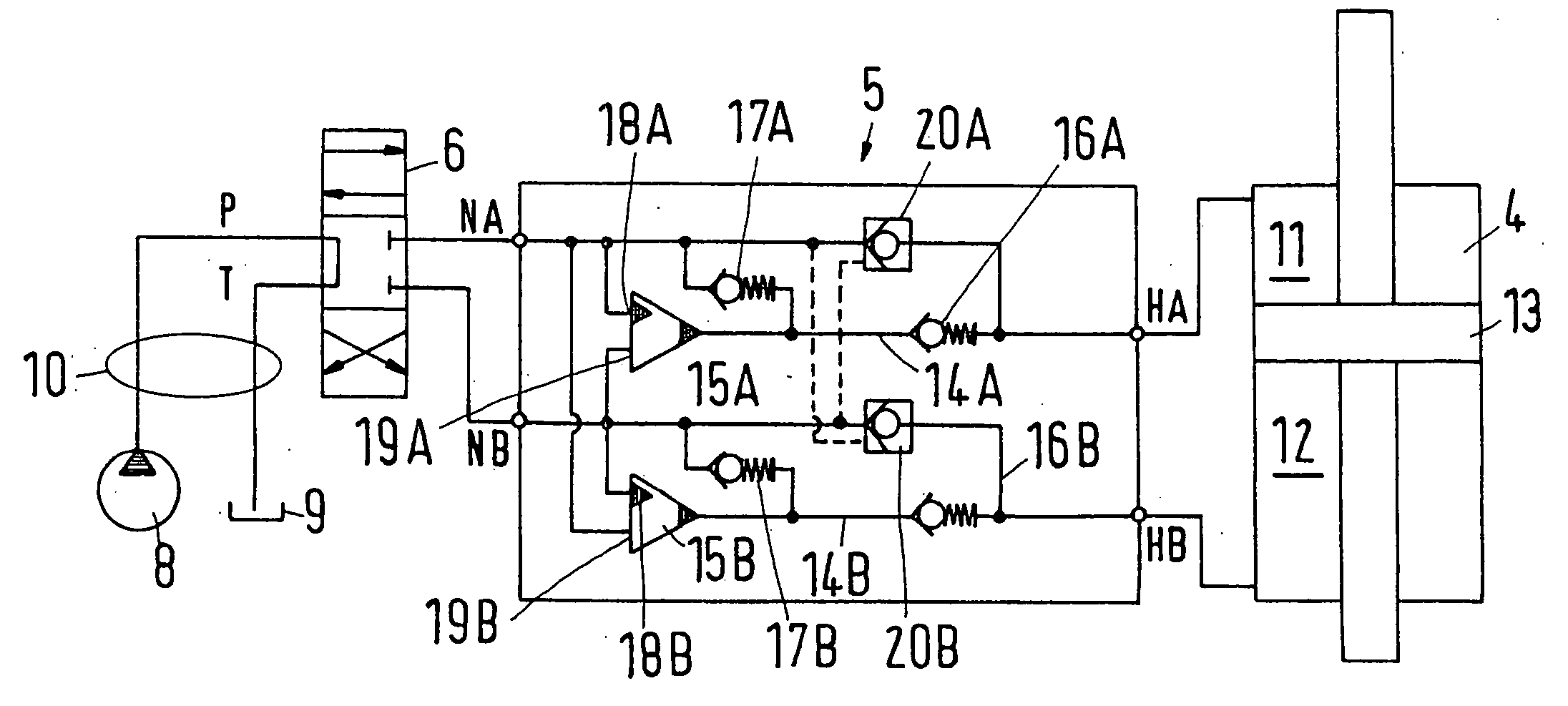

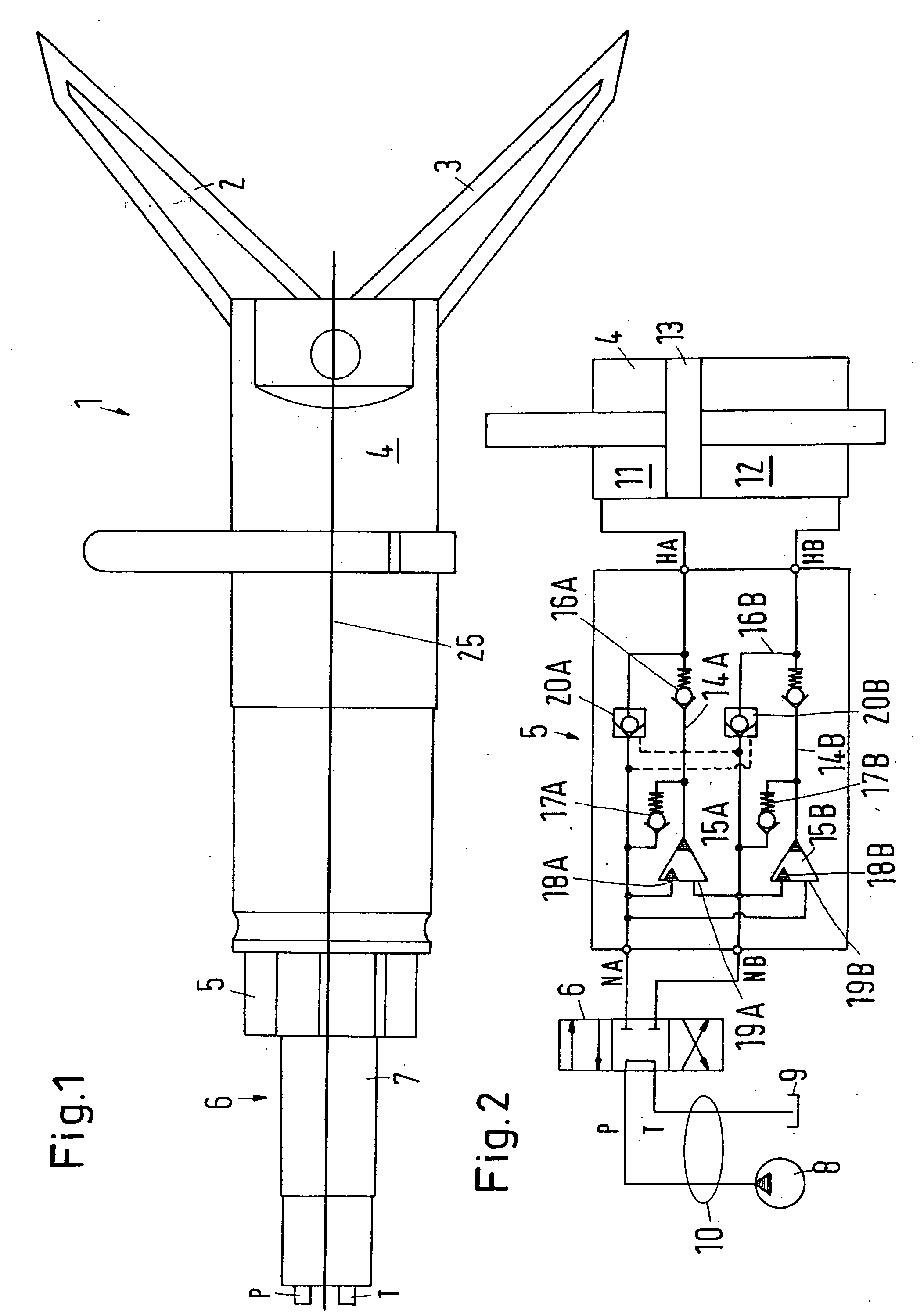

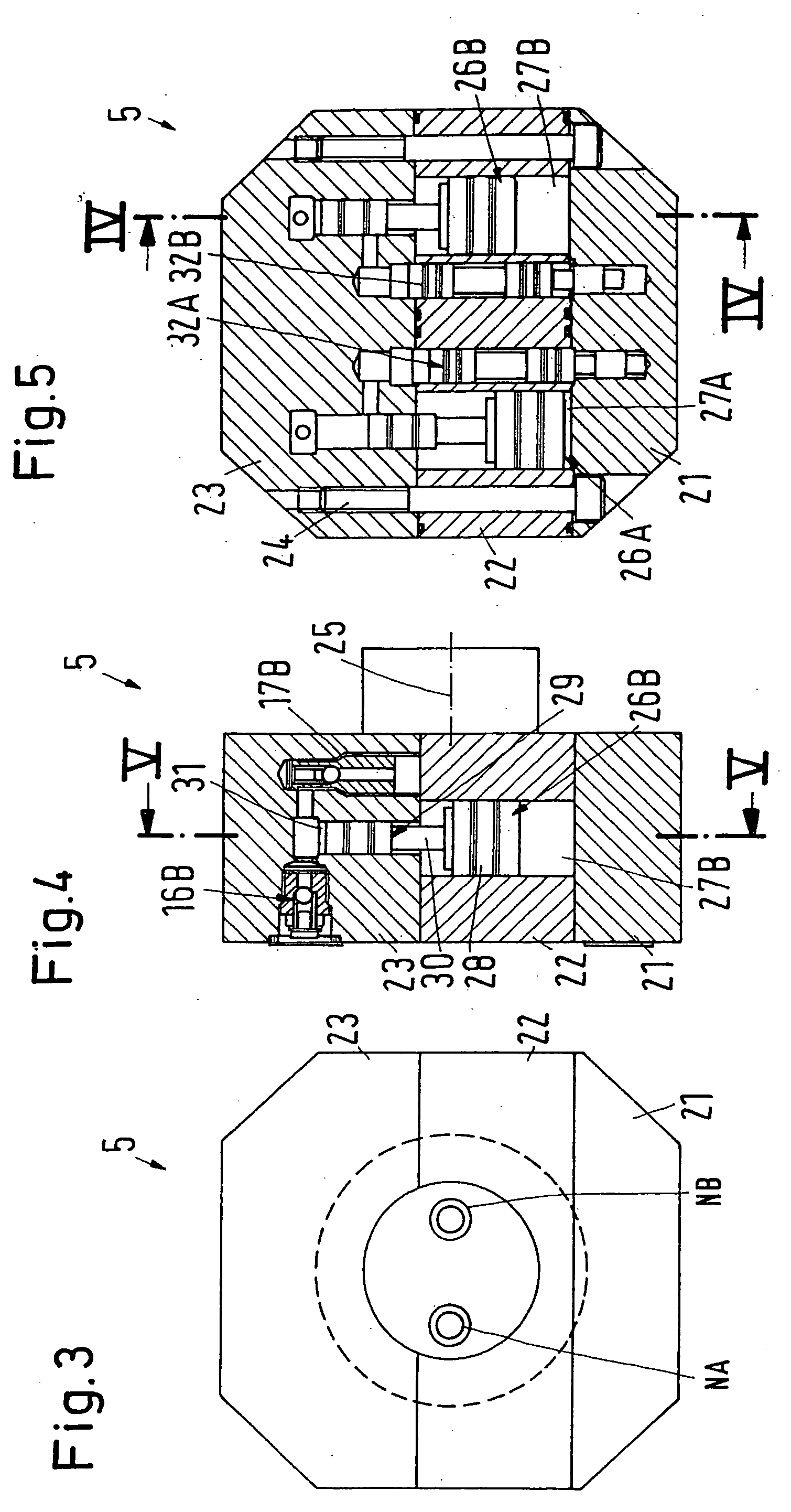

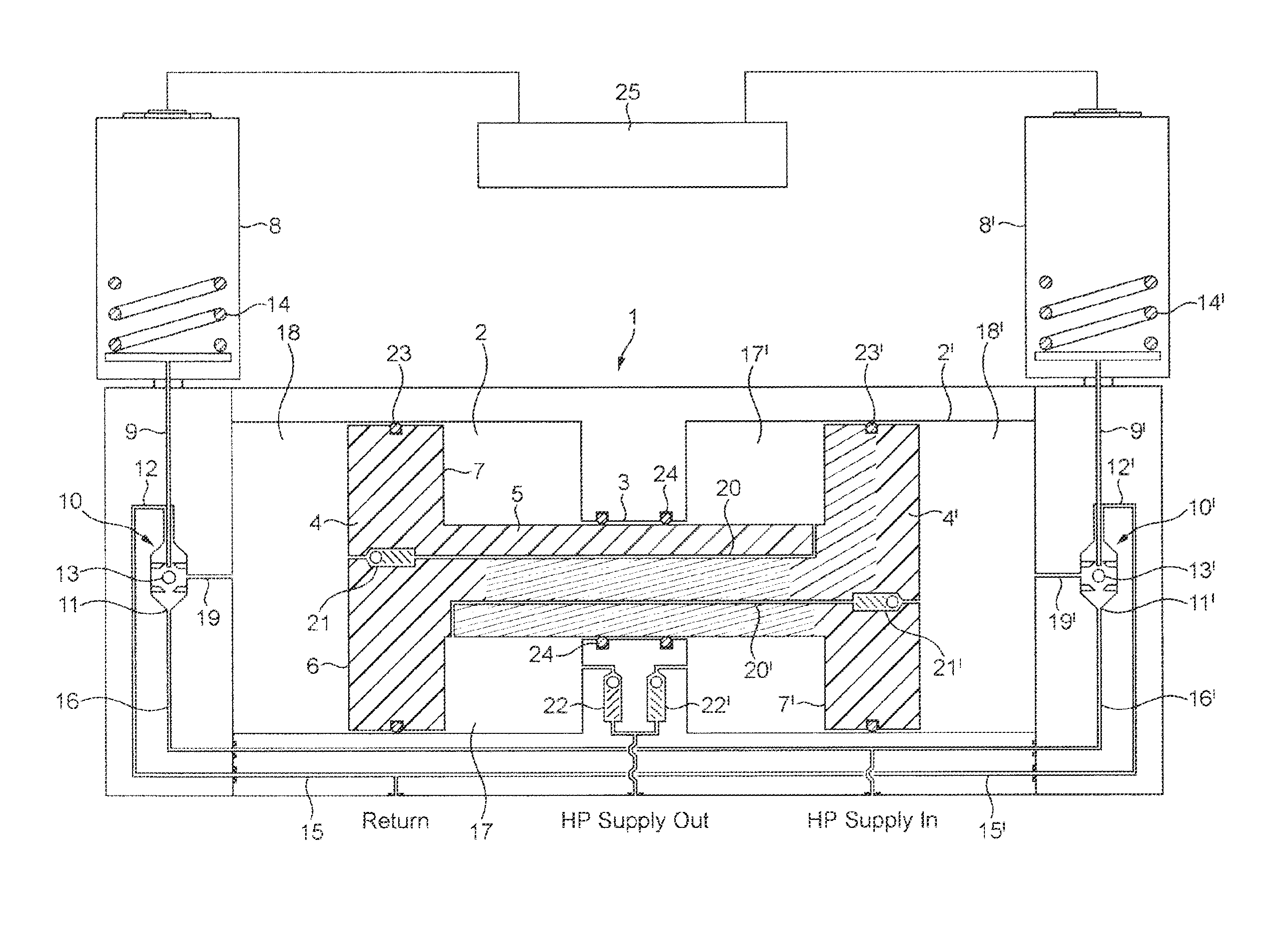

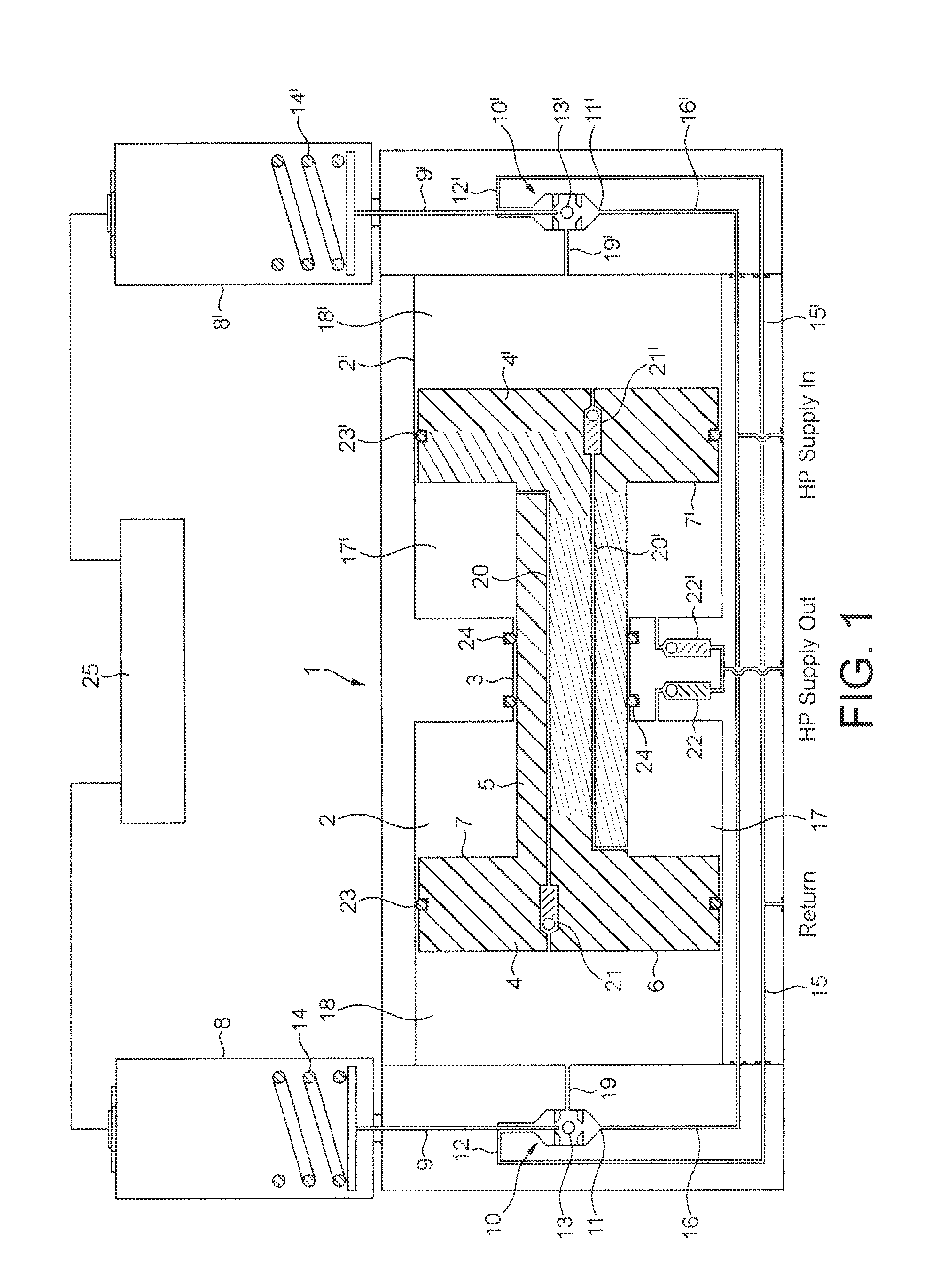

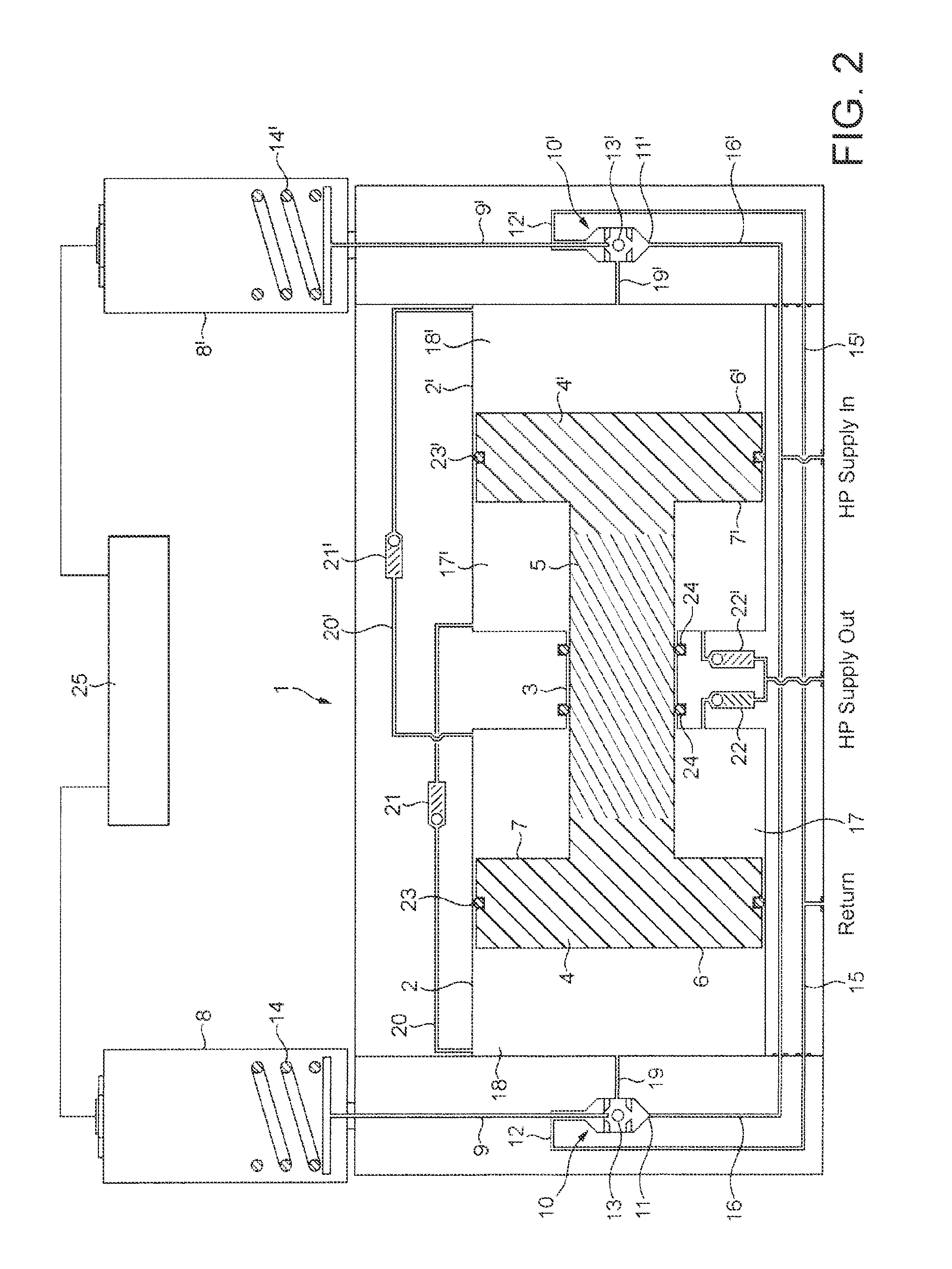

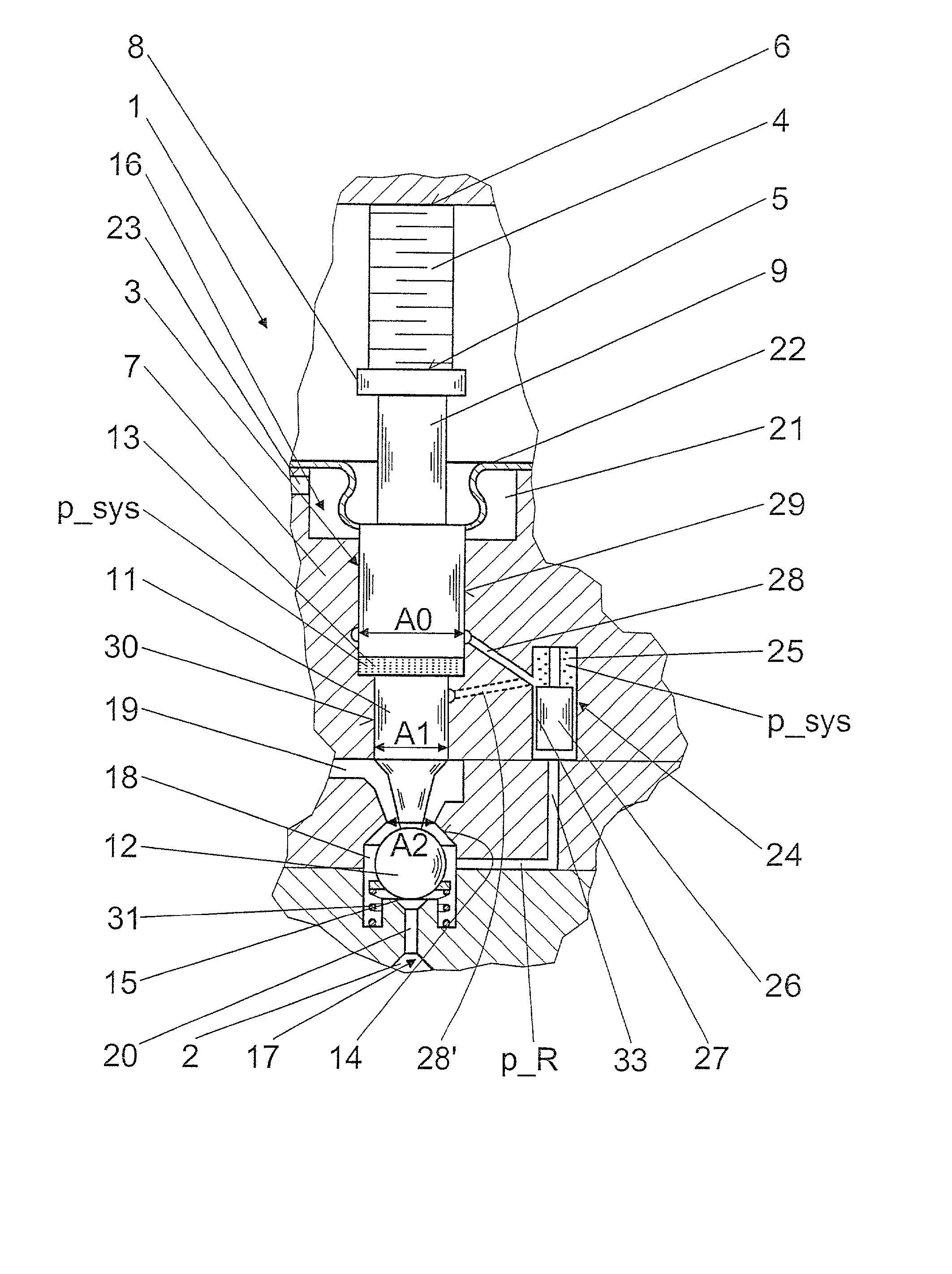

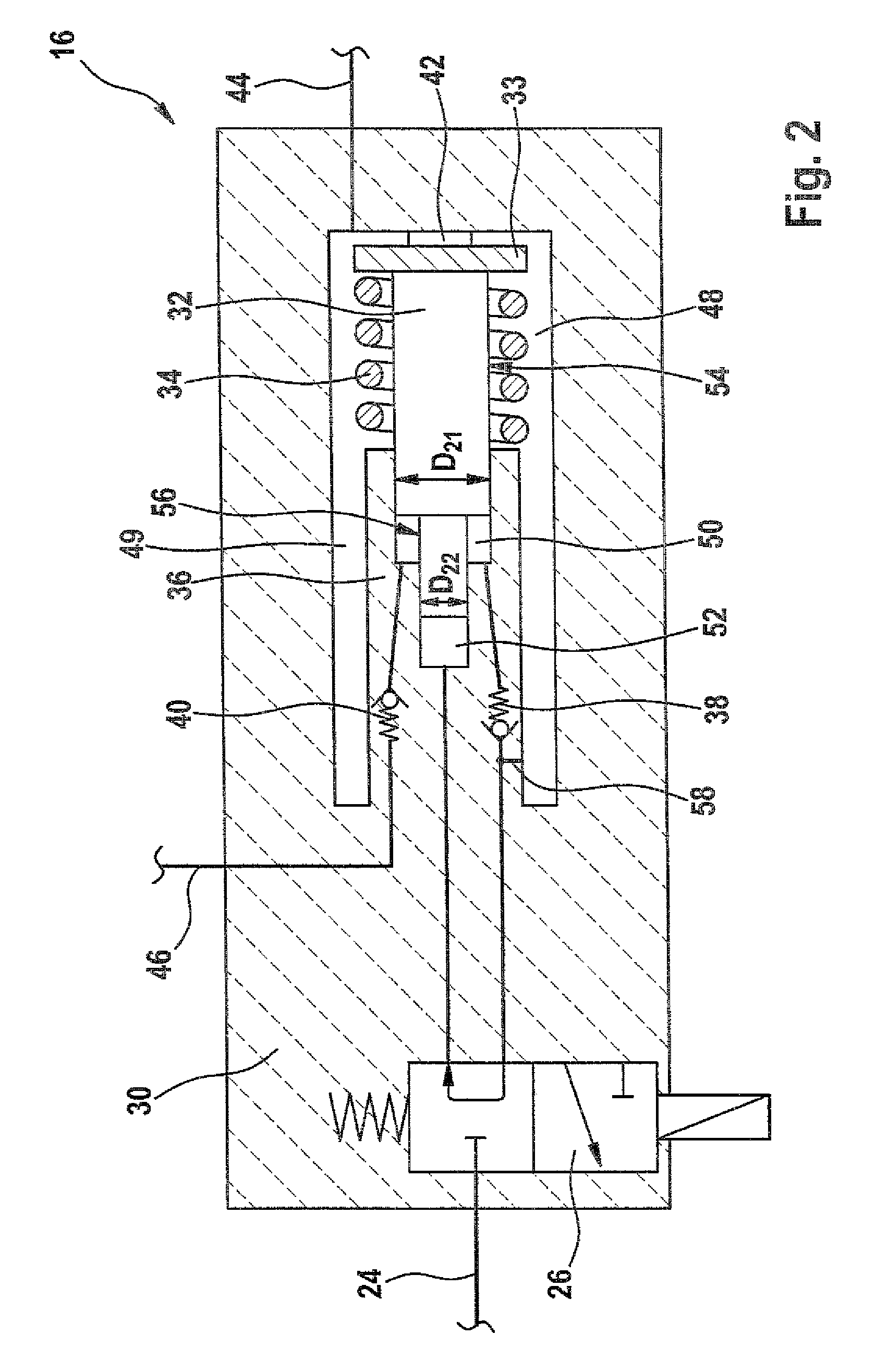

Double-acting hydraulic pressure intensifier

A double-acting hydraulic pressure intensifier includes a supply connection, a return connection, a high-pressure connection. An intensifier piston assembly includes a low-pressure piston arranged in a low-pressure cylinder and two high-pressure pistons connected to the low-pressure piston each arranged in a high-pressure cylinder. A switching valve assembly includes a displace able, hydraulically controlled valve element which on its two opposite sides in the direction of displacement has control pressure chambers with pressure application areas of different sizes, namely, a first control pressure chamber with a smaller pressure application area and a second control pressure chamber with a larger pressure application area. A stop plug is arranged between the second control pressure chamber and the supply connection.

Owner:MINIBOOSTER HYDRAULICS

Hydraulic pressure booster for ultra-high pressure tool

InactiveCN101498324AAchieve low pressure unloadingImprove reliabilityServomotor componentsFluid-pressure convertersUltra high pressureEngineering

The invention belongs to the field of the hydraulic device, in particular relates to a hydraulic intensifier (8) of a superhigh pressure tool. The hydraulic intensifier (8) adopts a pressure cylinder (3), a reversing valve (1) and a hydraulic control one-way valve (2) to form a pressurizing loop, a pressure cylinder piston is arranged in the pressure cylinder (3) and is used for dividing the pressure cylinder into a poleless cavity, a pole cavity and a pressurizing cavity, a top pole (4) is arranged on an end cover of the poleless cavity of the pressure cylinder, the pressure cylinder piston is a hollow part, an one-way valve (5), a center hole (7) and the pressurizing cavity are arranged in the hollow, and the inlet end of the one-way valve (5) is positioned in a position which opposites to the top pole (4). When the piston completely withdraws, the top pole can touch the one-way valve (5) to communicate the one-way valve, the outlet end of the one-way valve (5) is communicated with the pressurizing cavity by the center hole (7), and the hydraulic control one-way valve (2) is arranged on an oil circuit of the pole cavity of the pressure cylinder (3). The hydraulic intensifier has compact structure, and the pipeline connection between the valves and the pressure cylinders is saved to reduce system leakage. The invention has the advantages of convenient installation, low cost, stable operation, long service life, high work efficiency, strong temperature variation resistance, strong environmental pollution resistance, convenient maintenance, and the like and is suitable for the outdoor service on building sites for a long period.

