Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2619 results about "Liquid pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

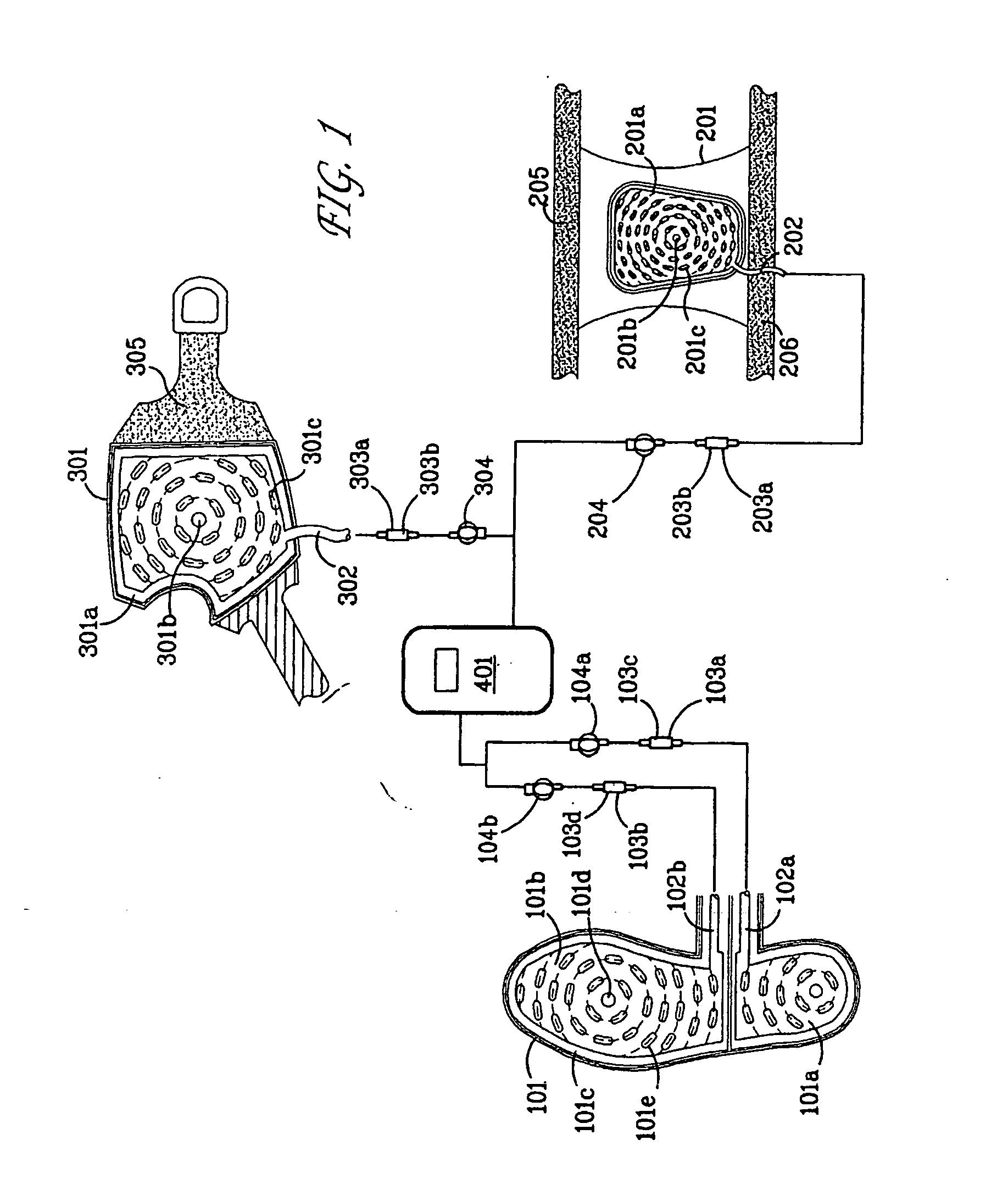

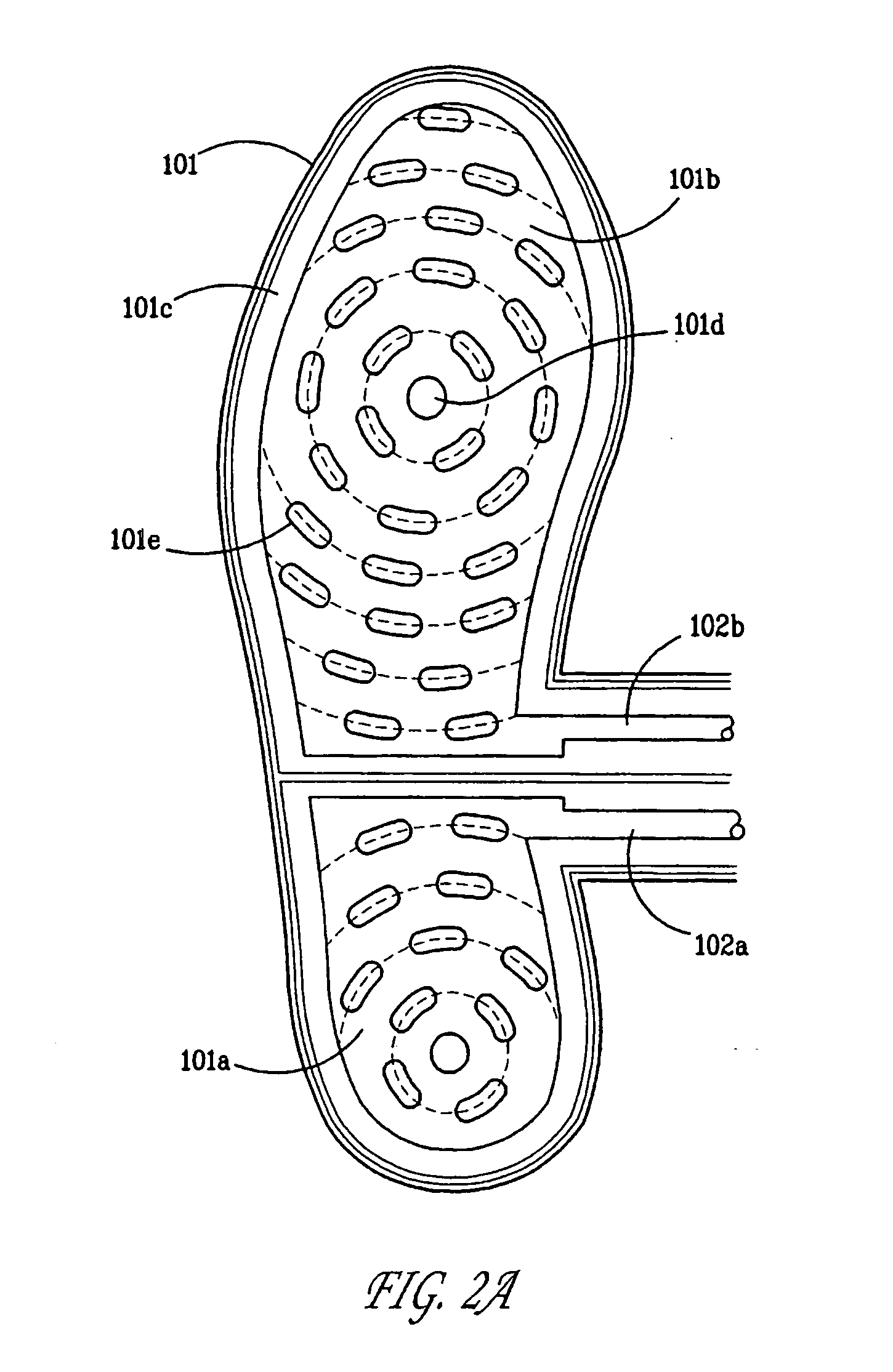

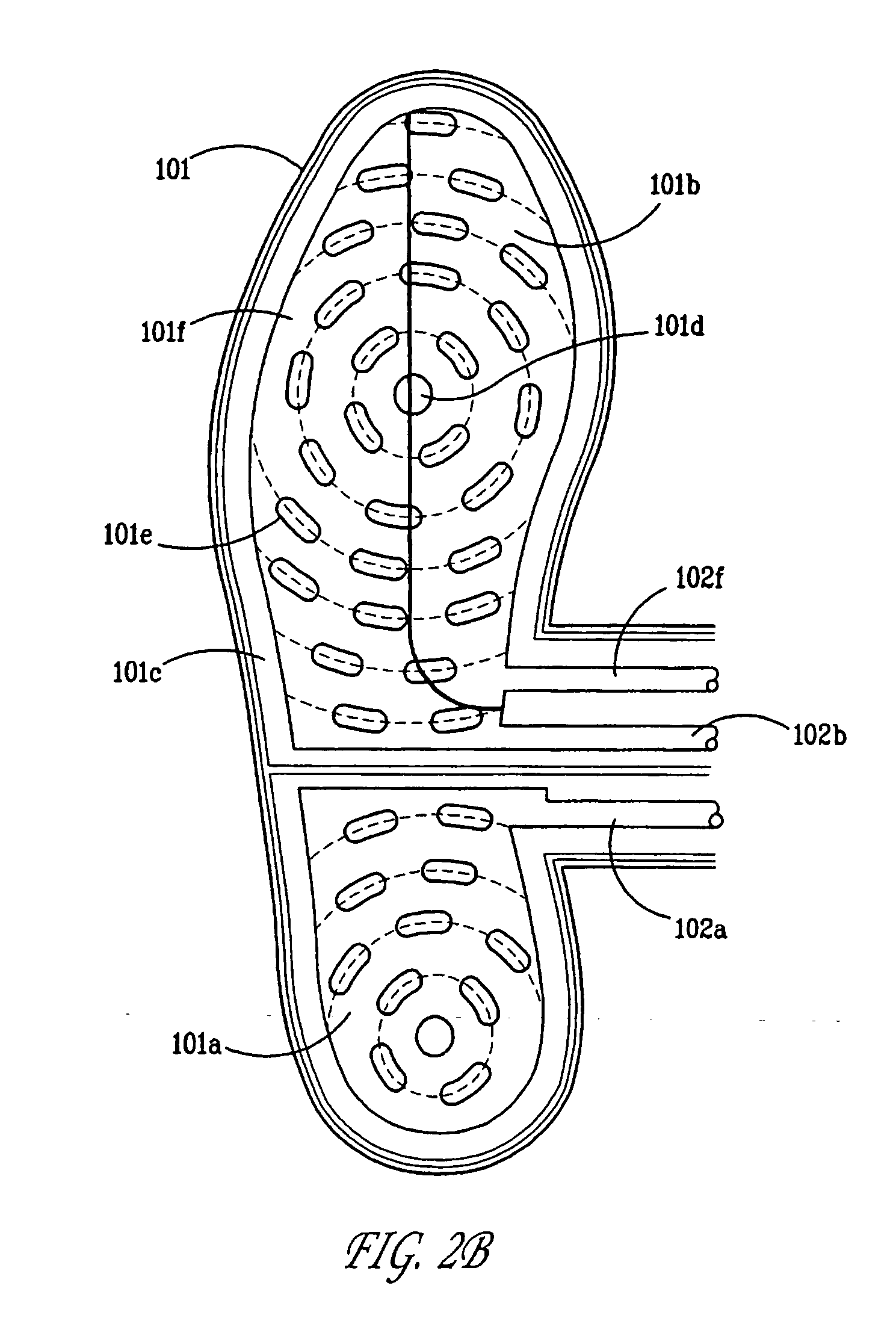

Force sensor system for use in monitoring weight bearing

InactiveUS20060282017A1Quality improvementNormalize gait patternElectrotherapySolesEngineeringBiological activation

A force sensor system for use in monitoring weight bearing on a location. The force sensor system comprises at least one a foot force sensor, a palm force sensor, and a knee force sensor. The foot force sensor comprises a flexible insole containing a plurality of inflatable pockets that are inflated with air or liquid. The palm force sensor and knee force sensor each comprise a wrap to be worn around the palm and knee, respectively. Each wrap comprises a pocket. Each pocket is connected to a tube that, in turn, connects with a pressure sensor and a connector coupling that is remote from the pocket. Each coupling contains a valve. The valve opens to allow inflation and deflation of each inflatable pocket. The pressure sensors measure the air or liquid pressure within each of the inflatable pockets, and convert the corresponding pressure signal into a suitable output signal medium, usually electrical signals. The output signal from the sensors provides accurate real time input data to a weight bearing biofeedback system or to control a stimulator for activation of an electronic orthosis to normalize dynamic gait patterns.

Owner:ANDANTE MEDICAL DEVICES

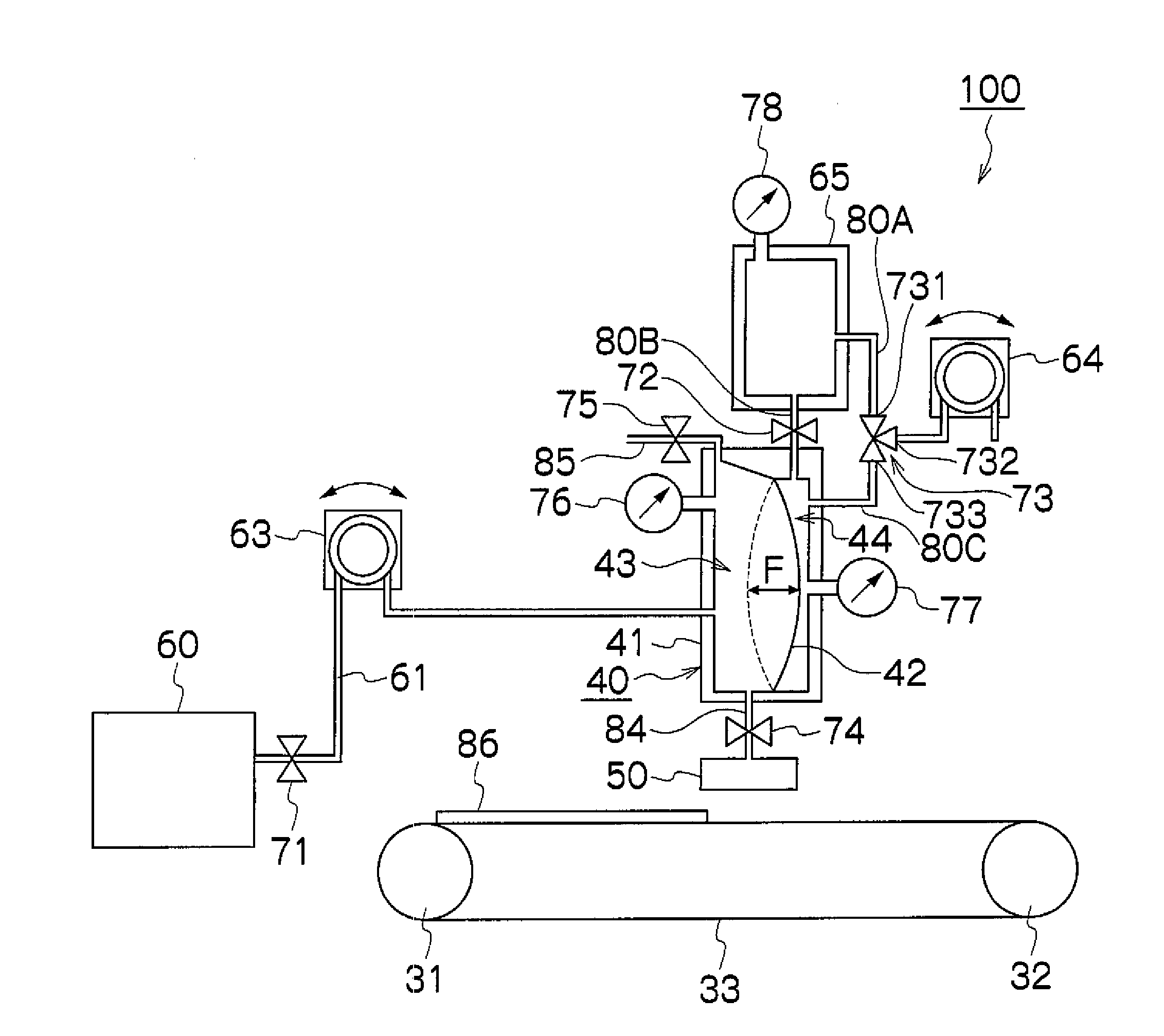

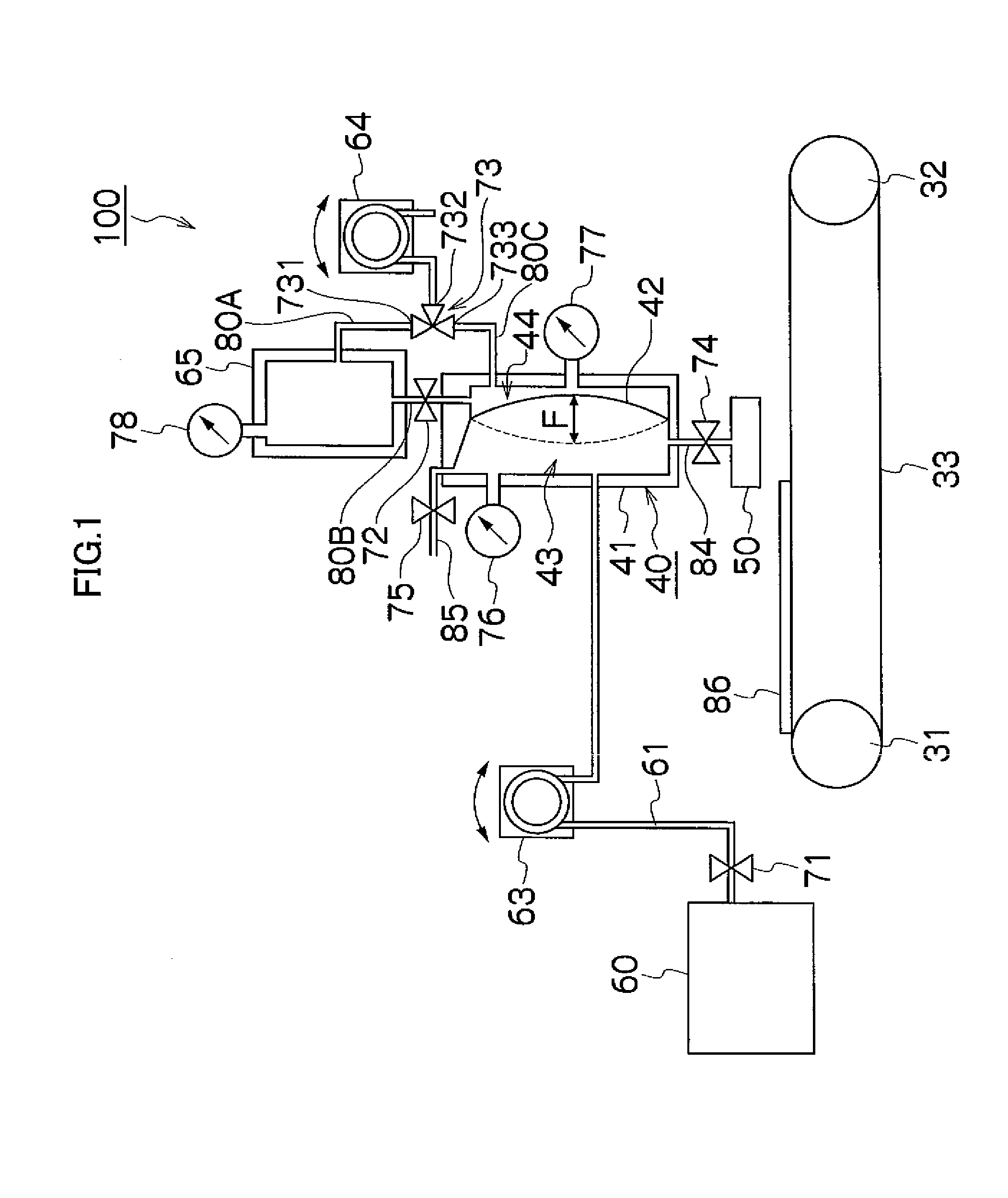

Pressure adjustment apparatus and image forming apparatus, and pressure adjustment method and liquid remaining amount determination method

InactiveUS20080198207A1Reduce flowShorten the timeOther printing apparatusHermetic sealImage formation

A pressure adjustment apparatus for adjusting a pressure of liquid inside a liquid ejection head including nozzles and flow channels includes: a tank; a pump; a buffer chamber; a first switching device; and a second switching device. The tank includes a movable film and a hermetically sealed container of a prescribed volume, the movable film dividing the hermetically sealed container into a gas chamber filled with gas and a liquid chamber filled with the liquid to be supplied to the liquid ejection head. The pump changes a pressure of the gas inside the gas chamber so as to adjust a pressure of the liquid inside the liquid chamber. The buffer chamber is filled with the gas and damps gas-flow pulsations caused by the pump. The first switching device connects and disconnects the buffer chamber and the gas chamber. The second switching device switches between a state where the pump is connected to the gas chamber without through the buffer chamber, and a state where the pump is connected to the buffer chamber.

Owner:FUJIFILM CORP

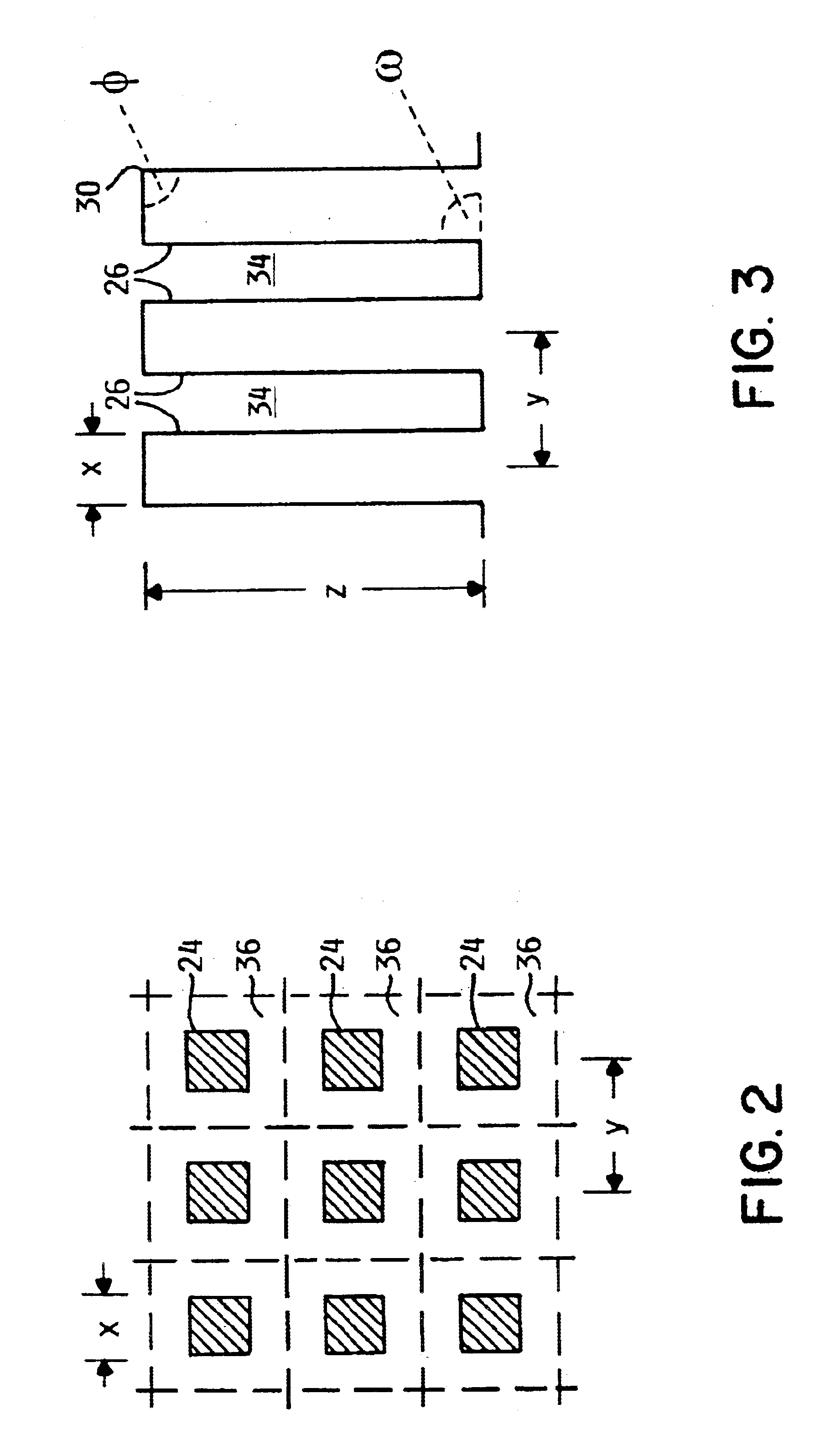

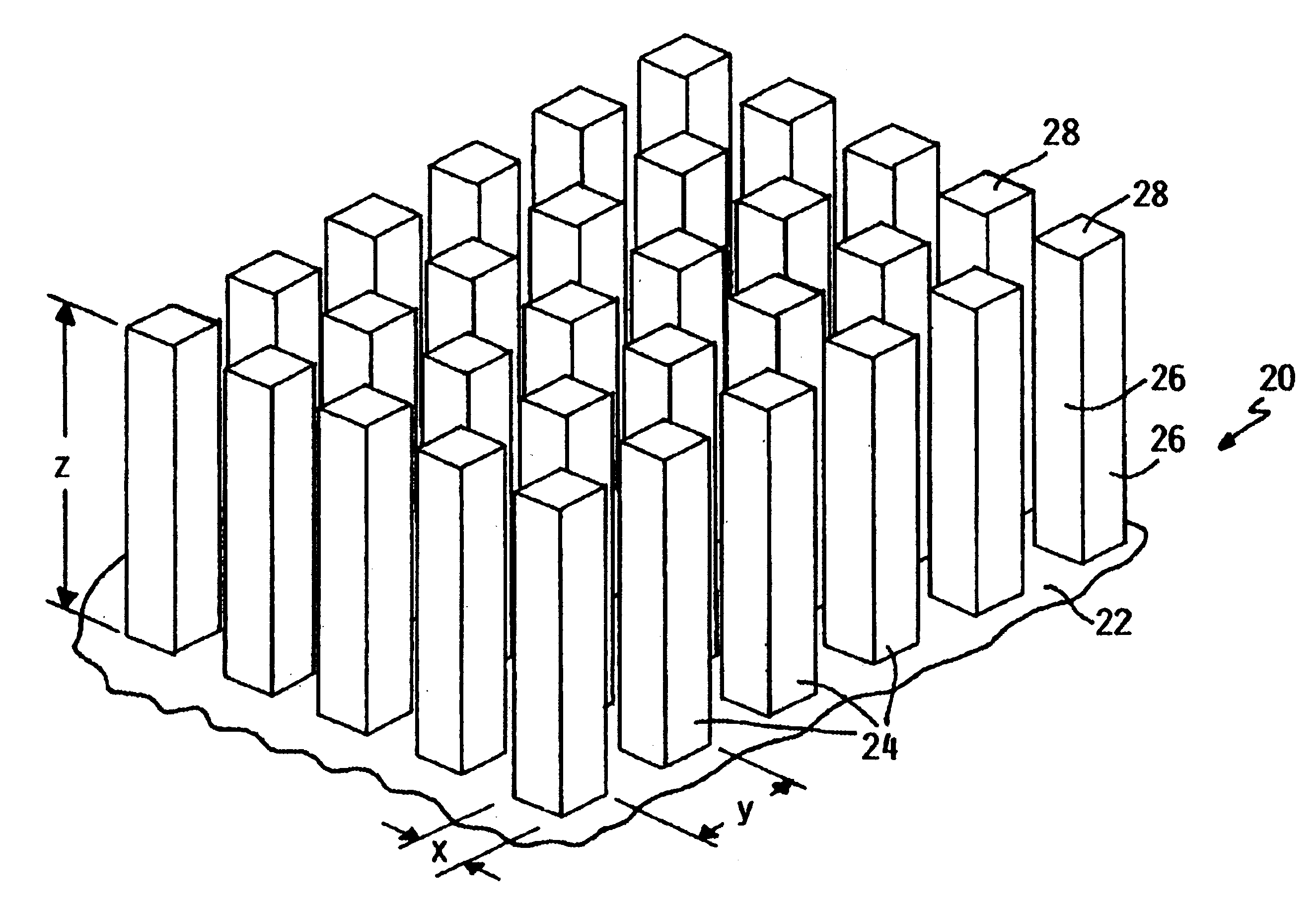

Ultraphobic surface for high pressure liquids

A durable ultraphobic surface that is capable of retaining ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γcos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

