Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129 results about "Chemical dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical Dissolution. Chemical dissolution is a much more modern and less labor-intensive way of removing wax. It is quite simple: a pysanka is placed into a degreasing solution, and the wax dissolves off.

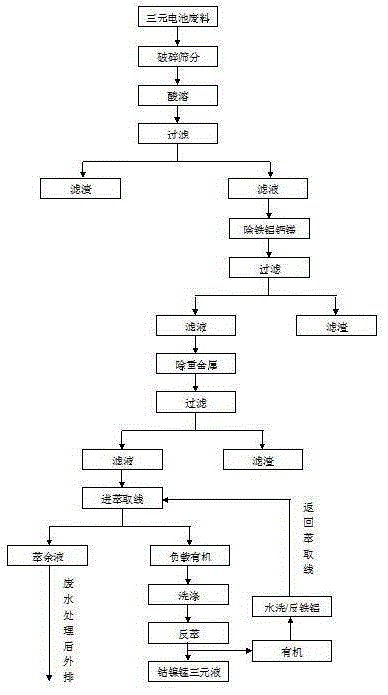

Treatment method for waste LiMn1-x-yNixCoyO2 ternary battery cathode material

ActiveCN105206889ASimple processImplement directional loopWaste accumulators reclaimingProcess efficiency improvementManganesePre treatment

The invention relates to a treatment method for a waste LiMn1-x-yNixCoyO2 ternary battery cathode material and belongs to the field of waste battery treatment. The method comprises the following steps: (1), pretreatment; (2), chemical dissolution; (3), chemical impurity removal; (4), extraction, deep impurity removal and enrichment of cobalt, nickel and manganese. By adopting the treatment method for the waste LiMn1-x-yNixCoyO2 ternary battery cathode material, the full utilization and directional circulation of nickel, cobalt and manganese in the waste LiMn1-x-yNixCoyO2 ternary battery cathode material can be realized, the comprehensive recovery rate of nickel, cobalt and manganese is high and the treatment cost is low.

