Method for plating surfaces of Ni-Cr alloy wires with zinc at low temperature

A technology of alloy wire and ni-cr, which is applied in metal processing equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems that the film removal method is difficult to work, the crystal is hard, and the reliability is low, so as to improve the performance of the joint , good metallurgical bonding, the effect of improving strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

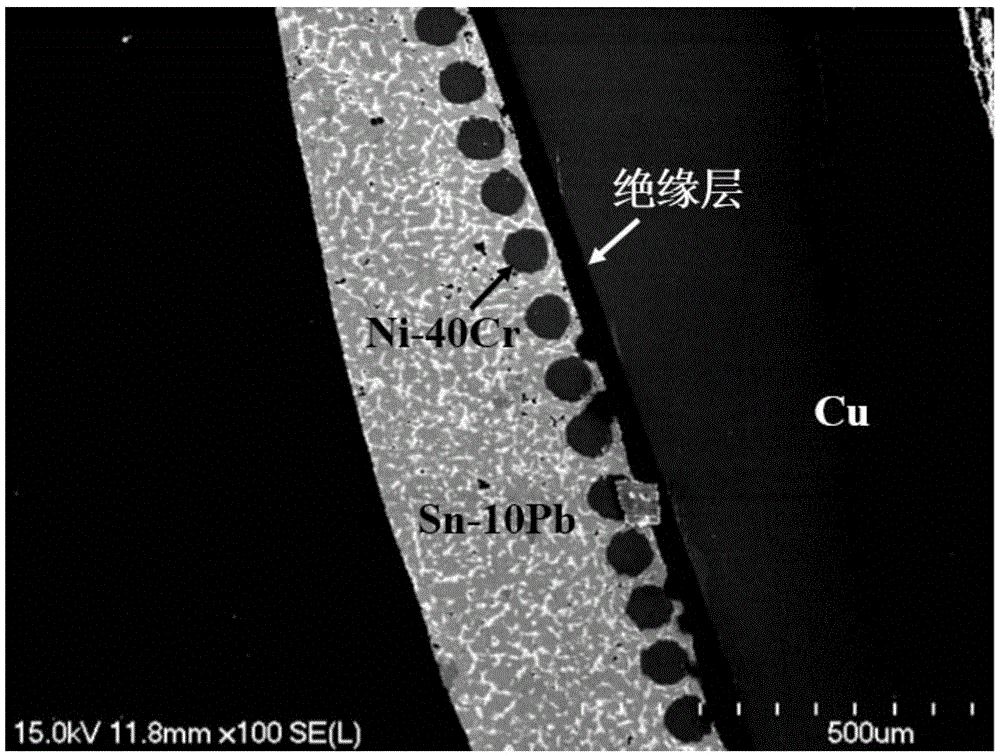

[0030] The invention discloses a process method for low-temperature tin plating on the surface of Ni-Cr alloy wire, using Sn-10Pb as solder.