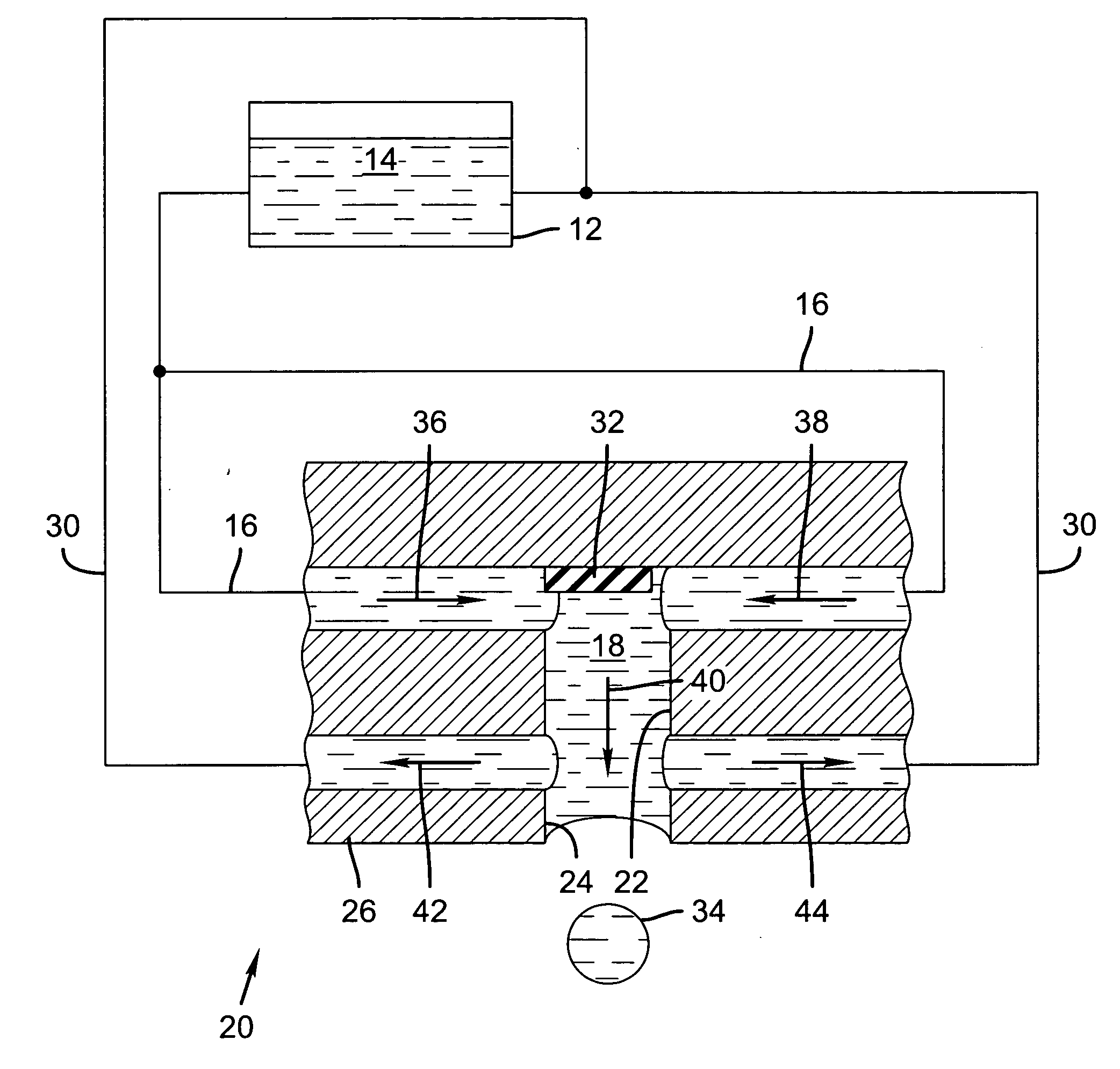

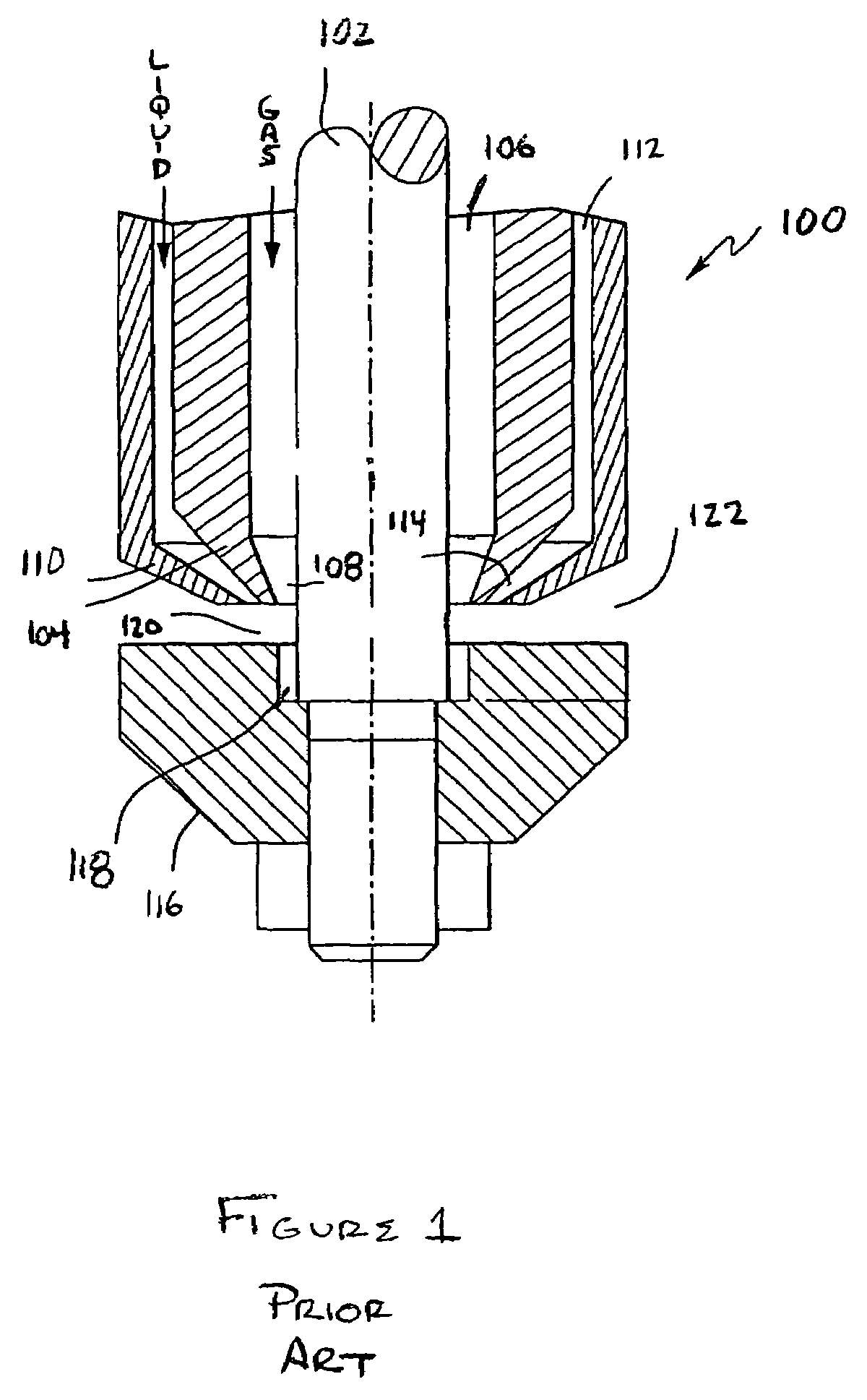

Drop on demand print head with fluid stagnation point at nozzle opening

InactiveUS20070291082A1Increase response timeReduce limitationInking apparatusCombustion chamberEngineering

A drop on demand ink jet print head has a chamber with a plurality of liquid passages into and out of said chamber, such that liquid is continuously moved into the chamber to a stagnation point adjacent to the nozzle opening, whereat the fluid comes substantially to rest, and out of the chamber from the stagnation point such that vector sum of liquid flow derived forces within the liquid channels is neutral. An actuator associated with the chamber is adapted to selectively increase the pressure of the liquid at the stagnation point to thereby eject a liquid drop from the nozzle opening. Continuous fluid flow internal to the system decreases the time to refill the fire chamber directly behind the nozzle opening after droplet ejection. This in turn dramatically increases the response time of the system.

Owner:EASTMAN KODAK CO

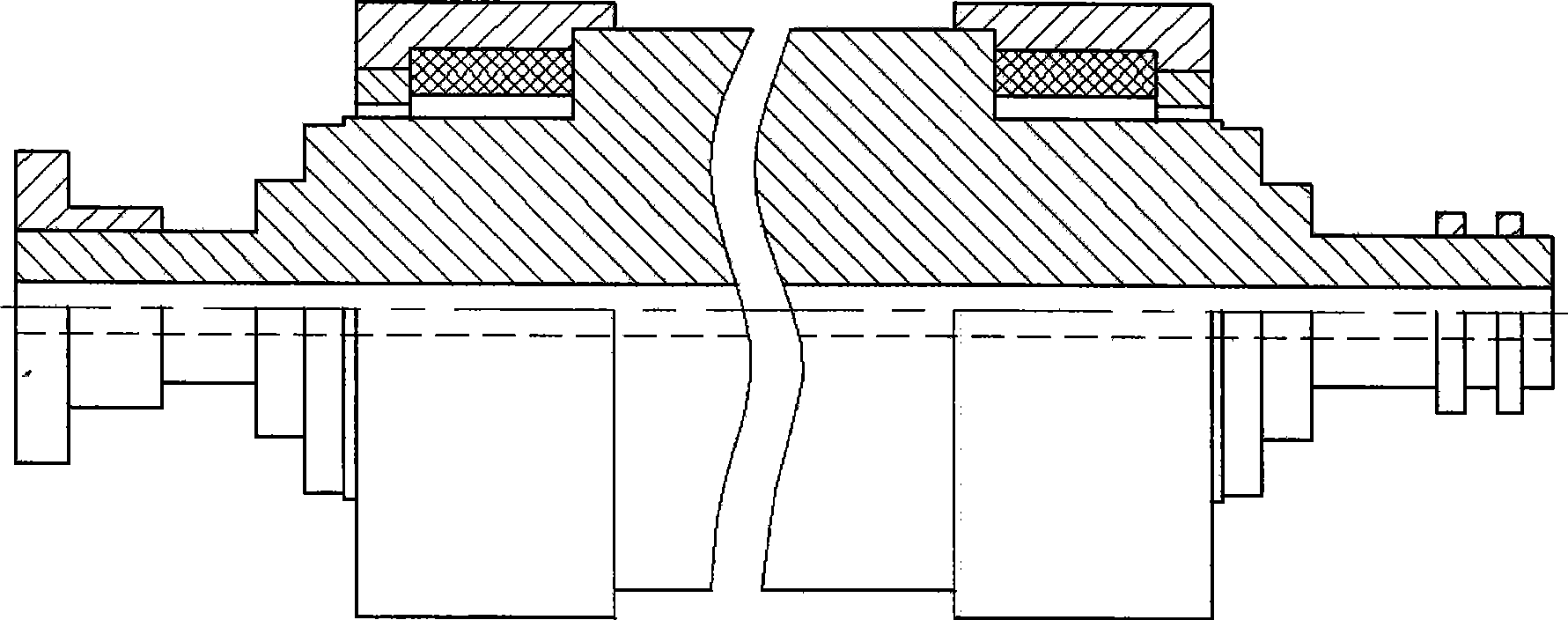

Irregular-section tubular body and axle beam for torsion beam and method of manufacturing the same

The invention provides a method of manufacturing an irregular section tubular body and axle beam. The axle beam has a tubular worked body that has sealed liquid therein and is press-formed by upper and lower press molds. One of the press molds has a convex mold portion to form a concave portion concaved in an axis perpendicular direction at an axial part of the axle beam. The press-forming of the tubular worked body is completed by a one stroke process using liquid pressure that increases as the internal volume of the worked body decreases due to formation of the concave portion. The concave portion extends substantially the length of the axle beam and has a substantially U-shaped or V-shaped cross-section forming a closed and sealed space.

Owner:TOYOTA JIDOSHA KK

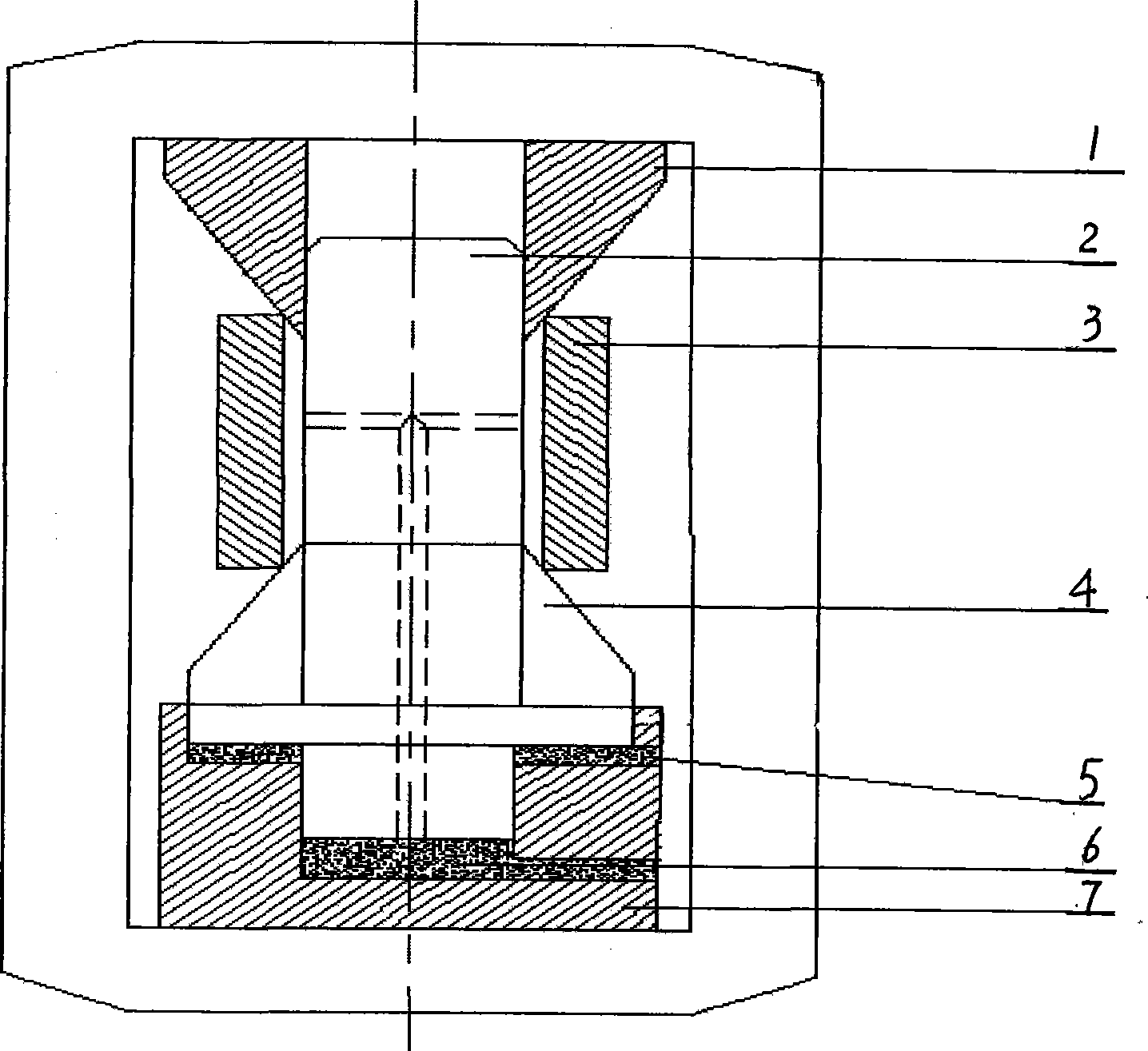

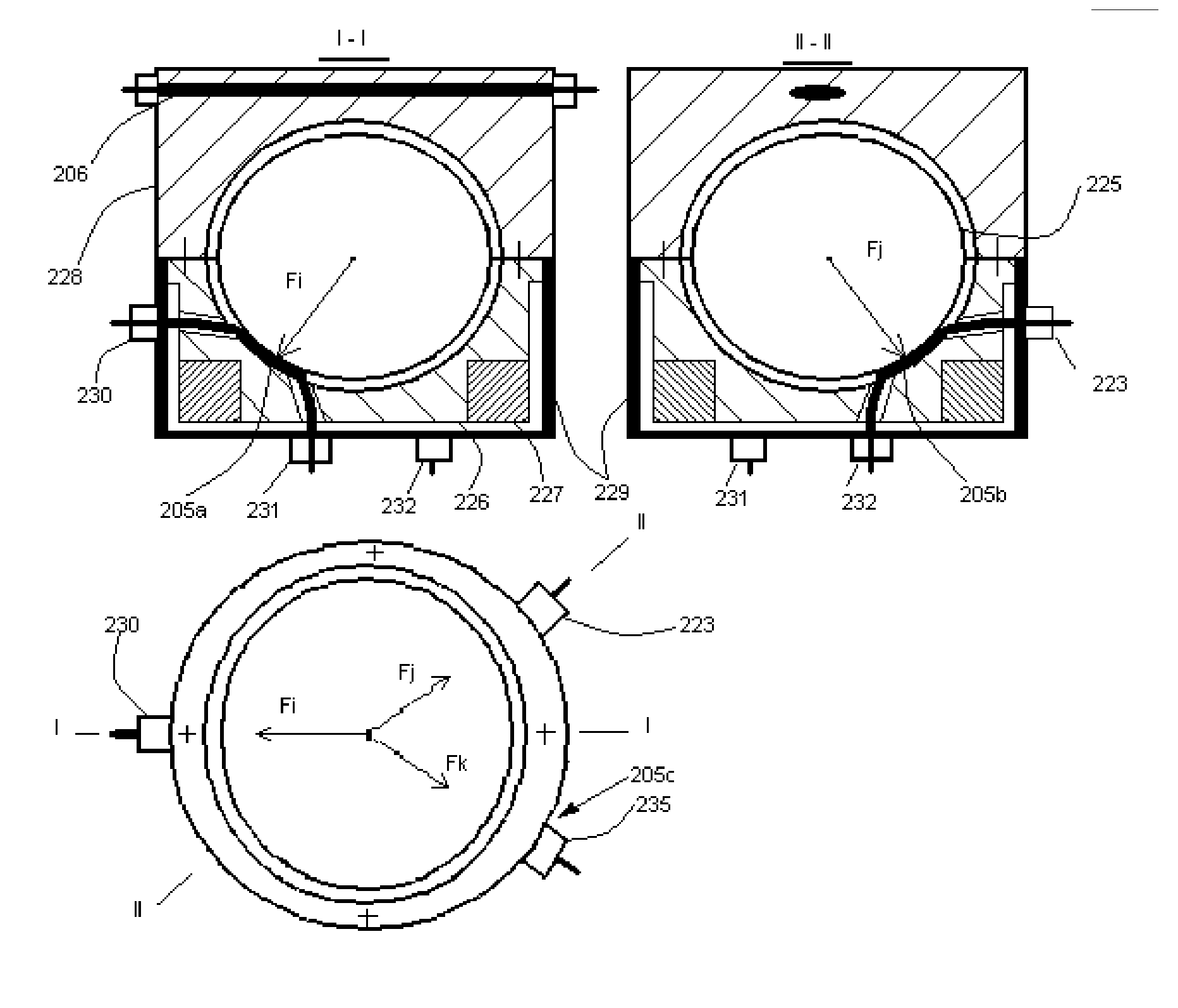

Shroud ring external fluid infusion hydraulic pressure expanding and reinforcing process for turbine generator

InactiveCN101367104AHigh forming precisionImprove general performanceMetal-working apparatusFluid infusionEngineering

The invention relates to a process for strengthening the bulging of external fluid replenishing hydraulic of a protective ring of a turbine generator, which is applied to the turbine generator field. High-pressure liquid produced by an external high-pressure pump passes through a passage of a high-pressure cylinder and is injected into a closed space formed by a upper fixed cone mould, a lower movable cone mould and the protective ring by a passage in a force-reduction column of a mould part in order that the protective ring generates plastic deformation under the action of hydraulic pressure, thereby achieving the aim of strengthening the protective ring; through adjusting low pressure of liquid in a low-pressure cylinder, the stress size of a contact part between the protective ring and the mould is adjusted so as to achieve the aim of sealing and adjusting the shape and the size of the protective ring; and a displacement sensor is used to monitor the bulging size of the protective ring. The process no longer occupies large-scale hydraulic press equipment, uses a load-bearing frame with a simple structure and small dimension and an external liquid replenishing cylinder to replace a hydraulic press for strengthening the protective ring; the bulging process can substantially reduce force, is easy to control the forming process, can repeatedly bulge, greatly improve the forming precision of the protective ring and reduce the machining allowance by 1 / 3 than the routine common hydraulic bulging; and the mould has a simple structure, convenient mounting and detachment, strong universality and low production cost and can achieve higher economical benefit.

