Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164 results about "Independent feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

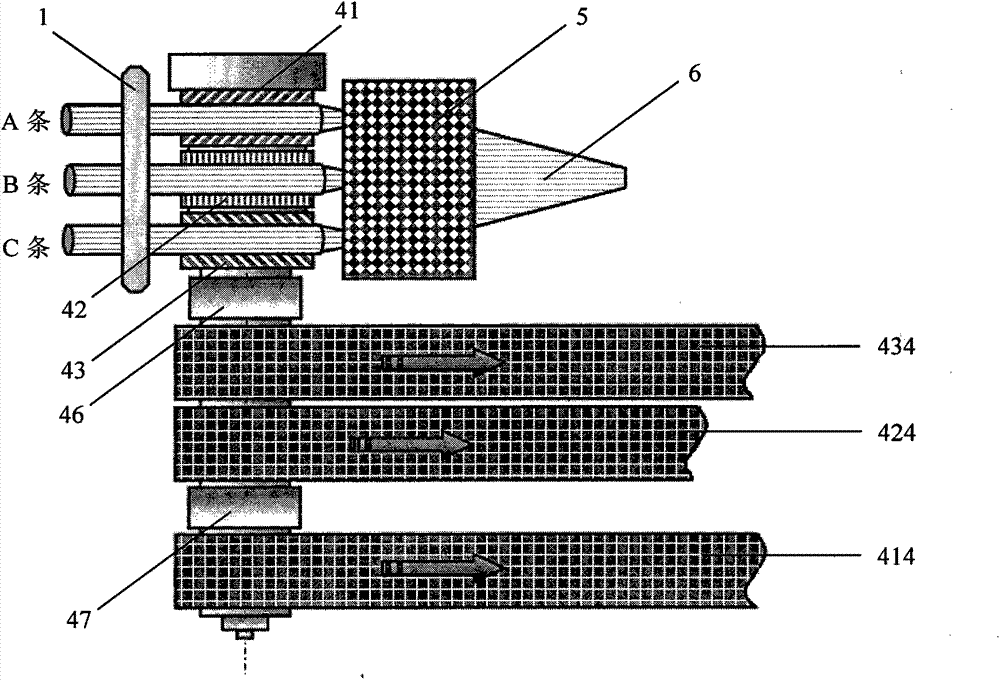

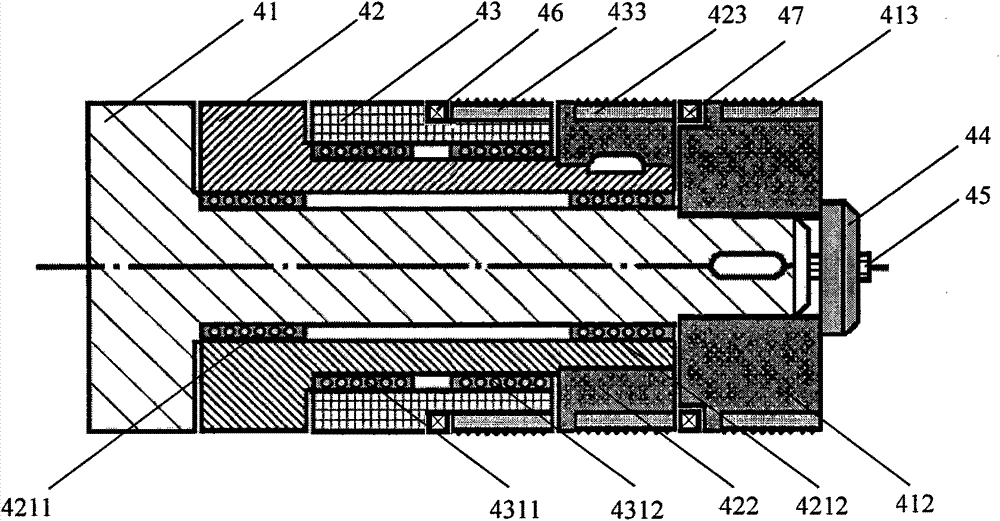

Rotor spinning melange yarn forming method and device and product

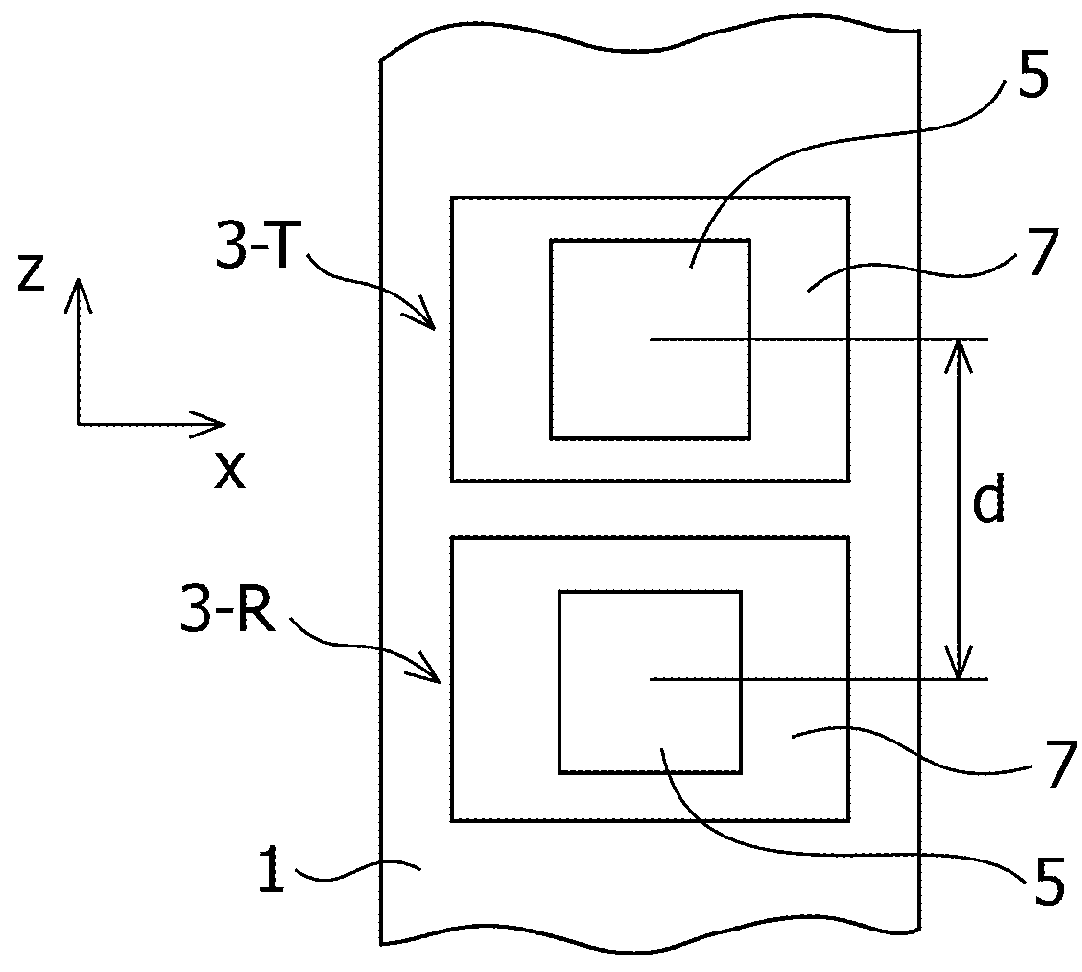

The invention discloses a rotor spinning melange yarn forming method and device and product. On a rotor spinning machine, two or more fiber strips enter a feeding mechanism through a striping gate and a horn mouth, the feeding mechanism contains at least two independently controlled feeding rollers and can control the independent feeding of at least two fiber strips, different fiber strips are of different colors, or of different color combinations, or of different fiber components, the feeding speed of each fiber strip is controllable, the feeding can be conducted at different time sections, and the feeding speeds of all the fiber strips are independently changeable or simultaneously changeable; through the implement of continuous constant-speed feeding or segmentation variable speed feeding of different fiber strips, continuous constant feeding or segmentation variable feeding of the fiber strips is controlled; the fed fiber strips break away from a combing roller, are transferred to a delivery pipe, and then enter a spinning cup depending on the centrifugal force of the combing roller and the action of added air flow after the opening and carding actions of the combing roller; single fibers of different components are mixed, condensed and twisted in the spinning cup to form rotor spinning melange yarn blended by monochrome or polychromatic fiber, or with segmentation color effect, uniform linear density or changing linear density.

Owner:JIAXING UNIV

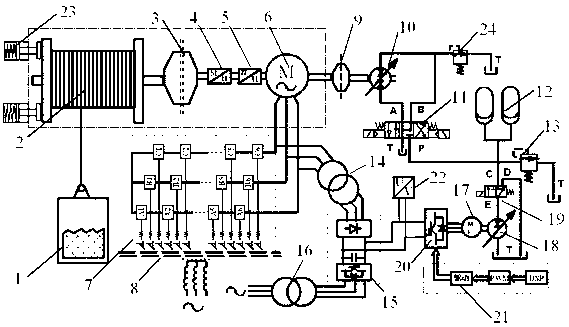

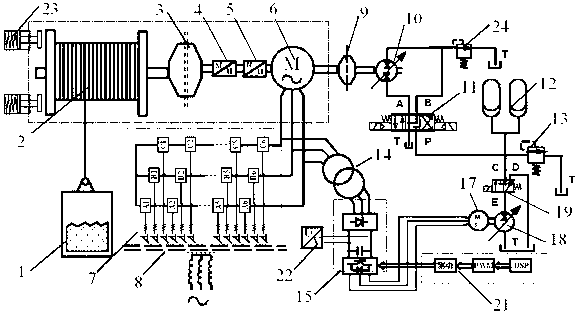

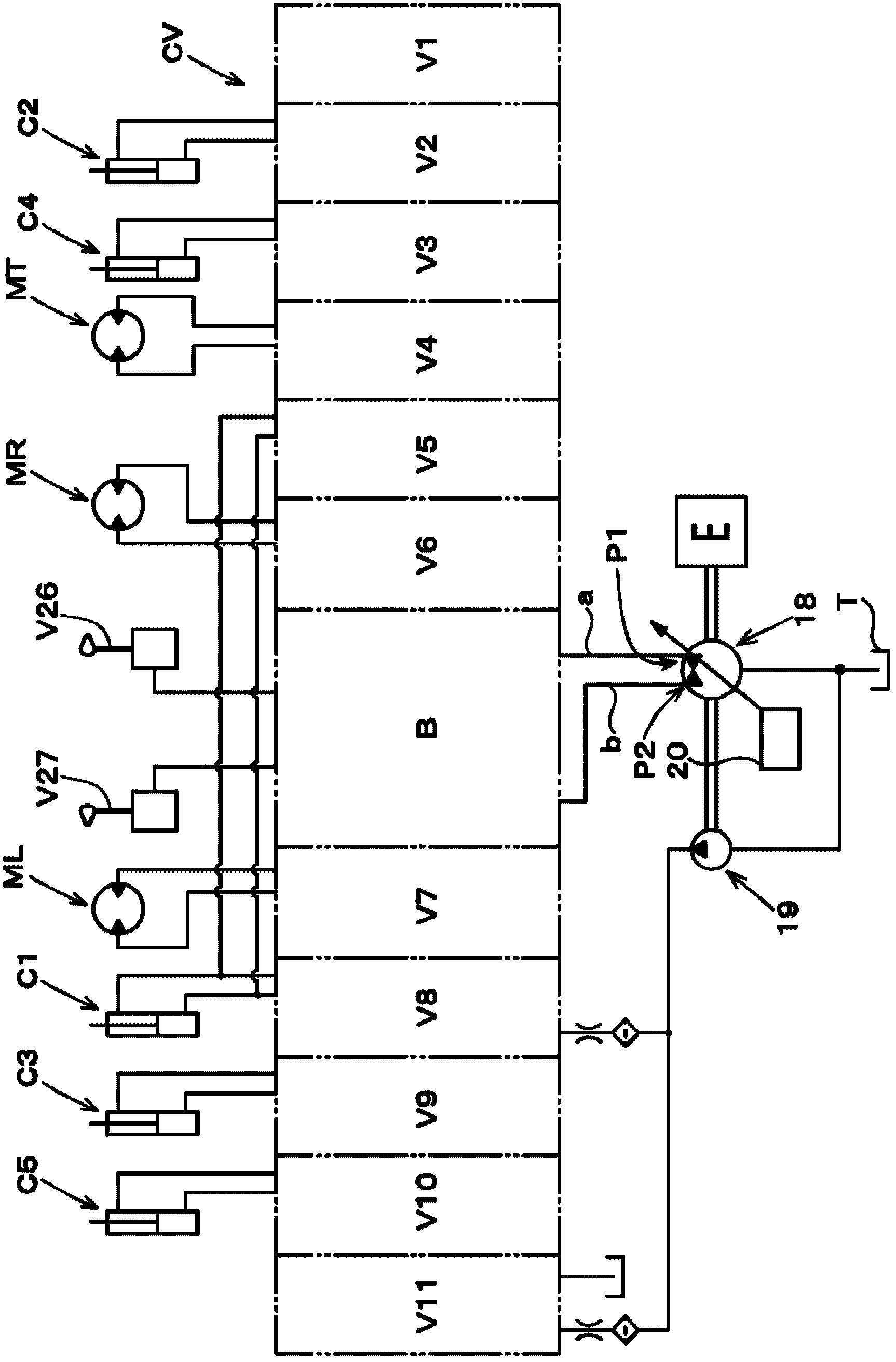

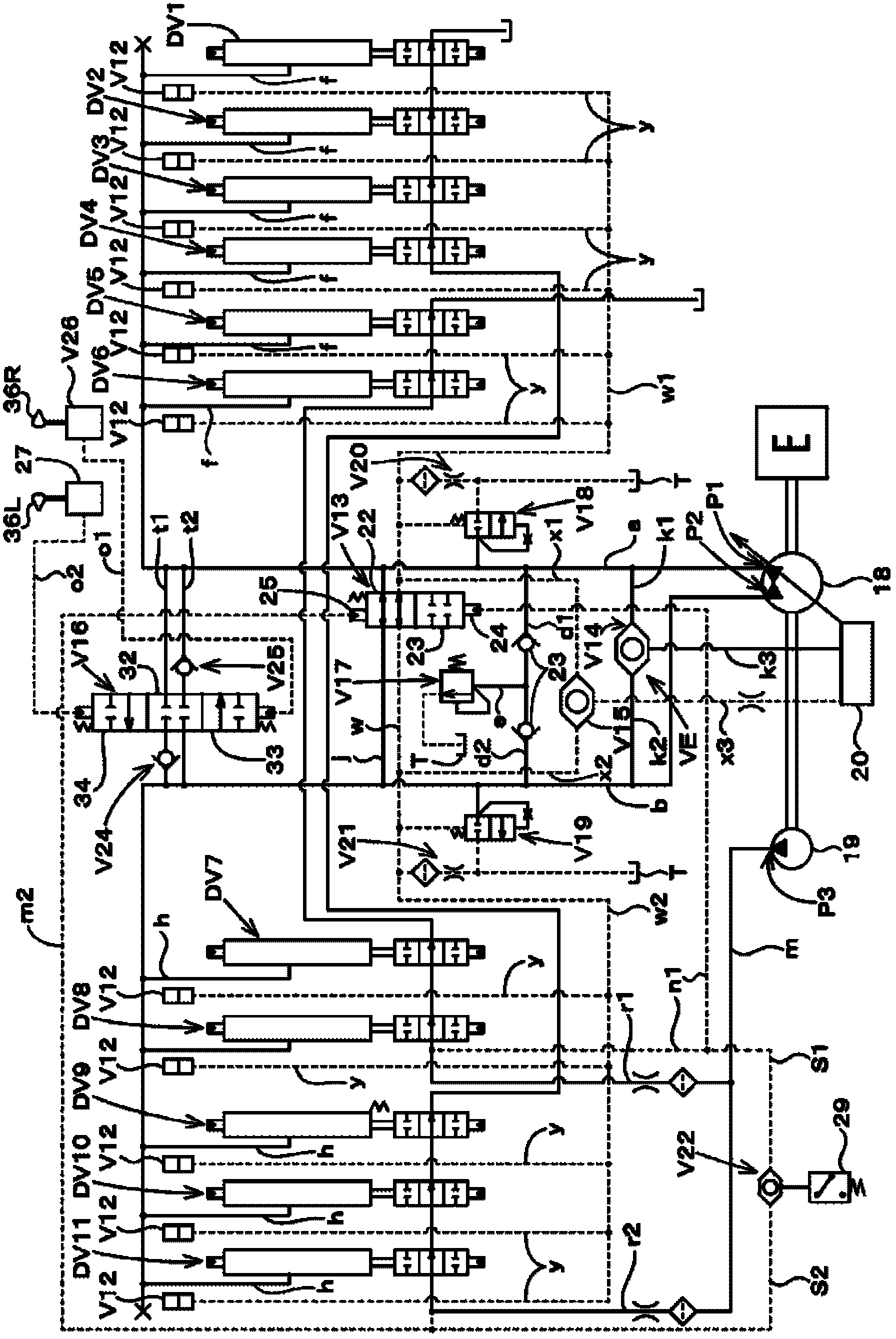

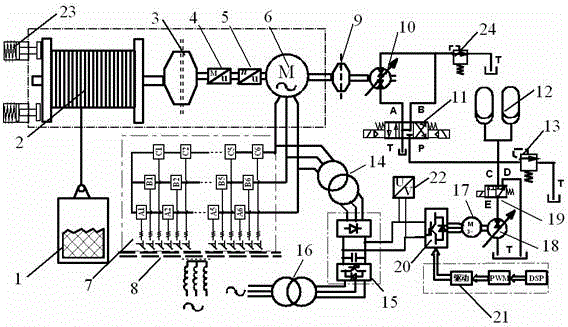

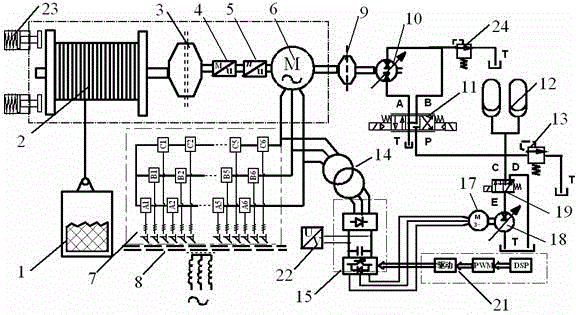

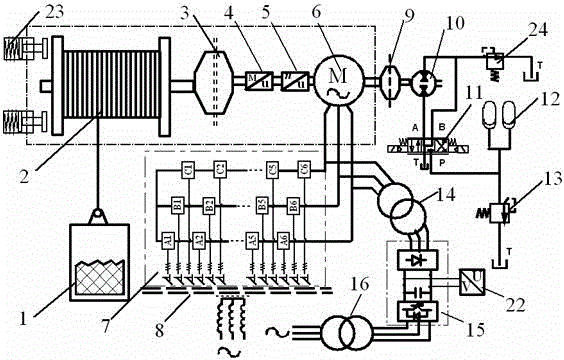

Electro-hydraulic hybrid driving mine lifting device and control method thereof

The invention provides an electro-hydraulic hybrid driving mine lifting device and a control method thereof. A lifting motor is connected with a first hydraulic pump / motor through a clutch, the input end of the lifting motor is connected with a primary winding of a step-down transformer, the primary winding of the step-down transformer is connected with the output end of a cascade type high voltage frequency converter, a secondary winding of the step-down transformer is connected with the input end of a low voltage frequency converter, and an independent feeding unit is formed by connecting a boosting transformer and a high voltage alternating current power grid. The control method includes: part of energy is stored through an energy accumulator and fed to save energy during uplink, downlink and brake of a lifting machine and a winch. The electro-hydraulic hybrid driving mine lifting device and the control method of the electro-hydraulic hybrid driving mine lifting device improve braking and decelerating performance of the motor and shorten braking time of the motor. Compared with an electro-hydraulic hybrid driving mine lifting device adopting a super capacitor and a flywheel battery, the electro-hydraulic hybrid driving mine lifting device adopts the hydraulic energy accumulator to store energy and is mature in technology, reliable in operation and long in service life.

Owner:TAIYUAN UNIV OF TECH

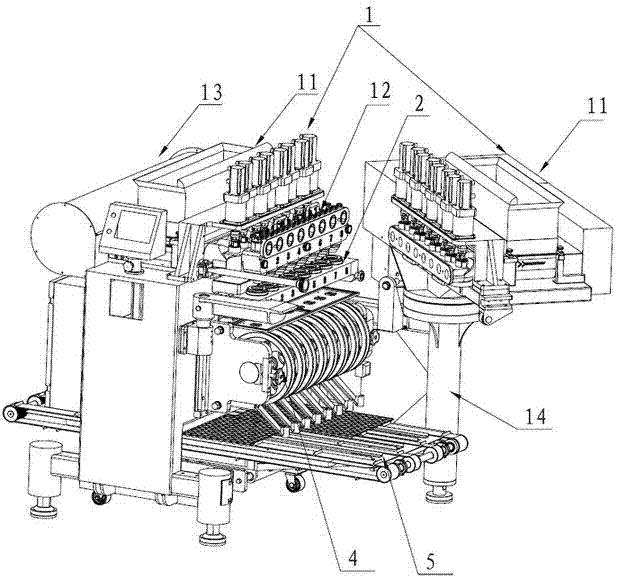

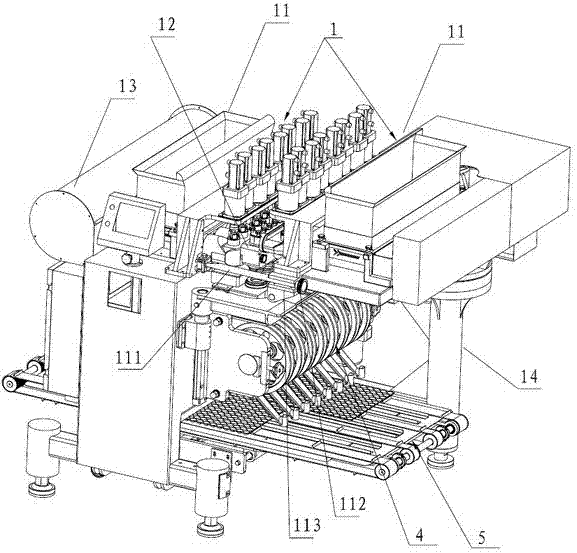

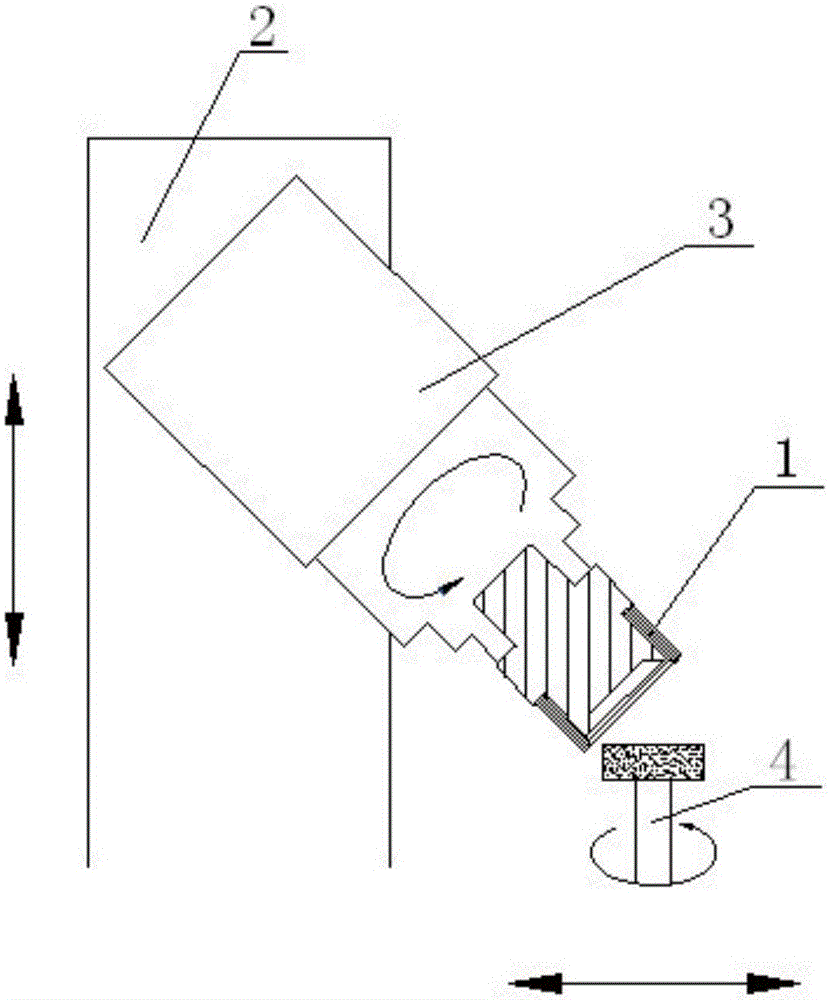

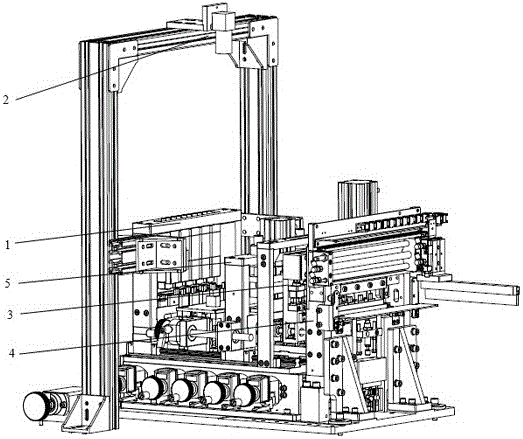

Molding method for food with round shape

ActiveCN102228305AEasy to disassembleEasy to installFood coatingFood shapingEngineeringIndependent feeding