Owner:BEIJING UNION UNIVERSITY

Device and method for internal pressure forming of reducer pipes

The invention relates to a device and method for internal pressure forming of reducer pipes. The invention aims to solve the following problems: matching among die assembly, loading at both sides and the like needs to be controlled for realizing internal high pressure forming of the existing reducer pipes; the working units are various; the forming precision is difficult to ensure; and the processing cost is higher. The device is assembled by an upper punch, a workbench, a plunger type cylinder, a high-pressure oil pipe, a base, a die set, a lower punch, female dies, die sleeves and a hydraulic supercharger and has reducer die cavities. The method comprises the following steps: assembling the base, the die set, the lower punch and the die sleeves mounted with the female dies; placing a pipe blank into a female die cavity; placing the upper punch into the pipe blank; extruding the pipe blank by an ordinary press; pushing the base and the lower punch to ascend by hydraulic oil; and continuously supercharging the liquid in the cavity of the pipe blank under forming by the hydraulic supercharger until the outer wall of the pipe blank is fit with the inner walls of the female die cavity and the reducer die cavities, thus completing internal pressure forming of the reducer pipes. The invention is used for processing and forming the reducer pipes.

Owner:HARBIN UNIV OF SCI & TECH

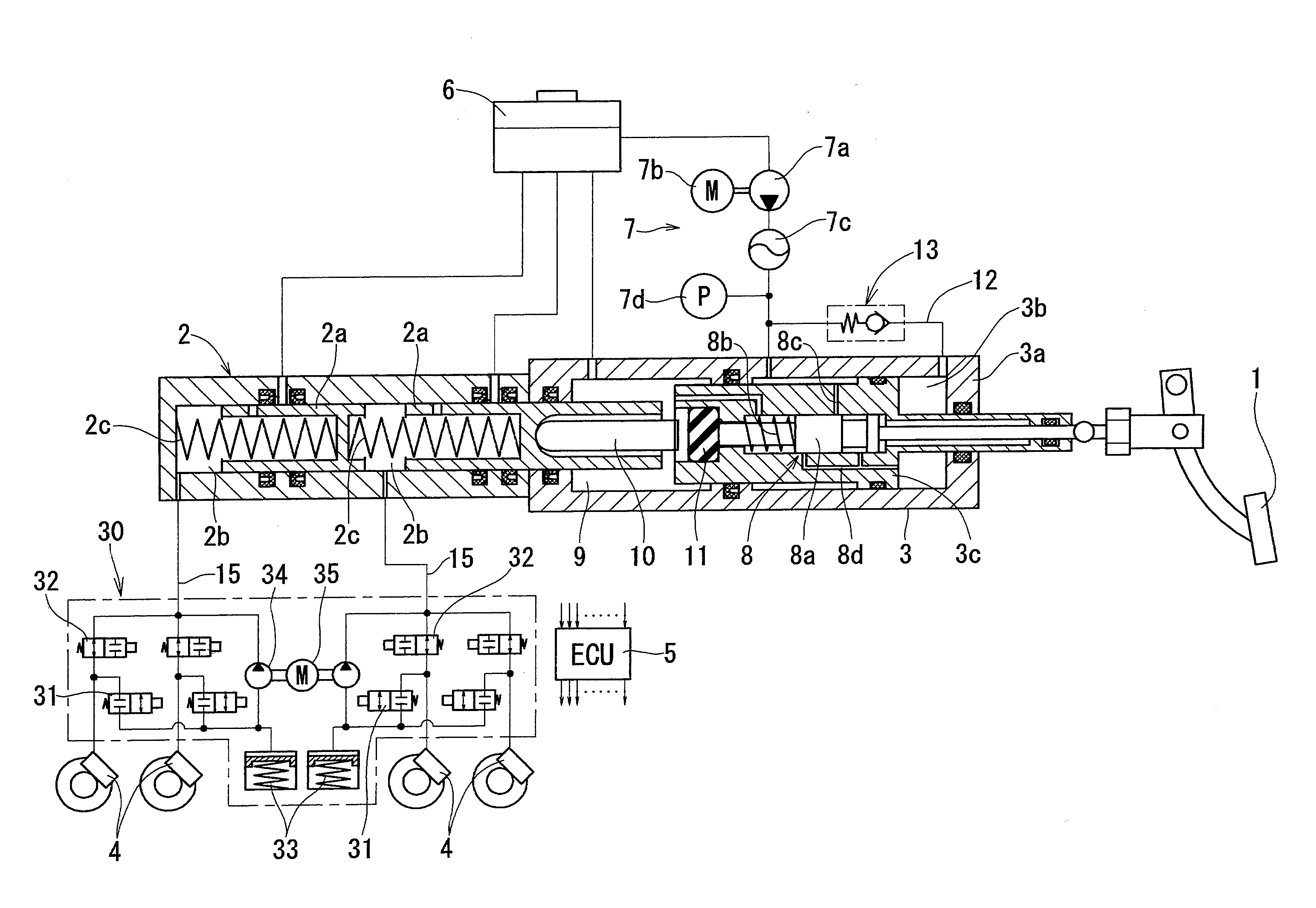

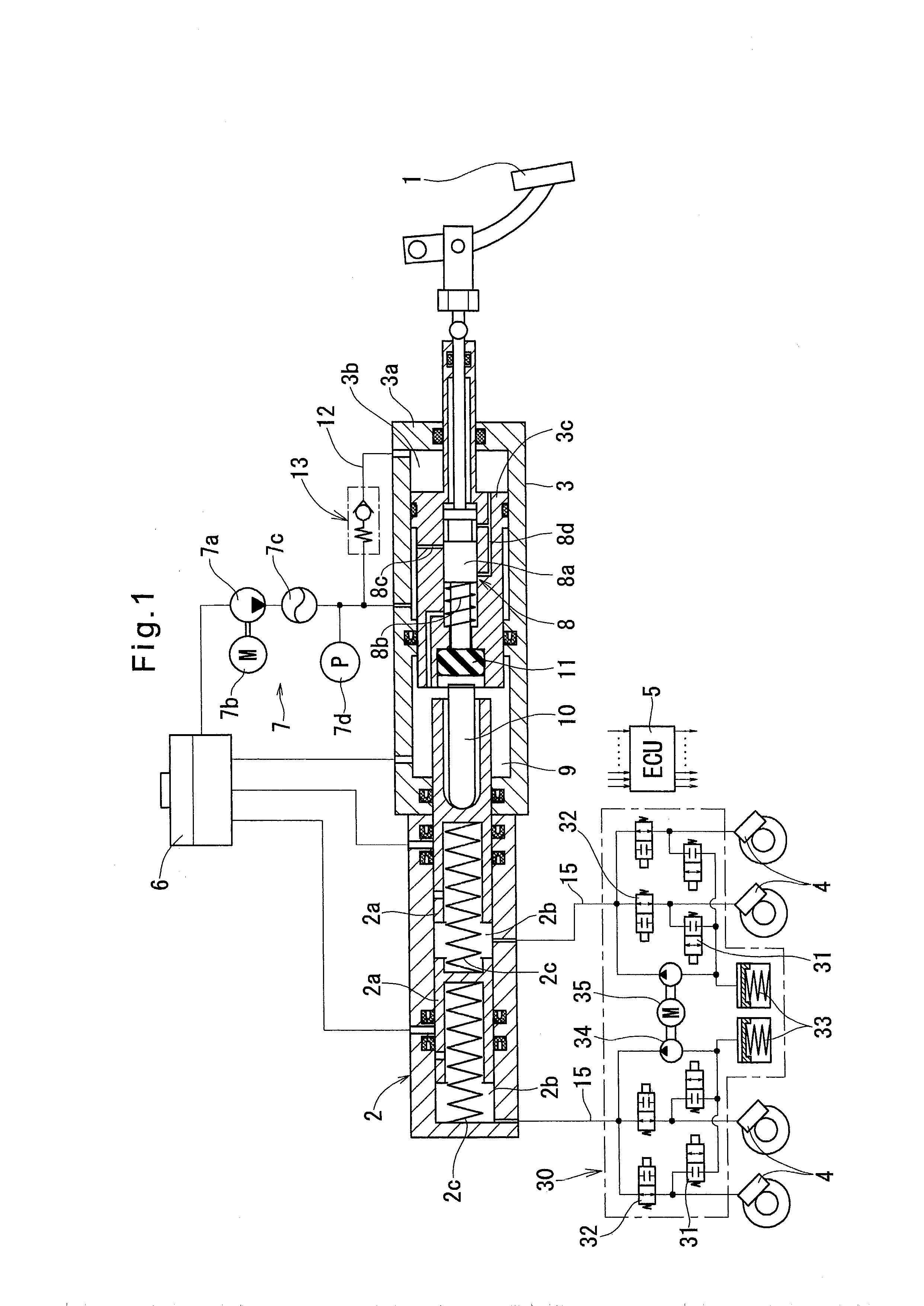

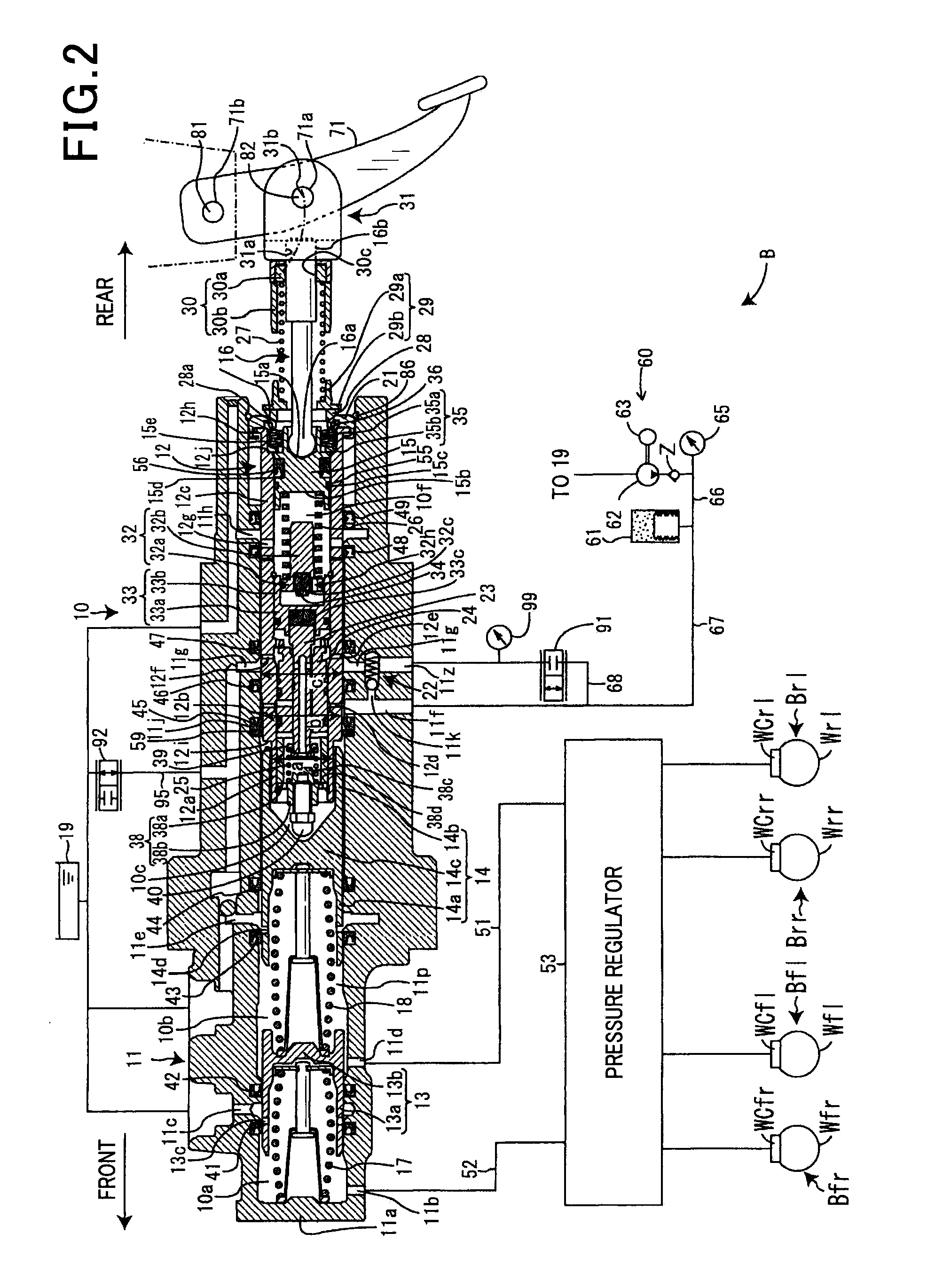

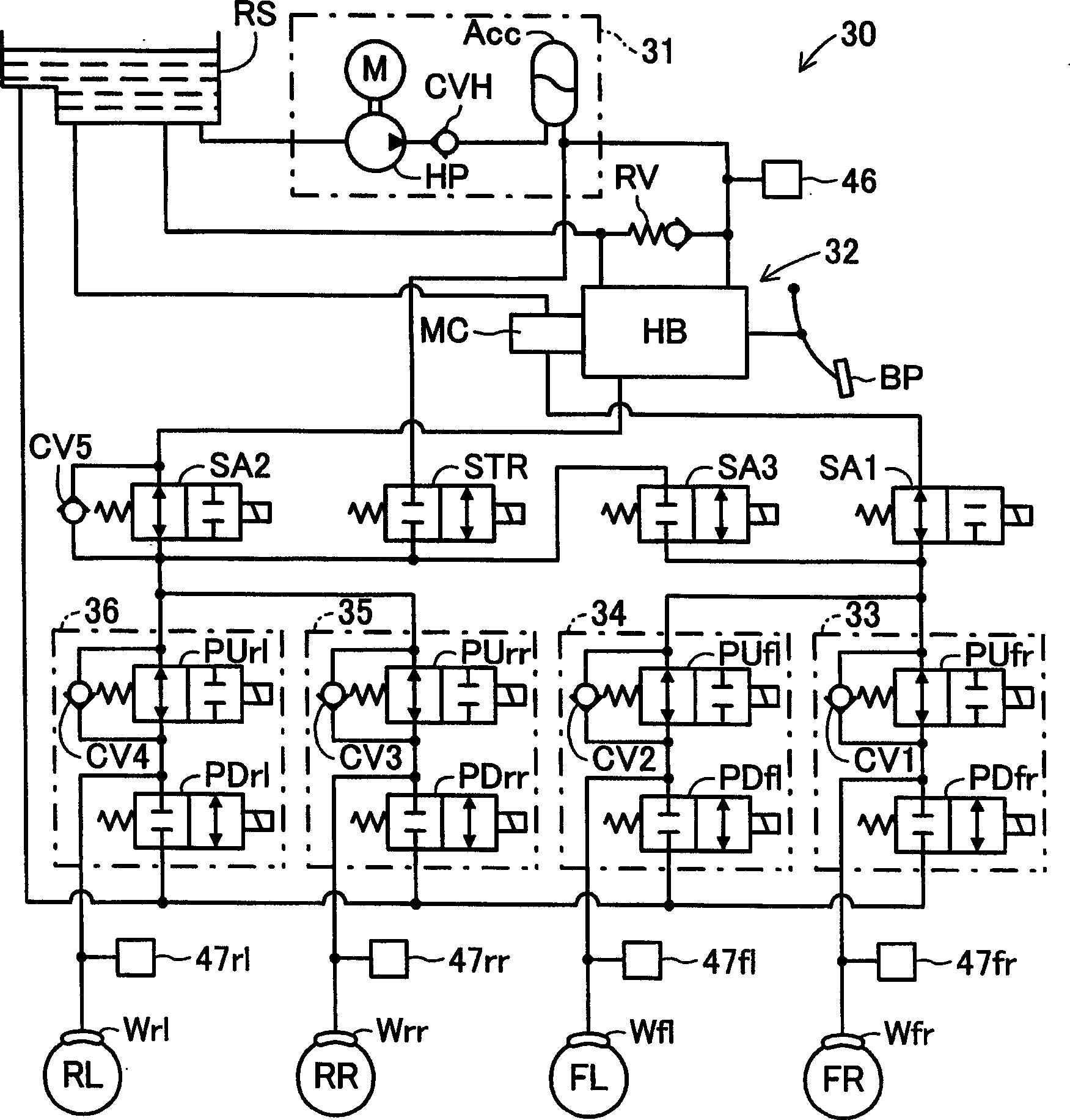

Hydraulic booster and hydraulic brake system using the same

ActiveUS20130175851A1Avoid pressure risesReduced durabilityBraking action transmissionBrake action initiationsEngineeringCheck valve

A hydraulic brake system is proposed which includes a hydraulic booster for boosting brake operation, and a circulation type pressure control unit. The hydraulic brake system further includes a hydraulic booster including an auxiliary hydraulic pressure source, a pressure regulator for adjusting the hydraulic pressure supplied therefrom to a value corresponding to an operating amount of a brake operating member and introducing the thus adjusted hydraulic pressure into a boost chamber, and a boost piston for actuating a master piston with a force boosted by an assisting force generated by the hydraulic pressure introduced into the boost chamber. The hydraulic booster further includes a hydraulic line bypassing the pressure regulator and extending from the boost chamber to the auxiliary hydraulic pressure, and a check valve provided in the hydraulic line and configured to allow only a discharge of hydraulic pressure from the boost chamber into the auxiliary hydraulic pressure source.