Owner:SHENYANG HEAVY MACHINERY GROUP

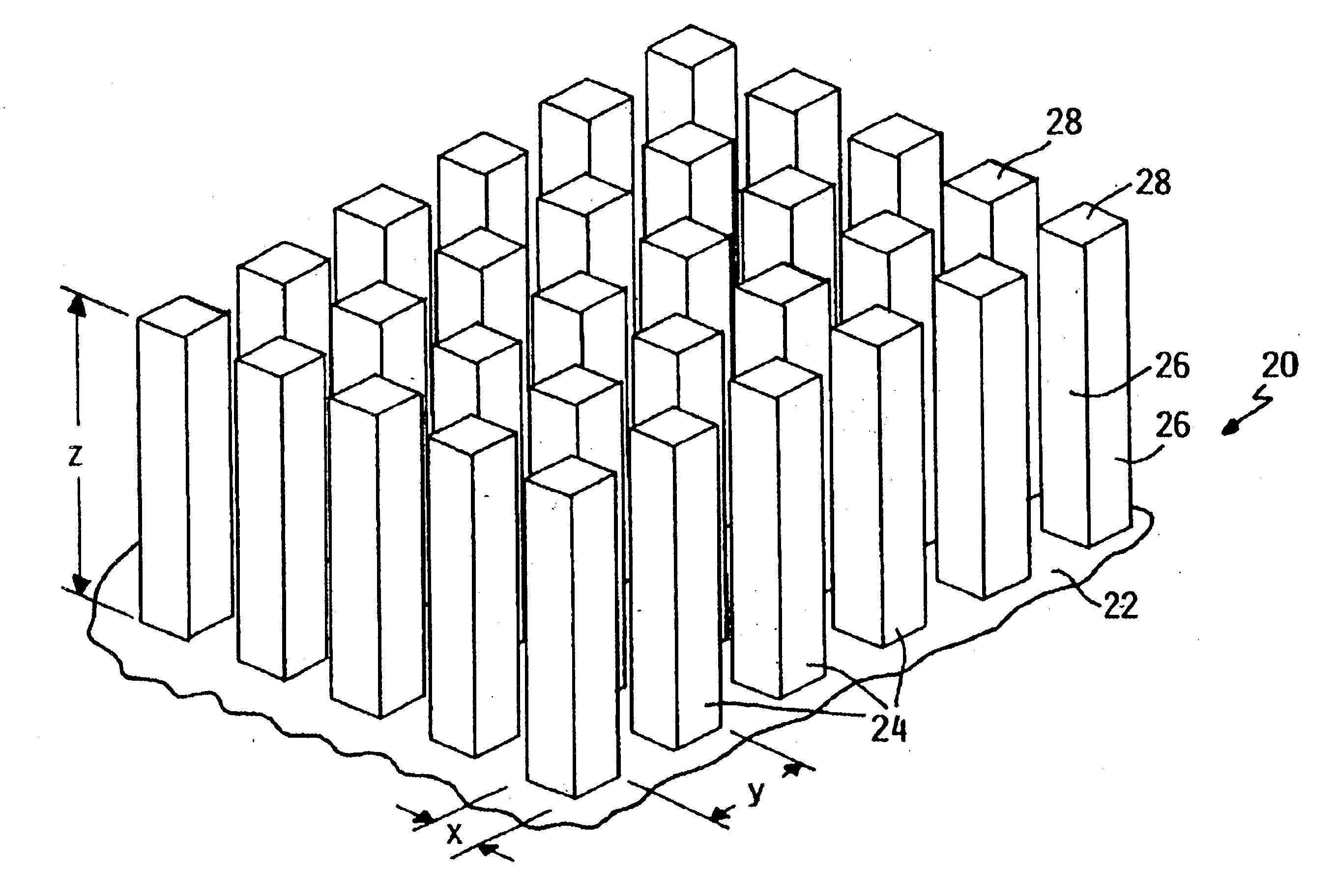

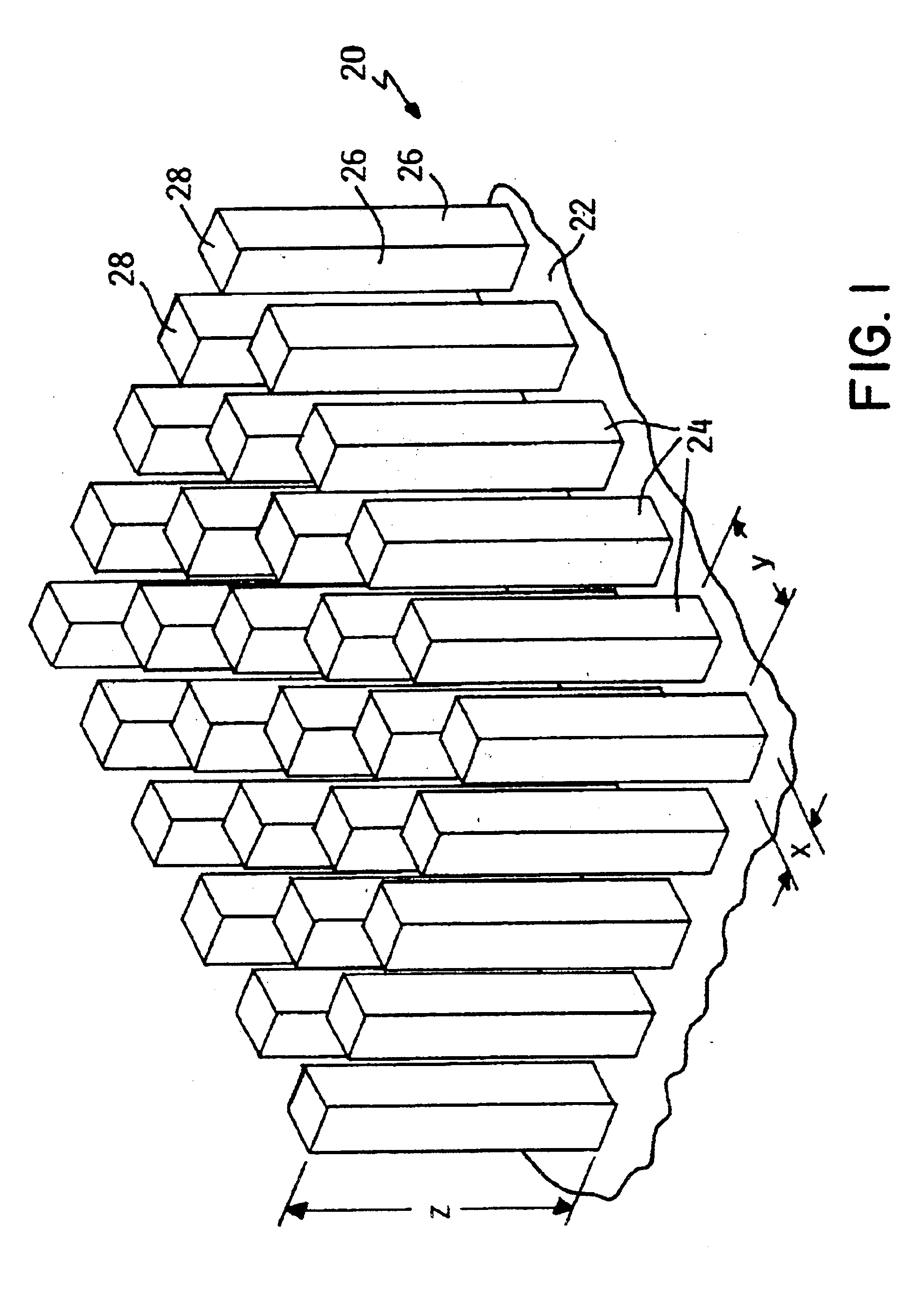

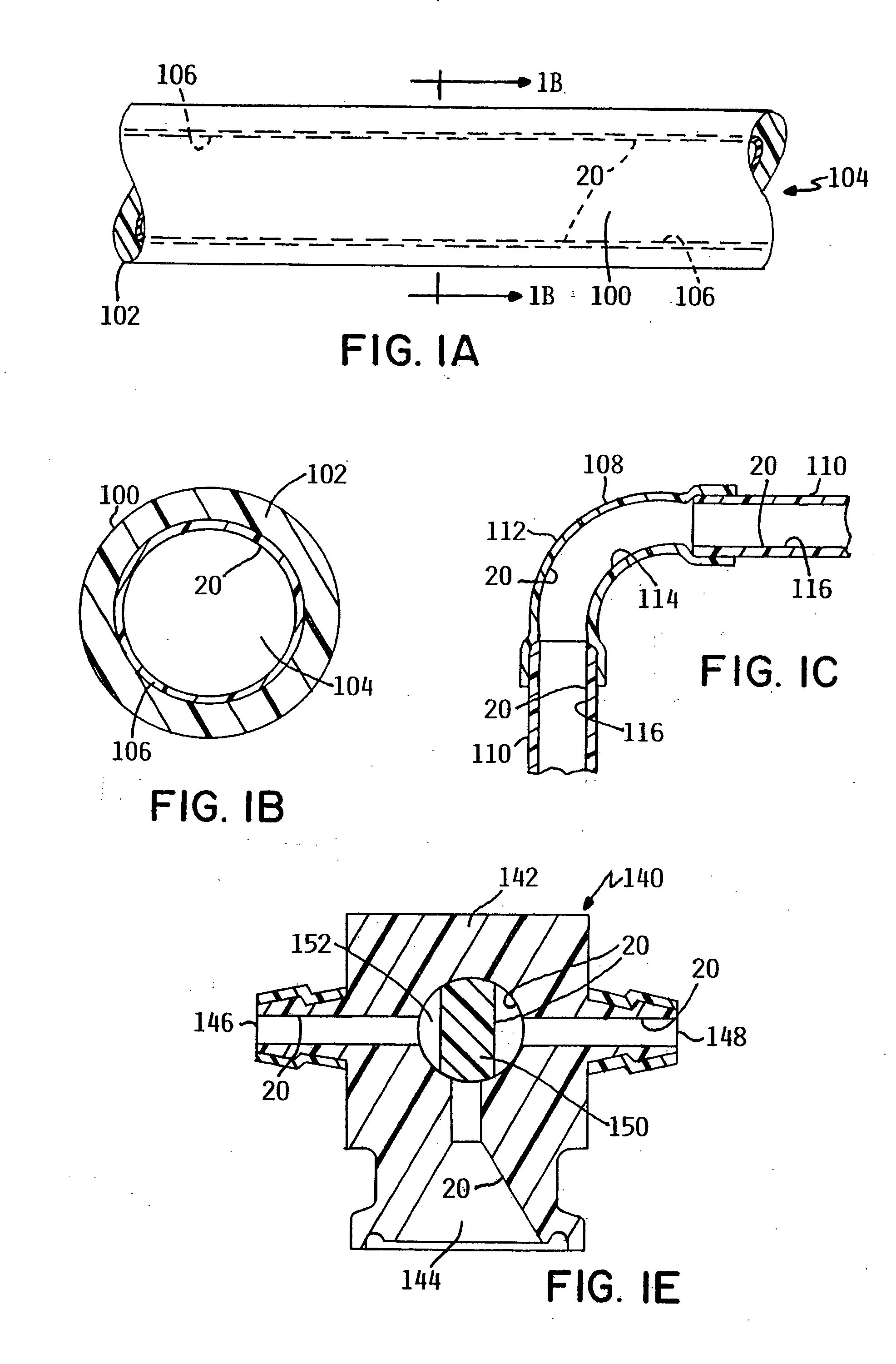

Fluid handling component with ultraphobic surfaces

InactiveUS6845788B2Reduce frictionImprove system efficiencyMaterial nanotechnologyFouling preventionVolumetric Mass DensityContact line

A fluid handling component having a durable ultraphobic fluid contact surface that is capable of exhibiting ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γcos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

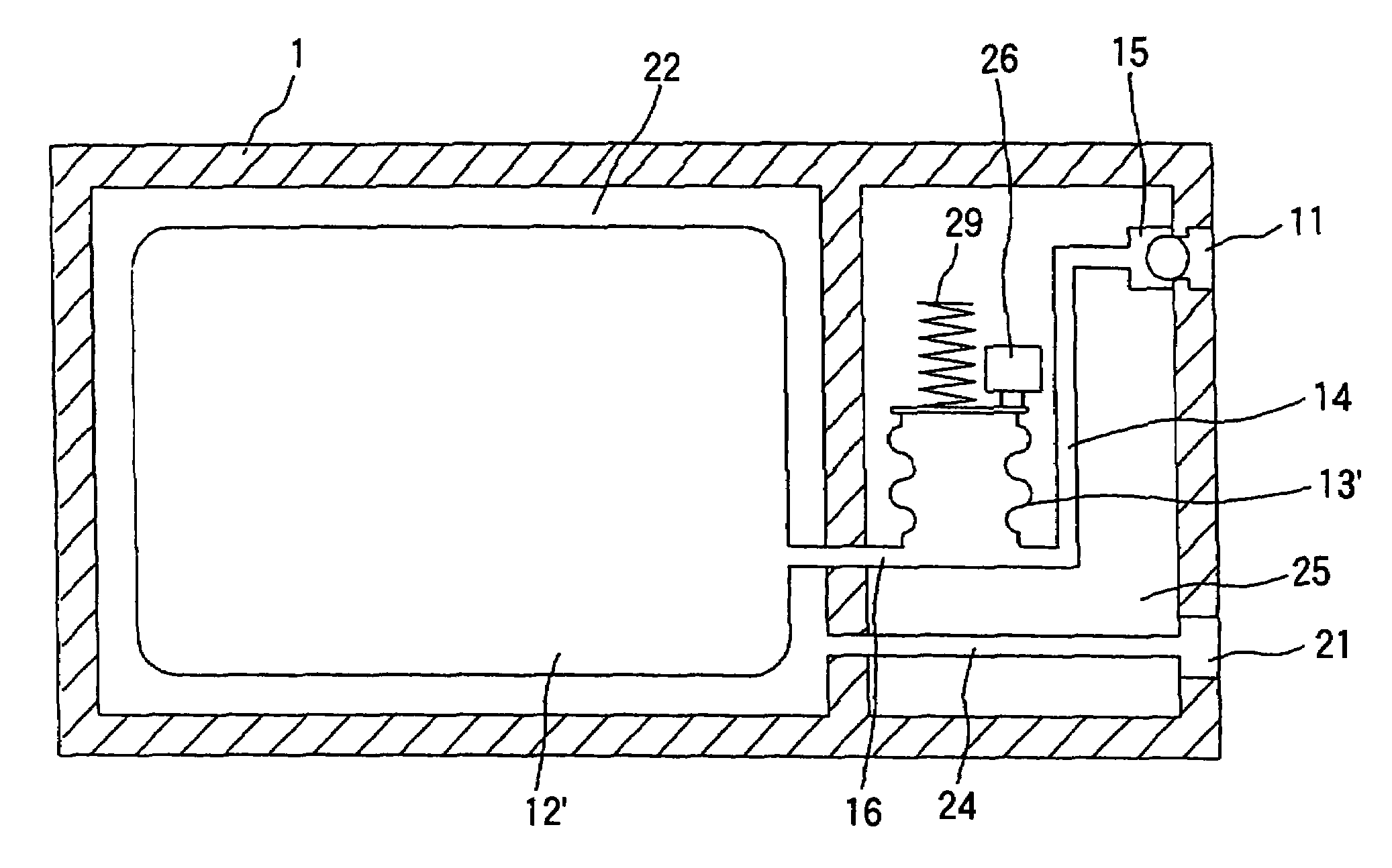

Drainage system for cerebrospinal fluid

ActiveUS20080033400A1The structure is easy to operateImprove accuracyFluid parameterWound drainsControl mannerEngineering

The object of providing a cerebrospinal fluid drainage system 1 which reacts precisely to changes in pressure in the cerebrospinal fluid, with ease of operation, is achieved by the present invention in that a pump 5 is used for draining the cerebrospinal fluid (liquor), wherein operating measured values supplied by sensors act as controlled variable for the operation of the pump. The pressure in the liquor line currently measured by a pressure sensor 10, the liquor pressure in the intracranial cavity being treated, measured intracorporeally by a pressure sensor, and / or the volume of liquor already pumped out, as operating measured value, can, for example, serve as the basis for operational control of the pump of the liquor drainage system. The liquor drainage system according to the invention has the advantage that the liquor is drained not only simply on the basis of the excess pressure in the intracranial cavity being treated, but is actively pumped out of the intracranial cavity in a controlled manner, in particular with constant measurement of the liquor pressure. In this way the pumping capacity can be regulated depending on requirement and the drainage pressure or the liquor pressure kept reliably within a specific pressure range.

Owner:MOLLER MEDICAL

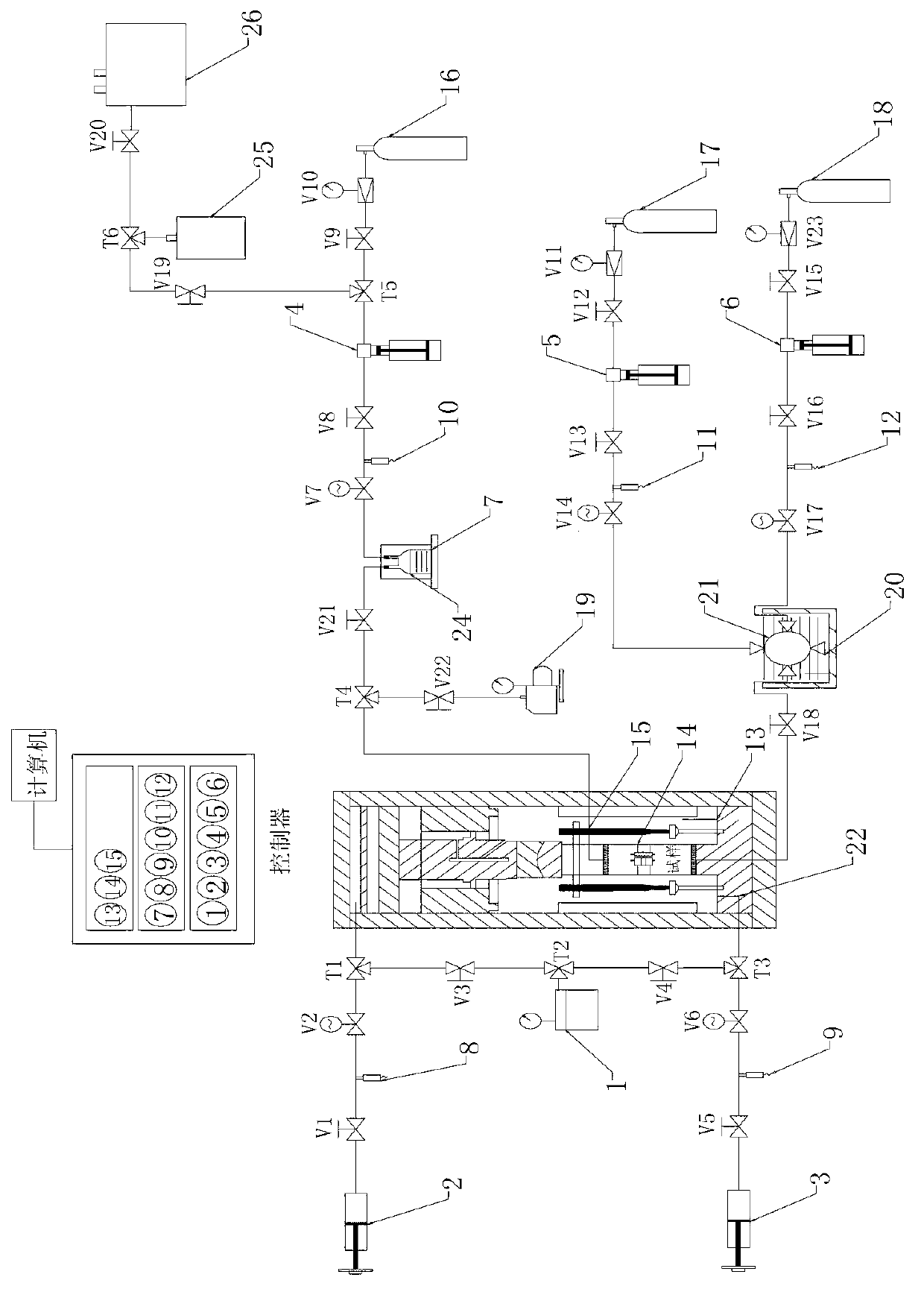

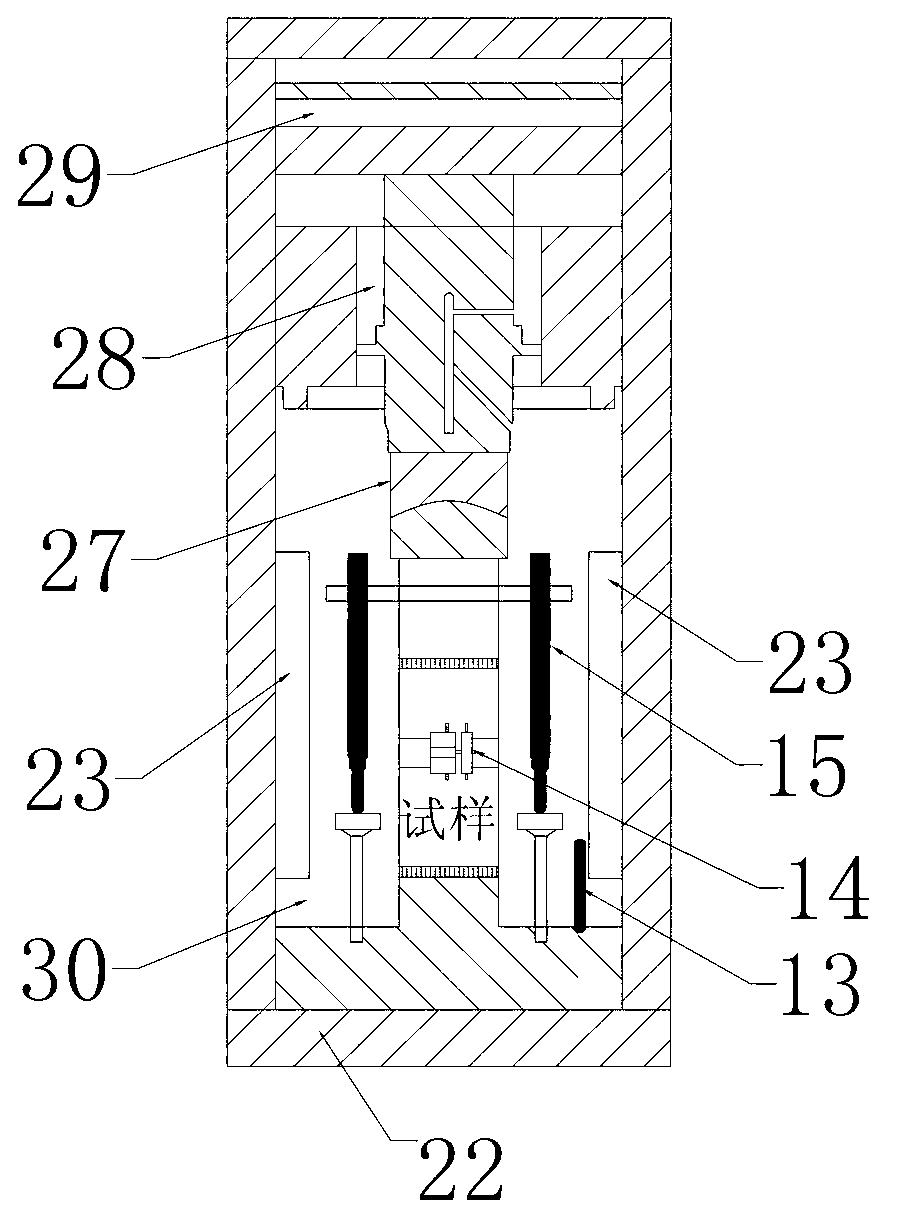

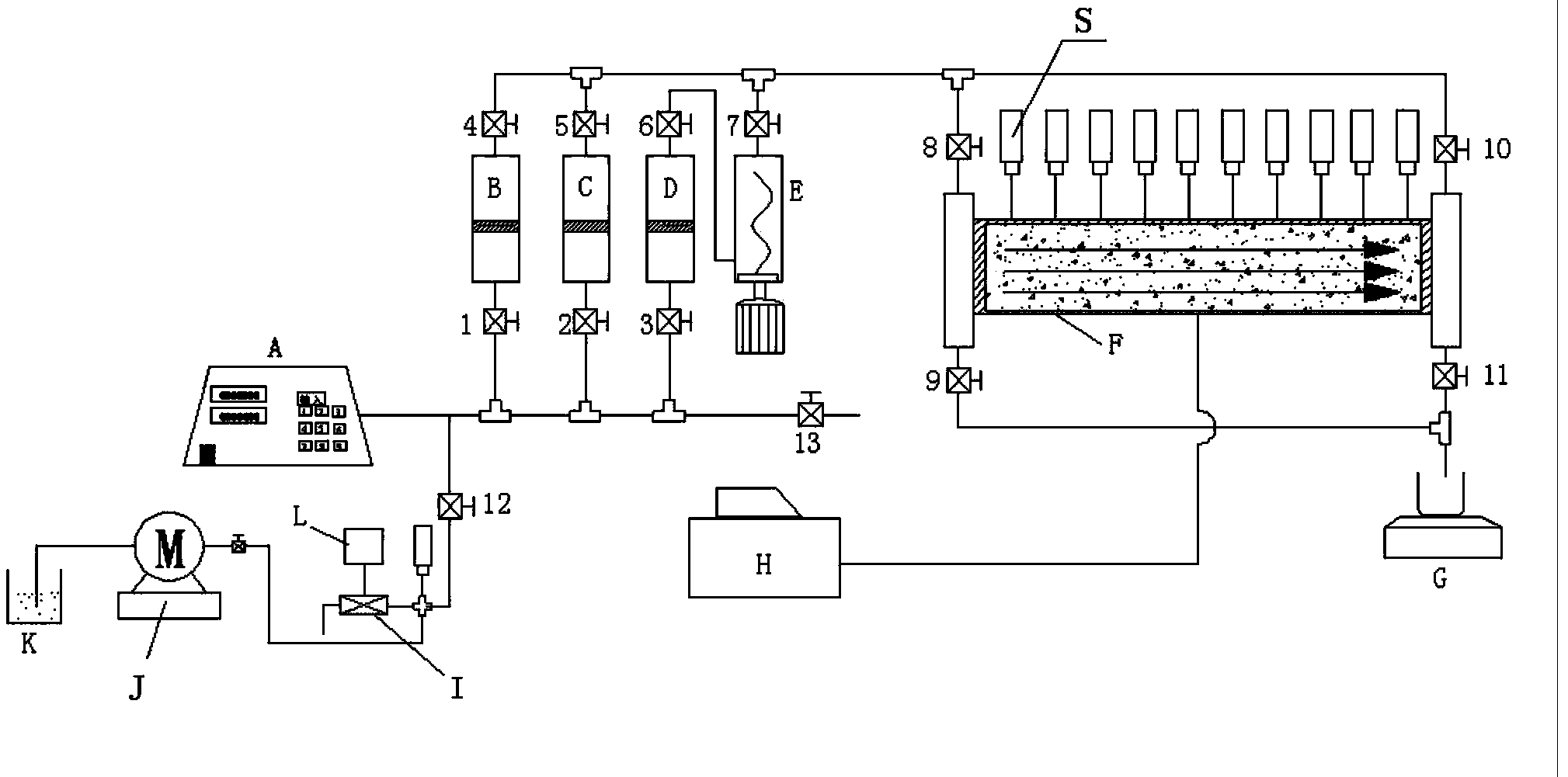

Device and method for gas bearing shale-seepage-temperature coupling and displacement experiment

ActiveCN103278428AEnables permeability determinationImprove stabilitySurface/boundary effectMaterial strength using tensile/compressive forcesRock engineeringAxial pressure

The invention belongs to the field of rock engineering, and in particular relates to a device and a method for a gas bearing shale-seepage-temperature coupling and displacement experiment. The experimental device comprises a triaxial pressure cavity, an axial pressure loading system, a confining pressure loading system, an upstream gas pressure loading system, an upstream liquid pressure loading system, a downstream gas pressure loading and collecting system, a downstream liquid collecting system, a multi-component mixed gas collecting system, a vacuumizing device, a heating system and a data collection control system. The experimental method comprises the following steps of: fixing a test piece; applying confining pressure; applying axial pressure; heating; vacuumizing; applying upstream liquid pressure (or pre-saturated methane); applying upstream gas pressure (or applying upstream gas pressure); injecting multi-phase mixed fluid (or applying another upstream liquid pressure); performing pre-adsorptive saturation by the test piece (injecting multi-component constant-proportion mixed gas); and collecting. The experimental device can be used for applying triaxial stress to the test piece according to the actual stress condition, and remolding a stress environment according to the fact.

Owner:NORTHEASTERN UNIV

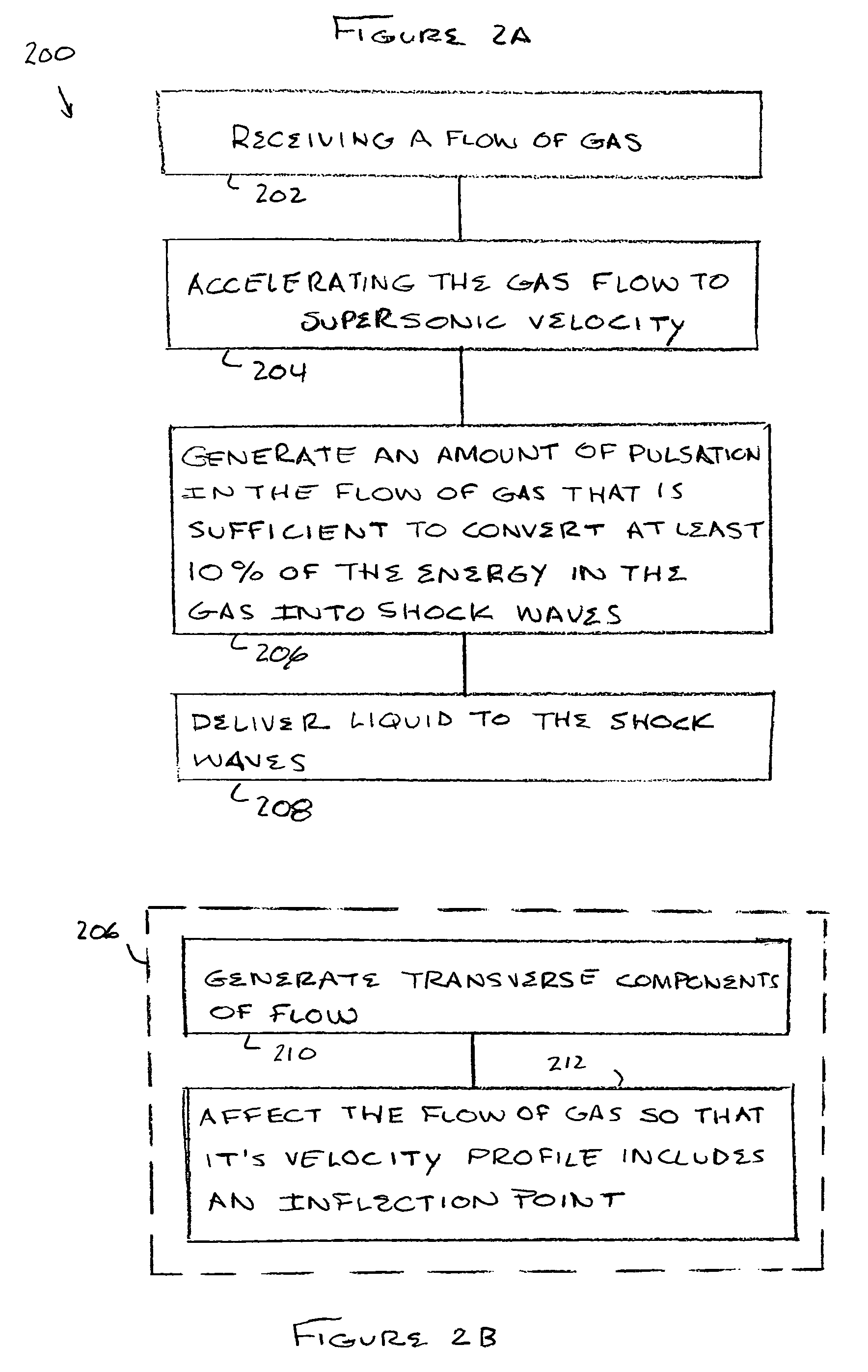

Apparatus comprising an atomizer and method for atomization

InactiveUS7080793B2Improve atomization efficiencyReduce variationMovable spraying apparatusSpray nozzlesEngineeringGas pressure

The illustrative embodiment of the present invention is an atomizer, a method for atomization, and a system that includes an atomizer. In some embodiments, an atomizer in accordance with present invention operates at substantially higher efficiency than known atomizers. Furthermore, in some embodiments, the present atomizer is capable of operating at lower gas pressure and lower liquid pressure than most known atomizers, as is desirable for certain fire-suppression applications. Additionally, in some embodiments, the atomizer is configured with only three parts and is very easy to manufacture.

