Aluminum or magnesium alloy casting sand core removing device and method

A cleaning device and a technology for magnesium alloys, which are applied in the field of sand core cleaning devices, can solve the problems of difficulty in cleaning sand cores of aluminum or magnesium alloy castings, long cleaning cycles, etc., and achieve the effects of easy control, good cleaning effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

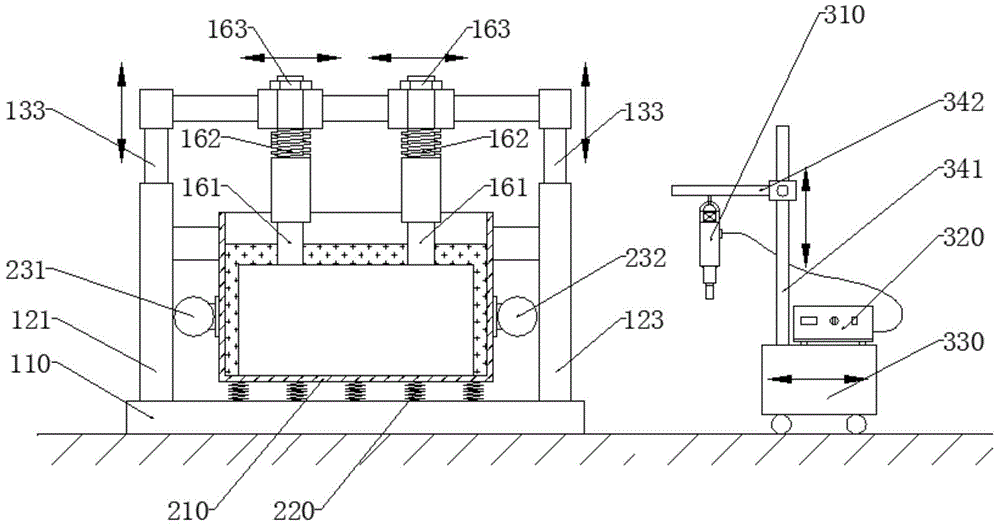

[0057] Embodiment 1: be used for the cleaning of water-soluble sand core, comprise the steps:

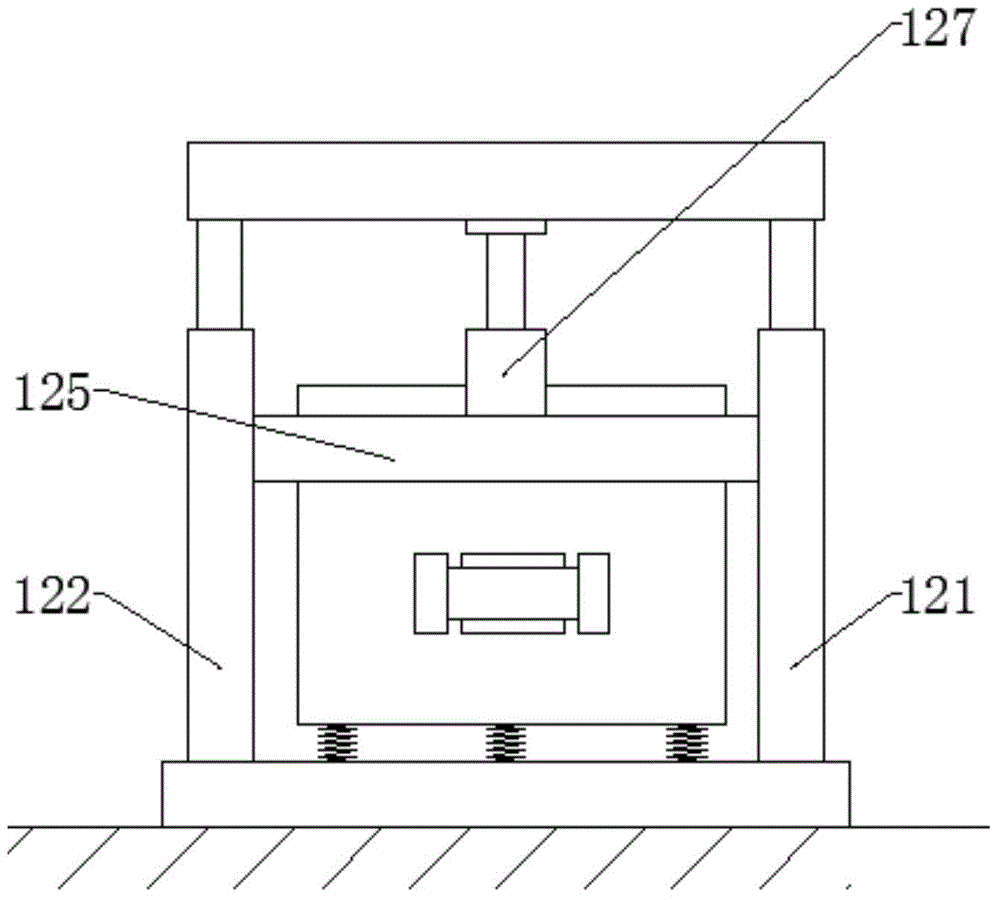

[0058] (1) Soaking step: Hang the aluminum alloy casting to be cleaned into the cleaning tank from the upper part of the sand core cleaning device, contact the bottom end of the pressure rod of the buffer component with the casting, and press the casting; then inject clean water until the entire sand core is submerged , soak for 30 minutes;

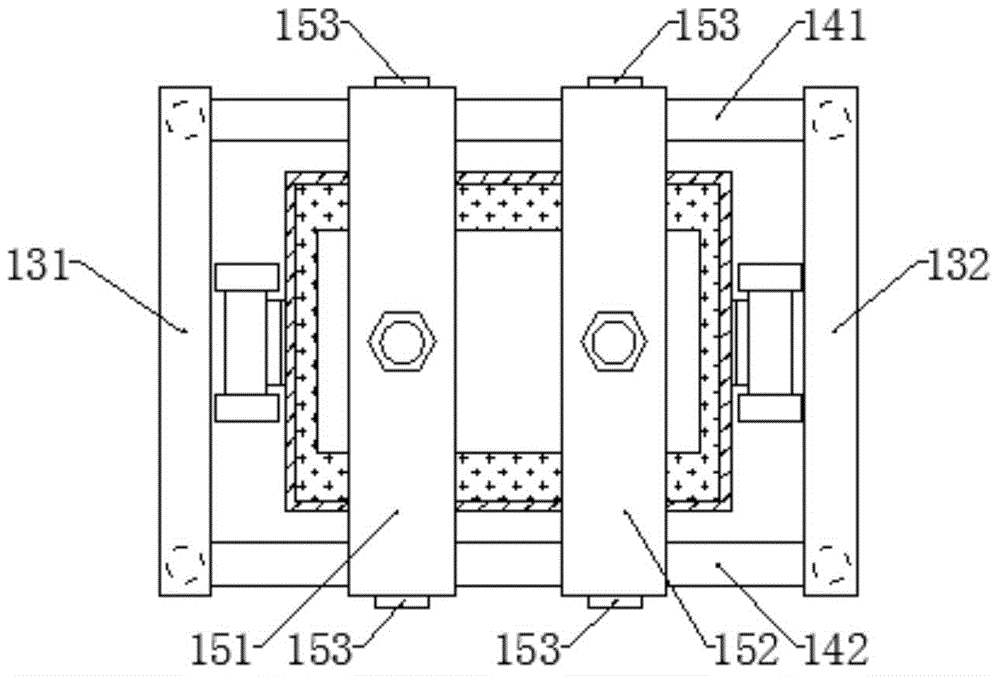

[0059] (2) Vibration step: start the left and right vibrating motors to drive the cleaning tank and the casting to vibrate. The exciting force of the vibrating motor is 1800N, vibrate for 20 minutes, and the softened, dissolved and broken sand cores are discharged from the inner cavity of the casting;

[0060] (3) Ultrasonic impact step: Insert the ultrasonic concentrator into the cleaning solution, close to the sand core of the casting, the ultrasonic power is 2000W, and the ultrasonic cleaning time is 10 minutes, to clean the sand core that i...

Embodiment 2

[0062] Embodiment 2: Used for cleaning water-soluble sand cores.

[0063] The difference with embodiment 1 is: in the step (2), the excitation force of the vibration motor is adjusted to 3000N, and the vibration is 10 minutes; in the step (3), the power of the ultrasonic wave is 1000W, and the cleaning time is 40 minutes.

Embodiment 3

[0064] Embodiment 3: for the cleaning of resin sand core.

[0065] The difference with Example 1 is: in the step (1), the casting is a magnesium alloy casting, and the cleaning solution is a 1% NaOH alkali solution, soaked for 60 minutes; in the step (3), the power of the ultrasonic wave is 1000W, and the cleaning time is 20 minutes .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com