Owner:ADVICS CO LTD

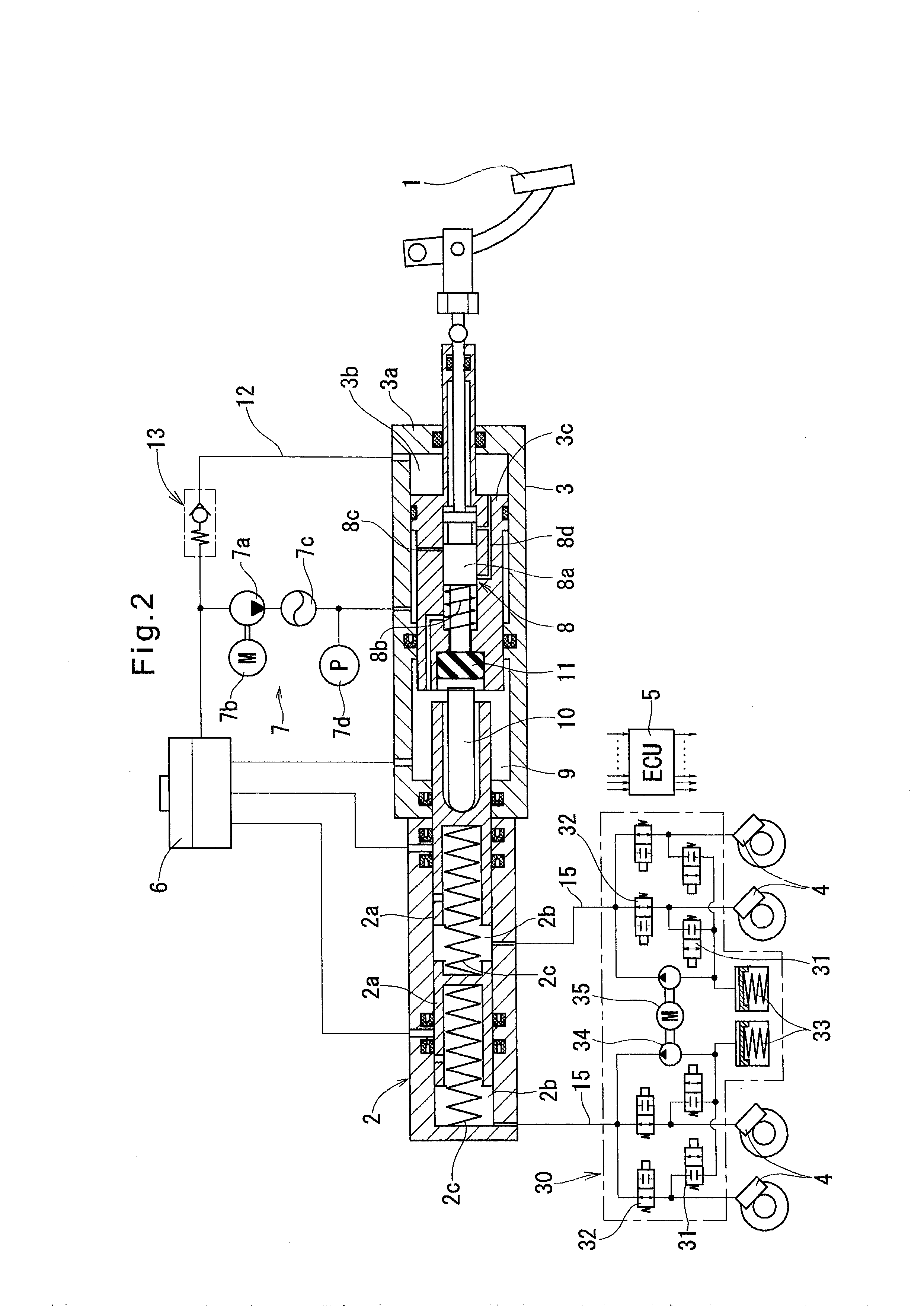

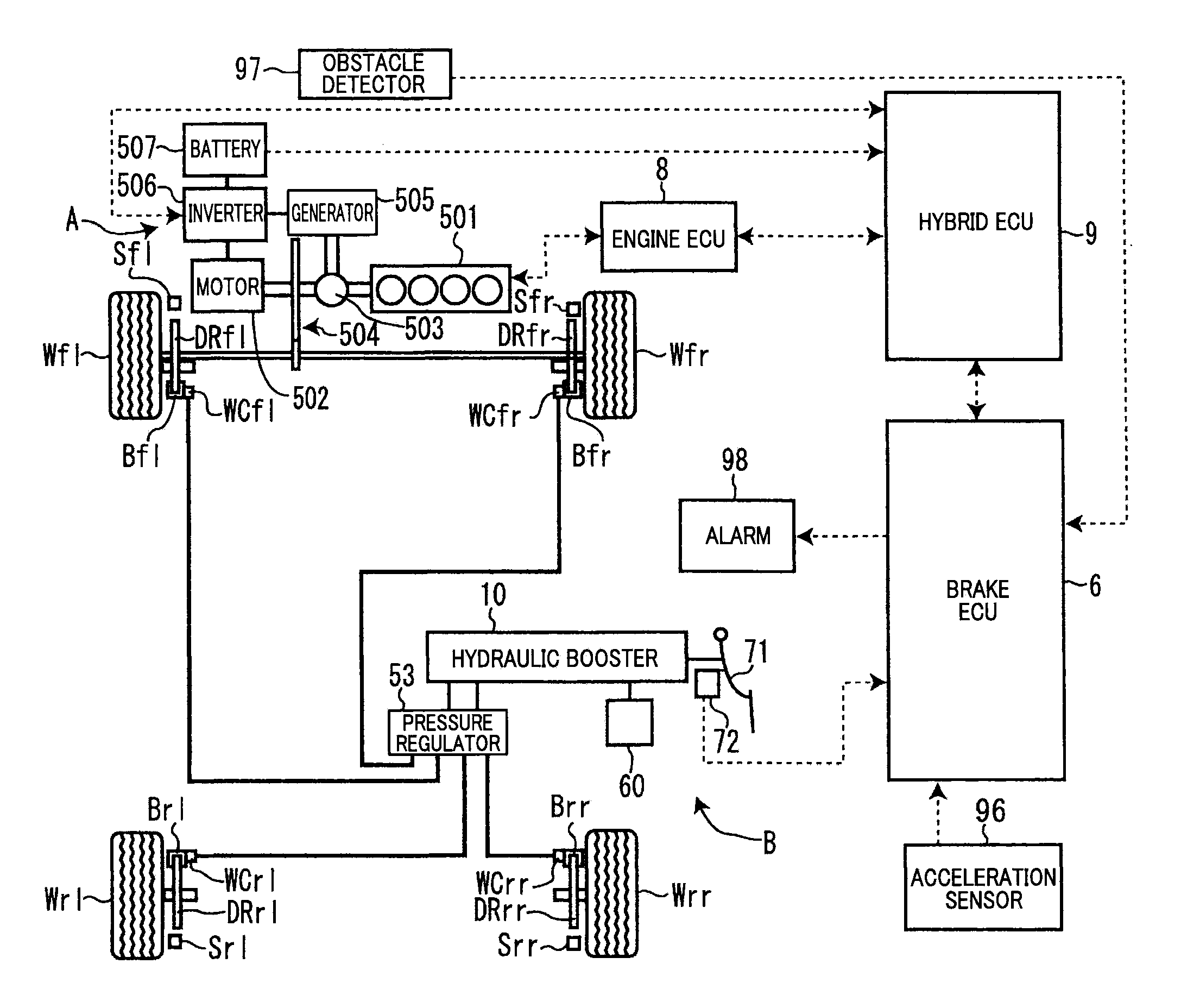

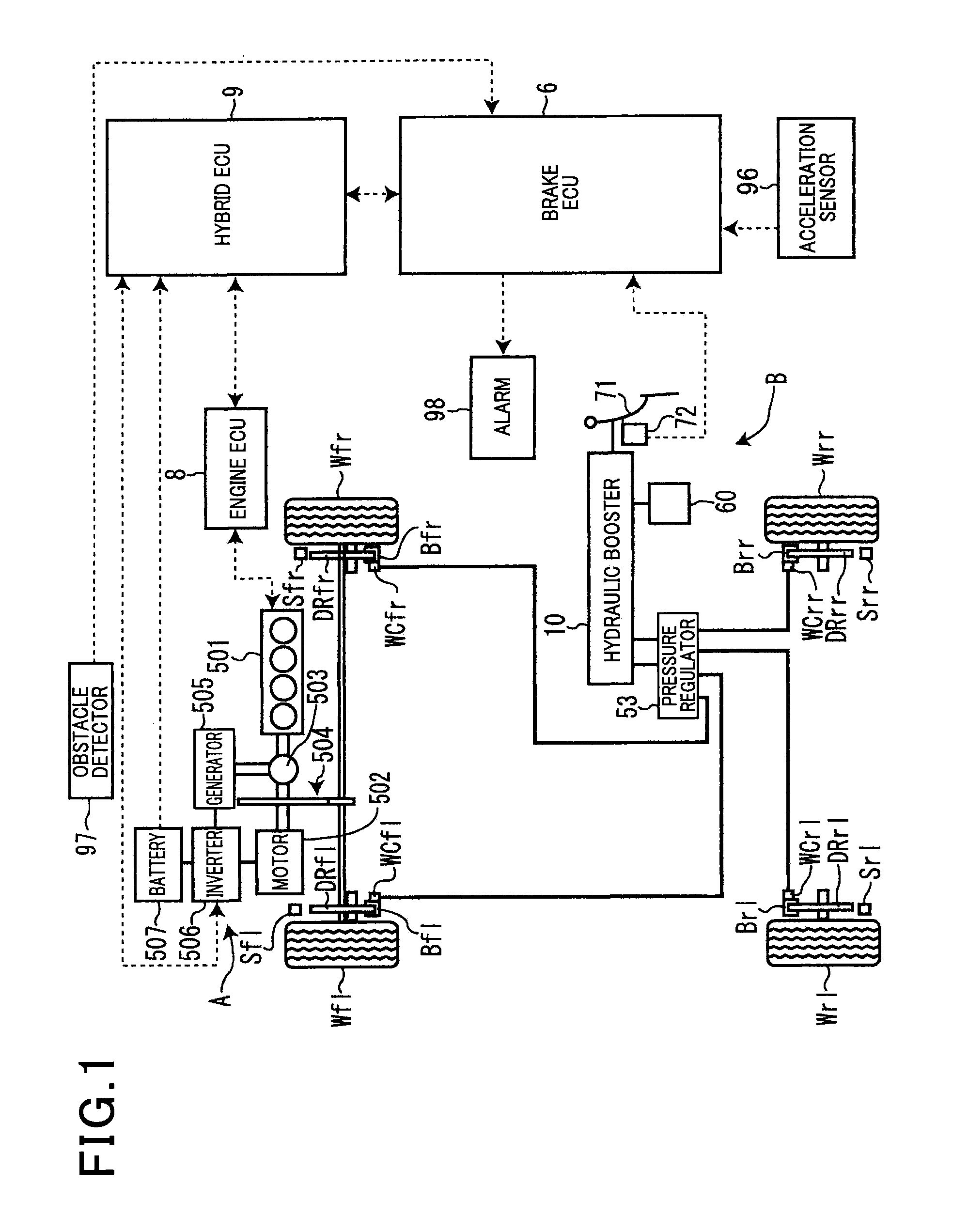

Braking apparatus for vehicle with collision avoidance mechanism

ActiveUS20150210256A1Easy to installImprove installabilityAutomatic initiationsFluid braking transmissionSpool valveSolenoid valve

A braking apparatus for a vehicle is provided which includes a hydraulic booster to make wheels of the vehicle produce frictional braking force, a solenoid valve, and a collision avoidance controller. The solenoid valve selectively exerts the hydraulic pressure of brake fluid stored in an accumulator on a spool valve in the booster. When determining that there is a risk of a collision with an obstacle, the collision avoidance controller opens the solenoid valve to achieve emergency braking to minimize the risk of the collision. Basically, emergency braking is achieved by installing the solenoid valve to selectively exert the hydraulic pressure on the spool valve, thus allowing an emergency avoidance braking system to be constructed with a minimum of equipment and facilitating the mountability of the braking apparatus in the vehicles.

Owner:ADVICS CO LTD

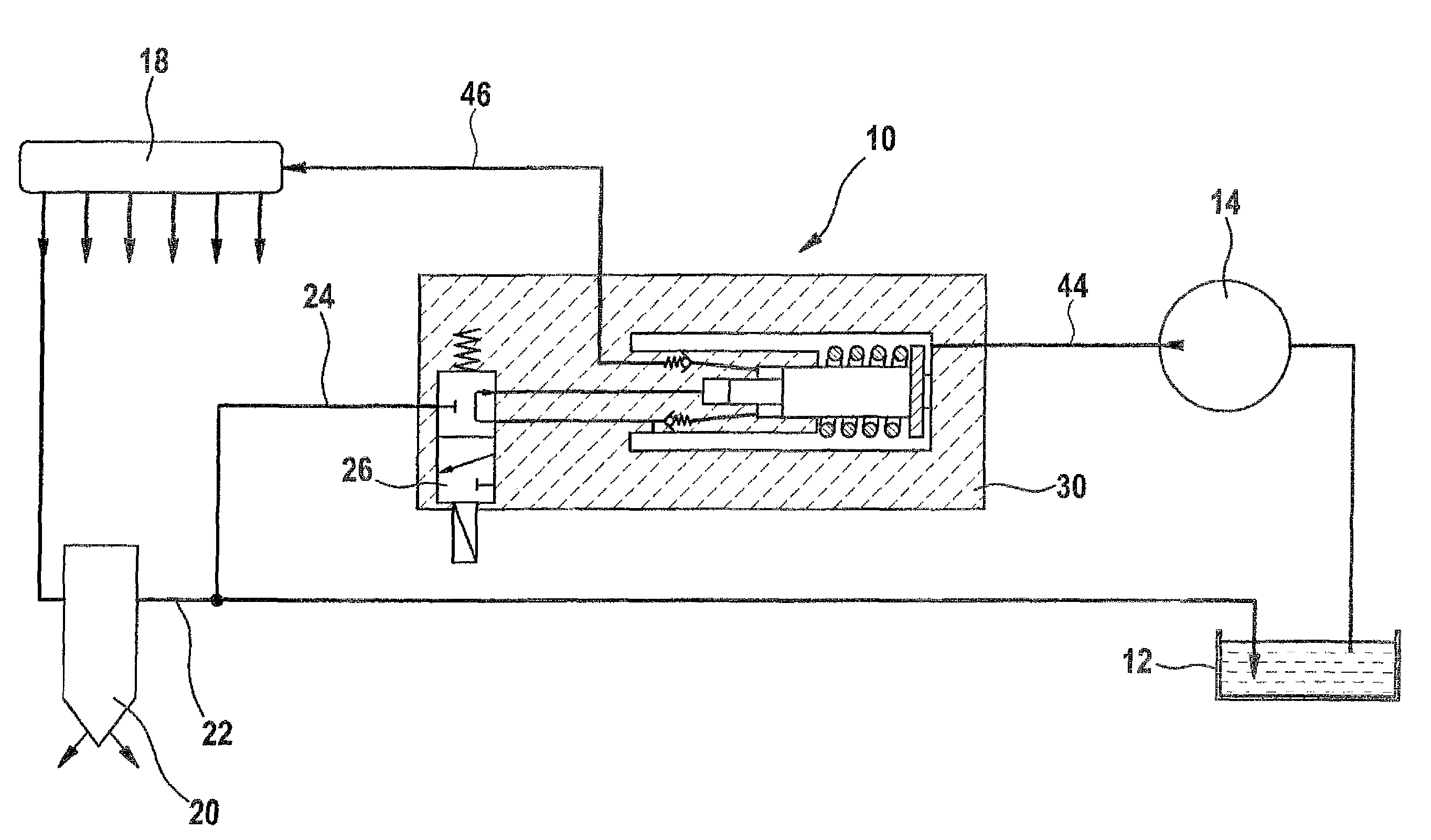

Fuel injection system with pressure boosting

InactiveUS8245694B2Improve efficiencyMinimization requirementsMachines/enginesFuel injecting pumpsExternal combustion engineHigh pressure

The invention relates to a fuel injection system for an internal combustion engine having a high pressure pump, a high pressure reservoir, a plurality of fuel injectors, a hydraulic pressure booster, and a control valve for actuating the hydraulic pressure booster. The hydraulic pressure booster is provided centrally for all of the fuel injectors. The central hydraulic pressure booster is disposed between the high pressure pump and the high pressure reservoir.

Owner:ROBERT BOSCH GMBH

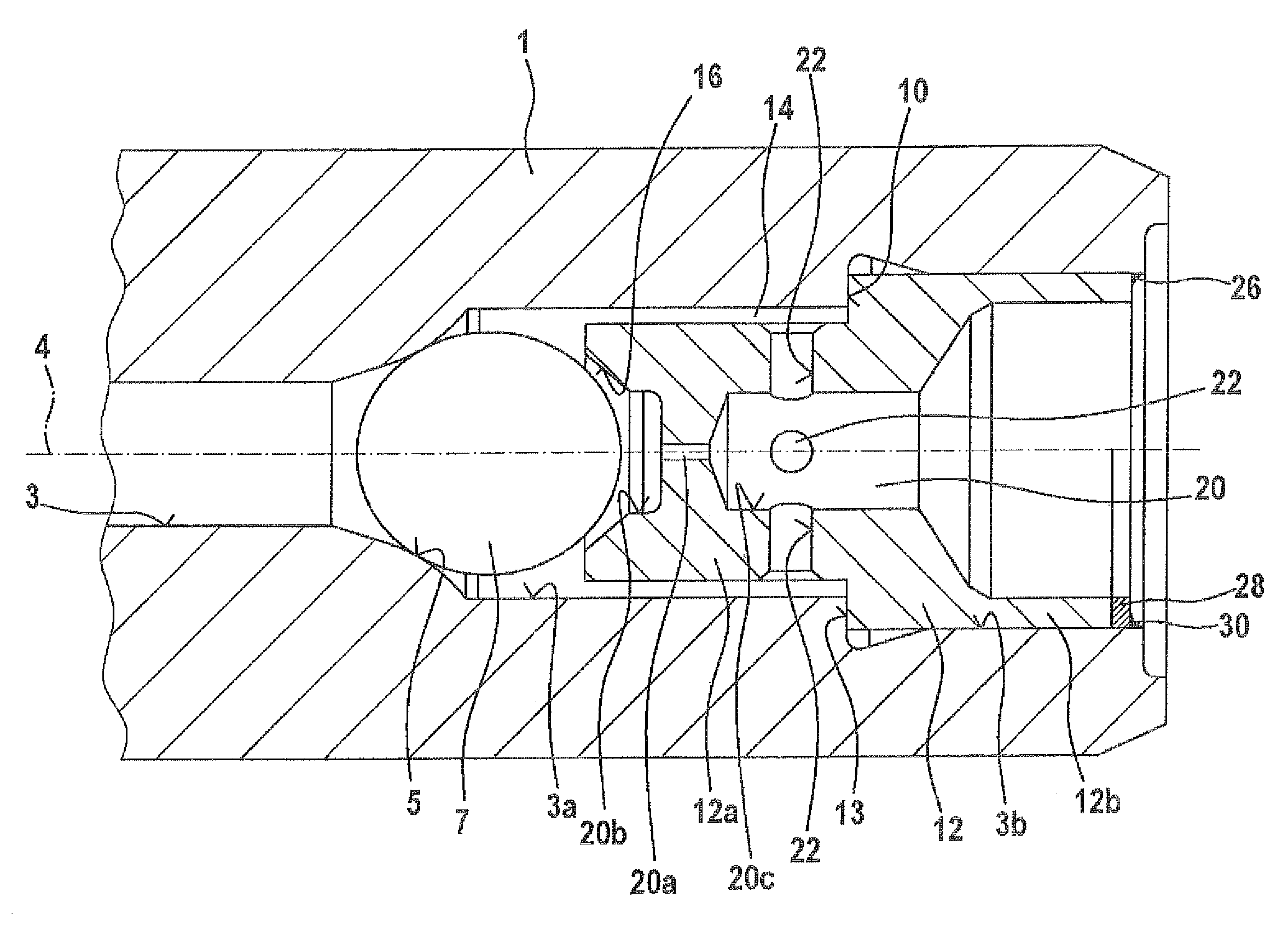

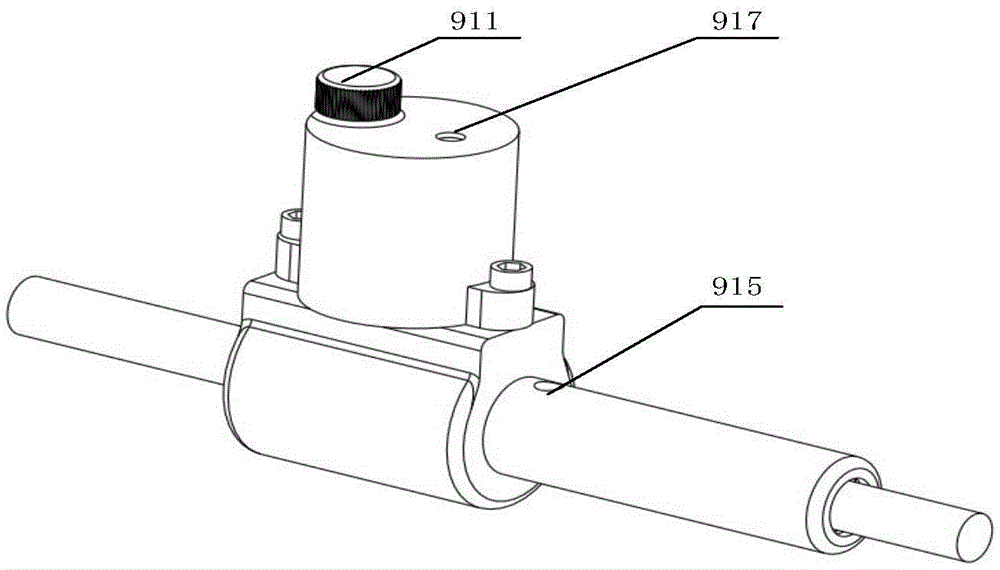

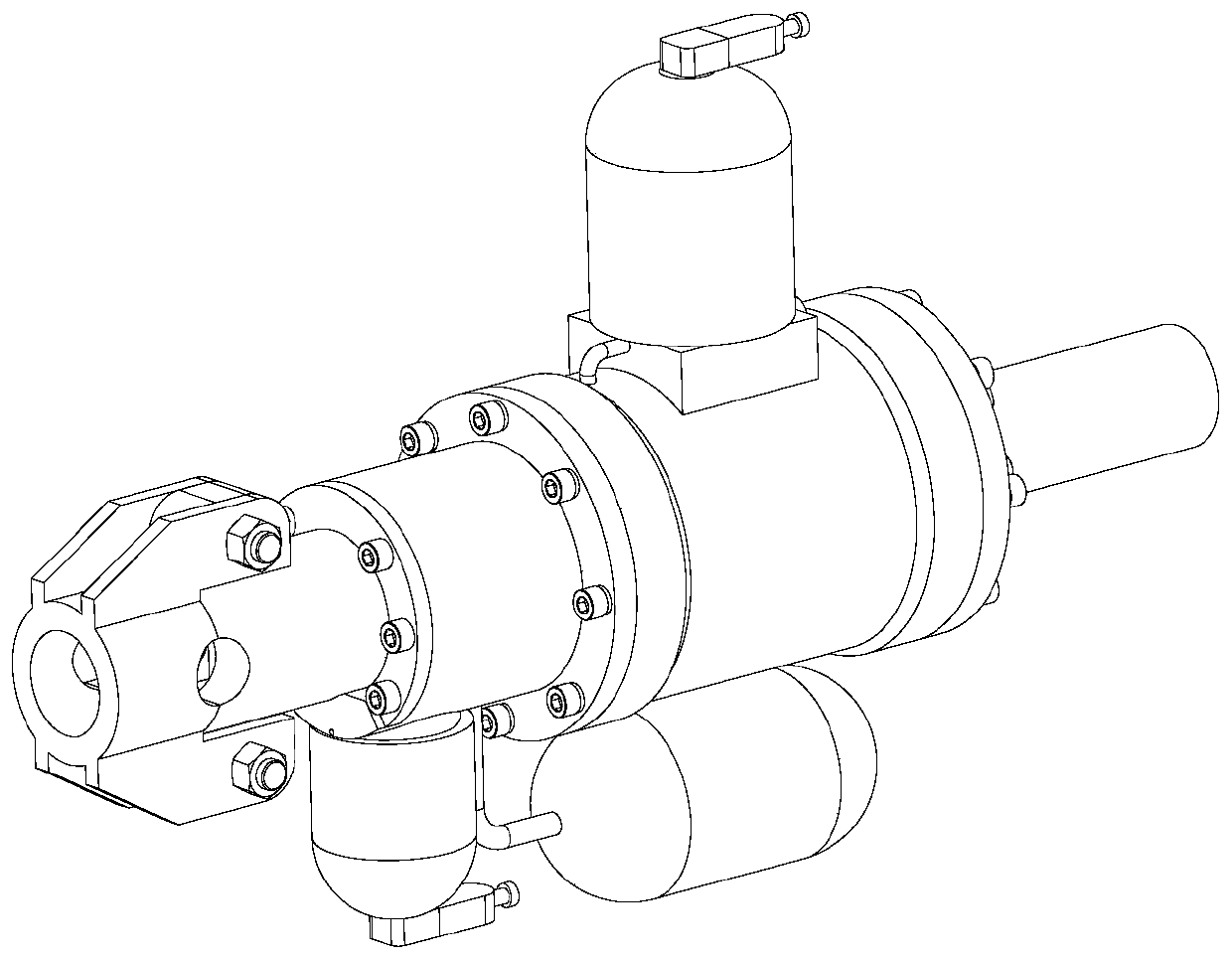

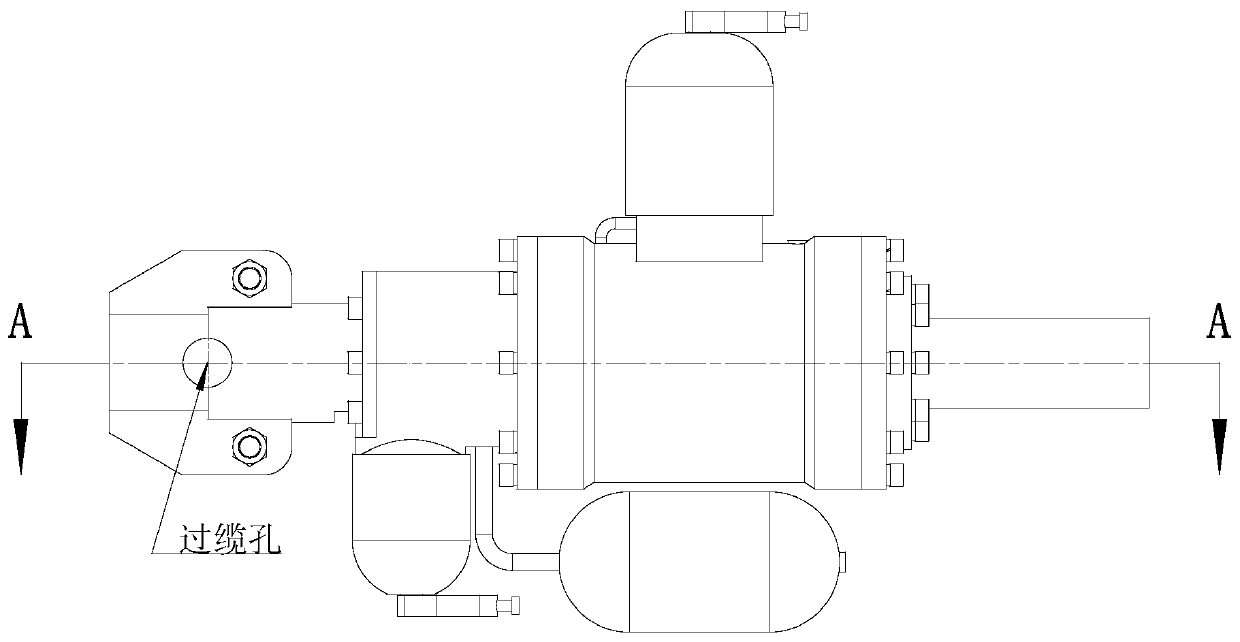

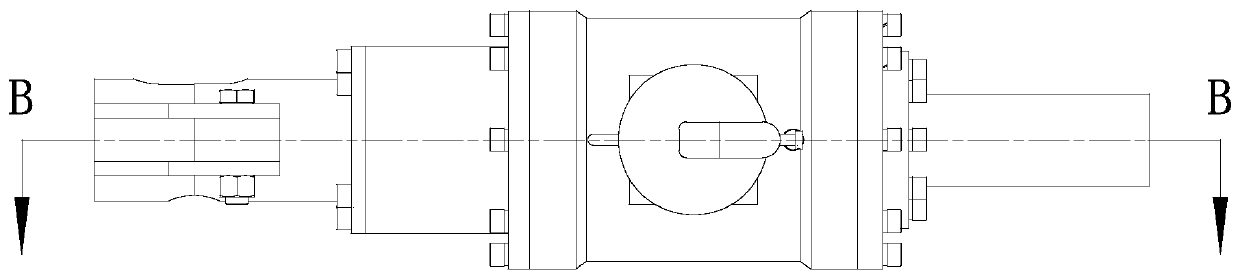

Sealed hydraulic intensifier

A sealed hydraulic intensifier has a sealed hydraulic cylinder actuator having a cylinder defining a piston chamber, a piston fitted in the piston chamber of the cylinder, and a piston rod connected to the piston, and a pressure controller disposed adjacent to the piston chamber of the sealed hydraulic cylinder actuator to control.

