Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

851 results about "Hydraulic accumulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydraulic accumulator is a pressure storage reservoir in which a non-compressible hydraulic fluid is held under pressure that is applied by an external source of mechanical energy. The external source can be an engine, a spring, a raised weight, or a compressed gas. An accumulator enables a hydraulic system to cope with extremes of demand using a less powerful pump, to respond more quickly to a temporary demand, and to smooth out pulsations. It is a type of energy storage device.

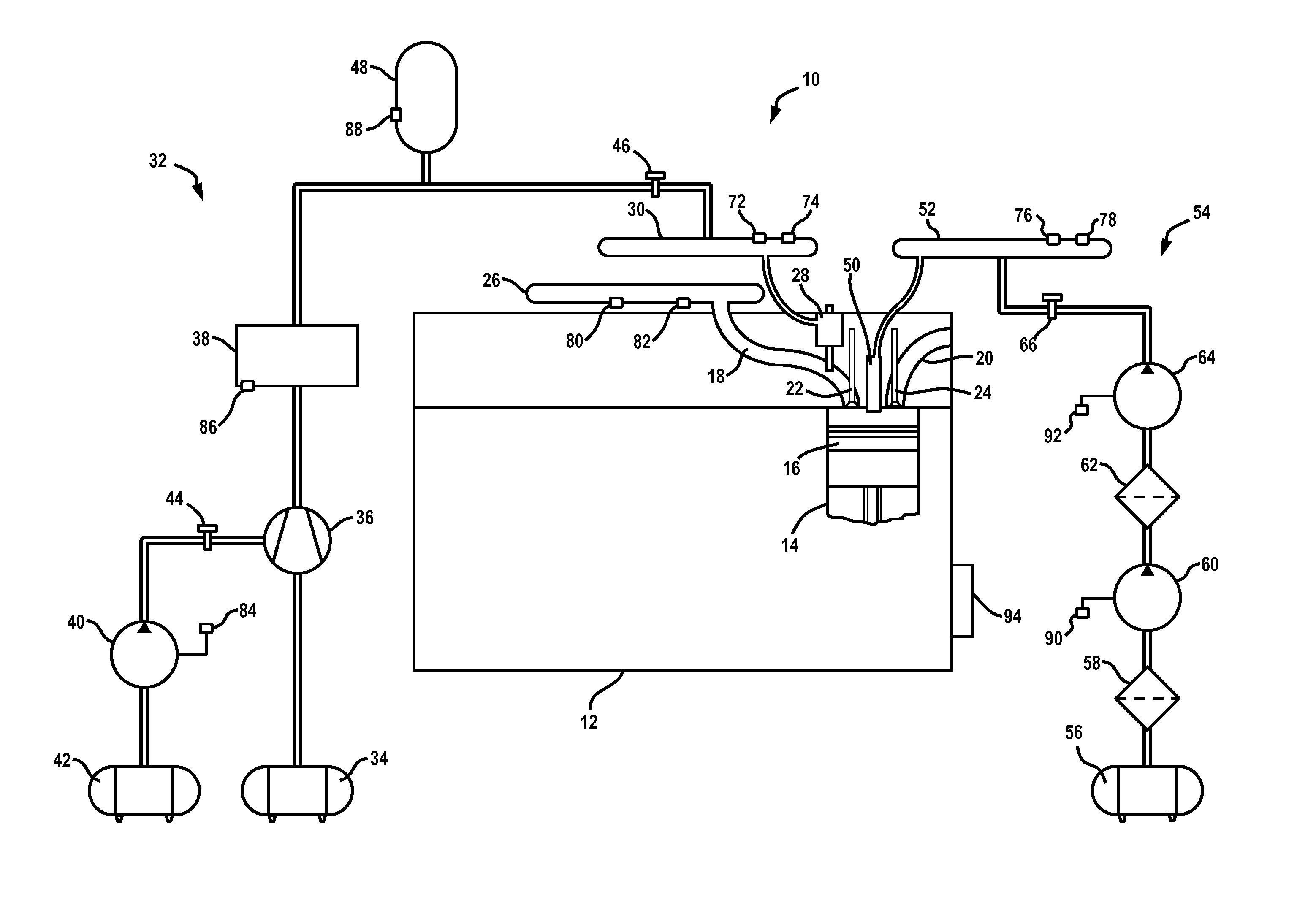

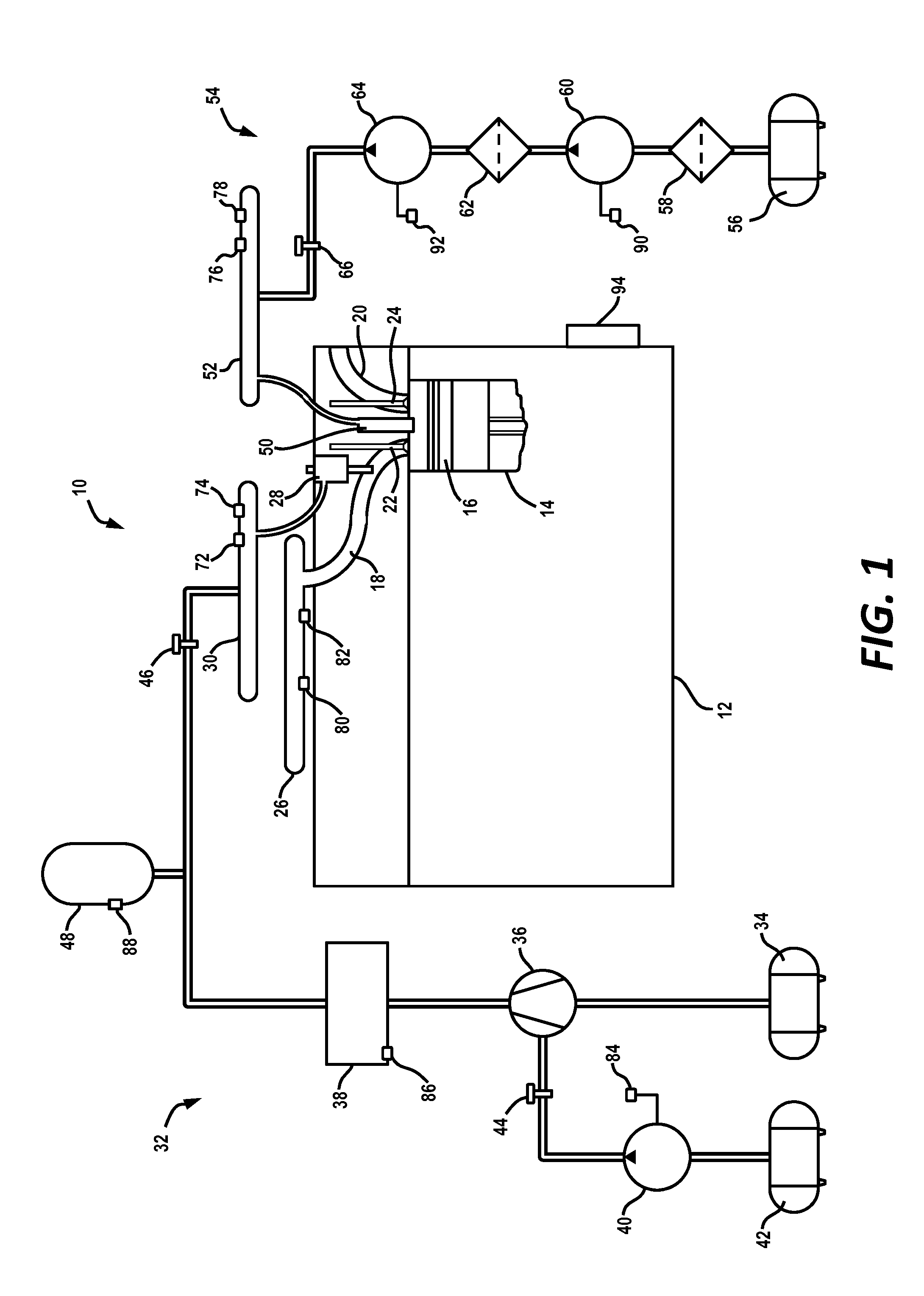

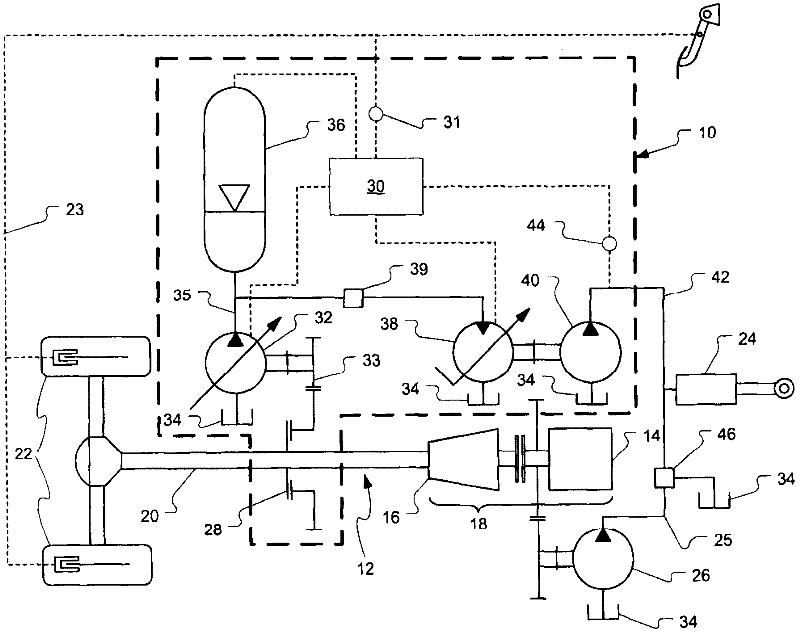

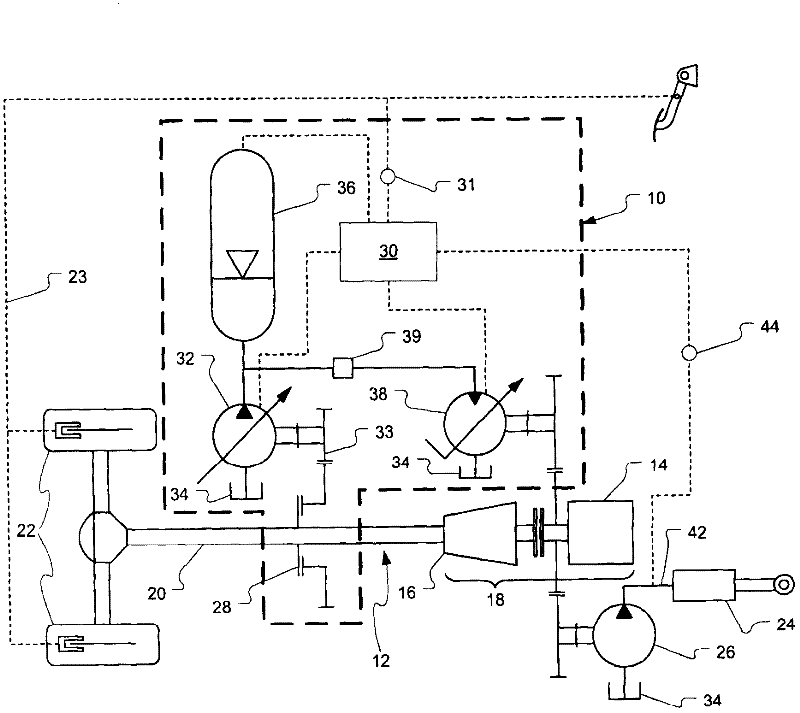

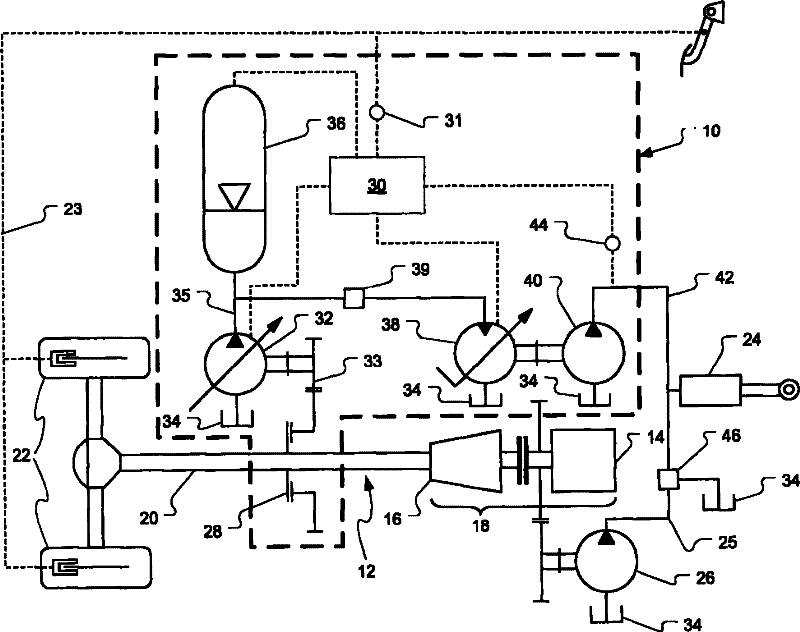

Hybrid Pump Control for Multi Fuel Engine System

ActiveUS20150226140A1High energyElectrical controlInternal combustion piston enginesHydraulic pumpElectro hydraulic

In an engine system of a machine having a multi fuel engine system, an energy accumulator is provide to accumulate and store energy when the engine system is in a low engine power usage or low engine load state, and to discharge energy from the energy accumulator when the engine system is in a high engine usage or high engine load state. The energy accumulator may be implemented, for example, in the form of a gaseous fuel accumulator that delivers gaseous fuel to the engine, a hydraulic fuel accumulator that provides pressurized fluid to power a fuel pump, or a battery pack that powers an electric hydraulic pump.

Owner:CATERPILLAR INC

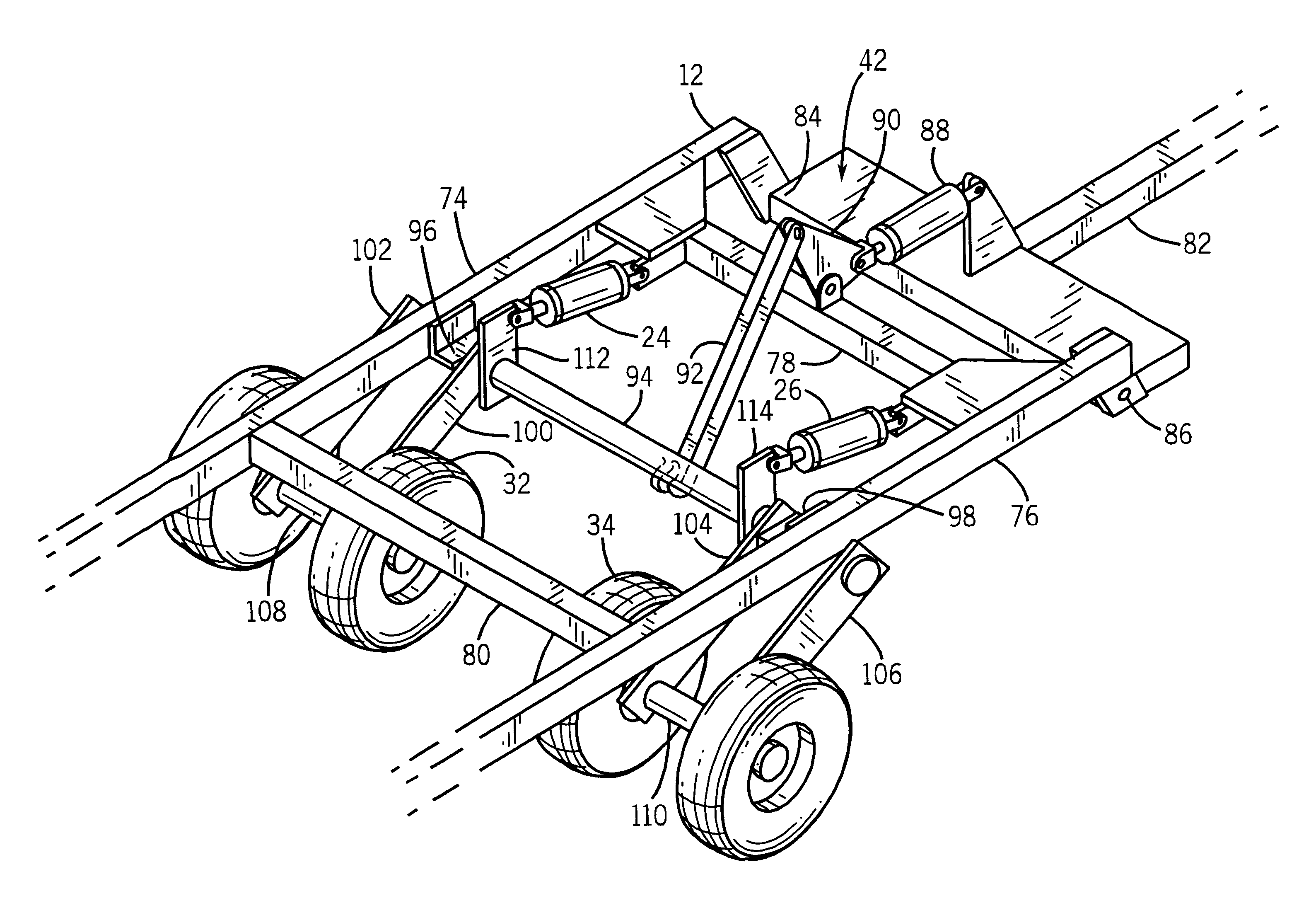

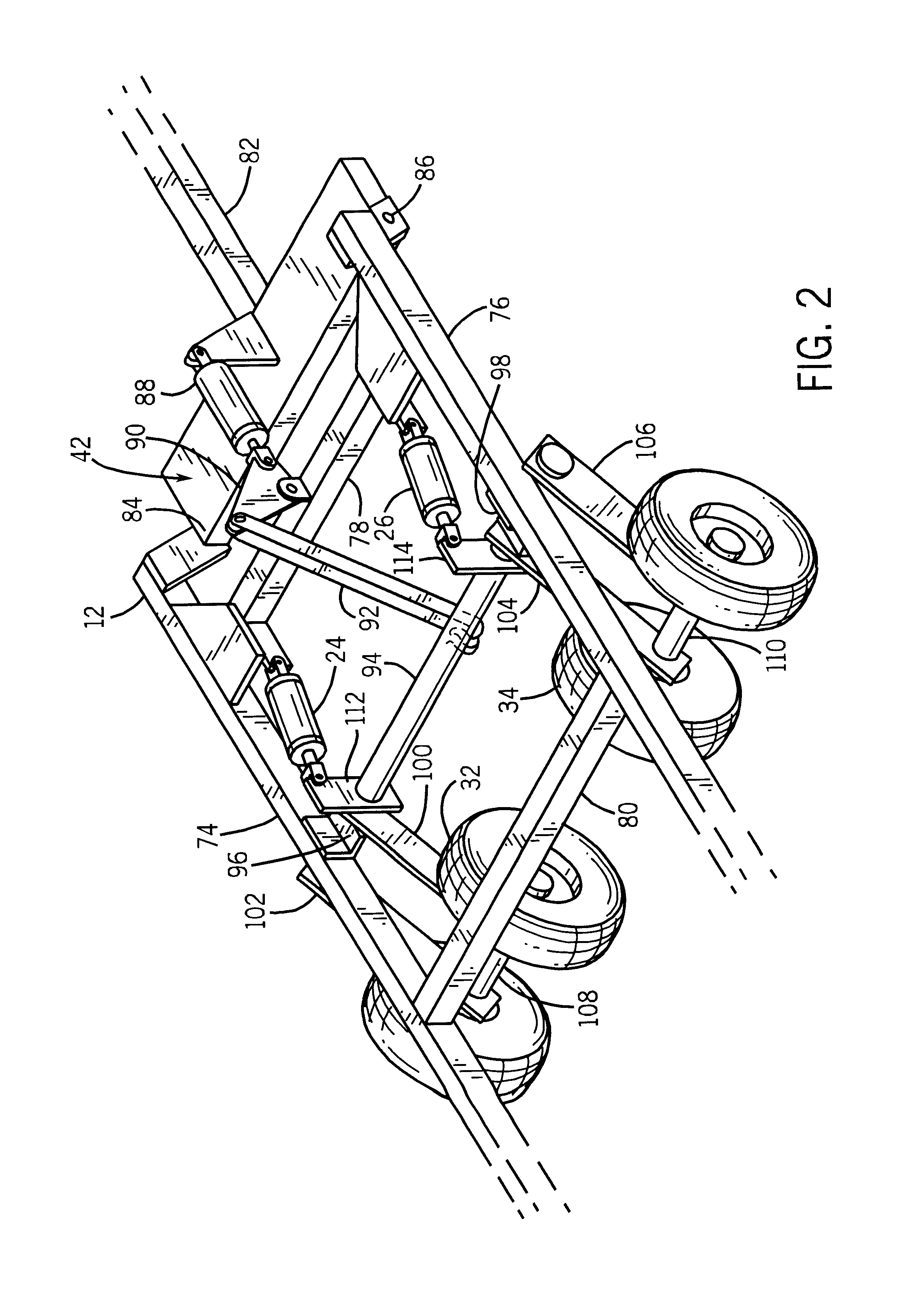

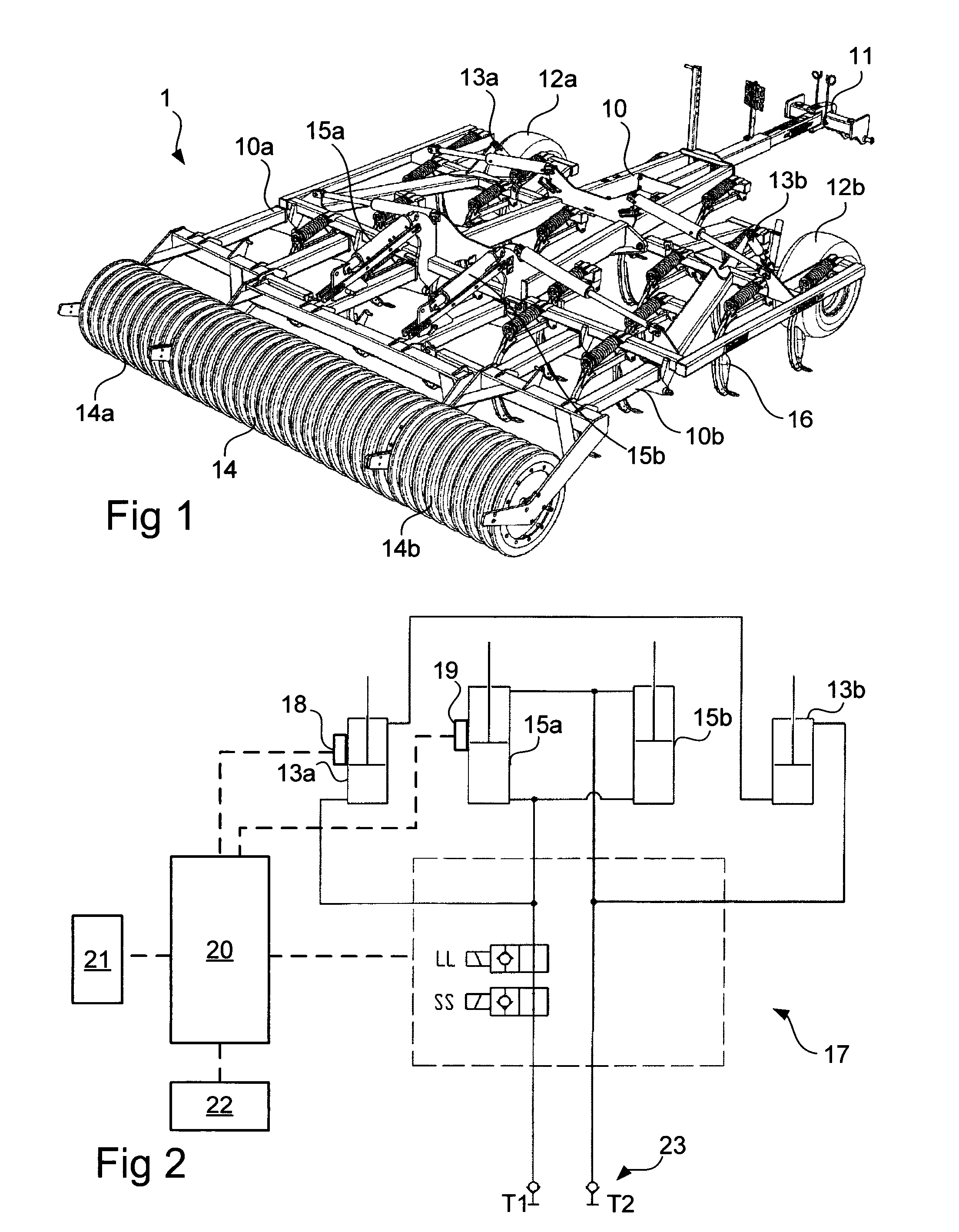

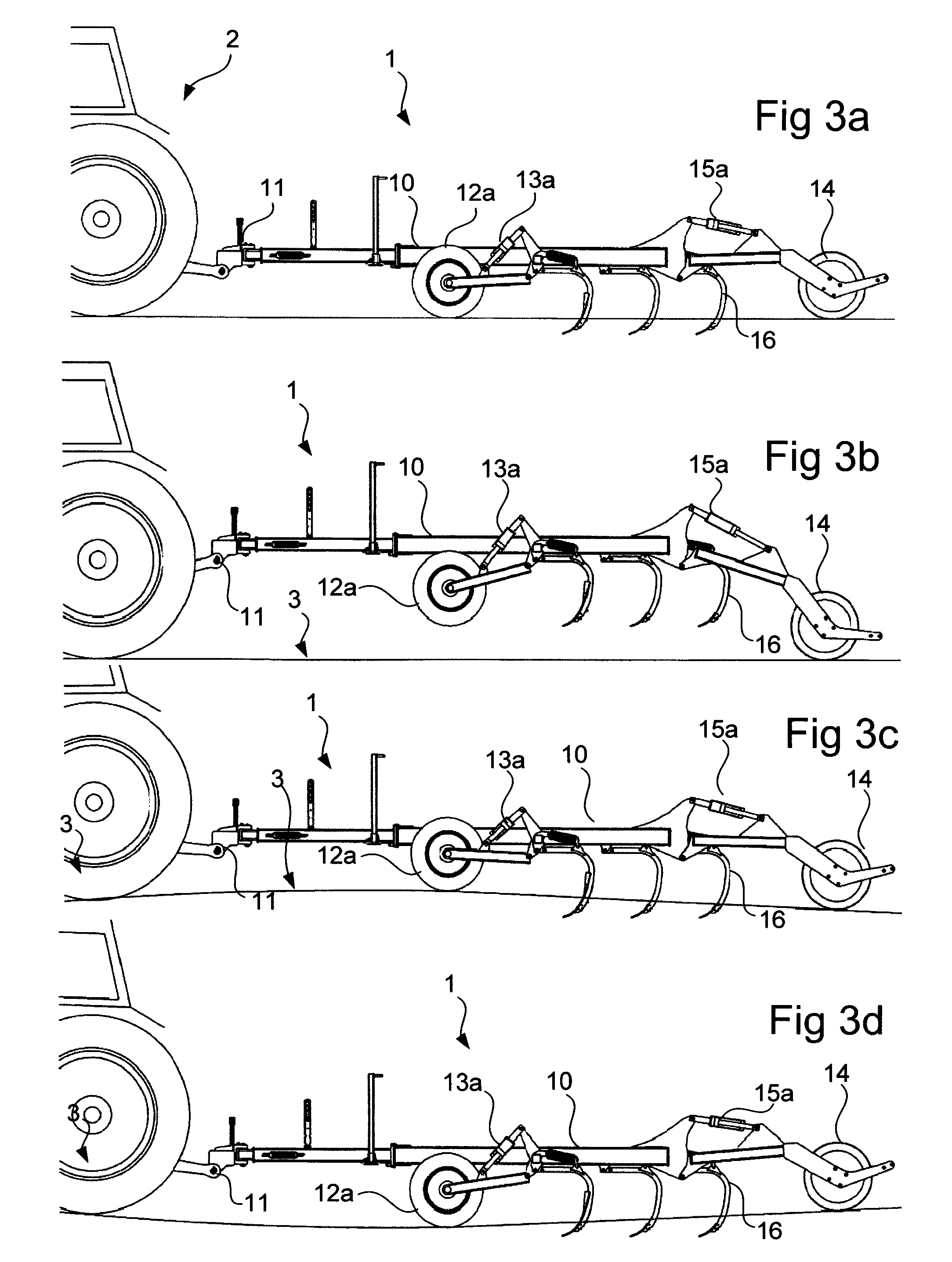

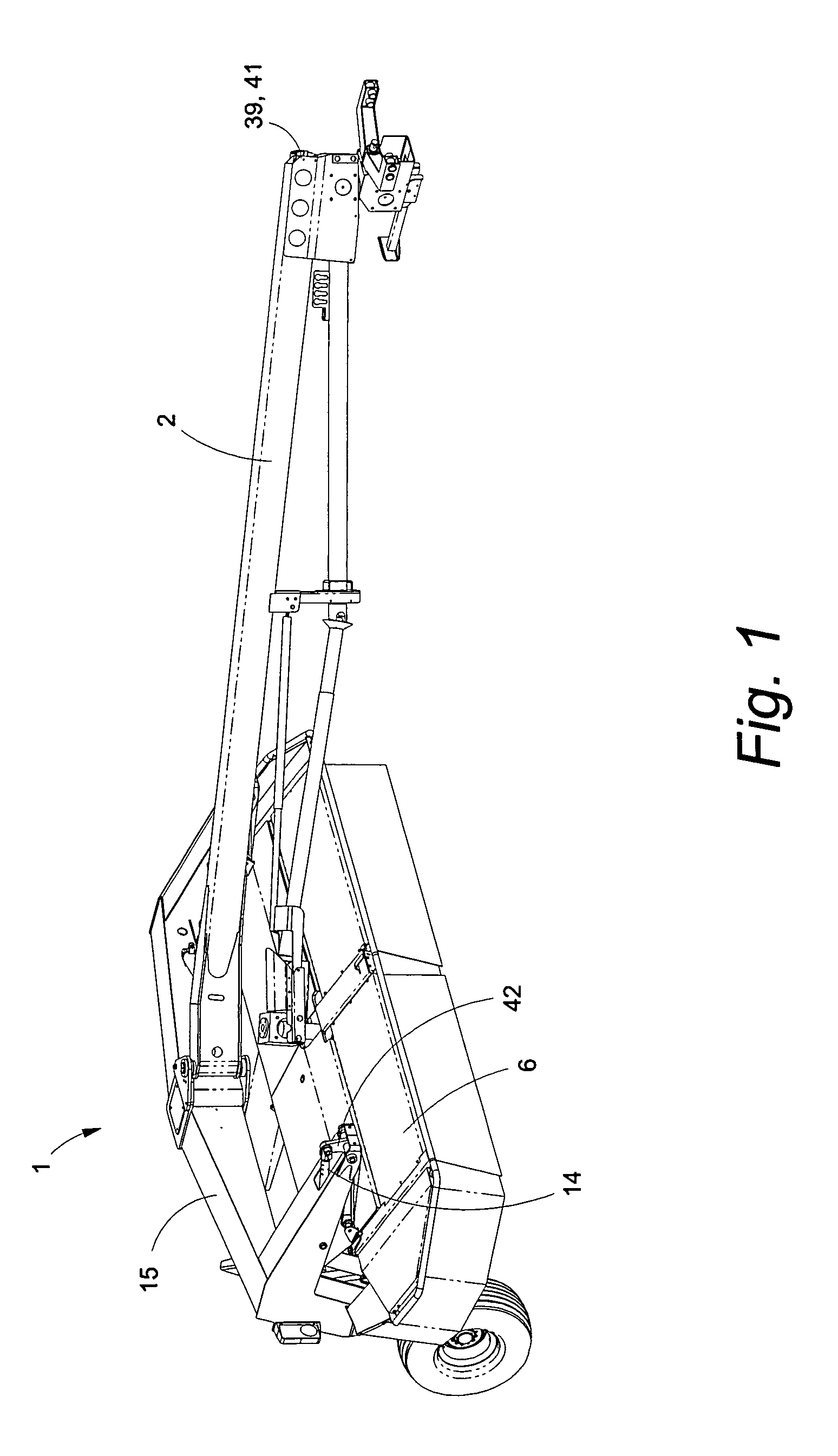

Self leveling towed implement

An implement has a tongue used to tow the implement that can be raised or lowered with respect to the rest of the implement. The tongue is raised or lowered by a hydraulic cylinder. The raising and lowering ports of the cylinder are connected to two hydraulic accumulators to permit the tongue to flex up or down while the implement is towed through the field. These accumulators are disconnected from the cylinder when the wings of the implement are lifted and the implement is towed over the road to prevent the implement from oscillating backwards and forward about an axis defined by its wheels.

