All-vanadium ion redox flow battery electrolyte and preparation method thereof

A liquid flow battery and vanadium ion technology, applied in the direction of fuel cells, acidic electrolytes, aqueous electrolytes, etc., can solve the problem of high cost, achieve the effects of reducing raw material costs, improving electrolysis efficiency, and large energy consumption for electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

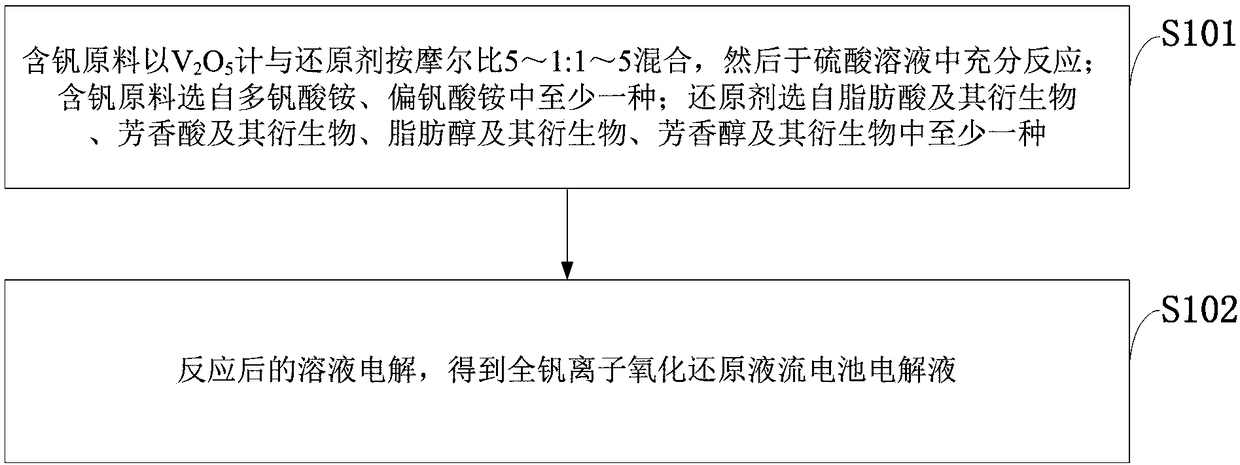

[0028] Such as figure 1 As shown, the preparation method of the all-vanadium ion redox flow battery electrolyte provided by the embodiment of the present invention includes the following steps:

[0029] S101: Raw material containing vanadium with V 2 o 5 It is mixed with reducing agent at a molar ratio of 5-1:1-5, and then fully reacted in sulfuric acid solution; the vanadium-containing raw material is selected from at least one of ammonium polyvanadate and ammonium metavanadate; the reducing agent is selected from fatty acids and their At least one of derivatives, aromatic acids and their derivatives, aliphatic alcohols and their derivatives, aromatic alcohols and their derivatives;

[0030] S102: Electrolyzing the solution after the reaction to obtain an electrolyte solution for the all-vanadium ion redox flow battery.

[0031] The vanadium-containing raw material in step S101 is V 2 o 5 The molar ratio of the meter to the reducing agent is 2-1:1-4; the concentration of...

Embodiment 1

[0036] Example 1 Preparation of all-vanadium ion redox flow battery electrolyte by the method of the present invention