Owner:TOSHIBA MASCH CO LTD

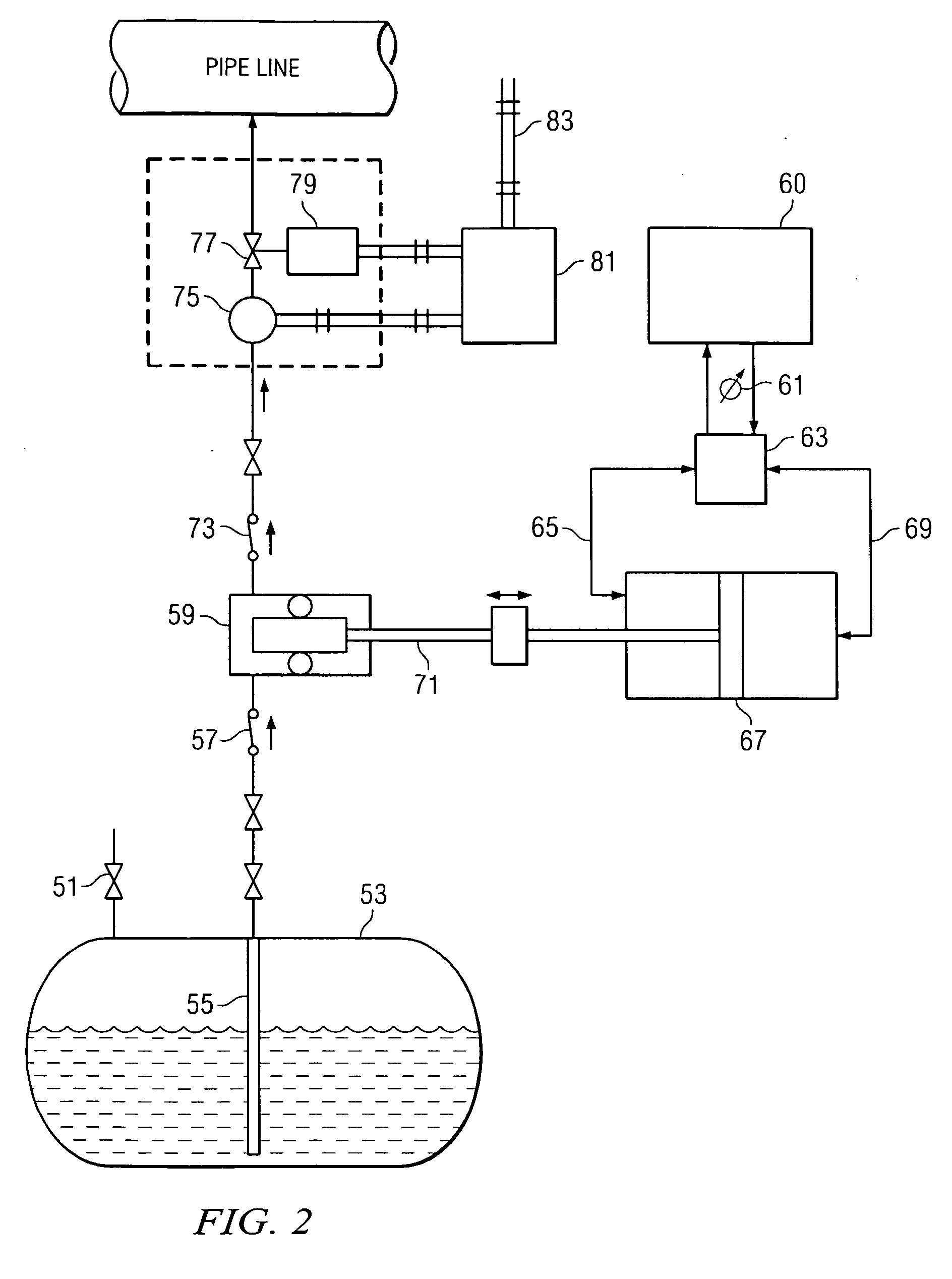

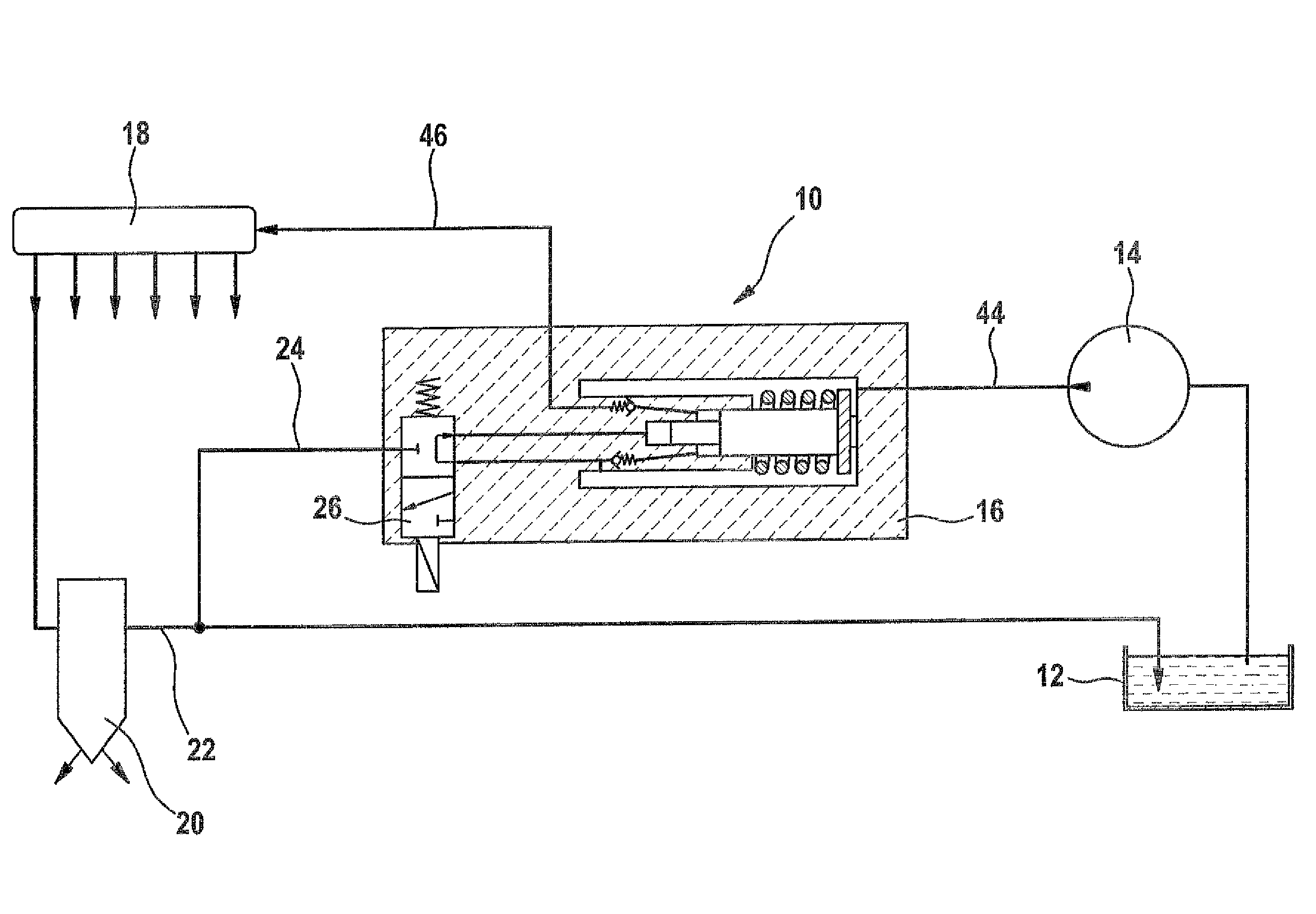

Dual-service system and method for compressing and dispensing natural gas and hydrogen

InactiveUS20060071016A1Easy to switchFacilitate pressureLiquid fillingFrozen sweetsGas coolerMethane

A dual service system and method for selectively compressing and dispensing methane, hydrogen, and variable mixtures of methane and hydrogen for use as a gaseous fuel. The use of an in-line gas density meter, hydraulic intensifier, pressurized gas cooler, optional intermediate storage and multiple dispensers are disclosed. An inline gas density meter is used in combination with a programmable logic controller and a control valve on the hydrogen supply line to create a closed feedback loop for selectively controlling the hydrogen content of the resultant pressurized fuel gas.

Owner:INTEGRYS TRANSPORTATION FUELS

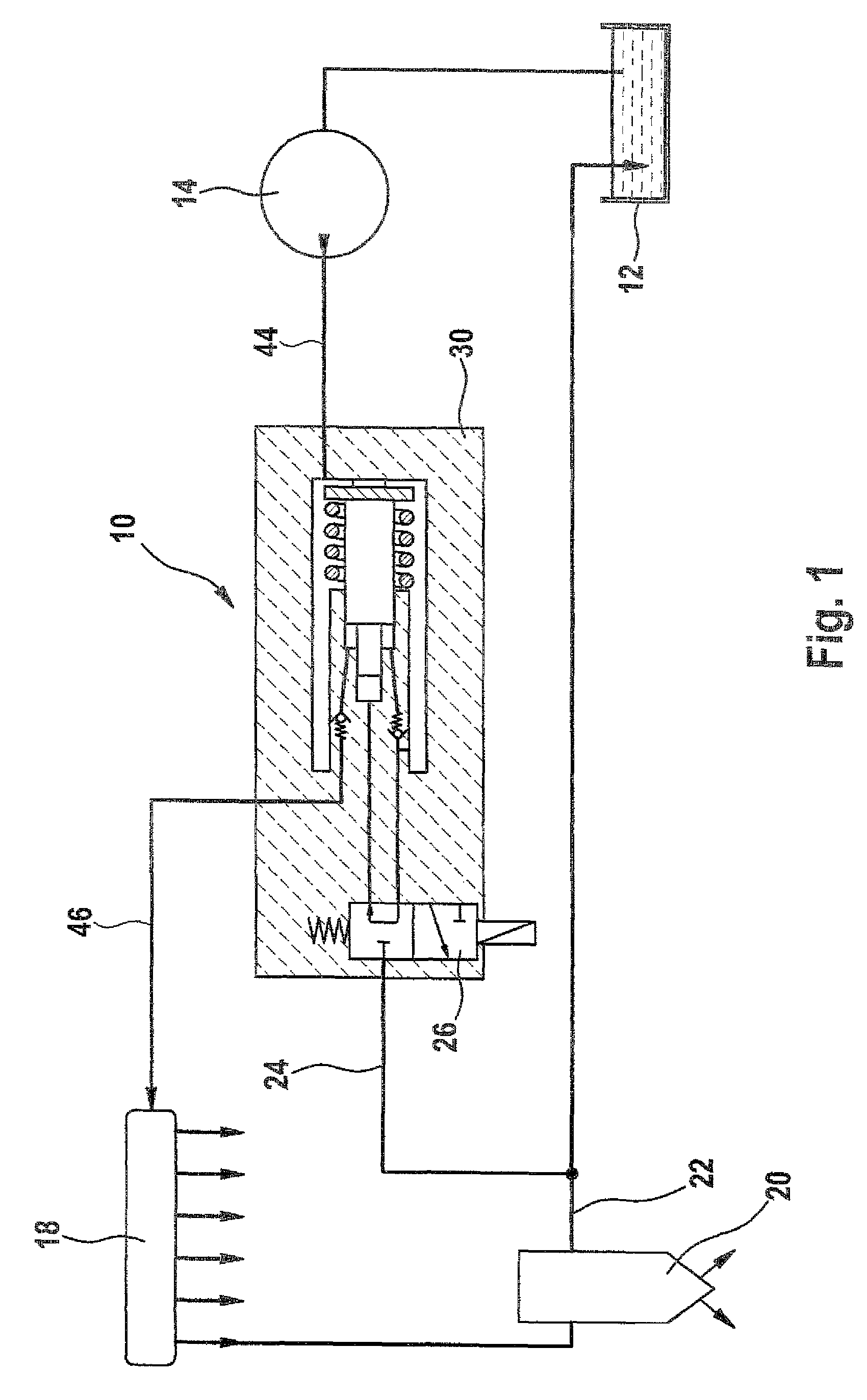

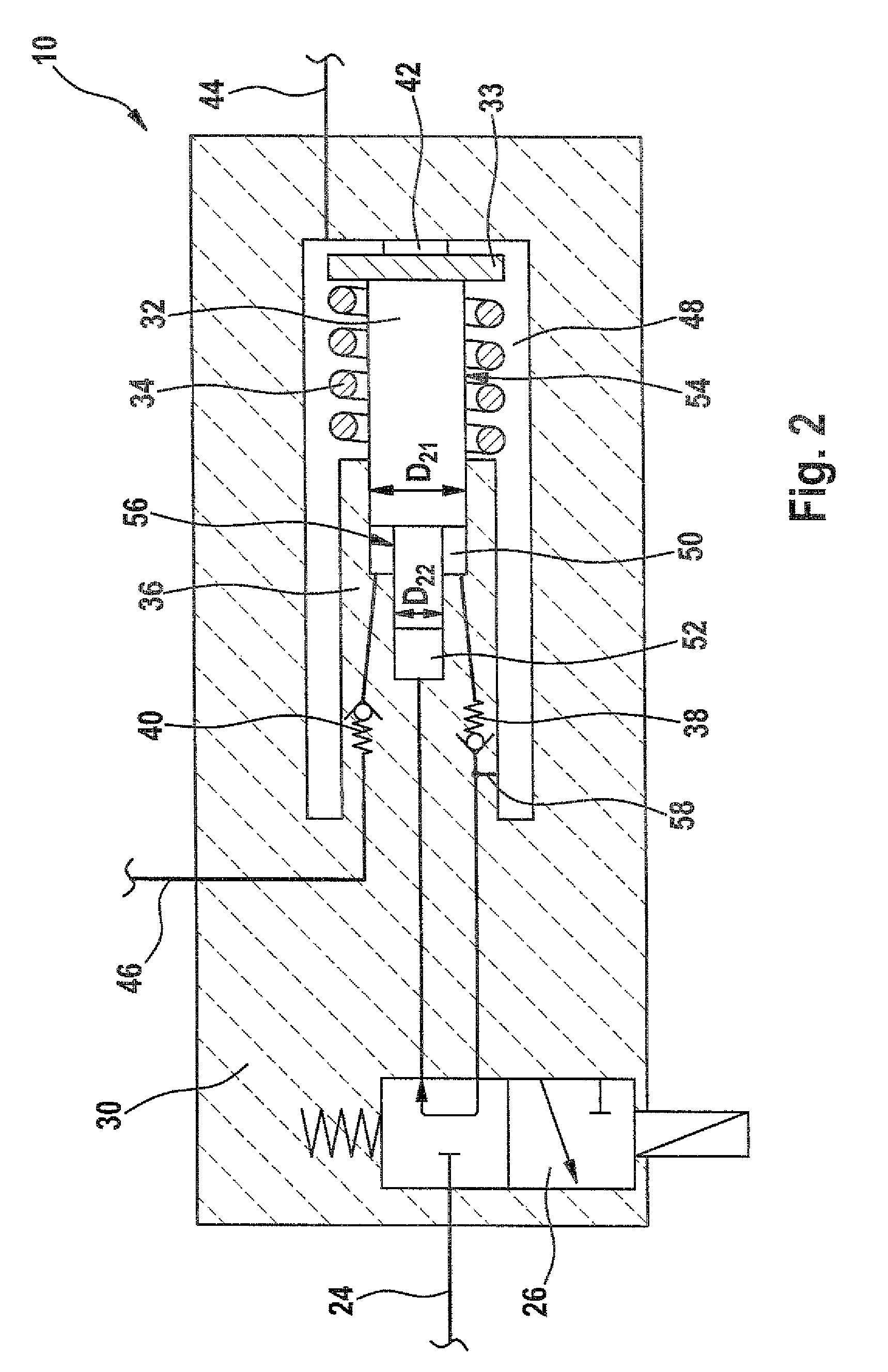

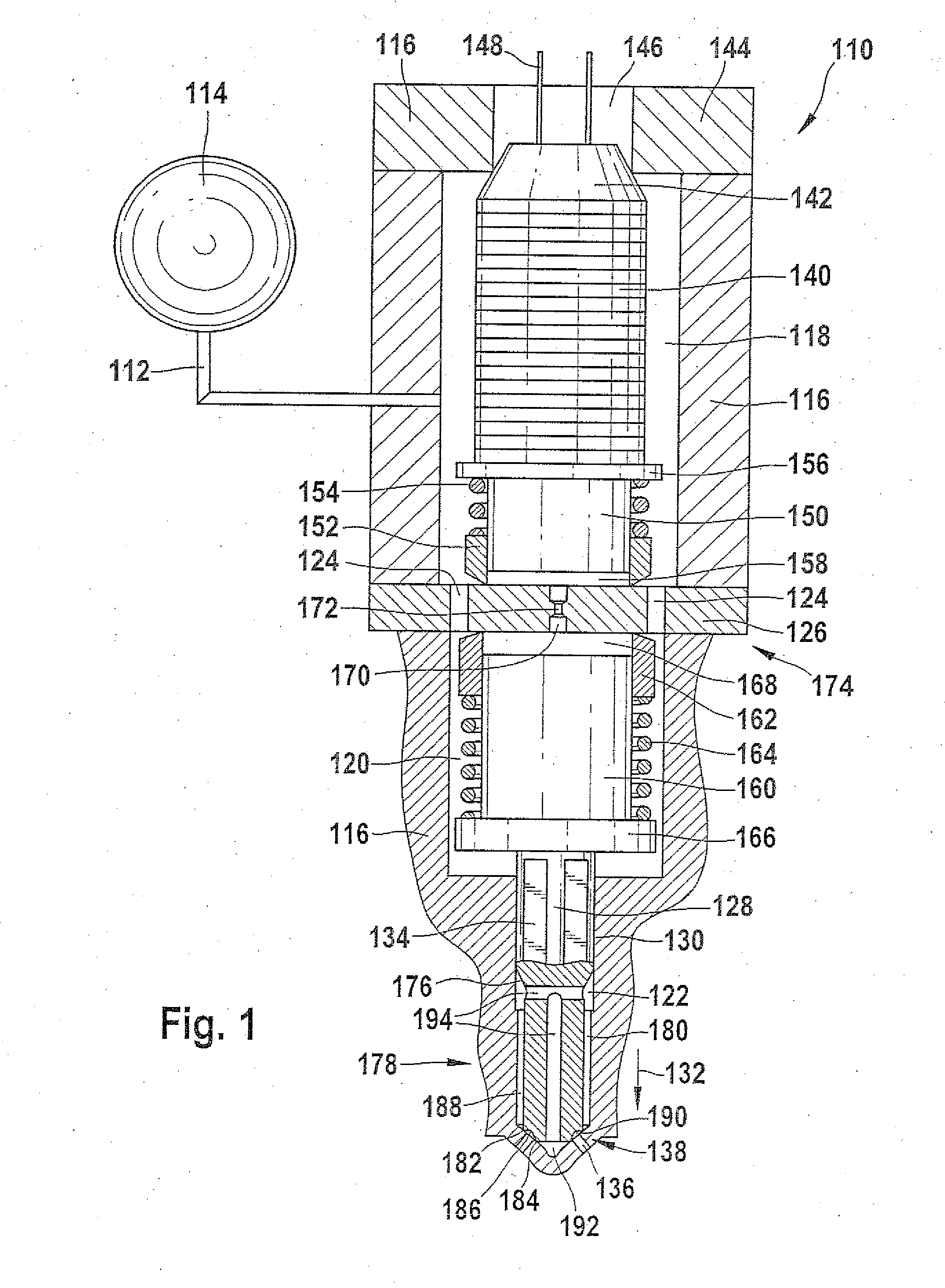

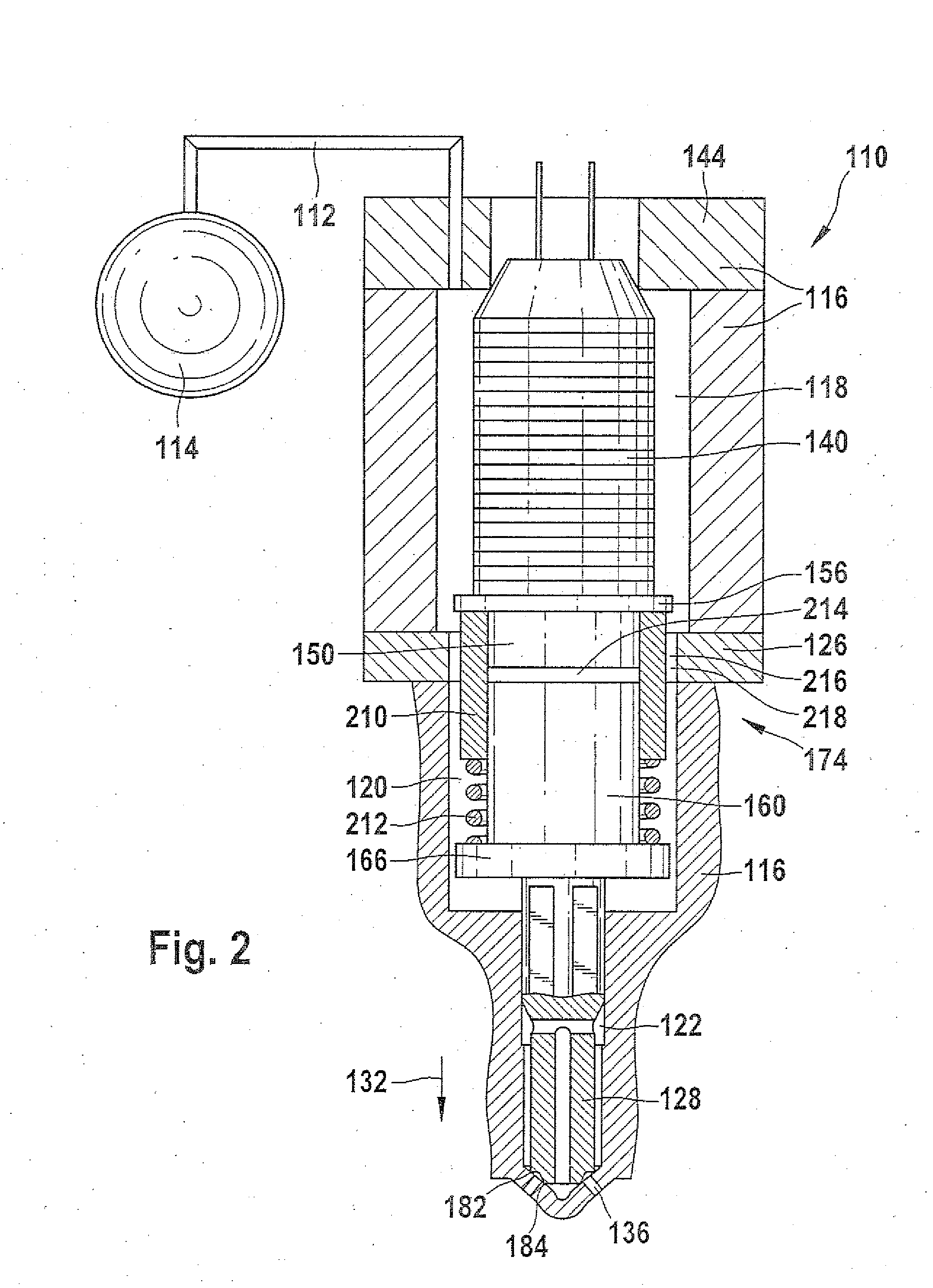

Hydraulic tool

ActiveUS20050178121A1Easy flow controlEasy to handleBreathing protectionRotary clutchesEngineeringVALVE PORT

A hydraulic tool has a motor, a valve, a hydraulic intensifier and a supply connector. The hydraulic intensifier is arranged between the valve and the motor. The valve and the motor are arranged behind one another in a longitudinal direction of the tool. The hydraulic intensifier has at least one intensifier piston having a movement direction that is positioned at a first angle greater than 0° relative to the longitudinal direction of the tool.

Owner:MINIBOOSTER HYDRAULICS

Valve for controlling fluids

InactiveUS6531712B1Low production costSimple designOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

A valve for controlling fluids is proposed, which has a piezoelectric actuator (5) and a hydraulic pressure intensifier which transmits the stroke of the piezoelectric actuator (5). The hydraulic pressure intensifier has a pressure chamber (7) and a piston element (10) with a transmission surface area (12). The hydraulic pressure intensifier can actuate a valve member (18) that is connected to the piston element (10). A mechanical pressure intensifier is interposed between the hydraulic pressure intensifier and the valve member (18).

Owner:ROBERT BOSCH GMBH

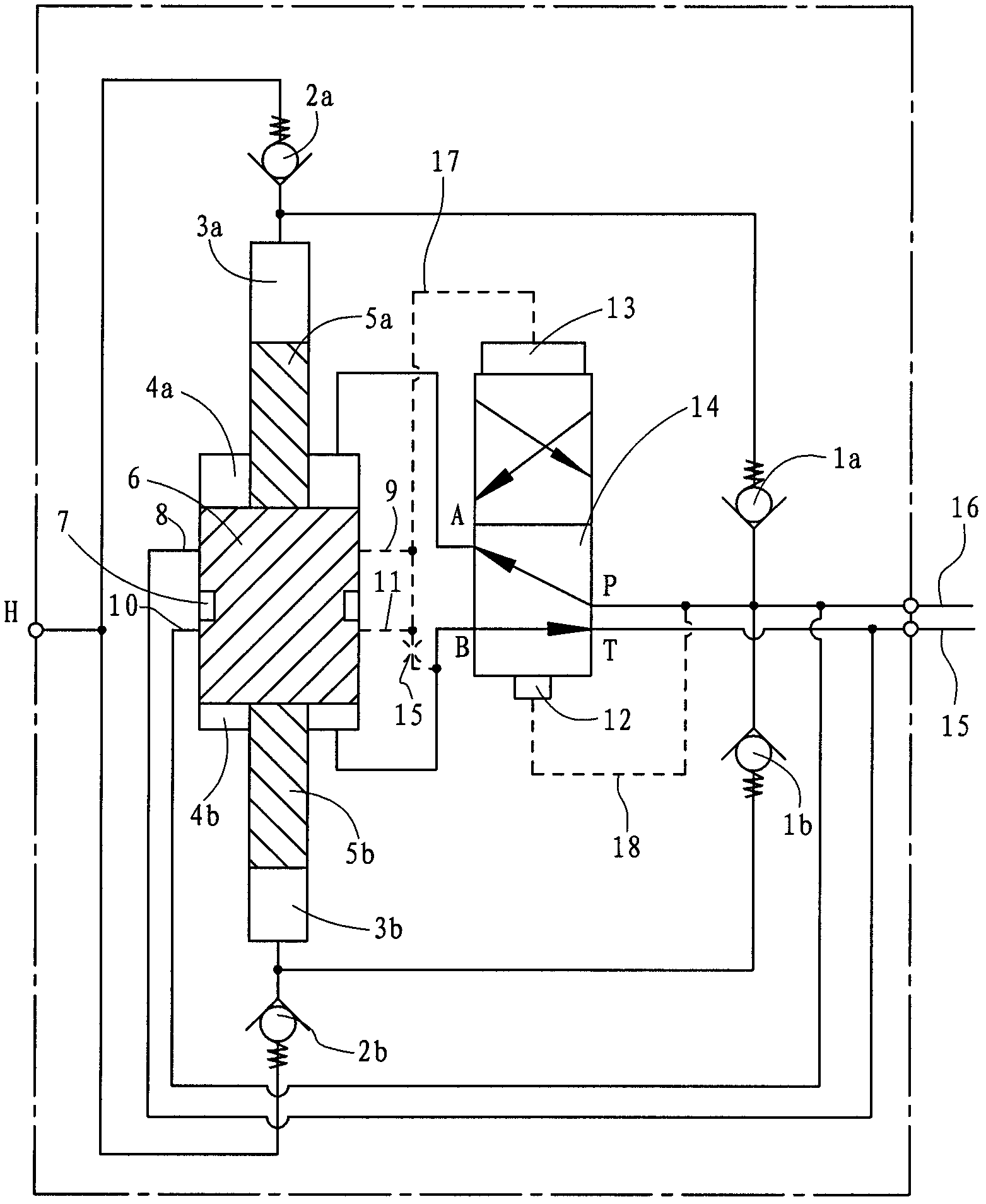

High pressure intensifiers

ActiveUS20140072454A1Increase surface areaEliminates complex and expensiveFlexible member pumpsServomotorsFluid controlEngineering

A hydraulic intensifier comprising a reciprocating differential piston arrangement and a controller configured to control the supply of low pressure hydraulic fluid to the intensifier is provided. The controller comprises at least one solenoid operated pilot valve and electronic operator configured to operate the pilot valve.