Owner:BLUE LEAF I P INC

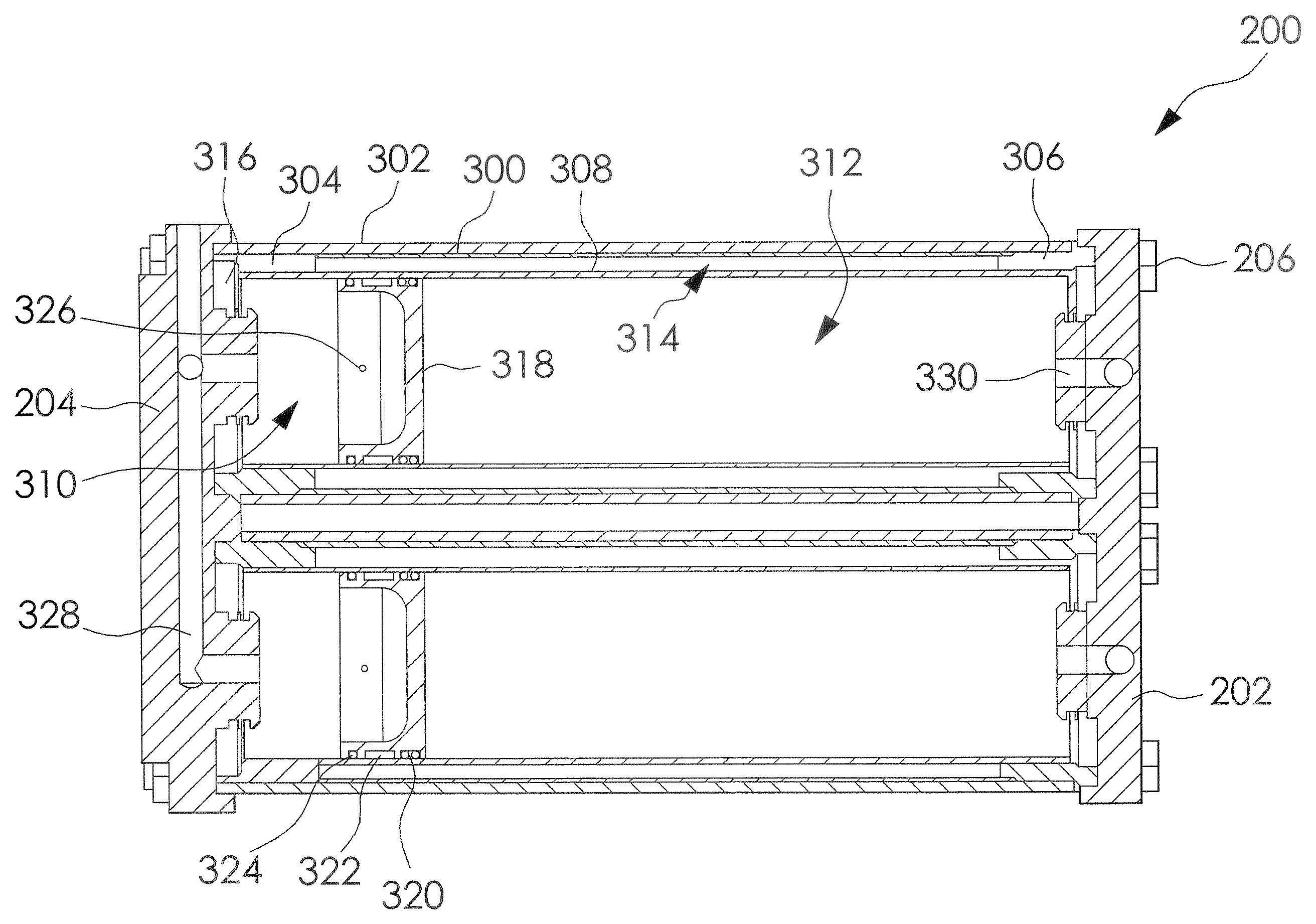

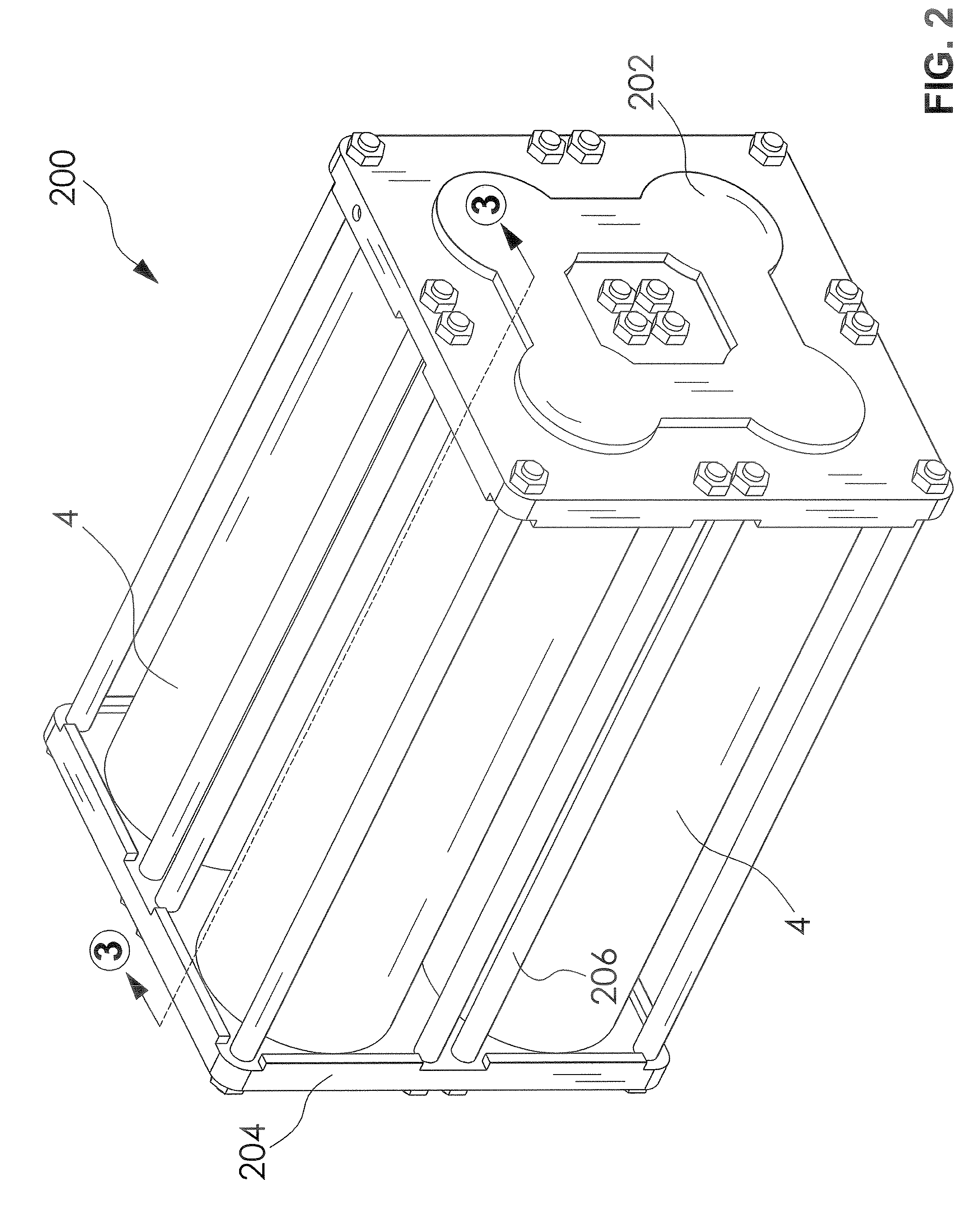

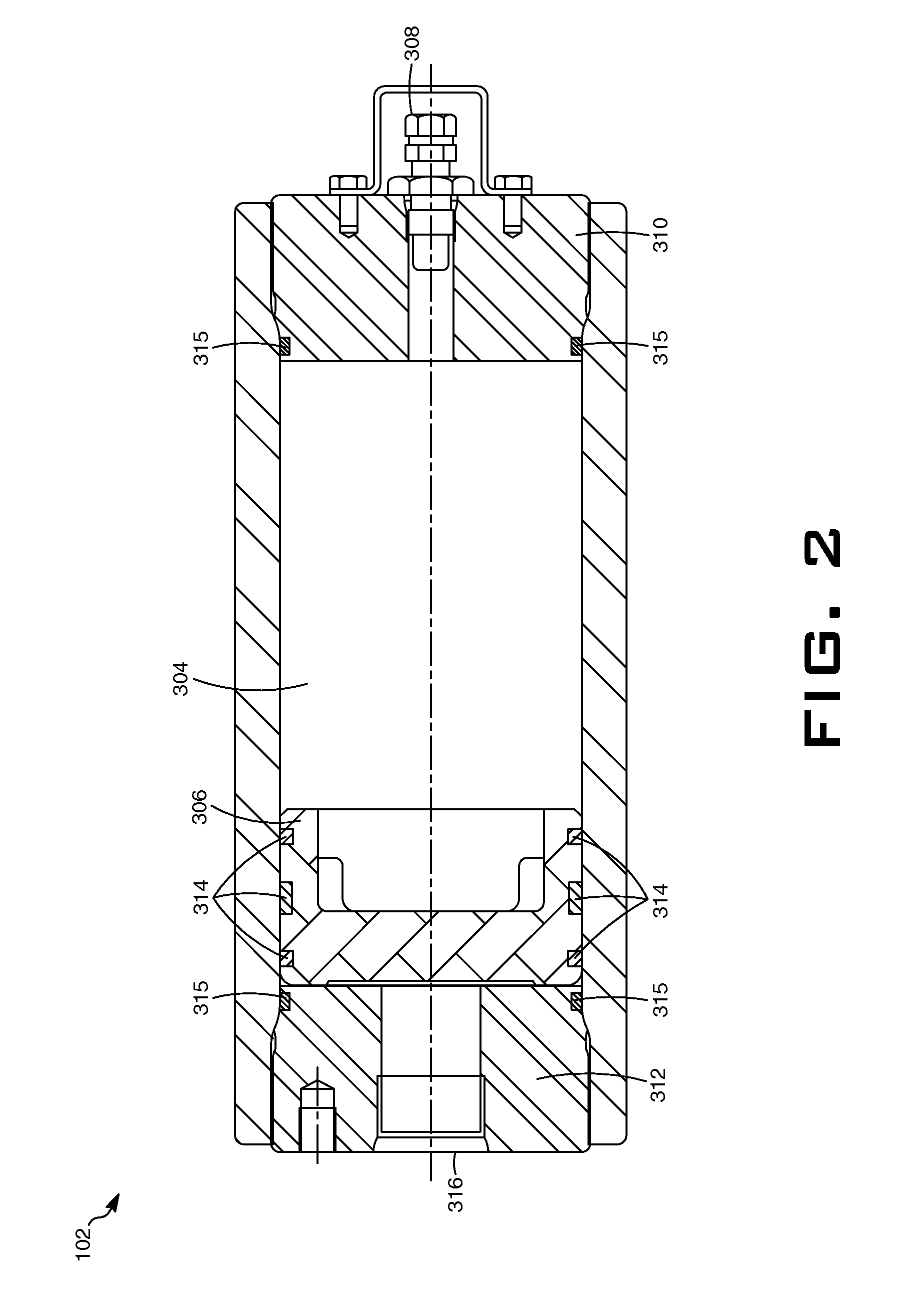

Compact hydraulic accumulator

InactiveUS20080308168A1Light weightEasy maintenanceFluid couplingsCheck valvesWorking fluidGas cylinder

A lightweight, optimally efficient, easily serviced, piston-in-sleeve high pressure accumulator is provided. The accumulator includes one or more cylindrical composite pressure vessel separate end cap manifolds. A piston slidably disposed in a thin impermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Gas is provided in a volume between the impermeable internal sleeve and the composite pressure vessel wall. Additional gas is optionally provided in gas cylinders. Further components are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle.

Owner:NRG ENTERPRISES

Hydraulic accumulator health monitor

A system and method to diagnose the operational health of a hydraulic accumulator are provided. The system can include a hydraulic accumulator selectively coupled to a hydraulic actuator, such as a swing motor. The accumulator can be charged by movement of the actuator. A pressure sensor can be associated with the accumulator to determine an accumulator pressure. A controller can be connected to the pressure sensor. The controller can determine a charge curve based on a relationship between an actuator operational parameter associated with the actuator movement and the accumulator pressure. The controller can compare the charge curve to a previously defined charge curve or range to determine an error between the charge curve and the previously defined charge curve or range. The degree of the error can be associated with the operational health of the accumulator, and if too large, the operator may be notified of the status.

Owner:CATERPILLAR INC

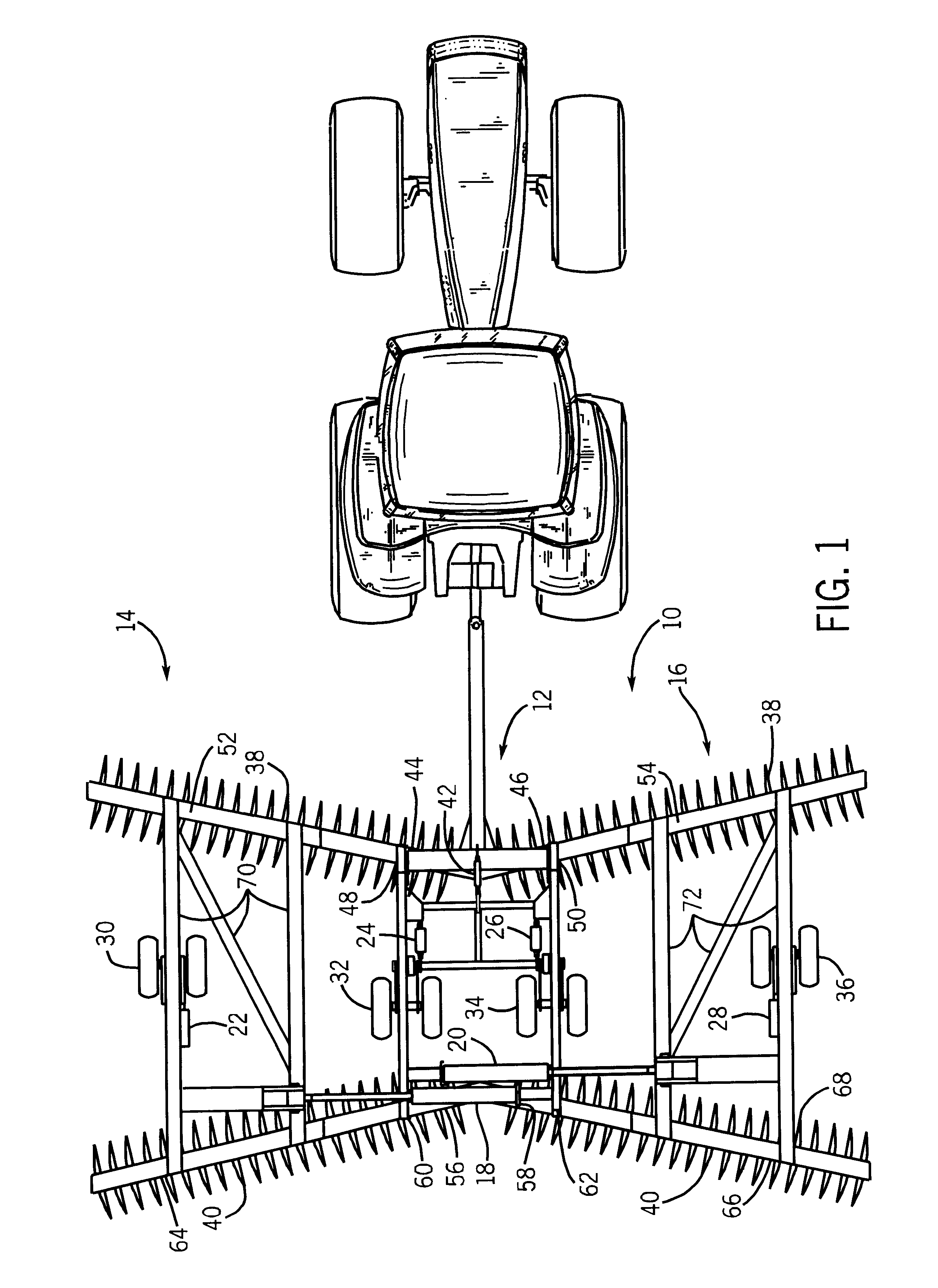

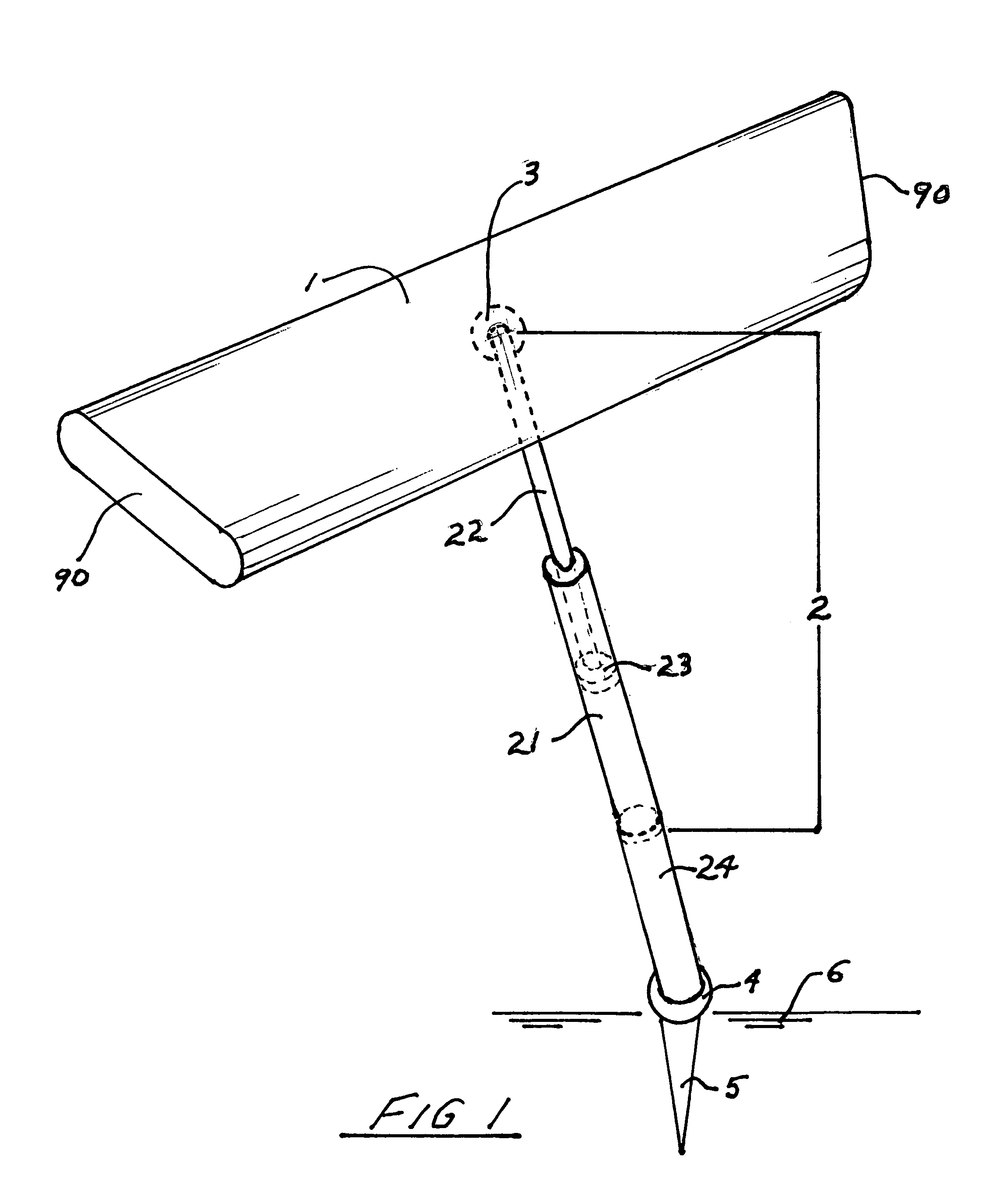

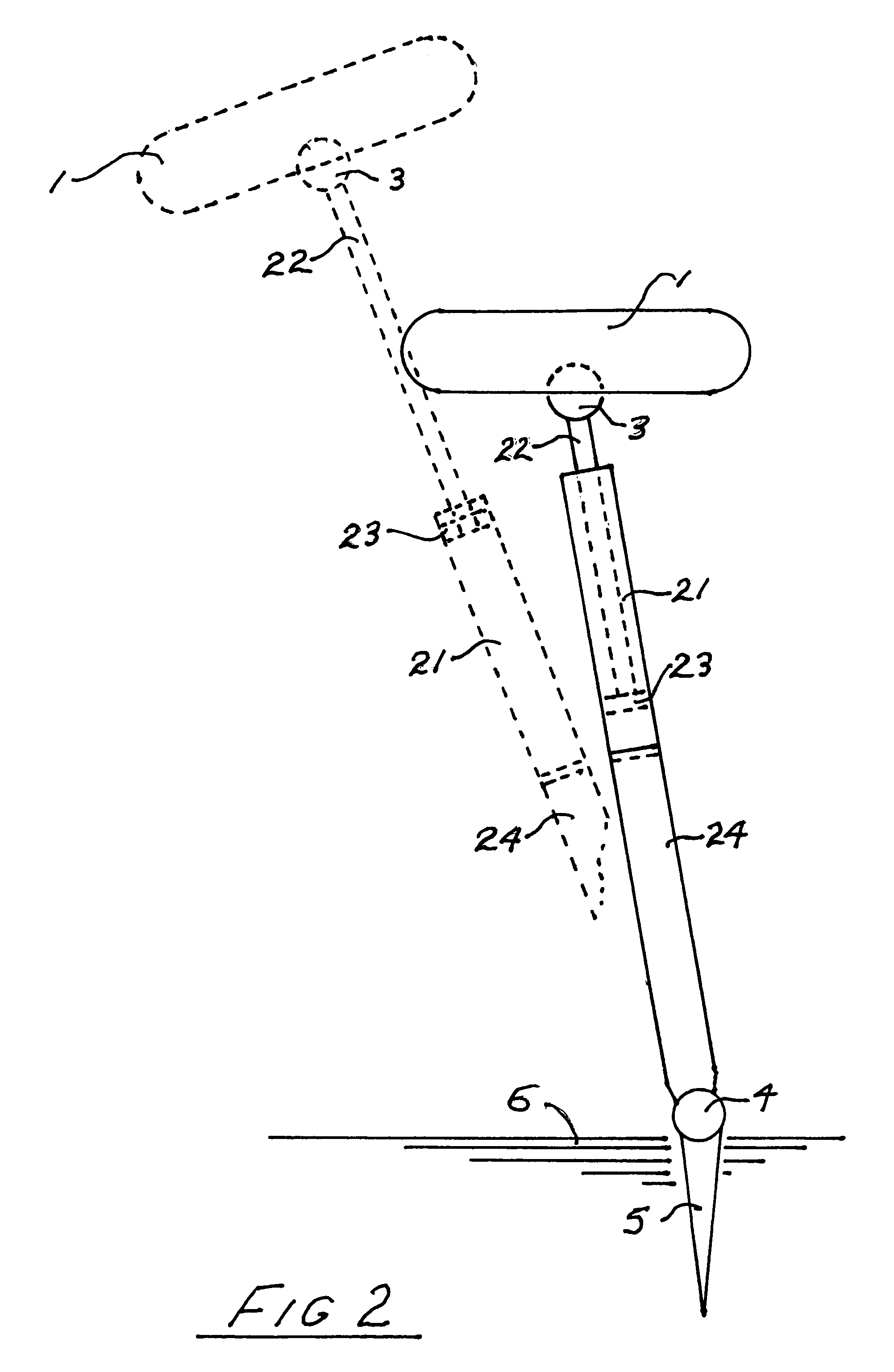

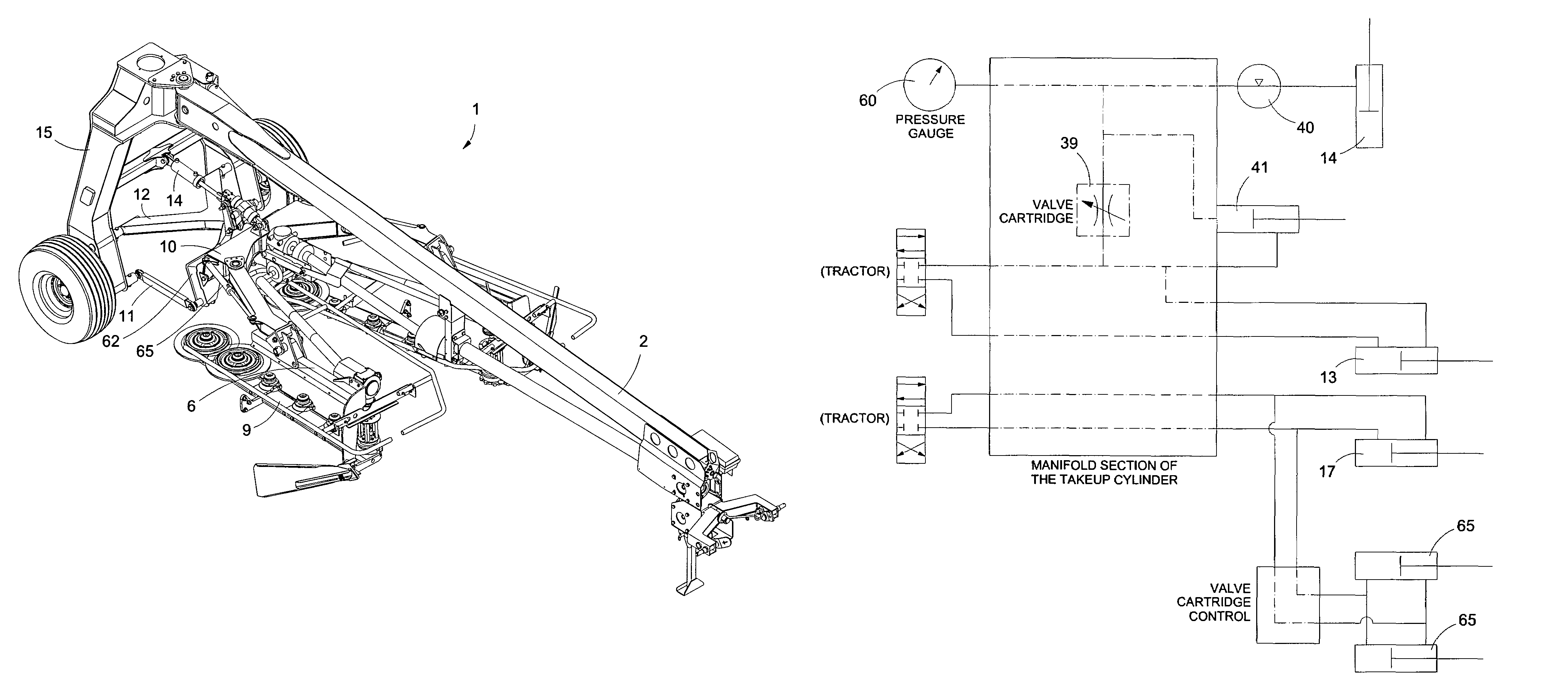

Suspension System for Wheel Rakes

A suspension system for rakes having at least one floating rake wheel has a hydraulic cylinder is used for both lift and suspension of the floating rake wheel. A hydraulic accumulator provides expansion room for hydraulic fluid to move in and out of the hydraulic cylinder during suspension.