Owner:浙江三晟化工有限公司

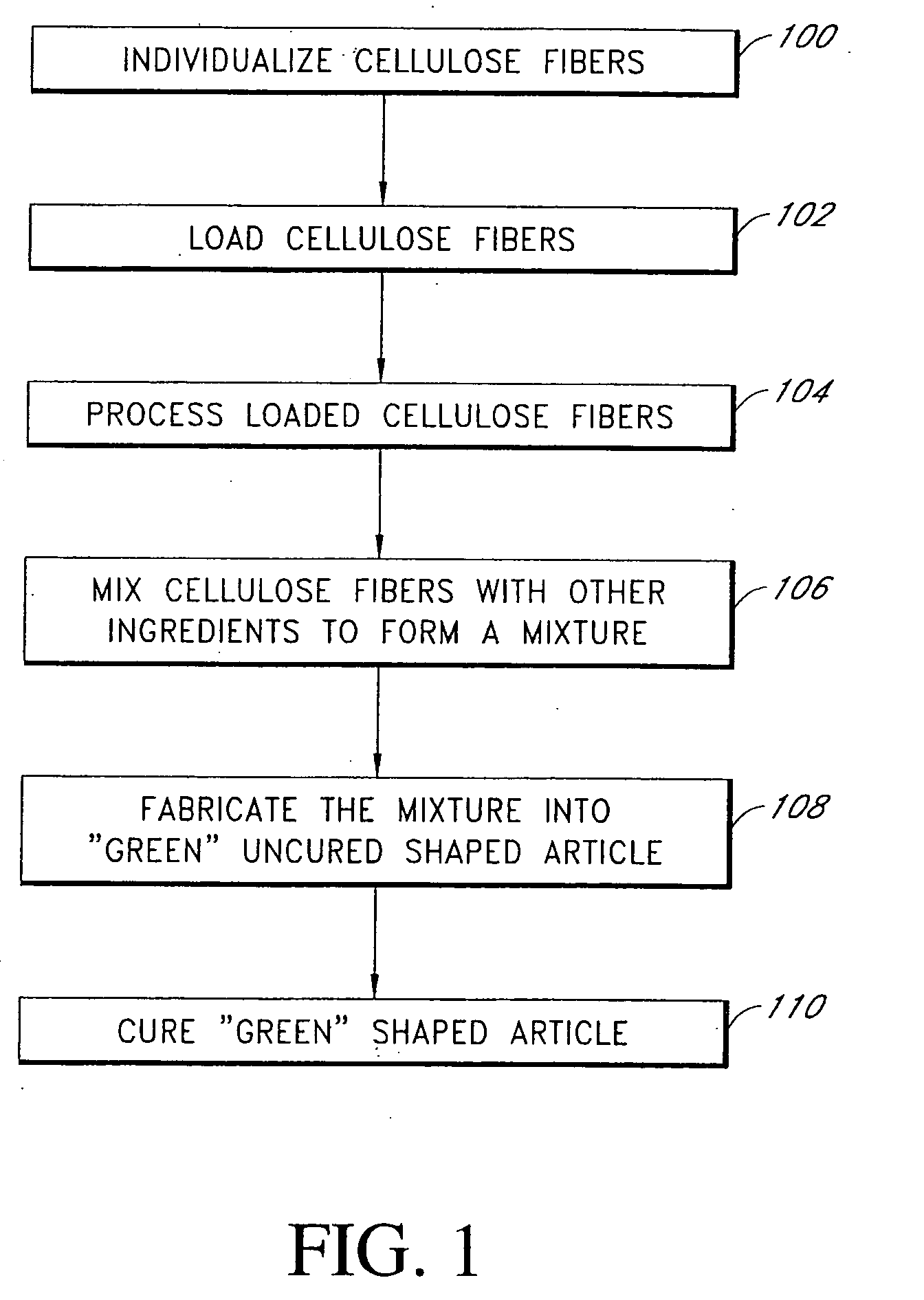

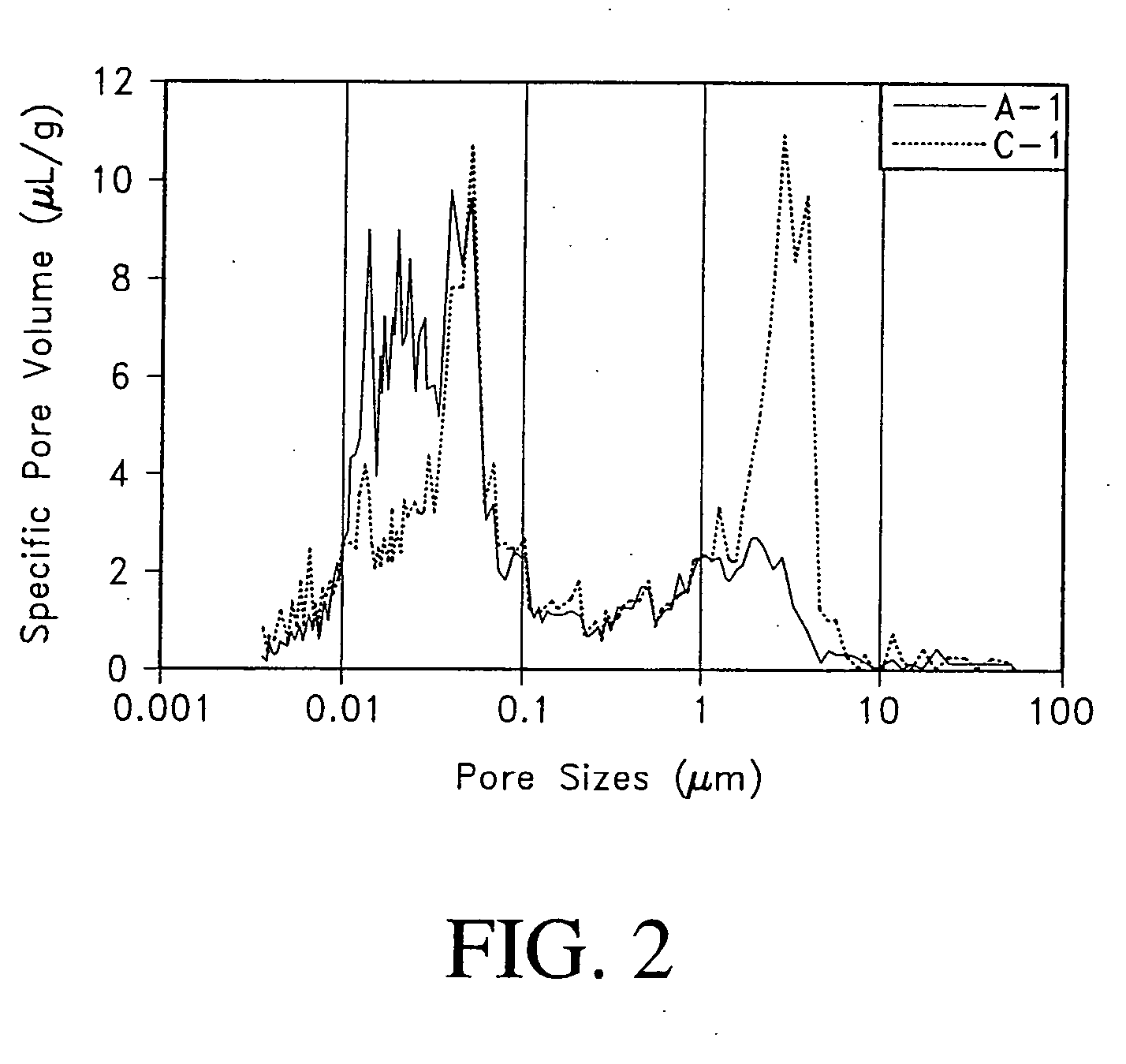

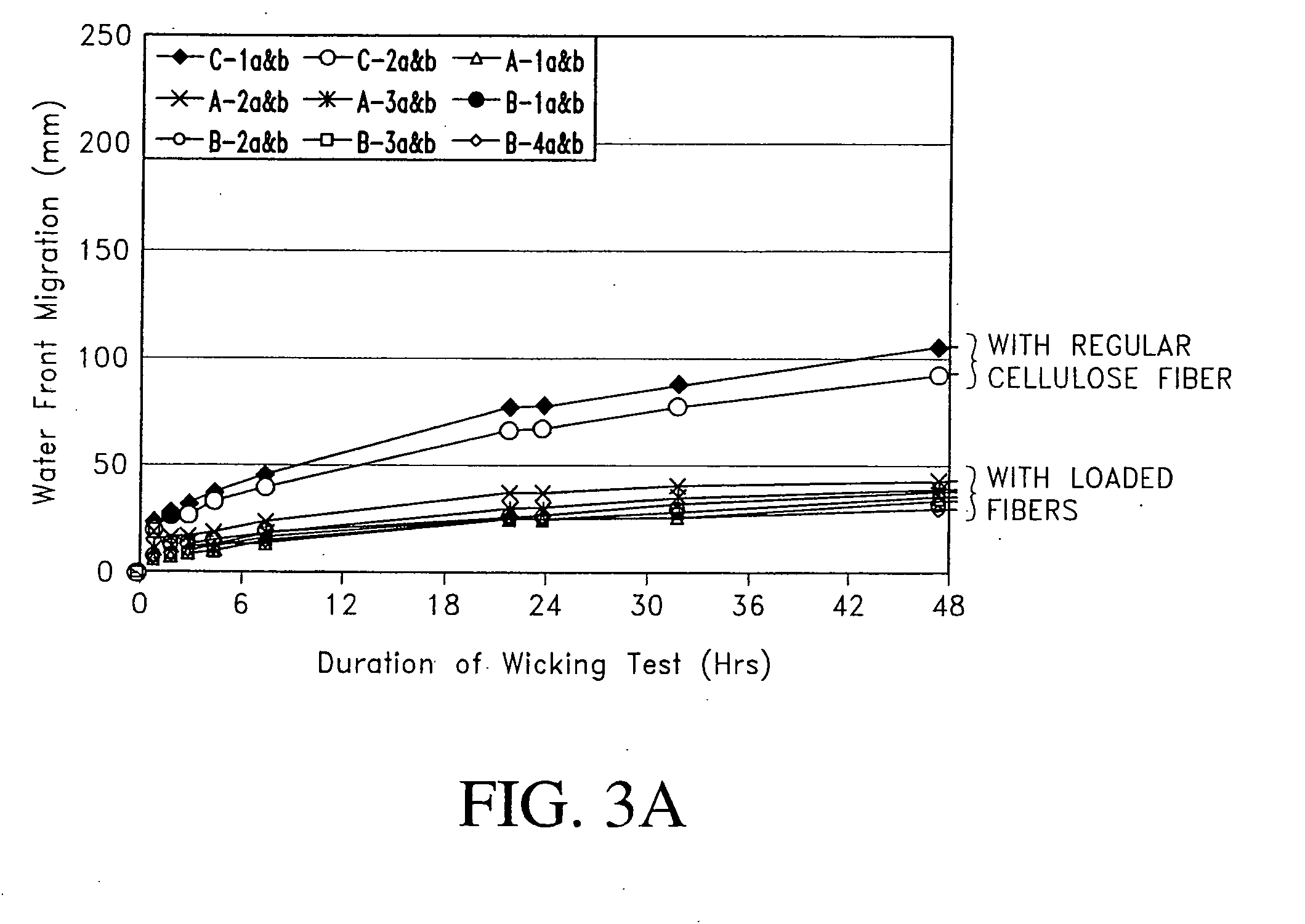

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

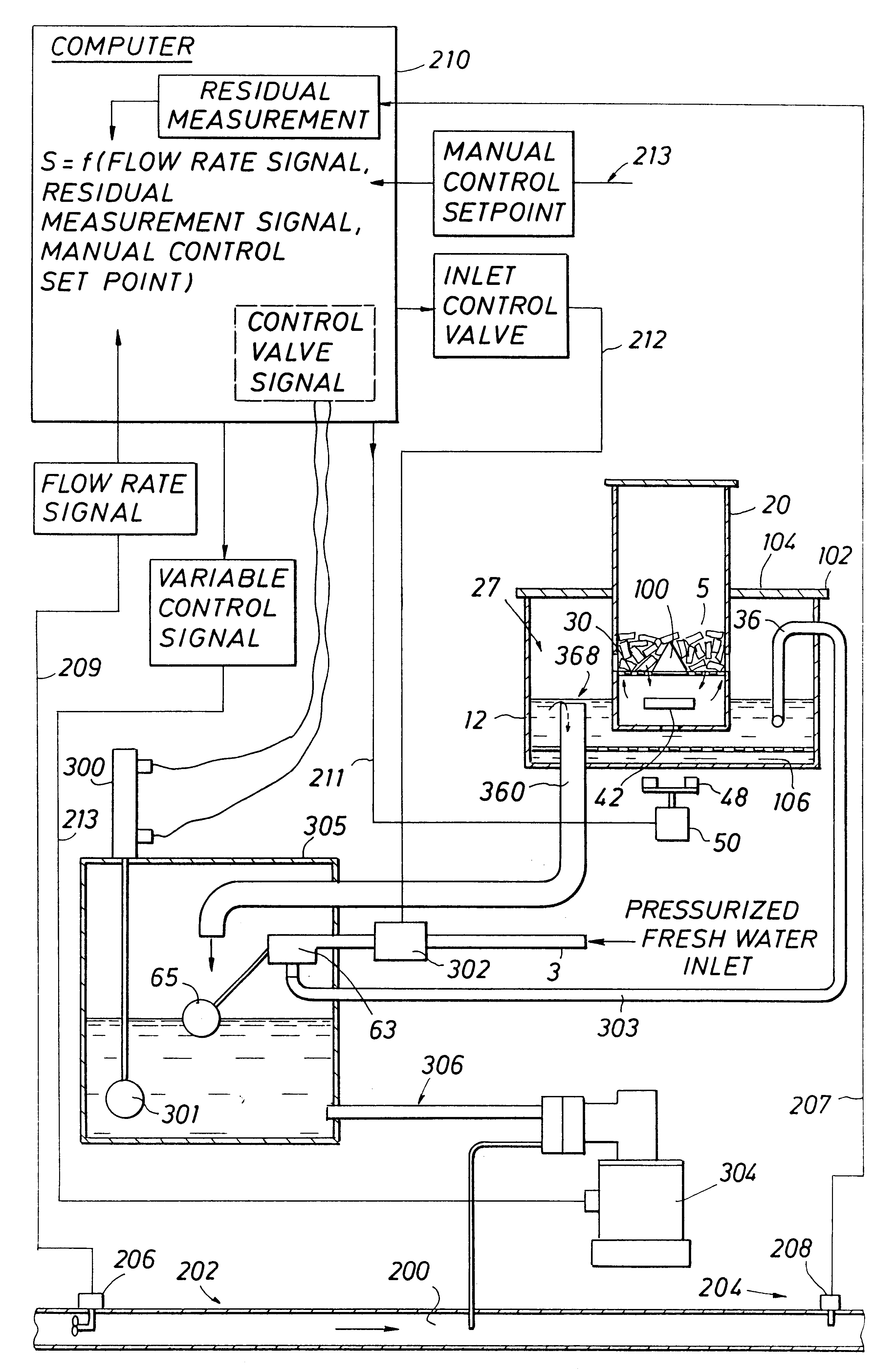

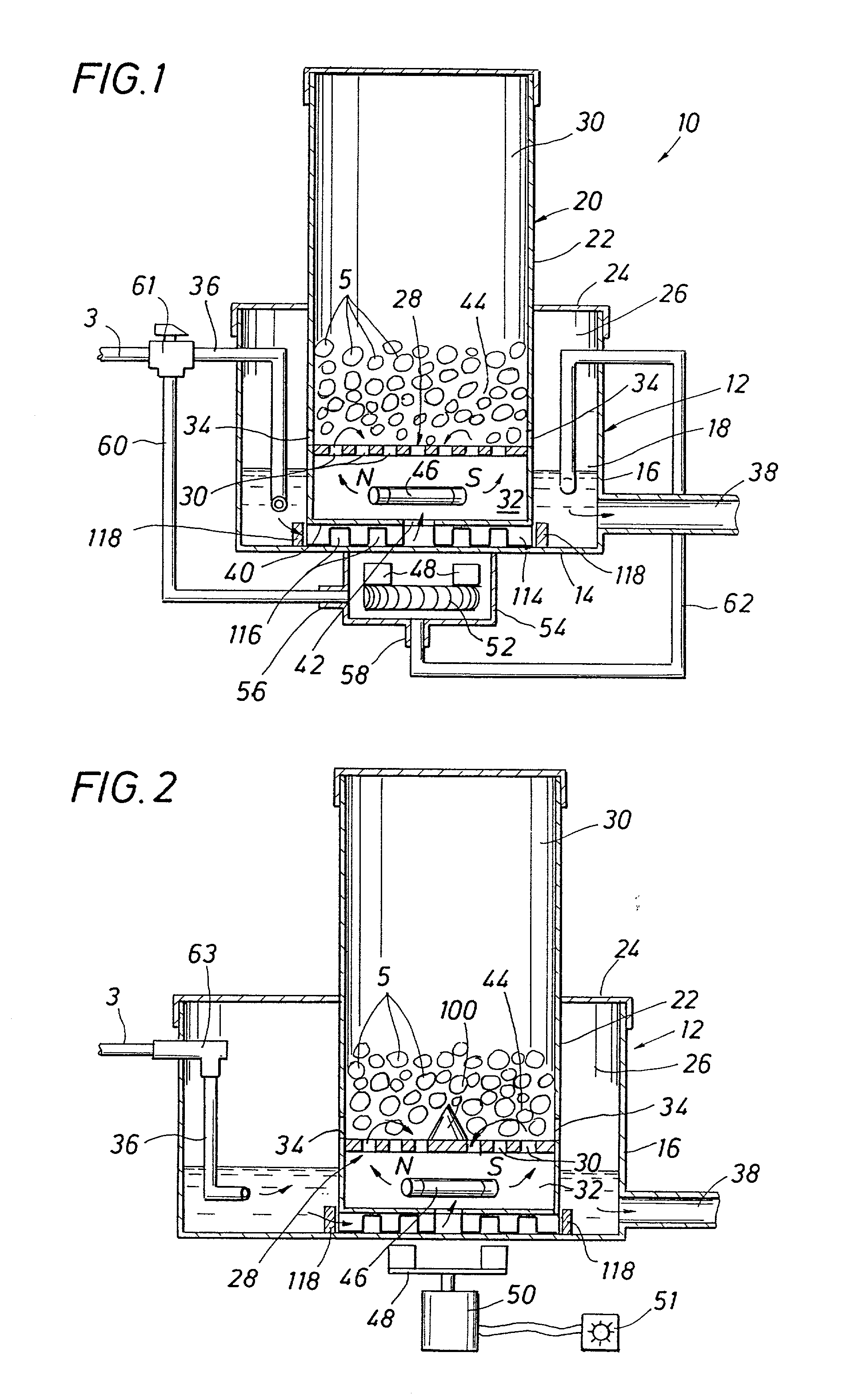

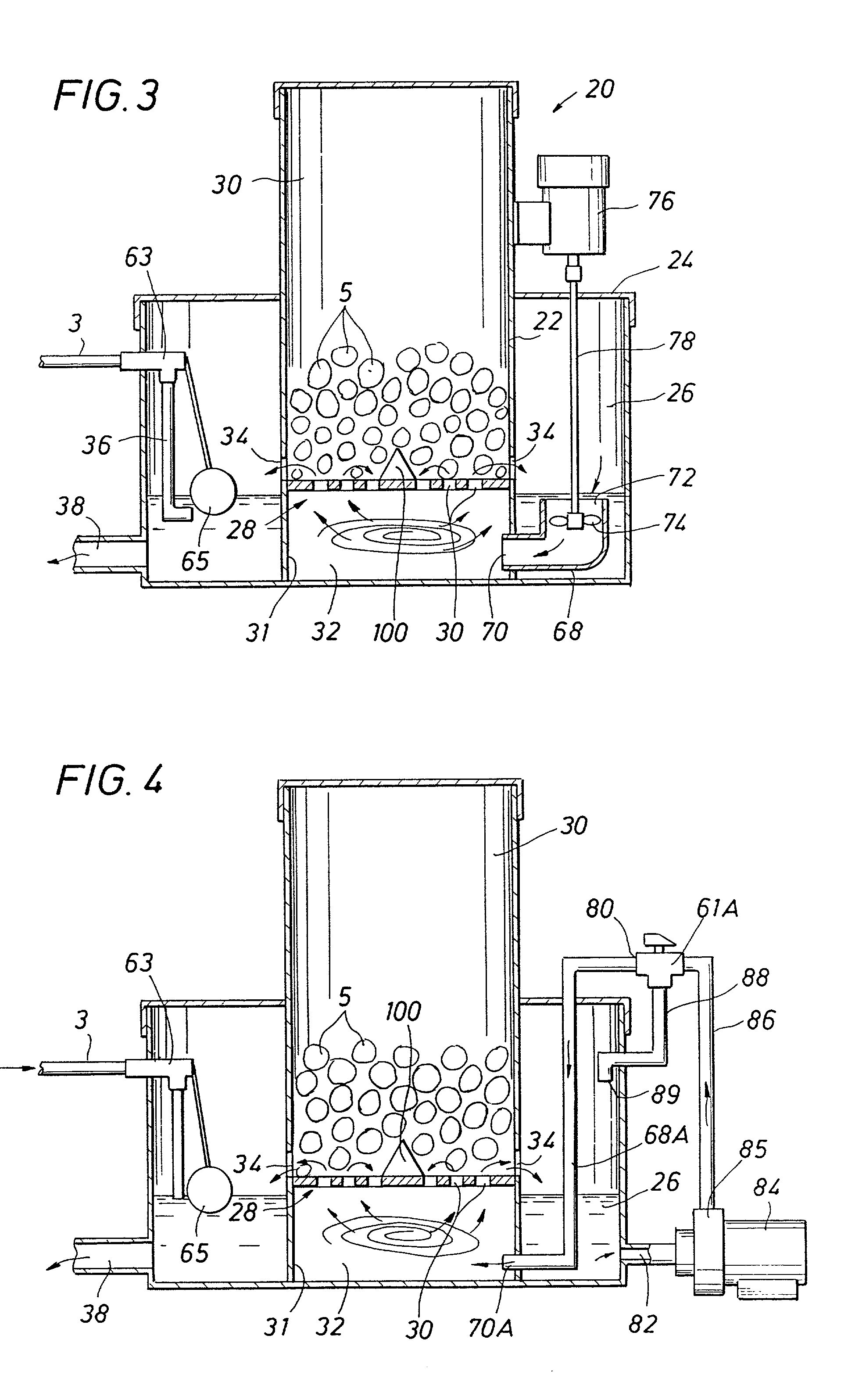

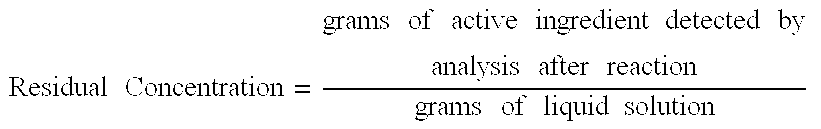

Chlorination apparatus and method

Apparatus and method for dissolving chemical tablets for creating a variable rate of chemical dissolution in a stream of constant flow rate of untreated liquid, especially water. The apparatus includes a housing in which a container is placed. The container includes a sieve plate or perforated grid which separates the container into an upper chamber in which chemical tablets are stored and a lower mixing chamber. A collection reservoir is defined in an annular outside the container wall and inside of the housing. Several arrangements are illustrated by which a vortex of liquid is generated of controllable variable intensity in the lower or mixing chamber thereby creating uneven liquid pressure beneath the perforated grid as a function of radial distance. As a result, fluid passes aggressively through outer radial perforations or holes in the grid and which impinge on the chemical tablets stacked on the grid. The liquid circulates in the upper chamber from the outward radial position toward the center of the grid plate, while eroding the tablets, and returns to the mixing chamber. A portion of the liquid exits into the collection reservoir. Liquid communication also exits from a hole in the bottom of the lower mixing chamber, which is open to the collection reservoir. Varying the intensity of the vortex varies the rate of chemical dissolution, yet the flow rate of liquid through the apparatus is constant.

Owner:HAMMONDS TECHN SERVICES

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

A product comprising a cold water soluble film wherein: a) the film comprises a copolymer of vinyl alcohol (VOH) with a minor amount of 2-acrylamido-2-methyl propane sulfonic acid in free acid form or as a salt of the free acid (AMPS); and b) the film has a harsh chemical dissolution time of less than about 80 seconds measured by the harsh chemical dissolution test method after 8 weeks.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Production method of bamboo chemical dissolving pulp

ActiveCN101457494ASimple switching processHighly corrosiveWashing/displacing pulp-treating liquorsDigestersMaterial consumptionDissolving pulp

Aiming at the current situation of the cotton dissolving pulp and the wood dissolving pulp and the characteristics of the bamboo and the defects in the existing preparation of the dissolving pulp, the invention provides a method for preparing a chemical bamboo dissolving pulp. The chemical dissolving pulp produced can be widely applied in the cellulose derivative industries such as spinning viscose fiber, nitrocellulose and acetate fiber. The method comprises the following steps of: material preparation, cooking, screening, scrubbing, bleaching and paper making. The cooking procedure comprises two grades of cooking steps, wherein the primary cooking procedure is continuous cooking and the secondary cooking procedure is continuous cooking or intermittent cooking; and the bleaching procedure is elemental chlorine free bleaching or totally chlorine free bleaching. The invention solves the problems existed in the cooking and bleaching procedures. The chemical bamboo dissolving pulp can be prepared with high efficiency, low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

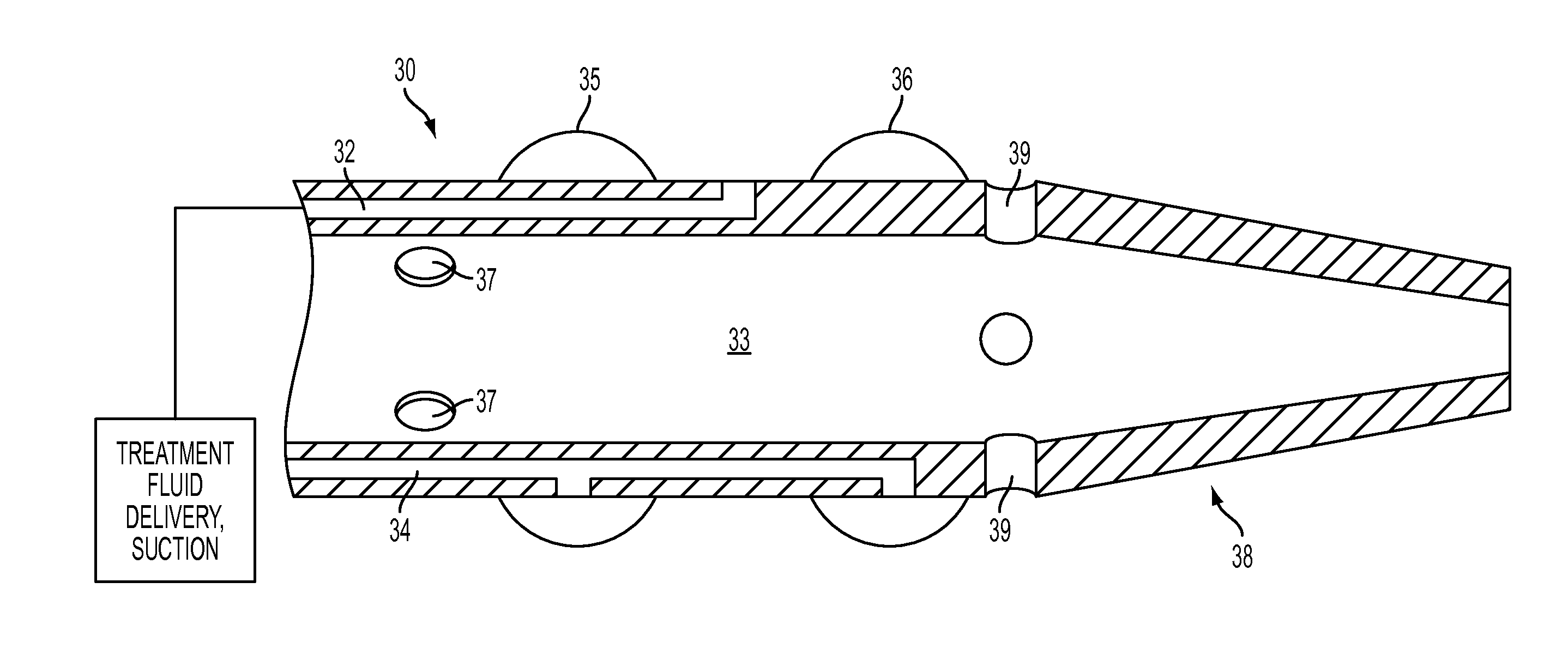

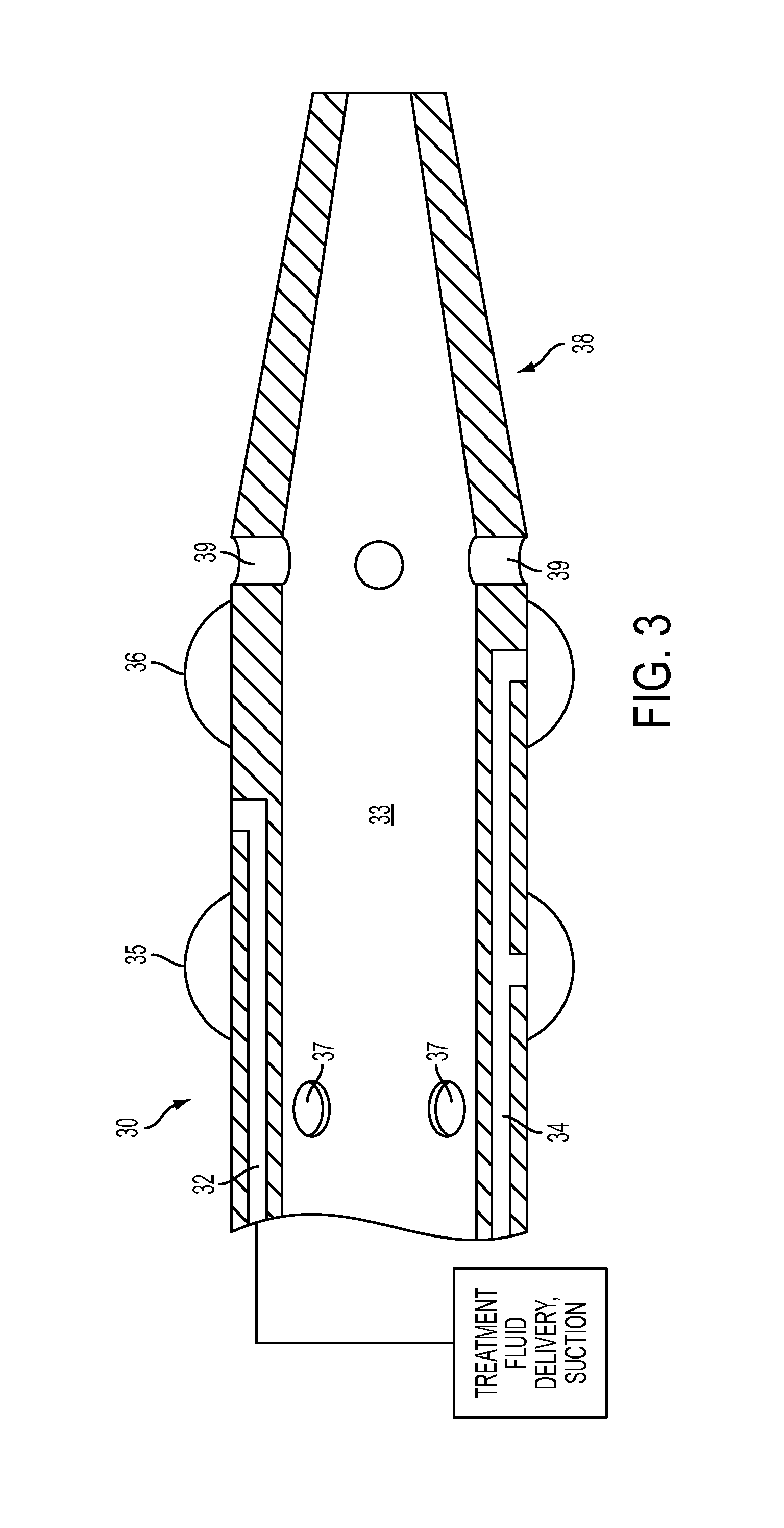

System for treating arterial obstructions

ActiveUS20120302953A1Less specialized trainingSufficient supplyStentsBalloon catheterDouble balloon catheterBlood vessel

An apparatus, a kit and a method for rapidly restoring blood flow through, and removing a clot from, a blood vessel by chemical dissolution. The essential components include an instrument for preventing the flow of debris downstream of the clot, a coronary catheter constructed to be introduced into the blood vessel and a double balloon catheter that has a tapered tip and that can form an enclosed space containing the clot and via which dissolution fluid can be brought into contact with the clot.

Owner:DON MICHAEL INT

Whiten method for preparing bamboo chemical dissolving pulp and application thereof

InactiveCN101446053AIncrease contentImprove physical strengthWashing/displacing pulp-treating liquorsPulp bleachingMaterial consumptionDissolving pulp

Aiming at current situations of cotton and wood dissolving pulp, characters of bamboo material and many disadvantages existing in the existing whiten method for preparing dissolving pulp, the invention provides a whiten method for preparing bamboo material chemical dissolving pulp. The chemical dissolving pulp produced by the invention can be widely applied to derivant industry of celluloses, such as spinning viscose fiber, cellulose nitrate, acetate fiber, etc. The whiten method in the invention uses element-free chlorine bleaching or total chlorine free bleaching, thereby solving the problems existing in the whiten method of bamboo material chemical dissolving pulp and preparing bamboo material chemical dissolving pulp high-efficiently with low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

A product comprising a cold water soluble film wherein: a) the film comprises a copolymer of vinyl alcohol (VOH) with a minor amount of 2-acrylamido-2-methyl propane sulfonic acid in free acid form or as a salt of the free acid (AMPS); and b) the film has a harsh chemical dissolution time of less than about 80 seconds measured by the harsh chemical dissolution test method after 8 weeks.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Method for preparing biological medical porous implant material

ActiveCN102796907AReduce sintering deformationStrong mechanical propertiesTransportation and packagingMetal-working apparatusBiocompatibility TestingSlurry

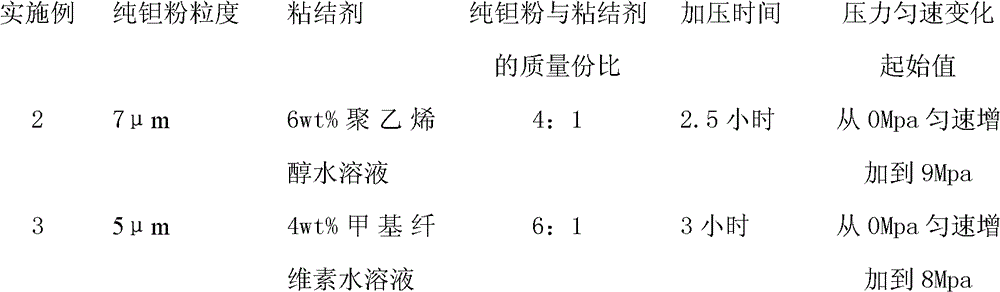

The invention discloses a method for preparing a porous tantalum biological medical implant material. The method comprises the following steps of: uniformly mixing pure tantalum powder and a binding agent to obtain tantalum powder slurry; placing a high polymer resin template support which has the porosity of 20 to 50 percent and of which pores are completely communicated in a three-dimensional way in a steel die; pouring the prepared tantalum powder into the steel die until the high polymer resin template support is immersed; slowly and uniformly applying pressure to the periphery of the steel die to ensure that the tantalum powder can be fully and completely filled into the high polymer resin template support, wherein the applied pressure is increased from 0 Mpa to10 Mpa at constant speed, and the time required by the pressure application process is 2 to 5 hours; performing chemical dissolution to remove the high polymer resin template support to obtain a green body framework of porous tantalum; and performing aftertreatment such as degreasing, sintering and the like to obtain the biological medical porous tantalum implant material. A product prepared by the method is a green body of the porous metal material of which pores are completely communicated in the three-dimensional way, and the green body is sintered to form the porous metal implant material of which the pores are completely communicated in the three-dimensional way, so that the porous metal implant material is high in biocompatibility.