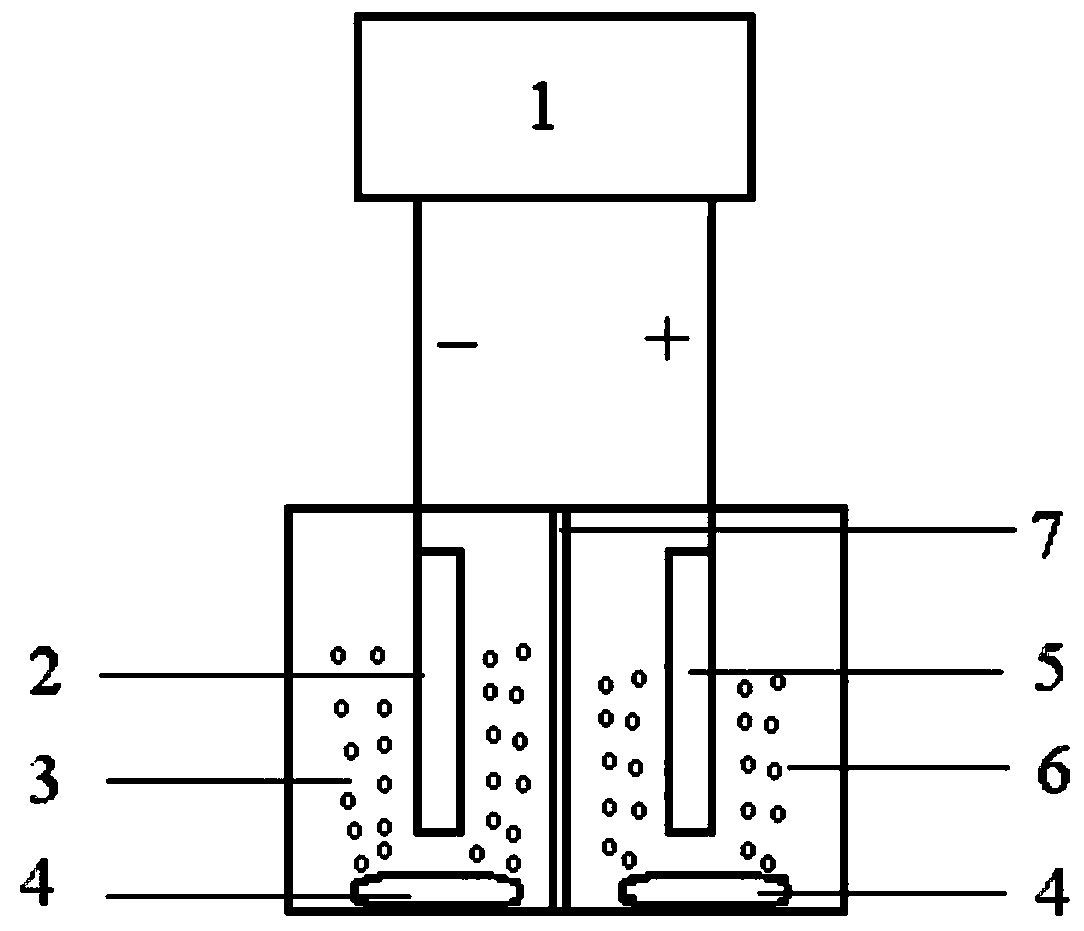

[0037] Take by weighing ammonium polyvanadate 112g (containing V 2 o 5 48%), poured into 150mL of 10mol / L sulfuric acid solution, bubbling and stirring to disperse the ammonium polyvanadate evenly, controlling the temperature at 90°C, and bubbling and stirring the gas flow rate to 500L / s; weighed 38g of oxalic acid, and added it in 8 times In the above reaction solution, after reacting for 0.5h, let it stand for 10min, move the solution into the negative half cell of the electrolytic cell, and add an equal volume of 3mol / L sulfuric acid solution to the positive half cell for electrolytic reaction. The positive half cell adopts DSA electrode, the negative half cell adopts porous graphite electrode, the positive and negative electrode area ratio is 1:1, and the quantity ratio is 1:5. 2 The average current density is electrolyzed, the temperature is controlle...

Embodiment 2

[0039] Example 2 Preparation of all-vanadium ion redox flow battery electrolyte by the method of the present invention

[0040] Take by weighing ammonium polyvanadate 150g (containing V 2 o 5 55%), poured into 150mL of 5mol / L sulfuric acid solution, bubbling and stirring to disperse the ammonium polyvanadate evenly, controlling the temperature at 80°C, and bubbling and stirring air flow of 1000L / s; Weighing 57g of propionic acid, divided into 10 times Add it into the above reaction solution, after reacting for 1 hour, let it stand for 20 minutes, move the solution into the negative half cell of the electrolytic cell, and add an equal volume of 2.5mol / L sulfuric acid solution to the positive half cell for electrolytic reaction. The positive half cell adopts DSA electrode, and the negative half cell adopts porous graphite electrode. 2 The average current density of electrolysis is carried out, the temperature is controlled at 60 ° C, bubbling and stirring, the electrolysis tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com