Owner:VERMEER MFG CO

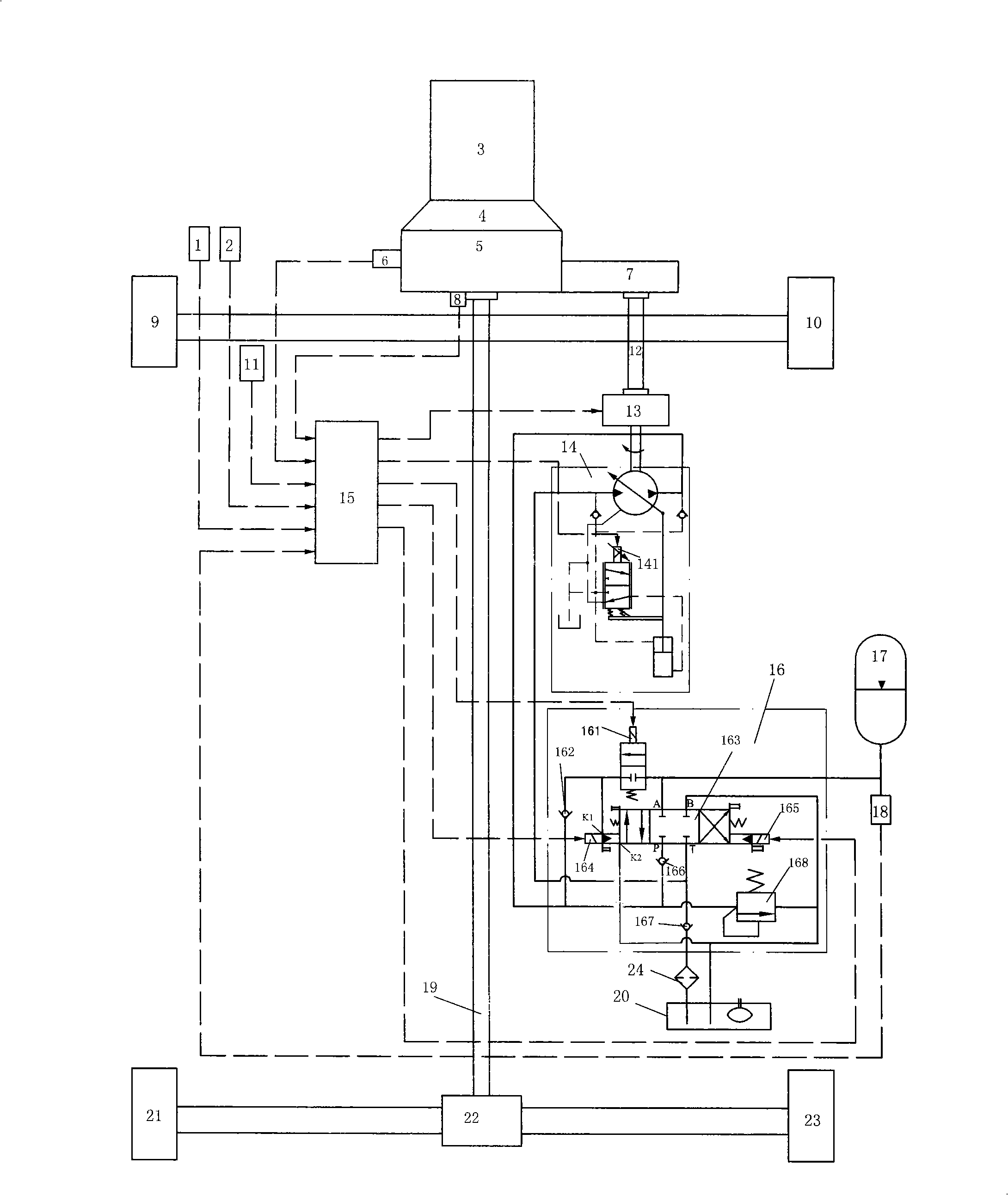

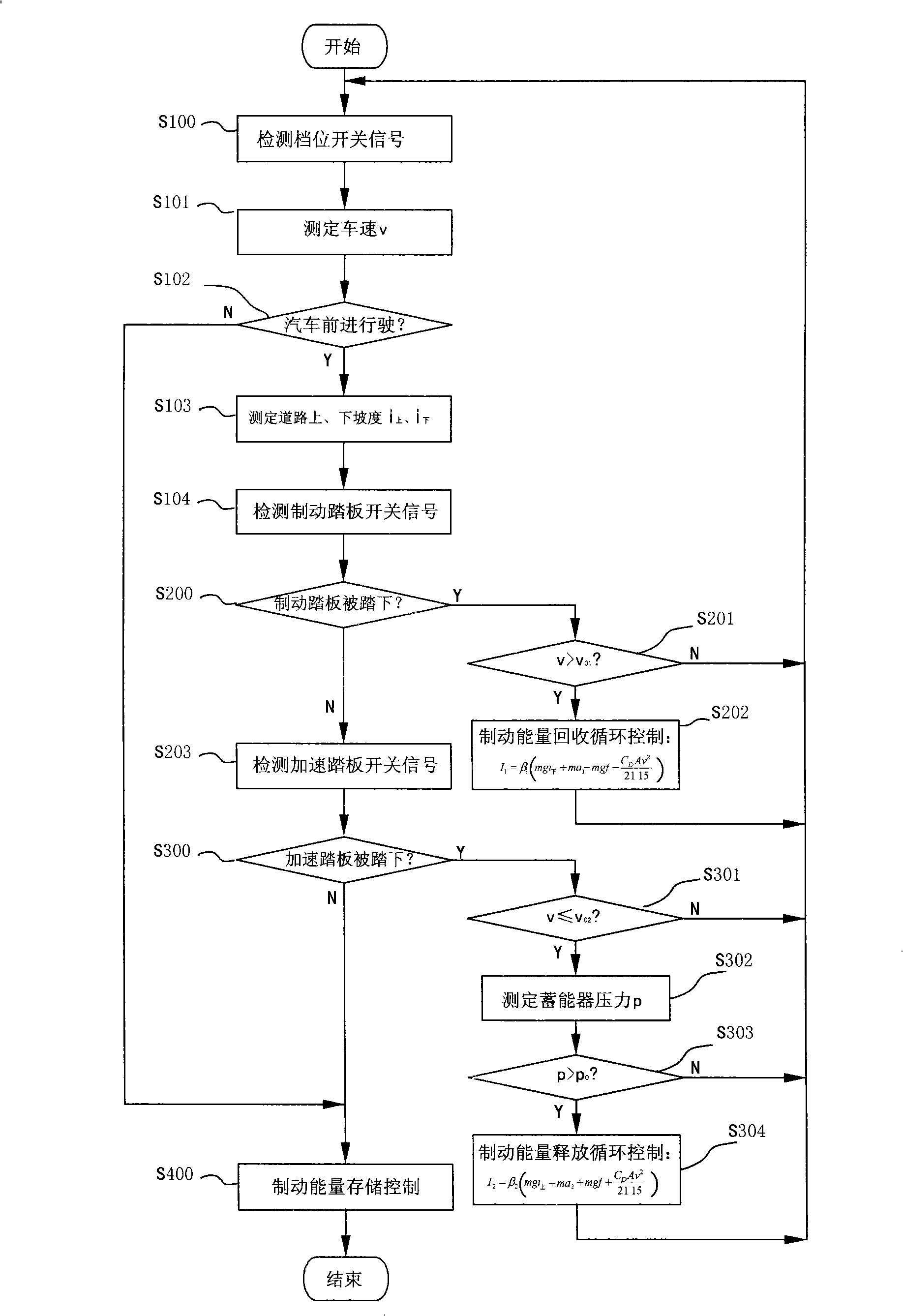

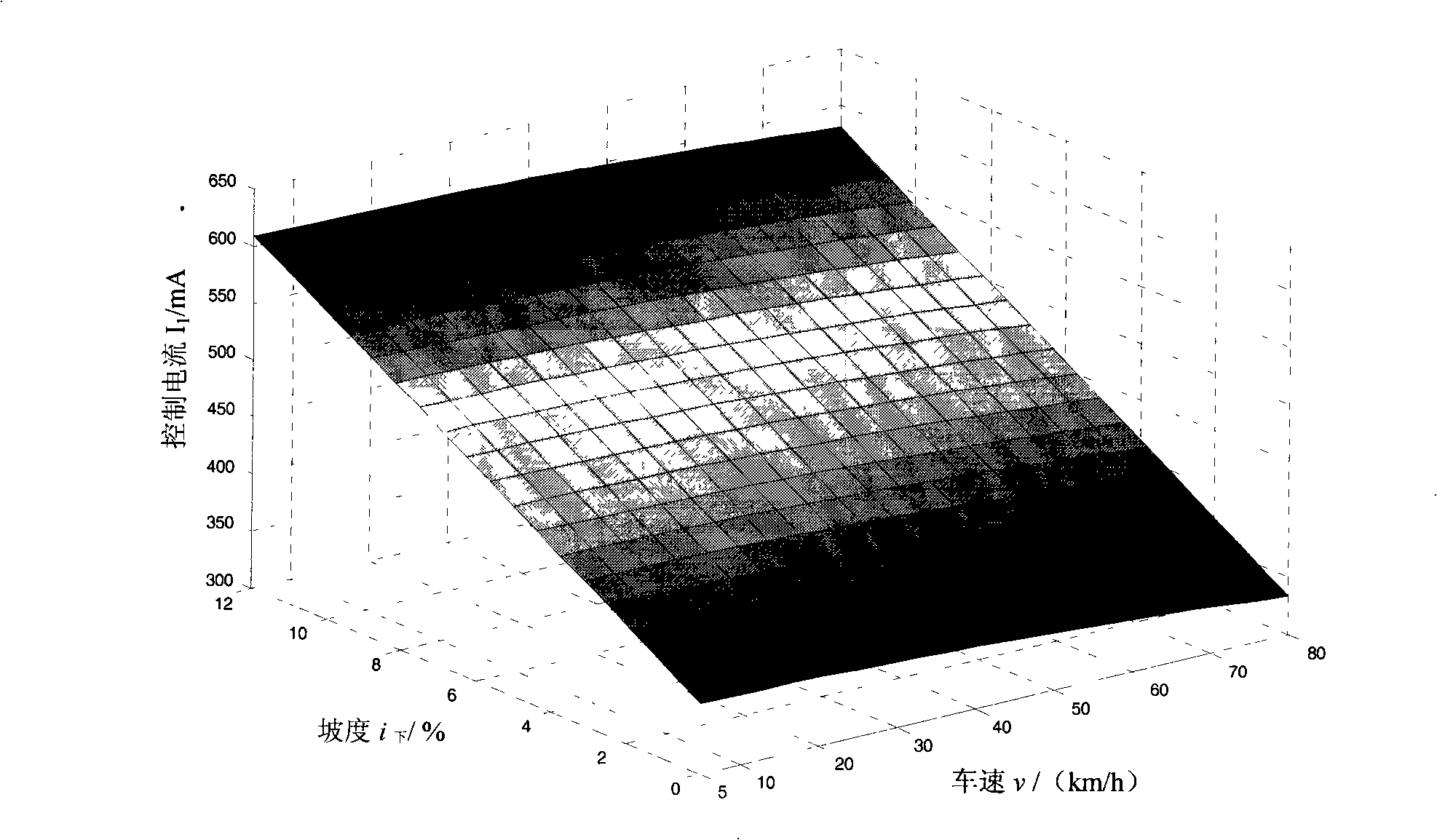

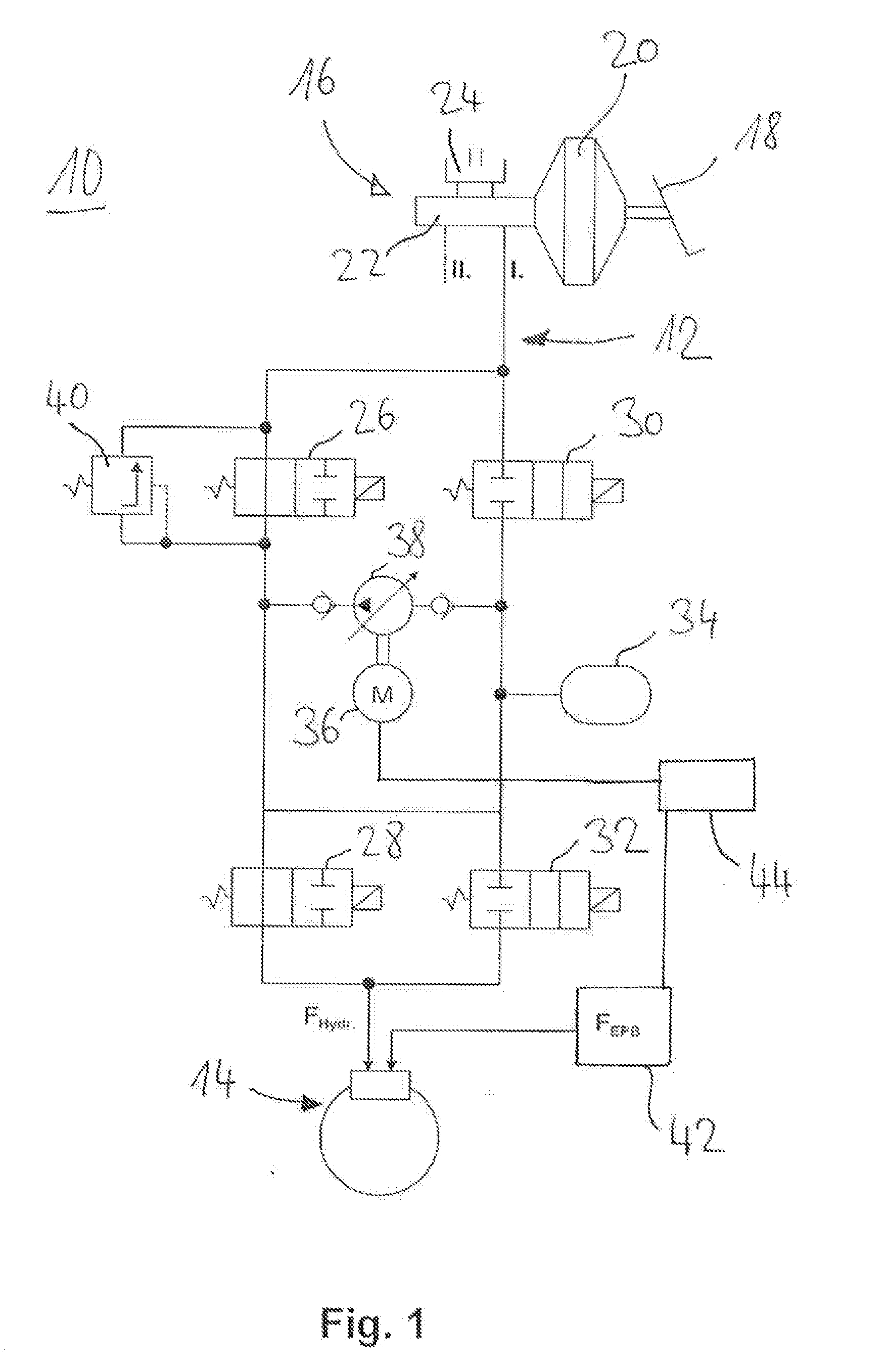

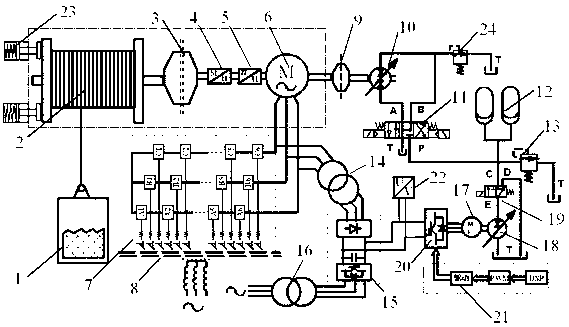

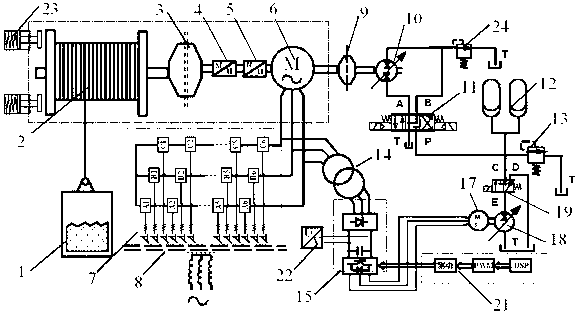

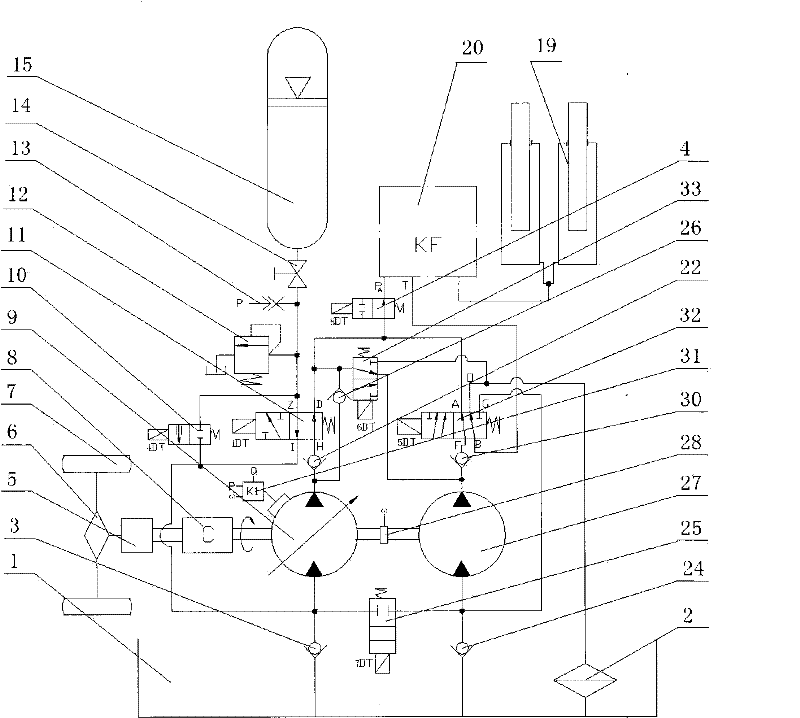

Automobile brake energy regeneration control device and system

InactiveCN101332774AAutomatic determination of driving statusAutomatic determination of road conditionsElectrodynamic brake systemsHydraulic control unitElectromagnetic clutch

The invention provides a vehicle brake energy regeneration control method and system; the system comprises a hydraulic energy accumulator, a variable pump / motor, an electromagnetic clutch, a brake pedal switch, an acceleration pedal switch, a gear switch, a road slope sensor, a speed sensor, a pressure sensor of the energy accumulator, a hydraulic control unit and an electric control unit; the system automatically identifies the acceleration or brake intention of a driver, automatically detects the running state of the vehicle and the road slope situation, calculates the control current I1 of the proportional electric magnet of the variable pump / motor on different downgrade road slopes or horizontal roads and at different speeds by adopting the formula (I), calculates the control current I2 of the proportional electric magnet of the variable pump / motor on different upgrade road slopes or horizontal roads and at different speeds by adopting the formula (II) and carries out brake energy releasing circulation control, so as to control the running stability of the vehicle and improve the recovery rate as well as the regeneration rate of the brake energy.

Owner:SHANDONG UNIV OF TECH

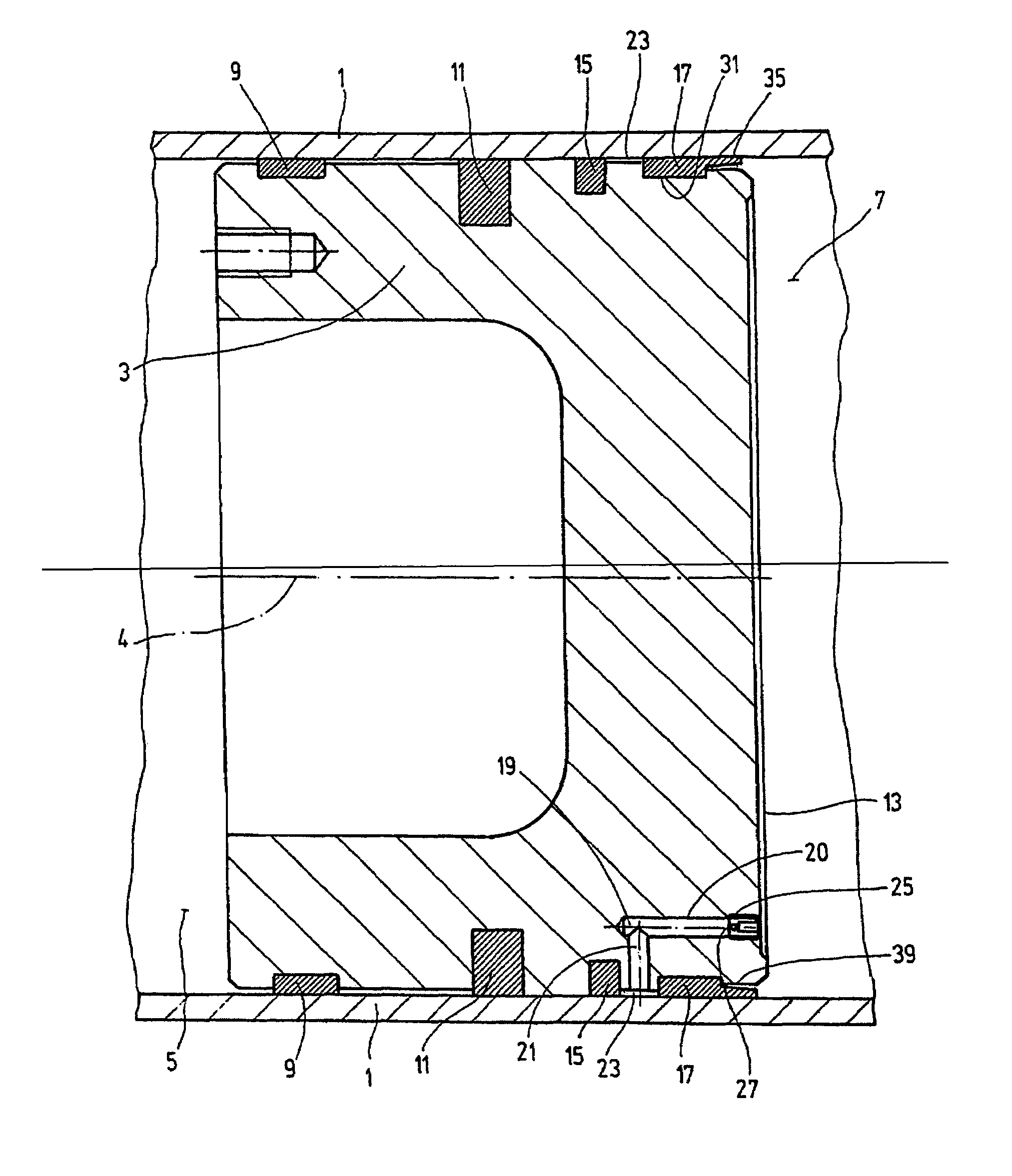

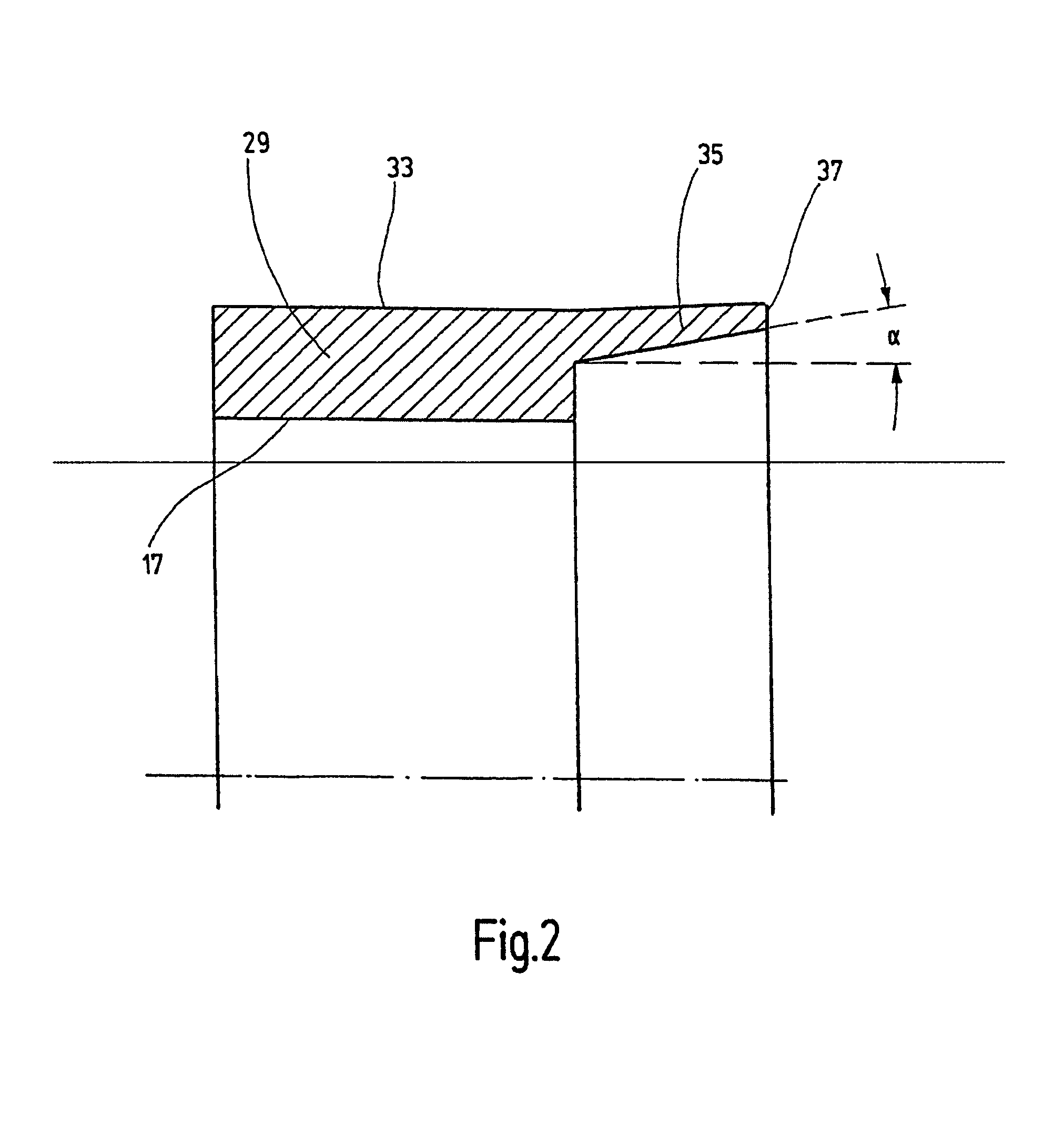

Hydraulic accumulator

ActiveUS7322377B2Guaranteed long-term operationReduction of the passage cross-sectionPiston ringsBraking action transmissionMechanical engineeringPiston

A hydraulic accumulator includes a piston (3) capable of moving in an accumulator housing (1) in its axial direction and separating a gas side (5) from a liquid side (7) of the accumulator housing (1). Guide elements (9, 17) designed to co-operate with the accumulator housing wall (1), as well as at least one sealing element (15), are arranged at the periphery of the piston. The sealing element is arranged offset in the axial direction relative to the guide elements (9, 17), and is located between the guide elements. In the piston (3), a pressure compensating channel (19) forms, at the piston periphery, a liquid flow path between the liquid side (7) and a space (2) located between the guide element (17) nearest to the liquid side (7) and the sealing element immediately next in the axial direction. A device (25) reducing the cross-section of the passage of the pressure compensating channel (19) is located in it.

Owner:HYDAC TECH GMBH

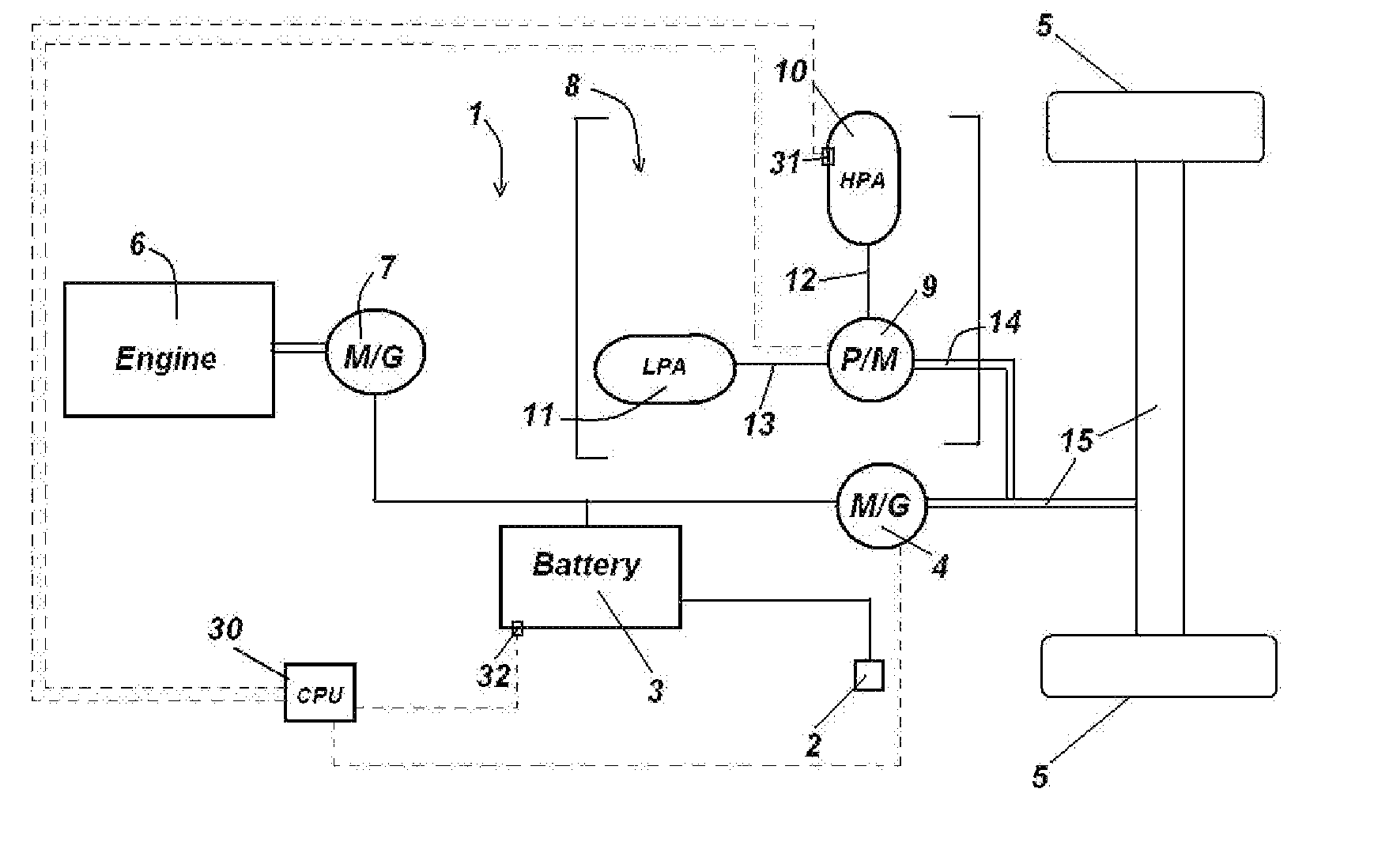

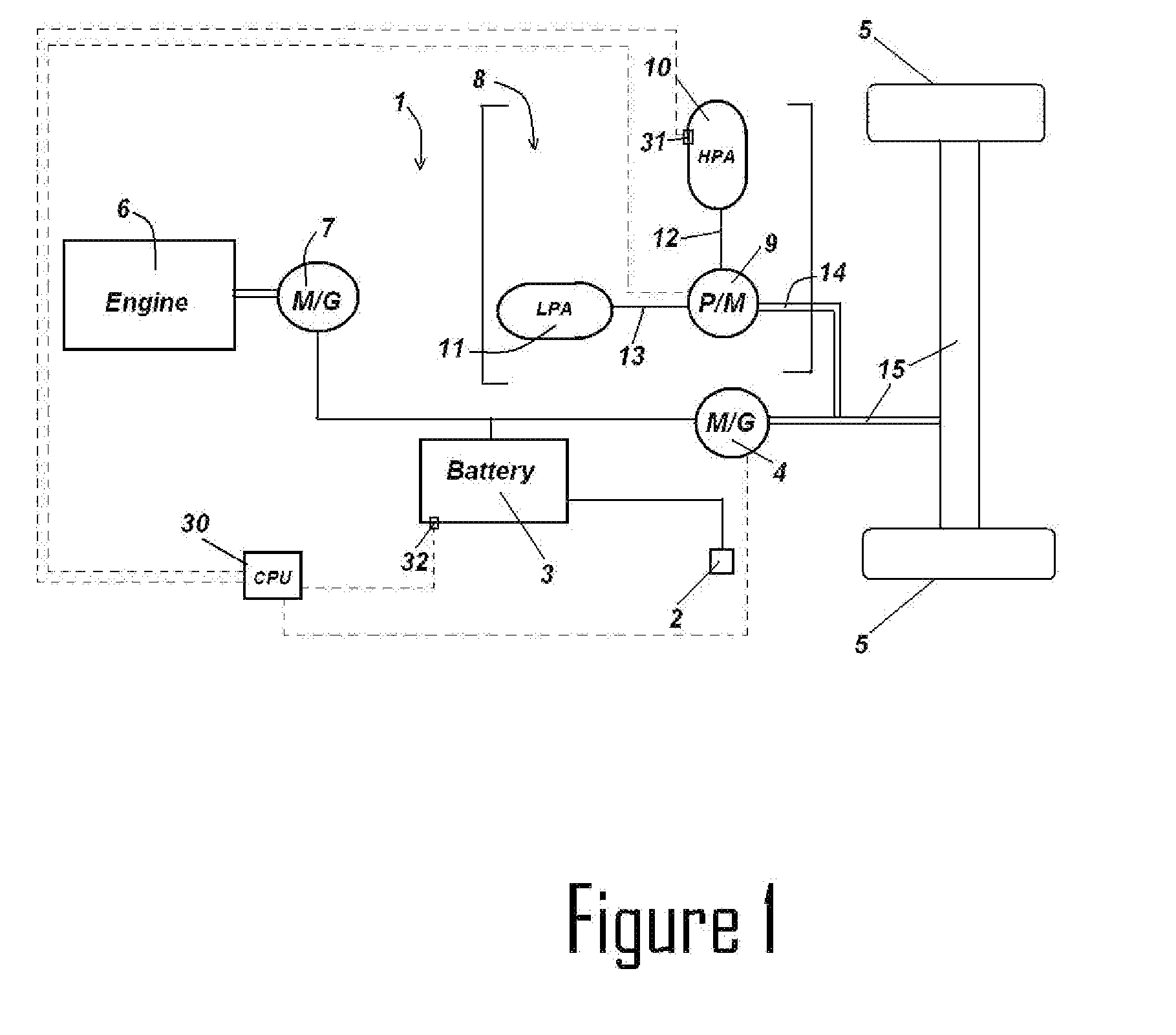

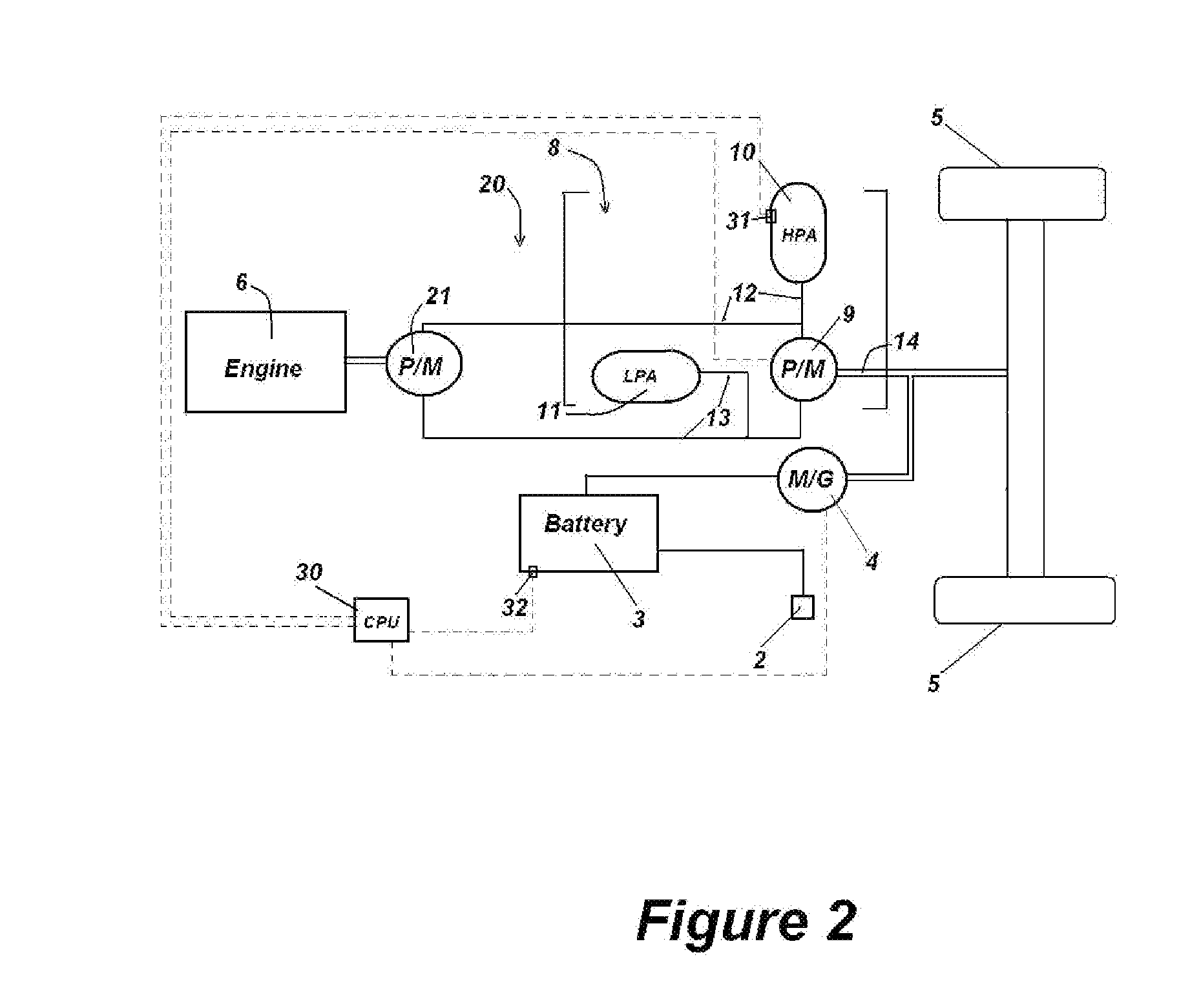

Hydraulic-Electric Regenerative Energy Storage System

InactiveUS20100151989A1Reduce demandDurable energyAuxillary drivesBraking element arrangementsCost effectivenessHydraulic pump