Owner:BAKER HUGHES ENERGY TECH UK LTD

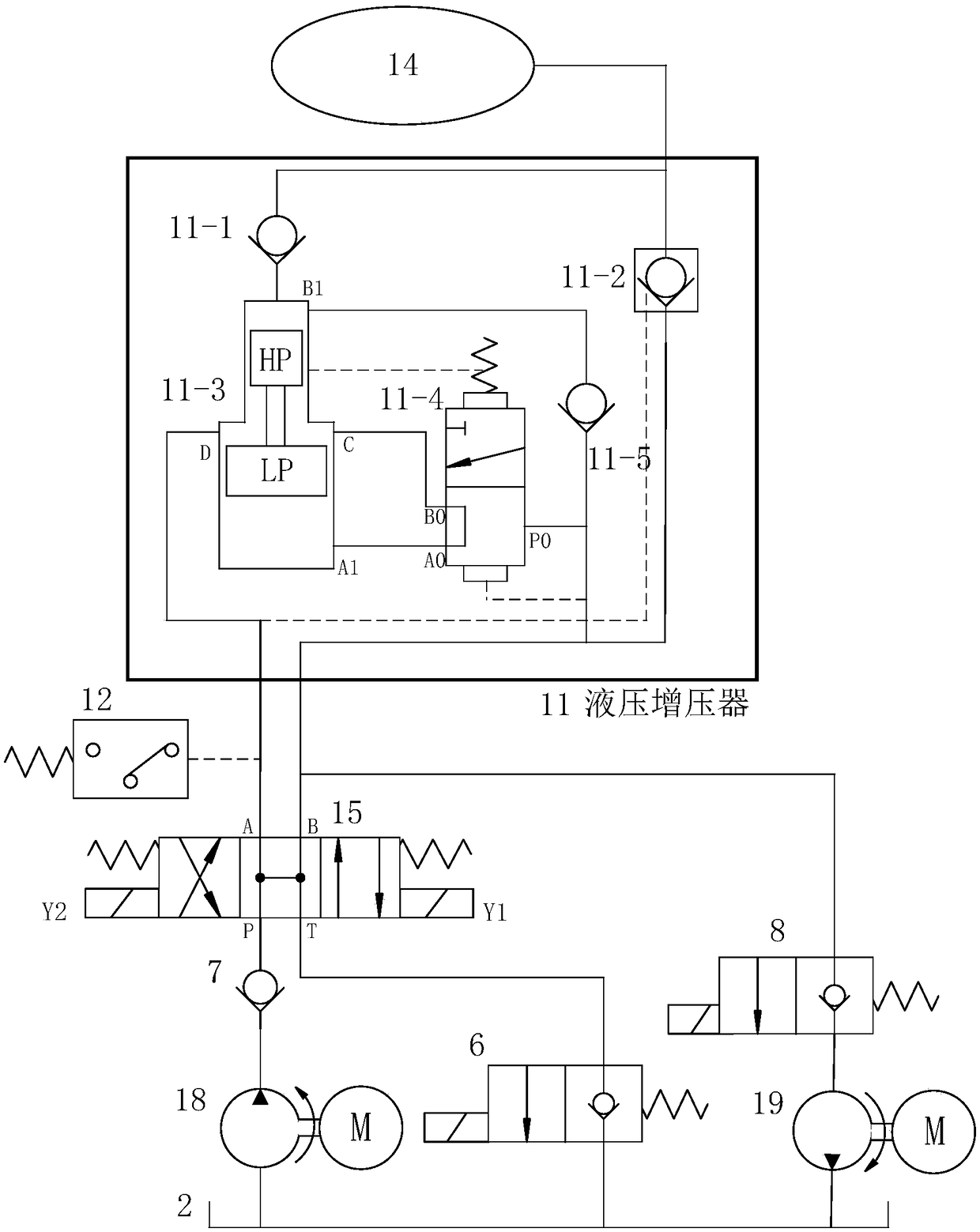

Buoyancy regulating system and method of full-ocean-depth underwater glider

ActiveCN109334926AIncrease pressureSmall footprintUnderwater vesselsUnderwater equipmentFuel tankHydraulic pump

The invention belongs to the technical field of hydraulics, and specifically discloses a buoyancy regulating system and method of a full-ocean-depth underwater glider. The buoyancy regulating system comprises an internal oil tank, an external oil bag, an oil-filling oil passage and an oil-draining oil passage, wherein the oil-filling oil passage and the oil-draining oil passage are arranged between the internal oil tank and the external oil bag; the oil-filling oil passage comprises a first hydraulic pump, a one-way valve, a three-position four-way electromagnetic directional control valve anda hydraulic pressure booster which are sequentially connected through an oil passage pipeline; the oil-draining oil passage comprises a second on-off valve and a second hydraulic pump connected through the oil passage pipeline; the second on-off valve is connected to the hydraulic pressure booster; and the second hydraulic pump is connected to the internal oil tank and used for draining the oil from the external oil bag into the internal oil tank through the hydraulic pressure booster, the second on-off valve and the second hydraulic pump in sequence. The buoyancy regulating system and methodof the full-ocean-depth underwater glider solve the problem that an existing buoyancy regulating device can not work under the condition of full sea depth, that the weight, size and power consumptionare relatively large, and that the working range is relatively small. The buoyancy regulating system and method of the full-ocean-depth underwater glider achieve the purpose of greatly increasing theoutput hydraulic oil pressure under the condition of slightly increasing the size.

Owner:HUAZHONG UNIV OF SCI & TECH

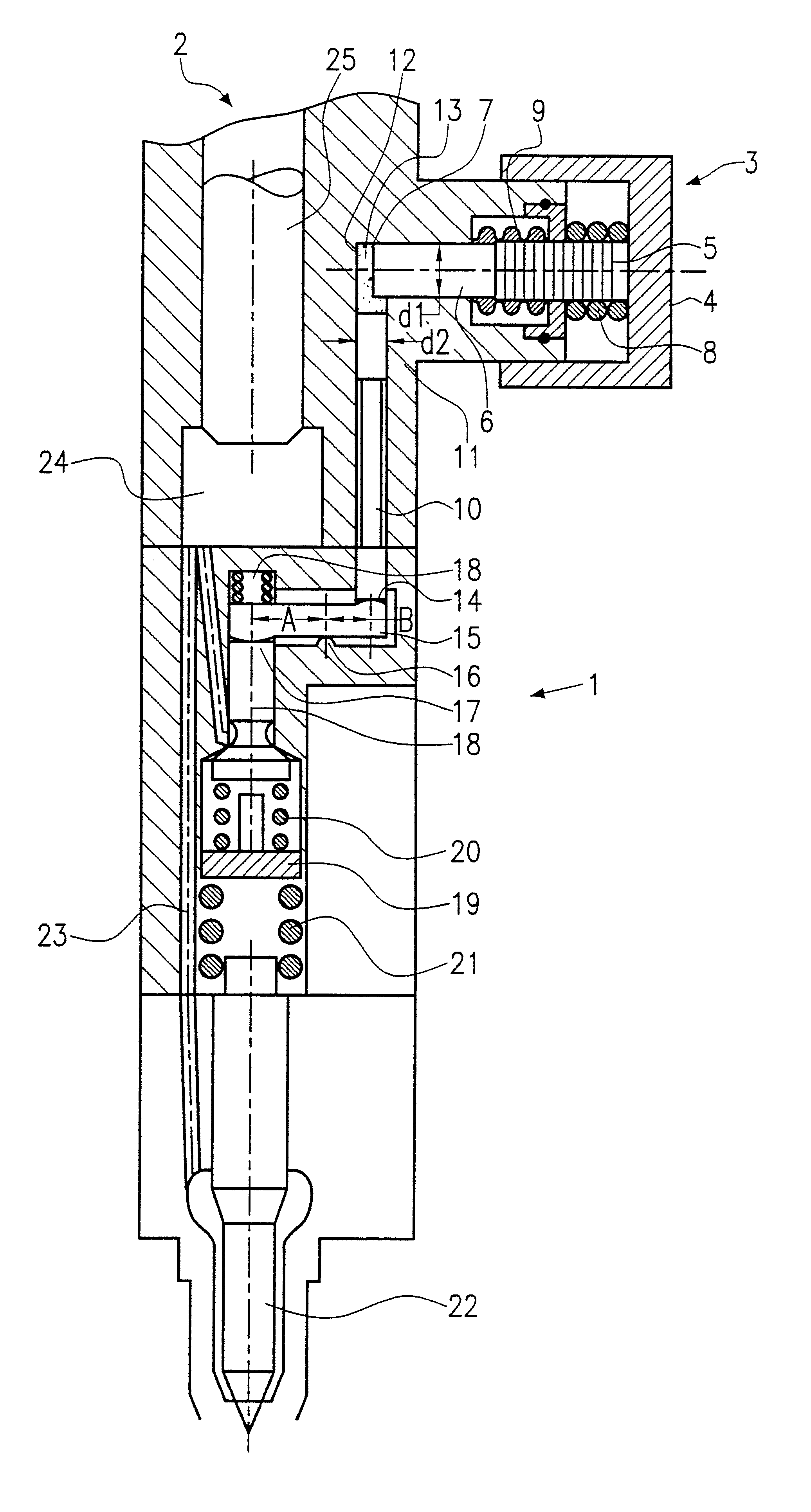

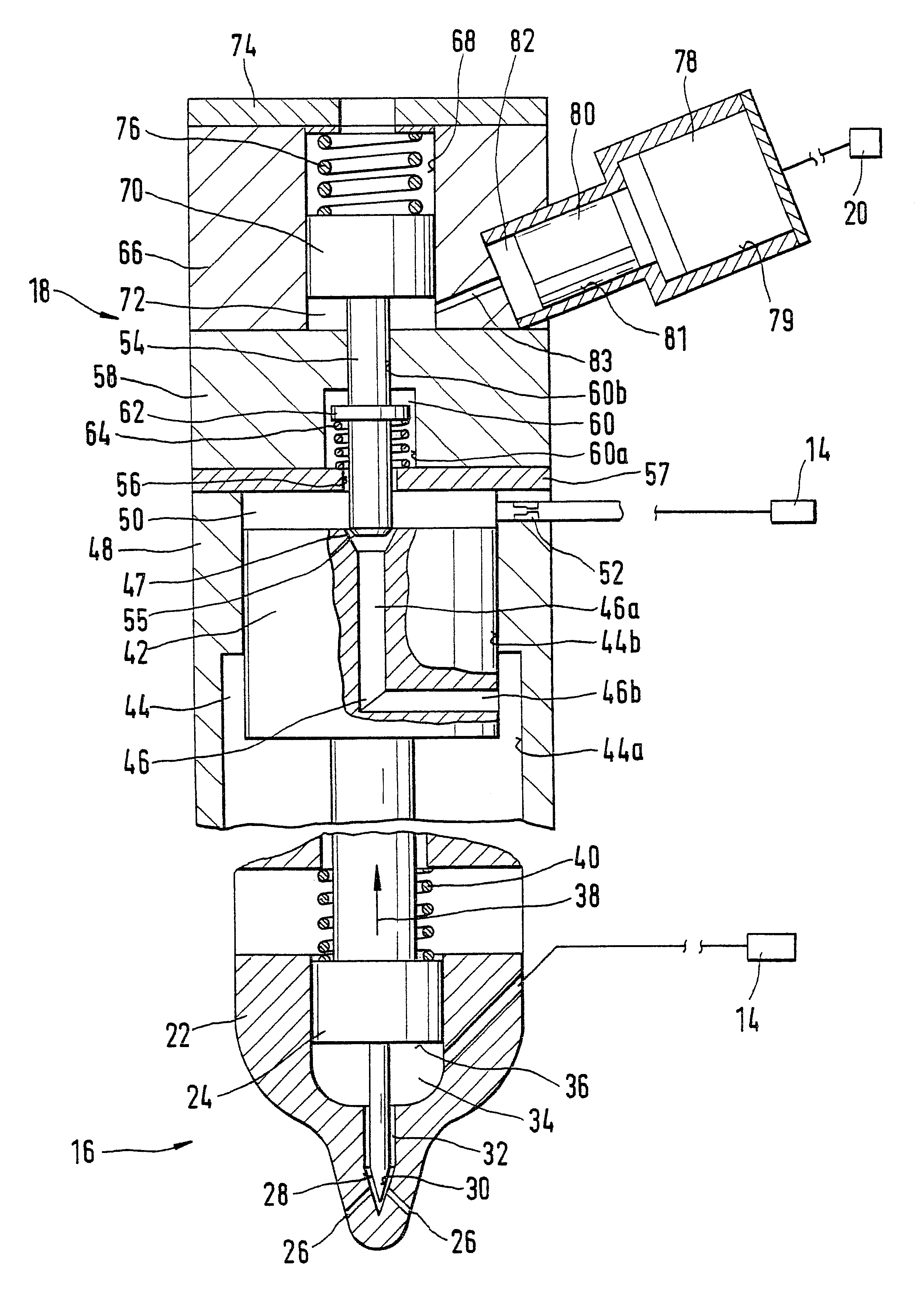

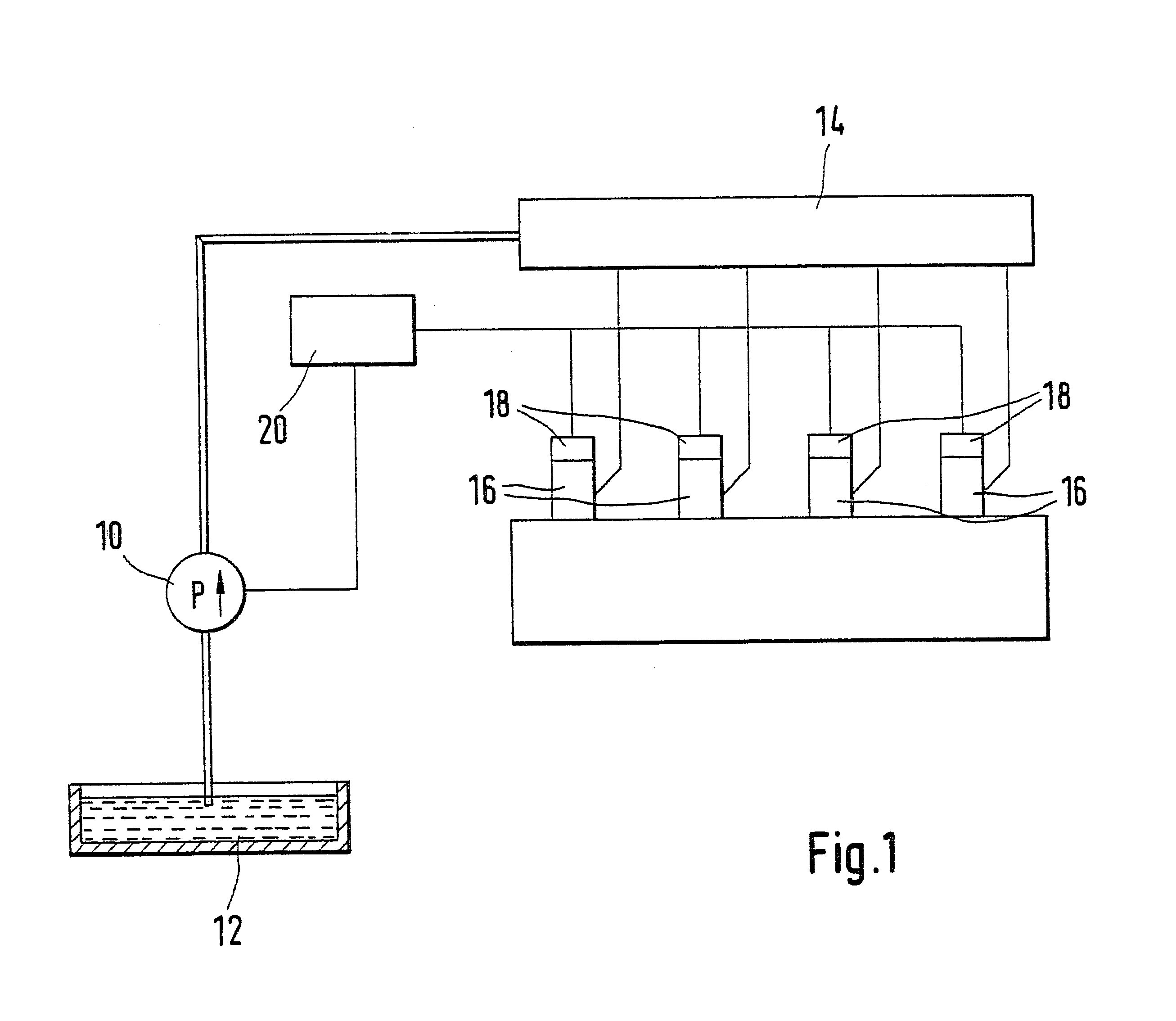

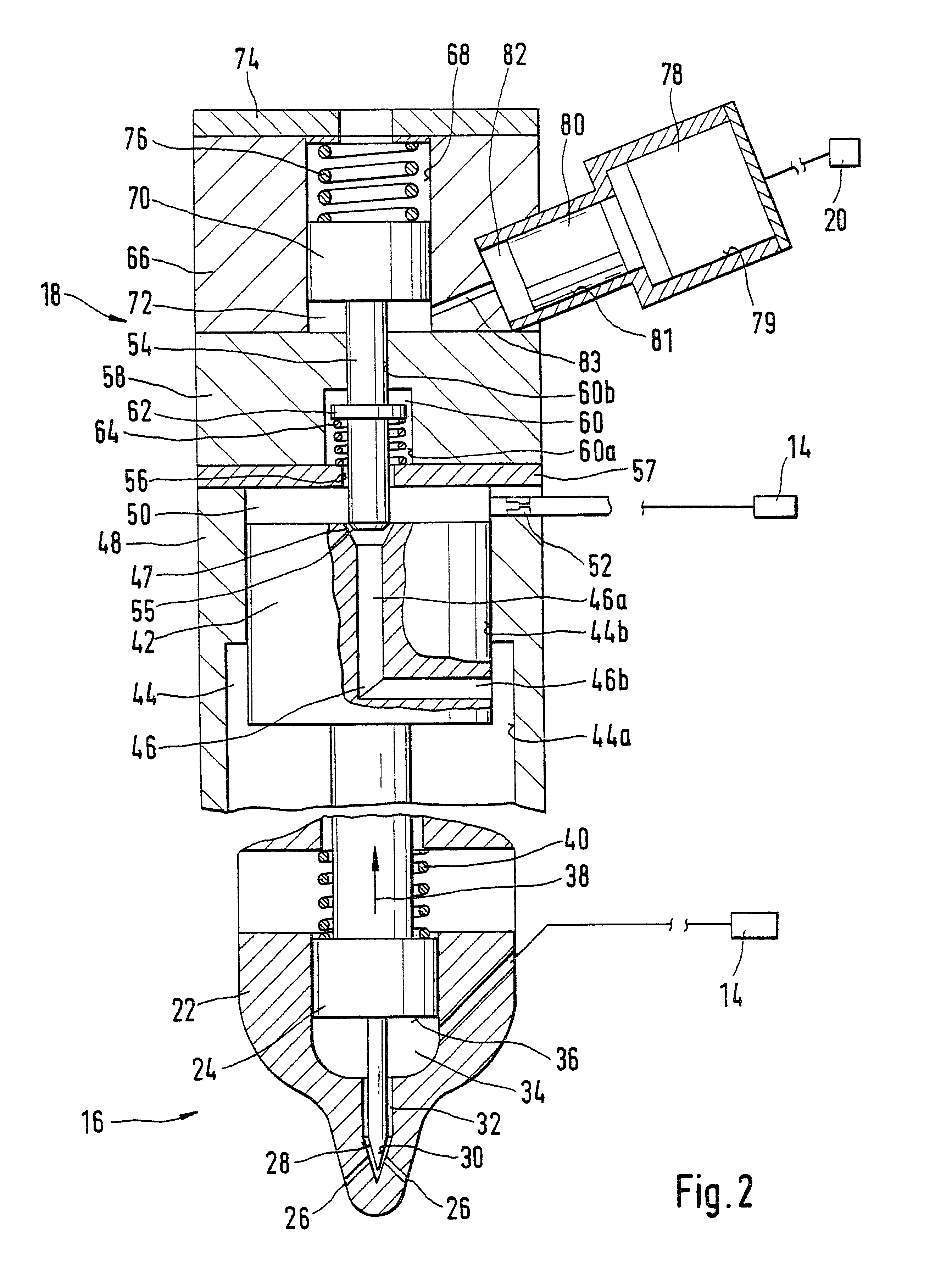

Fuel injection valve for internal combustion engines

InactiveUS6527198B1Size can be small and lowWeight can be small and lowMovable spraying apparatusSpray nozzlesCombustionPiezoelectric actuators

The fuel injection valve (16) has an injection valve member (24), by which at least one injection opening (26) is controlled.The motion of the injection valve member (24) is varied by a control valve (18) that has a control valve member (54) by which the pressure in a control pressure chamber (50) is controlled in that the control valve member controls a relief chamber (46) in a closing piston (42) that defines the control pressure chamber (50) and that by means of the pressure prevailing in the control pressure chamber (50) urges the injection valve member (24) in its closing direction. The control valve member (54) is displaceable via a hydraulic boost by a piezoelectric actuator (78), as a result of which the piezoelectric actuator opens or closes the relief chamber (46). The control valve member (54) cooperates as a valve seat with the orifice (47) of the relief chamber (46) at the closing piston (42), and its cross-sectional area in the control pressure chamber (50) is at least approximately equal to the cross-sectional area of the orifice (47) of the relief chamber (46), so that because of the pressure in the control pressure chamber (50), no force is exerted on the control valve member (54), and only a slight force is required to displace it.

Owner:ROBERT BOSCH GMBH

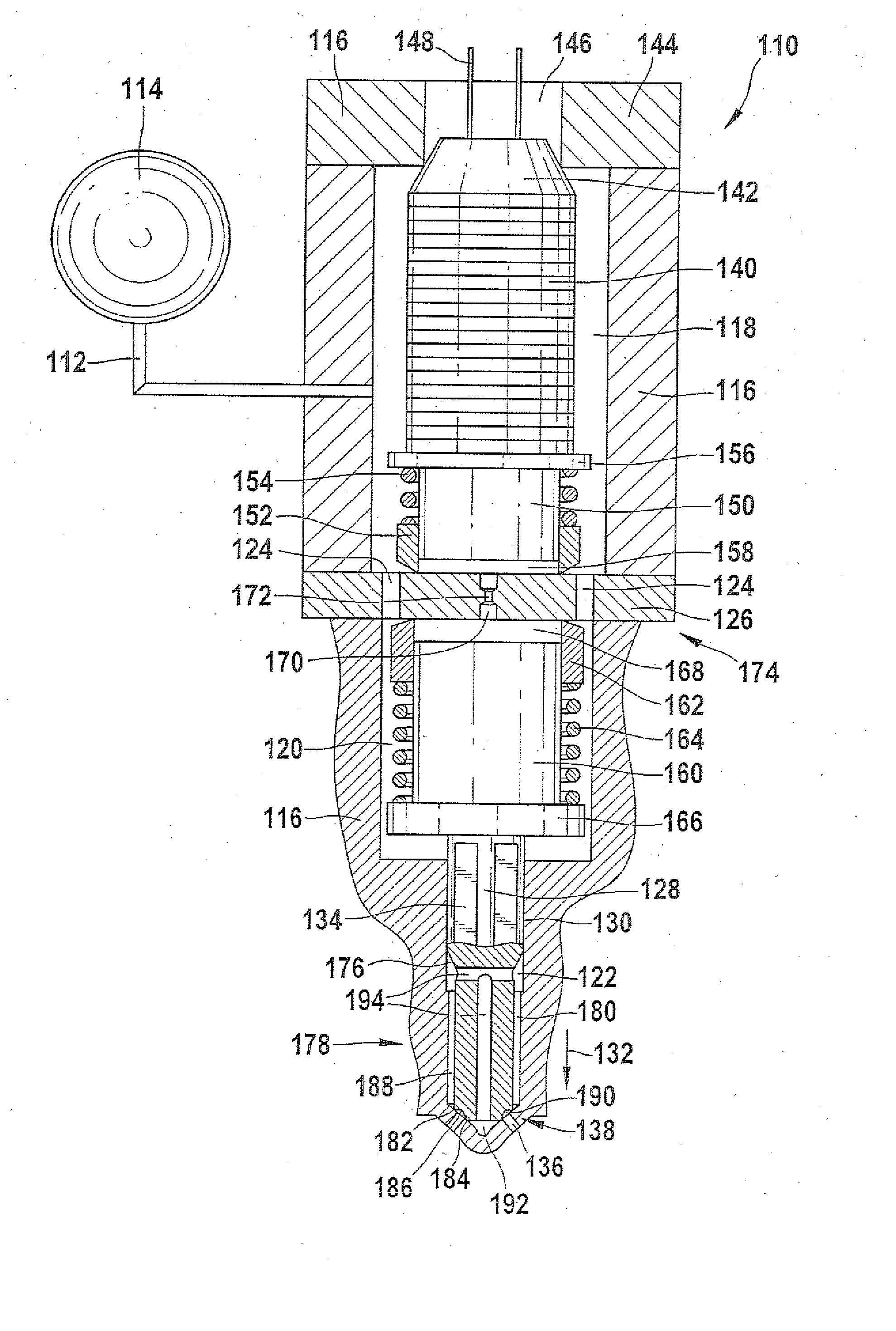

Fuel Injector with Direct-Controlled Injection Valve Member with Double Seat

InactiveUS20080099583A1Shorten the lengthImprove control accuracyMachines/enginesFuel injecting pumpsPiezoelectric actuatorsEngineering

A fuel injector is supplied with fuel under pressure via a high-pressure source and has direct control of an injection valve member by a piezoelectric actuator via a hydraulic booster. The injection valve member of the fuel injector furthermore has a double seat and the injection valve member is provided with two sealing seats which subdivide a nozzle chamber of the fuel injector into three subchambers. When the injection valve member is closed, a first subchamber and a third are in fluidic communication with one another and are supplied with fuel. The second subchamber, which is in communication with injection openings, is conversely fluidically decoupled from the subchambers by the sealing seats. This proposed disposition, with a combination of direct needle control and a double seat of the injection valve member has the advantage that unthrottling of the fuel injector occurs at a very short injection valve member stroke. As a result, even short piezoelectric actuators can in particular be used.