Owner:CHONGQING RUNZE PHARM CO LTD

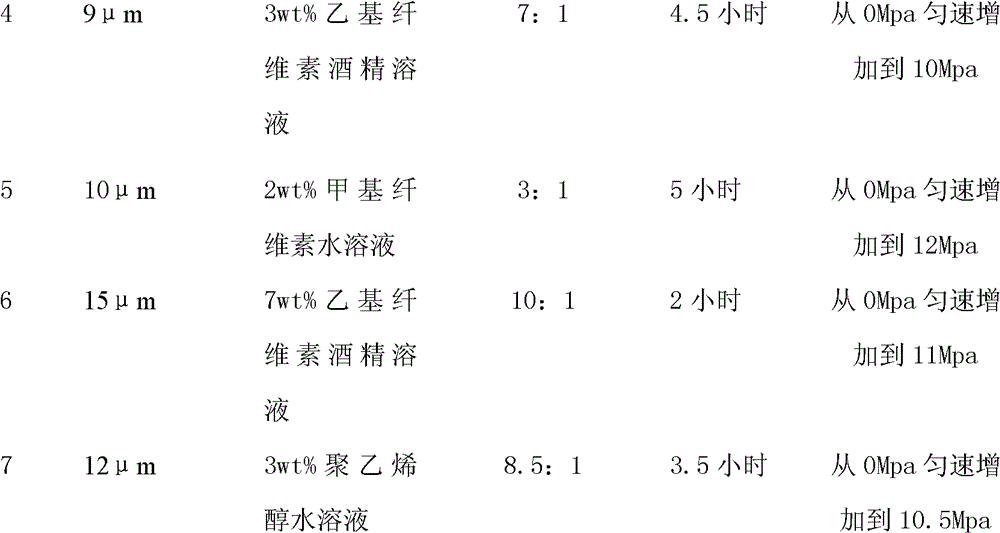

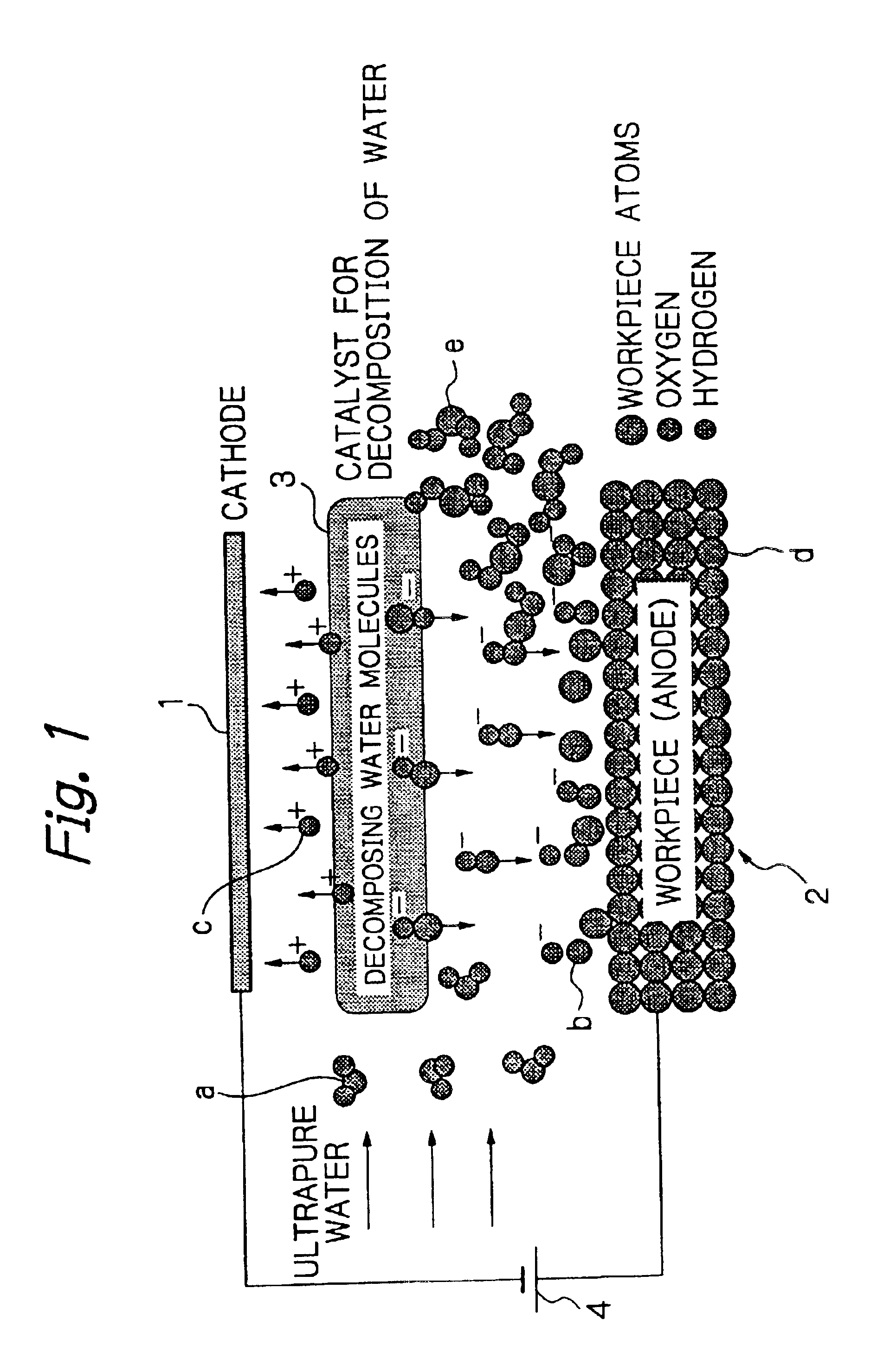

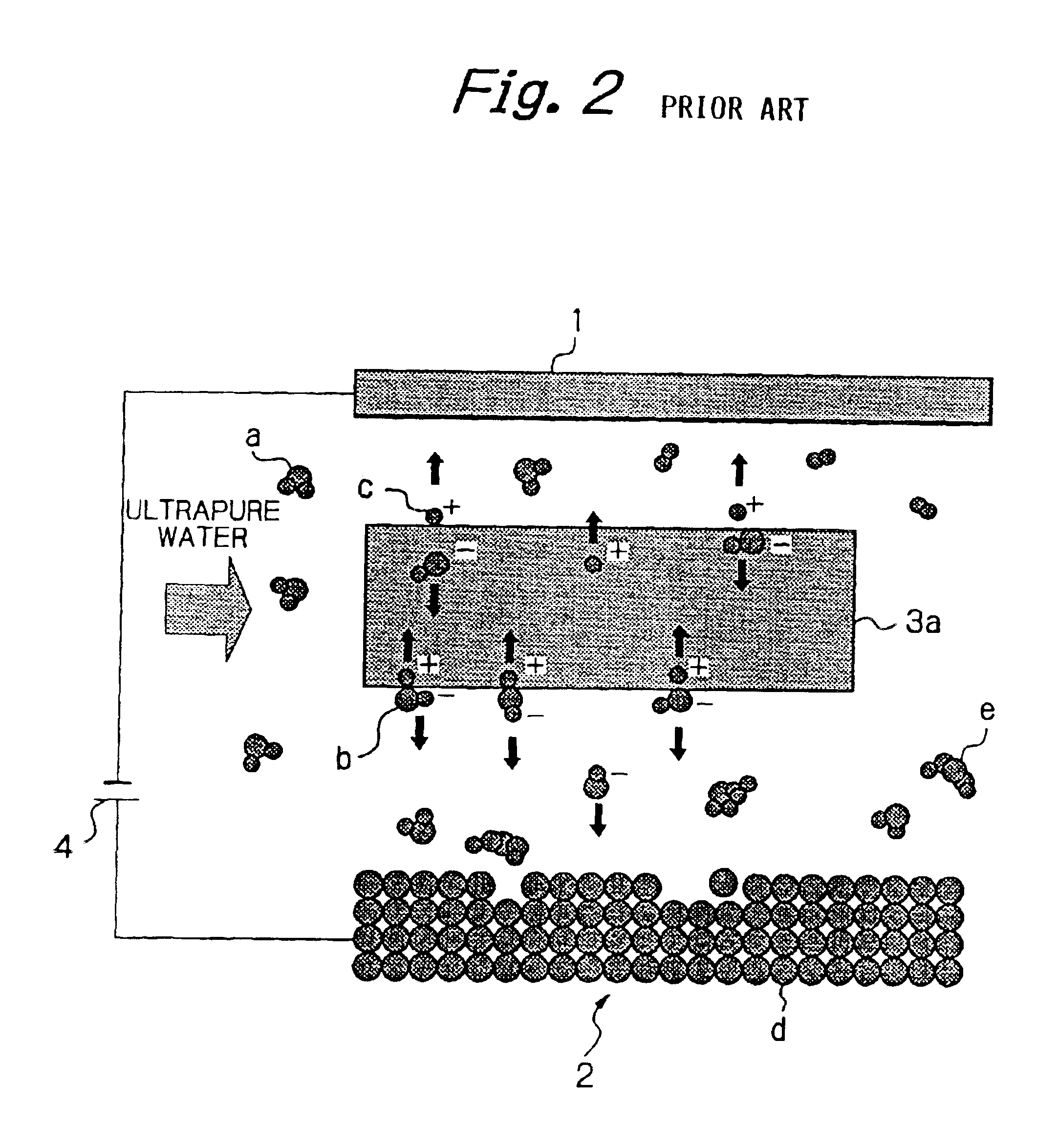

Electrolytic machining method and apparatus

An anode as a workpiece, and a cathode opposed to the anode with a predetermined spacing are placed in ultrapure water. A catalytic material promoting dissociation of the ultrapure water and having water permeability is disposed between the workpiece and the cathode. A flow of the ultrapure water is formed inside the catalytic material, with a voltage being applied between the workpiece and the cathode, to decompose water molecules in the ultrapure water into hydrogen ions and hydroxide ions, and supply the resulting hydroxide ions to a surface of the workpiece, thereby performing removal processing of or oxide film formation on the workpiece through a chemical dissolution reaction or an oxidation reaction mediated by the hydroxide ions. Thus, clean processing can be performed by use of hydroxide ions in ultrapure water, with no impurities left behind on the processed surface of the workpiece.

Owner:MORI YUZO +1

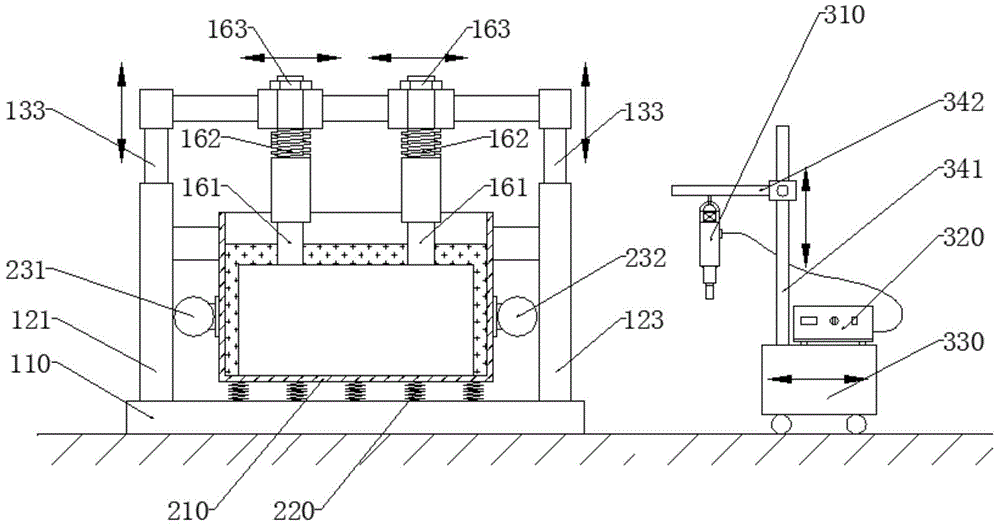

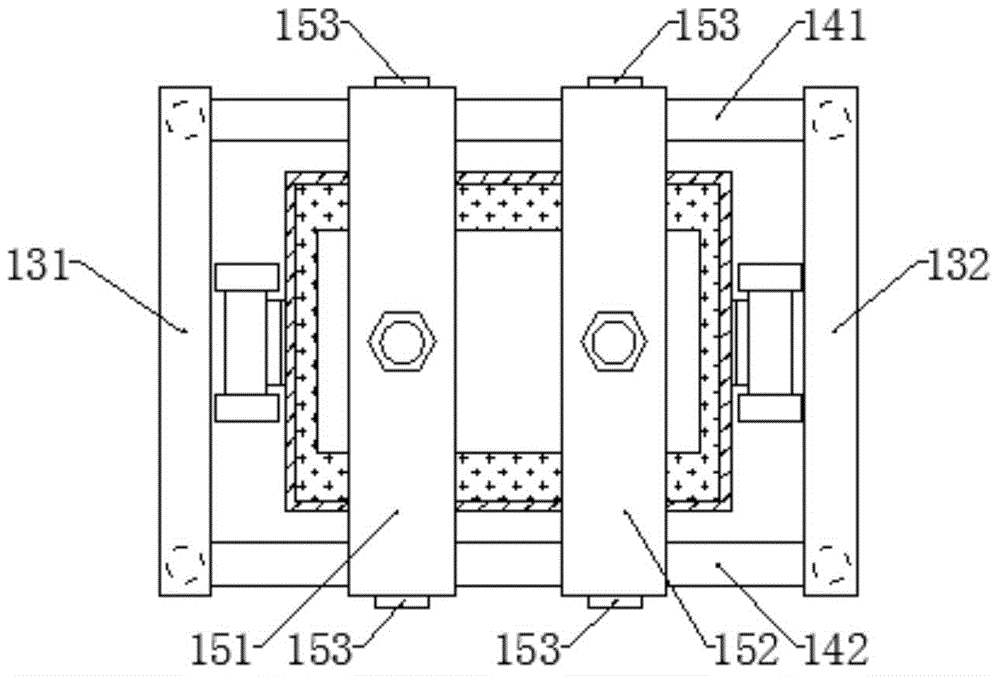

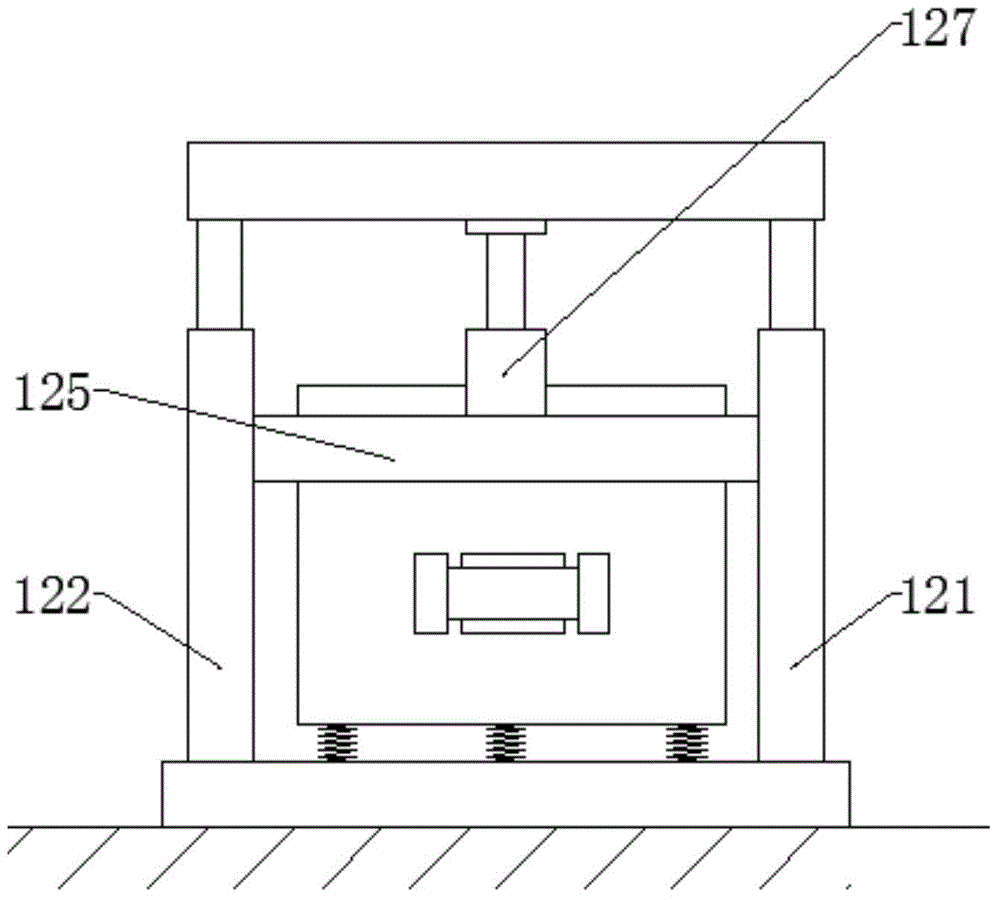

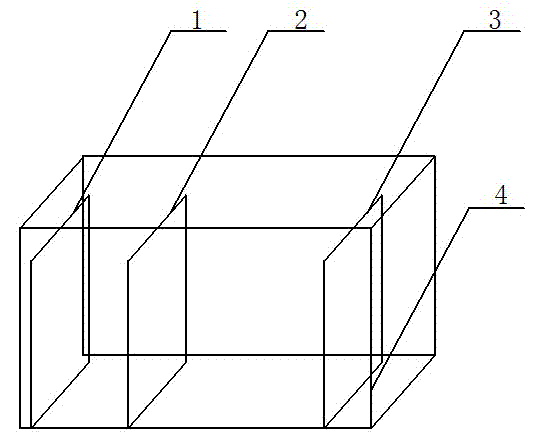

Aluminum or magnesium alloy casting sand core removing device and method

The invention relates to a sand core removing device and method, in particular to an aluminum or magnesium alloy casting sand core removing device and method. The aluminum or magnesium alloy casting sand core removing device and method solve the problems that in the prior art, thin-walled complex aluminum or magnesium alloy casting sand core removing is difficult and the removing period is long, and are used for efficiently removing thin-walled complex aluminum or magnesium alloy casting sand cores. The aluminum or magnesium alloy casting sand core removing device comprises a casting compressing assembly and a mechanical vibrating assembly, and further comprises an ultrasonic wave removing assembly. The aluminum or magnesium alloy casting sand core removing method comprises the steps of soaking, vibration and ultrasonic wave impacting. The aluminum or magnesium alloy casting sand core removing device is simple in structure, low in energy consumption and easy to control. The aluminum or magnesium alloy casting sand core removing device and method integrate the effects of chemical dissolution, vibration crushing and ultrasonic wave cavitation removing, and are good in casting cleaning effect, high in efficiency and applicable to efficiently removing thin-walled complex aluminum or magnesium alloy casting sand cores.