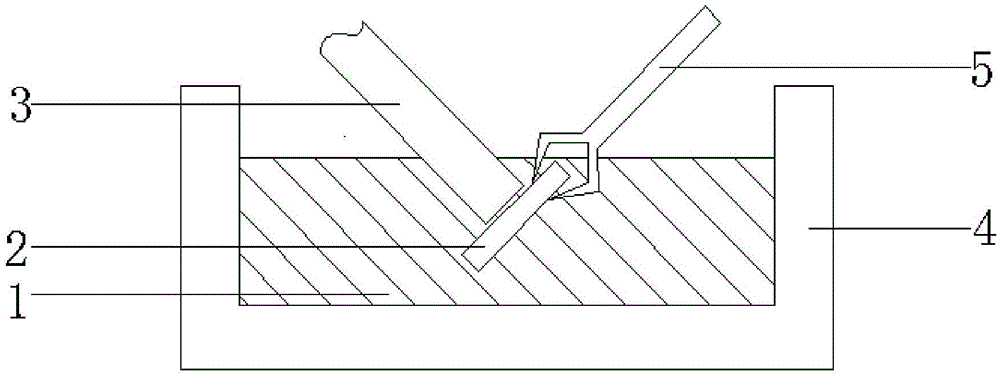

[0031] Such as figure 1 As shown, melt the Sn-10Pb solder 1 in the tin melting furnace 4, so that the solder liquid level is enough to immerse the ultrasonic welding head, and at the same time, it is convenient to hold the Ni-Cr alloy wire 2 and extend into the solder liquid surface to carry out welding; Sn- The melting point of 10Pb solder 1 is about 183°C, then adjust the temperature of the tin melting furnace 4 to 230°C, and set the parameters of the ultrasonic generator at the same time, so that the vibration time of the ultrasonic welding head is 8 seconds, the vibration frequency is 25KHz, and the amplitude is 20μm; KBrO 3 - the hydrochloric acid mixed solution is coated on the welding surface of the Ni-Cr alloy wire 2, the KBrO 3 -in a mixed solution of hydrochloric acid, KBrO 3 The percentage by mass is 0.1%; the ultrasonic w...

Embodiment 2

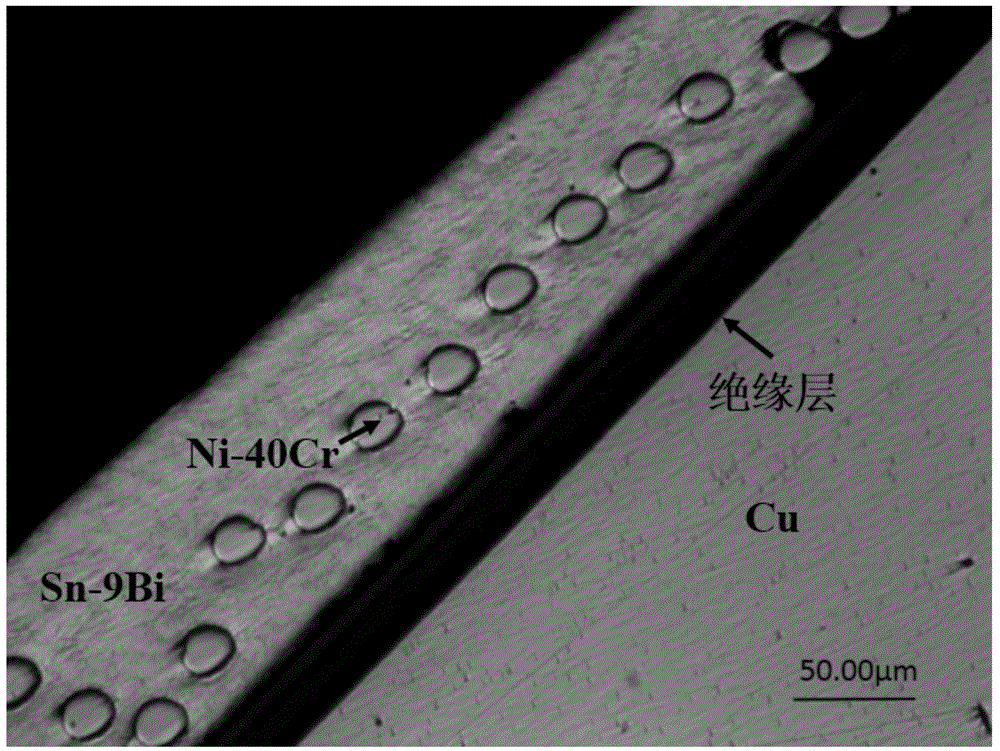

[0034] A process method for low-temperature tin plating on the surface of Ni-Cr alloy wire, using Sn-9Bi as solder.

[0035] Such as figure 1 As shown, melt the Sn-9Bi solder 1 in the tin melting furnace 4, so that the solder liquid level is enough to immerse the ultrasonic welding head, and at the same time, it is convenient to hold the Ni-Cr alloy wire 2 and extend into the following solder liquid level for welding; then adjust The temperature of the tin melting furnace 4 reaches 180° C., and the melting point of the Sn-9Bi solder 1 is about 145° C. At the same time, the parameters of the ultrasonic generator are set so that the ultrasonic welding head vibrates for 5 seconds, the vibration frequency is 20 KHz, and the amplitude is 10 μm; KBrO 3 - the hydrochloric acid mixed solution is coated on the welding surface of the Ni-Cr alloy wire 2, the KBrO 3 -in a mixed solution of hydrochloric acid, KBrO 3 The percentage by mass is 5%; the ultrasonic welding head is immersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com