Method for preparing high-nickel long-cycle single-crystal lithium ion battery positive-pole material

A technology for lithium ion batteries and cathode materials, which is applied in the field of lithium ion power batteries for new energy vehicles, can solve the problems of poor normal temperature and high temperature cycle performance, low compaction density, poor storage capacity, etc., and achieves improved normal temperature and high temperature cycle performance. , uniform coating, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

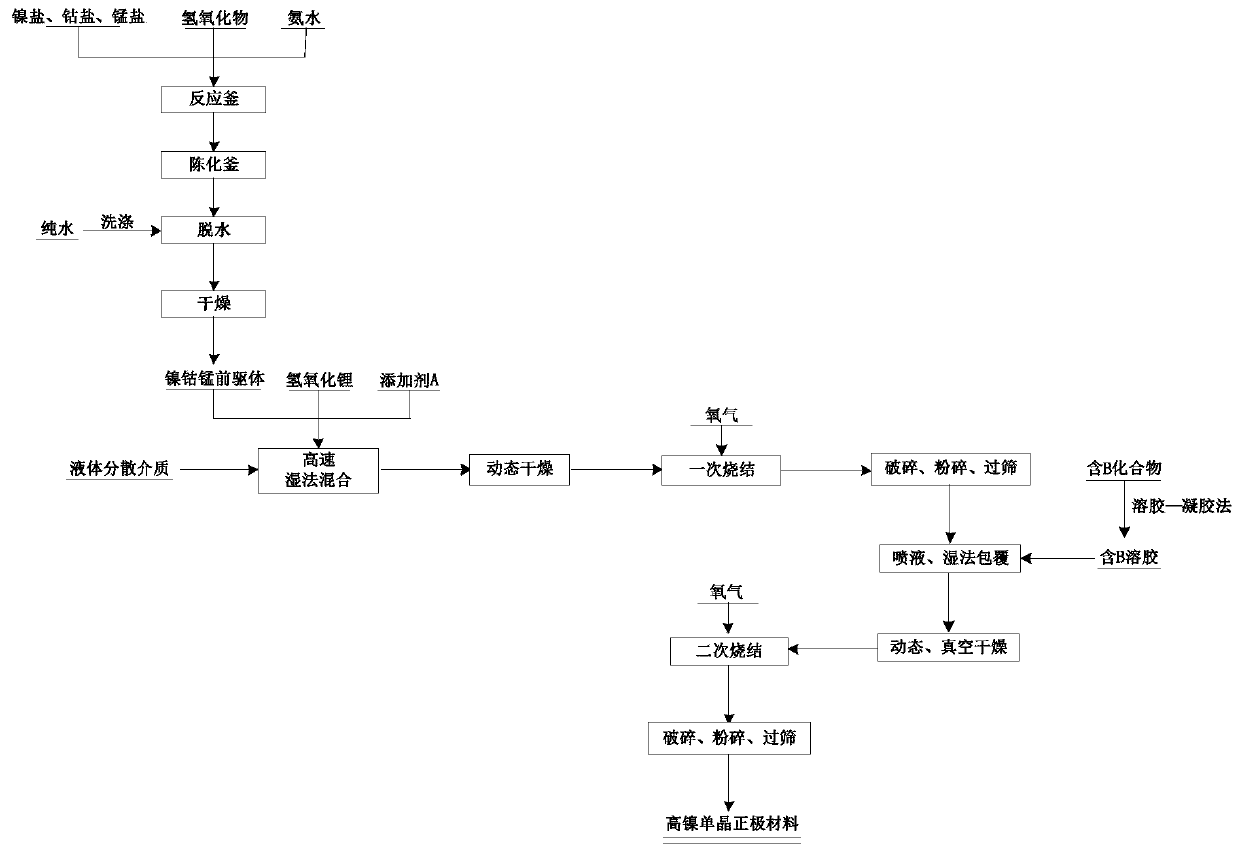

[0047] This embodiment provides a method for preparing a high-nickel, long-cycle single crystal lithium-ion battery positive electrode material, comprising the following steps:

[0048] (1) Mix soluble nickel salt, cobalt salt, manganese salt, alkali metal hydroxide and ammonia water, and flow into a reaction kettle with bottom liquid and protective gas for constant temperature co-precipitation, and solidify the spilled material after sufficient reaction Liquid separation, aging, centrifugation, and drying to obtain spherical high-nickel NCM ternary precursor materials; wherein the co-precipitation reaction conditions are as follows: according to the molar ratio of nickel ions: cobalt ions: manganese ions is 0.85:0.1:0.05, the preparation of metal The total ion concentration is 2mol / L; the concentration of NaOH solution is prepared to be 8mol / L, and the concentration of ammonia solution is prepared to be 120g / L; the three solutions are respectively fed into the reaction kettle ...