The invention relates to the field of processing filling food, in particular to a molding method for food with round shape, comprising the following steps that: A, charging: skin and stuffing are added in feeding assemblies of a split type feeding system of a molding machine for food with round shape; B, compositing: the skin and stuffing of the feeding assembly are allowed to enter a skin-stuffing complex; C, cutting off: the skin and stuffing output by the skin-stuffing complex are cut off by a cutting assembly which is connected with a cutting lift assembly, the cutting assembly is driven by the cutting lift assembly to realize the cutting function and moving up and down simultaneously; D: ball-kneading: the cutting-off skin and stuffing are put into a ball-kneading device for kneading into balls; and E, discharging on the plate: the products obtained by ball-kneading are transferred to a discharging plate assembly from the ball-kneading device. According to the invention, the two independent feeding assemblies and the skin-stuffing complex have the advantages of simple disassembling and installation, when cleaning or maintaining the parts, only at least one feeding assembly needs be disassembled from the skin-stuffing complex to carry out the cleaning and the maintenance. Because the disassembling is realized by simple rotation, the present disassembling mode is simplified with saving the disassembling time and improving the work efficiency.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

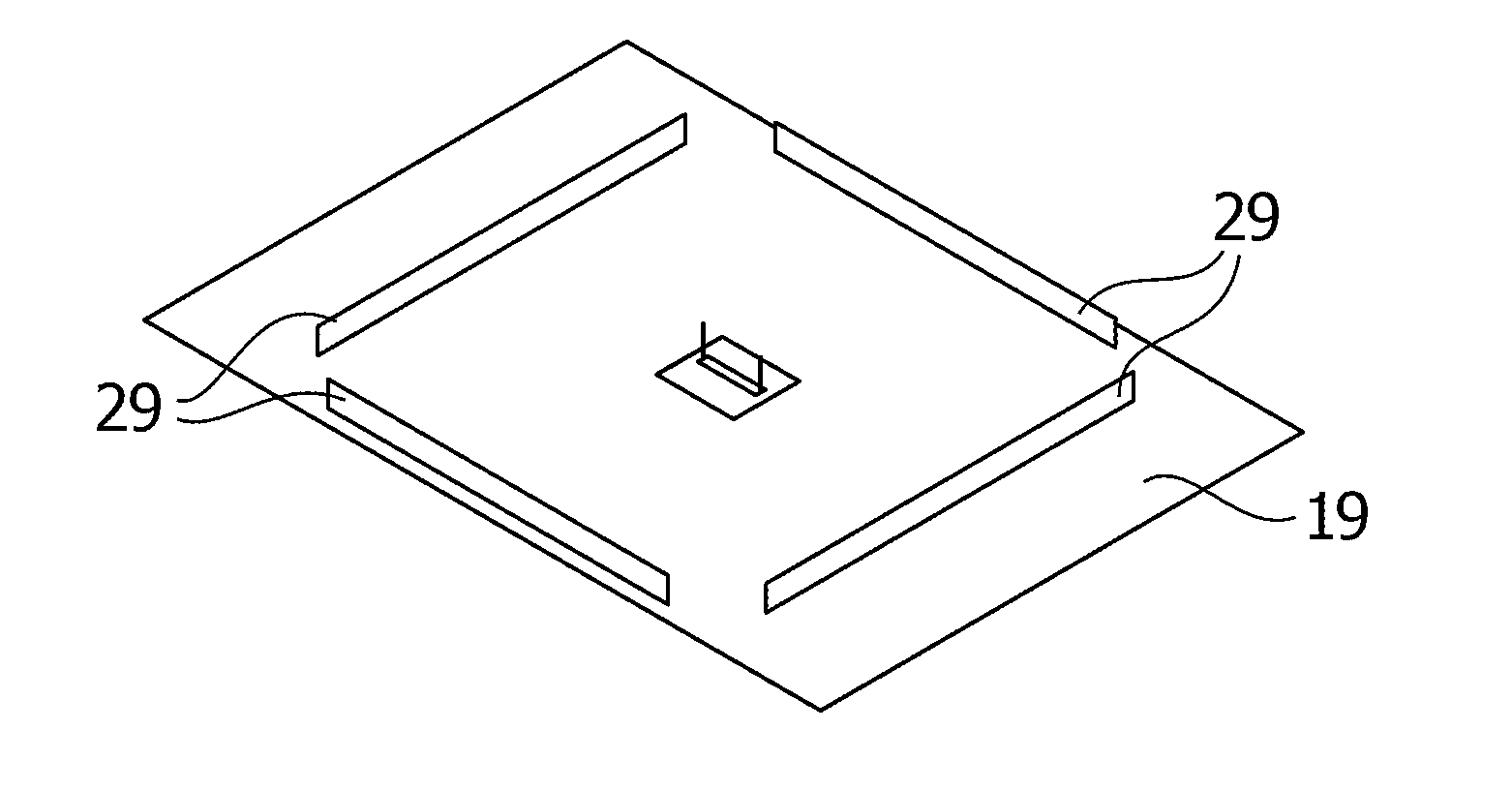

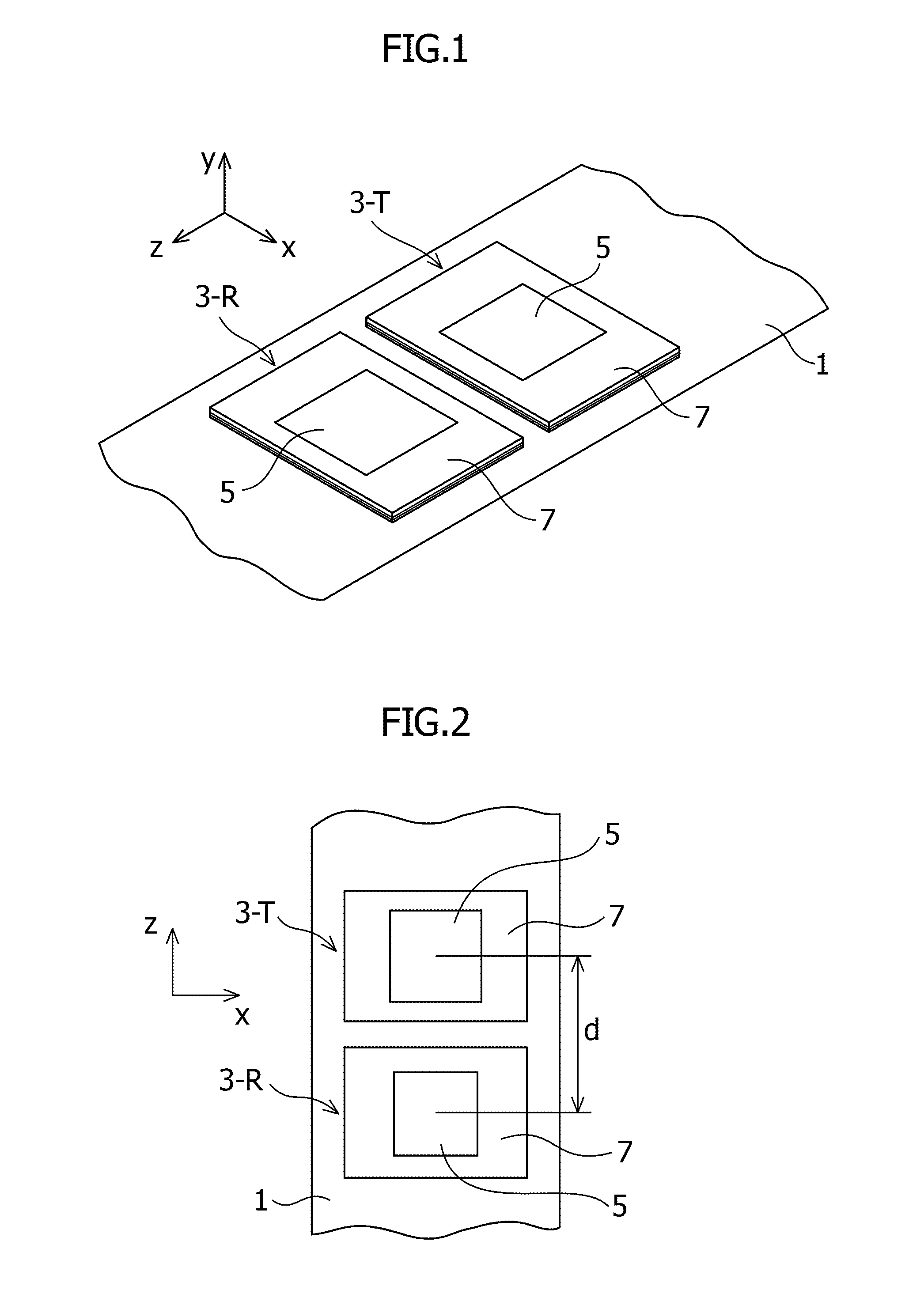

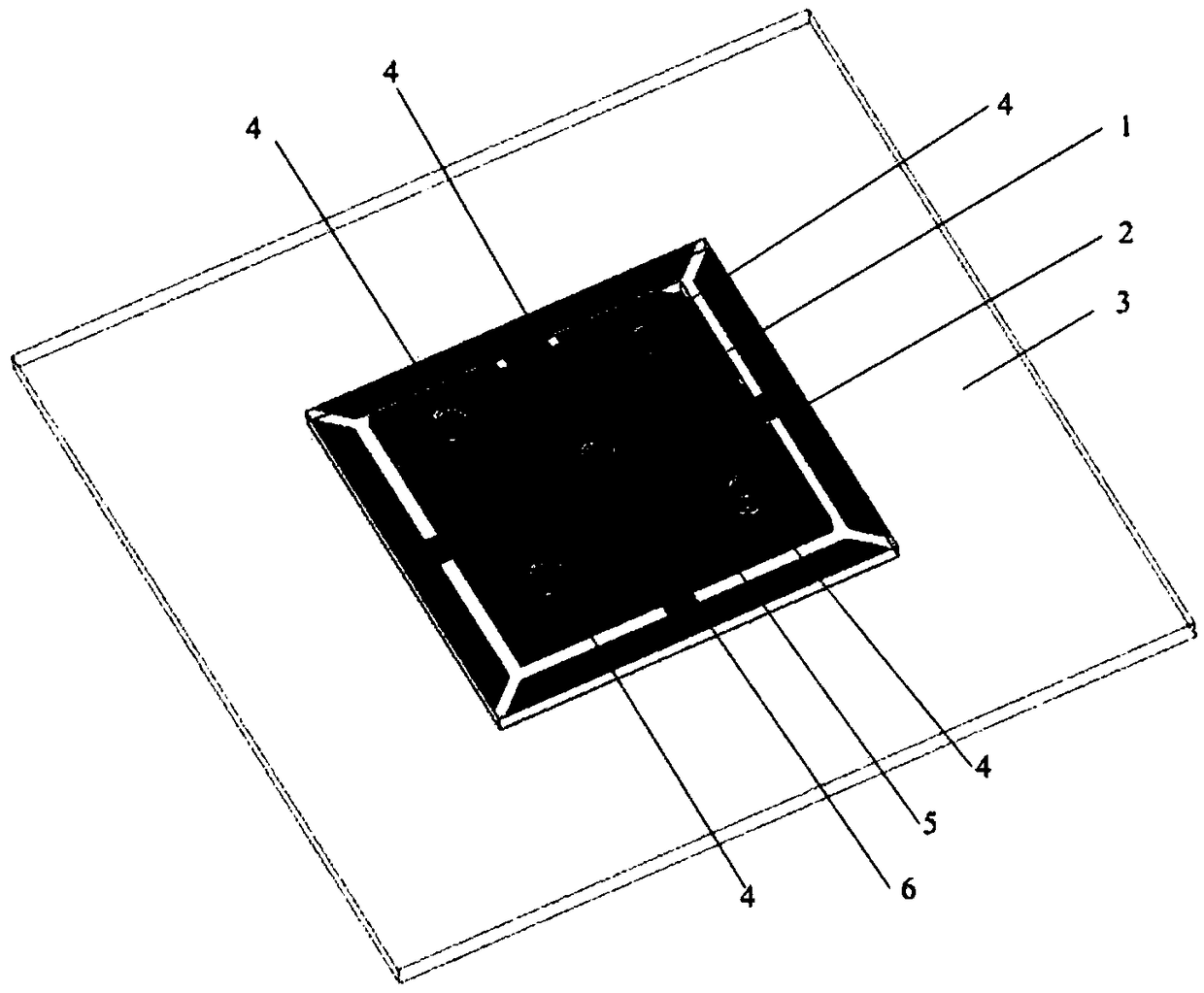

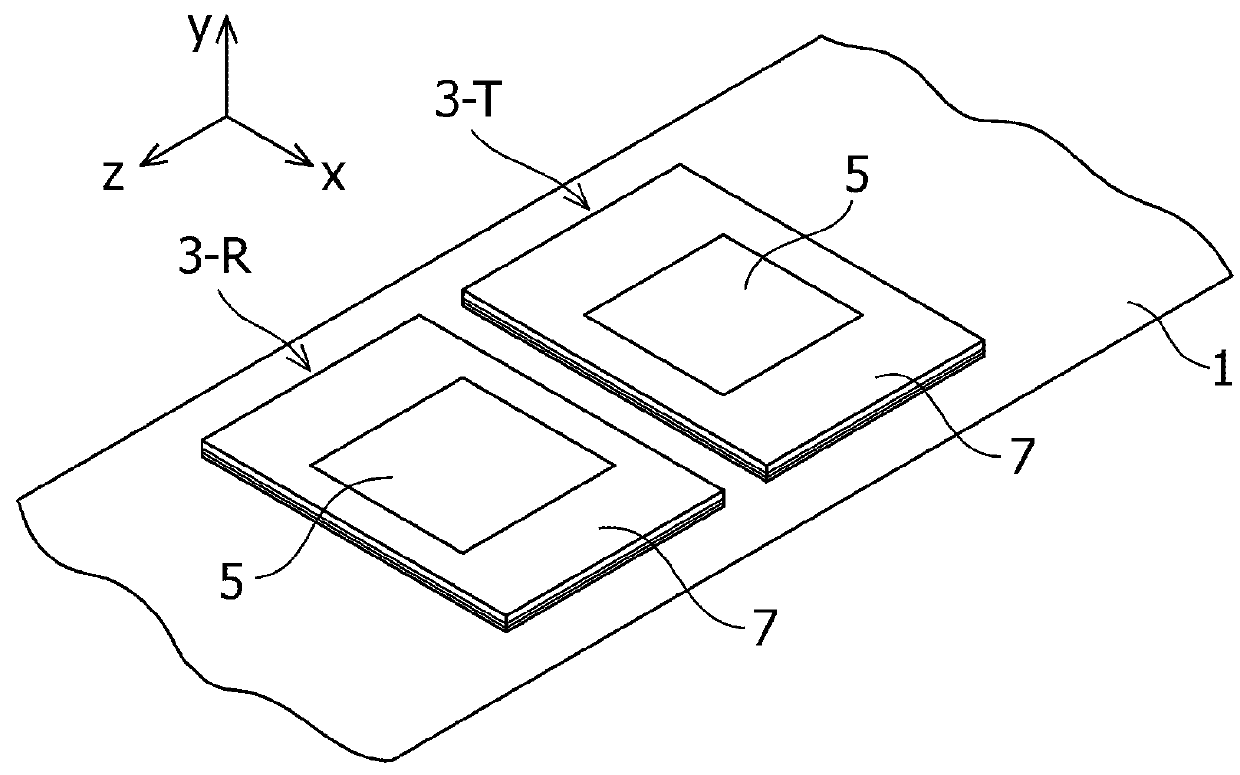

Transmitting-receiving-separated dual-polarization antenna

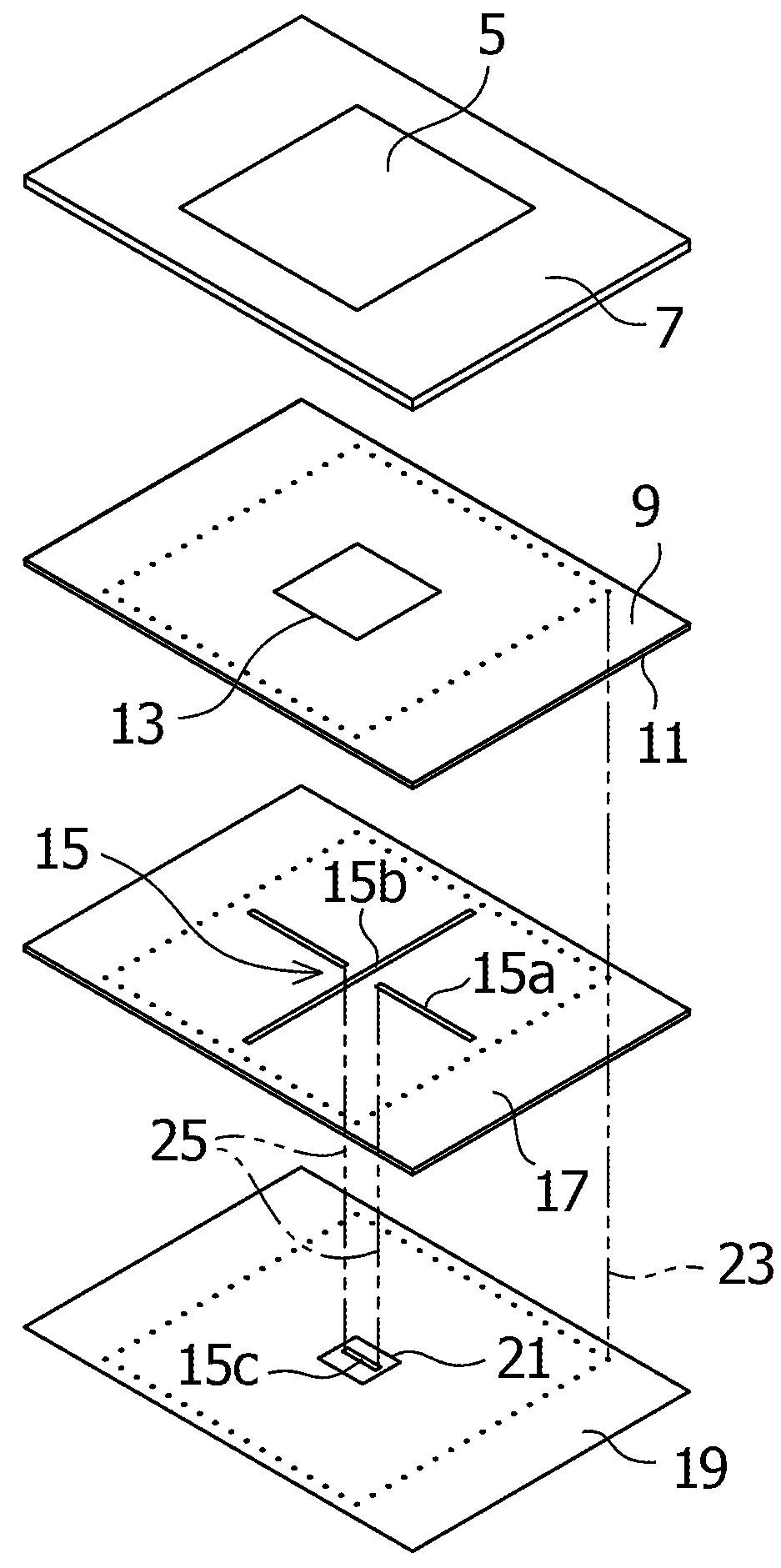

ActiveUS20150180116A1CouplingReduce couplingIndividually energised antenna arraysPolarised antenna unit combinationsElectrical conductorCoupling

To reduce coupling between transmission and reception while implementing sharing of polarized waves for both the transmitting band and the receiving band at the same time. Patch antenna for transmitting band and patch antenna for receiving band, which are arranged at predetermined spacing, include an upper-stage ground conductor; a lower-stage ground conductor; a feed line which is arranged among the ground conductor and the lower-stage ground conductor; a feed slot which is formed on the upper-stage ground conductor; a patch which is electromagnetically coupled with the feed line via the feed slot; and electromagnetic shielding members which are connected with the upper-stage ground conductor and the lower-stage ground conductor in a state in which the electromagnetic shielding members are located around the feed line. The feed line includes independent feeding conductors corresponding to respective polarized waves.