Owner:HUAZHONG UNIV OF SCI & TECH

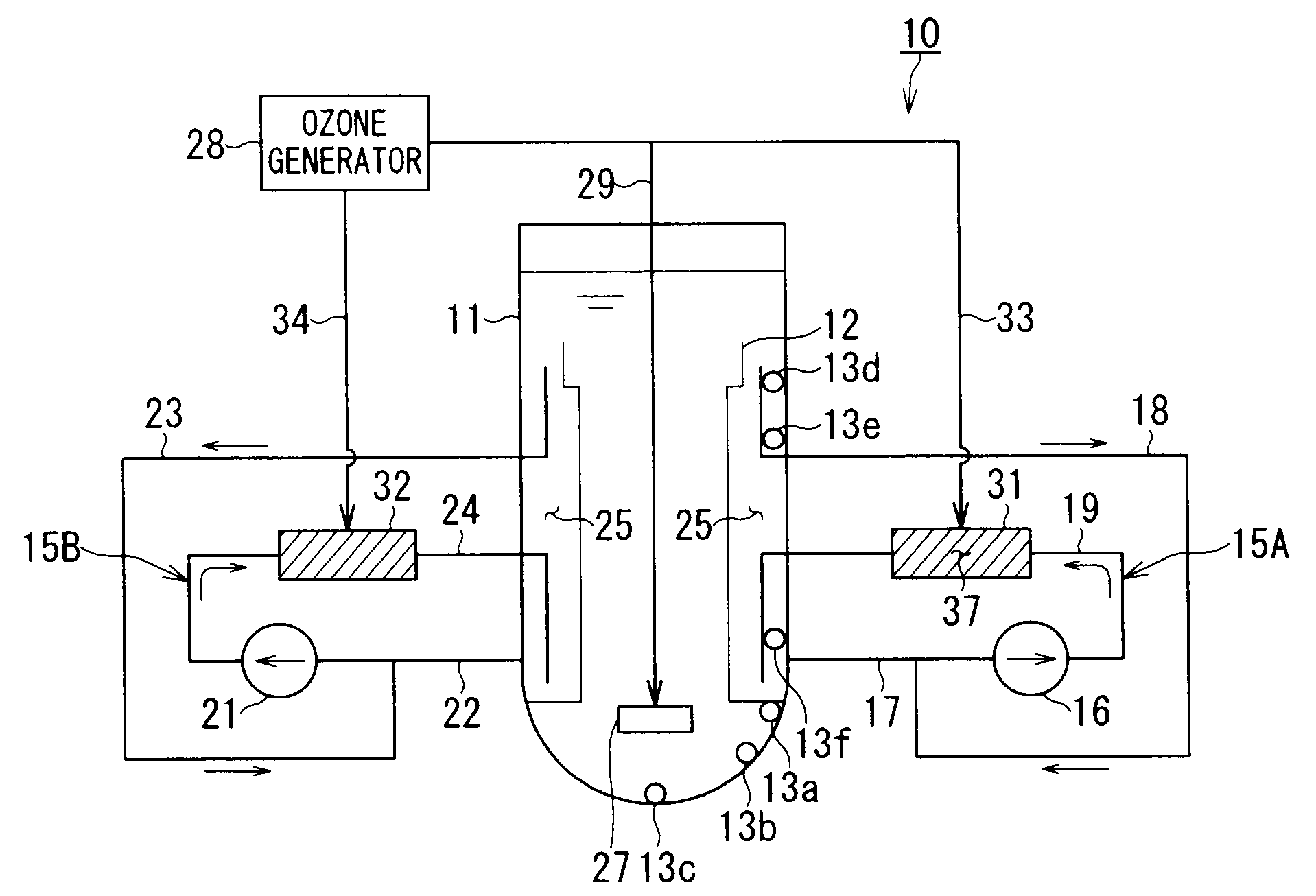

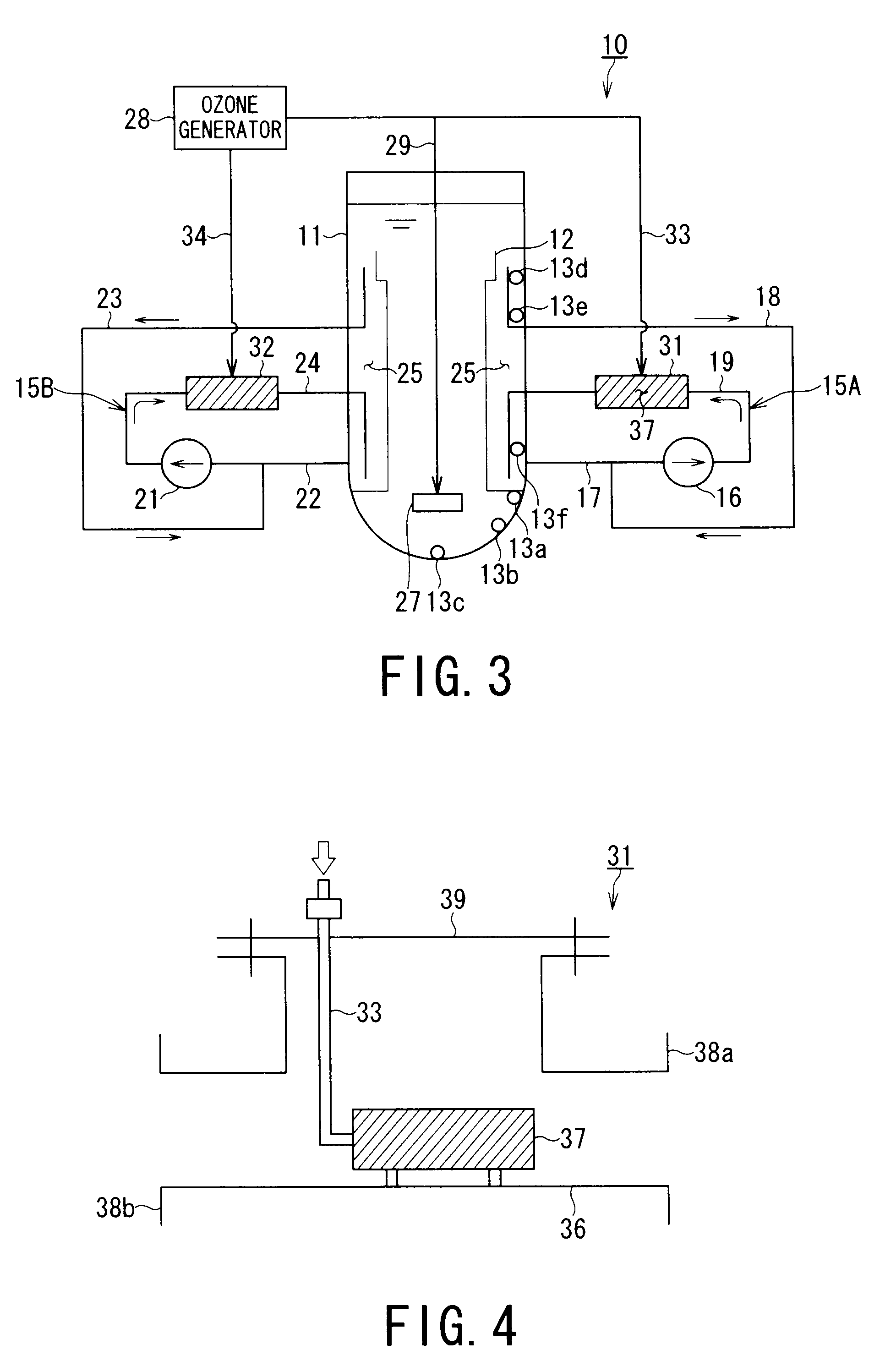

Chemical decontamination apparatus and decontamination method therein

InactiveUS20100168497A1Maintaining soundnessExcellent decontaminationLighting and heating apparatusHollow article cleaningRadioactive agentGas supply

A chemical decontamination apparatus of the present invention chemically dissolves radioactive substance-containing oxide films formed or adhering on the surface of a decontamination object by using ozone water to conduct decontamination. The chemical decontamination apparatus includes an ozone generating unit for generating ozone gas, an ozone supplying device for supplying the generated ozone gas to an ozone supplying unit in water, and a sintered metal element 37 which is disposed in the ozone supplying unit and to which ozone gas is supplied from the ozone supplying device. The ozone gas supplied to a sintered metal element interior from the ozone supplying device is allowed to flow out of the element into water so as to generate ozone water.

Owner:KK TOSHIBA

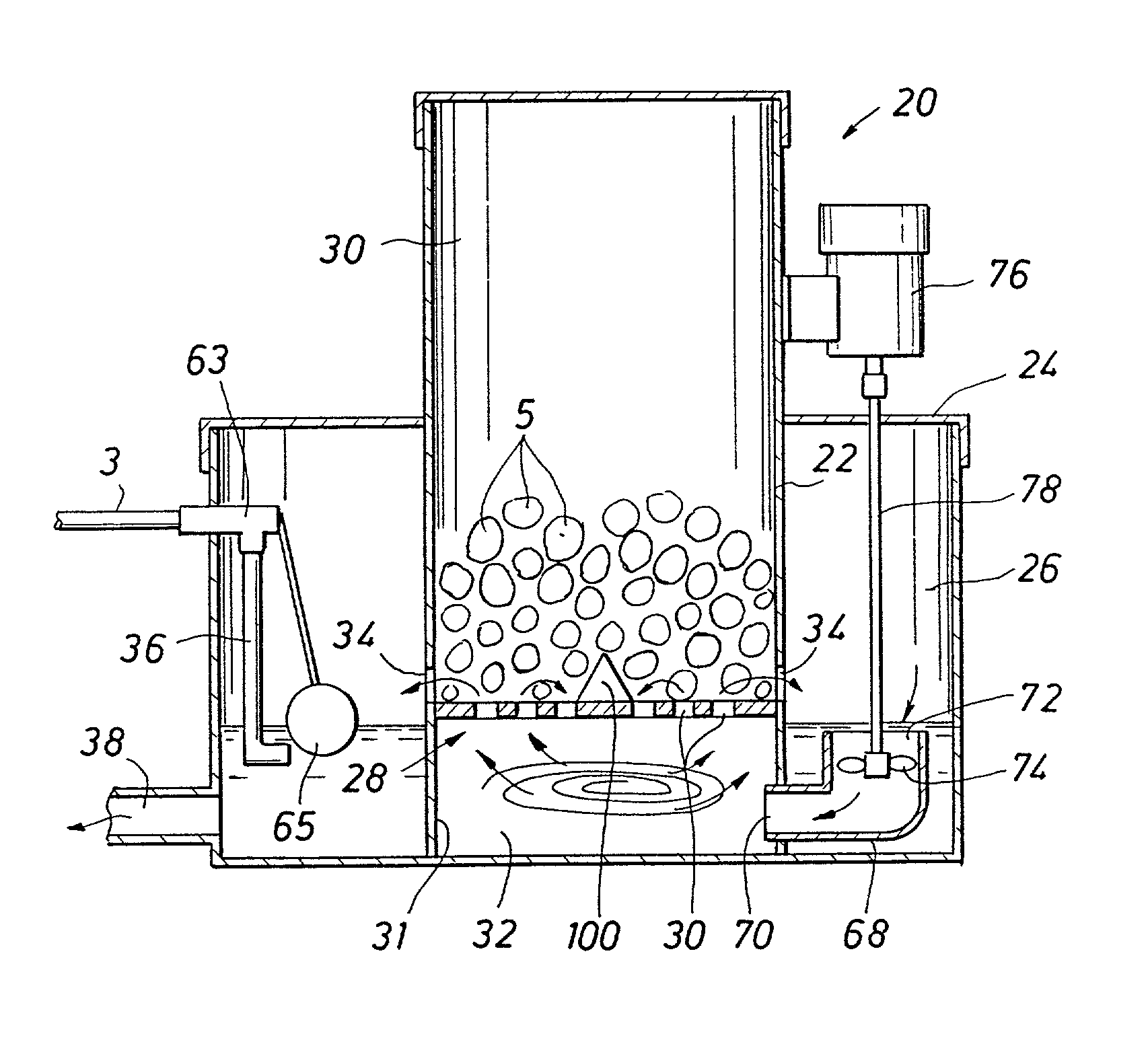

Chlorination apparatus and method

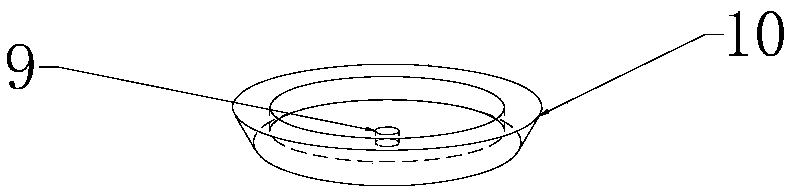

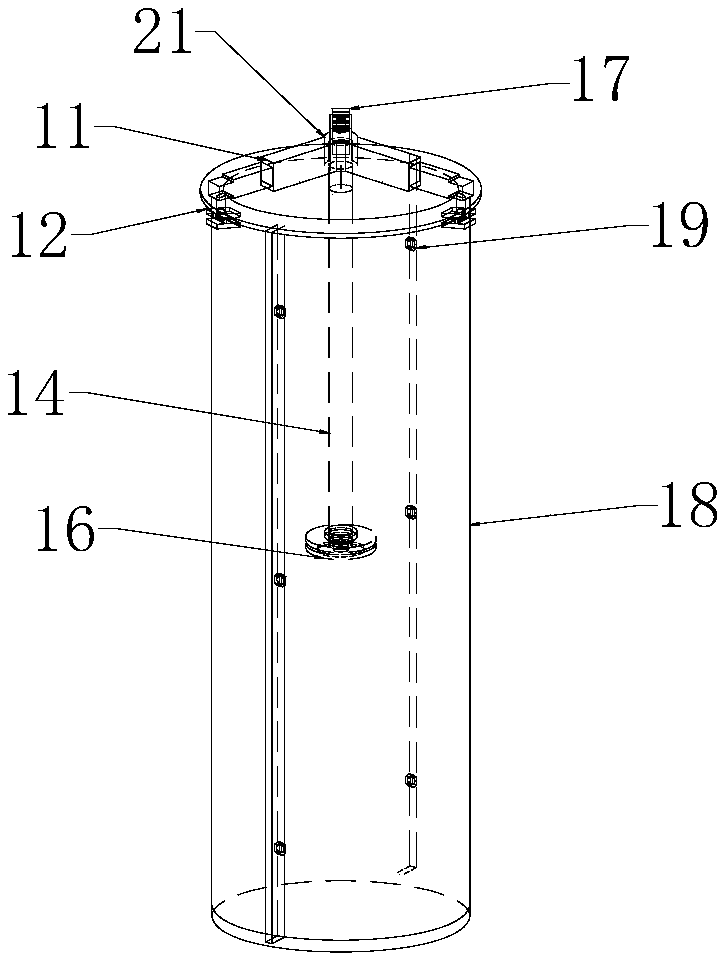

InactiveUS20020030004A1Other chemical processesDissolving using flow mixingRadial positionEngineering

Apparatus and method for dissolving chemical tablets for creating a variable rate of chemical dissolution in a stream of constant flow rate of untreated liquid, especially water. The apparatus includes a housing in which a container is placed. The container includes a sieve plate or perforated grid which separates the container into an upper chamber in which chemical tablets are stored and a lower mixing chamber. A collection reservoir is defined in an annular outside the container wall and inside of the housing. Several arrangements are illustrated by which a vortex of liquid is generated of controllable variable intensity in the lower or mixing chamber thereby creating uneven liquid pressure beneath the perforated grid as a function of radial distance. As a result, fluid passes aggressively through outer radial perforations or holes in the grid and which impinge on the chemical tablets stacked on the grid. The liquid circulates in the upper chamber from the outward radial position toward the center of the grid plate, while eroding the tablets, and returns to the mixing chamber. A portion of the liquid exits into the collection reservoir. Liquid communication also exits from a hole in the bottom of the lower mixing chamber, which is open to the collection reservoir. Varying the intensity of the vortex varies the rate of chemical dissolution, yet the flow rate of liquid through the apparatus is constant.

Owner:HAMMONDS TECHN SERVICES

Chemical dissolution of poly(vinylalcohol) item or woven or non-woven fabric with antimicrobial action

InactiveUS6184340B1Easy disposalSolve the antibacterial effect is not goodBiocideSolid waste disposalSolubilityAntimicrobial action

With the advent of disposable items made from or bonded by polyvinylalcohol polymers, particularly highly hydrolyzed polyvinylalcohol of limited water solubility, the disposal of used contaminated items has become a significant problem. These disposable products are typically used once and then discarded. During use, the items often come into contact with infective biological liquids and solids that can contain bacteria, viral particles, fecal matter, blood, mucus, etc. This large volume of disposable and often contaminated materials poses a significant problem to the hospitality and healthcare industries. Previously, such disposables are often sterilized using autoclave (high temperature steam) digestion to render the pathogen content substantially harmless. Such a process is time consuming due to the large volume of disposable materials and can be energy wastefull. We have found that polyvinylalcohol containing fabric materials can be treated with an aqueous alkaline treatment or with an alkaline oxidant for the purpose of rendering the pathogens harmless and dissolving the polyvinylalcohol non-woven for disposal purposes.

Owner:ECOLAB USA INC

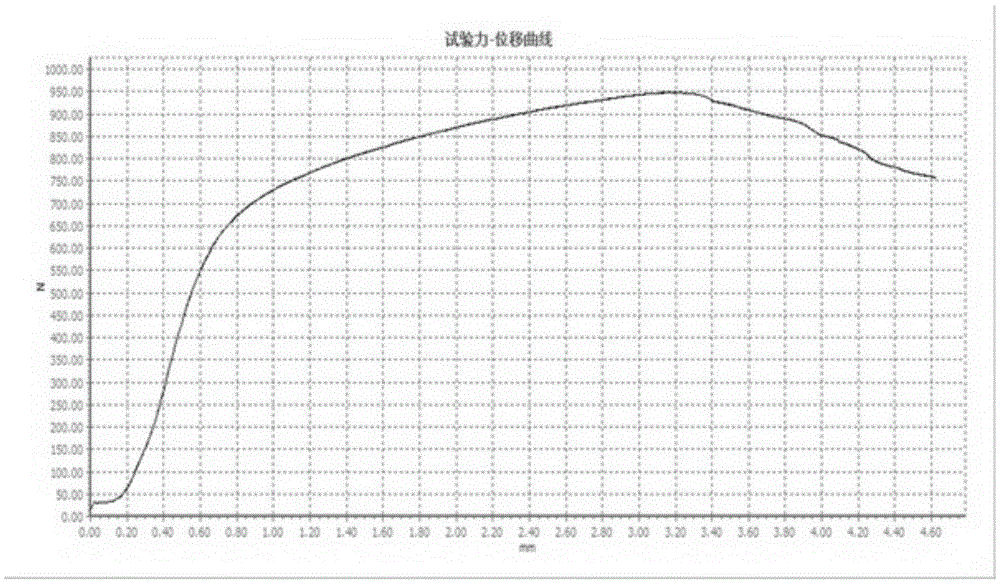

Hydraulic structure concrete hydraulic fracture test device, concrete manufacturing mold and test method

ActiveCN108693043AImprovements not involvedAccelerated corrosionPreparing sample for investigationMaterial strength using tensile/compressive forcesChemical effectsTest sample

Owner:HOHAI UNIV

Secondary decatizing method for preparing bamboo chemical dissolving pulp and application thereof

InactiveCN101446052ASimple switching processImprove efficiencyDigestersPulping with inorganic basesMaterial consumptionDissolving pulp

Aiming at current situations of cotton and wood dissolving pulp, characters of bamboo material and many disadvantages existing in the existing method for preparing dissolving pulp, the invention provides a secondary stewing method for preparing bamboo material chemical dissolving pulp. The produced chemical dissolving pulp can be widely applied to derivant industry of celluloses, such as spinning viscose fiber, cellulose nitrate, acetate fiber, etc. The invention uses two-stage stewing step, wherein the first stage stewing process is continuous stewing, and the second stewing process is continuous stewing or batch stewing. The invention solves problems existing in stewing processes of the method for preparing dissolving pulp so that the bamboo material chemical dissolving pulp is prepared high-efficiently with low energy consumption, low material consumption and low pollution.

Owner:宜宾长毅浆粕有限责任公司

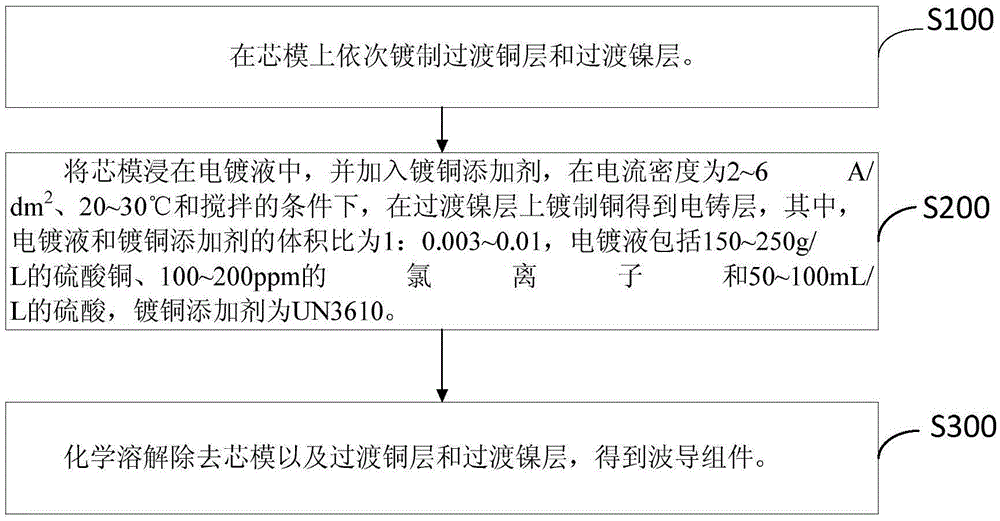

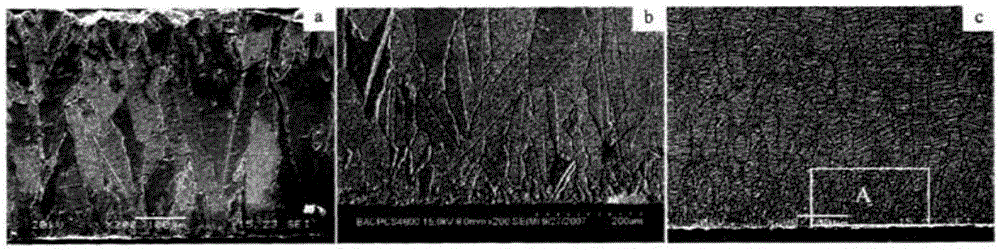

Electrotyping forming method of waveguide assembly

The invention discloses an electrotyping forming method of a waveguide assembly. The electrotyping forming method includes the following steps that a transition copper layer and a transition nickel layer are sequentially manufactured on a mandrel in a plating manner; the mandrel is soaked in a plating solution, a copper plating additive is added, copper is manufactured on the transition nickel layer in a plating manner obtain an electroformed layer under the stirring condition that the current density is 2-6 A / dm<2> and the temperature is 20-30 DEG C, wherein the size ratio of the plating solution to the copper plating additive is 1:(0.003-0.01), the plating solution comprises copper sulfate of 150-250 g / L, chloride ions of 100-200 ppm, and sulfuric acid of 50-100 mL / L, and UN3610 serves as the copper plating additive; and the mandrel, the transition copper layer and the transition nickel layer are removed through chemical dissolution, and the waveguide assembly is obtained. By means of the electrotyping forming method of the waveguide assembly, the electroformed layer which is fine in crystallization, compact in texture and good in tenacity can be obtained by selecting the appropriate plating solution, the appropriate copper plating additive and the appropriate copper plating condition, machining of the waveguide assembly is facilitated, and the rate of qualified products is increased.