A hydraulic energy storage system (comprising a hydraulic pump / motor, a high pressure hydraulic accumulator, a low pressure hydraulic accumulator / reservoir, and interconnecting hydraulic lines) is incorporated into a EV, HEV, or PHEV to provide hydraulic regenerative braking and propulsive assistance for the vehicle. Implementation of the low cost and long-lasting hydraulic energy storage system in the vehicle, together with the electric energy storage system (comprising a motor / generator and battery pack) of the vehicle, allows significantly reduced demands and higher operating efficiencies for the battery pack, thereby facilitating a more cost-effective, efficient and / or durable overall energy storage system for the vehicle.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Wave energy conversion system

InactiveUS7042112B2Easy extractionHigh yieldGas turbine plantsPiston pumpsThermal energyForms of energy

Owner:SEAWOOD DESIGNS

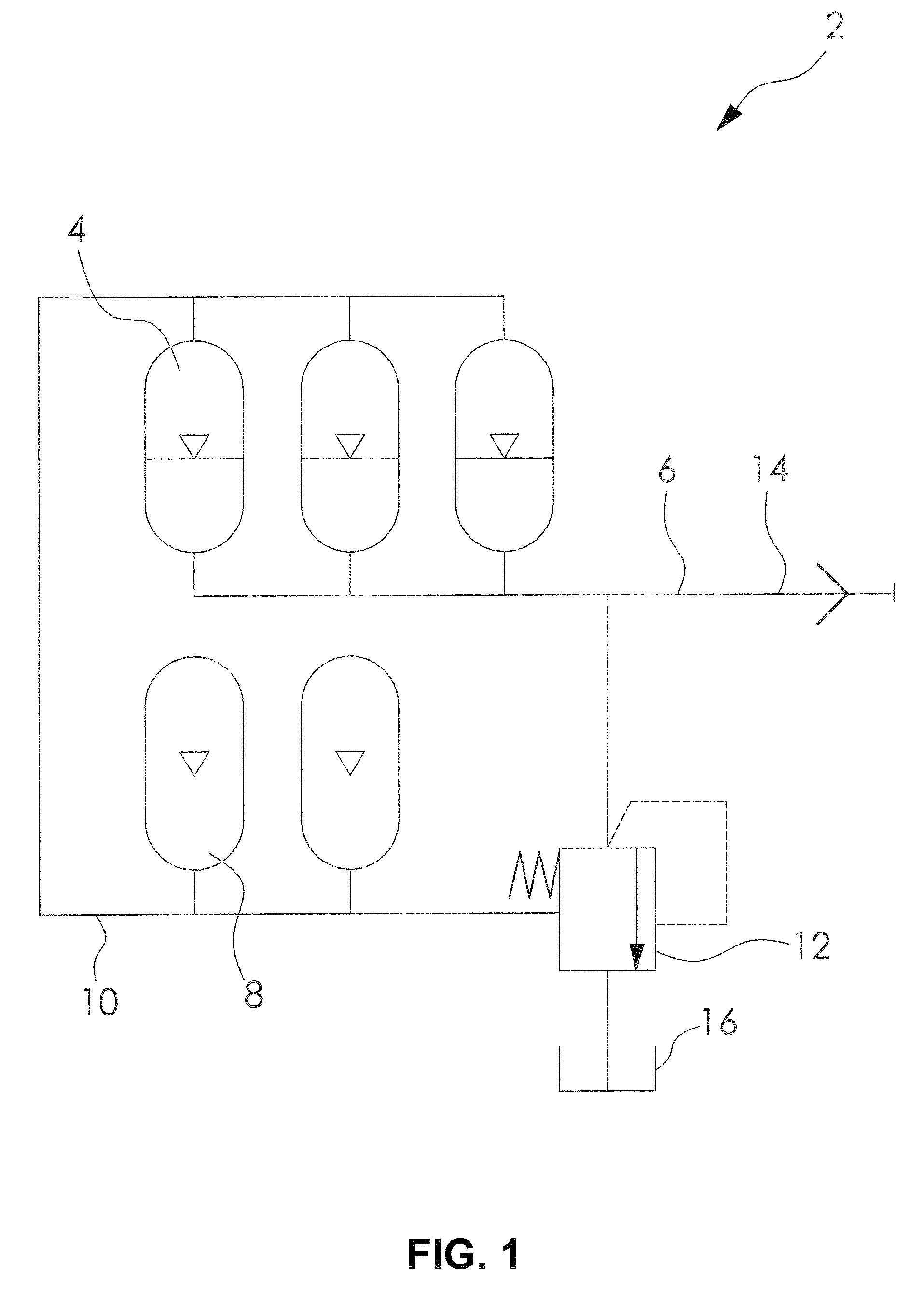

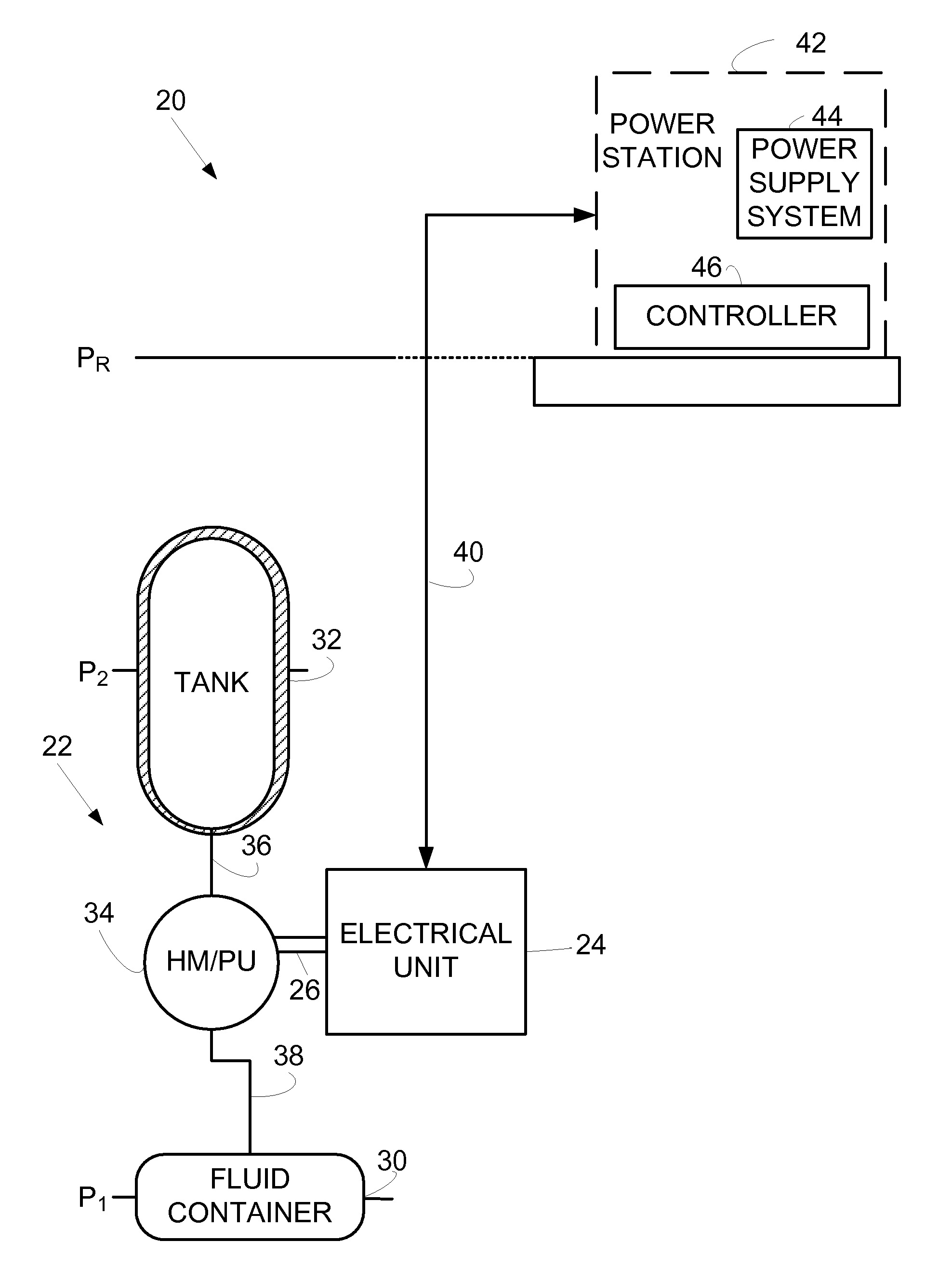

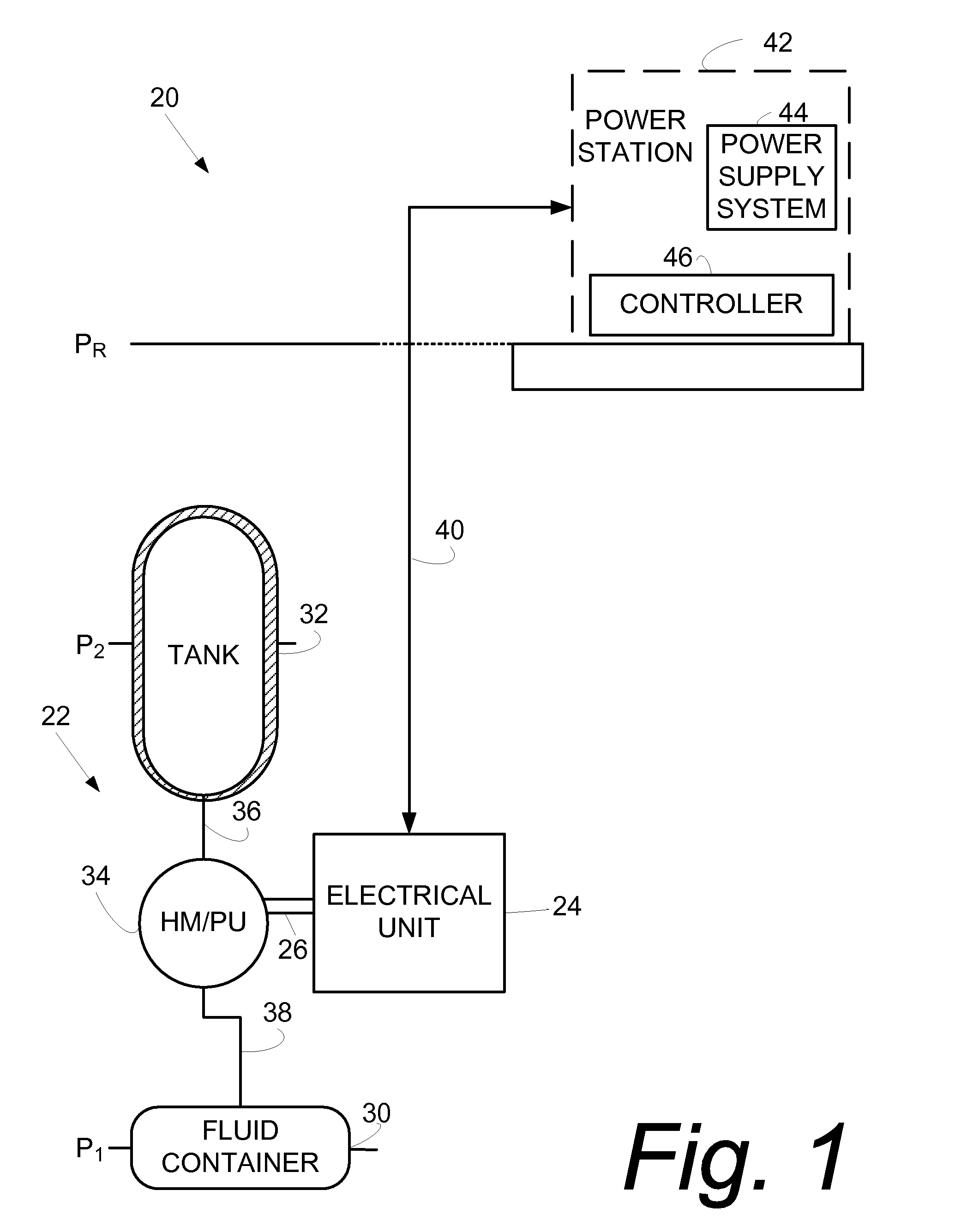

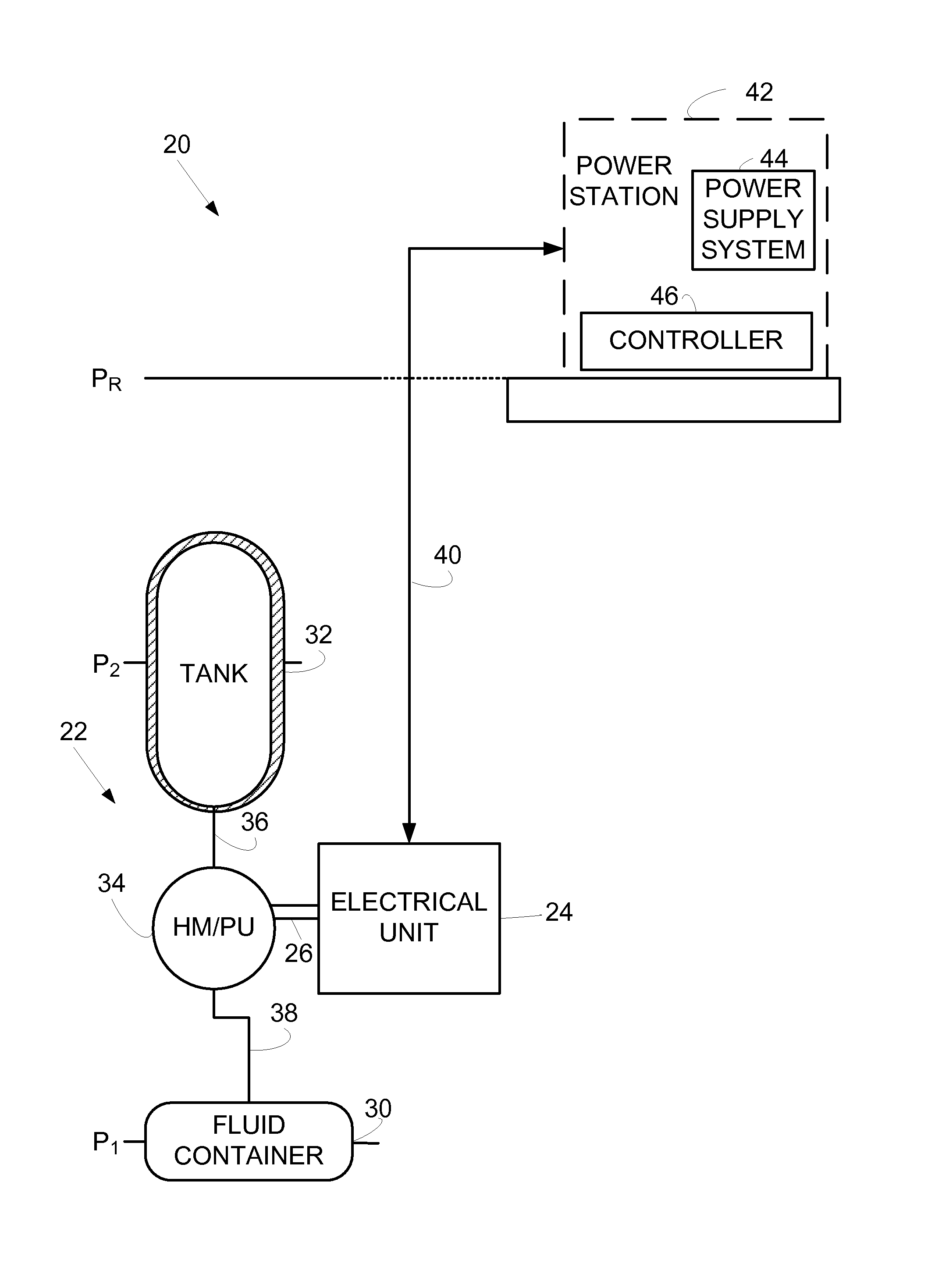

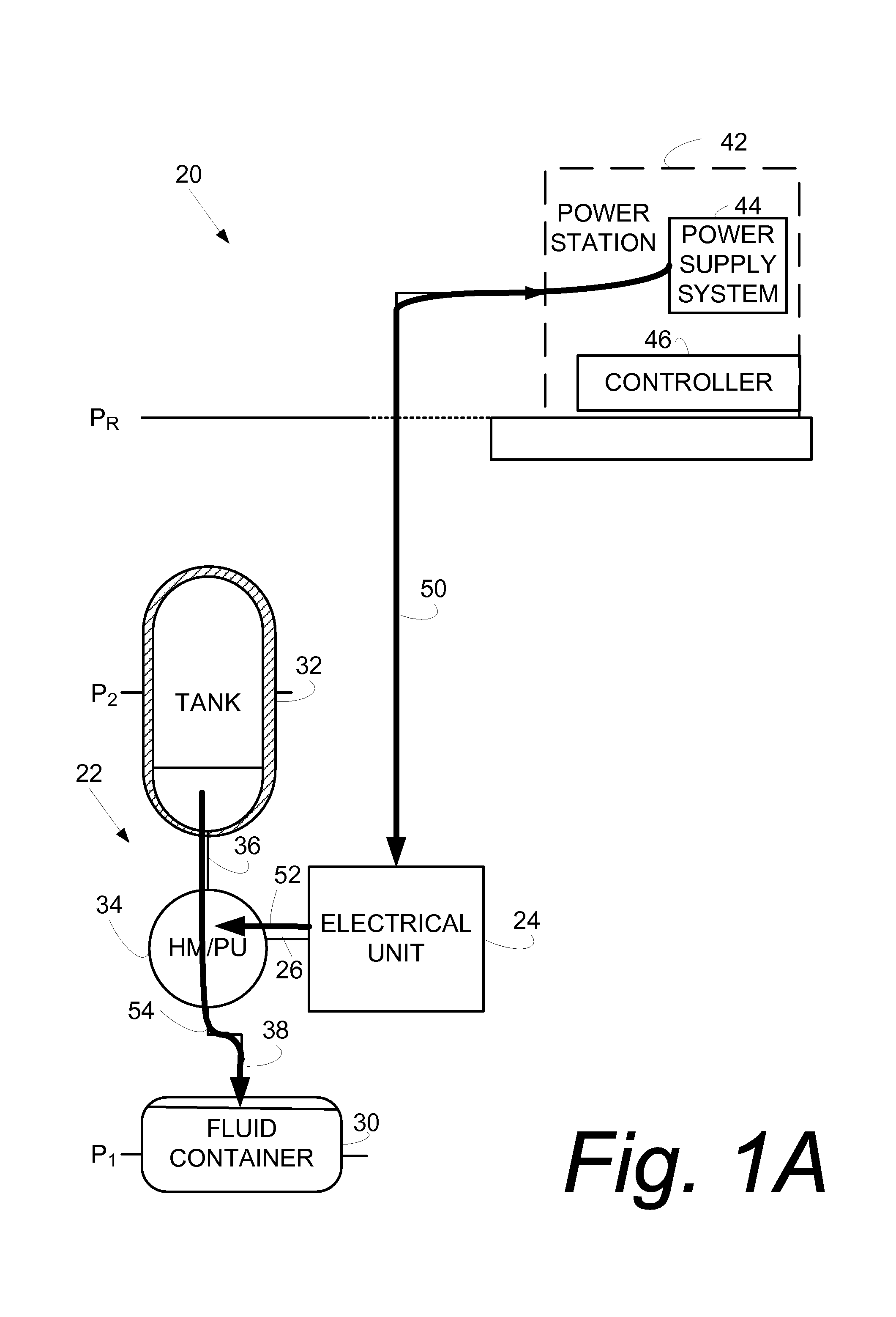

Hydraulic energy accumulator

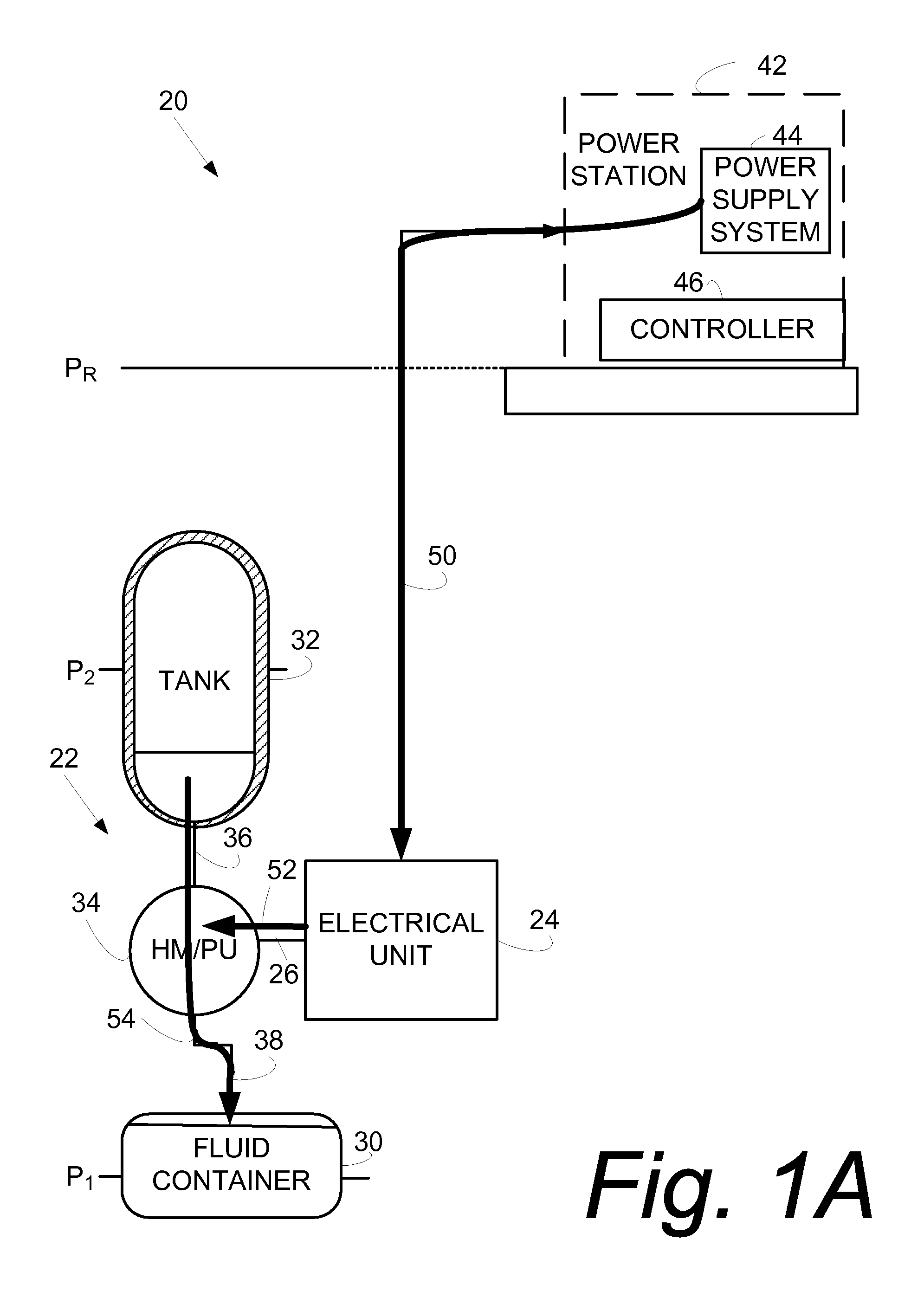

Example energy storage systems (20, 20′, 20″) comprises a fluid circuit (22, 22′, 22″) and an electrical unit (24, 24′, 24″) configured to operate as a motor in a first phase of operation and to operate as a generator in a second phase of operation. The fluid circuit (22, 22′, 22″) comprises a first fluid container (30, 30′, 30″) situated so content of the first fluid container experiences a first pressure level; a tank (32, 32′, 32″) having its content at a second pressure level (the second pressure level being less than the first pressure level): and, a first hydraulic motor / pump unit (34, 134, 34″connected to communicate a first working fluid between the tank and the first fluid container. In the first phase of operation electricity is supplied to the first hydraulic / motor unit (34, 134, 34″) whereby the first hydraulic / motor unit transmits the first working fluid from the tank into the first fluid container (30, 30′, 30″). In the second phase of operation pressurized first working fluid in the first fluid container (30, 30′, 30″) is transmitted from the first fluid container through the first hydraulic / motor unit 34, 134, 34″) to the tank (32, 32′, 32″), thereby causing the electrical unit (24, 24′, 24″) to generate electricity.