Owner:BORISOV YULIAN Y +1

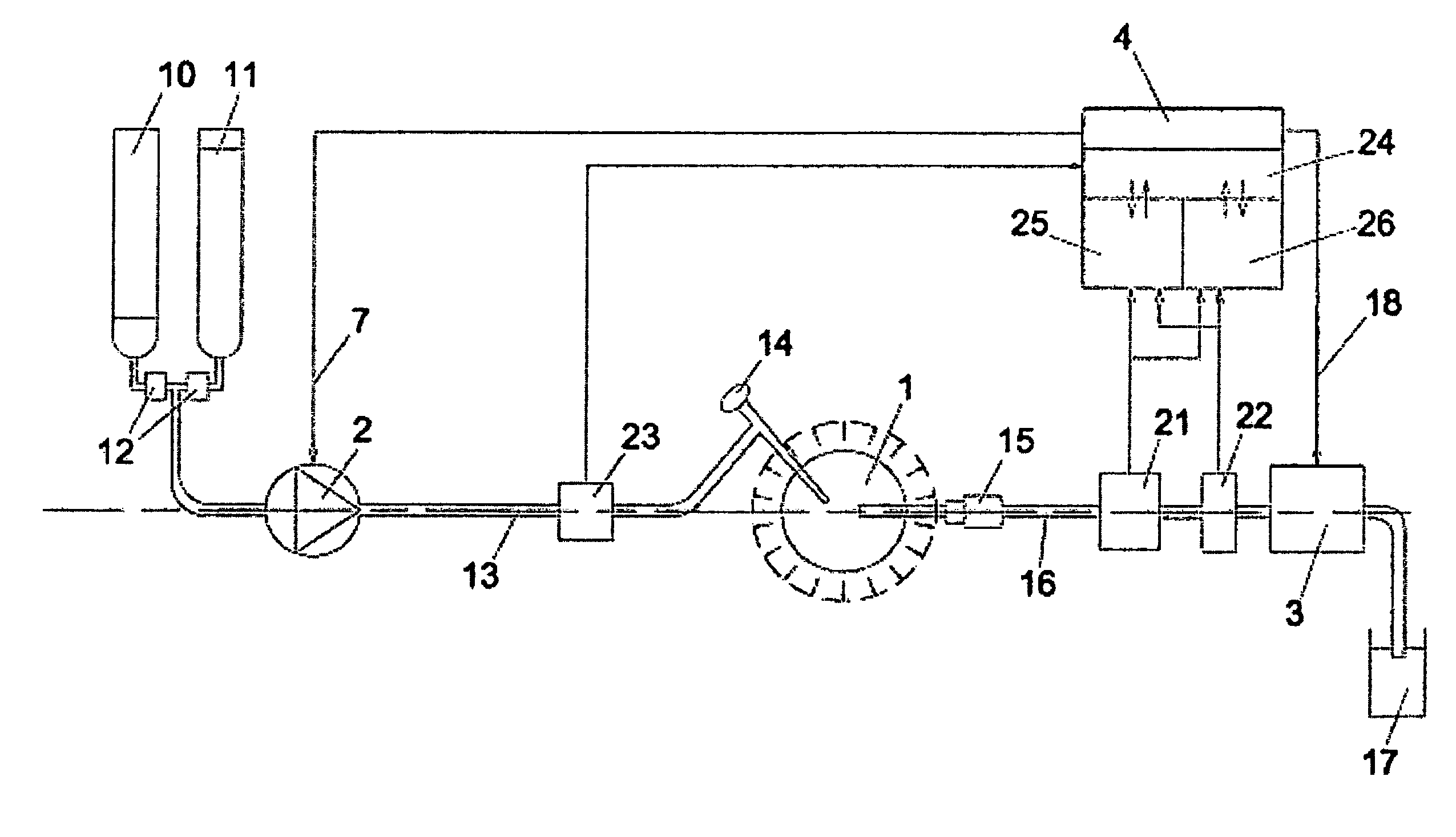

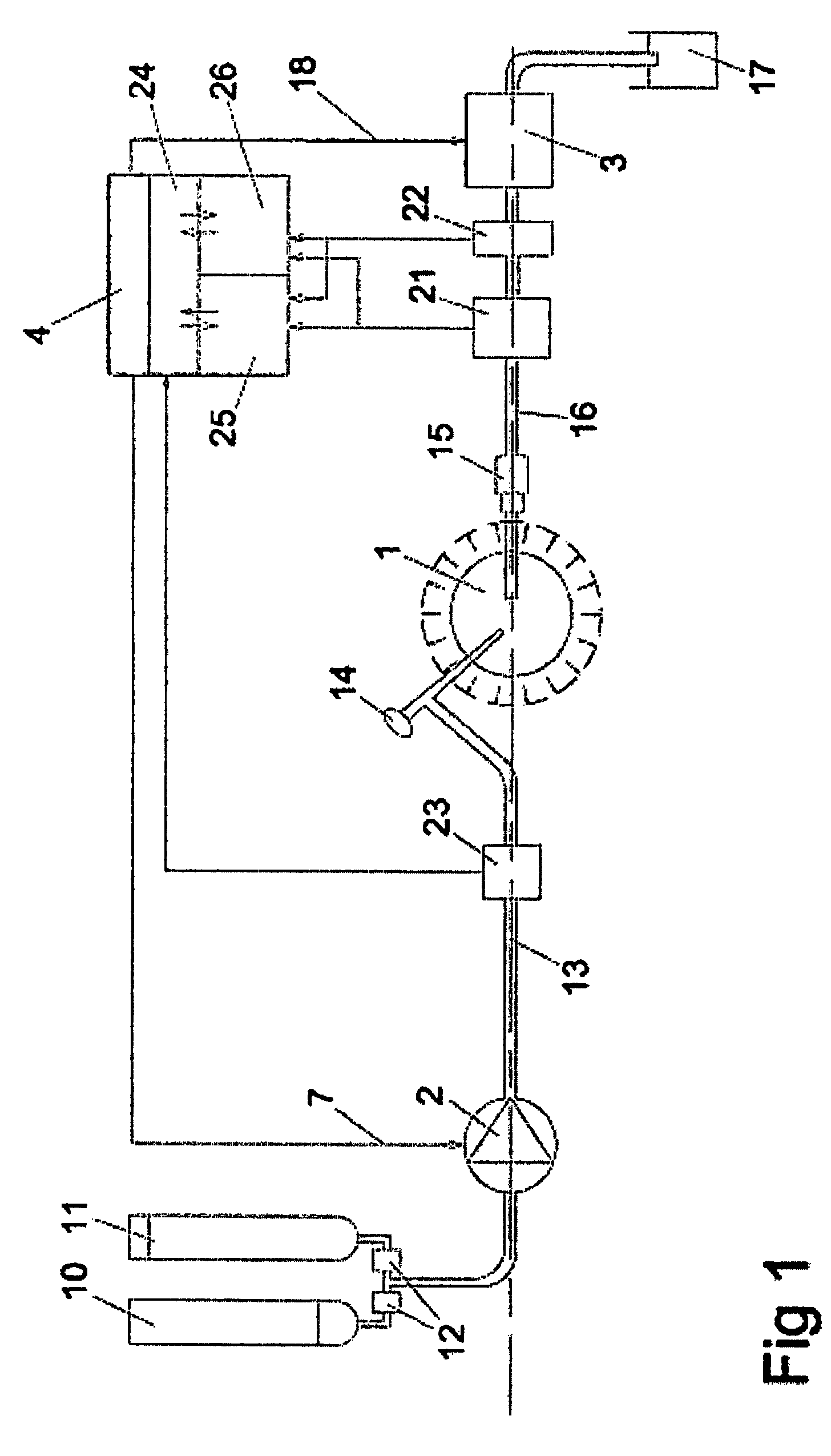

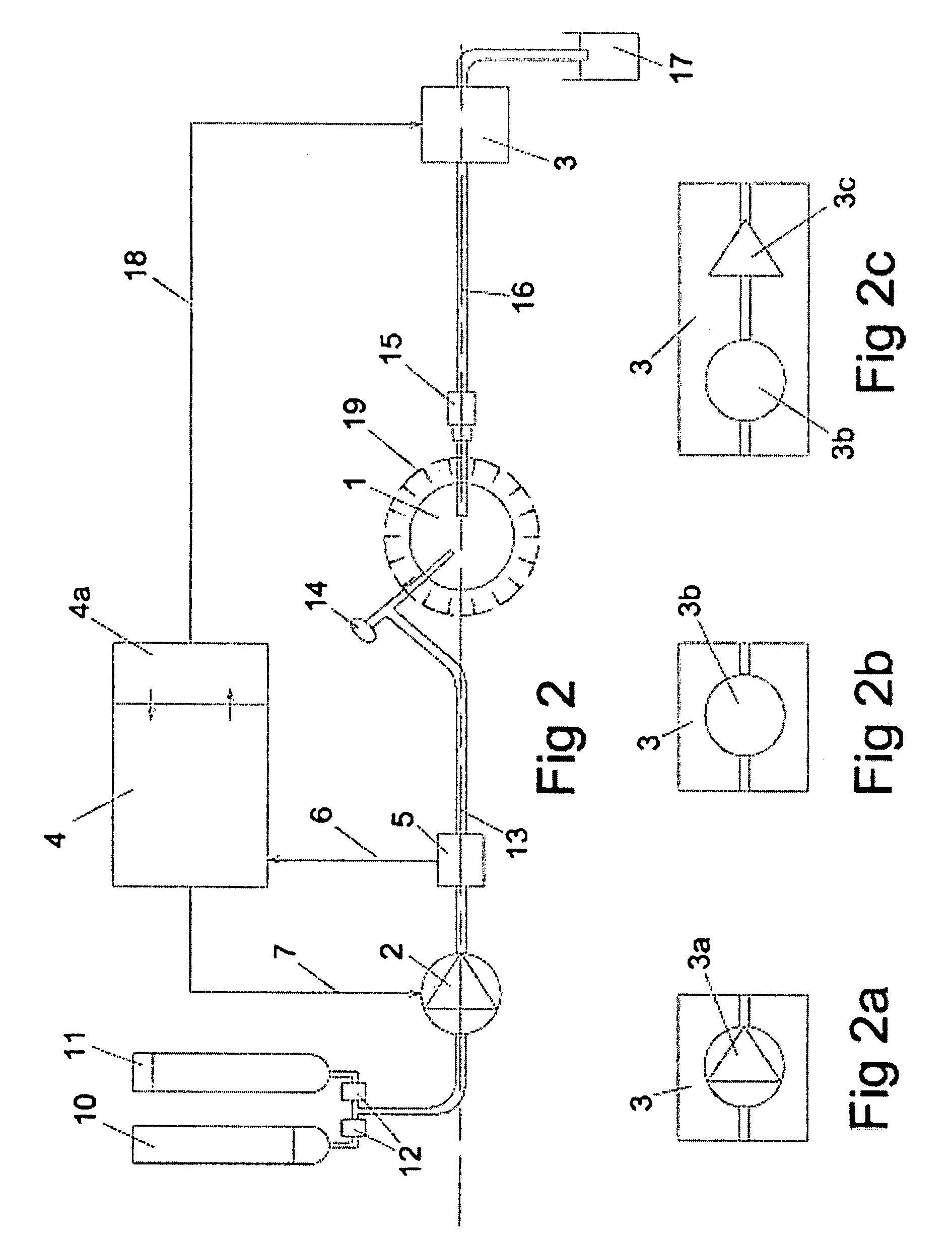

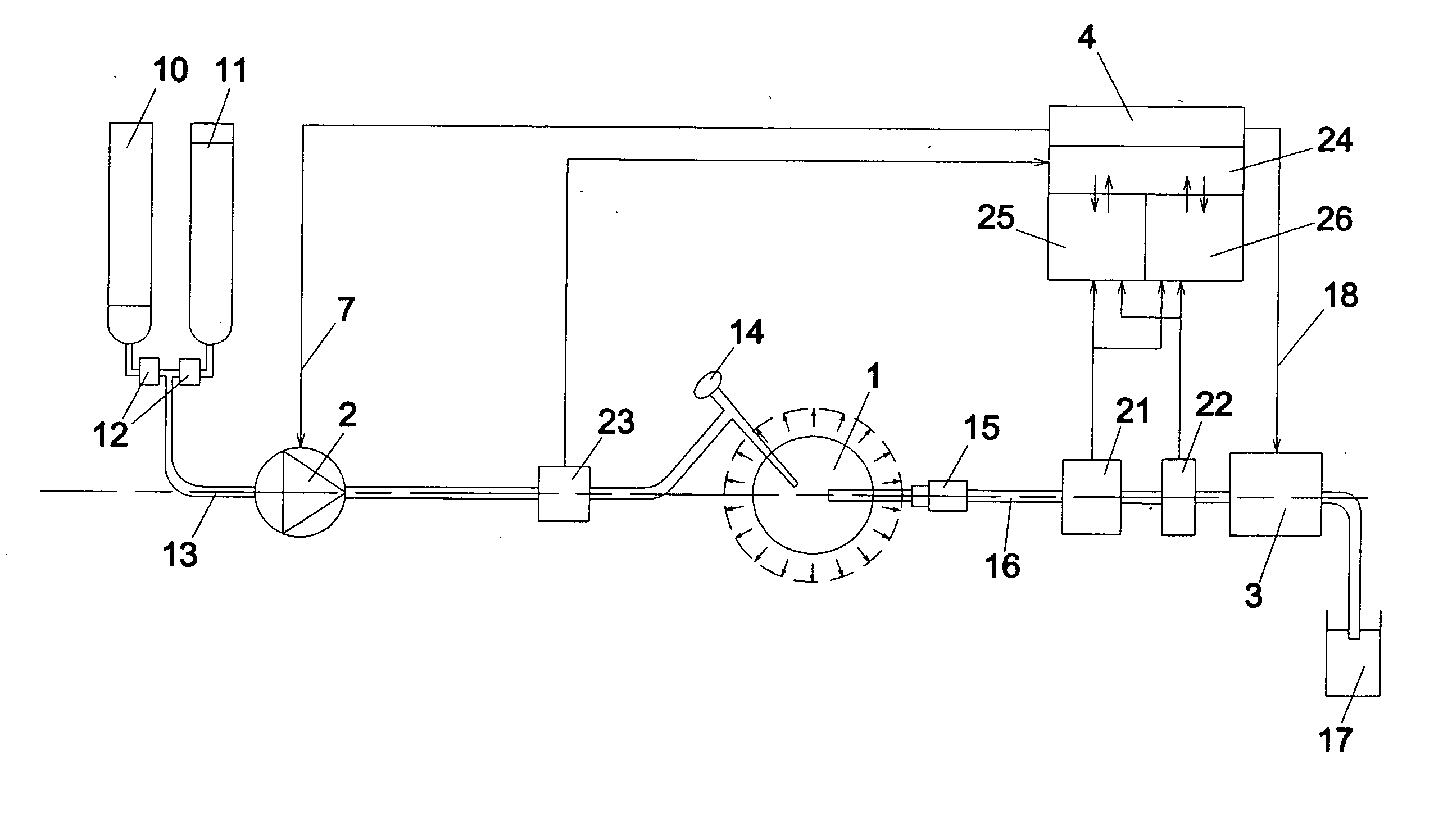

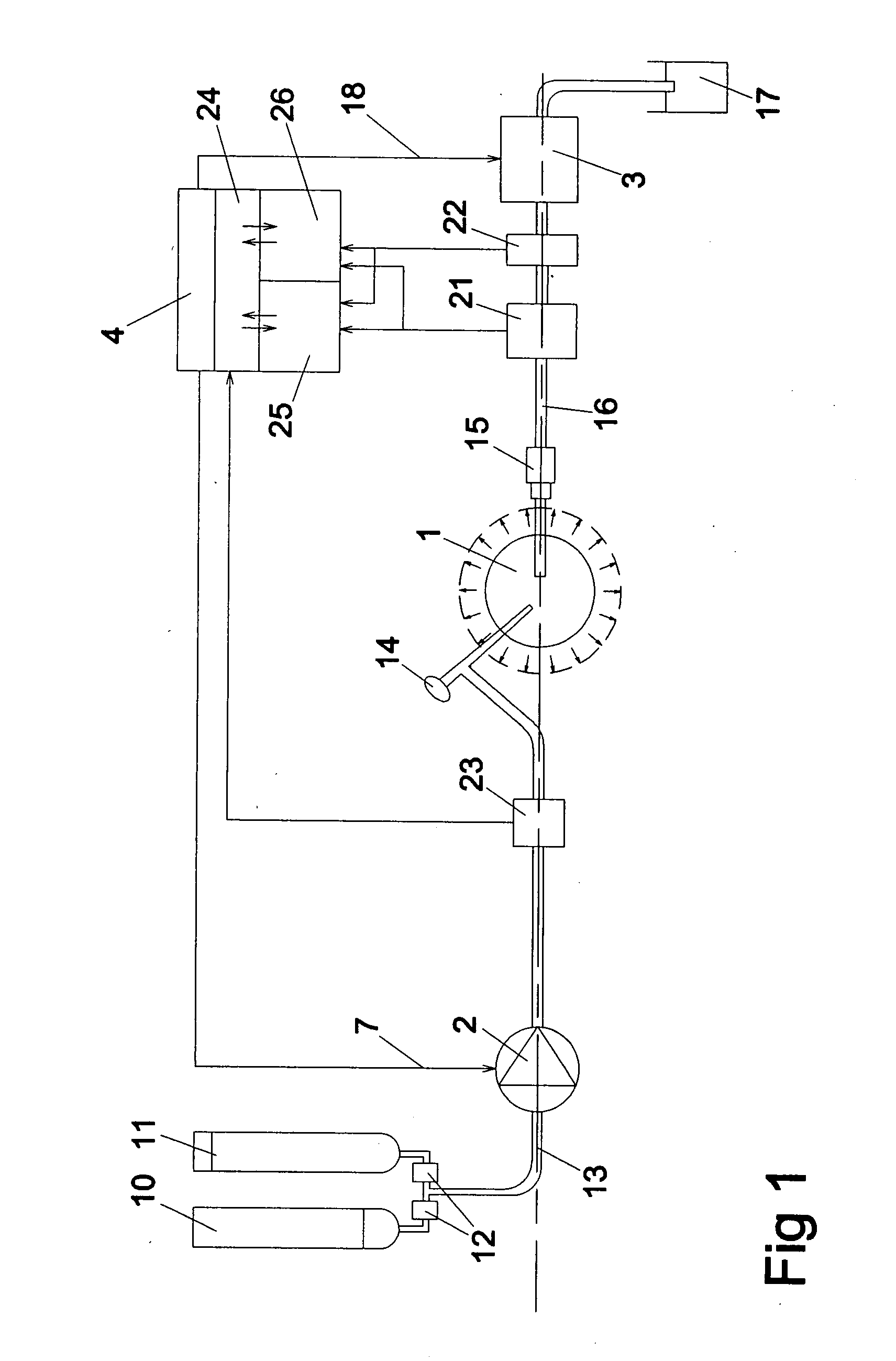

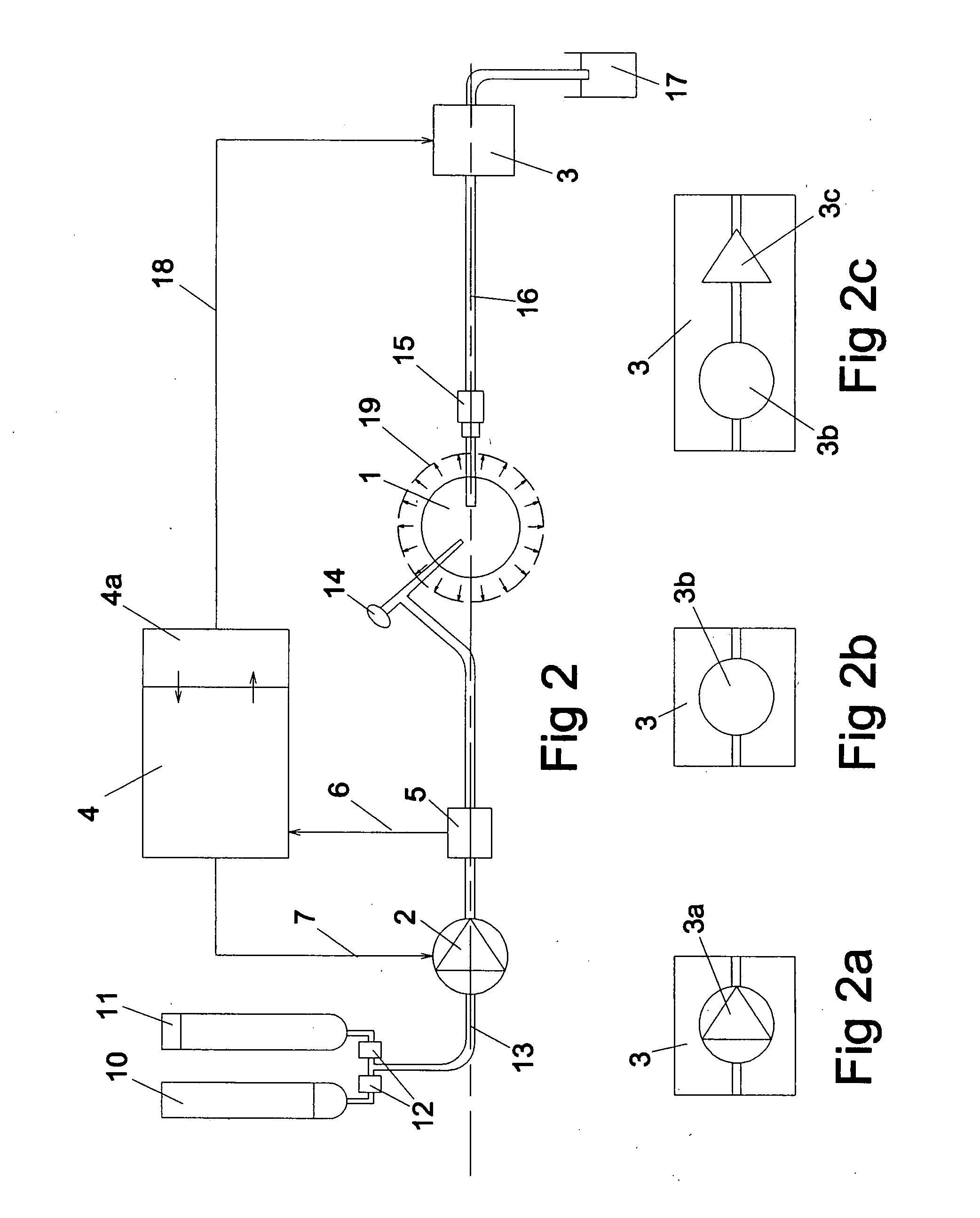

Method and device for irrigation of body cavities

ActiveUS7981073B2Minimize timeReduce differential pressureEndoscopesMedical devicesAutomatic controlRed blood cell

A pressure and a vision regulation method and device for irrigation of a body cavity (1), in which an inflow liquid pump (2) pressurizes the irrigation liquid in a feed line (13) and an outflow device (3) or an external suction source (20) drains the irrigation liquid from the body cavity (1) through a tubing (16) into a waste container (17). A control unit (4) controls either the inflow liquid pump (2) only or both the inflow liquid pump (2) and the outflow device (3) depending on an inflow irrigation liquid pressure from a pressure sensor (5). The method and the device are combined with a method for detecting blood cells, red blood cells, haemoglobin and / or debris in liquid coming from a surgical site to provide an automatic control and rinsing system with clear vision in the viewing area of the operational site.

Owner:TENNESSEE MEDICAL INNOVATIONS INC

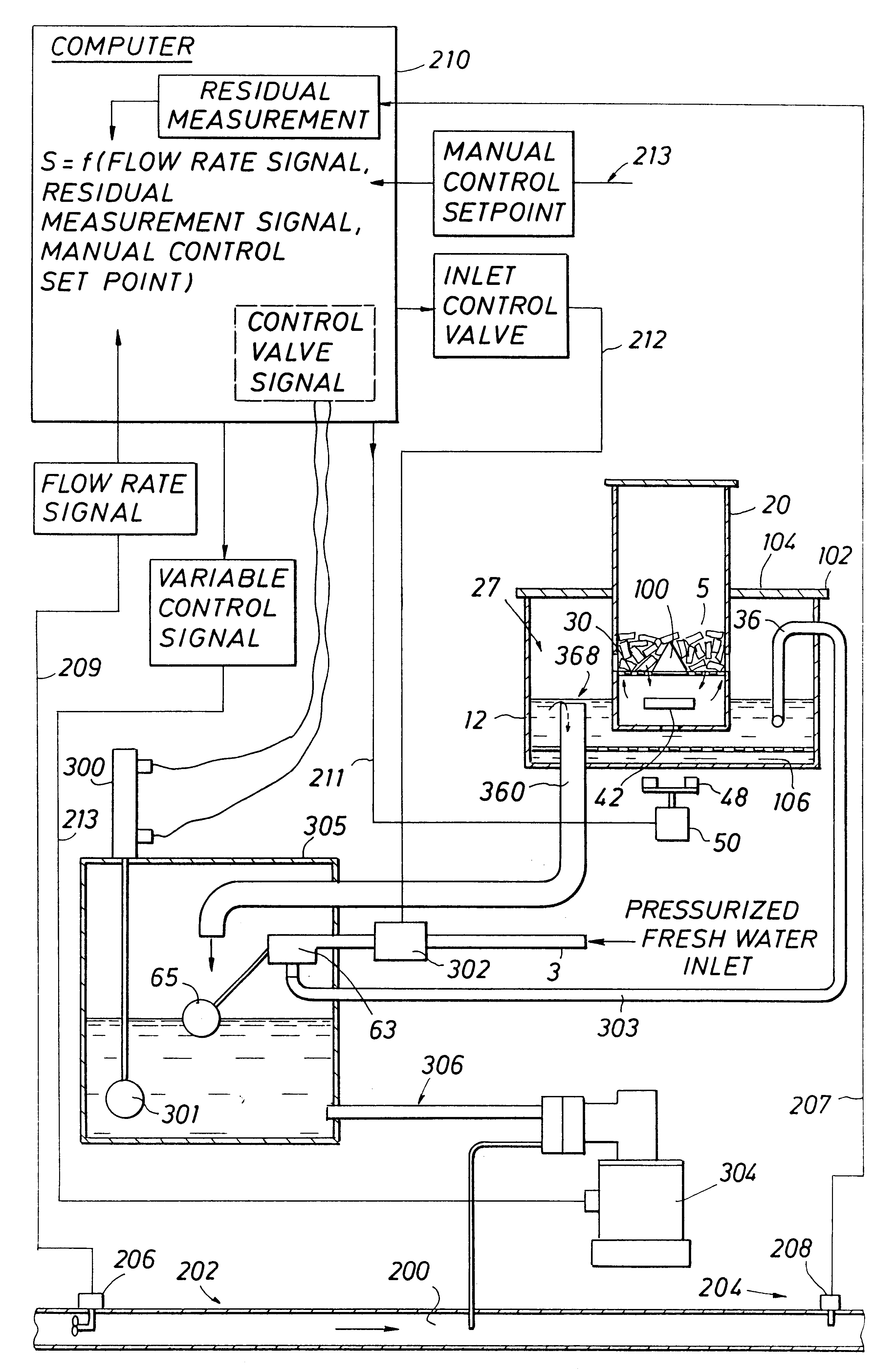

Chlorination apparatus and method

Apparatus and method for dissolving chemical tablets for creating a variable rate of chemical dissolution in a stream of constant flow rate of untreated liquid, especially water. The apparatus includes a housing in which a container is placed. The container includes a sieve plate or perforated grid which separates the container into an upper chamber in which chemical tablets are stored and a lower mixing chamber. A collection reservoir is defined in an annular outside the container wall and inside of the housing. Several arrangements are illustrated by which a vortex of liquid is generated of controllable variable intensity in the lower or mixing chamber thereby creating uneven liquid pressure beneath the perforated grid as a function of radial distance. As a result, fluid passes aggressively through outer radial perforations or holes in the grid and which impinge on the chemical tablets stacked on the grid. The liquid circulates in the upper chamber from the outward radial position toward the center of the grid plate, while eroding the tablets, and returns to the mixing chamber. A portion of the liquid exits into the collection reservoir. Liquid communication also exits from a hole in the bottom of the lower mixing chamber, which is open to the collection reservoir. Varying the intensity of the vortex varies the rate of chemical dissolution, yet the flow rate of liquid through the apparatus is constant.