Owner:HUNAN AEROSPACE HUNAYU COMM TECH CO LTD

Testing method of electrotinning uniform plating capacity

InactiveCN102866079ASimple test methodAvoid bias in resultsWeighing by removing componentEngineeringMaterials science

The invention provides a testing method of electrotinning uniform plating capacity. The testing method comprises the following steps of: processing a near cathode and a remote cathode in an electroplating bath by oil removing and micro-etching, and then drying; weighing to obtain the weight m1 of the near cathode and the weight m2 of the remote cathode; connecting the cathode to the positive pole of a rectifier; connecting the near cathode and the remote cathode to the negative pole of the rectifier; turning on a current to start electroplating; then drying the near cathode and the remote cathode after the electroplating; then weighing to obtain the weight m1' of the electroplated near cathode and the weight m2' of the electroplated remote cathode; and calculating the uniform plating capacity. The testing method provided by the invention is simple; two cathode plates are weighed after being carried out same pre-processing and drying during a test, so that the bias of a result due to chemical dissolving of an oxidizing layer can be avoided; and an accurate testing result is achieved.

Owner:XINFENG ZHENGTIANWEI ELECTRONICS TECH

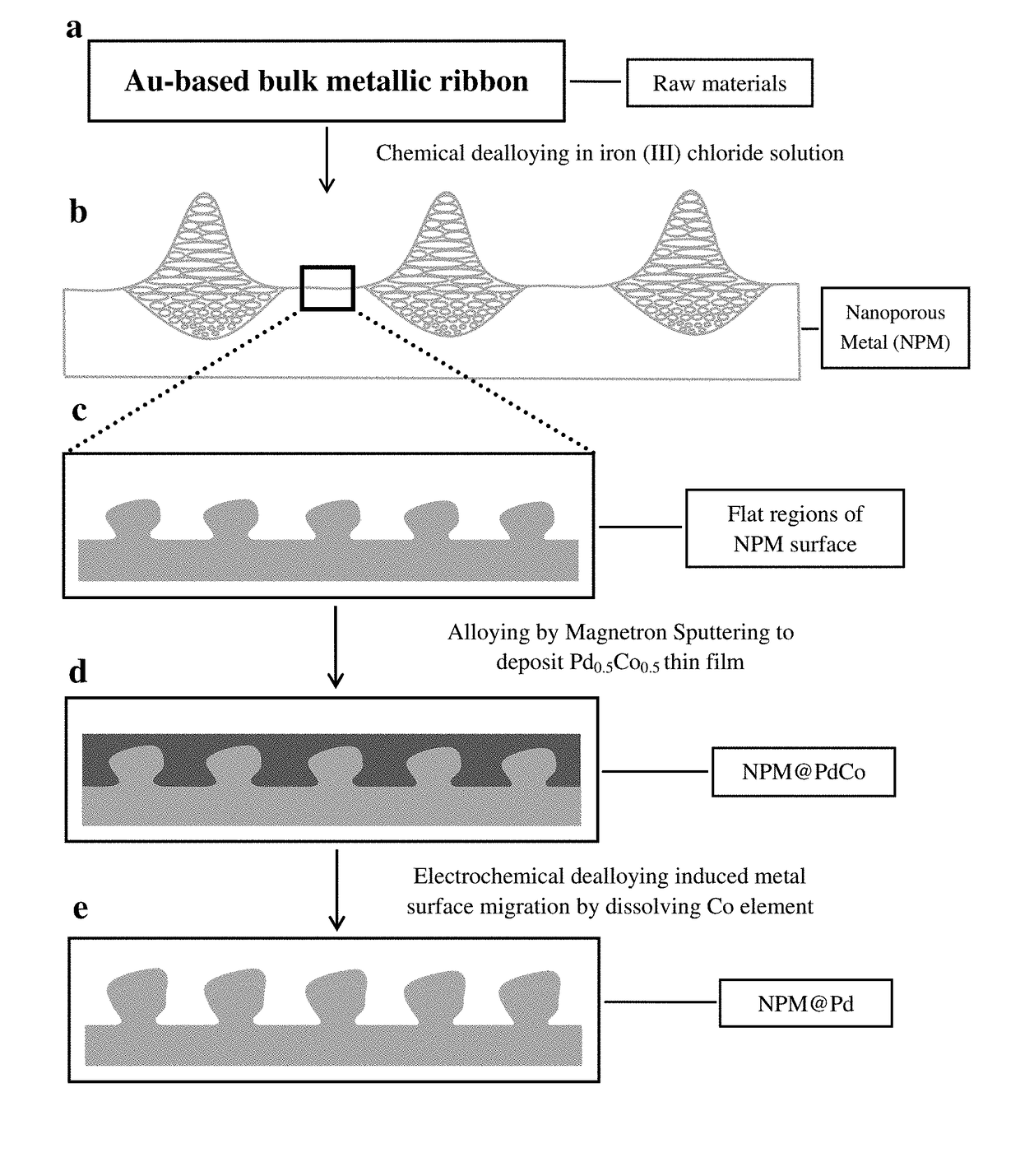

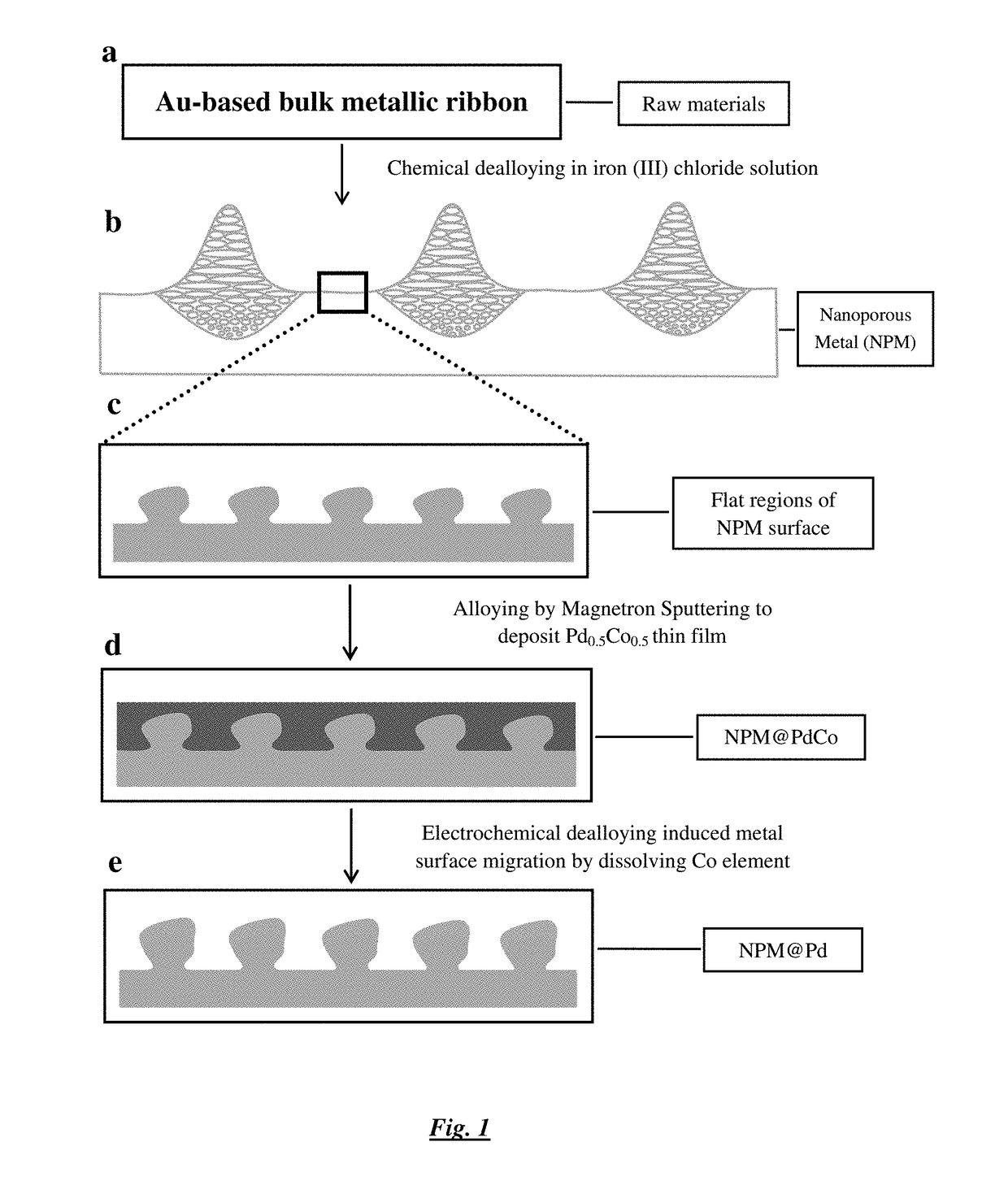

Method of fabricating nanoporous metal structure

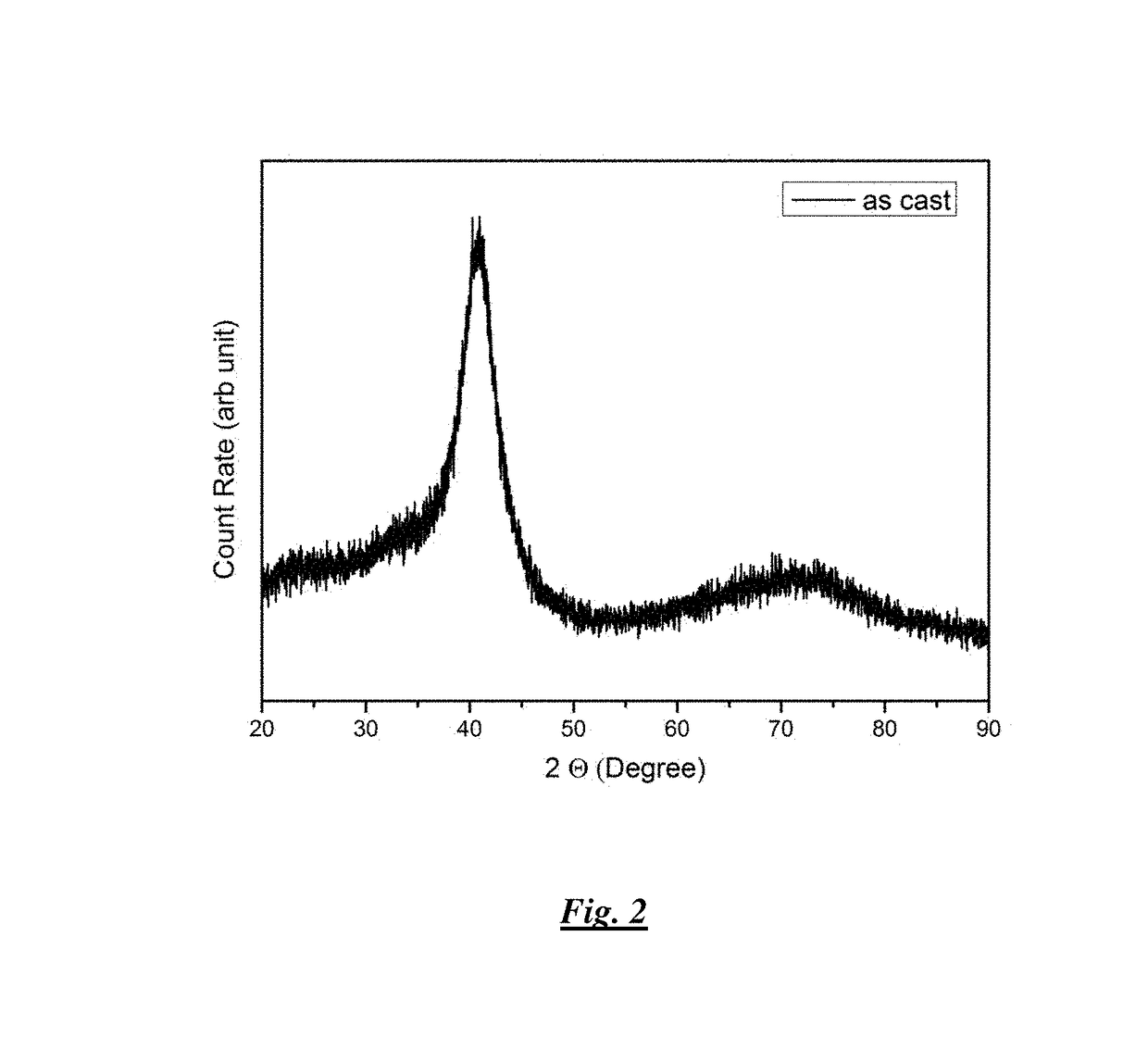

A method of fabricating a nanoporous metal structure, such as a nanoporous metal (NMP) supported Pd catalyst suitable for use in a direct methanol fuel cell (DMFC), is includes the steps of (a) providing a piece of Au55Cu25Si20 alloy glass ribbon with a thickness of 50 μm, (b) dealloying the piece of alloy glass ribbon by reacting with iron (III) chloride solution to form a free-standing NPM ribbon, (c) depositing a thin film of PdCo of a thickness of 100 nm on the NPM ribbon by RF magnetron sputtering with Pd0.5Co0.5 (atomic percent) as target in an argon atmosphere, and (d) electrochemically dissolving some of the Co on the thin film of PdCo to induce migration of Au from the NPM ribbon to the thin layer of PdCo.