Owner:YSHAPE

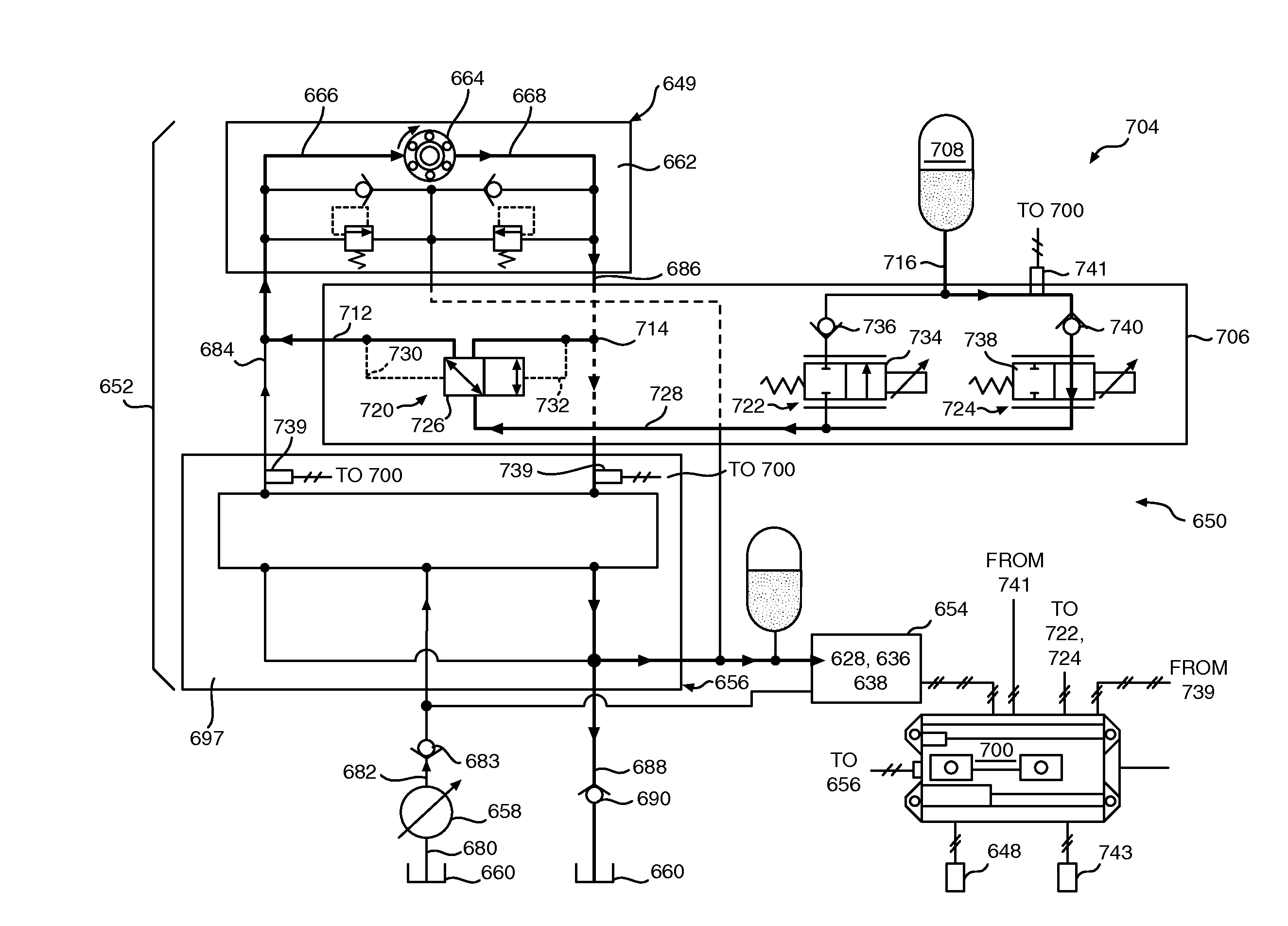

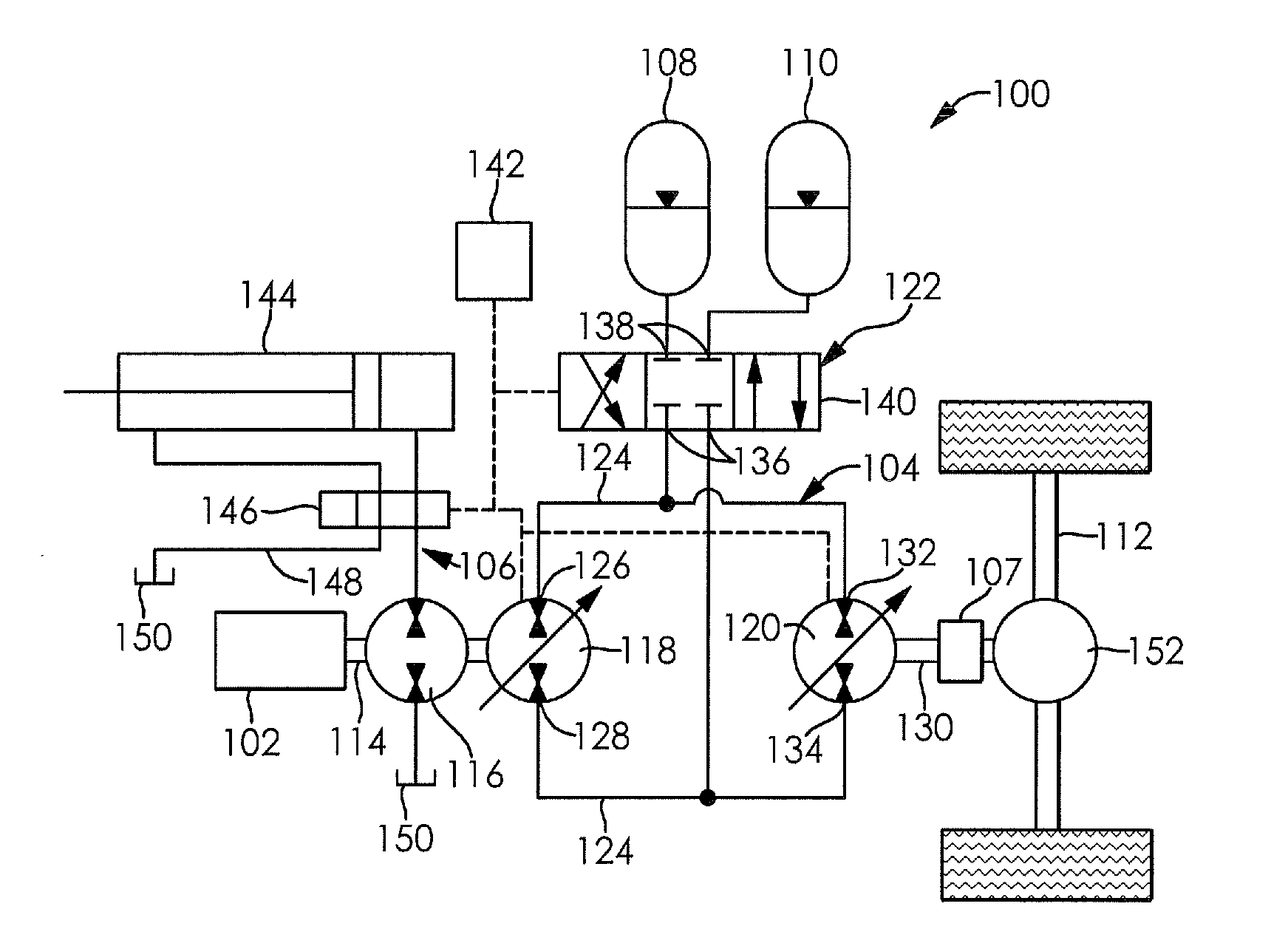

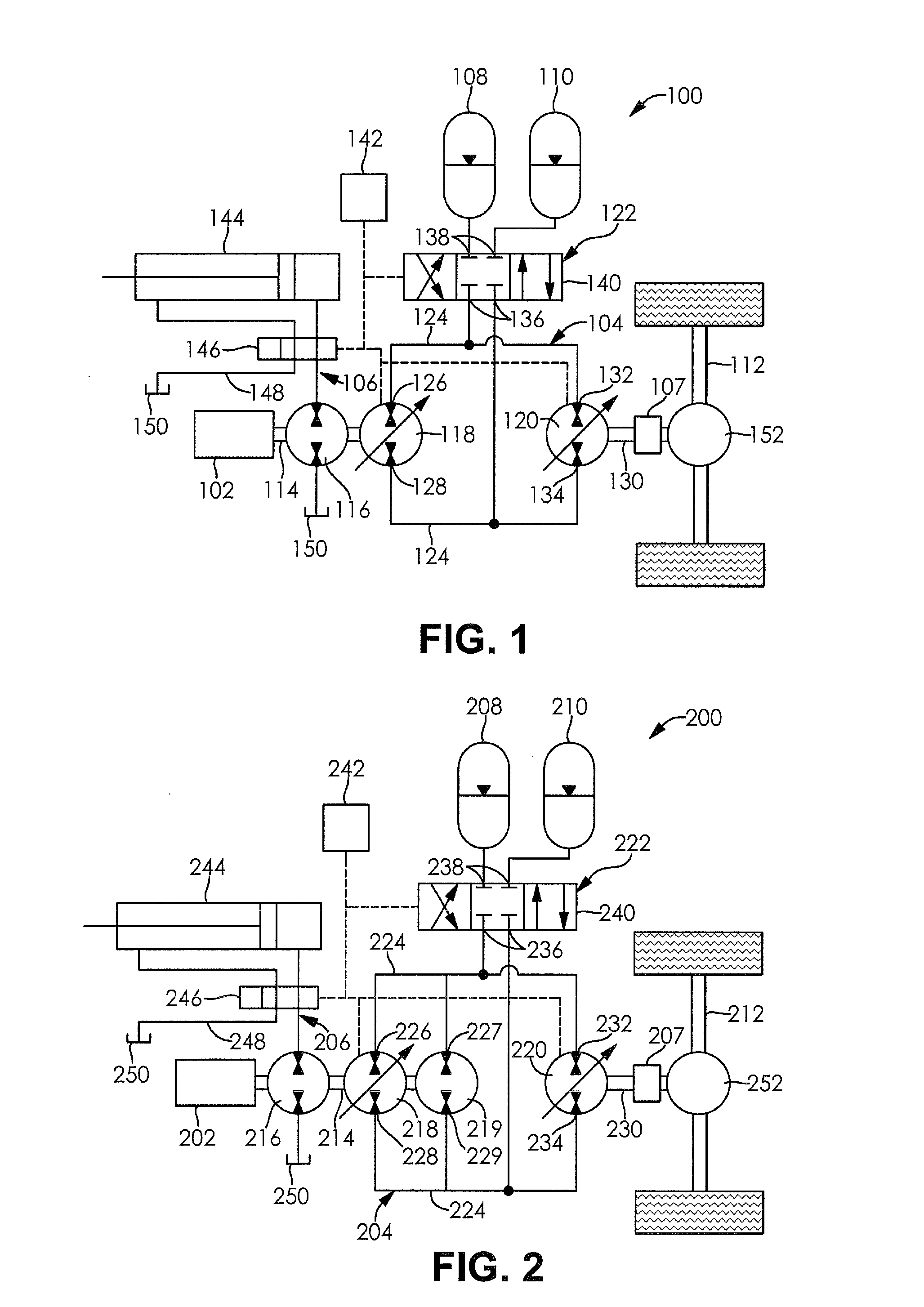

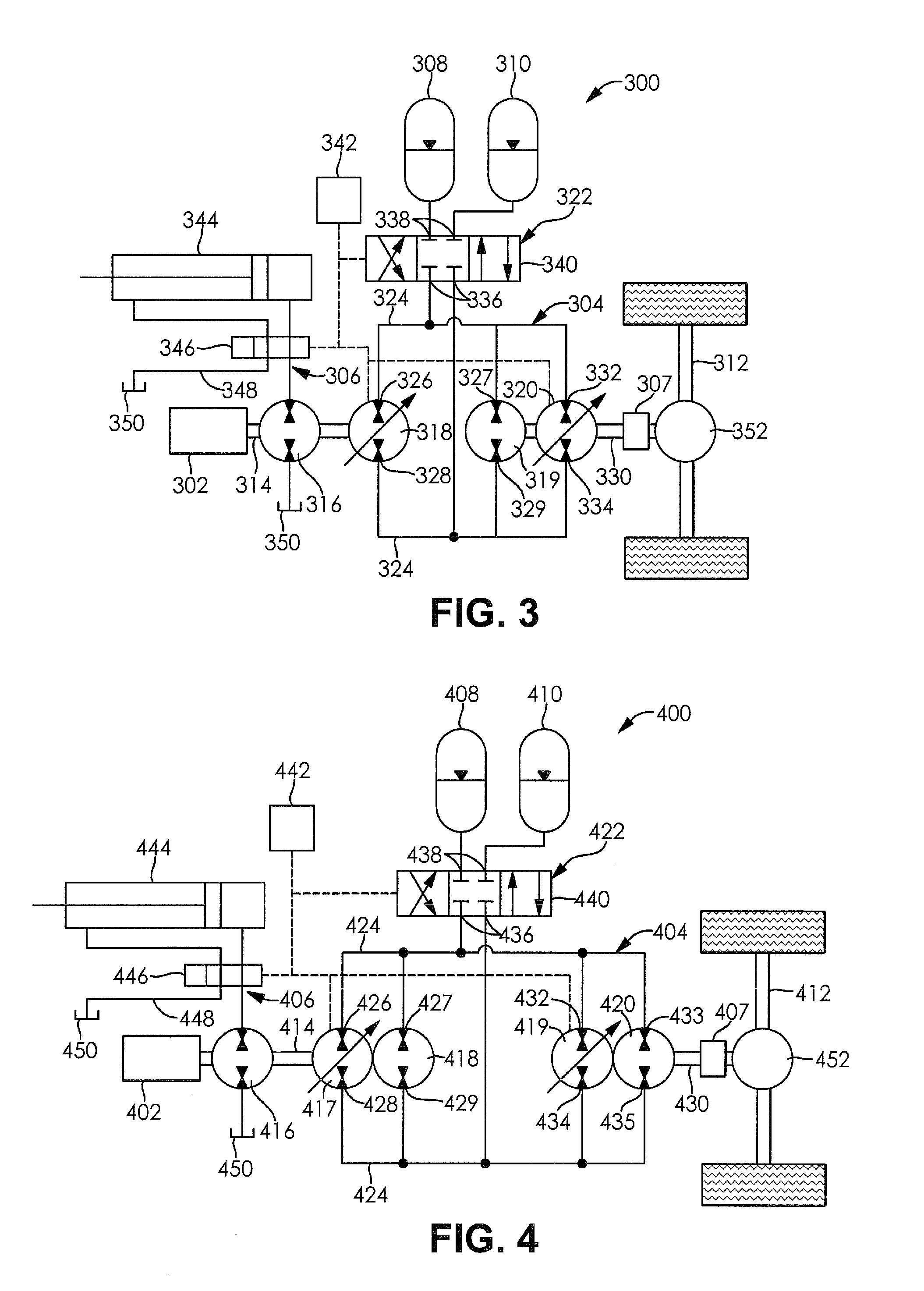

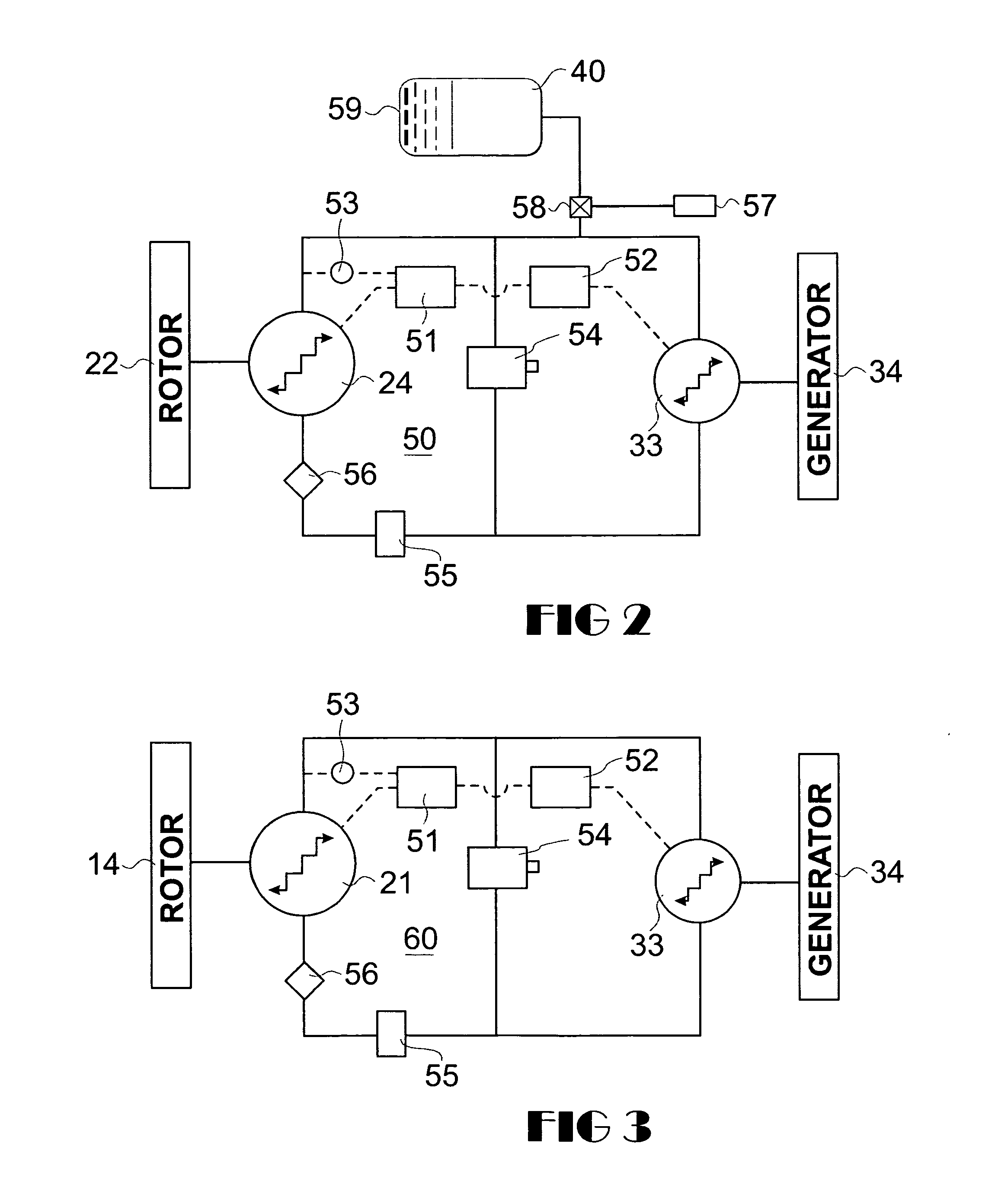

Accumulator assisted hydrostatic driveline and optimization method thereof

InactiveUS20120240564A1Easily procuredEasily servicedRotary clutchesAccumulator installationsState of chargeEngineering

A hydrostatic driveline for a vehicle, a method for minimizing a fuel consumption rate of the vehicle, and a method for tracking an optimal state of charge function for a hydrostatic accumulator are provided. The driveline includes a power source, a drive axle, a first fluid accumulator, a second fluid accumulator, an auxiliary circuit including a first pump drivingly engaged with the power source, and a drive circuit including a second pump drivingly engaged with the power source, a motor drivingly engaged with the drive axle, and a directional valve. The second pump is in fluid communication with the directional valve and the directional valve in fluid communication with the first fluid accumulator and the second fluid accumulator. The directional valve may be selectively controlled to direct fluid from the second pump and the motor to the first fluid accumulator and the second fluid accumulator.

Owner:DANA BELGIUM

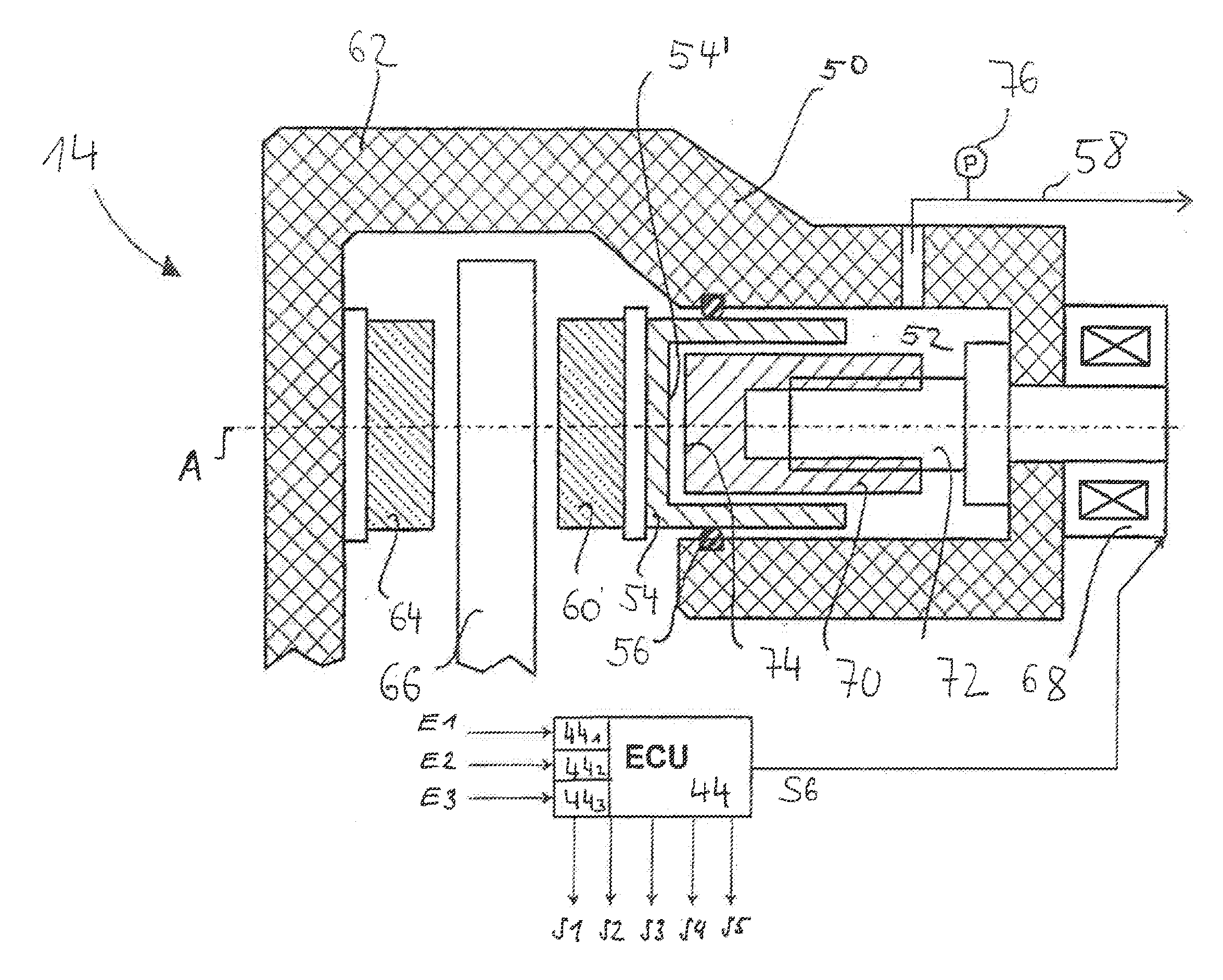

Procedure for Actuating a Hydraulic Parking Brake

ActiveUS20110042171A1Increase the amount of fluidReduce background noiseAnalogue computers for trafficMechanically actuated brakesEngineeringActuator

A procedure for actuating a parking brake is described, the parking brake comprising a brake piston which is received in a hydraulic chamber and is displaceable within the hydraulic chamber by means of a hydraulic actuator on the one hand and a mechanical actuator on the other. During operation of the parking brake the mechanical actuator is activated in a first step in order to displace the brake piston in the hydraulic chamber in such a way that a volume of a hydraulic fluid contained in the hydraulic chamber is increased. At a subsequent time the hydraulic actuator is activated in order to build up or increase a clamping force of the parking brake. The hydraulically generated or increased clamping force is then maintained by means of the mechanical actuator.

Owner:LUCAS AUTOMOTIVE GMBH

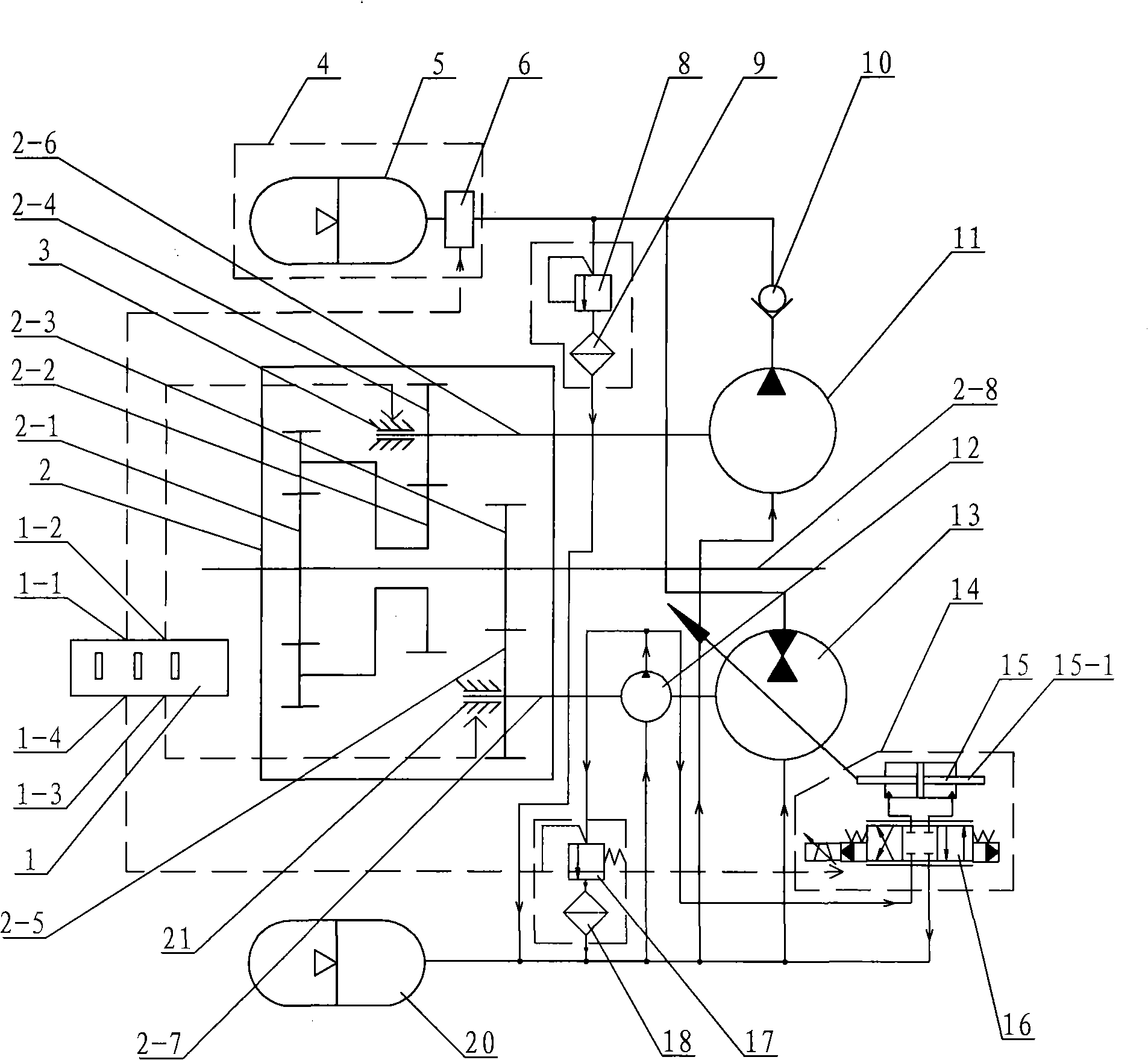

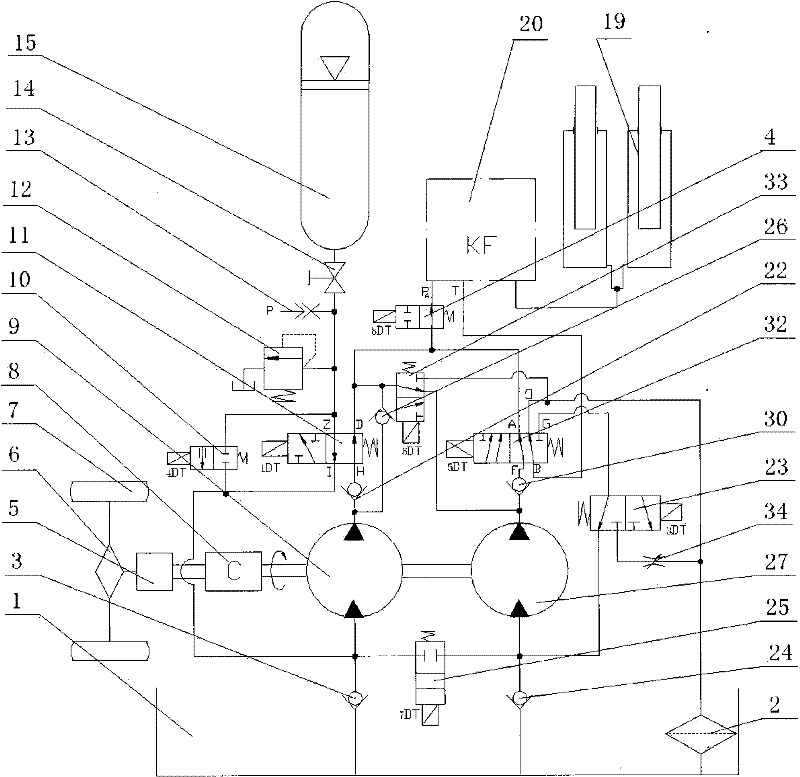

Vehicle braking kinetic-energy regeneration device

InactiveCN101337499AImprove fuel economyImprove powerGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive shaftHydraulic pump

A vehicle braking kinetic-energy regenerative device relates to a petrol-saving attachment for reclaiming the vehicle braking kinetic-energy, and aims to solve the problem of poor energy-saving effect in the prior vehicle braking kinetic-energy regenerative device. In the vehicle braking kinetic-energy regenerative device, a first brake and a slippage pump are respectively arranged at two ends of a first driven shaft; a second brake and a hydraulic pump motor are respectively arranged at two ends of a second driven shaft; a control oil-channel hydraulic pump is arranged at the middle part of the second driven shaft; an electrohydraulic change valve is connected with a high-pressure hydraulic accumulator; and a central control unit is respectively connected with the brakes, the second brake, the hydraulic pump motor and the electrohydraulic change valve. The vehicle braking kinetic-energy regenerative device recycles the vehicle braking kinetic-energy when the vehicle brakes, and drives the vehicle by releasing the recycled energy when the vehicle starts. The work efficiency of the energy is improved by the active stamping of the slippage pump. The vehicle braking kinetic-energy regenerative device is applicable to city buses and engineering vehicles, and can improve the kinetic performance and the braking performance of vehicles only by slightly reforming the prior vehicles.