Owner:HAMMONDS TECHN SERVICES

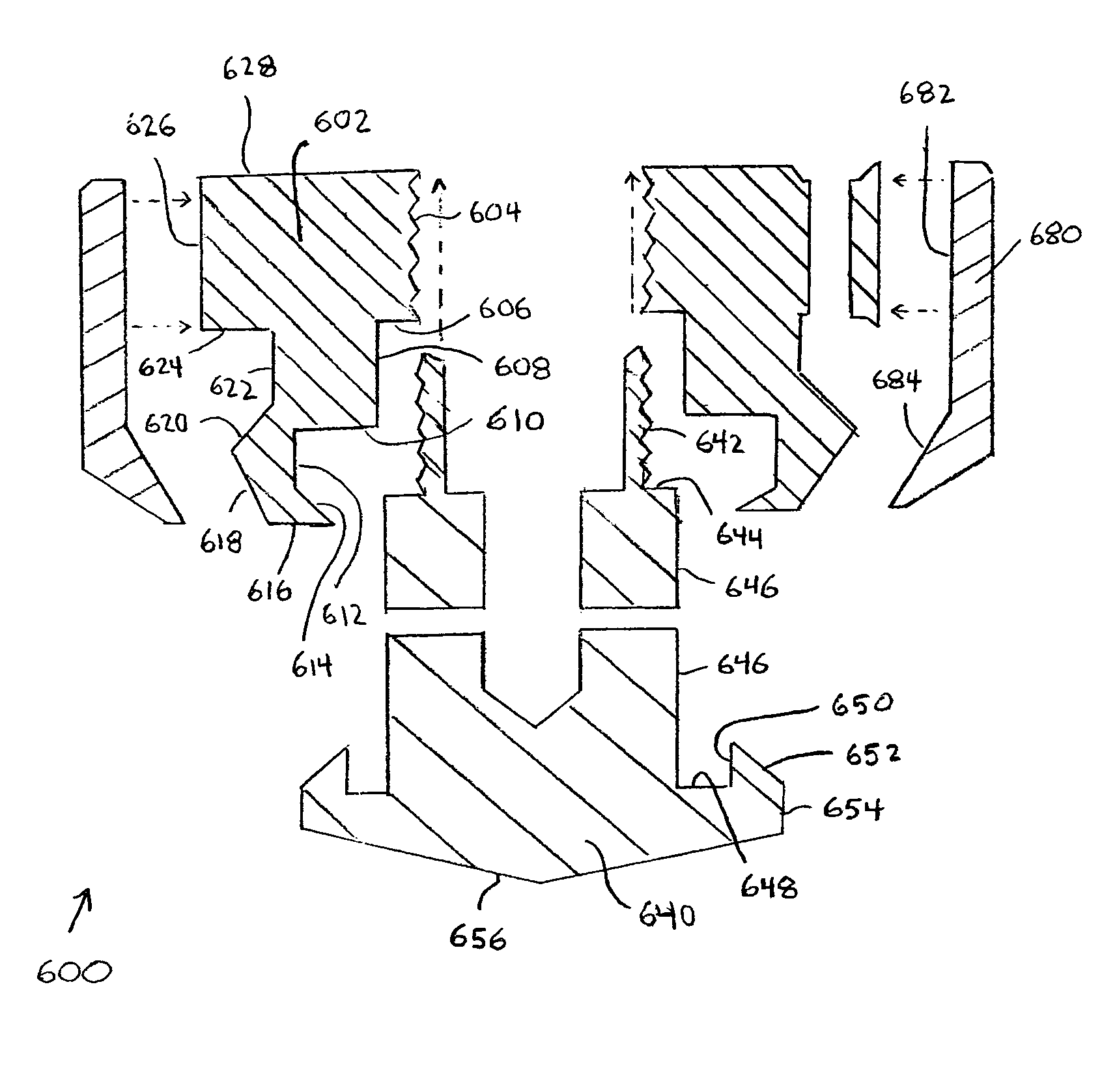

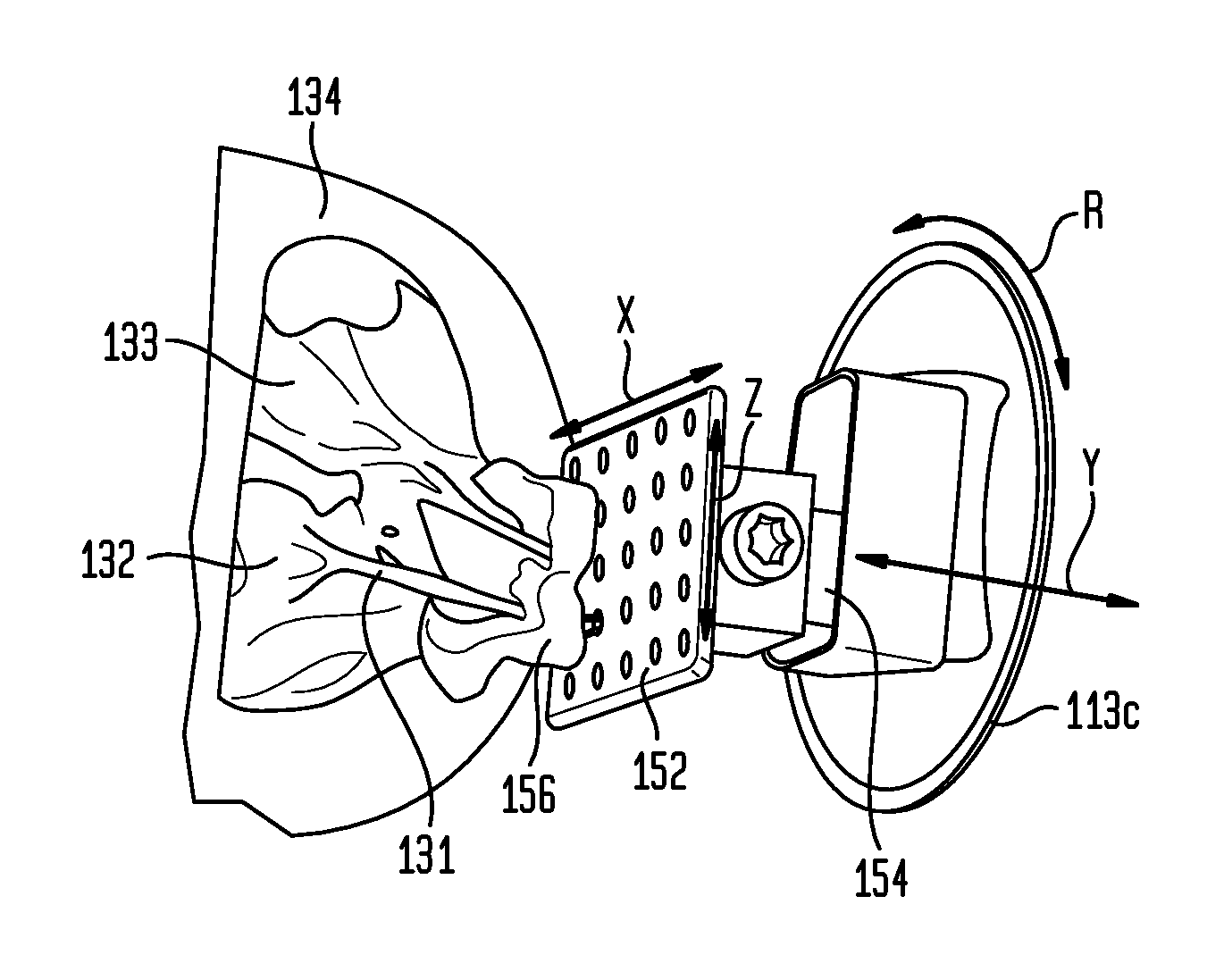

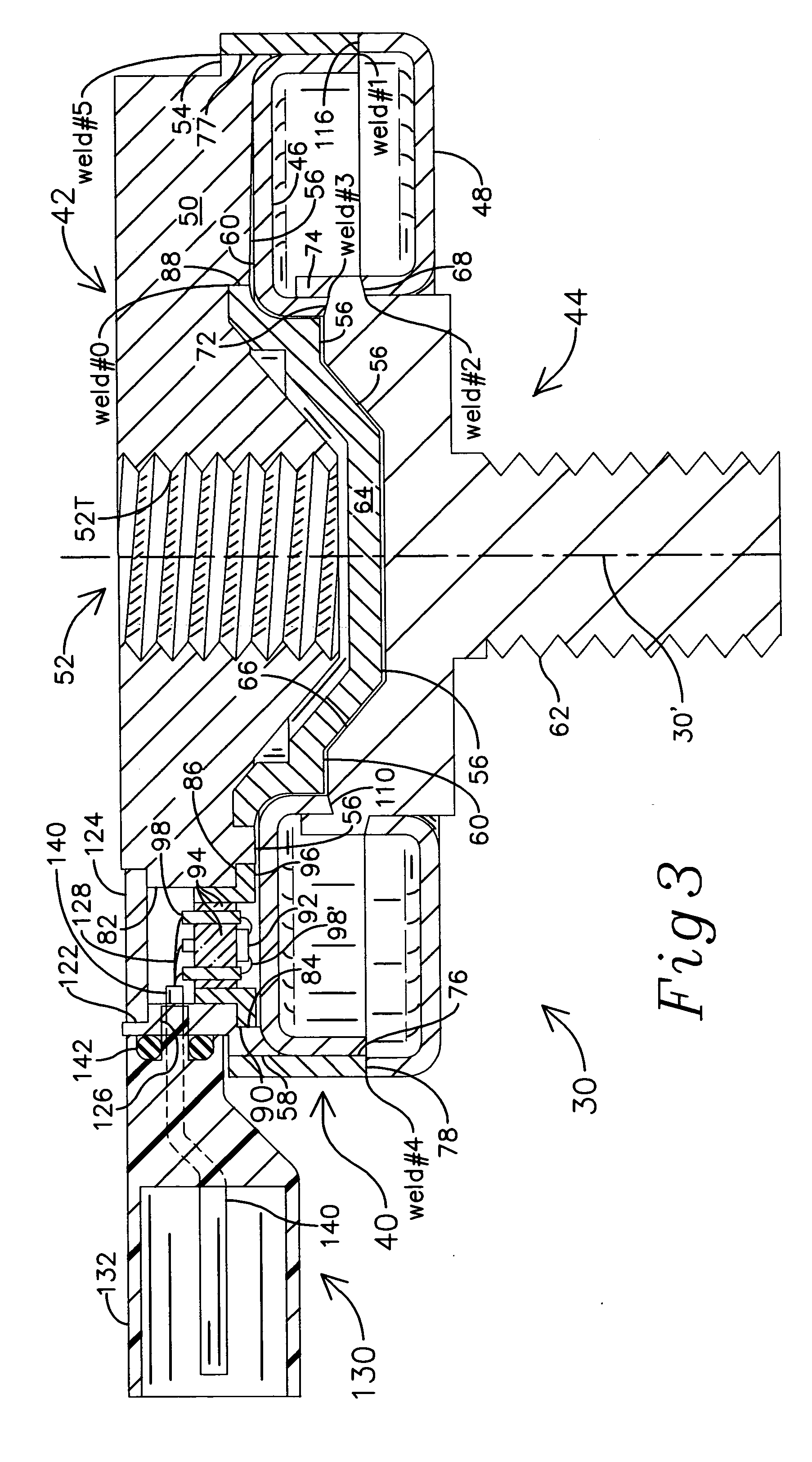

Simulated environment for transcatheter heart valve repair

InactiveUS20140277407A1Heart valvesPreparing sample for investigationChordae tendineaeLiquid pressure

An apparatus for applying liquid pressure to resected tissue may include a fixture, a papillary assembly coupled to the fixture and having first and second spaced apart papillary attachment elements, and a resected mitral valve attached to the fixture. The fixture may have a first chamber, a second chamber, and an internal panel extending between the first and second chambers. The resected mitral valve may be attached to the internal panel and may have a posterior leaflet, an anterior leaflet, and tendinae chordae. The tendinae chordae may each be attached at a first end to the posterior leaflet or the anterior leaflet and at a second end to one of the papillary attachment elements. A first group of the tendinae chordae may be attached to the first papillary attachment element, and a second group of the tendinae chordae may be attached to the second papillary attachment element.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

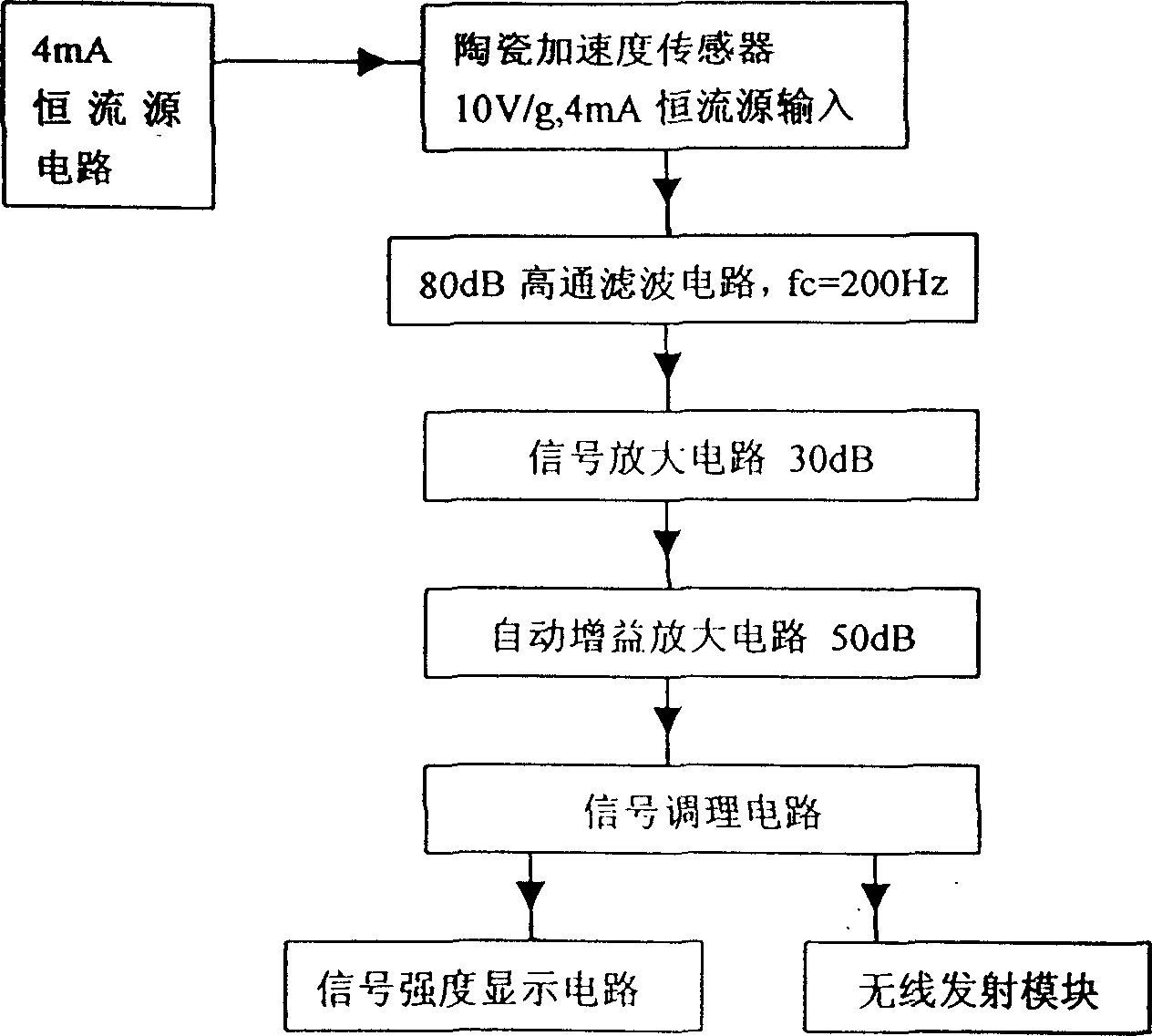

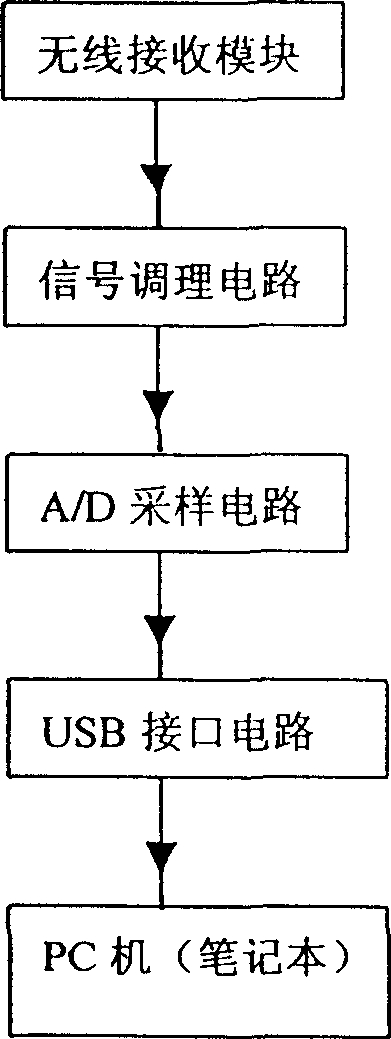

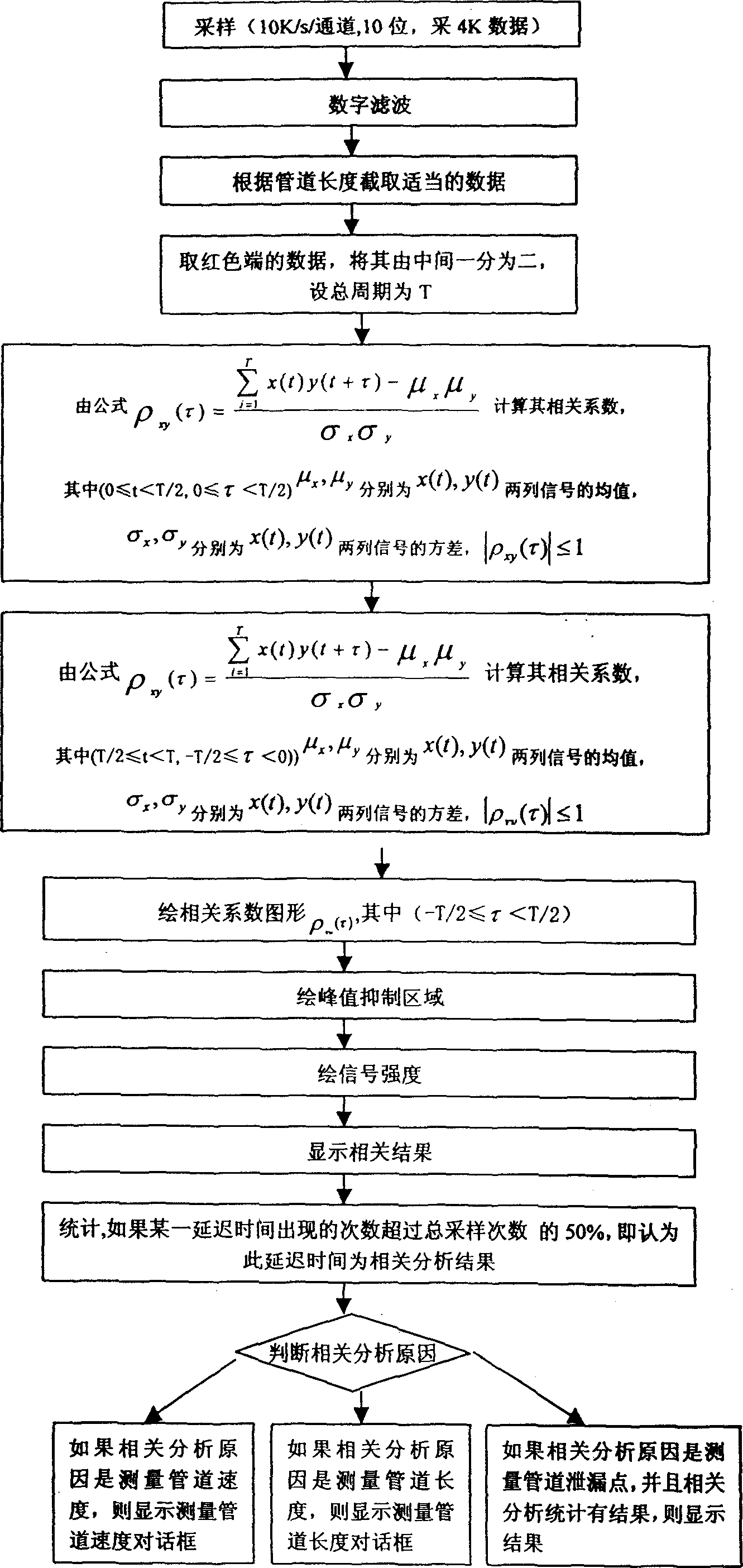

Method and apparatus for detecting leakage of liquid pressure pipeline

InactiveCN1755342AEasy to set upImprove detection accuracyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateLine tubingSound wave

The invention discloses a liquid pressure pipe leakage measuring method and apparatus which comprises the following steps: positioning the two sensors inside the measuring pipe on the two sides explored pipe wire of the tested leakage pipe to obtain the noise signal, doing high pass filter, signal amplify and auto-gaining to the noise signal, finding the corresponding audio range signal, sending the noise signal to the leakage location analysis system by the cable on by wireless type, ascertaining the time differential of the two sensors by the multi-analysis of the two signals by the leakage location analysis system, computing the distance between the leakage point to the two sensors by the time differential and the transmitting speed of the distance and the sound wave of the two sensors.

Owner:北京埃德尔黛威新技术有限公司

Droplet ejection device

A droplet ejection device includes a liquid ejection head, a supply flow path, a supply pump, and a supply flow path pressurizer. The supply flow path supplies the liquid to the head and for which a first depressurization threshold is specified in advance. The supply pump sucks the liquid, pressurizes the sucked liquid and supplies the sucked liquid to the head via the supply flow path, and keeps a pressure of liquid in the supply flow path near to a predetermined supply flow path target pressure. The supply flow path pressurizer pressurizes the pressure of liquid in the supply flow path if the pressure of liquid in the supply flow path falls to less than or equal to the first depressurization threshold.

Owner:FUJIFILM CORP

High-temperature and high-pressure plugging / sticking preventing simulation evaluation device and method

The invention relates to a high-temperature and high-pressure plugging / sticking preventing simulation evaluation device and method. The device comprises a well drilling liquid pressure control unit, a liquid storage unit, a stratum model, a plugging liquid temperature control unit and a confining pressure unit. The stratum model is provided with a crack simulating stratum forms, and a pressure sensor is distributed on the crack. The pressure and the temperature of plugging liquid entering the stratum model and pressure applied to the stratum model are controlled, pressure values of different depths of the crack are measured through the pressure sensor, and flow of the plugging liquid is measured according to a weighing method. The high-temperature and high-pressure plugging / sticking preventing simulation evaluation device and method can evaluate the plugging effect of different plugging materials and plugging slurry under the same condition and provide scientific research methods for the research of plugging well leakage and extrusion theories, the preparation of plugging agents which are strong in staying performance, forming of process technologies of preventing the plugging agents from sticking backwards, the building of laboratory plugging simulation evaluation method standards and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid container

The invention provides a liquid container for storing liquid to be supplied to a liquid consuming apparatus. The liquid container is constructed such that pressurized fluid is sent to its inside so that the liquid in the inside is delivered to the outside. The liquid container includes a container body which stores the liquid in its inside. The container body includes a pressurized fluid introduction port for introducing the pressurized fluid to the inside and a liquid delivery port for delivering the liquid to the outside. A detection unit is provided in the container body and outputs an output signal which is changed in accordance with a change in pressure of the liquid in the inside of the container body.