Owner:CITY UNIVERSITY OF HONG KONG

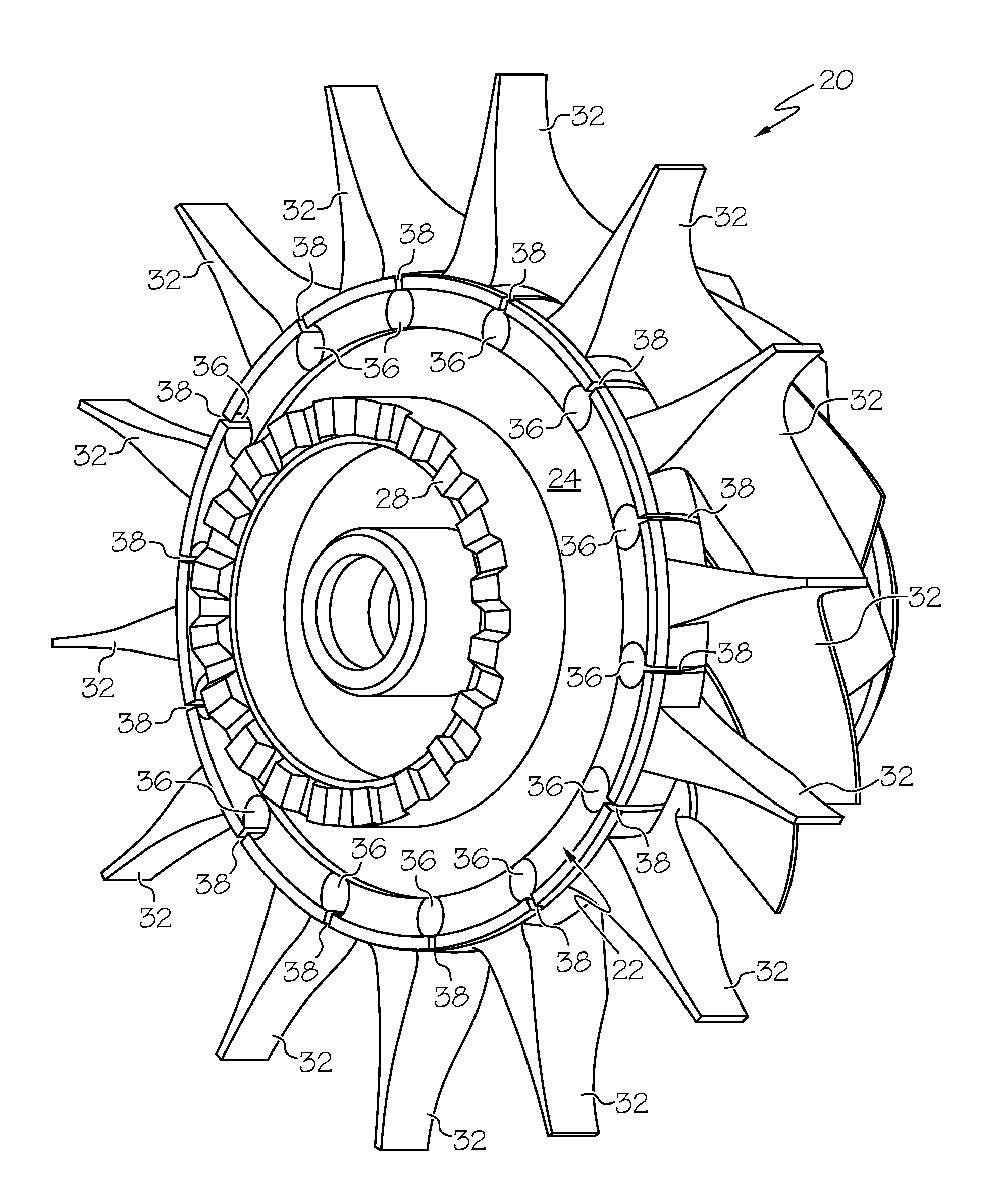

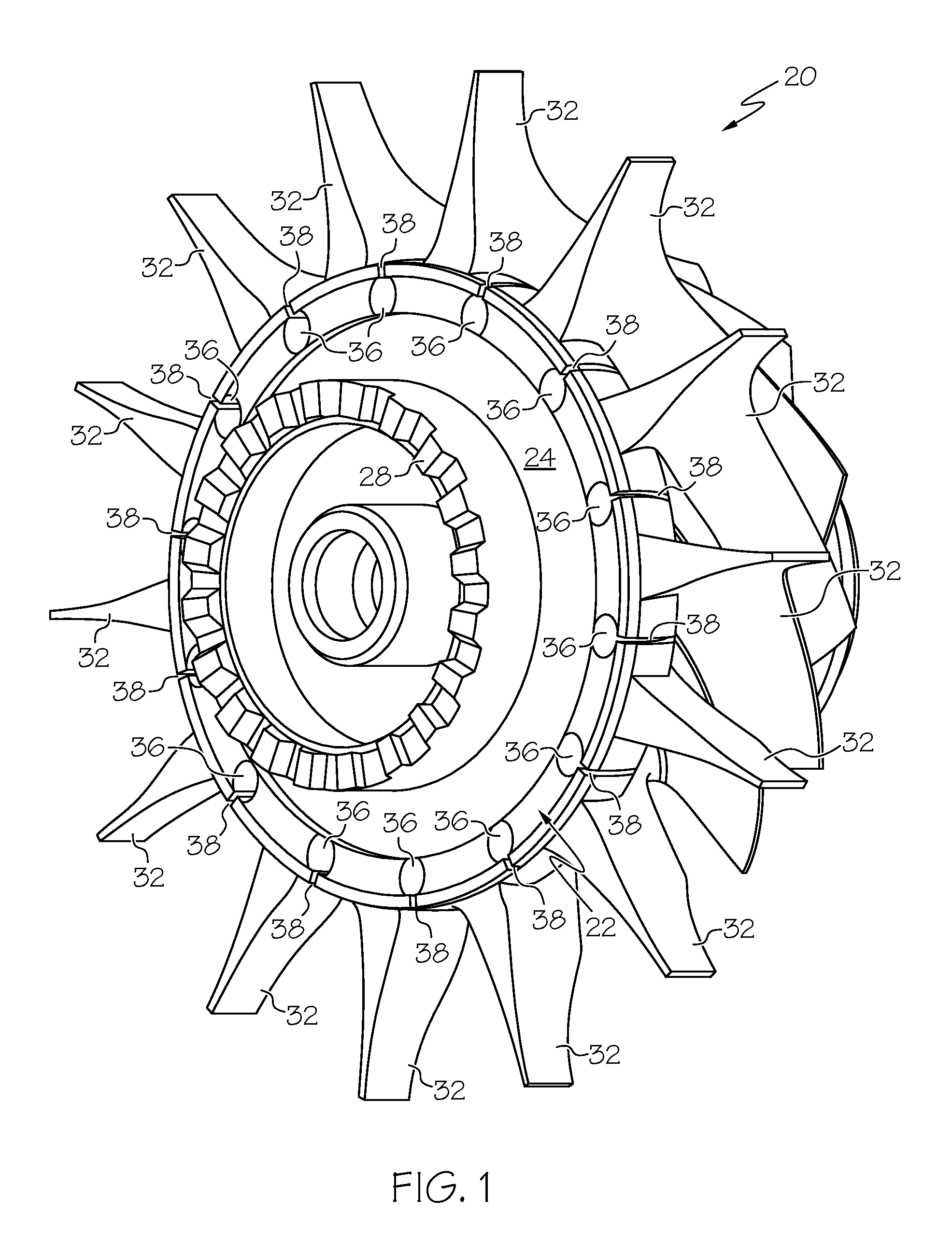

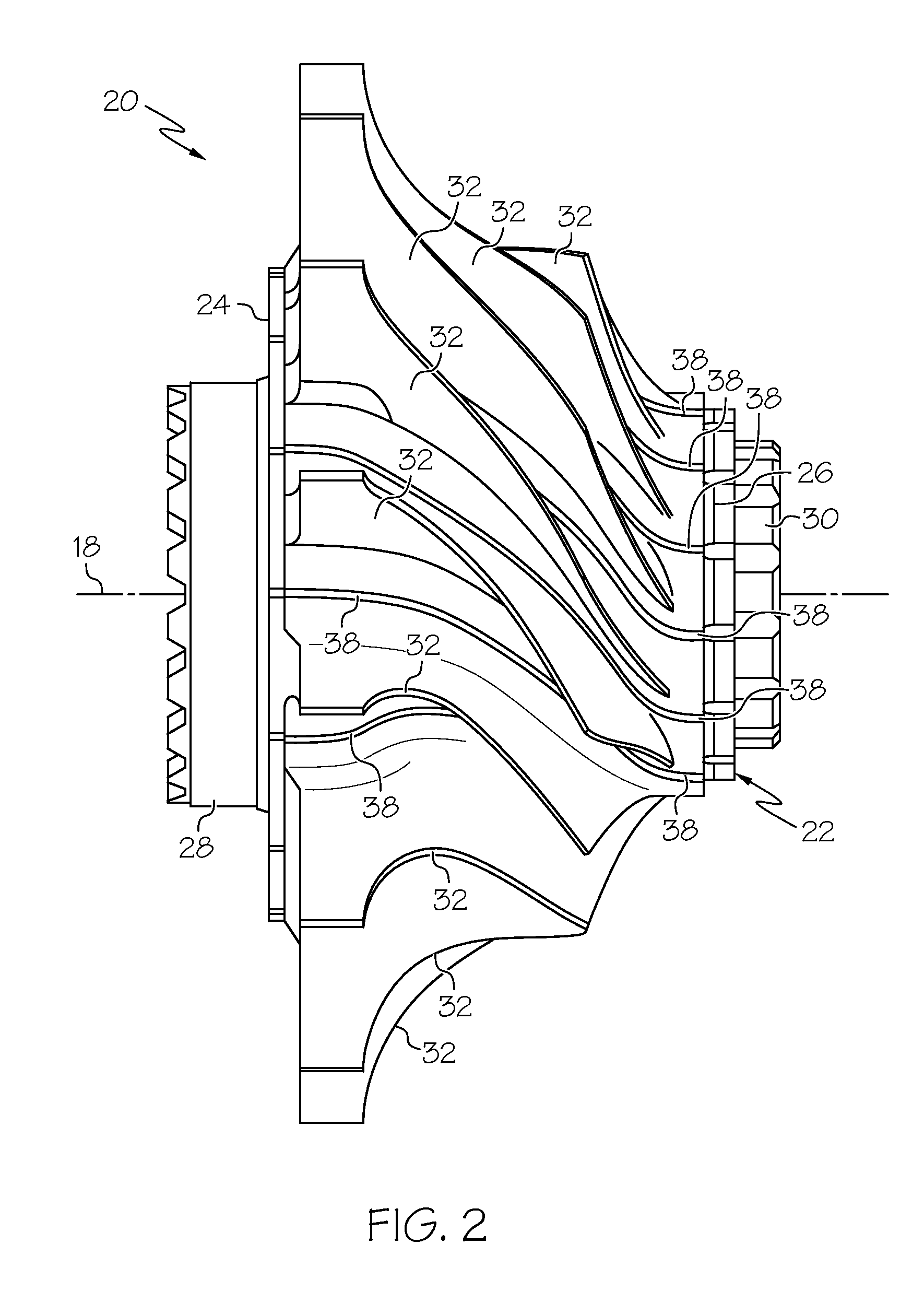

Methods for producing gas turbine engine rotors and other powdered metal articles having shaped internal cavities

Embodiments of a methods for producing gas turbine engine rotors and other powdered metal articles having shaped internal cavities are provided. In one embodiment, the method includes consolidating a powdered metal body utilizing a hot isostatic pressing process to produce a rotor preform in which elongated sacrificial tubes are embedded. Acid or another solvent is directed into solvent inlet channels provided in the elongated sacrificial tubes to chemically dissolving the elongated sacrificial tubes and create shaped cavities within the rotor preform. The rotor preform is subject to further processing, such as machining, prior to or after chemical dissolution of the elongated sacrificial tubes to produce the completed gas turbine engine rotor.

Owner:HONEYWELL INT INC

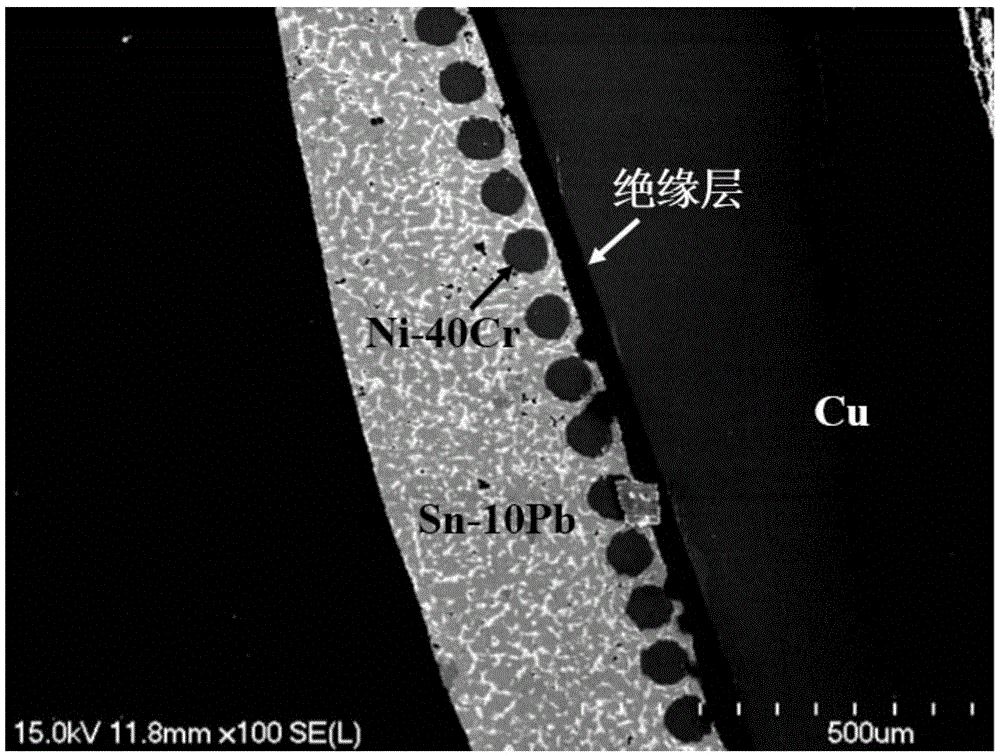

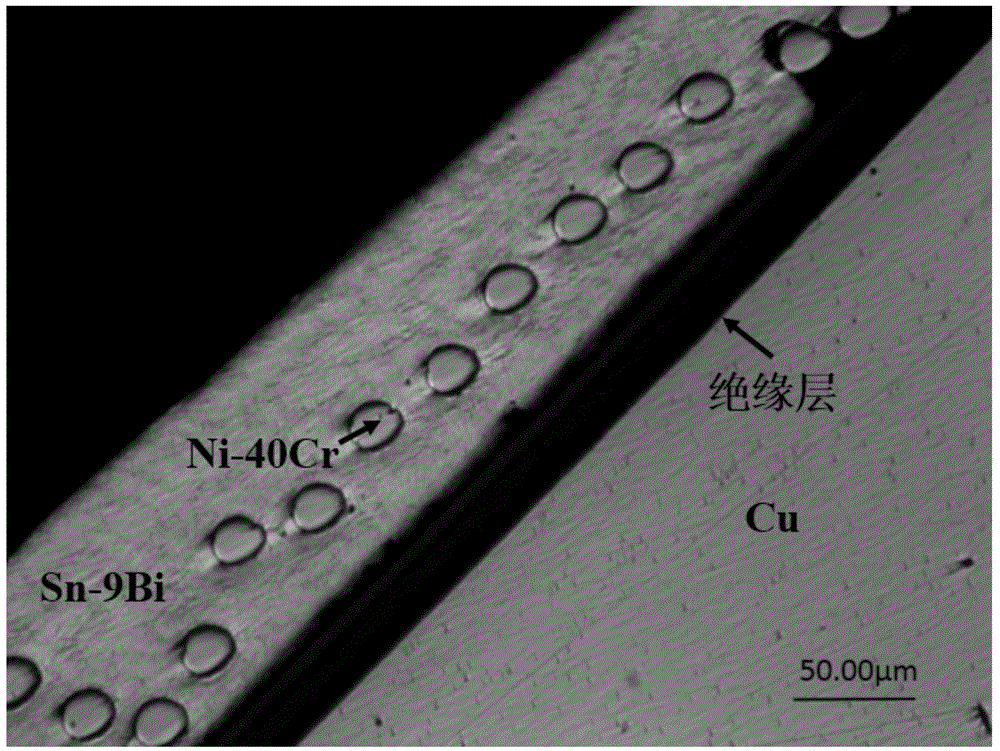

Method for plating surfaces of Ni-Cr alloy wires with zinc at low temperature

ActiveCN105598541ACoated evenlyGood metallurgical bondSoldering apparatusWelding/soldering/cutting articlesTinningUltrasonic cavitation

The invention provides a method for plating the surfaces of Ni-Cr alloy wires with zinc at a low temperature. The method includes the following steps of melting zinc base brazing filler metal in a zinc melting device, adjusting the temperature in the zinc melting device till the zinc base brazing filler metal is molten and the brazing temperature is 120-250 DEG C, conducting chemical dissolution on welding surfaces of the Ni-Cr alloy wires, soaking the Ni-Cr alloy wires and an ultrasonic welding head of an ultrasonic welding device in the molten zinc base brazing filler metal so that the Ni-Cr alloy wires can be perpendicular to an ultrasonic welding rod of an ultrasonic welding device and make contact with the bottom of the ultrasonic welding rod, starting an ultrasonic generator of the ultrasonic welding device, and taking out the Ni-Cr alloy wires after ultrasonic vibration is conducted for 2-60 seconds to complete the zinc plating process. By means of the technical scheme, surface chemical dissolution is combined with ultrasonic cavitation treatment, quite good alloy combination between Sn base welding flux and the Ni-Cr alloy wires is achieved at a low temperature, and welding reliability is improved.

Owner:深圳市昌龙盛机电技术有限公司 +1

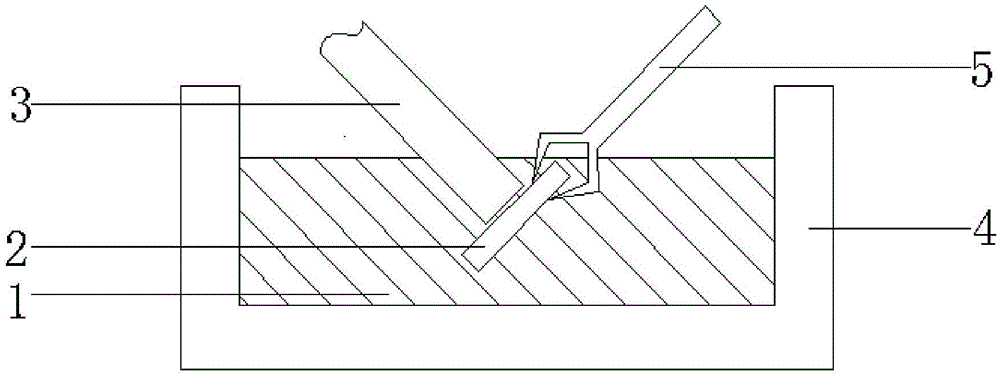

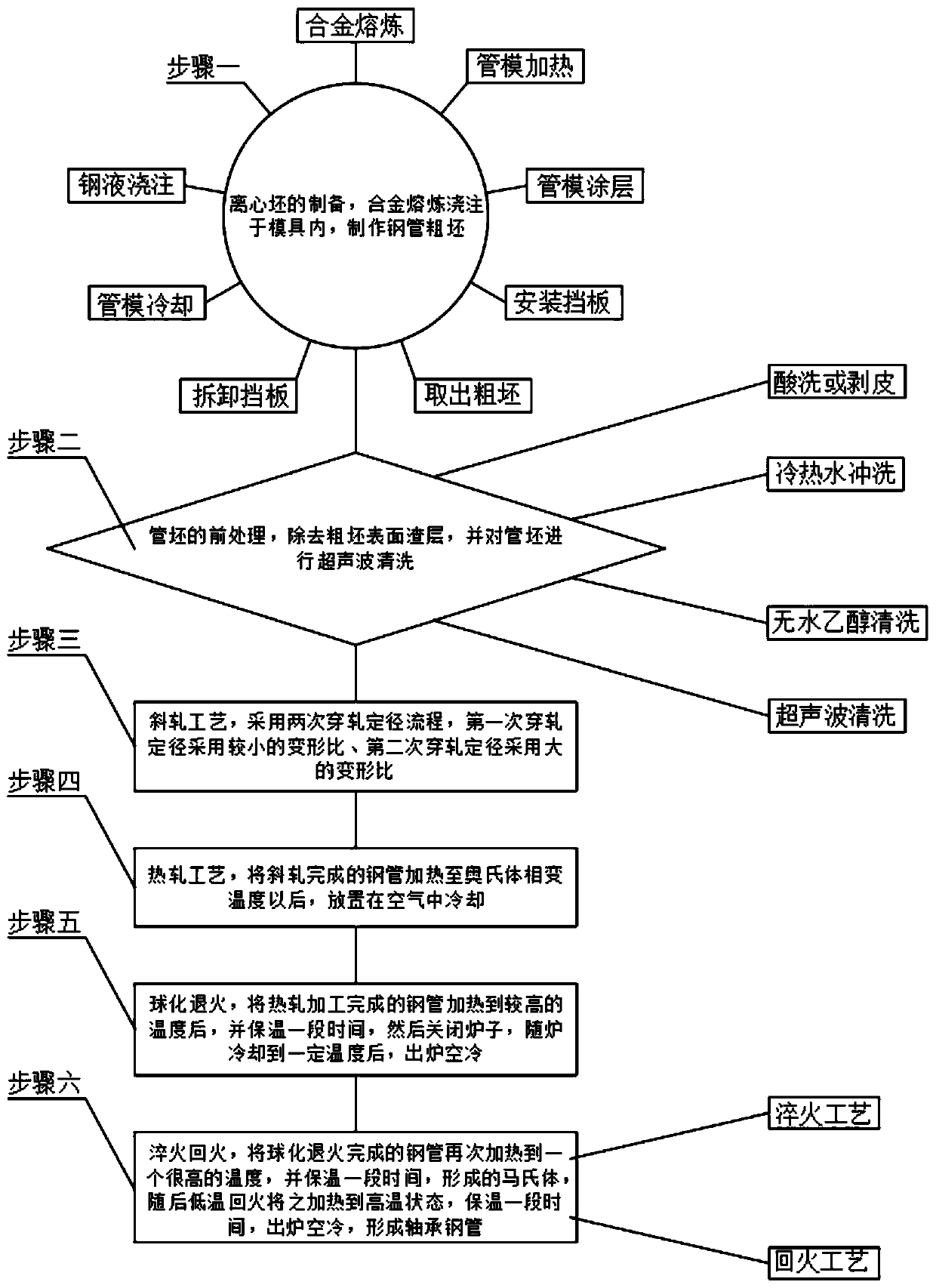

Hot working production process of bearing steel tube

InactiveCN110241294AImprove solubilityEnhanced chemical dissolutionCleaning using liquidsUltrasonic cavitationSlag

The invention is applicable to the technical field of hot working, and provides a hot working production process of a bearing steel tube. The process comprises the following steps of, 1, preparing a centrifugal blank, smelting and pouring an alloy into a mold to prepare a steel tube rough blank; and 2, pre-treating the tube blank, removing a slag layer on the surface of the rough blank, and carrying out ultrasonic cleaning on the tube blank. The purpose of thoroughly removing carbon deposits is achieved by combining the ultrasonic cavitation effect with the dissolution effect of the carbon deposits by a decarbonizer, the impact effect generated by the ultrasonic vibration in a liquid and the high-speed micro-jet generated by the ultrasonic cavitation on the solid interface and the liquid interface can remove or weaken the carbon deposits on the surface of the steel tube, and meanwhile, due to the ultrasonic stirring effect, the dissolution of the carbon deposits is accelerated, the chemical dissolution effect of the decarbonizer on the carbon deposits is enhanced, the carbon deposits on the surface of the steel tube is removed, so that the problems that the metal deformation of the inner surface of a hollow billet is severe, the internal structure is poor, the defects such as cracks and internal bending are easily generated during the cross piercing of the steel tube are avoided.