Owner:HARBIN INST OF TECH

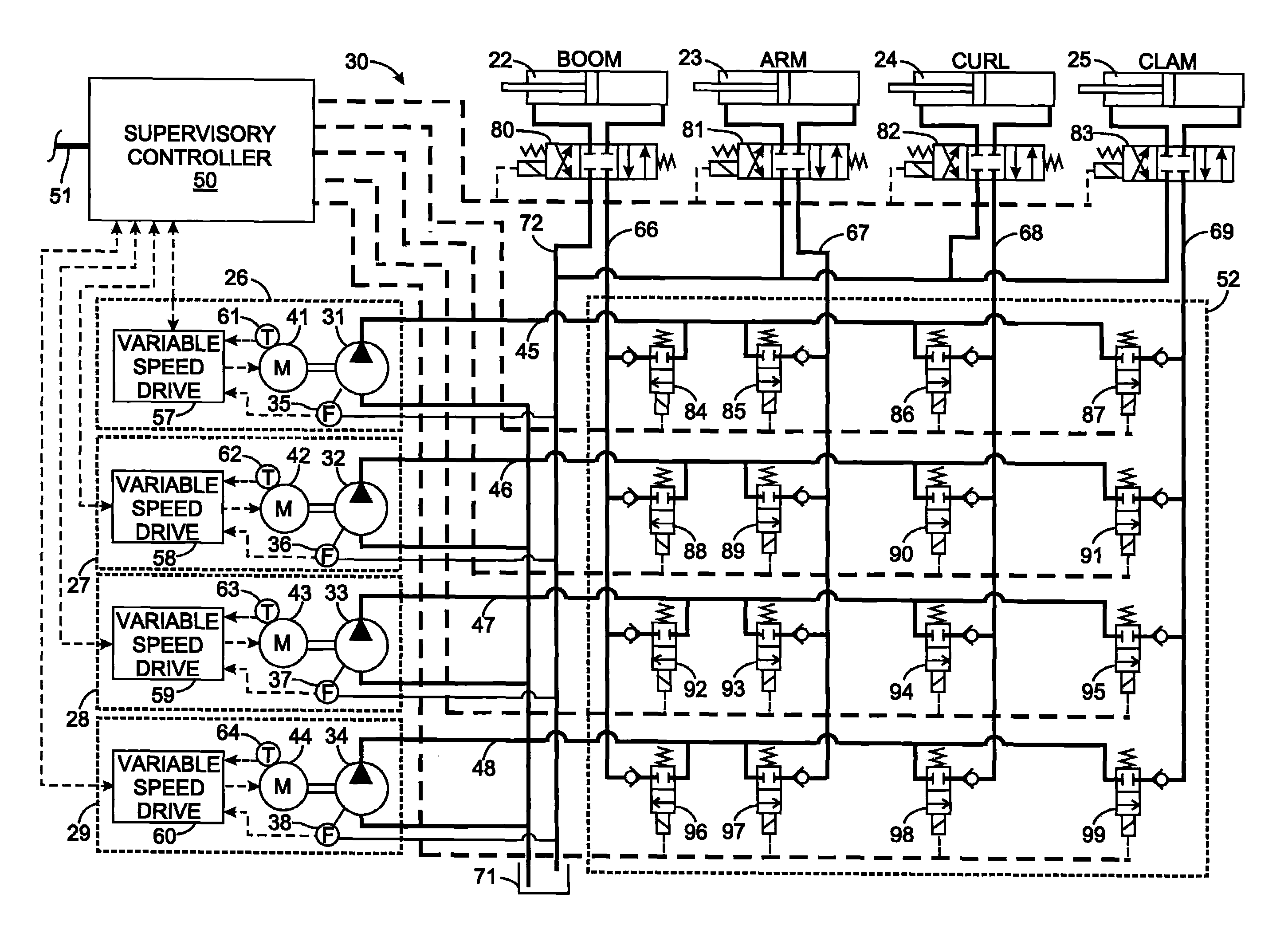

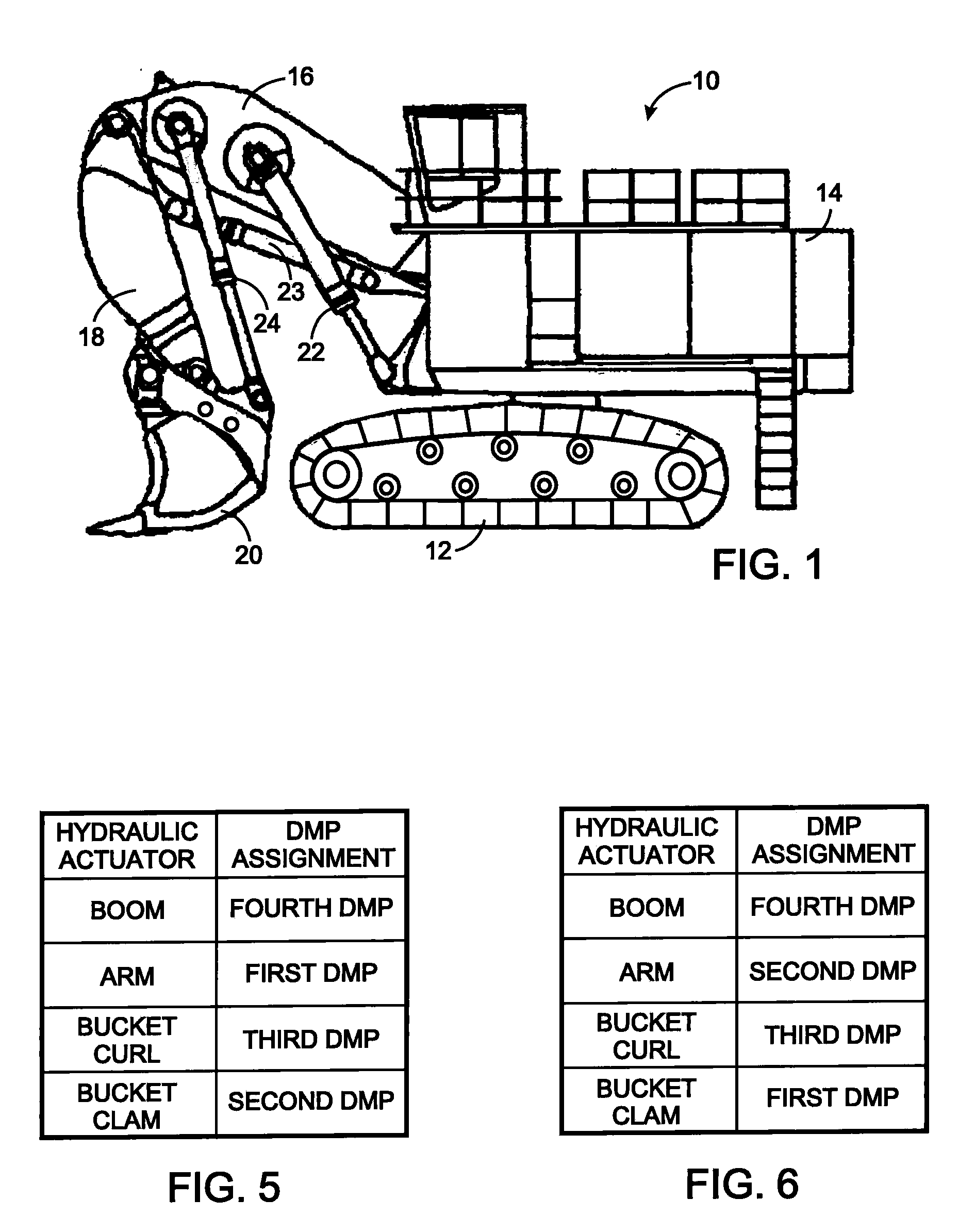

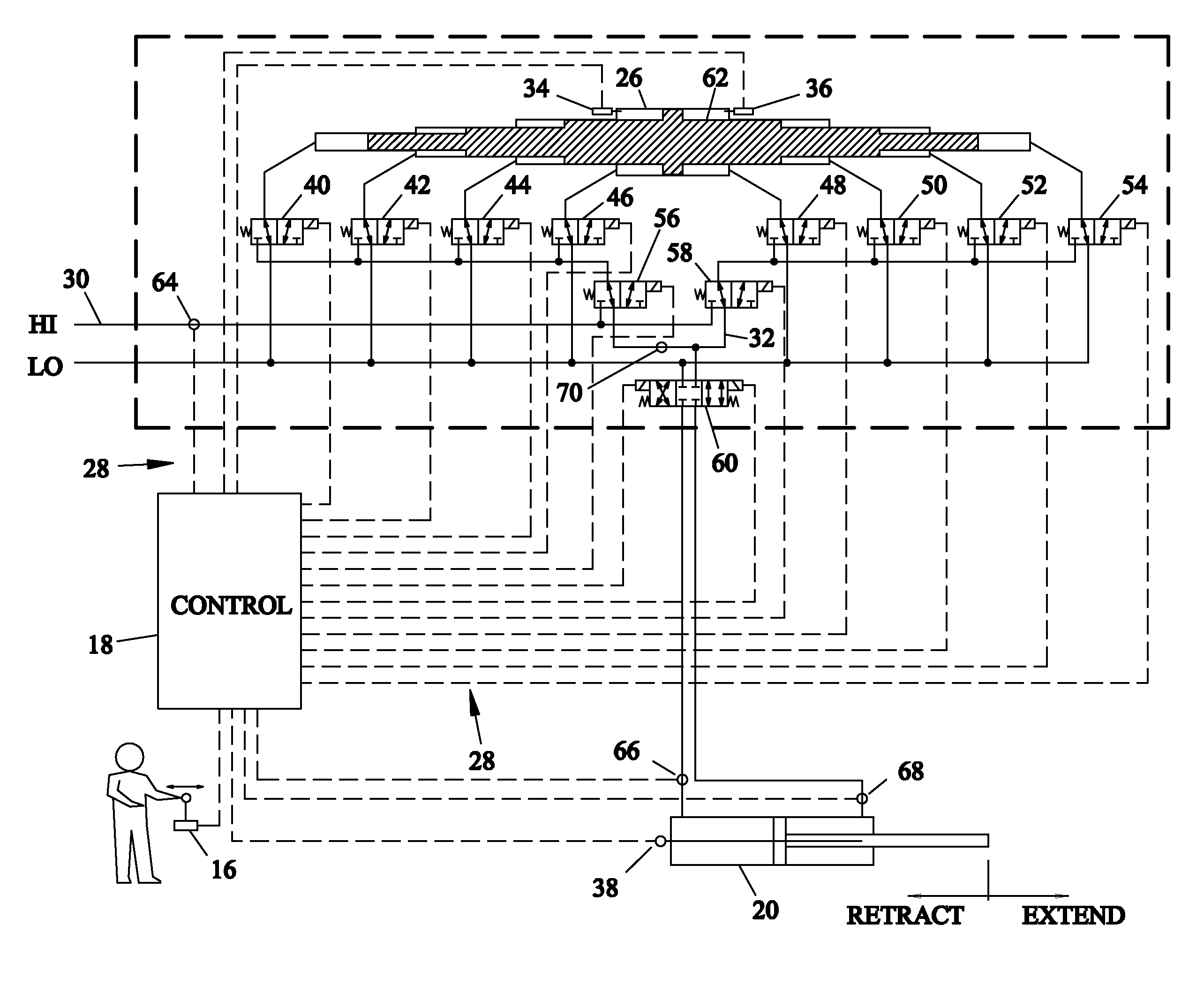

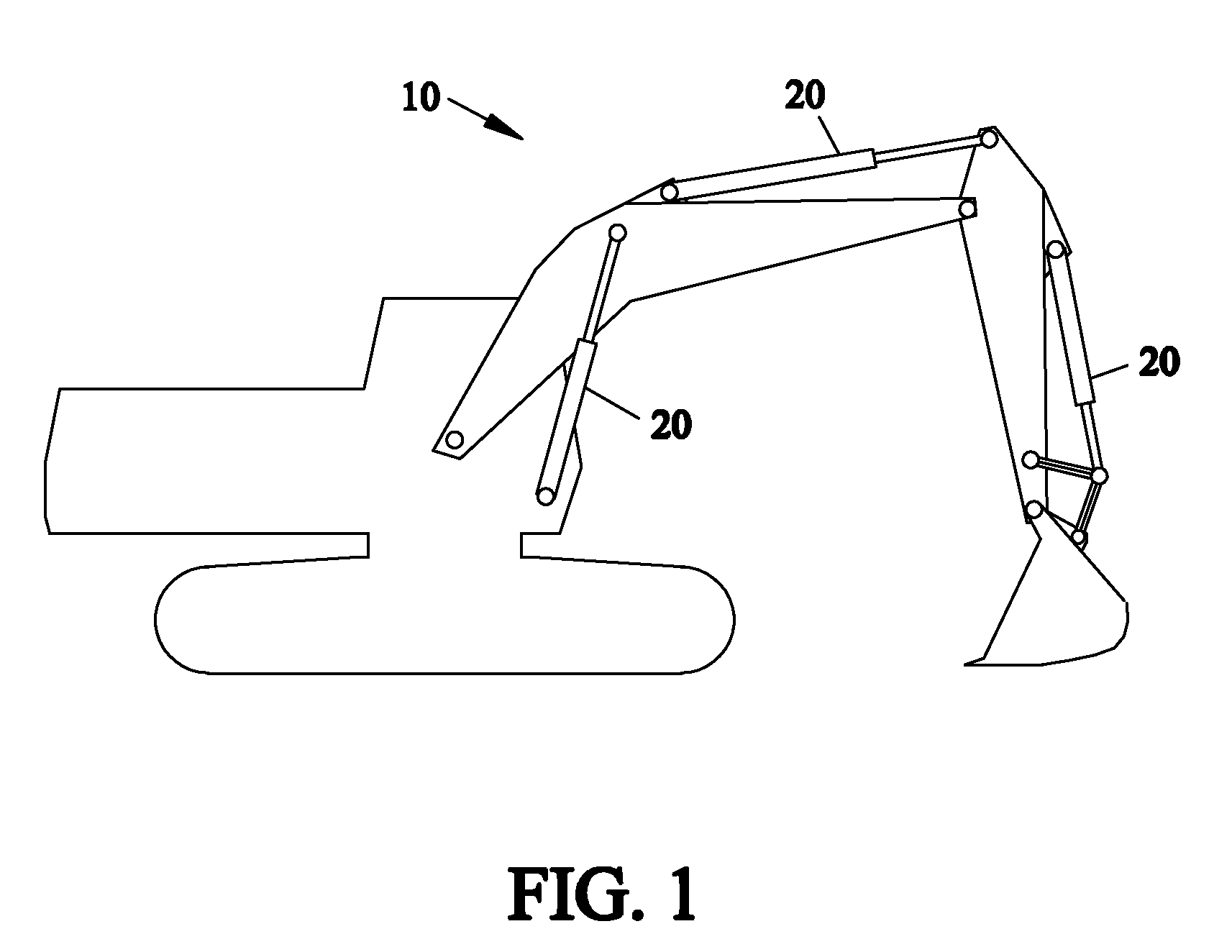

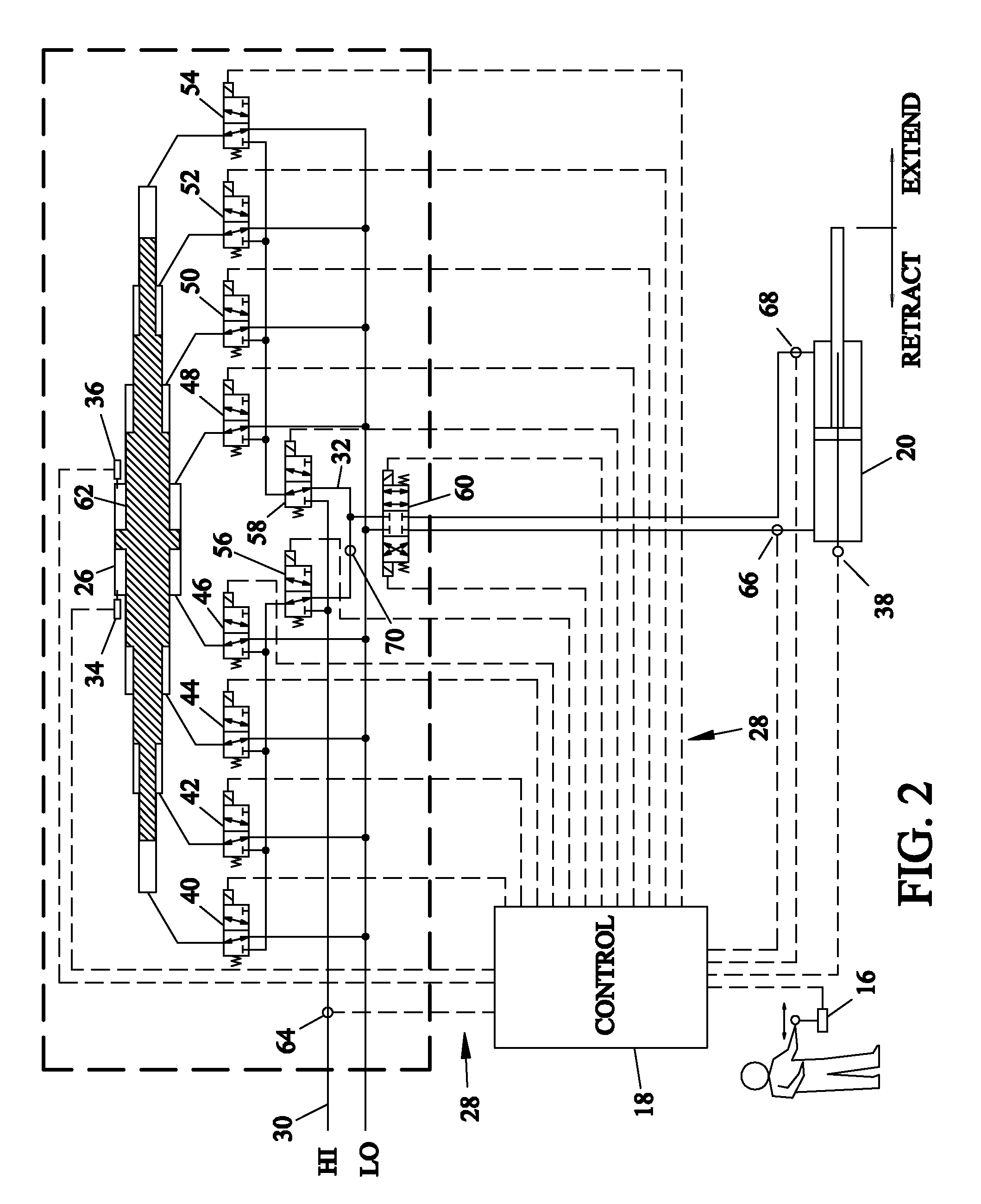

Technique for controlling pumps in a hydraulic system

A hydraulic system includes a plurality of pumps that provide pressurized fluid to a plurality of hydraulic actuators some of which work more that others. That system is controlled by producing a usage value for each of the plurality of pumps which indicates an amount that the respective pump has worked. One of the pumps is assigned to each hydraulic actuator in response to the usage values. The pumps with lower usage values are assigned to hydraulic actuators which work more, so as to equalize the use of each pump. The assignment of pumps to hydraulic actuators changes with changes in the usage values for the plurality of pumps. When a given one of the plurality of hydraulic actuators is to operate, hydraulic fluid is routed from the assigned pump to that given one of the plurality of hydraulic actuators.

Owner:BUCYRUS INTERNATIONAL

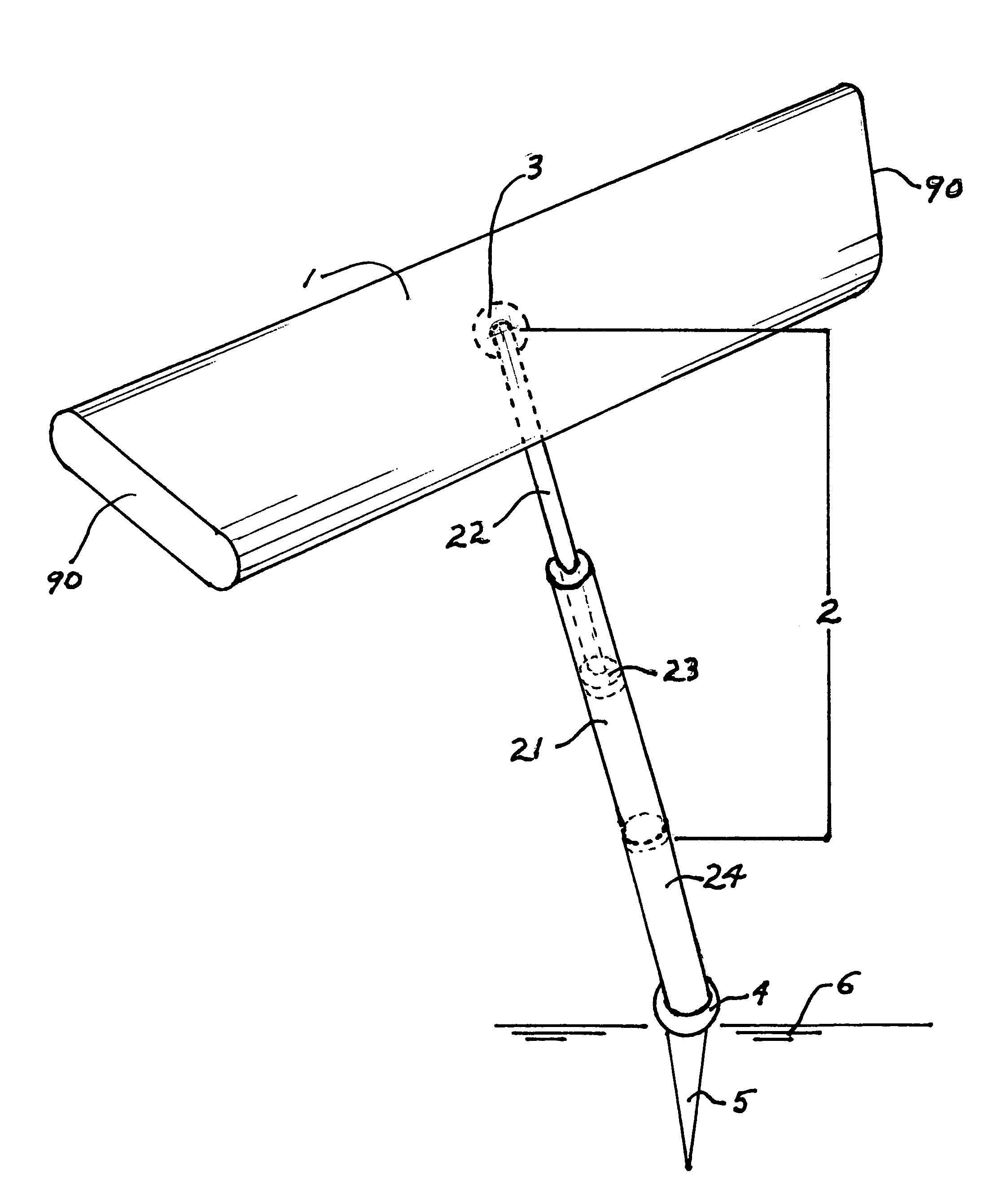

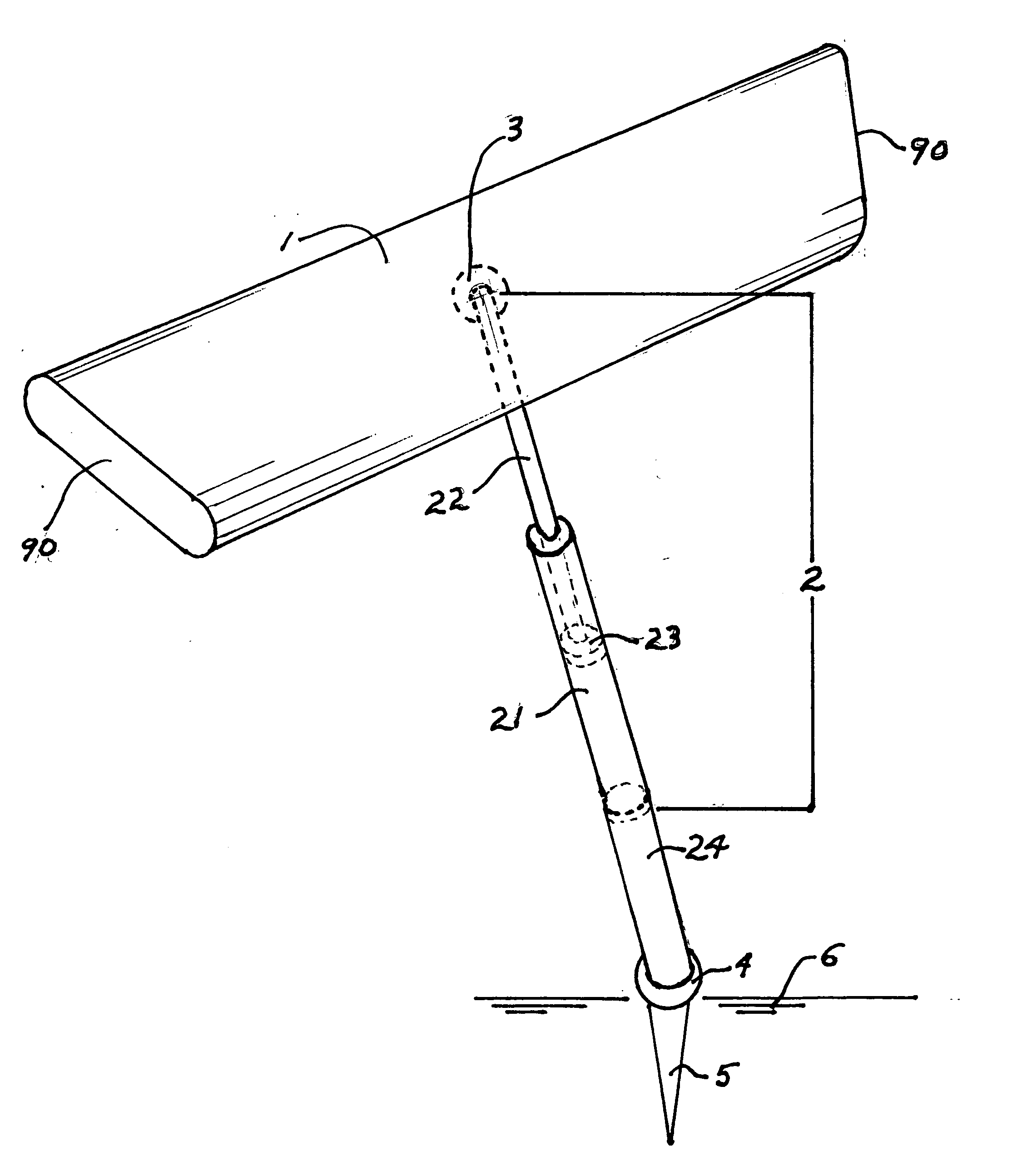

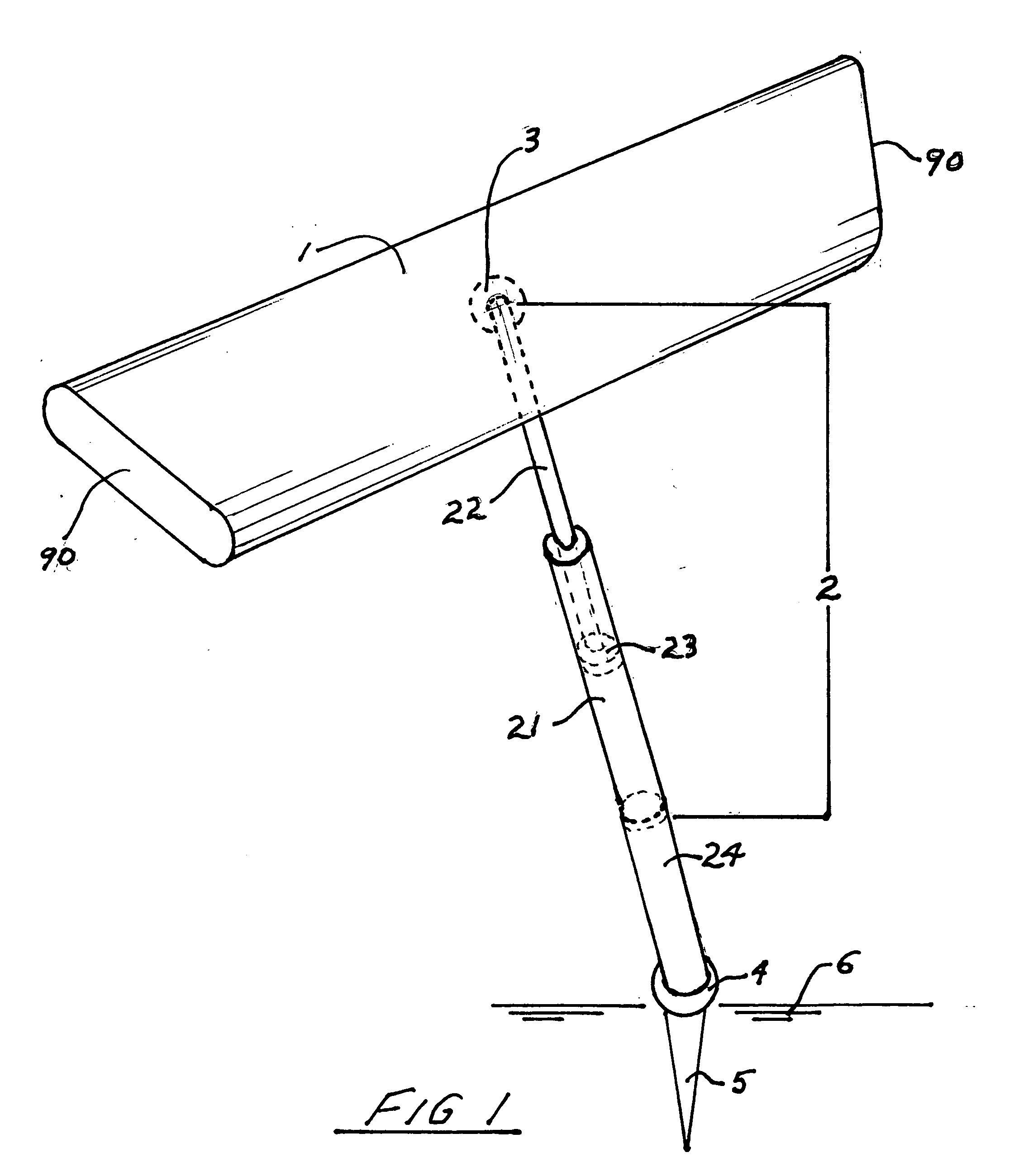

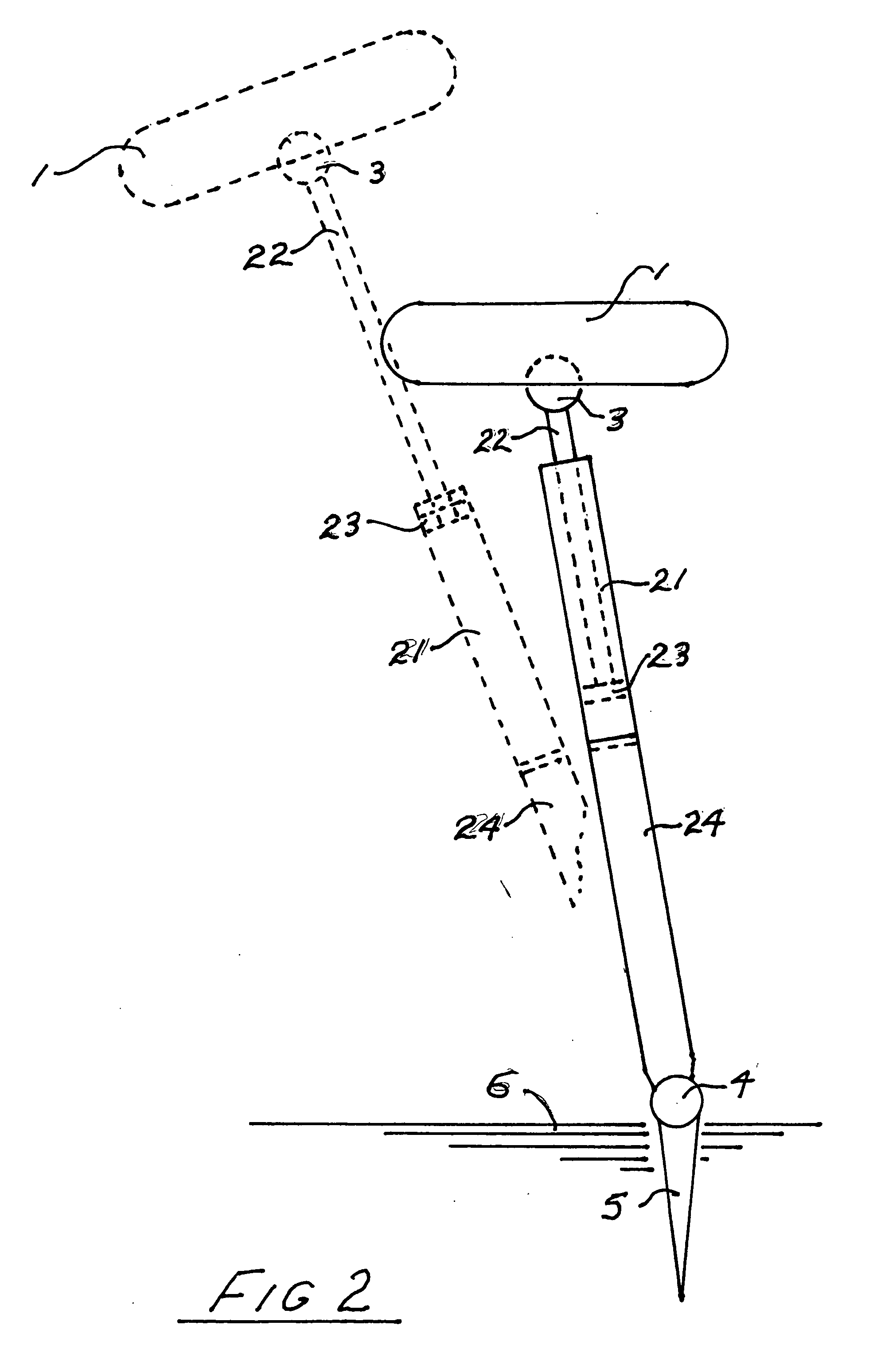

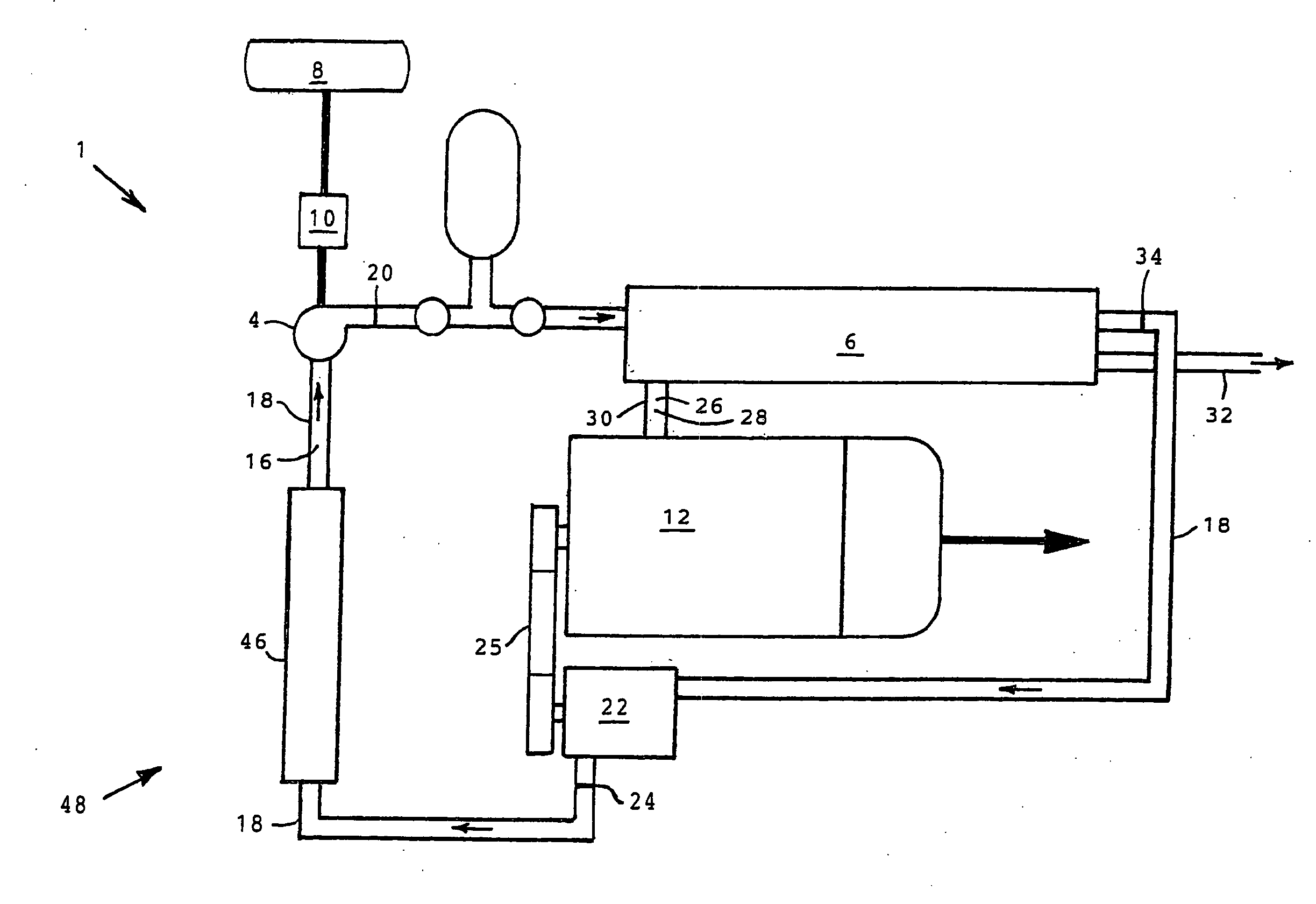

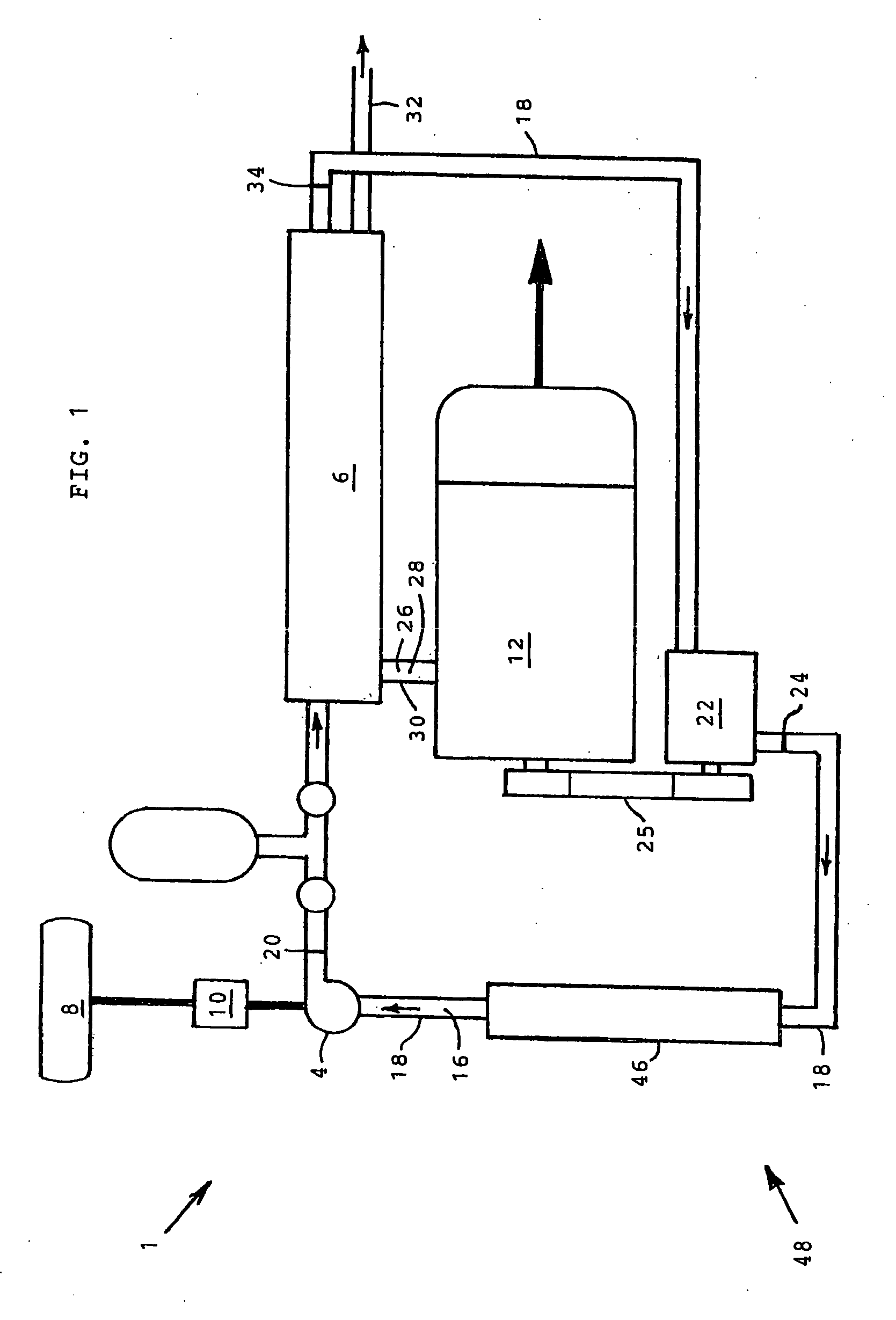

Wave energy conversion system

InactiveUS20050167988A1Reduce wearExtended component lifeGas turbine plantsPiston pumpsThermal energyForms of energy

An omni-directional system configured to convert the kinetic and potential energy in ocean waves to electrical energy or in some special cases to other forms of energy such as heat, mechanical and pressure energy. The system employs a float moored by a single hydraulic cylinder anchored to the seabed. Wave energy is captured as the float is displaced vertically and horizontally in response to wave action extending the hydraulic cylinder that in turn forces fluid under high pressure to the float where appropriate valves, hydraulic accumulators, and variable displacement hydraulic motors are arranged to drive electric generators. A secondary benefit of the system is the reduction of near shore erosion.