Owner:DENKI KOGYO CO LTD +1

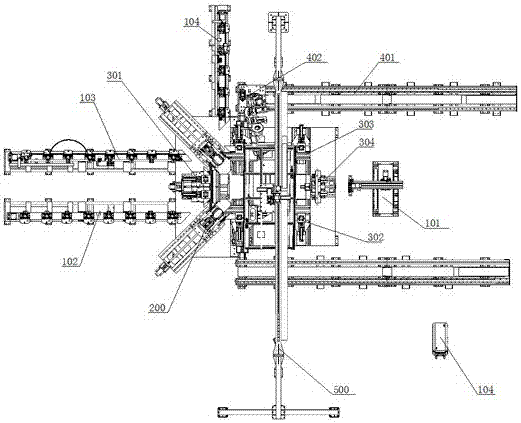

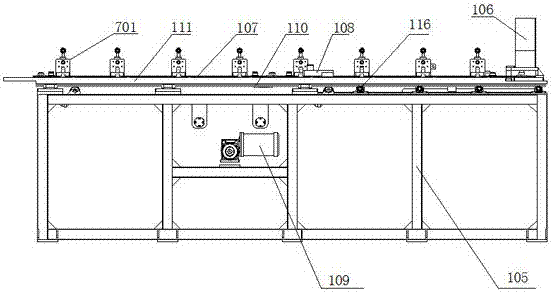

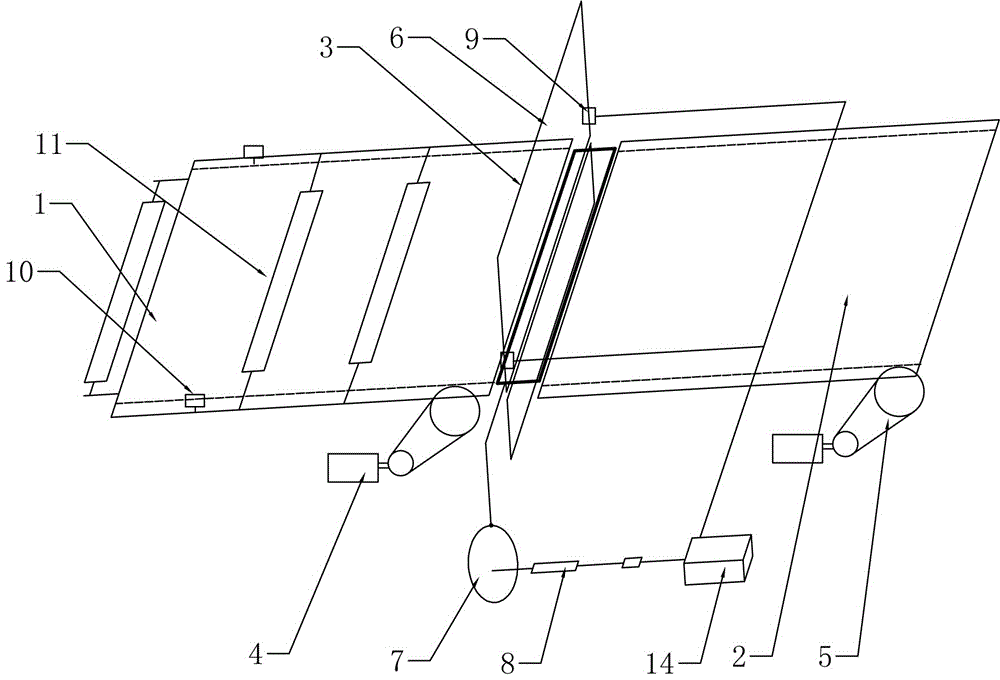

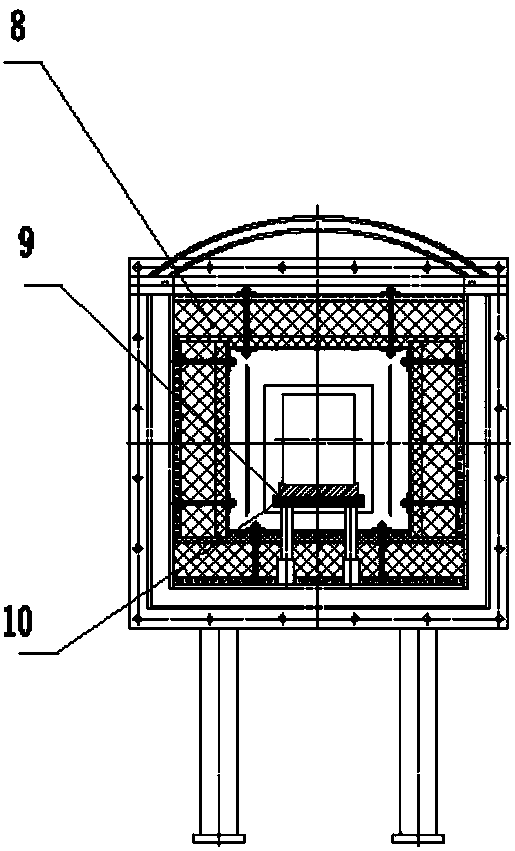

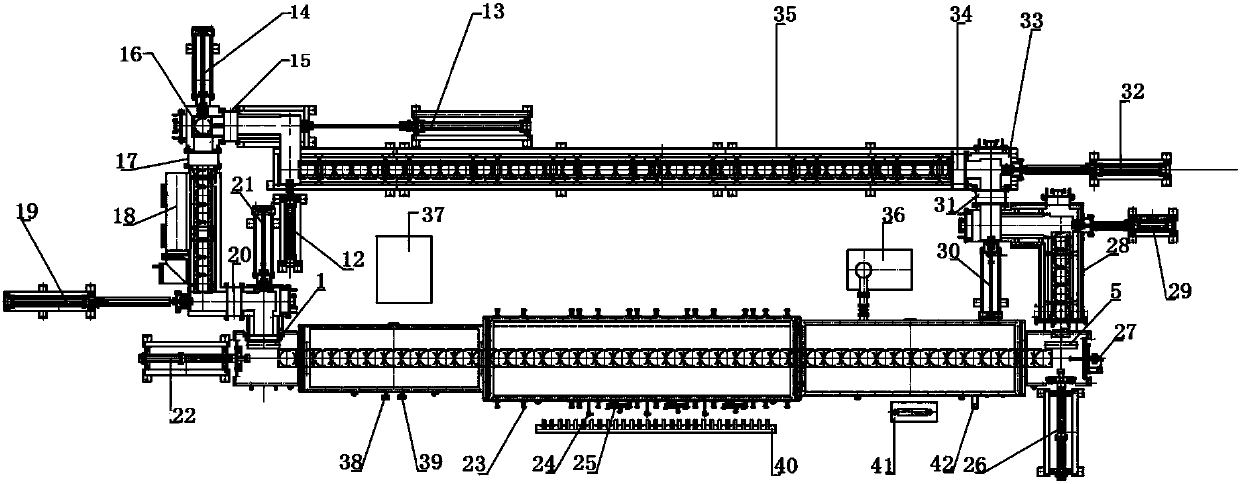

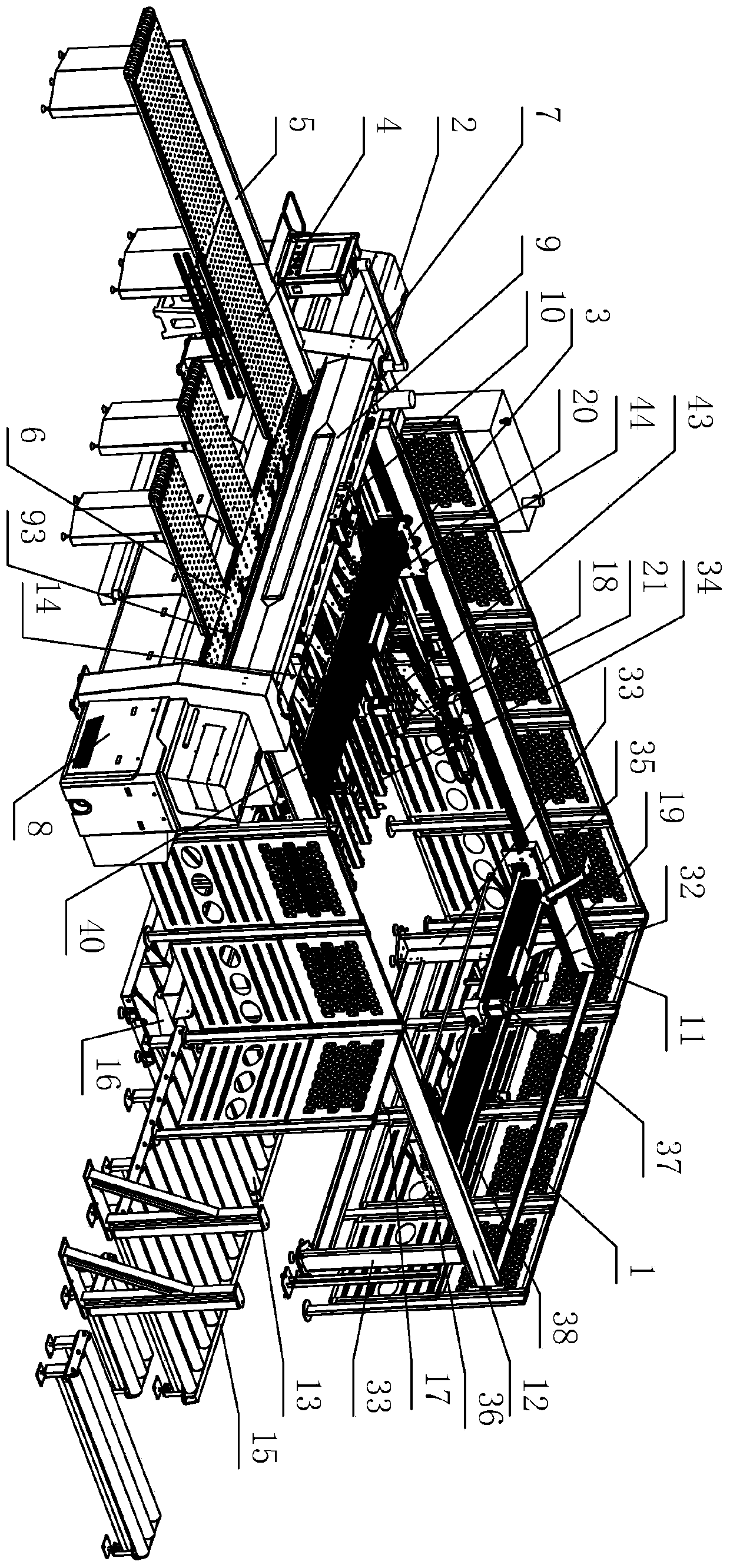

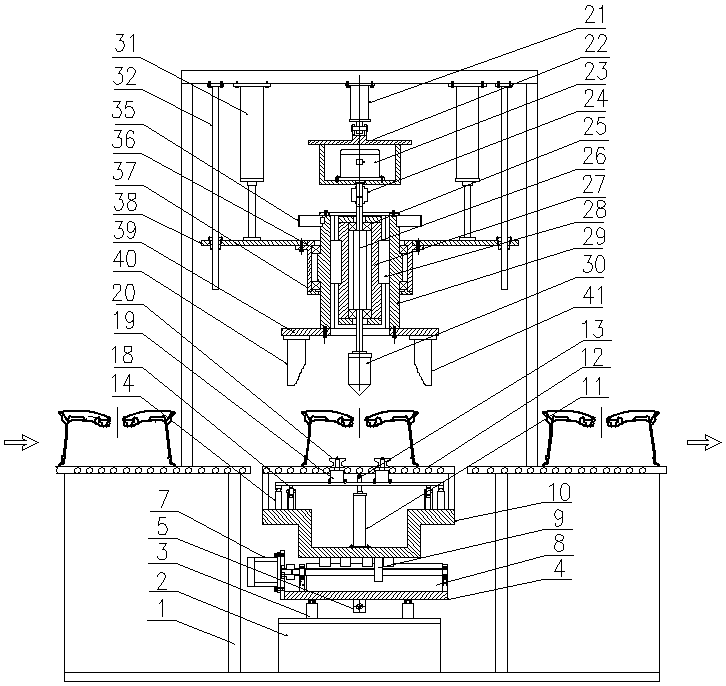

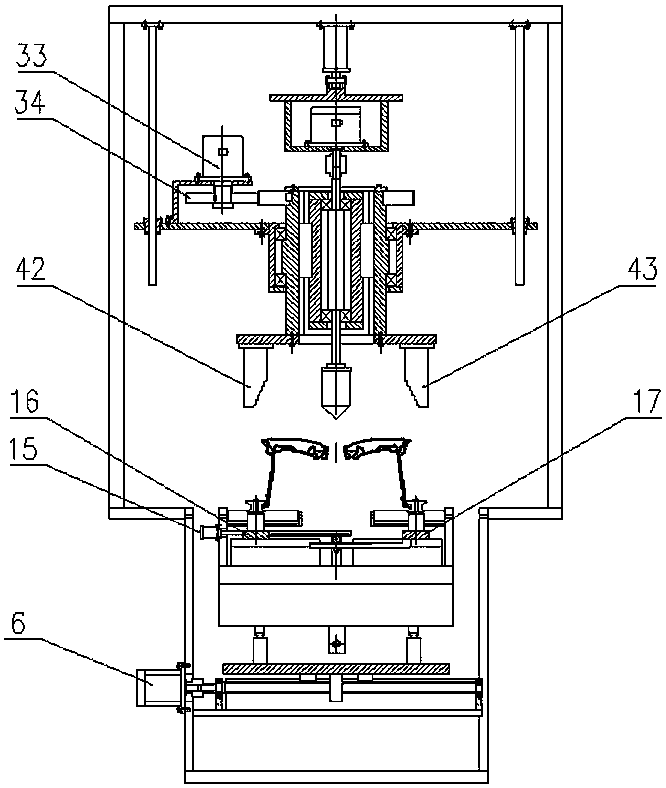

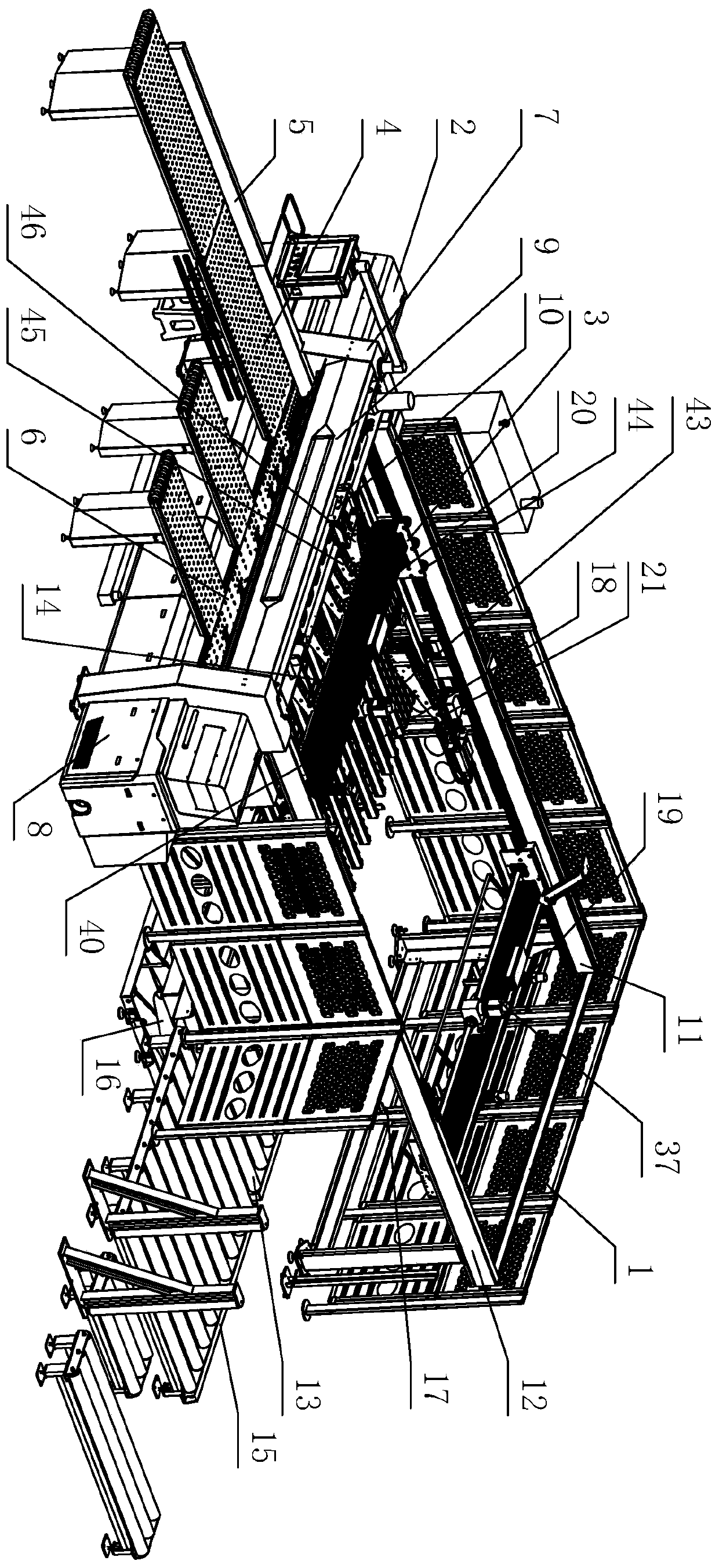

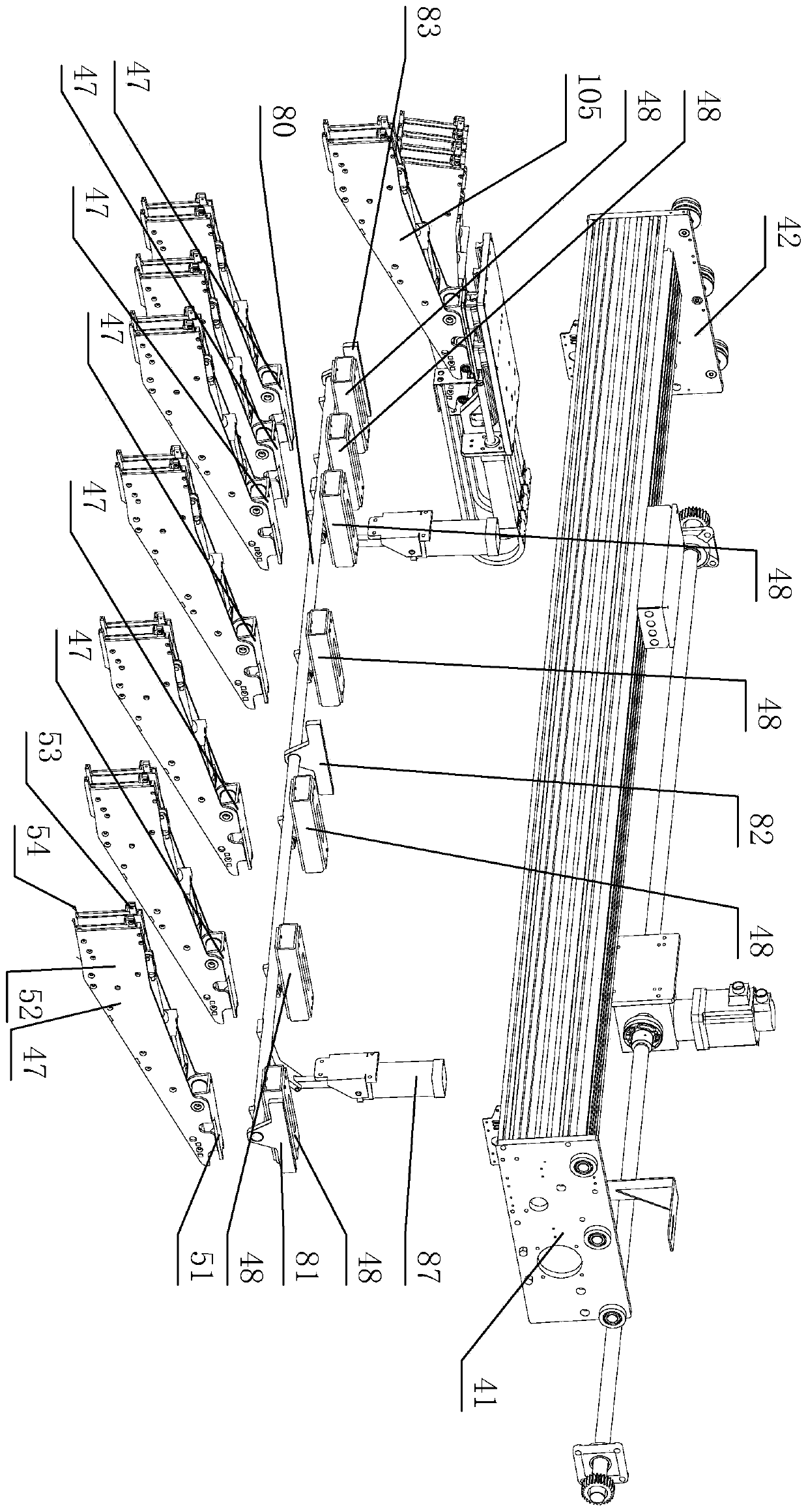

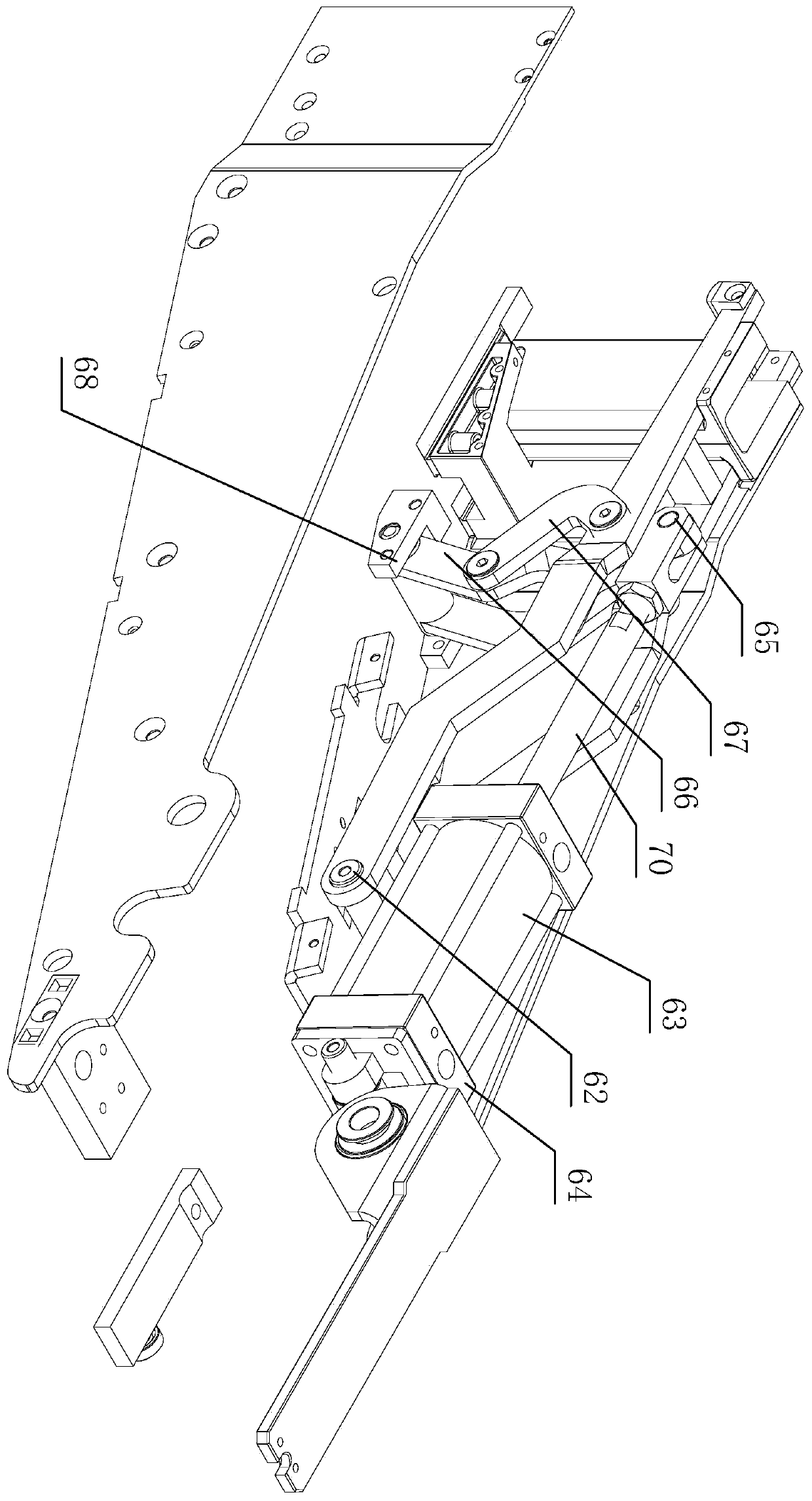

Automatic machining device of anti-theft door frame and control system thereof

ActiveCN107199411AQuality improvementAchieve unmannedWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention provides an automatic machining device for an anti-theft door frame, and a control system of the automatic machining device, and the automatic machining device integrates the functions of automatic feeding, cutting, assembling with welding. The automatic machining device comprises a feeding mechanism, a cutting mechanism, an assembling platform, a welding mechanism, a discharging mechanism and a control mechanism. The assembling platform is quadrilateral. The feeding mechanism, the cutting mechanism, the welding mechanism and the discharging mechanism surround the assembling platform. The feeding mechanism conveys a frame profile to the assembling platform in a longitudinal crossing and four-side independent feeding mode. The assembling platform is used for fixing the frame profile and moving the frame profile on the platform so that the cutting mechanism and the welding mechanism can obtain the machining position. The cutting mechanism is used for machining the frame profile on the assembling platform. The welding mechanism is used for welding the frame profile on the assembling platform. The discharging mechanism is sued for transferring the frame profile or a finished door frame out of the assembling platform. The control mechanism is used for controlling operation of the feeding mechanism, the cutting mechanism, the assembling platform, the welding mechanism and the discharging mechanism, and unmanned and intelligentized production is achieved.