Owner:SEIKO EPSON CORP

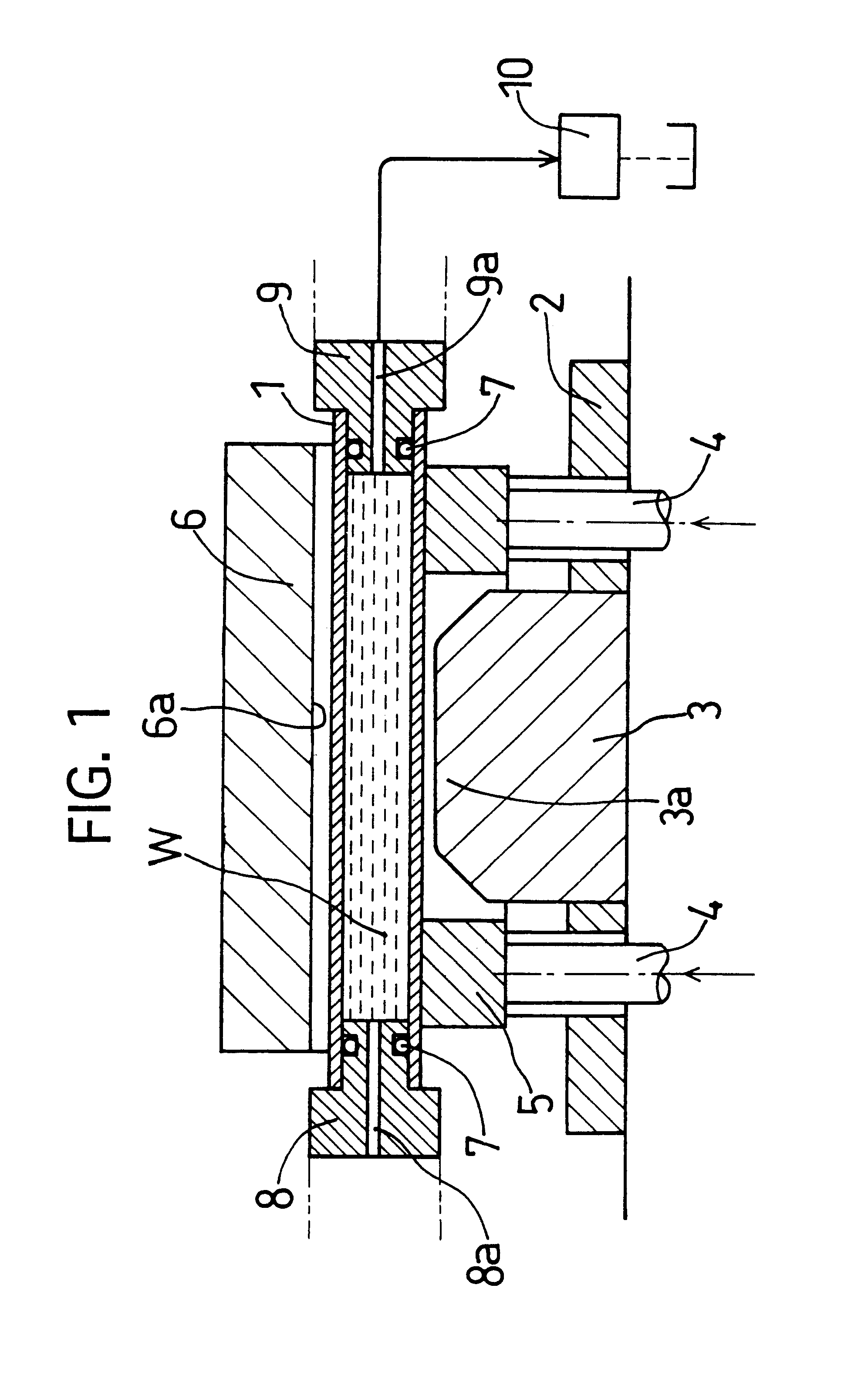

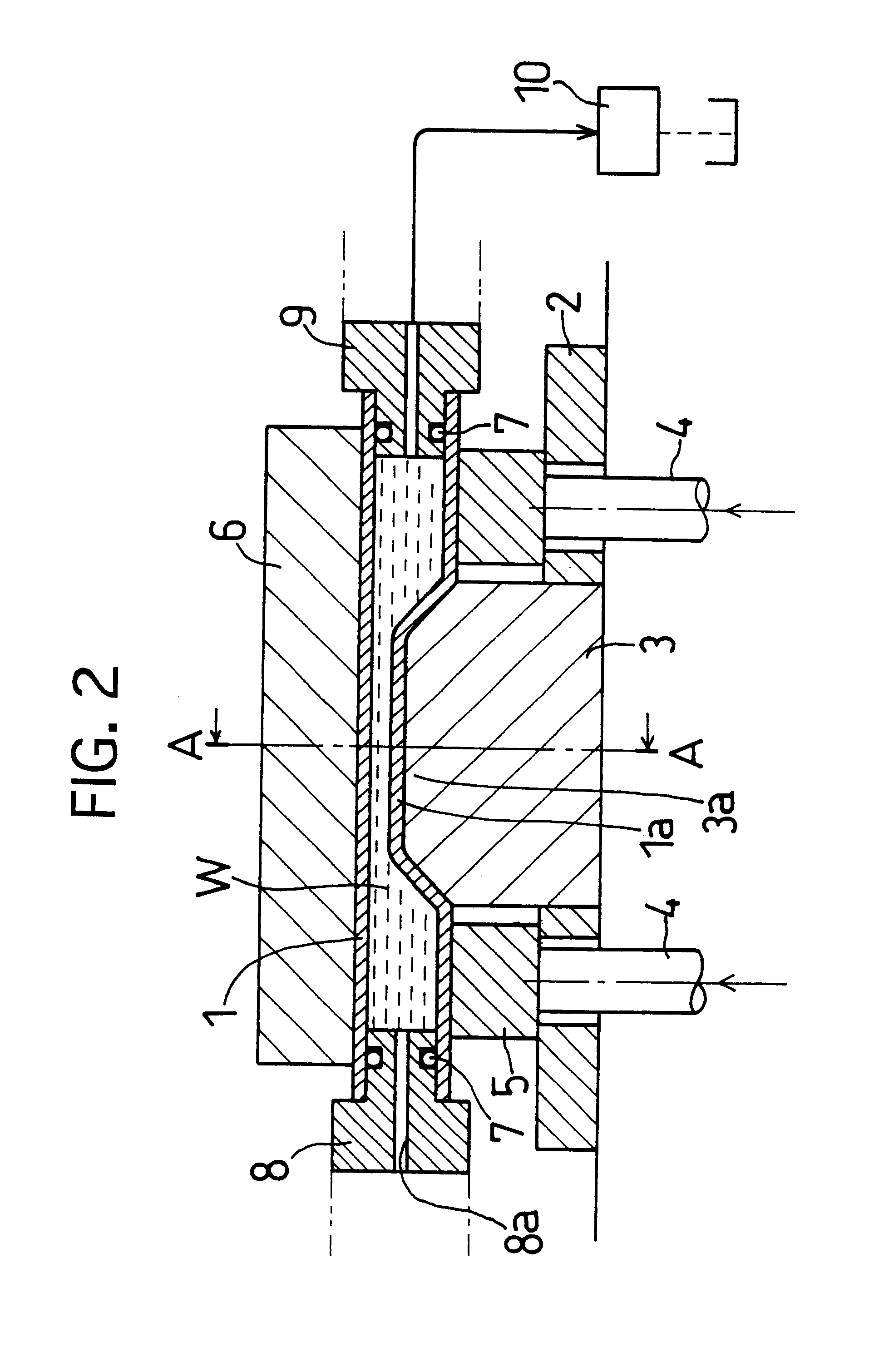

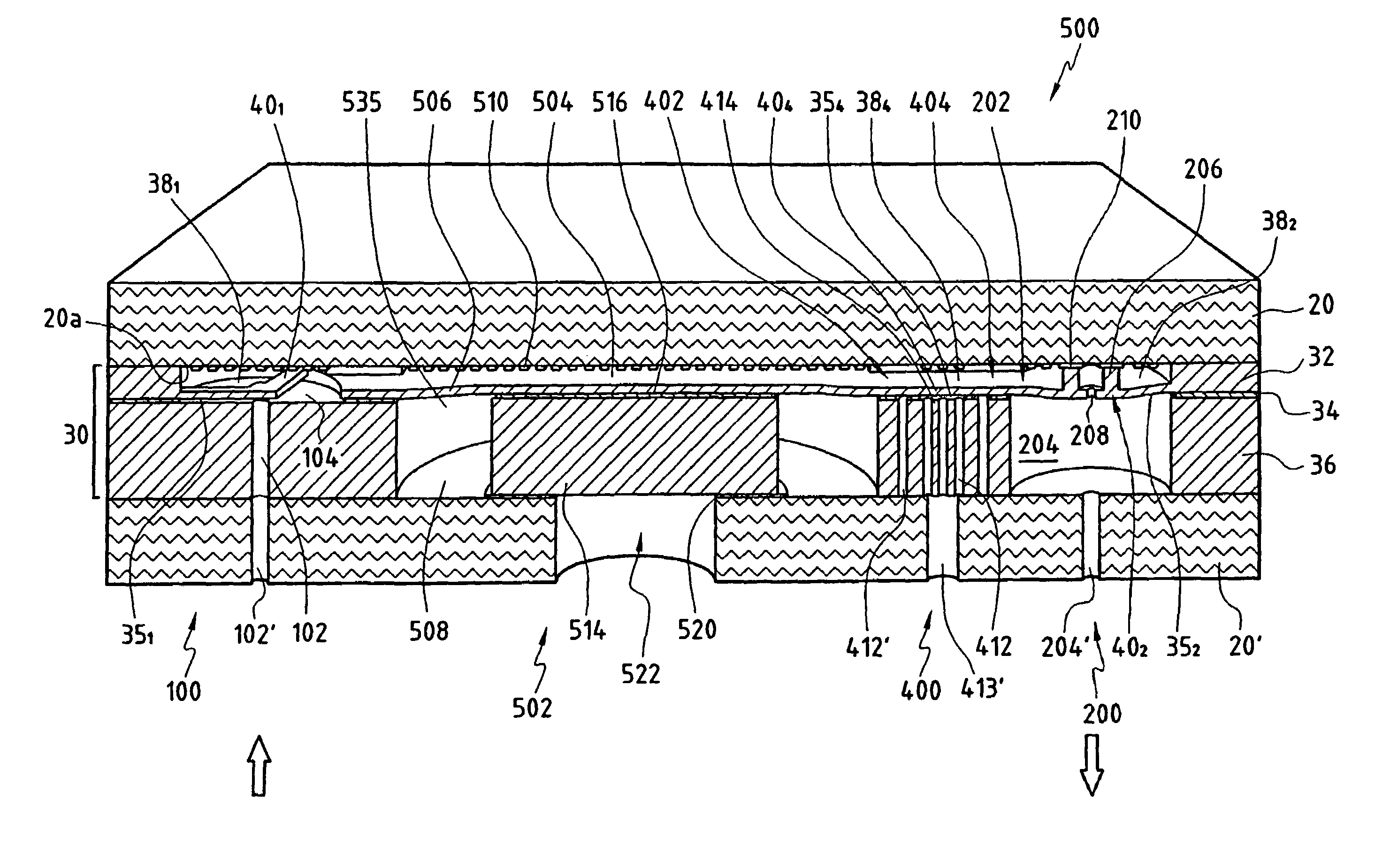

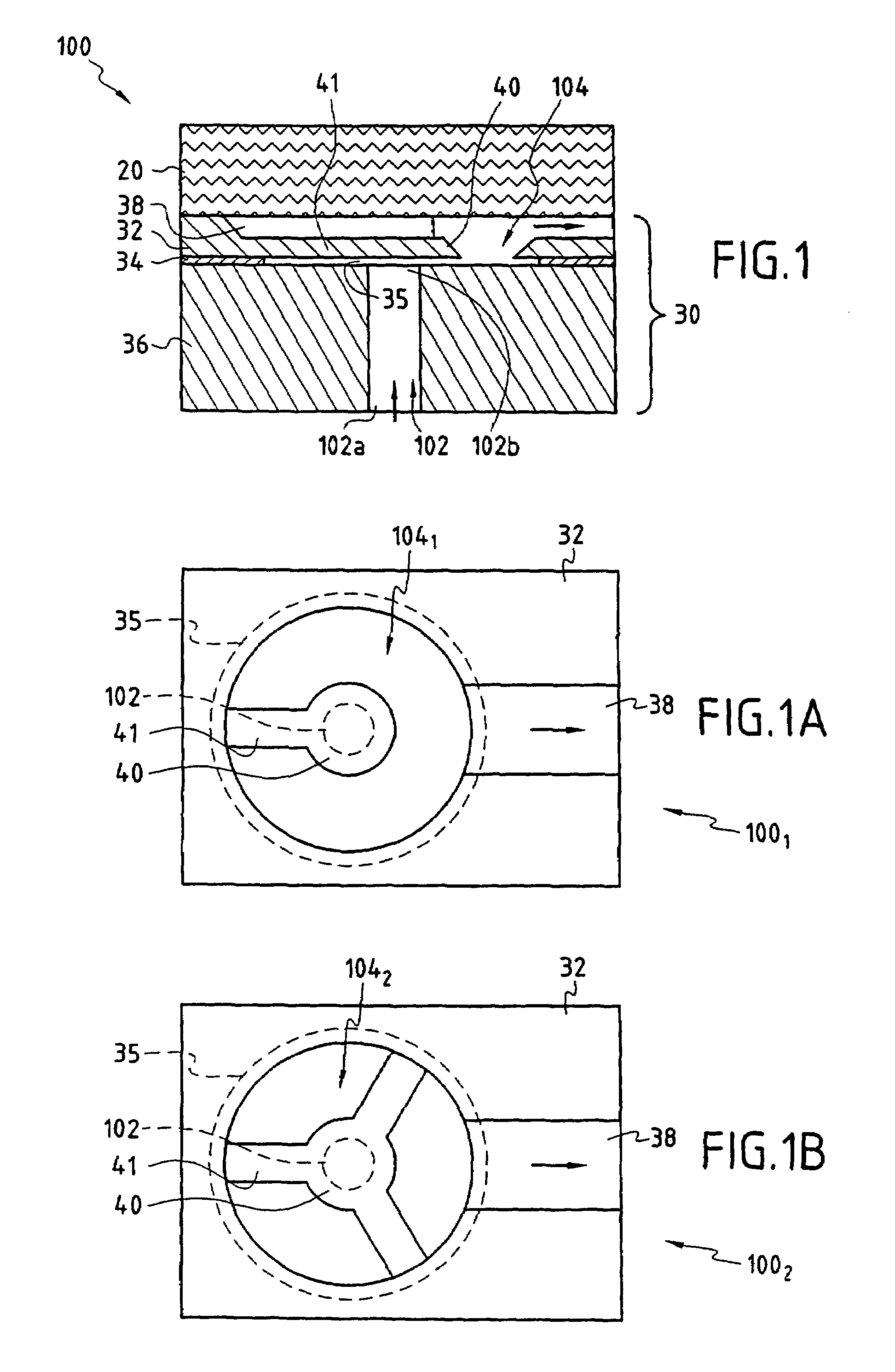

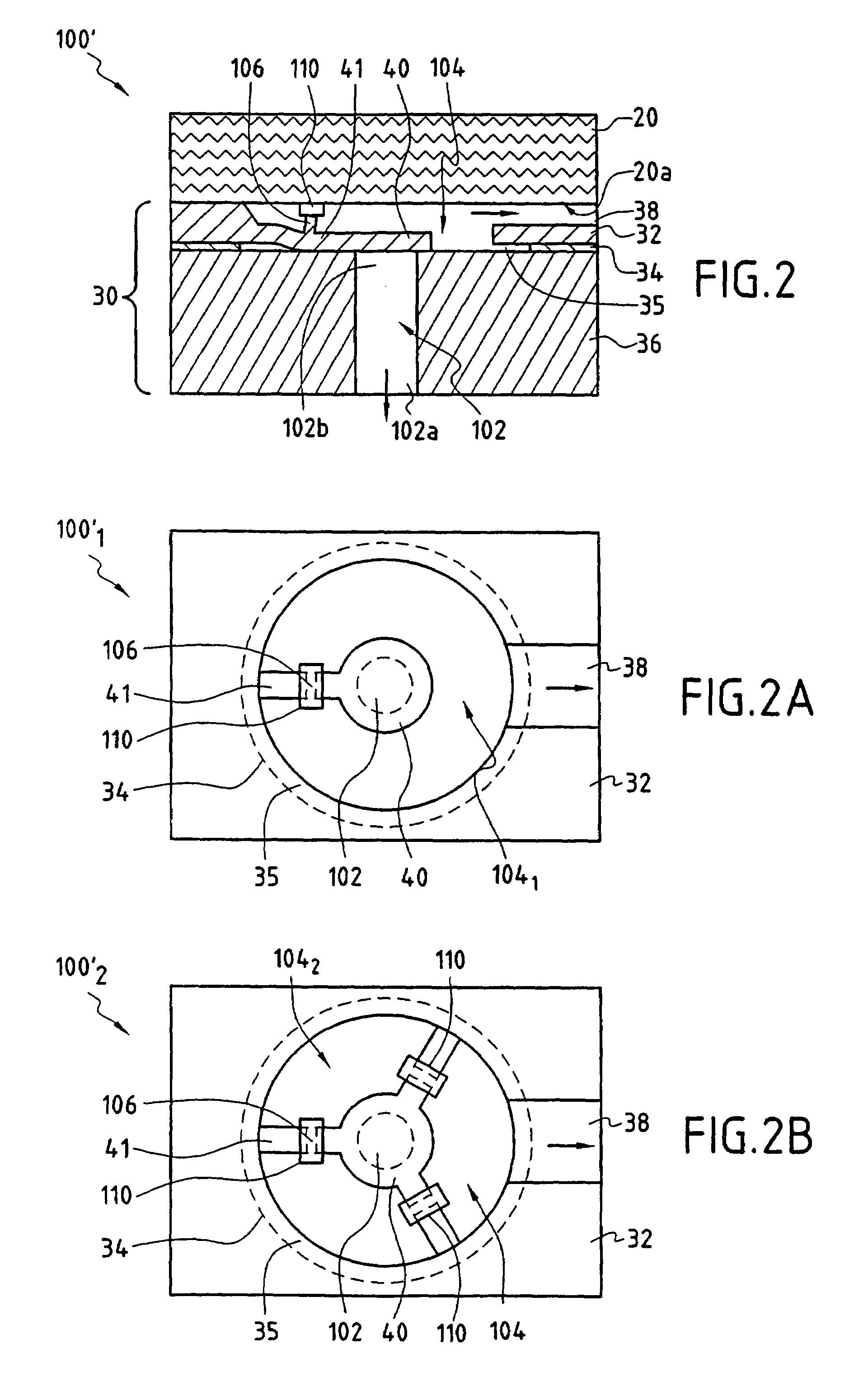

Micromachined fluidic device and method for making same

InactiveUS7311503B2Reliably madeMinimizing dead volumeFunctional valve typesFluid pressure measurement by electric/magnetic elementsEngineeringSilicon

The fluid-flow device (100) of the invention comprises a stack (30) covered by a closure wafer (20), said stack (30) comprising a support wafer (36), a layer of insulating material (34), and a silicon layer (32). The closure wafer (20) and / or said silicon layer (32) are machined so as to define a cavity (38) between said closure wafer (20) and said silicon layer (32), said support wafer (36) has at least one duct (102) passing right through it, said layer of insulating material (34) presenting at least one zone (35) that is entirely free of material placed at least in line with said duct (102) so as to co-operate with said cavity (38) to define a moving member (40) in said silicon layer (32), the moving member being suitable under the pressure of liquid in said cavity (38) for reversibly moving towards said support wafer (36) until contact is made between said moving member (40) and said support wafer (36).

Owner:DEBIOTECH SA

Water and/or alcohol water secondary injection system for diesel engines

InactiveUS20070131180A1Emission reductionImprove fuel efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberFuel efficiency

A system for reducing the emissions of the oxides of nitrogen(NOx) and improving the fuel efficiency of a diesel engine having at least one combustion chamber and a camshaft and a crankshaft and an intake port and an operator controlled throttle with at least one electronically actuated diesel fuel injector; a diesel fuel supply reservoir communicatively connected with the diesel fuel injector and including diesel fuel pumping means for maintaining diesel fuel pressure at the inlet of the diesel fuel injector; at least one electronically actuated water and / or alcohol injector; a water and / or alcohol supply reservoir communicatively connected with the water and / or alcohol injector and including water and / or alcohol pumping means for maintaining liquid pressure at the inlet of the water and / or alcohol injector; and an electronic regulating means for controlling the rate at which atomized diesel fuel and water and / or alcohol are independently injected respectively into the combustion chamber and intake port. The electronic regulating means is being operatively connected to the injectors and is responsive to one or more of air temperature in the air intake manifold, the position of the throttle, the intake manifold pressure, the camshaft position, the crankshaft position, the engine rotational speed wherein the amount of water and / or alcohol injected into the intake port is controlled as a function of both the amount of diesel fuel and alcohol injected and the ratio of diesel fuel and alcohol to air in the combustion fuel mixture to reduce NOx emissions and improve fuel efficiency over the operating range of the diesel engine.

Owner:UCHICAGO ARGONNE LLC

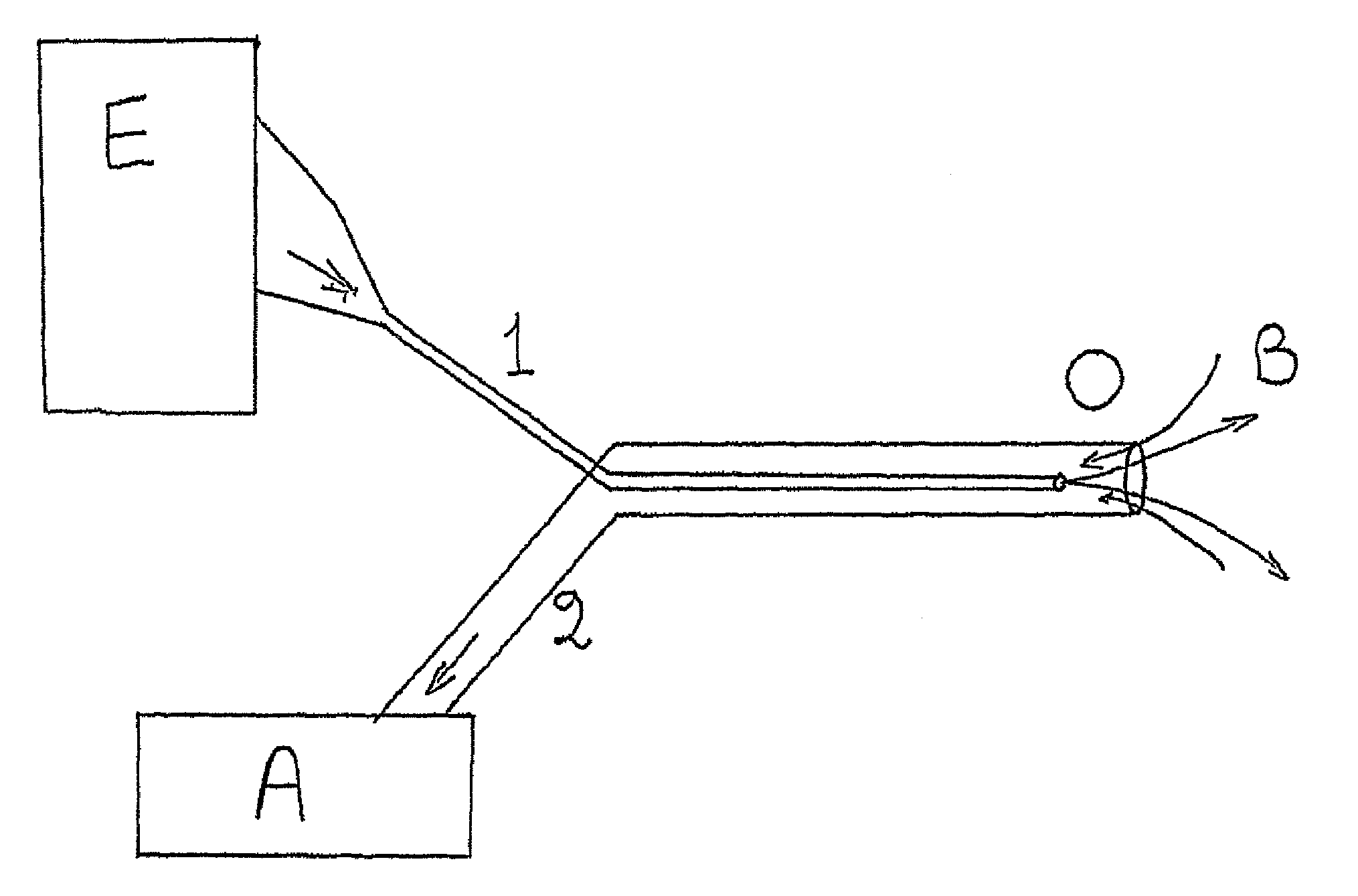

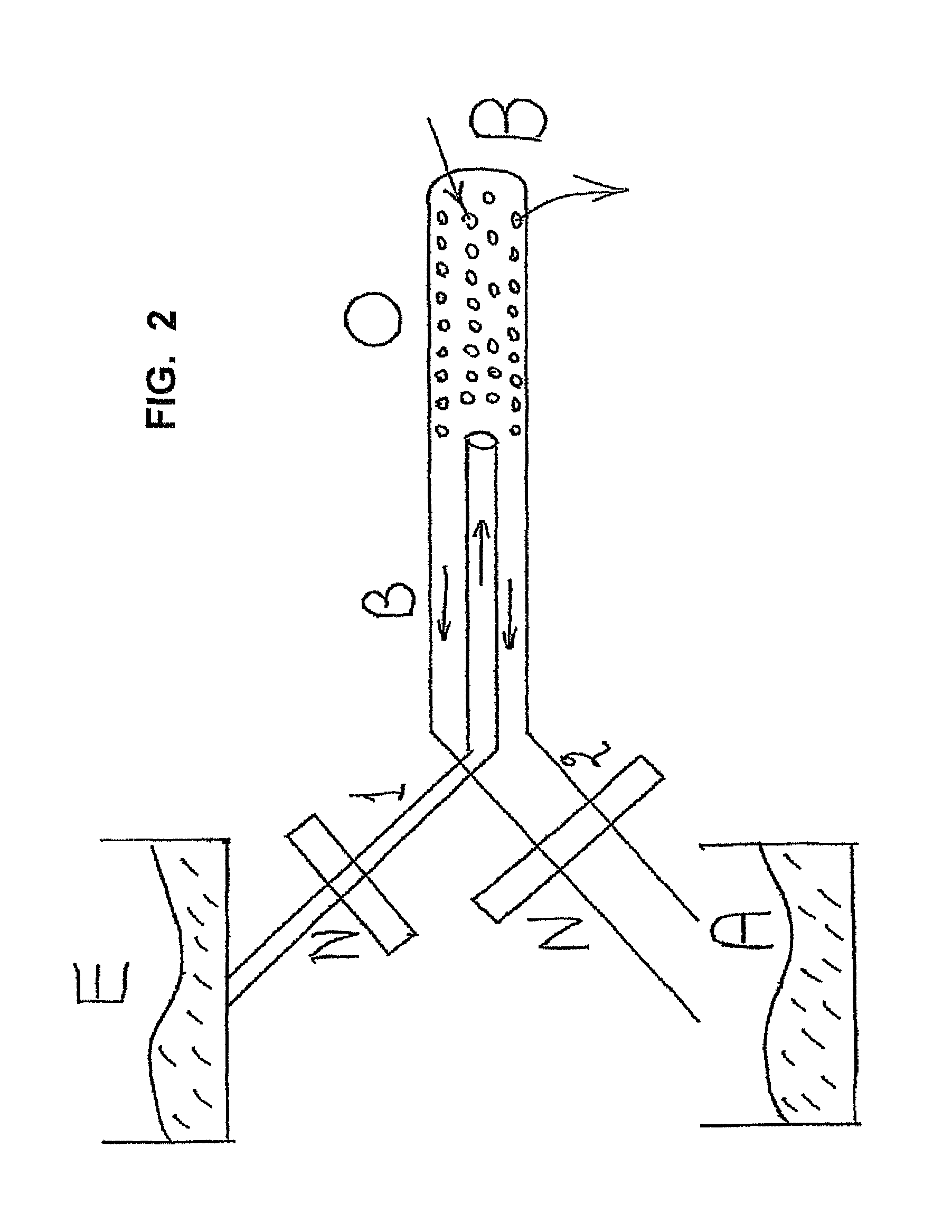

Method and device for irrigation of body cavities

ActiveUS20070249993A1Accelerate liquid flowGood blood pressureEndoscopesMedical devicesAutomatic controlRed blood cell

A pressure and a vision regulation method and device for irrigation of a body cavity (1), in which method an inflow liquid pump (2) pressurizes the irrigation liquid in a feed line (13) and in which an outflow device (3) or an external suction source (20) drains the irrigation liquid from the body cavity (1) through a tubing (16) into a waste container (17) and in which a control unit (4) controls either the inflow liquid pump (2) only or both the inflow liquid pump (2) and the outflow device (3) depending on an inflow irrigation liquid pressure from a pressure sensor (5), where the first control unit (4) compares the inflow irrigation liquid pressure and flow with pressures calculated to correspond to pressure in the body cavity for the respective flow for a nominal surgical site and that a matching between the calculated values and the inflow irrigation liquid pressures is made by altering the effect of either the inflow liquid pump (2) only or the inflow liquid pump (2) and / or the outflow device (3) and / or the shut off valve. The above-mentioned pressure registration method and the device for irrigation of a body cavity is combined with an method for detecting blood cells, red blood cells, haemoglobin and / or debris in liquid coming from a surgical site so an automatically control and rinsing system is achieved keeping a clear vision in the viewing area of the operational site.