Owner:ROBERT BOSCH GMBH

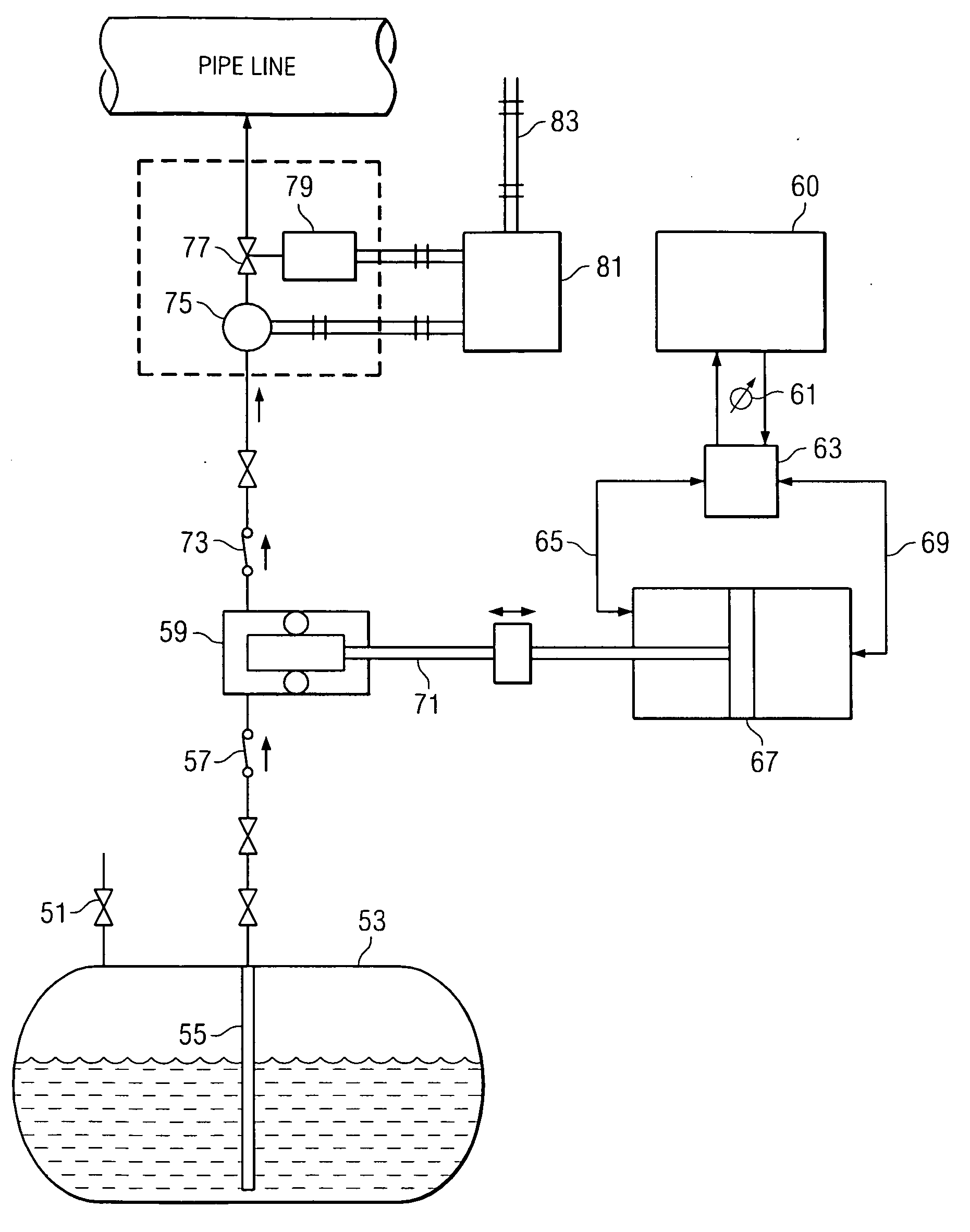

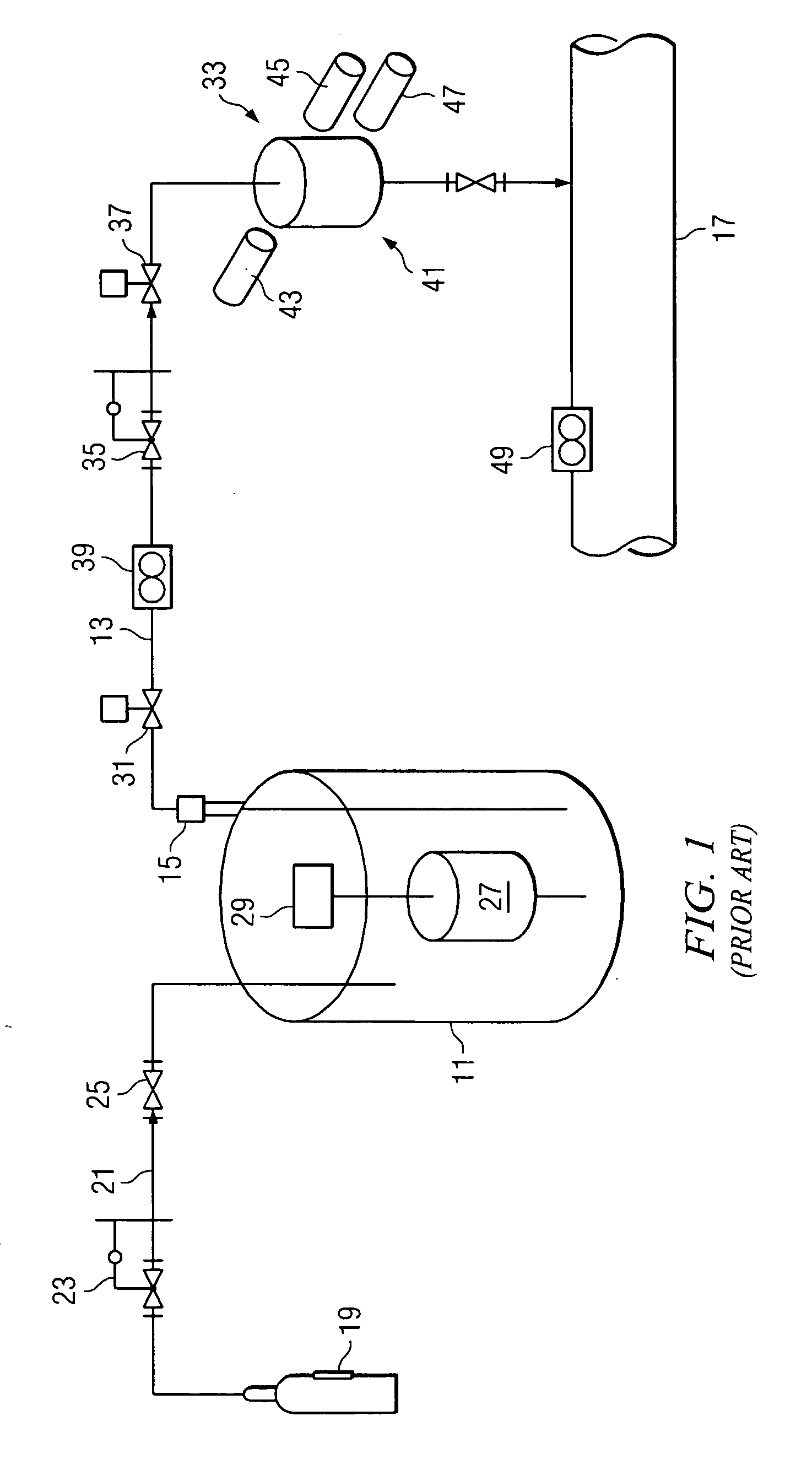

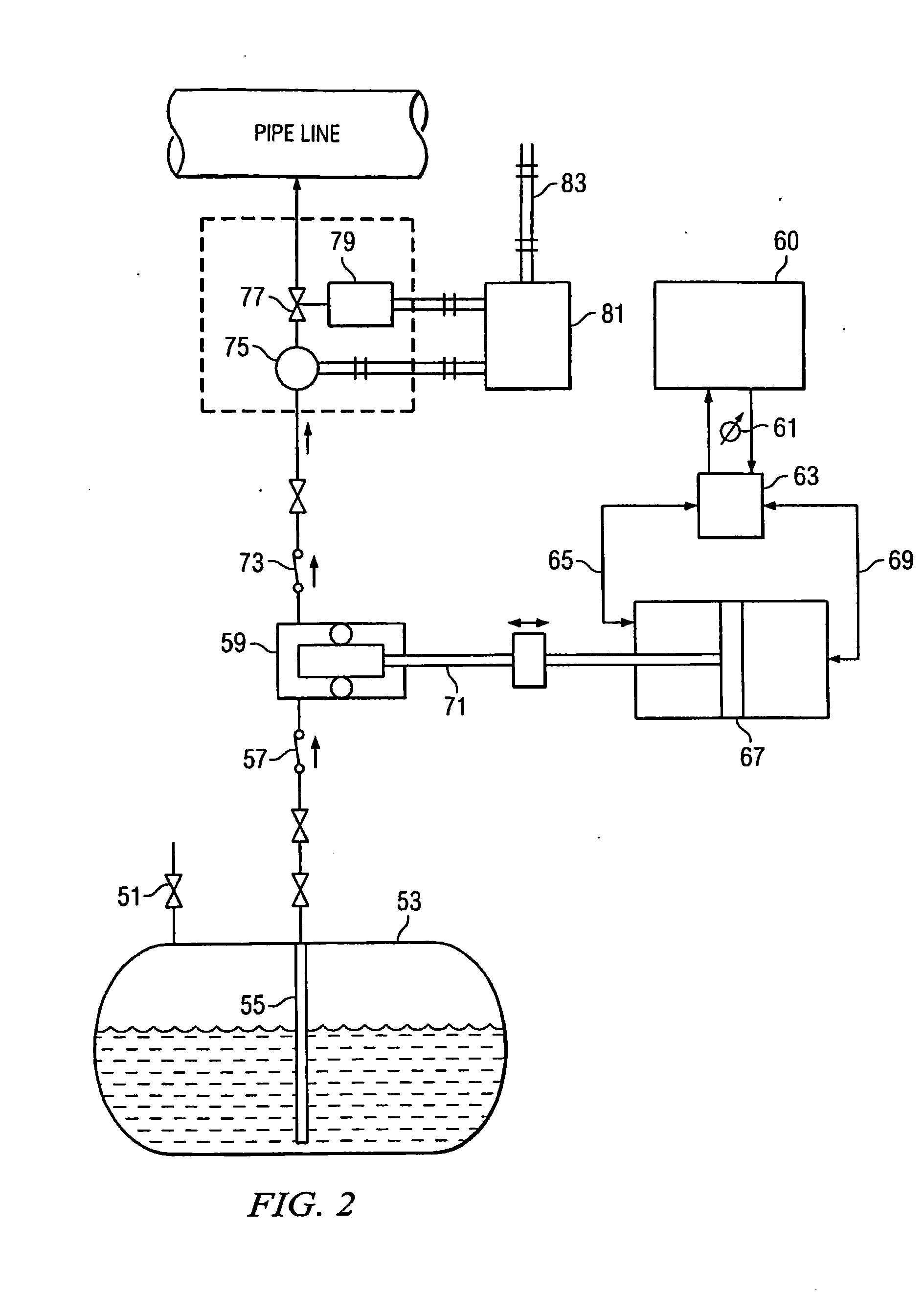

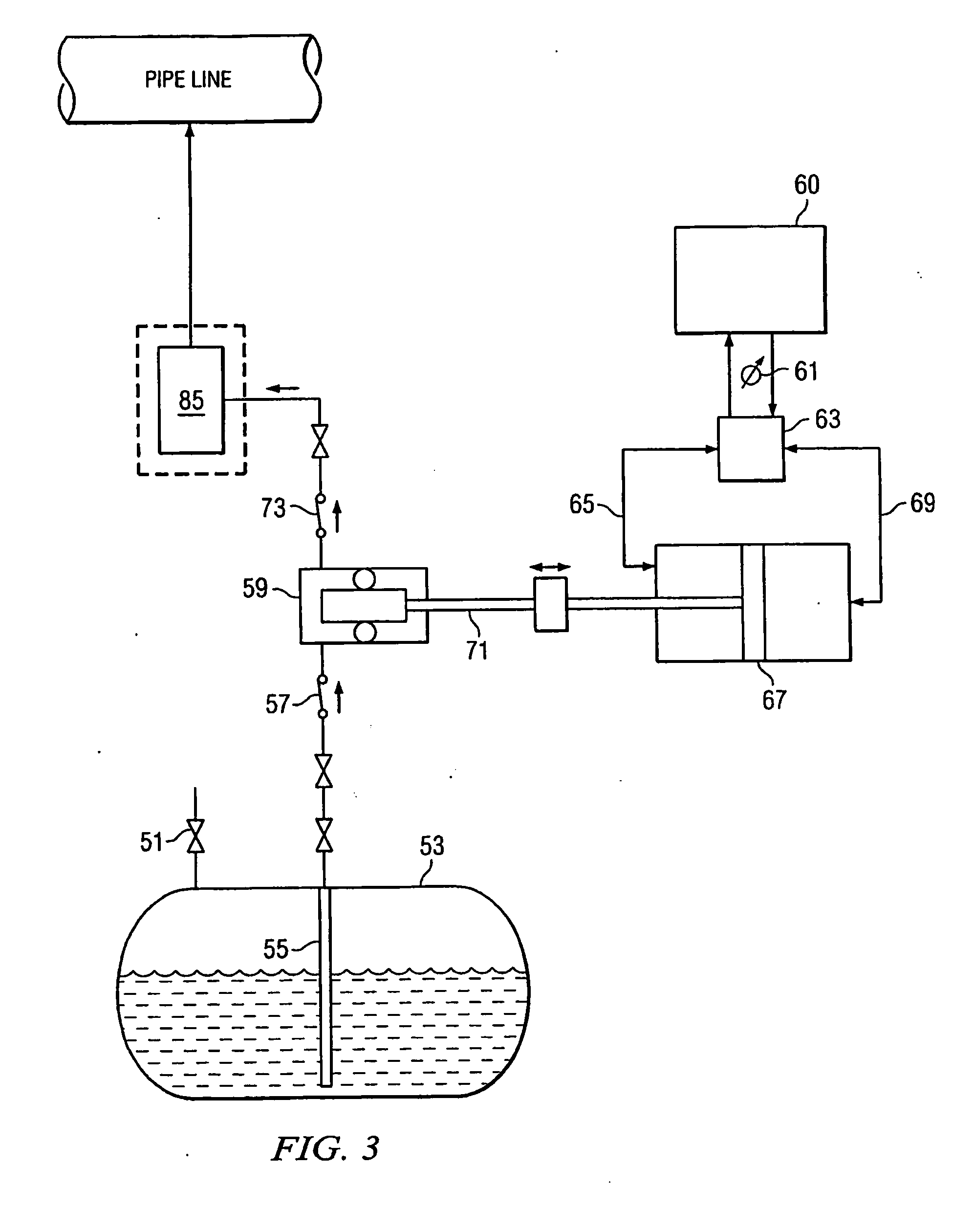

Self Optimizing Odorant Injection System

ActiveUS20090242035A1High volume odorizationSafe perception levelFlow mixersUsing liquid separation agentAmbient pressureEngineering

A system is shown for injecting a chemical, such as an odorant, from a chemical supply into a fluid containing system such as a natural gas pipeline or an LPG pipeline. A tank of odorant is maintained at a pressure above ambient, but below the pressure of the pipeline. An injection conduit communicates the odorant tank with the pipeline. A hydraulic pressure booster is located in the injection conduit for pressurizing the chemical to a pressure above that of the pipeline, the hydraulic booster having a first side which communicates with the chemical in the injection conduit and another, isolated side which is exposed to hydraulic pressure but which is isolated from the chemical being injected. A flow control valve may be located within the injection conduit for metering chemical to be injected into the pipeline.

Owner:LINC ENERGY SYST

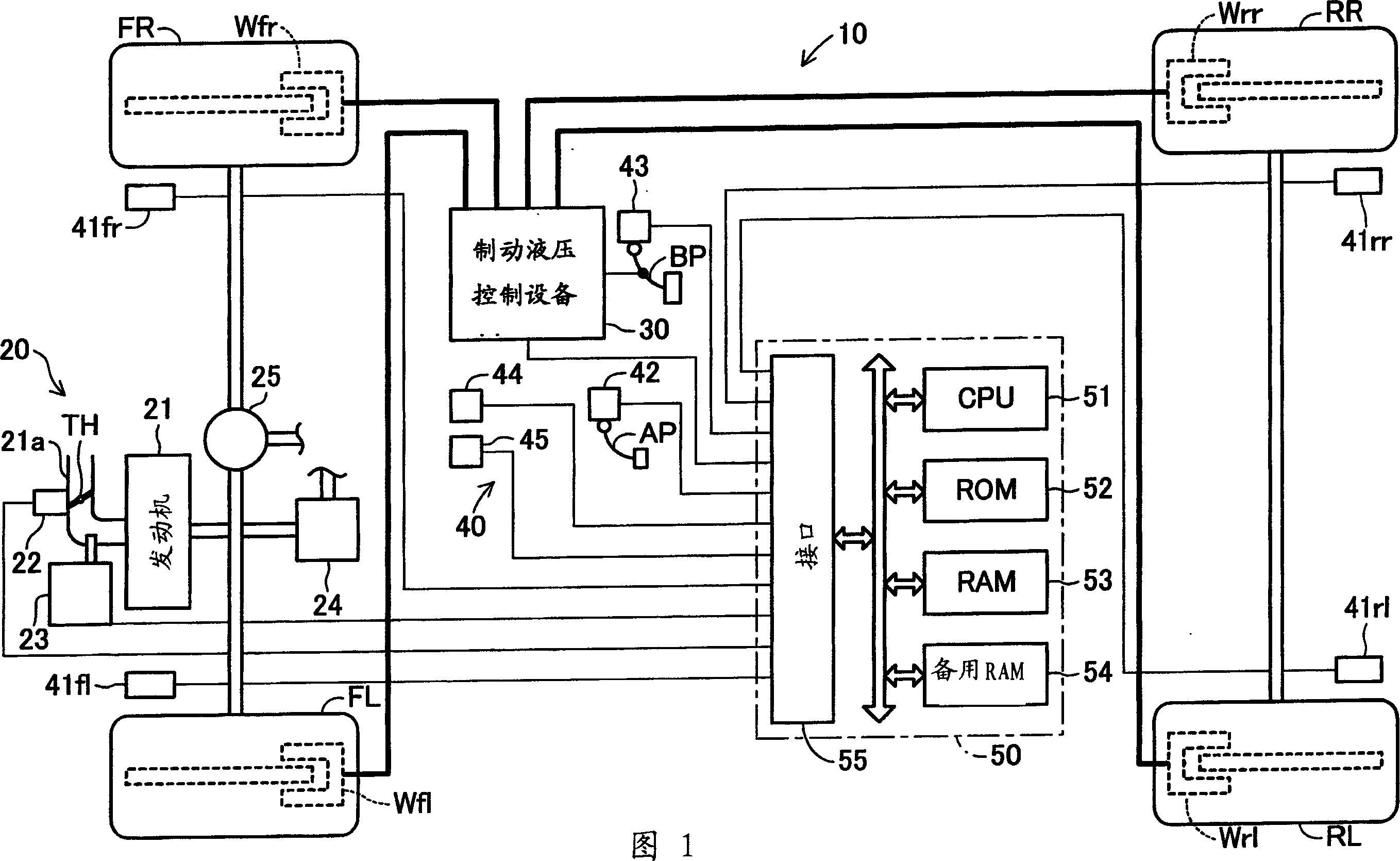

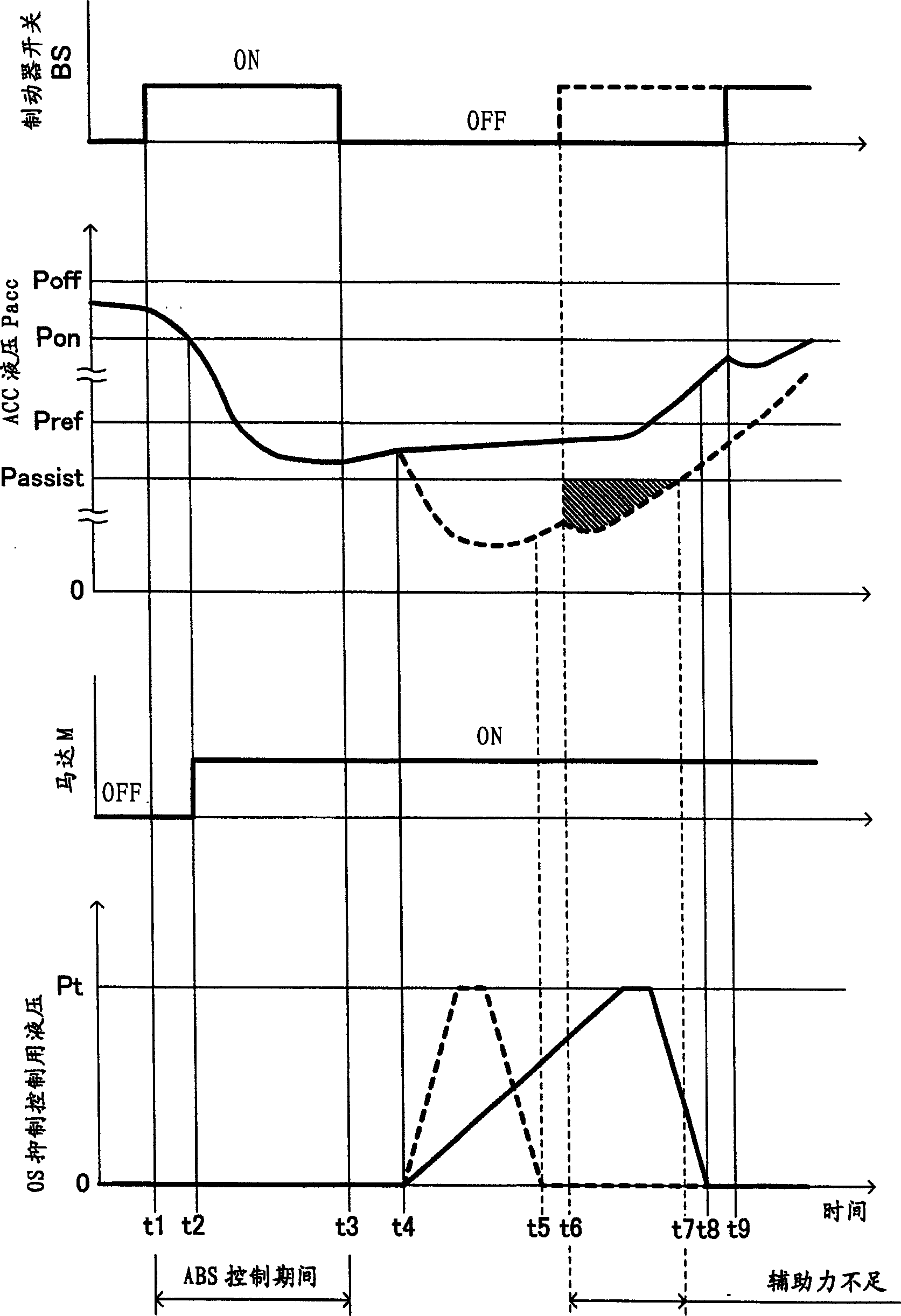

Vehicle motion control apparatus

This apparatus is applied to a vehicle brake apparatus provided with a hydraulic booster operated by utilizing an accumulator hydraulic pressure that is adjusted to a predetermined high pressure (not less than a lower limit value) by a drive control of a hydraulic pump. This apparatus executes an automatic pressurization control by controlling plural solenoid valves with the use of the accumulator hydraulic pressure. The increasing slope of the brake hydraulic pressure during the automatic pressurization control is determined on the basis of the vehicle motion state. The increasing slope is restricted to be not more than a predetermined restriction value, in case where the accumulator hydraulic pressure at the time of starting the automatic pressurization control is less than 'a reference hydraulic pressure that is greater than a minimum value of the accumulator hydraulic pressure necessary for assisting the brake operation by the hydraulic booster and smaller than the lower limit value'.