Owner:YONGKANG JIEDICI ROBOT TECH CO LTD

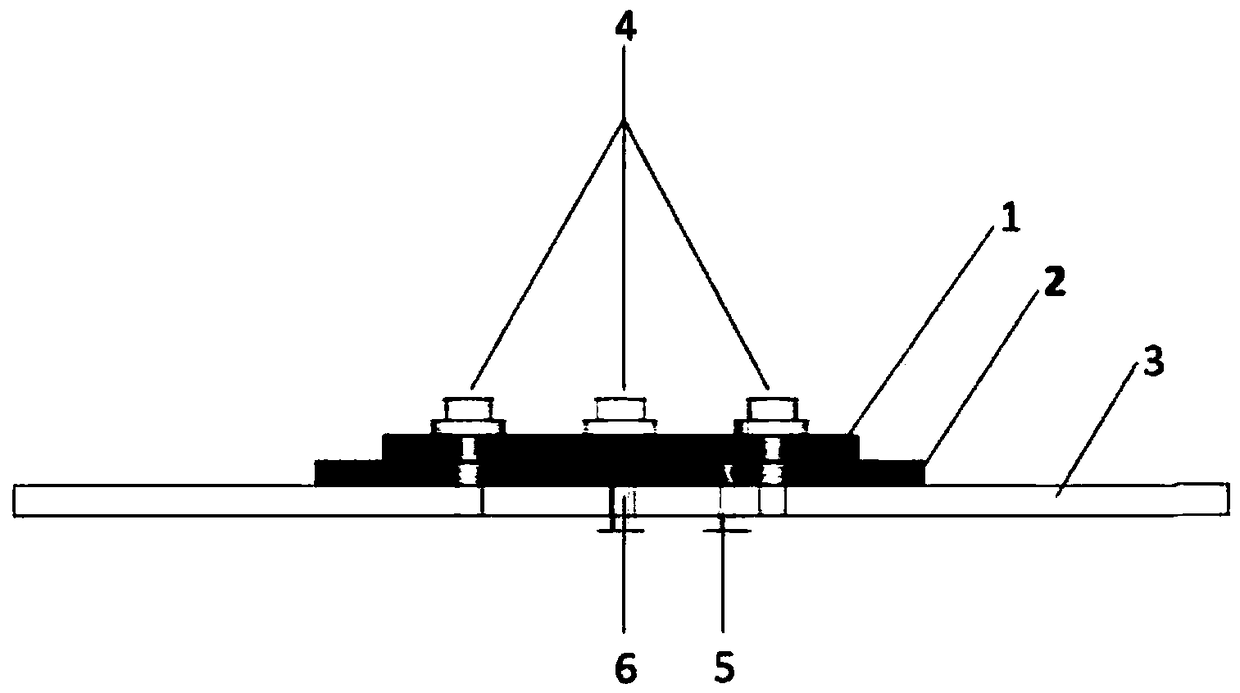

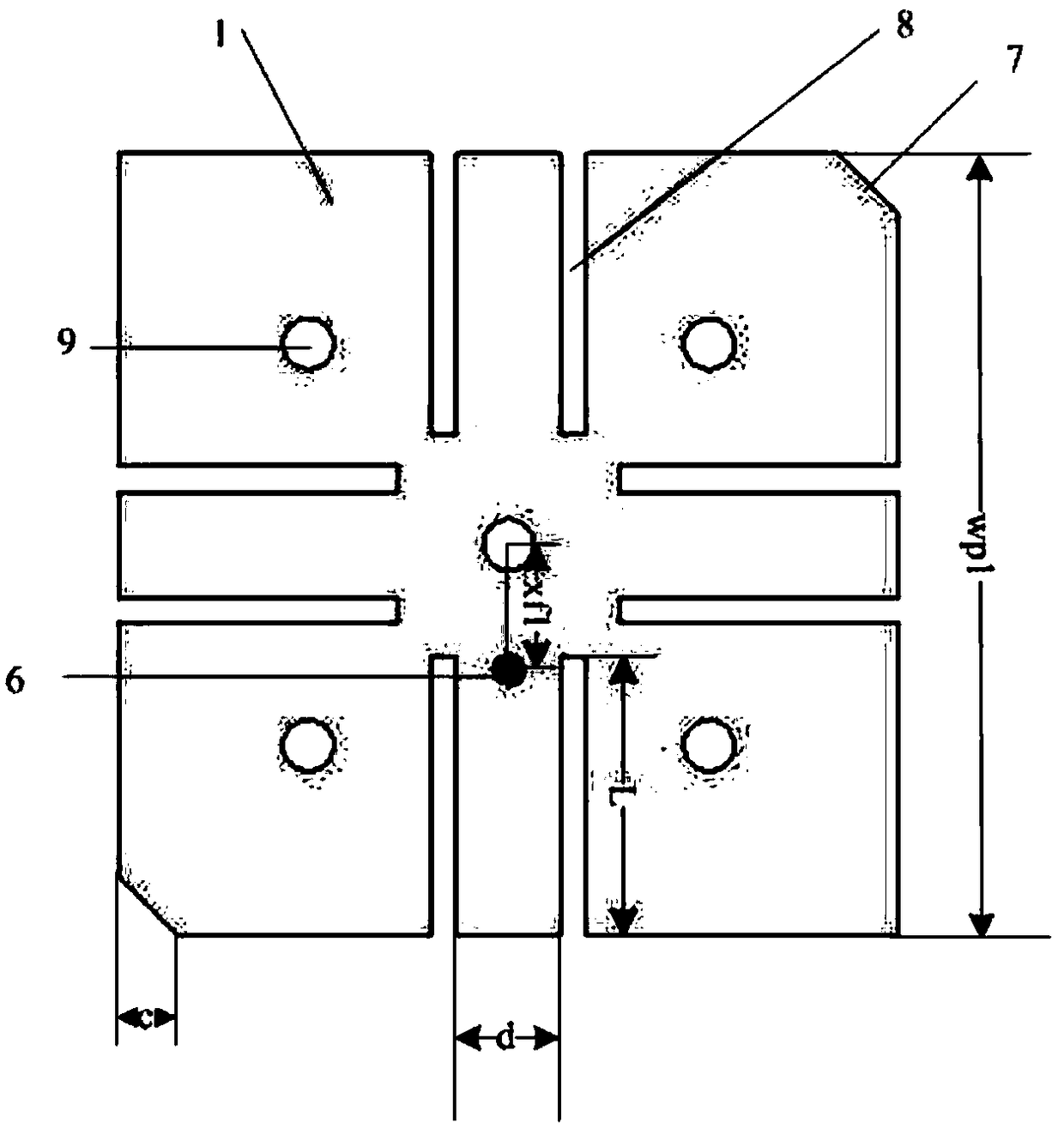

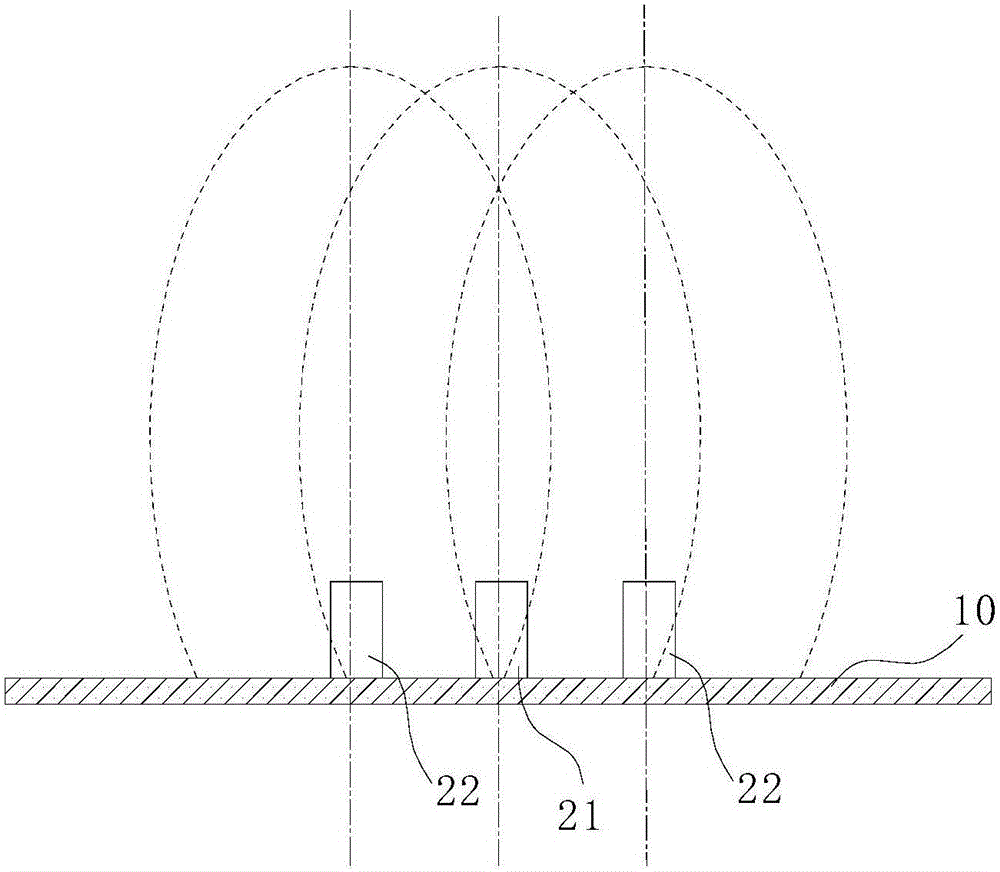

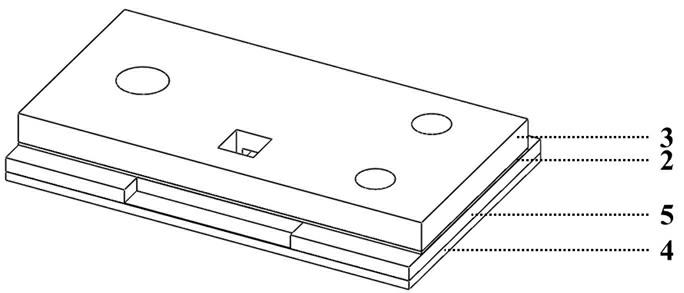

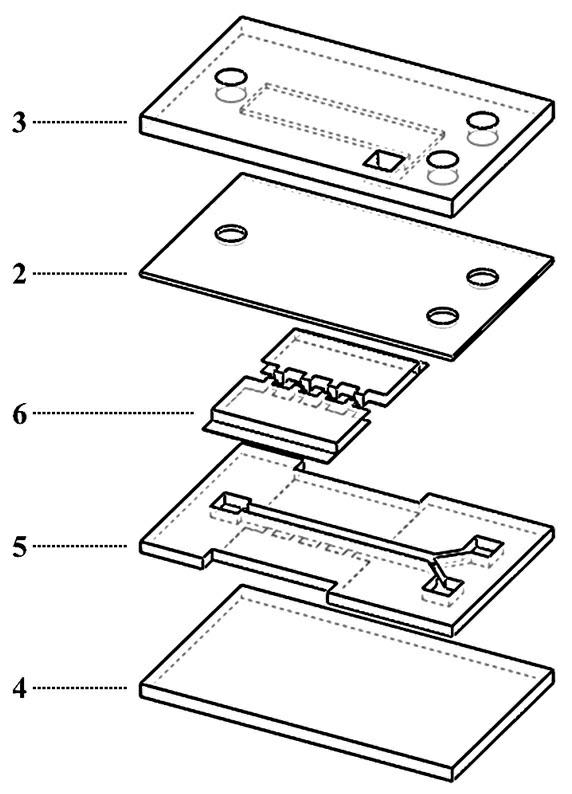

Double-fed dual-frequency dual-circular-polarization microstrip patch antenna

InactiveCN109301444ALow profileReduce volumeParticular array feeding systemsAntenna supports/mountingsMicrostrip patch antennaAntenna polarization

The invention discloses a double-fed dual-frequency dual-circular-polarization microstrip patch antenna and aims at providing a circularly polarized microstrip patch antenna with the random frequencyratio and antenna polarization mode. The antenna is characterized in that an upper patch feed point is arranged at a patch axis and a lower patch feed point is arranged at a lower square patch diagonal line to form a double-feed mode with two feed points in independent feeding. A perturbation element is formed at the corner cut of the diagonal line of an upper square microstrip patch and two degeneracy dies that are arranged orthogonally in a phase difference of 90 degrees are excited, so that currents at the patch flow circularly along center areas of the tops of four groups of groove lines of the patch to realize high-frequency-point circular polarization. Unequal-length T branches are loaded at the opposite angles around a lower microstrip antenna patch covered by the upper microstrip antenna patch and two degeneracy dies that are arranged orthogonally in a phase difference of 90 degrees are excited, so that the currents on the patch flow circularly along the T-shaped branches at the edge of the patch to realize low-frequency-point circular polarization. The upper antenna and the lower antenna are laminated concentrically to form a dual-frequency dual-circle polarization workingstate.

Owner:10TH RES INST OF CETC

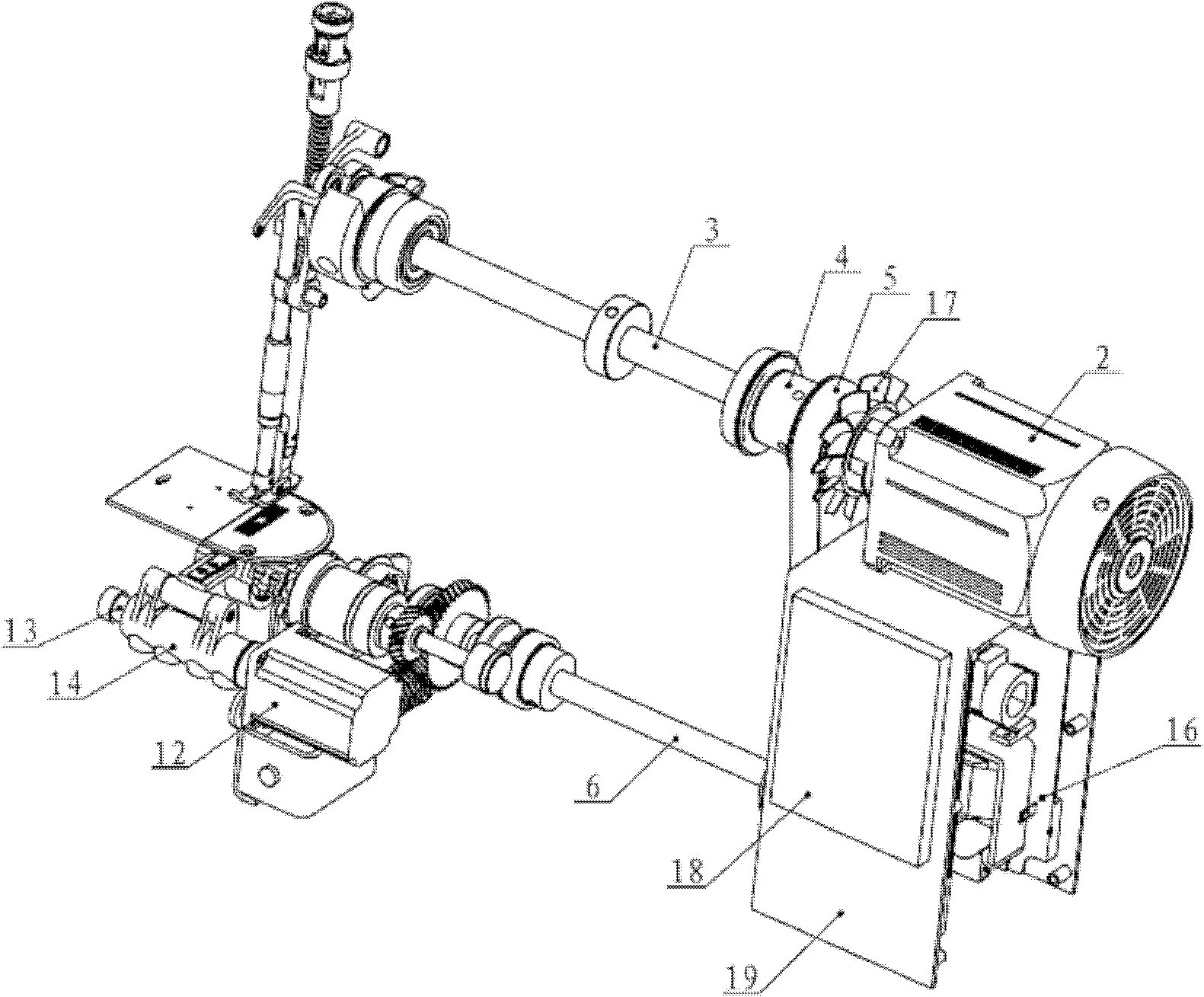

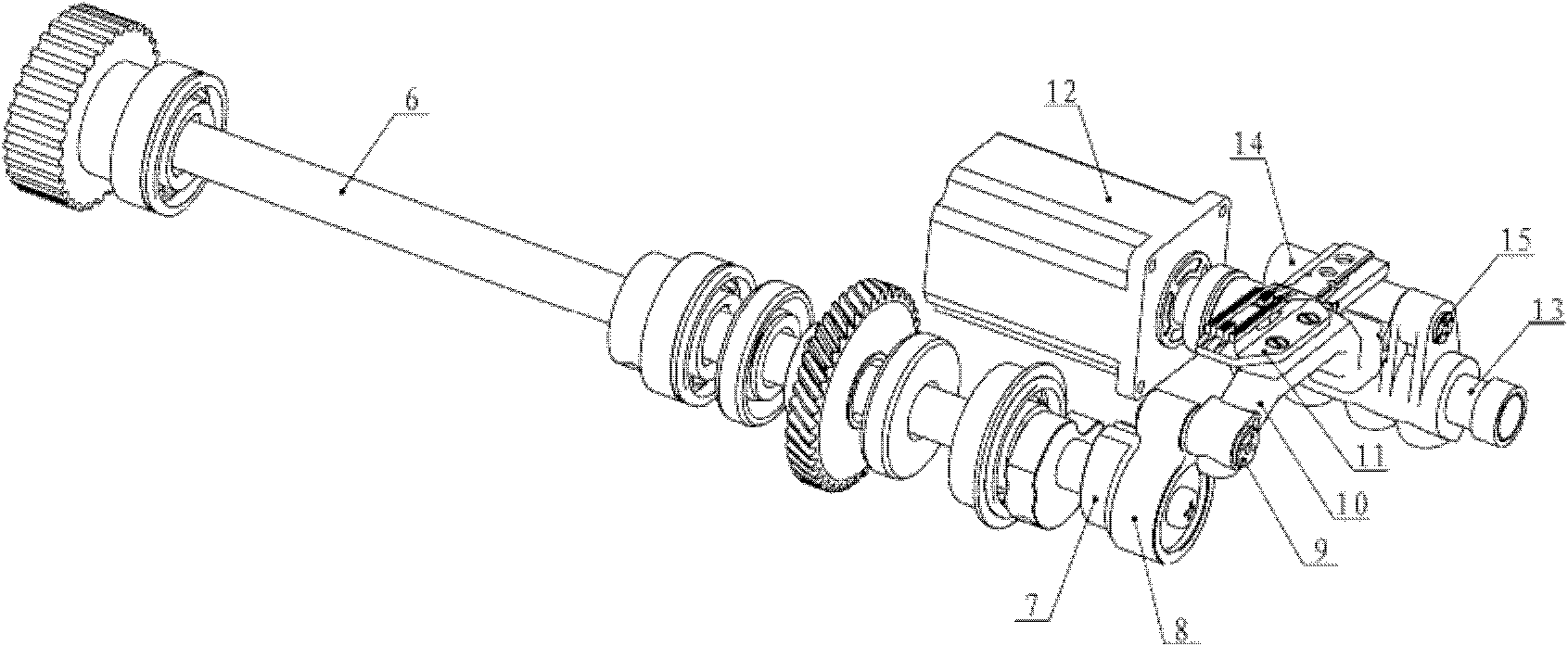

Dual-motor driven computerized sewing machine

InactiveCN102154787AReduce transmission noiseReduce vibrationProgramme-controlled sewing machinesWork-feeding meansMotor driveDisplay device

The invention discloses a dual-motor driven computerized sewing machine. The machine is characterized in that an independent feeding servo motor is directly installed on a feeding rack of a machine body and synchronously coordinates with the positioning signal of a main servo motor driving a main shaft to swing to feed the cloth. The computerized sewing machine designed in the invention has the following beneficial effects: 1. the independent feeding servo motor is directly installed on the feeding rack of the computerized sewing machine and synchronously coordinates with the positioning signal of the main servo motor driving the main shaft to swing to feed the cloth; the mechanical parts and electromagnet assemblies such as mechanical connecting rods, swing cams and the like are removed;and the transmission noises and vibration are reduced; 2. automatic backstitching and manual backstitching can be synchronously carried out via the turnover operating position set by the main motor and the backstitching speed is simultaneously increased; 3. the problems of oilless lubrication and pollution can be solved; the sewing machine assembly technology and manufacturing cost and processes can be simultaneously reduced; and volume production is easy to realize; and 4. a display can be installed in front of the machine body on the right so as to be convenient for operation and observation.