Owner:TENNESSEE MEDICAL INNOVATIONS INC

Fluid exchange catheter system

ActiveUS8398581B2Create pressureMulti-lumen catheterMedical devicesFluid infusionBiological materials

A catheter system that can be used for concurrent fluid infusion and aspiration in humans, animals and biological material, at a wide range of flow rates, without any blockage problems. The system has devices that control the infused liquid's pressure changes accordingly to the aspirated liquid's pressure changes, in order to allow accurate and safe fluid exchange flow control and create changes of pressures at the catheter's tip that do not allow the catheter's blockage.

Owner:IRRAS

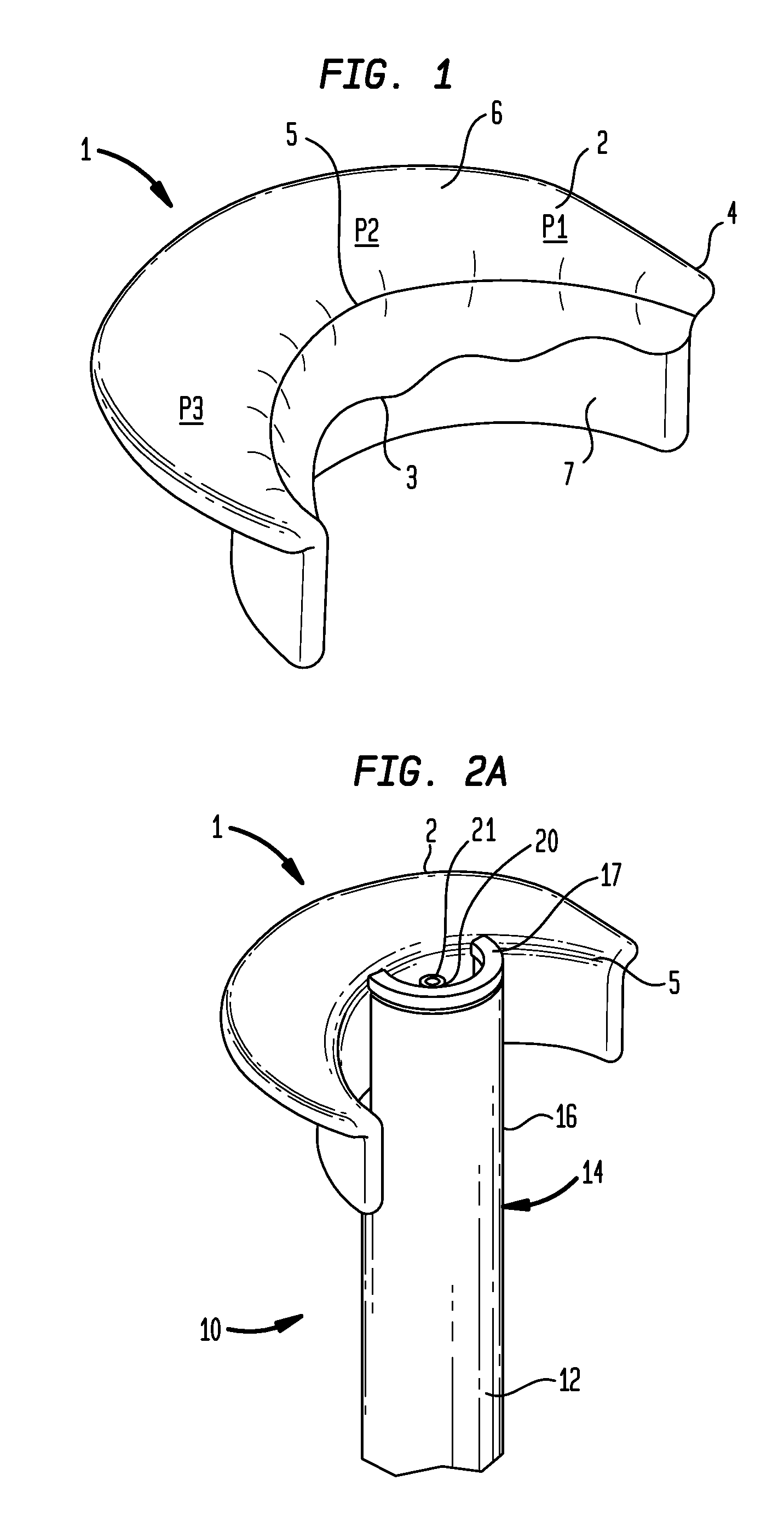

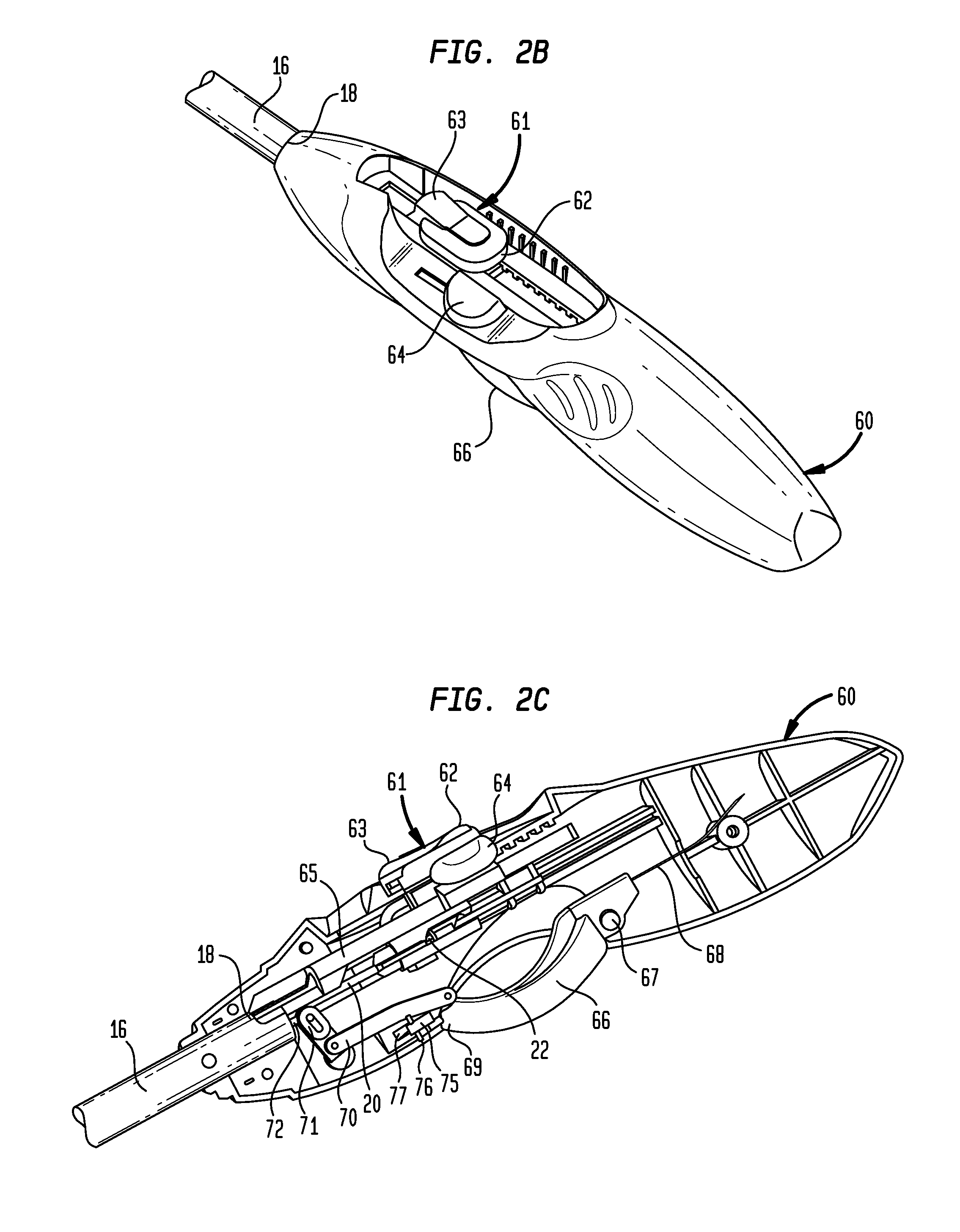

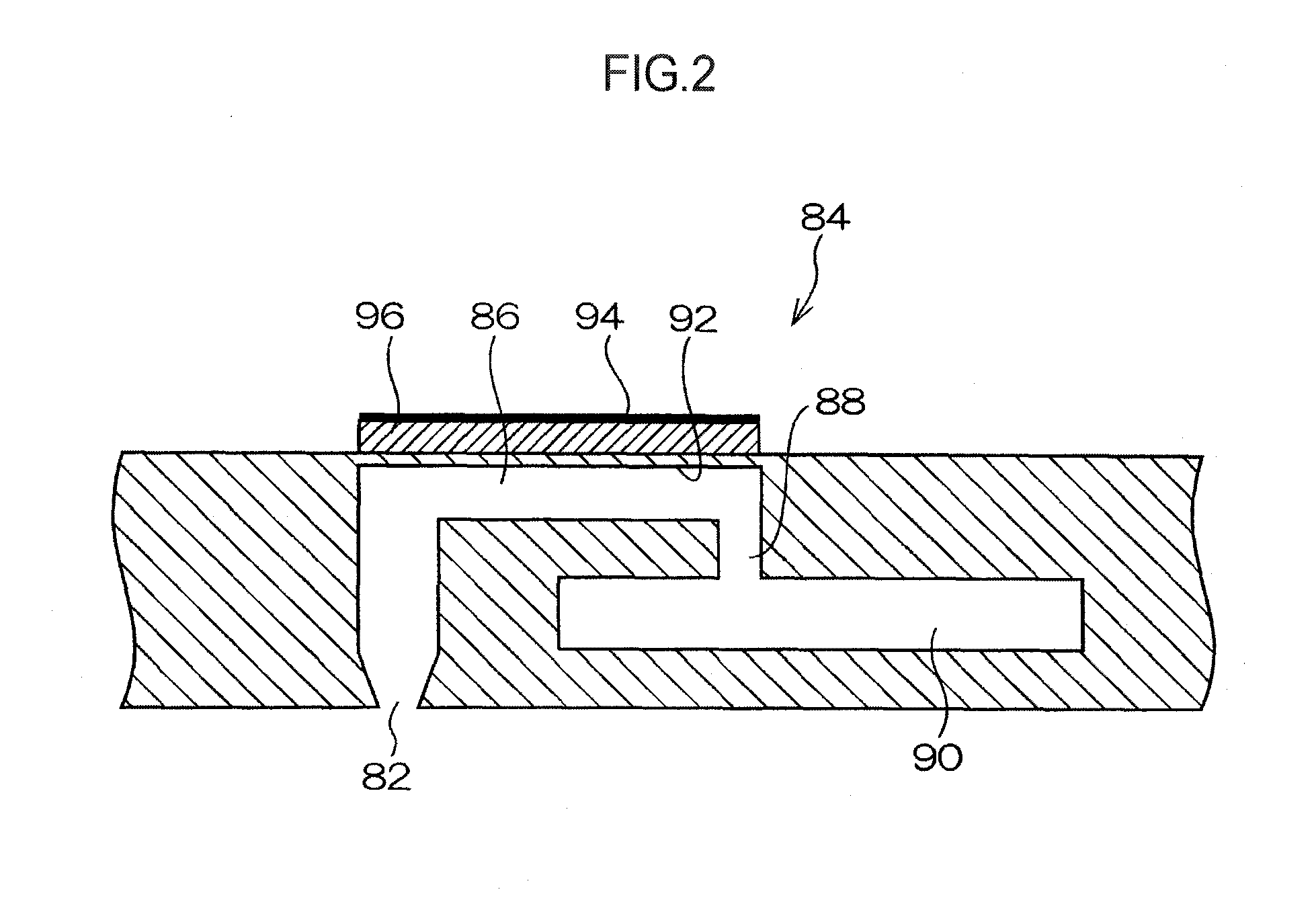

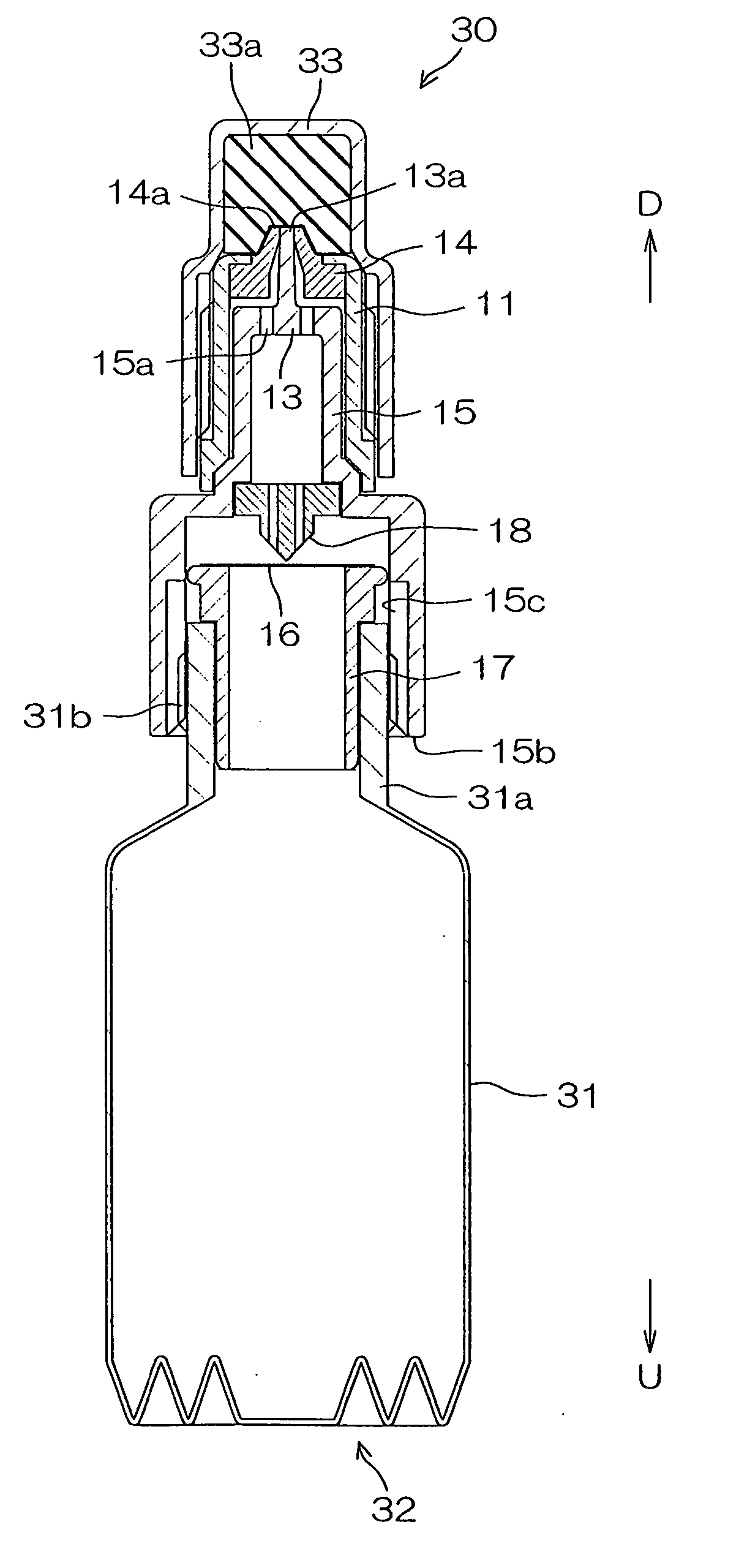

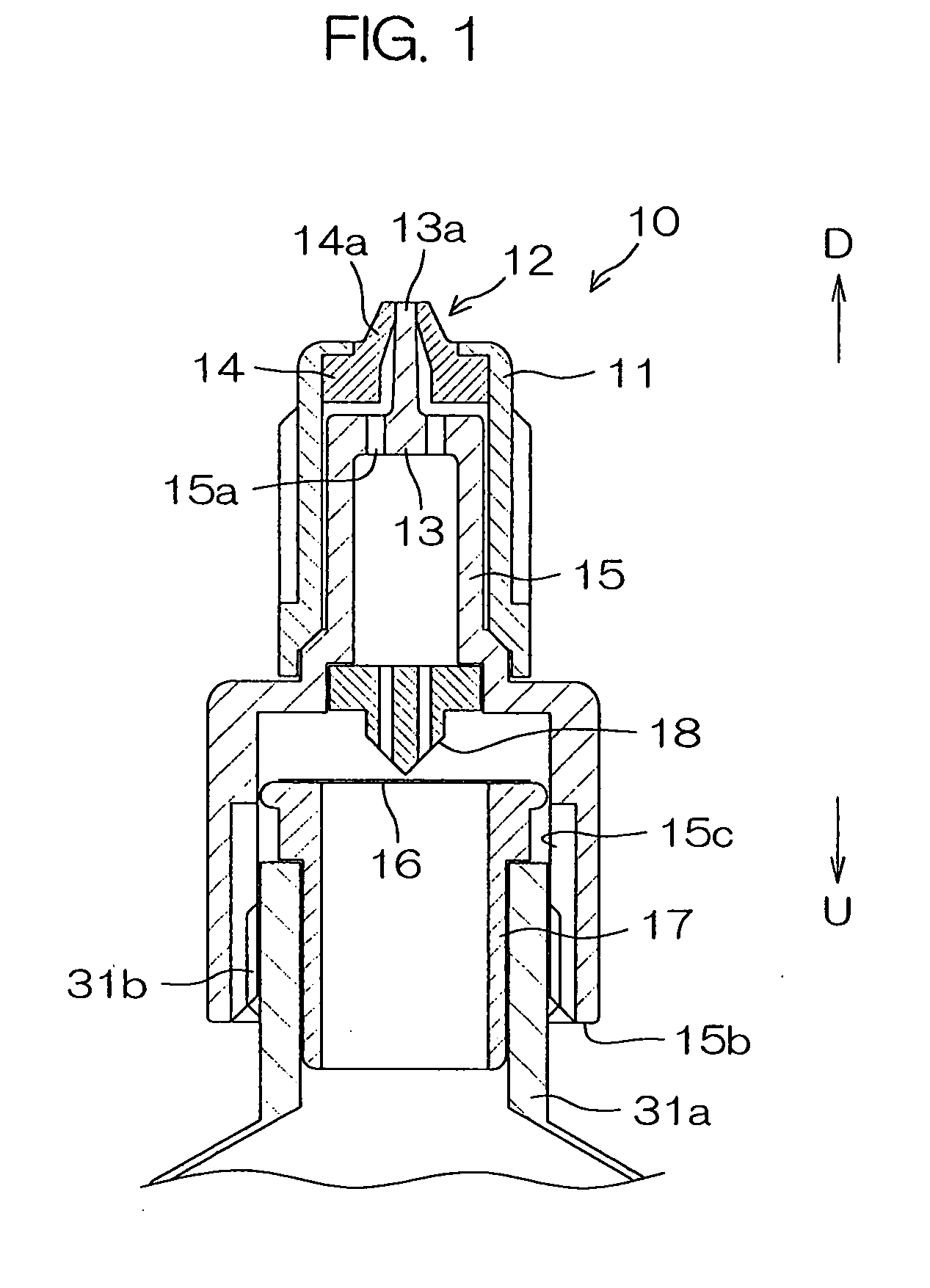

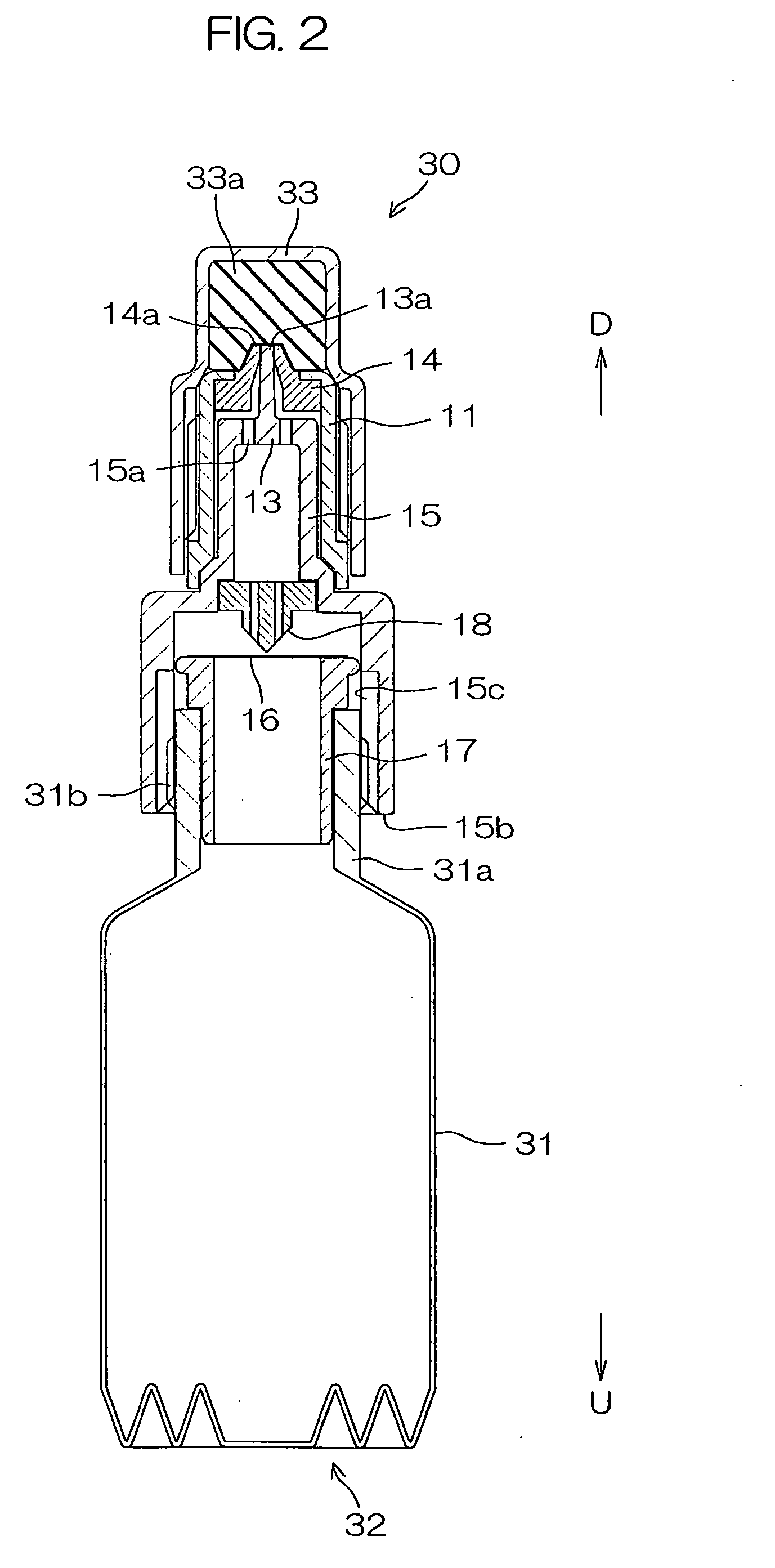

Delivery device, delivery container, and eye dropper provided with the same

InactiveUS20070093765A1Aseptic condition can be ensuredEliminating and reducing useClosuresDispensing apparatusAntiseptic AgentSqueeze bottle

The present invention has an object to provide a delivery device that is capable of preventing a content liquid from flowing back and achieving aseptic delivery of liquid drop (dripping), and provide a delivery container, and an eye dropper that can eliminate or reduce the use of an antiseptic agent and achieve smooth delivery of the liquid. The delivery device 10 of the present invention comprises the outlet portion 11 of a substantially bottomed tubular shape having the outlet orifice 12, the valve element support portion 13 of substantially cylindrical shape that is secured in the outlet portion 11 with a distal end 13a thereof exposed through the outlet orifice 12 to the outside of the outlet portion 11, and a valve element 14 that is secured in the outlet portion 11 with a distal end 14a thereof exposed through the outlet orifice 12 to the outside of the outlet portion 11. The distal end 14a of the valve element makes contact with the valve element support portion 13 so as to close the outlet orifice 12 when there is no liquid pressure applied to the distal end portion from the upstream U, and deforms so as to form a flow passage between the distal end portion and the valve element support portion 13 when subjected to liquid pressure applied from the upstream U. The delivery container 30 of the present invention has the delivery device 10 installed at the mouth 31a of the squeeze bottle 31.

Owner:OTSUKA PHARM CO LTD

Fiber optic strain sensor and associated data acquisition system

InactiveUS20060104561A1Reduce disadvantagesSubsonic/sonic/ultrasonic wave measurementFluid pressure measurement by electric/magnetic elementsData acquisitionEngineering

A fiber optic polarimetric strain sensor and associated data acquisition system capable of all-optical measurements of physical parameters, such as structural strain, gas and liquid pressure, acceleration and vibration, gas and liquid flow rate, and force without fire and explosion hazards associated with conventional strain gage technologies, such as resistance foil strain gages. The polarimetric strain sensor houses a sensitive element—a length of single mode optic fiber—changing polarization of a single-mode optical signal running in the fiber under some mechanical affects, specifically twisting and radial compressing. A linearly-polarized light passes the sensor, which causes polarization deviation of the light, particularly, polarization plane rotation under mentioned above twisting or compressive stresses applied to a sensitive element of the sensor. A multi-channel time division multiplexing data acquisition system that includes polarization analyzer indicates the polarization state deviation caused by the strain, so allow measuring the parameters. The invention may be embodied for measurements of any phenomenon that can be transformed in stress on an optical fiber.