Owner:ZHEJIANG JIANLI CO LTD

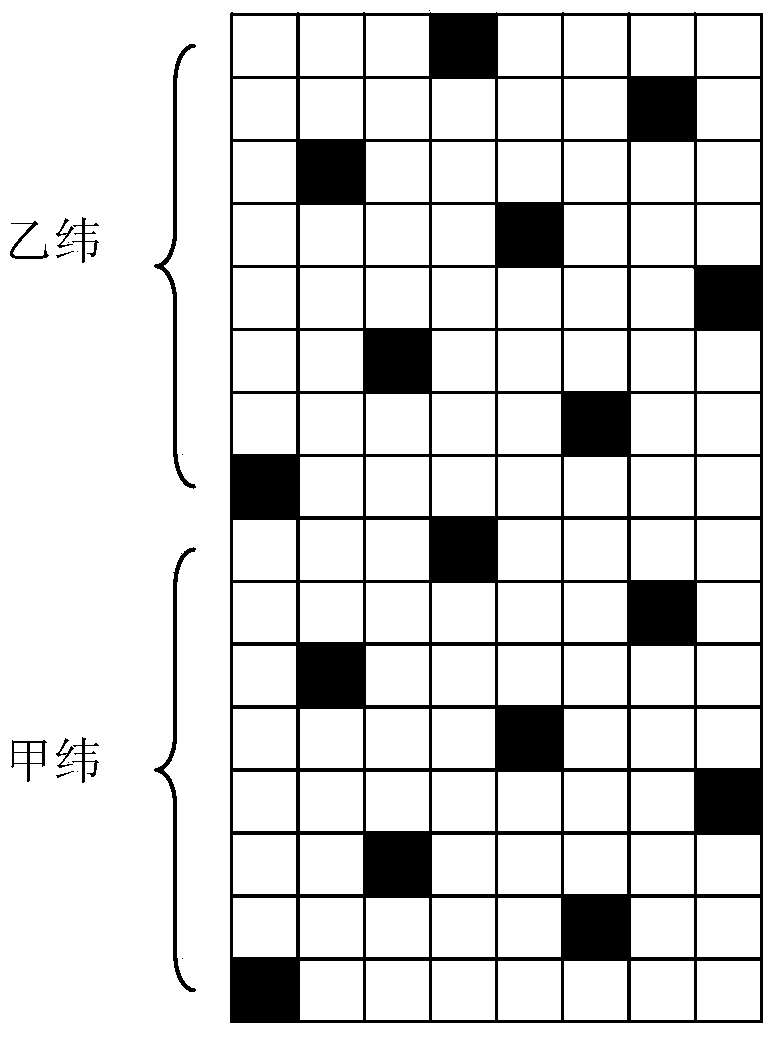

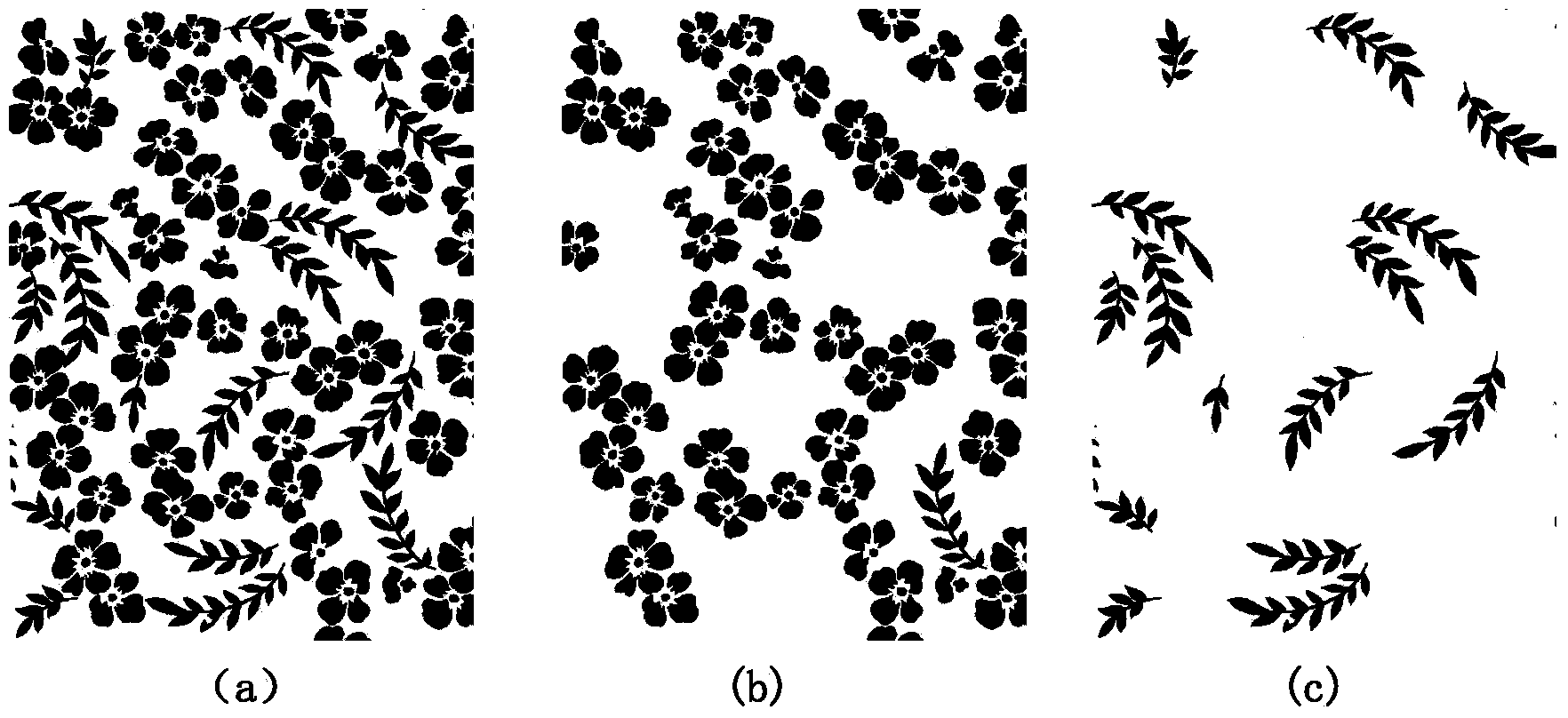

Multi-effect burnt-out woven fabric processing method

The invention discloses a multi-effect burnt-out woven fabric processing method. According to the method, two or three kinds of fiber which show different chemical dissolution characteristics in an acid solution and an alkaline solution are adopted to make yarn, tamet or weft face single-layer woven fabric or double-warp and double-weft woven fabric is obtained by means of the yarn, and burning out printing is conducted twice through acid burning out paste and alkaline burning out paste respectively to form double-effect and multi-effect burnt-out woven fabric. According to the fabric obtained with the method, burnt-out uneven three-dimensional floral patterns are obtained, two burnt-out effects that the first kind of fiber is shown and the second kind of fiber is burnt out, and the second kind of fiber is shown and the first kind of fiber is burnt out are obtained in one piece of woven fabric, or three burnt-out effects that the first kind of fiber is shown and the second kind of fiber is burnt out, the second kind of fiber is shown and the first kind of fiber is burnt out, and the third kind of fiber is shown and the first kind of fiber and the second kind of fiber are burnt out are obtained in one piece of woven fabric, and after graded multicolor dyeing is conducted in the finishing process, patterns with single-color or multi-color effects are obtained, and the appearance of a product is extremely unique and novel.

Owner:湖州南太湖时尚创意城投资发展有限公司

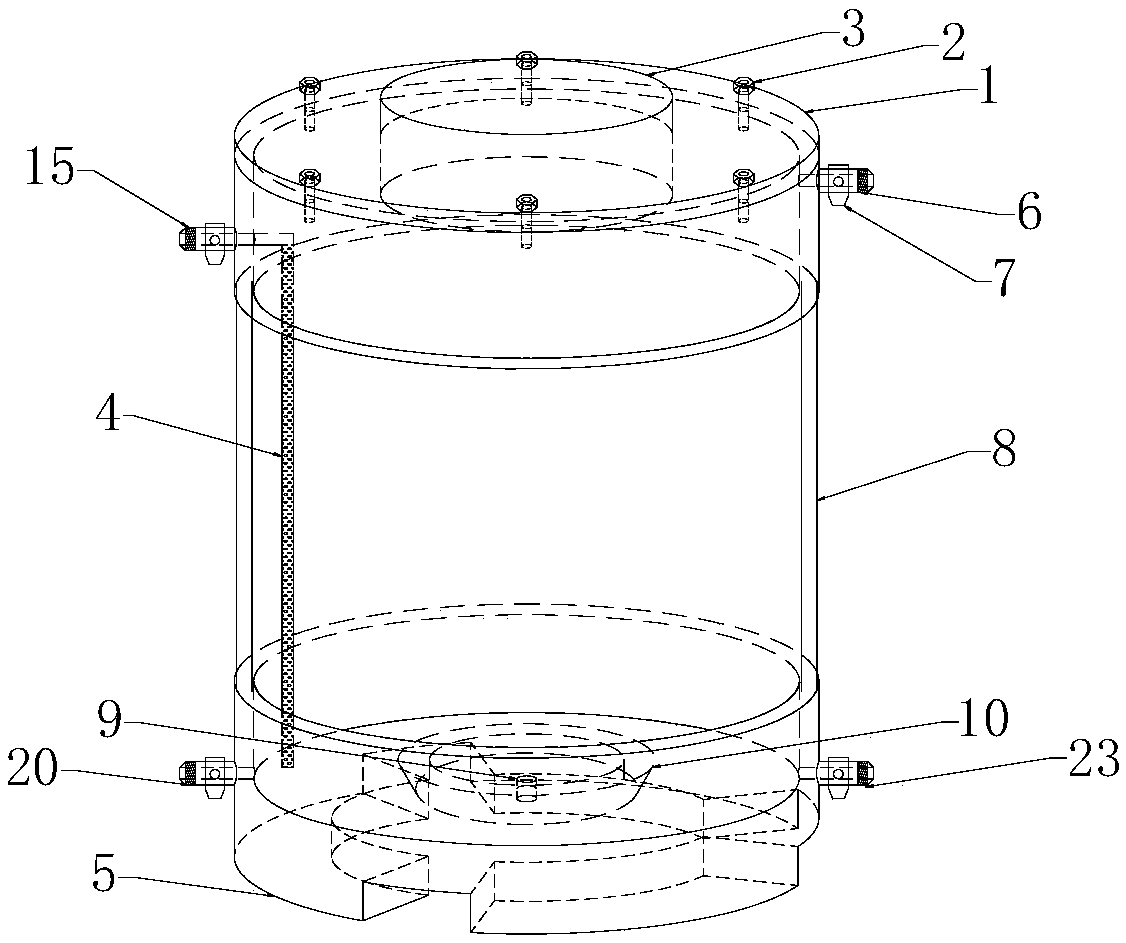

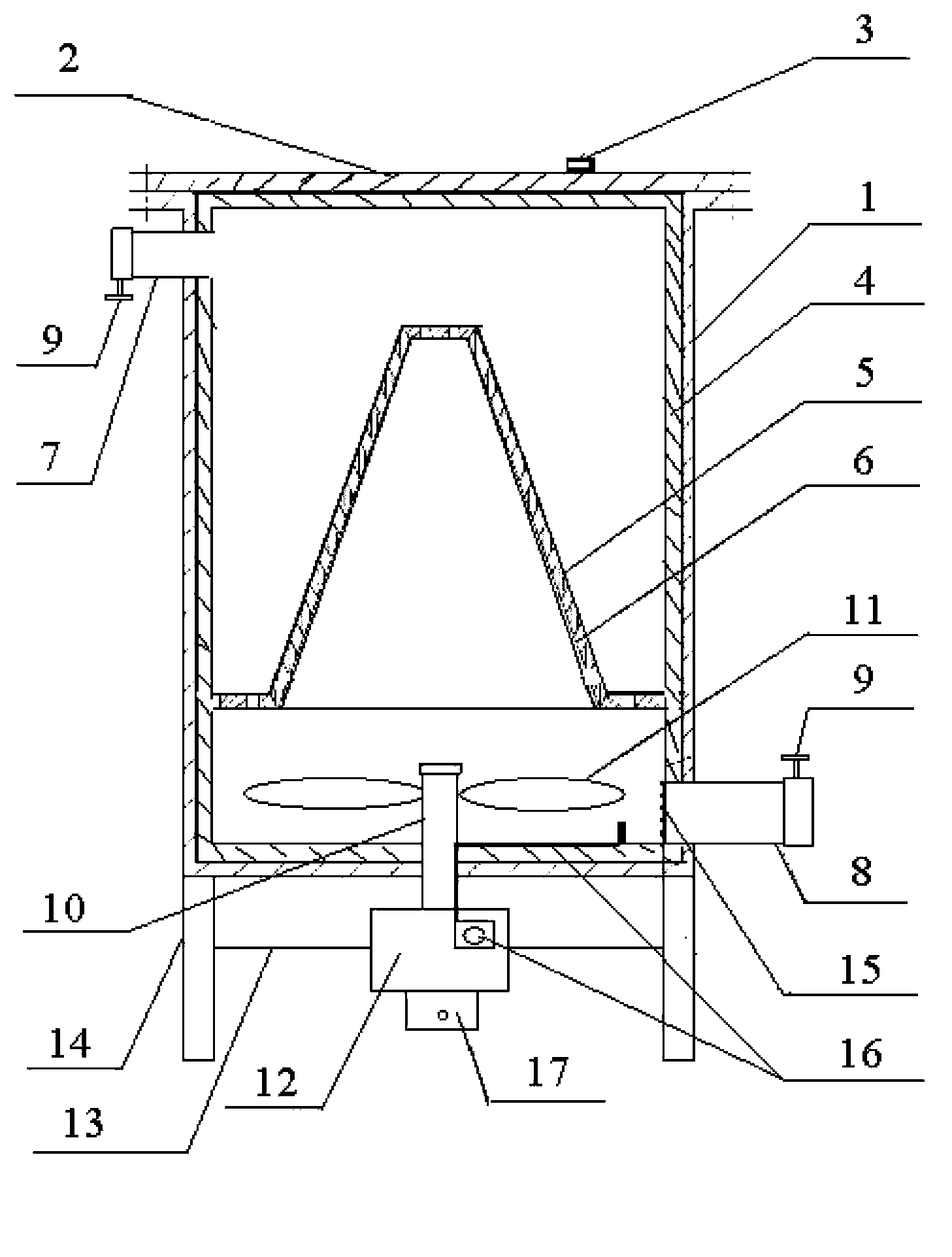

Novel chemical dissolution device

InactiveCN103908905AImprove solubilityIncrease friction collisionRotary stirring mixersMixer accessoriesFrequency changerPower unit

The invention provides a novel chemical dissolution device, which comprises a kettle body and a kettle cover. The upper end of the kettle body is provided with a feed inlet, the lower end is provided with a discharge port, and the feed inlet and the discharge port are both equipped with a valve. The kettle body is internally provided with a stirring shaft, which is equipped with stirring paddles. The stirring shaft is connected to a power unit. The novel chemical dissolution device is characterized in that the kettle body and the kettle cover are in seal connection by a flange, the kettle cover is equipped with handle, the kettle body is internally provided with a screen cylinder, screen pores are uniformly disposed on the bottom around the screen cylinder and the cylinder wall, the discharge port is provided with a filter screen, and a temperature sensor is arranged at the discharge port in the kettle body. The power unit is connected to a frequency changer. The dissolution device has the advantages of simple structure, small volume, convenient use, more effective control of the dissolution process, fast dissolution speed, and good dissolution effect, etc.

Owner:TIANJIN PENGDELI CHEM

Chemical dissolution and cleaning dredging method for crystallization blockage of karst tunnel drainage system

ActiveCN108412544AEfficient removalThe construction method is simple and effectiveHollow article cleaningDrainageChemical reactionPlastic materials

The invention relates to a chemical dissolution and cleaning dredging method for crystallization blockage of a karst tunnel drainage system. The problems that blockage of the drainage system by karstcrystallization universally exists in tunnel engineering in karst areas, and a serious threat to safety and long-term operation of a tunnel engineering structure is brought are solved. According to the chemical dissolution and cleaning dredging method for crystallization blockage of the karst tunnel drainage system, a polymer carboxylic acid type organic acid reagent with the concentration of 2000-2200 ppm and the dichromate index of 17.71-20% is adopted as a dissolution and cleaning solvent. The chemical dissolution and cleaning dredging method comprises the construction steps of electromagnetic detection of blockage points, arrangement of dissolution and cleaning pipelines, a chemical dissolution phase, auxiliary dredging measures, a cycle cleaning stage, and blockage of dissolution andcleaning pipeline holes. The dissolution and cleaning solvent is environmentally friendly, does not react with cement-based and PVC plastic materials, and can effectively clear karst crystal substances of the drainage system. The construction method can effectively solve the problem of blockage of the drainage system by karst crystallization universally existing in tunnel engineering in the karstareas.

Owner:NANJING UNIV OF TECH +2

Method for solving problem of turbidness of cooled tea beverage through using microbes for degrading caffeine

InactiveCN101755977AIncrease health functionSolve the cold after the muddyTea alkaloid content reductionMicroorganismHypha

The invention provides a method for solving the problem of turbidness of a cooled tea beverage through microbes for degrading caffeine. The invention is characterized in that the method comprises the following steps: preparing saccharomyces Candia sp. and water into damping liquid according to a mass ratio of 1 / 200 to 700; and spraying the damping liquid onto tea for uniformly distributing the saccharomyces Candia sp. onto the tea for degradation for 3 to 7 days. The water content of the raw material tea after the damping is between 16 and 20 percent. The method utilizes the microbial microzyme for naturally degrading the caffeine in the tea. Compared with the chemical dissolution technology, the invention has the advantages that the cost is lower than 20 percent of that in the prior art, the chemical pollution can not be introduced, and in addition, the microzyme amylase has good health care effect on human bodies. Particularly, the microzyme can grow the hypha for propagation when the tea has high water content, so the tea generates after fermentation. Thereby, the control on the water content in the damping tea is very important.

Owner:冯磊

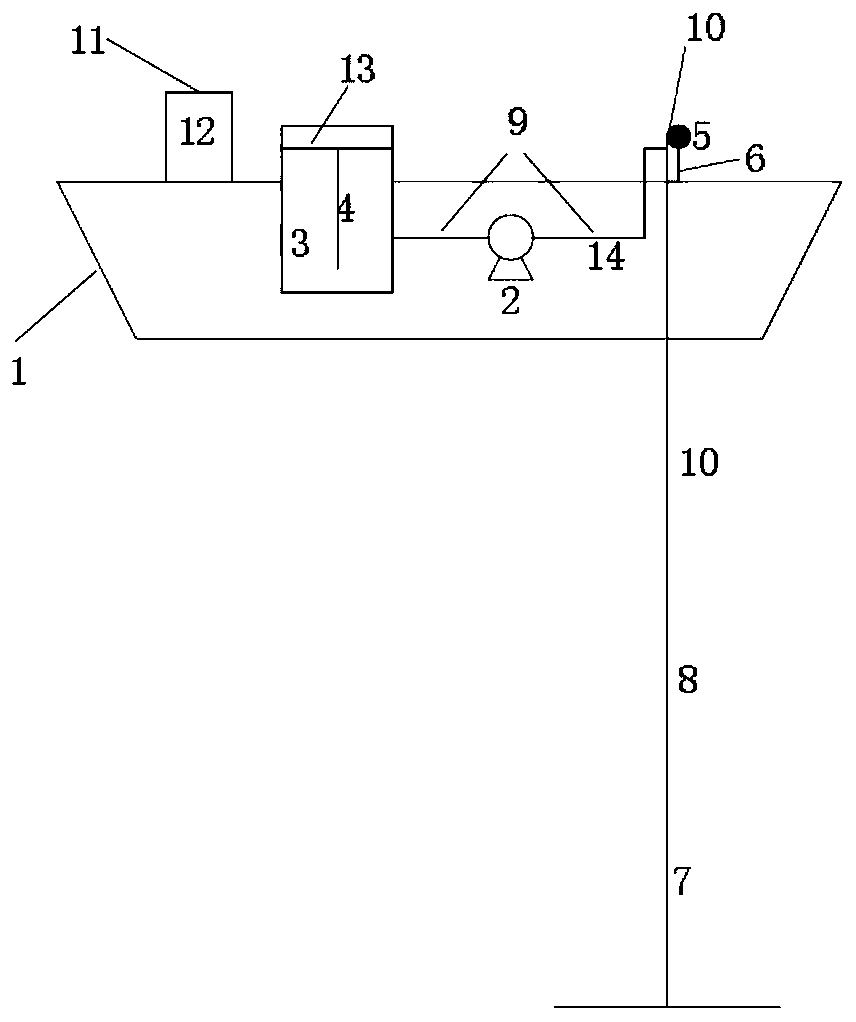

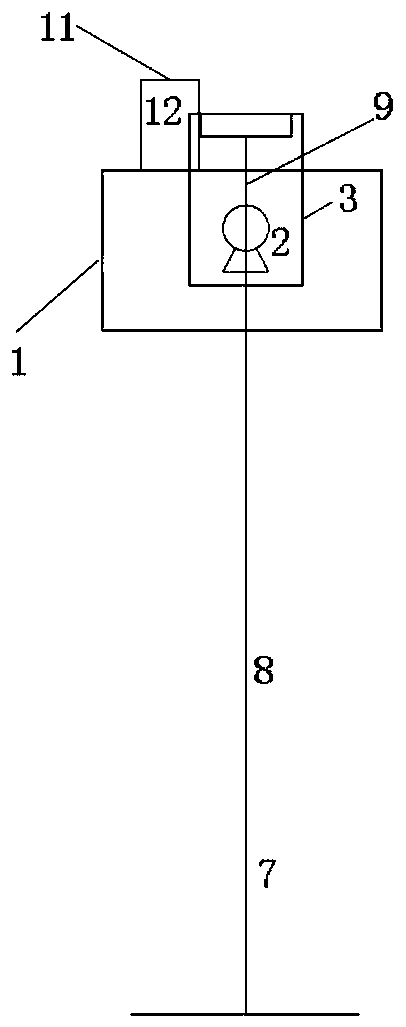

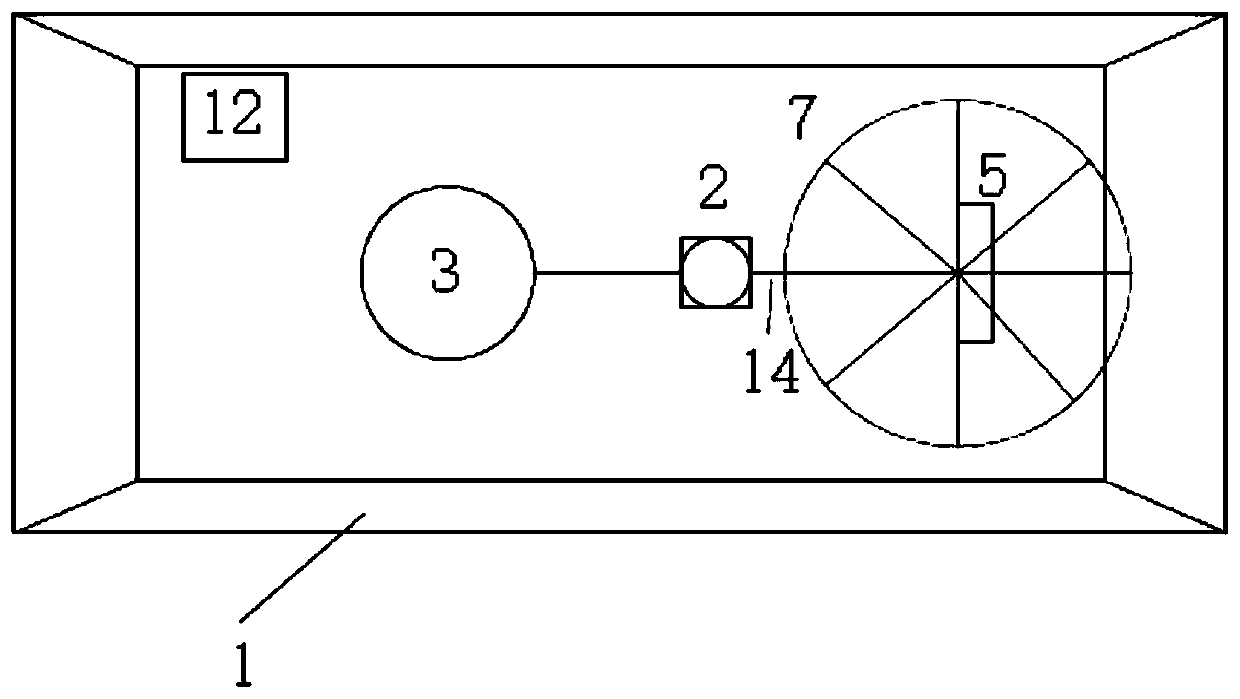

Automatic chemical mixing and feeding integrated device for lake reservoirs

PendingCN110252190AAutomatic and efficient mixingAutomatic and efficient dosingFlow mixersTransportation and packagingEmergency treatmentChemical solution

The invention discloses an automatic chemical mixing and adding integrated device for lake reservoirs. The automatic chemical mixing and adding integrated device comprises a floating body system for providing buoyancy to the integrated device, a chemical dissolution system for dissolving solid chemicals to provide chemical solutions, a feeding system for feeding the chemical solutions into the lake reservoirs, a control system, and a power supply device for powering all electric equipment on the integrated device. The chemical dissolution system and the feeding system are arranged on the floating body system. An inlet of the feeding system is connected with an outlet of the chemical dissolution system through a pipe system. An outlet of the feeding system is connected with a liftable chemical distribution system through a pipe system. The control system is connected with the floating body system to control the movement of the floating body system, is connected with the chemical dissolution system to control the concentration of the chemicals of the chemical dissolution system, and is connected with the feeding system to control feeding of the chemical solutions. By the integrated device, automatic mixing and feeding of the chemicals for emergency treatment of the lake reservoirs are realized.