Owner:上海富山精密机械科技有限公司

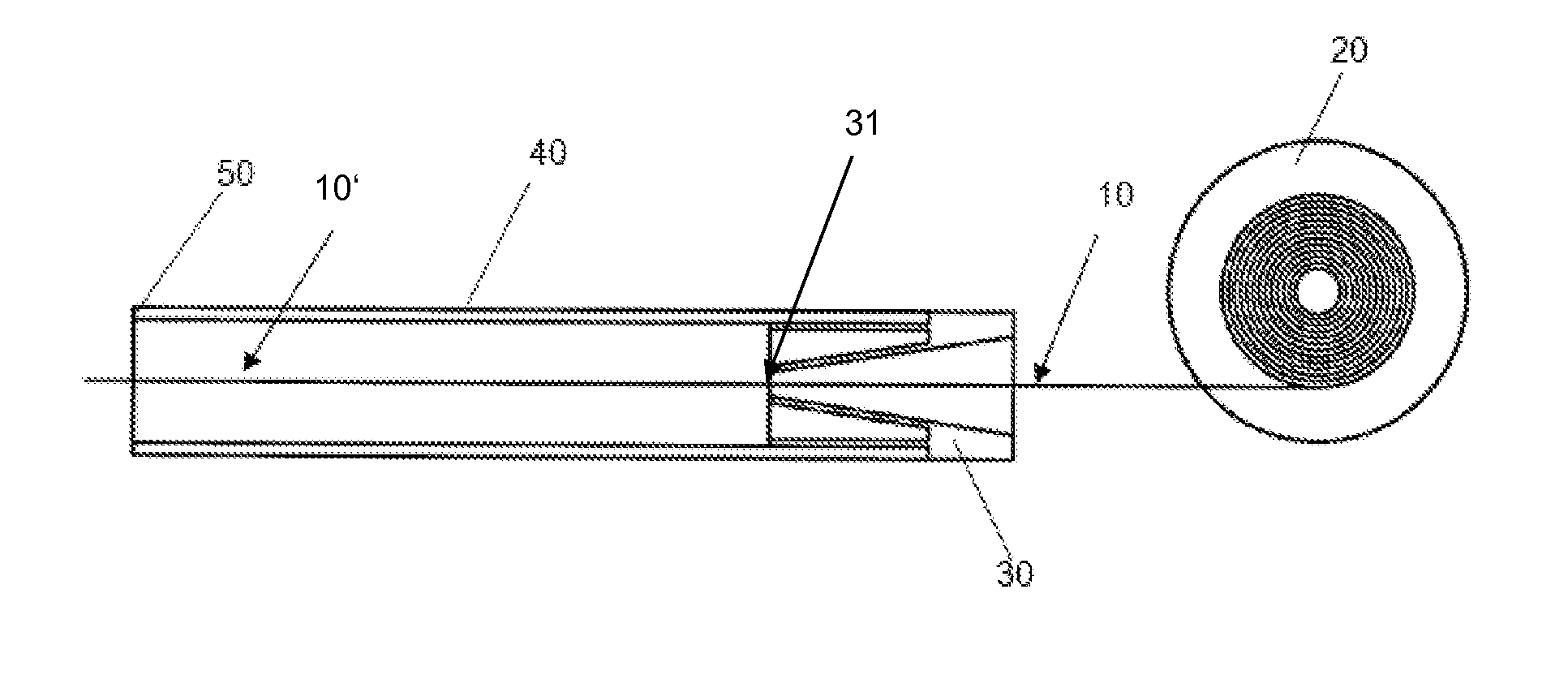

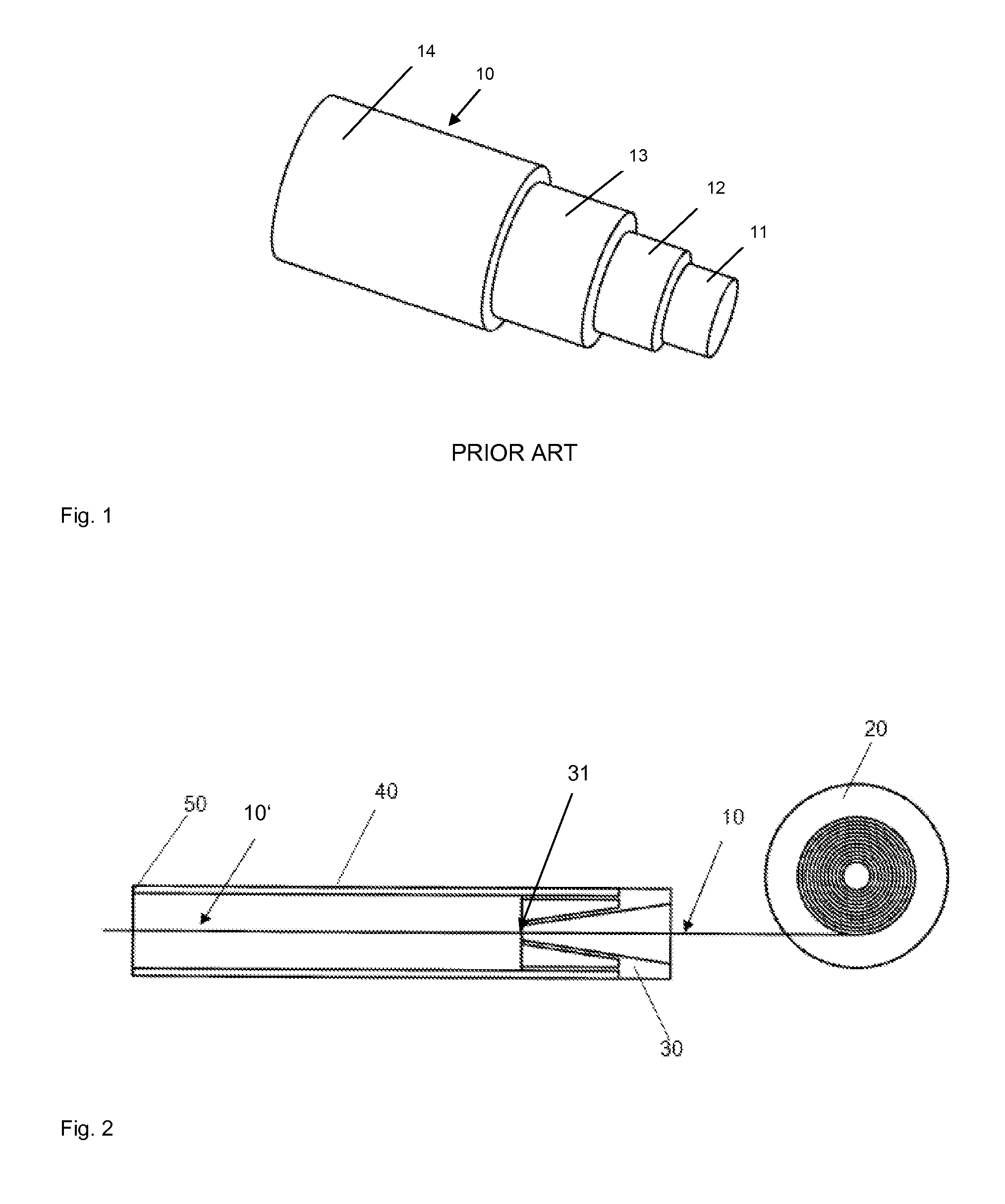

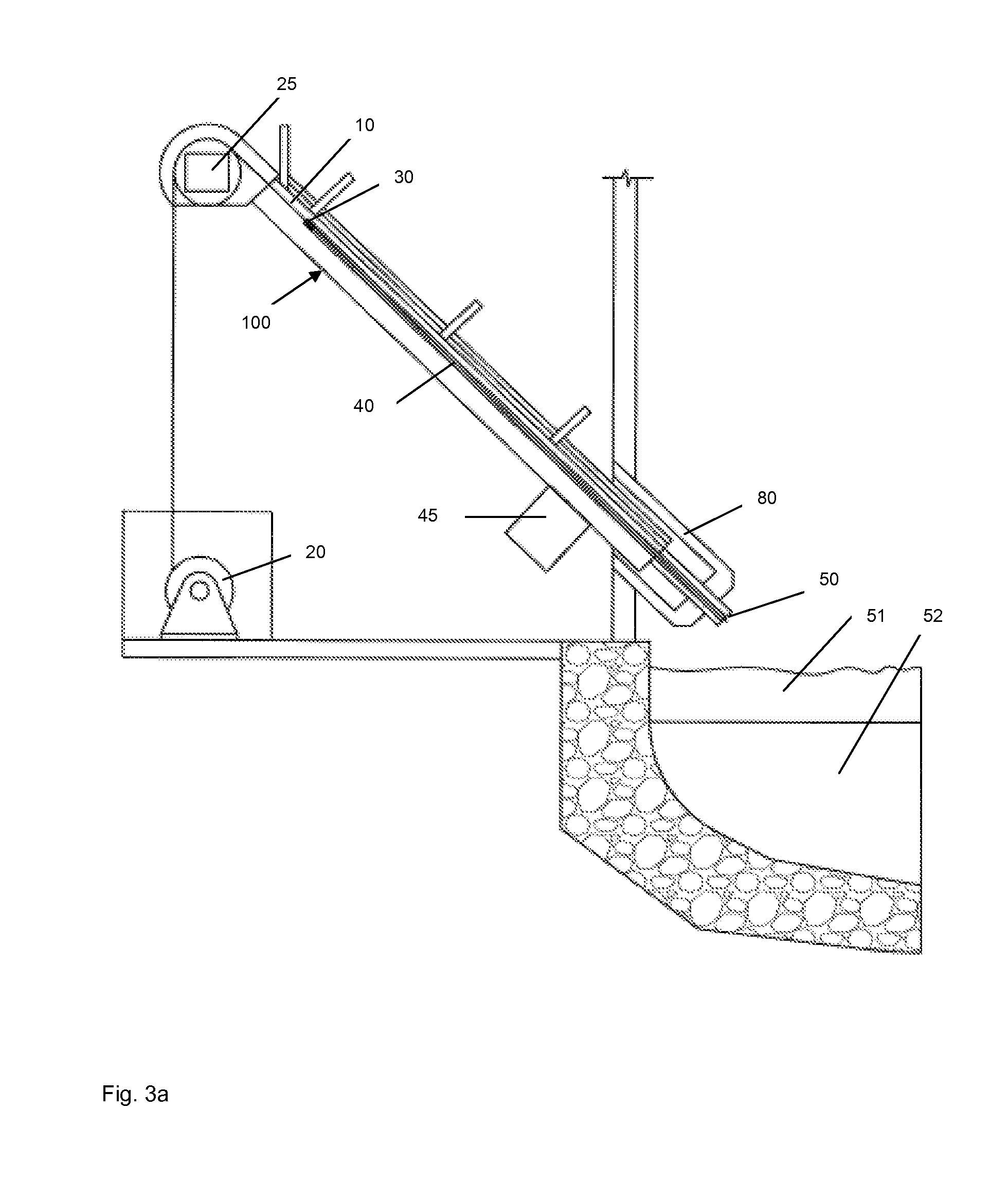

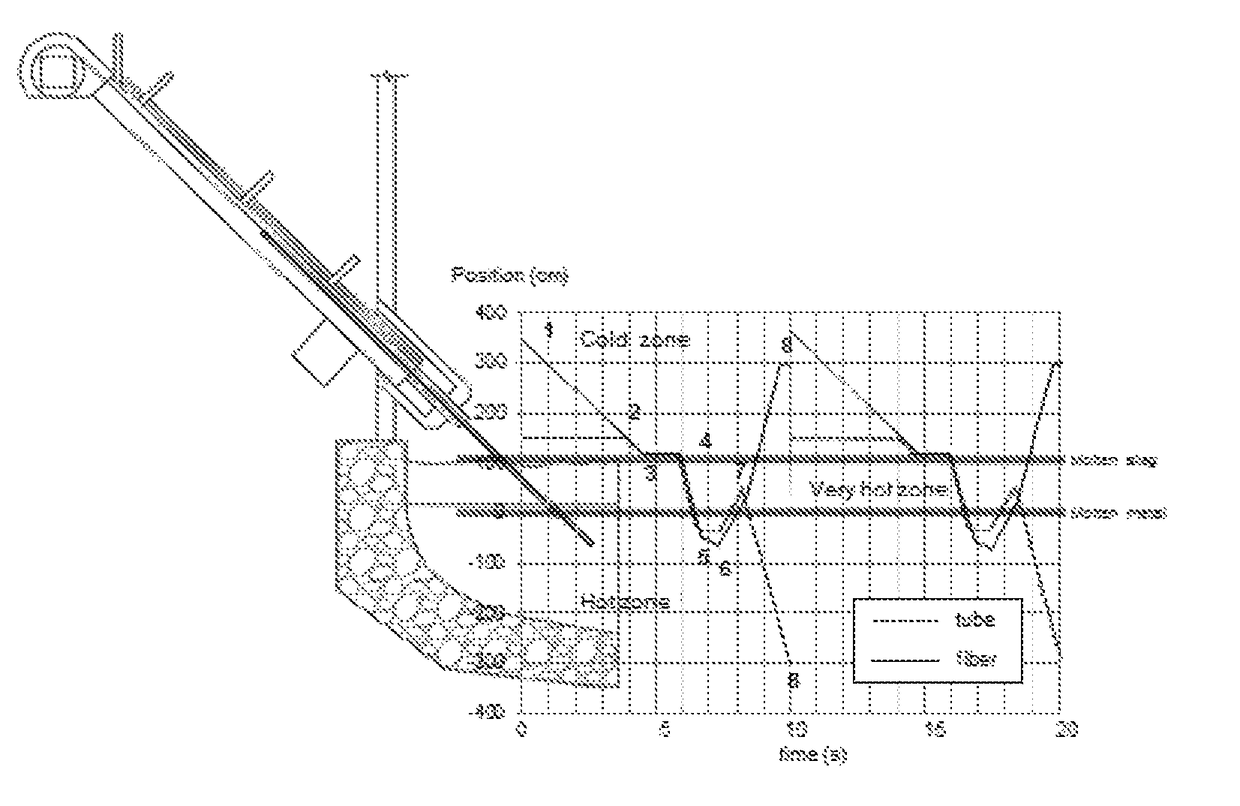

Method and apparatus for measuring the temperature of a molten metal

ActiveUS20140321504A1Low costHigh sampling frequencyThermometer detailsThermometers using physical/chemical changesGuide tubeMaterials science

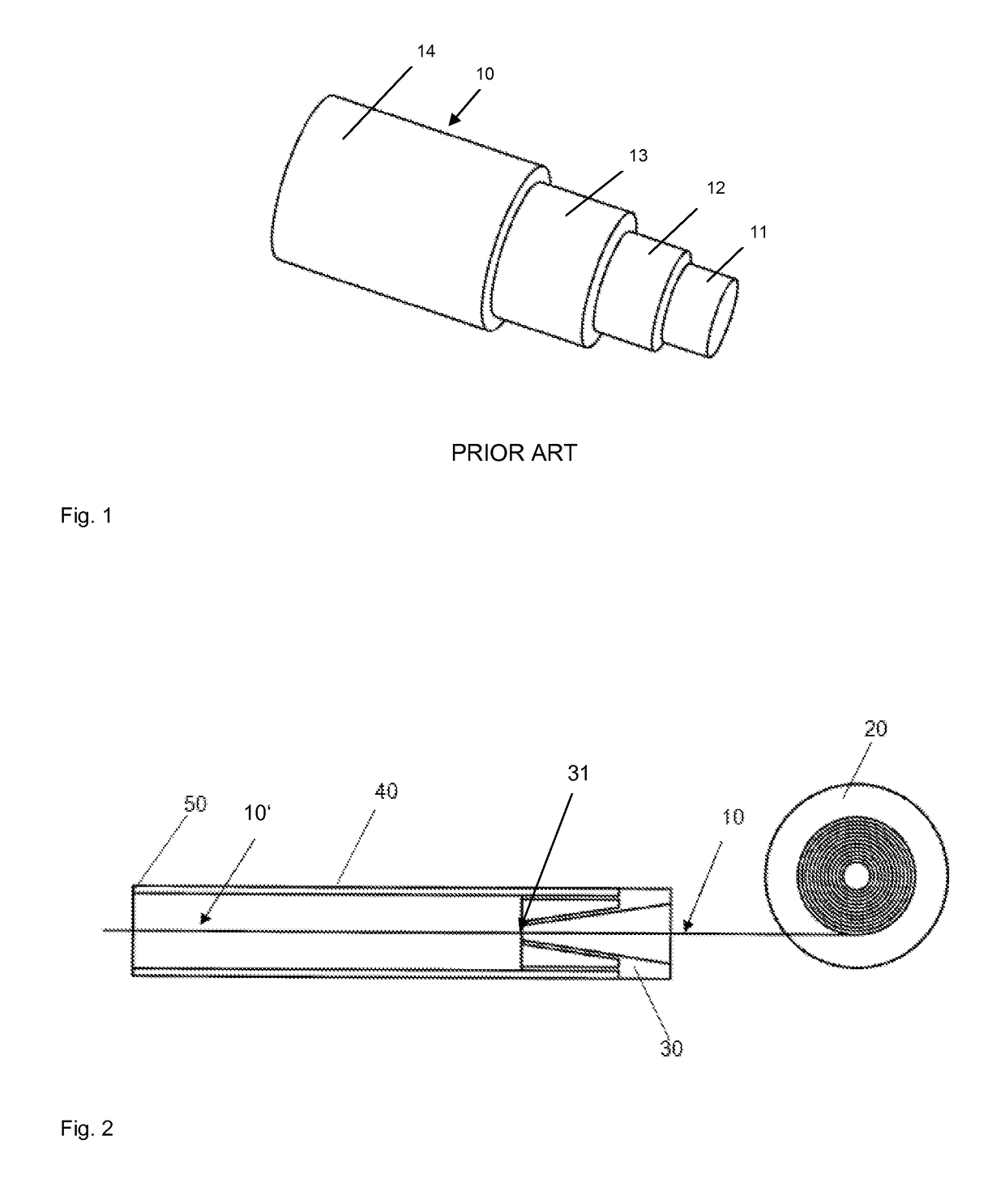

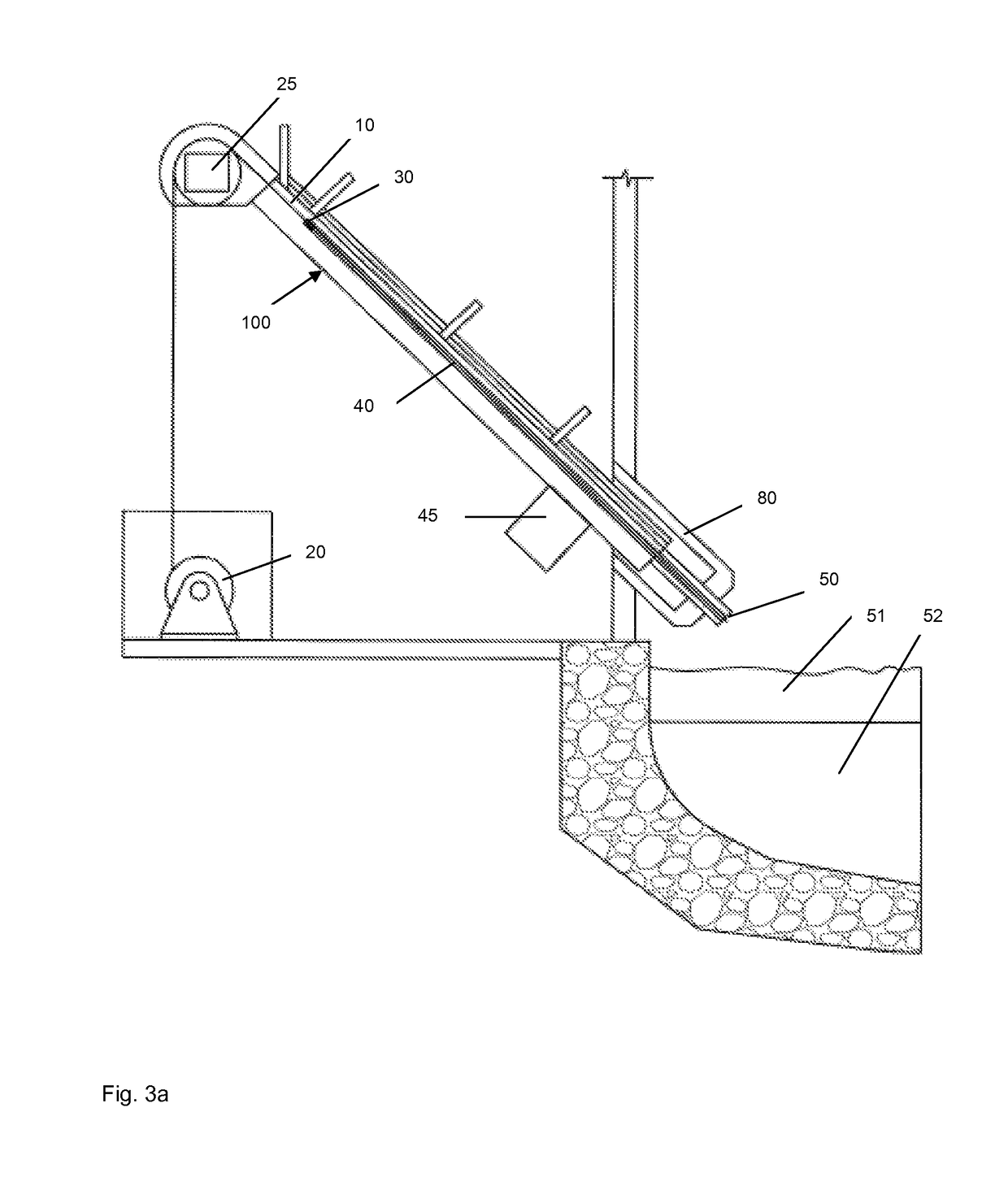

A method, device and apparatus are provided for measuring the temperature of a melt, particularly of a molten metal, with an optical fiber, fed into the melt through a disposable guiding tube. The optical fiber and an immersion end of the tube are immersed into the melt and have feeding speeds which are independent from each other. An elastic plug is arranged within the tube or at an end of the tube opposite the immersion end. The optical fiber is fed through the elastic plug, and the elastic plug reduces a gap between the optical fiber and the tube, which has a larger inner diameter than the outer diameter of the optical fiber. The apparatus includes a fiber coil and a feeding mechanism for feeding the optical fiber and the tube, including at least two independent feeding motors, one for feeding the optical fiber and one for feeding the tube.