Owner:IVTSENKOV GENNADII

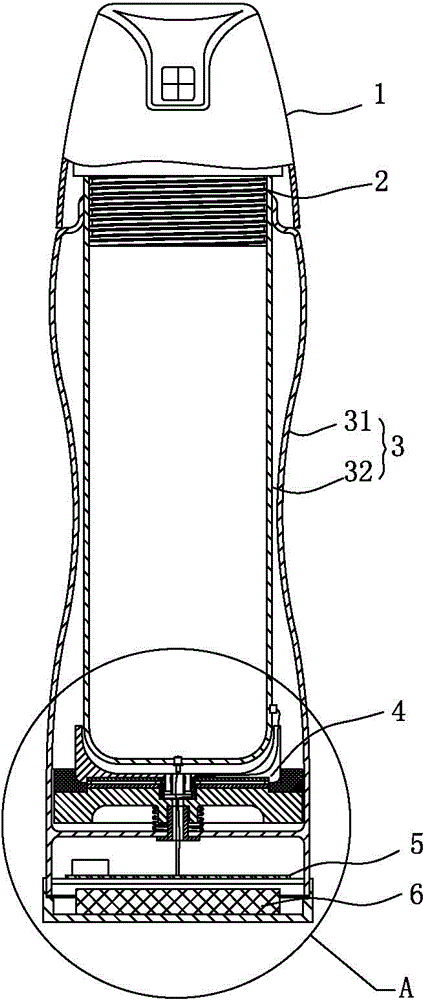

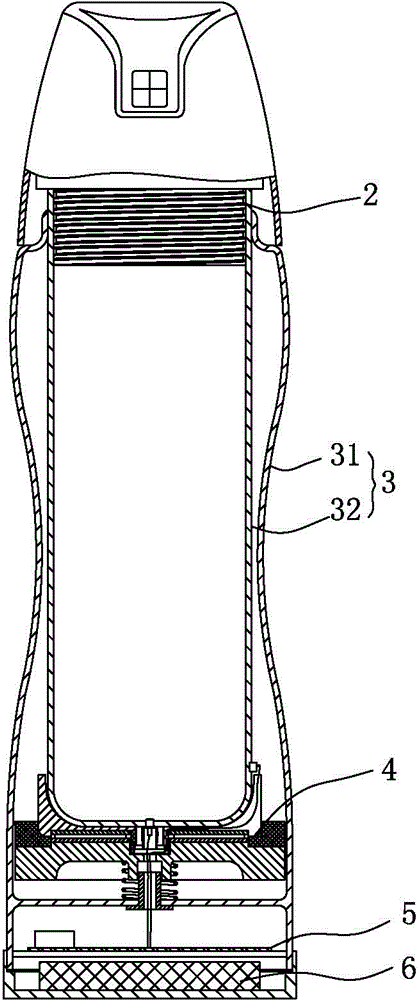

Intelligent vacuum cup

The invention discloses an intelligent vacuum cup capable of prompting and metering. The intelligent vacuum cup comprises a cup body, a cup lid and an upper lid, wherein a temperature sensor is arranged on the outer wall of a liner; a liquid pressure sensor is arranged at the bottom of the liner; a displayer is arranged on a housing; a mainboard is arranged below the liner; the mainboard can respectively detect the temperature and the water volume of the liner through the temperature sensor and the liquid pressure sensor, and displays the detected result through the displayer. According to the intelligent vacuum cup disclosed by the invention, the liquid pressure sensor can be used for detecting the water volume in the liner; the total volume of water drunk every day can be calculated by continuously detecting the water volume in the liner; the water volume information in the liner can be displayed by the displayer to be prompted or transmitted to a mobile terminal such as a mobile phone through a Bluetooth device on the mainboard, and then counted or prompted by APP software on the mobile terminal; a refrigerating / heating device refrigerates or heats the liner through a semiconductor refrigerating / heating chip, and further can be separated from the liner through an electromagnet when the liner does not need to be heated or refrigerated, so as to improve the thermal insulation effect of the liner.

Owner:功夫动漫股份有限公司

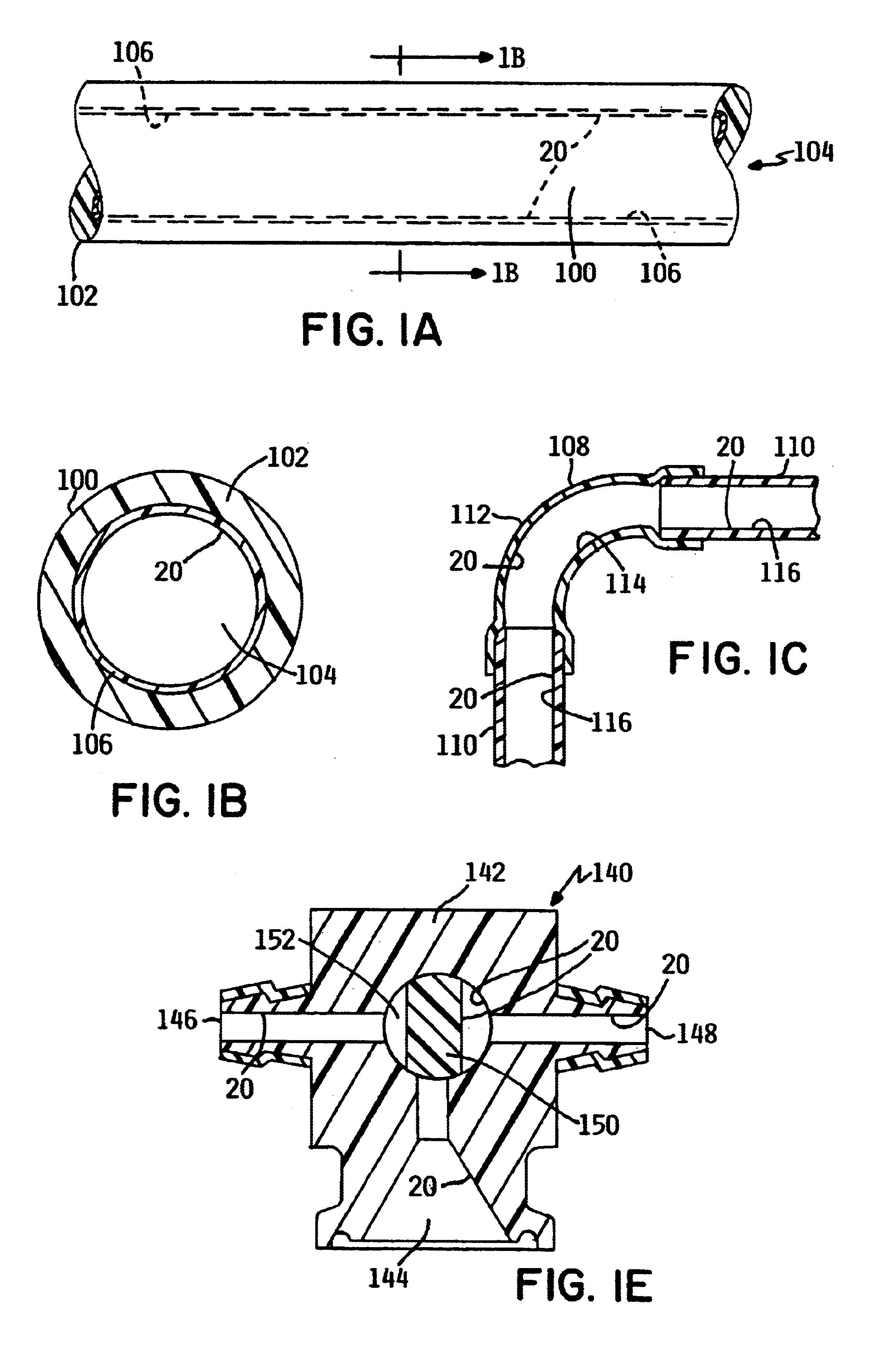

In-Line Mini Sprinklers System and Method and Apparatus for Making Same

The present invention relates to An in-line system of mini sprinklers, comprising a tubular conduit having inner and outer surface areas, fitted for a liquid flow under pressure through it and formed with at least one opening along its length; and at least one mini sprinkler unit that is at least substantially embedded within said tubular conduit, coupled to flow of said liquid within it and mounted to it around said opening, and comprises—a mobile liquid distributing assembly movable through said opening, such that when liquid's pressure in said tubular conduit increases, said liquid distributor moves and protrudes beyond said outer surface area of said tubular conduit in order to sprinkle said liquid outwards of said tubular conduit.

Owner:RIVULIS PLASTRO LTD

Fluid handling component with ultraphobic surfaces

InactiveUS20050145285A1Reduce frictionImprove system efficiencyMaterial nanotechnologyConveyorsVolumetric Mass DensityEngineering

A fluid handling component having a durable ultraphobic fluid contact surface that is capable of exhibiting ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γ cos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

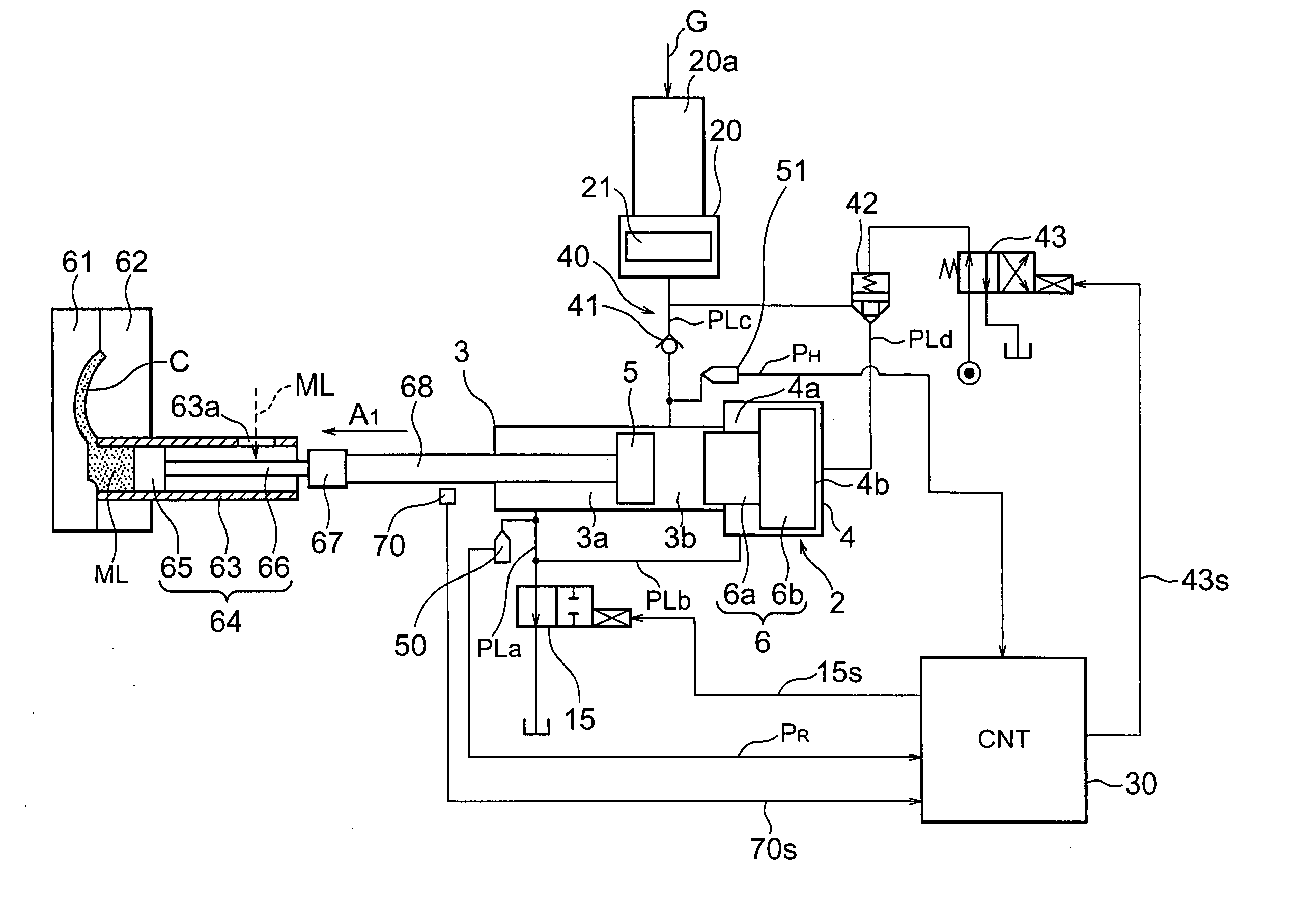

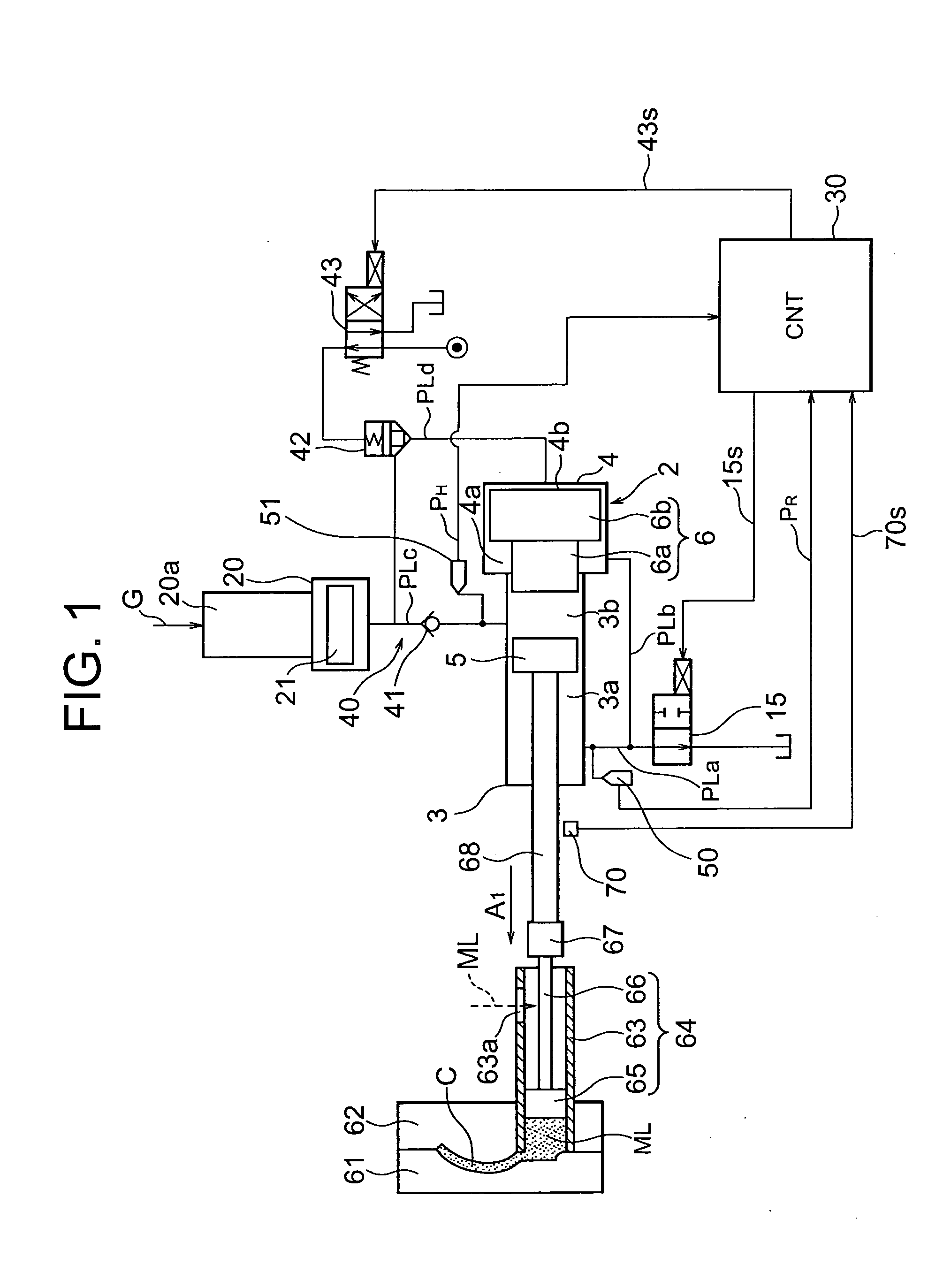

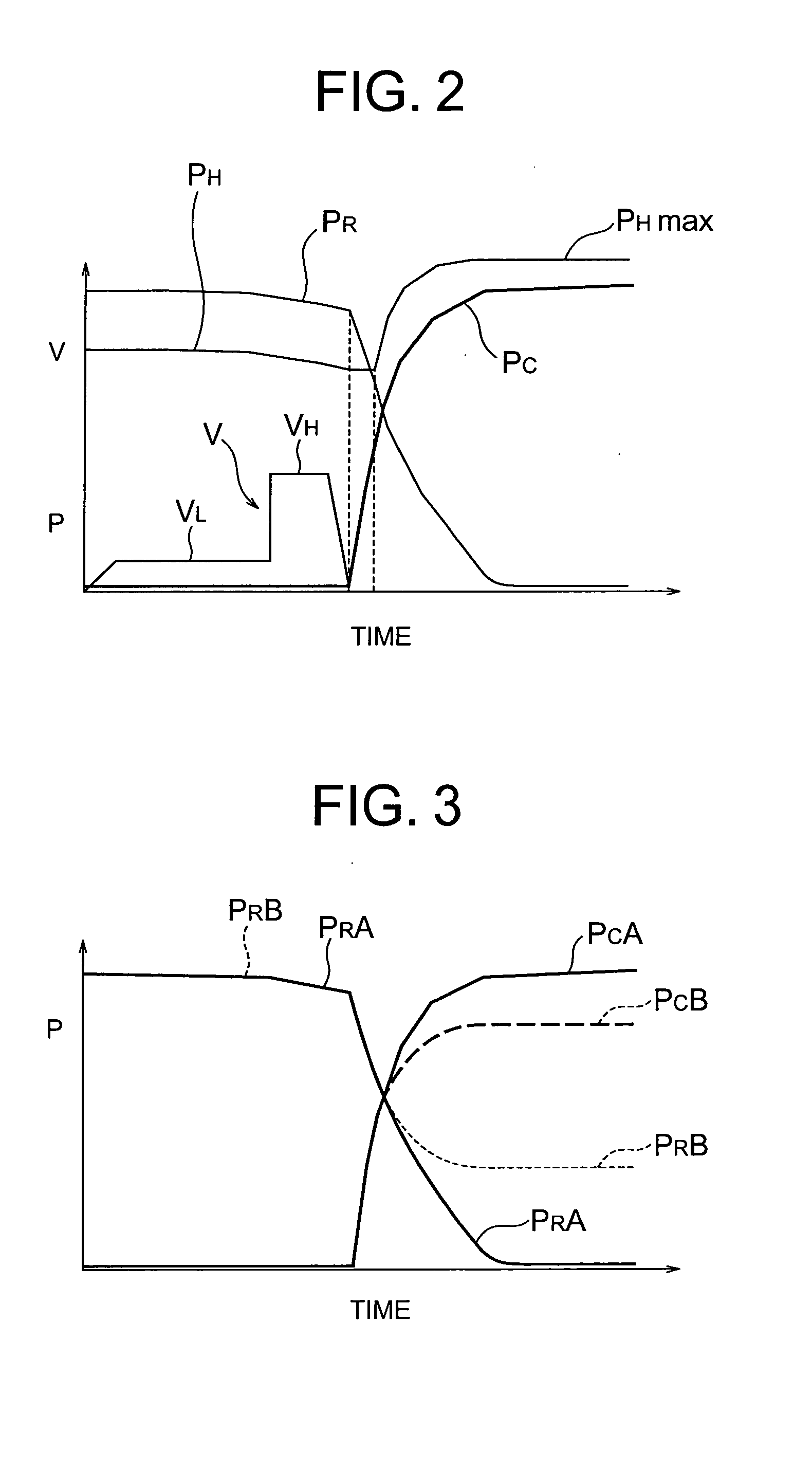

Injection system and casting method of die casting machine

An injection system of a die casting machine giving the necessary casting pressure without adjusting the accumulator side, provided with an injection cylinder including an injection piston linked with the injection plunger and a booster piston arranged behind the injection piston, an accumulator for supplying a pressurized liquid of a predetermined pressure, a liquid pressure circuit for supplying the pressurized liquid from the accumulator to the injection cylinder, driving the injection piston, then driving the booster piston, a control valve for controlling a flow rate of the pressurized liquid discharged from the front side of the injection piston of the injection cylinder so as to control a flow rate of the injection piston, and controlling the pressure of the pressurized liquid at the front side of the injection piston by the timing of closing the control valve to determine the final value of the casting pressure.

Owner:TOSHIBA MASCH CO LTD

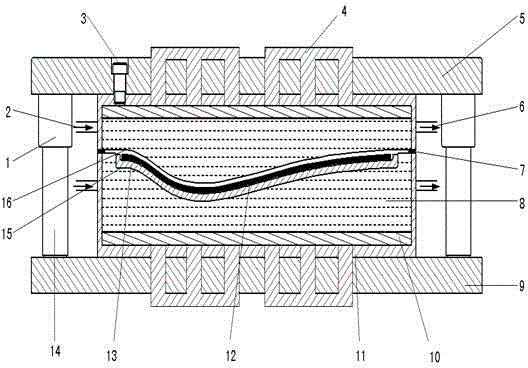

Microwave-hydro-forming method and device of composite material

The invention discloses a microwave-hydro-forming method and device of a composite material. The microwave-hydro-forming method is characterized in that the composite material is heated up by adopting microwaves; in the heating process, balanced liquid pressure is applied to upper and lower surfaces of a composite material manufactured piece; the composite material manufactured piece is effectively compacted and cured. The device mainly comprises an array microwave generator, a liquid pressure control system and a mold opening and closing system. According to the invention, the difficulties that the composite material in the traditional autoclave forming technology is rapid in forming speed, is high in temperature and pressure control hysteresis quality, and is high in cost are solved; the microwave-hydro-forming method and device have wide market value and application prospect in the technical field of forming the composite material with high performance and low cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Load cell and seat occupant weight sensing system

InactiveUS20060103192A1Large thermal expansion coefficientIncrease volumeVehicle seatsStoolsSeat beltEngineering

A load cell particularly useful for a seat occupant weight sensing system includes a liquid filled chamber and a pressure sensor providing an electric signal indicating the pressure in the liquid. Four load cells supporting a seat provide four signals that are added to determine the weight of the seat occupant. The load cell comprises two flanged conical springs stressed to provide preload. One of the springs also forms part of the surface of the liquid filled chamber. The two springs operate in concert to resist side forces and moments. The load cell is responsive to both compressive and tensile forces while being substantially unaffected by lateral forces and moments. A seat belt tension sensor may be included to measure seat belt tension. Preferred manufacturing methods provide low cost,

Owner:NORTON PETER

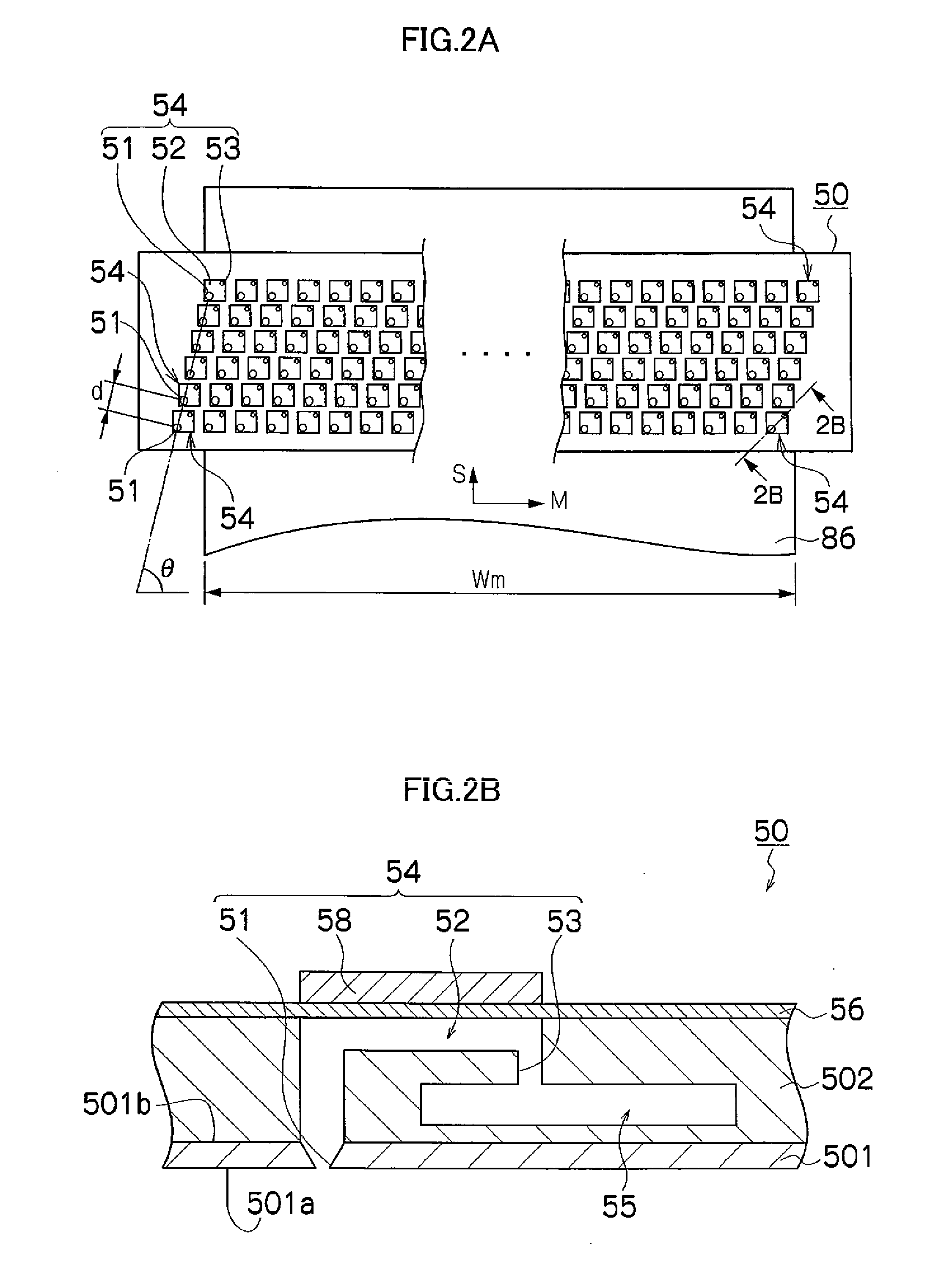

Droplet discharging head and image forming apparatus

A droplet discharging head includes: a nozzle substrate that includes a nozzle opening to discharge a droplet therethrough; a liquid chamber substrate that includes liquid pressure chambers communicating with the nozzle openings; a vibration plate arranged to face the nozzle substrate with the liquid chamber substrate interposed therebetween; piezoelectric elements that are provided to face the liquid pressure chambers with the vibration plate interposed therebetween and are arranged in a predetermined direction; a driving element provided, in a flip-chip implementation, on a flow path substrate that includes the nozzle substrate, the liquid chamber substrate, the vibration plate, and the piezoelectric elements; and a first reinforcing wire that is disposed to at least one of the flow path substrate and the driving element, has a band shape extending in a direction along a row of the piezoelectric elements, and is connected to a common electrode shared by the piezoelectric elements.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com