Owner:ADVICS CO LTD

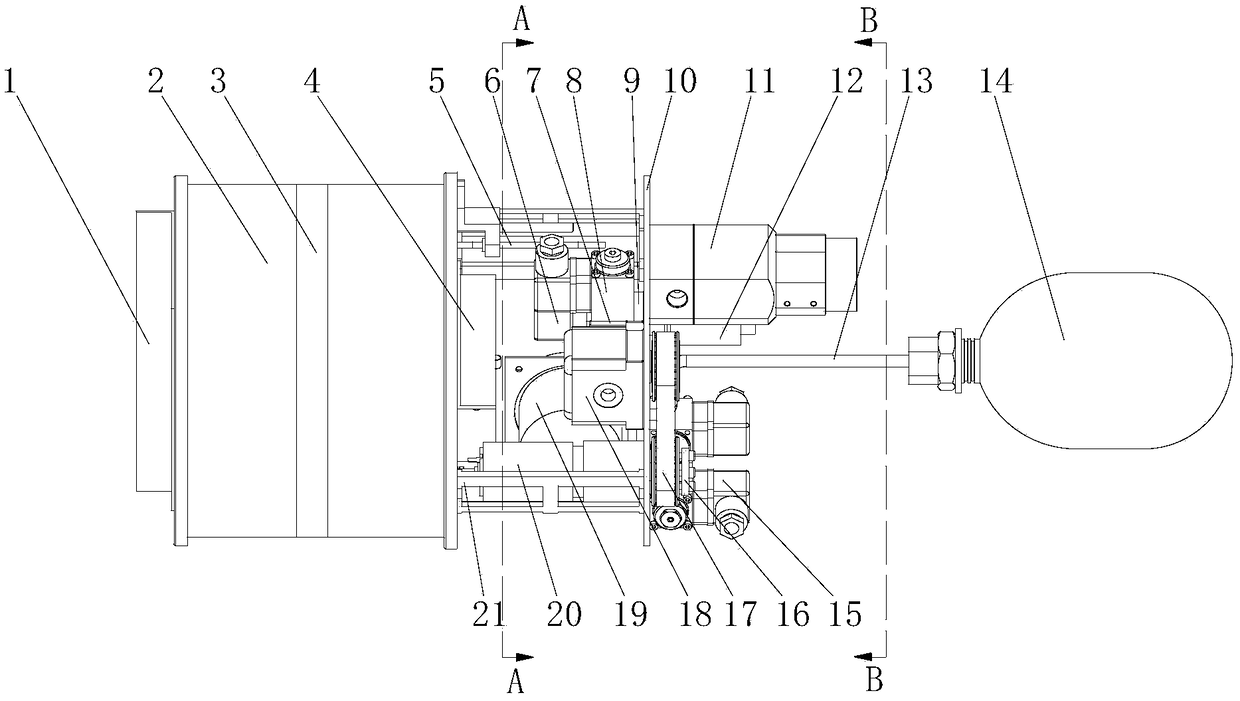

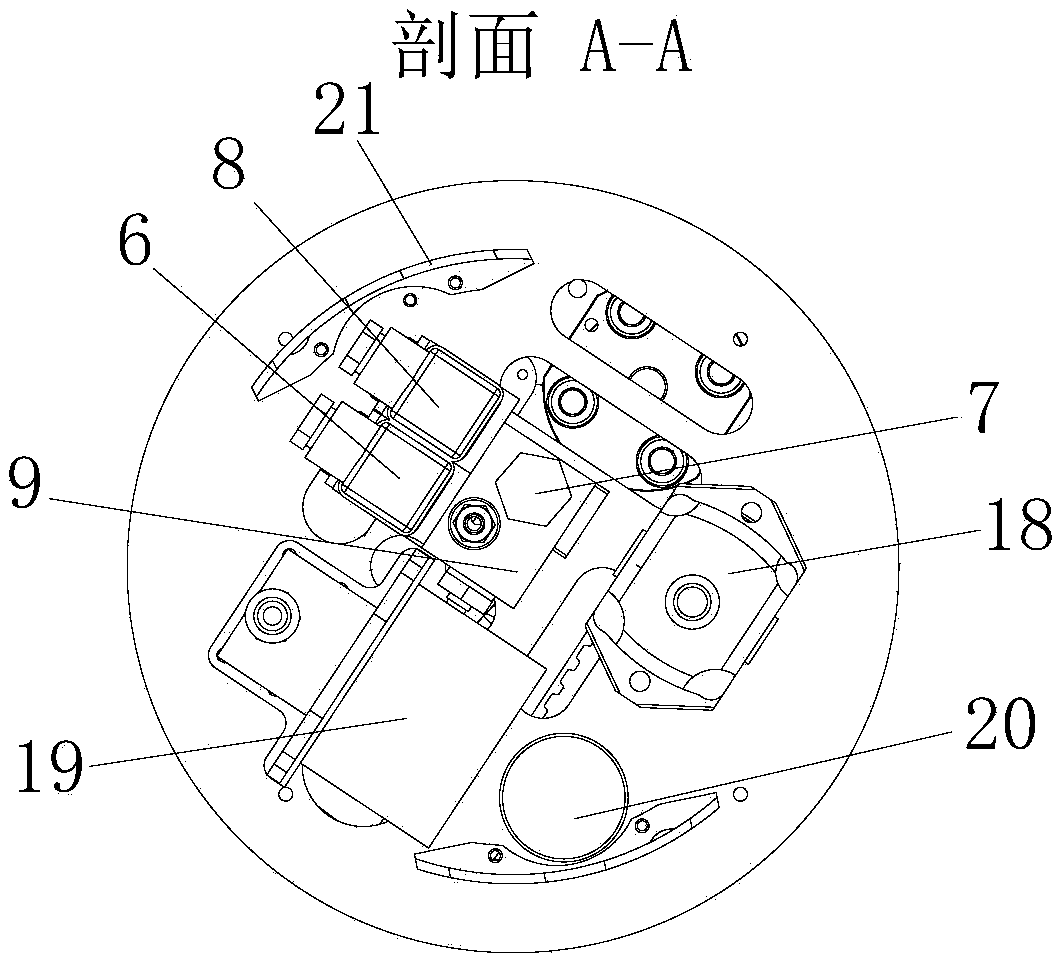

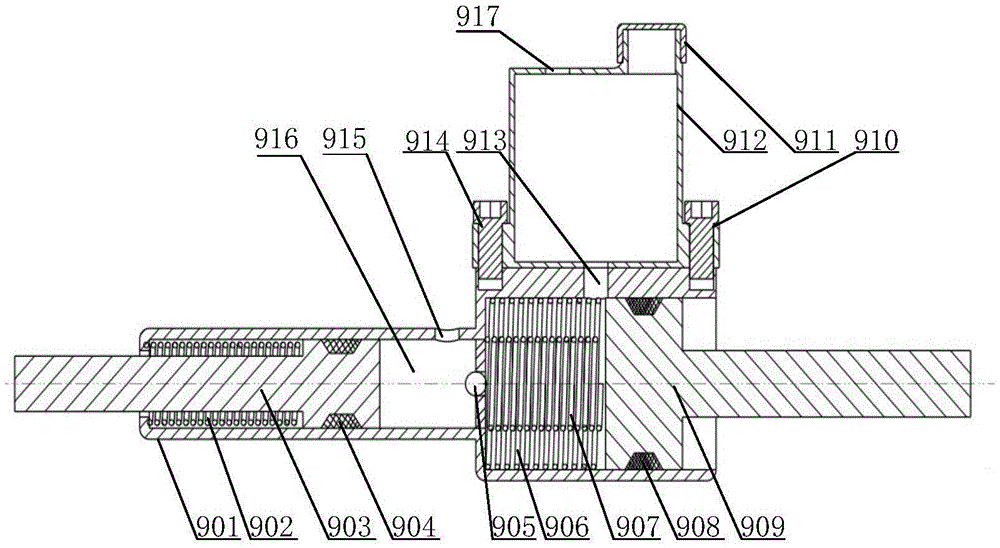

Compact type hydraulic supercharger

ActiveCN108644162AReduce noiseHighly integratedFluid-pressure convertersMechanical engineeringPlunger

The invention relates to a compact type hydraulic supercharger. The compact type hydraulic supercharger is characterized by comprising a valve shell, a left cylinder body with a left plunger cavity, aright cylinder body with a right plunger cavity, a T-shaped piston with an axial channel, a large valve core, a small valve core, a left plunger and a right plunger, wherein the diameter of the largevalve core is larger than that of a valve port, the left plunger is arranged in the left cylinder body and can slide leftward and rightward, the inner end of the left plunger is connected with the left end of the axial channel of the piston and can slide leftward and rightward along with the piston, and the inner end of the right plunger is connected with the right end of the axial channel of thepiston and can slide leftward and rightward along with the piston. The compact type hydraulic supercharger is high in integration level and compact in size. When the second outlet end of a first through-flow hole communicates with an oil return cavity and the left plunger cavity, the left end and the right end of the piston both have certain distances from the bottom surfaces of the correspondingcylinder bodies, so that the effect that reversing of a hydraulic operated directional valve assembly is completed before the piston collides with two end covers is guaranteed. Thus, no impact vibration is generated, and noise is low.

Owner:佛山市力能液压机械有限公司

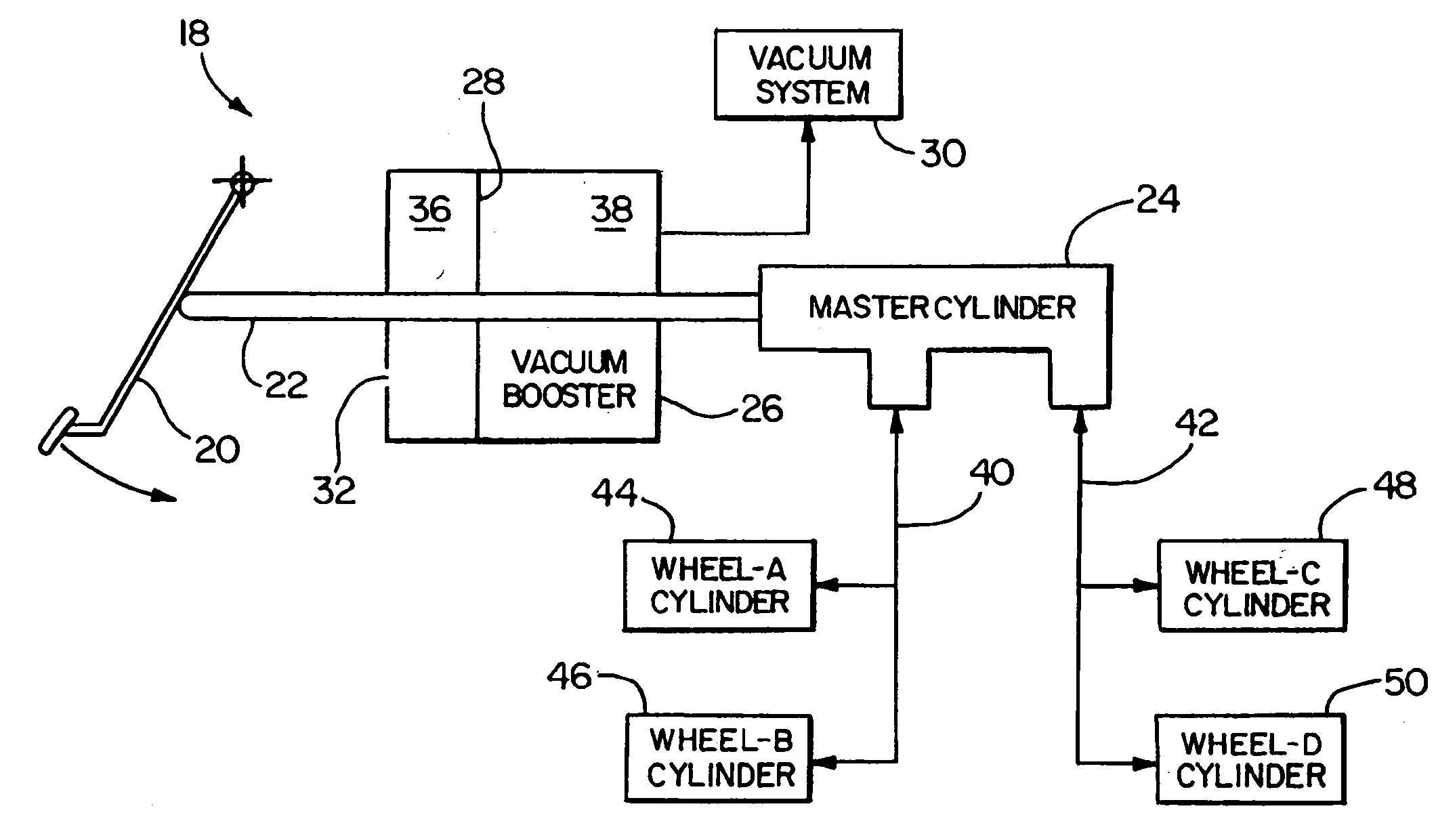

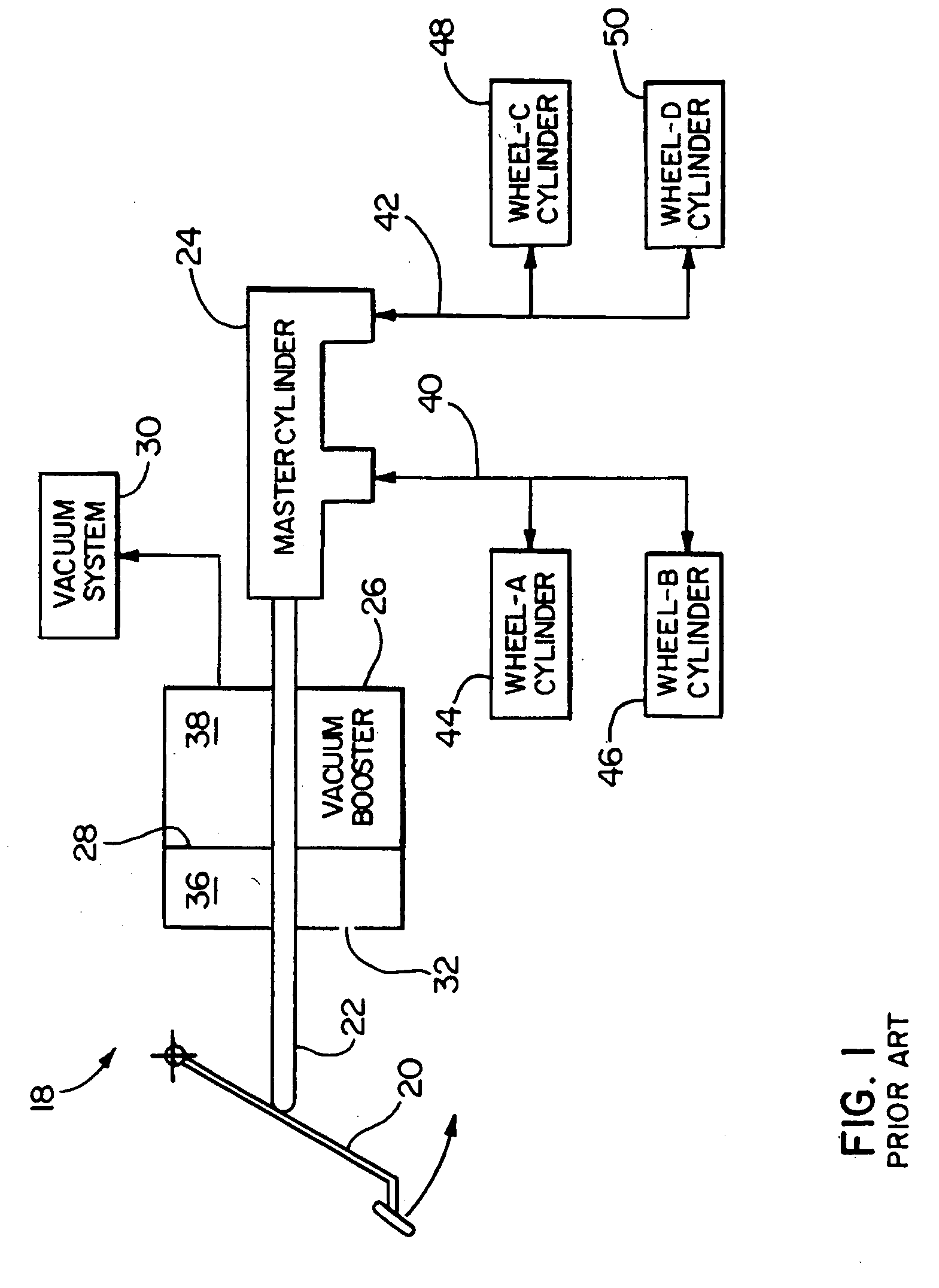

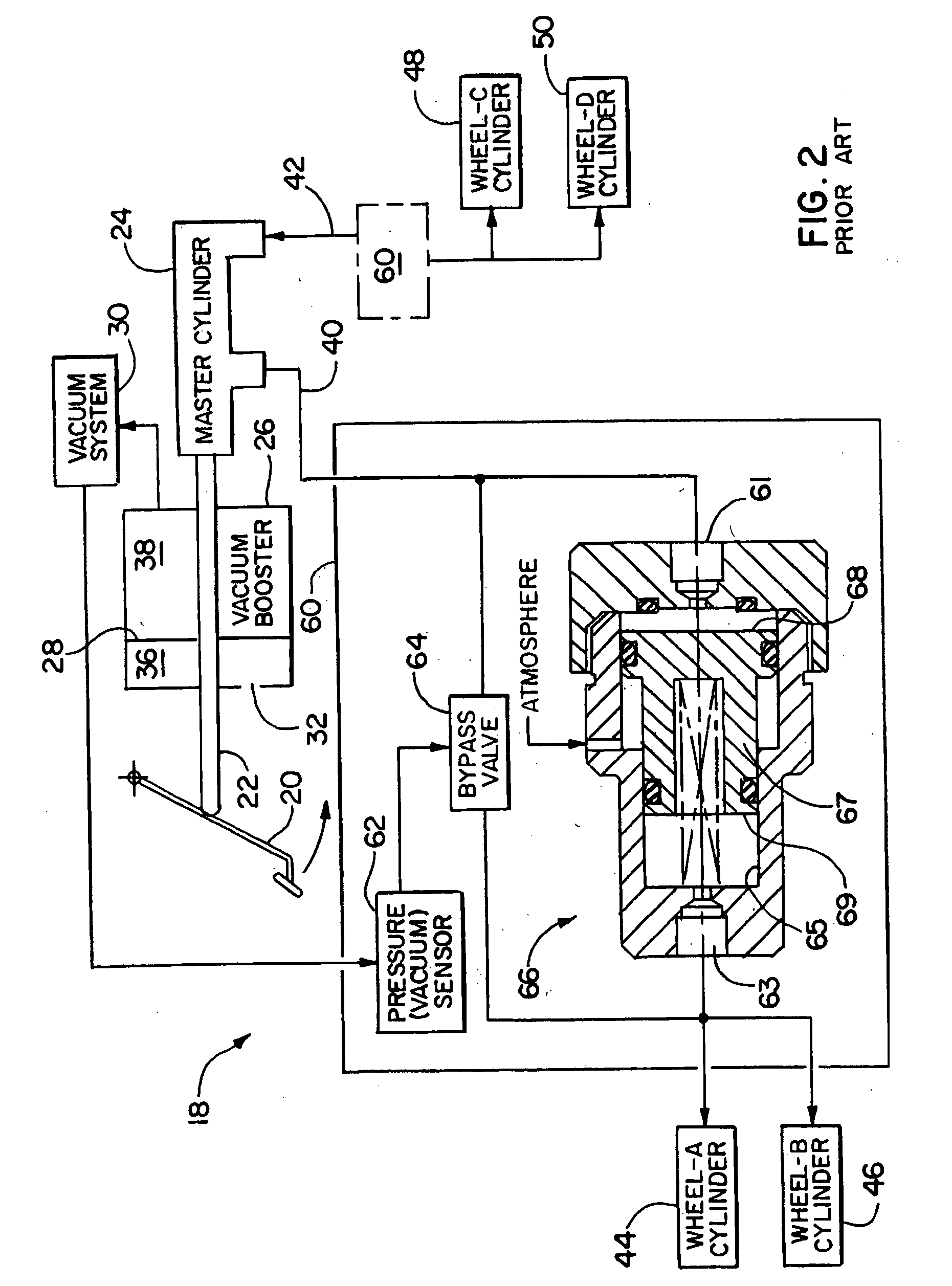

Vacuum actuated brake pressure intensifier

A power brake apparatus includes a hydraulic pressure intensifier apparatus, having a hydraulic pressure intensifier controlled by a vacuum powered actuator. The hydraulic pressure intensifier defines a circuit for hydraulic fluid having an intensifier inlet for receiving hydraulic fluid from a master cylinder of the power brake apparatus at a master cylinder pressure, and an intensifier outlet for selectively delivering hydraulic pressure to a braking device at either the master cylinder pressure or at an intensified pressure higher than the master cylinder pressure. The vacuum powered actuator selectively controls the hydraulic pressure intensifier to deliver hydraulic fluid at the intensifier outlet at the master cylinder pressure when vacuum is available for providing power braking and at the intensified hydraulic pressure when vacuum is not available.

Owner:DELPHI TECH INC

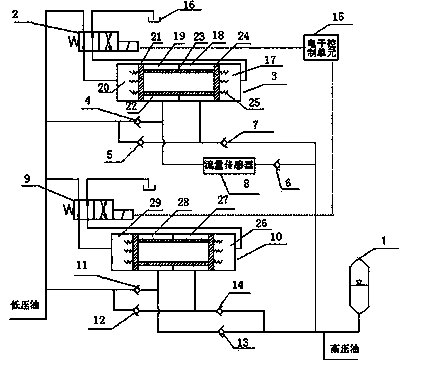

Hydraulic pressurizing energy recovery system and control device

InactiveCN104074812AEasy dischargeSimple structureFluid-pressure convertersFluid-pressure actuator componentsSolenoid valveFuel tank

Provided are a hydraulic pressurizing energy recovery system and a control device. Two sets hydraulic pressurizing energy recovery systems are provided, the first set hydraulic pressurizing energy recovery system is composed of a first solenoid valve, a first hydraulic pressurizer, a first check valve, a second check valve, a third check valve and a fourth check valve, and the second set hydraulic pressurizing energy recovery system is composed of a second solenoid valve, a second hydraulic pressurizer, a fifth check valve, a sixth check valve, a seventh check valve and an eighth check valve. The control device of each hydraulic pressurizing energy recovery system comprises an electronic control unit and a flow sensor. The rest hydraulic devices comprise an energy accumulator and an oil tank. Low-pressure oil is converted into high-pressure oil through a first pressure amplifier and a second pressure amplifier and is stored in the energy accumulator, and pressurizing energy recovery is completed. According to signals of the flow sensor, the electronic control unit controls the first solenoid valve and the second solenoid valve to be opposite in working position, and controls the first pressure amplifier and the second pressure amplifier to be opposite in moving direction, therefore hydraulic shocking is avoided.