Owner:SEAWOOD DESIGNS

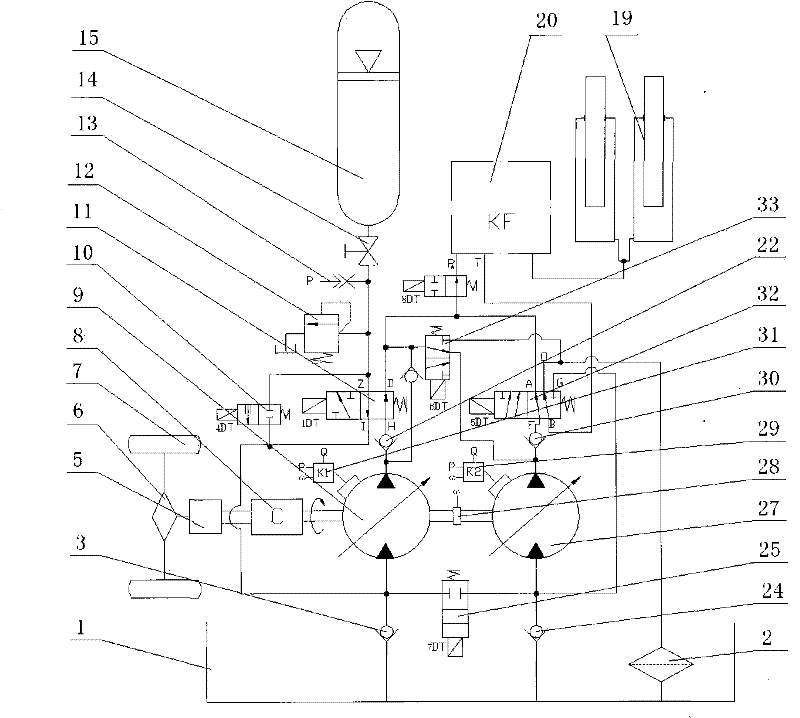

Electro-hydraulic hybrid driving mine lifting device and control method thereof

The invention provides an electro-hydraulic hybrid driving mine lifting device and a control method thereof. A lifting motor is connected with a first hydraulic pump / motor through a clutch, the input end of the lifting motor is connected with a primary winding of a step-down transformer, the primary winding of the step-down transformer is connected with the output end of a cascade type high voltage frequency converter, a secondary winding of the step-down transformer is connected with the input end of a low voltage frequency converter, and an independent feeding unit is formed by connecting a boosting transformer and a high voltage alternating current power grid. The control method includes: part of energy is stored through an energy accumulator and fed to save energy during uplink, downlink and brake of a lifting machine and a winch. The electro-hydraulic hybrid driving mine lifting device and the control method of the electro-hydraulic hybrid driving mine lifting device improve braking and decelerating performance of the motor and shorten braking time of the motor. Compared with an electro-hydraulic hybrid driving mine lifting device adopting a super capacitor and a flywheel battery, the electro-hydraulic hybrid driving mine lifting device adopts the hydraulic energy accumulator to store energy and is mature in technology, reliable in operation and long in service life.

Owner:TAIYUAN UNIV OF TECH

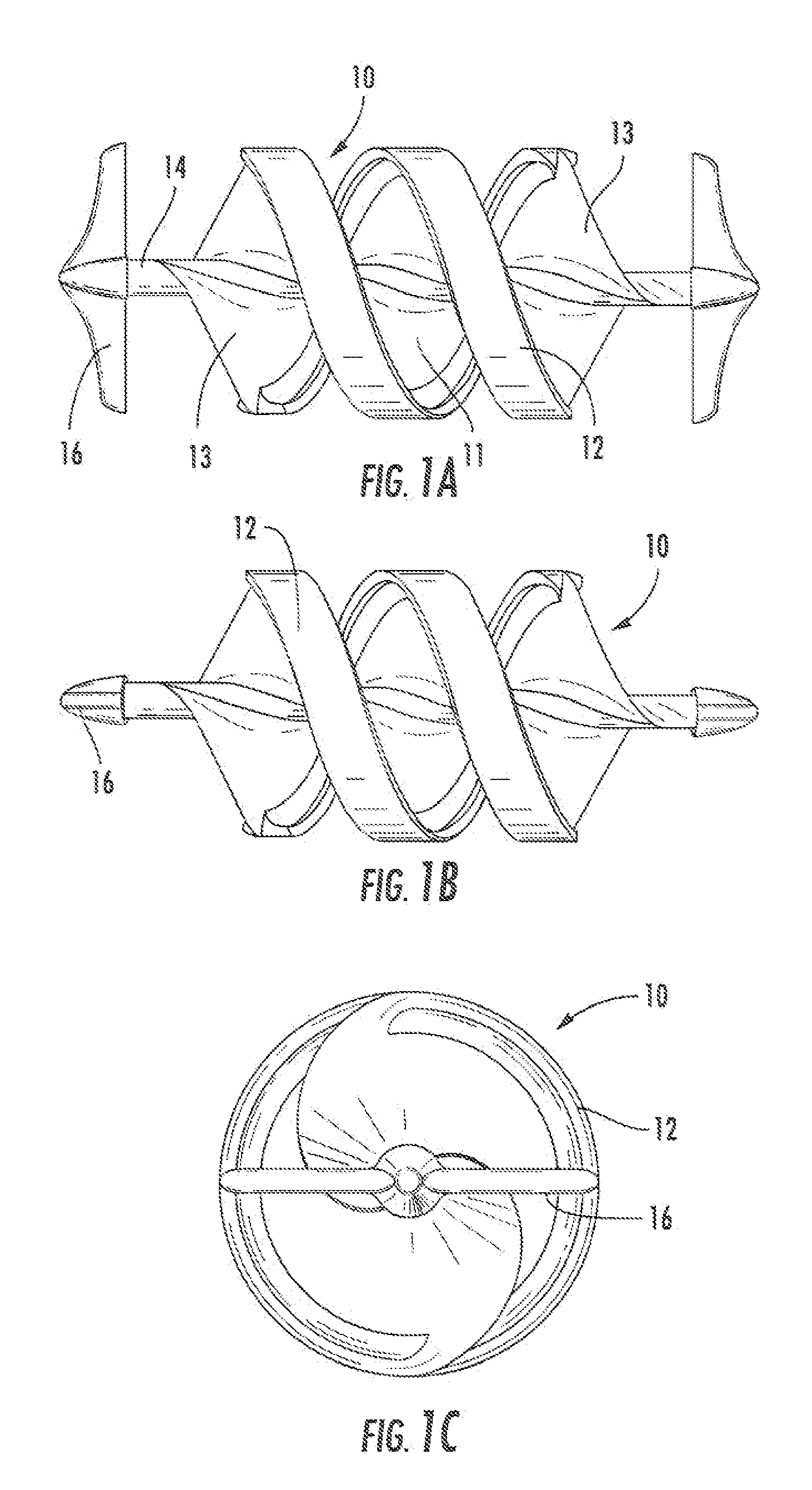

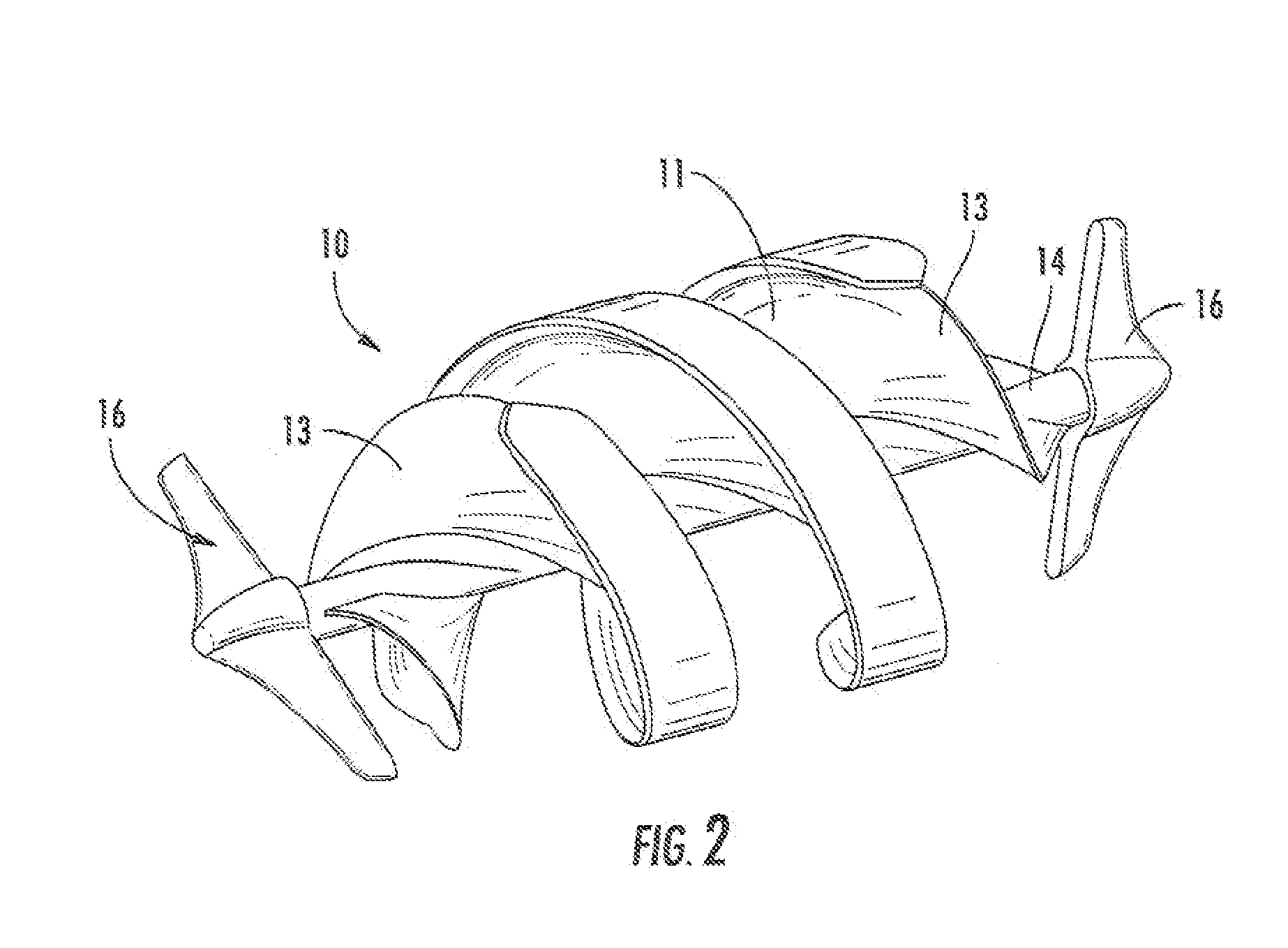

Tapered helical auger turbine to convert hydrokinetic energy into electrical energy

A helical auger turbine and hydrokinetic device for use with electrical generators for producing electricity. The auger turbine includes a generally helical turbine blade rotatably mounted on a central shaft, which may be tapered at each end, and a flange extending perpendicularly to an edge of the turbine blade. At least one turbine blade support connection is included for connecting the central shaft to a support structure. An electrical generator may be powered by the helical auger turbine, that can be used in a tidal water flow. The helical auger turbine can operate a high pressure pump connected to a hydraulic accumulator for storing pressurized hydraulic fluid from the high pressure pump. An electrical generator can be operated by hydraulic fluid delivered from the hydraulic accumulator at times of slow water flow. A plurality of helical auger turbines can be horizontally oriented under water, tethered to legs of an ocean platform such as an oil rig secured to the seabed.

Owner:ANDERSON JR WINFIELD SCOTT

Energy-saving travelling type hydraulic transport machine

The invention relates to an energy-saving travelling type hydraulic transport machine. According to the invention, an added hydraulic element and an original hydraulic system of the transport machine are used for partially converting potential energy before dropping down a heavy object and kinetic energy before braking a vehicle to pressure energy of fluid and storing the pressure energy in a hydraulic energy accumulator during the frequent lifting, dropping-down, braking and starting processes of the travelling type hydraulic transport machine, and the stored pressure energy is used for lift the heavy object and start the vehicle next time, so that the mechanical energy (the potential energy and the kinetic energy) obtained by power consumption can be regenerated partially, thereby reducing load and power of a power machine for driving an oil pump and starting the vehicle; since the potential energy of the heavy object and the kinetic energy of the vehicle, which are obtained by power consumption, can be partially regenerated during the process of re-lifting the heavy object and re-starting the vehicle, high recovery and regeneration efficiency can be achieved and the effects of energy saving and emission reducing are very remarkable. The energy-saving travelling type hydraulic transport machine is simple and easy to operate and has the advantages of low investment and long service life. The energy-saving travelling type hydraulic transport machine can be configured during new construction or added during transformation of the old machine.

Owner:JINAN JENHANG ENERGY SAVING TECH

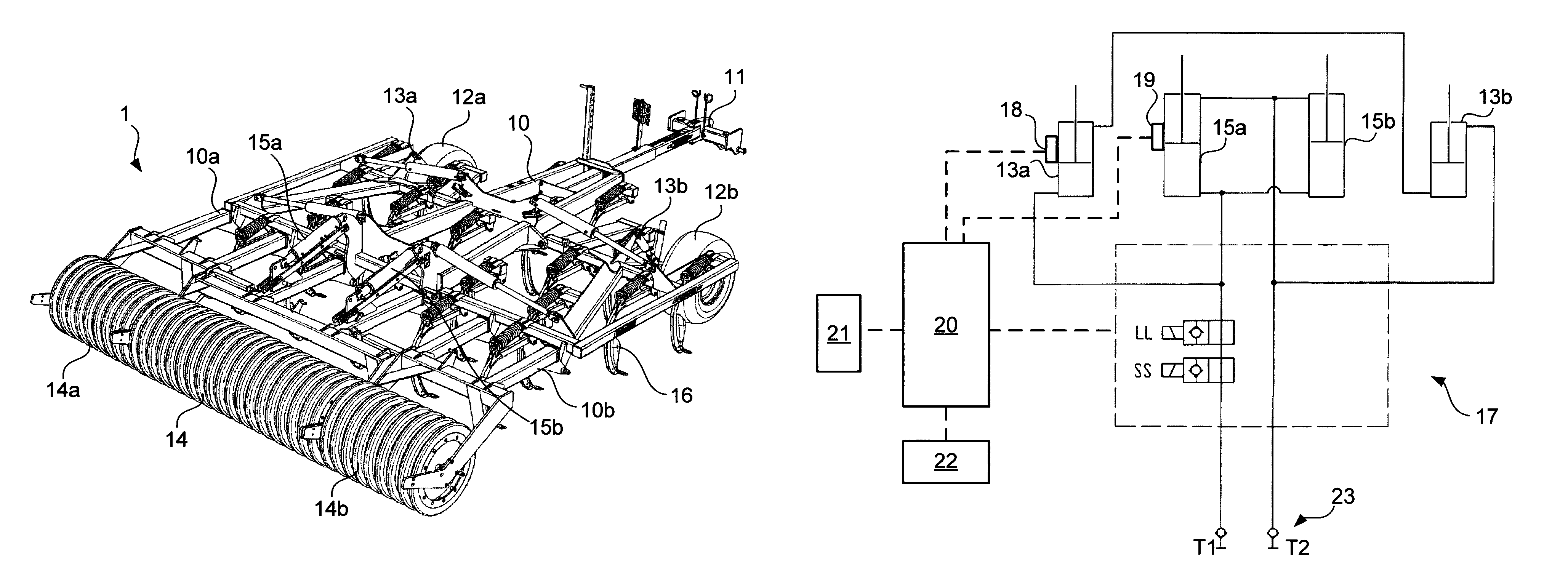

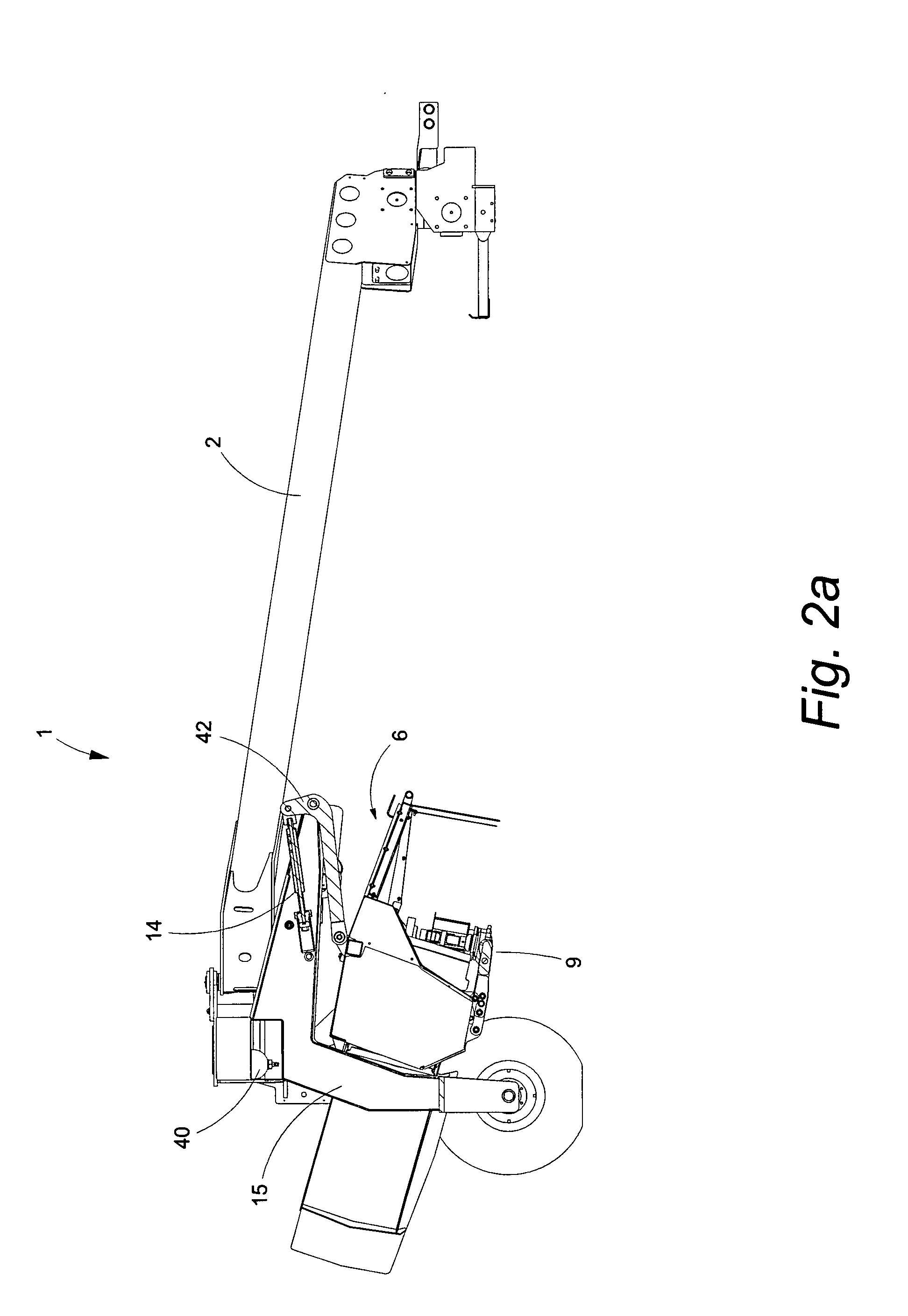

Agricultural implement and method of controlling an agricultural implement

ActiveUS9301439B2Simple systemEasy to carrySpadesAgricultural machinesAgricultural engineeringActuator

Owner:VADERSTAD HLDG

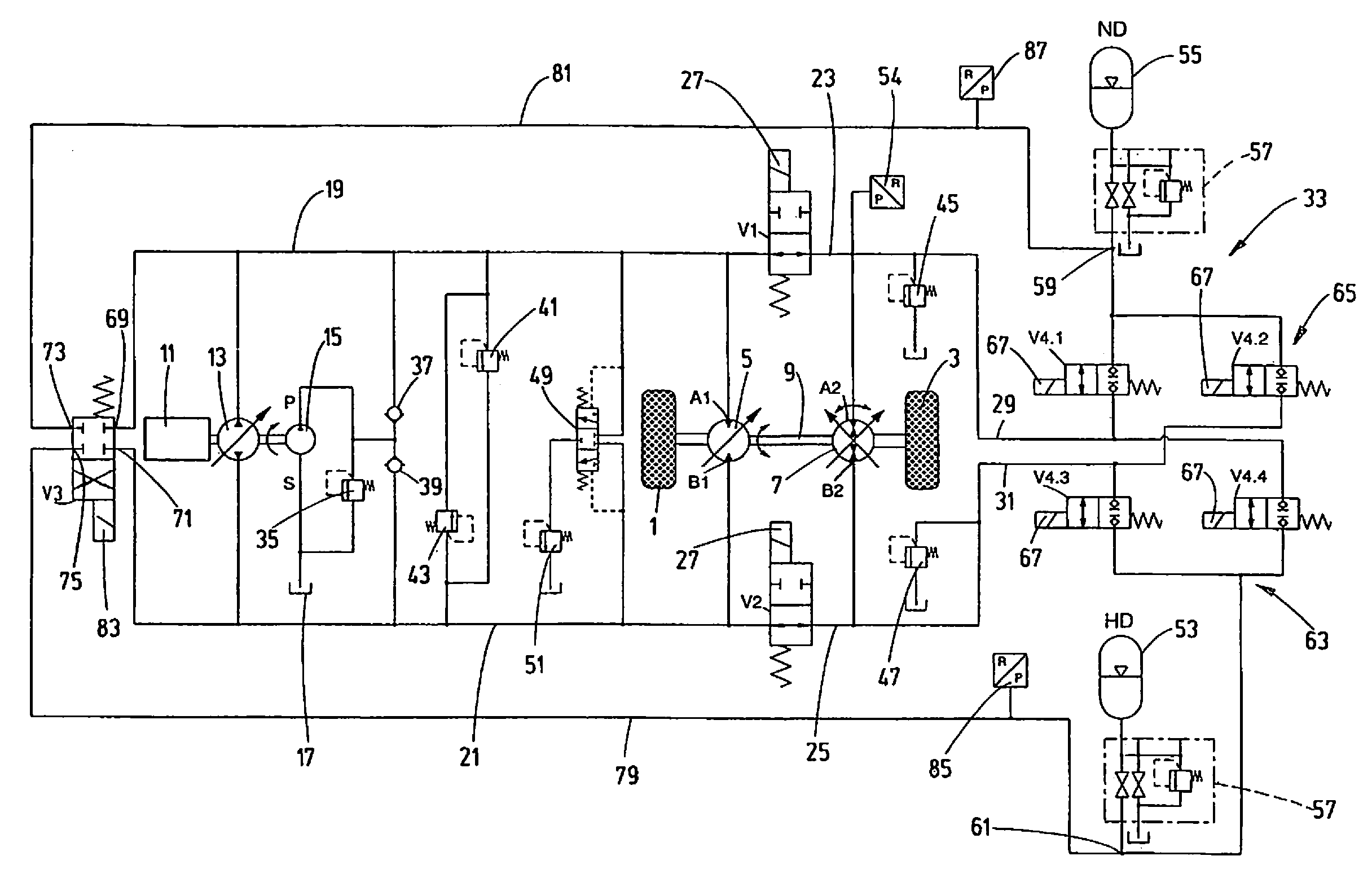

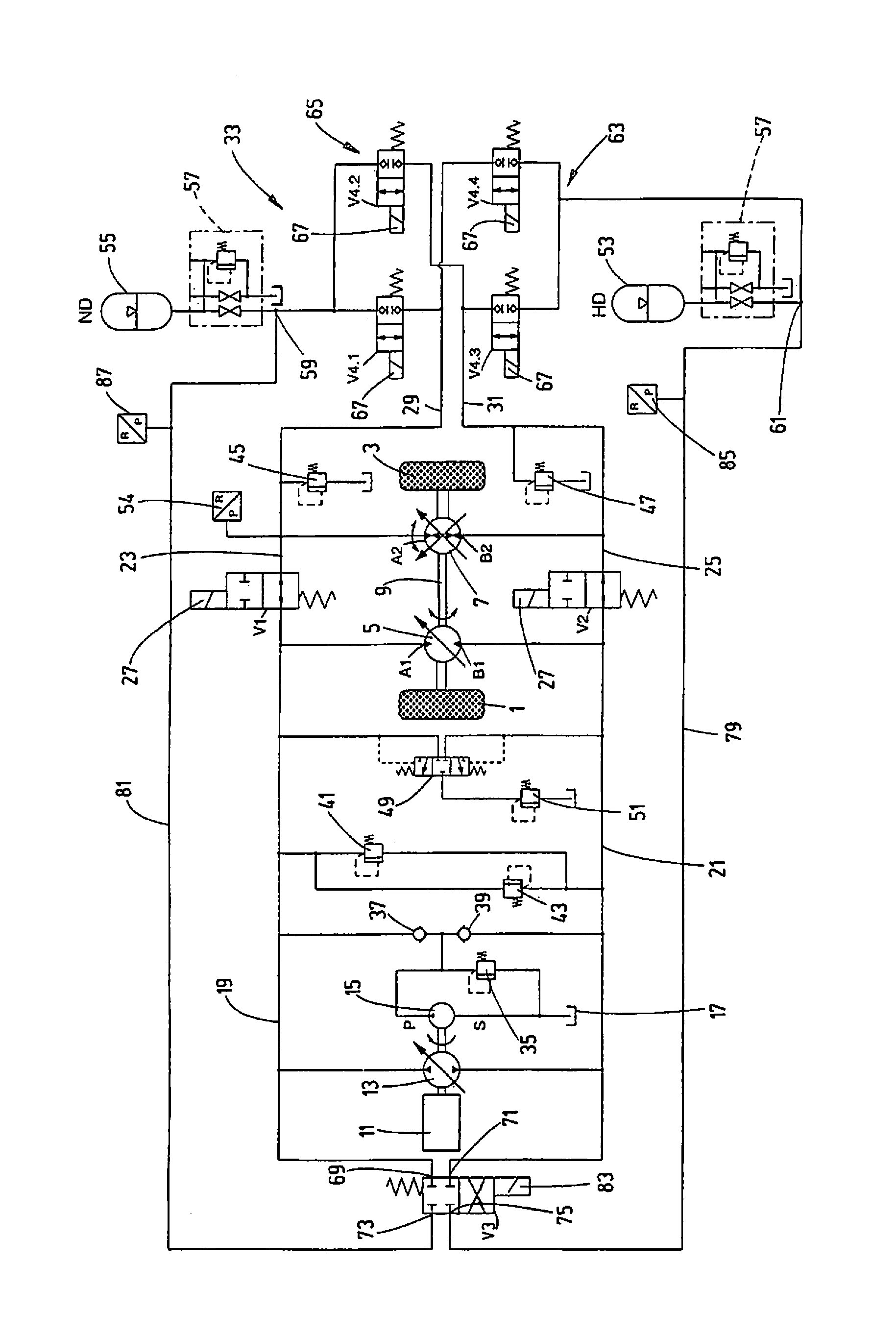

Hydrostatic drive system

ActiveUS8959905B2Simple structureImprove responseFluid couplingsGas pressure propulsion mountingLine tubingMotor drive

A hydrostatic drive system has a motor-driven hydraulic pump (1) connected to at least one hydraulic drive unit (7) by a first working line (19) and a second working line (21) forming a hydraulic circuit. The drive unit is connected to a gear set (1, 3). A first hydraulic accumulator (53) for accumulating pressure energy can be connected to one of the working lines (19, 21). A second hydraulic accumulator (55) can be connected to the other working line (19, 21). A valve device (V1, V2) permits the segment (23, 25) of each working line (19 or 21) extending to the drive unit (7) to be separated to separate an accumulator part (33) from the part of the circuit with the hydraulic pump (13). The accumulator part includes the hydraulic accumulators (53, 55) and at least one drive unit.