Owner:HERALUS ELECTRO NITE INT NV

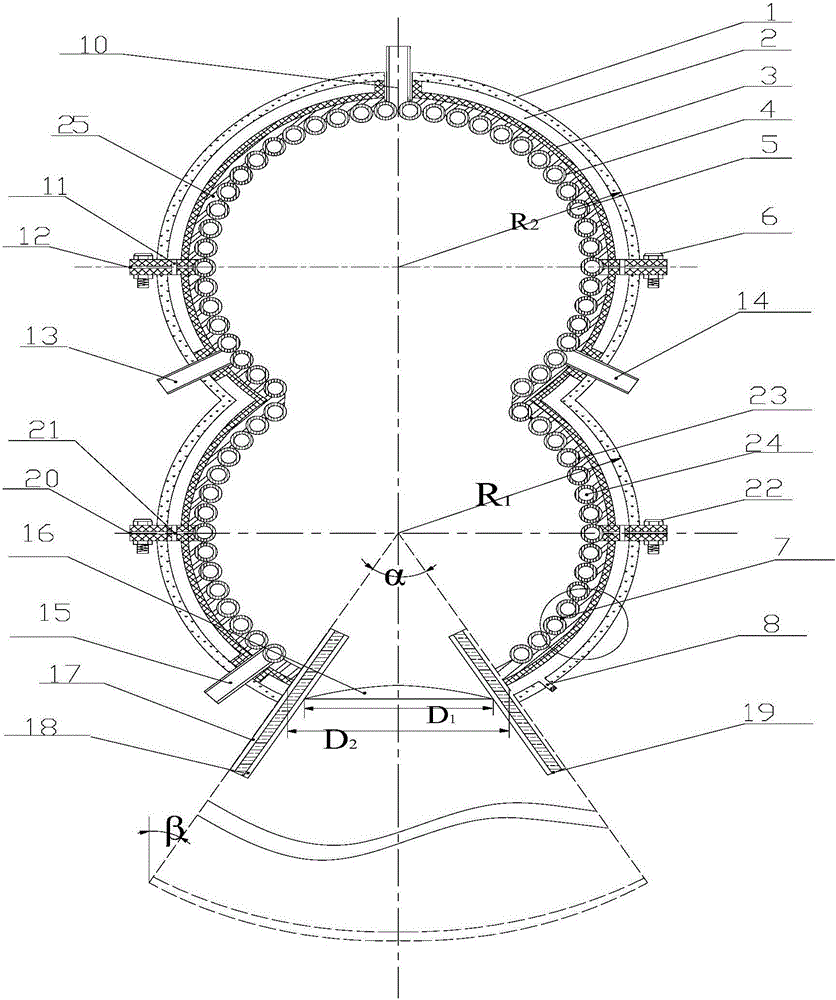

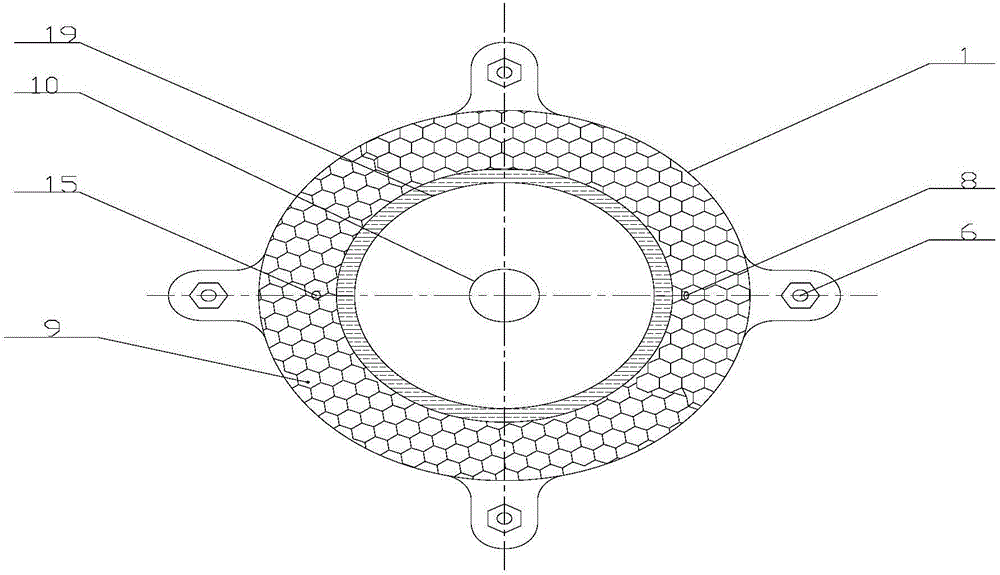

Semi-embedding type eight-shaped cavity type solar receiver and working method thereof

InactiveCN105841363AReduce convective heat lossEfficient heat absorptionSolar heating energySolar heat collector controllersLight reflectionHeat losses

The invention discloses a semi-embedding type eight-shaped cavity type solar receiver and a working method thereof. The solar receiver comprises a regular hexagonal convex mirror, a glass housing, a heat insulation vacuum layer, a steel inner shell, a soft heat transfer layer, a helical heat exchange coil tube, a heat conductive fluid, light reflection type wind shields and a cavity mouth convex mirror, wherein different from the traditional heat absorber, the solar receiver is in an eight shape, and independent feeding and discharge holes are formed in a low-temperature heating part and a high-temperature heating part and can be used for heating working media with different temperature requirements in a middle-high temperature solar heat utilization system and transporting the media with different temperatures respectively; the media can be secondarily heated by utilizing the focusing action of the regular hexagonal convex mirror; semi-embedding type connection between the soft heat transfer layer and the helical heat exchange coil tube makes the coil tube more uniformly heated, and thus heat spots are prevented from occurring; and through the focusing and closing actions of the cavity mouth convex mirror, the effects of efficiently absorbing heat and reducing convective heat loss can be reached.

Owner:SOUTH CHINA UNIV OF TECH

Large cast steel long cylindrical piece feeding process method

ActiveCN104014745ABlank weight is lightImprove inner qualityFoundry mouldsFoundry coresRoughcastMachining

The invention relates to the technical field of large cast steel pieces and in particular relates to a large cast steel long cylindrical piece feeding process method. The method comprises the following steps: casting a large cast steel long cylindrical piece, and dividing the piece into two independent feeding areas in the axial direction, namely an upper feeding area and a lower feeding area respectively; feeding the upper feeding area by adopting an open riser, forming a chilling block tail end area at the boundary of adjacent independent feeding areas through separated external chill, and performing automatic feeding; and feeding the lower feeding area through a kiss riser, shielding the overheat influence of bottom return casting through external chill at the tail end of the lower feeding area, and lengthening the feeding distance. According to the separated external chill and kiss riser, internal feeding is eliminated, the gas cutting workload is reduced, the weight of the rough casting is reduced, and the machining cost is reduced. Meanwhile, the inherent quality of the casting is improved, and the overall casting inspection reaches over level 2.

Owner:TANGSHAN DONGFANG HUASHENG GOOD WEAR RESISTING HIGH TECH

Working machine

ActiveCN102839709AEnsure steeringEnsure operabilityServomotorsSoil-shifting machines/dredgersWork performanceHydraulic pump

The invention claims a working machine is set with shunt type of the hydraulic pump working machine it can ensure the steering performance and the working device the working performance and it can well energy saving. The work machine is configured to drive the driving device to drive the front working device at the same time or the drive running device and the operation device for the running independent v13 valve is switched to a current position when it does not drive the front working device to drive the running device when said running independent valve is switched into the independent feeding position. The work machine is set with the load sensitive system the drive running device to drive the front of the working device at the same time and driving travelling device and the front working device when any one of the condition that the load sensitive system are both based on liquid pressure pump discharge pressure and hydraulic executing mechanism of the highest load pressure the difference between the pressure control hydraulic pump is discharged out of the flow.

Owner:KUBOTA LTD

Automatic fixed-length cutting machine for rubber and cutting method

ActiveCN106584539ACutting length is accurateOvercoming adhesionsMetal working apparatusEngineeringRubber sheet

Provided is an automatic fixed-length cutting machine for rubber and a cutting method. The automatic fixed-length cutting machine mainly comprises a feeding conveyor belt, a discharging conveyor belt and a middle cutting mechanism. The feeding conveyor belt is driven by an independent feeding motor. The discharging conveyor belt is driven by an independent discharging motor. The cutting mechanism comprises a shearing blade. The shearing blade is driven by a cam and a rotary air cylinder. The feeding motor, the discharging motor and the rotary air cylinder are all controlled by a PLC to be started. According to the automatic fixed-length cutting machine for the rubber, by arranging the feeding conveyor belt, the discharging conveyor belt and the middle cutting mechanism, the PLC is used for control, and the technical problems that the cut length of rubber sheets is unstable, operation and adjustment are difficult in the continuous production process, and the yield of the rubber sheets is low are solved.

Owner:湖北华润科技有限公司

Ultra-high-temperature nitriding continuous tunnel furnace

ActiveCN108020081ASolve the problems of long length, large space occupation and large energy lossRealize fully automatic closed loopFurnace typesEngineeringOxygen

The invention discloses an ultra-high-temperature nitriding continuous tunnel furnace. The furnace comprises an aerobic charging area, a feeding area, a furnace body and a discharging area, wherein the areas are connected in sequence to form a rectangular loop structure, and the areas are independent from one another; the feeding area, the furnace body and the discharging area are of a sealed cavity structure, and the aerobic charging area is of a non-sealing structure; and rails are laid in all the areas, and the materials enter and exit from the areas in a one-way mode. The sintering temperature of the ultra-high-temperature nitriding continuous tunnel furnace can reach 2000 DEG C, and the unique annular structure layout realizes the full-automatic closed circulation of the materials ascompactly as possible, rapid cooling and independent feeding and discharging of the materials in the furnace can be realized, the size is small, and the atmosphere in the furnace is uniform; the circulating production process of discharging the material at one end and feeding the material at the other end can be realized, and the nitriding process of the batch materials is realized; hydraulic propelling is adopted, the whole process is controlled by computers, manual intervention is not needed, and automatic continuous operation is realized; and the furnace is stable and reliable in material running, high in safety performance and low in labor intensity.

Owner:钢研工程设计有限公司

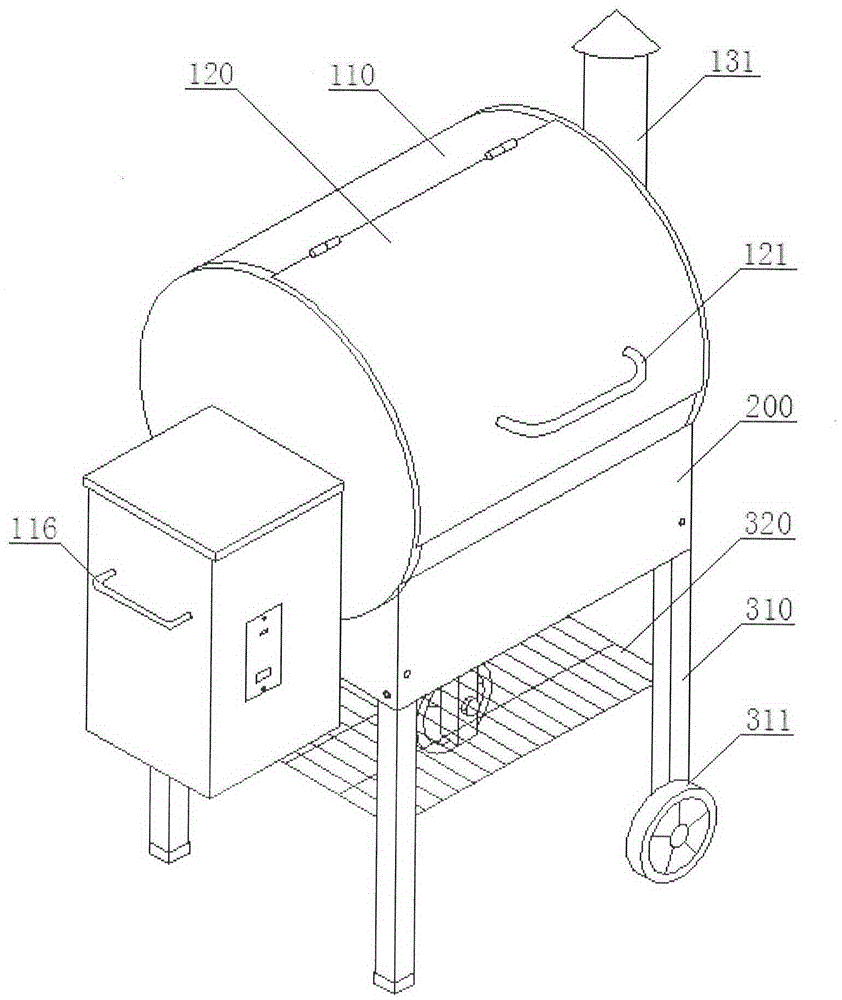

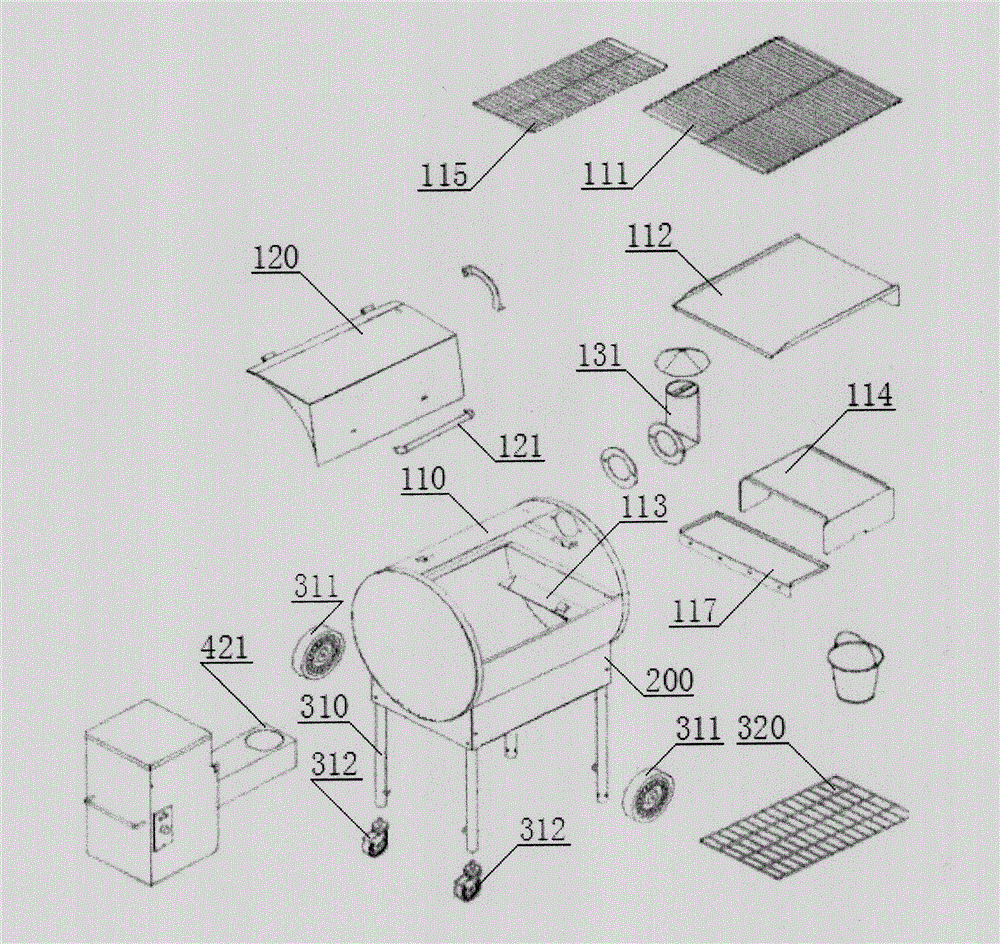

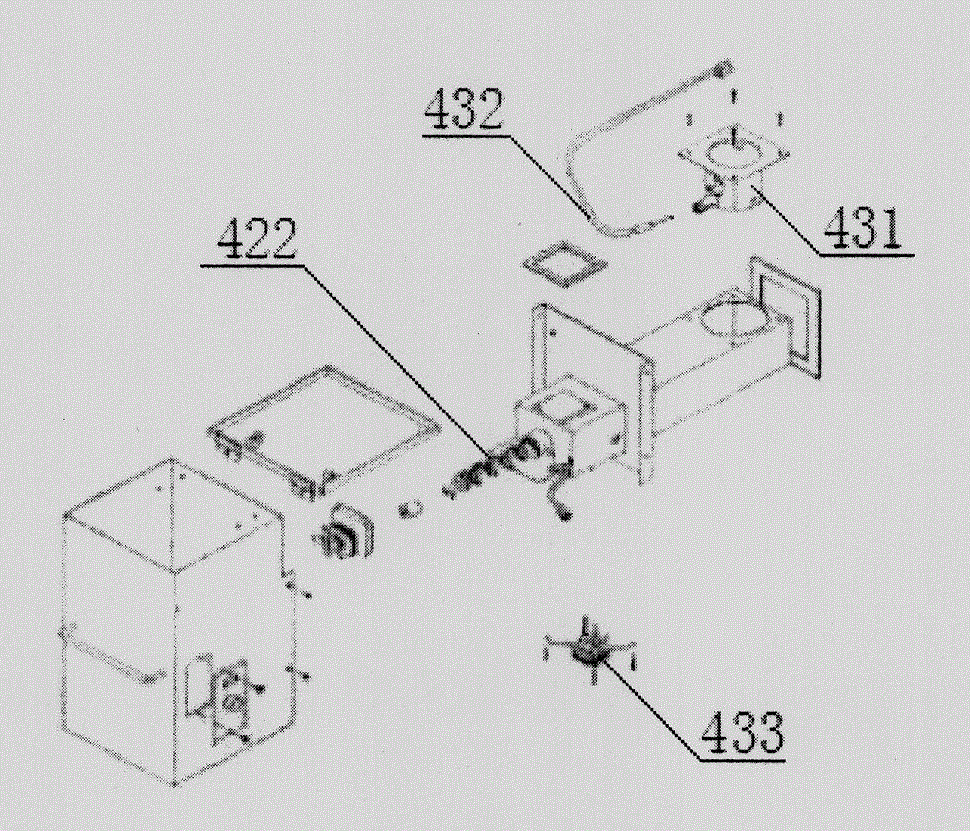

Barbecue oven

PendingCN105708345APrevent improper volatilizationReduce adverse effectsRoasters/grillsThermal energyHeat conducting

The invention relates to a barbecue furnace, comprising a furnace body, a furnace body base, a furnace body support leg and a heat energy supply device, and the furnace body support leg includes at least three support legs. The furnace body includes a furnace body shell and a flip cover of the furnace body shell. A barbecue mesh is arranged horizontally in the middle of the furnace cavity. A chimney port is arranged on the inner wall of the furnace shell above the barbecue mesh. An oil receiving pan is arranged in the furnace cavity below the barbecue mesh. , the grease dripping from the grill mesh will flow into the oil sink on the inner wall of the furnace shell along the oil receiving pan. The heat energy supply device includes a fuel storage tank, a fuel conveying device and a furnace core device. The fuel conveying device includes a conveying pipeline and an electric screw pushing device. The furnace core device includes a furnace chamber, an ignition nozzle and a blowing fan. The upper cover of the furnace chamber is provided with a fire-proof and heat-conducting plate. The barbecue of the invention adopts the openable and closed structure of the barbecue and the independent feeding unit to shield the heat radiation generated by the barbecue, prevent the improper volatilization of oil fume, and effectively alleviate the adverse effects of the barbecue operation on the environment.

Owner:WUXI FURONG LASER TECH CO LTD

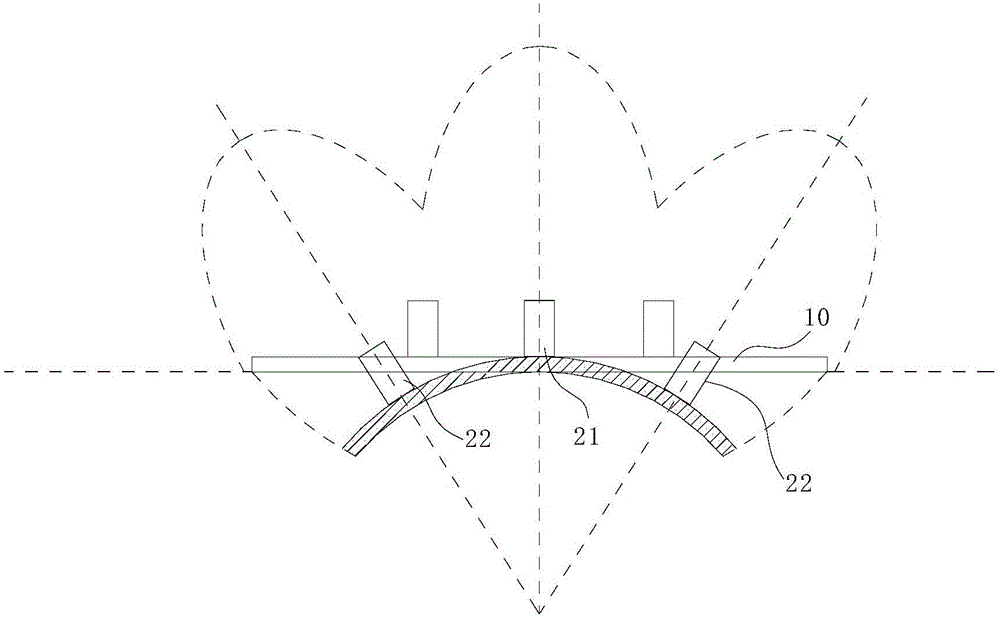

Bending antenna array and layout method thereof

InactiveCN106356647AEasy to prepareEasy to useIndependent non-interacting antenna combinationsElectricityImpedance matching

The invention discloses a bent antenna array and a layout method thereof. The antenna array comprises a substrate and a plurality of same unit antennas arranged on the substrate, the plurality of unit antennas independently feed and include a central antenna and a row of peripheral antennas which are collinear with the center antenna and are symmetrically arranged on the two sides of the central antenna; the substrate is flexible and bent toward the back with the central antenna as the center, so that the peripheral antennas are symmetrically arranged on the two sides of the curved surface of the substrate. According to the invention, the directional diagram of the antenna array is adjusted by bending the substrate, the fabrication and application methods of the antenna array are simple, and the performance of the assembled unit antenna is not changed; each unit antenna is configured as independent feeding, and can be re-matched and integrated via a back-end circuit after feeding, so as to reduce the impedance matching difficulty and accuracy between the antennas. In addition, the number of the unit antennas can be increased or decreased according to the actual requirements to meet the communication needs, and the practicability is high.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Electric generator bent axle machining technology

The invention discloses a bent axle machining technology, particularly relates to an electric generator bent axle machining technology, and belongs to the technical field of bent axle machining and manufacturing. A segmented bent axle comprises front, middle and rear sections. The front, middle and rear sections are formed by connecting and assembling cone holes, which are matched with connectingarms in shaft neck taper, of connecting rod necks. Overall rough machining is carried out firstly; segmented semi-finishing is carried out after sawing; and overall precise machining is carried out after assembly to obtain a complete bent axle connecting rod assembly. Compared with the technology of segmented independent feeding and machining, during the overall rough machining, the problem of machining accuracy decrease caused by inconsistent positioning standards in segmented independent machining can be avoided to the greatest extent. The phase angle of the bent axle can be easily controlled during machining, and foundation is laid for accurate assembly connection of sections. Normal machining equipment is adopted during machining by the technology, and therefore requirements to the machining equipment are effectively lowered, and machining efficiency is improved.

Owner:芜湖肯昌机电有限公司

High-speed computer plate cutting saw, control system and machining method

ActiveCN111546430AEasy to guarantee synchronous movementSimple structureFeeding devicesControl systemControl engineering

A high-speed computer plate cutting saw comprises a main clamping and feeding device provided with a first main clamp tong device and a second main clamp tong device and an auxiliary clamping and feeding device provided with an auxiliary clamp tong device. A control system comprises a main clamping and feeding device control unit and an auxiliary clamping and feeding device control unit. The mainclamping and feeding device control unit comprises a first main clamp tong mechanism control unit and a second main clamp tong mechanism control unit. The auxiliary clamping and feeding device controlunit comprises an auxiliary clamp tong mechanism control unit. The second main clamp tong mechanism control unit and the auxiliary clamp tong mechanism control unit comprise clamping control units and moving and turnover control units. A working method comprises the step of adopting one feeding manner of asynchronous feeding of the main clamping and feeding device and the auxiliary clamping and feeding device, synchronous feeding of the main clamping and feeding device and the auxiliary clamping and feeding device, independent feeding of the main clamping and feeding device and independent feeding of the auxiliary clamping and feeding device. The advantages that plates of two different kinds of lengths can be sawn through sawing of the same time, and efficiency can be improved by one time.

Owner:NANXING MACHINERY CO LTD

Machining grinding machine and method for taper holes

InactiveCN105058178ASatisfy the requirement of coaxialityImprove efficiencyRevolution surface grinding machinesGrinding drivesIndependent groupEngineering

The invention provides a machining grinding machine and method for taper holes. The machining grinding machine comprises feeding mechanisms, grinding mechanisms and a clamping mechanism. Two sets of independent feeding mechanisms and two sets of independent grinding mechanisms are arranged. Each group of the grinding mechanism comprises second motors and a grinding wheel. The two second motors are fixedly connected with the corresponding independent group of the feeding mechanism. Output shafts of the two motors are fixedly connected with the grinding wheels respectively. The central axes of the two grinding wheels coincide with each other and the grinding faces of the two grinding wheels are erected opposite to each other. The grinding faces of the two grinding wheels are conical surfaces which are consistent with the tapers of the taper holes to be machined. The clamping mechanism is fixedly installed on a grinding machine base and located between the two grinding wheels. According to the machining grinding machine and method for the taper holes, a forming grinding mode is adopted; only one-time clamping operation of a workpiece needs to be conducted to achieve the synchronous machining of the taper holes in the two ends of the workpiece, so that the forming machining efficiency and the machining precision of the taper holes in the workpiece are improved greatly; moreover, the coaxiality of the taper holes in the two ends of the workpiece can reach up to 0.01 so that the coaxiality requirement of the taper holes in the two ends of the workpiece can be fully met.