Embodiment 2

[0055] This embodiment provides a method for preparing a high-nickel, long-cycle single crystal lithium-ion battery positive electrode material, comprising the following steps:

[0056] (1) Mix soluble nickel salt, cobalt salt, manganese salt, alkali metal hydroxide and ammonia water, and flow into a reaction kettle with bottom liquid and protective gas for constant temperature co-precipitation, and solidify the spilled material after sufficient reaction Liquid separation, aging, centrifugation, and drying to obtain a spherical high-nickel NCM ternary precursor material; wherein the co-precipitation reaction conditions are as follows: according to the solution of nickel ion: cobalt ion: manganese ion molar ratio of 0.8:0.1:0.1, prepare metal The total ion concentration is 1.5mol / L, the concentration of the prepared NaOH solution is 8mol / L, and the concentration of the prepared ammonia solution: 100g / L; the three solutions are respectively passed into the reaction kettle at 80ml...

Embodiment 3

[0063] This embodiment provides a method for preparing a high-nickel, long-cycle single crystal lithium-ion battery positive electrode material, comprising the following steps:

[0064] (1) Mix soluble nickel salt, cobalt salt, manganese salt, alkali metal hydroxide and ammonia water, and flow into a reaction kettle with bottom liquid and protective gas for constant temperature co-precipitation, and solidify the spilled material after sufficient reaction Liquid separation, aging, centrifugation, and drying to obtain a spherical high-nickel NCM ternary precursor material; wherein the co-precipitation reaction conditions are as follows: according to a solution with a molar ratio of nickel ions: cobalt ions: manganese ions of 0.7:0.15:0.15, the metal The total ion concentration is 1.5mol / L, the concentration of the prepared NaOH solution is 8mol / L, and the concentration of the prepared ammonia solution is 100g / L; the three solutions are simultaneously passed into the reaction kett...

PUM

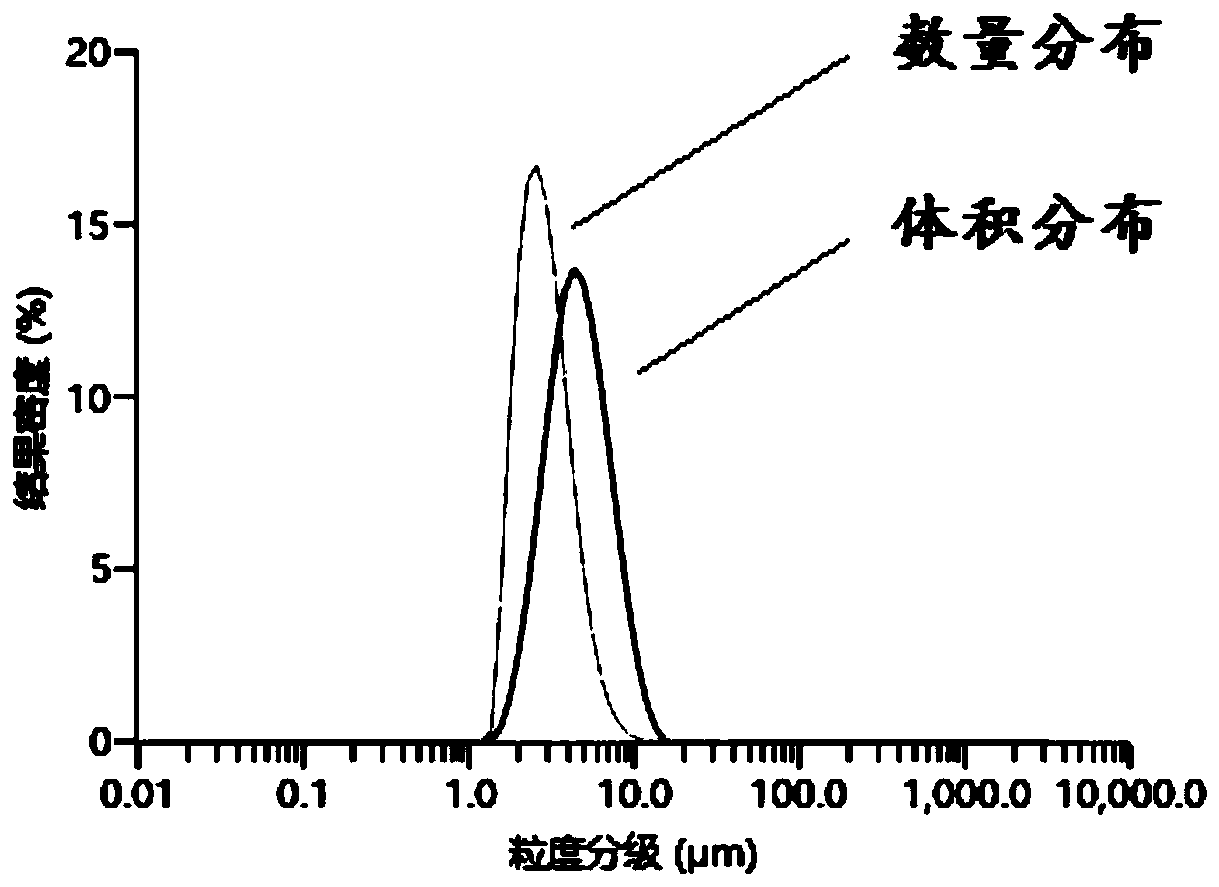

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com