Owner:唐山市曹妃甸供水有限责任公司 +1

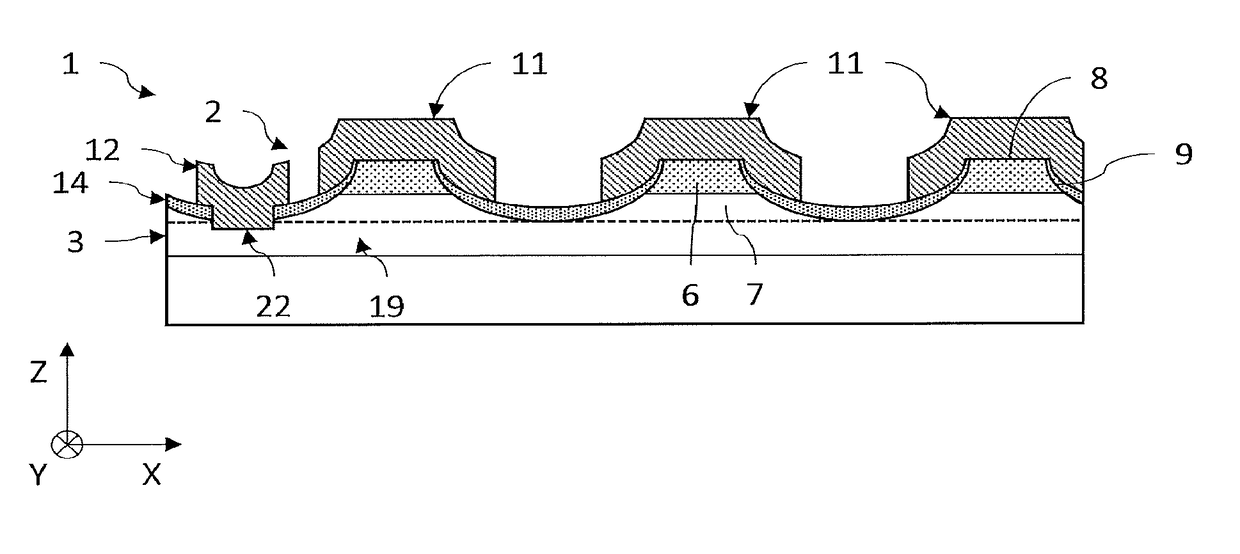

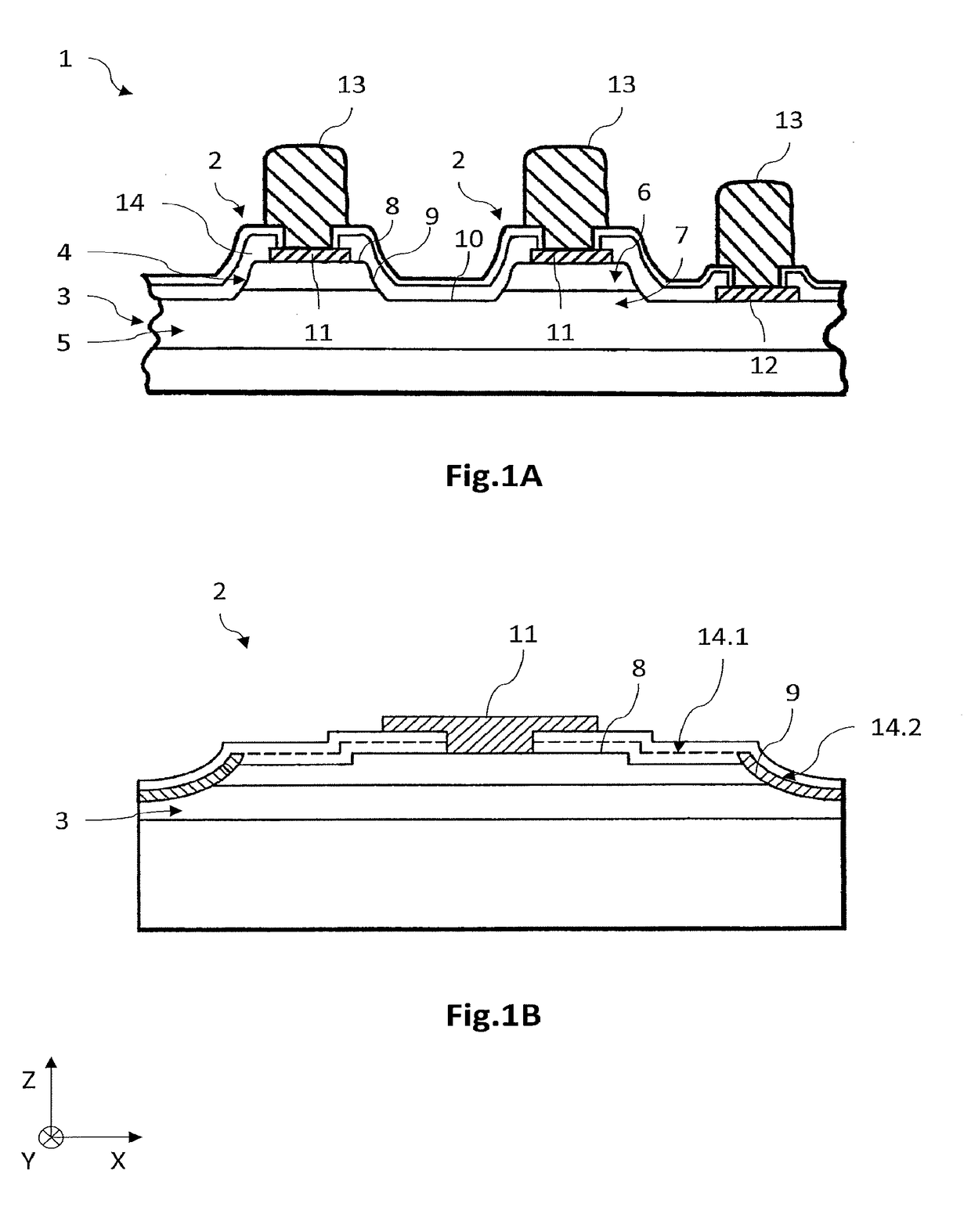

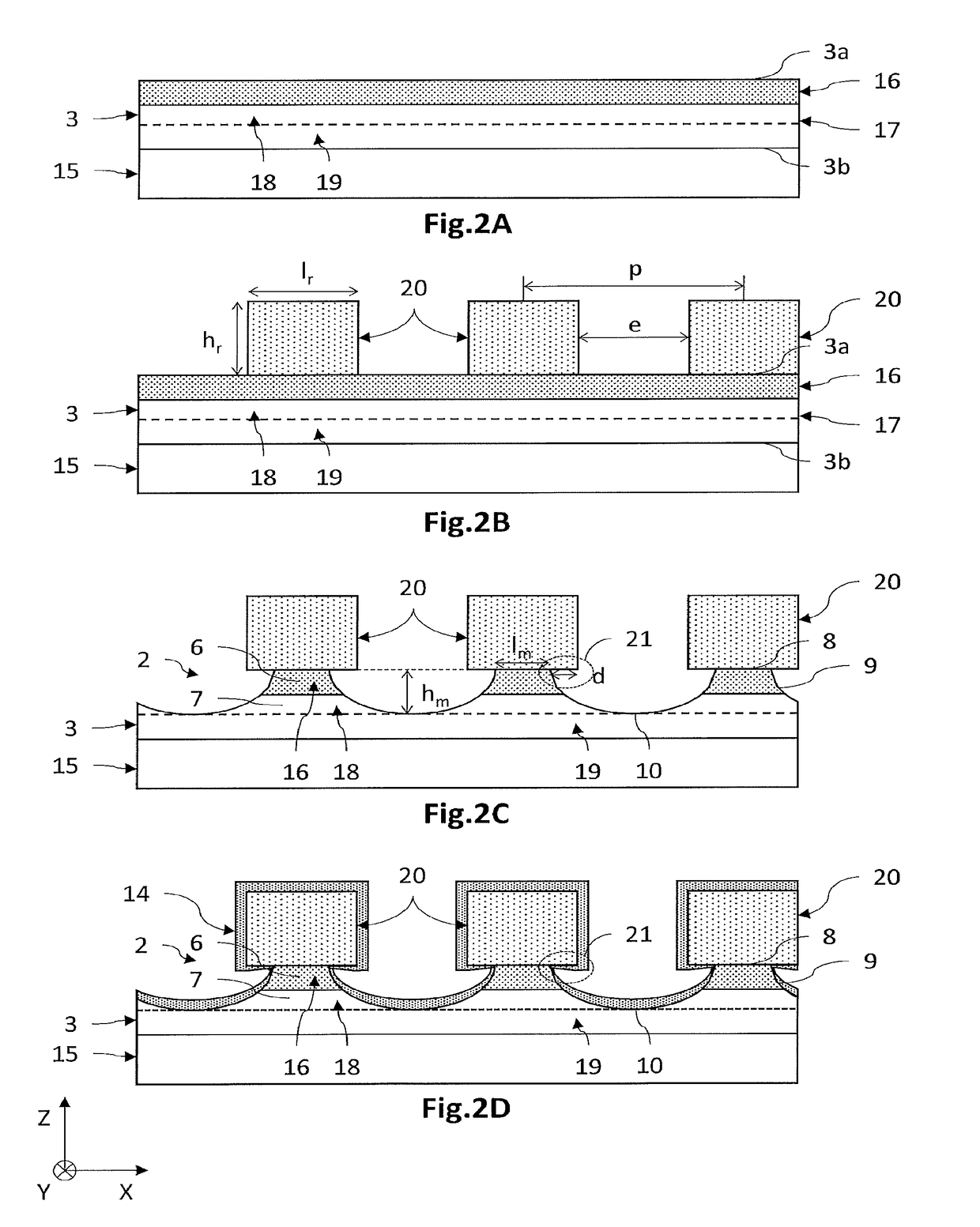

Process for producing an array of mesa-structured photodiodes

ActiveUS20180309016A1Reduce thicknessFinal product manufactureSolid-state devicesEngineeringPhotodiode

The invention pertains to a process for producing an array (1) of mesa-structured photodiodes (2), including at least the following steps:a) producing a useful layer (3);b) producing an etch mask formed of a plurality of etch pads (20);c) wet-etching part of the useful layer (3) located between the etch pads (20), forming a plurality of mesa-structured photodiodes (2), producing a recess (21);d) conformally depositing a passivation layer (14);e) removing the etch pads (20) by chemical dissolution;f) producing conductive pads (11).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

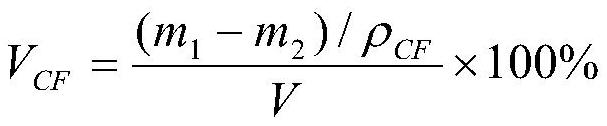

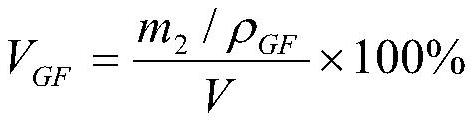

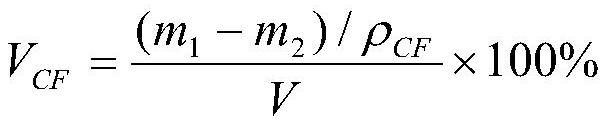

Method for testing fiber volume content of composite material

InactiveCN112540024AThe test result is accurateEasy to operateWeighing by removing componentGlass fiberCarbon fibers

The invention provides a method for testing the fiber volume content of a composite material. The method comprises the following steps of: obtaining the volume of a composite material sample; completely decomposing a resin matrix in the composite material sample by adopting a chemical dissolution method, and separating carbon fibers from glass fibers to obtain a solution containing a mixture of the carbon fibers and the glass fibers; filtering, cleaning and drying the solution, and weighing to obtain the total mass of the carbon fibers and the glass fibers; calcining the dried mixture of the carbon fibers and the glass fibers by adopting a physical calcining method to fully decompose the carbon fibers in the mixture, cooling, and weighing residual substances to obtain the mass of the glassfibers; and calculating the volume contents of the carbon fibers and the glass fibers in the composite material sample by adopting a formula. The volume contents of the carbon fibers and the glass fibers in the composite material are tested by adopting a method of combining a chemical dissolution method and a physical calcination method, the test result is accurate, the operation is convenient, and the production and the application are convenient.

Owner:廊坊市飞泽复合材料科技有限公司

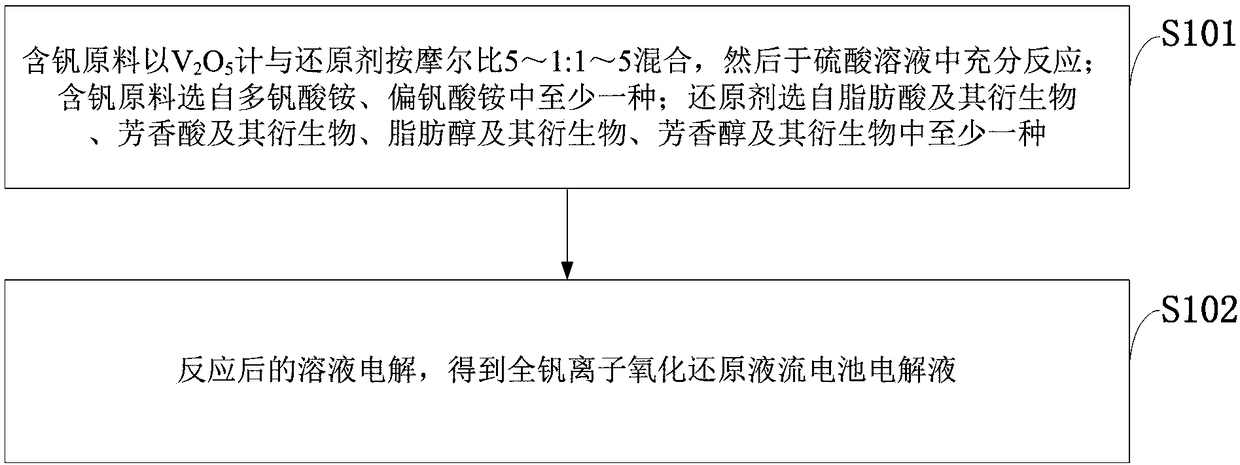

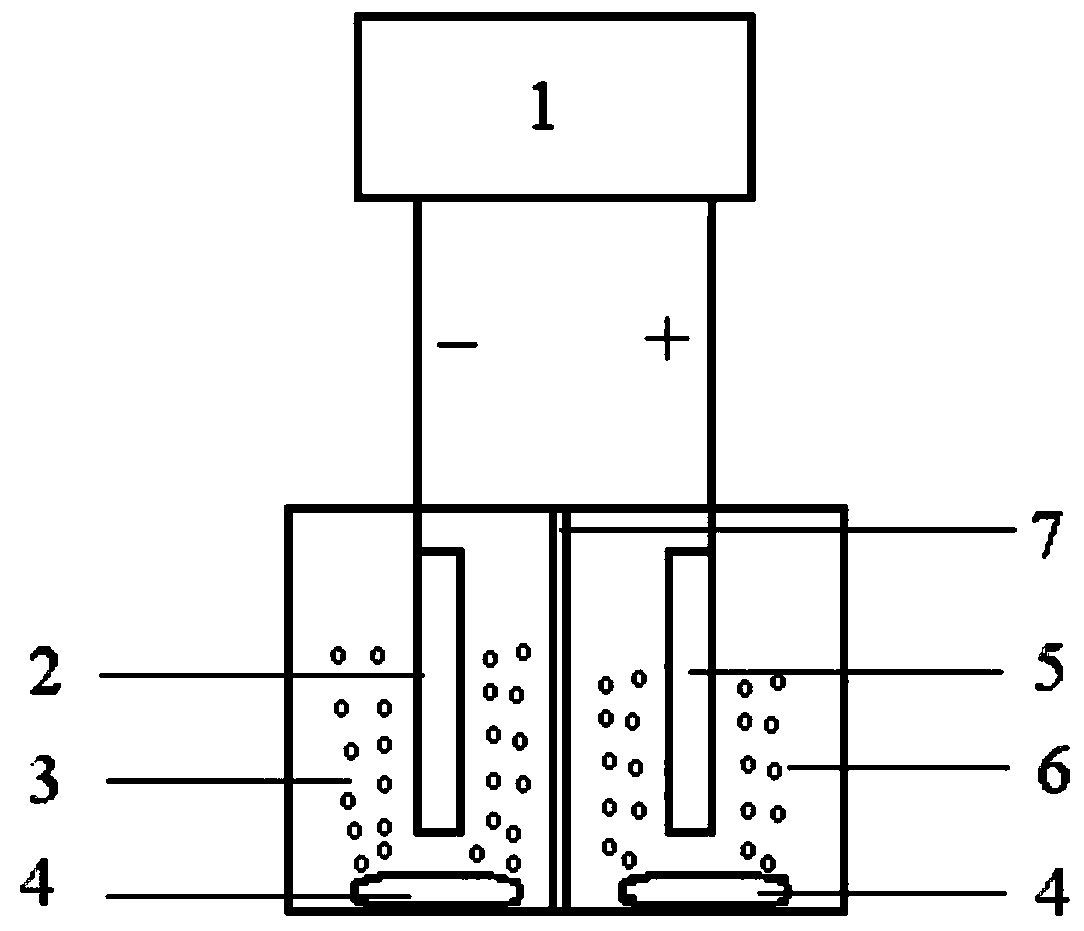

All-vanadium ion redox flow battery electrolyte and preparation method thereof

InactiveCN108808052AHigh battery charging and discharging efficiencyLow costRegenerative fuel cellsAcid electrolytesElectrolysisSlag

The invention discloses all-vanadium ion redox flow battery electrolyte and a preparation method thereof. The preparation method comprises the following steps: preparing a vanadium-containing raw material by mixing V2O5 and a reducing agent in a molar ratio of (5 to 1):(1 to 5), and then fully reacting in a sulfuric acid solution; electrolyzing the reacted solution to obtain the all-vanadium ion redox flow battery electrolyte. According to the invention, an intermediate product, namely ammonium polyvanadate or ammonium metavanadate, obtained by extracting vanadium from vanadium slag, is takenas a raw material, and the vanadium battery electrolyte is prepared by a chemical dissolution and electrolysis preparation two-step method, and compared with a conventional electrolyte preparation process with V2O5 as a raw material, the preparation method does not require a final V2O5 product, which significantly reduces the raw material cost.

Owner:四川星明能源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com