Owner:自贡中兴耐磨新材料有限公司

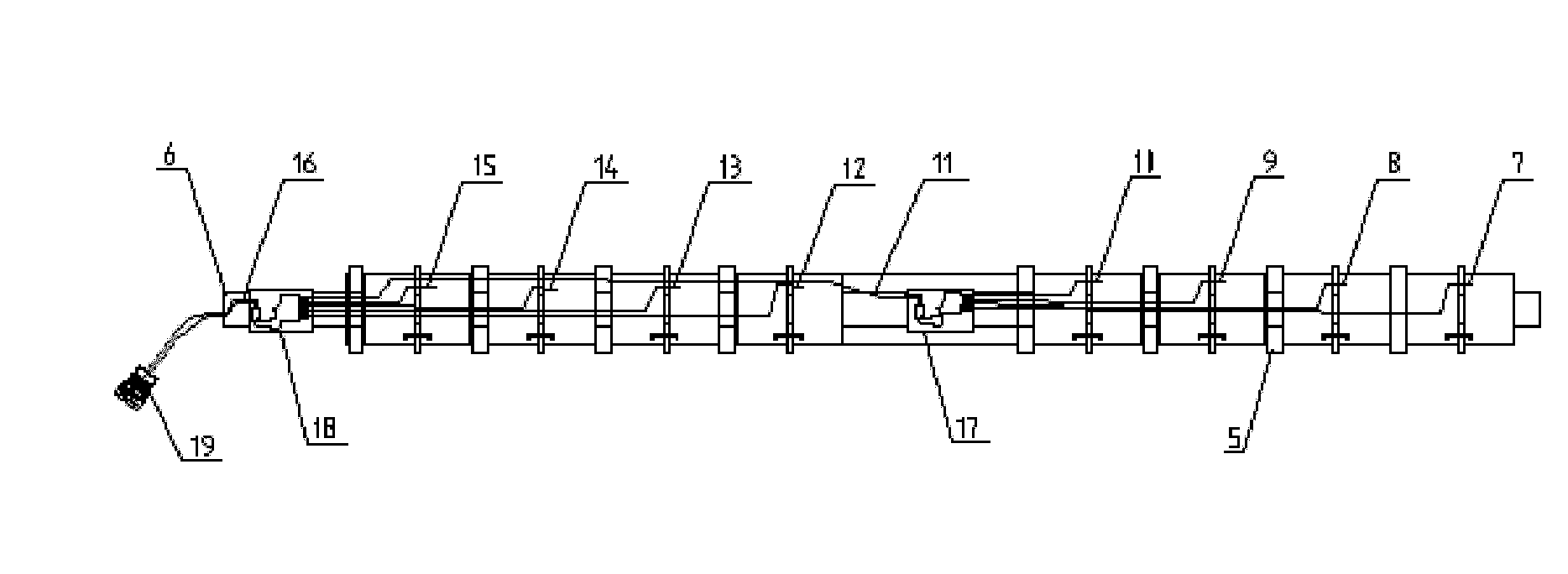

Device for removing wheel tool receiving ridge burrs

PendingCN108057931AWide versatilityImprove coaxialityEdge grinding machinesAutomatic control devicesBall screwElectric machinery

A device for removing wheel tool receiving ridge burrs is composed of a rack (1), a base (2), a guide rail I (3), a movable plate I (4), a ball screw I (5), a longitudinal motor (6), a transverse motor (7), a guide rail II (8), a ball screw II (9), a movable plate II (10), an electric cylinder (11), a moving roller bed (12), a circle center measuring sensor (13), an inner bearing (25), a shaft (26), a sleeve (27), a guiding key (28), a hollow shaft (29), a ridge cone tool (30), an outer air cylinder (31), a left blade (40), a right blade (41) and the like. By means of the device, outer side wheel edge and cap groove edge tool receiving ridge burrs can be removed at the same time, through inner side and outer side deburring tool integration, the space is saved, inner side and outer side independent feeding and independent rotating are achieved, tools on the inner side and the outer side have higher coaxiality, and the deburring effect is better.

Owner:CITIC DICASTAL

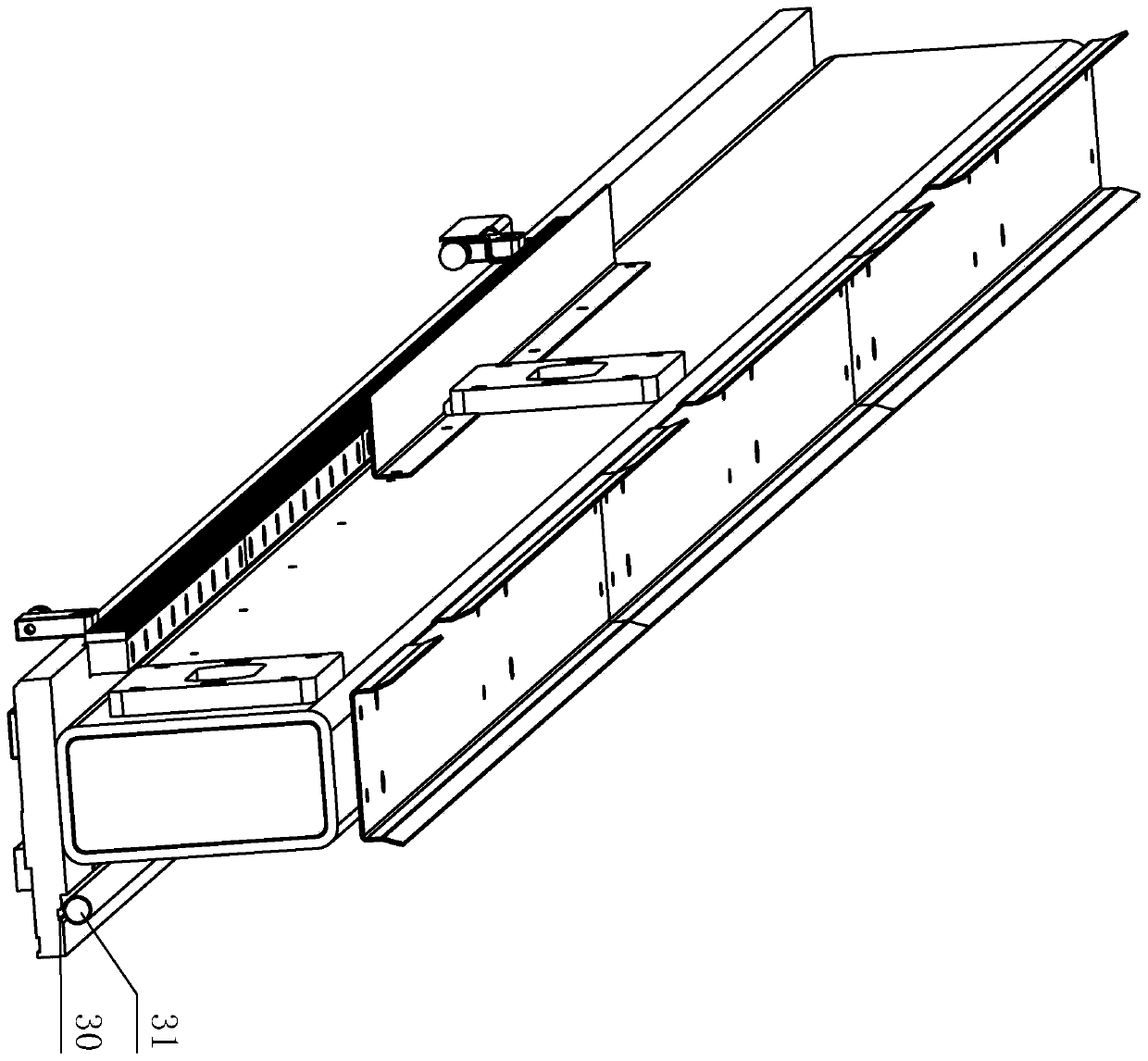

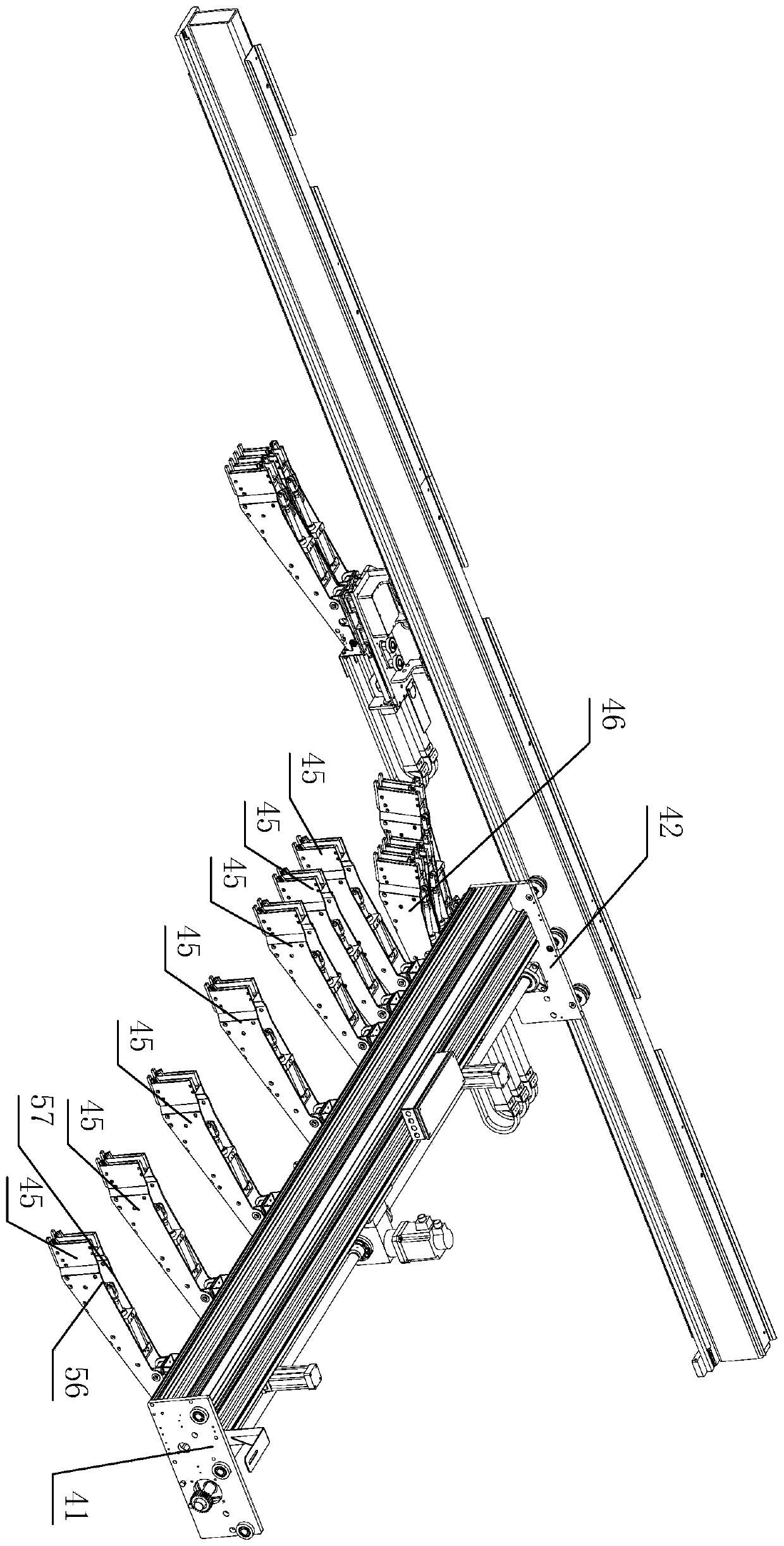

Reflective welding strip arranging device

ActiveCN105871329AEnsure consistencyPhotovoltaic monitoringPhotovoltaic energy generationEngineeringFixed length

The invention relates to a reflective welding strip arranging device, and belongs to the field of photovoltaic equipment. The reflective welding strip arranging device comprises a tension mechanism, wherein a back channel of the tension mechanism is provided with a visual detection mechanism for detecting welding strip consistence; a back channel of the visual detection mechanism is provided with a feeding mechanism; the feeding mechanism comprises a plurality of independent feeding parts of which the quantity corresponds to the quantity of welding strips, and is used for adjusting single welding strips; a cutting mechanism is arranged on a back channel of the feeding mechanism; the cutting mechanism is provided with a cutter, and is used for cutting off the welding strips. According to the reflective welding strip arranging device, the visual detection mechanism and the plurality of independently-moving feeding parts are provided, so that cutting of the welding strips is realized, and the consistency of cut fixed-length reflective welding strips is ensured.

Owner:WUXI AUTOWELL TECH

Method for manufacturing grinding material of nylon brush thread, and extrusion equipment

InactiveCN100526046CIncrease productionProduct quality is stable and superiorEngineeringAluminium oxide

The invention relates to a method for manufacturing abrasive nylon brush filaments and its extrusion equipment. The invention solves the problem that the production equipment is easily damaged in the process of producing abrasive nylon brush filaments, and the production efficiency of the prior art is low and the time is long and low yield problems. The invention improves the extruding equipment, changing from one feeding hopper to two feeding hoppers. Its manufacturing method is to adopt the continuous production process of online shaping, use nylon 610 or nylon 1010 as the base material, choose silicon carbide or aluminum oxide with a particle size range of 100-1000 mesh as the abrasive, soak it with a silane coupling agent, and dry it. Then it is mixed with nylon according to the proportion of 20-30% of the total weight, and is fed by separate and independent feeding method, plasticized, melted, extruded, drawn, shaped, recycled and packaged as a finished product.

Owner:陈耀华

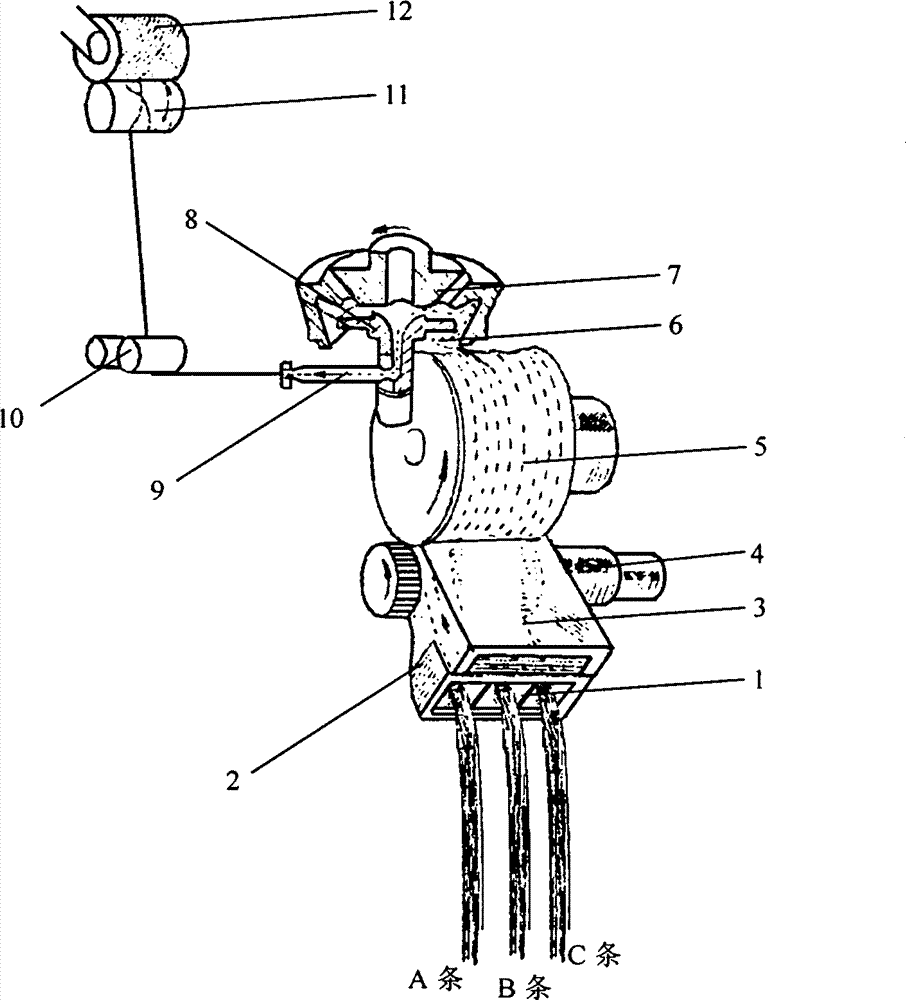

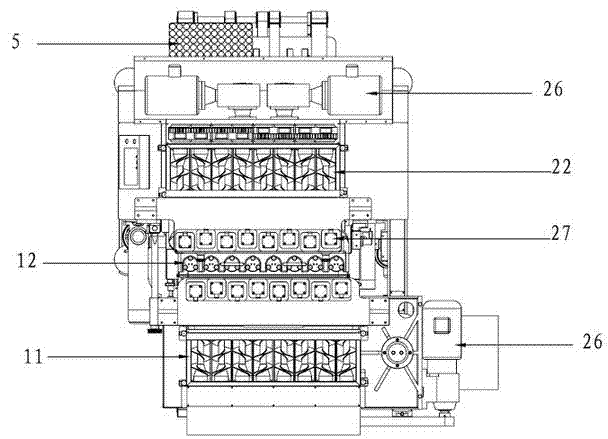

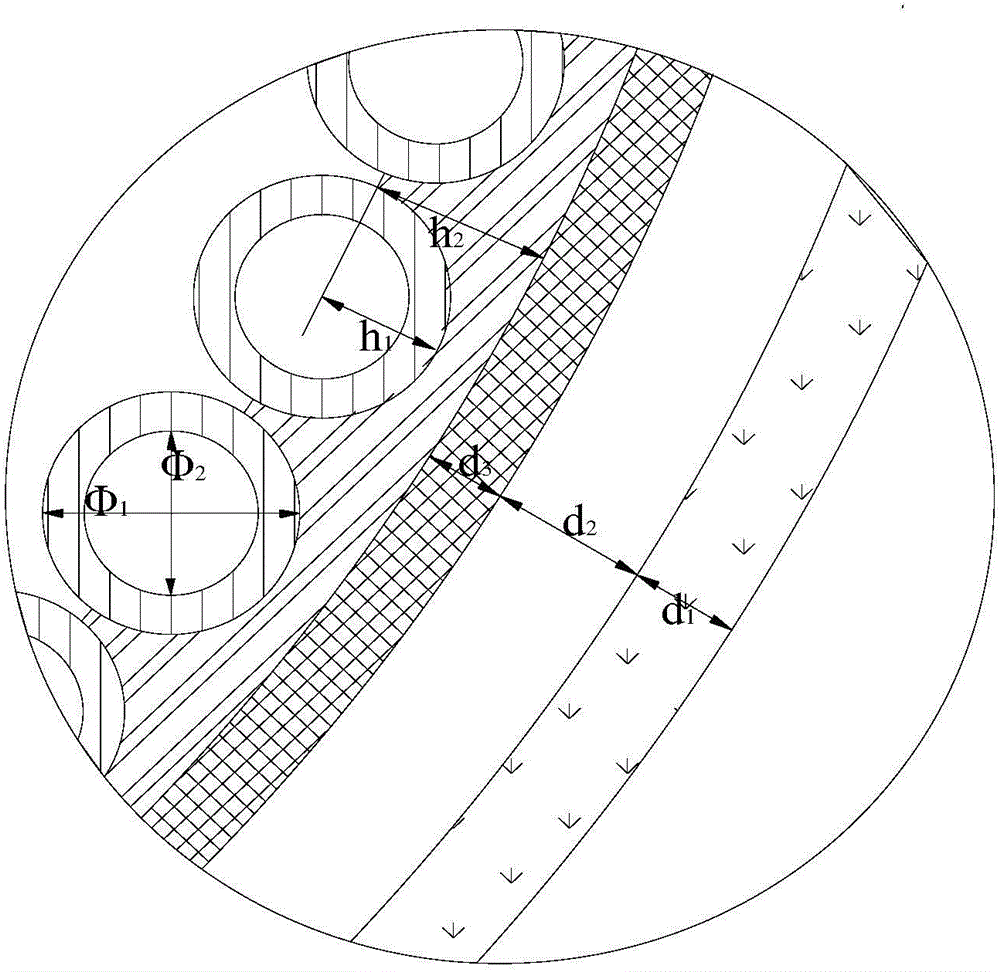

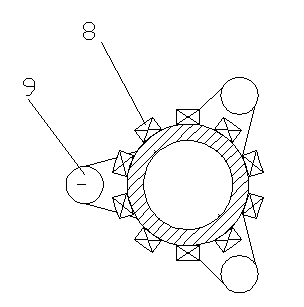

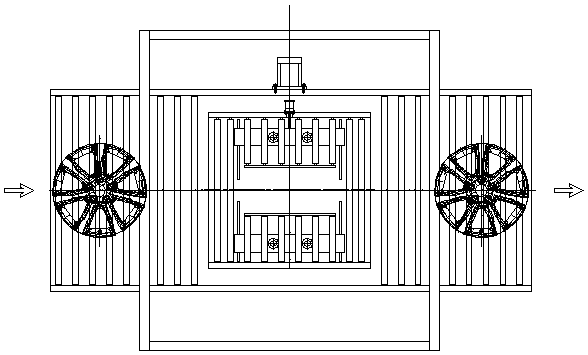

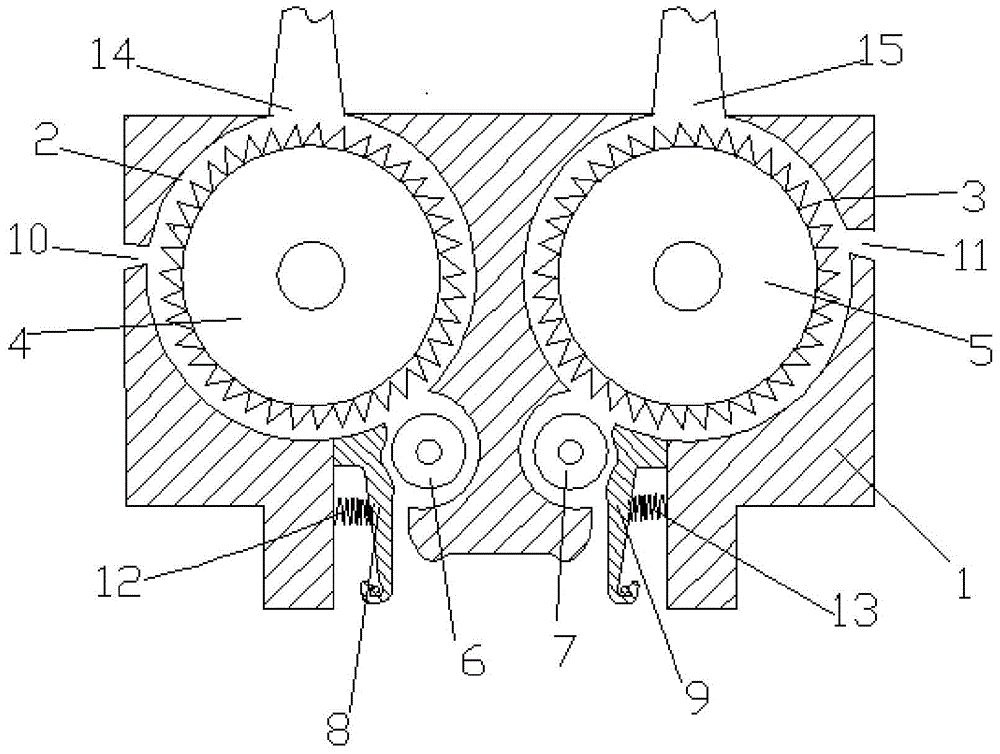

Dual feed carding mechanism

ActiveCN103911697AImprove combing effectAvoid damageContinuous wound-up machinesOpen-end spinning machinesYarnCarding

The invention relates to a dual feed carding mechanism, in particular to a dual feed carding mechanism of a rotor spinning machine. The dual feed carding mechanism comprises two independent feeding devices, two independent carding devices and two channels. The left and right feeding devices are arrayed symmetrically; the left and right carding devices are arrayed symmetrically, and left and right carding rollers, as the main components, are respectively arranged in left and right carding cavities; the left and right channels are respectively communicated with the left and right carding devices. According to the dual feed carding mechanism, features of a feeding carding mechanism of a traditional rotor spinning machine are changed, original single fiber feeding and carding is replaced with dual fiber feeding and carding during rotor spinning, the single fibers entering the rotor are provided with two independent channels, defects of the rotor spinning for blended yarn spinning and novel yarn production are overcome accordingly, using field of the rotor spinning is expanded effectively, and varieties of rotor yarns are enriched.

