Hydraulic pressure booster for ultra-high pressure tool

A hydraulic supercharger, ultra-high pressure technology, applied in the direction of fluid pressure converter, fluid pressure actuating device, servo motor components, etc. The effect of strong pollution, long service life and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

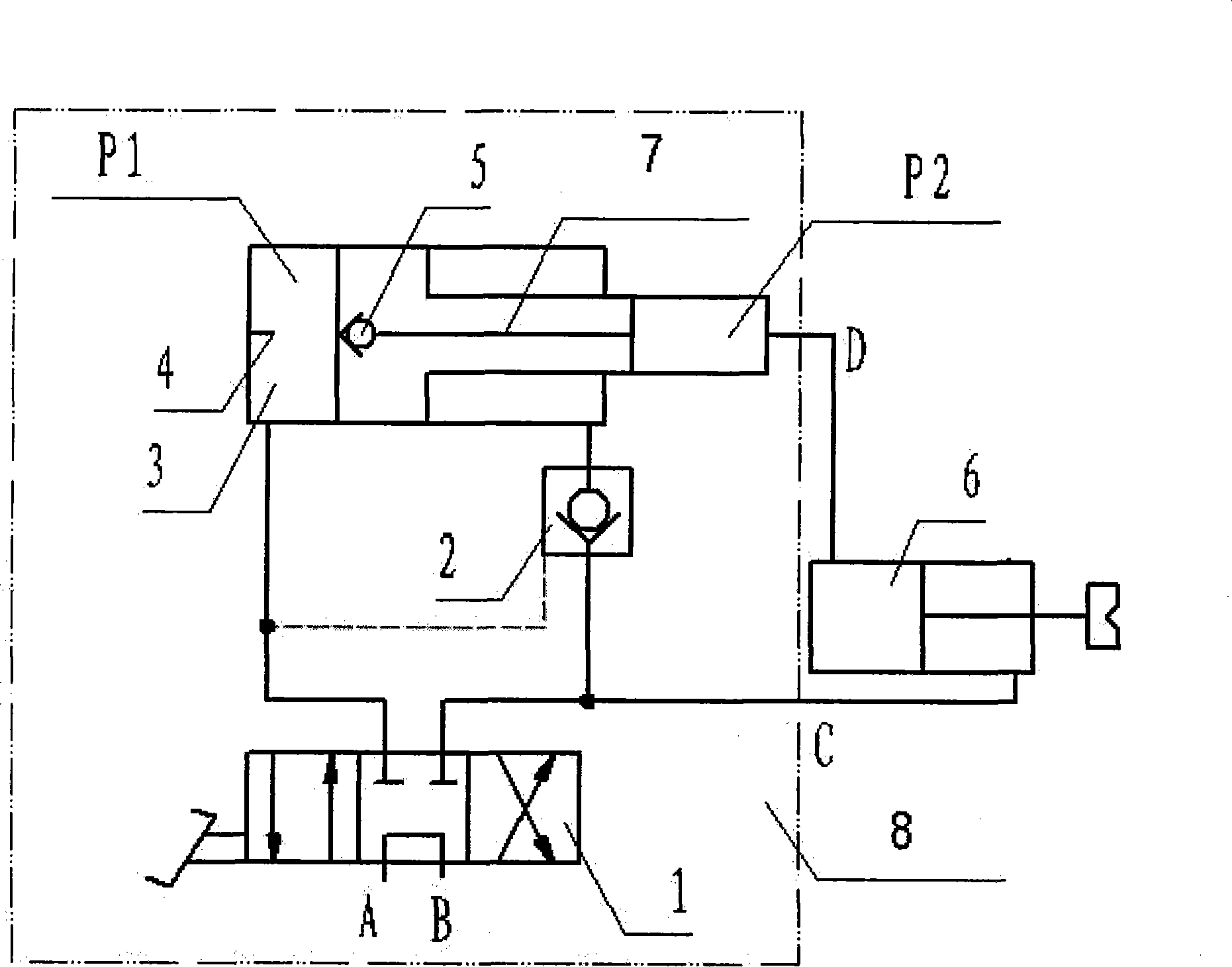

[0029] like figure 1 As shown, the booster 8 of the present invention uses a booster cylinder 3, a conventional pressure element reversing valve 1, and a hydraulic control check valve 2 to form a booster circuit. The booster cylinder 3 is provided with a booster cylinder piston, and the booster cylinder piston separates the booster cylinder into a rodless cavity, a rod cavity and a booster cavity. A push rod 4 is arranged on the end cover of the rodless chamber of the pressurized cylinder. The piston of the booster cylinder is a hollow part, and a check valve 5 and a central hole 7 are arranged in the hollow, and communicate with the pressurization chamber P2. When the piston is fully retracted, the push rod will touch the one-way valve 5 to conduct it, and the outlet end of the one-way valve 5 communicates with the pressurization chamber P2 through the central hole 7 . The pressurized cylinder 3 has a hydraulic control check valve 2 on the oil circuit of the rod cavity.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com