Hydraulic structure concrete hydraulic fracture test device, concrete manufacturing mold and test method

A technology of hydraulic concrete and hydraulic splitting, which is applied to the preparation of test samples and the use of stable tension/pressure to test the strength of materials. The effect of the sealing effect

Active Publication Date: 2018-10-23

HOHAI UNIV

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are few test methods for hydraulic splitting of concrete under the coupling actio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

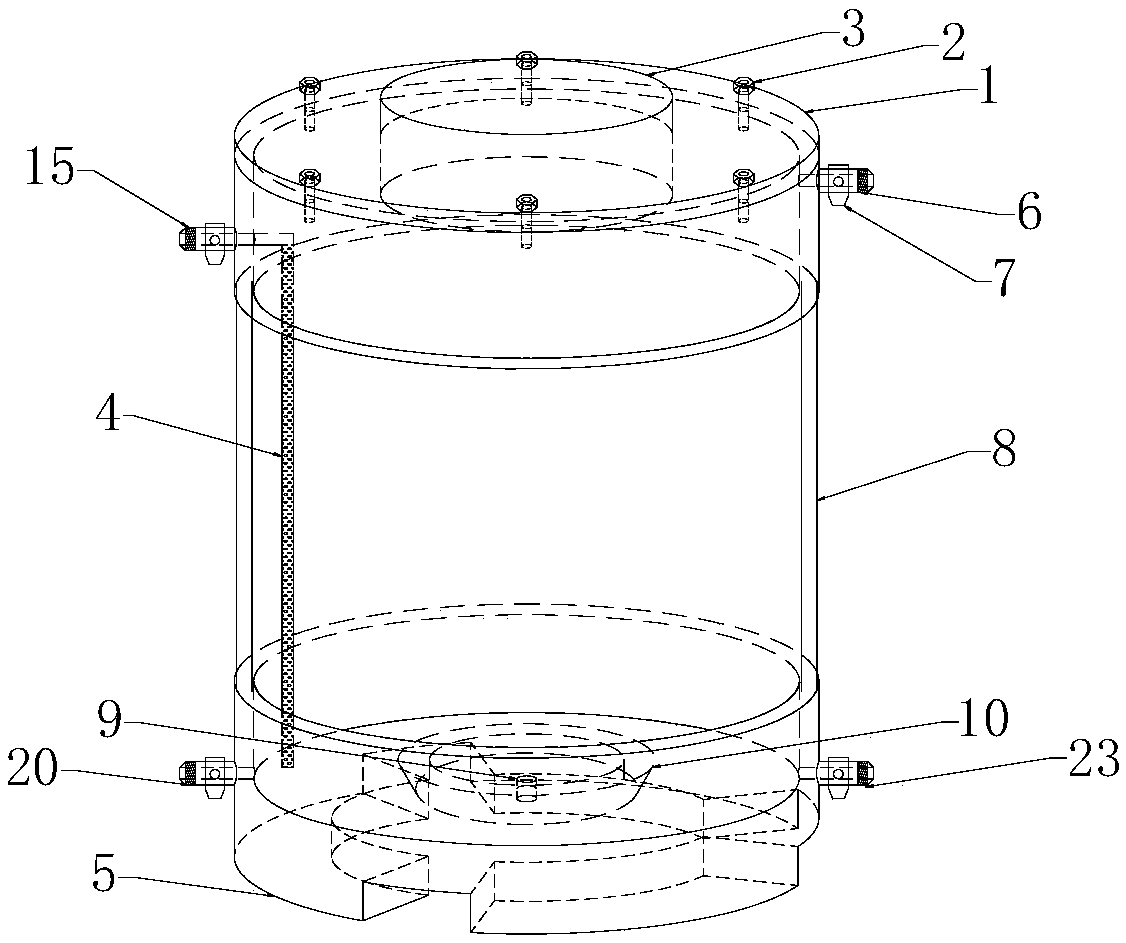

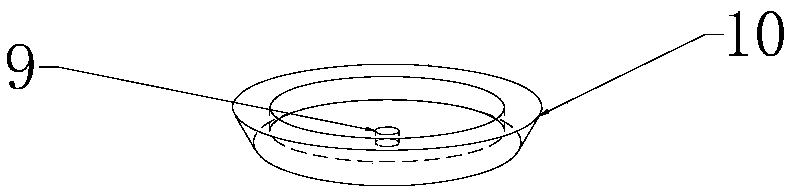

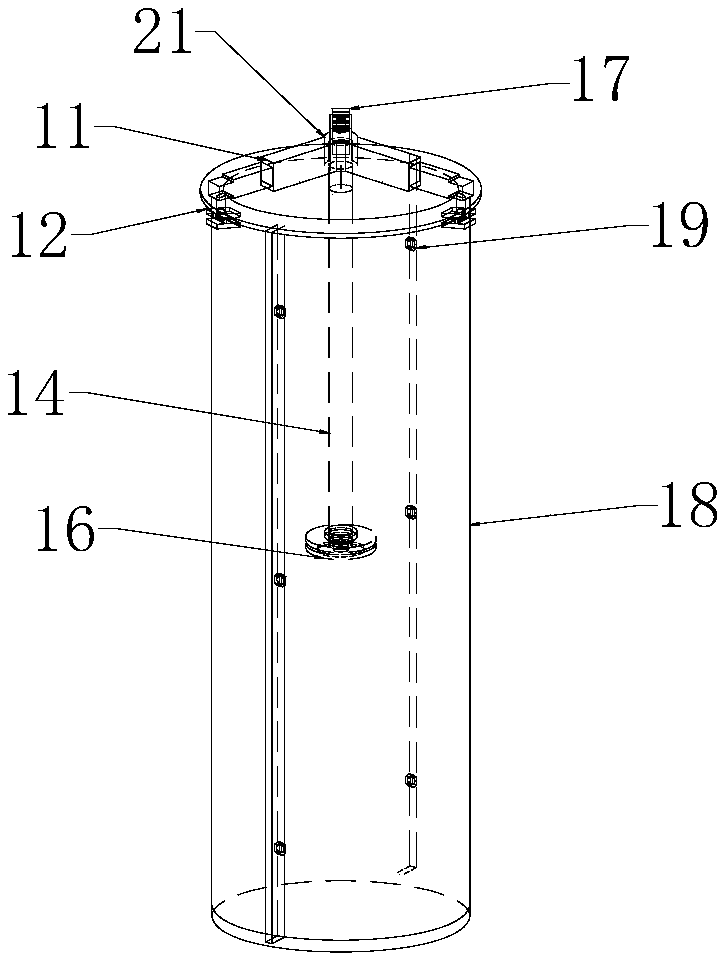

The invention discloses a hydraulic structure concrete hydraulic fracture test device, a concrete manufacturing mold and a test method. A concrete test sample uses a test sample crack sealing sleeve to be matched with a movable shaft pressure post to be fixed and sealed in a pressure chamber; a hydraulic loading system and an axial pressure loading system are mutually matched to simulate a hydraulic structure concrete storage chemical field, stress field and flow seepage field. The fracture deterioration mechanism of joint effects of physical effects, chemical effects and mechanical effects simultaneously received by the permanent hydraulic structure concrete structure in the practical engineering can be studied; meanwhile, the hydraulic structure concrete hydraulic fracture test study after the soaking corrosion solution soaking dry and wet circulation effects or hydraulic structure concrete hydraulic fracture test study after high hydraulic gradient water chemical dissolution corrosion and soaking corrosion can be realized; the reference value is provided for studying the long-time stability problem of the hydraulic structure concrete structure.

Description

technical field [0001] The invention relates to the field of concrete structures in civil engineering and water conservancy engineering, and is suitable for studying the law and mechanism of the degradation of mechanical properties of concrete structures that are permanently in contact with the water environment for a long time under the coupled action of stress-chemical-seepage, and can also explore concrete specimens in different conditions. Failure law and mechanism of hydraulic fracturing under stress environment. The invention also provides a test device for hydraulic cracking of hydraulic concrete under the coupling action of stress-chemical-seepage. Background technique [0002] With the rapid development of my country's water conservancy and the improvement of dam-building technology, there are still a large number of high concrete dams under construction in my country, and the dam height has exceeded 200m. Due to the influence of construction technology, temperatur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12G01N1/36

Inventor 吴琼徐力群沈振中陶韵成刘得潭史亚旋张宏伟邱丽婷汪瑞欣邵文捷

Owner HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com