Owner:QINGDAO UNIV

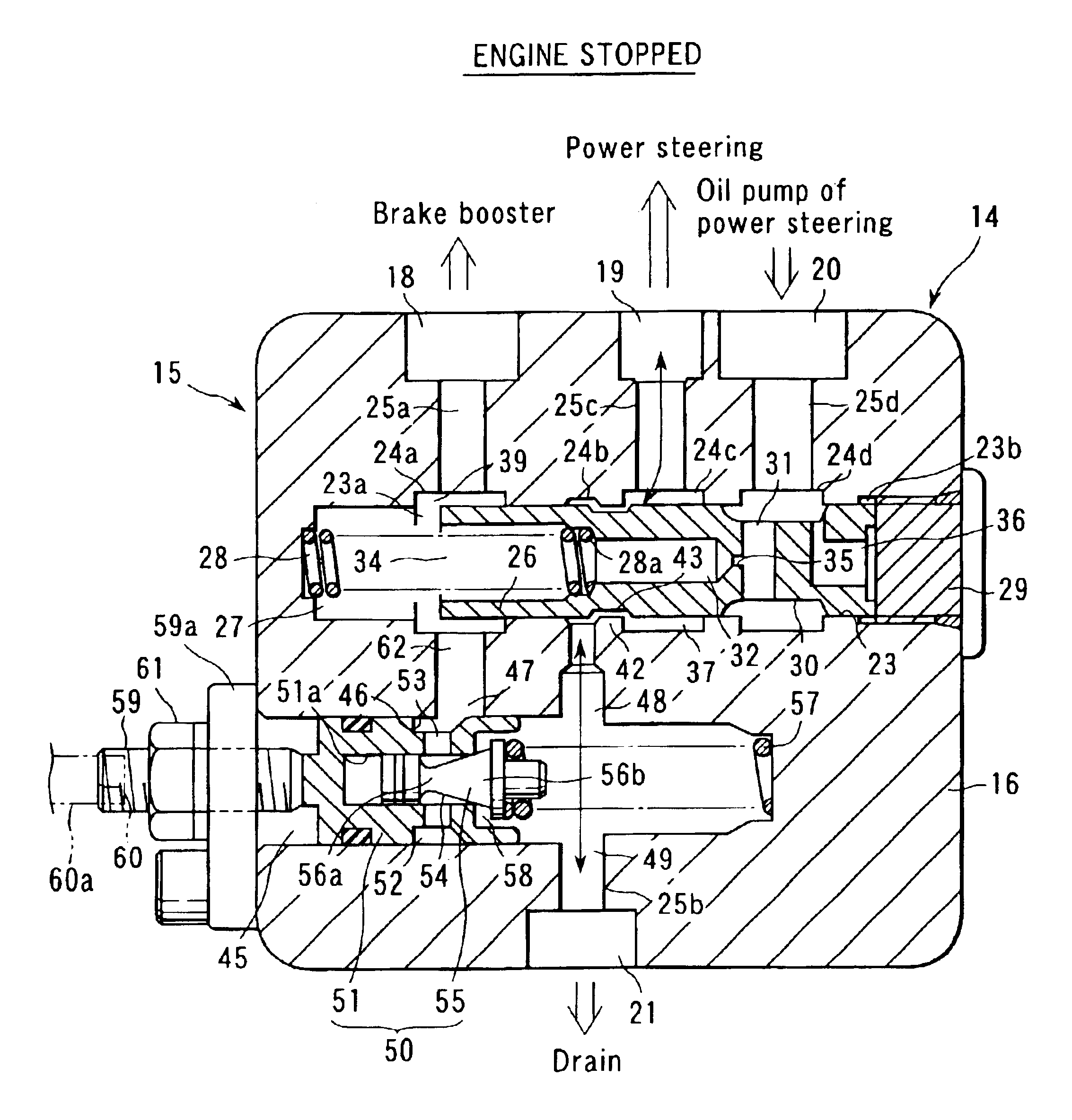

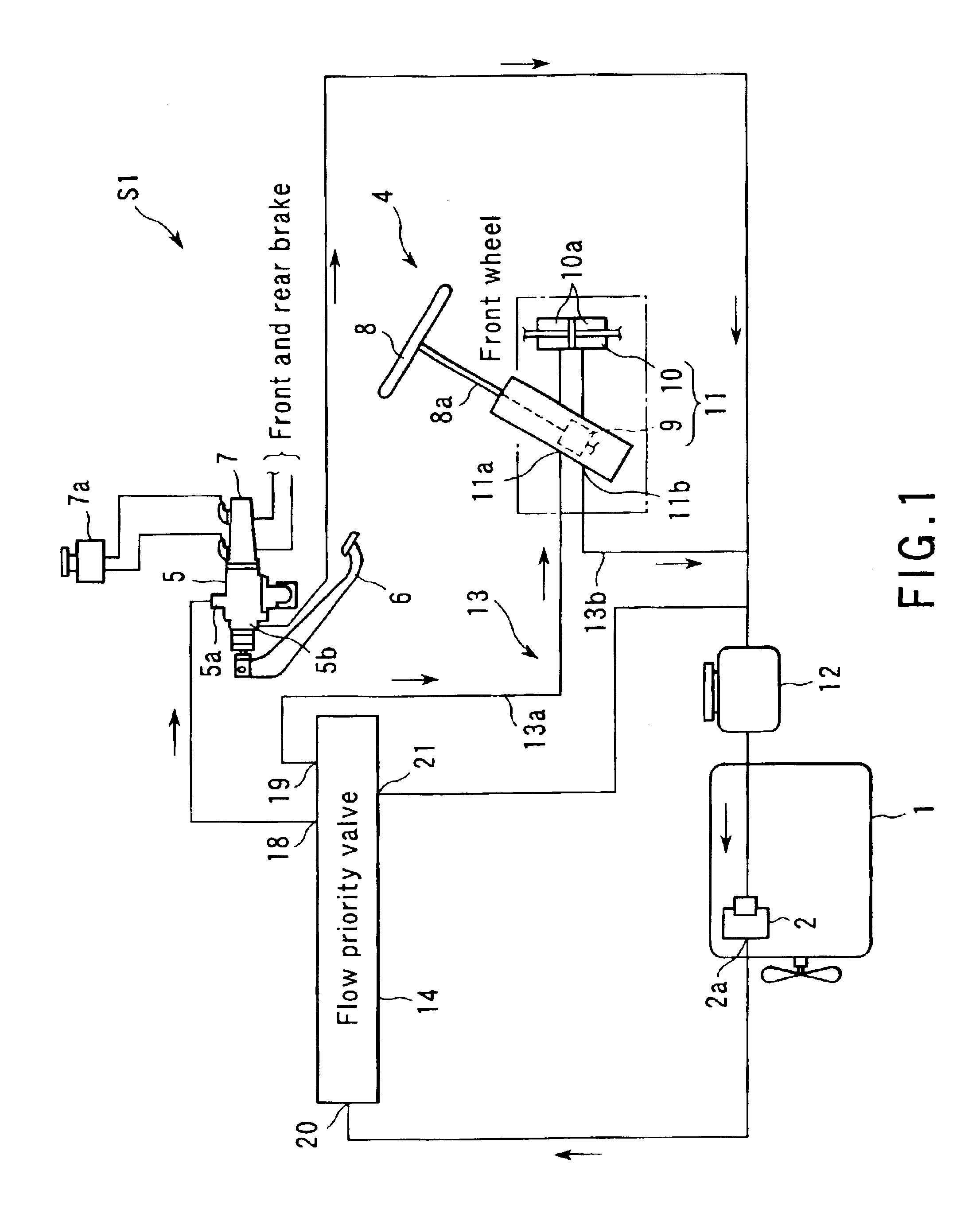

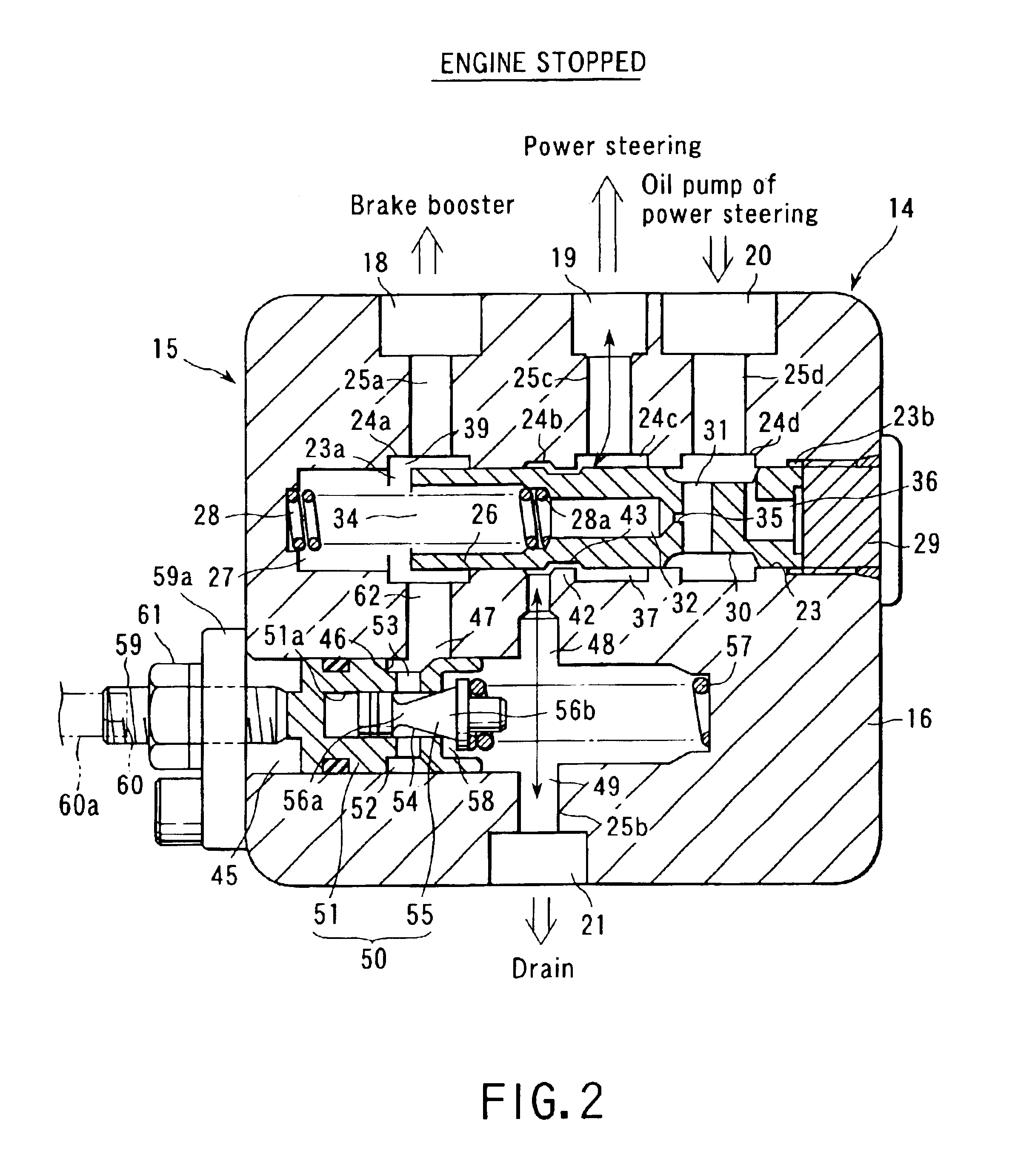

Hydraulic booster brake system

InactiveUS6959639B2Simple structureContainment leakBraking action transmissionServomotor componentsHydraulic pumpHydraulic fluid

A hydraulic booster brake system includes a flow priority valve connected to a discharge portion of a hydraulic pump. To the flow priority valve are connected a brake booster and a power steering booster in parallel. The flow priority valve supplies a stipulated flow quantity of a hydraulic fluid in a total flow quantity of the hydraulic fluid discharged by the hydraulic pump to the brake booster by priority. A relief valve is provided between a brake port and a drain port. A valve body of the relief valve can adjust a relief pressure by turning a screw shaft for relief pressure adjustment.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Check valve, and injector with hydraulic booster and check valve

The invention relates to a check valve with a spherical valve element whose service life and operating reliability is considerably increased in relation to conventional check valves. The improved check valve is used in an injector for a fuel injection system of an internal combustion engine, having a hydraulic pressure booster.

Owner:ROBERT BOSCH GMBH

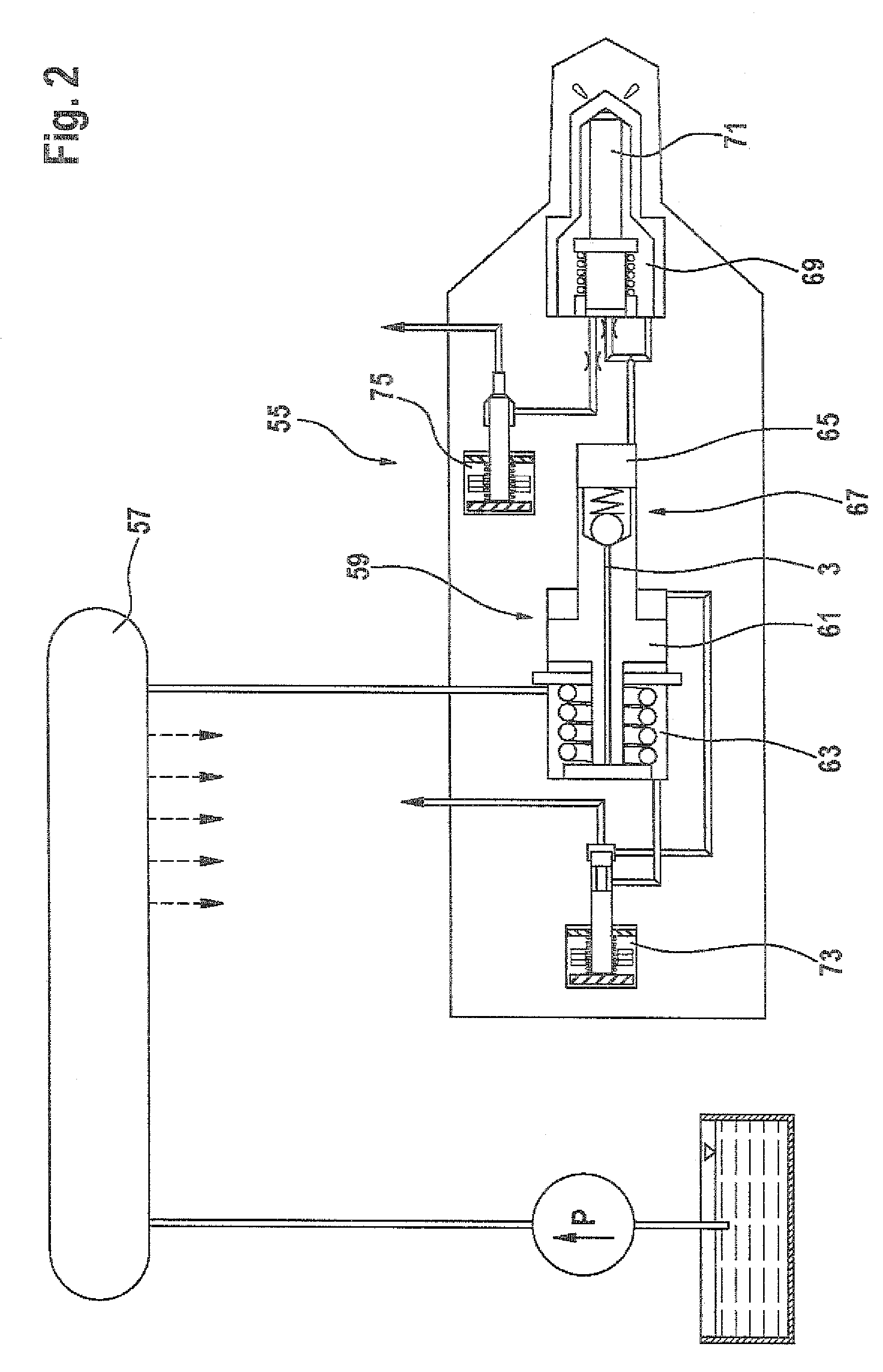

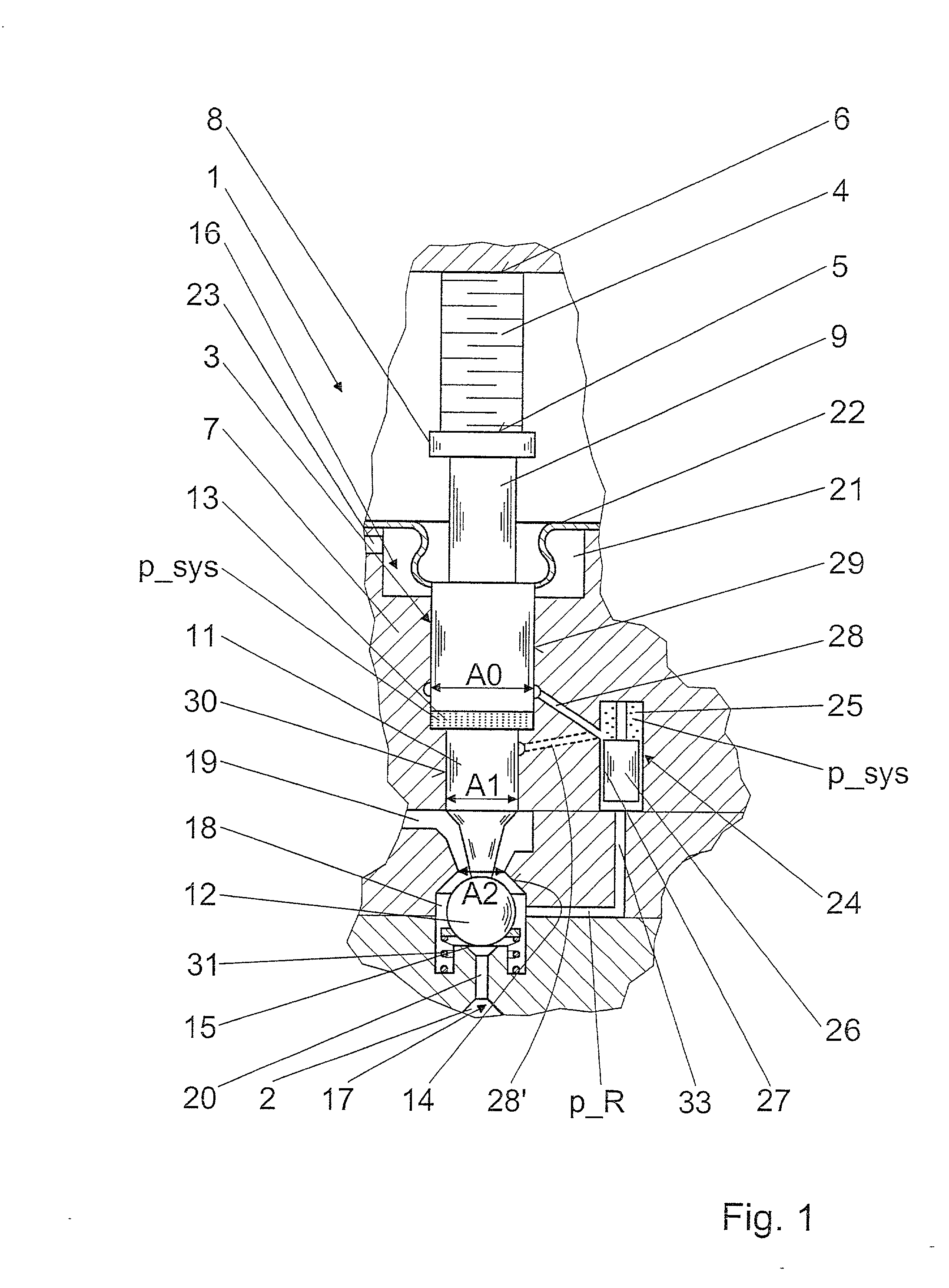

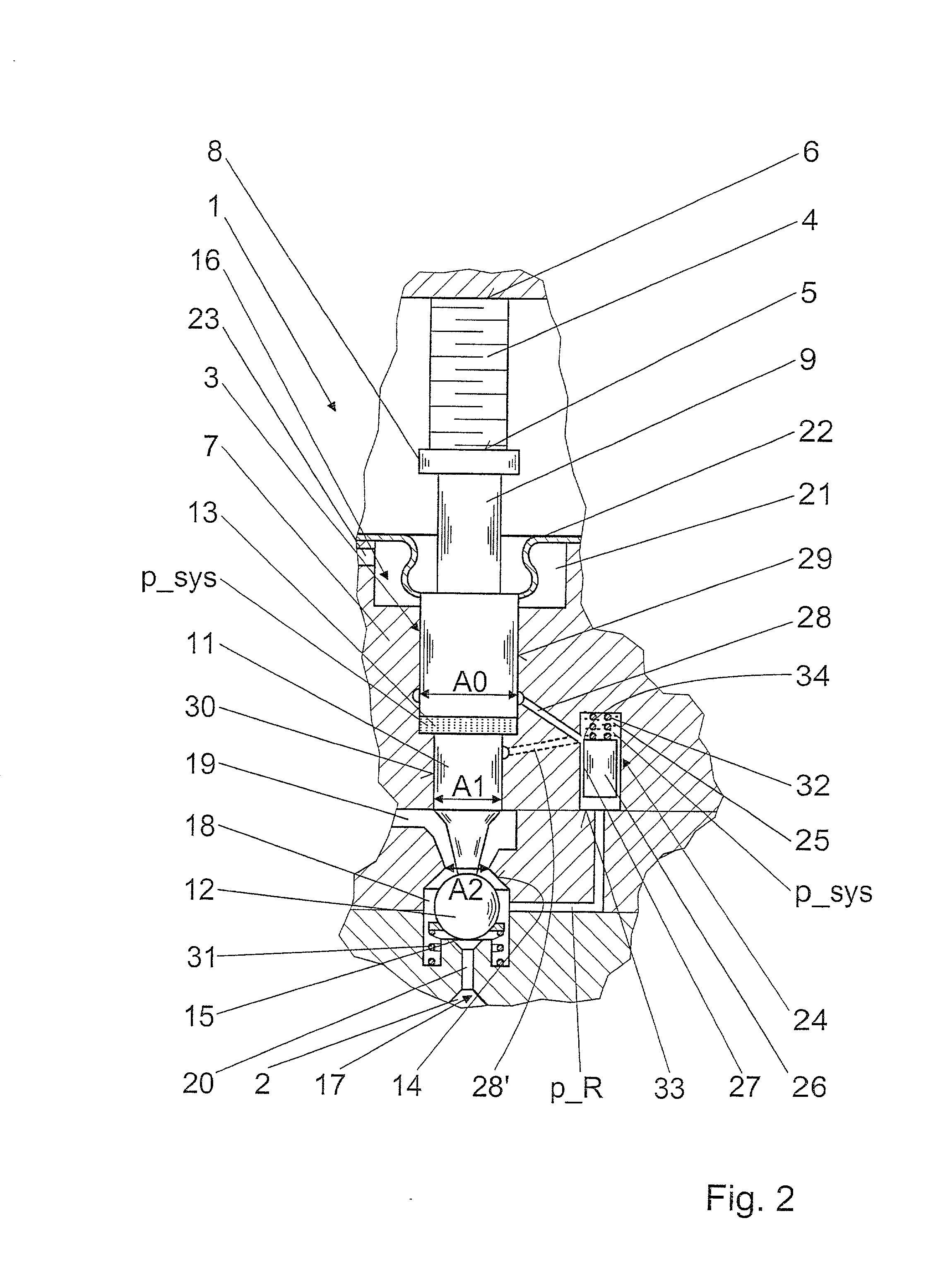

Valve for controlling liquids

InactiveUS20020104976A1Reduce voltageIncrease system pressureOperating means/releasing devices for valvesMovable spraying apparatusLine tubingSystem pressure

The invention relates to a valve for controlling fluids, having an actuator unit (4) for actuating a valve member (3) which has a first piston (9) and a second piston (11), separated from it by a hydraulic chamber (13), and which actuates a valve closing member (12) that divides a low-pressure region (16) at system pressure from a high-pressure region (17). For leakage compensation, a filling device (27) connectable to the high-pressure region (17) is provided with a hollow chamber (25), in which a throttle body (26) is disposed such that a line (33) leading to the high-pressure region (17) discharges into the hollow chamber (25) on one end of the throttle body (26), and on the other end a system pressure line (28) leading to the hydraulic booster branches off. The system pressure (p_sys) is built up as a function of the prevailing pressure (p_R) in the high-pressure region (17), by means of geometrically defining the throttle body (26), a gap (27) surrounding it, and the dimensions of the piston (9) along which the system pressure is reduced (<cross-reference target="DRAWINGS">FIG. 1< / cross-reference>).

Owner:ROBERT BOSCH GMBH

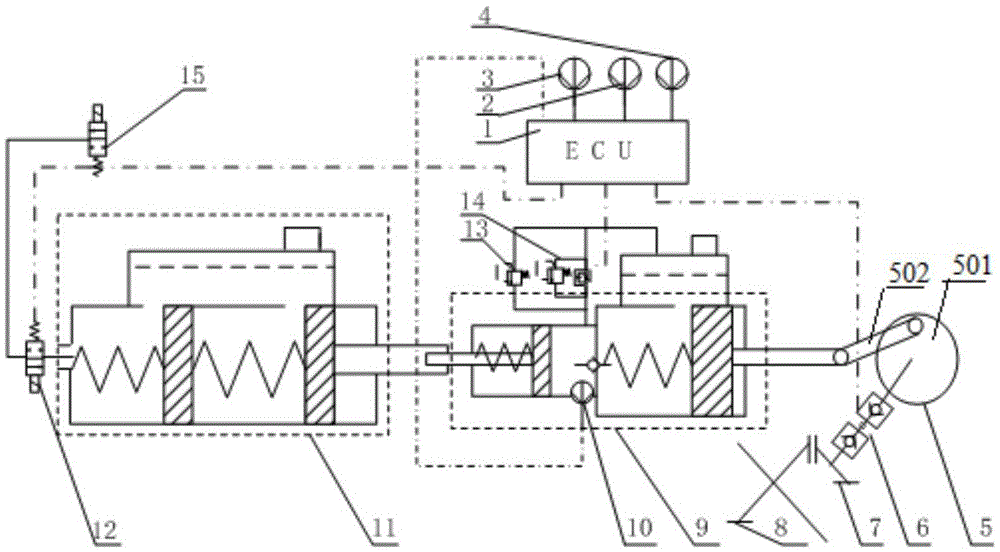

Automatic emergency braking system for automobiles and control method of automatic emergency braking system

ActiveCN105667476ARun fastImprove reliabilityBraking action transmissionAutomatic initiationsAutomatic brakingHigh pressure

The invention relates to an automatic emergency braking system for automobiles and a control method of the automatic emergency braking system, belonging to the field of safe driving of vehicles. The automatic emergency braking system comprises a detection mechanism, an execution mechanism, a hydraulic pressurizing device, an auxiliary braking main cylinder and an electronic control unit; the hydraulic pressurizing device is driven by a driving force of a driving shaft of an automobile to control the pressure of hydraulic oil in a high-pressure cavity of the hydraulic pressurizing device to control a piston a to move, and the piston a pushes the auxiliary braking main cylinder so as to realize grading braking; and the electronic control unit calculates whether the automobile is located at a first safe position S1, a second safe position S2, a second dangerous position S3 or a first dangerous position S4 in real time according to the speed of the automobile or the distance from the automobile to a barrier and controls the execution mechanism to work according to the distance of the automobile, so as to stably and efficiently realize the automatic braking of the automobile. According to the automatic emergency braking system, the hydraulic pressurizing device is driven by virtue of the driving shaft of the automobile, so that the power consumption of an additional electric motor is avoided during the braking, and therefore, the energy consumption is reduced; and by virtue of the grading braking, the riding comfort level is improved.

Owner:TRW AUTOMOTIVE COMPONENTS SHANGHAI

Self-Optimizing Odorant Injection System

ActiveUS20120167465A1Accurately odorizeDeliver small to large volume/strokeFlow mixersMixing methodsThermodynamicsMechanical engineering

A method for injecting a chemical, such as an odorant, from a chemical supply into a fluid-containing system such as a natural gas or an LPG pipeline. A tank of odorant is maintained at a pressure above ambient, but below pipeline pressure. An injection conduit communicates the odorant tank with the pipeline. A hydraulic pressure booster is located in the injection conduit for pressurizing the chemical to a pressure above that of the pipeline. Flow-control apparatus located within the injection conduit for metering chemical to be injected into the pipeline is either (a) drip-style metering valve adjustable between a drop-wise setting and a steady-flow setting or (b) a pair of valves one of which is a flow valve allowing larger volumes to be injected and the other which is a drop-wise flow valve for metering smaller volumes of the chemical.

Owner:LINC ENERGY SYST

Deep-sea emergency reciprocating cable cutting device without built-in power source

ActiveCN111156220AAvoid defacementExtended service lifeServomotor componentsFluid-pressure convertersHydraulic cylinderSolenoid valve

The invention discloses a deep-sea emergency reciprocating cable cutting device without a built-in power source, and belongs to the technical field of marine deep submergence detection equipment. According to the deep-sea emergency reciprocating cable cutting device without the built-in power source, a piston top rod, a hollow piston rod and a top rod cover form a hydraulic cylinder structure form, the hollow piston rod, a cylinder tail cover, a cylinder barrel, a plunger barrel and a plunger head form a hydraulic supercharger structure form, the sea water pressure is converted into the built-in hydraulic oil pressure by using the control of a two-position two-way sea water solenoid valve and a hydraulic on-off valve, the oil pressure is used as the power for shearing, after once shearing,a cutter head can be restored to the initial position by using the sea water pressure, and reciprocating and frequent shearing action of a cable is achieved accordingly; and meanwhile, as the oil-water separation design is adopted in the deep-sea emergency reciprocating cable cutting device, a main moving part can be prevented from being polluted by sea creatures.

Owner:QINGDAO HISUN OCEAN EQUIP

Pressure boosting system for at least one fuel injector

InactiveUS8161947B2Improve efficiencyReduce gapFuel injecting pumpsPiston pumpsPiston GuideInternal combustion engine

The invention relates to a pressure boosting system for at least one fuel injector of a high pressure injection system of an internal combustion engine, having a hydraulic pressure booster that is actuated by a control valve. The hydraulic pressure booster is configured with a pressure boosting piston, which comprises a first pressure booster piston part having a first diameter and a second pressure booster piston part having a second diameter, wherein the first diameter is greater than the second diameter. The pressure booster piston is disposed within a hydraulic reservoir chamber, onto which pressure is applied, together with the first pressure booster piston part having the greater diameter, wherein the accumulator chamber in turn is configured within a base body. The base body has a piston guide body for at least one of the pressure booster piston parts. The piston guide body is at least partially surrounded by an annular space, which is part of the hydraulic accumulator chamber.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com