Microwave-hydro-forming method and device of composite material

A composite material and hydroforming technology, applied in the field of microwave-hydroforming methods and devices, microwave heating and curing composite materials, can solve problems such as uneven force, and achieve the effect of good openness and good convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

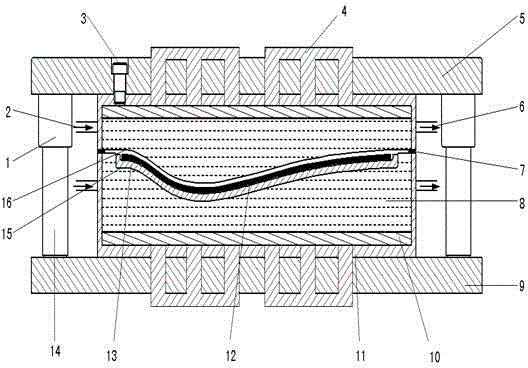

[0023] Such as Figure 1-2 shown.

[0024] A microwave-hydroforming method for composite materials: the key is to apply balanced liquid pressure to the upper and lower surfaces of a composite material part 12 during microwave heating of the composite material, so as to effectively compact the composite material part 12 . The upper and lower pressure-resistant and high-temperature-resistant rubber capsules 15, 16 and the sealing ring 7 form a closed space, and the two rubber capsules 15, 16 are tightly attached to the composite material and the mold 13 respectively by vacuuming. The microwave generated by the microwave generator 4 heats and cures the composite material. During the curing process, the liquid pressure generated by the fluid medium in the upper and lower rubber bladders is applied to the composite material and the surface of the mold to provide uniform compaction force. The pressure adjustment range in the upper and lower rubber bladders is between 0 and 20MPa. ...

Embodiment 2

[0028] Such as Figure 1-2 shown.

[0029] A microwave-hydroforming device for composite materials, which includes an upper rubber bladder 15, a lower rubber bladder 16, a mold 13, an array microwave generator 4, and a mold opening and closing system. In addition to the opening and closing functions of the mold opening and closing system, It is also possible to apply external pressure after closing so that the upper rubber bladder 15 and the lower rubber bladder 16 simultaneously press the sealing ring 7 to form a closed space, and the composite material part 12 is placed on the mold 13, and the mold 13 and the composite material part 12 are located at the In the above-mentioned confined space; the upper rubber bag 15 and the lower rubber bag 16 are filled with a fluid medium 8 and are respectively provided with a liquid medium input port 2 for pressurization and a liquid medium output port 6 for decompression, The enclosed space is connected with a vacuum air outlet 17; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com