Owner:DONGHUA UNIV +1

Method and apparatus for measuring the temperature of a molten metal

ActiveUS9726545B2Low costSolve the real problemThermometers using physical/chemical changesSensing heat from liquidsGuide tubeMaterials science

A method, device and apparatus are provided for measuring the temperature of a melt, particularly of a molten metal, with an optical fiber, fed into the melt through a disposable guiding tube. The optical fiber and an immersion end of the tube are immersed into the melt and have feeding speeds which are independent from each other. An elastic plug is arranged within the tube or at an end of the tube opposite the immersion end. The optical fiber is fed through the elastic plug, and the elastic plug reduces a gap between the optical fiber and the tube, which has a larger inner diameter than the outer diameter of the optical fiber. The apparatus includes a fiber coil and a feeding mechanism for feeding the optical fiber and the tube, including at least two independent feeding motors, one for feeding the optical fiber and one for feeding the tube.

Owner:HERAEUS ELECTRO NITE INT NV

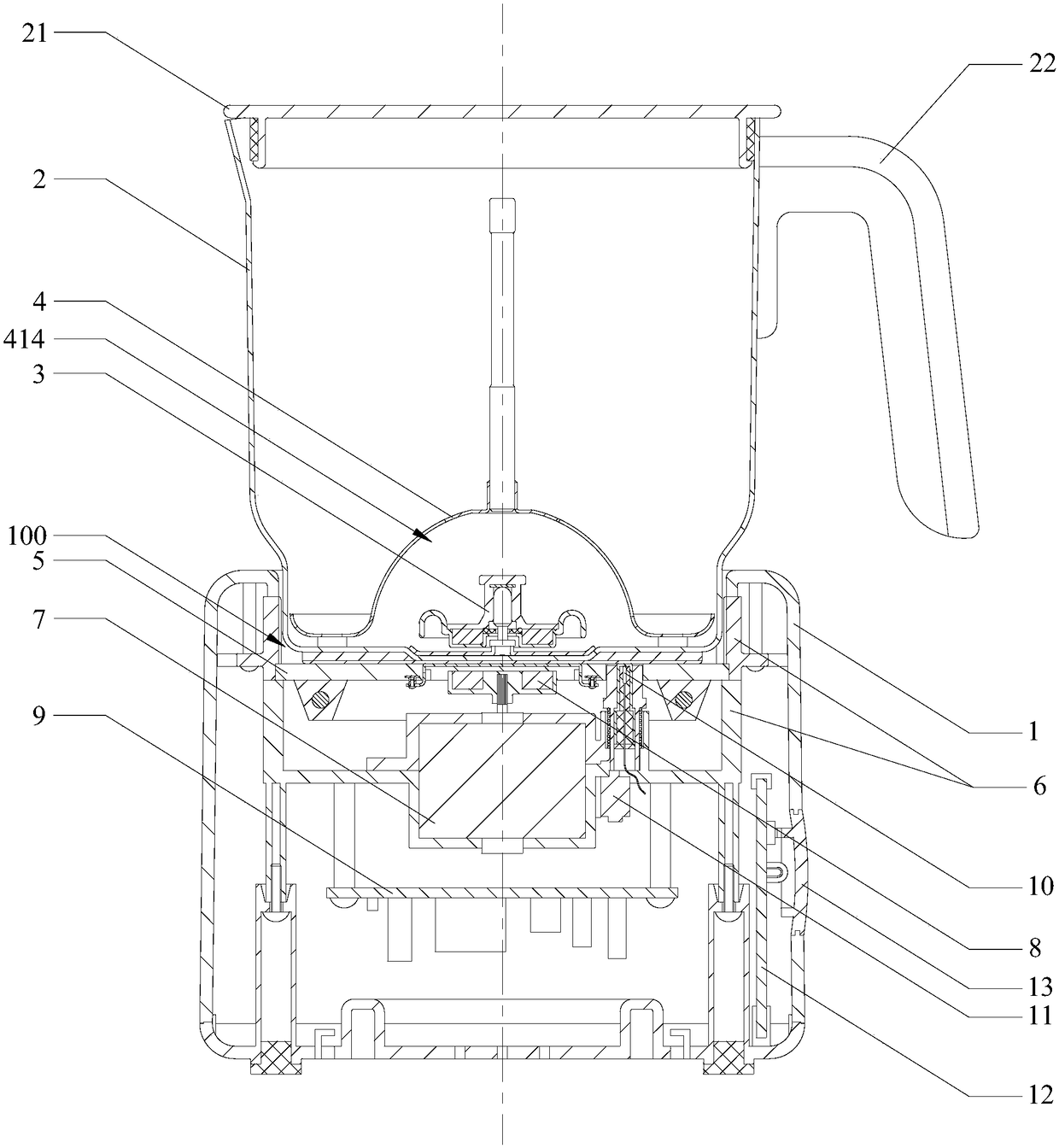

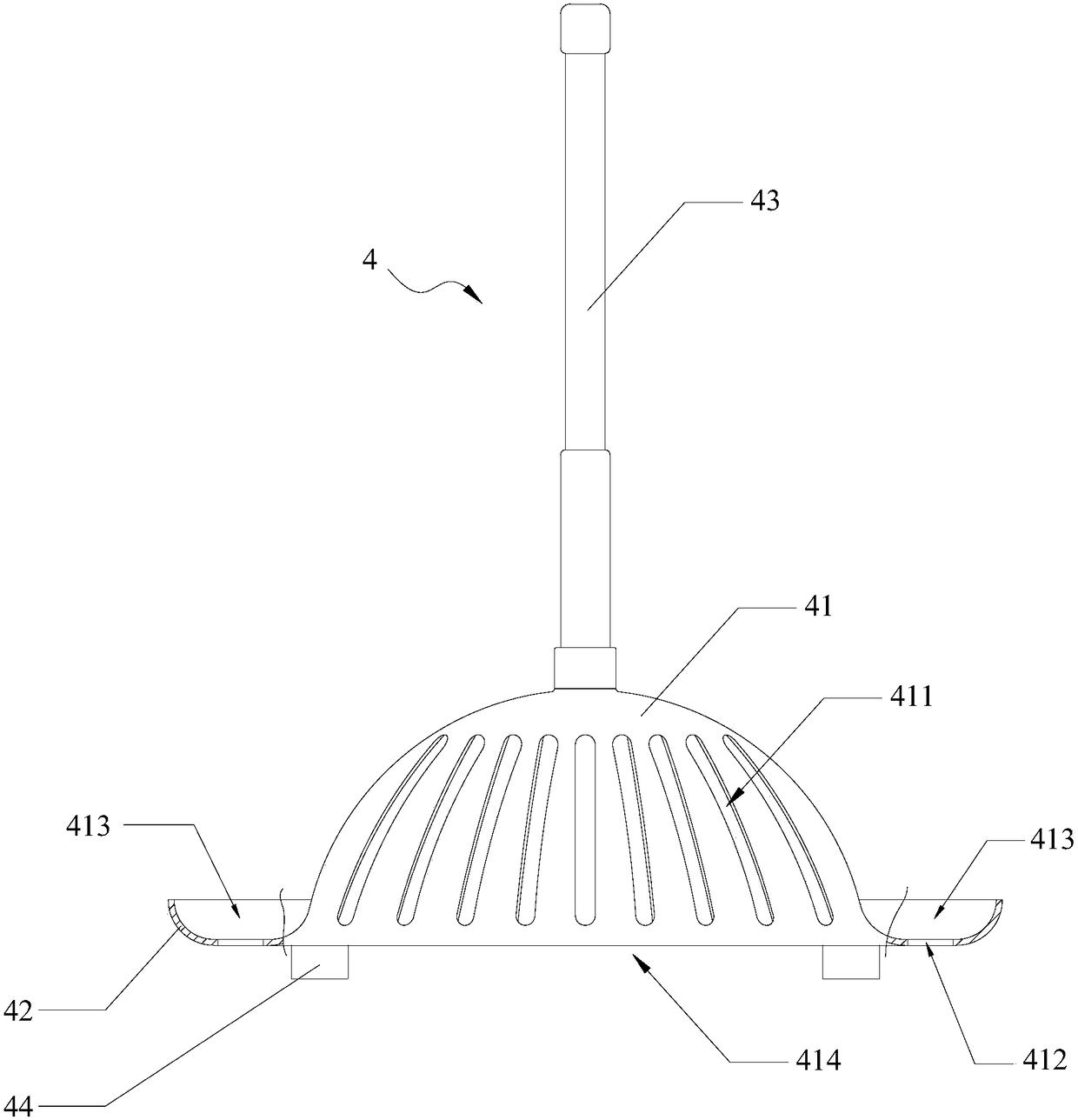

Liquid beverage stirring machine

PendingCN108420337AMeet the needs of making a variety of liquid beveragesImprove user experienceKitchen equipmentBlock effectIndependent feeding

The invention provides a liquid beverage stirring machine which comprises a base, a container cup, a stirring machine assembly and a feeding basket. A positioning groove is formed at the center of theinner bottom surface of the container cup. The stirring assembly is removably arranged in the positioning groove. The feeding basket can be accommodated in the container cup and has a gap with the stirring assembly. The stirring machine utilizes an independent feeding basket. When a user wants to add chocolate bars or a sugar bars with different sizes and shapes during the heating and stirring process of the liquid beverage, whether the chocolate bars or the sugar bars with different shapes are added before or during the heating and stirring process of the liquid beverage, the chocolate barsor the sugar bars and the like can be firstly contained in the annular area of the feeding basket, and then are put into the container cup along with the feeding basket. Due to the blocking effect ofthe feeding basket, the chocolate bars or candy bars and the like are unable to contact with the stirring machine during the stirring process, thereby, effectively solving the technical problem that the stirring machine of a milk foam machine can be easily jammed when chocolate bars or a sugar bars are added during the heating and stirring process of the milk.

Owner:熊兴剑

Control system and working method of computer panel saw

ActiveCN111496945AReduce manufacturing costImprove efficiencyMulti-purpose machinesWorking accessoriesControl systemControl engineering

The invention discloses a control system and a working method of a computer panel saw. The control system of the computer panel saw comprises a main work clamp feeding device control unit and an auxiliary work clamp feeding device control unit, wherein the main clamp feeding device control unit comprises a first main clamp mechanism control unit and a second main clamp mechanism control unit, theauxiliary work clamp feeding device control unit comprises an auxiliary clamp mechanism control unit, the first main clamp mechanism control unit comprises an overturning control unit and a clamping control unit, and the second main clamp mechanism control unit and the auxiliary clamp mechanism control unit each comprise a clamping control unit and a moving and overturning control unit; and the working method comprises the step of using one of the feeding modes of asynchronous feeding of a main work clamp feeding device and an auxiliary work clamp feeding device or synchronous feeding of the main work clamp feeding device and the auxiliary work clamp feeding device or independent feeding of the main work clamp feeding device or independent feeding of the auxiliary work clamp feeding device. The system has the advantages that two plates with different lengths can be sawed at the same time, so that the efficiency can be doubled.

Owner:NANXING MACHINERY CO LTD

Transmitting-receiving-separated dual-polarization antenna

ActiveUS9379434B2CouplingReduce couplingAntenna supports/mountingsRadiating elements structural formsElectrical conductorCoupling

Owner:DENKI KOGYO CO LTD +1

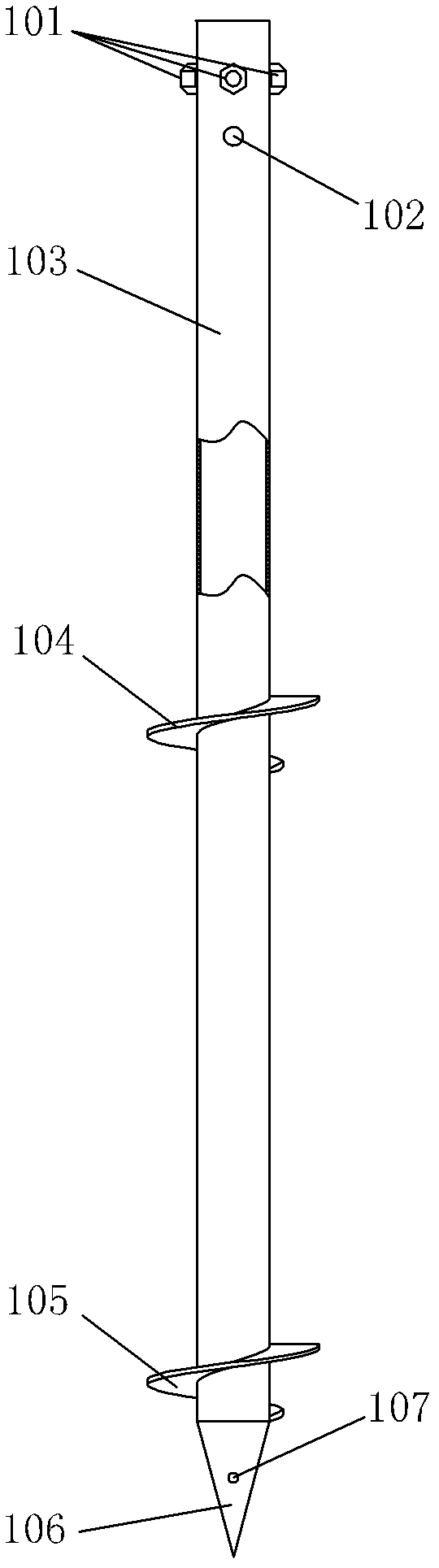

Automatic molding device of pointed cone for helix ground pillar production

InactiveCN102699172AGuarantee processing qualityIncrease productivityMetal-working feeding devicesPositioning devicesEngineeringManipulator

The invention discloses an automatic molding device of a pointed cone for helix ground pillar production. The automatic molding device comprises a plurality of cone mills which are distributed in parallel; a rack G is arranged on the feeding side of the plurality of cone mills; a plurality of feeding robots, a feeding device and a discharging device are arranged on the rack G; a plurality of feeding robots are arranged corresponding to the plurality of cone mills one to one; the feeding device comprises a feeding table which can be used for paving tubing in inclination; a plurality of feeding inlets are formed on the feeding table; a material guide sliding groove is arranged below each feeding inlet; a quantitative feeding device is arranged inside the material guide sliding groove; the quantitative feeding device comprises a rotary rod and a feeding rotary disc fixed on the rotating rod; a feeding notch for positioning tubing is arranged on the circumference of the feeding rotary disc; and the rotary rod is driven to rotate by a servo motor. With the adoption of the technical scheme, the spinning molding of the pointed cone part on a tubular pillar body of a helix ground pillar is realized; a plurality of machine tables are adopted for feeding uniformly and each machine table adopts an independent feeding robot for independent feeding, so that not only be the machining quality ensured, but also the production efficiency is high, stable and reliable.

Owner:浙江博雷重型机床制造有限公司

Electro-hydraulic hybrid driving mine lifting device and control method thereof

The invention provides an electro-hydraulic hybrid driving mine lifting device and a control method thereof. A lifting motor is connected with a first hydraulic pump / motor through a clutch, the input end of the lifting motor is connected with a primary winding of a step-down transformer, the primary winding of the step-down transformer is connected with the output end of a cascade type high voltage frequency converter, a secondary winding of the step-down transformer is connected with the input end of a low voltage frequency converter, and an independent feeding unit is formed by connecting a boosting transformer and a high voltage alternating current power grid. The control method includes: part of energy is stored through an energy accumulator and fed to save energy during uplink, downlink and brake of a lifting machine and a winch. The electro-hydraulic hybrid driving mine lifting device and the control method of the electro-hydraulic hybrid driving mine lifting device improve braking and decelerating performance of the motor and shorten braking time of the motor. Compared with an electro-hydraulic hybrid driving mine lifting device adopting a super capacitor and a flywheel battery, the electro-hydraulic hybrid driving mine lifting device adopts the hydraulic energy accumulator to store energy and is mature in technology, reliable in operation and long in service life.

Owner:TAIYUAN UNIV OF TECH

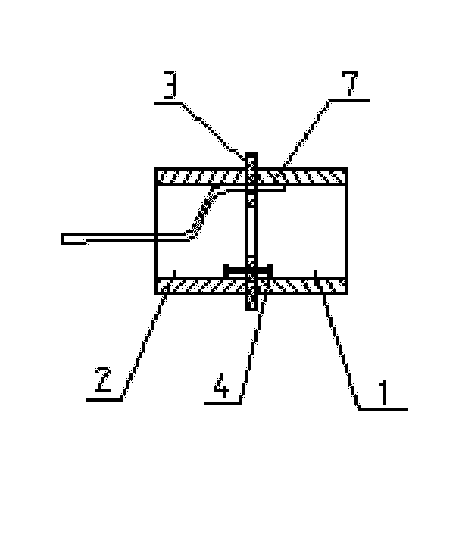

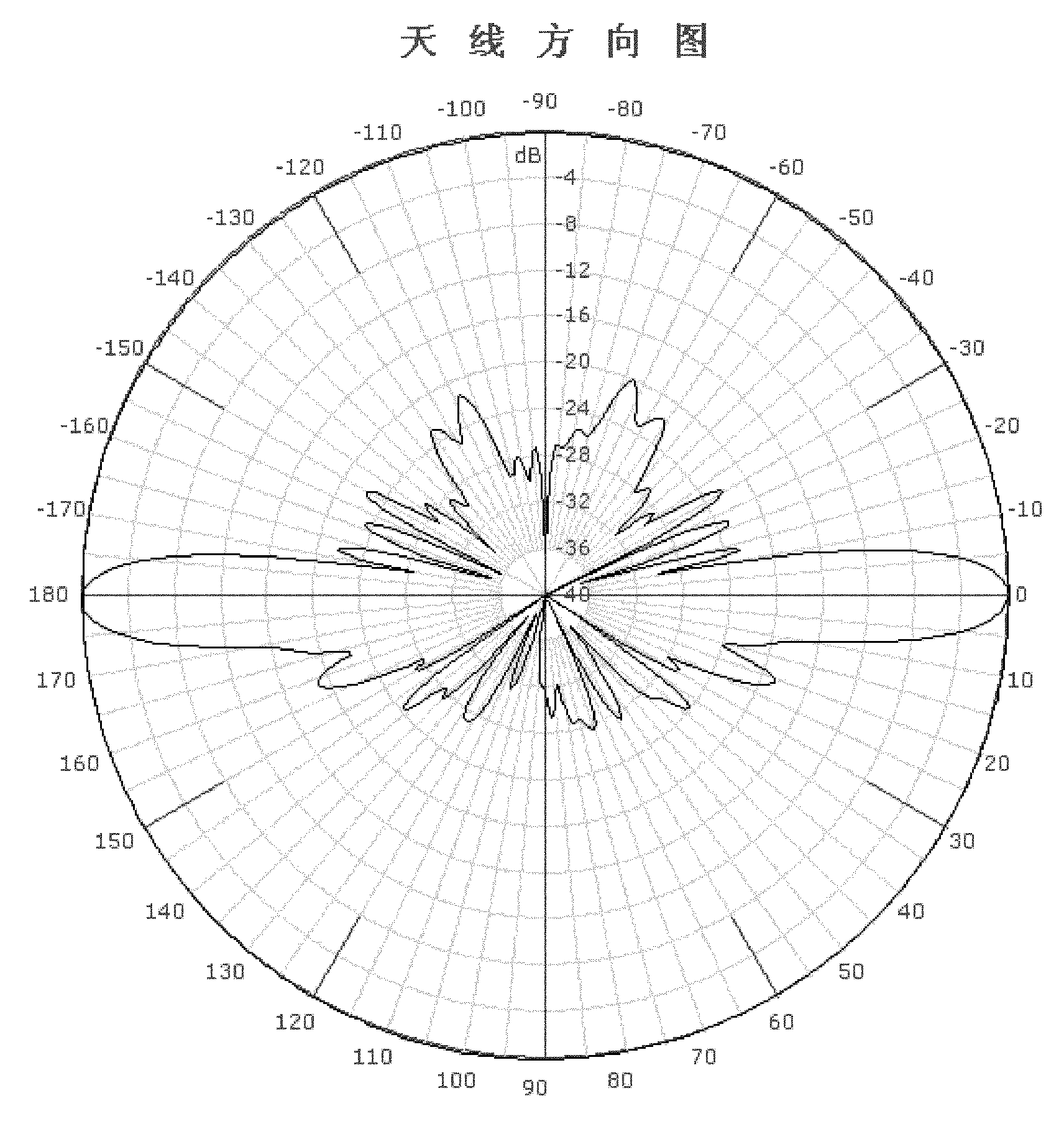

Long term evolution (LTE) double-frequency high-grain omnidirectional antenna

InactiveCN102110876ARealize multi-frequency workImprove radiation efficiencyAntenna arraysRadiating elements structural formsEpoxyElectrical conductor

The invention discloses a long term evolution (LTE) double-frequency high-grain omnidirectional antenna, mainly overcoming the defects of narrow bandwidth and low grain of a frequency range used by the existing omnidirectional antenna. The omnidirectional antenna comprises n radiation oscillators, two matching networks and a hollow external conductor, wherein each radiation oscillator comprises an upper radiator (1) and a lower radiator (2); the upper radiator (1) and the lower radiator (2) are connected by the annular medium sleeve (3) of epoxy medium; a metal short circuit device (4) penetrates through the middle of the annular medium sleeve (3); one side of the annular medium sleeve (3) is welded with a first feeding coaxial line (7) to form an broadband independent feeding radiation unit of which the frequency band is 1880-2600MHz; and an upper matching network (17) and a lower matching network (18) are respectively connected to the middle end and the bottom end of a hollow external conductor (6) to realize antenna input impendence matching and direct-current earthing. The long term evolution (LTE) double-frequency high-grain omnidirectional antenna has the advantages of simple structure and high wide double-frequency gain and can be used for broadband mobile communication network systems.

Owner:西安新海天通信有限公司

Cell electrofusion chip device based on surface microelectrode array and deformation membrane structure

InactiveCN102304475AControl deformationRealize independent samplingStress based microorganism growth stimulationMicroorganism fixing/supporting apparatusElectricityMicroelectrode

The invention relates to a cell electrofusion chip device based on a surface microelectrode array and a deformation membrane structure. The cell electrofusion chip device is composed of a surface microelectrode array chip and a top-layer deformation membrane structure, wherein the surface microelectrode array chip is divided into a quartz base layer, a microelectrode array layer and a polymer microchannel layer; the microelectrode array is in a sandwich structure and is attached to the polymer microchannel layer, thereby avoiding the cell blockage problem caused by the traditional tooth-shaped projection electrode structure and simultaneously guaranteeing the integration level and better fusion efficiency of the microelectrode; the deformation membrane structure is composed of a flexible deformation membrane and an air pressure adjusting device; the flexible deformation membrane covers the microchannel; and the flexible deformation membrane deforms under the action of air pressure applied by the air pressure adjusting device, protrudes downwards and enters the microchannel to form a partition wall, thereby dividing the microchannel into two microchannels and realizing independent feeding and pairing of different cells. The device can be widely applied in the fields of genetics, distant hybridization breeding of animals and plants, developmental biology, drug screening, monoclonal antibody preparation, mammal cloning and the like.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com