Owner:HYDAC TECH GMBH

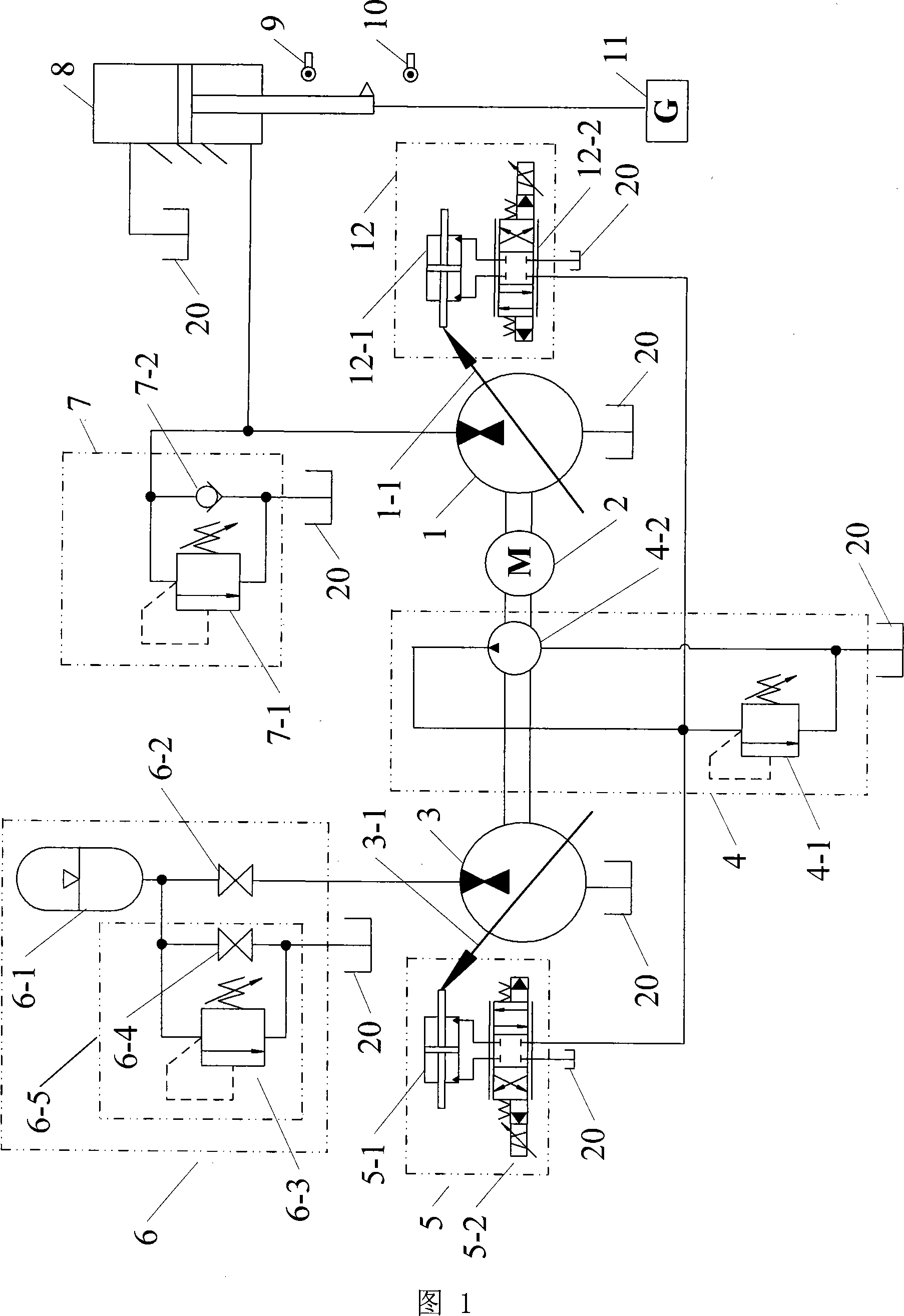

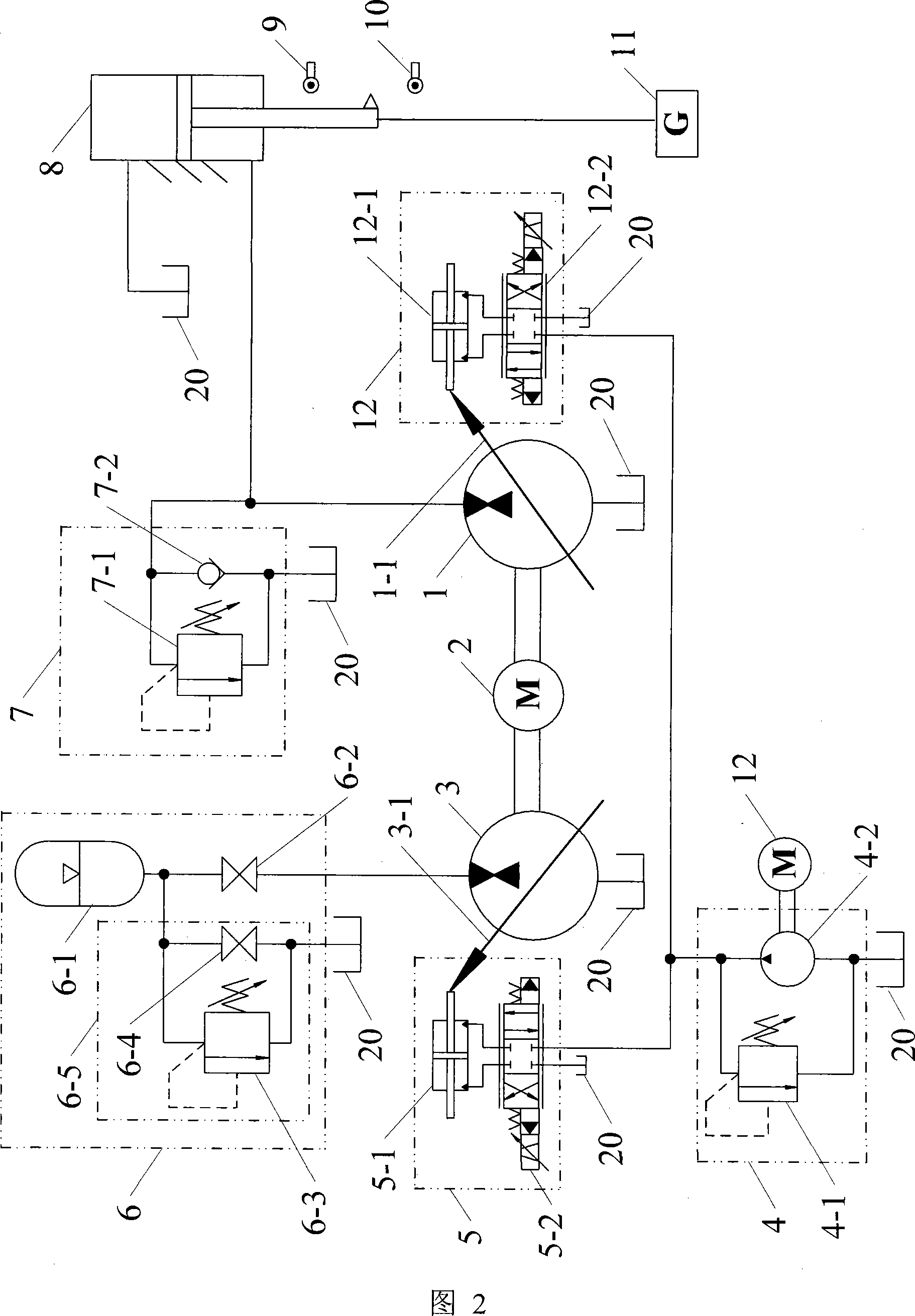

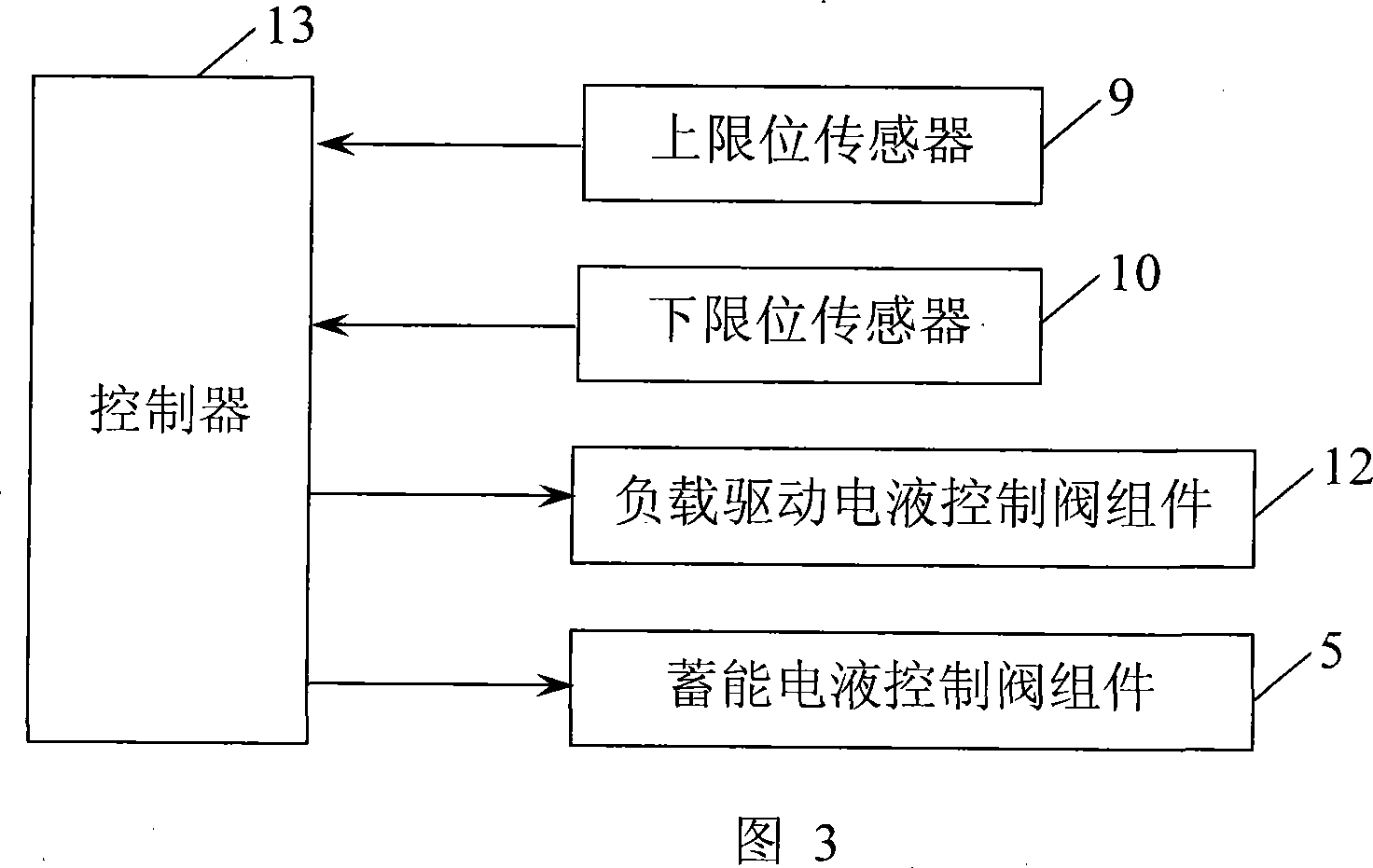

Energy-store state-liquid driving device of secondary flow-regulation coupling hydraulic energy accumulator

InactiveCN101070864AAchieve energy saving effectReduce installed powerFluid-pressure actuator componentsHydraulic pumpSmall range

The invention provides a secondary Regulation flow coupled hydraulic accumulator storage hydrostatic transmission device, relating to a secondary hydrostatic transmission method and systems. It solves the contradiction between constant coltage net which only allows pressure to change in small range and hydraulic pressure accumulator energy recovery subsystems which need to change pressure in a large range existing in the secondary regulation hydrostatic transmission system. It adopts hydraulic pressure accumulator to output hydraulic oil and drives hydraulic pressure storage pump or motor and electric motor to drive hydraulic oil cylinder to work with load. When the load need to descend, load-driven hydraulic pump or motor and storage Hydraulic Pump or Motor change work condition respectively and recover and storage the potential energy which is produced by the hydraulic oil cylinder. When the load need to up run, energy storage hydraulic pump or motor and load driver Hydraulic Pump or Motor change work condition respectively and do the above work again. This invention can be used in the hoist nd hydraulic pumping and so on.

Owner:HARBIN INST OF TECH

Tapered helical auger turbine to convert hydrokinetic energy into electrical energy

Owner:ANDERSON JR WINFIELD SCOTT

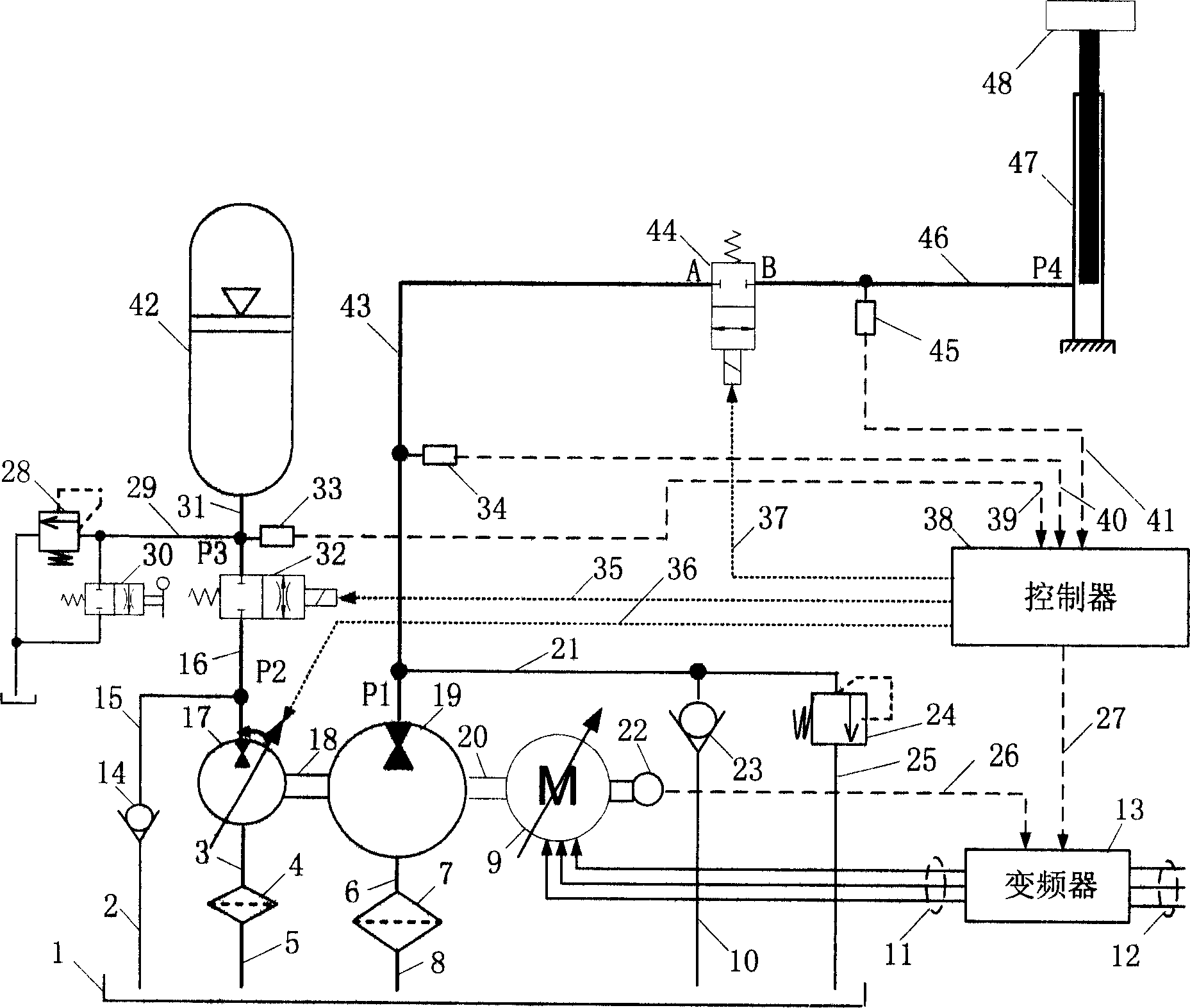

Energy saving hydraulic lifting system of variable hydraulic counterweight

InactiveCN1987124ANo wasteReduce installed powerServomotorsElevatorsFrequency changerHydraulic motor

An energy-saving hydraulic lift system with variable hydraulic counterweight for the real-time match with load is composed of a primary loop consisting of frequency variator, AC asynchronous motor, quantitative pump / motor, and hydraulic cylinder or hydraulic motor, and a secondary loop consisting of hydraulic energy accumulator (hydraulic counterweight) for recovering the all energy generated by lowering load and variable pump / motor. Said asynchronous motor provides the only energy needed by system efficiency and friction loss.

Owner:ZHEJIANG UNIV

Braking energy recovery system for vehicles and vehicles equipped with the system

ActiveCN102300754AOvercome or alleviate shortcomingsAuxillary drivesHydrostatic brakesHydraulic motorDrive shaft

A braking energy recovery system adapted for use on a vehicle and a vehicle having such a system installed. The vehicle has an engine-transmission assembly, a driveshaft, a braking system and an auxiliary system. The energy recovery system comprises a first pump, a hydraulic accumulator and a hydraulic motor. The first pump is a variable displacement hydraulic pump. The hydraulic accumulator is connected to the first pump and is operative to store hydraulic fluid under pressure. The hydraulic motor is hydraulically connected to the accumulator to receive hydraulic fluid. The motor is adapted to drive a second hydraulic pump, which is hydraulically connected to the auxiliary system, using hydraulic energy stored in the accumulator.

Owner:14156048 CANADIAN CO

Digital hydraulic system

InactiveUS20090178399A1Optimize energy usageMost efficientFluid couplingsAccumulator installationsControl systemHydraulic fluid

A control system for a work machine having a hydraulic energy source, a hydraulic accumulator, a digital hydraulic system having a digital hydraulic transformer, a hydraulic actuator and a movable element. The hydraulic accumulator being fluidically couplable with the hydraulic energy source. The digital hydraulic system including a digital hydraulic transformer fluidically couplable with the hydraulic accumulator. The hydraulic actuator being fluidically couplable with the digital hydraulic transformer. The movable element being movable by the hydraulic actuator. The control system including means to estimate at least one of potential energy and kinetic energy in the movable element; means to measure a fill level of hydraulic fluid in the hydraulic accumulator; and means to vary the amount of hydraulic energy added to the hydraulic accumulator by the hydraulic energy source responsive to the potential energy, the kinetic energy and / or the fill level of the hydraulic accumulator.

Owner:DIGITAL HYDRAULICS

Suspension system for a floating header on an agricultural implement

A suspension system for fixed-frame, towed agricultural implements having at least one floating head. A hydraulic cylinder is used for both lift and suspension of the floating head. A hydraulic accumulator provides expansion room for hydraulic fluid to move in and out of the hydraulic cylinder during suspension.

Owner:VERMEER MFG CO

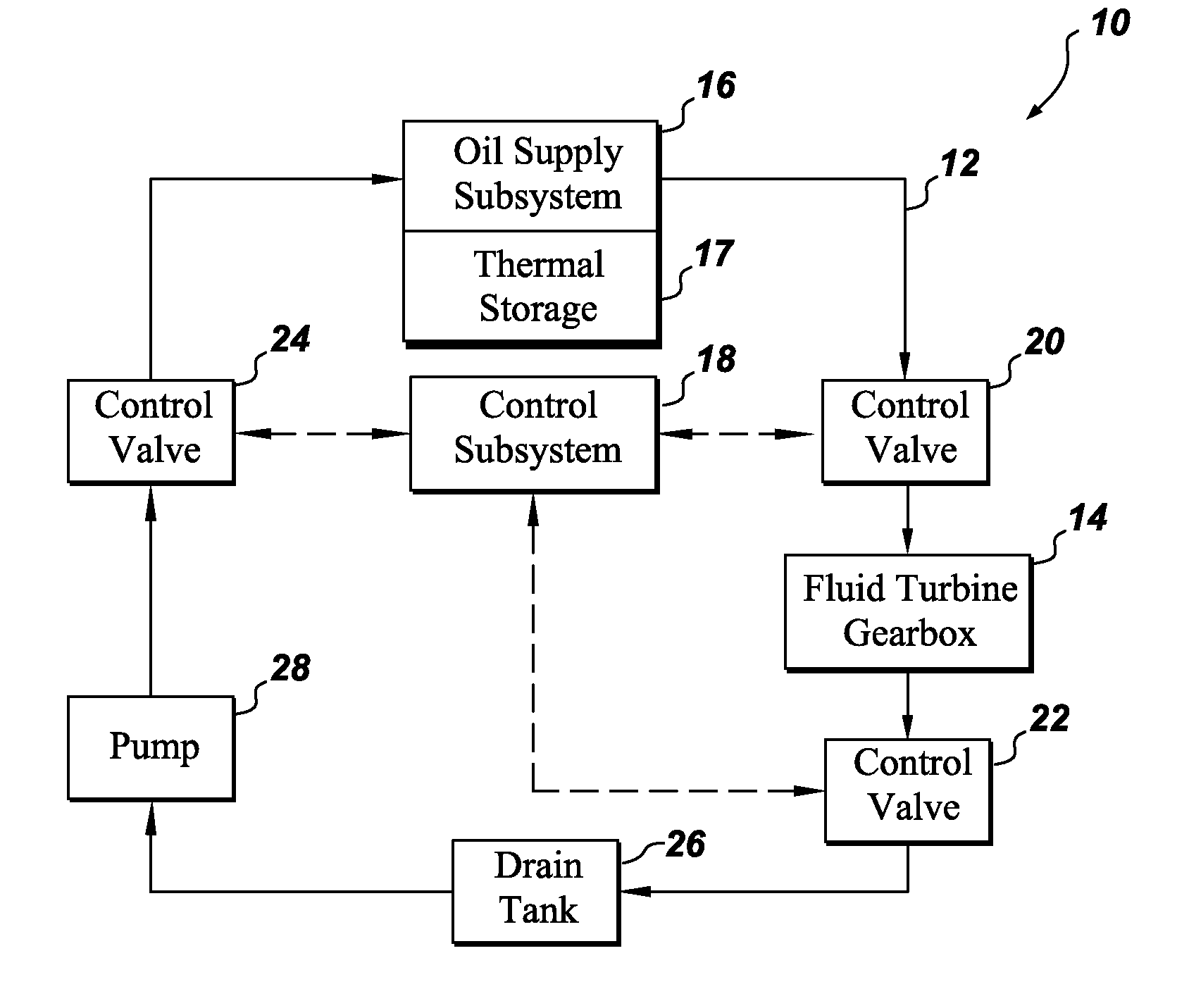

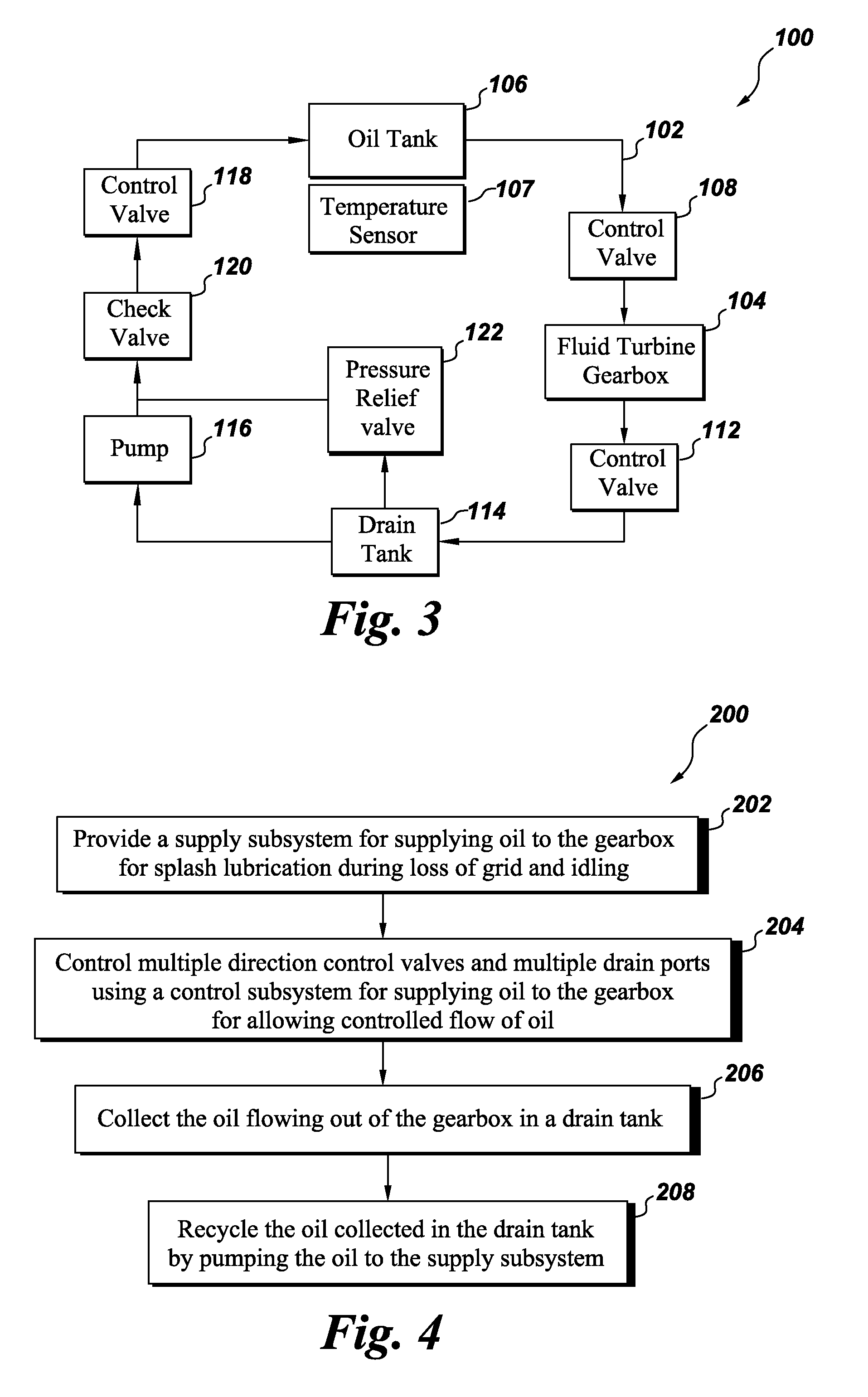

Lubrication of fluid turbine gearbox during idling or loss of electric grid

A lubrication system for a fluid turbine is provided. The system includes a supply subsystem for providing oil via an oil tank or a hydraulic accumulator to a gearbox of the fluid turbine for lubrication during at least one of idling or loss of electric grid. The system also includes a control subsystem for controlling the flow in the lubrication system.

Owner:GENERAL ELECTRIC CO

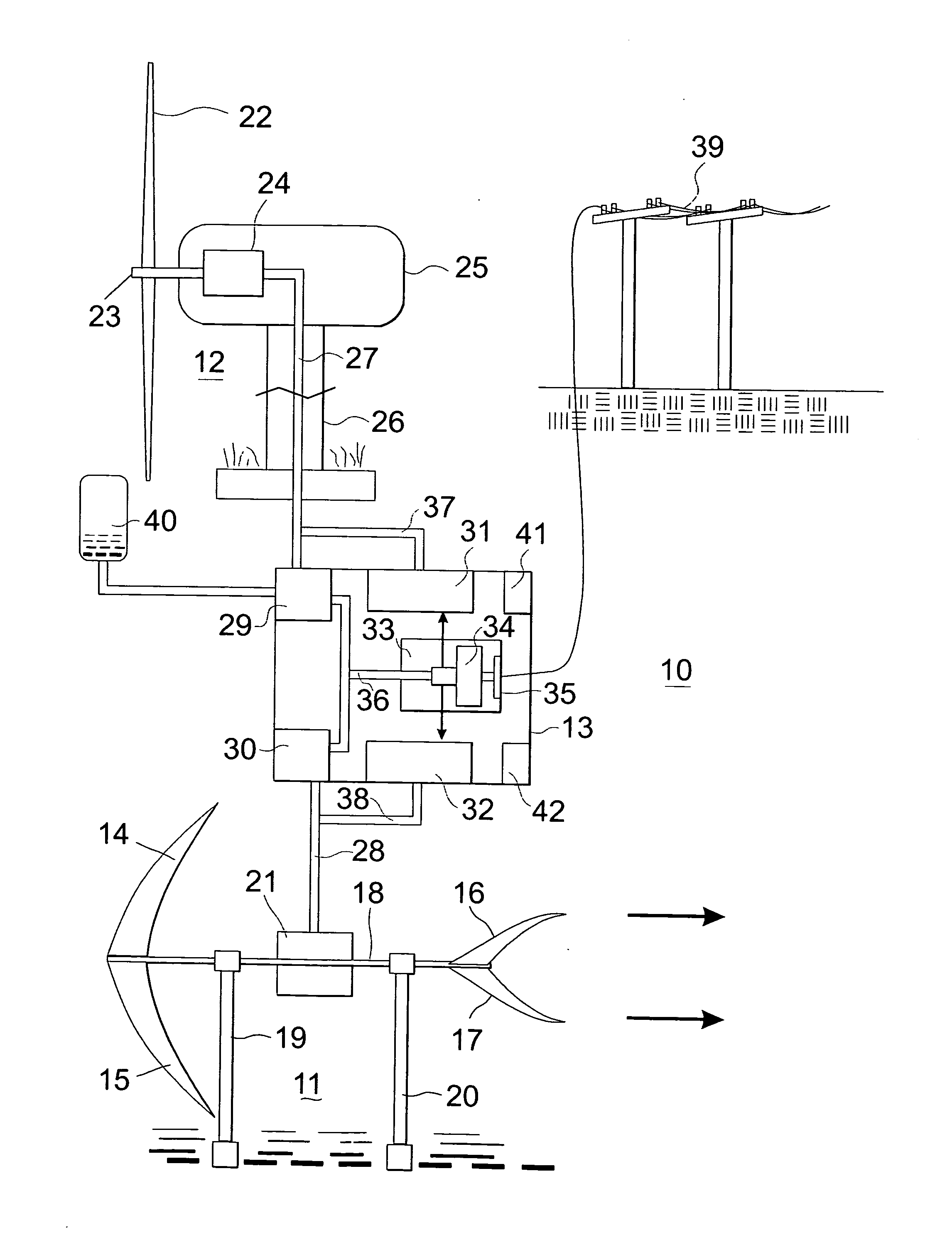

Hydraulic tidal and wind turbines with hydraulic accumulator

Tidal and wind turbines utilize a hydraulic drive-train to transfer the kinetic energy in moving currents to a generator located ground level for producing electricity for the grid. A rotor shaft transfers the mechanical energy from the rotors to a hydraulic pump which converts the mechanical energy into fluid energy which is transferred to a high pressure manifold and then to hydraulic motor for converting the fluid energy into rotational mechanical energy which spins a generator coupled to the motor. A high pressure manifold is coupled to a hydraulic accumulator for storing the fluid energy for later use.

Owner:CARR FRED K

Hydraulic hybrid power system

InactiveUS20100133031A1Big economyLow costAuxillary drivesElectrodynamic brake systemsHigh pressureHydraulic pressure

According to the present invention a pump is driven by one or more wheels of a hydraulic hybrid vehicle during braking. The inertial energy of the vehicle powers the pump during braking of the vehicle, and the pump pumps a hydraulic liquid into an hydraulic accumulator that stores the fluid at its elevated pressure. When additional power is required by the vehicle, the liquid is released into a heat exchanger that transfers heat from the exhaust gas of the engine to the liquid causing at least a portion of the liquid to become gaseous. The heated fluid is then fed into an expander that generates shaft power by expanding the pressurized and heated gaseous and / or liquid fluid mixture. The preferred embodiment of the present invention operates under the Rankine cycle or steam engine cycle where the liquid compression function is performed using power from regenerative braking, and the liquid heating and vaporization function is performed using exhaust gas waste heat. The present invention shows potential for more than tripling the regenerative braking power of hydraulic hybrid vehicles, thereby providing a large improvement in vehicle fuel economy.

Owner:MENDLER EDWARD CHARLES

Hydraulic energy accumulator

Example energy storage systems (20, 20′, 20″) comprises a fluid circuit (22, 22′, 22″) and an electrical unit (24, 24′, 24″) configured to operate as a motor in a first phase of operation and to operate as a generator in a second phase of operation. The fluid circuit (22, 22′, 22″) comprises a first fluid container (30, 30′, 30″) situated so content of the first fluid container experiences a first pressure level; a tank (32, 32′, 32″) having its content at a second pressure level (the second pressure level being less than the first pressure level): and, a first hydraulic motor / pump unit (34, 134, 34″) connected to communicate a first working fluid between the tank and the first fluid container. In the first phase of operation electricity is supplied to the first hydraulic / motor unit (34, 134, 34″) whereby the first hydraulic / motor unit transmits the first working fluid from the tank into the first fluid container (30, 30′, 30″). In the second phase of operation pressurized first working fluid in the first fluid container (30, 30′, 30″) is transmitted from the first fluid container through the first hydraulic / motor unit 34, 134, 34″) to the tank (32, 32′, 32″), thereby causing the electrical unit (24, 24′, 24″) to generate electricity.

Owner:YSHAPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com